Single/multi-layer magnetic conductive sheet for wireless charging and preparation method thereof

A technology of wireless charging and magnetic conductive sheet, which is applied in the manufacture of inductors/transformers/magnets, electromagnetic wave systems, circuits, etc., can solve the problems affecting the miniaturization development of wearable electronic terminals, not easy to continuously prepare, and the development of thin portable electronic terminals. and other problems, to achieve the effect of continuous and uniform insulation treatment process, improve charging efficiency, improve inductance and quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

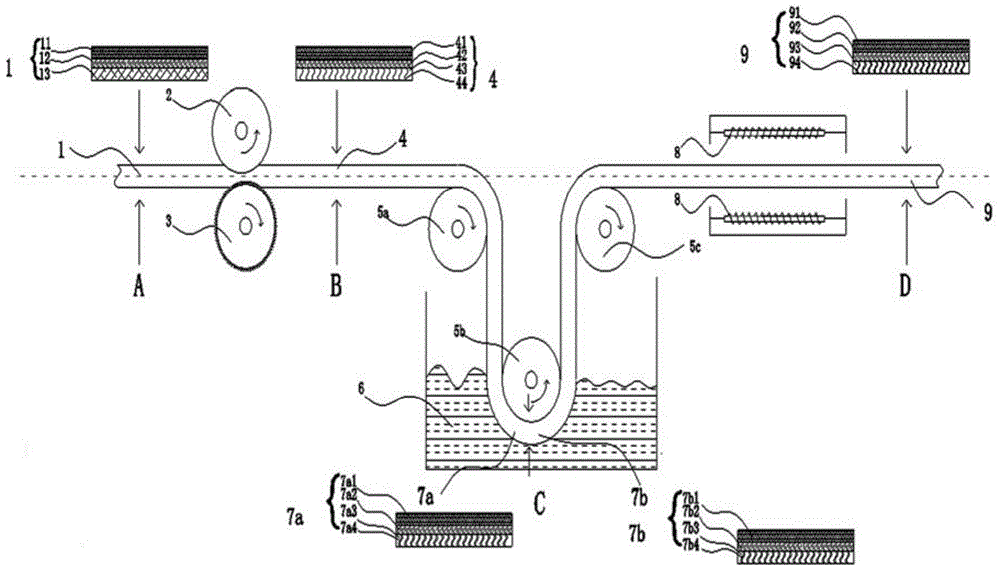

Method used

Image

Examples

preparation example Construction

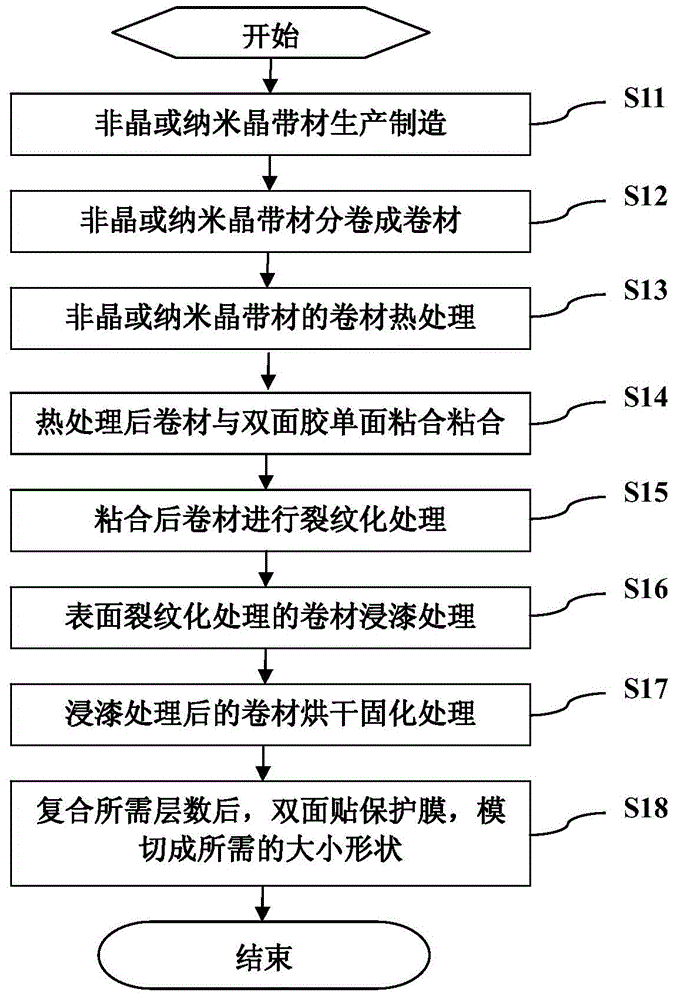

[0049] The method for preparing the single-layer magnetic conductive sheet for wireless charging includes the following steps:

[0050] The manufacturing steps of amorphous or nanocrystalline ribbons. The production of amorphous or nanocrystalline ribbons used in the method of the present invention is a conventional production method in the field, such as a rapid solidification method, which will not be repeated here.

[0051] In the heat treatment step, continuous heat treatment is performed on the coil of the amorphous or nanocrystalline strip, and the strip after the heat treatment is in a coil shape; preferably, the heat treatment temperature range of the amorphous strip is 380-520°C (for example, 385°C, 400°C, 420°C, 450°C, 460°C, 470°C, 490°C, 510°C), the heat treatment temperature range of the nanocrystalline ribbon is 450-650°C (such as 455°C, 470°C, 490°C, 520°C) , 550℃, 582℃, 600℃, 640℃). More preferably, the heat treatment time of the amorphous strip is 60-240min (such ...

Embodiment 7-12

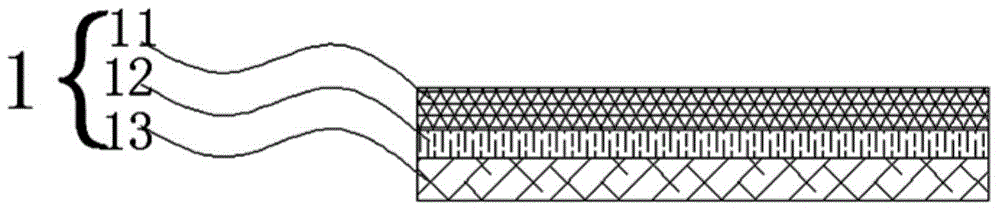

[0086] The two single-layer magnetic permeable sheets of Example 1 are combined into a double-layer magnetic permeable sheet to obtain the double-layer magnetic permeable sheet of Example 7. The specific compounding method is as follows: First, peel off both sides of the single-layer magnetic permeable sheet The release film on the glue, and then the double-sided adhesive of the single-layer magnetic sheet of the release film from the glass is adhered to the protective film surface of the magnetic sheet of the other single-layer magnetic sheet, thereby forming the double According to this method, the two single-layer magnetic sheets of Example 2 are combined into a double-layer magnetic sheet to obtain the double-layer magnetic sheet of Example 8. The two single-layer magnetic sheets of Example 3 The magnetic conductive sheet is combined into a double-layer magnetic conductive sheet to obtain the double-layer magnetic conductive sheet of Example 9; the two single-layer magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com