Patents

Literature

579results about "Spark gaps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

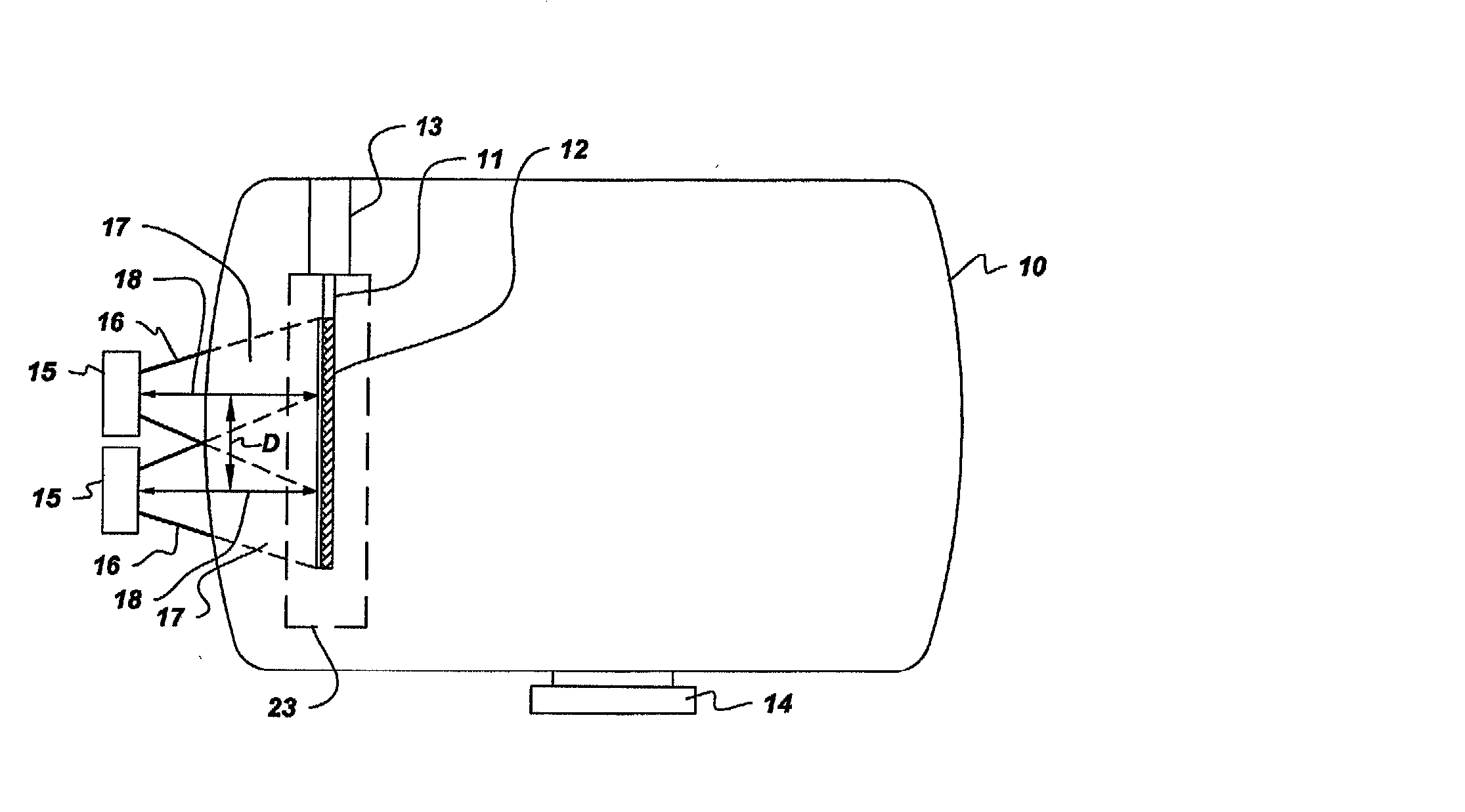

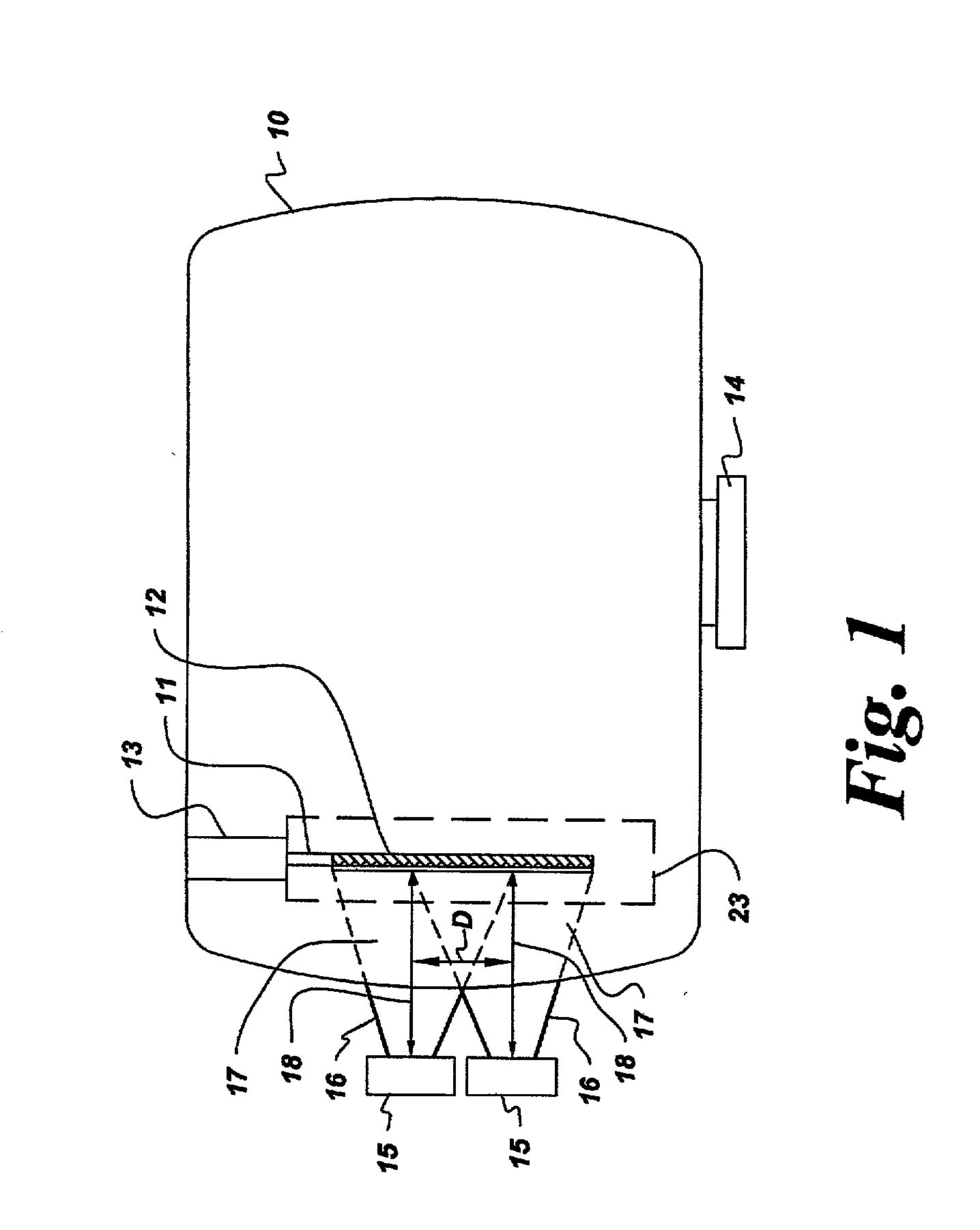

Methods and apparatus for producing enhanced interference pigments

InactiveUS6241858B1Interference be notGood effectElectric discharge heatingPigment preparation by PVD/CVD methodsGas phaseVaporization

Methods and apparatus are provided for uniformly depositing a coating material from a vaporization source onto a powdered substrate material to form a thin coalescence film of the coating material that smoothly replicates the surface microstructure of the substrate material. The coating material is uniformly deposited on the substrate material to form optical interference pigment particles. The thin film enhances the hiding power and color gamut of the substrate material. Physical vapor deposition processes are used for depositing the film on the substrate material. The apparatus and systems employed in forming the coated particles utilize vibrating bed coaters, vibrating conveyor coaters, or coating towers. These allow the powdered substrate material to be uniformly exposed to the coating material vapor during the coating process.

Owner:JDS UNIPHASE CORP

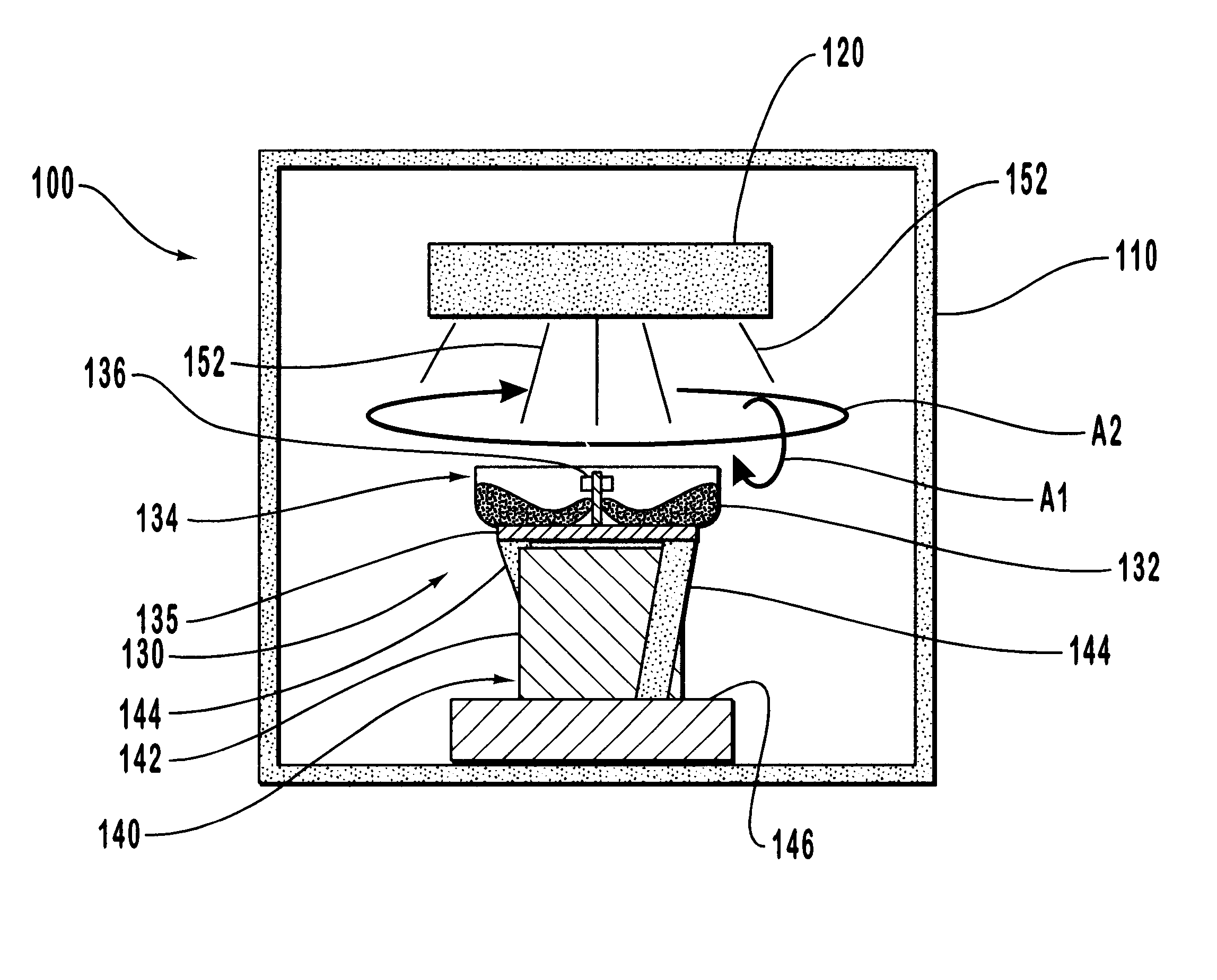

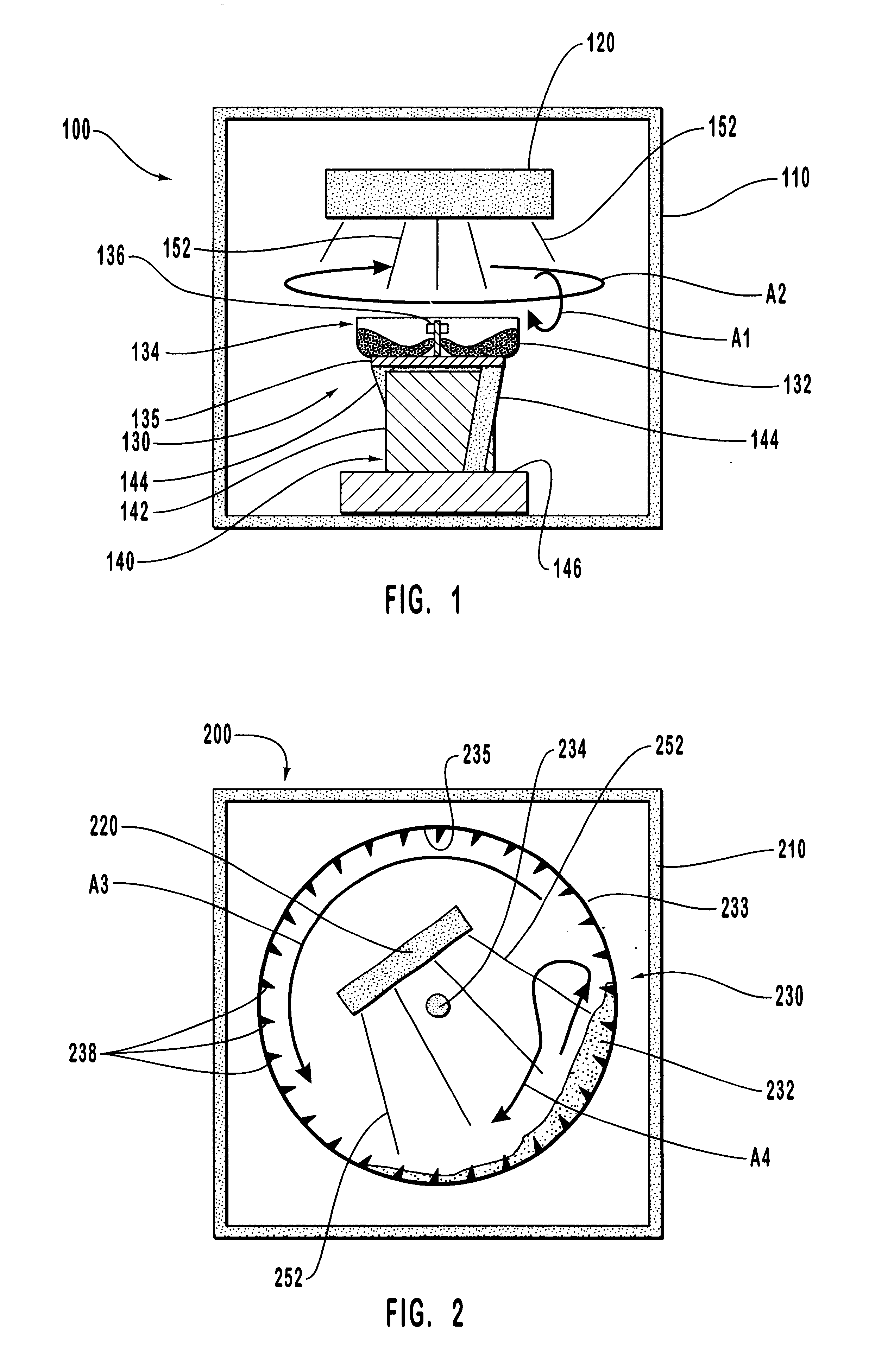

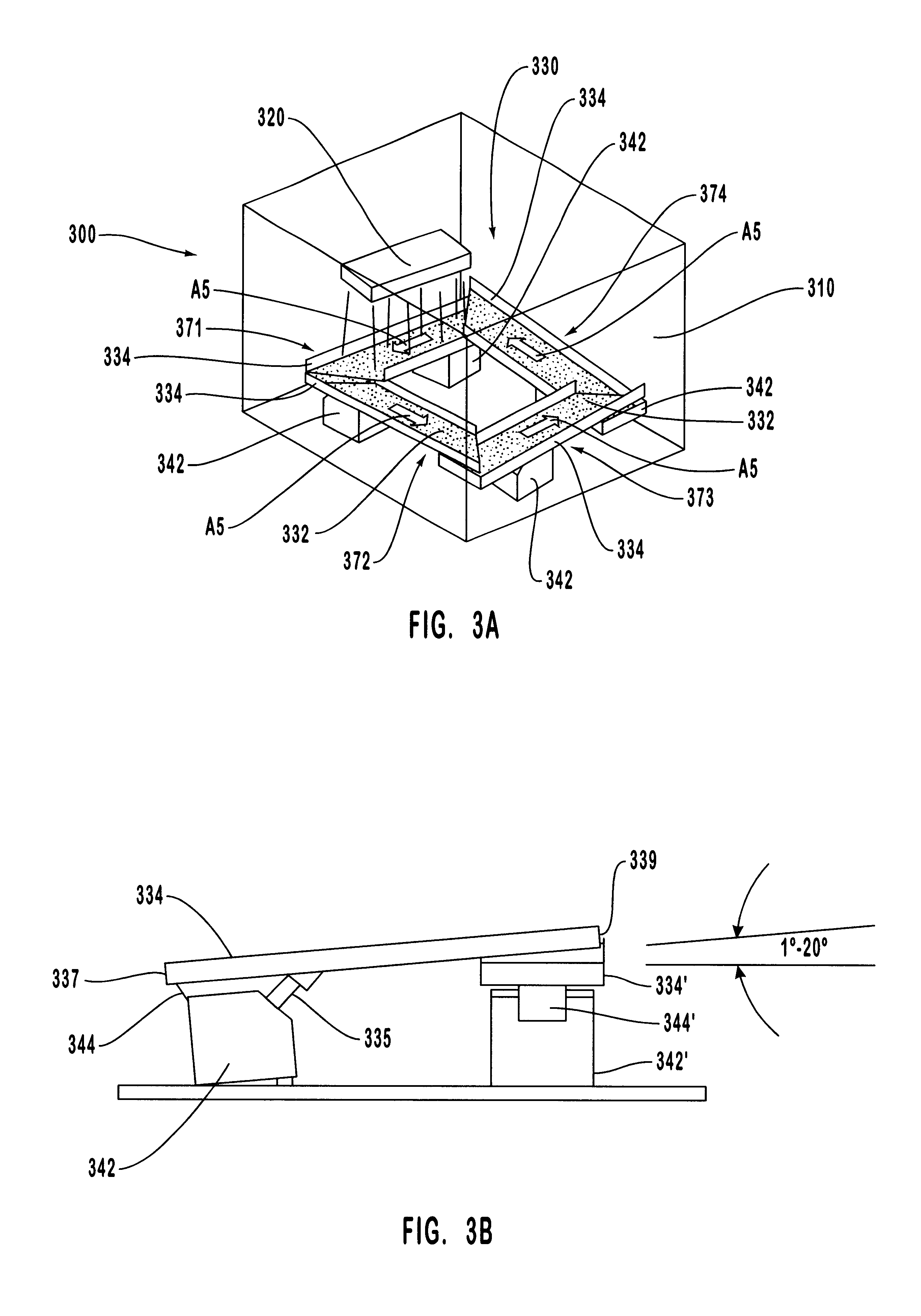

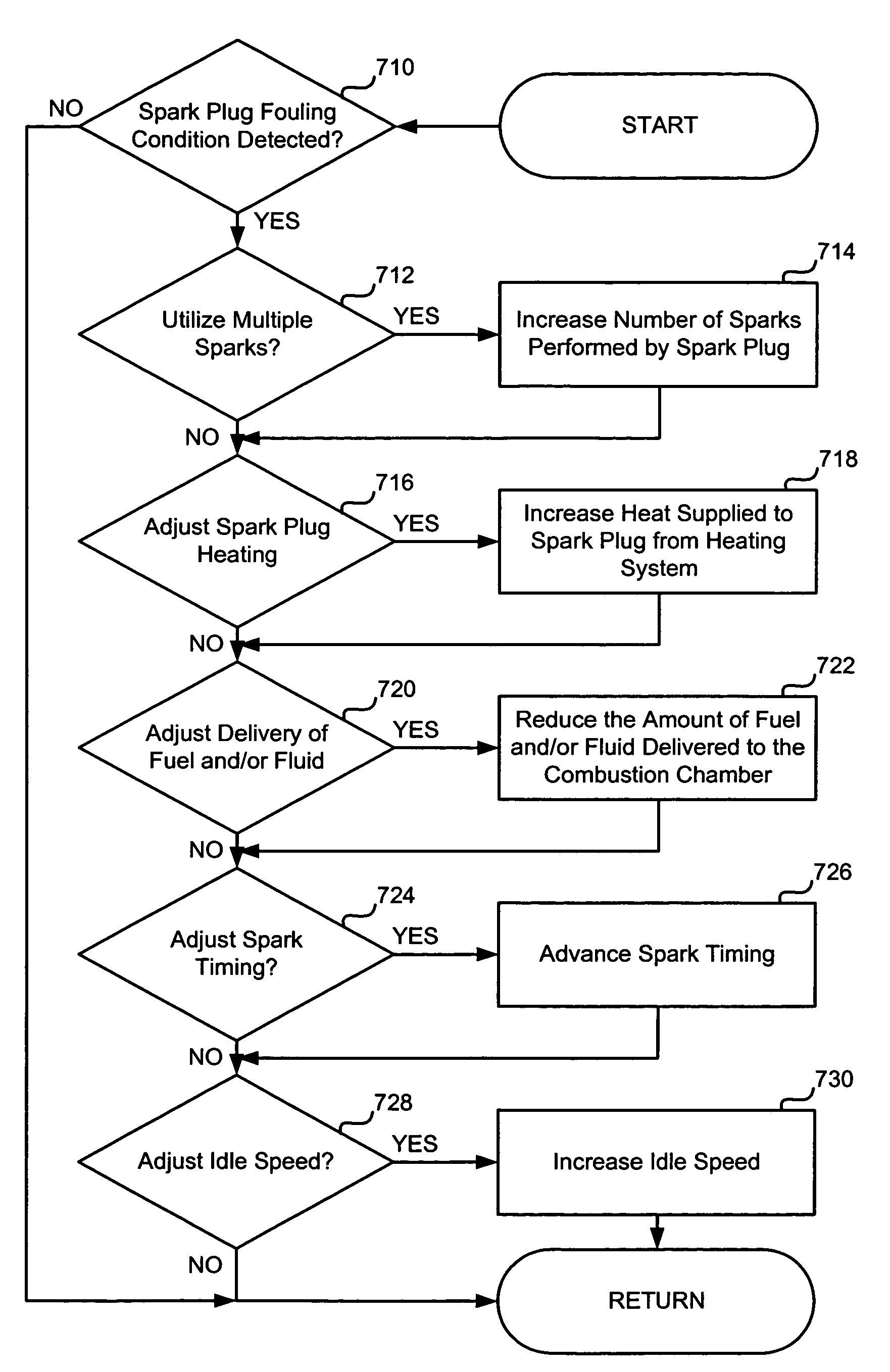

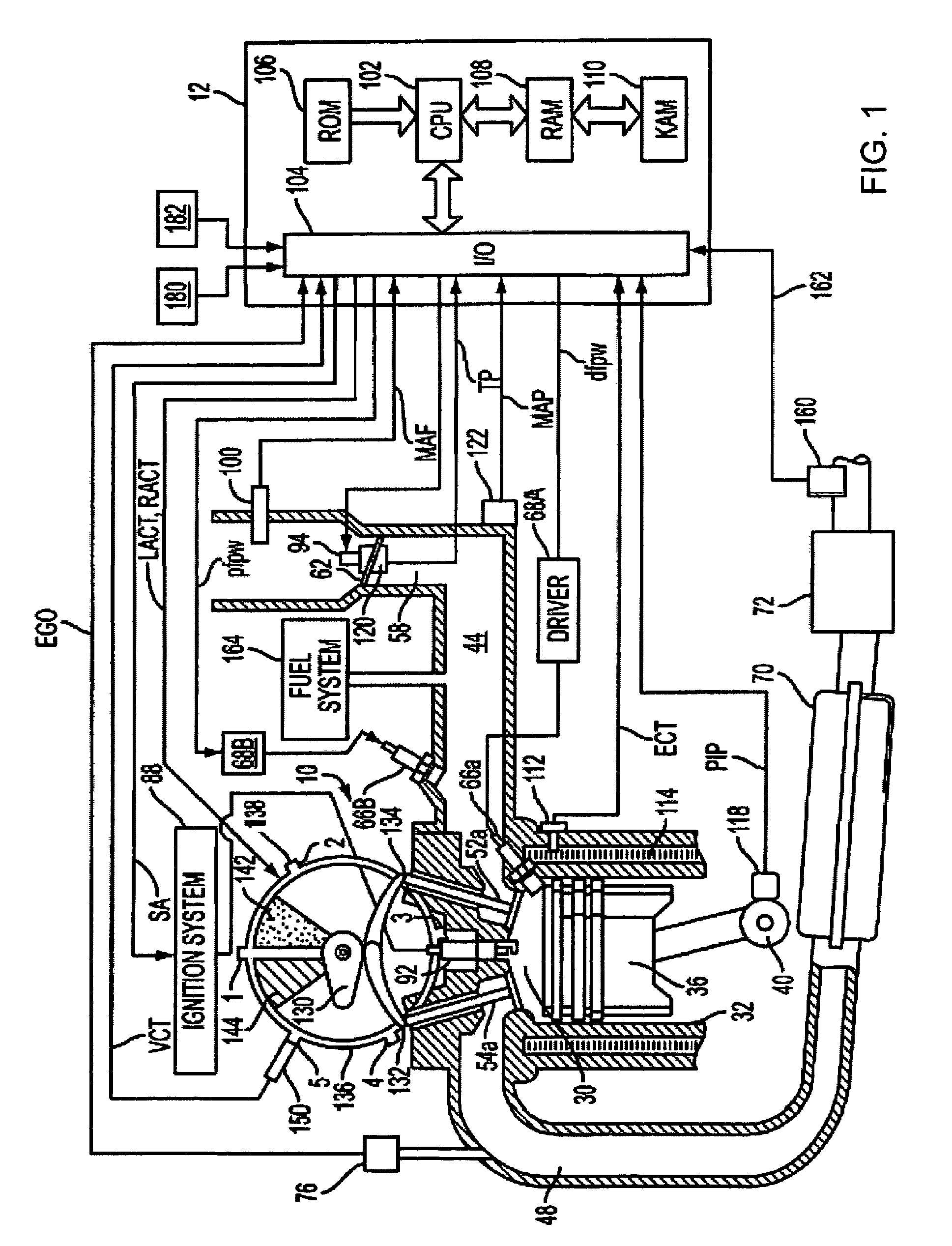

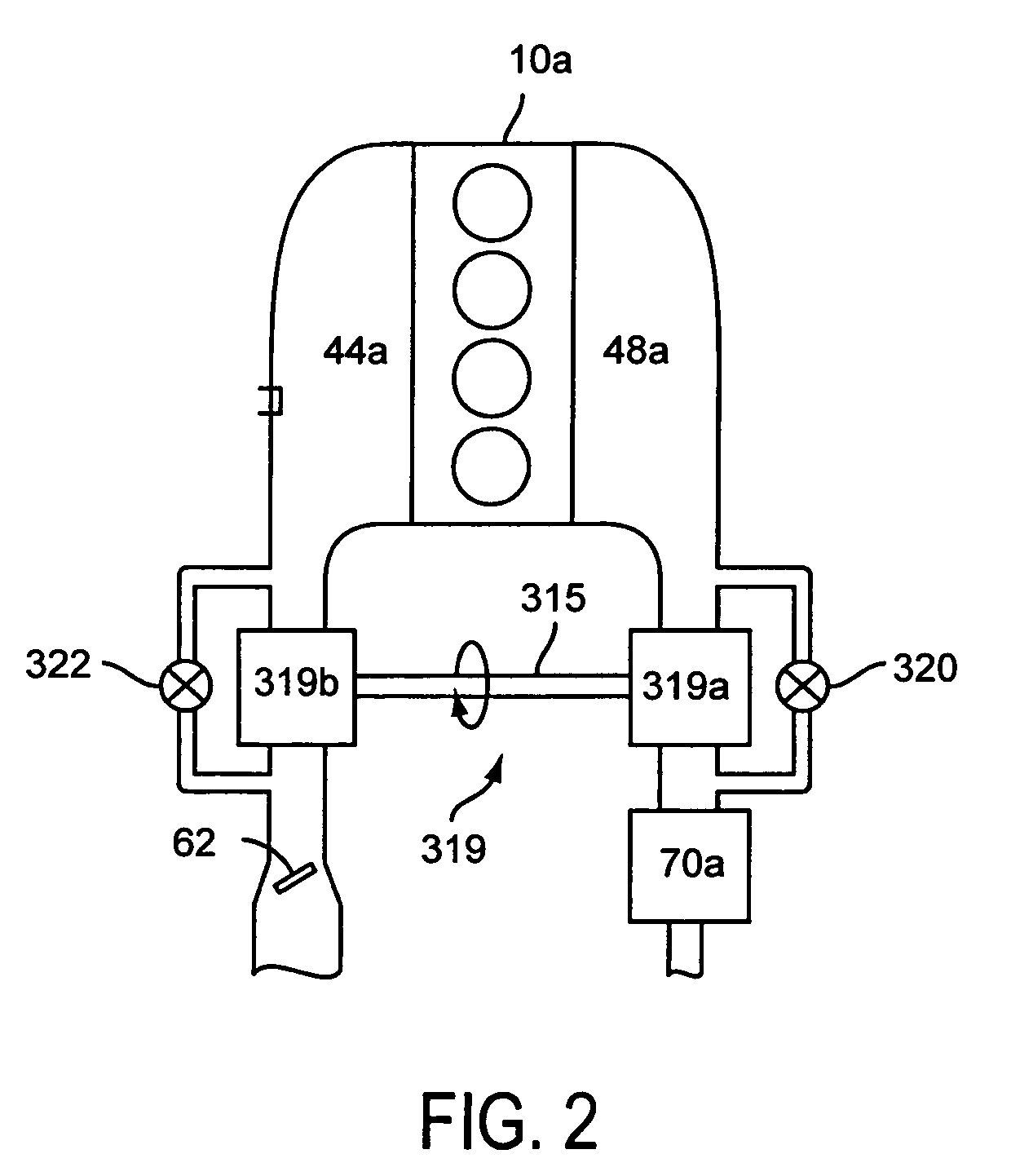

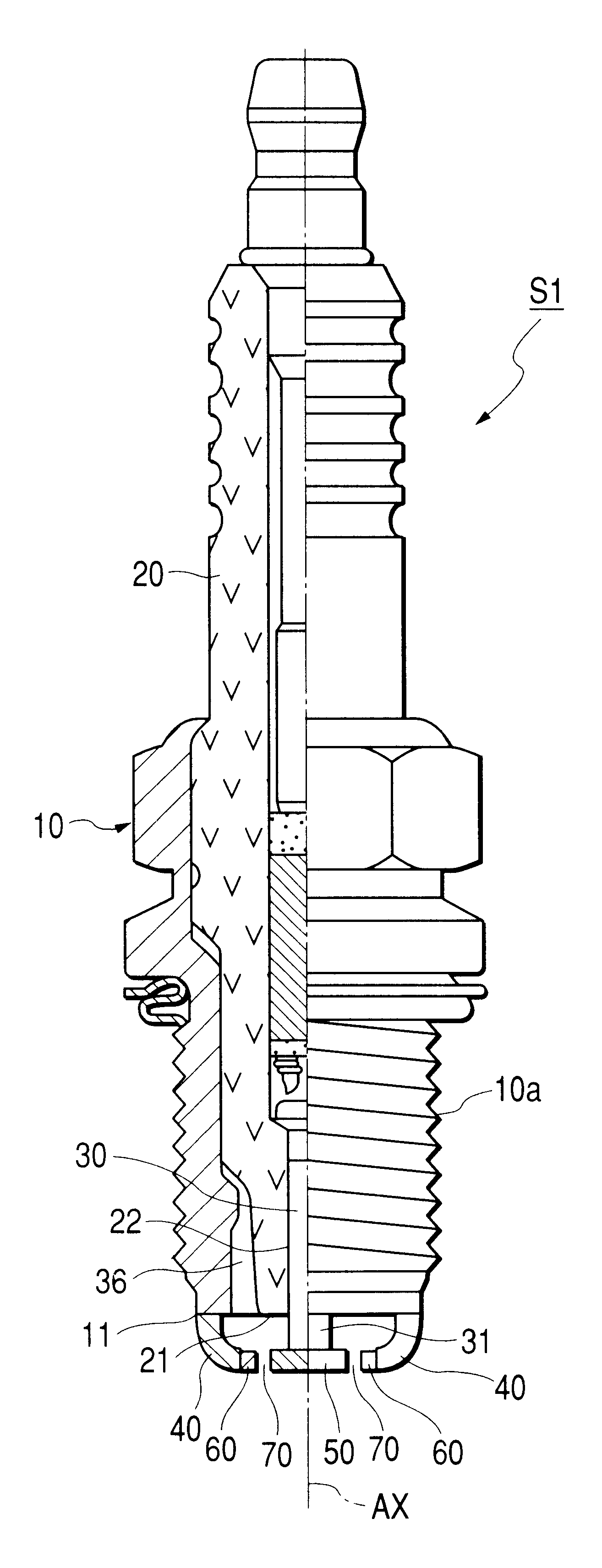

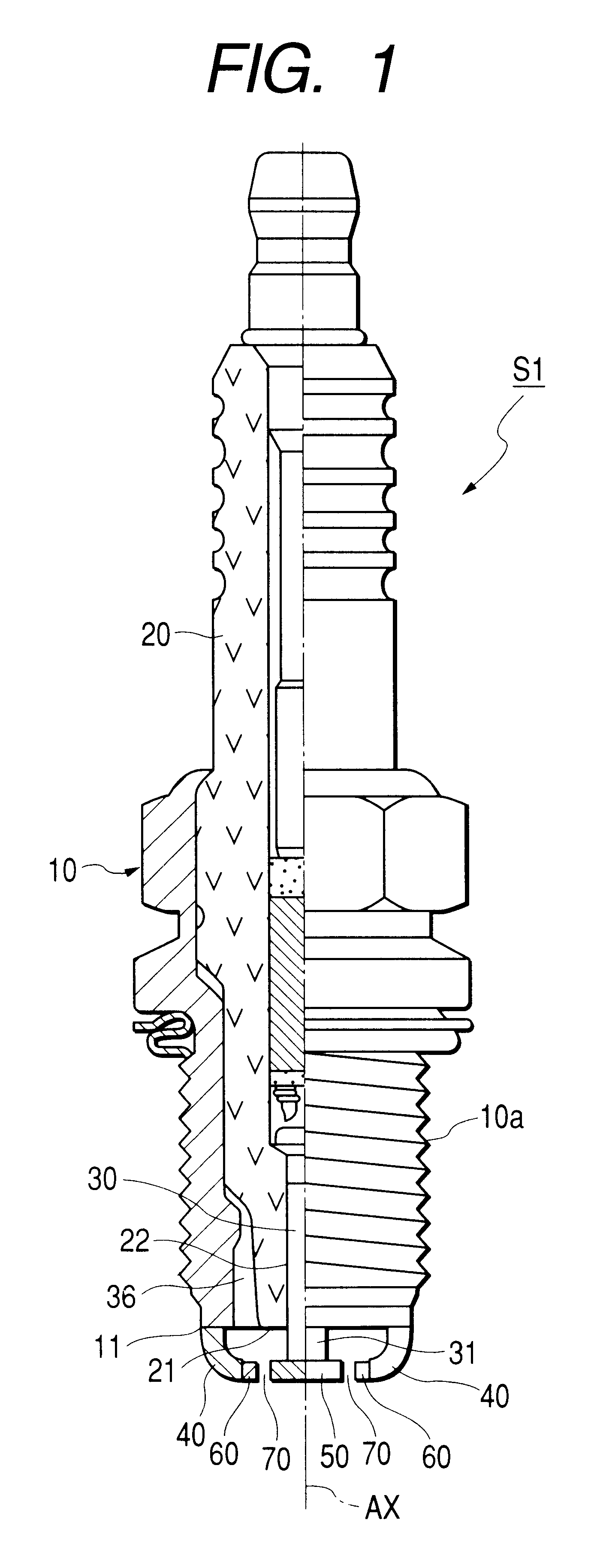

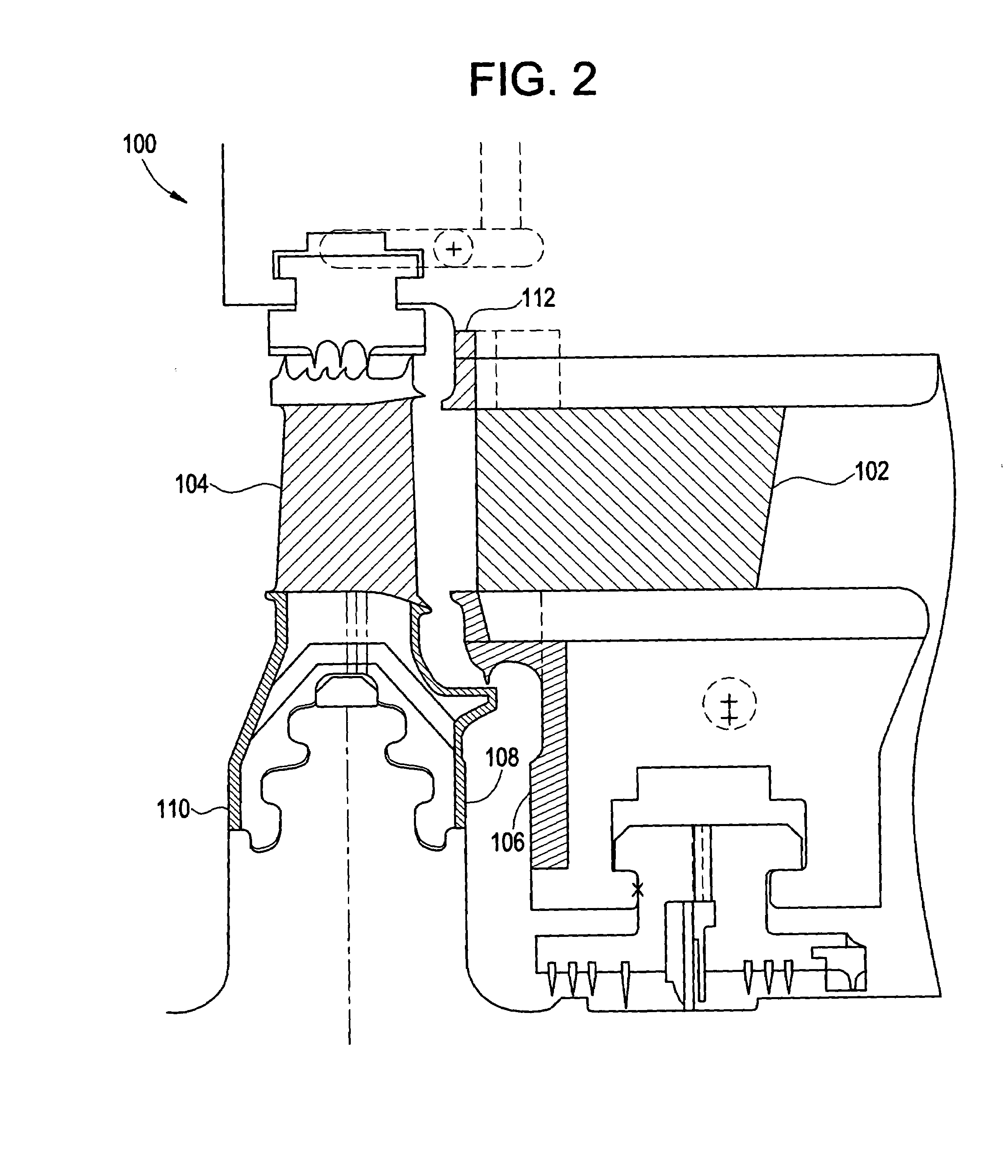

Spark plug heating for a spark ignited engine

A system for an engine of a vehicle, comprising of at least one combustion chamber located in the engine, a delivery system configured to deliver a fuel and a fluid to the combustion chamber, an ignition system including a spark plug configured to ignite the fuel within the combustion chamber, a spark plug heating system configured to supply heat to the spark plug, and a control system configured to vary an amount of heat supplied to the spark plug by the spark plug heating system responsive to a condition of the ignition system.

Owner:FORD GLOBAL TECH LLC

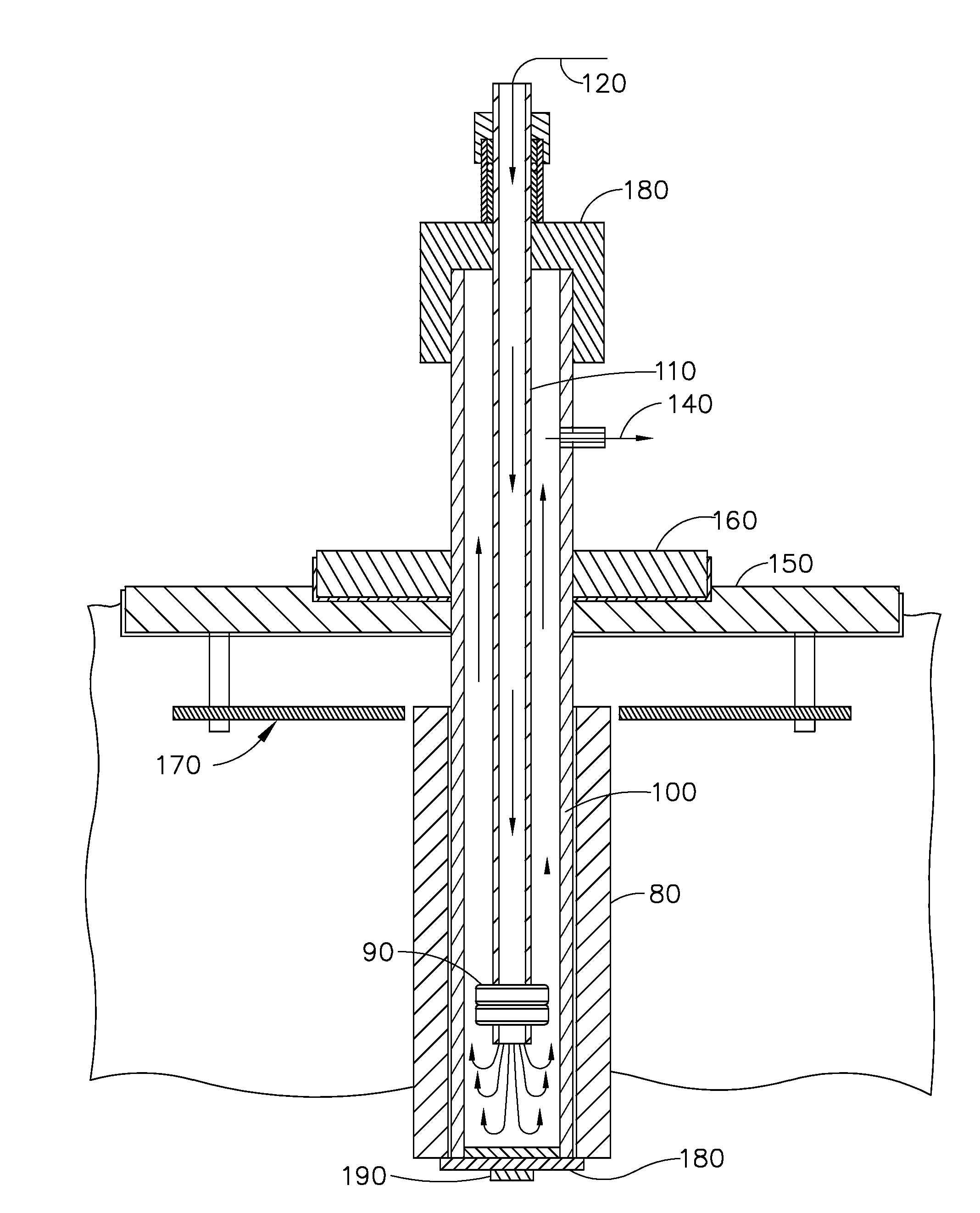

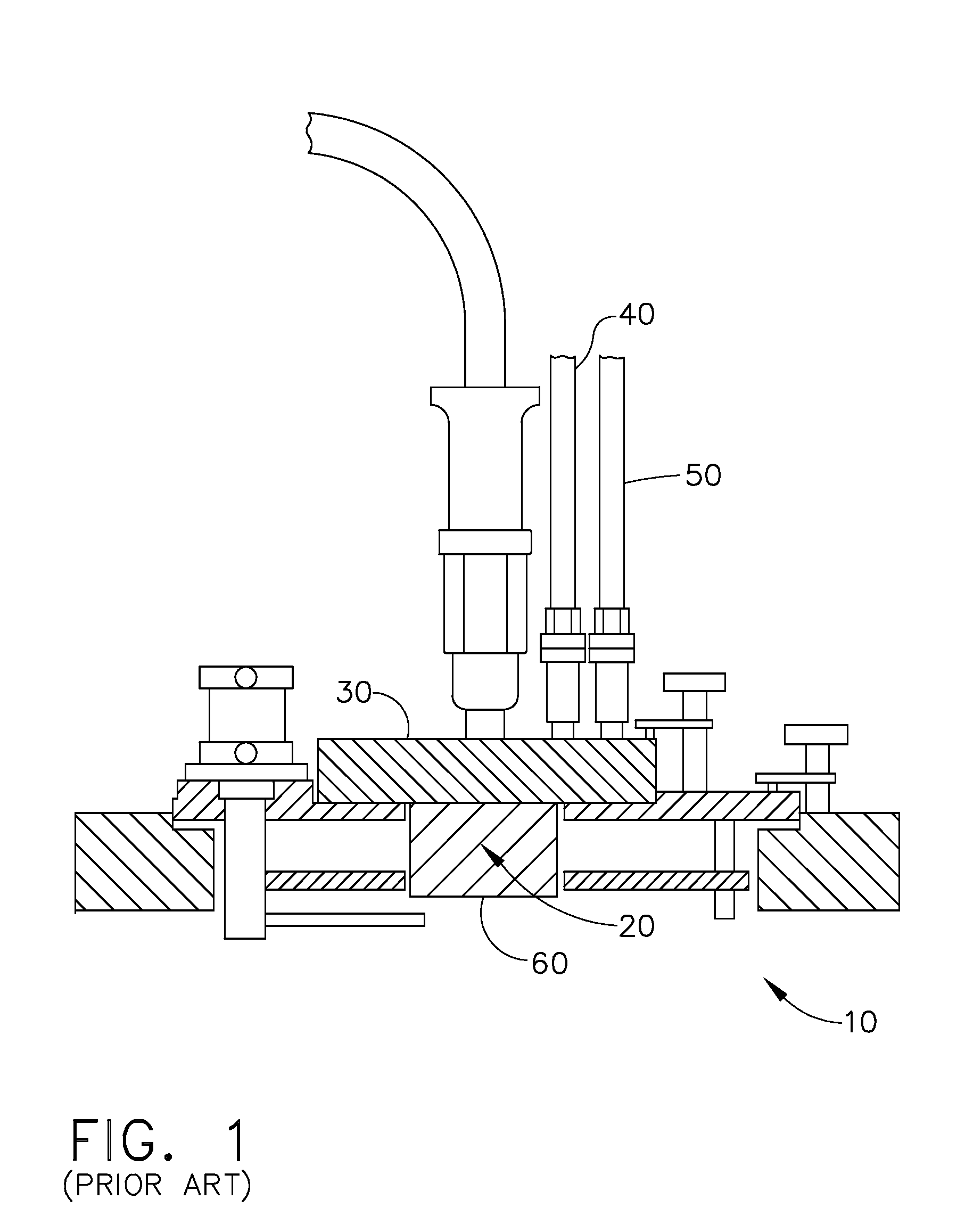

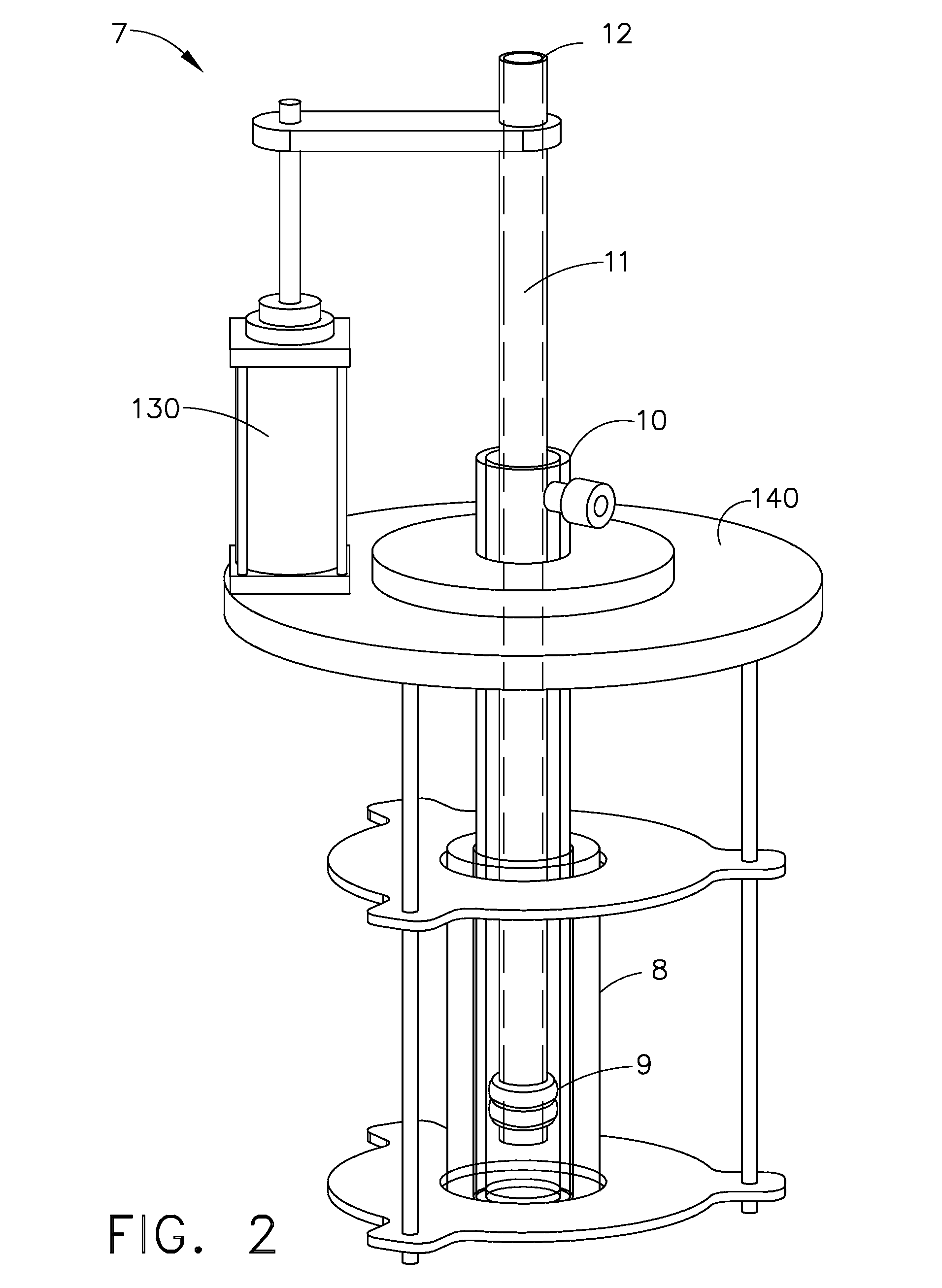

Method and apparatus for cathodic arc ion plasma deposition

InactiveUS20080138529A1Easy to operateConvenient lengthMolten spray coatingVacuum evaporation coatingPlasma depositionDeposition process

A method and apparatus for depositing a coating material on a surface of a substrate by an ion plasma deposition process using a hollow cathode is disclosed. The cathode may be a substantially cylindrical hollow cathode. A plasma arc is formed on the outer circumference of the cathode to remove coating material from the cathode, which is then deposited on a surface of a substrate. An internal arc drive magnet is contained within the hollow bore of the cathode and cooling is provided to the magnet during operation.

Owner:GENERAL ELECTRIC CO

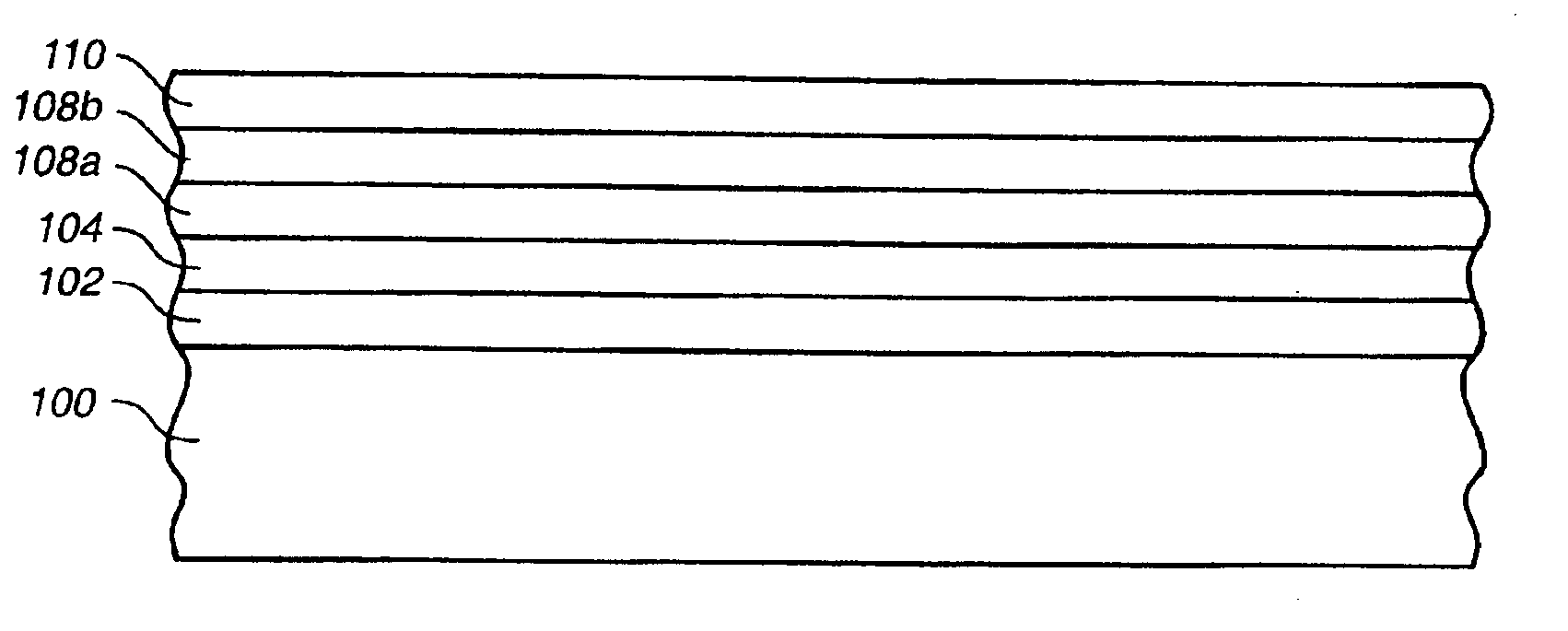

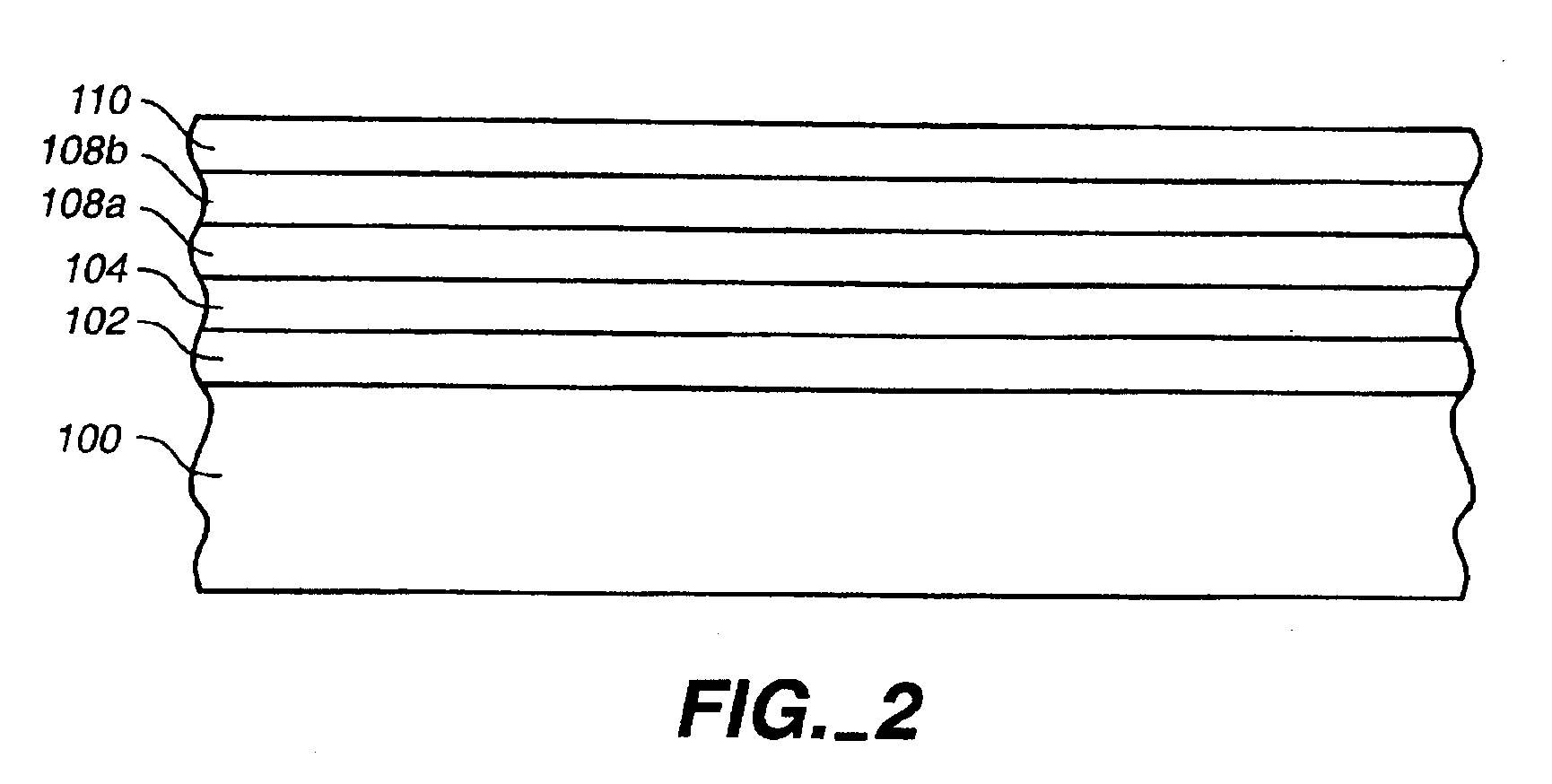

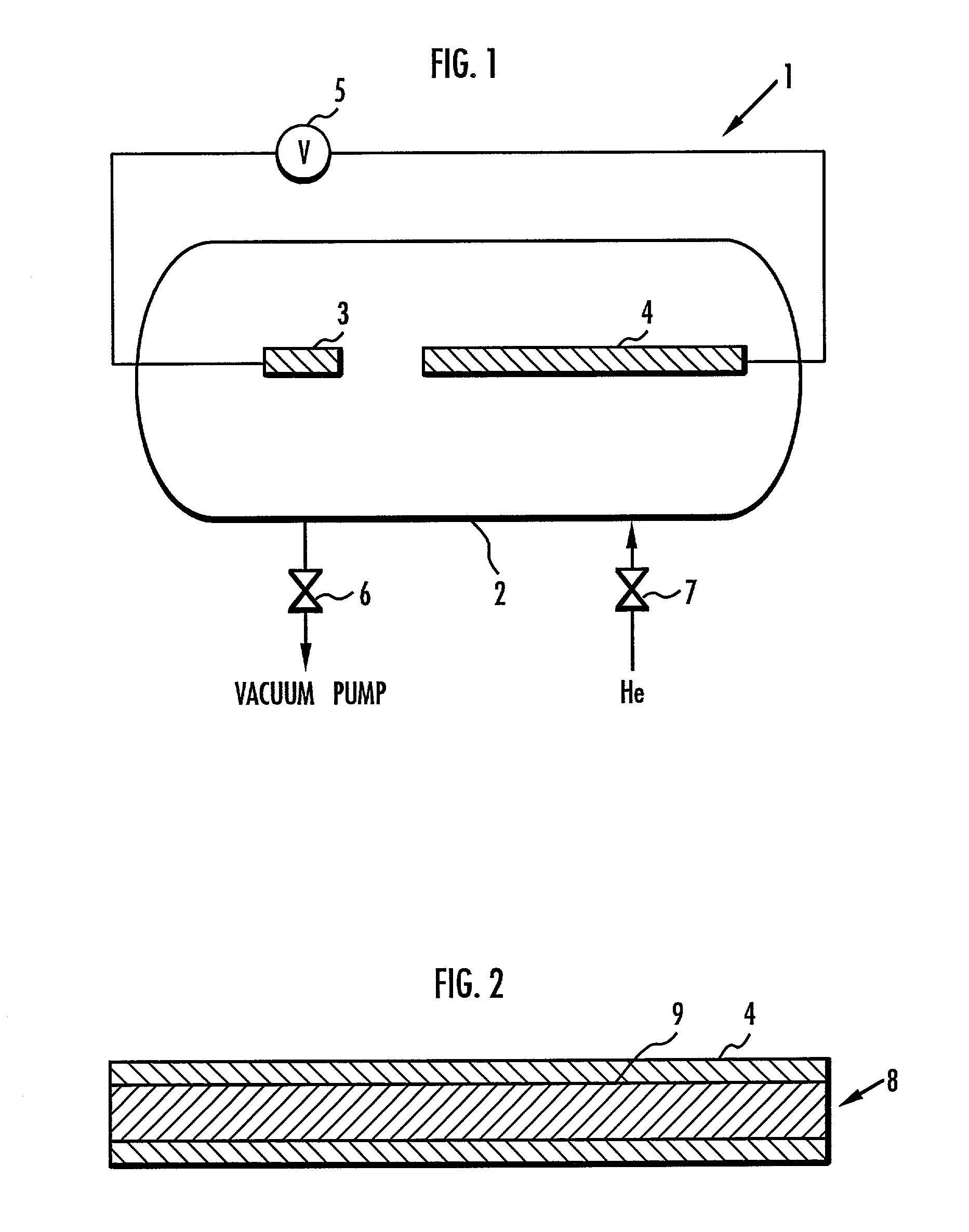

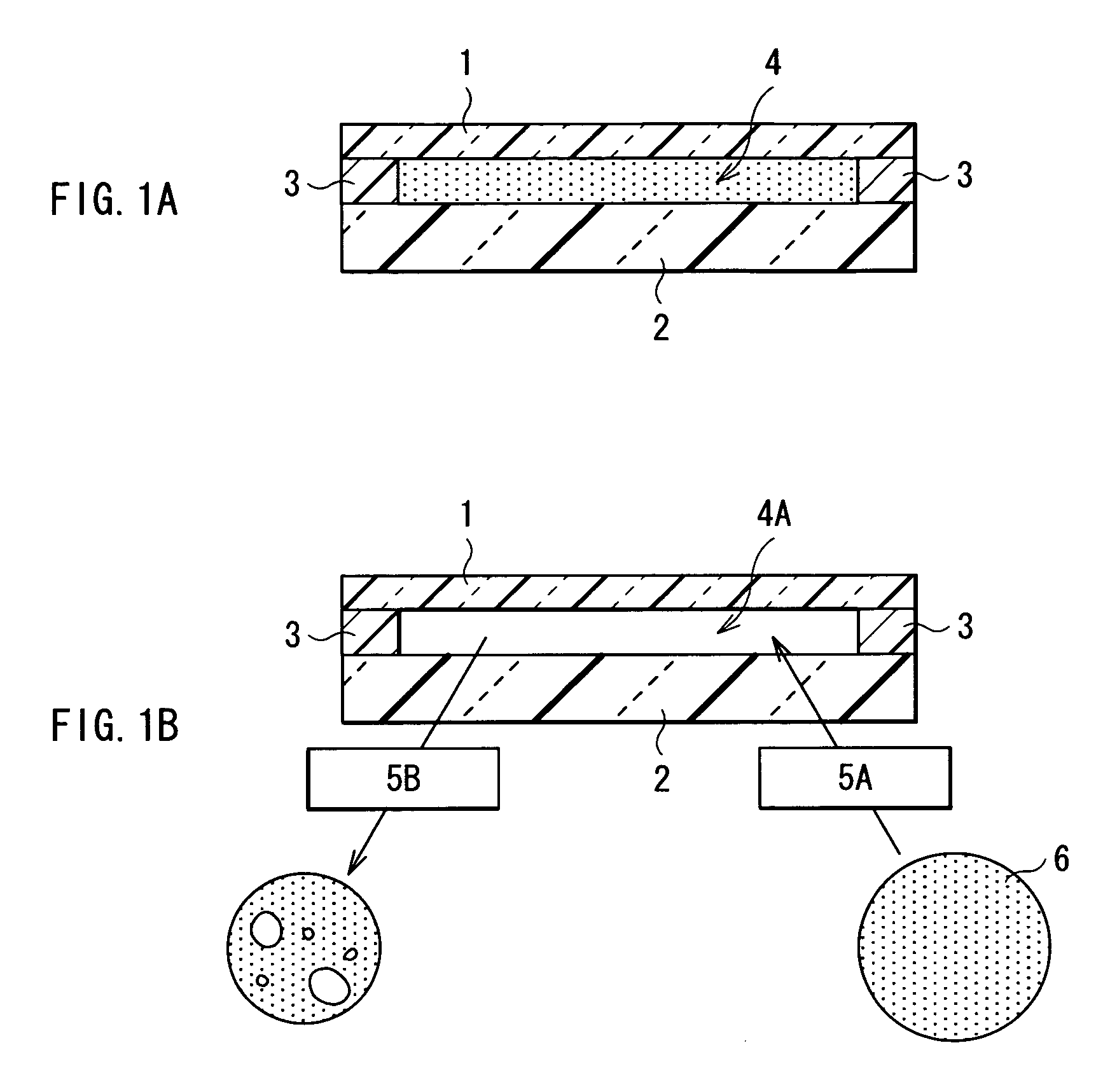

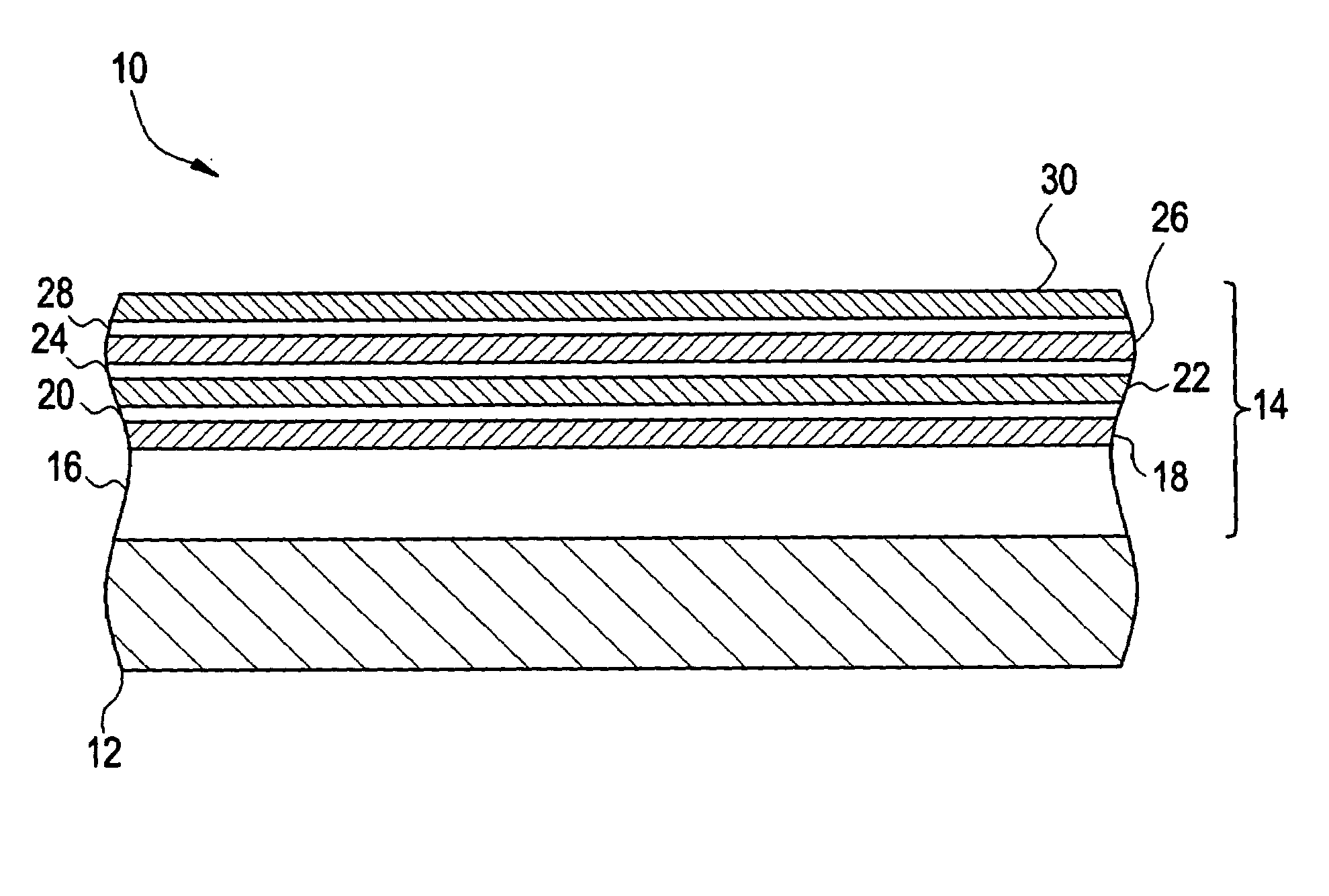

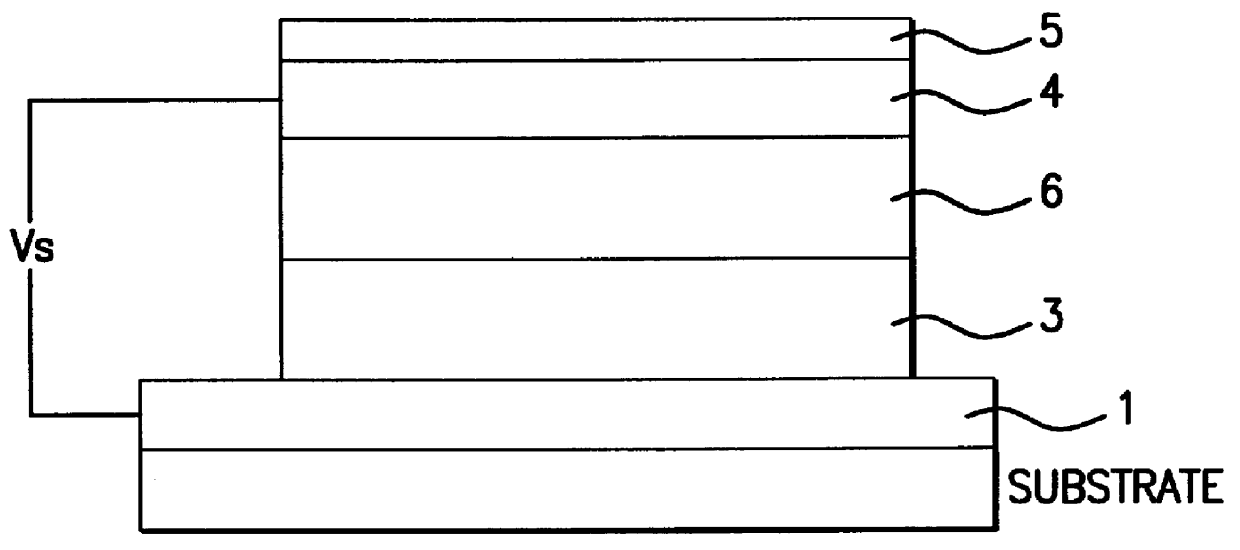

Magnetic disk comprising a first carbon overcoat having a high SP3 content and a second carbon overcoat having a low SP3 content

InactiveUS6855232B2Increase contentResists wearLayered productsVacuum evaporation coatingCarbon layerPerfluoropolyether

A method for making a magnetic disk comprises forming first and second protective carbon layers on a magnetic layer. The first protective carbon layer is predominantly SP3 carbon. The second protective carbon layer comprises about 50% or less SP3 carbon. The second protective carbon layer is very thin, e.g. between 0.1 and 1.0 nm thick. A lubricant layer (e.g. a perfluoropolyether lubricant) is applied to the second protective carbon layer. The second protective carbon layer facilitates improved cooperation between lubricant and the disk.

Owner:WESTERN DIGITAL TECH INC

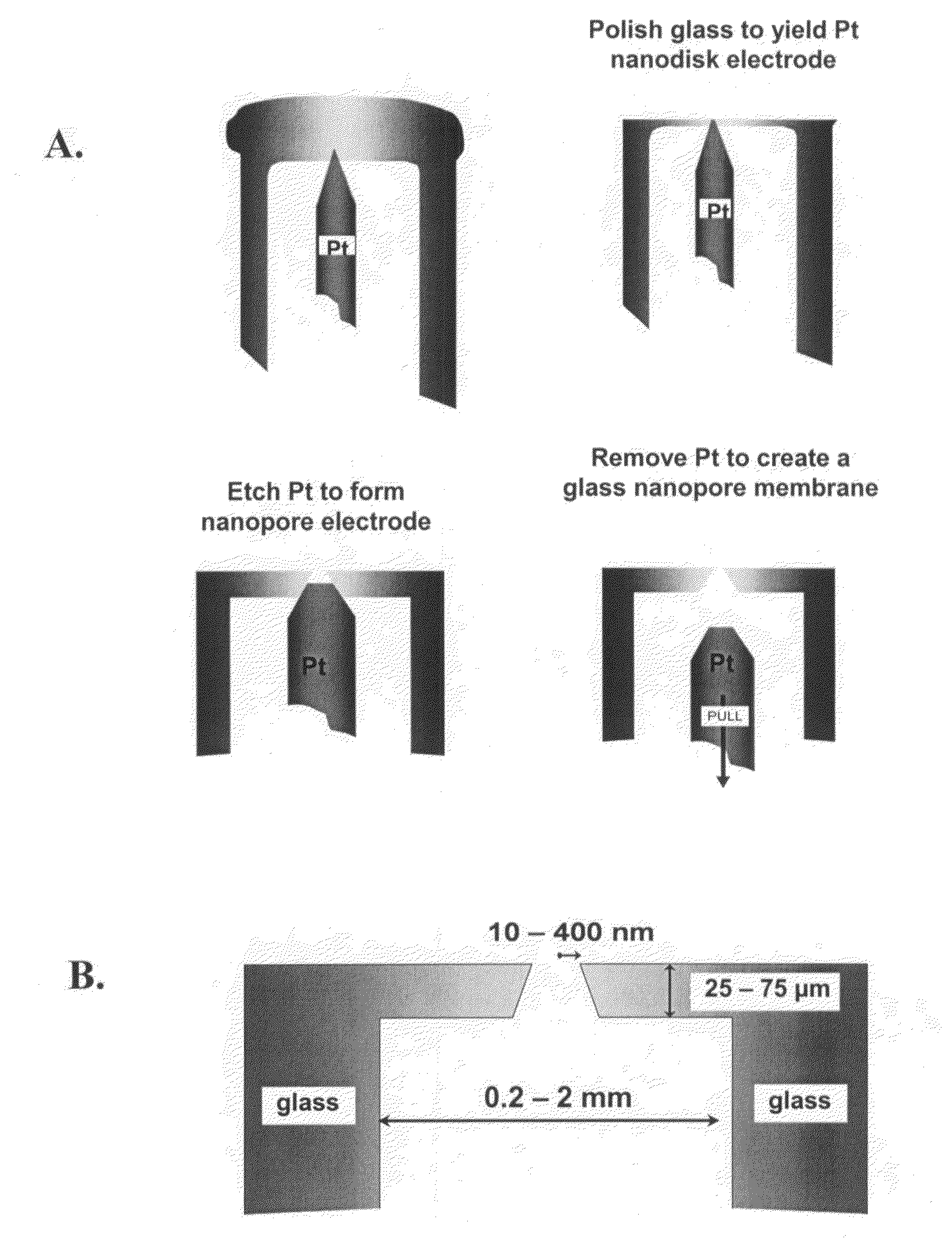

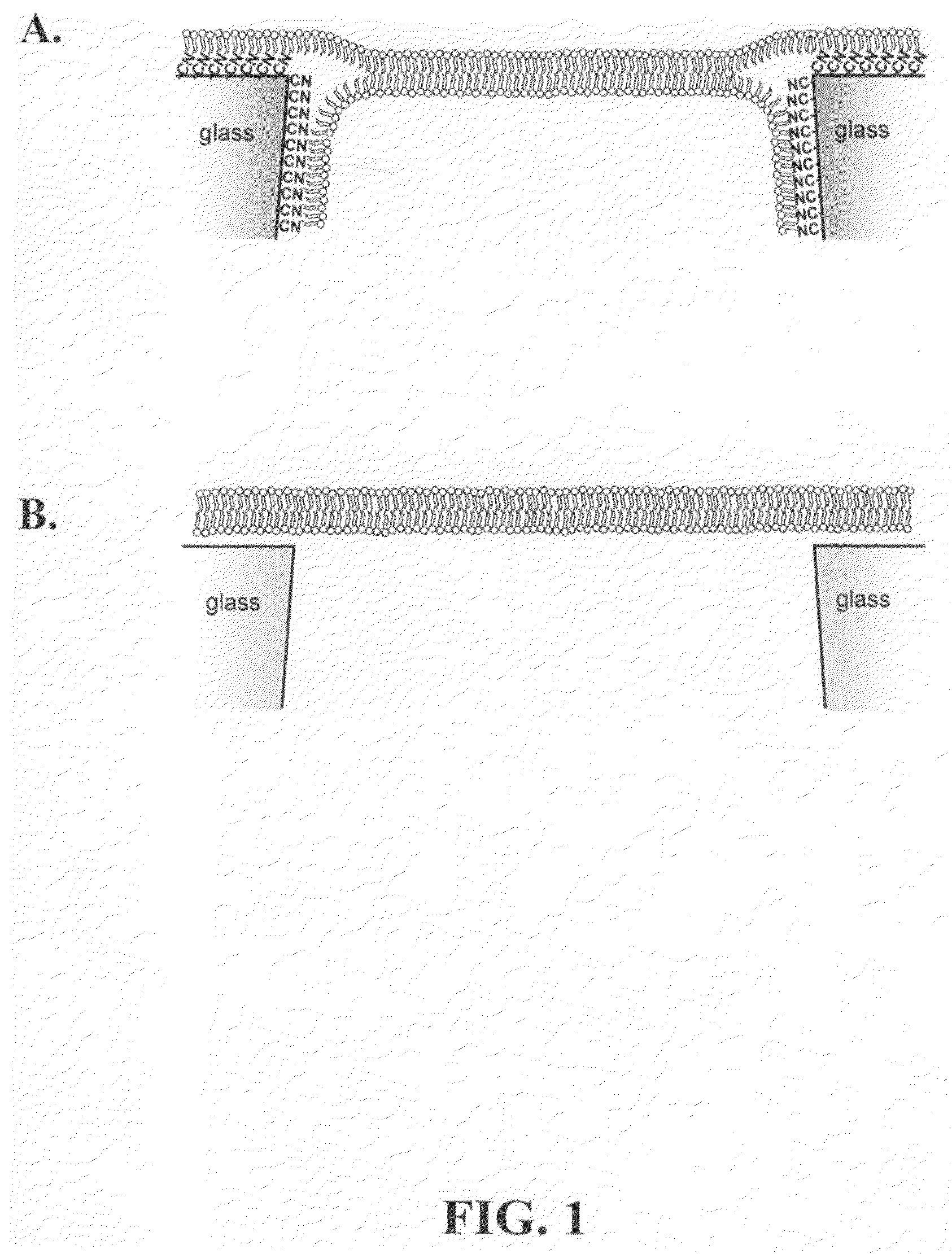

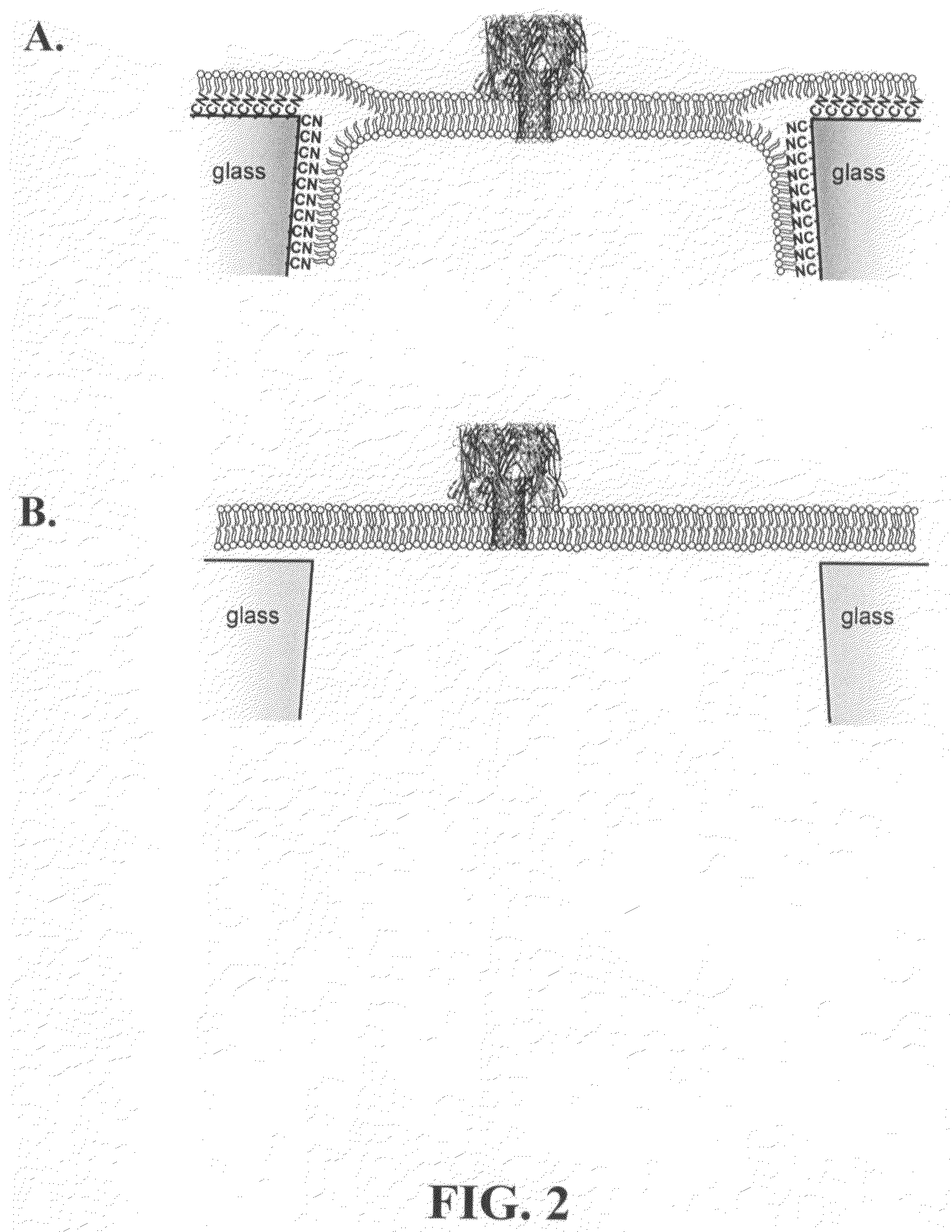

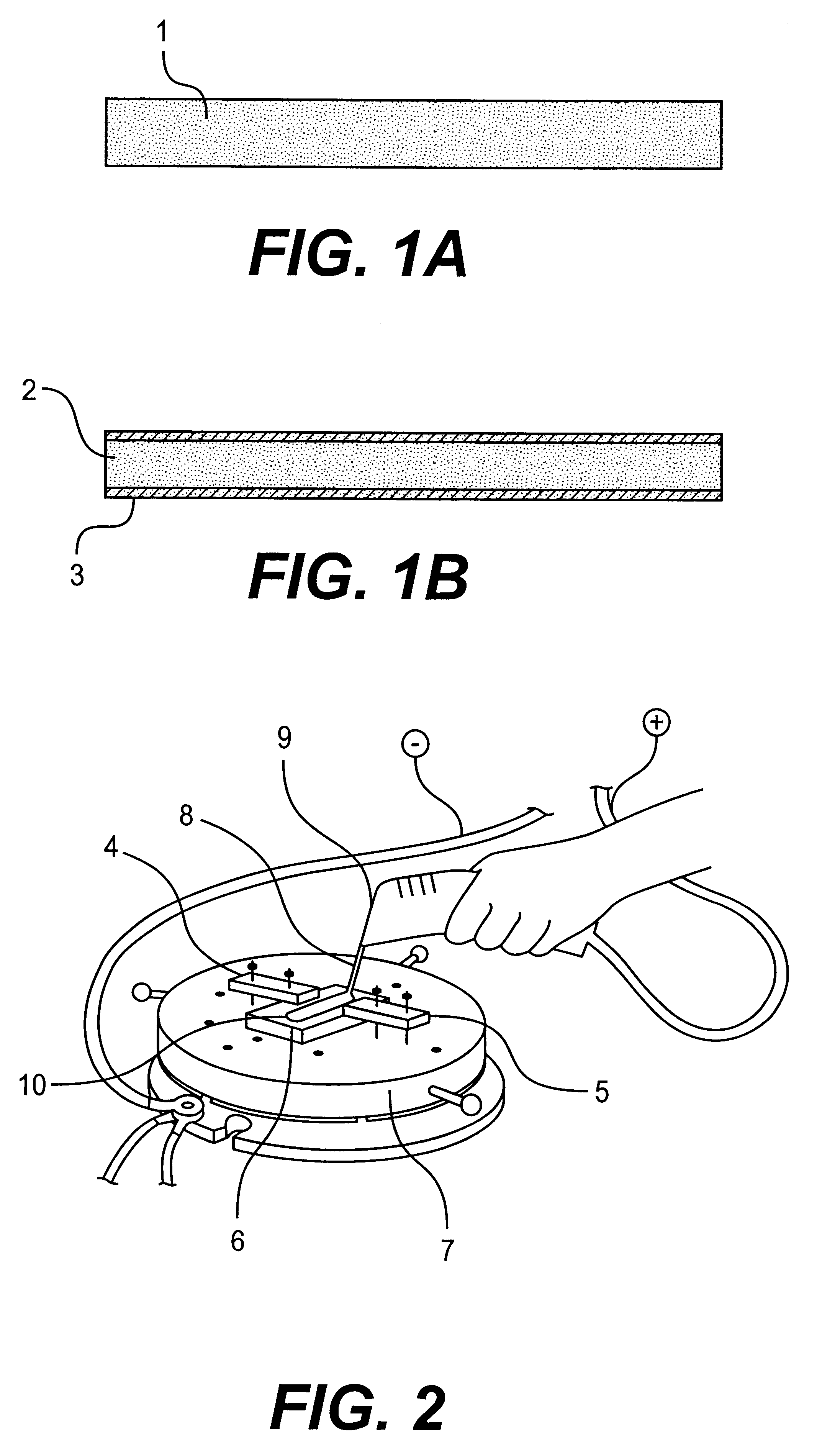

Nanopore platforms for ion channel recordings and single molecule detection and analysis

ActiveUS7777505B2Determining of stabilityGood fluiditySpark gapsResistance/reactance/impedenceLipid formationSpontaneous generation

A nanopore device includes a membrane having a nanopore extending there through forming a channel from a first side of the membrane to a second side of the membrane. The surface of the channel and first side of the membrane are modified with a hydrophobic coating. A first lipid monolayer is deposited on the first side of the membrane, and a second lipid monolayer is deposited on the second side of the membrane, wherein the hydrophobic coating causes spontaneous generation of a lipid bilayer across the nanopore orifice. Sensing entities, such as a protein ion channel, can be inserted and removed from the bilayer by adjusting transmembrane pressure, and adapter molecules can be electrostatically trapped in the ion channel by applying high transmembrane voltages, while resistance or current flow through the sensing entity can be measured electrically.

Owner:UNIV OF UTAH RES FOUND

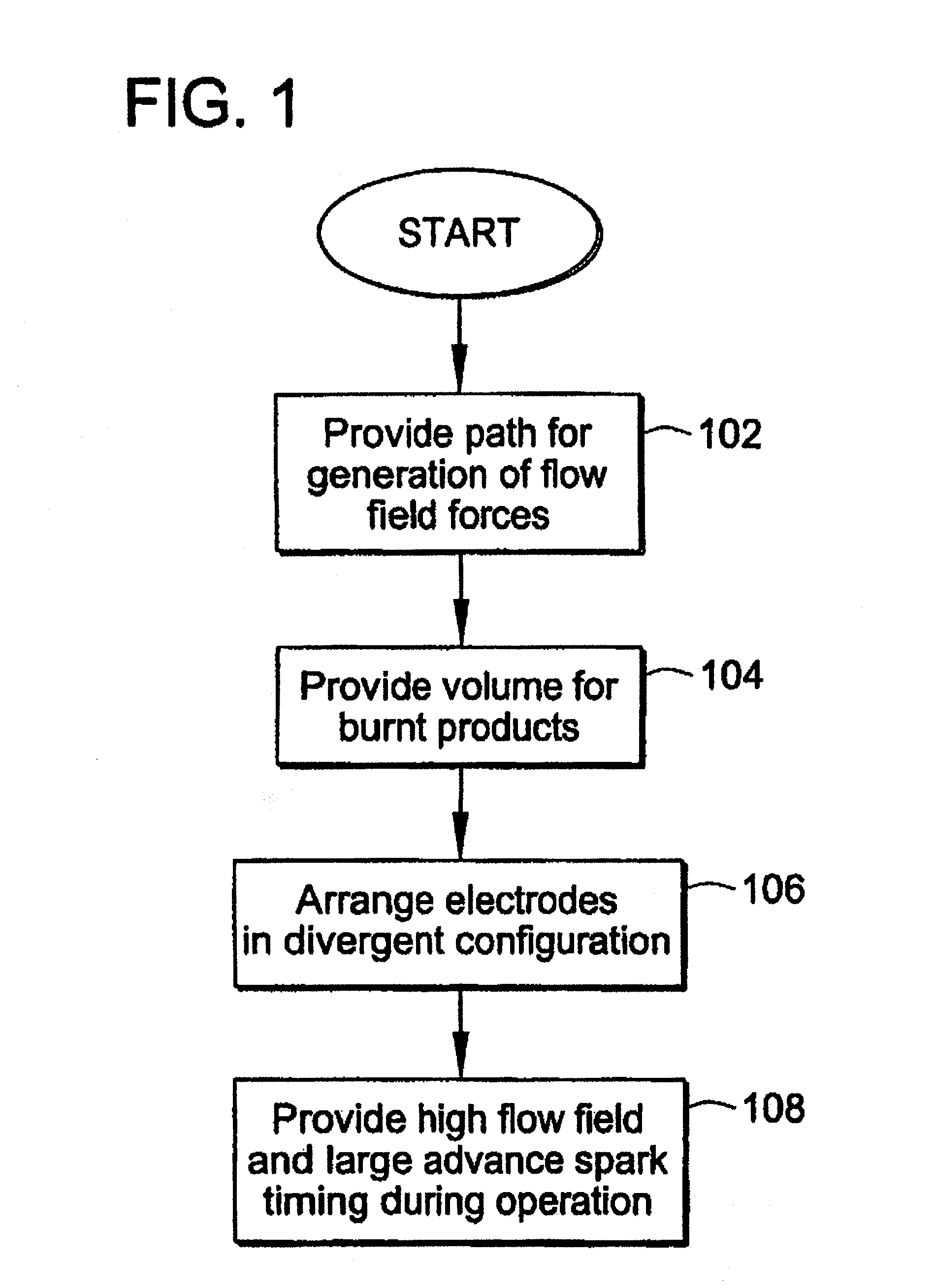

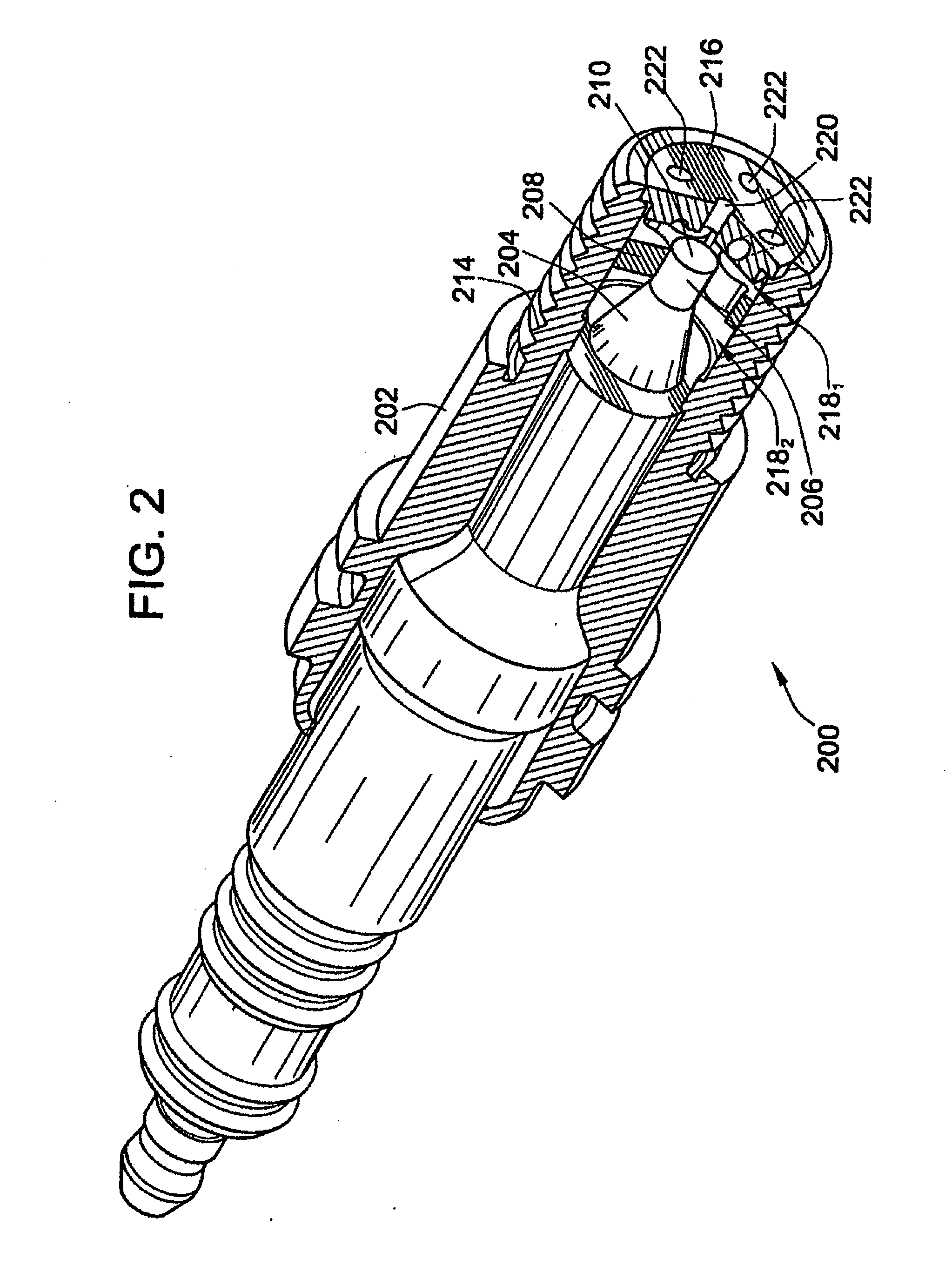

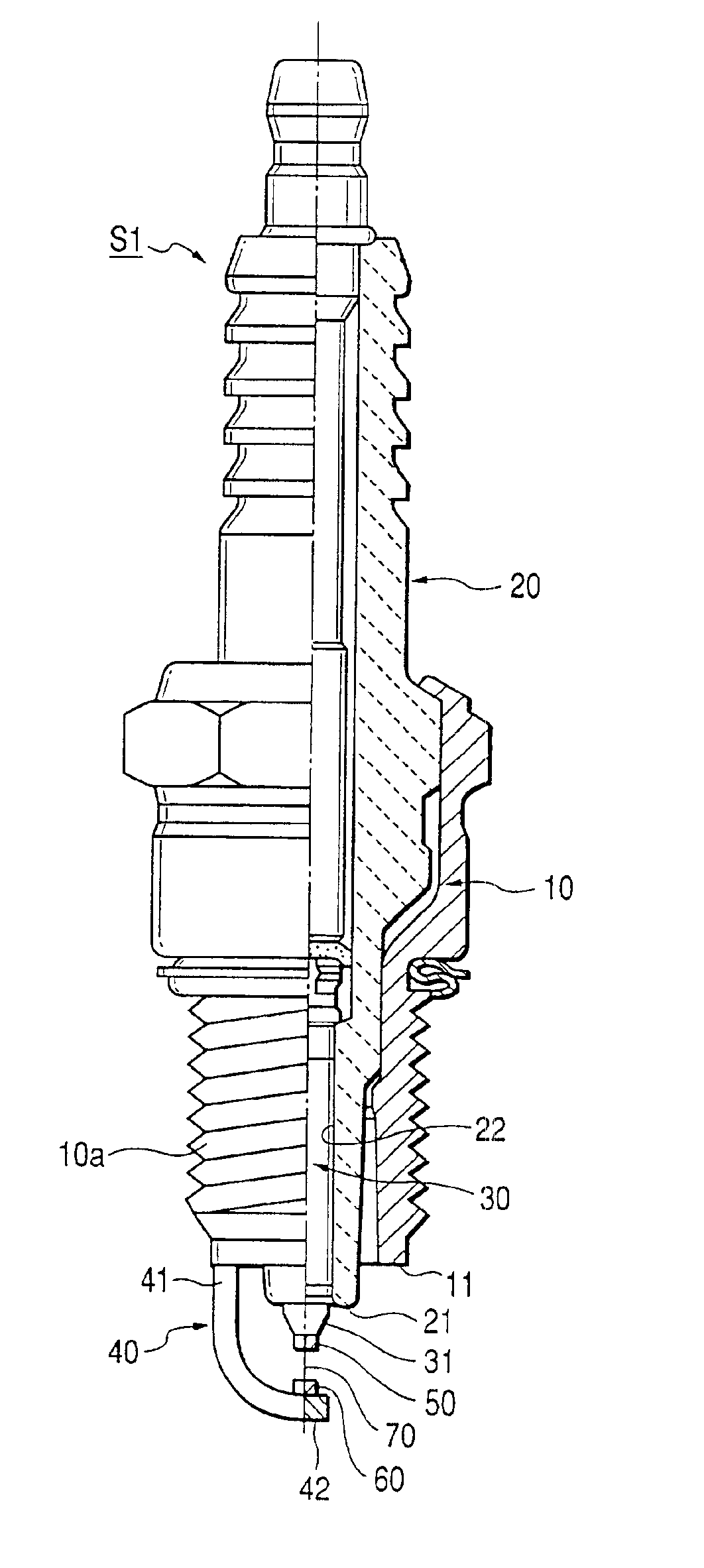

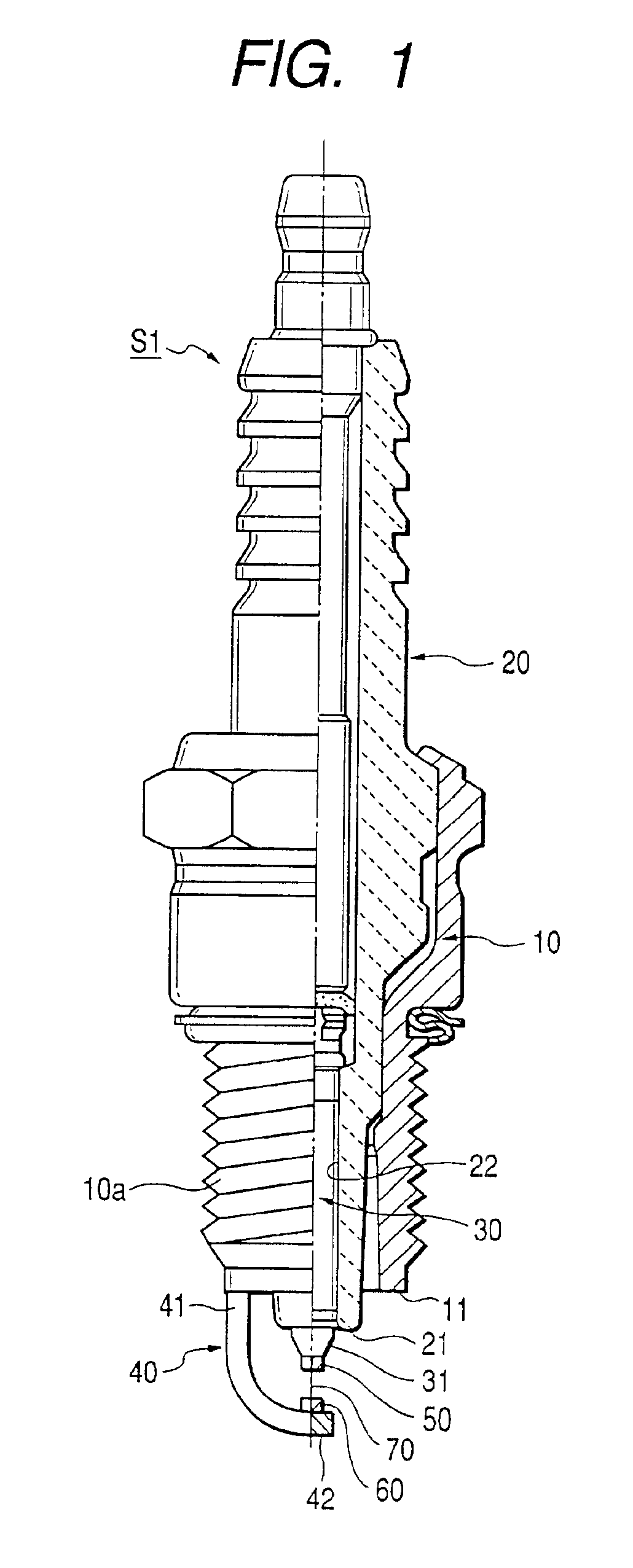

Pre-Chamber Spark Plug

ActiveUS20090309475A1Maximize spark plug lifeReduce erosionSpark gapsInternal combustion piston enginesElectricityElectrode erosion

A method and apparatus to maximize spark plug life in pre-chamber spark plugs operating with ultra-lean mixtures and / or elevated engine BMEP is presented. Electrode erosion is reduced by spreading discharge energy over a wider surface area, maintaining fuel concentration in the spark gap, controlling gas static pressure during discharge, and maintaining safe electrode temperature. Energy is spread via a swirling effect created by periphery holes in an end cap, resulting in a lower specific energy discharge at the electrodes. Divergently configured electrodes reduce the spark voltage at high operating pressures and the energy required for ignition. The flow field generated at the electrodes prevents electrical shorts due to water condensation and avoids misfire. The center electrode insulation provides an effective heat transfer path to prevent electrode overheating and pre-ignition. The volume behind the electrodes provides a volume for burnt products from previous combustion cycles and leads to more reliable ignition.

Owner:WOODWARD GOVERNOR CO

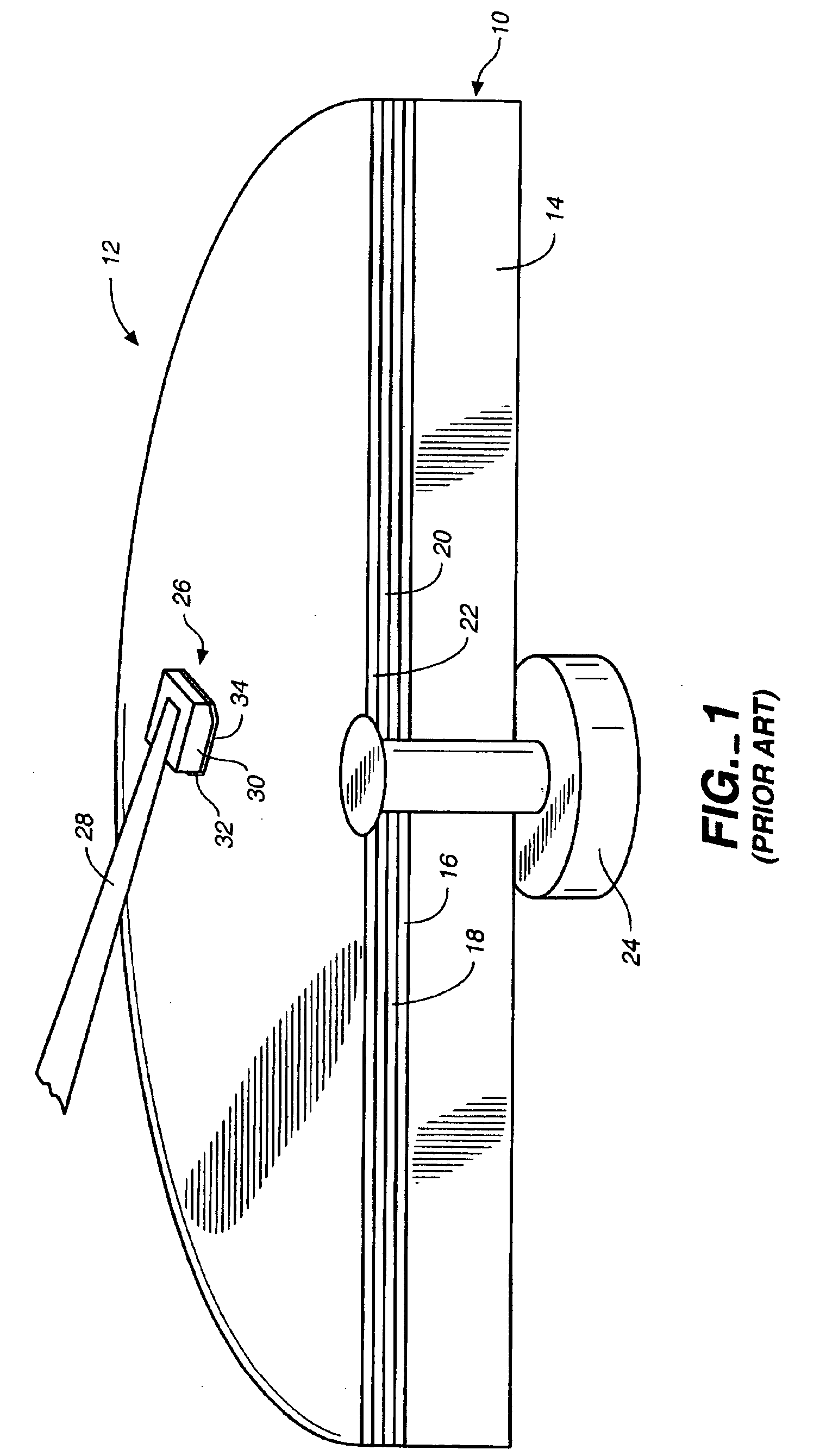

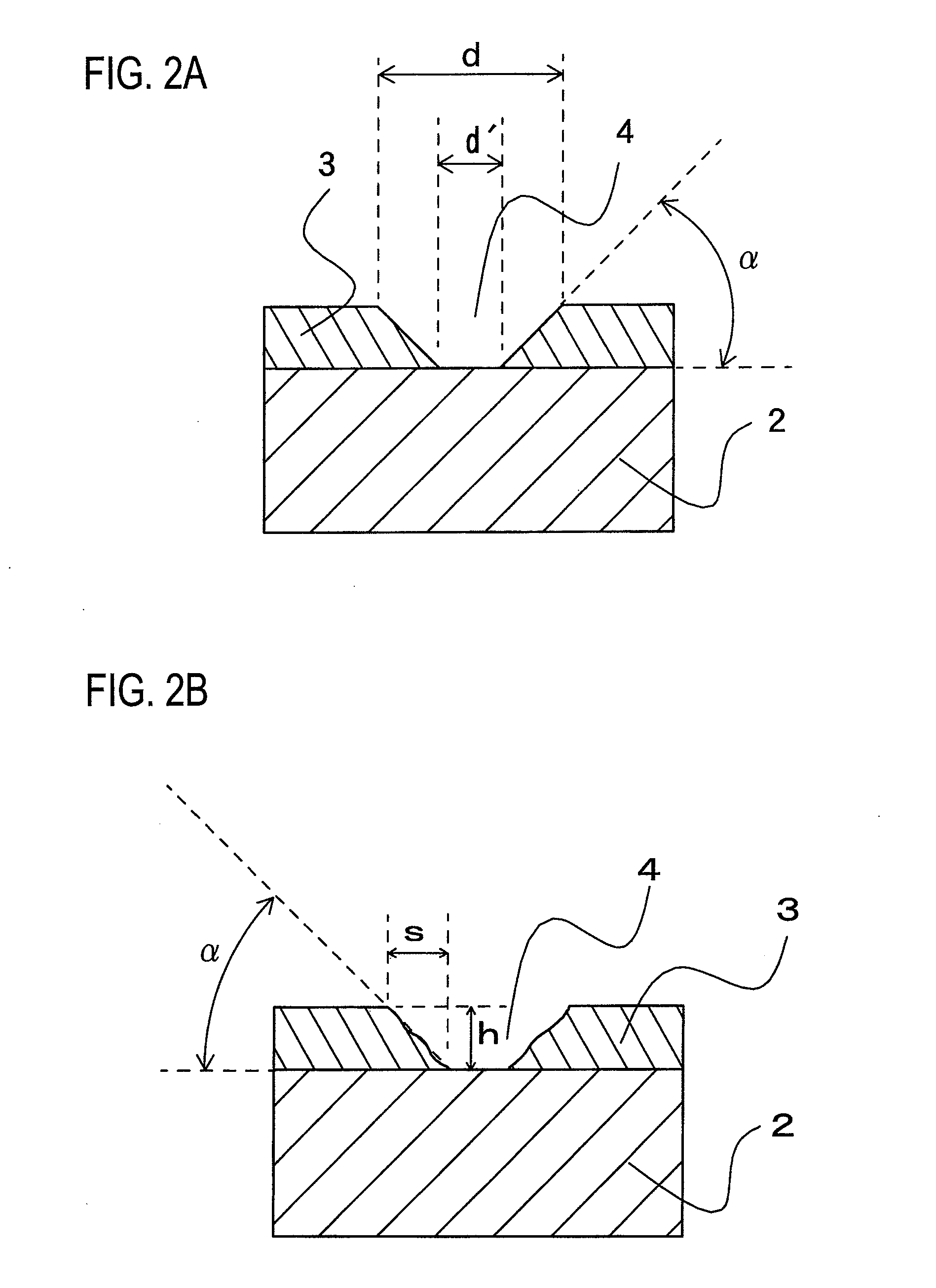

Engraved plate and substrate with conductor layer pattern using the same

InactiveUS20100021695A1High precision and miniaturization of patterningFlat surfaceMagnetic/electric field screeningLayered productsElectrical conductorEngineering

Owner:HITACHI CHEM CO LTD

Methods for producing enhanced interference pigments

InactiveUS6524381B1Enhancement in electron generation rateIncrease deposition rateElectric discharge heatingPigment preparation by PVD/CVD methodsGas phaseVaporization

Methods and apparatus are provided for uniformly depositing a coating material from a vaporization source onto a powdered substrate material to form a thin coalescence film of the coating material that smoothly replicates the surface microstructure of the substrate material. The coating material is uniformly deposited on the substrate material to form optical interference pigment particles. The thin film enhances the hiding power and color gamut of the substrate material. Physical vapor deposition processes are used for depositing the film on the substrate material. The apparatus and systems employed in forming the coated particles utilize vibrating bed coaters, vibrating conveyor coaters, or coating towers. These allow the powdered substrate material to be uniformly exposed to the coating material vapor during the coating process.

Owner:JDS UNIPHASE CORP

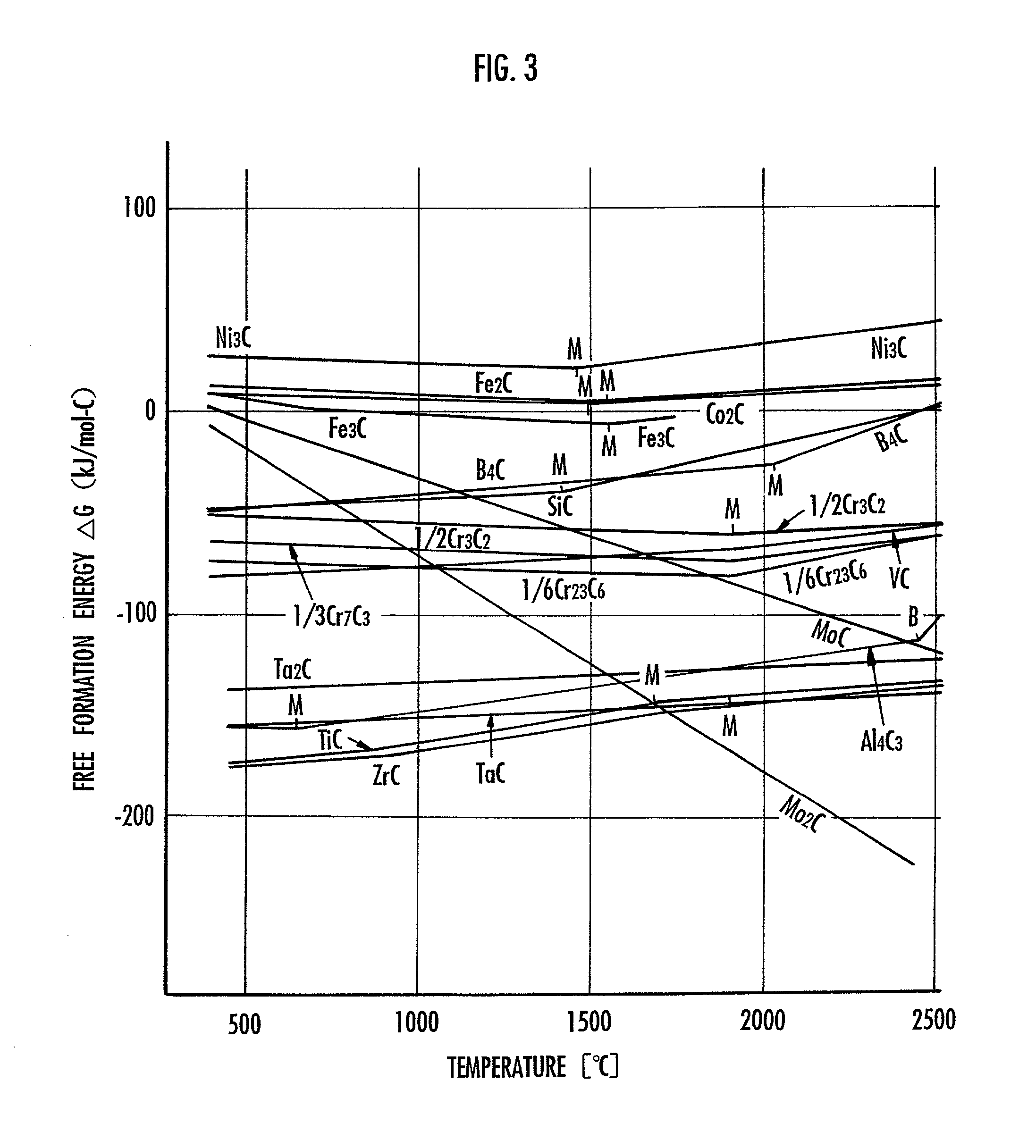

Method of manufacturing carbon nanotube

There is provided a method of manufacturing a carbon nanotube so as to be able to increase the yield of a web and to increase the amount of a carbon nanotube contained in the web. A high-energy heat source is caused to act on carbon in the presence of catalysts. The catalysts include a main catalyst made of at least one metal which is selected from the group consisting of an iron group element, a platinum group element, and a rare earth element, and an auxiliary catalyst made of a material which causes an exothermic reaction in a process of generating the web including the carbon nanotube. The auxiliary catalyst is made of a material for generating a carbide more stable in terms of thermal energy than a carbide generated by the main catalyst. The free formation energy of the carbide generated from the material is smaller than the free formation energy of the carbide generated by the main catalyst. The main catalyst is made of at least one metal which is selected from the group consisting of Fe, Co, Ni, Rh, Ru, Pd, Pt, Y, La, and Ce. The auxiliary catalyst is made of at least one material selected from the group consisting of Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W, B, Al, and Si. Typically the main catalyst is made of Ni-Y, and the auxiliary catalyst is made of Ti.

Owner:HONDA MOTOR CO LTD

Spark plug and its manufacturing method

InactiveUS20020130602A1Satisfactory propertyImprove adhesion strengthSpark gapsSparking plugs manufactureFree energiesAlloy

Noble metallic tips, made of a Pt alloy or an Ir alloy, are fixed to electrode base materials. The electrode base materials are an alloy containing a chief element selected from the group consisting of Ni, Fe, and Co and a plurality of additive elements. At least two kinds of additive elements contained in this alloy have a standard free energy of formation smaller than that of the chief element.

Owner:DENSO CORP

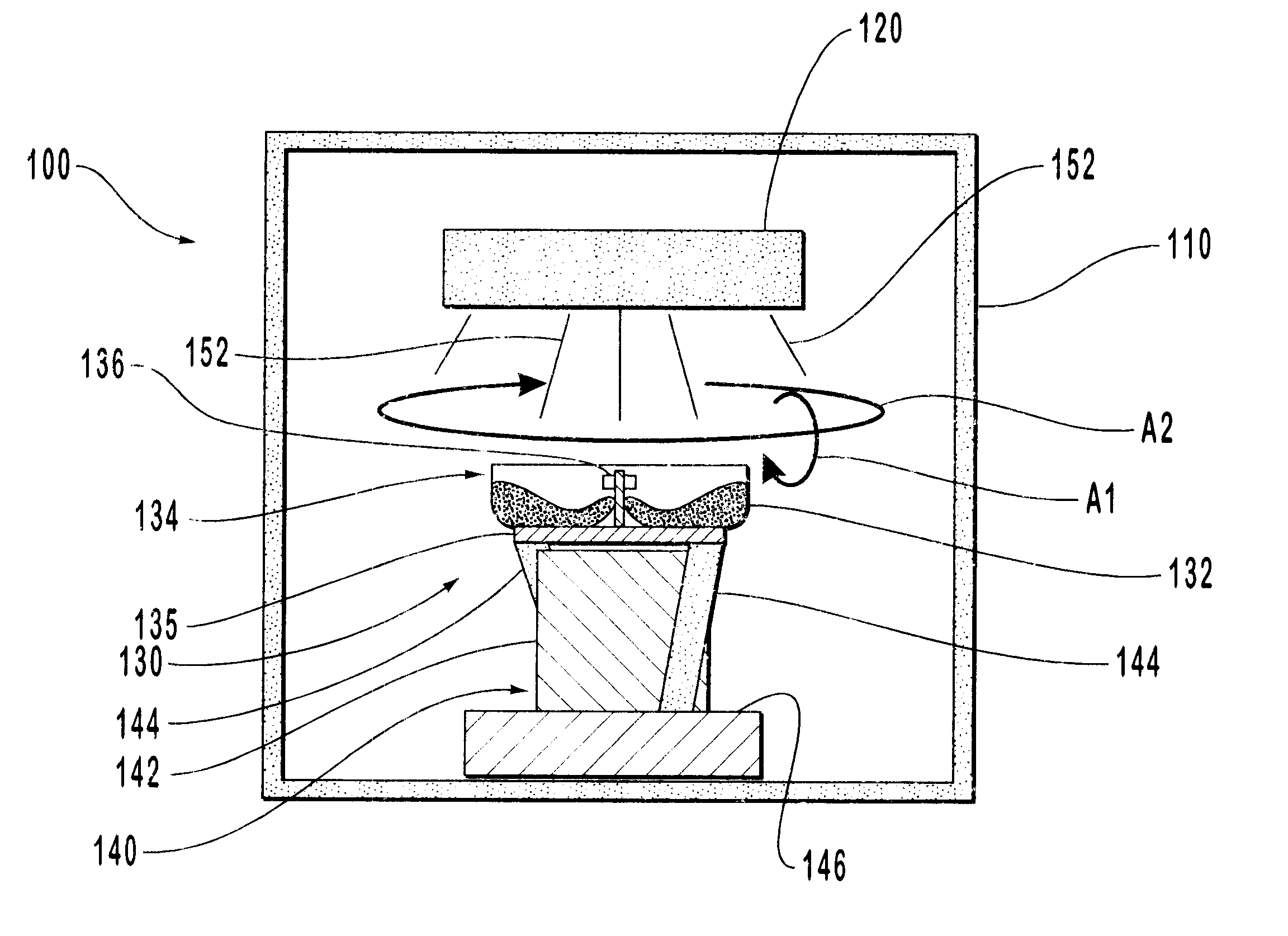

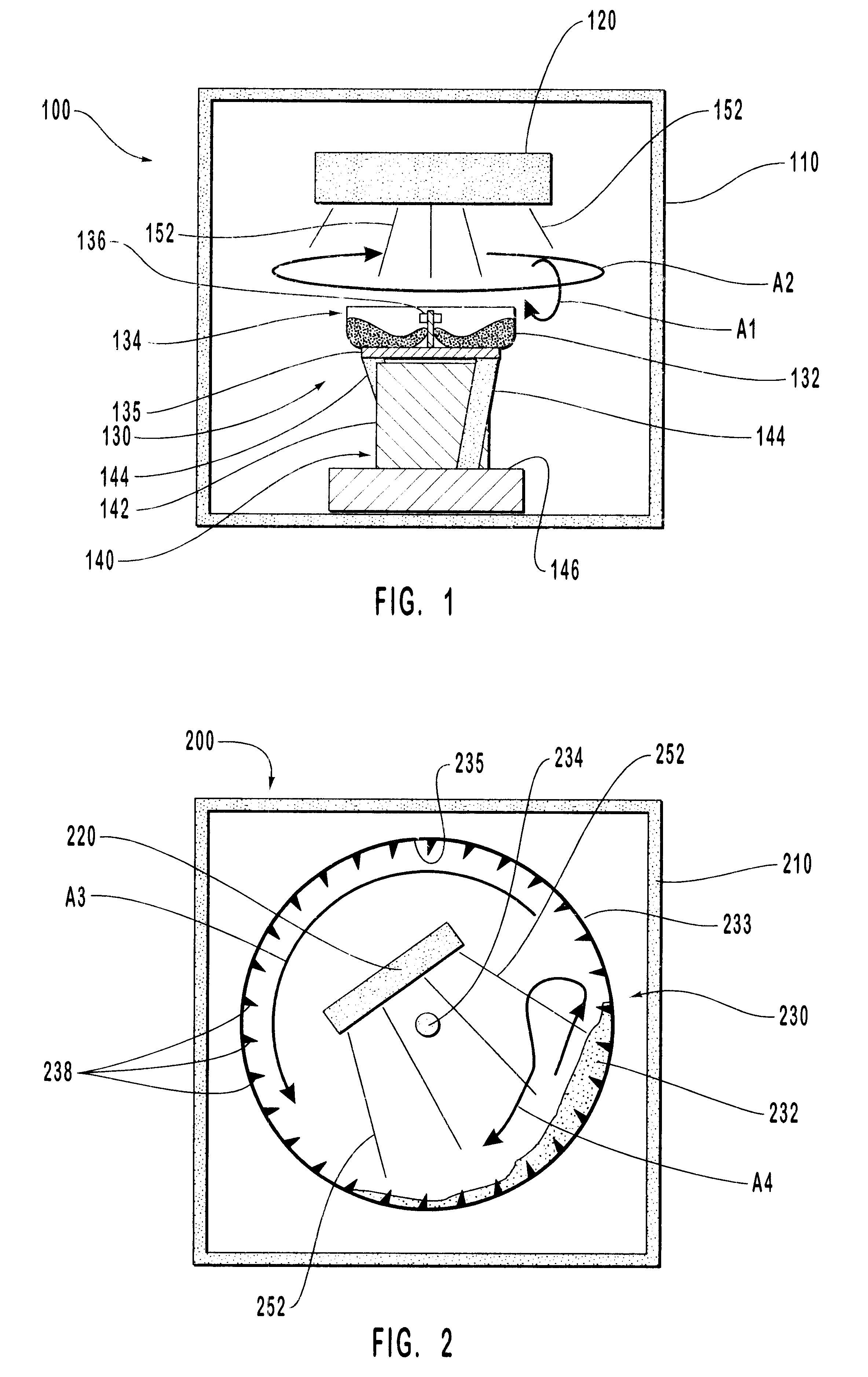

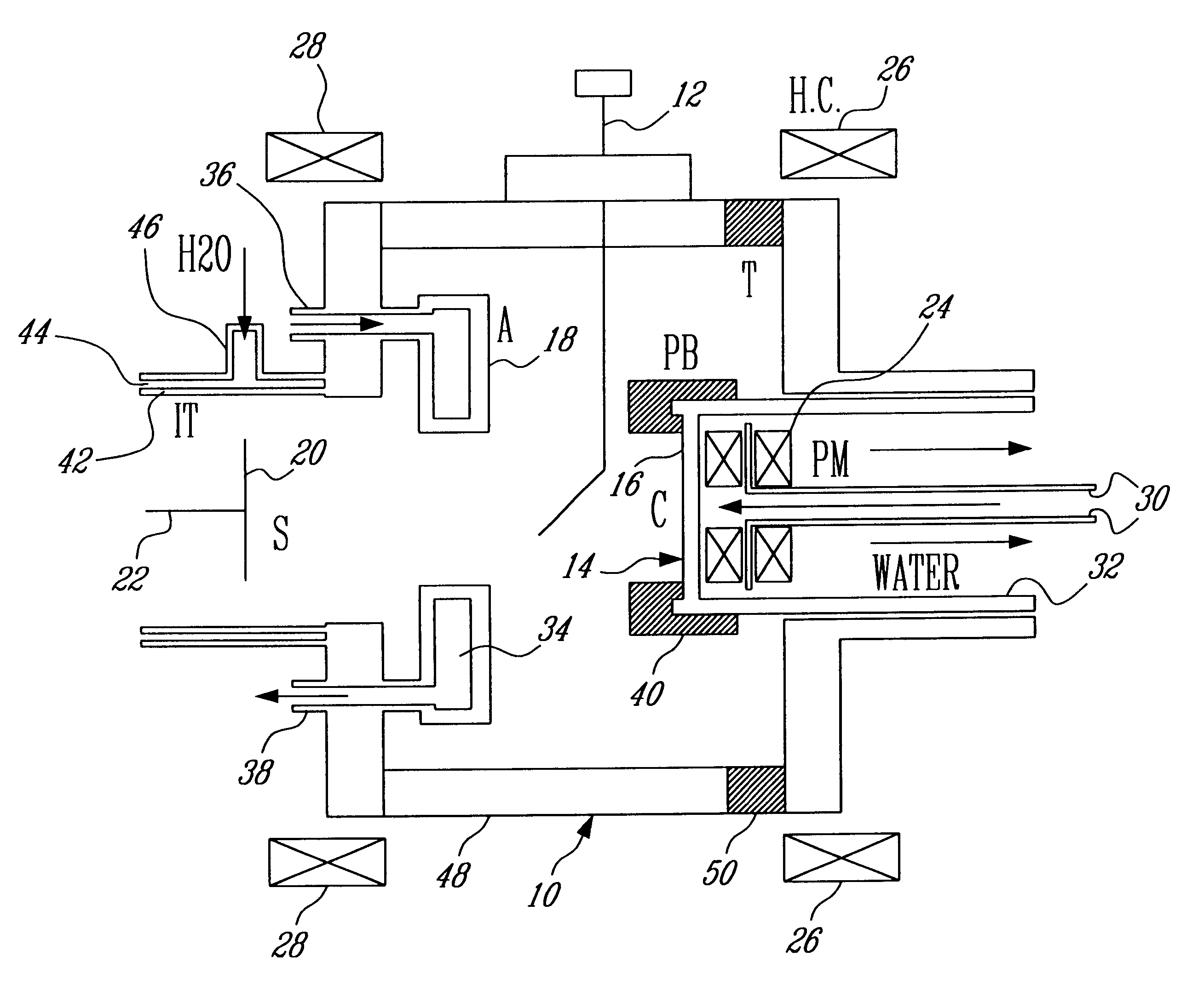

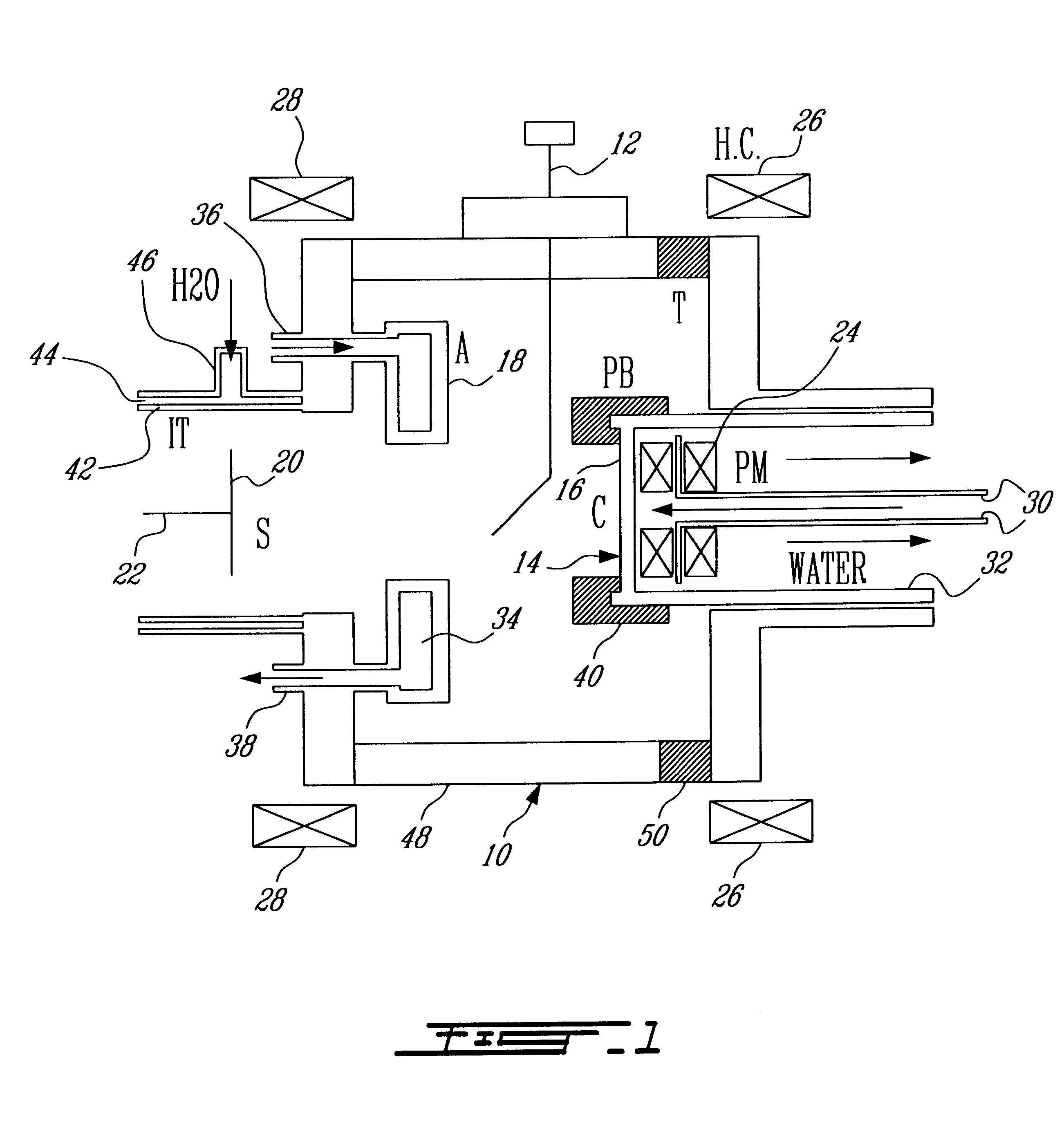

Apparatus and method for large area chemical vapor deposition using multiple expanding thermal plasma generators

InactiveUS20030072881A1Efficient coatingDesirable propertySpark gapsElectric discharge tubesThermoplasticGas phase

Chemical vapor deposition is performed using a plurality of expanding thermal plasma generating means to produce a coating on a substrate, such as a thermoplastic and especially a polycarbonate substrate. The substrate is preferably moved past the generating means. Included are methods which coat both sides of the substrate or which employ multiple sets of generating means, either in a single deposition chamber or in a plurality of chambers for deposition of successive coatings. The substrate surfaces spaced from the axes of the generating means are preferably heated to promote coating uniformity.

Owner:SABIC INNOVATIVE PLASTICS IP BV

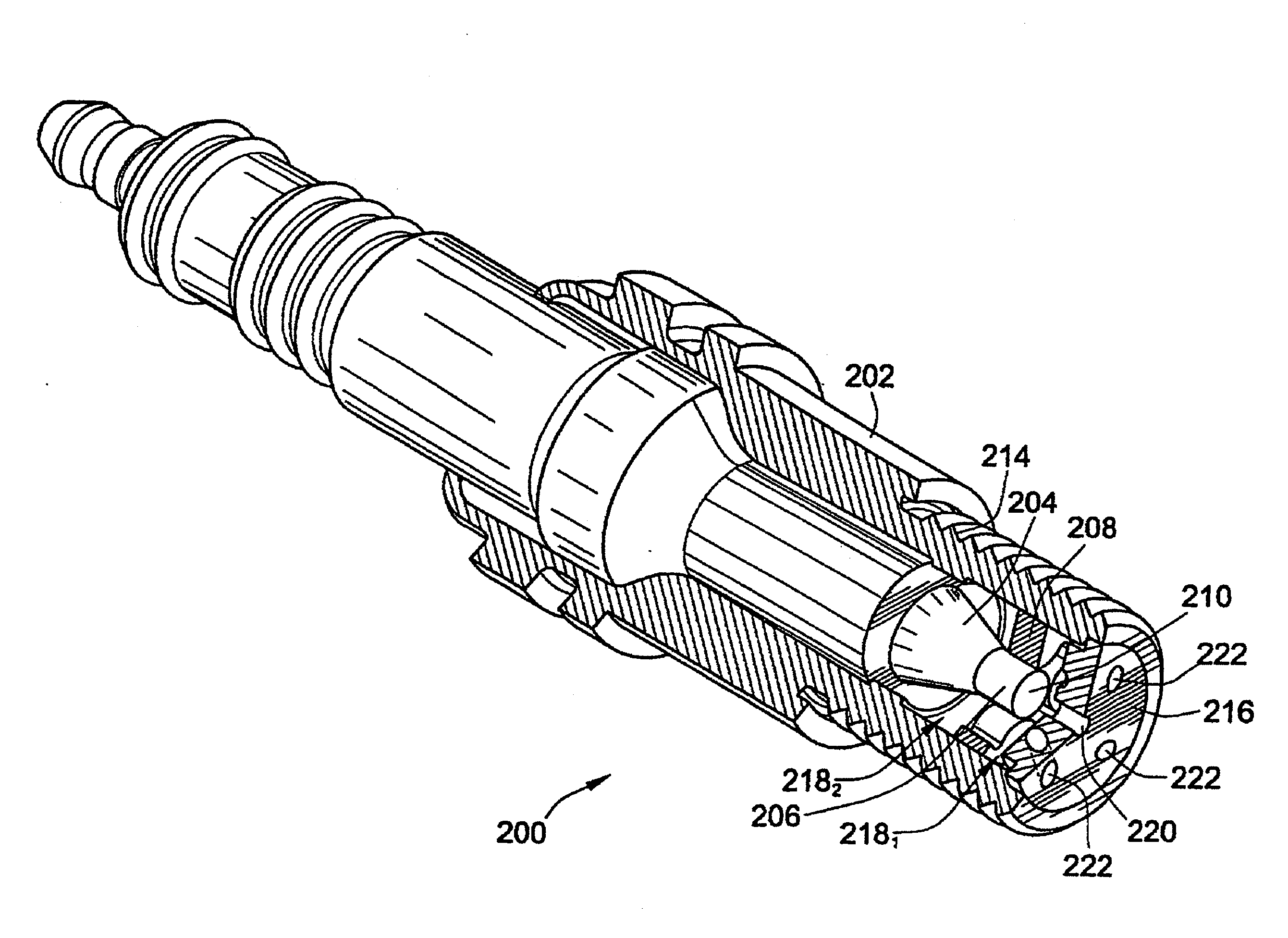

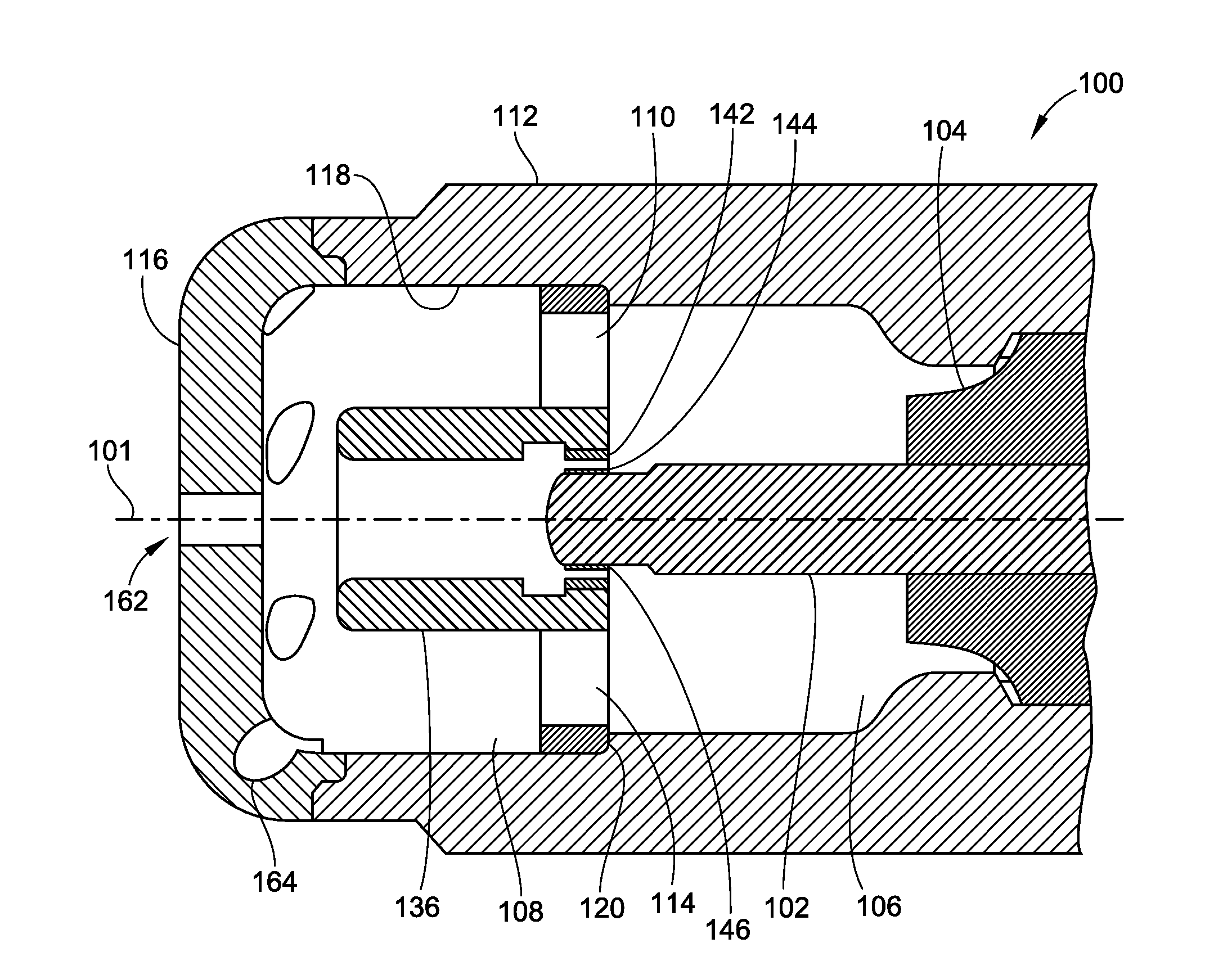

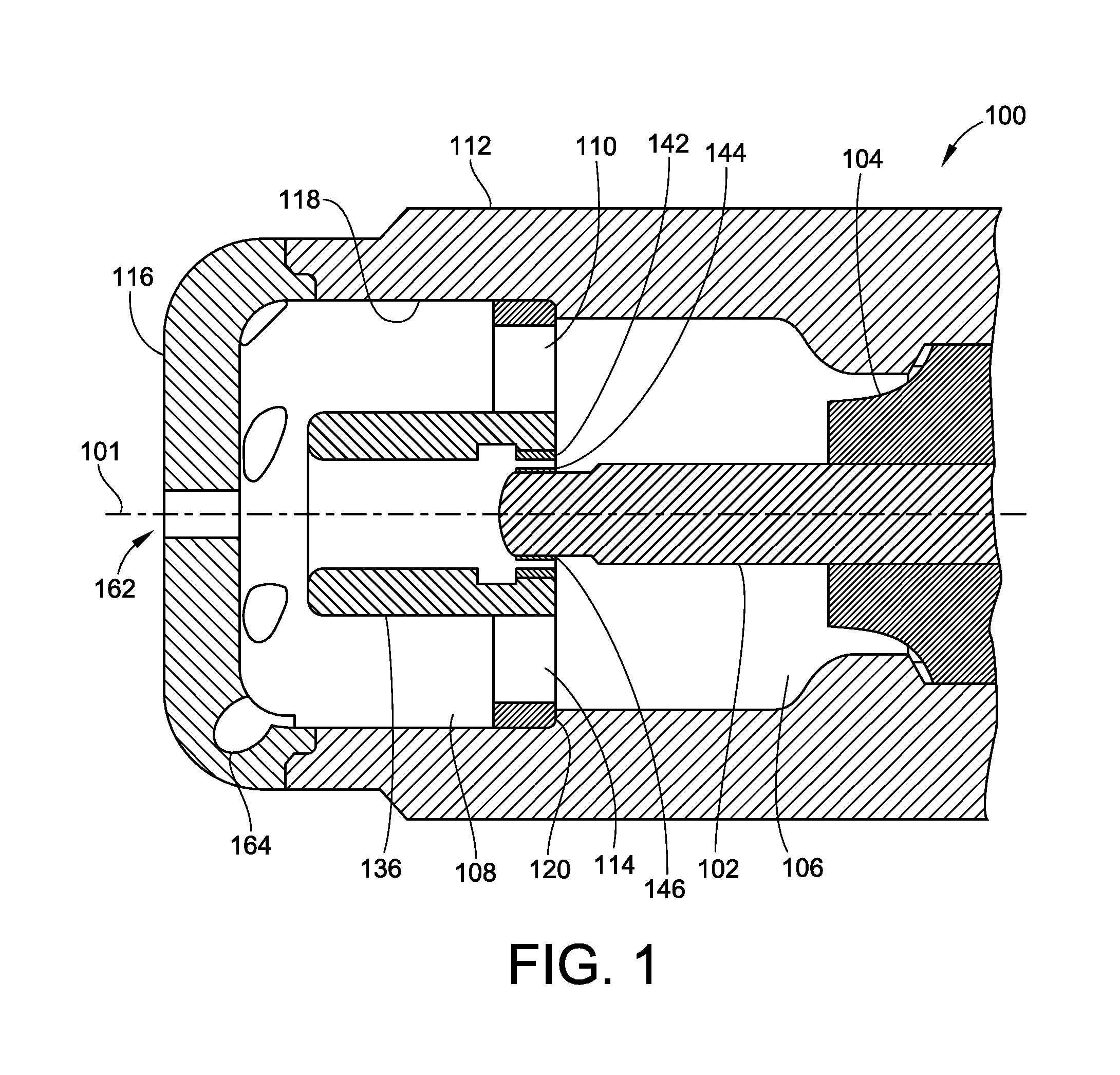

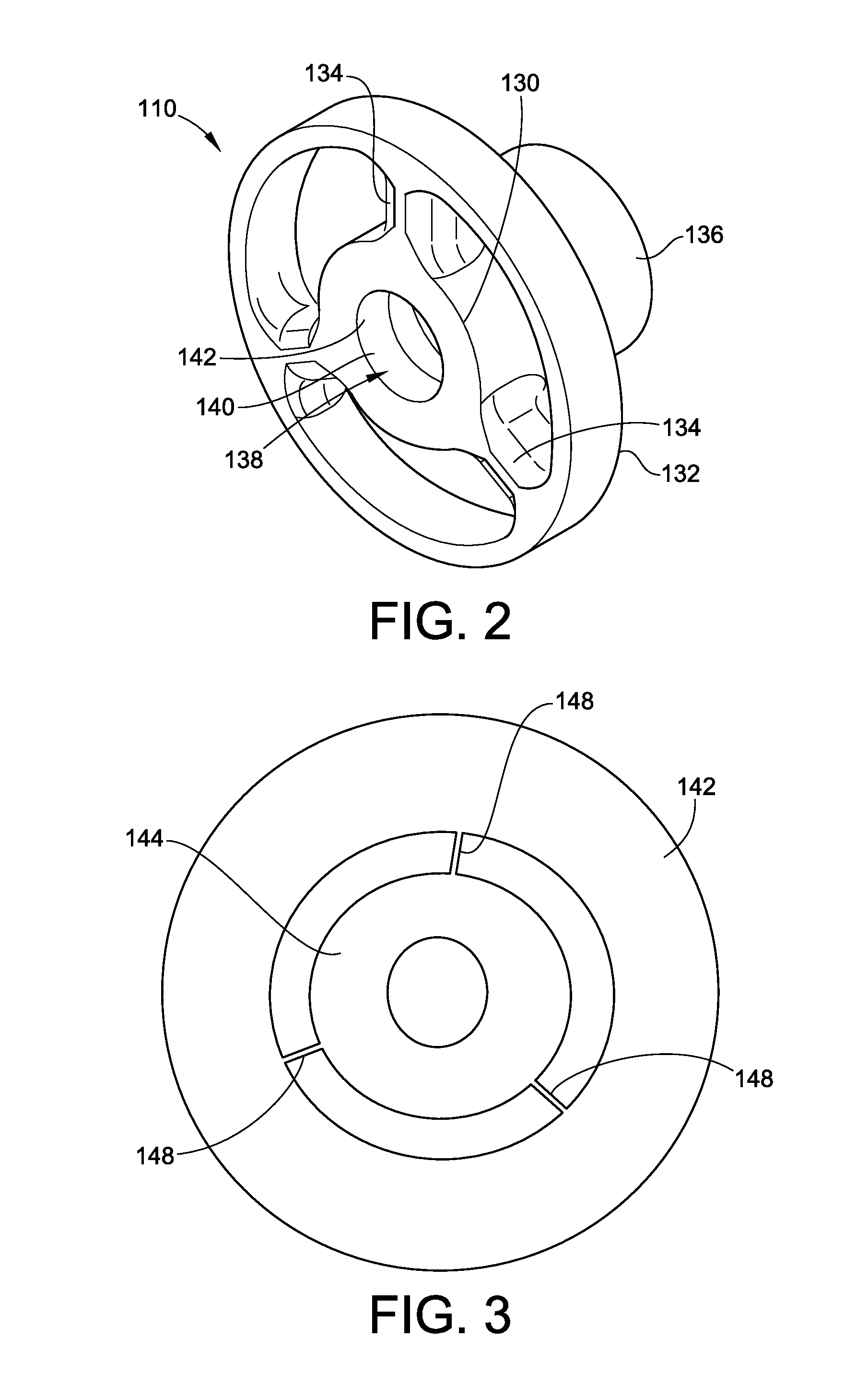

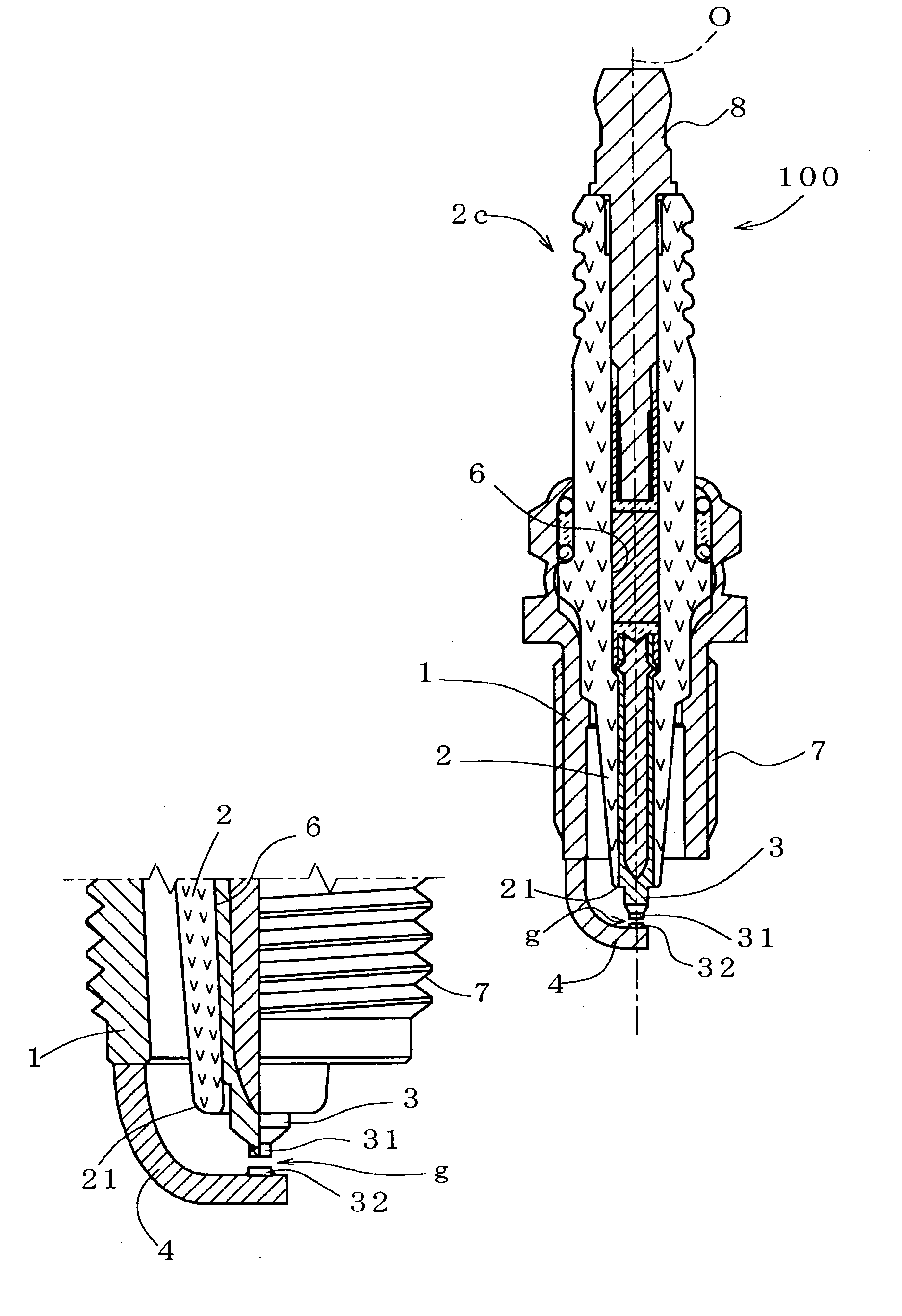

Pre-chamber spark plug with tubular electrode and method of manufacturing same

ActiveUS20120125279A1Improve flowHigh trafficSpark gapsInternal combustion piston enginesEngineeringAlloy

A pre-chamber spark plug that includes a shell, and an end cap attached to the shell. Additionally, the pre-chamber spark plug includes an insulator disposed within the shell. In a particular embodiment, a center electrode has a first portion surrounded by the insulator, and a second portion that extends from the insulator into a pre-chamber. The pre-chamber defined by the shell and end cap. In a further embodiment, a ground electrode is attached to the shell. In particular embodiments, the ground electrode is tubular in shape and includes an inner spark surface ring spaced in surrounding relation to the center electrode to create a spark gap, an outer ring attached to the shell, and a plurality of rounded spokes connecting the inner and outer rings. In a particular embodiment, the ground and center electrodes accommodate attachment of precious metal alloys to increase electrode surface life.

Owner:WOODWARD GOVERNOR CO

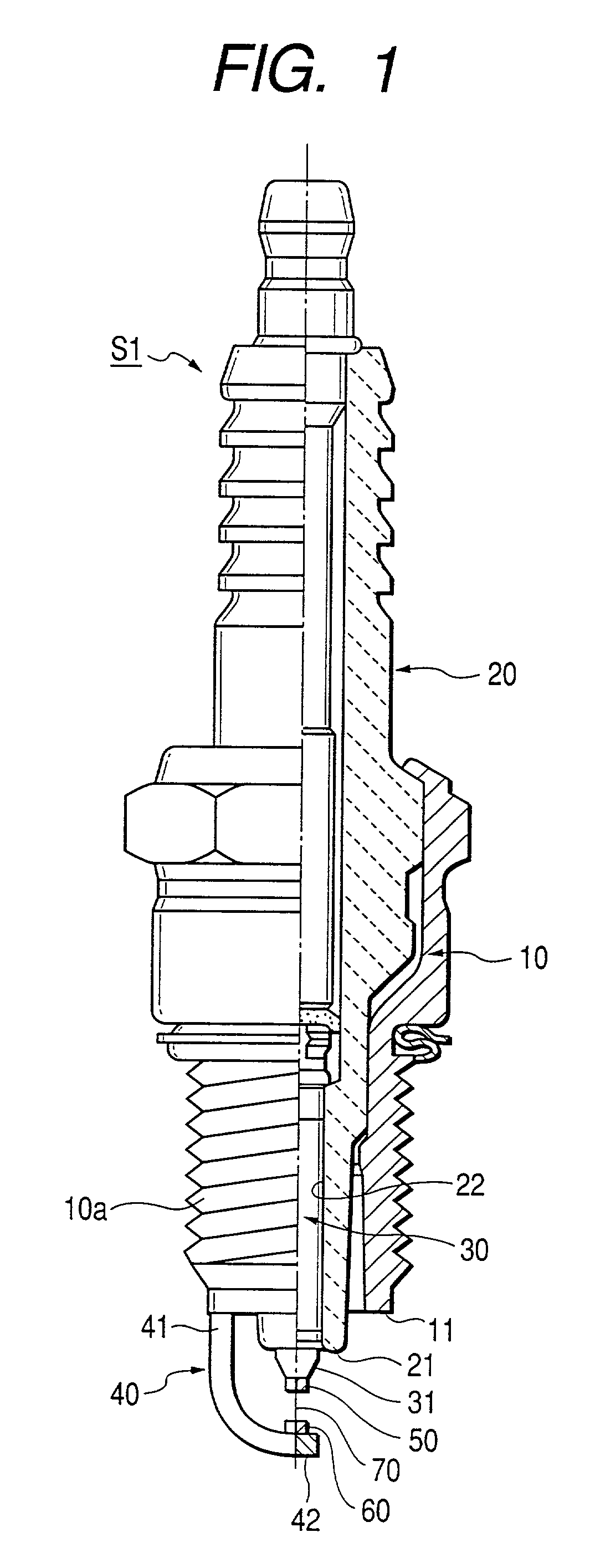

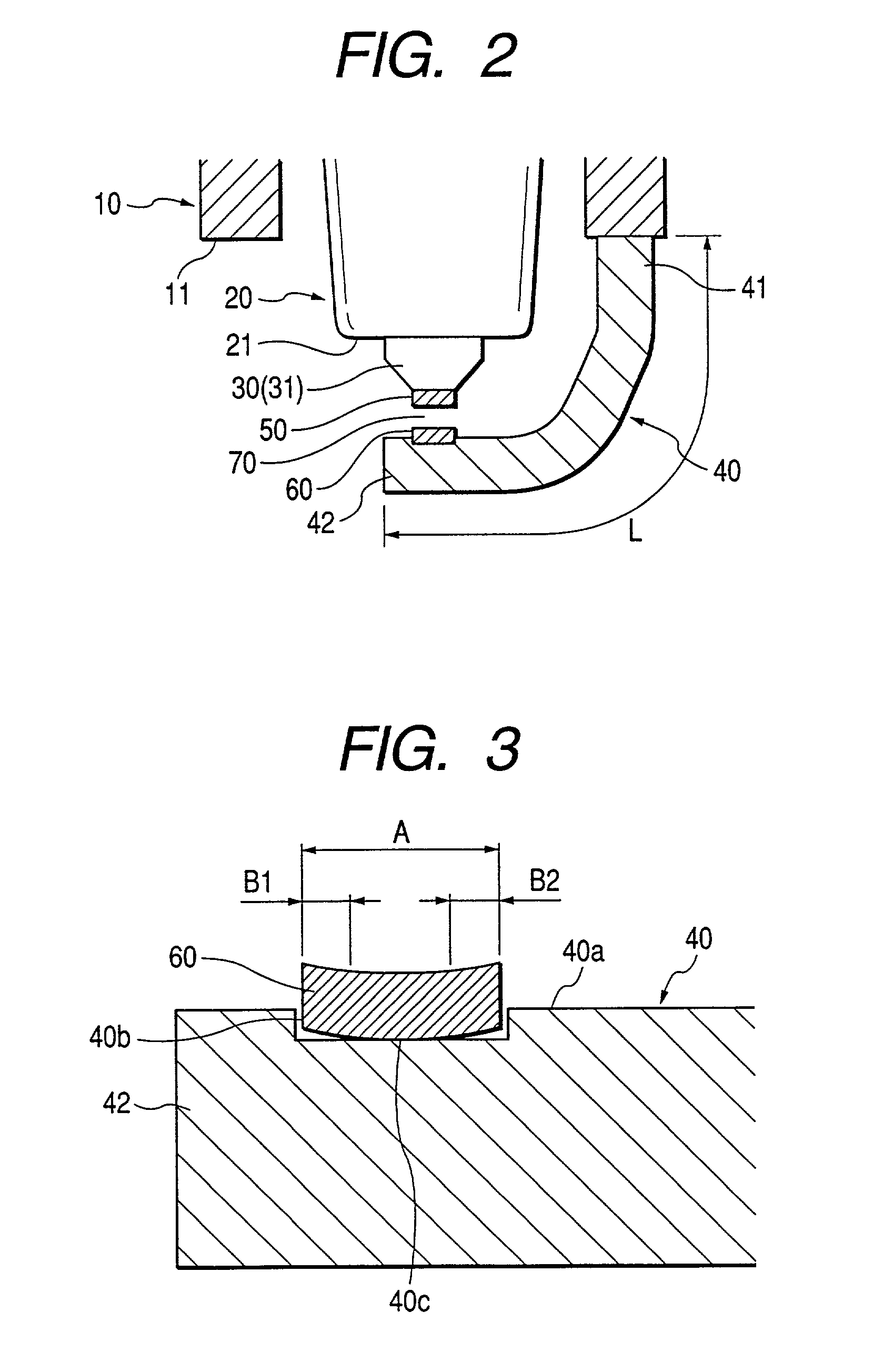

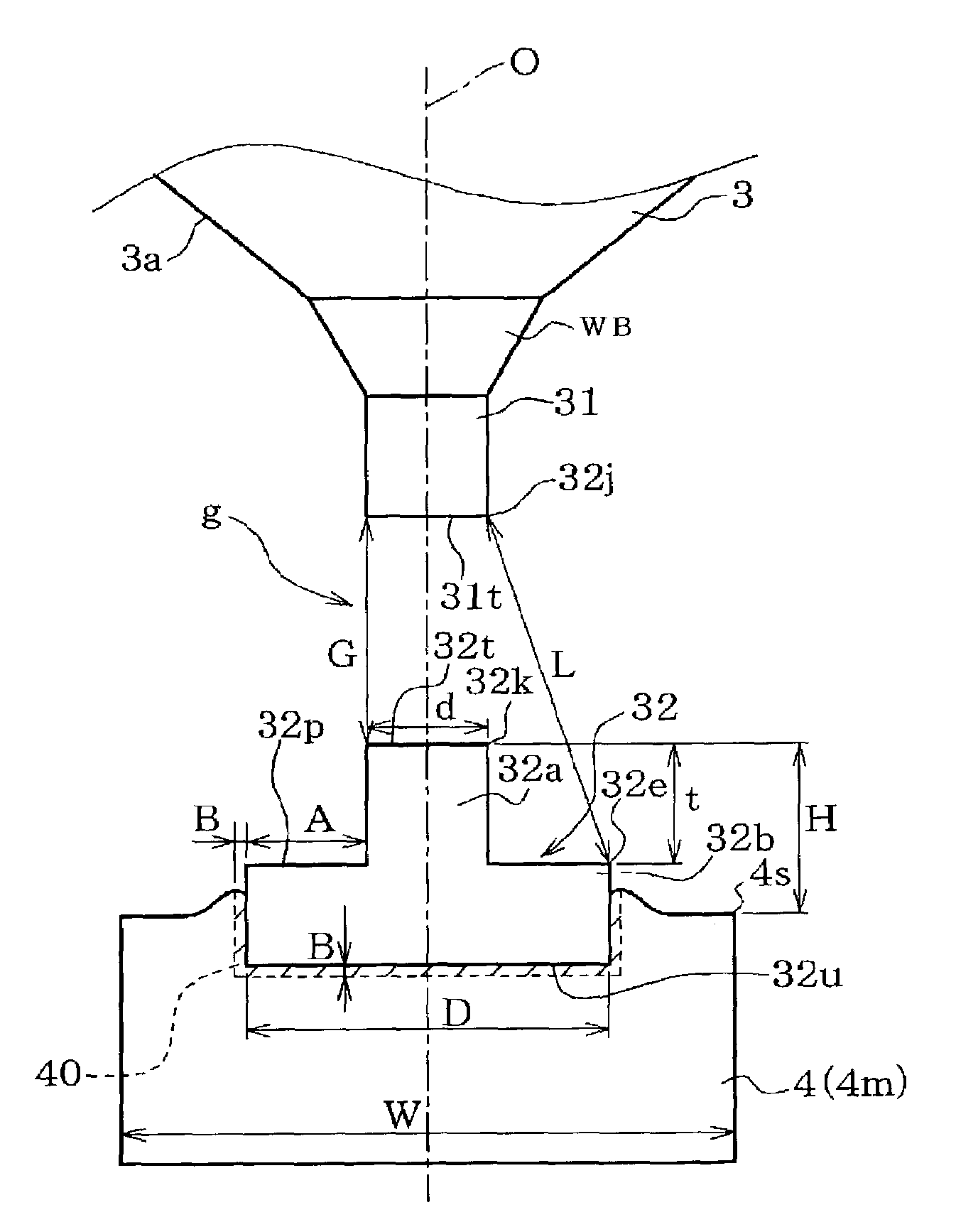

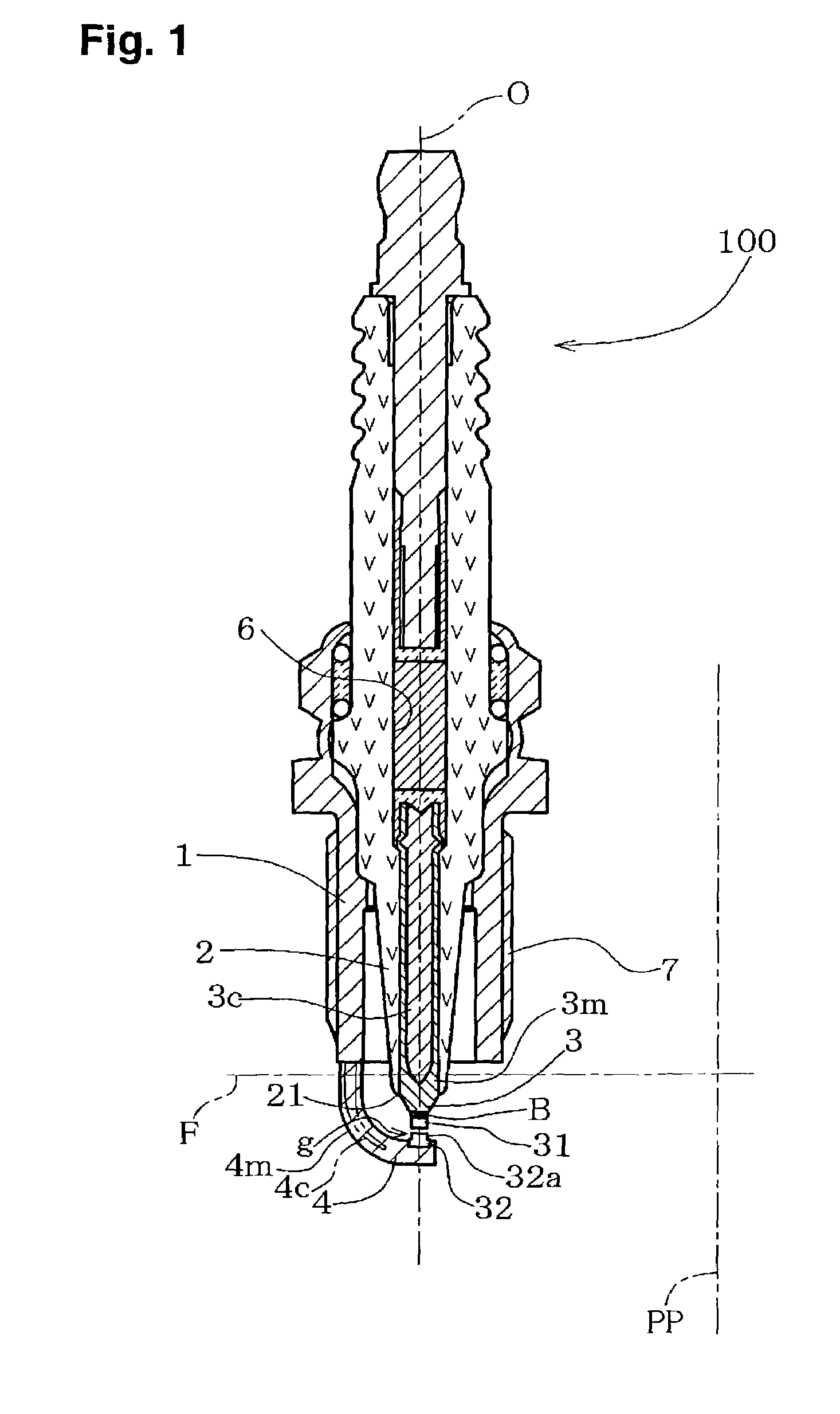

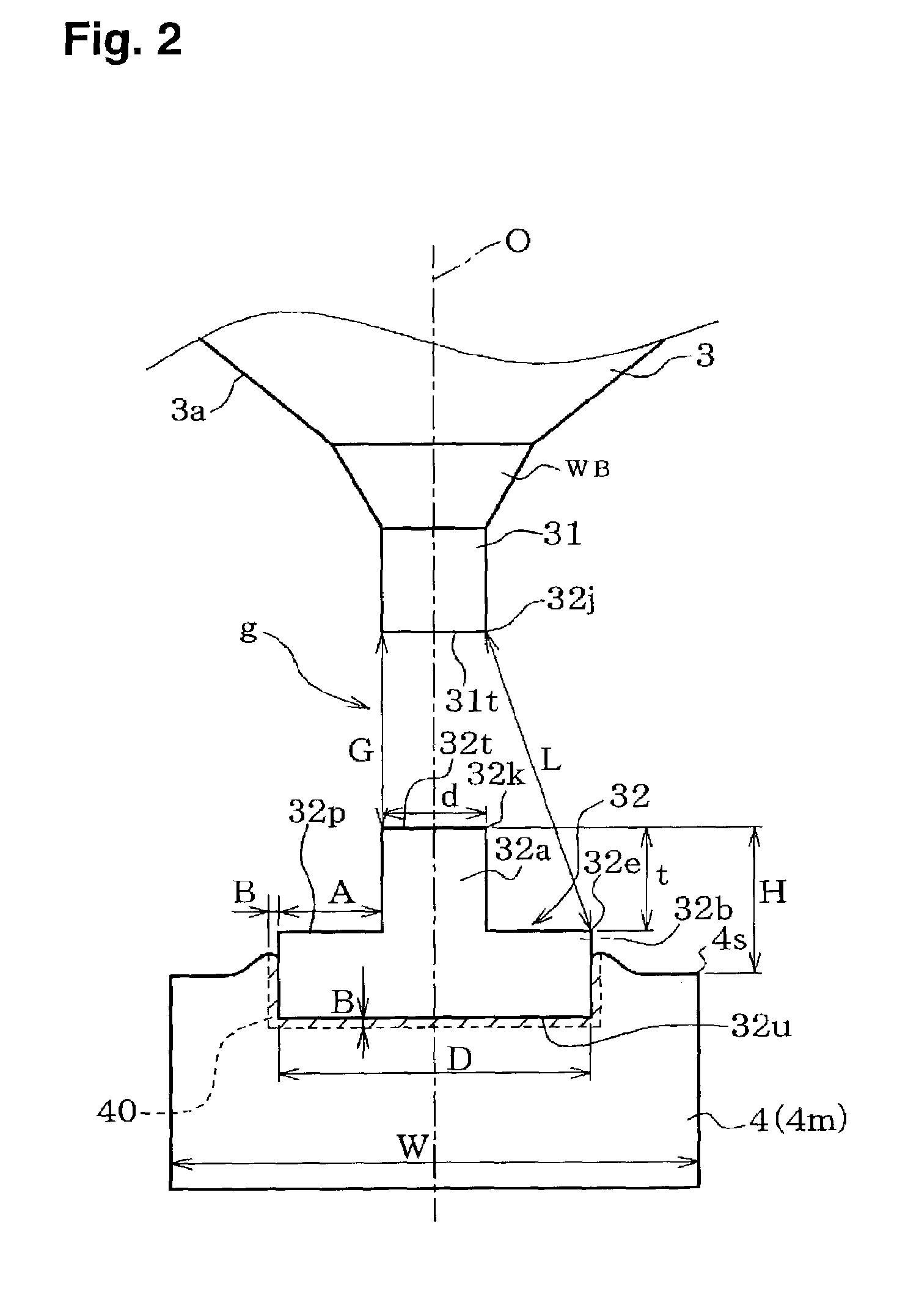

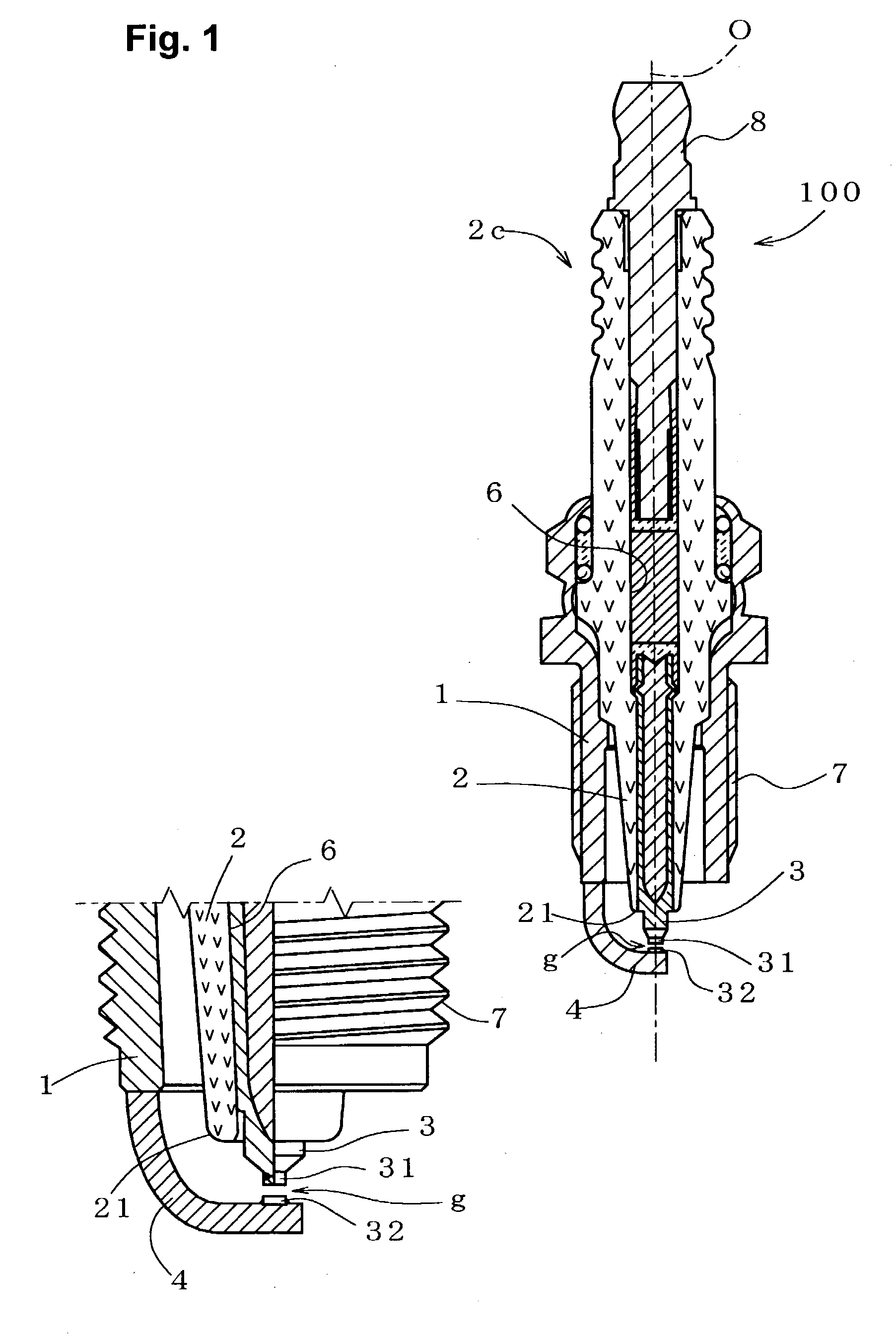

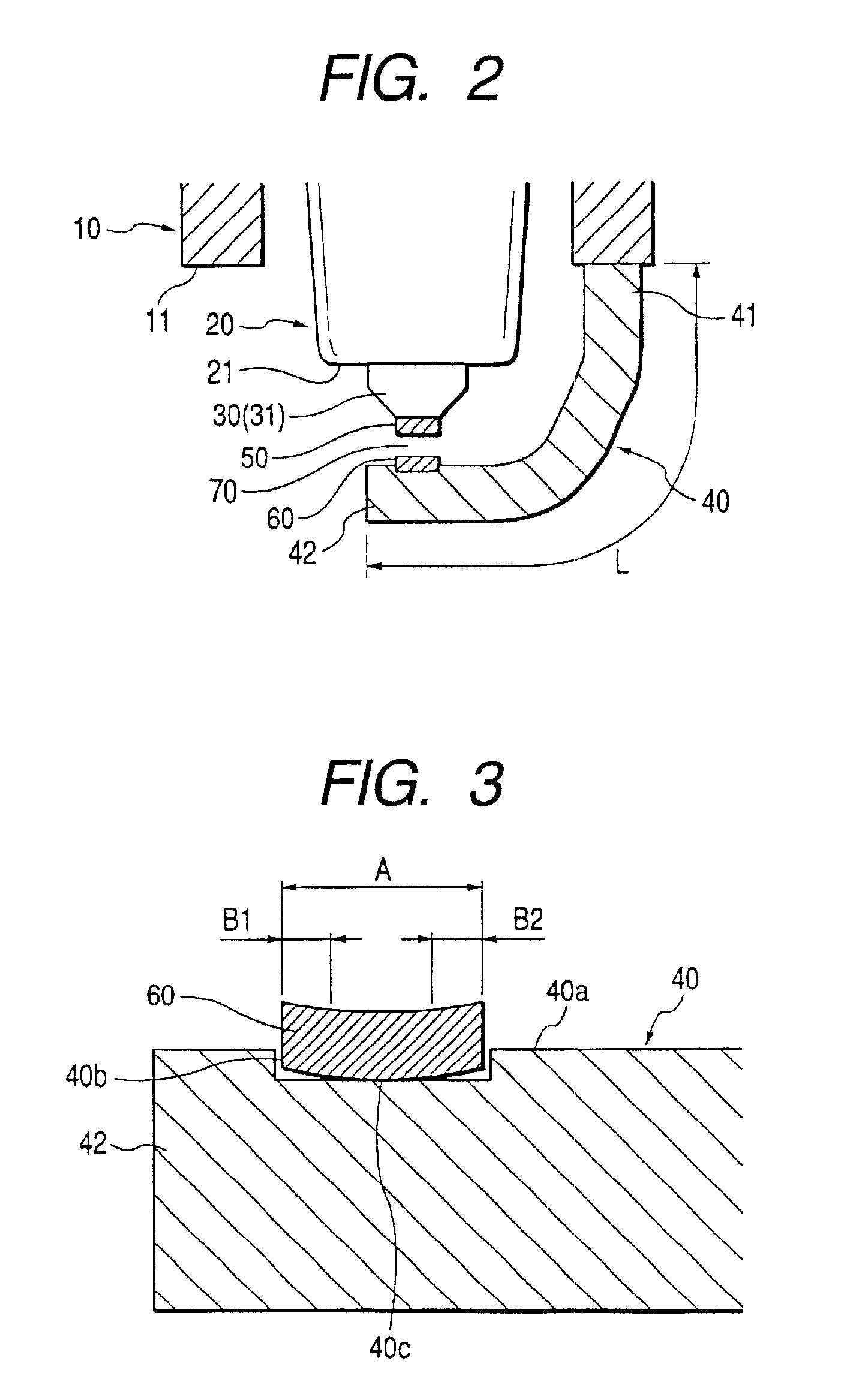

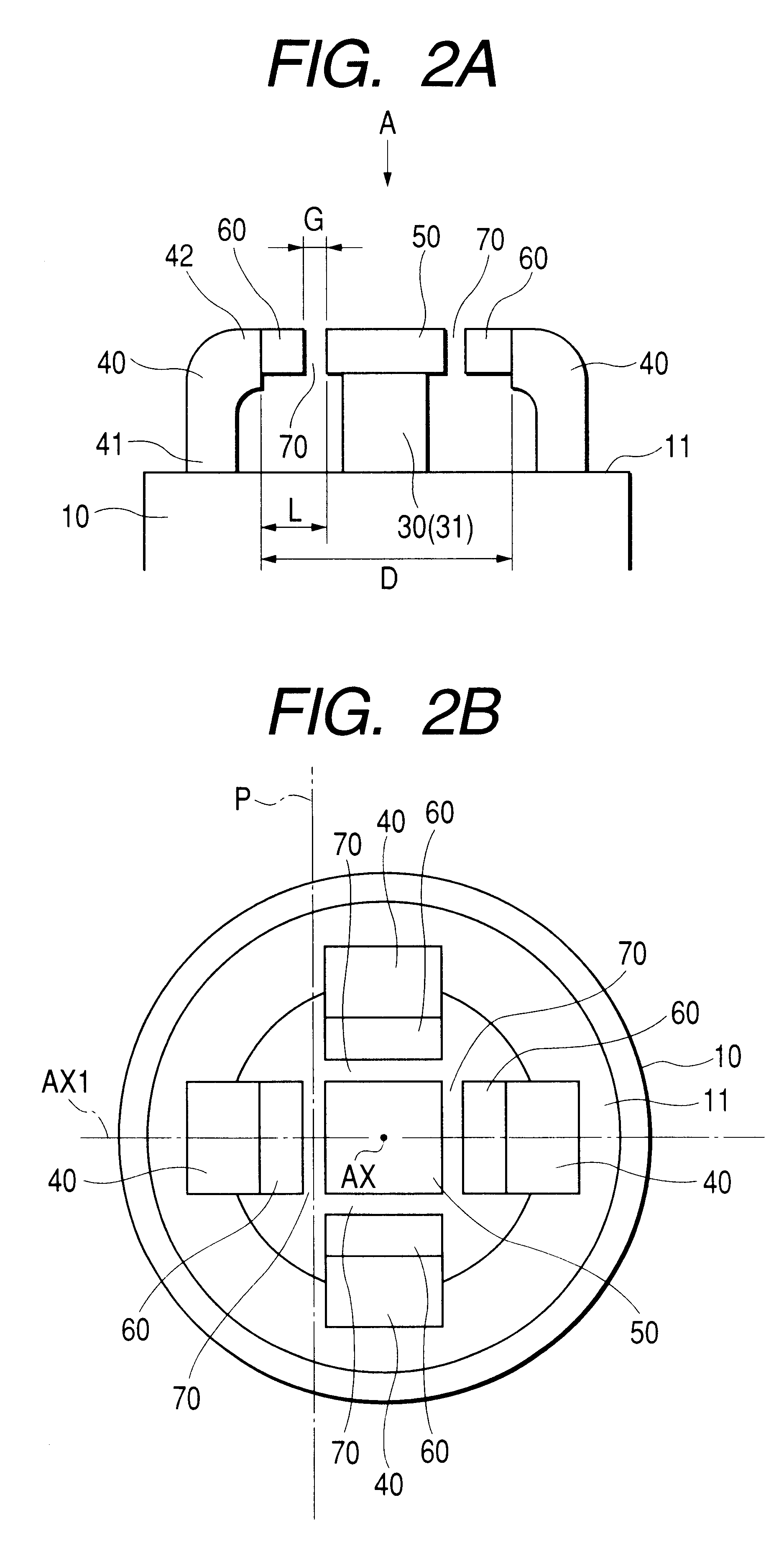

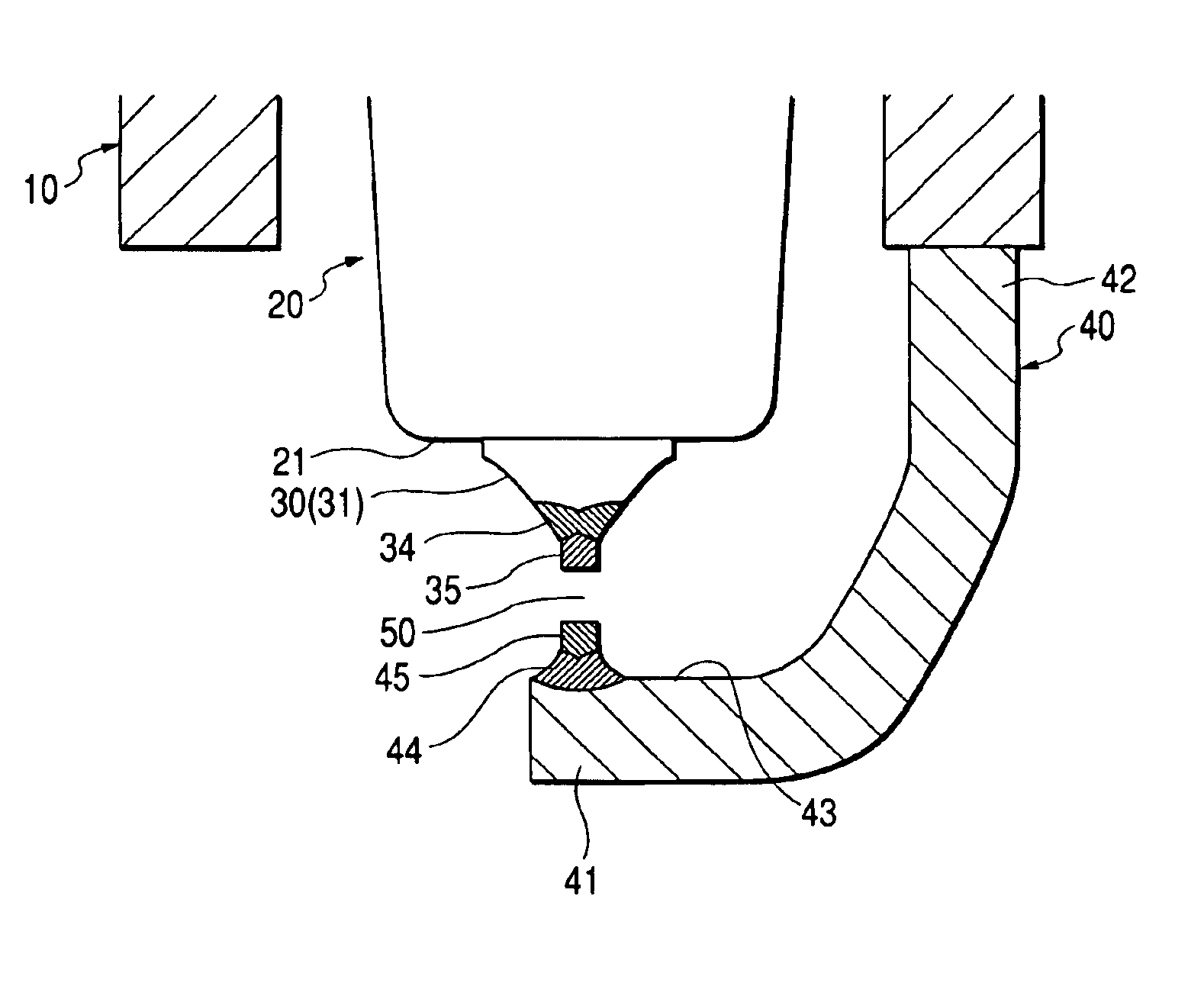

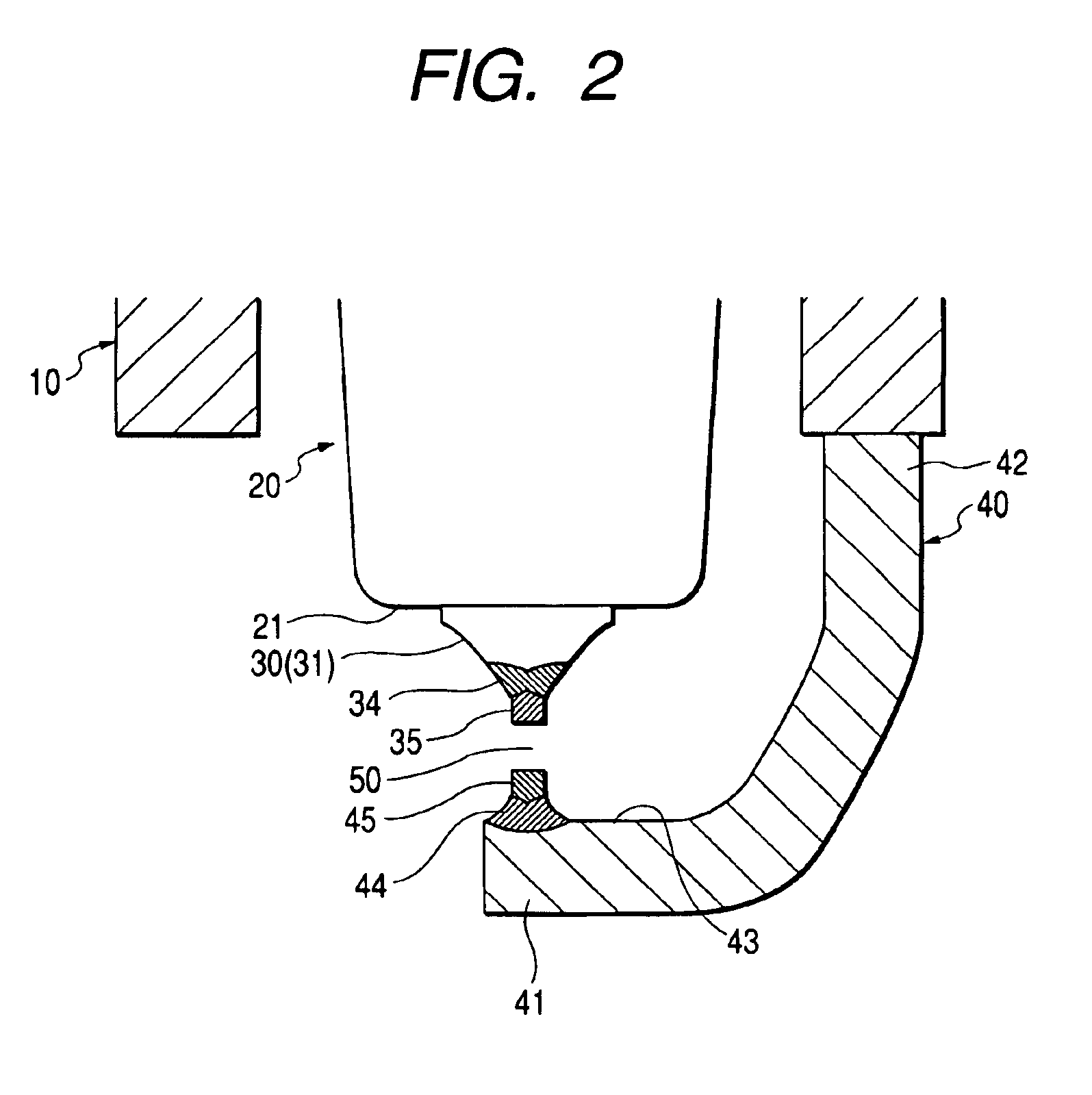

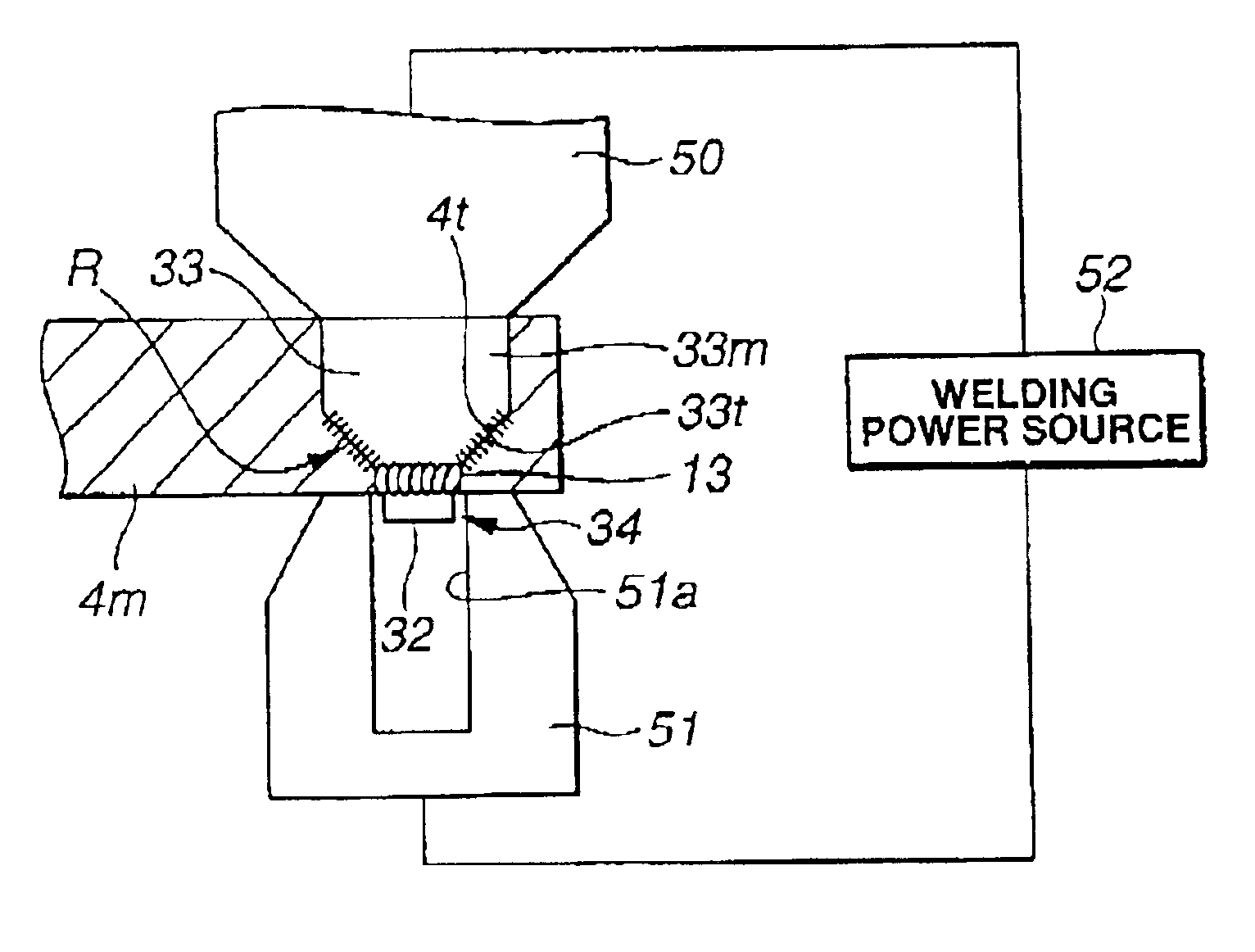

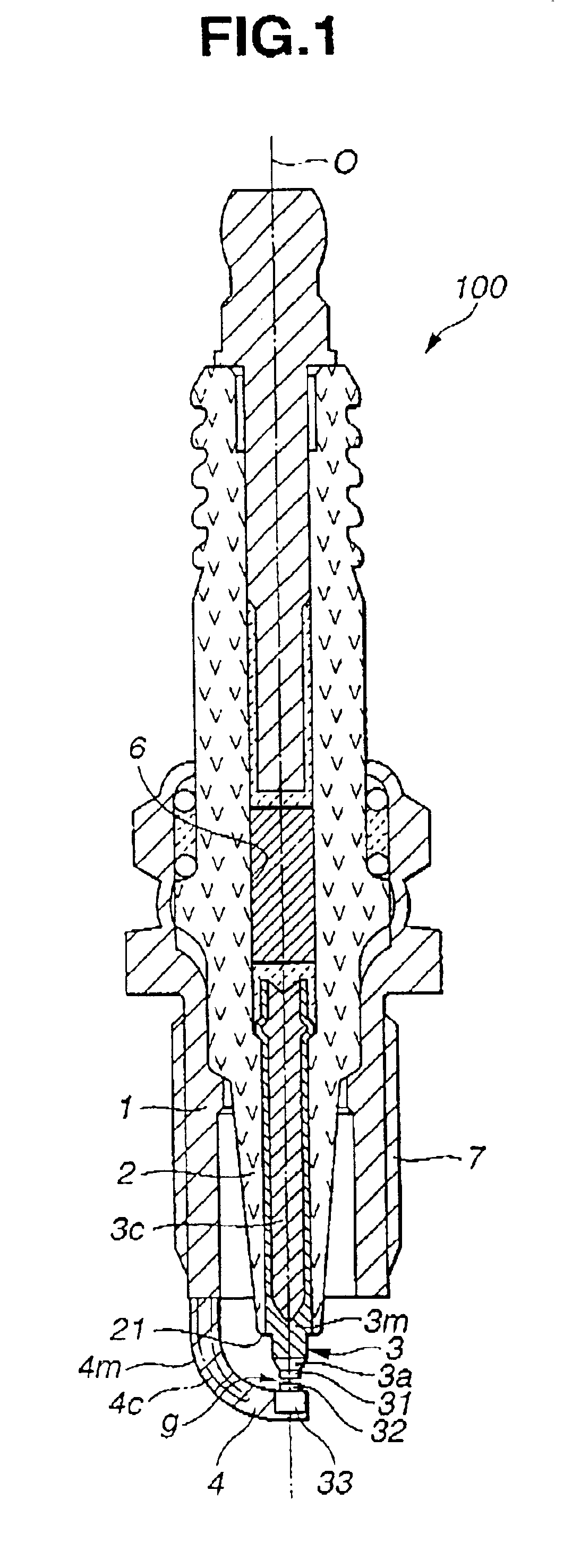

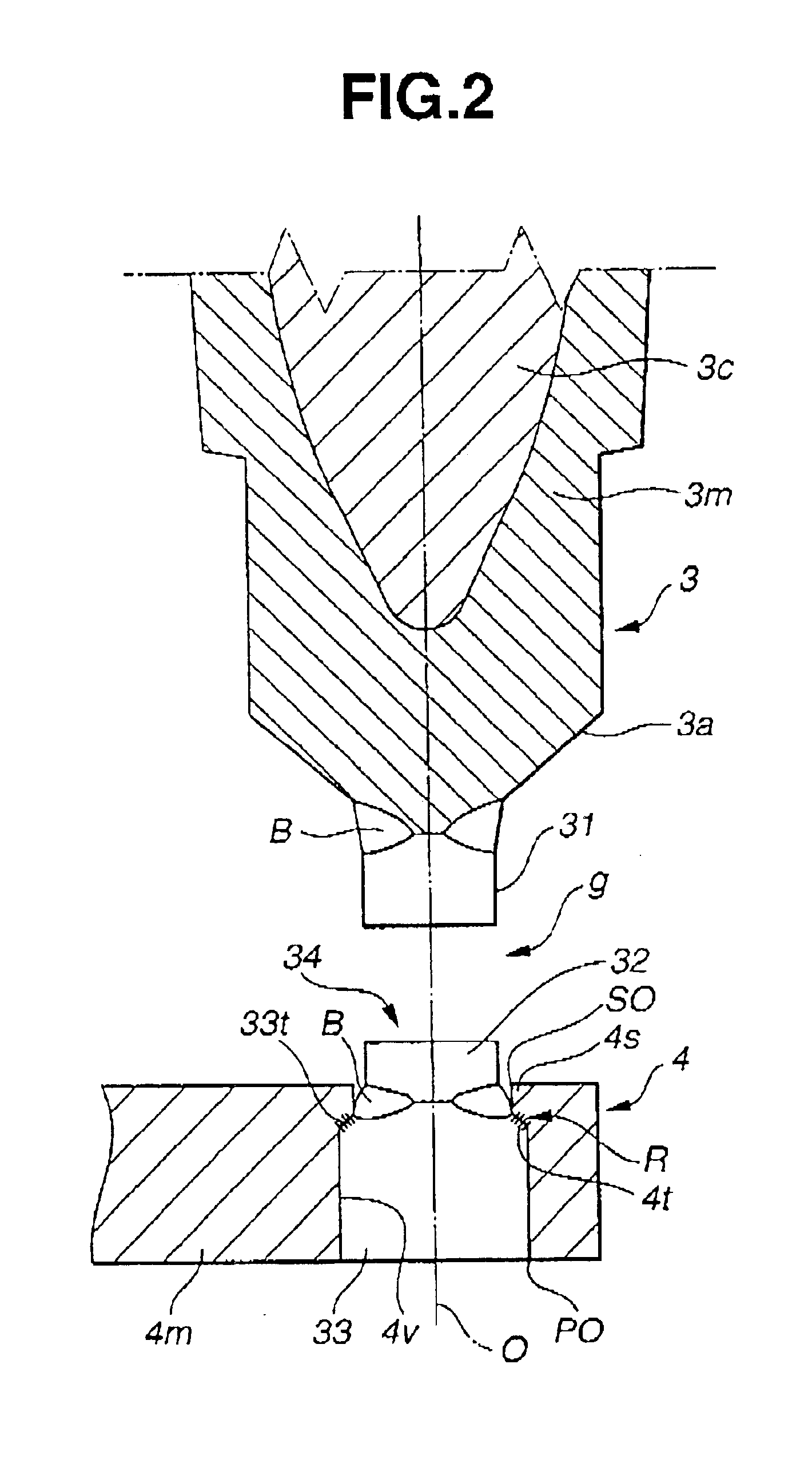

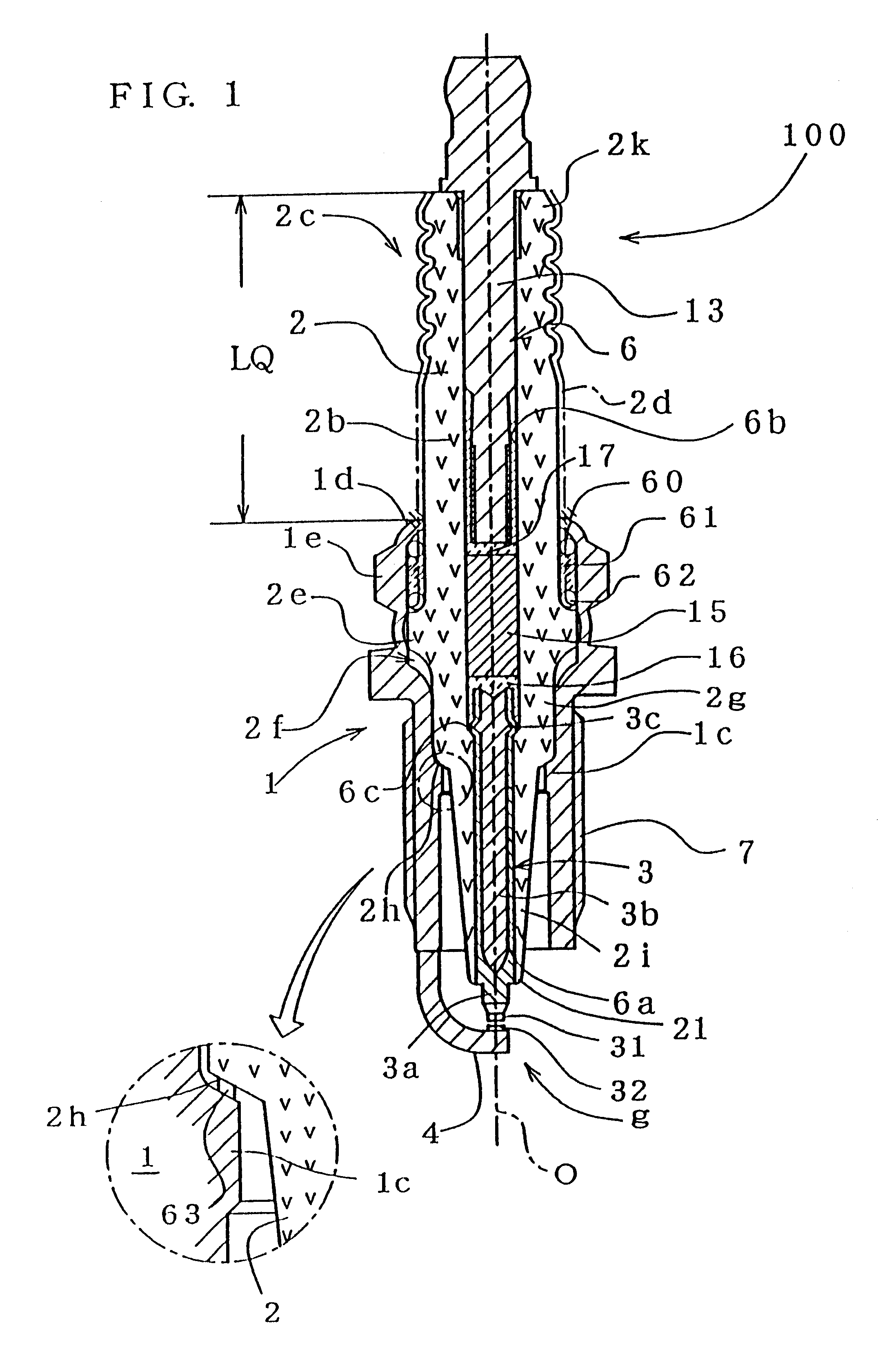

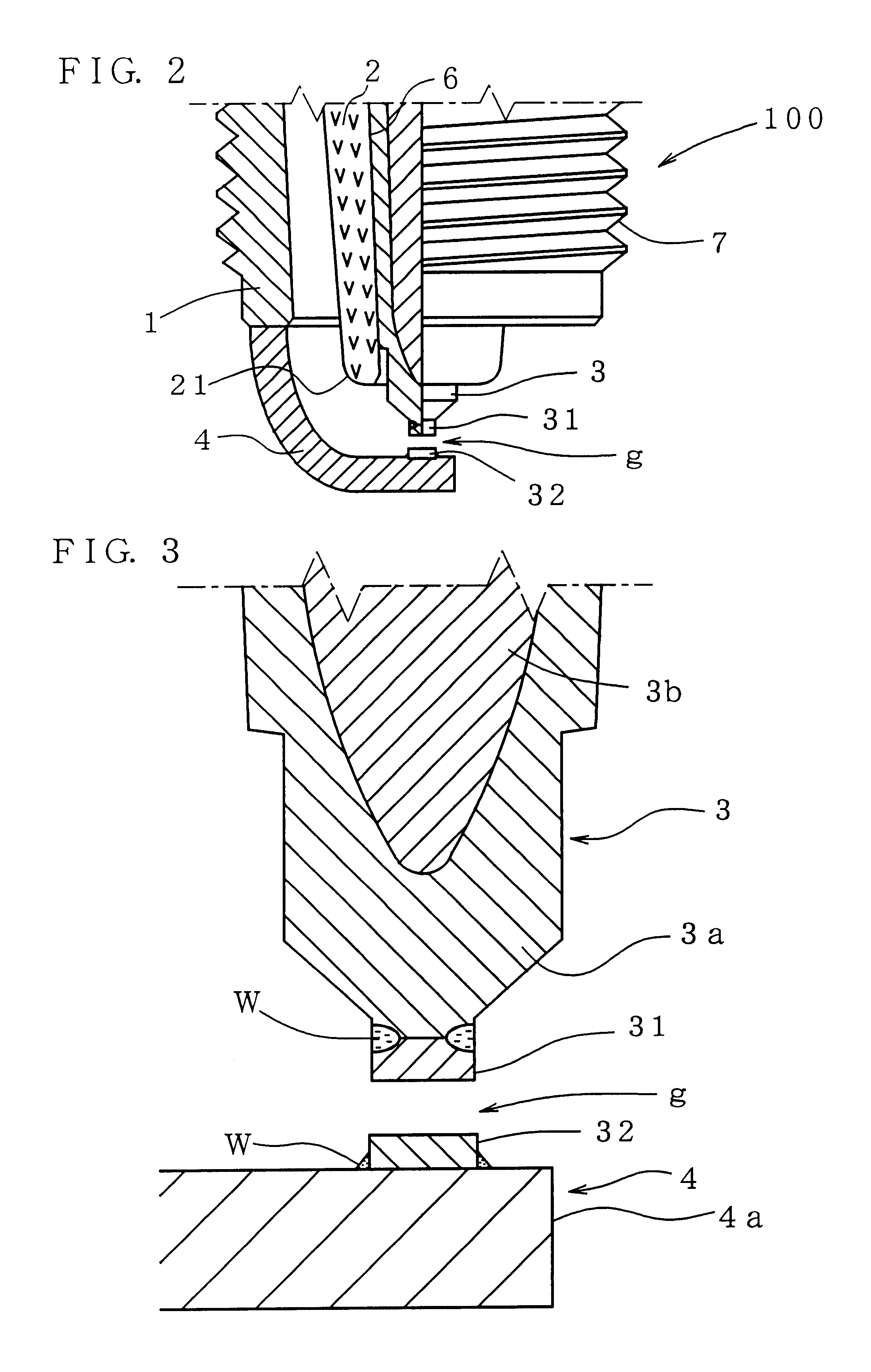

Spark plug and method for manufacturing the spark plug

InactiveUS7084558B2OptimizationJoining process can be facilitatedSpark gapsSparking plugs manufactureIn planeAlloy

A ground-electrode spark portion 32 is formed from a noble metal which contains Pt as a main component, and is joined to a main metal portion of the ground electrode 4 via an alloy layer which has a thickness ranging from 0.5 μm to 100 μm and in which the noble metal that constitutes the ground-electrode spark portion 32 and the metal that constitutes the main metal portion of the ground electrode 4 are alloyed with each other. The ground-electrode spark portion 32 is configured such that a distal end surface 32t facing a spark discharge gap g is smaller in diameter than a bottom surface 32u joined to the ground electrode 4; and the distal end surface 32t is protrusively located beyond the side surface 4s of the ground electrode 4. When the ground-electrode spark portion 32 is viewed in plane from the distal end surface 32t, a portion of the surface of the ground-electrode spark portion 32 is viewed as a peripheral exposed-region surface 32p which is exposed on the side surface 4s of the ground electrode 4 so as to surround the distal end surface 32t.

Owner:NGK SPARK PLUG CO LTD

Method for manufacturing a spark plug, and spark plug

A method for manufacturing a spark plug which reduces the generation of spatters and the possibility of insufficient weld strength resulting from penetration depth insufficiency of a weld metal portion is disclosed. In accordance with the method, a chip joint face formation portion of a center electrode is formed from a heat-resistant alloy predominantly containing Fe or Ni. A noble metal chip is attached to a chip joint face of the chip joint face formation portion to thereby form a chip-attached assembly. A full-circled laser-beam weld metal portion is formed on the chip-attached assembly in such a manner as to intrude into the noble metal chip and into the chip joint face formation portion. A graded-index-type fiber optic cable is used as an optical transmission path extending between a laser beam generator and an optical emission section. A laser beam which is transmitted from the laser beam generator through the cable irradiates the chip-attached assembly while being condensed.

Owner:NGK SPARK PLUG CO LTD

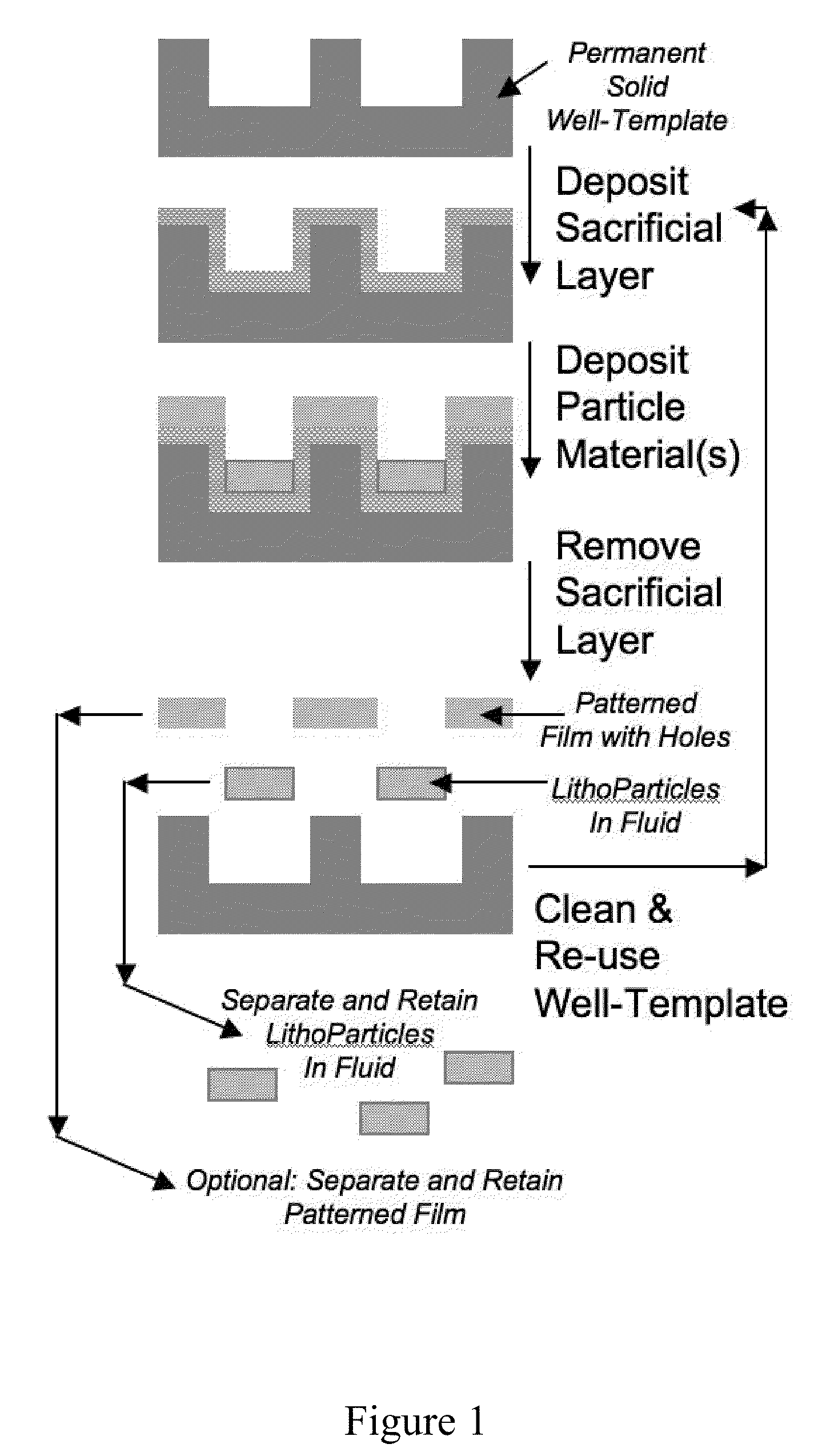

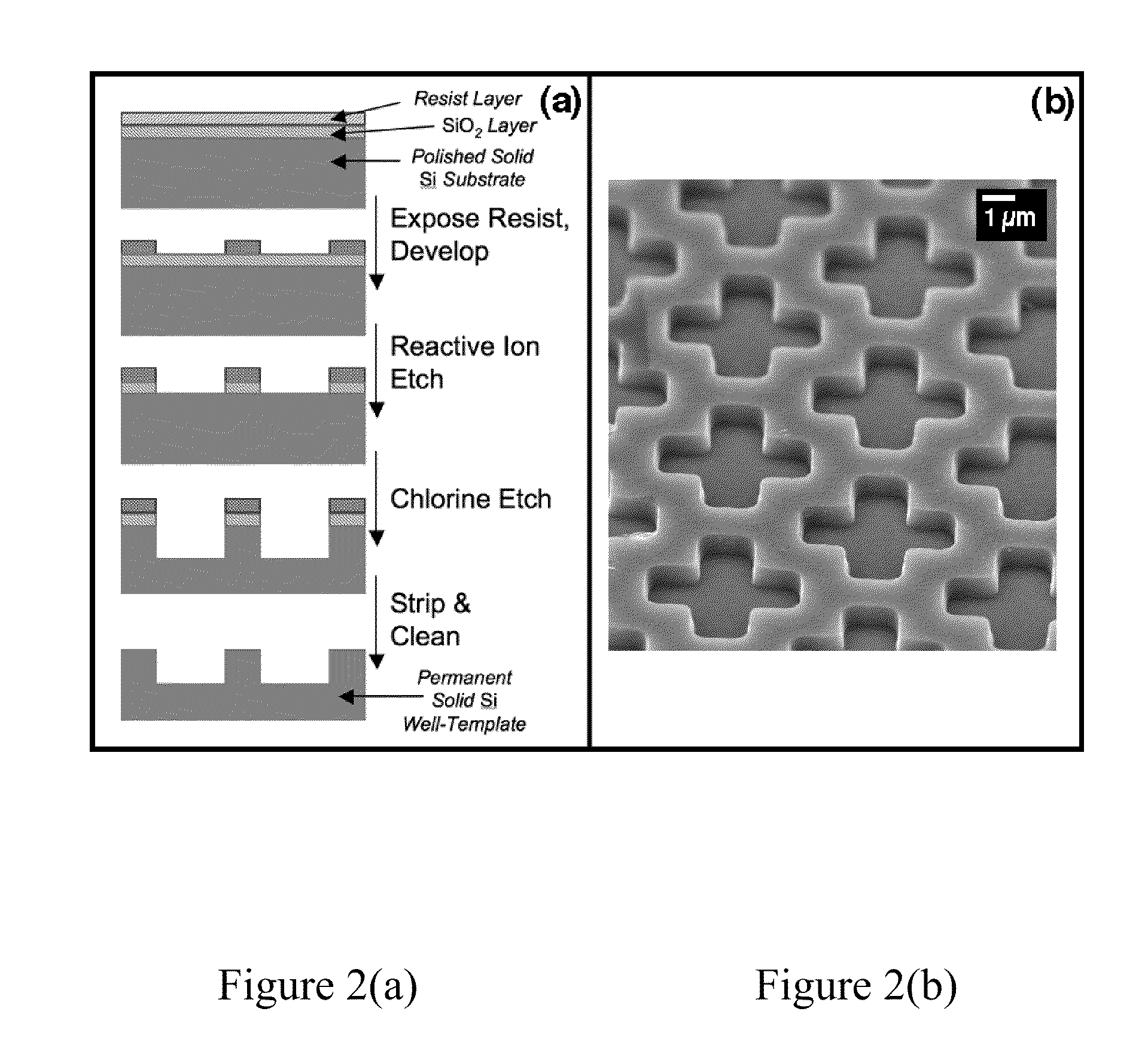

Mechanical process for creating particles in fluid

InactiveUS20100021985A1Impart propertyNanomagnetismLiquid surface applicatorsSurface geometryMaterials science

A method of producing at least one of microscopic and submicroscopic particles includes providing a template that has a plurality of discrete surface portions, each discrete surface portion having a surface geometry selected to impart a desired geometrical property to a particle while being produced; depositing a constituent material of the at least one of microscopic and submicroscopic particles being produced onto the plurality of discrete surface portions of the template to form at least portions of the particles; separating the at least one of microscopic and submicroscopic particles comprising the constituent material from the template into a fluid material, the particles being separate from each other at respective discrete surface portions of the template; and processing the template for subsequent use in producing additional at least one of microscopic and submicroscopic particles. A multi-component composition includes a first material component in which particles can be dispersed, and a plurality of particles dispersed in the first material component. The plurality of particles is produced by methods according to embodiments of the current invention.

Owner:RGT UNIV OF CALIFORNIA

Spark plug and its manufacturing method

InactiveUS6885135B2Satisfactory propertyImprove adhesion strengthSpark gapsSparking plugs manufactureFree energiesAlloy

Noble metallic tips, made of a Pt alloy or an Ir alloy, are fixed to electrode base materials. The electrode base materials are an alloy containing a chief element selected from the group consisting of Ni, Fe, and Co and a plurality of additive elements. At least two kinds of additive elements contained in this alloy have a standard free energy of formation smaller than that of the chief element.

Owner:DENSO CORP

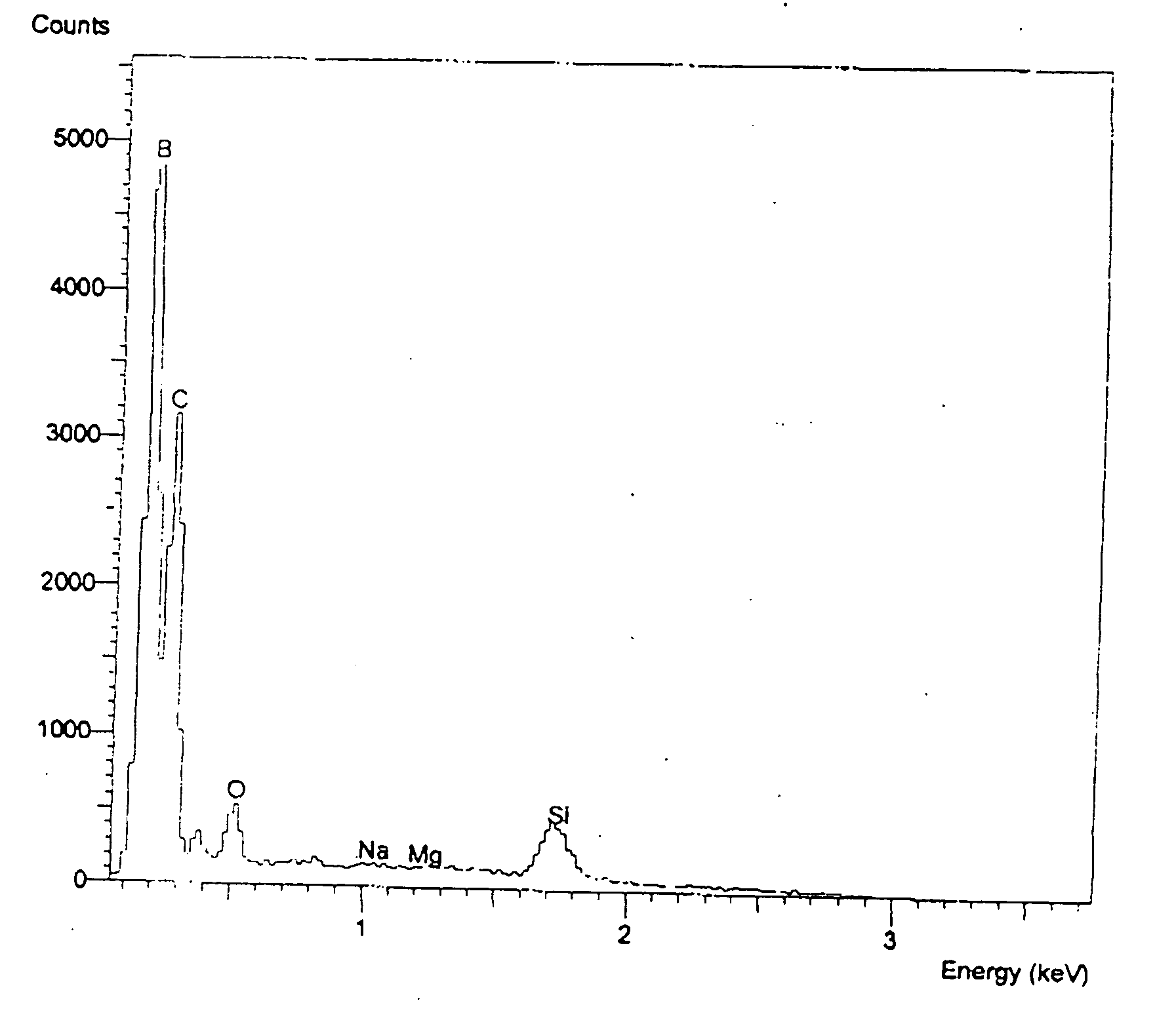

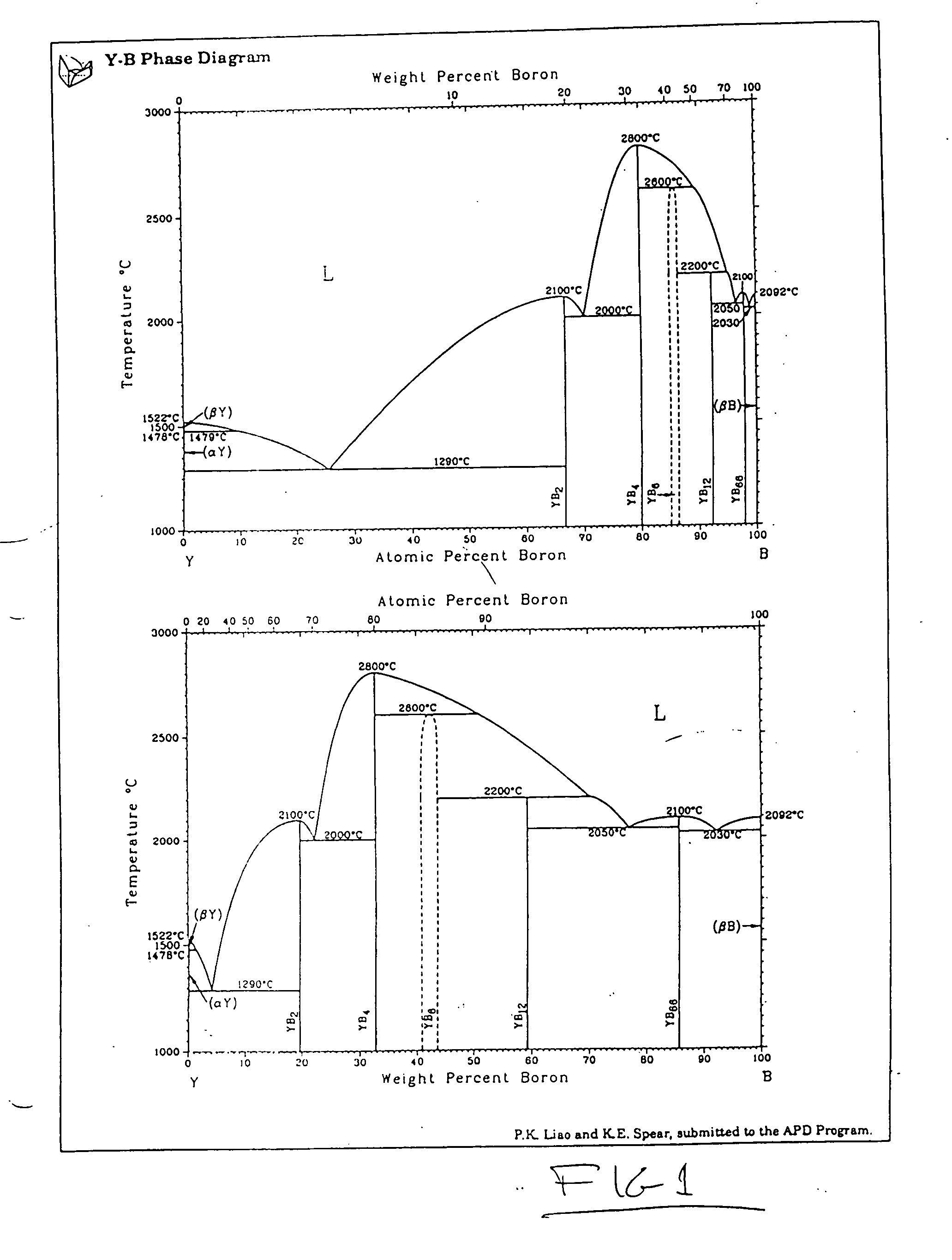

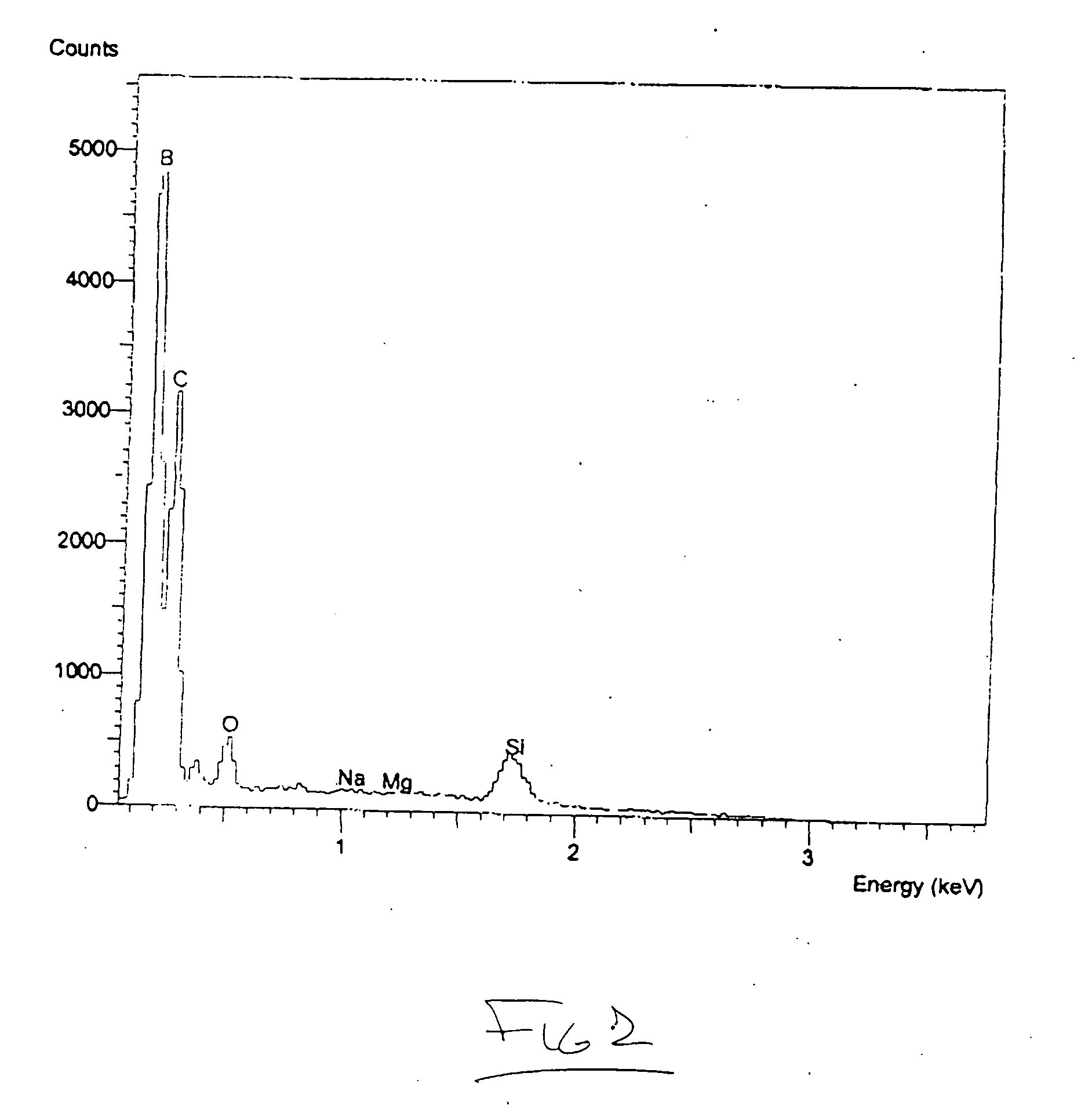

Method for depositing boron-rich coatings

InactiveUS20050208218A1Not readyReduce usageSpark gapsLiquid surface applicatorsLutetiumControl manner

A method is disclosed for coating substantially pure boron or highly boron-rich borides in a controlled manner. Such a method of coating of boron has a variety of applications, including surface chemical and wear protection, neutron absorption, prevention of impurity emission from heated filaments and ion beams, elimination of metal dust from vacuum systems, boridizing, boron cluster emission, and reactive chemistry. Borides with a boron-to-metal ratio of 20 or more are known to exist and may be used as a feedstock for substantially pure boron coatings for deposition processes requiring feedstock electrical conductivity, and / or enhanced reactivity. While most metal borides coincidentally produce significant metal vapor as a by-product, certain borides of yttrium, holmium, erbium, thulium, terbium, gadolinium, and lutetium have been identified as capable of producing substantially pure boron vapor.

Owner:IBADEX

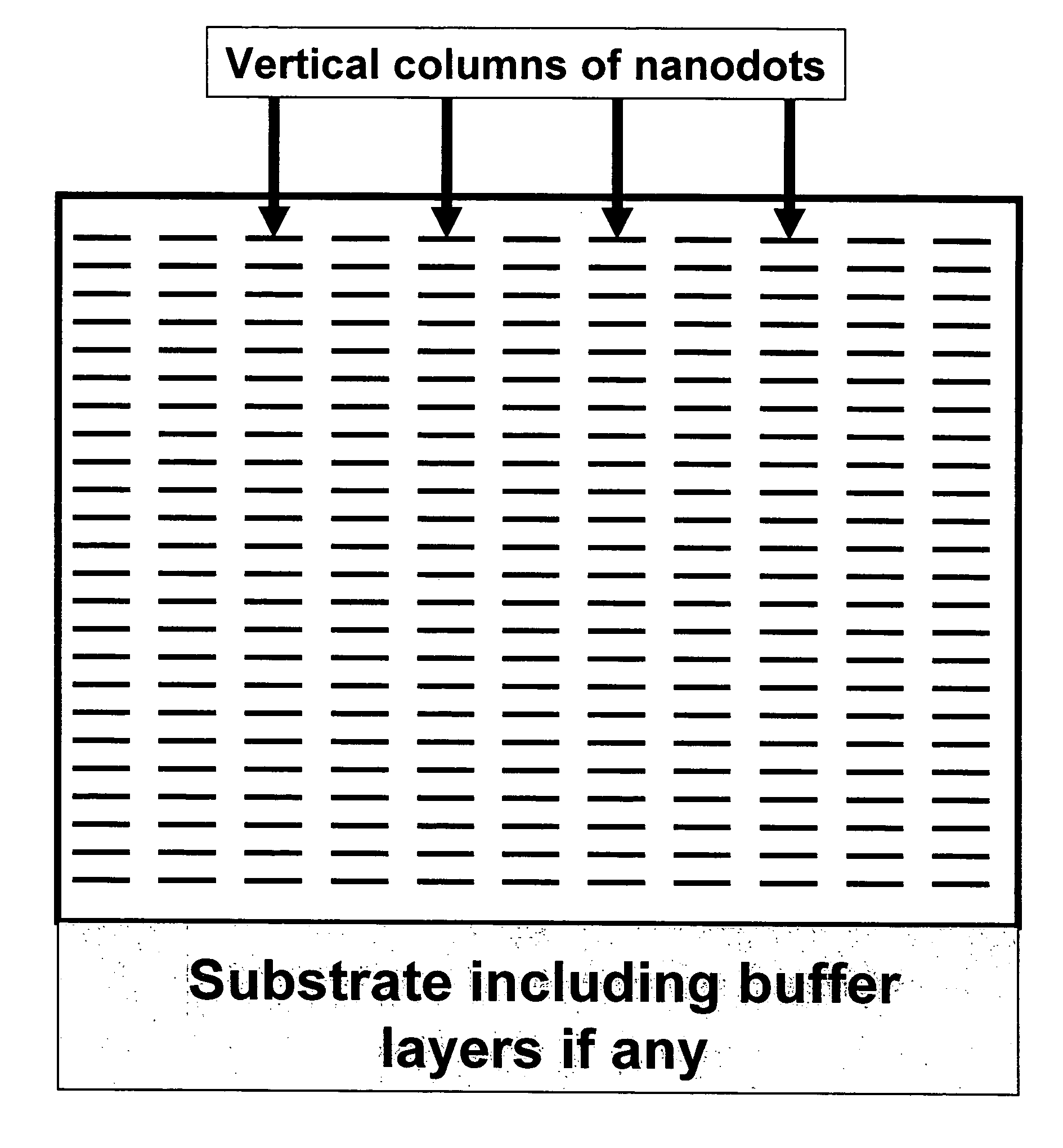

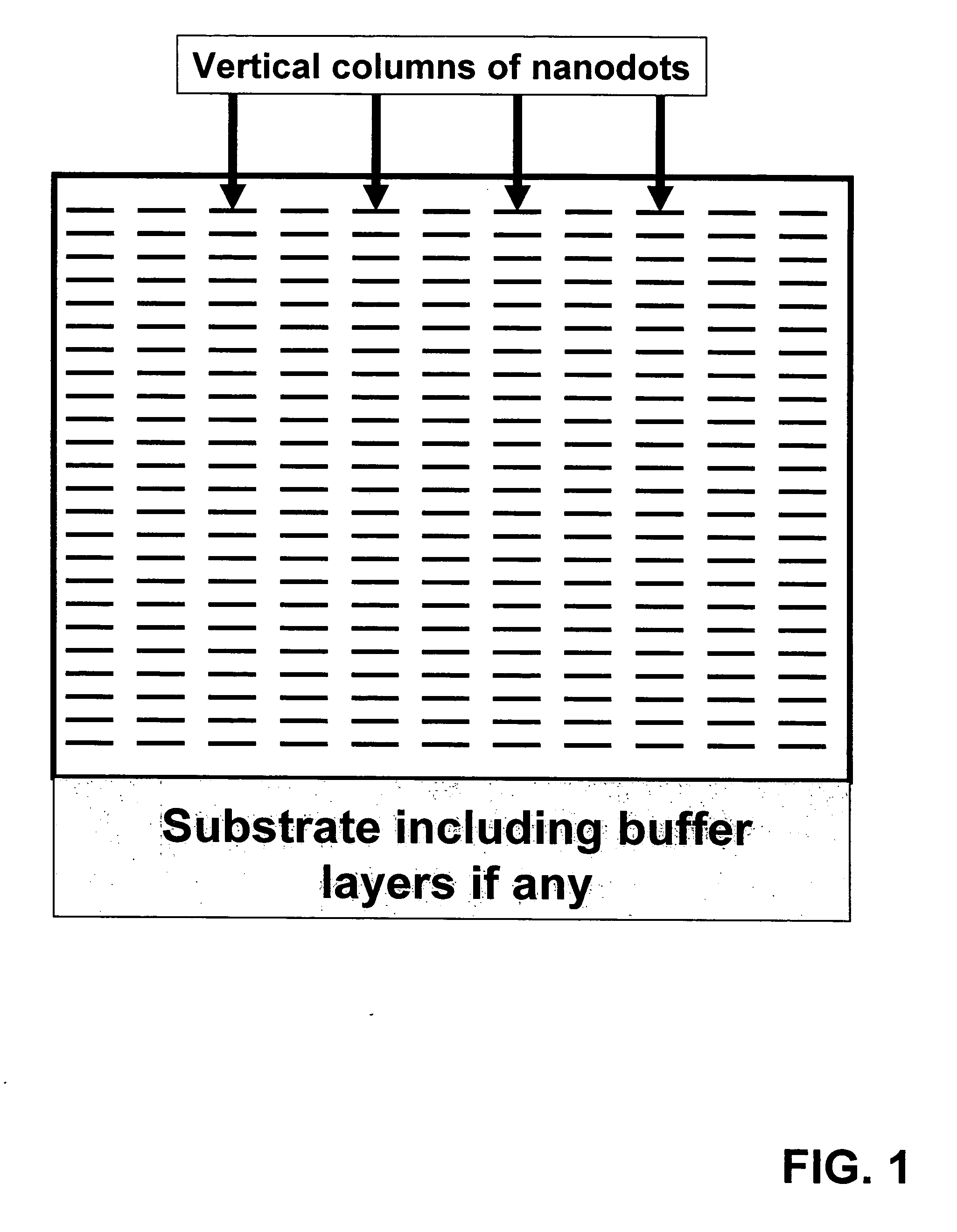

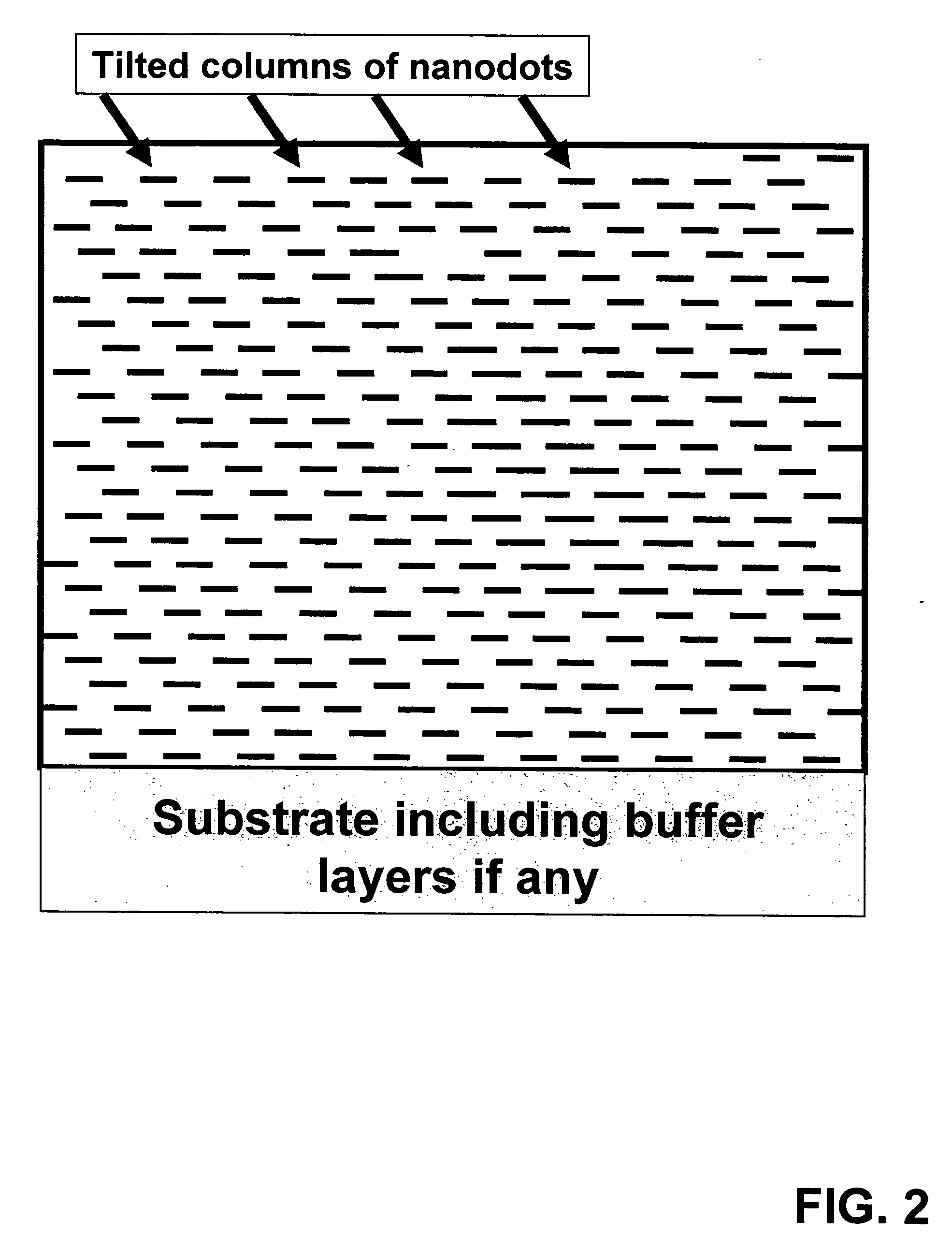

High performance electrical, magnetic, electromagnetic and electrooptical devices enabled by three dimensionally ordered nanodots and nanorods

InactiveUS20090088325A1Improve performanceVacuum evaporation coatingSputtering coatingNanodotPhotoluminescence

Novel articles and methods to fabricate same with self-assembled nanodots and / or nanorods of a single or multicomponent material within another single or multicomponent material for use in electrical, electronic, magnetic, electromagnetic and electrooptical devices is disclosed. Self-assembled nanodots and / or nanorods are ordered arrays wherein ordering occurs due to strain minimization during growth of the materials. A simple method to accomplish this when depositing in-situ films is also disclosed. Device applications of resulting materials are in areas of superconductivity, photovoltaics, ferroelectrics, magnetoresistance, high density storage, solid state lighting, non-volatile memory, photoluminescence, thermoelectrics and in quantum dot lasers.

Owner:GOYAL AMIT

Method of producing a spark plug

In producing a spark plug including a central electrode having a first chip including noble metal and an earth electrode having a second chip including the noble metal, a spark gap being disposed between the first and second chips, a chip including the noble metal. The chip is welded to an end of the central electrode and to an end of the earth electrode. The welded chip is cut to form the first and second chips and the spark gap.

Owner:DENSO CORP

Structure of spark plug designed to provide higher durability and ignitability of fuel

InactiveUS6853116B2Improve welding reliabilityImprove flammabilitySpark gapsFuel injection apparatusMaximum depthEngineering

An improved structure of a spark plug which provides higher durability and ignitability of a gaseous fuel. The spark plug consists of a center electrode, a ground electrode, a noble metal chip joined to a center electrode-opposed surface of the ground electrode by laser welding, and a fused portion that forms a weld of the noble metal chip and the ground electrode formed by materials of the ground electrode and the noble metal chip melted together. A sectional area of the noble metal chip traversing a length thereof is between 0.1 mm2 and 0.6 mm2. An unfused sectional area percentage that is a percentage of a sectional area of an unfused portion of a joined end of the noble metal chip within a range of a sectional area of the noble metal chip closest to the fused portion traversing the length of the noble metal chip is less than or equal to 50%. A melt angle that is an angle which a line extending through the fused portion along a maximum depth of the fused portion makes with the center electrode-opposed surface of the ground electrode is less than or equal to 60°.

Owner:DENSO CORP

Method of making a spark plug

InactiveUS6923699B2Restrict movementHigh melting pointLine/current collector detailsSpark gapsBiomedical engineeringGrounding electrodes

A method of making a spark plug having a noble metal chip joined to an electrode main body of a ground electrode by interposing therebetween an intermediate member. The method comprises the steps of prior to joining the noble metal chip to the electrode main body, joining the intermediate member and the noble metal chip together, placing a noble metal chip and intermediate member assembly on the electrode main body in a way as to allow the intermediate member to contact the electrode main body, and welding the electrode main body and the intermediate member together while restricting relative movement of the electrode main body and the intermediate member without applying an urging force to a joint between the intermediate member and the noble metal chip.

Owner:NGK SPARK PLUG CO LTD

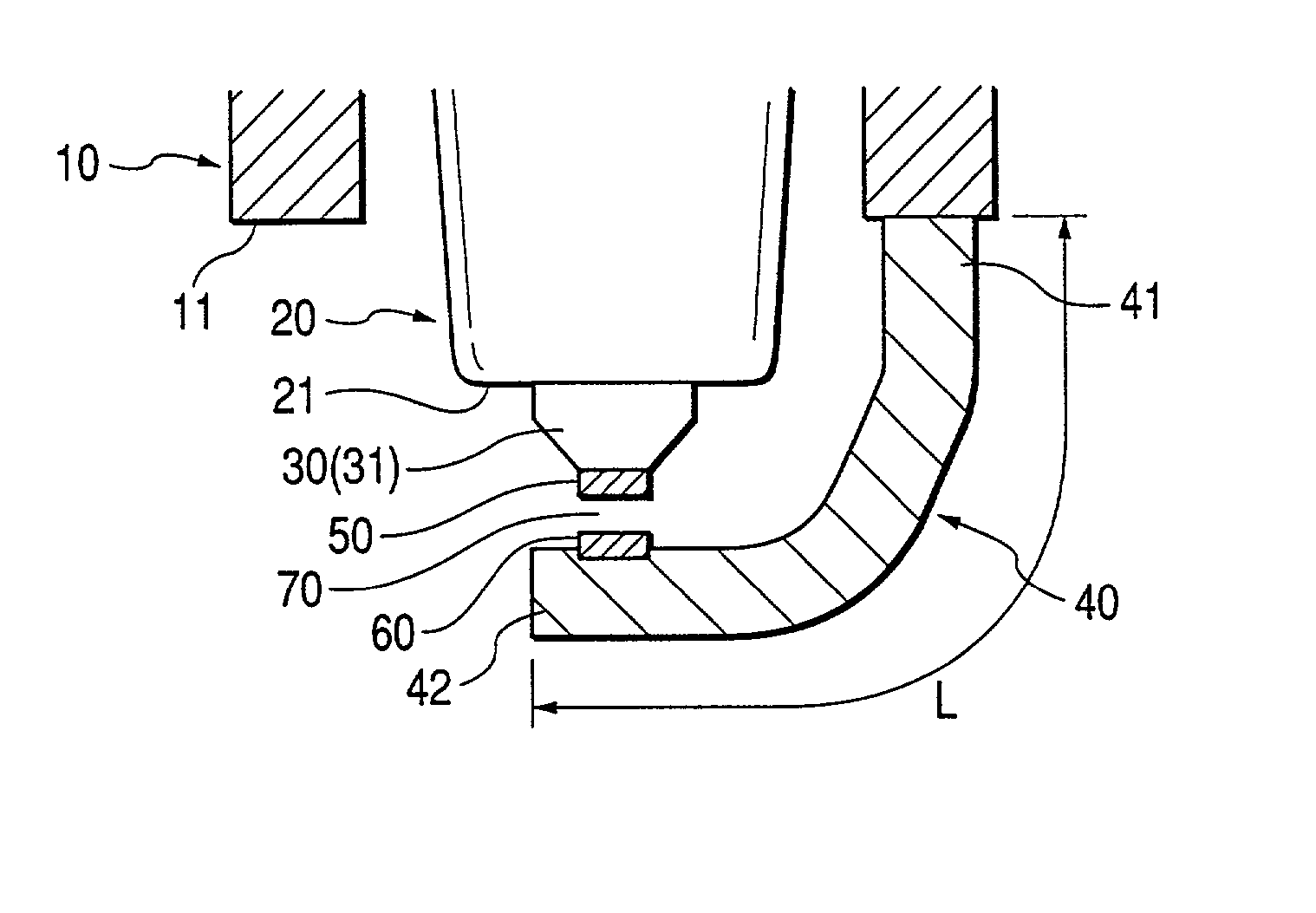

Electrode rod for spark deposition, process for the production thereof, and process for covering with superabrasive-containing layer

InactiveUS6336950B1Simple stepsSpark gapsMolten spray coatingSelf-propagating high-temperature synthesisBoride

An aspect of this invention is an electrode rod for spark alloying, comprising a compact of a first powder of a first component which comprises a metal selected from a group of Fe, Co, Ni, metals of 4a, 5a and 6a of the periodic table and Si, and a second powder of a second component which is capable of self-propagating high temperature synthesis to form with said first component carbide, nitride, boride, silicide or intermetallic compound, said first and second powders being mixed intimately with each other and formed into an axial rod. Another aspect is a method for the production of the electrospark alloying rod, comprising: mixing intimately a first powder of first component and a second powder of second component, said first component comprising at least one selected from Fe, Co, Ni, metals of groups 4a, 5a and 6a, Sn, Zn, Pb, Al and Cu, said second component comprising materials capable of SHS process to form a refractory (or intermetallic) compound, compressing said mixture, followed or not by further firing, and thereby forming an axial body with a bulk density 0.50 to 0.86 time the theoretical values for the corresponding substances. Still another aspect is a method for the deposition of a coating on a work by causing and holding an electric spark between said electrode rod and work, whereby transferring the materials of said first and second components to the surface of said work, and depositing thereon as a layer or more layers of such compound.

Owner:2 KANAGAWA +3

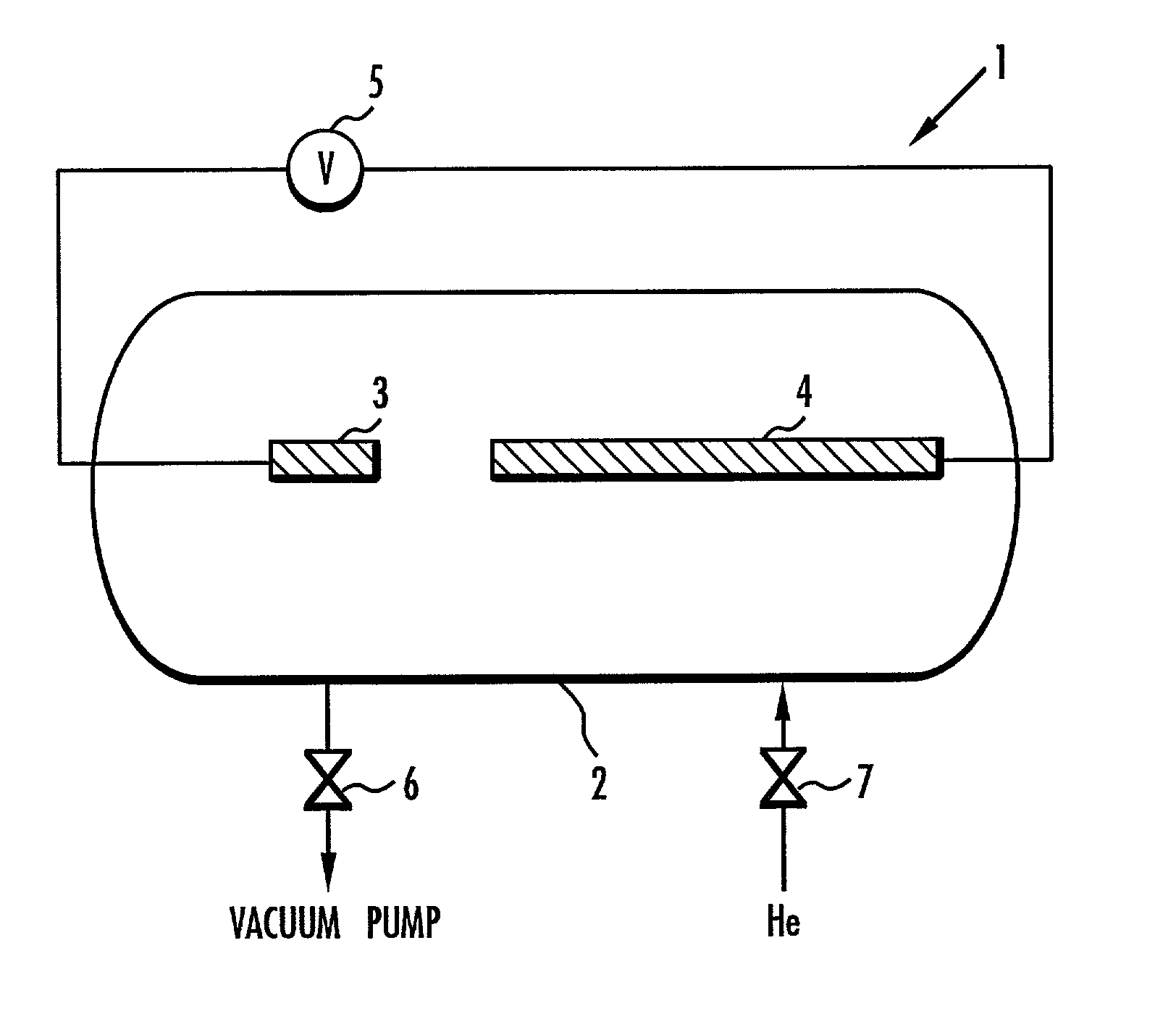

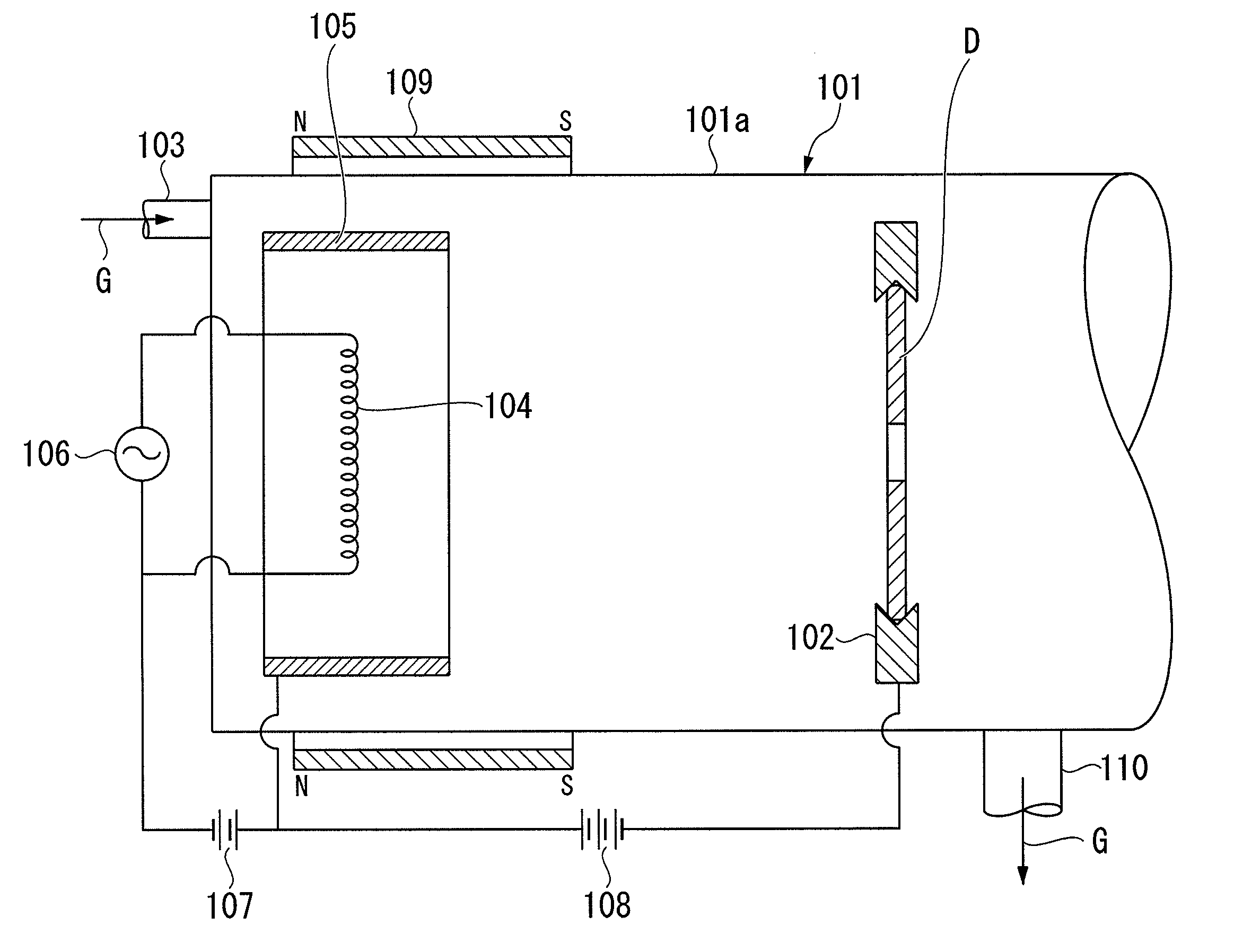

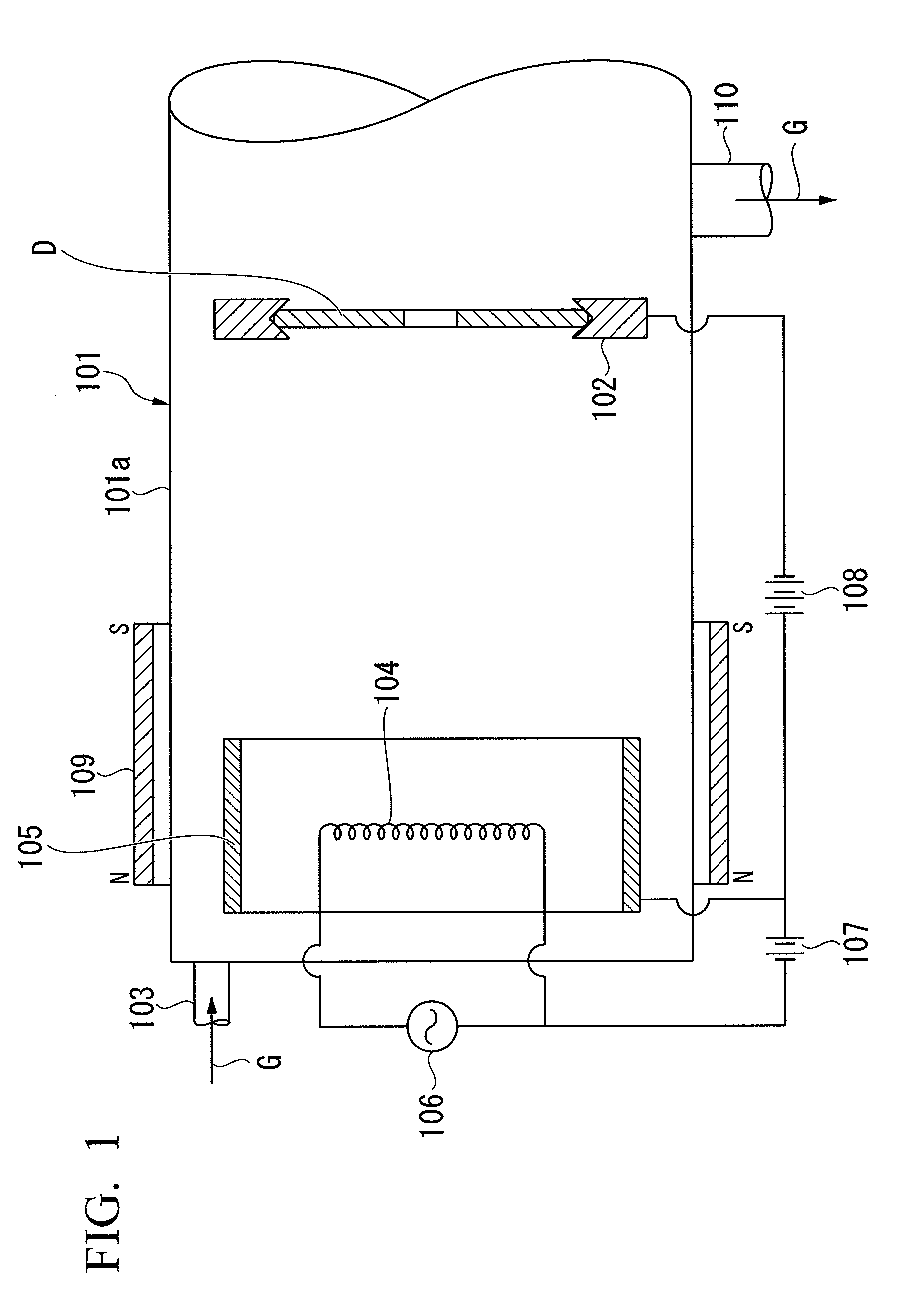

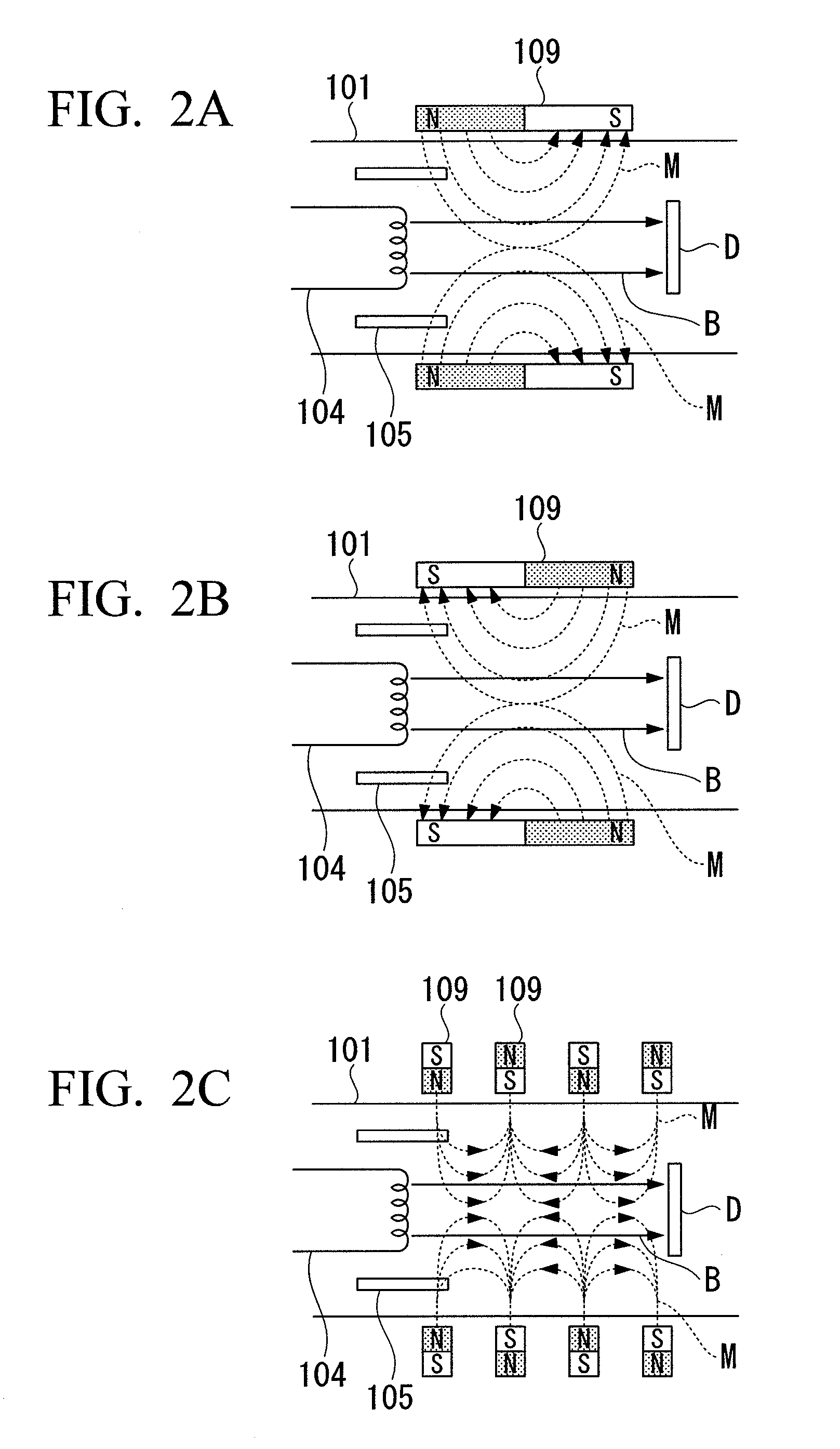

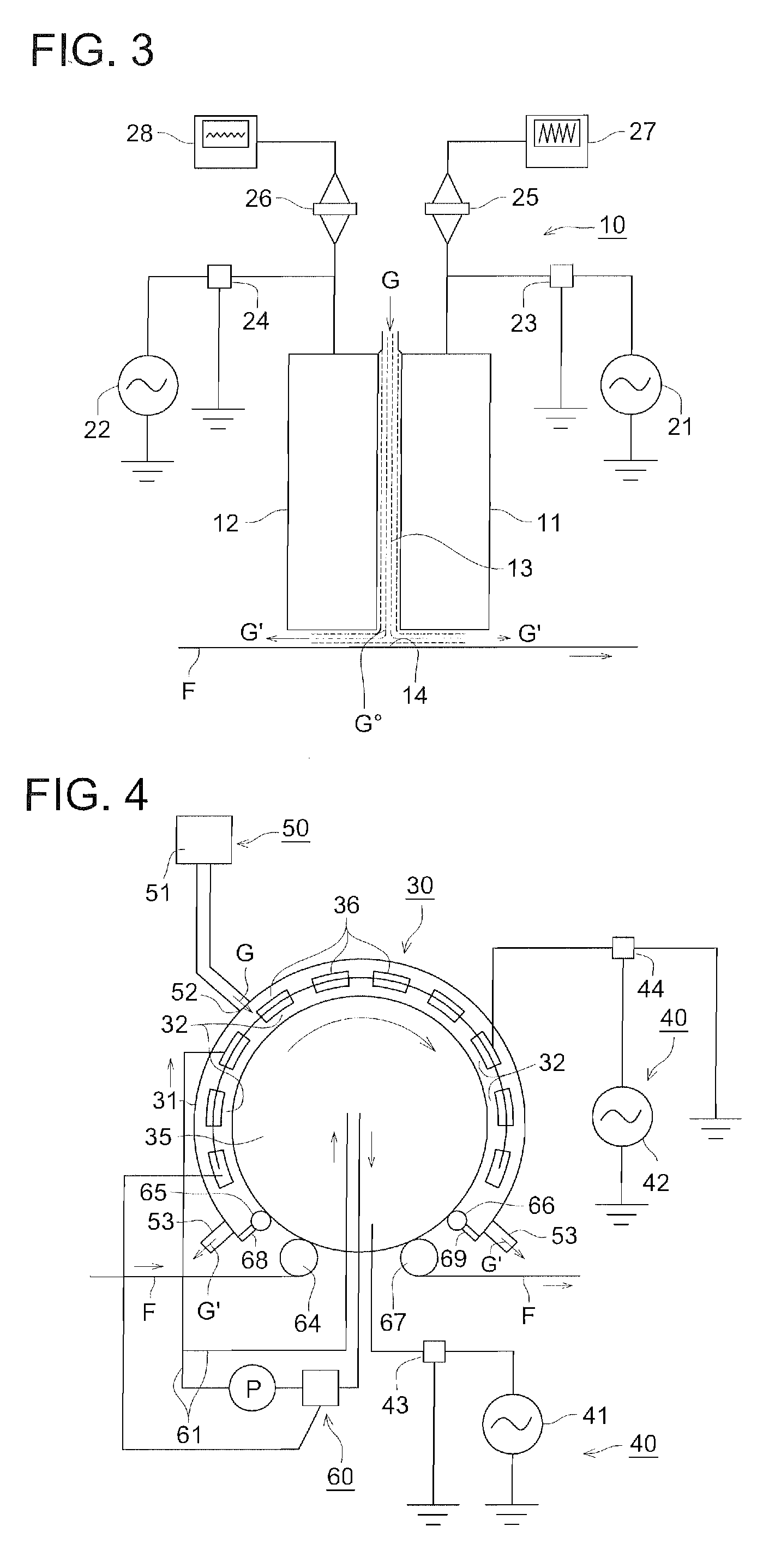

Method of forming carbon film, method of manufacturing magnetic recording medium, and apparatus for forming carbon film

InactiveUS20100028563A1High hardnessReduce thicknessSpark gapsMagnetic layer protectionCarbon filmInternal pressure

The present invention provides a carbon film forming method capable of forming a dense carbon film with high hardness. The carbon film forming method includes: introducing a raw material gas G including carbon into a deposition chamber 101 whose internal pressure is reduced; ionizing the raw material gas G using a discharge between a filament-shaped cathode electrode 104 heated by electrical power and an anode electrode 105 provided around the cathode electrode; and accelerating and radiating the ionized gas to the surface of a substrate D. A magnetic field is applied by a permanent magnet 109 to increase the ion density of the ionized gas accelerated and radiated to the surface of the substrate D. In this way, it is possible to form a carbon film with high hardness and high density on the surface of the substrate D.

Owner:SHOWA DENKO HD SINGAPORE PTE

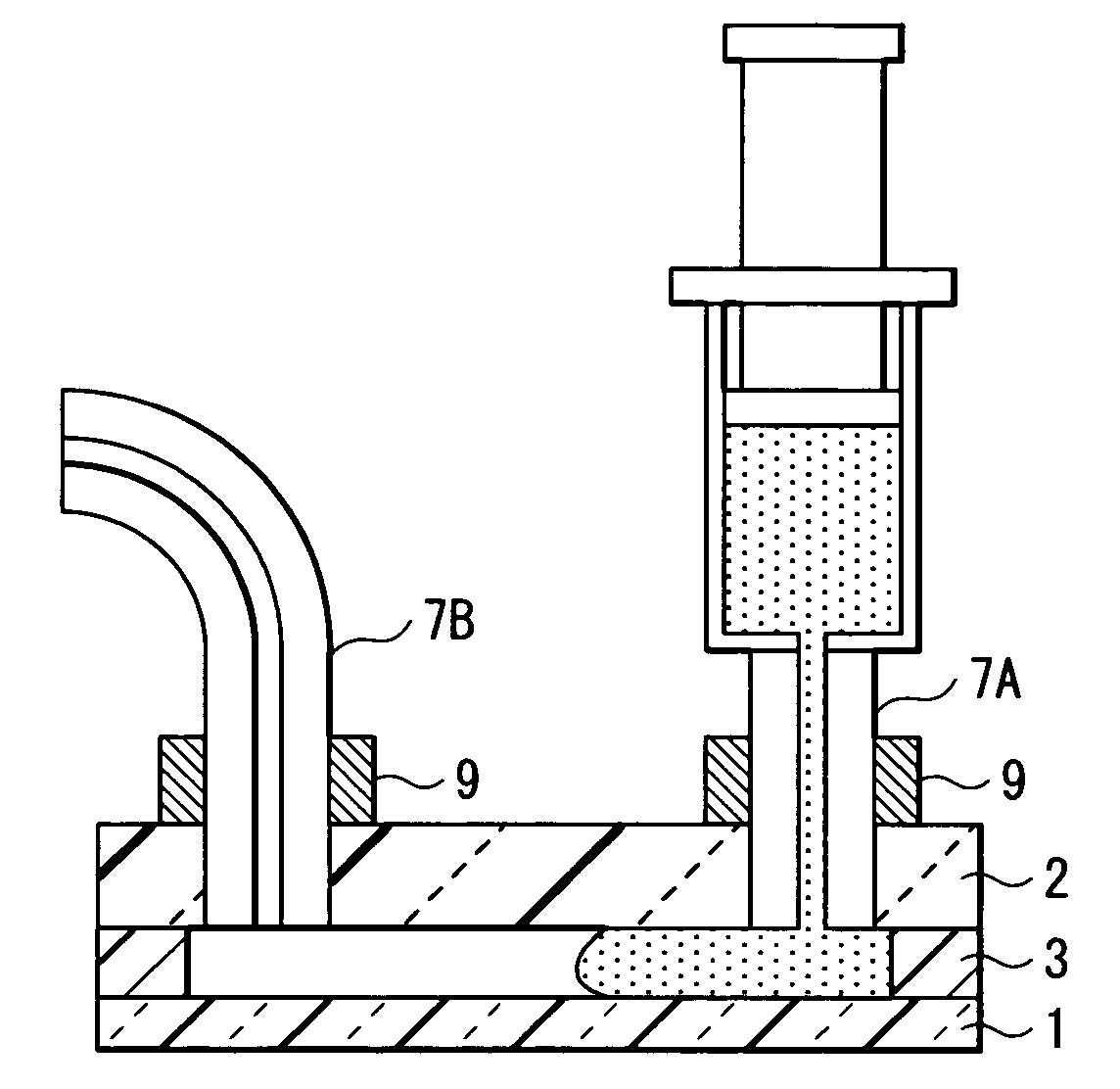

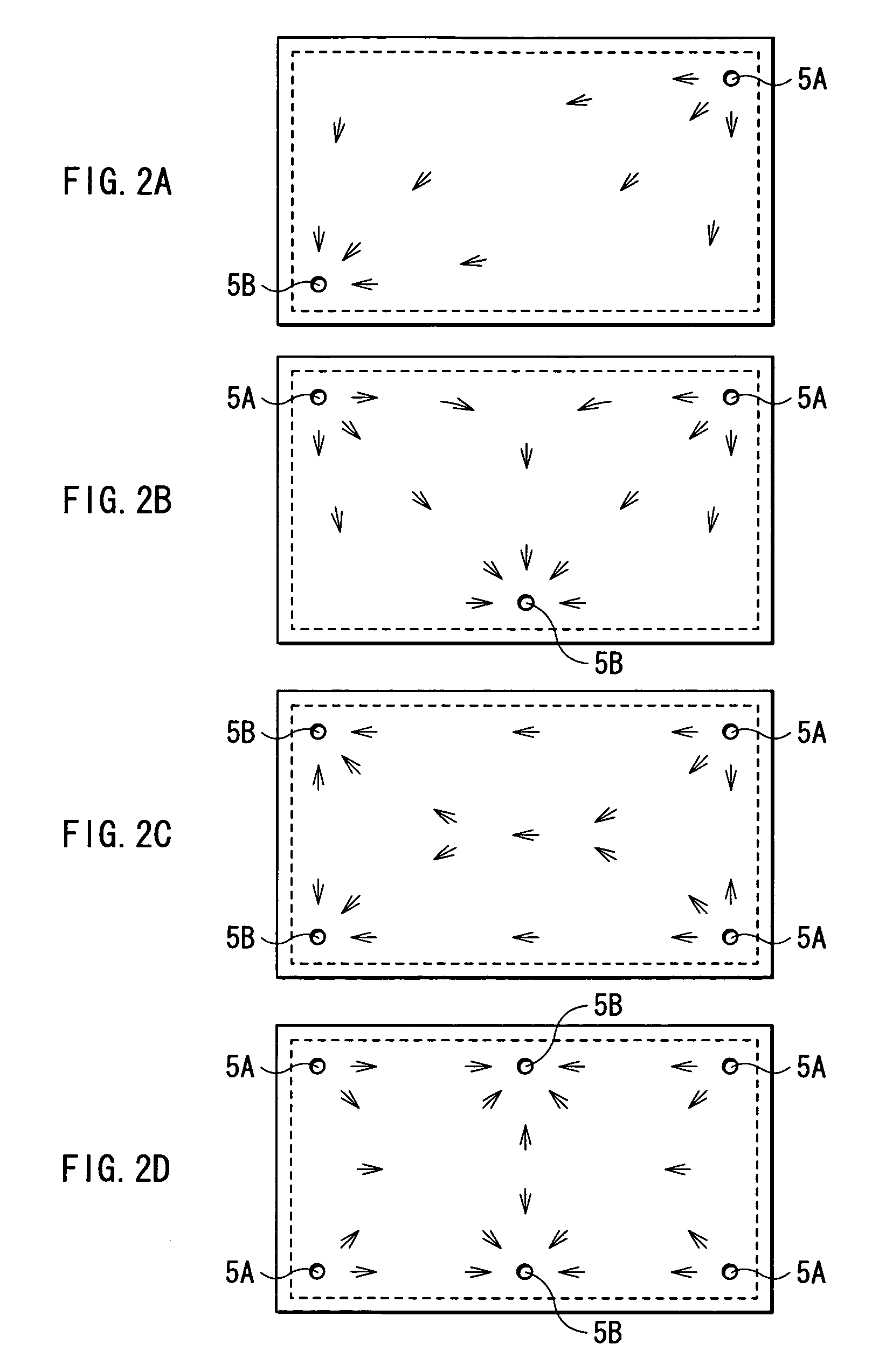

Electrodeposition display panel manufacturing method, electrodeposition display panel, and electrodeposition display device

An electrodeposition display panel manufacturing method capable of manufacturing a highly reliable display panel in a short time and effectively, an electrodeposition display panel, and an electrodeposition display device are provided. Openings (5A), (5B) are provided in a rear substrate (2) of the cell. A nozzle (7A) to which an injector (8) is connected on the other side is inserted into the opening (5A), and a nozzle (7B) is inserted into the opening (5B). On the other end side of the nozzle (7B), a container for recovering a spilled display material (6) and a decompressor are arranged. While the display material (6) is pressure-injected from the opening (5A), evacuation and discharging air bubbles and the like are performed from the opening (5B). Thereby, the display material (6) is filled in the cell.

Owner:SONY CORP

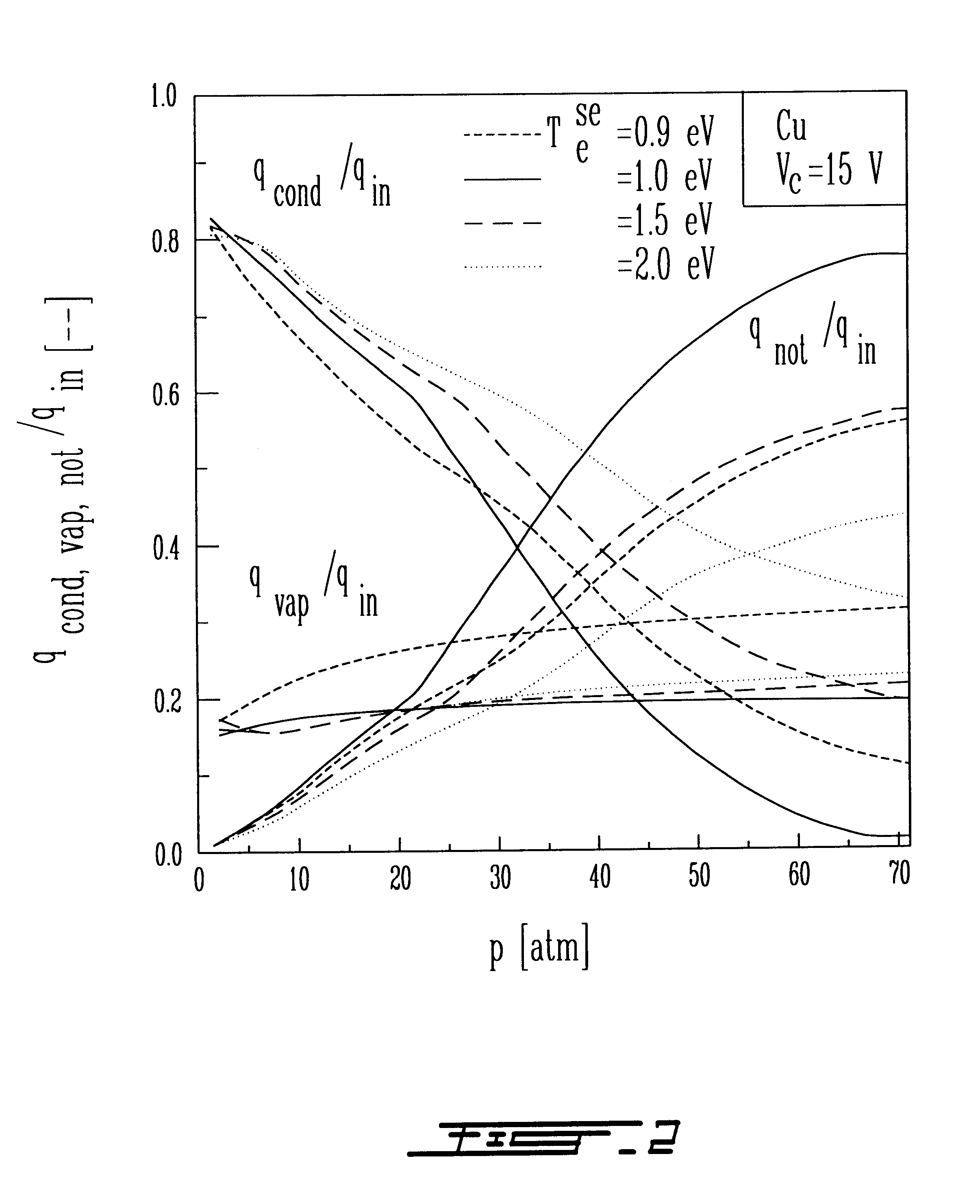

Particle-free cathodic arc carbon ion source

A method and apparatus for vacuum arc deposition of carbon on a substrate inhibits or eliminates emission of contaminating carbon particles in the ion plasma by maintaining an elevated local plasma pressure at the cathode or target surface, thereby minimizing the role of heat conduction in the creation of the particles and strongly increasing the electron emission cooling effects.

Owner:MCGILL UNIV

Erosion resistant coatings and methods of making

InactiveUS20080102296A1Engine manufactureEngine fuctionsElectron beam physical vapor depositionCathodic arc deposition

A coated turbine engine component includes a turbine engine component and an erosion resistant coating disposed on at least a portion of a surface of the turbine engine component using electron beam physical vapor deposition or ion plasma cathodic arc deposition.

Owner:GENERAL ELECTRIC CO

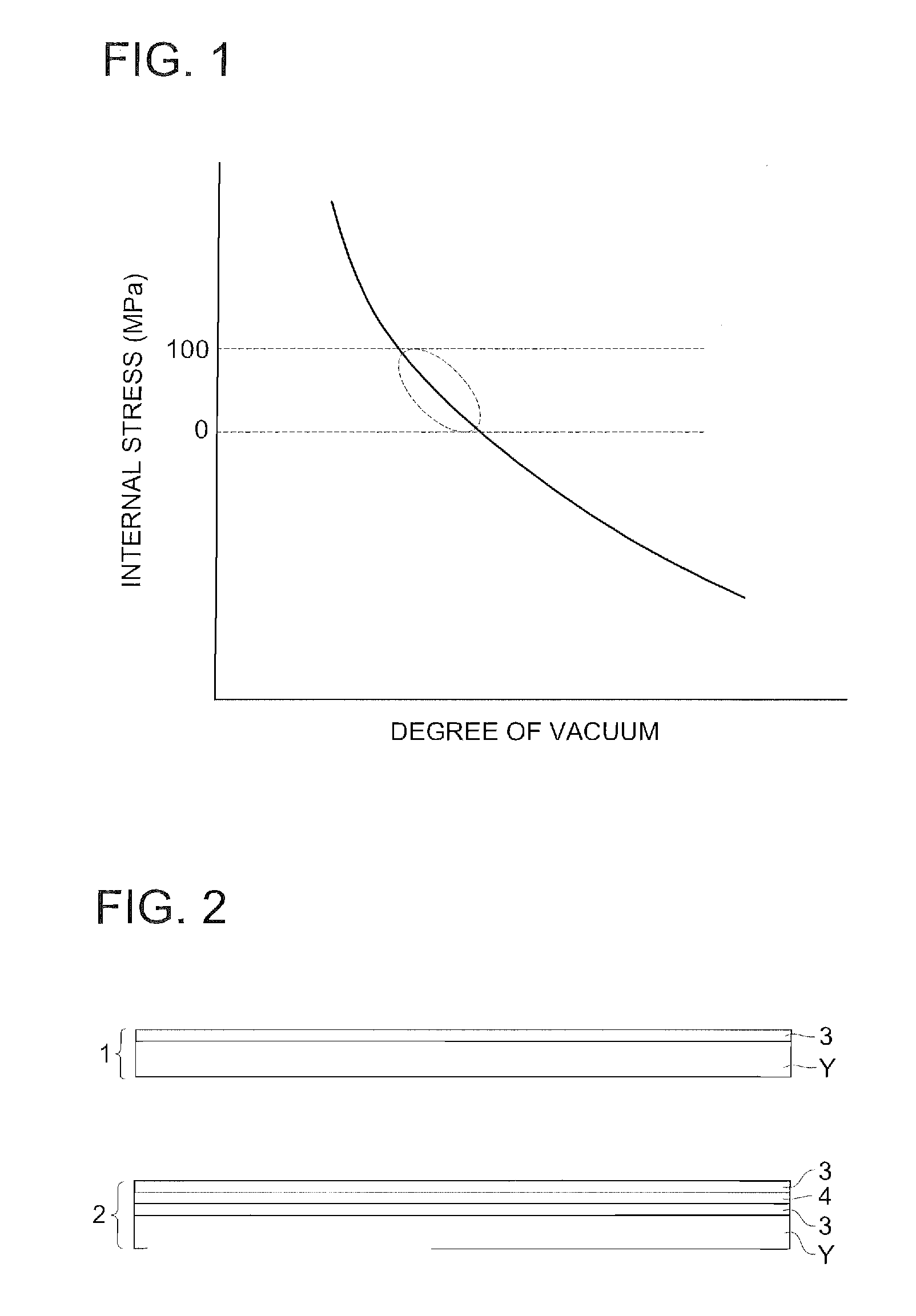

Gas barrier film, gas barrier film manufacturing method, resin substrate for organic electroluminescent device using the aforesaid gas barrier film, and organic electroluminescent device using the aforementioned gas barrier film

ActiveUS20090051272A1Superb adhesionIncreased durabilityVacuum evaporation coatingSolid-state devicesDensity ratioOrganic electroluminescence

A gas barrier film comprising a resin substrate provided thereon at least one layer of a ceramic film, wherein the density ratio Y (=ρf / ρb) satisfies 1≧Y≧0.95 and the ceramic film has a residual stress being a compression stress of 0.01 MPa or more and 100 Mpa or less, wherein ρf is the density of the ceramic film and ρb is the density of a comparative ceramic film being formed by thermal oxidation or thermal nitridation of a metal as a mother material of the ceramic film so as to being the same composition ratio of the ceramic film.

Owner:KONICA MINOLTA INC

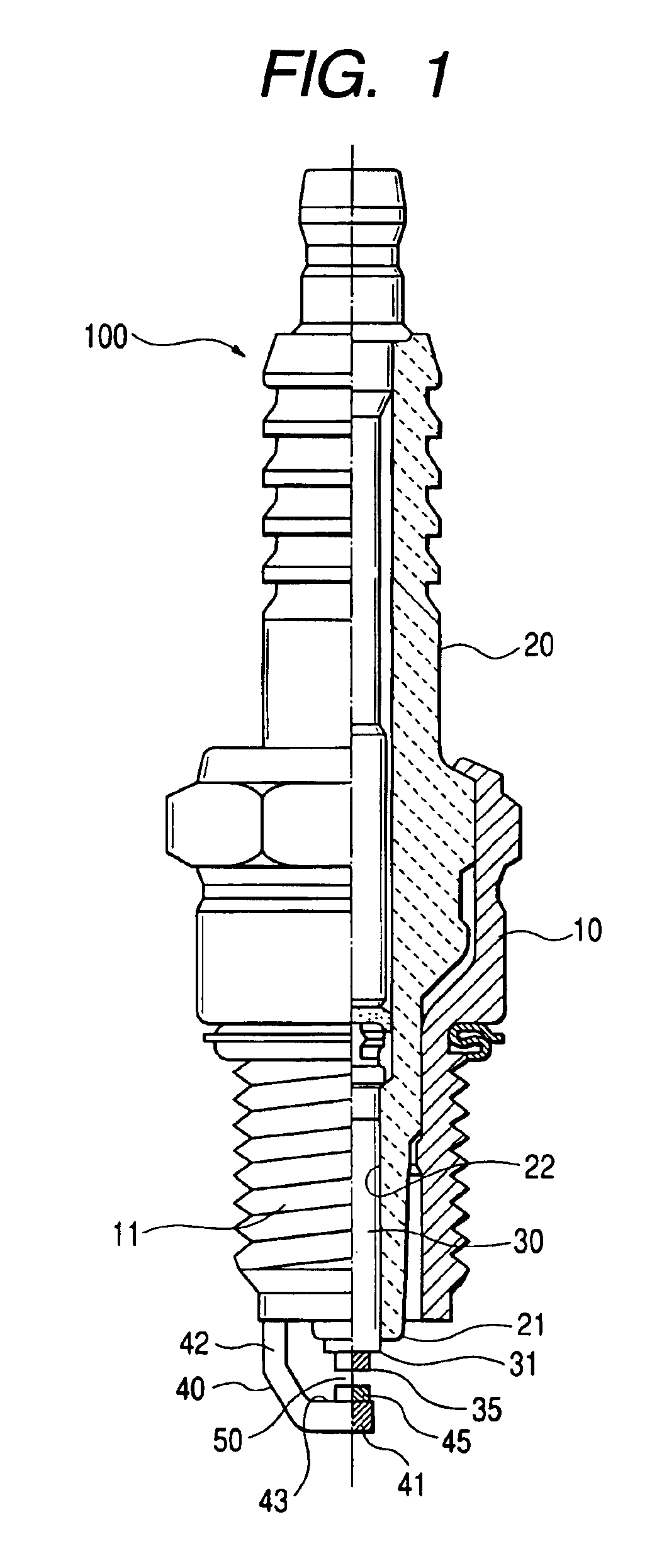

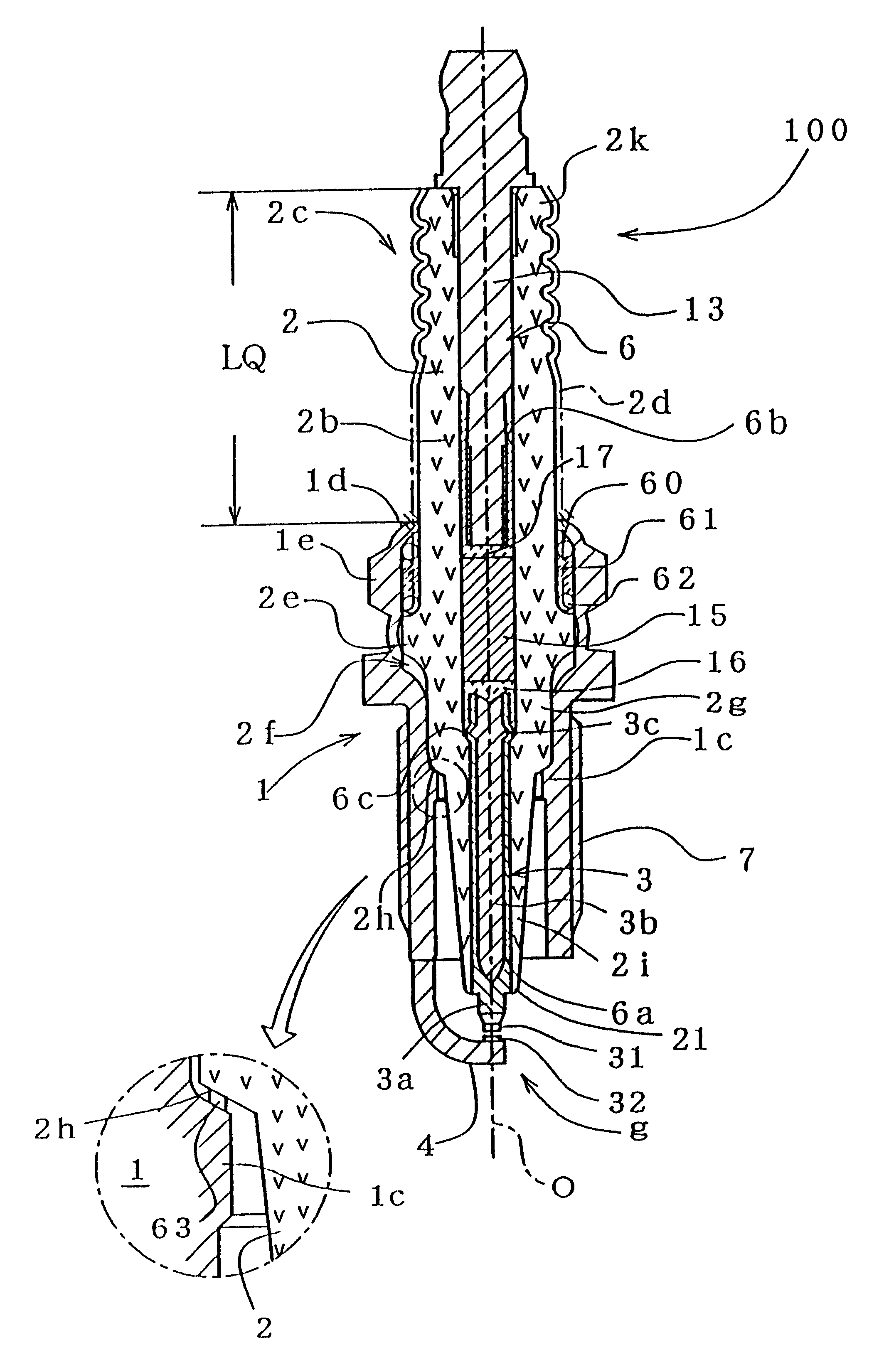

Spark plug, alumina insulator for spark plug, and method of manufacturing the same

InactiveUS6407487B1Low costLow production costSpark gapsCeramic shaping apparatusElectrical resistance and conductanceUltimate tensile strength

In insulator including alumina as a main component, a Na component in the insulator is set in the range of 0.07 to 0.5 wt % as Na2O. While the Na component content is as high as to have conventionally been regarded to be beyond the common sense, with this range of the Na component content, insulation resistance, mechanical strength and the like at high temperature are unexpectedly not reduced and an insulator with performances comparable to those of an insulator from conventional low soda alumina lower in Na component content than the above described range can be obtained. As a result, medium soda alumina and regular soda alumina that are much lower in cost than conventionally used low soda alumina can be used instead of the low soda alumina, so that dramatic reduction in production costs of insulator 2 for a spark plug 100 and in addition, of the spark plug 100 using the insulator 2 are realized.

Owner:NGK SPARK PLUG CO LTD

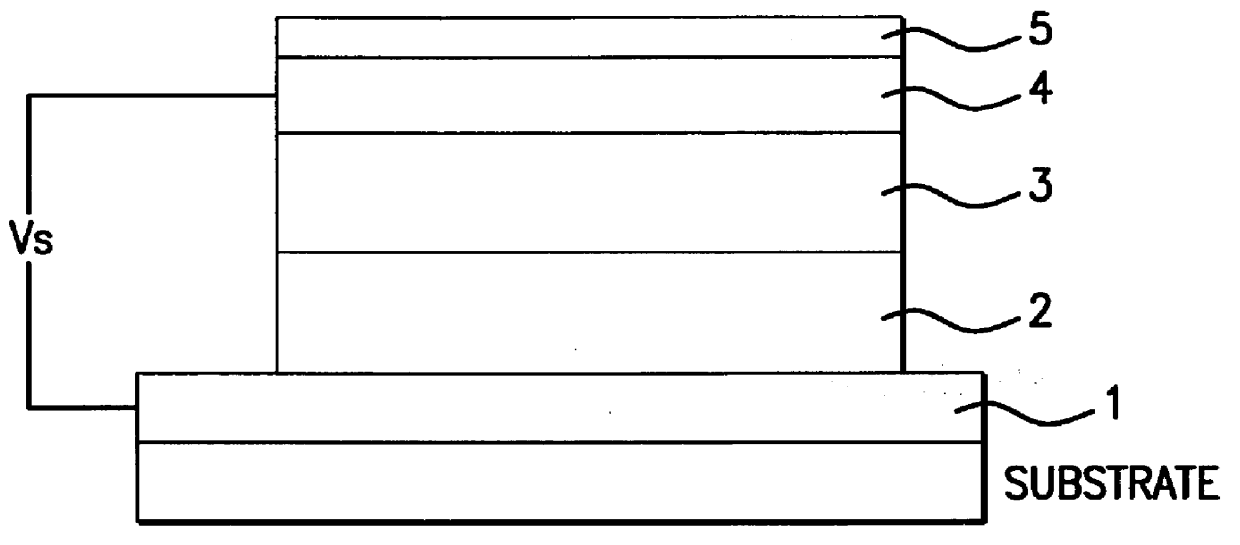

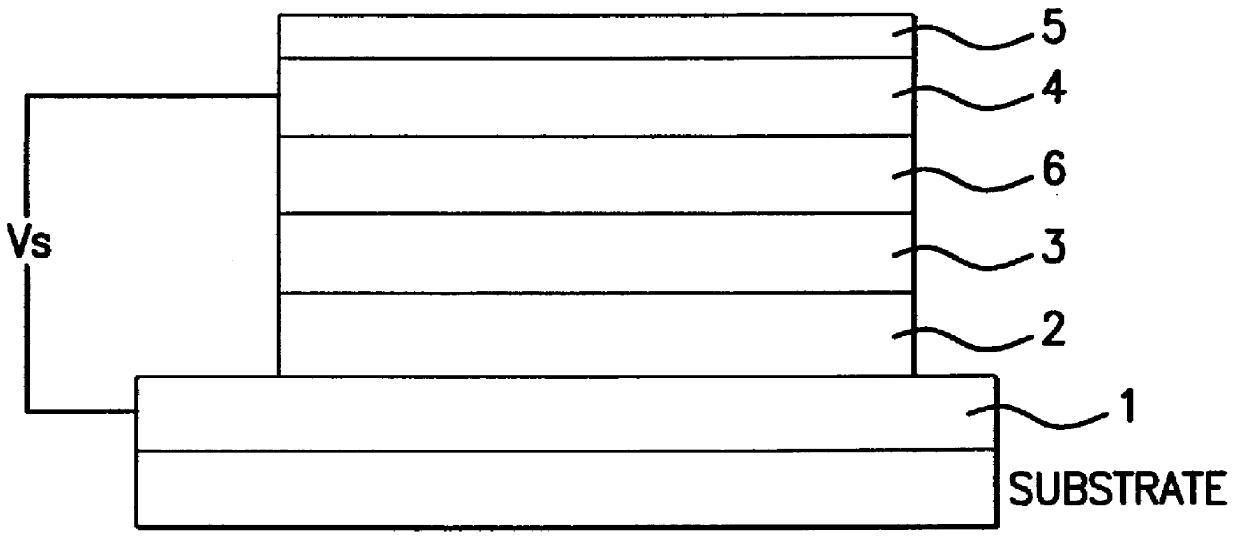

Organic electroluminescent element having an excimer light irradiated positive electrode and method of manufacturing the same

InactiveUS6060826ALow luminescence starting potentialLuminous properties are stableSpark gapsDischarge tube luminescnet screensOrganic layerOrganic electroluminescence

The purpose of the present invention is to provide an organic electroluminescent element having uniform surface luminescence, large luminescence intensity, and excellent stability over repeated use. The present invention provides a method of manufacturing an organic electroluminescent element using a positive electrode irradiated by excimer light when manufacturing an organic electroluminescent element comprising at least a substrate on which is sequentially formed a positive electrode, organic layer including an organic luminescent layer, and negative electrode, and an organic electroluminescent element manufactured by said method.

Owner:KONICA MINOLTA INC

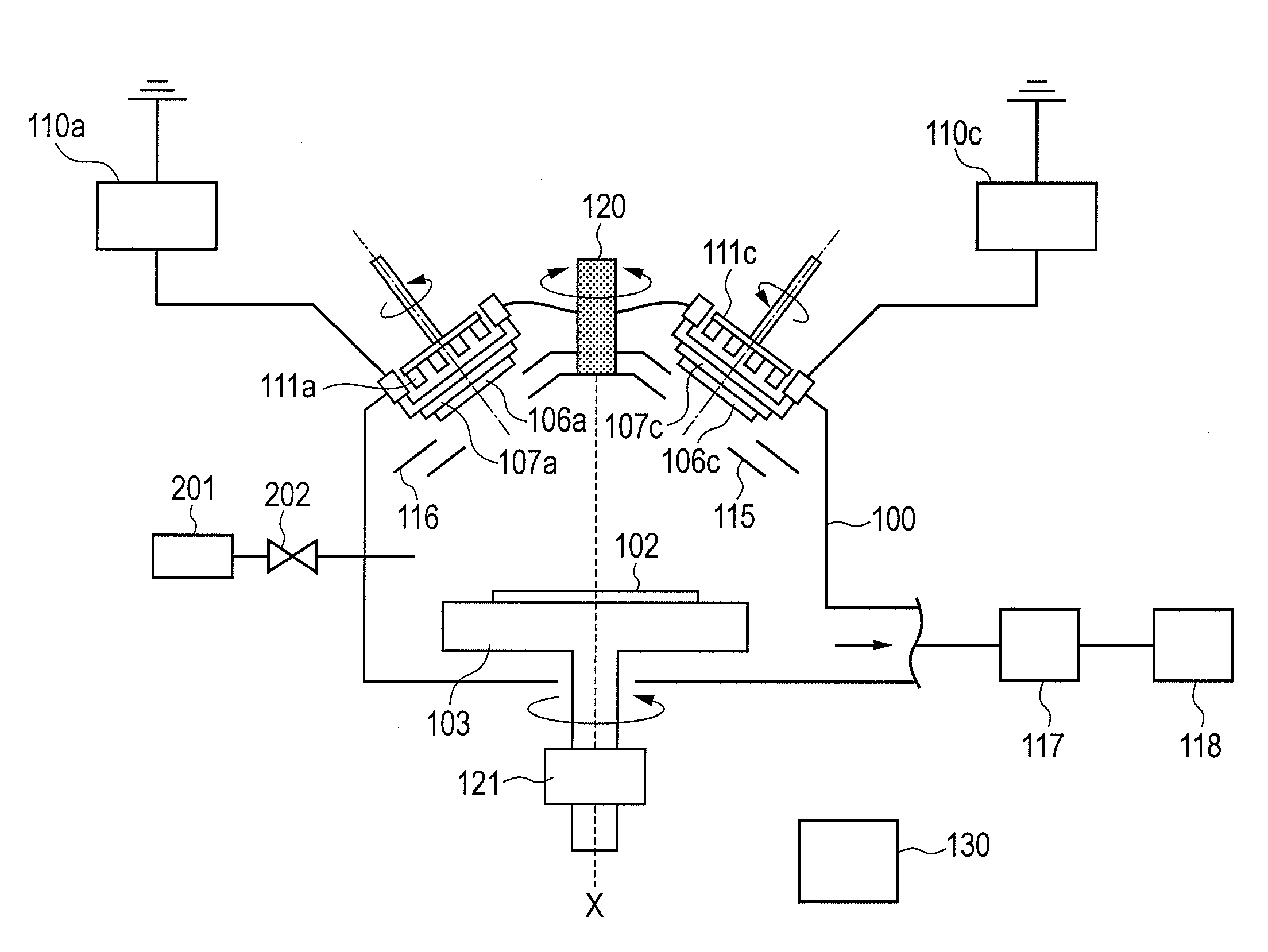

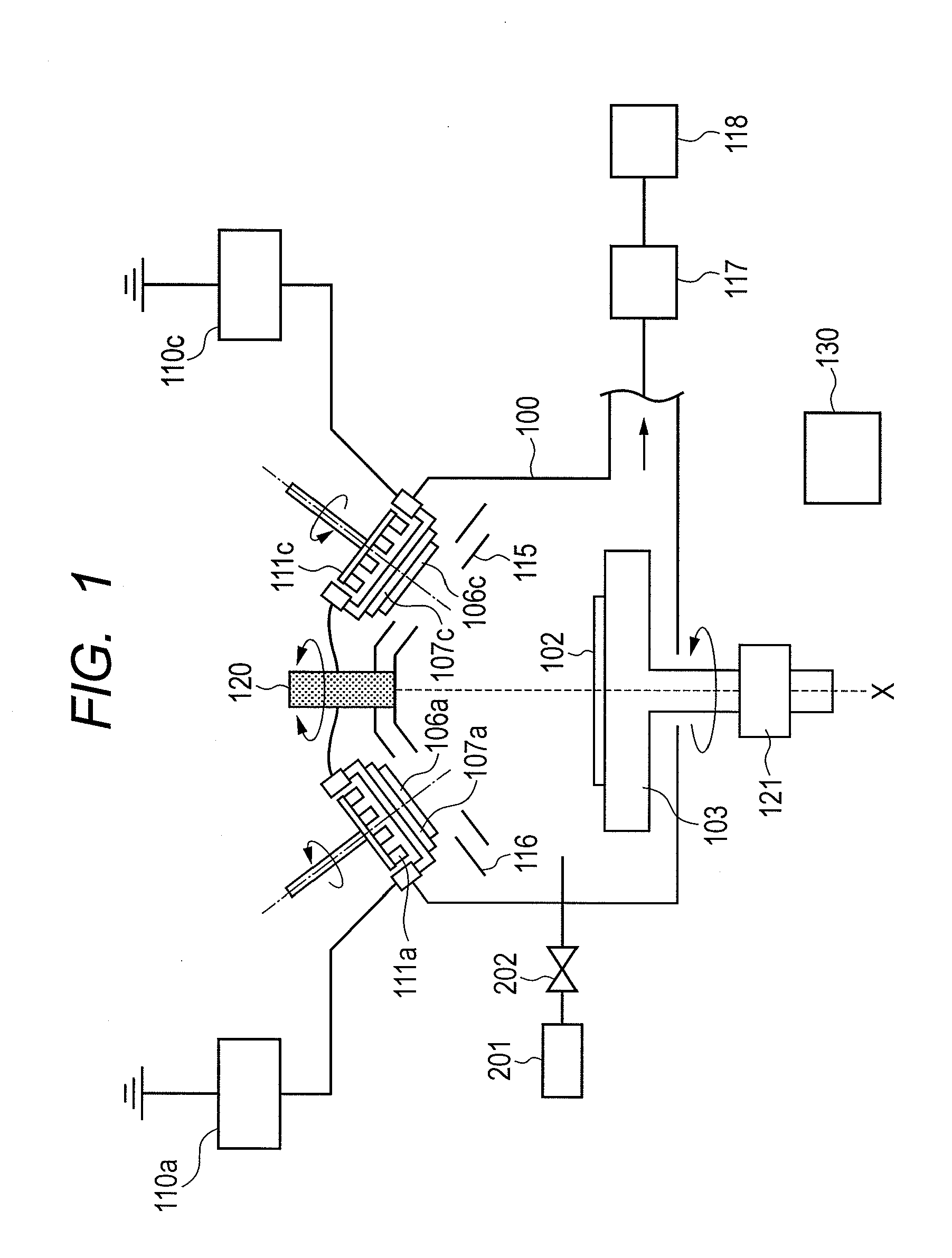

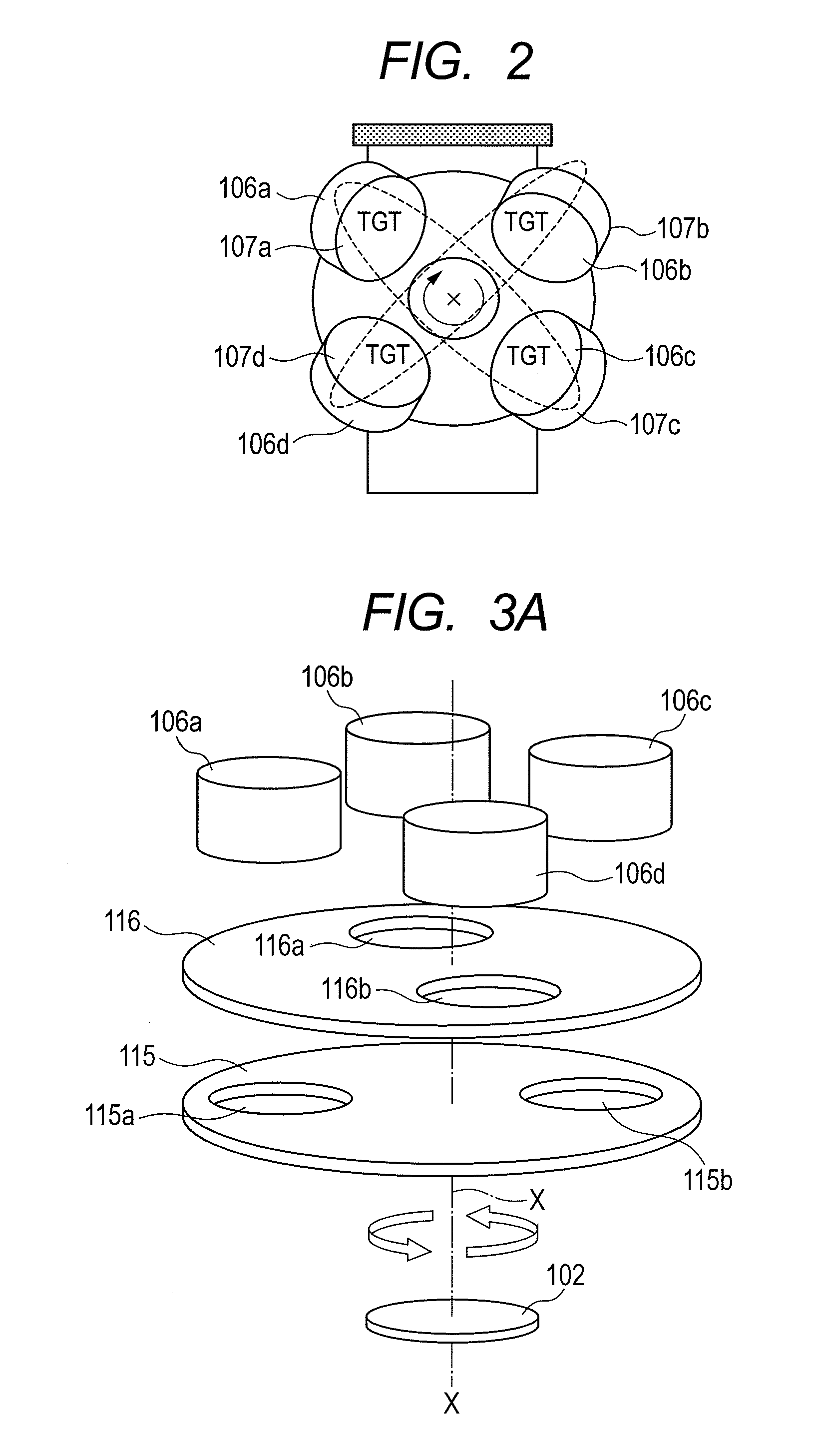

Sputtering apparatus and manufacturing method of electronic device

InactiveUS20120164354A1Efficiently laminate thin films in a short timeWithout lowering throughputSpark gapsLiquid surface applicatorsRotational axisEngineering

The present invention provides a sputtering apparatus that can efficiently laminate thin films in a short time without lowering throughputs, and a manufacturing method of an electronic device. The sputtering apparatus according to an embodiment of the present invention includes a rotatable substrate holder, four target holders obliquely arranged with respect to the substrate holder, and a first shutter and a second shutter that each are provided between the target holders and the substrate holder and have two holes arranged two-fold symmetrical with respect to a rotational axis X. Two of the four target holders are first group target holders arranged two-fold symmetrical with respect to the rotational axis X, and the other two target holders are second group target holders arranged between the first group target holders and two-fold symmetrical with respect to the rotational axis X.

Owner:CANON ANELVA CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com