Non-contact type flexible magnetic conductive slice for charging and preparation method therefor

A non-contact, thin-sheet technology, which is applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of unfavorable development of thin portable electronic terminals and affect the miniaturization of wearable electronic terminals, and achieve continuous High production efficiency, improved charging efficiency, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

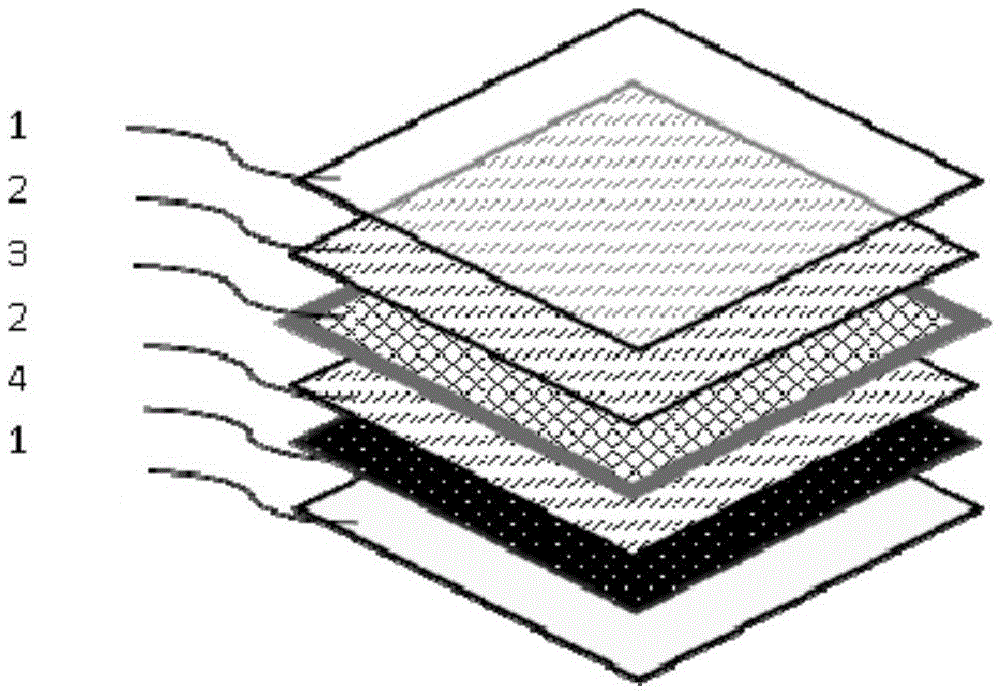

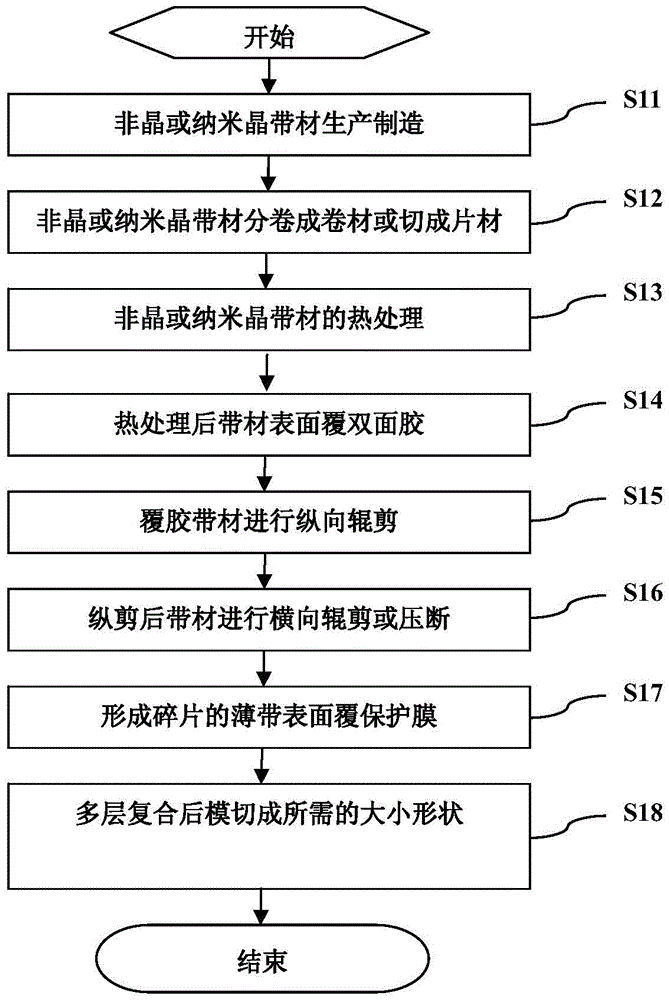

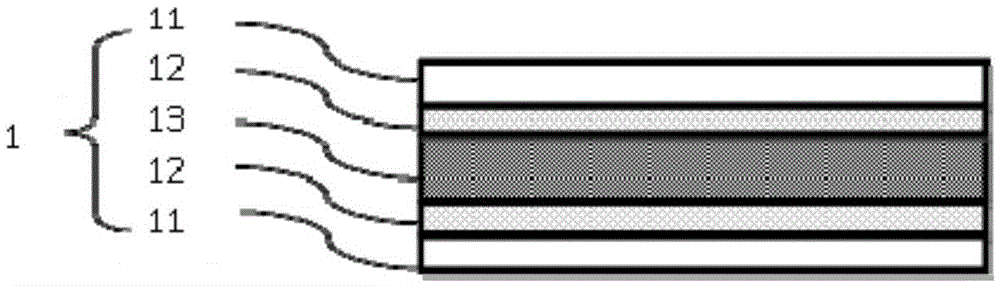

[0059] The preparation method for the single-layer magnetically conductive sheet includes: heat treatment, carrier film coating, longitudinal roll shearing, transverse roll shearing or transverse rolling, and protective film coating process; in the heat treatment process, the amorphous or nanocrystalline ribbon is Heat treatment in the range of 380-650°C (such as 390°C, 420°C, 450°C, 480°C, 500°C, 520°C, 550°C, 580°C, 600°C, 620°C, 645°C); In the process, the outer surface (upper and / or lower surface) of the single-layer amorphous or nanocrystalline ribbon after heat treatment is covered with a carrier film, and the thin film as the carrier is used to protect the fragile ribbon and prevent subsequent breakage The strip falls off during the process; in the longitudinal roller shearing process, the longitudinal roller shear is carried out on the strip covered with the carrier film, that is, it is cut along the length direction of the strip and broken, so that the strip The mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com