Method for preparing high-porosity porous ceramic material

A technology of porous ceramics and porosity, which is applied in the direction of ceramic products, applications, and other household appliances, and can solve the problems of excessive shrinkage, cracking, and inability to effectively maintain porosity of the green body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

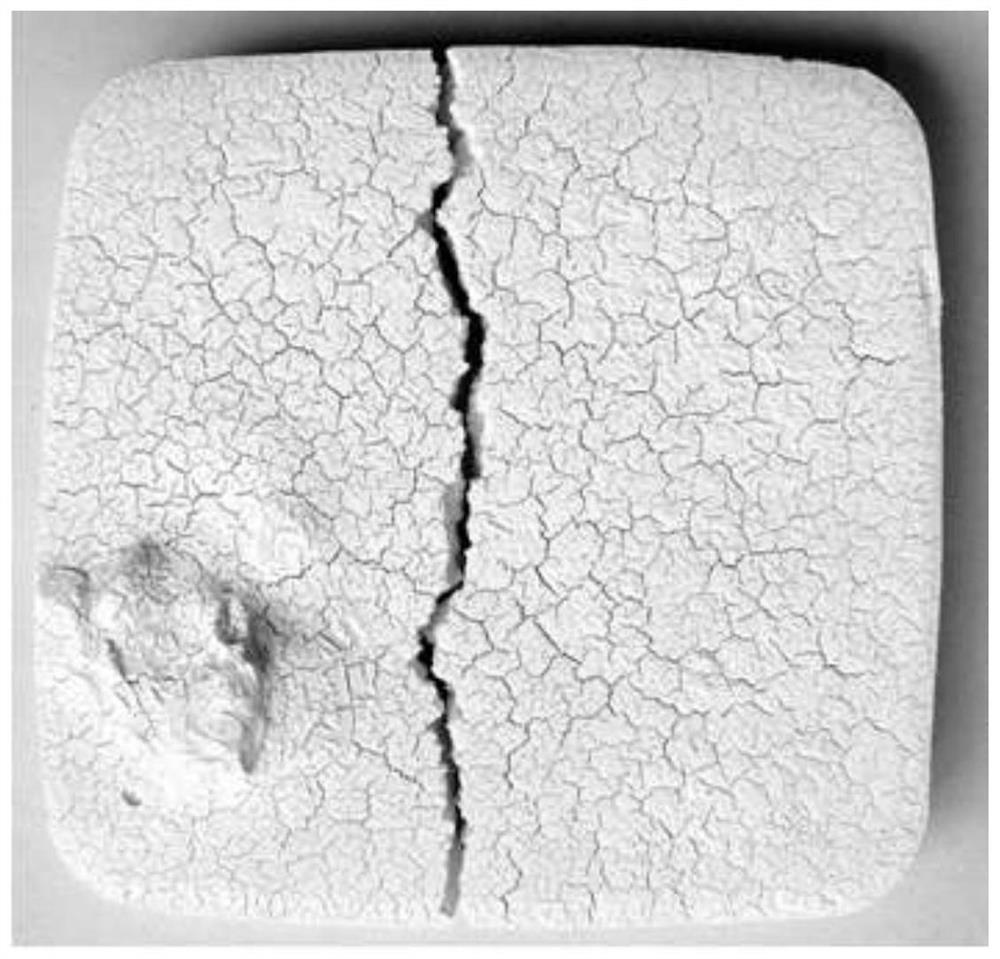

[0057] Example 1: Comparison of samples with pore-forming agent and ceramic fiber added and samples without pore-forming agent and ceramic fiber added.

[0058] In order to verify the effect of the pore forming agent and ceramic fiber on the wet billet, the following four groups of samples were prepared in this embodiment. The preparation process is as follows:

[0059] 500g deionized water, 60g acrylamide, and 6g N,N'-methylenebisacrylamide were stirred and mixed to form a water-based solution; the water-based solution, 200g ZrO 2 The powder and 3g of ammonium polyacrylate were mixed and ball-milled at a speed of 100 rpm for 12 hours to obtain a slurry;

[0060] The obtained slurry was equally divided into four parts, numbered sample 1, sample 2, sample 3 and sample 4 respectively. Further add raw materials according to the formula in the table below, and ball mill for 12 hours at a speed of 100 rpm.

[0061]

[0062] Add 20.5g of 20%wt ammonium persulfate aqueous solut...

Embodiment 2

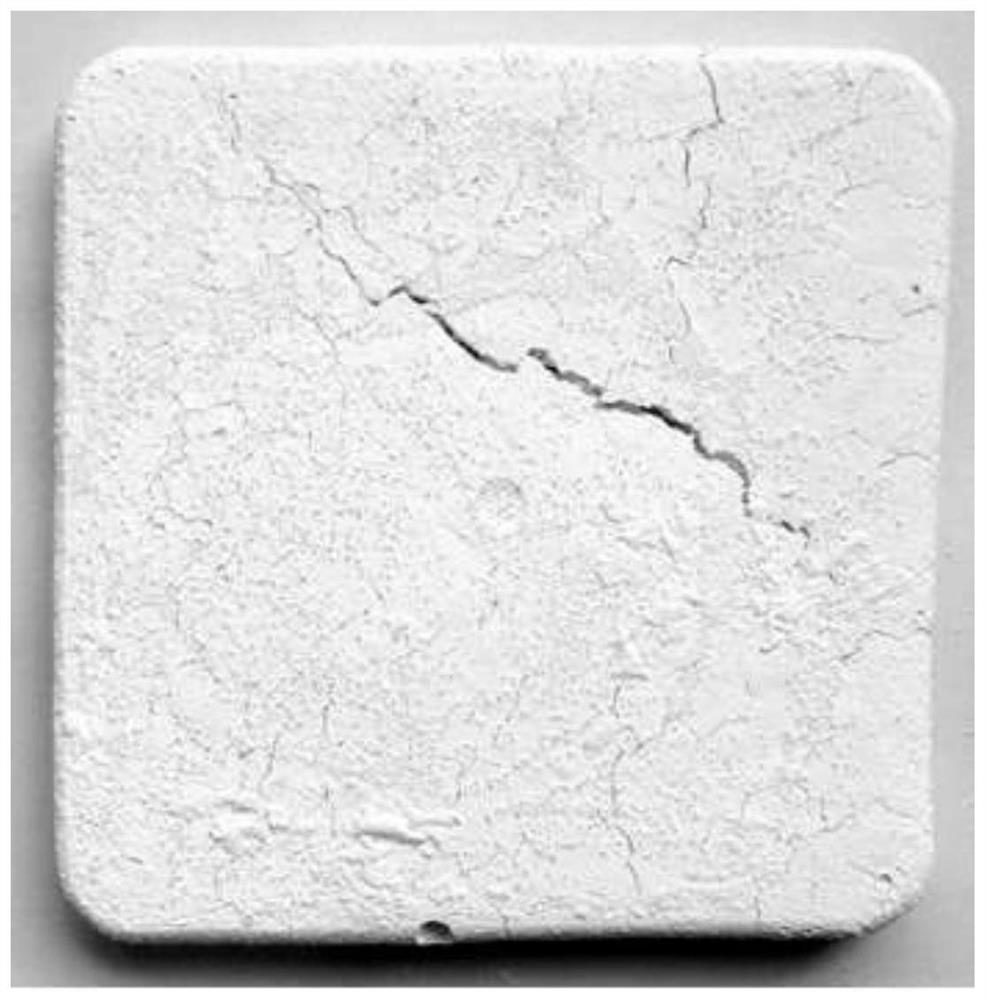

[0068] Embodiment 2: determination of ceramic fiber content

[0069] The slurry was prepared according to the formula of Example 1 above. Divide the resulting slurry into 5 parts, press ZrO 2 The mass ratio of the powder, respectively adding ceramic fiber, the ratio is 0%, 5%, 8%, 15%, 18%. The five samples were ball milled for 12 h at a speed of 50 rpm.

[0070] Add 20.5g of 20%wt ammonium persulfate aqueous solution and 2g of N,N,N',N'-tetramethylethylenediamine to the above five samples respectively, stir well and quickly pour them into the polypropylene mold coated with silicone oil , the size of the mold is 145mm×145mm×70mm, and the thickness of the injection mold is 20mm; the mold is placed in a water bath at 55°C for curing; the wet billet that has been cured and the temperature has dropped to room temperature is removed from the mold; the wet billet is vacuum freeze-dried Drying, the vacuum freeze-drying process is as follows: freeze at -60°C for 8h, then vacuumize ...

Embodiment 3

[0075] In this example, the organic monomer is acrylamide, the crosslinking agent is N,N'-methylenebisacrylamide, the dispersant is ammonium polyacrylate, and the catalyst is N',N'-tetramethylethylenediamine. The initiator is ammonium persulfate.

[0076] The preparation process proceeds as follows:

[0077] 307g deionized water, 44.4g acrylamide, 4.4g N,N'-methylenebisacrylamide were mixed together and fully stirred until a clear and transparent solution (i.e. water-based solution); the water-based solution, 145g ZrO 2 The powder and 3 g of ammonium polyacrylate were mixed and ball-milled for 12 hours to obtain a slurry;

[0078] 21.7g PMMA microspheres and 14.5g alumina fibers were added to the obtained slurry, and ball milled at a speed of 100 rpm for 12h to obtain a premixed liquid;

[0079] Add 20.5g of 20%wt ammonium persulfate aqueous solution and 2g of N,N,N',N'-tetramethylethylenediamine to the obtained premixed solution, stir well and pour it into a polypropylene m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com