Method for Recovering Hydrocarbons from Subterranean Formations

a technology of hydrocarbon recovery and subterranean formations, applied in the direction of fluid removal, borehole/well accessories, insulation, etc., to achieve the effect of limiting the damage potential of surface water zones, and minimizing damage to near surface water zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

:

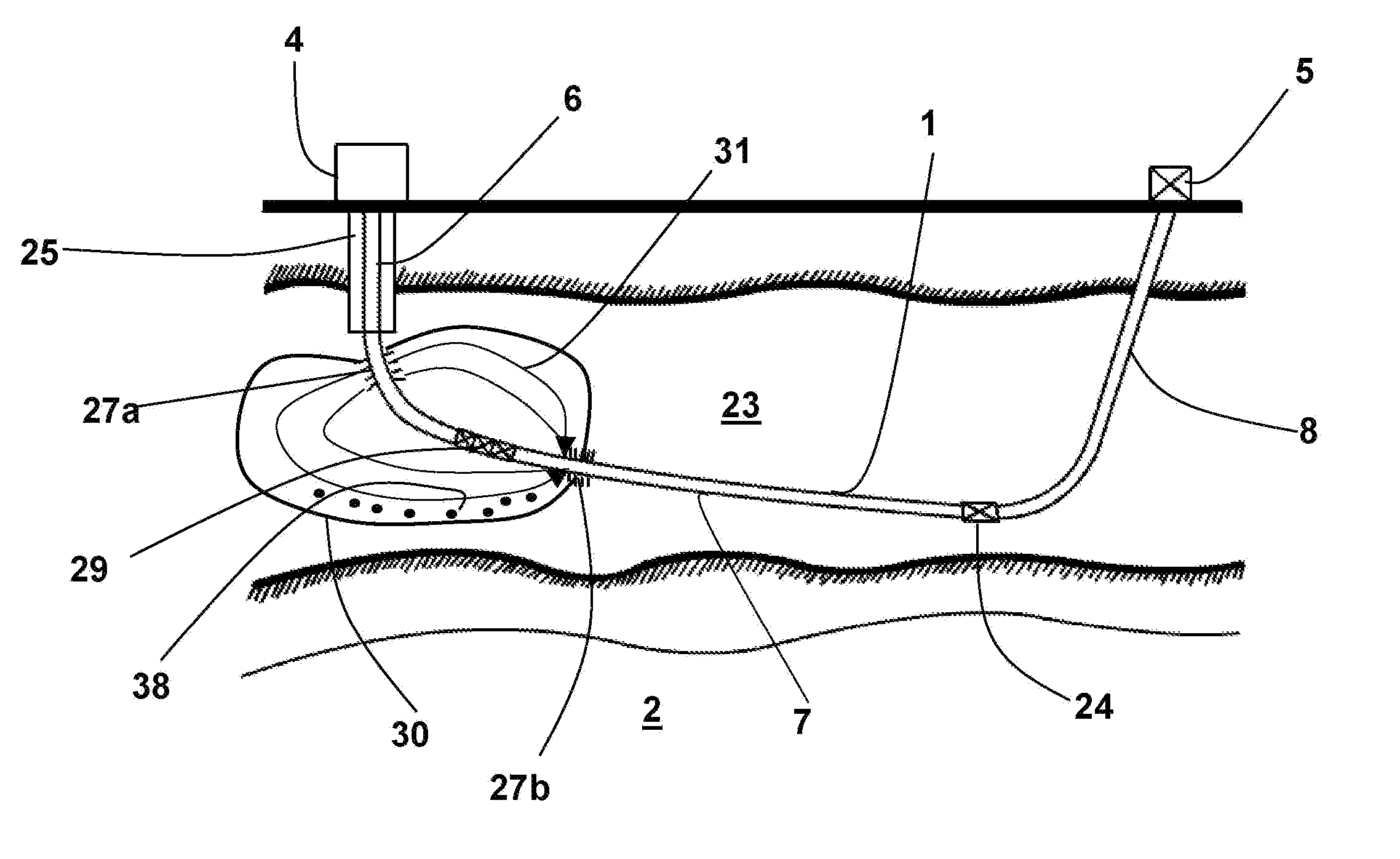

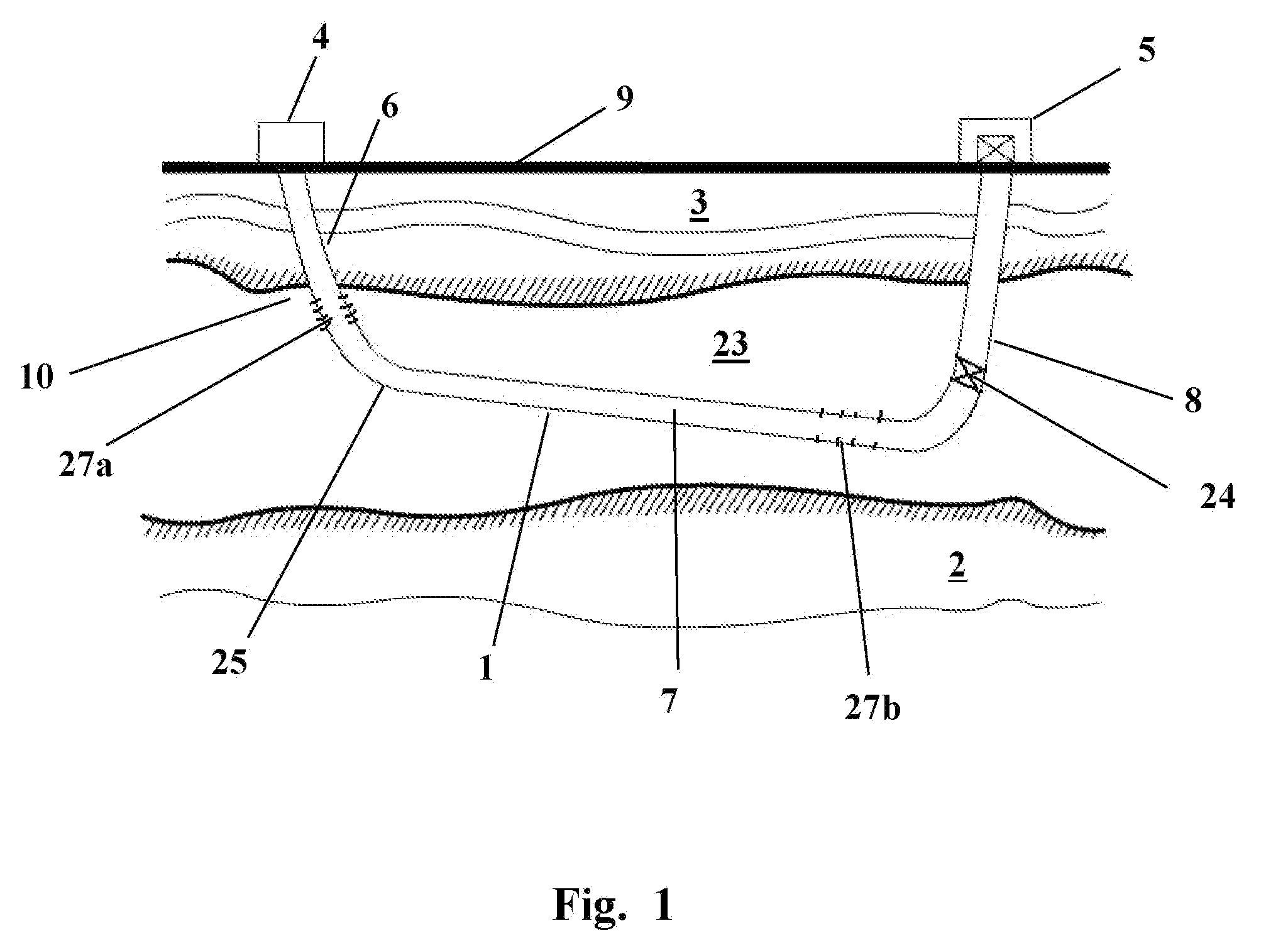

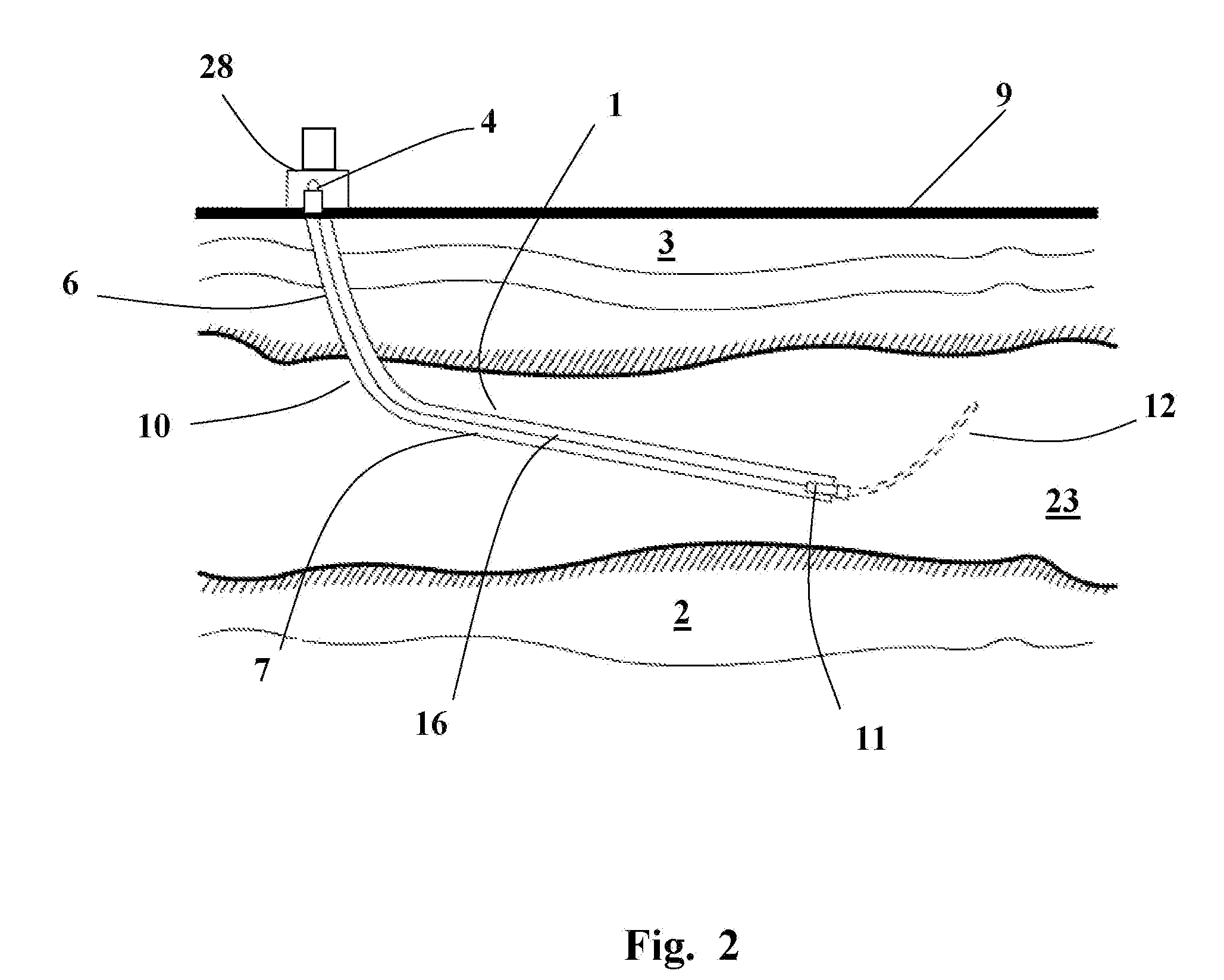

[0125] Referring now to the drawings wherein like reference numerals designate corresponding elements throughout all the figures and referring in particular to FIG. 1. an improved method for extracting hydrocarbons according to an example embodiment of the invention includes a wellbore 1 consisting of three primary sections. As shown in steps 100, 101, 102, in FIG. 13 and in FIG. 1, a downward section 6, a lateral section 7 and an upward section 8 are drilled with conventional oilfield equipment. The downward section 6 has an entry wellhead 4 and is more or less vertically drilled depending on the nature of the recovery operations. Within the scope of this description a horizontal well or horizontal well section means a well or well section, which is substantially at or close to horizontal inclination. The horizontal or lateral section 7 is drilled in the producing oil formation 23, which is a porous medium containing oil, gas and water in the pore spaces. The upward section 8 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com