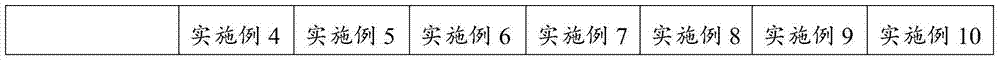

Patents

Literature

450 results about "Strength loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Therefore was the mean strength loss in these 2 decades in contrast to literature larger than estimated. These results support the hypothesis that the accelerated process of muscle mass and strength loss starts earlier nearby the 40 th life year. The pathophysiology of strength and muscle mass loss with aging process is complex27.

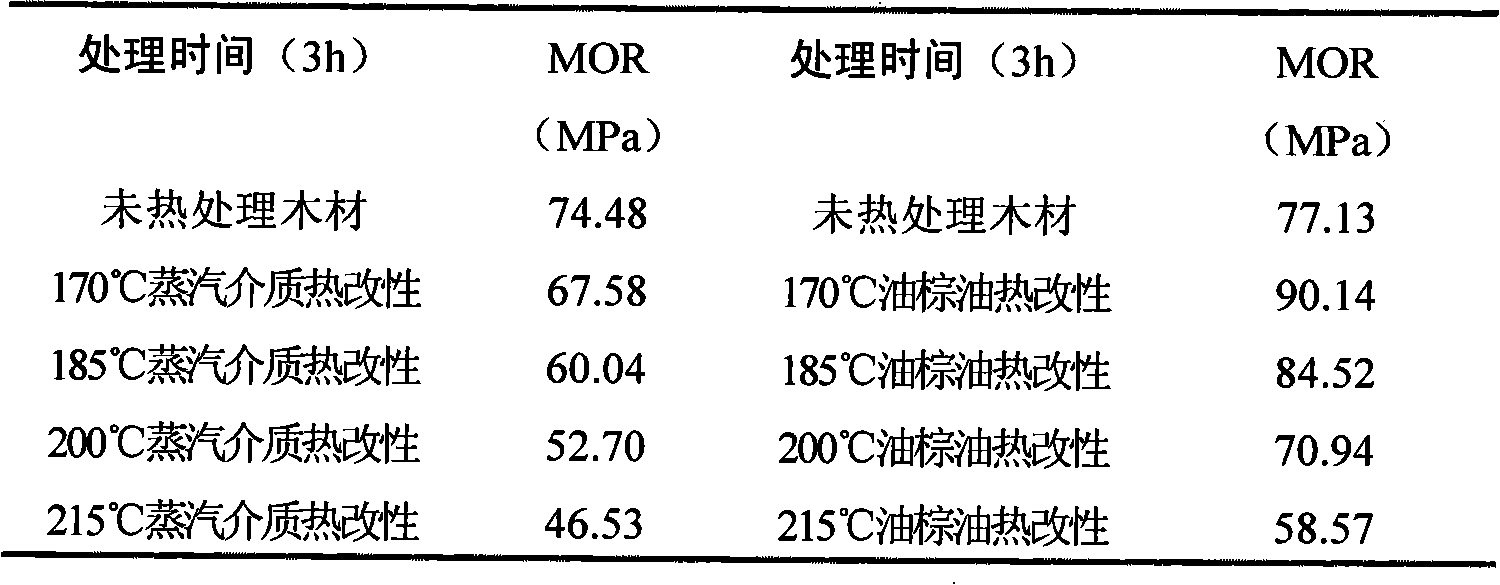

Method for producing charred wood by heat treatment

InactiveCN101069972AGuaranteed drying qualityShorten the timeWood treatment detailsWood charring/burningStrength lossMoisture

The invention relates to a preparation method of heat-treatment charred wood. It aims at providing the charred wood with short treatment cycle, small wood strength loss, industrialized and high maneuverability. It contains stages of preparing, preheating, heating, insulation and cooling. In the heating stage, heat the medium in the stove to 95-105 C degree with the speed of 10-18 C degree / h. Then, heat the materials to 120-130 C degree with the speed of 3-8 / C degree h for high temperature drying and reduce the inner moisture content of the woods to nearly 0. Finally, heat them to 185-220 C degree with the speed of 12-20 C degree / h. The intermittent steam-jet method is adopted to complete steam-jet treatment during the heating.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method of improving the thermo-mechanical properties of fiber-reinforced silicon carbide matrix composites

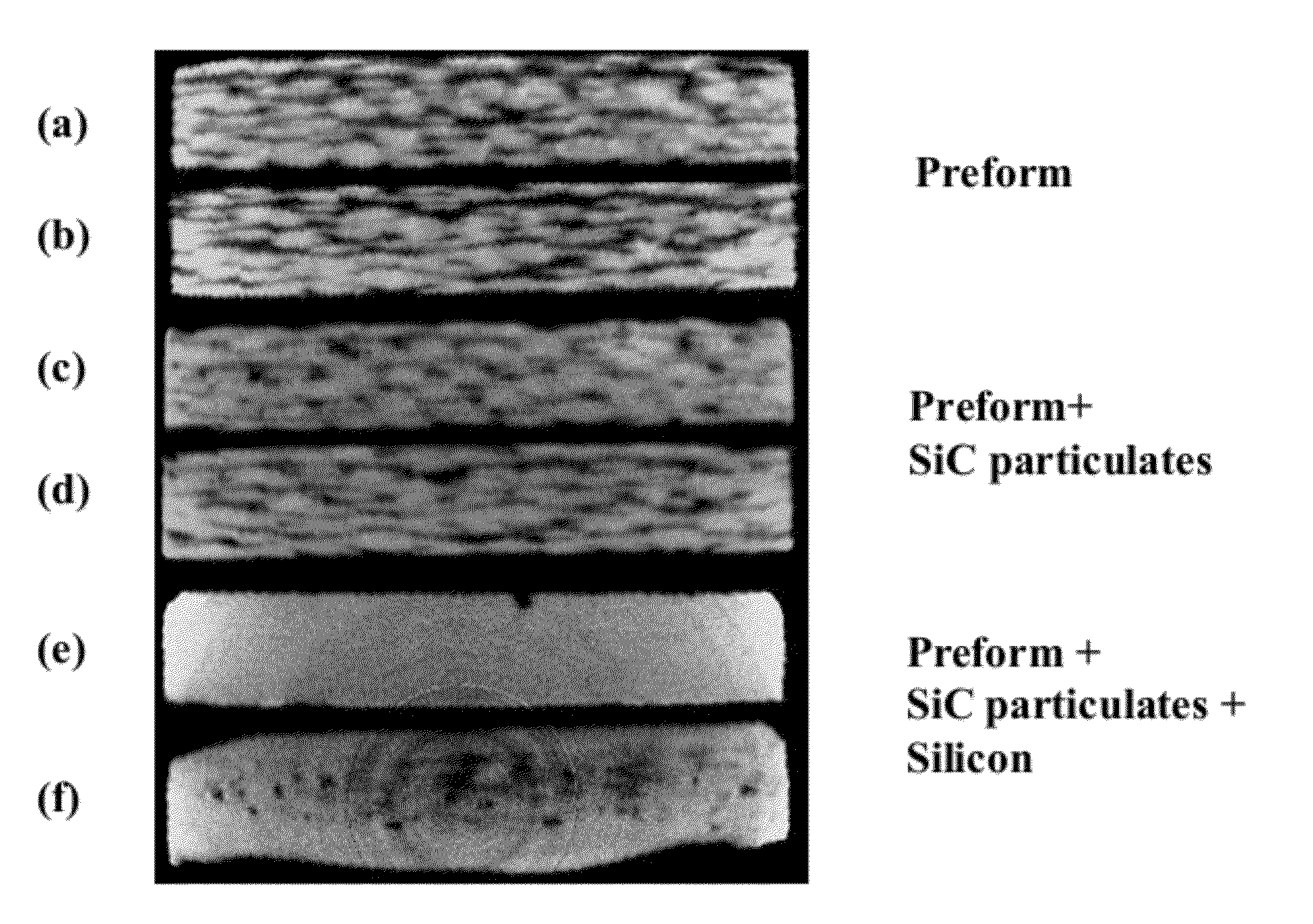

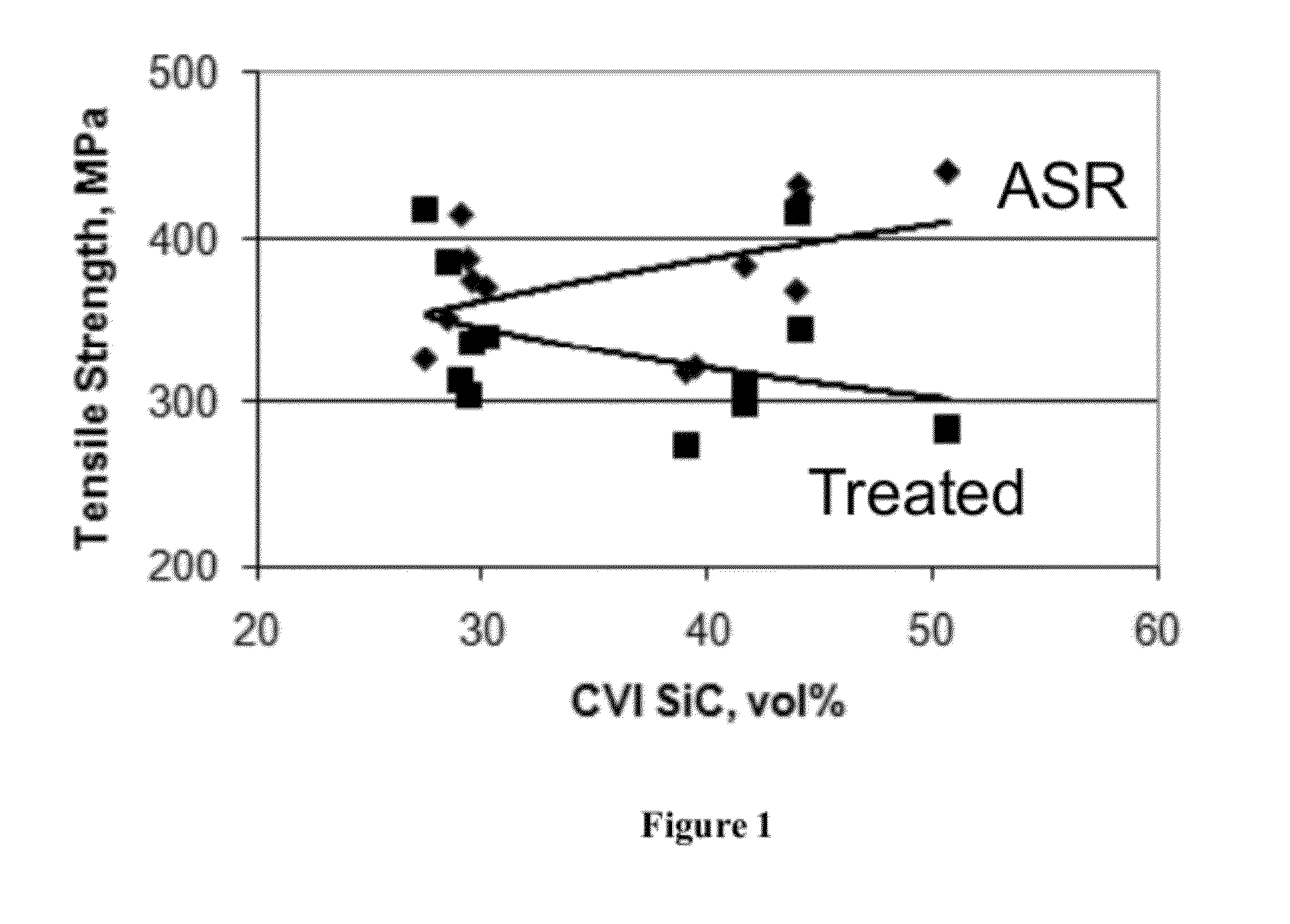

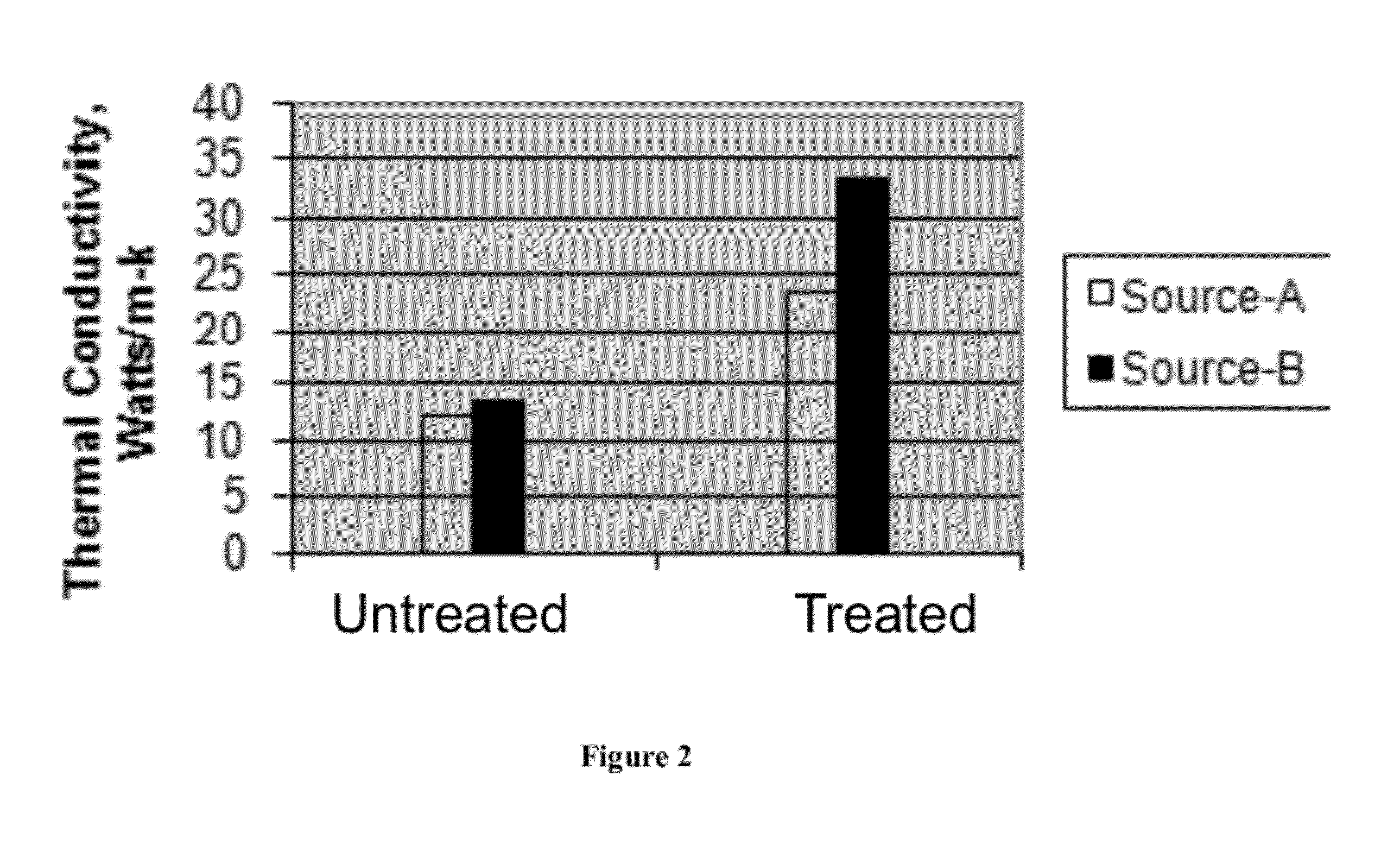

InactiveUS20120076927A1Improve featuresImprove propertiesCeramic shaping apparatusCoatingsParticulatesGas phase

A thermal treatment process for improving thermo-mechanical properties of ceramic matrix composite materials such as silicon carbide (SiC) matrix composites is described. The treatment process removes excess silicon and / or other process-related defects from the SiC-based matrix as well as the fiber interfacial coating. This invention can be practiced with minimal strength loss for as-fabricated composites formed from high-strength continuous-length ceramic and carbon-based fibers that are functionally stable to 1600° C. and above. The invention provides a method for significantly improving composite thermal conductivity and creep resistance, and for reducing composite porosity. It has been demonstrated using state-of-the-art 2D woven SiC / SiC composites containing Sylramic-iBN SiC fibers, boron-nitride-based interfacial coatings, and hybrid matrices that are based on SIC formed by chemical vapor infiltration (CVI) and by a combination of CNI, SiC particulate infiltration, polymer infiltration and pyrolysis, and melt infiltration of silicon, silicon-based alloys, and silicides.

Owner:US SEC THE ARMY THE

Phosphate fast repairing building material

InactiveCN101381219AHarden fastStrong acid and alkali resistanceSolid waste managementPhosphateUltimate tensile strength

The invention discloses a phosphate quick repairing building material, which belongs to the technical field of building engineering. The material comprises the following components in weight percentage: 30 to 45 percent of dihydric phosphate, 5 to 25 percent of metal oxide powder, 20 to 60 percent of fly ash and 5 to 10 percent of regulated-set material. In the invention, as required by the project, the consumption of the regulated- set material can be adjusted, thereby realizing the setting and hardening time from a few minutes to a few hours. The material has the advantages of high binding strength, no final strength loss and micro expansion during the setting and the hardening, and can be applied in various fields, particularly the material can still be quickly set and hardened at low temperature.

Owner:SHANGHAI JIAO TONG UNIV

Environmental-protection type gypsum-based putty powder for building

InactiveCN1454945AHigh bonding strengthImprove construction efficiencyFilling pastesWater solubleWater holding

The present invention relates to an environment-protecting gypsum base building putty powder, which uses building gupsum as main setting hardening component, and utilizes the composite retarding agent to resolve the problems of that the building gupsum can be quickly set and hardened and single retarding agent can be resulted into large strength loss. Said invention adopts inorganic mineral powder and cellulose ether composition to reduce material cost and improve water-holding property of putty, and adopts water-soluble adhesive powder to raise cohesional strength of building putty, and said environment-protecting type gypsum base building putty powder is a single component solid powder, has no harmful substance, and has good construction property, and said putty surface is fine and smooth.

Owner:CHONGQING UNIV

Wood heat treatment method

ActiveCN101224593AReduce defects such as crackingReduce the degree of strength lossWood dampingOxygen contentEqualization

The invention provides a thermal processing method of timber and belongs to the technical field of the heat treatment of timber. The specific procedures are: (1) the timber is placed in a heat treatment chamber by yard; (2) the temperature and oxygen content of the first stage are set, namely, the temperature is 80-150 DEG C and the oxygen content is 12-21%, the treatment time maintains 0.5-1.5 hours for each centimeter thickness of the timber; (3) the temperature and oxygen content of the second stage are set, namely, the temperature is 150-200 DEG C and the oxygen content is 6-12%, the treatment time maintains 0.5-2 hours for each centimeter thickness of the timber;(4) the temperature and oxygen content of the third stage are set, namely, the temperature is180-260 DEG C and the oxygen content is 2-6%, the treatment time maintains 1.5-2 hours for each centimeter thickness of the timber; (5) the fourth stage is a cooling and equalization treatment stage, the indoor temperature is lowered to less than 100 DEG C, then equalization treatment on the water ratio of the timber is carried out in the way of spray-steaming, then the temperature is lowered to 40-50 DEG C after the water ratio of timber meets the product requirement, and the treated timber is taken out. The method can prominently reduce the problems of the prior art that the strength loss is serious with a great deal of defects.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

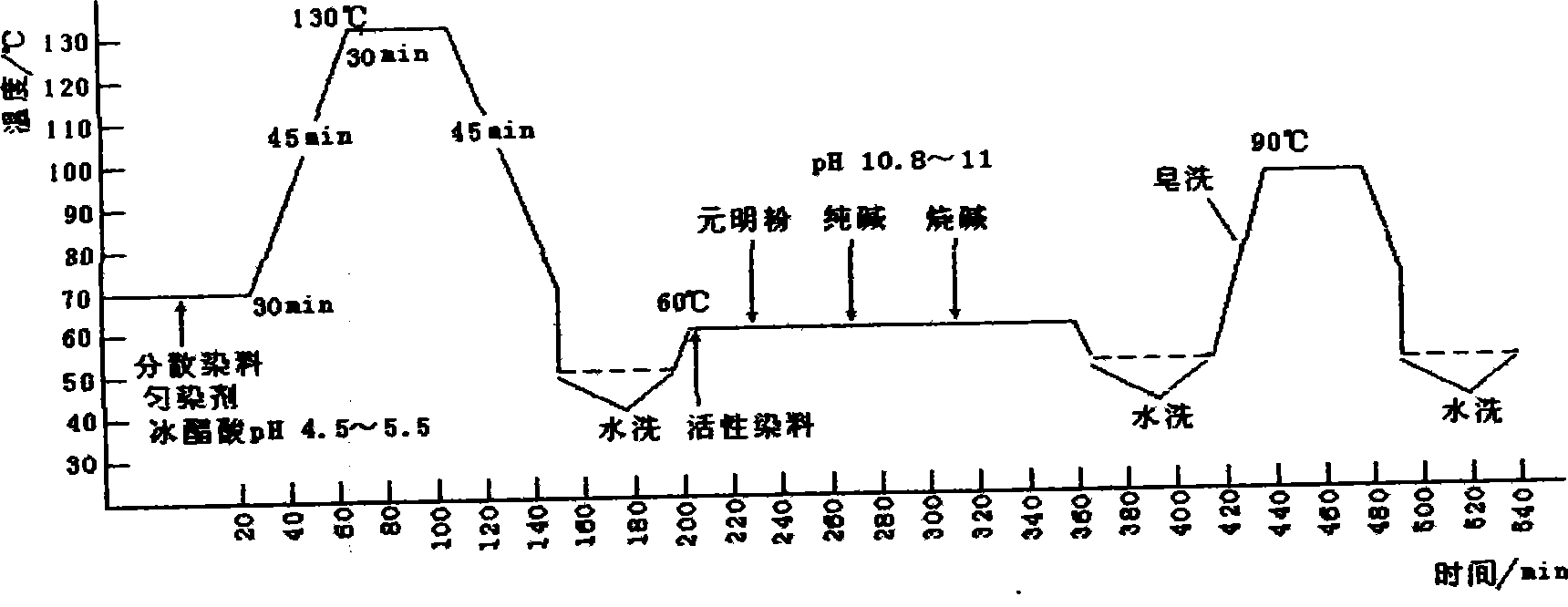

Dyeing and finishing process for sea silk fabric

InactiveCN101413207AStrong damageSoft touchDry-cleaning apparatus for textilesBleaching apparatusFiberTextile printer

The invention discloses a dyeing and finishing technology for seaweed fiber fabrics, which belongs to the technical field of textile printing and dyeing. The dyeing and finishing technology comprises the following steps of pre-treatment, dyeing and after-treatment, wherein pre-treatment adopts the treatment technology of enzyme-deoxidized annealing and bleaching-bath method; and the fabrics are placed into a dye jar with a bath ratio between 1 to 5 and 1 to 30 at a normal temperature, added with an immersing working fluid, heated to a temperature of between 70 and 100 DEG C, bleached, subjected to heat insulation for 30 to 60 minutes, subjected to water scrubbing and standby for dyeing. The dyeing and finishing technology adopts the treatment technology of enzyme-deoxidized annealing and bleaching-bath method; the capillary effect of the fabrics is more than 10.5 centimeters; the brightness reaches more than 82; and the strength loss is less than 10 percent. The dyeing technology of one bath two stage process shortens the processing time for 50 percent, is energy-saving and reduces consumption.

Owner:ZHEJIANG GANGLONG WEAVING TECH

Method for preparing polyacrylate/nano-SiO2 compound coating agent by using reactive emulsifier

InactiveCN101831230AImprove electrical performanceGood optical performanceCoatingsLeather surface finishingAdhesivePolymer chemistry

The invention relates to a method for preparing polyacrylate / nano-SiO2 compound coating agent which is suitable for bottom layer coating in clothing leathers and instep leathers, by using a reactive emulsifier. The polyacrylate has excellent optical stability, chemical resistance and favorable adhesive property and is widely used as an adhesive, a coating film-forming agent, a functional film, and a medical polymer and in the fields of water treatment and the like, but polyacrylate emulsion has the defects of embrittlement at low temperature, stickiness and strength loss at high temperature, easy after tack and the like, which restrict the application range and the use value of the polyacrylate emulsion. In the invention, the polyacrylate / nano-SiO2 compound coating agent is prepared by substituting conventional emulsifier with reactive emulsifier by utilizing the nanometer effect of an inorganic nanometer material and synchronously adopting a conventional emulsion polymerization method and a sol-gel method. The compound coating agent prepared by the invention has fine granules, excellent adhesive force, good filling capacity, strong water resistance and flexible and transparent formed film, and meanwhile, the damages to the human body and the environment, which are caused by the use of large amount of emulsifiers, are reduced.

Owner:SHAANXI UNIV OF SCI & TECH

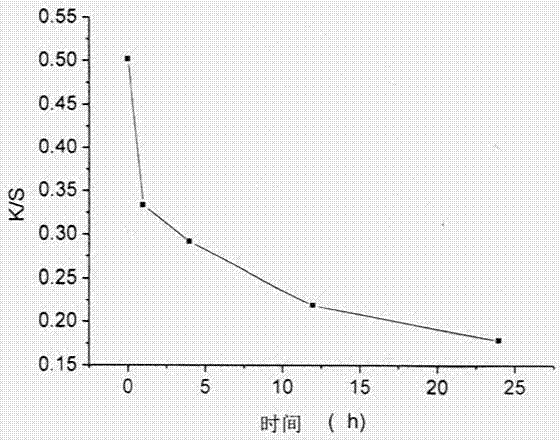

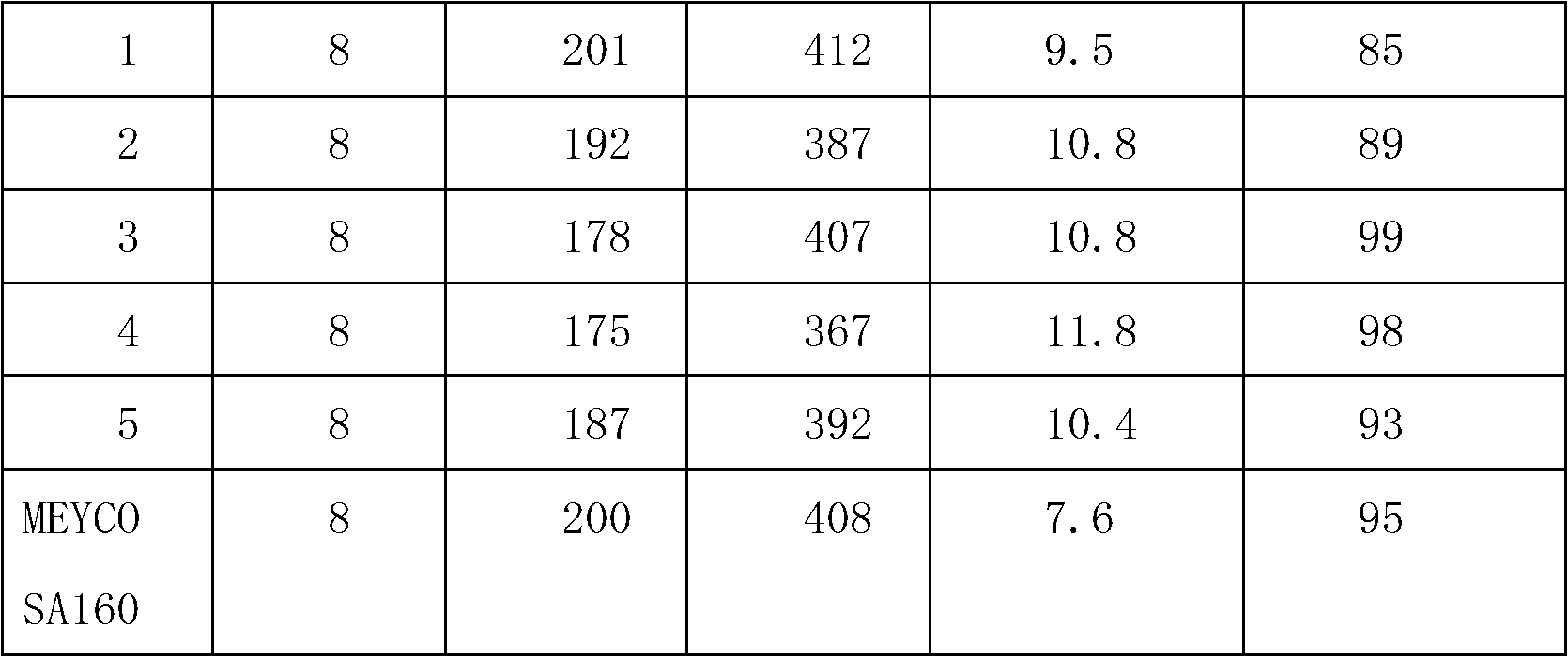

Preparation method of modified nano titanium dioxide finishing agent with uvioresistant and self-cleaning double effects

The invention relates to a finishing method of rutile type nano titanium dioxide with ultraviolet absorption and self-cleaning performance for polyester-cotton fabric. An organic silane coupling agent (KH560) is utilized to carry out surface modification onto rutile type nano TiO2 through main two steps: (1), adding the rutile type nano titanium dioxide powder into alcohol to prepare alcohol liquor with mass concentration of 1%-5%, treating for a certain time by adopting ultrasonic or mechanical stirring or microwave-ultrasonic homogenizing, so that the nano titanium dioxide powder is uniformly dispersed in the alcohol; (2), adding a coupling agent which accounts for 1%-5% of the titanium dioxide into the alcohol liquor, regulating pH to neutral, stirring uniformly, reacting for 1 hour-3 hours at the constant temperature of 70 DEG C-90 DEG C to obtain the modified nano titanium dioxide finishing liquor. The modified nano TiO2 finishes the polyester-cotton fabric, the finished and dyed fabric is placed under an ultraviolet lamp with special ultraviolet wavelength for being irradiated for a certain time, and the finished fabric is measured to have uvioresistant and self-cleaning performances. The preparation method disclosed by the invention is simple and strong in operation practicability; the fabric can obtain the uvioresistant and self-cleaning performances at the same time; moreover, the nano titanium dioxide has protective effect for strength loss of the fabric.

Owner:上海拓纳化学新材料有限公司

Silica sand composition, formed body and preparation method for formed body

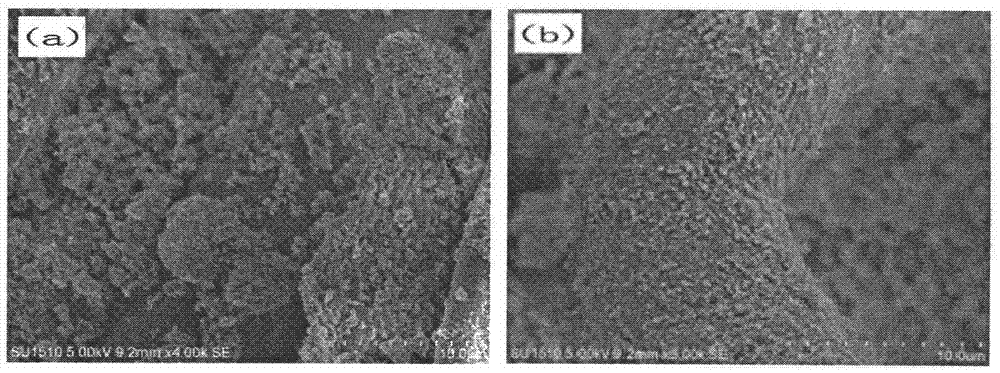

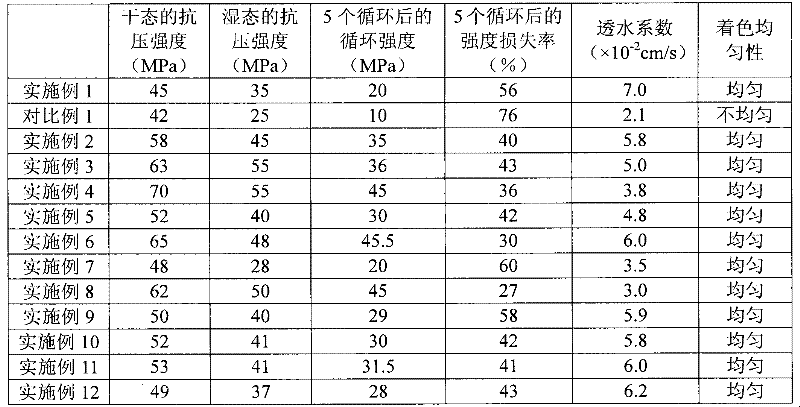

The invention provides a silica sand composition which comprises silica sand having a polymer coating and a first binder, wherein, the polymer coating is a cured second binder, and the first binder and the second binder are respectively one or more selected from the group consisting of an acrylic acid resin adhesive, an epoxy resin adhesive and a polyurethane adhesive. The invention also provides a preparation method for a formed body and the formed body prepared by using the method. The method comprises the steps of mixing of all the components of the silica sand composition, molding and curing of the first binder. The formed body prepared from the composition by using the method has good water permeability, high strength and an excellent strength retention rate, and has a compressive strength of 45 to 70 MPa when in a dry state, a compressive strength of 28 to 55 MPa when in a wet state, a cyclic strength of 20 to 45.5 MPa after 5 cycles, a strength loss rate of only 27 to 60% and a permeability coefficient of 3 to 7 cm / s.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

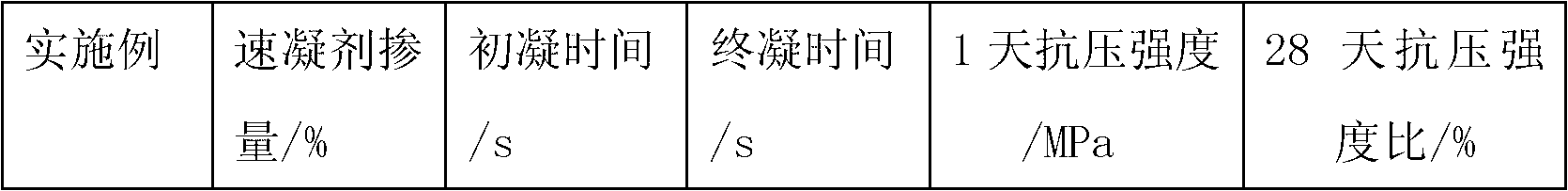

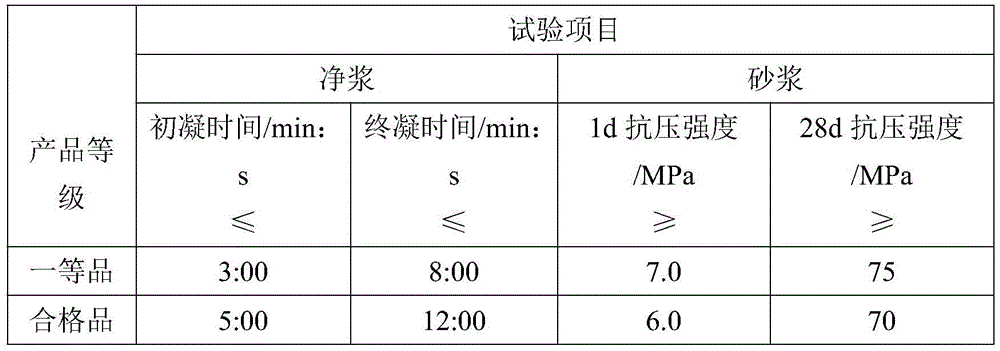

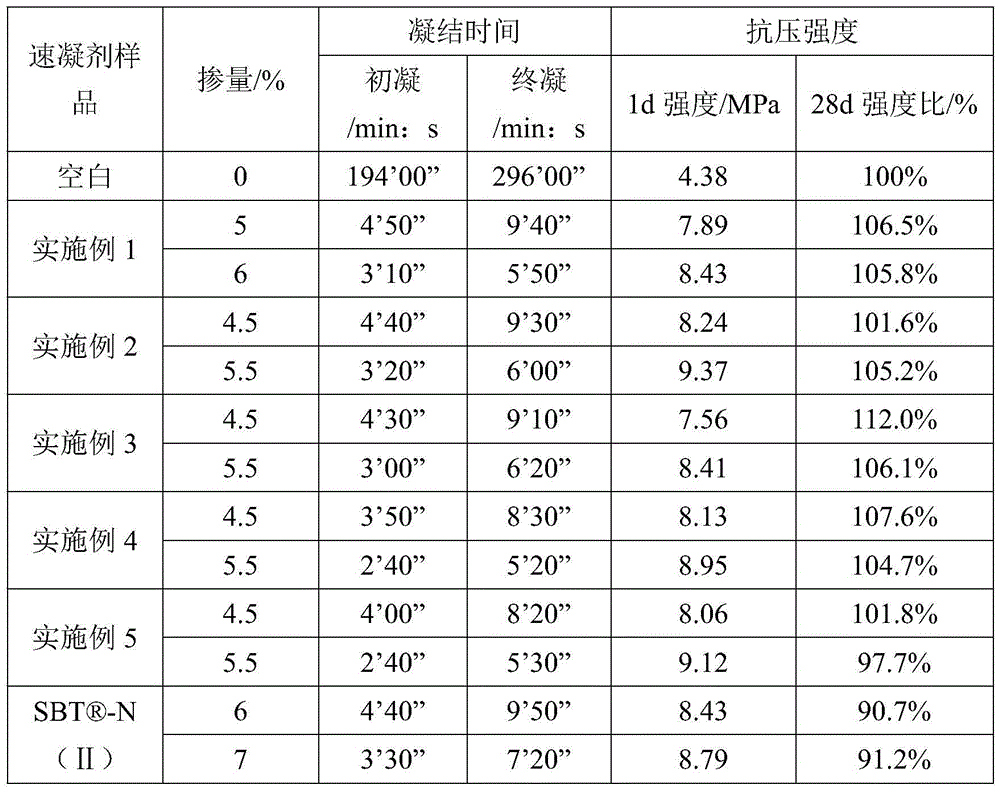

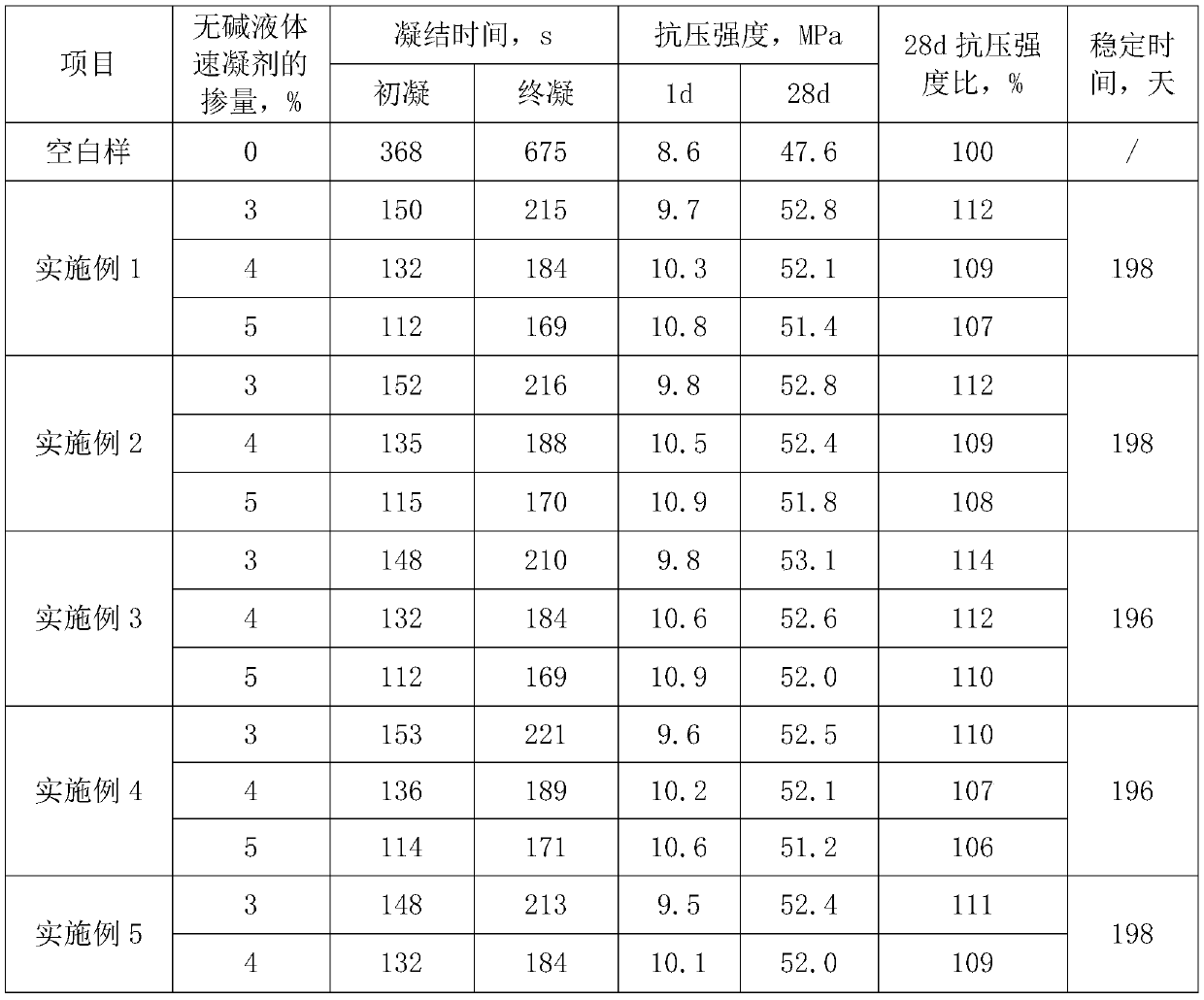

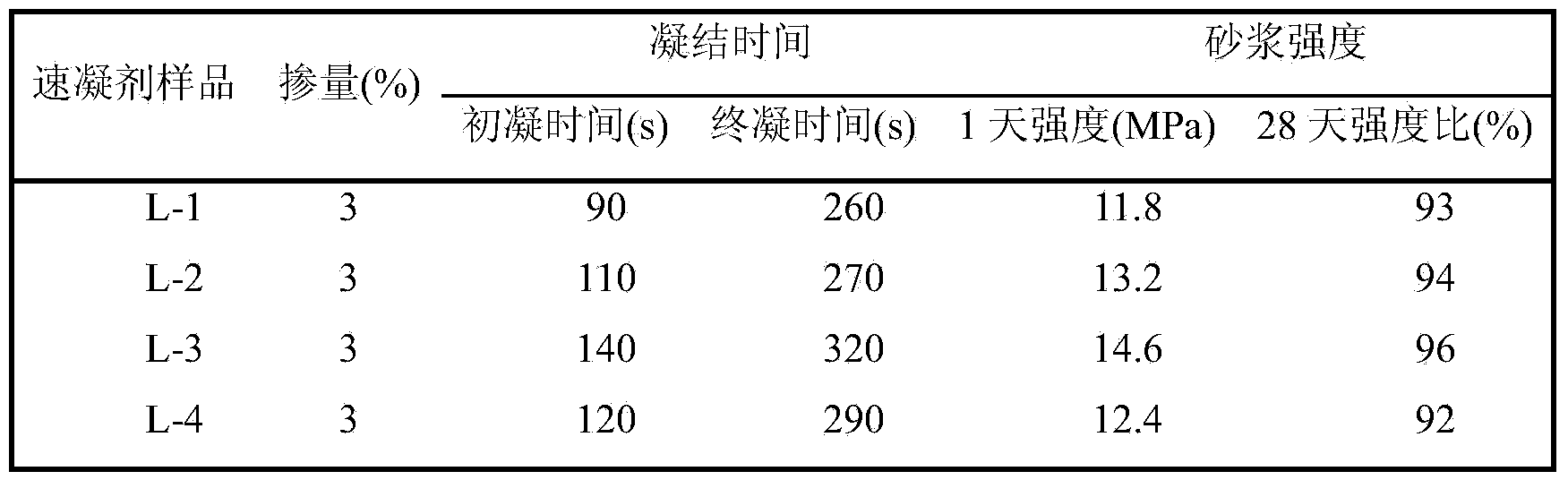

Alkali-free liquid accelerator and preparation method and application thereof

The invention discloses an alkali-free liquid accelerator, which is free of alkali in raw materials and preparation. The accelerator is composed of 30-80% of aluminum sulfate, 1-10% of hydroxy carboxylic acid, 4-15% of organic amine, 3-10% of polyhydric alcohols, 1-5% of inorganic acid and the balance of water. The accelerator disclosed by the invention is high in early strength, low in long-term strength loss, good in caking property and low in resilience value; as a result, environment-friendly no-pollution construction can be realized; the synthetic process of the accelerate is simple and moderate in reaction conditions; and therefore, the accelerate is an excellent-performance alkali-free liquid accelerator.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

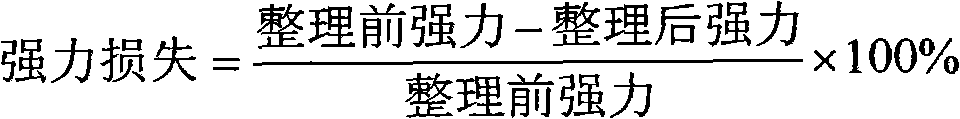

Formaldehydeless permanent press finishing agent for fabric and preparation method and application thereof

ActiveCN101956322AOvercome lossImprove wrinkle resistanceVegetal fibresPotassium persulfatePolymer science

The invention discloses a novel formaldehydeless permanent press finishing agent for a fabric and a preparation method and application thereof. The formaldehydeless permanent press finishing agent for the fabric is prepared by performing a polymerization reaction on acrylamide, glyoxal, phthalic anhydride, sulfuric acid, potassium persulfate and the like. The product of the invention is mainly used for performing noniron finish on the fabric and improving the firmness of a dyed fabric and a printed fabric. Compared with the conventional N-methylol acrylamide resin, the permanent press finishing agent has prominent advantages of excluding of formaldehyde and crease resilience equivalent to or surpassing those of etherfied 2D (etherfied dimethylol dihydroxy ethylene urea) after being used for finishing a cotton fabric; and compared with the conventional formaldehydeless resin, the agent has the advantages of high crease resilience, strength loss less than that of a polycarboxylic formaldehydeless resin, cost lower than those of dimethylol dihydroxy ethylene urea (DMeDHEU) and butanetetracarboxylic acid (BTCA) and cost performance far higher than that of a polycarboxylic resin.

Owner:SICHUAN YIXIN TECH

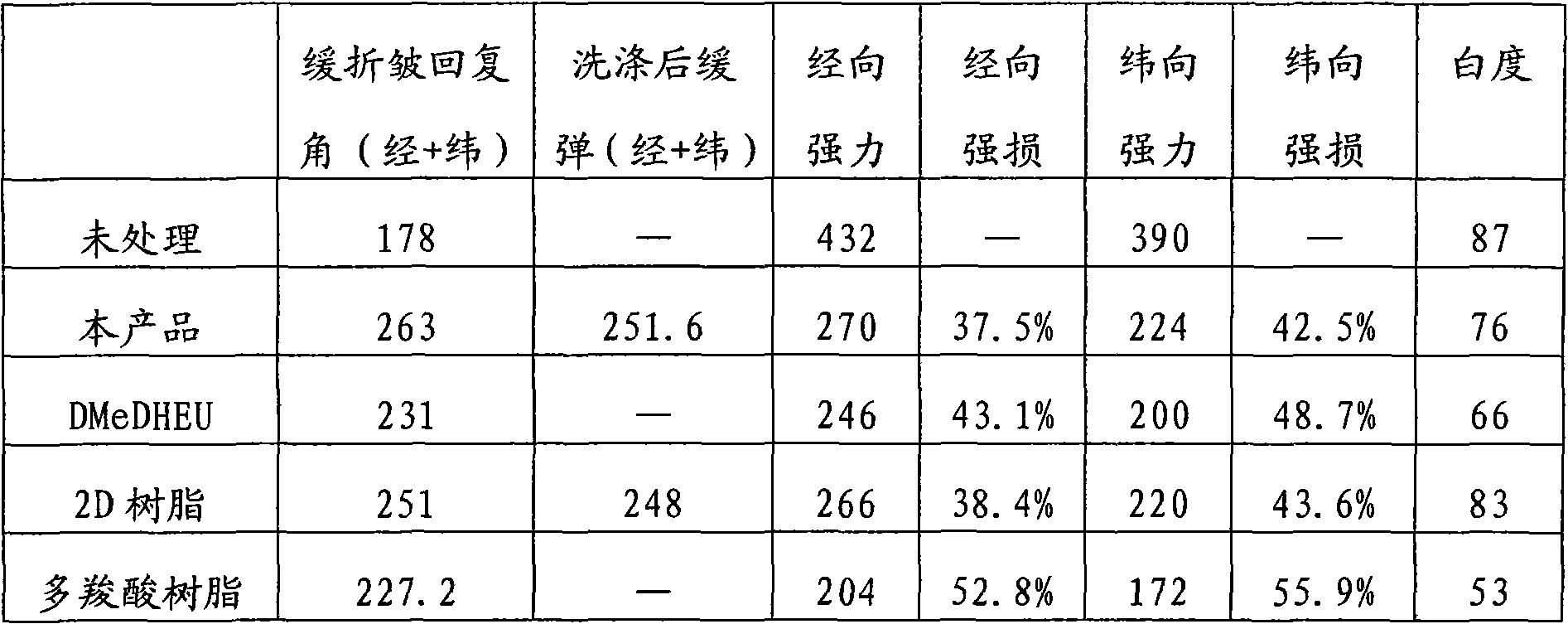

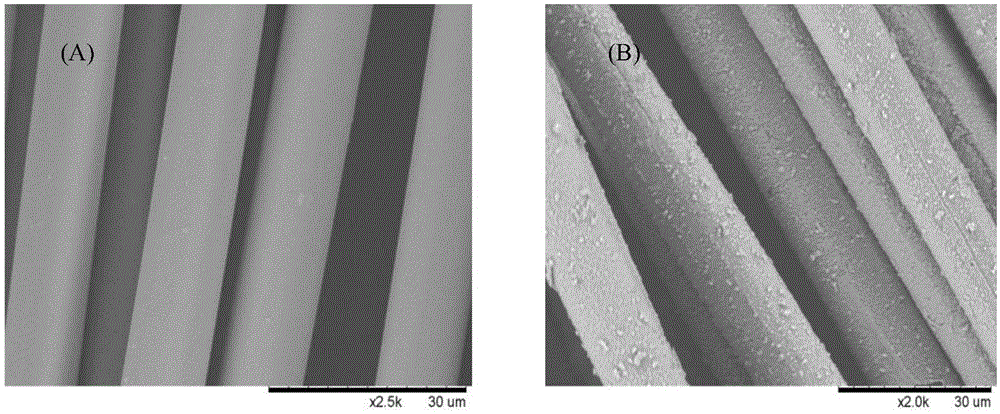

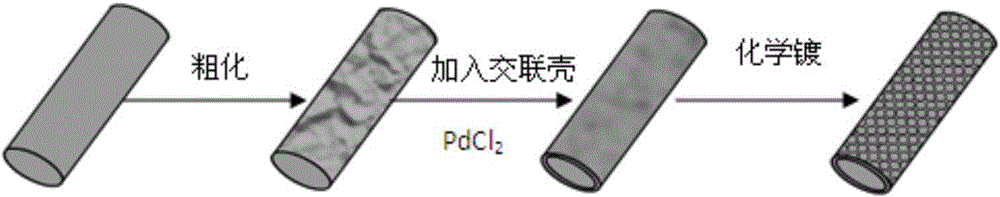

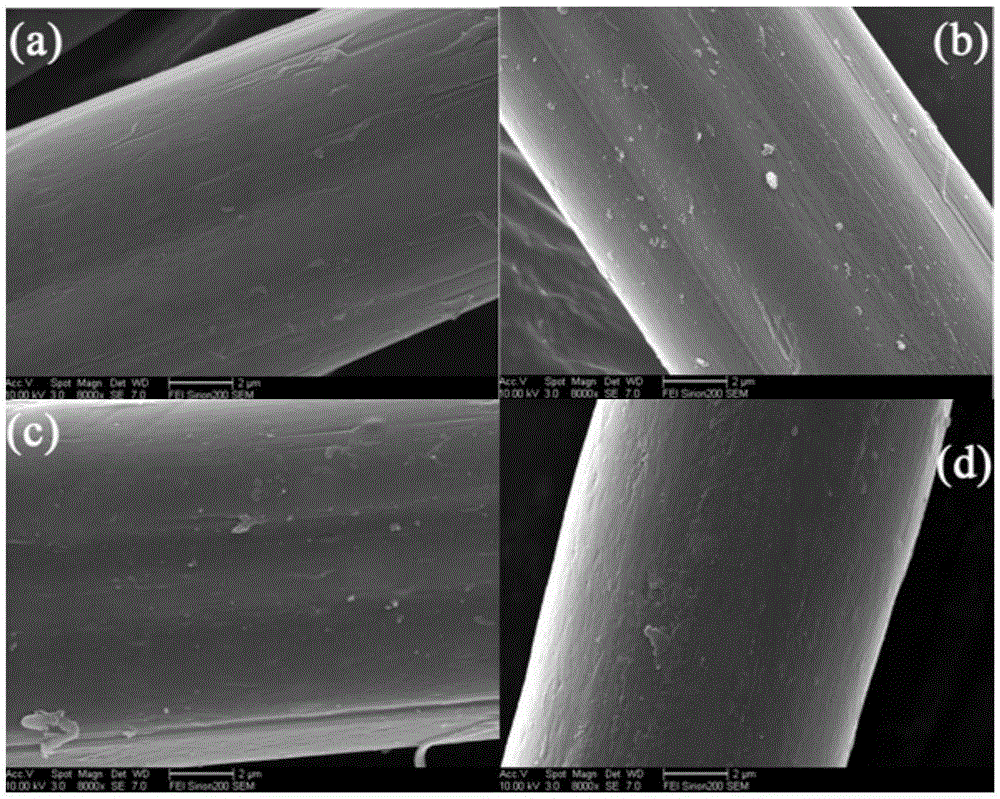

Method for chemical silver-plating of aramid conductive fibers

InactiveCN104532553AReduce dosageChange fastness is not good, poor durability and other issuesFibre typesLiquid/solution decomposition chemical coatingCooking & bakingRoom temperature

The invention relates to a method for chemical silver-plating of aramid conductive fibers. The method comprises the following steps: (1) preparing an acidic potassium permanganate solution, soaking aramid fibers, performing supersonic treatment at 20-50 DEG C for 20-40 minutes, then taking out the fibers, washing and drying; (2) dropwise adding a crosslinking agent into a chitosan solution under a low-temperature condition, stirring, soaking the aramid fibers, heating to room temperature, padding and baking; (3) preparing a palladium chloride solution, soaking the aramid fibers, and drying; and (4) preparing a silver-plating solution, soaking the aramid fibers, performing chemical silver-plating, and drying. The aramid conductive fibers prepared by the method provided by the invention are small in strength loss and high in conductivity (the fiber resistance is less than or equal to 0.4 ohm / cm), the reaction condition is mild, and the treatment method is simple, convenient and feasible.

Owner:DONGHUA UNIV

Low-addition-amount environment-friendly alkali-free chlorine liquid accelerator and preparation method thereof

The invention discloses a low-addition-amount environment-friendly alkali-free chlorine liquid accelerator. The low-addition-amount environment-friendly alkali-free chlorine liquid accelerator is prepared from, by mass, 45-55% of aluminum sulphate, 5-10% of magnesium sulfate, 5-10% of alcohol amine, 1-5% of organic acid, 1-5% of high-molecular polymer, 0-3% of a stabilizing agent and the balance water. The aluminum sulphate is at the industrial level, and the mass fraction percent of alumina is larger than or equal to 16.00. The magnesium sulfate is at the industrial level, and the alcohol amine is diethanolamine or triethanolamine. The organic acid is oxalic acid, formic acid or benzoic acid. The high-molecular polymer is polyacrylic acid or polyacrylamide. The stabilizing agent contains citric acid. The organic acid is used as a coagulation accelerating component and a pH adjusting agent, and on the basis that no alkali exists, the accelerator is stable and free of strength loss within 28 days, and concrete resilience is small, the addition amount is remarkably reduced; polyacrylic acid is used, not only is later-stage strength not affected, but also the stability of a solution is improved, and the stable time of the accelerator is longer than half a year.

Owner:WUHAN UNIV OF TECH

Method for thermally modifying wood by oil palm oil

ActiveCN102152361AFast heat transferHigh boiling pointWood treatment detailsIncrease sizeRoom temperature

The invention relates to a method for thermally modifying wood by oil palm oil. The method comprises the following steps of: stacking the wood stably, and then placing the wood stack in a treating tank; heating up the oil palm oil and then filling to the treating tank, completely covering the wood by the oil palm oil, heating up the wood, and keeping the temperature for 0.5-3 hours for thermally modifying the wood when the temperature of the wood reaches 200-215 DGE C; and stopping heat supply, then discharging the oil palm oil immediately, filling atomized water into the treating tank to gradually cool the wood, and then naturally cooling the wood to the room temperature (30 DEG C) so as to complete the treatment. The method in the invention is simple in process; the wood is isolated from the air by the oil palm oil; the wood is effectively prevented from oxidation and degradation; the thermal treatment features in fast heating speed, short treating period and low cost; the treated wood features in increased size stability, small bending resistance intensity loss, high corrosion resistance, high intensity, good durability and the like; and the wood is convenient for industrial application, and can be widely used for the indoor and outdoor furniture, landscapes, finishing materials and the like.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

Method for improving performance of superhigh temperature heat-treated wood

ActiveCN101774195APlay a protective effectAvoid or reduce strength lossCoating impregnationCoatingsBorideAqueous solution

The invention belongs to the field of wood modification, in particular to a method for improving the performance of superhigh temperature heat-treated wood. In the method, boride is selected to prepare aqueous solution; then, the wood is impregnated with the boride aqueous solution to ensure that the drug-loading rate of the boride in the wood is between 2.8 and 12kg / m3; after air drying, the wood is dried and heated to realize improvement of the performance of the superhigh temperature heat-treated wood. The method has simple process and low cost, and pretreats the wood by using the boride before heat treatment so as to play roles in protecting the wood, reducing degradation of hemicellulose and the like, avoiding or reducing strength loss of the wood in high temperature heat treatment, making up the defect that the heat-treated wood does not resist worm damage, and improving the application value of the heat-treated wood.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

Method for manufacturing split ultrafine fiber hydro-entangled nonwoven fabric by adopting mechanical fiber spreading

InactiveCN101760902ANo pollution in the processReduce consumptionNon-woven fabricsStretchingWeb structureWeightlessness

The invention relates to a method for manufacturing a split ultrafine fiber hydro-entangled nonwoven fabric by adopting mechanical fiber spreading, which comprises the following steps of: together finishing the fiber spreading and splitting of two different component fibers of a split fiber in a nonwoven fabric by adopting two mechanical fiber spreading methods, i.e. a hydro-entangling method and a bidirectional stretching method with no environment pollution, no weightlessness and low strength loss, and finally preparing the ultrafine fiber hydro-entangled nonwoven fabric containing two different components. Through detection, the fineness of a univalve fiber after fiber spreading is 0.05-0.50, the average fiber spreading ratio is 80 percent, the weight-loss ratio is 0 percent, and the average strength loss is 1.2 percent. The method has simple operation, no use of a chemical agent, little fiber damage, less energy consumption and no environment pollution. The prepared ultrafine fiber nonwoven fabric has the excellent characteristics of high strength, air permeability, moisture permeability, strong adsorption capacity, three-dimensional disorderly fiber web structure, chamois-like appearance and the like and can be widely applied to the fields of high-grade synthetic leather, artificial chamois, high-grade wiping fabrics and the like.

Owner:DONGHUA UNIV

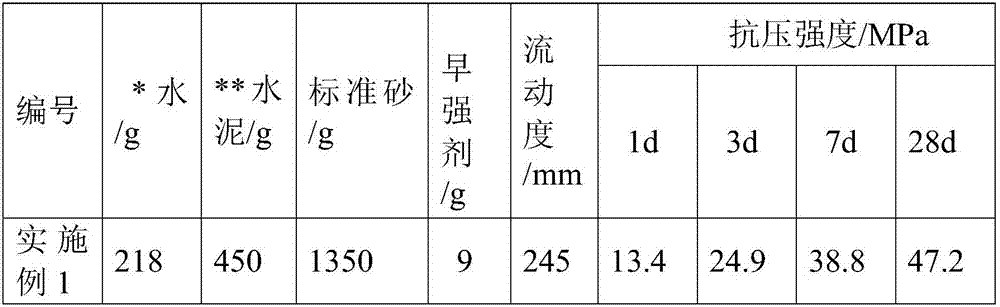

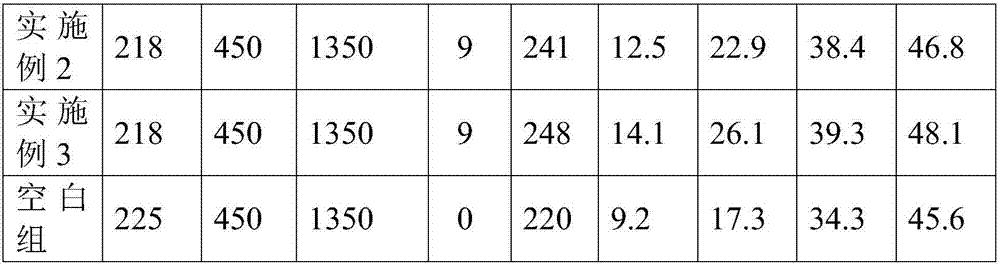

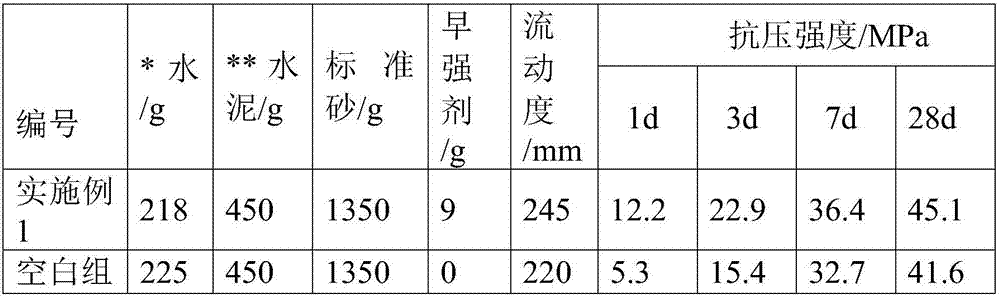

Crystal nucleus concrete early strength agent and preparation method thereof

The invention discloses a crystal nucleus concrete early strength agent and a preparation method thereof. 1,000 parts of crystal nucleus concrete early strength agent are prepared from the following raw materials in parts by weight: 100-150 parts of a polymer, 20-50 parts of sodium metasilicate pentahydrate, 60-90 parts of calcium nitrate tetrahydrate and the balance of deionized water. The preparation method comprises the steps of firstly adding the polymer to a three-neck flask, adding the deionized water to form a base solution, putting the flask into a hot water bath, controlling the temperature and stirring; taking the sodium metasilicate pentahydrate, and adding the deionized water to prepare a solution A; taking the calcium nitrate tetrahydrate and adding the deionized water to prepare a solution B; dropwise adding the solution A and the solution B to the base solution at the same rate, carrying out heat preservation on the product, stirring and reacting; and finally quickly cooling a product to a room temperature to obtain the final product, namely the crystal nucleus concrete early strength agent. The crystal nucleus concrete early strength agent is good in performance, is capable of making concrete solidified quickly, is short in demolding time and not easy to collapse and has a certain water reducing effect, and the later strength loss of the concrete is small.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

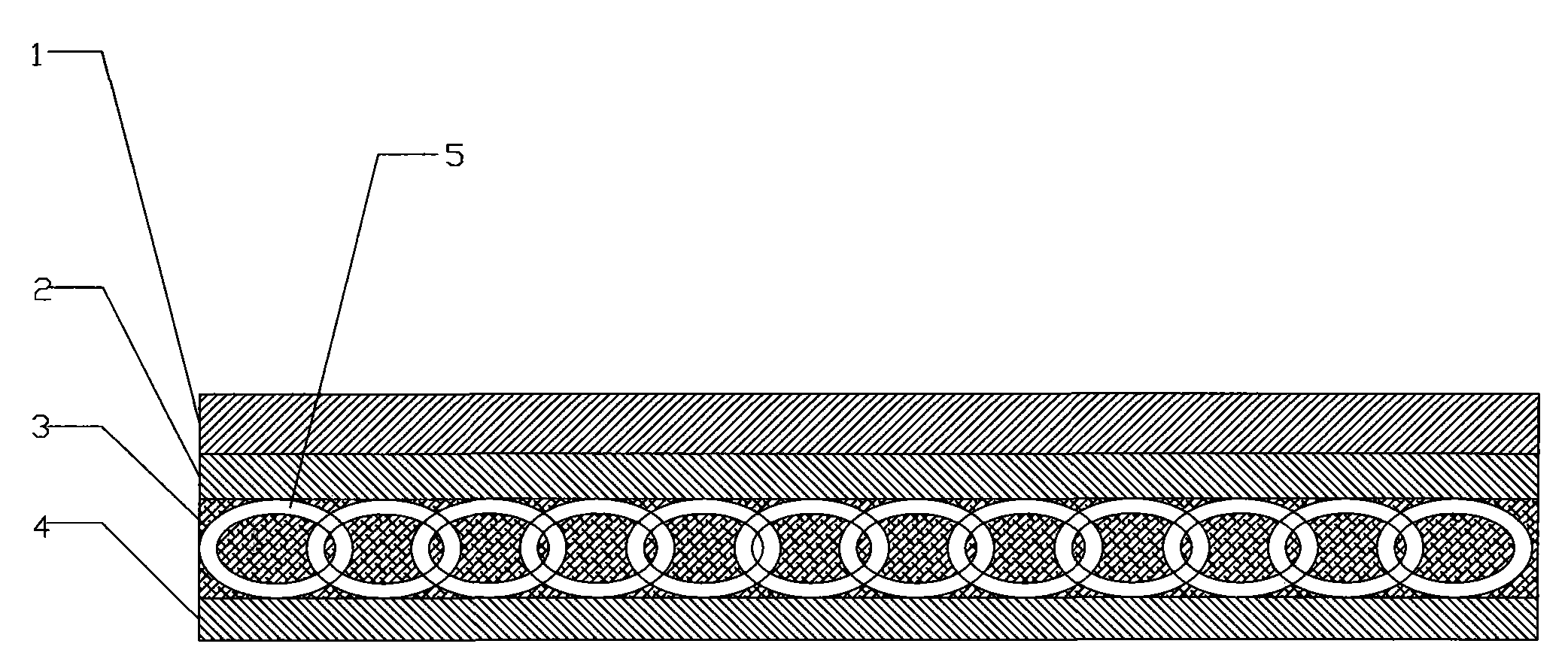

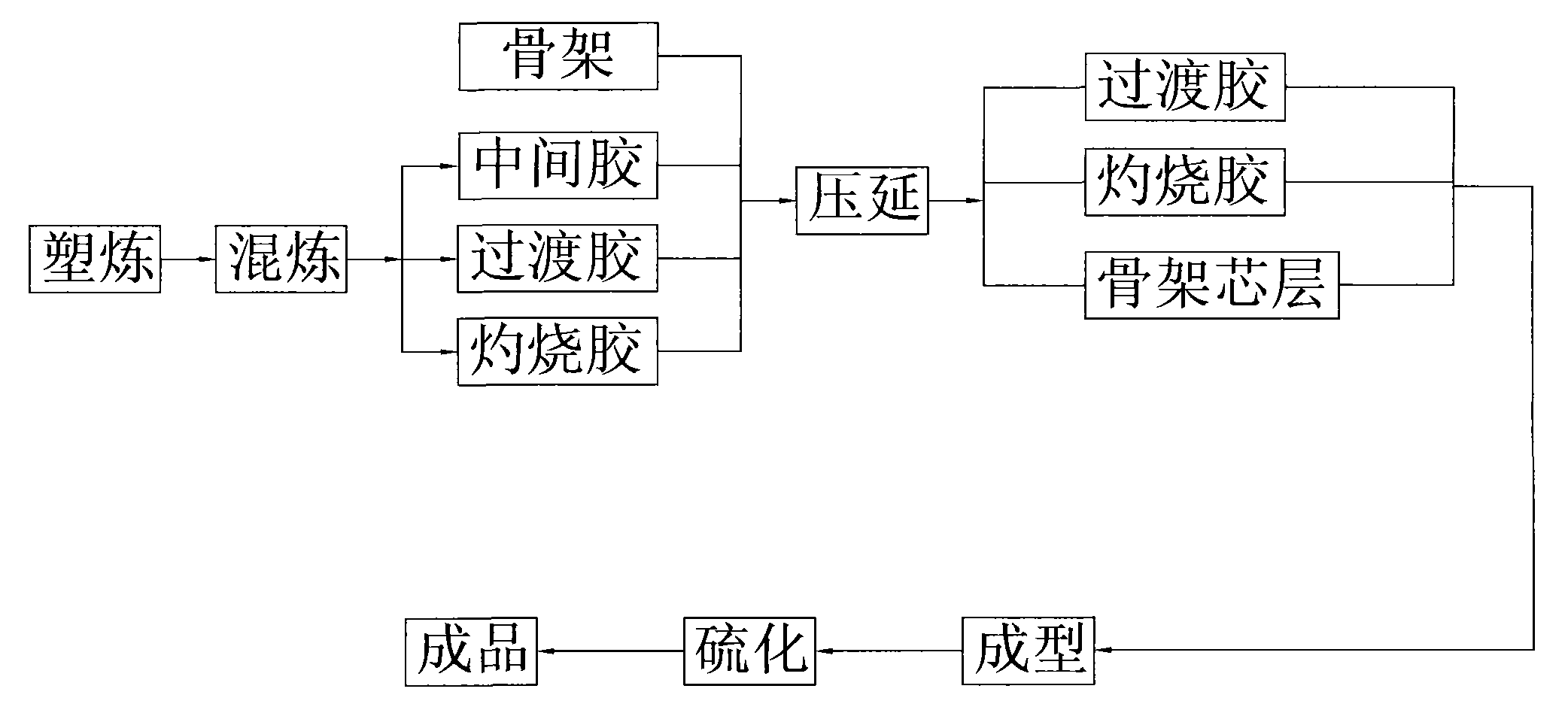

Firing resistant conveying belt for metal screen and method for producing same

InactiveCN101648644AImprove resistance to burningHigh strengthConveyorsLaminationSurface layerVulcanization

The invention relates to a firing resistant conveying belt for a metal screen and a method for producing the same. The conveying belt comprises a skeleton core layer and a heat resistant strong transition layer coated on the outer surface of the skeleton core layer, wherein the upper surface of the heat resistant strong transition layer is coated with a high-temperature firing resistant surface layer; and the skeleton core layer consists of a metallic skeleton and a middle glue layer extruded in the metallic skeleton. The production method comprises the steps of plastication, mixing, calendering, forming and vulcanization. Due to the multi-layer structure, the conveying belt has the advantages of much high high-temperature resistant ability, high strength and no delaminating and bubbling during conveying and the like, has the characteristics of small strength loss at a high temperature, no contraction deformation and insusceptibility to fracture, and has a greatly prolonged service life.

Owner:赵建军

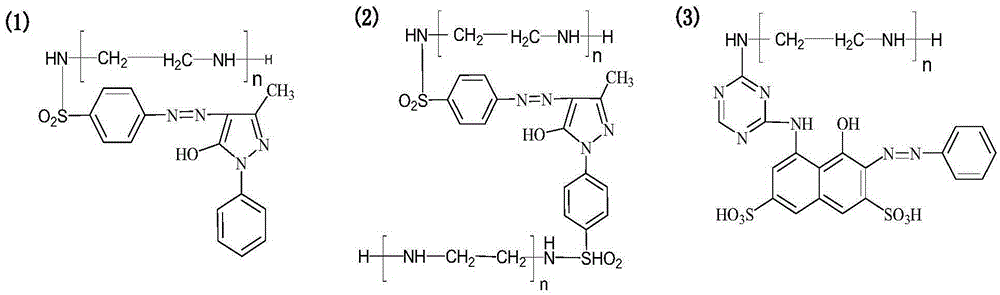

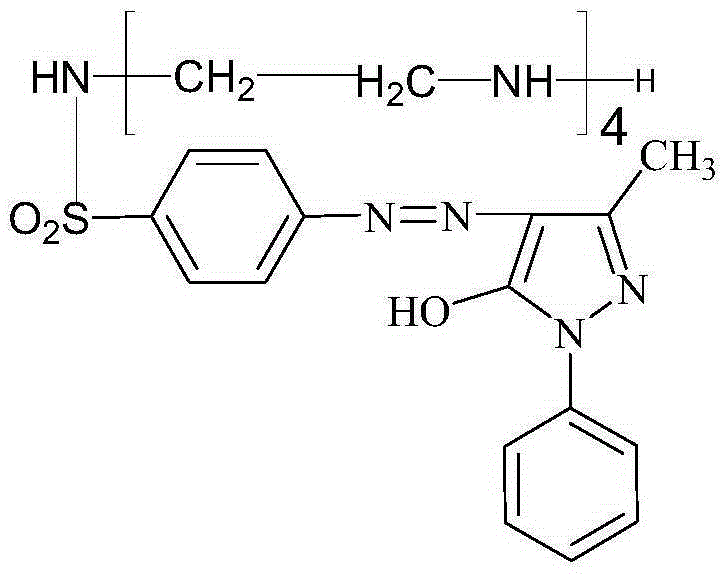

Dyeing method for calcium alginate fibers

The invention belongs to the technical field of fiber dyeing, and particularly relates to a dyeing method for calcium alginate fibers. According to the dyeing method for the calcium alginate fibers, dye containing polyethylene polyamine framework structures is adopted to dye the calcium alginate fibers; the defect that the fibers are damaged due to the fact that inorganic salt needs to be added for dyeing accelerating in the dyeing process of traditional dye is fundamentally overcome, and the strength loss of the fibers after dyeing is small; meanwhile, compared with the weaker intermolecular force and hydrogen-bond interaction between general direct dye and the fibers, the acting force between molecules of the dye and the fibers is higher, and then the advantages of being higher in dye-uptake rate and soaping fastness and the like are achieved; the dyed fibers are uniform and bright in color and meet the dyeing requirements of the calcium alginate fibers, and the dyeing method is economical in energy and environmentally friendly.

Owner:SHANDONG UNIV OF TECH

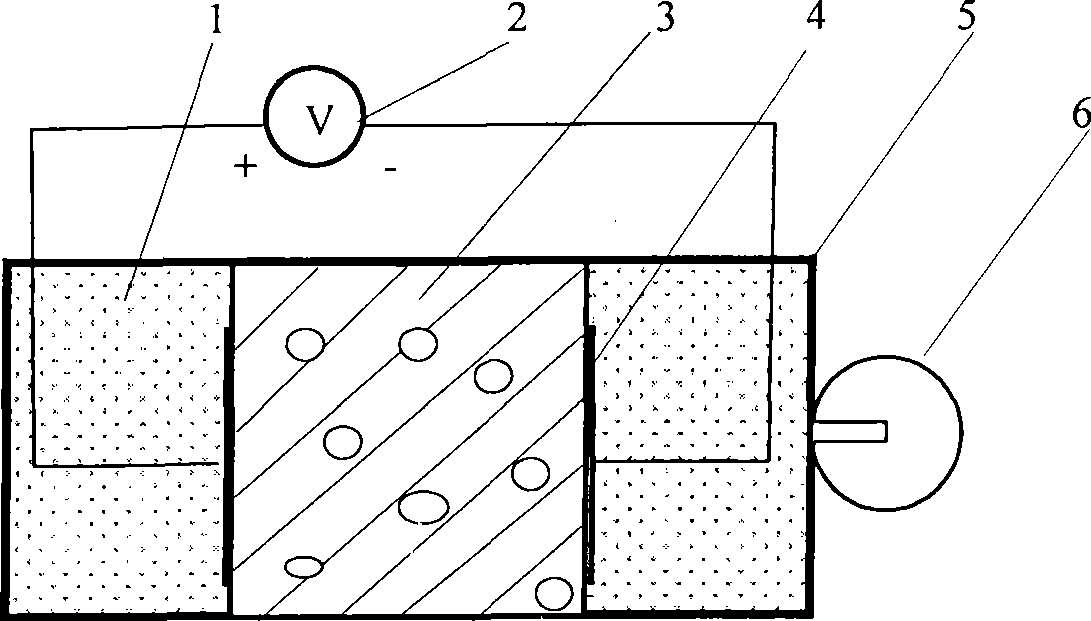

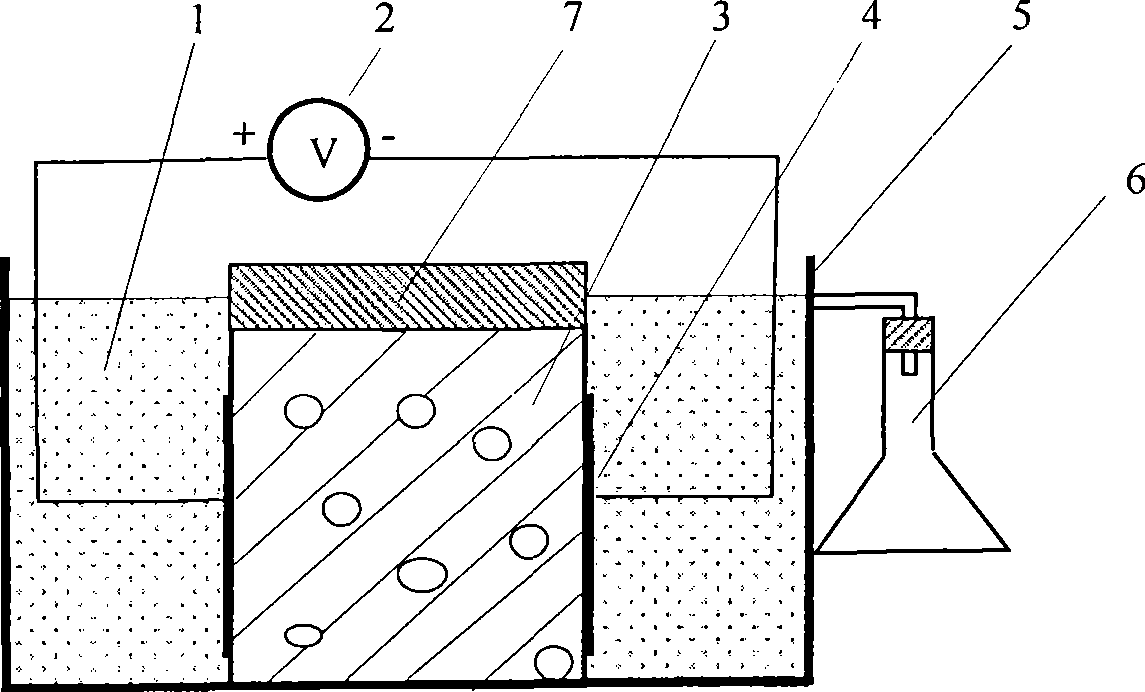

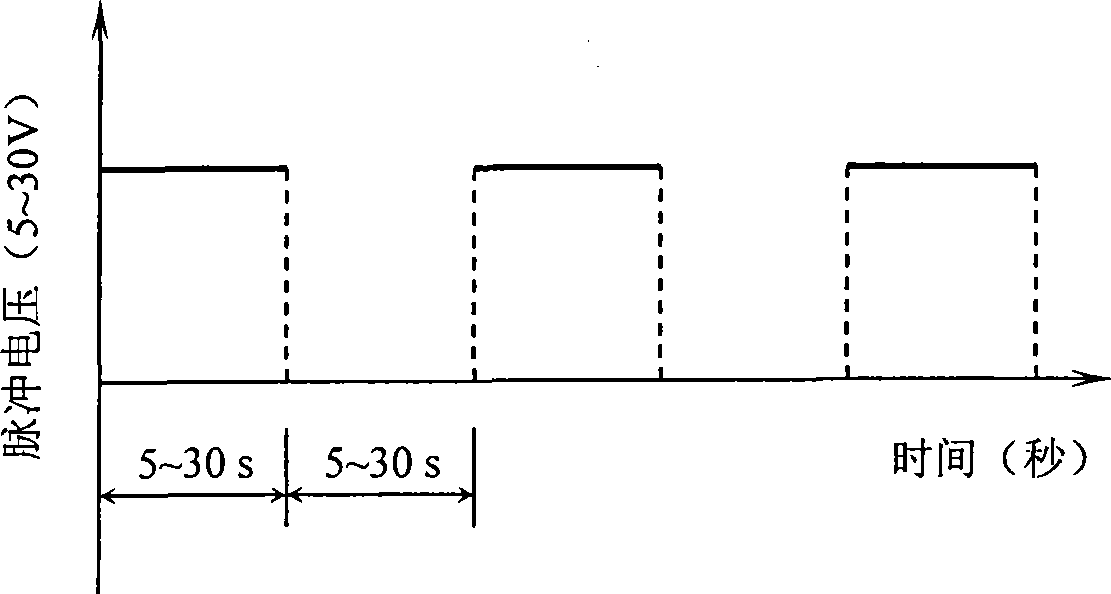

Anti-sulphates corrosive test method and test device of cement concrete

InactiveCN101435816AQuickly judge the sulfate corrosion resistanceQuickly judge corrosion performanceMaterial strength using tensile/compressive forcesMaterial testing goodsDiffusionPulse voltage

The invention relates to a method for testing the sulphate erosion resistance of cement concrete and a device thereof. The method utilizes a principle of electroosmosis pulse technology, promotes the diffusion of sulphate ions to the inside of the cement concrete and rapidly detects the performance of sulphate erosion resistance of the cement concrete; and the capacity for resisting sulphate erosion of the cement concrete is judged according to the quality change and the strength loss value of the cement concrete. In the testing method, a concrete test piece is placed into a sulphate environment; and according to the condition of reaction between the sulphate ions and a hydration product of the concrete test piece under the action of pulse voltage, the performance of sulphate erosion resistance of the concrete is rapidly judged. The testing method has small testing strength and short period; the whole testing process is completed by only 7 days; and a testing result is rather accurate and can really reflect the situation of the concrete eroded in the sulphate environment.

Owner:CHONGQING UNIV

Calcium sulfate retarder and preparation method thereof

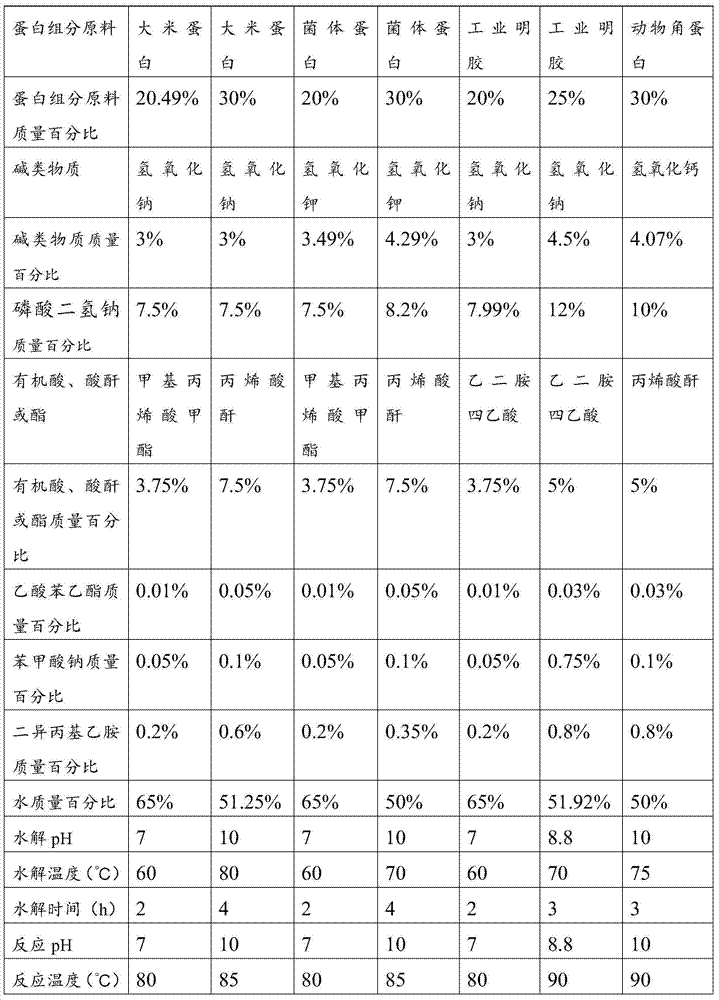

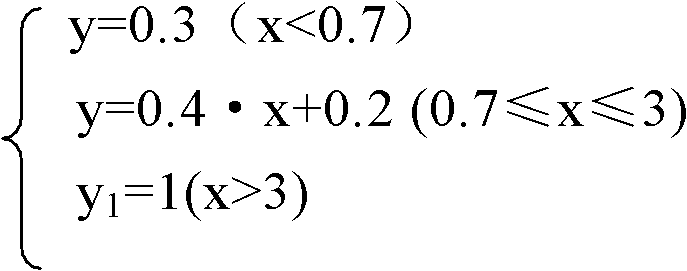

The invention relates to the field of gypsum building materials, and discloses a calcium sulfate retarder. The calcium sulfate retarder is prepared from the following components in percentage by mass: 20-30 percent of a protein component raw material, 3-5 percent of an alkaline substance, 7.5-15 percent of sodium dihydrogen phosphate, 3.75-7.5 percent of organic acid, anhydride or ester, 0.01-0.05 percent of phenethyl acetate, 0.05-0.1 percent of sodium benzoate, 0.2-0.8 percent of diisopropylethylamine and 50-65 percent of water. The invention further discloses a method for preparing the calcium sulfate retarder. The calcium sulfate retarder is used for regulating the coagulation of building gypsum, and has the characteristics of low cost, good delayed coagulation effect and small strength loss.

Owner:SUZHOU XINGBANG CHEM BUILDING MATERIALS

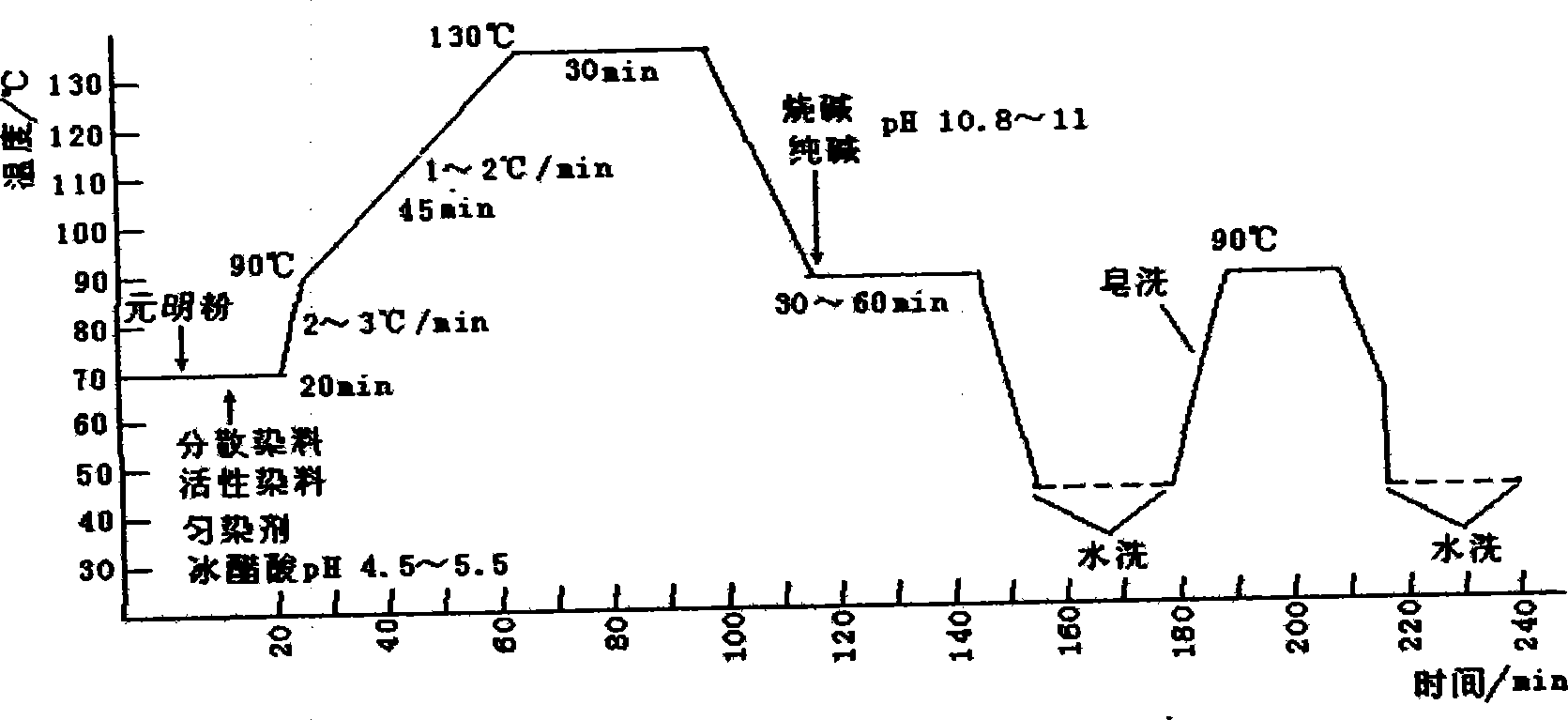

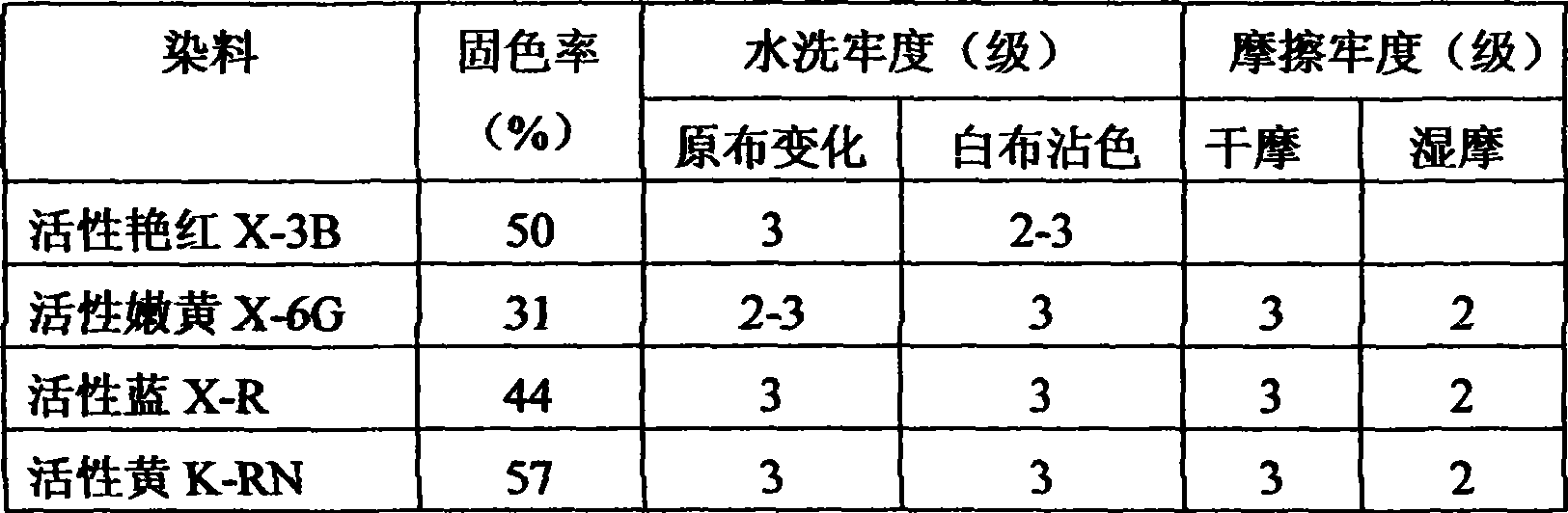

Dyeing method of wool textile with low energy consumption and low damage and wool fabric

ActiveCN102206924AAvoid damageEfficient use ofDyeing processAnimal fibresPolymer scienceStrength loss

The invention discloses a dyeing method of a wool textile with low energy consumption and low damage, comprising the following procedures: a pre-processing procedure, a dyeing procedure, an acid neutralizing procedure and an insect prevention procedure; the pre-processing procedure is carried out in a pre-processing fluid with a pH value of 8.2 to 8.7; the dyeing procedure is carried out in a dyeing fluid with a pH value of 4.5-7; and the acid neutralizing procedure is performed in a post-processing fluid with a pH value of 4-6. The invention further relates to a wool fabric manufactured according to the dyeing method of the wool textile with low energy consumption and low damage. Due to the adoption of the dyeing method disclosed by the invention, the dyeing temperature can be reduced from 98 DEG C in the conventional technique to 80-90 DEG C, the strength loss rate of the wool during the dyeing stage can be controlled at about 30%, and the dyed wool textile has good cloth surfaces and good color fastnesses.

Owner:上海嘉麟杰纺织科技有限公司

Surface treatment method of aramid fiber III

The invention provides a surface treatment method of aramid fiber III, comprising preparation of surface treating agent, surface treatment, drying and the like. The method can improve the flexibility of the aramid fiber III, perfects hand feeling, reduces strength loss caused by factors such as bending and the like in the subsequent operation process, and more importantly improves the surface polarity of the aramid fiber III, thus improving the interface adhesive property of aramid fiber III / epoxy composite material, and further enhancing the interlaminar shear strength of the aramid fiber III / epoxy composite material, wherein the interlaminar shear strength reaches 45-55Mpa. Furthermore, the method is simple and safe in operation, and solvent can be recovered, so that on-line continuous treatment can be easily realized; and the performance of the aramid fiber III is not attenuated, and the aramid fiber III / epoxy resin prepared by aramid fiber which is placed for a longer time has the shear strength being the same as that of the aramid fiber III / epoxy resin treated just now.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Non-iron finishing method for piece-dyed pure cotton fabric

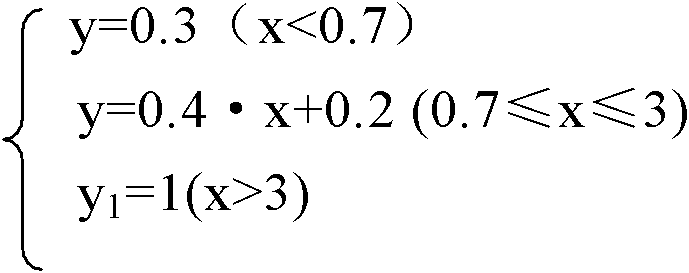

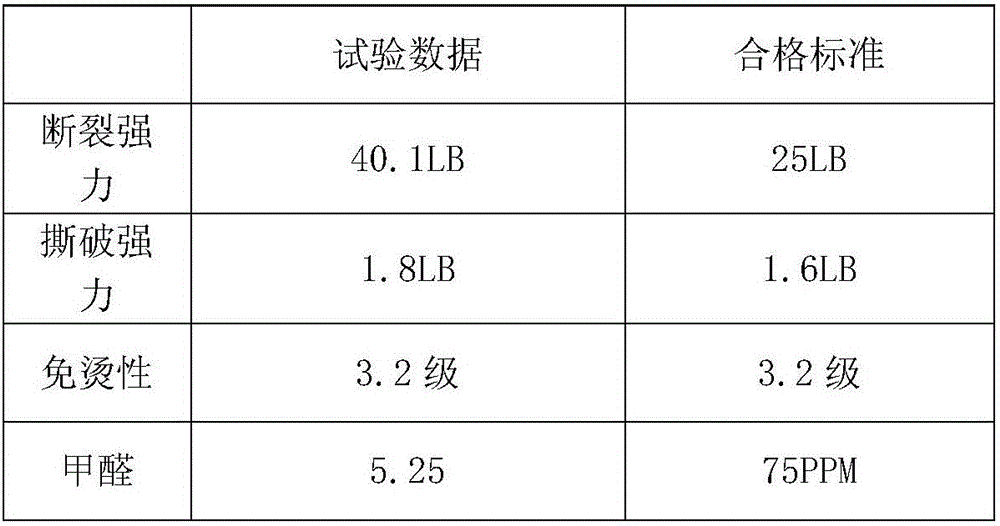

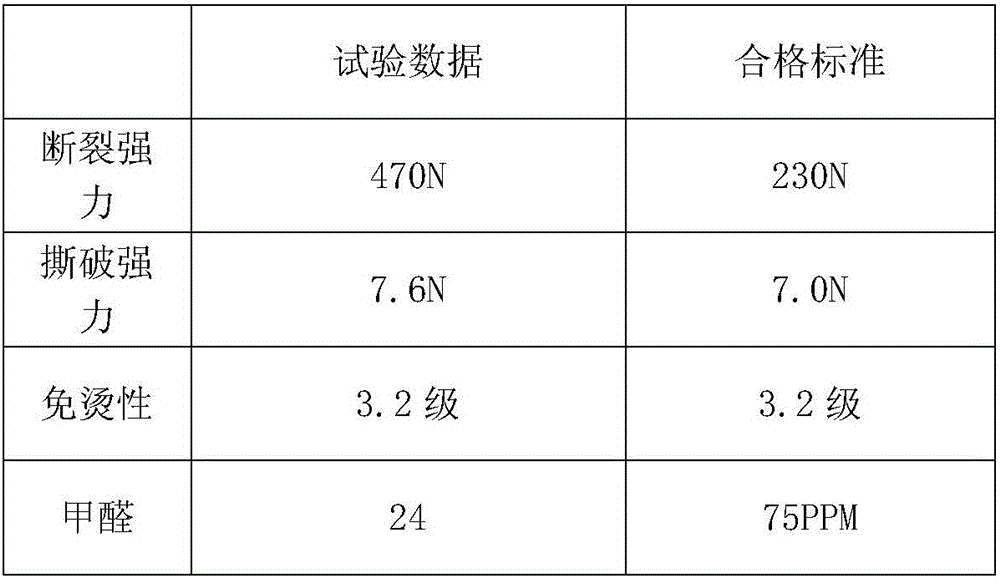

InactiveCN105714559AGuaranteed responsePrevent strong damageSucessive textile treatmentsLiquid/gas/vapor removalFiberEngineering

The invention provides a non-iron finishing method for piece-dyed pure cotton fabric. The non-iron finishing method is characterized by comprising technological processes in sequence as follows: cloth turning, singeing, desizing and scouring, bleaching, mercerizing, liquid ammonia finishing, non-ironing, baking, washing, tentering, pre-shrinking as well as checking and packaging, wherein an intelligent non-iron technology is adopted for the fabric, resin and fibers are subjected to a crosslinking reaction sufficiently, formaldehyde and strength loss caused by resin residues are avoided, strength repair is avoided in a dyeing and finishing process, the content of formaldehyde of a cloth cover can be reduced, and the increase of formaldehyde can be prevented; with the adoption of non-iron finishing, the appearance of the fabric washed 5 times with an AATCC 124 method can reach level 3.2 or higher, and the content of formaldehyde is 60 PPM or lower through testing with a JIS L1041:2011 / 8.1.4B method. The processed fabric is soft and comfortable to wear, is environment-friendly and has an excellent non-iron effect.

Owner:鲁丰织染有限公司

Alkali-free liquid accelerator and preparation method thereof

ActiveCN110451844AHigh solid contentGood quick setting effectAluminium sulfatesAluminium sulfateOrganic acid

The invention discloses an alkali-free liquid accelerator and a preparation method thereof, and relates to the technical field of concrete admixtures. The technical solution main point is that the alkali-free liquid accelerator comprises the following components in parts by weight: 45-55 parts of polyaluminium sulfate, 3-5 parts of an organic acid, 0.5-1 part of an inorganic acid, 2-4 parts of a stabilizer, 1-2 parts of an early strength agent, 1-2 parts of a thickener, and 40-50 parts of water. By combination of polyaluminium sulfate with the organic acid, the inorganic acid and the stabilizer, the prepared accelerator has the advantages of low blending amount, good quick-setting effects and low strength loss.

Owner:重庆腾治科技有限公司

Heat-resistant and high-strength concrete having gradient enclosing structure, and preparation method thereof

ActiveCN106116333AHigh bonding strengthIncrease internal effective humiditySolid waste managementFiberAluminate

The present invention discloses a heat-resistant and high-strength concrete having a gradient enclosing structure. The heat-resistant and high-strength concrete comprises an inner layer high-strength and heat-resistant concrete and an outer layer high heat-resistant concrete from inside to outside, wherein the inner layer high-strength and heat-resistant concrete adopts a silicate-based cement, fly ash, mineral powder, river sand, basalt graded gravel, toughening fiber, a polycarboxylic acid water reducing agent, an inner curing light aggregate and water as raw materials, and the outer layer high heat-resistant concrete adopts an aluminum-based cement, aluminum sand, aluminum stone, hollow fiber, a polycarboxylic acid water reducing agent, an inner curing light aggregate and water as raw materials. According to the present invention, the gradient enclosing structure is designed, such that the generated calcium aluminate and the generated dicalcium aluminate in the outer layer high heat-resistant concrete in the high temperature environment can be converted into the non-hydrated alumina ceramic phase at the high temperature, and the non-hydrated alumina ceramic phase is firmly bonded with the aluminum stone, the aluminum sand and the like so as to significantly increase the high-temperature resistance; and the large doping amount of the fly ash and the mineral powder are used in the inner layer high-strength and heat-resistant concrete, such that the durability is ensured, and the disadvantages of rapid strength loss in the high temperature environment and the like of the existing ordinary silicate heat-resistant concrete can be effectively solved.

Owner:HUBEI UNIV

Preparation method of low-alkali polymer high-efficient liquid setting-accelerator for sprayed concrete

The invention discloses a preparation method of a low-alkali polymer high-efficient liquid setting-accelerator for sprayed concrete. The preparation method comprises the following steps: (1) preparing an aluminate mother solution; (2) preparing a modifying agent; (3) preparing a low-alkali polymer high-efficient liquid setting-accelerator. The disclosed low-alkali polymer high-efficient liquid setting-accelerator has a uniform and stable property and strong adaptability; the mixing amount is 2 to 4% of the cement mass, the initial setting time is within 2 minutes, the final setting time is within 5 minutes, the strength loss in the later stage of concrete is within 10%; furthermore, the liquid setting-accelerator can efficiently reduce the dust amount and resilience value during the sprayed concrete construction and improves the strength of sprayed concrete.

Owner:SHANDONG UNIV

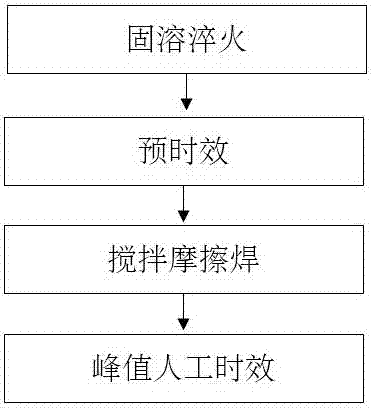

Preparation technology of 6-series aluminum alloy friction stir welding member

ActiveCN107570862AReduce manufacturing costLittle loss of strengthNon-electric welding apparatusFriction weldingPeak value

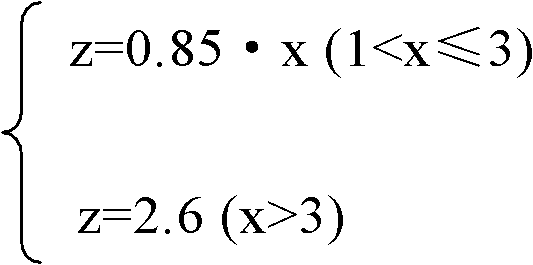

The invention discloses a preparation technology of a 6-series aluminum alloy friction stir welding member. The preparation technology mainly comprises the steps of on-line or off-line solution hardening, preageing, friction stir welding, peak-value artificial ageing and the like. According to the preparation technology of the 6-series aluminum alloy friction stir welding member, a 6-series aluminum alloy material is subjected to low-temperature preageing treatment after being subjected to solution hardening to enable the strength of aluminum alloy to keep low in a certain time, then frictionstir welding is conducted, forced cooling is conducted in a welded high-temperature area while welding is conducted to enable a solution hardening effect to be achieved, and peak-value artificial ageing is conducted on the overall member after welding is completed, so that it is guaranteed that the strength loss at the welded portion is low, and the ratio of the tensile strength of a weld joint tothe tensile strength of a base material is larger than or equal to 0.85.

Owner:广西南南铝加工有限公司

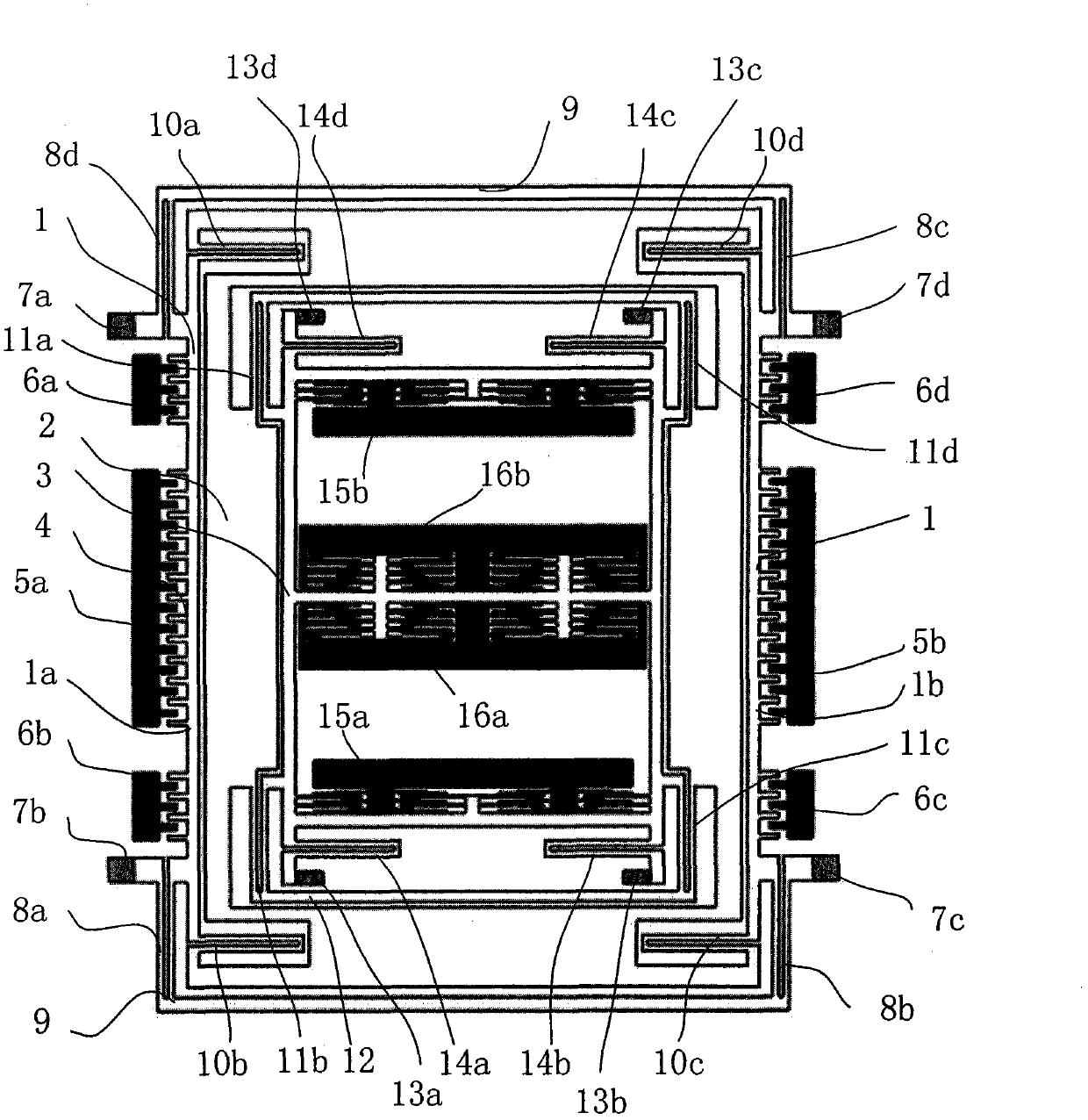

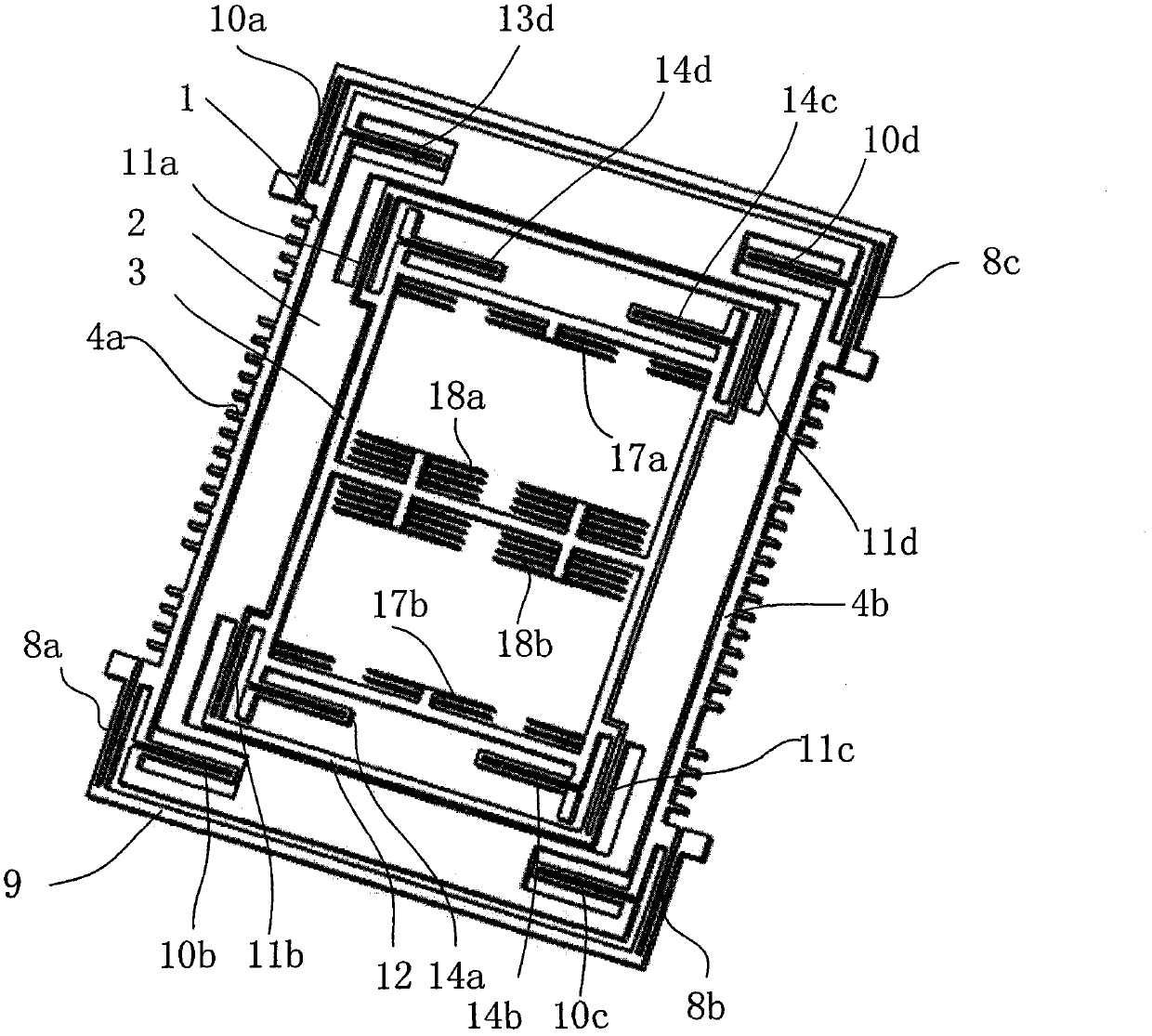

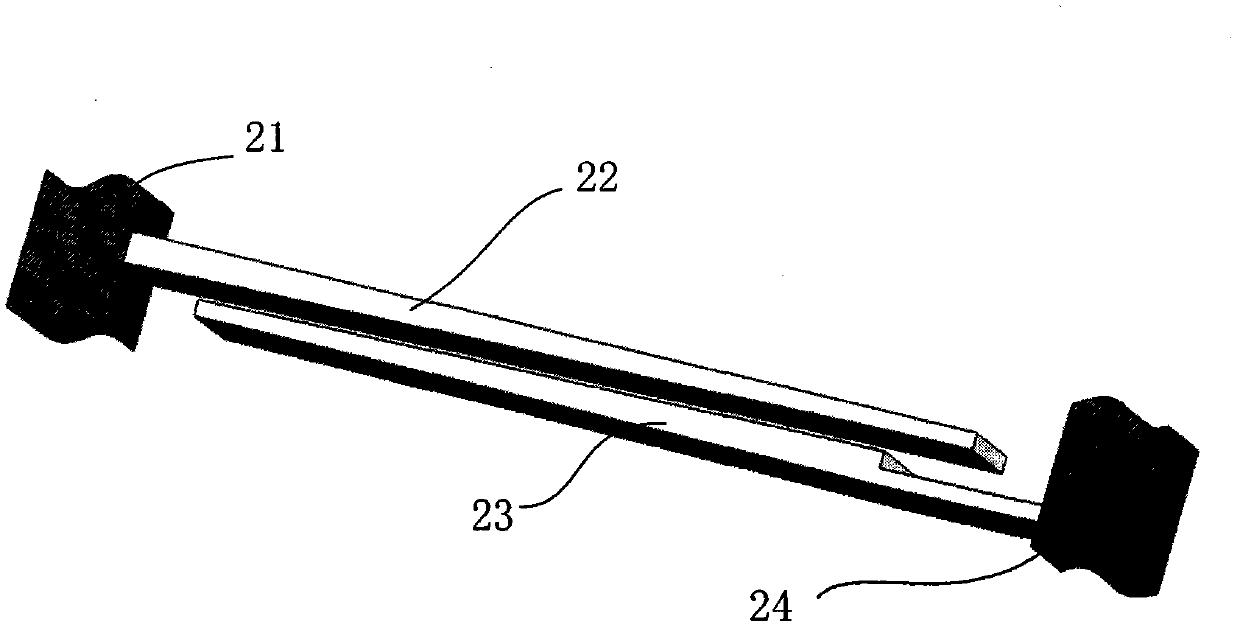

Internal and external truss type three-frame micro-mechanical gyro structure

ActiveCN102435185AMinimize Coupling ErrorLightweightSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesEngineeringUltimate tensile strength

The invention belongs to a micro-mechanical gyro structure technology field, and relates to an internal and external truss type three-frame micro-mechanical gyro structure. The structure comprises an external frame, an internal frame and a medium frame, wherein the external frame comprises two separation blocks and two groups of trussed girders. Each group of trussed girder comprises two folding beams and a truss, and the external side of each separation block has a comb electrode. Two ends of each trussed girder are connected with one folding beam respectively, the two groups of trussed girders are connected by the separation blocks, and then the external frame is formed. The external frame is fixed on the anchor points at the outer end of the structure by four folding beams, and the left and the right parts of the external frame are connected to form a complete frame by the truss. The two ends of the medium frame are separate type double-folding beams, and the external frame and the medium frame are connected by the separate type double-folding beams. The medium frame and the internal frame are connected by the truss type double-folding beams, a comb electrode is arranged in the internal frame, and the internal frame is connected to the internal anchor points of the gyro structure by four separate type double-folding beams. The structure of the invention reduces the quantity of useless mass blocks, and raises gyro susceptibility. The special hexagon pore structure minimizes the structural strength loss, and the shape of the step type comb electrode enhances the gyro stability.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

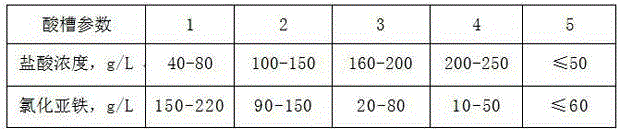

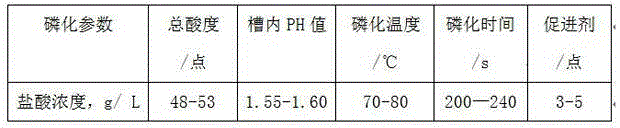

Production process of high-strength pre-stressed steel strands

InactiveCN105312341AHigh tensile strengthLow relaxation rateMetallic material coating processesExtrusion cleaning devicesPre stressPre stressing

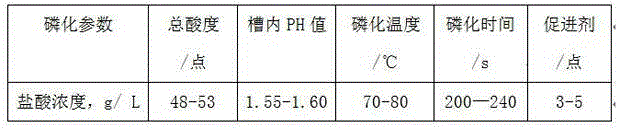

The invention discloses a production process of high-strength pre-stressed steel strands. The produced steel strands are structurally characterized in that the steel strands are 1mm in length and 7mm in width; the diameter of the steel strands is 15.20mm; the tensile strength of the steel strands is 2000MPa; the steel strands are produced by 82B coil rod high-carbon wires with diameter phi being 14mm which serve as the raw materials; the coil rods are pickled for 420 seconds by hydrochloric acid to carry out phosphorization; the maximum speed of drawing finished coils is 4m / s; the maximum part compression ratio and the absolute deformation cannot occur in the same pass during drawing; the stabilization treatment tension of the steel strands is 44-47% of the breakage tension of the steel strands; the tempering temperature is 385+ / -5 DEG C; the strength loss of the steel strands remains 1.5-3.5% so as to ensure that the steel strands obtain high relaxation resistance; the high strength loss is avoided.

Owner:GUIZHOU WIRE ROPE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com