Patents

Literature

3386 results about "Tubing types" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plumbing tubes and stainless steel tubes are some of the most widely used types of tubing available. Steel plumbing tubes are designed for purposes in potable water distribution, underground water service, medical gas service, radiant heating, oil distribution systems and drainage systems.

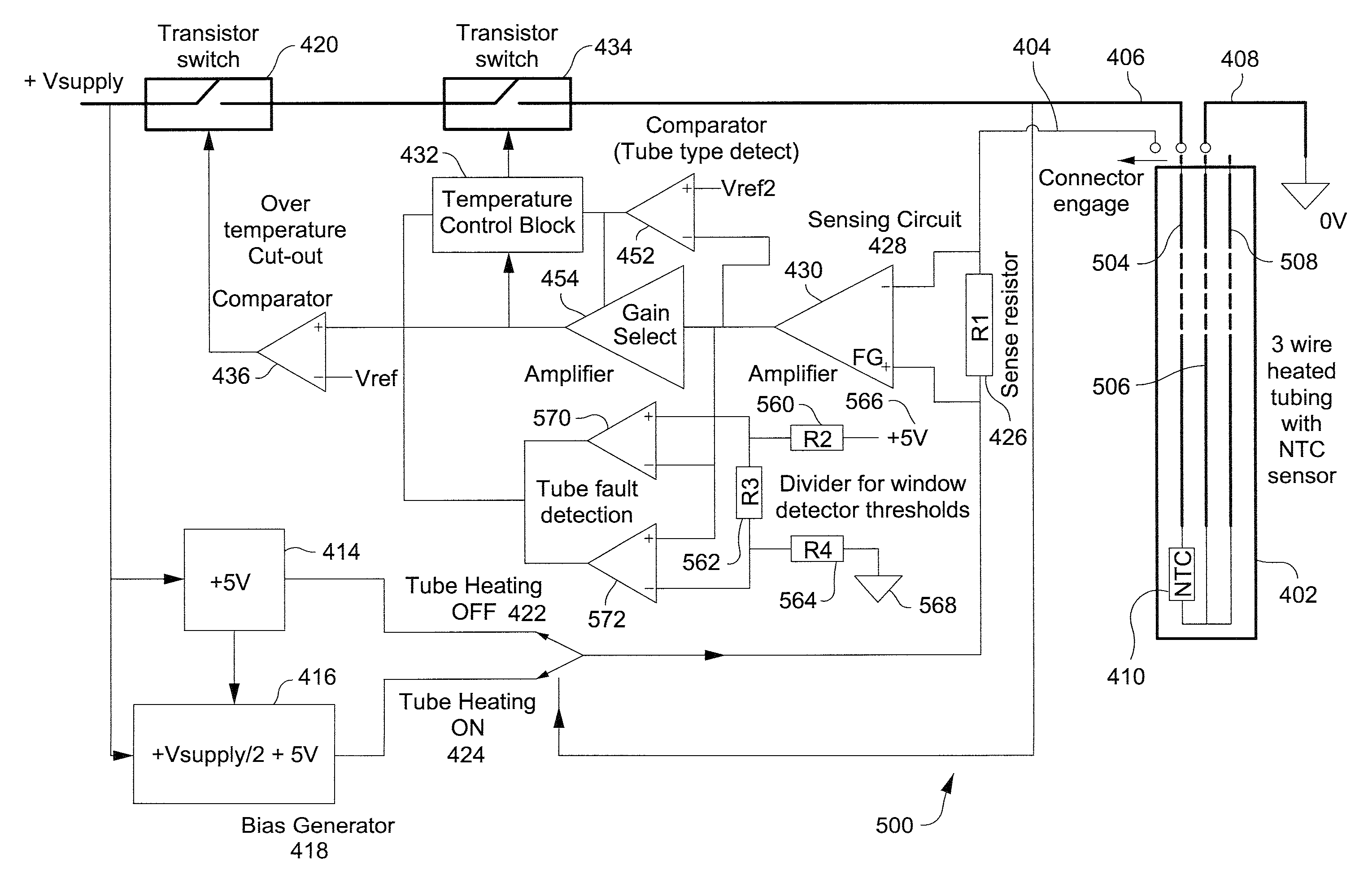

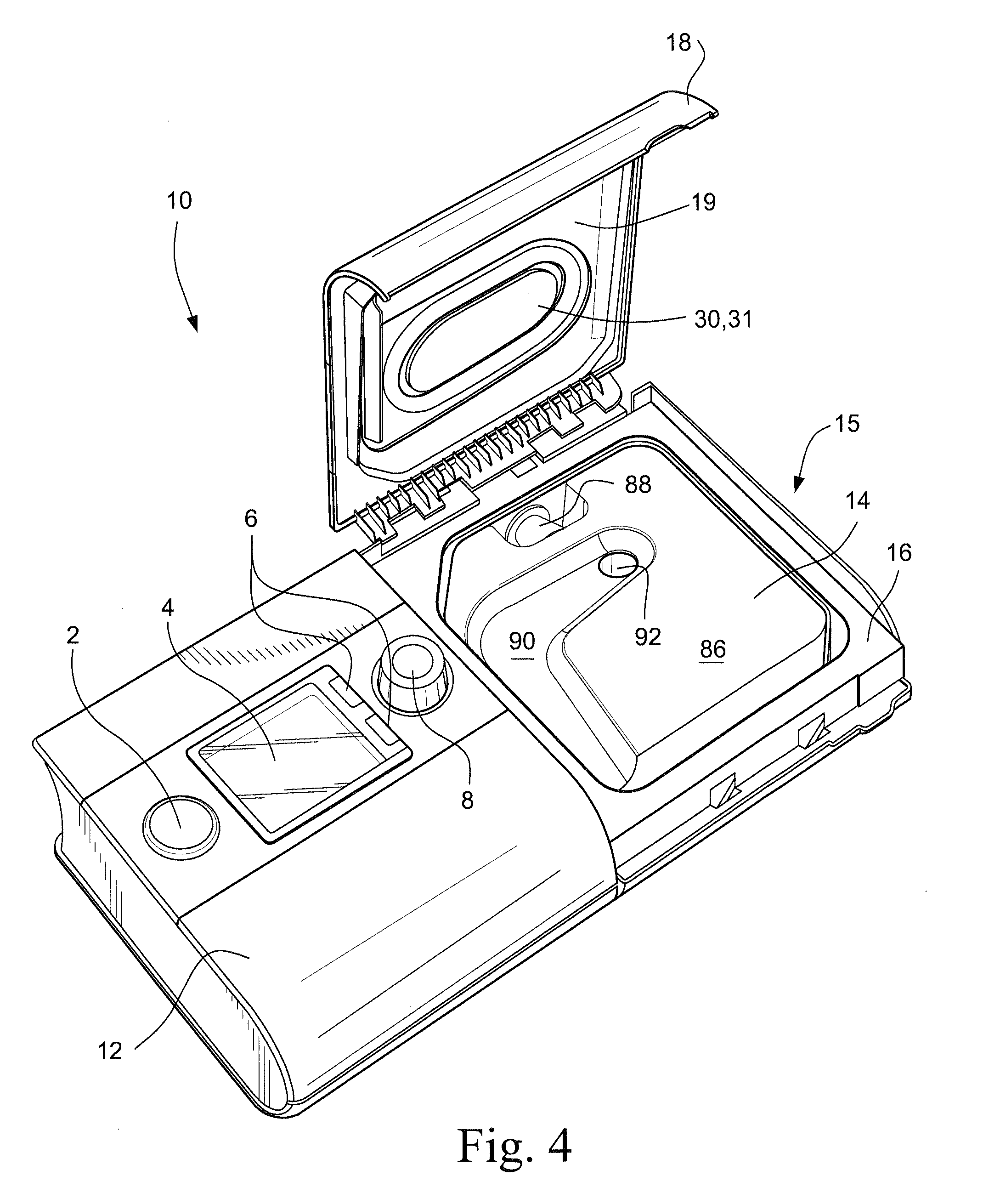

Wire heated tube with temperature control system, tube type detection, and active over temperature protection for humidifier for respiratory apparatus

ActiveUS8733349B2Reduce condensationAvoid overall overheatingOther heat production devicesRespiratory masksTemperature controlWater vapor

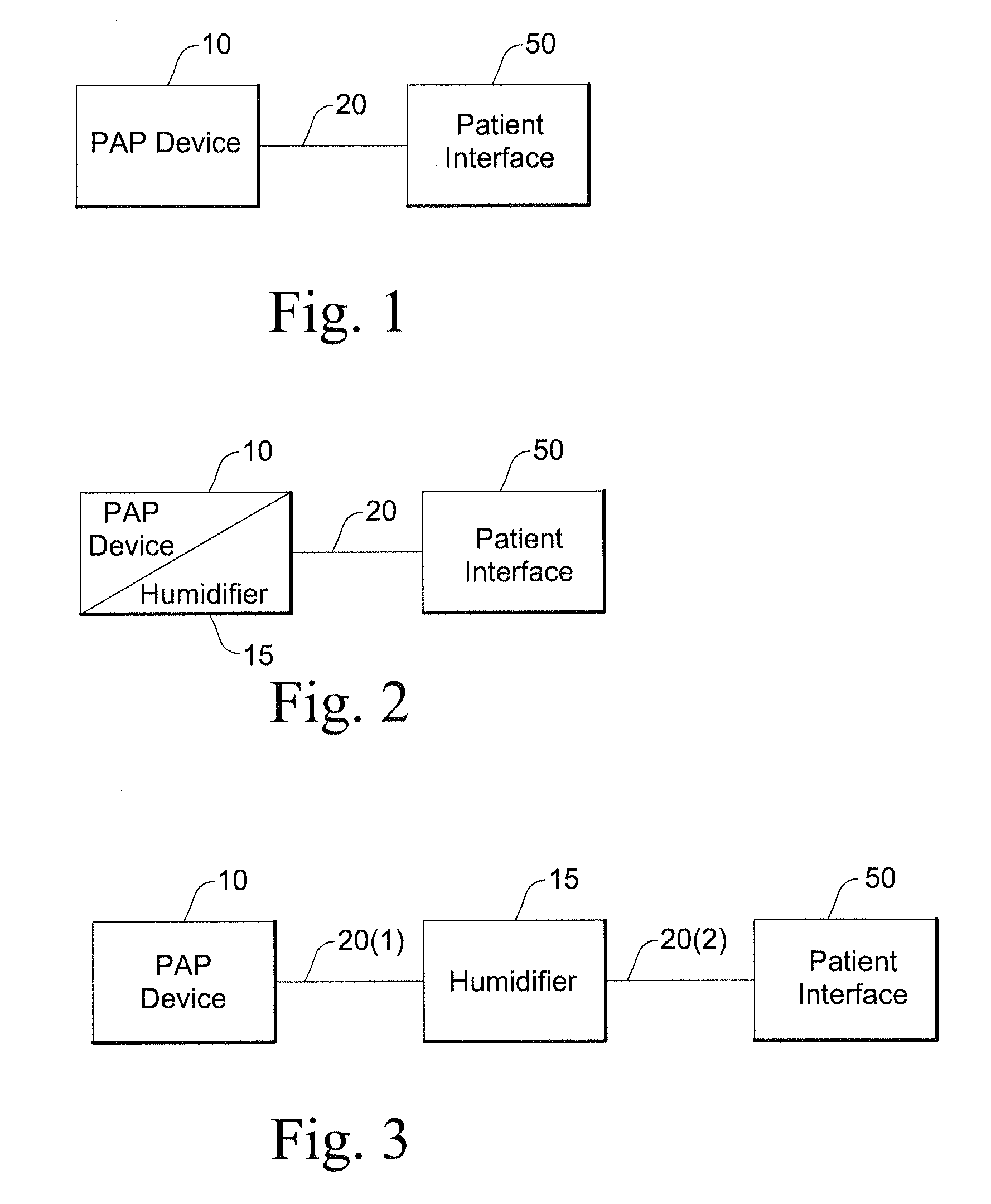

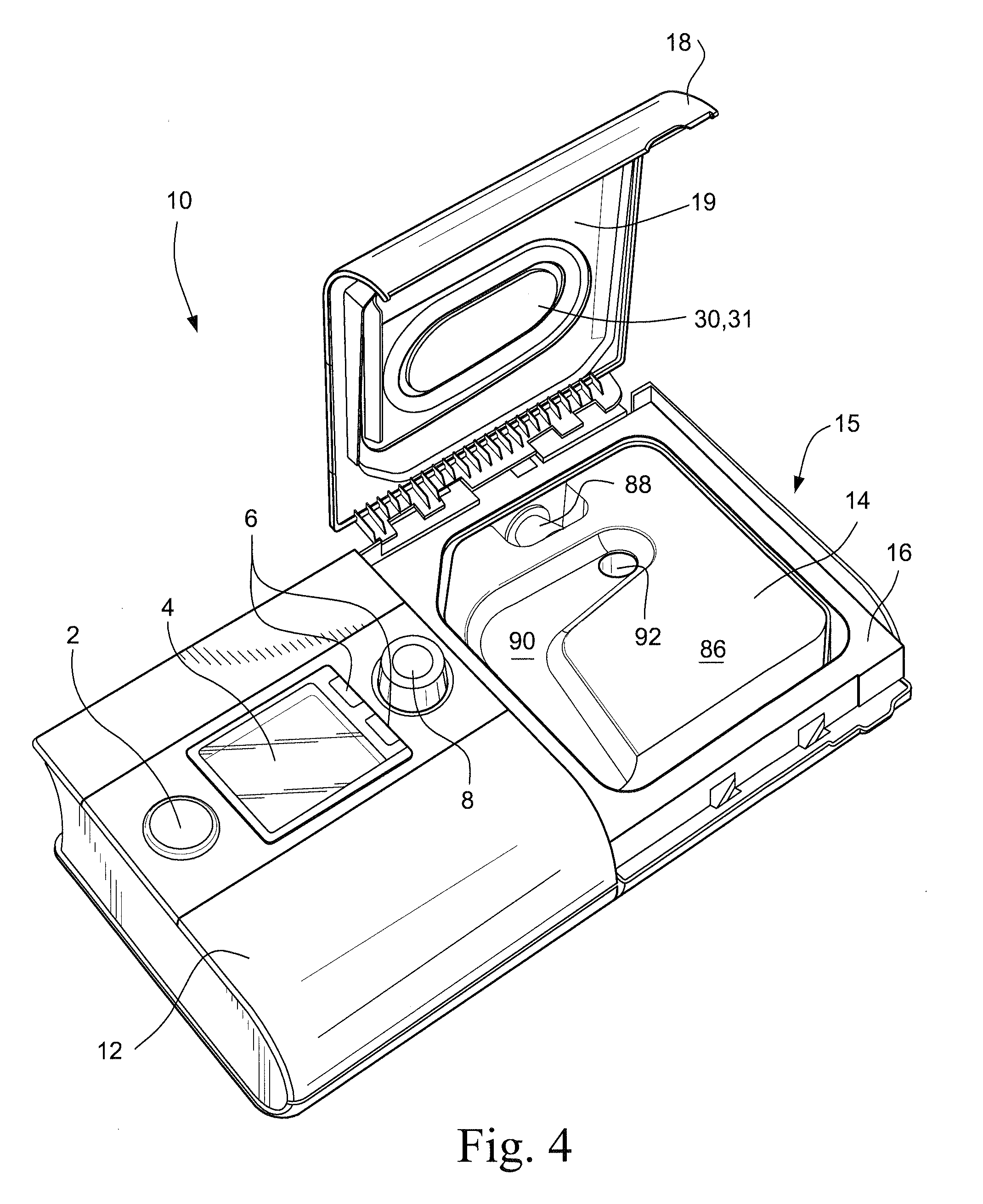

A PAP system for delivering breathable gas to a patient includes a flow generator to generate a supply of breathable gas to be delivered to the patient; a humidifier including a heating plate to vaporize water and deliver water vapor to humidify the supply of breathable gas; a heated tube configured to heat and deliver the humidified supply of breathable gas to the patient; a power supply configured to supply power to the heating plate and the heated tube; and a controller configured to control the power supply to prevent overheating of the heating plate and the heated tube.

Owner:RESMED LTD

Wire heated tube with temperature control system, tube type detection, and active over temperature protection for humidifier for respiratory apparatus

ActiveUS20110023874A1Avoid overall overheatingReduce condensationRespiratory device testingOther heat production devicesTemperature controlWater vapor

A PAP system for delivering breathable gas to a patient includes a flow generator to generate a supply of breathable gas to be delivered to the patient; a humidifier including a heating plate to vaporize water and deliver water vapor to humidify the supply of breathable gas; a heated tube configured to heat and deliver the humidified supply of breathable gas to the patient; a power supply configured to supply power to the heating plate and the heated tube; and a controller configured to control the power supply to prevent overheating of the heating plate and the heated tube.

Owner:RESMED LTD

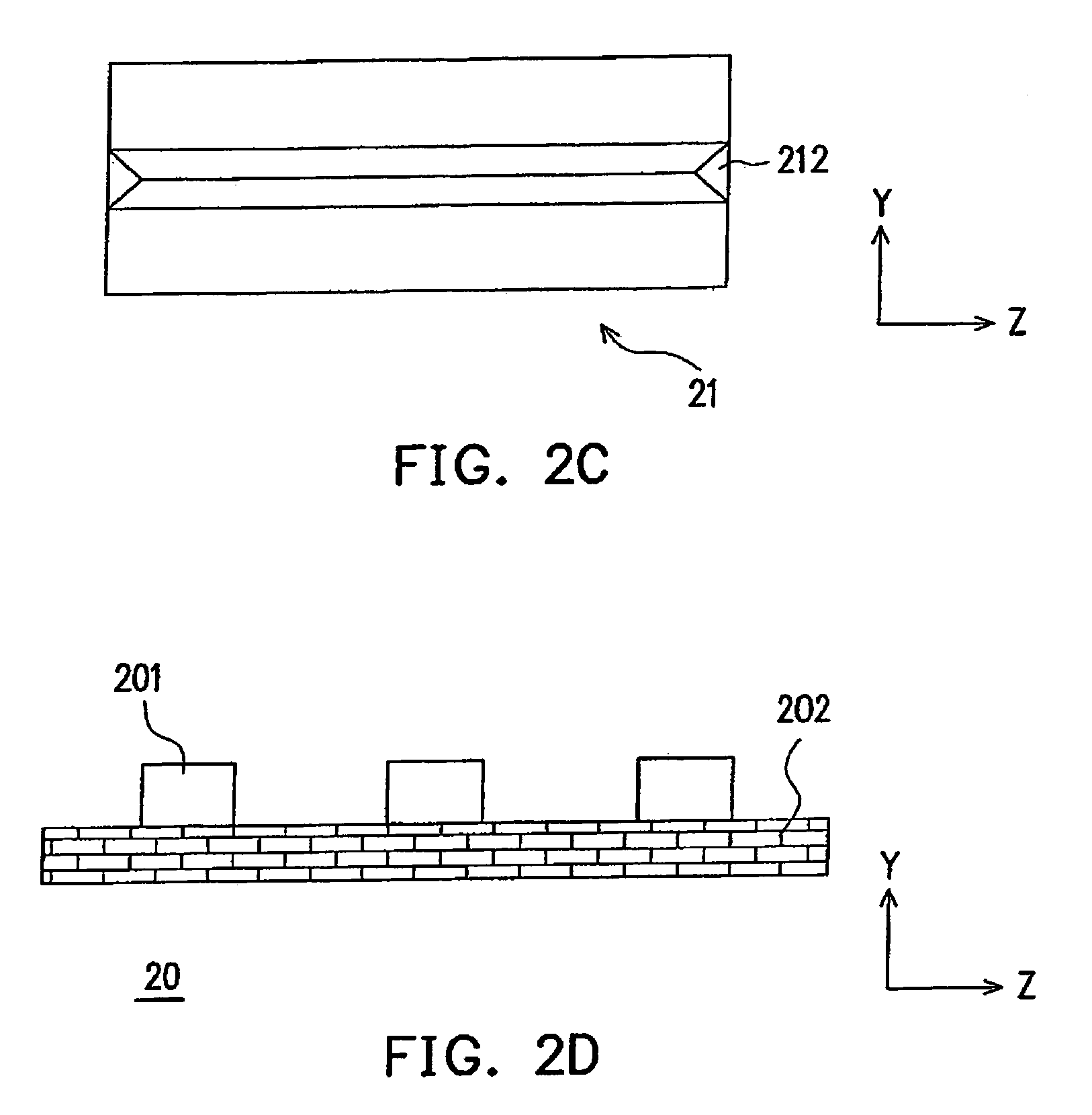

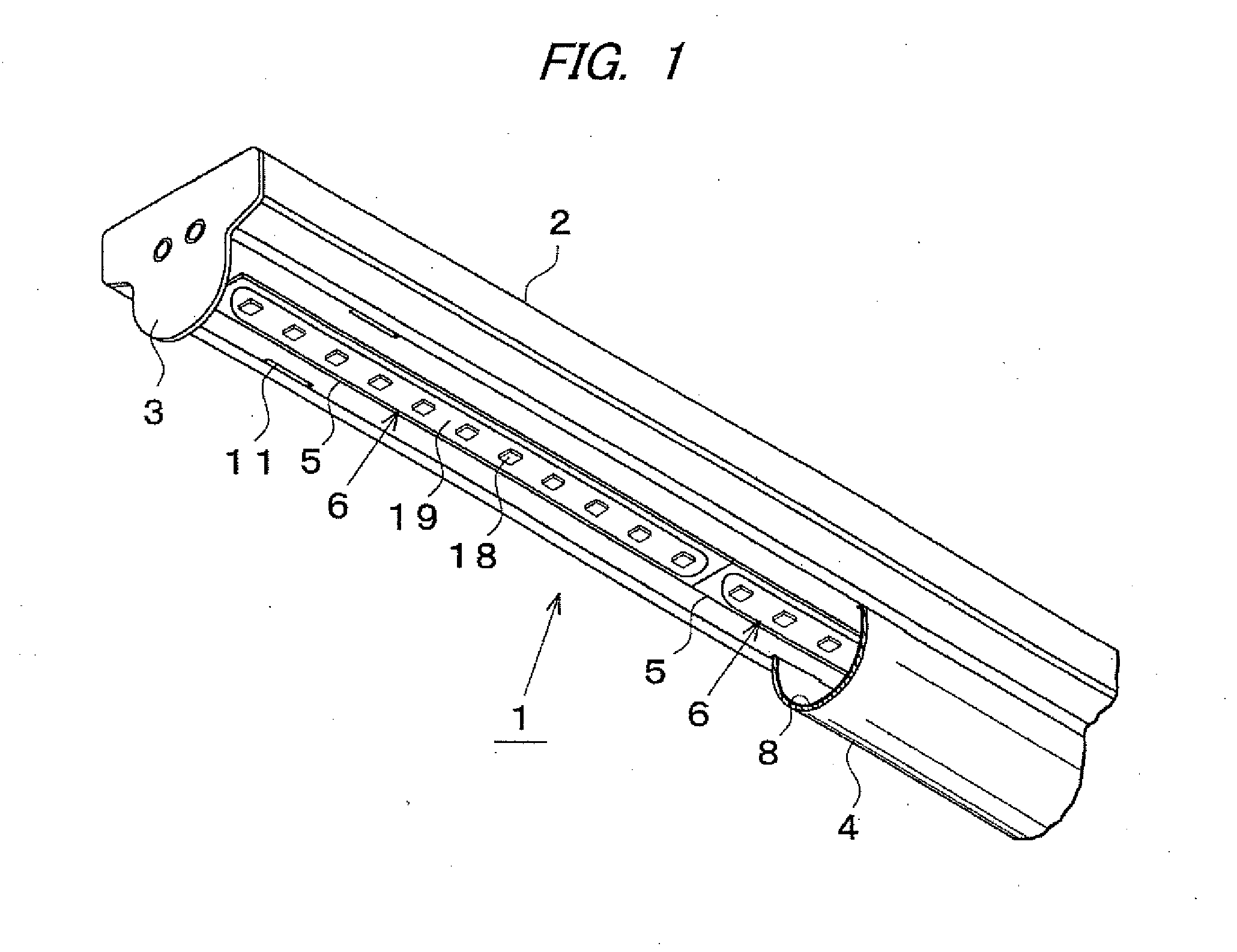

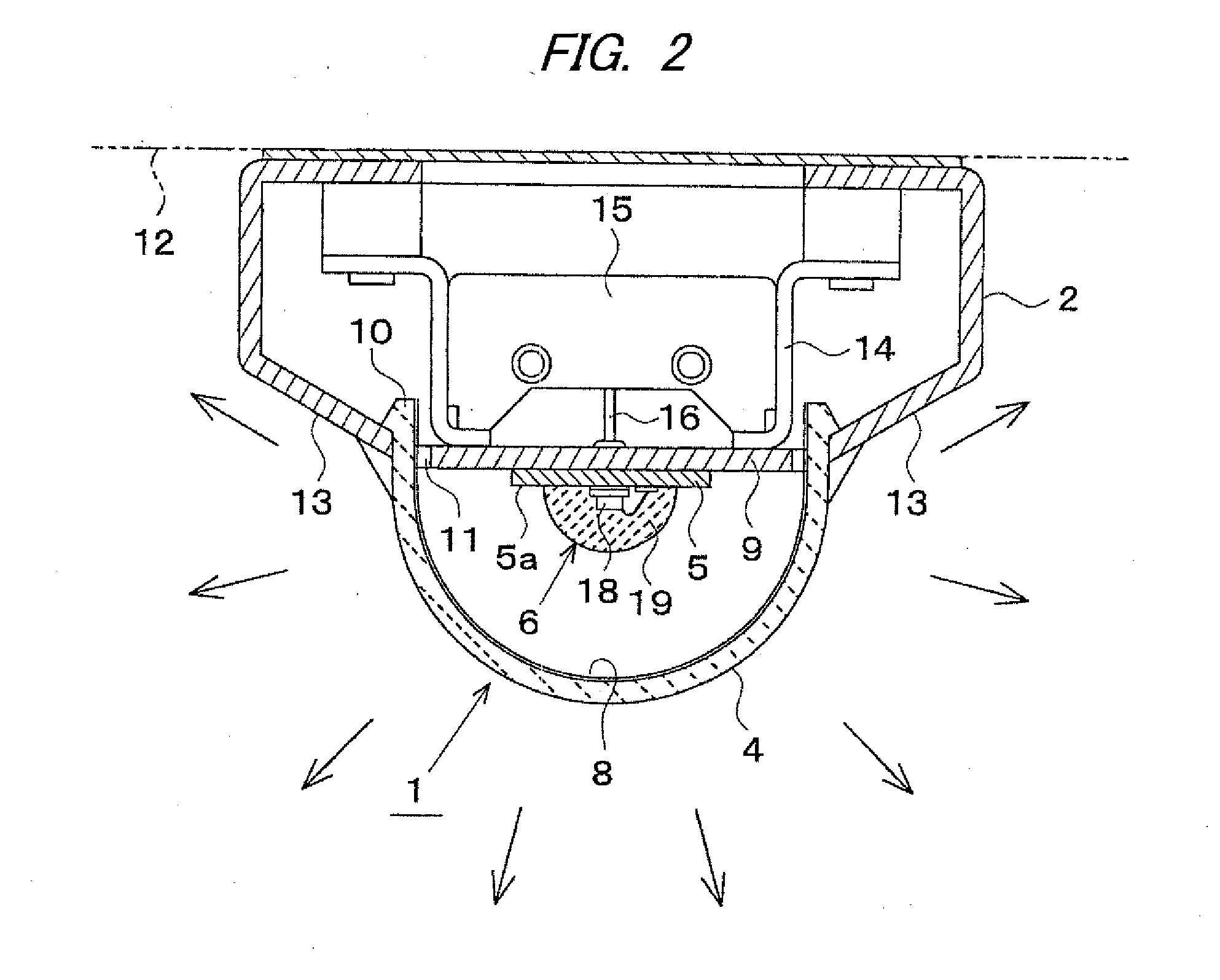

LED light source

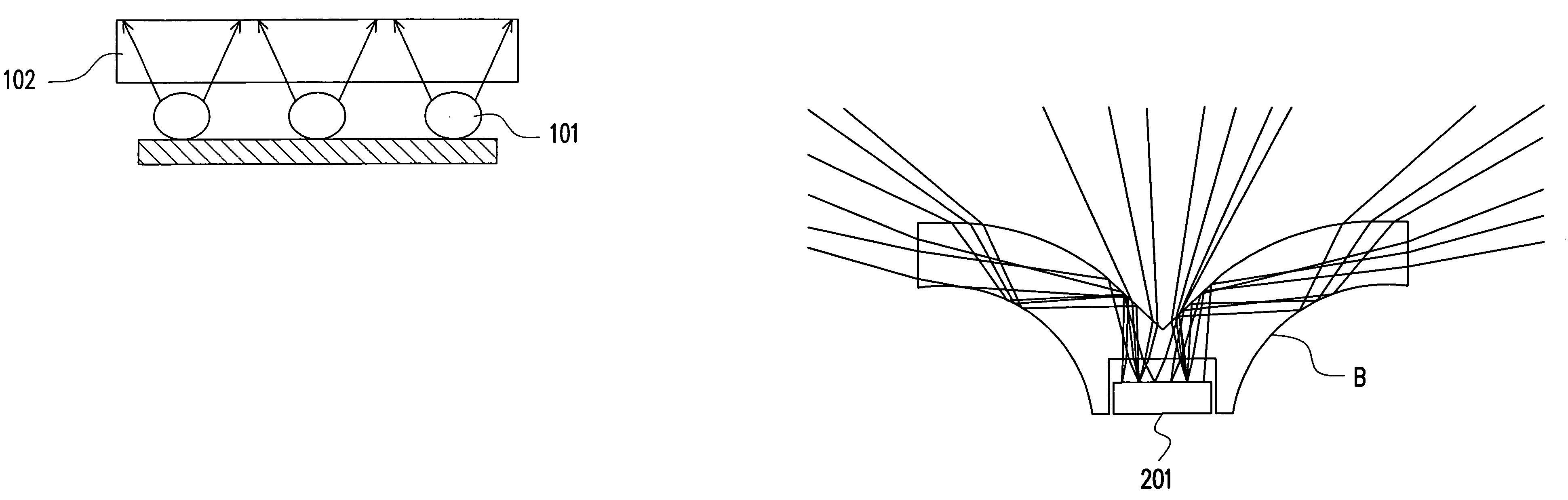

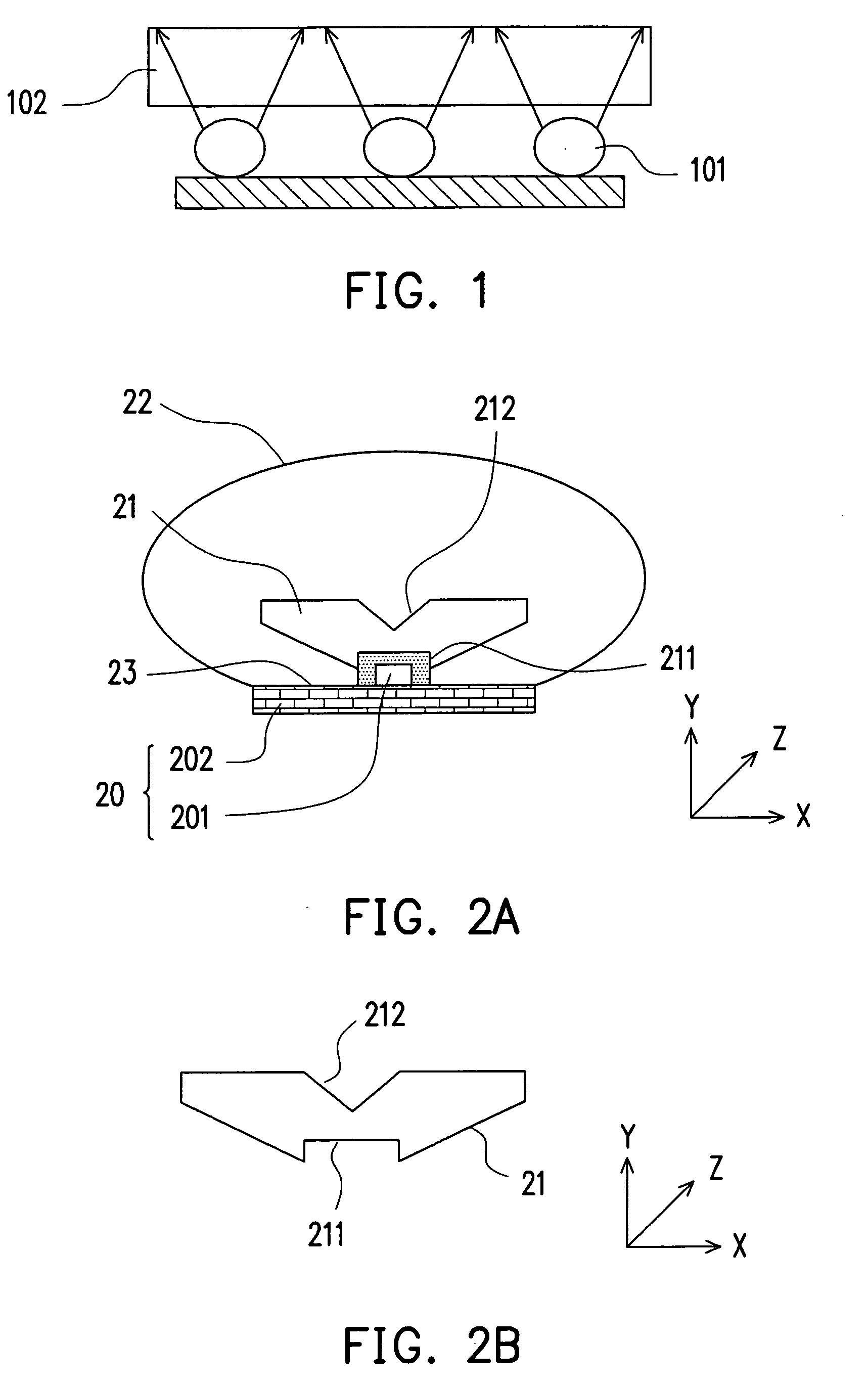

ActiveUS7246931B2Uniform brightnessReduce thicknessPoint-like light sourceLighting heating/cooling arrangementsLight guideLight-emitting diode

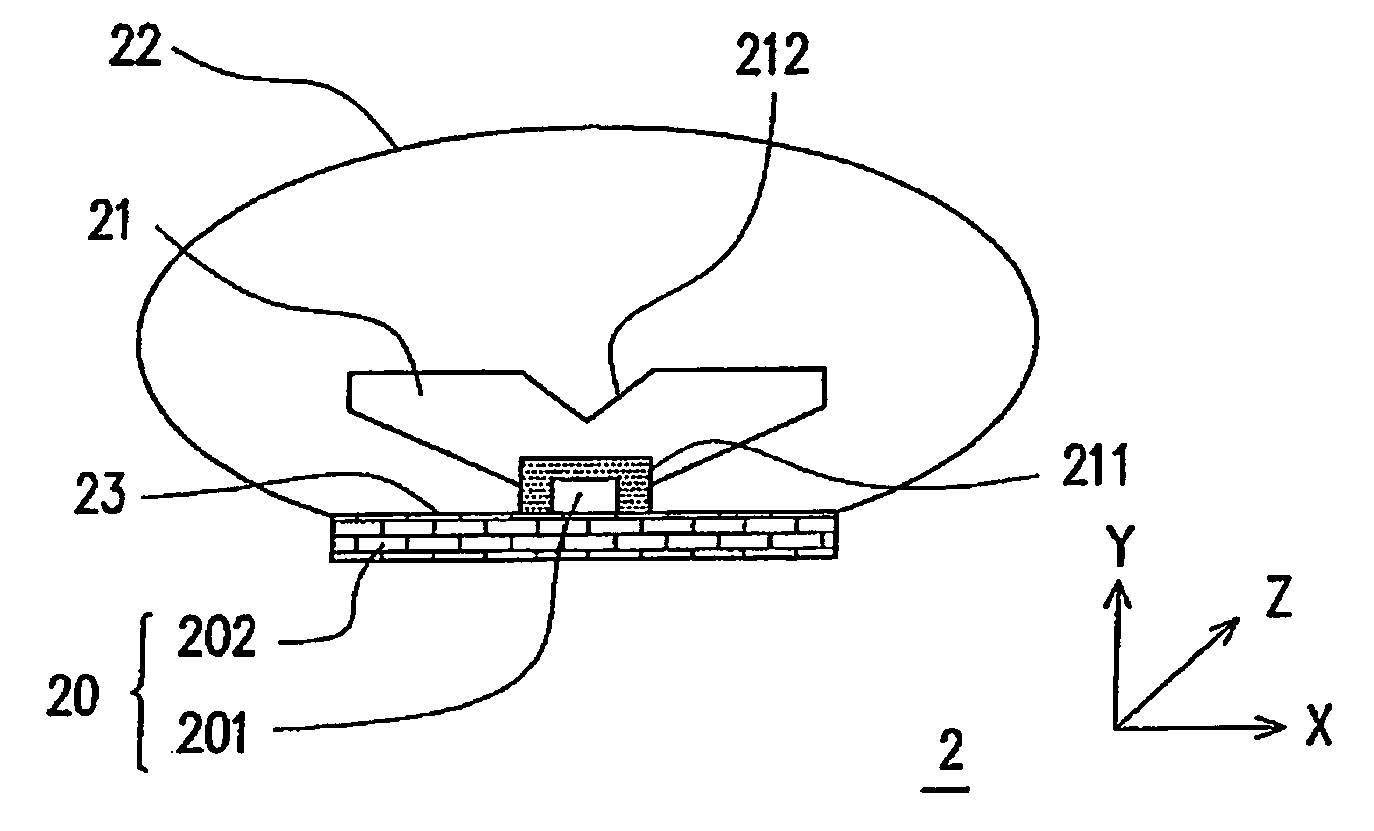

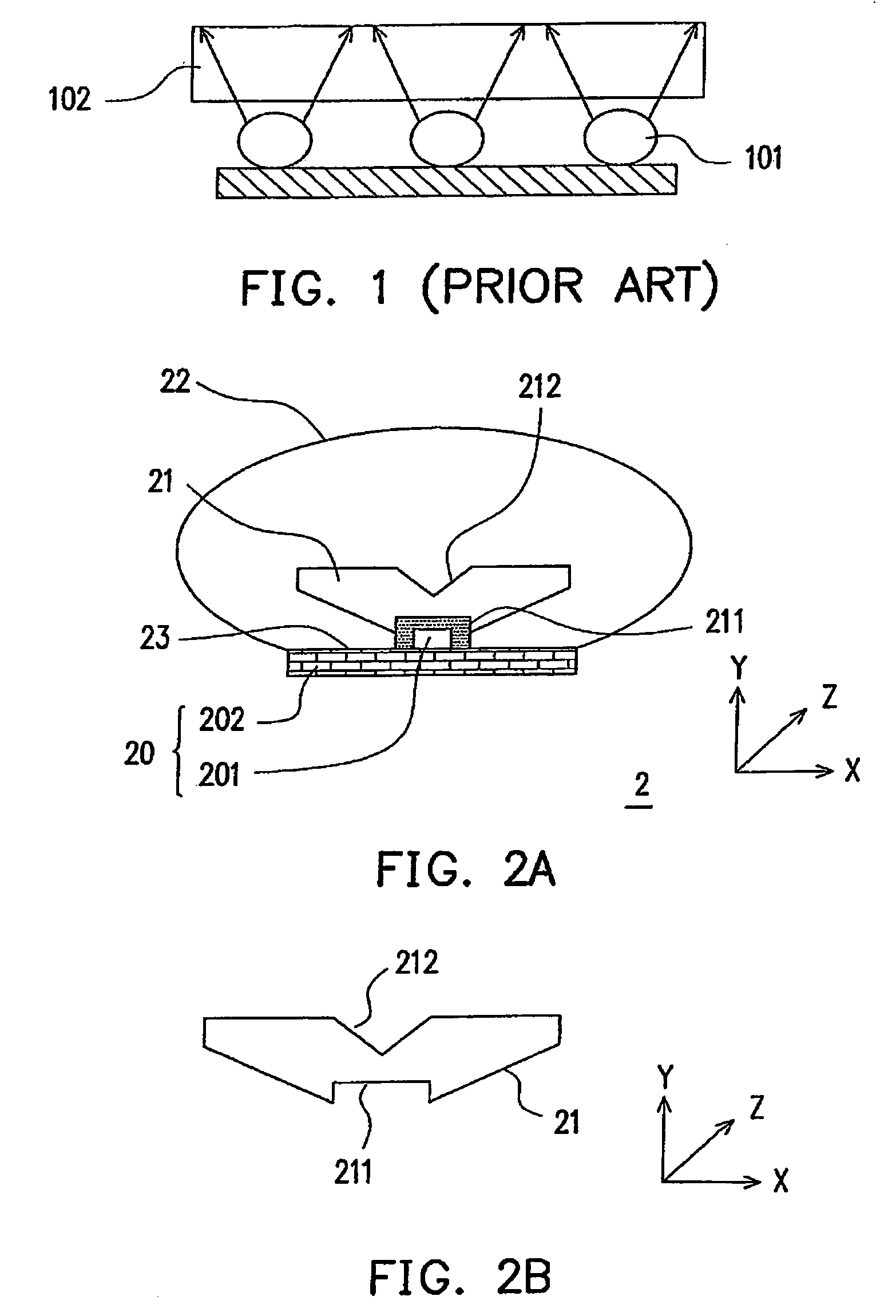

A tube type light emitting diode light source including a light source generator, a light guide and a diffuser is provided. The light source generator includes LEDs arranging in a line. The light guide has a grooved light incident surface and a grooved light-guiding surface. The grooved light incident surface encompasses the LEDs, and the grooved light-guiding surface is adapted for changing the propagating direction of an incident light. The diffuser covers the light guide.

Owner:EPISTAR CORP

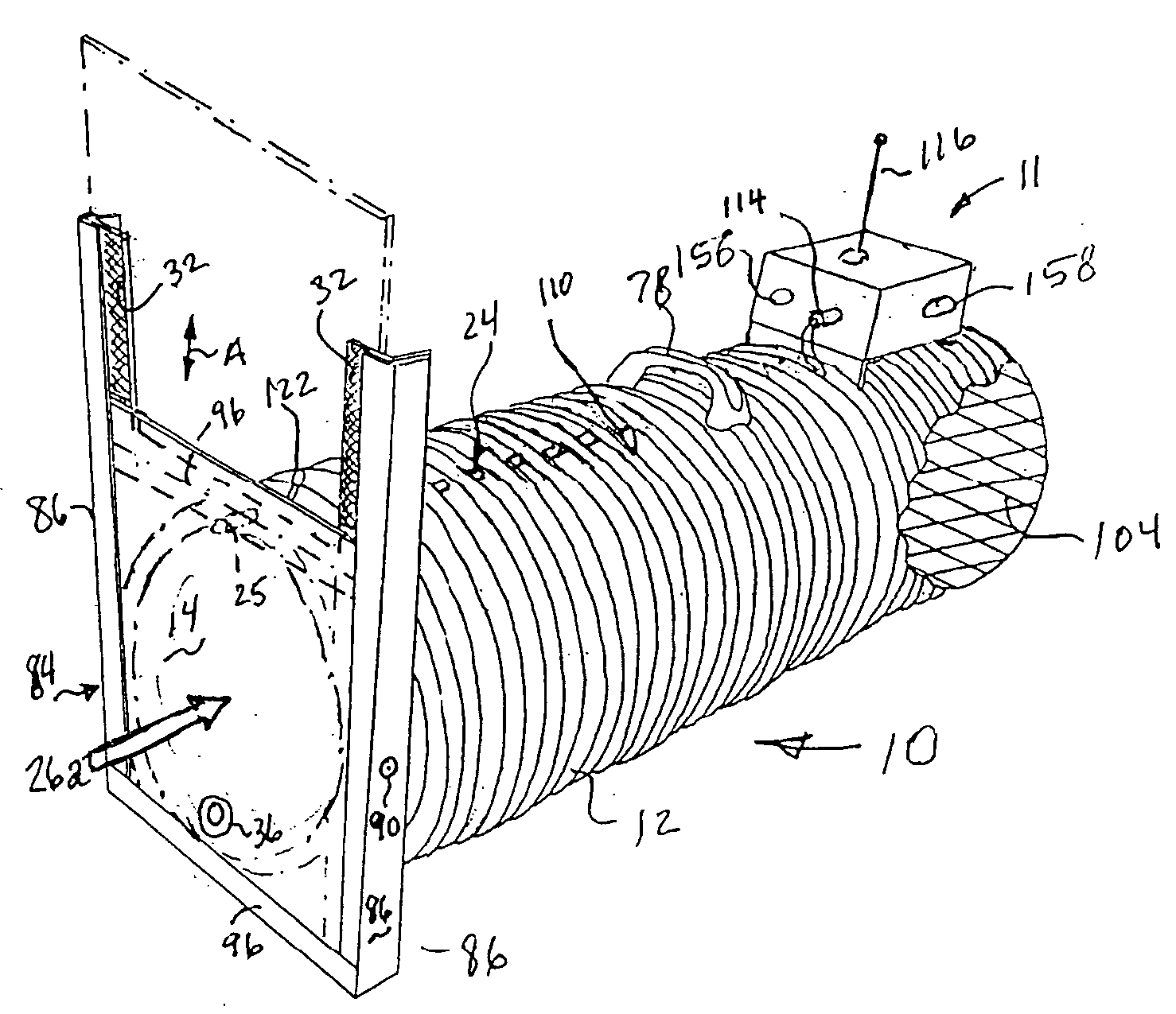

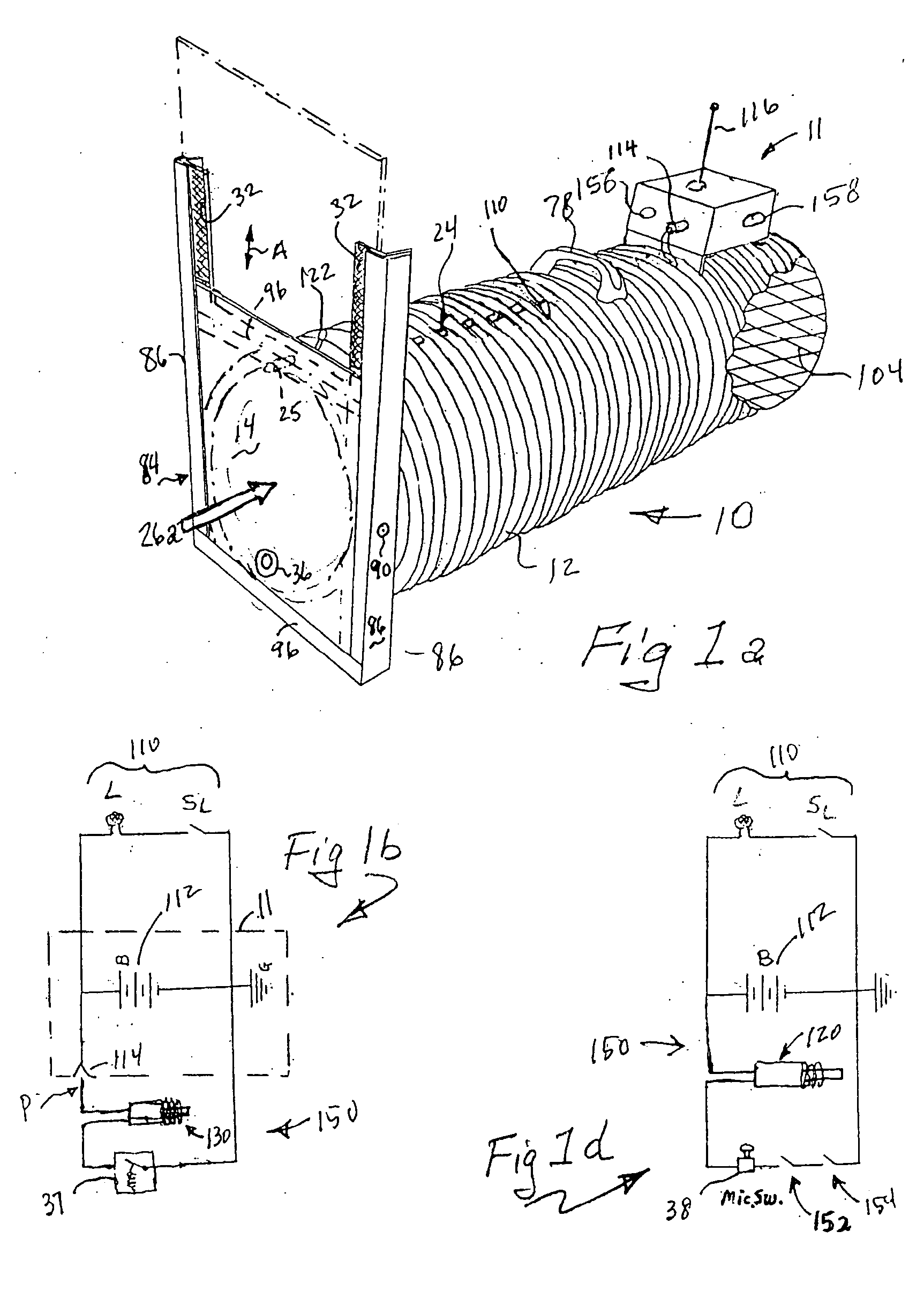

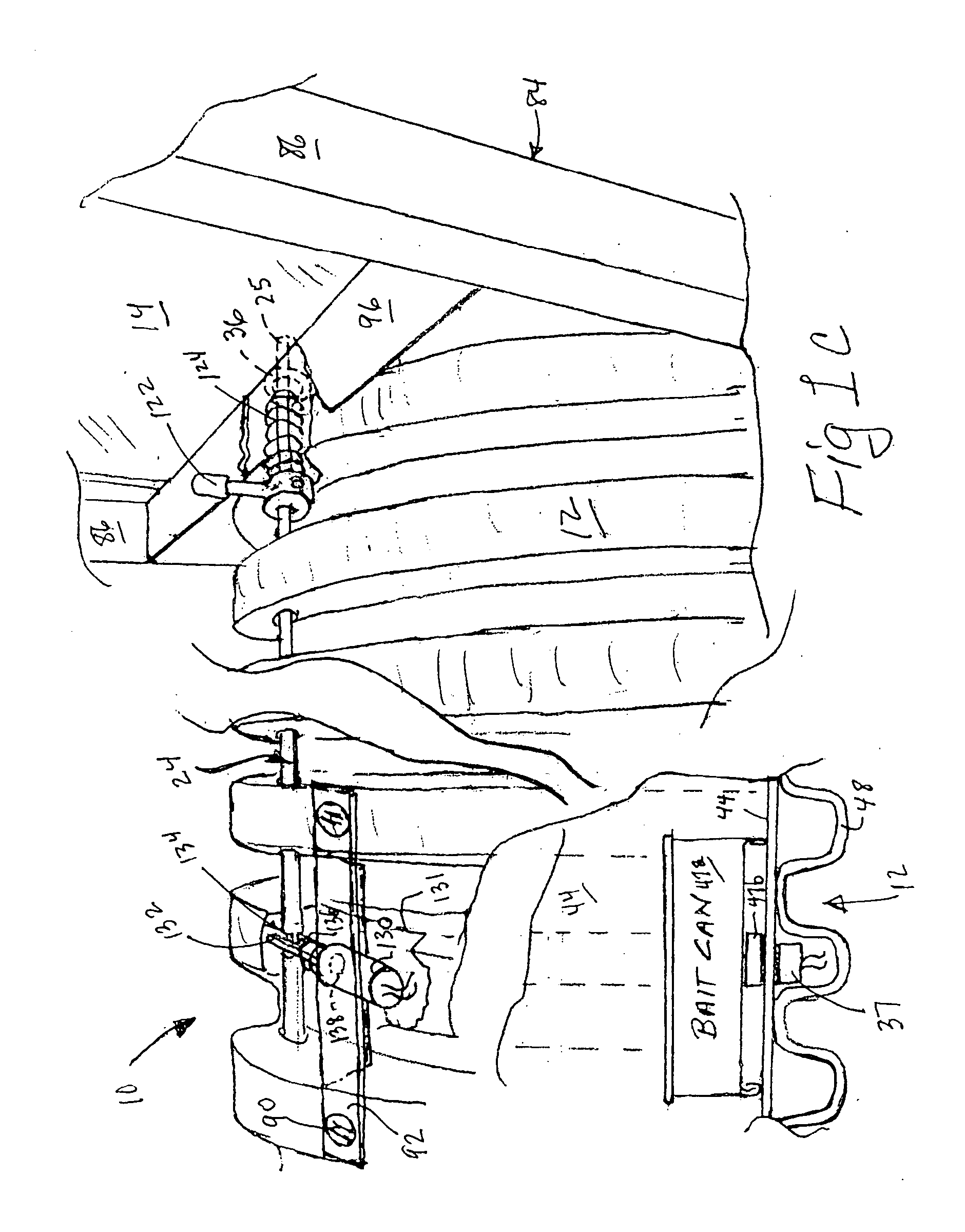

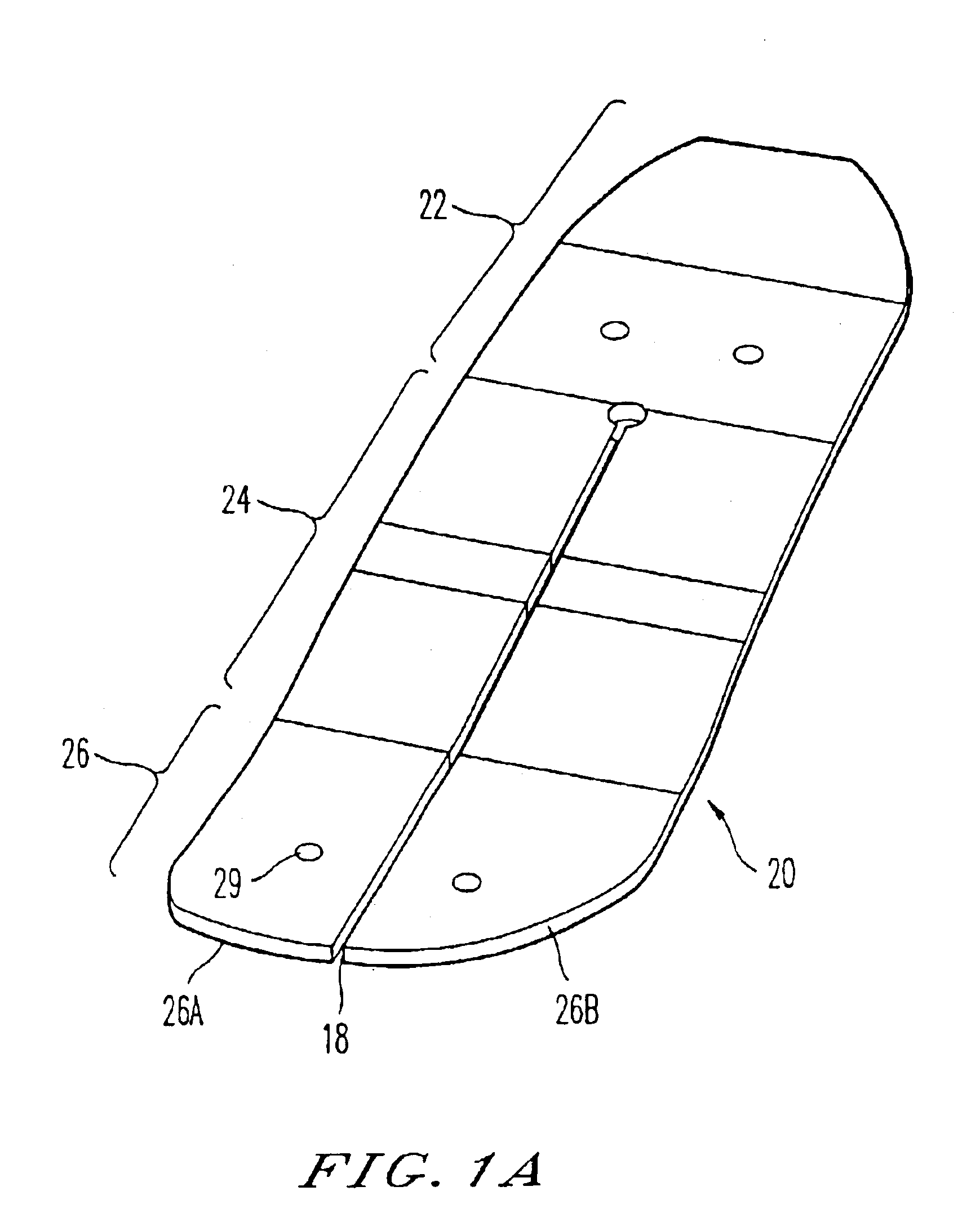

Humane tubular trap, remote trap monitoring system and method and programs for monitoring multiple traps

InactiveUS20050097808A1Attracts and calmsPreventing heat prostrationAnimal huntingTransmission systemsCommunications systemTrapping

Tube-type animal trap systems for the humane non-injurious, non-invasive trapping of animals, and to methods and systems for electronic remote trap monitoring and management. The invention includes mechanical and electric / electronic, tube-type traps, and to electronic data communications systems that enable remote monitoring of the status of any type of trap (e.g., is the trap tripped or not). Computer systems at a remote home base permit simultaneous management of multiple traps in the field, including enabling management via the Internet.

Owner:VORHIES JAMES FREDERICK +2

LED light source

ActiveUS20060126343A1Uniform brightnessReduce thicknessPoint-like light sourceLighting heating/cooling arrangementsLight guideLight-emitting diode

A tube type light emitting diode light source including a light source generator, a light guide and a diffuser is provided. The light source generator includes LEDs arranging in a line. The light guide has a grooved light incident surface and a grooved light-guiding surface. The grooved light incident surface encompasses the LEDs, and the grooved light-guiding surface is adapted for changing the propagating direction of an incident light. The diffuser covers the light guide.

Owner:EPISTAR CORP

Method for controlling defrosting operation of air-conditioner

InactiveCN104515330AMechanical apparatusSpace heating and ventilation safety systemsEngineeringTubes types

The invention relates to a method for controlling defrosting operation of an air-conditioner; when one defrosting operation period is completed or one defrosting operation period is divided into a plurality of stages, an outdoor condensate fan is controlled to operate reversely for a certain time t at the end of each stage and blows off defrosted water on a condenser. The method for controlling defrosting operation of the air-conditioner is particularly applicable to the air-conditioner with the condenser using a micro-channel special structure; the fan of the outdoor unit is utilized sufficiently; during the defrosting operation, the condensate fan of the outdoor unit is controlled to operate reversely within a short time and blows off the defrosted water on the condenser, so that the purpose of completely defrosting is achieved; and the method is also applicable to other air conditioners with finned tube type condensers.

Owner:HAIER GRP CORP +1

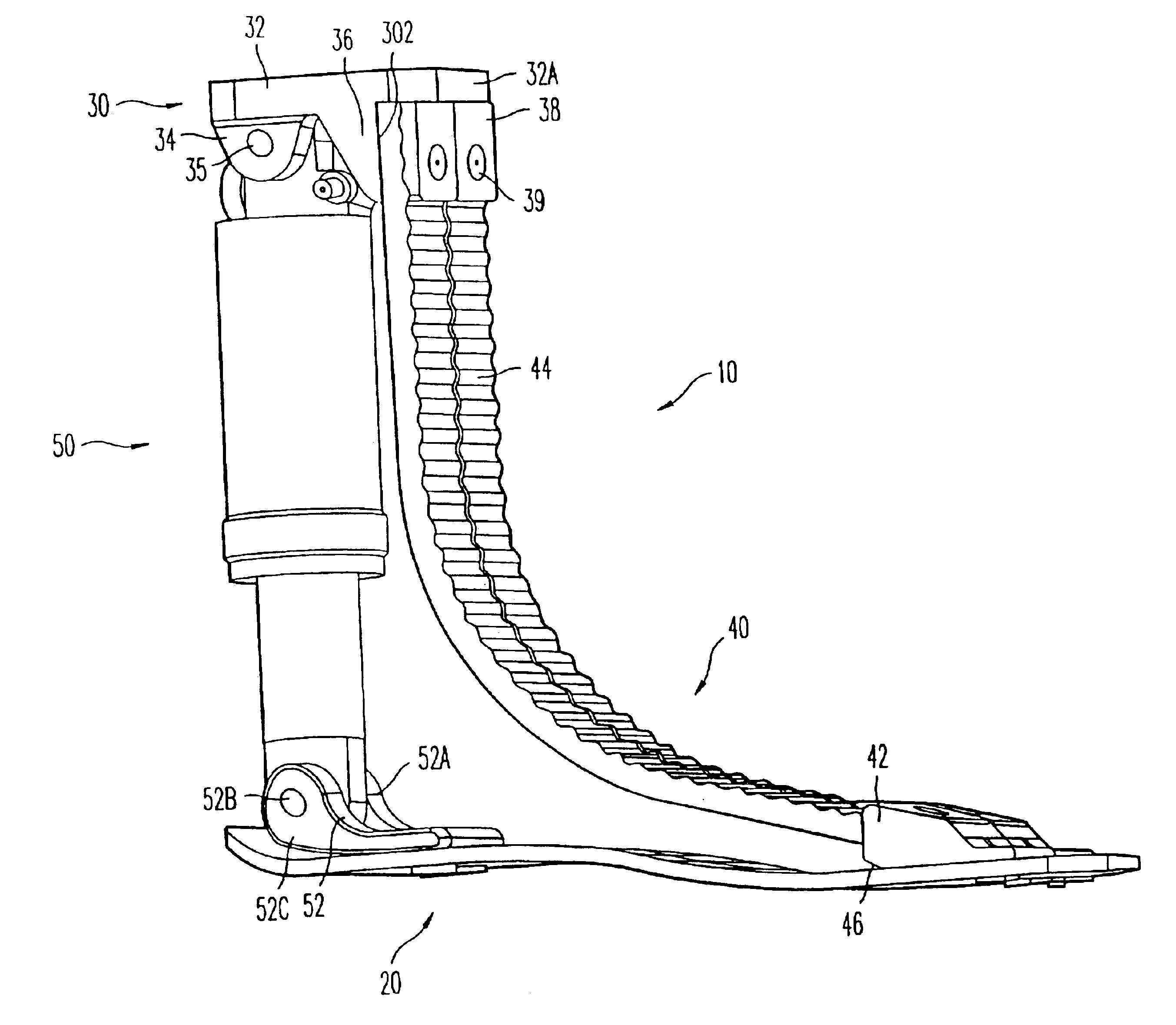

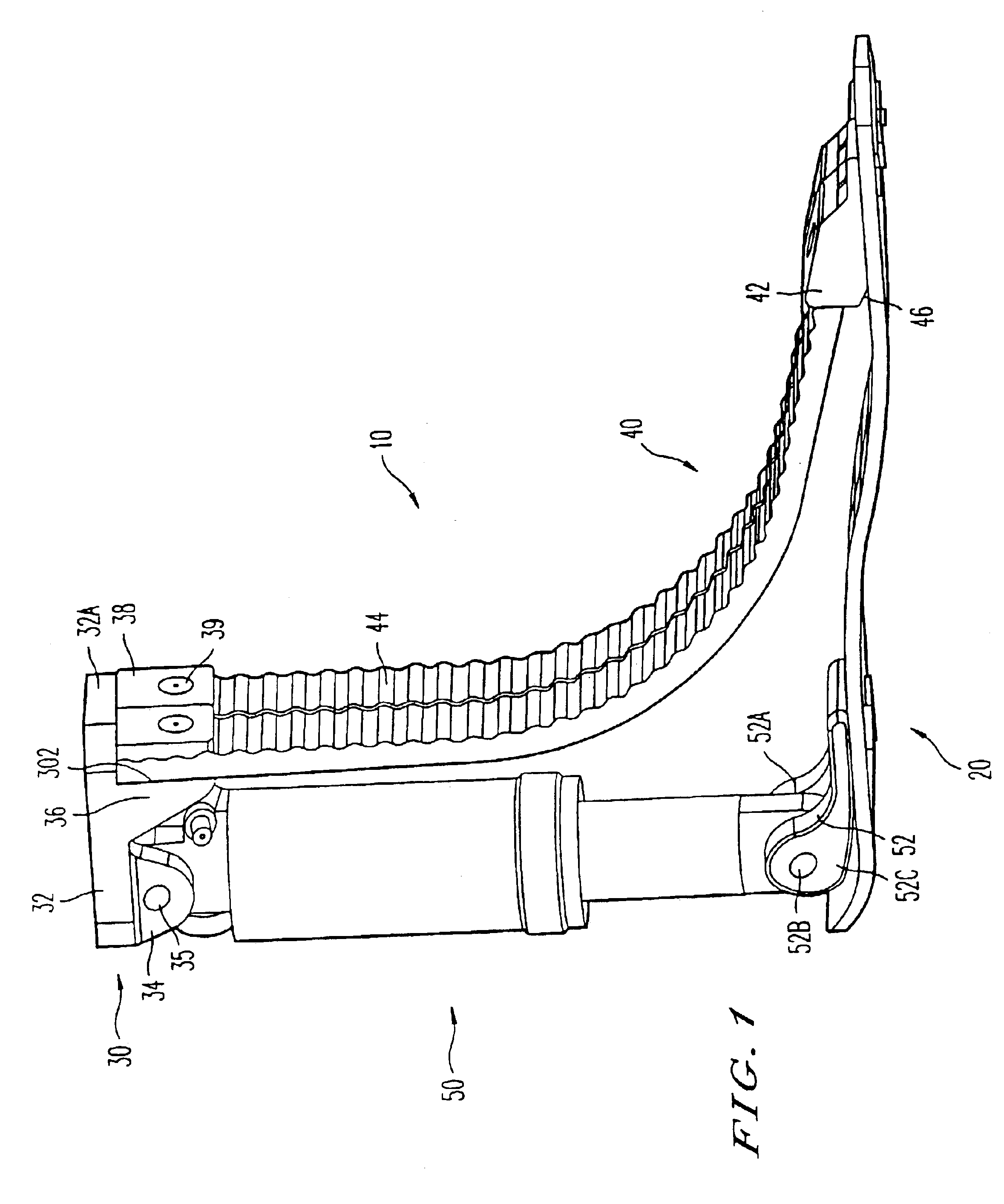

Prosthetic foot having shock absorption

InactiveUS6863695B2Efficiently transferring energyAbsorb energyArtificial legsEngineeringTubes types

A prosthetic foot includes an adapter element securable to a residual limb, a foot plate having a heel portion and a toe portion along the length thereof, at least one toe spring connected between the adapter element and the toe portion of the foot plate, and a heel spring connected between the adapter element and the heel portion. The heel spring may be a leaf spring or a tube type shock absorber. The concave side of the leaf spring exhibits a plurality of transverse ribs. Alternatively, a tubular pylon may have a collar mounted thereon for movement along the length of the pylon. A toe spring and a heel spring extend from the collar to form toe and heel portions of the prosthetic foot. A further heel spring is connected between the heel portion and another end of the pylon, and a non-extensible band extends between the heel portion and the collar. As another alternative, a tubular pylon has one end securable to a residual limb, and a collar is mounted to the pylon for movement along the length of the pylon. At least one toe spring is connected between the collar and the toe portion of a foot plate, while a heel spring is connected between the heel portion of the foot plate and another end of the pylon.

Owner:THE OHIO WILLOW WOOD CO INC

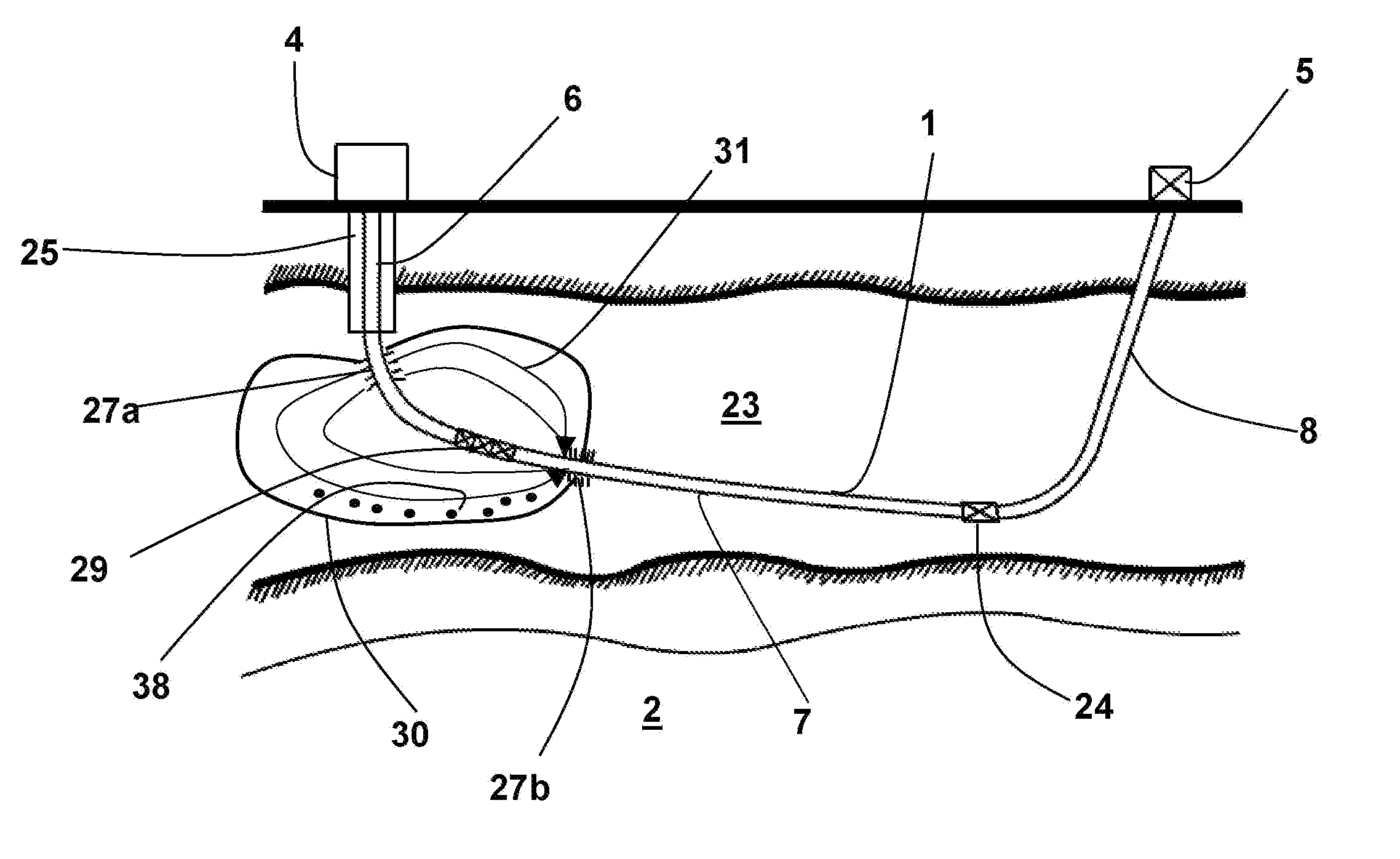

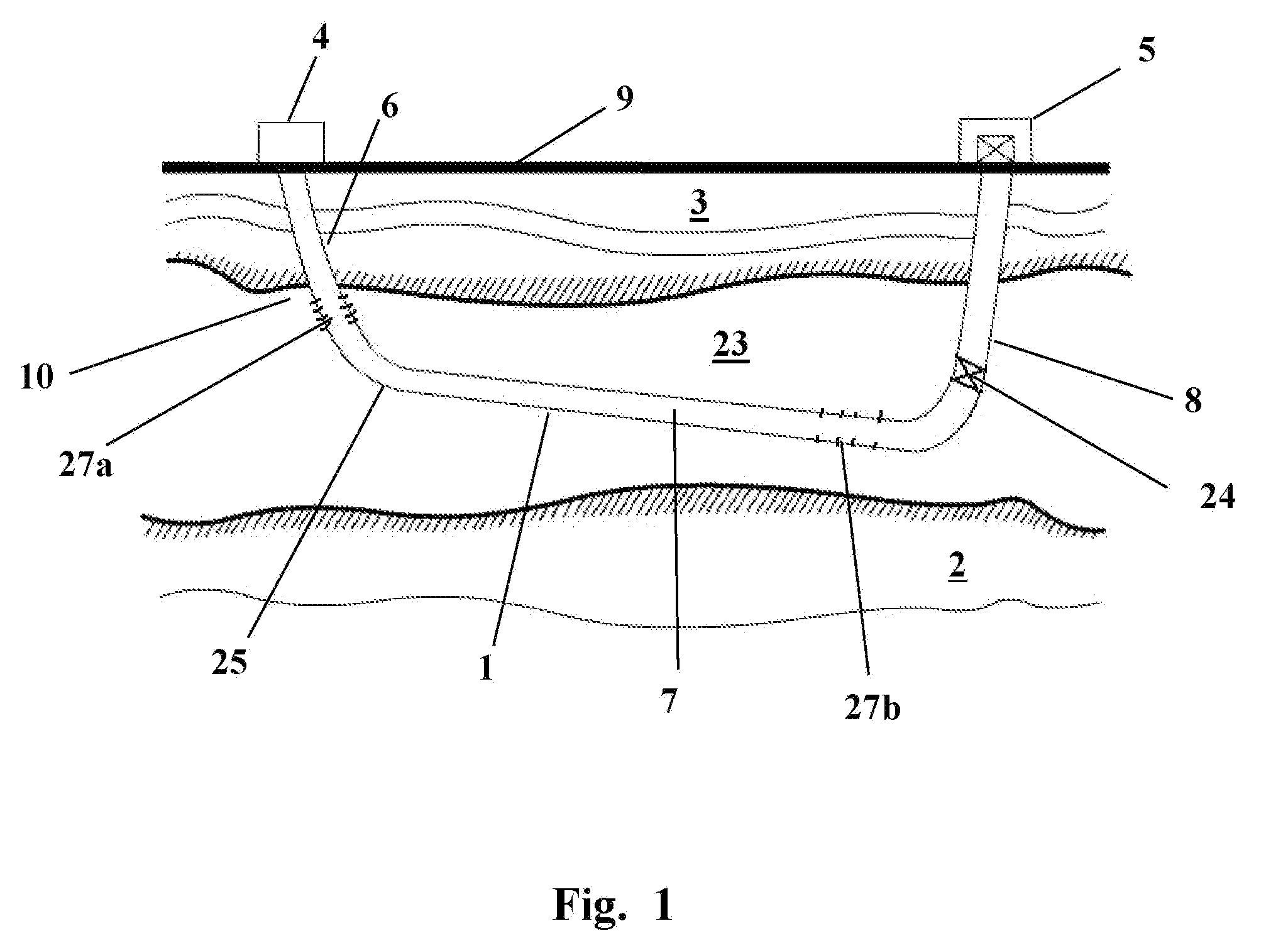

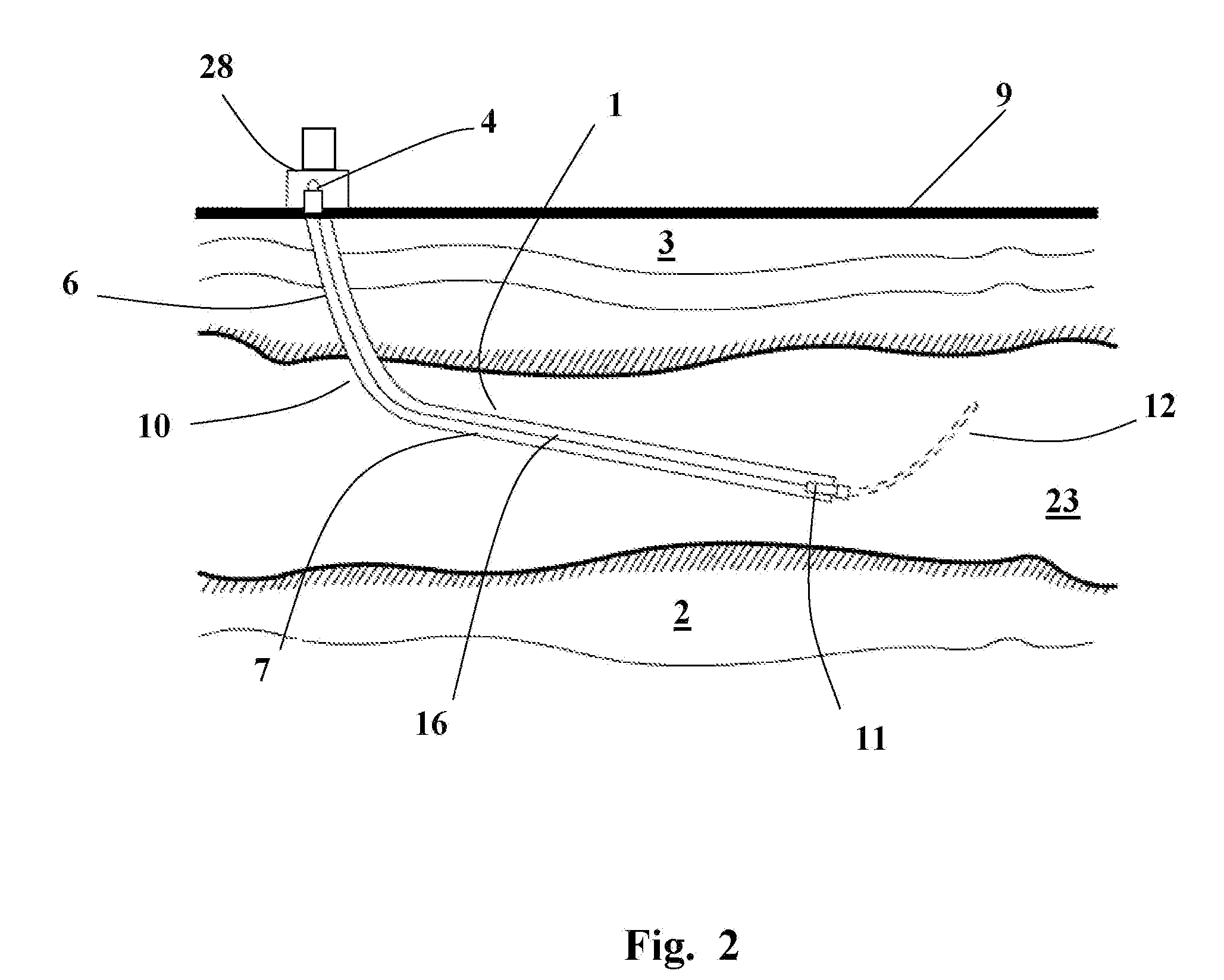

Method for Recovering Hydrocarbons from Subterranean Formations

InactiveUS20060175061A1Minimize damageLimited surfaceInsulationFluid removalWater productionTubes types

Recovery of viscous hydrocarbon from subterranean formations is assisted by using a plurality of novel U-tube type wells, each with dual wellheads, a moveable wellbore packer, a lateral section with a concentric communication zone and with sequential injection production perforations in which heat is injected into the proximal perforations and hot oil and produced fluids are produced from the distal perforations, the whole process being controlled by modulating the production flow where the wellbore fluids are controlled to act as a hydraulic seal to limit bypass of injected fluids. The injection-production displacement process moves axially along the wellbore in a sequential manner as hydrocarbon volumes are depleted by injected fluid displacement of oil and oil and water production.

Owner:CRICHLOW HENRY B

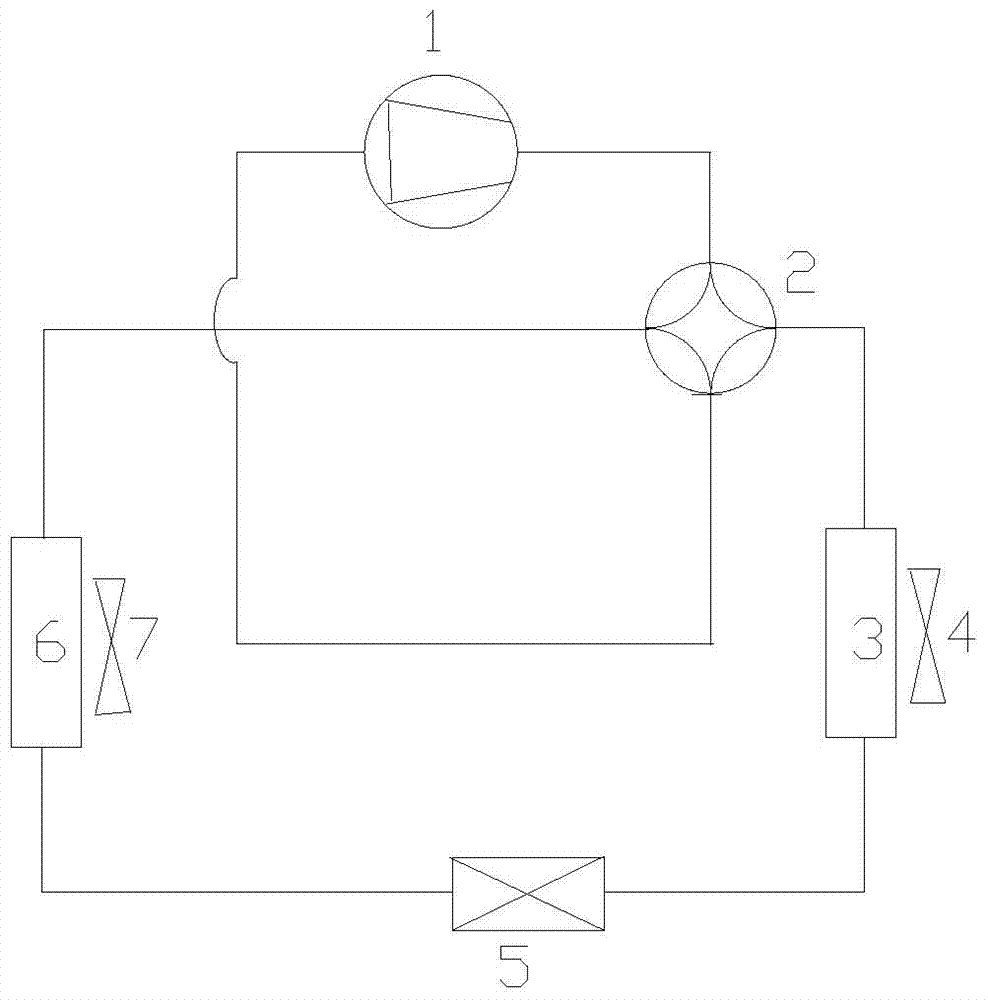

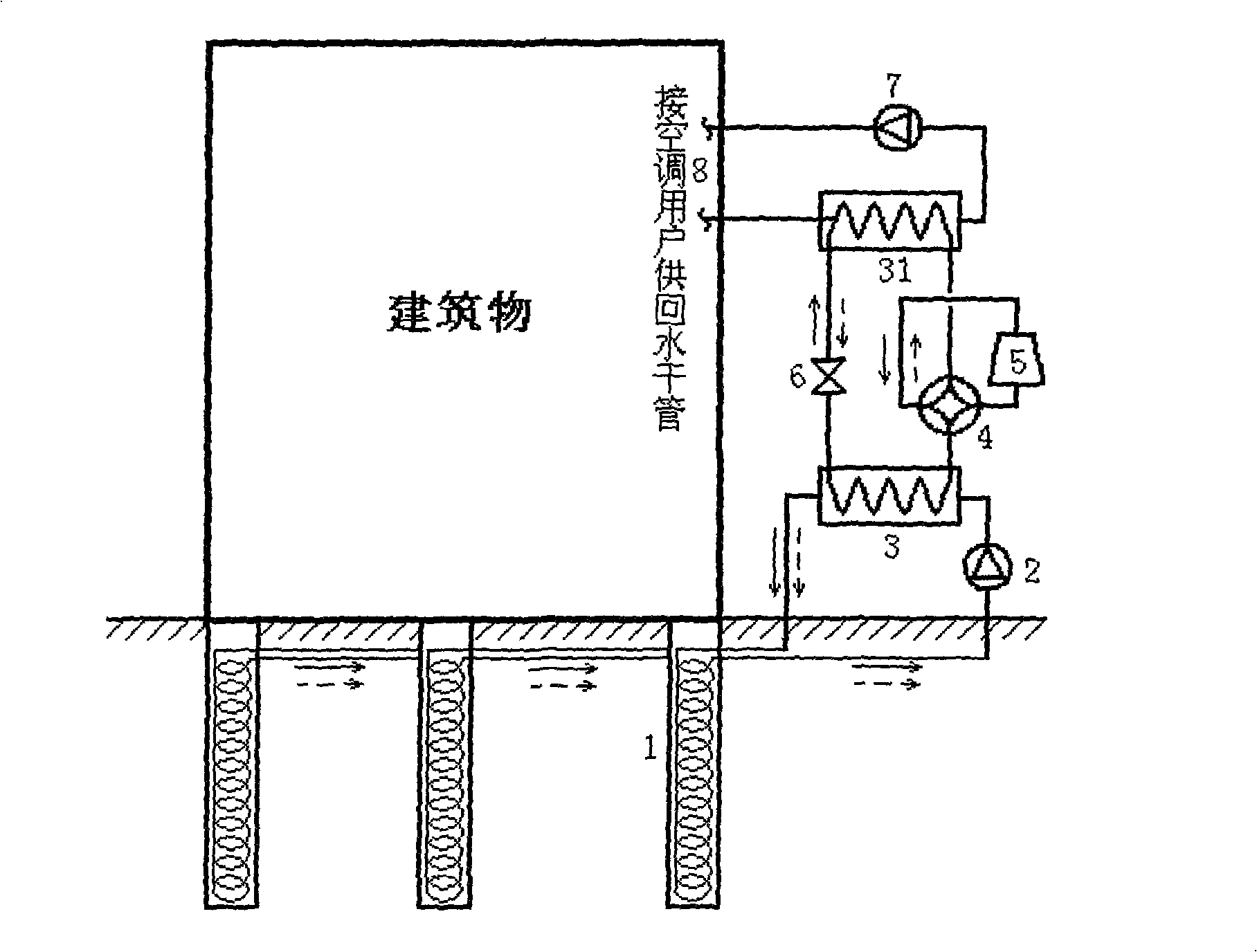

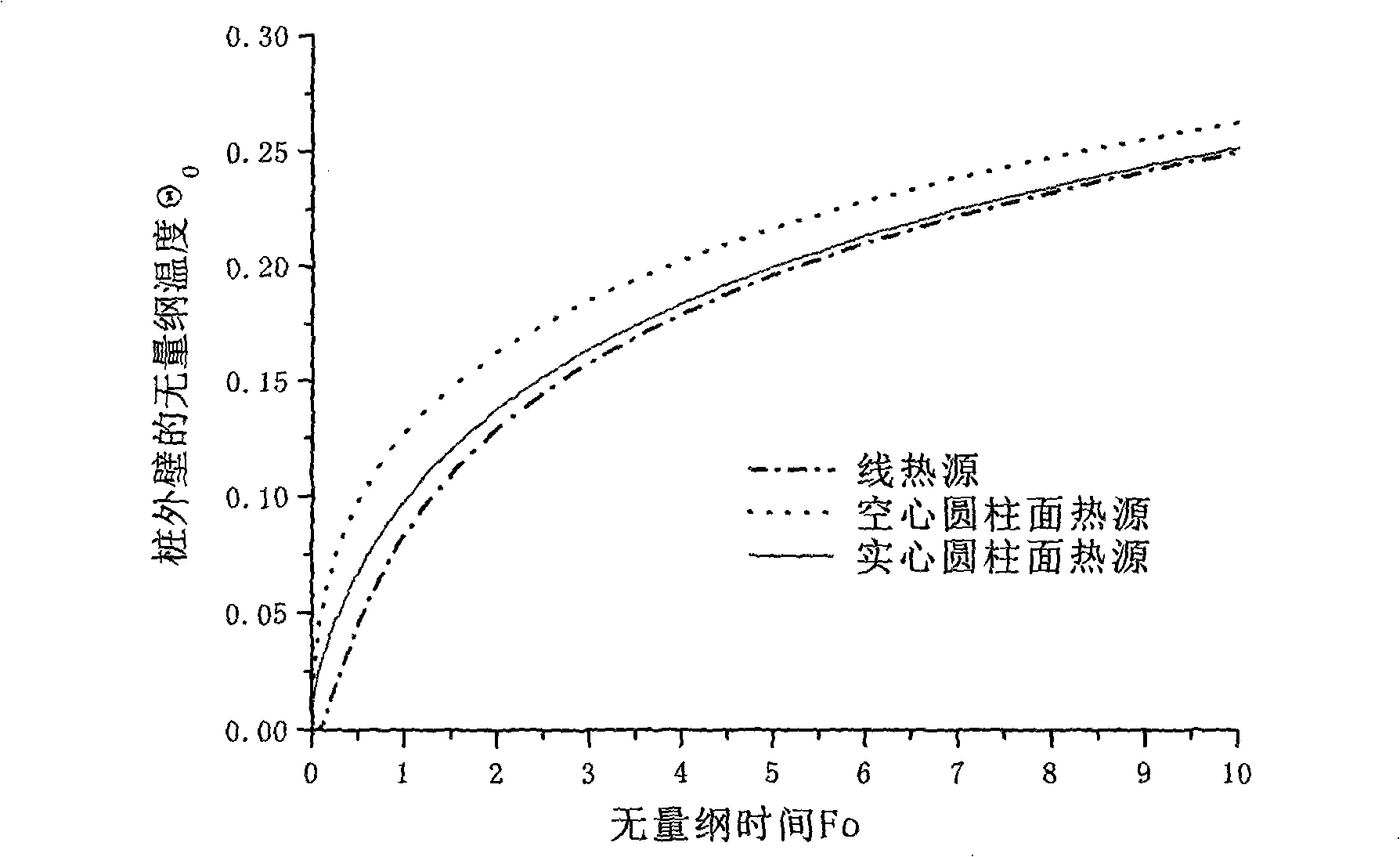

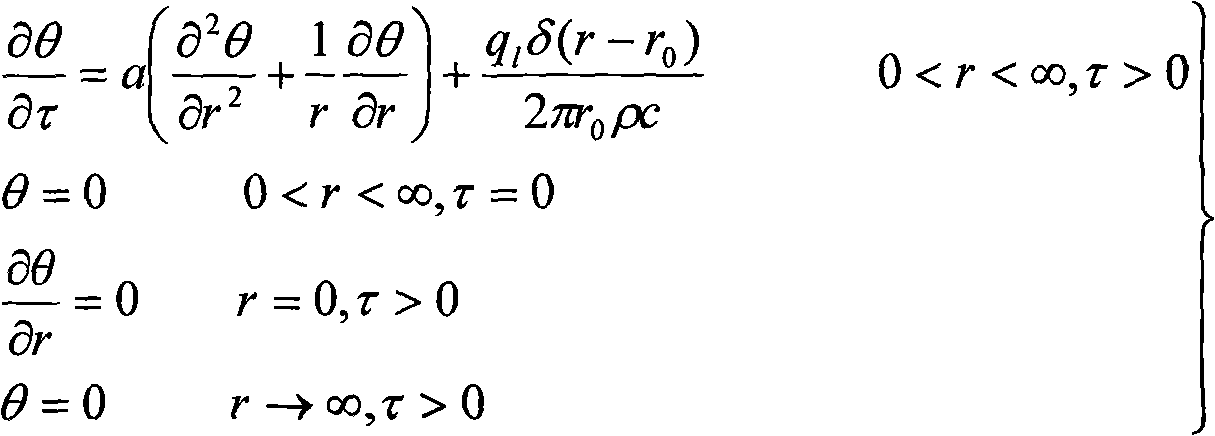

Pile imbedded helix tube type ground source heat pump system and heat transferring model of terrestrial heat exchanger thereof

ActiveCN101408359ASmall footprintReduce initial investmentHeat pumpsOther heat production devicesHeat transmissionEnd system

The invention discloses a pile-embedding spiral pipe typed ground source heat pump system and a heat transmission model of a geothermal heat exchanger thereof. A solid cylindrical surface heat source model is put forward for the first time and two analytic solution expressions of the heat transmission model is worked out by the Green function method. The system can sufficiently utilizes the underground area of a building, saves a great amount of expenses for boring and pipe embedding, reduces the initial investment of the ground source heat pump system, improves the construction efficiency and has convenient and quick construction. Furthermore, the heat transmission model of the pile-embedding spiral pipe geothermal heat exchanger can quantitatively analyze the effects of all parameters of the pile-embedding spiral pipe geothermal heat exchanger on the heat transmission capability and provides a basis for the engineering design. The structure of the pile-embedding spiral pipe typed ground source heat pump system comprises the geothermal heat exchanger which is connected with an air conditioning heat pump system by pipelines; the air conditioning heat pump system is connected with a conveying and end system in the building; the geothermal heat exchangers have the quantity of more than one; and each geothermal heat exchanger forms the pile-embedding spiral pipe-typed geothermal heat exchanger by building pile foundations and spiral pipes which are embedded in the pipe foundations.

Owner:山东中瑞新能源科技有限公司

Nerve tissue engineering tube type bracket and method for making same

InactiveCN1593354APromote regenerationPrevent intrusionTubular organ implantsCell adhesionMetabolite

Disclosed is a nervous tissue engineering tubular supporting stand and method for making same, wherein the nervous tissue engineering tubular supporting stand comprises a chitosan pipe wall and biological source filling base material with axial multiple passages, and the method consists of preparing semipermeable chitosan hollow pipe with 1-5mm of inside diameter, pouring large biological molecule solvent such as chitosan, collagen or gelatine, and utilizing special-purpose die arrangement and lyophilization technology. The obtained multiple-pass nerve channel with bionic construction is beneficial for cell adhesion, migration and leading of neuraxon directional growth, and suitable of the renovation and regeneration of nerve damages.

Owner:TSINGHUA UNIV

Method for preparing electrode system, electrode system prepared therefrom, and electric device comprising the same

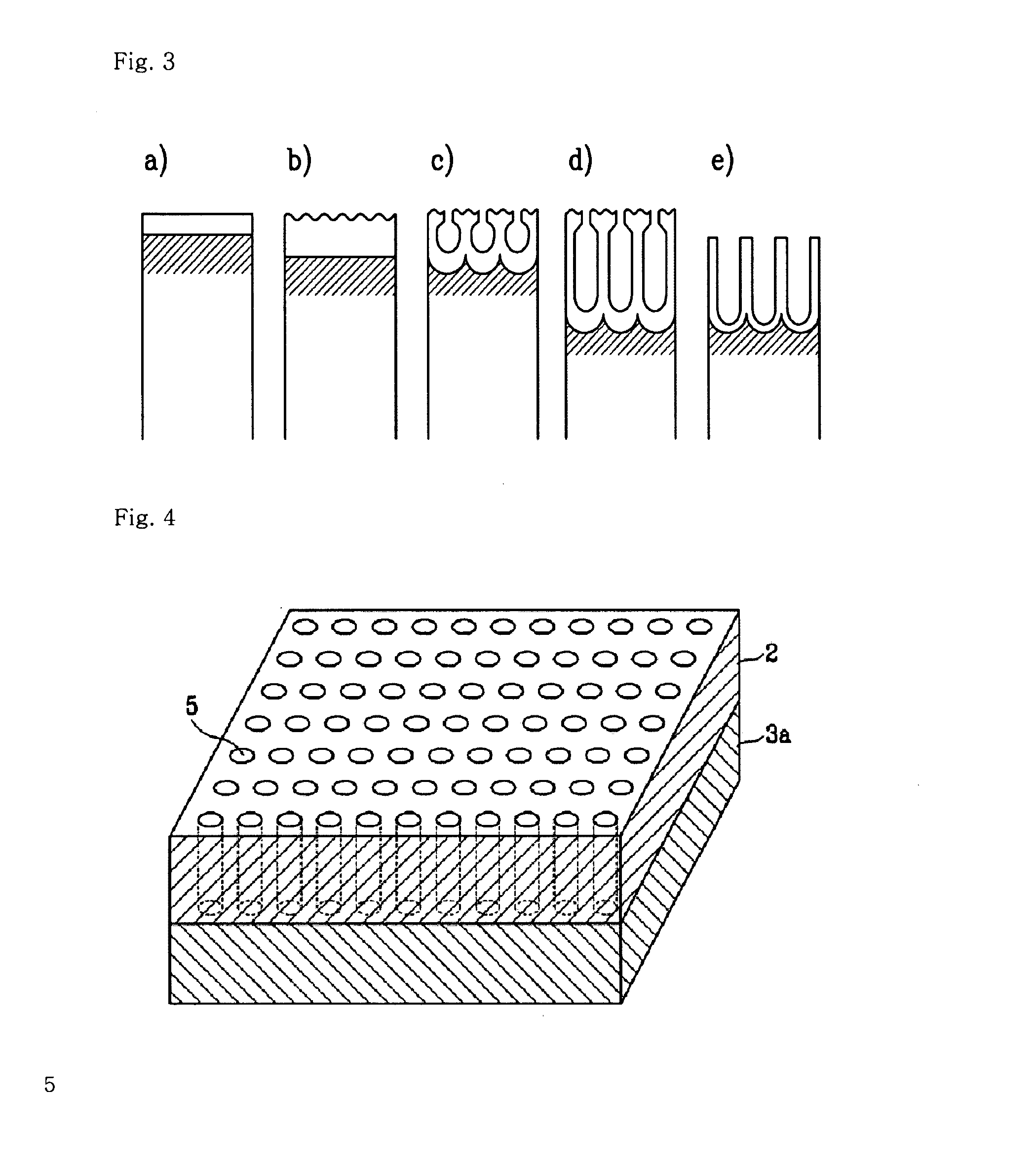

ActiveUS20050117194A1Improve response speedRaise transfer toHybrid capacitor electrodesFinal product manufactureElectron holeSupercapacitor

Provided are a method for preparing an electrode system, an electrode system prepared therefrom, and an electric device including the same. The method includes the steps of forming a porous template having nanopores on a first electrode, wherein a diameter of the nanopores is between 5 to nm 500 nm; and forming a rod-type / tube-type second electrode inside the nanopores which are connected to the first electrode, the electrode system prepared therefrom, and an electric device including the same. With the large surface area, the electrode system of the present research improves efficiency and performance of various electric devices. The contrast and respond speed of the electrochromic device can be increased, and the number of electron-hole pairs of a solar cell is increased. The loss of electron-hole pairs is minimized, and charge storage of the supercapacitor and charge respond speed is heightened.

Owner:LG CHEM LTD

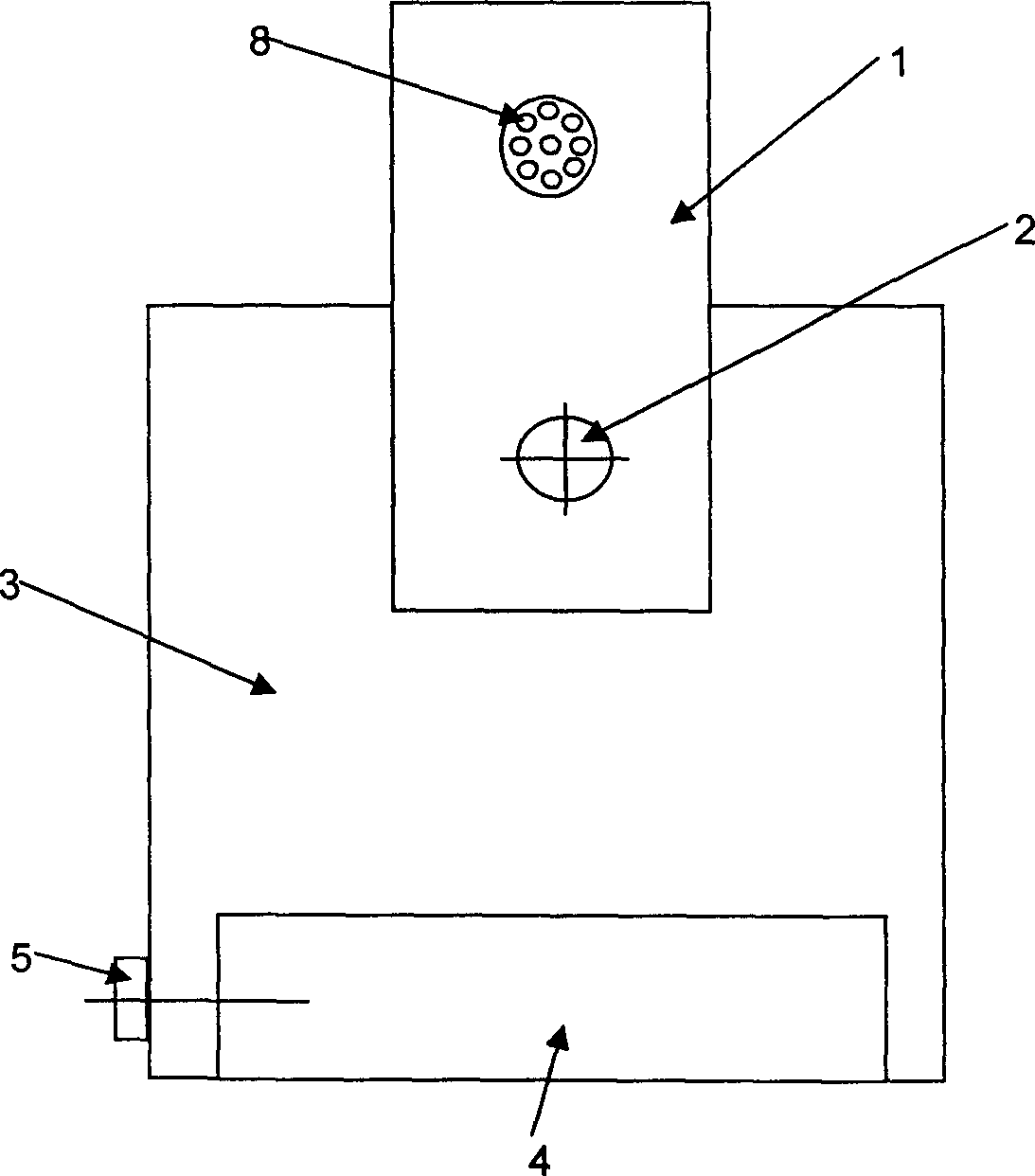

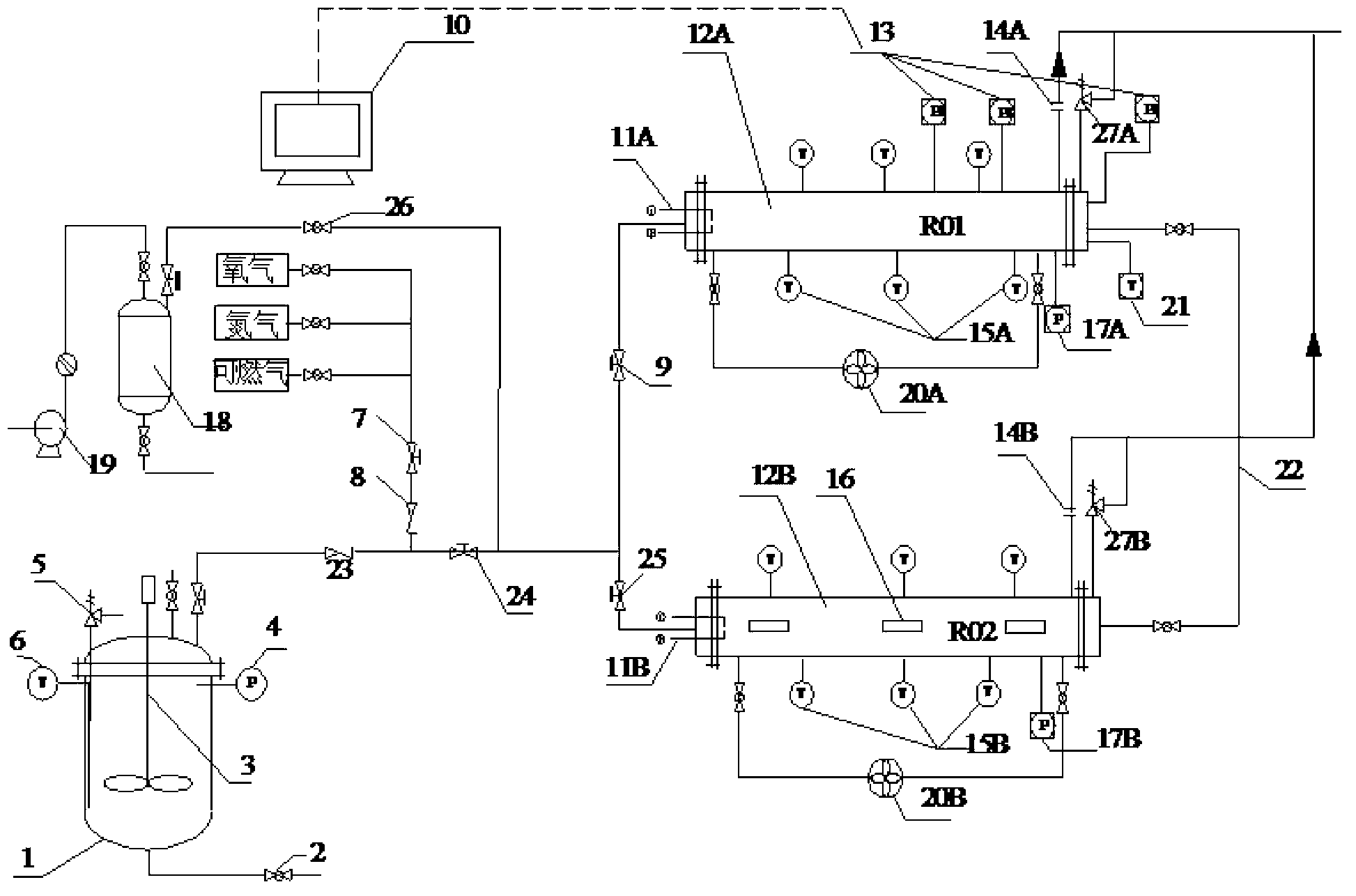

High-temperature high-pressure explosion limit tester, method for determining explosion limit, and application thereof

The invention provides a novel high-temperature high-pressure explosion limit tester comprising a raw material gas supply apparatus, an explosion determination device, a vacuum generating device, and a controlling device. The explosion determination device is mainly composed of a pressure sensor, a temperature sensor, and an igniter. The explosion determination device is used for determining explosion limit, explosion pressure and explosion temperature of the gas or vapor. The vacuum generating device is used in vacuum pumping upon the explosion determination device. The controlling device is used for determining, controlling and collecting experimental data generated during the experiment. Compared with prior arts, the high-temperature high-pressure explosion limit tester provided by the invention has a temperature testing range of room temperature to 400 DEG C, which is higher than 200 DEG C which is a maximal temperature of instruments in existing standards; the tester provided by the invention has a pressure range of normal pressure to 2.2MPa, which is higher than 1.38MPa which is a maximal pressure of instruments in existing standards; and the tester provided by the invention has a test volume of 10L, which is larger than that of an existing tube-type explosion limit tester, such that a wall effect can be better reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible tube type solid-liquid processing machine with filtering, heat-exchange and hot compression function

InactiveCN1966129ALow costSimplify equipment componentsSemi-permeable membranesStationary filtering element filtersSlagEngineering

The invention relates to a flexible tubular solid liquid processor, with filter, heat exchange and thermal extraction functions, wherein the filter element at least comprises one flexible tubular membrane unit, upper flange room and lower flange room; the hydraulic extracting system comprises pressure container, extract pump and tubes; the material liquid of container can be filtered by the tubular filter membrane of membrane unit, and said material liquid can be used as work medium to extract the concentrated material liquid in the filter room of membrane unit and discharge filter slag; the pressure container or the filter room of membrane unit can be filled with medium to exchange heat, to realize thermal filter or extraction; the filter element is arranged on the bearing base inside the pressure container; the filter rotator can rotate the filter element to realize cross-flow filter; and the invention can be arranged with gas or water reverse tube and vacuum filter tube; the slag discharge system comprises slag discharger or tubular inner / outer membrane scraper, or vibration slag discharger, or compression slag discharger.

Owner:张民良

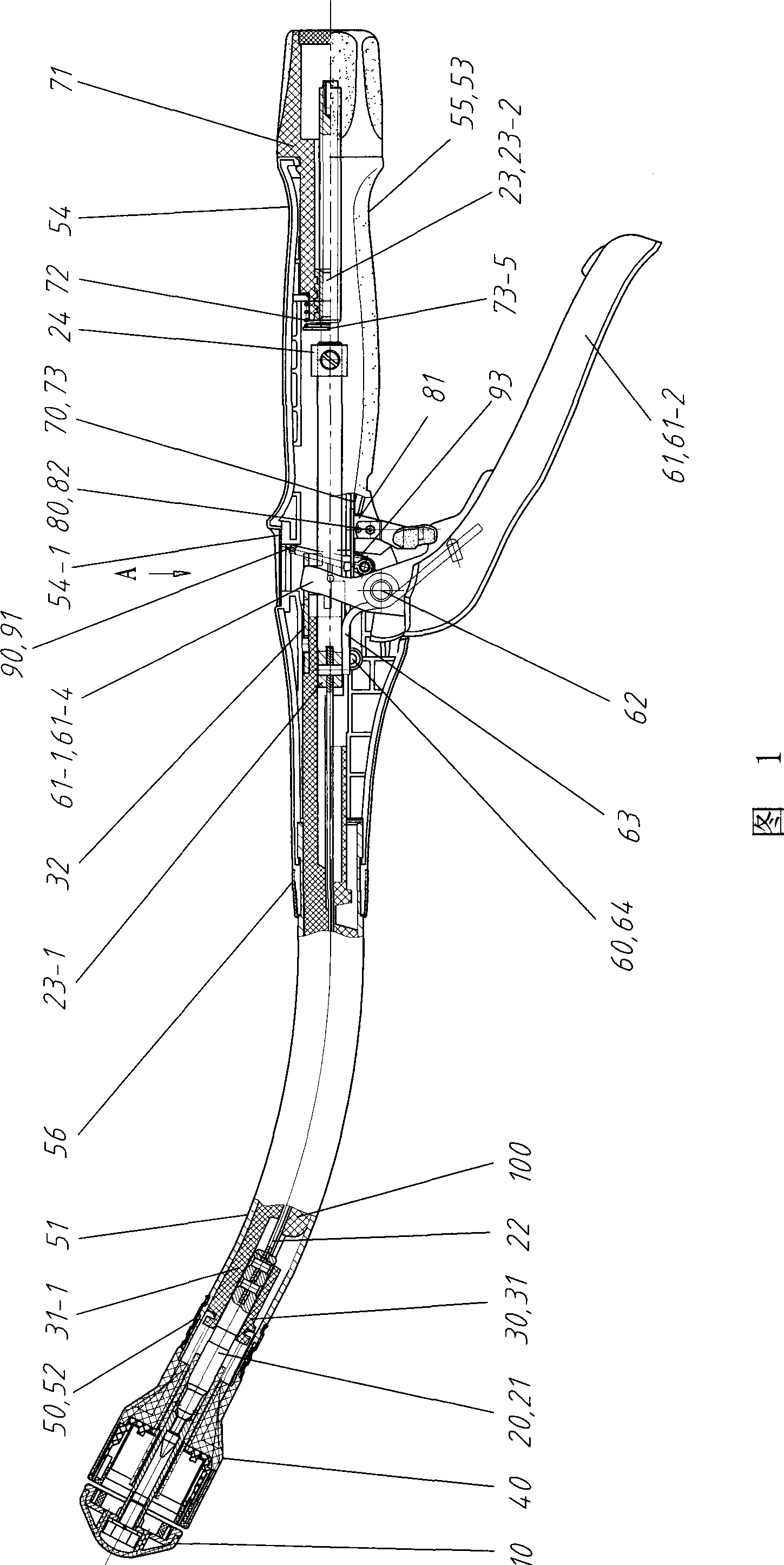

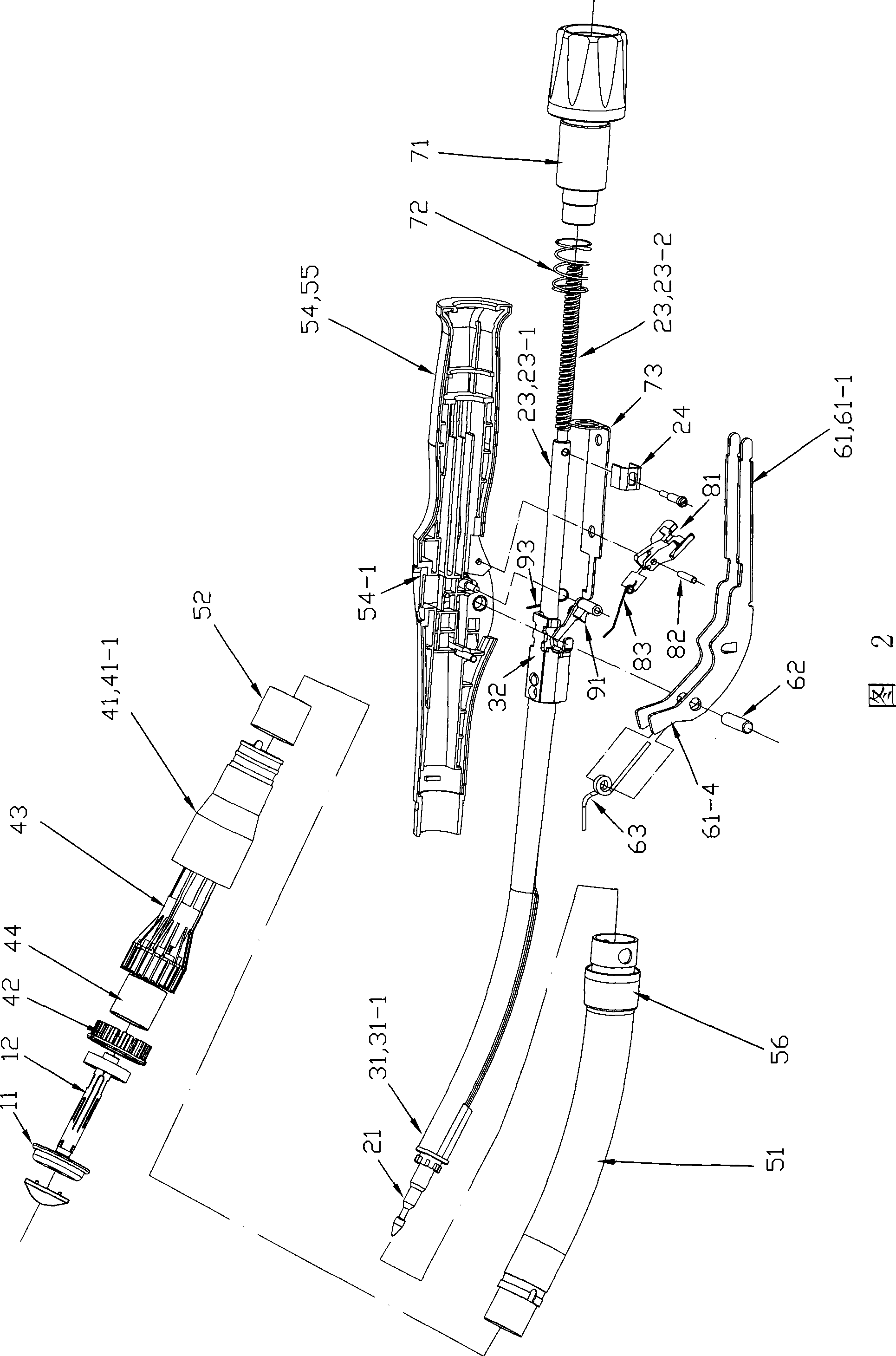

Tube type anastomat with insurance device and main body of anastomat thereof

ActiveCN101416895AAudio-visual function is completeGood effectSurgical staplesEngineeringTubes types

The invention relates to a tubular stapler with a safety device and a stapler body. The stapler comprises a staple pressing seat component, a staple and a stapler body, wherein, the stapler body comprises a spindle component, a push rod component, a staple box component, a shell component, a movable handle, an adjusting nut, a safety block and an indicator. The stapler has an interlock function of the indication on a green zone by the indicator and the automatic start-up of the safety block. By observing the indication of the indicator on the green zone and the clang given by the safety block for automatic start-up, the stapler can give double hints to a clinician that an anastomosis zone is entered and the anastomosis distance can be continued to be slightly adjusted by considering the thickness of tissue, and then the clinician can move the movable handle to realize the anastomosis of cutting. Therefore, the tubular stapler can prevent the percussion beyond the predetermined scope and is convenient, safe and reliable in operation.

Owner:CHANGZHOU XIN NENG YUAN MEDICAL STAPLER

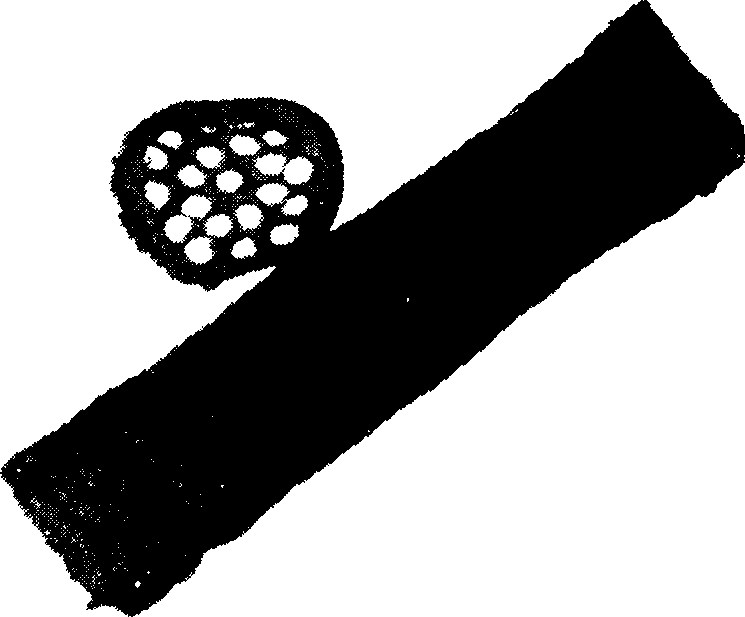

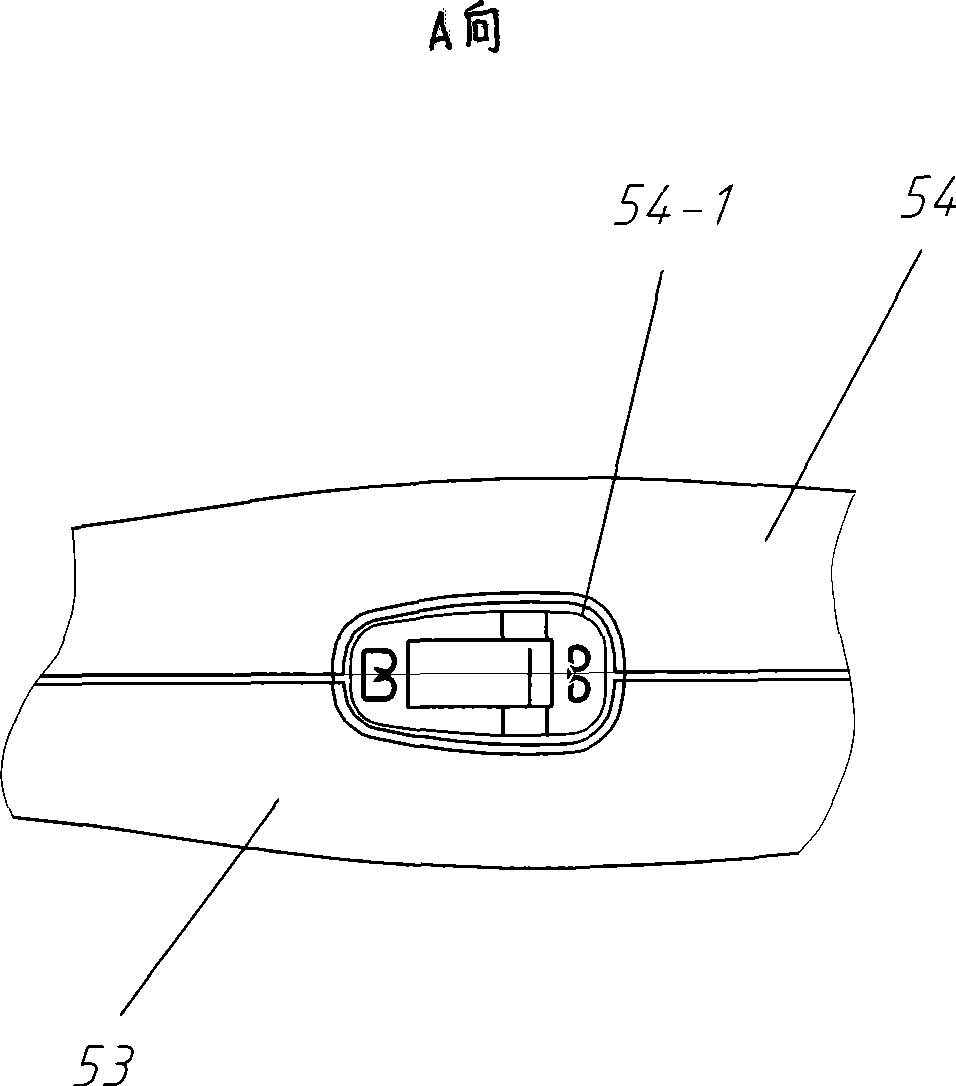

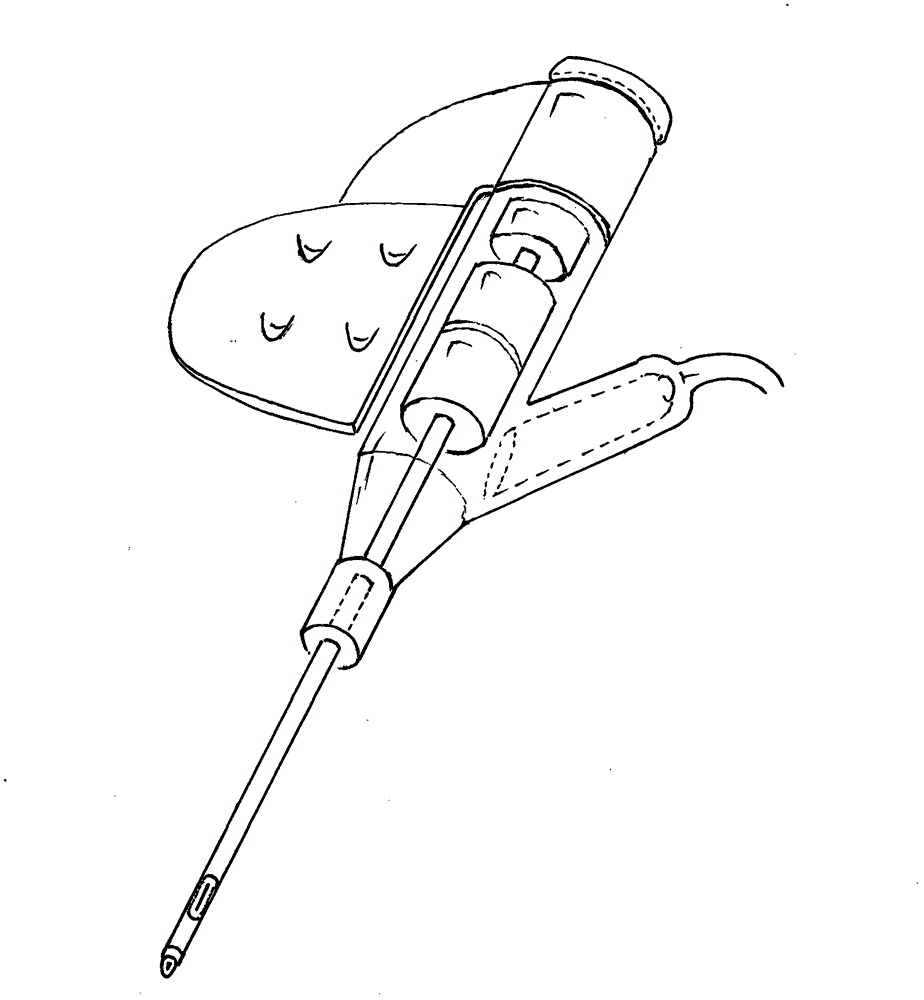

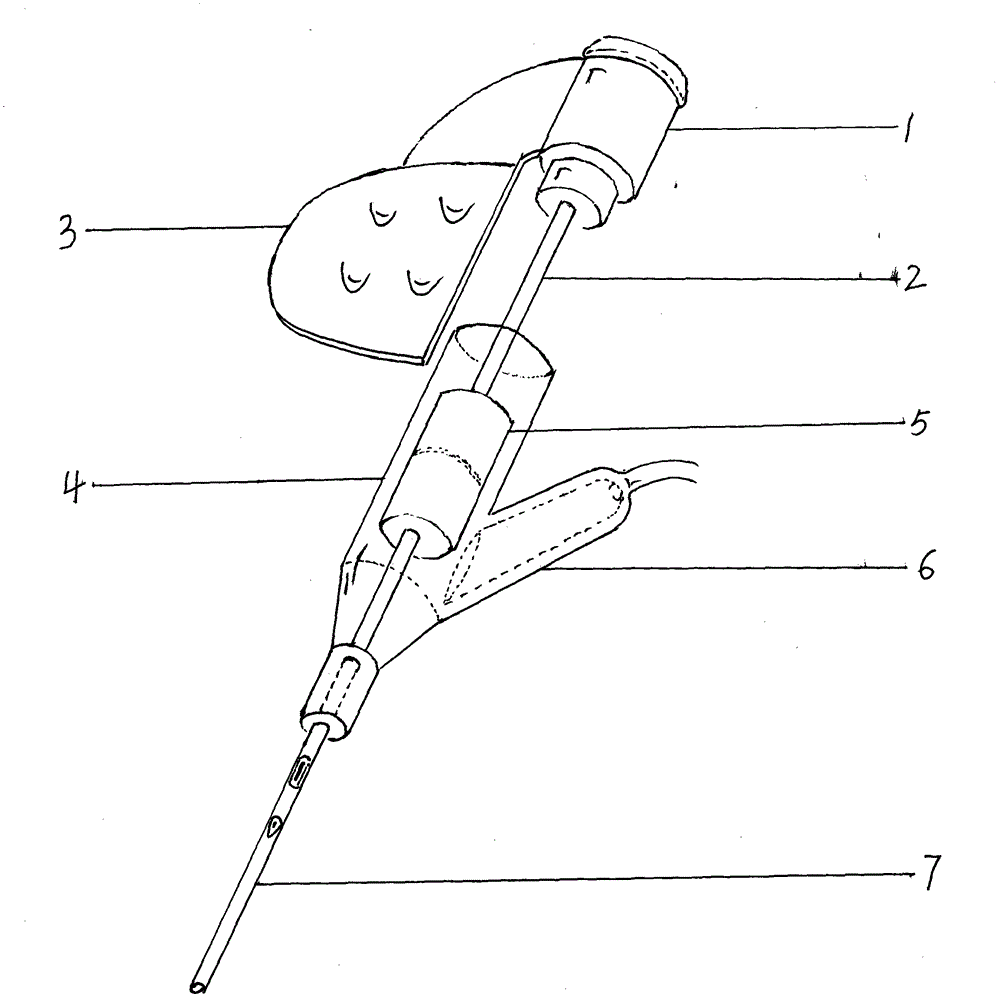

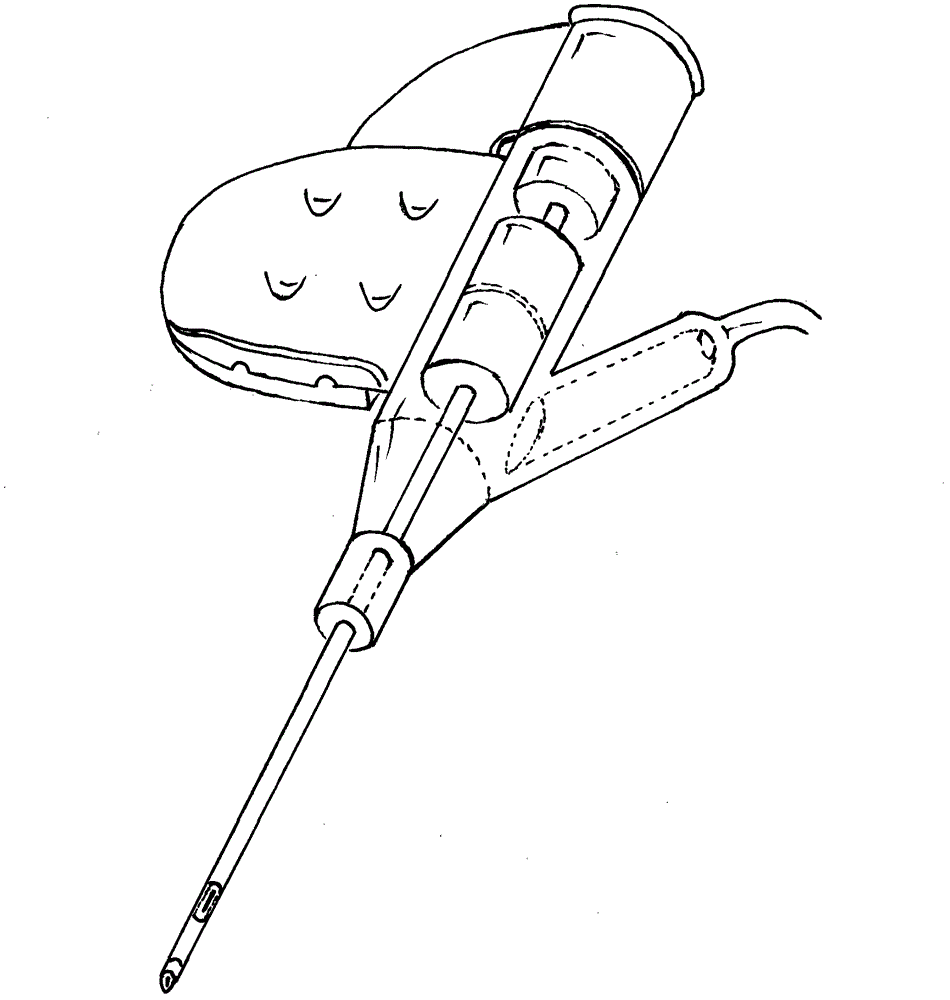

Disposable single hand insertion tube type vein detaining needle

InactiveCN102716541AImprove stabilityReduces the chance of puncturing blood vesselsGuide needlesInfusion needlesNursing techniquesFront edge

The invention relates to a disposable single hand insertion tube type vein detaining needle (shown as in the abstract drawing) which can simplify the operation process of a nursing technique, improve the venipuncture success rate, relive patients' pain and save medial treatment materials. On the basis of the original vein detaining needle, the handle of the detaining needle is transformed into an anastomosis handle, the anastomosis handle extends forwards about 2 mm, two longitudinal semicircular bulges are designed on the upper surface of the anastomosis handle, a miniature baffle plate is additionally arranged on the rear edge of the lower surface of the anastomosis handle, four protuberances are designed on the lower surface of the anastomosis handle, an anastomosis side wing is additionally arranged on a trocar bed of the indwelling needle, two semicircular grooves are designed in the lower surface of the anastomosis side wing to be matched with the longitudinal semicircular bulges on the upper surface of the handle, a miniature baffle plate is additionally arranged on the front edge of the anastomosis side wing, and four protuberances are designed on the lower surface of the anastomosis side wing. During venipuncture, after blood returning, a cannula is pushed into a vessel by the thumb of a right hand without the need of exchanging hands, so that the delivering of a detaining needle cannula by a single hand can be achieved, the operation process is simplified, the vessel is not liable to puncture, the success rate is improved, and the patients' pain is relieved.

Owner:许春燕

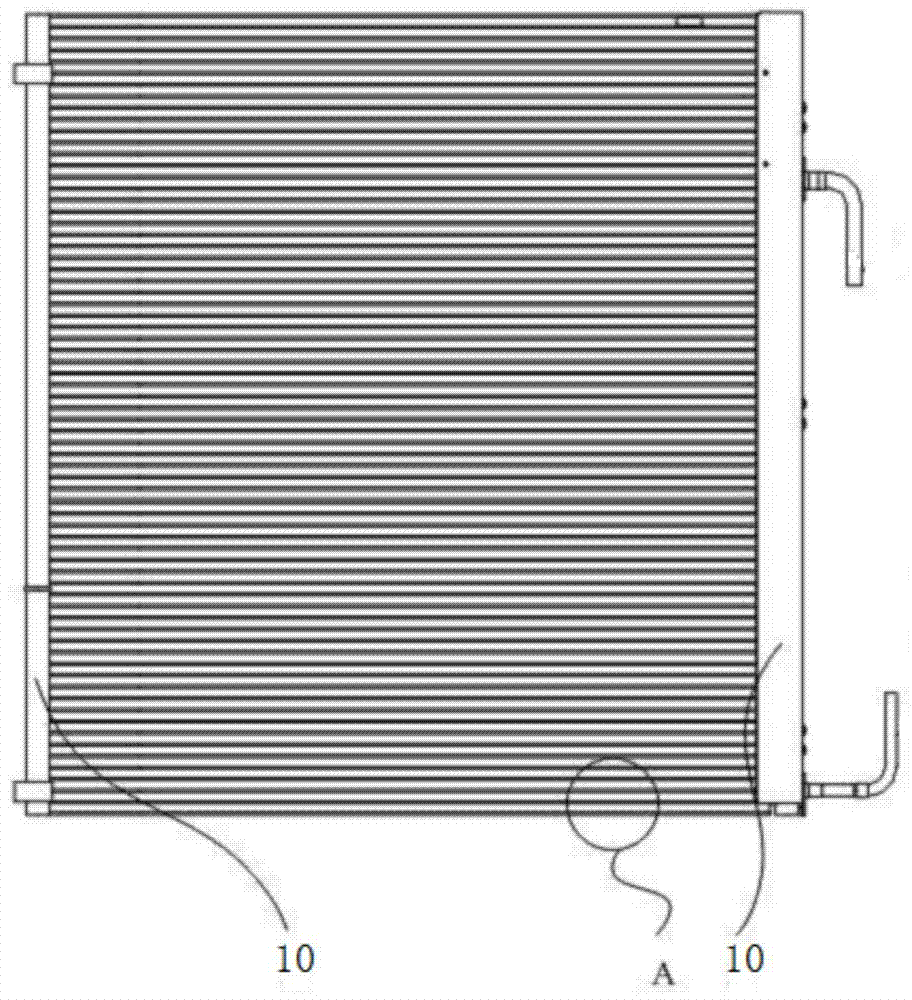

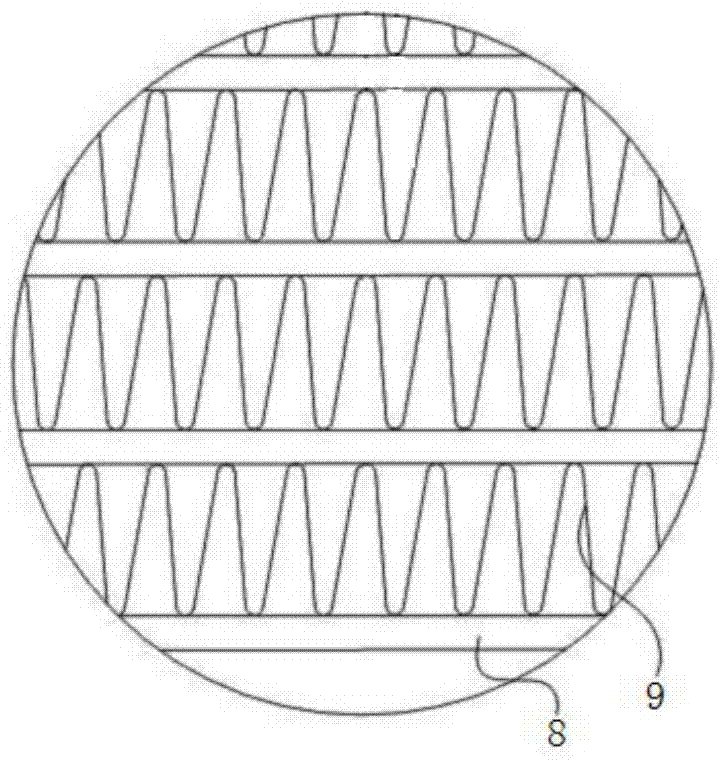

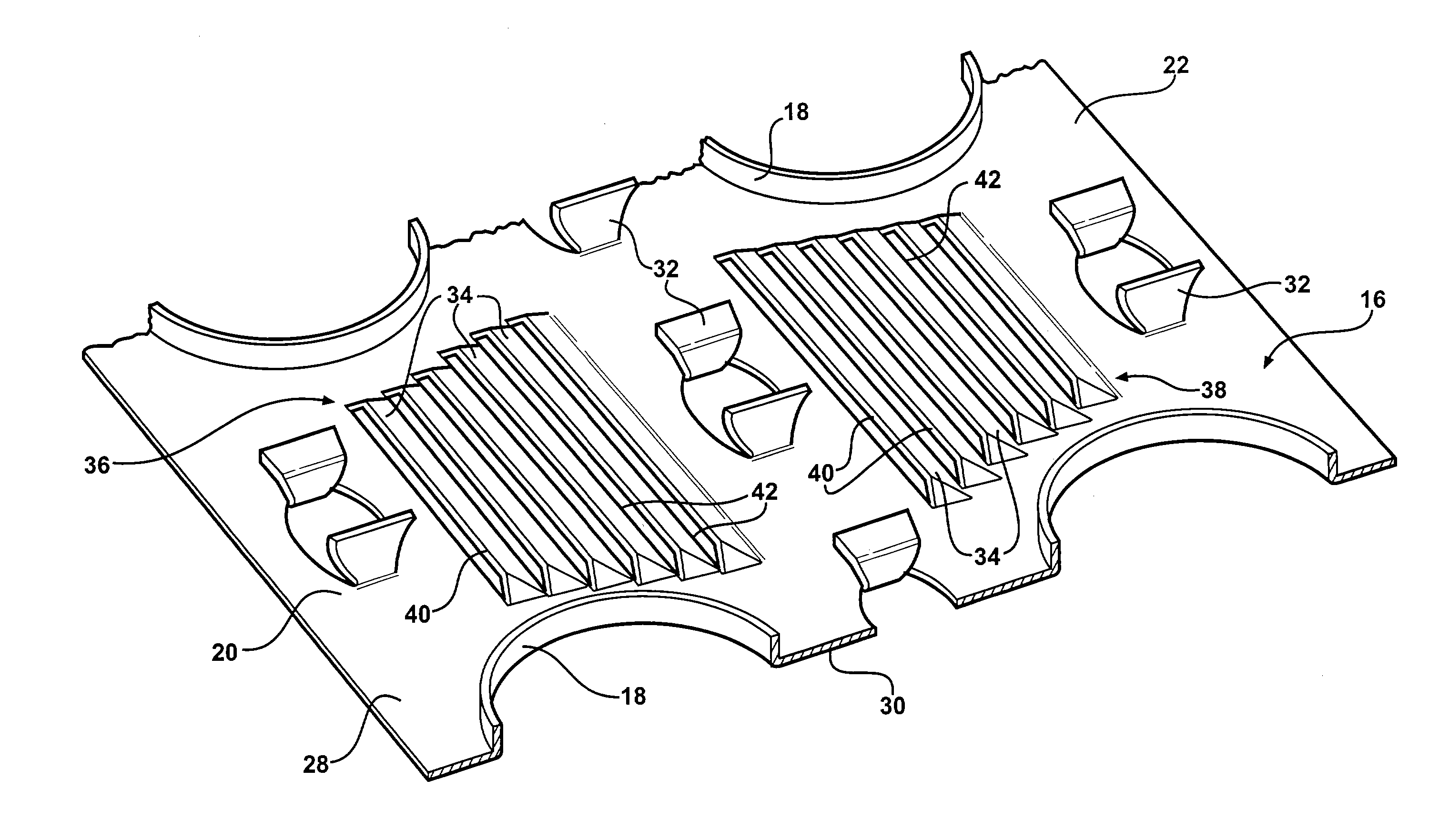

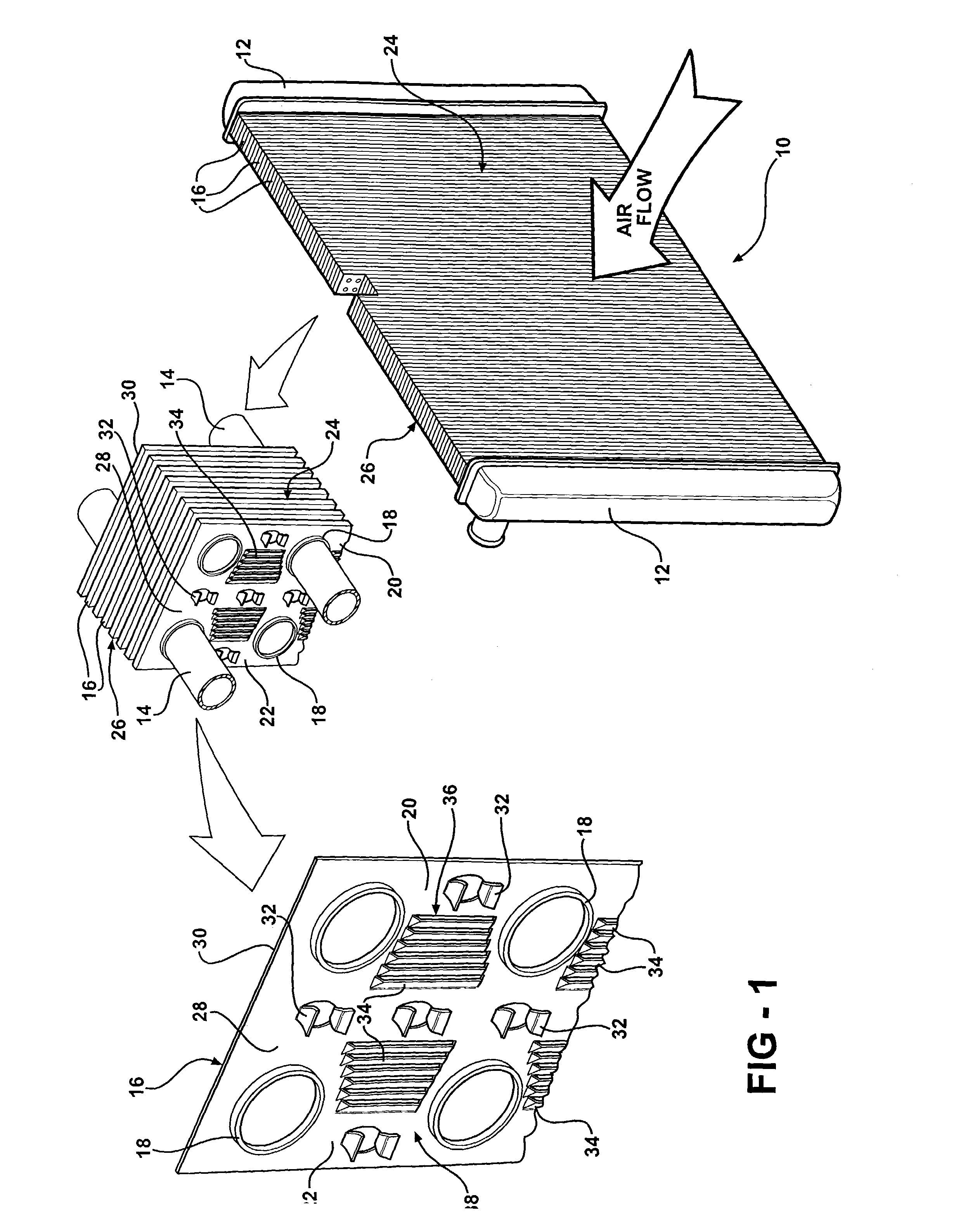

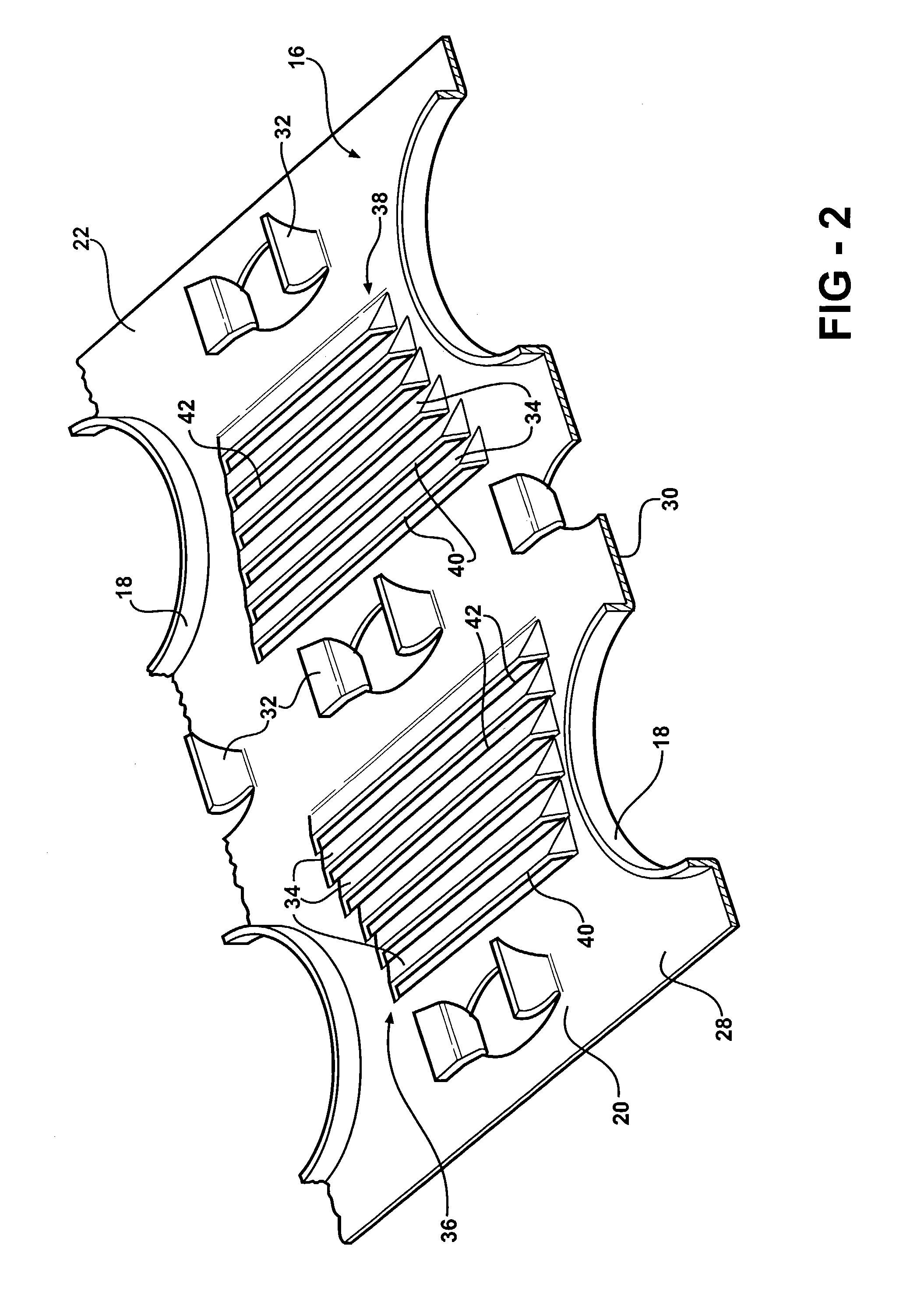

Fin-and-tube type heat exchanger

ActiveUS7021370B2Improve heat transfer performanceMinimize air pressure dropEvaporators/condensersStationary conduit assembliesEngineeringLouver

A heat exchanger having fins disposed adjacent to each other with tubes passing through the fins to interconnect the fins. Louvers are formed in each of the fins with each louver extending at an angle with respect to the fins. An upstream portion of the interconnected fins define an incoming airflow side of the heat exchanger and a downstream portion of the interconnected fins define an outgoing airflow side of the heat exchanger. The louvers define a first bank of louvers formed in each of the upstream portions of the fins facing the incoming airflow side of the heat exchanger. The louvers also define a second bank of louvers formed in each of the downstream portions of the fins facing the incoming airflow side of the heat exchanger. Hence, all of the louvers on the fins are facing the same direction for minimizing the air pressure drop, while increasing a heat transfer between the fins, tubes, and the air flow.

Owner:MAHLE INT GMBH

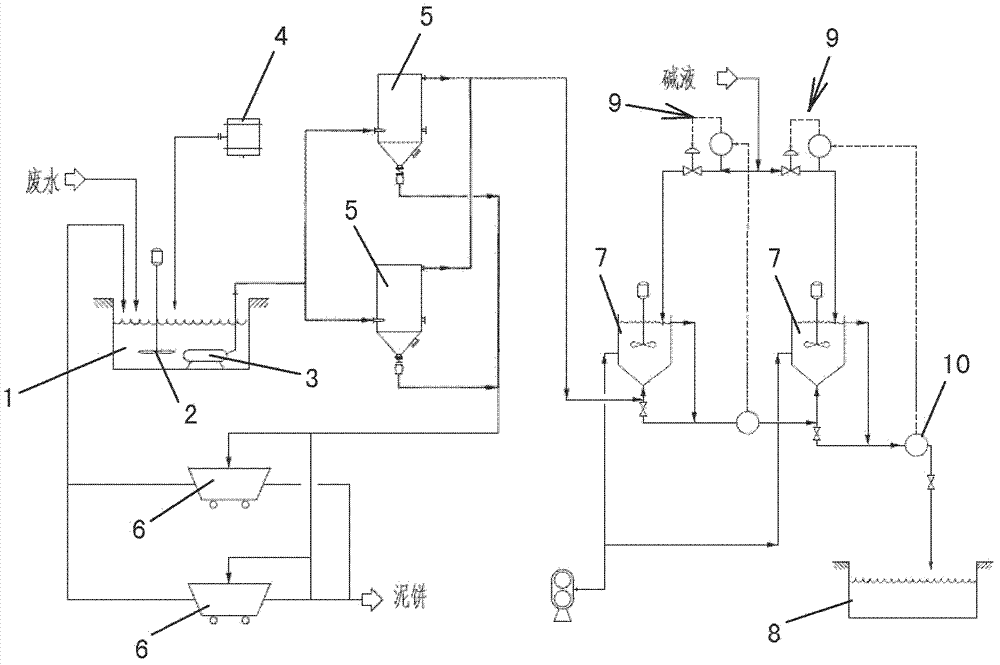

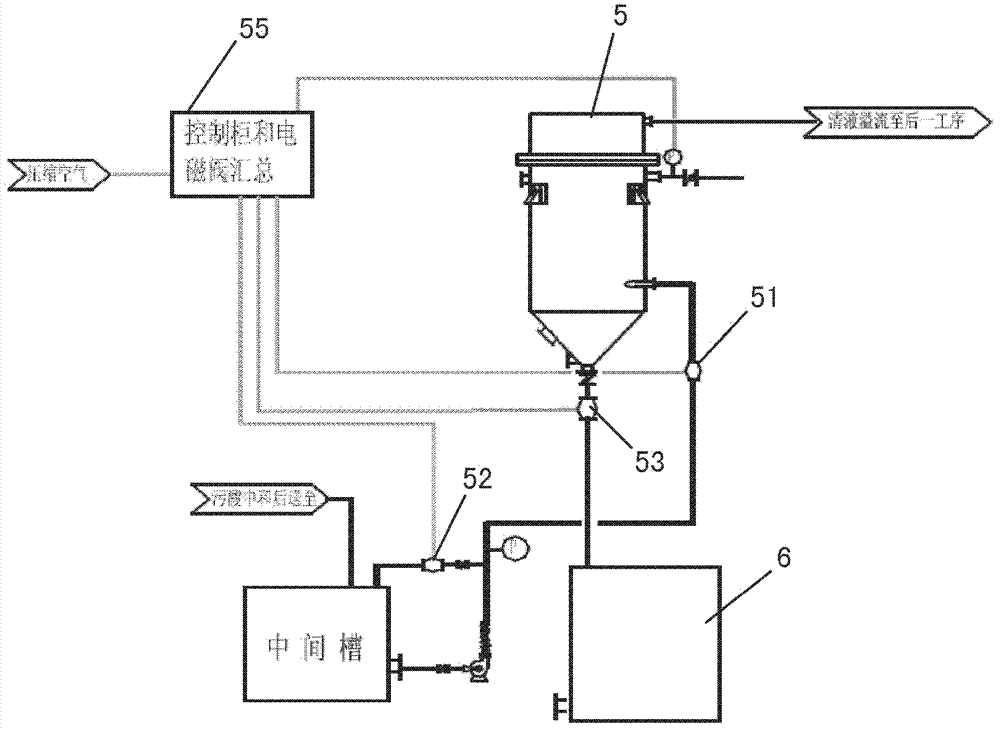

Catalytic cracking fume desulfuration wastewater treatment process

ActiveCN102815808AImprove effluent qualityEasy to operateMultistage water/sewage treatmentParticulatesChemical oxygen demand

A catalytic cracking fume desulfuration wastewater treatment process is characterized in that wastewater is discharged to a slurry pool and is mixed with a flocculating agent, a stirrer is used for stirring the wastewater and the flocculating agent, the wastewater and the flocculating agent are mixed evenly, the wastewater after being mixed is discharged to an expansion tube type filter and is subjected to the coagulation reaction at the lower end of the expansion tube type filter, small particulate matters in the wastewater are flocculated, large flocculating bodies are formed, the solid-liquid separation is achieved through the filtration of a filtering film, thick slag and supernatant fluid are obtained, the supernatant fluid is discharged to an oxidation tank further, the thick slag is subjected to back washing and enters a subsequent filtering box, the thick slag is concentrated and dewatered in the filtering box, mud cakes which are concentrated are transported outwards, the water of dehydration returns to the slurry pool again, is mixed with the wastewater and is processed again, the false chemical oxygen demand (COD) which contains sulfite and bisulfite is oxidized and removed by the supernatant fluid in the oxidation tank, and the sewage which meets standards is discharged. Compared with the prior art, the process has the advantages that the area occupied by devices is small, the operation cost is low, the solid and the liquid can be separated completely, the working environment of workers is good, device parameters can be set in accordance with parameters of different materials, and the application is wide.

Owner:CHINA PETROLEUM & CHEM CORP +3

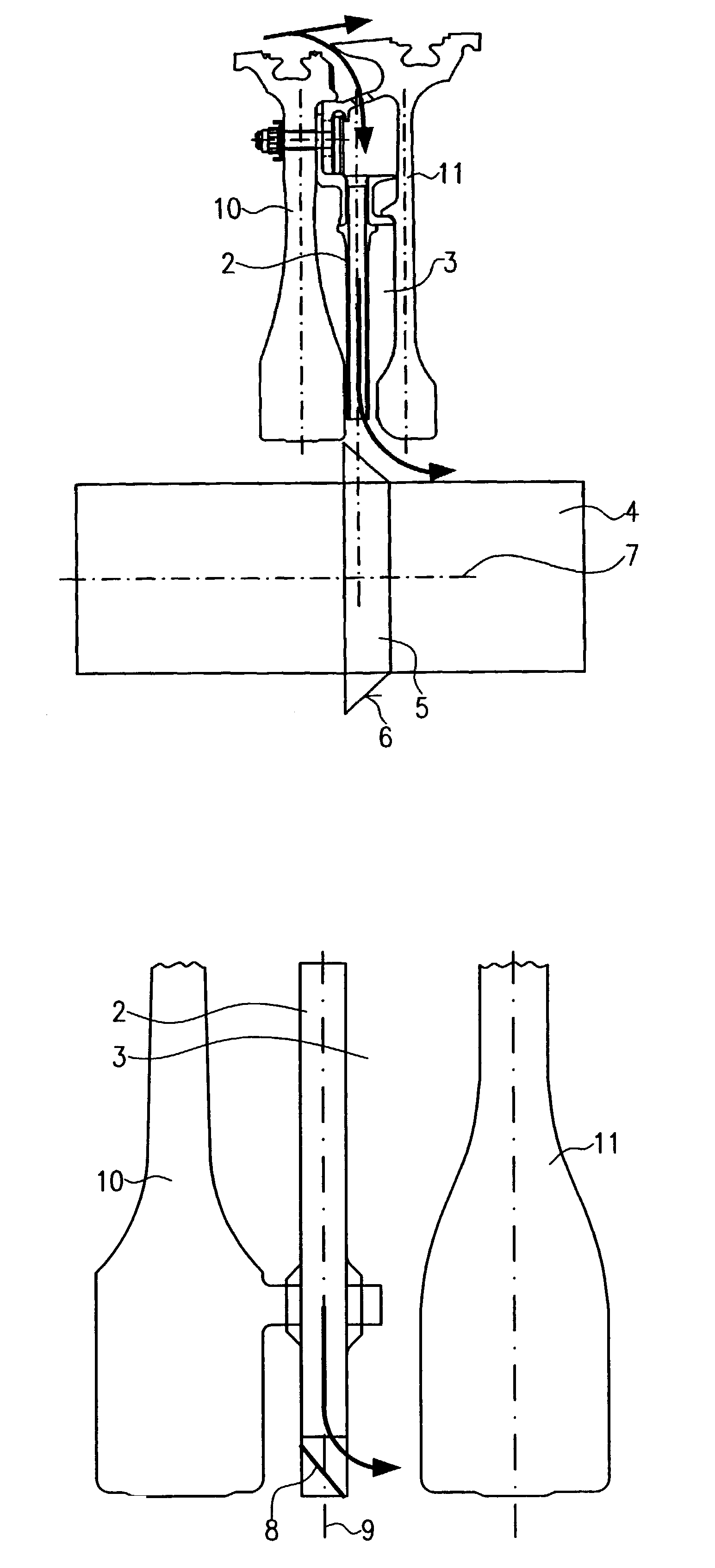

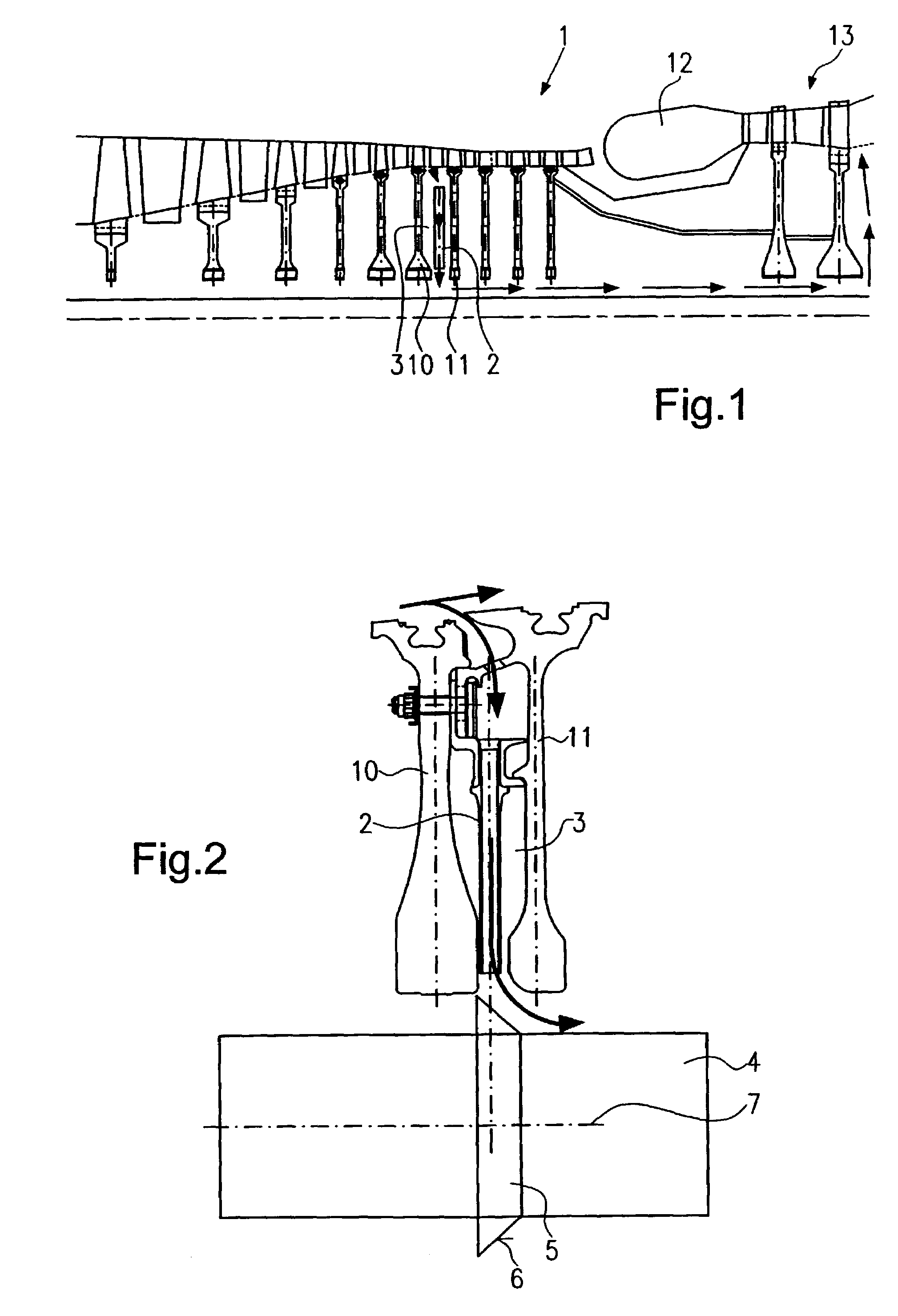

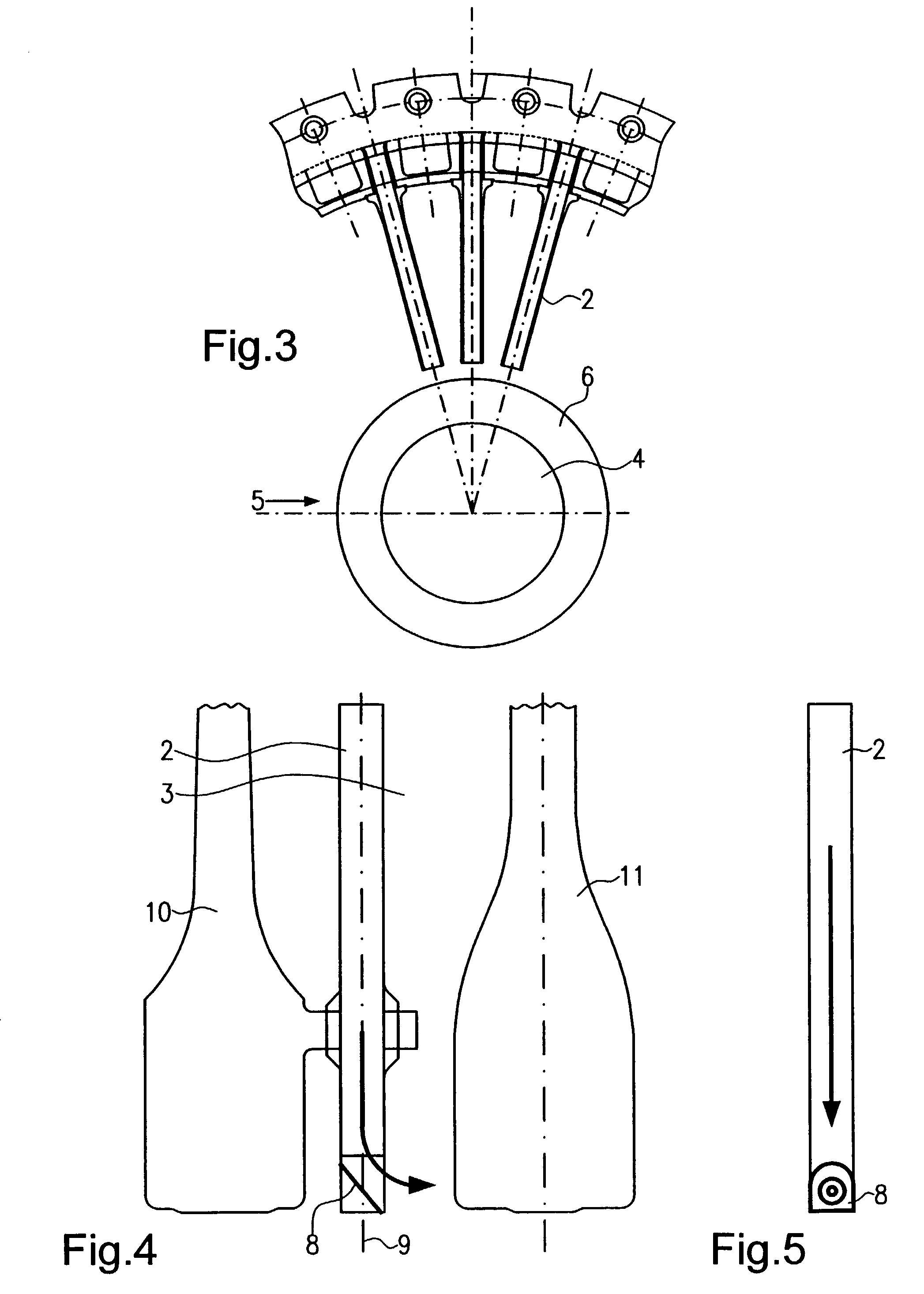

Vortex reducer in the high-pressure compressor of a gas turbine

InactiveUS7159402B2Reduction of deflection pressure lossSmooth deflectionPump componentsEngine fuctionsReducerEngineering

A tube-type vortex reducer for the conduction of cooling air in a compressor 1 of a gas turbine with at least one radial secondary air tube 2 arranged in a disk interspace 3, includes a deflector arranged in a discharge area of the secondary air tube for the deflection of the secondary air flow into an axial direction or away from an axial direction.

Owner:ROLLS ROYCE DEUT LTD & CO KG

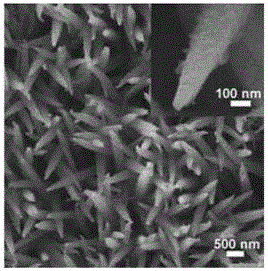

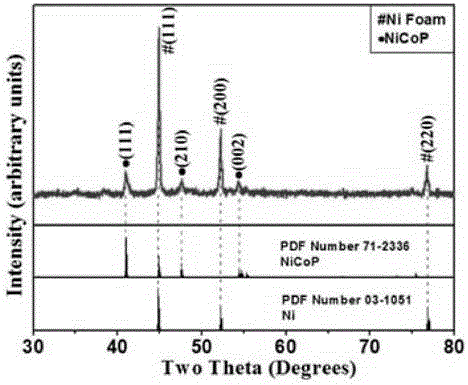

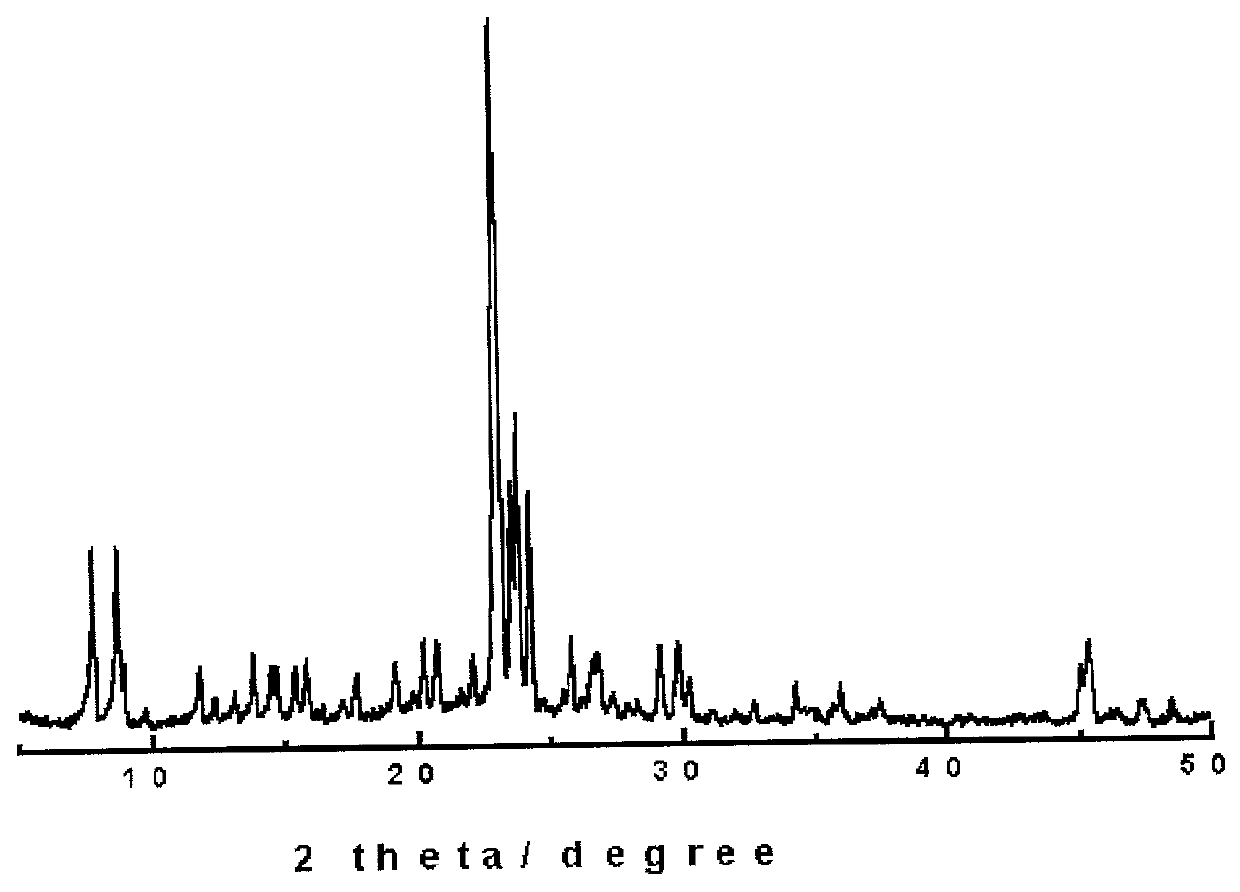

Preparation method for NiCoP nanowire electro-catalytic electrode

InactiveCN105951123AAvoid introducingSimple preparation processMaterial nanotechnologyElectrode shape/formsNanowireReactive material

The invention discloses a preparation method for a NiCoP nanowire electro-catalytic electrode. A NiCo salt nanowire is adopted as a phosphorization precursor, hypophosphite is used as a phosphorus source, and the phosphorization process of the NiCo salt nanowire is achieved by controlling the annealing technique in a stored program control tube type annealing furnace. The diameter of the NiCoP nanowire obtained through the method is 140 nanometers, the length of the obtained NiCoP nanowire is about 3.2 micrometers, and the surface of the nanowire is roughly and evenly grown on a 3D netty foamed nickel substrate, so that the specific surface area and the electric conductivity of an electro-catalytic material are effectively improved, and the electro-catalytic hydrogen evolution performance and stability of an electrode material are improved. The electro-catalytic hydrogen production performance of the electrode is tested in 1M of a KOH electrolyte, the overpotential under the electric current density of 10 mA / cm<2> is 109 mV, and the Tafel slope is 88.5 mV / dec, so that the material has the superior electro-catalytic hydrogen production performance compared with common electro-catalytic hydrogen evolution materials. Meanwhile, the preparation technique is simple, the equipment requirement is conventional, reactive materials are abundant, price is low, and the electrode is environmentally friendly.

Owner:HUBEI UNIV

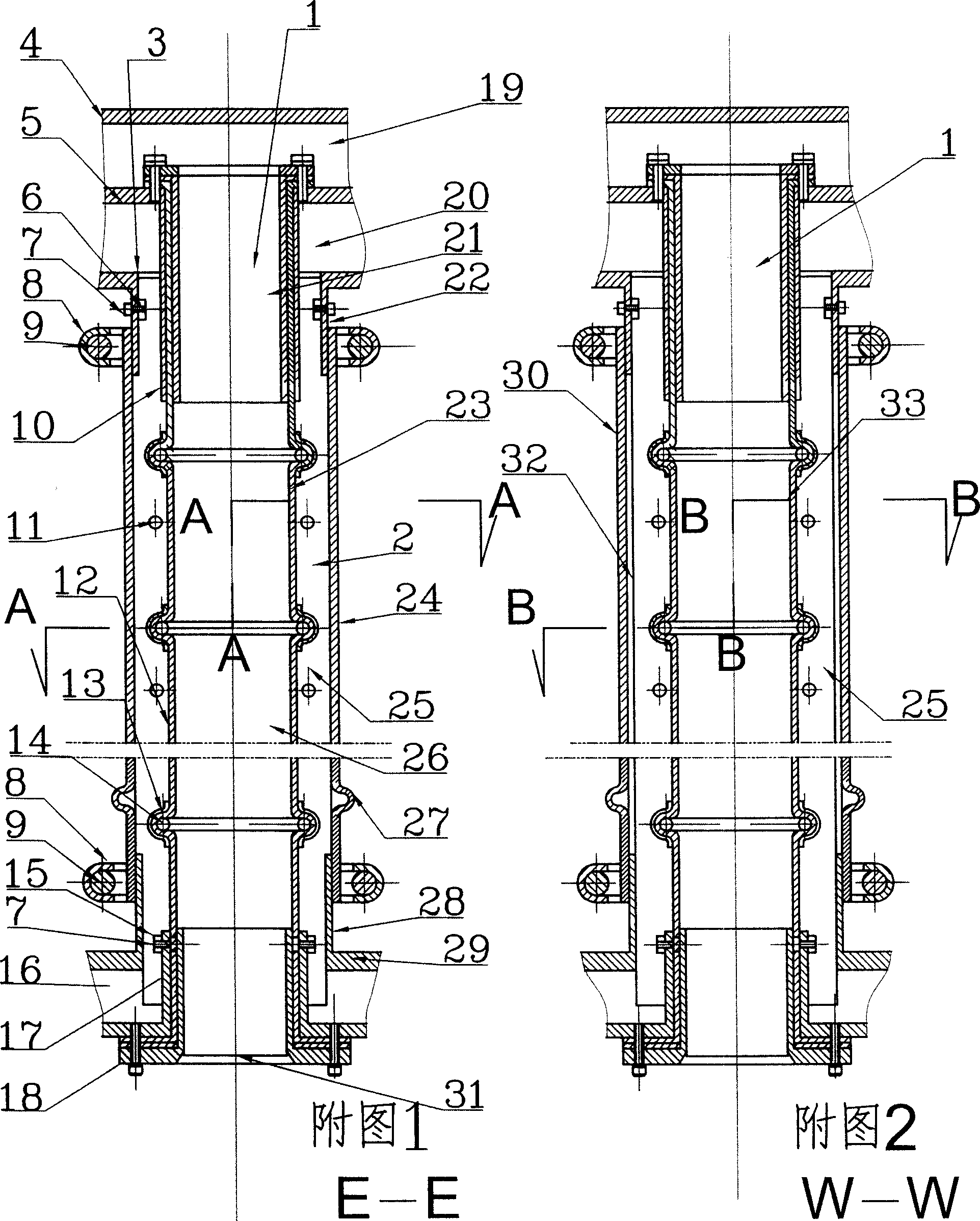

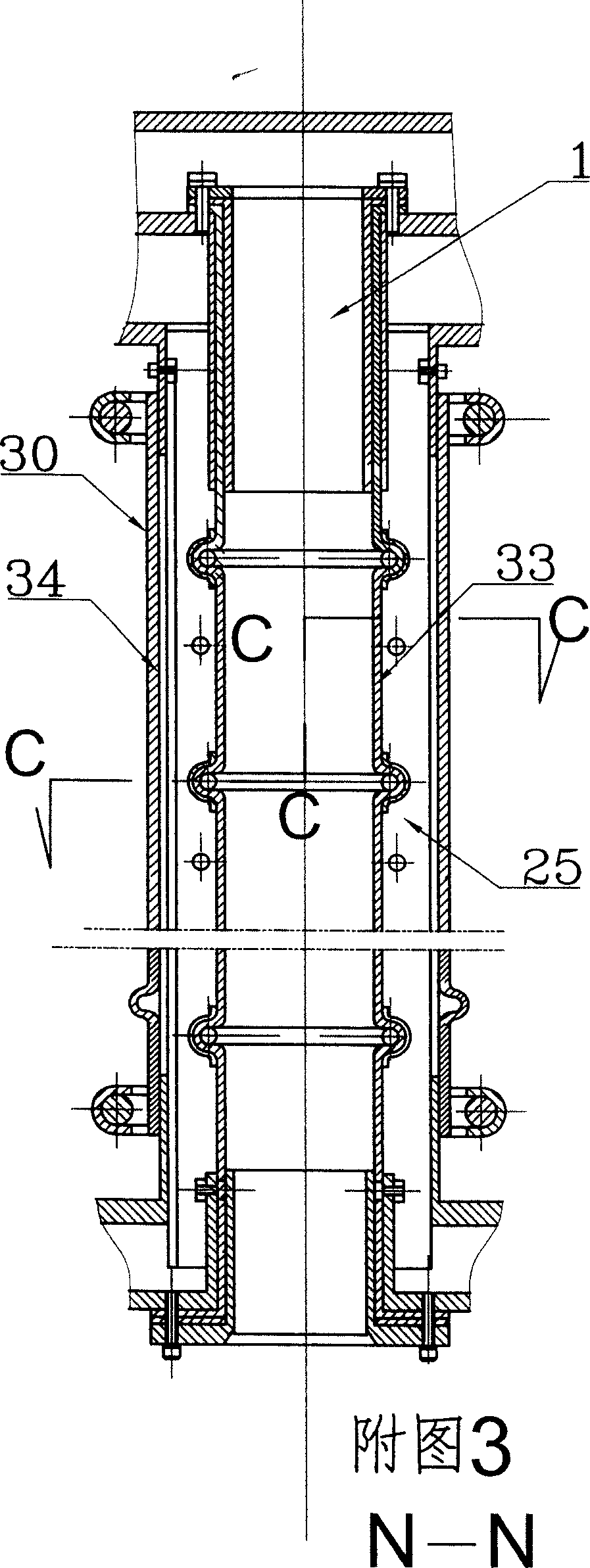

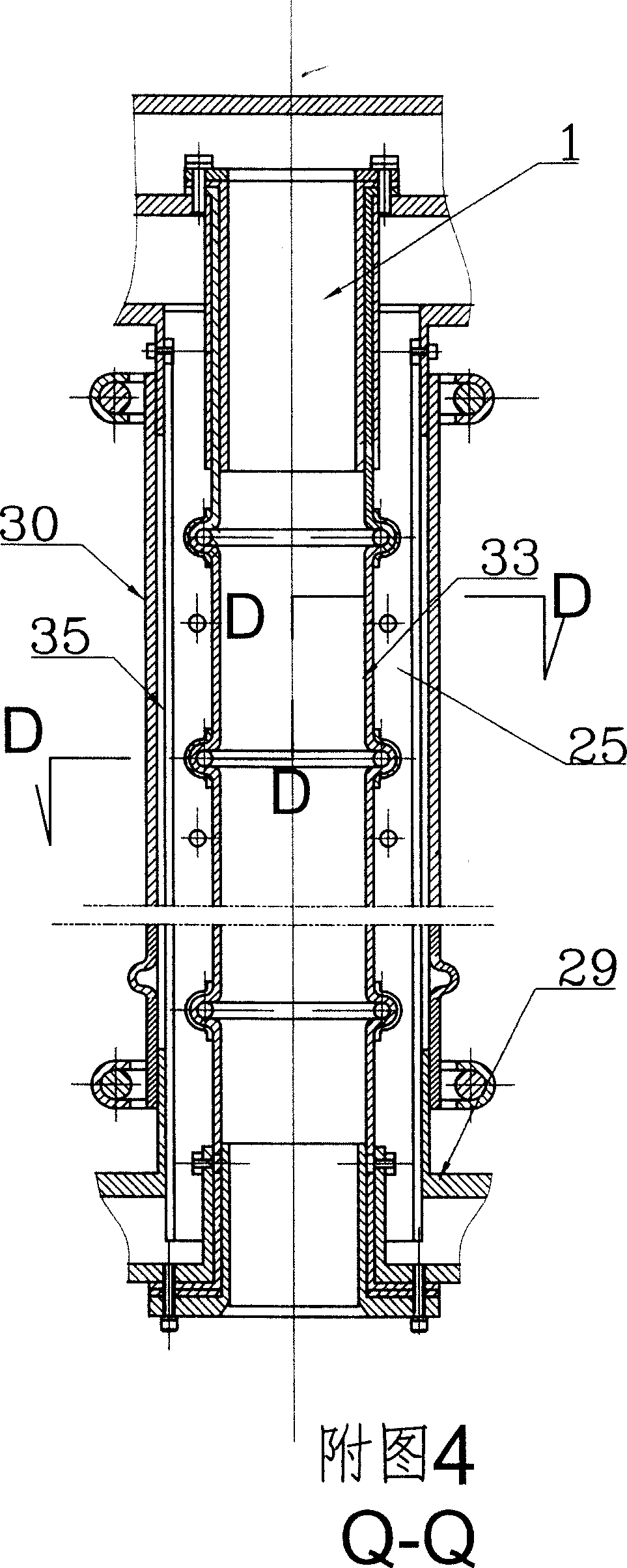

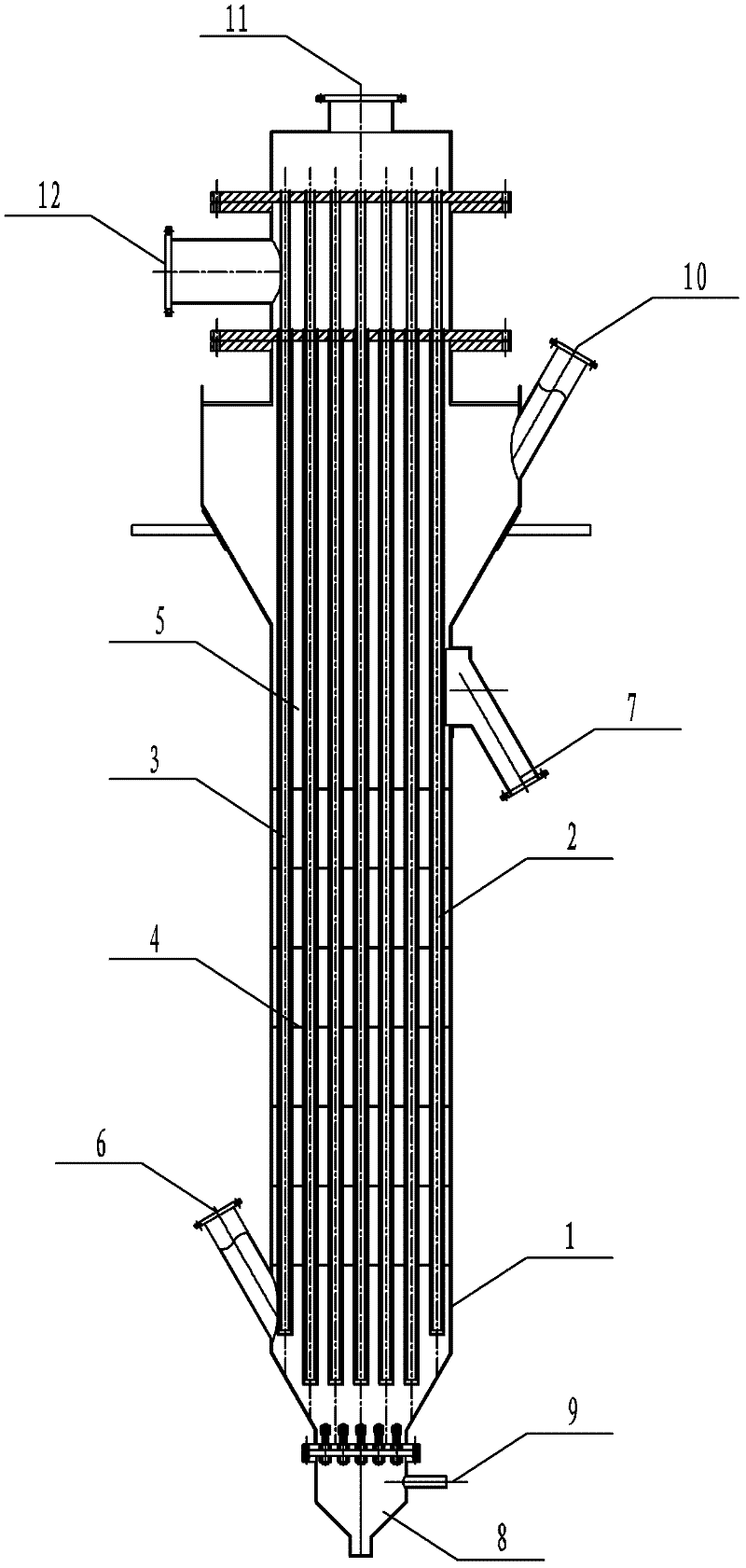

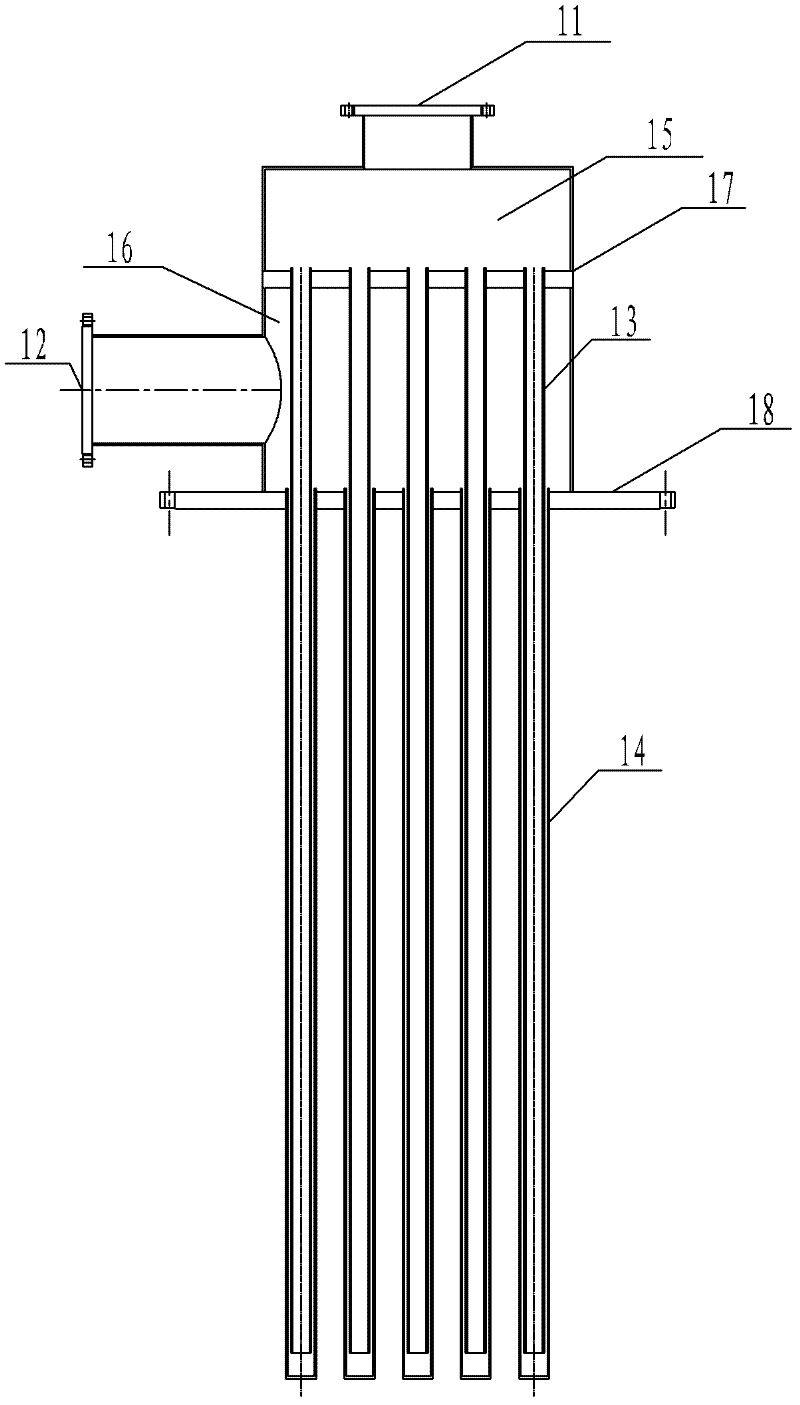

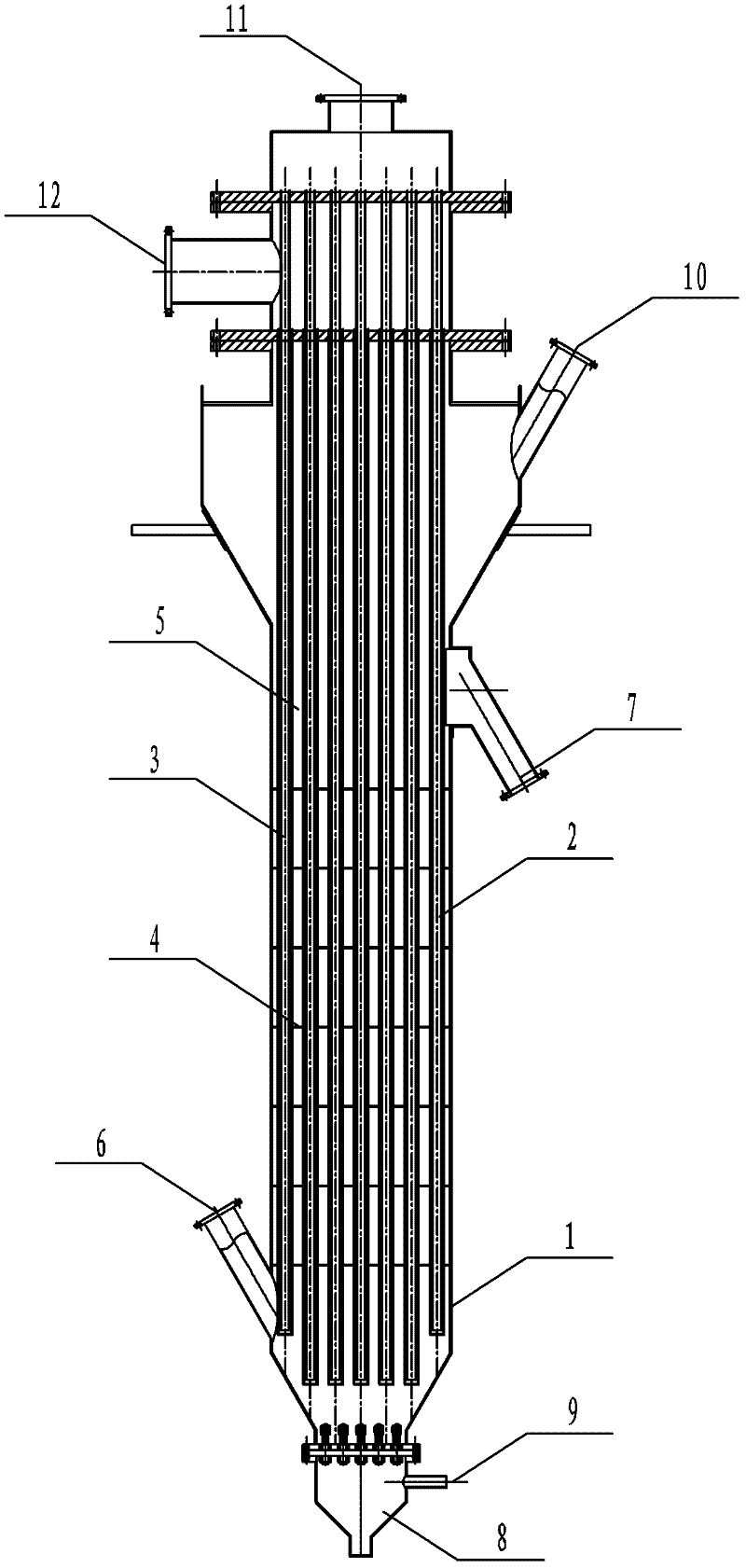

Fluidized reduction furnace for producing high-purity vanadium trioxide and production method

The invention relates to a fluidized reduction furnace for producing high-purity vanadium trioxide, which comprises a fluidized bed reactor and a built-in heat exchange component, wherein the heat exchange component is a tube type heat exchanger, and a heat exchange tube is vertically provided with at least two layers of sieve mesh plates to form at least three layers of fluidized reaction chambers. The invention also provides a fluidized reduction method for producing the high-purity vanadium trioxide. The fluidized reduction furnace and the fluidized reduction method have the advantages that firstly, materials in each layer are in a fully-mixed state, and material flow among the layers is in a plug flow state; secondly, the multi-stage fluidized reduction conditions are provided, raw materials enter from the lowermost layer, are reduced step by step and are purified gradually, and the running stability and the operating rate of equipment are improved in a manner of reduction step by step; and thirdly, the fluidized reduction furnace can be used for producing the high-purity vanadium trioxide, and the vanadium grade is larger than 67.9 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

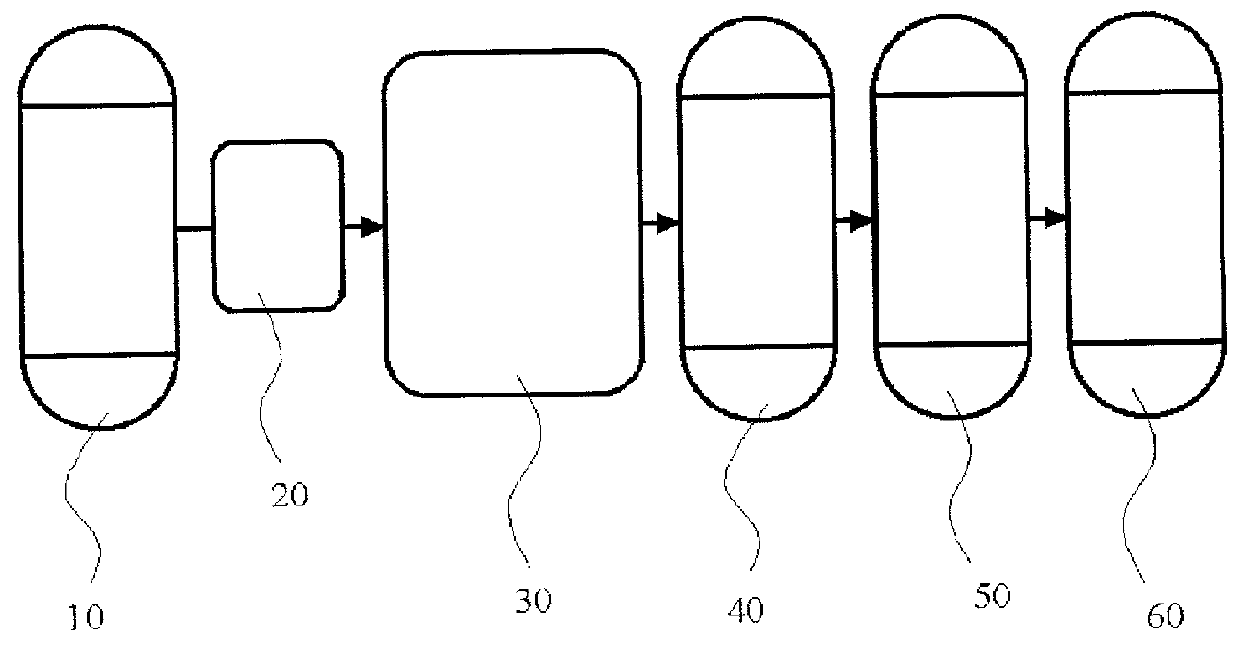

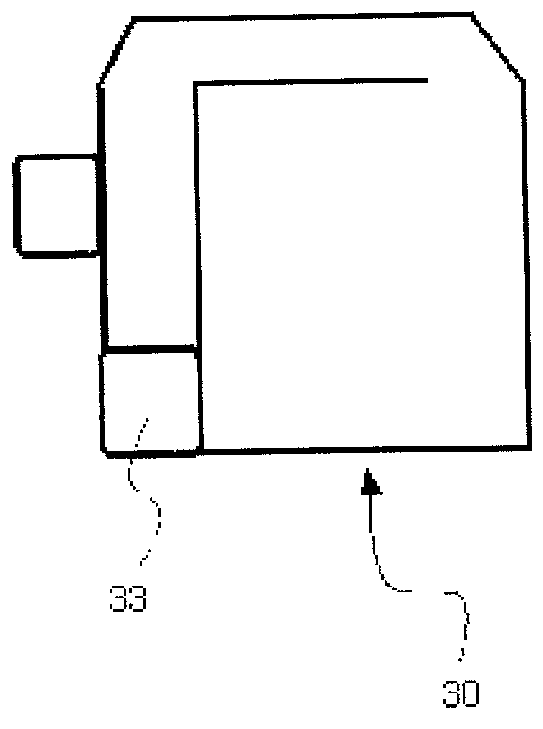

Continuous process and apparatus for preparing inorganic materials employing microwave

This invention relates to a continuous microwave synthesis process of inorganic materials and its apparatus and more particularly, to the process of synthesizing inorganic materials prepared in a manner such that after preparing a mixed solution of precursor materials for various inorganic materials such as porous molecular sieve, layered compounds and ceramics, this mixed solution is continuously added to a tube-type microwave reactor using a slurry pump for the synthesis and crystallization of inorganic materials. Thus the manufacturing process of this invention has the following advantages: (1) the reaction time is further shortened by several to tens of minutes for crystallization, compared to the conventional hydrothermal reaction requiring a prolonged time, (2) the continuous manufacturing and collection processes of this invention can give access to mass-scale production of inorganic materials with relatively small facility, compared to the conventional batch hydrothermal or microwave synthesis, and (3) less amount of organic templating agent can be required during the manufacture of porous molecular sieve.

Owner:KOREA RES INST OF CHEM TECH

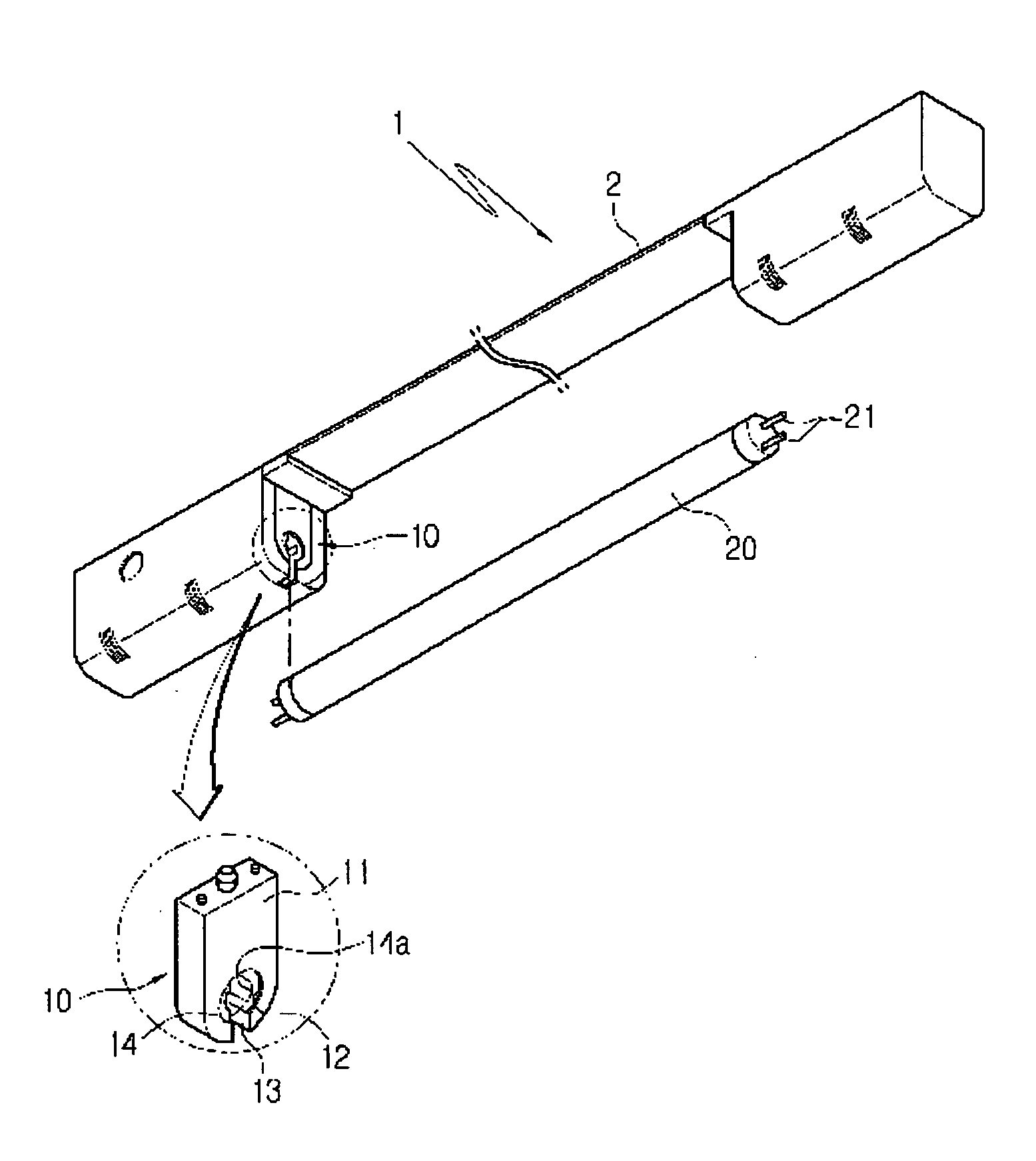

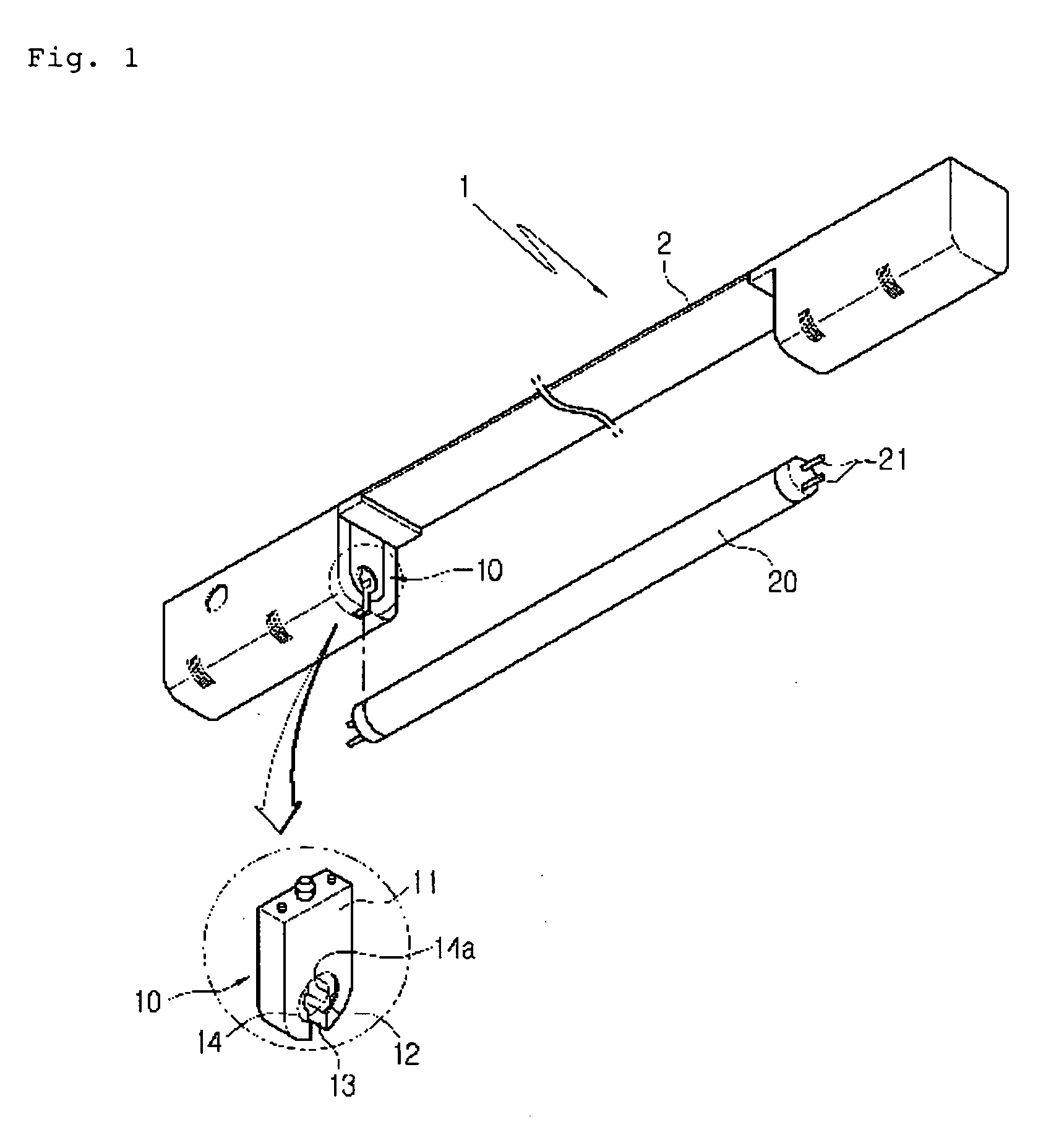

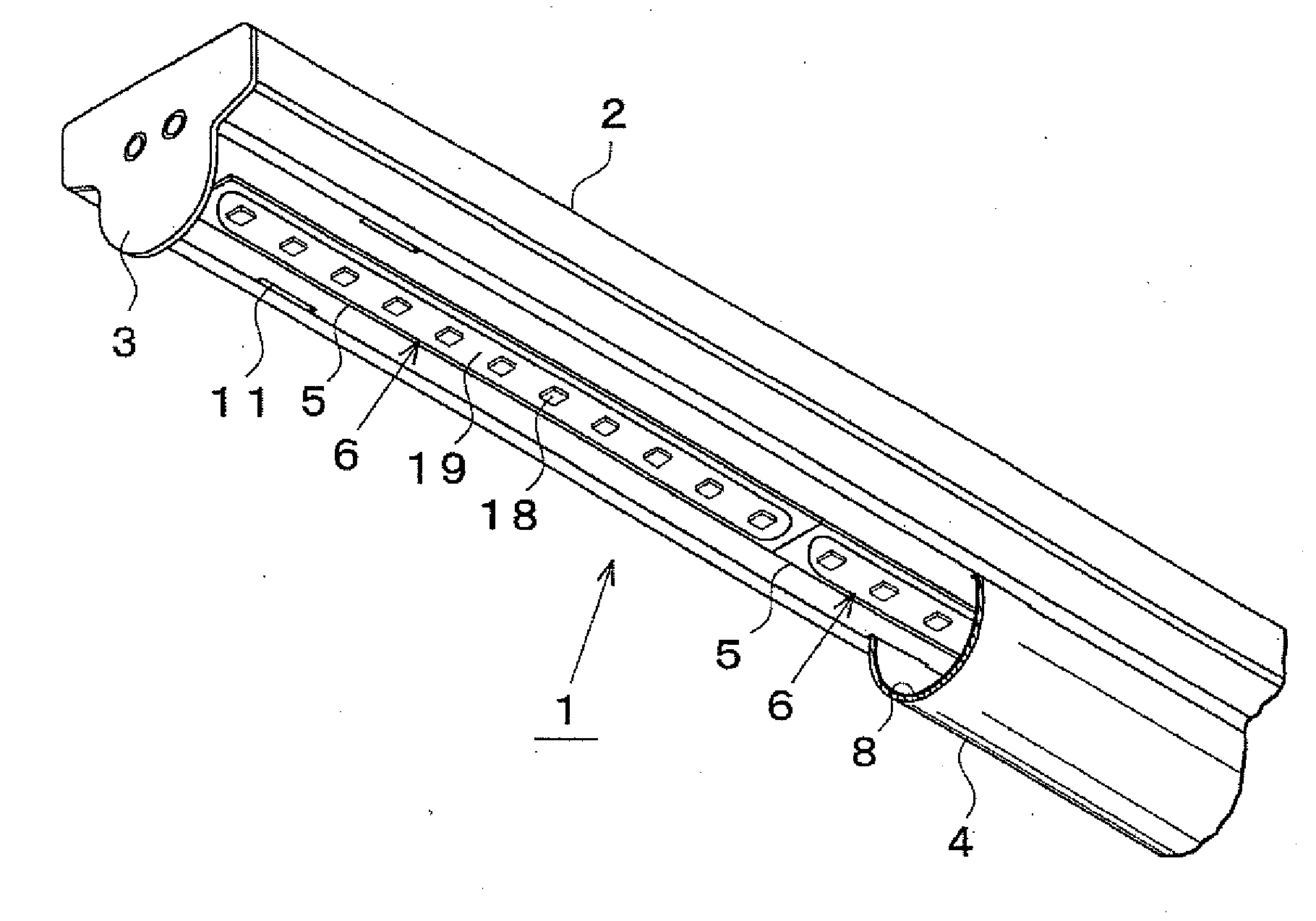

Fluorescent lighting fixtures

InactiveUS20060012981A1Beautiful appearanceImprove lighting effectsCoupling device connectionsNon-electric lightingElectricityFluorescence

The present invention relates to fluorescent lighting fixtures, which are aligned in series at regular intervals, which are easily connected one another, and which prevent discontinuation of illumination occurring between fluorescent lamps. The fluorescent lighting fixture includes: a fluorescent lamp having a tube type lamp body, auxiliary tubes mounted at the tops of both ends of the lamp body, and terminal pins inwardly formed at an end of each auxiliary tube; a body having a stabilizer mounted therein for lighting the fluorescent lamp, connection terminals located at both ends thereof at a predetermined interval and electrically connected with the stabilizer; and sockets mounted at both ends of the body, each of the sockets having a support slit formed in the outer surface thereof for fixing and supporting the terminal pins of the fluorescent lamp, and a receiving slit for allowing the terminal pins to be inserted into the support slit.

Owner:FEELUX CO LTD

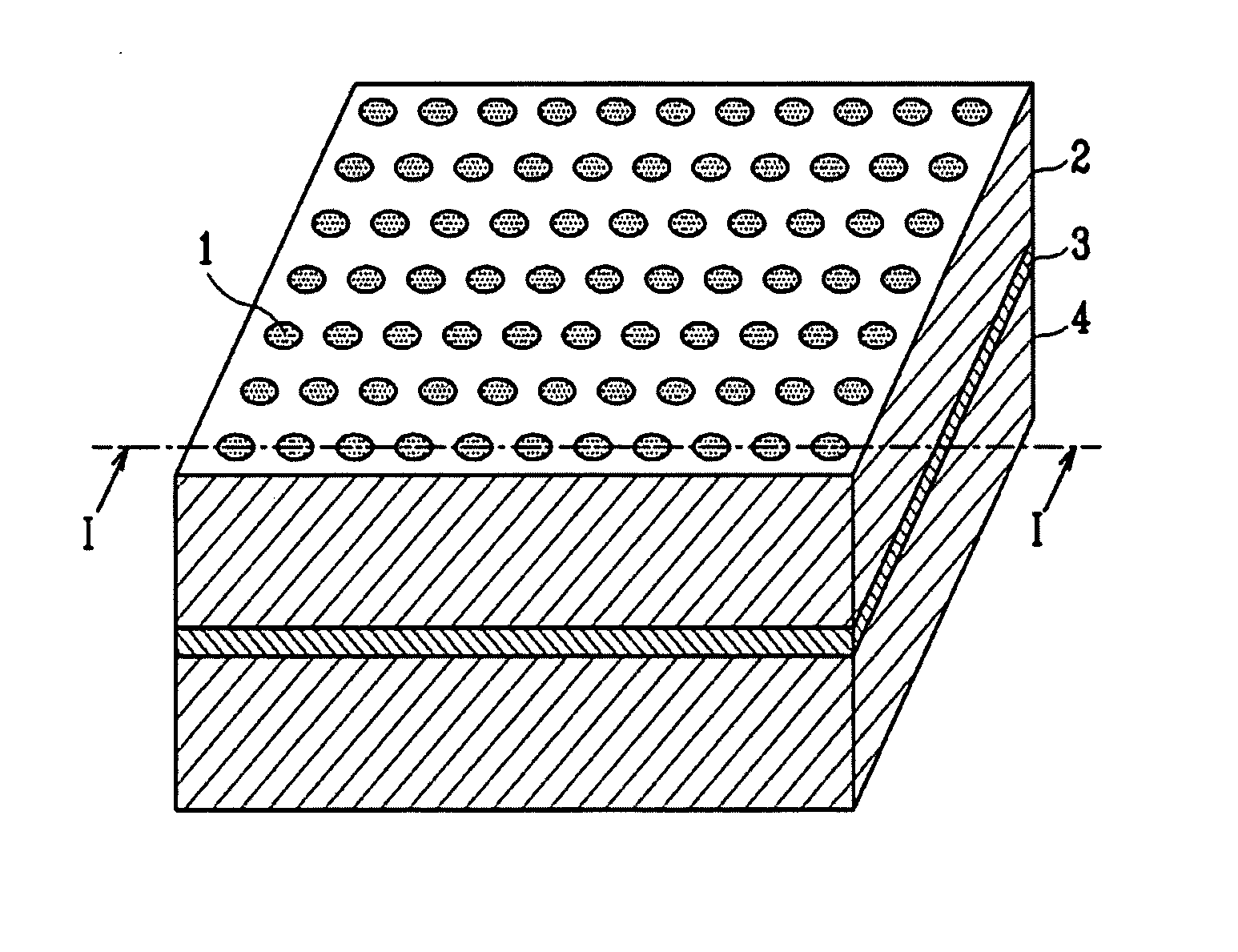

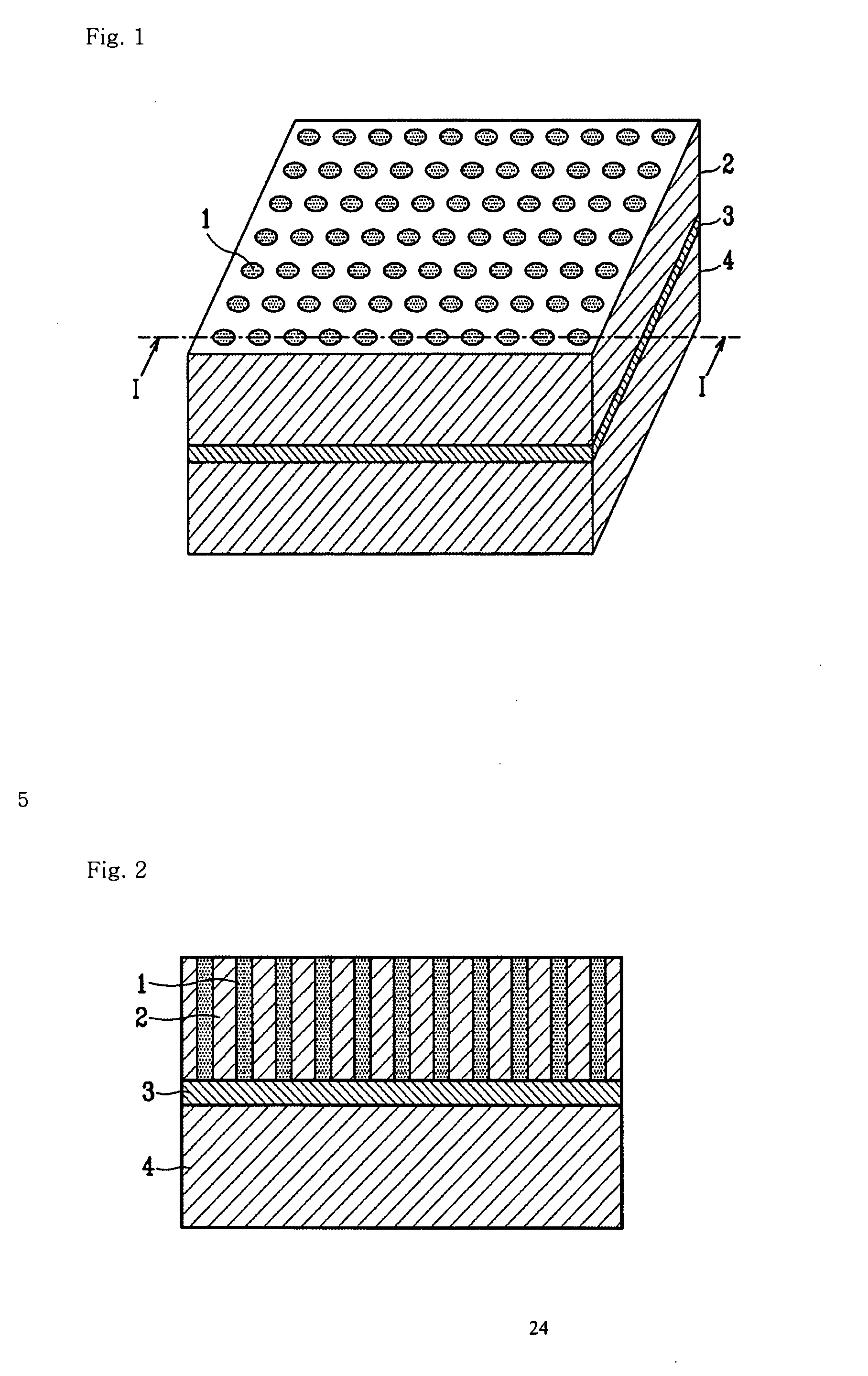

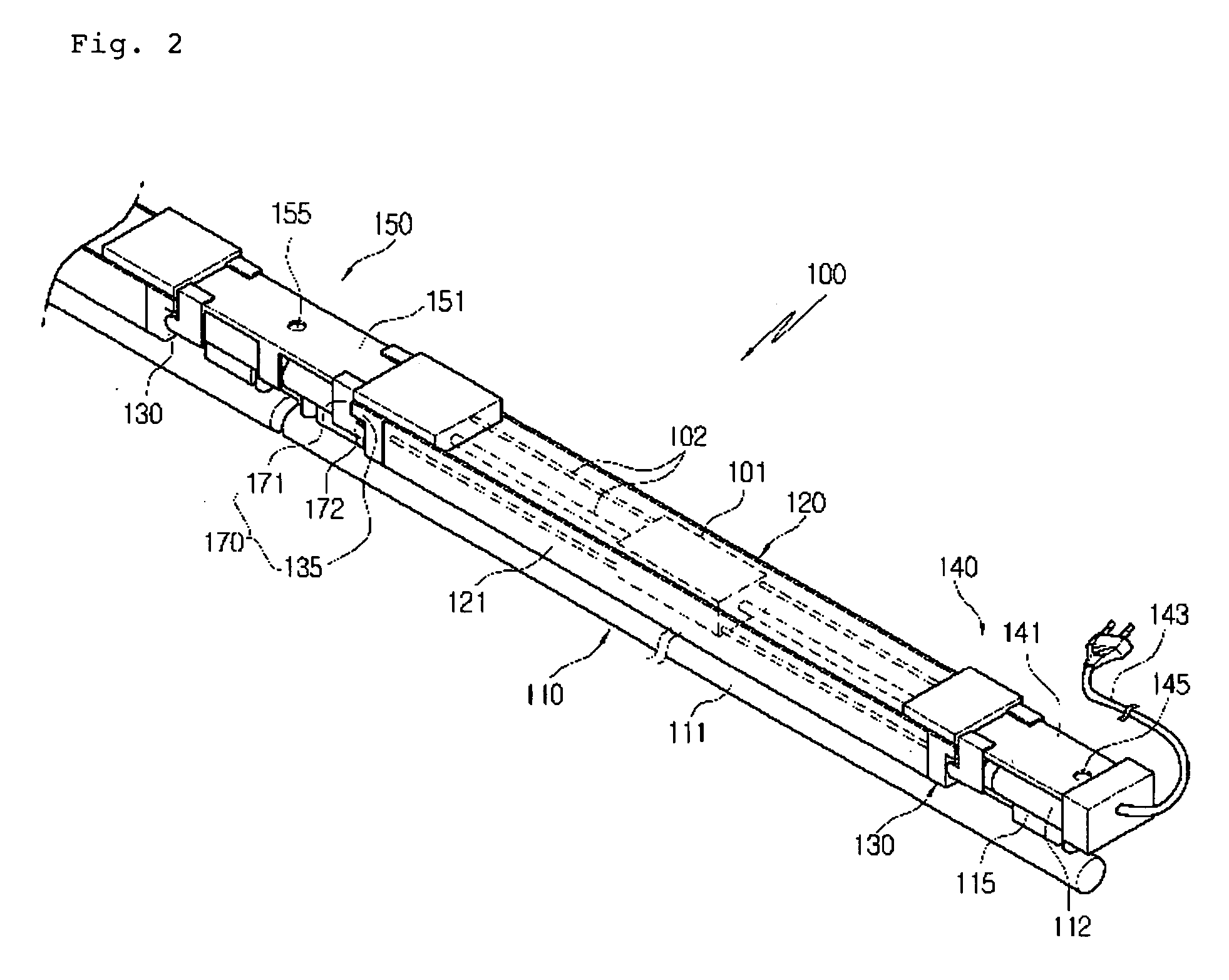

Fluorescent tube type LED lamp

InactiveUS20120236533A1Sufficient amountPoint-like light sourceElongate light sourcesFluorescenceEngineering

A fluorescent tube type LED lamp includes an elongated lamp body that has a largest dimension in a longitudinal direction, a light source substrate mounted on the lamp body, a light transmissive cover attached to the lamp body, and an LED unit mounted on the light source substrate such that the LED unit extends in the longitudinal direction of the lamp body. The LED unit includes a plurality of LED chips mounted on the light source substrate, and a transparent encapsulant encapsulating the LED chips. The encapsulant is molded such that the encapsulant is raised from the light source substrate. The LED unit radiates light from an entire surface of the encapsulant in an angular range including a region lateral to the lamp body.

Owner:KOITO MFG CO LTD

Method for manufacturing outdoor recombination bamboo floorings

InactiveCN102371608AGood physical propertiesNot prone to crackingWood working apparatusMicrowaveSolarisation

The invention discloses a method for manufacturing outdoor recombination bamboo floorings. The method comprises the following steps of: preparing net type bamboo bundle; manufacturing bamboo filaments; carrying out multi-tube type microwave treatment; drying and gluing the bamboo filaments; drying the glued bamboo filaments; assembling blanks; pressing; hacking; sanding; and obtaining the outdoor recombination bamboo floorings. The outdoor recombination bamboo floorings prepared by the method disclosed by the invention are good in physical property, uniform in density and steady in property. The recombination bamboo floorings are difficult in phenomenon, such as crack, filament jump, expansion and the like, under the outdoor bad conditions, such as solarisation, rain and the like. The preparation process of the outdoor recombination bamboo floorings disclosed by the invention is low on environmental pollution. The production raw material is bamboo wood. Therefore, the cost is low; and resources can be saved.

Owner:ZHEJIANG FORESTRY UNIVERSITY

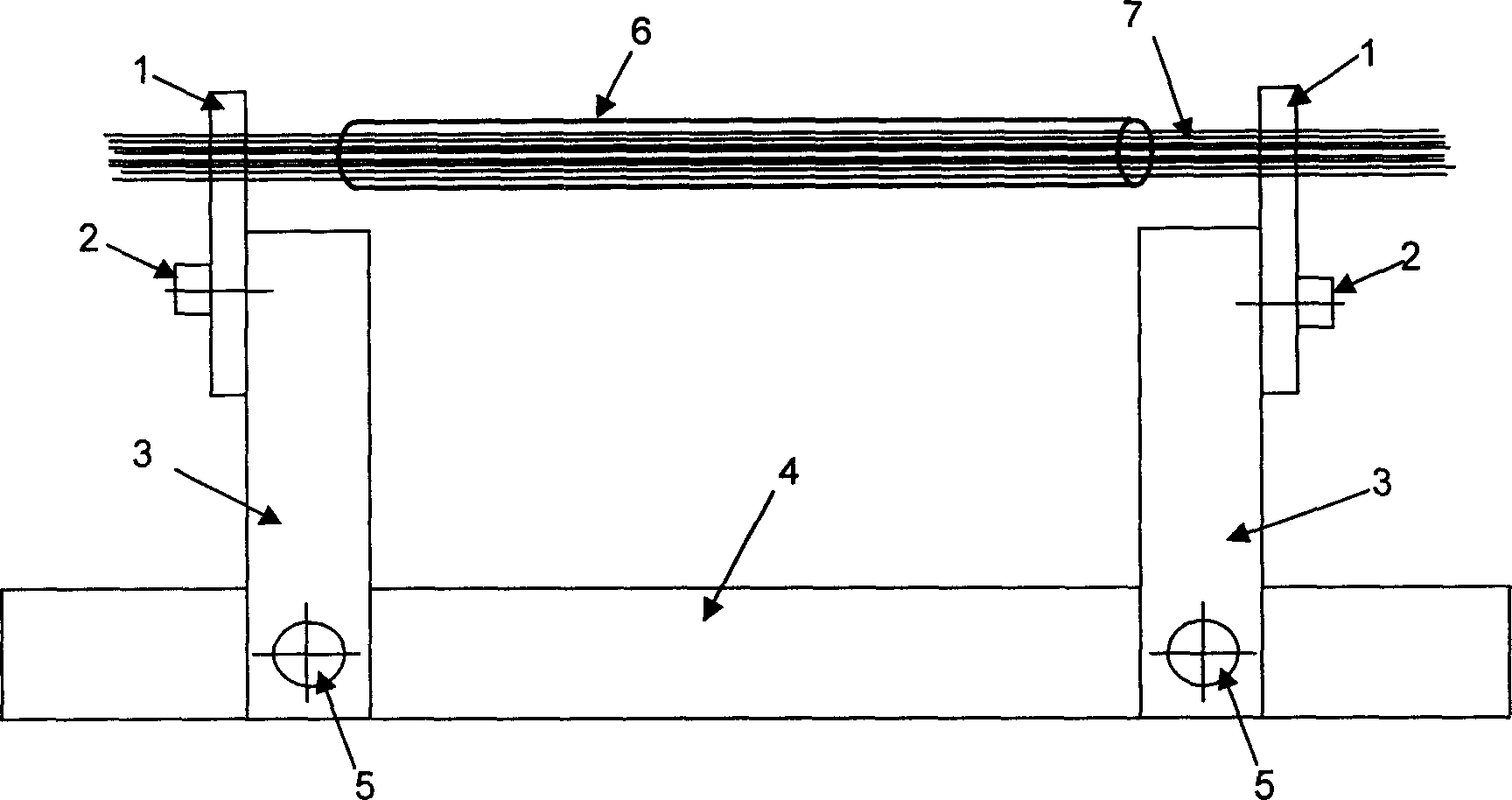

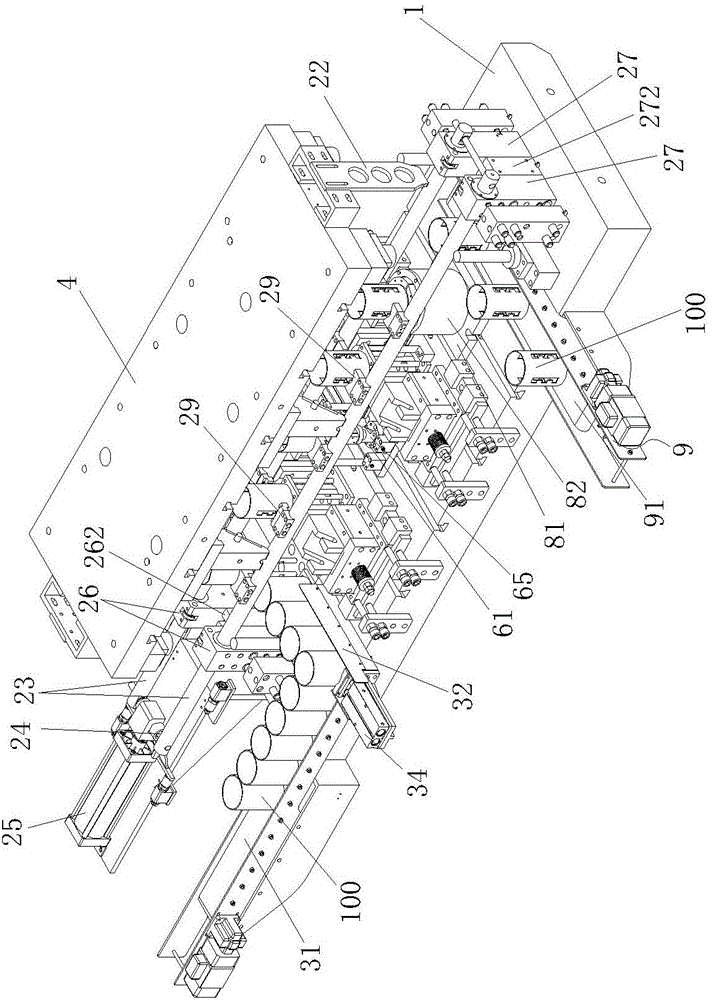

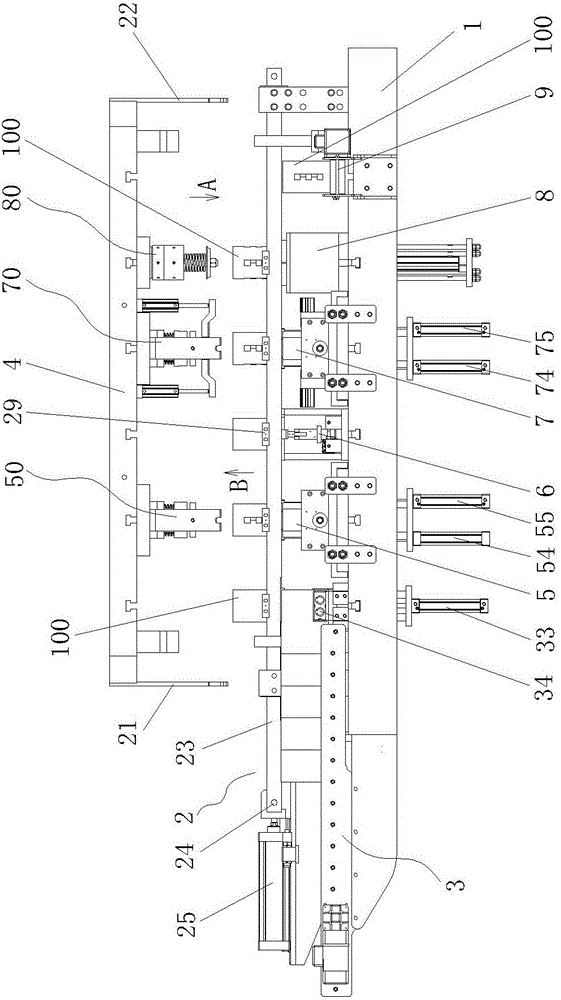

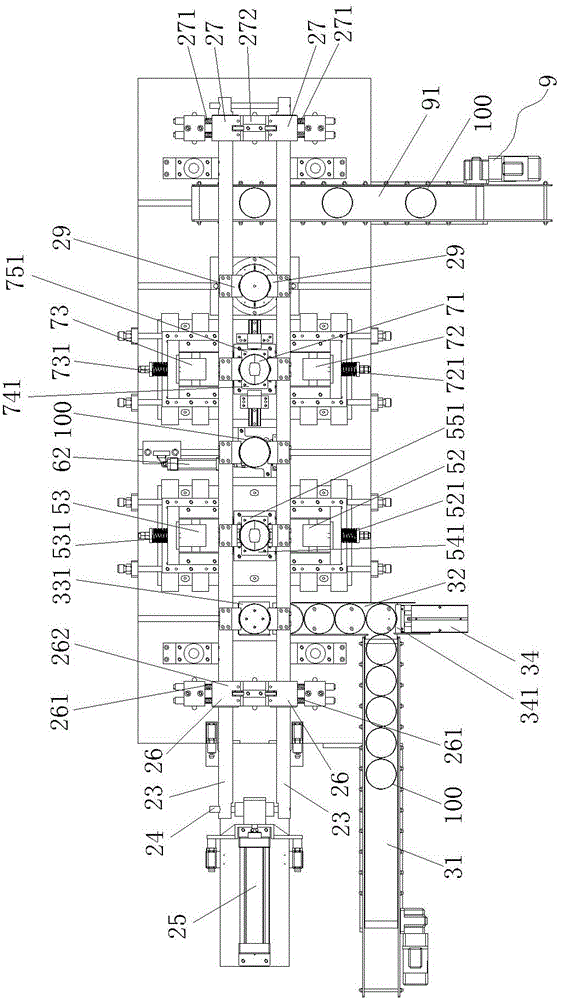

Punching production line for punching circular tube type workpiece

InactiveCN102873159AReduce labor intensityReduce operational riskMetal-working feeding devicesStripping-off devicesProduction linePunching

The invention discloses a punching production line for punching a circular tube type workpiece. The punching production line comprises a press machine, wherein a moving mechanism and a feeding mechanism are assembled on an operating platform of the press machine, the moving mechanism sequentially clamps the circular tube type workpiece from one station to another station, and the feeding mechanism conveys the circular tube type workpiece from the outside to an initiation position from where the moving mechanism clamps; a first side punching lower die, a first circular tube type workpiece rotating mechanism, a second side punching lower die, a circular tube type workpiece shaping lower die and a discharging mechanism which discharges a circular tube type workpiece out of the operating platform of the press machine are at least assembled on the operating platform of the press machine below the moving mechanism; a first drive and a pressing component which are matched with the first side punching lower die and a second drive and the pressing component which are matched with the second side punching lower die are assembled on a sliding block of the press machine; and a press-in component which is matched with the shaping lower die is arranged. According to the punching production line, one press machine can be used for simultaneously carrying out multiple processing on the circular tube type workpiece, the production efficiency and automation degree are high, and the labor intensity and operation risk of operators are effectively reduced.

Owner:厦门锻压机床有限公司

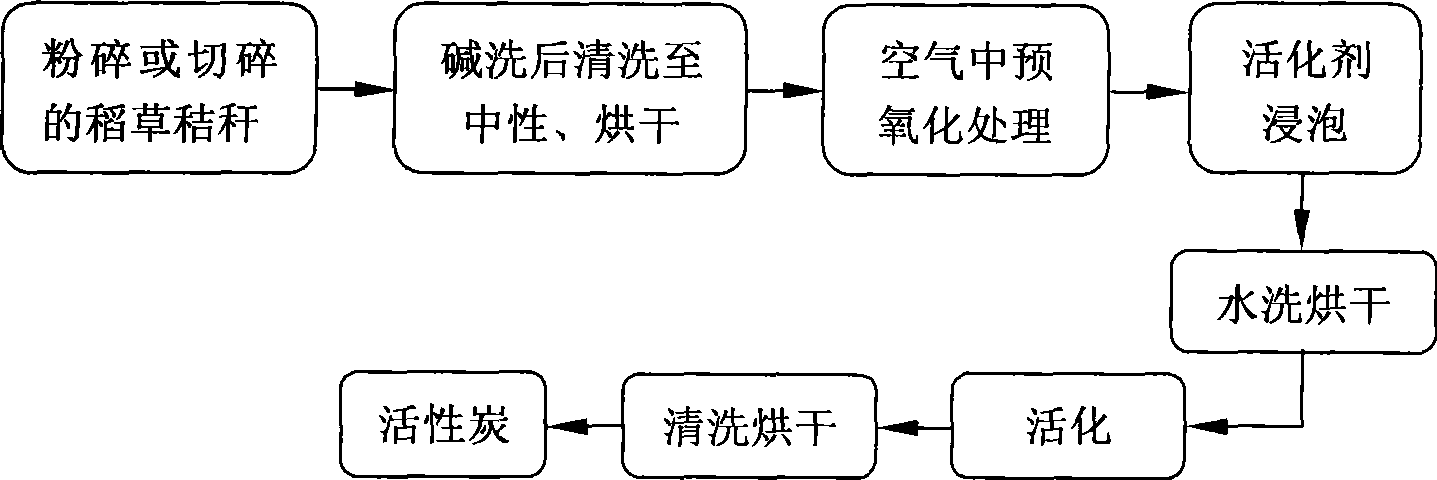

Method for preparing active carbon from straw stalk

The invention relates to a method for preparing active carbon from rice straw. The method comprises taht: (1) the collected rice straw is subjected to alkali cleaning, cleaned to neutrality, dried, and cut or pulverized; (2) the rice straw is added into an activator solution, evenly stirred, soaked for 12 to 24 hours, subjected to solid-liquid separation, cleaned and dried; (3) the rice straw prepared in step (2) is put in a barrate type oven and pre-oxygenated for 1 to 2 hours; (4) the pre-oxygenated rice straw is put in a tube-type carbide furnace, heated for temperature rise under the protection of nitrogen gas, and activated; and (5) the activated rice straw is washed by water till pH is between 6.5 and 7.5, and dried at 105 DEG C to prepare the active carbon. The active carbon prepared by the method has good adsorption performance; the adsorptive value of methylthionine chloride reaches between 200 and 300 mL / g; and the preparation process is simple, economical and environment-friendly, meets requirement of clean production and circular economy development, and has good industrial application prospect.

Owner:DONGHUA UNIV

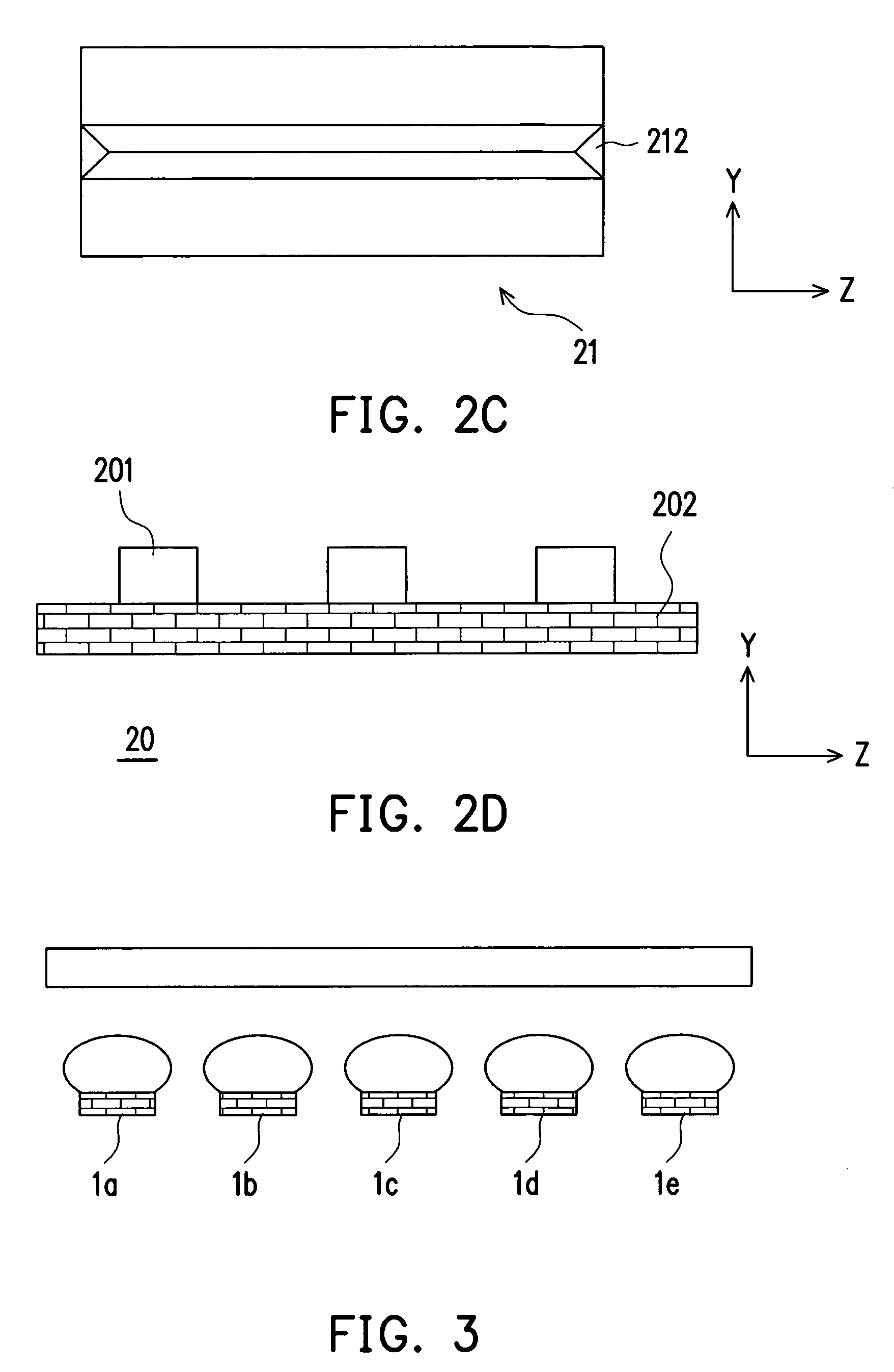

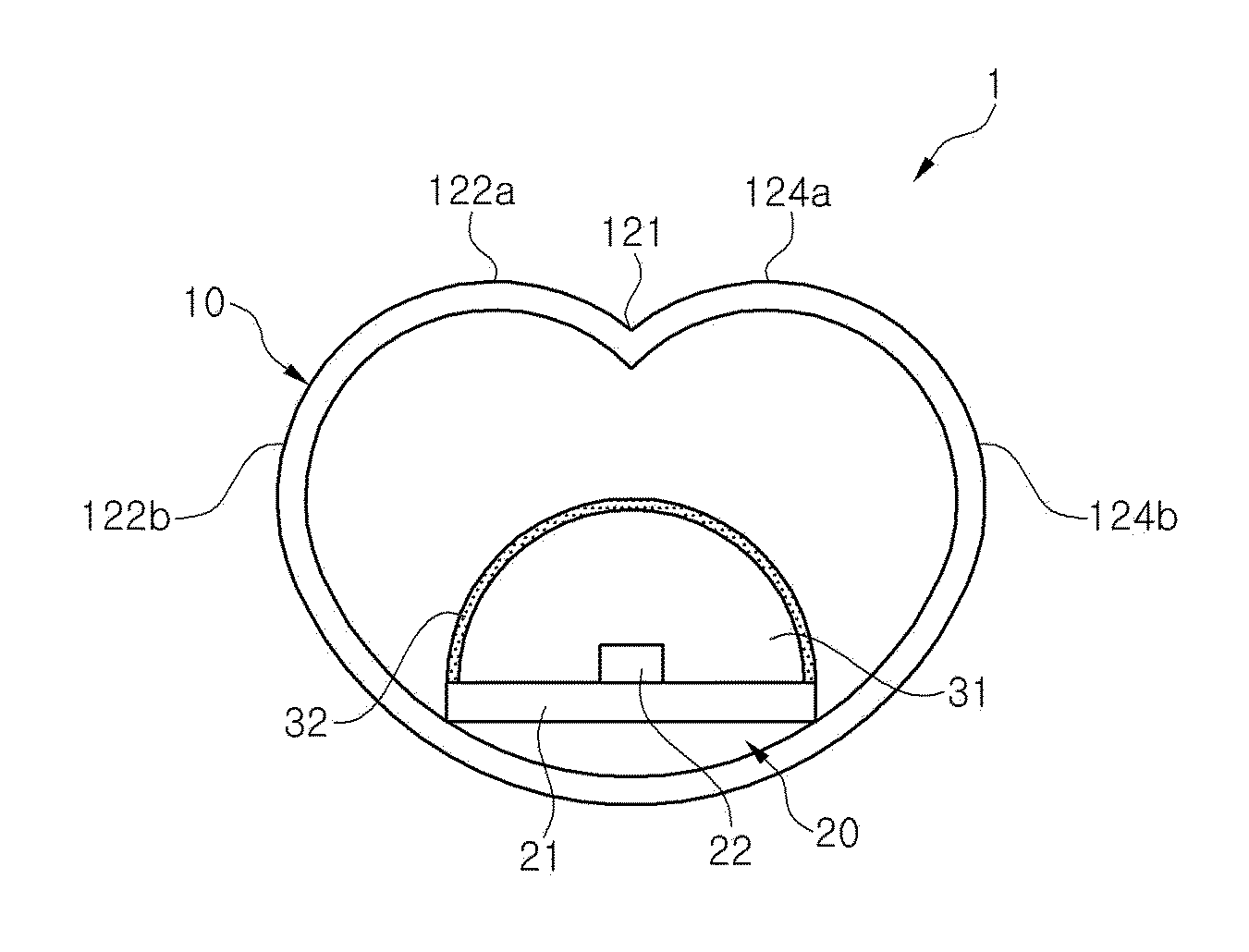

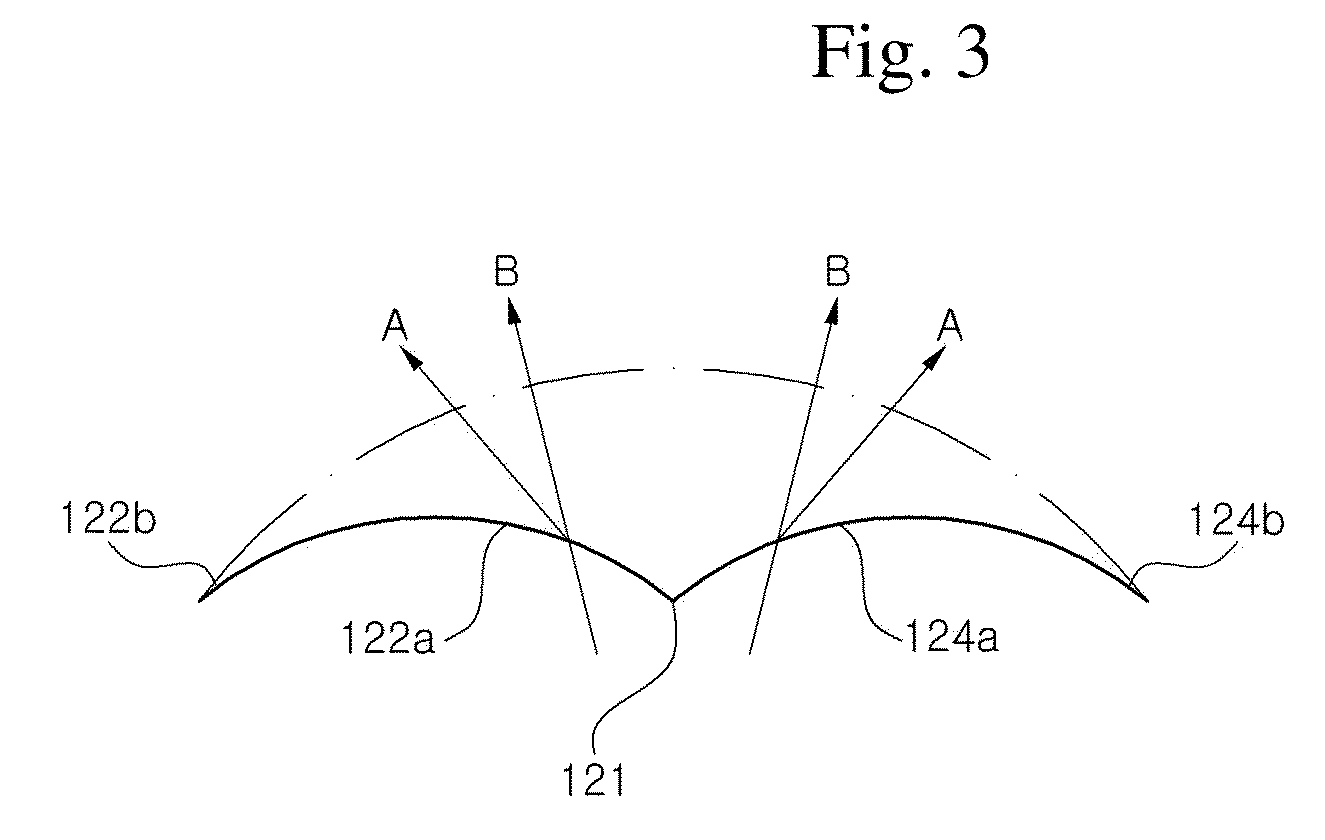

Tube-type or channel-type LED lighting apparatus

InactiveUS20100265693A1Reduce lossesImproved angular distributionNon-electric lightingPoint-like light sourceLed arrayEffect light

A light emitting diode (LED) lighting apparatus that may be used as interior lighting or advertisement lighting is disclosed. The LED lighting apparatus includes a channel-type or tube-type optical housing with a light emission surface and an LED array arranged in the optical housing. The light emission surface includes a valley line and a first inner ridge and a second inner ridge disposed on opposing sides of the valley line, and the LED array includes a plurality of LEDs whose centers are arranged along the valley line.

Owner:SEOUL SEMICONDUCTOR

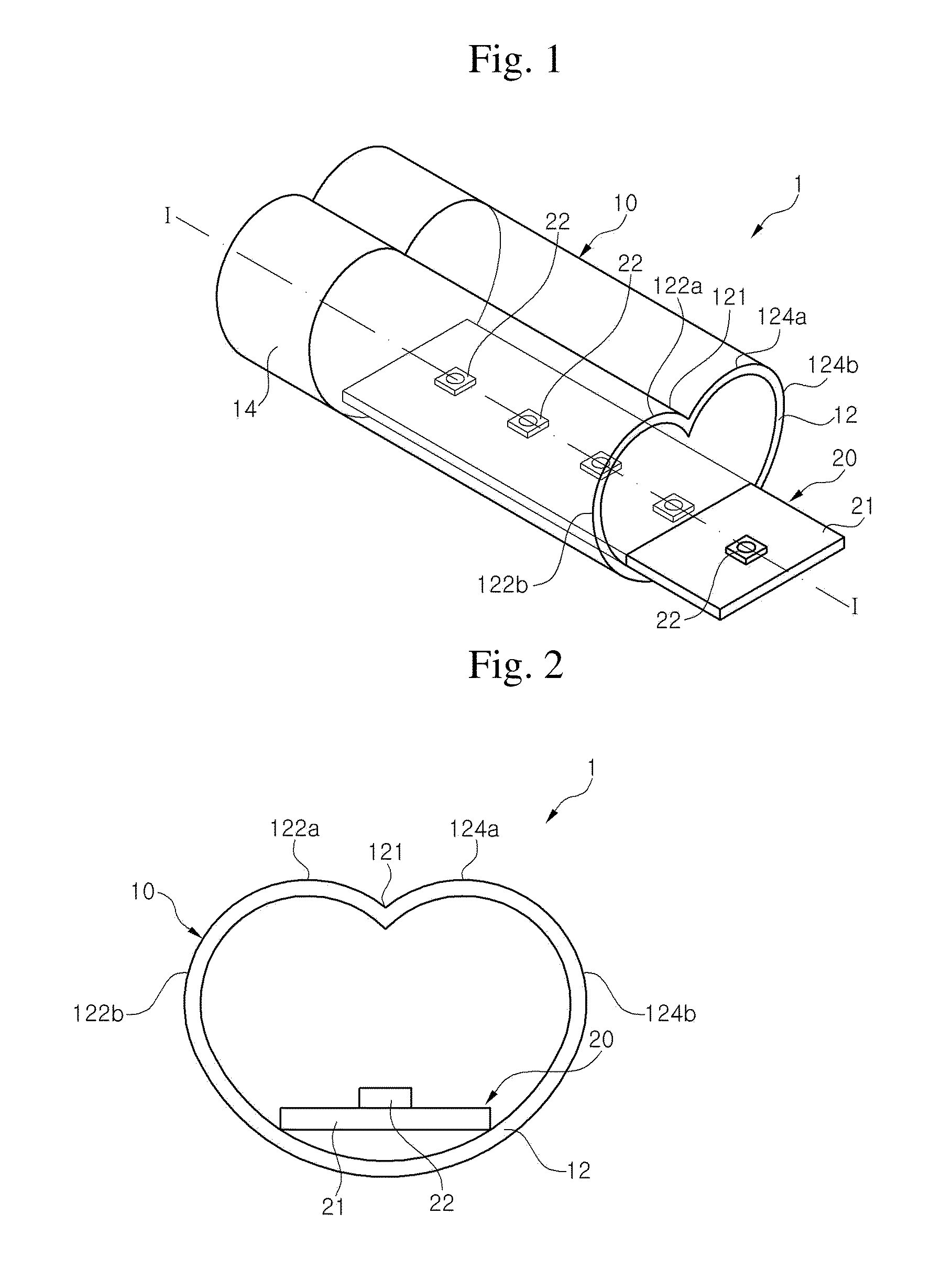

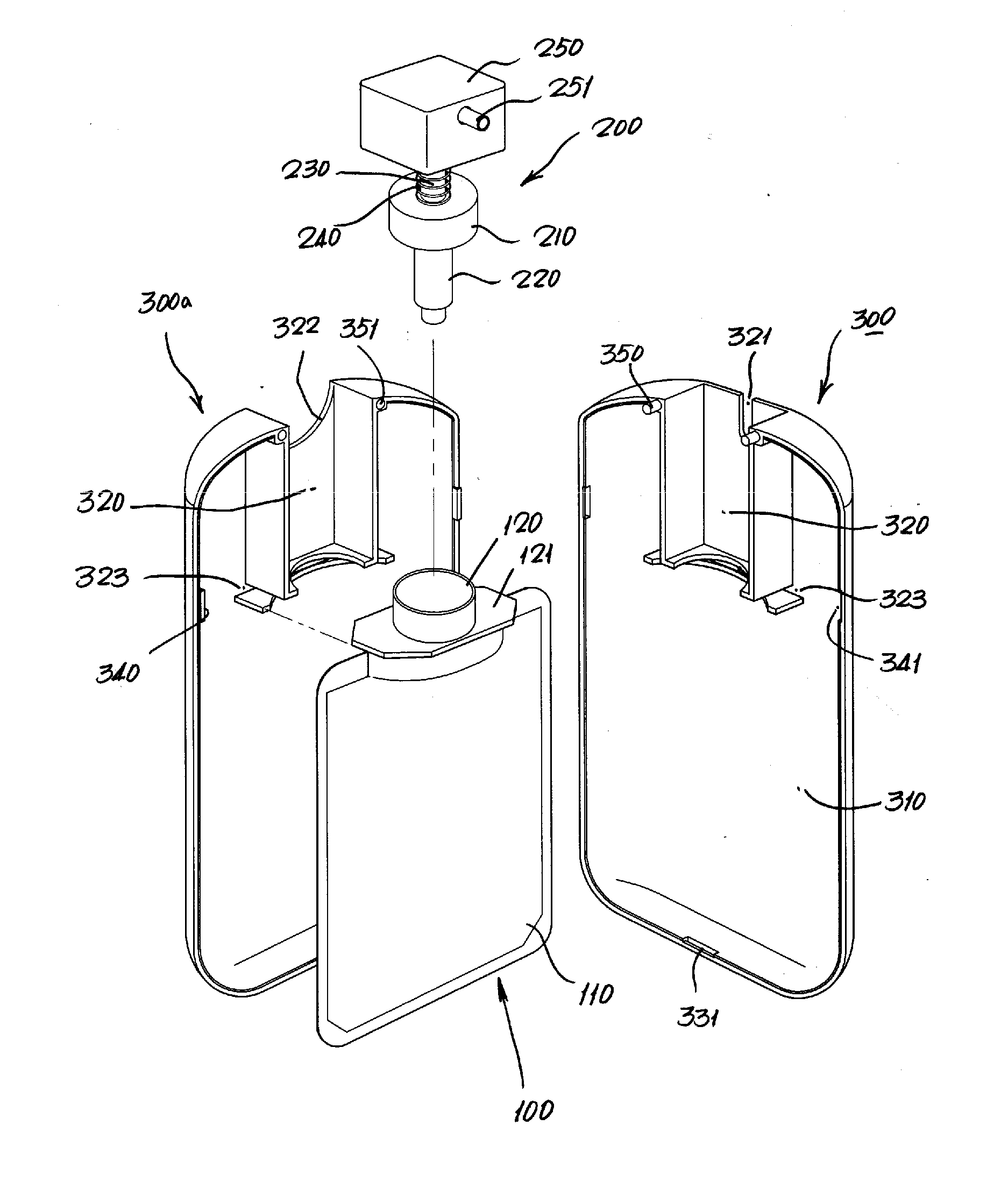

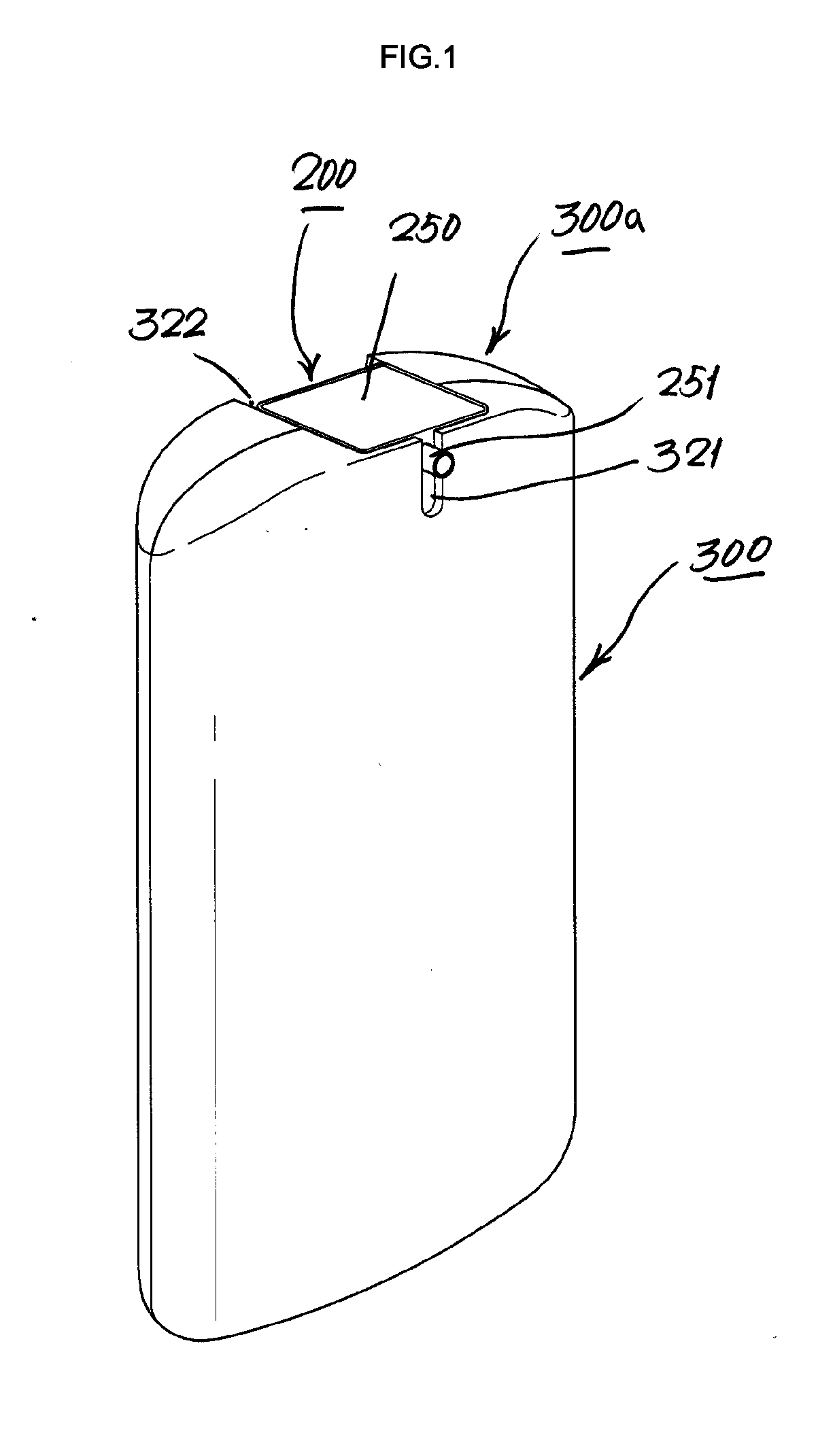

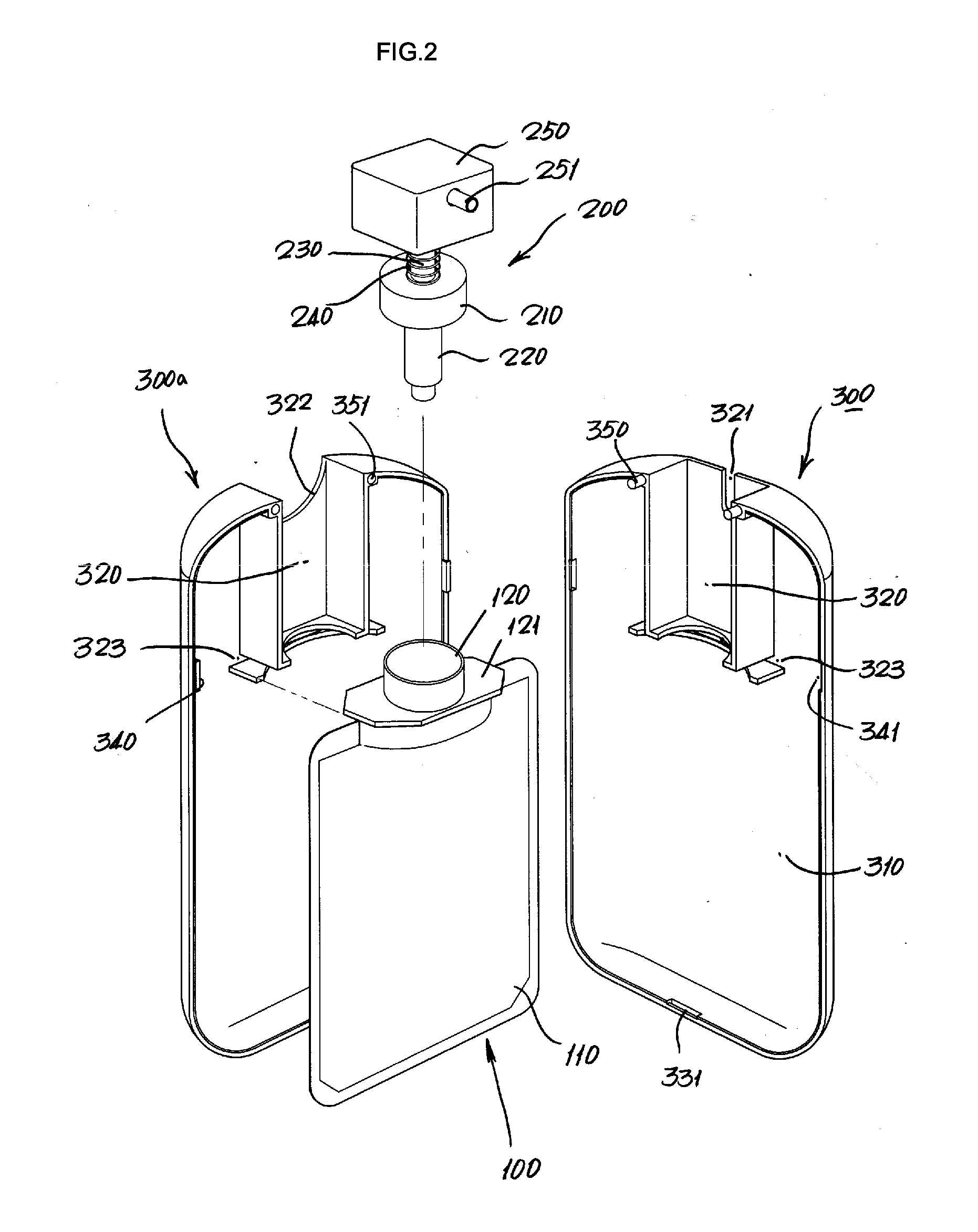

Openable cosmetic case of dual structure protecting tube

InactiveUS20110220682A1Easy to disassembleSimple contentLarge containersLiquid transferring devicesEngineeringHot melt

The invention relates to an openable cosmetic case of a dual structure protecting a tube, and more particularly, to an openable cosmetic case of a dual structure protecting a tube wherein a tube-type inner case to which an airless pump is engaged is made of rigid material and is protected by an outer case that can be disassembled and assembled and the airless pump performs a pumping operation under state in which the pump is completely mounted in the outer case without being exposed to the outside, thereby improving structure and operation properties and protecting the tube of the inner case from the exterior shock, pressure and ultraviolet rays.The cosmetic case has a dual structure in which a pair of outer cases that can be disassembled and assembled protect a tube-type inner case to which an airless pump is mounted. The inner case 100 is formed into a tube shape comprising a bag 110 that is made of flexible material and safely stores the contents and an injection pipe 120 that is heat-fused to an upper part of the bag 110 and has a connection piece 121 at an outer periphery. The outer cases 300, 300a are structured to be symmetrical to each other and have a mount space 310 in which the inner case is mounted and a vertical operation chamber 320 to which the airless pump is mounted, a lower part of the operation chamber 320 is formed with a connection recess 323 to which a connection piece 122 of the inner case is connected, one outer case 300 is formed with a nozzle guide hole 321 and the other outer case 300a is formed with a finger guide hole 322 having a semi-sphere shape. The airless pump 200 is mounted in the operation chamber 320 of the outer cases 300, 300a and performs a pumping operation with being supported to the operation chamber.

Owner:TOLY KOREA

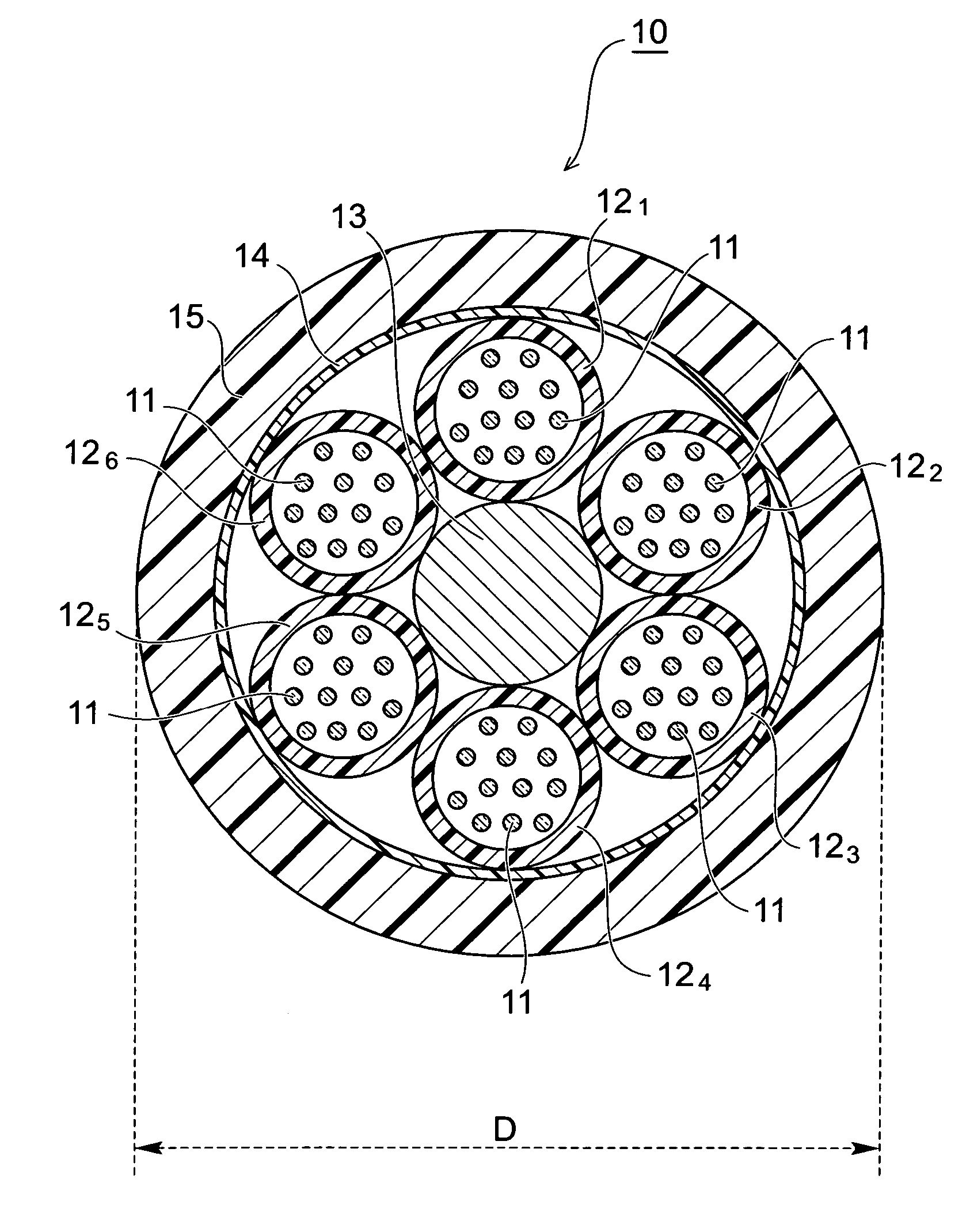

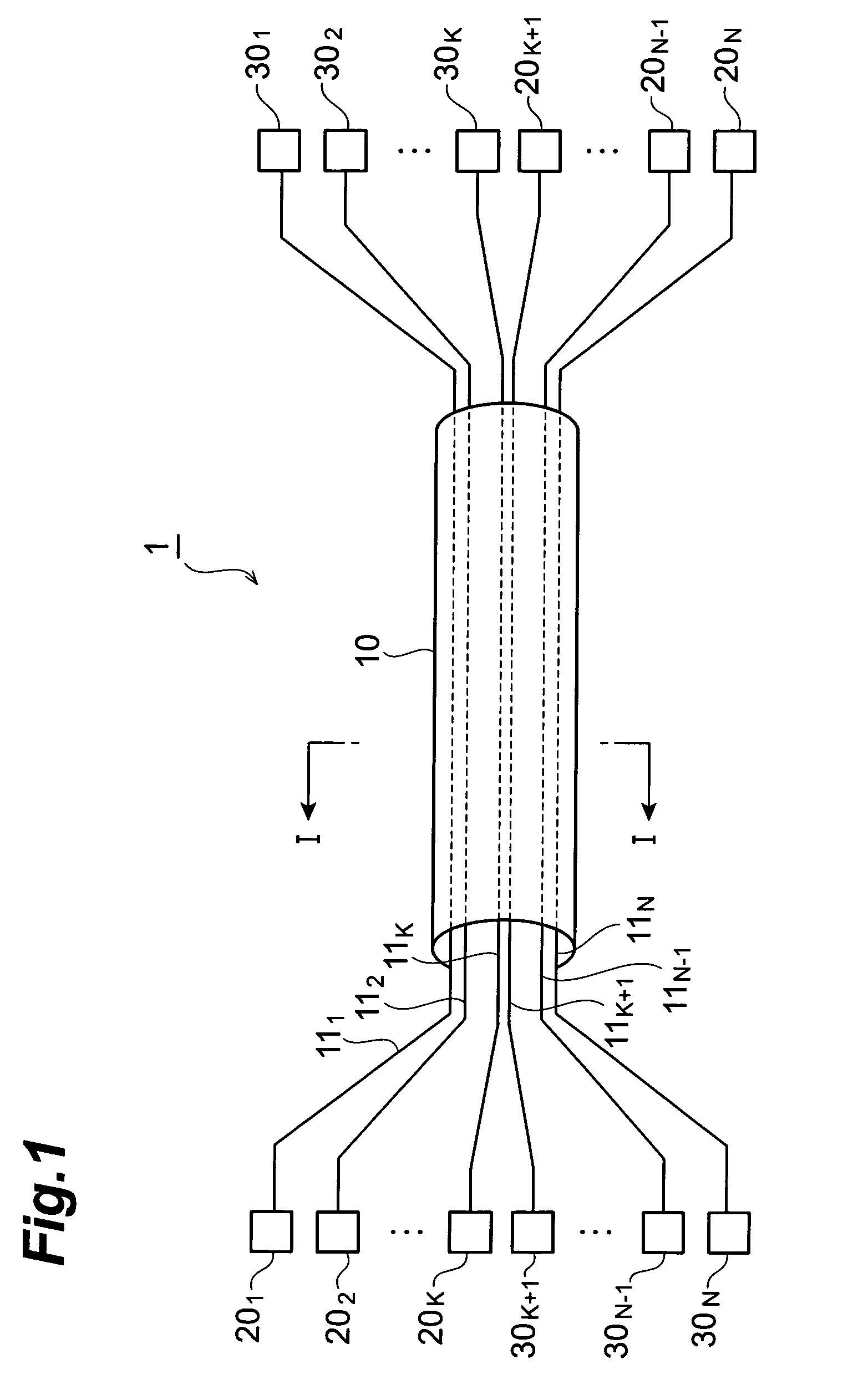

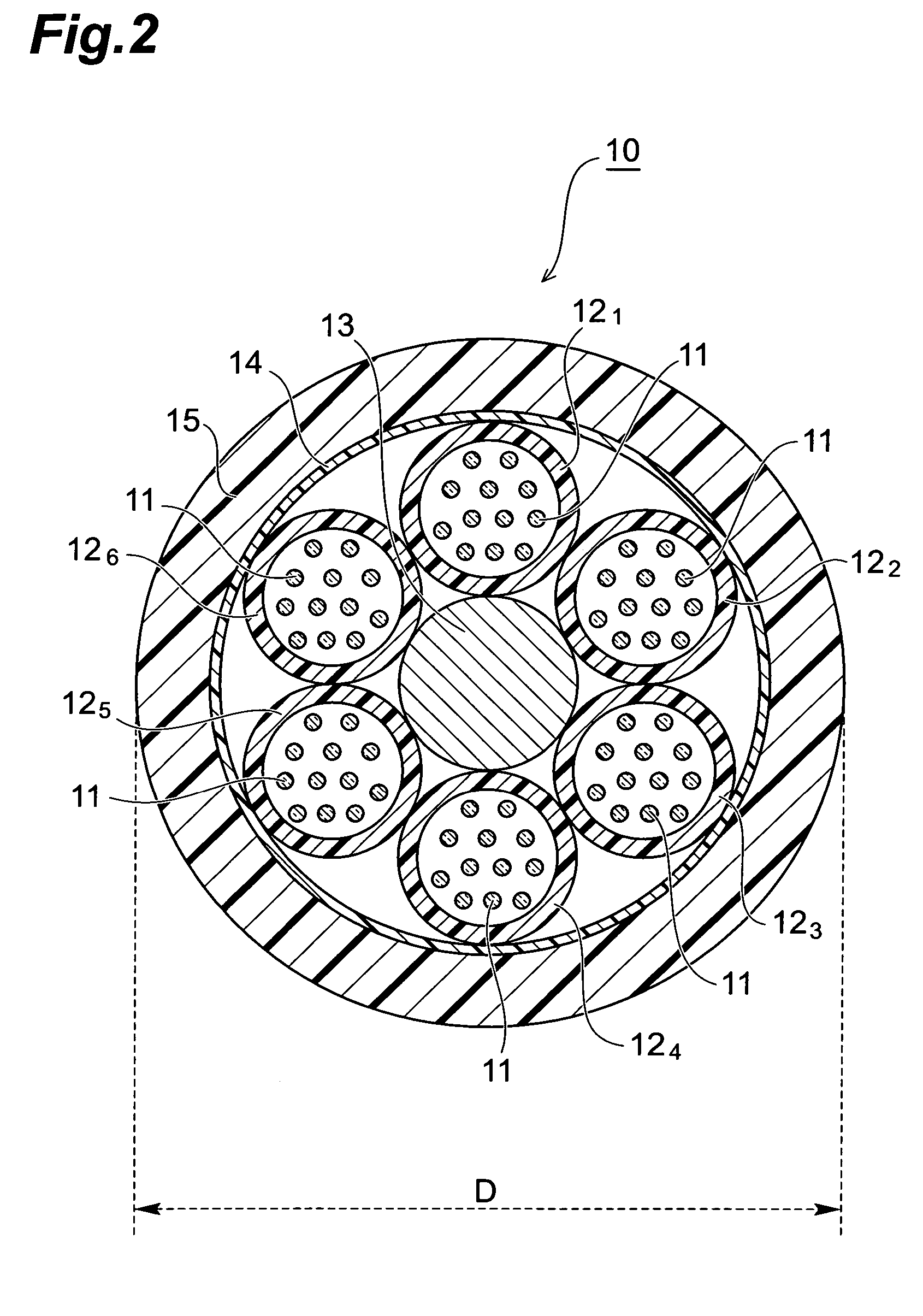

Optical cable

ActiveUS7321709B2Reduce the overall diameterImprove sealing efficiencyFibre mechanical structuresFiberEngineering

An optical cable according to the present invention relates to an optical cable having a construction to enable reduction of a cable outer diameter, and / or improvement of contained efficiency of coated optical fibers while an increase of transmission loss in each coated optical fiber is suppressed. The optical cable has a loose-tube type of structure constructed by: a tension member; a plurality of tubes stranded together around the tension member; and an outer sheath covering the outer periphery of the plurality of tubes. One or more coated optical fibers are contained in each tube. A ratio of A / B is 6.3 or more but 7.0 or less, where each coated optical fiber has a mode field diameter A in a range of 8.6±0.4 μm at a wavelength of 1.31 μm, and where a fiber cutoff wavelength thereof is B μm.

Owner:SUMITOMO ELECTRIC IND LTD +1

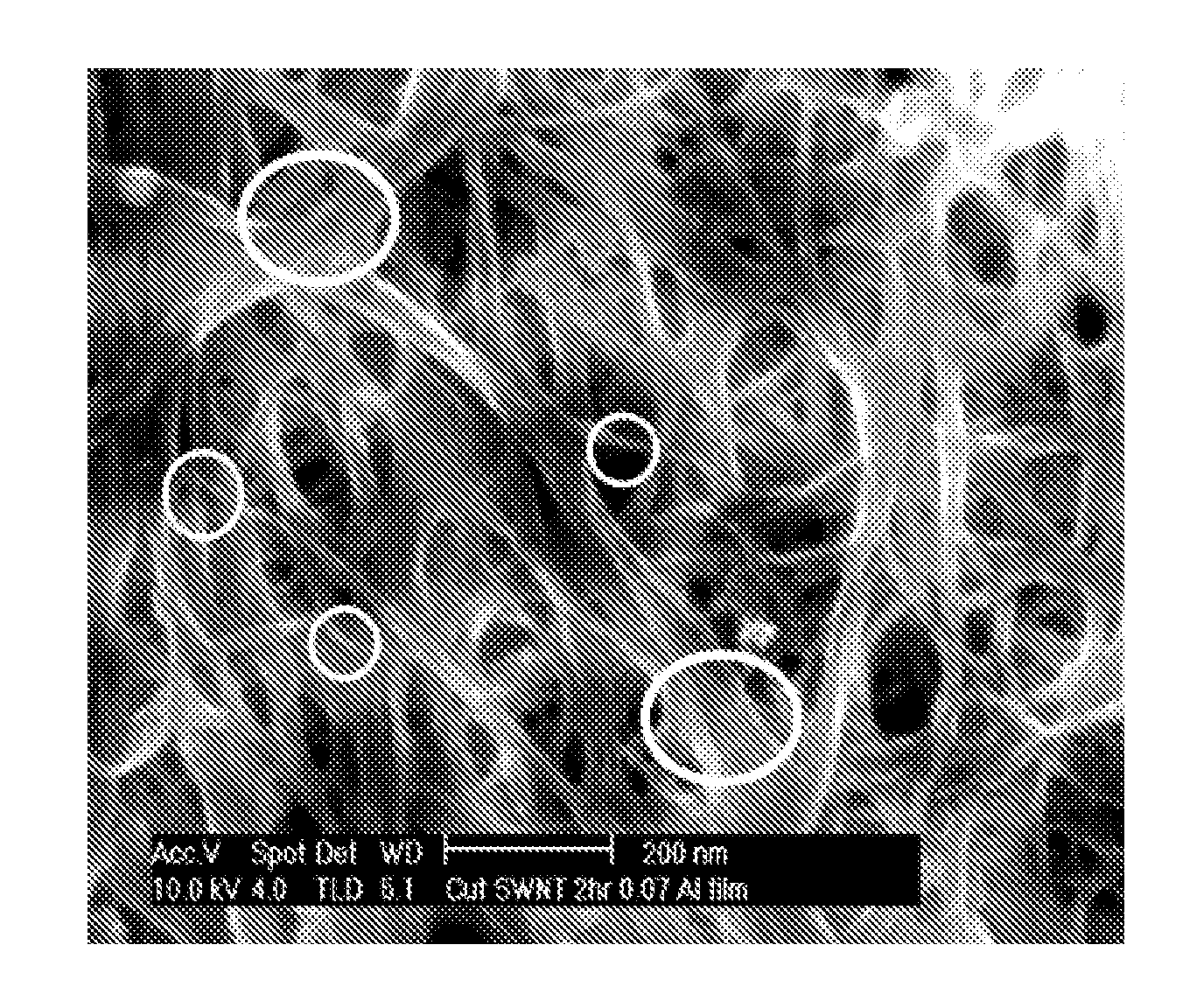

Modified Carbon Nanotubes and Methods of Forming Carbon Nanotubes

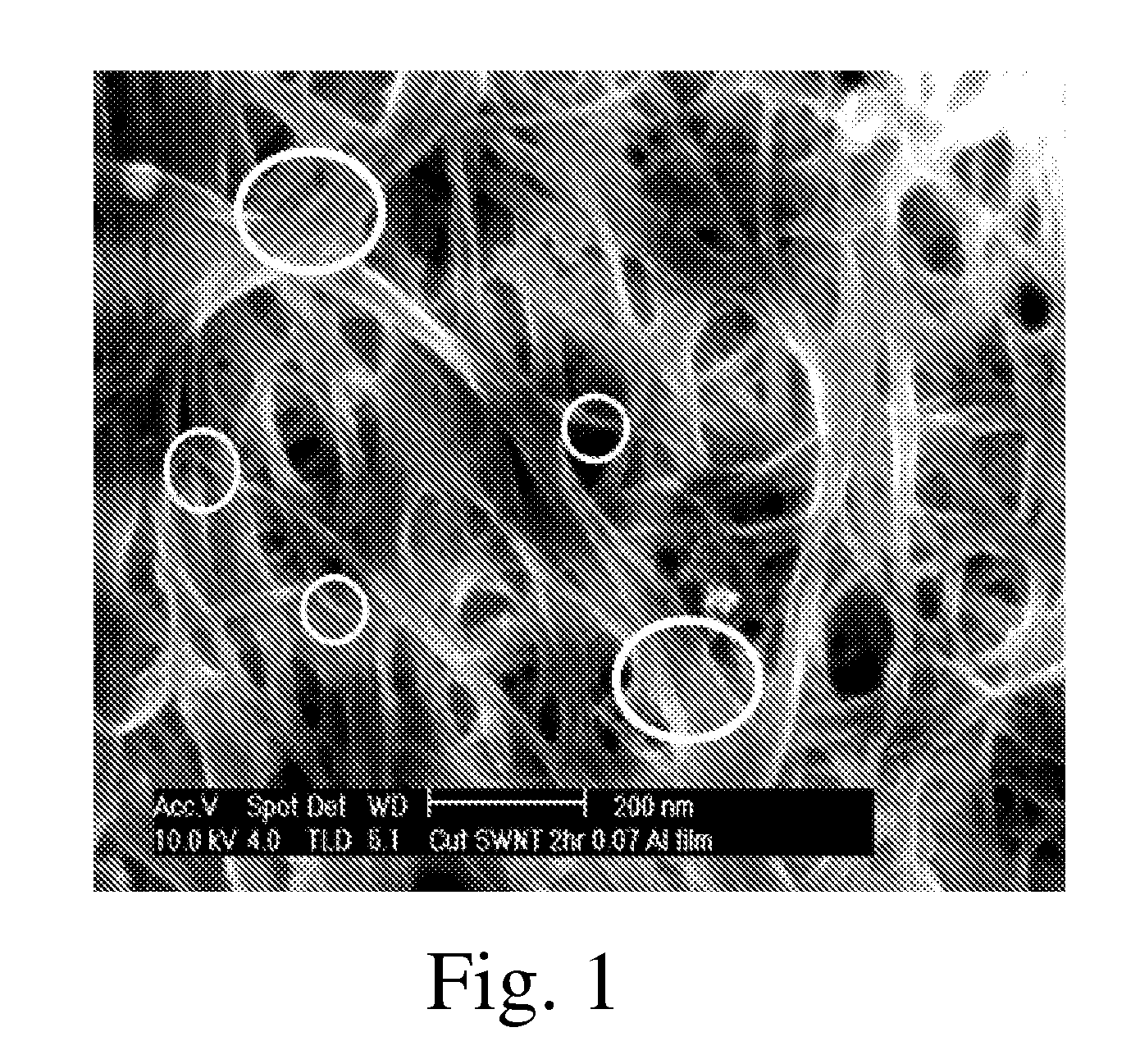

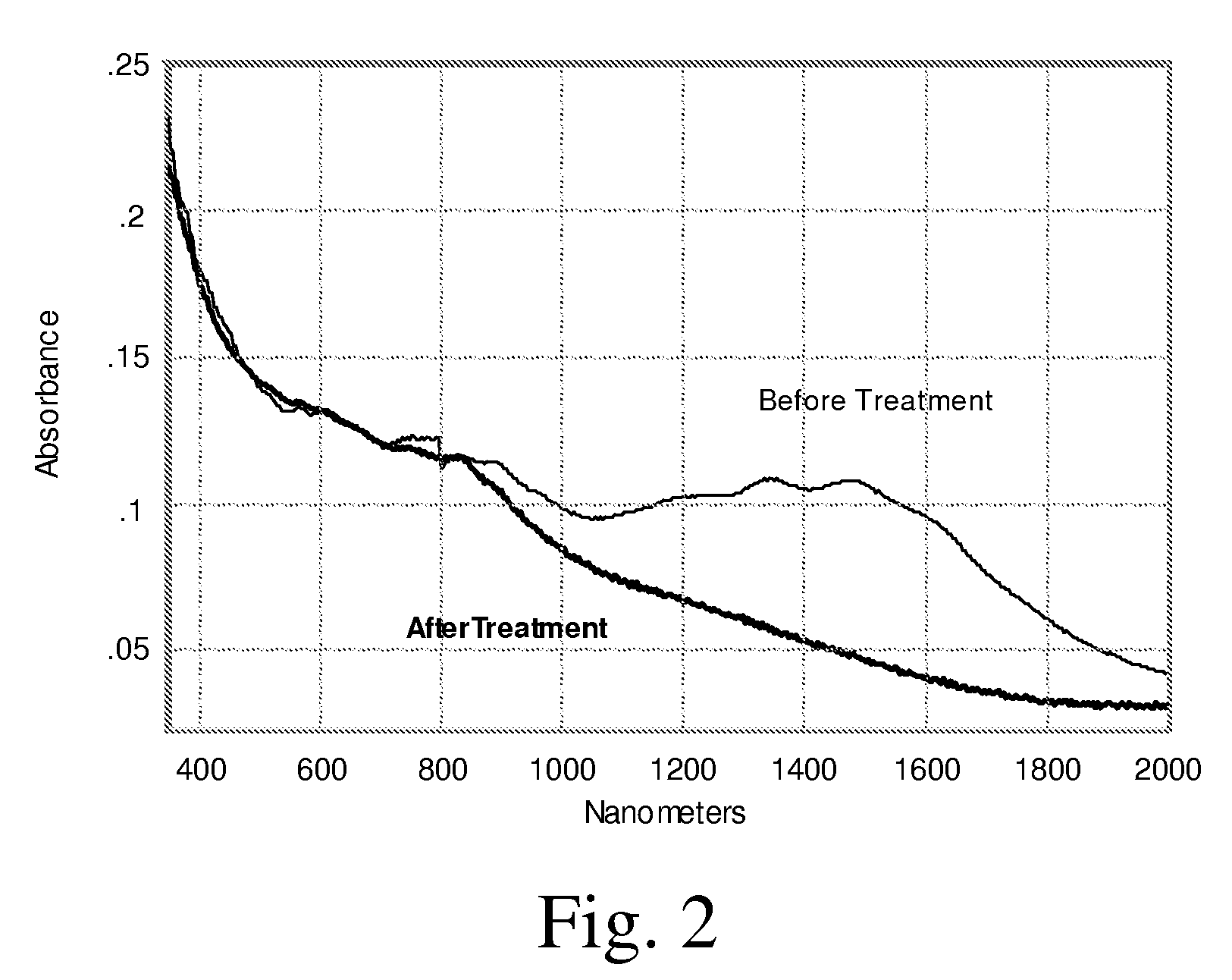

ActiveUS20090142581A1Improved near infrared (NIR) transmittanceImprove work functionMaterial nanotechnologyLayered productsDopantModified carbon

In this invention, processes which can be used to achieve stable doped carbon nanotubes are disclosed. Preferred CNT structures and morphologies for achieving maximum doping effects are also described. Dopant formulations and methods for achieving doping of a broad distribution of tube types are also described.

Owner:BATTELLE MEMORIAL INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com