Patents

Literature

178 results about "Low pressure plasma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

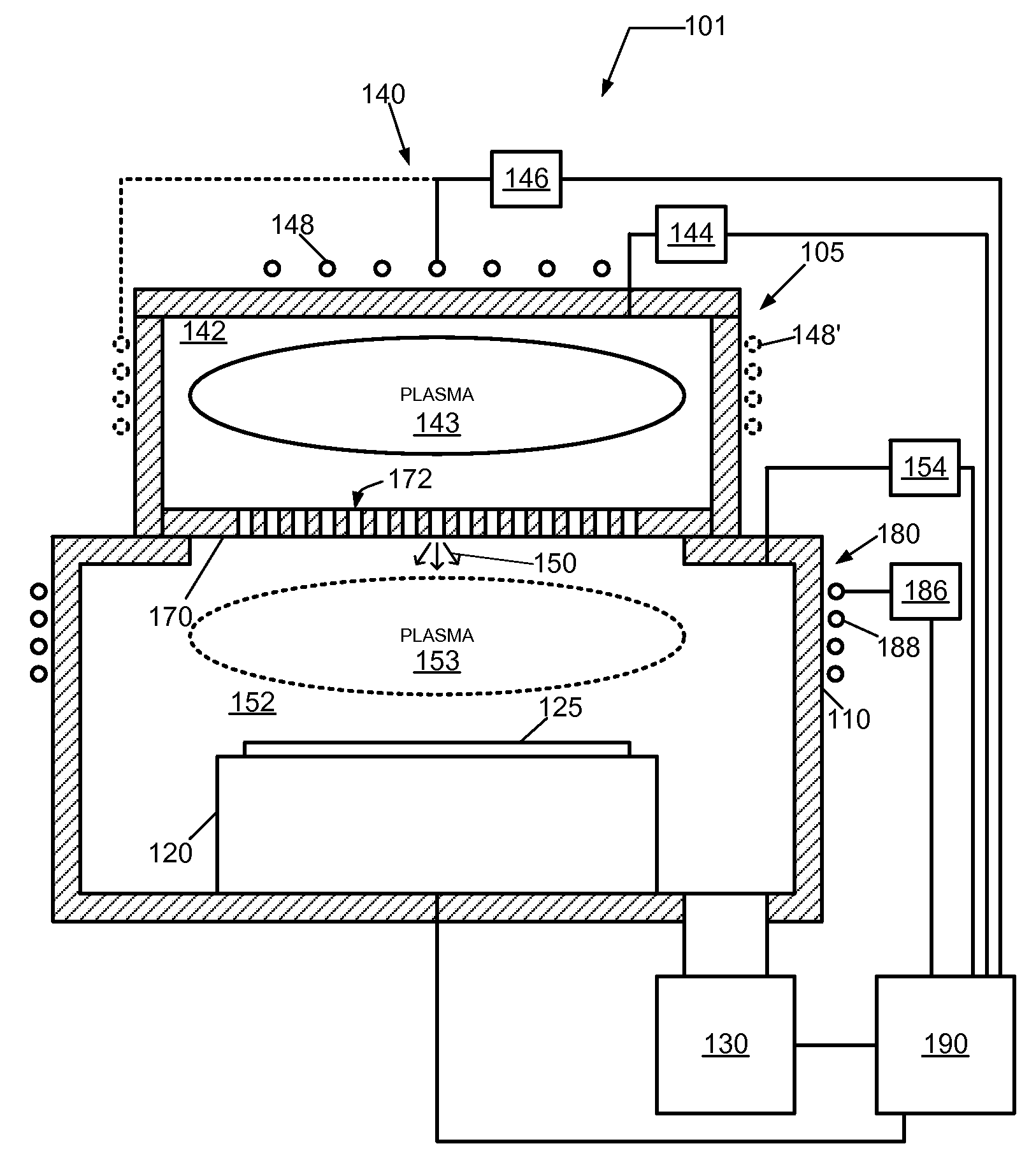

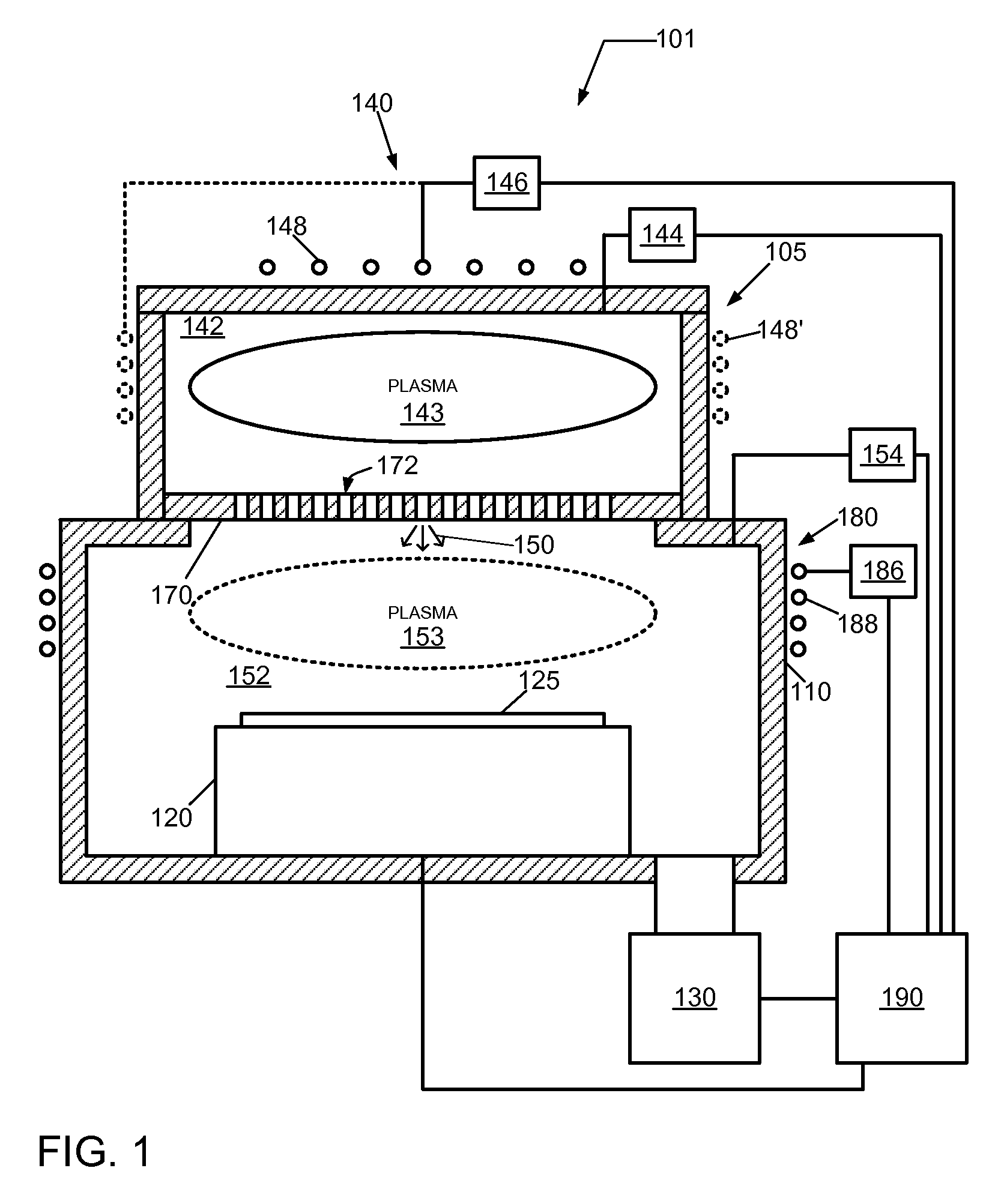

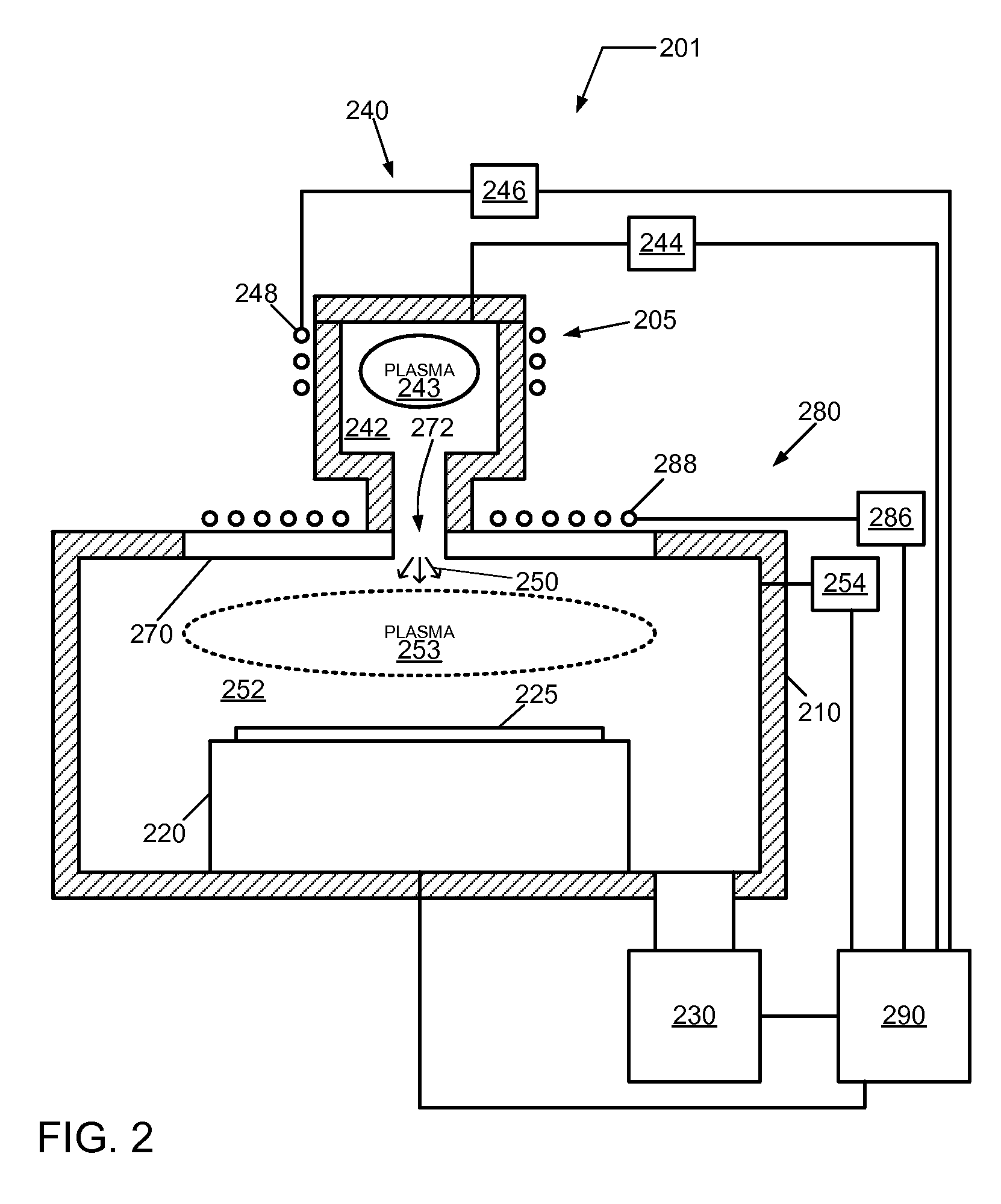

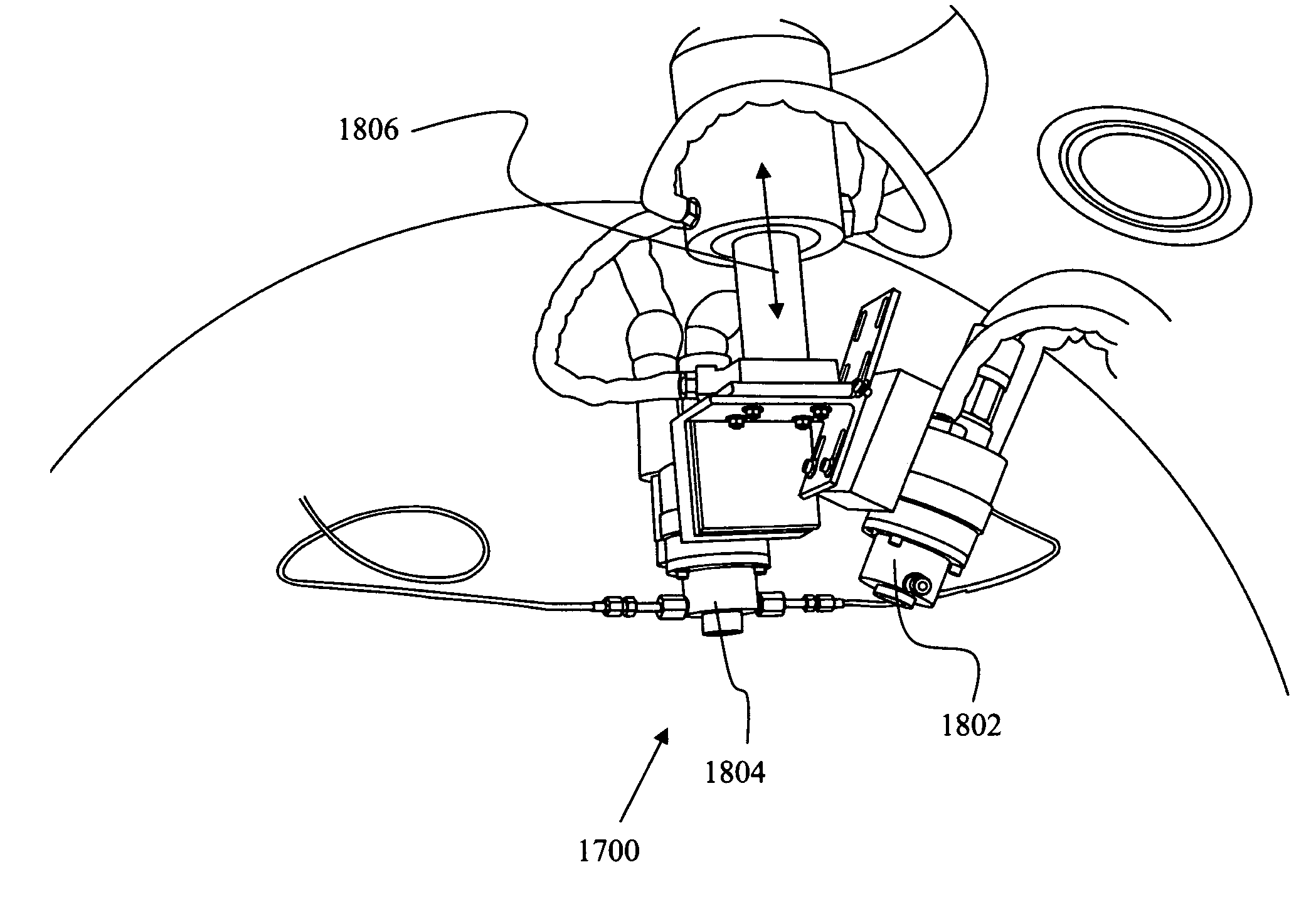

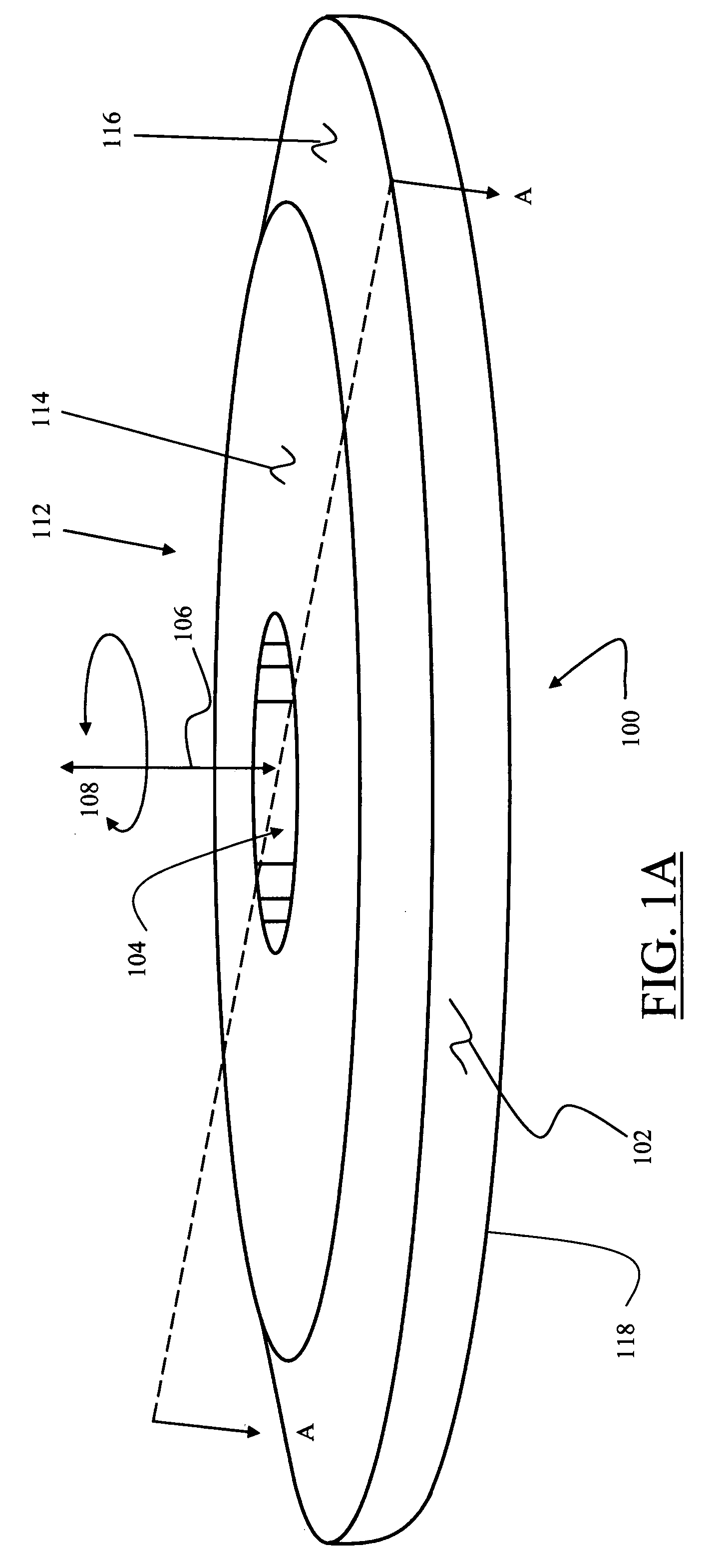

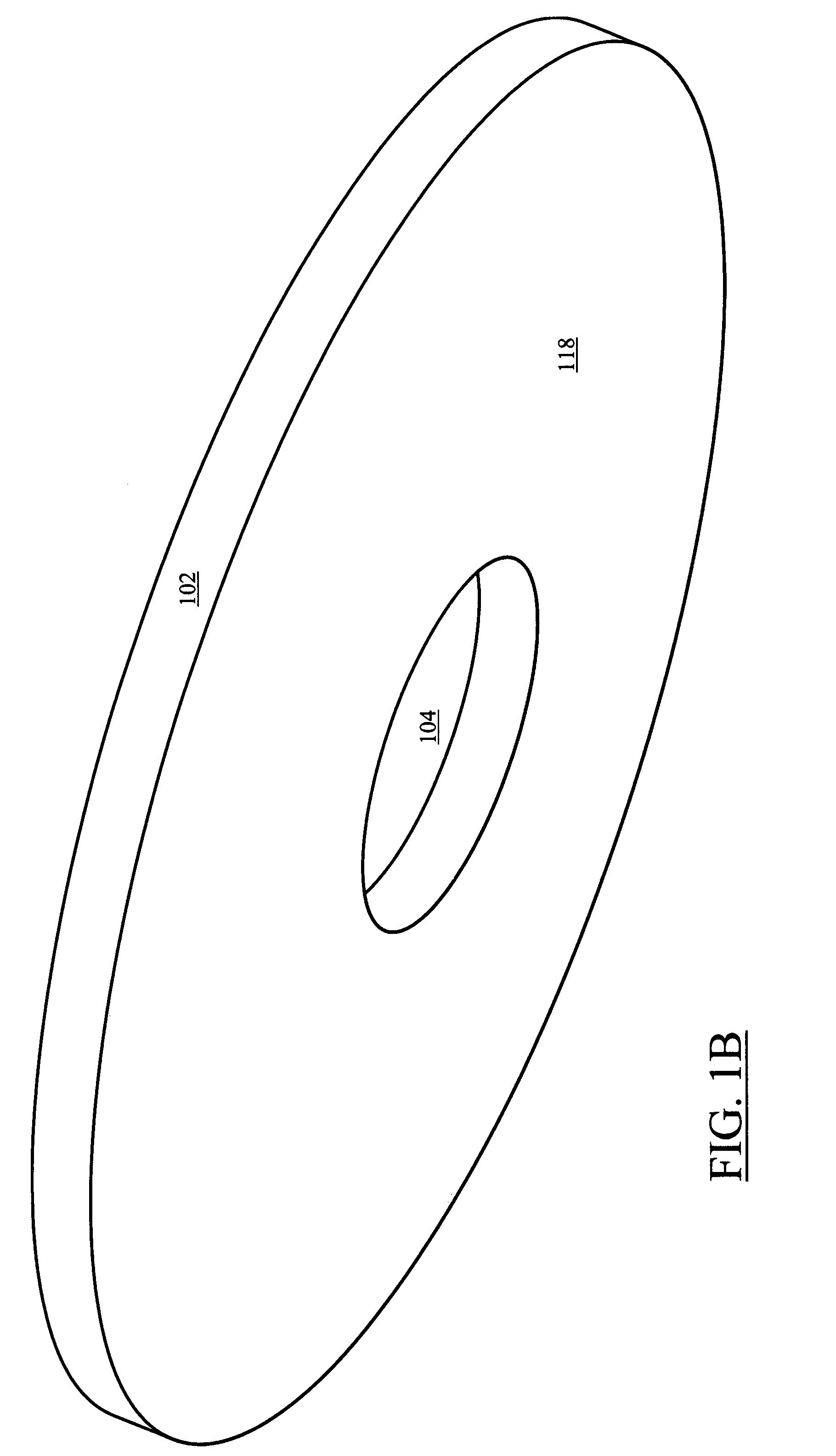

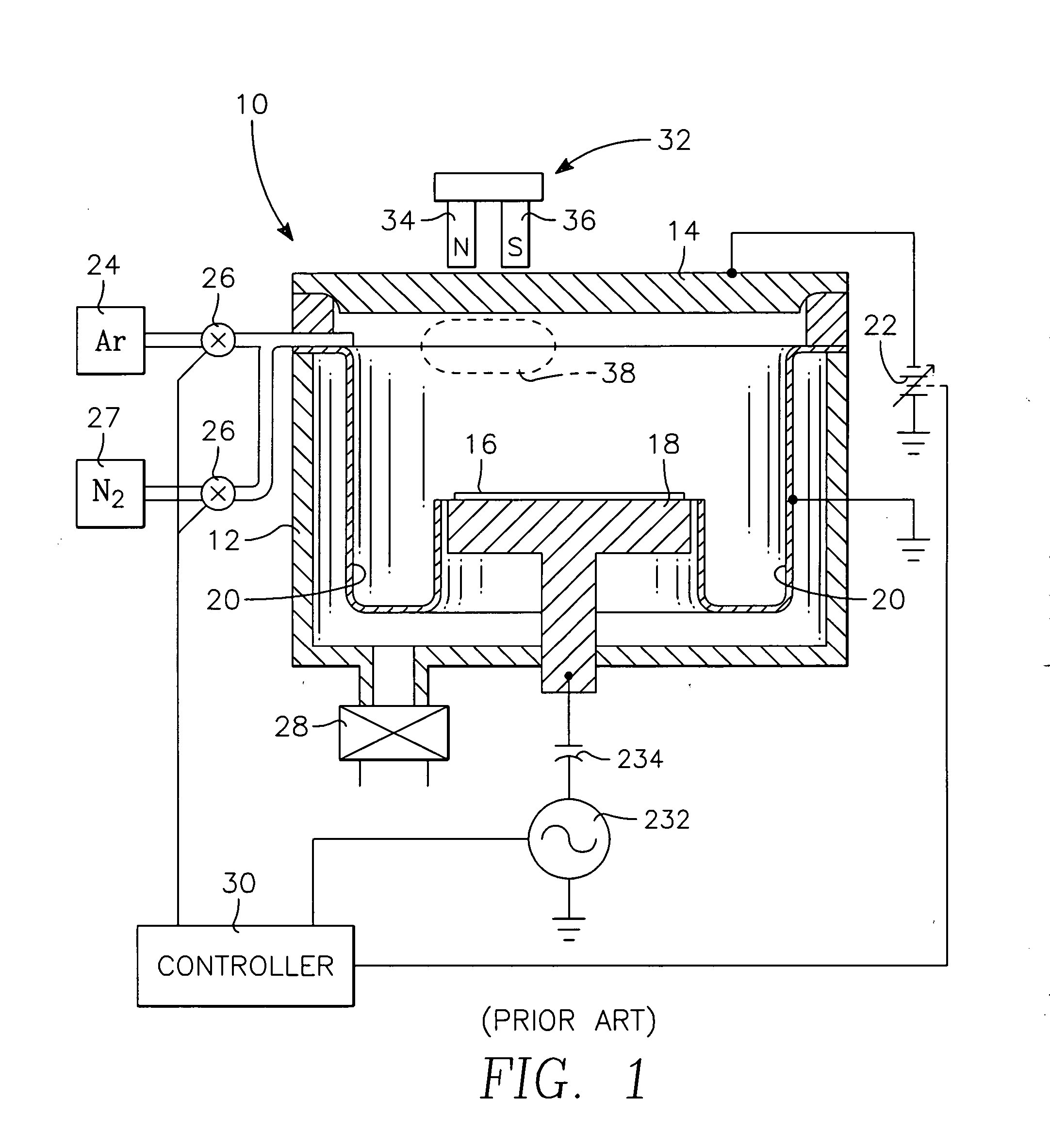

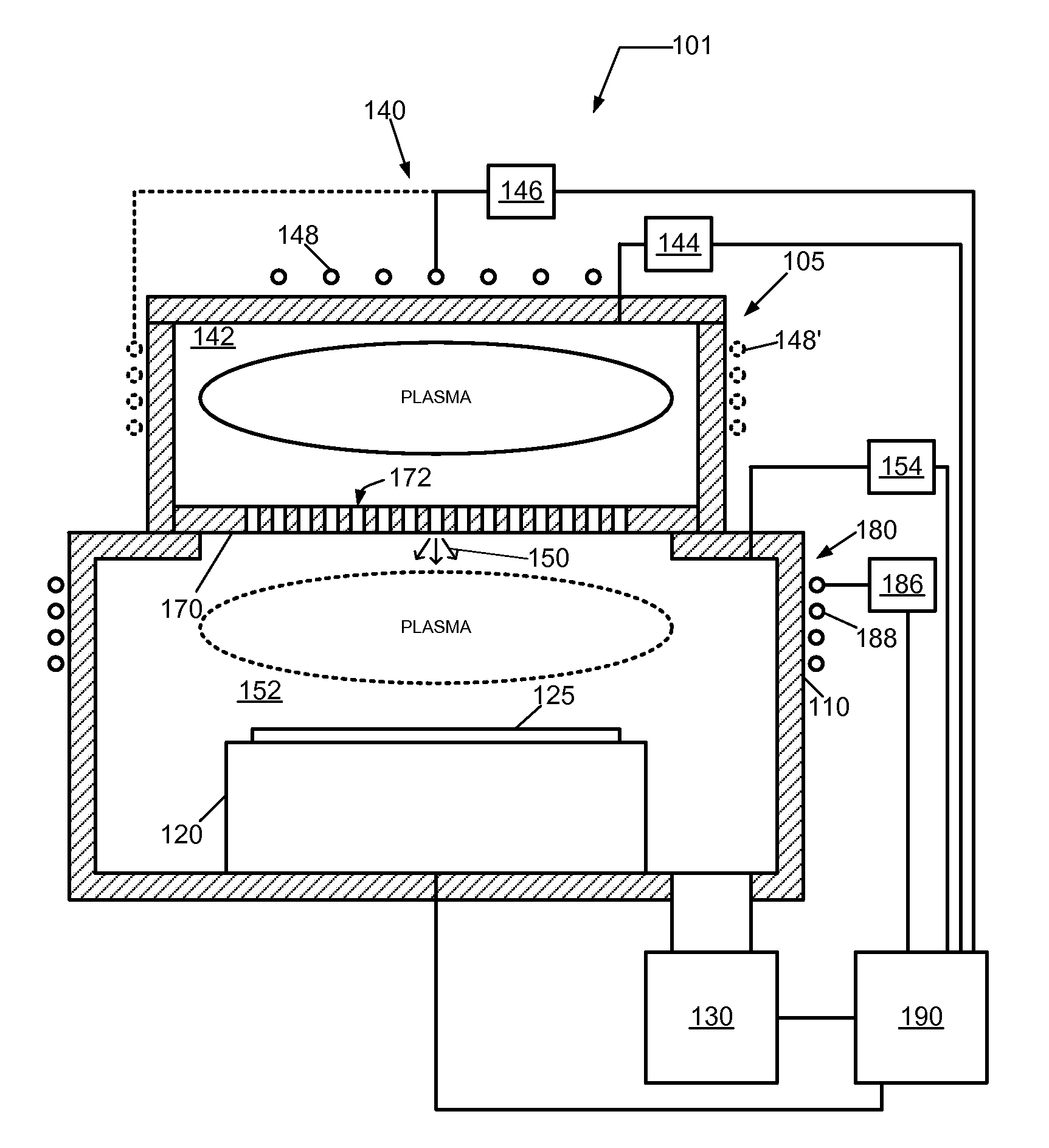

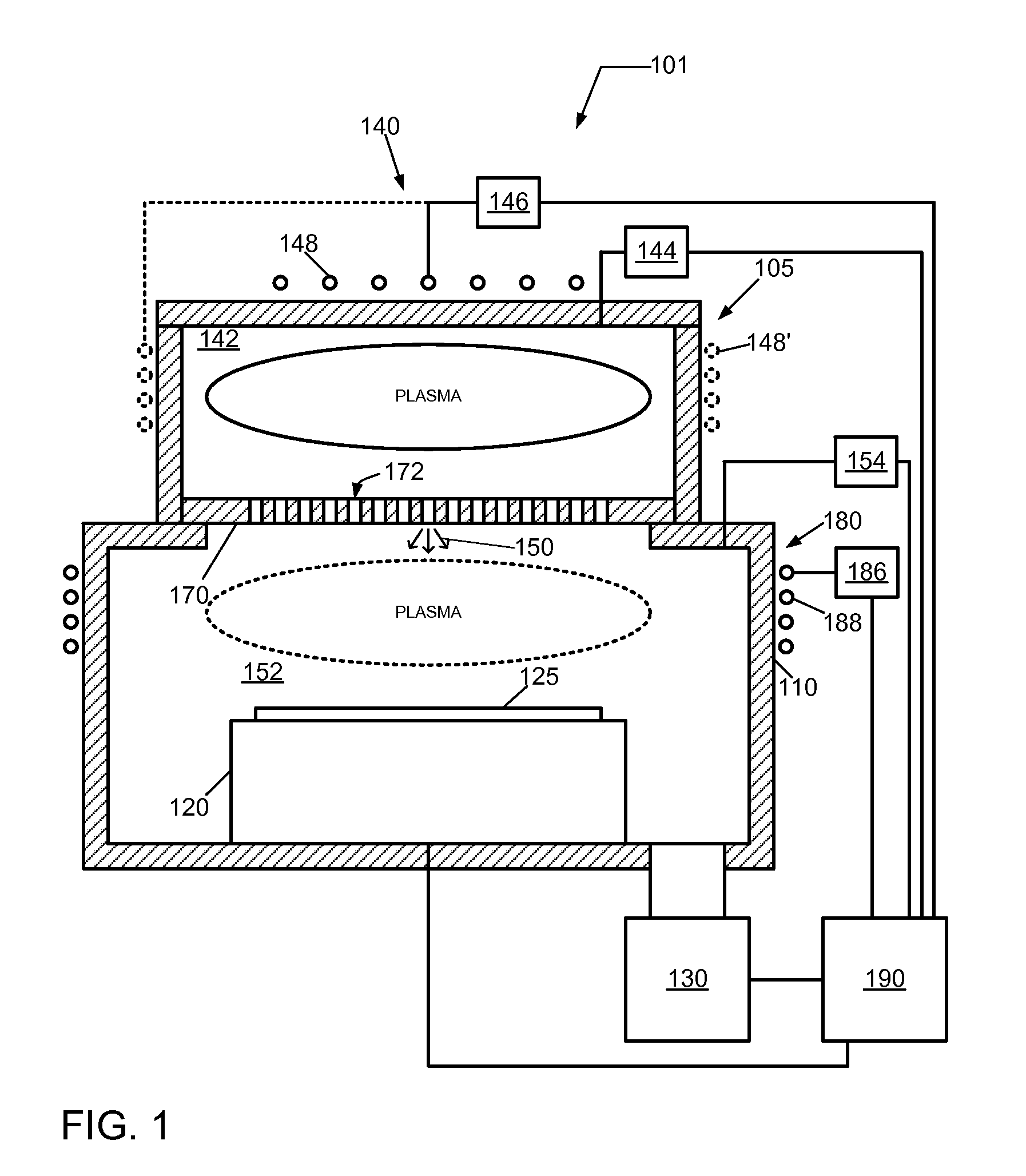

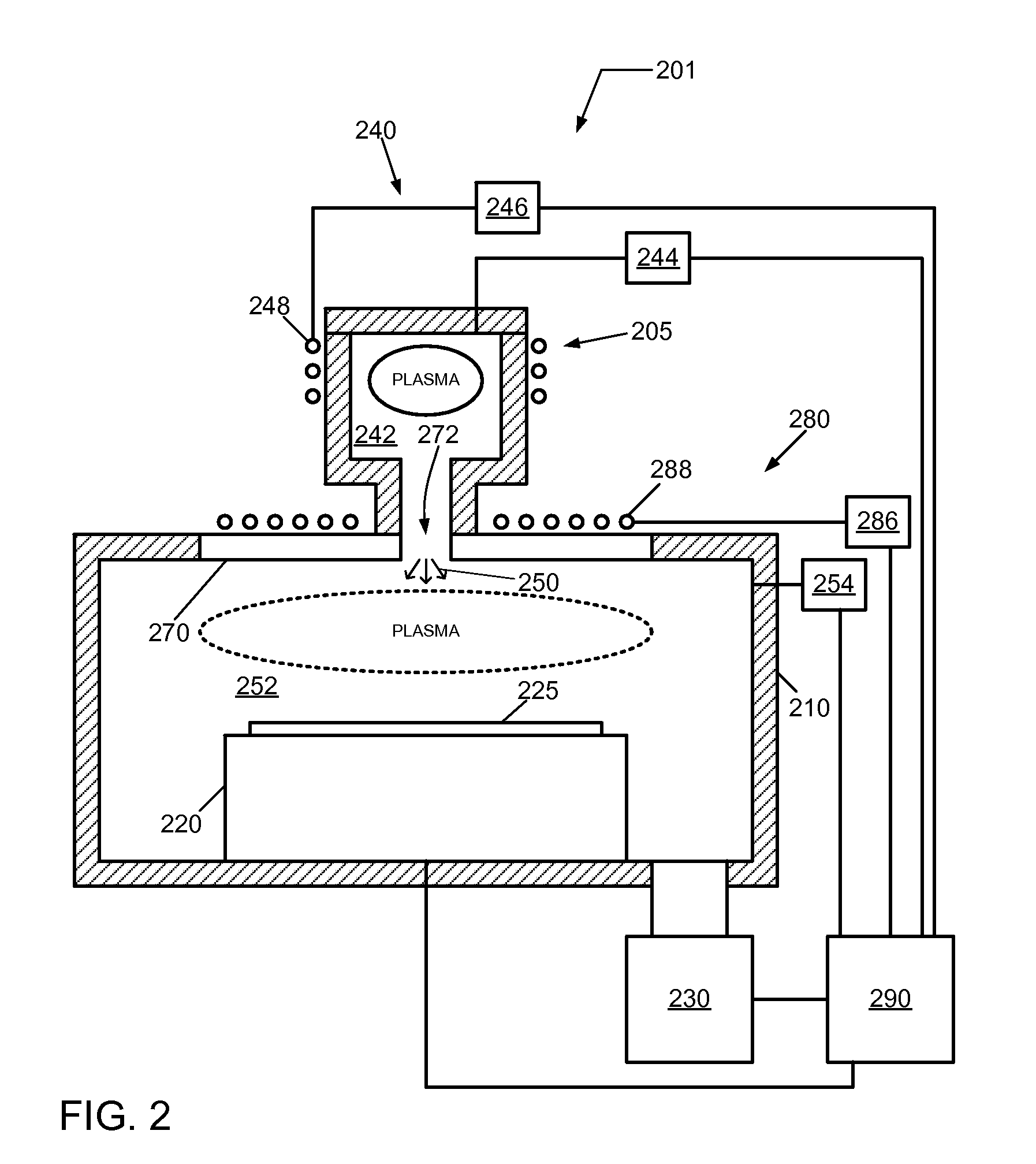

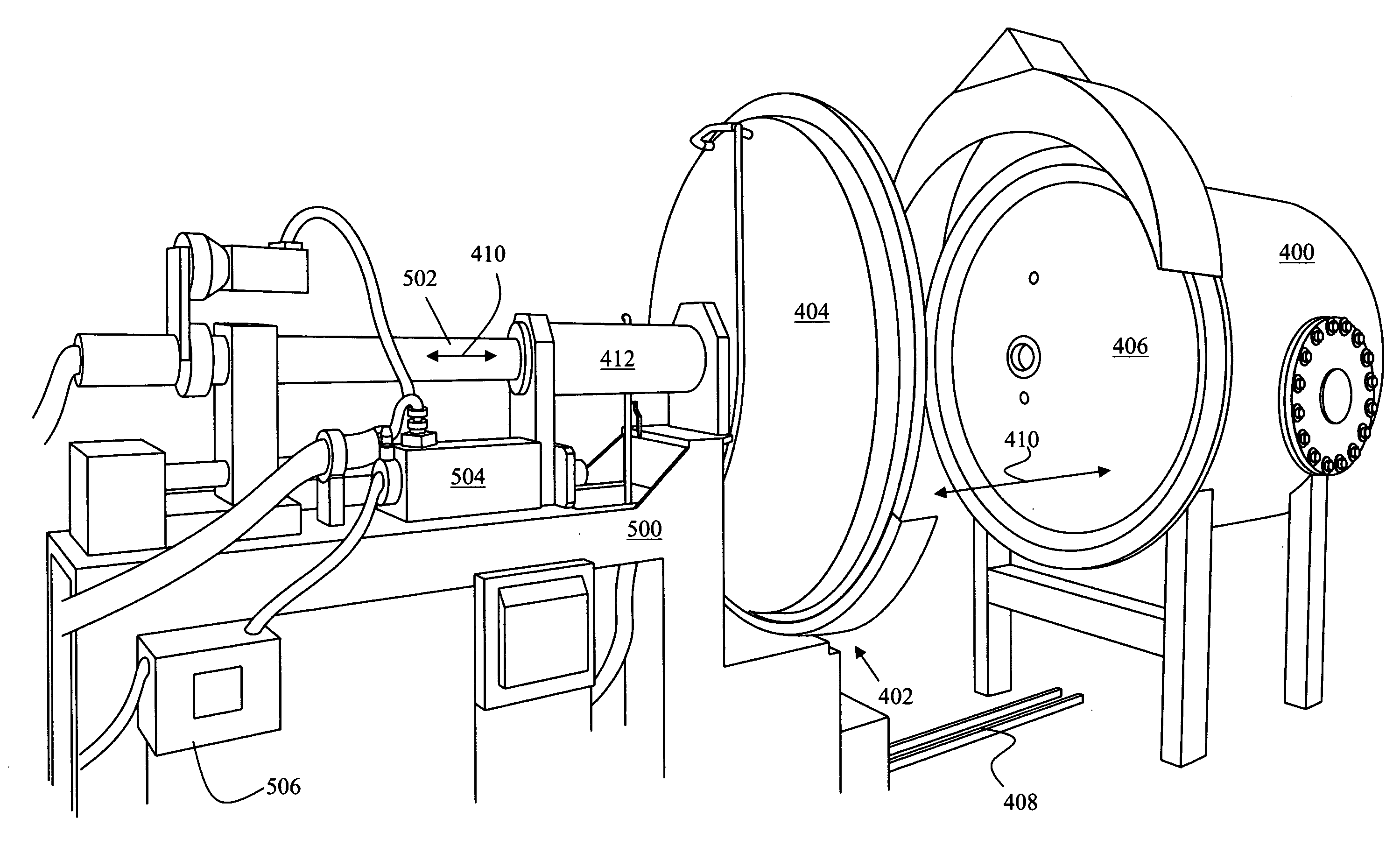

Method and system for low pressure plasma processing

Method and system for treating a substrate with plasma under low pressure conditions is described. A plasma processing system comprises a plasma generation chamber having a first plasma region and a process chamber having a second plasma region disposed downstream of the first plasma region. A plasma generation system is coupled to the plasma generation chamber and configured to create a first plasma in the first plasma region, while a plasma heating system is coupled to the process chamber and configured to heat electrons supplied to the second plasma region from the first plasma region to form a second plasma. A substrate holder coupled to the process chamber is configured to support a substrate and expose the substrate to the second plasma.

Owner:TOKYO ELECTRON LTD

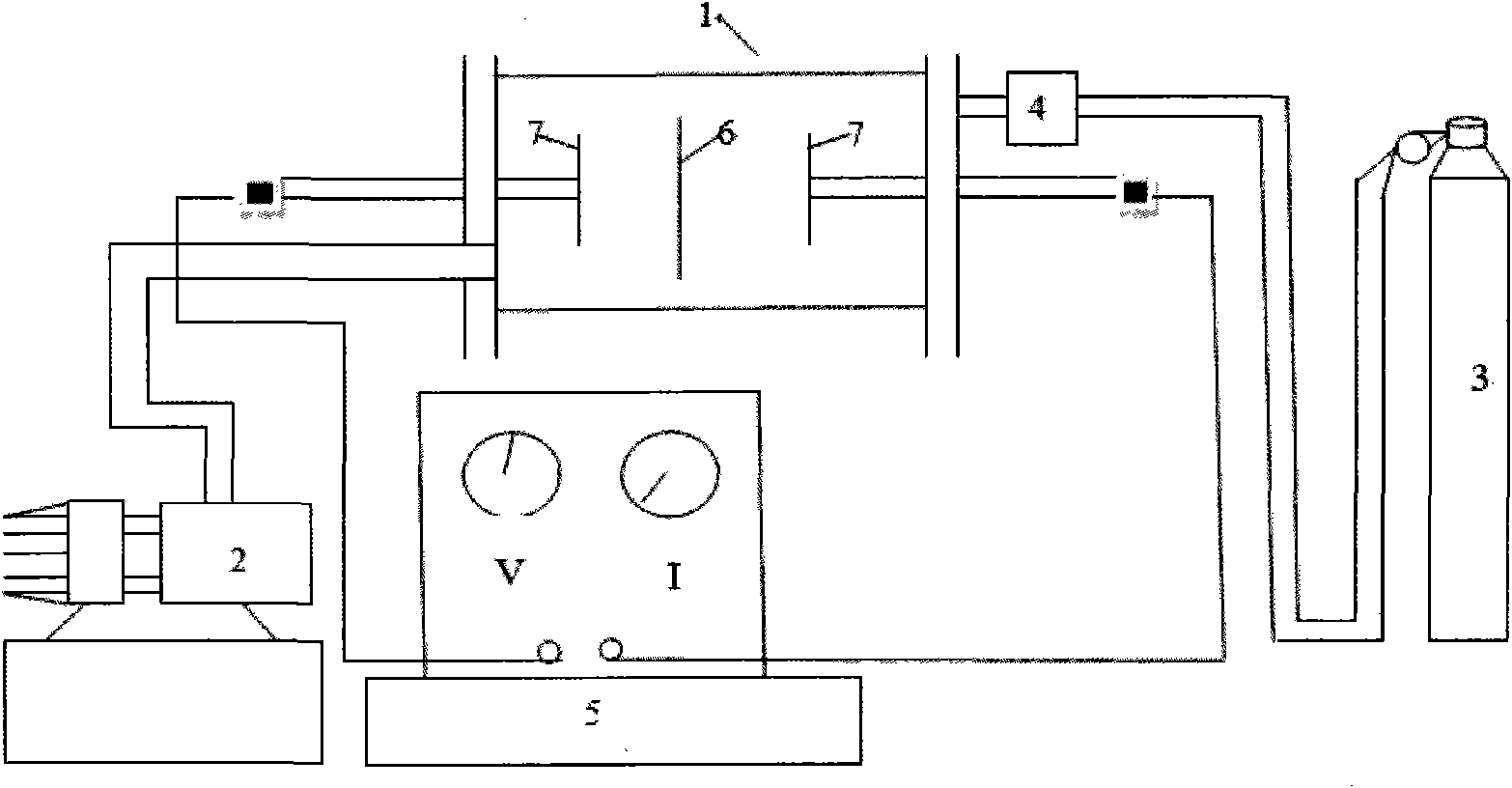

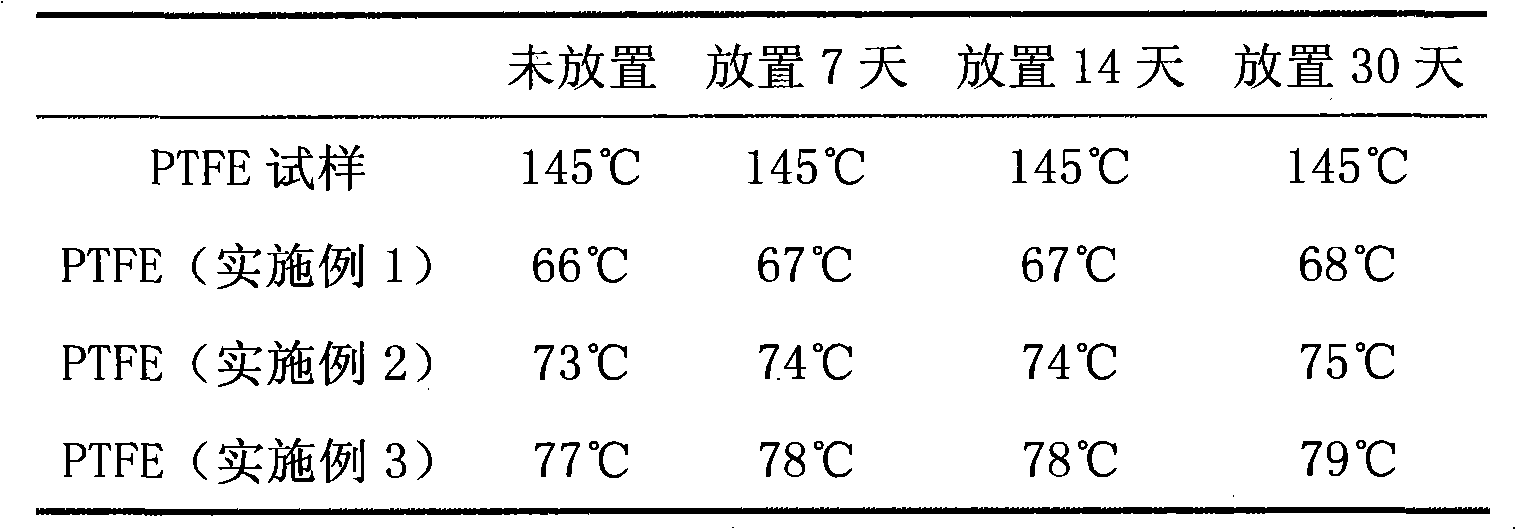

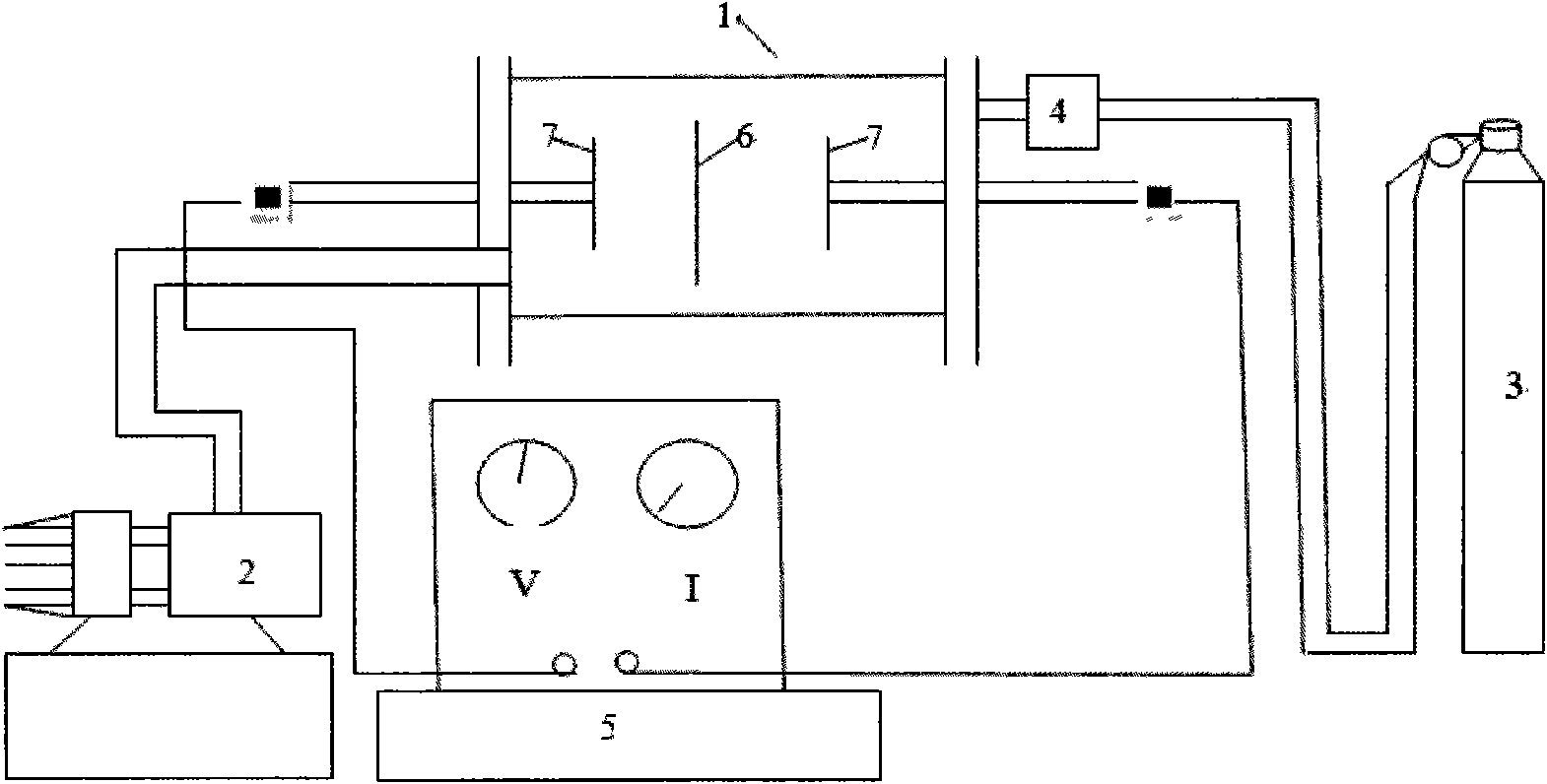

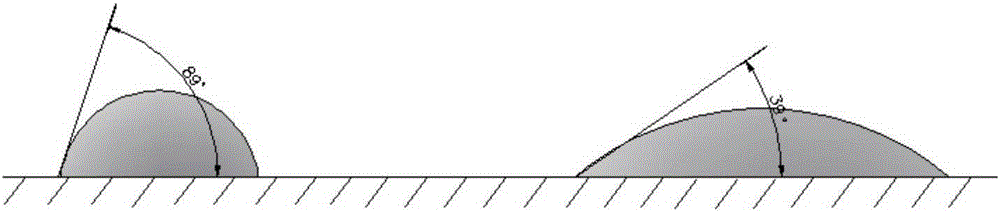

Surface hydrophilic modification method for polytetrafluoroethylene bulked membrane

InactiveCN101890314ASimple processEfficient treatment processSemi-permeable membranesWater layerLow pressure plasma

The invention relates to a surface hydrophilic modification method for a polytetrafluoroethylene bulked membrane, which is characterized by comprising the steps of: pretreating a polytetrafluoroethylene membrane by adopting low-pressure glow discharge plasma to make the surface of the polytetrafluoroethylene membrane generate active groups, and grafting acrylic acid to form a relatively stable hydrophilic layer. The method has the advantages that: the active groups are generated on the surface of the polytetrafluoroethylene membrane by low-pressure plasma treatment, and the relatively stable hydrophilic layer can be formed on the surface of the membrane by acrylic acid grafting treatment, so that the hydrophilicity of the polytetrafluoroethylene membrane is effectively improved, and the effect is lasting; and the polytetrafluoroethylene membrane is treated by the low-pressure plasma induction and acrylic acid grafting, so the treatment method is simple, high-efficiency, water and energy-saving, and suitable for industrialized production.

Owner:DONGHUA UNIV

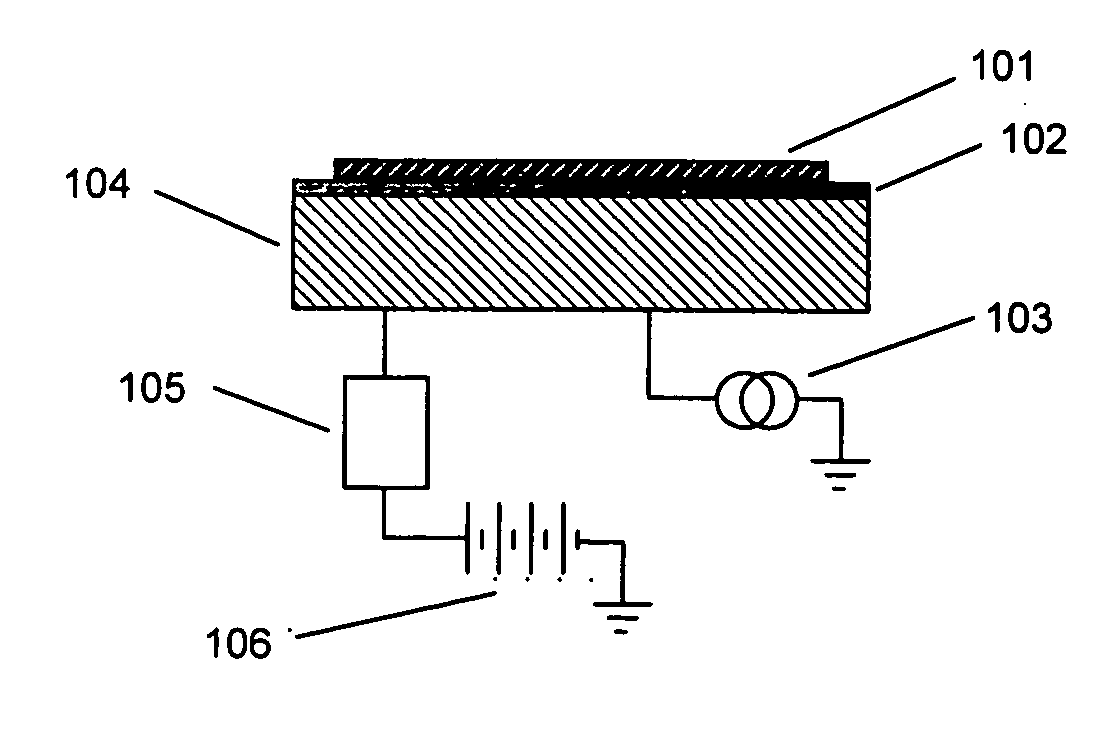

Clamp for holding and efficiently removing heat from workpieces

InactiveUS20050036267A1Effectively safely clampIncrease resistanceSemiconductor/solid-state device manufacturingEmergency protective arrangement detailsEtchingCelsius Degree

The invention described in this disclosure is an apparatus and method for clamping semiconductor wafers or other substrates or workpieces during etching, CVD, or surface modification processes. The purpose of the invention is to achieve improved heat transfer during processing between the wafer / substrate and a temperature controlled pedestal used for supporting it in the process chamber. The typical level of process heat put into the wafer during plasma-based etching or deposition processes will be up to about 10 Watts per centimeter squared while the maximum acceptable temperature differential between wafer / substrate and pedestal is less than about 100 Celsius. In such low gas pressure environments typical for plasma-based processes, the heat removal from the wafer / substrate by gaseous conduction may be inadequate to meet requirements. This invention achieves excellent heat transfer to the pedestal from the wafer / substrate when there is a thin, resilient, electrically insulating layer (tape) bonded to the wafer / substrate or the pedestal. Wafer / substrate clamping for improved process heat removal is achieved by a combination of vacuum clamping of the wafer / substrate beginning prior to evacuation of the processing chamber, along with or followed by electrostatic clamping of the wafer / substrate which continues during processing. The invention also permits the wafer / substrate to be rapidly and safely released from the electrostatic clamping when the chamber is returned to atmospheric pressure by a providing a slight pressure increase, above atmospheric pressure, between wafer and pedestal. The pedestal may have some roughening or narrow grooves on the wafer clamping surface, and some small holes from its surface leading to an evacuated plenum or channel within the pedestal. Alternatively, the pedestal may have a layer of a porous metal extending from its surface down to the evacuated channel or plenum which permits gas to be evacuated. These structures allow vacuum pumping of gas that might otherwise be trapped between the insulating layer and the pedestal. When a wafer / substrate is placed on the pedestal by loading at atmospheric pressure, vacuum pumping through the pedestal is commenced. This causes the workpiece to be pressed to the pedestal clamping surface with approximately atmospheric pressure compressing the soft layer against its clamping surface. This provides sufficient contact of the soft layer with the pedestal to greatly improve heat transfer from the wafer / substrate to the pedestal. A voltage is applied to the pedestal, beginning any time after the wafer is on the pedestal, to further clamp the wafer electrostatically. As the processing chamber is then pumped down to operating pressure for processing the electrostatic clamping voltage maintains sufficient pressure of the wafer / substrate against the pedestal to maintain the heat conductive contact between the soft layer and the pedestal. This permits good heat conduction to be maintained during the low pressure plasma-based etching or CVD processing. Following processing when the wafer / substrate is to be removed it may be rapidly de-clamped from the electrostatic clamping by application of a slight over-atmospheric pressure in the reservoir or pumping channels within the pedestal.

Owner:SAVAS STEPHEN EDWARD +1

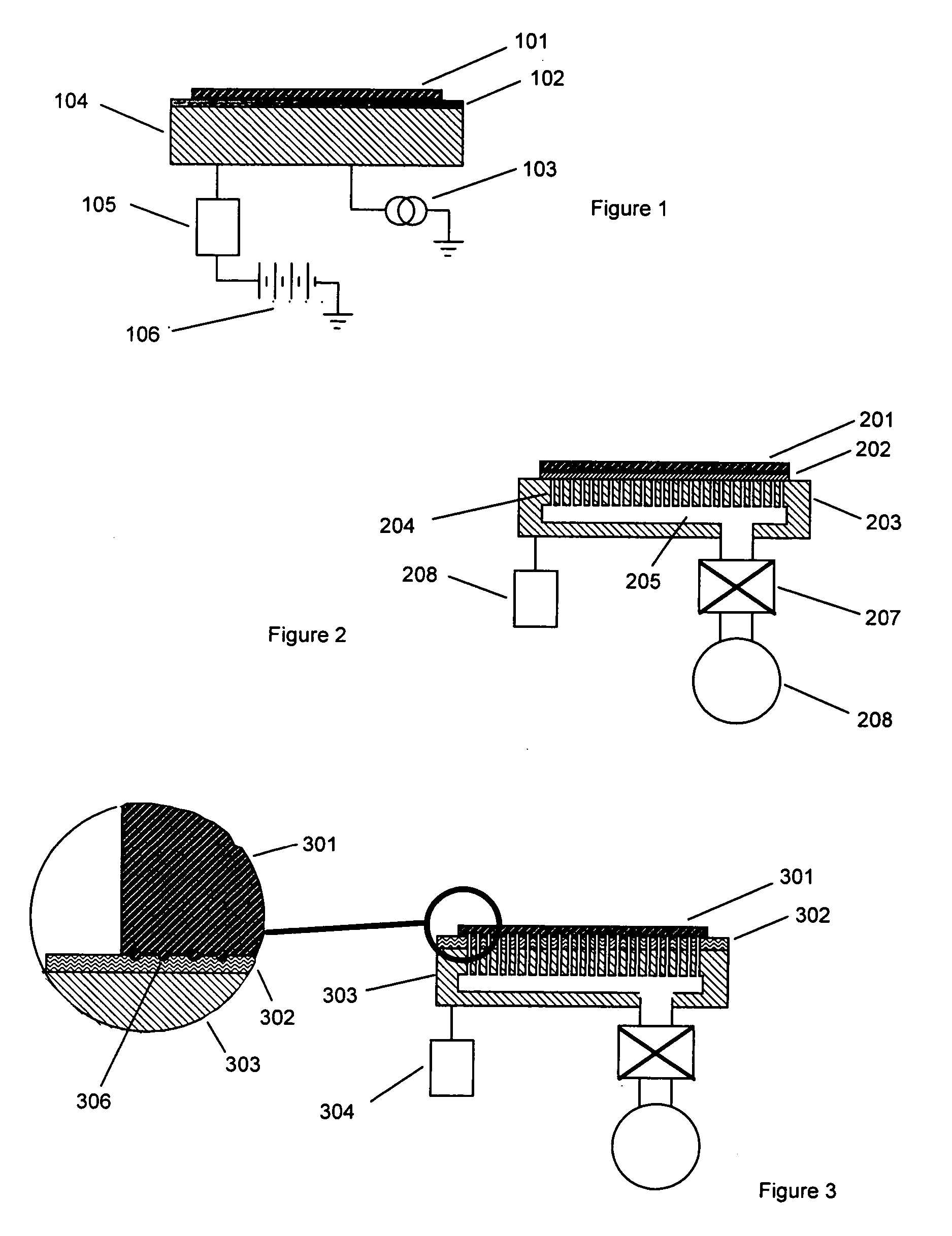

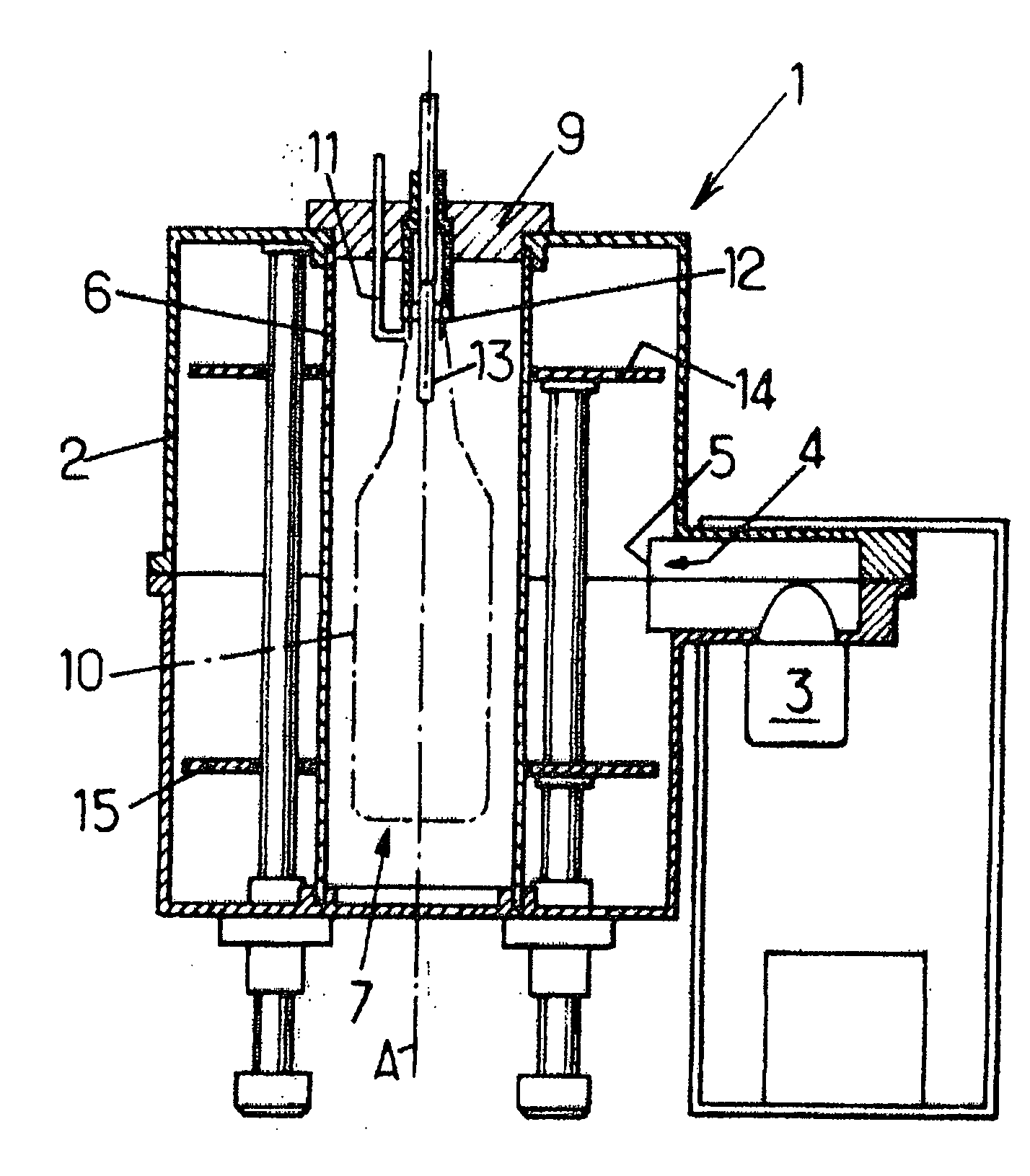

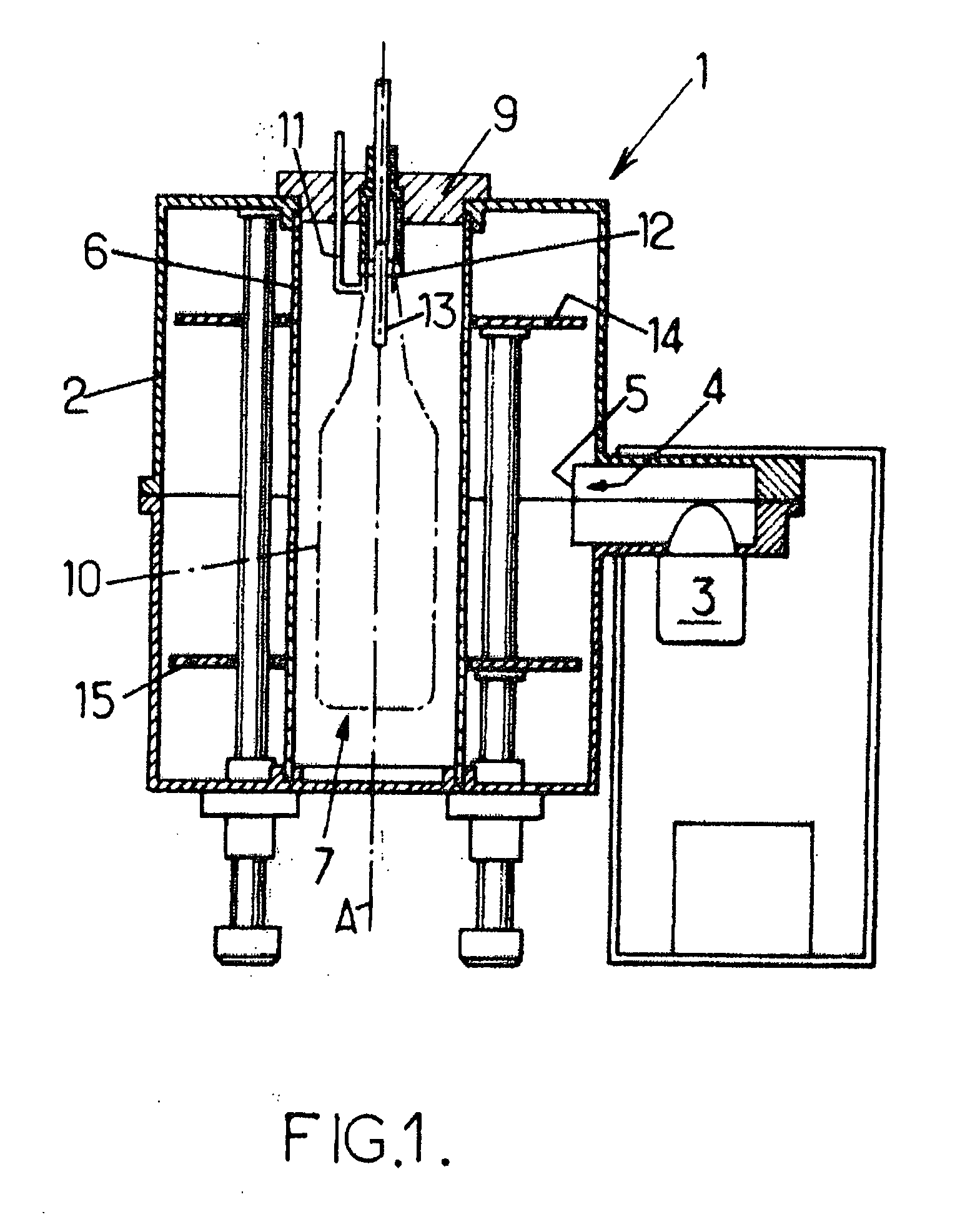

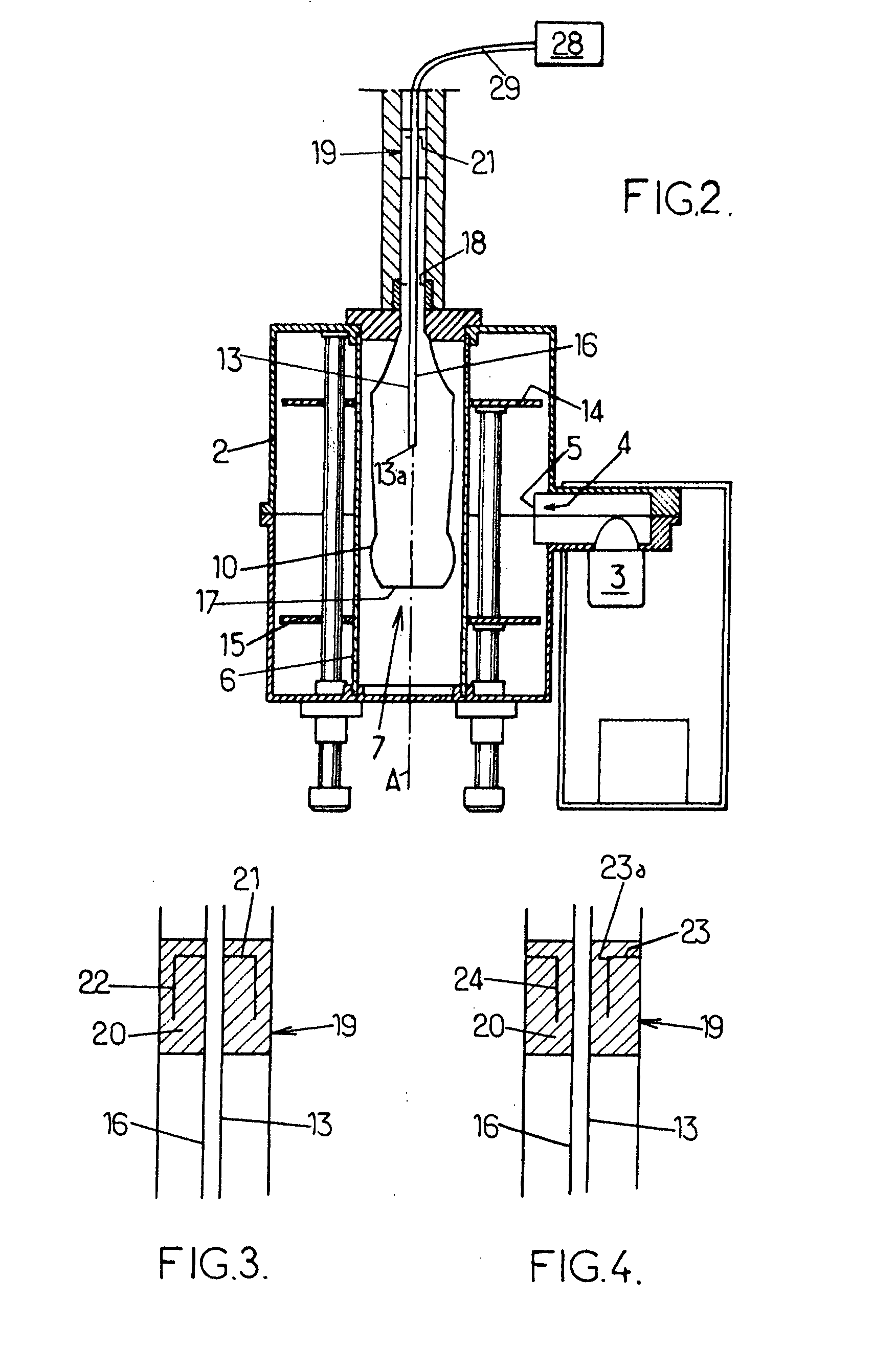

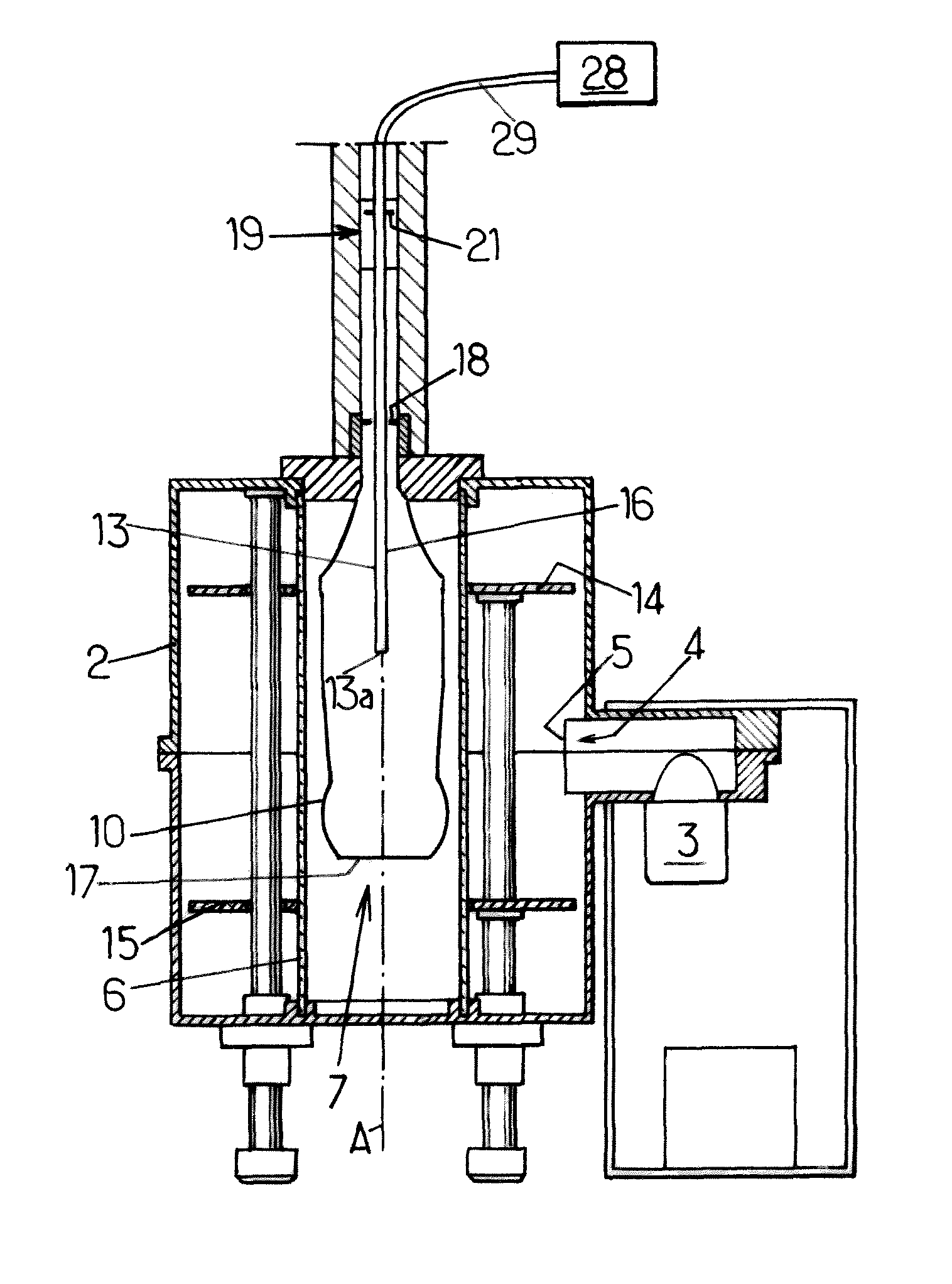

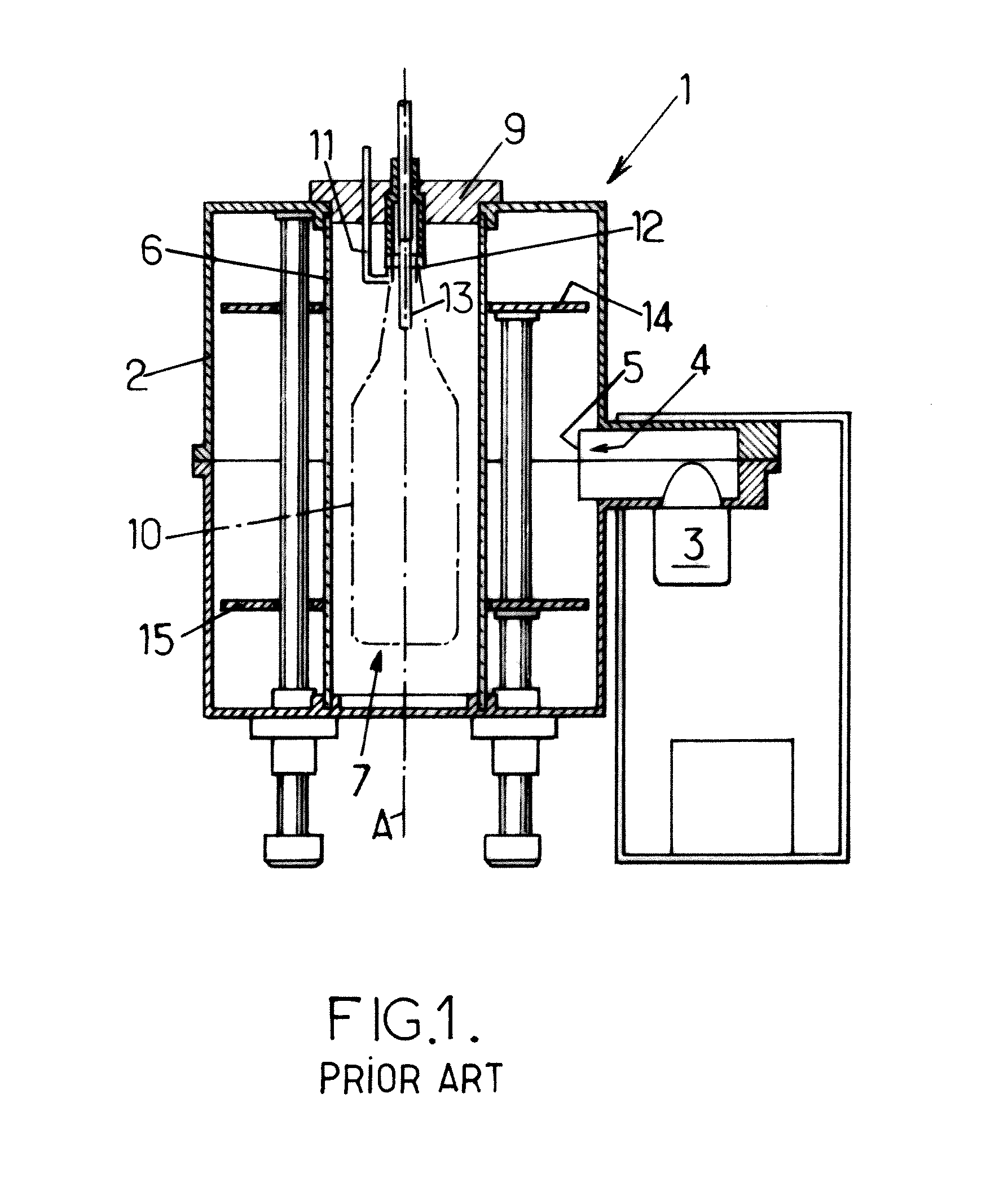

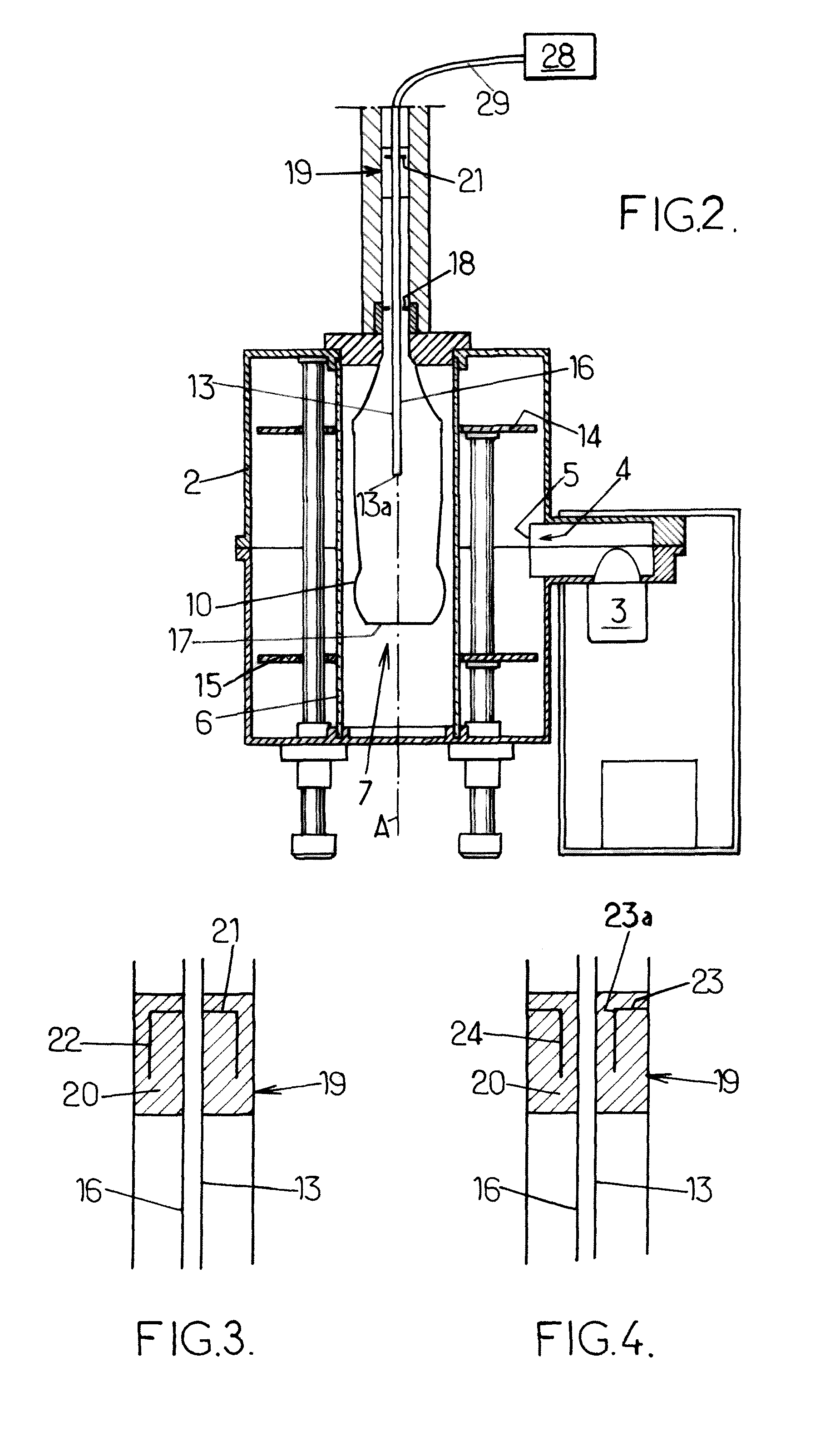

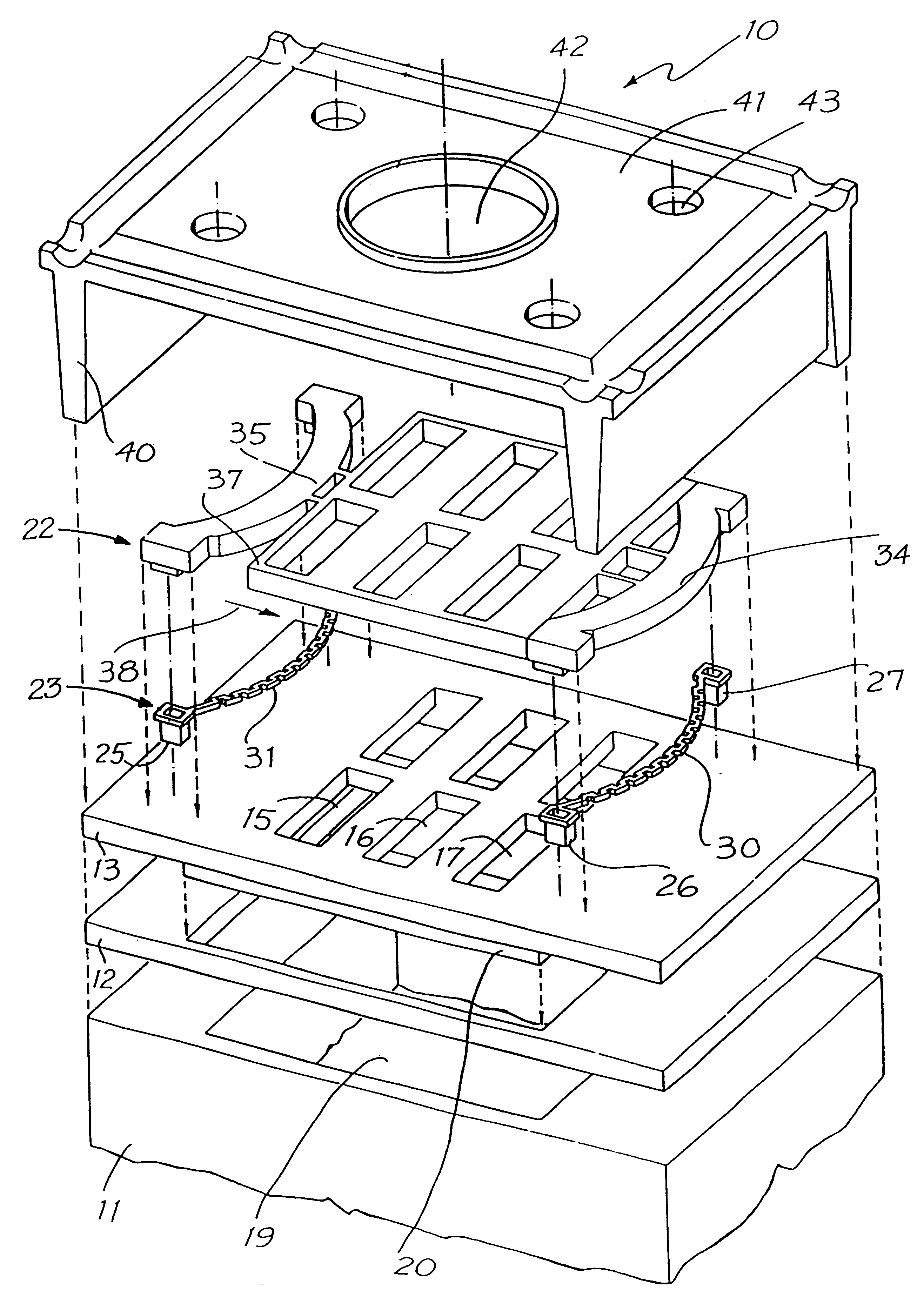

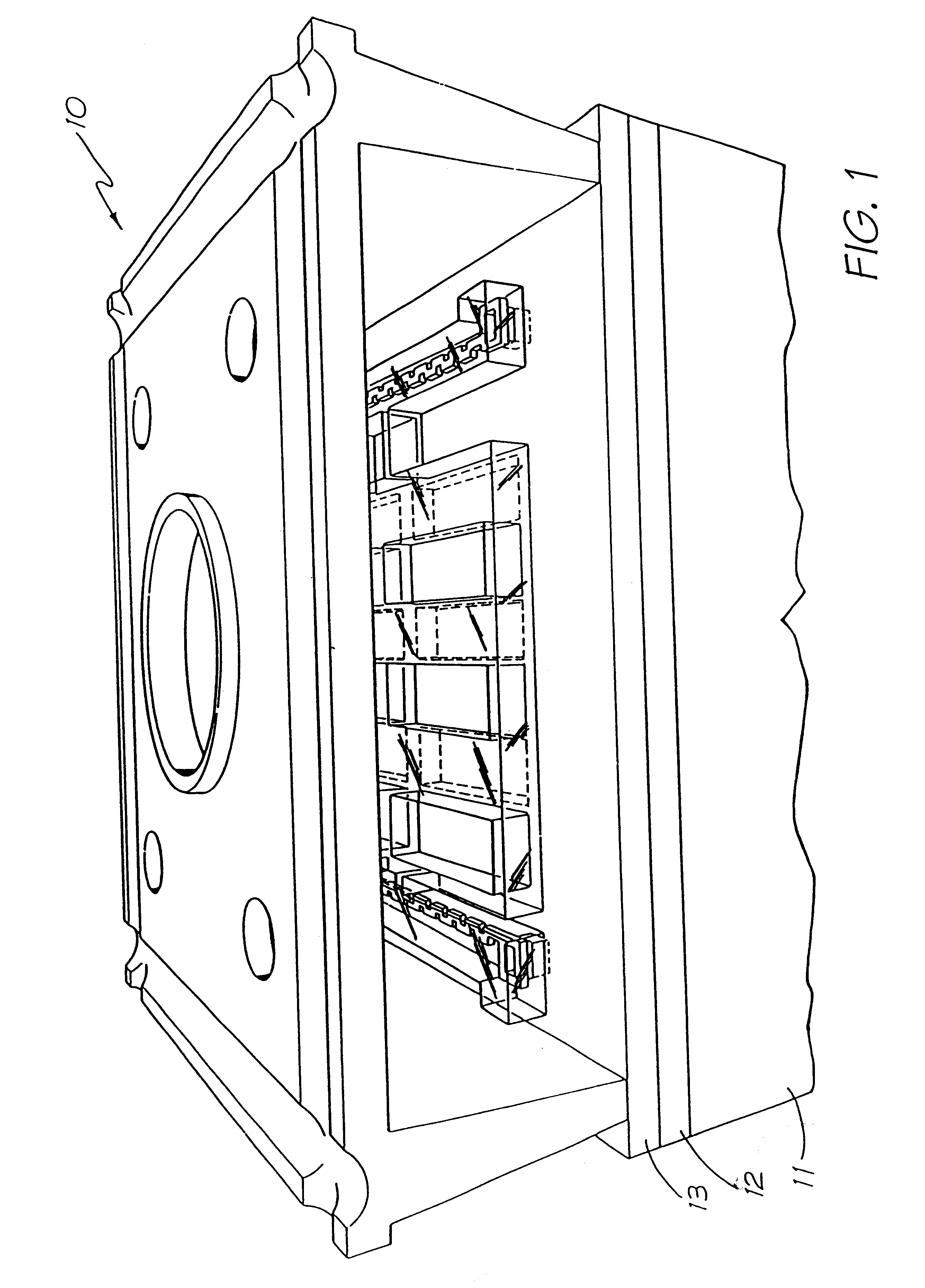

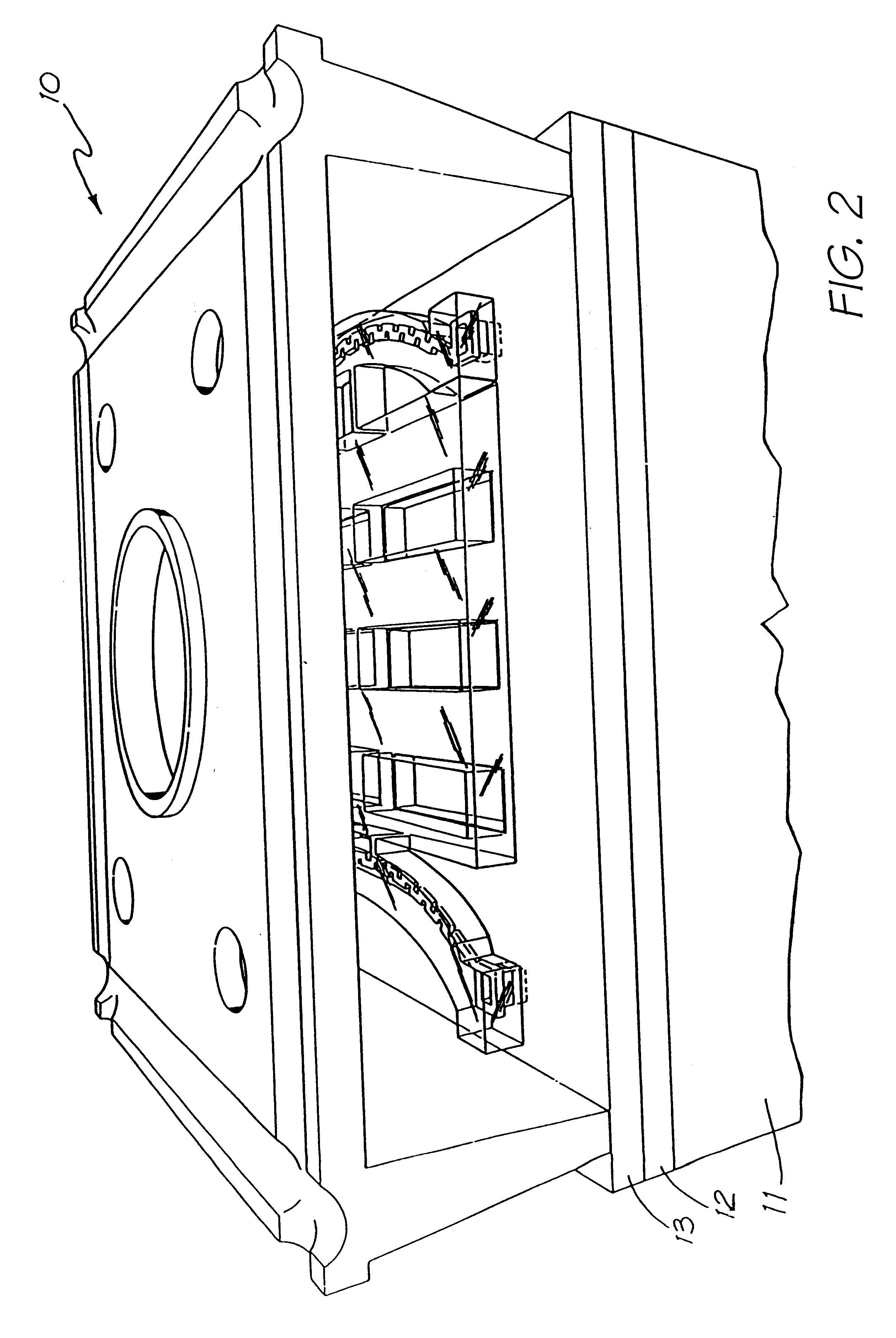

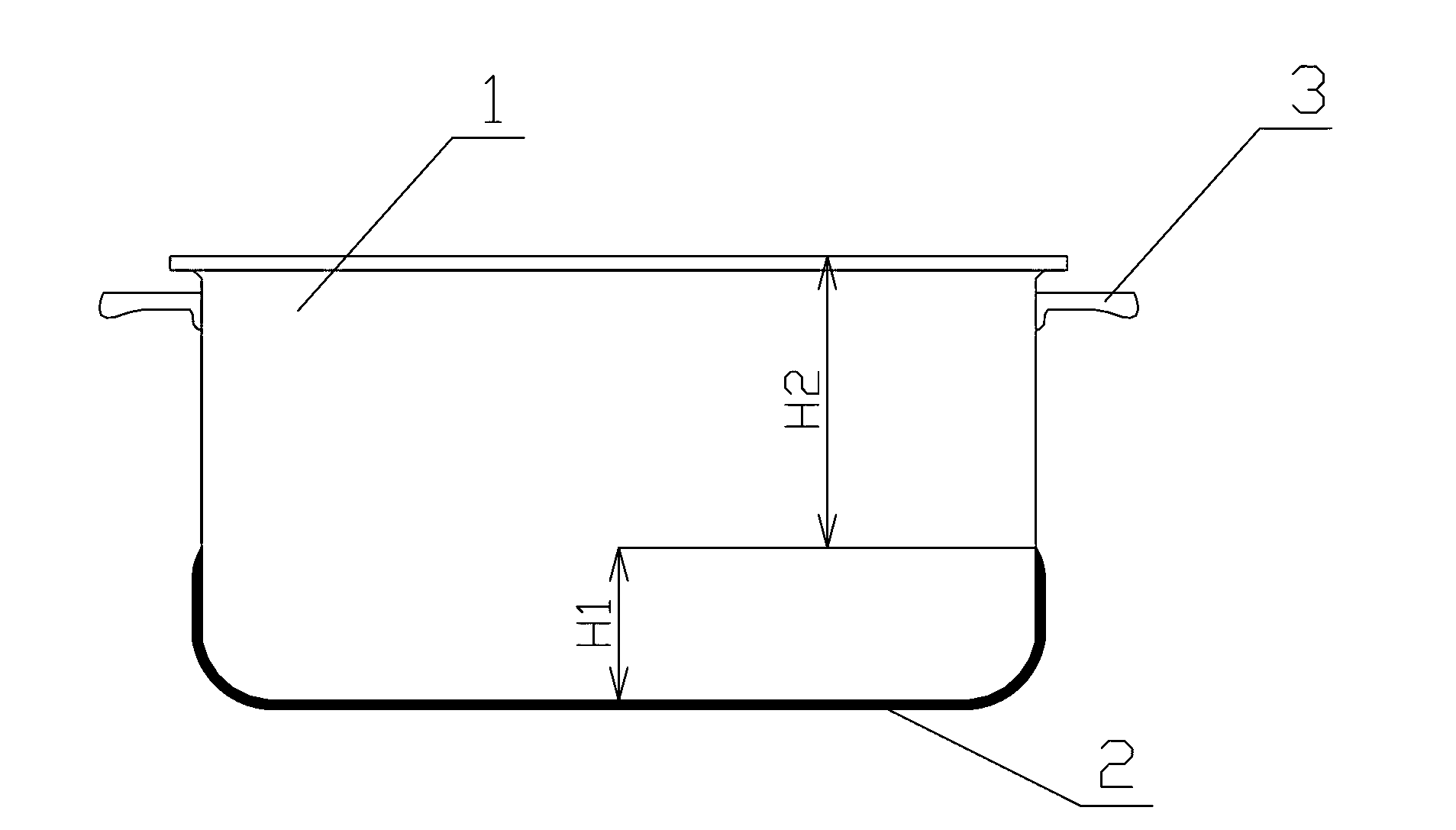

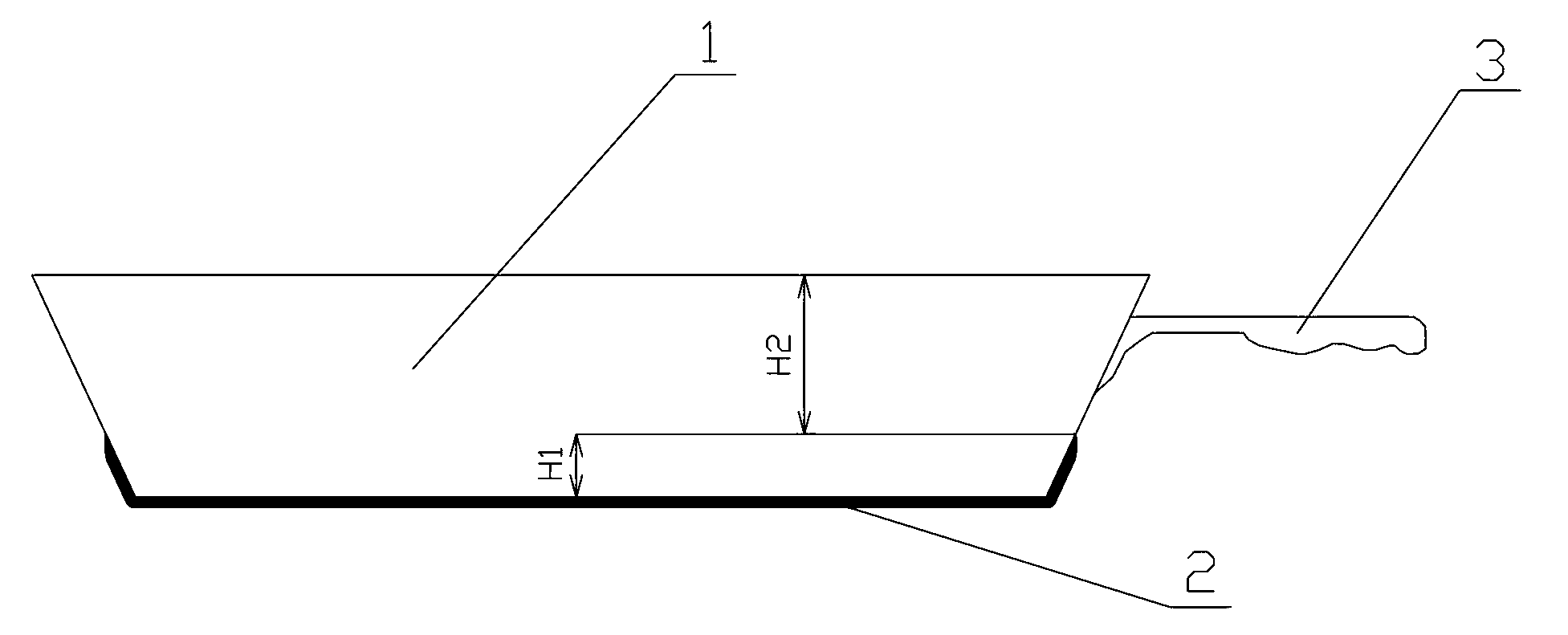

Device for depositing a coating on an internal surface of a container

InactiveUS20080011232A1Improve blockageReduce the amount requiredLiquid surface applicatorsElectric discharge tubesMicrowaveEngineering

Device for depositing a coating on an internal surface of a container (10), of the type in which the deposition is carried out by means of a low-pressure plasma created inside the container (10) by excitation of a precursor gas by microwave-type electromagnetic waves. An injection tube (13) is provided that dips into the container (10) to a length of between one quarter and one half of the total height of the container (10) in question, between the top (18) and the bottom (17) of the container (10), said length of the injection tube (13) constituting a longitudinal antenna (16) capable of picking up a UHF electromagnetic wave generated by said generator (3) and of propagating the HT ignition signal, a UHF short-circuit (19) in the form of a plate (21, 23, 25) being provided on the injection tube (13) in such a way that the face of said plate (21, 23, 25) on the cavity side defines a point of zero amplitude of the electromagnetic wave propagating along said injection tube (13), the length between said short-circuit (19) and the free end (13a) of said injection tube (13) corresponding to an odd number of quarter-wavelengths so as to obtain a maximum amplitude, that is to say an antinode, at the free end (13a) of the injection tube (13).

Owner:SIDEL PARTICIPATIONS SAS

Method for the application of a conformal nanocoating by means of a low pressure plasma process

InactiveCN102821873ALow costCoating thicknessDielectric materialsElectric discharge tubesNanostructureNanometre

The invention relates to a conformal nanocoating applied by a low pressure plasma process. The invention also relates to a method for making such a conformal nanocoating on a three-dimensional nanostructure, in particular a three-dimensional structure containing electrically conductive and non-conductive elements.

Owner:EUROPLASMA

Device for depositing a coating on an internal surface of a container

InactiveUS7975646B2Stable ignitionEasy to igniteLiquid surface applicatorsElectric discharge tubesMicrowaveEngineering

Device for depositing a coating on an internal surface of a container, of the type in which the deposition is carried out by means of a low-pressure plasma created inside the container by excitation of a precursor gas by microwave-type electromagnetic waves. An injection tube is provided that dips into the container to a length of between one quarter and one half of the total height of the container in question, between the top and the bottom of the container said length of the injection tube constituting a longitudinal antenna capable of picking up a UHF electromagnetic wave generated by said generator and of propagating the HT ignition signal, a UHF short-circuit in the form of a plate being provided on the injection tube in such a way that the face of said plate on the cavity side defines a point of zero amplitude of the electromagnetic wave propagating along said injection tube, the length between said short-circuit and the free end of said injection tube corresponding to an odd number of quarter-wavelengths so as to obtain a maximum amplitude, that is to say an antinode, at the free end of the injection tube.

Owner:SIDEL PARTICIPATIONS SAS

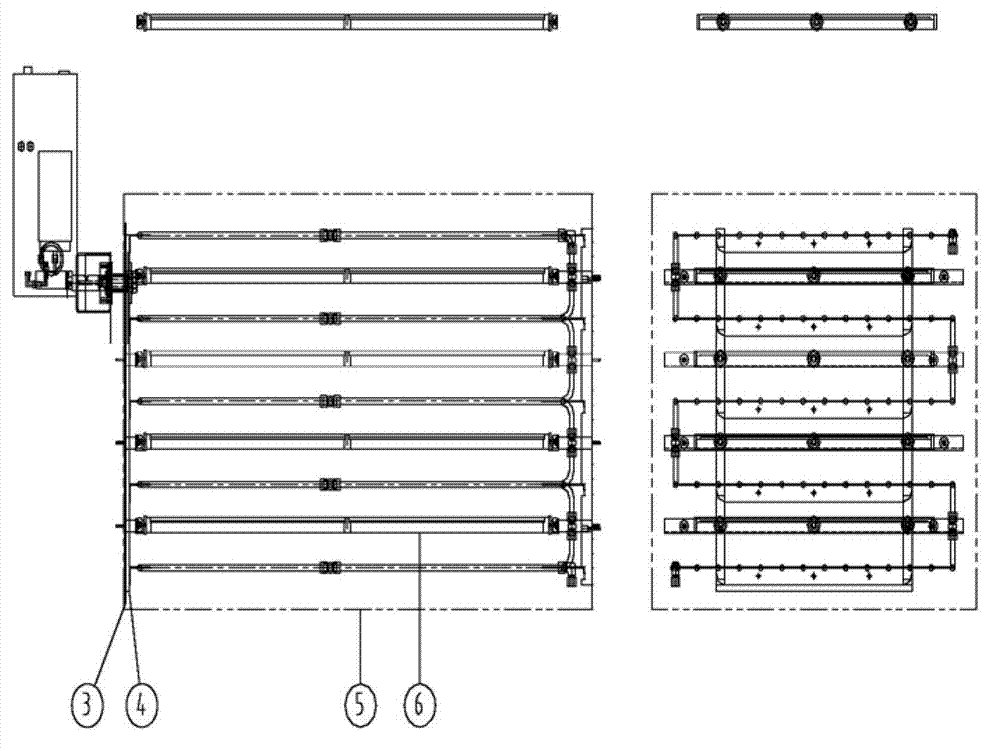

Buckle grill oscillating pressure ink jet printing mechanism

This patent describes an inkjet print nozzle having a shuttered ejection mechanism that is reliant upon the utilisation of a buckling device to activate the shutter. The shutter is located between the nozzle chamber and the ink supply source, the shutter being activated on demand to allow ink to pass through the shutter means and to thereby cause ink to be ejected from the nozzle chamber. The shutter can be activated by a buckle actuation mechanism attached to the shutter plate. The actuator can comprise a serpentine conductive material such as copper encased within an expansive material, such as polytetrafluoroethylene, having a high coefficient of thermal expansion such that, upon heating of the serpentine conductive material, the material concertinas so as to expand at a similar rate to the expansive material. The ink supply includes an ink supply channel interconnecting the shutter through the high density low pressure plasma etching of a hole in the ink jet wafer. The ink supply is driven with a substantially sinusoidal ink pressure so as to eject ink when the shutter is open. The shutter can be kept open during a subsequent high pressure time of the varying pressure sufficient to cause the nozzle chamber to be rapidly refilled so that the chamber is ready for ejection of ink upon the next opening of the shutter.

Owner:ZAMTEC +1

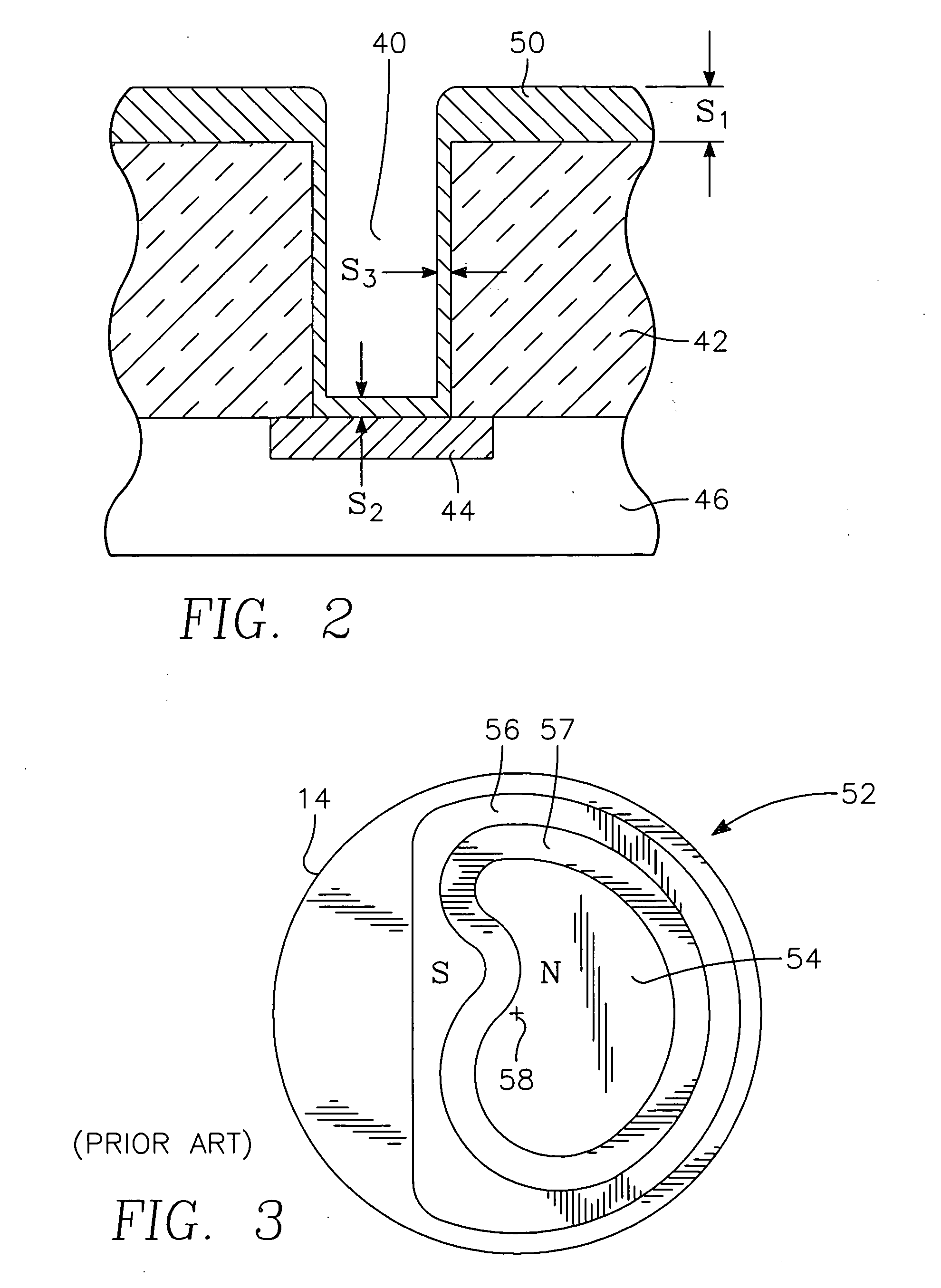

High density low pressure plasma sprayed focal tracks for X-ray anodes

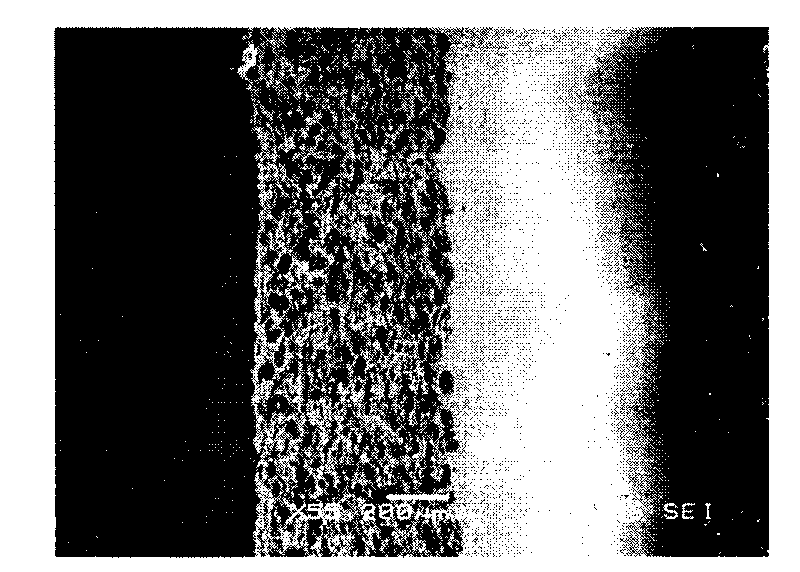

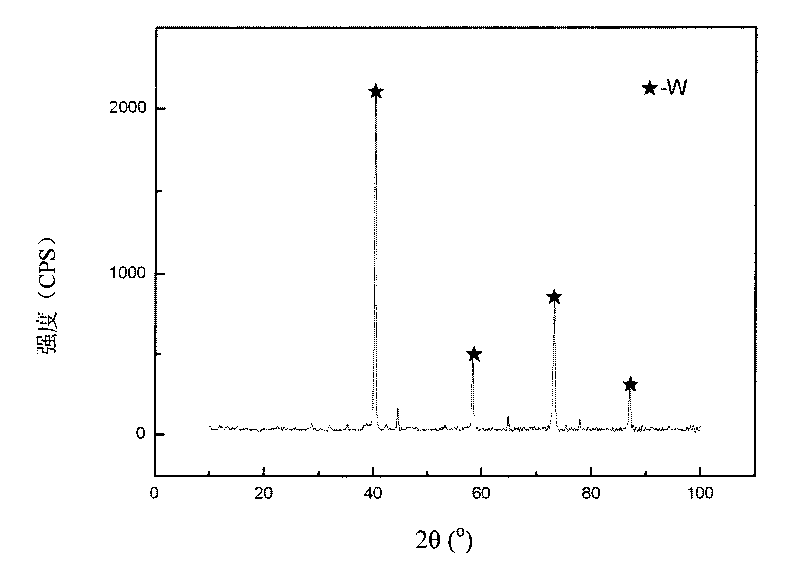

InactiveUS7601399B2Avoid heat conductionReduce pressureLiquid surface applicatorsMolten spray coatingSoft x rayRhenium

This invention involves the application of dense, metallurgically bonded deposits of tungsten and tungsten rhenium coatings onto preformed based x-ray anodes to be used as focal tracks. The coatings are applied by low pressure DC plasma spraying. The invention also includes heat treatments that further densify the as-applied coatings improving their suitability for use as focal tracks.

Owner:SURFACE MODIFICATION SYST

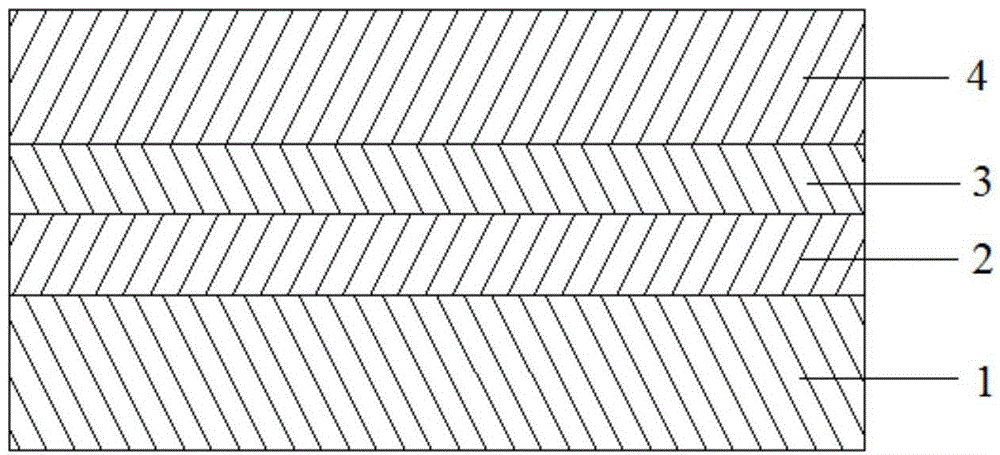

Preparation method for thermal-barrier coating

InactiveCN103668191AVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionGas phase

A preparation method for a thermal-barrier coating comprises the following steps: performing ultrasonic cleaning on alloy or stainless steel successively by gasoline and alcohol, and then performing corundum sand-blast processing; employing ultrasonic flame spraying, low-pressure plasma spraying, atmosphere plasma spraying, cold spraying or electron beam-physical vapor deposition to prepare a NiCoCrAlYTa or NiAl bonding layer with a thickness of 50-200 mu m on the surface of alloy or stainless steel; employing low-pressure plasma spraying, atmosphere plasma spraying, plasma spraying-physical vapor deposition or electron beam-physical vapor deposition to prepare a ZrO2-7 wt% of Y2O3 ceramic layer with a thickness of 100-300 mu m on the above bonding layer; employing magnetron sputtering to prepare an aluminium film with a thickness of 5-30 mu m on the above ceramic layer; and performing heat treatment on the thermal-barrier coating with the aluminium film. The preparation method provided by the invention is capable of improving the anti-oxidation property and the corrosion resisting property of the thermal-barrier coating.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Low temperature plasma terylene dyeing method

InactiveCN1948610AStrengthen restrictionsImprove dyeing effectUltrasonic/sonic fibre treatmentDyeing processLow temperature plasmaAnalytical chemistry

The invention relates to a staining method of terylene by low temperature plasma. Steps are as follows: (1) Dacron is physical modified by low temperature plasma. Impulse normal pressure plasma or impulse low pressure plasma is applied to deal with dacron.(2) Cationic dye is used for dyeing, which is clean, fast, non-pollution and low cost.

Owner:DONGHUA UNIV

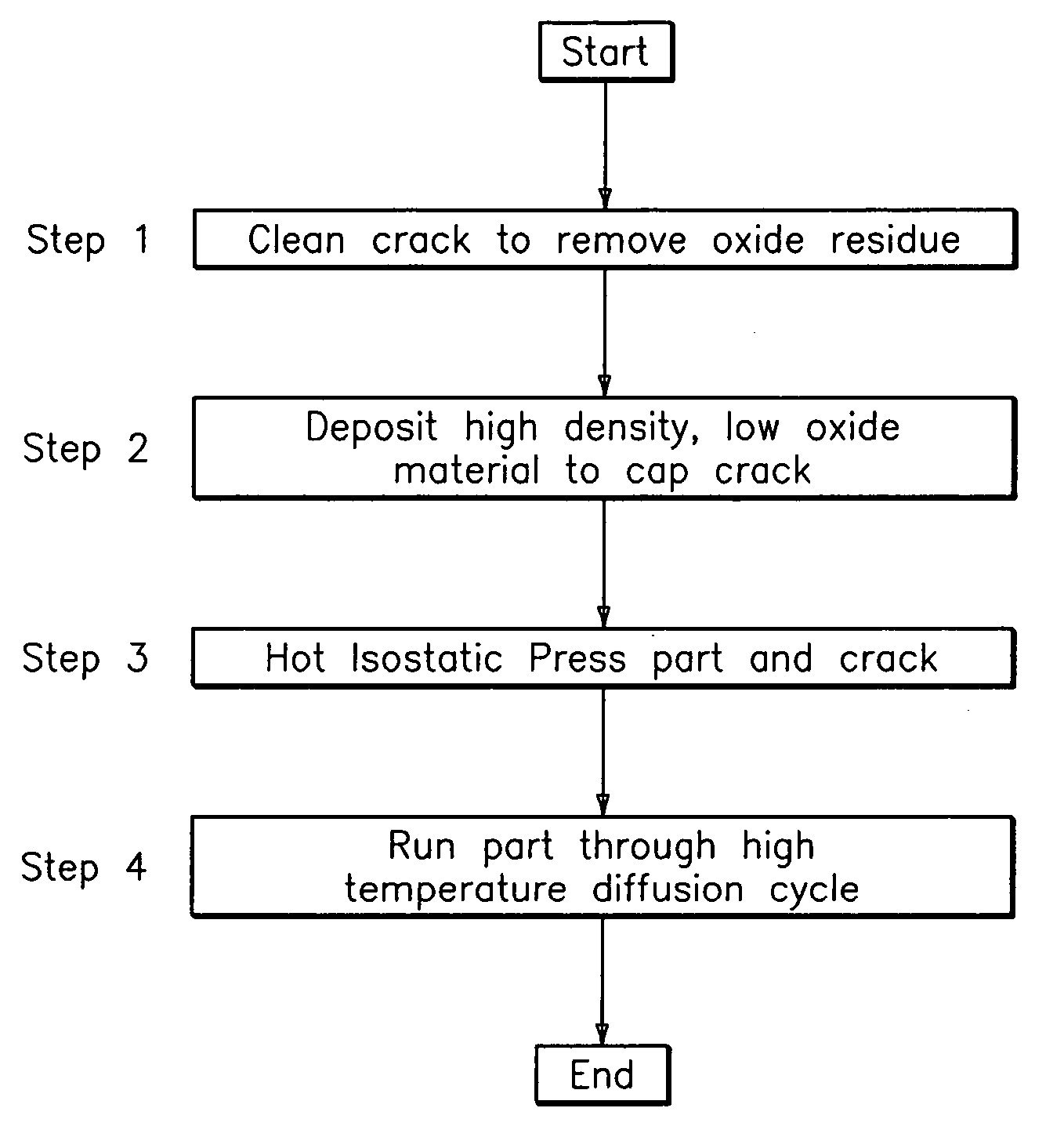

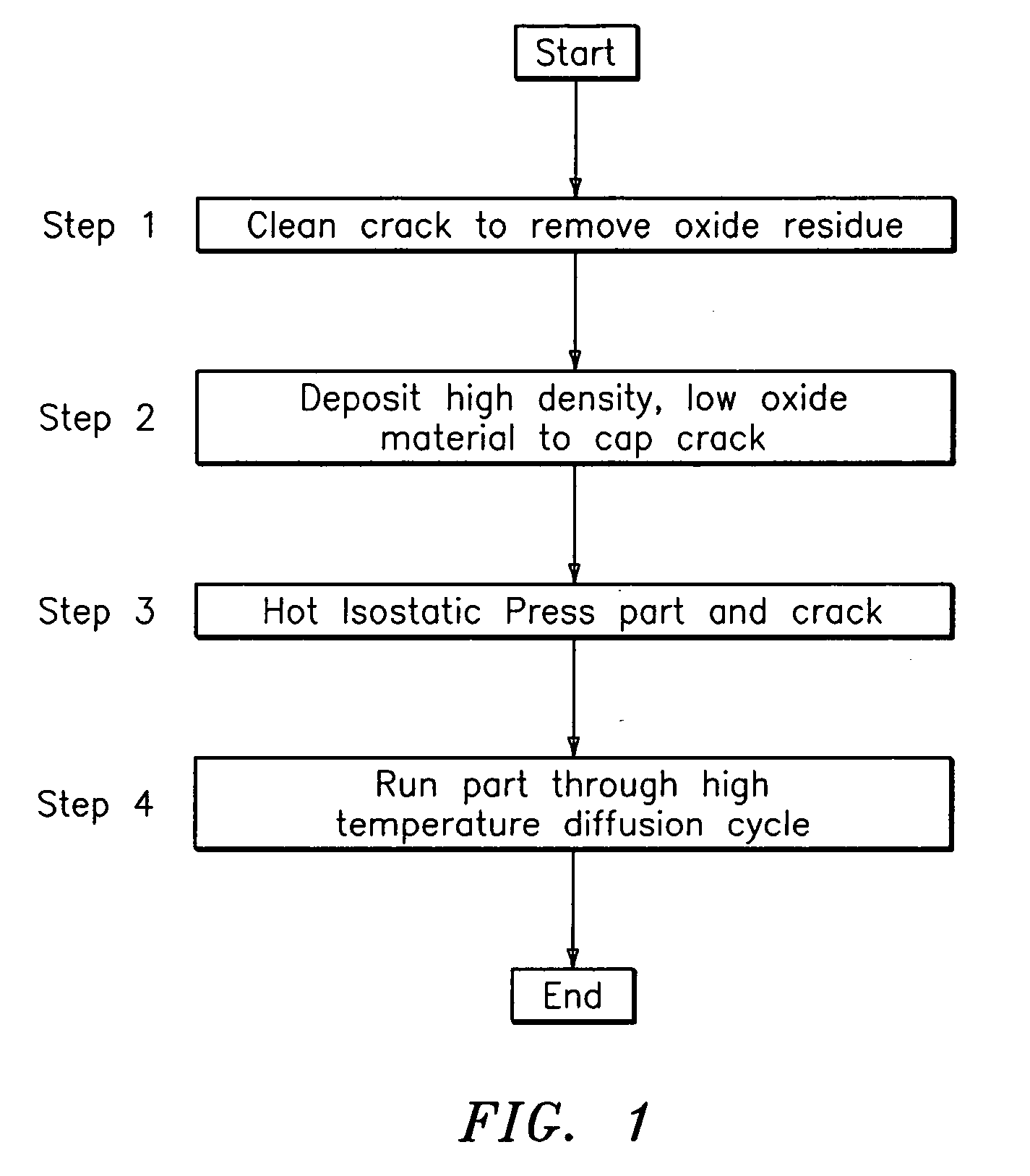

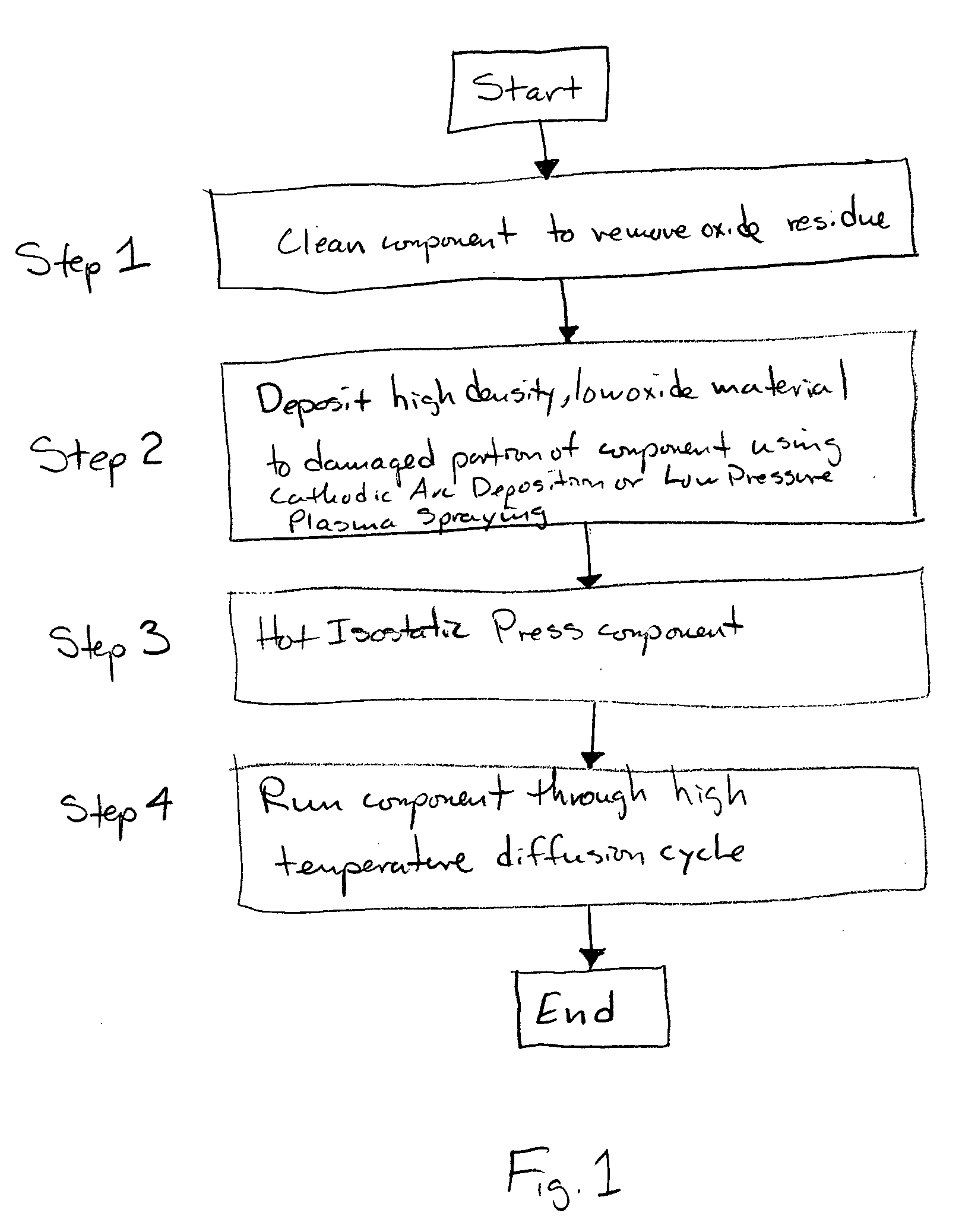

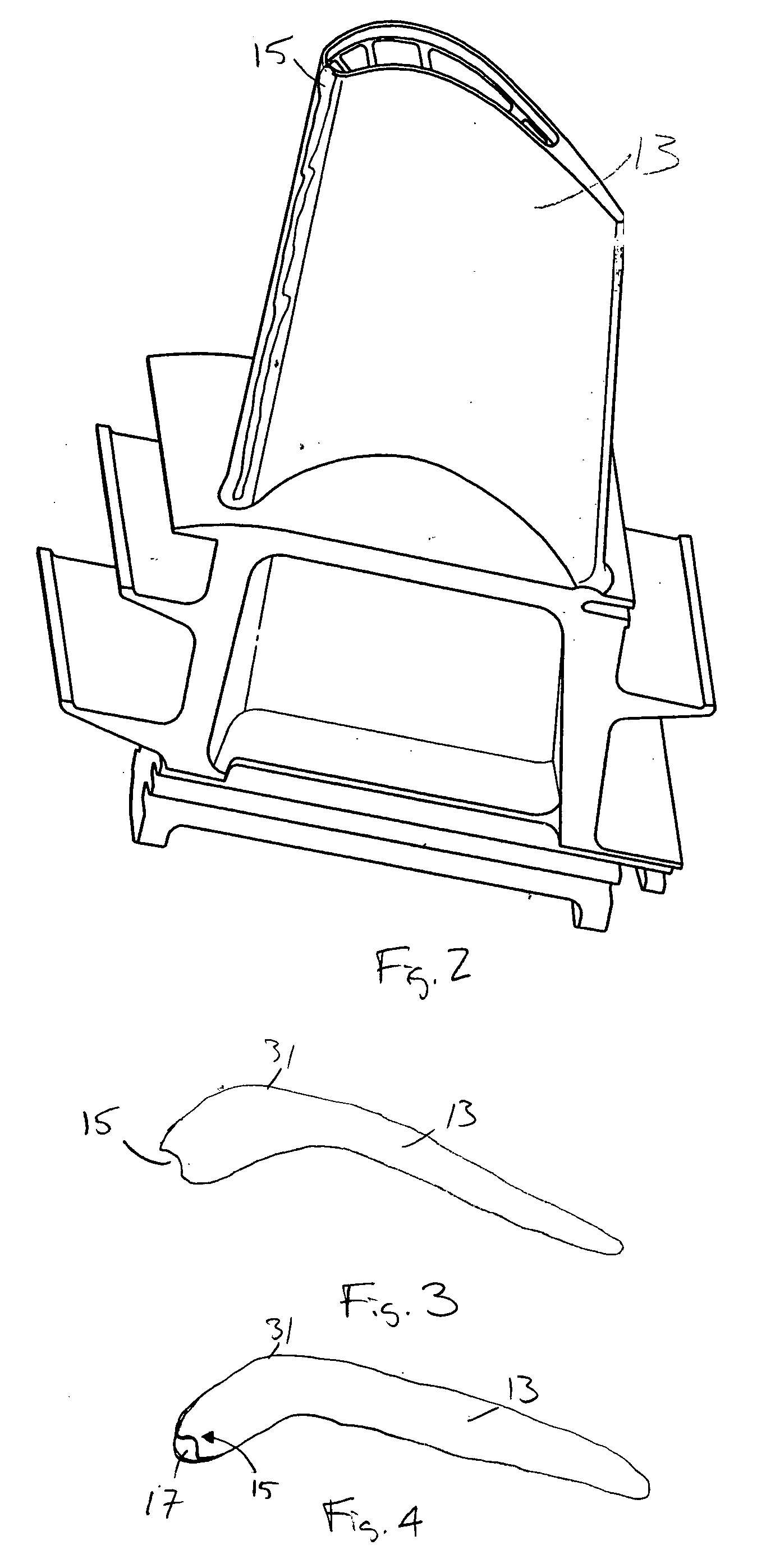

Turbine component crack repair using cathodic arc and/or low pressure plasma spraying and hip

A method for repairing cracks in a metal part comprising the steps of providing a metal part having a crack, cleaning the crack to remove an oxide layer, depositing a repair alloy via at least one of cathodic arc deposition and low pressure plasma spraying to cover the crack, and heating the part at a temperature and pressure sufficient to close the crack.

Owner:RAYTHEON TECH CORP

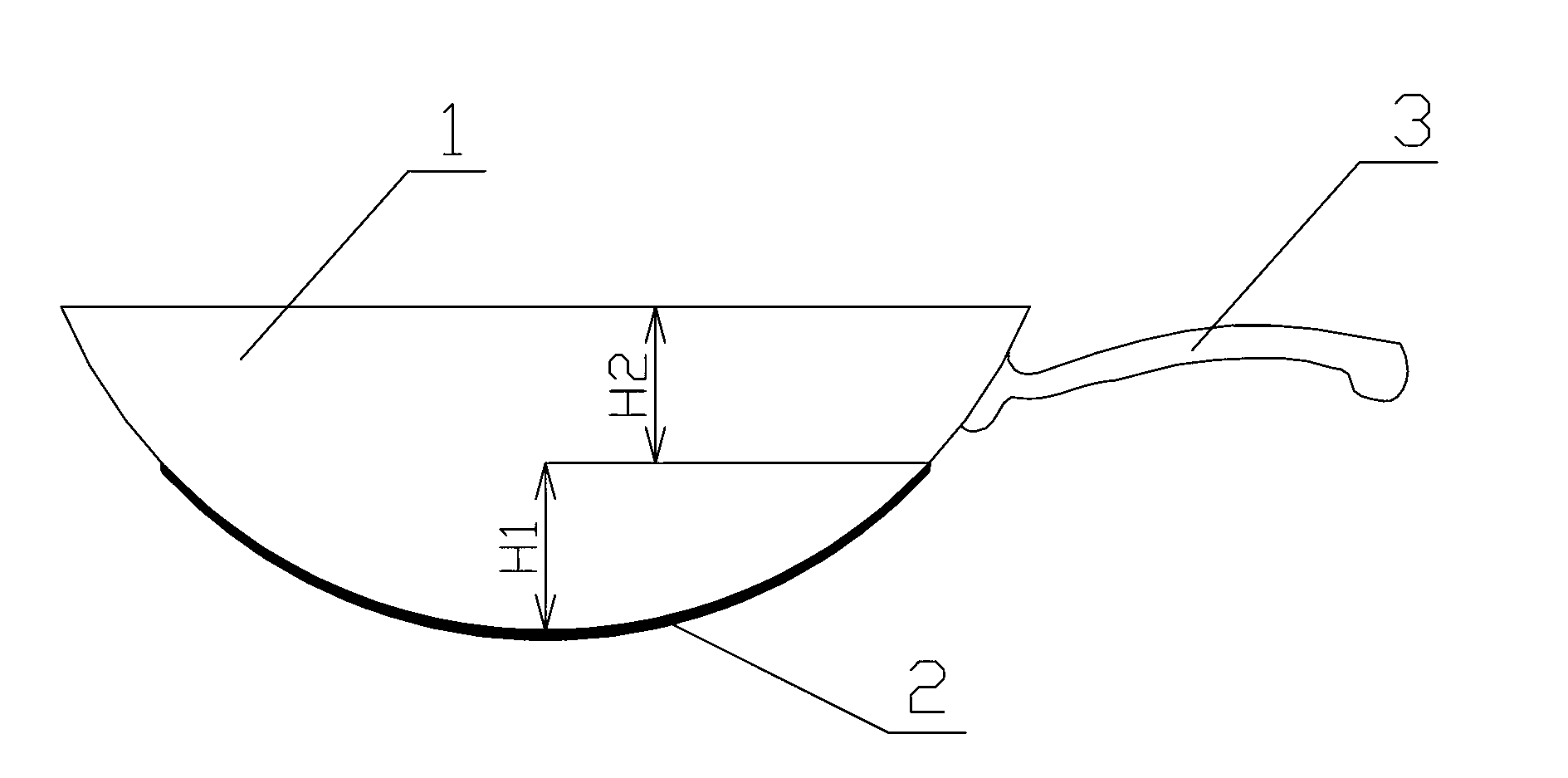

Manufacturing method of titanium copper compound pot

ActiveCN102697378ANice appearanceBright appearanceCooking-vessel materialsMolten spray coatingAfter treatmentSand blasting

The invention discloses a manufacturing method of a titanium copper compound pot; the method comprises the following steps: 1, punching a pure titanium plate to make a pot body; 2, sand blasting the lower part of the outer surface of the pot body and coating insulating gel at the upper part of the outer surface and the inner surface for protection; 3, etching treatment; 4, presoaking nick plating treatment; 5, plating a copper layer; 6, placing the pot body plated with a copper layer in after-treatment solution for soaking treatment; and 7, removing the insulating gel after cleaning, and then mounting a pot handle to obtain the titanium copper compound pot. The invention further discloses another manufacturing method of a titanium copper compound pot; the method comprises the following steps: 1, punching a pure titanium plate to make a pot body; 2, sand blasting the lower part of the outer surface of the pot body and protecting the upper part of the outer surface and the inner surface with a steel die; 3, spraying a copper layer through low-pressure plasma; and 4, polishing, cleaning and mounting a pot handle to obtain the titanium copper compound pot. The titanium copper compound pot manufactured through the methods is firm and durable, can resist corrosion, is light in weight, does not contain nickel, ferrum, aluminium or other undesirable allergic elements, and is suitable for popularization and universalization.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

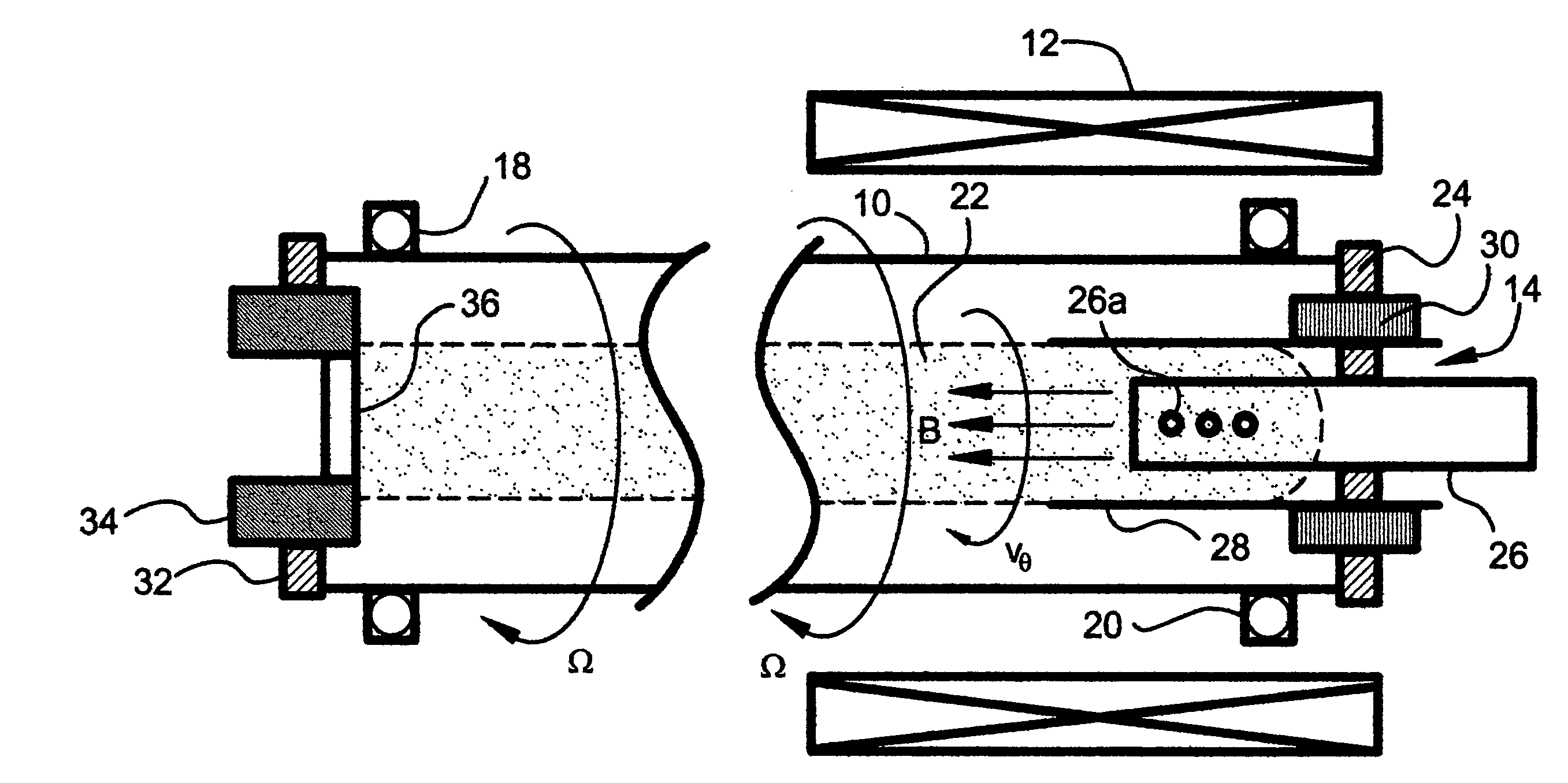

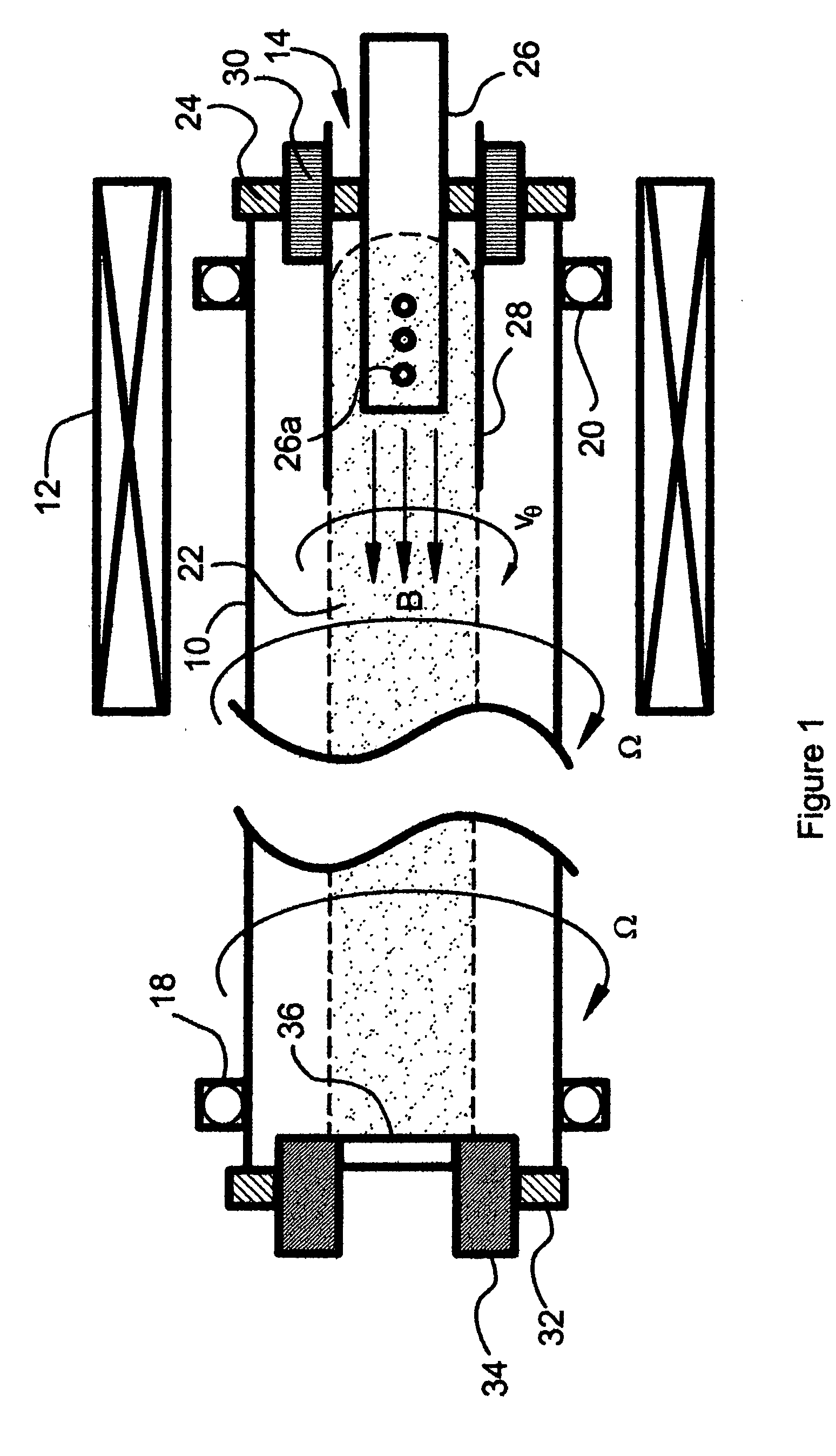

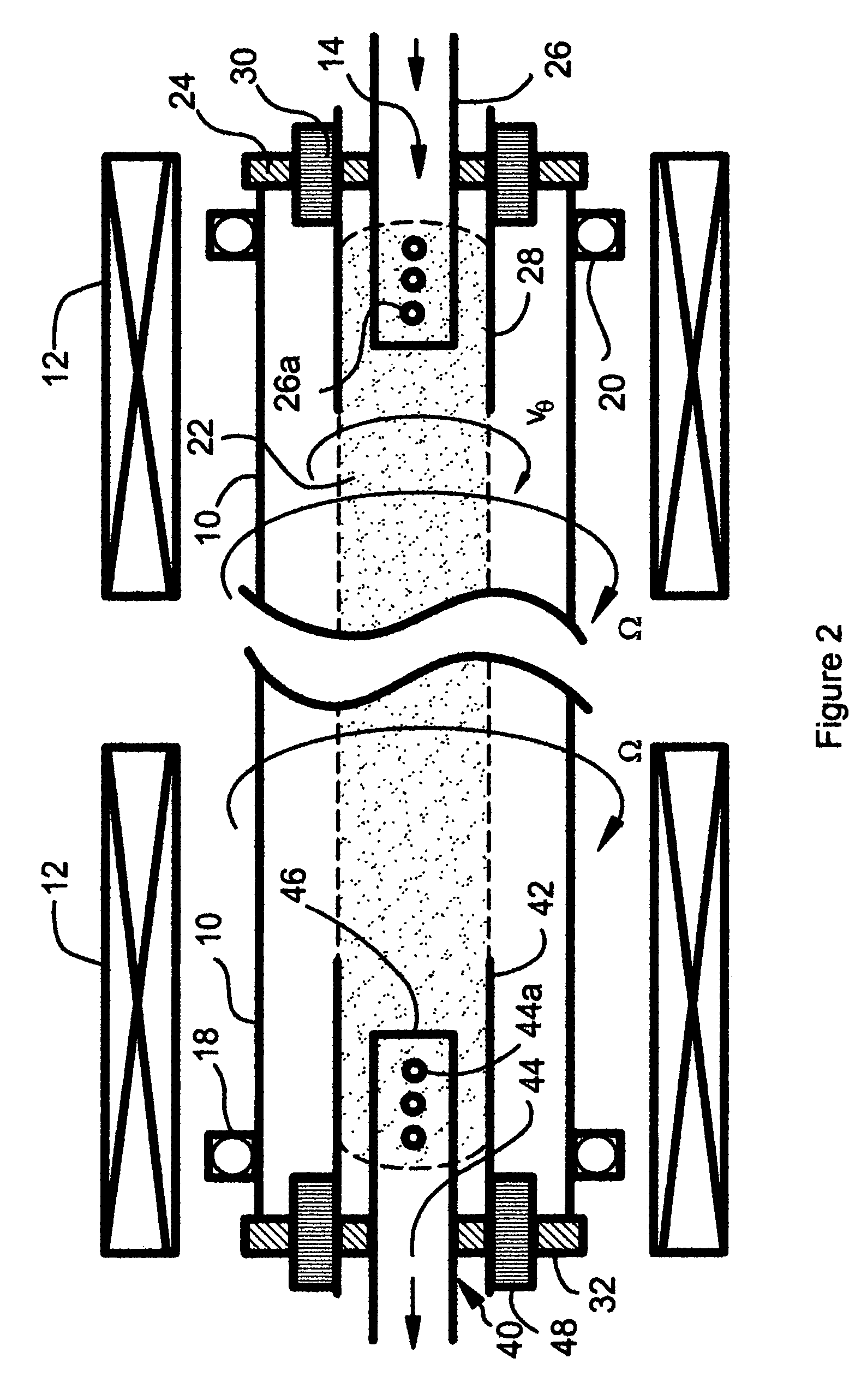

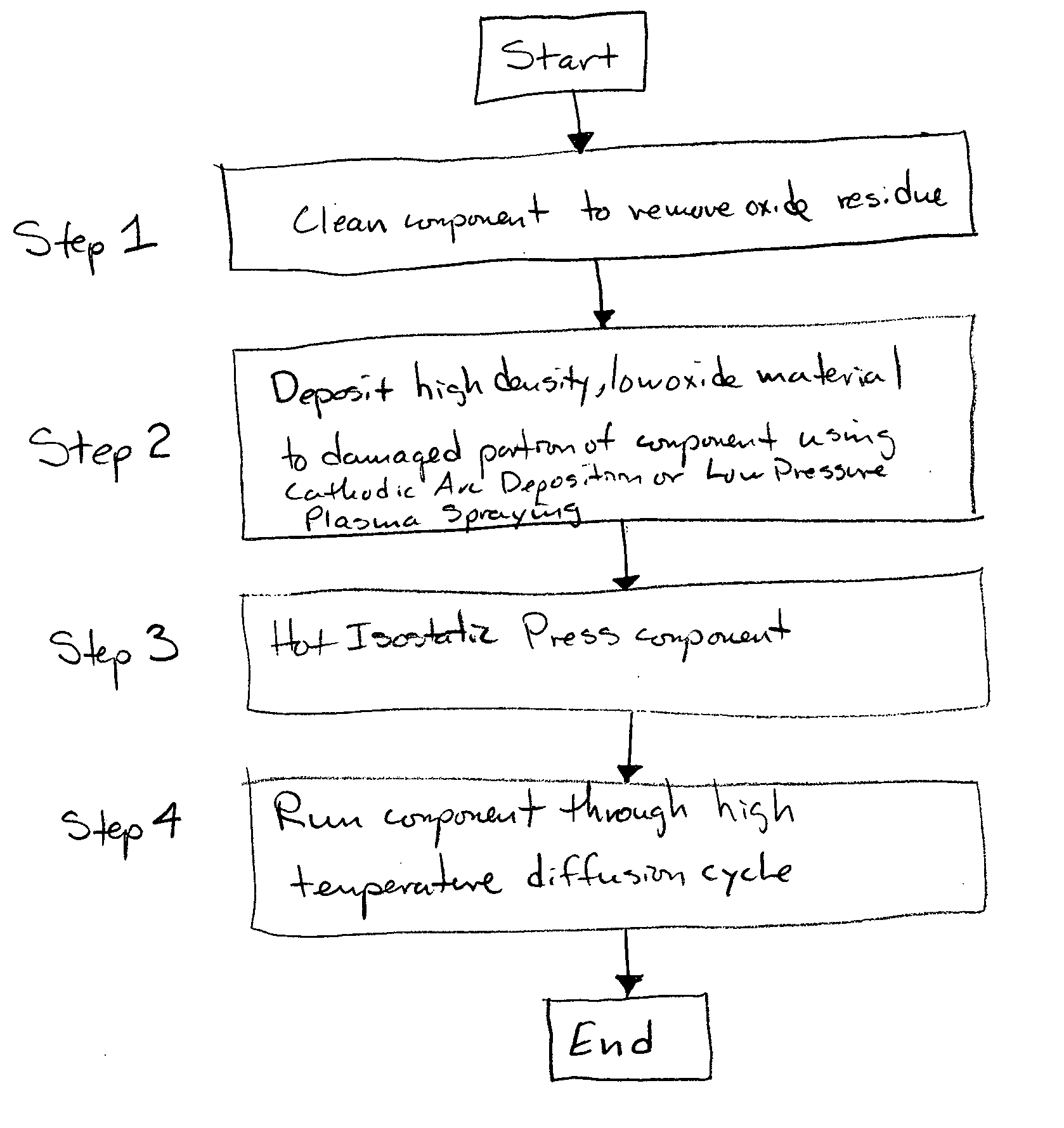

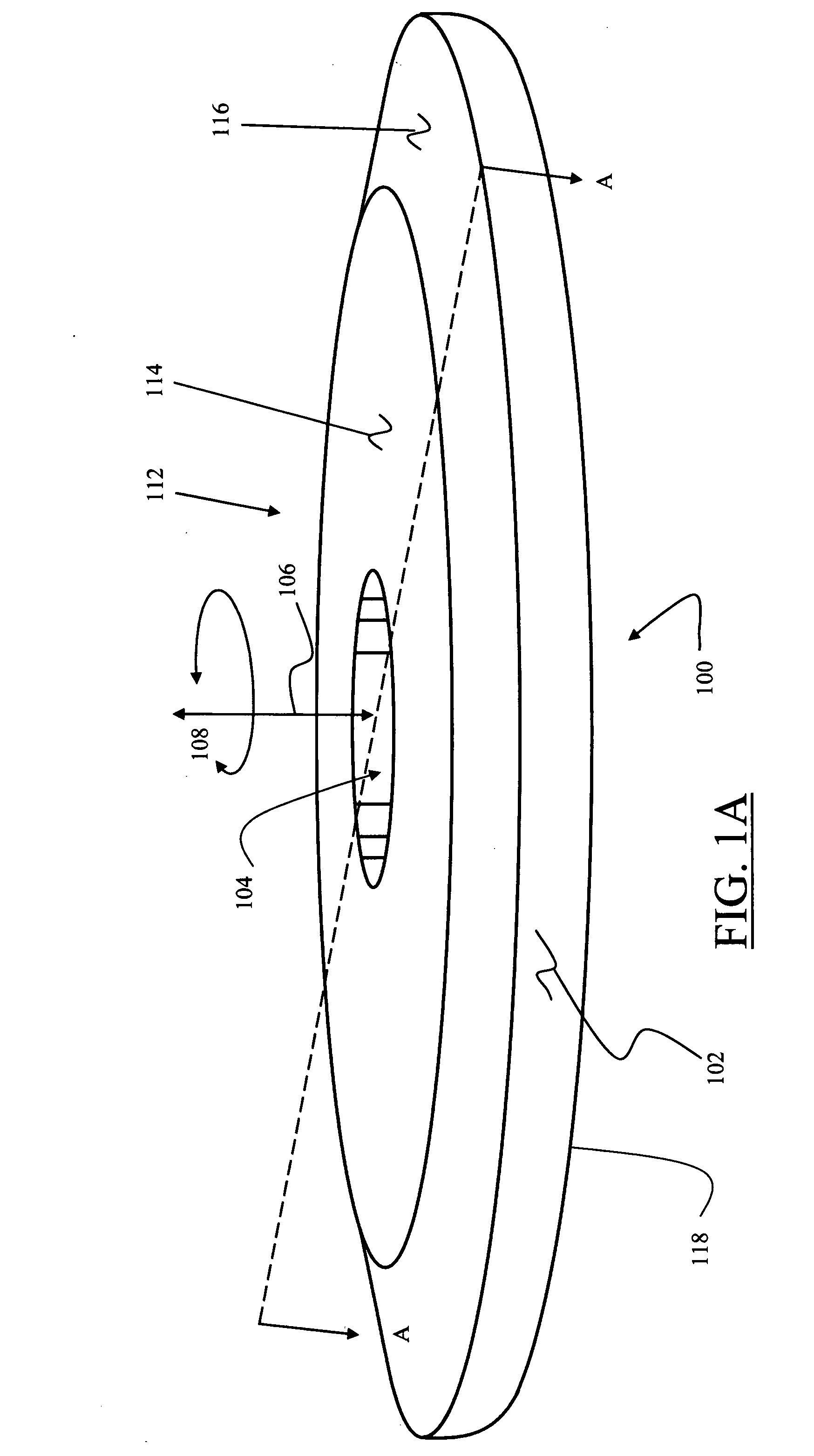

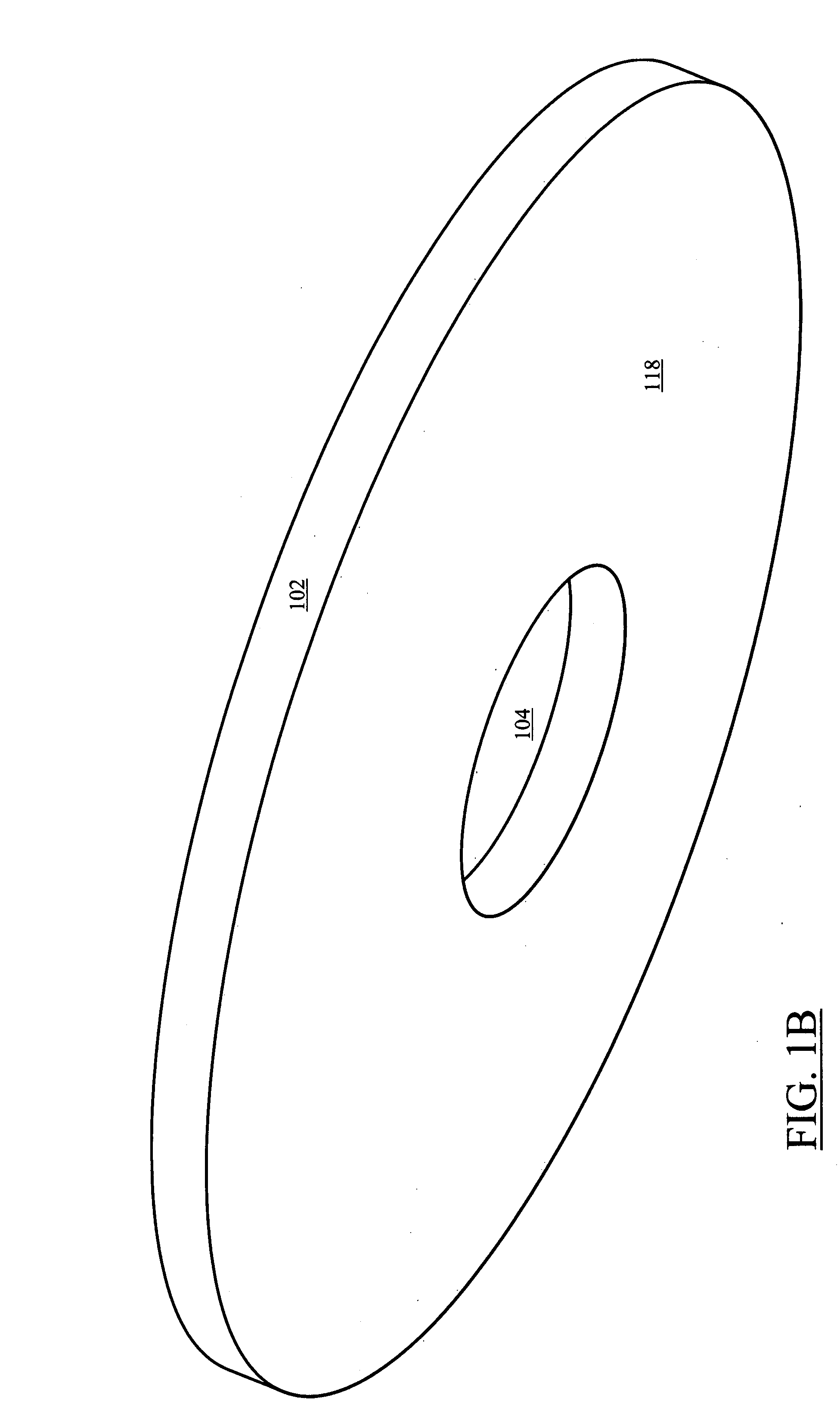

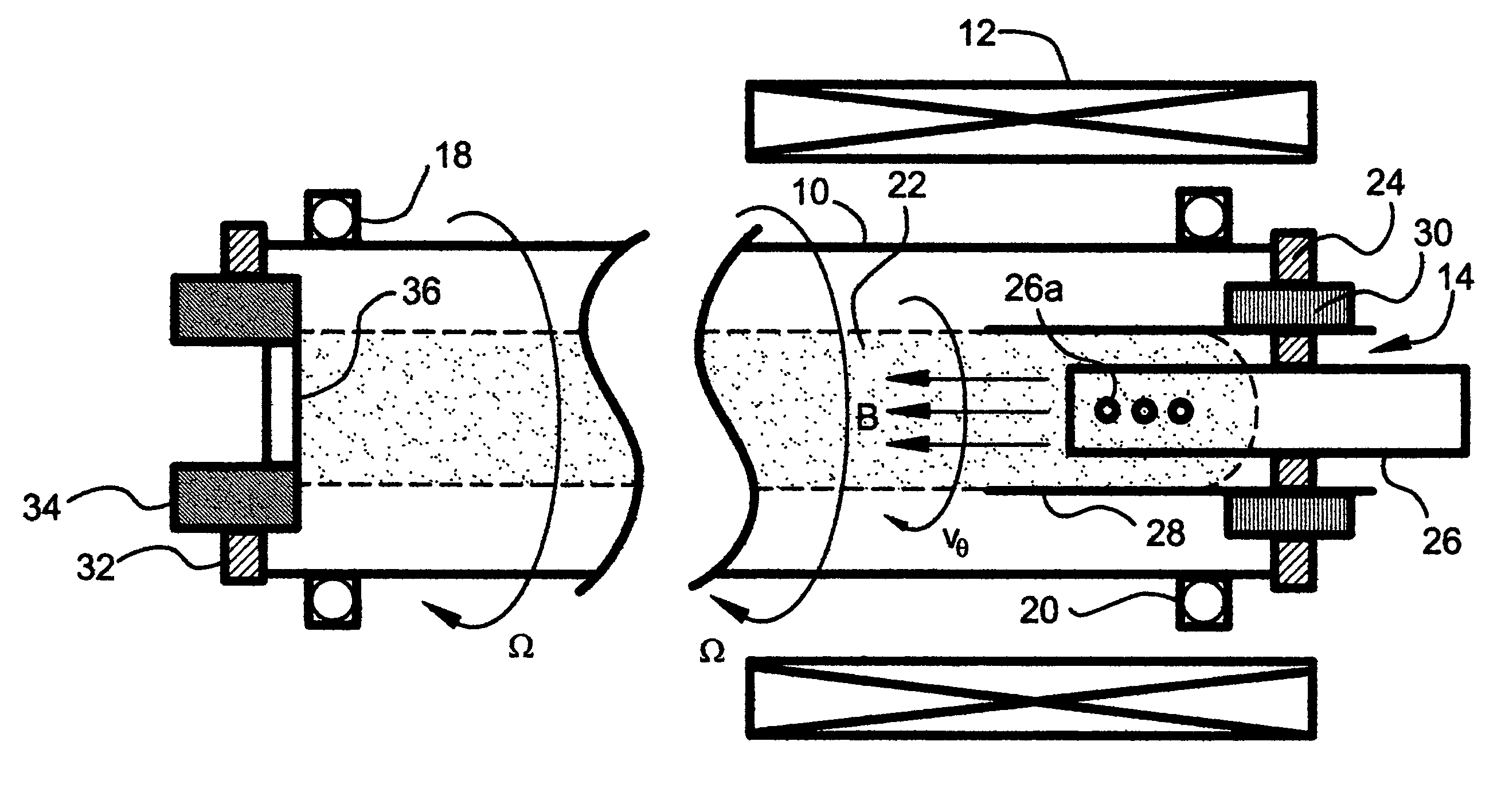

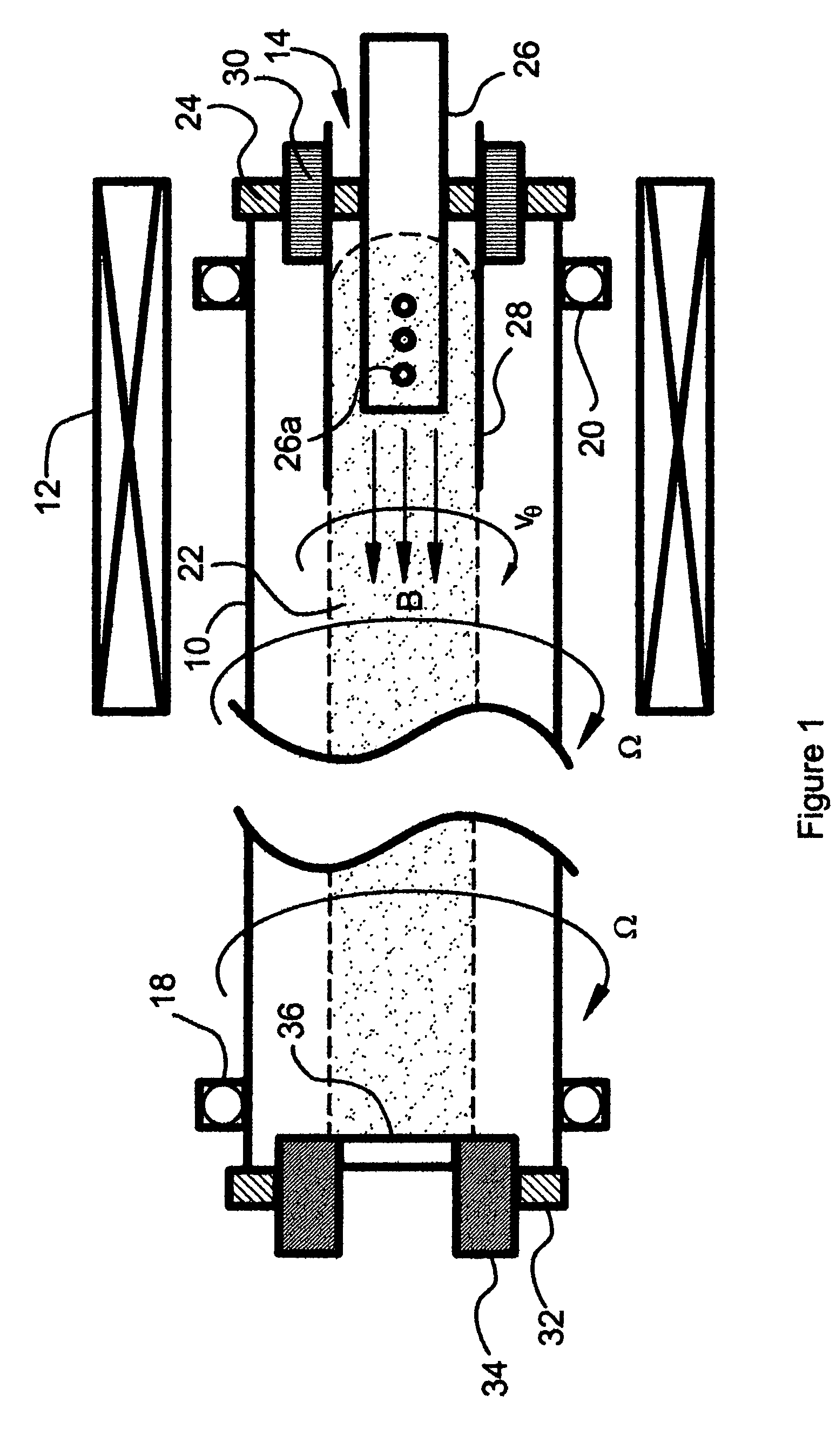

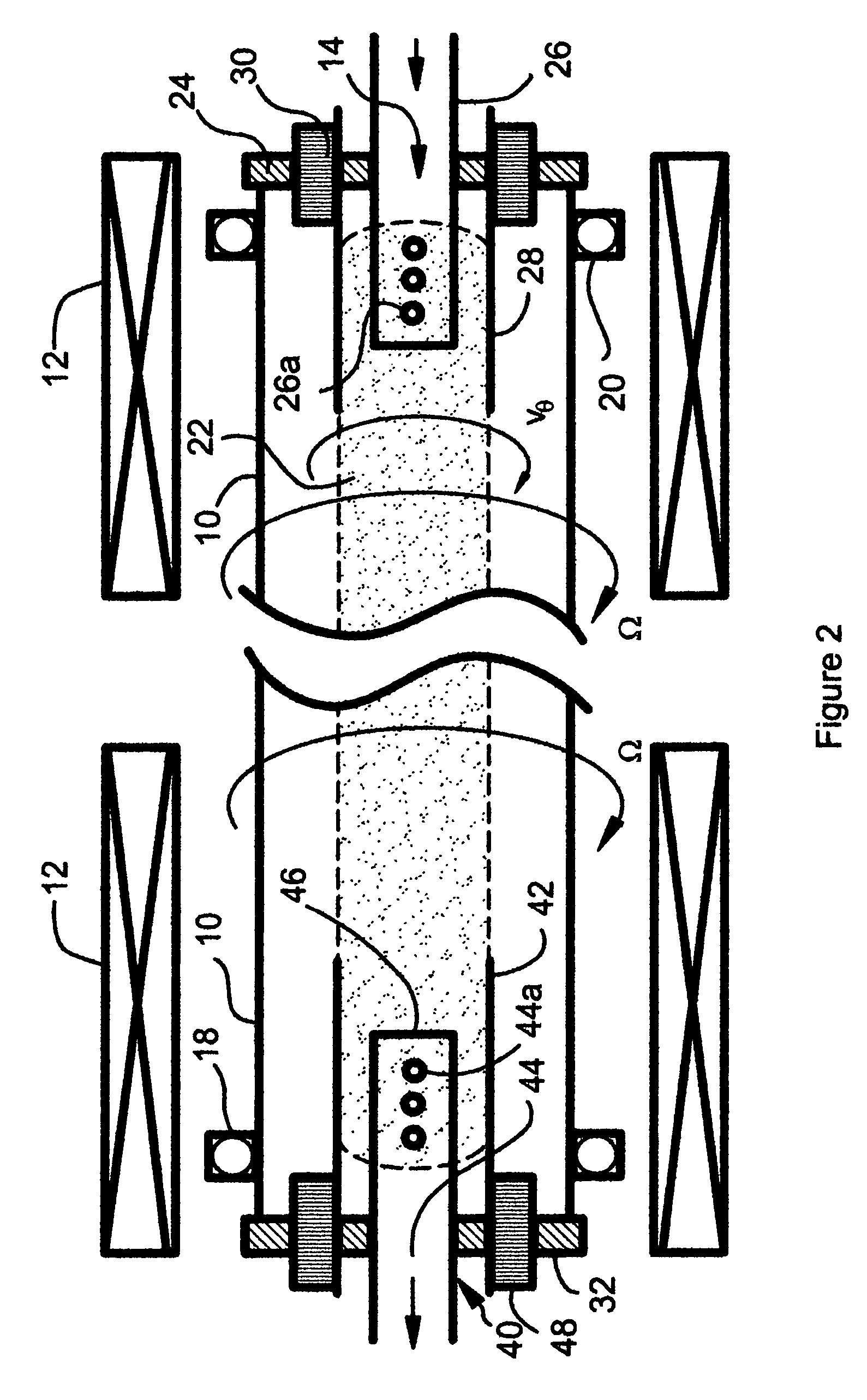

Soft x-ray laser based on Z-pinch compression of rotating plasma

InactiveUS20060232215A1Reduce light lossIncrease currentBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangementsMagnetic tension forceVolumetric Mass Density

A method and apparatus for producing soft x-ray laser radiation based on z-pinch compression of a rotating low pressure plasma column are disclosed. A rotating, low pressure plasma column is created by electric discharge or by laser excitation inside a containment tube. Rotation of the plasma may be induced by viscous drag caused by rotation of the tube, or by magnetically driven rotation of the plasma as it is created in a plasma gun in the presence of an axial magnetic field, or both. A high power electrical discharge is then passed axially through the rotating plasma column to produce a rapidly rising axial current, resulting in z-pinch compression of the rotating plasma column radially inwardly with resultant stimulated emission of soft x-ray radiation in the axial direction. A rotating containment tube used in combination with magnetically driven rotation of the plasma column results in a concave electron density profile that in turn results in reduced wall ablation and also reduced refraction losses of the resultant soft x-rays.

Owner:FARTECH

Cool wool knitted fabric and processing method thereof

InactiveCN103194908AImprove hydrophilicityIncrease the number of hydrophilic groupsWeft knittingPhysical treatmentCooling effectWool fiber

The invention discloses a cool wool knitted fabric and a processing method of the cool wool knitted fabric. The fabric is processed by respectively carrying out hydrophilic and hydrophobic processing on wool fibers scaled and lightened through enzyme treatment and then blending the hydrophilic and hydrophobic wool fibers according to an appropriate proportion, wherein the hydrophilic processing method is low-pressure plasma treatment. The processing method is characterized by respectively carrying out hydrophilic and hydrophobic processing on the wool fibers scaled and lightened through enzyme treatment; and blending the hydrophilic and hydrophobic wool fibers according to an appropriate proportion, wherein the hydrophilic processing method is low-pressure plasma treatment; and the hydrophobic processing method is characterized by using a three-proofing finishing agent for hydrophobic processing. The processing method of the cool wool fabric is simple in production process. The produced cool wool fabric product has good fastness to washing and an excellent cool effect and is especially suitable for spring and summer sportswear.

Owner:SHANGHAI JIALE

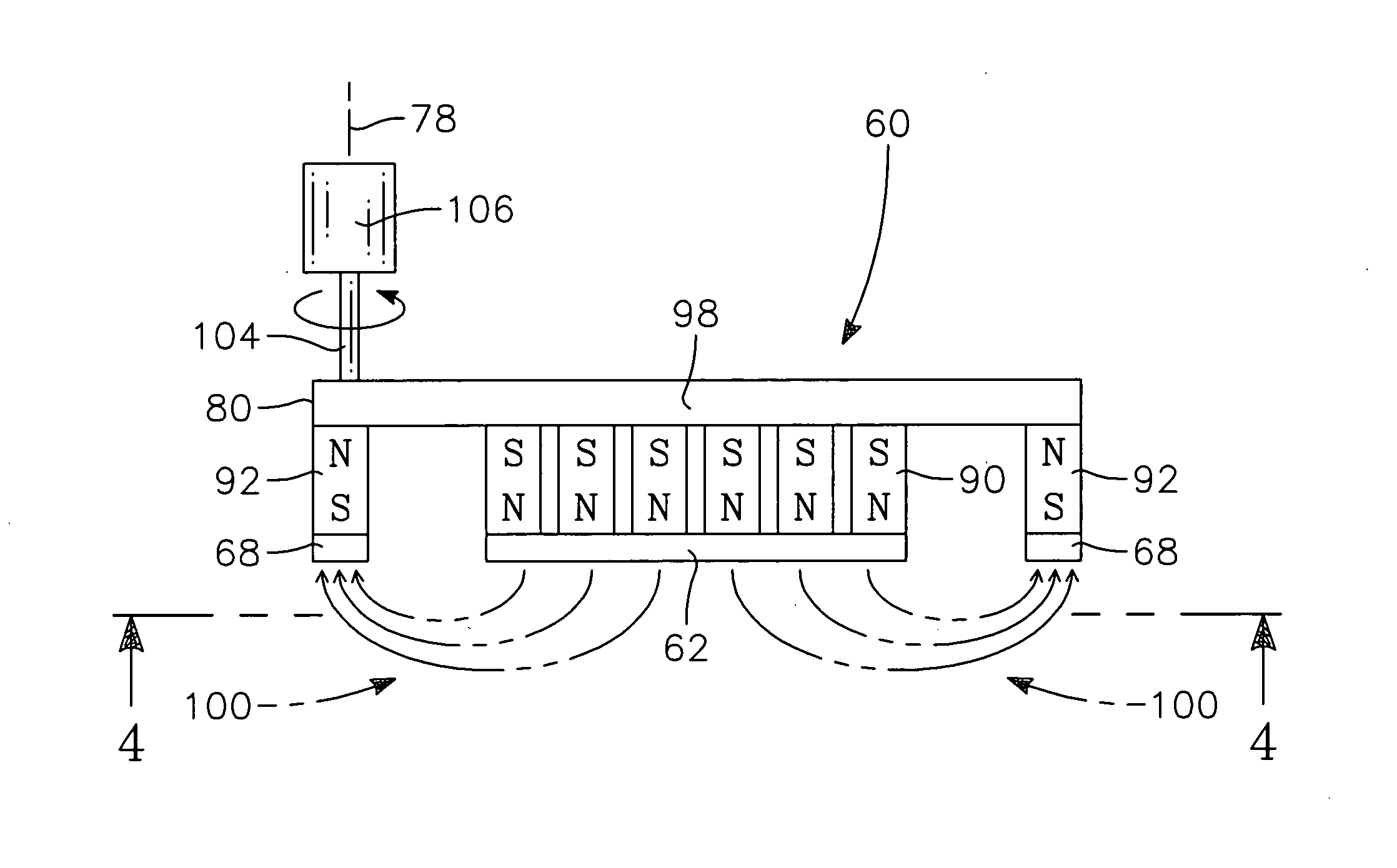

Sputtering using an unbalanced magnetron

InactiveUS20050051424A1Increase plasma densityIncrease powerCellsElectric discharge tubesSputteringIonization

A sputtering process and magnetron especially advantageous for low-pressure plasma sputtering or sustained self-sputtering, in which the magnetron has a reduced area but full target coverage. The magnetron includes an outer pole face surrounding an inner pole face with a gap therebetween. The outer pole of the magnetron of the invention is smaller than that of a circular magnetron similarly extending from the center to the periphery of the target and has a substantially larger total magnetic intensity. Thereby, sputtering at low pressure and high ionization fraction is enabled.

Owner:FU JIANMING +3

Turbine component restoration using cathodic ARC/LPPS

A method for repairing cracks in a metal part comprising the steps of providing a metal part having a worn portion, cleaning the worn portion to remove an oxide layer, depositing a restoration alloy to cover the worn portion via a deposition process selected from the group consisting of cathodic arc deposition and Low Pressure Plasma Spray (LPPS) deposition.

Owner:UNITED TECH CORP

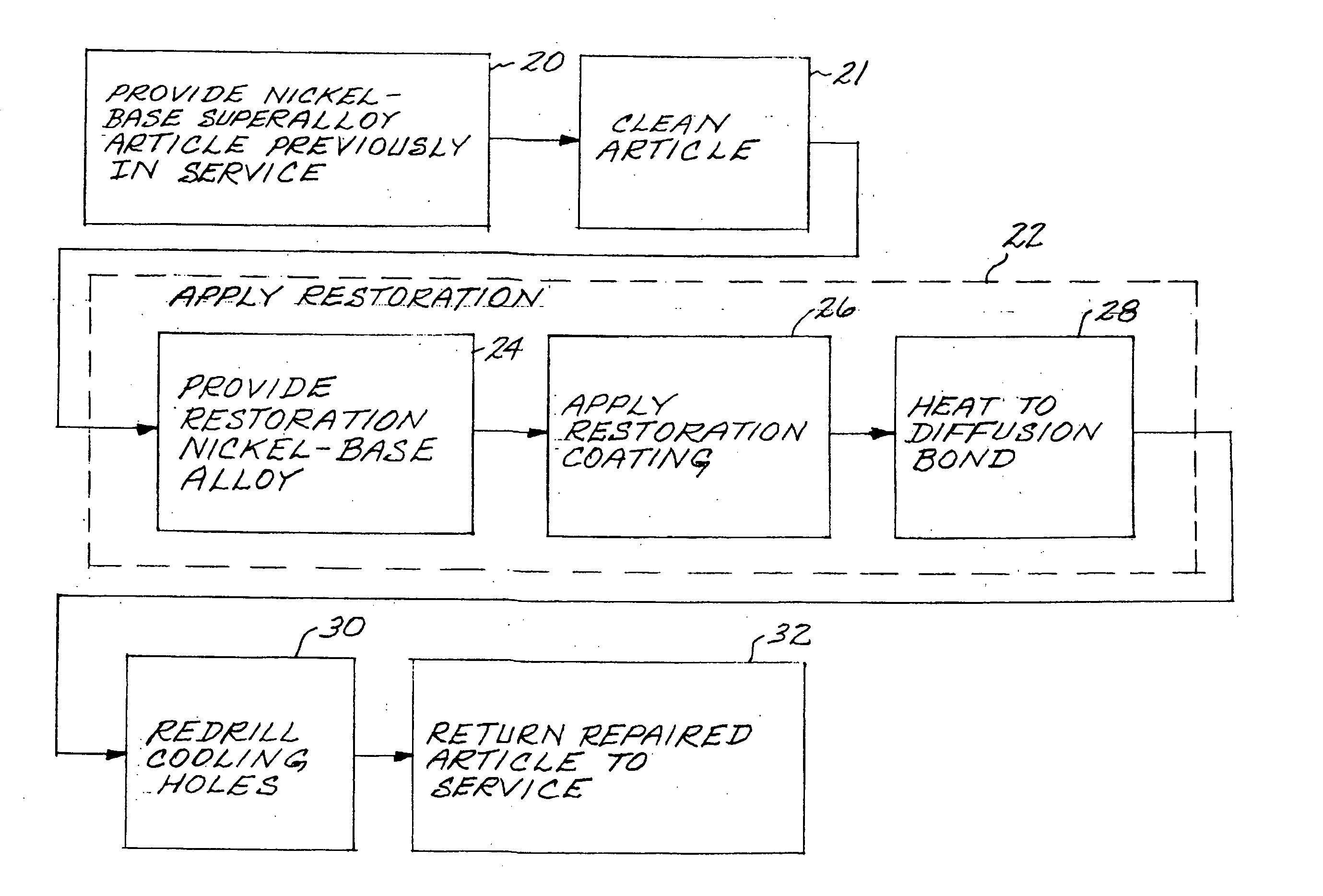

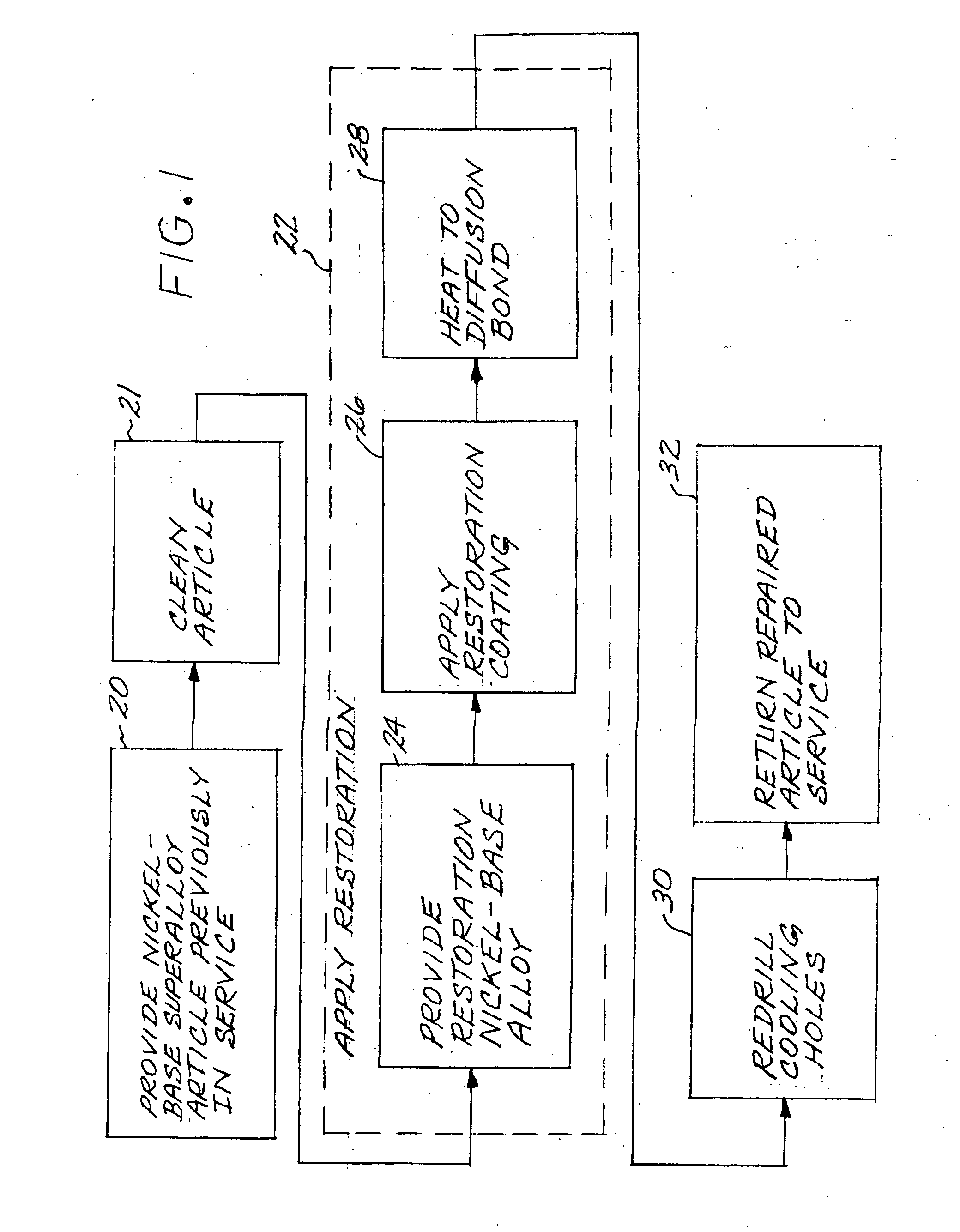

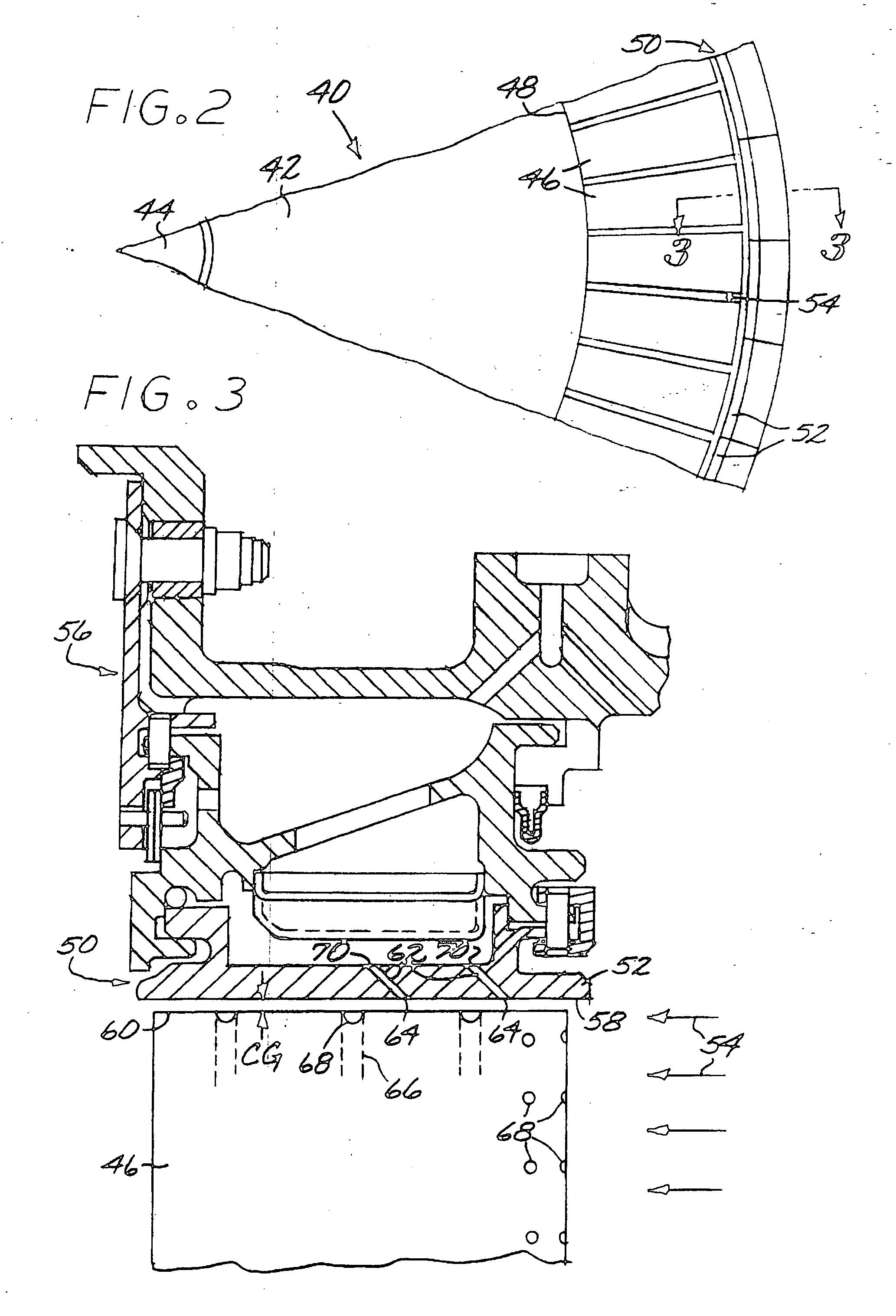

Method for HVOF or LPPS restoration coating repair of a nickel-base superalloy article

A method for repairing a nickel-base superalloy article, such as a gas turbine stationary flowpath shroud having flowpath cooling holes therein that has previously been in service, includes the steps of providing the nickel-base superalloy article that has previously been in service; and applying a restoration to a surface of the article. The restoration is applied by the steps of providing a restoration nickel-base alloy, wherein the restoration nickel-base alloy preferably has no more than about 15 weight percent chromium and no more than about 0.01 percent yttrium, thereafter applying a restoration coating of the restoration nickel-base alloy to the surface of the article by a hyper-velocity oxyfuel metal spray process or a low-pressure plasma spray process, and thereafter heating the article with the restoration coating applied to the surface thereof to a sufficiently high temperature to diffusion bond the restoration coating to the surface of the article. The article is then returned to service.

Owner:GENERAL ELECTRIC CO

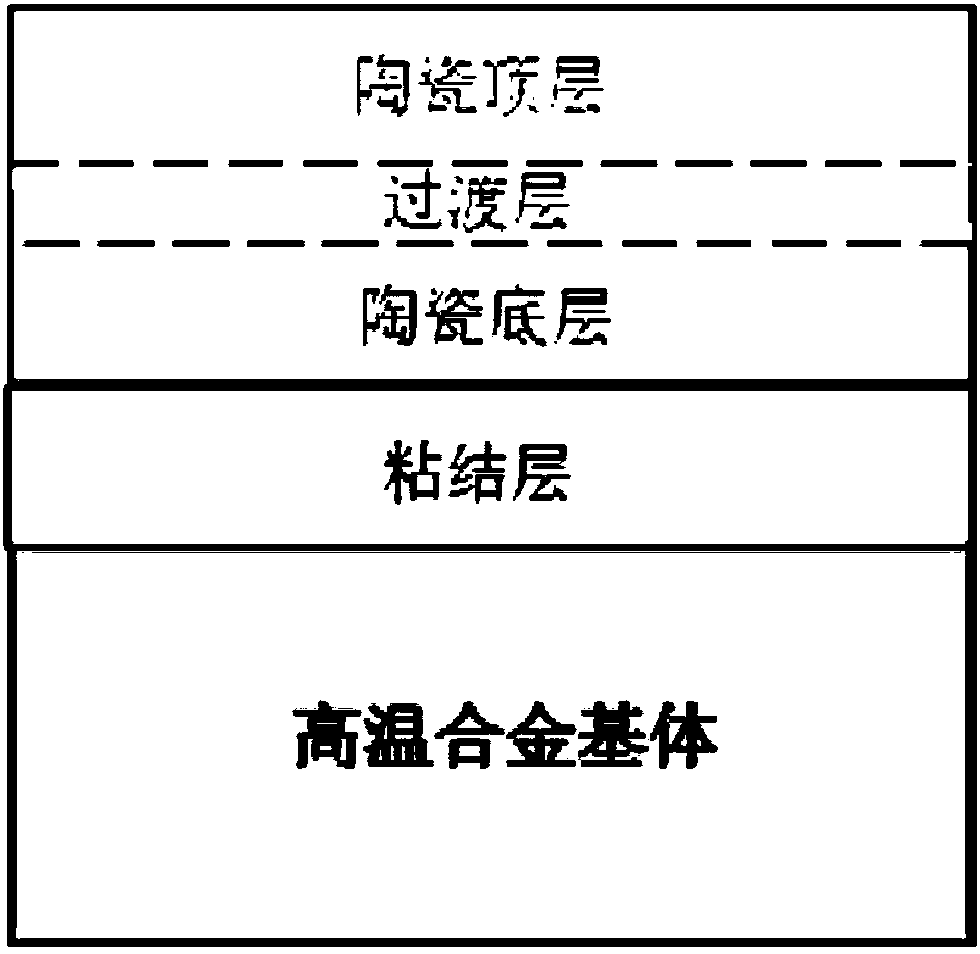

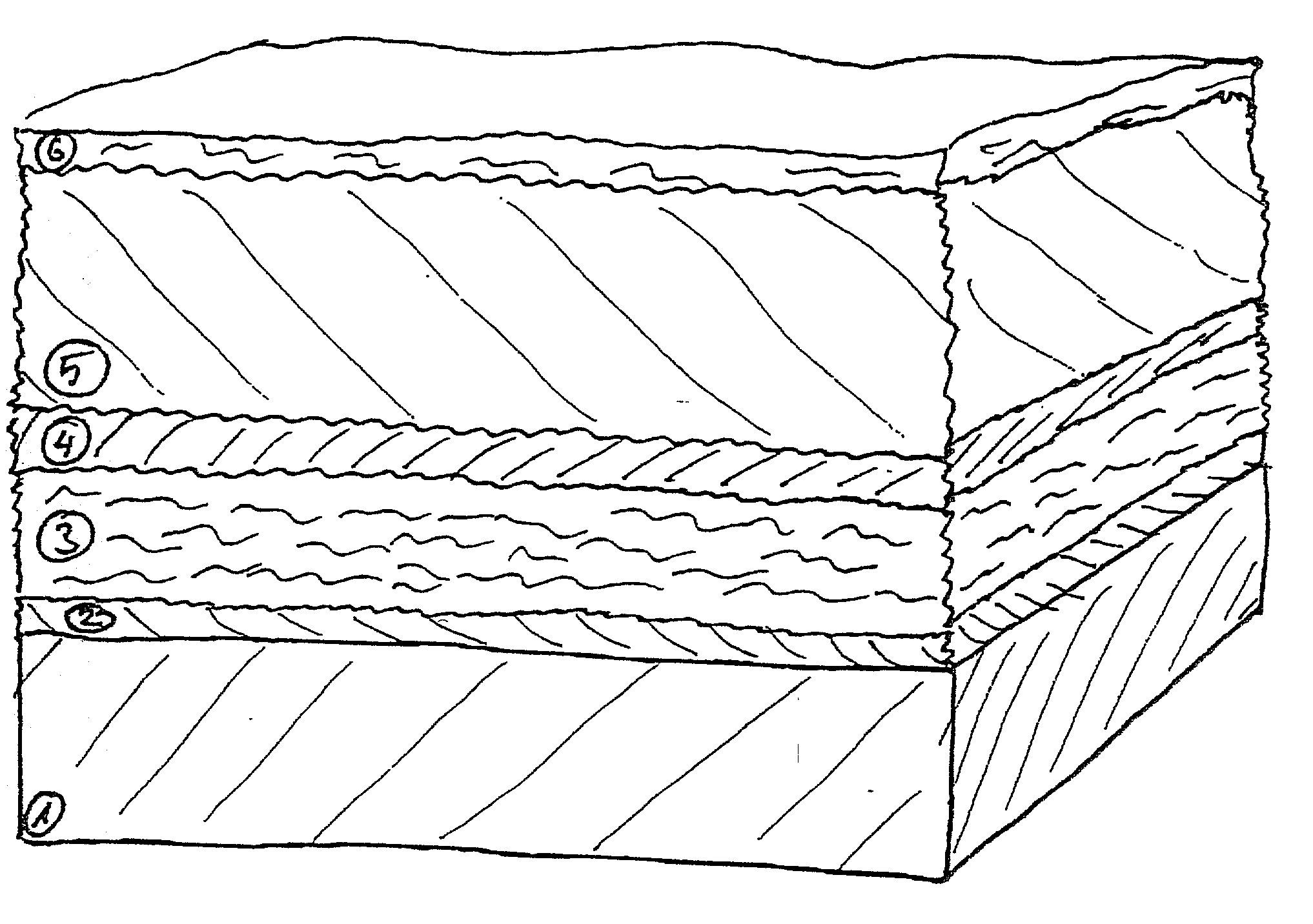

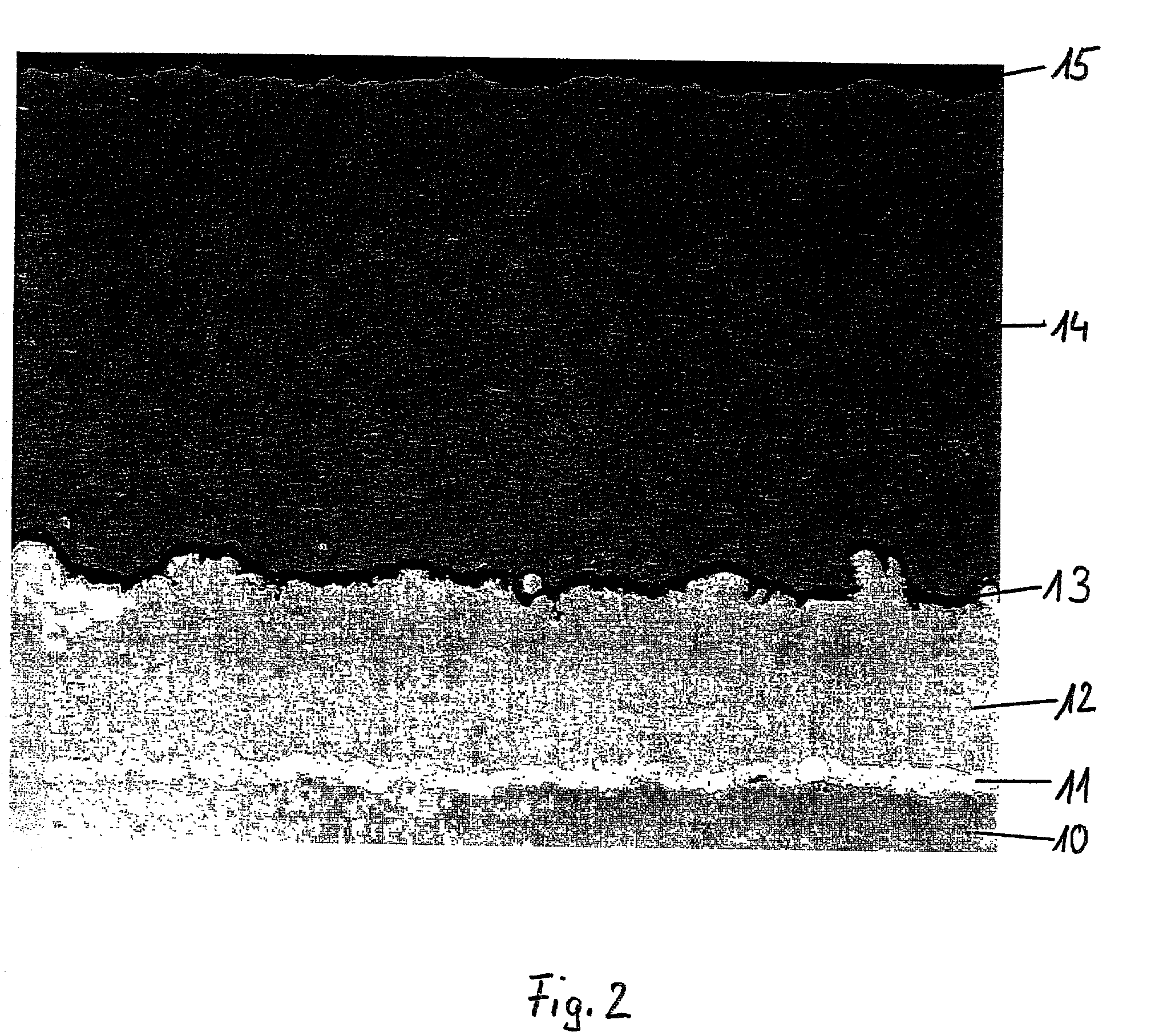

Gradient thermal barrier coating with continuous change of compositions at interface of double ceramic layers and preparation method of coating

ActiveCN108468011AImproved thermal shock lifeImprove the interface binding forceMolten spray coatingSurface layerThermal barrier coating

The invention discloses a gradient thermal barrier coating with continuous change of compositions at an interface of double ceramic layers and a preparation method of the coating. The gradient thermalbarrier coating has a substrate, a bonding layer, the ceramic underlayer, a transition layer and the ceramic surface layer which are disposed from bottom to top in sequence, wherein the compositionson the transition layer between the ceramic underlayer and the ceramic facing layer are continuously changed. The thermal barrier coating can be prepared by a plasma spraying process, and typical preparation processes include atmospheric plasma spraying, ultra-low pressure plasma physical multiphase deposition and the like. The obtained thermal barrier coating no longer has the problem of crackingand spalling at the interface of the double ceramic layers during thermal cycle, so that the thermal shock resistance life of the thermal barrier coating is greatly prolonged.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

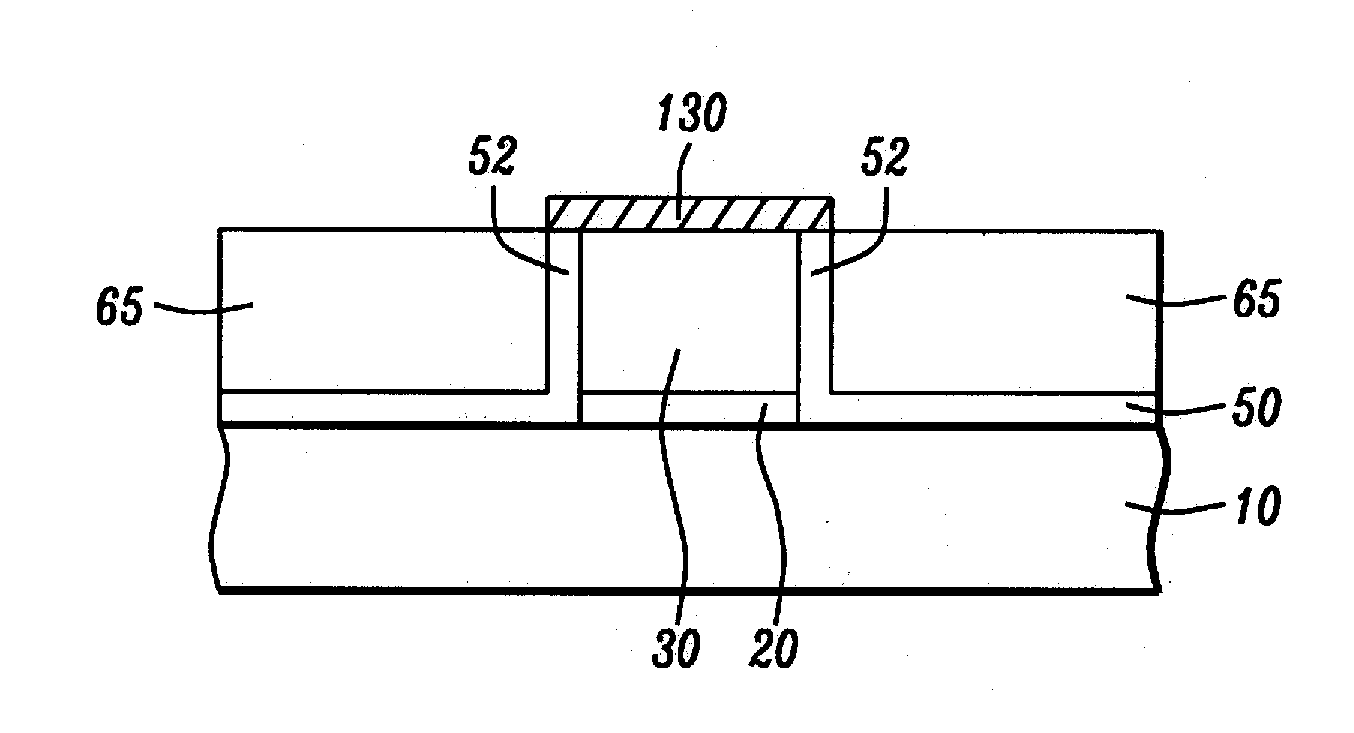

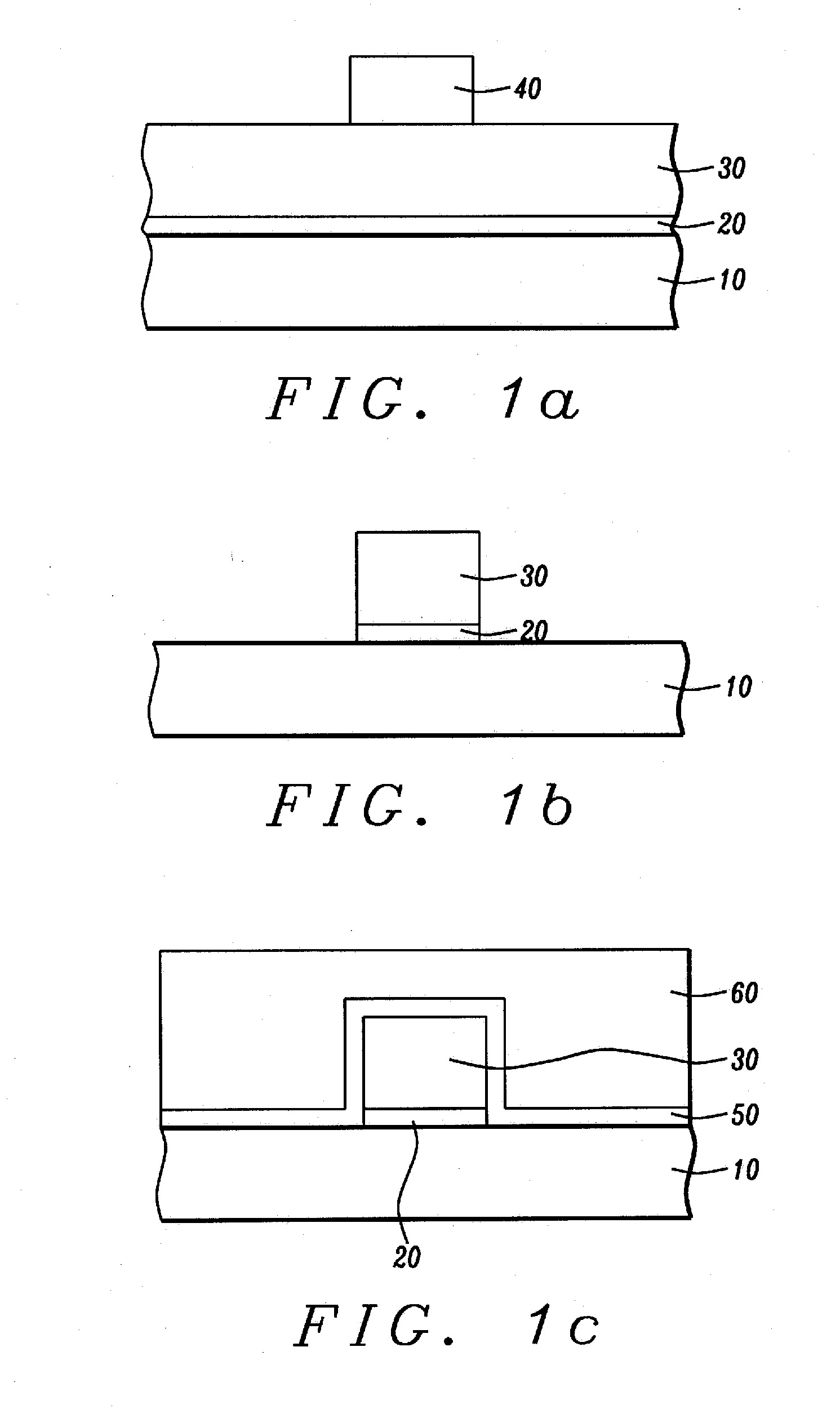

Metal Protection Layer over SiN Encapsulation for Spin-Torque MRAM Device Applications

InactiveUS20140061827A1Efficient oxidationImprove etch selectivityMagnetic measurementsSemiconductor/solid-state device manufacturingBit lineSpins

A magnetic thin film deposition is patterned and protected from oxidation during subsequent processes, such as bit line formation, by an oxidation-prevention encapsulation layer of SiN. The SiN layer is then itself protected during the processing by a metal overlayer, preferably of Ta, Al, TiN, TaN or W. A sequence of low pressure plasma etches, using Oxygen, Cl2, BCl3 and C2H4 chemistries provide selectivity of the metal overlayer to various oxide layers and to the photo-resist hard masks used in patterning and metal layer and thereby allow the formation of bit lines while maintaining the integrity of the SiN layer.

Owner:HEADWAY TECH INC

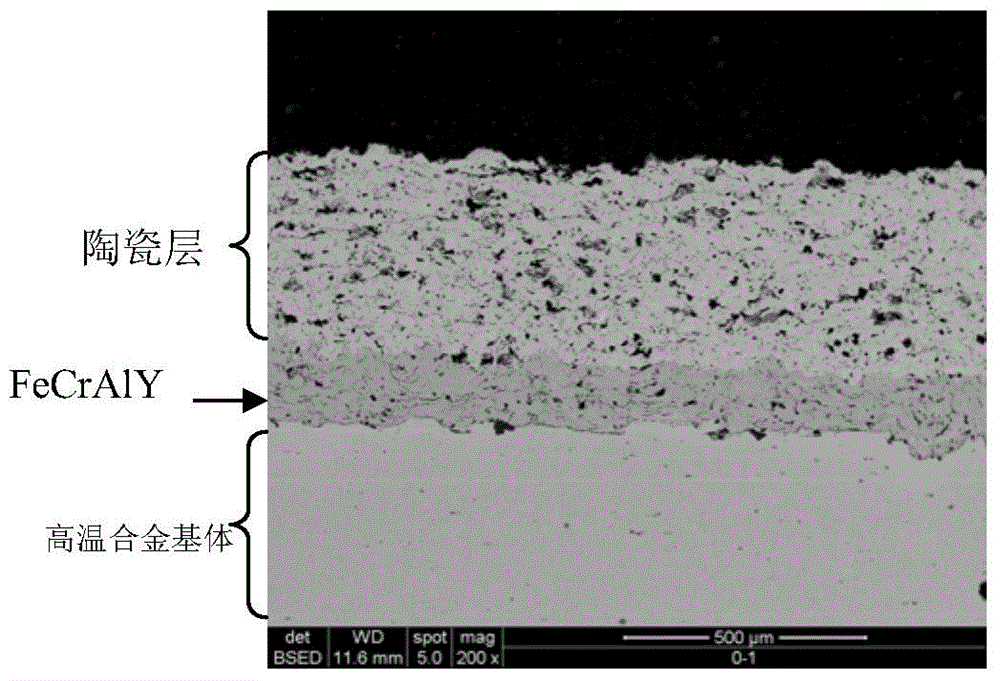

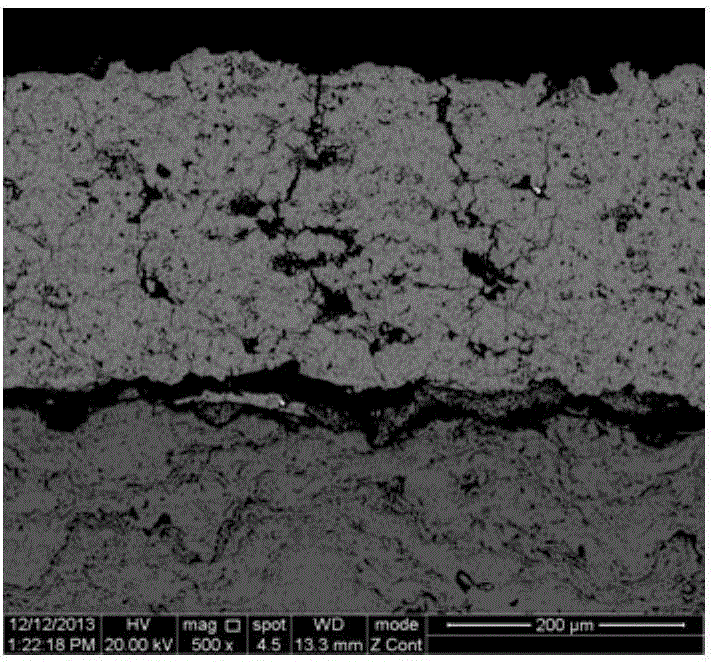

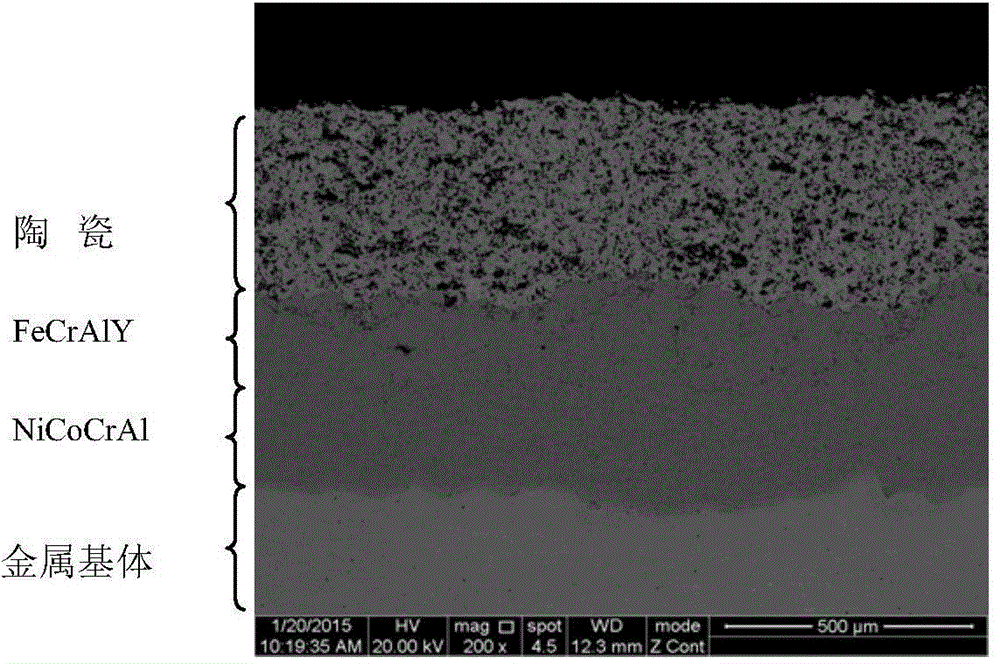

Preparation method of thermal barrier coating containing long-service-life antioxidant bonding layer

InactiveCN104630686APromote growthImprove antioxidant capacityMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionGas phase

The invention relates to a preparation method of a thermal barrier coating containing a long-service-life antioxidant bonding layer. The preparation method comprises the following steps: (1) sequentially performing deoiling and sand blasting treatment on a high-temperature alloy matrix; (2) preparing a metal bonding layer on the high-temperature alloy matrix by virtue of atmosphere plasma spraying, low-pressure plasma spraying, high-speed oxygen flame spraying or high-speed compressed air flame spraying; and (3) then depositing a ceramic layer on the metal bonding layer by virtue of atmosphere plasma spraying, high-speed oxygen flame spraying, supersonic plasma spraying, solution plasma spraying or electron beam physical vapor deposition. Compared with the prior art, the thermal barrier coating prepared by using an FeCrAlY bonding layer, disclosed by the invention, has higher working temperature and slower oxidation layer growth rate compared with that of a conventional MCrAlY thermal barrier coating (M refers to Ni and Co) so as to avoid the interfacial properties of the bonding layer and the ceramic layer from forming a brittle Ni2Al2O4 phase; and the thermal barrier coating has excellent high-temperature oxidation resistance and longer service life.

Owner:HENAN PULAIMU COATING TECH +1

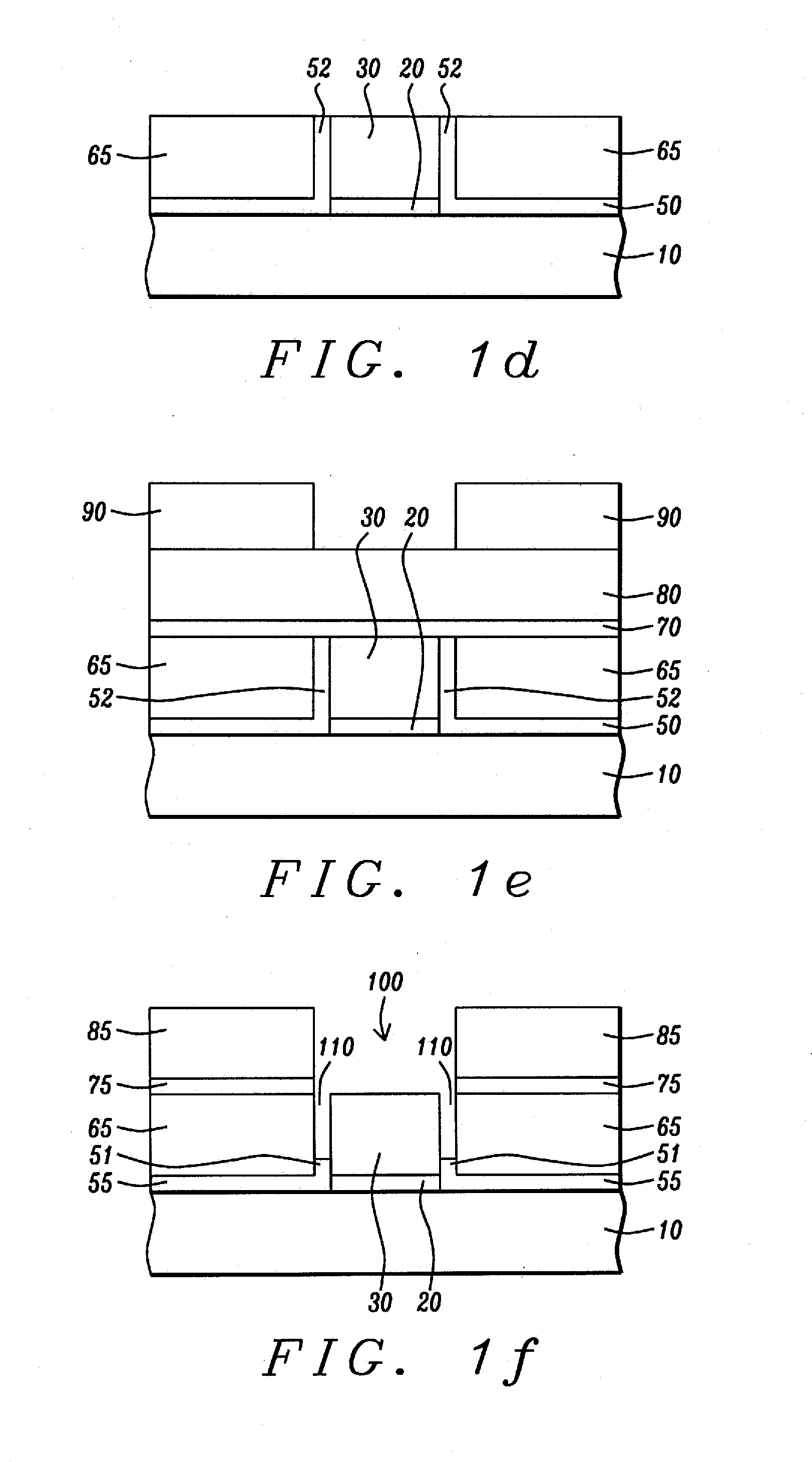

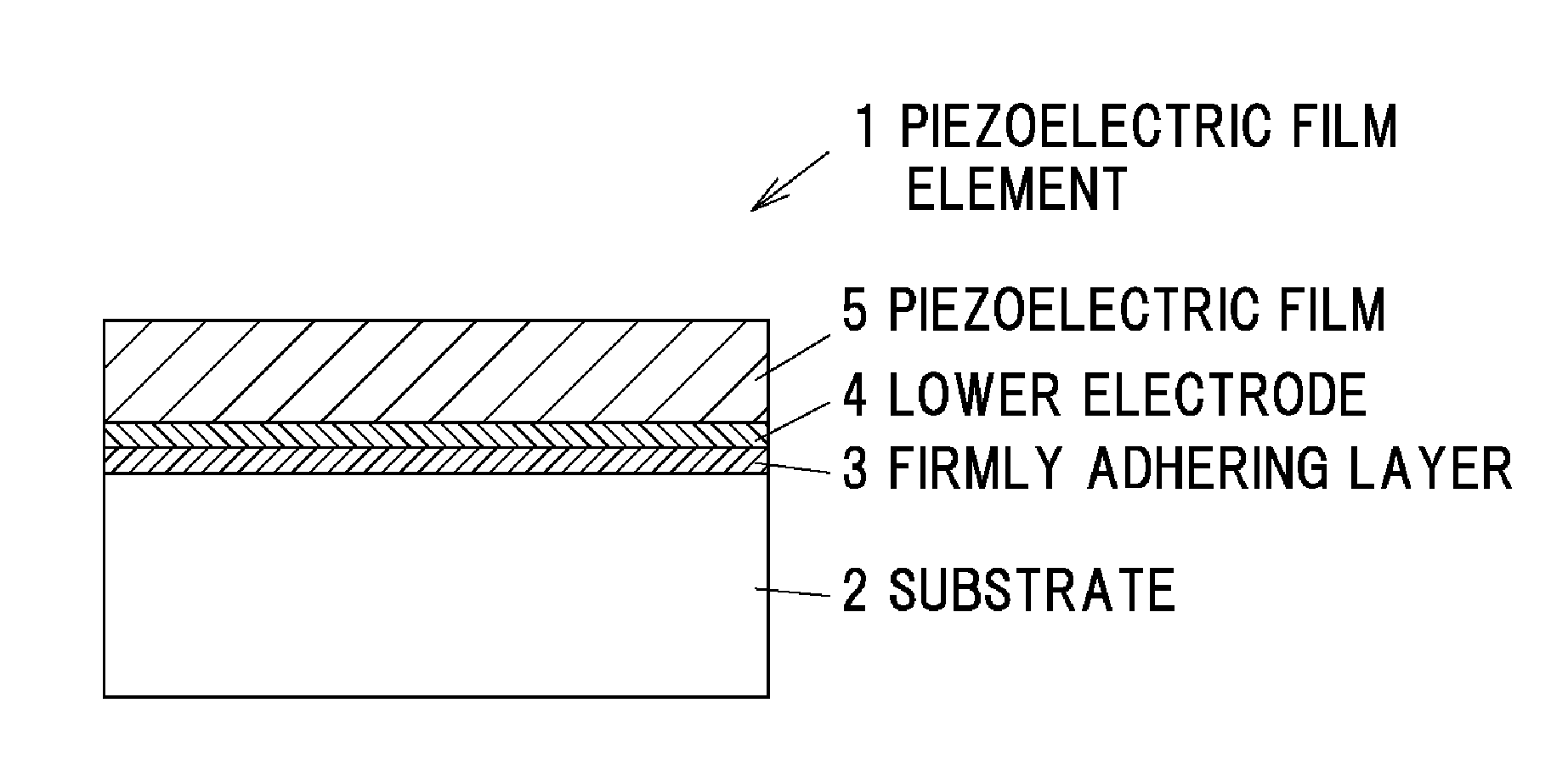

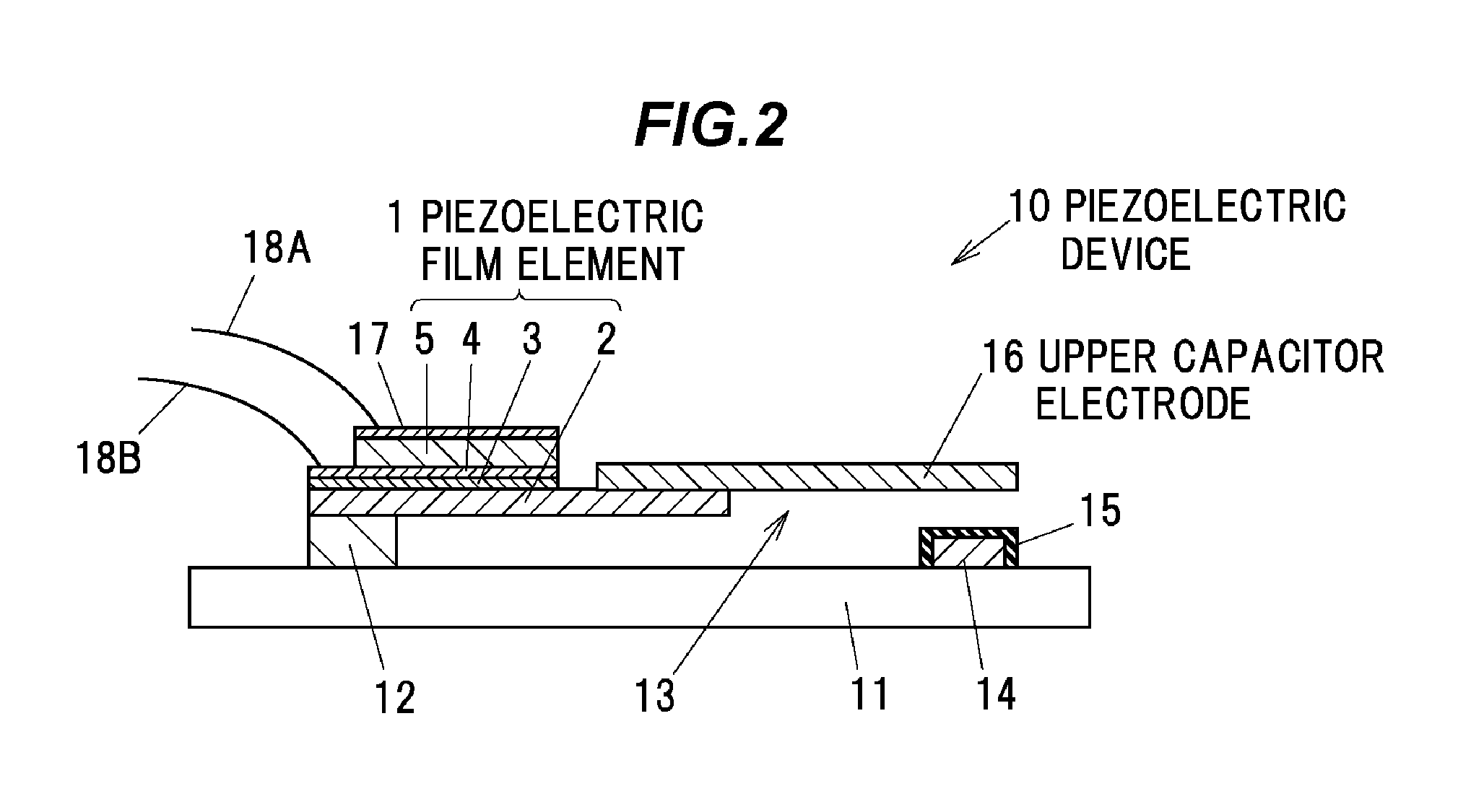

Manufacturing method of piezoelectric film element, piezoelectric film element and piezoelectric device

ActiveUS20130038176A1Increase etch rateResidue reductionPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesReactive gasOptoelectronics

A manufacturing method of a piezoelectric film element includes forming a piezoelectric film including a lead-free alkali niobate based compound having a perovskite structure represented by a compositional formula of (K1-xNax)NbO3 on a substrate, and dry-etching the piezoelectric film by using a low-pressure plasma including a fluorine system reactive gas.

Owner:SUMITOMO CHEM CO LTD

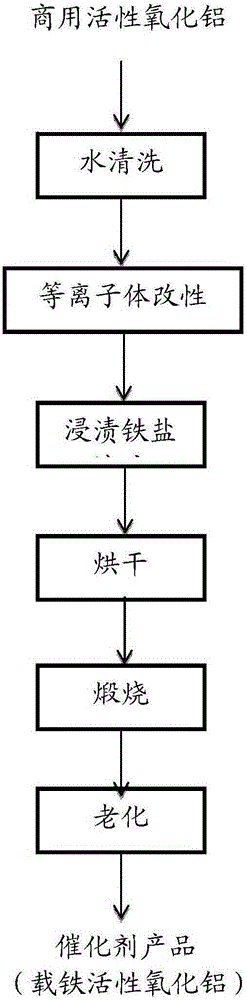

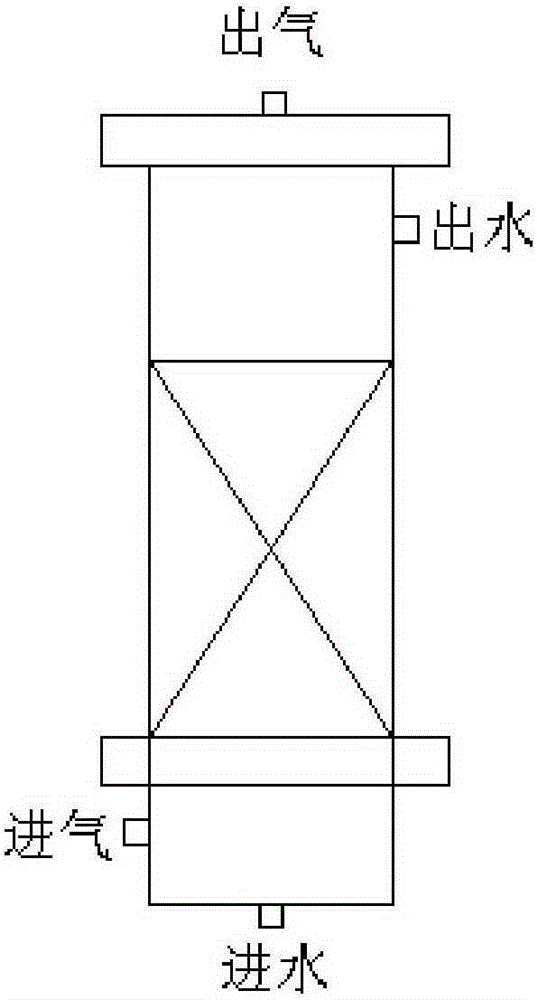

Aluminium-oxide-supported iron oxides catalyst, preparation method and application thereof to organic wastewater processing

InactiveCN105289610ACompletely degradedIncrease reaction rateMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationIron saltsWater processing

The invention discloses a preparation method for an aluminium-oxide-supported iron oxides catalyst, and application of the catalyst to organic wastewater processing. The preparation method comprises the following steps: (1) firstly cleaning an aluminium oxide particle with clean water, and then modifying the aluminium oxide particle by using a low-pressure plasma, so as to obtain modified aluminium oxide; (2) fully dipping the modified aluminium oxide obtained in the step (1) in an iron salt solution, and then drying, so as to obtain iron-loaded aluminium oxide; and (3) calcining the iron-loaded aluminium oxide obtained in the step (2), so as to obtain the aluminium-oxide-supported iron oxides catalyst after calcining is finished. The aluminium-oxide-supported iron oxides catalys obtained by employing the preparation method possesses the advantages of being fast in reaction speed, relatively thorough in organics degradation, high in ozone utilization rate and the like during organic waste water processing.

Owner:建德市环保科技创新创业中心有限公司 +1

Method for preparing copper-base tungsten coating through compounded process of laser and thermal spraying

ActiveCN101717910AImprove heat resistanceImprove thermal shock resistanceMolten spray coatingThermal sprayingCoating system

The invention relates to a method for preparing a copper-base tungsten coating through a compounded process of laser and thermal spraying. The method is characterized by comprising the following steps of: preparing a nickel base alloy transition bottom layer on the surface of a copper matrix by using a low pressure plasma coating system, and remelting the transition bottom layer with laser beams; and then preparing an intermediate transmission layer and the tungsten coating of a Ni-W alloy by using the low pressure plasma coating system, and then remelting with the laser beams to obtain the tungsten coating. By using a gradient coating structure, the method effectively solves the problem of thermal stress caused by mismatching of the coefficient of thermal expansion of the copper and the tungsten, and improves the cohesion strength of the tungsten coating and the matrix, the tungsten coating and the tungsten coating. The coating and the matrix can achieve metallurgical bonding by using the laser beam remelting, bonding property is also improved and the tungsten coating with compact surface is obtained. The tungsten coating prepared by the method has excellent anti-heat radiation and anti-thermal shock properties and is suitable to be used as heated end component materials in equipment, such as first wall material in a ray target, a rocket nozzle, an airplane nozzle throat and a nuclear fusion device.

Owner:GUANGDONG INST OF NEW MATERIALS

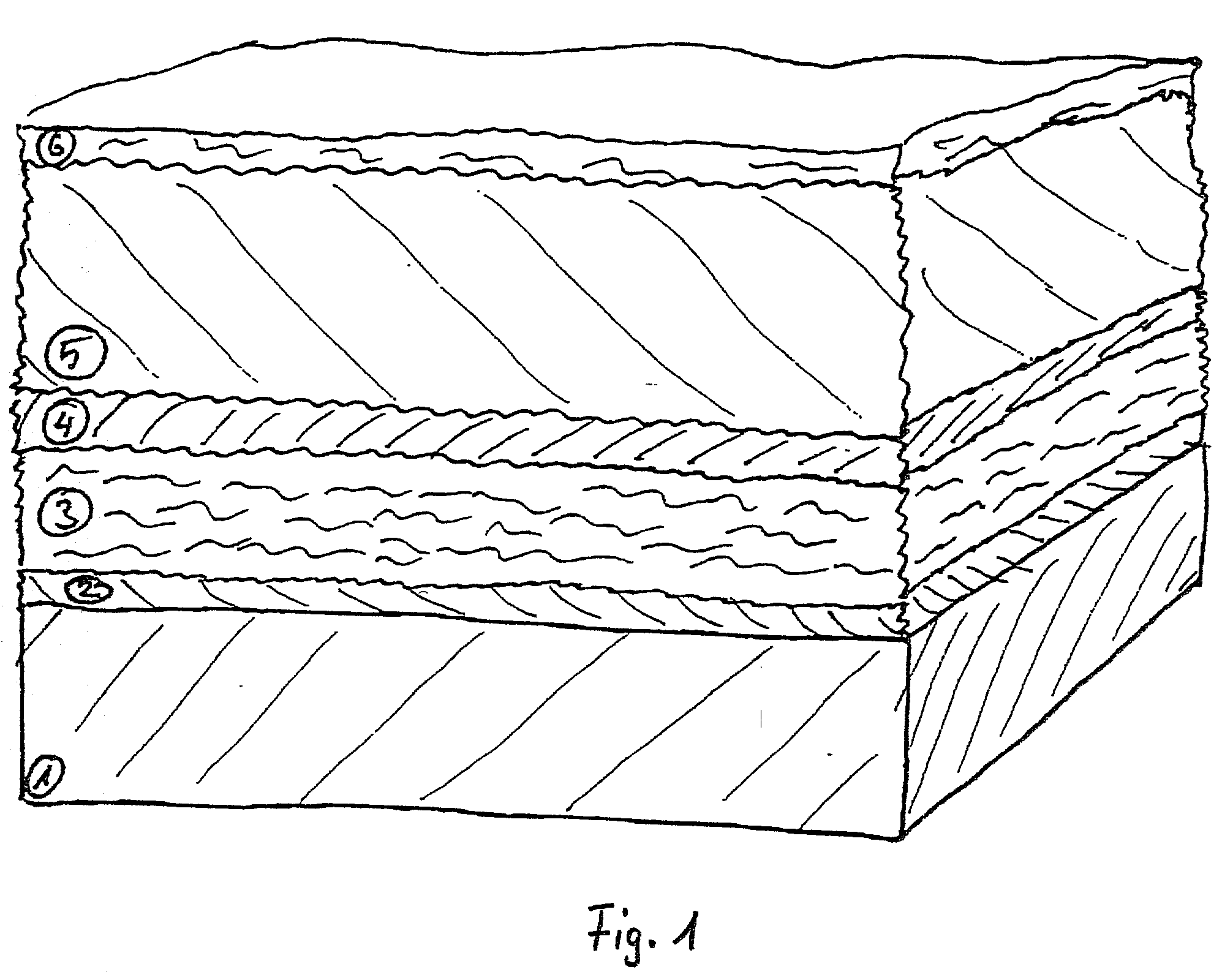

Process for applying a heat shielding coating system on a metallic substrate

The invention provides a process for applying a heat shielding coating system on a metallic substrate. The coating system comprises at least three individual layers selected from the group of barrier layer, hot gas corrosion protection layer, protection layer, heat barrier layer, and smoothing layer. The coating system is applied to the metallic substrate by low pressure plasma spraying in a single operation cycle. This process enables the layers to be applied in an arbitrary sequence. The process is preferably used in applying a coating system to a turbine blade, particularly a stator or a rotor blade of a stationary gas turbine or of an aircraft engine, or to another component in a stationary or aircraft turbine that is subjected to hot gas.

Owner:SULZER METRO AG

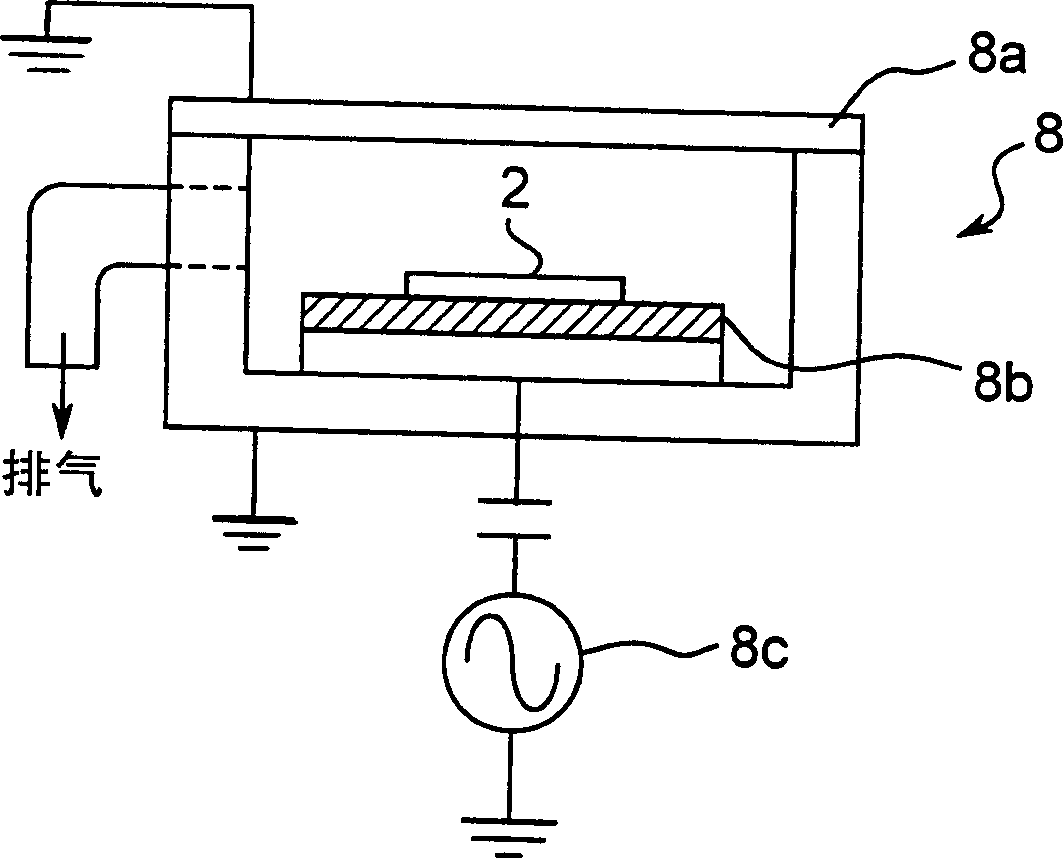

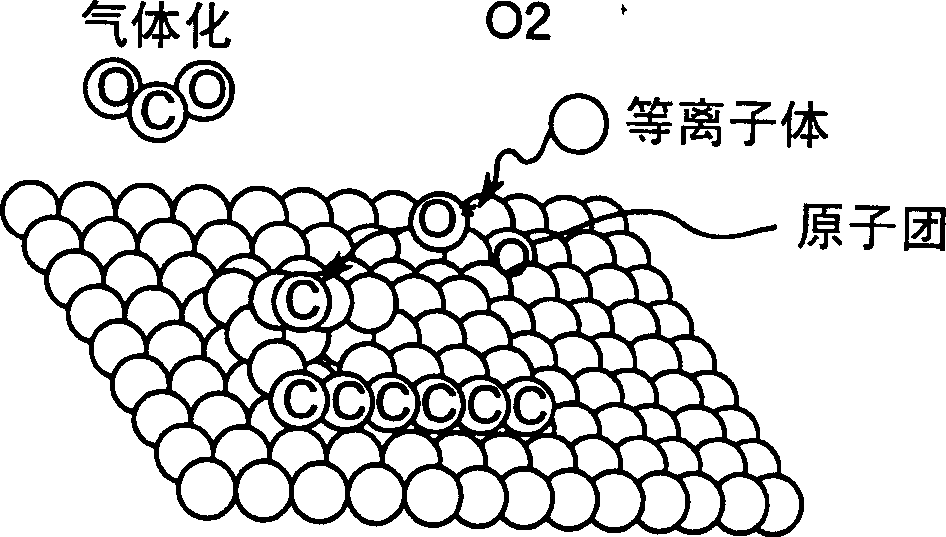

Negative pressure plasma device and cleaning method

InactiveCN1411920AAvoid pollutionIncrease production capacityElectric discharge tubesSolid-state devicesHigh frequency powerProduct gas

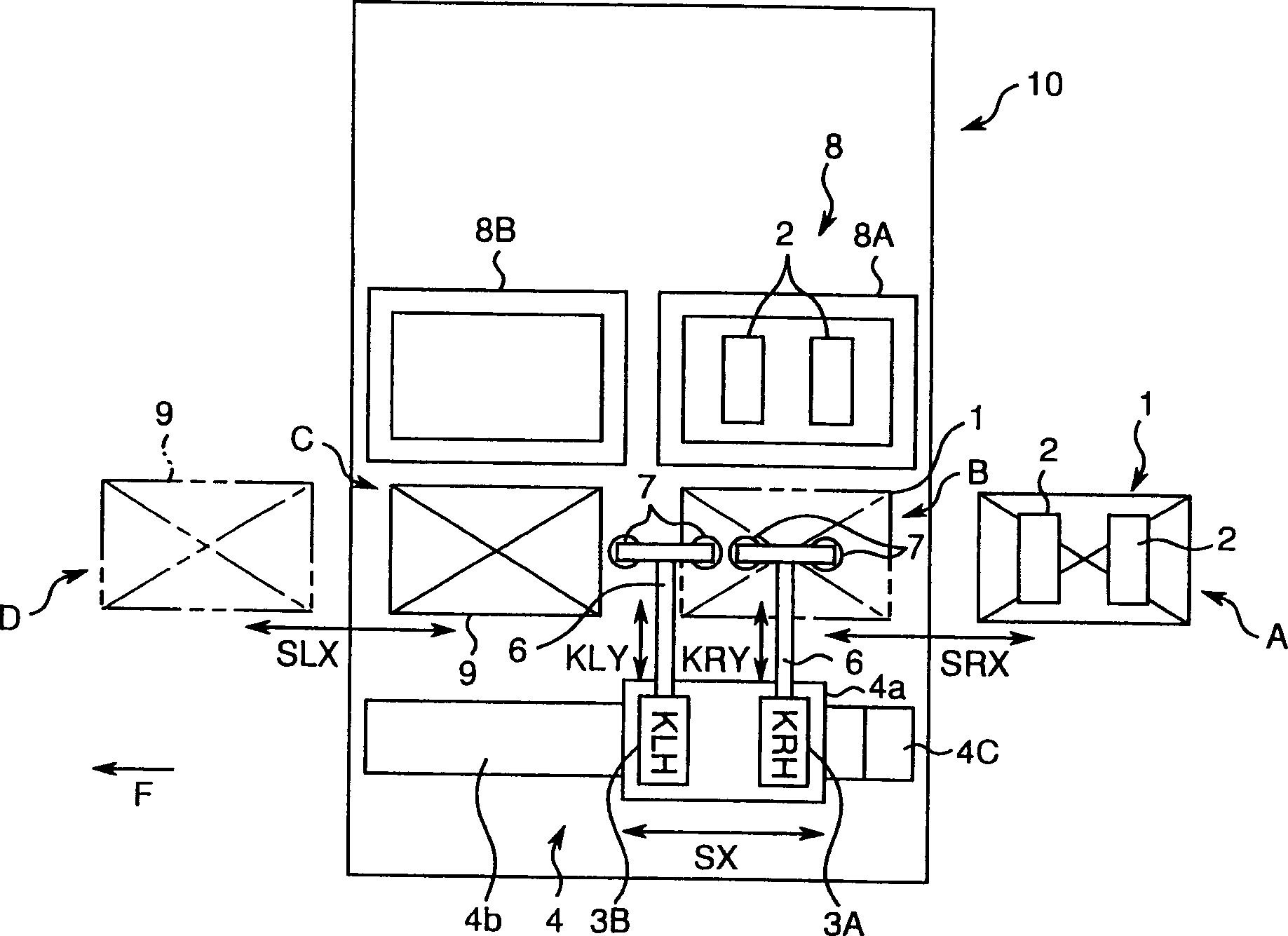

There are provided a low pressure plasma processing apparatus and method by which a throughput can be improved, film contamination can be effectively prevented, and a film can be readily managed. A film substrate (2) is carried in from the outside of a plasma processing apparatus main body (2) to a substrate carrying position (B) in the plasma processing apparatus main body, the film substrate positioned at the substrate carrying position is carried into a chamber (8), a reaction gas is introduced while the chamber is being evacuated, high frequency power is applied under low pressure to generate plasma so that plasma processing is performed to remove organic matter from the film substrate, and the film substrate subjected to plasma processing is taken out from the chamber and positioned at a substrate carrying-out position (C) in the plasma processing apparatus main body and carried out of the plasma processing apparatus main body.

Owner:PANASONIC CORP

Method for plasma processing over wide pressure range

InactiveUS20090142929A1Electric discharge tubesDecorative surface effectsHigh pressureMaterials science

A method for treating a substrate with plasma over a wide pressure range is described. The method comprises exposing the substrate to a low pressure plasma in a process chamber. Further, the method comprises exposing the substrate to a high pressure plasma in the process chamber.

Owner:TOKYO ELECTRON LTD

Composite gradient hydrogen-resistant coating for high-temperature evacuated collector tube and preparation method thereof

ActiveCN103895282AThickness is easy to controlImprove compactnessMolten spray coatingSolar heat devicesWater bathsFurnace temperature

The invention discloses a composite gradient hydrogen-resistant coating for a high-temperature evacuated collector tube and a preparation method thereof. The preparation method comprises the following steps of carrying out Ni-Cr-Al transition layer preparation by a low-pressure plasma spraying device under the conditions of current of 300-800A, voltage of 40-100V, H2 flow of 5-100L / min, Ar flow of 5-100L / min, chamber pressure of 1000-10000Pa, a spraying speed of 1-20mm / s and a spraying distance of 10-100mm, putting a cleaned sample into a quartz glass tube, carrying out sealing, carrying out vacuum-pumping until pressure is <10Pa, feeding argon into the quartz glass tube until pressure is 100000Pa, carrying out vacuum-pumping, carrying out circulation twice, stopping argon feeding, feeding hydrogen into the quartz glass tube until pressure is 100000Pa, carrying heating under the condition of a preset furnace temperature of 500-1200 DEG C, carrying out heating in water bath having a temperature of 5-60 DEG C when the furnace temperature is in a range of 500-1200 DEG C, feeding H2 into H2O and then into a reaction zone to provide low-oxygen partial pressure of 10<-24> to 10<-16>Pa, and keeping the temperature for 1-20h under the conditions of the furnace temperature of 500-1200 DEG C and the water-bath temperature of 0-60 DEG C to obtain the Al2O3-Cr2O3 composite gradient hydrogen-resistant coating having the thickness of 0.1-20 microns. The coating is a double-layer structure comprising an alumina inner layer and a chrome oxide external layer. The hydrogen-resistant coating has a high bonding degree with the base and has hydrogen resistance improved by 100-120 times. The preparation method has simple processes and a low cost.

Owner:GRIMAT ENG INST CO LTD

High density low pressure plasma sprayed focal tracks for X-ray anodes

InactiveUS20080181366A1Decrease vacuum pressureAvoid heat conductionLiquid surface applicatorsMolten spray coatingSoft x rayRhenium

This invention involves the application of dense, metallurgically bonded deposits of tungsten and tungsten rhenium coatings onto preformed based x-ray anodes to be used as focal tracks. The coatings are applied by low pressure DC plasma spraying. The invention also includes heat treatments that further densify the as-applied coatings improving their suitability for use as focal tracks.

Owner:SURFACE MODIFICATION SYST

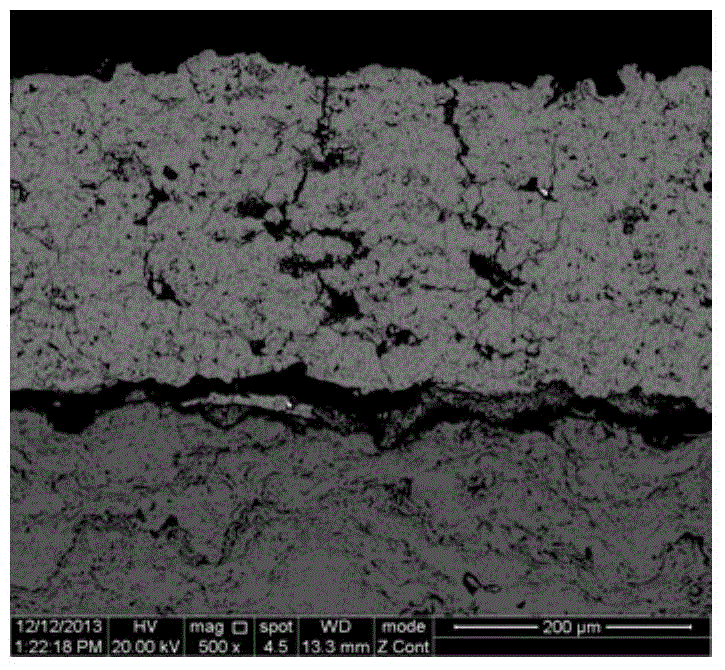

Preparation method of thermal barrier coating containing bilayer structure of bonding layers

InactiveCN104674217AIncrease temperatureStop the spreadMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionFragility

The invention relates to a preparation method of a thermal barrier coating containing a bilayer structure of bonding layers. A metal substrate is subjected to deoiling and sand blasting treatment; a first bonding layer is deposited on the metal substrate through low-pressure plasma spraying, high-velocity oxygen flame spraying or high-velocity compressed air flame spraying; a second bonding layer is deposited through atmosphere plasma spraying, high-velocity oxygen flame spraying or high-velocity compressed air flame spraying; a ceramic thermal insulating layer is deposited on the second bonding layer through atmosphere plasma spraying, high-velocity oxygen flame spraying, solution plasma spraying or an electron beam physical vapor deposition technology. Compared with conventional MCrAlY thermal barrier coating adopting a single bonding layer, M is Ni, Cr and the like, the prepared thermal barrier coating adopting the double bonding layers has higher use temperature, Ni2Al2O4 fragility phase is avoided for the interfacial properties of the bonding layers and the ceramic layer, sufficient Al is supplied, roughness of an interface is kept, the coating has more excellent oxidation resistance and organization structure stability, and the service life of the coating is greatly prolonged.

Owner:HENAN PULAIMU COATING TECH +1

Soft x-ray laser based on z-pinch compression of rotating plasma

InactiveUS7679027B2Increase currentImprove uniformityBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangementsElectric dischargeStimulated emission

A method and apparatus for producing soft x-ray laser radiation. A low pressure plasma column is created by electric discharge or by laser excitation inside a rotating containment tube. Rotation of the plasma is induced by viscous drag caused by rotation of the tube, or by magnetically driven rotation of the plasma as it is created in a plasma gun in the presence of an axial magnetic field, or both. A high power electrical discharge is then passed axially through the rotating plasma column to produce a rapidly rising axial current, resulting in z-pinch compression of the rotating plasma column, with resultant stimulated emission of soft x-ray radiation in the axial direction. A rotating containment tube used in combination with magnetically driven rotation of the plasma column results in a concave electron density profile that results in reduced wall ablation and also reduced refraction losses of the soft x-rays.

Owner:FARTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com