Patents

Literature

1708 results about "Hydrogen compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen combined with oxygen, is water (H2O). Hydrogen combined with carbon, forms different compounds such as methane (CH4), coal, and petroleum. Hydrogen is also found in all growing things—biomass. It is also an abundant element in the earth's crust.

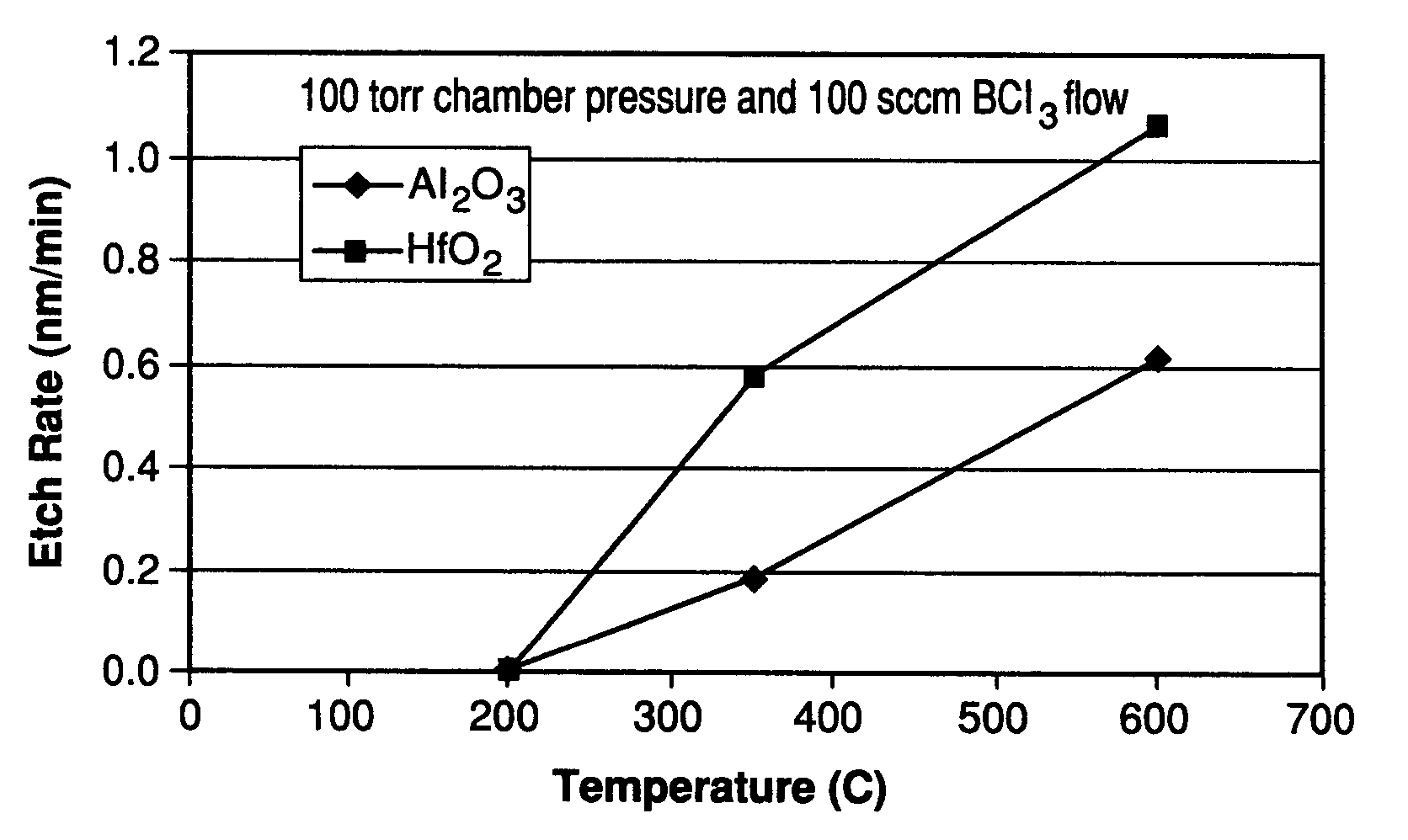

Method for etching high dielectric constant materials and for cleaning deposition chambers for high dielectric constant materials

A process for the removal of a substance from a substrate for etching and / or cleaning applications is disclosed herein. In one embodiment, there is provided a process for removing a substance having a dielectric constant greater than silicon dioxide from a substrate by reacting the substance with a reactive agent that comprises at least one member from the group consisting a halogen-containing compound, a boron-containing compound, a hydrogen-containing compound, nitrogen-containing compound, a chelating compound, a carbon-containing compound, a chlorosilane, a hydrochlorosilane, or an organochlorosilane to form a volatile product and removing the volatile product from the substrate to thereby remove the substance from the substrate.

Owner:VERSUM MATERIALS US LLC

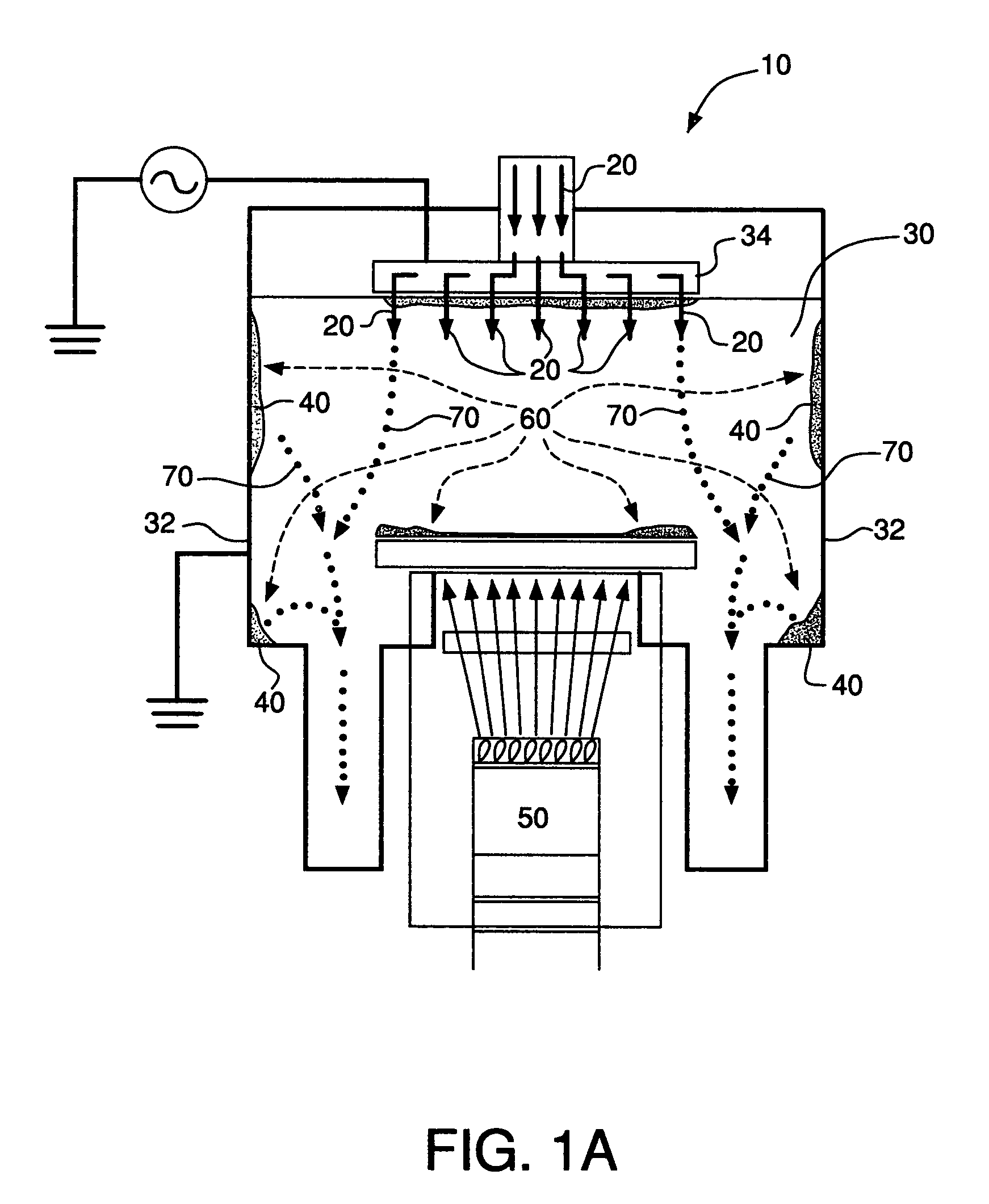

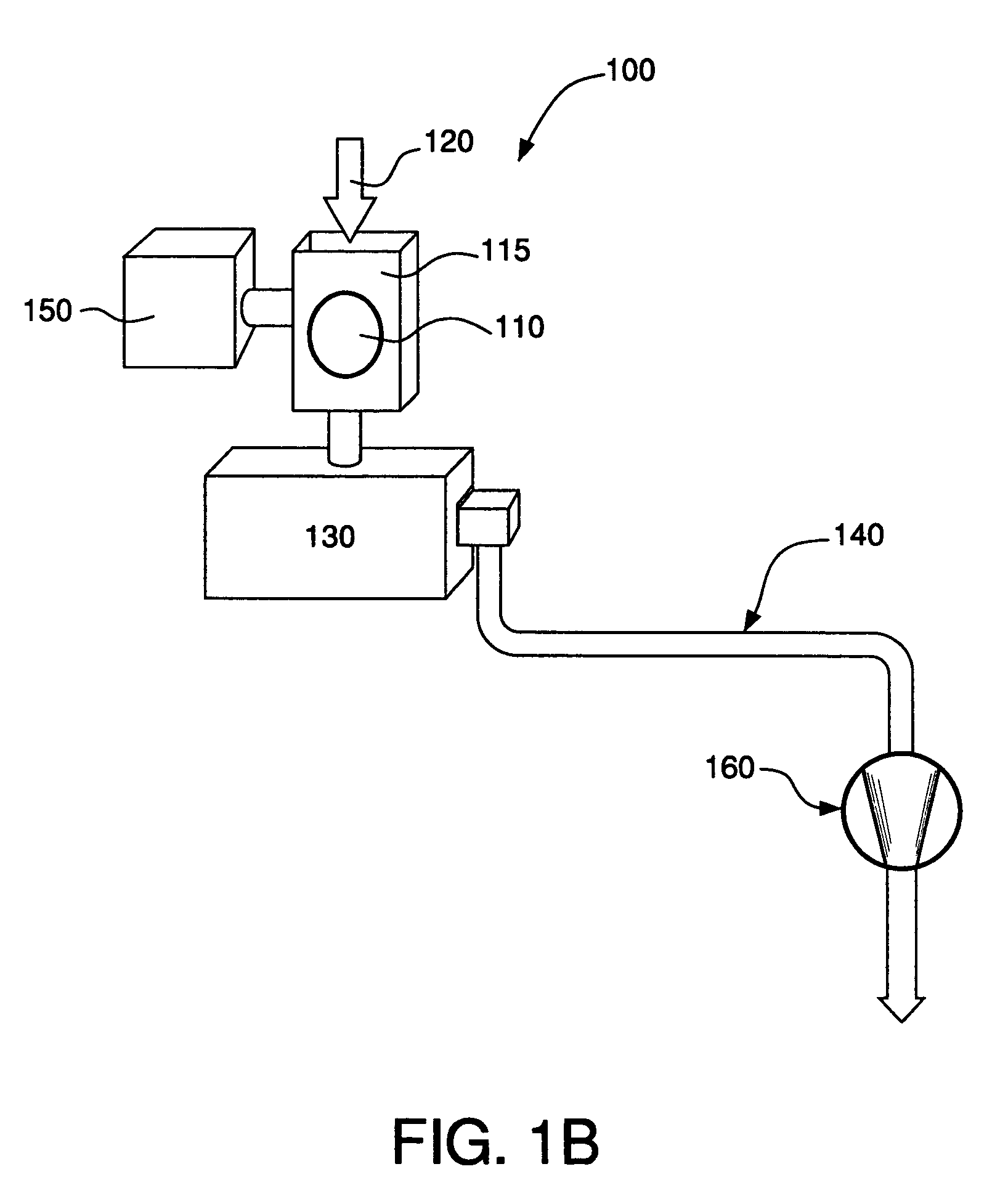

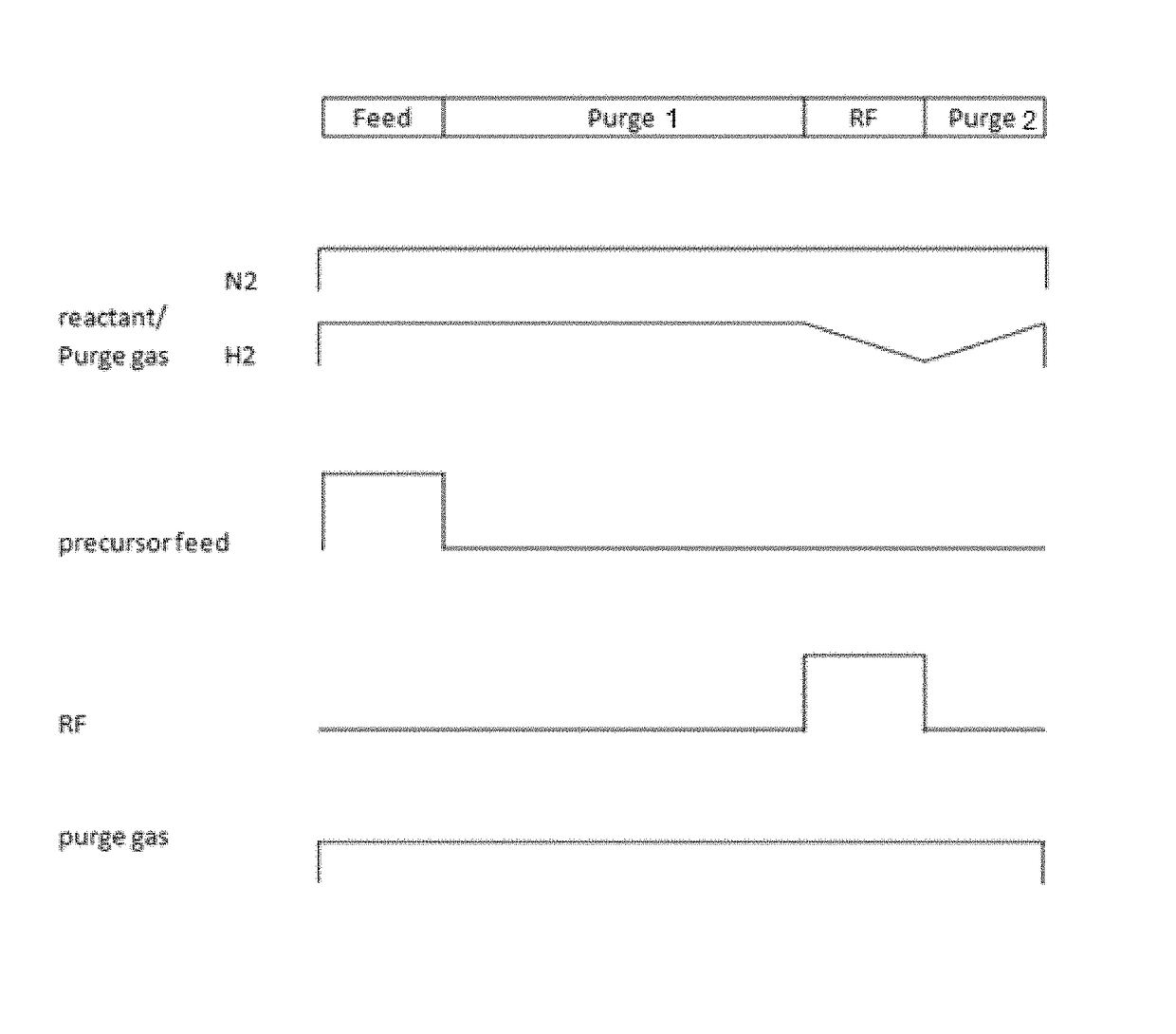

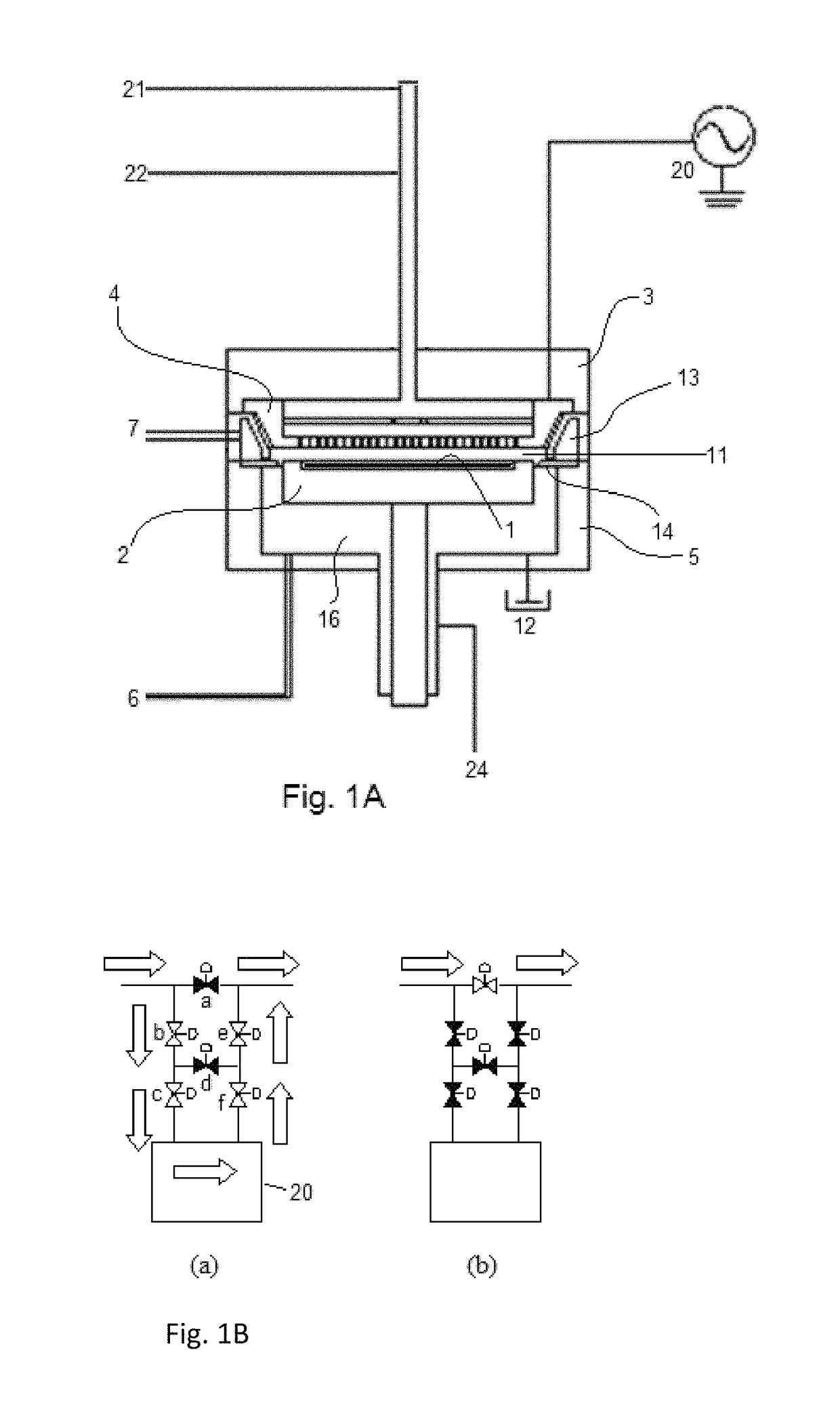

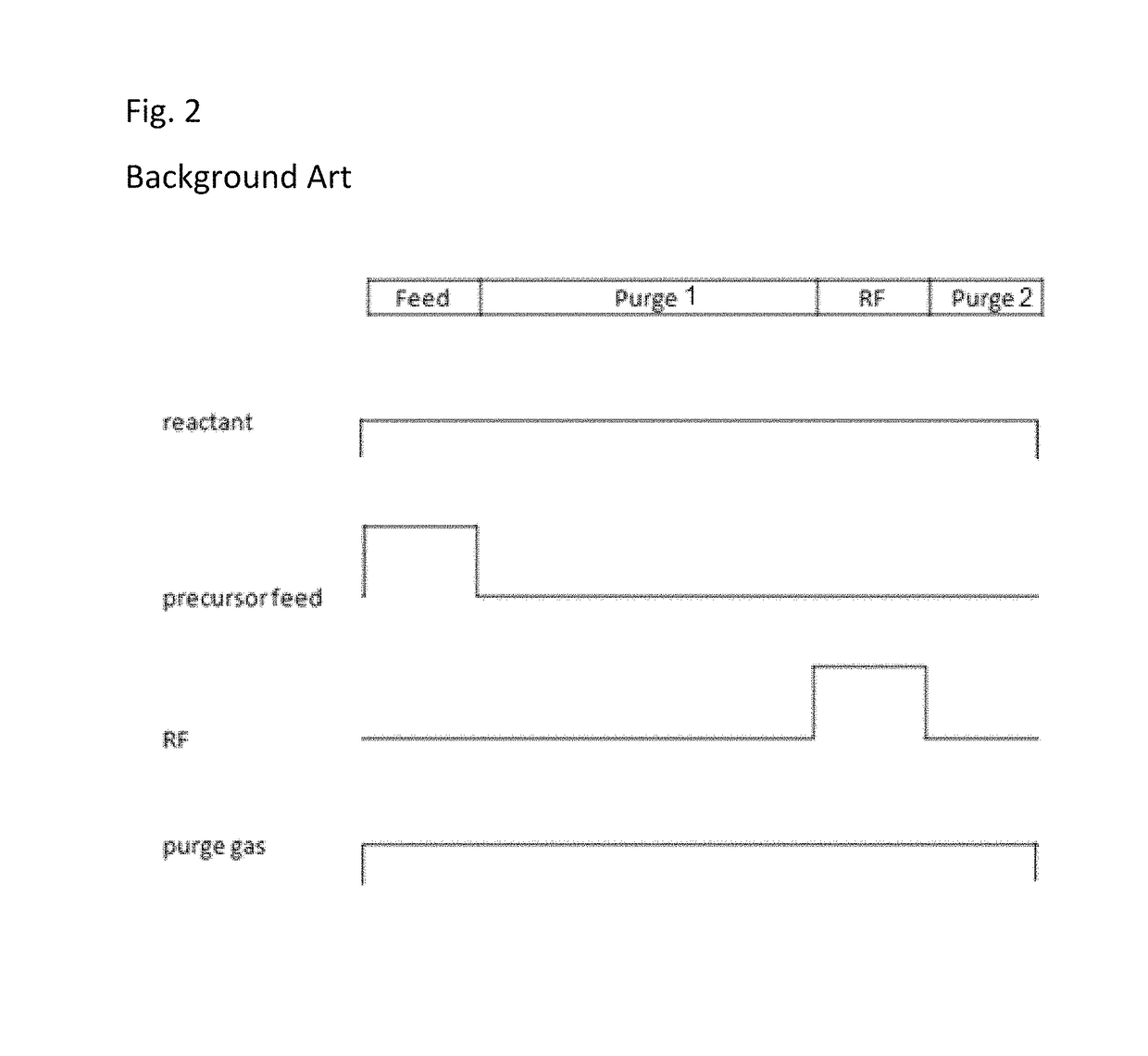

Method of plasma-assisted cyclic deposition using ramp-down flow of reactant gas

ActiveUS9984869B1Electric discharge tubesSemiconductor/solid-state device manufacturingHydrogenOxygen

A method is for forming a nitride or oxide film by plasma-assisted cyclic deposition, one cycle of which includes: feeding a first reactant, a second reactant, and a precursor to a reaction space where a substrate is placed, wherein the second reactant flows at a first flow ratio wherein a flow ratio is defined as a ratio of a flow rate of the second reactant to a total flow rate of gases flowing in the reaction space; and stopping feeding the precursor while continuously feeding the first and second reactants at a flow ratio which is gradually reduced from the first flow ratio to a second flow ratio while applying RF power to the reaction space to expose the substrate to a plasma. The second reactant is constituted by a hydrogen-containing compound or oxygen-containing compound.

Owner:ASM IP HLDG BV

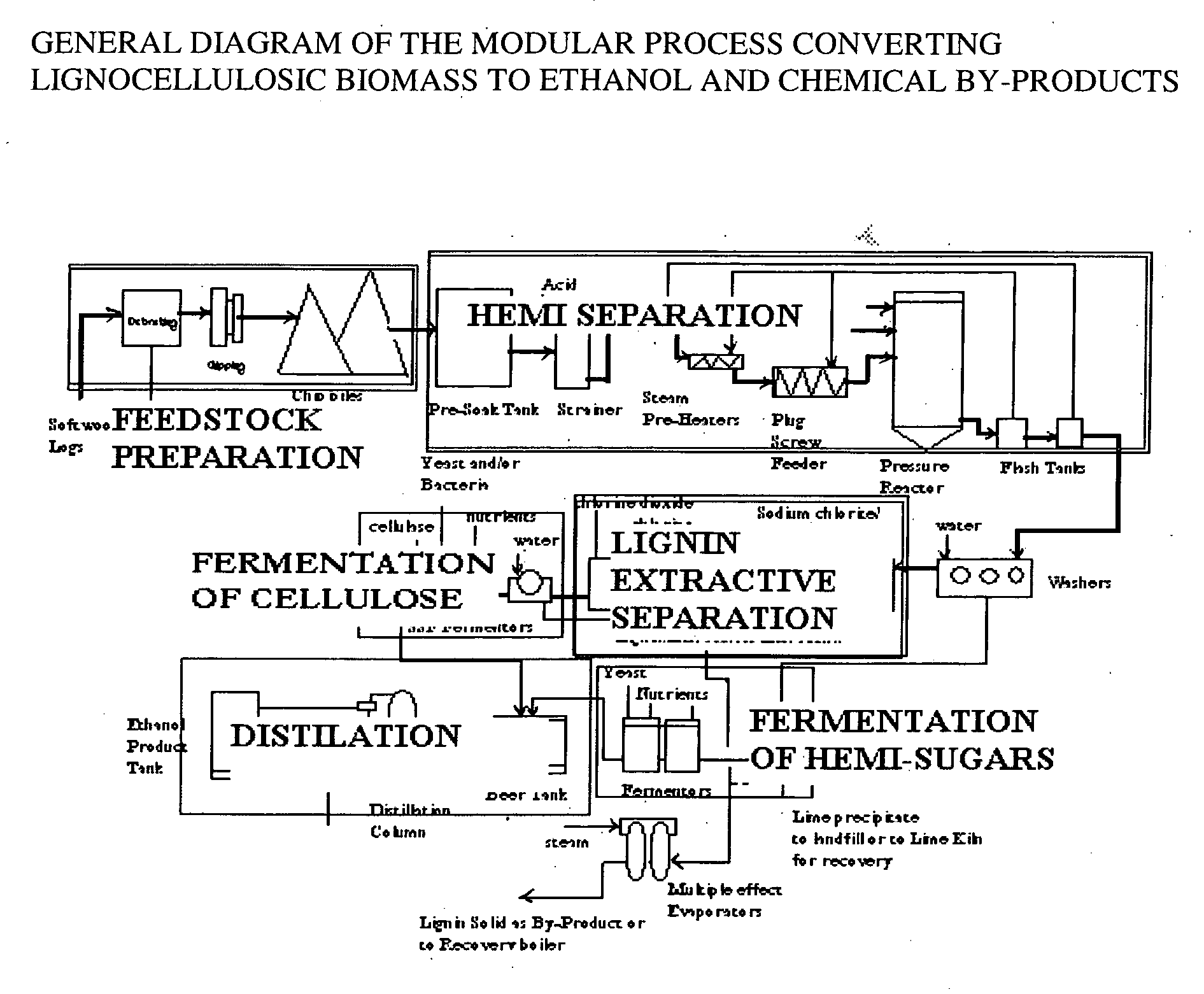

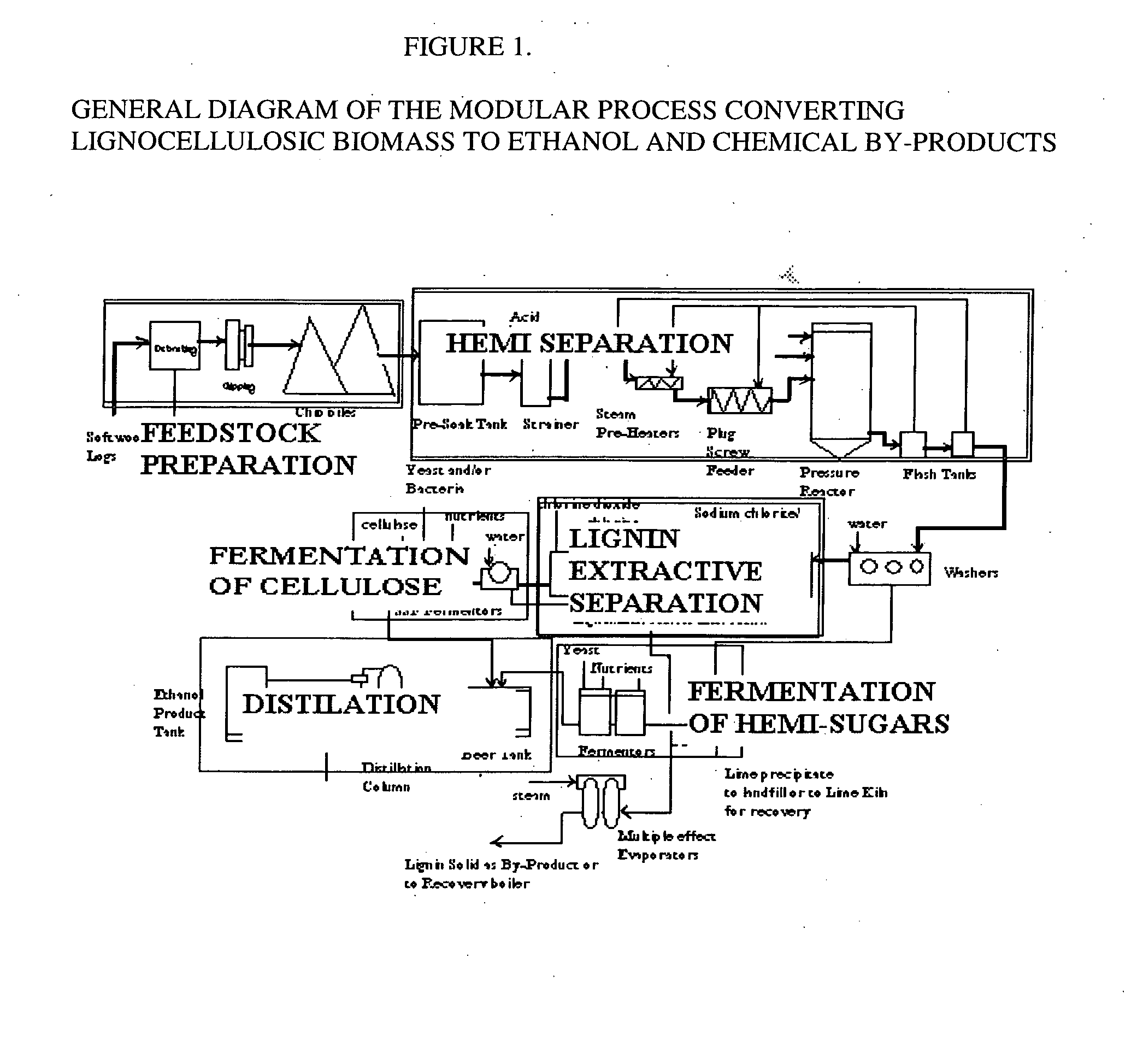

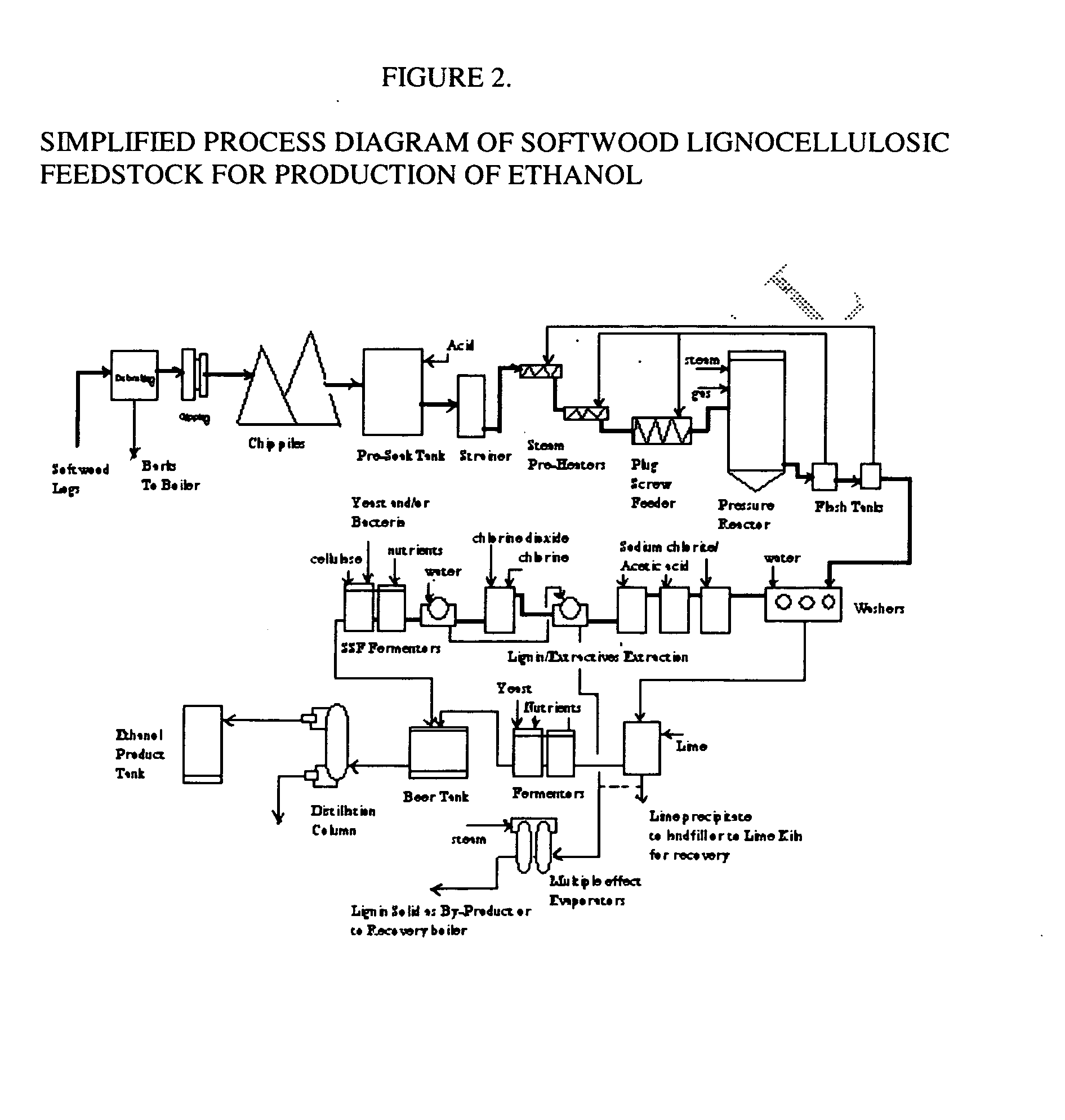

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

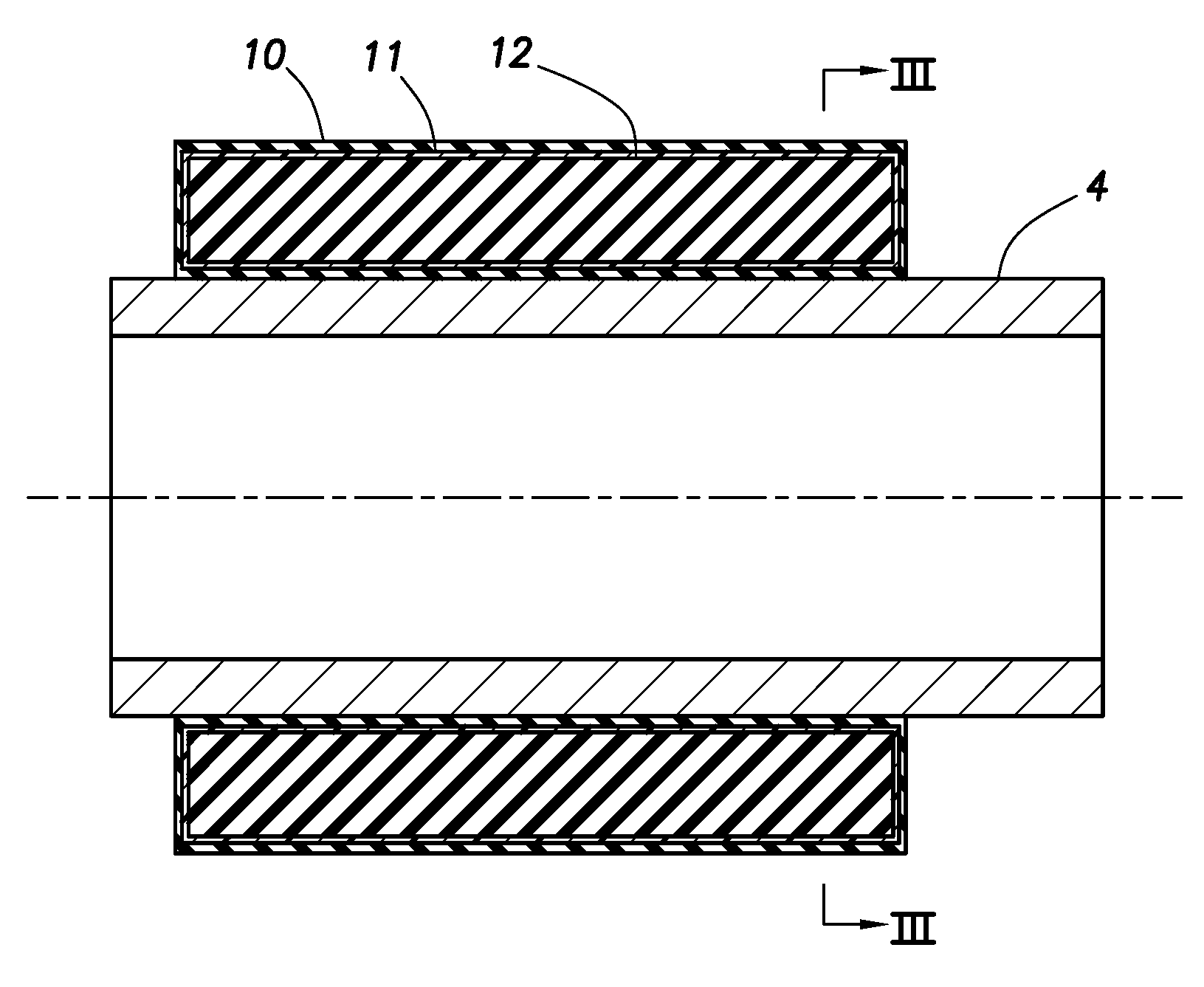

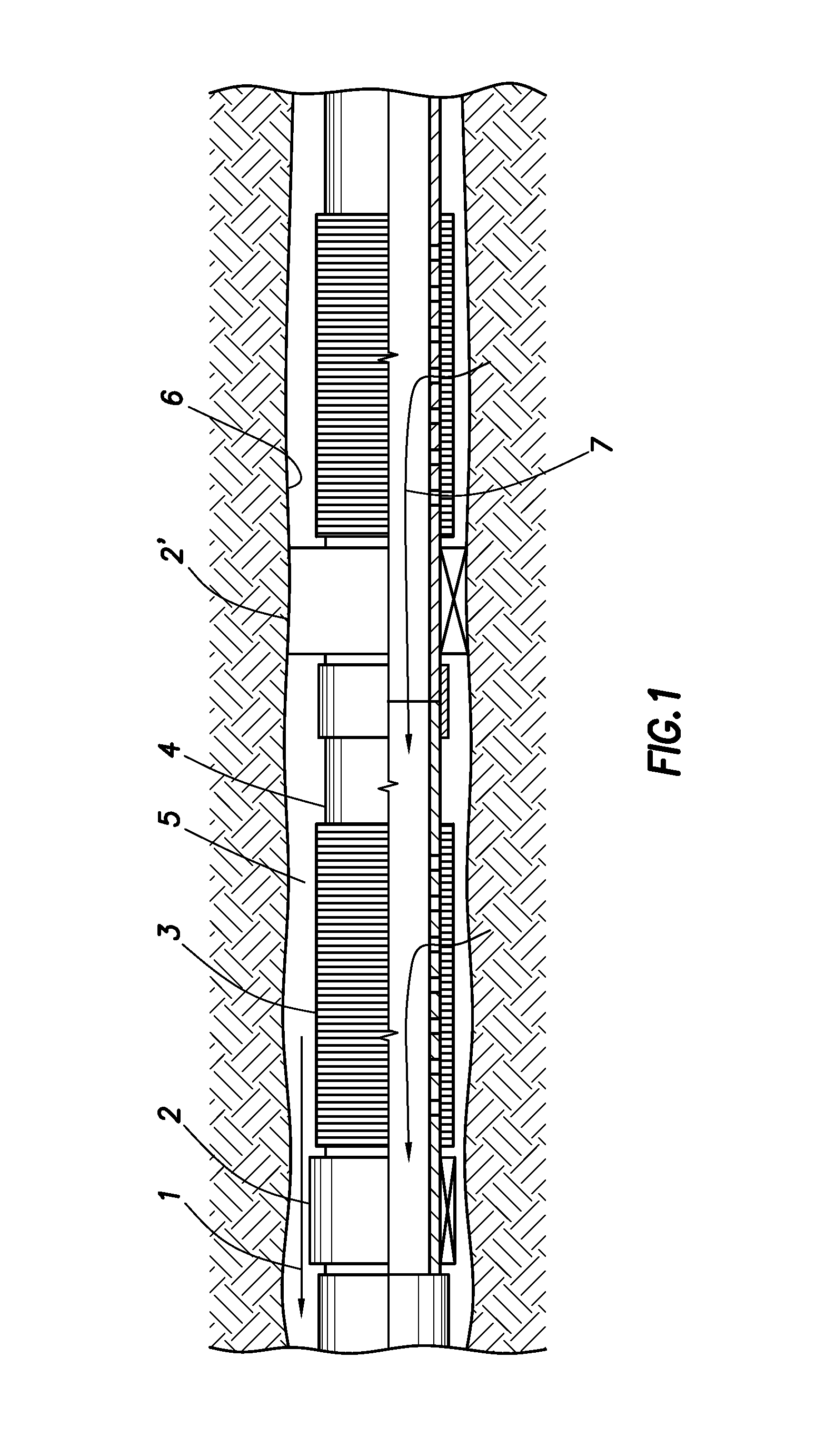

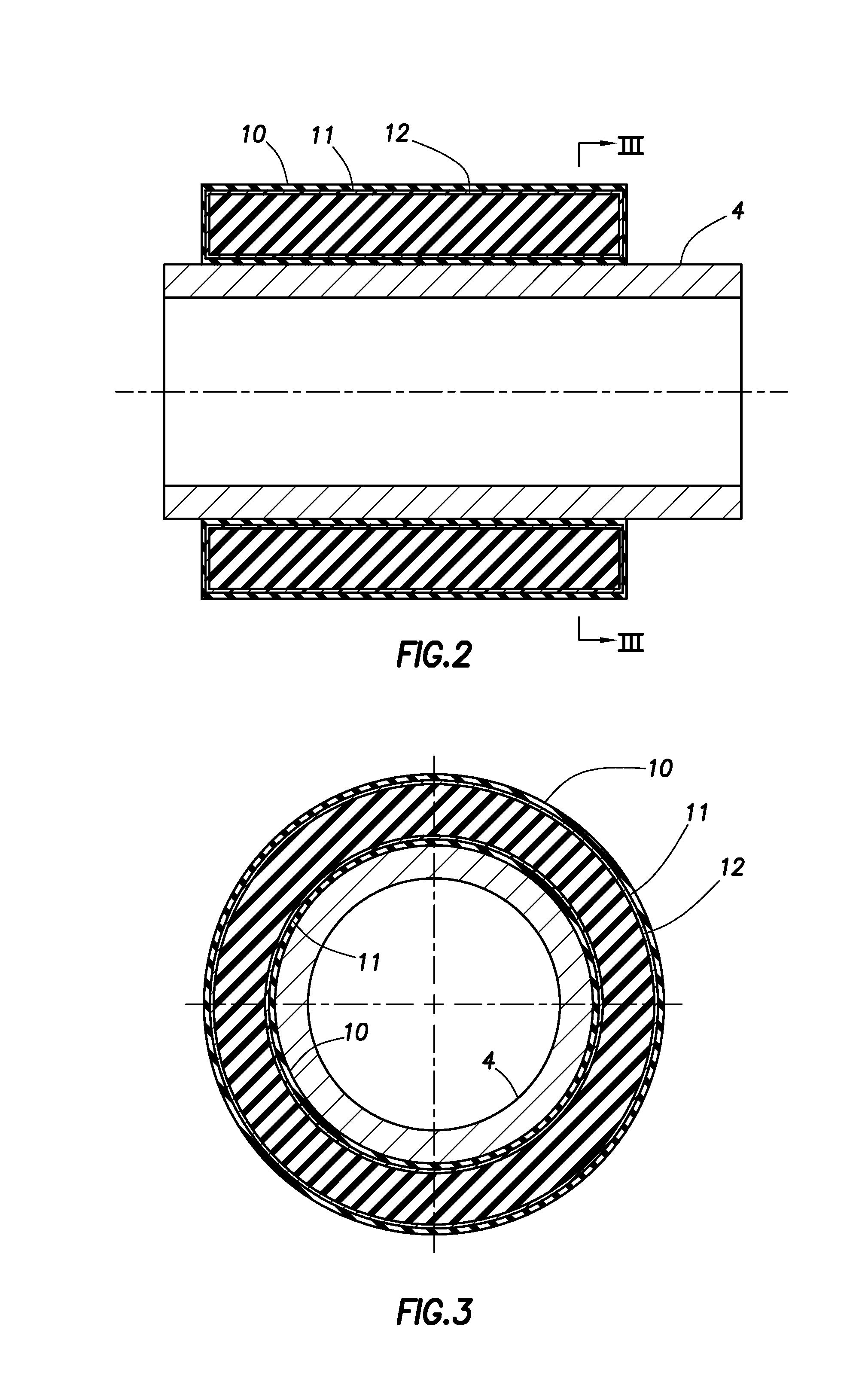

Well packing

InactiveUS7143832B2Less expandedSimple and reliable deviceFluid removalSealing/packingEngineeringProduction tubing

Annular packer (2) arranged on the outside of a production tubing (4) said packer comprises a core (12) comprising elastic polymer swelling by absorption of hydrocarbons. The core (12) may be surrounded by an external mantle of rubber (10), which is permeable to hydrocarbons and may be equipped with a reinforcement (11). The core (12) swells by absorption of hydrocarbons and the packer (2) expands thus in order to seal the annular space (5) between the production tubing (4) and the well wall (6).

Owner:HALLIBURTON ENERGY SERVICES INC

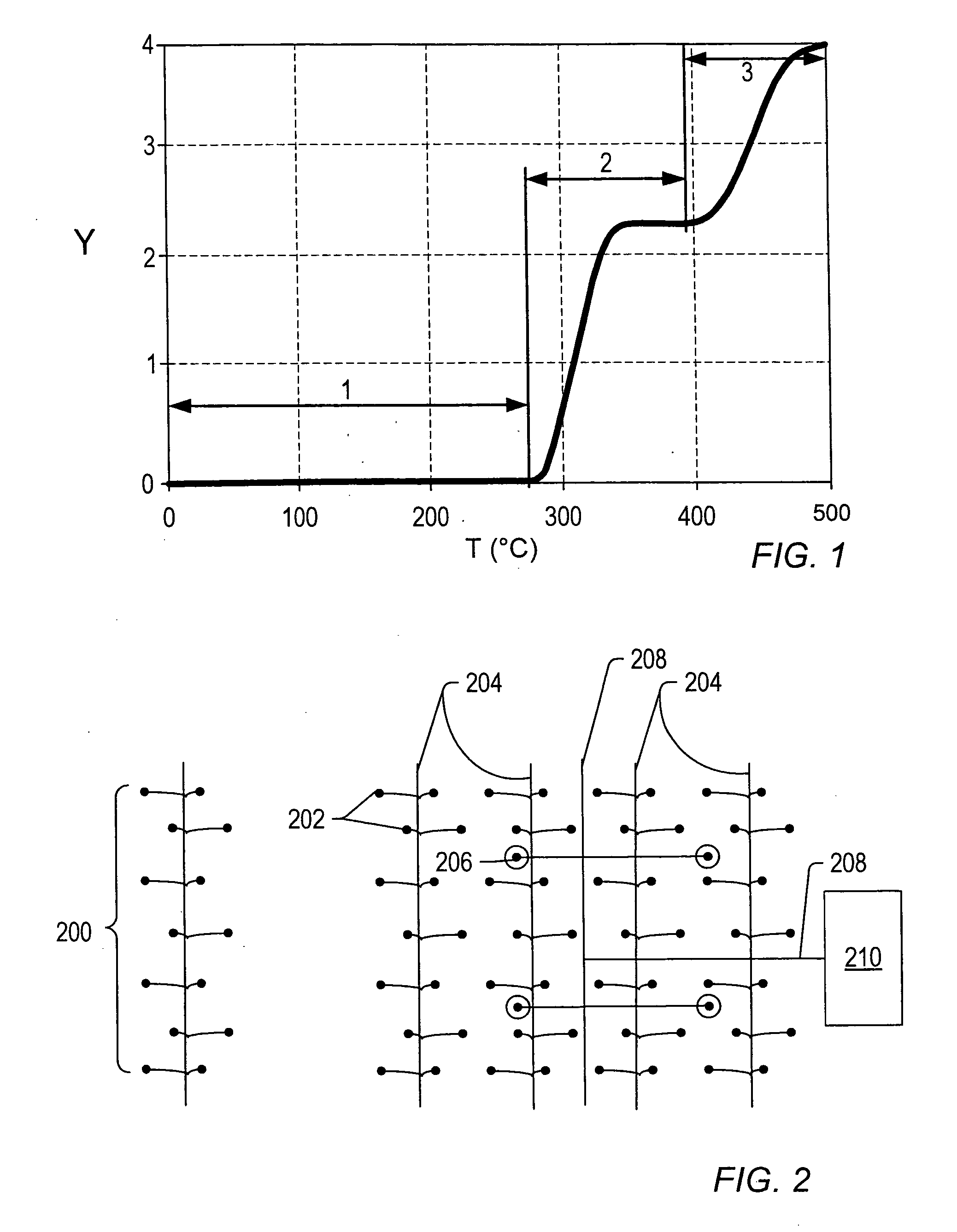

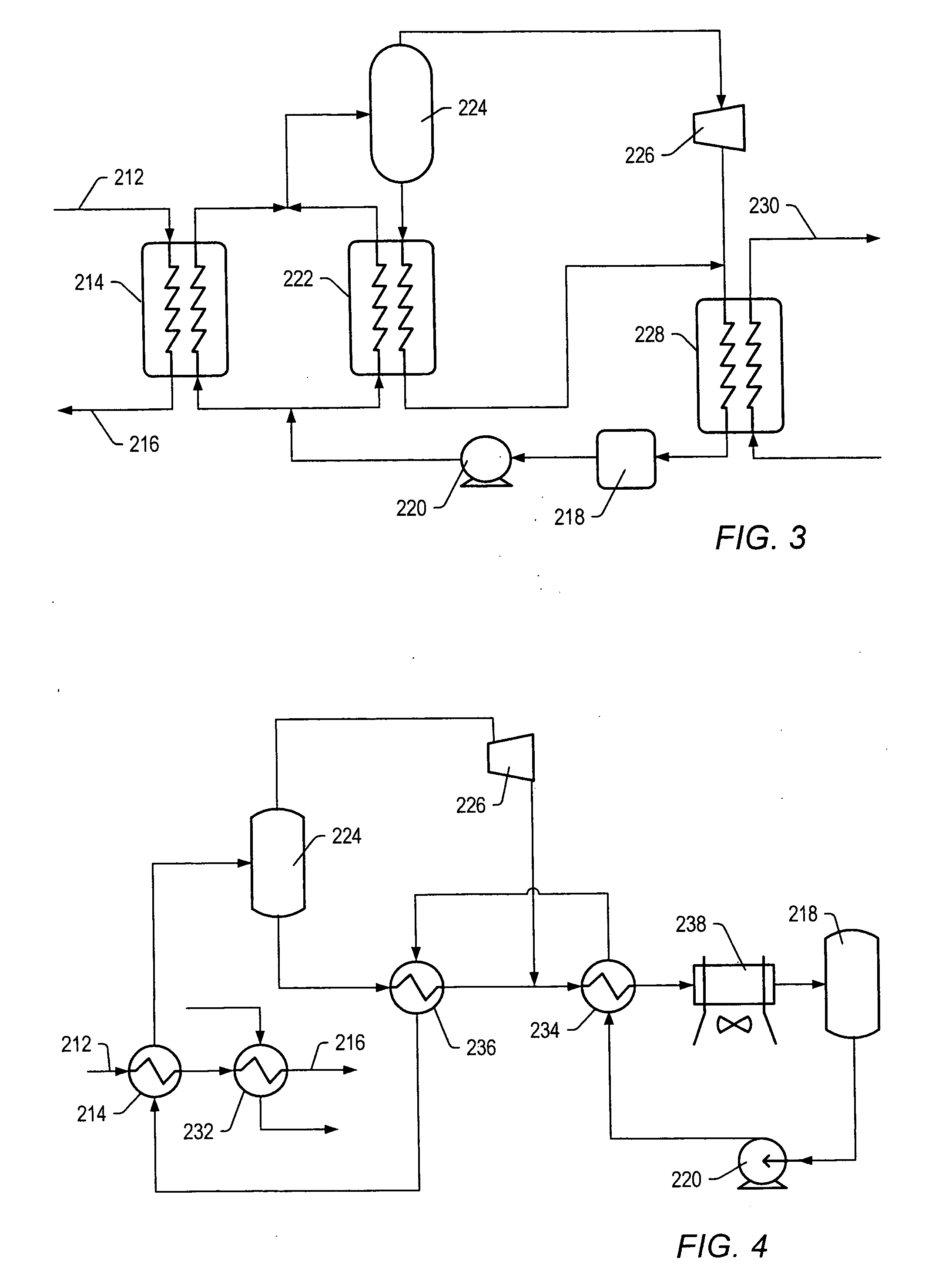

Cogeneration systems and processes for treating hydrocarbon containing formations

InactiveUS20070095536A1Thermal non-catalytic crackingCatalytic crackingElectricityNuclear engineering

A system for treating a hydrocarbon containing formation includes a steam and electricity cogeneration facility. At least one injection well is located in a first portion of the formation. The injection well provides steam from the steam and electricity cogeneration facility to the first portion of the formation. At least one production well is located in the first portion of the formation. The production well in the first portion produces first hydrocarbons. At least one electrical heater is located in a second portion of the formation. At least one of the electrical heaters is powered by electricity from the steam and electricity cogeneration facility. At least one production well is located in the second portion of the formation. The production well in the second portion produces second hydrocarbons. The steam and electricity cogeneration facility uses the first hydrocarbons and / or the second hydrocarbons to generate electricity.

Owner:SHELL OIL CO

Coal Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

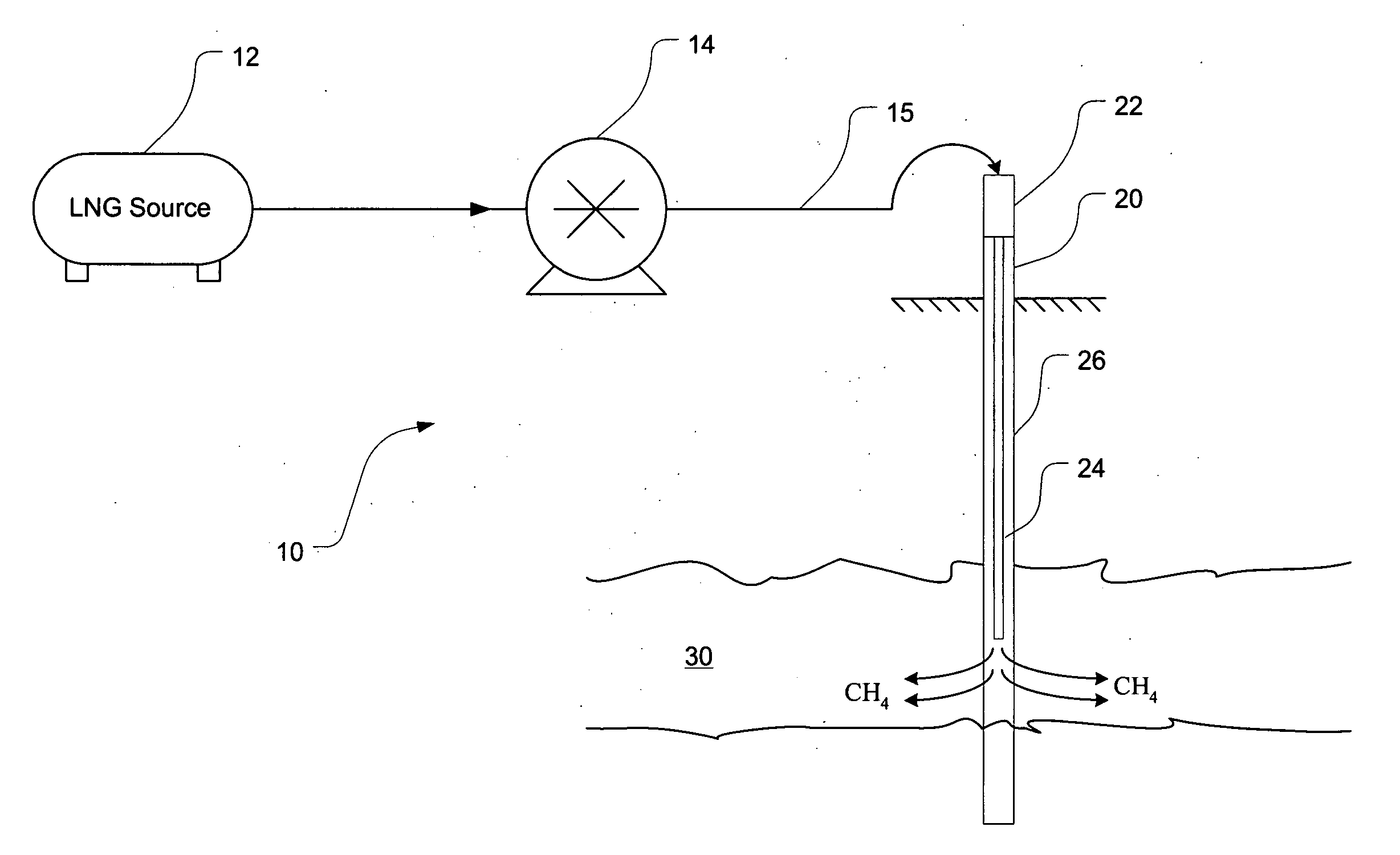

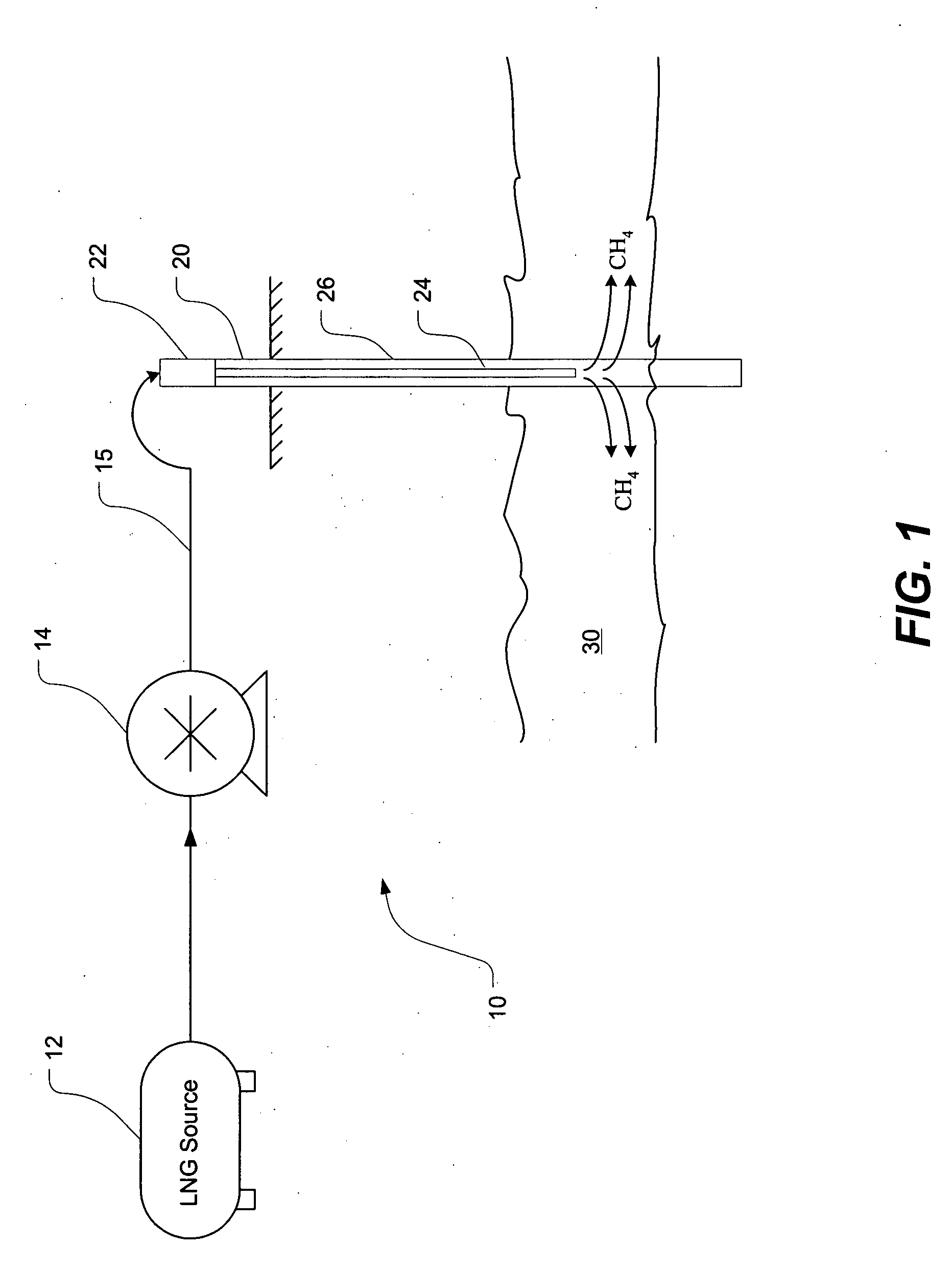

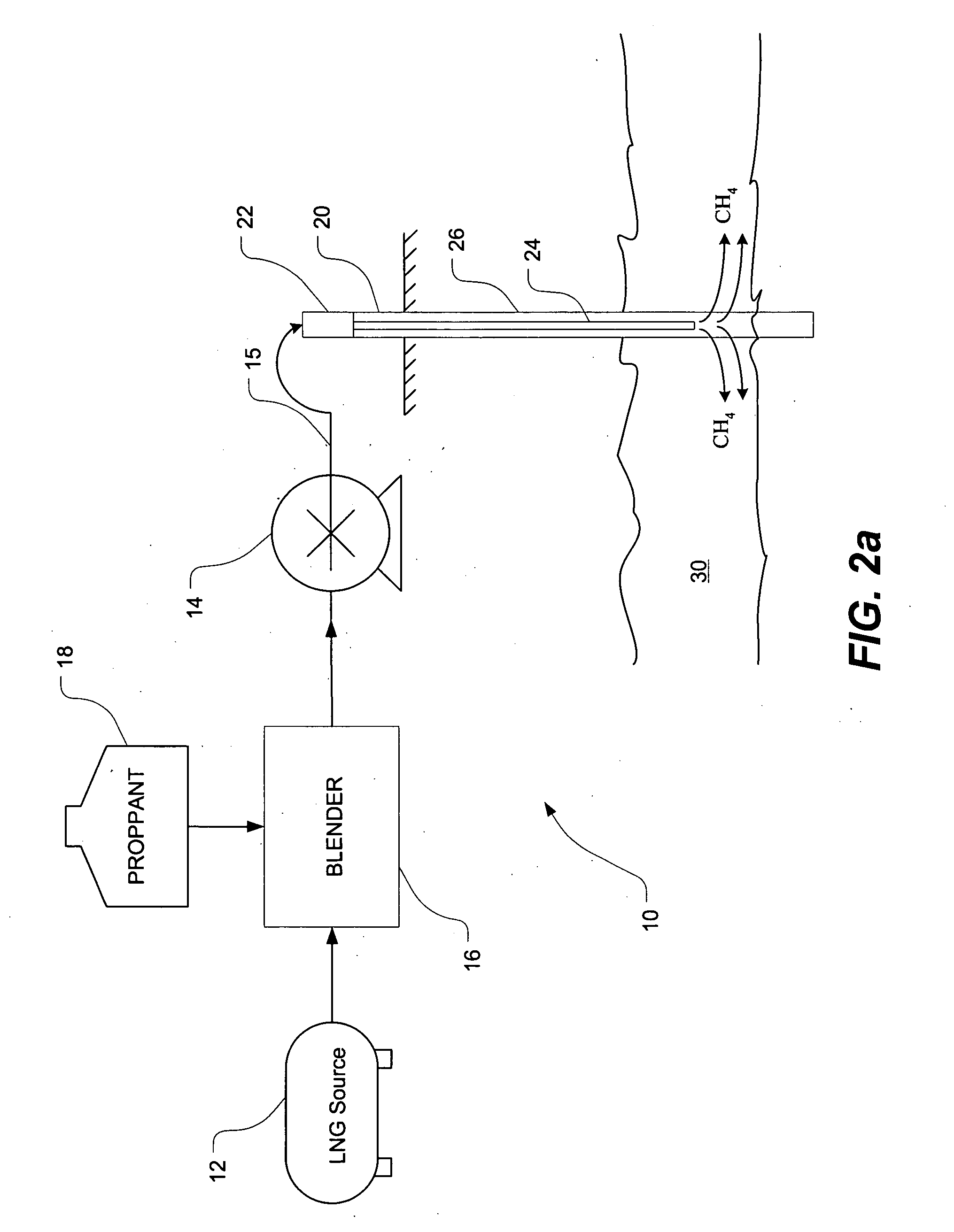

Method and apparatus for stimulating a subterranean formation using liquefied natural gas

InactiveUS20060065400A1Shorten production timeLow costSurveyFluid removalFracturing fluidHydrogen compounds

Liquefied natural gas is used as a fracturing fluid to stimulate production of hydrocarbons from and / or injectability of fluids into subterranean formations. Proppants may be blended with the LNG prior to pumping the liquefied natural gas into the well. Optionally, the liquefied natural gas is heated after it is pumped and before it is introduced into the subterranean formation.

Owner:SMITH DAVID RANDOLPH

Coal Compositions for Catalytic Gasification

ActiveUS20090217590A1Drying solid materials with heatGaseous fuelsPtru catalystHydrocotyle bowlesioides

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

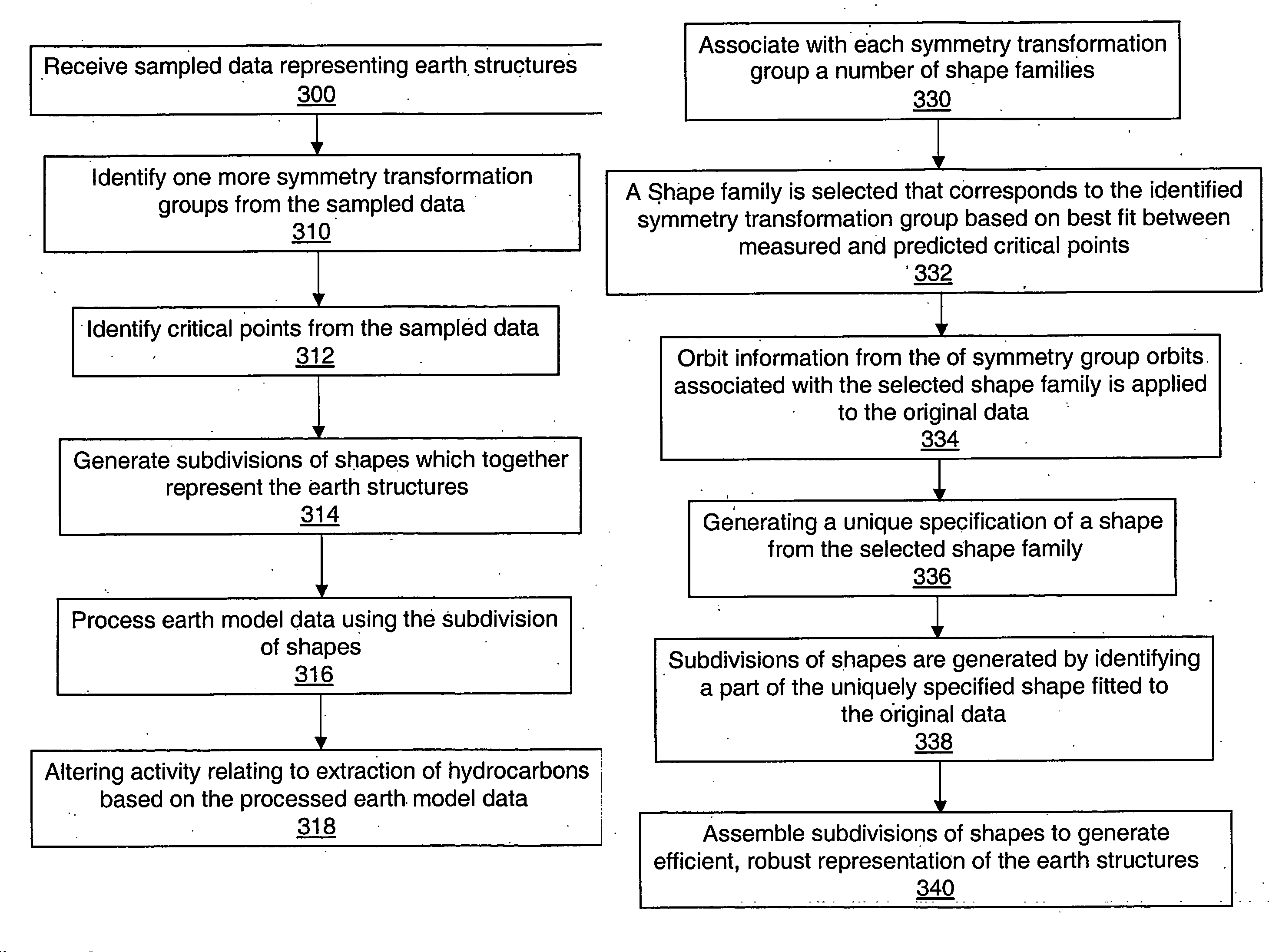

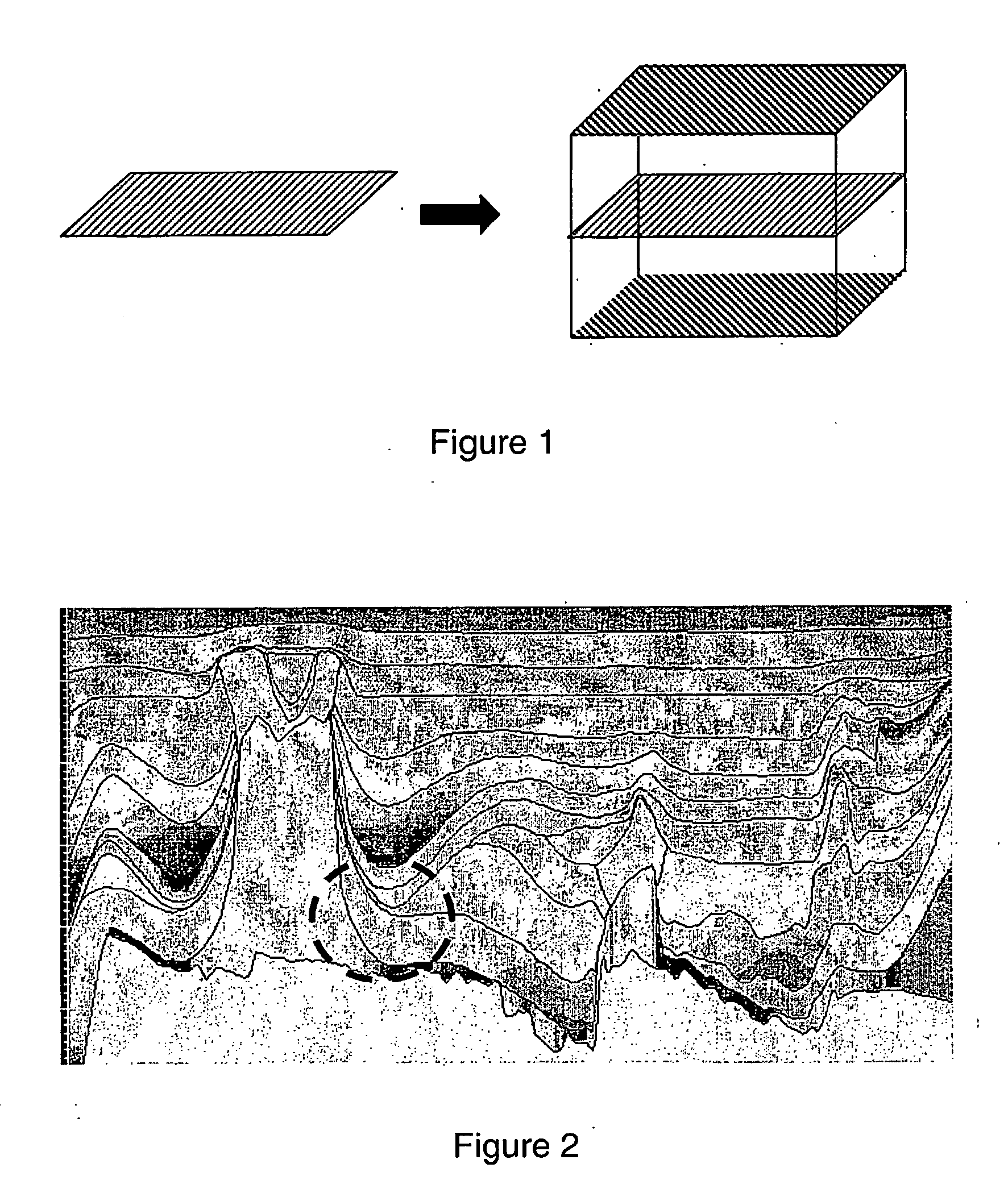

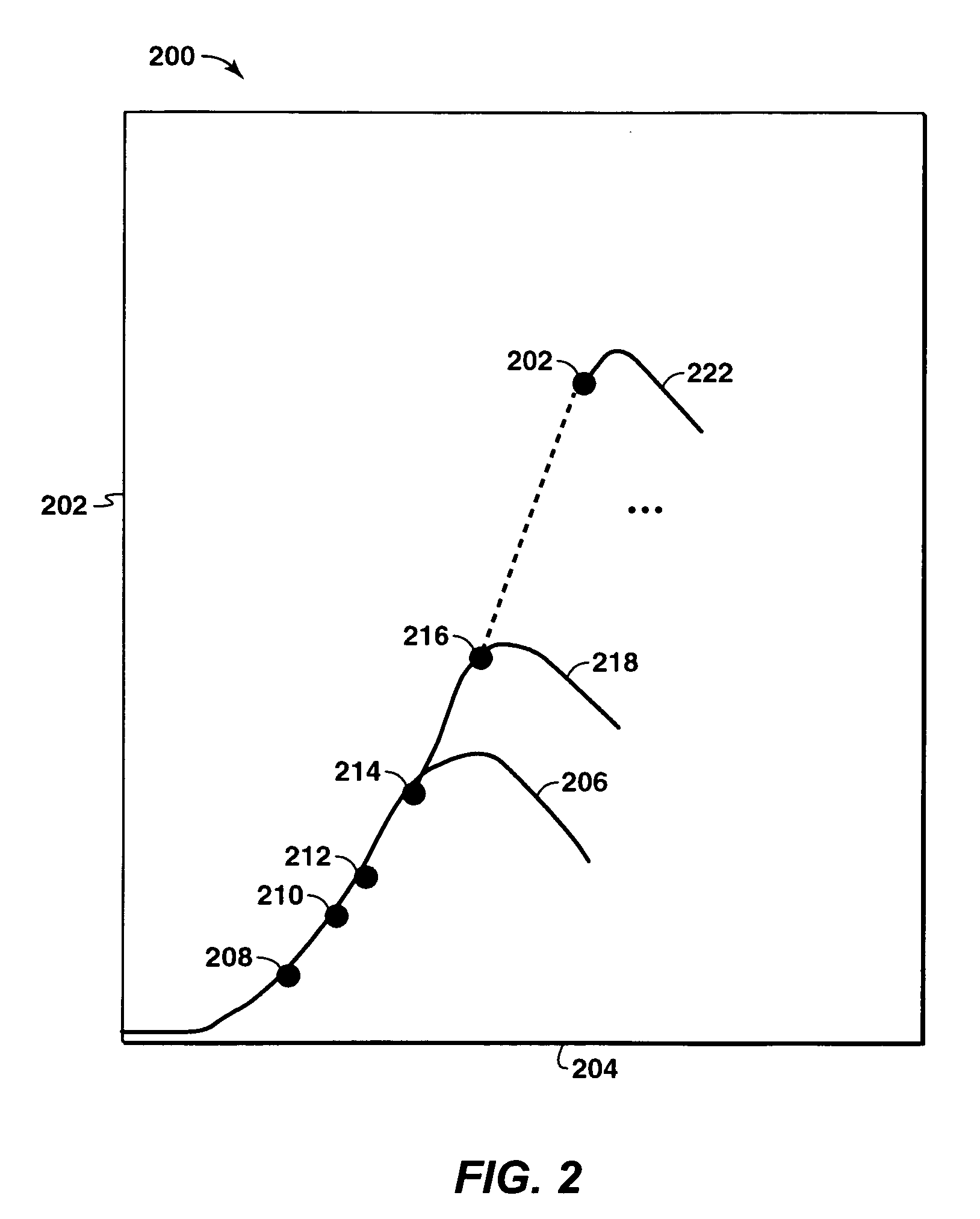

System and method for representing and processing and modeling subterranean surfaces

InactiveUS20060235666A1Enhance memoryImprove efficiencyGeological measurementsAnalogue processes for specific applicationsCrucial pointHydrocotyle bowlesioides

Methods and systems are disclosed for processing data used for hydrocarbon extraction from the earth. Symmetry transformation groups are identified from sampled earth structure data. A set of critical points is identified from the sampled data. Using the symmetry groups and the critical points, a plurality of subdivisions of shapes is generated, which together represent the original earth structures. The symmetry groups correspond to a plurality of shape families, each of which includes a set of predicted critical points. The subdivisions are preferably generated such that a shape family is selected according to a best fit between the critical points from the sampled data and the predicted critical points of the selected shape family.

Owner:SCHLUMBERGER TECH CORP

Self adaptive cement systems

InactiveUS20070137528A1Avoid seizuresInhibit migrationSolid waste managementDrilling compositionSelf-healingChemical products

A self-adaptive cement system includes cement, water and at least one additive that reacts or and expands in contact with oil and gas. Several chemical products have been identified including rubber alkylstyrene, polynorbornene, resins such precrosslinked substituted vinyl acrylate copolymers and diatomaceous earth. These additives have the effect of making the cement self-healing in the event of physical failure or damage such as micro-annuli. The self healing property is produced by the contact with subterranean hydrocarbon fluids, the potential repair mechanism is thus activated if and when needed in case of start of loss of zonal isolation. In another embodiment, the expansion is deliberately induced by pumping a hydrocarbon fluid in the vicinity of the set cement.

Owner:SCHLUMBERGER TECH CORP

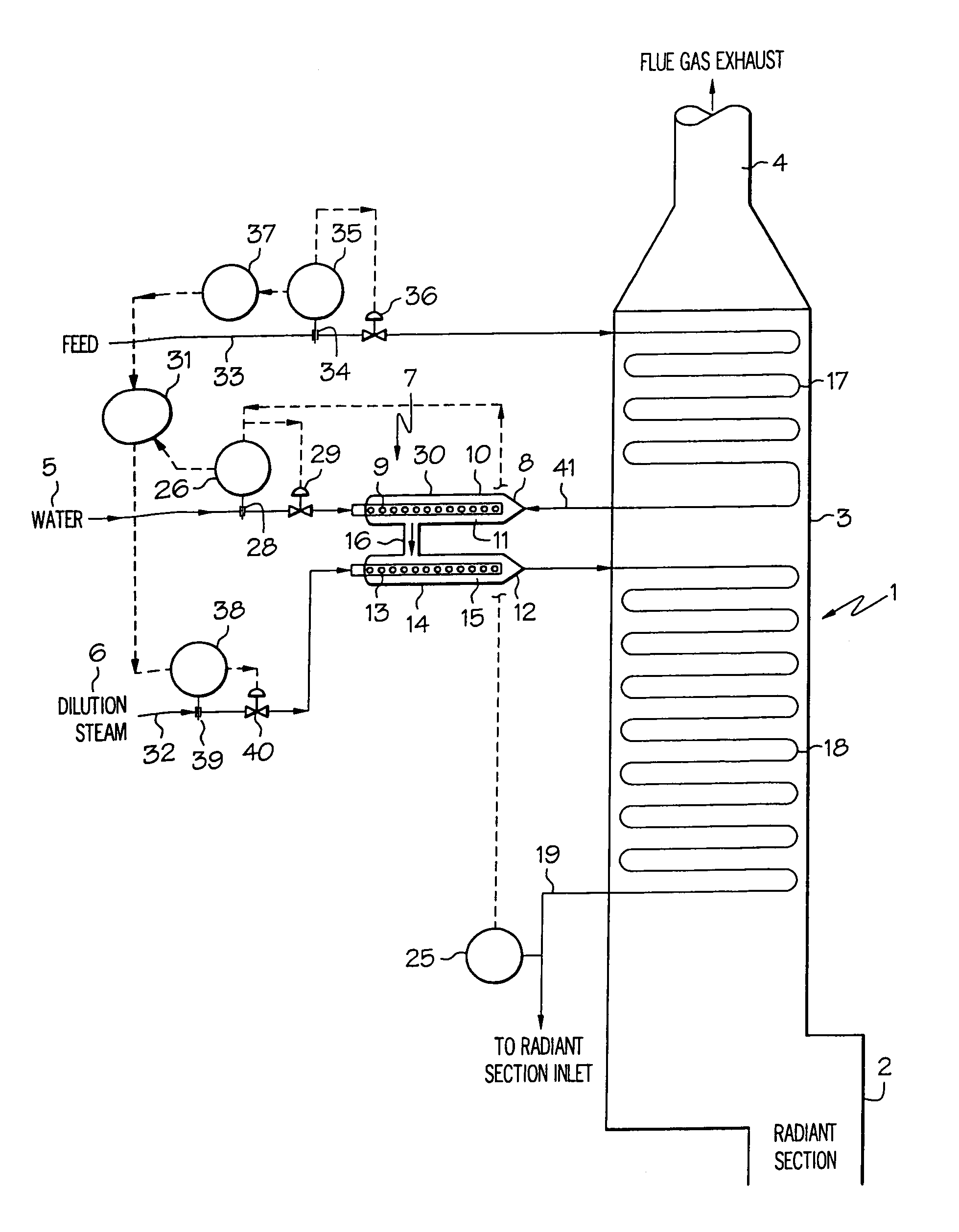

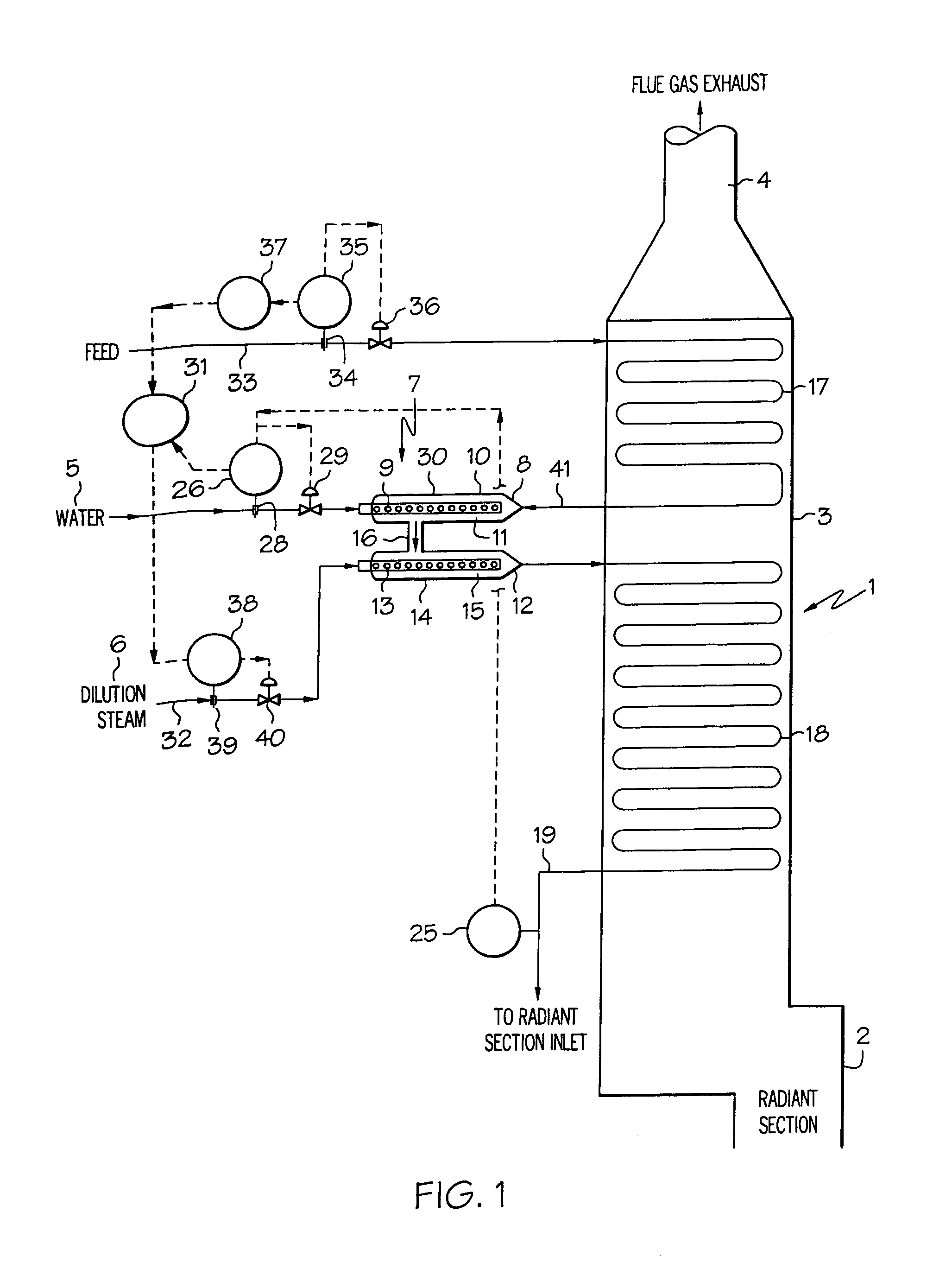

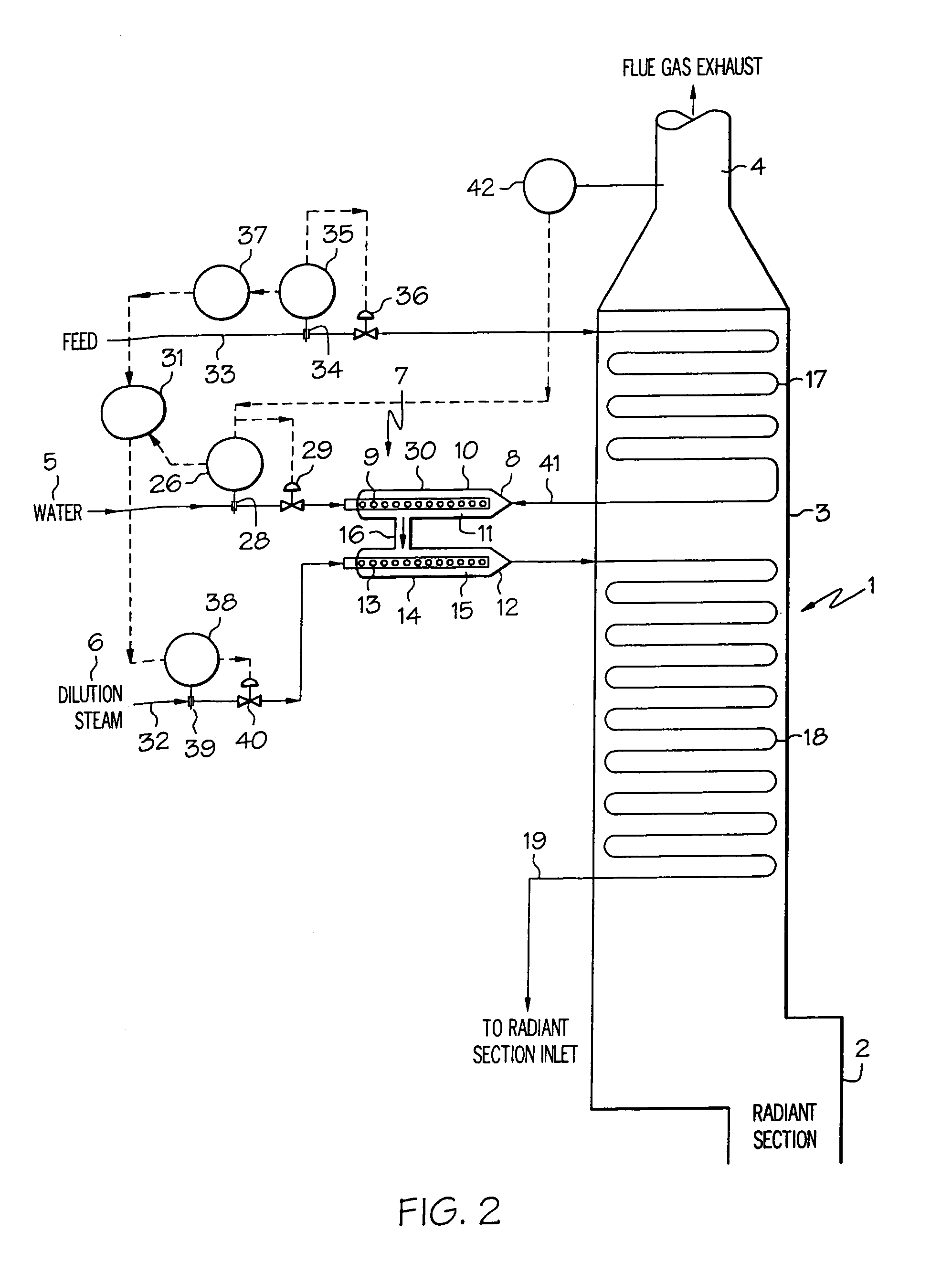

Process for cracking hydrocarbon feed with water substitution

InactiveUS7090765B2Thermal non-catalytic crackingHydrocarbon oil cracking processHydrocarbonHydrocotyle bowlesioides

A process for treating hydrocarbon feed in a furnace, the process comprising: (a) heating hydrocarbon feed, (b) adding water to the heated feed, (c) adding dilution steam to the heated feed to form a mixture, (d) heating the resulting mixture and feeding the resulting heated mixture to the furnace, wherein the water in (b) is added in an amount of from at least about 1% to 100% based on water and dilution steam by weight.

Owner:EXXONMOBIL CHEM PAT INC

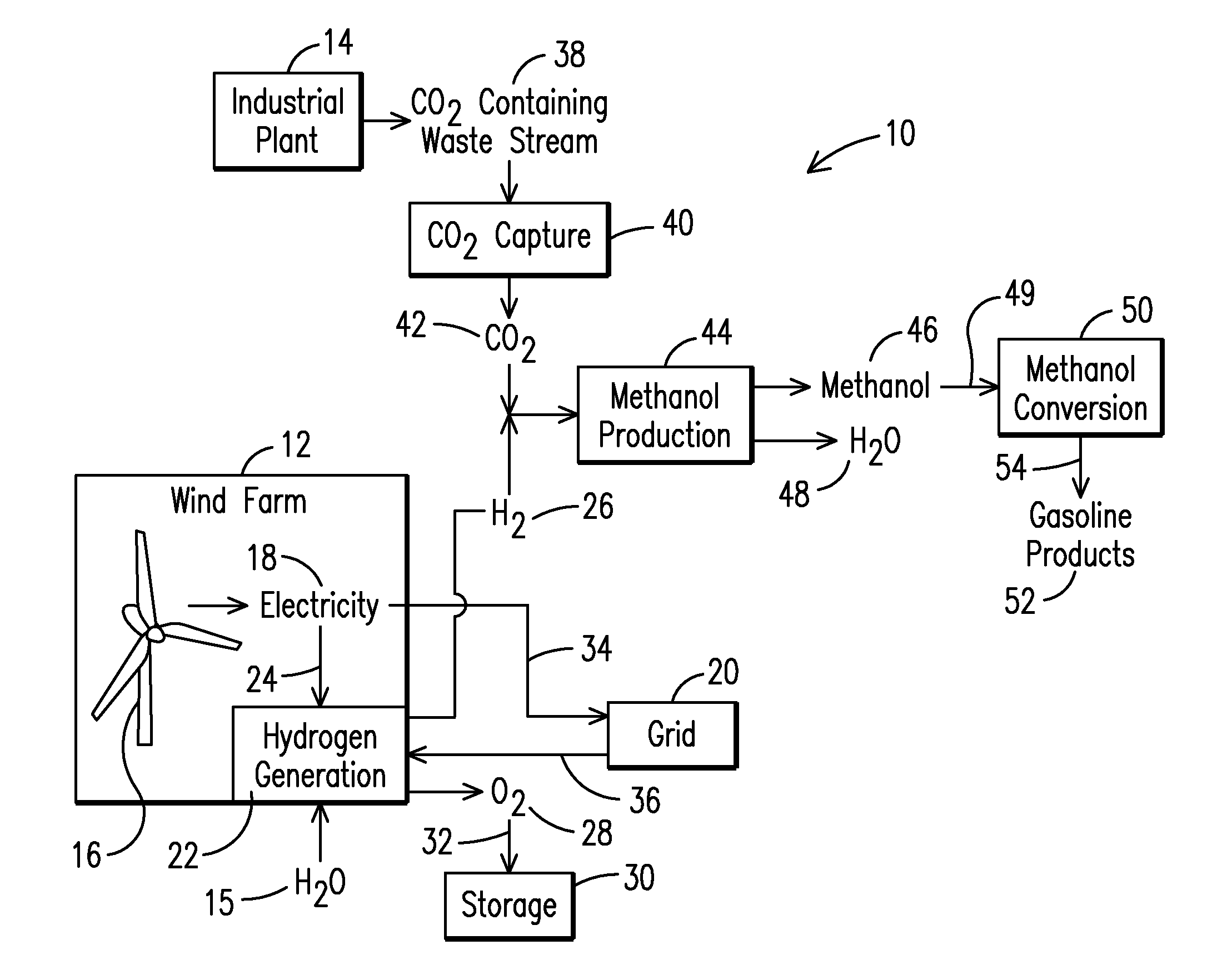

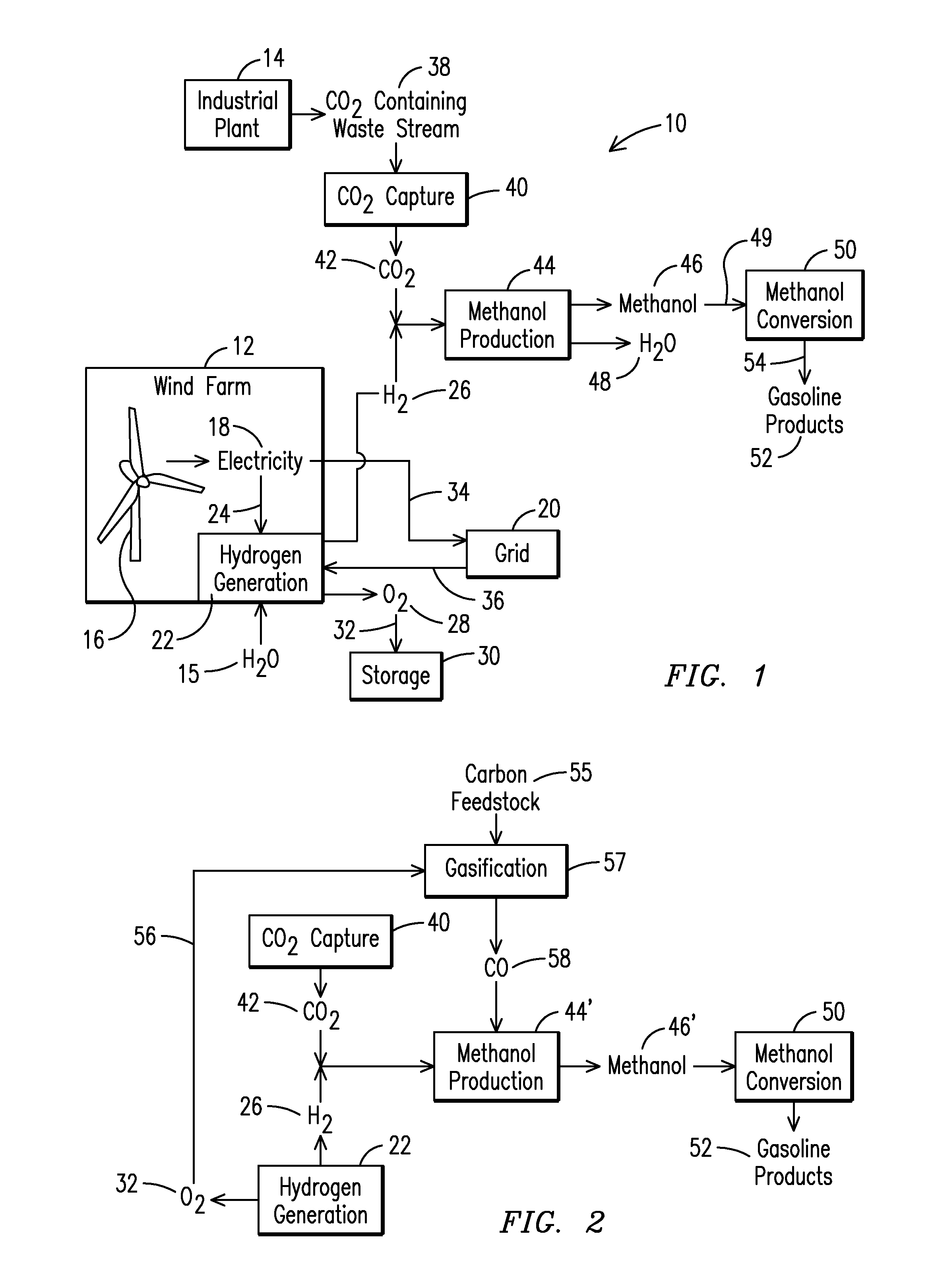

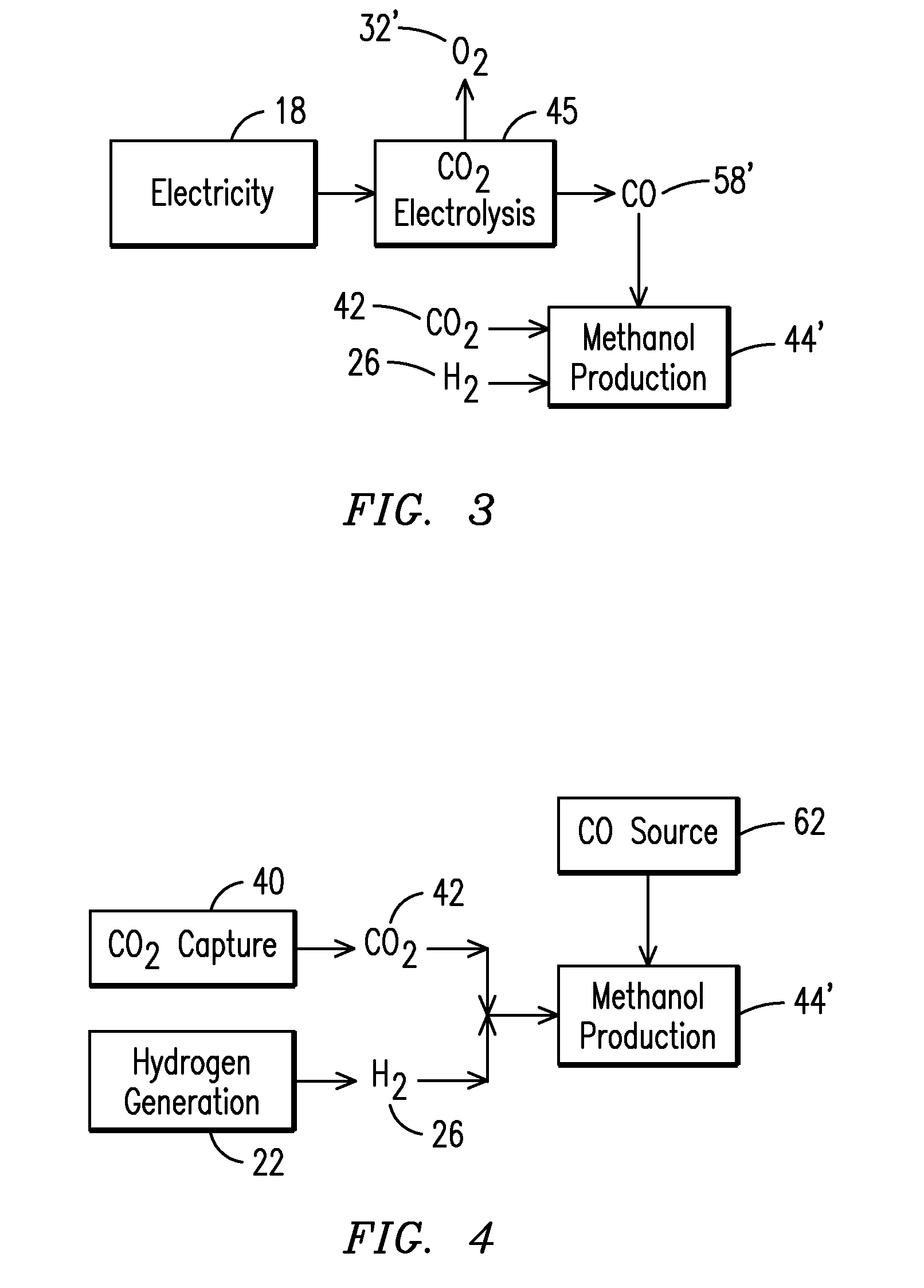

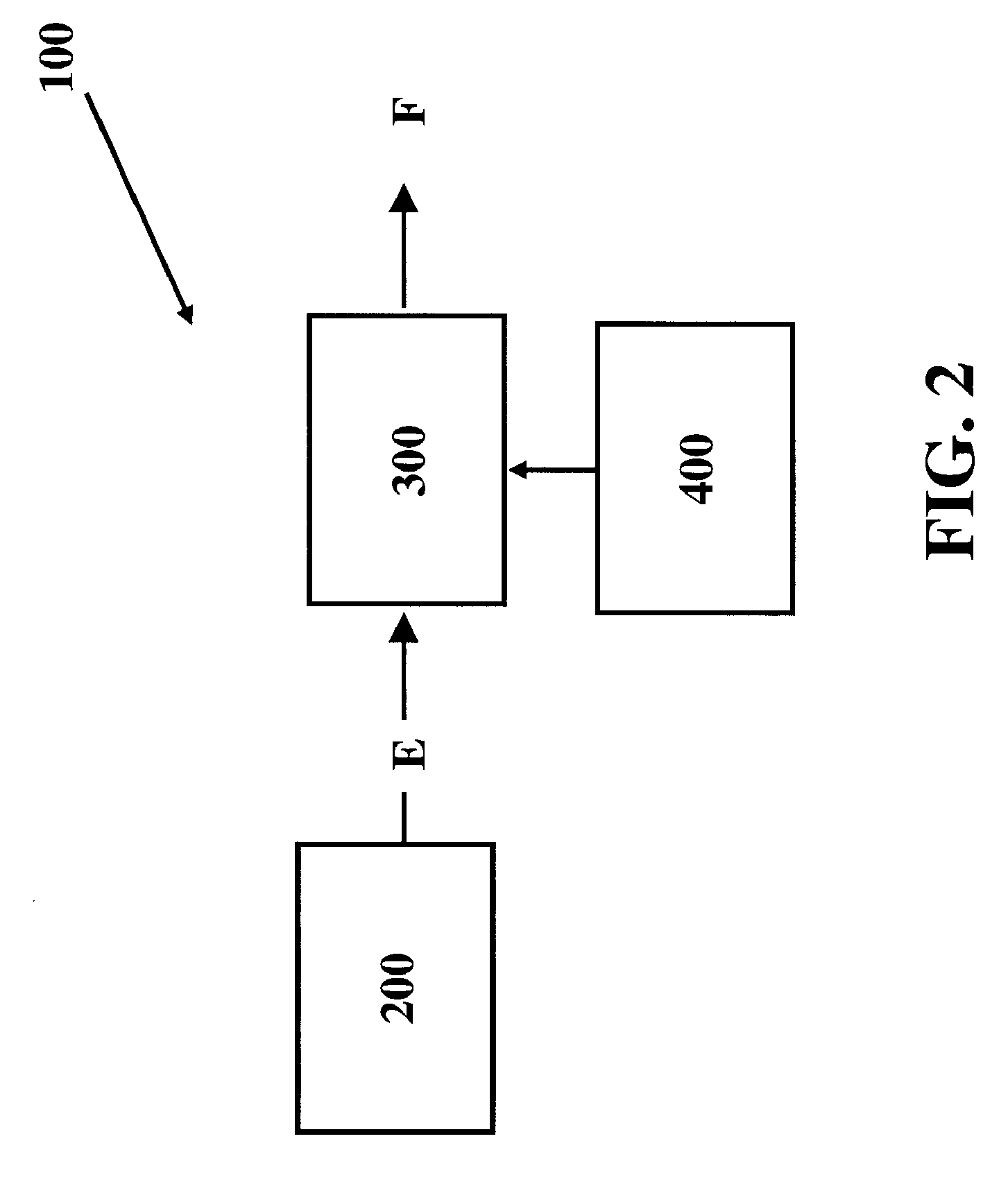

Production of Fuel Materials Utilizing Waste Carbon Dioxide and Hydrogen from Renewable Resources

ActiveUS20090289227A1Emission reduction for energy storageHydrogen/synthetic gas productionChemistryRenewable resource

The present invention is directed to a method for utilizing CO2 waste comprising recovering carbon dioxide from an industrial process that produces a waste stream comprising carbon dioxide in an amount greater than an amount of carbon dioxide present in starting materials for the industrial process. The method further includes producing hydrogen using a renewable energy resource and producing a hydrocarbon material utilizing the produced hydrogen and the recovered carbon dioxide.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Production of low sulfur syngas from natural gas with C4+/C5+ hydrocarbon recovery

Sour natural gas is processed to remove the sulfur compounds and recover C4+ / C5+ hydrocarbons by scrubbing the gas with an amine solution to remove most of the sulfur, followed cooling the gas to remove C4+ / C5+ hydrocarbons and more sulfur compounds as liquid condensate to produce a gas having less than 20 vppm of total sulfur. The condensate is sent to a fractionator to recover the C4+ / C5+ hydrocarbons. The sulfur and hydrocarbon reduced gas is contacted first with zinc oxide and then nickel, to produce a gas having less than 10 vppb of total sulfur which is passed into a synthesis gas generating unit to form a very low sulfur synthesis gas comprising a mixture of H2 and CO. This synthesis gas is useful for hydrocarbon synthesis with increased life of the hydrocarbon synthesis catalyst and greater hydrocarbon production from the hydrocarbon synthesis reactor. Contacting the synthesis gas with zinc oxide further reduces the sulfur content to below 3 vppb.

Owner:EXXON RES & ENG CO

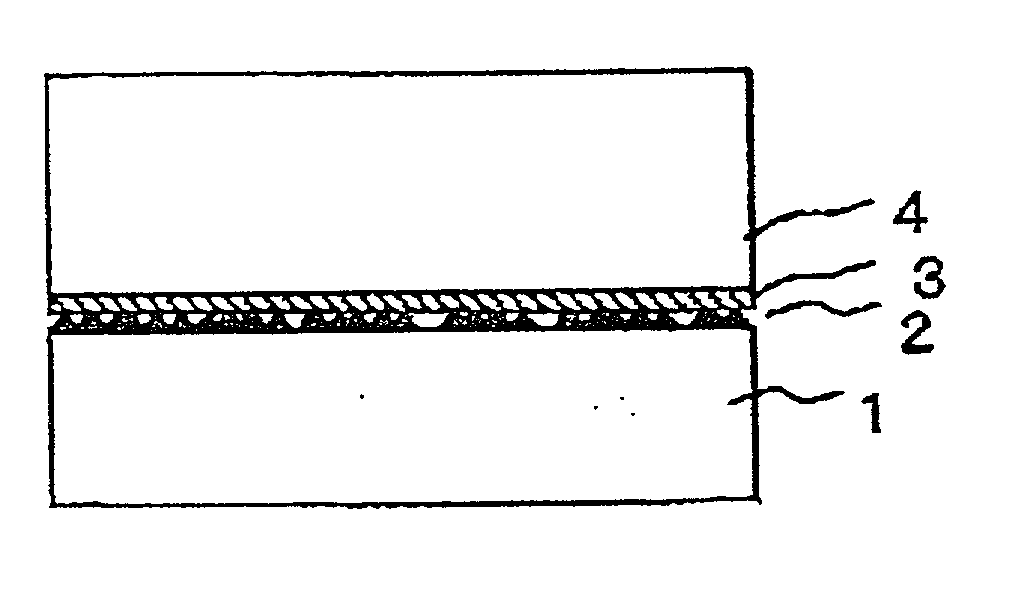

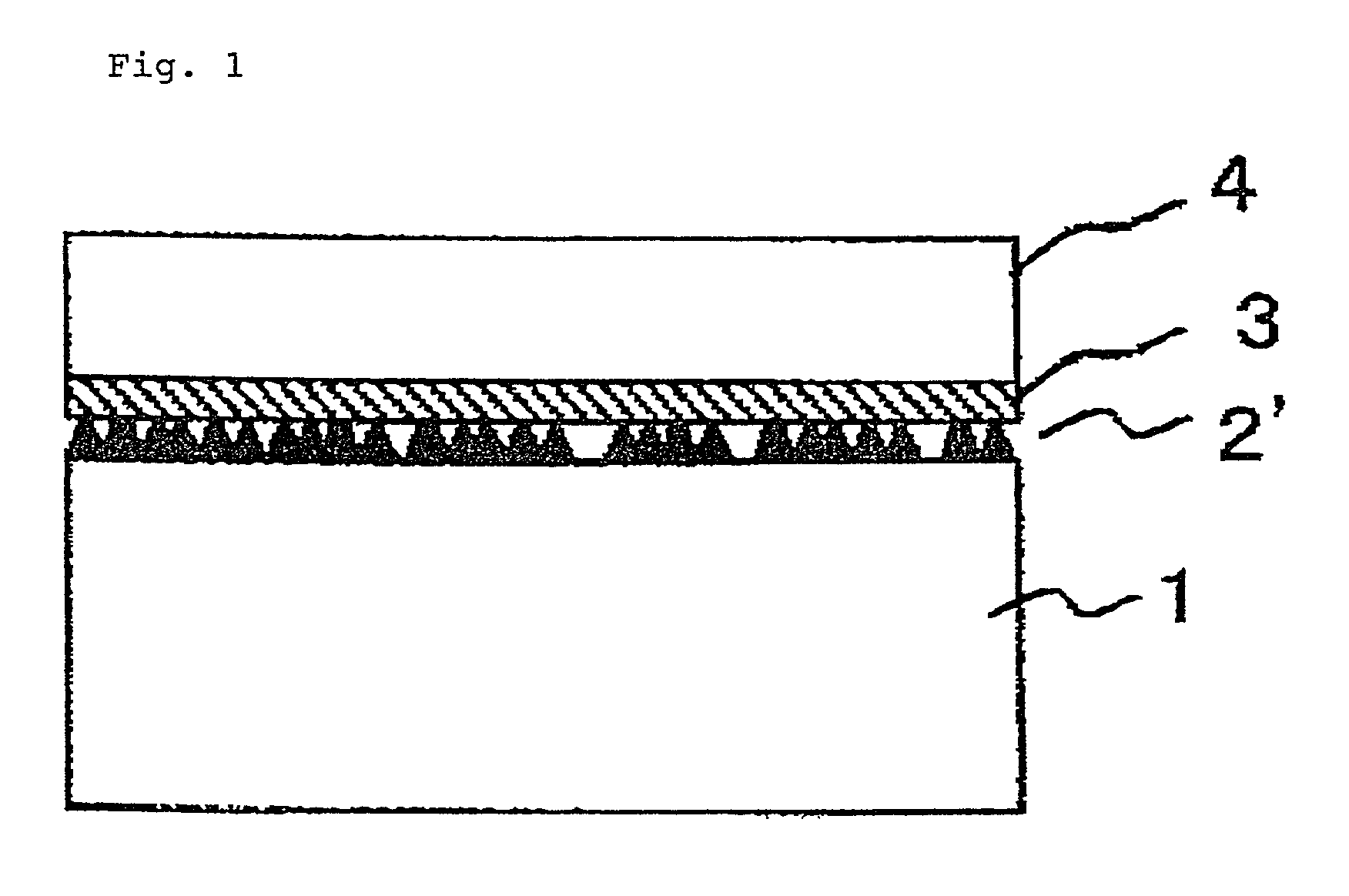

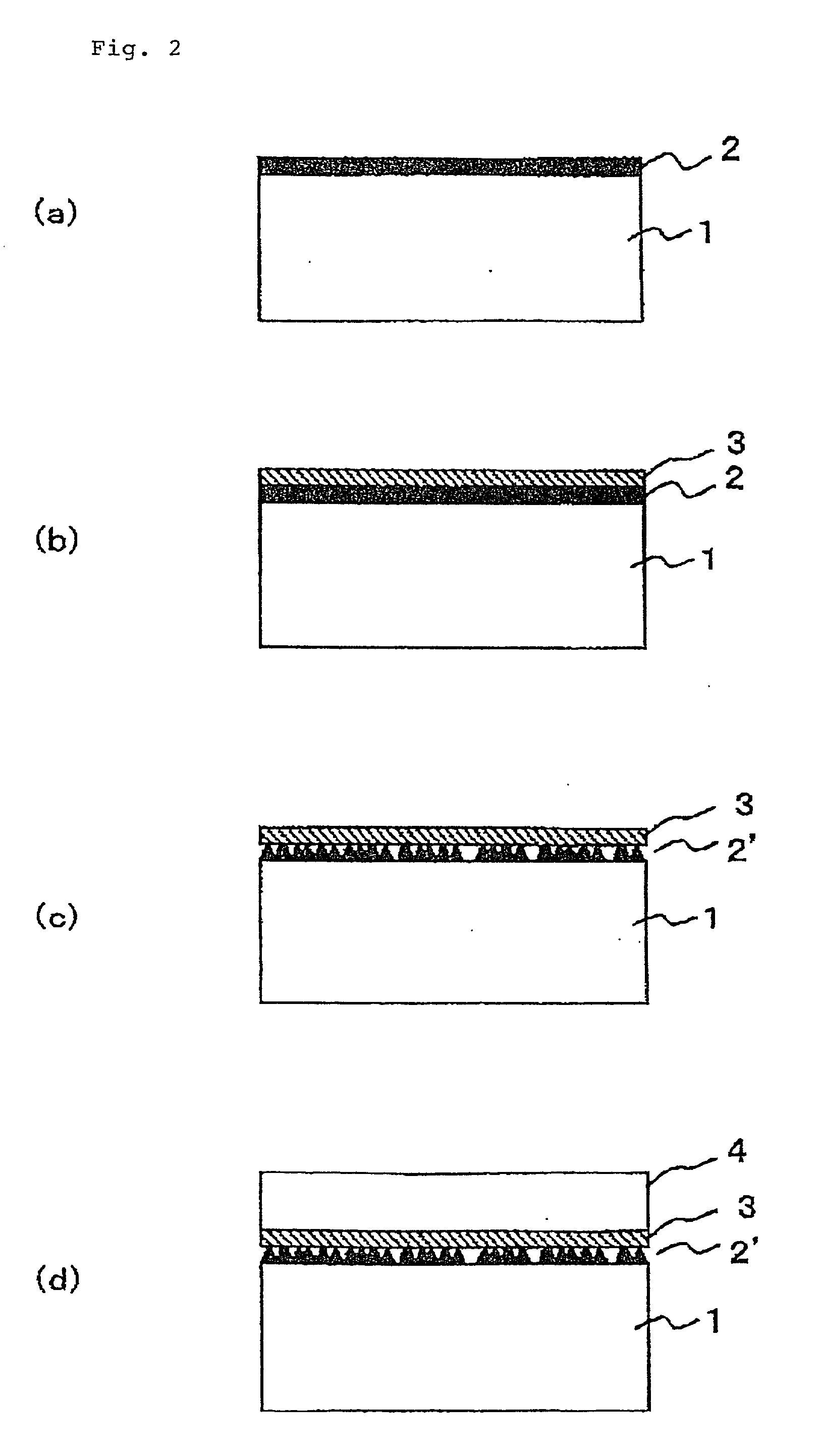

Semiconductor substrate made of group III nitride, and process for manufacture thereof

InactiveUS20020197825A1Reduce defect densityImprove crystal qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingHydrogen compoundsTitanium

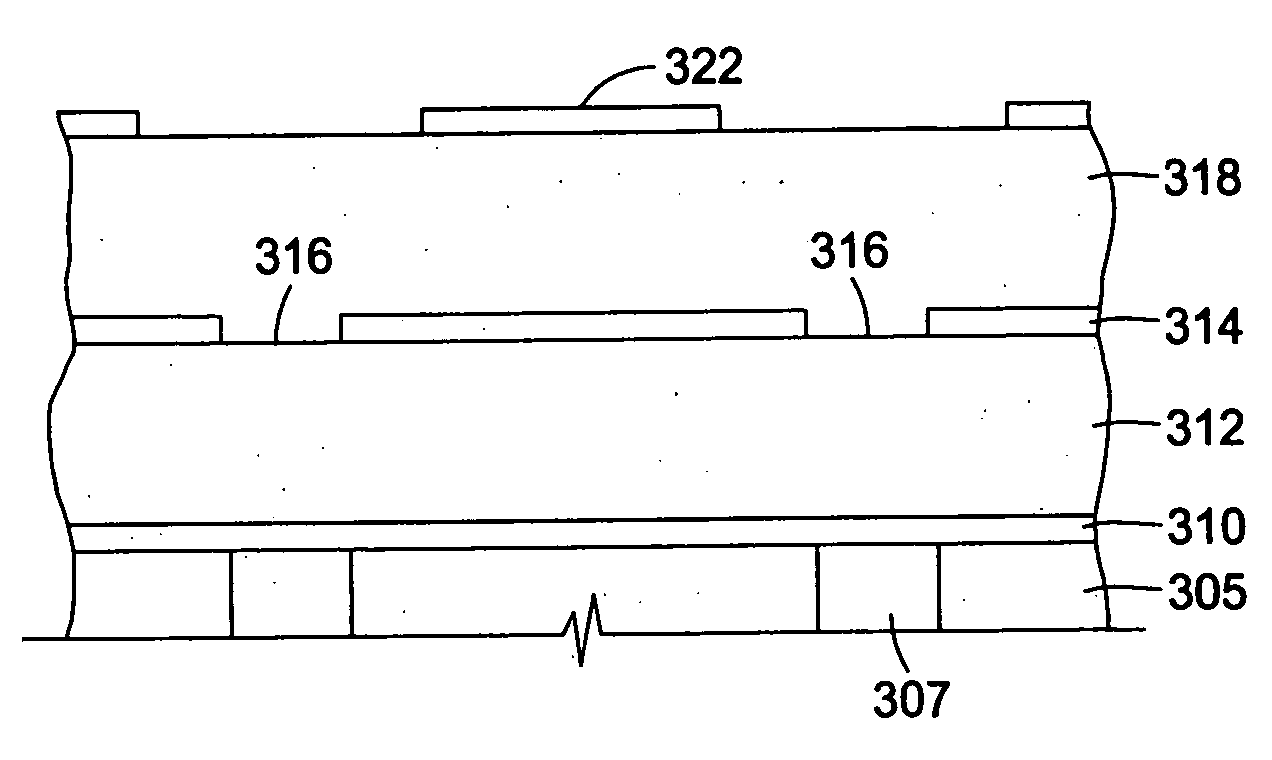

To provide a semiconductor substrate of a group III nitride with low defect density and little warp, this invention provides a process comprising such steps of: forming a GaN layer 2 on a sapphire substrate 1 of the C face ((0001) face); forming a titanium film 3 thereon; heat-treating the substrate in an atmosphere containing hydrogen gas or a gas of a compound containing hydrogen to form voids in the GaN layer 2; and thereafter forming a GaN layer 4 on the GaN layer 2'.

Owner:SUMITOMO CHEM CO LTD

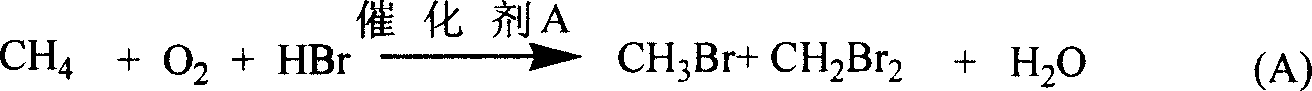

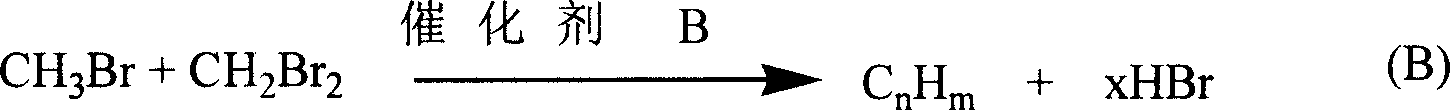

Flow process for synthesizing C3 to C13 high hydrocarbons by methane through non-synthetic gas method

The invention discloses a new flow path to make C3-C13 hydrocarbonate at the beginning with methane, which is characterized by the following: transmitting methane into CH3Br and CH2Br2 acted by oxygen and HBr / H2O; reacting CH3Br and CH2Br2 in the second reactor to make C3-C13 hydrocarbonate and HBr; adopting HBr as circulated reacting dielectric in the making course of CH3Br and CH2Br2; making the transmitting rate of methane to 32.0% and the selectivity of CH3Br to 80-0% and the selectivity of CH2Br2 to 0.67%; entering the product in the first reactor and residual reacting material into the second reactor directly; making the transmitting rate of methane in the first reactor to 30.0% and total selectivity of CH3Br and CH2Br2 to 88% in the first reactor and the transmitting rate of CH3Br and CH2Br2 to 100% in the second reactor.

Owner:MICROVAST POWER SYST CO LTD

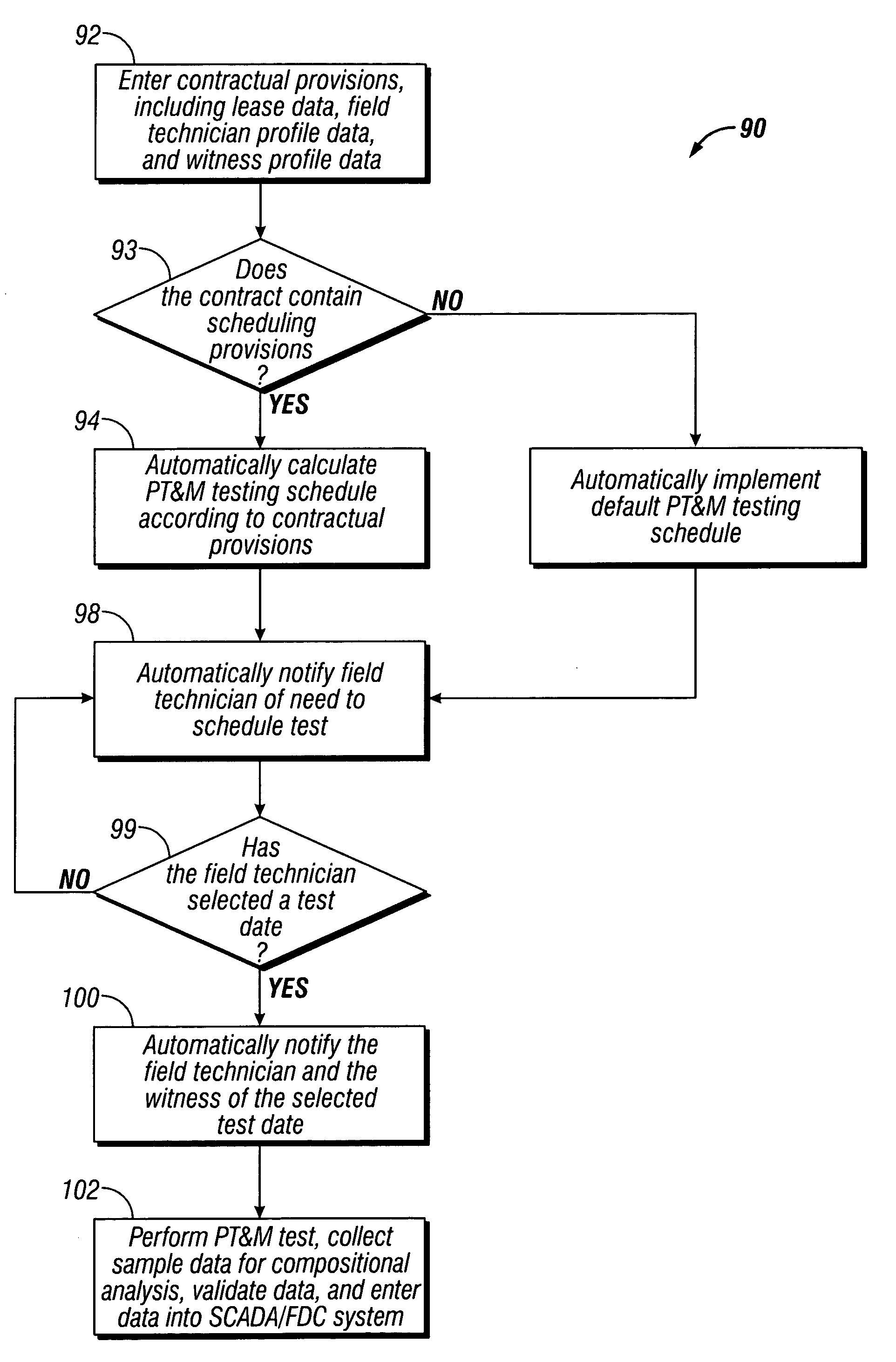

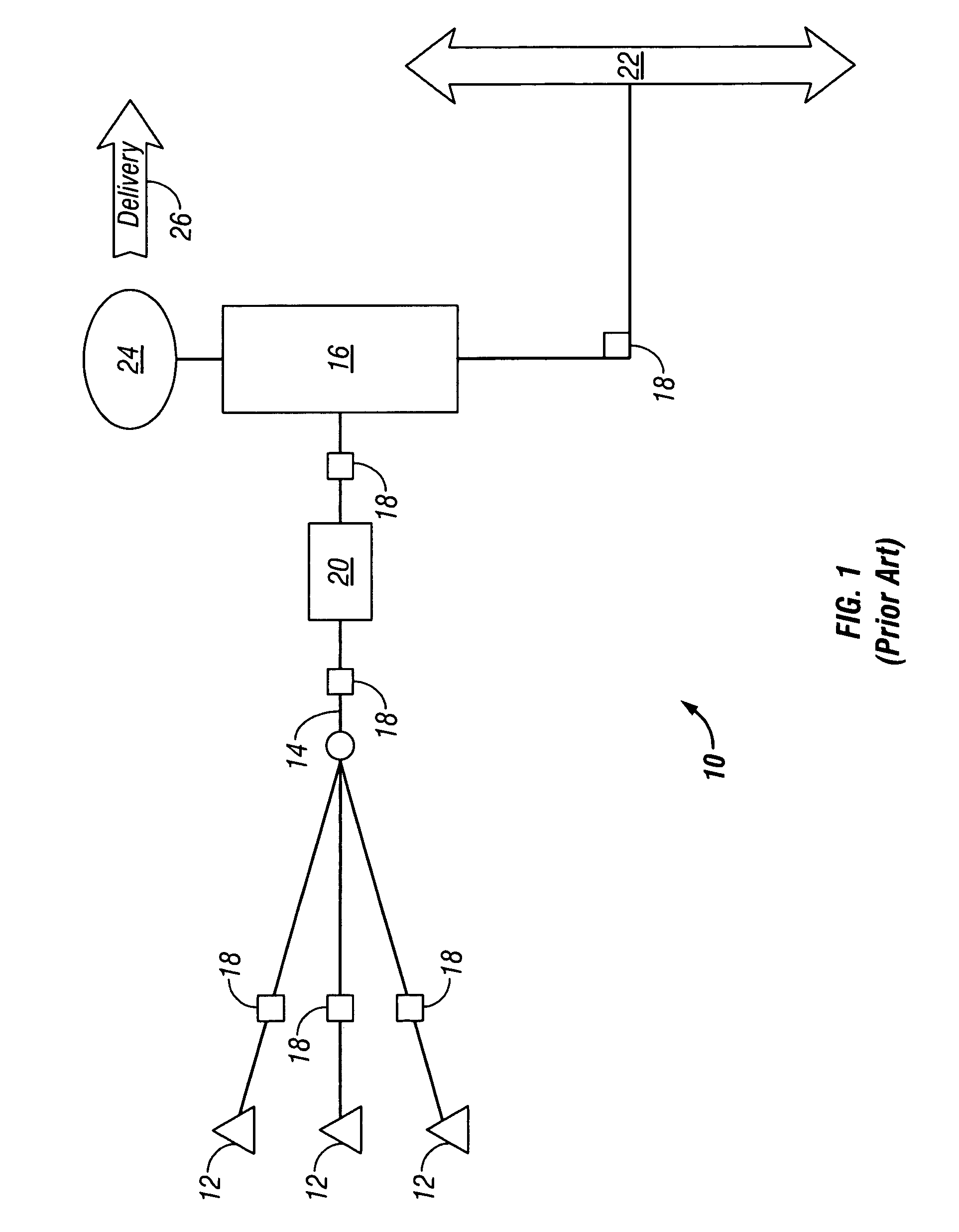

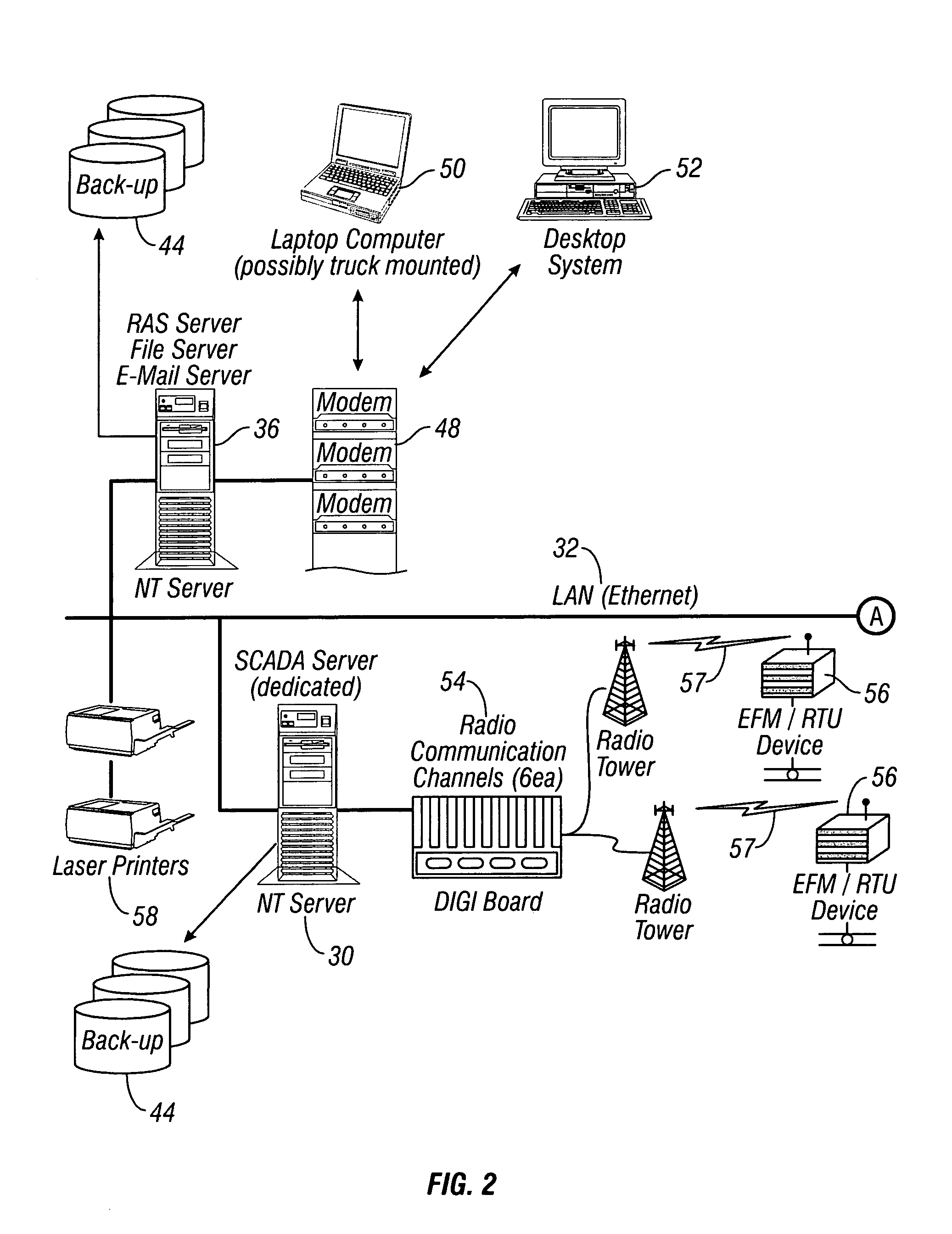

Method for automated management of hydrocarbon gathering systems

InactiveUS6978210B1Electric/magnetic detection for well-loggingPermeability/surface area analysisData storingData store

The invention is a method for automated management of hydrocarbon gathering systems. Measurement data is automatically collected from automated measurement and control devices that are located in a hydrocarbon production system The data that is collected is compared with data stored in a database. The comparison of data is used to automatically schedule tests of the plurality of automated measurement and control devices. The invention also automatically collects well test data, system balance data, and hydrocarbon composition data and uses the collected data to manage the hydrocarbon production and delivery process. The invention also automatically generates periodic grid reports concerning the status of the gathering system.

Owner:CONOCOPHILLIPS CO

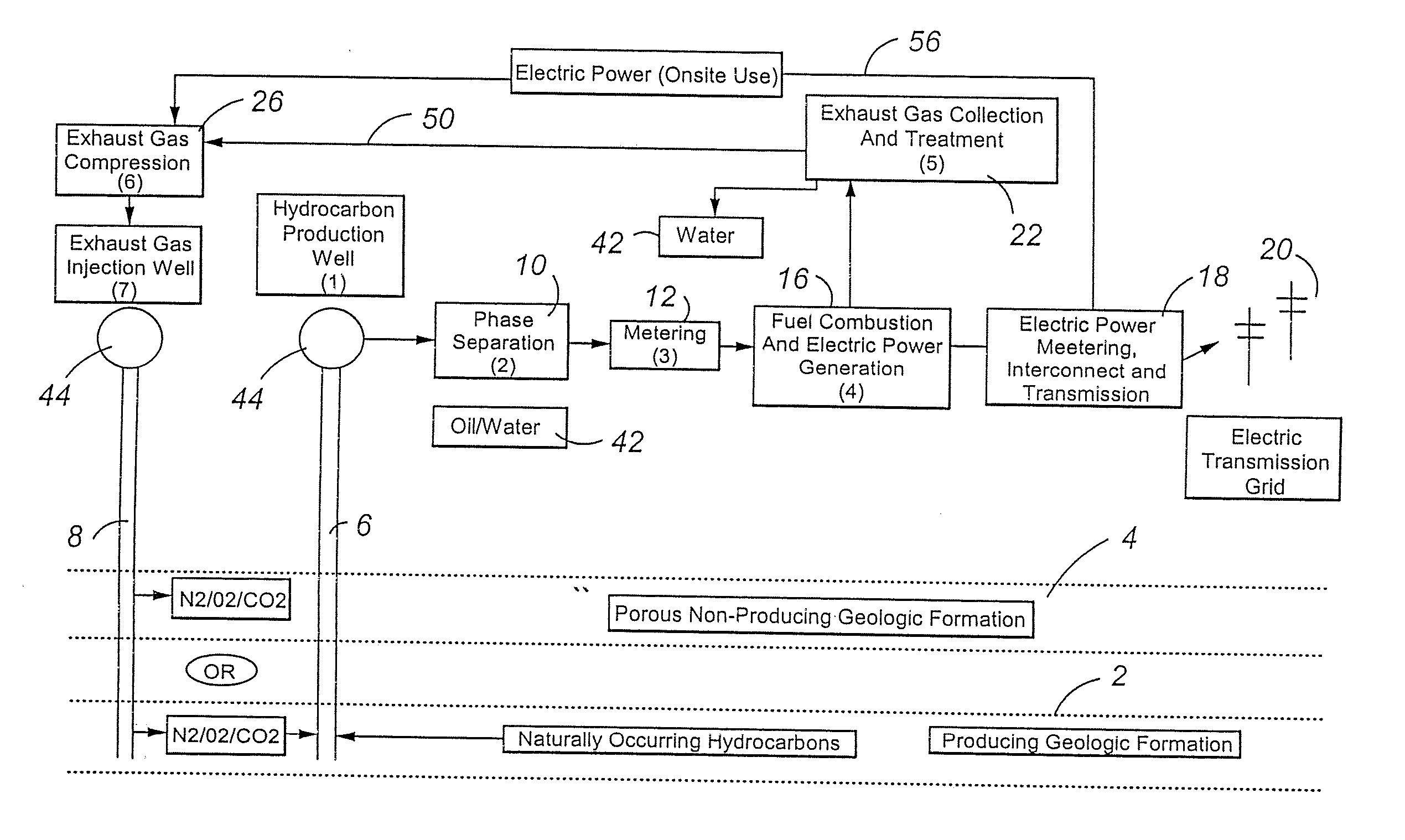

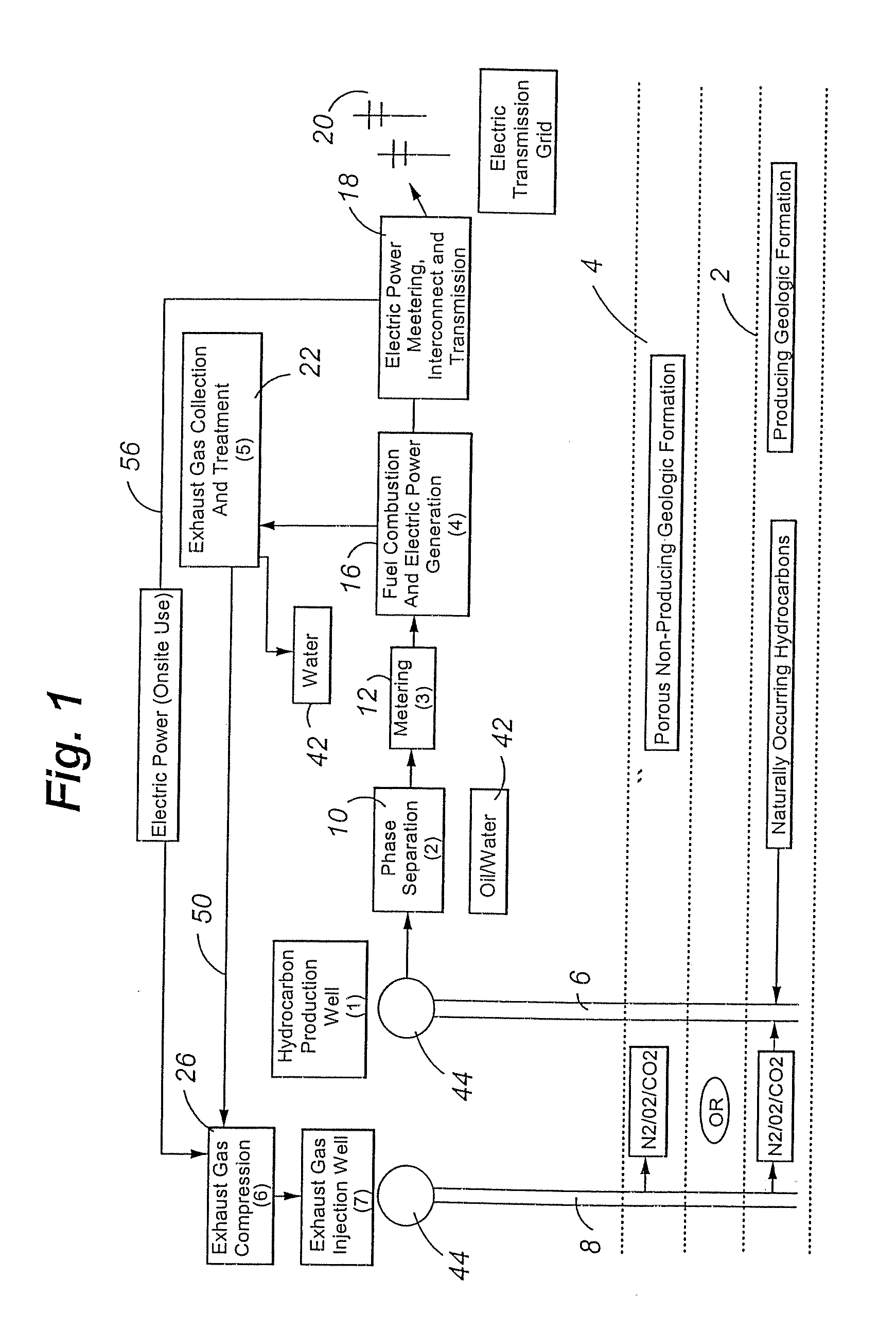

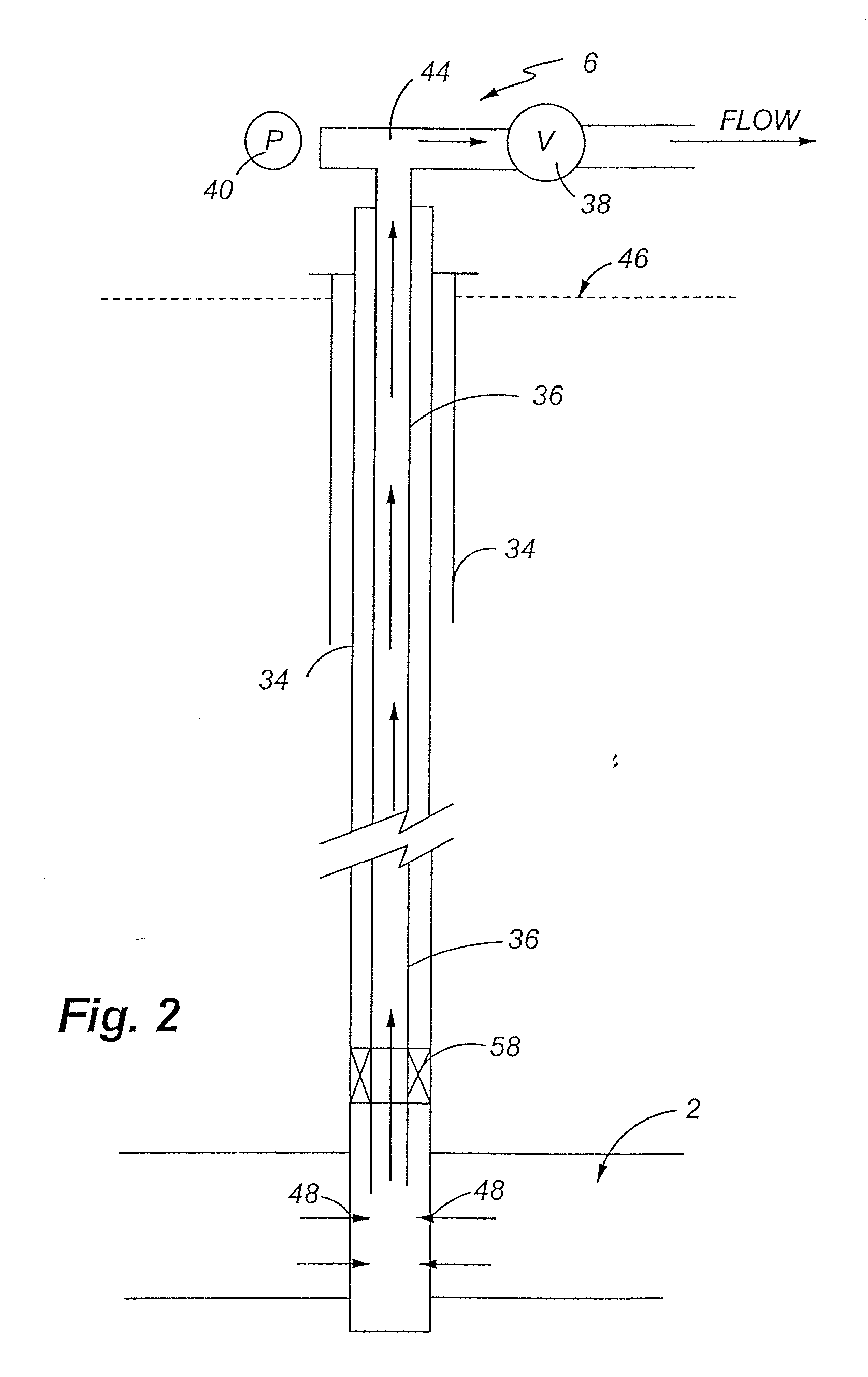

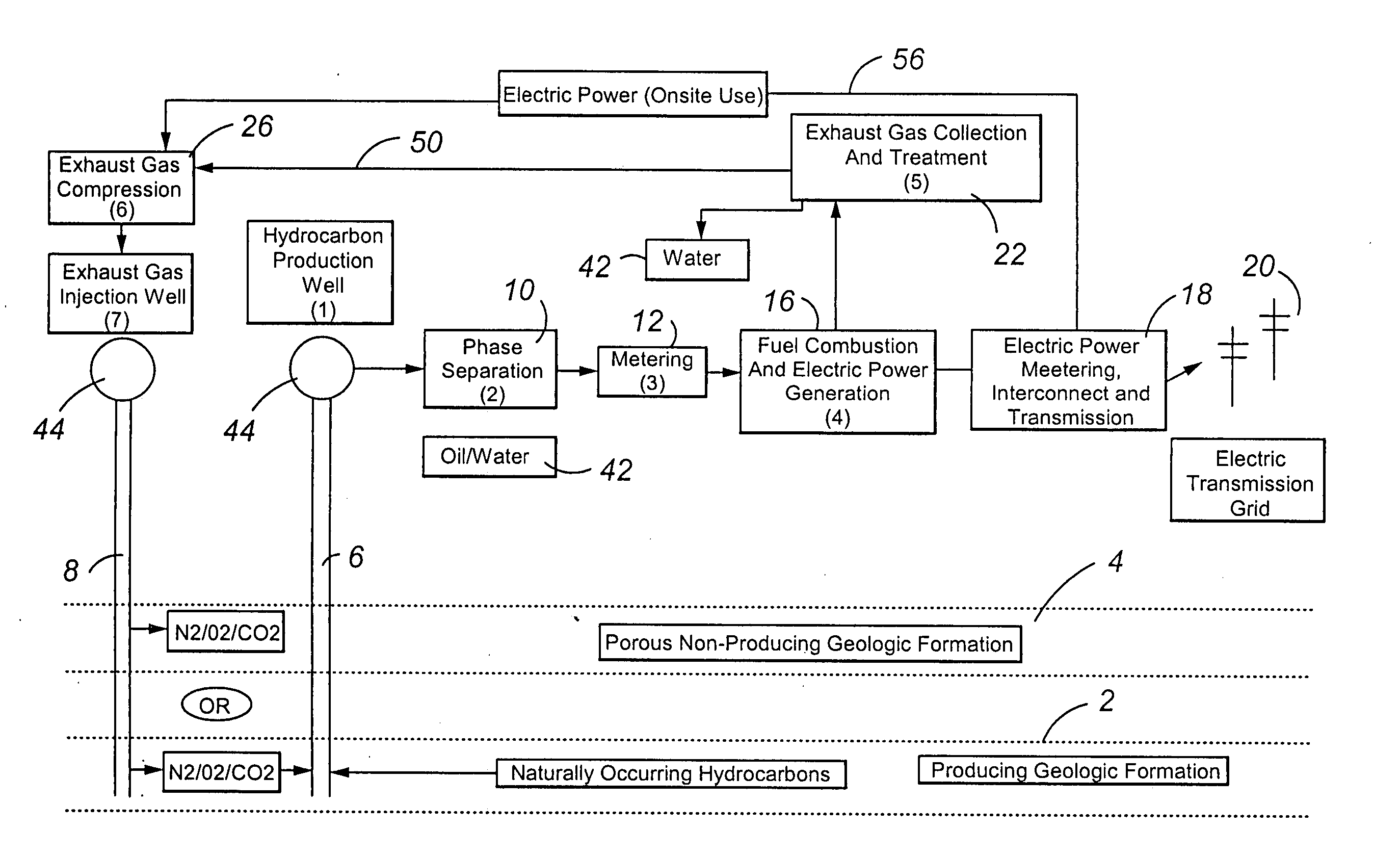

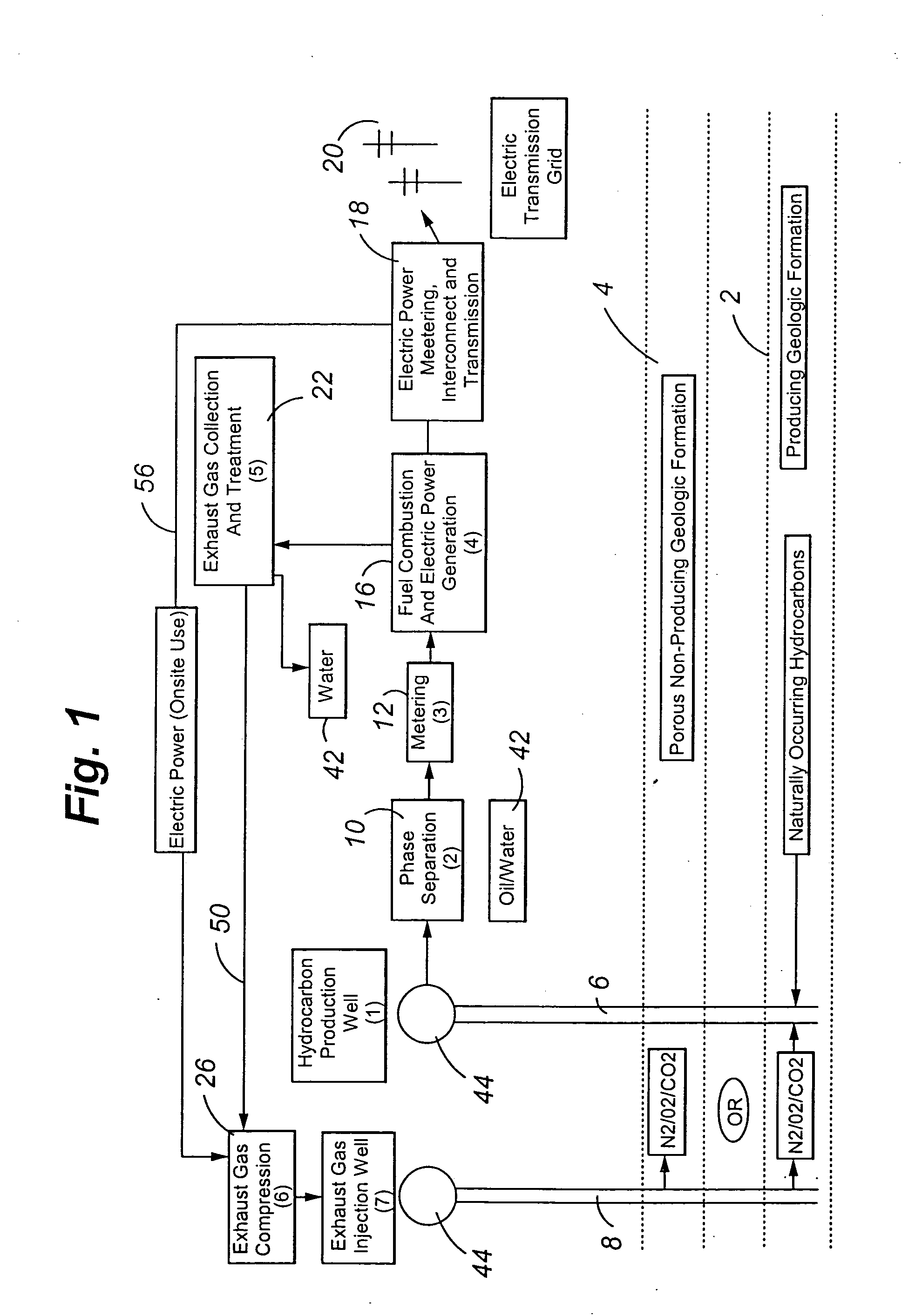

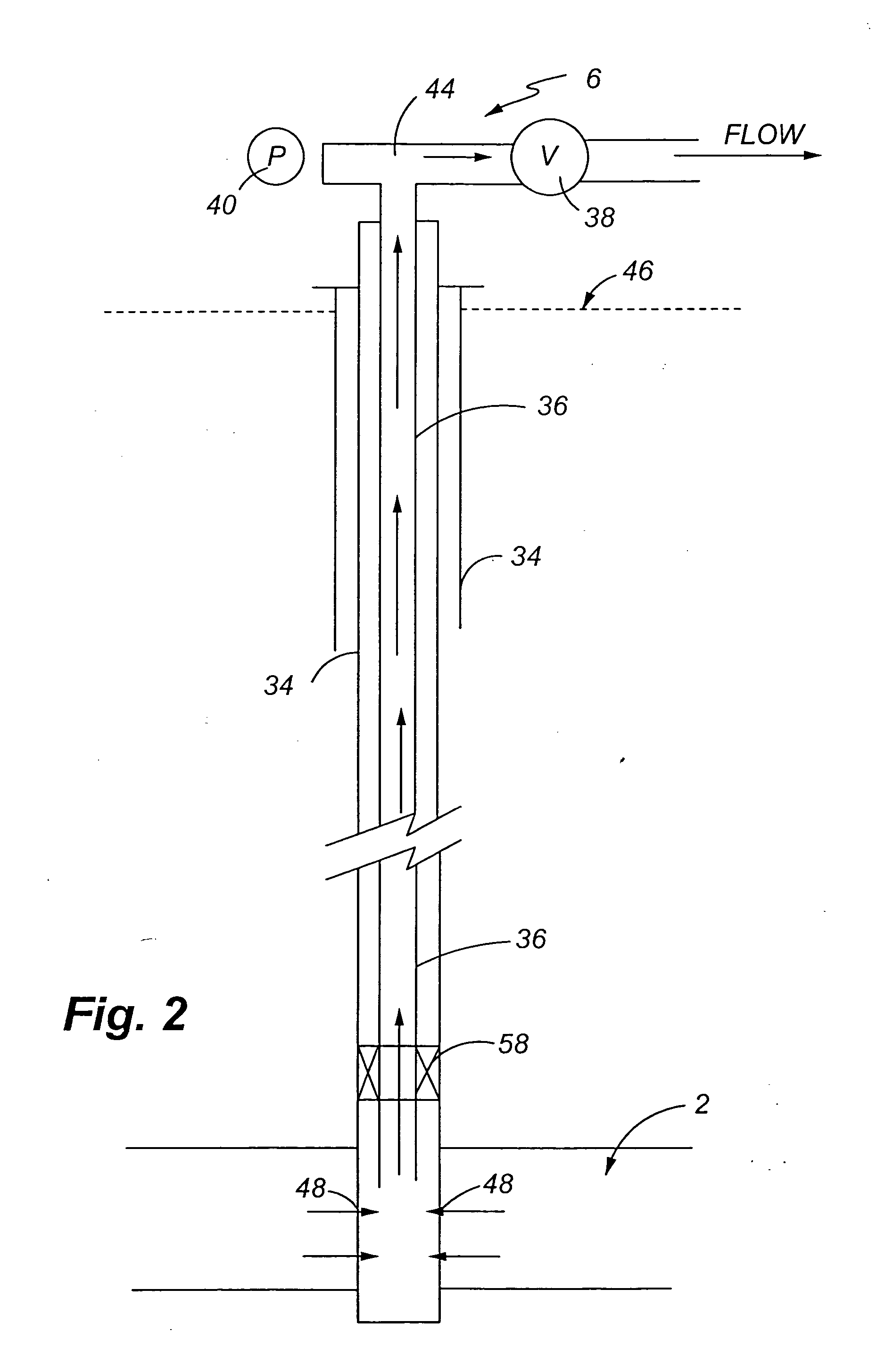

Method and apparatus for generating pollution free electrical energy from hydrocarbons

InactiveUS20080017369A1Cost effectivePollution free energyFluid removalThermal energyHydrocotyle bowlesioides

The present invention relates to the generation of substantially pollution free energy by utilizing hydrocarbons to create electrical energy, while reinjecting exhaust fumes or other byproducts into a subterranean formation. The present invention further relates to managing and supplying this electrical energy to at least one of a variety of subprocesses for producing a fuel product, such as hydrogen or ethanol. Alternatively, electrical power can be generated from a non-hydrocarbon source such as thermal, solar, wind or other power source to produce electrical energy, which in turn may be used to produce fuel products or other forms of usable energy. Thus, remote, low reserve oil and gas fields may be exploited and produced without requiring the construction of expensive gas transmission lines.

Owner:PRODN RESOURCES

Method and apparatus for generating pollution free electrical energy from hydrocarbons

InactiveUS20060054318A1Cost effectivePollution free energyFluid removalHydrogen compoundsExhaust fumes

The present invention relates to the generation of substantially pollution free energy by utilizing hydrocarbons to create electrical energy, while reinjecting exhaust fumes or other byproducts into a subterranean formation. Thus, remote, low reserve oil and gas fields may be exploited and produced without requiring the construction of expensive gas transmission lines.

Owner:PRODN RESOURCES

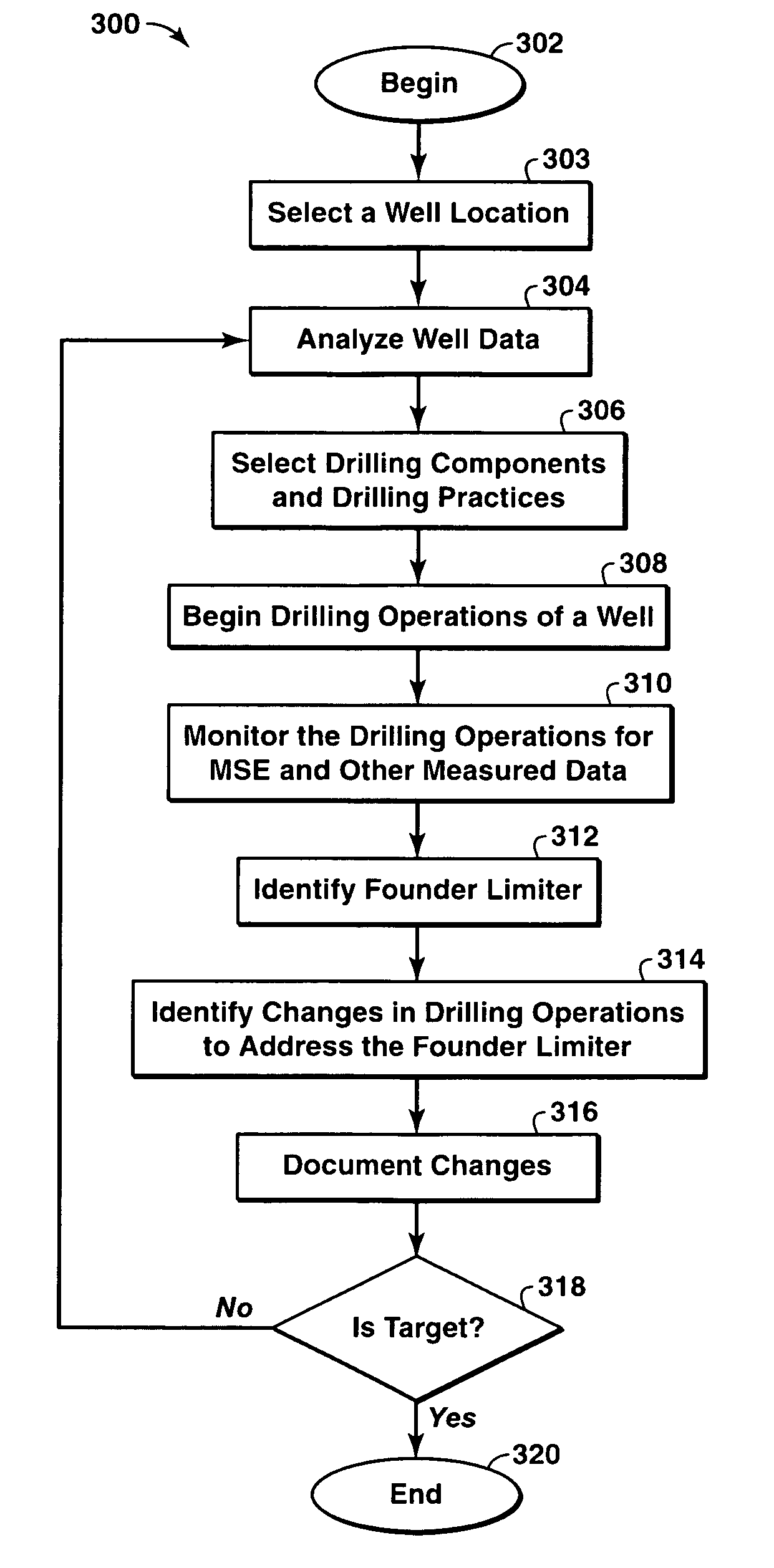

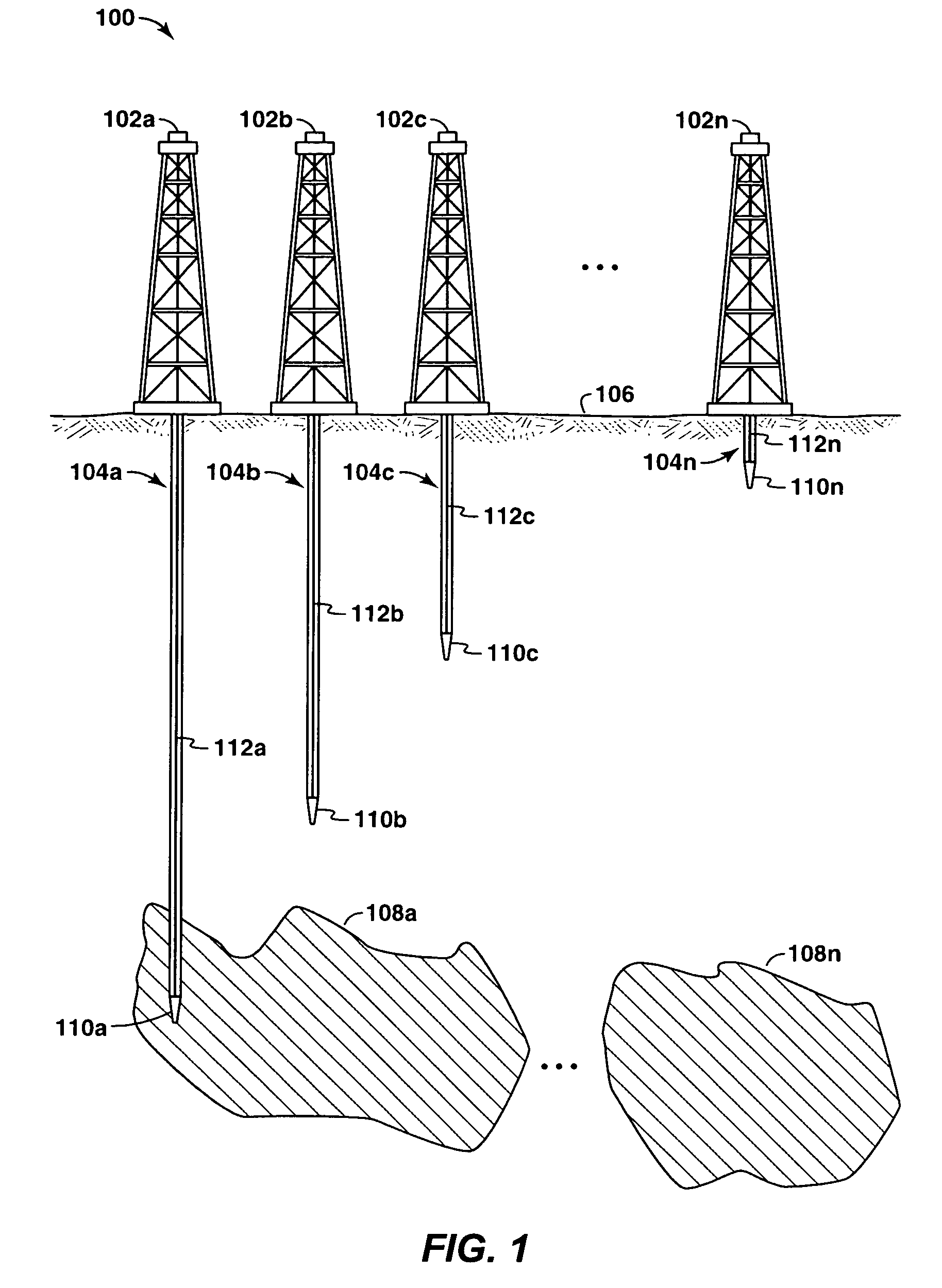

Method of drilling and production hydrocarbons from subsurface formations

A method associated with the production of hydrocarbons. In one embodiment, a method for drilling a well is described. The method includes identifying a field having hydrocarbons. Then, one or more wells are drilled to a subsurface location in the field to provide fluid flow paths for hydrocarbons to a production facility. The drilling is performed by (i) estimating a drill rate for one of the wells; (ii) determining a difference between the estimated drill rate and an actual drill rate; (iii) obtaining mechanical specific energy (MSE) data and other measured data during the drilling of the one of the wells; (iv) using the obtained MSE data and other measured data to determine one of a plurality of limiters that limit the drill rate; (v) adjusting drilling operations to mitigate one of the plurality of limiters; (vi) and iteratively repeating steps (i)-(v) until the subsurface formation has been reached by the drilling operations.

Owner:EXXONMOBIL UPSTREAM RES CO

Viscosified treatment fluids comprising scleroglucan or diutan and associated methods

InactiveUS20050261138A1Low viscositySufficient pressureConstructionsFluid removalHydrocotyle bowlesioidesFluid composition

The present invention relates to viscosified treatment fluids comprising gelling agents that comprise scleroglucan or diutan, and their use in industrial and oil field operations. In certain embodiments, the present invention provides methods of treating a portion of a subterranean formation with a viscosified treatment comprising a gelling agent that comprises scleroglucan or diutan. Methods of fracturing, gravel packing, and producing hydrocarbons also are provided. Viscosified treatment fluid compositions and methods of making such exemplary compositions are provided as well.

Owner:HALLIBURTON ENERGY SERVICES INC

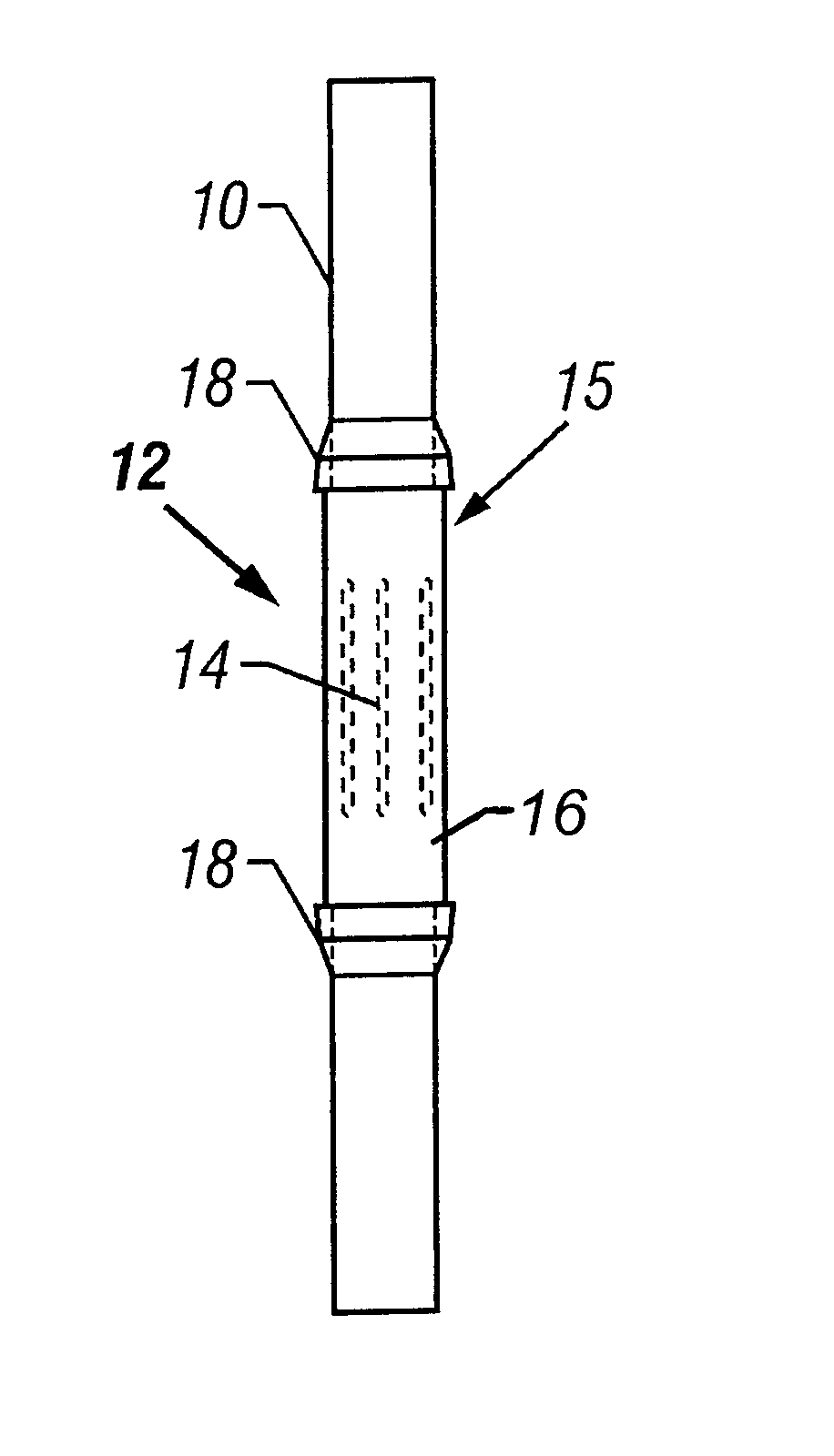

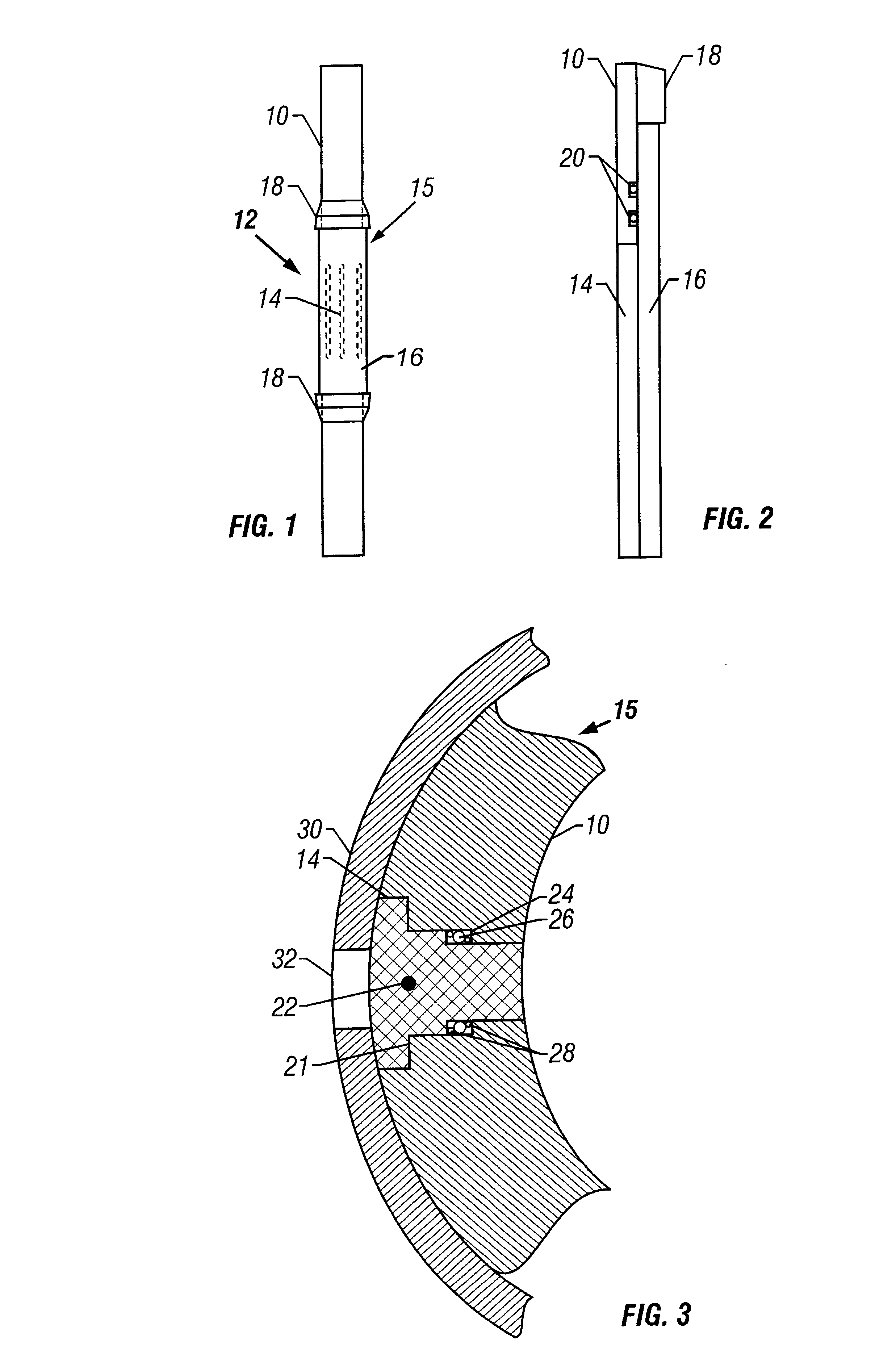

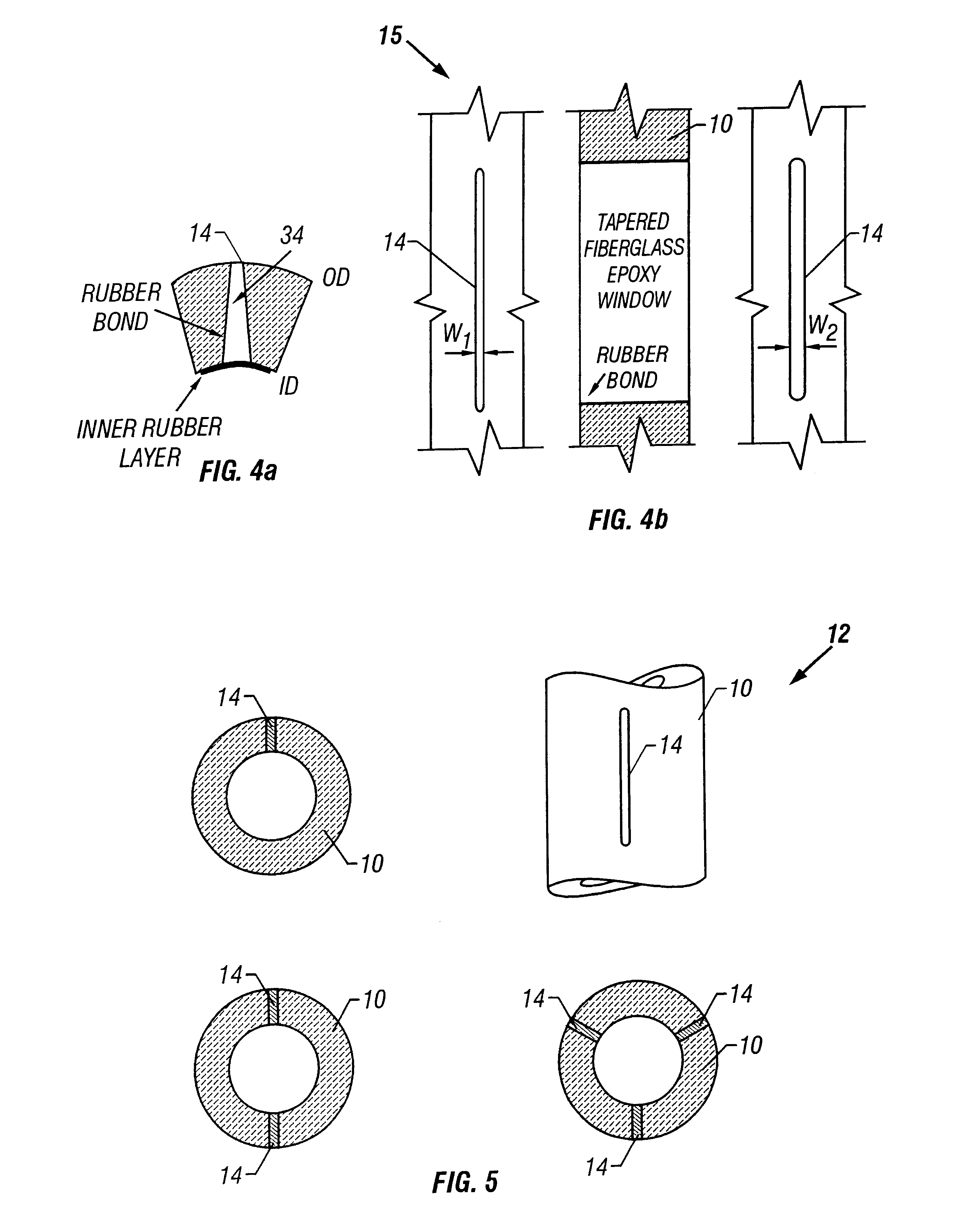

System and method for monitoring a reservoir and placing a borehole using a modified tubular

Systems and methods for monitoring a characteristic of a subterranean hydrocarbon reservoir and for placing a borehole in the vicinity of a well in an earth formation. New well completion systems with slotted stations are utilized to provide through-casing signal-transmission and / or reception. Hydraulic isolation between the interior and the exterior of the completion is provided by pressure barrier means at the slotted stations. The completions permit temporary or permanent monitoring of changes in reservoir saturation with the use of mobile sources / sensors. The completions also form part of a system for accurately placing a well within a desired distance and orientation relative to an existing well.

Owner:SCHLUMBERGER TECH CORP

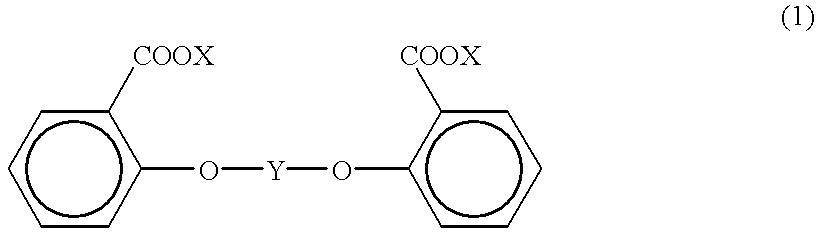

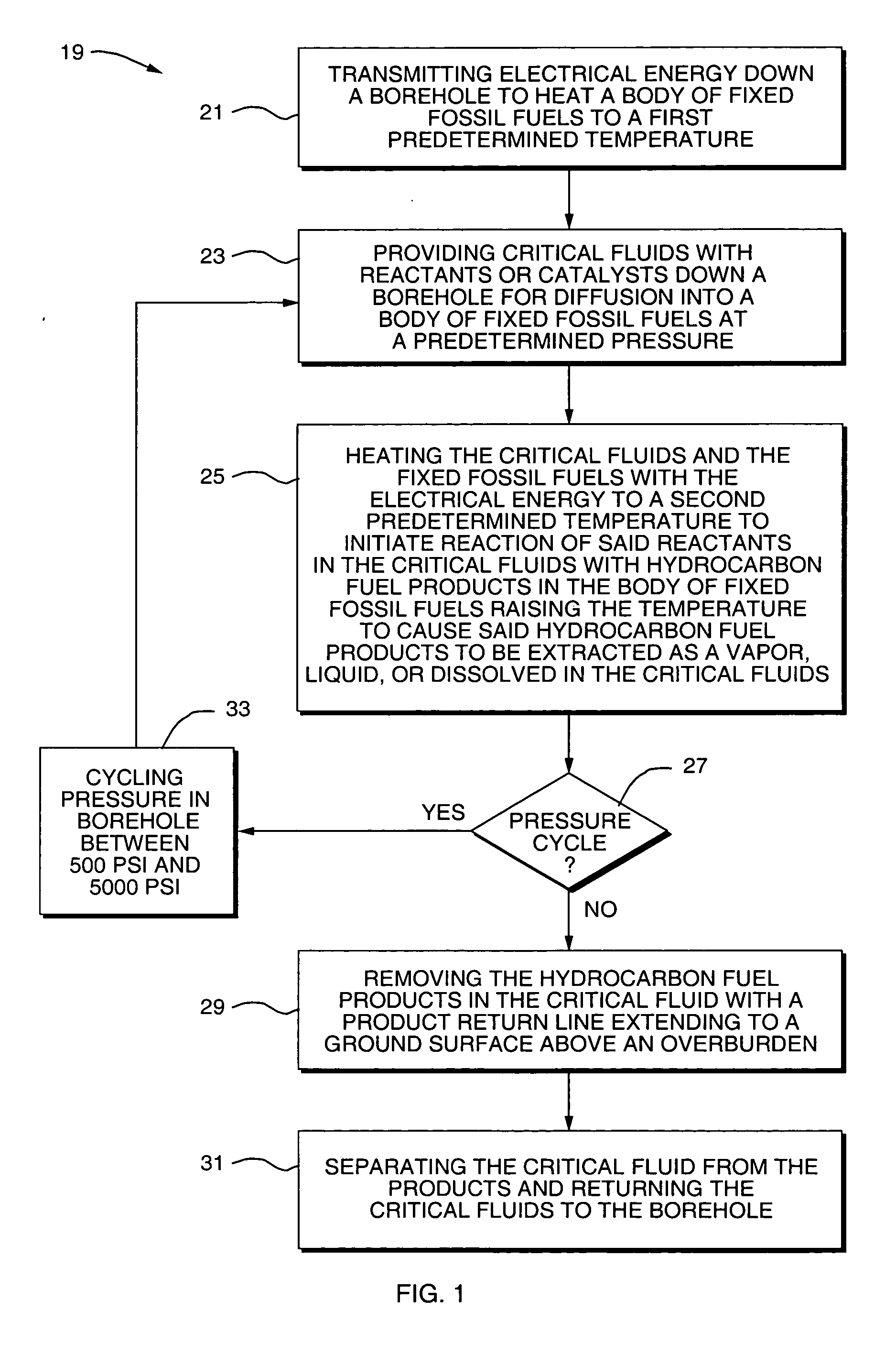

Process for producing aromatic polycarbonate

An aromatic polycarbonate and an active-hydrogen compound are subjected to the transesterification reaction in the presence of a transesterification catalyst under a reduced pressure condition followed by reaction with a salicylic acid ester derivative expressed by the following chemical formula (1),{wherein X is methyl or ethyl, and Y is a carbonyl group or a divalent functional group expressed by the following formula (2),(where Z is an alkylene group having a carbon number of 1 to 30, an arylene group having a carbon number of 6 to 30 or an aralkylene group having a carbon number of 7 to 30)}.An aromatic polycarbonate having a high molecular weight can be produced by this process.

Owner:TEIJIN LTD

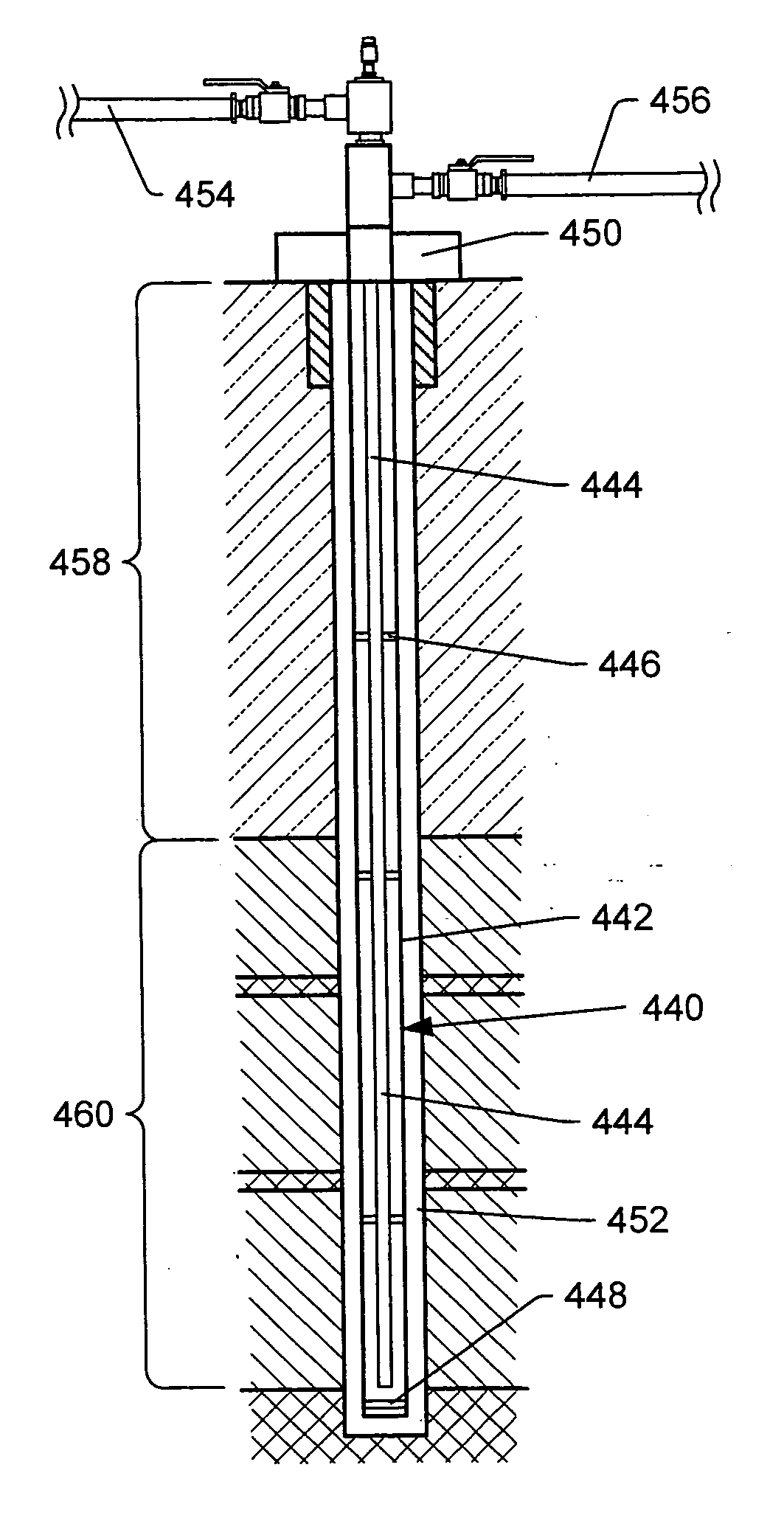

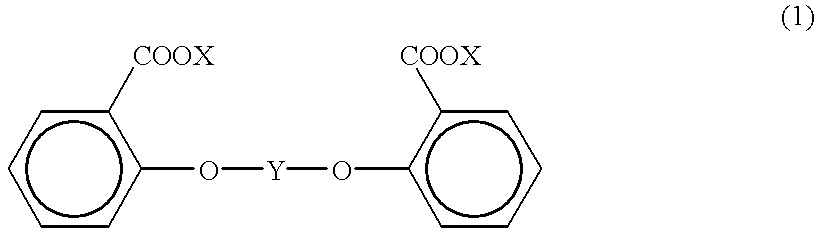

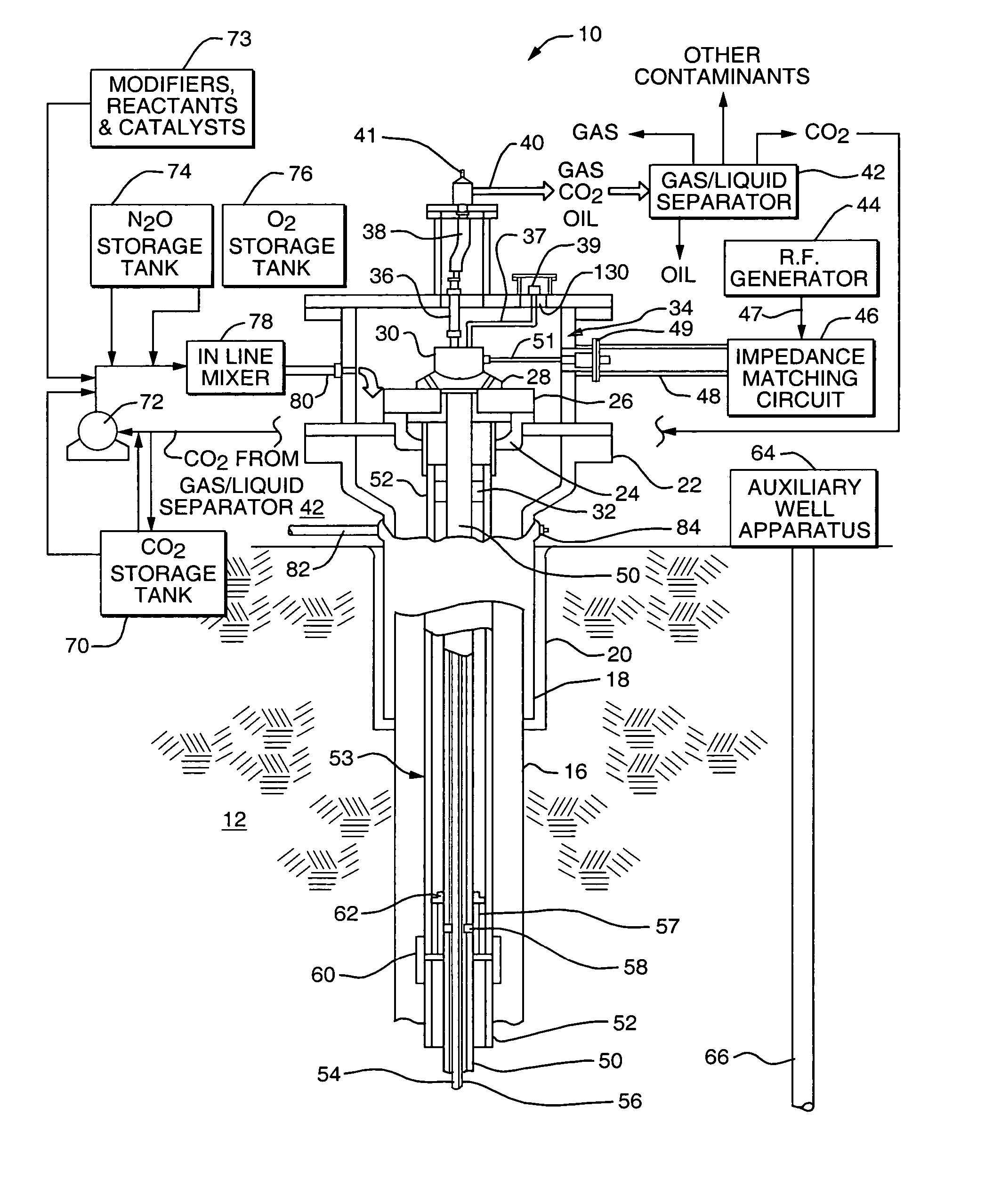

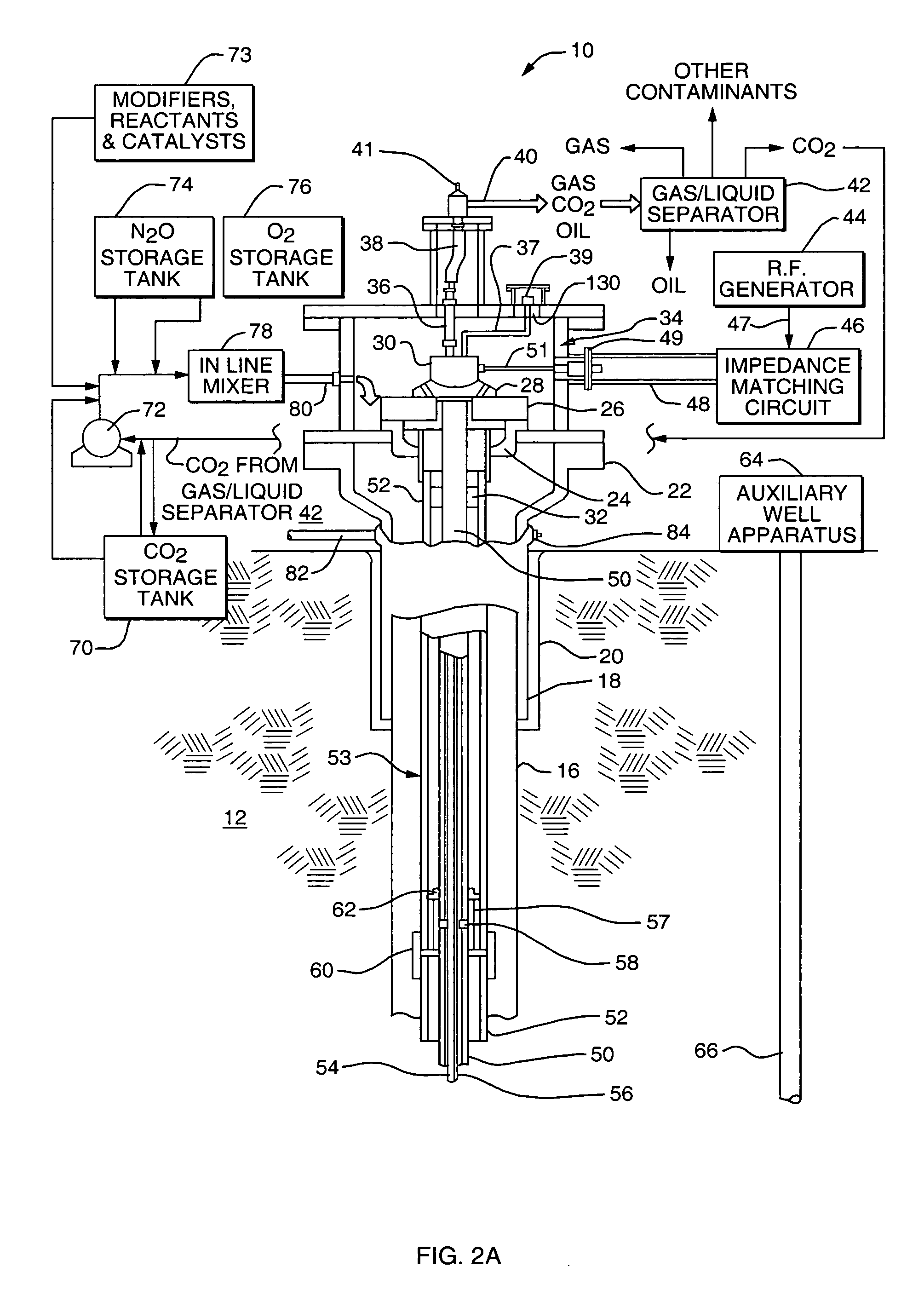

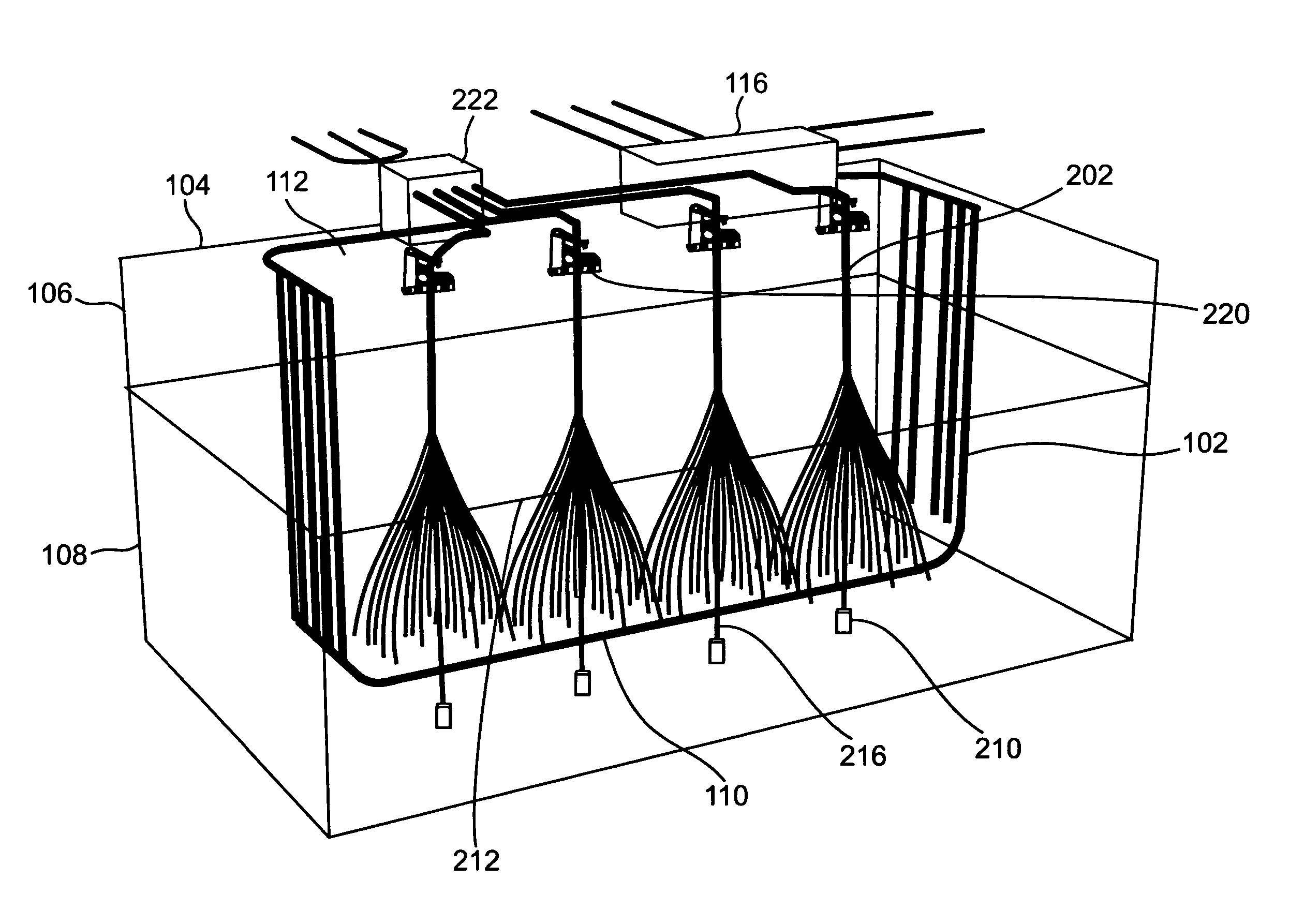

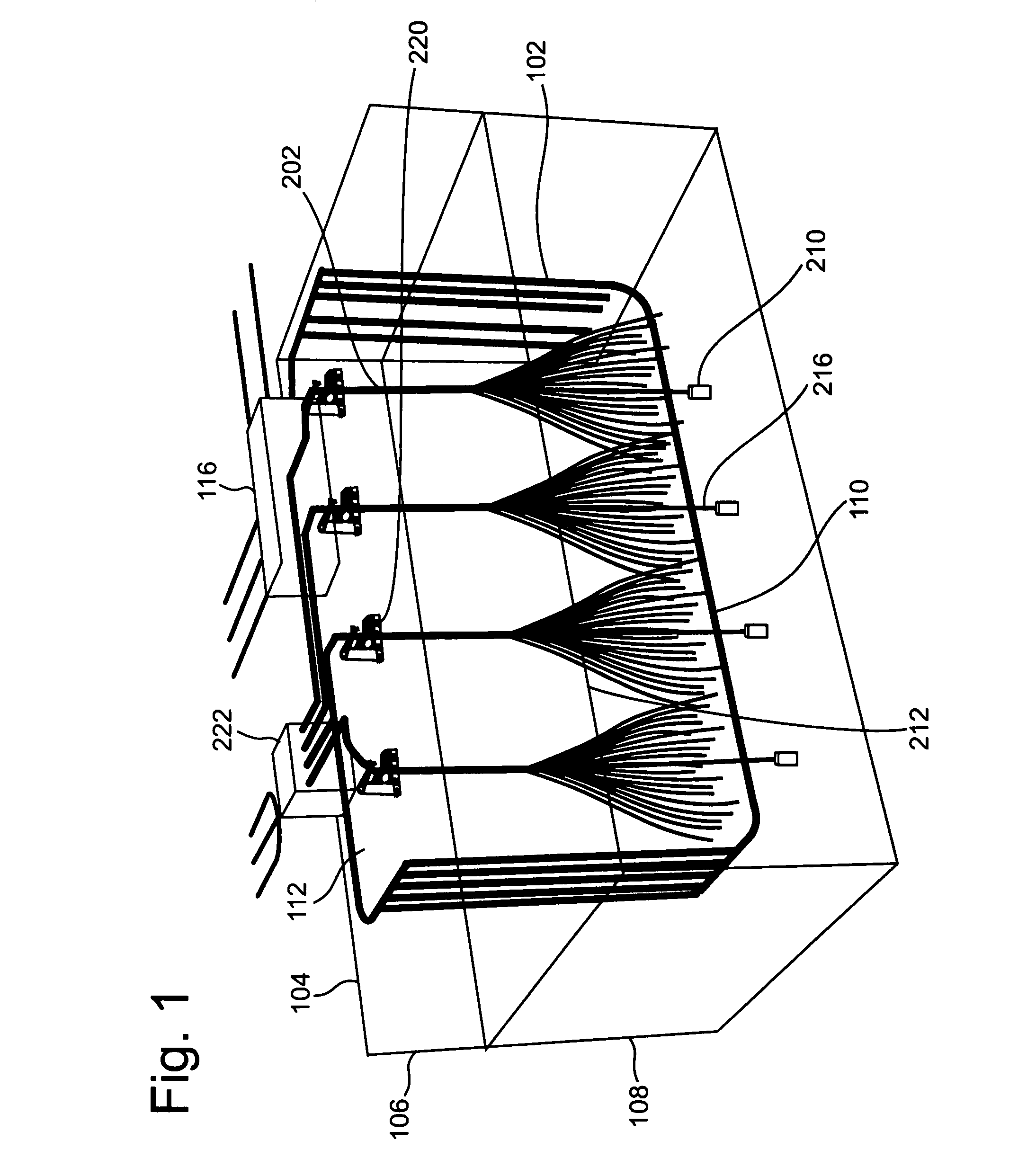

Apparatus for extraction of hydrocarbon fuels or contaminants using electrical energy and critical fluids

ActiveUS20070137852A1Eliminate electromagnetic radiationEfficient heatingInsulationFluid removalHydrogen compoundsChemistry

The extraction of hydrocarbon fuel products such as kerogen oil and gas from a body of fixed fossil fuels such as oil shale is accomplished by applying a combination of electrical energy and critical fluids with reactants and / or catalysts down a borehole to initiate a reaction of reactants in the critical fluids with kerogen in the oil shale thereby raising the temperatures to cause kerogen oil and gas products to be extracted as a vapor, liquid or dissolved in the critical fluids. The hydrocarbon fuel products of kerogen oil or shale oil and hydrocarbon gas are removed to the ground surface by a product return line. An RF generator provides electromagnetic energy, and the critical fluids include a combination of carbon dioxide (CO2), with reactants of nitrous oxide (N2O) or oxygen (O2).

Owner:SCHLUMBERGER TECH CORP

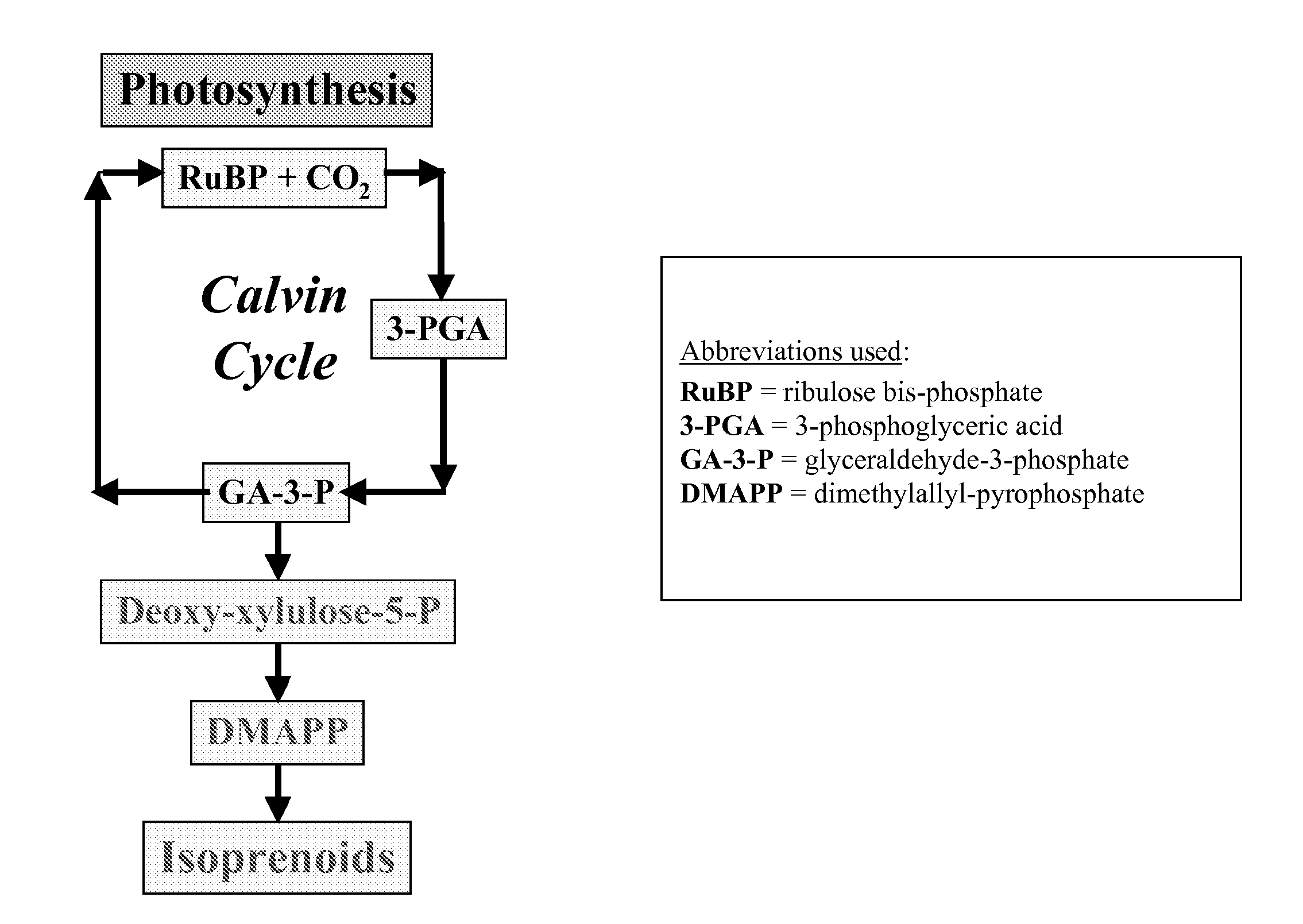

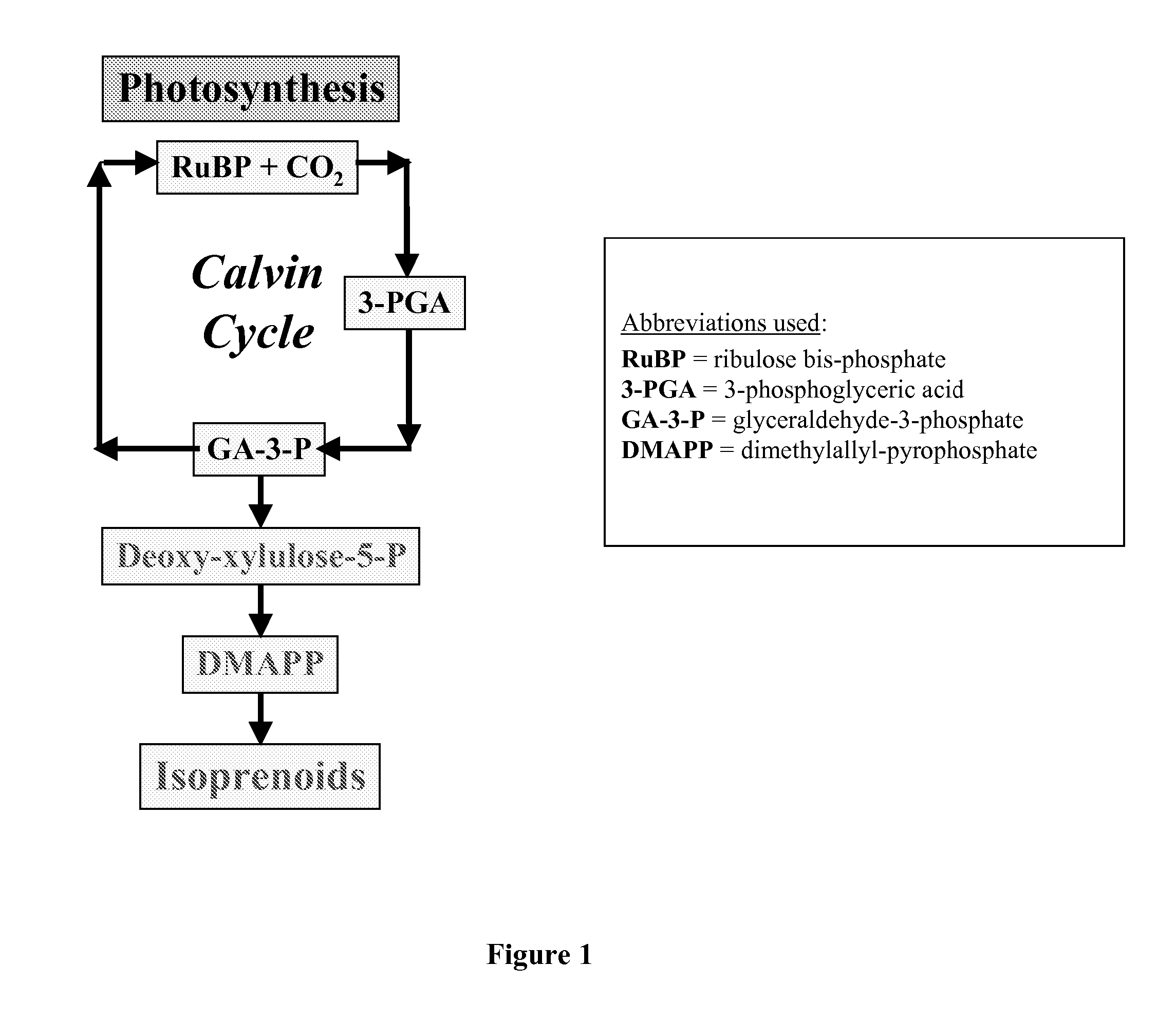

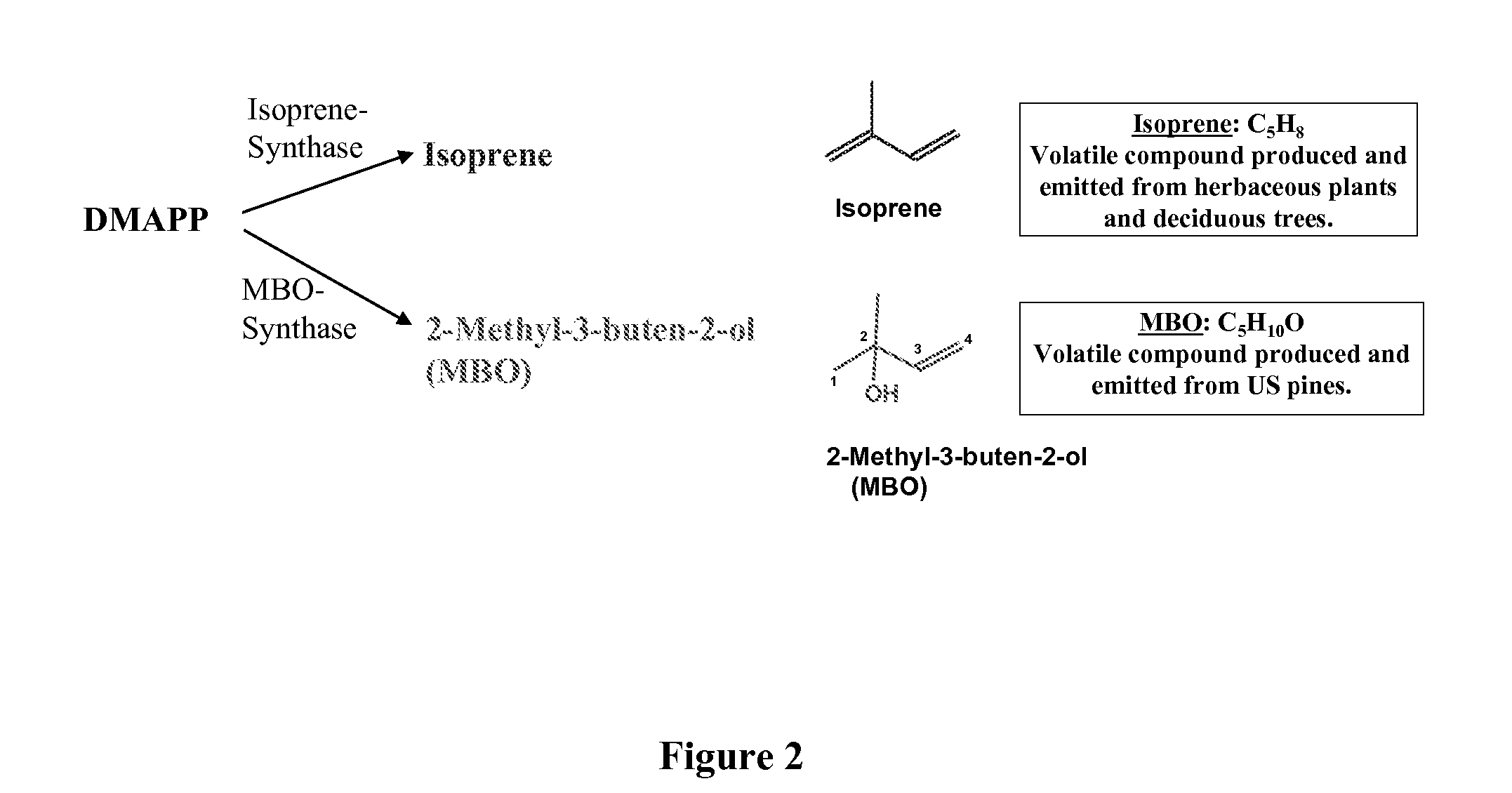

Short chain volatile hydrocarbon production using genetically engineered microalgae, cyanobacteria or bacteria

ActiveUS20080038805A1Promote reproductionLow costBacteriaUnicellular algaePhylum CyanobacteriaCyanobacteria

The present invention provides methods and compositions for producing isoprene hydrocarbons from microalgae, cyanobacteria, and photosynthetic and non-photosynthetic bacteria.

Owner:RGT UNIV OF CALIFORNIA

In situ method and system for extraction of oil from shale

ActiveUS20070193743A1Easy to moveAvoid insufficient temperatureInsulationFluid removalClosed loopEarth surface

A system and process is disclosed for retorting oil shale and extracting shale oil and other hydrocarbons therefrom, in which a cased heat delivery well is drilled generally vertically through an overburden and then through a body of oil shale to be retorted to the bottom thereof, generally horizontally under the body of oil shale to be retorted, and then back to the earth surface. Heat energy is transmitted conductively to the body of oil shale to be retorted from a closed loop heat delivery module in the well, the module comprising a fluid transmission pipe containing a heating fluid heated to at least a retorting temperature. Heat energy is also transmitted to the body of oil shale to be retorted above the fluid transmission pipe by vapor conduits that conduct retort vapors upward through the body of oil shale to be retorted; the ascending retort vapors condense and reflux, delivering their latent heat of vaporization to the body of oil shale to be retorted, and the condensed retort liquids descend. If not recycled, the retort liquids are collected in a sump at the bottom of a production well and are transmitted to the surface for processing. The vapor conduits communicate at upper ends thereof with the production well, so that vapors that do not reflux are collected in the production well and are transmitted to the surface for processing.

Owner:AMERICAN SHALE OIL

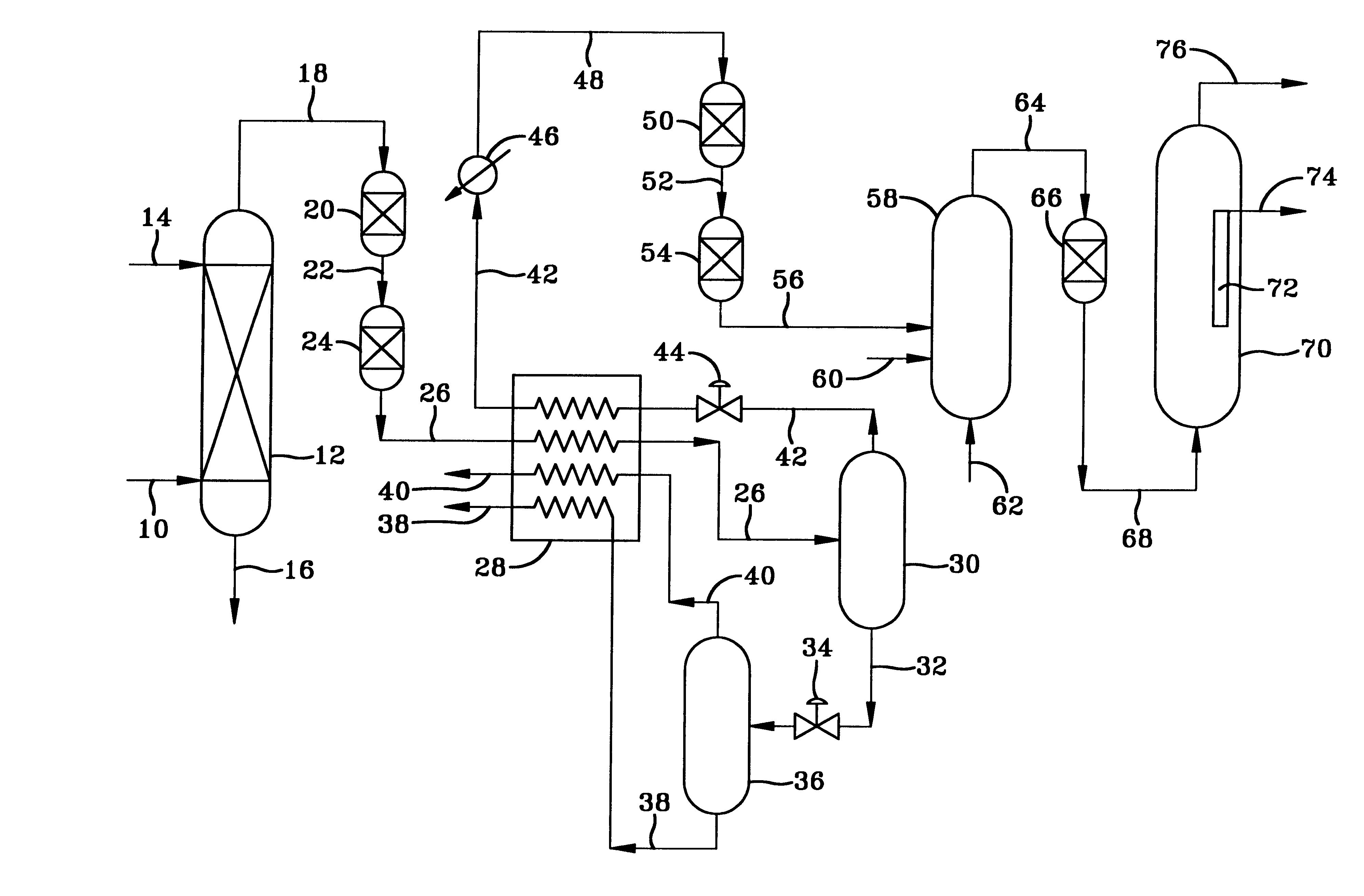

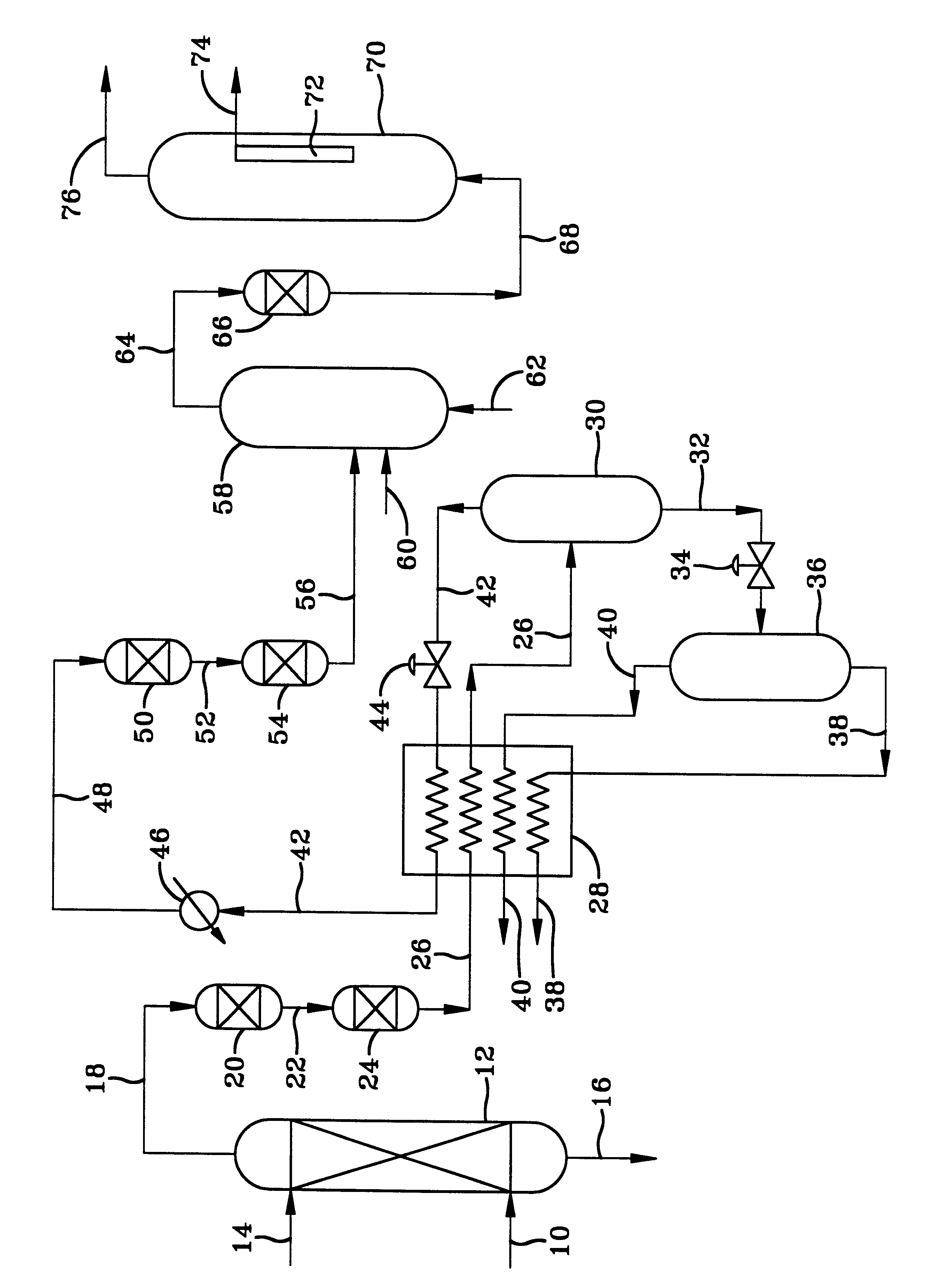

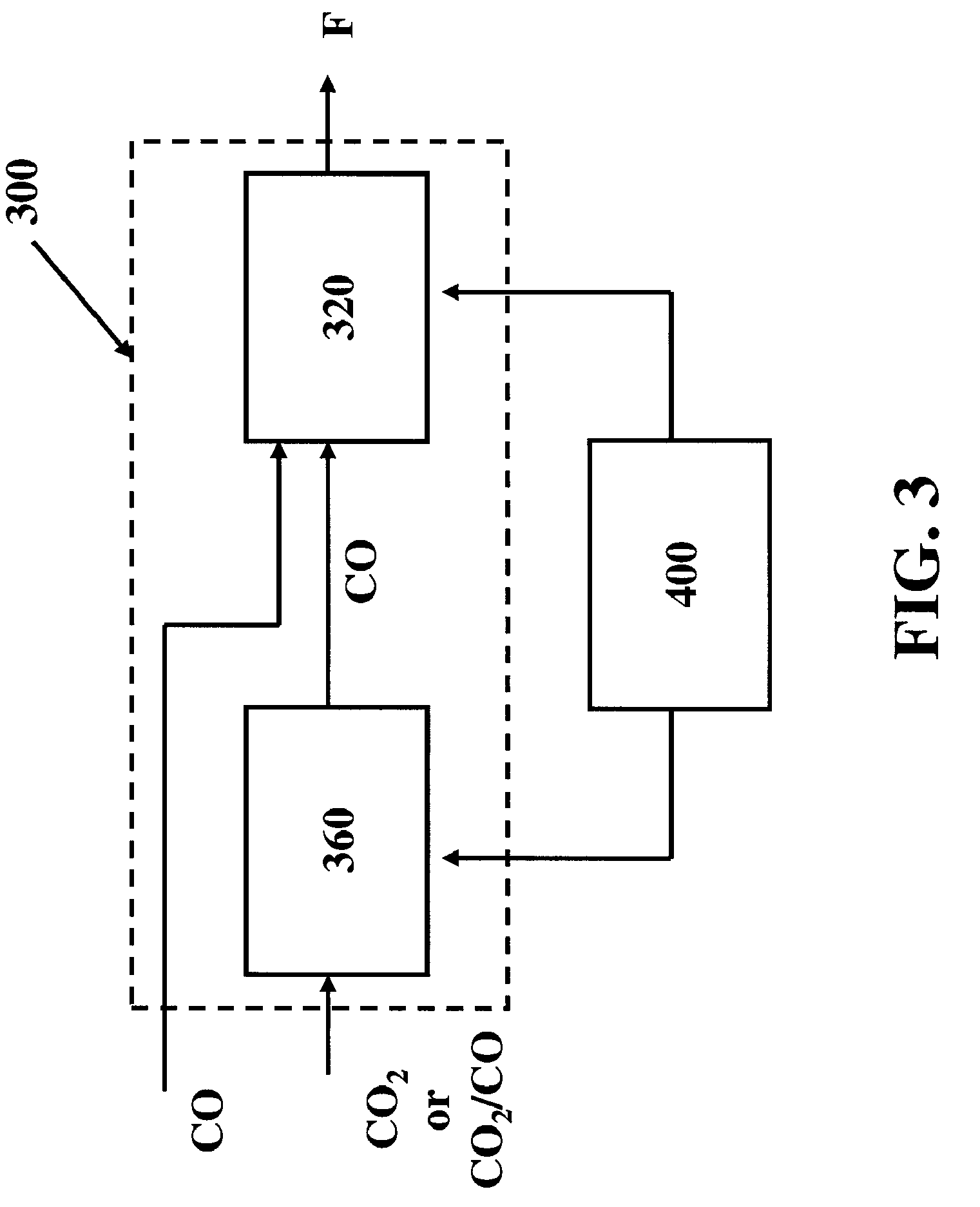

Systems, methods, and compositions for production of synthetic hydrocarbon compounds

InactiveUS20060211777A1Efficient processingReduce energy lossElectrolysis componentsLiquid hydrocarbon mixture productionKeroseneHydrocotyle bowlesioides

A process and system for producing hydrocarbon compounds or fuels that recycle products of hydrocarbon compound combustion—carbon dioxide or carbon monoxide, or both, and water. The energy for recycling is electricity derived from preferably not fossil based fuels, like from nuclear fuels or from renewable energy. The process comprises electrolysing water, and then using hydrogen to reduce externally supplied carbon dioxide to carbon monoxide, then using so produced carbon monoxide together with any externally supplied carbon monoxide and hydrogen in Fischer-Tropsch reactors, with upstream upgrading to desired specification fuels—for example, gasoline, jet fuel, kerosene, diesel fuel, and others. Energy released in some of these processes is used by other processes. Using adiabatic temperature changes and isothermal pressure changes for gas processing and separation, large amounts of required energy are internally recycled using electric and heat distribution lines. Phase conversion of working fluid is used in heat distribution lines for increased energy efficiency. The resulting use of electric energy is less than 1.4 times the amount of the high heating value of combustion of so produced hydrocarbon compounds when carbon dioxide is converted to carbon monoxide in the invention, and less than 0.84 when carbon monoxide is the source.

Owner:FUELCOR LLC

Absorbable implants and methods for their use in hemostasis and in the treatment of osseous defects

ActiveUS20050065214A1Stimulate bone healing processLower potentialBiocidePowder deliveryBarium saltTG - Triglyceride

Two (or more), -component, body-implantable, absorbable, biocompatible, putty, and non-putty hemostatic tamponades for use in surgery. Component 1 is a finely powdered bulking material, preferably less than 50 microns, e.g. the calcium, magnesium, aluminum, or barium salts of saturated or unsaturated carboxylic acids containing about 6 to 22 carbon atoms, hydroxyapatite, DBM, polyglycolide, polylactide, poldioxinones, polycaprolactones, absorbable glasses, gelatin, collagens, mono, and polysaccharides starches. Component 2, a dispersing vehicle, may be esters of C8-C18 monohydric alcohols with C2-C6 aliphatic monocarboxylic acids; C2-C18 monohydric alcohols with polycarboxylic acids; C8-C30 monohydric alcohols; tocopherol and esters thereof with C2-C10 aliphatic monocarboxylic acids or polycarboxylic acids; absorbable 10-14C hydrocarbons; free carboxylic acids such as oleic, capric, and lauric; dialkyl ethers and ketones; alkyl aryl ethers and ketones, polyhydroxy compounds and esters and ethers thereof; (ethylene oxide / propylene oxide copolymers), oils e.g. olive oil, castor oil and triglycerides.

Owner:ABYRX

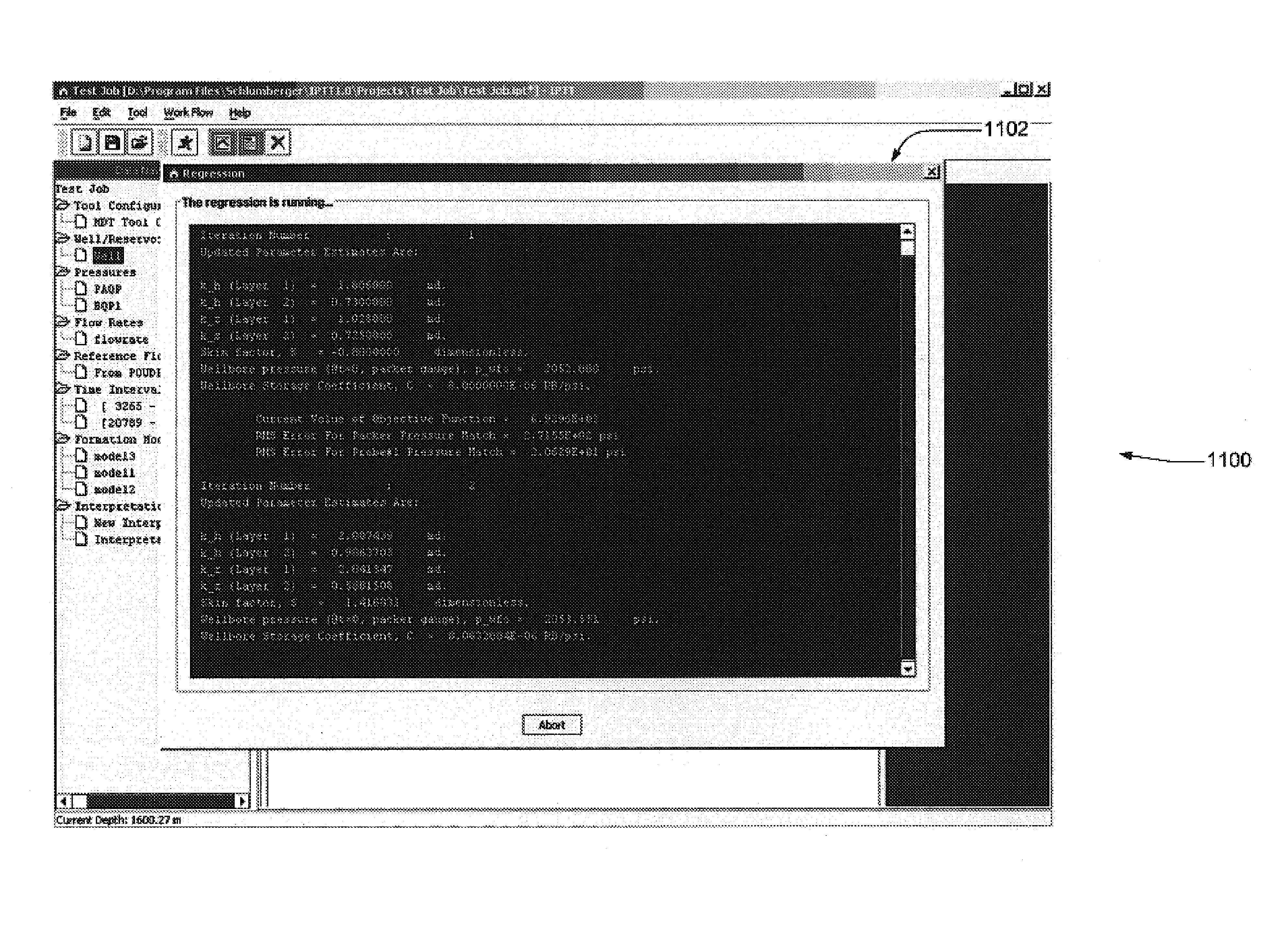

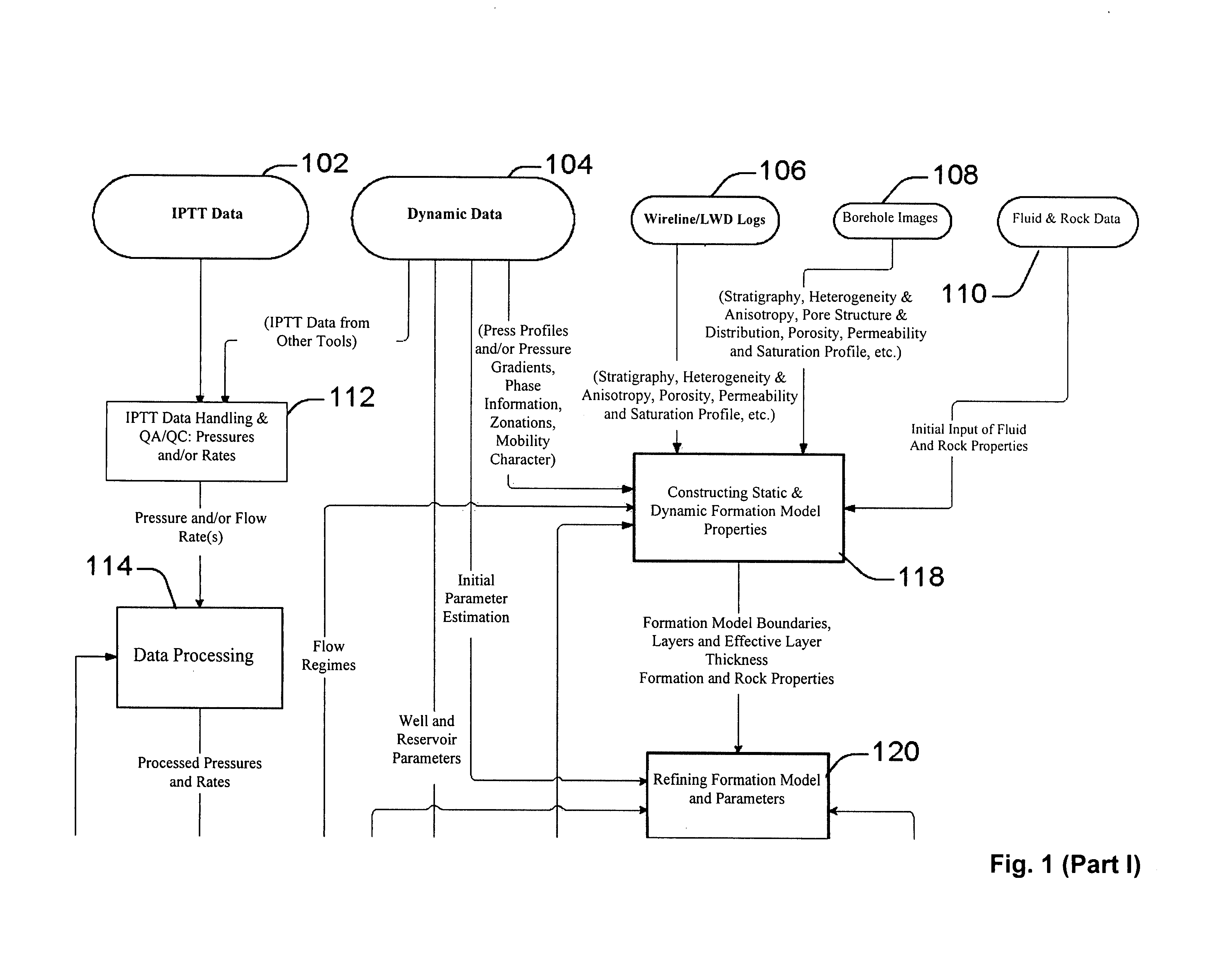

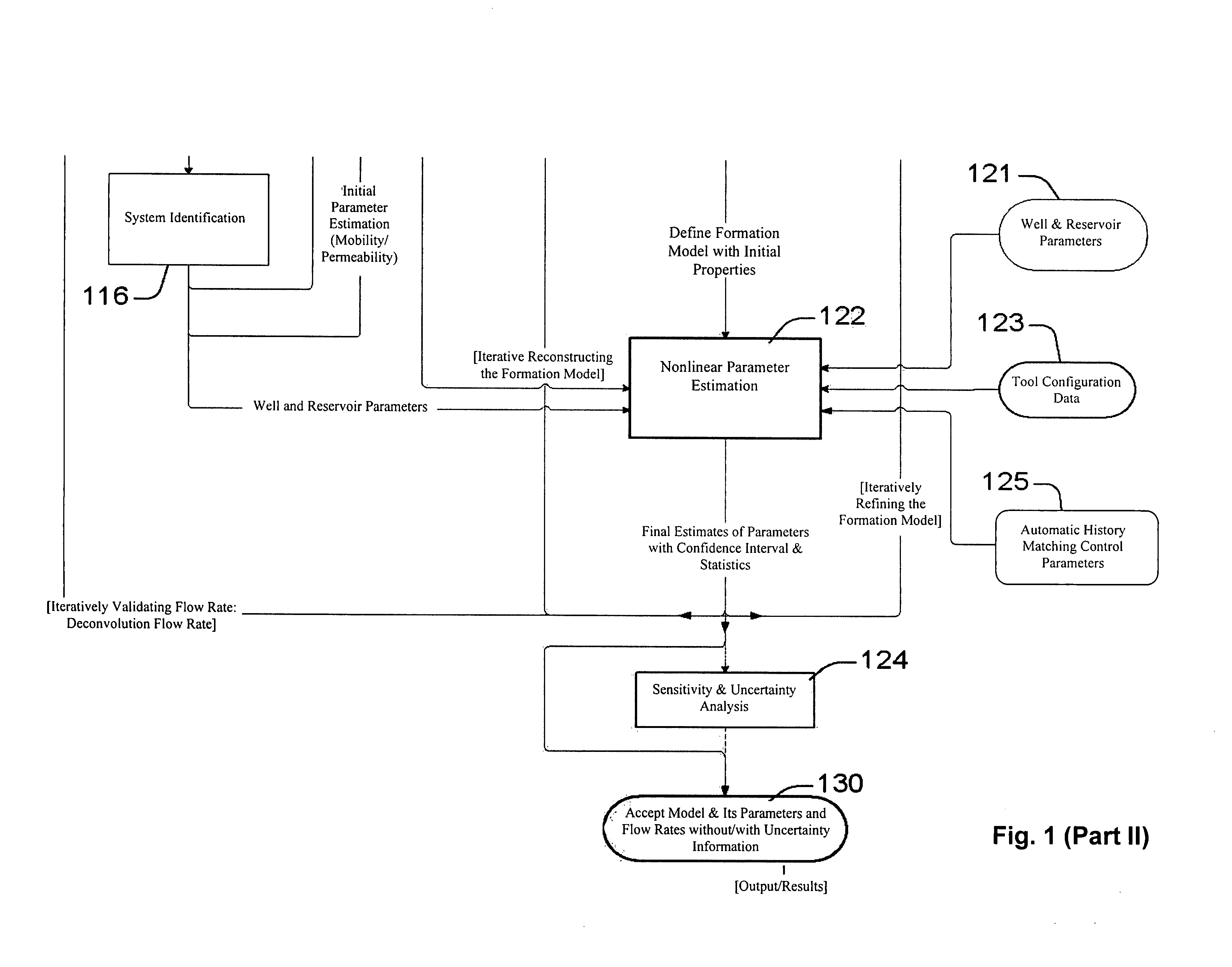

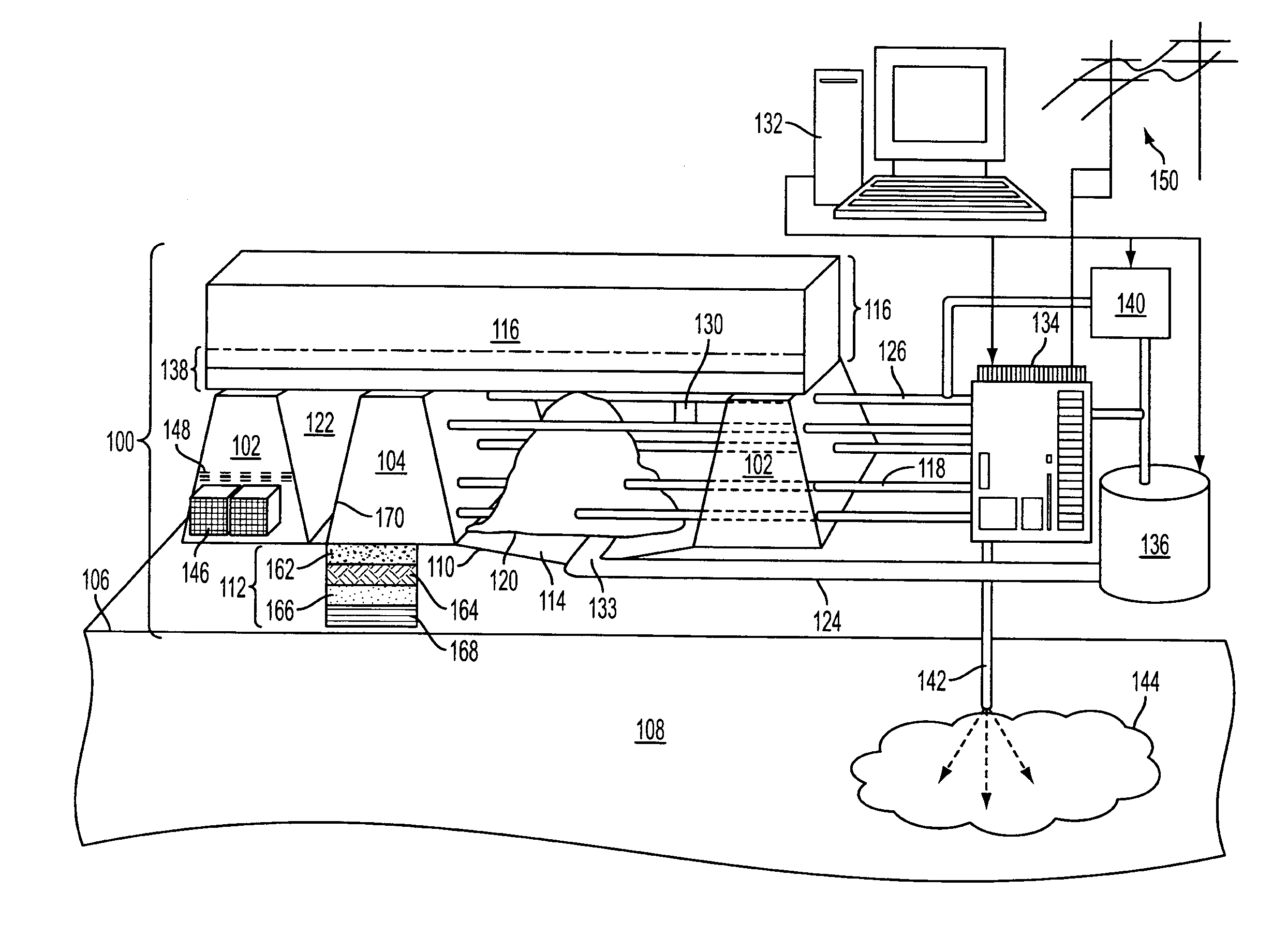

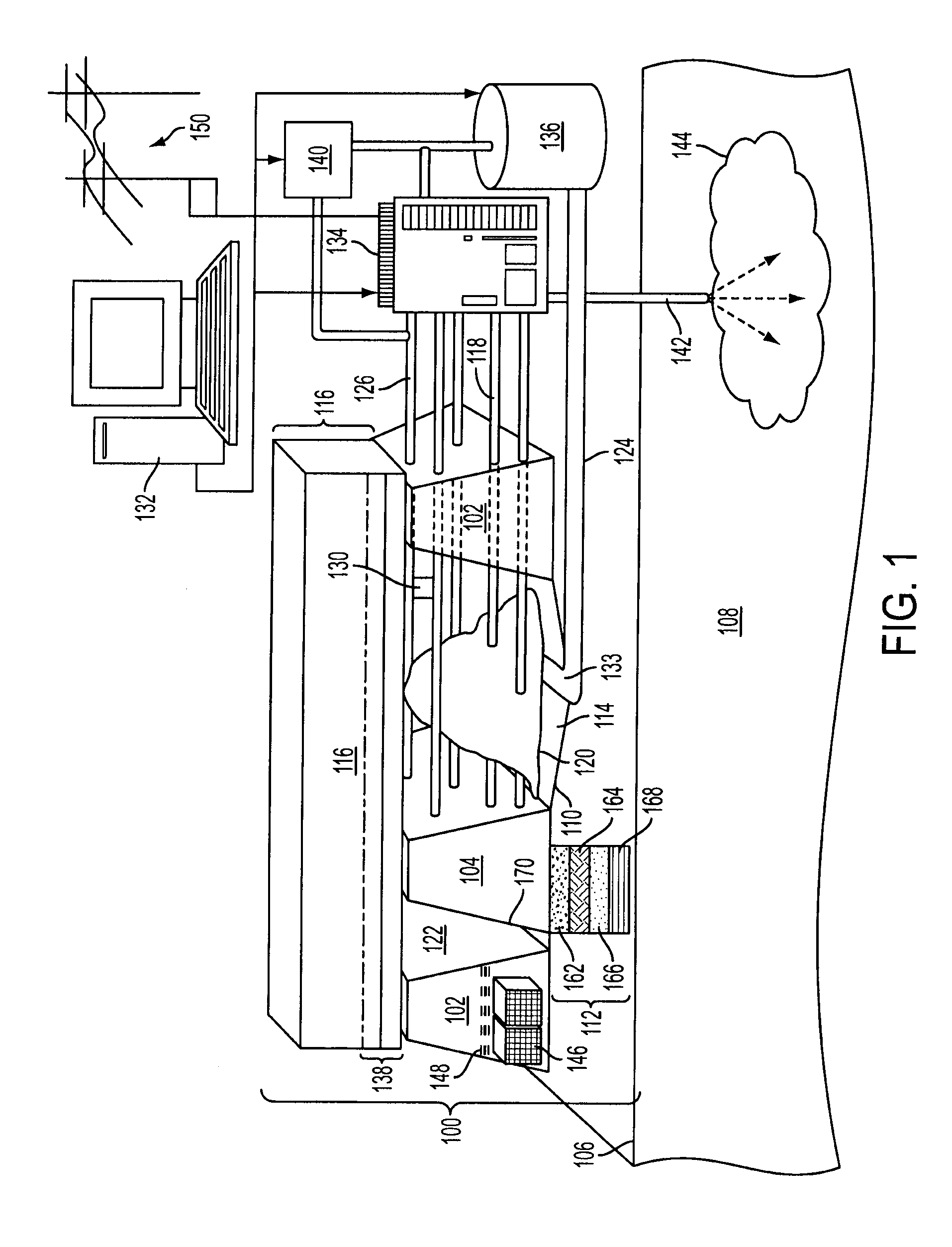

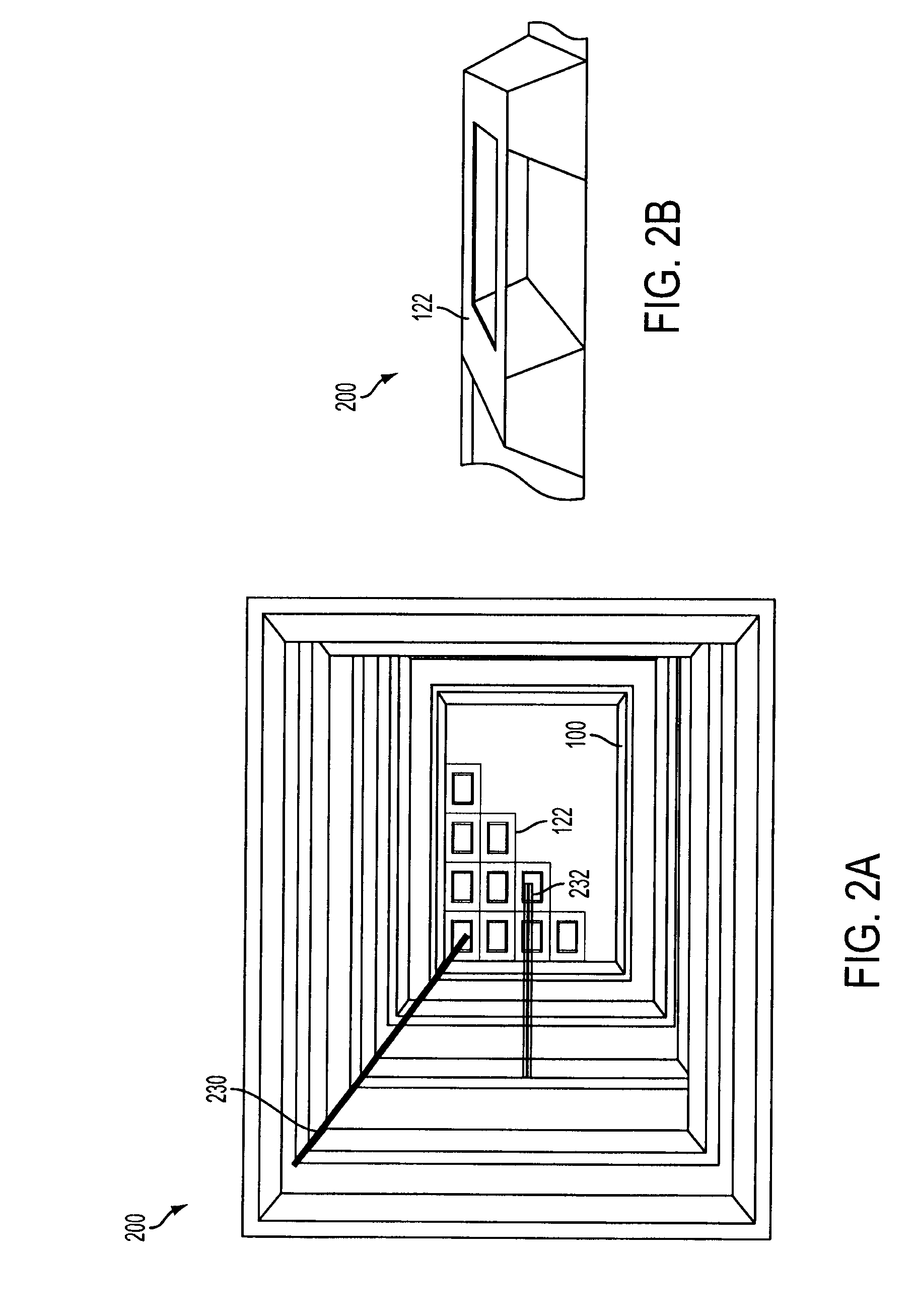

System and methods of characterizing a hydrocarbon reservoir

ActiveUS7277796B2Facilitating in performing data processing operationEasy to operateElectric/magnetic detection for well-loggingPermeability/surface area analysisCompressibilityIterative method

A technique is described for interpretation of IPTT tests. In one implementation, the technique may be configured or designed to standardize the complete interpretation procedure of IPTT in a heterogeneous reservoir, using if available, modern wireline logs (such as, for example, nuclear magnetic resonance and imaging), dynamic data from wireline formation testers and / or any other relevant information (such as, for example, geological description, core data and local knowledge) as constraints on the interpretation. Additionally, an iterative method may be used to define formation layering. An advanced regression technology may also be used to obtain optimized horizontal and vertical permeabilities of reservoir layers. Further a graphical user interface (GUI) based IPTT workflow technique of the present invention provides an integrated user-friendly interpretation platform for analyzing formation testing pressures and flow rate measurements in order to estimate the values and associated uncertainties of local characteristics of a hydrocarbon reservoir such as, for example, local permeability, local reservoir pressure, local compressibility, etc.

Owner:SCHLUMBERGER TECH CORP

Methods of recovering hydrocarbons from hydrocarbonaceous material using a constructed infrastructure and associated systems

ActiveUS20080190818A1Reduce processing costsIncrease volume outputThermal non-catalytic crackingSolid waste disposalEngineeringHydrocarbon

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a constructed permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

Method of depositing an amorphous carbon film for etch hardmask application

InactiveUS20050202683A1Photomechanical apparatusSemiconductor/solid-state device manufacturingDual frequencyAnti-reflective coating

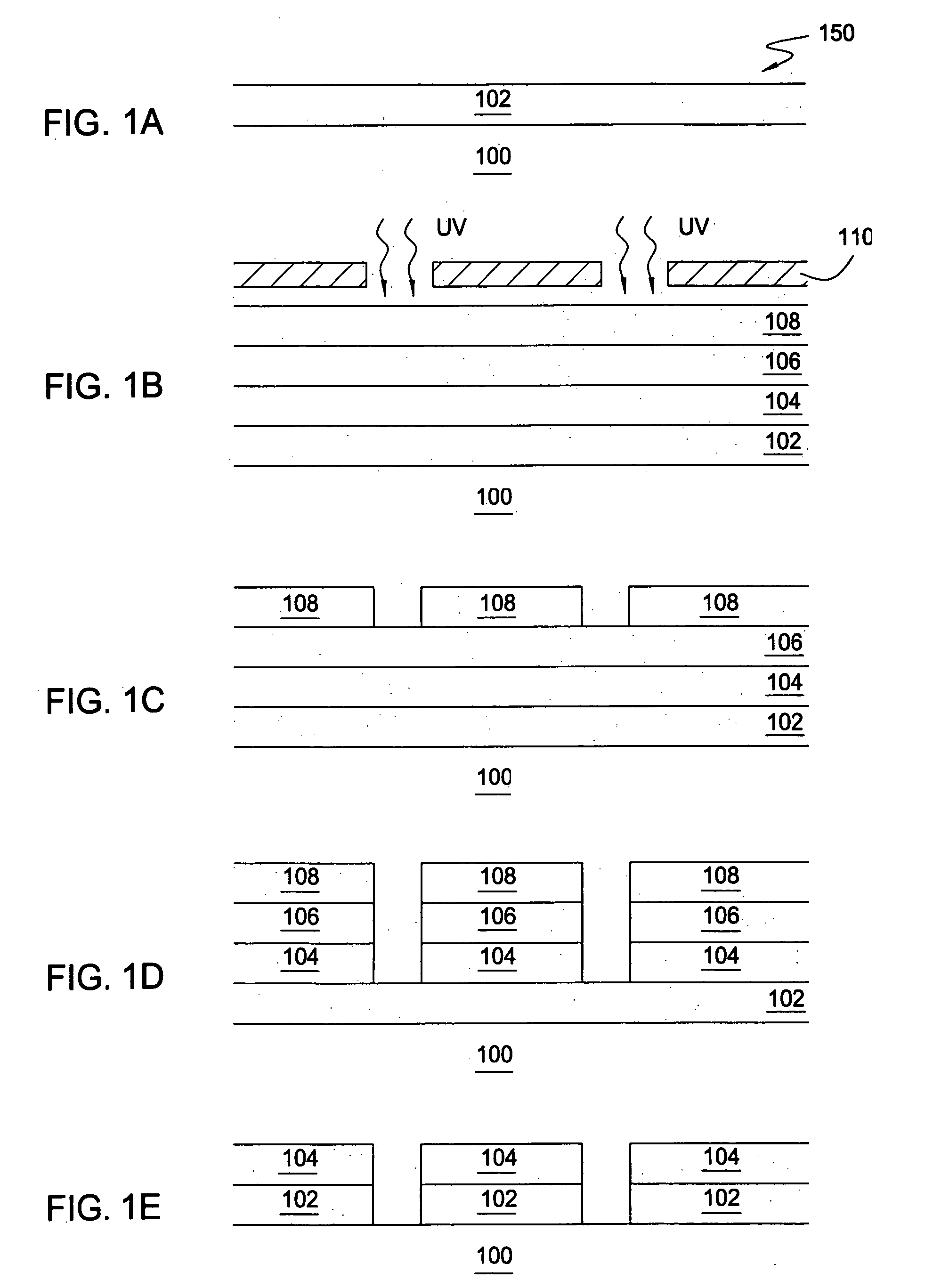

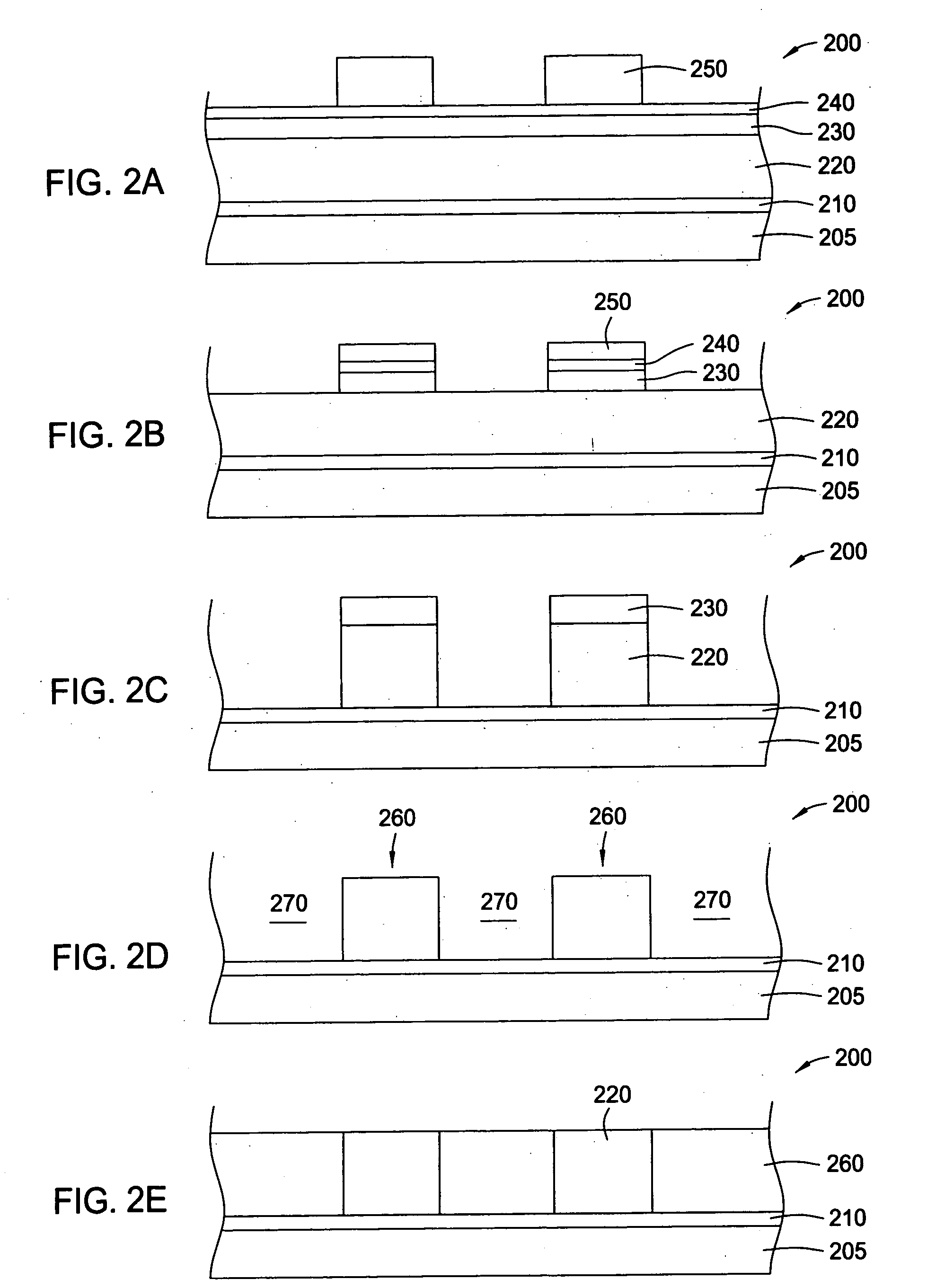

Methods are provided for depositing amorphous carbon materials. In one aspect, the invention provides a method for processing a substrate including forming a dielectric material layer on a surface of the substrate, depositing an amorphous carbon layer on the dielectric material layer by introducing a processing gas comprises one or more hydrocarbon compounds and an argon carrier gas, and generating a plasma of the processing gas by applying power from a dual-frequency RF source, etching the amorphous carbon layer to form a patterned amorphous carbon layer, and etching feature definitions in the dielectric material layer corresponding to the patterned amorphous carbon layer. The amorphous carbon layer may act as an etch stop, an anti-reflective coating, or both.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com