Patents

Literature

47 results about "Cathodic arc deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

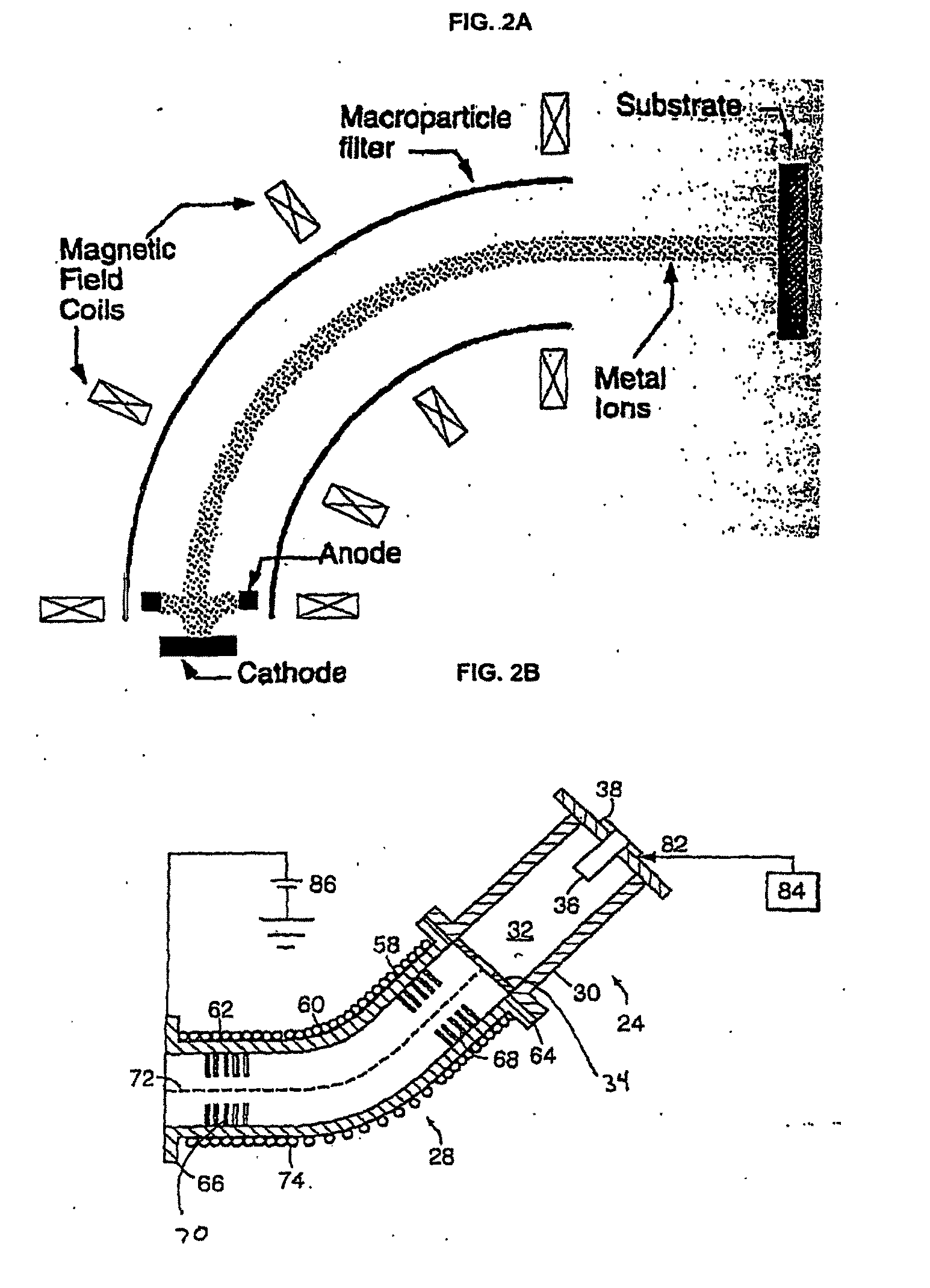

Cathodic arc deposition or Arc-PVD is a physical vapor deposition technique in which an electric arc is used to vaporize material from a cathode target. The vaporized material then condenses on a substrate, forming a thin film. The technique can be used to deposit metallic, ceramic, and composite films.

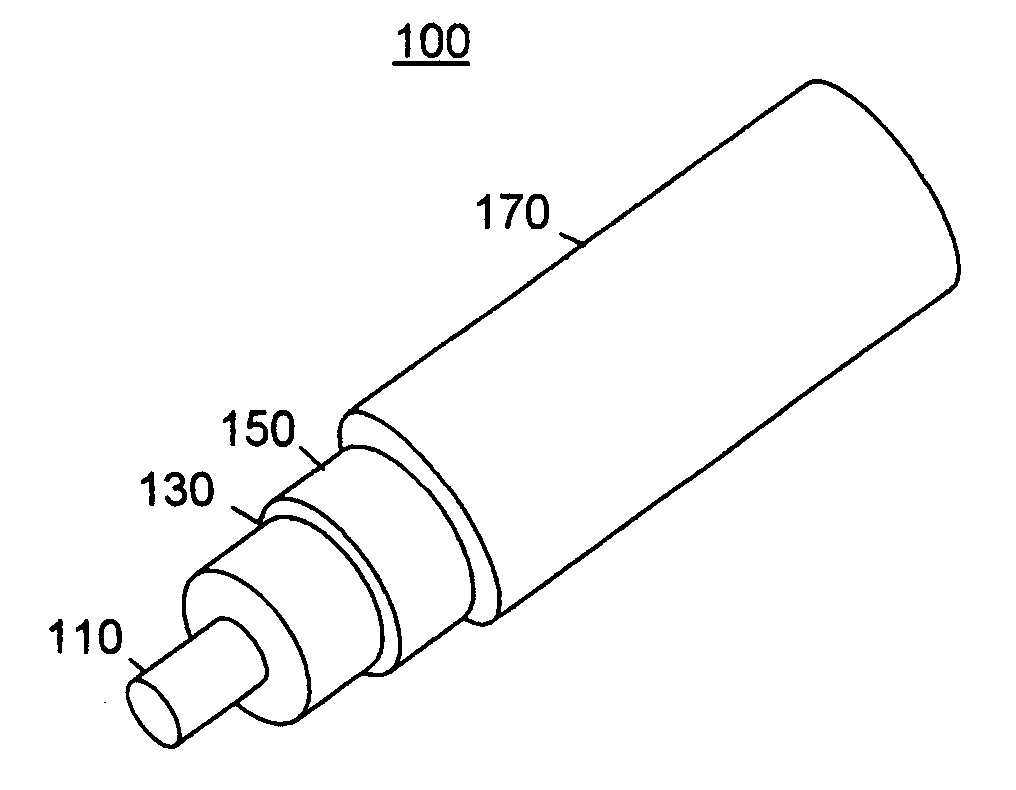

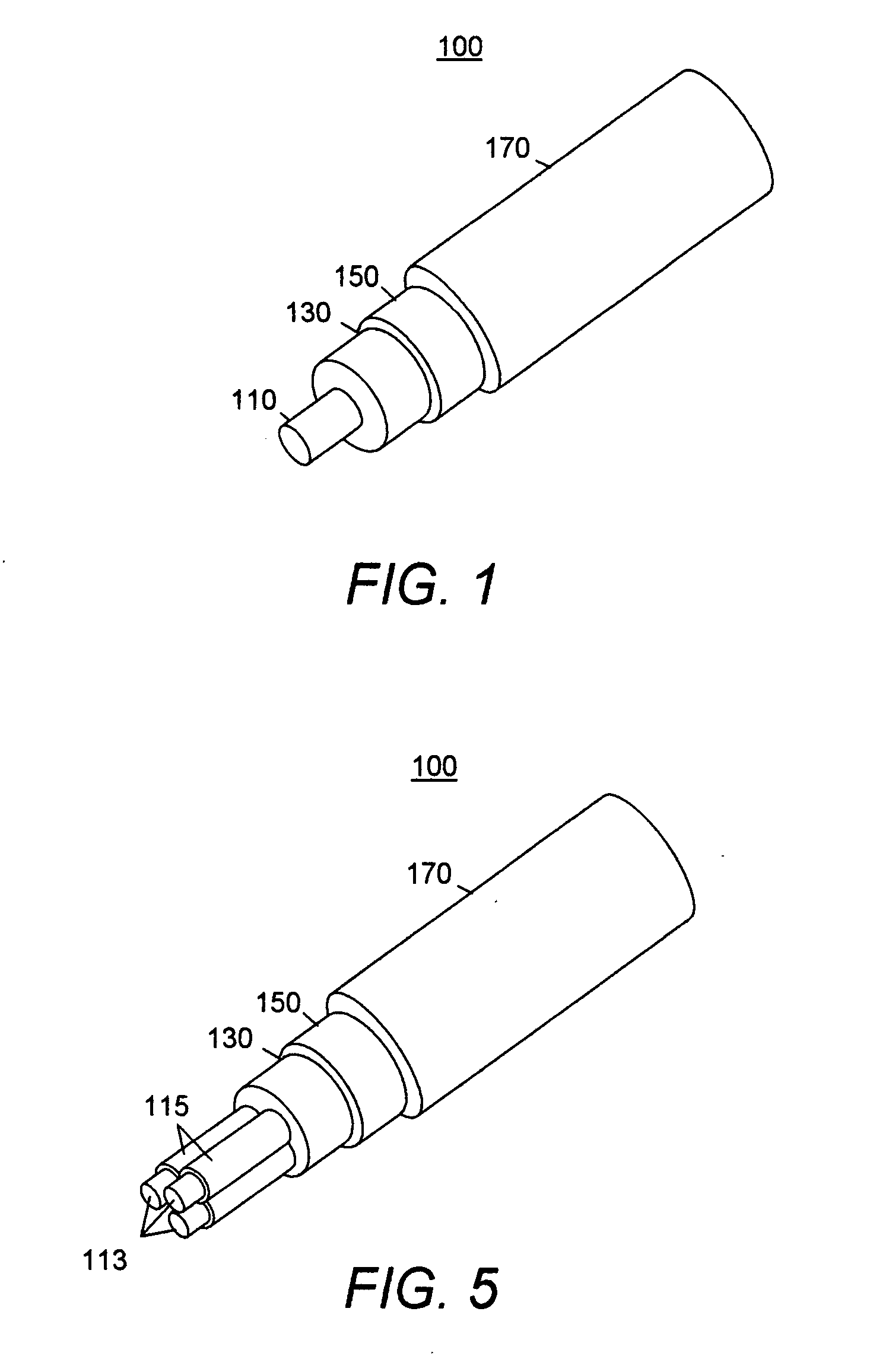

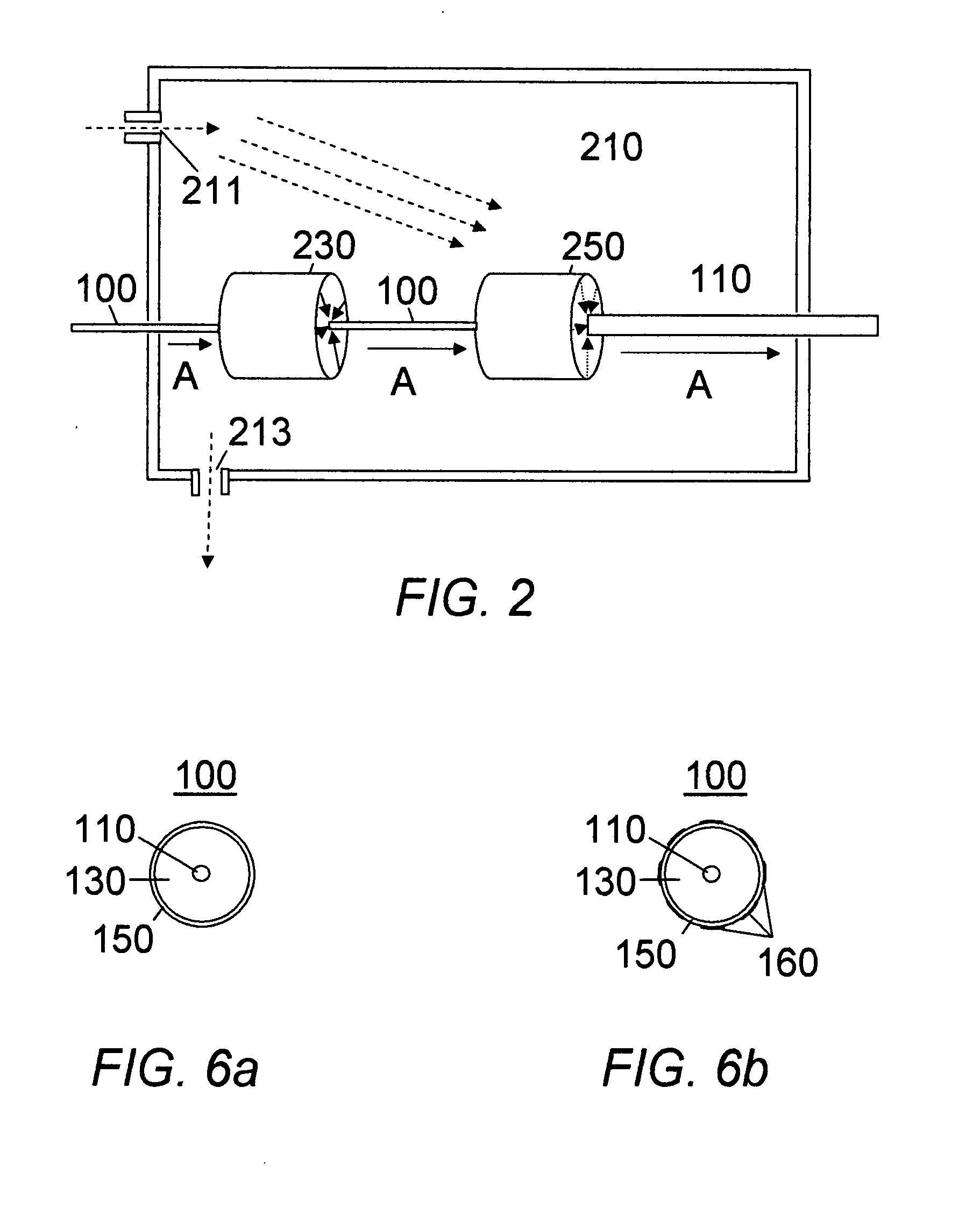

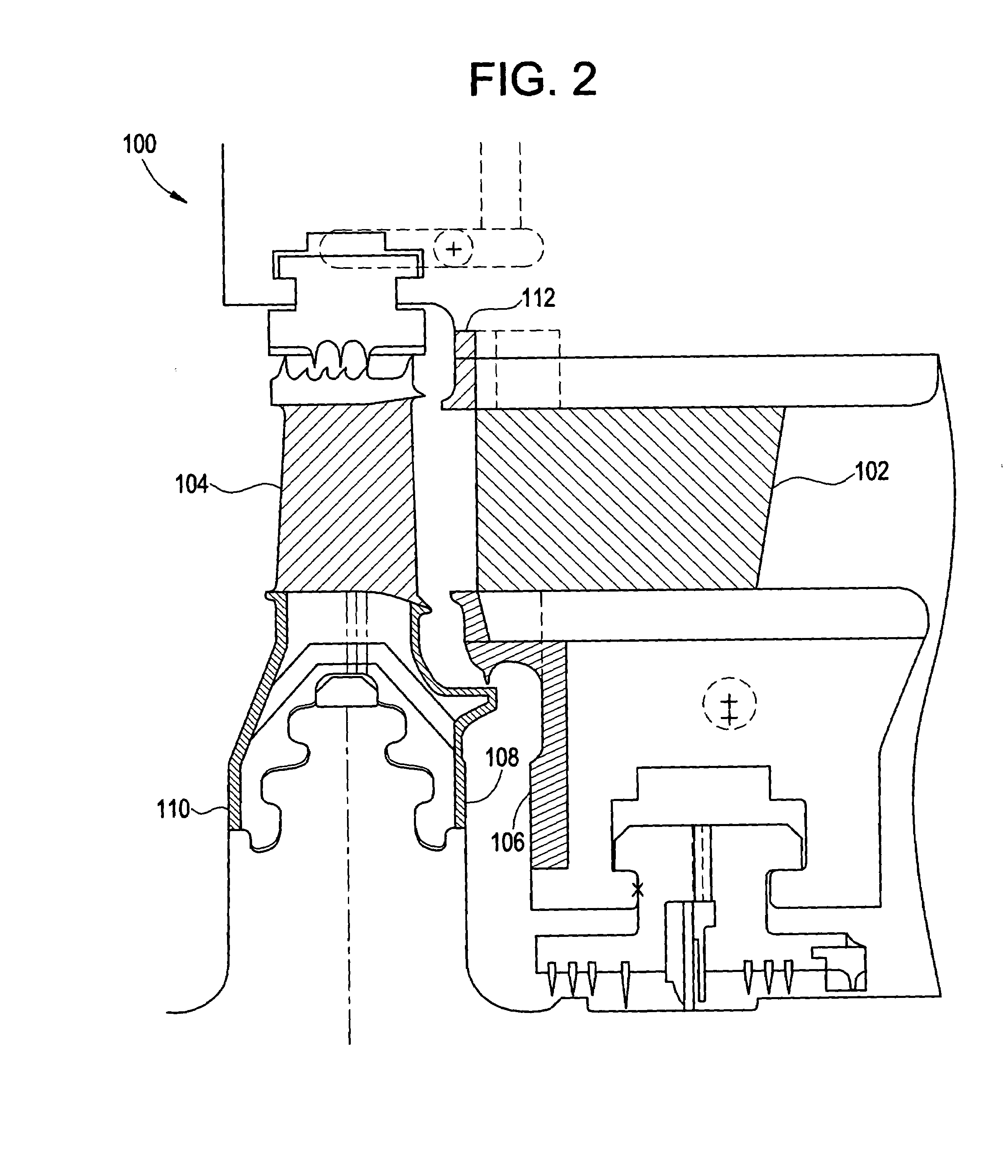

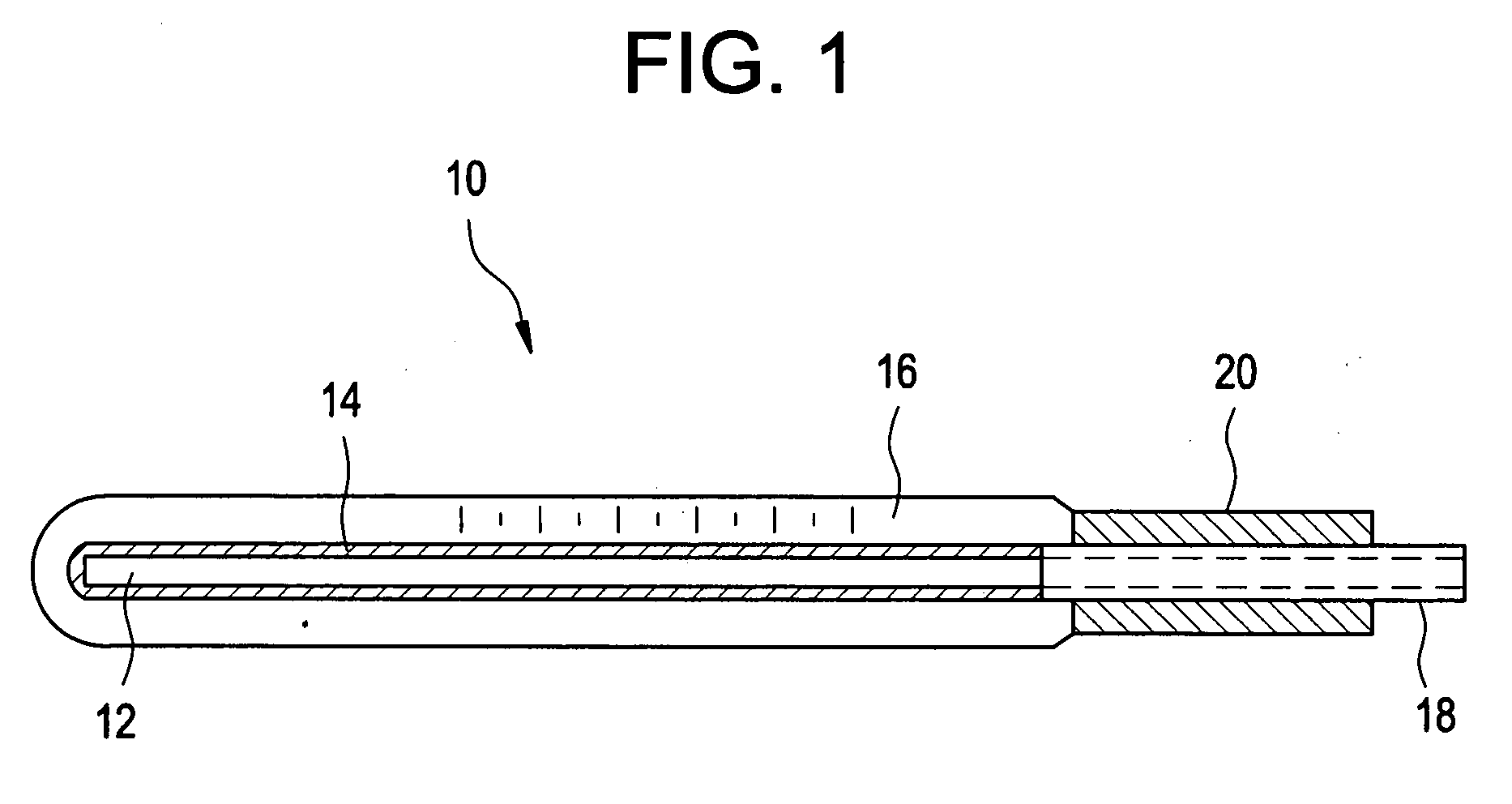

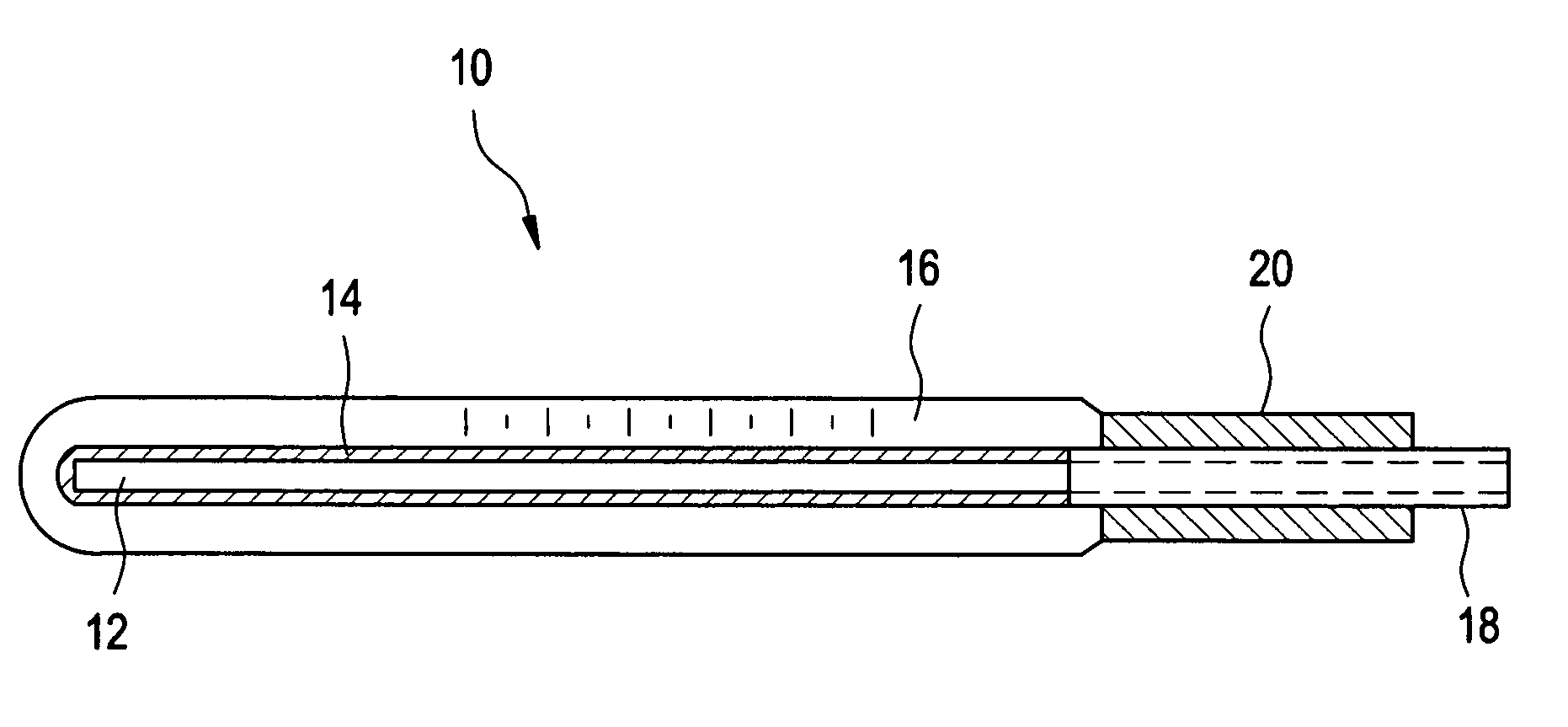

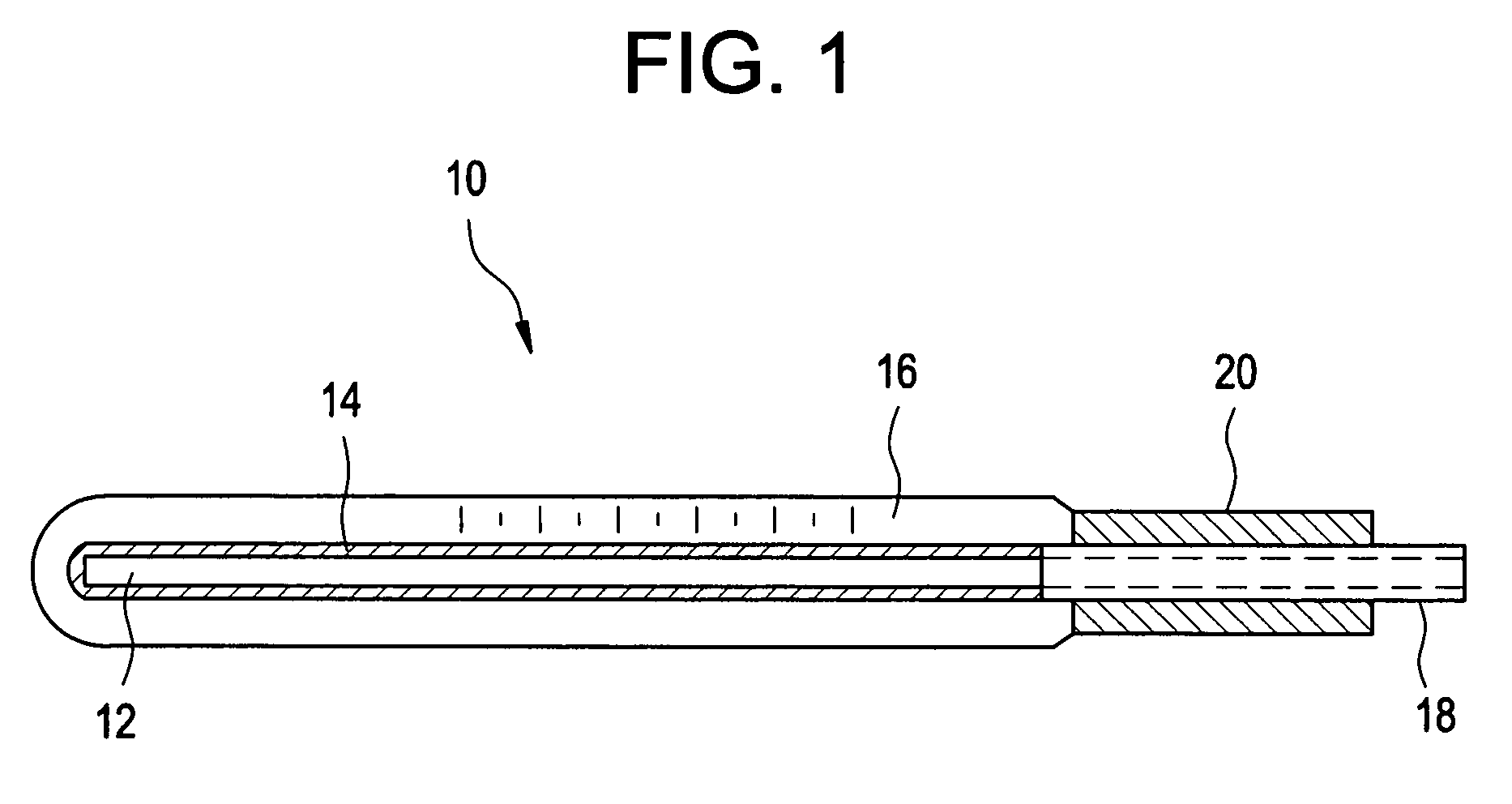

Multi-layer cable design and method of manufacture

InactiveUS20080060832A1Economically manufacturedVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsCathodic arc depositionFiber

A novel method of designing and fabricating flexible and lightweight cable [100] having a central conductor [110], a dielectric layer [130], an outer conductor [150] and an insulation coating [170] using thin film technology is disclosed. The dielectric layer [130] is ‘grown’ on dielectric layer [130] using electrophoretic deposition to a specified thickness, based upon its intended use. It may include nano-diamonds. Ion beam assisted deposition is used to metalize the cable dielectric layer [130]. This may be ion beam assisted sputtering, ion beam assisted evaporative deposition or ion beam assisted cathodic arc deposition. In an alternative embodiment, the outer conductor may be etched to provide greater flexibility, or to add a piezoelectric layer. The central conductor [110] may be created from dielectric fibers [113] which are metalized as described above. The piezoelectric layer added to create ultrasonic transducer cables.

Owner:RAZAVI ALI

Method for preparing multi-metal element doped diamond film

InactiveCN101787512AImprove performanceVacuum evaporation coatingSputtering coatingCathodic arc depositionIon bombardment

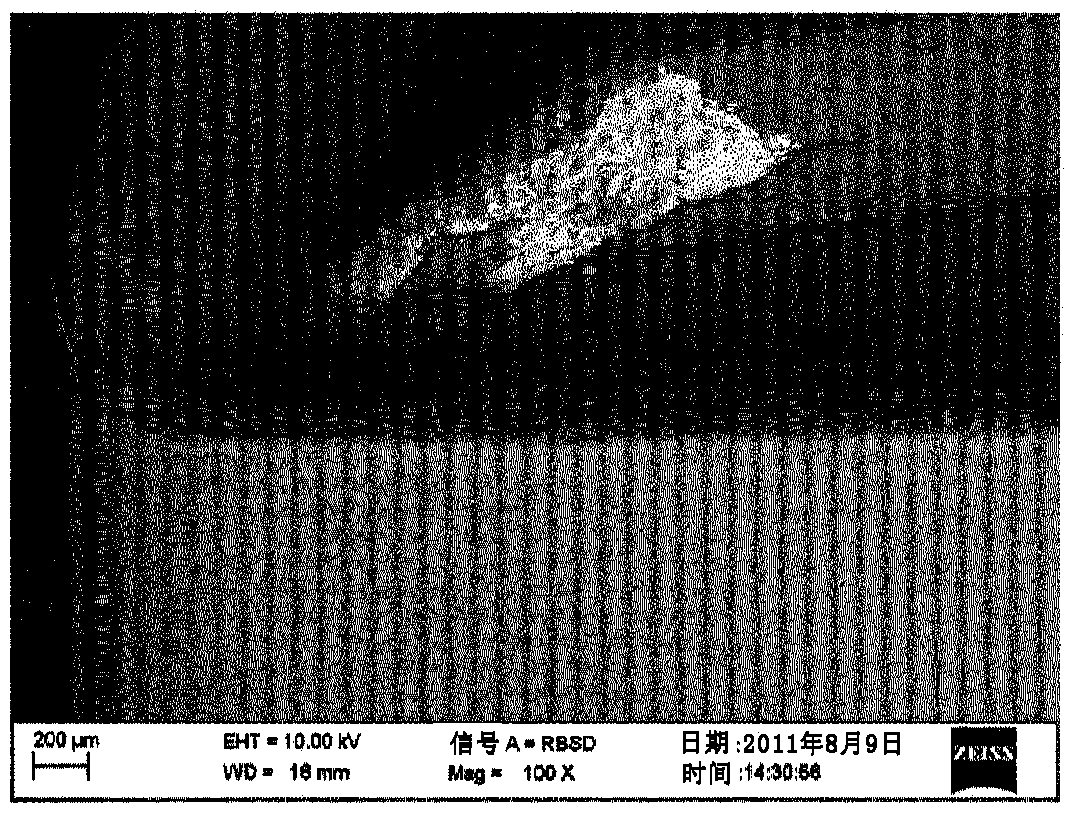

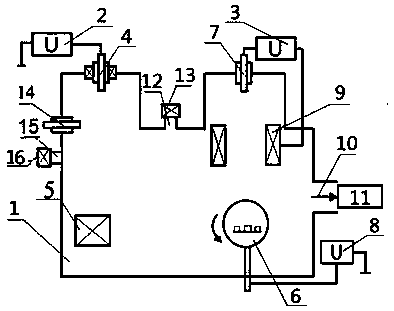

The invention discloses a method for preparing a multi-metal element doped diamond film, which is characterized by comprising the following steps: removing a pollution layer on matrix surface by using the ultrasonic cleaning technology, carrying out ion beam bombardment cleaning on the matrix surface by using inert gas ion beam produced by an ion source, carrying out metal ion bombardment cleaning on the matrix surface by using metal ions produced by a cathodic arc source under a condition of high workpiece negative bias, preparing a gradient transition layer by using a cathodic arc deposition or ion beam assisted magnetron sputtering (IBAMS), and synthesizing a multi-metal element doped DLC film on the transition layer by using ion beam deposition and mosaic composite target magnetron sputtering, wherein the ion beam deposition is realized by introducing carbon gas in the ion source; and the mosaic composite target doped multiple metal are used, and the main body material of the mosaic composite target can be any one of Ti, Cr, W, Zr, Nb and Ta, and the mosaic block material is one or more of other metals except the above main body materials.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

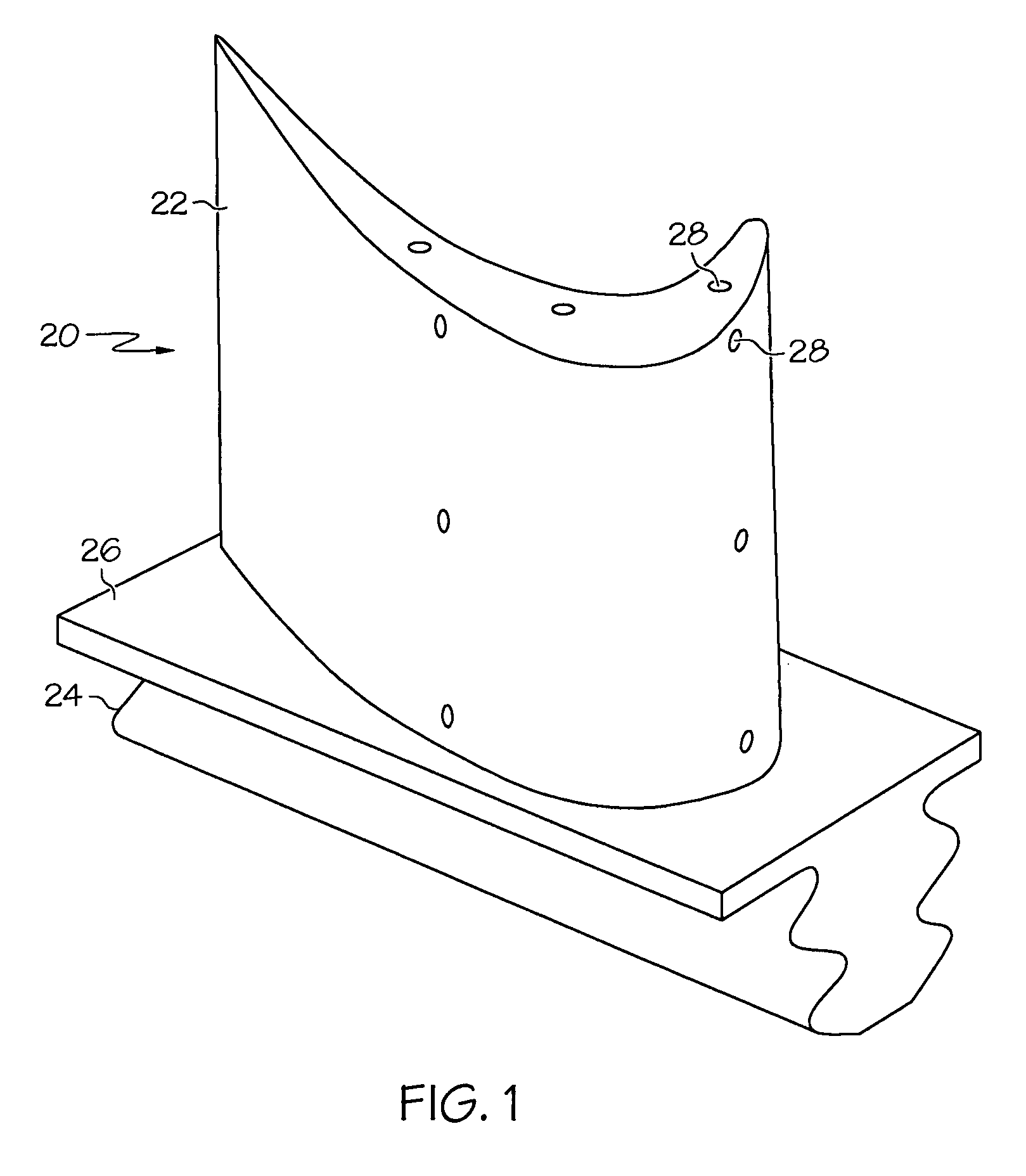

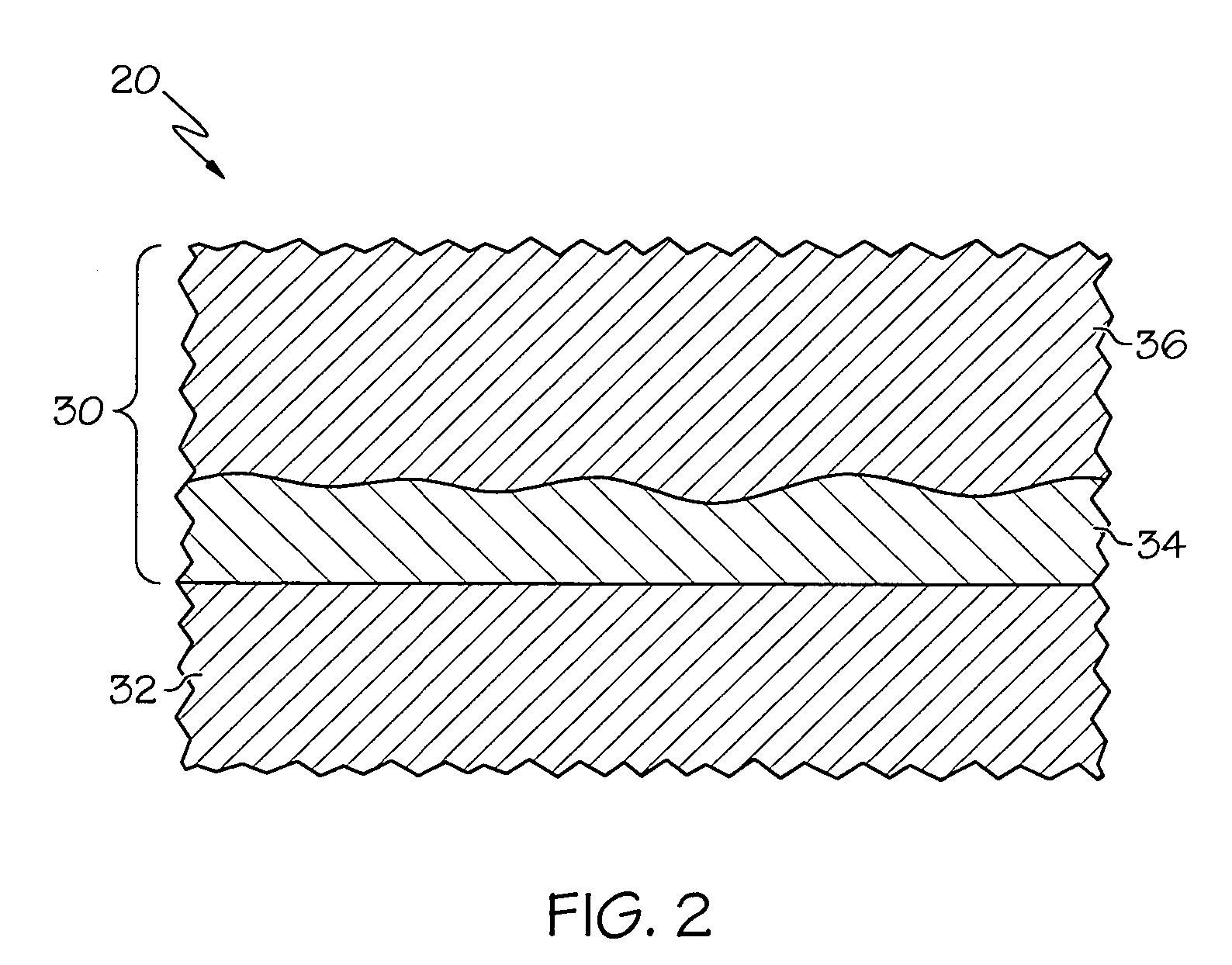

Erosion resistant coatings and methods of making

InactiveUS20080102296A1Engine manufactureEngine fuctionsElectron beam physical vapor depositionCathodic arc deposition

A coated turbine engine component includes a turbine engine component and an erosion resistant coating disposed on at least a portion of a surface of the turbine engine component using electron beam physical vapor deposition or ion plasma cathodic arc deposition.

Owner:GENERAL ELECTRIC CO

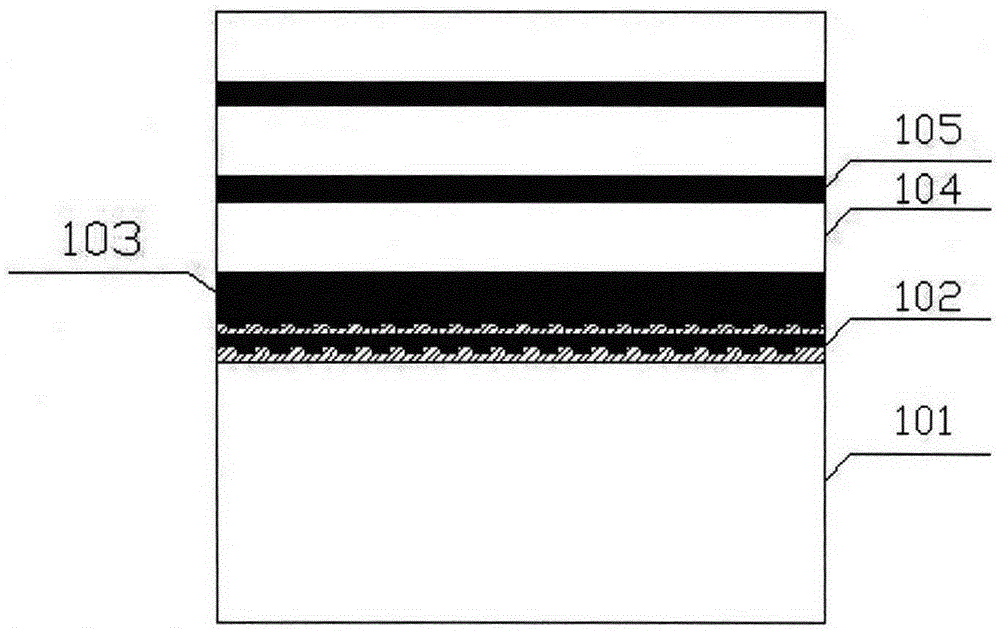

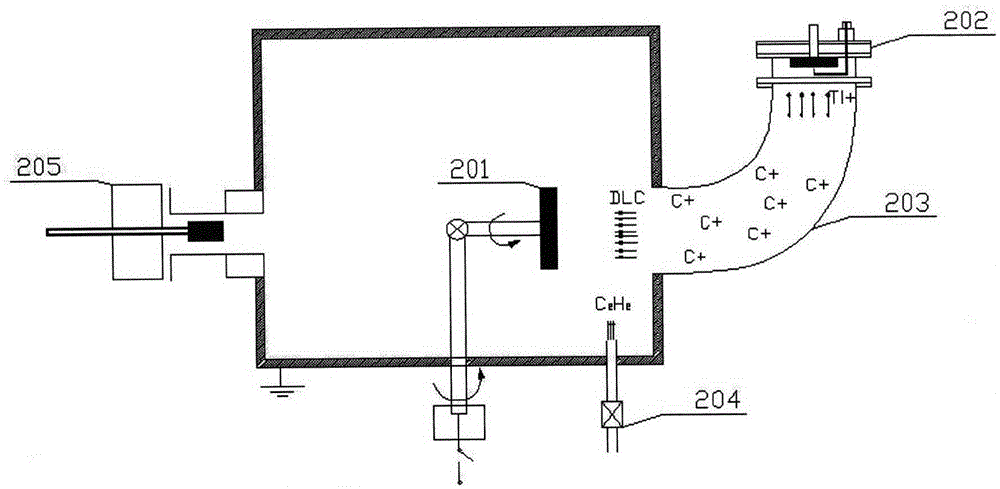

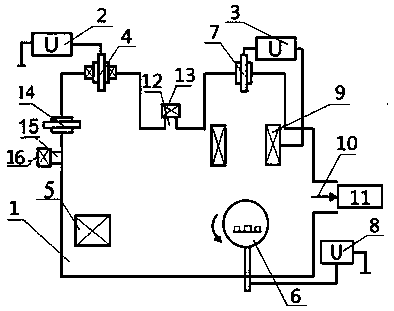

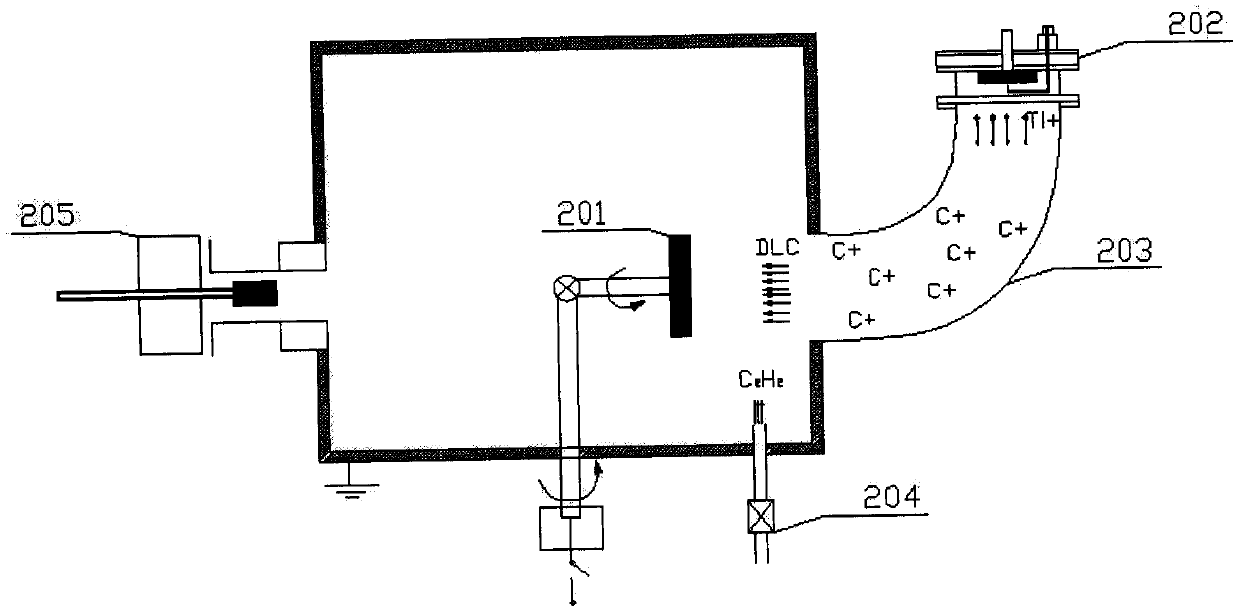

Method for preparing DLC (diamond-like carbon) thick films by means of efficient magnetic filter plasma deposition

ActiveCN105755442AEffective filteringFacilitate separate control of the ionization processVacuum evaporation coatingSputtering coatingCathodic arc depositionDiamond-like carbon

The invention discloses a method for preparing Metal carbide-inlaid Diamond-like Carbon (MC / DLC) films with the thicknesses larger than 30 micrometers, belongs to the field of preparation of hard abrasion-resistant coatings, and particularly relates to a technology for preparing MC / DLC thick films by the aid of magnetic filter plasma deposition processes.MC / DLC thick film structures comprise ion injection pinning layers, metal transition layers and the MC / DLC films.The method has the advantages that the DC / DLC films prepared by the aid of ion injection technologies, magnetic filter technologies and cathodic arc deposition technologies are high in binding force, the arc current intensity, the magnetic field intensity of bent pipes and the gas inflow of gas with carbon are controlled in deposition procedures, accordingly, the thicknesses, the hardness, the rub resistance and the abrasion resistance of the MC / DLC thick films can be optimized, and the high-quality MC / DLC thick films can be prepared by the aid of the method; magnetic filter plasma deposition equipment for implementing the method has proprietary intellectual property rights and is easy to operate, processes are mature, the MC / DC films can be produced on a large scale, and the method is suitable for deposition application to high-hardness abrasion-resistant coatings in all industrial components such as bearings of cutters.

Owner:BEIJING NORMAL UNIVERSITY

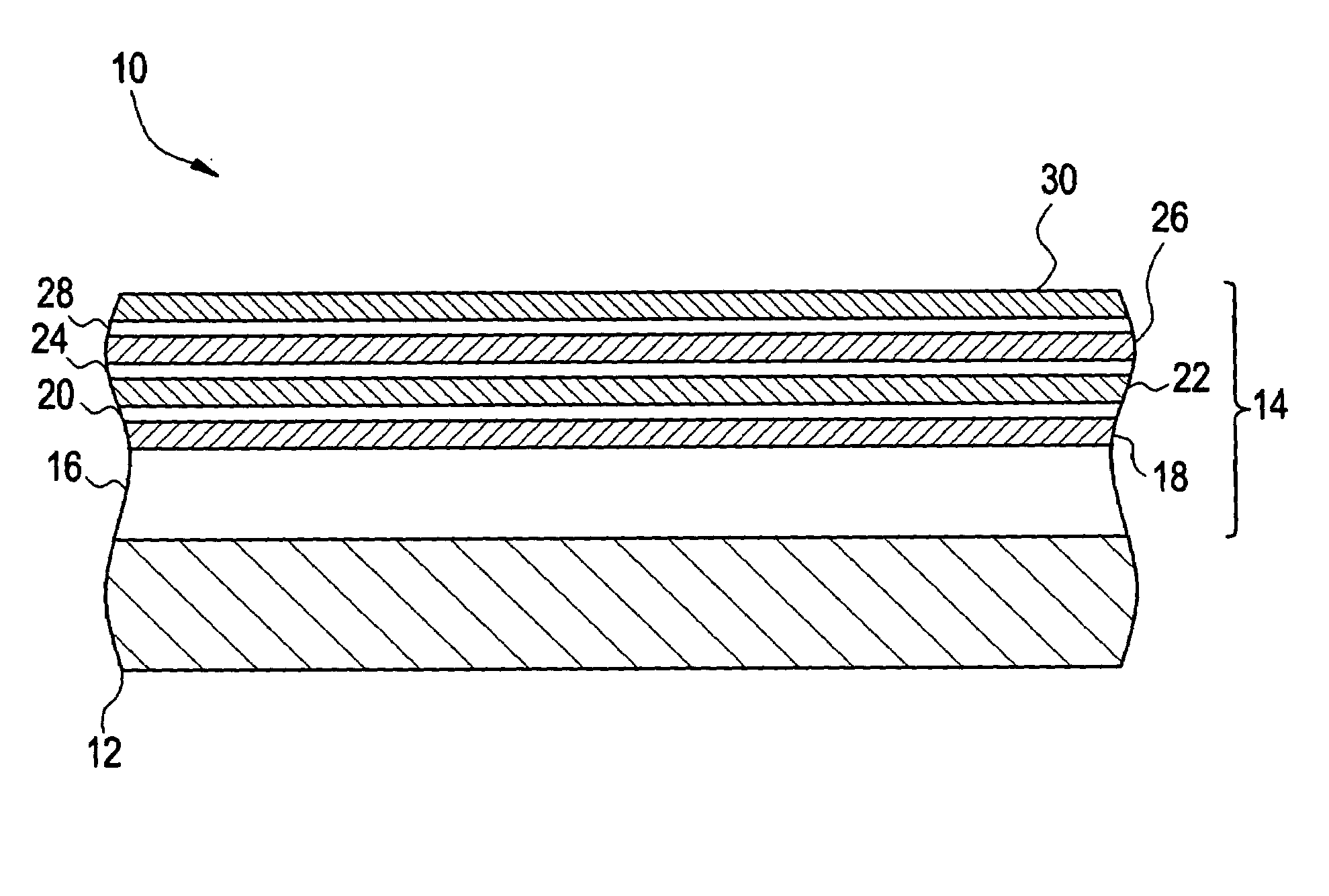

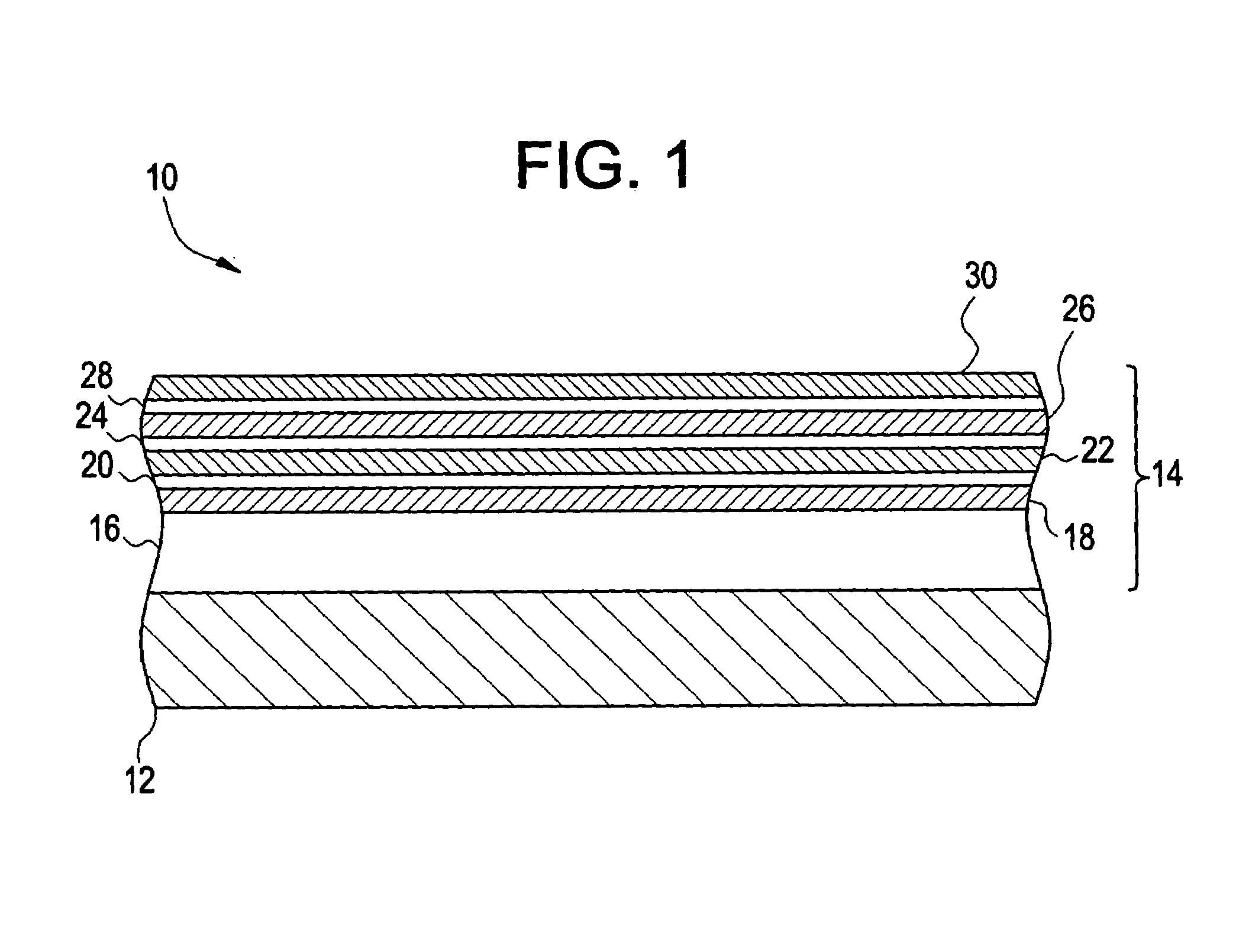

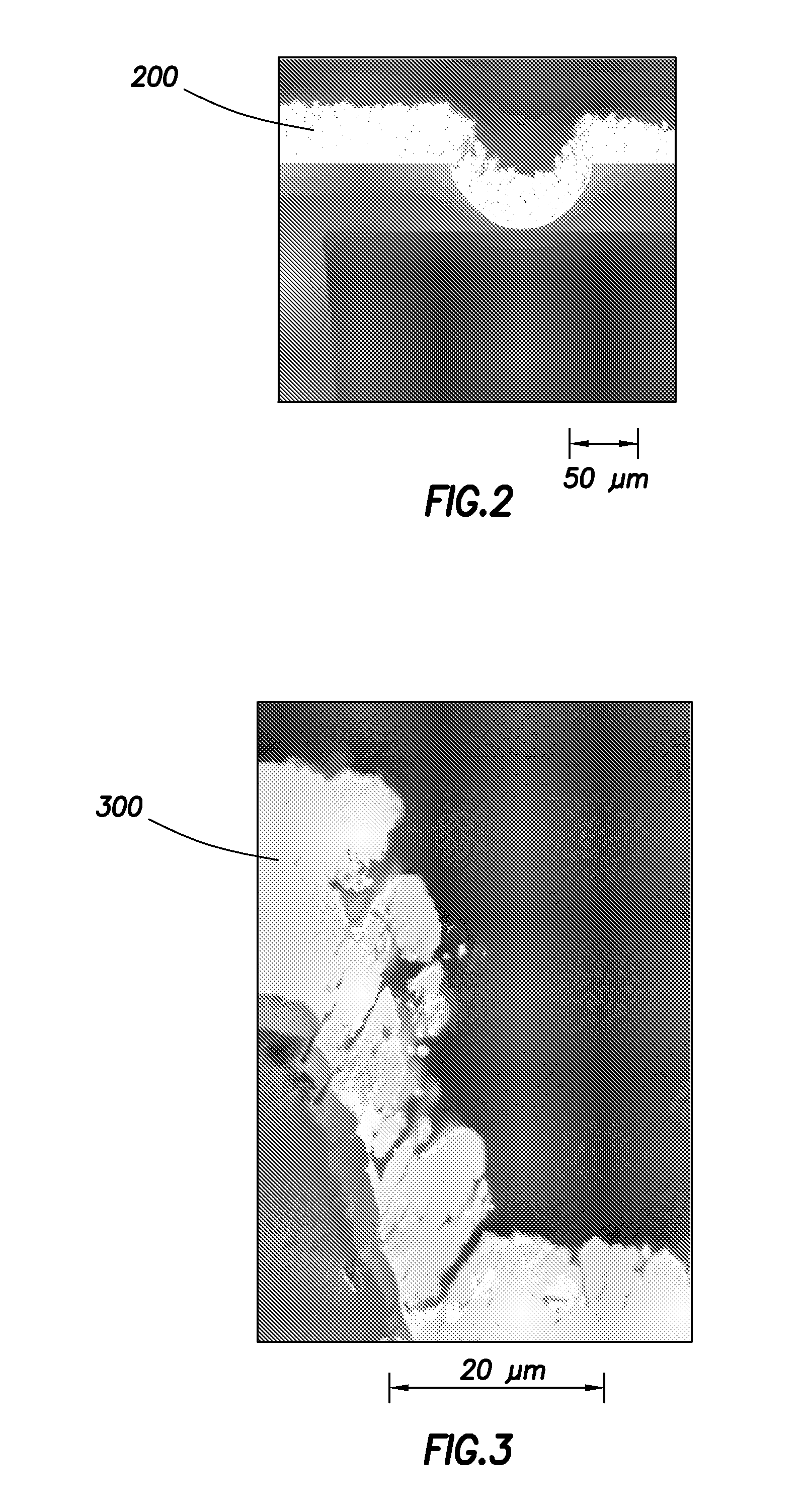

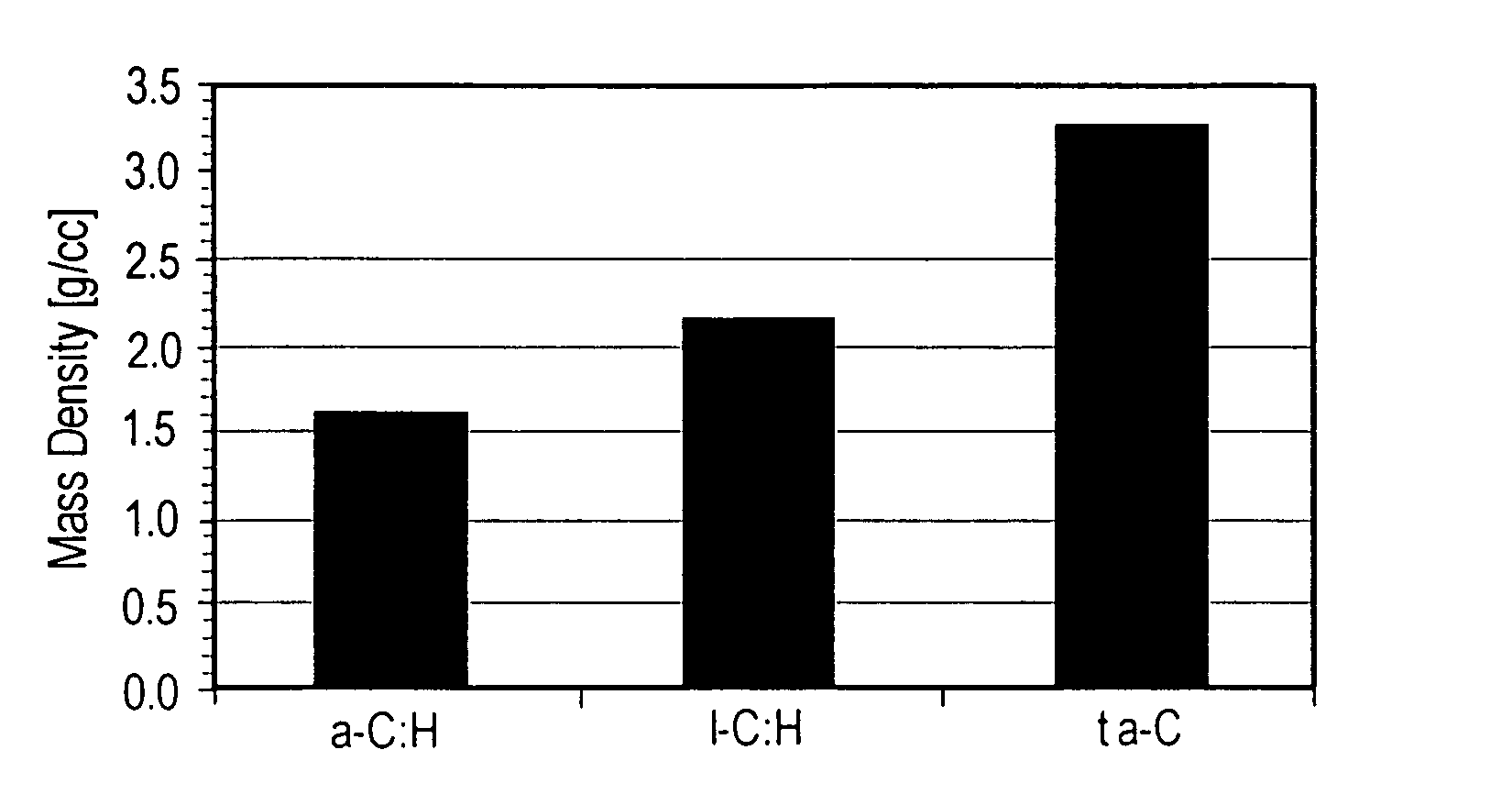

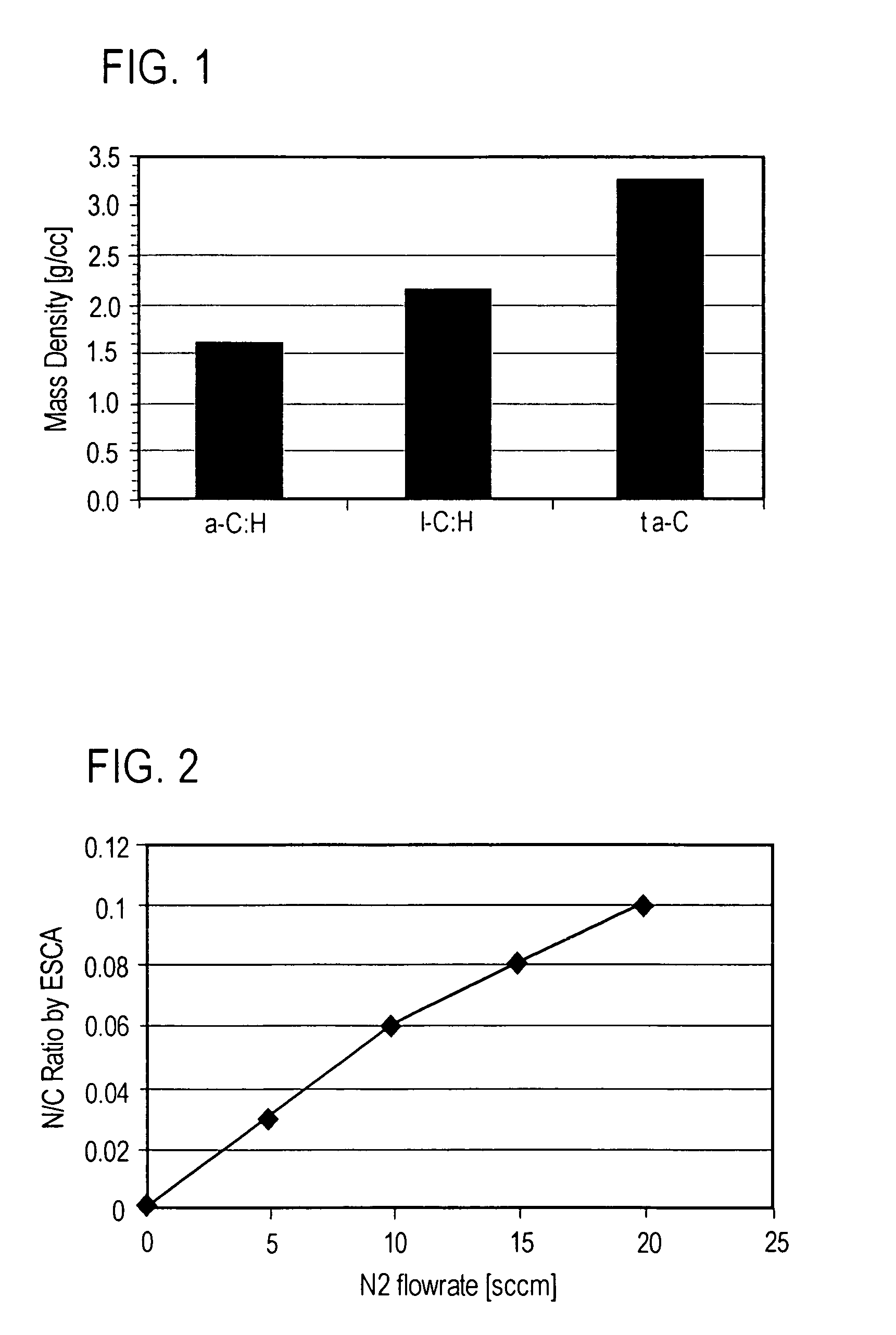

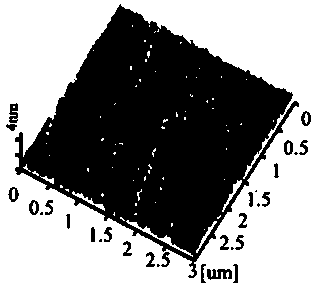

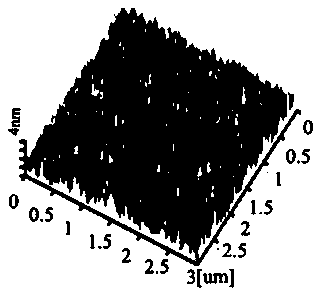

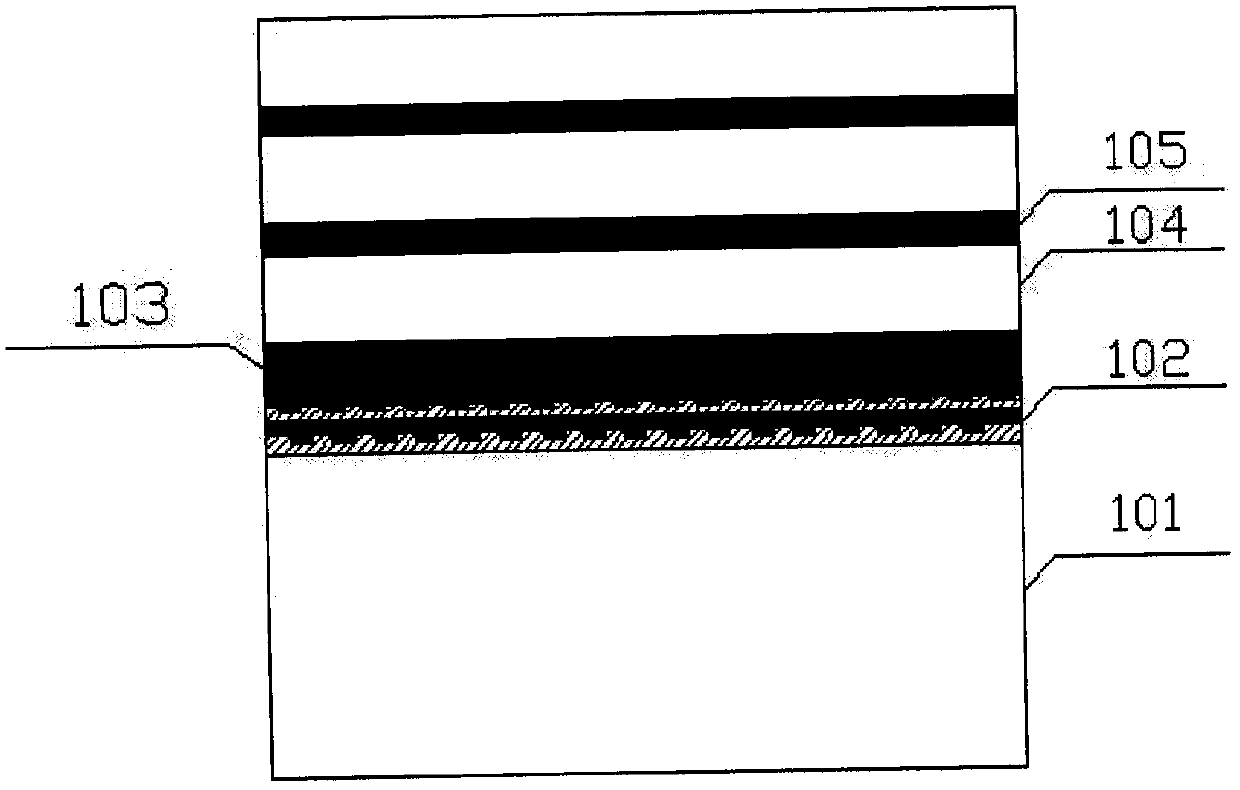

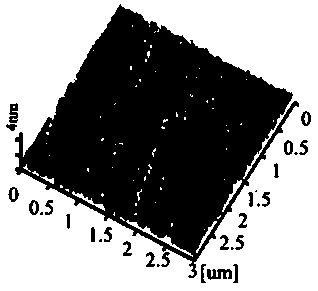

Dual-layer carbon-based protective overcoats for recording media by filtered cathodic ARC deposition

InactiveUS20050181238A1Well formedLiquid surface applicatorsProtective coatings for layersCathodic arc depositionNitrogen doped

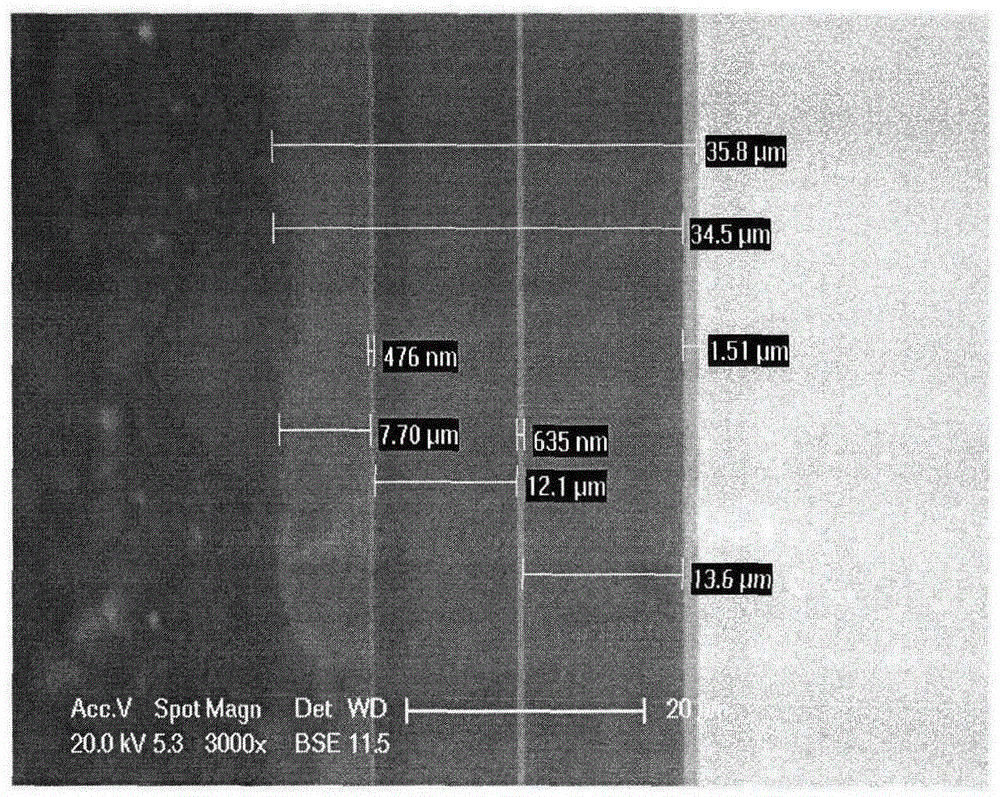

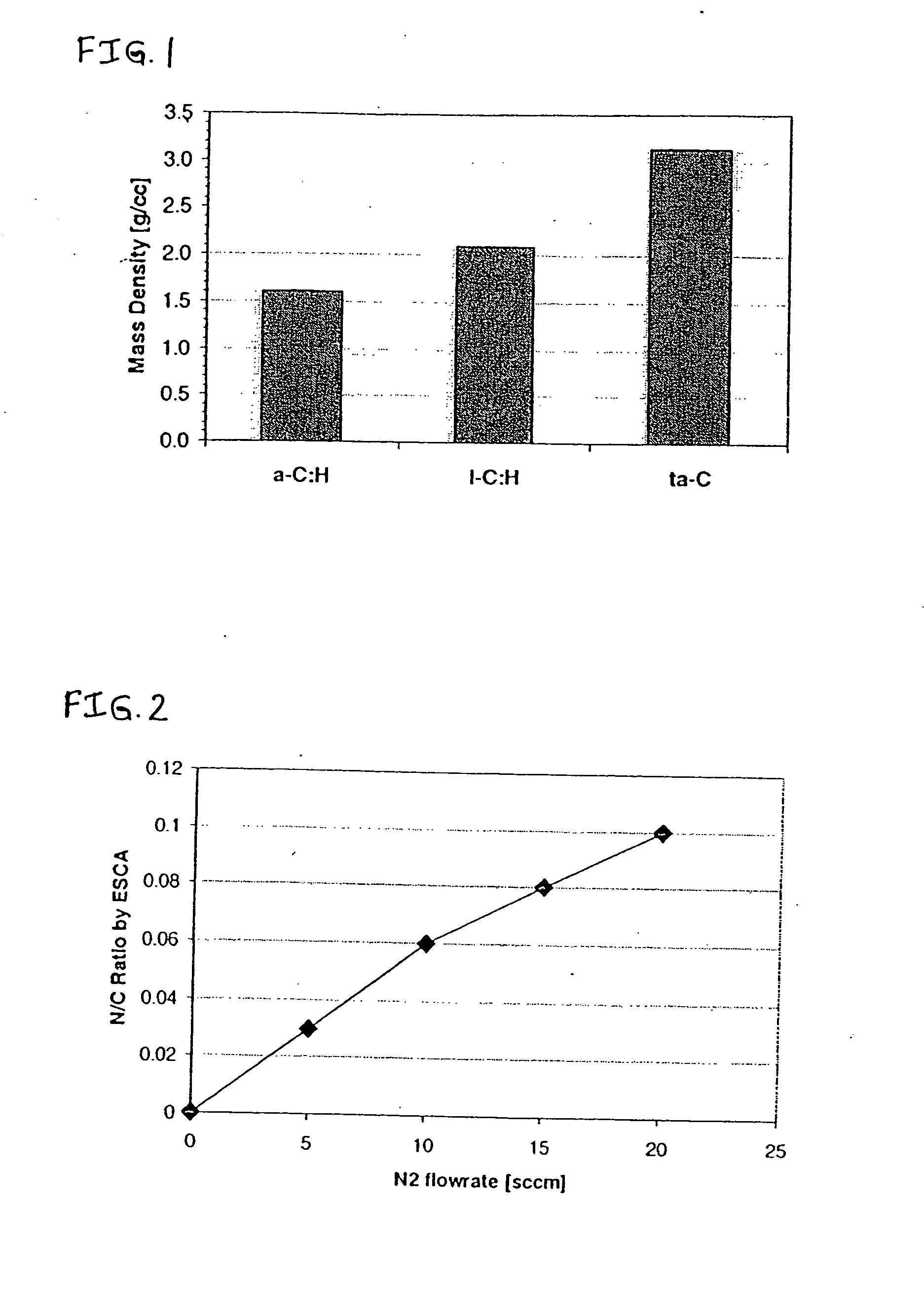

A recording medium, comprising: (a) a substrate having at least one surface; (b) a stacked plurality of thin film layers on the at least one surface and including at least one magnetic or magneto-optical (MO) recording layer; and (c) a protective overcoat layer on an outer surface of an outermost layer of the layer stack, comprising: (i) a first sub-layer layer (c1) of undoped tetrahedral amorphous carbon (ta-C) formed by filtered cathodic arc deposition (FCAD) on the outer surface of the outermost layer of the stacked plurality of thin film layers and having a high mass density of carbon (C) atoms greater than about 2.5 gms / cm3; and (ii) a second sub-layer (c2) of nitrogen-doped tetrahedral amorphous carbon (ta-C:N) formed by FCAD on the undoped ta-C layer and having a high mass density of carbon (C) atoms greater than about 2.0 gms / cm3.

Owner:SEAGATE TECH LLC

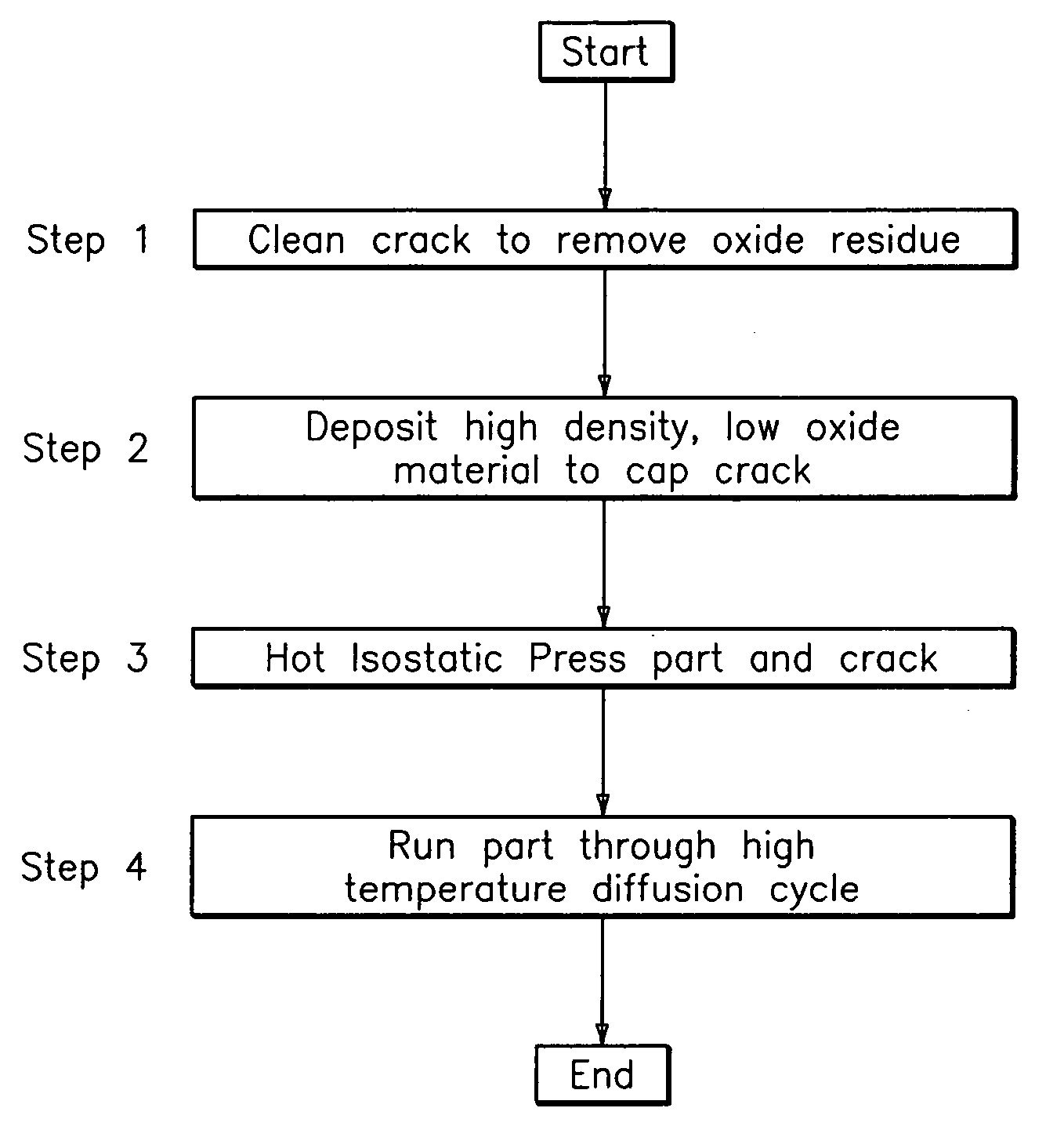

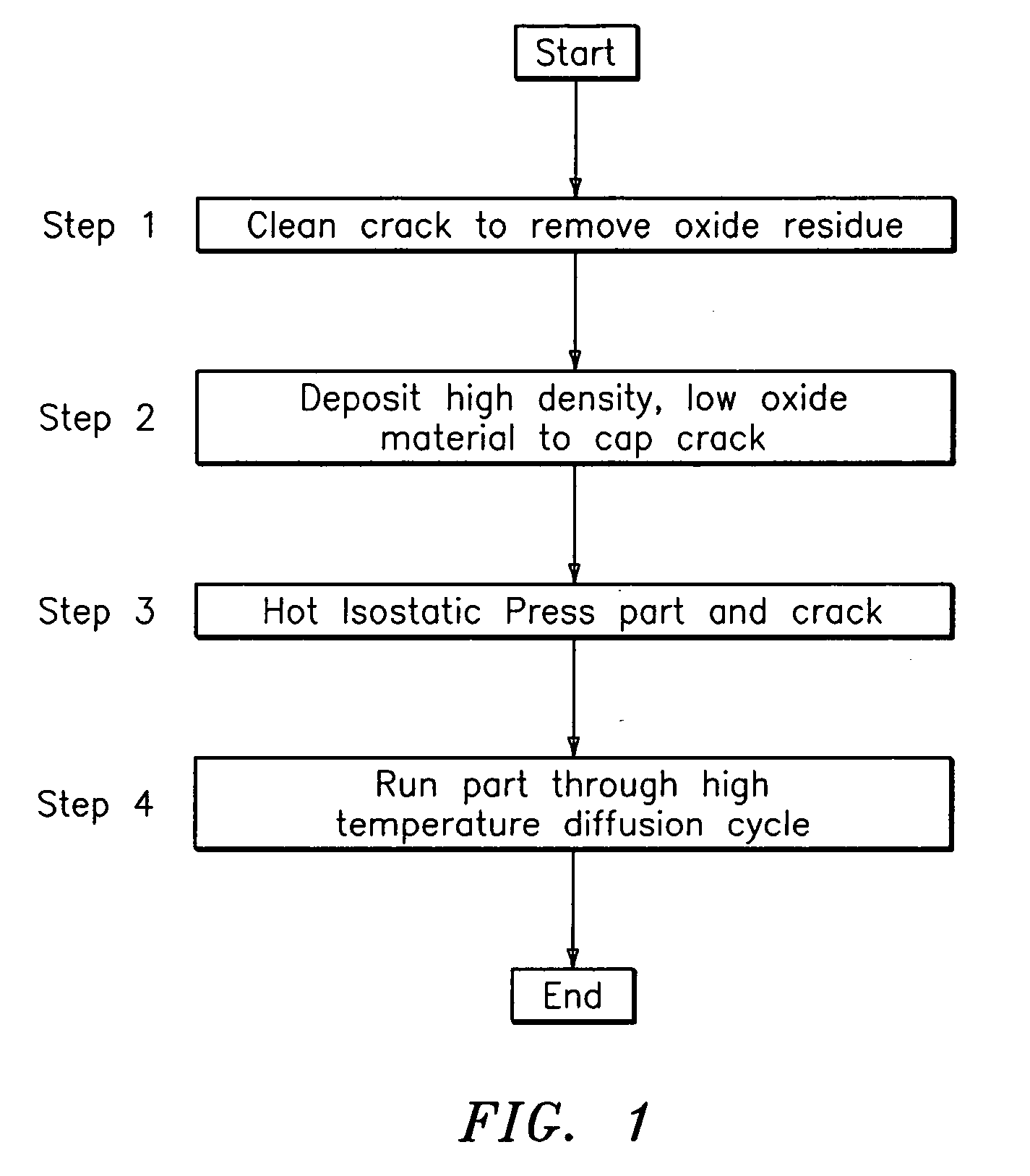

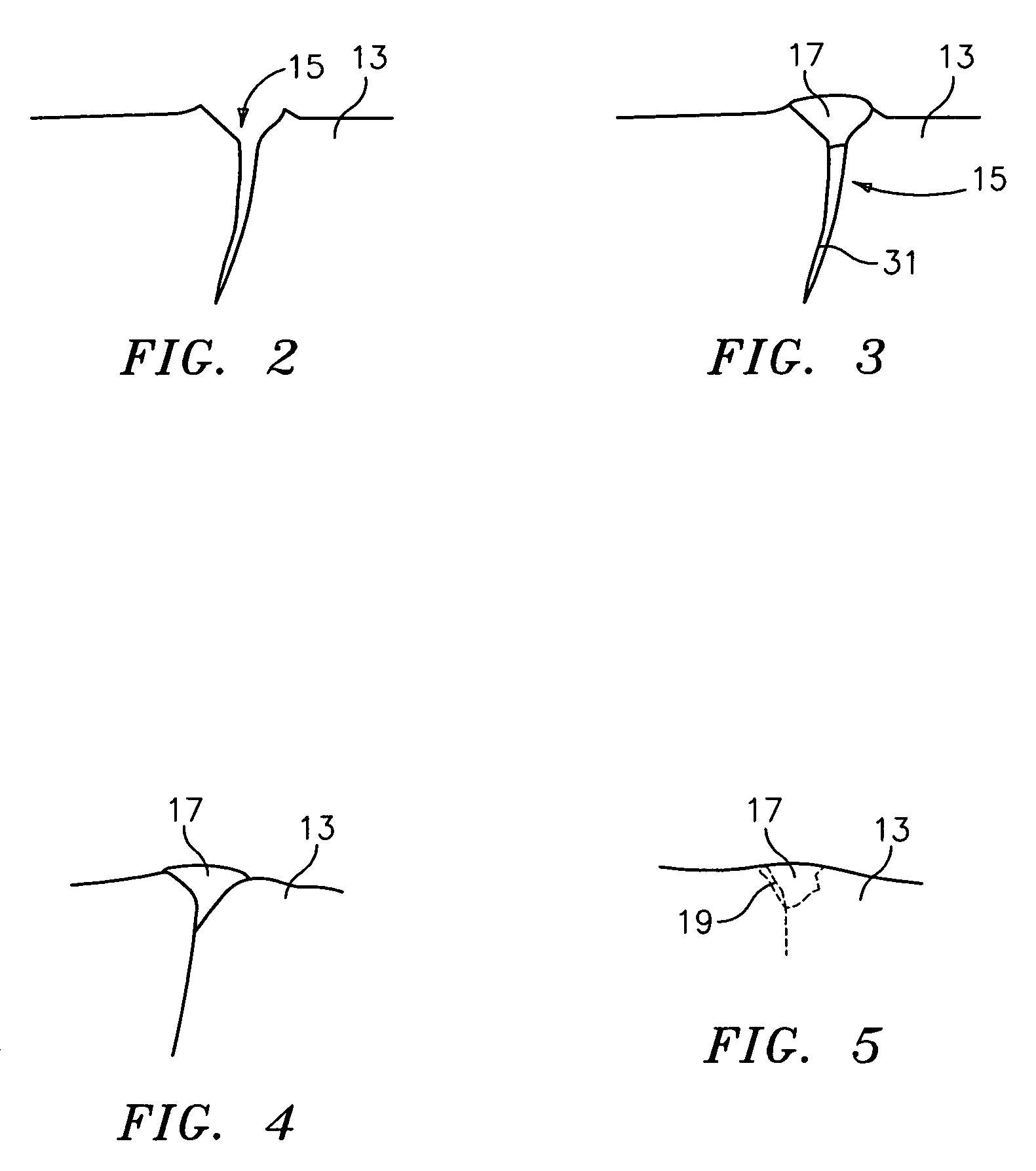

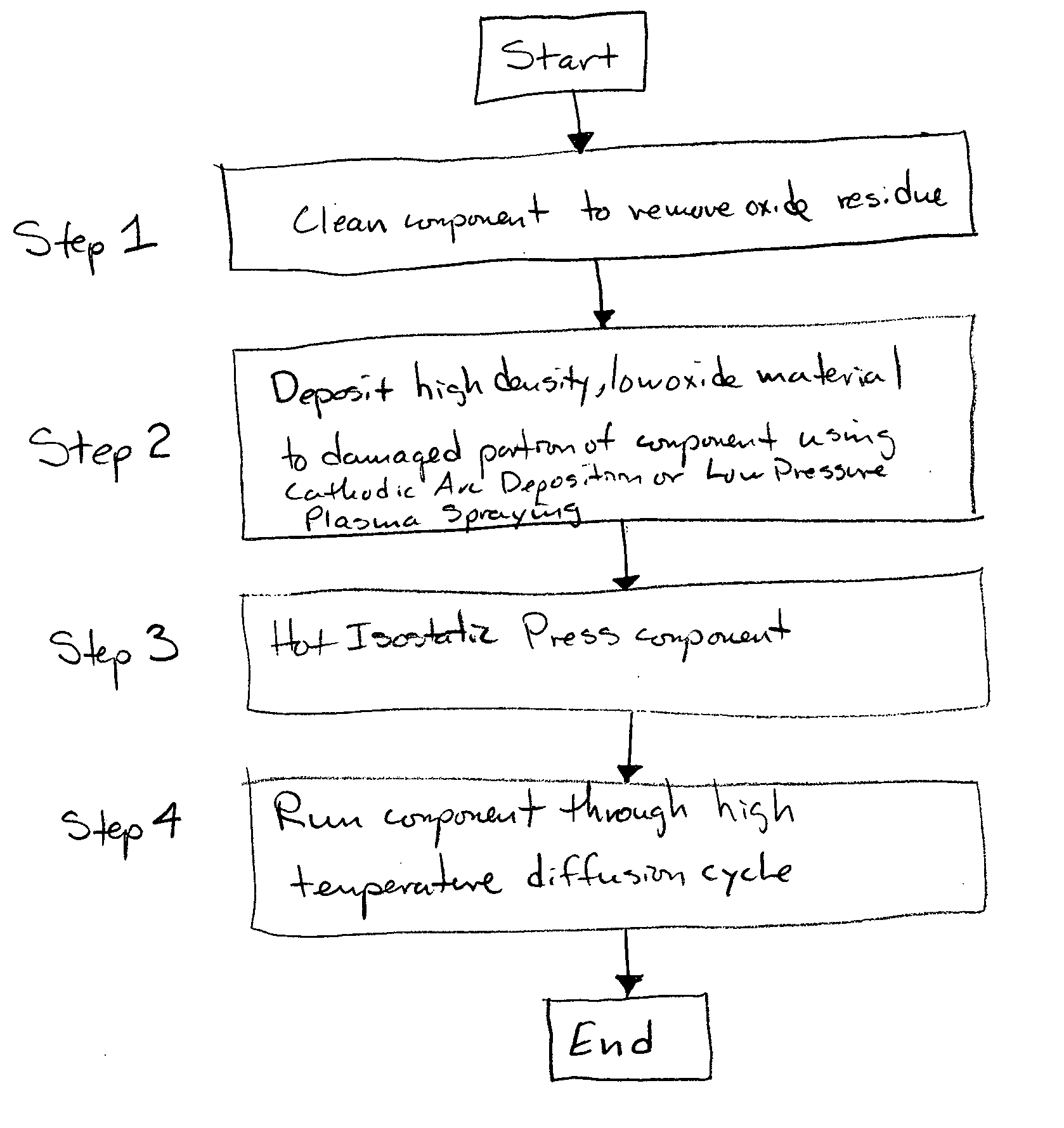

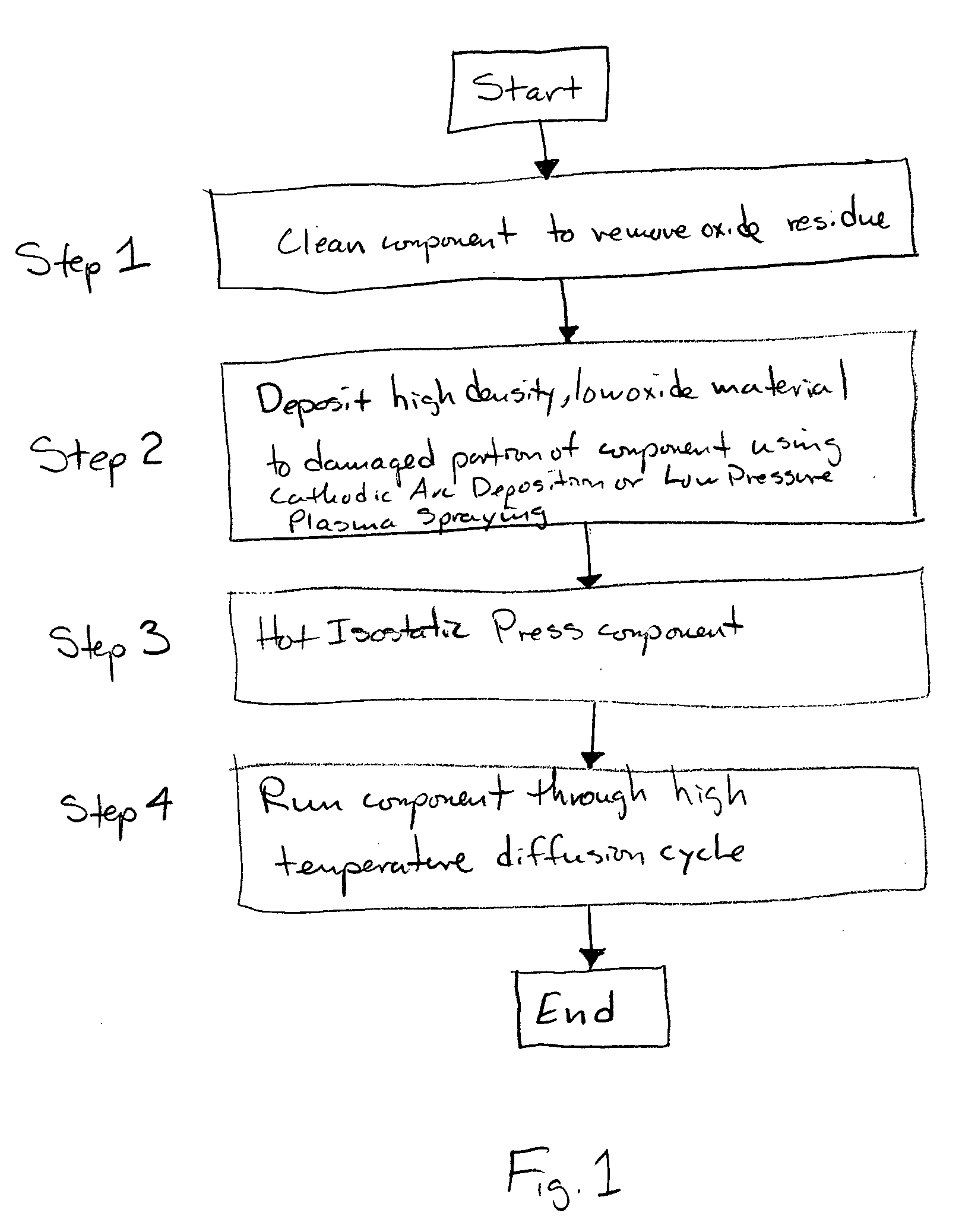

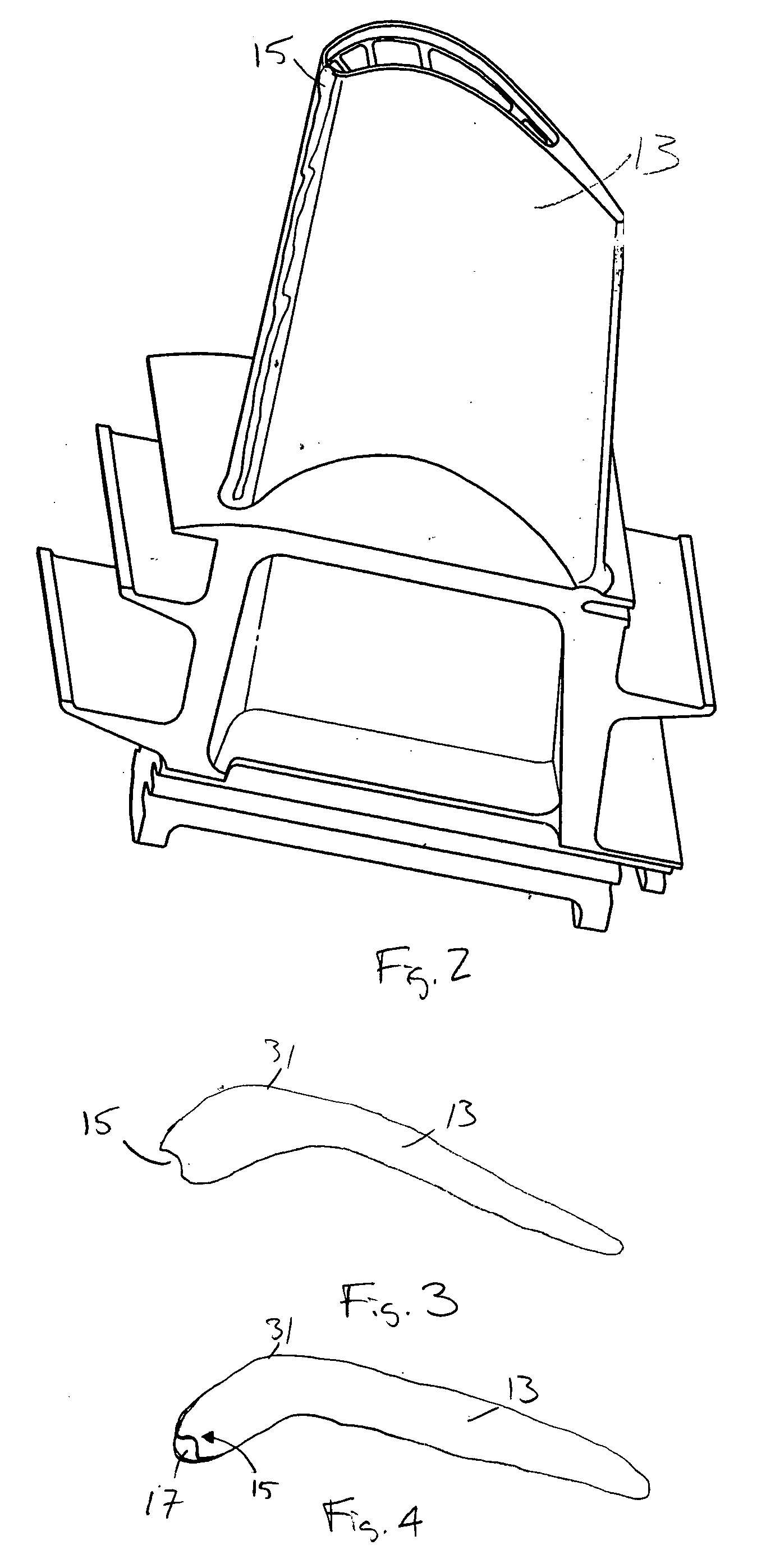

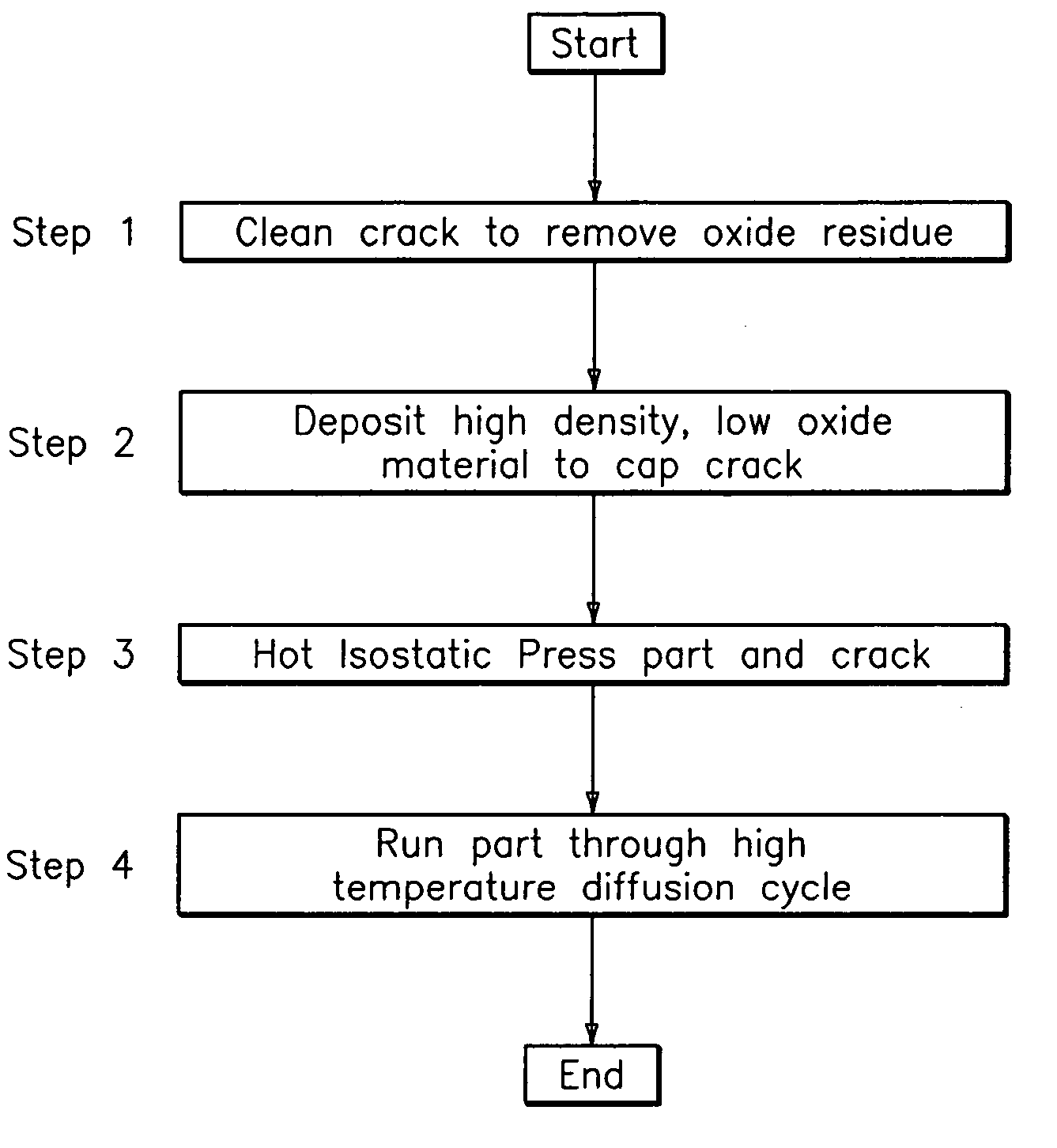

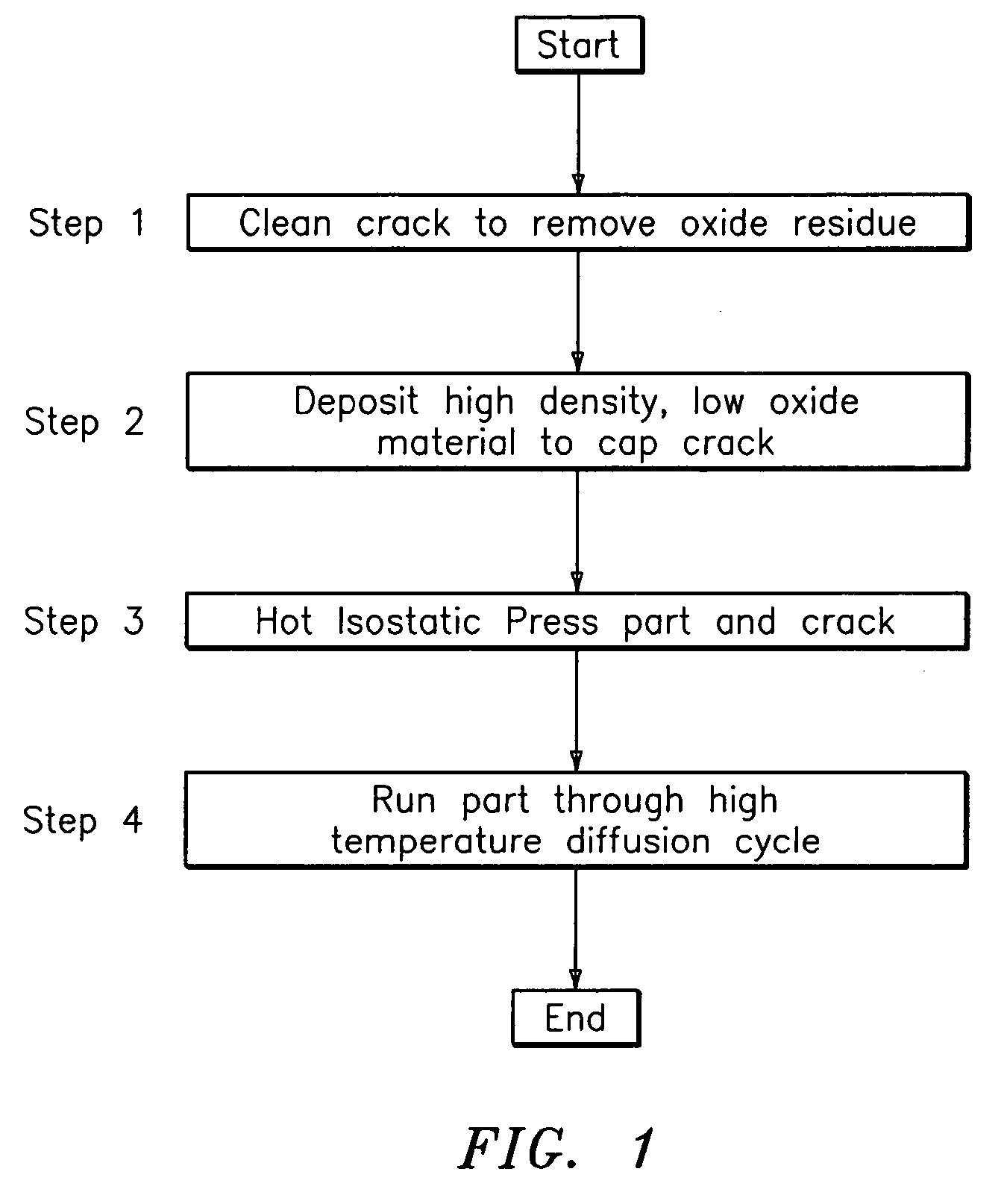

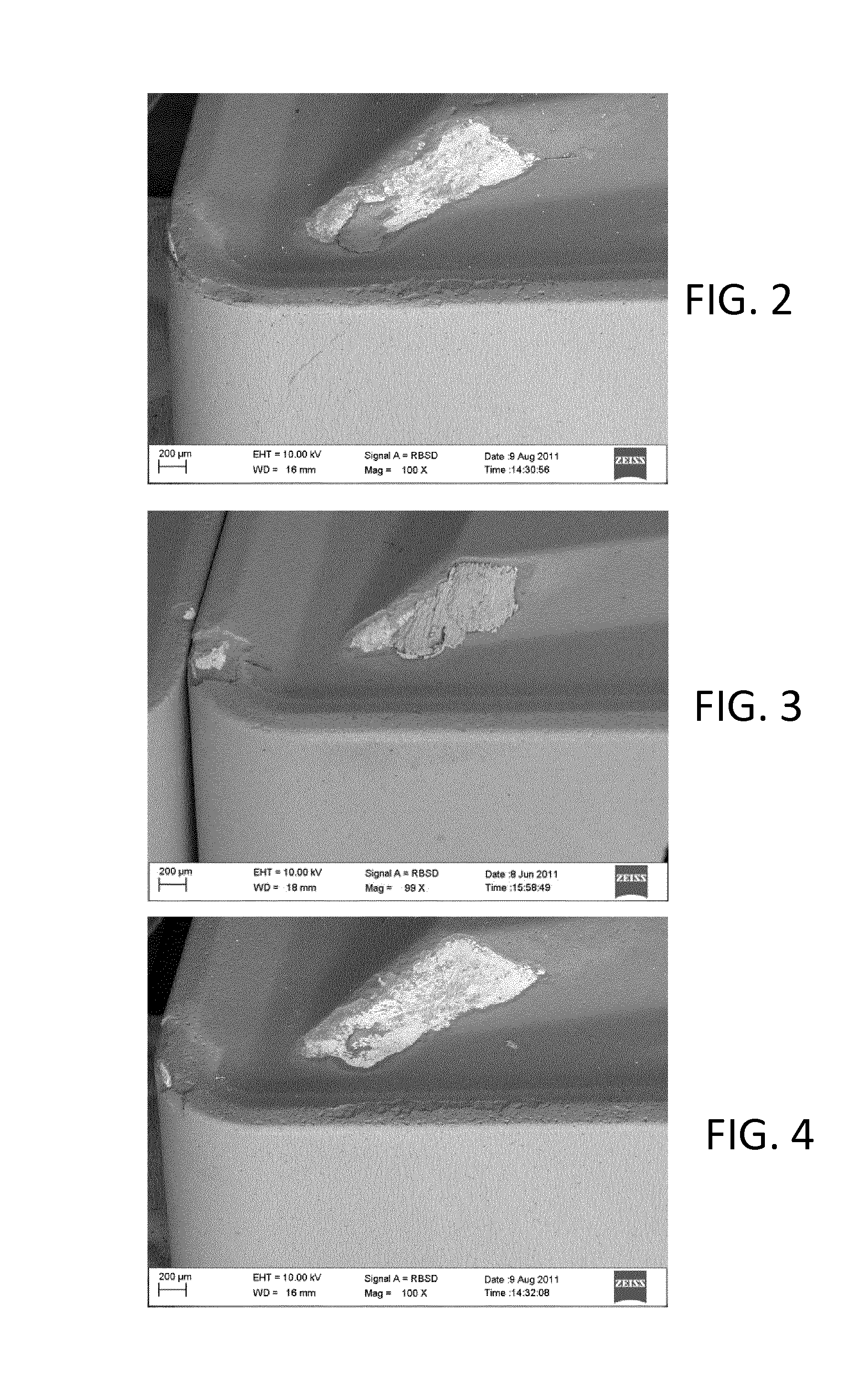

Turbine component crack repair using cathodic arc and/or low pressure plasma spraying and hip

A method for repairing cracks in a metal part comprising the steps of providing a metal part having a crack, cleaning the crack to remove an oxide layer, depositing a repair alloy via at least one of cathodic arc deposition and low pressure plasma spraying to cover the crack, and heating the part at a temperature and pressure sufficient to close the crack.

Owner:RAYTHEON TECH CORP

Turbine component restoration using cathodic ARC/LPPS

A method for repairing cracks in a metal part comprising the steps of providing a metal part having a worn portion, cleaning the worn portion to remove an oxide layer, depositing a restoration alloy to cover the worn portion via a deposition process selected from the group consisting of cathodic arc deposition and Low Pressure Plasma Spray (LPPS) deposition.

Owner:UNITED TECH CORP

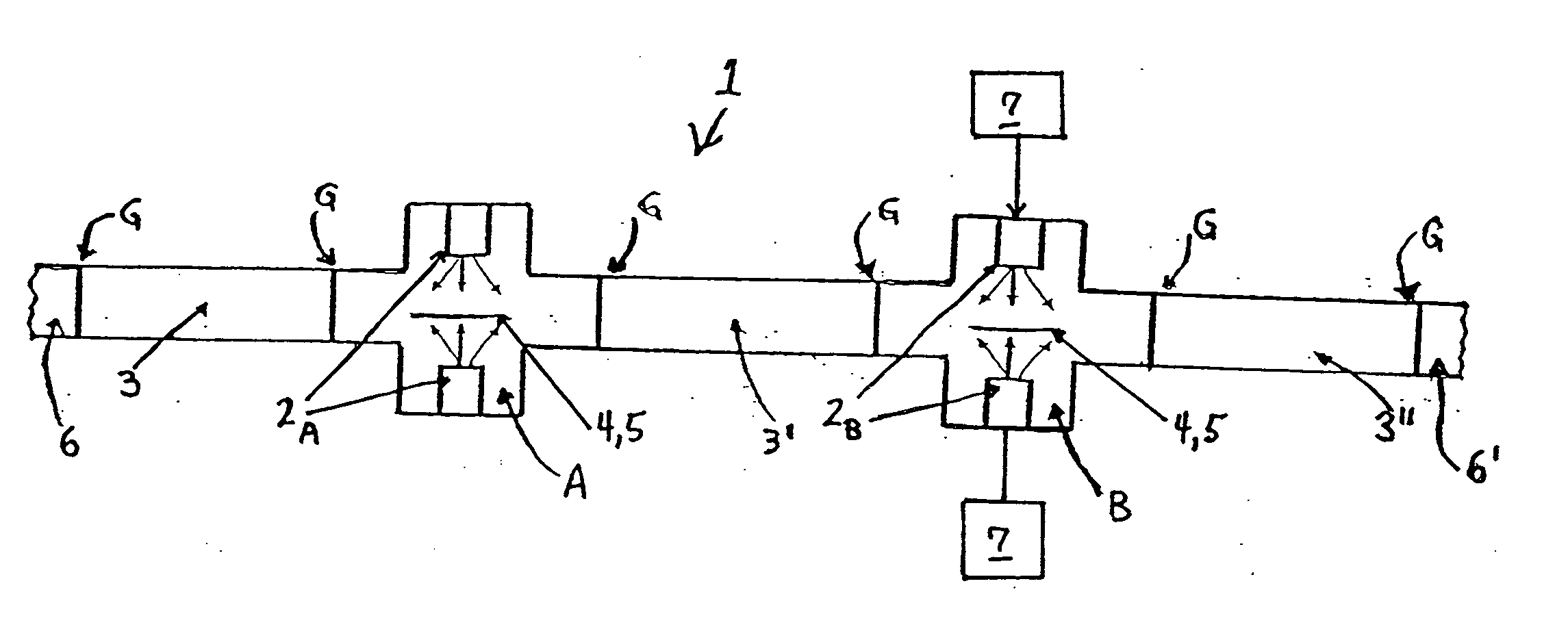

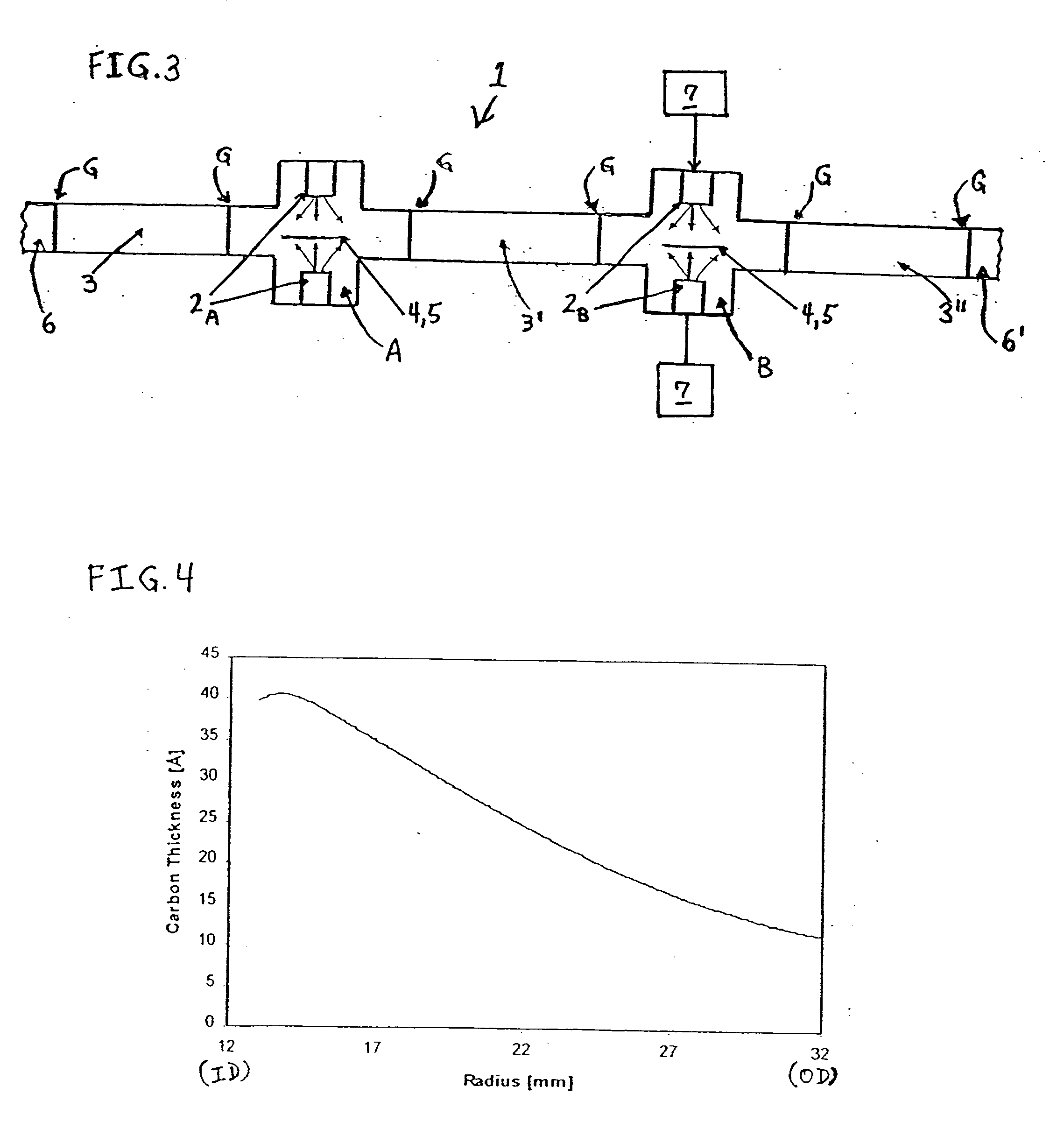

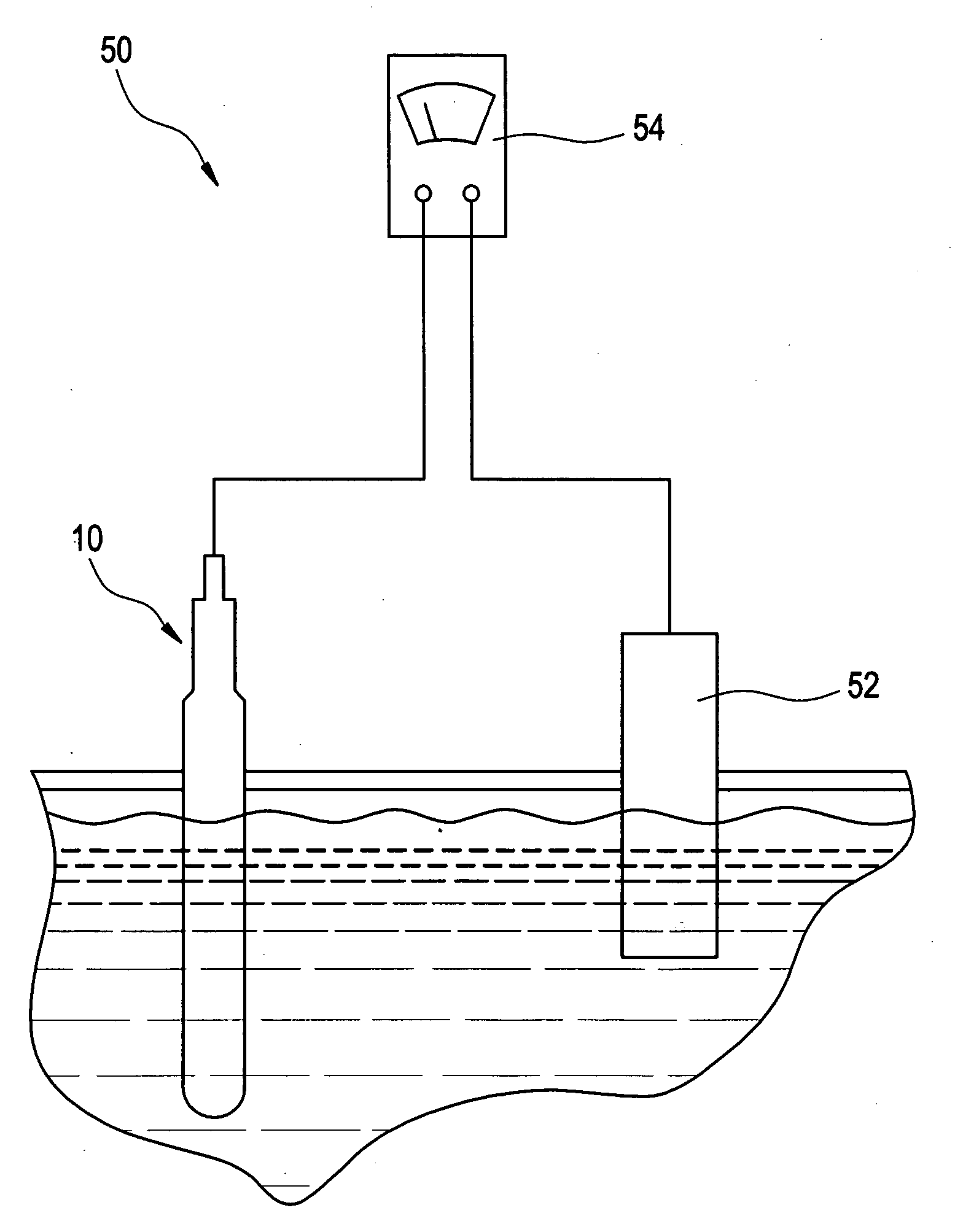

Thickness gradient protective overcoat layers by filtered cathodic arc deposition

InactiveUS20050249983A1Simple methodApparatus is enlargedCellsProtective coatings for layersCathodic arc depositionMaterials science

Owner:SEAGATE TECH LLC

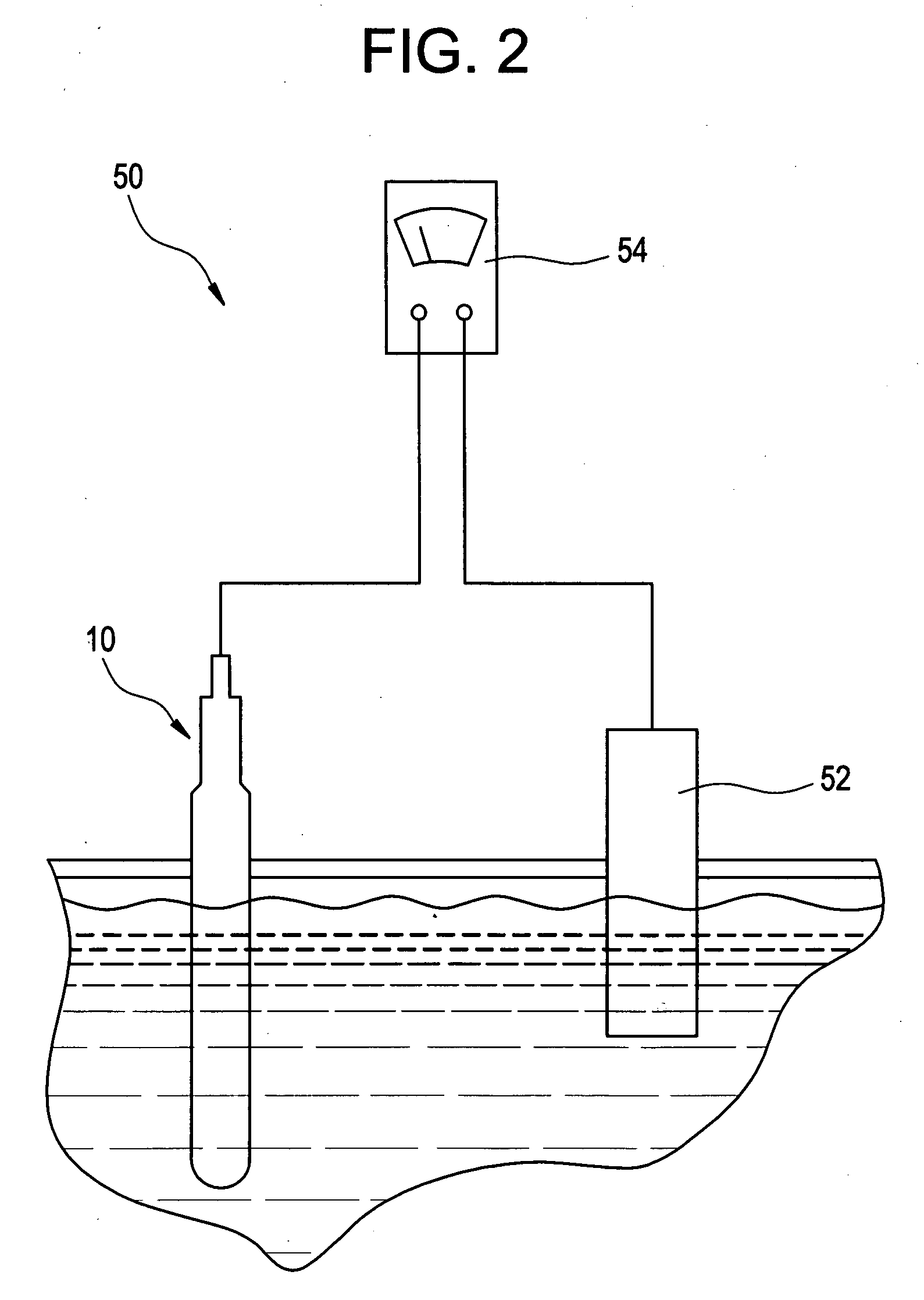

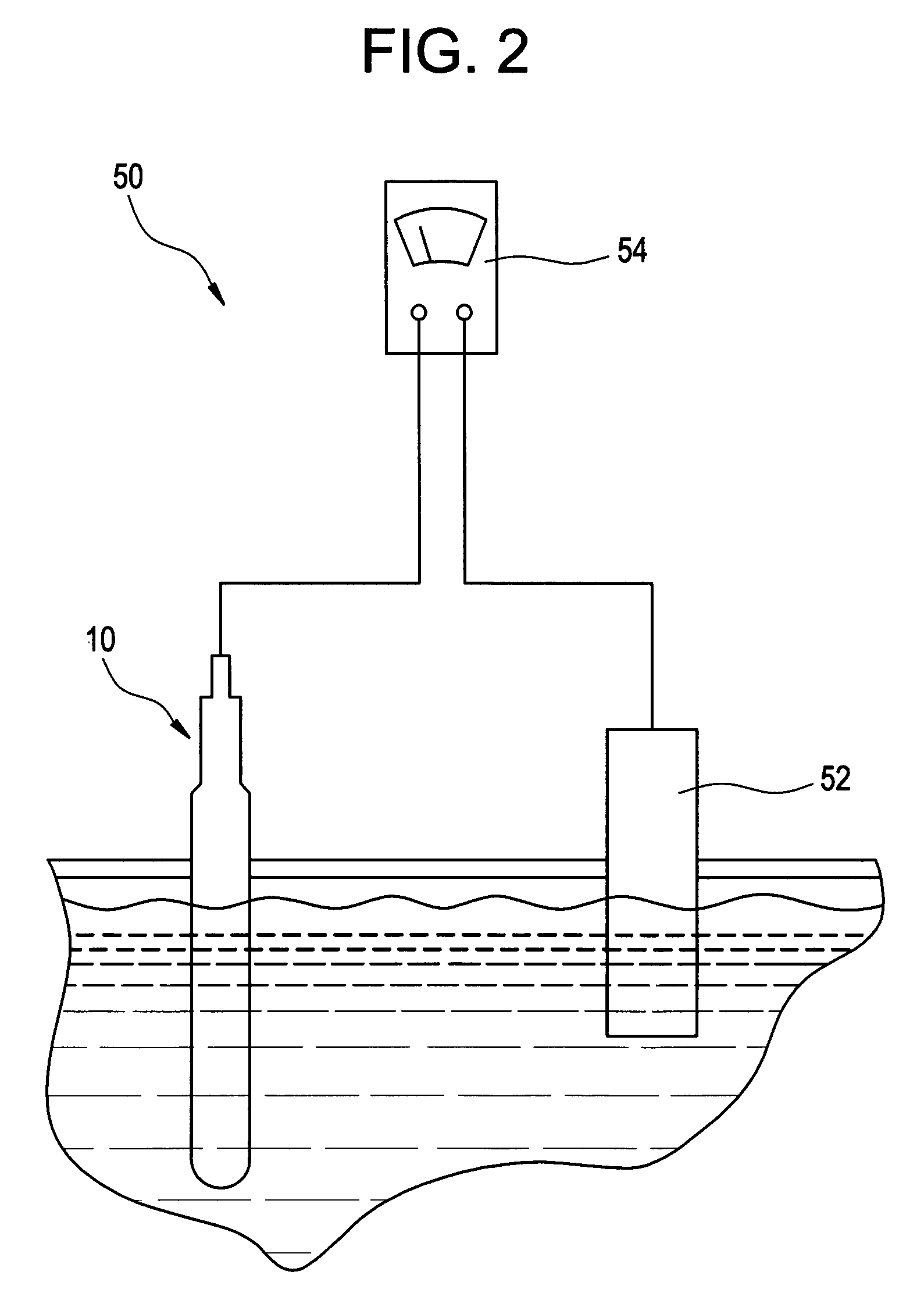

Electrochemical corrosion potential sensor and method of making

InactiveUS20080169205A1Weather/light/corrosion resistanceVolume/mass flow measurementCathodic arc depositionElectrical conductor

A sensor for measuring electrochemical corrosion potential includes an electrical conductor, a metal-oxide layer disposed on the electrical conductor, and a zirconia-containing layer disposed on the metal-oxide layer, wherein the zirconia-containing layer is disposed about the electrical conductor using thermal spraying, wire arc, ion plasma cathodic arc deposition, laser ablation, chemical vapor deposition, physical vapor deposition, electroplating, electroless plating, electrochemical oxidation, chemical oxidation, electrophoretic deposition, or radio-frequency sputtering.

Owner:BAKER HUGHES INC

Method for preparing metal sulfide diamond-like carbon composite film

InactiveCN101787521AVacuum evaporation coatingSputtering coatingCathodic arc depositionComposite film

The invention relates to a method for preparing a metal sulfide DLC composite film. The method is characterized by comprising the following steps: firstly using the ultrasonic washing technology to remove the surface contamination layer of a basal body; using the inert gas ion beam generated by an ion source to carry out the ion beam bombardment washing on the surface of the basal body; using the metal ion generated by a cathodic arc source to carry out the metal ion bombardment washing on the surface of the basal body under the high workpiece negative bias condition; using the cathodic arc deposition or ion beam assisted magnetron sputtering technology to prepare a gradient transition layer; using the ion beam deposition on an intermediate layer and magnetron sputtering technology to synthesize a doped DLC film doped with at least one metal element of W, Mo and Fe; and finally obtaining the high-sulfur metal sulfide / DLC composite film by using the ion vulcanization, wherein the ion beam deposition is realized by introducing carbonaceous gas to the ion source, and sulfureous gas is used as the sulfur source.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

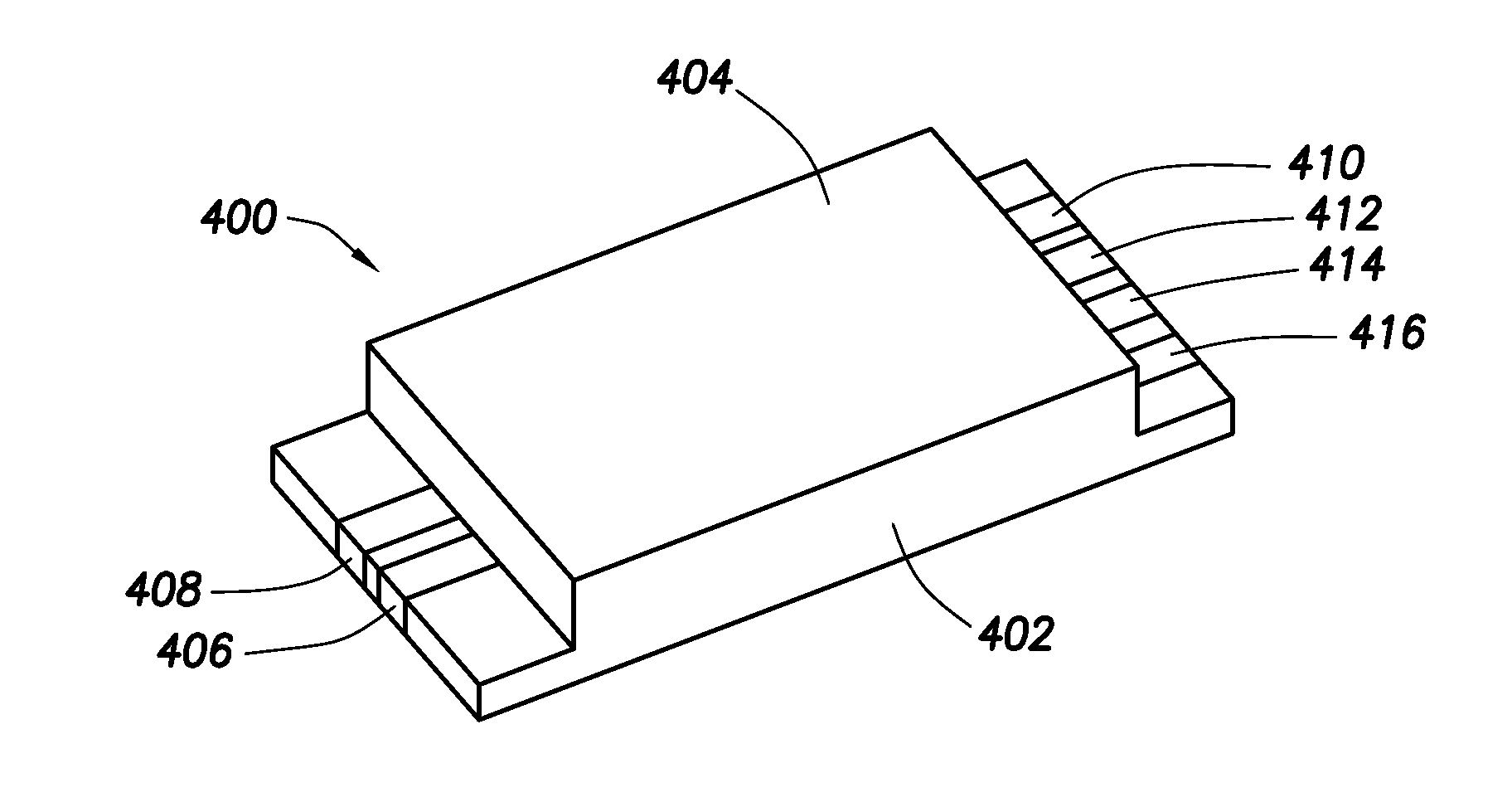

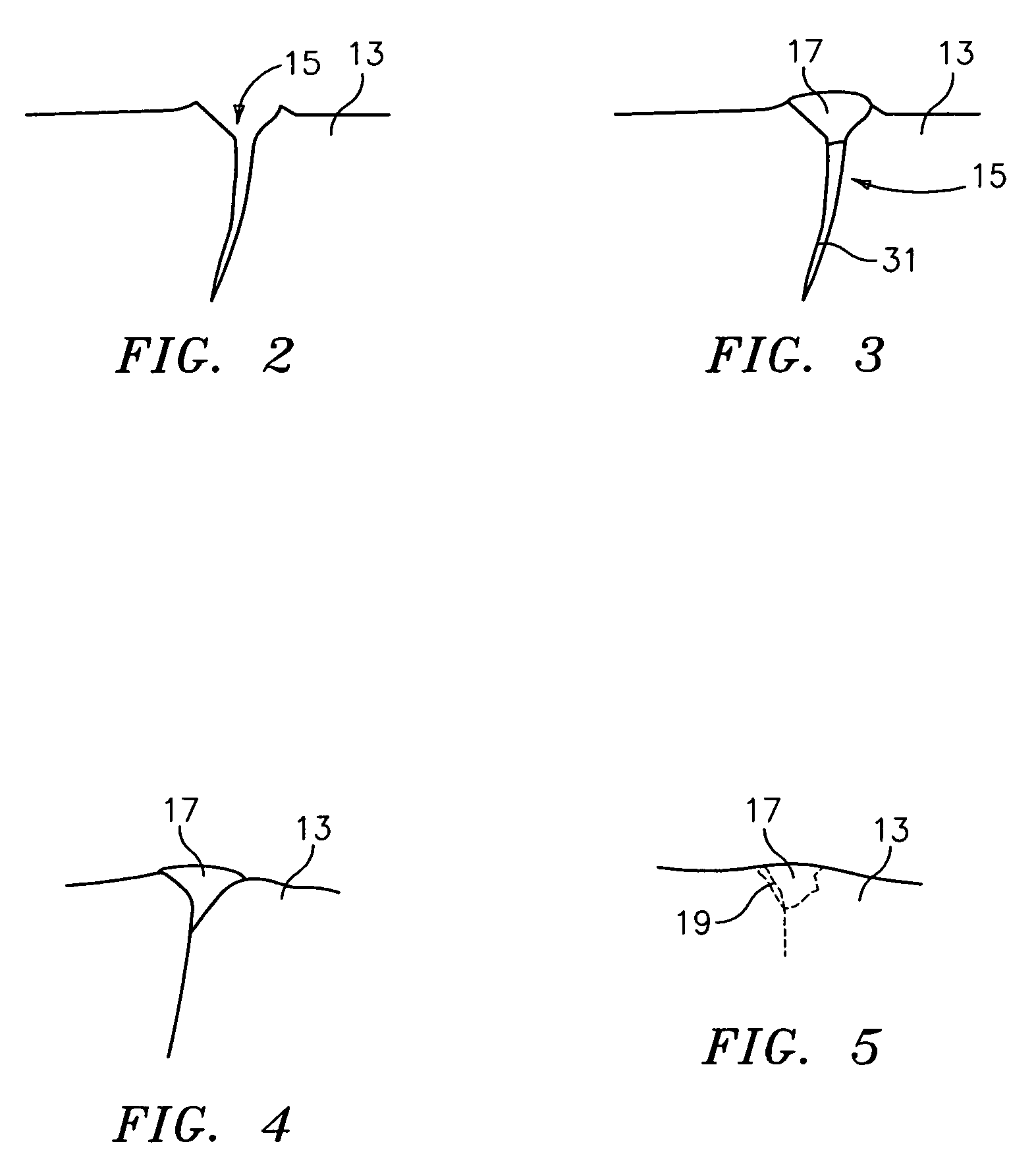

Solid-State Thin-Film Capacitor

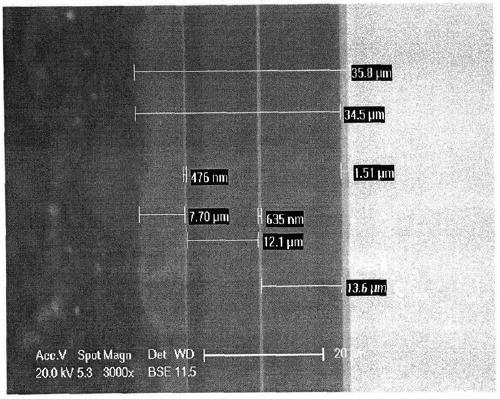

ActiveUS20120018844A1Small sizeFunction increaseThin/thick film capacitorSemiconductor/solid-state device manufacturingCathodic arc depositionCrenulation

Solid-state thin-film capacitors are provided. Aspects of the solid-state thin-film capacitors include a first electrode layer of a transition metal, a dielectric layer of an oxide of the transition metal, and a second electrode layer of a metal oxide. Also provided are methods of making the solid-state thin-film capacitors, as well as devices that include the same. The capacitor may have one or more cathodic arc produced structures, i.e., structures produced using a cathodic arc deposition process. The structures may be stress-free metallic structures, porous layers and layers displaying crenulations. Aspects of the invention further include methods of producing capacitive structures using chemical vapor deposition and / or by sputter deposition.

Owner:PROTEUS DIGITAL HEALTH INC

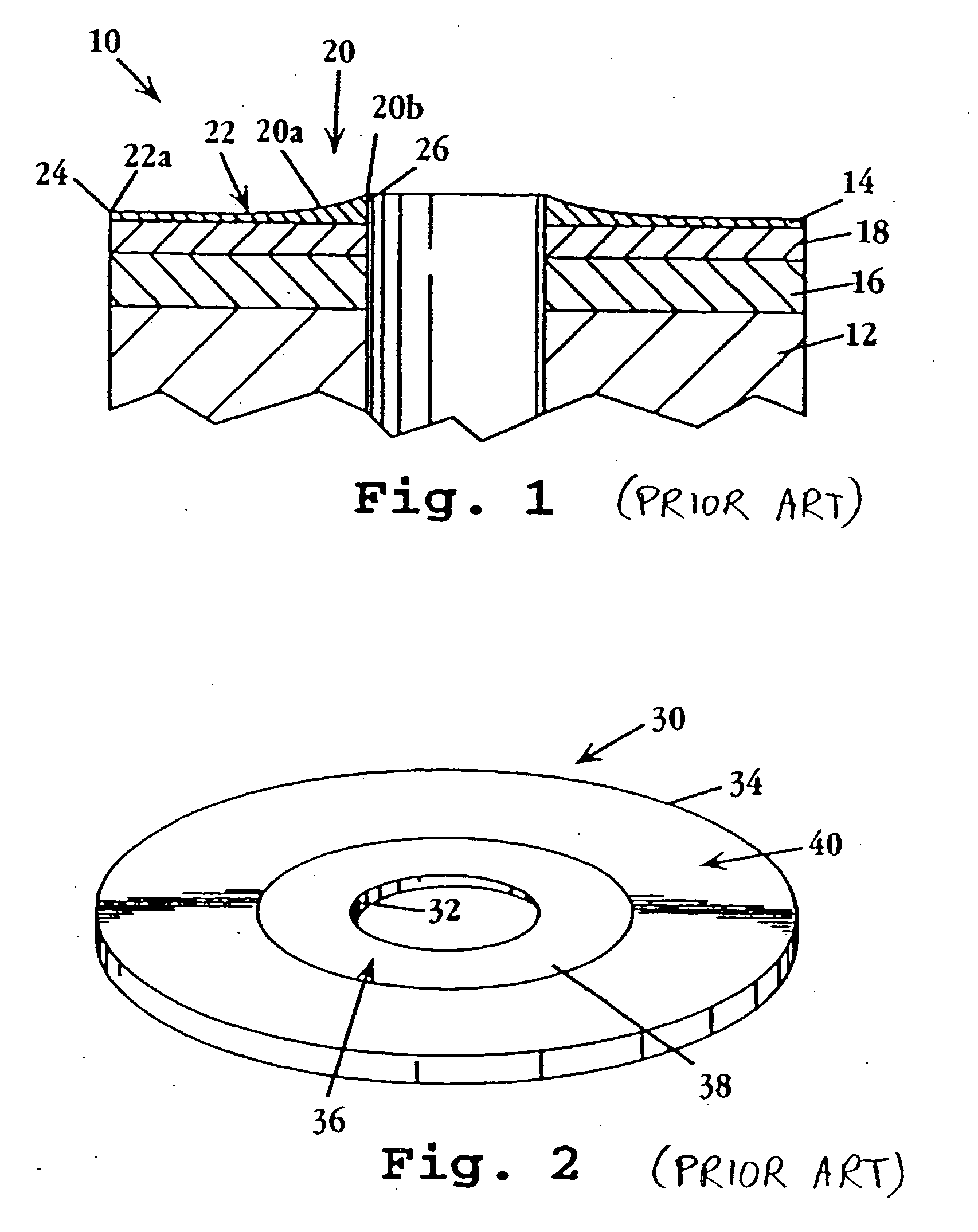

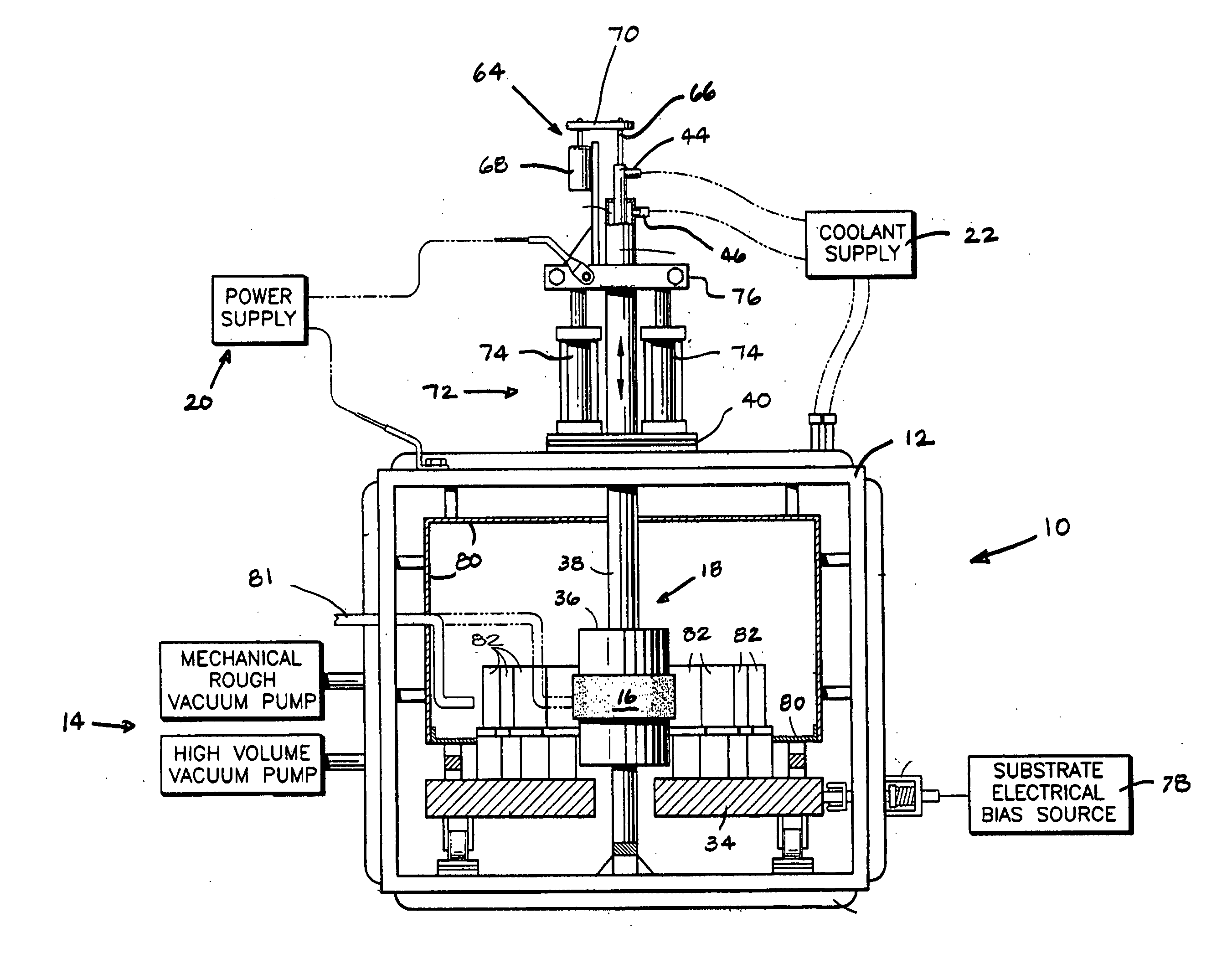

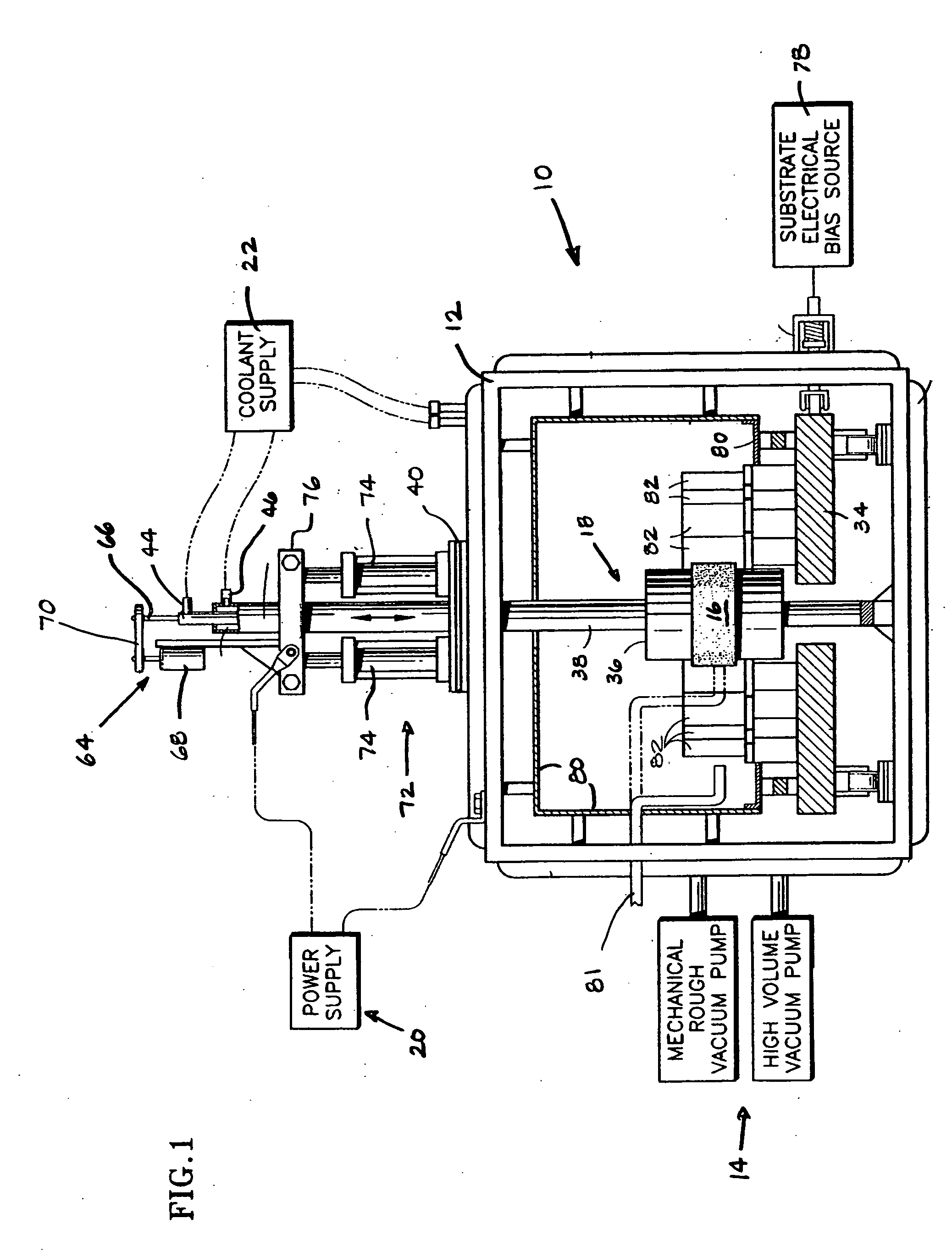

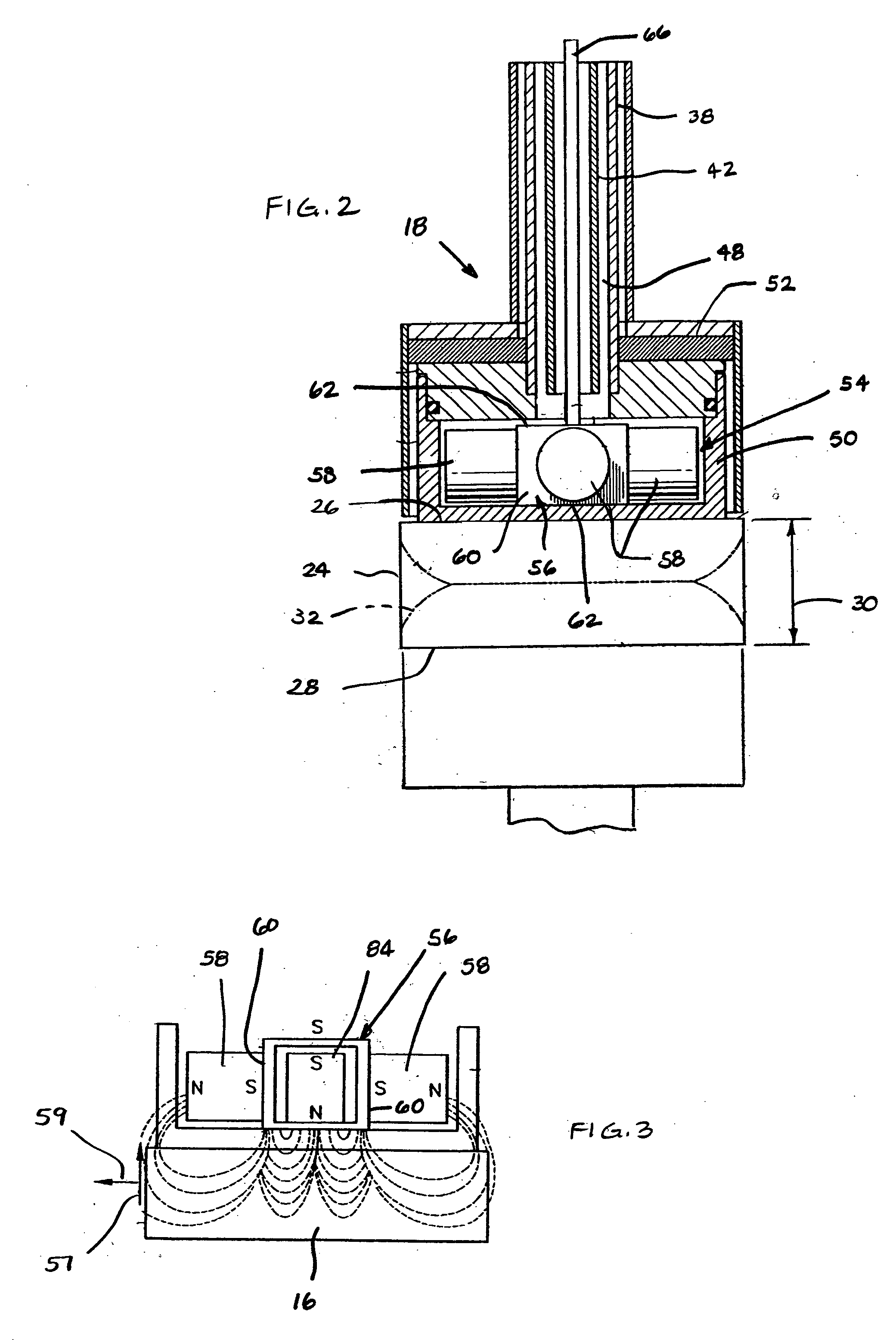

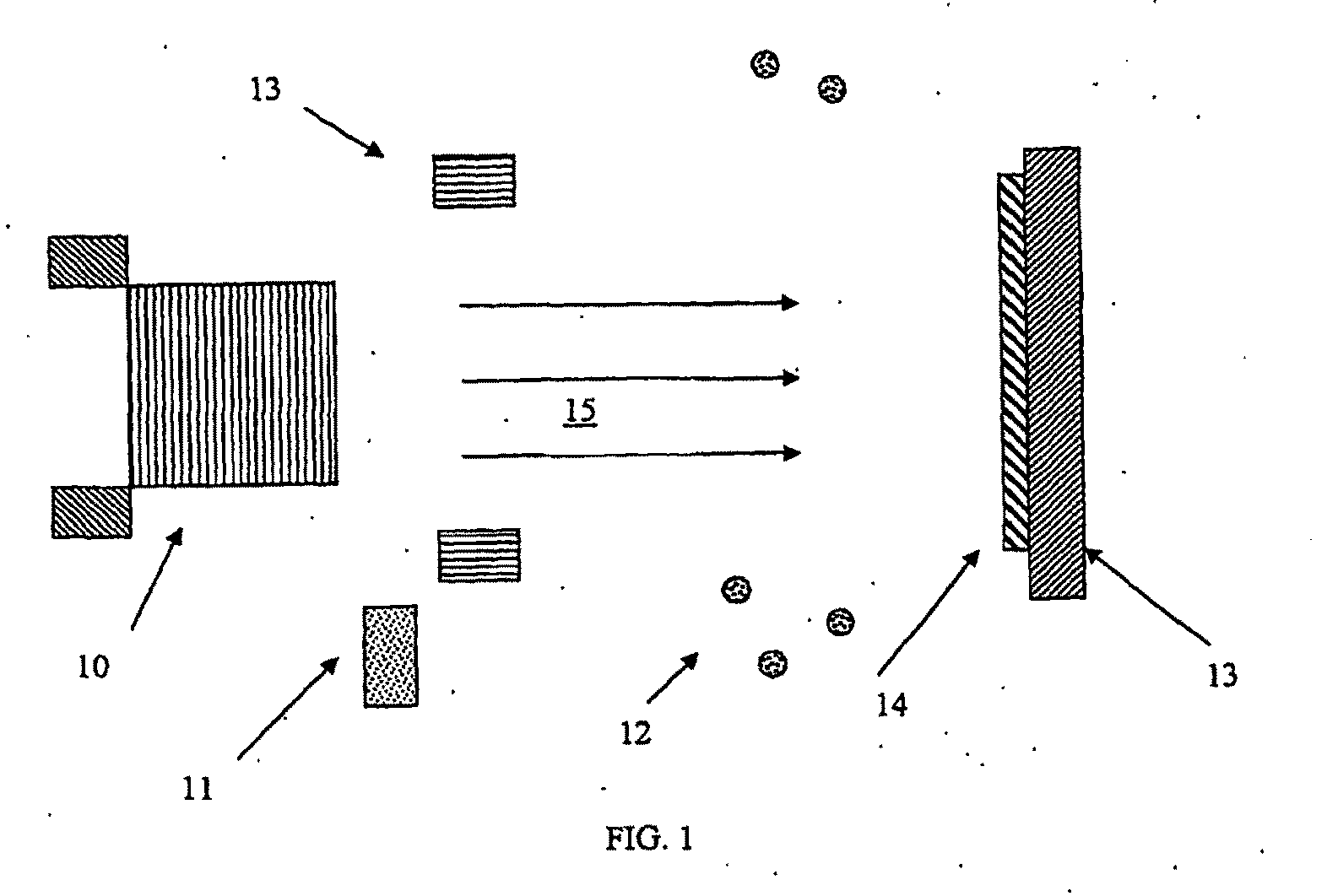

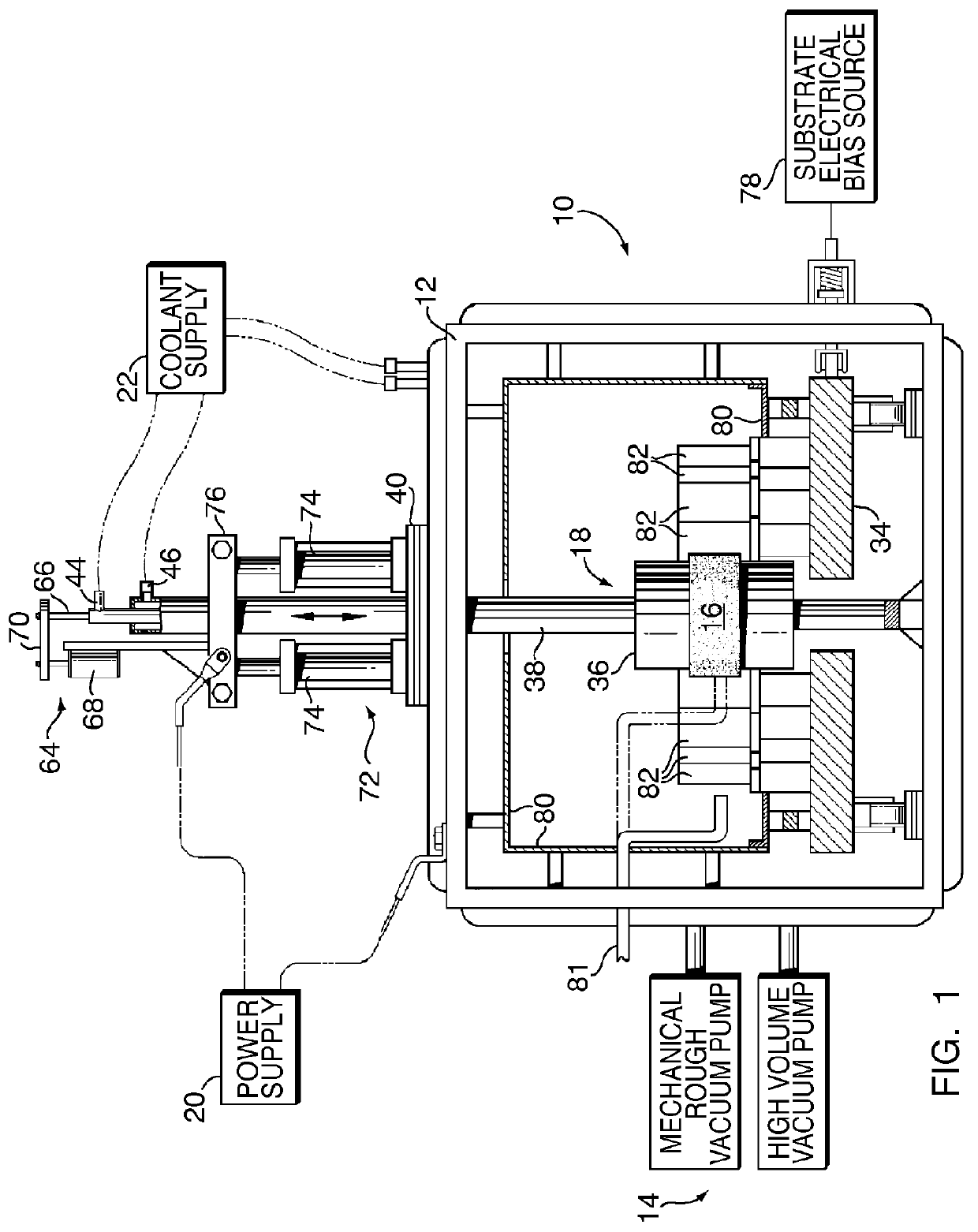

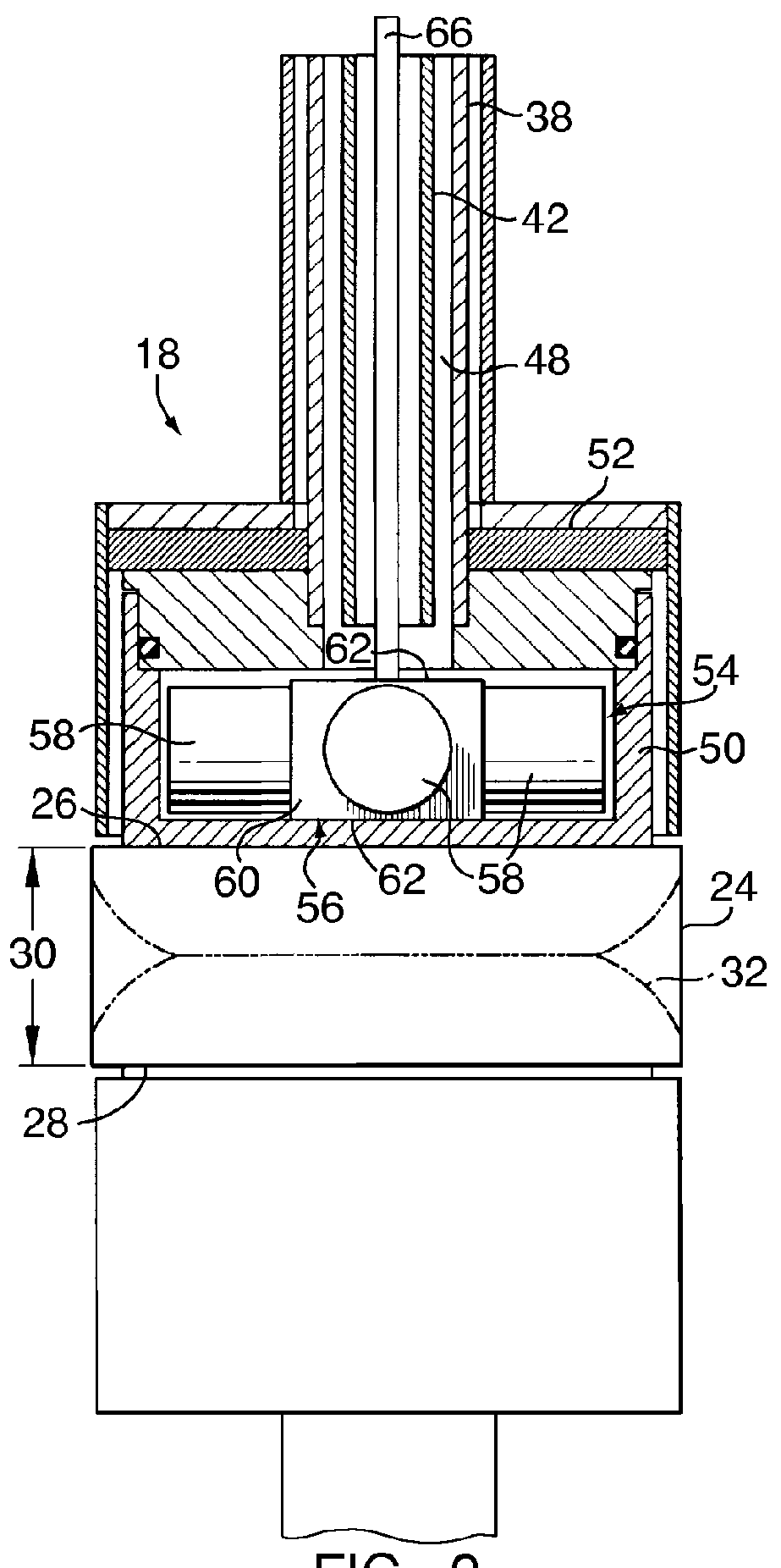

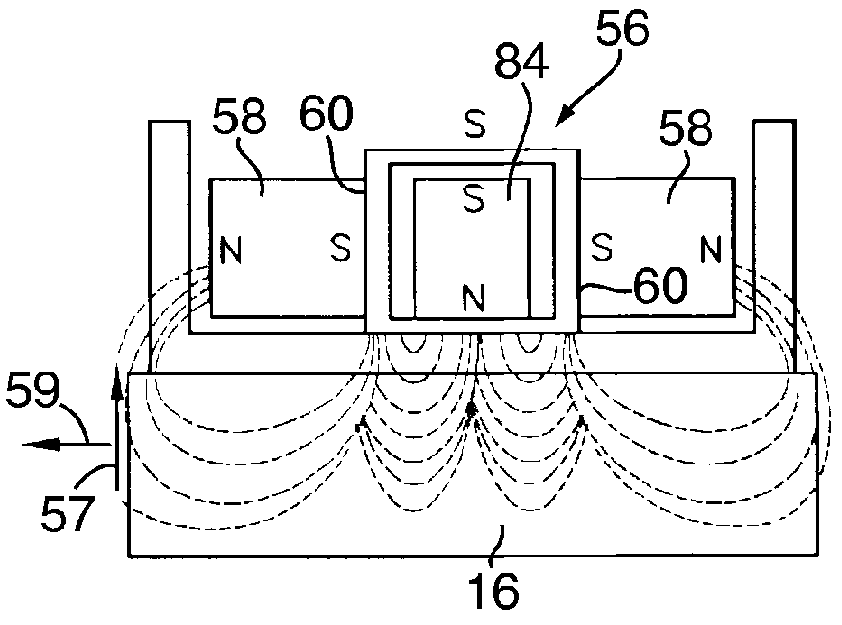

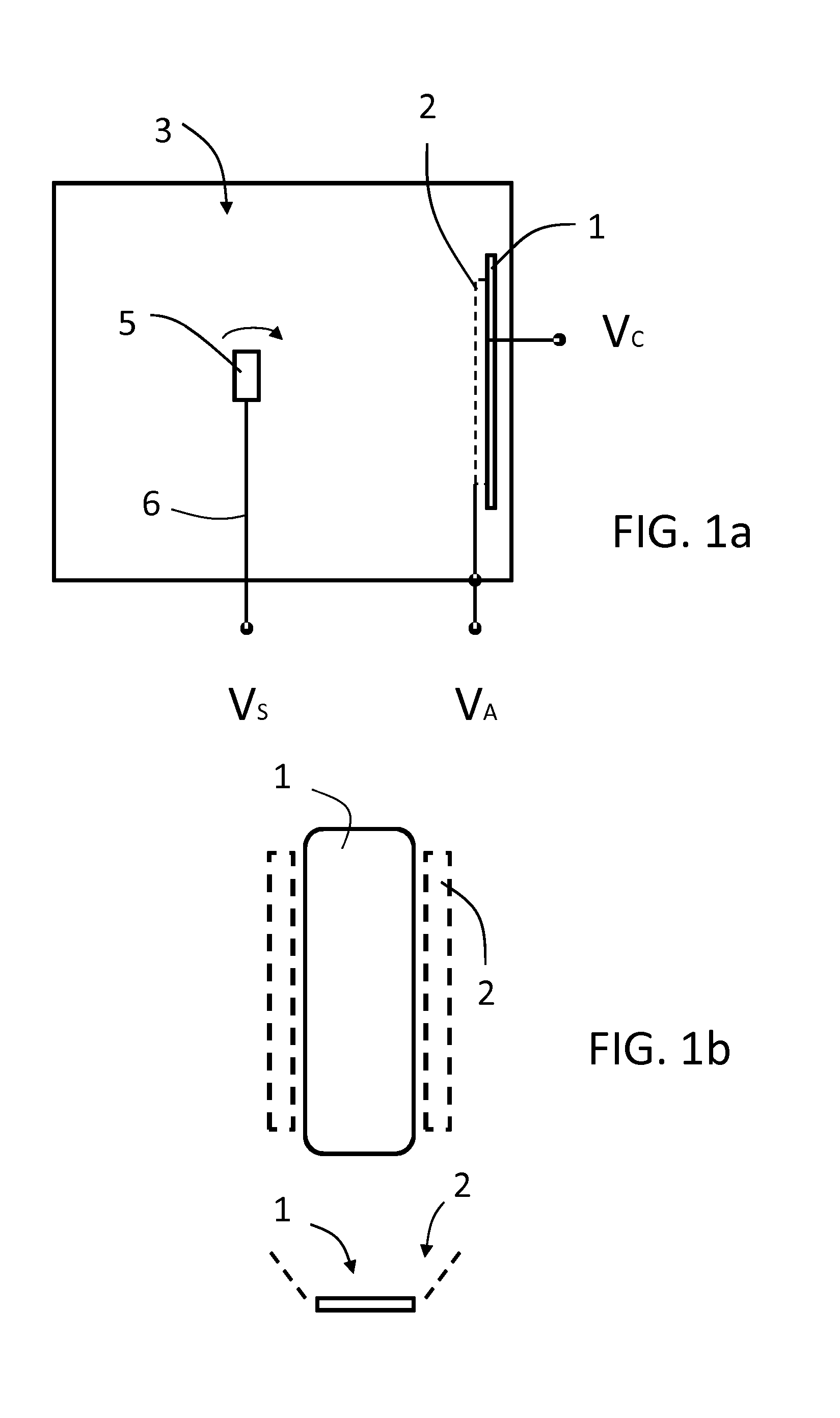

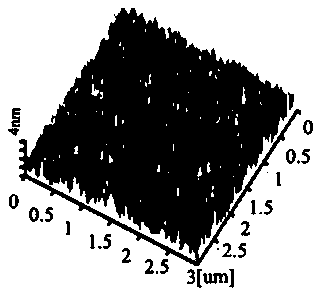

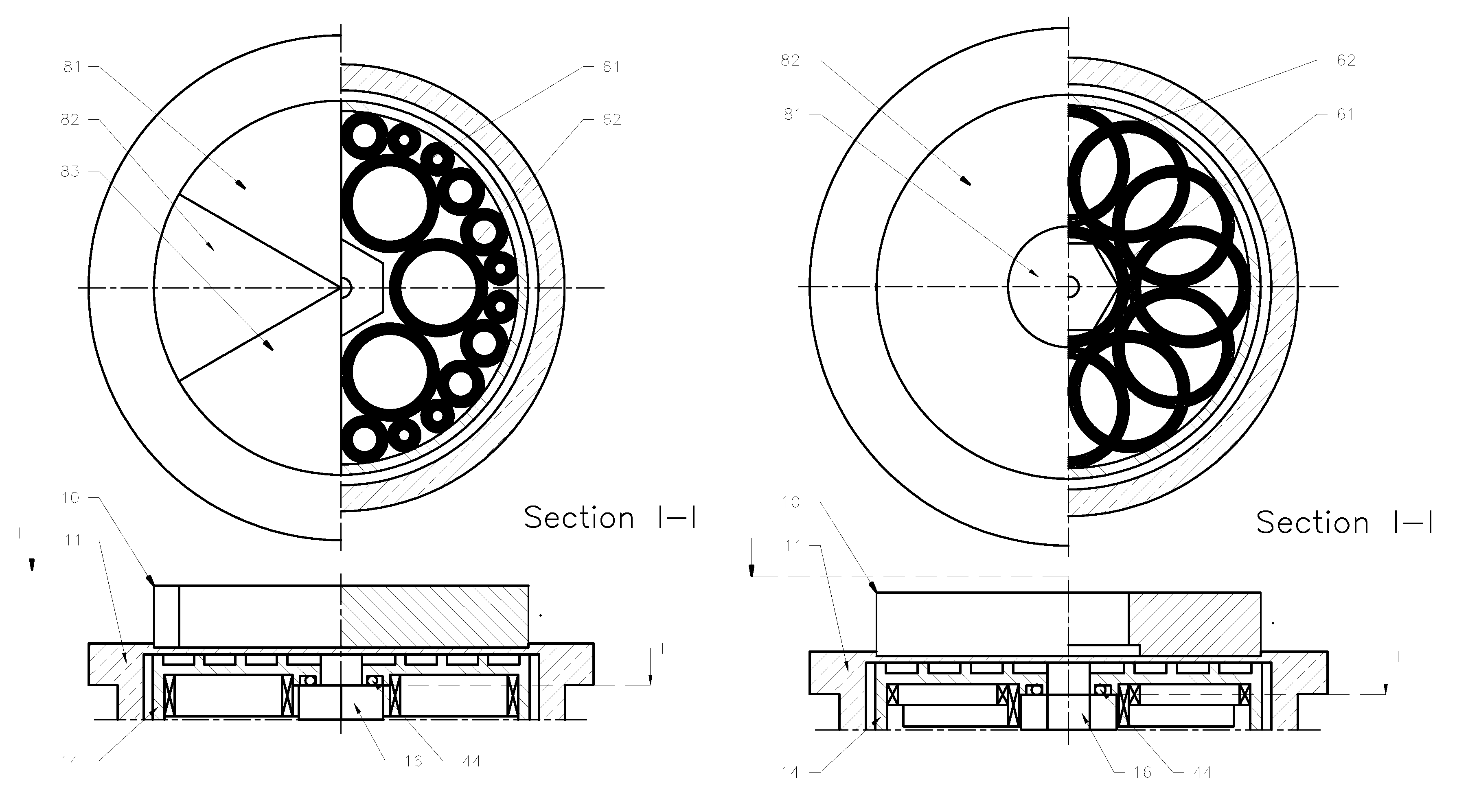

Method and apparatus for cathodic arc deposition of materials on a substrate

ActiveUS20060124450A1Rate of depositionMaintain integrityCellsElectric discharge tubesCathodic arc depositionEngineering

A method for applying a coating by a cathodic is provided. The method includes the steps of: a) providing a cathodic arc coater that includes a power source and utilizes a disk-shaped cathode, the cathode having an evaporative surface extending between a first end surface and a second end surface, wherein the evaporative surface has an area; b) determining a maximum acceptable power density for the evaporative surface; and c) applying a magnitude of electrical current from the power source to the cathode, wherein the electrical current magnitude divided by the area is equal to or less than the maximum acceptable power density for the evaporative surface.

Owner:RTX CORP

Method for preparing anti-lock thread coating through PVD

ActiveCN104451584ASolve the problem of deadlock failureAchieve activationVacuum evaporation coatingSputtering coatingCathodic arc depositionArgon atmosphere

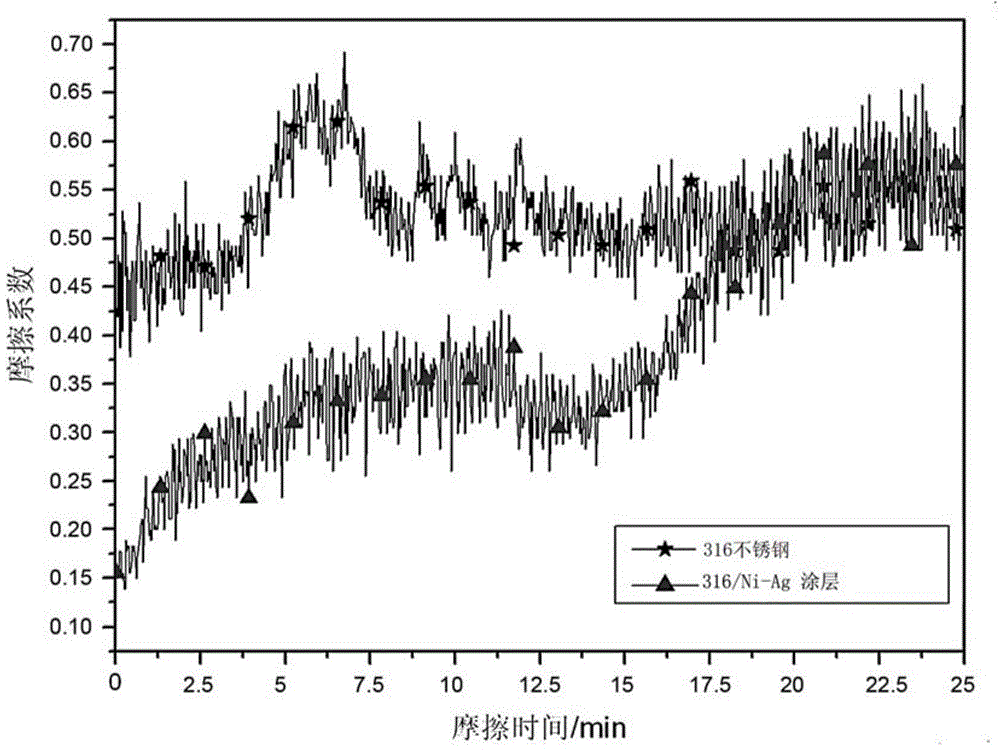

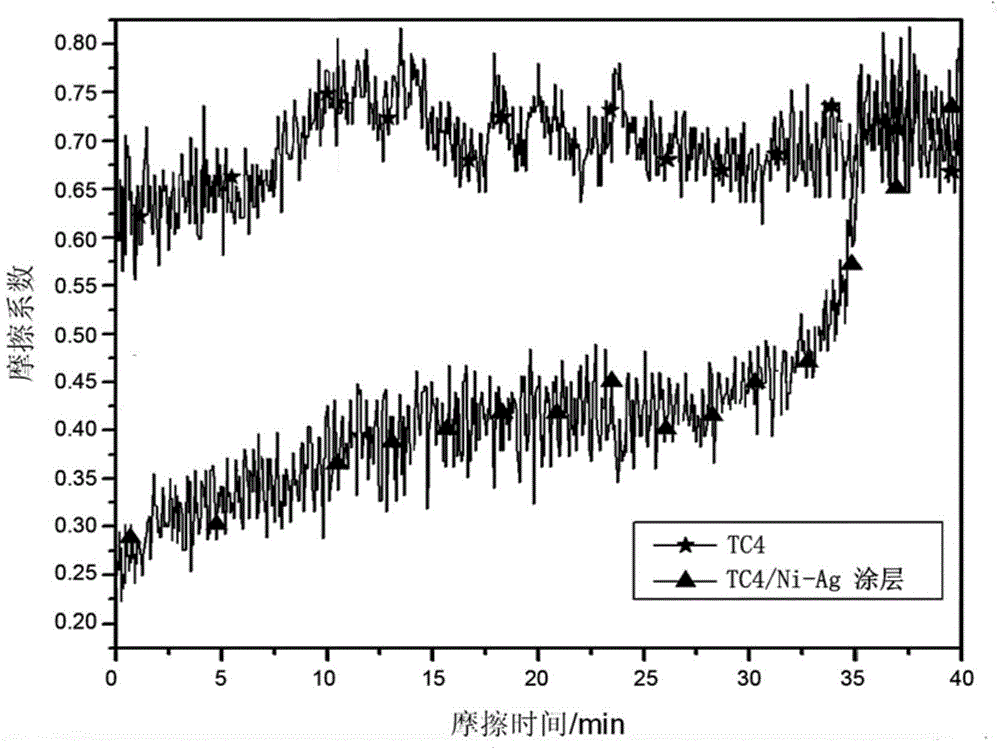

The invention discloses a method for preparing an anti-lock thread coating through PVD (physical vapor deposition). The method for preparing the anti-lock thread coating through PVD comprises the following steps: (1) polishing the surface of a metal thread, removing oil stain, and dewatering; (2) spraying sand to roughen the surface of the metal thread; (3) putting the metal thread into vacuum cathodic arc deposition equipment, and sputter-etching to obtain a surface activated metal thread; (4) introducing argon into the vacuum cathodic arc deposition equipment, and plating a film on the surface activated metal thread for the first time to obtain a metal thread with a nickel coating on the surface; and (5) plating a film on the metal thread for the second time in an argon atmosphere by using a pure-silver cathodic arc source to obtain a metal thread with a nickel composite coating on the surface. Because the wear resistant anti-lock coating is prepared on the surface of the metal thread through PVD, the prepared wear resistant anti-lock thread coating has a strong bonding force, can resist corrosion, is low in friction coefficient and is highly reliable, the purposes of improving the fastening force of a screw and preventing the metal thread from being occluded and locked can be achieved, and the metal thread can serve a long time under heavy load, corrosion and other harsh environment.

Owner:西安赛福斯材料防护有限责任公司

Turbine component crack repair using cathodic arc and/or low pressure plasma spraying and HIP

A method for repairing cracks in a metal part comprising the steps of providing a metal part having a crack, cleaning the crack to remove an oxide layer, depositing a repair alloy via at least one of cathodic arc deposition and low pressure plasma spraying to cover the crack, and heating the part at a temperature and pressure sufficient to close the crack.

Owner:RTX CORP

Dual-layer carbon-based protective overcoats for recording media by filtered cathodic ARC deposition

InactiveUS7175926B2Well formedLiquid surface applicatorsProtective coatings for layersCathodic arc depositionNitrogen doped

A recording medium, comprising:(a) a substrate having at least one surface;(b) a stacked plurality of thin film layers on the at least one surface and including at least one magnetic or magneto-optical (MO) recording layer; and(c) a protective overcoat layer on an outer surface of an outermost layer of the layer stack, comprising:(i) a first sub-layer layer (c1) of undoped tetrahedral amorphous carbon (ta-C) formed by filtered cathodic arc deposition (FCAD) on the outer surface of the outermost layer of the stacked plurality of thin film layers and having a high mass density of carbon (C) atoms greater than about 2.5 gms / cm3; and(ii) a second sub-layer (c2) of nitrogen-doped tetrahedral amorphous carbon (ta-C:N) formed by FCAD on the undoped ta-C layer and having a high mass density of carbon (C) atoms greater than about 2.0 gms / cm3.

Owner:SEAGATE TECH LLC

Method for preparing aluminum-nitrogen co-doped diamond-like-like composite film

ActiveCN108677144AEasy to release internal stressReduce internal stressVacuum evaporation coatingSputtering coatingCathodic arc depositionComposite film

The invention discloses a method for preparing an aluminum-nitrogen co-doped diamond-like composite film. Two dual-excitation energy source cathode arc coating devices with different characteristics are configured by adopting an ion source-assisted cathode arc deposition technology, one dual-excitation energy source cathode arc coating device adopts a direct-current arc evaporation cathode sourceand is used for installing an aluminum target, and the other dual-excitation energy source cathode arc coating device adopts a pulsed arc evaporation cathode source and is used for installing a graphite target; nitrogen gas is taken as reaction gas in the deposition process, nitrogen gas (N2) is ionized into ionic nitrogen (N<+>) through an ion source, the aluminum target installed on the direct-current arc evaporation cathode source and the graphite target installed on the pulsed arc evaporation cathode source achieve sputtering deposition on the surface of a workpiece by rotating the workpiece, and the component-controllable aluminum-nitrogen co-doped diamond-like composite film is obtained. According to the method for preparing the aluminum-nitrogen co-doped diamond-like composite film,the film is doped with N in an ion mode, and hard aluminum nitride (AlN) and metal Al nanocrystalline particles are promoted to be formed in the diamond-like composite film; and the diamond-like composite film has the advantages of being smooth in surface, high in hardness and toughness and low in stress.

Owner:北京物科国华技术有限公司

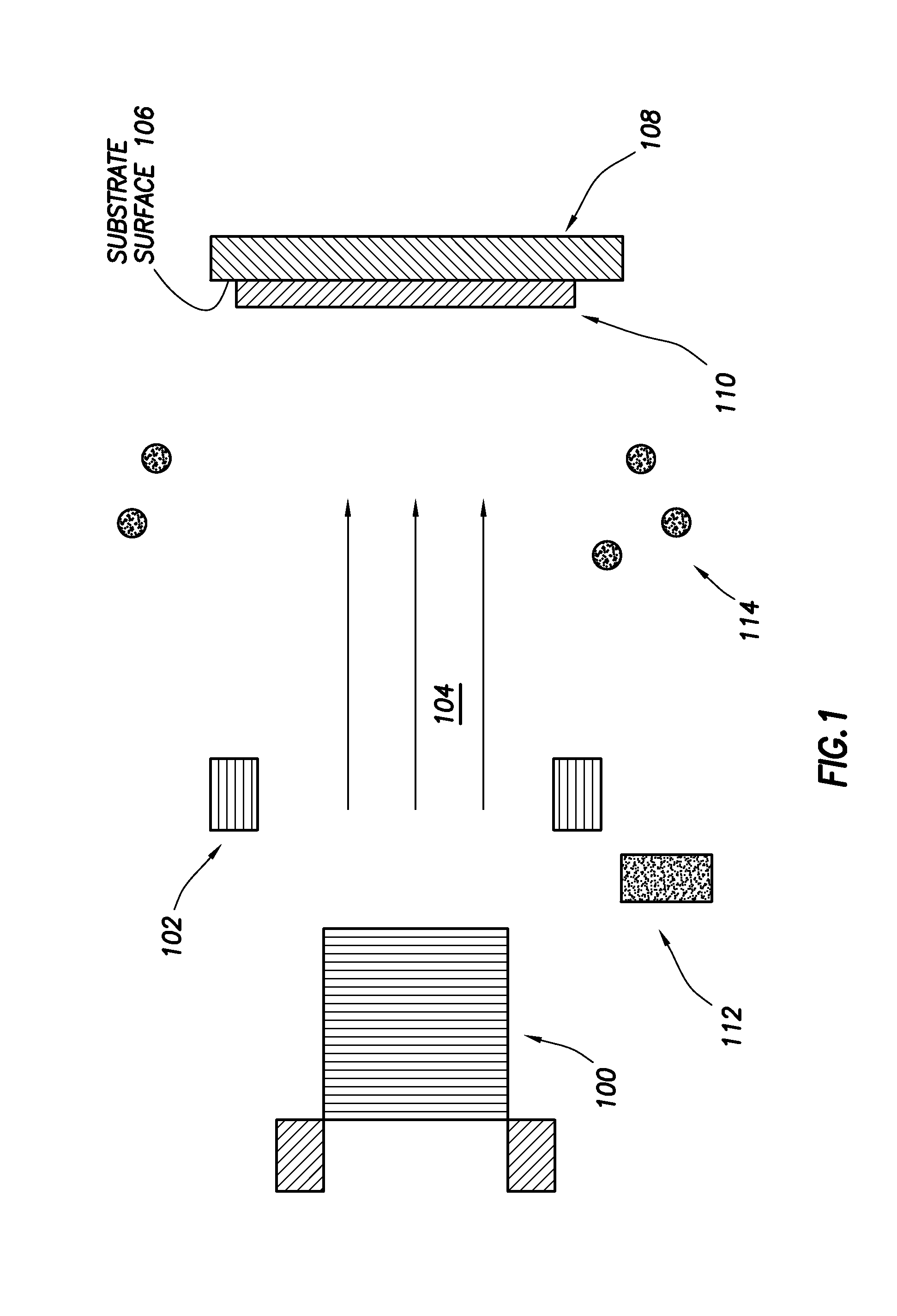

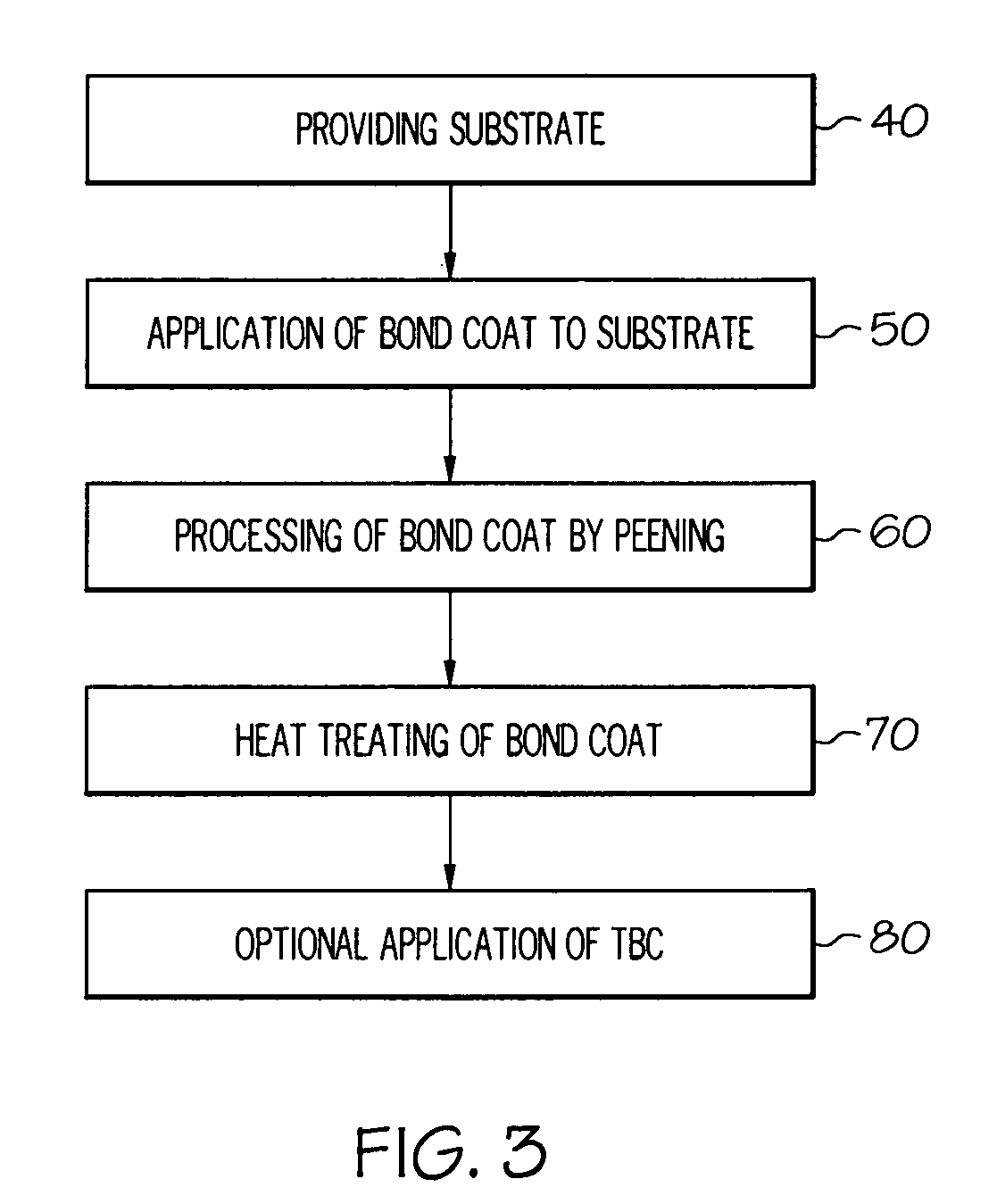

Bond coat process for thermal barrier coating

InactiveUS20070207339A1Improve coating structureMolten spray coatingBlade accessoriesCathodic arc depositionCoated surface

Methods provide for depositing a bond coat of a thermal barrier coating (TBC) system for a component designed for use in a hostile thermal environment. The method includes providing an article substrate having a substrate surface, forming a bond coat on the substrate by depositing a beta-phase Ni—Al bond coat by cathodic arc deposition, processing the bond coat by peening to improve the coating structure, and heat treating the bond coat. Also disclosed is a turbine blade comprising a nickel-base superalloy substrate, a bond coat on the surface of the substrate, and a ceramic thermal barrier coating overlying the bond coat surface.

Owner:GENERAL ELECTRIC CO

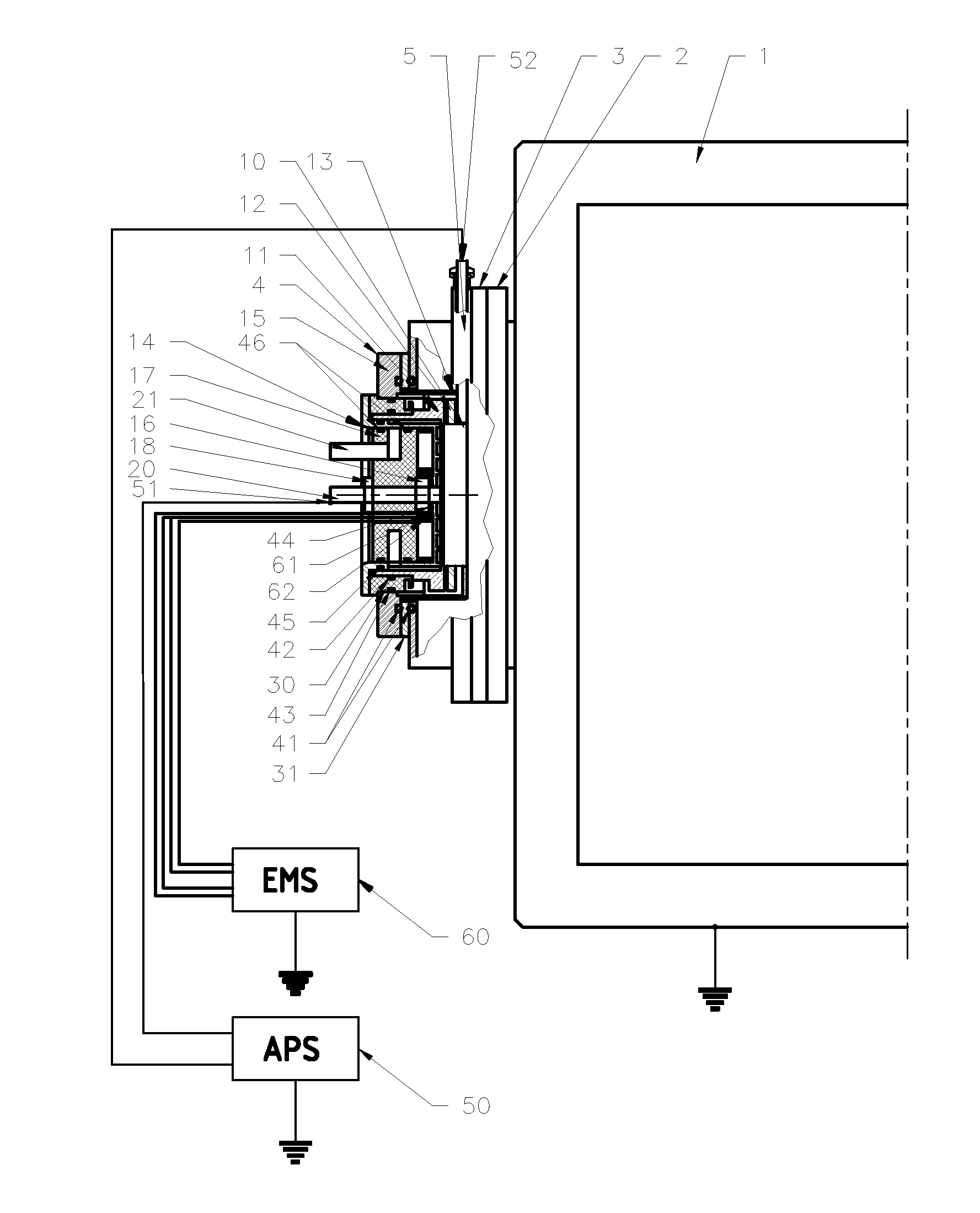

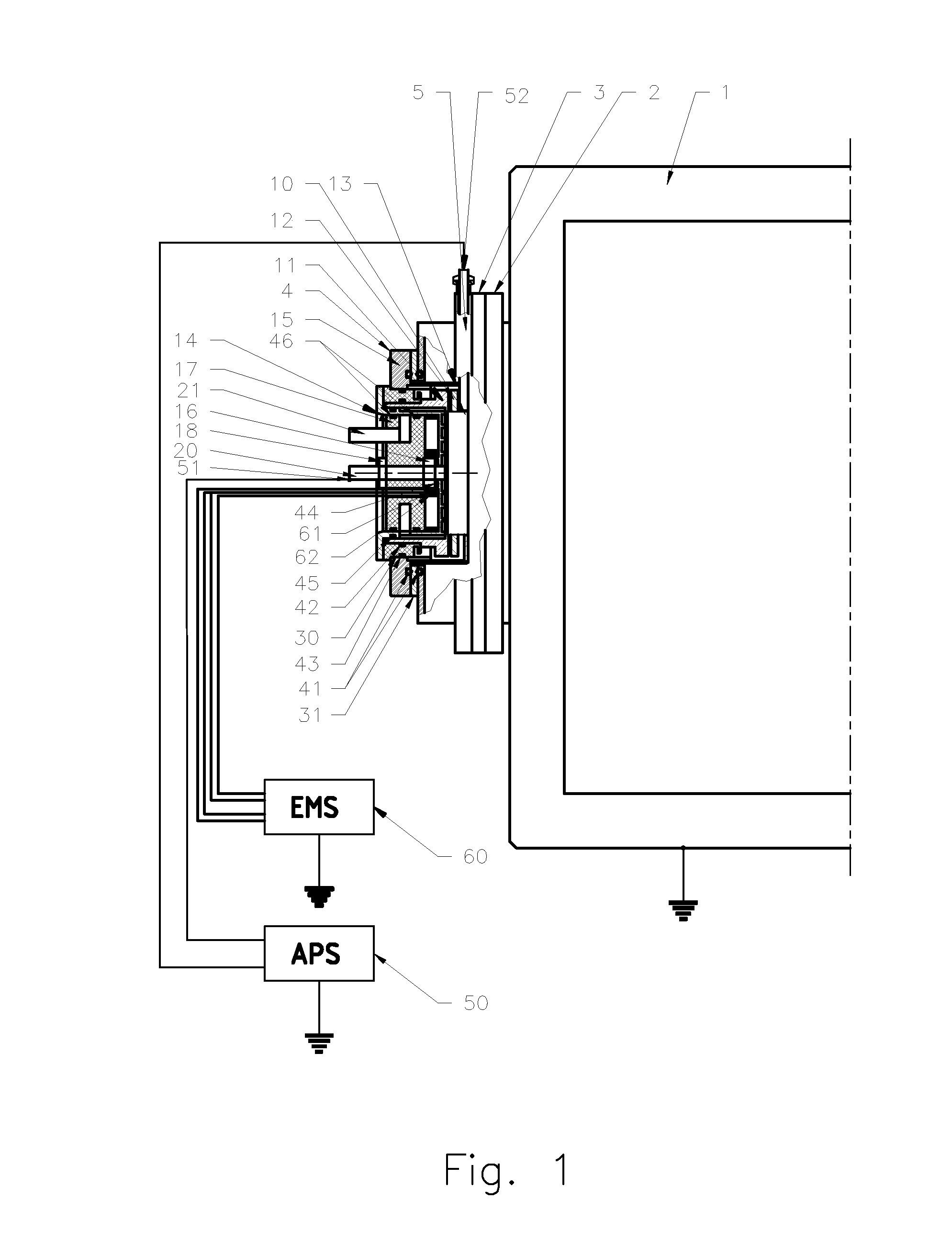

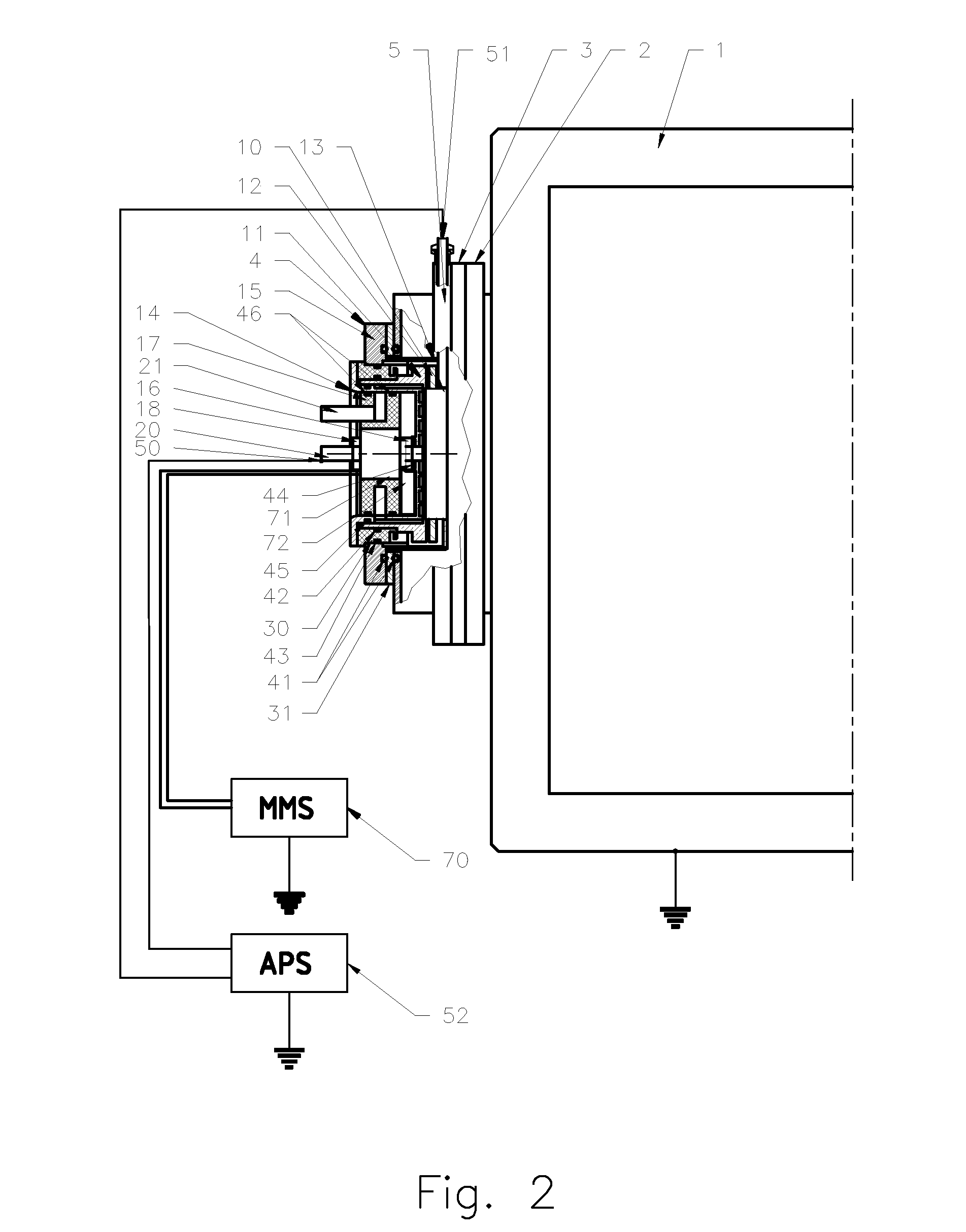

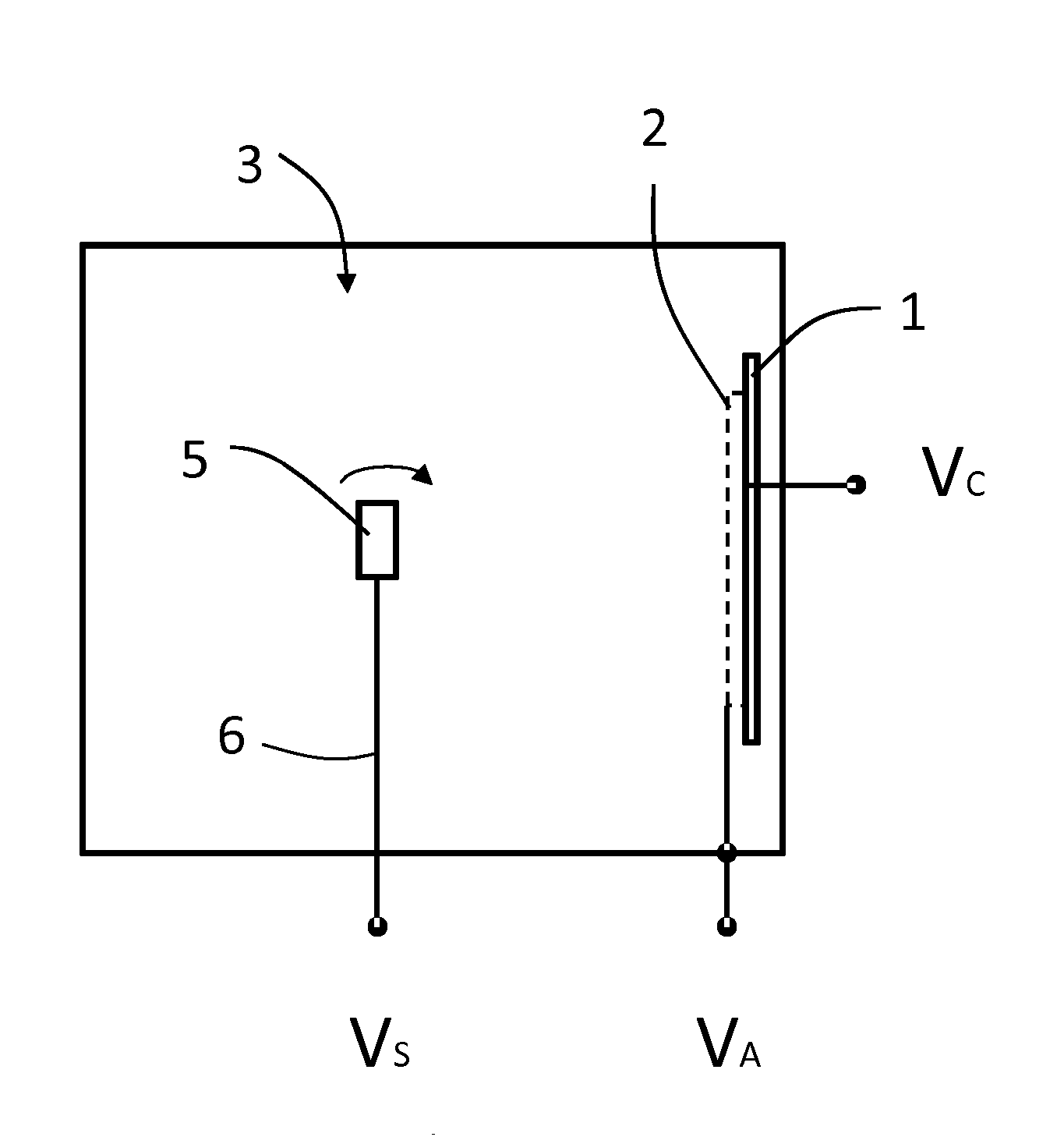

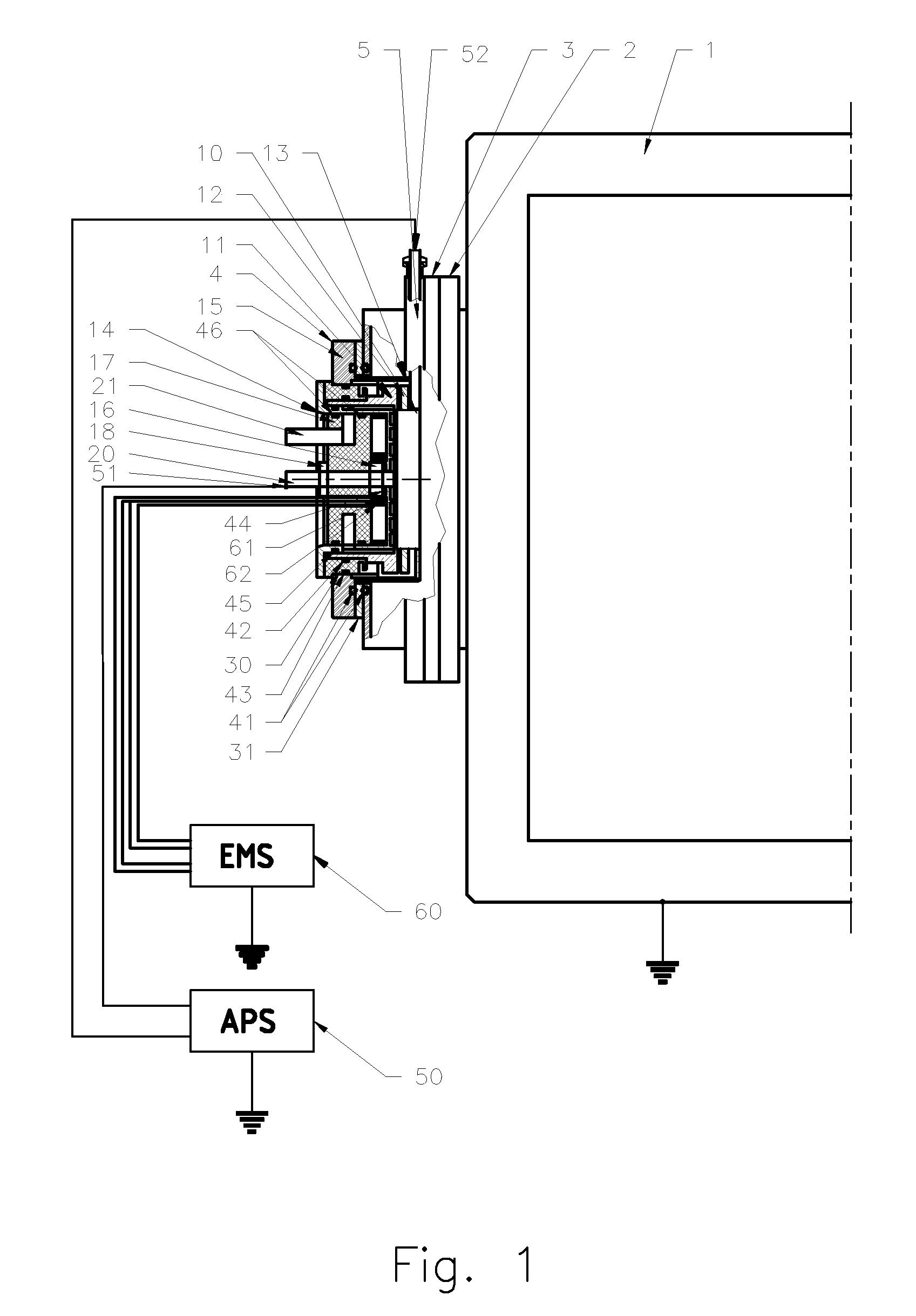

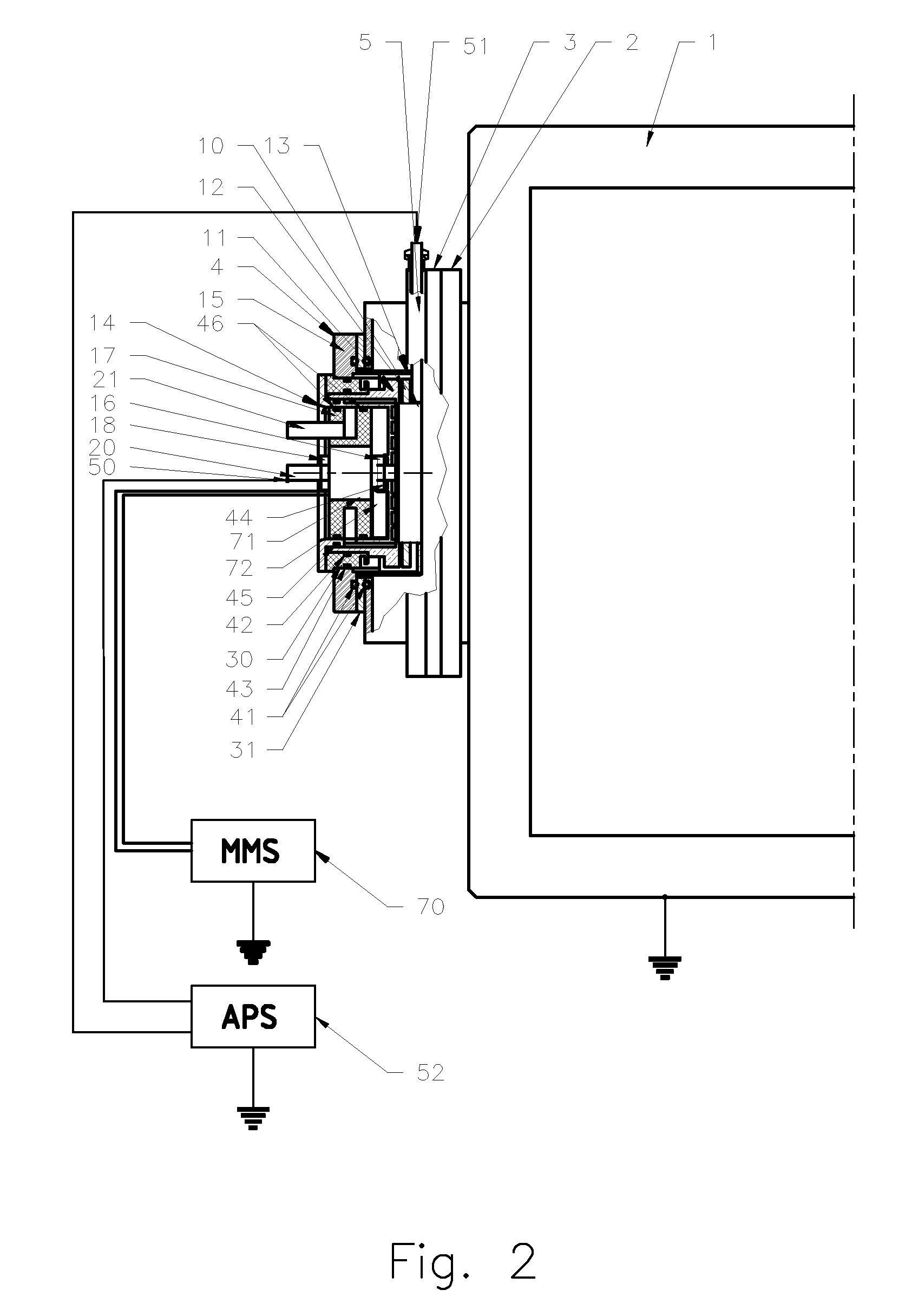

Arc pvd plasma source and method of deposition of nanoimplanted coatings

ActiveUS20130032469A1Simple design and operationCellsElectric discharge tubesCathodic arc depositionSingle process

The invention relates to a method and an apparatus for applying metallic, ceramic or composite thin film coatings onto parts, components and tools (e.g. gas turbine engine compressor blades or cutting tools) by a cathodic arc deposition technique. The method and the apparatus allows for a continually changing structure of the applied film by nanoimplanting atoms, molecules, compounds or other chemical species and structures of different materials thus coating a substrate during a single process. Furthermore, during the same process it allows for creating a coating with specific parameters as required. For instance: hardness, smoothness, corrosion resistance, erosion resistance.

Owner:ENVAEROSPACE

Method for restoring or regenerating an article

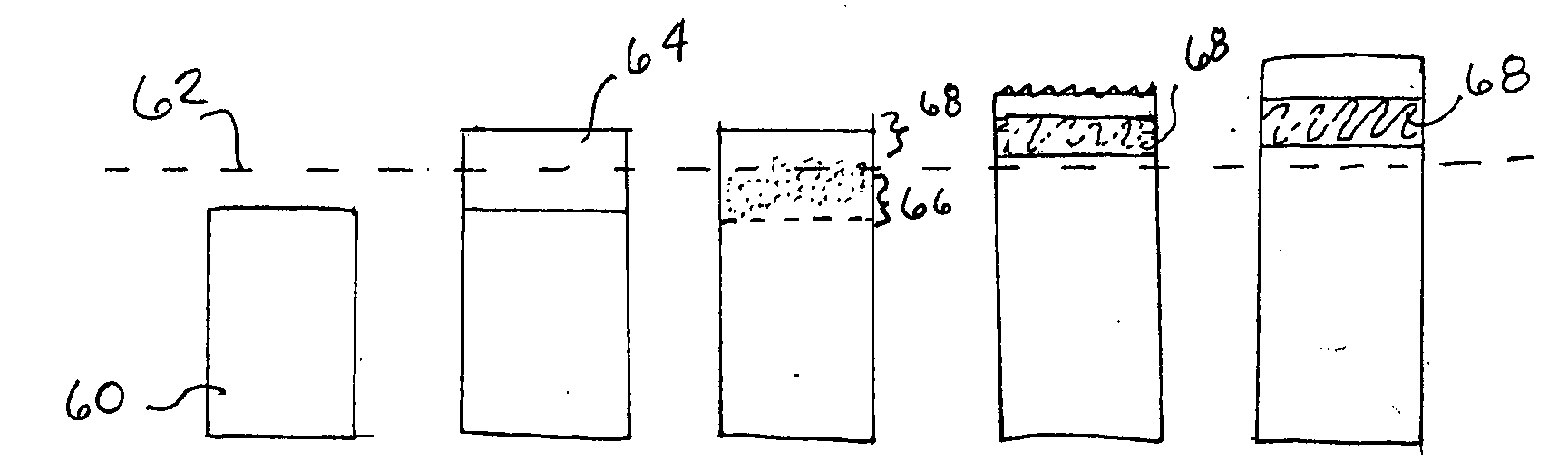

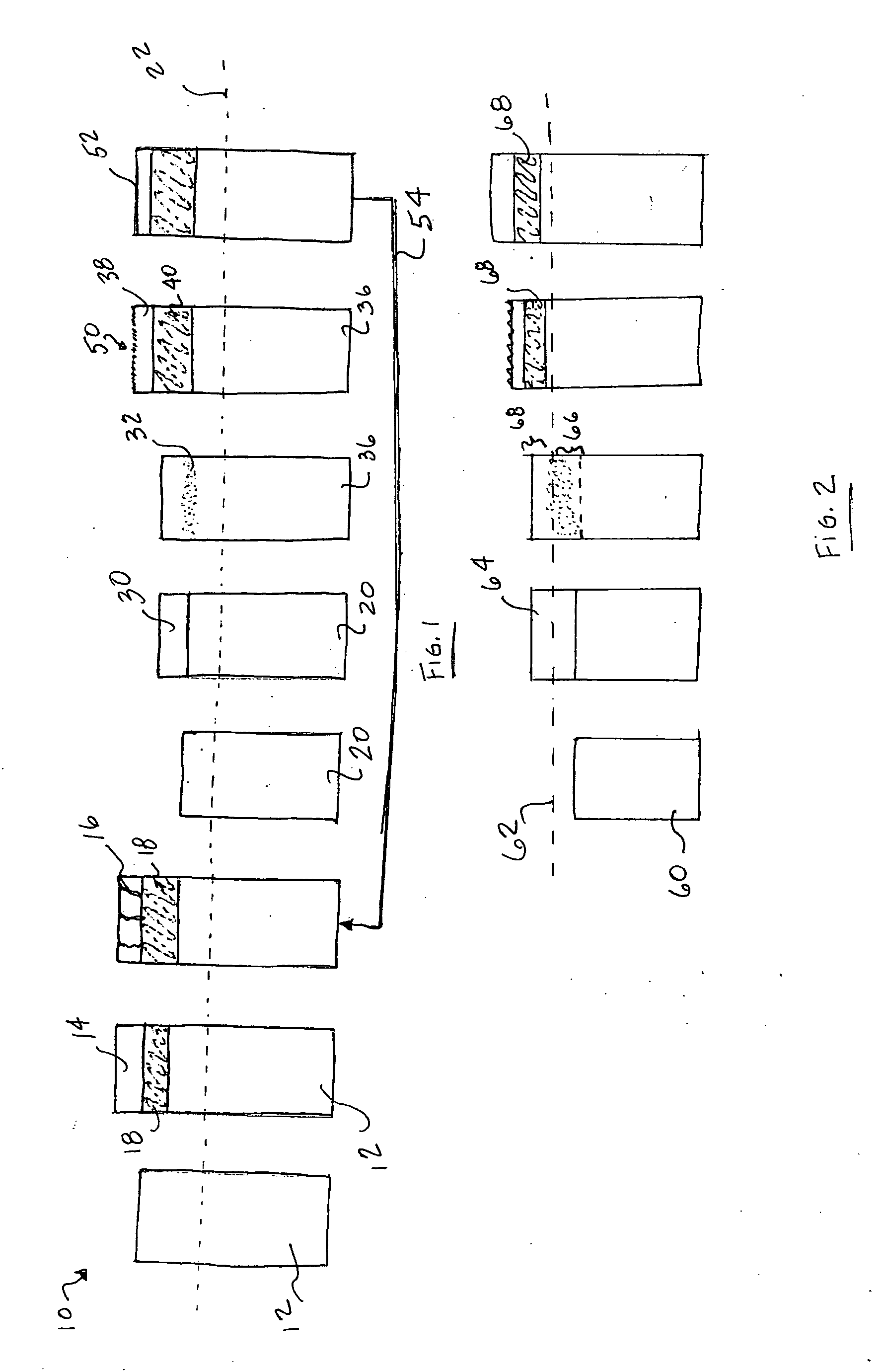

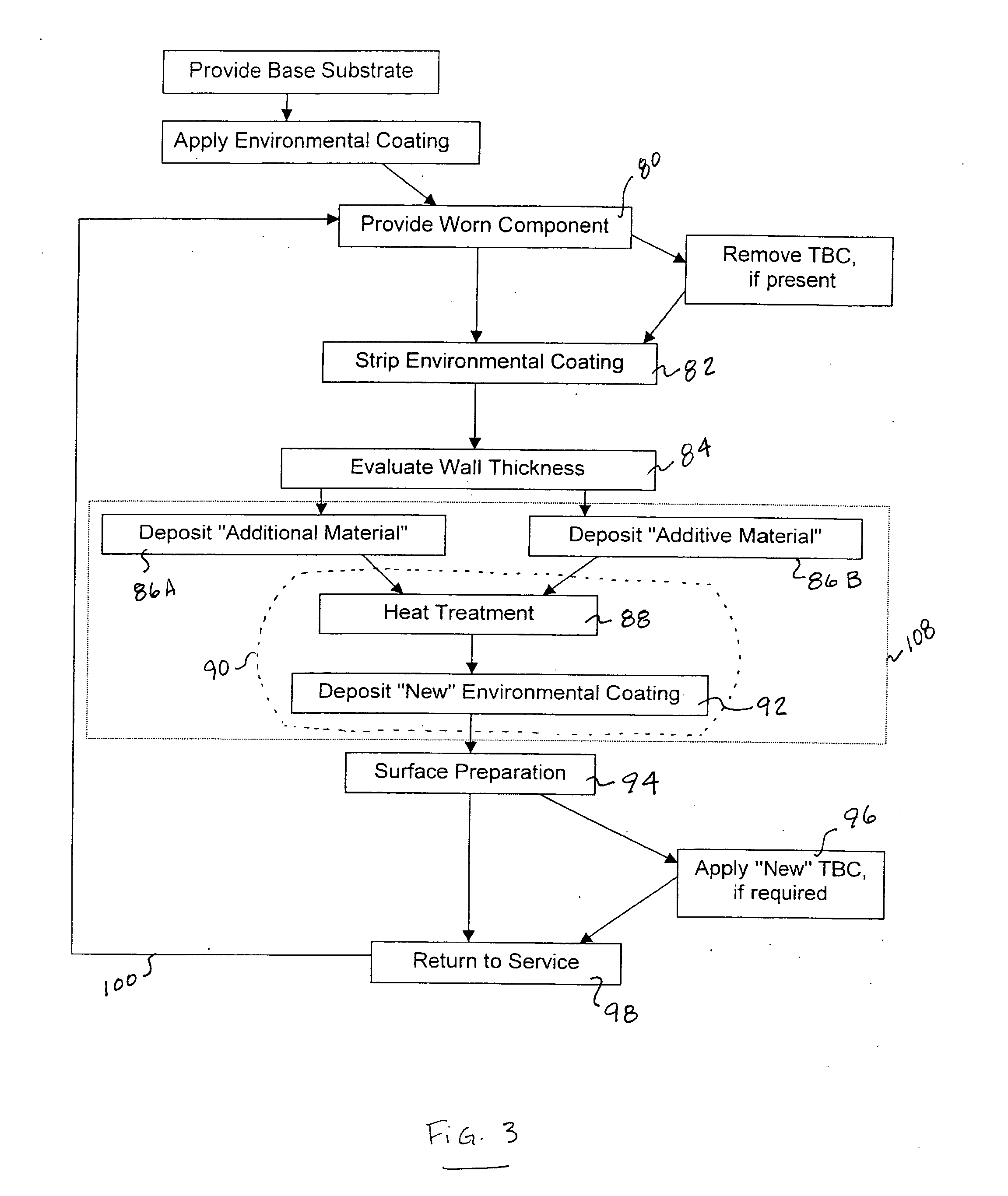

A method for restoring or regenerating an article, particularly a component for use in a gas turbine engine, includes providing a residual substrate comprised of a first material, evaluating a wall thickness of the residual substrate, and depositing a layer of a second material overlying at least a portion of the residual substrate. The second material is substantially similar in composition to the first material. The layer is deposited by vapor phase deposition, ion plasma deposition, cathodic arc deposition, sputtering, and combinations thereof. An environmental coating is deposited onto the component by vapor phase deposition, cathodic arc deposition, and combinations thereof. The method may include a heat treatment at temperatures between about 1500° F. to about 2300° F. (about 816° C. to about 1260° C.) for between about 2 to about 24 hours. The method may include a surface treatment such as grit blast polishing. Following use of the restored / regenerated component, the repair process may be repeated. At least a non-structural portion of the deposited layer may be removed during a subsequent repair. A load-bearing portion of the deposited layer, if present, may be retained on the residual substrate during a subsequent repair.

Owner:GENERAL ELECTRIC CO

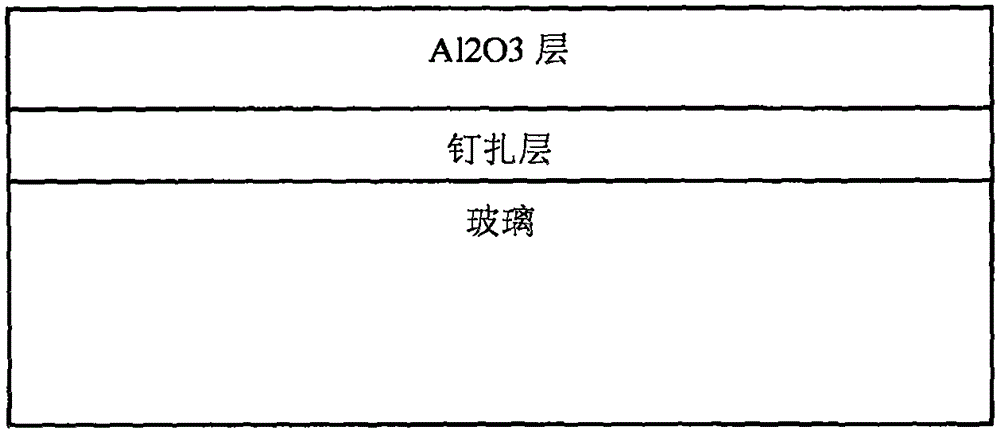

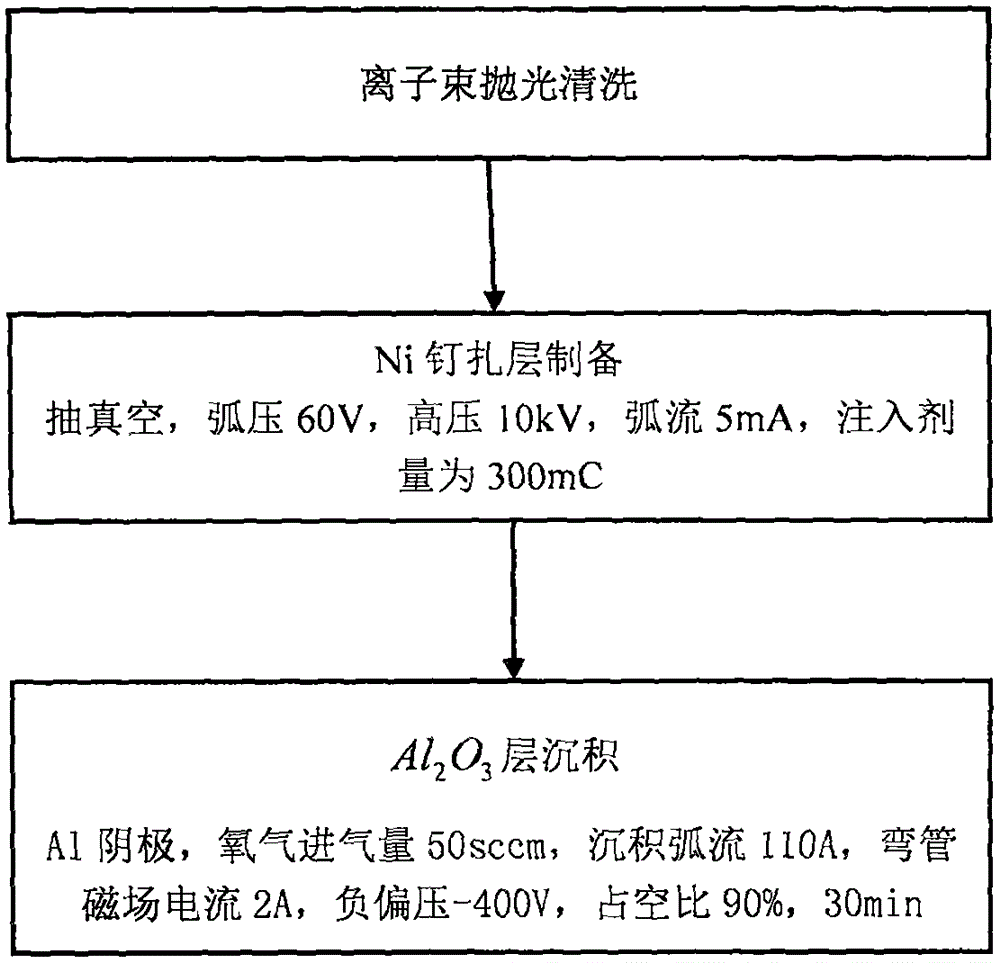

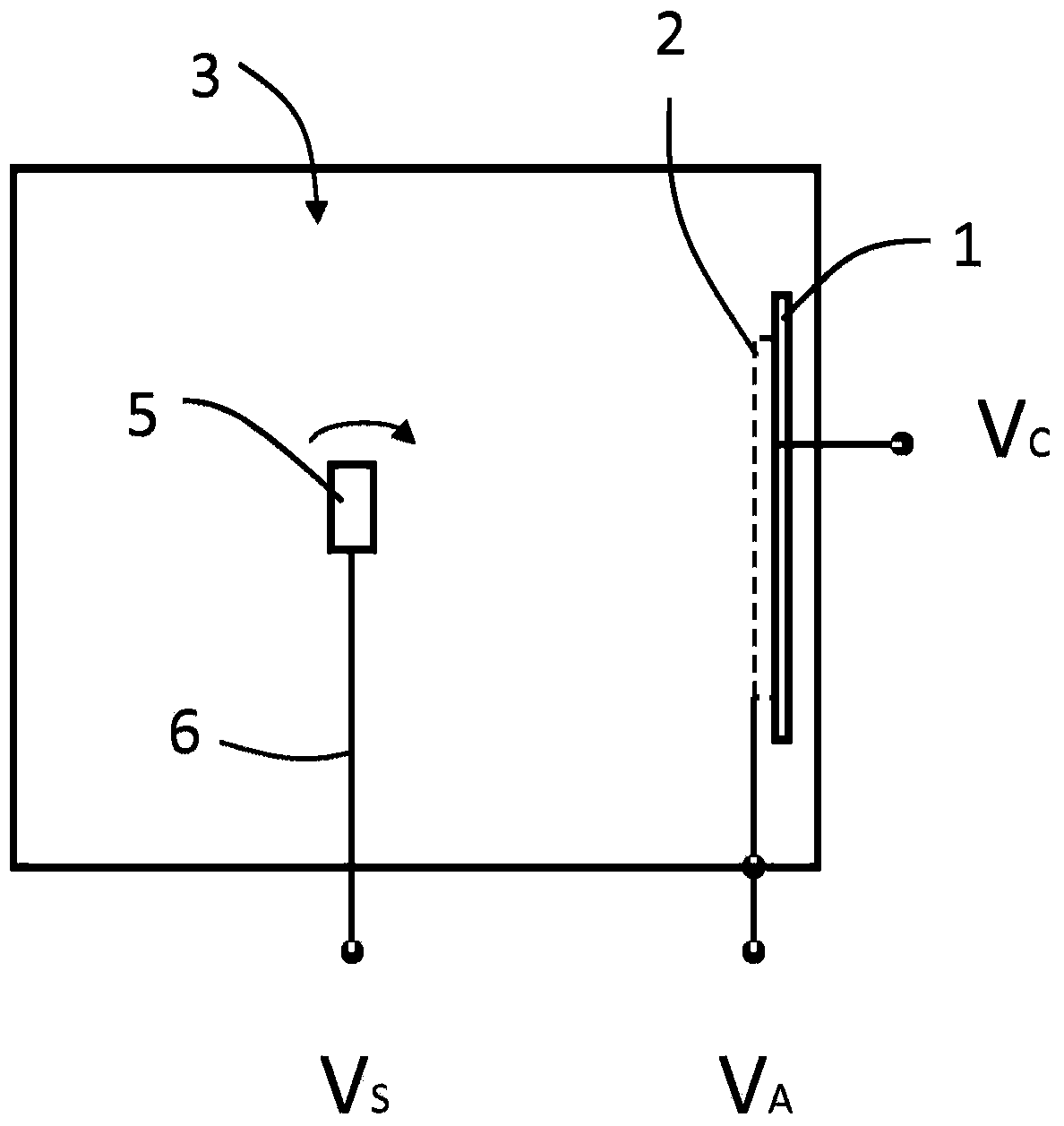

Method for preparing cellphone screen scratch-resistant aluminum oxide coating by ion beam dual-filtering deposition technique

ActiveCN105755429AEffective filteringHigh hardnessVacuum evaporation coatingSputtering coatingCathodic arc depositionPlasma deposition

The invention discloses a method for depositing Al2O3 film on glass and is applicable to cellphone screen surface coating, wherein a technique for preparing Al2O3 film by magnetically filtered plasma deposition is particularly related.The Al2O3 film structurally comprises an ion injection pinning layer and an Al2O3 film layer.The invention is intended to prepare high-cohesive Al2O3 film by combining ion injection technique, magnetic filtration technique and cathodic arc deposition technique and optimize the thickness, hardness, wear resistance, corrosion resistance and light transmittance of Al2O3 by controlling arc current intensity, bend magnetic field intensity and oxygen intake in the deposition process so as to prepare high-quality Al2O3 film, replacing a sapphire cellphone screen.Dual-magnetic filtering plasma deposition equipment is used herein, the equipment is simple to operate, and the method is mature, is available for batch production and is suitable for application in electronic product screen protection.

Owner:BEIJING NORMAL UNIVERSITY

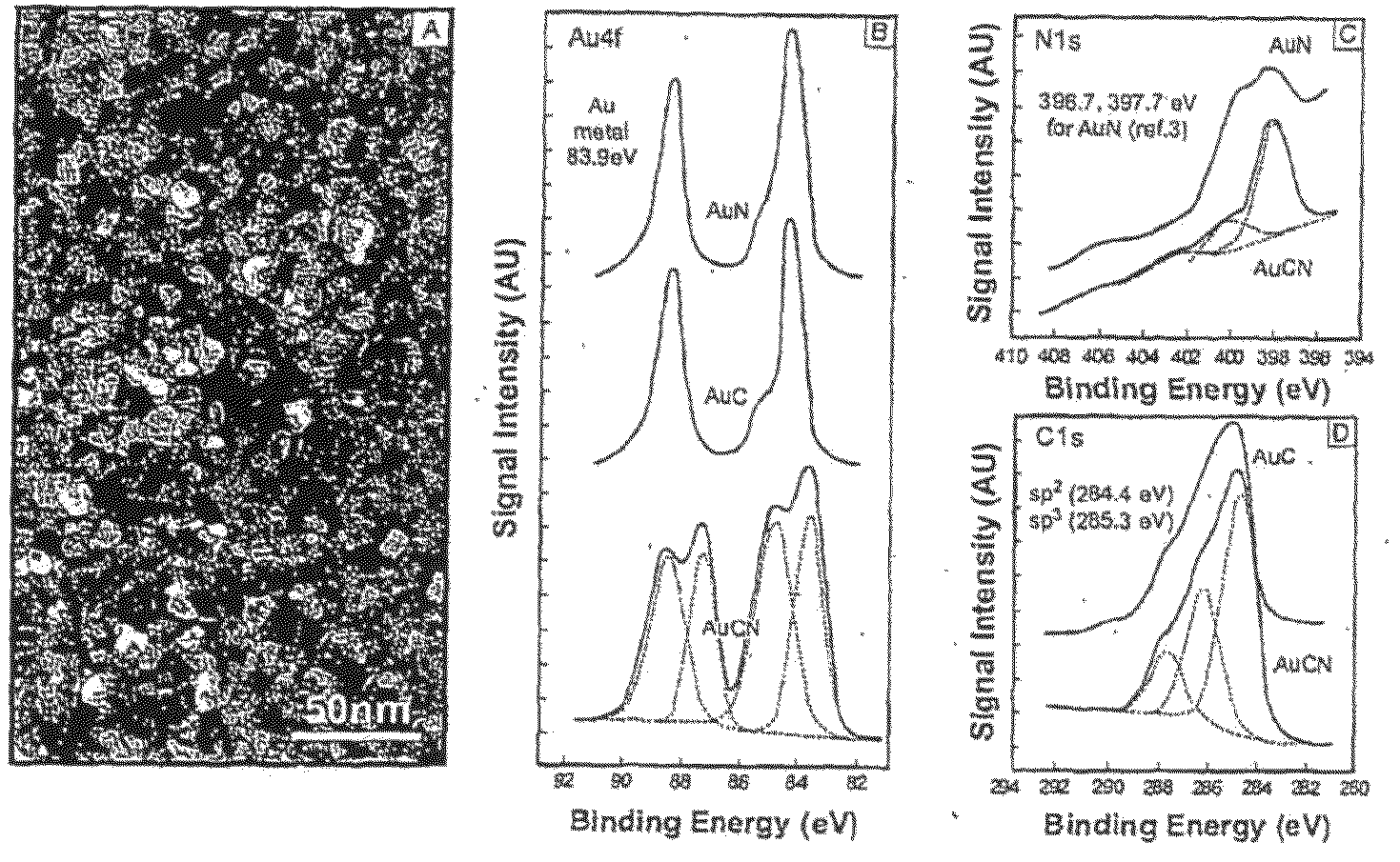

Metal binary and ternary compounds produced by cathodic arc deposition

InactiveUS20100143232A1Easy to produceElectric discharge tubesNitrogen-metal/silicon/boron binary compoundsCathodic arc depositionMedical device

The present invention allows the relatively easy production of binary and ternary compounds of metals, including noble metals. Embodiments of the invention allow, for the first time, the production of novel compositions of metal compounds, such as thick, stress-free single-phase binary and ternary compositions of metals, and porous compositions of such compounds. As such, the present invention allows for the production of metal compounds and / or compositions of matter thereof that have not before been possible, thereby providing for important new materials that find use in a multitude of different applications, including medical device and non-medical device applications.

Owner:PROTEUS DIGITAL HEALTH INC

Coated cutting tool

InactiveCN104011256AElectric discharge tubesVacuum evaporation coatingCathodic arc depositionMetallurgy

The present invention provides a coated cutting tool comprising a substrate and a coating, where the coating comprises at least one compound layer deposited by cathodic arc deposition, which has a thickness of 10-30 [mu]m characterized in that the coating has internal stress ranges from low tensile stresses, lower than 0.2GPa, to compressive stresses, lower than 3GPa.

Owner:LAMINA TECH

Method and apparatus for cathodic arc deposition of materials on a substrate

ActiveUS8241468B2Rate of depositionMaintain integrityCellsElectric discharge tubesCathodic arc depositionPower flow

A method for applying a coating by a cathodic is provided. The method includes the steps of: a) providing a cathodic arc coater that includes a power source and utilizes a disk-shaped cathode, the cathode having an evaporative surface extending between a first end surface and a second end surface, wherein the evaporative surface has an area; b) determining a maximum acceptable power density for the evaporative surface; and c) applying a magnitude of electrical current from the power source to the cathode, wherein the electrical current magnitude divided by the area is equal to or less than the maximum acceptable power density for the evaporative surface.

Owner:RTX CORP

Coated cutting tool

ActiveUS20140377023A1Improve wear resistanceImprove performanceElectric discharge tubesVacuum evaporation coatingCathodic arc depositionMetallurgy

The present invention provides a coated cutting tool comprising a substrate and a coating, where the coating comprises at least one compound layer deposited by cathodic arc deposition, which has a thickness of 10-30 μm characterized in that the coating has internal stress ranges from low tensile stresses, lower than 0.2 GPa, to compressive stresses, lower than 3 GPa.

Owner:LAMINA TECH

A method for preparing dlc thick film by high-efficiency magnetic filtration plasma deposition

ActiveCN105755442BEffective filteringFacilitate separate control of the ionization processVacuum evaporation coatingSputtering coatingCathodic arc depositionDiamond-like carbon

The invention discloses a method for preparing Metal carbide-inlaid Diamond-like Carbon (MC / DLC) films with the thicknesses larger than 30 micrometers, belongs to the field of preparation of hard abrasion-resistant coatings, and particularly relates to a technology for preparing MC / DLC thick films by the aid of magnetic filter plasma deposition processes.MC / DLC thick film structures comprise ion injection pinning layers, metal transition layers and the MC / DLC films.The method has the advantages that the DC / DLC films prepared by the aid of ion injection technologies, magnetic filter technologies and cathodic arc deposition technologies are high in binding force, the arc current intensity, the magnetic field intensity of bent pipes and the gas inflow of gas with carbon are controlled in deposition procedures, accordingly, the thicknesses, the hardness, the rub resistance and the abrasion resistance of the MC / DLC thick films can be optimized, and the high-quality MC / DLC thick films can be prepared by the aid of the method; magnetic filter plasma deposition equipment for implementing the method has proprietary intellectual property rights and is easy to operate, processes are mature, the MC / DC films can be produced on a large scale, and the method is suitable for deposition application to high-hardness abrasion-resistant coatings in all industrial components such as bearings of cutters.

Owner:BEIJING NORMAL UNIVERSITY

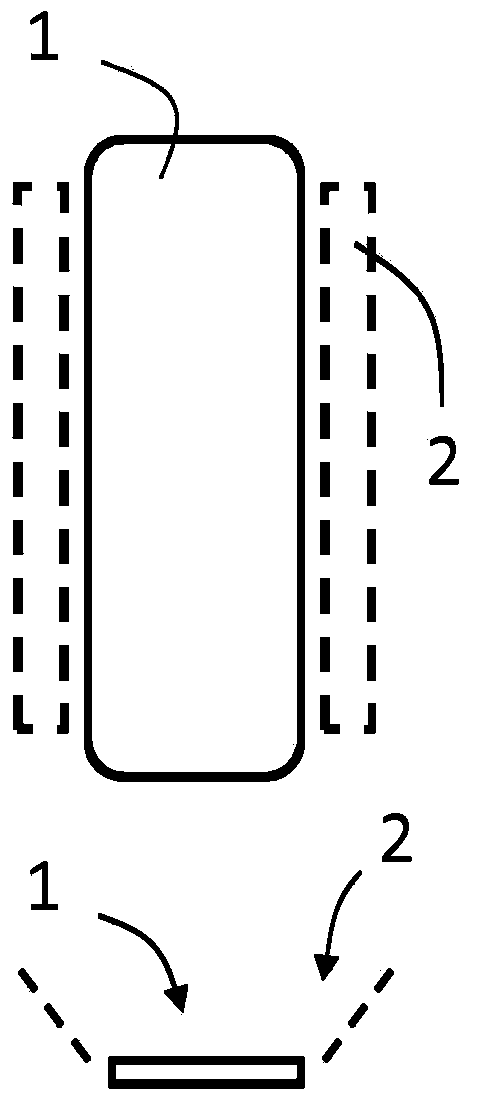

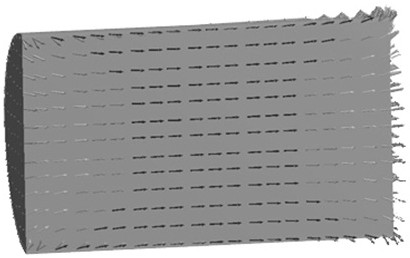

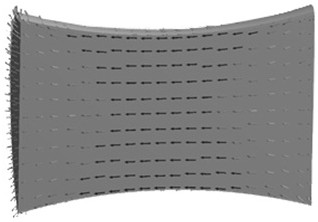

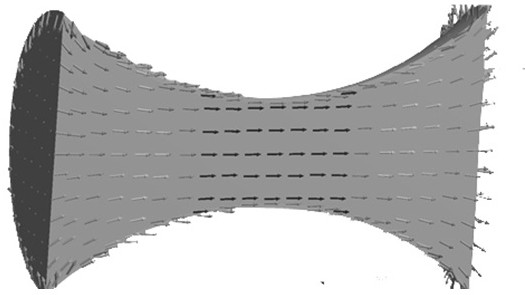

Variable-angle variable-diameter magnetic filtered cathode arc thin film deposition equipment and method

The invention provides variable-angle variable-diameter magnetic filtered cathode arc thin film deposition equipment and method. The equipment comprises a cathode arc generating system, a plasma transmission system, a vacuum coating cavity and a power source. The cathode arc generating system comprises an arc generator and a target. The plasma transmission system comprises a variable-diameter magnetic filtered pipeline, an electromagnetic coil and a scanning electromagnetic coil. The electromagnetic coil is wound around the variable-diameter magnetic filtered pipeline, and the variable-diameter magnetic filtered pipeline is in a double-horn shape with the two ends larger than the middle. As the variable-diameter magnetic filtered pipeline in the double-horn shape with the two ends larger than the middle is designed in the cathode arc deposition equipment, in cooperation with the electromagnetic coil wound around the variable-diameter magnetic filtered pipeline, focusing and deflectingelectromagnetic fields can guide plasma flow towards a substrate, neutral macroparticles not affected by the electromagnetic fields continue to advance along a straight line from a cathode to be filtered, and through the design of the simple magnetic filtered pipeline, dense uniform cathode arc thin films can be obtained.

Owner:JIHUA LAB

Method for preparing metal sulfide diamond-like carbon composite film

InactiveCN101787521BVacuum evaporation coatingSputtering coatingCathodic arc depositionVulcanization

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

A method for preparing aluminum-nitrogen co-doped diamond-like composite film

ActiveCN108677144BReduce roughnessQuality improvementVacuum evaporation coatingSputtering coatingCarbon compositesCathodic arc deposition

The invention discloses a method for preparing an aluminum-nitrogen co-doped diamond-like composite film. Two dual-excitation energy source cathode arc coating devices with different characteristics are configured by adopting an ion source-assisted cathode arc deposition technology, one dual-excitation energy source cathode arc coating device adopts a direct-current arc evaporation cathode sourceand is used for installing an aluminum target, and the other dual-excitation energy source cathode arc coating device adopts a pulsed arc evaporation cathode source and is used for installing a graphite target; nitrogen gas is taken as reaction gas in the deposition process, nitrogen gas (N2) is ionized into ionic nitrogen (N<+>) through an ion source, the aluminum target installed on the direct-current arc evaporation cathode source and the graphite target installed on the pulsed arc evaporation cathode source achieve sputtering deposition on the surface of a workpiece by rotating the workpiece, and the component-controllable aluminum-nitrogen co-doped diamond-like composite film is obtained. According to the method for preparing the aluminum-nitrogen co-doped diamond-like composite film,the film is doped with N in an ion mode, and hard aluminum nitride (AlN) and metal Al nanocrystalline particles are promoted to be formed in the diamond-like composite film; and the diamond-like composite film has the advantages of being smooth in surface, high in hardness and toughness and low in stress.

Owner:BEIJING WUKE GUOHUA TECH CO LTD

Arc PVD plasma source and method of deposition of nanoimplanted coatings

InactiveUS9153422B2Simple design and operationCellsElectric discharge tubesCathodic arc depositionSingle process

The invention relates to a method and an apparatus for applying metallic, ceramic or composite thin film coatings onto parts, components and tools (e.g. gas turbine engine compressor blades or cutting tools) by a cathodic arc deposition technique. The method and the apparatus allows for a continually changing structure of the applied film by nanoimplanting atoms, molecules, compounds or other chemical species and structures of different materials thus coating a substrate during a single process. Furthermore, during the same process it allows for creating a coating with specific parameters as required. For instance: hardness, smoothness, corrosion resistance, erosion resistance.

Owner:ENVAEROSPACE

Electrochemical corrosion potential sensor and method of making

InactiveUS7758743B2Weather/light/corrosion resistanceVolume/mass flow measurementCathodic arc depositionThermal spraying

A sensor for measuring electrochemical corrosion potential includes an electrical conductor, a metal-oxide layer disposed on the electrical conductor, and a zirconia-containing layer disposed on the metal-oxide layer, wherein the zirconia-containing layer is disposed about the electrical conductor using thermal spraying, wire arc, ion plasma cathodic arc deposition, laser ablation, chemical vapor deposition, physical vapor deposition, electroplating, electroless plating, electrochemical oxidation, chemical oxidation, electrophoretic deposition, or radio-frequency sputtering.

Owner:BAKER HUGHES HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com