Patents

Literature

1164 results about "Embrittlement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Embrittlement is a loss of ductility of a material, making it brittle. Embrittlement is used for any phenomena where a hostile environment compromises a stressed material's mechanical performance. Various materials have different mechanisms of embrittlement. Due to these various mechanisms, embrittlement manifests in a variety of ways, from slow crack growth to a reduction of tensile ductility and toughness. Often, cyclical stresses or environments lead to embrittlement.

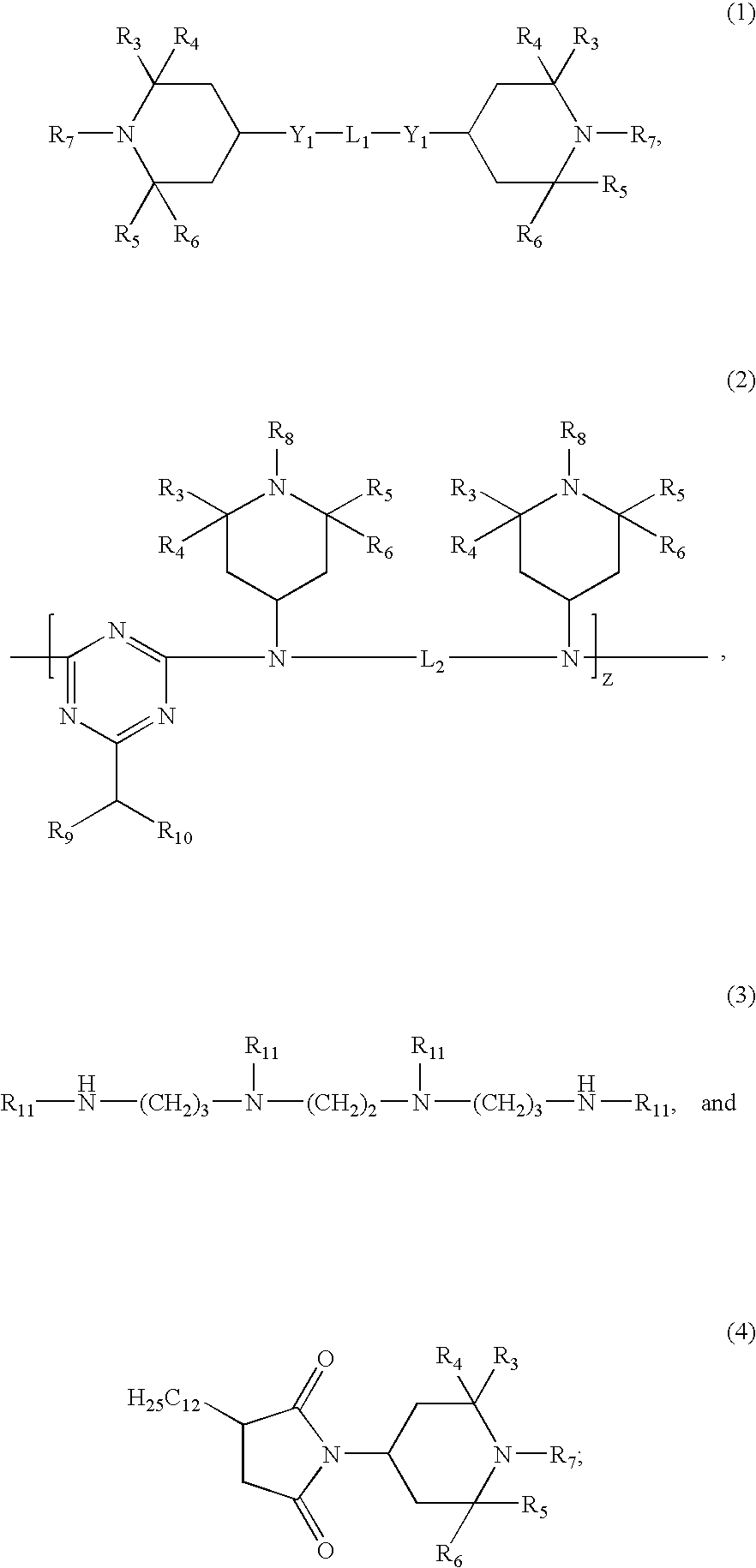

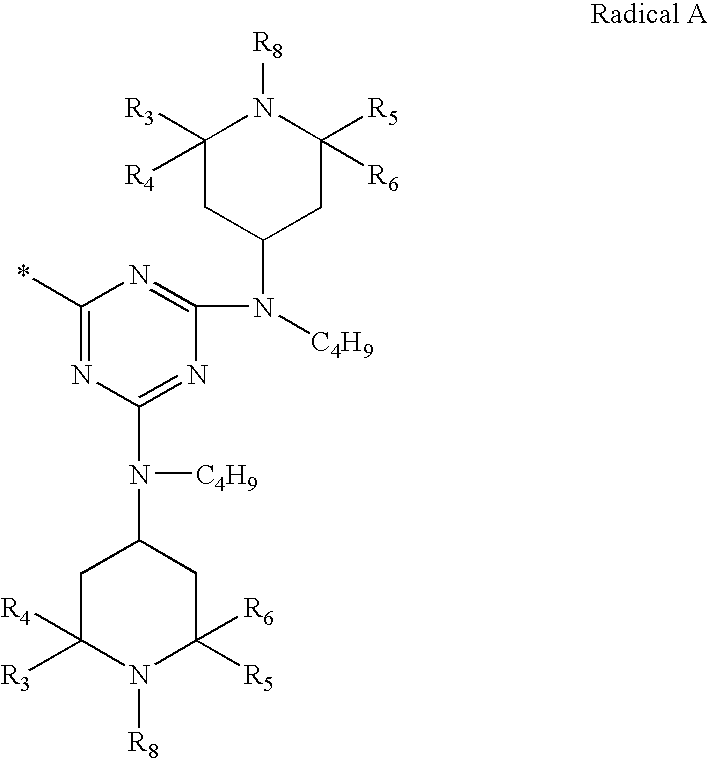

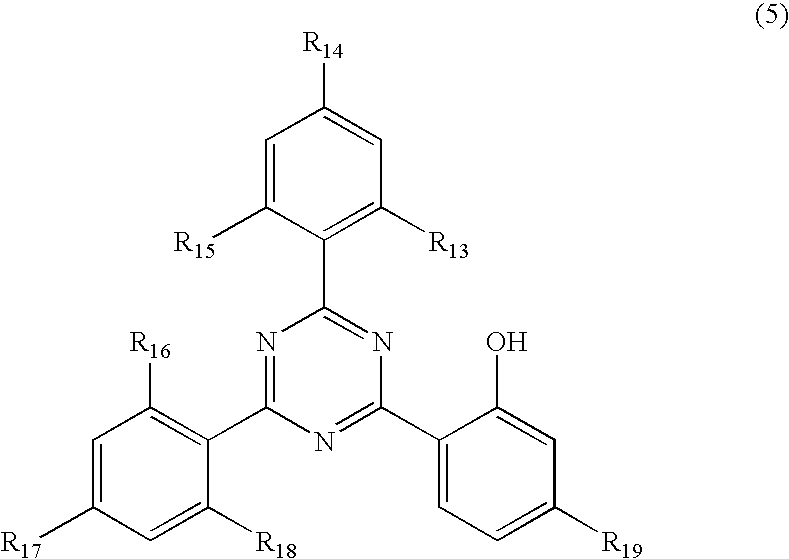

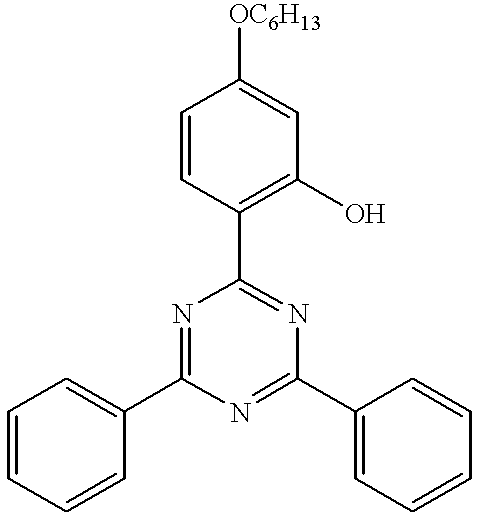

Stabilized aliphatic polyester compositions

Disclosed are stabilized aliphatic polyester compositions comprising an aliphatic polyester, a HALS, and a tris-aryl-S-triazine UV absorber that show low embrittlement, haze formation, and discoloration during weathering. Also disclosed are aliphatic polyester compositions comprising aliphatic polyester, a hindered amine light stabilizer, a triazine UV absorber, and a phosphite that exhibit low color prior to weathering but retain good clarity, color, and excellent impact strength after exposure to weathering conditions. The aliphatic polyester compositions may be used prepare shaped articles such as, for example, films, sheets, bottles, tubes, profiles, fibers, and molded articles.

Owner:EASTMAN CHEM CO

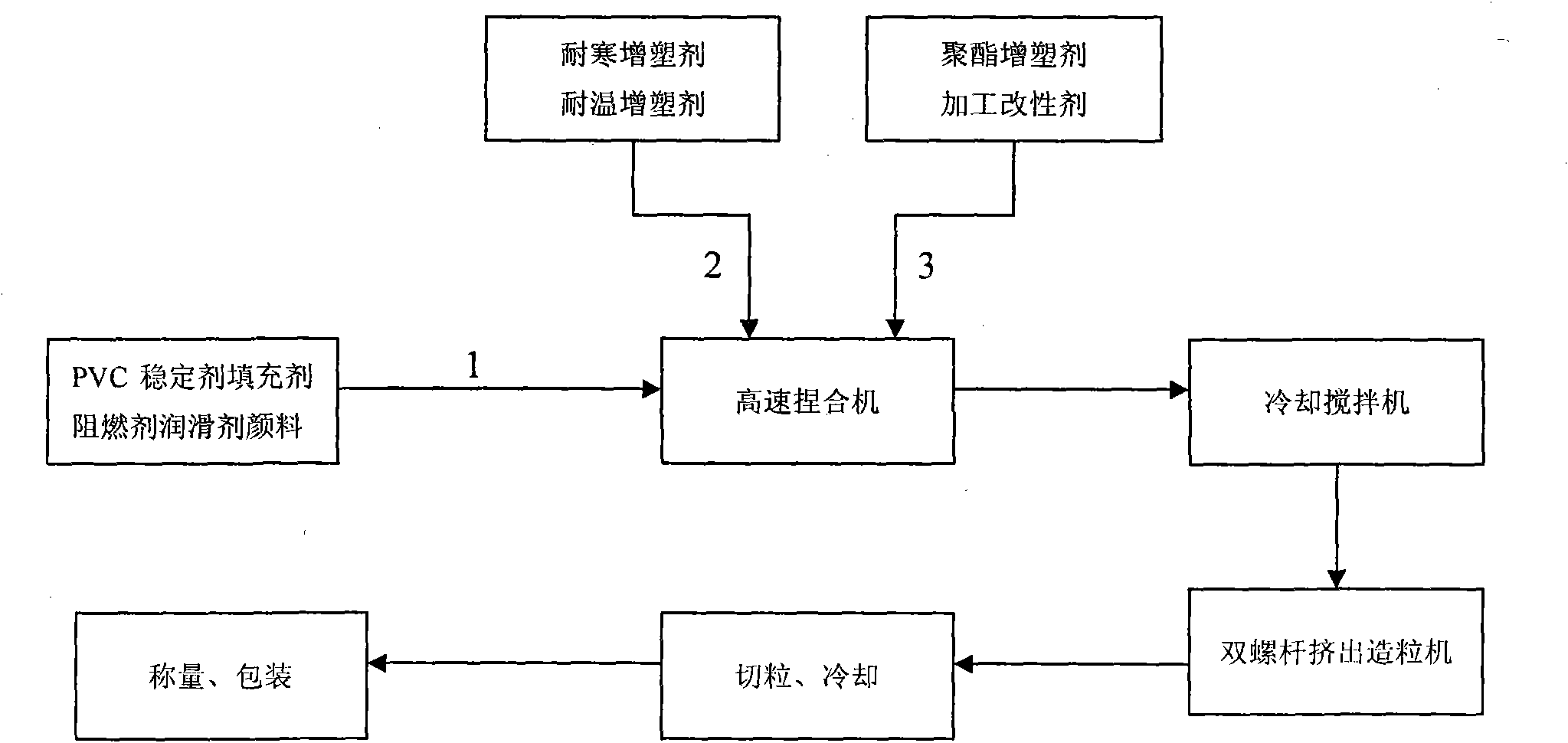

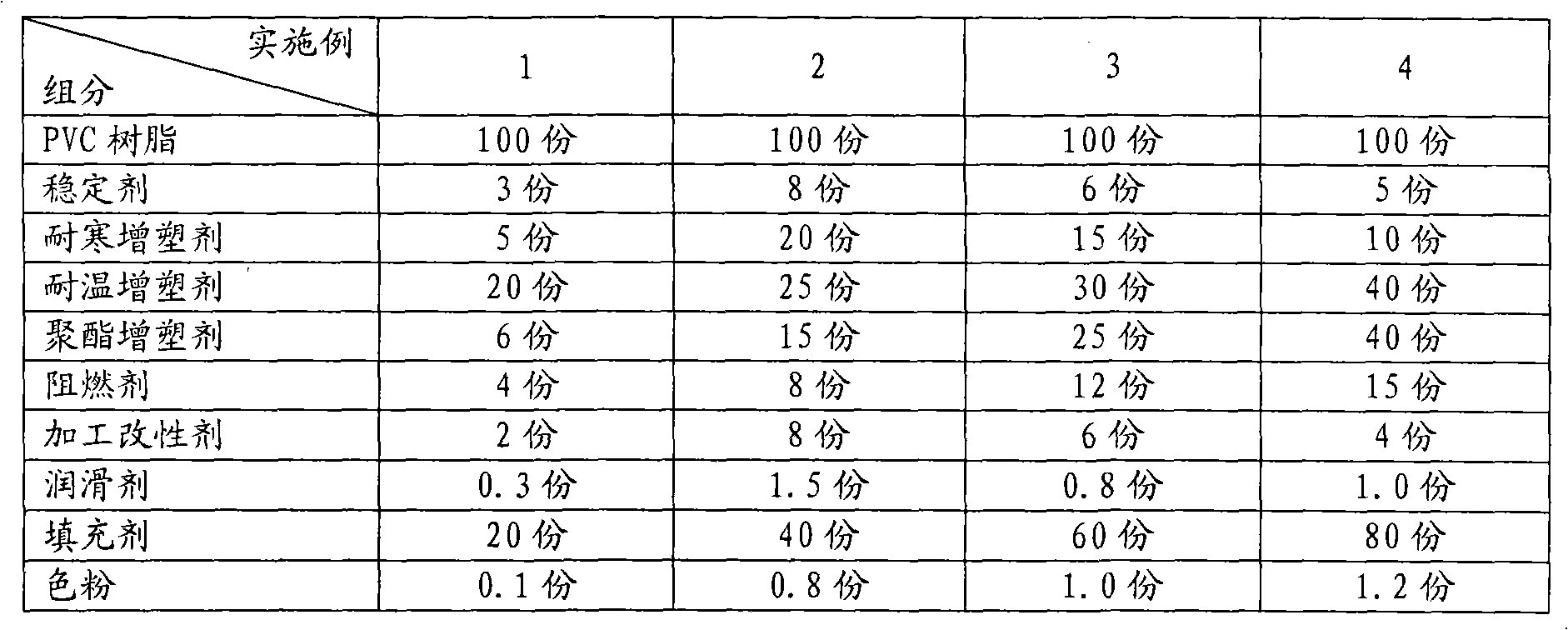

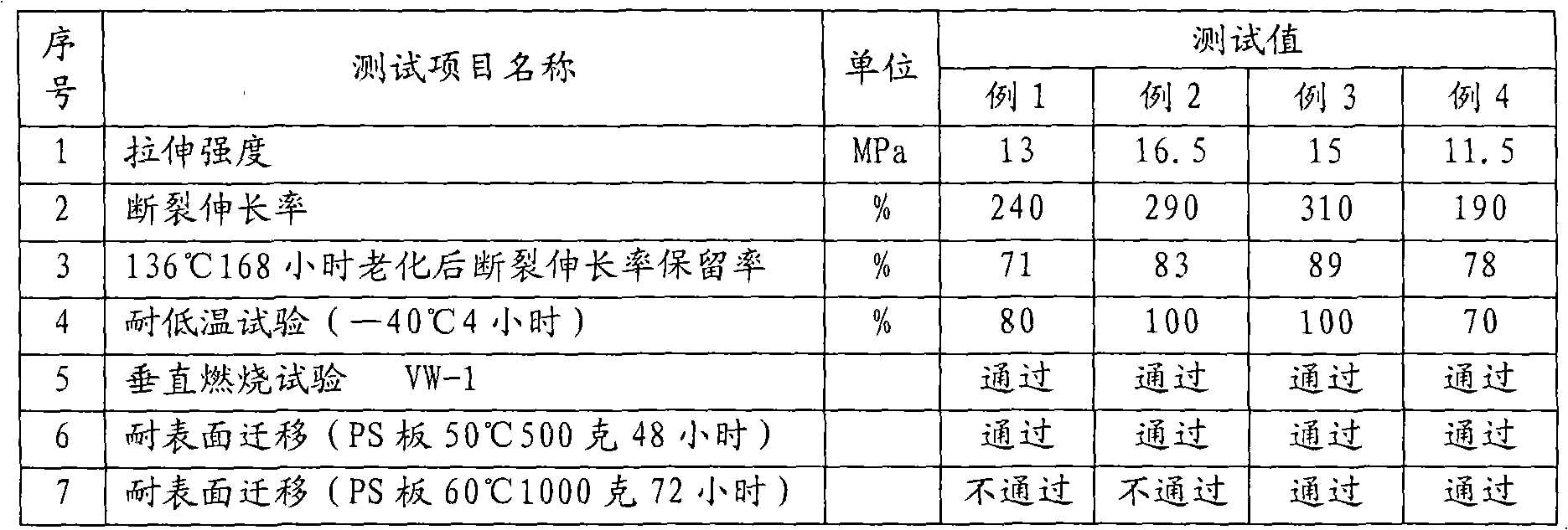

Cold-resistant temperature-resistant flame-retardant surface migration-resistant polrvinyl chloride insulating material

InactiveCN101967250AWon't breakNo migrationPlastic/resin/waxes insulatorsPolyesterEnvironmental resistance

The invention discloses a cold-resistant temperature-resistant flame-retardant surface migration-resistant polrvinyl chloride insulating material. The material comprises the following components in part by weight: 100 parts of polrvinyl chloride (PVC) resin, 5 to 20 parts of cold-resistant plasticizer, 20 to 40 parts of temperature-resistant plasticizer, 6 to 40 parts of polyester polymer plasticizer, 3 to 8 parts of environmentally-friendly heat stabilizer, 20 to 80 parts of filler, 4 to 15 parts of fire retardant, 2 to 8 parts of processing modifier, 0.3 to 1.5 parts of lubricant and 0.1 to 1.2 p[arts of toner. The polrvinyl chloride composite material of the invention has the comprehensive performance, such as low temperature embrittlement resistance, low temperature compact resistance, high temperature aging resistance, fire resistance, surface migration resistance and the like.

Owner:王长明

Centrifugal casting high-speed steel composite roll and manufacture method thereof

InactiveCN102615108AGood metallurgical bondHigh strengthRollsMetal rolling arrangementsNiobiumEconomic benefits

The invention relates to a centrifugal casting high-speed steel composite roll and a manufacture method thereof and belongs to the field of casting. The composite roll is composed of outer layer high-speed steel, middle layer graphitic steel and core high-strength nodular cast iron by centrifugal compounding. The centrifugal casting high-speed steel composite roll is based on the conventional high-carbon high-vanadium high-speed steel roll, the content of vanadium is appropriately reduced, niobium is added at the same time, and the Nb / V is controlled to be 0.3 to 0.5 so that Nb and V form complex carbide (V, Nb) C so as to avoid forming segregation under the action of centrifugal force. A roll core of the high-speed steel composite roll adopts high-strength nodular cast iron, and a multivariate graphite steel middle layer is poured between an outer layer and the roll core for preventing interfusing elements of Cr, B, and the like which cause embrittlement when the nodular cast iron is poured to be fused with the outer layer high-speed steel. Microalloying processing for refining the organization is carried out on a roll surface high-speed steel material and the middle layer graphitic steel so as to achieve the purpose of improving the thermal cracking capacity of the roll material. The centrifugal casting high-speed steel composite roll has high overall performance, long service life and good economic benefits.

Owner:BEIJING UNIV OF TECH

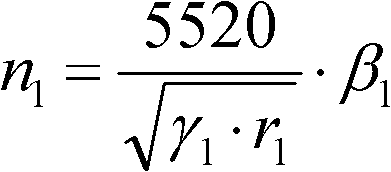

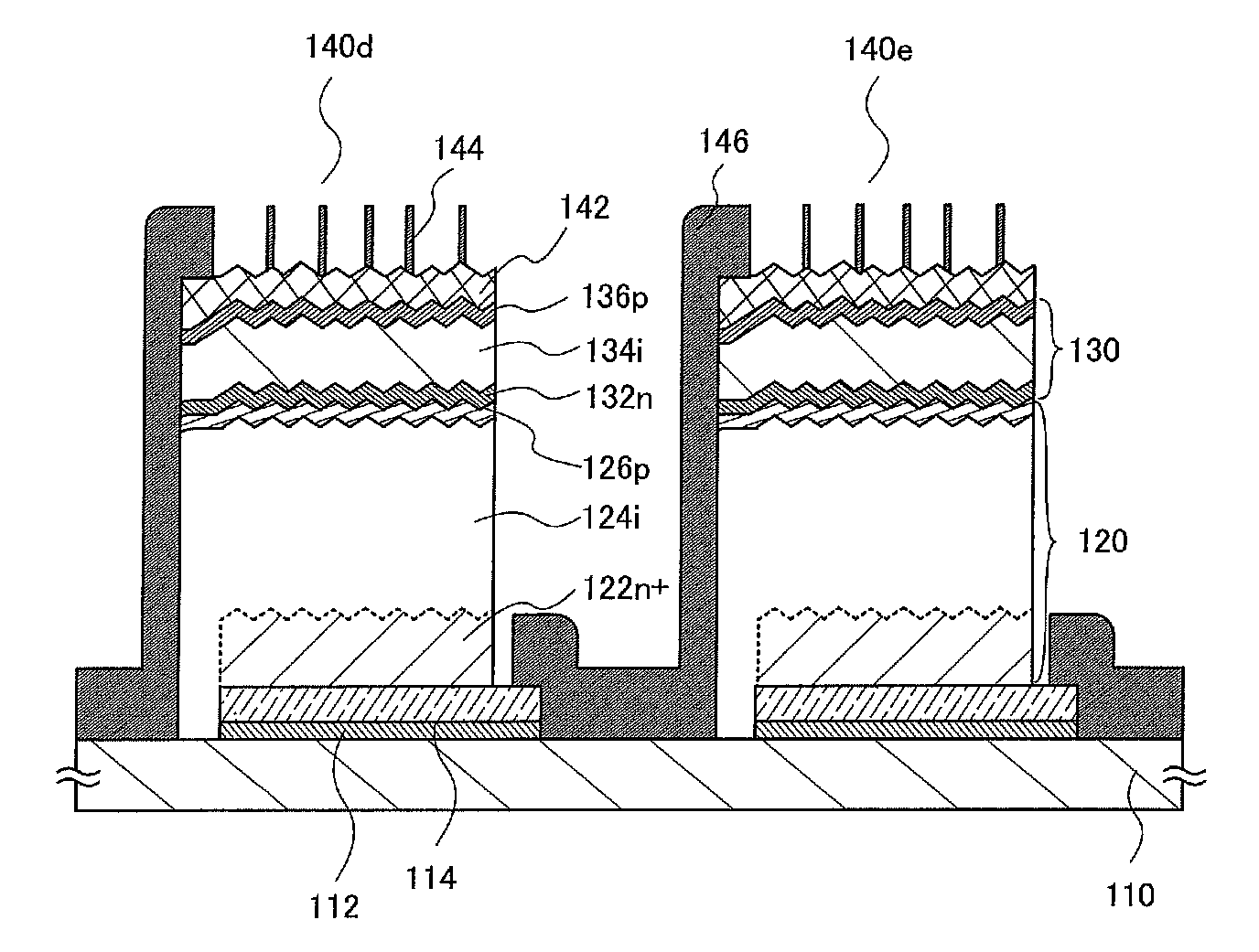

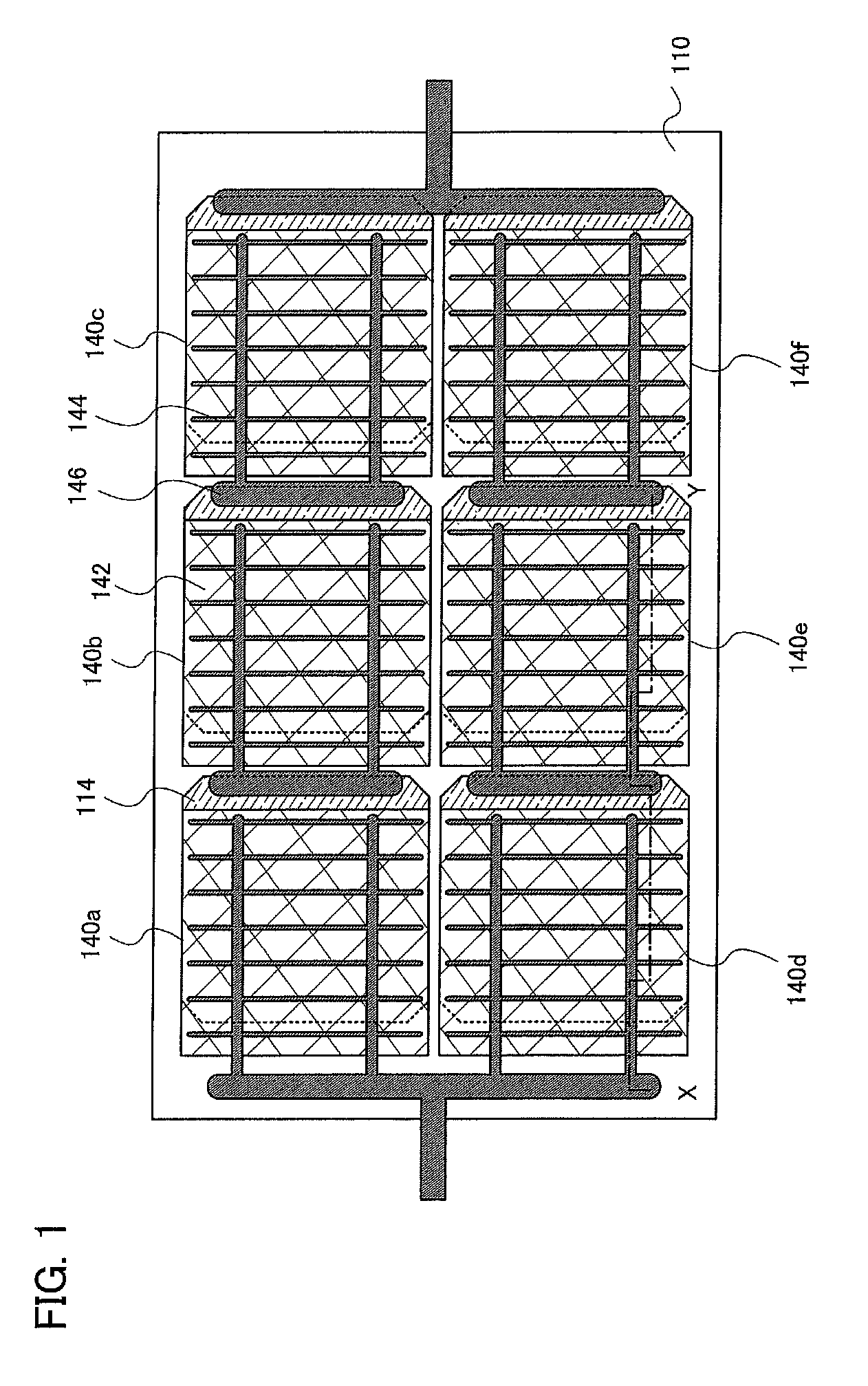

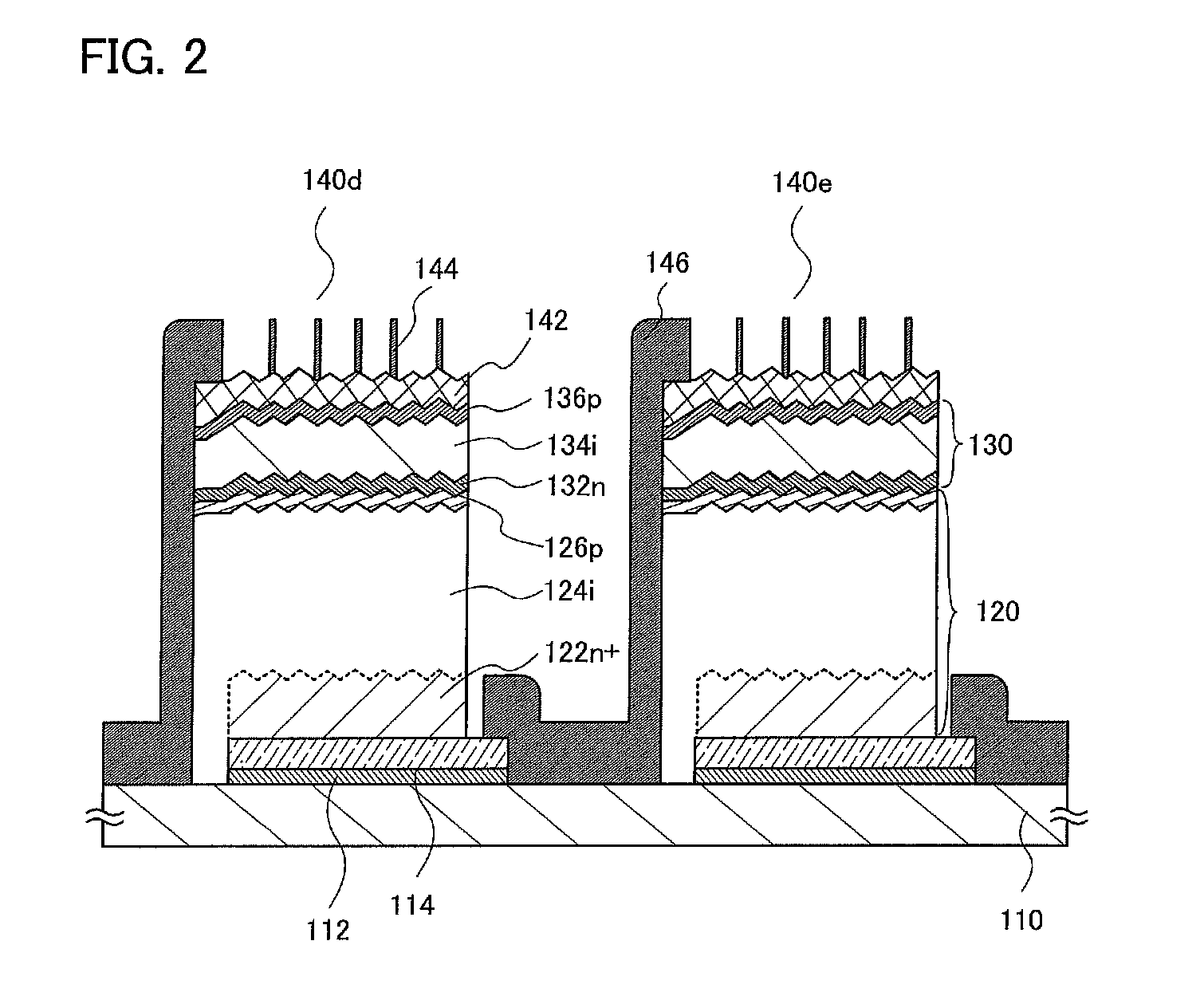

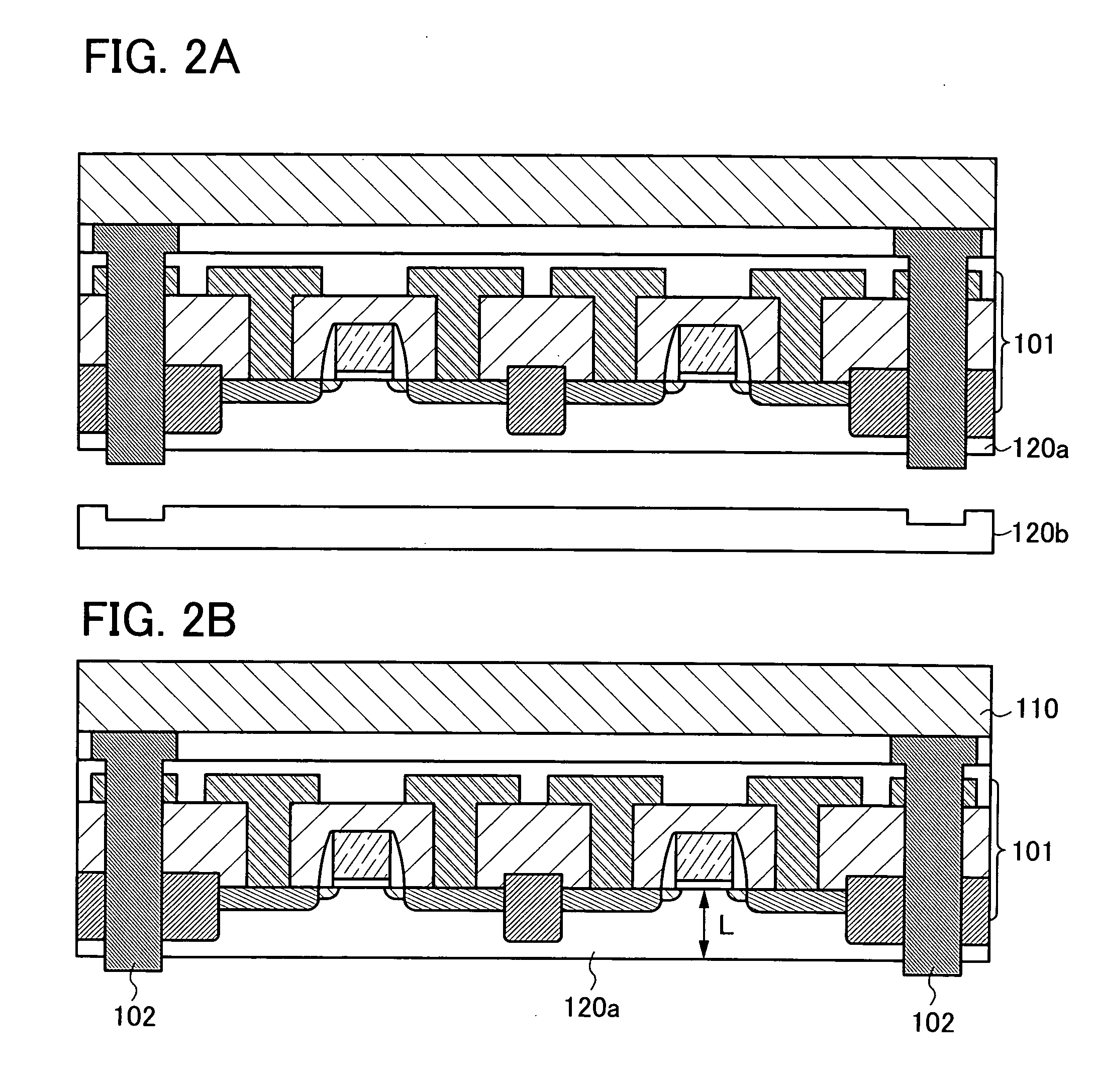

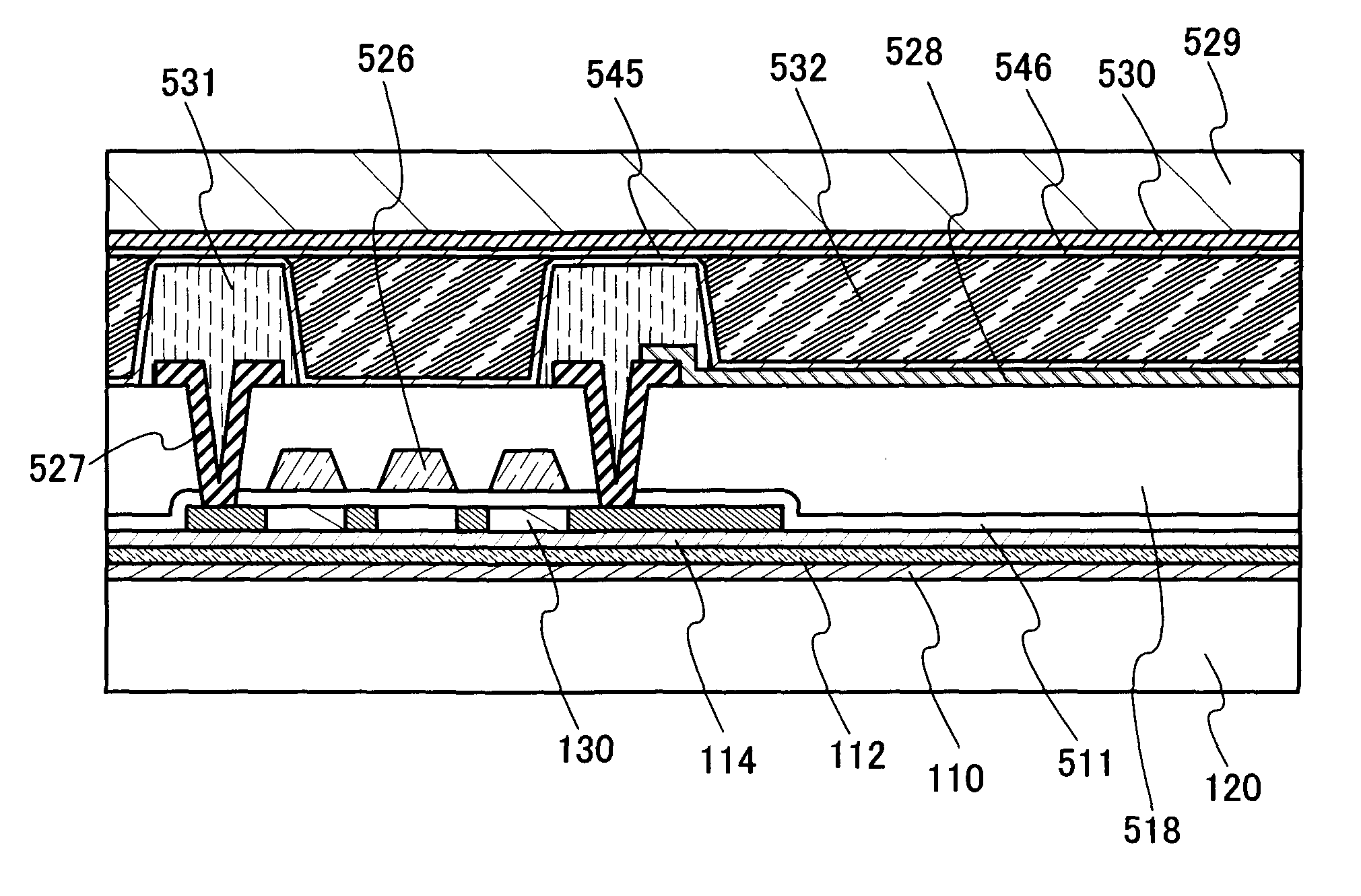

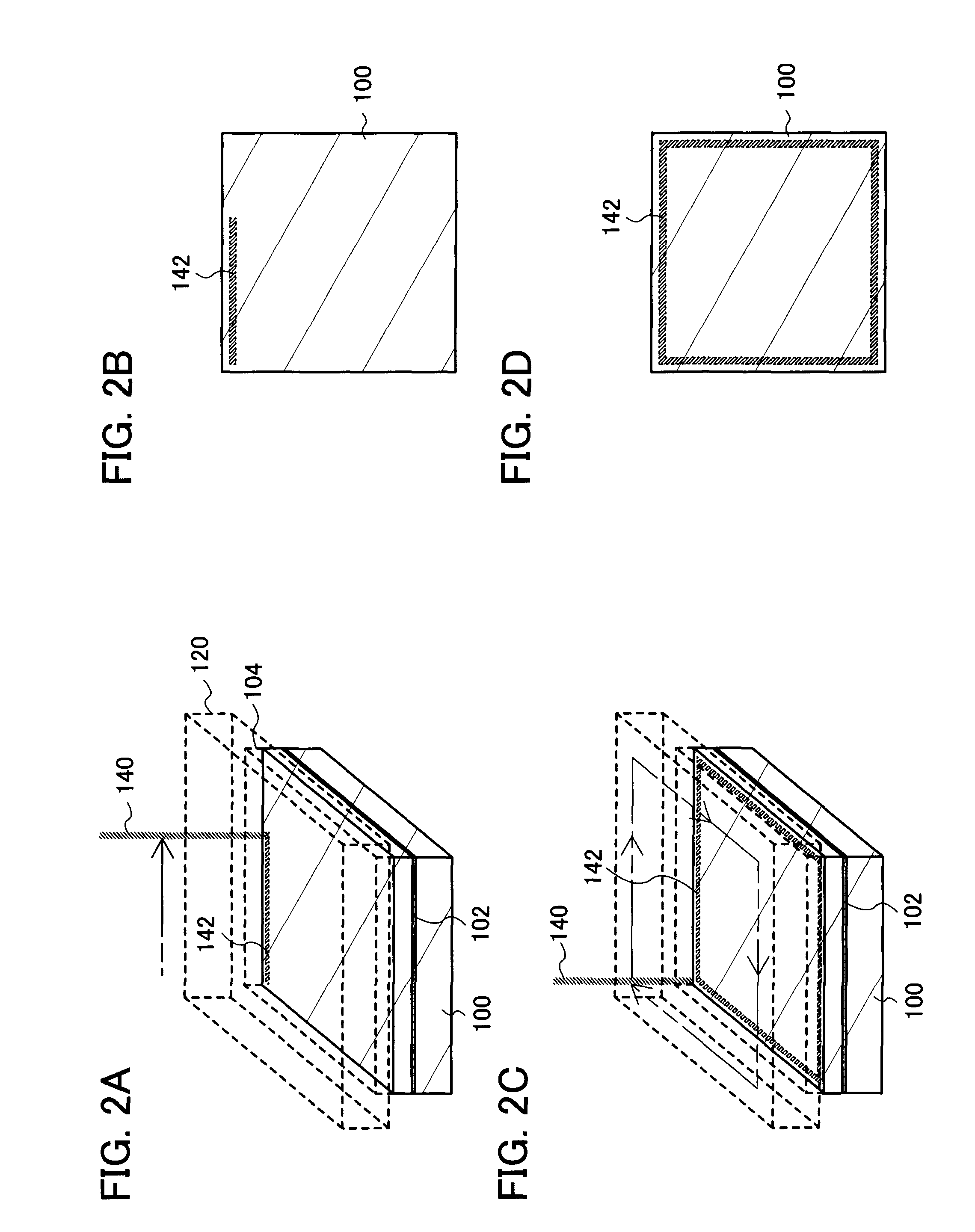

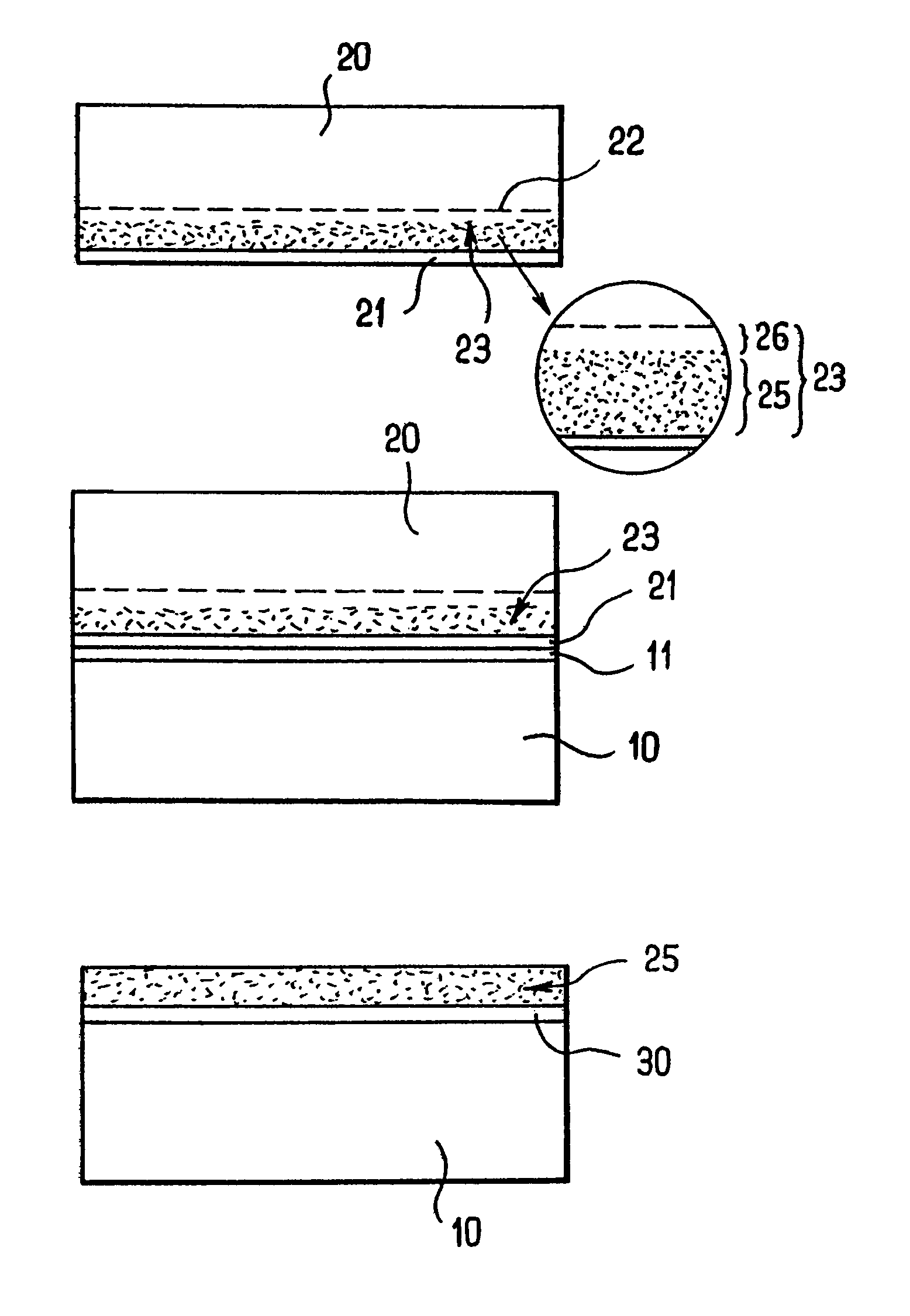

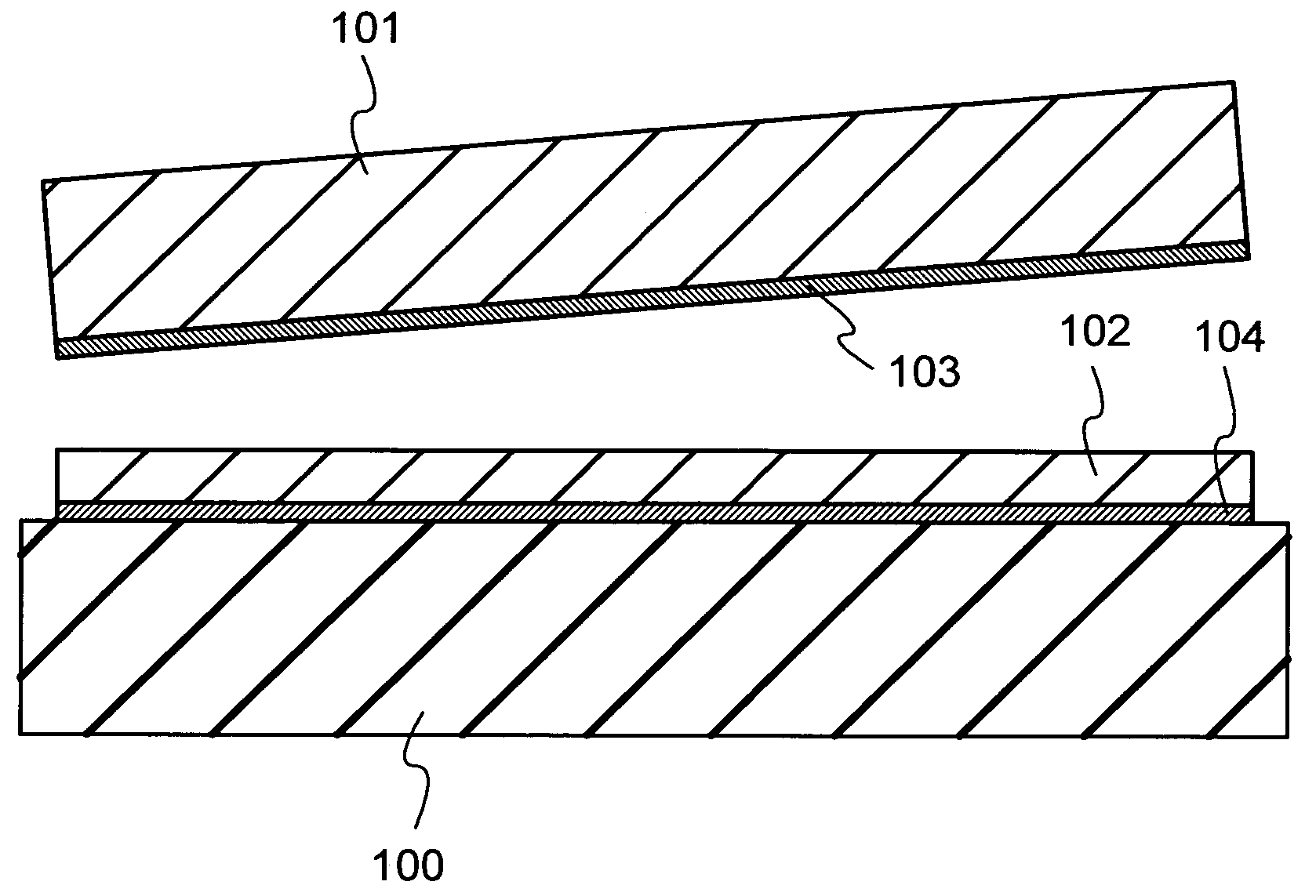

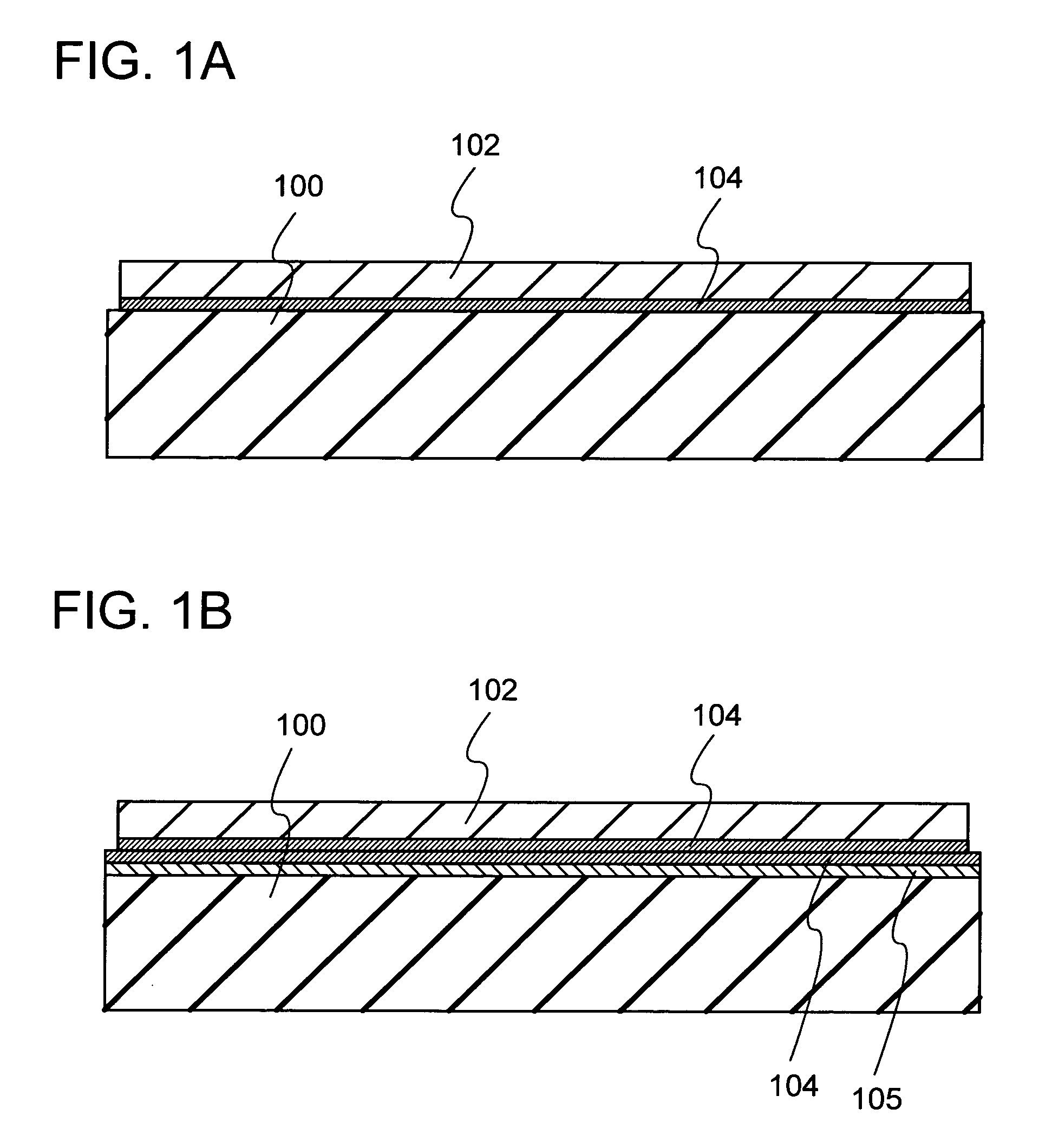

Photoelectric conversion device module and manufacturing method of the photoelectric conversion device module

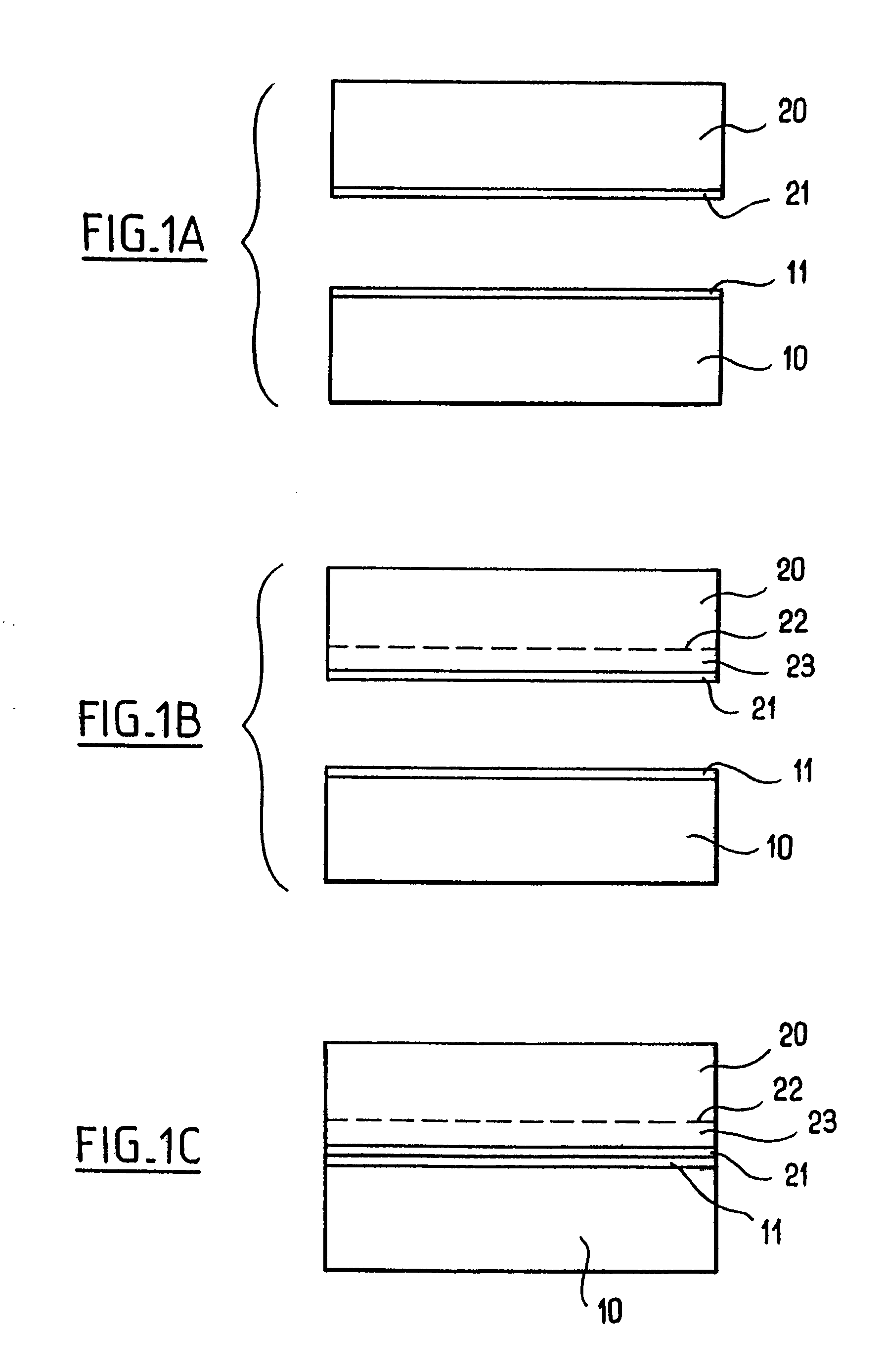

InactiveUS20090320897A1Improve photoelectric conversion efficiencyImprove efficiencyPV power plantsFinal product manufactureEtchingEngineering

A manufacturing method of a photoelectric conversion device module, wherein an insulating layer and a first electrode are formed over a base substrate; a plurality of single-crystal semiconductor substrates having a first conductivity type including embrittlement layers formed inside are attached; the plurality of single-crystal semiconductor substrates are separated at the embrittlement layers so that a plurality of stacked bodies including the insulating layer, the first electrode and a first single-crystal semiconductor layer is formed; a second single-crystal semiconductor layer is formed over the stacked bodies to form a first photoelectric conversion layer; a second photoelectric conversion layer including a non-single-crystal semiconductor layer is formed; a second electrode is formed; and selective etching is conducted to form photoelectric conversion cells which are element-separated, and a connecting electrode is formed to connect the second electrode of one photoelectric conversion cell and the first electrode of the other photoelectric conversion cell.

Owner:SEMICON ENERGY LAB CO LTD

Austenitic stainless steel

ActiveCN101784687AHigh strengthExcellent resistance to embrittlement crackingCrack resistanceMaterials science

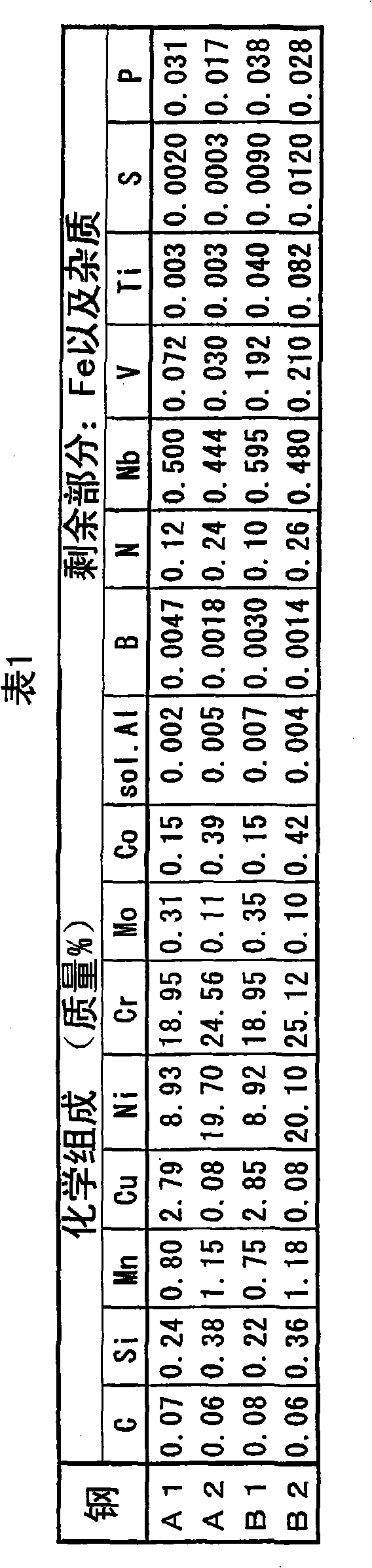

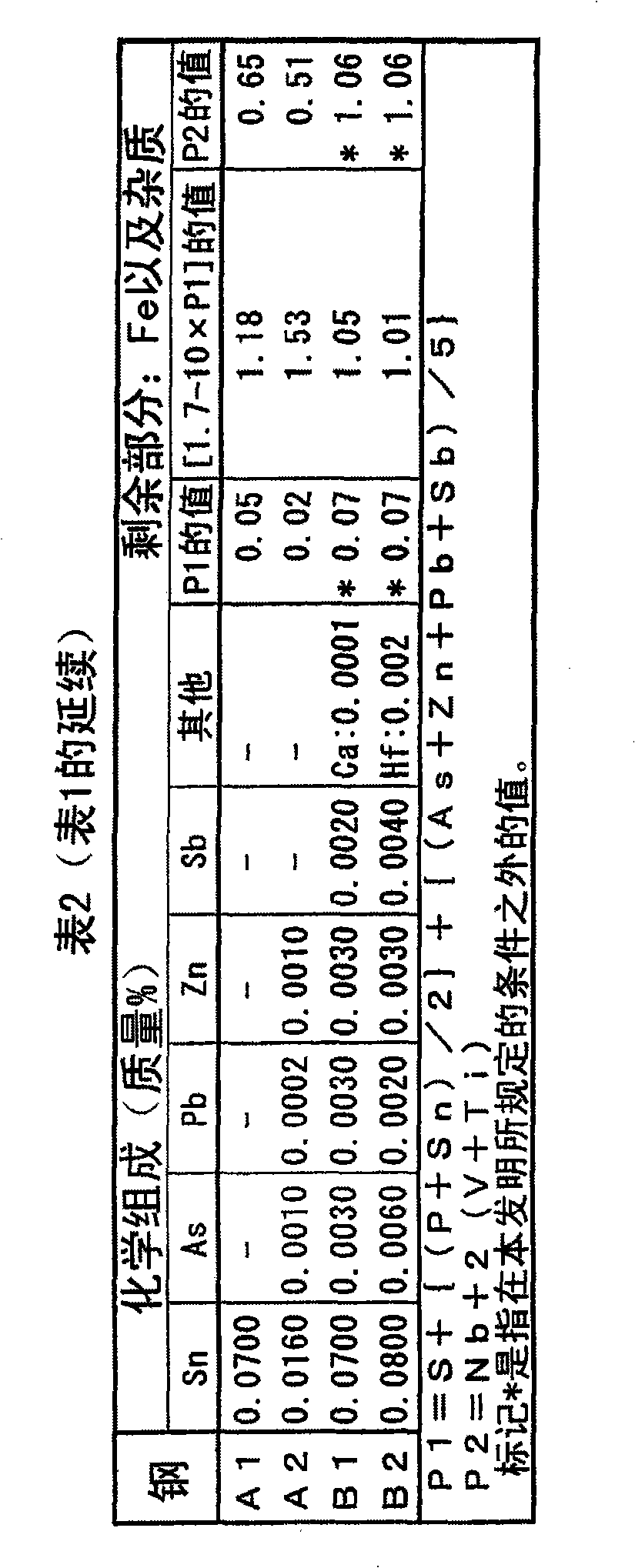

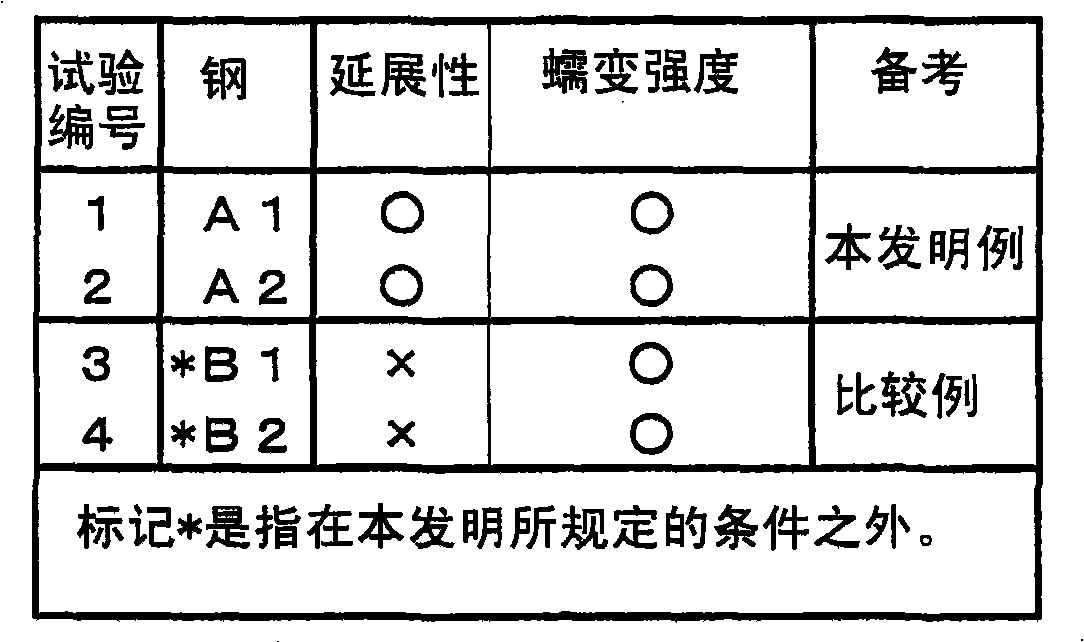

Disclosed is an austenitic stainless steel which comprises the following components: C: 0.04-0.18%, Si: 1.5% or less, Mn: 2.0% or less, Ni: 6-30%, Cr: 15-30%, N: 0.03-0.35%, and sol.Al: 0.03% or less, and which further comprises at least one component selected from 1.0% or less of Nb, 0.5% or less of V and 0.5% or less of Ti, with the remainder being Fe and impurities, wherein the impurities contain the following components: P: 0.04% or less, S: 0.03% or less, Sn: 0.1% or less, As: 0.01% or less, Zn: 0.01% or less, Pb: 0.01% or less and Sb: 0.01% or less, and wherein the following formulae are fulfilled: P1 = S+[(P+Sn) / 2]+[(As+Zn+Pb+Sb) / 5] = 0.06; and 0.2 = Nb+2(V+Ti) = 1.7-10xP1. The austenitic stainless steel has high strength and, when used in a welded part, can exhibit excellent embrittlement crack resistance during being used at a high temperature. The steel is suitable as a material for an instrument that is intended to be used at a high temperature for a long period, such as a boiler for power generation.

Owner:NIPPON STEEL CORP

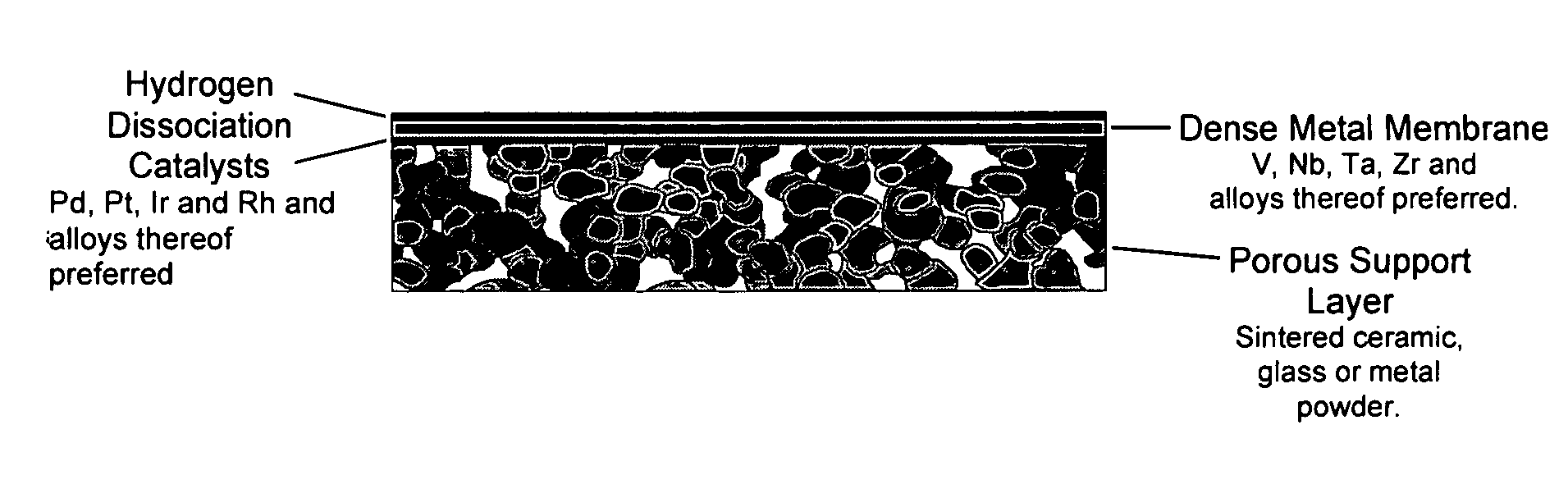

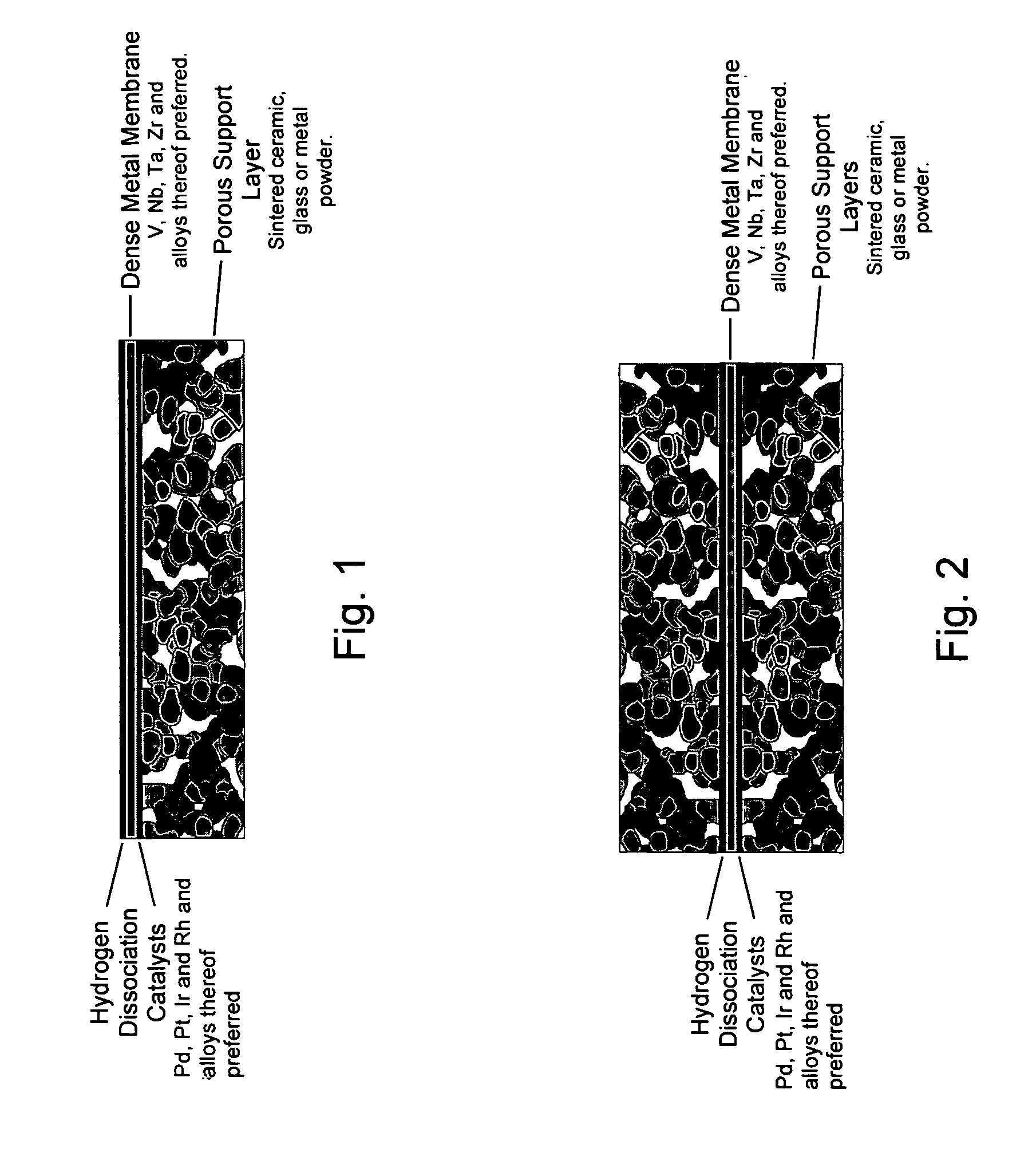

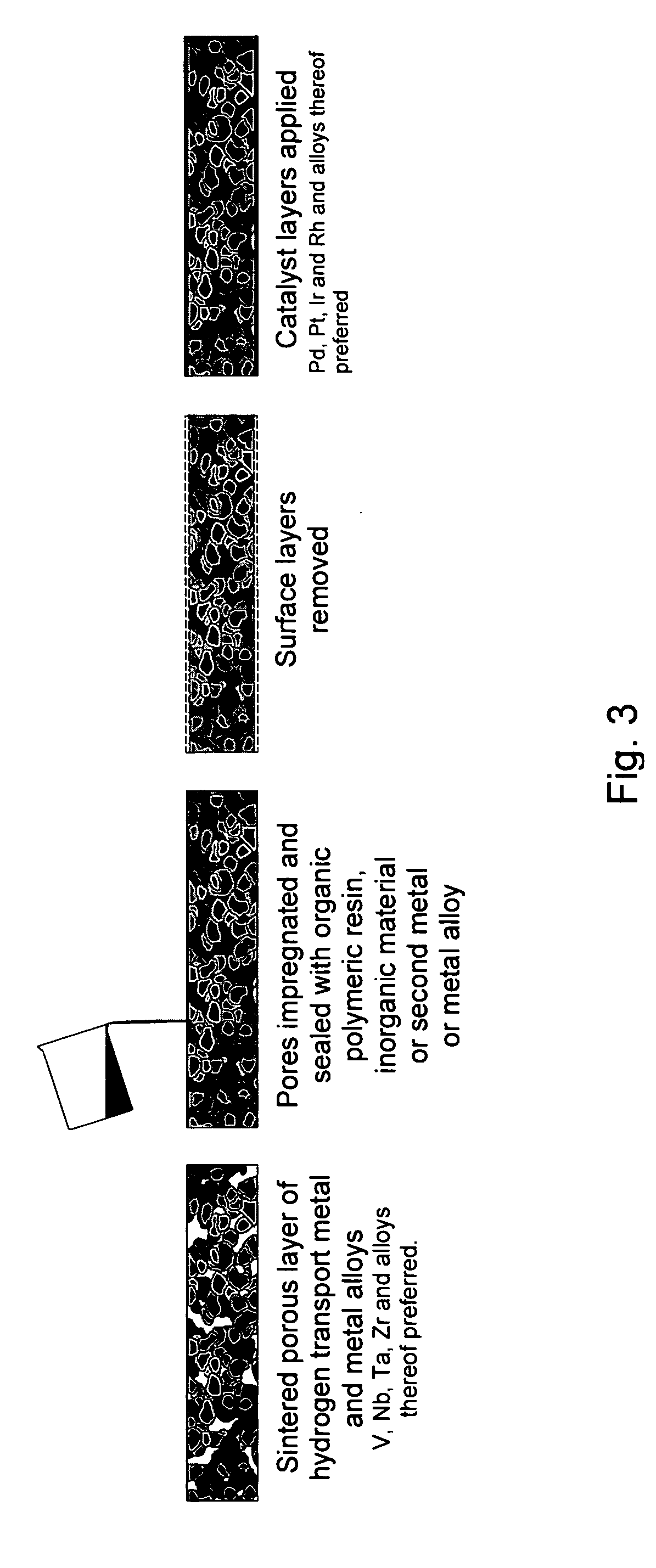

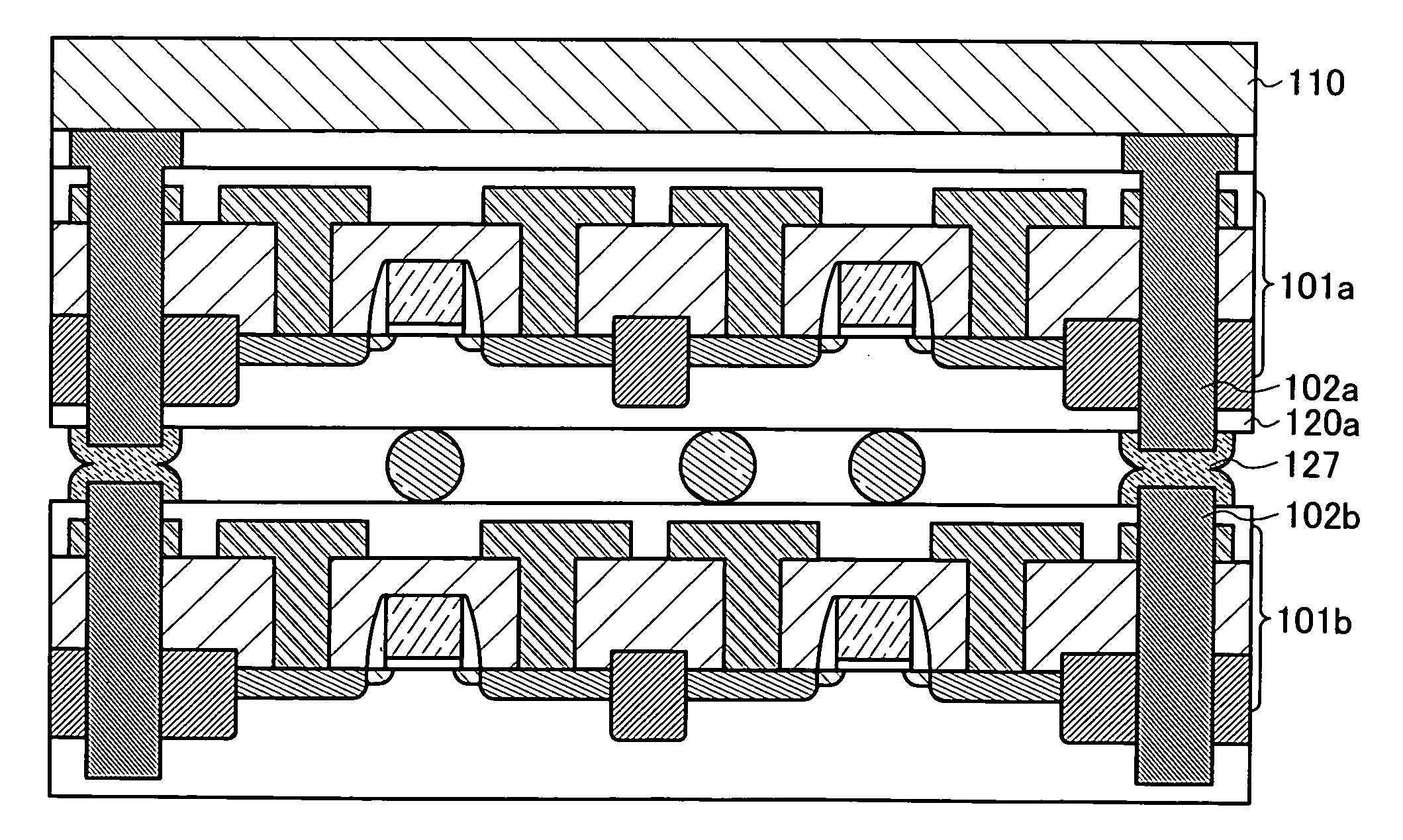

Hydrogen transport membranes

InactiveUS20050241477A1Thickness minimizationImprove permeabilitySemi-permeable membranesMembranesDifferential pressureMetal alloy

Composite hydrogen transport membranes used for extraction of hydrogen from gas mixtures are provided. Membranes are described comprising metals and metal alloys which exhibit high hydrogen permeability and which exhibit resistance to differential pressures across the membrane and wherein the metals and alloys are protected from embrittlement by hydrogen. Support materials of the membranes are selected in some cases to be lattice matched to the metals and alloys. In specific embodiments, membranes useful in the invention contain binary, ternary or quaternary alloys of vanadium which exhibit high hydrogen permeability and improved strength and / or longevity in application.

Owner:ELTRON RES

Composite multilayer bearing material

InactiveUS6194087B1Reduce hardnessImprove carrying capacityElectrolytic coatingsShaftsDiffusion barrierCobalt

A composite material for plain bearings comprises a backing layer, a bearing metal layer consisting of a copper alloy with a copper content of from 50 to 95 wt. % or an aluminum alloy with an aluminum content of from 60 to 95 wt. %, a diffusion barrier layer and an overlay, applied by electroplating, consisting of a lead-free, tin and copper-containing alloy. The invention provides a composite multilayer material whose overlay, applied by electroplating, does not exhibit any embrittlement even at relatively high temperatures, irrespective of the copper content. The overlay preferably comprises from 8 to 30 wt. % copper, 60 to 97 wt. % tin and 0.5-19 wt. % cobalt.

Owner:FEDERAL MOGUL WIESBADEN

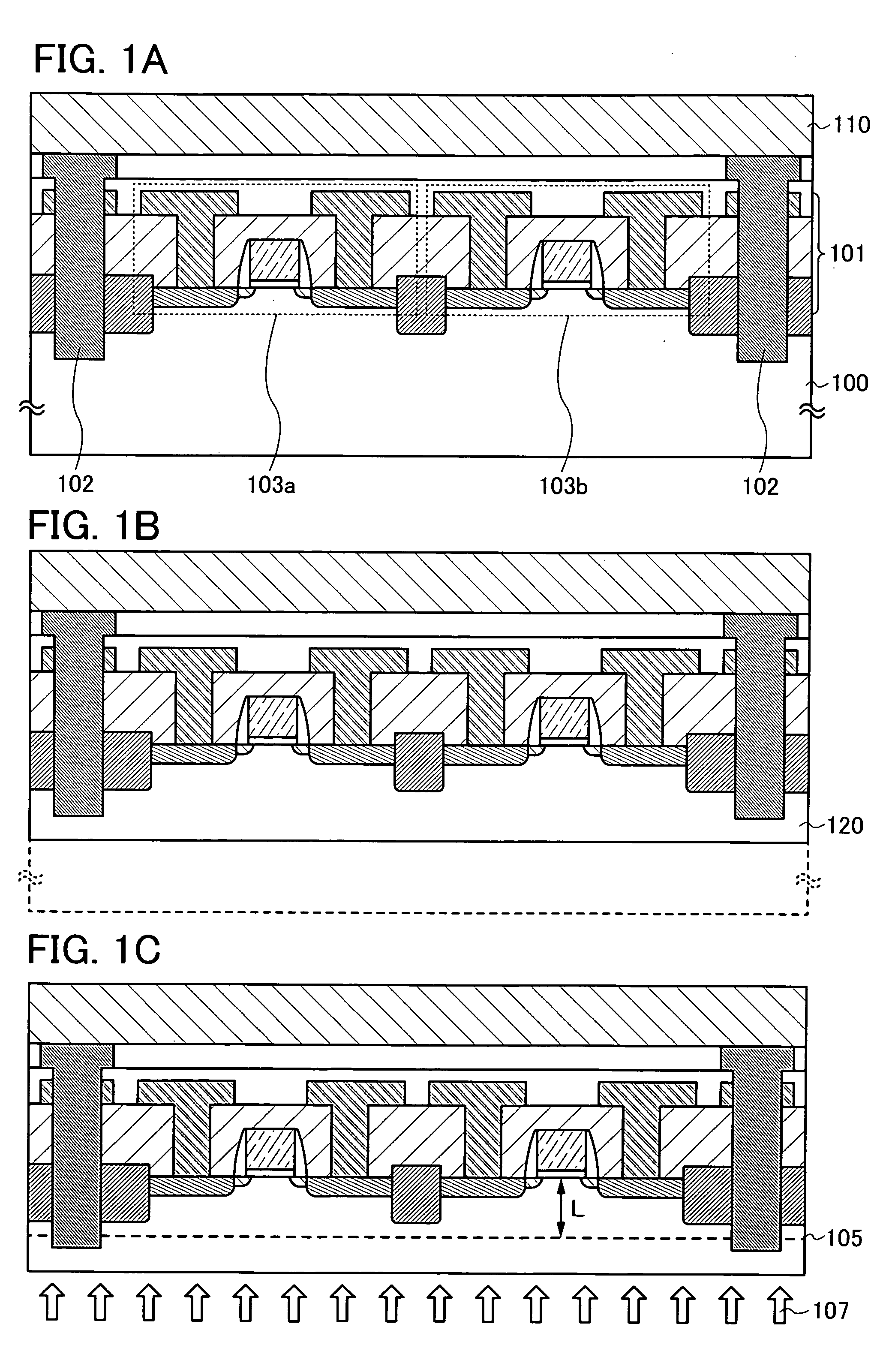

Semiconductor device and manufacturing method for the same

InactiveUS20090051046A1High bulk densitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A semiconductor substrate provided with an integrated circuit is polished by CMP or the like, and the semiconductor substrate is made into a thin film by forming an embrittlement layer in the semiconductor substrate and separating a part of the semiconductor substrate; thus, semiconductor chips such as IC chips and LSI chips which are thinner than ever are obtained. Moreover, such thinned LSI chips are stacked and electrically connected through wirings penetrating through the semiconductor substrate; thus, a three dimensional semiconductor integrated circuit with improved packing density is obtained.

Owner:SEMICON ENERGY LAB CO LTD

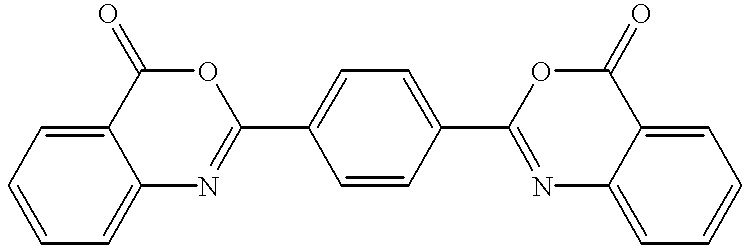

Hydrolysis-resistant, transparent, biaxially oriented film made from a crystallizable thermoplastic, and process for its production

InactiveUS6855758B2Maintain good propertiesLow shrinkageAluminium compoundsOrganic chemistryPolyesterThermoplastic

The invention relates to transparent, biaxially oriented and heat-set films having one or more layers and compris, as main constituent, at least one crystallizable thermoplastic, in particular a polyester, and also comprise at least one hydrolysis stabilizer. The hydrolysis stabilizer is preferably a phenolic compound, an oxazoline, and / or a monomeric or polymeric carbodiimide, where appropriate combined with an organic phosphite. It is preferably added in the form of a masterbatch. The film exhibits low longitudinal and transverse shrinkage. On exposure to moisture and heat it shows practically no embrittlement and retains its ultimate tensile strength. The additional functionality is preferably that the film has been made UV-resistant, or flame-retardant, or on one side or on both sides has been coated, or is sealable, and / or has been corona- or flame-treated. The film is generally produced by extrusion or coextrusion, the hydrolysis stabilizer being added in the form of a predried or precrystallized masterbatch.

Owner:MITSUBISHI POLYESTER FILM

Method and apparatus for fiber Bragg grating production

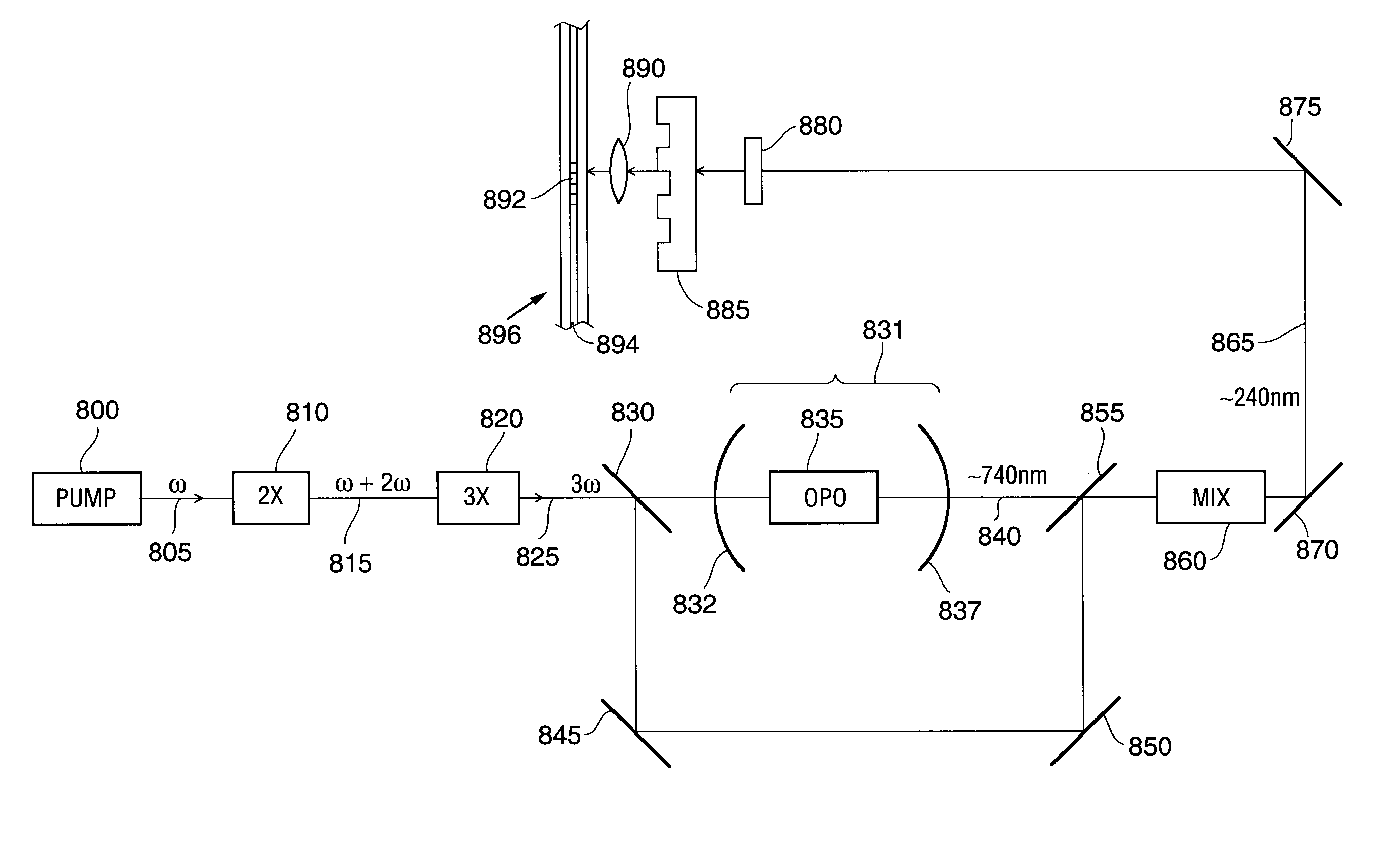

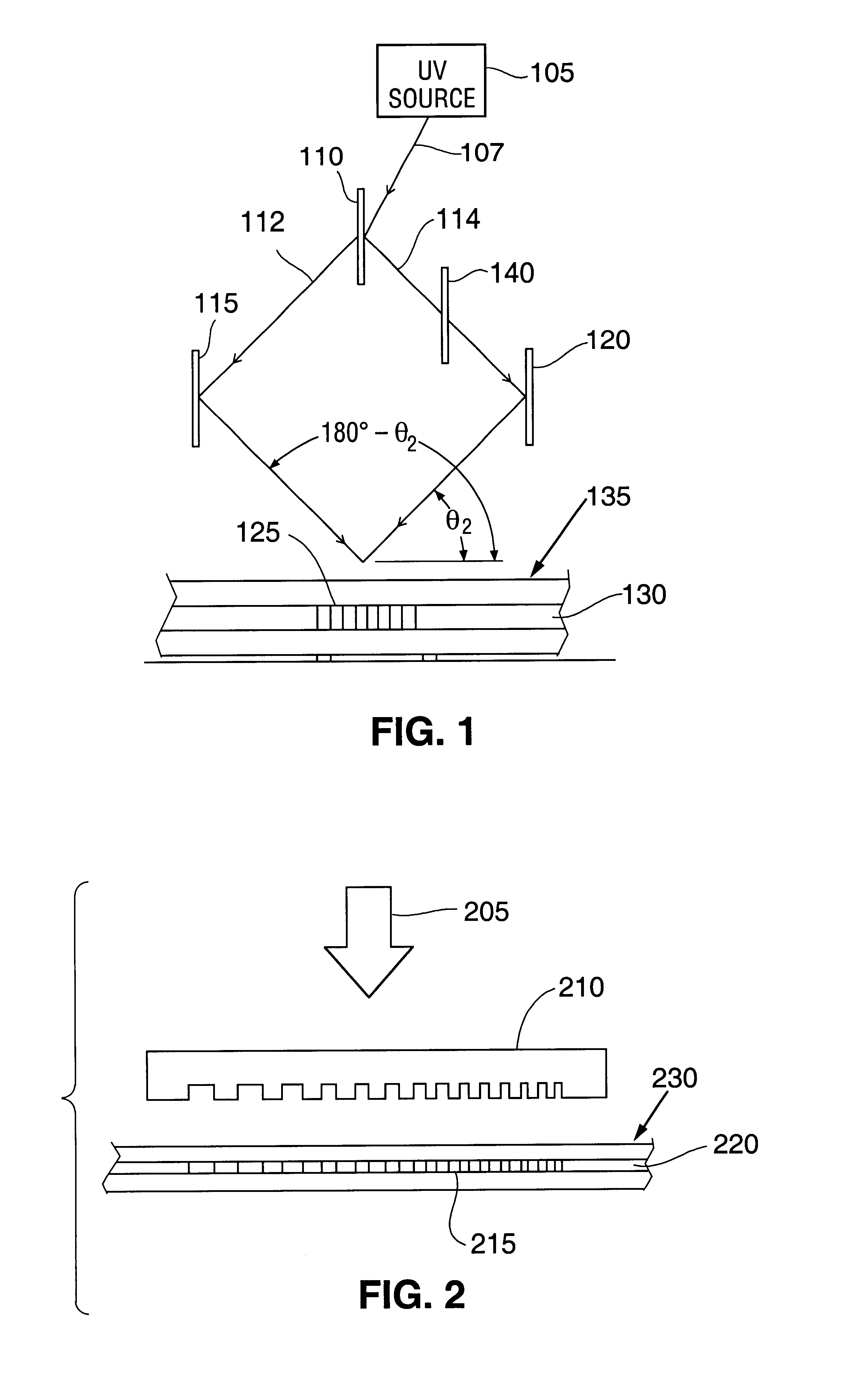

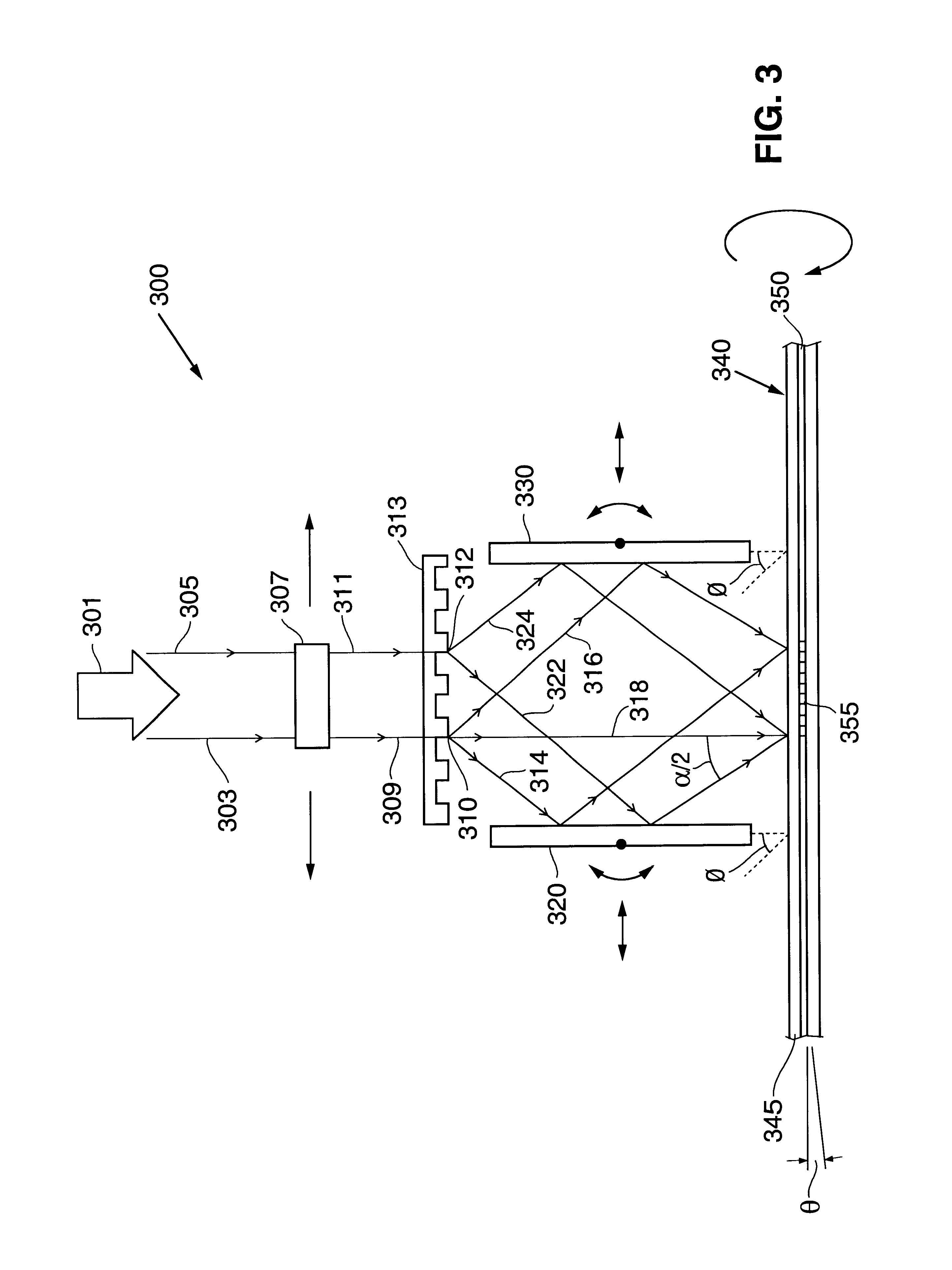

Fiber Bragg writing devices comprising solid state lasers are provided. The solid state lasers comprise optical parametric oscillators and emit moderate peak-power output beams at wavelengths which are suitable for efficient production of fiber Bragg gratings without causing embrittlement of the optical waveguide. These solid state lasers generate output beams with wavelengths of approximately 240 nm, in order to match the primary absorption peak in the ultraviolet range for a typical optical waveguide. Some of these solid state lasers generate tunable wavelength beams using an optical parametric oscillator (“OPO”), then generate harmonics of these tunable beams. Other lasers mix the tunable beam with fixed wavelengths derived from the pump laser to reach the desired output wavelength.

Owner:LOCKHEED MARTIN CORP

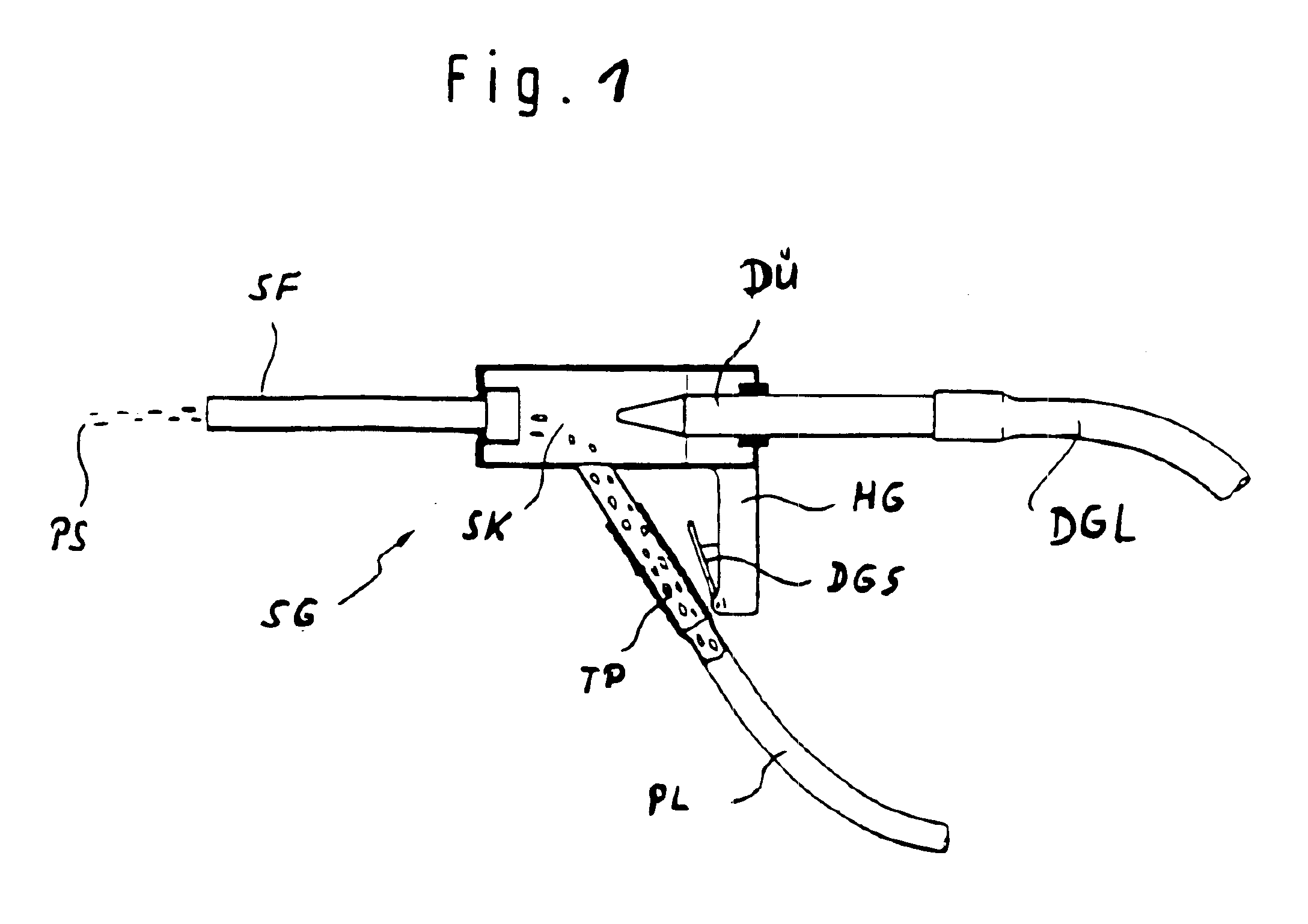

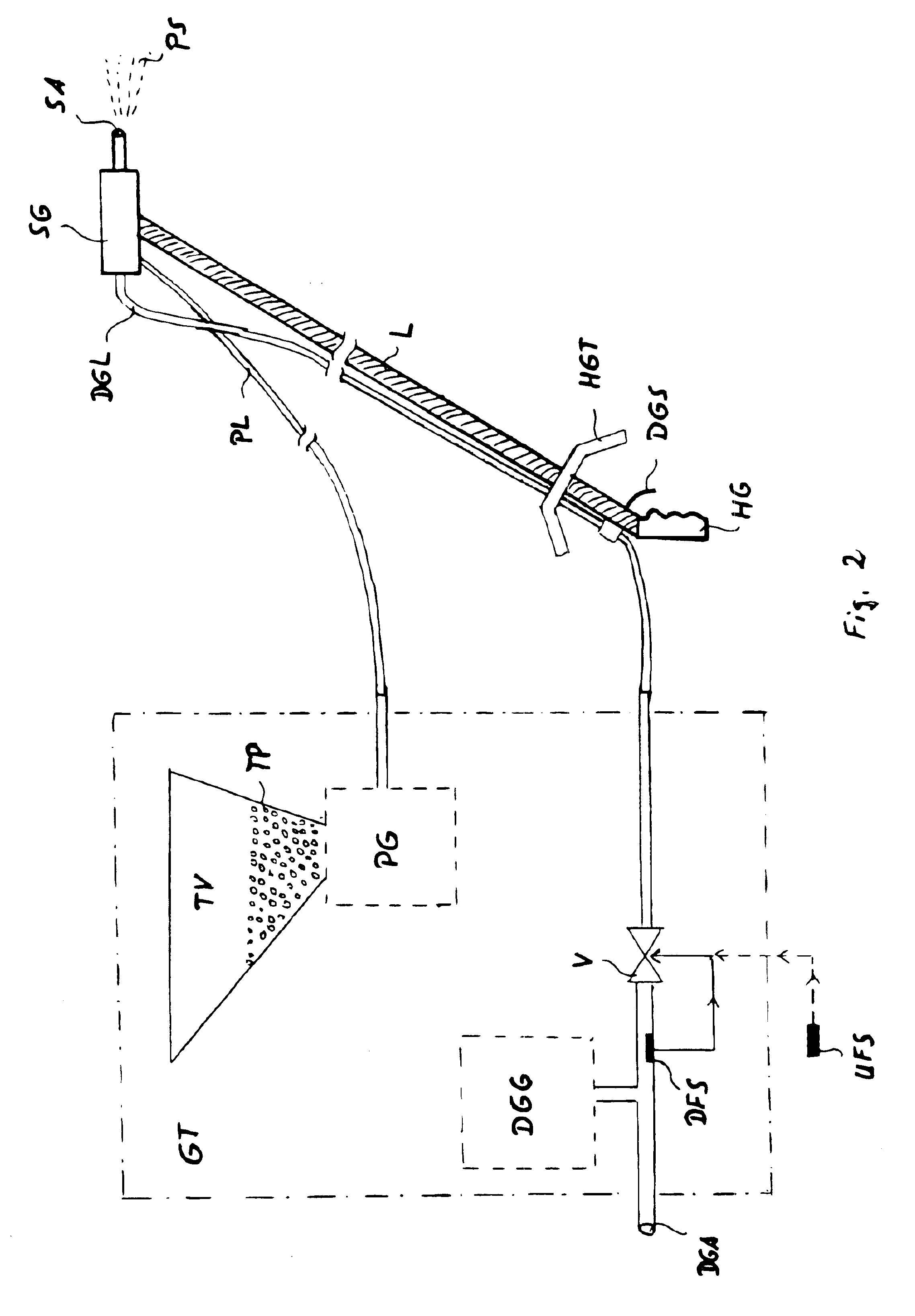

Method and device for cleaning high-voltage carrying installation component parts

InactiveUS6863594B2Without endangering safetyProtected installationBlast gunsPipeline systemsEngineeringCleaning methods

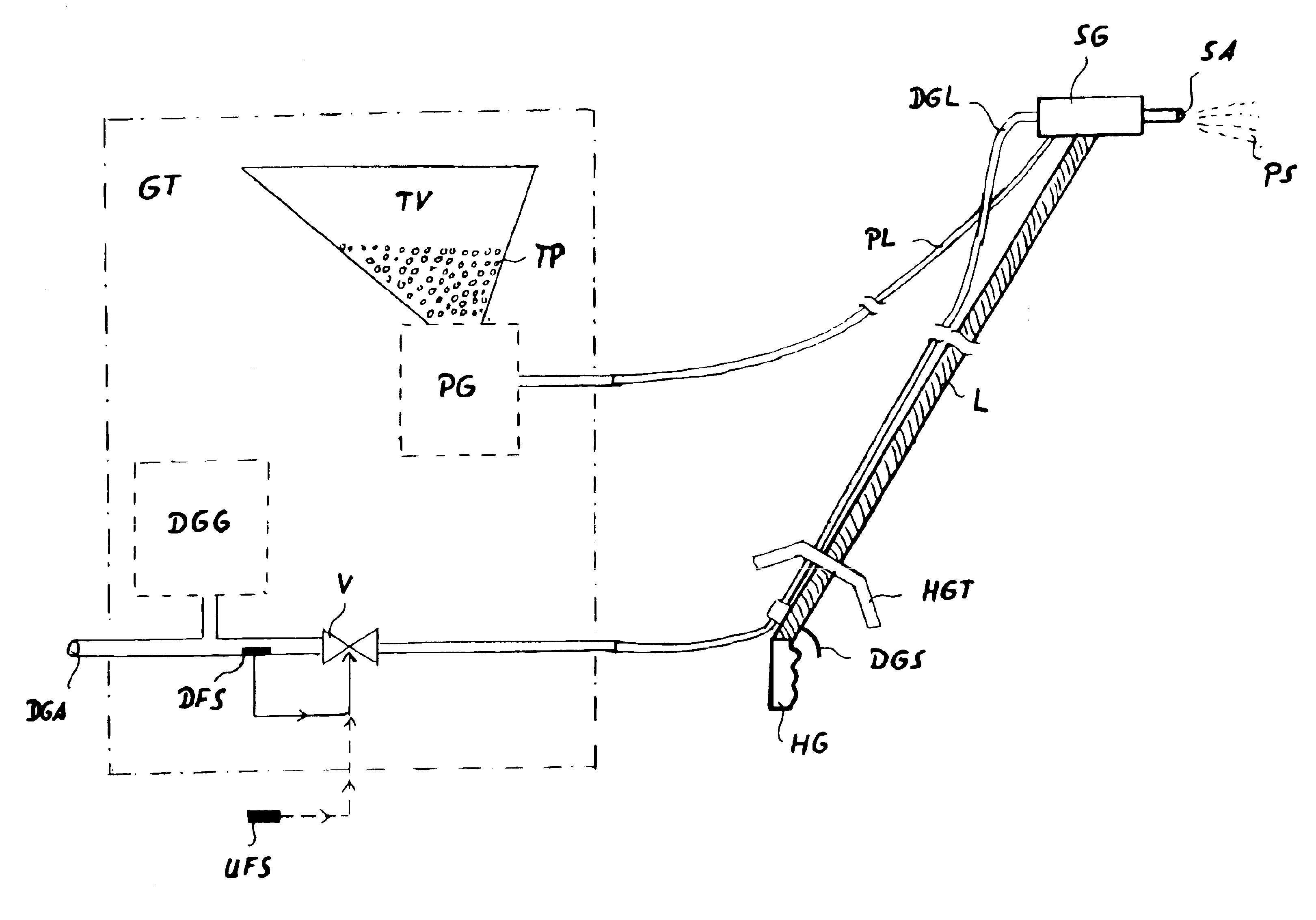

A cleaning method and a corresponding cleaning device offer adequate protection to individuals, devices and installations, for cleaning component parts of installations that carry an electrical high-voltage and which are not disconnected during cleaning. Towards this end, the component parts to be cleaned are subjected to the action of a two-phase particle stream (PS) consisting of a compressed gas (DGA) serving as a carrier medium and of carbon dioxide ice particles (TP) carried therein. Possible superficial accumulations of dirt are removed from the component parts by way of low-temperature embrittlement and by the kinetic energy of the impacting carbon dioxide particles. The carbon dioxide ice particles themselves sublimate without leaving residues. A sufficiently safe distance of cleaning personnel from the high-voltage carrying insulation component parts is ensured by the provision of an electrically insulating distance mechanism (L, SFR) that is provided approximately in the form of a lance (L) or of a stream guided tube (SFR). A further increase in protection is offered by monitoring the quantity of moisture of compressed gas and / or ambient air, whereby the cleaning device is immediately shut off when predetermined limiting values are exceeded.

Owner:PREISING PAUL ERIC

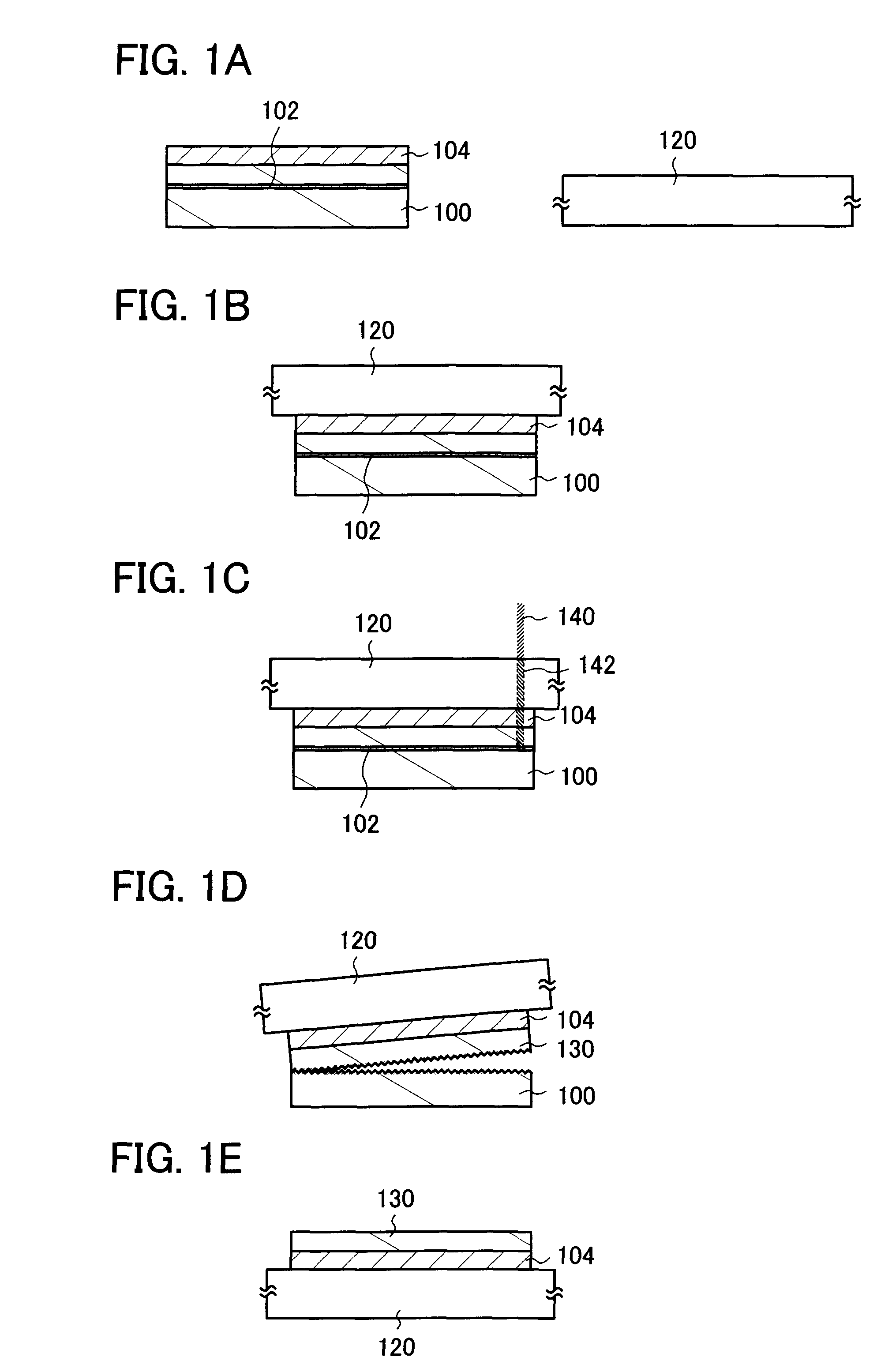

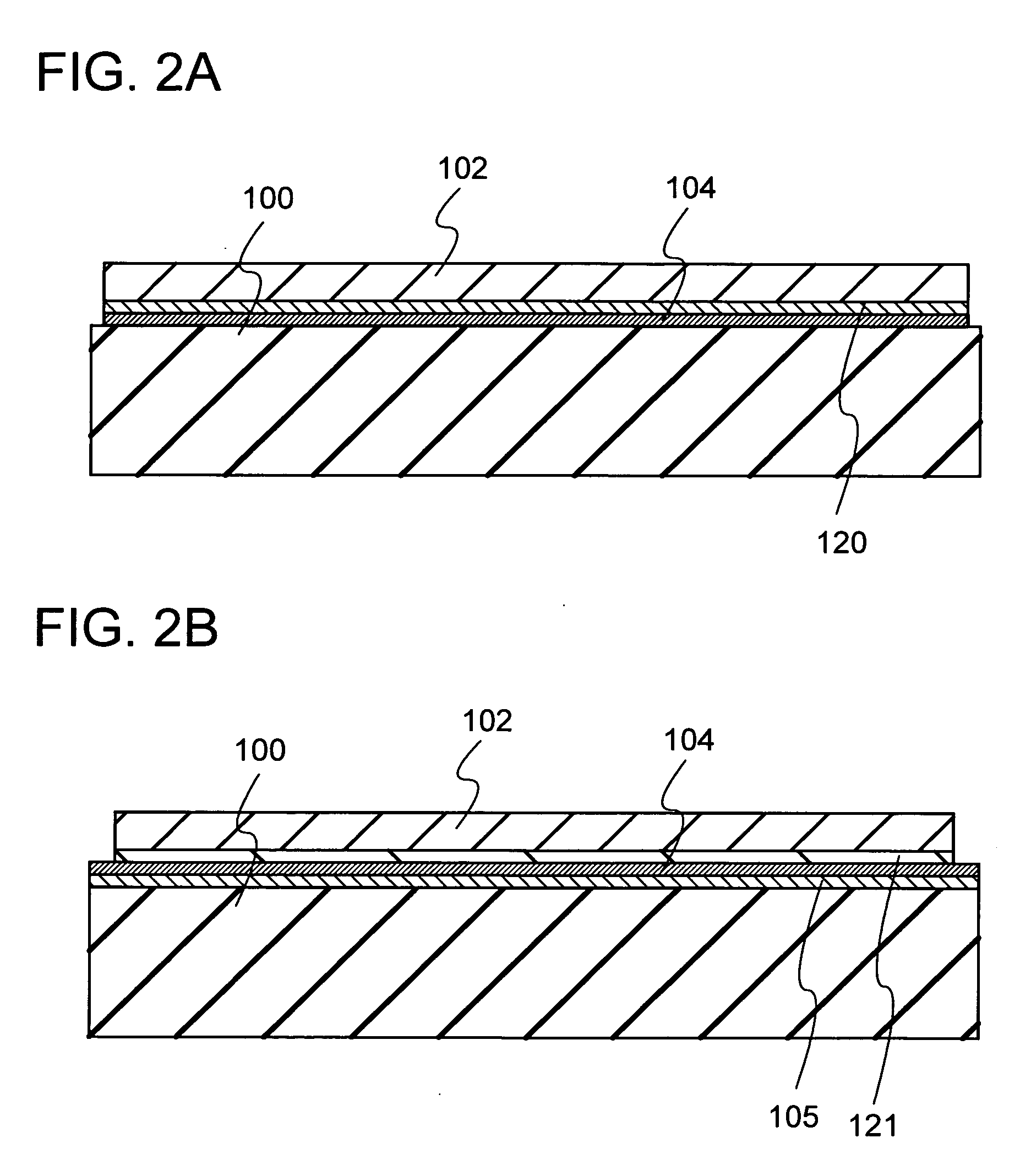

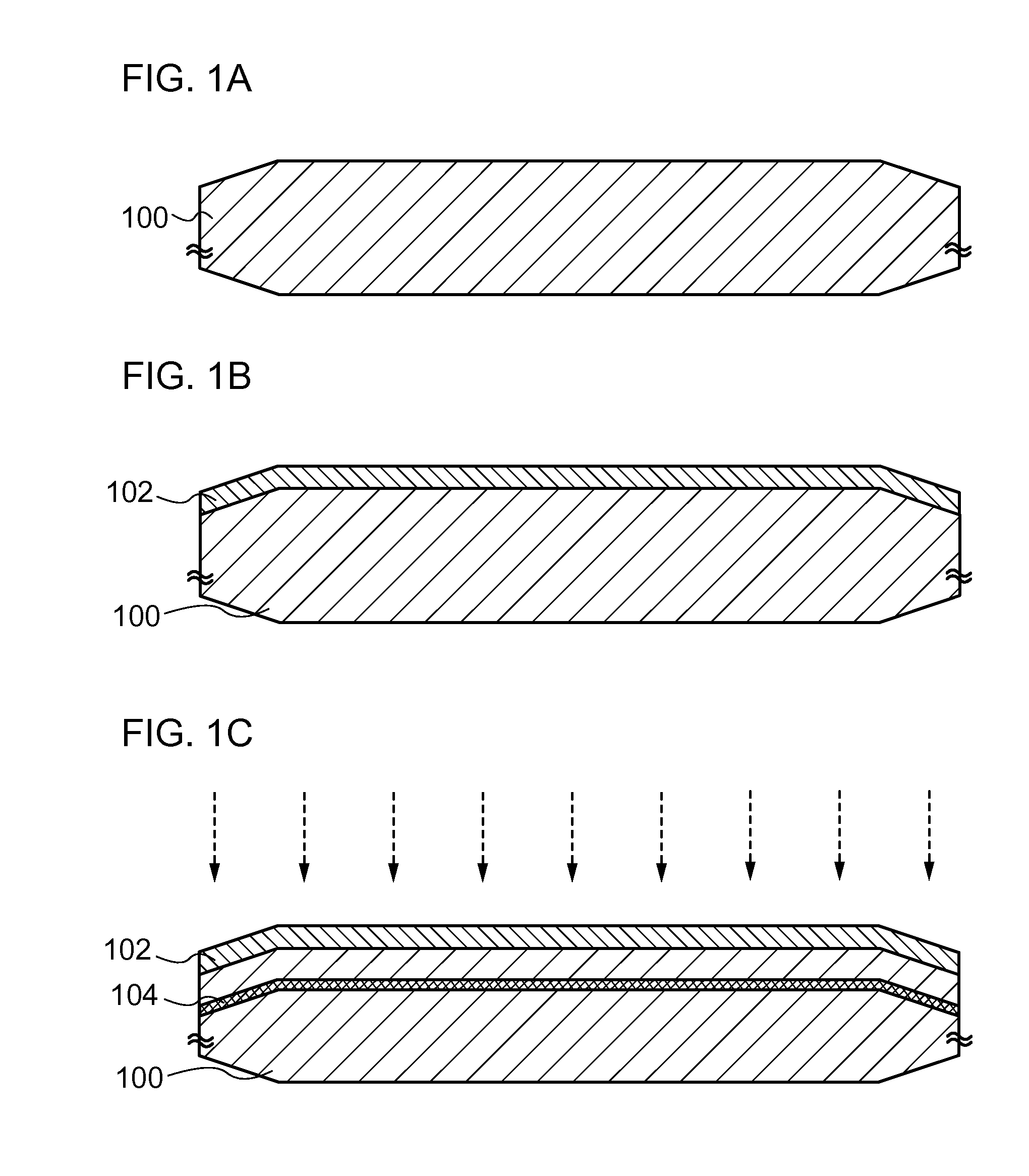

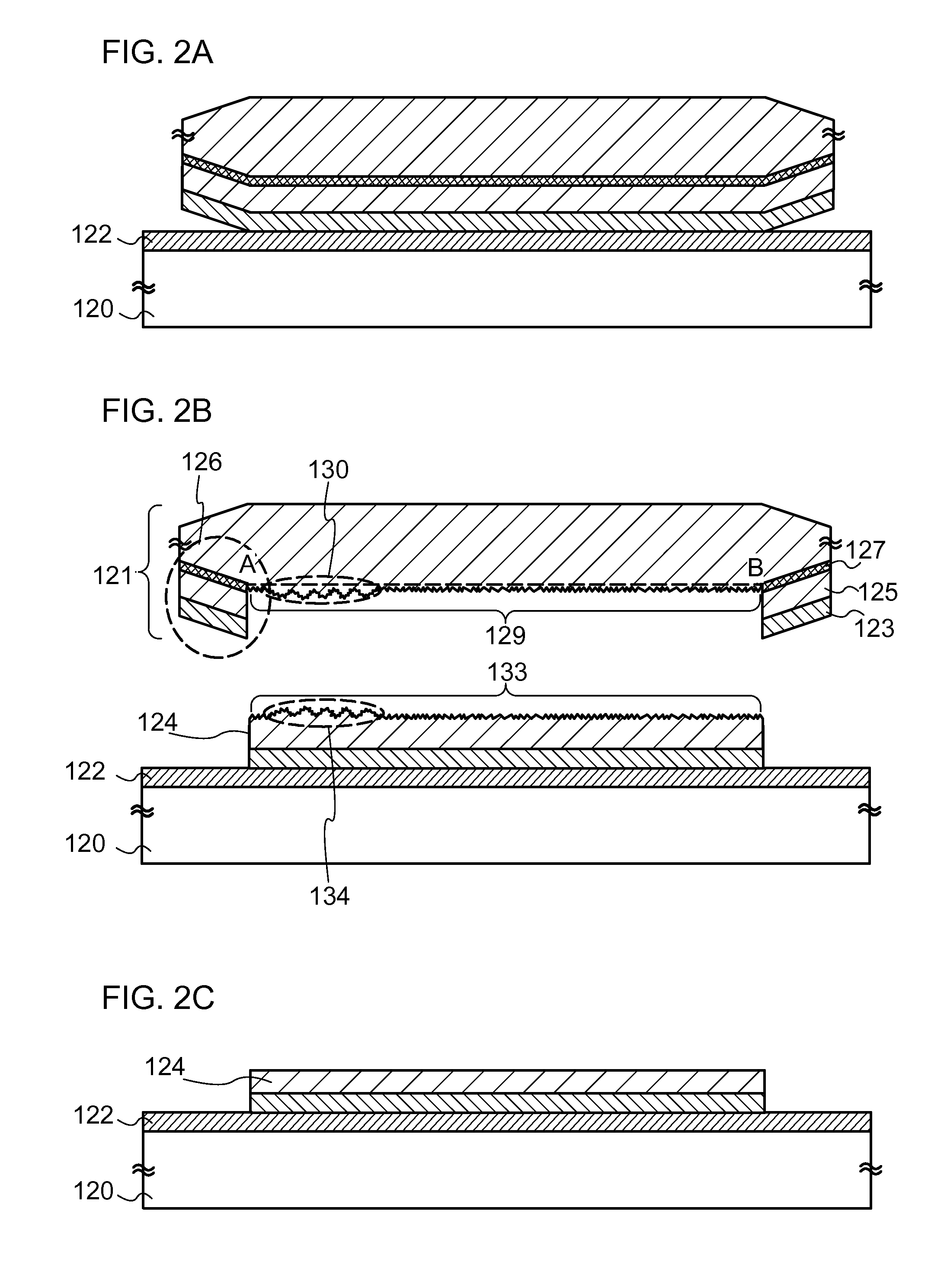

Manufacturing method of soi substrate

InactiveUS20090029525A1Improve throughputImprove productivitySolid-state devicesSemiconductor/solid-state device manufacturingSoi substrateLaser beams

A manufacturing method of an SOI substrate with high throughput. A semiconductor layer separated from a semiconductor substrate is transferred to a supporting substrate, thereby manufacturing an SOI substrate. First, the semiconductor substrate serving as a base of the semiconductor layer is prepared. An embrittlement layer is formed in a region at a predetermined depth of the semiconductor substrate, and an insulating layer is formed on a surface of the semiconductor substrate. After bonding the semiconductor substrate and a supporting substrate with the insulating layer interposed therebetween, the semiconductor substrate is selectively irradiated with a laser beam; accordingly, embrittlement of the embrittlement layer progresses. Then, using a physical method or heat treatment, the semiconductor substrate is separated; at that time, the region where the embrittlement has progressed in the embrittlement layer serves as a starting point.

Owner:SEMICON ENERGY LAB CO LTD

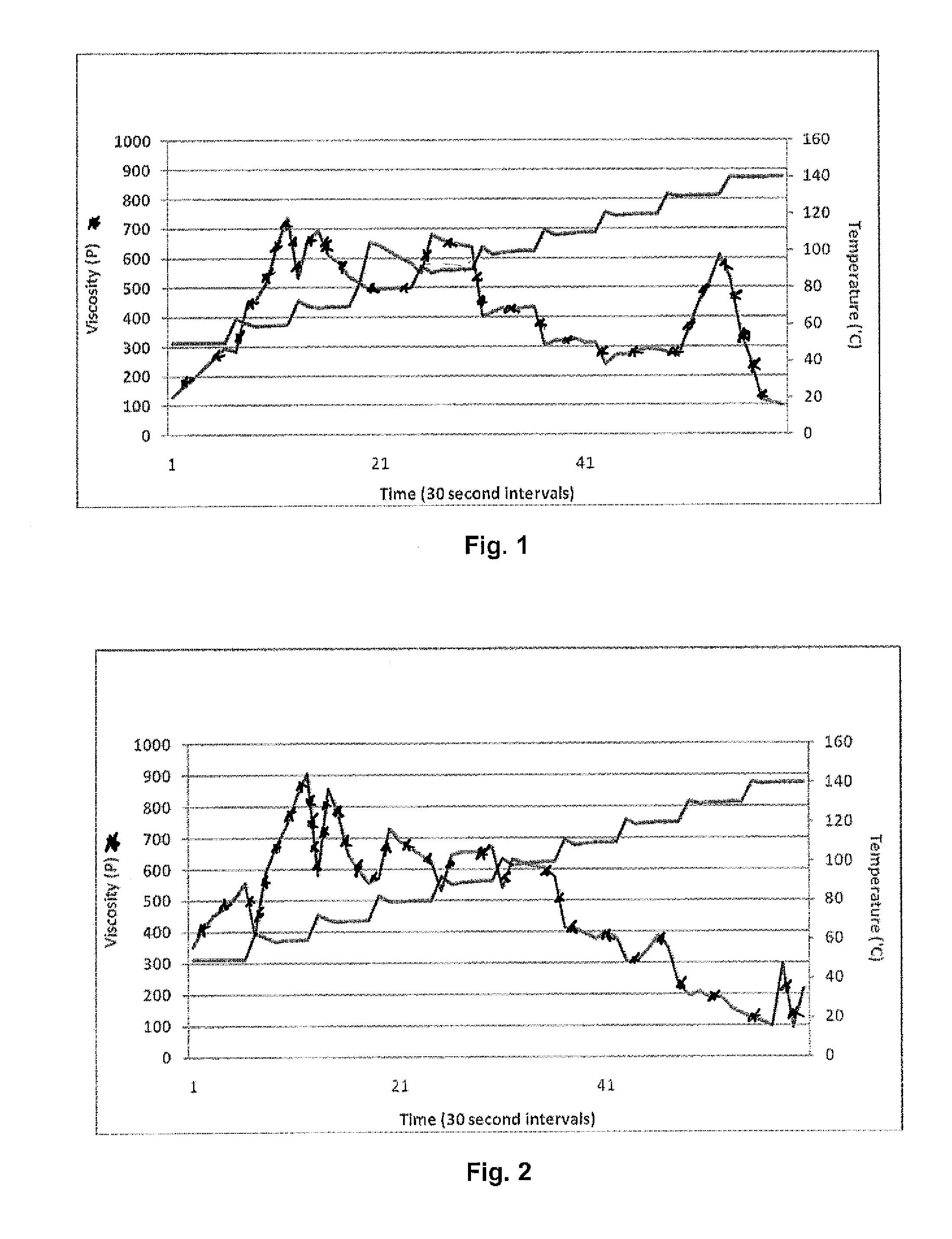

Melt-blended protein composition

A melt-processed protein composition formed from a protein, plasticizer, and an electrophilic reagent is provided. The electrophilic reagent, for instance, may be selected to undergo a nucleophilic addition reaction with free sulfhydryl and / or thiyl radicals to help minimize the formation of disulfide crosslinking bonds that could otherwise lead to protein aggregation during melt processing. To enhance the degree to which the electrophilic reagent can limit crosslinking, a plasticizer is also employed that helps to mediate the adsorption of the electrophilic reagent into the internal structure of the protein, where it can be more stably retained. Furthermore, the temperature and shear rate employed during melt blending may also be selected to be relatively low to help limit polypeptide dissociation, thereby minimizing the impact of aggregation and embrittlement.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method for preparing low fats fishbone leisure food

InactiveCN101176561AMeet health requirementsImprove processing levelFood preparationSnack foodHuman health

The utility model relates to a preparation method of a fishbone snack food with low fat, which belongs to the technical field of the snack food handling. The utility model uses fishbone, which is the leftovers in the marine product processing as material; after rinsing, fishy smell removal, washing, curing, embrittlement, and flavour treating, the fishbone is made into the fishbone snack food product with low fat. The utility model can cure the fishbone adequately by means of the autoclave steaming; and then removes the moisture content by means of the microwave to embrittle the products. Themethod gets rid of the deep fry, has low fat, can meet the requirements of the human health adequately. The method of preparing the fishbone snack food with low fat for filling calcium is easy and quick, and is very good for improving the processing level of the farm products, the livestock products and the marine products in our country, and can bring along great economic benefits. The utility model uses the castoff as material to reduce the production cost, and prepares new products.

Owner:JIANGNAN UNIV

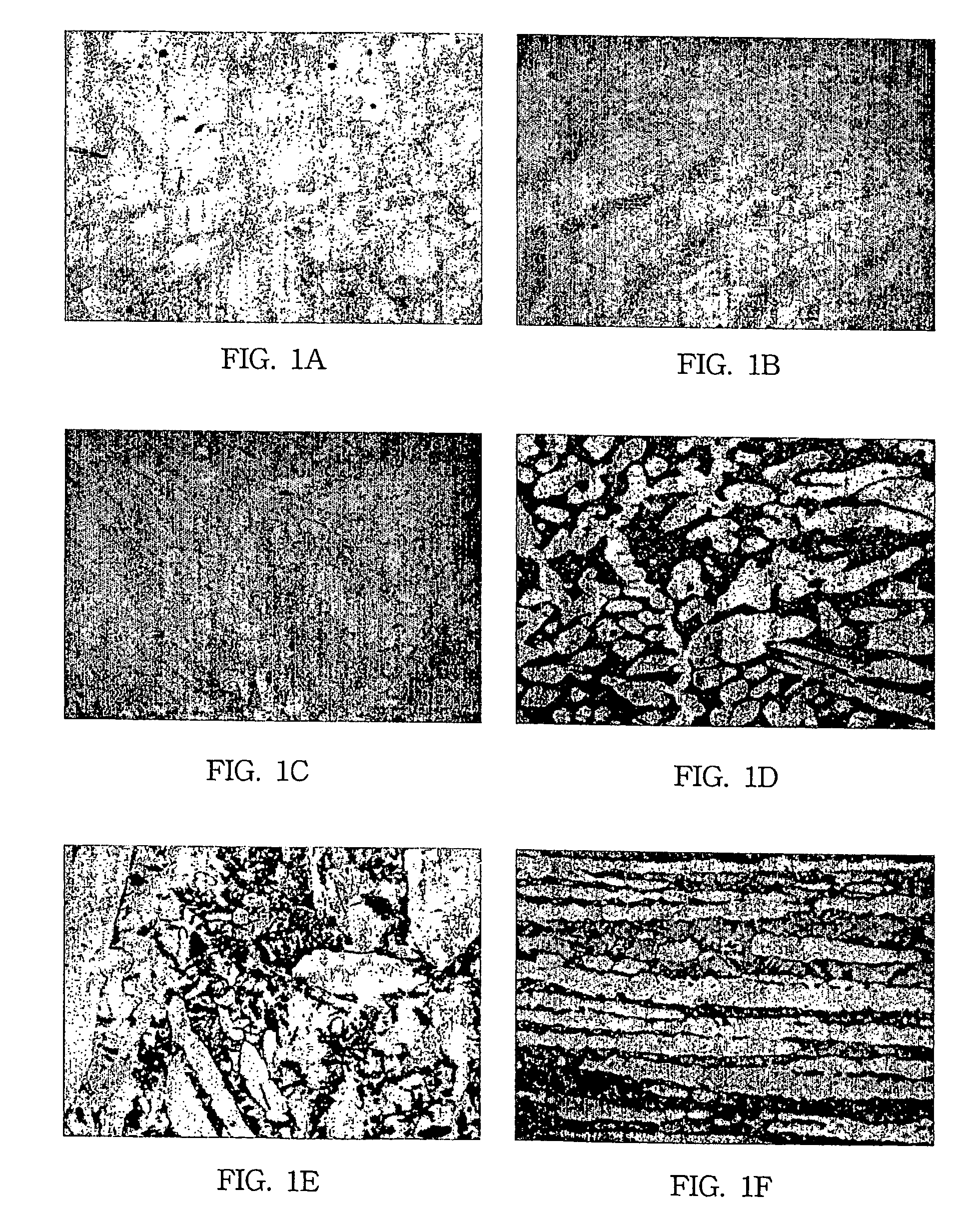

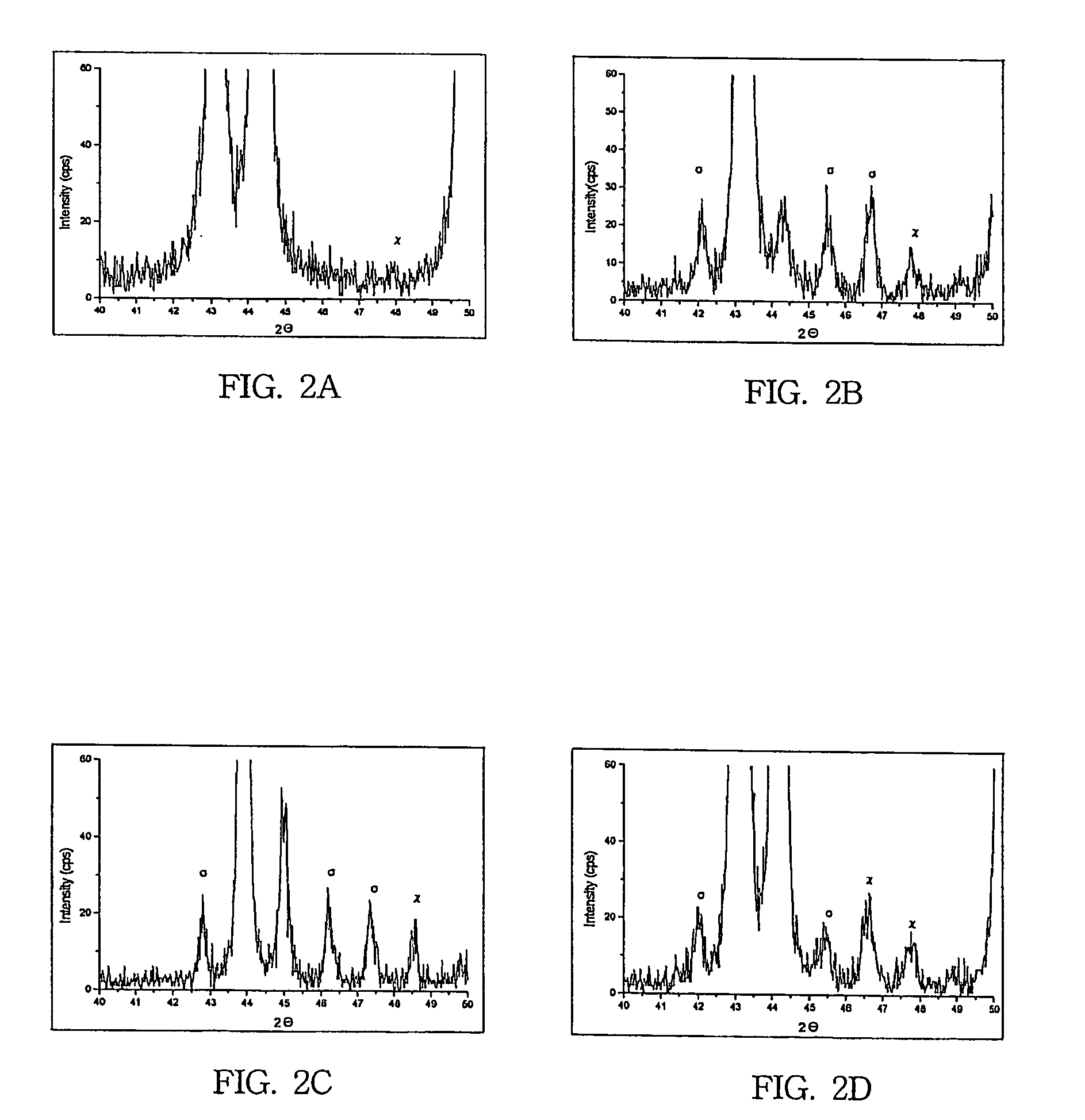

High-grade duplex stainless steel with much suppressed formation of intermetallic phases and having an excellent corrosion resistance, embrittlement resistance castability and hot workability

InactiveUS20050158201A1Eliminate brittlenessImprove corrosion resistanceChemical compositionCastability

Formation of intermetallic phases such as sigma (σ) and khi (χ) shows detrimental effects on the corrosion and mechanical properties of high-grade duplex stainless steel. The present invention provides high-grade duplex stainless steel with much suppressed formation of intermetallic phases, of which the chemical composition consists essentially, on a weight basis, of: Cr: 21.0%˜38.0%, Ni: 3.0%˜12.0%, Mo: 1.5%˜6.5%, W: 6.5% or less, Si: 3.0% or less, Mn: 8.0% or less, N: 0.2%˜0.7%, C: 0.1% or less, at least one element selected from the group consisting of Ba: 0.0001˜0.6% and one or more elements of Mischmetal (MM) and Y: 0.0001˜1.0% in total, and a balance of Fe and incidental impurities. The pitting resistance equivalent has a value of 40≦PREW≦67 defined by the following formula (1): PREW=wt. % Cr+3.3(wt. % Mo+0.5 wt. % W)+30 wt. % N ((1)The present high-grade duplex stainless steel exhibits an excellent corrosion resistance, embrittlement resistance, castability and hot workability.

Owner:YONG SO PARK

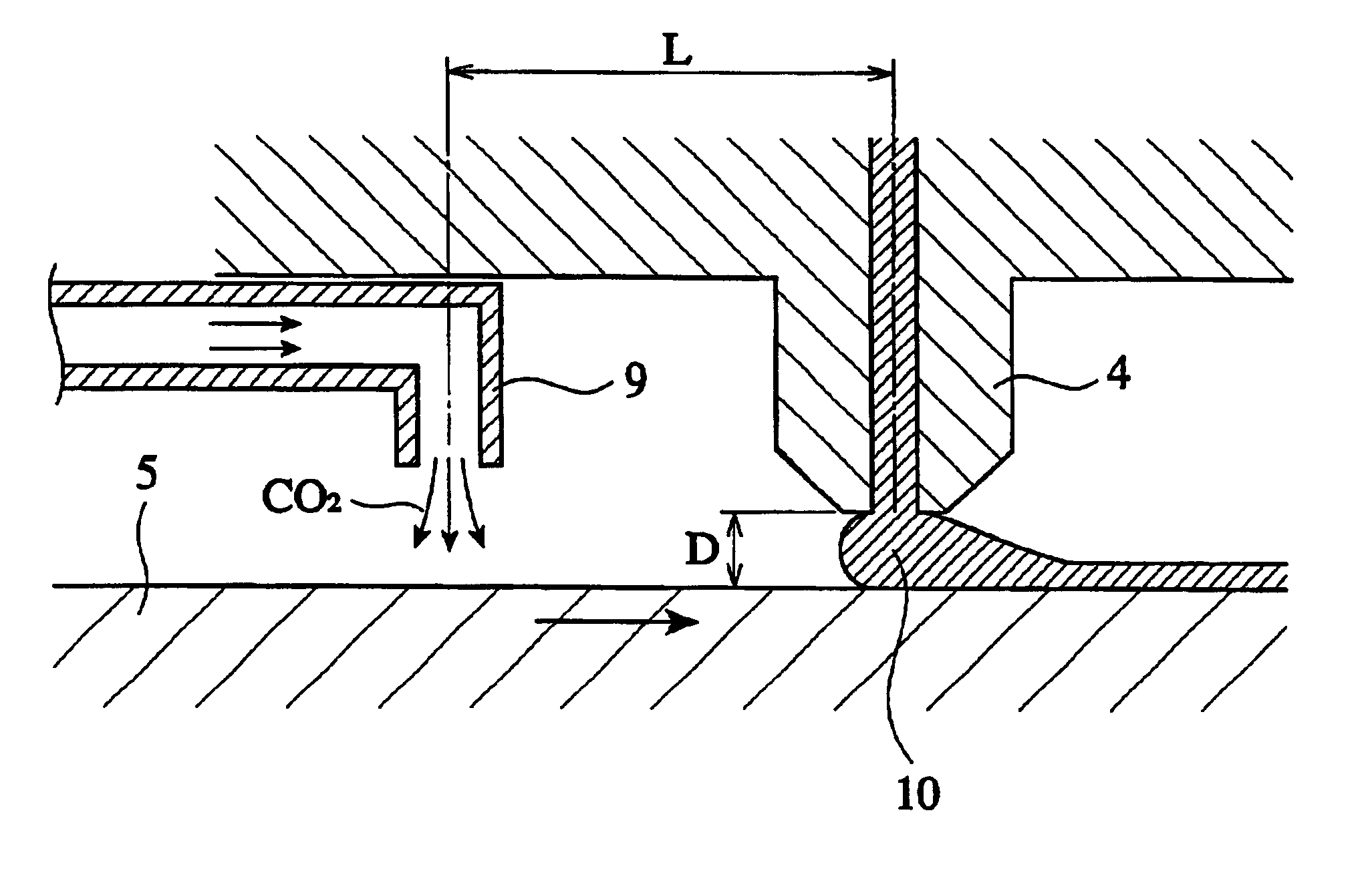

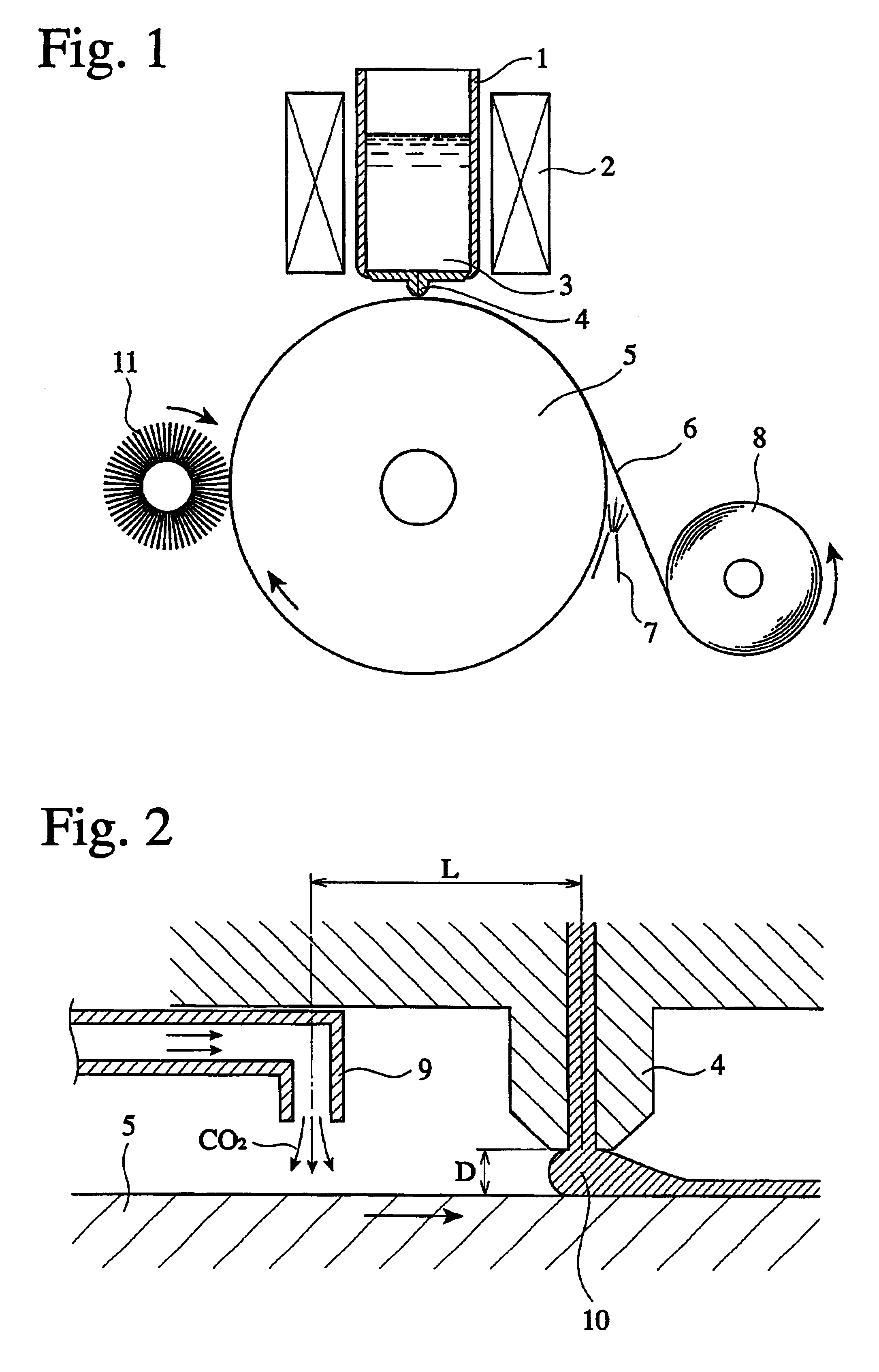

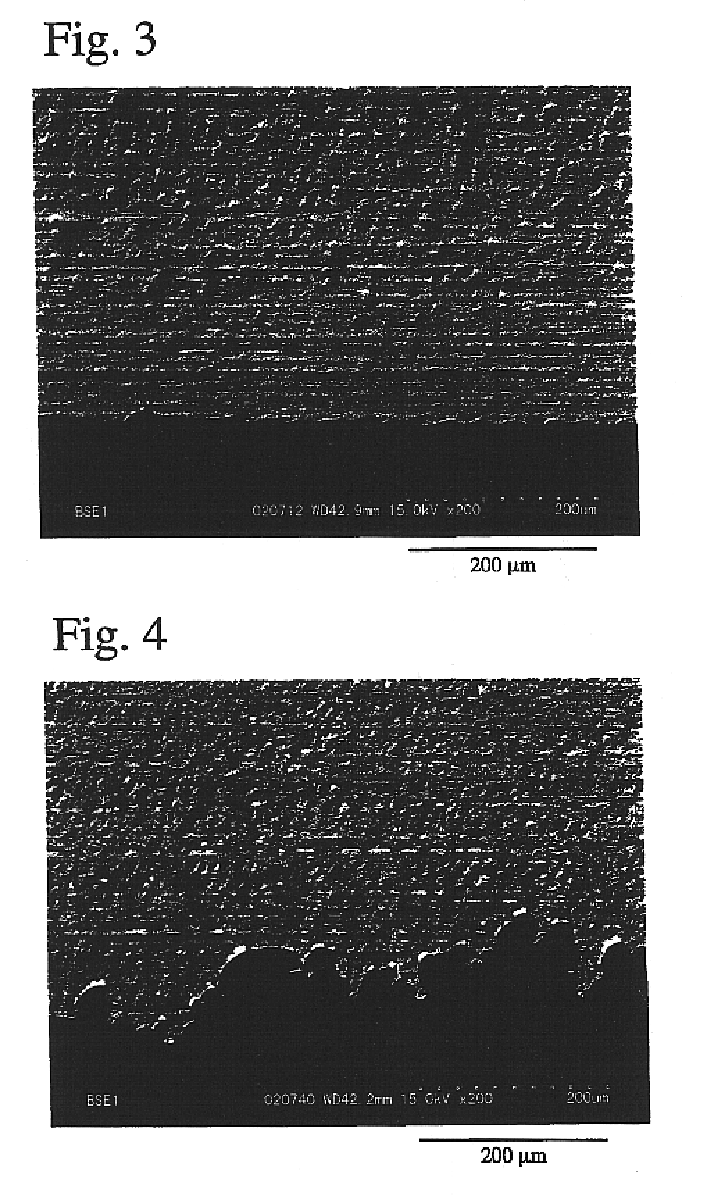

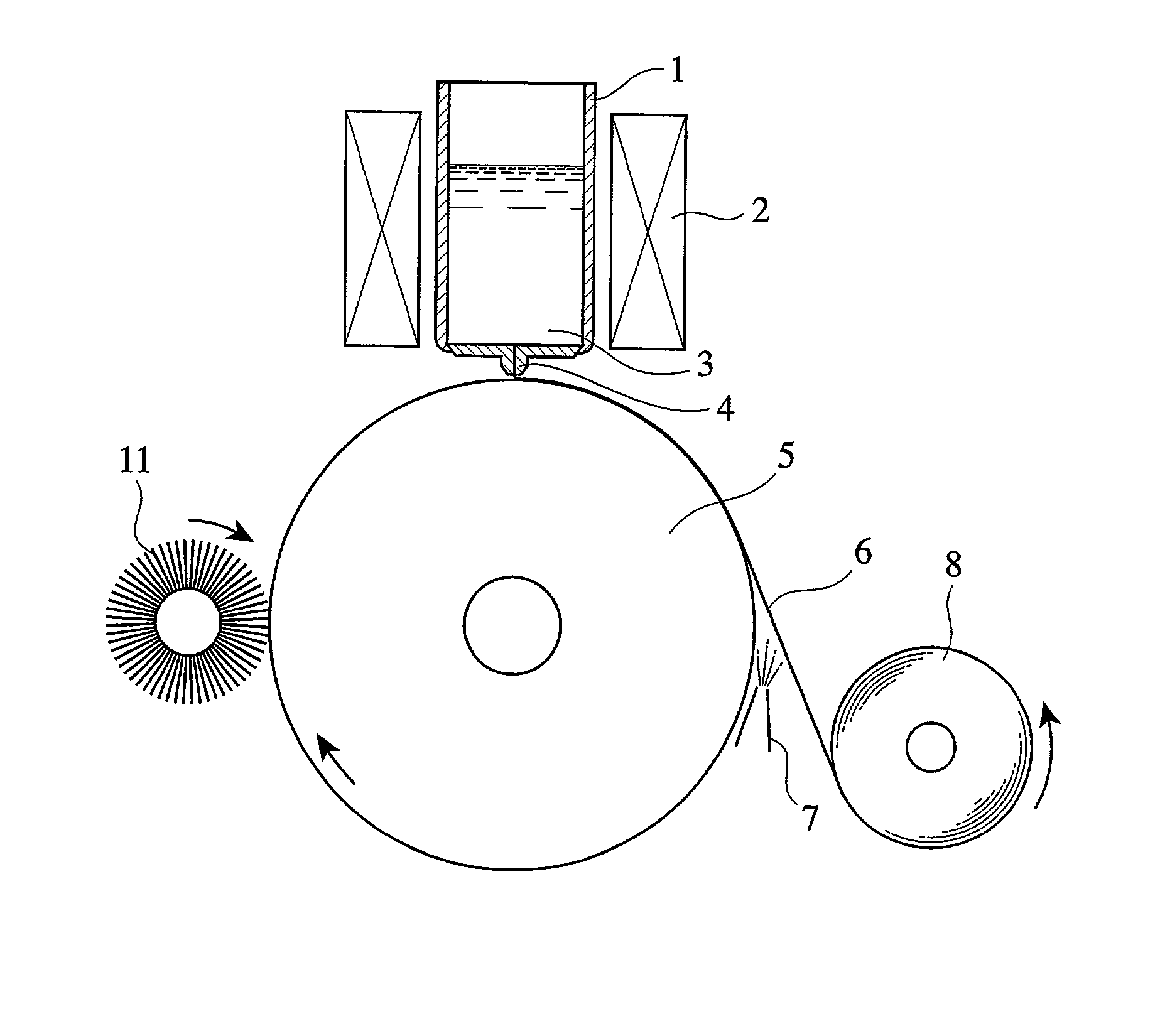

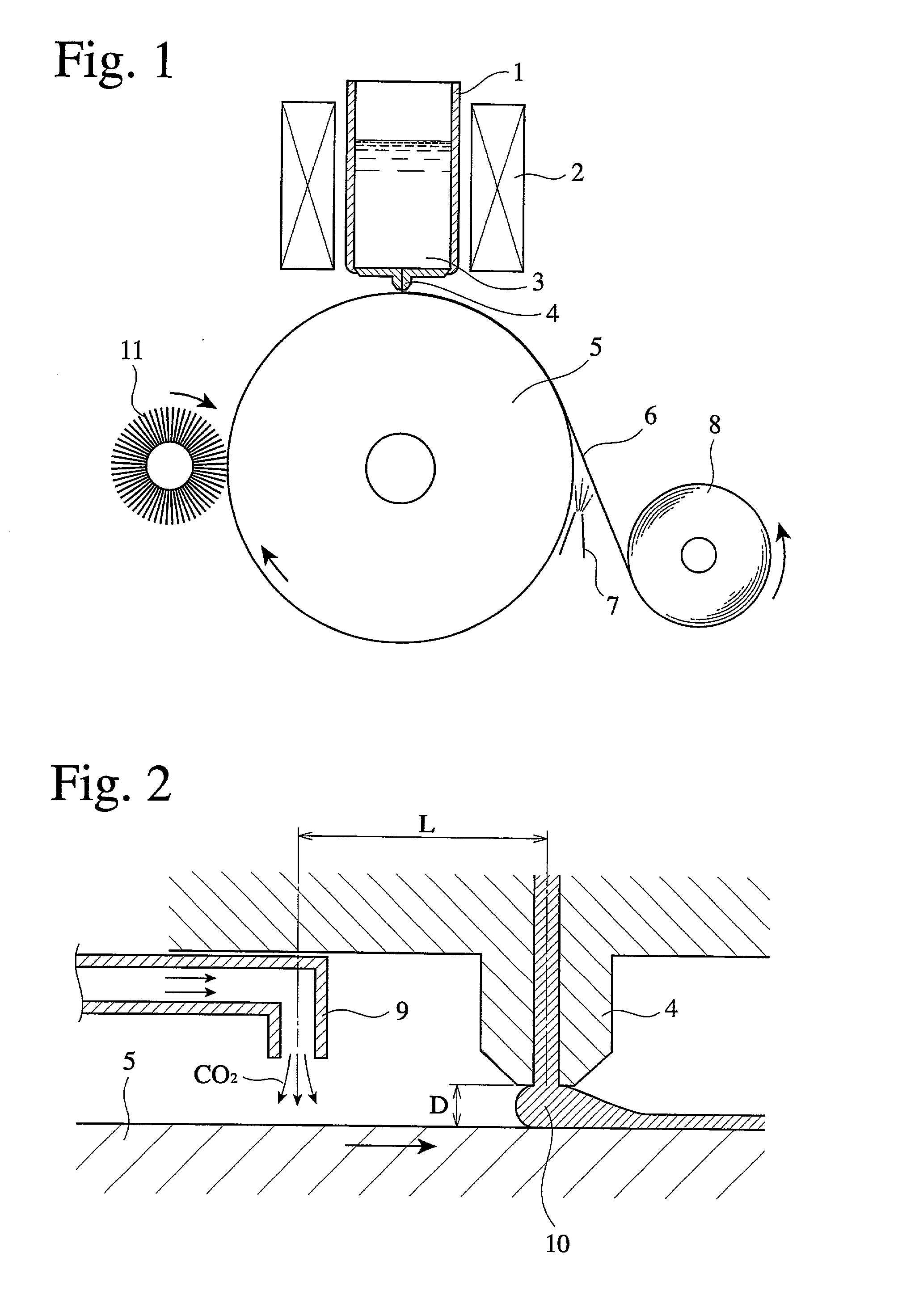

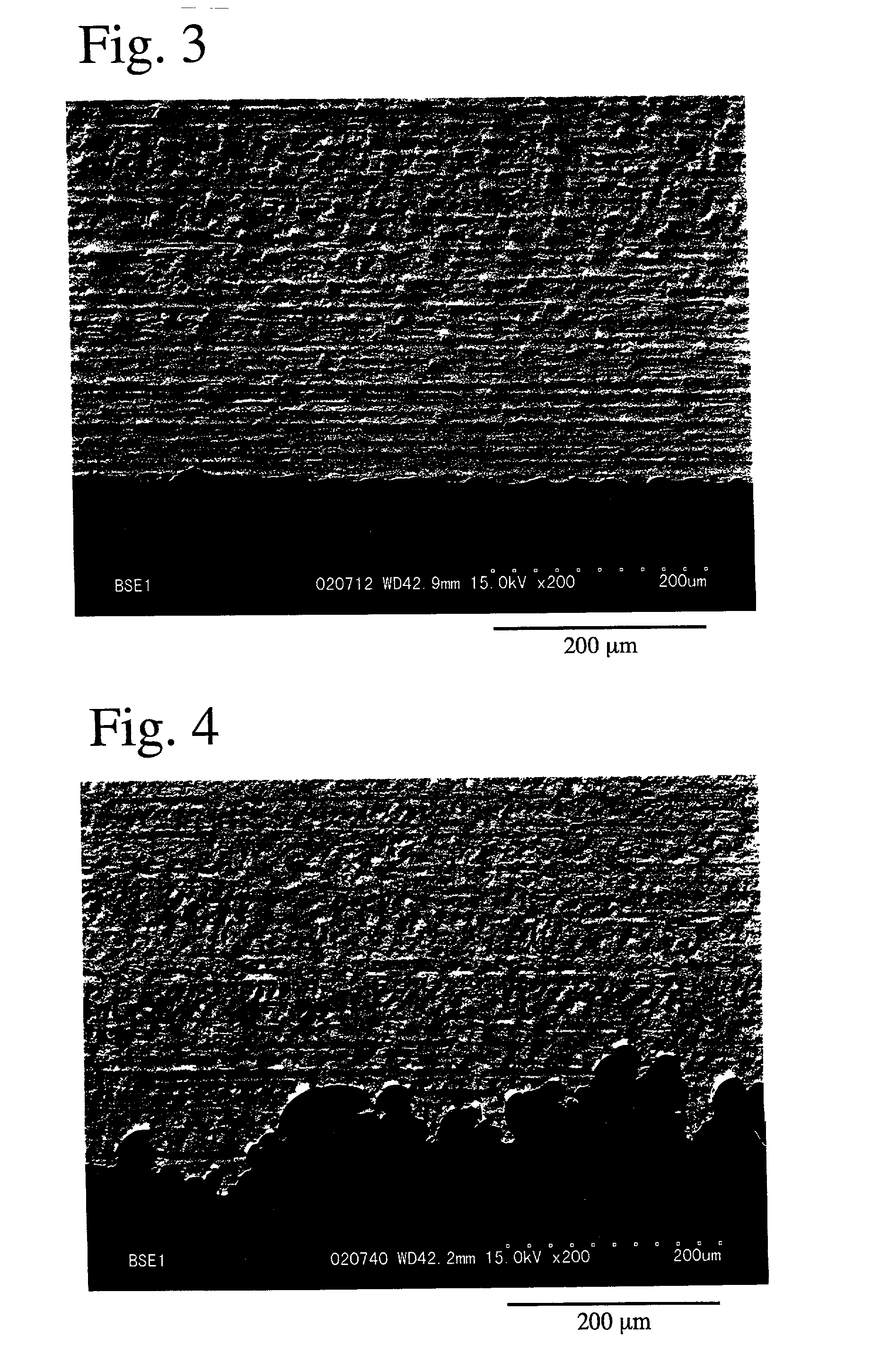

Method for producing amorphous alloy ribbon, and method for producing nano-crystalline alloy ribbon with same

An amorphous alloy ribbon free from embrittlement and crystallization and having excellent surface conditions and shape in edge portions is produced by (a) preparing an alloy melt having a composition comprising 13 atomic % or less of B and 15 atomic % or less of at least one selected from the group consisting of transition elements of Groups 4A, 5A and 6A, the balance being substantially Fe; (b) ejecting the alloy melt at a temperature from the melting point of the alloy +50° C. to the melting point of the alloy +250° C. through a nozzle onto the cooling roll rotating at a peripheral speed of 35 m / second or less, a distance between a tip end of the nozzle and the cooling roll being 200 mum or less; (c) starting to supply a gas based on CO2 to the alloy melt after the surface temperature of the cooling roll has become substantially constant; and (d) grinding the cooling roll while supplying the gas based on CO2.

Owner:HITACHI METALS LTD

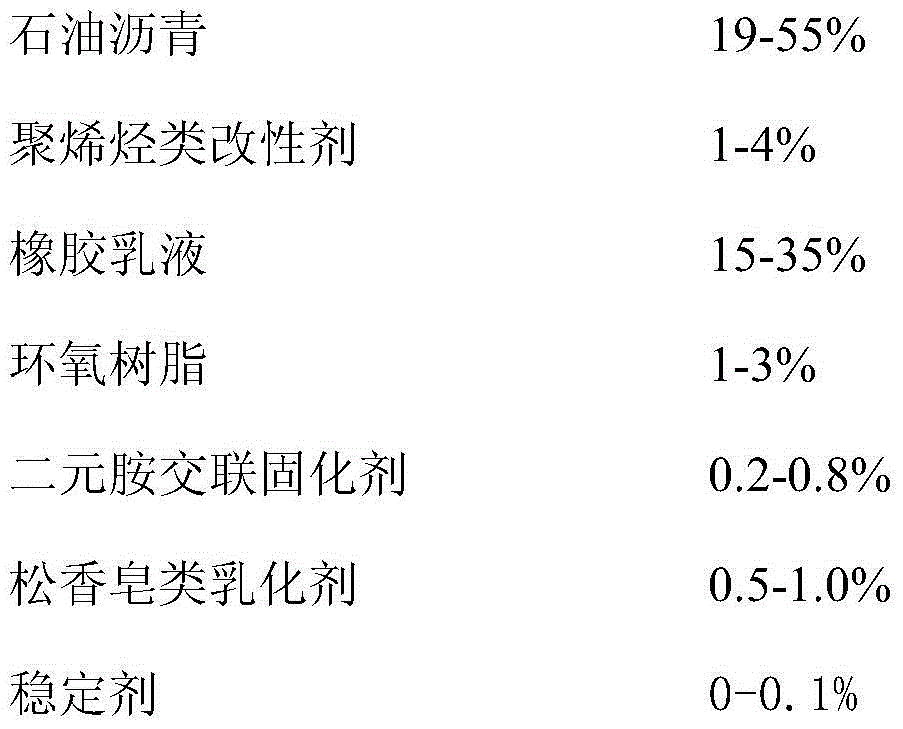

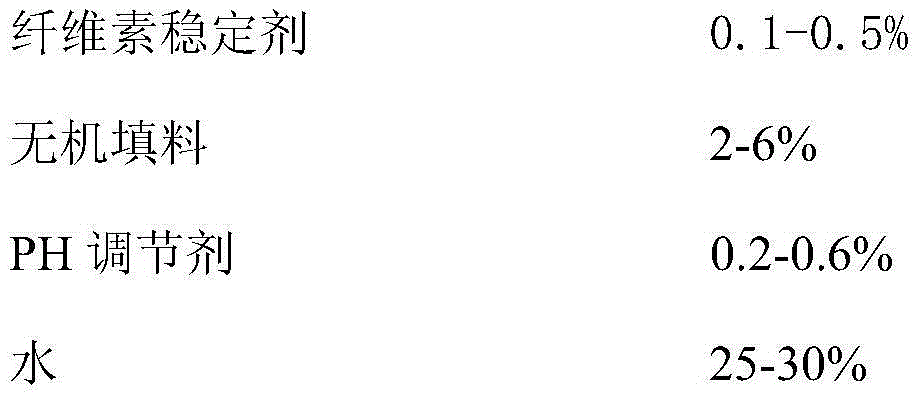

High-polymer modified water-emulsion asphalt-based thick waterproof paint and preparation method thereof

ActiveCN103555204AImprove low temperature performanceIncrease elasticityCellulose coatingsConjugated diene hydrocarbon coatingsHigh concentrationEpoxy

The invention discloses a high-polymer modified water-emulsion asphalt-based thick waterproof paint and a preparation method thereof. The paint is prepared by taking high-concentration ultrafine suspension microemulsion anion modified emulsified asphalt, a polyolefins modifier, rubber emulsions such as chloroprene rubber or butadiene styrene rubber or the like, multiple synthetic high-molecular polymers such as epoxy resin and the like, inorganic powders such as SiO2 and bentonite and the like as raw materials and mixing by employing a special production technology. Tests show that after a film is formed from the paint, no embrittlement happens at a low temperature of -20 DEG C, no flow happens at a high temperature of 120 DEG C, the elasticity recovery rate reaches up to 90%, and the paint can be stored stably for one year or more.

Owner:ZHEJIANG YUXI CORROSION CONTROL CORP

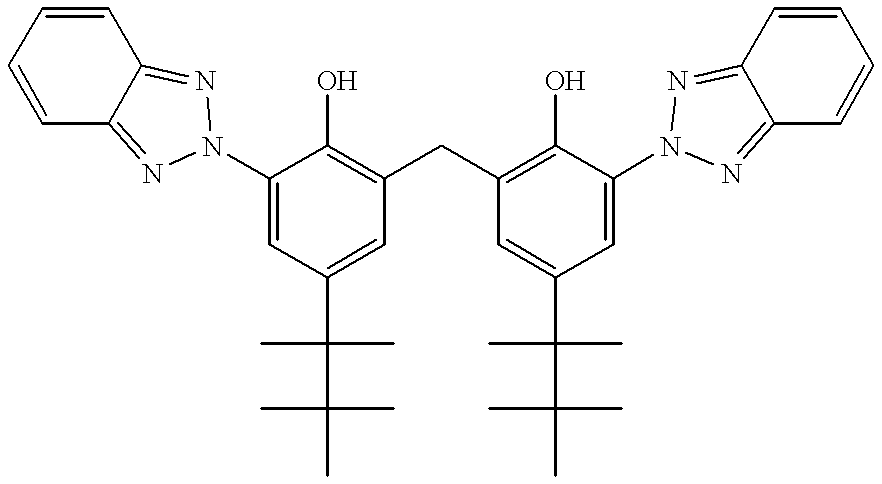

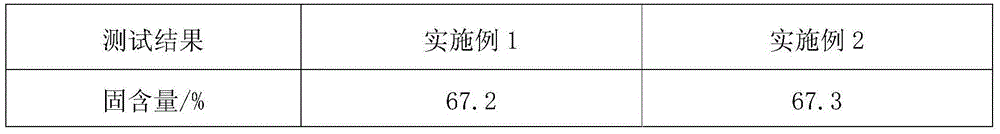

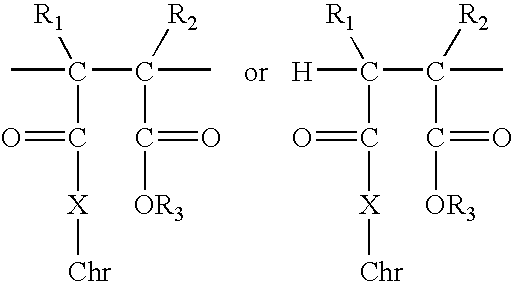

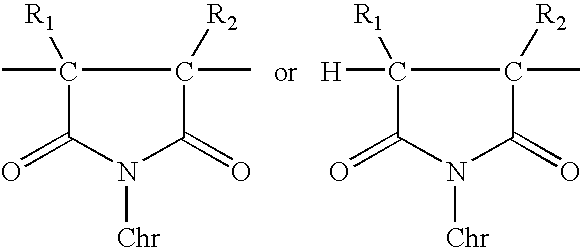

Polymer-bound UV absorbers in personal care compositions

ActiveUS20100189661A1Improve performanceImprove waterproof performanceCosmetic preparationsBiocidePersonal careUv spectrum

Personal care compositions comprising a polymer-bound UV absorber are described that provide enhanced properties, including customizable UV spectrum protection, broad-spectrum UV spectrum protection, water resistance, and labile UV stabilization. The polymer comprises anhydride functionality, such as maleic anhydride or a derivative thereof, and the UV absorber contains at least one hydroxyl, primary amine, or secondary amine group.The personal care compositions may be used to treat and / or protect against burns, cancers, erythema, lentigo (“liver spots”), keratotic lesions, wrinkles, and cellular changes of the skin; and / or color changes, embrittlement, lack of luster, tangles, split ends, and / or unmanageability of the hair.

Owner:ISP INVESTMENTS LLC

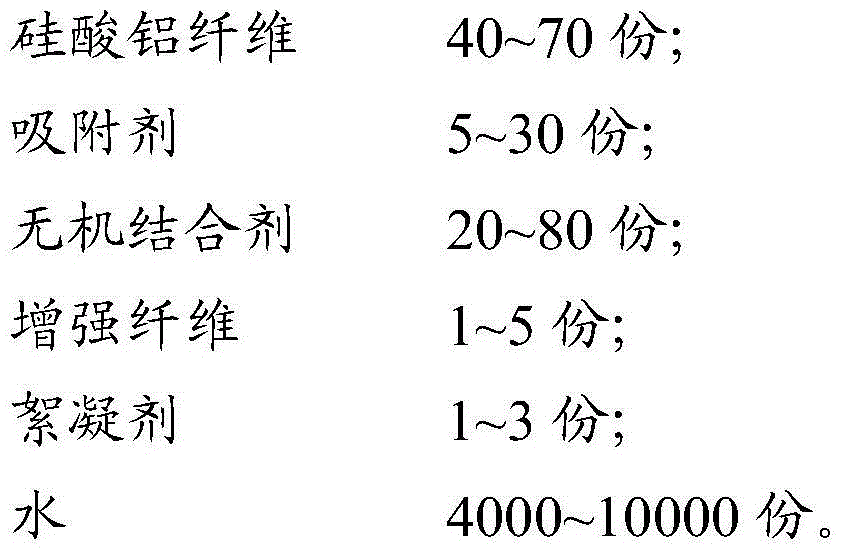

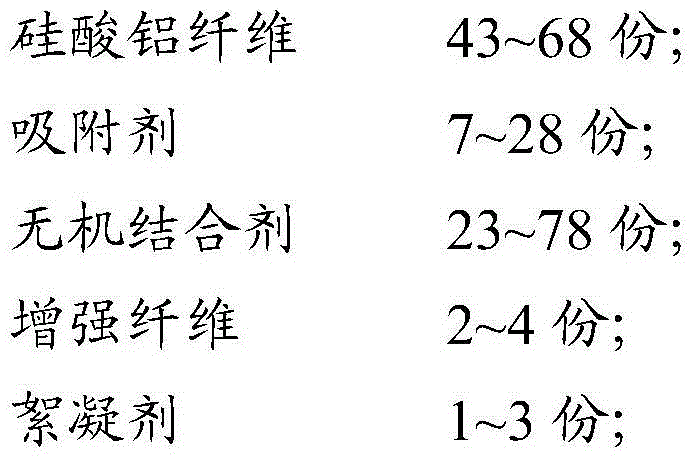

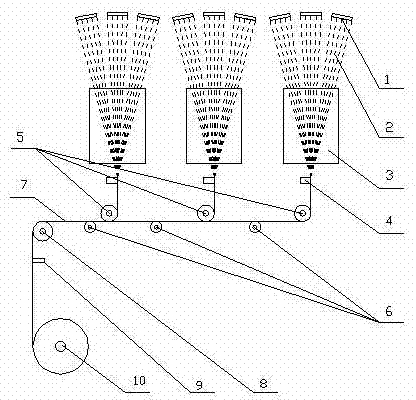

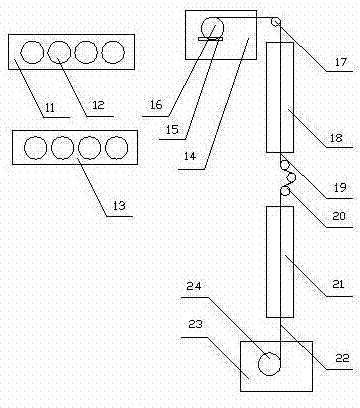

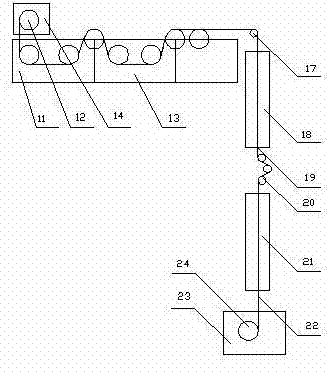

Ceramic fiber plate and preparation method thereof

The invention provides a ceramic fiber plate which is prepared from the following raw materials in parts by weight: 40-70 parts of aluminum silicate fibers, 5-30 parts of adsorbents, 20-80 parts of inorganic binding agents, 1-5 parts of reinforcing fibers, 1-3 parts of flocculants and 4000-10000 parts of water. The ceramic fiber plate contains no organic binding agent and can not generate the environmental protection problems of blackening, smoking, pungent smell and the like. The ceramic fiber plate provided by the invention can be obtained with no need of calcination through the matching use of the inorganic binding agents and the adsorbents, has the advantages of no embrittlement and good toughness, is high in compression strength through the matching use of the aluminum silicate fibers, the reinforcing fibers and the flocculants and is reduced in cost through no need of the calcination. An experimental result indicates that the ceramic fiber plate provided by the invention achieves the compression strength more than 0.25 MPa.

Owner:新疆鲁阳陶瓷纤维有限公司

Preparation method of continuous filament of asphalt-based carbon fiber

InactiveCN103046165ASmall diameterIncrease the number of filamentsNew-spun product collectionArtificial thread manufacturing machinesFiber bundleCarbonization

The invention discloses a preparation method of a continuous filament of an asphalt-based carbon fiber, and belongs to the field of carbon fiber production. The preparation method solves the problems that the existing spinning speed is lower, the fiber bundle damage is large, the infusibility efficiency is low, and doubling and embrittlement are easy. The preparation method comprises the specific process steps that a, spinning asphalt is extruded into fines by spinning position fusion, humidified, oiled and bundled to form a protogenic asphalt fiber bundle; b, double roller stranding and tensioning are conducted; c, the asphalt fiber bundle is wound on a spinning roller sleeve; d, an asphalt fiber reel is immersed in an oxidability liquid phase, and a liquid-phase oxidized fiber bundle reel is obtained; e, the reel is immersed in a high-temperature-resistant oil solution; the filament is unreeled and rollers are removed at a low speed; the oxidized fiber bundle continuously enters a continuous infusible furnace and a continuous low-temperature pre-carbonization furnace to form a pre-carbonization fiber bundle reel; and f, drawing heat treatment is conducted through a continuous carbon-fiber high-temperature carbonization furnace and a graphitization furnace, and then the continuous filament of the asphalt-based carbon fiber is obtained.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

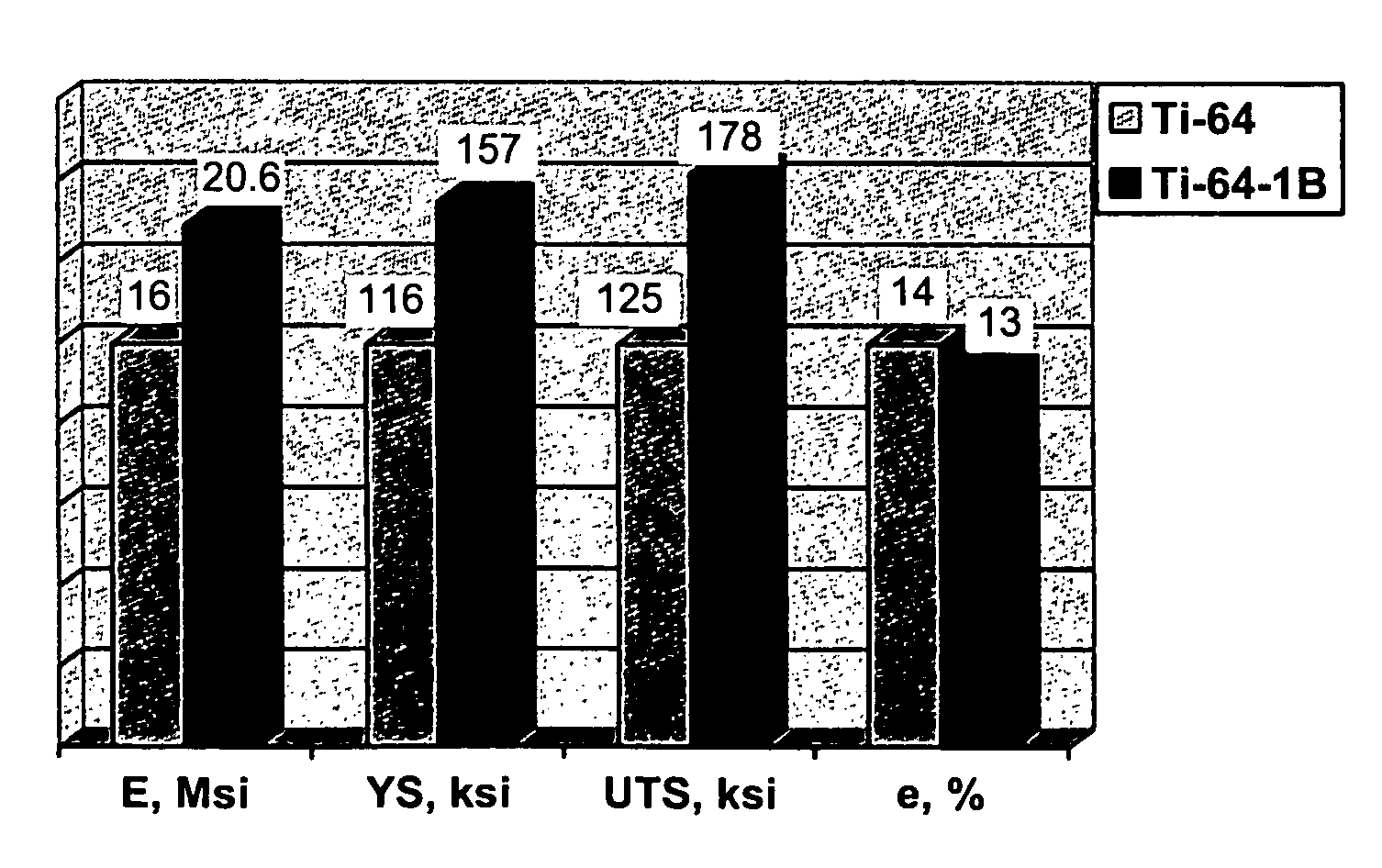

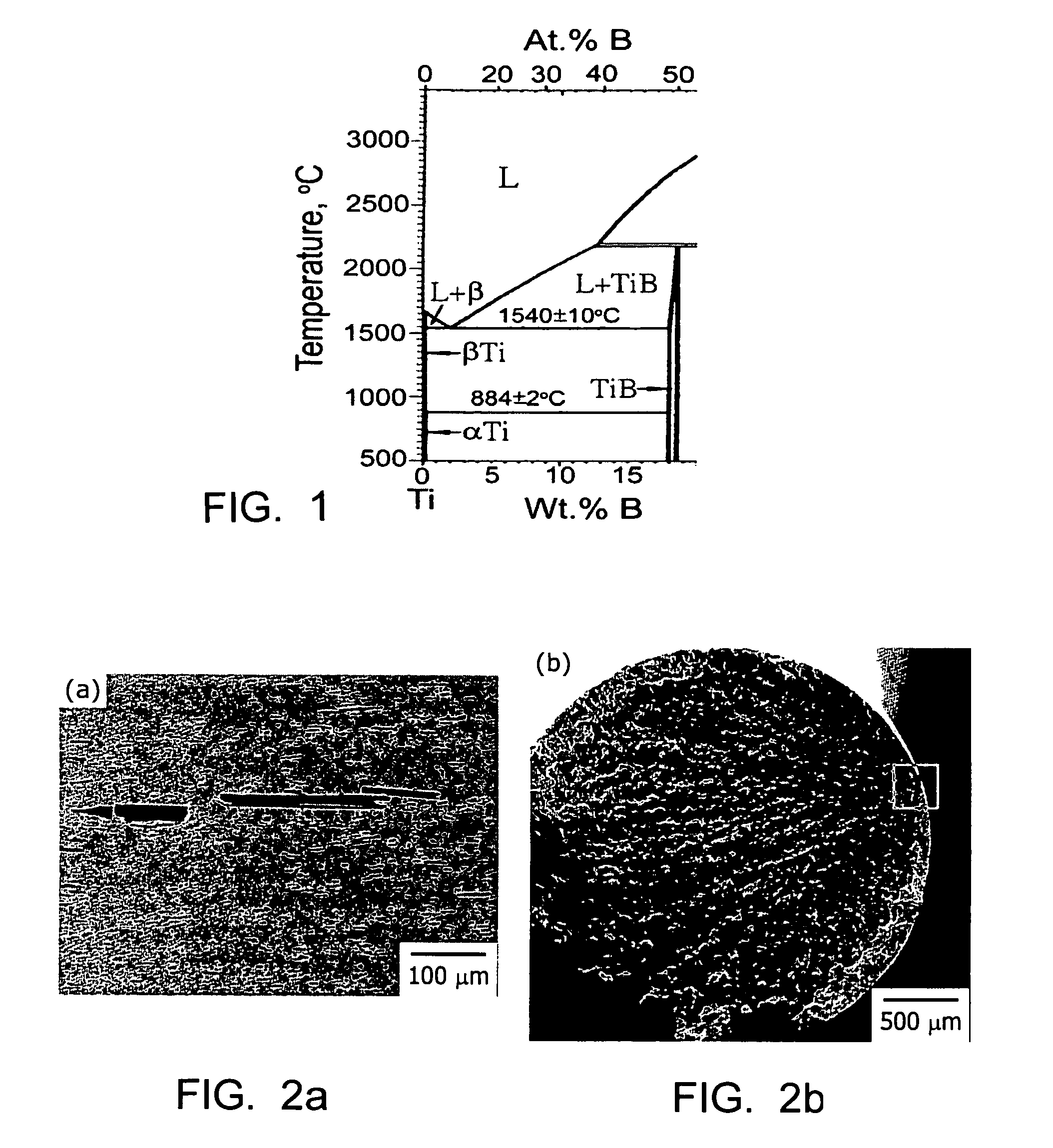

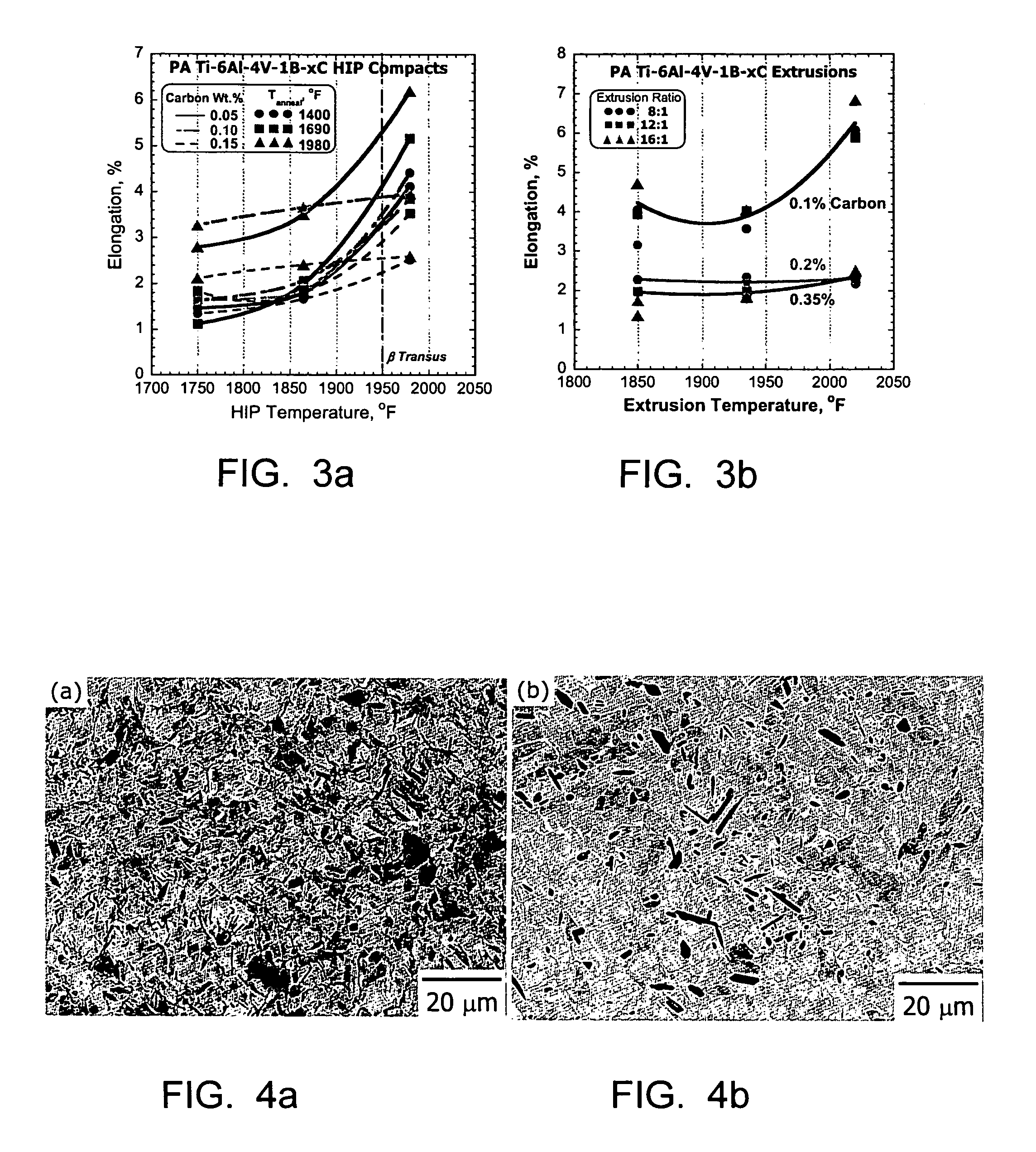

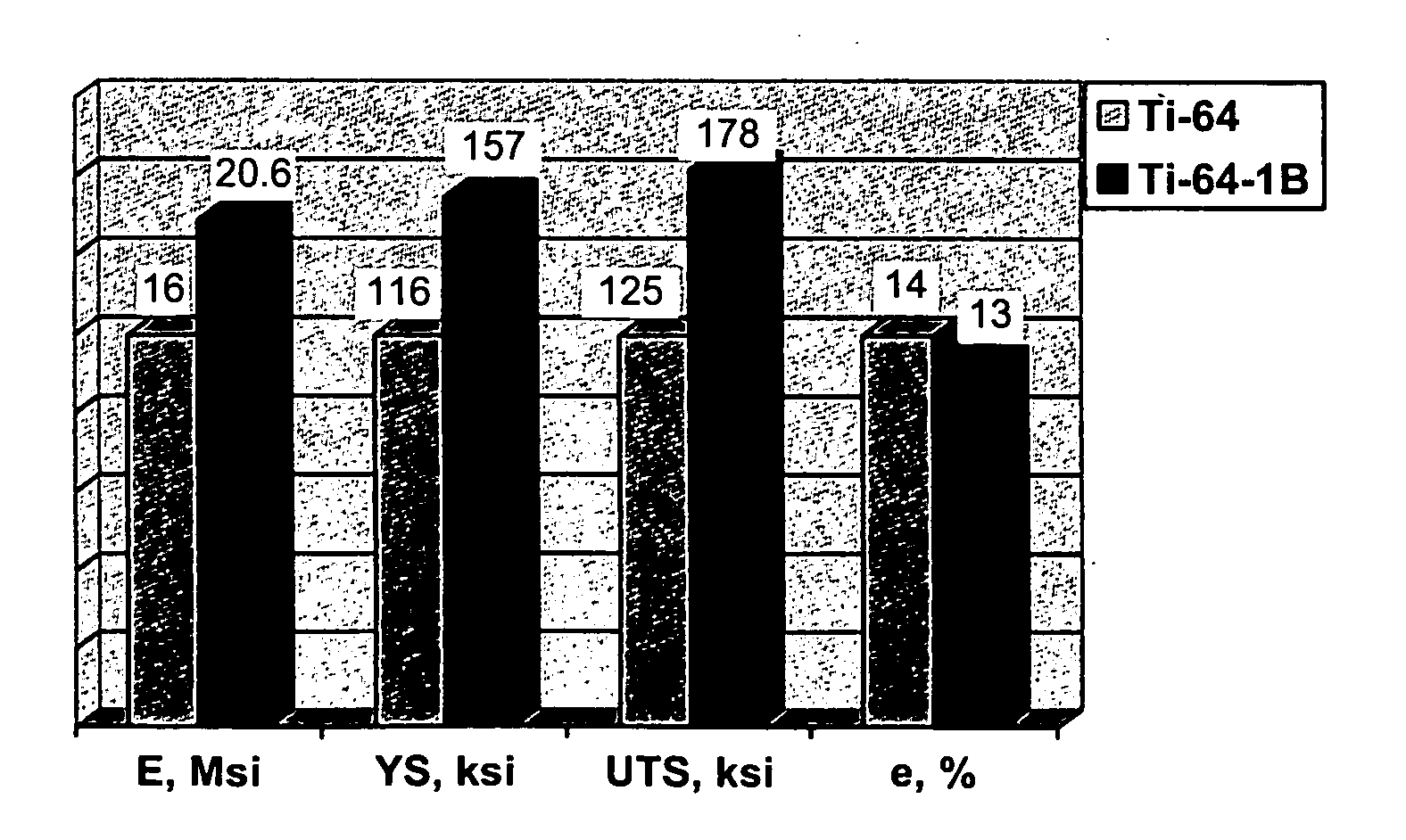

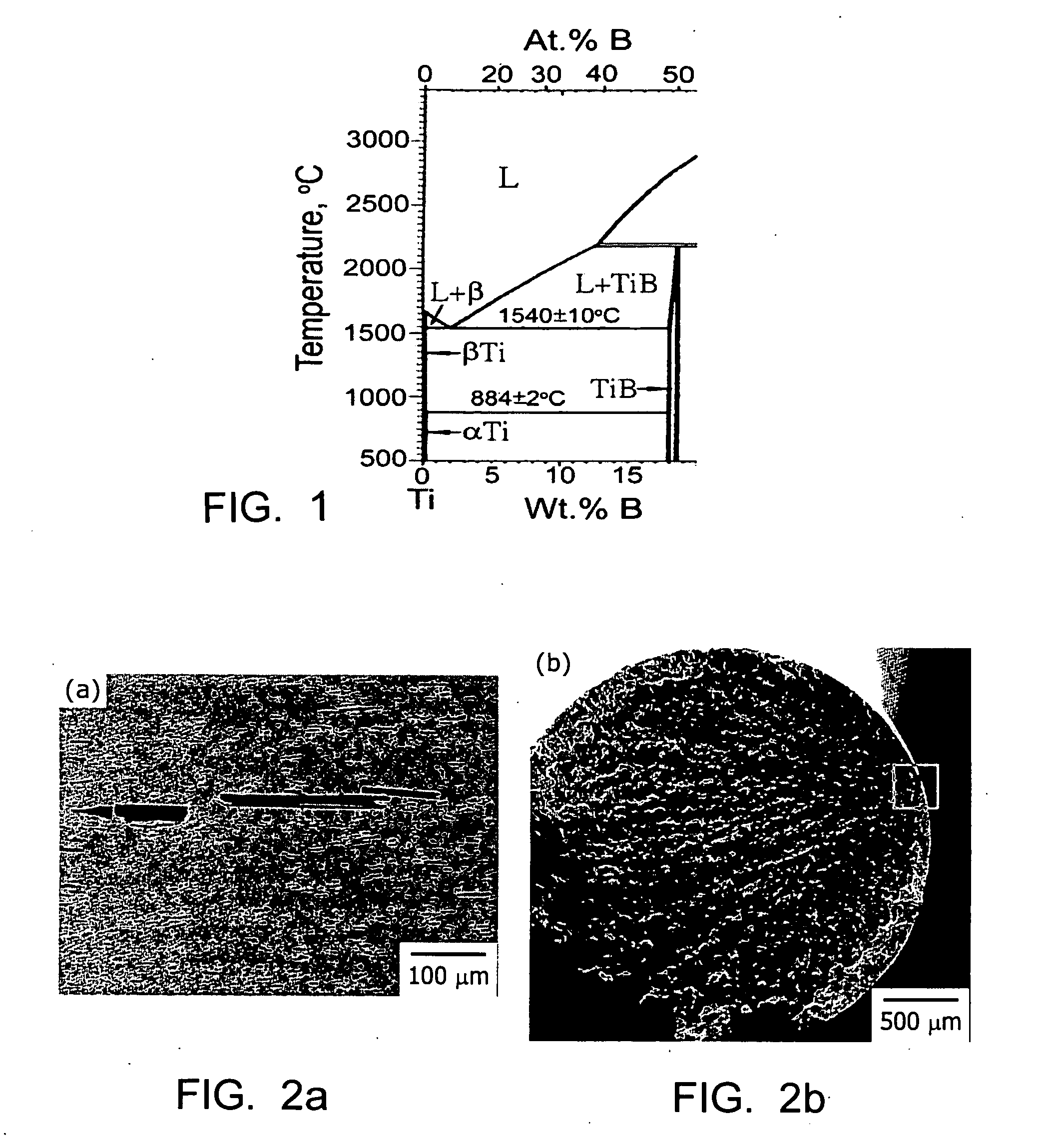

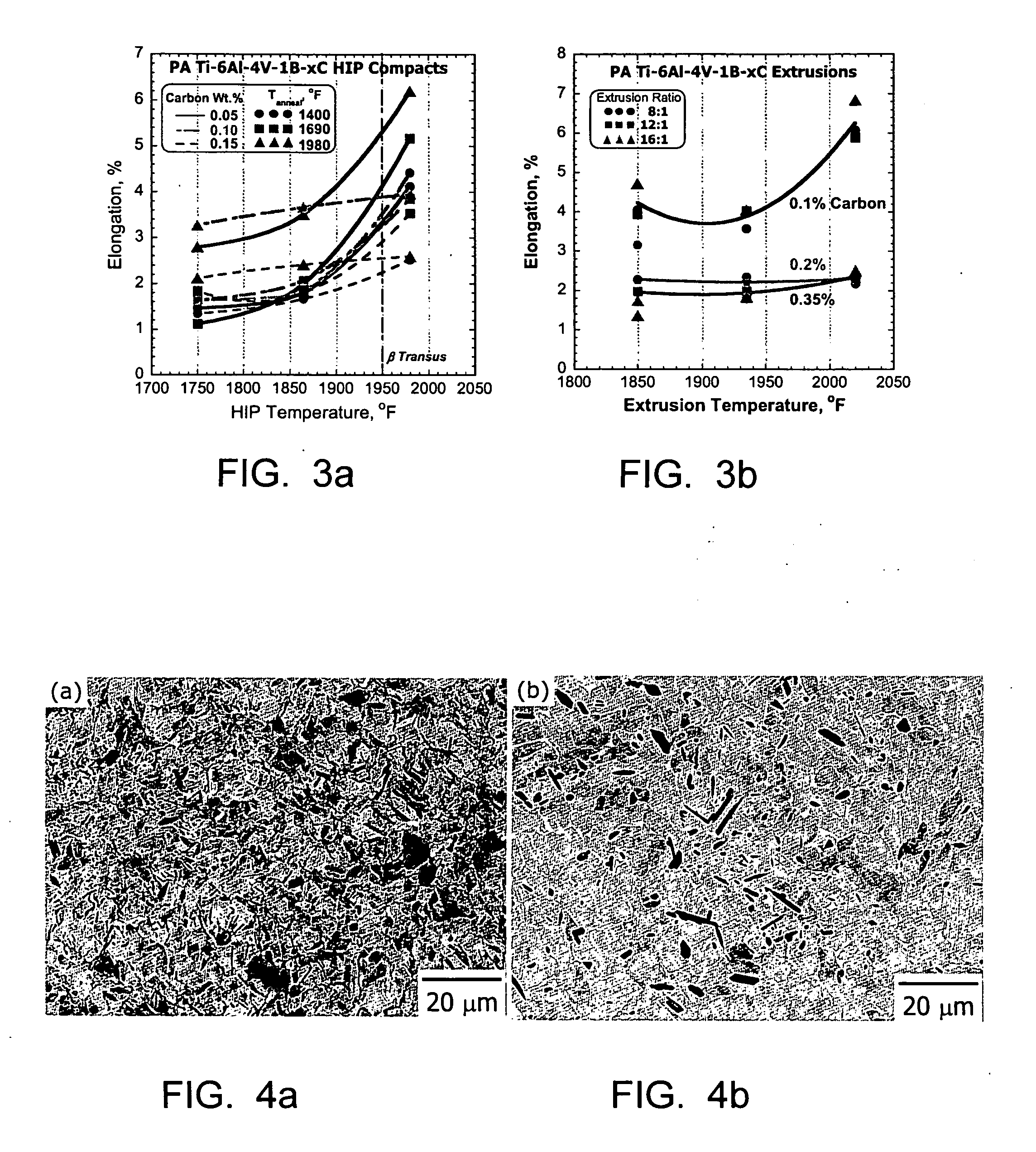

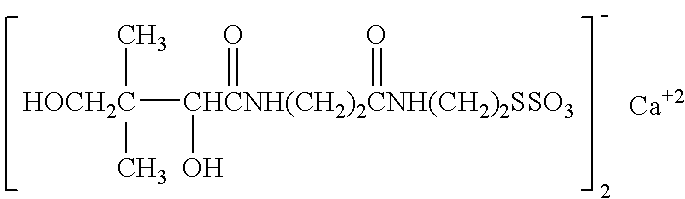

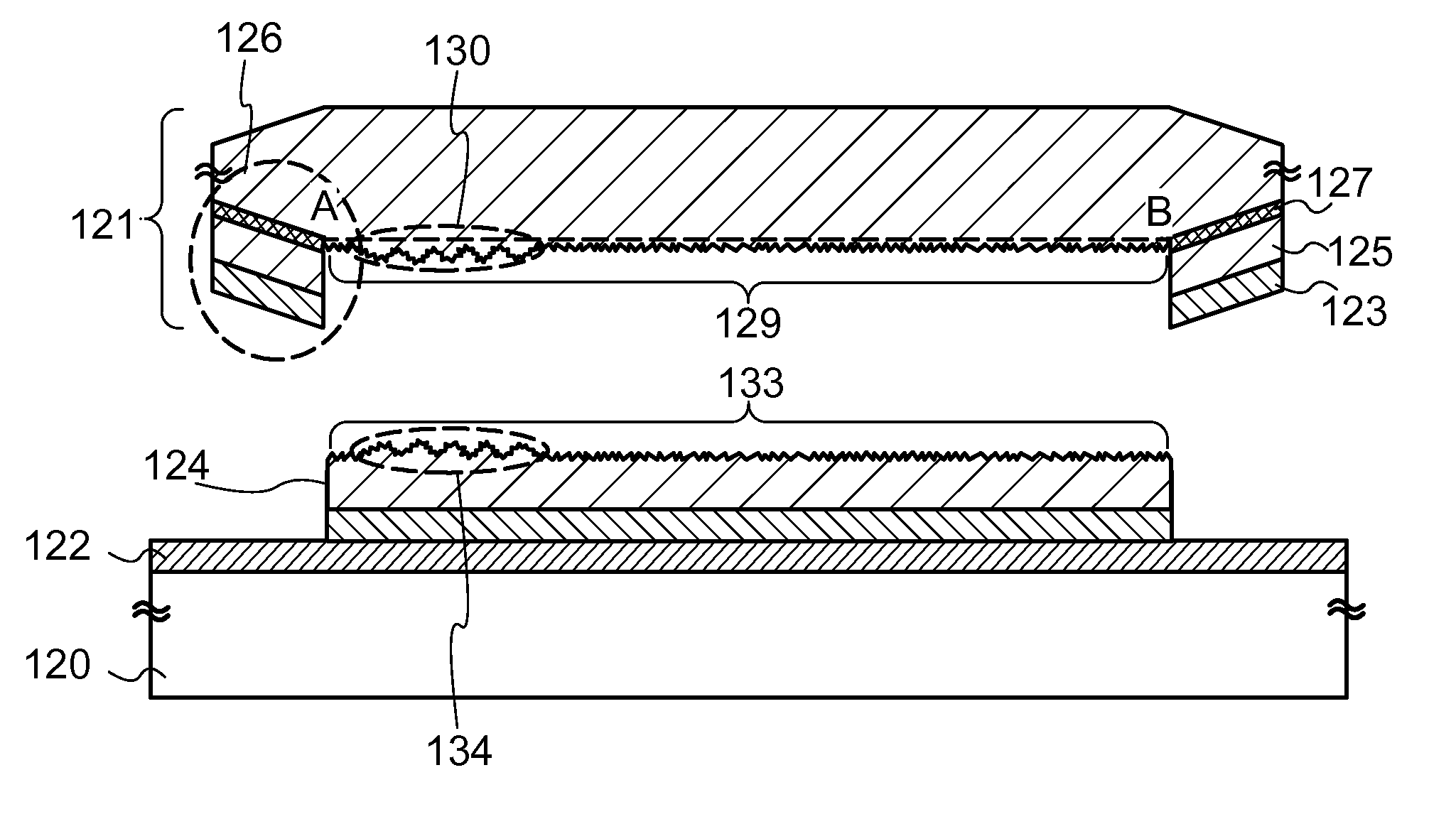

Method of producing high strength, high stiffness and high ductility titanium alloys

A method of producing a high strength, high stiffness and high ductility titanium alloy, comprising combining the titanium alloy with boron so that the boron concentration in the boron-modified titanium alloy does not exceed the eutectic limit. The carbon concentration of the boron-modified titanium alloy is maintained below a predetermined limit to avoid embrittlement. The boron-modified alloy is heated to a temperature above the beta transus temperature to eliminate any supersaturated excess boron. The boron-modified titanium alloy is deformed at a speed slow enough to prevent microstructural damage and reduced ductility.

Owner:ATI PROPERTIES +2

Wafer and method of producing a substrate by transfer of a layer that includes foreign species

ActiveUS7008859B2Improve uniformityImprove controllabilitySolid-state devicesSemiconductor/solid-state device manufacturingOptical propertyAtomic species

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES +1

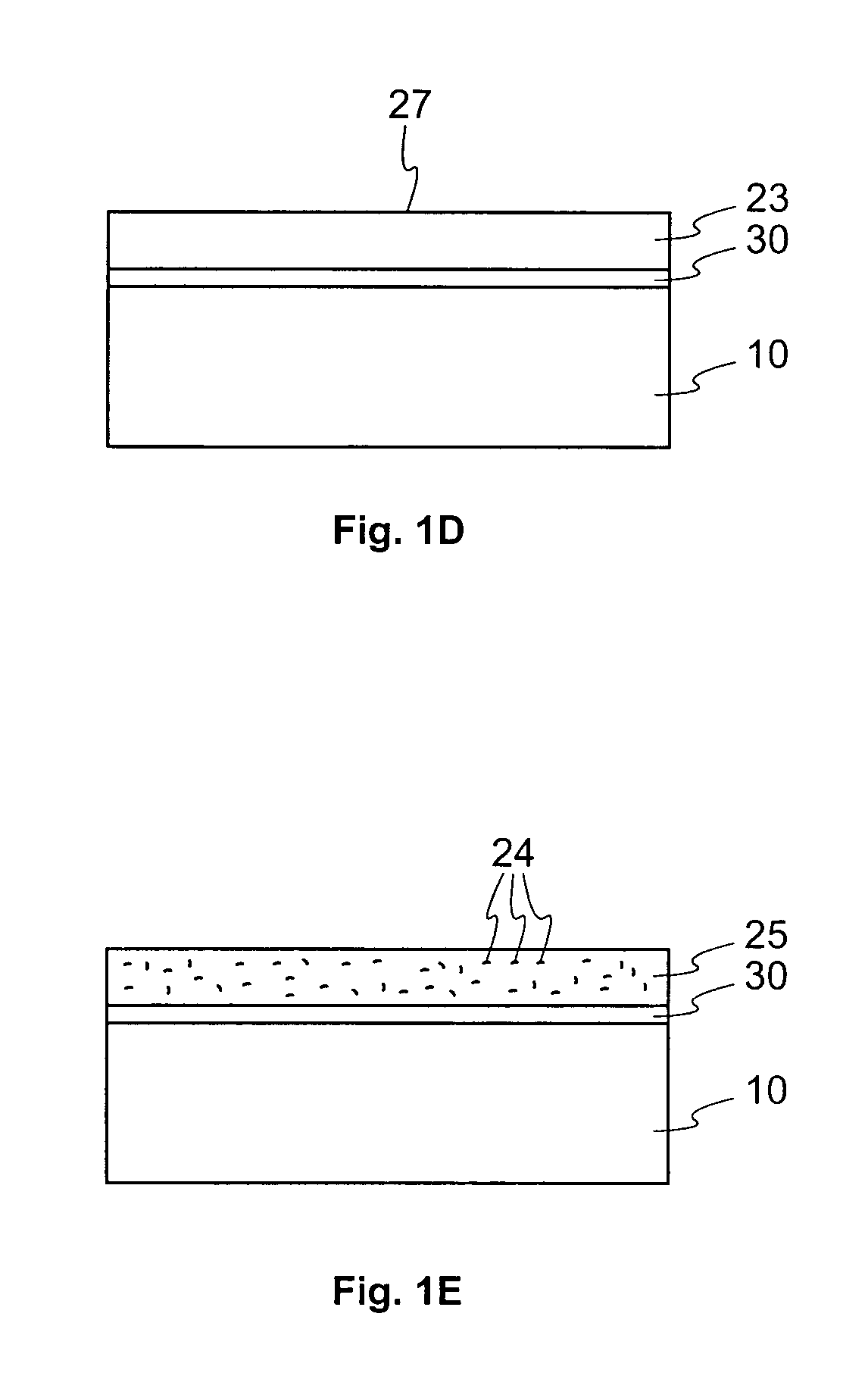

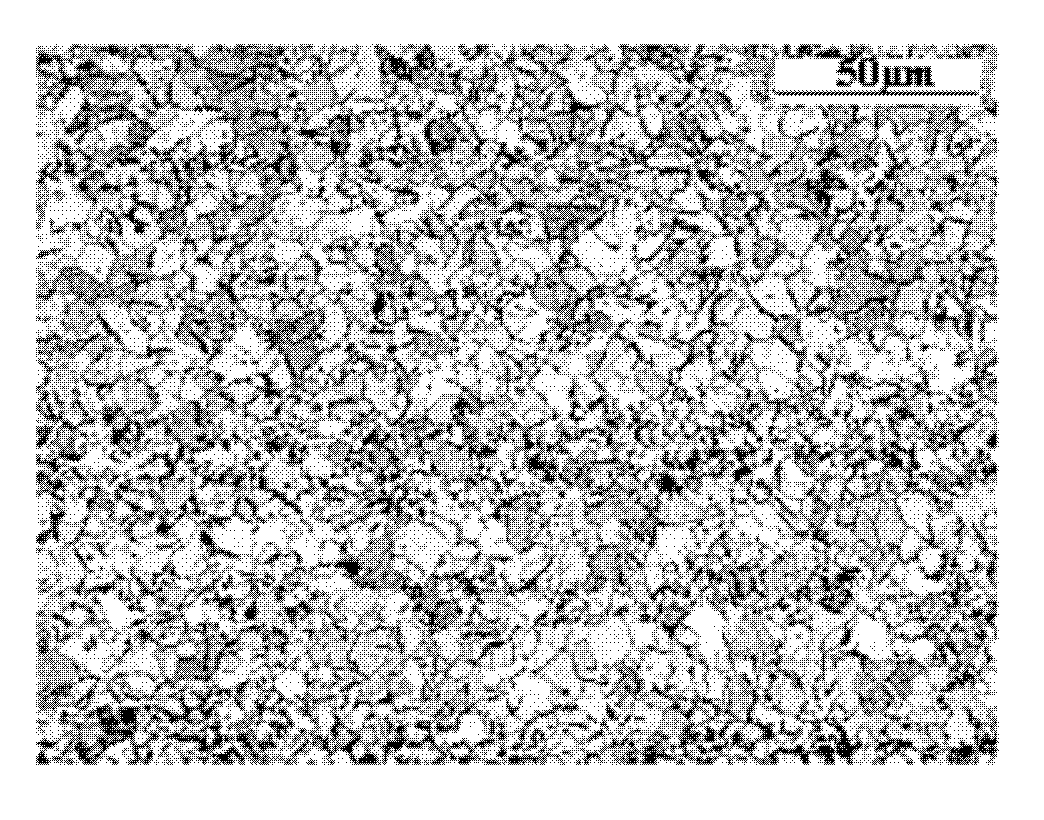

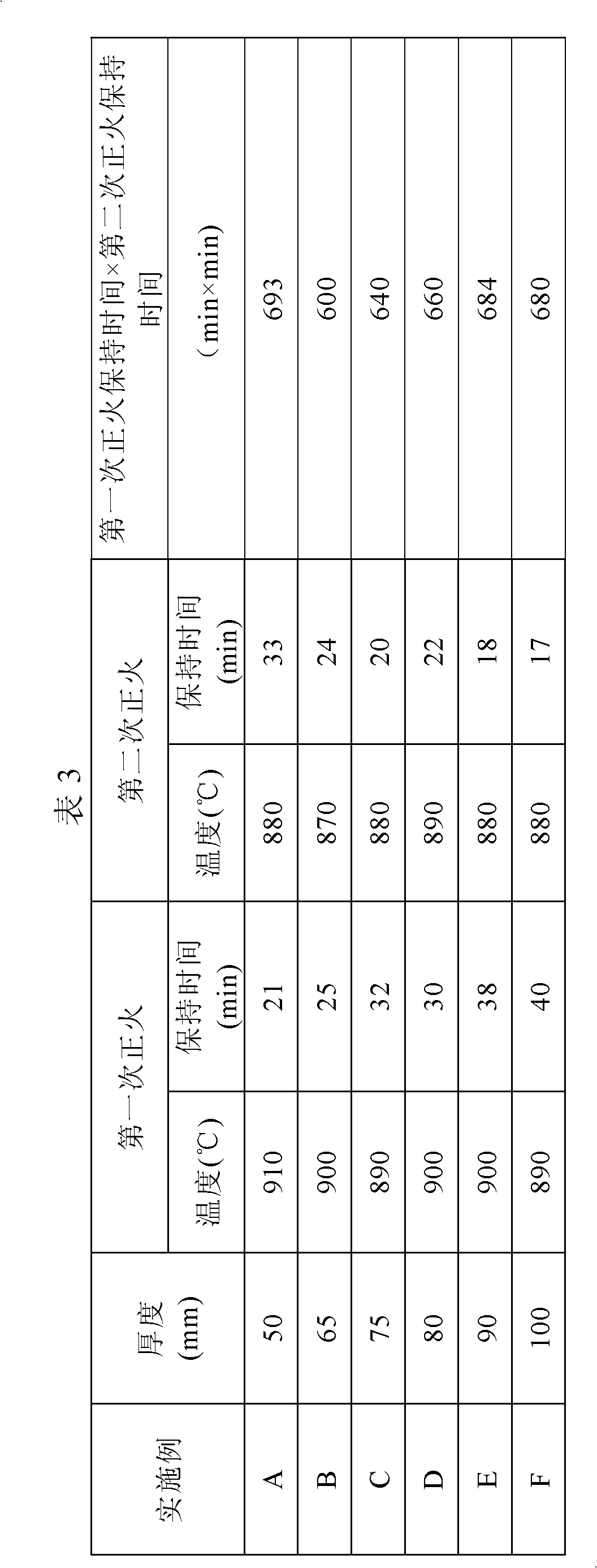

High tempering parameter PWHT embrittlement resistant, extra thick cryogenic steel plate and manufacture method thereof

ActiveCN102691007AIncrease the content of acid-soluble AlsExcellent anti-HICToughnessMaterials science

A high tempering parameter PWHT embrittlement resistant, extra thick cryogenic steel plate and a manufacture method thereof. The steel plate comprises, by weight, 0.030%-0.070% of C, Si no more than 0.15%, 1.30%-1.60% of Mn, P no more than 0.013%, S no more than 0.0025%, 0.040%-0.070% of Als, 0.10%-0.40% of Cu, 0.25-0.65% of Ni, 0.10%-0.30% of Cr, 0.05%-0.25% of Mo, 0.007%-0.013% of Ti, 0.010%-0.030% of Nb, 0.020%-0.050% of V, N no more than 0.0045%, 0.001%-0.004% of Ca, residual iron and unavoidable inclusions. According to optimized controlled rolling and two times of normalizing technology, the steel plate gains extremely high ultralow temperature toughness, excellent HIC / SCC resistance, weldability and bearing capacity of high heat input welding; and more importantly, the steel plate has excellent high tempering parameter PWHT embrittlement resistance characteristic, and is especially suitable for manufacture of large-scale LPG low temperature storage tank, low temperature storage tank for ship and ocean platform for ice ocean.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing polyacrylate/nano-SiO2 compound coating agent by using reactive emulsifier

InactiveCN101831230AImprove electrical performanceGood optical performanceCoatingsLeather surface finishingAdhesivePolymer chemistry

The invention relates to a method for preparing polyacrylate / nano-SiO2 compound coating agent which is suitable for bottom layer coating in clothing leathers and instep leathers, by using a reactive emulsifier. The polyacrylate has excellent optical stability, chemical resistance and favorable adhesive property and is widely used as an adhesive, a coating film-forming agent, a functional film, and a medical polymer and in the fields of water treatment and the like, but polyacrylate emulsion has the defects of embrittlement at low temperature, stickiness and strength loss at high temperature, easy after tack and the like, which restrict the application range and the use value of the polyacrylate emulsion. In the invention, the polyacrylate / nano-SiO2 compound coating agent is prepared by substituting conventional emulsifier with reactive emulsifier by utilizing the nanometer effect of an inorganic nanometer material and synchronously adopting a conventional emulsion polymerization method and a sol-gel method. The compound coating agent prepared by the invention has fine granules, excellent adhesive force, good filling capacity, strong water resistance and flexible and transparent formed film, and meanwhile, the damages to the human body and the environment, which are caused by the use of large amount of emulsifiers, are reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Method for producing amorphous alloy ribbon, and method for producing nano-crystalline alloy ribbon with same

InactiveUS20030041931A1Improve surface conditionGood edge shapeMaterials scienceNanocrystalline alloy

An amorphous alloy ribbon free from embrittlement and crystallization and having excellent surface conditions and shape in edge portions is produced by (a) preparing an alloy melt having a composition comprising 13 atomic % or less of B and 15 atomic % or less of at least one selected from the group consisting of transition elements of Groups 4A, 5A and 6A, the balance being substantially Fe; (b) ejecting the alloy melt at a temperature from the melting point of the alloy +50° C. to the melting point of the alloy +250° C. through a nozzle onto the cooling roll rotating at a peripheral speed of 35 m / second or less, a distance between a tip end of the nozzle and the cooling roll being 200 mum or less; (c) starting to supply a gas based on CO2 to the alloy melt after the surface temperature of the cooling roll has become substantially constant; and (d) grinding the cooling roll while supplying the gas based on CO2.

Owner:HITACHI METALS LTD

Method for manufacturing semiconductor substrate

InactiveUS20080248629A1Avoid pollutionVariation of depth is reducedSemiconductor/solid-state device manufacturingSingle crystalSilicon oxide

A method for manufacturing a semiconductor substrate is provided, which comprises a step of irradiating a single crystal semiconductor substrate with ions to form an embrittlement layer in the single crystal semiconductor substrate, a step of forming a silicon oxide film over the single crystal semiconductor substrate, a step of bonding the single crystal semiconductor substrate and a substrate having an insulating surface with the silicon oxide film interposed therebetween, a step of performing a thermal treatment, and a step of separating the single crystal semiconductor substrate with a single crystal semiconductor layer left over the substrate having the insulating surface.

Owner:SEMICON ENERGY LAB CO LTD

Method of producing high strength, high stiffness and high ductility titanium alloys

A method of producing a high strength, high stiffness and high ductility titanium alloy, comprising combining the titanium alloy with boron so that the boron concentration in the boron-modified titanium alloy does not exceed the eutectic limit. The carbon concentration of the boron-modified titanium alloy is maintained below a predetermined limit to avoid embrittlement. The boron-modified alloy is heated to a temperature above the beta transus temperature to eliminate any supersaturated excess boron. The boron-modified titanium alloy is deformed at a speed slow enough to prevent microstructural damage and reduced ductility.

Owner:ATI PROPERTIES +2

Bubble-free yellowing resistant polyurethane electronic potting adhesive composition and preparation method thereof

ActiveCN102174171AAddress inherent shortcomingsGuaranteed light transmittanceOther chemical processesPolyureas/polyurethane adhesivesWeather resistanceAlcohol

The invention relates to a bubble-free yellowing resistant polyurethane electronic potting adhesive composition and a preparation method thereof. The raw material of the composition is a double-component system which mainly comprises a polyatomic alcohol compound, a polyisocyanate compound and other accessory agents with favorable weather resistance; and the proportion of the mole equivalent weight of an isocyanate group to the mole equivalent weight of an active hydrogen compound component in the system is 1.0:0.8-1.0:1.5. The composition disclosed by the invention solves the problems of yellowing, embrittlement, hardening, breakage, and the like which are generated after long-term use, of the traditional transparent potting adhesive; the potting adhesive composition is produced by adopting the raw materials with favorable weather resistance and a special synthesis process; the composition also has excellent weather resistance, and the product can not generate the adverse phenomena after long-term use; and the composition can be applied to a flexible printed circuit board LED soft strip light bar products with extremely high requirements on bending performance and yellowing resistant performance and can be also greatly applied to the industries of optical devices, photoelectric and solar cell panels, and the like in quantity.

Owner:厦门誉匠复合材料有限公司

Composition containing hydroxyapatite and a calcium salt

InactiveUS20080160088A1Enhanced barrier functionSatisfies needCosmetic preparationsBiocideApatiteFree form

Composition containing, preferably in a physiologically acceptable medium, at least hydroxyapatite that is at least partially in free form and at least one calcium salt. Method of use. The invention method and composition is preferably used for preventing and / or reducing the embrittlement of the skin and / or semi-mucous membranes and / or for protecting the skin and / or semi-mucous membranes against water loss and / or external attack

Owner:LOREAL SA

Method for manufacturing soi substrate

It is an object to provide a method for, after a semiconductor film is separated, reprocessing a separated bond substrate into a reprocessed bond substrate which can be used for manufacturing an SOI substrate. The method for, after a semiconductor film is separated, reprocessing a separated bond substrate into a reprocessed bond substrate which can be used for manufacturing an SOI substrate includes the steps of forming an insulating film over a bond substrate; adding ions from a surface of the bond substrate to form an embrittlement layer; bonding the bond substrate to a glass substrate with the insulating film interposed therebetween; separating, at the embrittlement layer, the bond substrate into a semiconductor film which is bonded to the glass substrate with the insulating film interposed therebetween and a separated bond substrate; performing first wet etching using a solution containing hydrofluoric acid as an etchant on the separated bond substrate; performing second wet etching using an organic alkaline aqueous solution as an etchant on the separated bond substrate; performing thermal oxidation treatment on the separated bond substrate in an oxidizing atmosphere to which a gas containing halogen is added to form an oxide film on a surface of the separated bond substrate; performing third wet etching using a solution containing hydrofluoric acid as an etchant on the oxide film; and forming a reprocessed bond substrate by performing polishing on the separated bond substrate.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com