Needle tube type filling machine and filling method thereof

A needle-type, filling machine technology, applied in packaging, bottle filling, liquid bottling, etc., can solve problems such as inability to guarantee product filling quality, foam phenomenon, and inaccurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

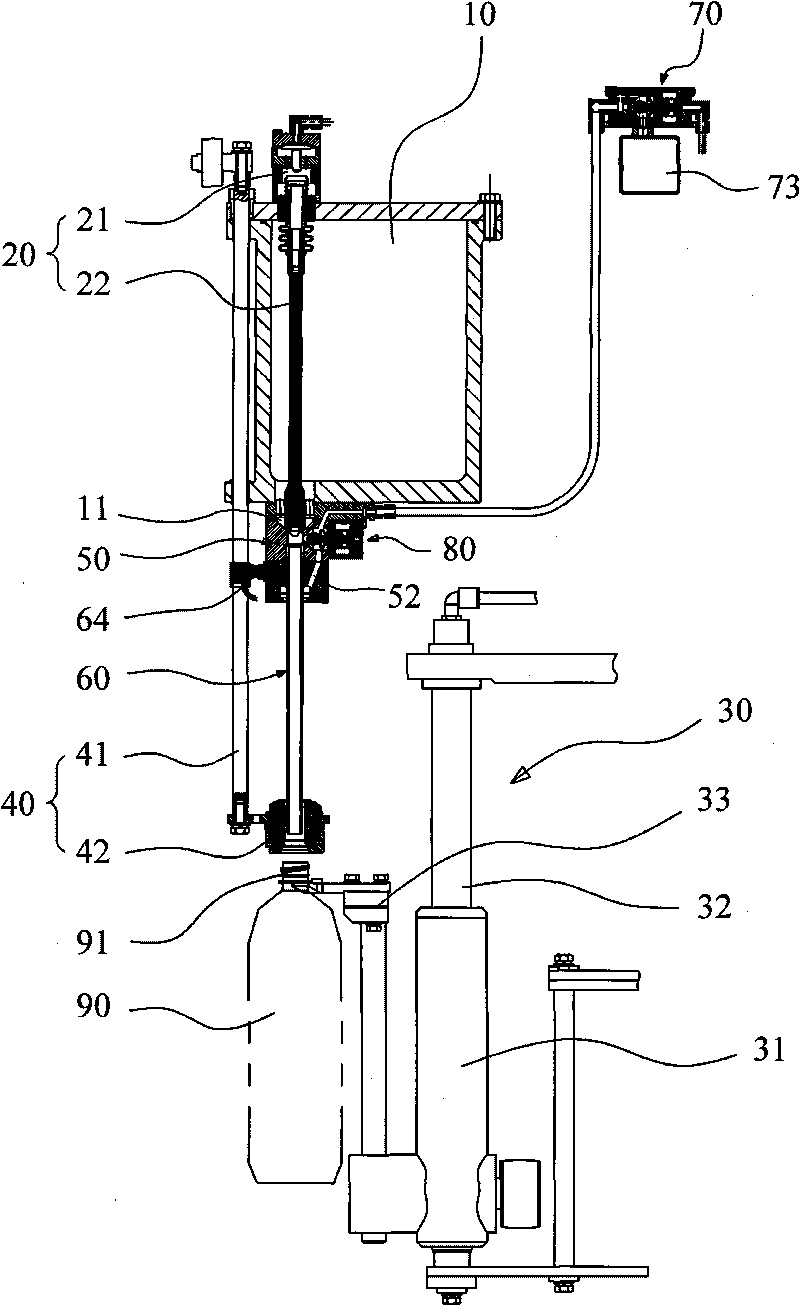

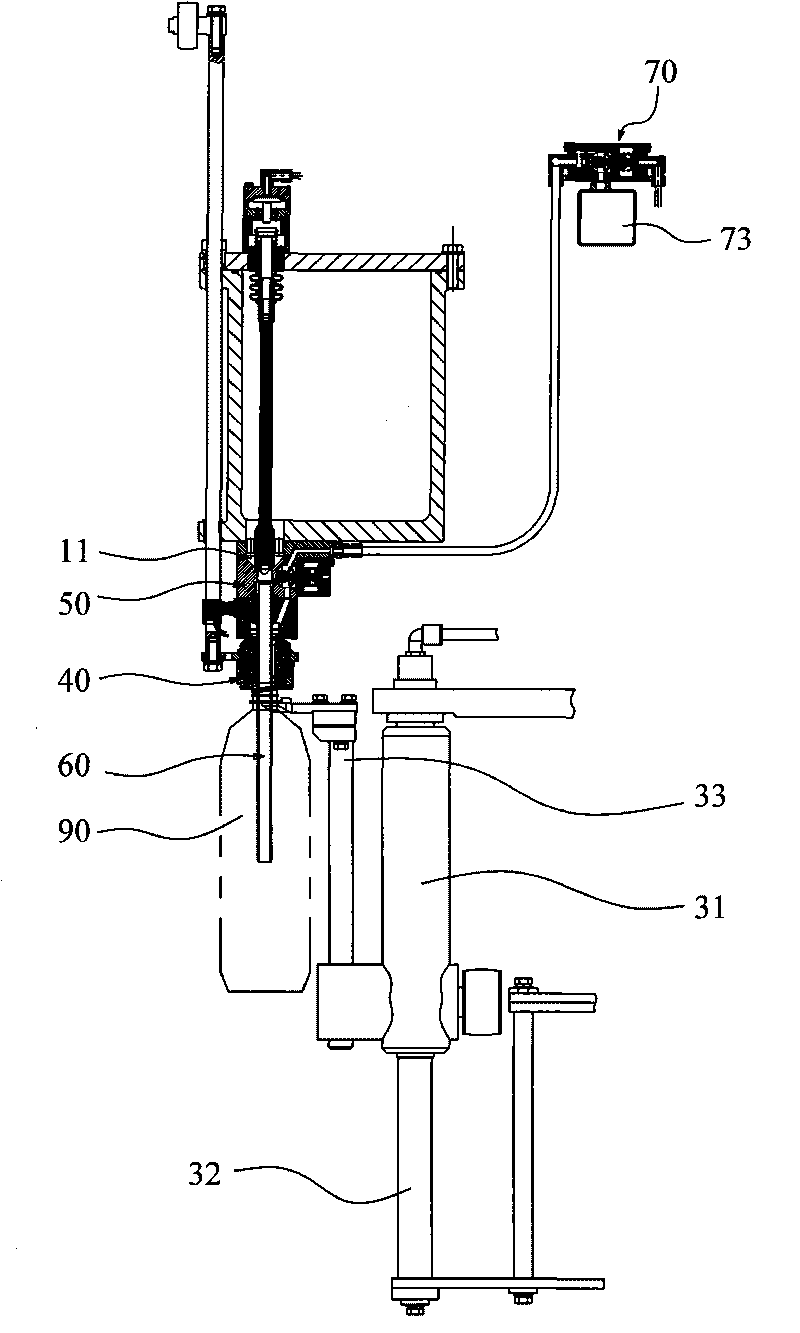

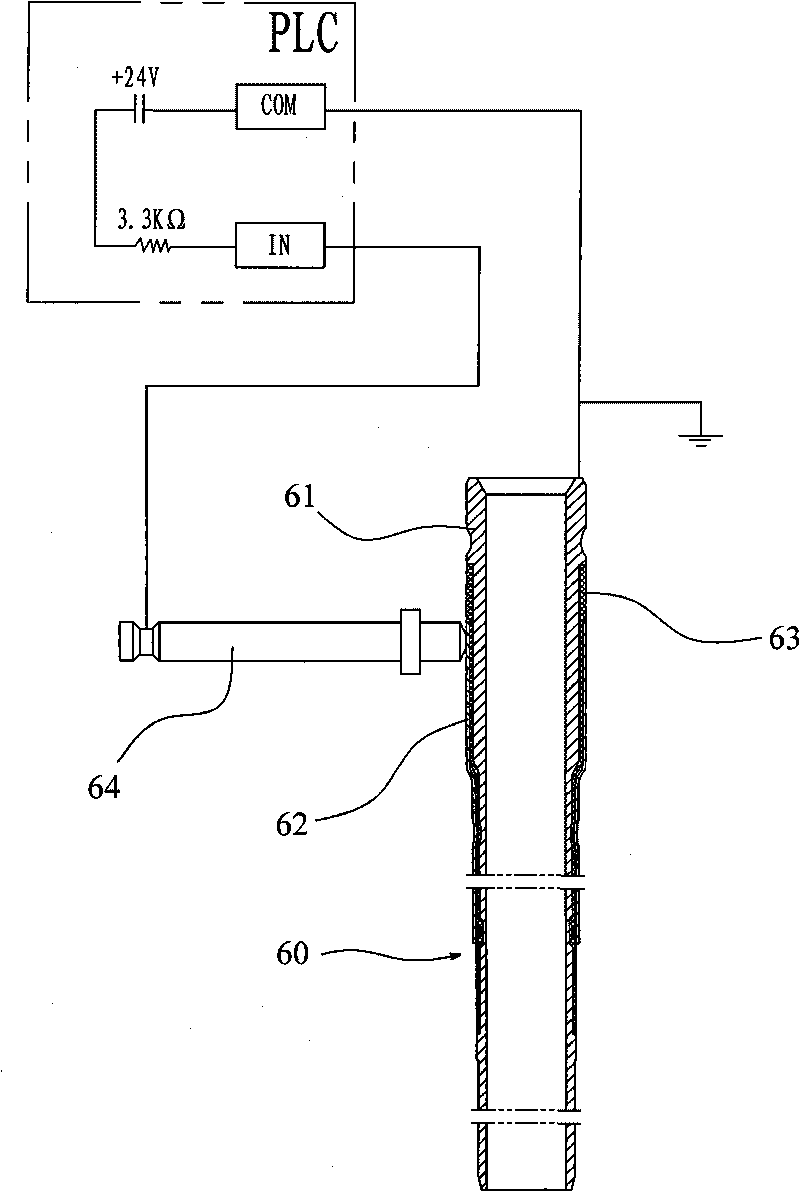

[0042] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the preferred embodiment of the present invention, including liquid storage tank 10, filling control valve 20, bottle lifting device 30, cover bottle device 40, needle tube fixing seat 50, perfusion needle tube 60, Speed control device 70 and vent control valve 80 .

[0043] Wherein, the liquid storage tank 10 is used as a liquid supply device for storing various perfusion liquids such as water, fruit juice, beverages or cola that need to be filled into the bottle body 90, and a bottle is arranged at the lower end of the liquid storage tank 10. Install outlet 11.

[0044] The filling control valve 20 is used to block and open the aforementioned filling outlet 11 at regular intervals according to a set program, so as to control the on-off time of the filling outlet 11, thereby achieving the purpose of controlling the filling volume. The filling control valve 20 in this embodiment is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com