Wood heat treatment method

A wood heat treatment and heat treatment method technology, applied in the field of wood heat treatment, can solve the problems of large decline in wood strength, difficulty in obtaining products with uniform quality, and reducing the value of treated wood, so as to reduce the loss of wood strength and expand the scope of use. The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

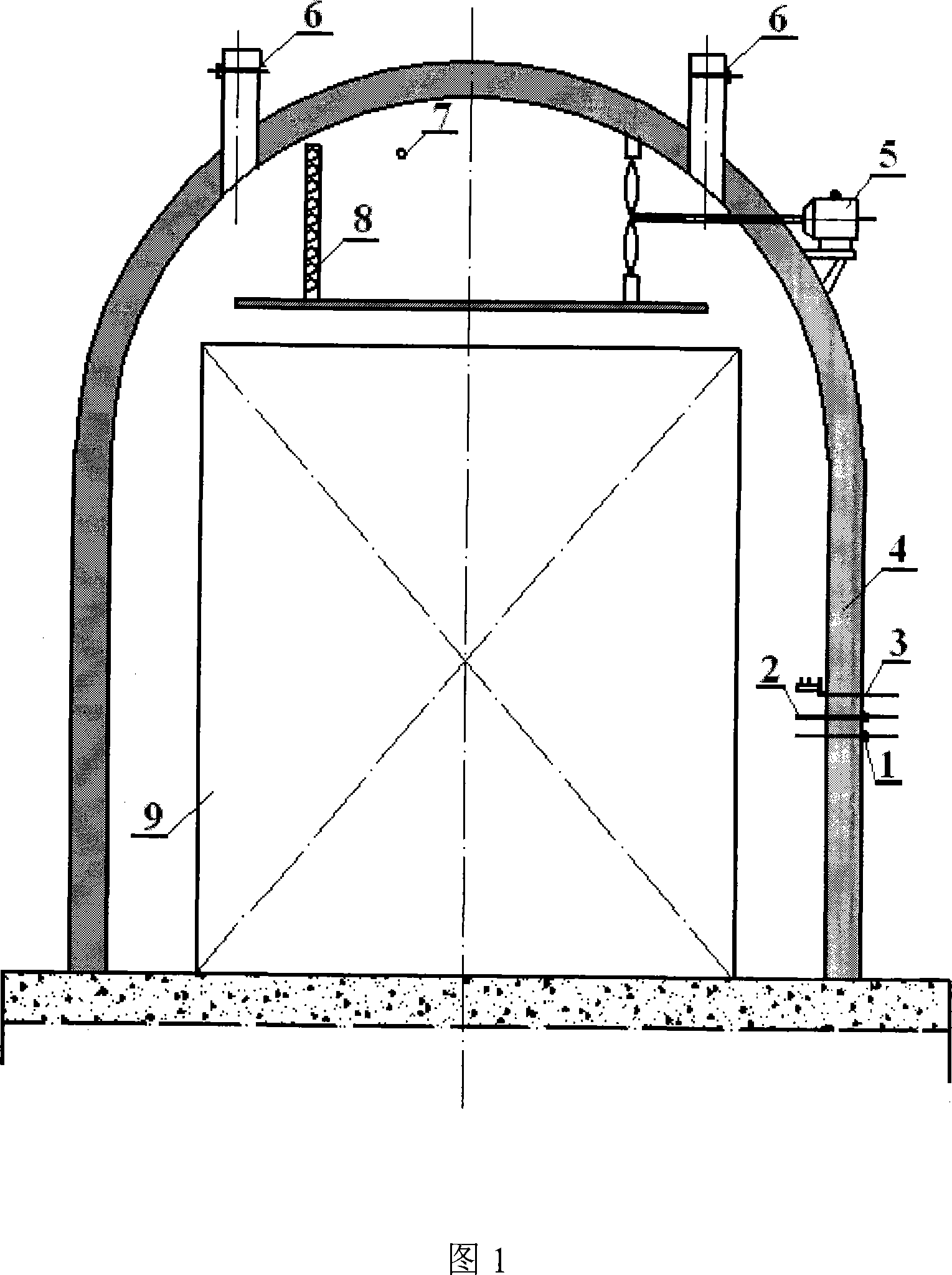

[0019] 1) Pile the poplar wood 9 with a thickness of 50 mm to be processed in the airtight space formed by the equipment housing 4 according to the wood drying method;

[0020] 2) Turn on the equipment circulation fan 5 to make the hot air medium circulate in the material pile at a speed of 1m / s in the processing equipment space;

[0021] 3) Start the heater 8 to make the temperature in the wood processing space reach the set temperature value of 80°C, and monitor the temperature through the temperature sensor 1; open the steam spray pipe 7, so that the oxygen content in the wood processing space reaches the set oxygen value. The content value is 21%, which is monitored by the oxygen content sensor 2. The temperature and oxygen content are controlled by turning on and off the heating and steaming, and the state is maintained for 7.5 hours;

[0022] 4) Then set the temperature to 150°C and the oxygen content to 12% for 5 hours;

[0023] 5) Then set the temperature and oxygen ...

example 2

[0027] 1) Pile the Chinese fir wood 9 with a thickness of 20mm to be processed in the airtight space formed by the equipment housing 4 according to the wood drying method;

[0028] 2) Turn on the equipment circulation fan 5 to circulate the hot air medium in the material pile at a speed of 1.5m / s in the processing equipment space;

[0029] 3) Turn on the heater 8 to make the temperature in the wood treatment space reach the set temperature value of 150° C., and turn on the steam spray pipe 7 to make the oxygen content in the wood treatment space reach the predetermined oxygen content value of 12%, and this state is maintained 1 hour time;

[0030] 4) Then set the temperature to 200°C and the oxygen content to 6% for 1 hour;

[0031] 5) Then set the temperature and oxygen content to 260°C and 2%, respectively, and maintain it for 1 hour;

[0032] 6) Turn off the heater 8 and steam spray pipe 7, open the dehumidification valve 6 to cool down, and when the temperature in the wo...

example 3

[0035] 7) Pile the birch wood 9 with a thickness of 4mm to be processed in the airtight space formed by the equipment housing 4 according to the wood drying method;

[0036] 8) Turn on the equipment circulation fan 5 to circulate the hot air medium in the processing equipment space at a speed of 5m / s in the processing space;

[0037] 9) Turn on the heater 8 to make the temperature in the wood treatment space reach the set temperature value of 120°C, turn on the steam spray pipe 7, and make the oxygen content in the wood treatment space reach the set oxygen content value of 15%, and this state is maintained 0.6 hours;

[0038] 10) Then set the temperature to 180°C, set the oxygen content to 8%, and maintain it for 0.8 hours;

[0039] 11) Then set the temperature and oxygen content to 220°C and 4%, respectively, and maintain it for 0.8 hours;

[0040] 12) Turn off the heater 8 and the spray steam pipe 7, open the dehumidification valve 6 to cool down, and when the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com