Patents

Literature

546results about How to "Reduce foaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-chlorinated concentrated all-in-one acid detergent and method for using the same

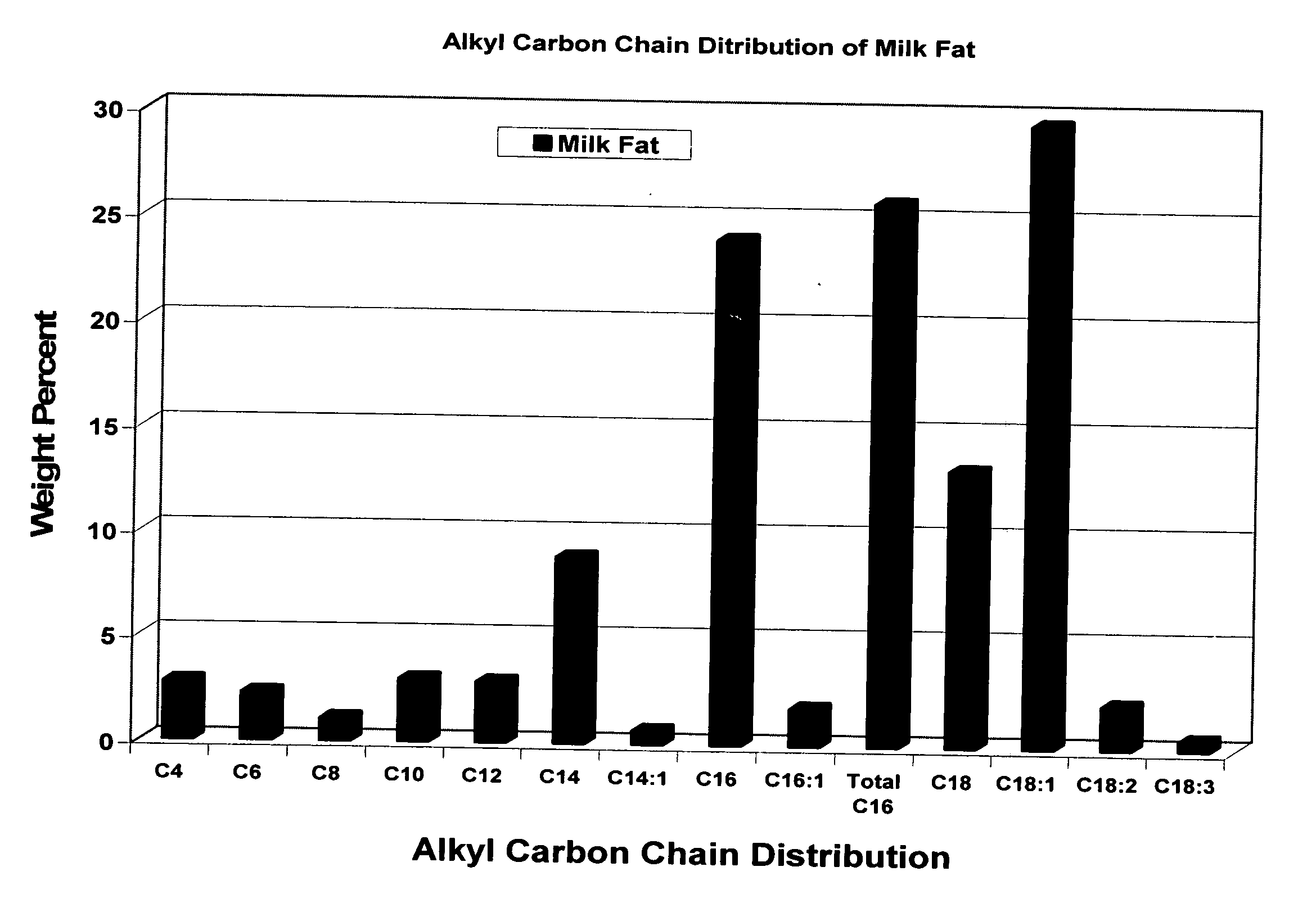

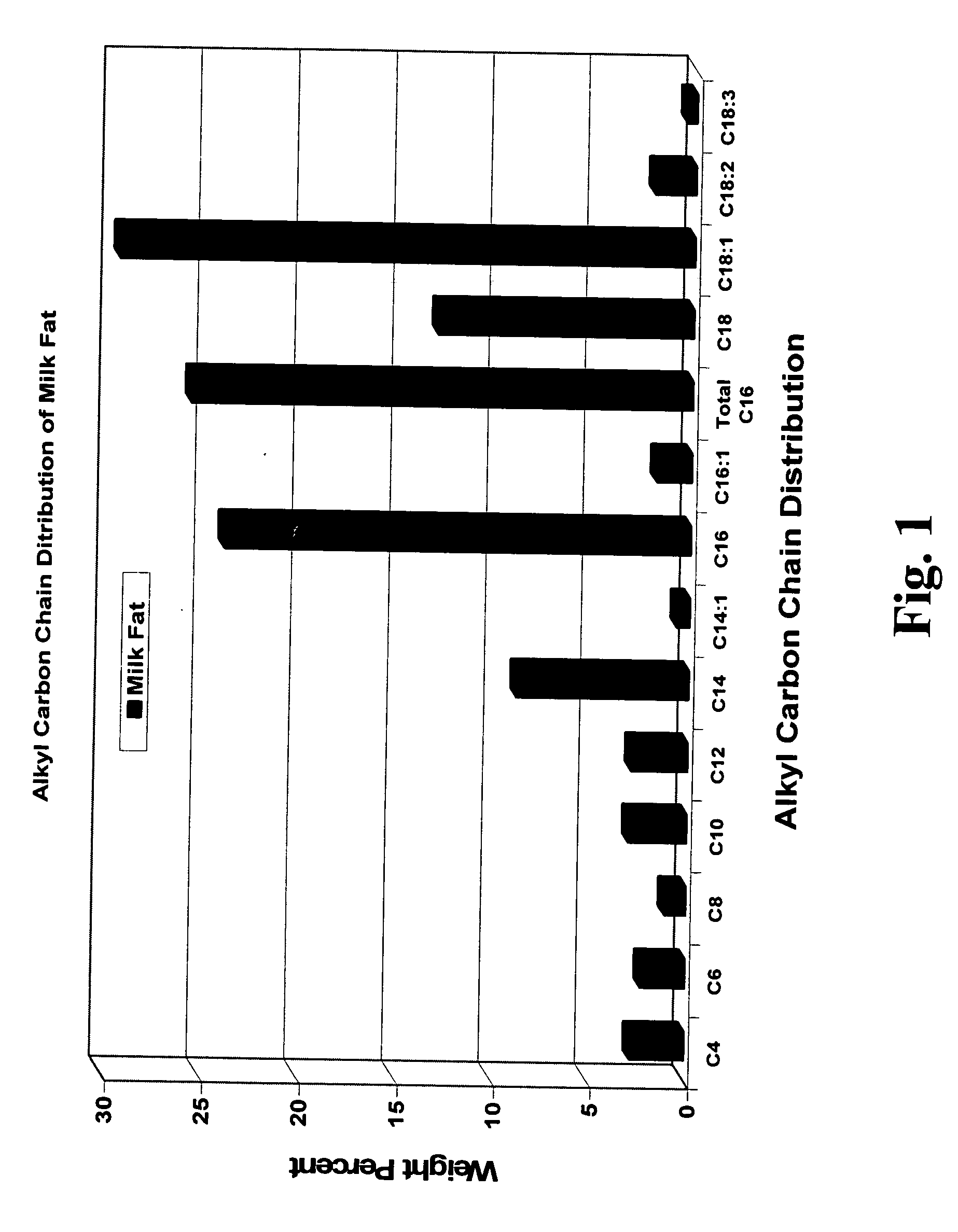

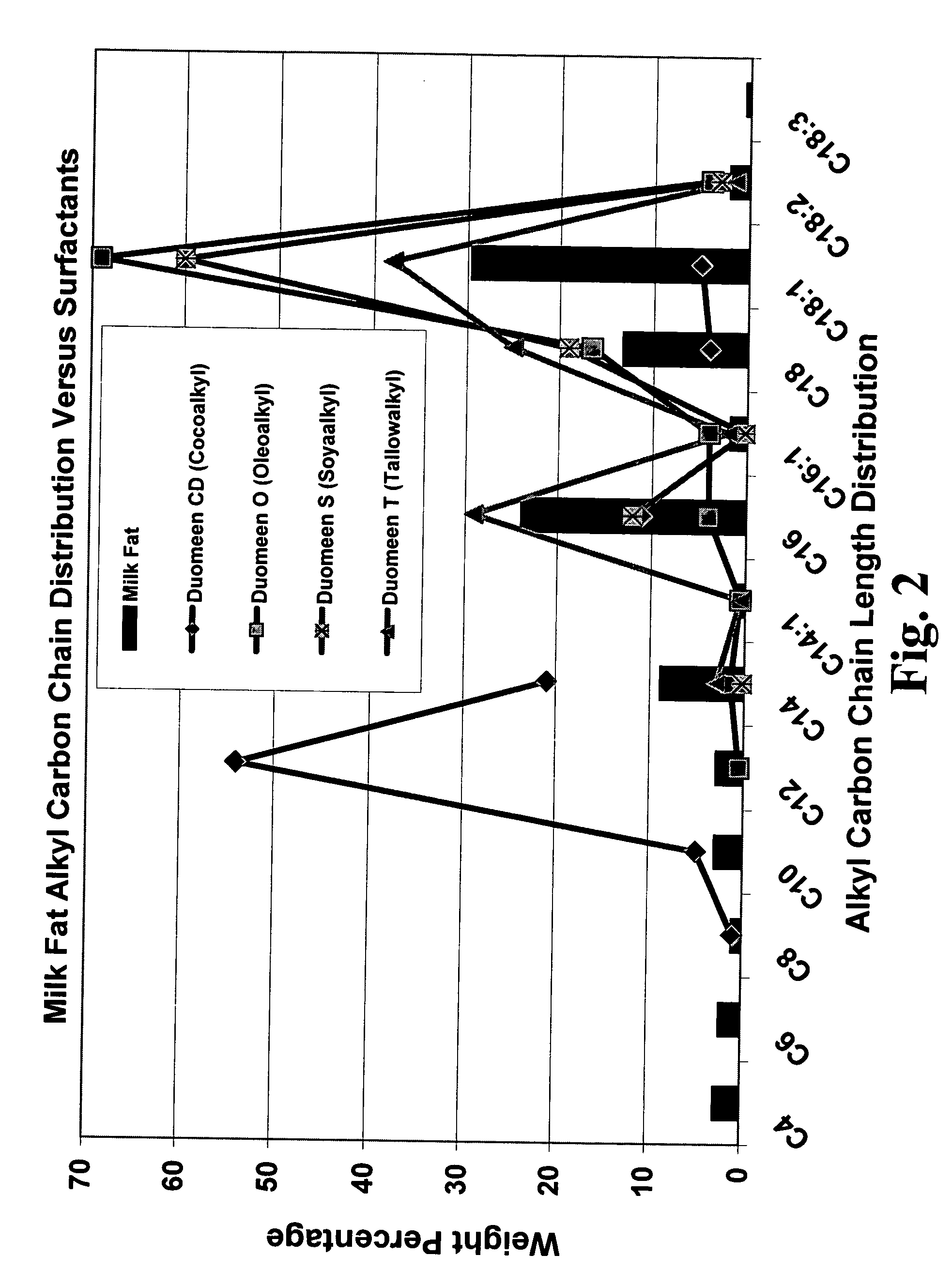

ActiveUS20060035808A1Improve disinfection effectEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsIngested foodAlkyl

Non-chlorinated concentrated acid detergent compositions and methods for using the same are provided. More particularly, the acid detergents comprise a quantity of a fatty alkyl-1,3-diaminopropane or salt thereof and optionally alkylsulfonic acid. The detergents form the basis for an all-in-one cleaning, sanitizing, and descaling composition for use on soiled surfaces, particularly surfaces contaminated with milk soils and other food soils.

Owner:DELAVAL HLDG AB

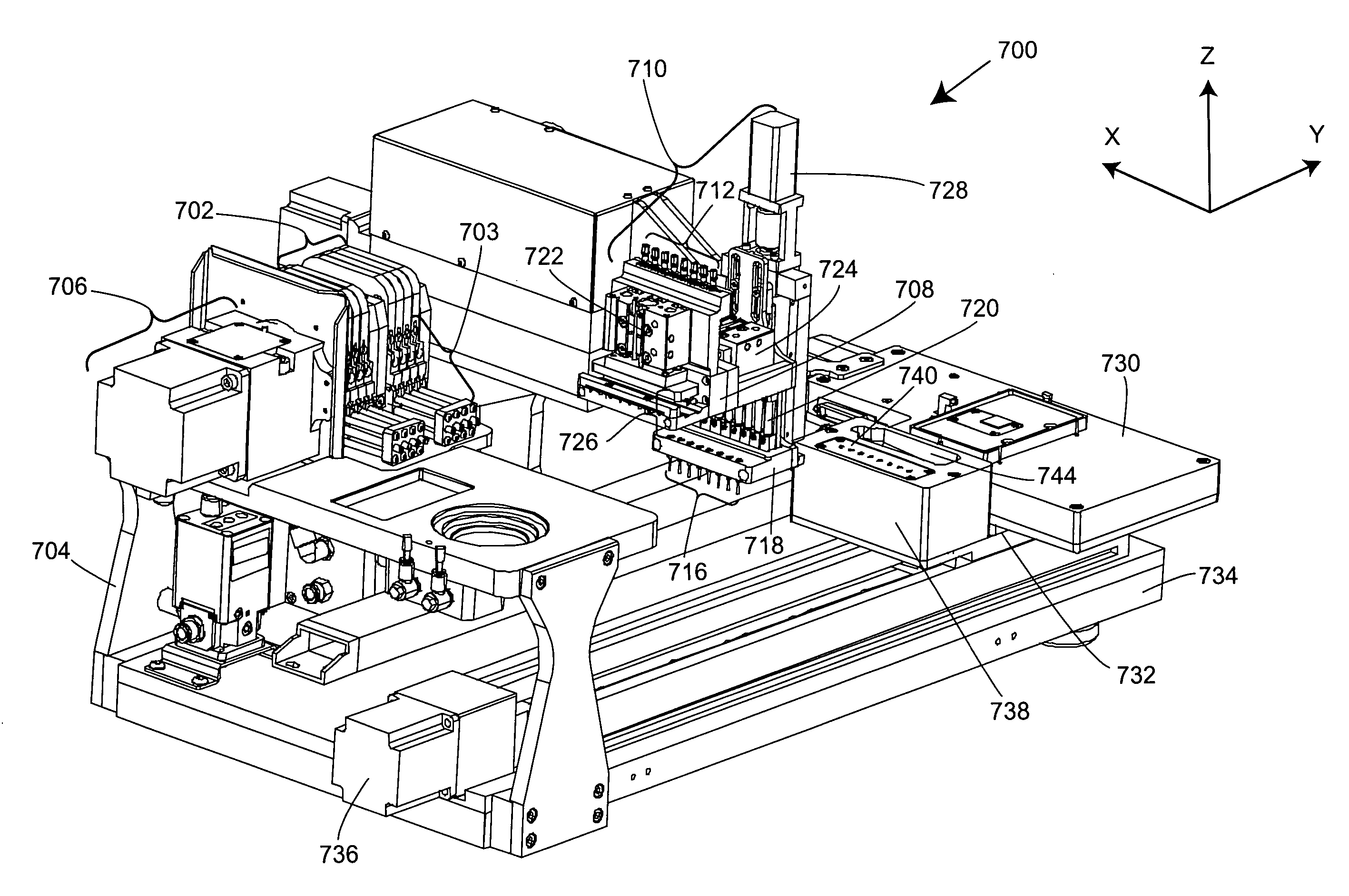

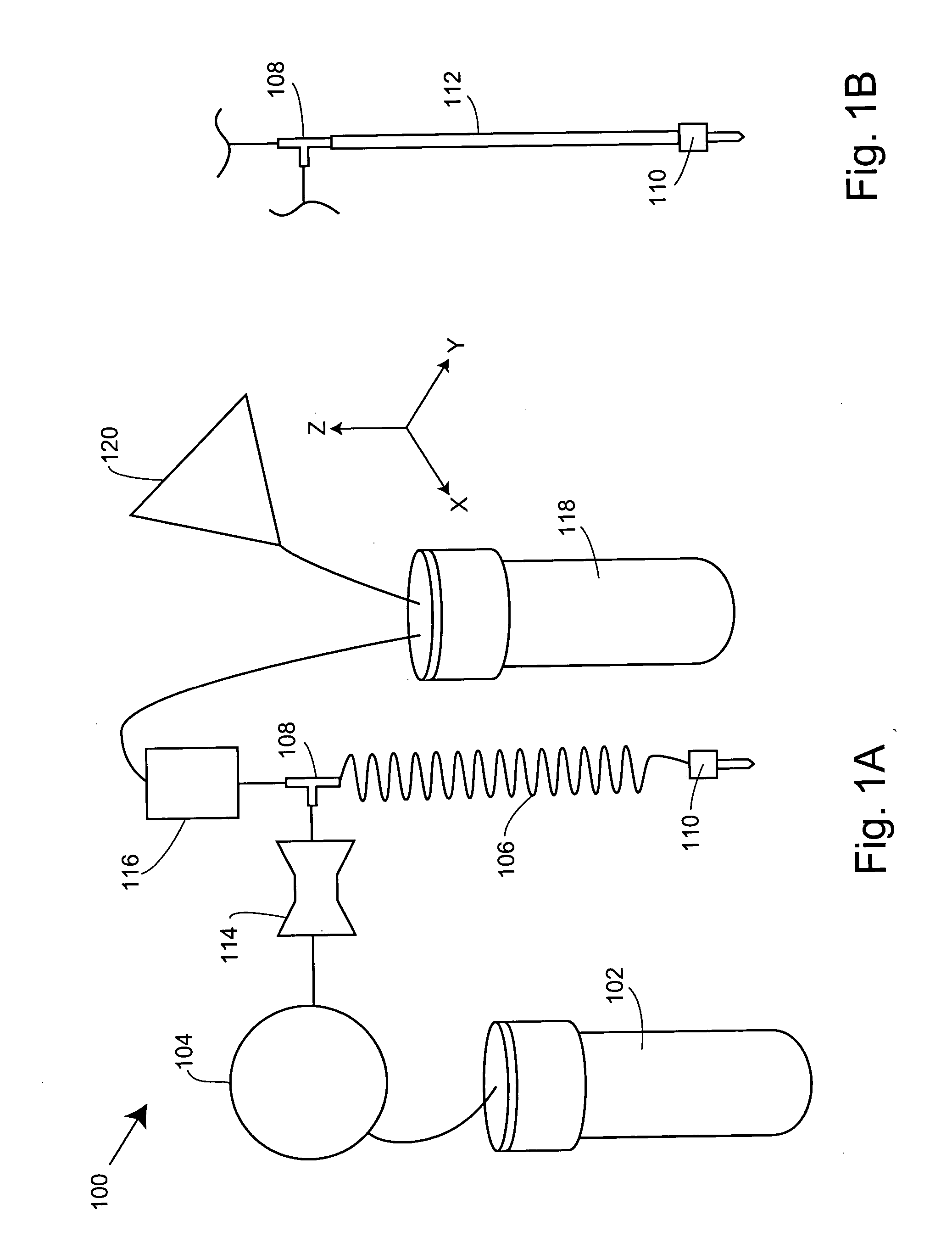

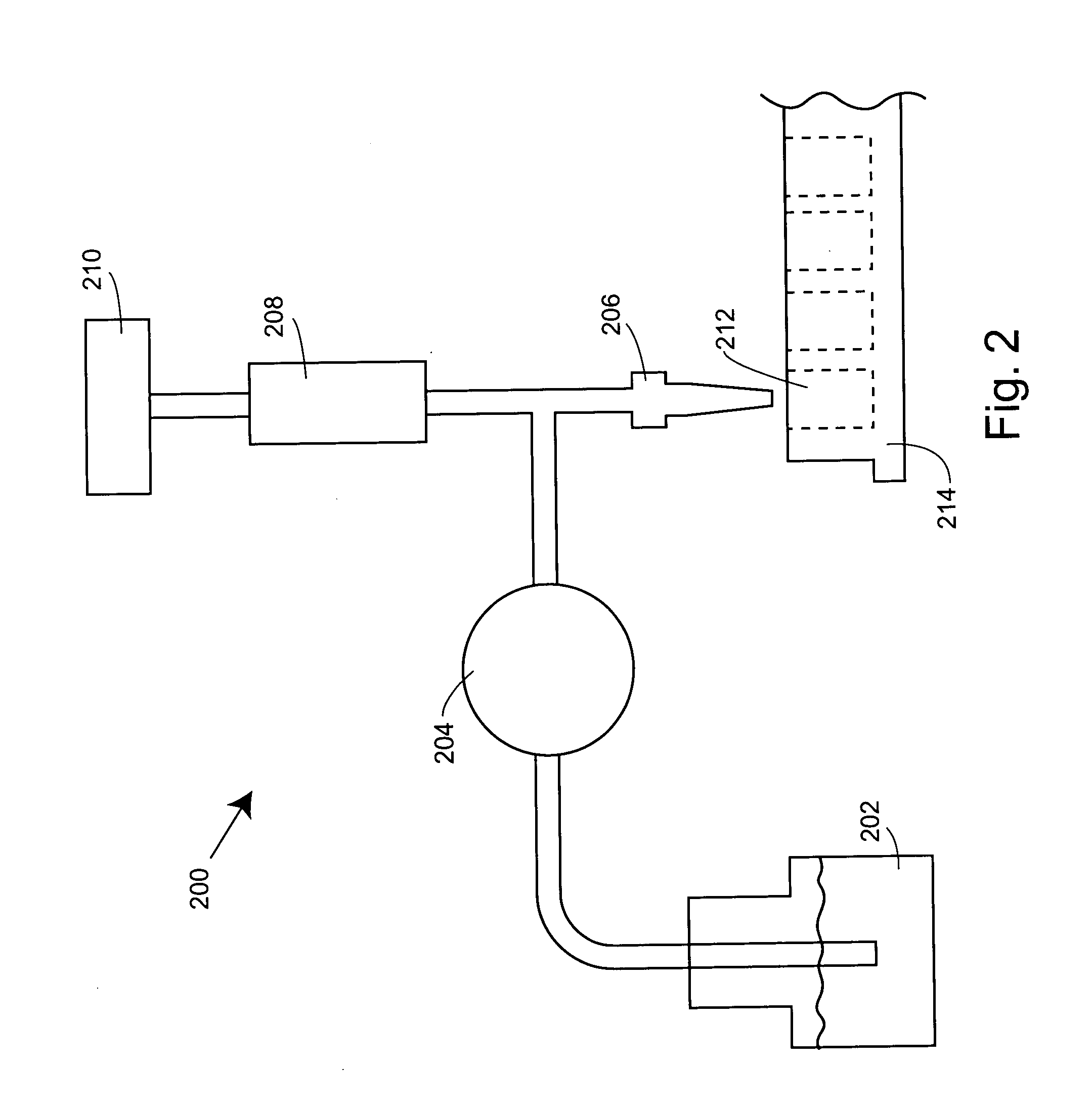

Dispensing systems, software, and related methods

InactiveUS20060002824A1Minimize disruptionReduce foamingAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionPeristaltic pumpSubstrate surface

The present invention provides dispensing systems that include peristaltic pumps and other pressure sources for the efficient delivery of accurate volumes of fluidic materials into the wells of multi-well containers or onto substrate surfaces. These systems are typically configured to dispense volumes of fluid having substantially uniform densities. Related computer program products and methods of dispensing fluidic materials are also provided.

Owner:IRM

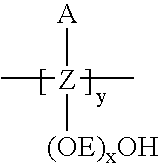

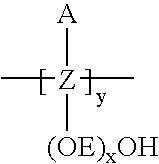

Process for extracting bitumen

Bitumen extraction done using a process comprising: (a) preparing a bitumen froth comprising particulate mineral solids and hydrocarbons dispersed in aqueous lamella in the form of an emulsion; (b) adding a sufficient amount of a paraffinic solvent to the froth to induce inversion of the emulsion and precipitate asphaltenes from the resultant hydrocarbon phase; (c) mixing the froth and the solvent for a sufficient time to dissolve the solvent into the hydrocarbon phase to precipitate asphaltenes; and (d) subjecting the mixture to gravity or centrifugal separation for a sufficient period to separate substantially all of the water and solids and a substantial portion of the asphaltenes from the bitumen; wherein a separation enhancing additive is present in the process. The separation enhancing additive is a polymeric surfactant that has multiple lipophilic and hydrophilic moieties, which can effect easier handling of asphaltene sludges and less foaming during solvent recovery.

Owner:MARATHON OIL SANDS +2

Compositions comprising poorly water soluble pharmaceutical agents and antimicrobial agents

ActiveUS20070117744A1Improve stabilityImprove filtering effectBiocideNanotechSide effectMicrobial agent

The present invention provides compositions comprising a poorly water soluble pharmaceutical agent, a carrier protein, and an antimicrobial agent, wherein significant microbial growth is inhibited in the composition. The amount of the antimicrobial agent in the composition may be below the level that induces a toxicological effect or at a level where a potential side effect can be controlled or tolerated. Also provided are compositions comprising a poorly water soluble pharmaceutical agent, a carrier protein, a sugar, and optionally an antimicrobial agent. Methods of using the compositions are also provided.

Owner:ABRAXIS BIOSCI LLC

Compositions comprising poorly water soluble pharmaceutical agents and antimicrobial agents

ActiveUS7771751B2Improve stabilityImprove filtering effectOrganic active ingredientsPowder deliverySide effectMicrobial agent

The present invention provides compositions comprising a poorly water soluble pharmaceutical agent, a carrier protein, and an antimicrobial agent, wherein significant microbial growth is inhibited in the composition. The amount of the antimicrobial agent in the composition may be below the level that induces a toxicological effect or at a level where a potential side effect can be controlled or tolerated. Also provided are compositions comprising a poorly water soluble pharmaceutical agent, a carrier protein, a sugar, and optionally an antimicrobial agent. Methods of using the compositions are also provided.

Owner:ABRAXIS BIOSCI LLC

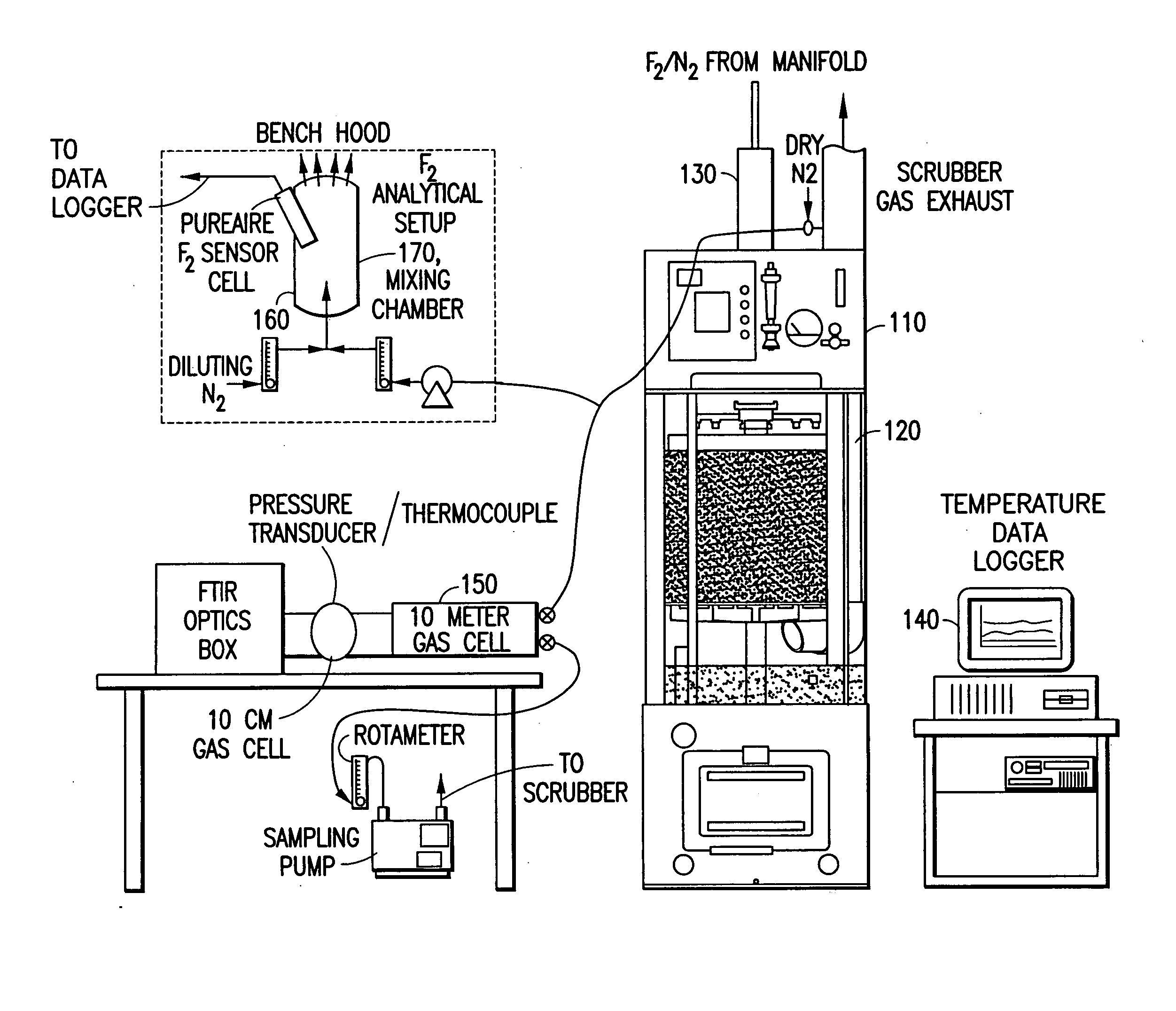

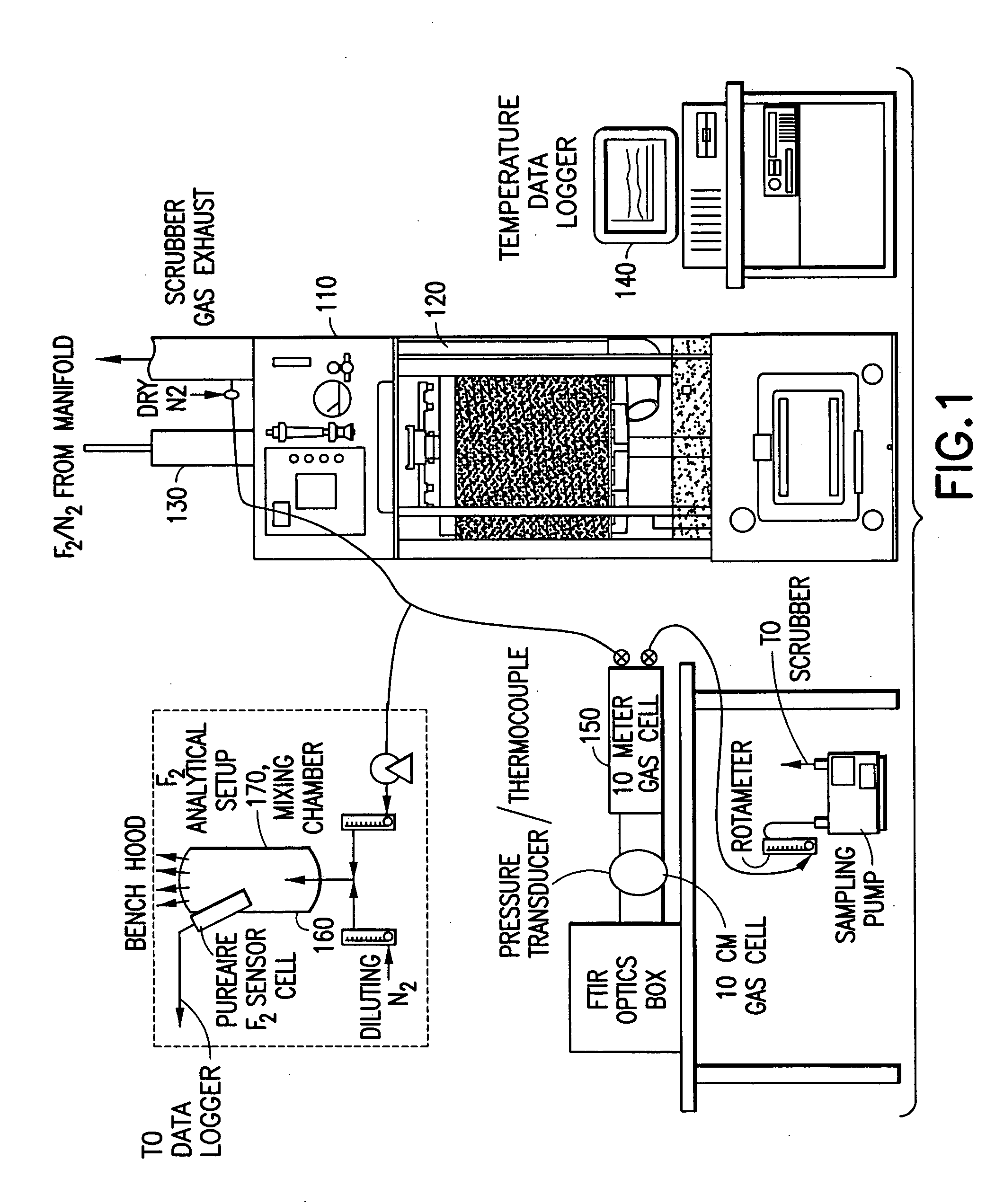

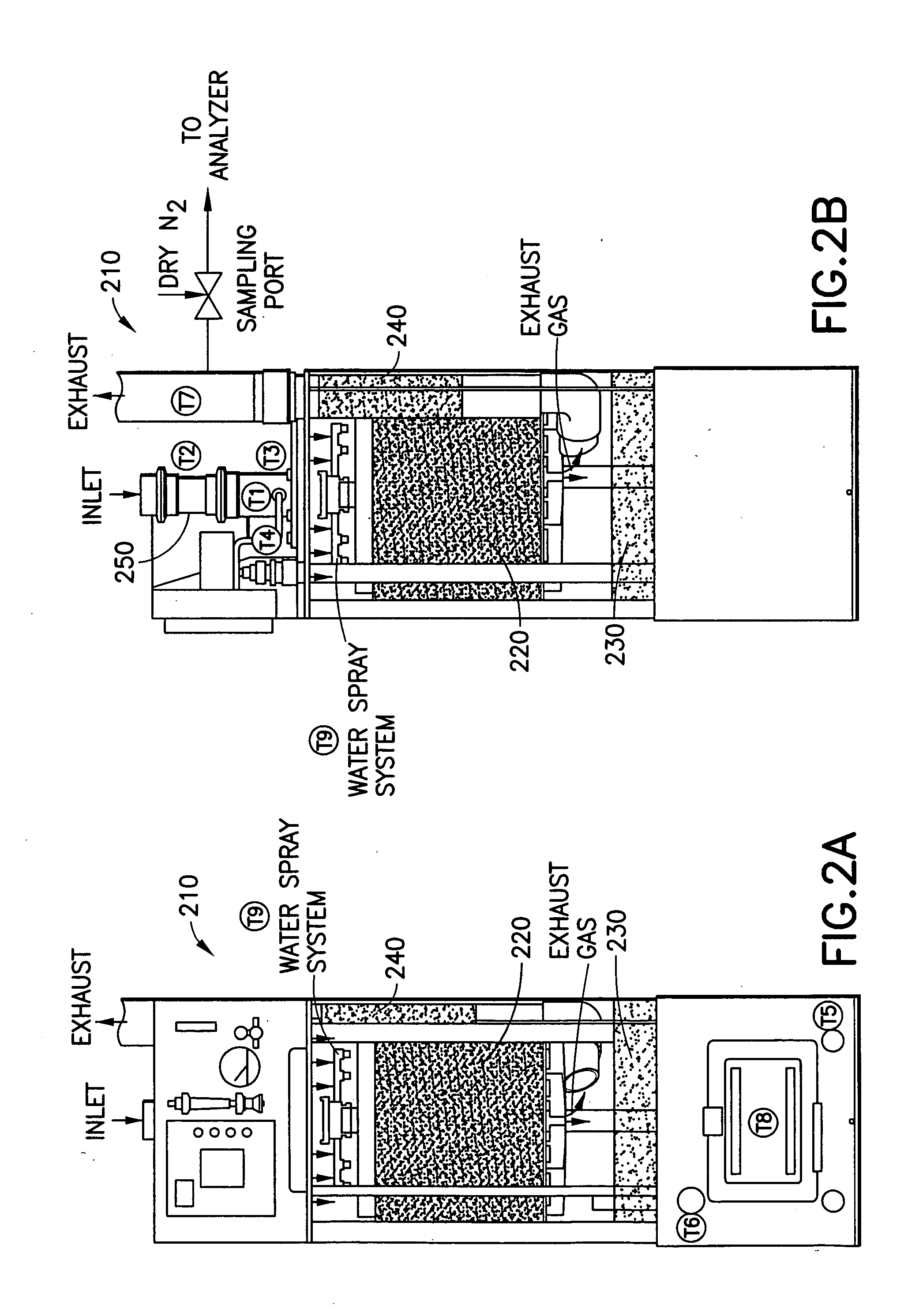

Apparatus and method for point-of-use treatment of effluent gas streams

InactiveUS20040213721A1Highly efficient mannerReduce foaming in the scrubbing systemProcess control/regulationHydrogenSilanesChlorofluorocarbon

A system for abating undesired component(s) from a gas stream containing same, such as halocompounds, acid gases, silanes, ammonia, etc., by scrubbing of the effluent gas stream with an aqueous scrubbing medium. Halocompounds, such as fluorine, fluorides, perfluorocarbons, and chlorofluorocarbons, may be scrubbed in the presence of a reducing agent, e.g., sodium thiosulfate, ammonium hydroxide, or potassium iodide. In one embodiment, the scrubbing system includes a first acid gas scrubbing unit operated in cocurrent gas / liquid flow, and a second "polishing" unit operated in countercurrent gas / liquid flow, to achieve high removal efficiency with low consumption of water. The scrubbing system may utilize removable insert beds of packing material, packaged in a foraminous containment structure. The abatement system of the invention has particular utility in the treatment of semiconductor manufacturing process effluents.

Owner:APPLIED MATERIALS INC

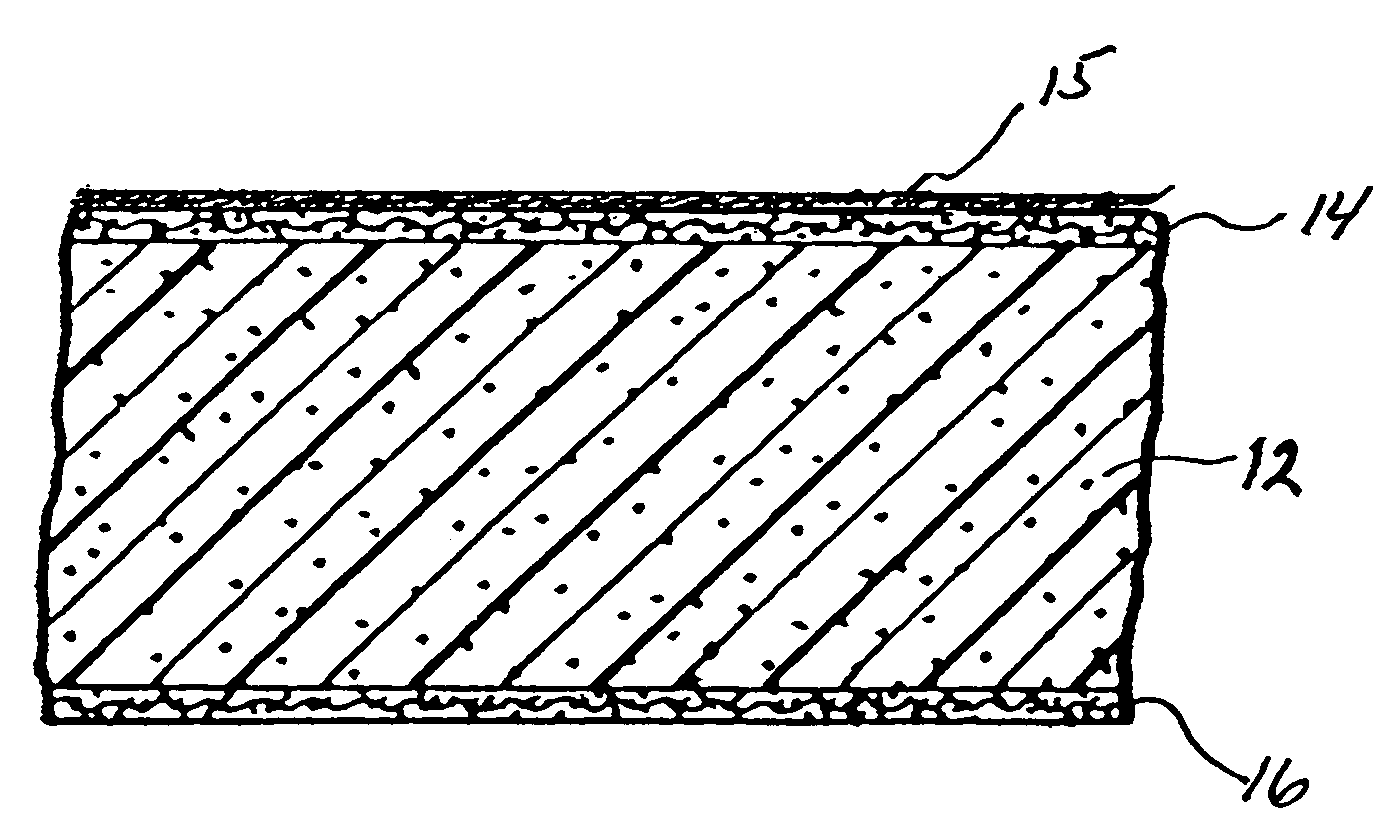

Soy composite materials comprising a reducing sugar and methods of making the same

InactiveUS20100129640A1Reduce slurry viscosityLow viscosityLayered productsPretreated surfacesEmulsionSoy flour

The present invention provides composite materials derived from formaldehyde-free aqueous binder compositions comprising defatted soy flour of no greater than 43 micron mesh particle size, polymer particles of at least one emulsion (co)polymer, and one or more reducing sugar. Also provided are methods of making and using composite materials containing the formaldehyde-free binder compositions.

Owner:ROHM & HAAS CO

Candlewax compositions with improved scent-throw

InactiveUS7588607B1Improve release of aromaPromote escapeSolid fuelsCapillary burnersPolymer scienceEngineering

A candlewax composition having improved scent-throw, and candles made from the composition, are provided. The candlewax composition includes at least a wax component and an antifoam agent. An effective amount of a scenting agent can be separately added by a candlemaker.

Owner:CAP DANIEL S

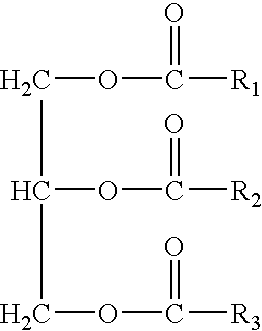

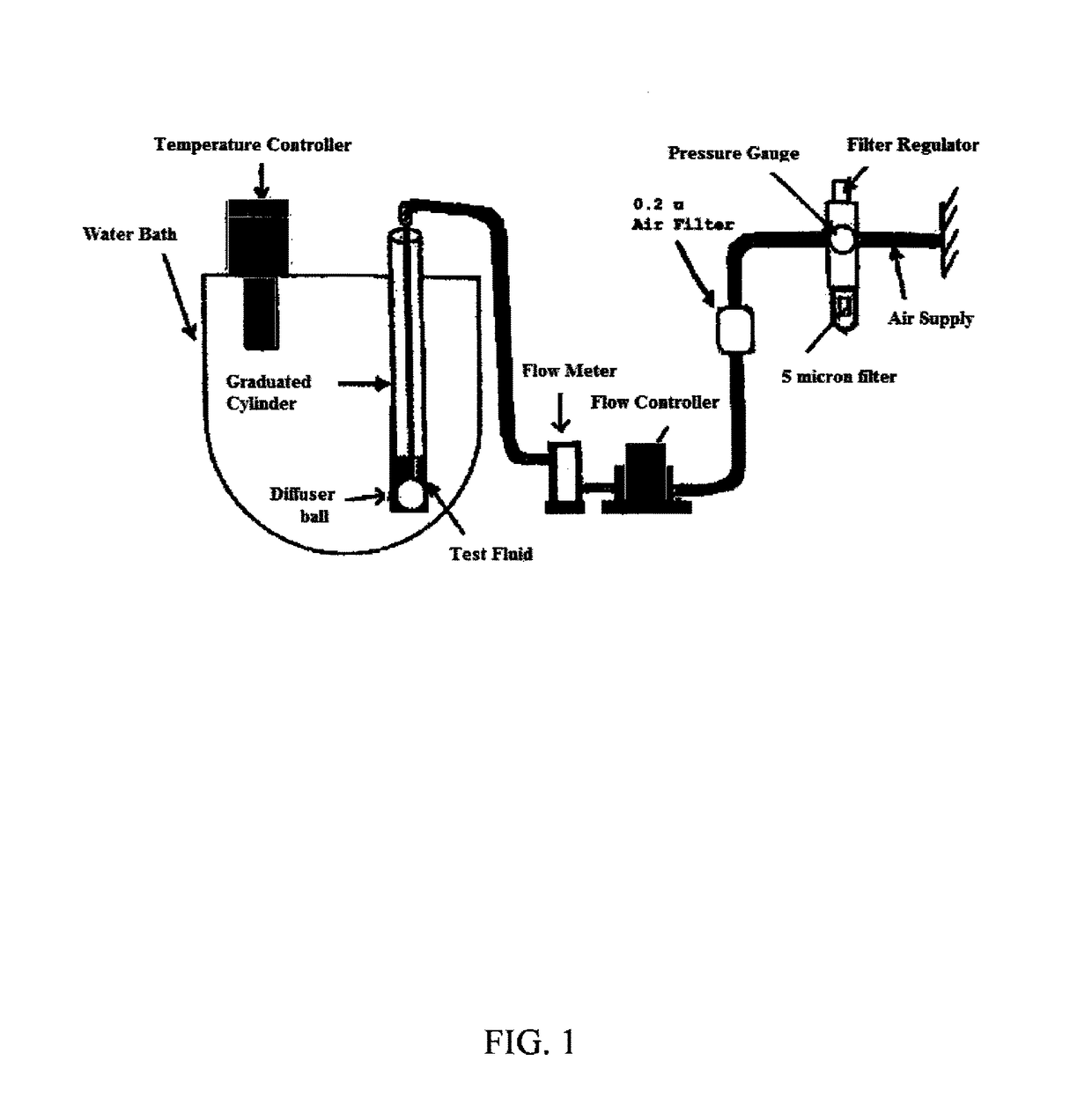

Process for extracting bitumen

ActiveUS20060113218A1Reduce foamingLiquid hydrocarbon mixture productionPolymeric surfaceParticulates

Bitumen extraction done using a process comprising: (a) preparing a bitumen froth comprising particulate mineral solids and hydrocarbons dispersed in aqueous lamella in the form of an emulsion; (b) adding a sufficient amount of a paraffinic solvent to the froth to induce inversion of the emulsion and precipitate asphaltenes from the resultant hydrocarbon phase; (c) mixing the froth and the solvent for a sufficient time to dissolve the solvent into the hydrocarbon phase to precipitate asphaltenes; and (d) subjecting the mixture to gravity or centrifugal separation for a sufficient period to separate substantially all of the water and solids and a substantial portion of the asphaltenes from the bitumen; wherein a separation enhancing additive is present in the process. The separation enhancing additive is a polymeric surfactant that has multiple lipophilic and hydrophilic moieties, which can effect easier handling of asphaltene sludges and less foaming during solvent recovery.

Owner:MARATHON OIL SANDS +2

Method for preparing sharp type epoxide resin binding agent diamond abrasive tool

ActiveCN103056788AImprove bindingInhibit sheddingAbrasion apparatusGrinding devicesFirming agentEpoxide

The invention discloses a method for preparing a sharp type epoxide resin binding agent diamond abrasive tool. A working layer is mainly made of diamond abrasive, an epoxide resin binding agent, a curing agent, an auxiliary abrasive, a filler and an auxiliary assistant. The method comprises steps of uniformly mixing 5-20 parts by mass of self-sharpening diamond, 5-28 parts by mass of auxiliary abrasive, 10-40 parts by mass of filler and 0.5-10 parts by mass of auxiliary assistant through a machine; uniformly mixing the mixture, 17-25 parts by mass of liquid epoxide resin and 5-25 parts of curing agent; injecting the fluid mixture to a plastic die through a pouring mode; and obtaining the sharp type epoxide resin binding agent diamond abrasive tool after curing. Compared with the method for preparing the abrasive tool through hot press molding, the method has the advantages that the process is simple, the energy is saved, the emission is reduced, the pollution of solid powder on the environment is reduced, the method is environment-friendly, the production speed is quick, the sharpening degree is high, the self-sharpening performance is good, the polishing effect is good and the service life is long.

Owner:惠安宇信金刚石工具有限公司

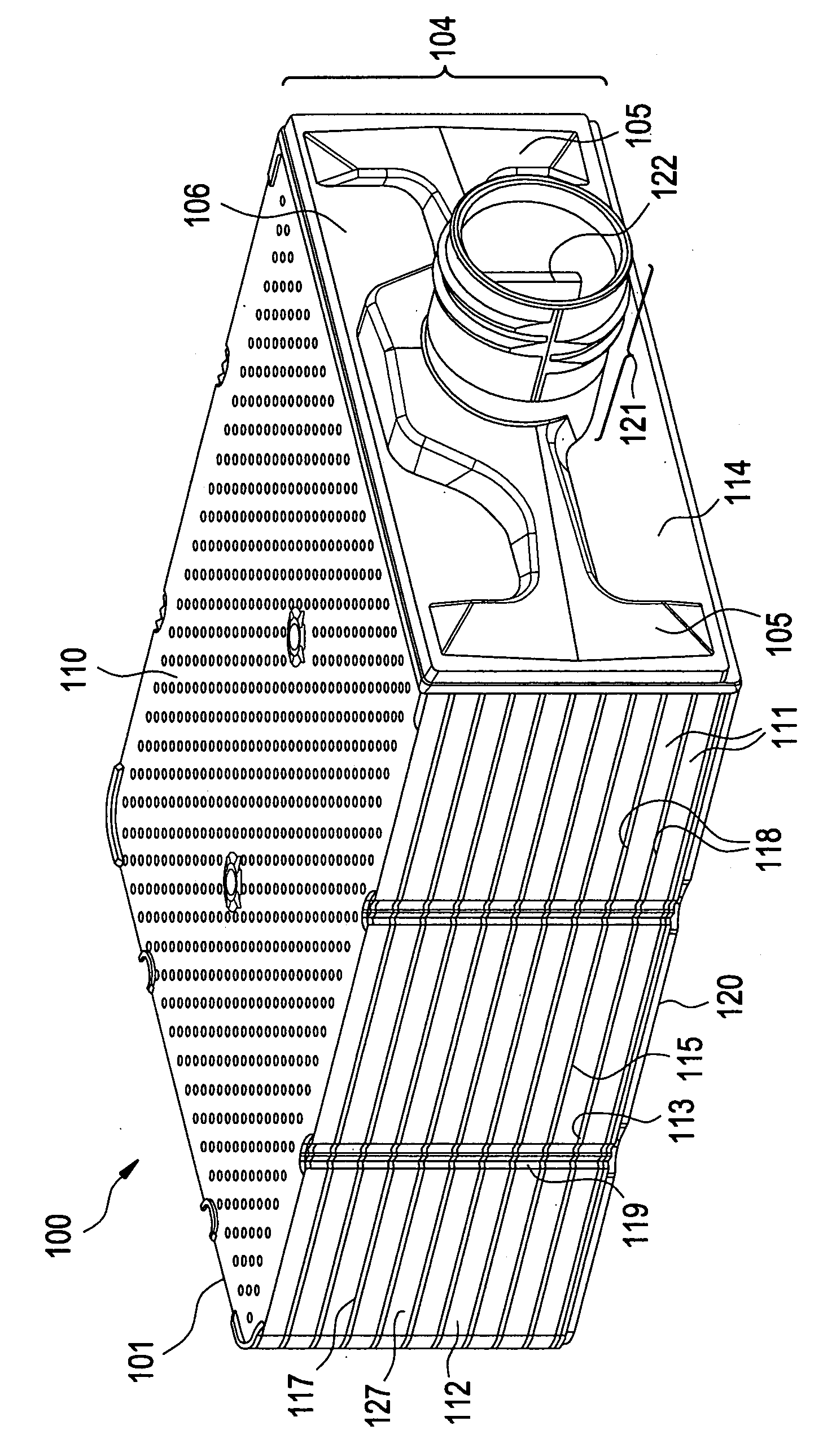

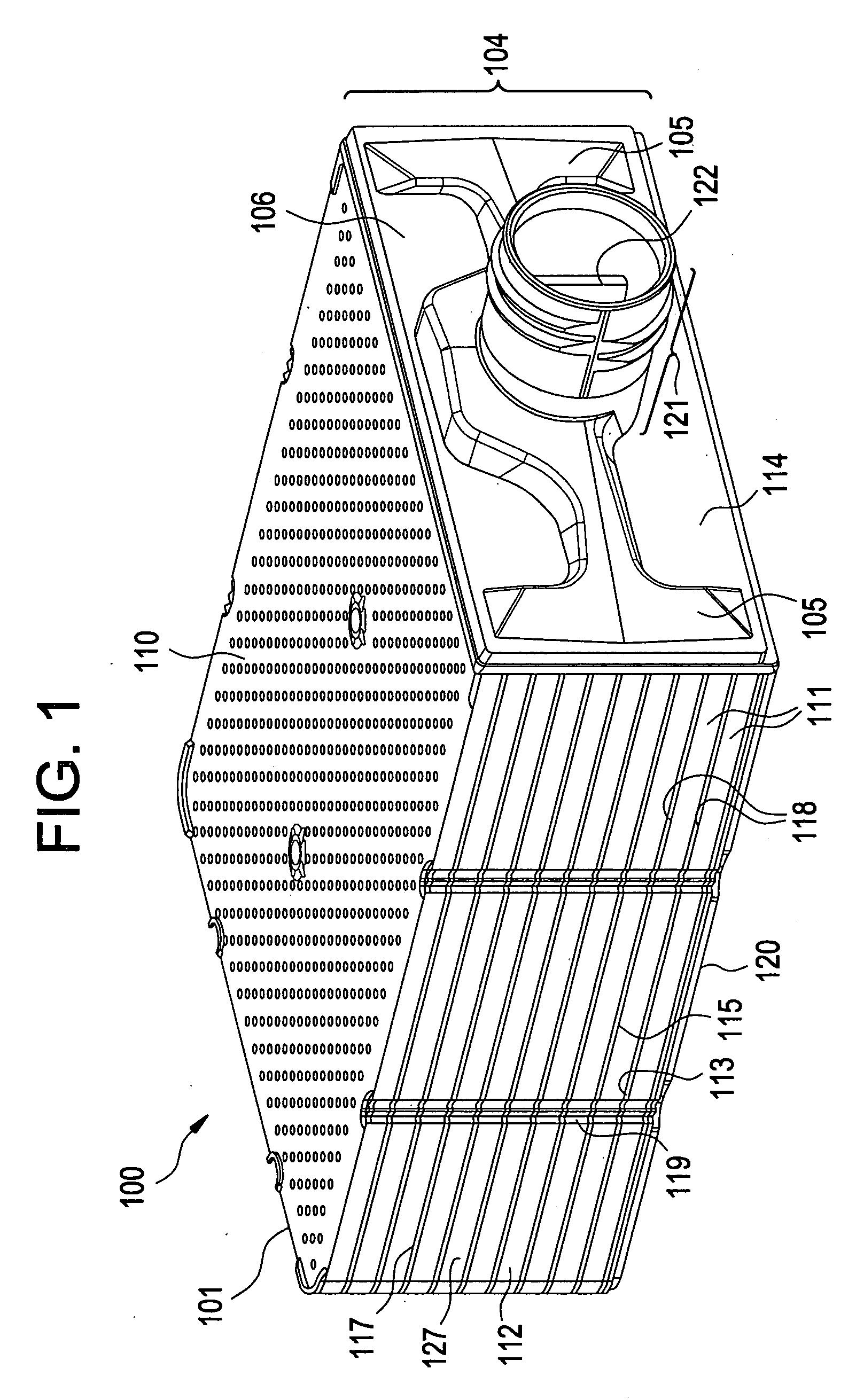

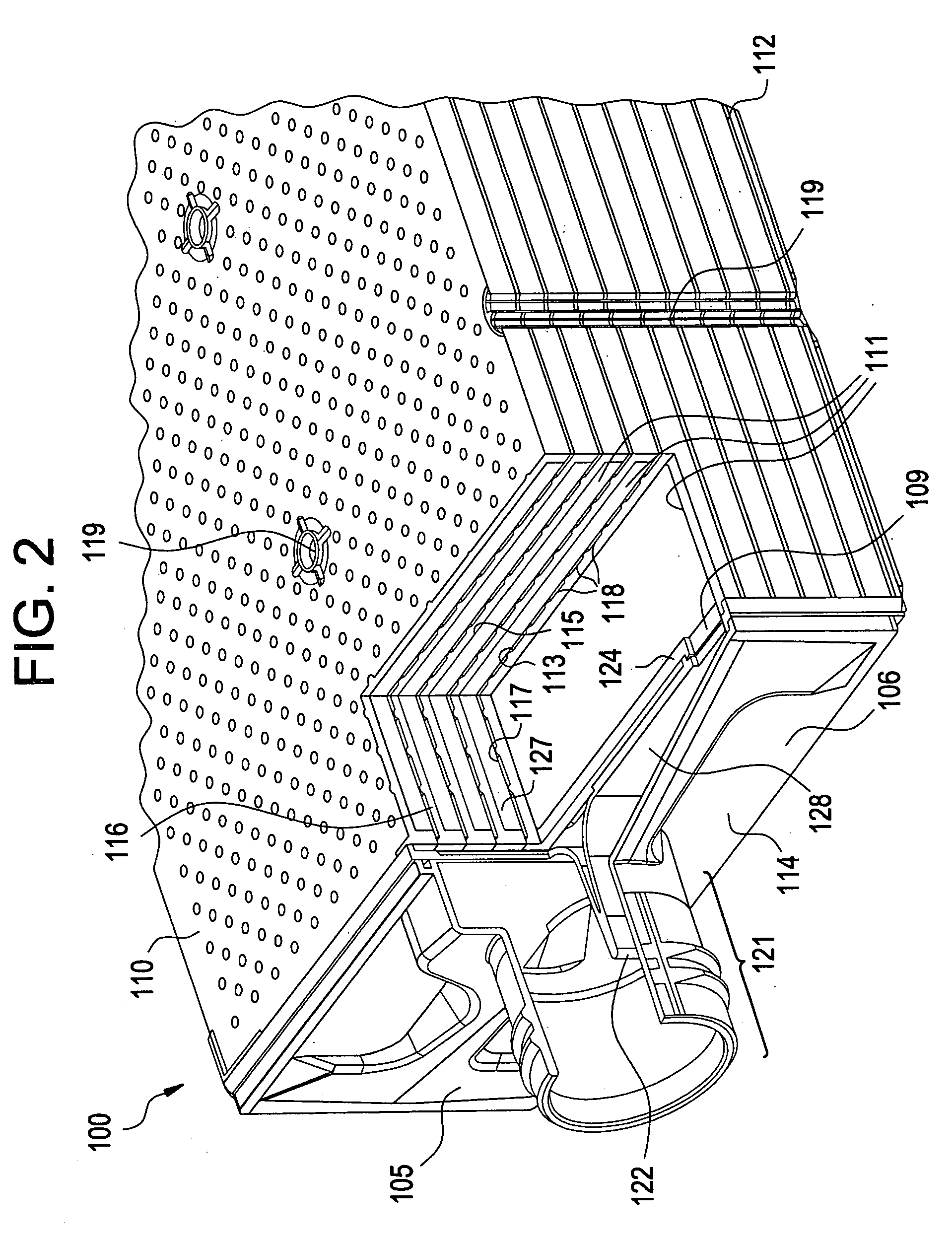

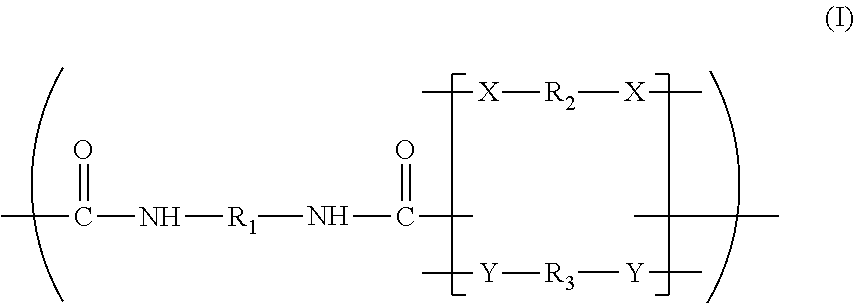

Device and method for reducing bubble formation in cell culture

ActiveUS20080206857A1Reduce bubblingReduce foamingBioreactor/fermenter combinationsBiological substance pretreatments3D cell cultureCell culture media

A device for minimizing the formation of bubbles or foam in cell culture is disclosed. The device has a manifold which directs the inflow of cells and cell culture media into a cell culture vessel so as to allow for displaced air or gas to vent from the cell culture vessel without mixing with the incoming cell culture media, thereby preventing the mixing of air and cell culture media and minimizing the formation of bubbles or foam inside the cell culture vessel.

Owner:CORNING INC

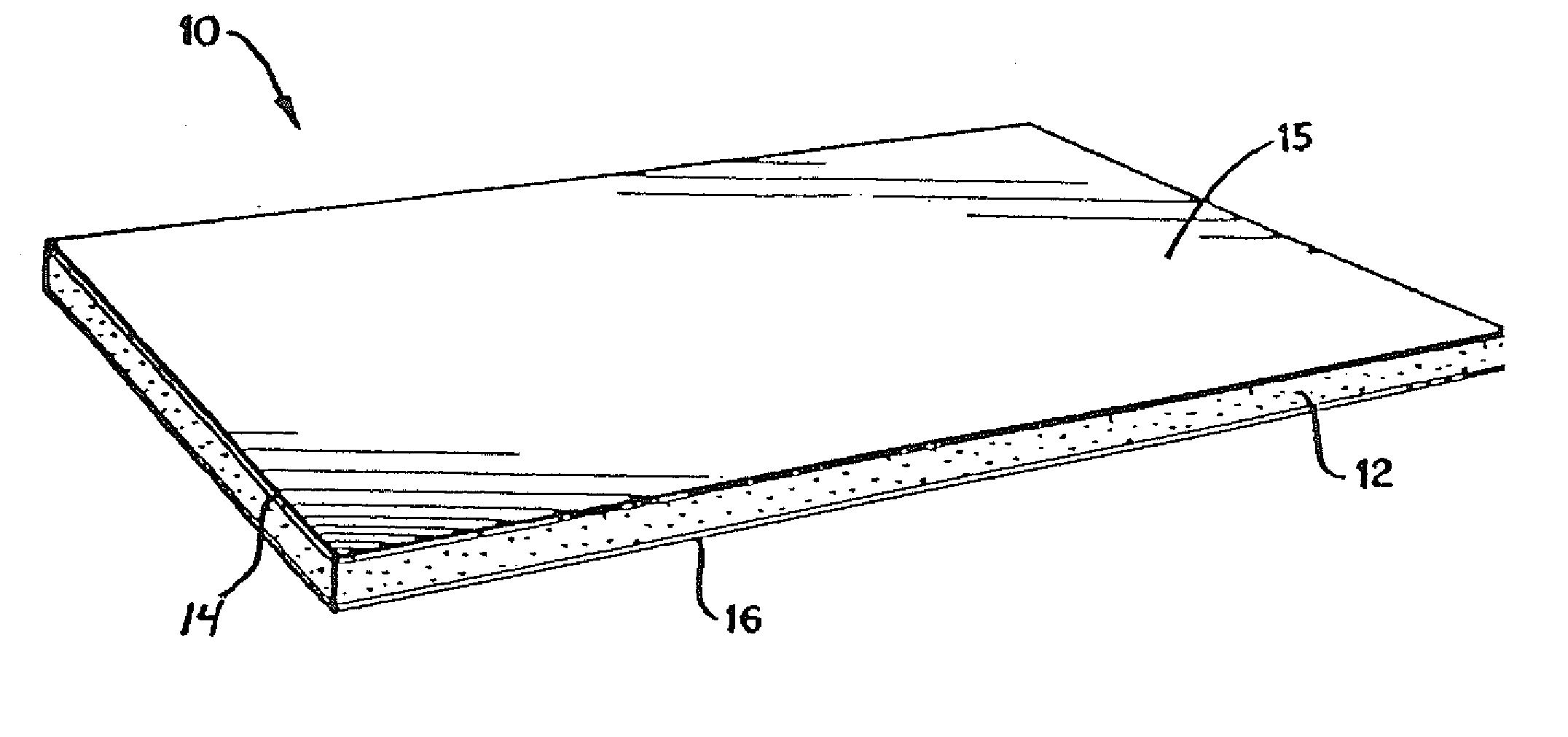

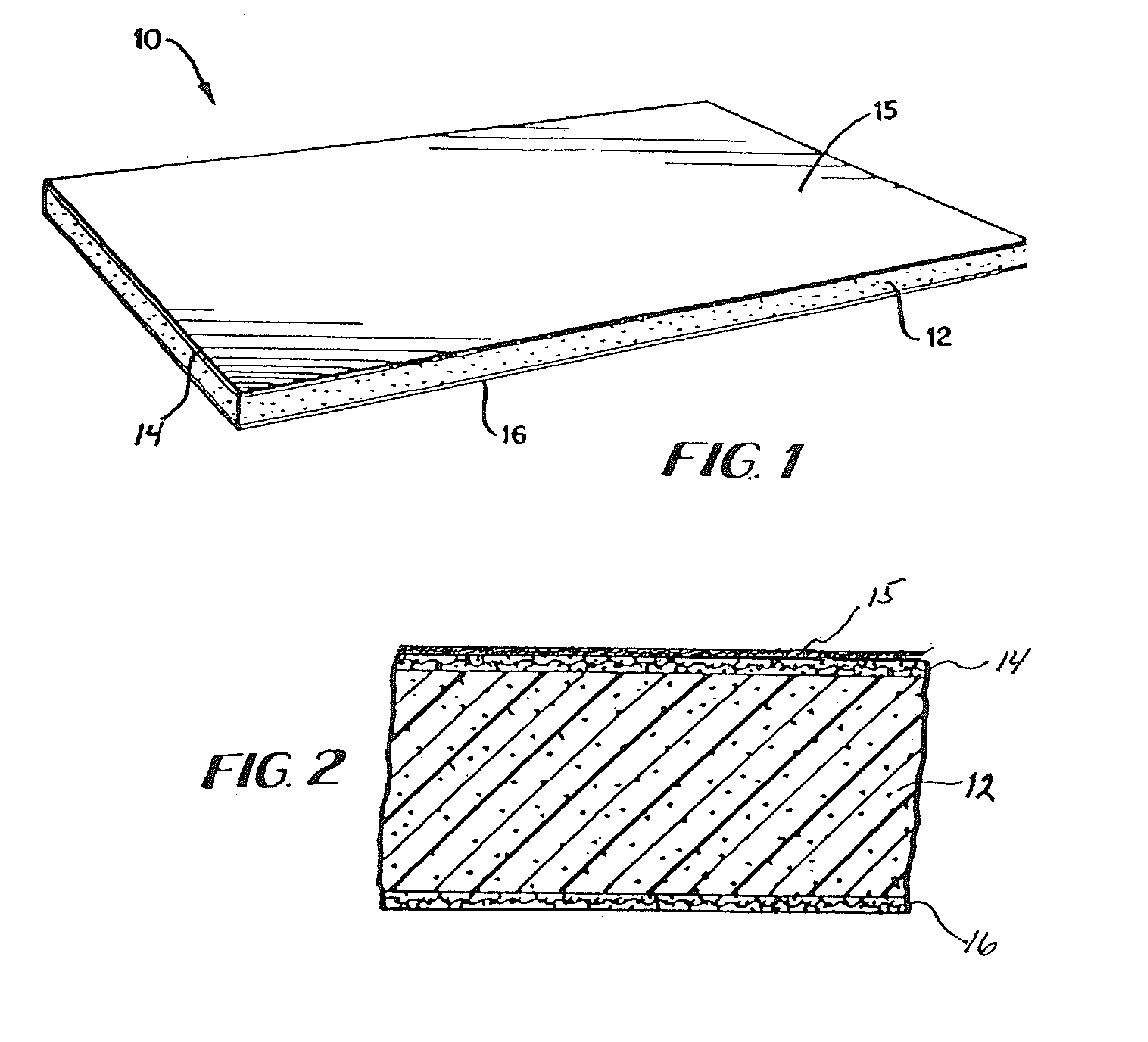

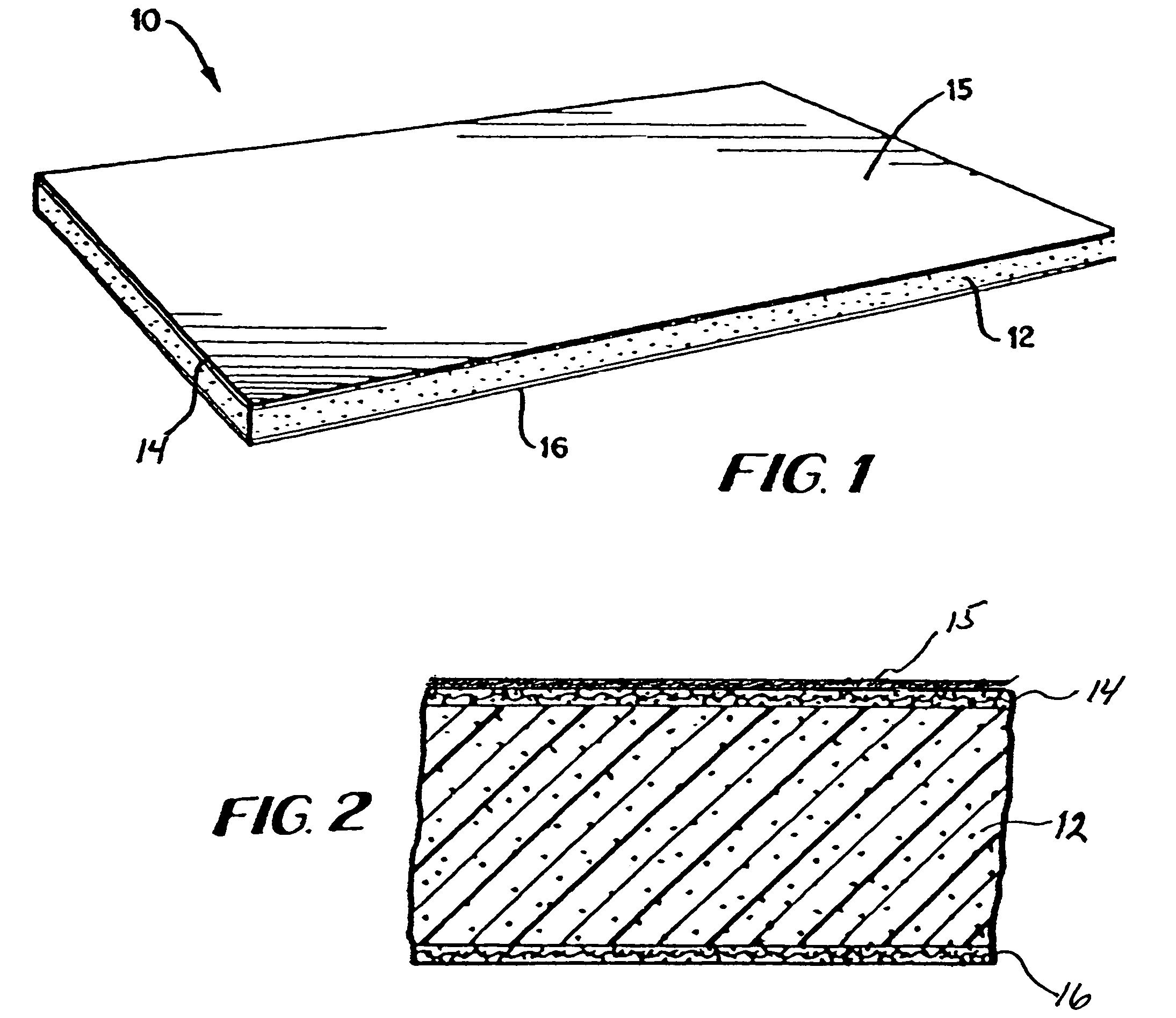

Gypsum Panel Having UV-Cured Moisture Resistant Coating and Method of Making Same

ActiveUS20090223618A1Excellent water resistance and vapor barrier propertyIncreased durabilityPretreated surfacesCoatingsFace sheetMoisture

Owner:GEORGIA PACIFIC GYPSUM LLC

Snack Cracker and Method for Making Same

InactiveUS20100215826A1Reduced level of saturated fatLower Level RequirementsDough treatmentLeguminous plant bakery productsChipped potatoesAdditive ingredient

The present invention discloses formulations for sheeted, baked fruit and vegetable crackers that have a light, crispy texture similar to a potato chip or cracker. Undehydrated ingredients are combined with dry ingredients and oil to make a dough, which is then sheeted and cut into pieces. The pieces are baked to produce vegetable and fruit snack crackers.

Owner:FRITO LAY TRADING CO GMBH

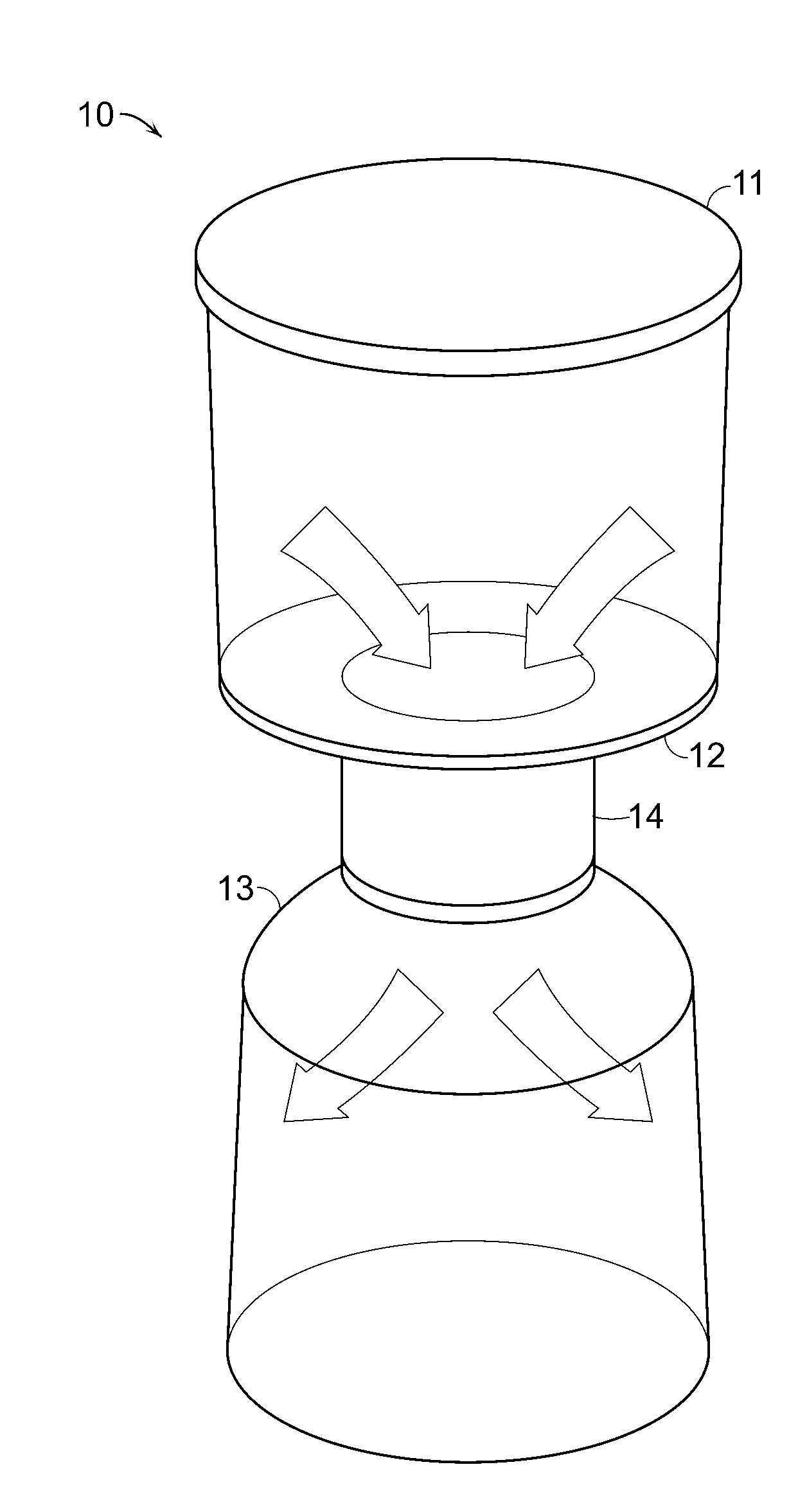

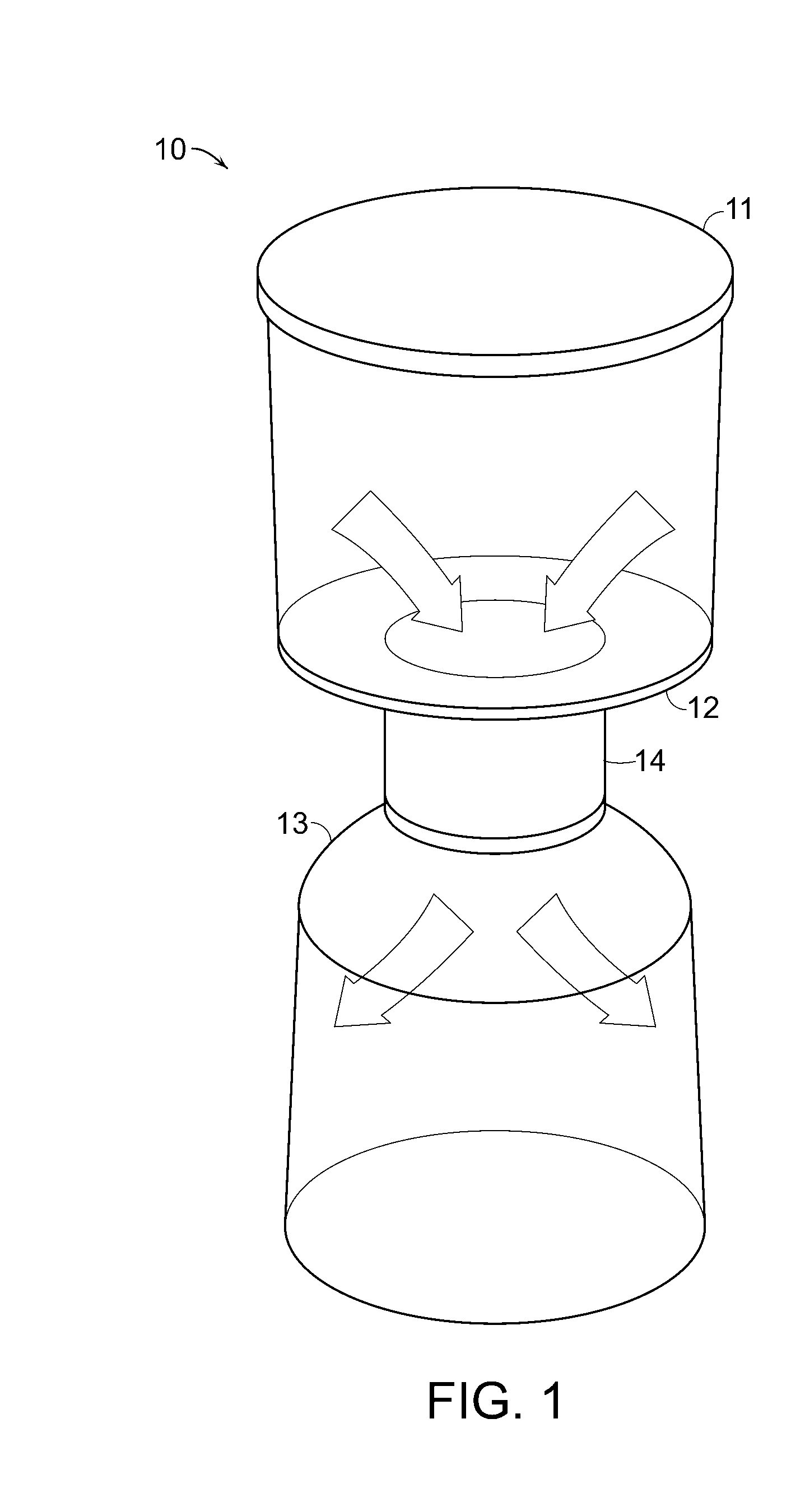

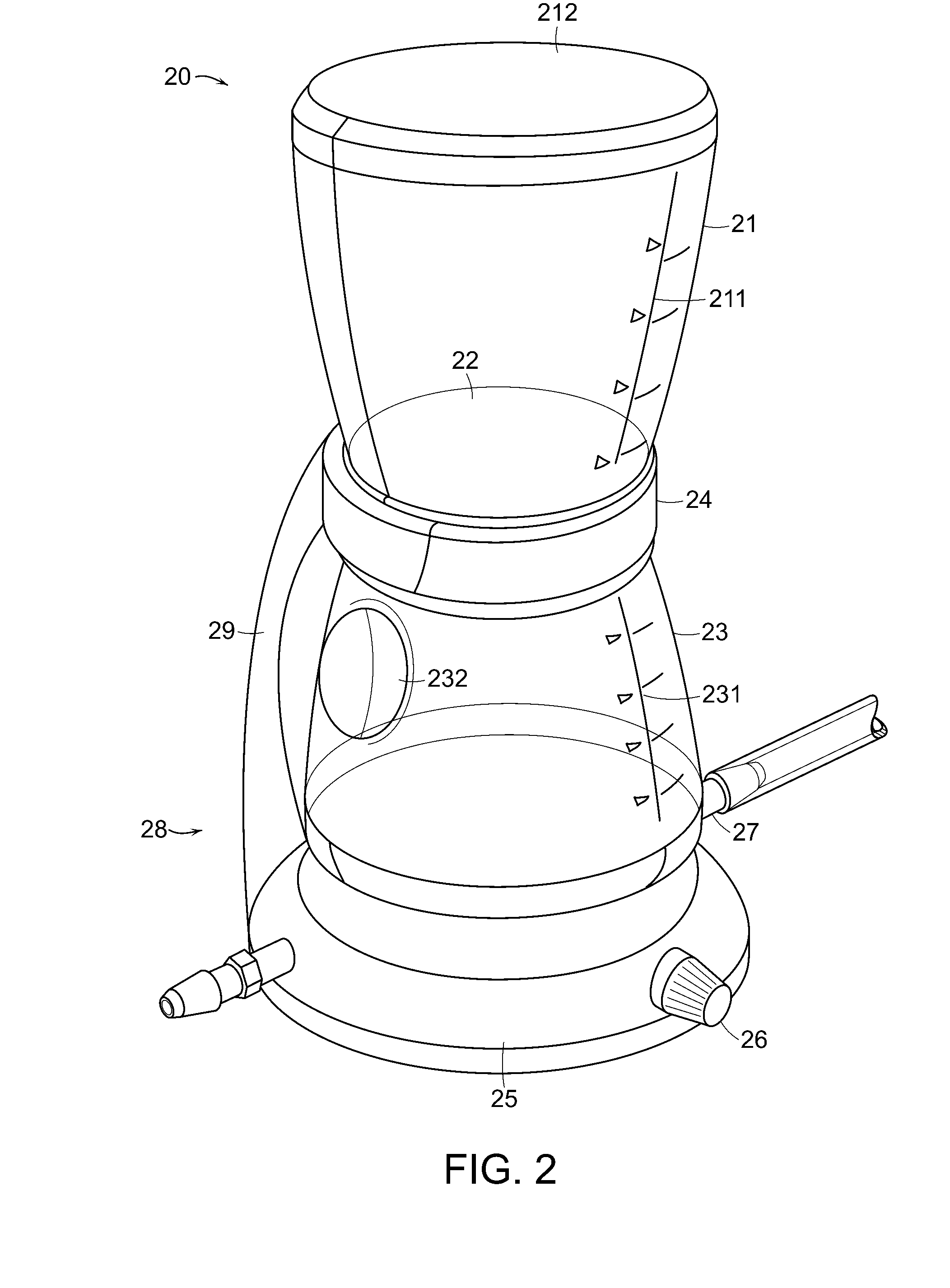

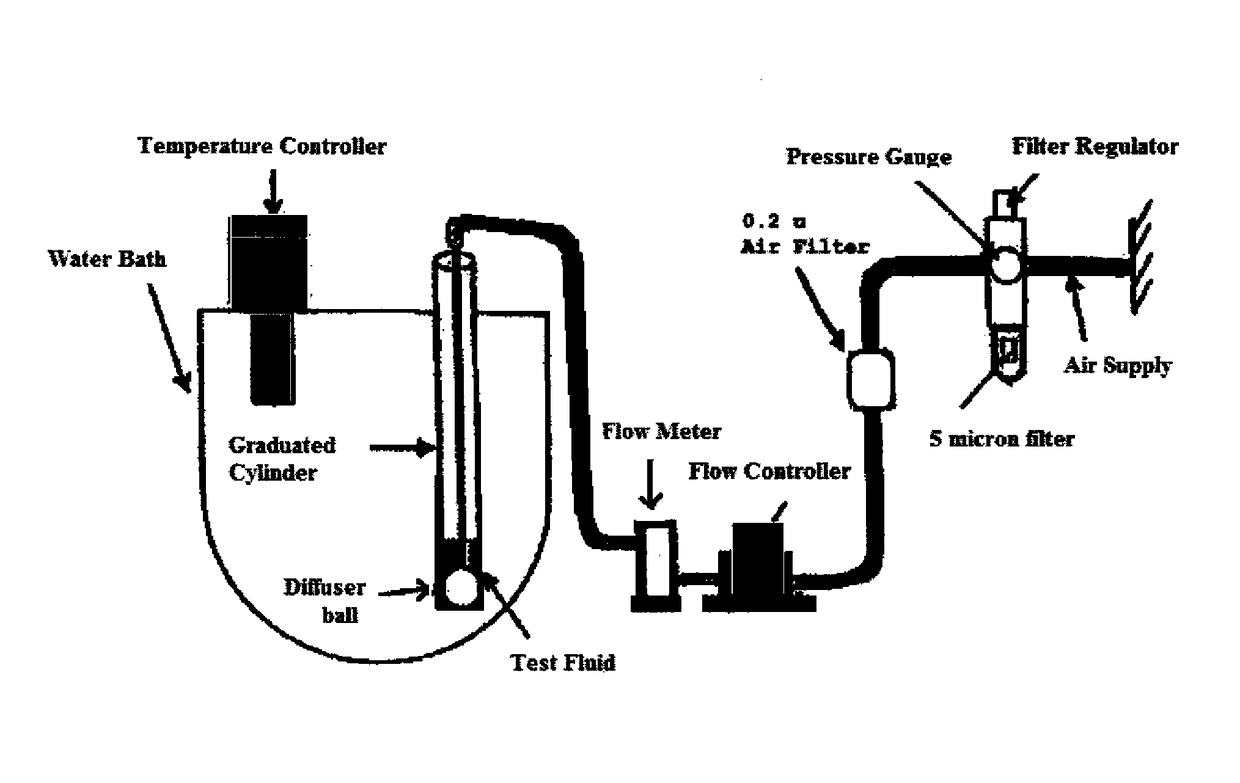

Methods and Apparatus for Foam Control in a Vacuum Filtration System

InactiveUS20080290040A1Reduces splashing and foamingReduce foamingSamplingLaboratory glasswaresFiltrationFilter system

A flow diverter, vacuum control and tilting of the liquid filtering system are used alternatively or in conjunction to reduce foam production in a filtered liquid sample. A liquid filtering system includes an upper sample reservoir, a filter and a lower storage bottle. A vacuum is applied below the sample filter to draw sample liquid through the sample filter into the storage bottle. A flow diverter may be used to direct flow of the filtered liquid sample onto a sidewall of the storage bottle or guide flow to a bottom of the storage bottle. The vacuum may be regulated to reduce foaming. The liquid filtering system may be tilted to direct fluid to the sidewall of the lower storage bottle and reduce foaming.

Owner:FOXX LIFE SCI

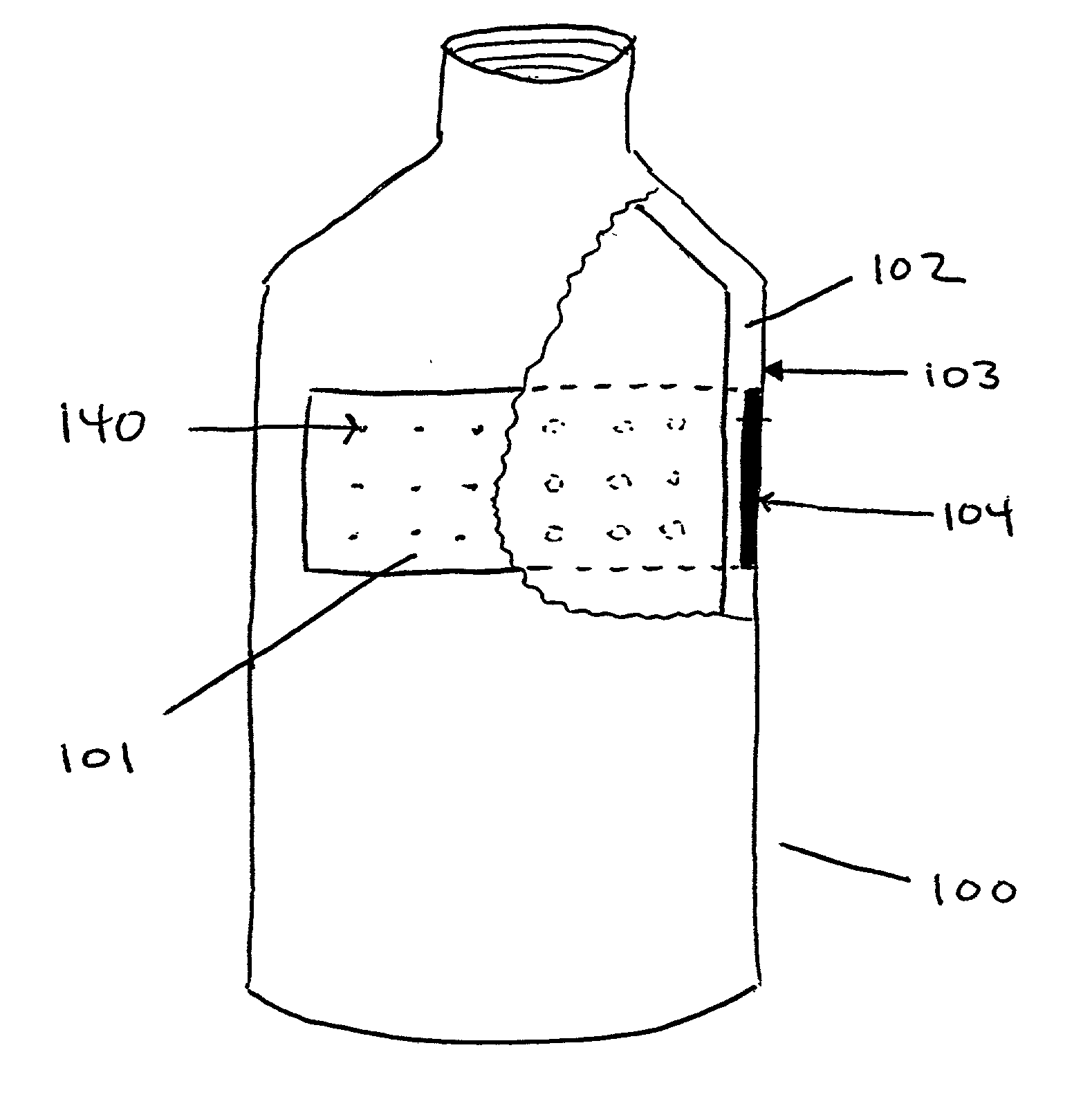

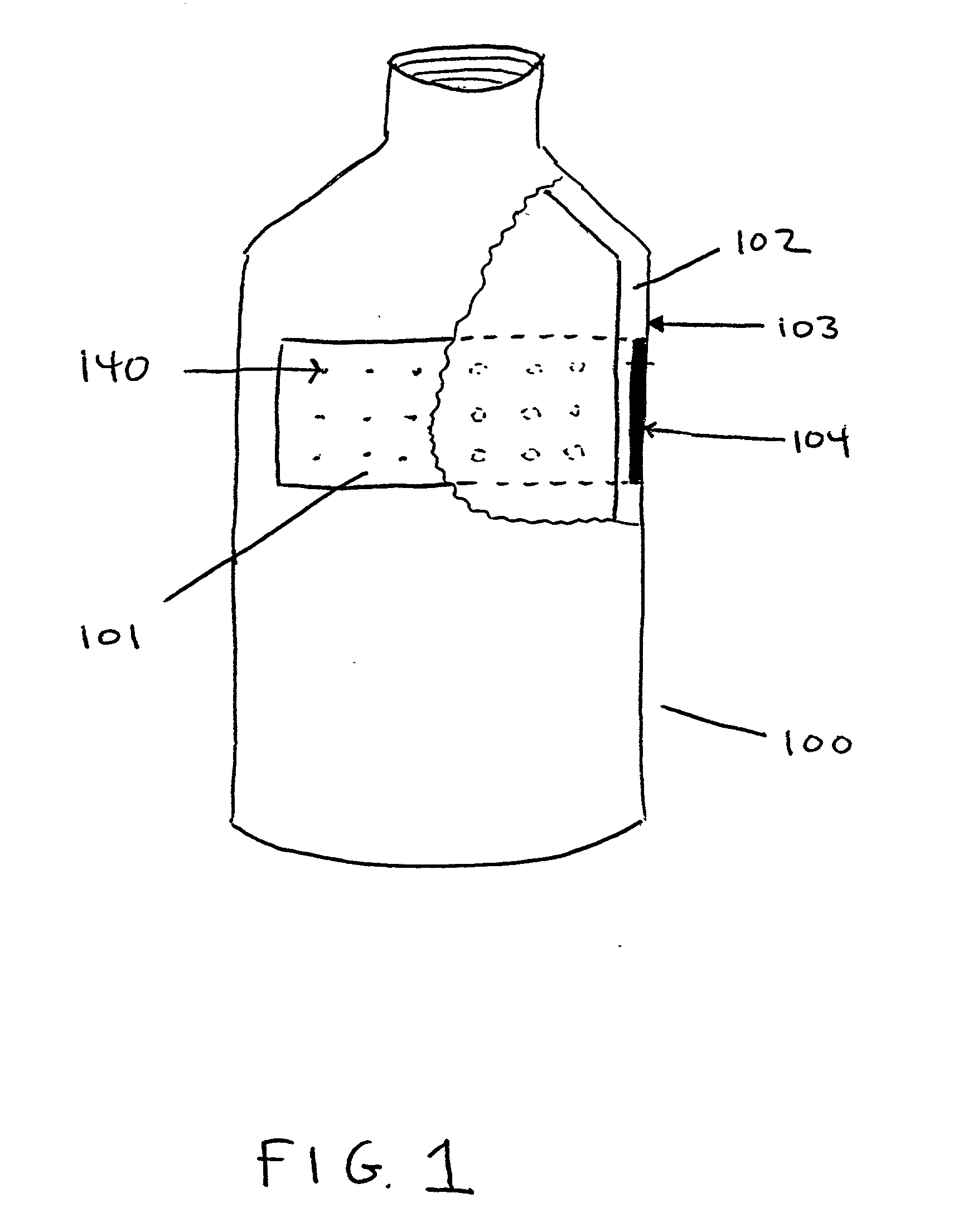

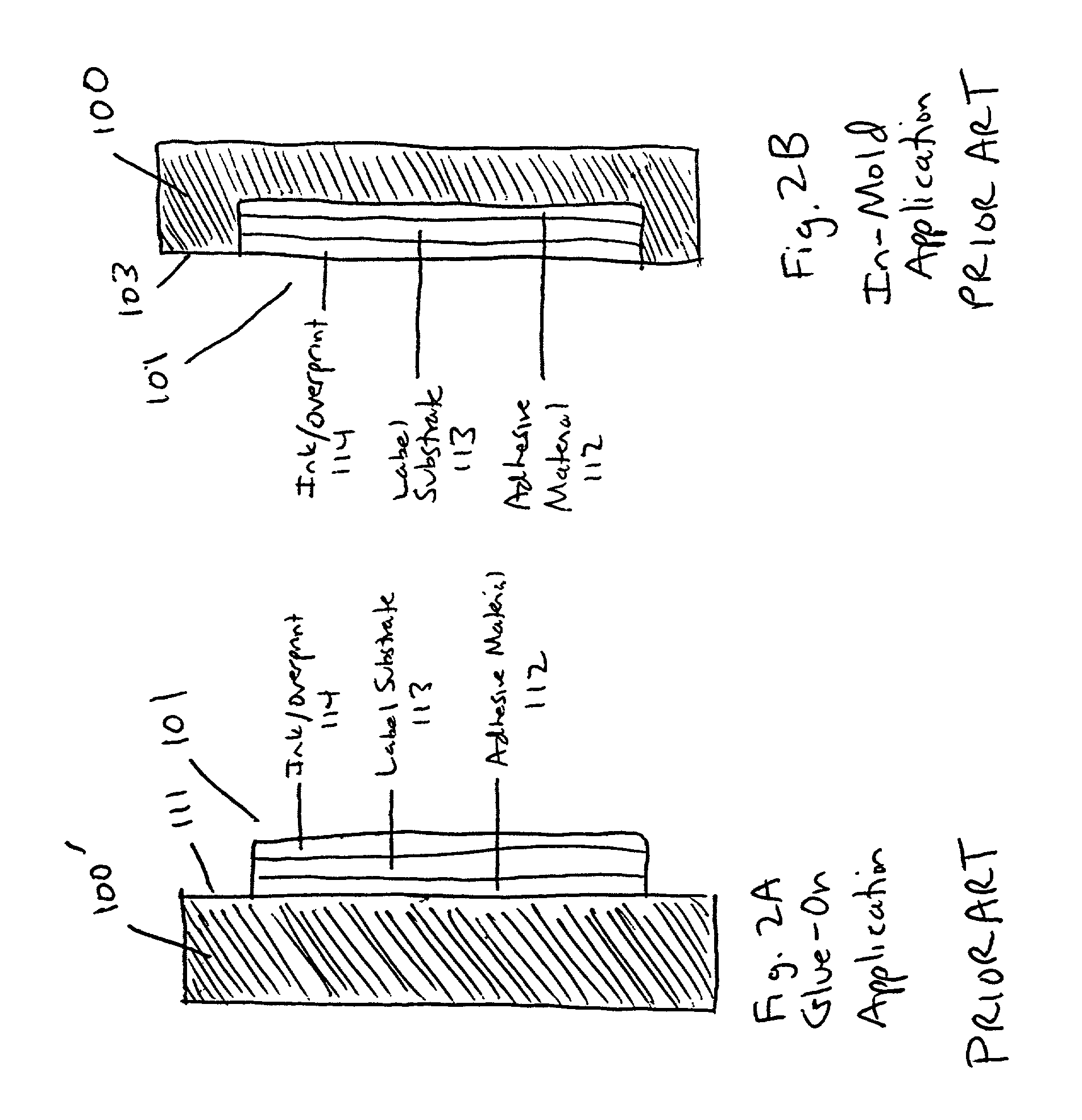

In-mold label with perforations

InactiveUS20020124945A1Reduce blisteringImpair aestheticStampsLayered productsIn-mould labellingEngineering

An improved method for preparing a molded plastic container with embedded label in which the label contains one or more perforations to reduce blistering during the blow molding process. In a preferred embodiment, the perforations are larger on one side of the label than the other to facilitate the release of gases that otherwise would be trapped behind the label.

Owner:MAIL WELL

Non-aqueous slurries used as thickeners and defoamers and method of using slurries in aqueous systems

InactiveUS20060160921A1Increase moistureReduce foamingAntifouling/underwater paintsThixotropic paintsParticulatesSlurry

A low VOC, HAPs free, substantially non-aqueous slurry for use as a rheology modifier in aqueous systems including but not limited to latex paints. The slurry comprises a particulate water-swelling polymer such as hydroxyethyl cellulose, mineral oil carrier liquid, a non-ionic surfactant, a particulate thickening agent, a defoamer, and optionally an amine component.

Owner:THE SHERWIN-WILLIAMS CO

Copper base material cleaning agent and preparation method thereof

The invention provides a copper base material cleaning agent. The copper base material cleaning agent is composed of, by weight, 0.05%-2% of organic acid activators, 0.05%-1% of a nonionic surface activator, 0.01%-0.6% of an anion surface activator, 0.005%-0.2% of an antioxidant, 0.005%-0.2% of a chelating agent, and the balance deionized water. In addition, the invention discloses a preparation method of the copper base material cleaning agent. The copper base material cleaning agent is free of attenuation and controlling over the attenuation, can be directly used, does not contain heavy metal, is free of residues and can meet the processing requirements for copper before hot dipping; the surface of a copper base material processed by the cleaning agent is pure and is free of dark spots, oil contaminations, fingerprints and the like; accessories obtained after tinplating are free of exposed copper, dark spots and other defects, and the surfaces of the accessories are smooth.

Owner:THE NORTHWEST MACHINE

Gypsum panel having UV-cured moisture resistant coating and method for making the same

ActiveUS7553780B2Excellent water resistance and vapor barrier propertyIncreased durabilityConstruction materialSynthetic resin layered productsFace sheetMoisture

Owner:GEORGIA PACIFIC GYPSUM LLC

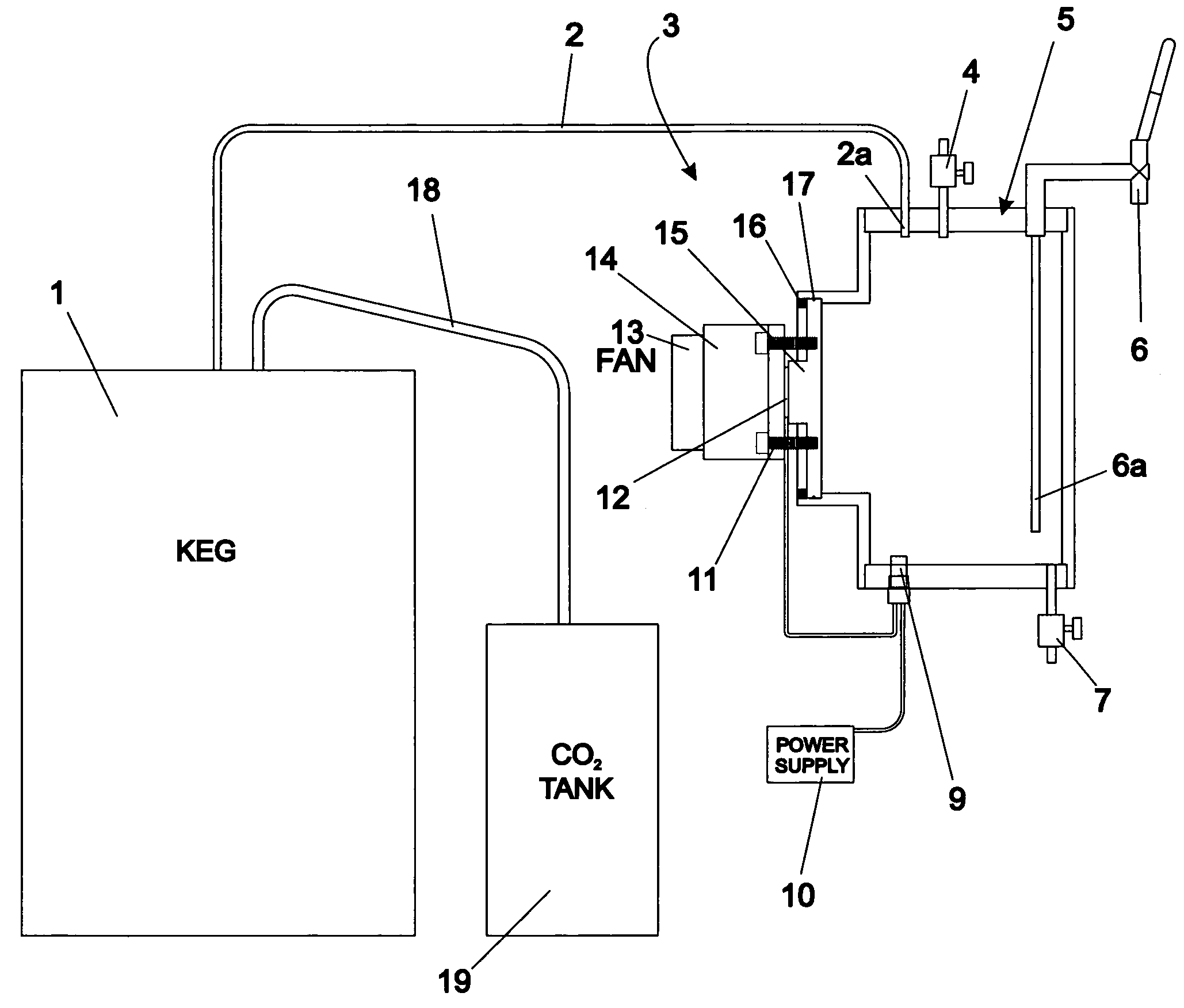

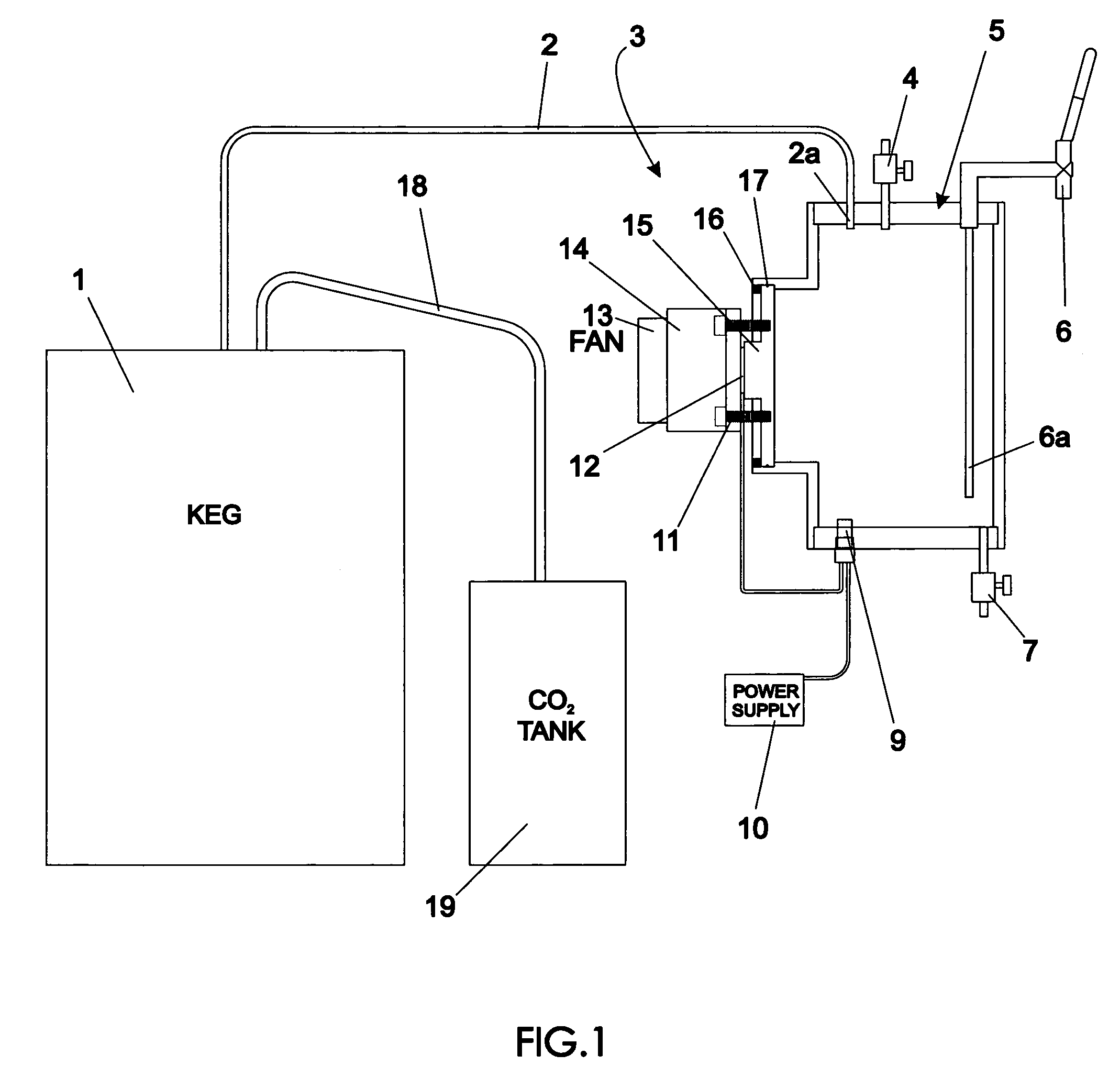

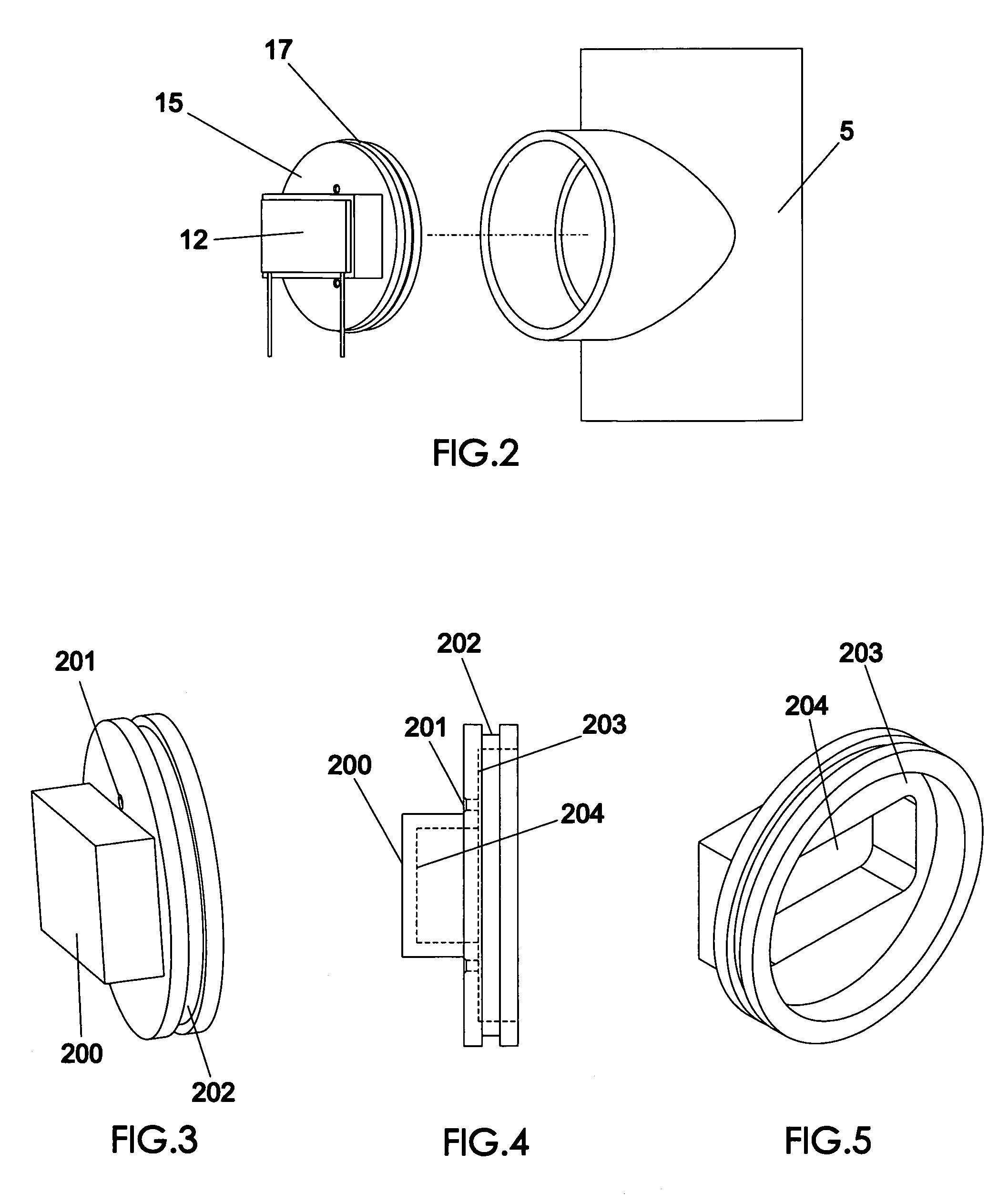

Compact portable beverage cooling system

InactiveUS7237390B1Efficiently cools beerHigh degreeMachines using electric/magnetic effectsLiquid dispensingEngineeringMechanical engineering

A cooling sink is positioned within a cooling chamber having a 0.75-1.50 gallon capacity, for directly contacting pressurized beer therein, the cooling sink having a substantial surface portion in contact with the beer for enabling heat extracted from said beer to be rapidly conveyed to said cooling device. The cooling sink has a deep trench therein for reducing the mass of the cooling portion while increasing the surface area contacting the beer. A valve is employed at the top of the cooling chamber to allow the cooling reservoir to be completely filled with beer during periods of use, and any developing undesired foam can be removed from time to time by opening this valve. Also, the pickup tube attached to the dispensing tap picks up beer from the bottom of the cooling chamber, to minimize foam in the beer dispensed.

Owner:NELSON LANCE

Non-foaming aqueous particle-free inkjet ink compositions

ActiveUS20180051184A1Unique balance of solubilityReduce foamingInksPrintingDefoamerHydrophilic-lipophilic balance

Colorless or colored coatings can be ink jetted onto a substrate using an aqueous particle-free inkjet ink composition that has a viscosity of less than 5 centipoises, and that includes a combination of an anionic polyether polyurethane and an anionic acrylic polymer or anionic styrene-acrylic polymer, in a total amount of less than or equal to 20 weight %. The composition can be colorless (free of colorants) or it can contain a suitable colorant to provide a color image. The composition also includes a defoamer that has a hydrophilic-lipophilic balance value of at least 3 and up to and including 5, and which is present in an amount of at least 0.15 weight % and up to and including 1 weight %. Such composition can be used in inkjet printing methods including recirculation apparatus and methods, and can be provided as part of an ink set.

Owner:EASTMAN KODAK CO

Low-foam middle-cloud-point environment-friendly water base metal cleaner composition and preparing method thereof

The invention provides a low-foam middle-cloud-point environment-friendly water base metal cleaner composition and a preparing method thereof, and belongs to the field of metal cleaners. The low-foam middle-cloud-point environment-friendly water base metal cleaner composition is composed of low-foam low-cloud-point nonionic surface active agents, low-foam anion surface active agents, triethanolamine oleic soap, triethanolamine, styrene acrylic three azole nitrogen, ethylene diamine tetraacetic acid, sodium carbonate, polyether, organosilicone, sodium hydroxide and deionized water, wherein solid-phase raw material and liquid-phase raw material are sequentially added to a reaction container according to a formulation and metering, the organosilicone and the deionized water are finally added to the reaction container, stirring is conducted for 10min to 20min under the condition of indoor temperature, and clear products with a pH value ranging from 9 to 10 are obtained. The triethanolamine oleic soap is a cloud point improving agent, good water solubility is achieved after the triethanolamine oleic soap and the triethanolamine are re-compounded according to the ratio, solubilizing ability of the low-foam low-cloud-point nonionic surface active agents is enhanced, therefore the temperature of the solution cloud point of the cleaner is improved to 45 DEG C, cleaning efficiency of the cleaner is improved, and the low-foam middle-cloud-point environment-friendly water base metal cleaner particularly suitable for high-pressure spraying cleaning is obtained.

Owner:BOER TECH WUHAN

Baked snack

InactiveUS20070098865A1Improve textureAdd flavorLeguminous plant bakery productsBaking mixturesHigh volume manufacturingGluten

A baked snack having a hollow stick shape obtained by baking a dough including an non-gelatinized flour and a gelatinized flour, wherein the dough does not substantially include active gluten. According to the present invention, a baked snack having a hollow stick shape that can be reliably shaped, easily melts in the mouth and is well-moistened with no powdery and dry texture is provided. In the baked snack of the present invention, a large amount of taste providing material can be blended in order to improve the taste thereof. The novel baked snack having the hollow stick shape suitable for the mass production and processing and having an even shape with reduced blistering can be provided without demanding any special device and complicated process.

Owner:EZAKI GLICO CO LTD

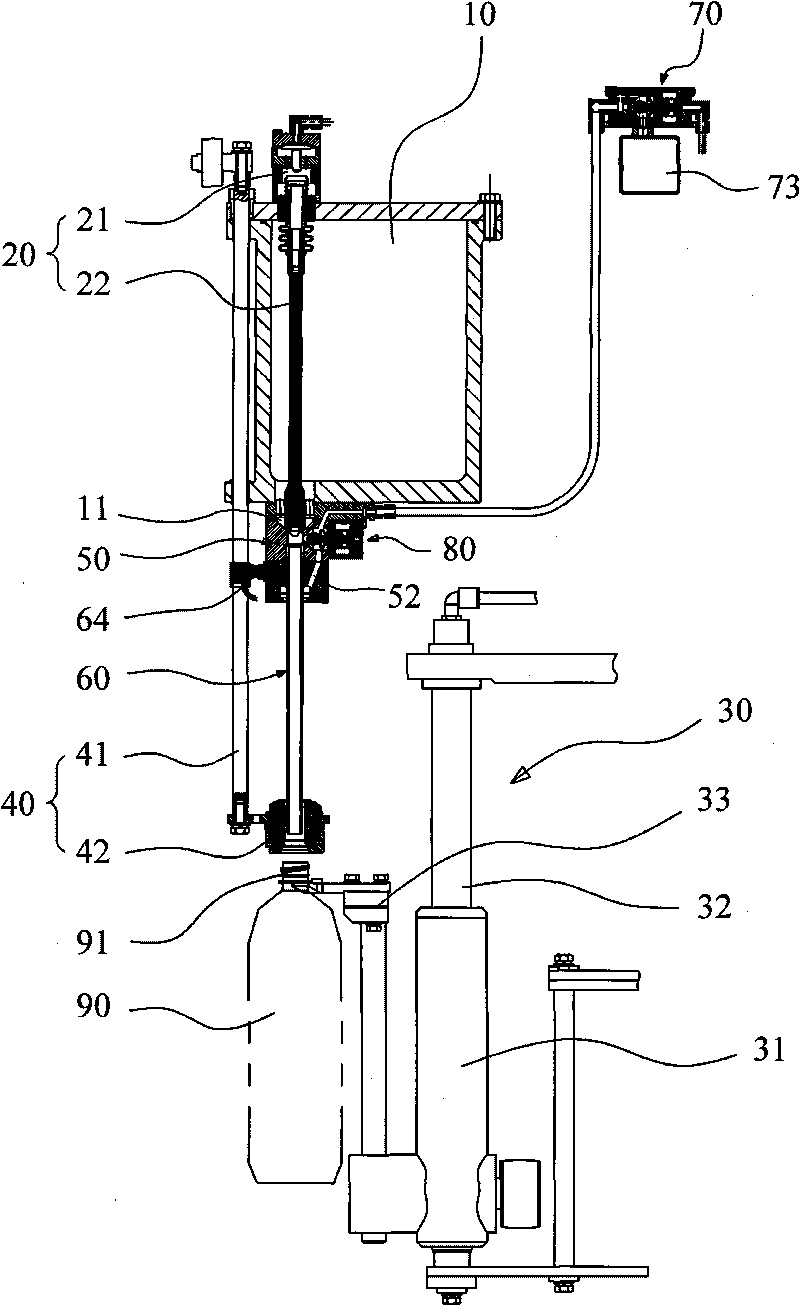

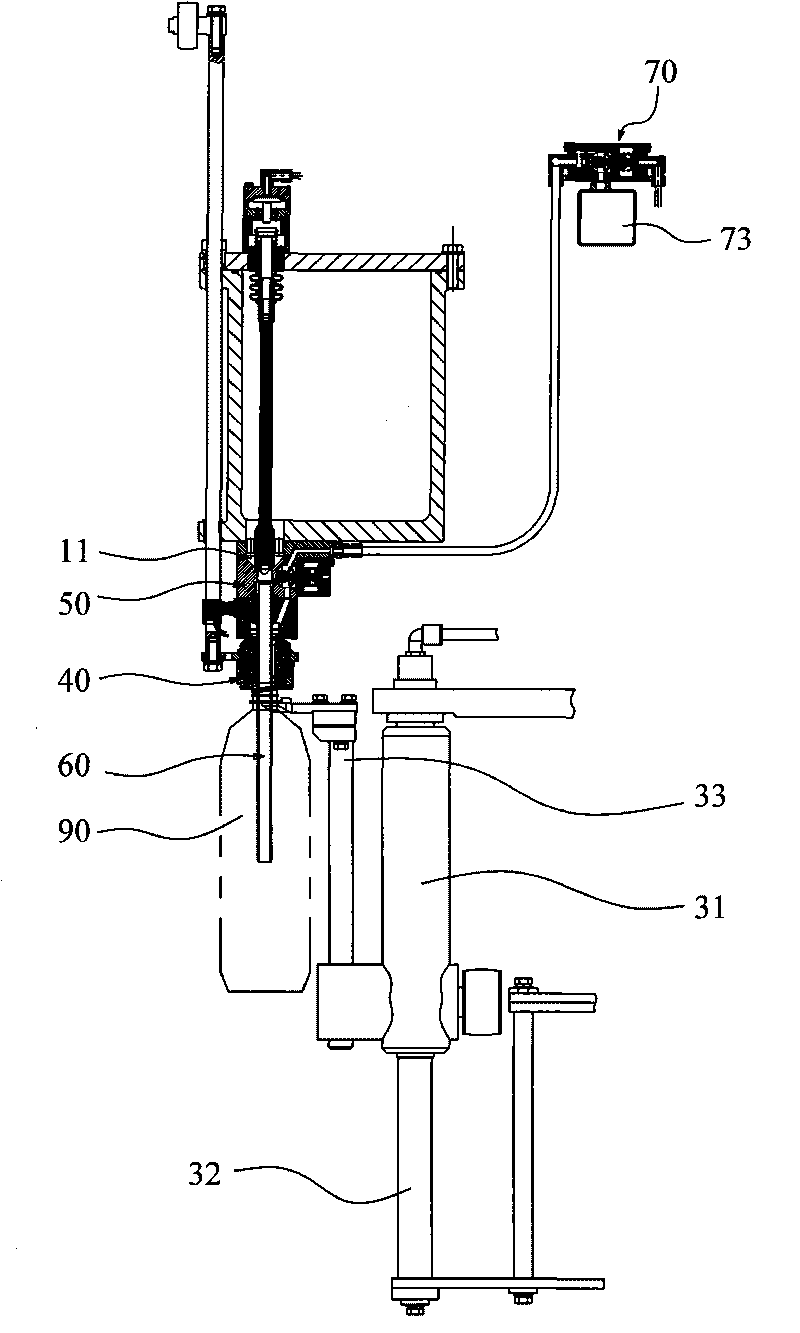

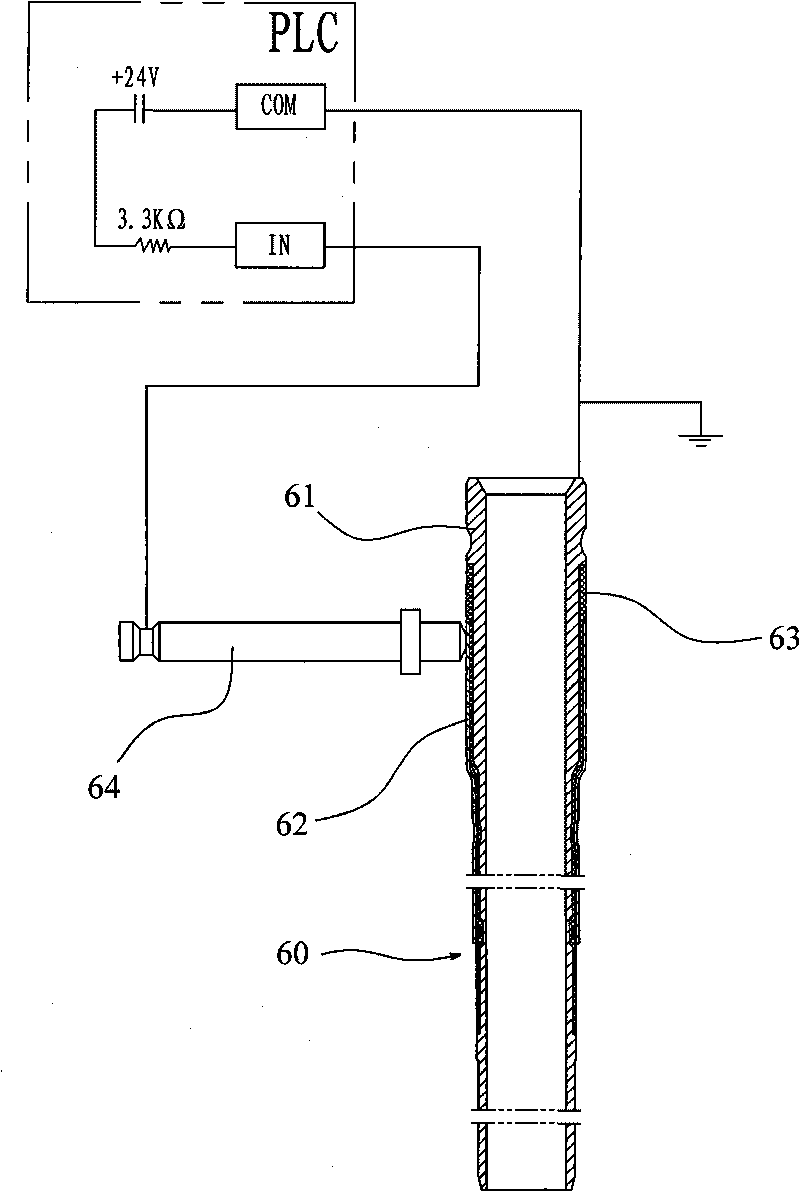

Needle tube type filling machine and filling method thereof

The invention discloses a needle tube type filling machine and a filling method thereof. The needle tube type filling machine comprises a liquid feeding device, a perfusion needle tube connected with the liquid feeding device and capable of extending into a bottle, and an exhaust passage capable of being hermetically communicated with a gap between the outer wall surface of the perfusion needle tube and the inner wall surface of an opening of the bottle, wherein a speed control device capable controlling the exhaust velocity of the needle tube type filling machine is arranged in the exhaust passage. The needle tube type filling machine is used for performing perfusion by extending the needle tube into the bottle so that the air in the bottle can be exhausted along the periphery of the needle tube, then the speed control device is used for controlling the air exhaust velocity to realize the effective control of the perfusion speed to ensure that the speed control during the perfusion is possible, and thus, a special perfusion mode of slow filling-quick filling-slow filling and the like is formed according to needs, and subsequently, foaming phenomena in the process of the perfusioncan be effectively reduced and the filling quality is improved.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

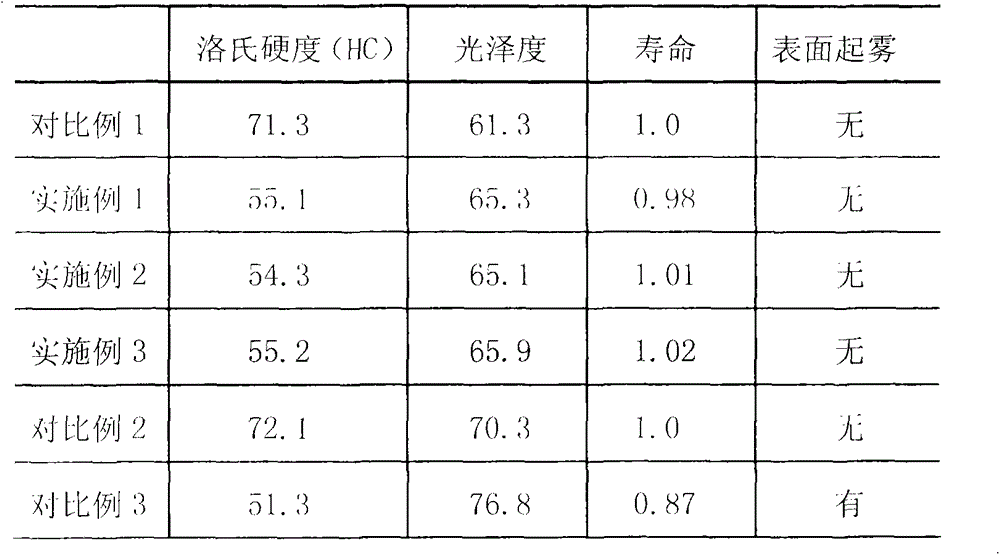

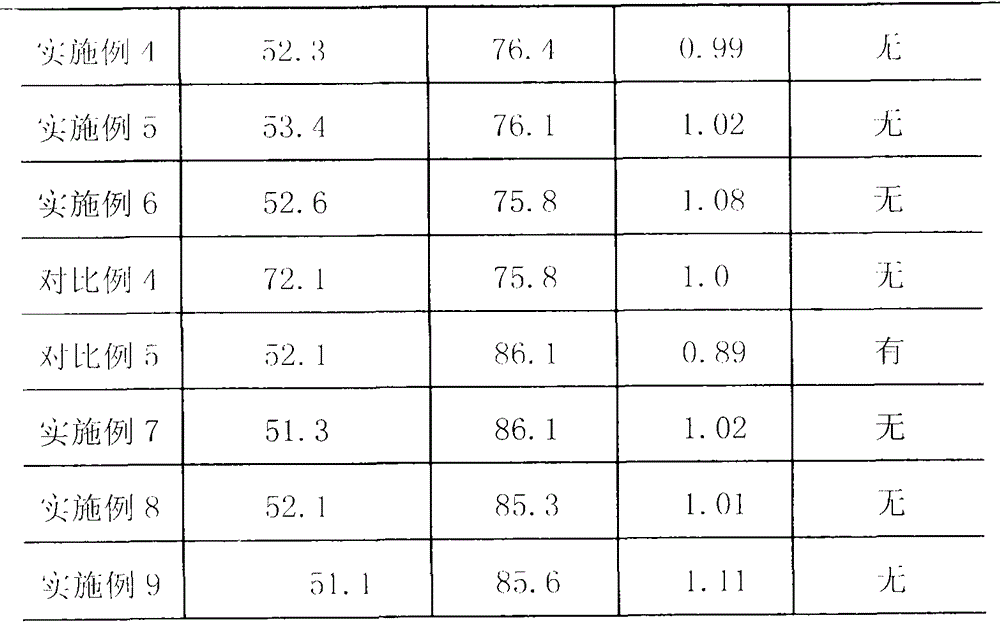

Preparation method for epoxy resin binding agent diamond grinding tool with high polishing performance

ActiveCN104057403ALow hardness valueReduce pollutionAbrasion apparatusGrinding devicesEpoxyRare earth

The invention discloses a preparation method for an epoxy resin binding agent diamond grinding tool with high polishing performance. A working layer is mainly prepared from a diamond grinding material, an auxiliary grinding material, epoxy resin, a curing agent, rare earth polishing powder, filler and a dilution agent. The preparation method comprises the steps of uniformly and mechanically mixing 5-20 parts of the diamond grinding material, 5-20 parts of the auxiliary grinding material, 5-25 parts of the rare earth polishing powder and 5-40 parts of the filler to obtain a first mixture, then uniformly mixing and stirring the first mixture with 20-40 parts of the epoxy resin, 7-15 parts of the curing agent and 0.5-10 parts of the dilution agent to obtain a final mixture, injecting the mixture with flowability into a plastic mold in a pouring manner, and curing the mixture to obtain the epoxy resin binding agent diamond grinding tool with high polishing performance. The materials are in percentage by mass. Compared with the conventional hot pressing molding method, the preparation method has the advantages that the technology is simple, the energy is saved, and the emission is reduced; the pollution, which is caused by solid dust, to the environment is reduced, and the production speed is high; compared with the conventional product in the foreign country, the epoxy resin binding agent diamond grinding tool has the advantages of good polishing effect, high polishing efficiency, few air hole defects of the grinding tool and the like.

Owner:惠安宇信金刚石工具有限公司

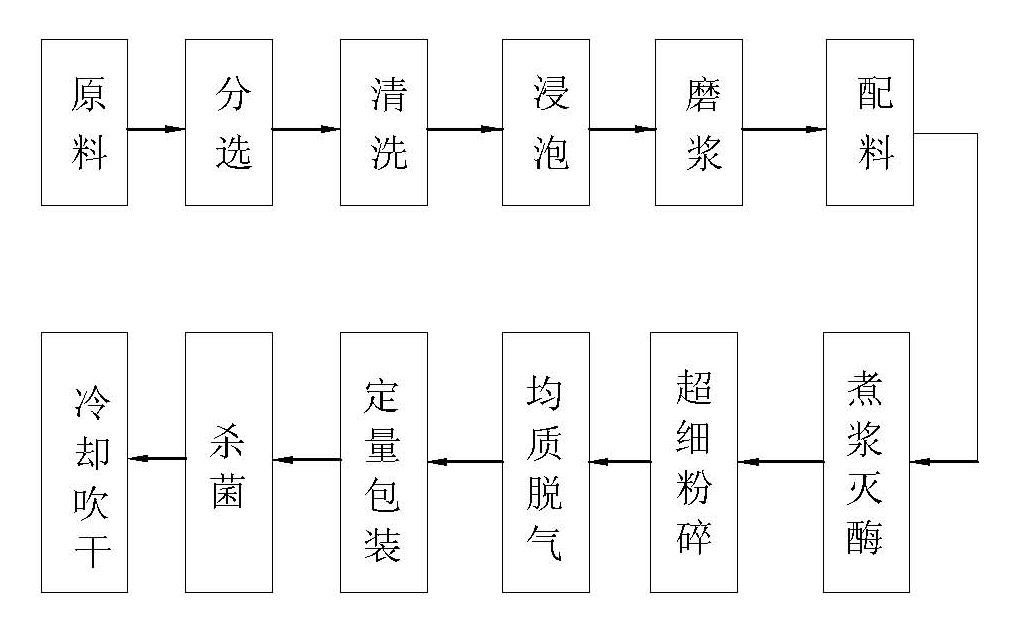

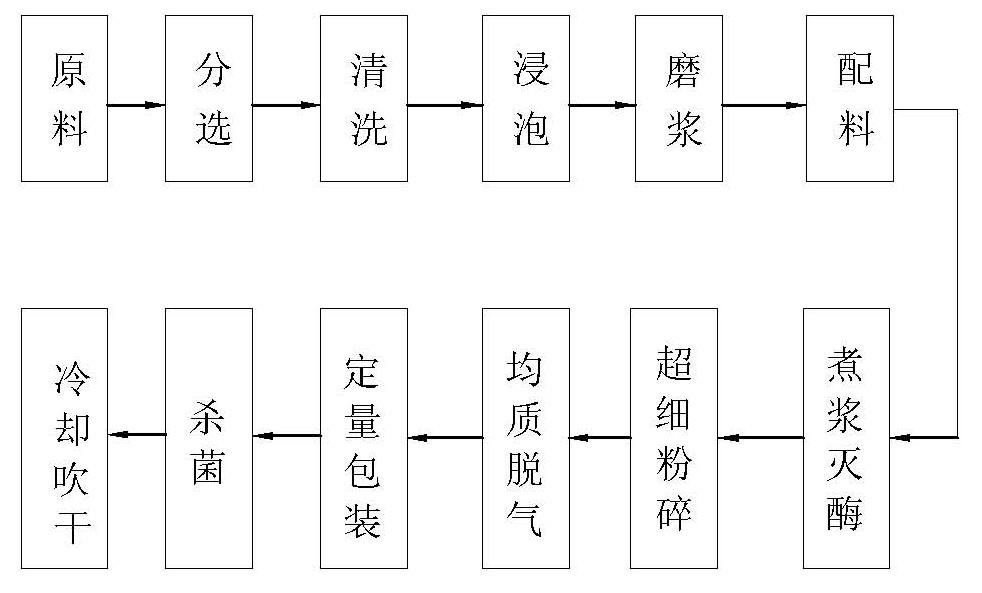

Method for preparing high-concentration soya-bean milk

InactiveCN102138591AWide range of particle sizesRich varietyMilk substitutesFood scienceHigh concentrationDietary fiber

The invention relates to a method for preparing high-concentration soya-bean milk. In the method for preparing the high-concentration soya-bean milk, the high-concentration soya-bean milk is prepared by sorting, cleaning and immersing soybeans, pulping, batching, stewing pulp, deactivating enzyme, performing superfine grinding, homogenizing, degassing, performing quantitative packaging, sterilizing, cooling, and blowing dry sequentially. Compared with the prior art, the method for preparing the high-concentration soya-bean milk has the advantages that: the high-concentration soya-bean milk has high nutritional value by adding abundant edible ingredients, and due to the full utilization of bean dregs, the content of dietary fibers in the soya-bean milk is improved. In addition, in the preparation process, bean immersing water is utilized effectively to realize the zero release of production and protect environment.

Owner:JOYOUNG CO LTD

High-grade noniron finishing method of deep dark pure cotton fabric

ActiveCN107938219AIncreased radial shrinkageImproves easy-care performanceTextile storage in superimposed formSingeingTextile printerMoisture absorption

The invention belongs to the technical field of textile printing and dyeing and particularly relates to a high-grade noniron finishing method of deep dark pure cotton fabric, comprising the sequentialsteps of spread-sewing, singeing, desizing, scouring, mercerizing, cold pad-batch dyeing, high temperature soaping, liquid ammonia finishing, pre-softening, primary pre-shrinking, noniron treating, curing, water washing, tentering and softening, and secondary pre-shrinking, wherein curing temperature is 120-130 DEG C, curing reaction time is controlled to 5-6 min, and the noniron step employs padding AP resin noniron aid. The high-grade noniron finishing method of deep dark pure cotton fabric has the advantages that radial stretch of the fabric can be improved, noniron state is retained afternoniron curing, and noniron property of the fabric can be improved accordingly; the deep dark pure cotton fabric is imparted good softness, breathability and moisture absorption and good washing fastness, never fades in long-term standing, has good ironing firmness, is suitable for batch production, and reaches grade 3.8 and above under AATCC-125 standard in terms of noniron property.

Owner:鲁丰织染有限公司

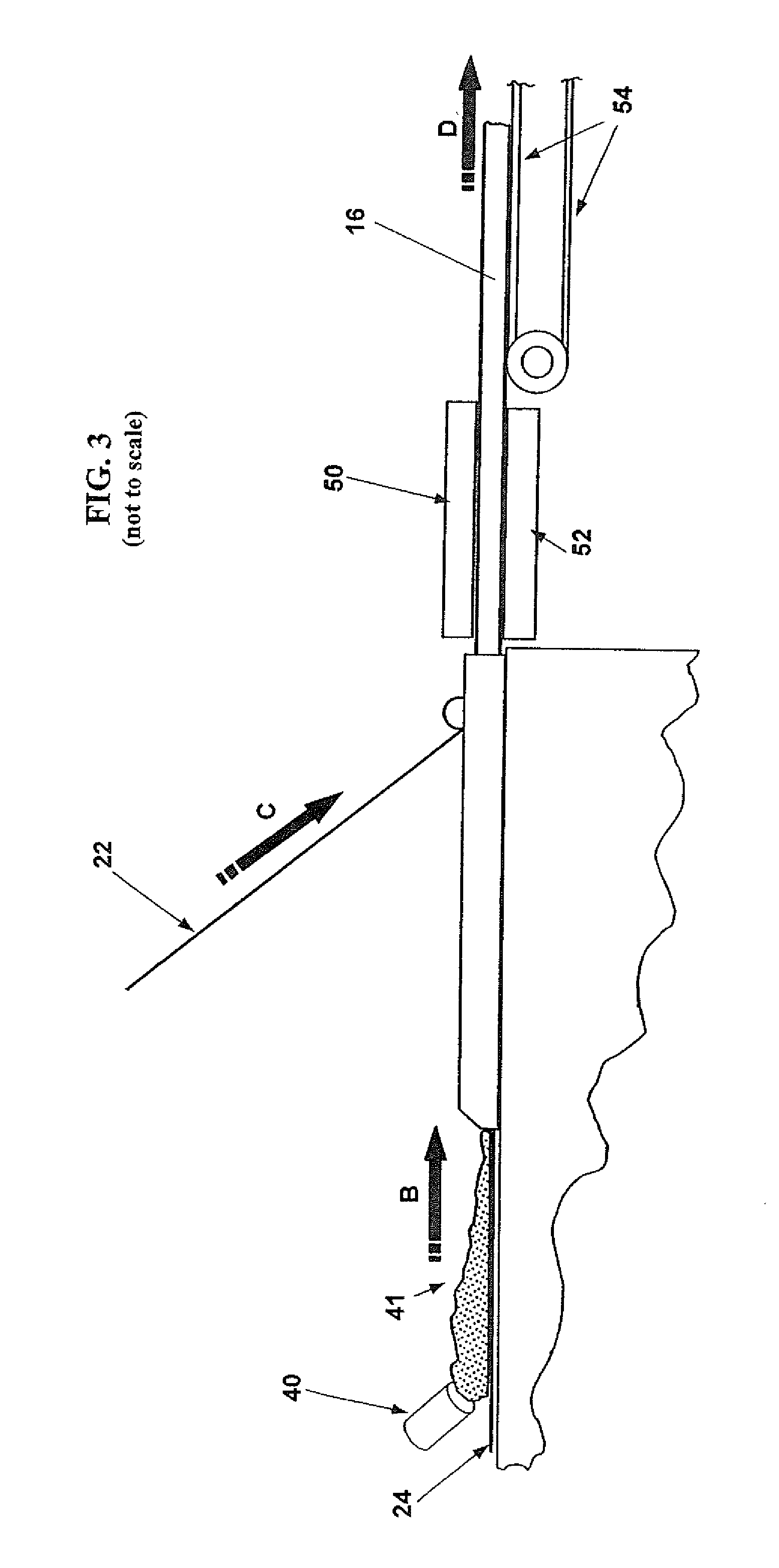

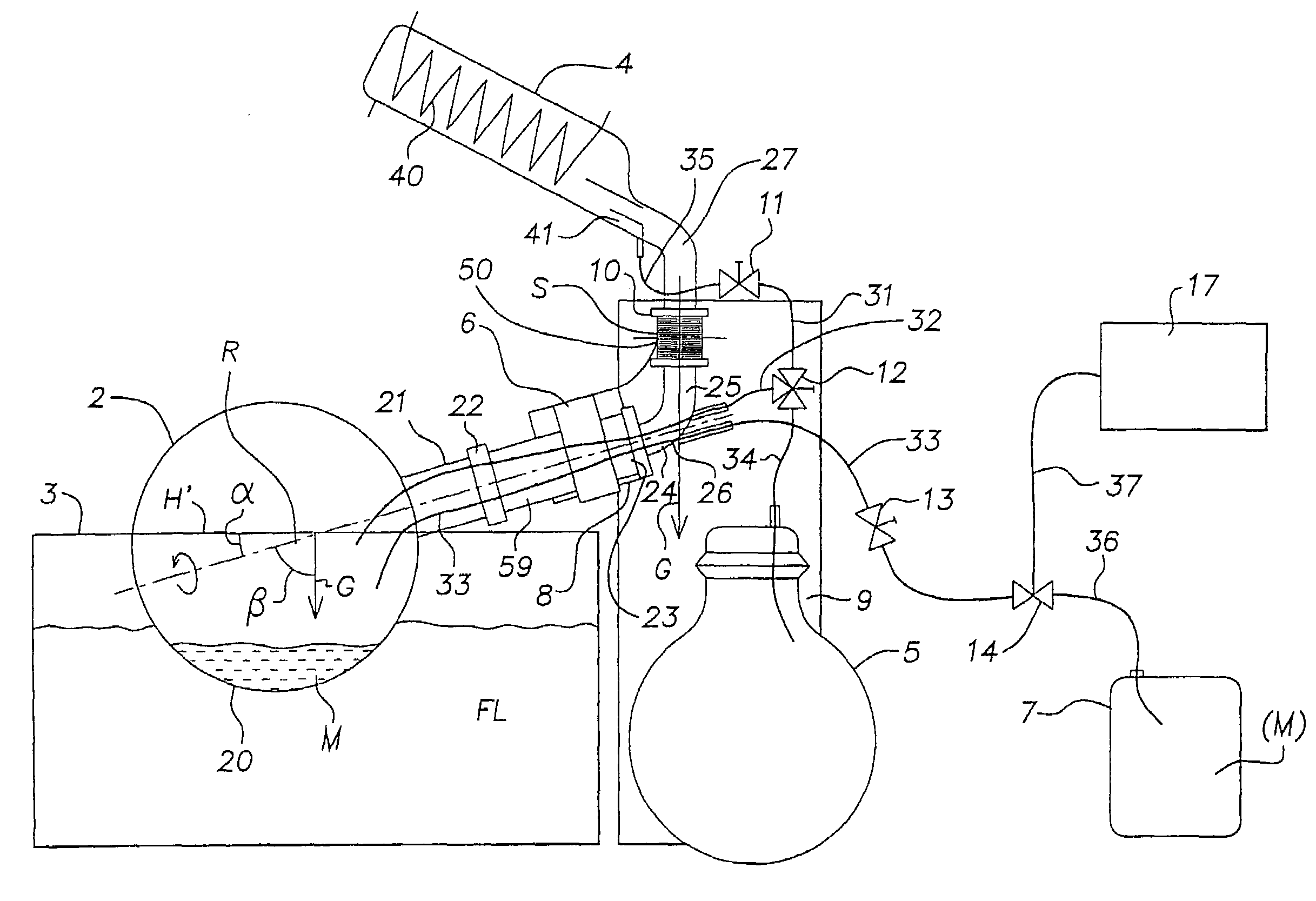

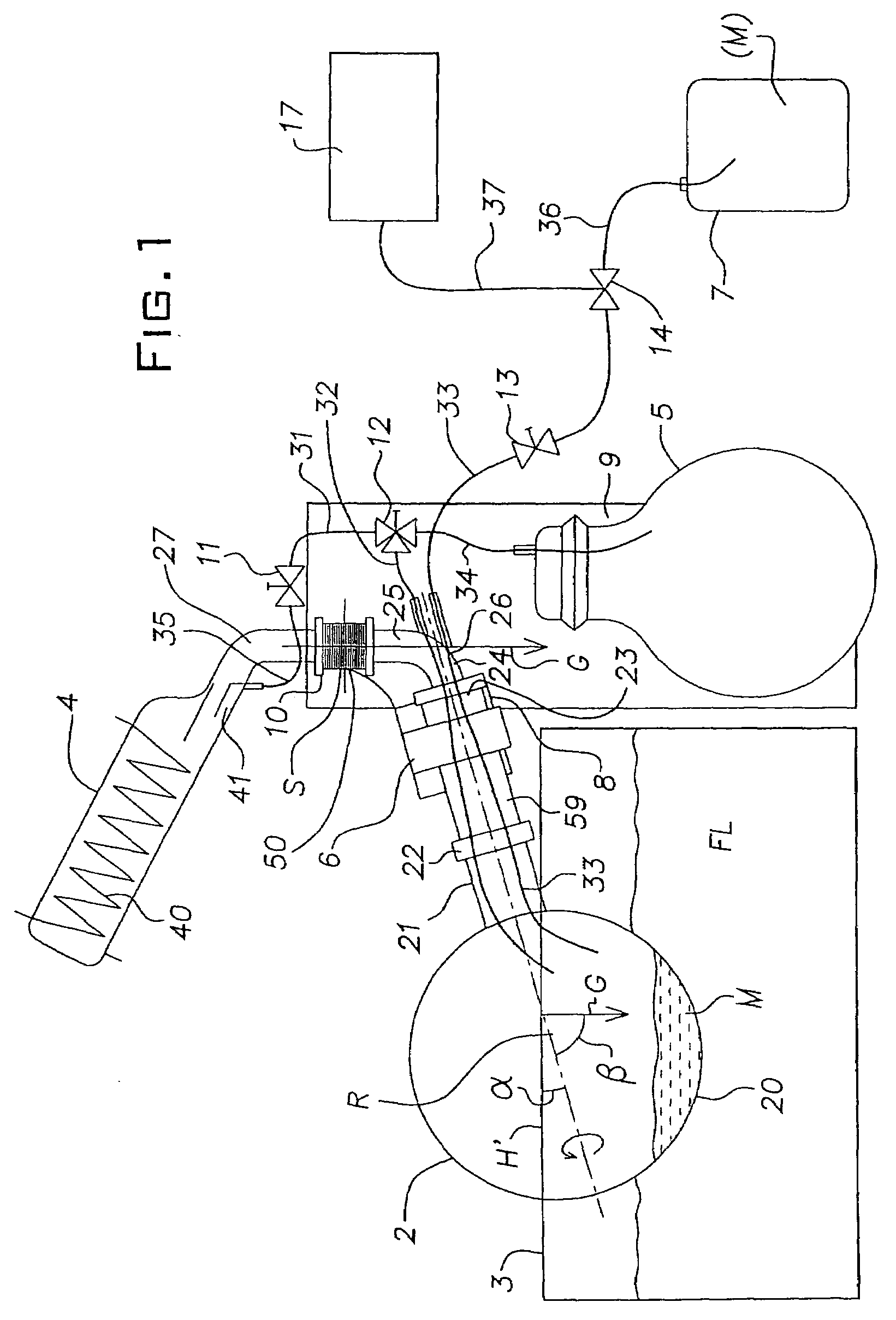

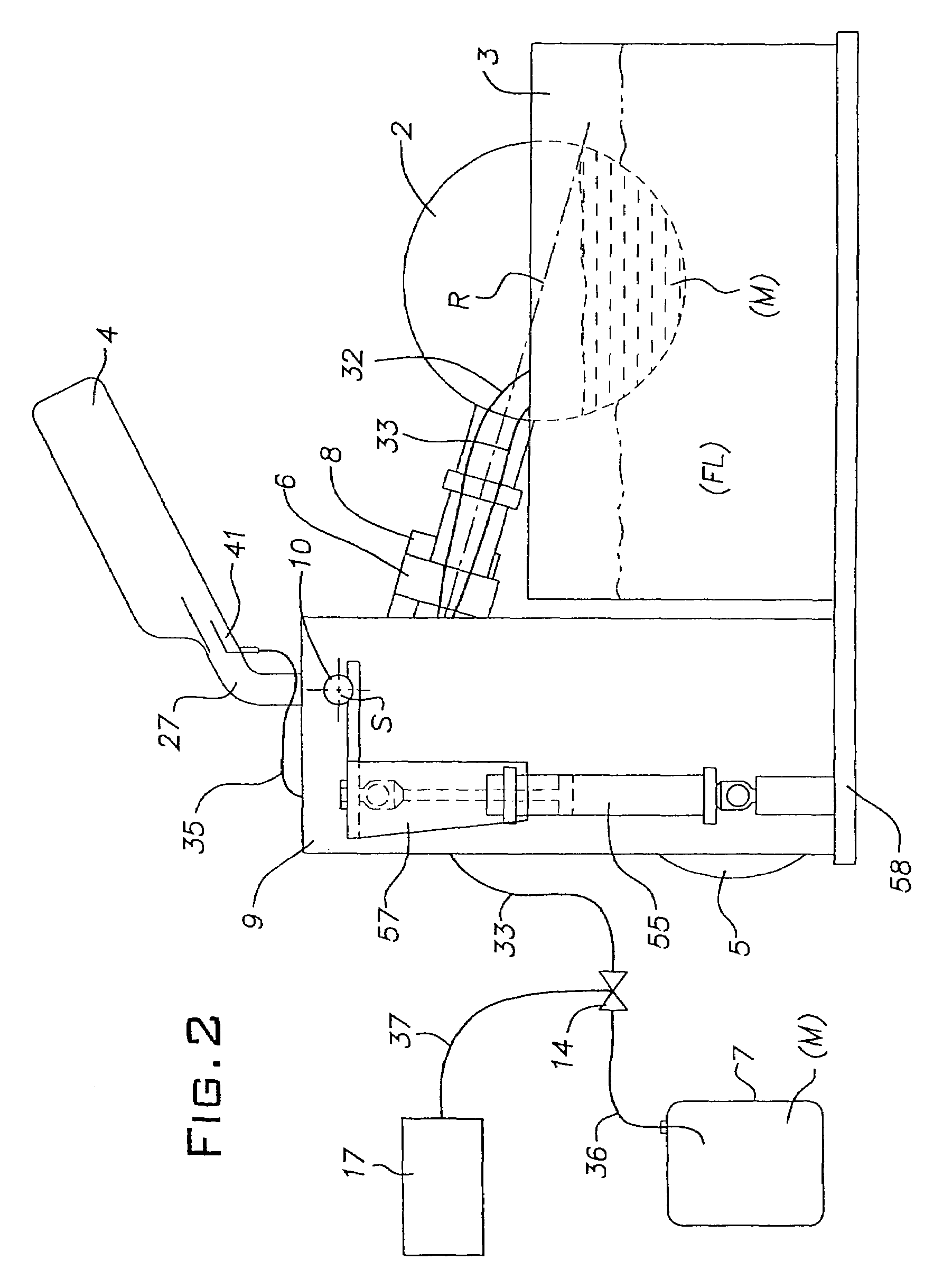

Rotary evaporation with variable dosage metering

InactiveUS7150807B2Accelerate evaporationReduce foamingDrying using combination processesDistillation regulation/controlTraffic volumeAutomatic control

Method and system for evaporating at least one substance. During at least one dosing phase (TG) a predefined or predefinable quantity of a product (M) which contains at least one substance to be evaporated is imported via a feed system (7, 14, 17, 33, 36) into a revolving vessel (2). The revolving vessel is rotated around an axis of rotation (R) and appropriate process conditions for the evaporation of at least one substance are generated or maintained. The flow (F) of the product (M) is automatically controlled or regulated by the feed system (14, 17) during the dosing phase (TG) in particular as a function of at least one process parameter and / or of at least one characteristic property of the product. The product (M) is imported into the revolving vessel (2) in the course of the dosing phase only during predefined feed periods (t1, t2) that are interrupted by intervening intervals and especially idle intervals (t1, t2). The flow or imported quantity of the product is less during the intervening intervals by at least a factor of 10 and preferably at least by a factor of 20 than during the feed periods and is essentially zero during the idle intervals. The time duration of the feed periods and / or of the intervening intervals is or can be modified during the dosing phase.

Owner:GENSER HANS GEORG

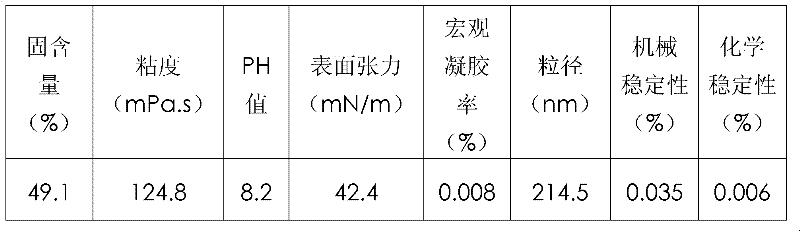

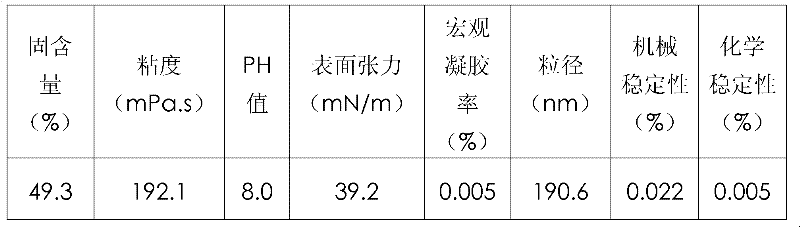

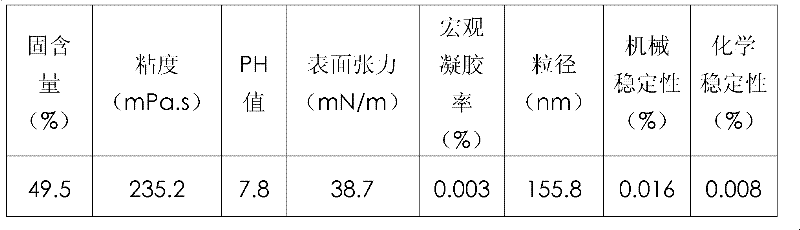

Carboxy styrene-butadiene latex special for coating paper

The invention discloses polymer emulsion special for coating paper. The polymer emulsion comprises the following raw materials in part by weight: 100 parts of monomer, 0.4 to 2 parts of composite emulsifier, 0.4 to 2 parts of macromolecular protective glue, 0.4 to 2 parts of initiator, 0.2 to 1.2 parts of molecular weight regulator, 0.02 to 0.1 part of chelating agent, 0.2 to 1 part of pH regulator and 100 to 150 parts of deionized water. Butadiene and styrene are used as main monomers and added with an unsaturated carboxylic acid functional monomer, the emulsifier is compounded by adopting an anionic emulsifier and a nonionic emulsifier, and the reaction stability is improved by using the water-soluble macromolecular protective glue; and the polymer emulsion is synthesized by feeding in a continuous dripping mode for high-temperature emulsion polymerization and adopting a reduced pressure flash degassing technology. The prepared carboxy styrene-butadiene latex can be used for bottom and surface coating of various paper products such as coated paper, white board paper and the like, and endows the coated paper with high glossiness, pigment bonding strength, surface water resistance and good printing adaptability.

Owner:GUANGDONG TENGLONG CHEM TECH

Low friction fabric

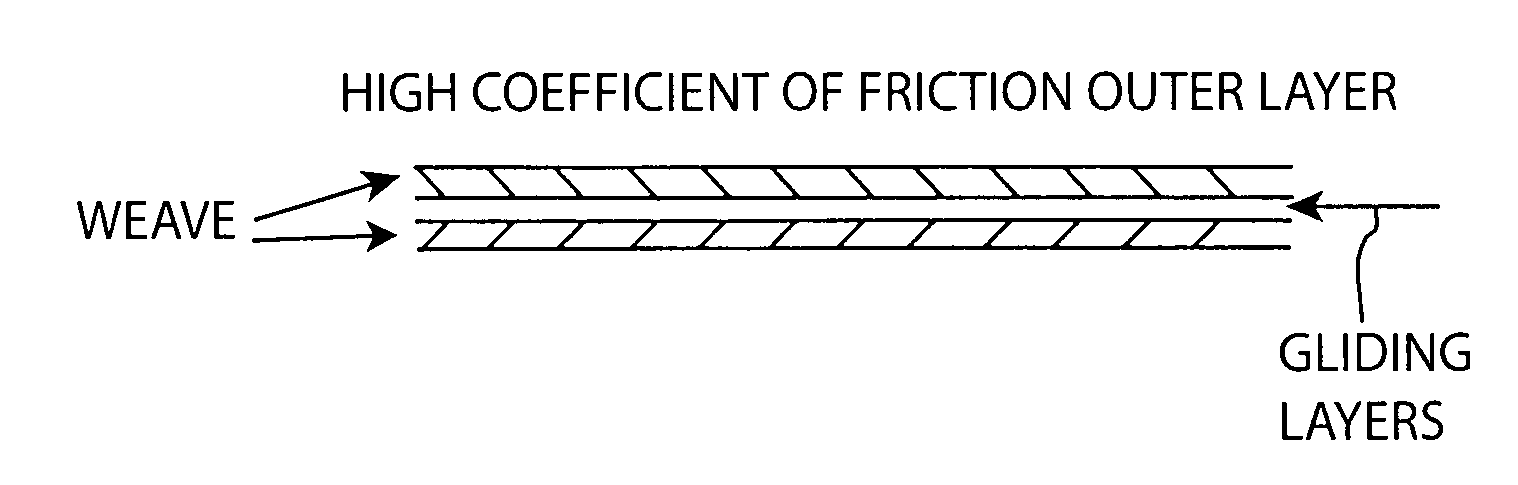

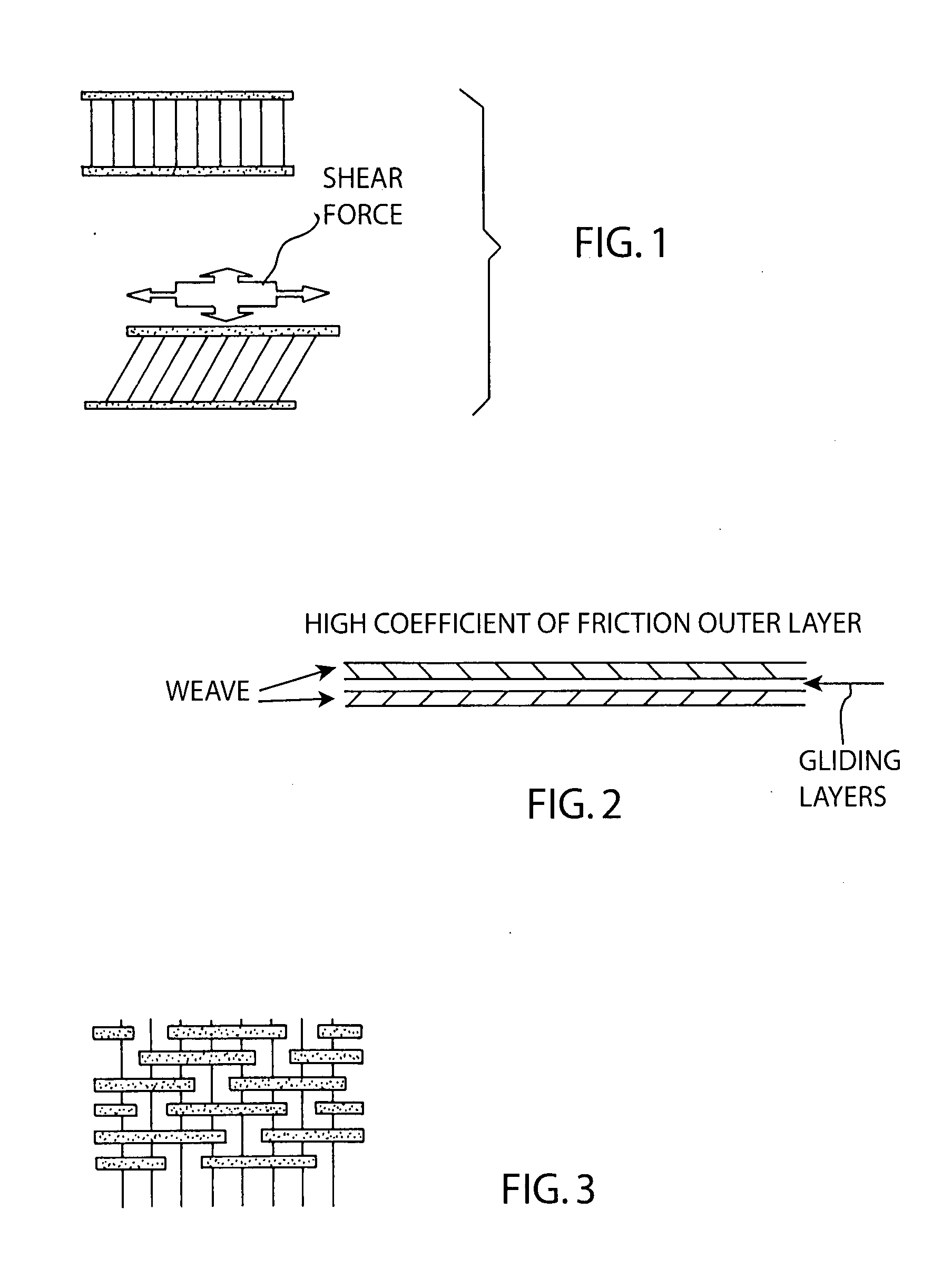

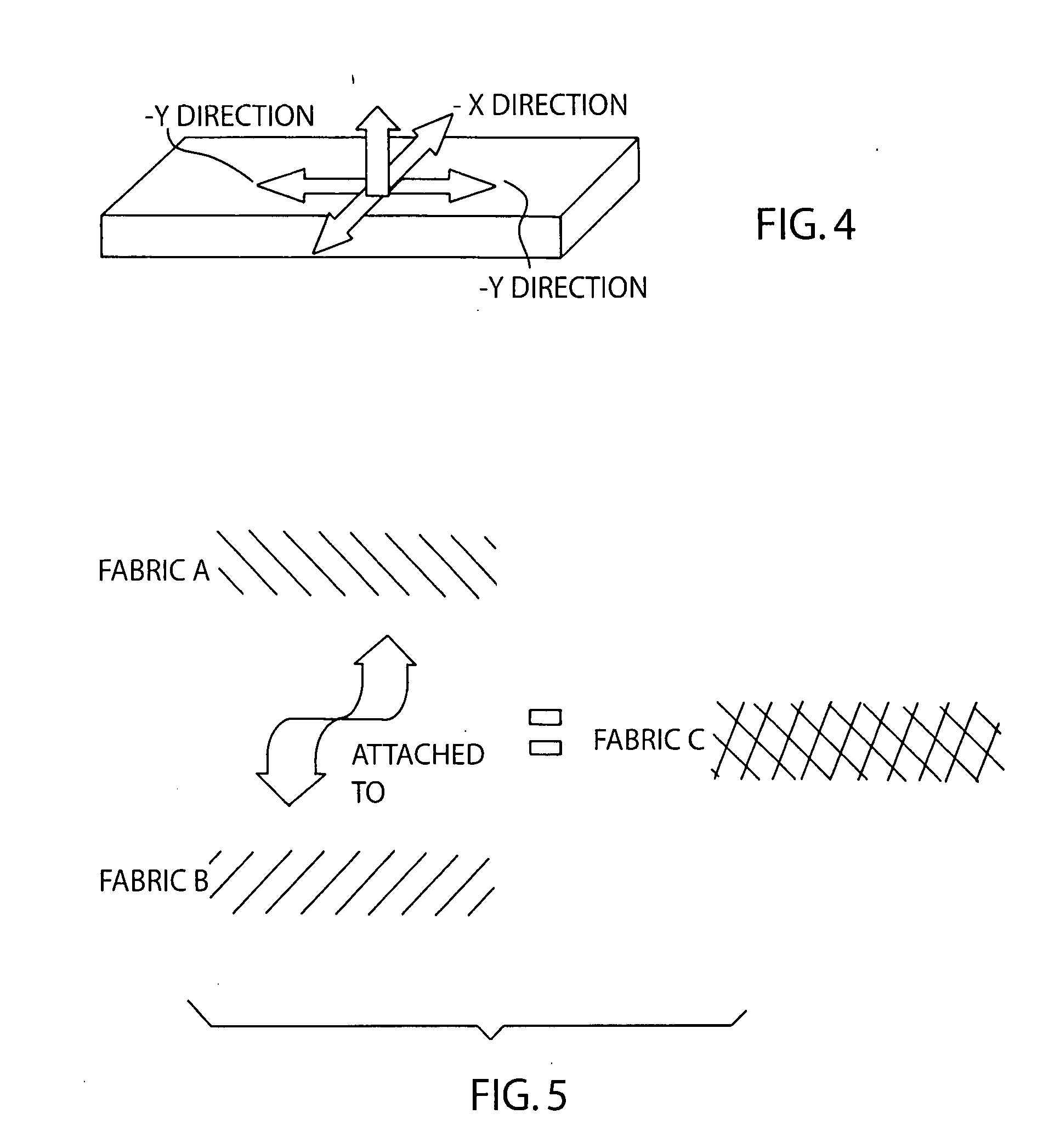

InactiveUS20080121305A1Low friction qualityReducing and eliminating likelihoodSolesOrnamental textile articlesPolyesterFiber

A low friction fabric constructed of a first layer of woven polyester fibers with an upper and lower woven surface attached to and adjacent a second layer of the same weave of polyester or similar fibers, the second layer having an upper and lower surface. Each of the woven layers comprising a straight yarn in the warp of the weave pattern with the weaves of the layers being oriented at a 90 degree angle to one another.

Owner:DATA TRACE PUBLISHING

Lead-free tin alloy electroplating compositions and methods

ActiveCN102051645AReduce foamingLiquid/solution decomposition chemical coatingSemiconductor devicesCyanideElectrolyte composition

Disclosed are electrolyte compositions for depositing a tin alloy on a substrate. The electrolyte compositions include tin ions, ions of one or more alloying metals, a flavone compound and a dihydroxy bis-sulfide. The electrolyte compositions are free of lead and cyanide. Also disclosed are methods of depositing a tin alloy on a substrate and methods of forming an interconnect bump on a semiconductor device.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com