Patents

Literature

1076 results about "Specific energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Specific energy is energy per unit mass. (It is also sometimes called "energy density," though "energy density" more precisely means energy per unit volume.) It is used to quantify, for example, stored heat and other thermodynamic properties of substances such as specific internal energy, specific enthalpy, specific Gibbs free energy, and specific Helmholtz free energy. It may also be used for the kinetic energy or potential energy of a body. Specific energy is an intensive property, whereas energy and mass are extensive properties.

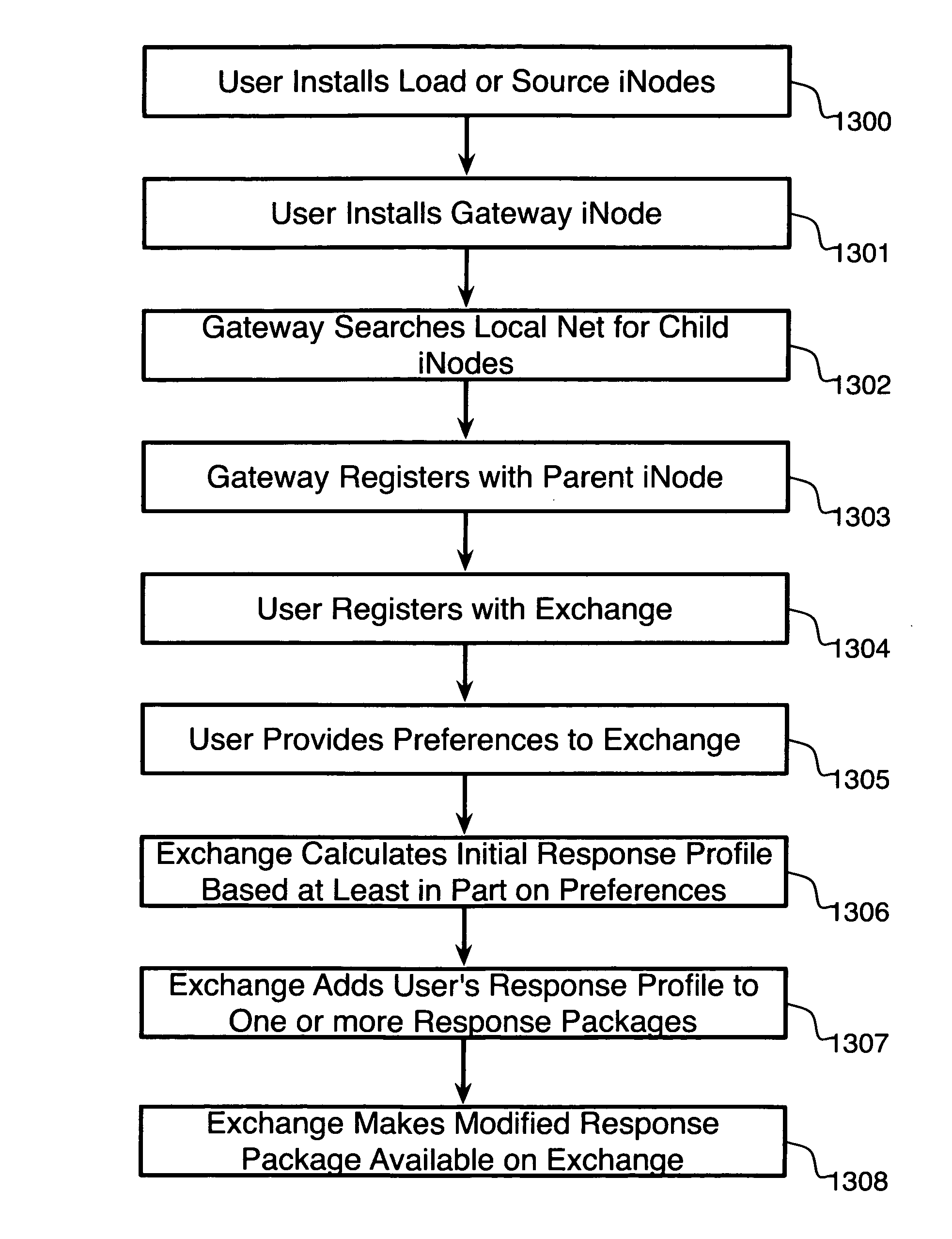

System and method for participation in energy-related markets

A multidimensional energy decision system, comprising a plurality of server systems, including at least a statistics server and an interface adapted to receive and send digital information from at least a client system, and further adapted to optionally communicate with the digital exchange via a packet-based data network, wherein the multidimensional energy decision system periodically optimizes operational parameters of client system for a specific time period and a specific energy asset from client system based on forecasted conditions, and directly, or upon decision confirmation from a client system, procures or makes dispatchable energy resources, related externalities, or related derivative financial products, available to a digital exchange or other parties, wherein upon the purchase of a listed asset by another party or across digital exchange, implements dispatch procedures to satisfy the issued contract and, optionally, provides monitoring and verification of performance, is disclosed.

Owner:CRABTREE JASON +6

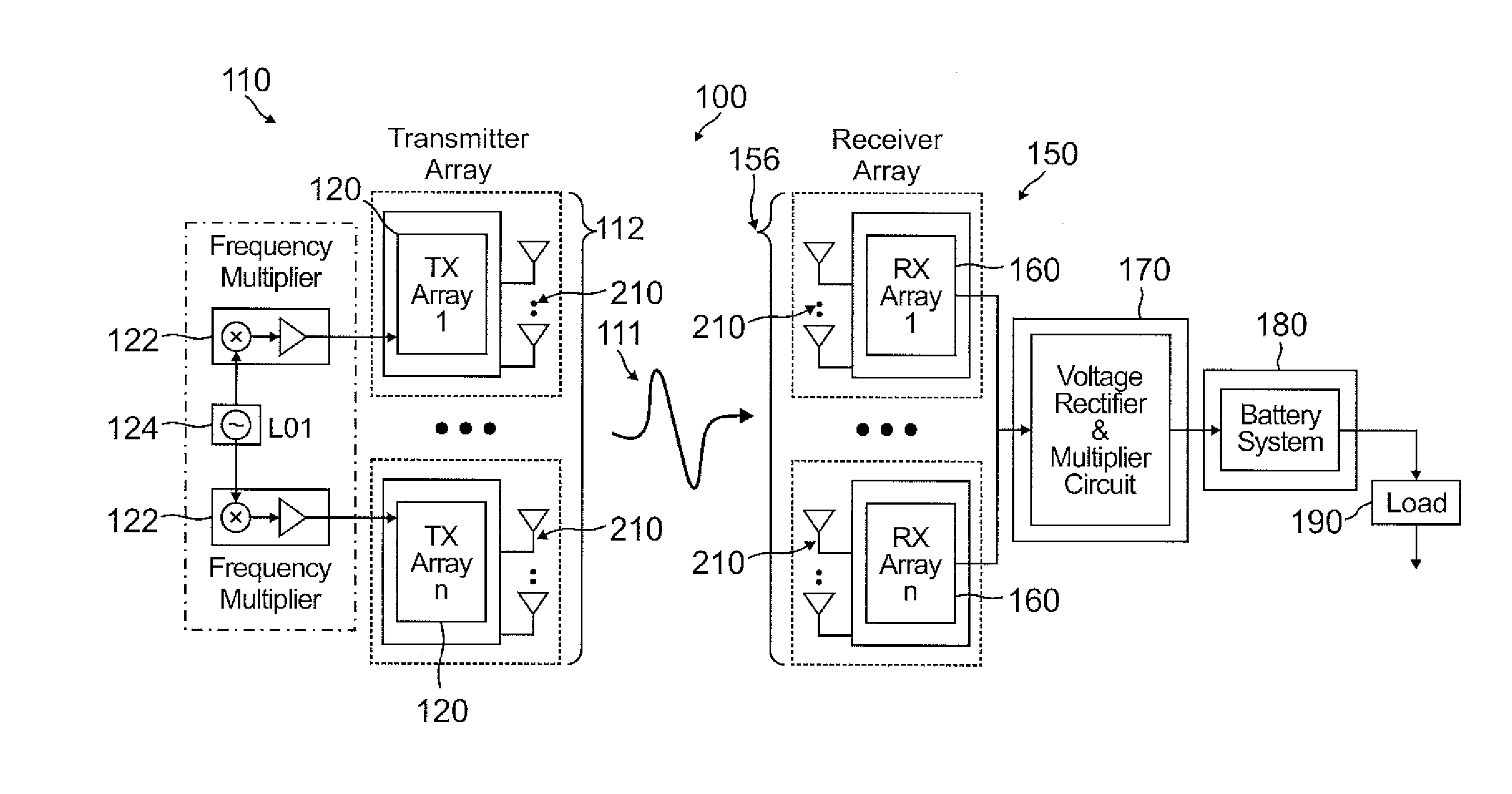

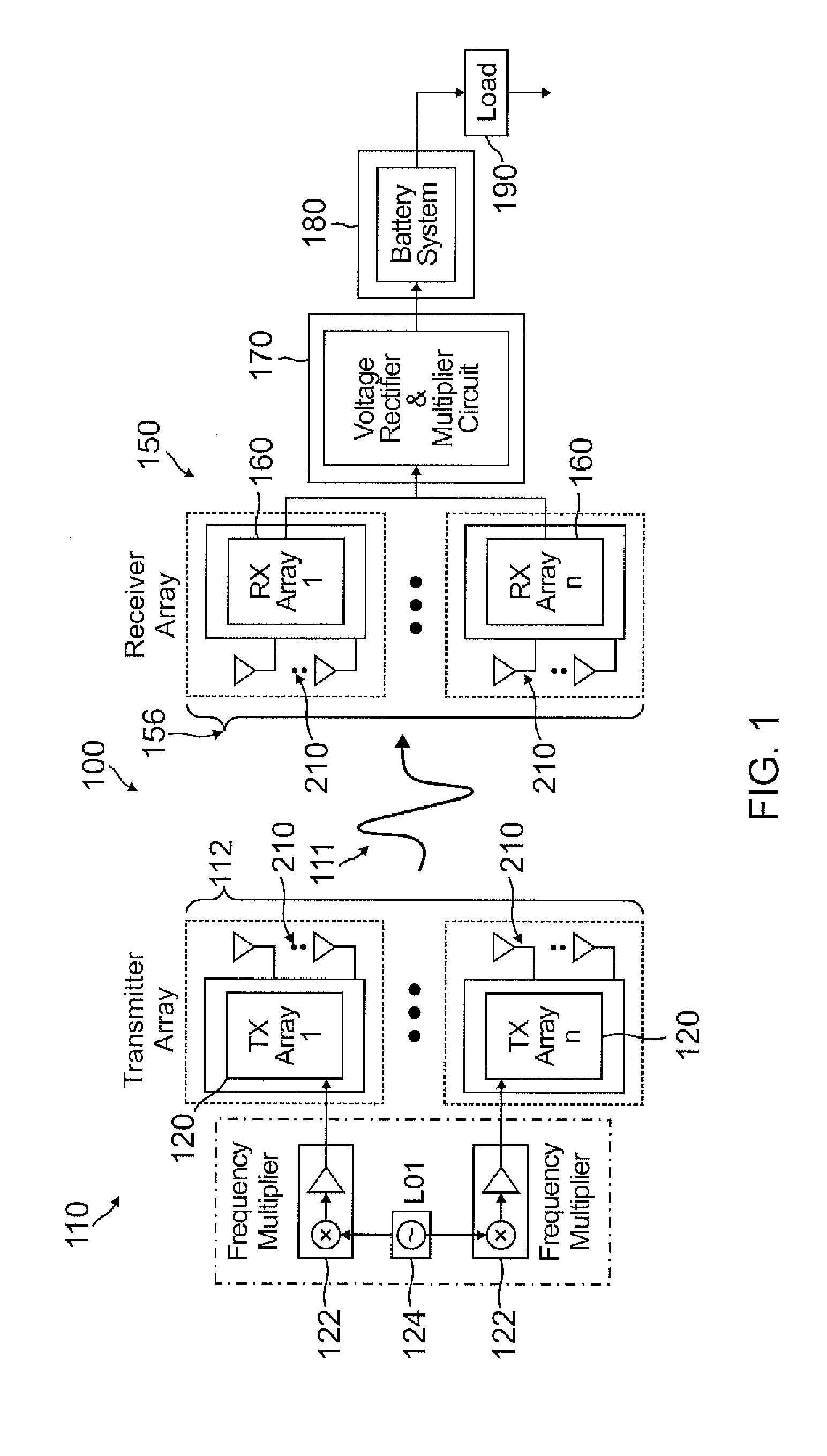

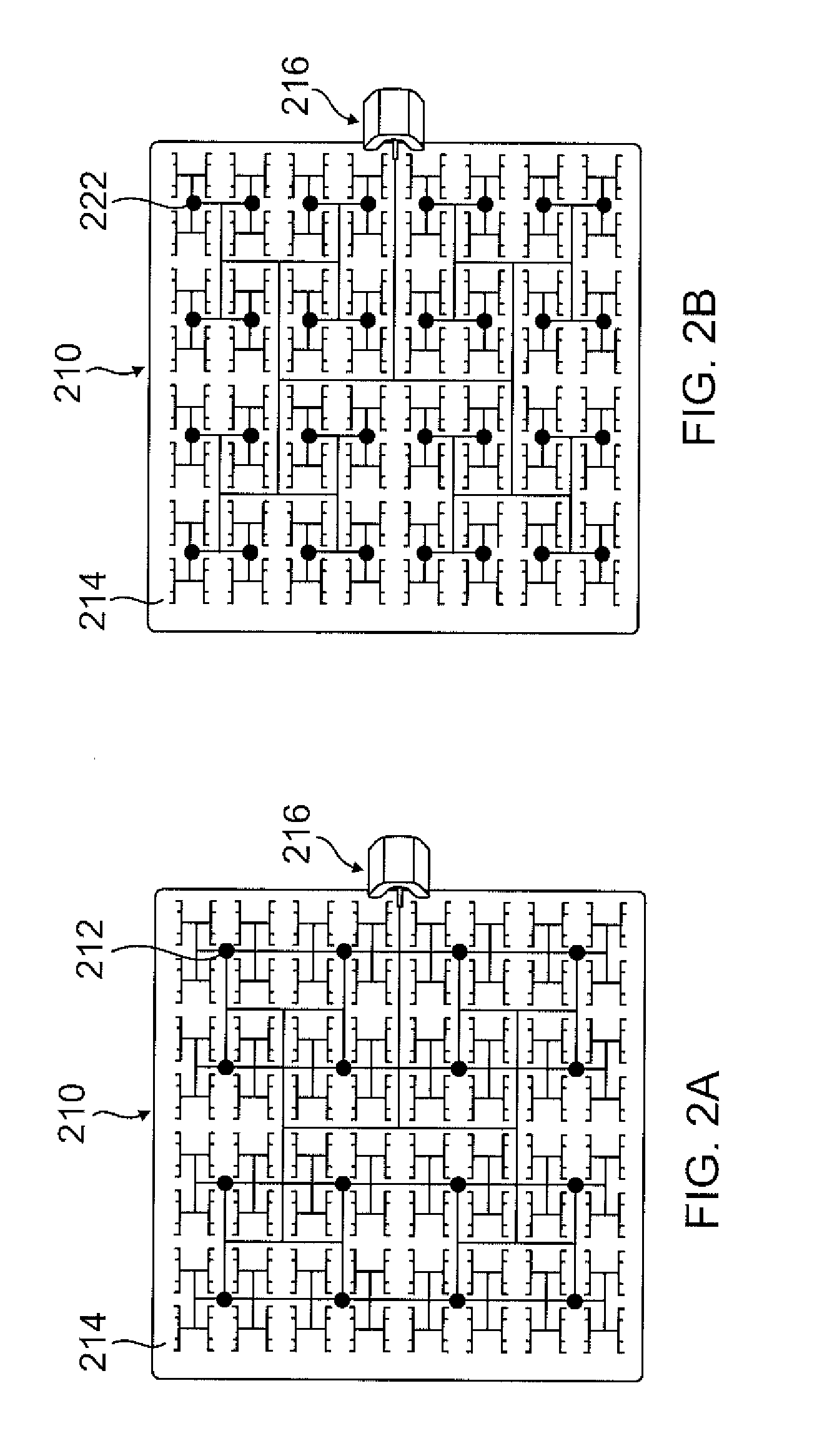

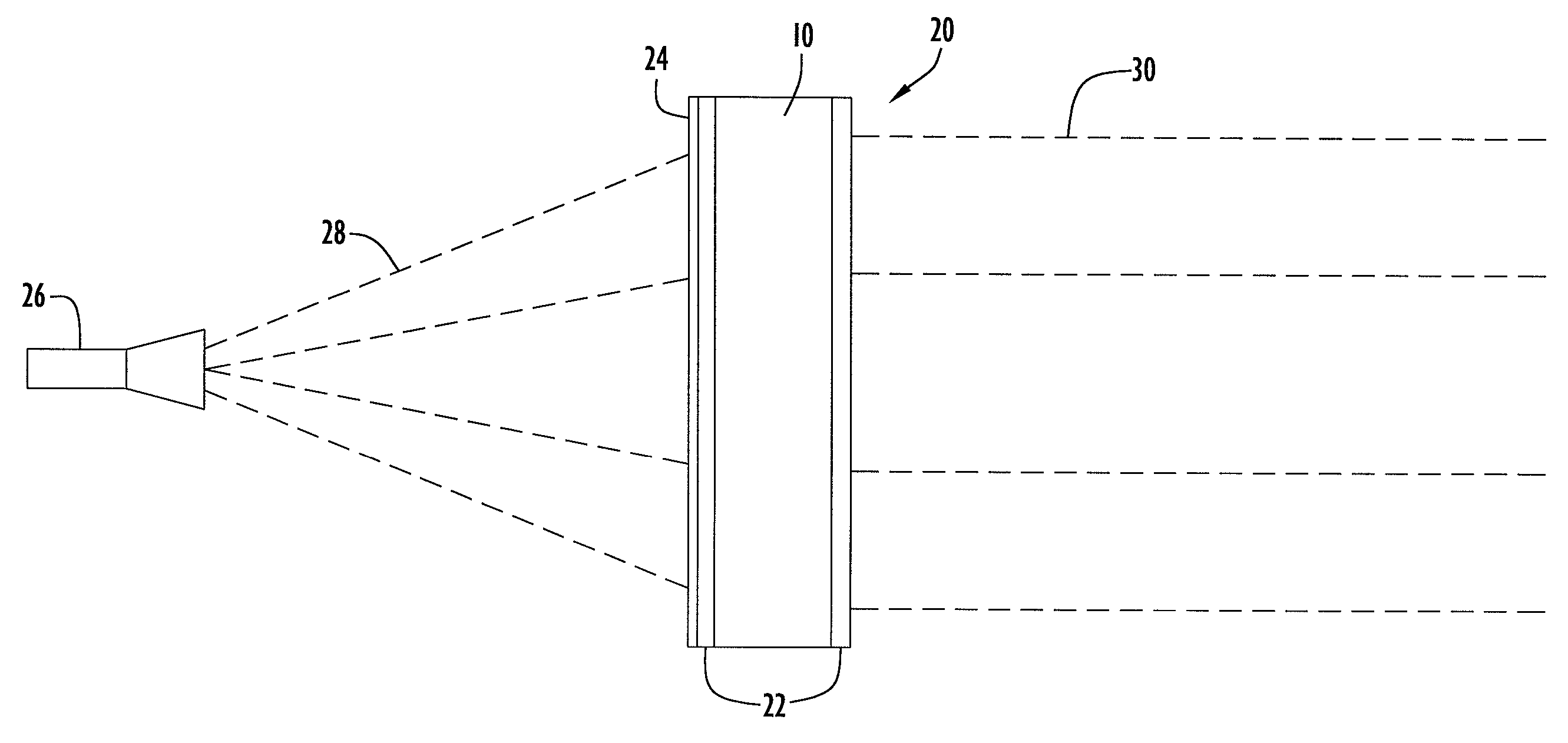

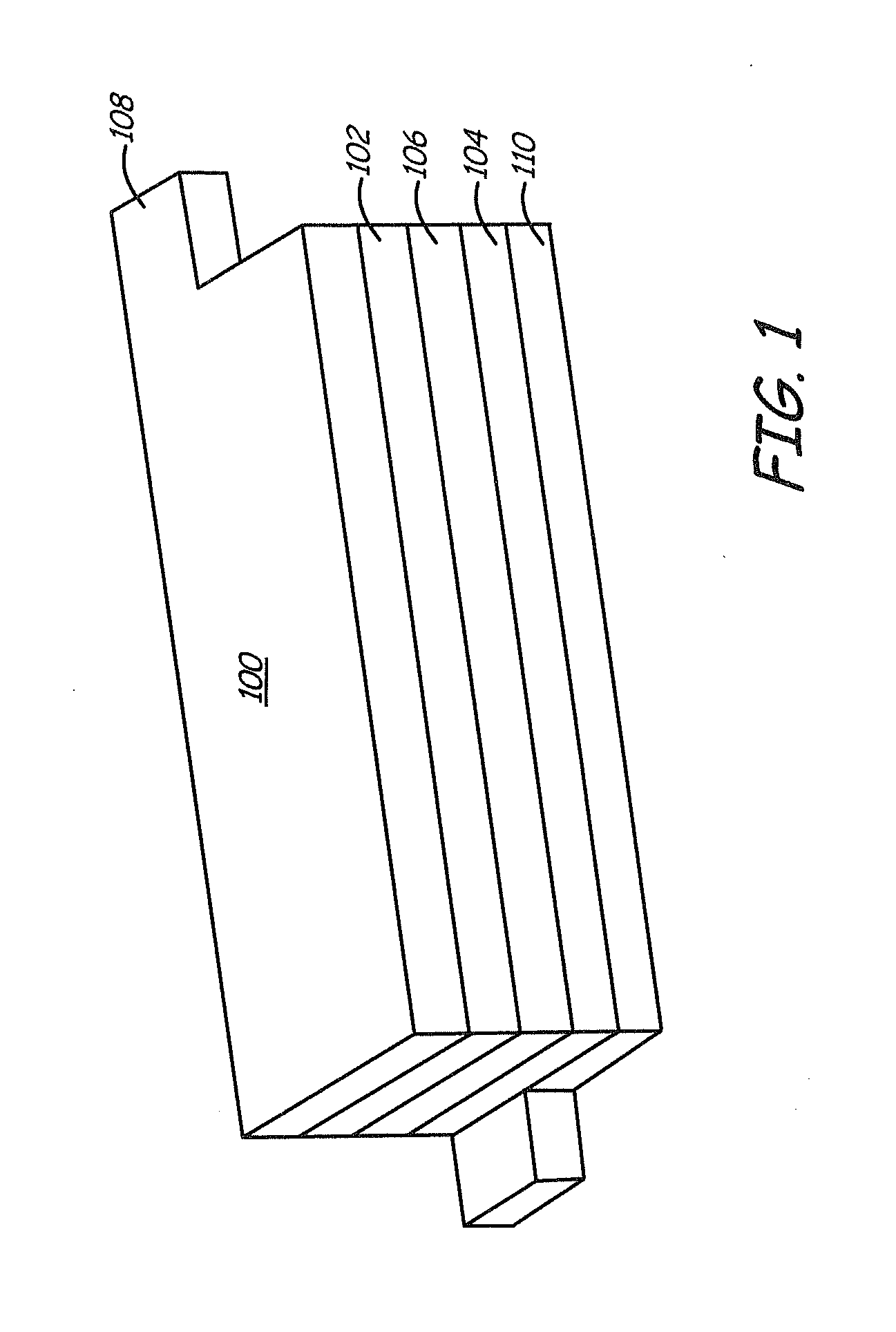

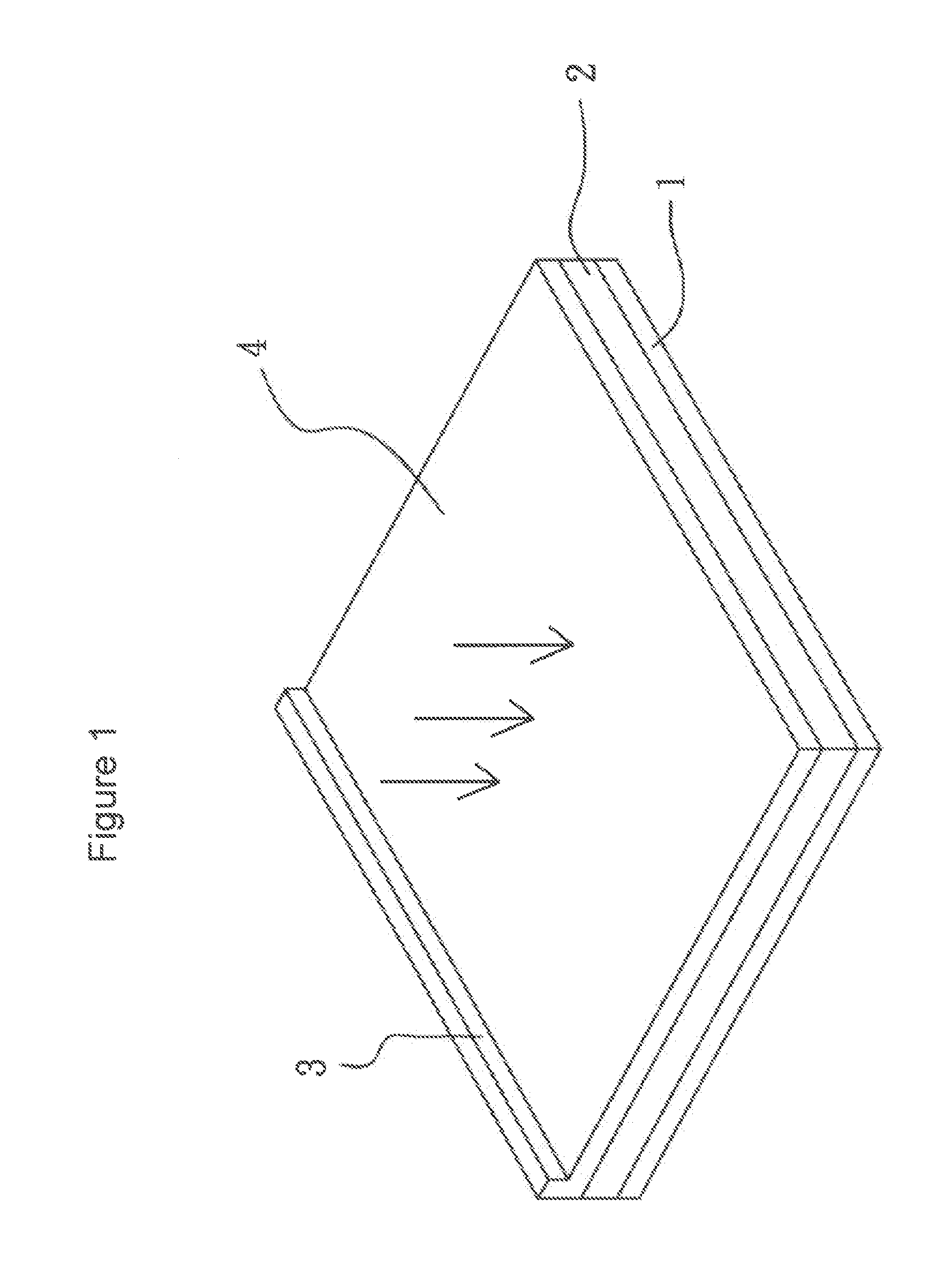

Flat panel, stationary or mobile, spatially beam-formed wireless energy delivery system

Methods and systems are provided for achieving delivery of power wirelessly using a highly beam-formed array of radio frequency (RF) transmitters as a source and a spatially beam-formed array of receivers that collect the impinged RF power and feed a multistage RF to direct current (RF-DC) conversion circuit that, for example, increases output voltage by doubling the voltage at each stage, while power delivery remains constant. One or more embodiments may provide energy wirelessly and—unlike conventional systems where the power flux density may be too low for applications where an energy density (specific energy) on the order of several mega-Joules per kilogram (MJ / Kg) is desired—may provide sufficient power flux density for many practical applications.

Owner:MOHAMADI FARROKH

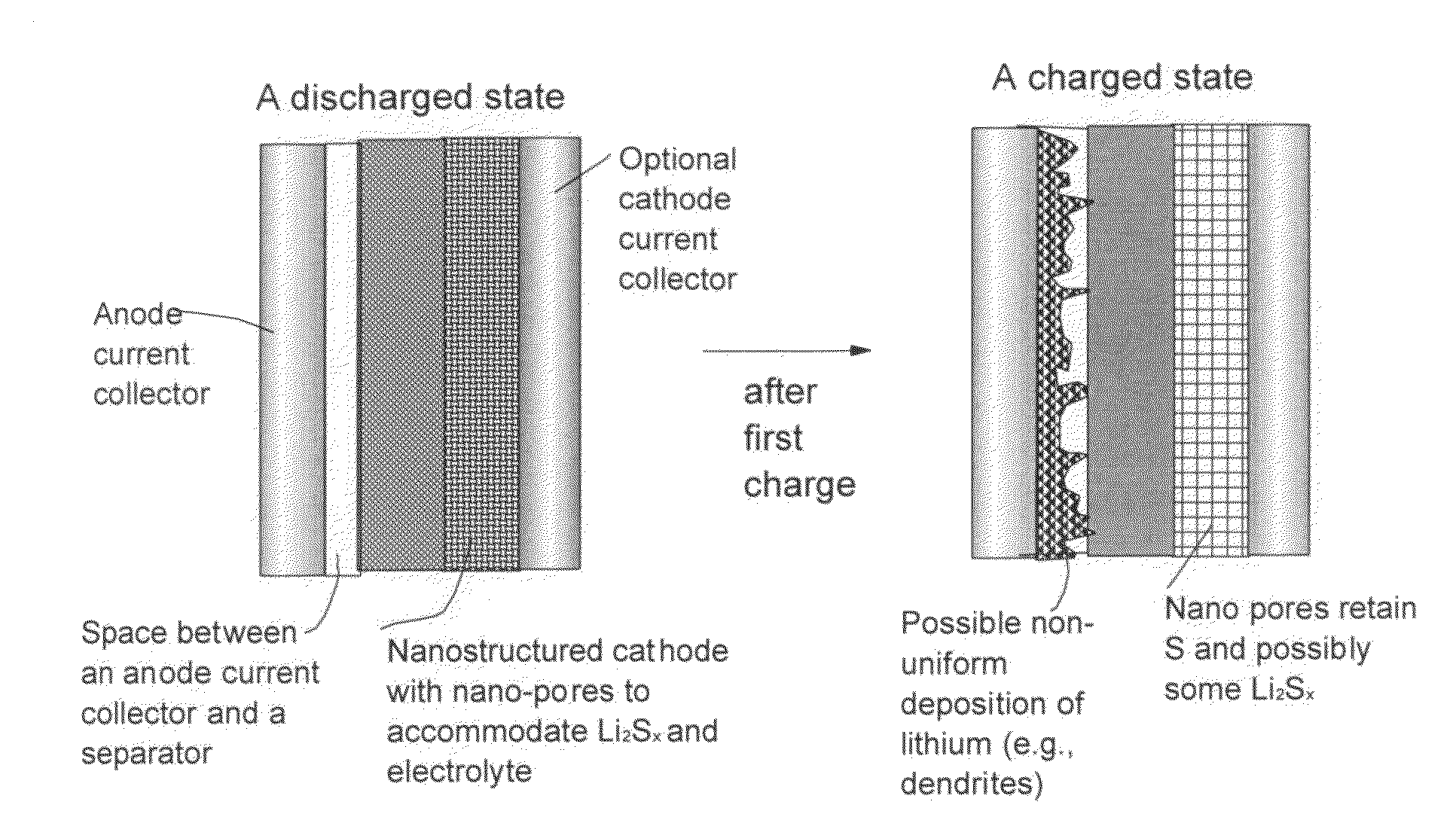

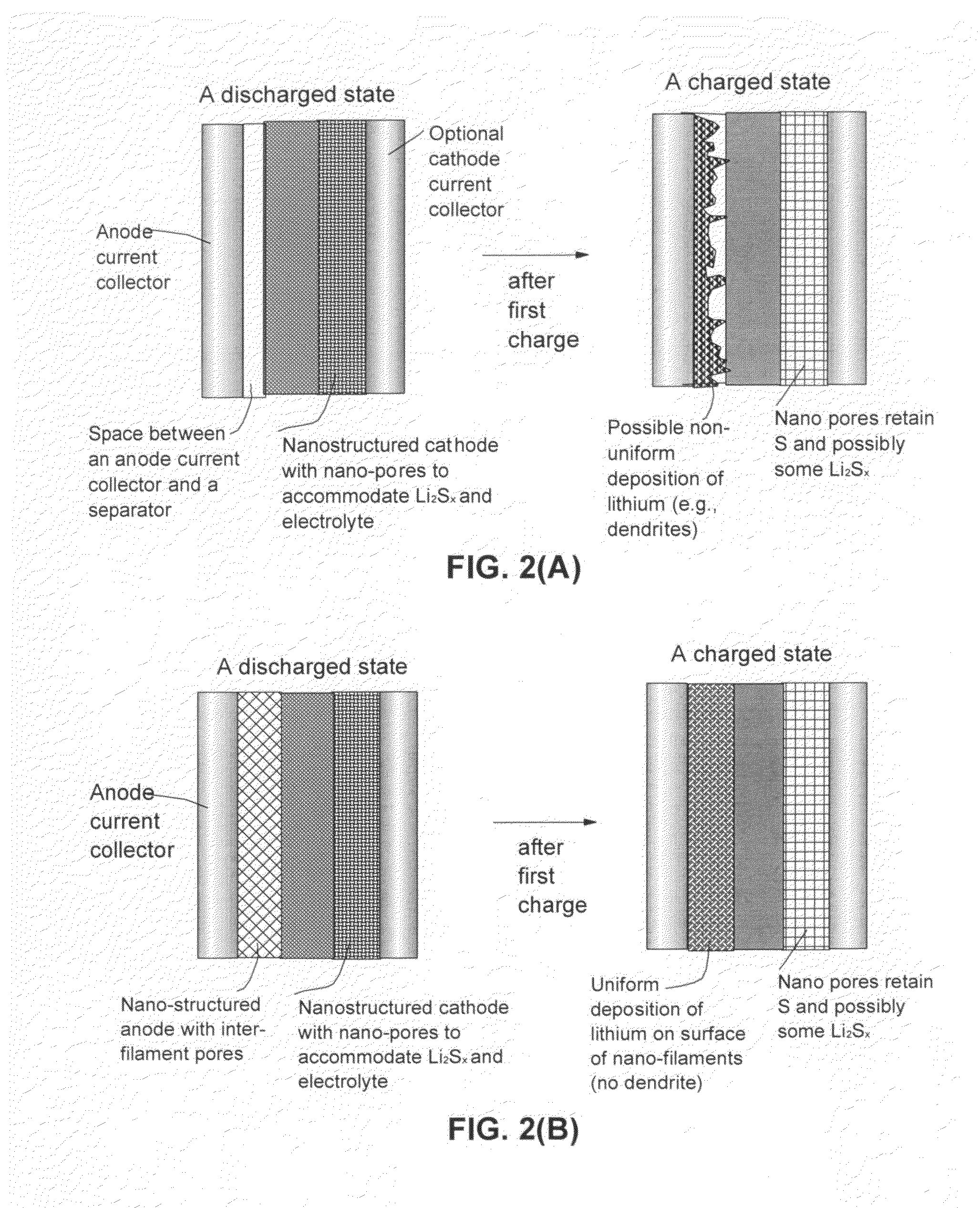

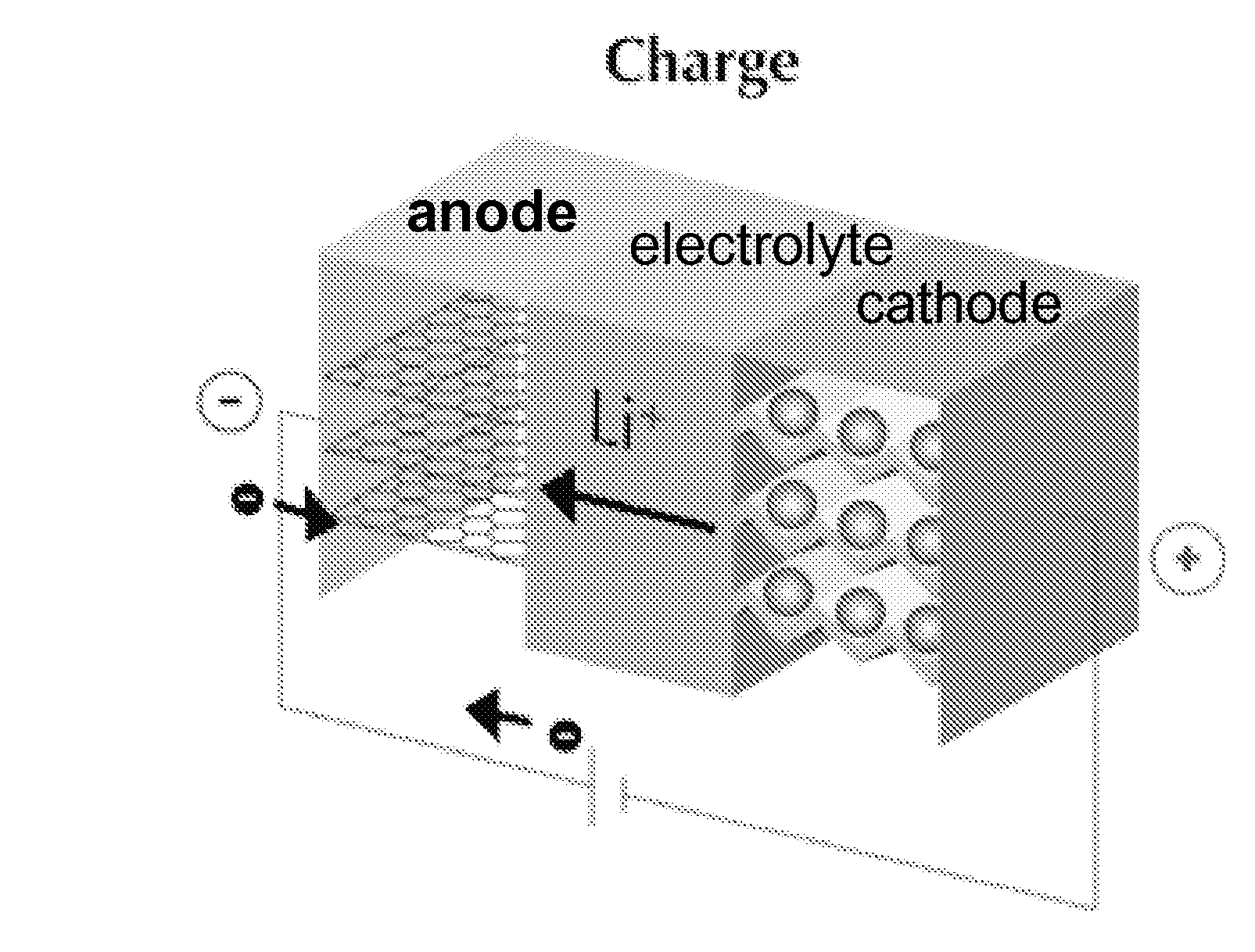

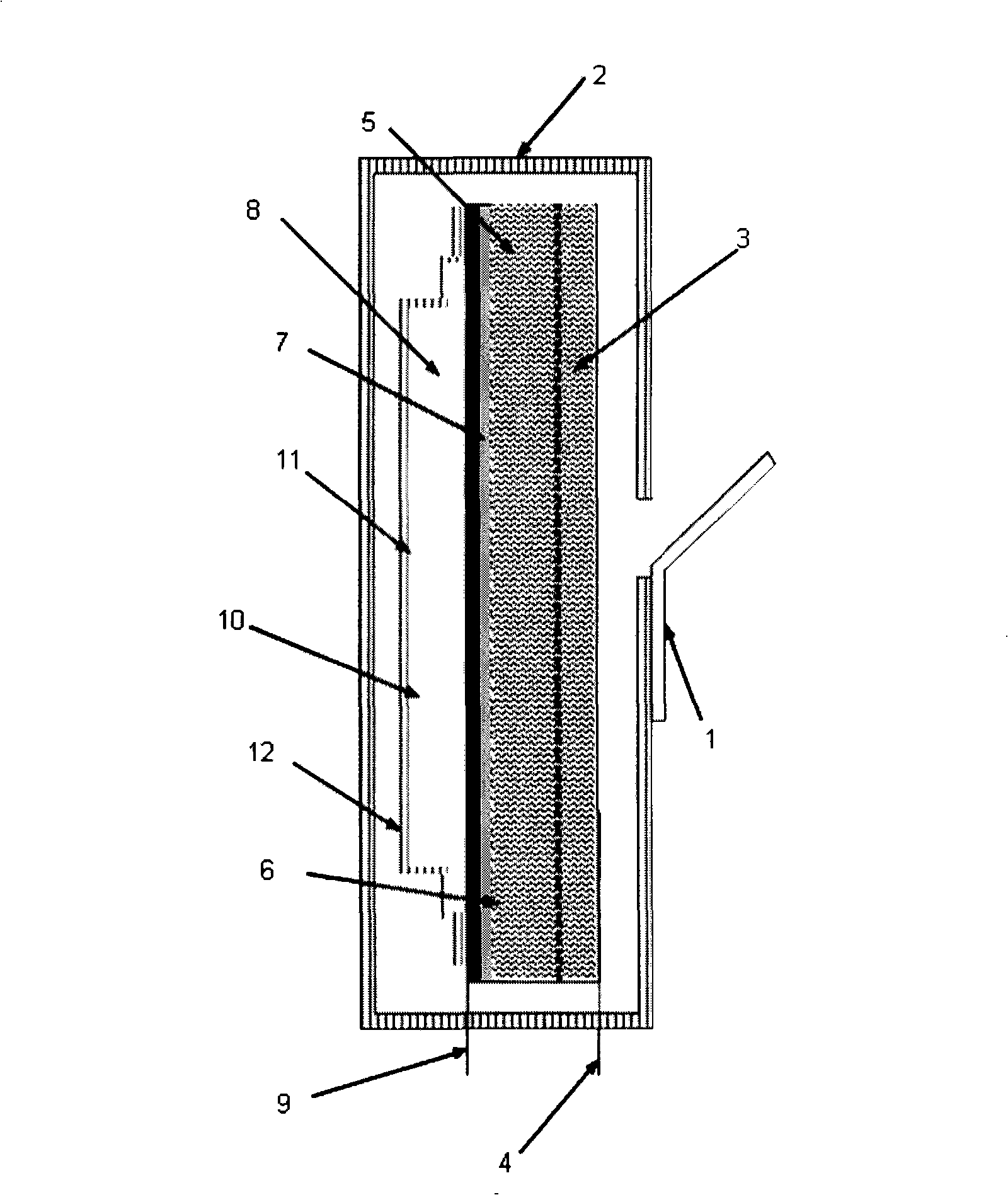

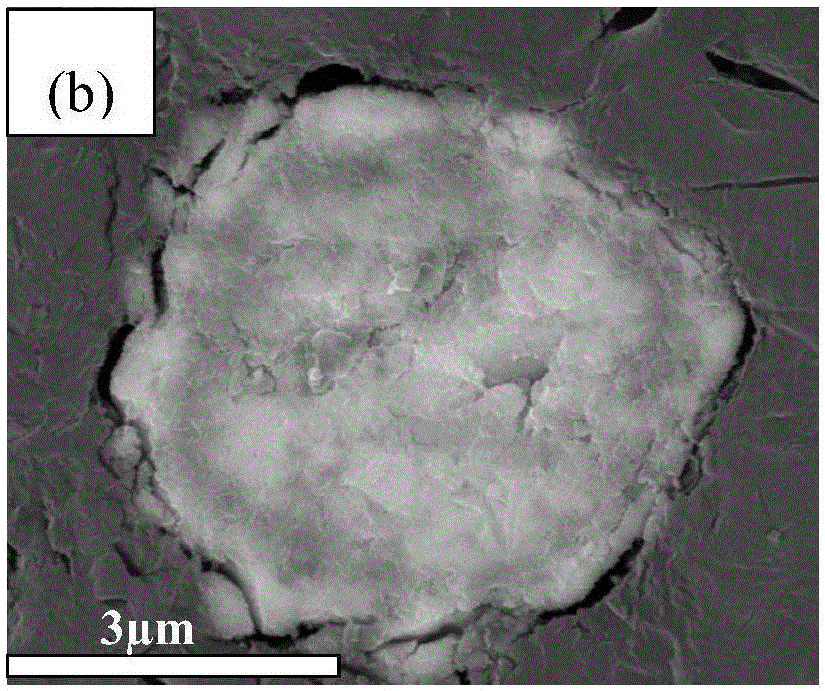

Lithium metal-sulfur and lithium ion-sulfur secondary batteries containing a nano-structured cathode and processes for producing same

ActiveUS20110165466A1High specific capacityImprove the immunityMaterial nanotechnologyElectrochemical processing of electrodesSpecific energyLithium metal

An electrochemical cell comprising an anode, electrolyte or an electrolyte / separator combination, and a nano-structured cathode, wherein the cathode comprises: (a) an integrated nano-structure of electrically conductive nanometer-scaled filaments that are interconnected to form a porous network of electron-conducting paths comprising pores with a size smaller than 100 nm (preferably smaller than 10 nm), wherein the filaments have a transverse dimension less than 500 nm (preferably less than 100 nm); and (b) powder or salt of lithium-containing sulfide (lithium polysulfide) disposed in the pores, or a thin coating of lithium-containing sulfide deposited on a nano-scaled filament surface wherein the lithium-containing sulfide is in contact with, dispersed in, or dissolved in electrolyte liquid and the lithium-containing sulfide-to-filament weight ratio is between 1 / 10 and 10 / 1 which is measured when the cell is in a fully discharged state. The cell exhibits an exceptionally high specific energy and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

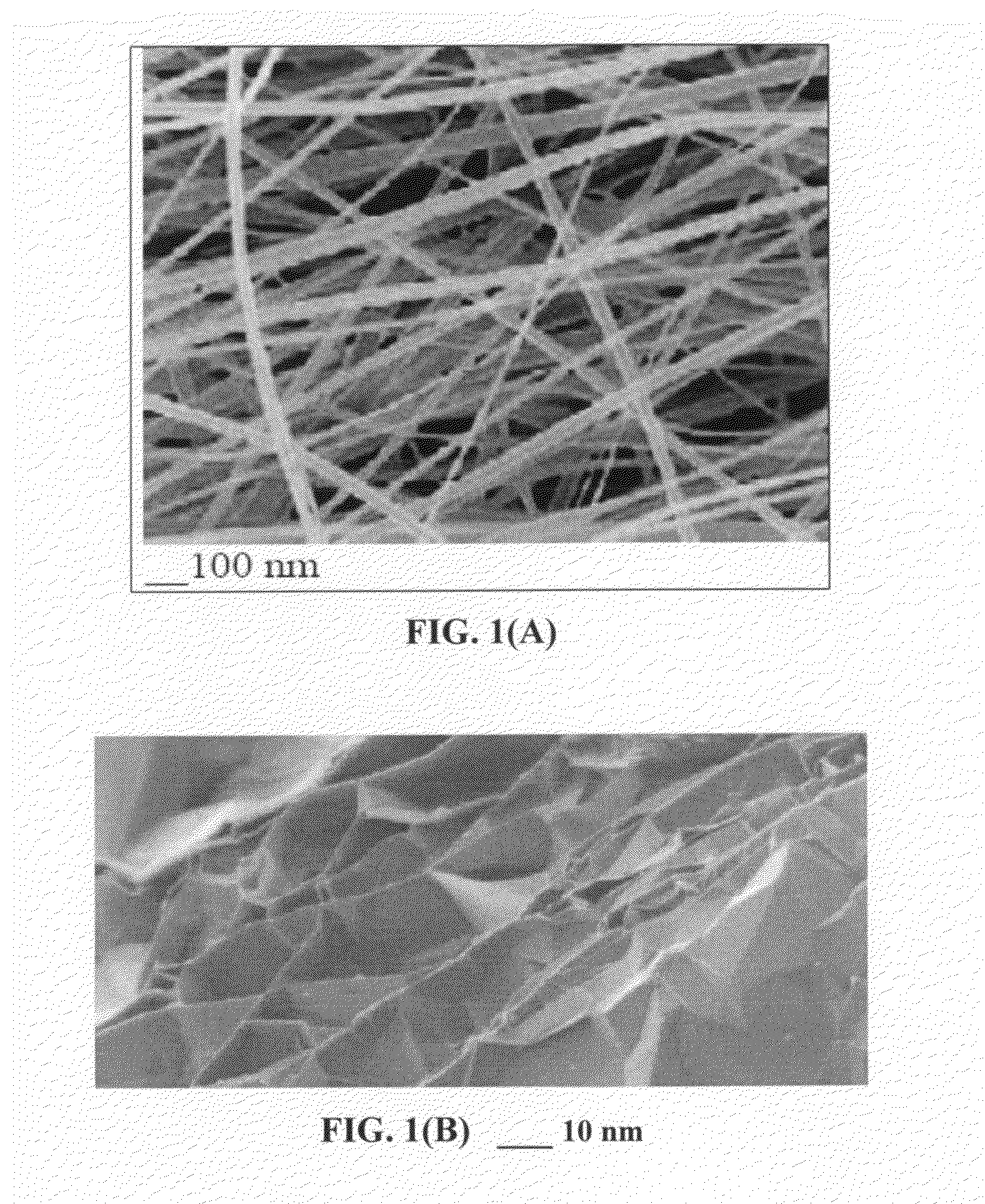

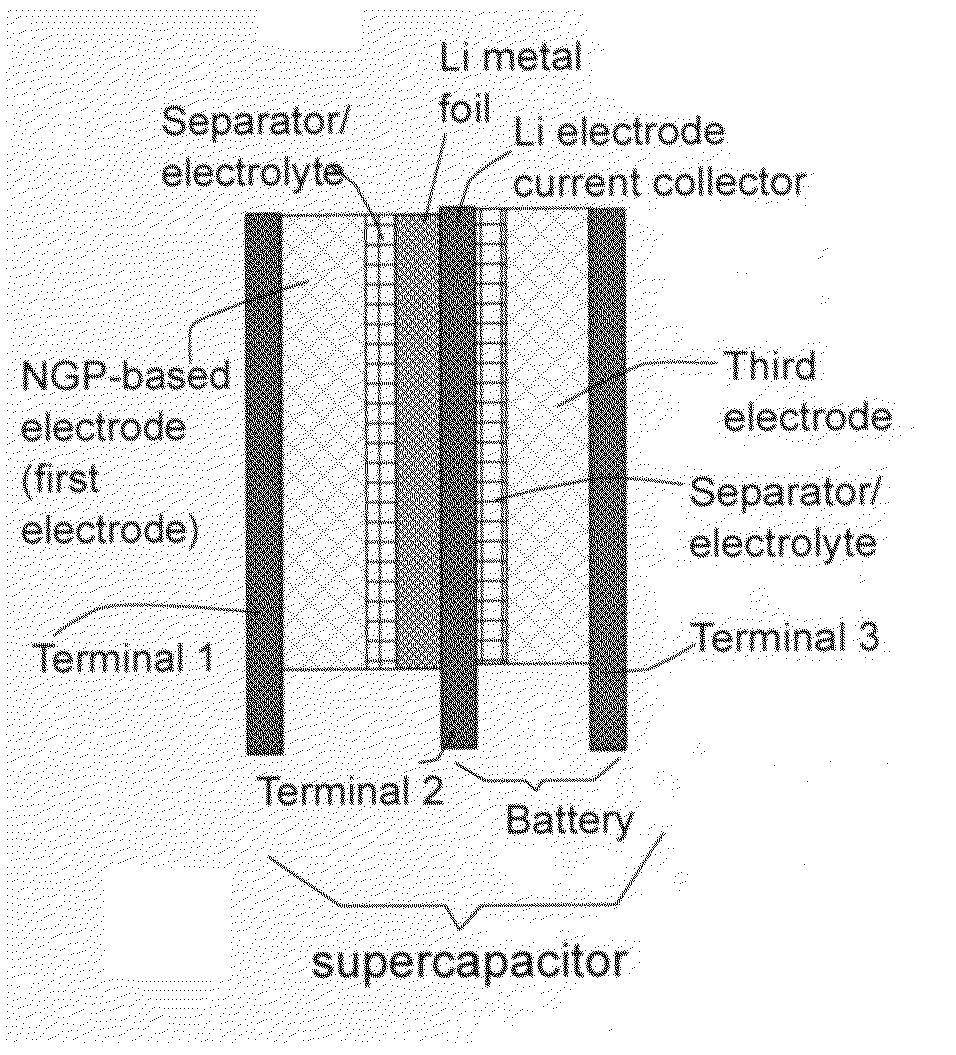

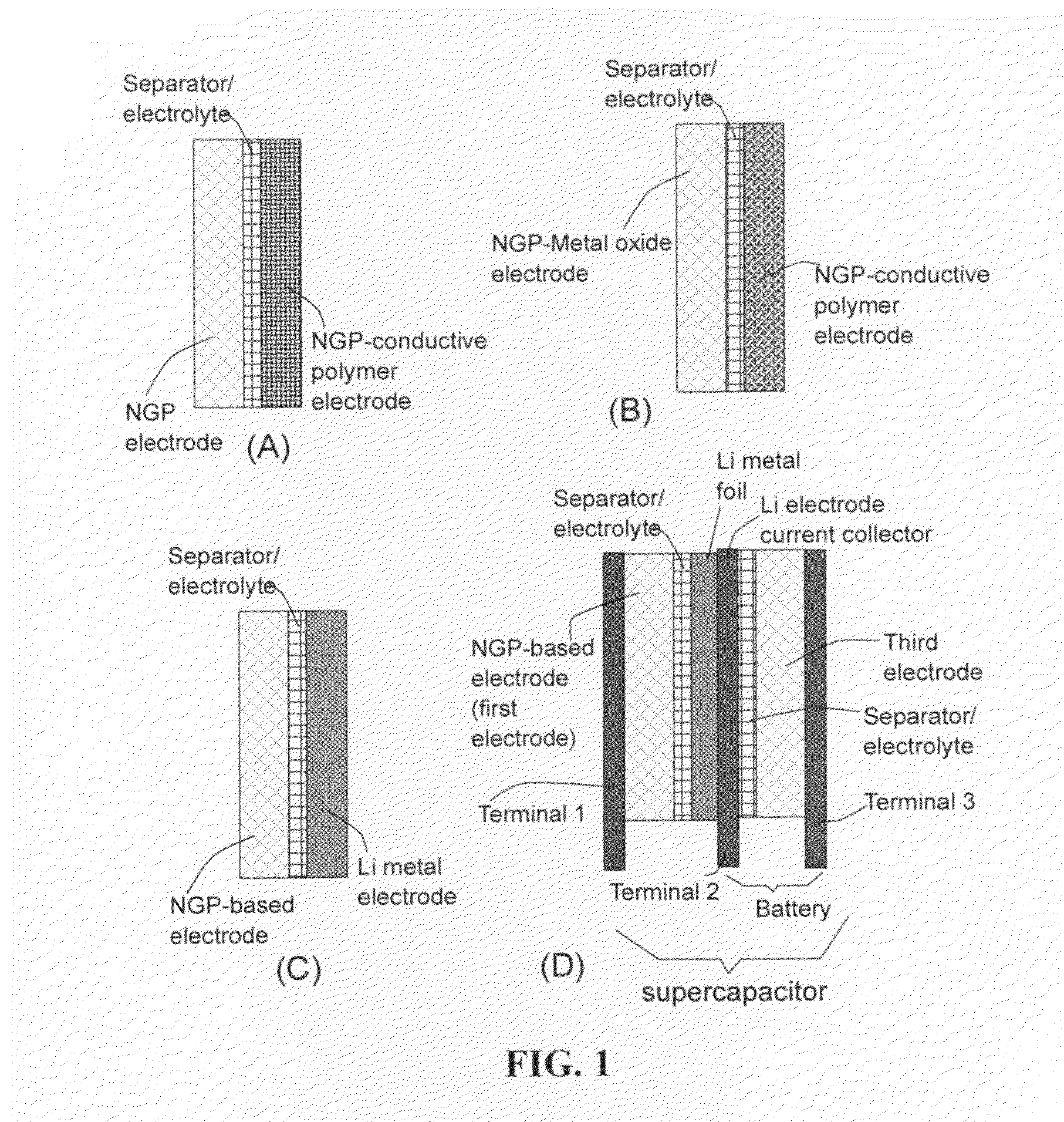

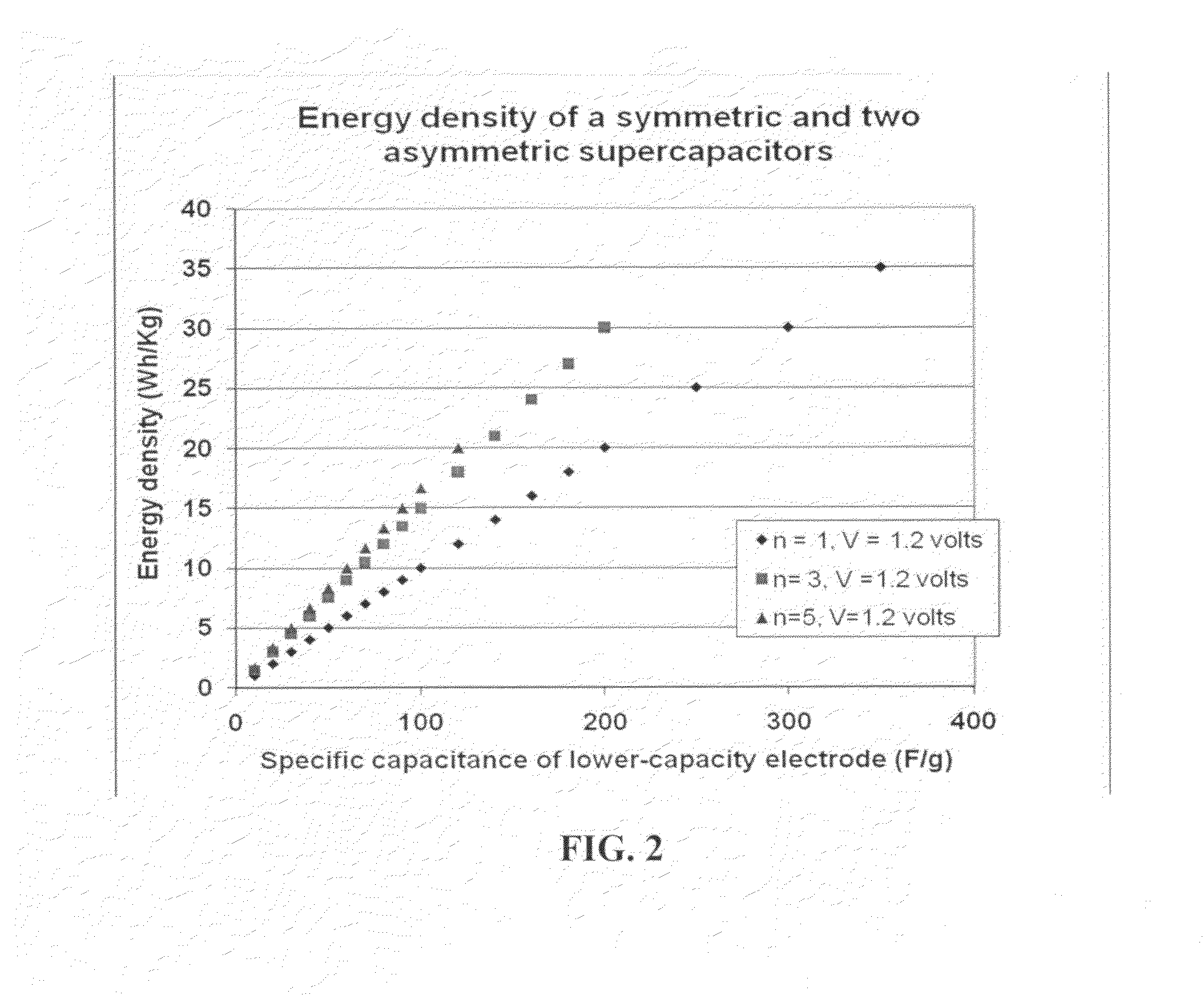

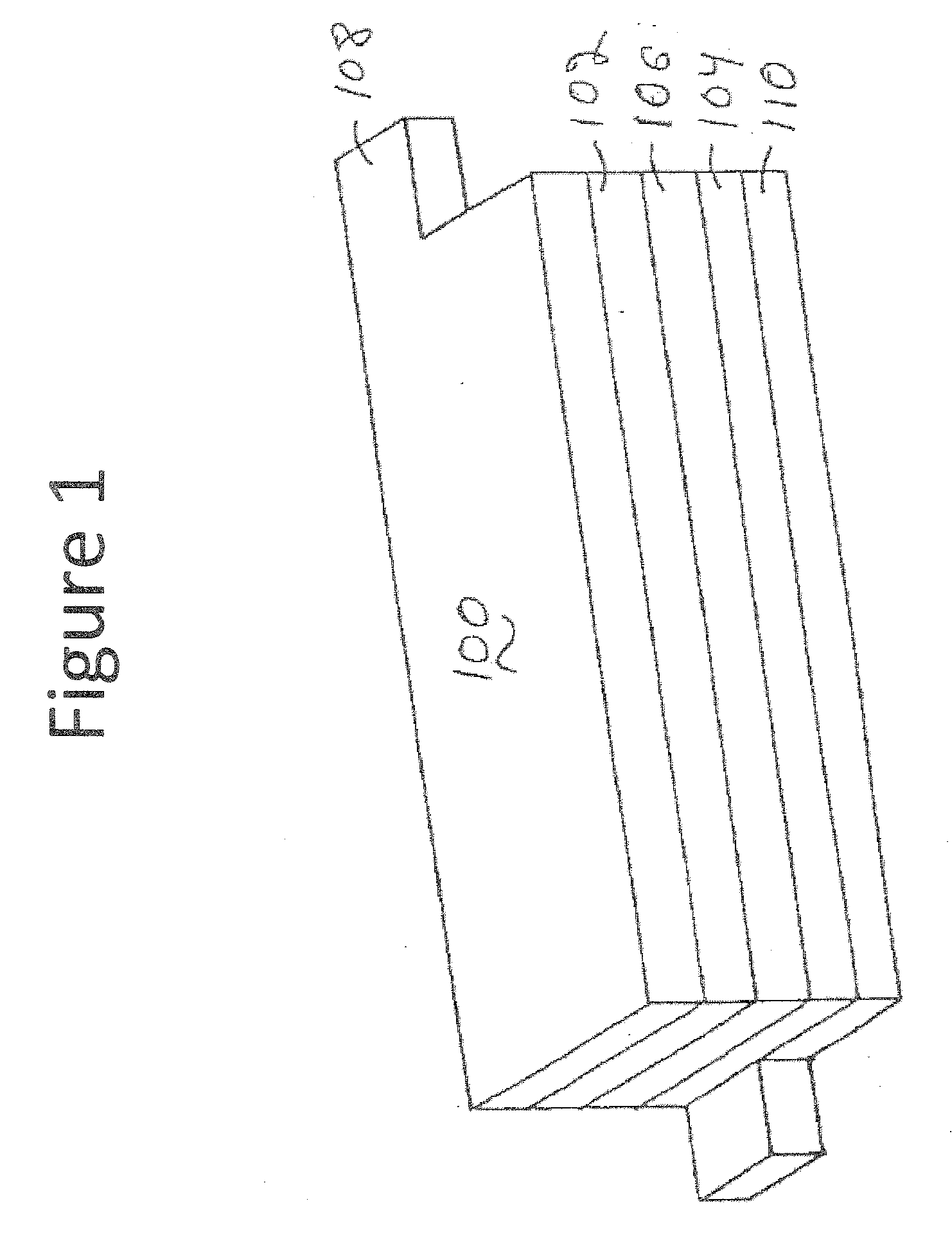

Flexible asymmetric electrochemical cells using nano graphene platelet as an electrode material

InactiveUS20110183180A1Excellent specific capacitanceLarge specific surface areaElectrochemical generatorsHybrid capacitor separatorsPlateletGraphene

A flexible, asymmetric electrochemical cell comprising: (A) A sheet of graphene paper as first electrode comprising nano graphene platelets having a platelet thickness less than 1 nm, wherein the first electrode has electrolyte-accessible pores; (B) A thin-film or paper-like first separator and electrolyte; and (C) A thin-film or paper-like second electrode which is different in composition than the first electrode; wherein the separator is sandwiched between the first and second electrode to form a flexible laminate configuration. The asymmetric supercapacitor cells with different NGP-based electrodes exhibit an exceptionally high capacitance, specific energy, and stable and long cycle life.

Owner:NANOTEK INSTR GRP LLC

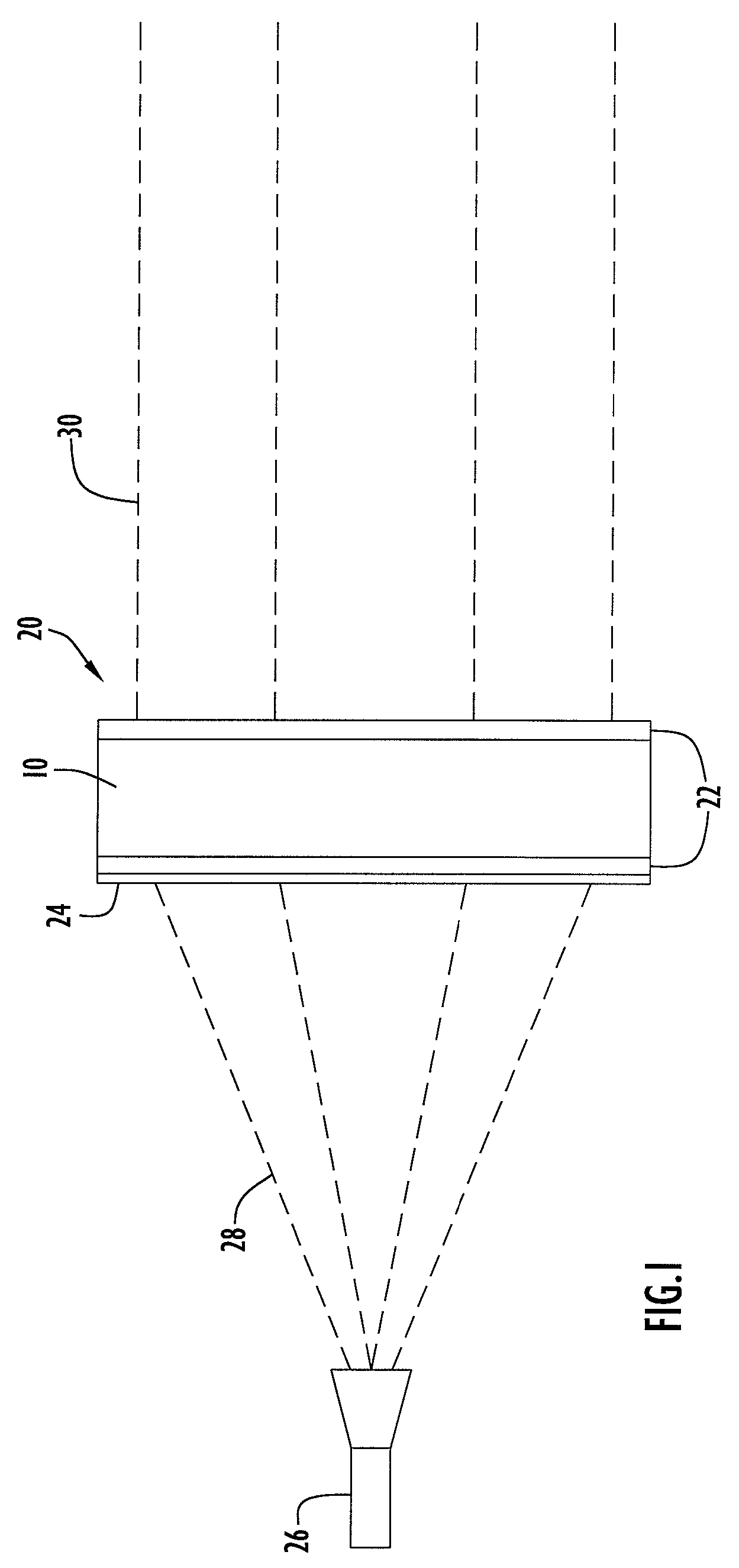

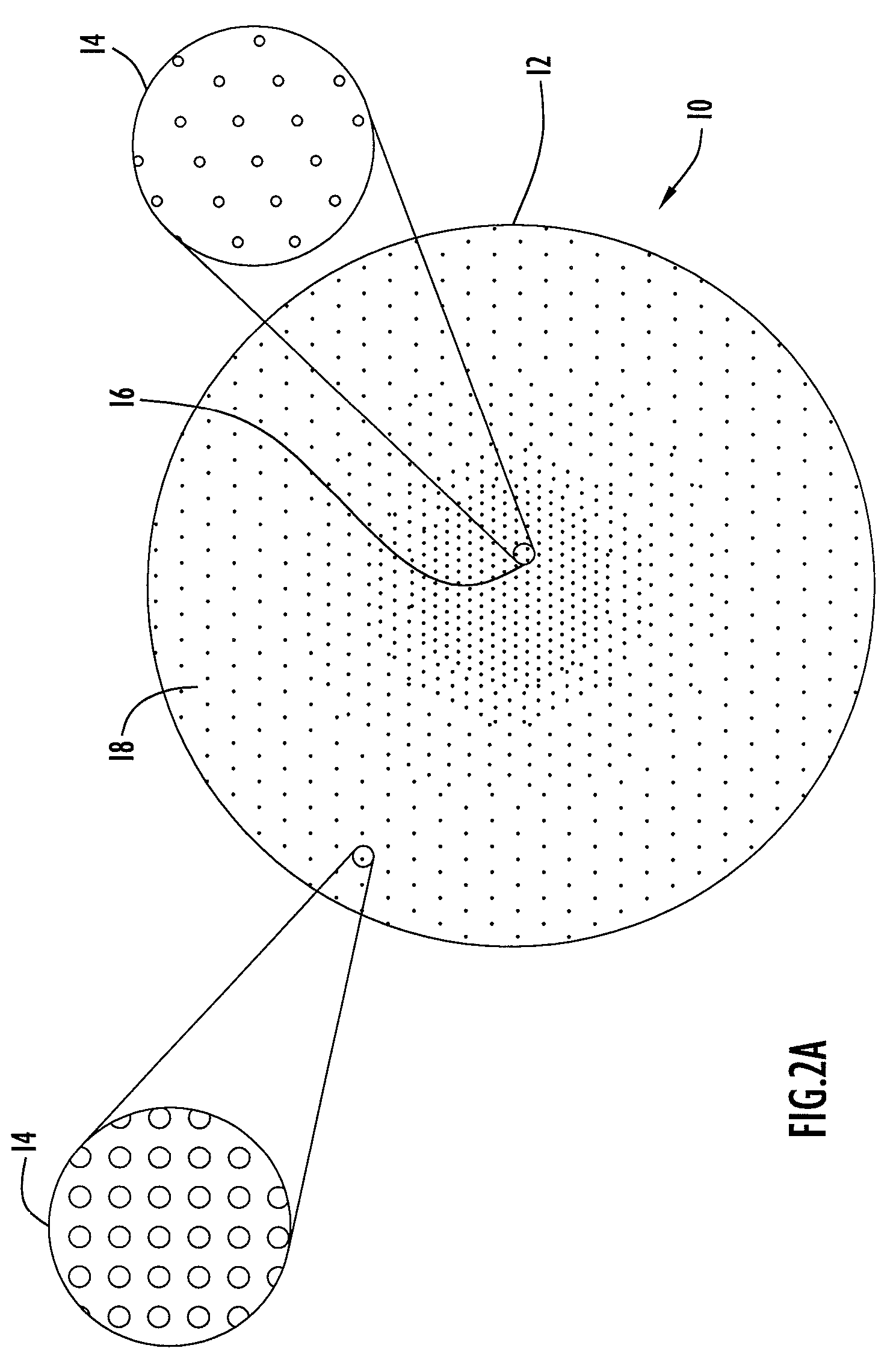

Radio frequency lens and method of suppressing side-lobes

ActiveUS7777690B2Weaken energyImproves Structural IntegrityAntennasPhotonic crystal structureCrystal structure

An RF lens according to the present invention embodiments collimates an RF beam by refracting the beam into a beam profile that is diffraction-limited. The lens is constructed of a lightweight mechanical arrangement of two or more materials, where the materials are arranged to form a photonic crystal structure (e.g., a series of holes defined within a parent material). The lens includes impedance matching layers, while an absorptive or apodizing mask is applied to the lens to create a specific energy profile across the lens. The impedance matching layers and apodizing mask similarly include a photonic crystal structure. The energy profile function across the lens aperture is continuous, while the derivatives of the energy distribution function are similarly continuous. This lens arrangement produces a substantial reduction in the amount of energy that is transmitted in the side-lobes of an RF system.

Owner:HARRIS CORP

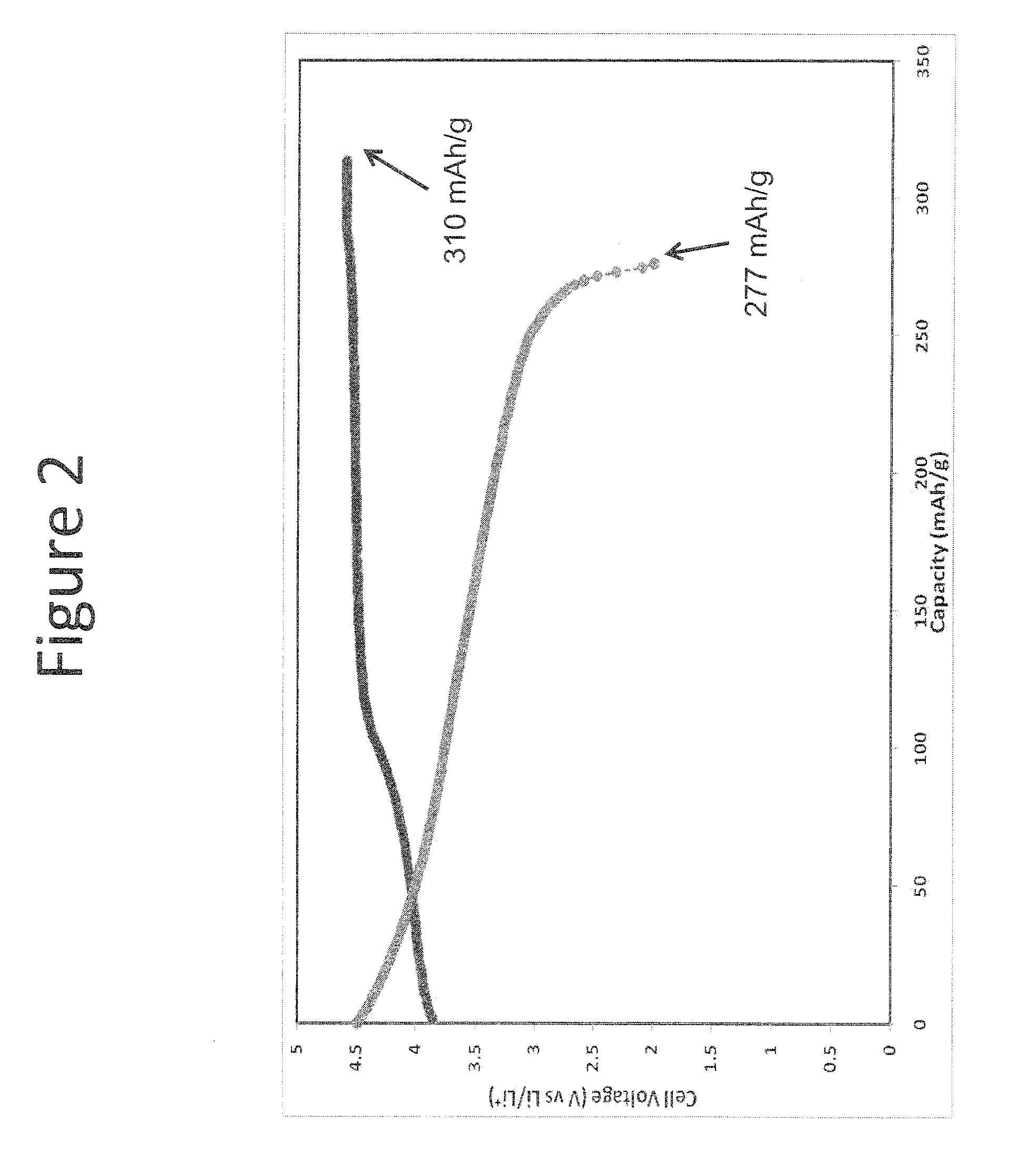

High Energy Lithium Ion Secondary Batteries

Lithium ion secondary batteries are described that have high total energy, energy density and specific discharge capacity upon cycling at room temperature and at a moderate discharge rate. The improved batteries are based on high loading of positive electrode materials with high energy capacity. This capability is accomplished through the development of positive electrode active materials with very high specific energy capacity that can be loaded at high density into electrodes without sacrificing performance. The high loading of the positive electrode materials in the batteries are facilitated through using a polymer binder that has an average molecular weight higher than 800,000 atomic mass unit.

Owner:IONBLOX INC

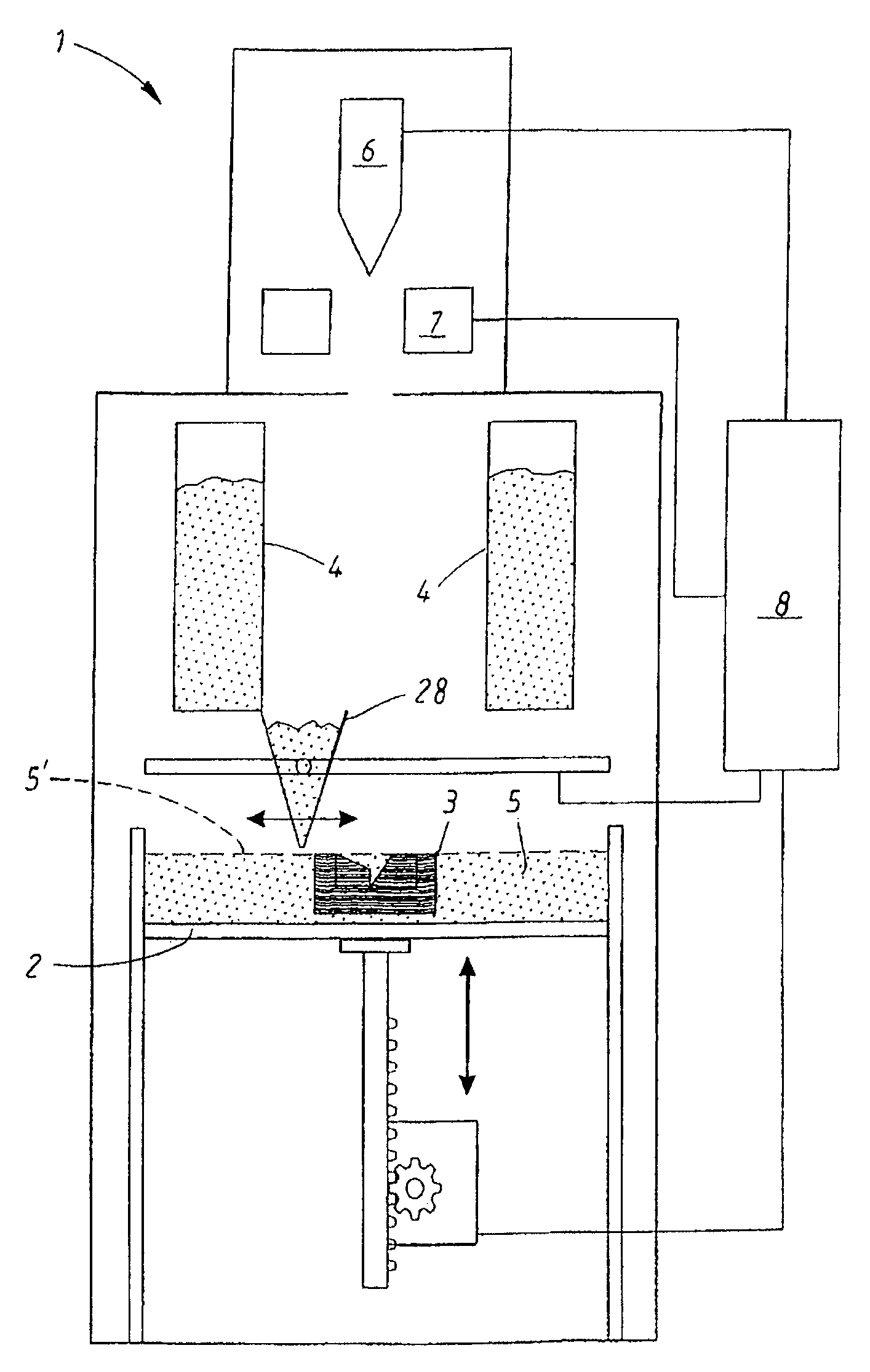

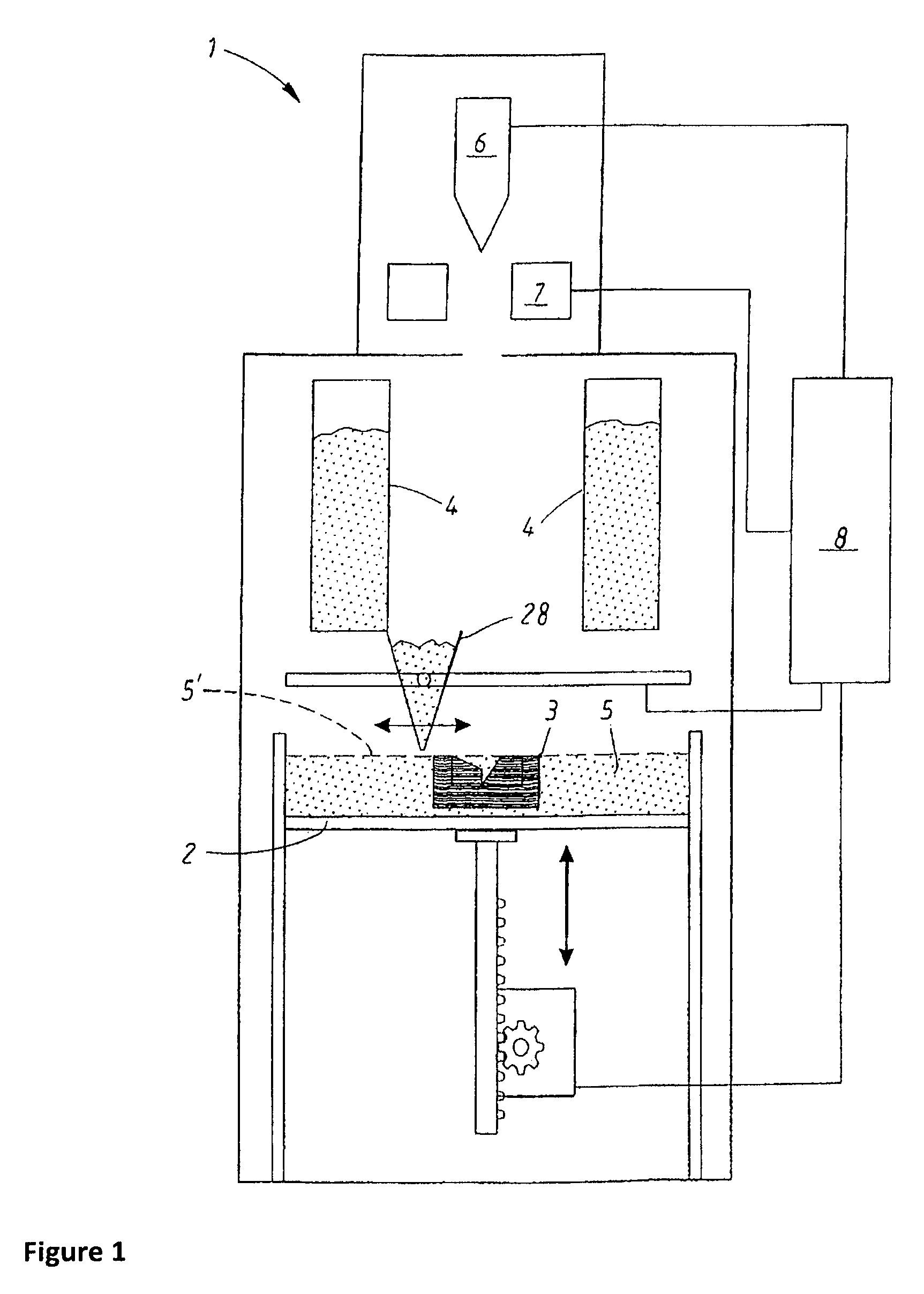

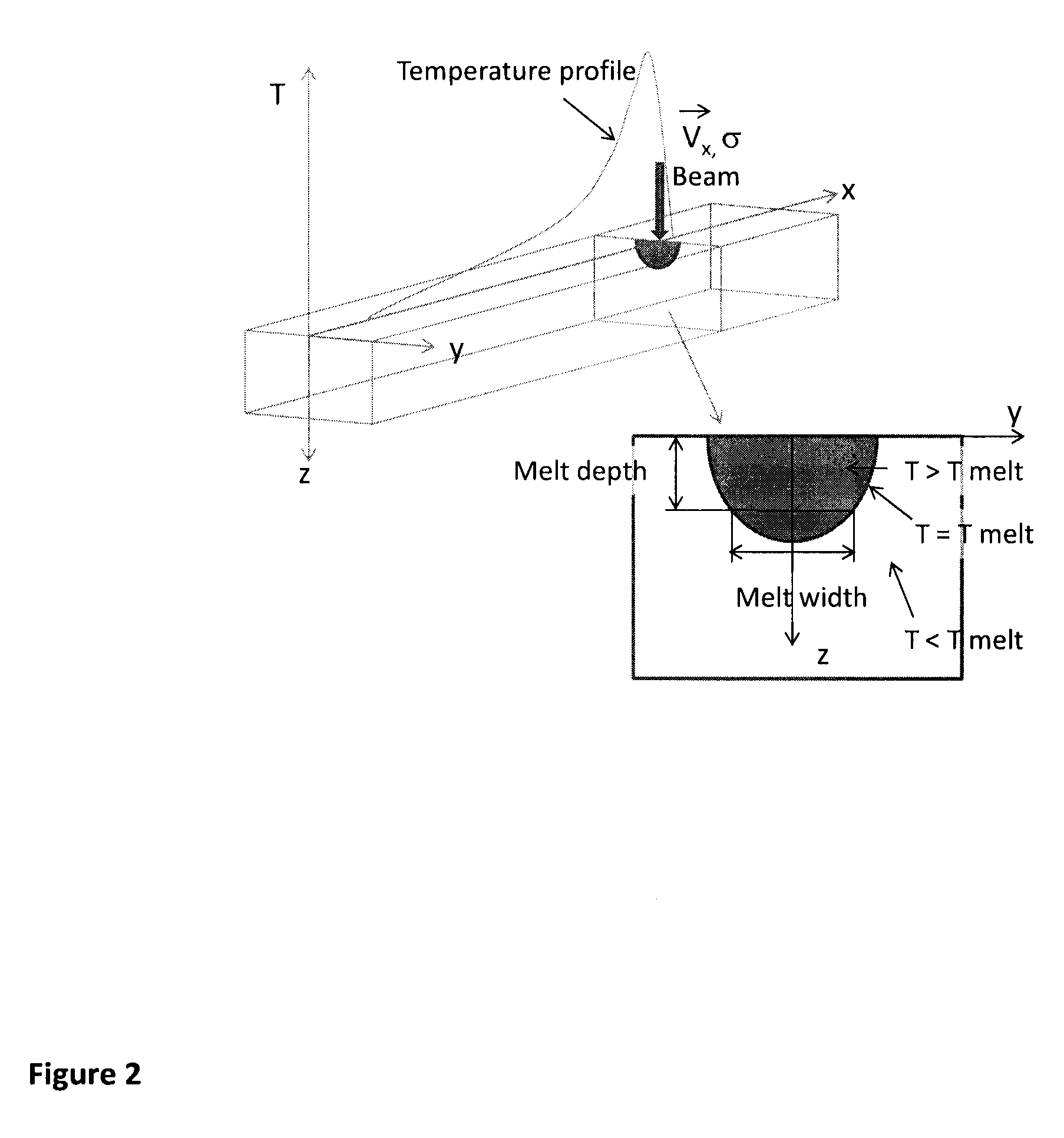

Method for production of a three-dimensional body

ActiveUS9073265B2Avoiding time-consuming re-calculationsAdditive manufacturing apparatusTemperatue controlMaterials scienceSupply energy

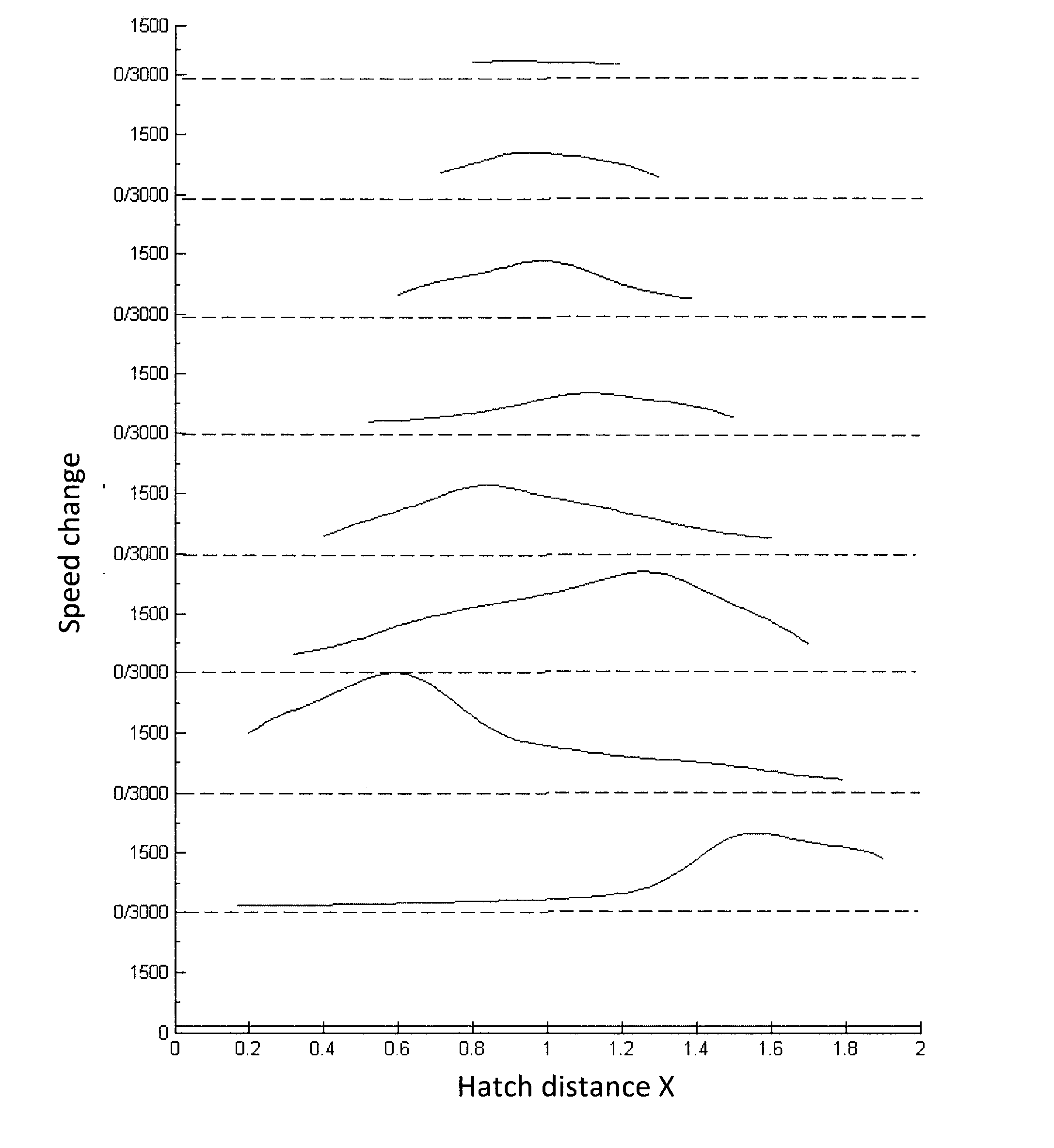

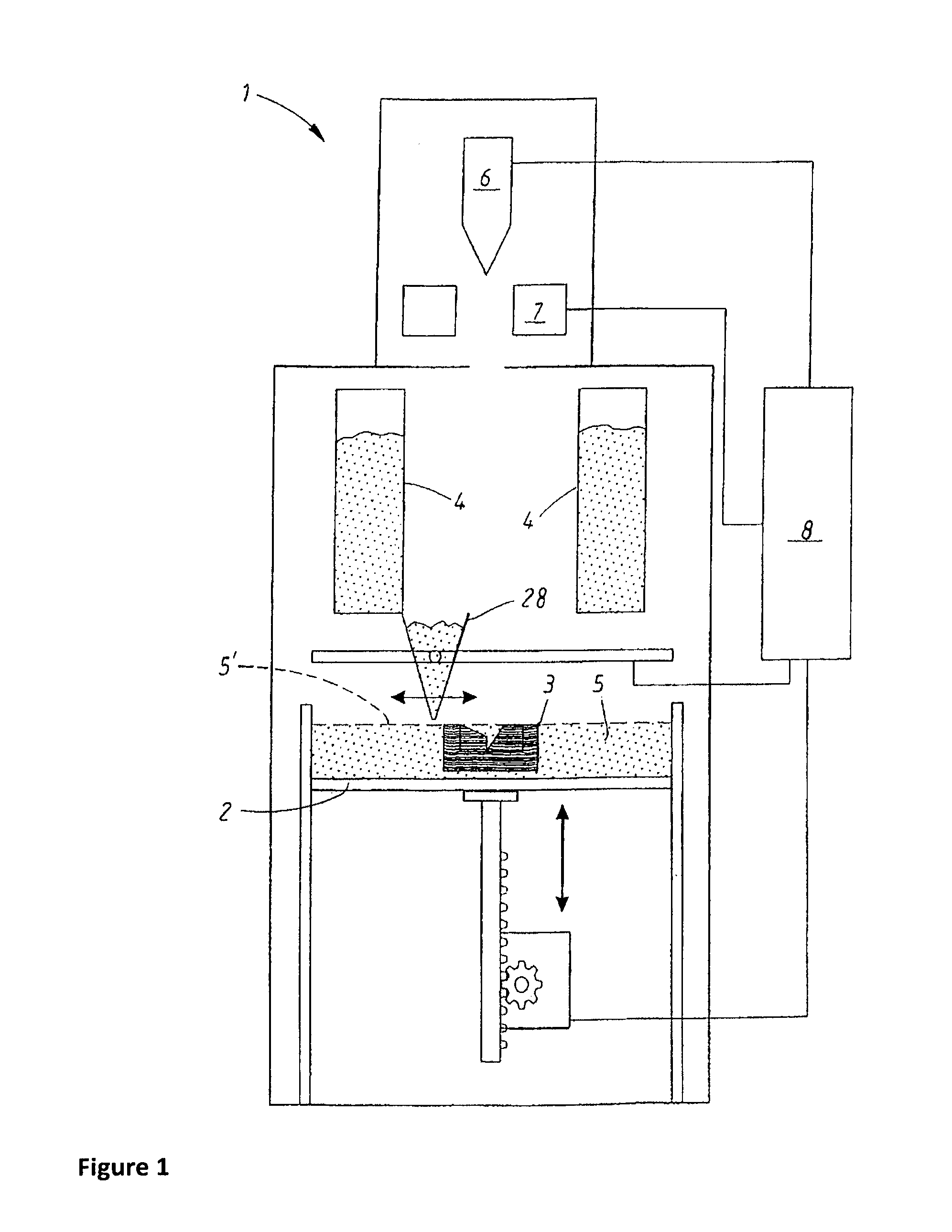

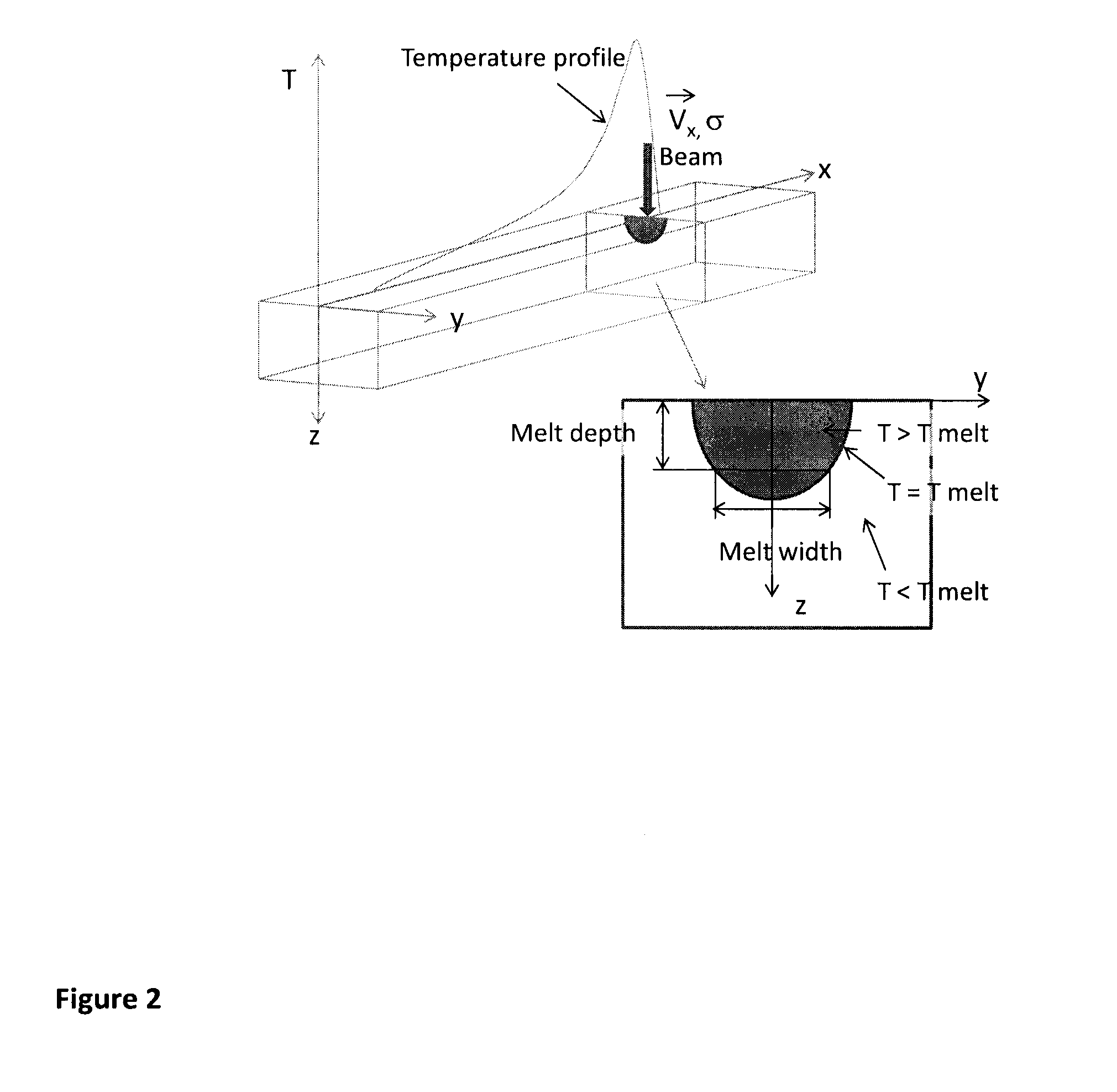

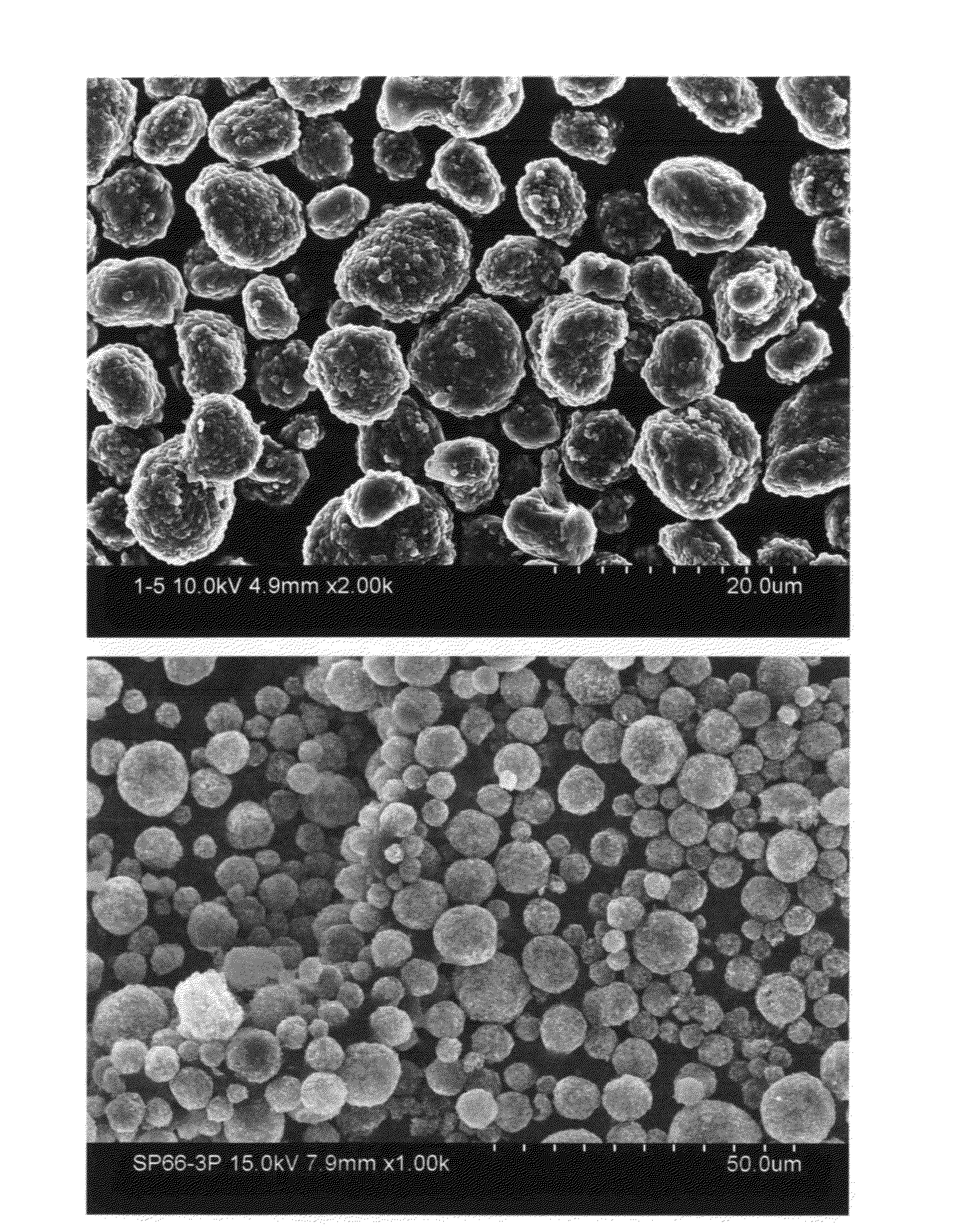

The invention concerns a method for production of a three-dimensional body by successively providing powder layers and fusing together of selected areas of said layers, which areas correspond to successive cross sections of the three-dimensional body, wherein the method comprises the following steps for at least one of said layers: applying the at least one powder layer onto a working area, and fusing together a selected area of the at least one powder layer by supplying energy from a radiation gun to the selected area. The invention is characterized in that it comprises the steps of: establishing an intended beam path that is to be used when fusing together the selected area of the at least one powder layer, calculating a temperature in the at least one powder layer along the intended beam path as a function of a specific energy deposition of an imaginary beam that is assumed to move along the intended beam path, adjusting the specific energy deposition of the imaginary beam along the intended beam path depending on the calculated temperature and on conditions set for the step of fusing together the selected area, and providing, based on the calculations and the adjustments, an operating scheme for the specific energy deposition of the real beam to be used for the intended beam path when fusing together the selected area of the at least one layer.

Owner:ARCAM AB

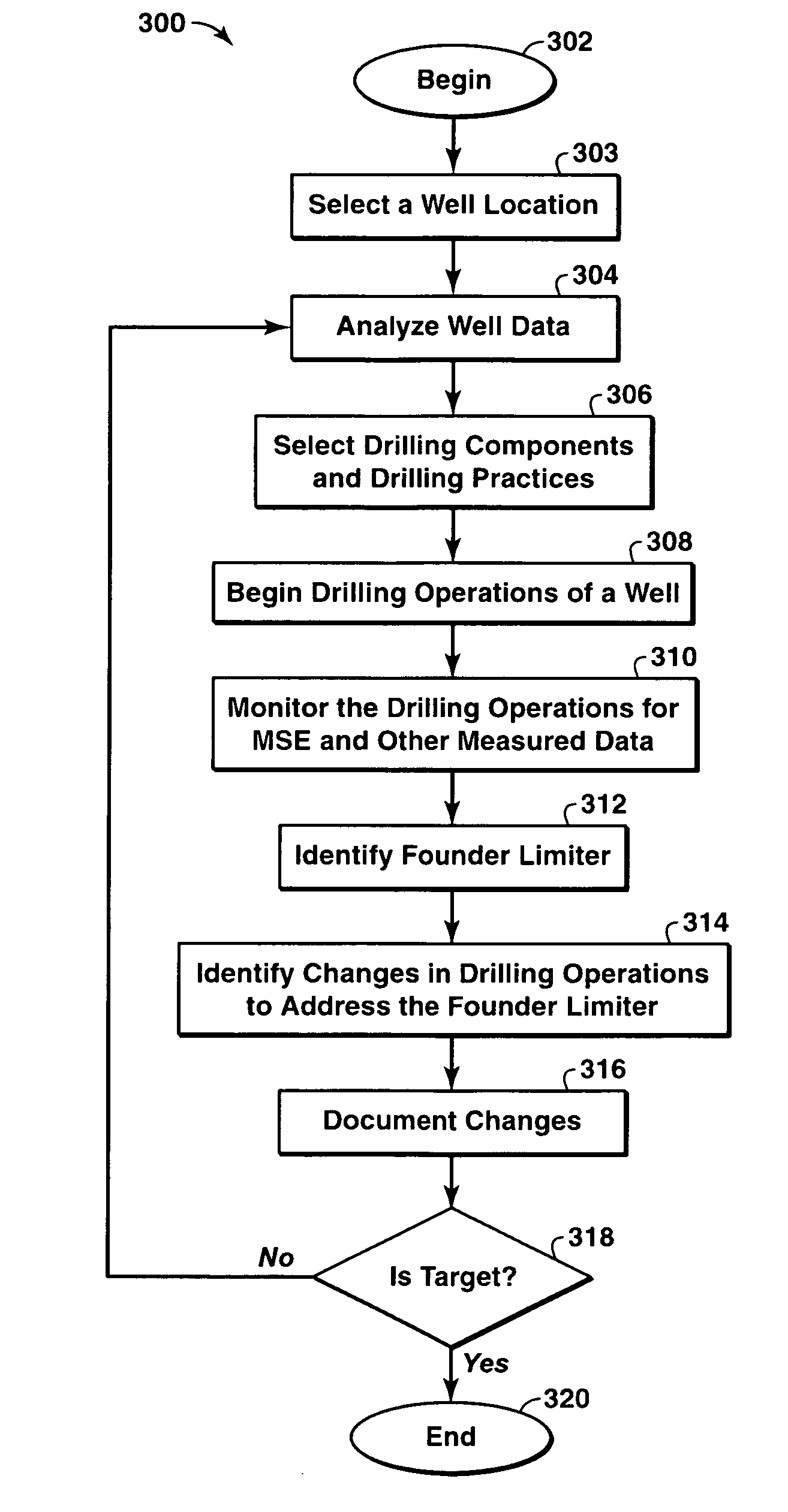

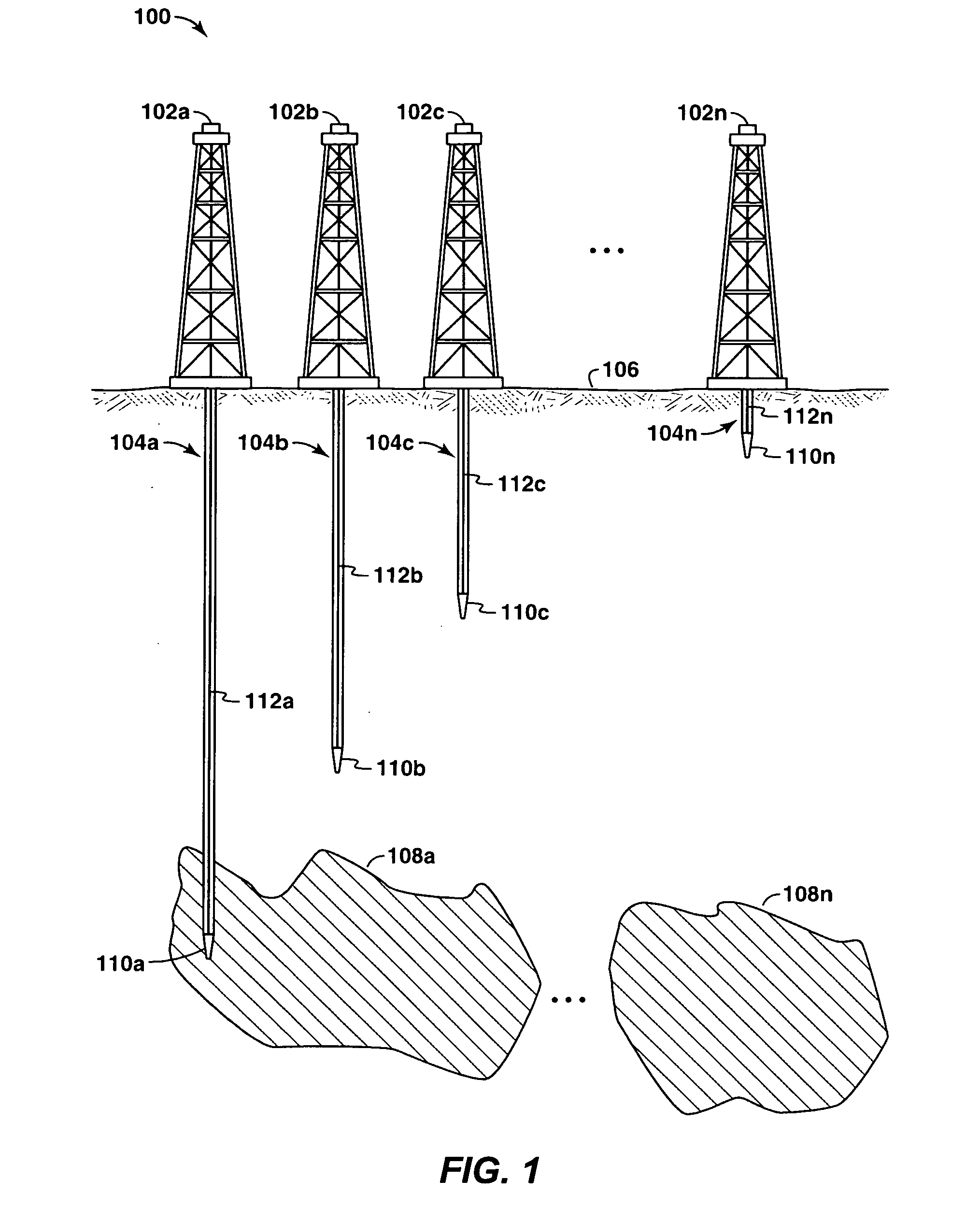

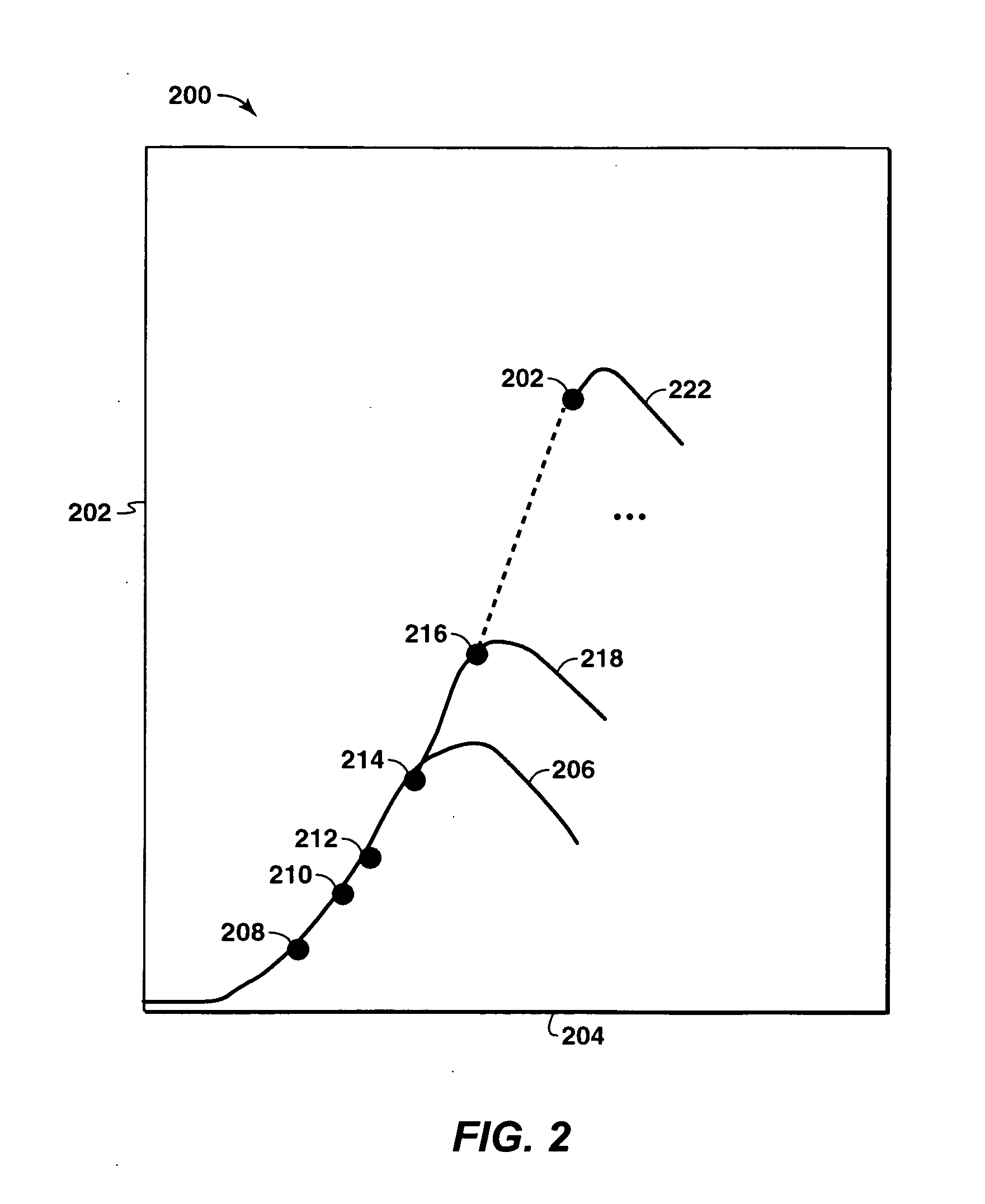

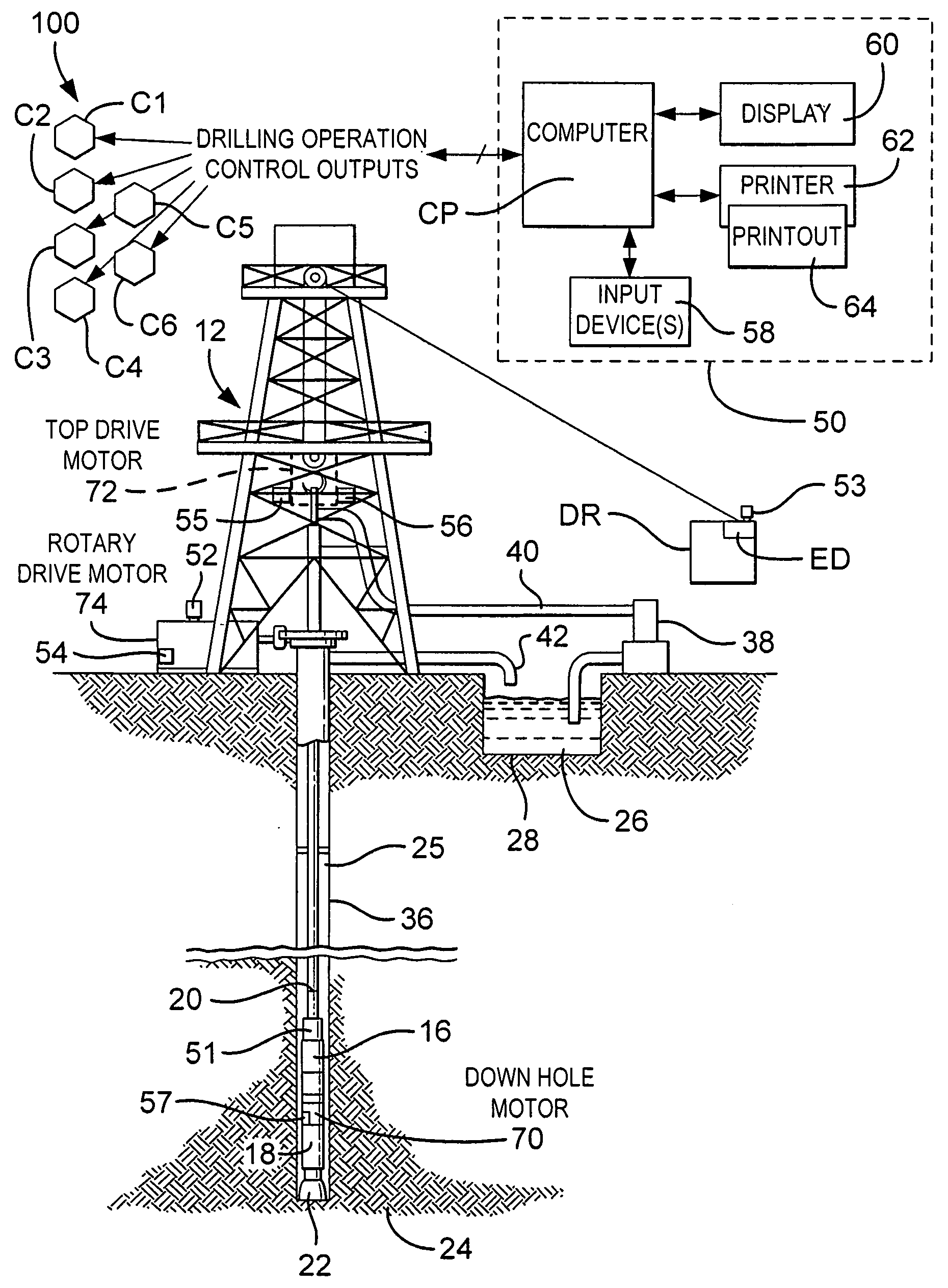

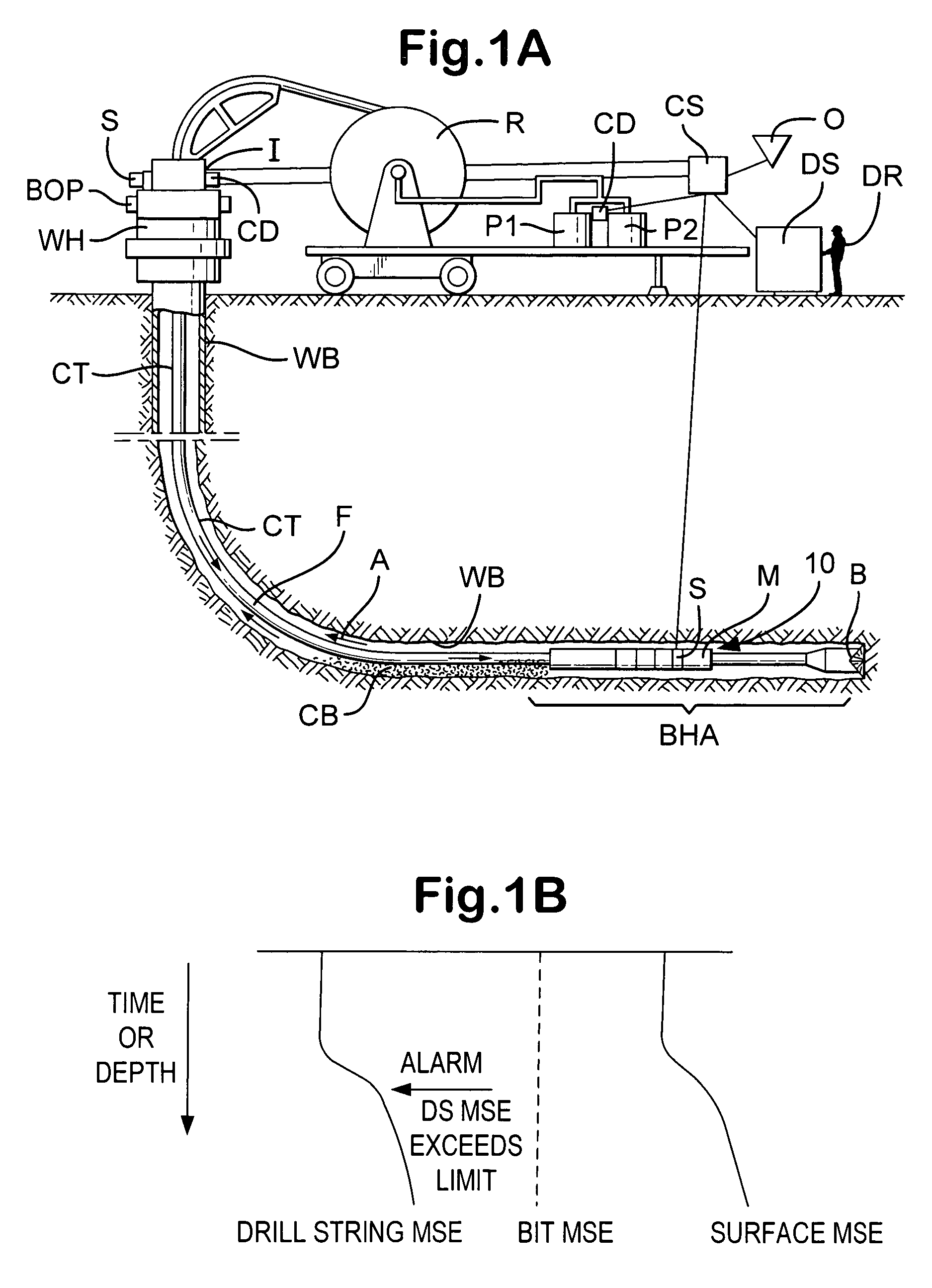

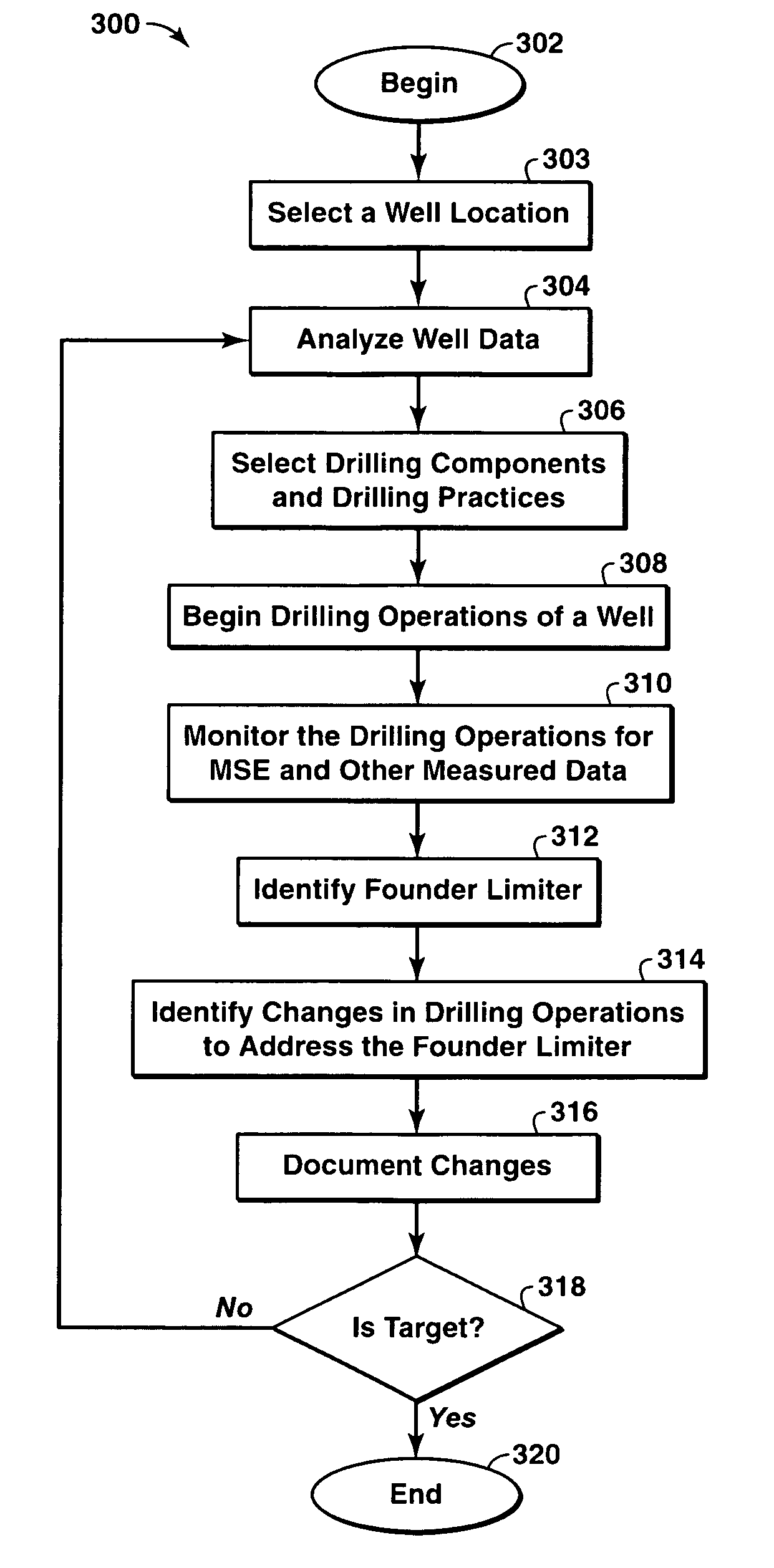

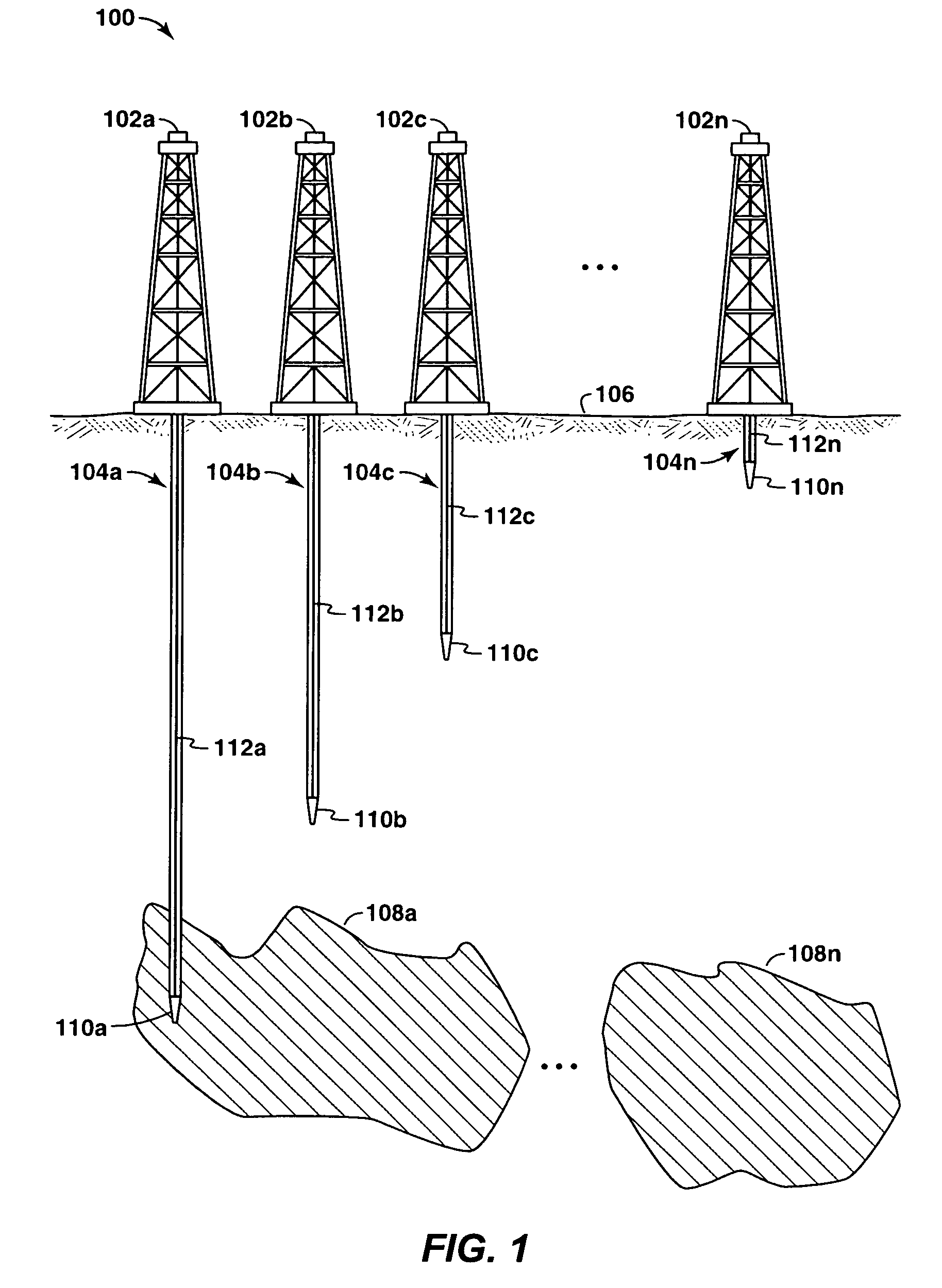

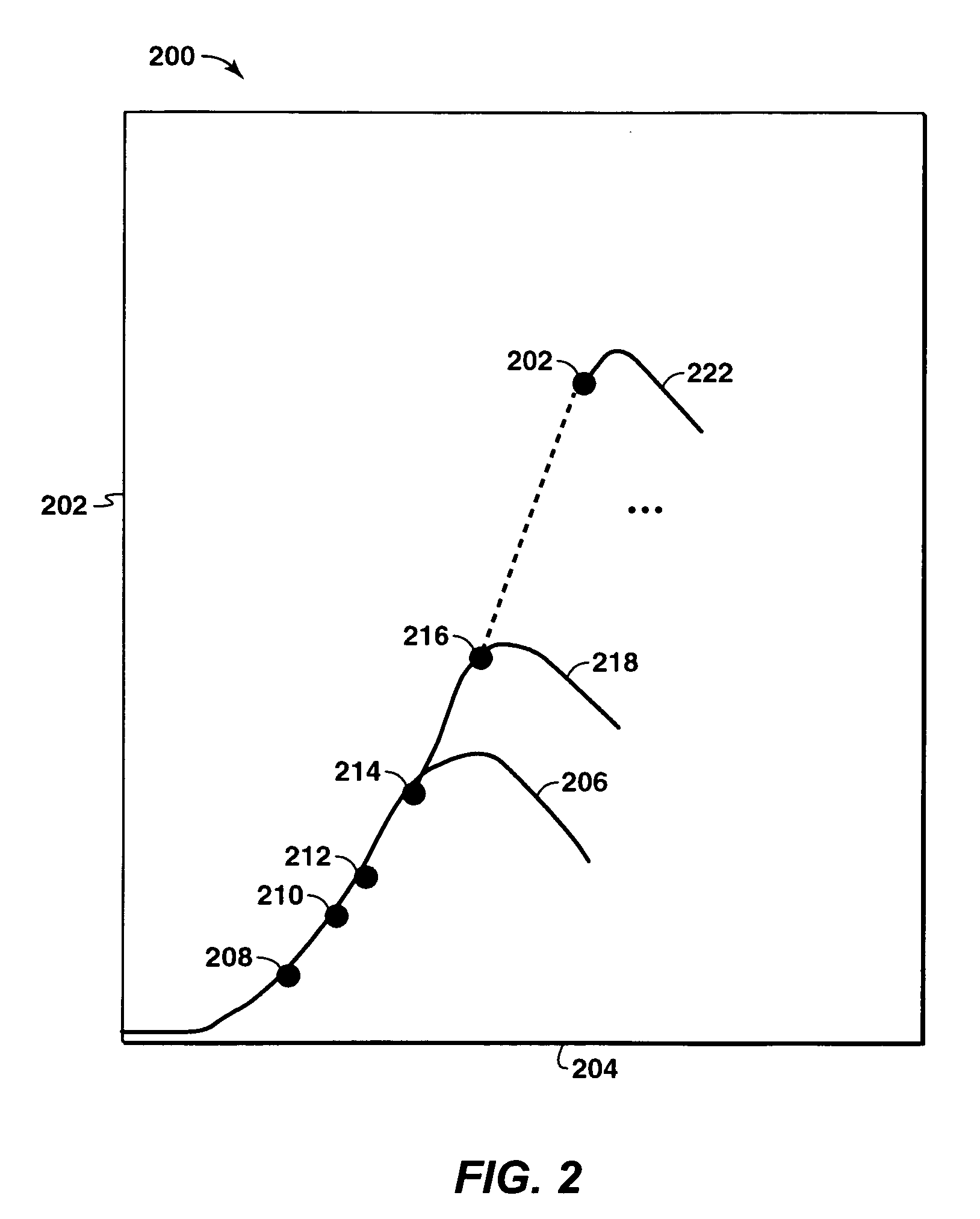

Method of Drilling and Production Hydrocarbons from Subsurface Formations

ActiveUS20090250264A1Increase drilling speedElectric/magnetic detection for well-loggingSurveyWell drillingDrill

A method associated with the production of hydrocarbons. In one embodiment, a method for drilling a well is described. The method includes identifying a field having hydrocarbons. Then, one or more wells are drilled to a subsurface location in the field to provide fluid flow paths for hydrocarbons to a production facility. The drilling is performed by (i) estimating a drill rate for one of the wells; (ii) determining a difference between the estimated drill rate and an actual drill rate; (iii) obtaining mechanical specific energy (MSE) data and other measured data during the drilling of the one of the wells; (iv) using the obtained MSE data and other measured data to determine one of a plurality of limiters that limit the drill rate; (v) adjusting drilling operations to mitigate one of the plurality of limiters; (vi) and iteratively repeating steps (i)-(v) until the subsurface formation has been reached by the drilling operations.

Owner:EXXONMOBIL UPSTREAM RES CO

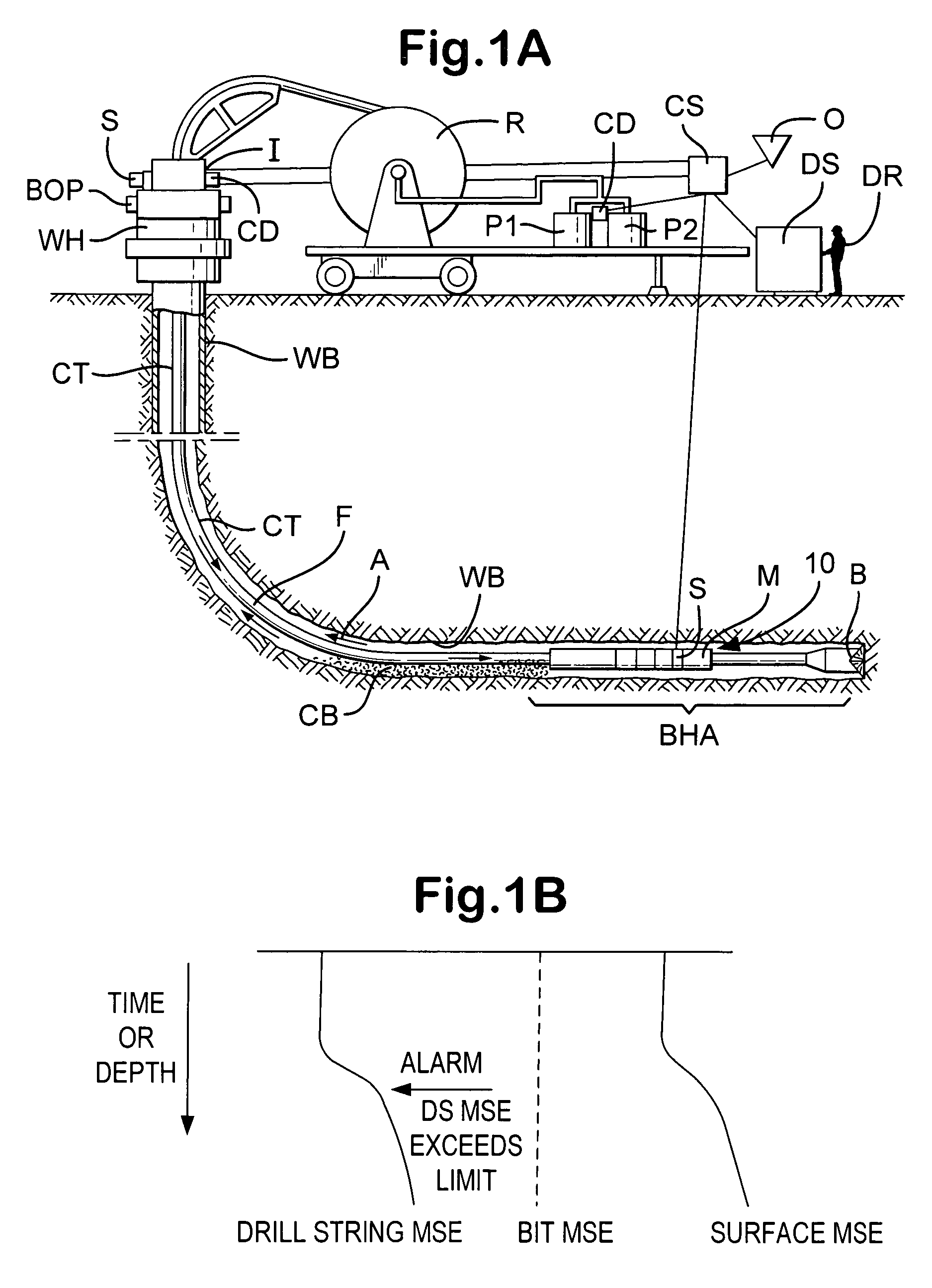

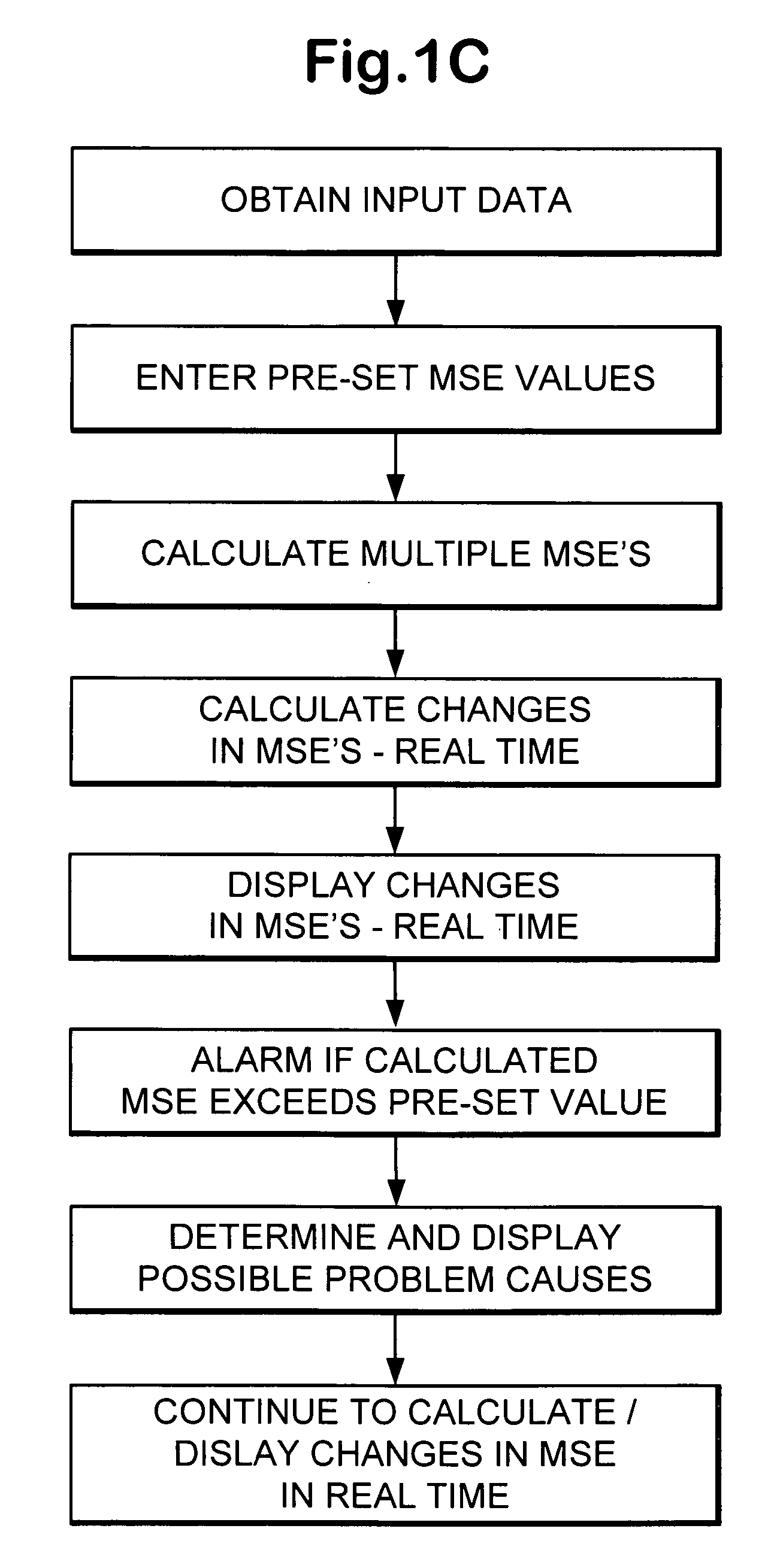

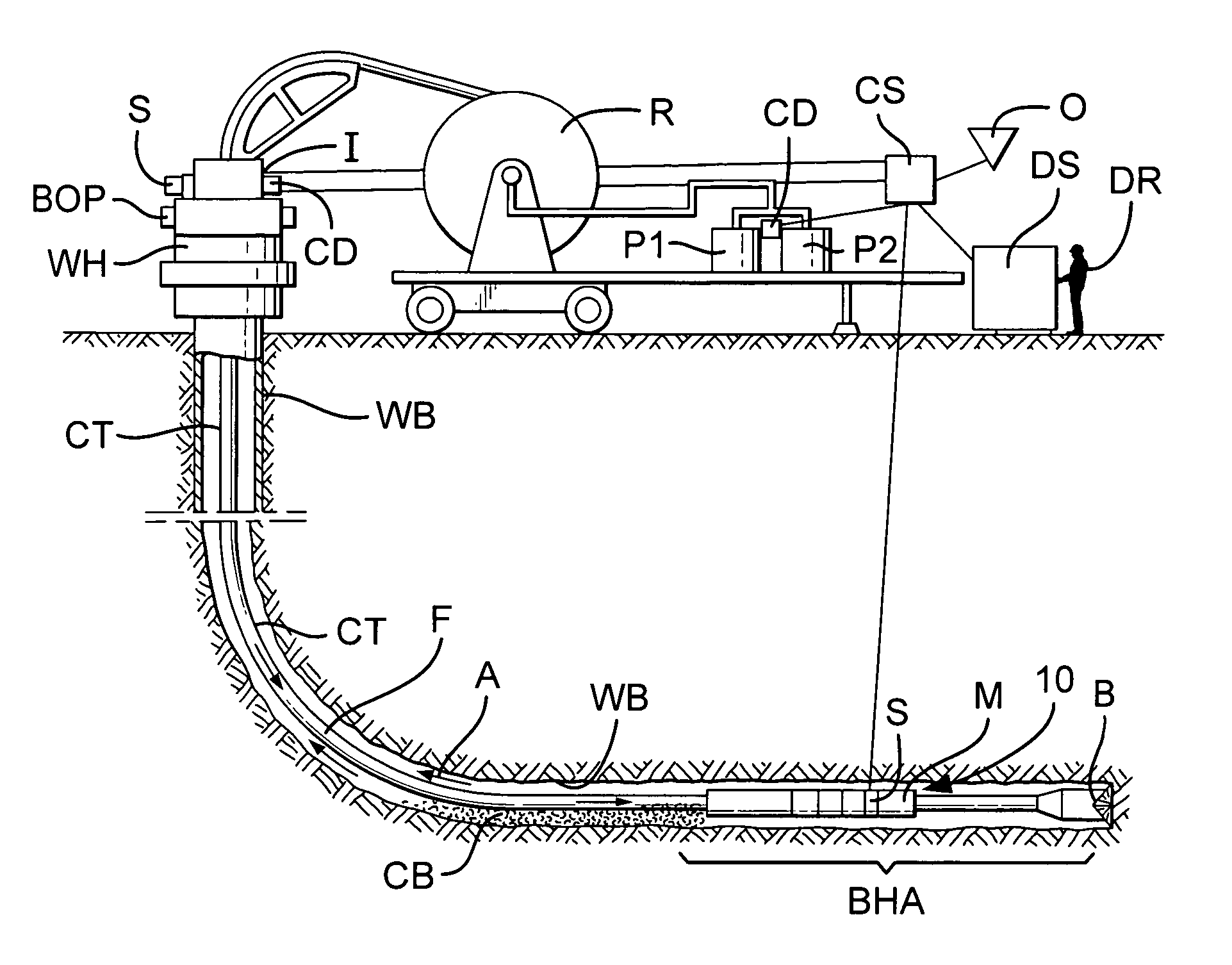

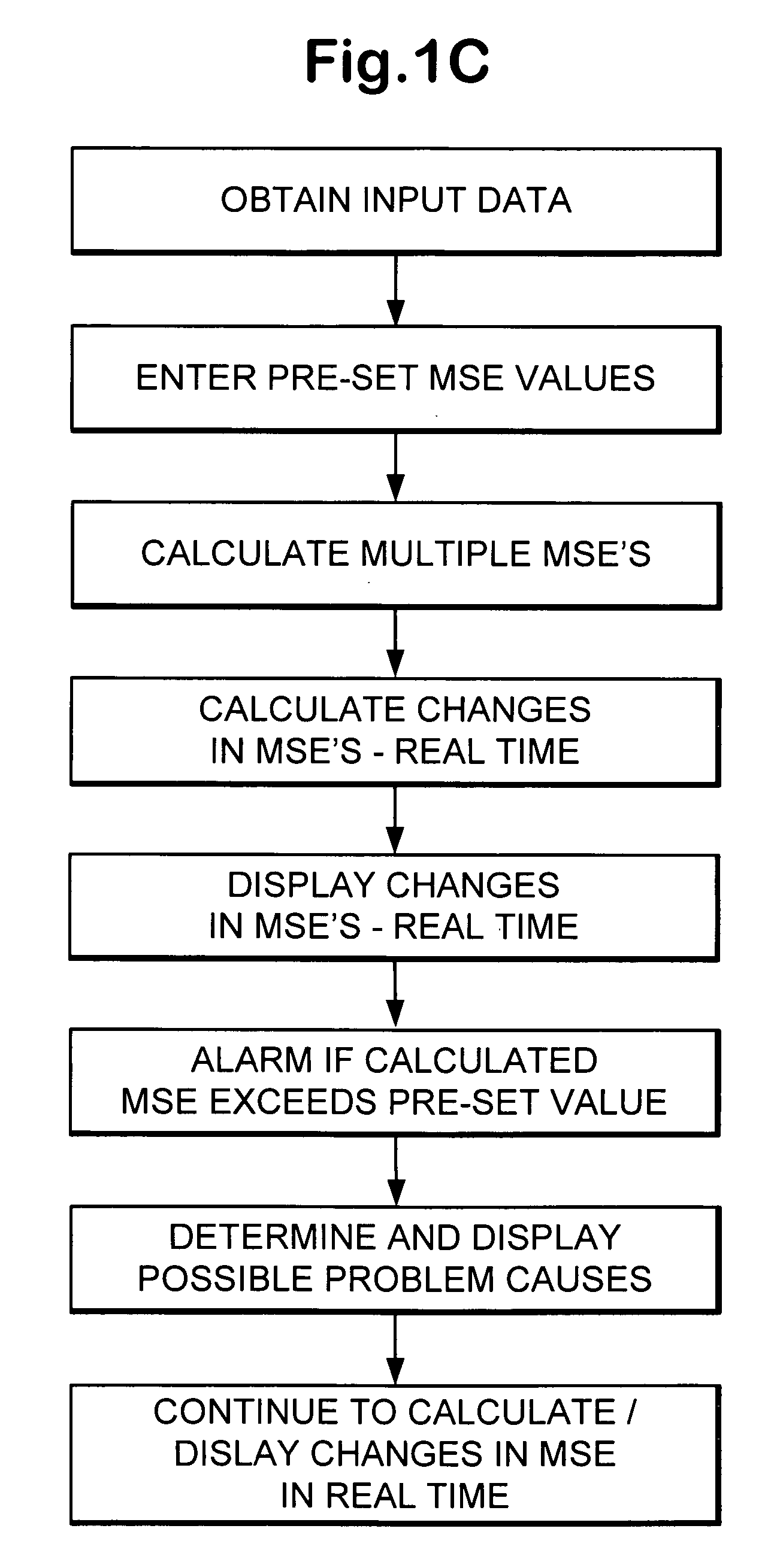

Wellbore operations monitoring and control systems and methods

ActiveUS7243735B2Enhances diagnostic potential and efficiency of diagnosisAccurate calculationSurveyMeasurement devices for drillingControl systemMonitoring and control

A method for a wellbore operation with a wellbore system, the method, in at least certain aspects, including acquiring with sensor systems data corresponding to a plurality of parameters, the data indicative of values for each parameter, each parameter associated with part of the wellbore system, and, based on said data, calculating a value for each of a plurality of mechanical specific energies each related to a mechanical specific energy for a part of the wellbore system; and, in some aspects, monitoring in real time the value of each of the mechanical specific energies; and, in certain aspects, using such determined values to alter, change, improve, or optimize operations.

Owner:VARCO I P INC

Wellbore operations monitoring & control systems & methods

A method for a wellbore operation with a wellbore system, the method, in at least certain aspects, including acquiring with sensor systems data corresponding to a plurality of parameters, the data indicative of values for each parameter, each parameter associated with part of the wellbore system, and, based on said data, calculating a value for each of a plurality of mechanical specific energies each related to a mechanical specific energy for a part of the wellbore system; and, in some aspects, monitoring in real time the value of each of the mechanical specific energies; and, in certain aspects, using such determined values to alter, change, improve, or optimize operations.

Owner:VARCO I P INC

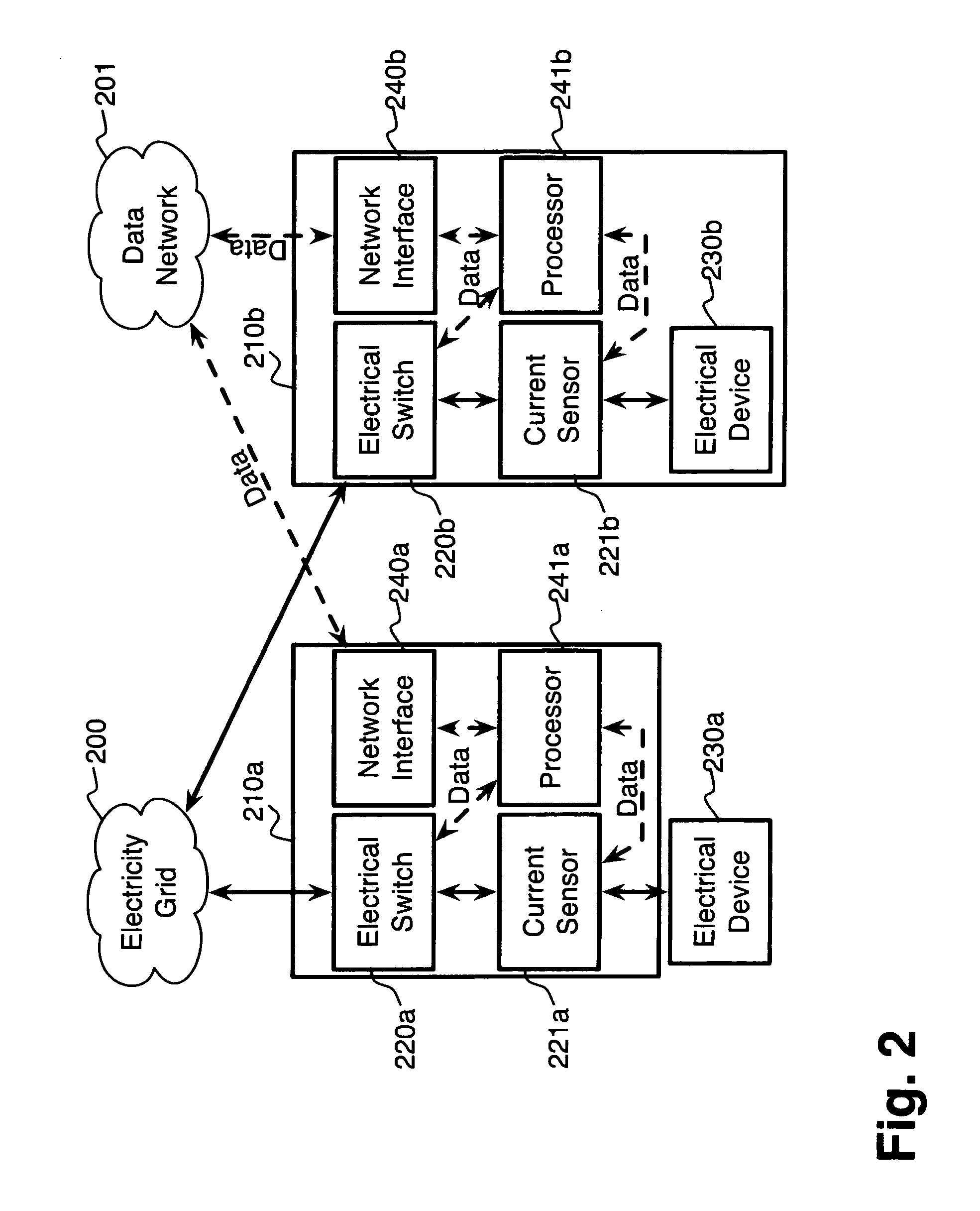

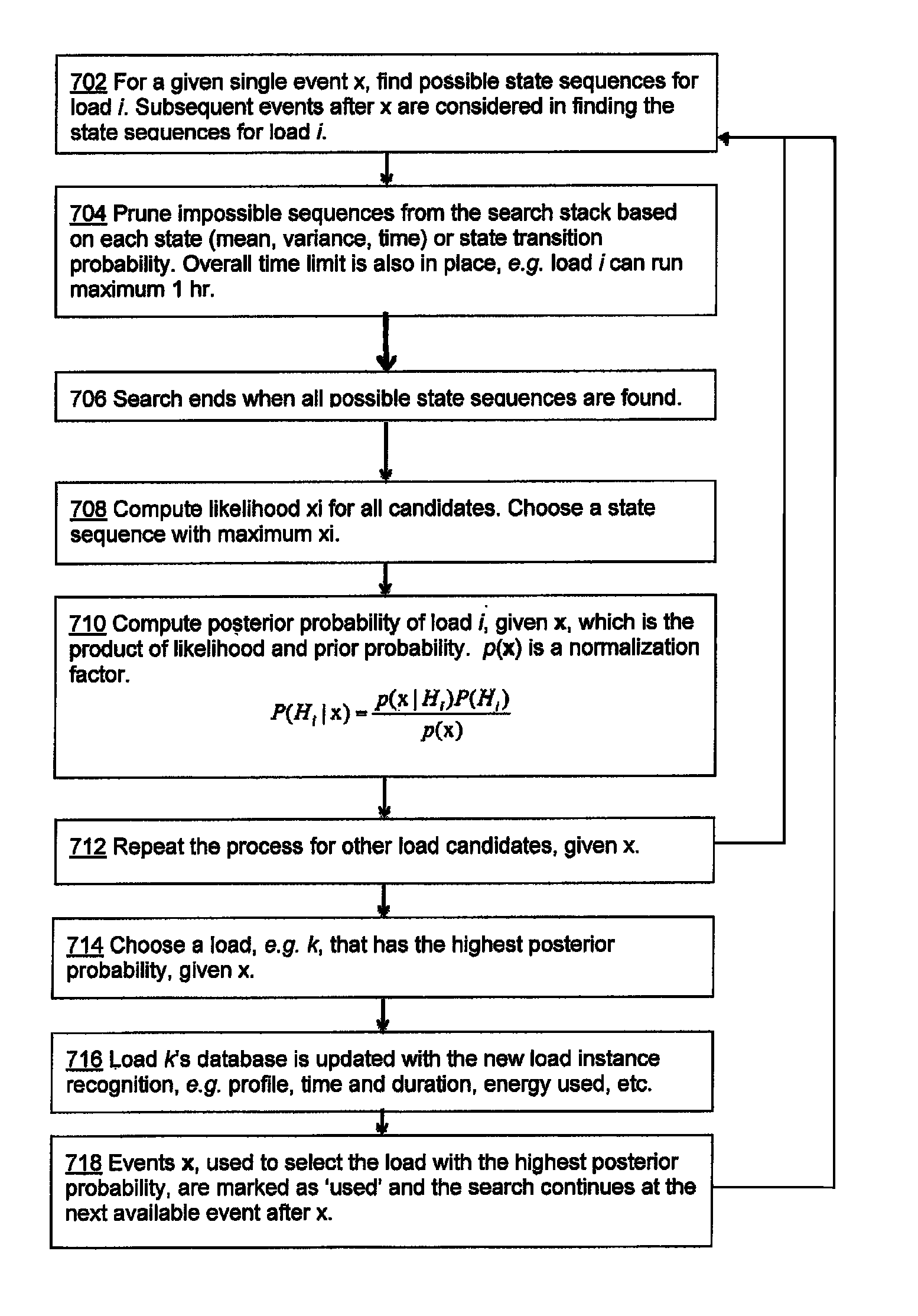

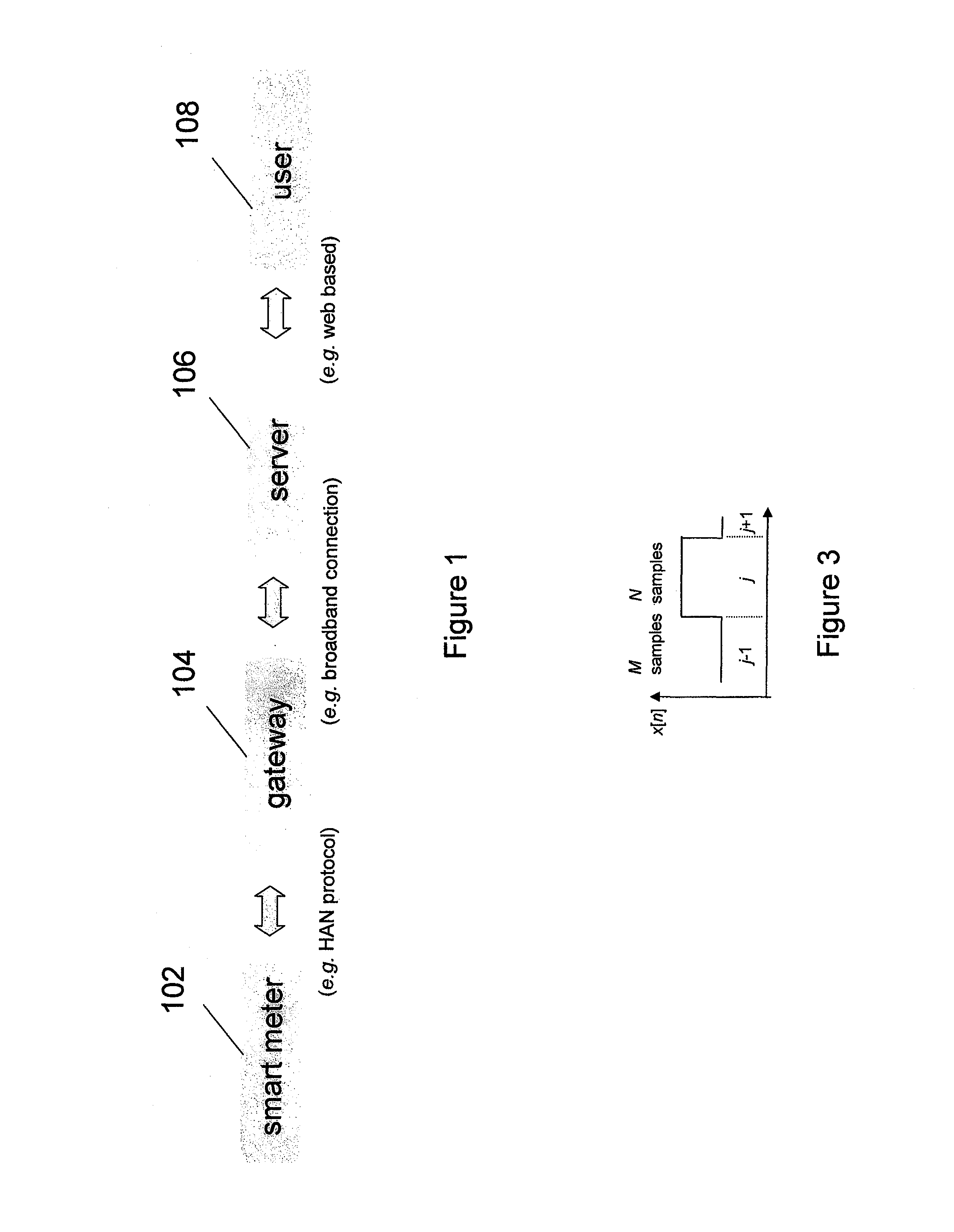

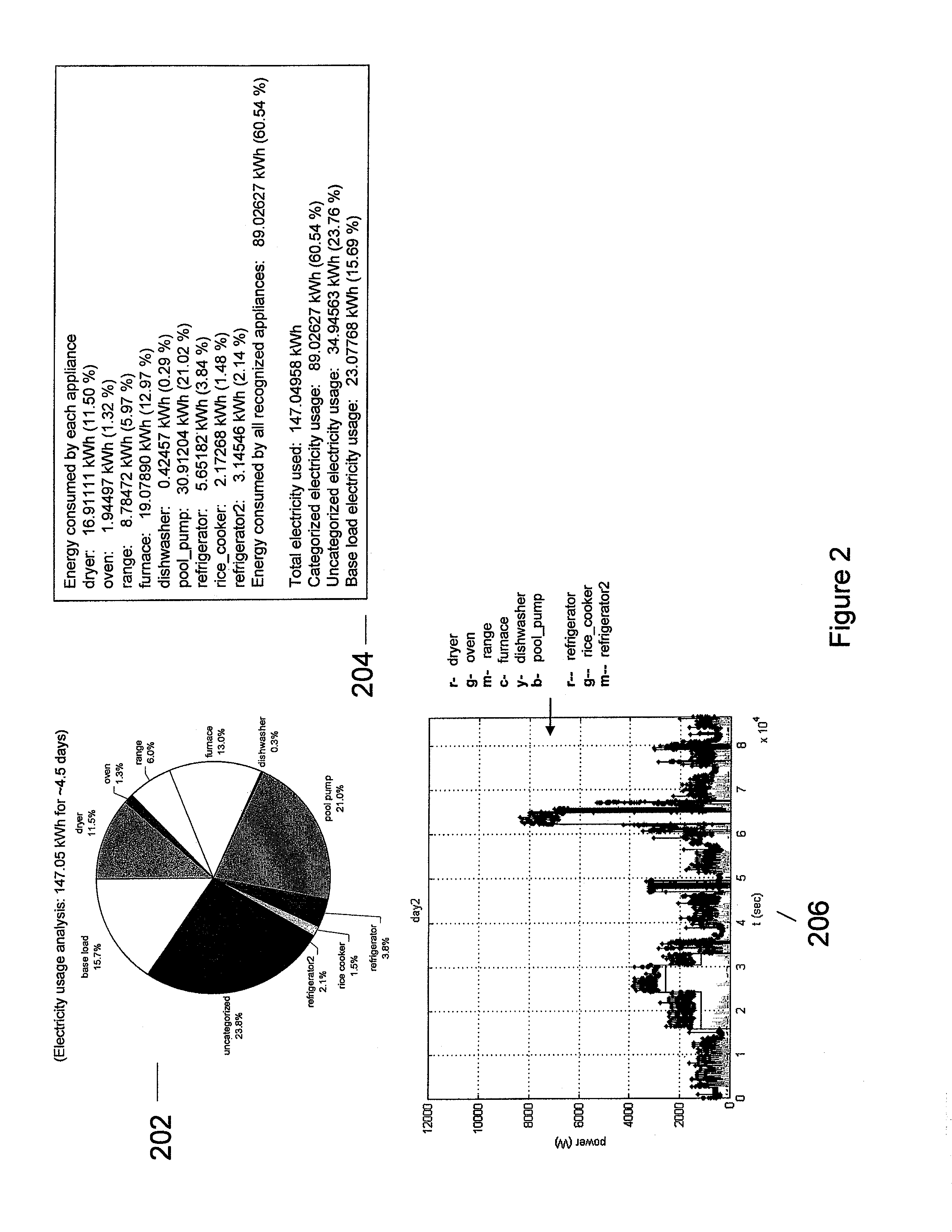

System and method for electric load recognition from centrally monitored power signal and its application to home energy management

InactiveUS8560134B1Mechanical power/torque controlData processing applicationsPower sensorRelevant information

A method and apparatus are provided for a home energy management platform. The platform includes using a whole house power sensor or subset thereof. Data from the power sensor are analyzed using advanced statistical and machine learning techniques for extracting detailed usage information and generating specific energy saving measures, among other relevant information. In an embodiment, a gateway console is provided that has various communication capabilities. The gateway console may communicate with and control HAN devices. The gateway console may collect data from the power sensor as well as HAN devices and upload such collected data to servers for the analysis processing. Certain amounts of data processing and analysis may be performed at a server or at the local level, such as at the power sensor, gateway, or other HAN device, as well. The platform may include a user interface, such as web, mobile, email, mail, phone call, etc.

Owner:LEE KWANGDUK DOUGLAS

Method of drilling and production hydrocarbons from subsurface formations

A method associated with the production of hydrocarbons. In one embodiment, a method for drilling a well is described. The method includes identifying a field having hydrocarbons. Then, one or more wells are drilled to a subsurface location in the field to provide fluid flow paths for hydrocarbons to a production facility. The drilling is performed by (i) estimating a drill rate for one of the wells; (ii) determining a difference between the estimated drill rate and an actual drill rate; (iii) obtaining mechanical specific energy (MSE) data and other measured data during the drilling of the one of the wells; (iv) using the obtained MSE data and other measured data to determine one of a plurality of limiters that limit the drill rate; (v) adjusting drilling operations to mitigate one of the plurality of limiters; (vi) and iteratively repeating steps (i)-(v) until the subsurface formation has been reached by the drilling operations.

Owner:EXXONMOBIL UPSTREAM RES CO

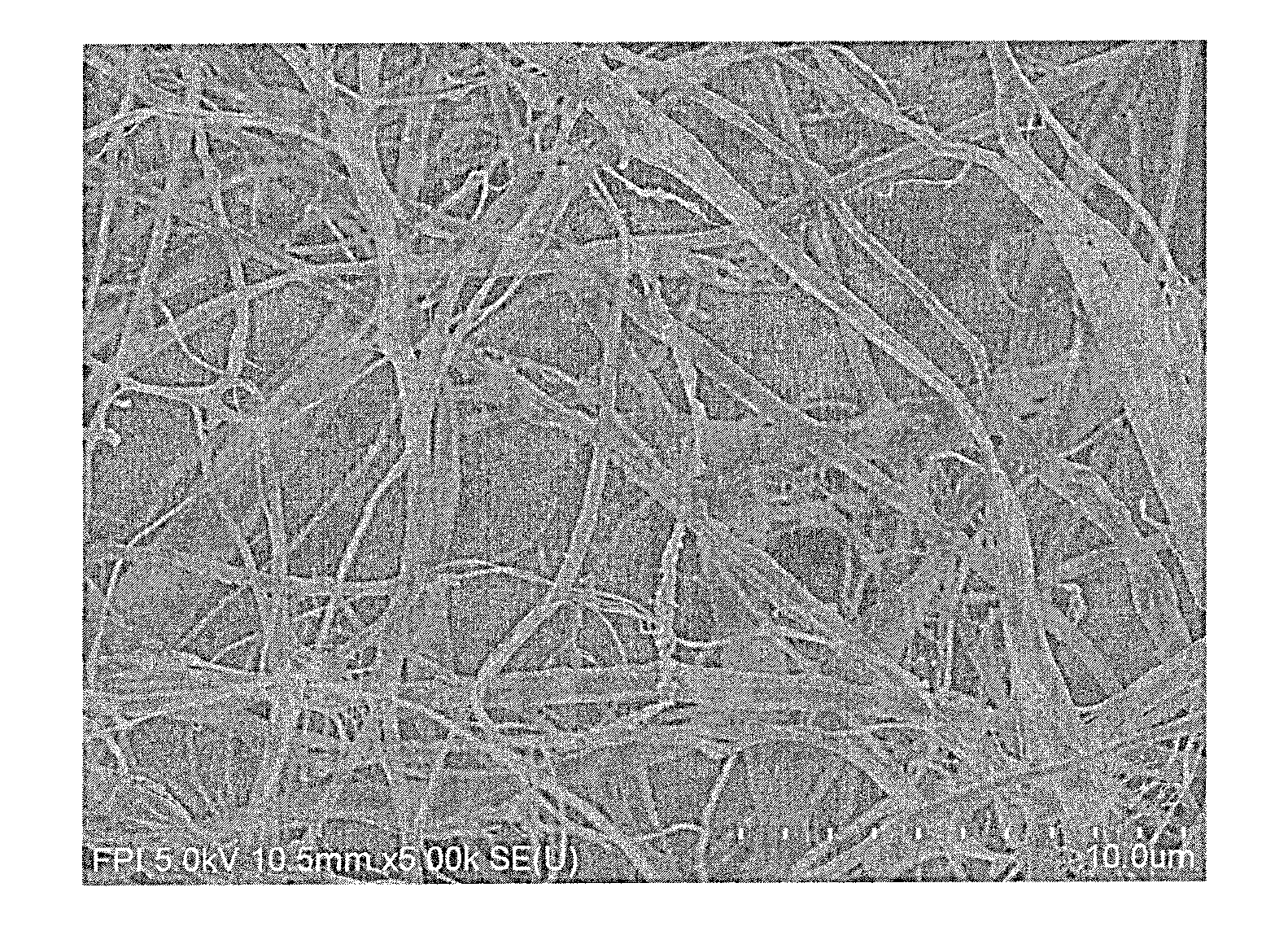

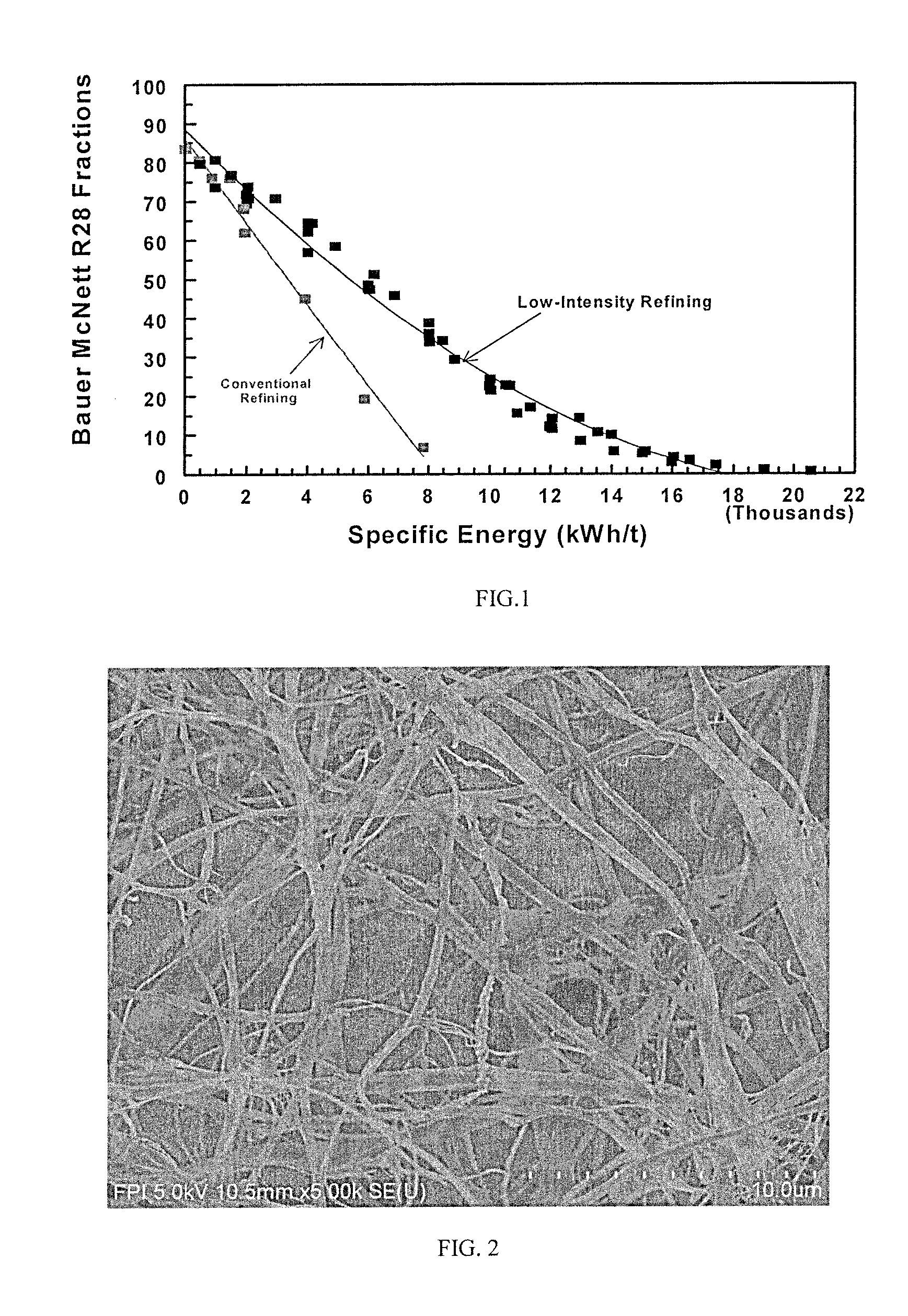

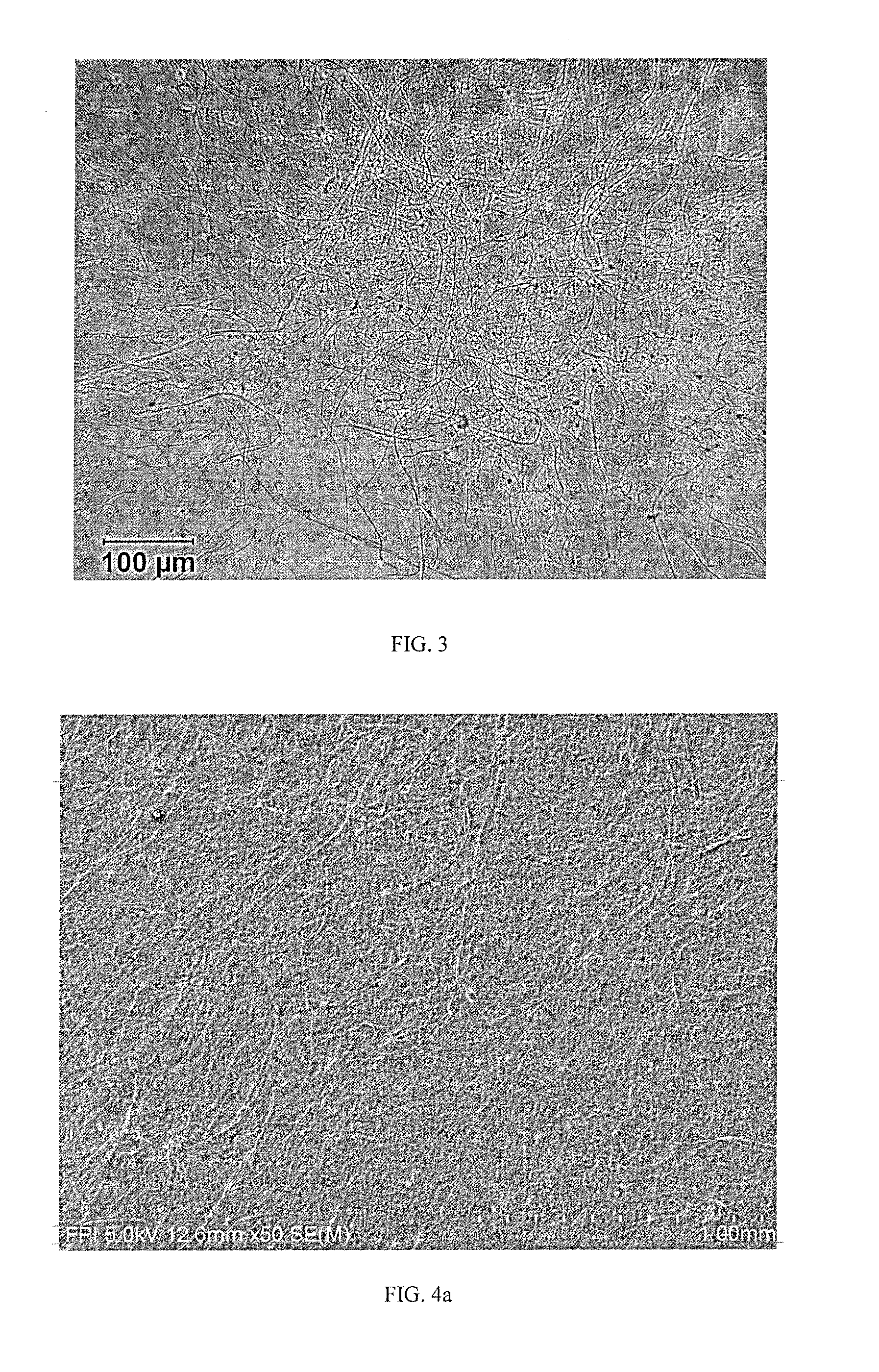

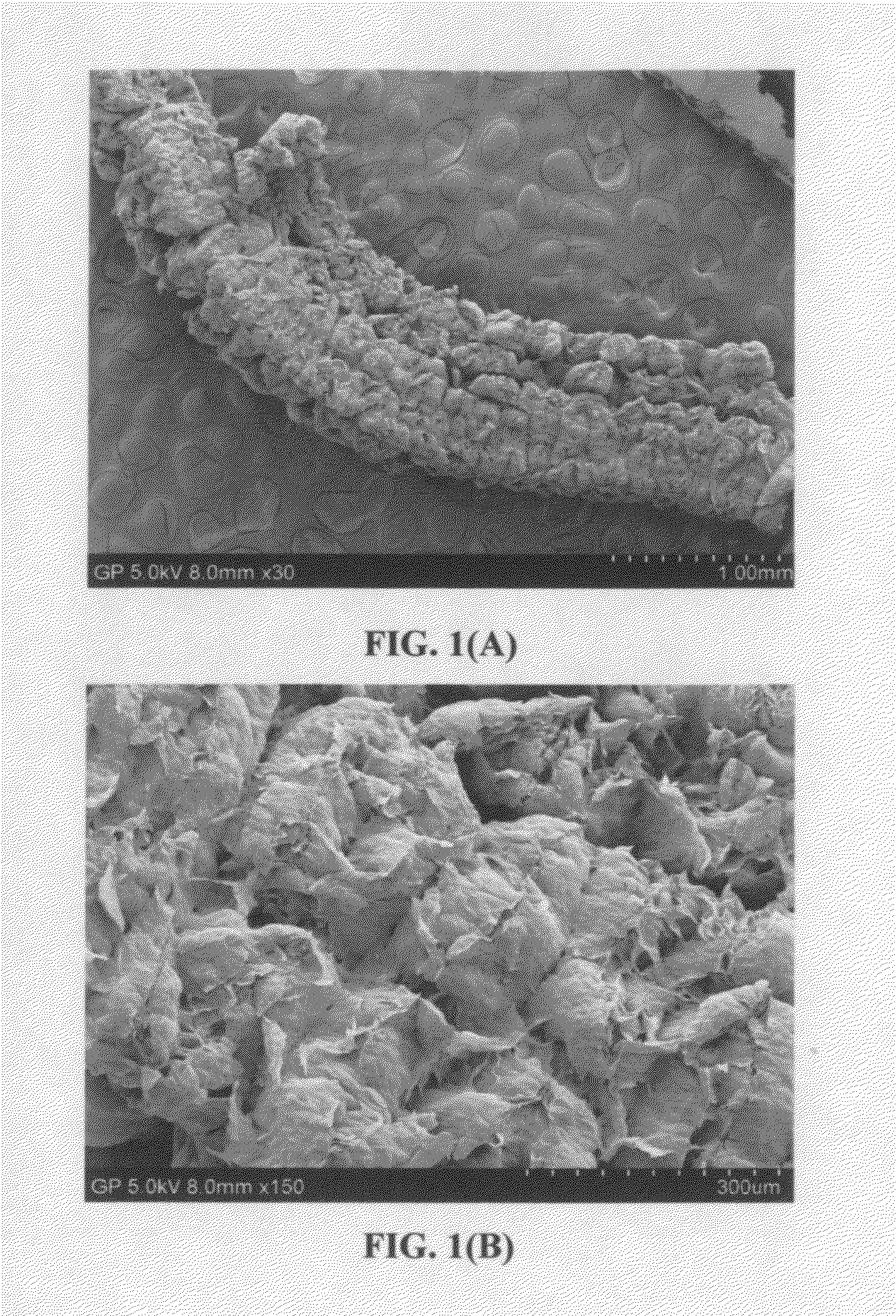

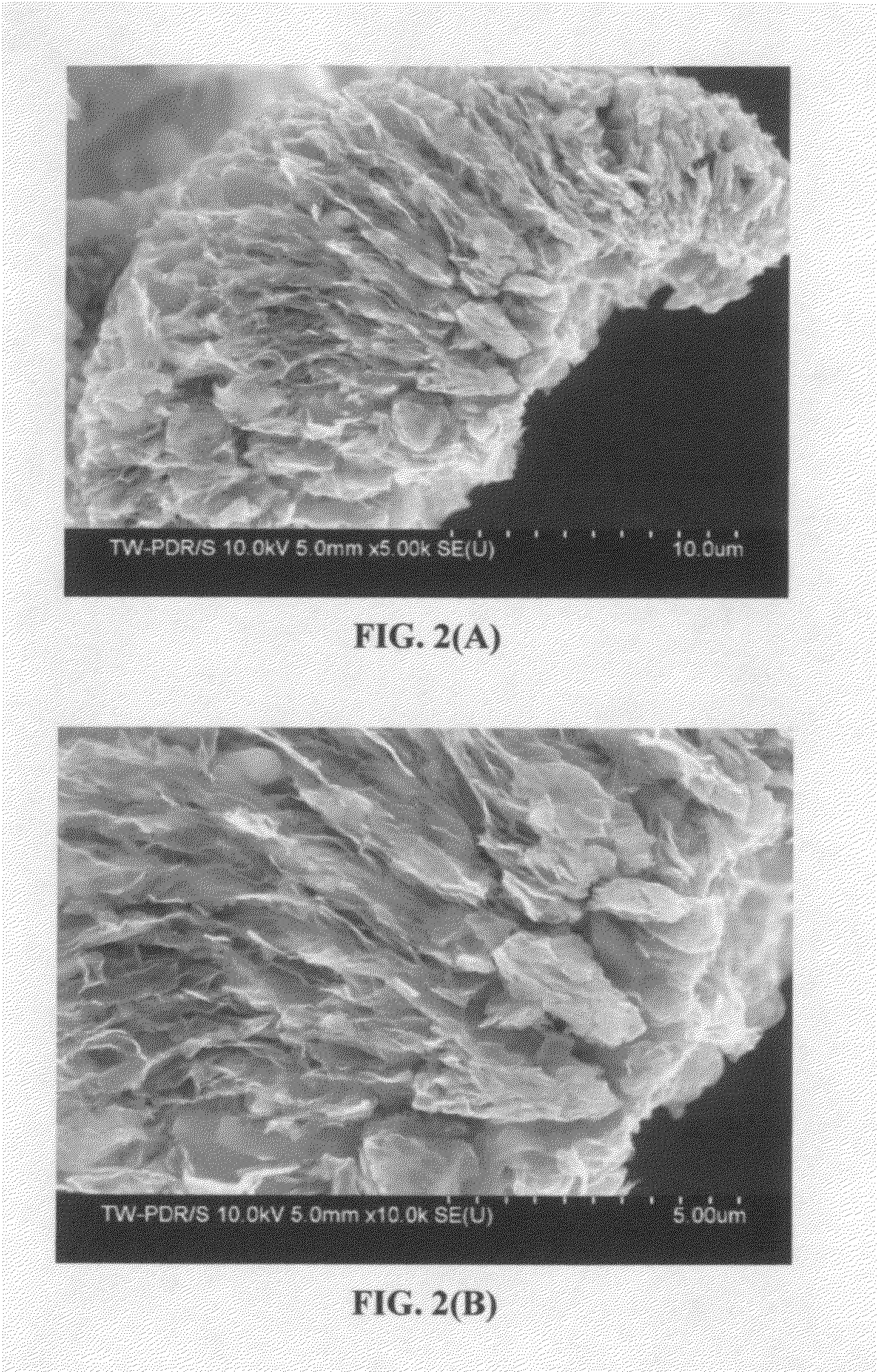

High aspect ratio cellulose nanofilaments and method for their production

ActiveUS20130017394A1High consistency refiningIncrease surface areaMaterial nanotechnologyFinely-divided cellulose conservationMicrometerPaperboard

A method to produce on a commercial scale, high aspect ratio cellulose nanofilaments (CNF) from natural lignocellulosic fibers comprises a multi-pass high consistency refining (HCR) of chemical or mechanical fibers using combinations of refining intensity and specific energy. The CNF produced represents a mixture of fine filaments with widths in the submicron and lengths from tens of micrometers to few millimeters. The product has a population of free filaments and filaments bound to the fiber core from which they were produced. The proportion of free and bound filaments is governed in large part by total specific energy applied to the pulp in the refiner, and differs from other cellulose fibrillar materials by their higher aspect ratio and the preserved degree of polymerization (DP) of cellulose, and are excellent additives for the reinforcement of paper, tissue, paperboard and the like. They display exceptional strengthening power for never-dried paper webs.

Owner:FPINNOVATIONS INC

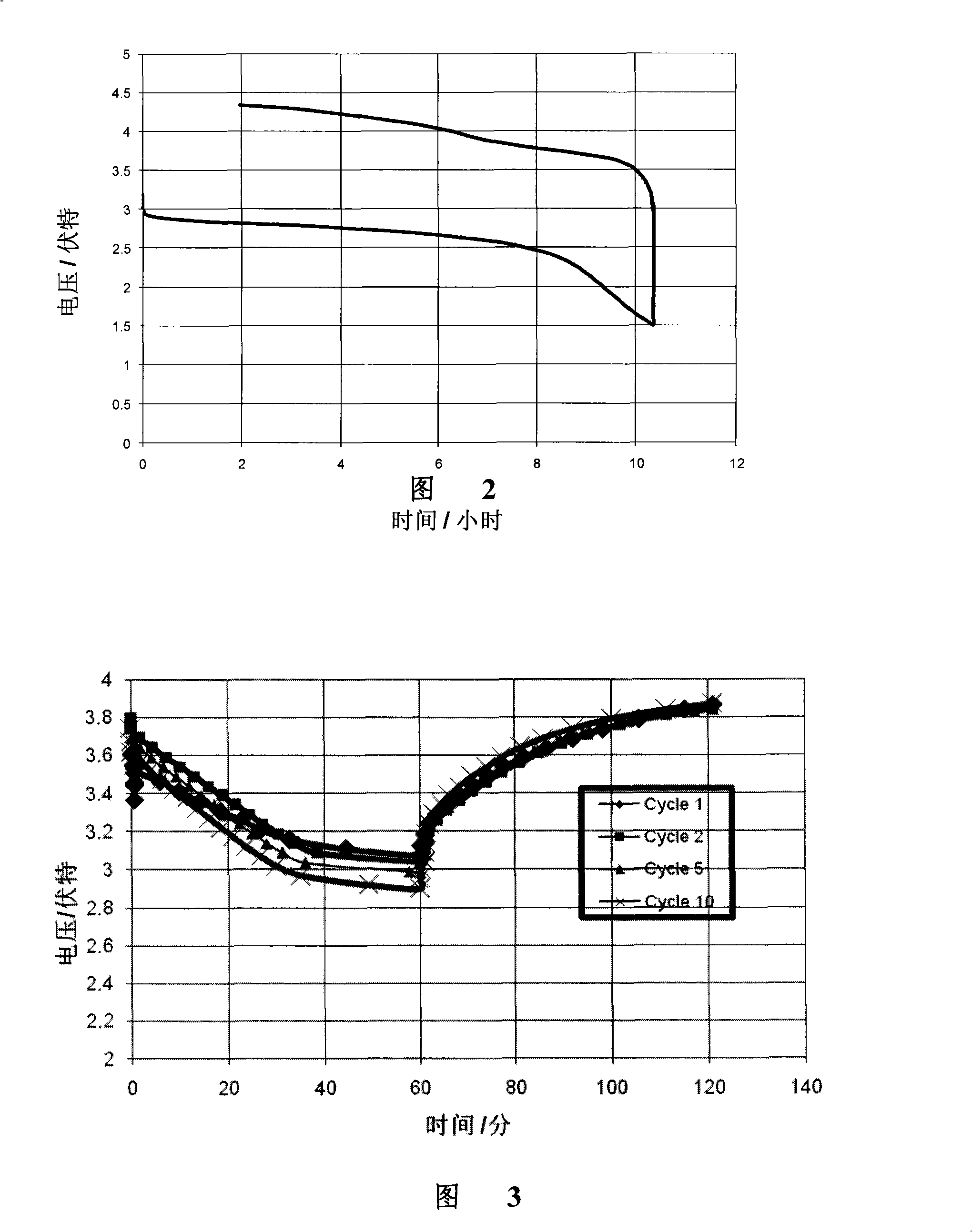

Lithium ion batteries with long cycling performance

ActiveUS20110017528A1Maintain discharge capacitySmall-sized cells cases/jacketsElectric propulsion mountingHigh energyEngineering

Batteries with high energy and high capacity are described that have a long cycle life upon cycling at a moderate discharge rate. Specifically, the batteries may have a room temperature fifth cycle discharge specific energy of at least about 175 Wh / kg discharged at a C / 3 discharge rate from 4.2V to 2.5V. Additionally, the batteries can maintain at least about 70% discharge capacity at 1000 cycles relative to the fifth cycle, with the battery being discharged from 4.2V to 2.5V at a C / 2 rate from the fifth cycle through the 1000th cycle. In some embodiment, the positive electrode of the battery comprises a lithium intercalation composition with optional metal fluoride coating. Stabilizing additive maybe added to the electrolyte of the battery to further improve the battery performance. The batteries are particularly suitable for use in electric vehicles.

Owner:IONBLOX INC

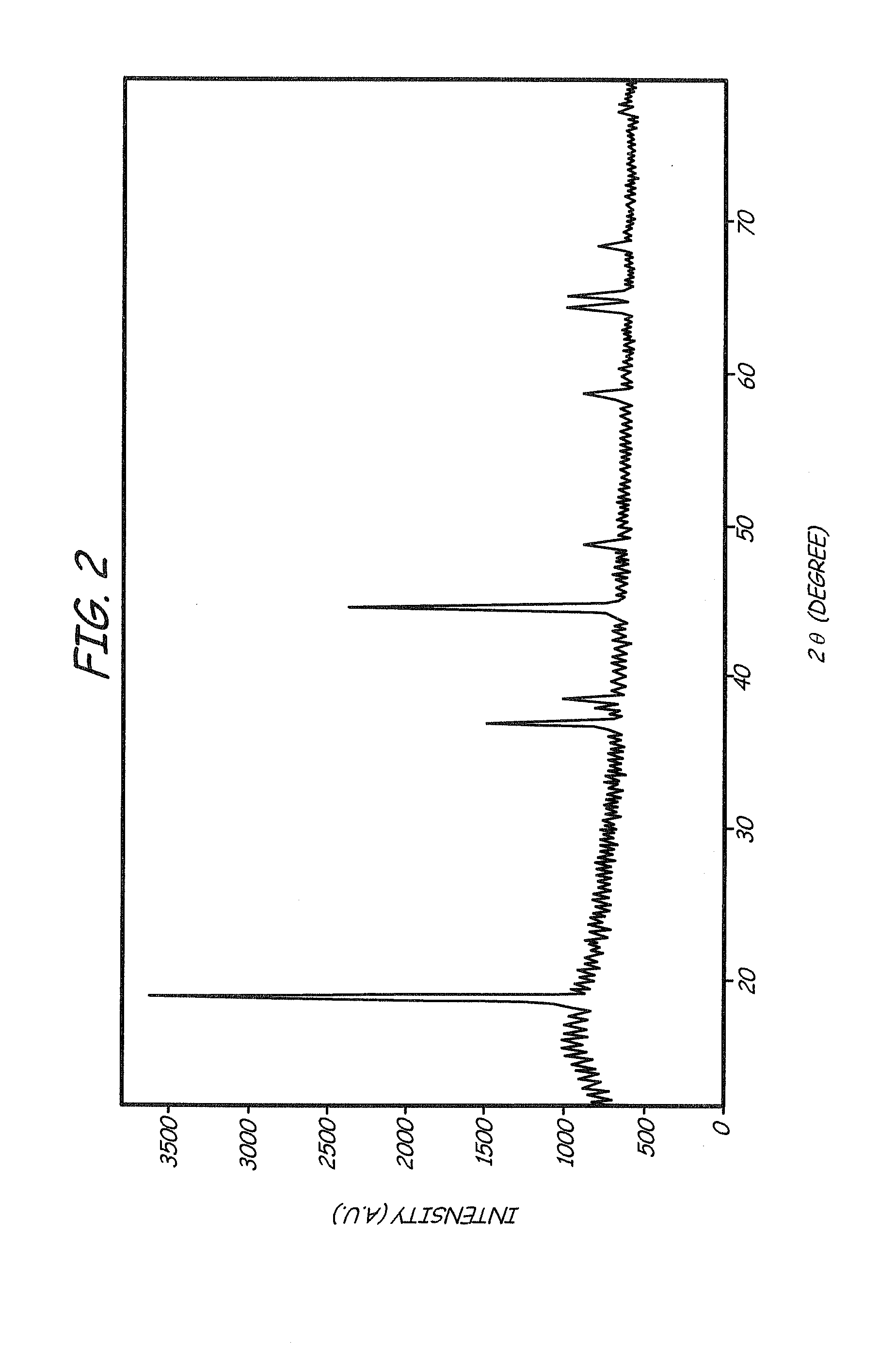

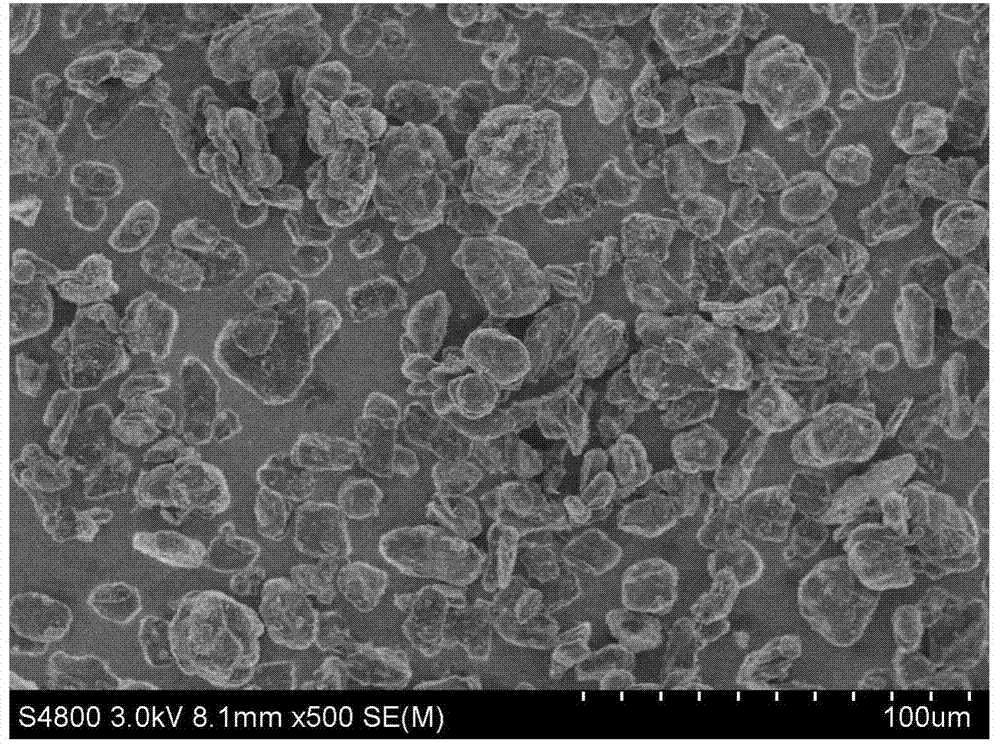

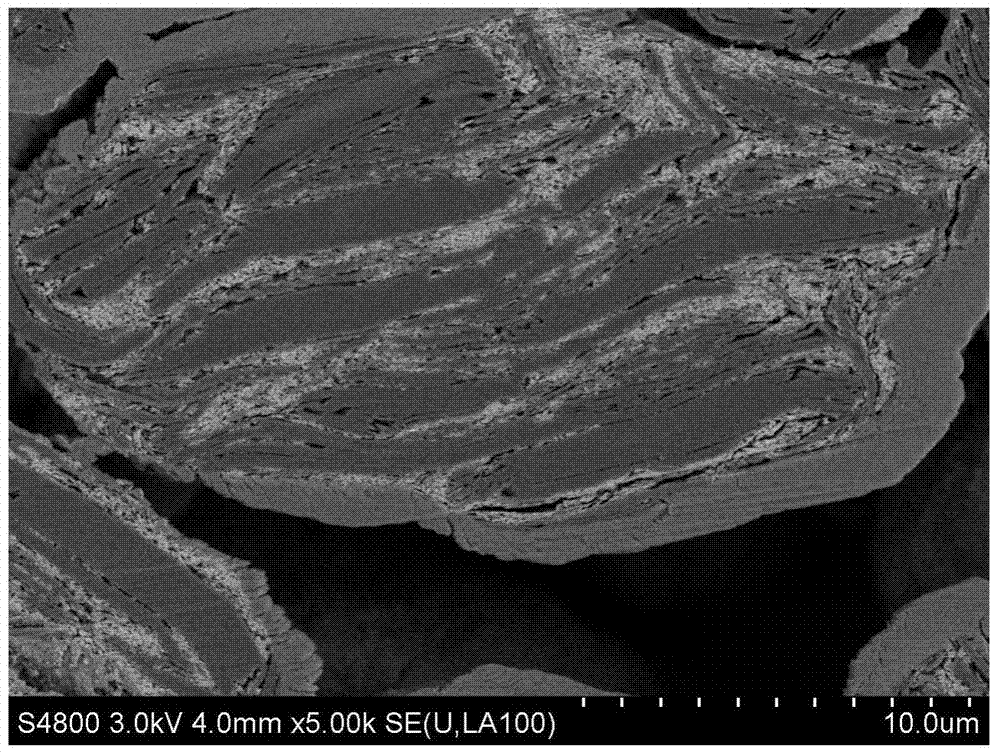

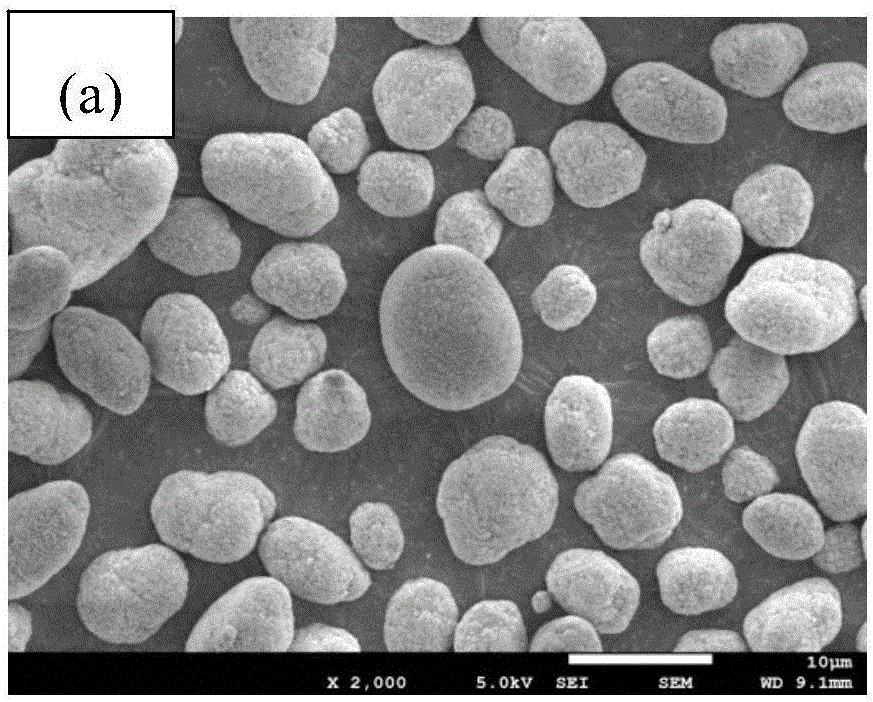

Lithium ion battery silicon-based composite anode material, preparation method thereof and battery

ActiveCN103682287AGood dispersionInhibit swellingCell electrodesSecondary cellsCarbon coatingRetention ratio

The invention relates to a lithium ion battery silicon-based composite anode material, a preparation method of the lithium ion battery silicon-based composite anode material, and a battery. The lithium ion battery silicon-based composite anode material adopts an embedded composite core-shell structure, a core has a structure formed by embedding nano silicon particles into a gap of an inner layer of hollowed graphite, and a shell is made from a non-graphite carbon material. According to the silicon-based composite anode material, mechanical grinding, mechanical fusing, isotropic compression processing and carbon coating technologies are combined, so that the nano silicon particles can be successfully embedded into the inner layer of the graphite and the surfaces of graphite particles are uniformly coated; the high-performance silicon-based composite anode material is obtained and is excellent in cycle performance (the 300-times cycle capacity retention ratio is more than 90%) and high in first efficiency (more than 90%); in addition, the silicon-based composite anode material is high in specific energy and compaction density, and can meet the requirements of a high-power density lithium ion battery; the preparation process is simple, the raw material cost is low, and the environment is protected.

Owner:BTR NEW MATERIAL GRP CO LTD

Lithium secondary batteries containing lithium salt-ionic liquid solvent electrolyte

ActiveUS20140342249A1Reduce electrical conductivityLow ionic conductivityFuel and secondary cellsCell electrodesNano structuringLithium metal

A rechargeable lithium metal or lithium-ion cell comprising a cathode having a cathode active material and / or a conductive supporting structure, an anode having an anode active material and / or a conductive supporting nano-structure, a porous separator electronically separating the anode and the cathode, a highly concentrated electrolyte in contact with the cathode active material and the anode active material, wherein the electrolyte contains a lithium salt dissolved in an ionic liquid solvent with a concentration greater than 3 M. The cell exhibits an exceptionally high specific energy, a relatively high power density, a long cycle life, and high safety with no flammability.

Owner:GLOBAL GRAPHENE GRP INC

Method for production of a three-dimensional body

ActiveUS20130300035A1Improve product performanceRelieve pressureAdditive manufacturing apparatusTemperatue controlLight beamSupply energy

The invention concerns a method for production of a three-dimensional body by successively providing powder layers and fusing together of selected areas of said layers, which areas correspond to successive cross sections of the three-dimensional body, wherein the method comprises the following steps for at least one of said layers: applying the at least one powder layer onto a working area, and fusing together a selected area of the at least one powder layer by supplying energy from a radiation gun to the selected area. The invention is characterized in that it comprises the steps of: establishing an intended beam path that is to be used when fusing together the selected area of the at least one powder layer, calculating a temperature in the at least one powder layer along the intended beam path as a function of a specific energy deposition of an imaginary beam that is assumed to move along the intended beam path, adjusting the specific energy deposition of the imaginary beam along the intended beam path depending on the calculated temperature and on conditions set for the step of fusing together the selected area, and providing, based on the calculations and the adjustments, an operating scheme for the specific energy deposition of the real beam to be used for the intended beam path when fusing together the selected area of the at least one layer.

Owner:ARCAM AB

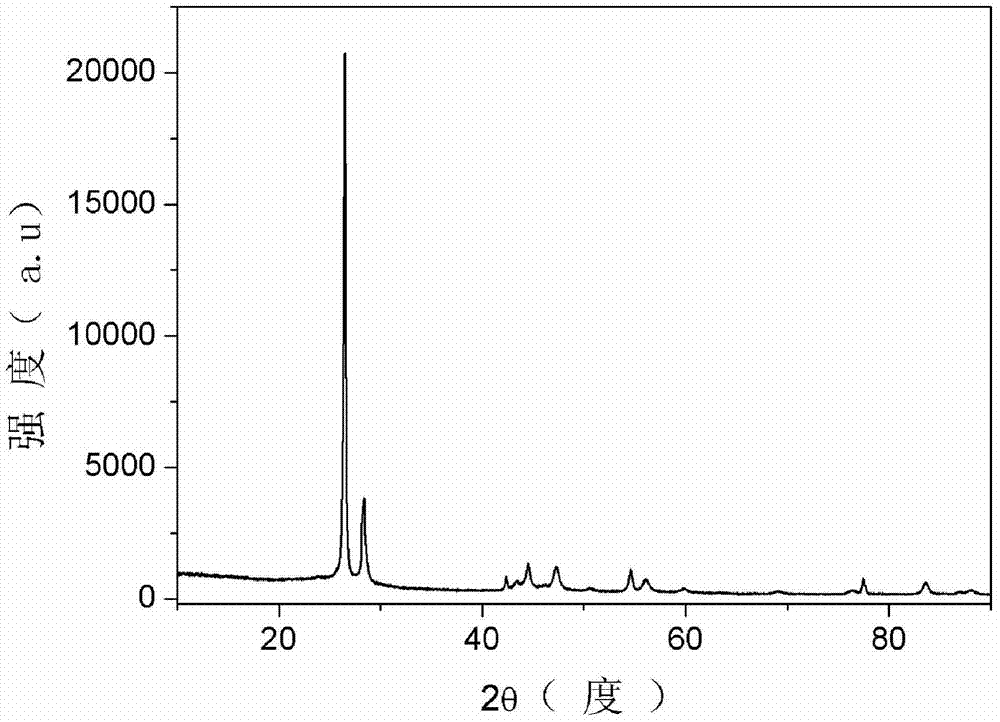

Novel carbon-sulfur compound for lithium-sulfur battery

InactiveCN101587951AIncrease profitIncrease specific energyCell electrodesSulfur compoundsElectric capacityInternal resistance

The invention relates to a novel carbon-sulfur compound for an anode material of a lithium-sulfur battery and a preparation method thereof. Sulfur is filled into a nano and micron hole of a matrix in an elementary substance way by taking a macroporous carbon material with high pore volume, electrical conductivity and specific surface area as the matrix, and the sulfur and carbon can also carry out combination reaction so as to prepare the novel carbon-sulfur compound of which the sulfur exists in one or more chemical states in a carbon material. The novel carbon-sulfur compound used as the anode material of the lithium-sulfur battery has the advantages that the high pore volume has large contained sulfur contents and can ensure high electric capacity; the small granularity of the sulfur can reduce a conductive distance between ions and electrons and increase the utilization ratio of the sulfur; and the adsorption characteristics of the high specific surface of the carbon material can inhibit a discharging intermediate product from dissolving and moving towards a cathode, reduce the self discharge, prevent a nonconductive discharging product, namely lithium sulfide from largely accumulating outside carbon particles and reduce internal resistance, therefore, the material can improve the specific energy, the specific power and the cycle performance of the lithium-sulfur battery.

Owner:NO 63971 TROOPS PLA

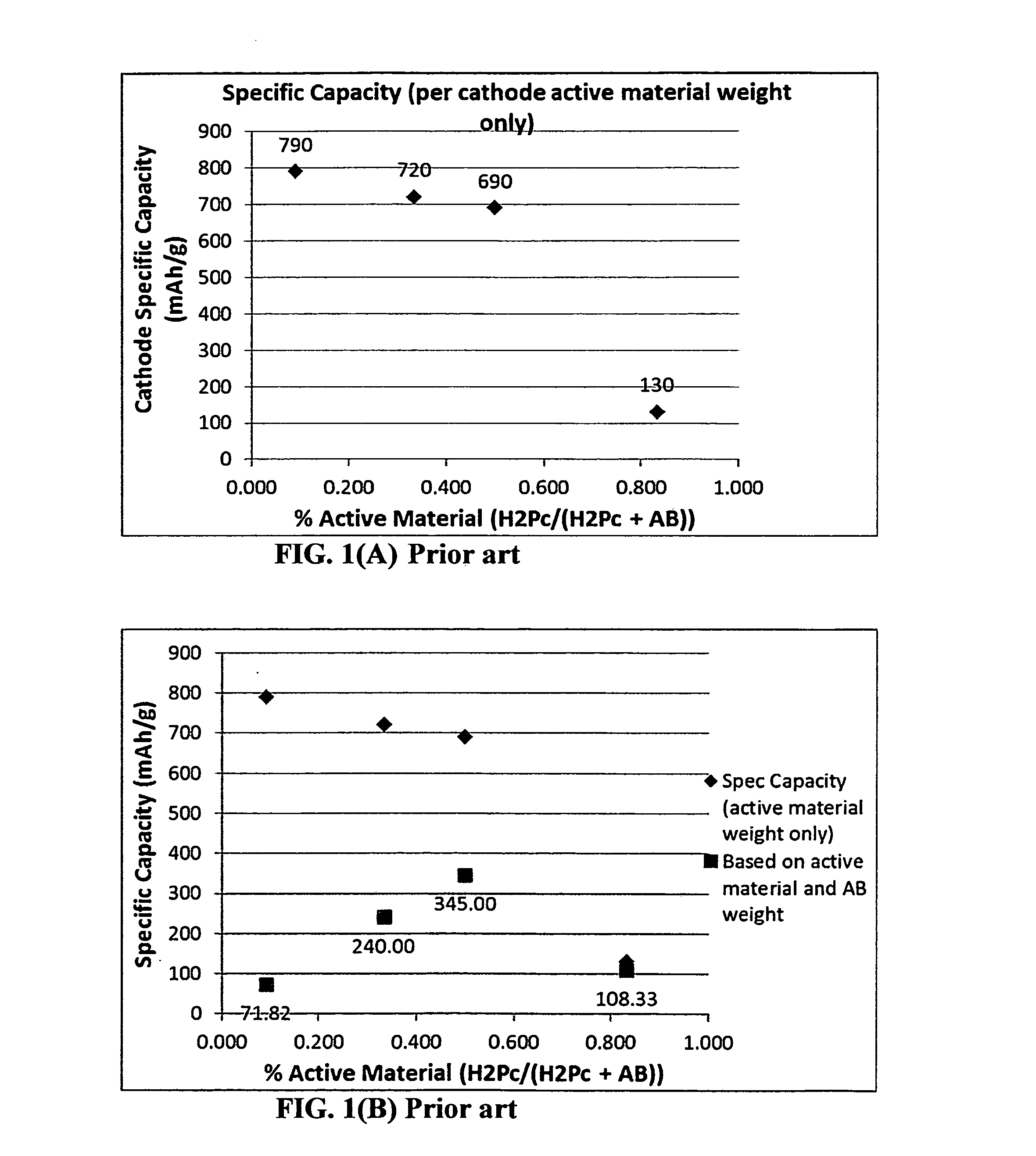

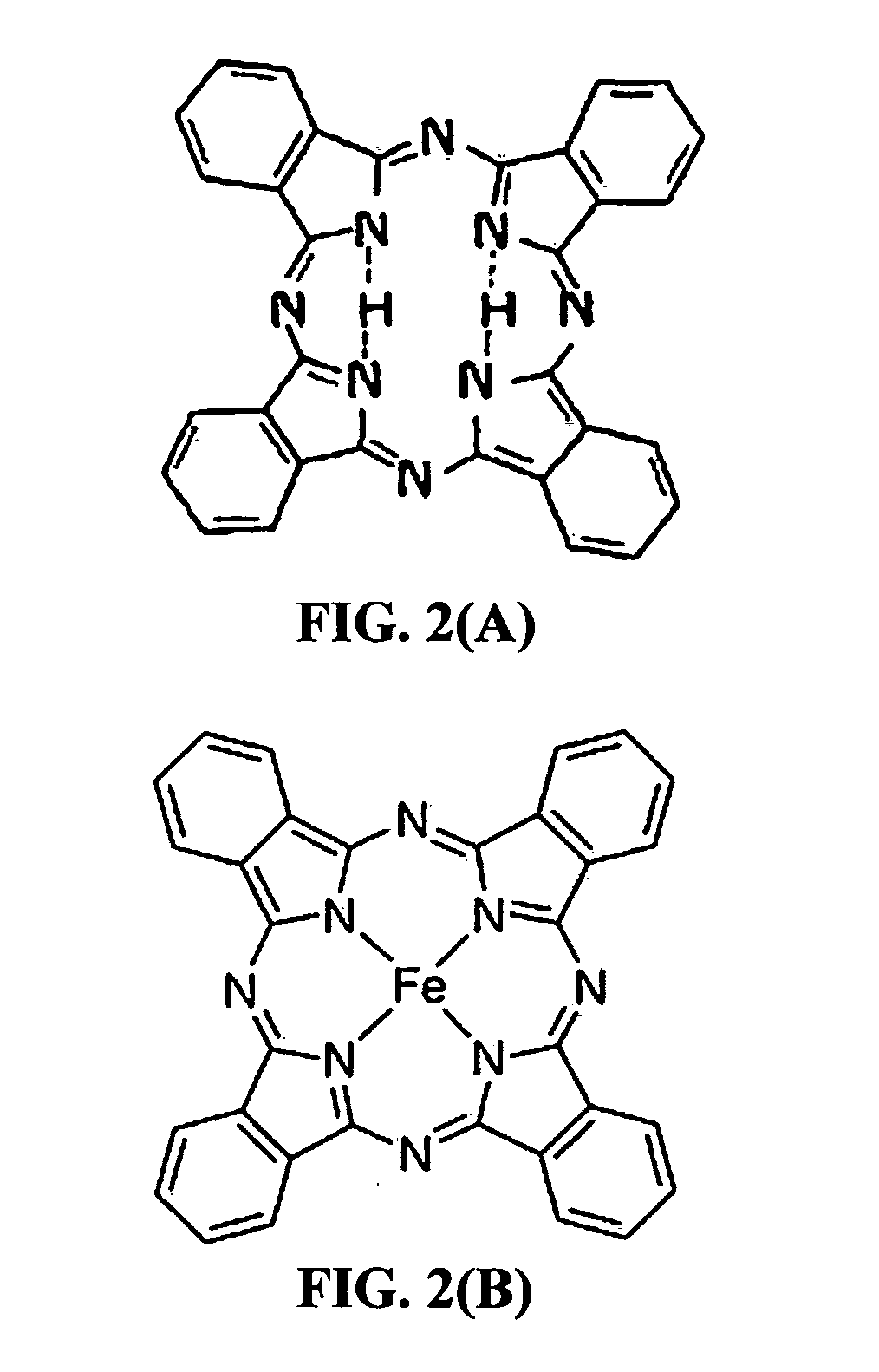

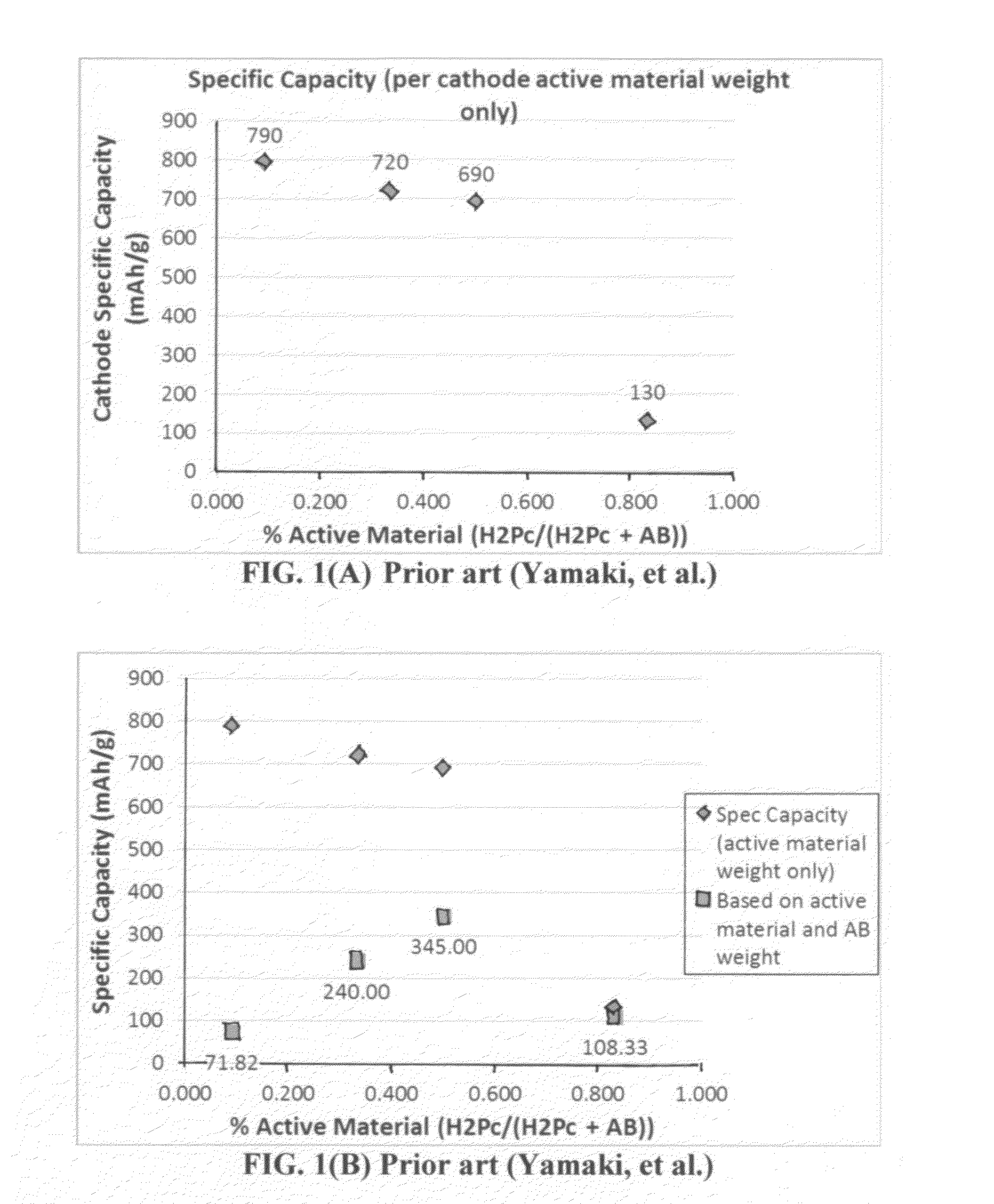

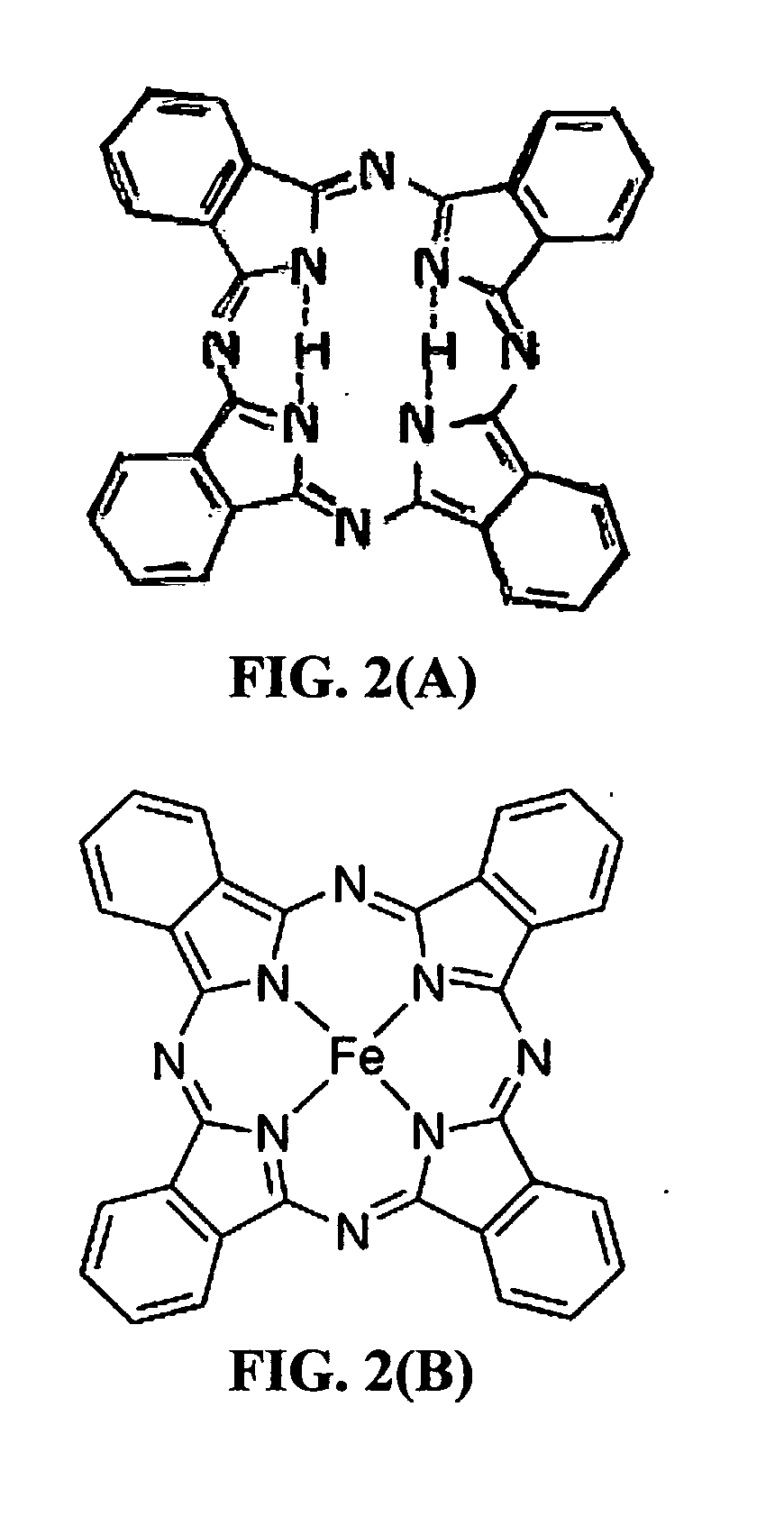

Encapsulated phthalocyanine particles, high-capacity cathode containing these particles, and rechargeable lithium cell containing such a cathode

ActiveUS20140072879A1High theoretical lithium storage capacityLow electricalMaterial nanotechnologySolid electrolyte cellsElectrical batteryPhthalocyanine

Disclosed is an electrode material comprising a phthalocyanine compound encapsulated by a protective material, preferably in a core-shell structure with a phthalocyanine compound core and a protective material shell. Also disclosed is a rechargeable lithium cell comprising: (a) an anode; (b) a cathode comprising an encapsulated or protected phthalocyanine compound as a cathode active material; and (c) a porous separator disposed between the anode and the cathode and / or an electrolyte in ionic contact with the anode and the cathode. This secondary cell exhibits a long cycle life, the best cathode specific capacity, and best cell-level specific energy of all rechargeable lithium-ion cells ever reported.

Owner:GLOBAL GRAPHENE GRP INC

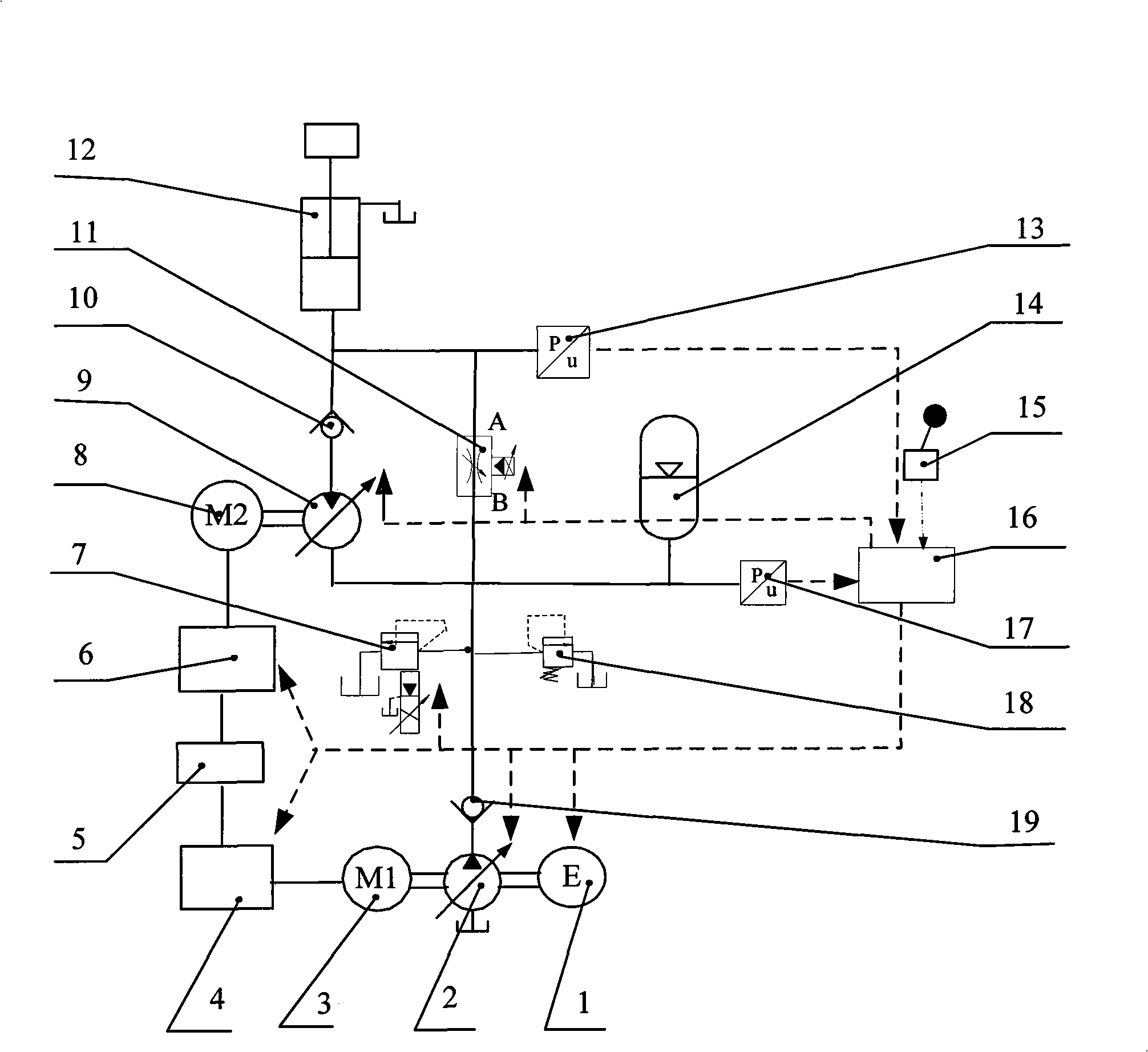

Energy recovery system of hybrid power engineering machinery energy accumulator-hydraulic motor

InactiveCN101408213AHigh specific powerFast absorptionAccumulator installationsGas pressure propulsion mountingHydraulic motorEnergy recovery

The invention discloses a hybrid power engineering mechanical accumulator-hydraulic motor energy recovery system. The system mainly comprises an engine, a variable pump, variable frequency motors, a variable motor, a signal control unit, an accumulator and a hydraulic implementation element, and the like. In the system, the variable motor is coaxially connected with a variable frequency motor M2 and forms a composite energy recovery system with the accumulator so as to recover the gravitational potential energy and braking energy in the lowering process of an implementation mechanism. The variable pump, the engine and a variable frequency motor M1 are coaxially connected; a hybrid power system which consists of the engine and the variable frequency motor M1 drives the hydraulic implementation mechanism to rise and lift heavy objects together with the accumulator. The system overcomes the defects that the variable motor-power generator energy recovery system responds slowly and the specific energy of the accumulator is low, enhances the dynamic response performance of the energy recovery system, improves the working conditions of power generation of an electric generator, and simultaneously can directly recover part of potential energy by the accumulator, thus raising the energy recovery efficiency of the system.

Owner:ZHEJIANG UNIV

Fluoride ion electrochemical cell

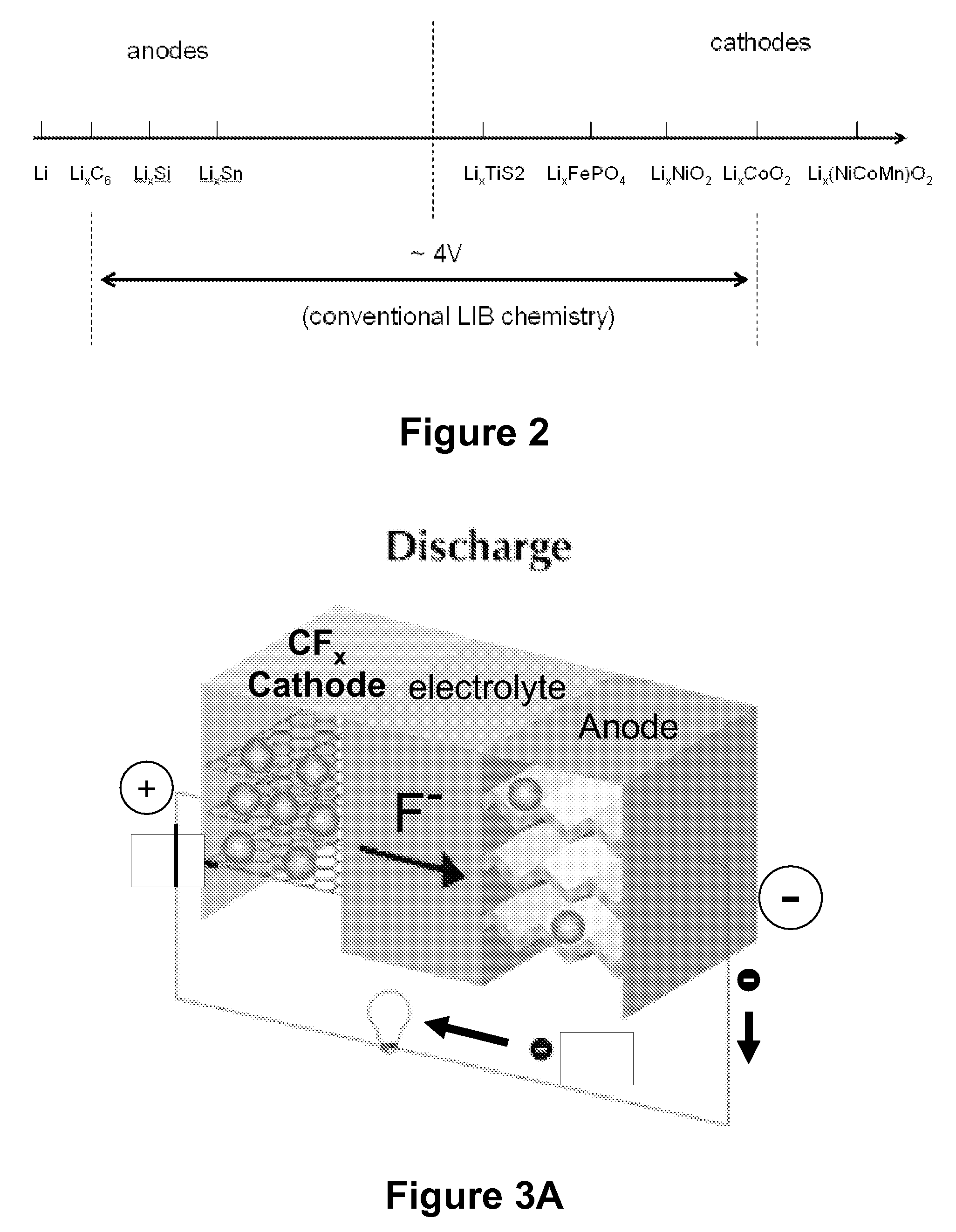

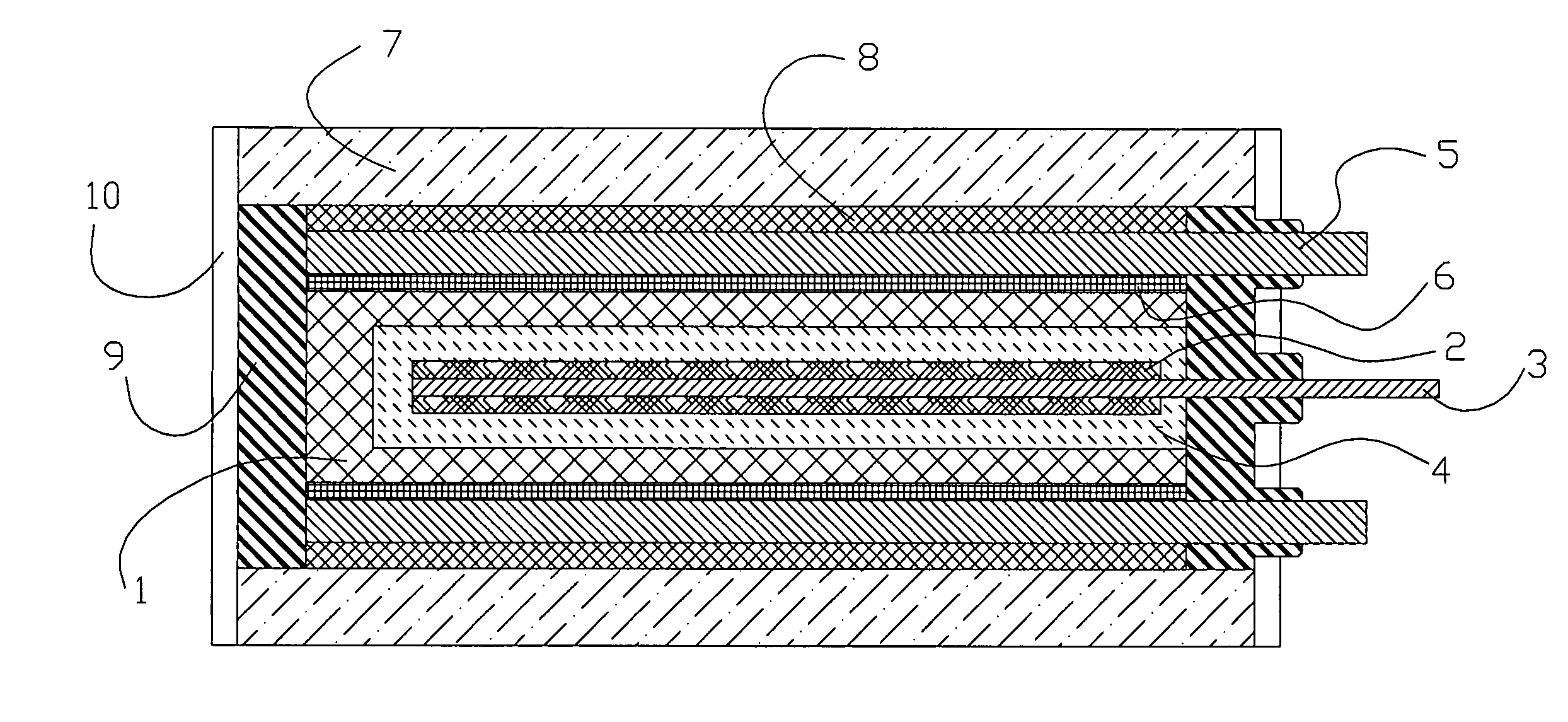

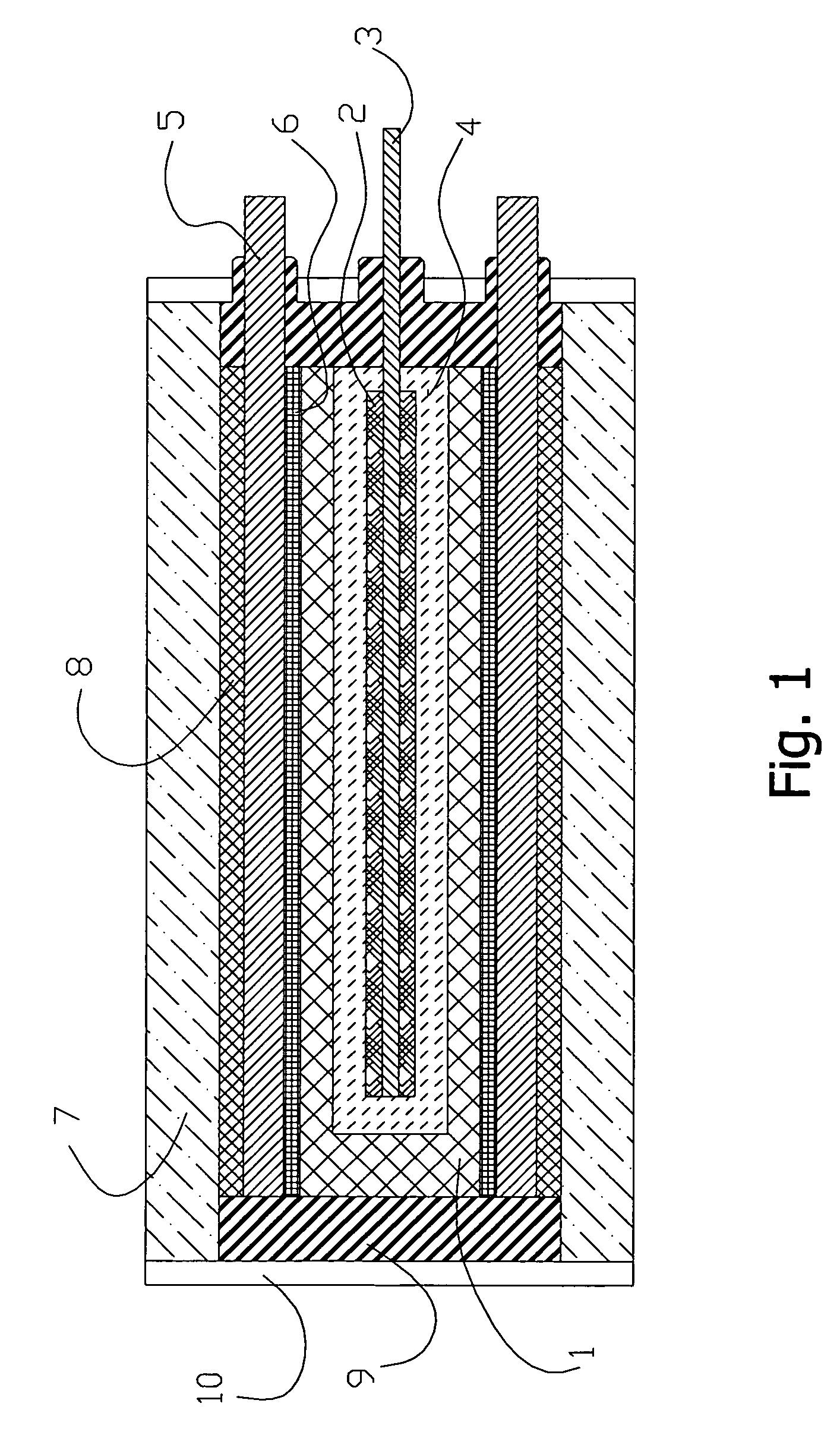

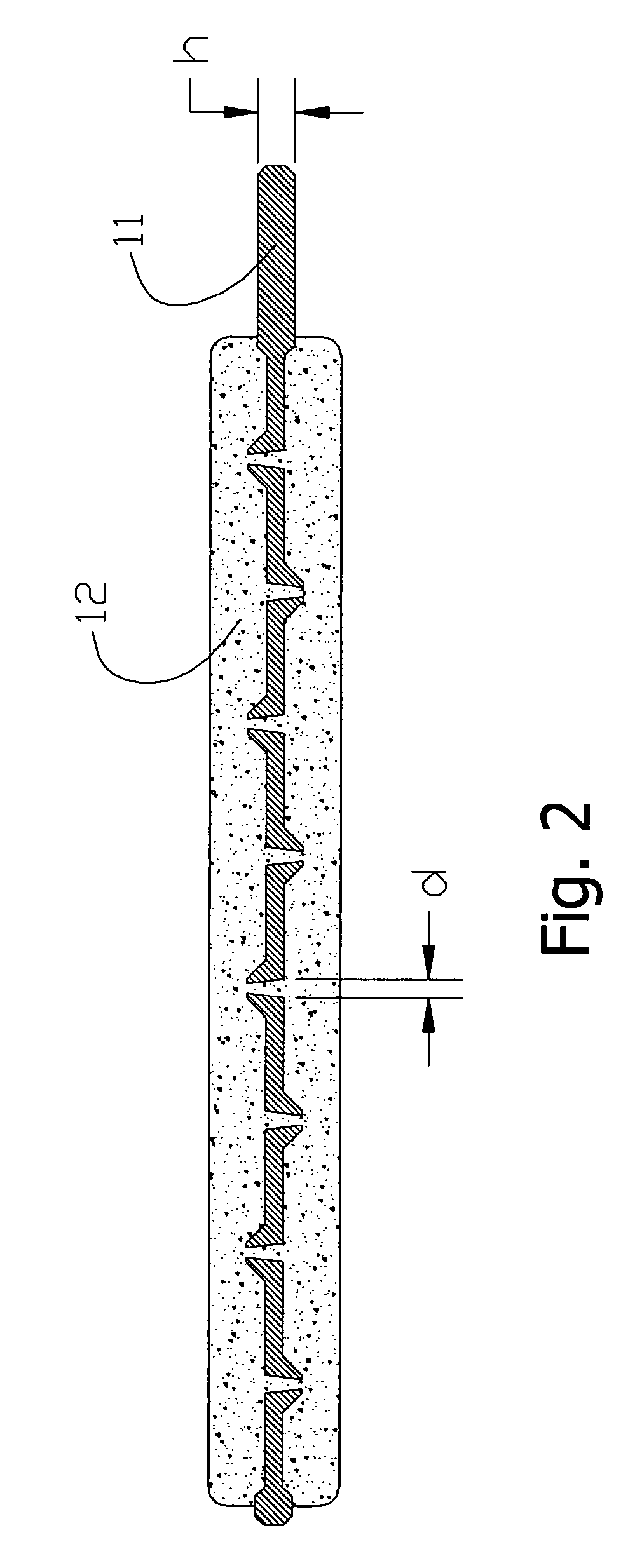

ActiveUS20090029237A1Improve performanceHigh energyAlkaline accumulatorsLead-acid accumulatorsMetallic lithiumState of art

The present invention provides electrochemical cells capable of good electronic performance, particularly high specific energies, useful discharge rate capabilities and good cycle life. Electrochemical cells of the present invention are versatile and include primary and secondary cells useful for a range of important applications including use in portable electronic devices. Electrochemical cells of the present invention also exhibit enhanced safety and stability relative to conventional state of the art primary lithium batteries and lithium ion secondary batteries. For example, electrochemical cells of the present invention include secondary electrochemical cells using anion charge carriers capable of accommodation by positive and negative electrodes comprising anion host materials, which entirely eliminate the need for metallic lithium or dissolved lithium ion in these systems.

Owner:CALIFORNIA INST OF TECH +1

Positive electrode of an electric double layer capacitor

InactiveUS7006346B2Inhibit sheddingLow corrosion rateHybrid capacitor electrolytesHybrid capacitor electrodesEngineeringElectric double-layer capacitor

Provided in the present invention is a positive electrode for use in an Electric Double Layer (EDL) Hybrid Electrochemical Capacitor (HEC). Embodiments of the invention can be further adapted produce an EDL HEC with a high specific energy value and a high maximum voltage value. Some aspects of an embodiment of the present invention, including the aforementioned positive electrode, also cooperate to provide an EDL HEC that has a relatively high cycleability.

Owner:AXION POWER INT

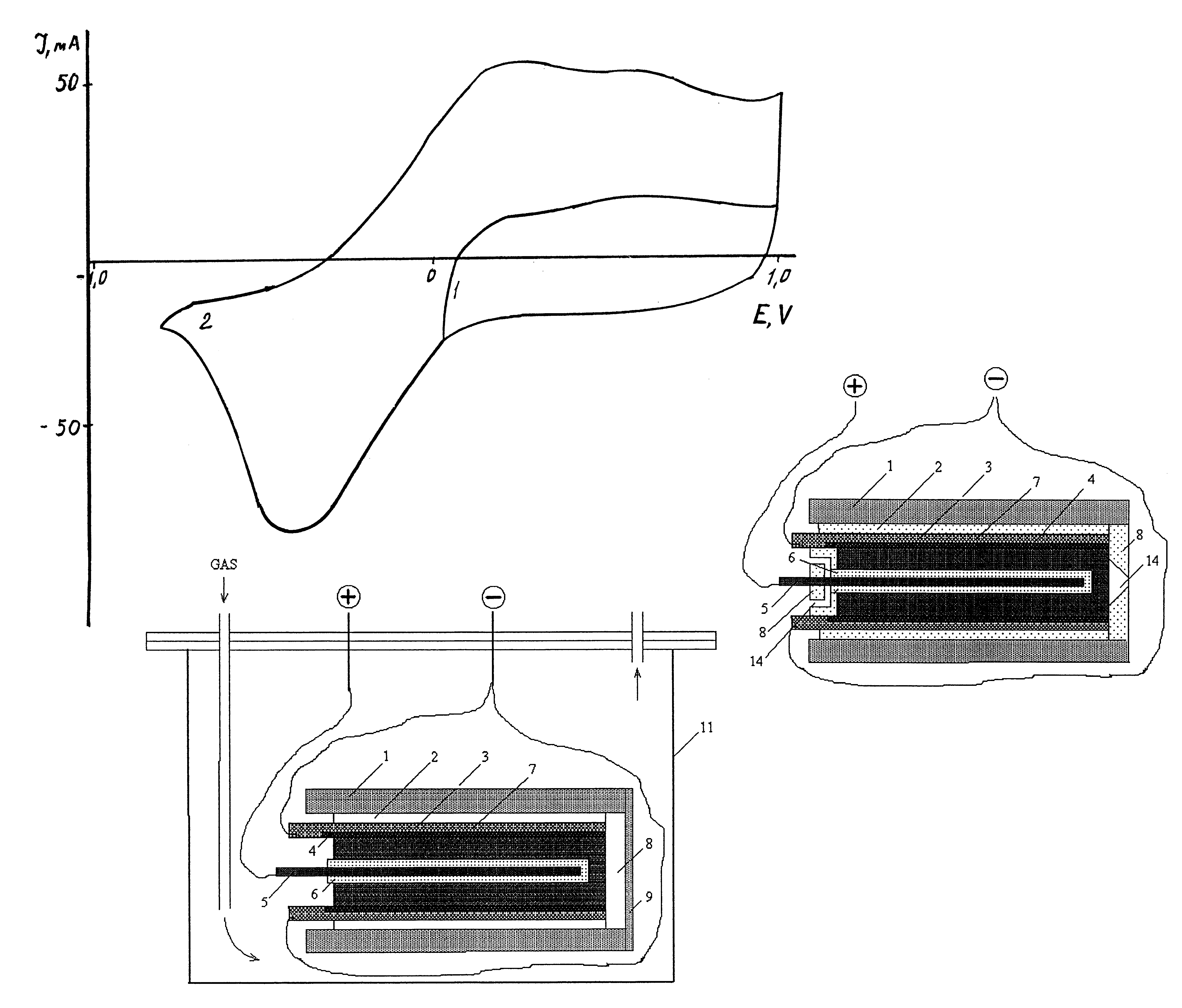

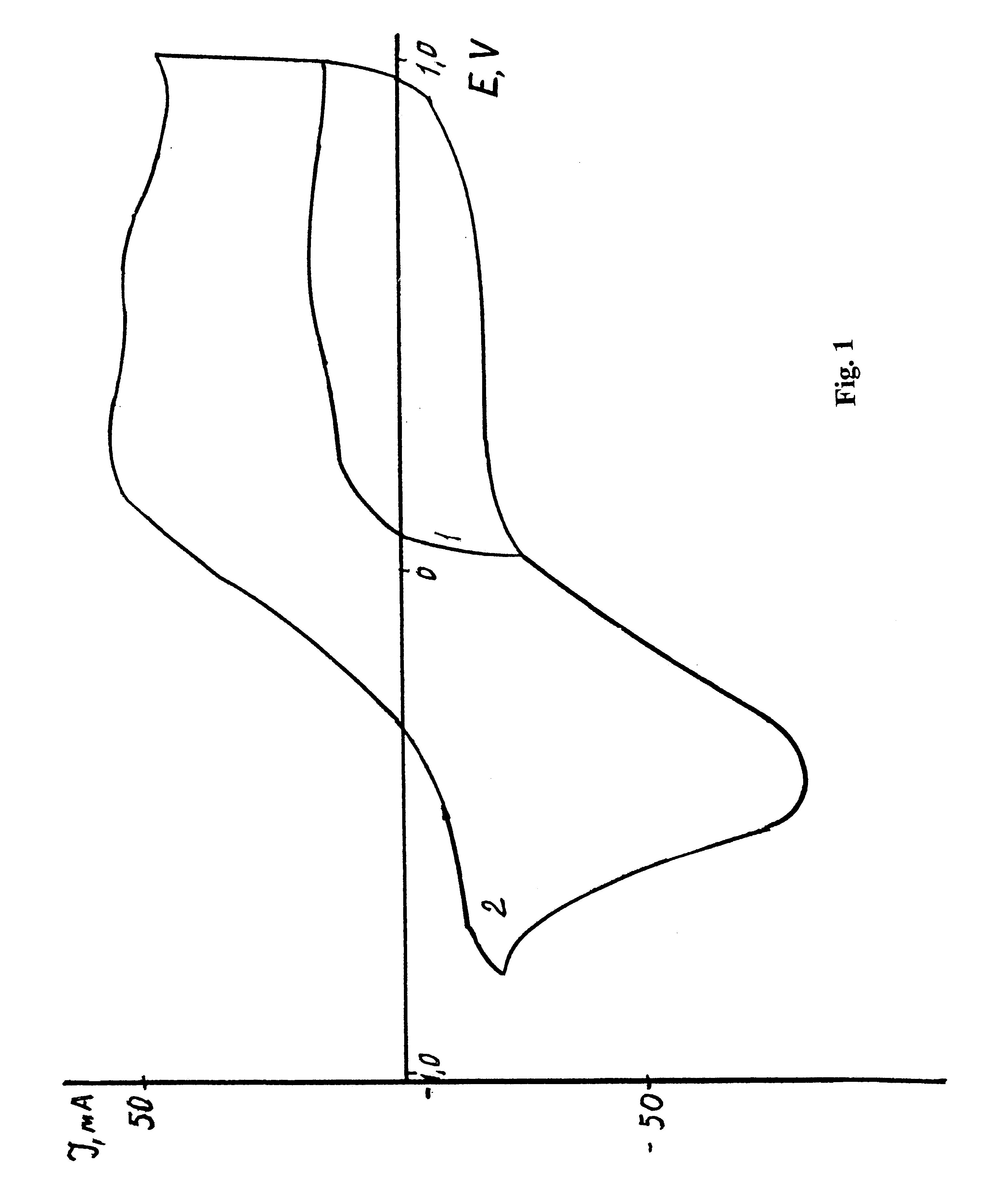

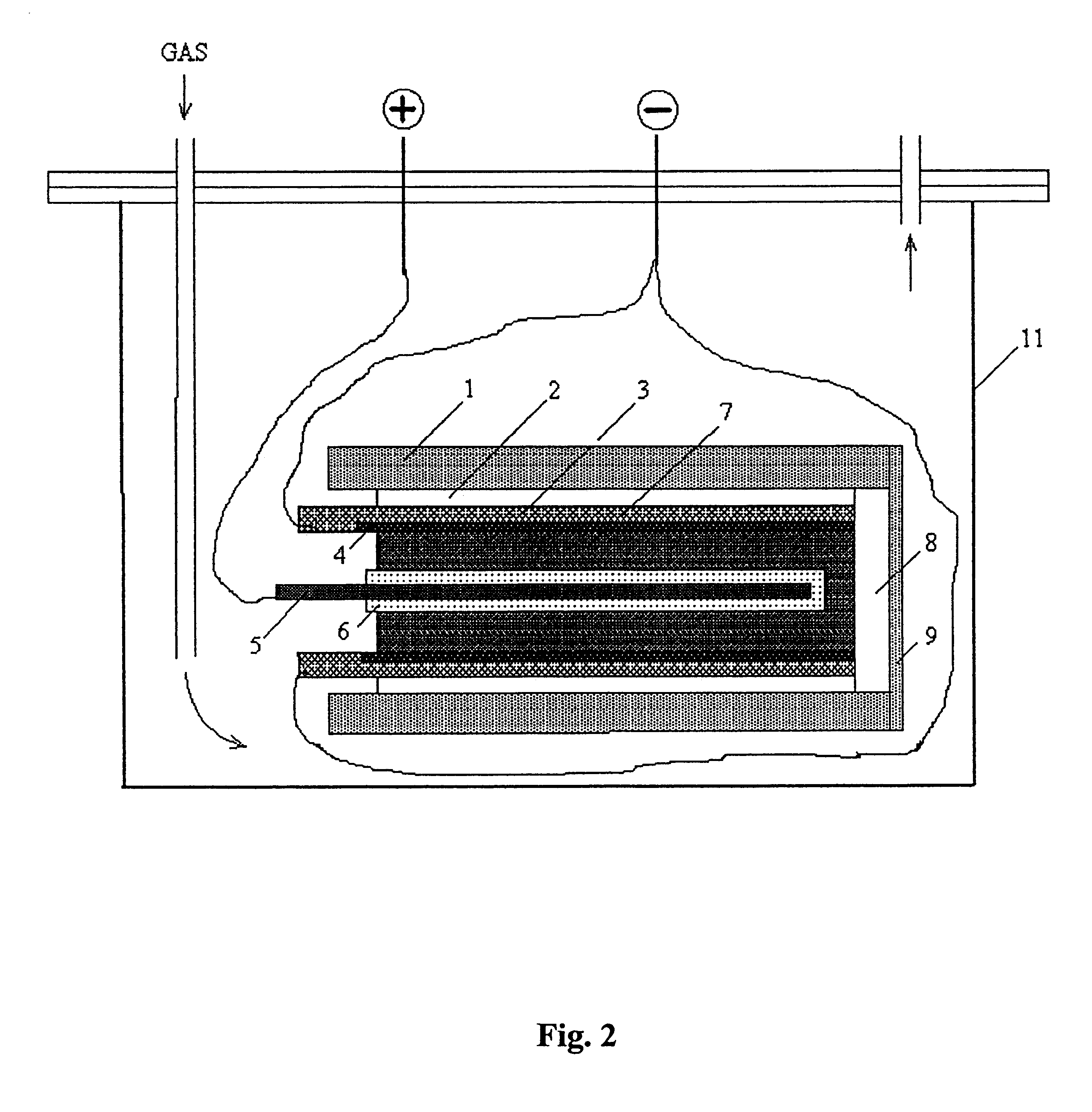

Method of formation and charge of the negative polarizable carbon electrode in an electric double layer capacitor

InactiveUS6706079B1Protecting/adjusting hybrid/EDL capacitorDouble layer capacitorsCapacitanceHydrogen

A method of formation and charge of a negative polarizable electrode of an electric double layer capacitor. The method can be used for manufacturing of high capacitance capacitors utilizing the energy of the electric double layer. The methods achieve hydrogen evolution on carbonaceous materials using very negative potentials. The methods provide an EDL capacitor, employing an aqueous electrolyte, with improved specific energy. The methods may also ensure the hermeticity of the capacitor. The methods include pretreating the electric double layer capacitor by keeping the negative polarizable electrode at a desired minimum potential prior to use. Desirably, the minimum potential ranges from about -0.25 to about -1.2 V vs. a reference hydrogen electrode.

Owner:WAINWRIGHT D WALKER

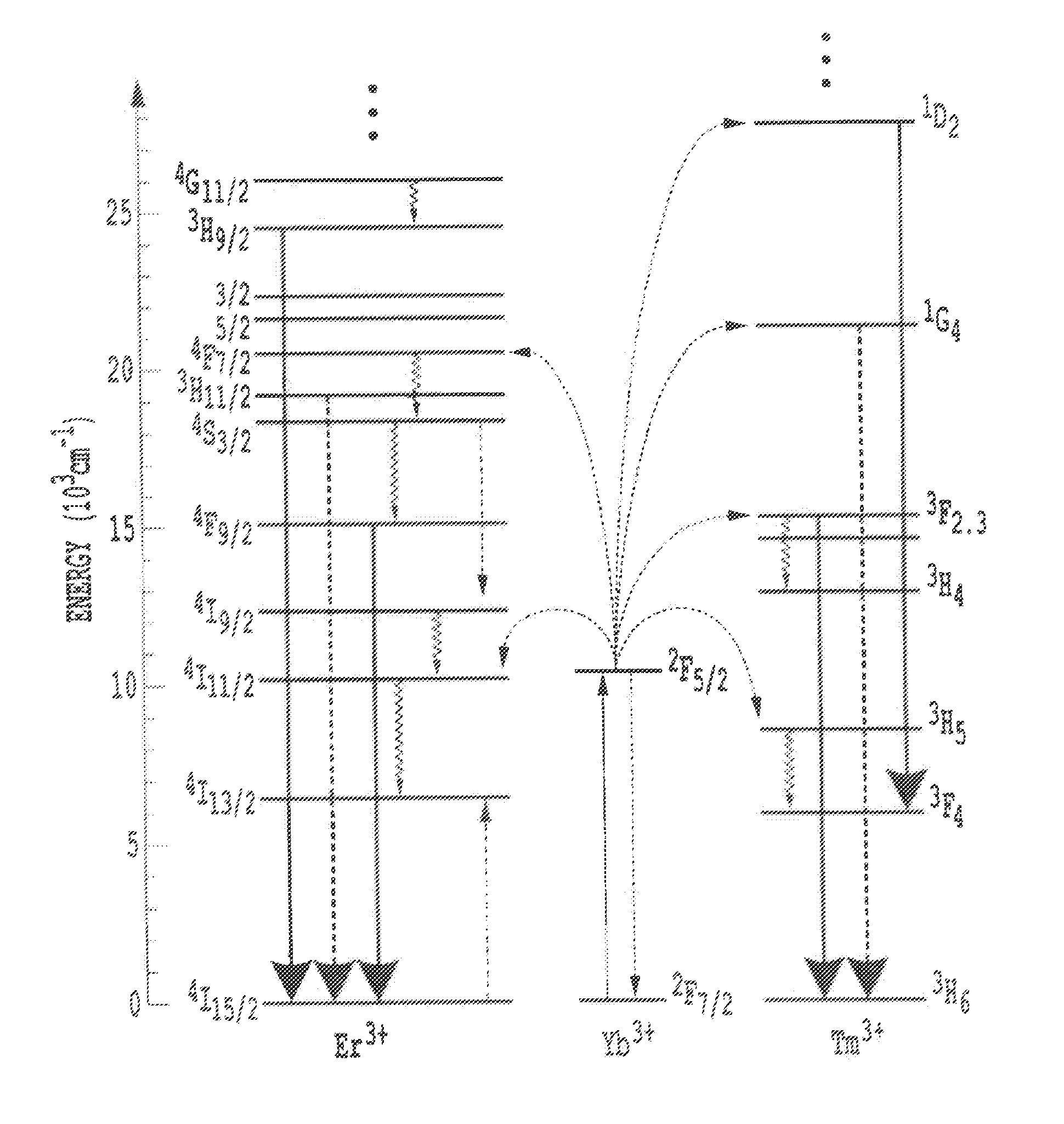

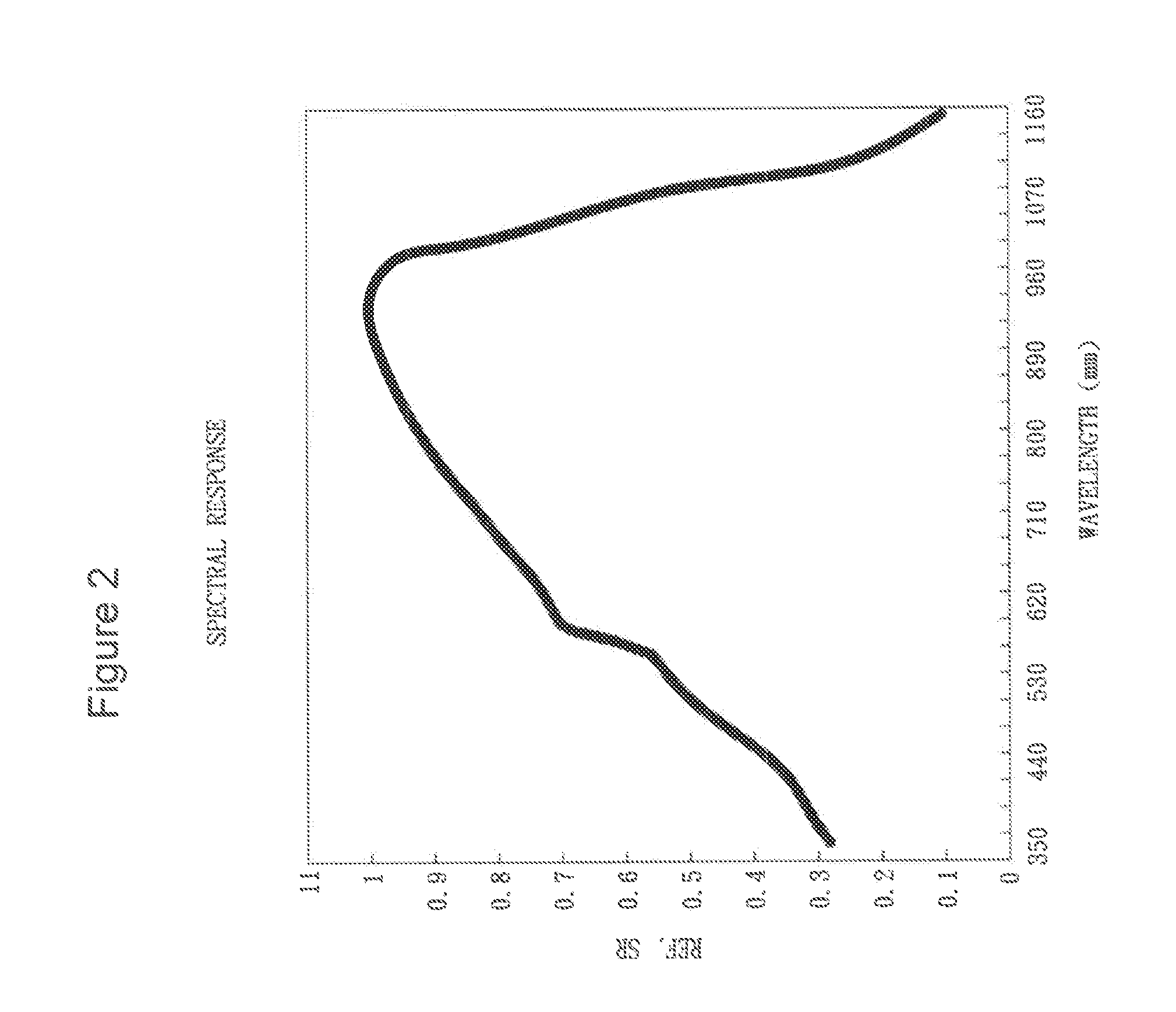

Up and down conversion systems for improved solar cell performance or other energy conversion

ActiveUS20110126889A1Weaken energyCladded optical fibreBundled fibre light guideElectric forceHigh energy

A system and a conversion element for power conversion. The power conversion system includes a power conversion device which produces electric power upon illumination and includes a light conversion device which down-converts and up-converts a radiant source of energy into a specific energy spectrum for the illumination of the power conversion device. The conversion element includes a first plurality of particles which upon radiation from a first radiation source radiate at a higher energy than the first radiation source, and includes a second plurality of particles which upon radiation from the first radiation source radiate at a lower energy than the first radiation source. At least one of the first plurality of particles and the second plurality of particles can be at least partially metal coated.

Owner:IMMUNOLIGTHT LLC +1

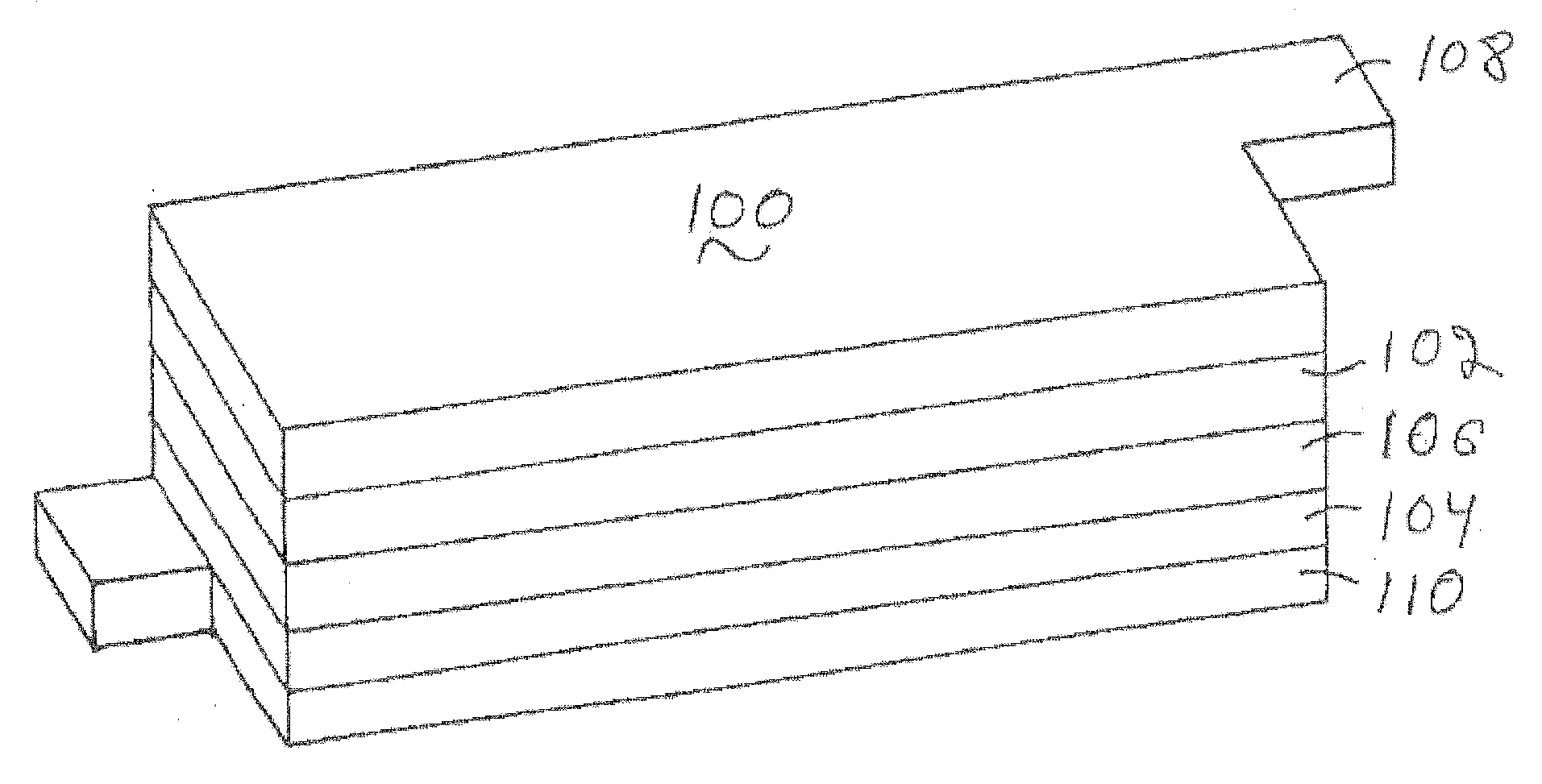

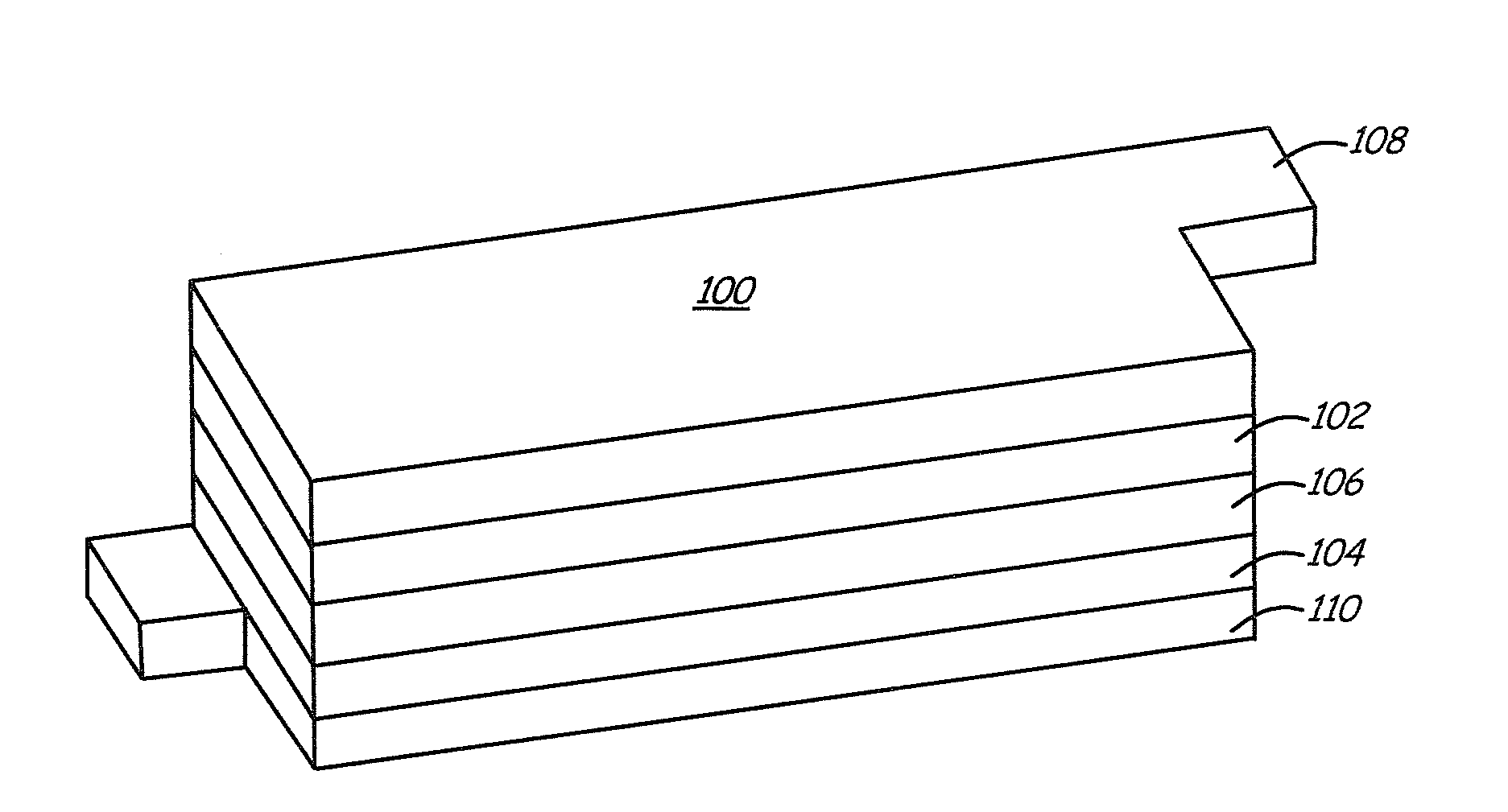

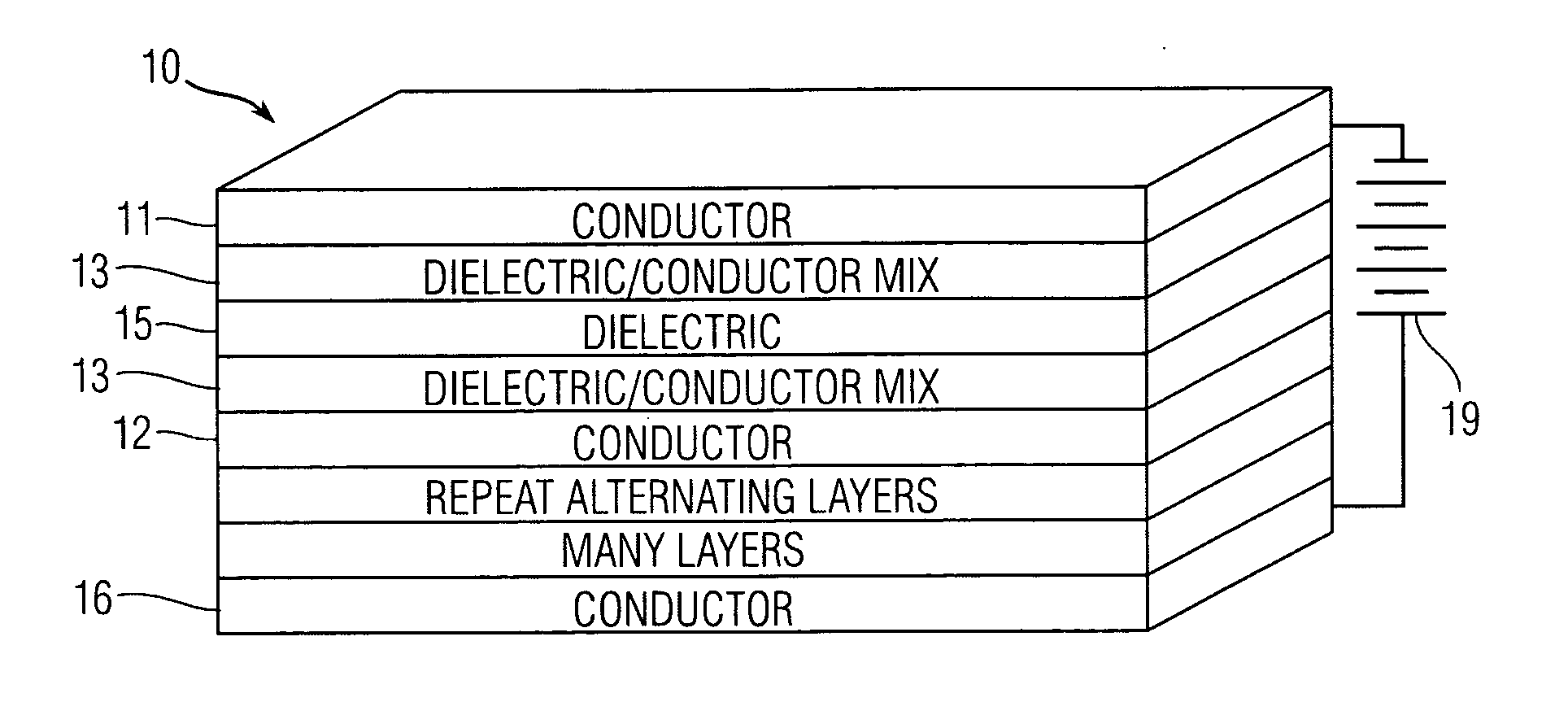

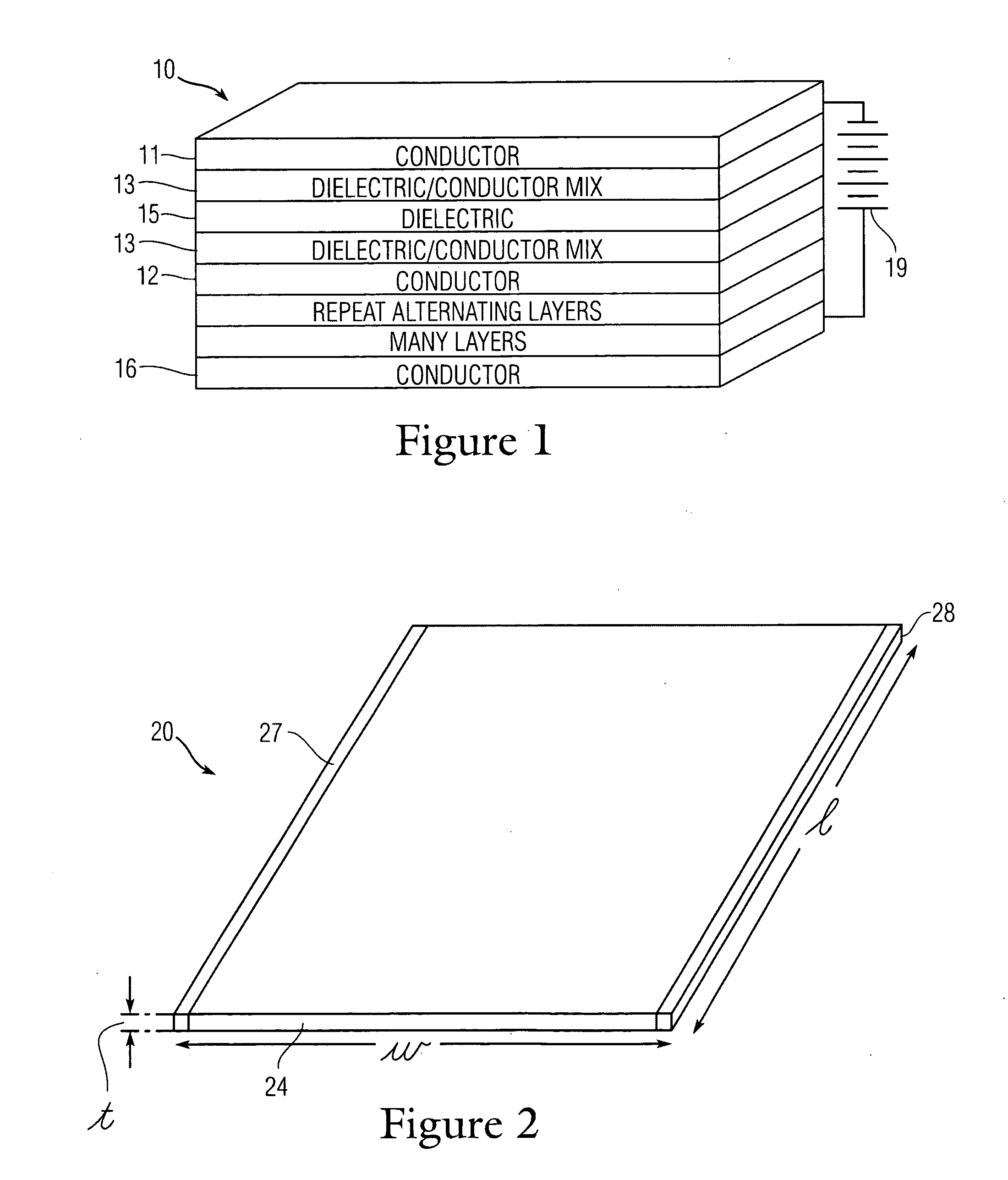

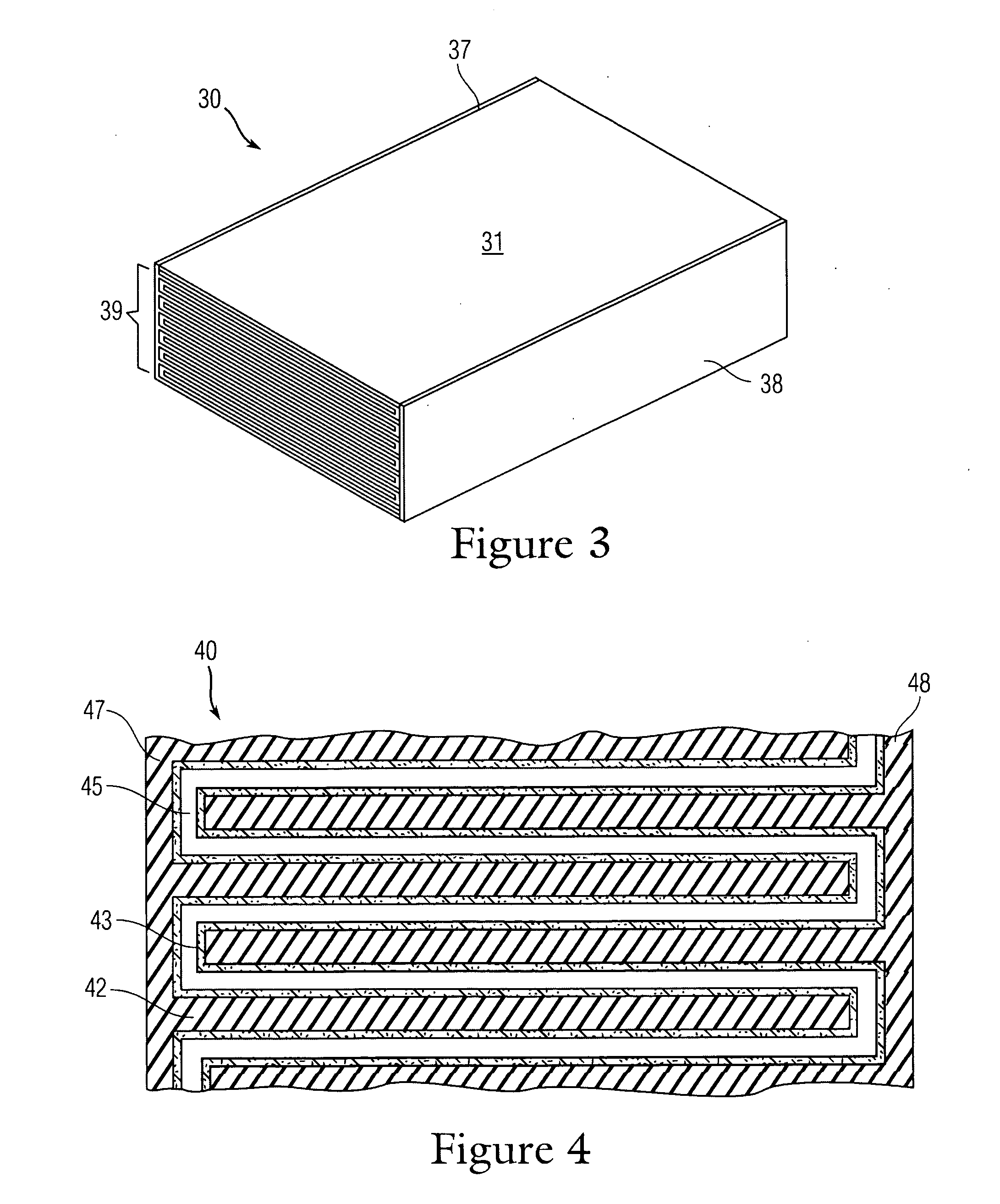

High performance capacitor with high dielectric constant material

InactiveUS20060120020A1Improve performanceHigh energy-density capacitorFixed capacitor dielectricStacked capacitorsElectrical conductorVolumetric Mass Density

A multilayered high performance capacitor formed of two or more conductors with a dielectric layer and one or more a dielectric-conductor interface layer sandwiched in between the conductors. The capacitor may be fabricated using many thin layers, at the nano level, providing a nanocapacitor. The capacitor may employ an interleaved structured where numerous conductor layers are interleaved with other conductor layers. The dielectric layers may be multilayered or a single layer and may consist of materials with high dielectric constants ranging from 800 to over 1 million, including materials in the perovskite-oxide family. The capacitor can be shaped, sized and the appropriate materials selected to obtain breakdown voltages within the range of 0.1 to over 11 MV / cm and to obtain specific energies and energy densities equivalent to or exceeding the power characteristics of known capacitors, fuel cells, and batteries. The nanocapacitor may be combined with other nanocapacitors to form stacks, packs, or grids of cells where the cells may be connected in series, parallel or both to provide increased energy or power characteristics

Owner:DOWGIALLO JR EDWARD J

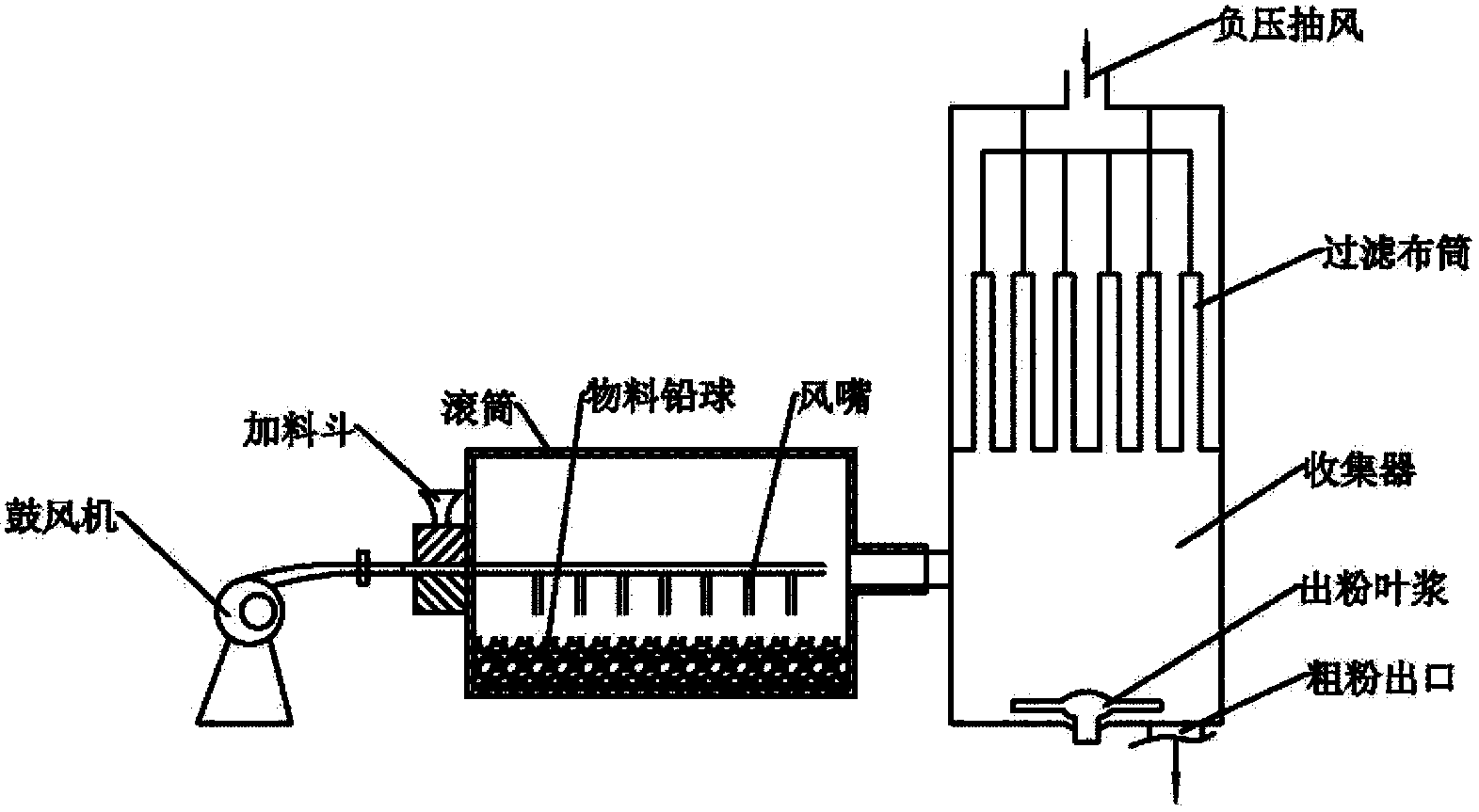

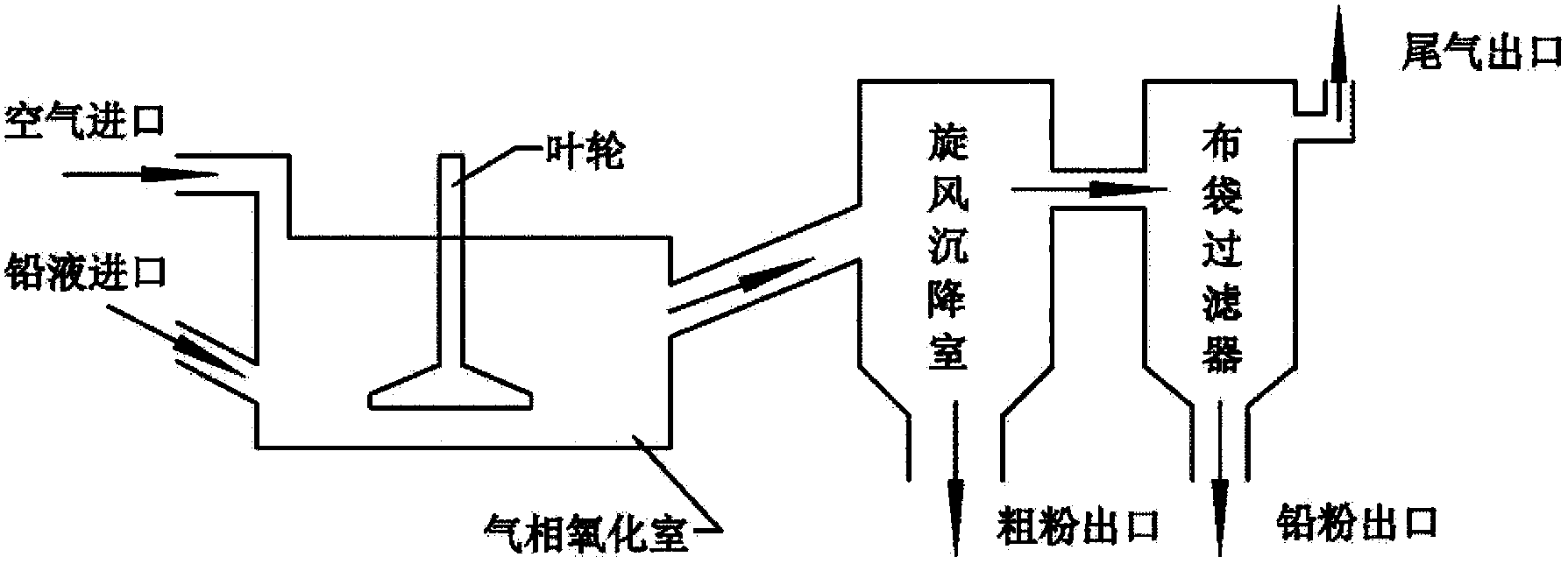

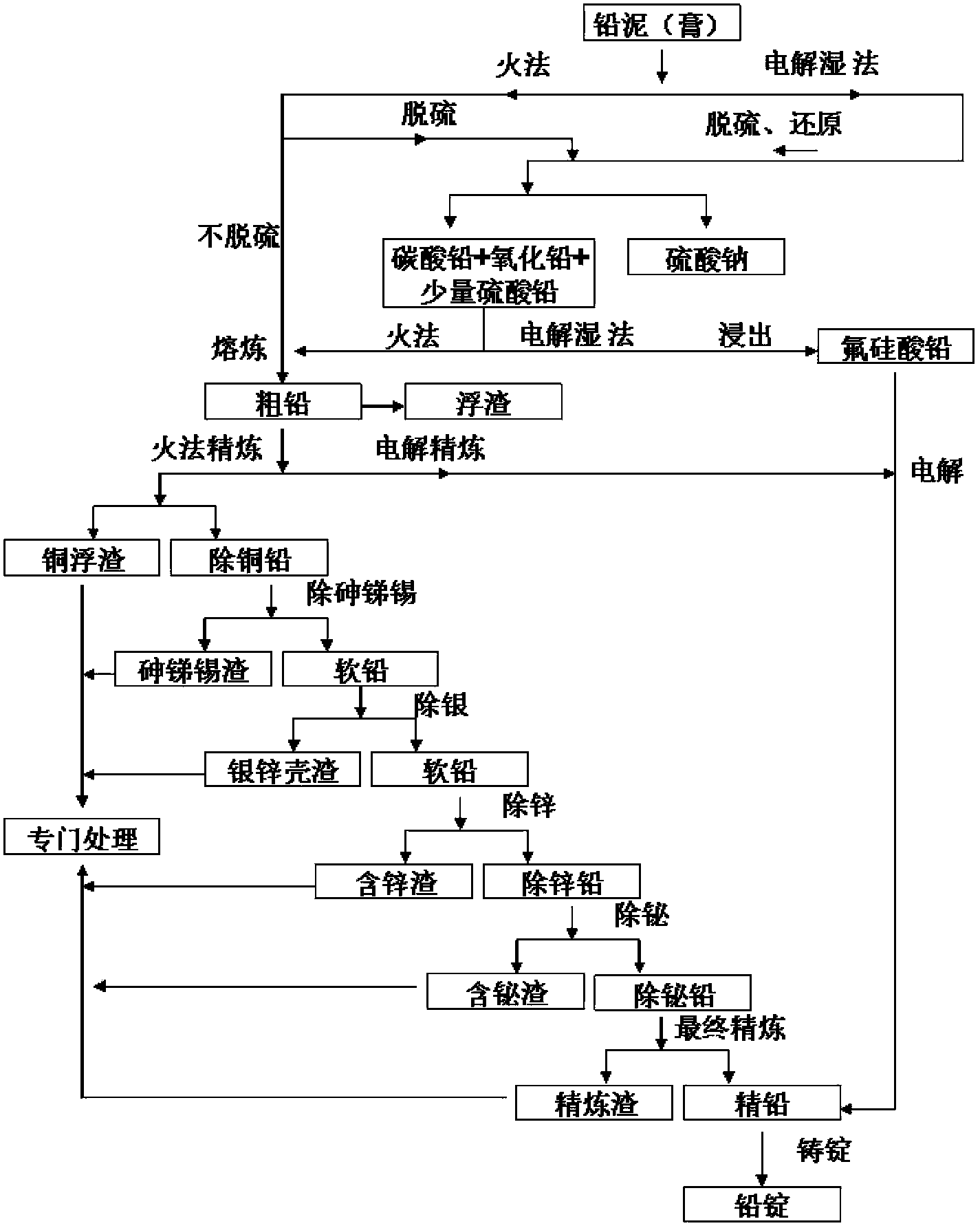

Methods and equipment for recovering waste diachylon by wet method and manufacturing electrode active material of high performance lead acid battery by wet method

ActiveCN103509949AIncrease profitLarge particle sizeWaste accumulators reclaimingProcess efficiency improvementElectrical batteryEngineering

The invention discloses methods and equipment for recovering waste diachylon by a wet method and manufacturing an electrode active substance material of a high performance lead acid battery by the wet method. The equipment comprises device required for a technology process by a chemical method, a chemical machinery method or an electrochemical machinery method. The active substance material provided by the invention can substantially raises an utilization rate of the active substance of the lead acid battery, specific energy of the battery and charging capability of the battery, simultaneously avoids generation and discharge of harmful substances such as lead gas, lead smoke, lead dust and SO2, raises a lead utilization rate in a production process, is beneficial for treating and recycling lead compounds and lead-containing liquid generated in a lead gas recovering process in a plate casting or welding technology, and reduces cost.

Owner:杨春晓

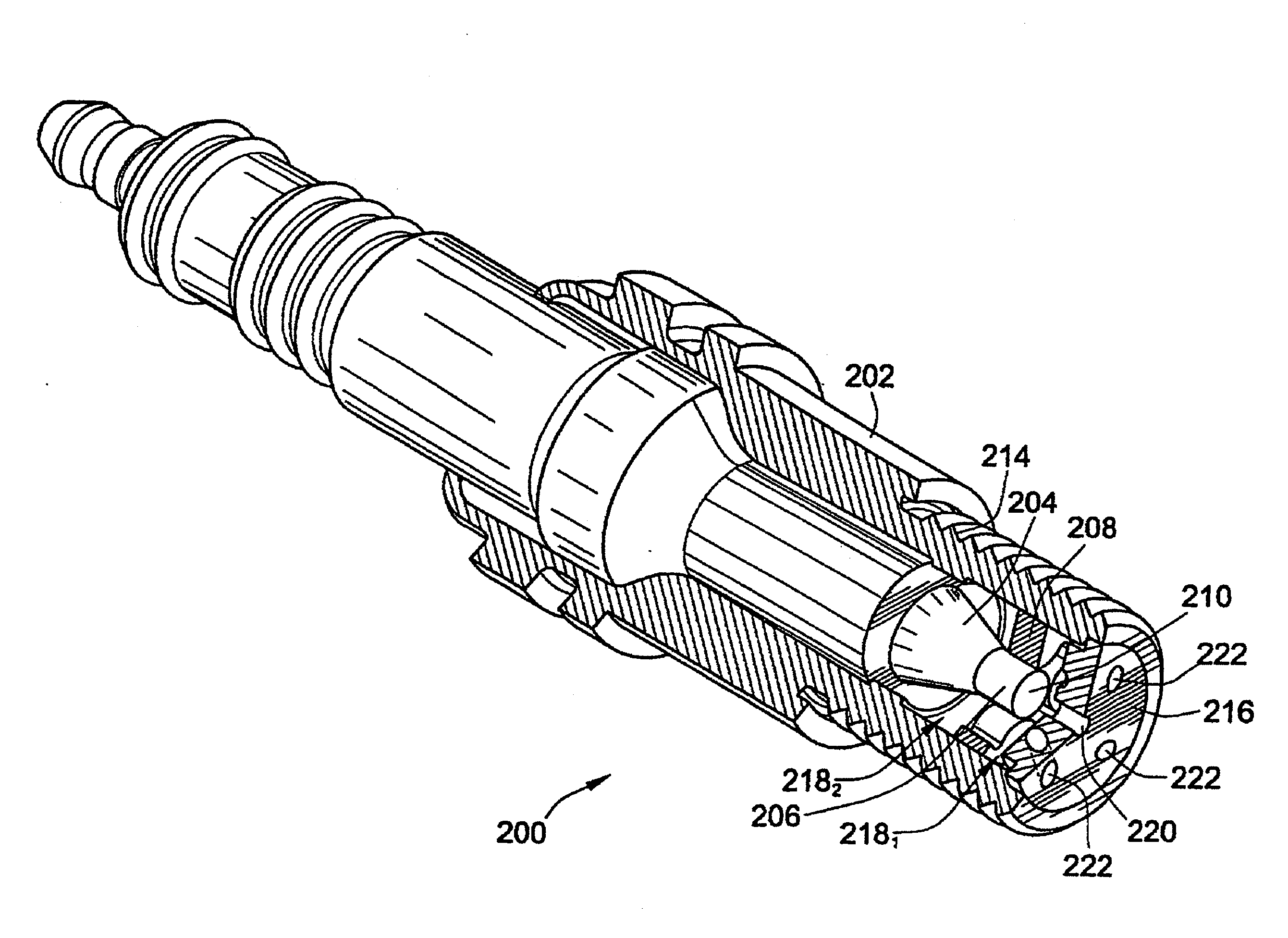

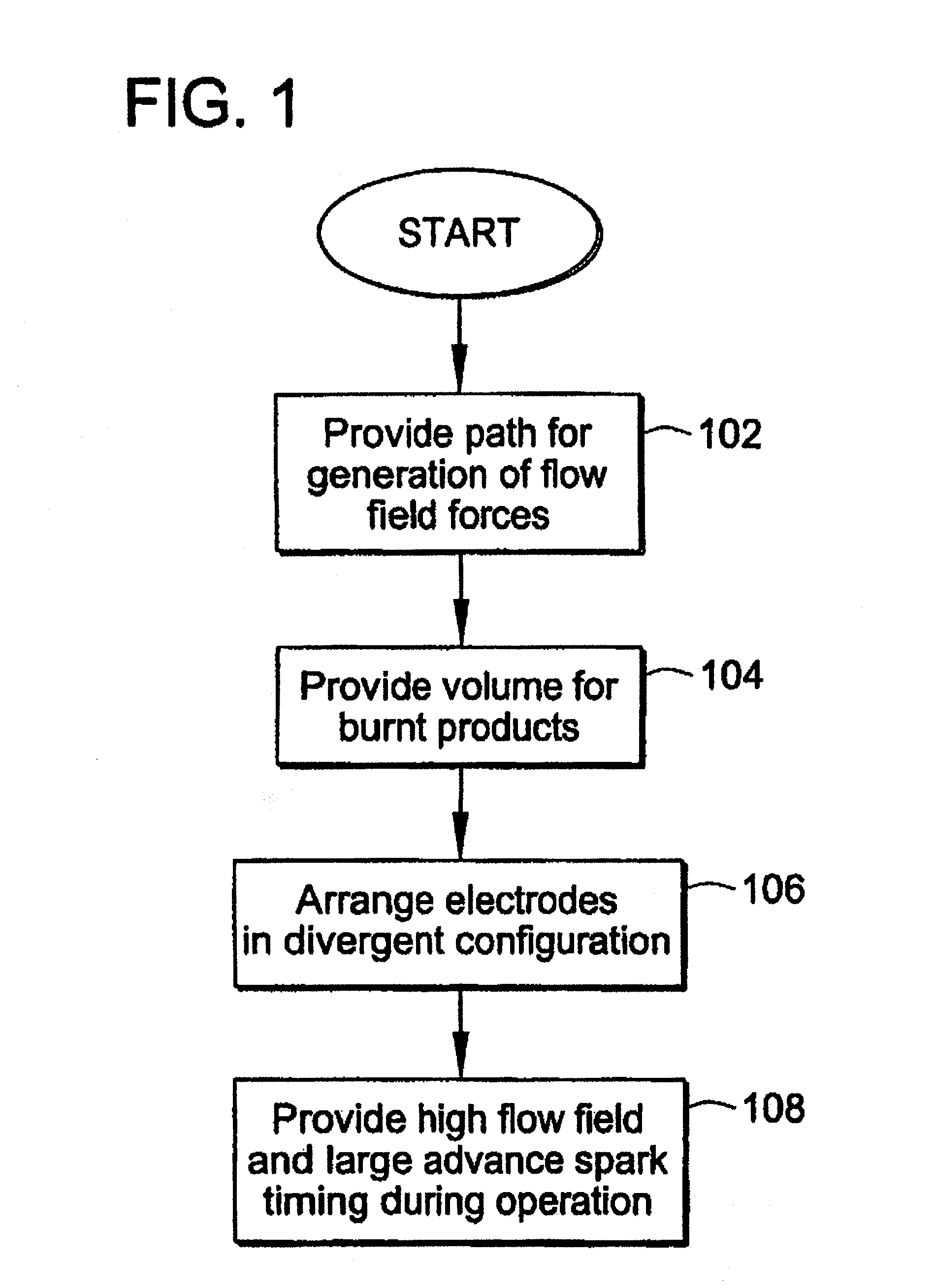

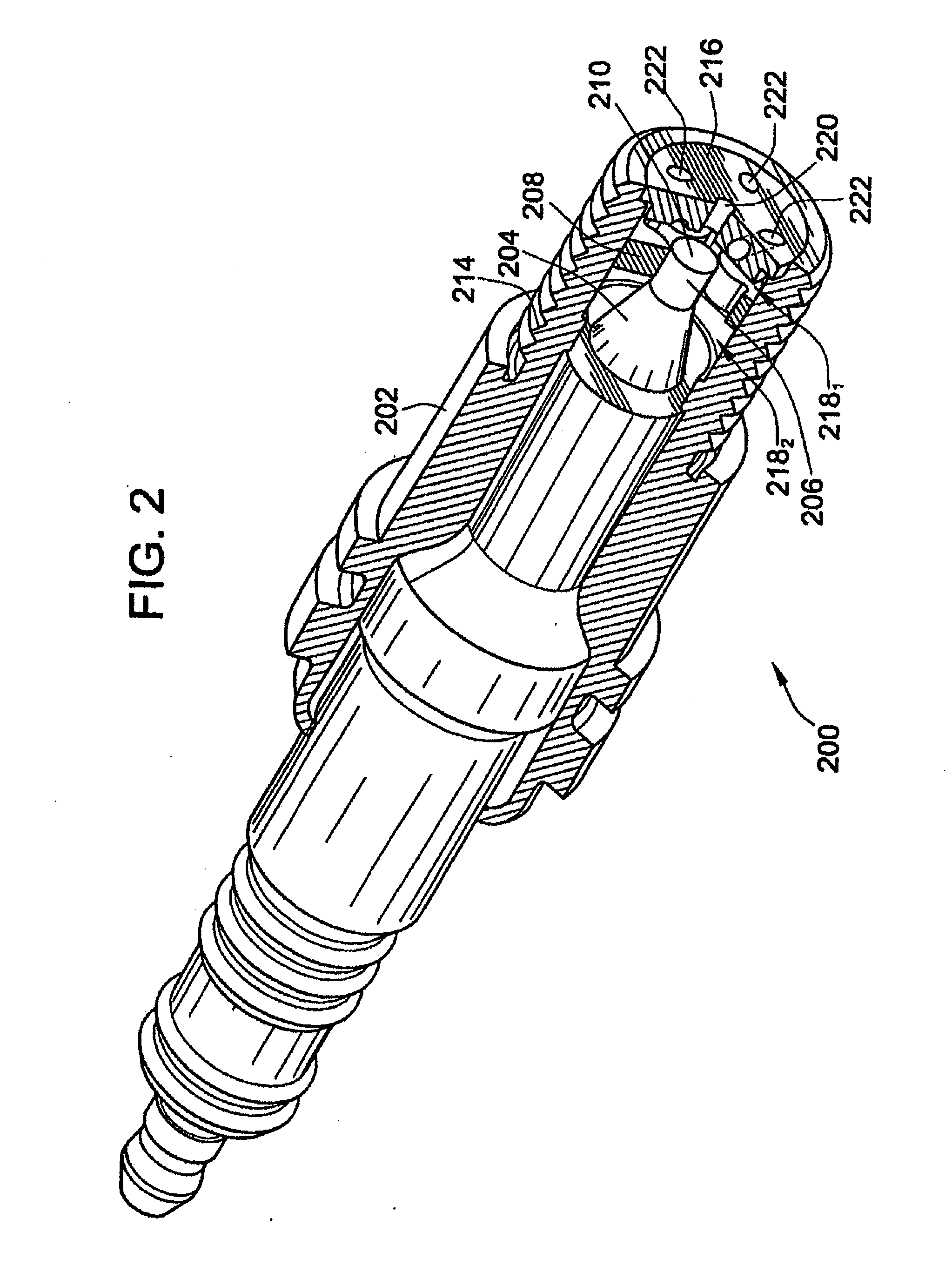

Pre-Chamber Spark Plug

ActiveUS20090309475A1Maximize spark plug lifeReduce erosionSpark gapsInternal combustion piston enginesElectricityElectrode erosion

A method and apparatus to maximize spark plug life in pre-chamber spark plugs operating with ultra-lean mixtures and / or elevated engine BMEP is presented. Electrode erosion is reduced by spreading discharge energy over a wider surface area, maintaining fuel concentration in the spark gap, controlling gas static pressure during discharge, and maintaining safe electrode temperature. Energy is spread via a swirling effect created by periphery holes in an end cap, resulting in a lower specific energy discharge at the electrodes. Divergently configured electrodes reduce the spark voltage at high operating pressures and the energy required for ignition. The flow field generated at the electrodes prevents electrical shorts due to water condensation and avoids misfire. The center electrode insulation provides an effective heat transfer path to prevent electrode overheating and pre-ignition. The volume behind the electrodes provides a volume for burnt products from previous combustion cycles and leads to more reliable ignition.

Owner:WOODWARD GOVERNOR CO

High ratio energy chargeable full-solid lithium air battery

InactiveCN101267057AImprove electrochemical performanceImprove securityFuel and primary cellsElectrochemical responseSpecific energy

The present invention belongs to electrochemical technical field, specifically a high specific energy charging full-solid lithium air battery. The battery structure is: firstly an air diffusion layer, then an air electrode, composed of a meso-porous carbon / manganese oxide composite material, an oxygen-reduction catalyst and a macromolecule lithium electrolyte, next a multilayer aqueous vapour cover, not only serving as a electrolyte layer of the battery, but also blocking water an oxidation entering of the air, finally a metal lithium. The whole battery is sealed in the multiplayer metal / plastic, a portable sealing is on the top of the air diffusion layer which is opened when the battery is used, closed when the battery is not used. The invention adopts lithium air battery made by the meso-porous carbon / manganese oxide composite material and the room temperature ionic liquid electrolyte, the capacity achieves 800mAh / g, cycling more than 50 times. In the lithium air battery, the metal lithium has effective protection, making the Li / O2 reaction only in the electrochemical reaction, the lithium air battery not only has battery electrochemical capability, but also has excellent safety ability.

Owner:FUDAN UNIV

Anode active material, preparation method of anode active material, high-performance anode slurry containing anode active material, and all-solid-state lithium ion battery

ActiveCN106784798AImprove mobilityImprove electrochemical performanceCell electrodesSecondary cellsInorganic compoundSulfide

The invention relates to an anode active material, a preparation method of the anode active material, high-performance anode slurry containing the anode active material, and an all-solid-state lithium ion battery. The anode active material is a nickel-rich type core-shell structure particle or a nickel-rich type core-shell structure particle coated with an inorganic compound coating layer at the surface; an inner core of the nickel-rich type core-shell structure particle is LiNixCoyMn1-x-yO2; the shell is nickel cobalt lithium aluminate. The invention also provides the high-performance anode slurry, which comprises the anode active material, a composite conductive agent, a composite bonding agent, an additive and an organic solvent, wherein the additive is sulfide solid electrolyte; the anode slurry is used for preparing an anode plate consisting of an anode current collector, an anode slurry layer and a modification layer; the anode plate, the sulfide solid electrolyte and a cathode plate are assembled into the all-solid-state lithium ion battery. The all-solid-state lithium ion battery has the prominent advantages of high mass specific energy, high volumetric specific energy, good rate capability, good cycle performance, high safety and the like, and has wide application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Rechargeable lithium cell having a meso-porous conductive material structure-supported phthalocyanine compound cathode

ActiveUS20130330611A1High oxygen contentIncreased riskMaterial nanotechnologyElectrode carriers/collectorsConductive polymerConductive materials

A rechargeable lithium cell comprising: (a) an anode comprising a prelithiated lithium storage material or a combination of a lithium storage material and a lithium ion source; (b) a hybrid cathode active material composed of a meso-porous structure of a carbon, graphite, metal, or conductive polymer and a phthalocyanine compound, wherein the meso-porous structure is in an amount of from 1% to 99% by weight based on the total weight of the meso-porous structure and the phthalocyanine combined, and wherein the meso-porous structure has a pore with a size from 2 nm to 50 nm to accommodate phthalocyanine compound therein; and (c) an electrolyte or electrolyte / separator assembly. This secondary cell exhibits a long cycle life and the best cathode specific capacity and best cell-level specific energy of all rechargeable lithium-ion cells ever reported.

Owner:GLOBAL GRAPHENE GRP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com