Patents

Literature

416results about How to "Avoid heat conduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

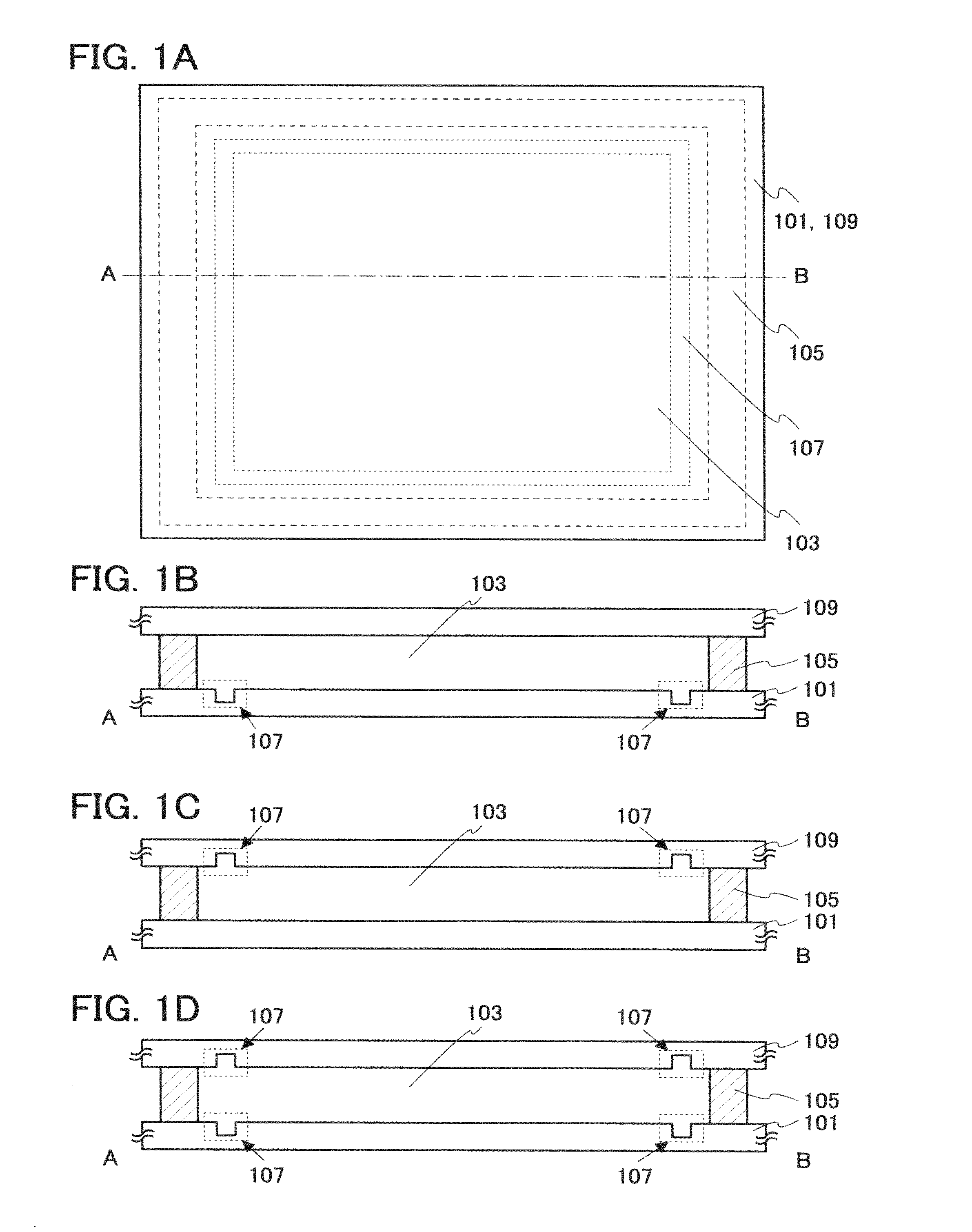

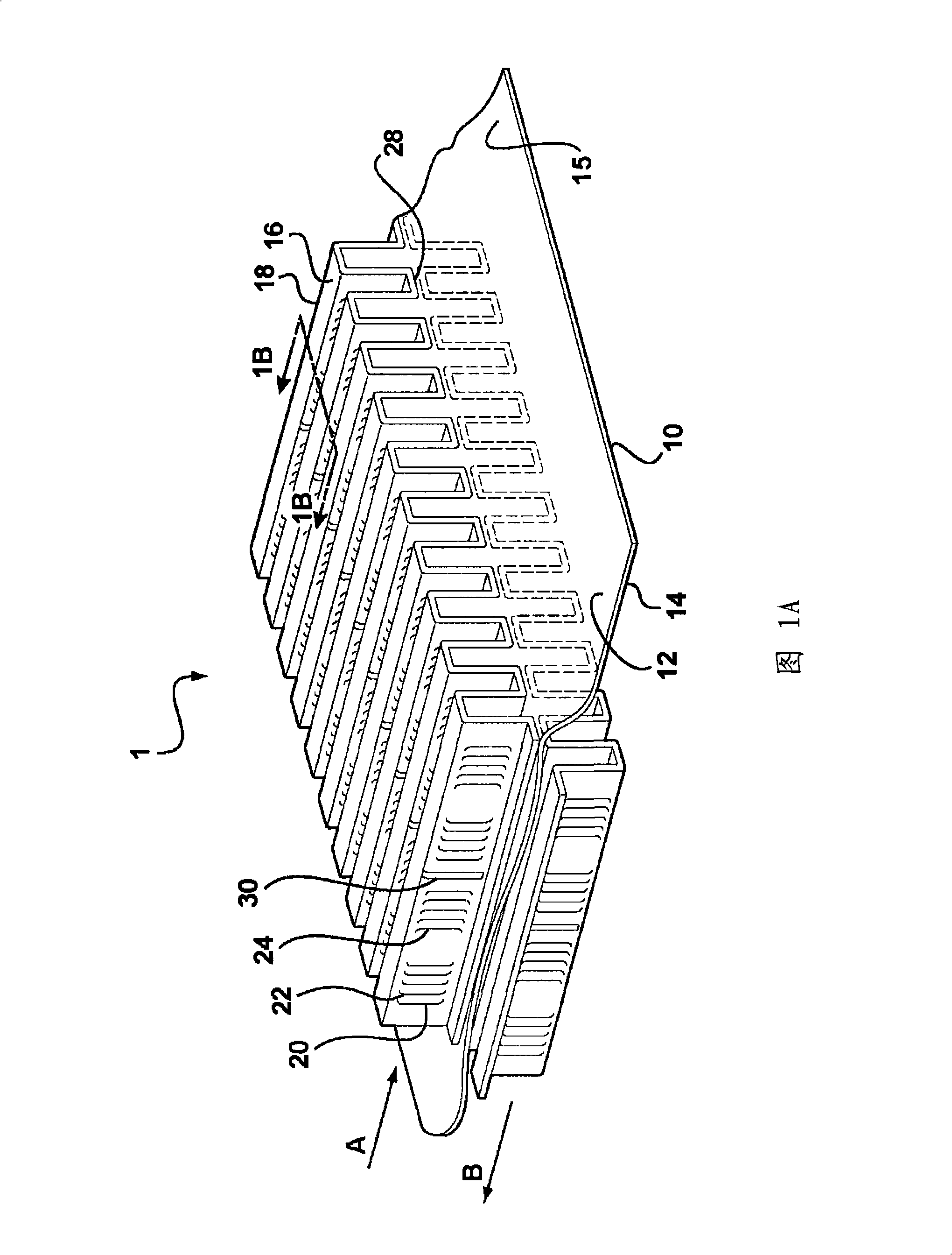

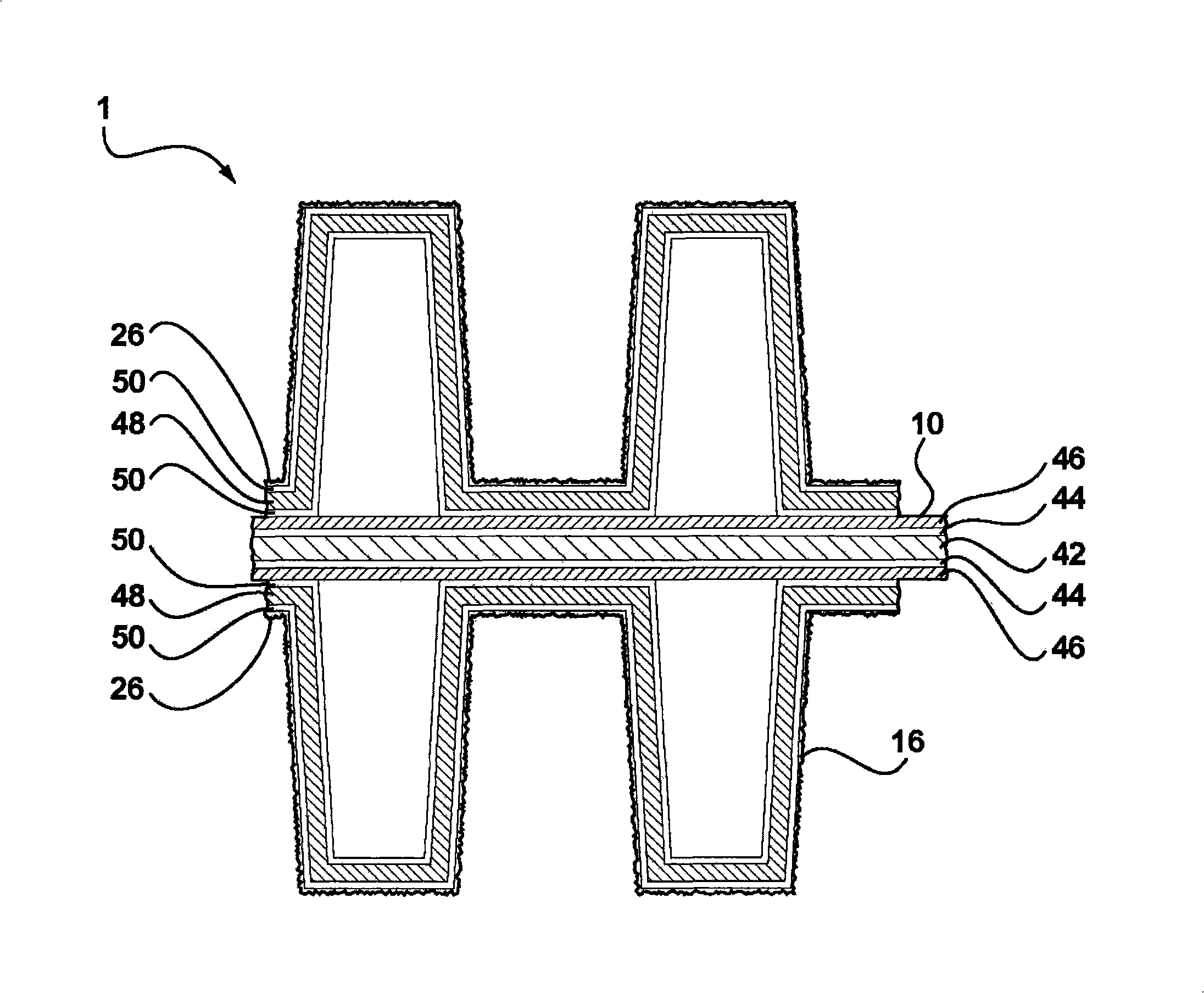

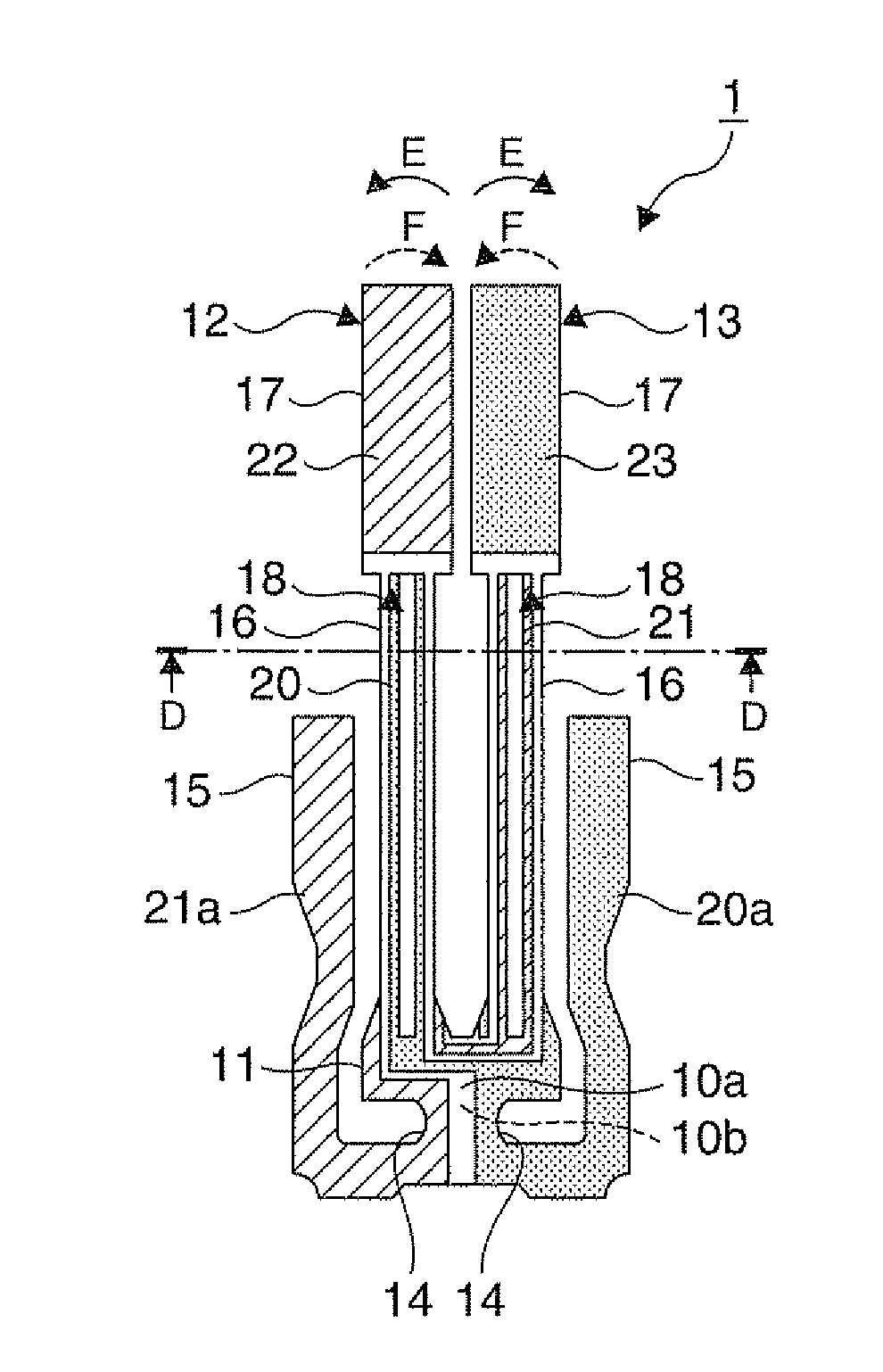

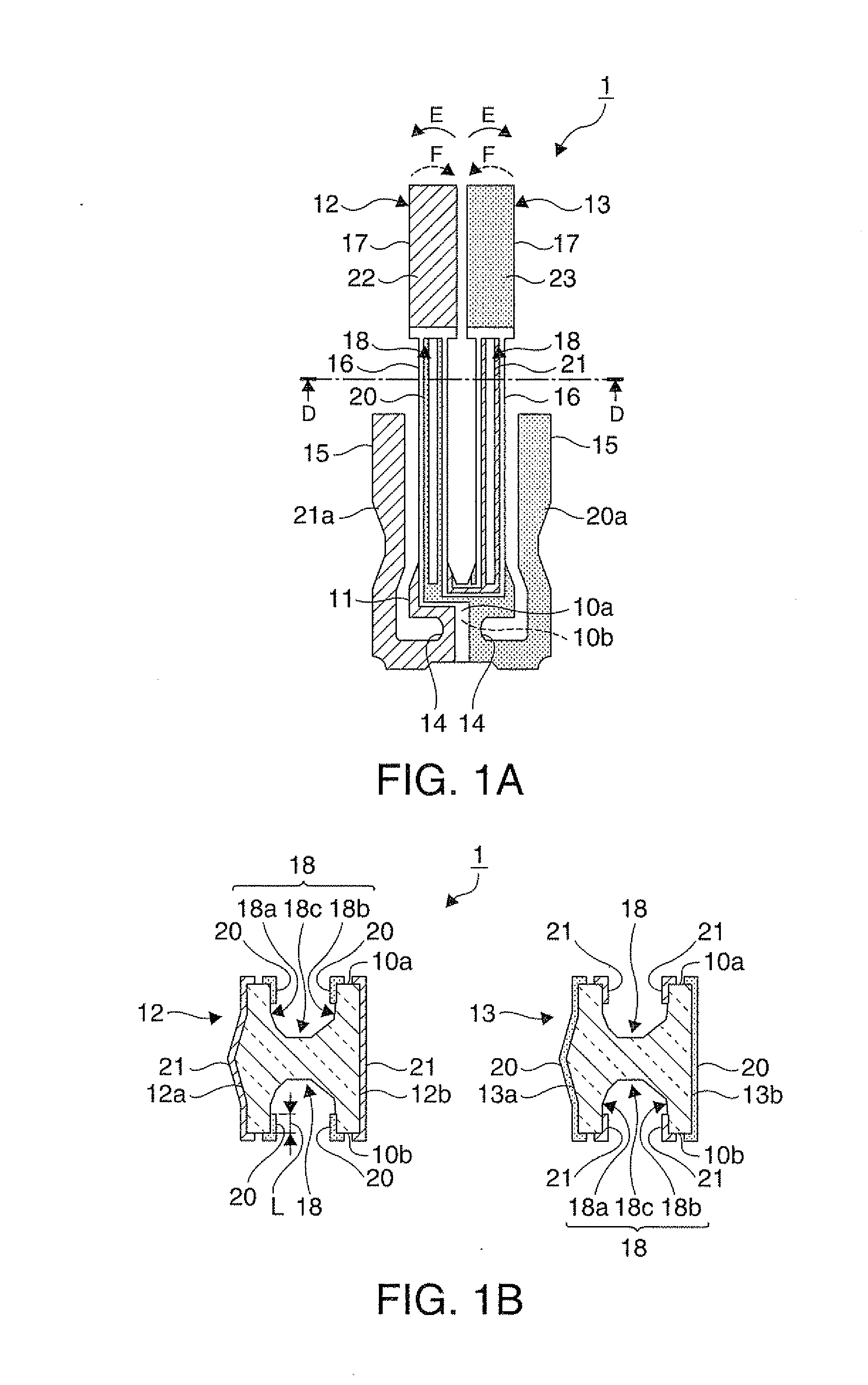

Sealing structure, device, and method for manufacturing device

ActiveUS20140252386A1Avoid heat conductionLow heat resistanceSolid-state devicesSemiconductor/solid-state device manufacturingSealantBiomedical engineering

Provided is a device in which heat conduction from a sealant to a functional element is suppressed and whose bezel is slim. The sealing structure includes a first substrate, a second substrate whose surface over which a sealed component is provided faces the first substrate, and a frame-like sealant which seals a space between the first substrate and the second substrate with the first substrate and the second substrate. The second substrate includes a groove portion between the sealant and the sealed component. The groove portion is in a vacuum or includes a substance whose heat conductivity is lower than that of the second substrate.

Owner:SEMICON ENERGY LAB CO LTD

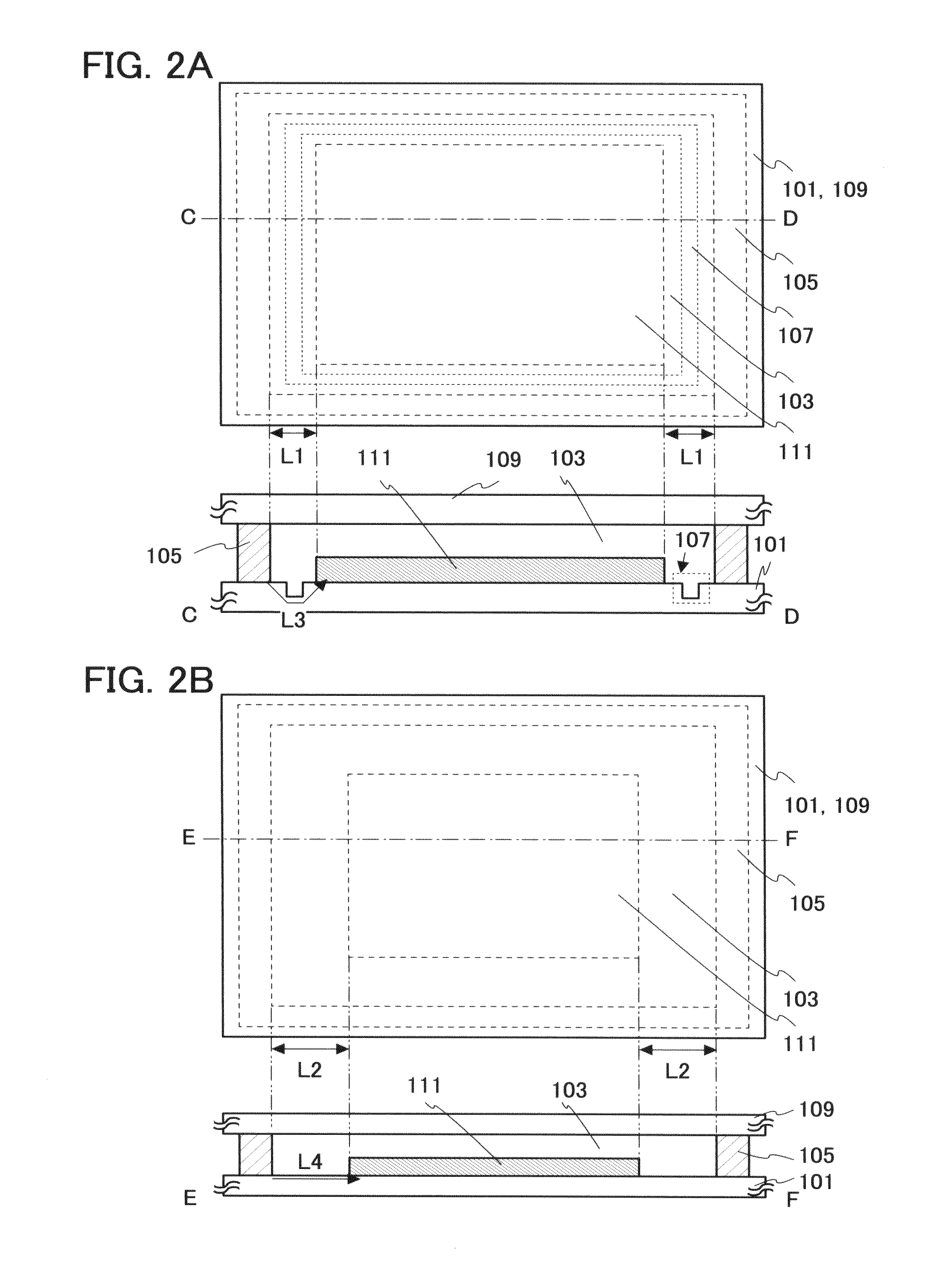

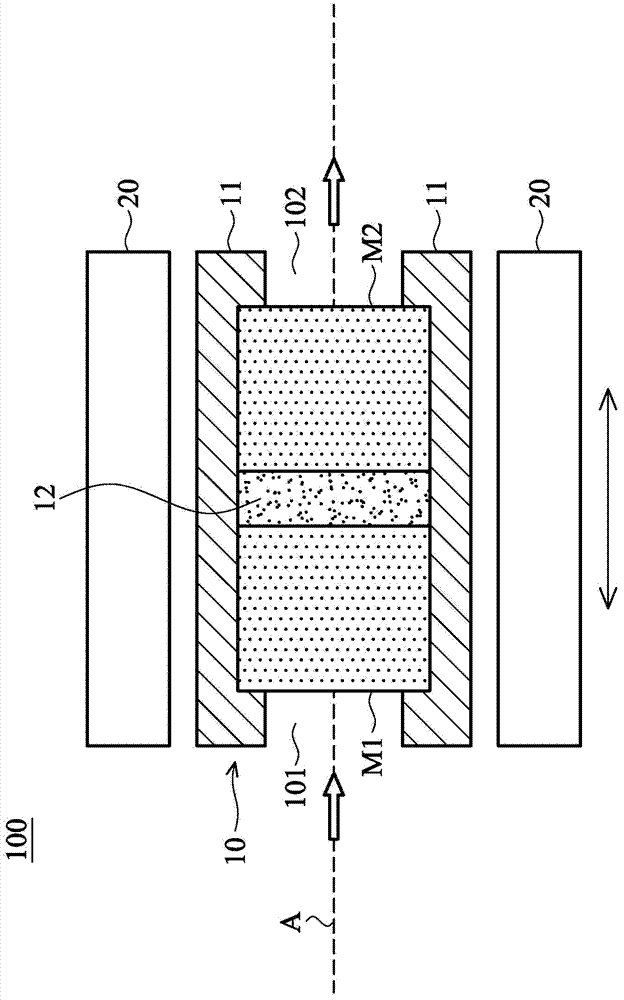

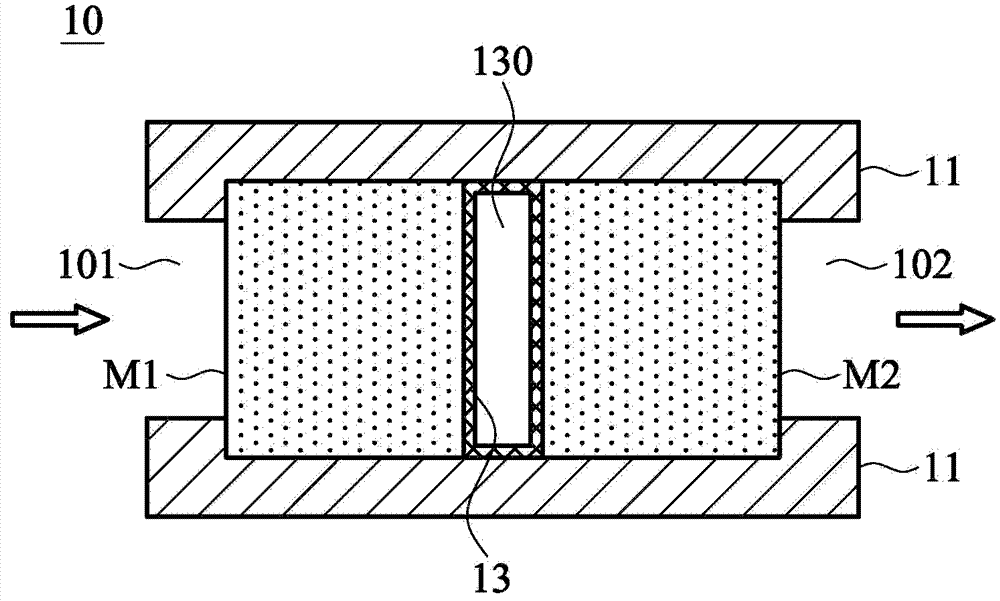

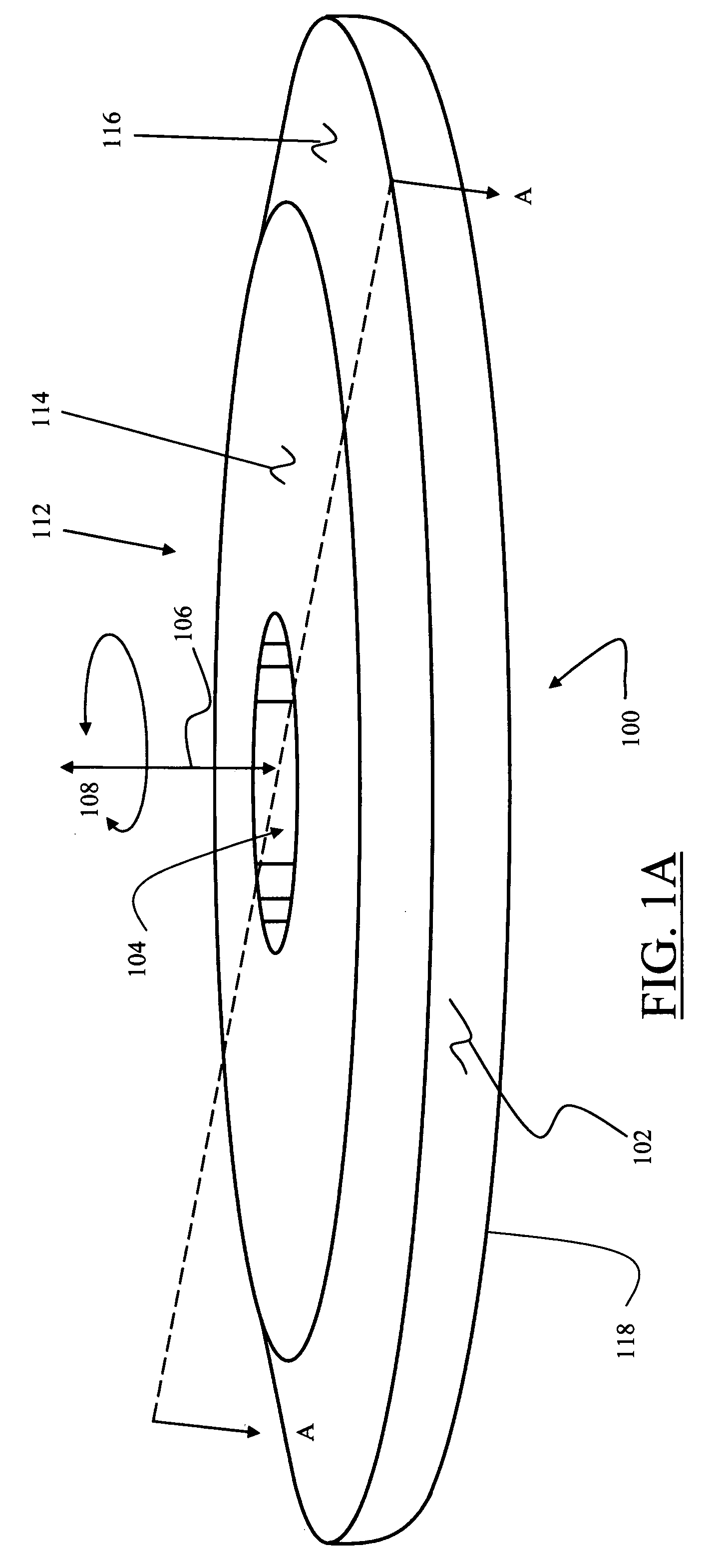

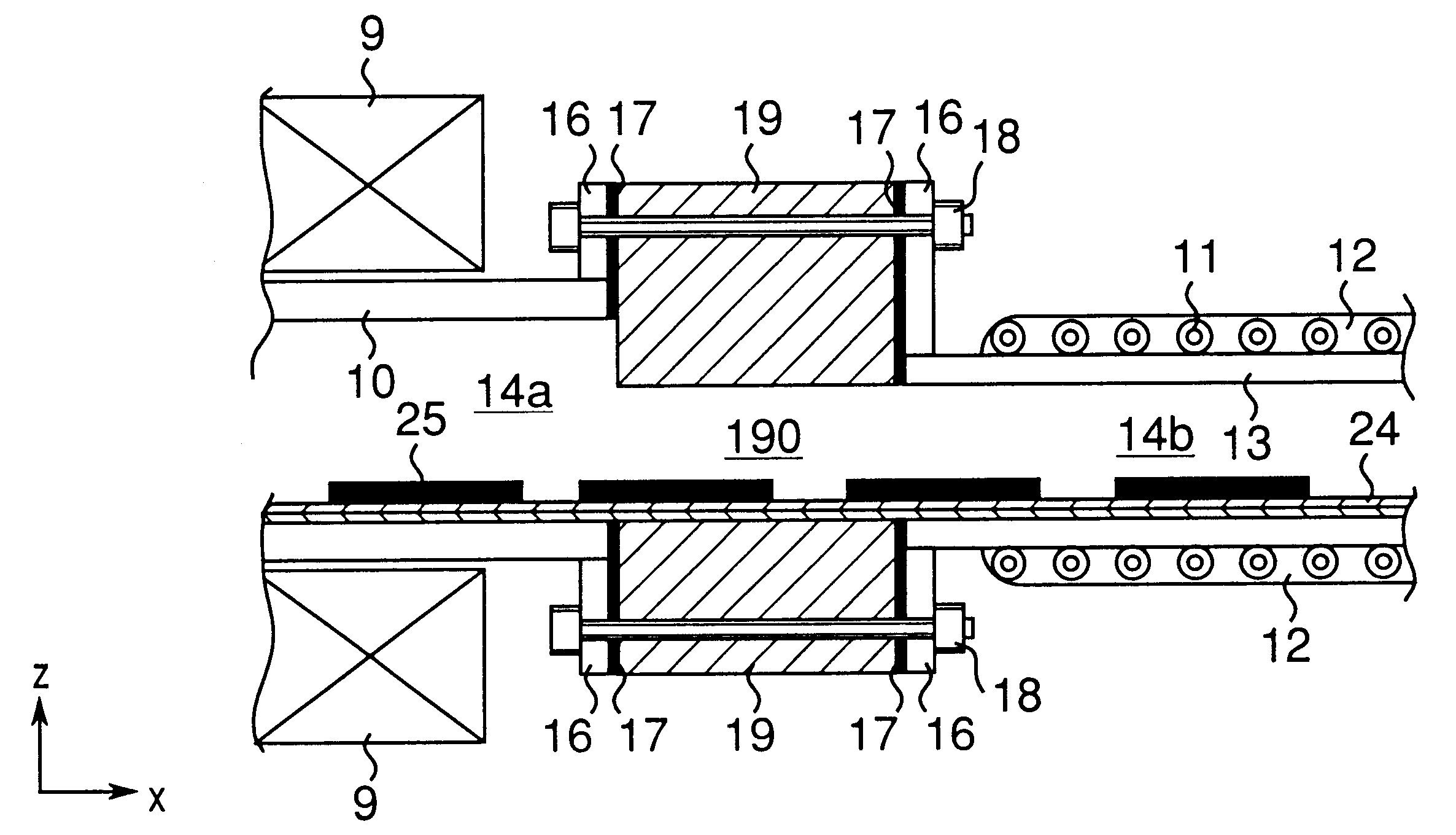

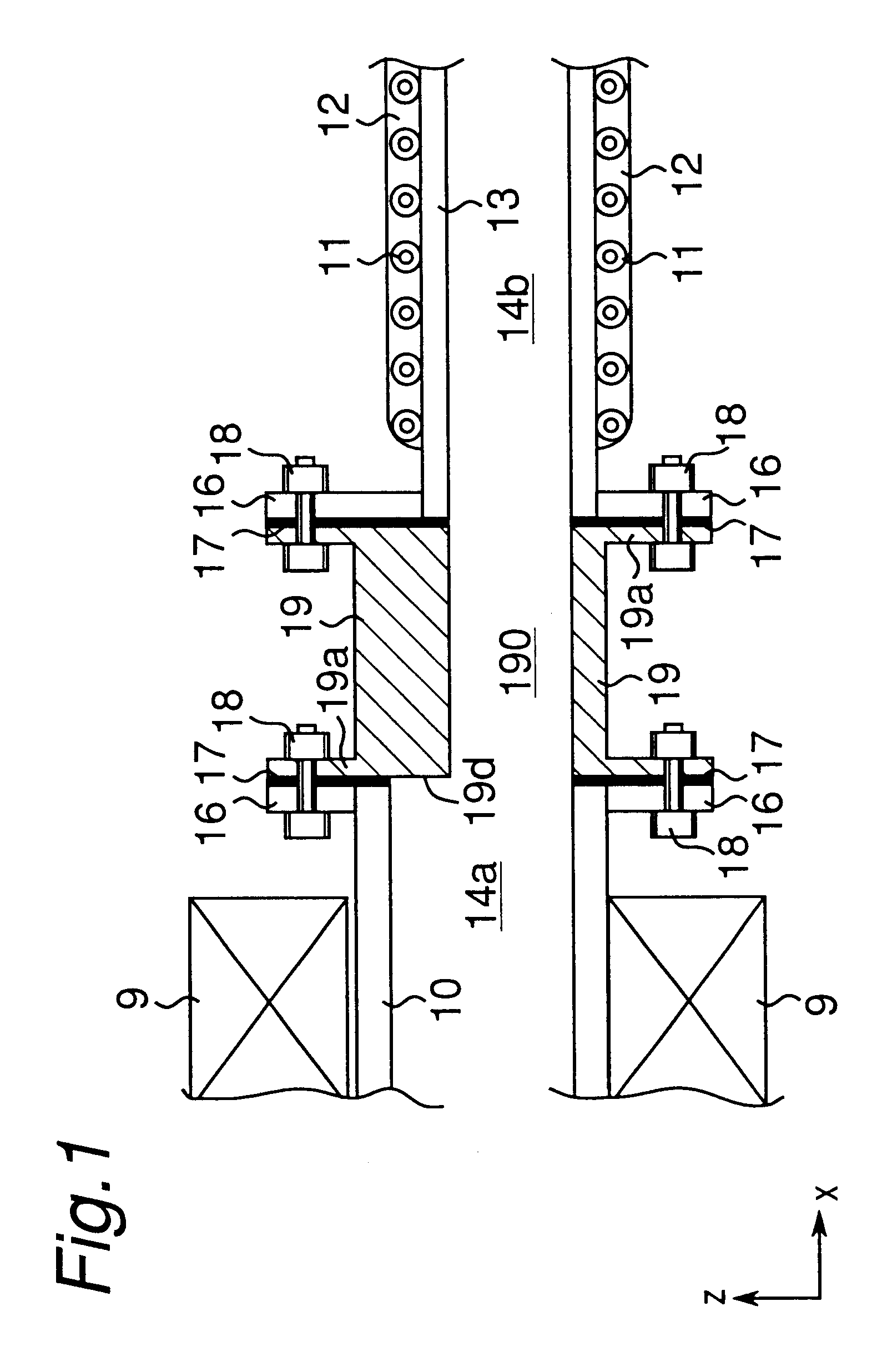

Magnetic refrigeration device and magnetic heating module thereof

InactiveCN103090583AAvoid heat conductionEnergy efficient heating/coolingMachines using electric/magnetic effectsMagnetic refrigerationHeat transfer fluid

Disclosed are a magnetic refrigeration device and a magnetic heating module thereof. The magnetic refrigeration device comprises a magnetic heating module and a magnet unit. The magnet unit reciprocates to act on different magnetic fields for the magnetic heating module. The magnetic heating module comprises a base, first magnetic heating material, second magnetic heating material and a heat insulation structure. The first and second magnetic heating materials are disposed in the base. The heat insulation structure is disposed between the first and second magnetic heating materials. Heat transfer fluid flows through the first and second magnetic heating materials so as to transfer heat between low temperature and high temperature ends of the magnetic heating module. The multiple different magnetic heating materials are disposed in the magnetic heating module, the heat insulation structure is disposed between the different magnetic heating materials, and accordingly heat transfer between the different magnetic heating materials can be avoided effectively and the magnetic heating module is widely applicable to various magnetic refrigeration devices.

Owner:DELTA ELECTRONICS INC

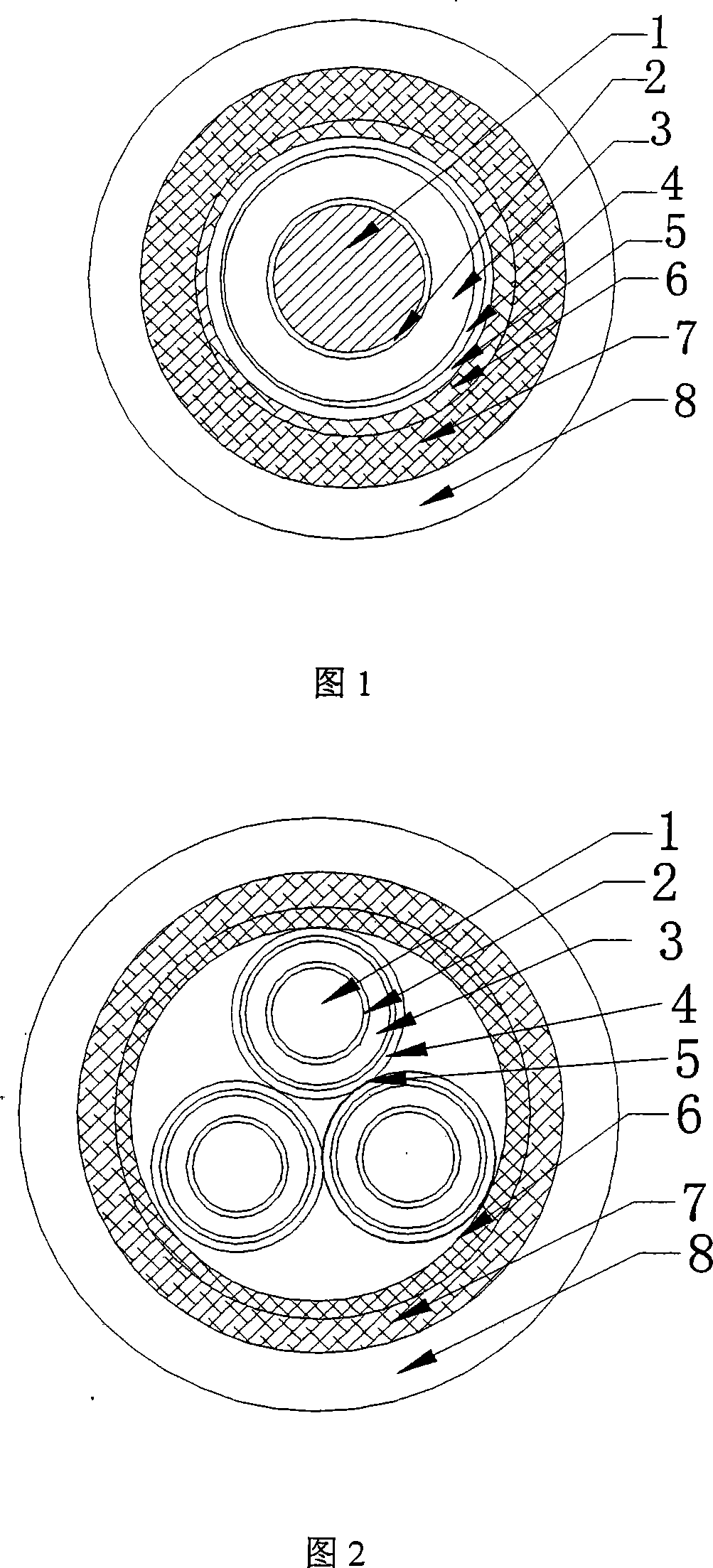

Medium-voltage fire-proof cable

ActiveCN101169993AGood tensile strengthGood fire and heat insulation performanceInsulated cablesInsulated conductorsThermal insulationCable transmission

The invention relates to a medium-voltage power transmission fire-resistant cable, which is characterized in that the outer fire-resistant layer of the medium-voltage cable core is made of fire-resistant inorganic fiber heat insulation layer on the inner side, and the outer side is a soft thermosetting elastomer for normal use. The composite fire-resistant and heat-insulating layer of the heat layer, the thermosetting elastomer, is composed of 30-50wt% silicon-based elastic material, 40-60wt% inorganic filler, 5-15wt% medium and low temperature frit, 4-10wt% vulcanizing agent, It is made by mixing extrusion molding and vulcanization. The composite fire-resistant and heat-insulating layer is a relatively soft sheath material when it is not exposed to flames, which can ensure good bending performance of the refractory structure in normal conditions, and quickly transforms into a shell-and-tube refractory and heat-insulating structure when it encounters fire or high temperature. In the fire-fighting environment, it can still maintain a certain period of time without being damaged, effectively preventing damage to the inner insulation caused by flames or high temperatures. When the flame temperature of the outer layer is 850°C, the temperature of the inner insulation surface is lower than 180°C. This fire-resistant and heat-insulating structure can be applied according to conventional cable production methods, and the production efficiency is extremely high.

Owner:FAR EAST CABLE +2

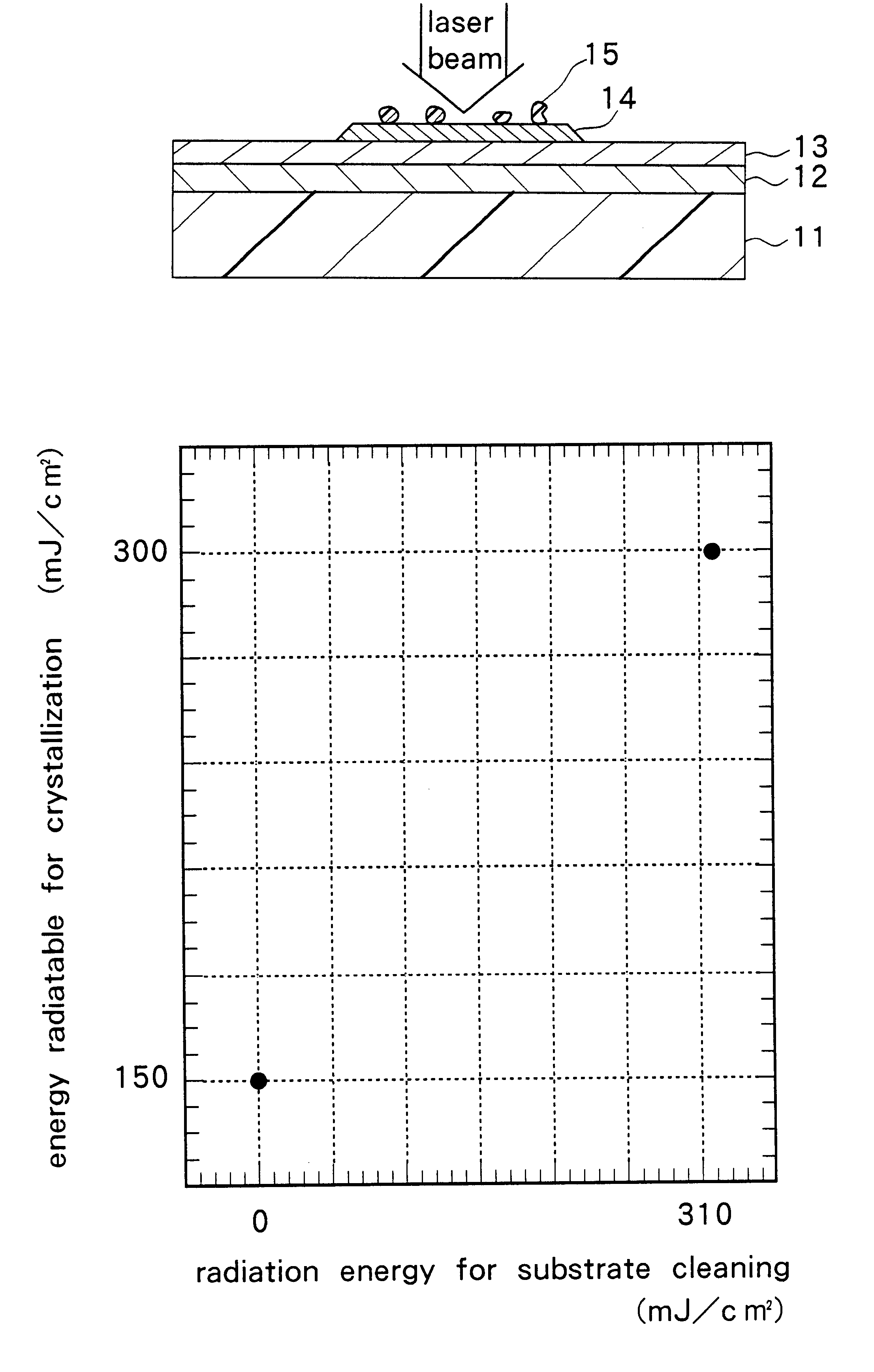

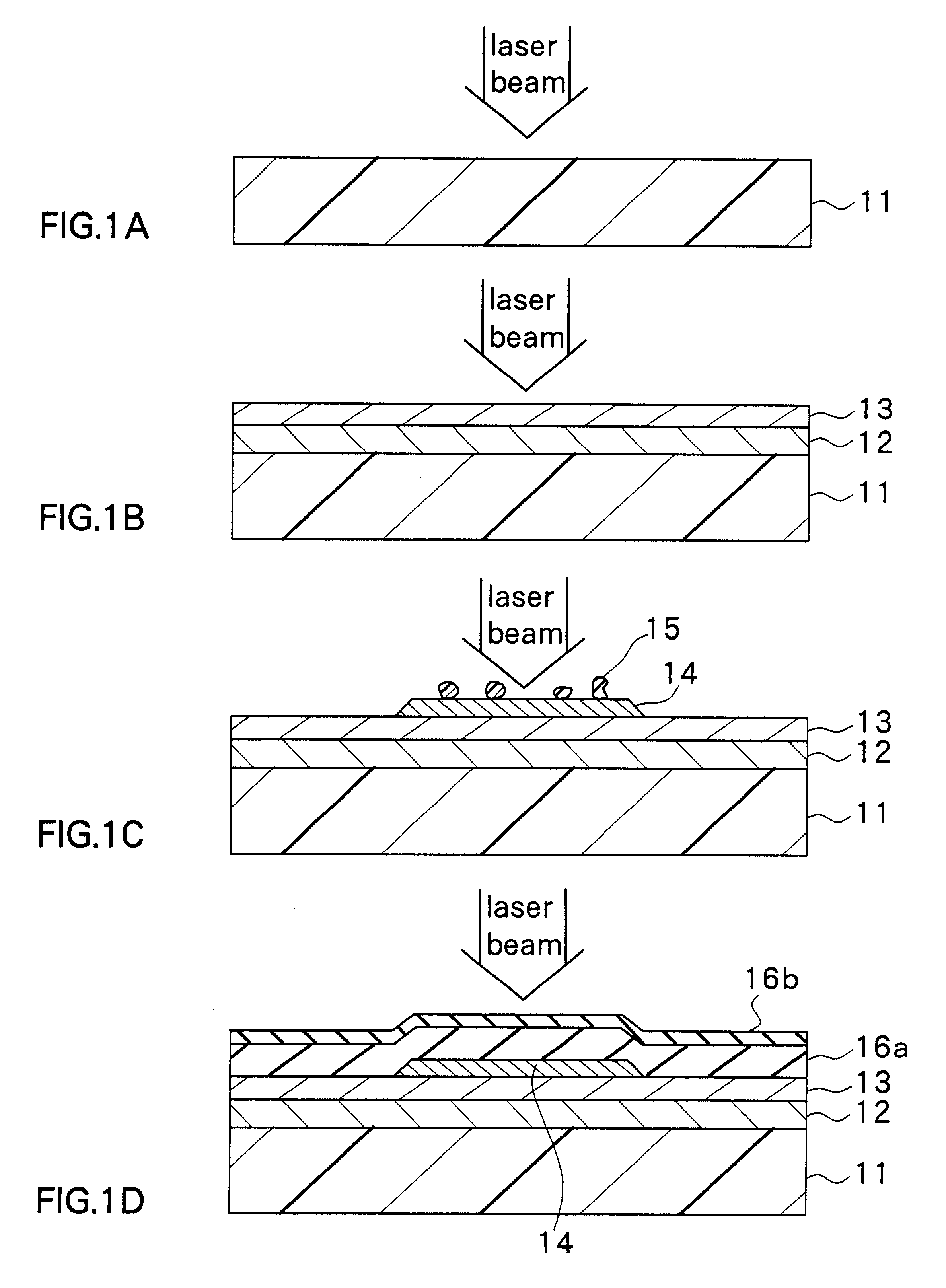

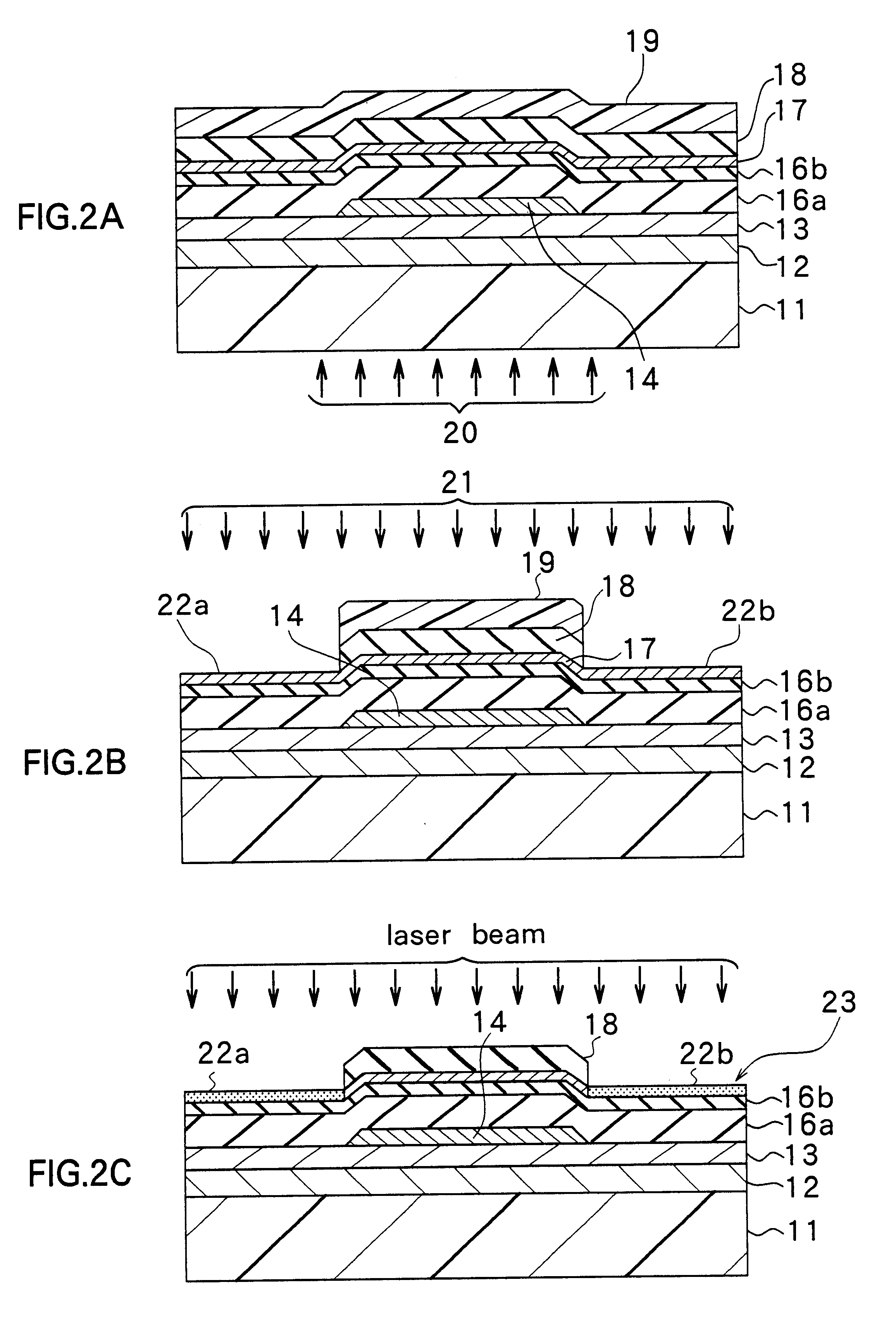

Method of forming a semiconductor thin film on a plastic substrate

InactiveUS6376290B1Avoid heat conductionPrevent penetrationTransistorSolid-state devicesResistLight beam

A method is provided for forming a semiconductor thin film which is free from damage to the film with radiation of a pulse laser beam with the optimum energy value for perfect polycrystallization. For forming an amorphous silicon thin film, a surface of a plastic substrate as a base and insulating layers are each radiated with a pulse laser beam for removing volatile contaminants like a resist as a pretreatment. Damage to the film caused by a gas emitted from the base substrate and the insulating layers resulting from volatile contaminants is thus prevented. A protective layer including a gas barrier layer and a refractory buffer layer is formed on the substrate. Gas penetration from the substrate to the amorphous silicon film is thereby prevented. Conduction of heat produced by energy beam radiation to the substrate is prevented as well. It is possible to increase energy intensity of energy beam radiated for polycrystallization of the amorphous silicon film to the optimal value for perfect polycrystallization.

Owner:SONY CORP

High density low pressure plasma sprayed focal tracks for X-ray anodes

InactiveUS7601399B2Avoid heat conductionReduce pressureLiquid surface applicatorsMolten spray coatingSoft x rayRhenium

This invention involves the application of dense, metallurgically bonded deposits of tungsten and tungsten rhenium coatings onto preformed based x-ray anodes to be used as focal tracks. The coatings are applied by low pressure DC plasma spraying. The invention also includes heat treatments that further densify the as-applied coatings improving their suitability for use as focal tracks.

Owner:SURFACE MODIFICATION SYST

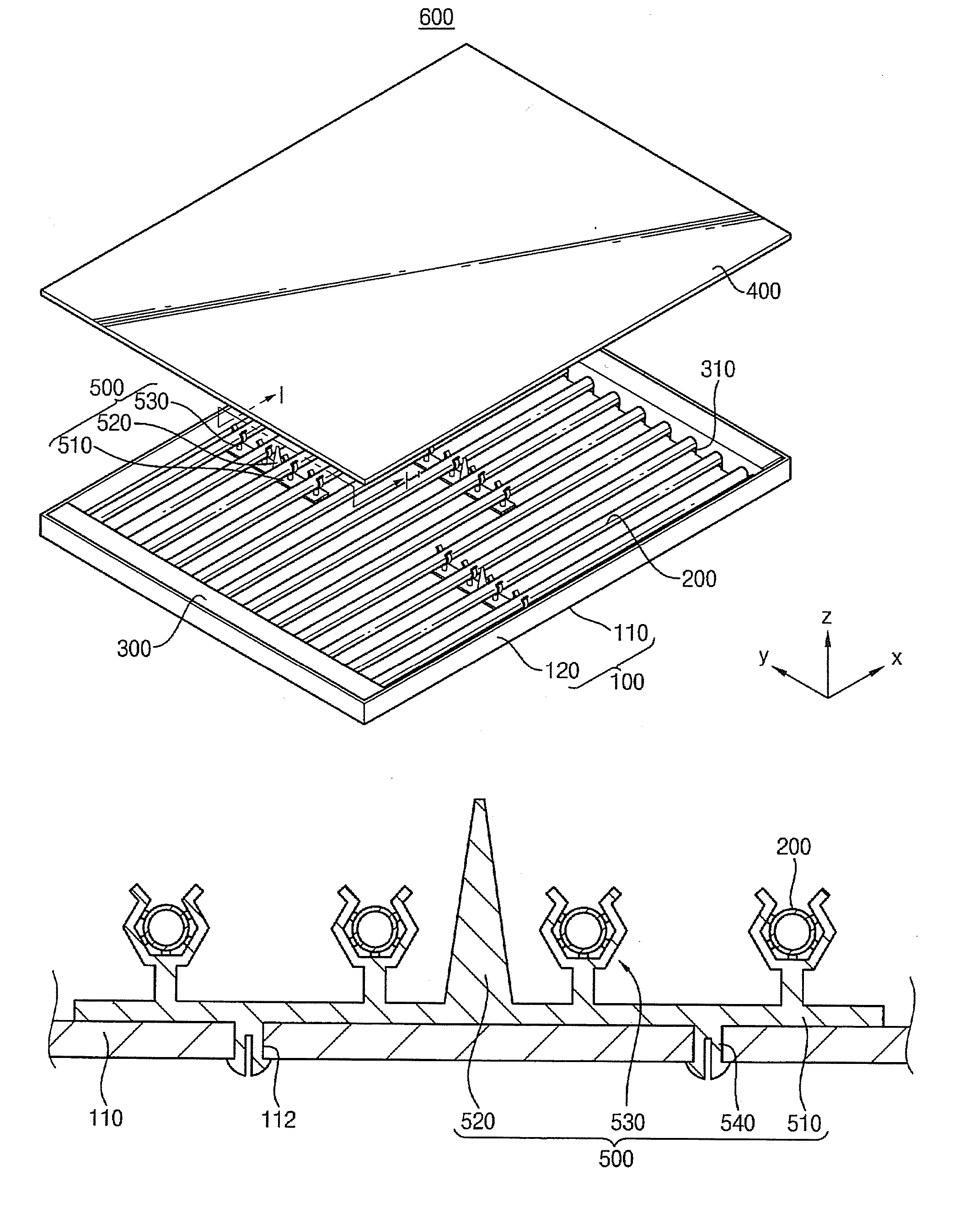

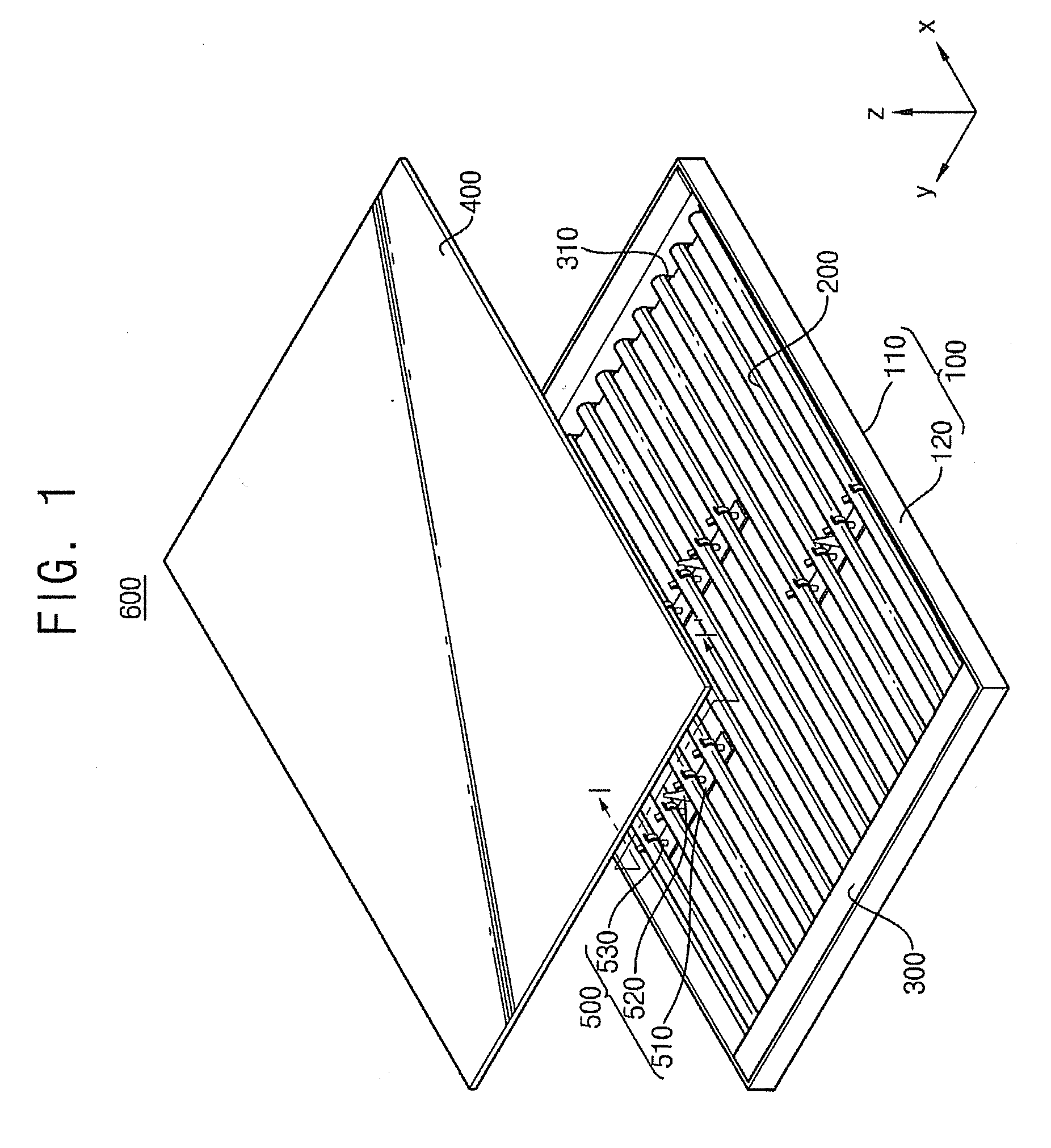

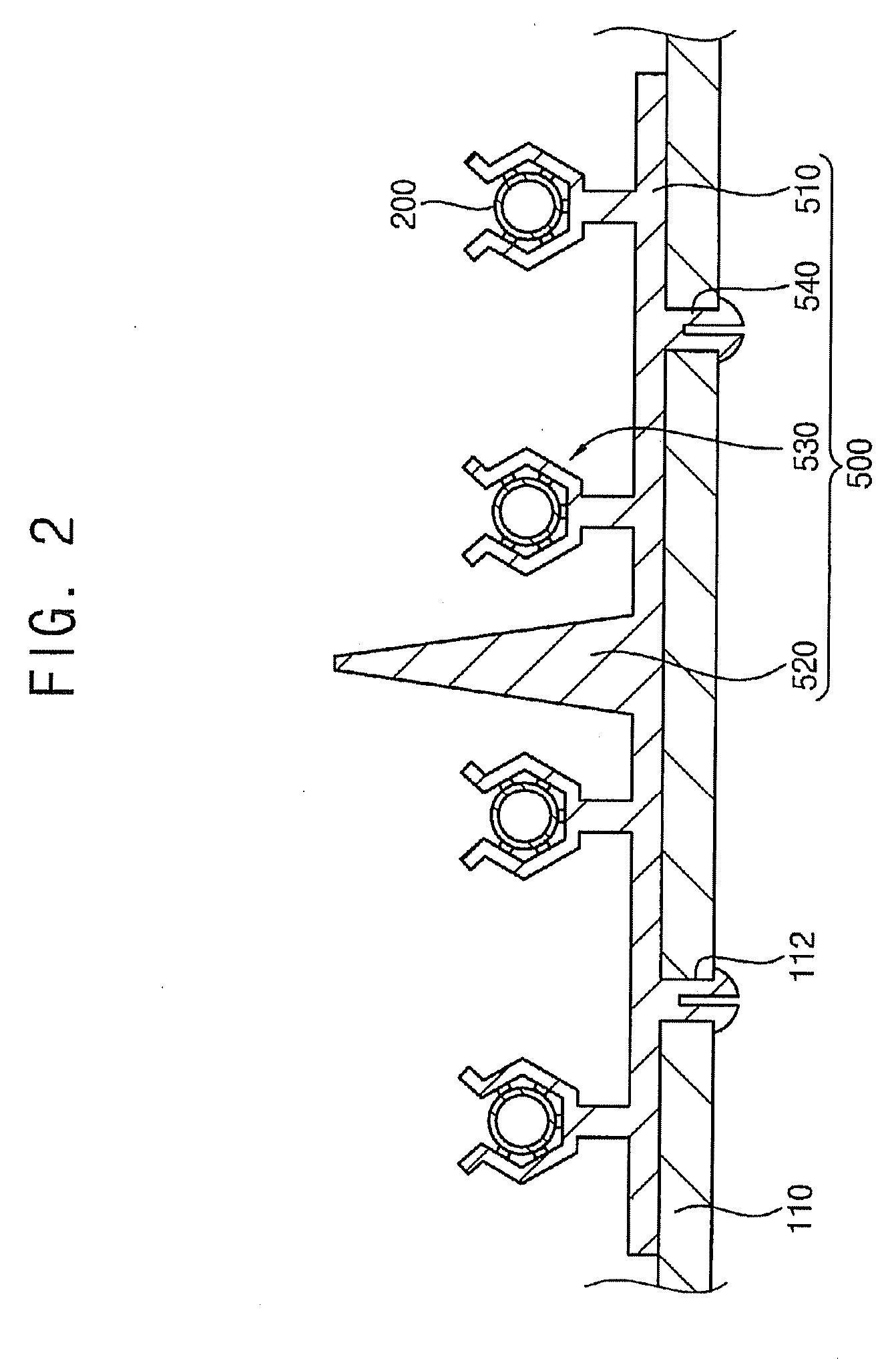

Backlight assembly and display device having the same

ActiveUS20070081322A1Reduce contact areaUniform brightnessElectric lightingIlluminated signsDisplay deviceDark spot

A backlight assembly includes a container, a plurality of lamps and a lamp-fixing member. The container includes a bottom face and side faces extending therefrom that define a receiving space. The lamps are arranged in parallel with each other in the container. The lamp-fixing member includes a support body installed in the container and arranged in a direction intersecting a lengthwise direction of extension of each of the lamps, a lamp-fixing portion protruding from the support body and covering a respective lamp, and a boss protruding from an inner face of the lamp-fixing portion and extending toward a center of the respective lamp to fix the respective lamp with a corresponding lamp-fixing portion via a point or line contact. Thus, a local decrease in temperature of the lamp covered by the lamp-fixing portion may be prevented to improve image display quality by preventing or eliminating dark spots.

Owner:SAMSUNG DISPLAY CO LTD

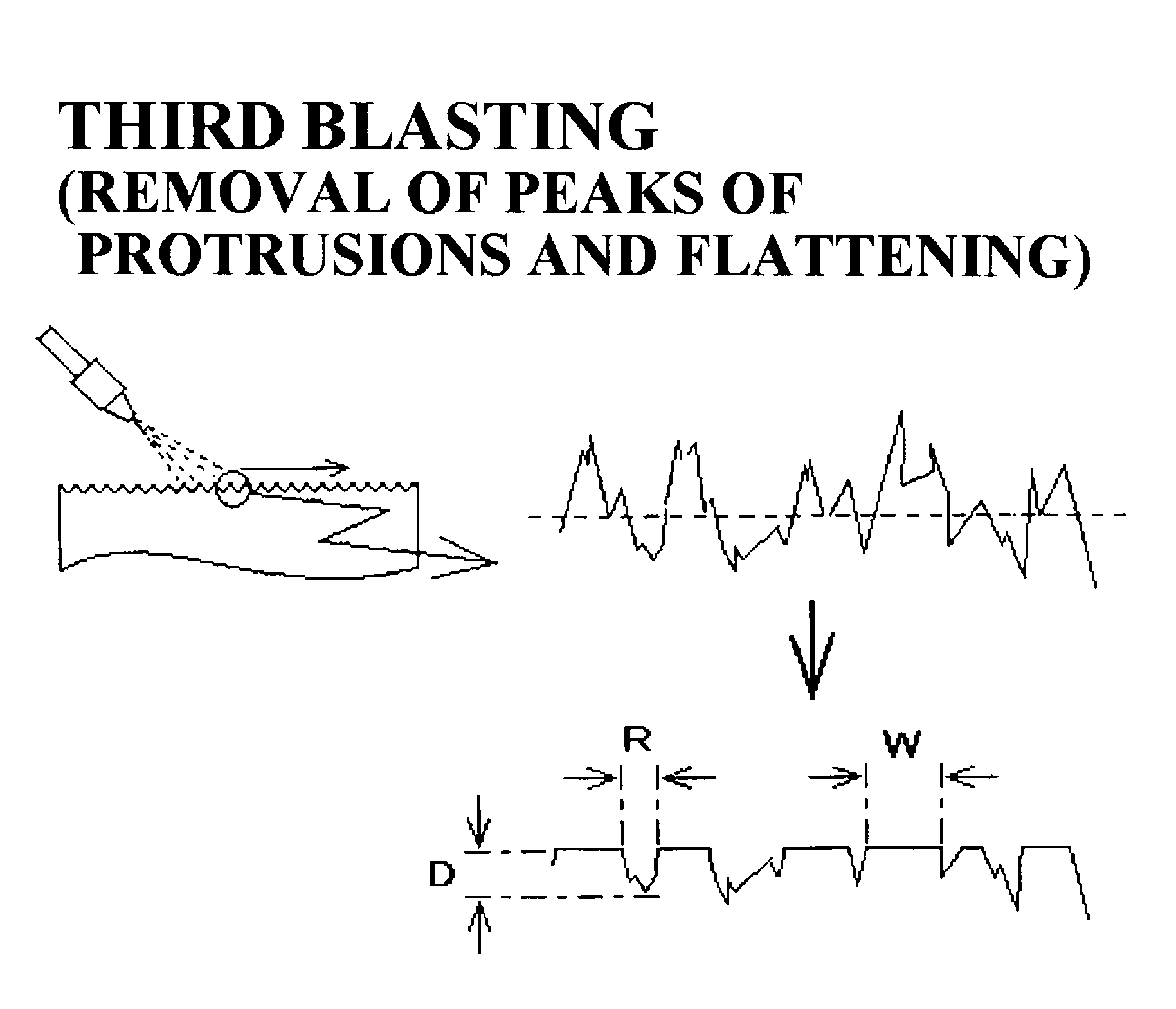

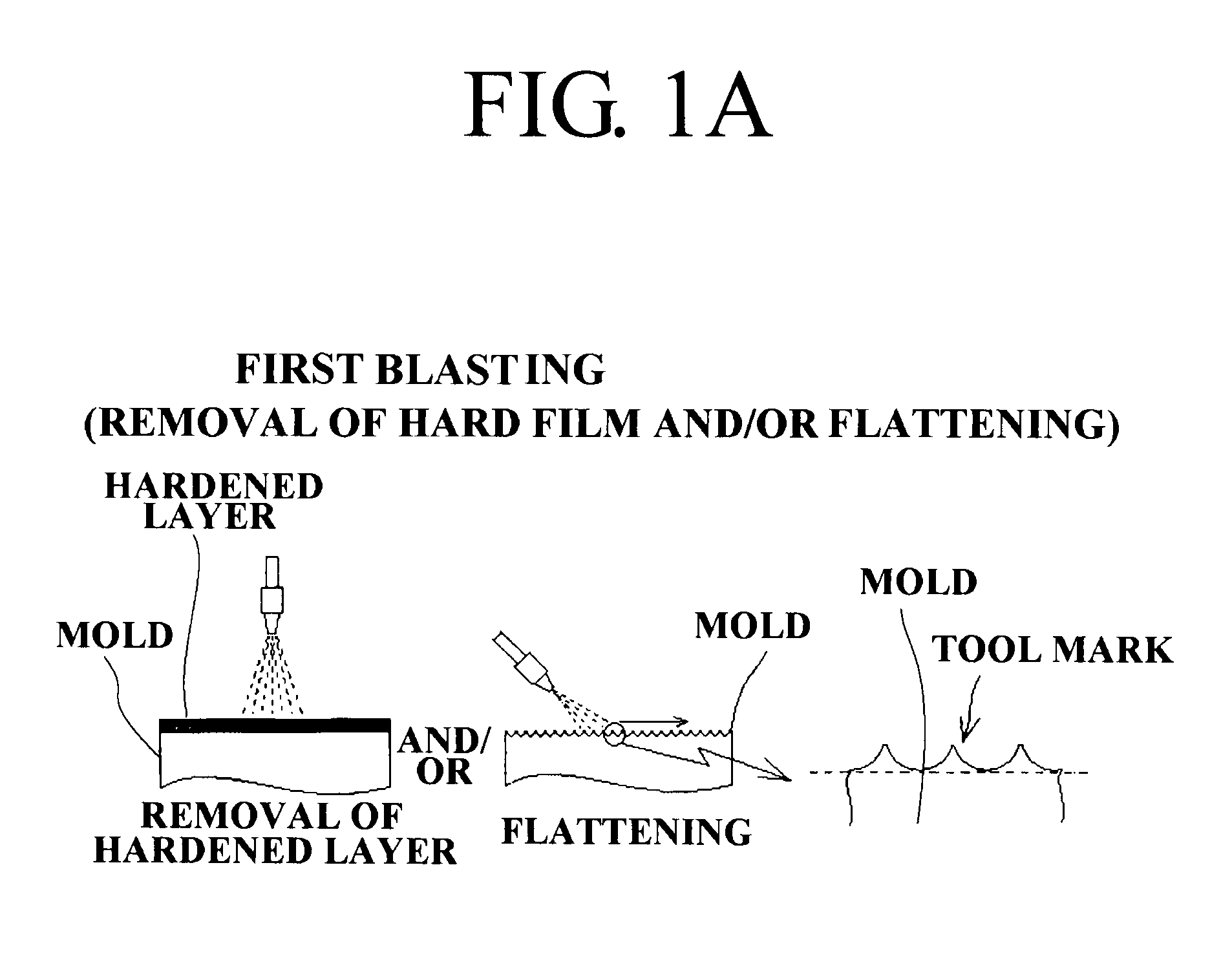

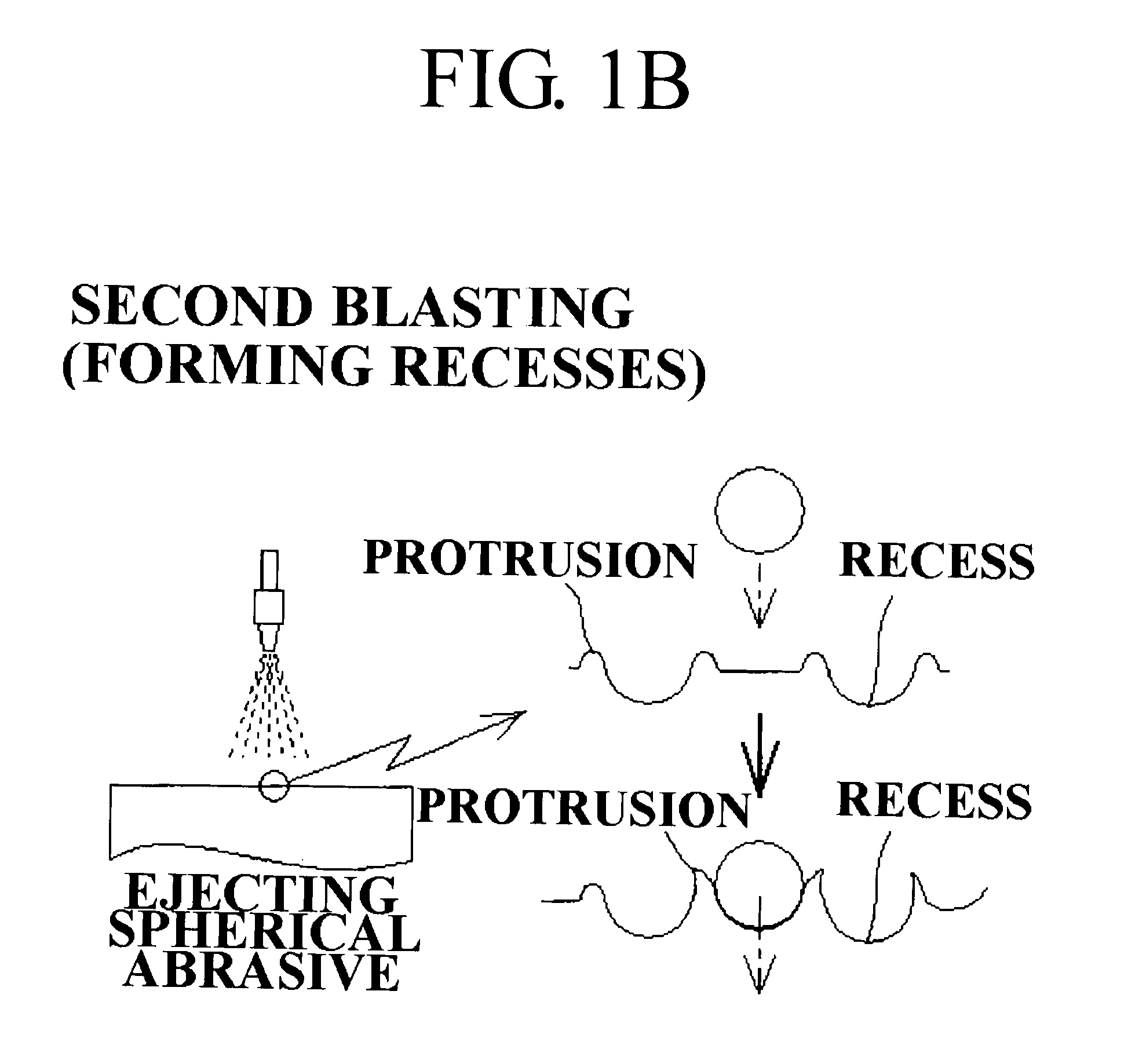

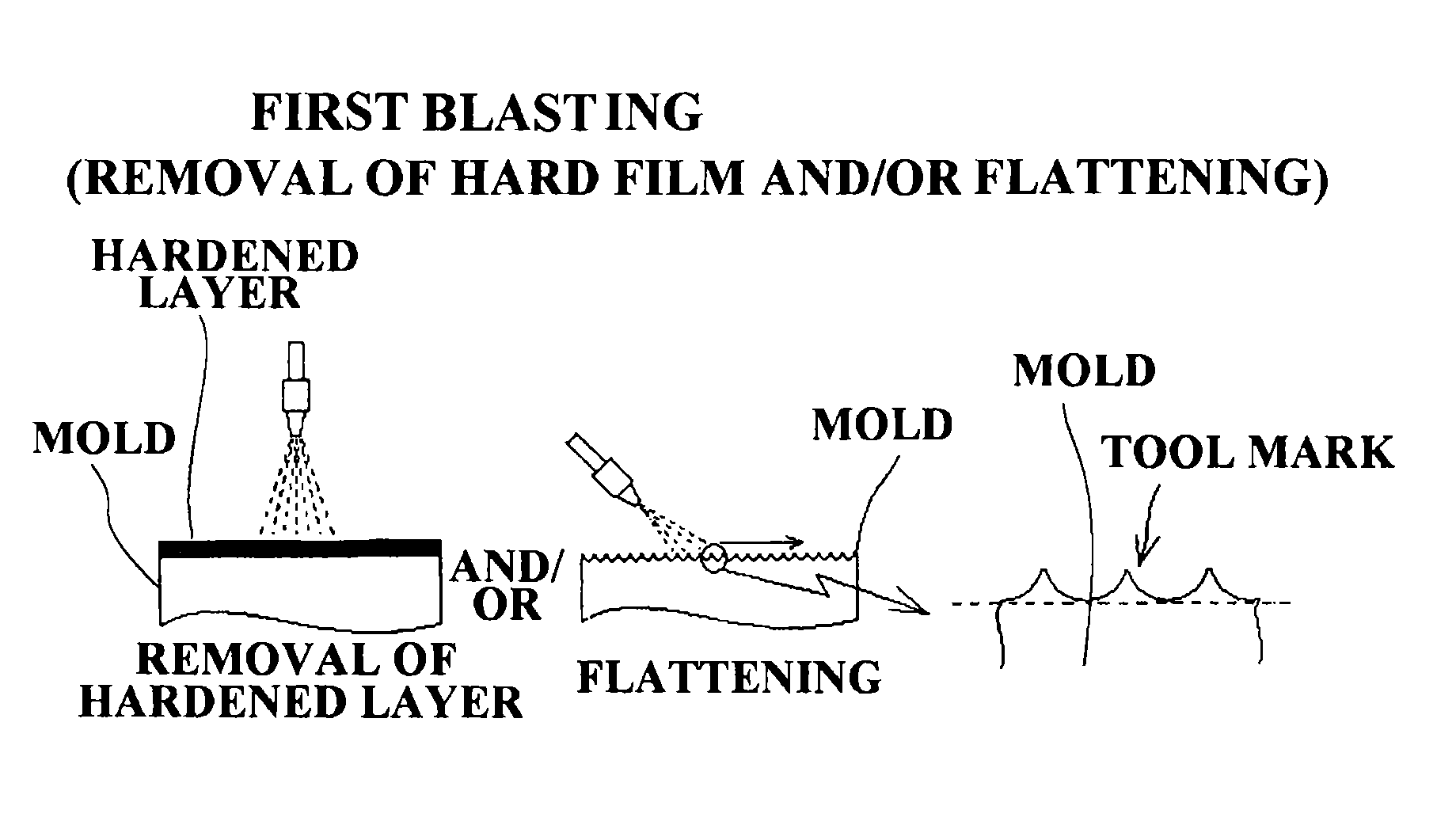

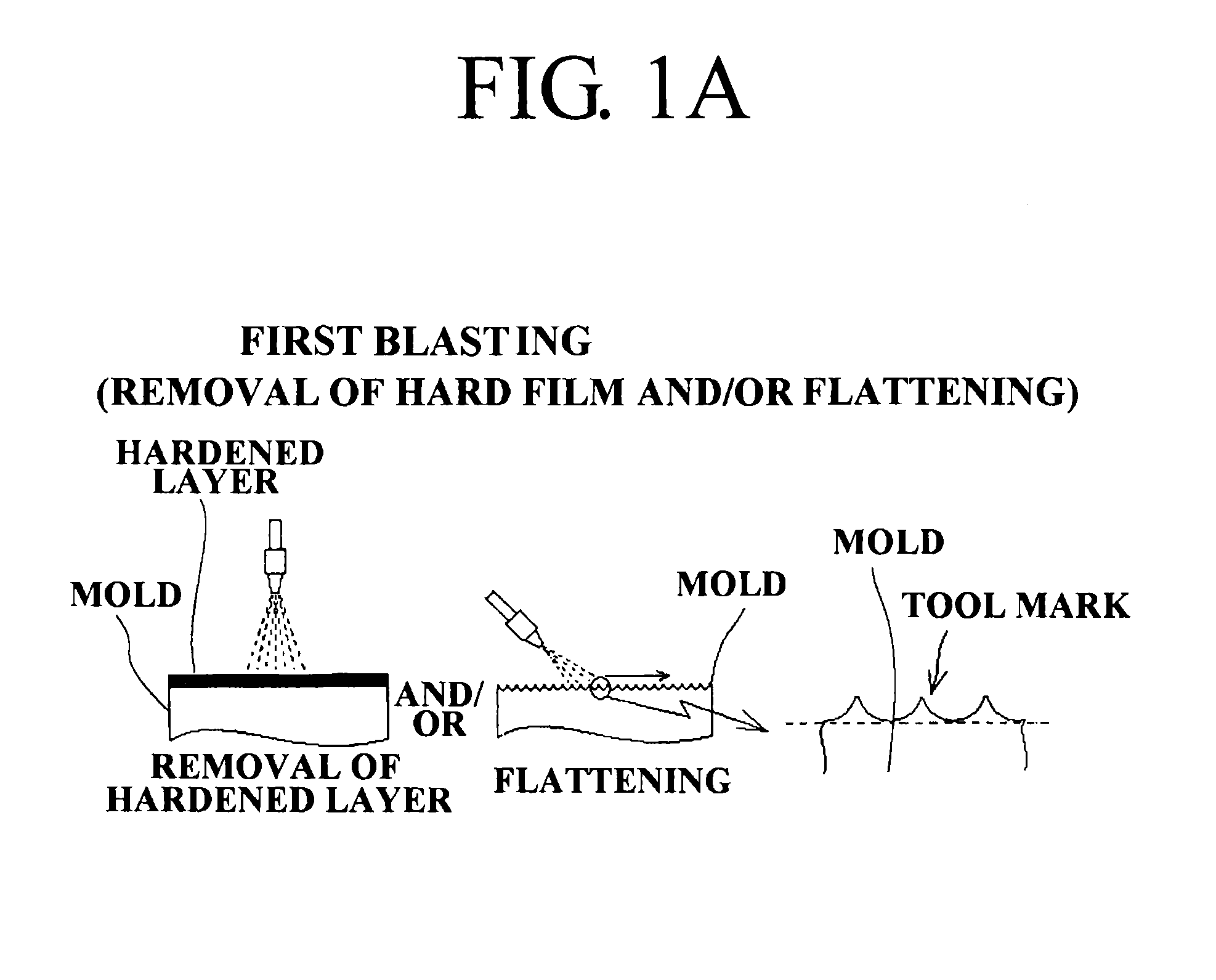

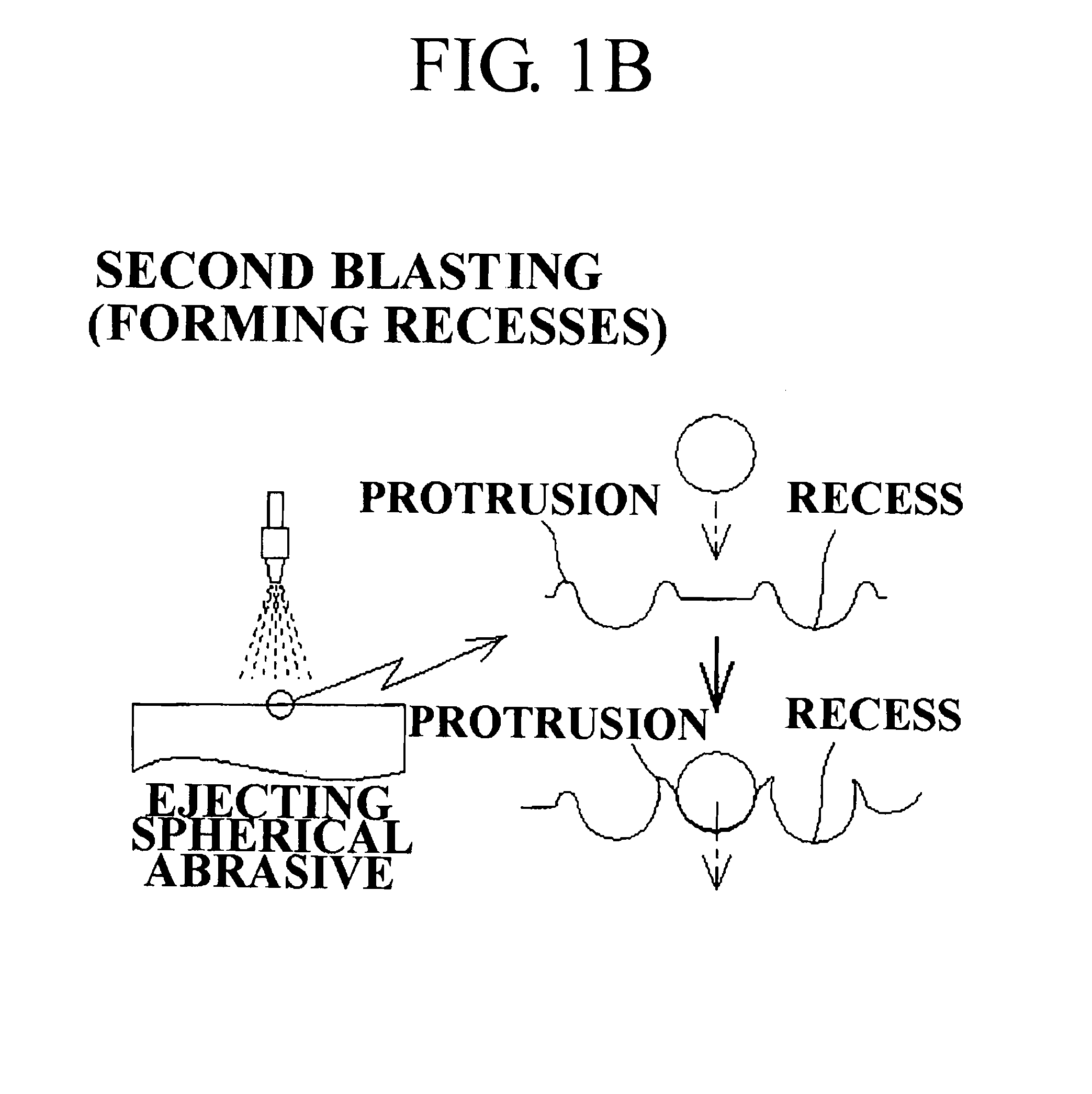

Method of treating surface of mold and mold having surface treated by said method

ActiveUS20120043044A1Good release effectEasy procedureFoundry mouldsFoundry coresElastomerAbrasive blasting

Provided is a method of treating a surface of a mold to achieve good demoldability and capable of preventing wearing of the mold by avoiding load concentration on one part of the surface of the mold. After a first blasting is performed on the surface of the mold to remove a hardened layer produced on the surface and / or to adjust the surface roughness, a second blasting is performed to create fine irregularities on the surface. Then, an elastic abrasive in which abrasive grains are carried on an elastic body, or a plate-like abrasive having a planar shape with a maximum length that is 1.5 to 100 times the thickness thereof, is ejected onto the surface of the mold at an inclined ejection angle such that the abrasive is caused to slide along the mold surface to flatten peaks of the irregularities created on the mold surface.

Owner:FUJI MFG CO LTD

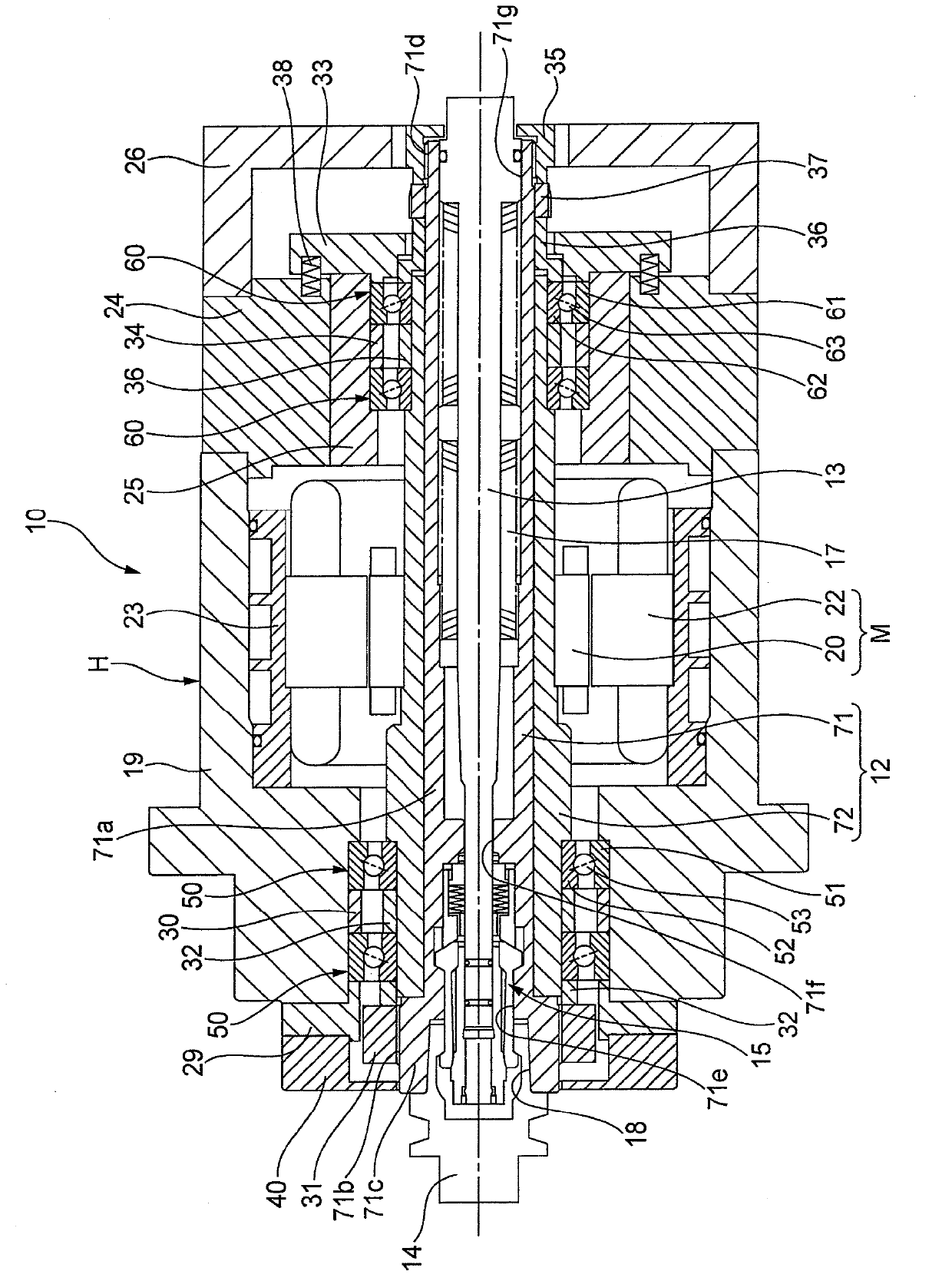

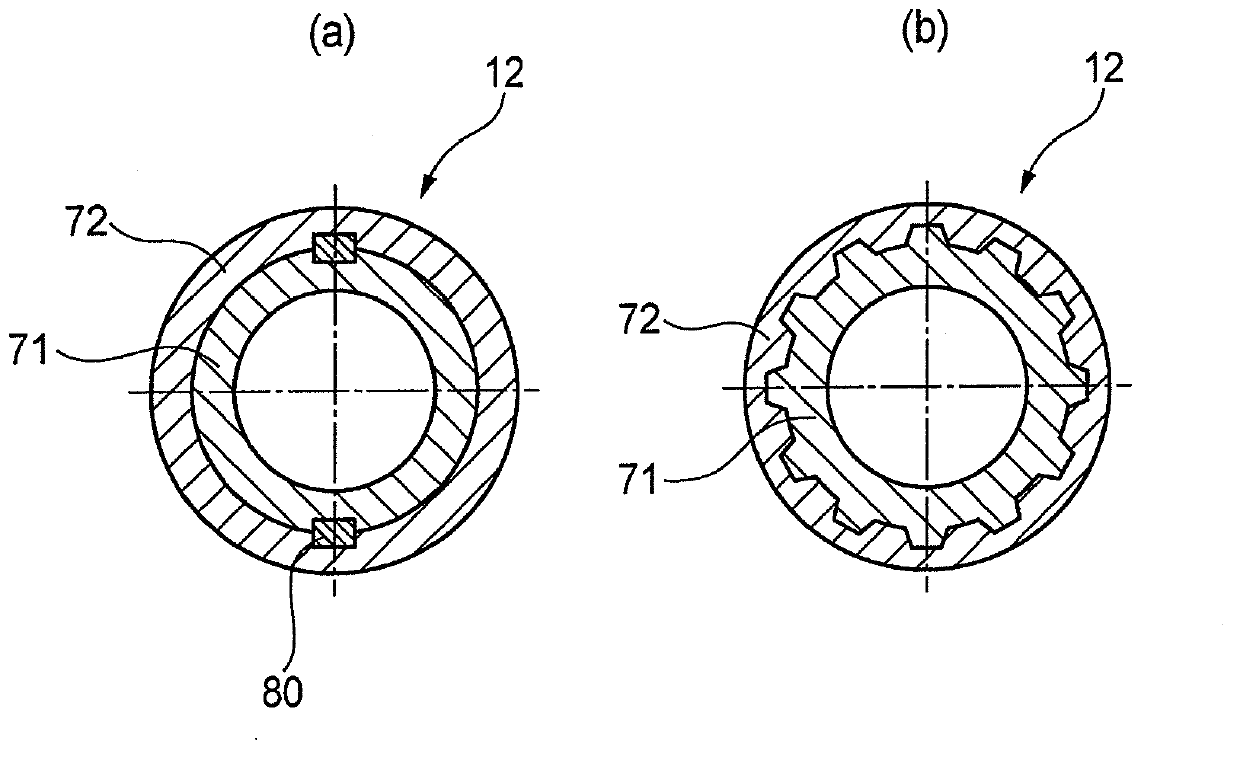

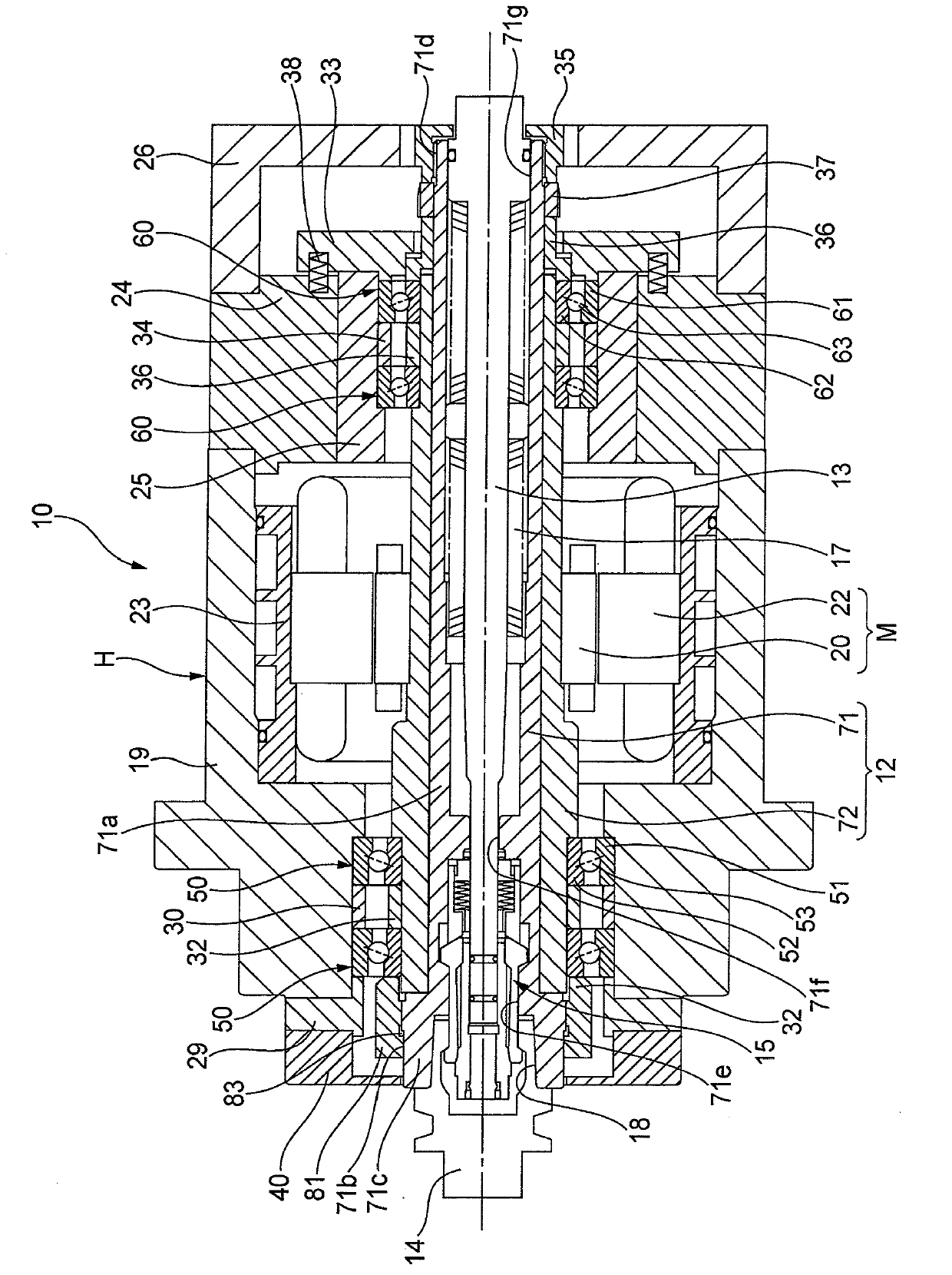

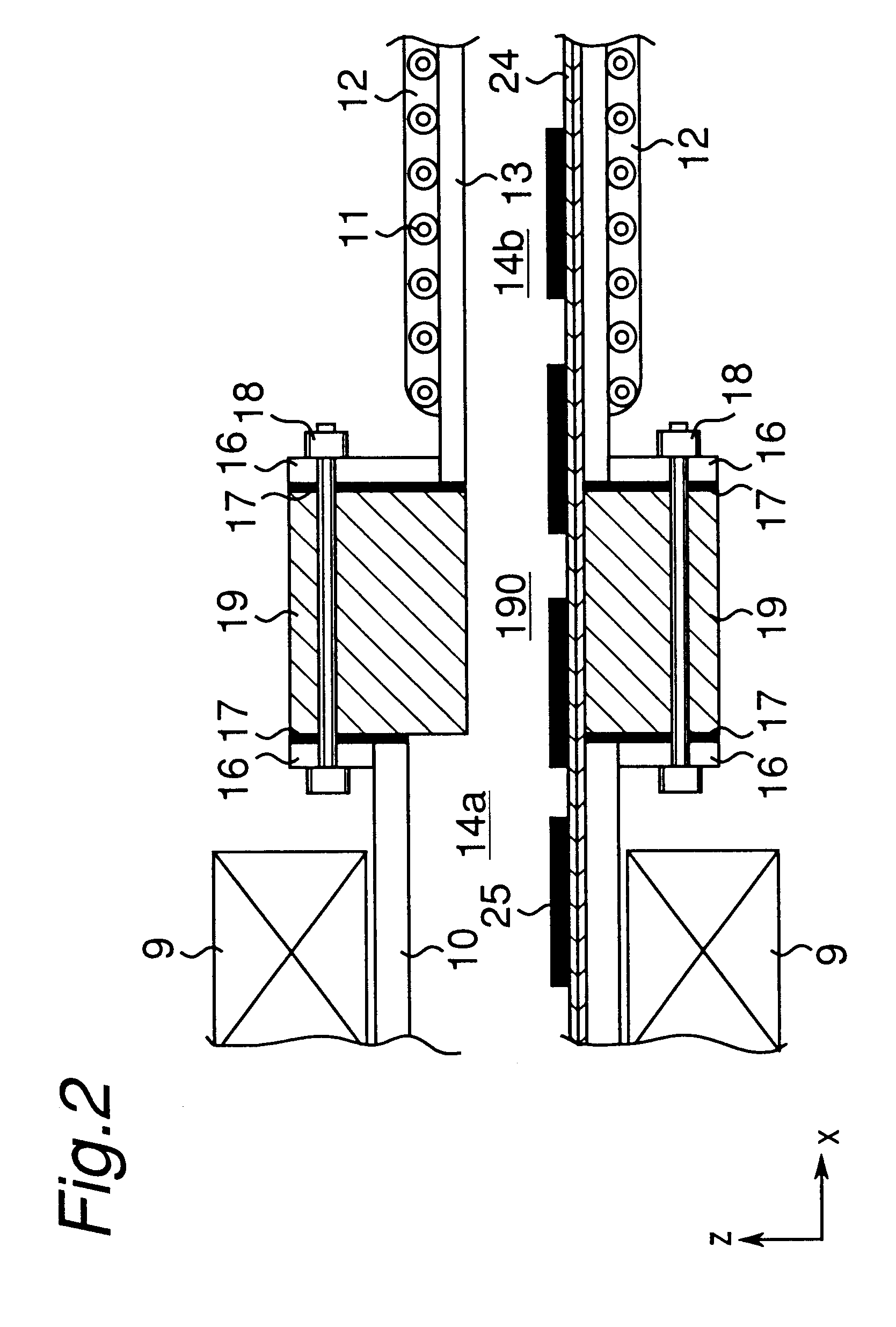

Main shaft apparatus

ActiveCN103003014AIncrease temperatureImprove machining accuracyLarge fixed membersMaintainance and safety accessoriesMetallic materialsEngineering

A main shaft apparatus (10) of a built-in motor system, wherein a rotary shaft (12) is provided with: a first cylindrical component (71) made of metal material; and a second cylindrical component (72) made of carbon fibre composite material, which is positioned on the outer peripheral surface of the first cylindrical component (71) and into the outer peripheral surface of which a rotor (20) fits. By virtue of this, the temperature increase of the rotary shaft and a bearing due to the heat produced by the rotor can be controlled and processing precision can be improved.

Owner:NSK LTD

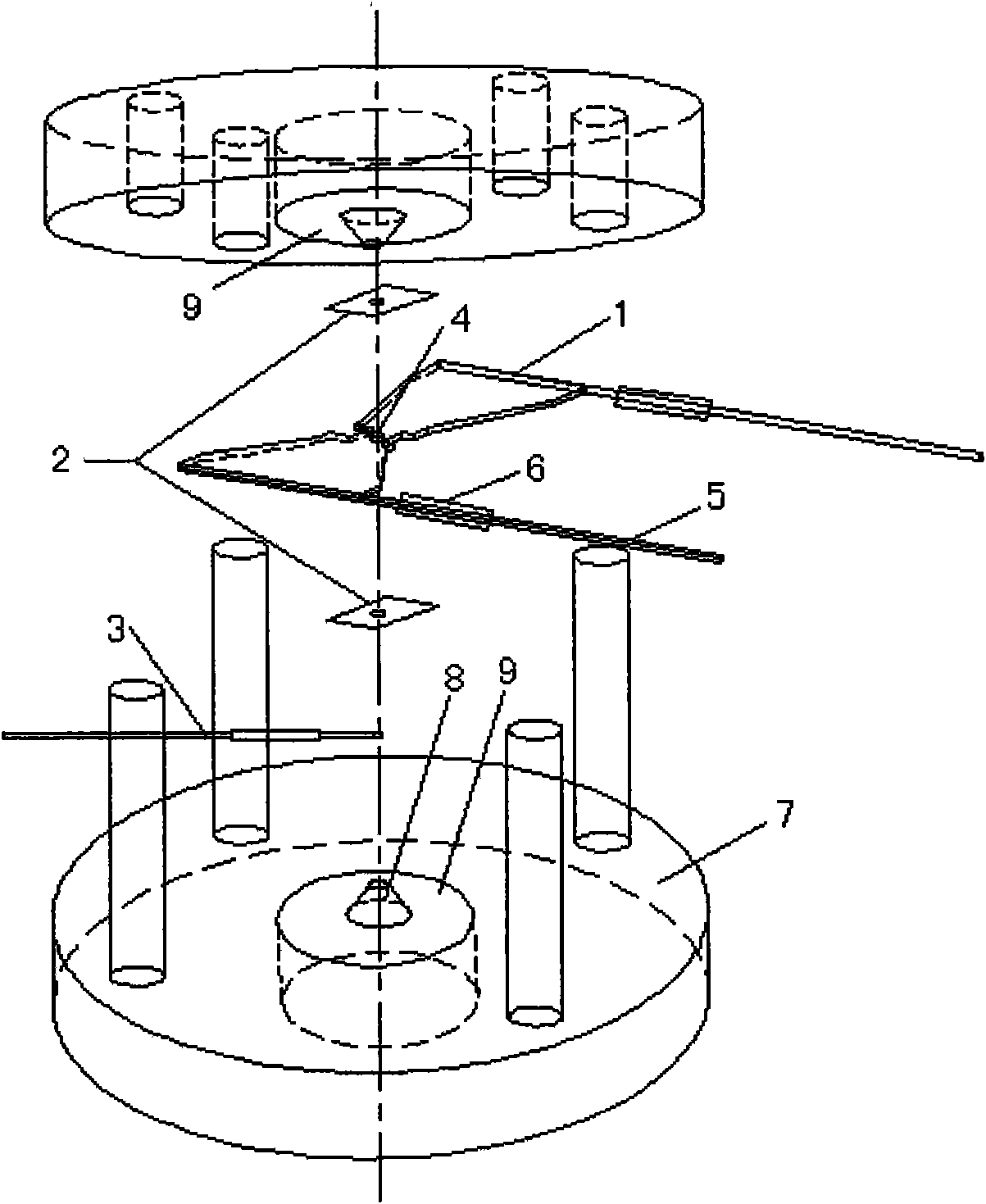

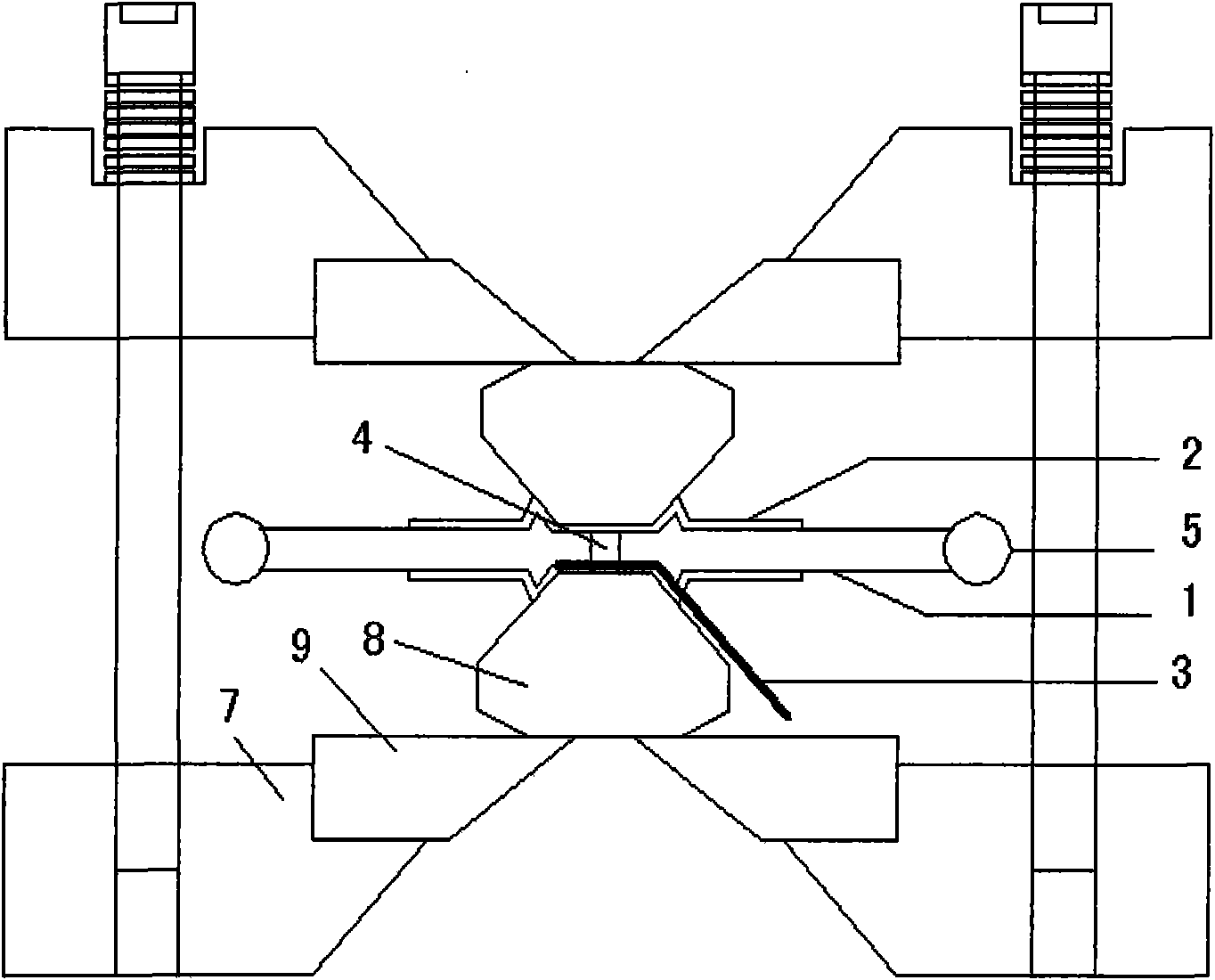

High temperature and high voltage experimental device for heating gasket

InactiveCN101566543AAvoid heat conductionSimple structureMaterial strength using tensile/compressive forcesRaman scatteringMicaEngineering

The invention relates to a high temperature and high voltage experimental device for heating a gasket, pertaining to the technical field of high temperature and high voltage. The structure of the device is as follows: two anvil cells (8) in diamond or white gem material form a top-to-top anvil and holes are opened in the center of a gasket (1) to be used as a sample heating chamber (4), the anvilcells (8) are arranged in the chamber body of a pressing machine (7) to be pressed; the central part of the gasket (1) is made into a shape with the central width smaller than the width in two ends; the position of the gasket (1) opposite to the anvil face of the anvil cells (8) is padded with a mica sheet used as an insulating and thermal-preventing layer (2); the two ends of the gasket (1) are respectively welded with conducting wires (5) which are used for charging the gasket (1) with direct current to realize local heating of sample chamber area in high voltage equipment. The experimentaldevice has simple structure, good repeatability and low cost, and the construction of the system can be easily completed in a high voltage laboratory. Therefore, the invention is a high-temperature and high-voltage technology with good potential.

Owner:JILIN UNIV

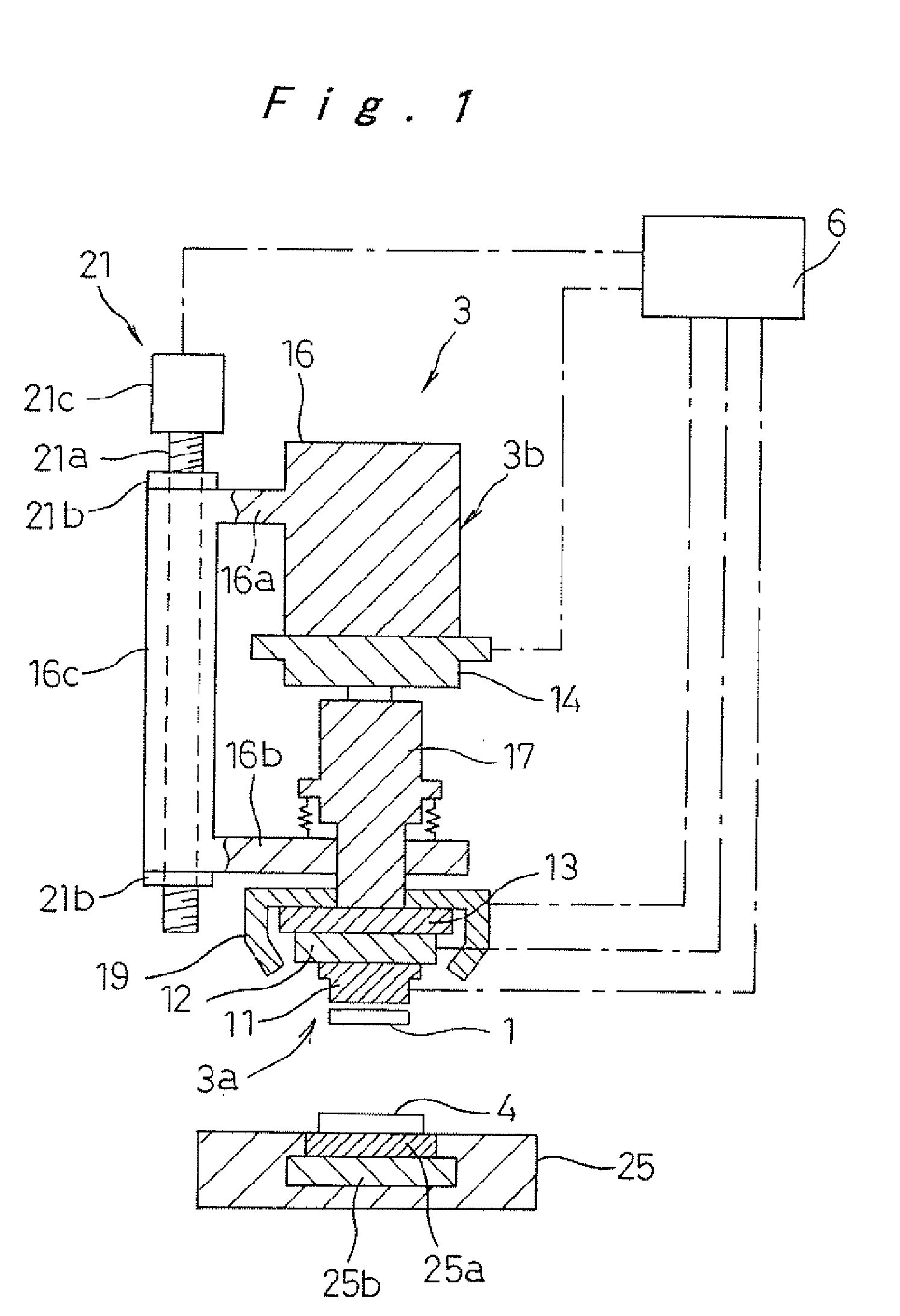

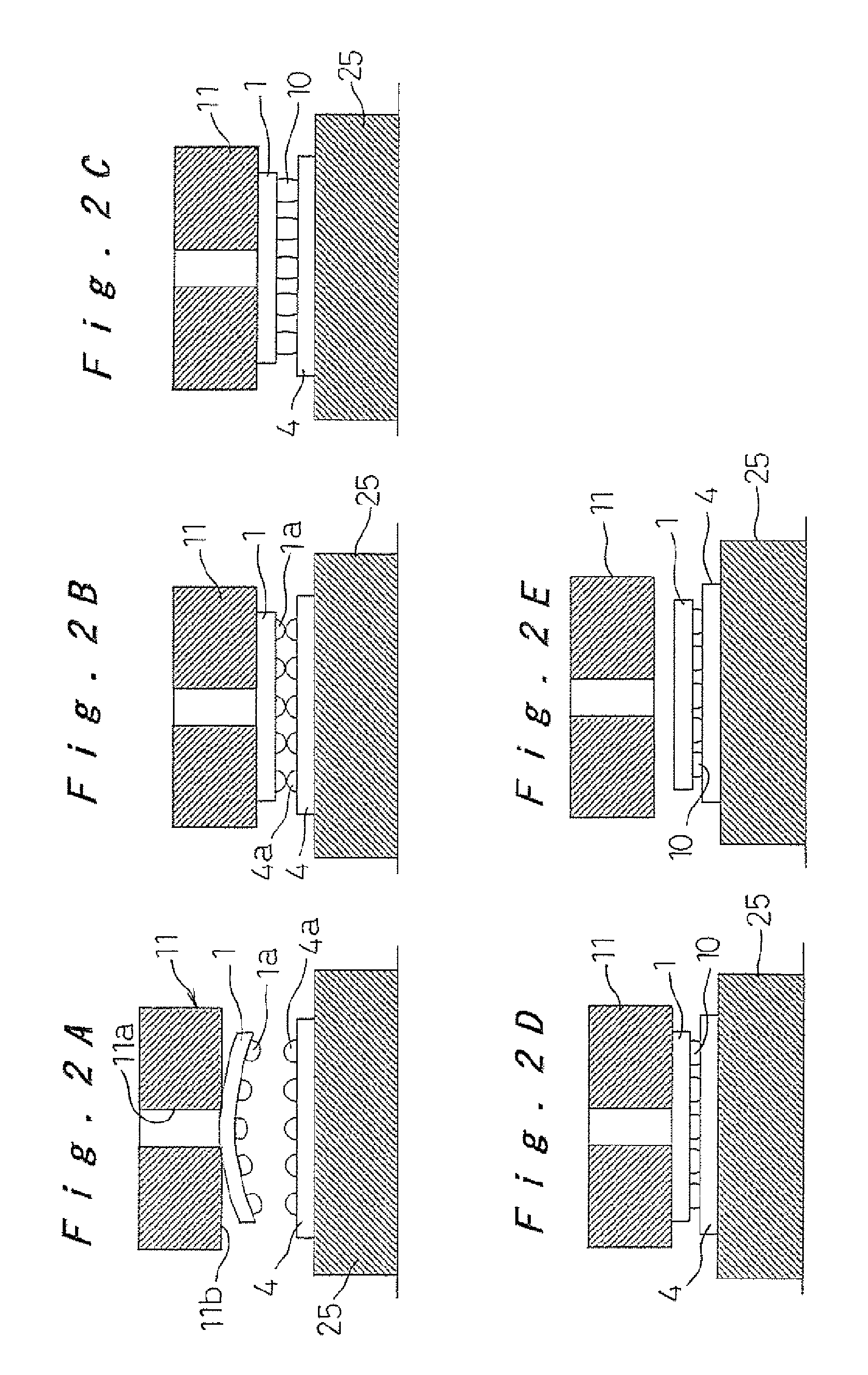

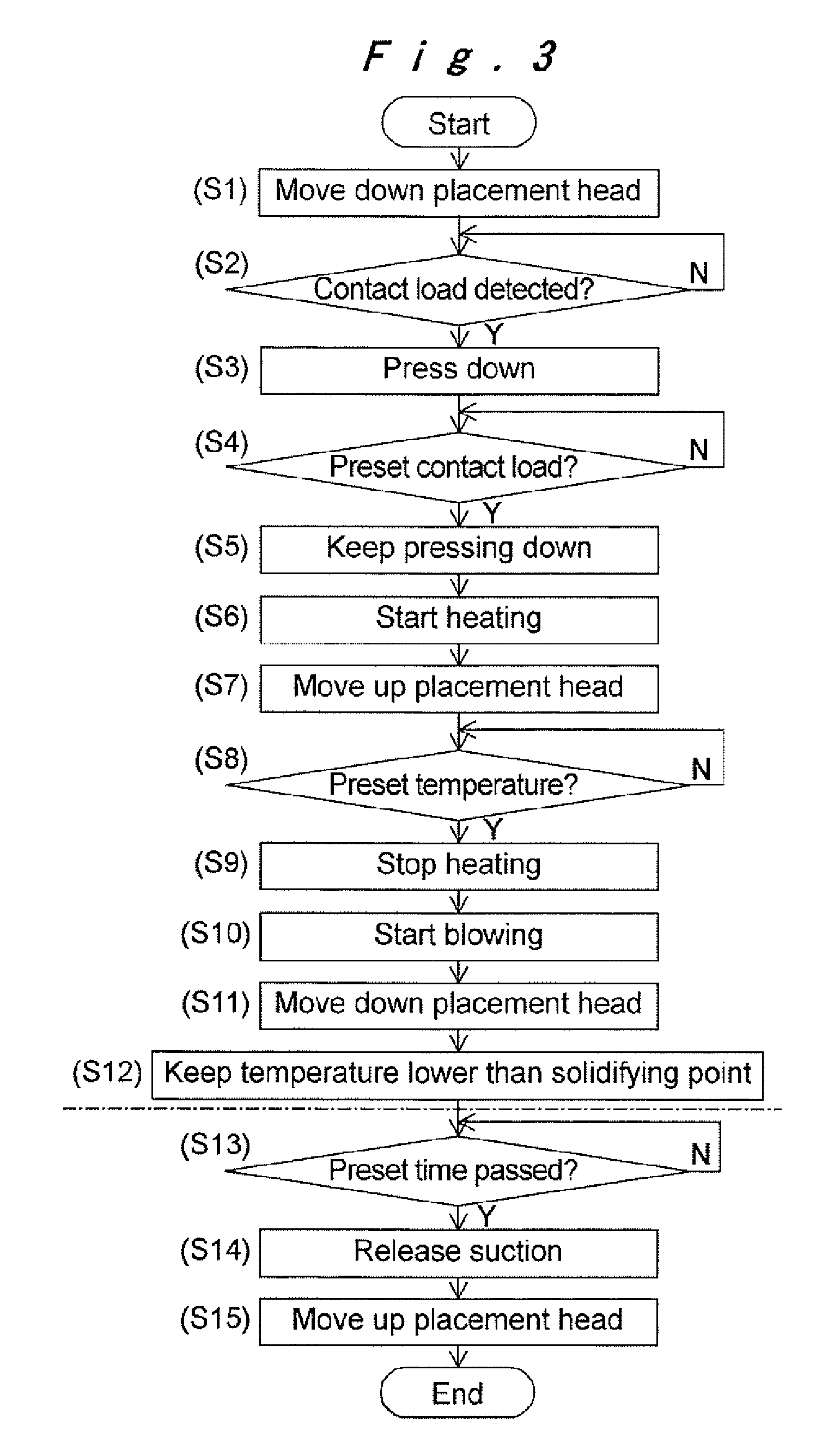

Component mounting method and component mounting apparatus

InactiveUS20070181644A1Avoid bond failureFlatness is easy to guaranteeCooking-vessel materialsPrinted circuit assemblingSuction stressEngineering

A method and an apparatus for mounting electronic components that enables precise mounting of electronic components, such as deformation-prone thin IC chips or fine-pitch and high-pin-count IC chips, on a substrate. Thin IC chips, which conventionally tend to lose flatness because of warping that occurs during production or deformation that occurs when picked up with a suction nozzle, are pressed against a substrate (4) with a preset load using a suction nozzle with a flat suction surface (11b) so as to correct deformation; the suction nozzle (11) is controlled to move up to make up for a decrease in the distance between the oppositely spaced IC chip and the substrate (4) that is caused by thermal expansion due to the heating for melting solder bumps (1a) on the electrodes; and the suction nozzle (11) is controlled to move down to mitigate the effect of a pulling-apart force applied to the molten parts as the thermally expanded parts cool down and contract.

Owner:PANASONIC CORP

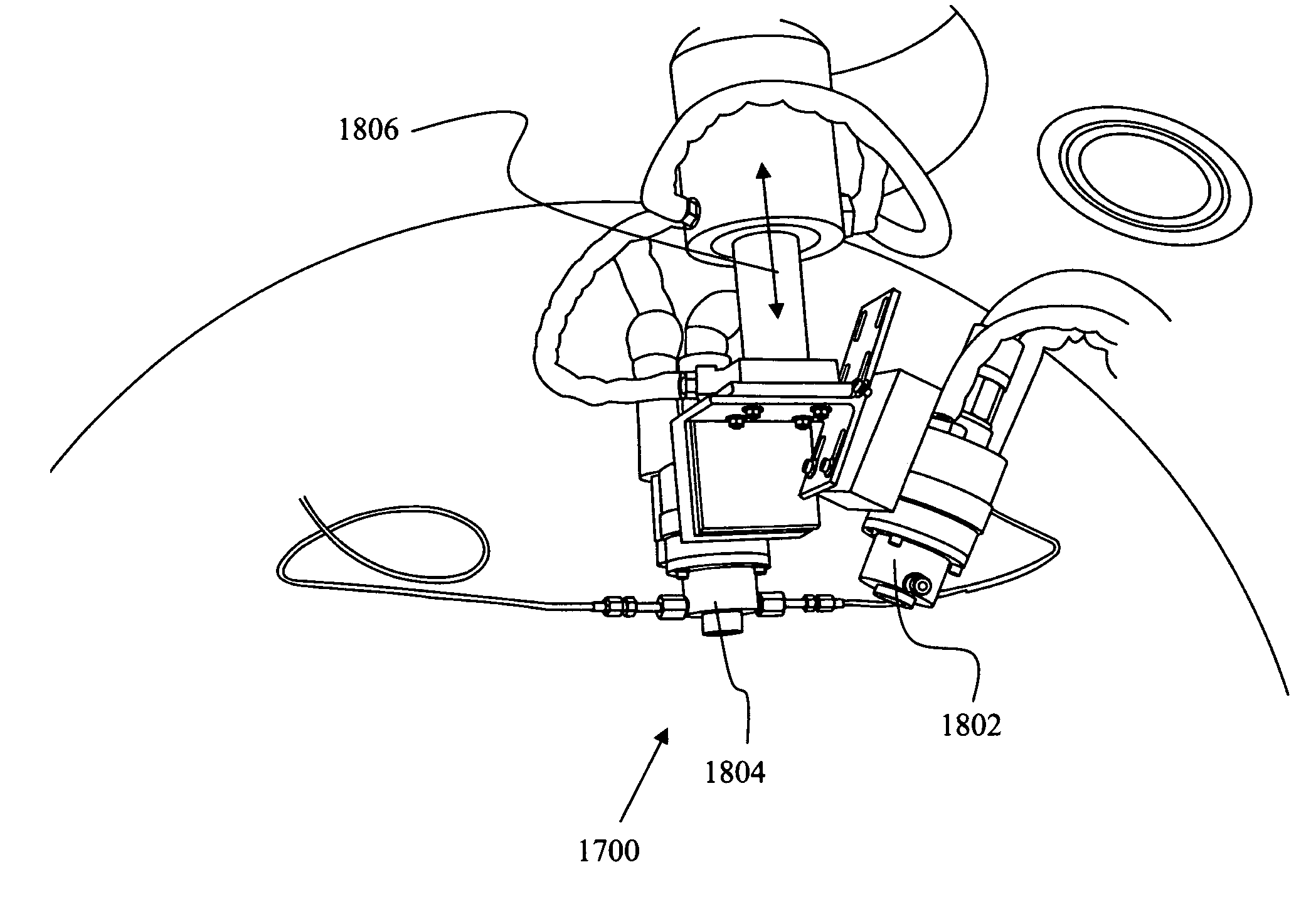

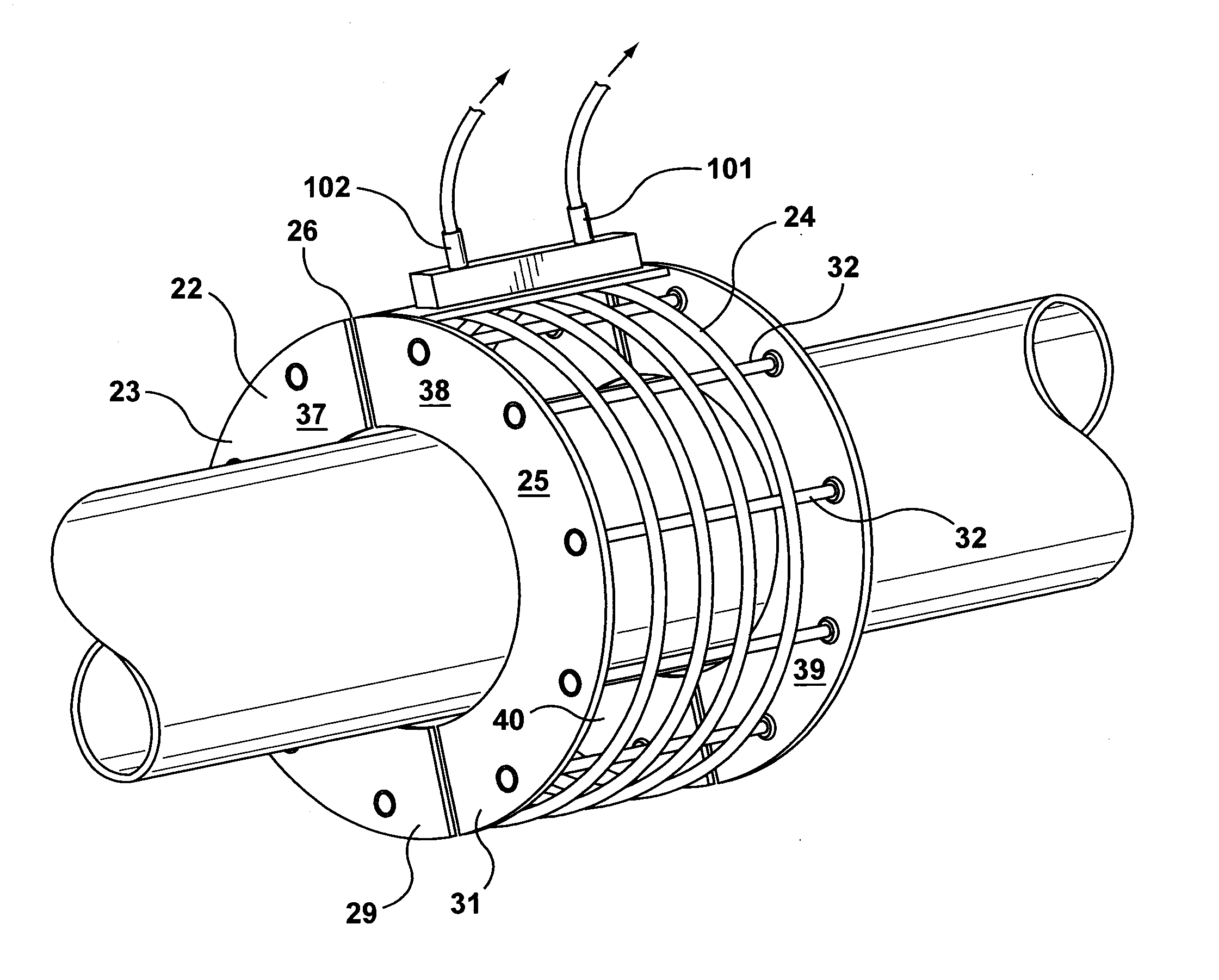

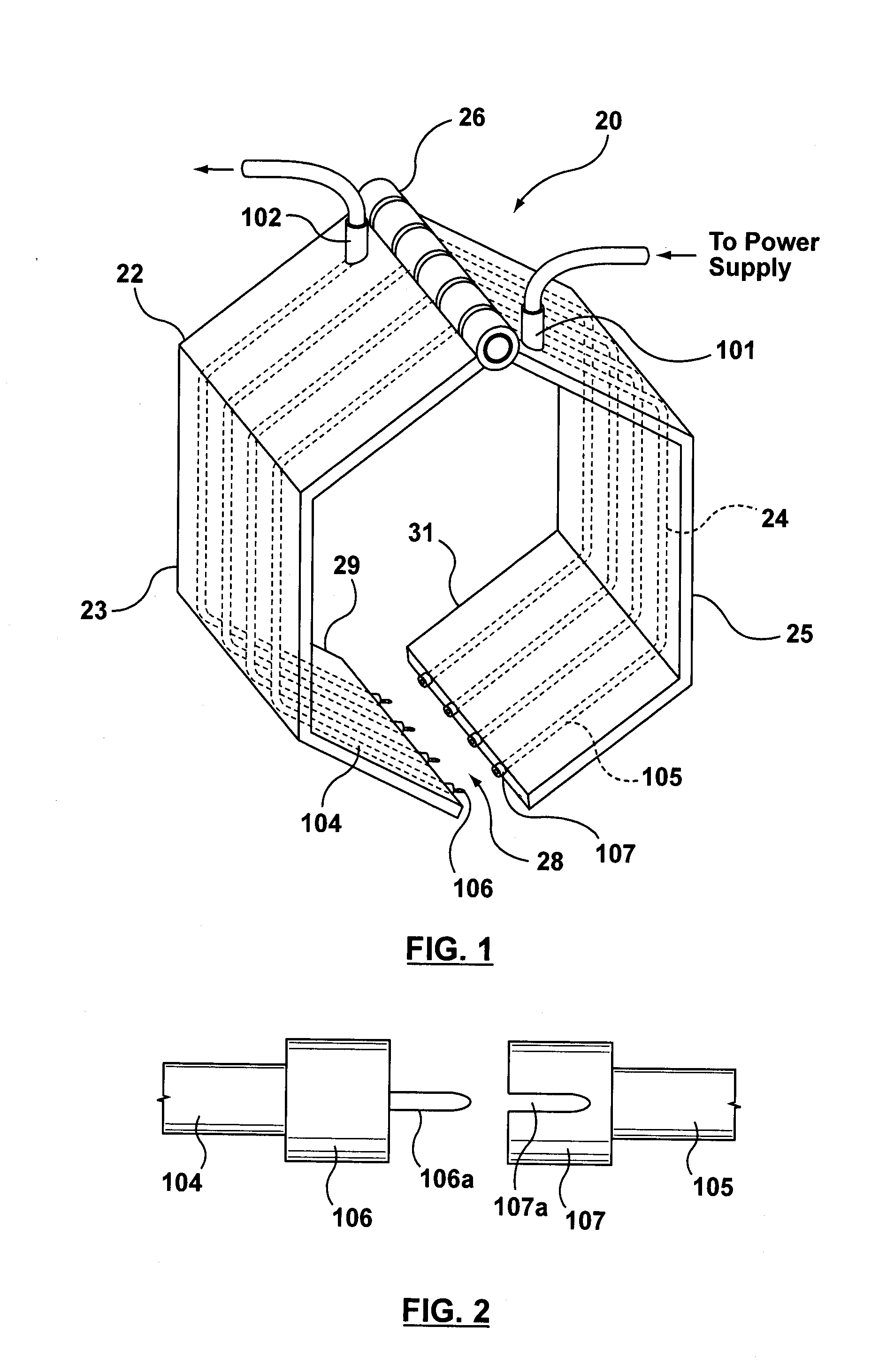

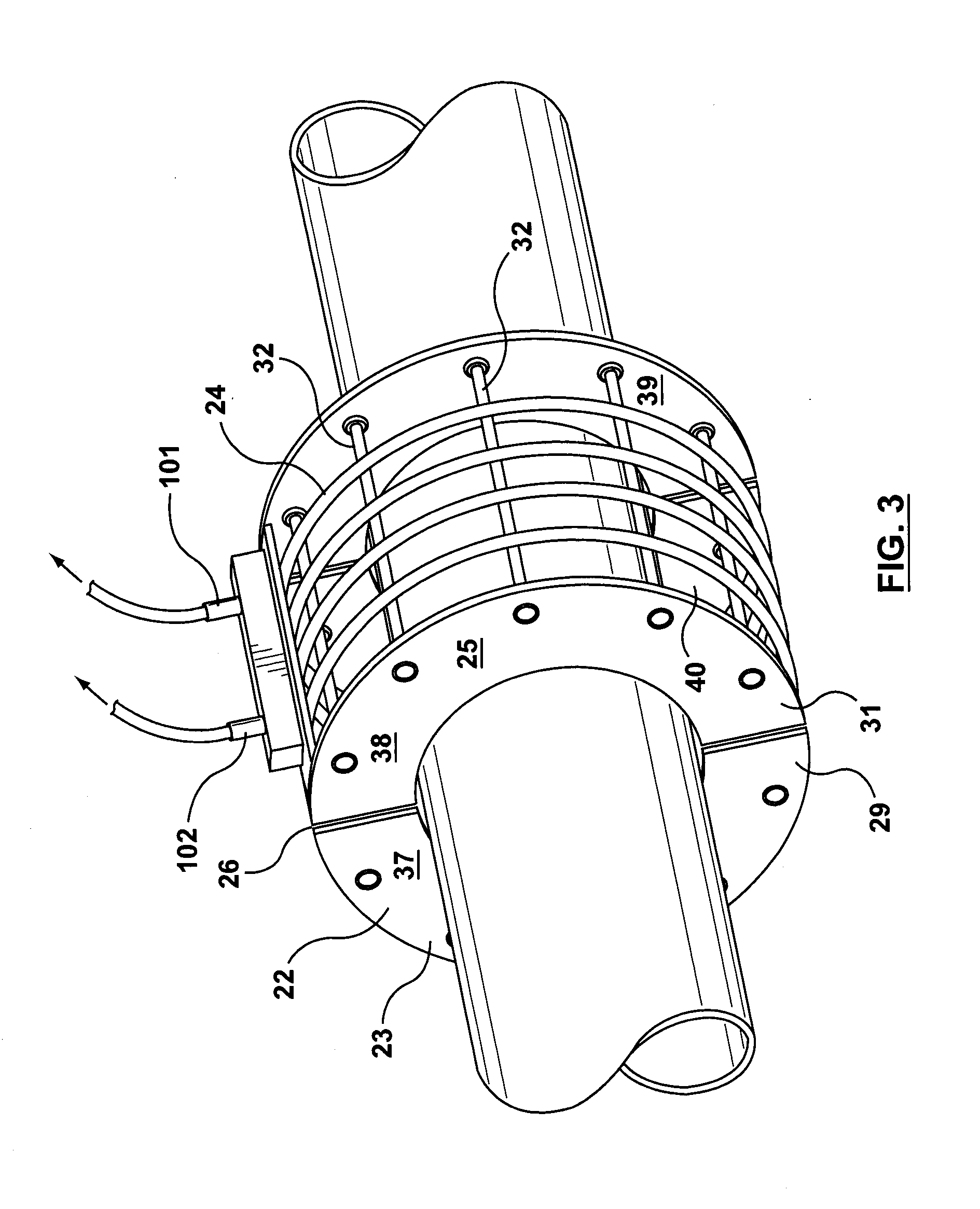

Induction heating apparatus for pipeline connections

InactiveUS20130341320A1Fast and efficient heatingAvoid heatingCoil arrangementsPipe heating/coolingElectrical and Electronics engineeringInduction heating

An induction heating apparatus for use in pre-heating pipe joints. The induction heating apparatus comprises a frame for applying around the pipe joint, and an induction heating coil made from Litz cable wires.

Owner:SHAWCOR LTD

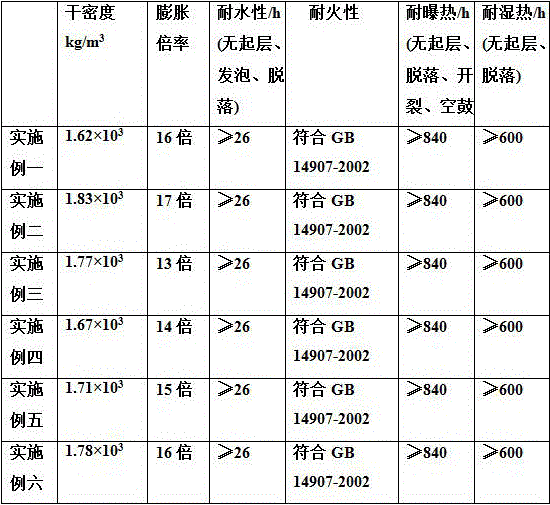

Ultrathin steel structure waterproof coating and preparation method thereof

ActiveCN105838171AImprove fire resistanceImprove insulation performanceFireproof paintsFiberSodium Bentonite

Ultrathin steel structure waterproof coating is characterized by being made from the following materials according to parts by weight: 5-20 parts of nano silicon dioxide aerosol, 15-45 parts of acrylic emulsion, 30-80 parts of melamine, 30-60 parts of pentaerythritol, 50-80 parts of ammonium polyphosphate, 10-15 parts of titanium dioxide, 5-15 parts of sepiolite fiber, 5-15 parts of talc, 5-15 parts of expansible graphite, 0.2-0.8 part of a waterborne wetting dispersant, 0.02-0.08 part of modified organic bentonite, and 0.05-0.2 part of a waterborne leveling agent. The preparation method comprises: weighing the components according to their ratio; adding the components sequentially into a high-speed dispersing machine for mixing and dispersing; standing and aging for 10-15 h; metering and packaging. The fireproof coating of the invention can reduce the increase in the steel structure loading to the coating and has no influence in the expanding and foaming process, expansion rate of a coating layer is high, heat isolating capacity of the fireproof coating can be improved greatly, and fire resistance of a steel structure can be improved greatly.

Owner:SICHUAN TIANFU FIRE MATERIAL

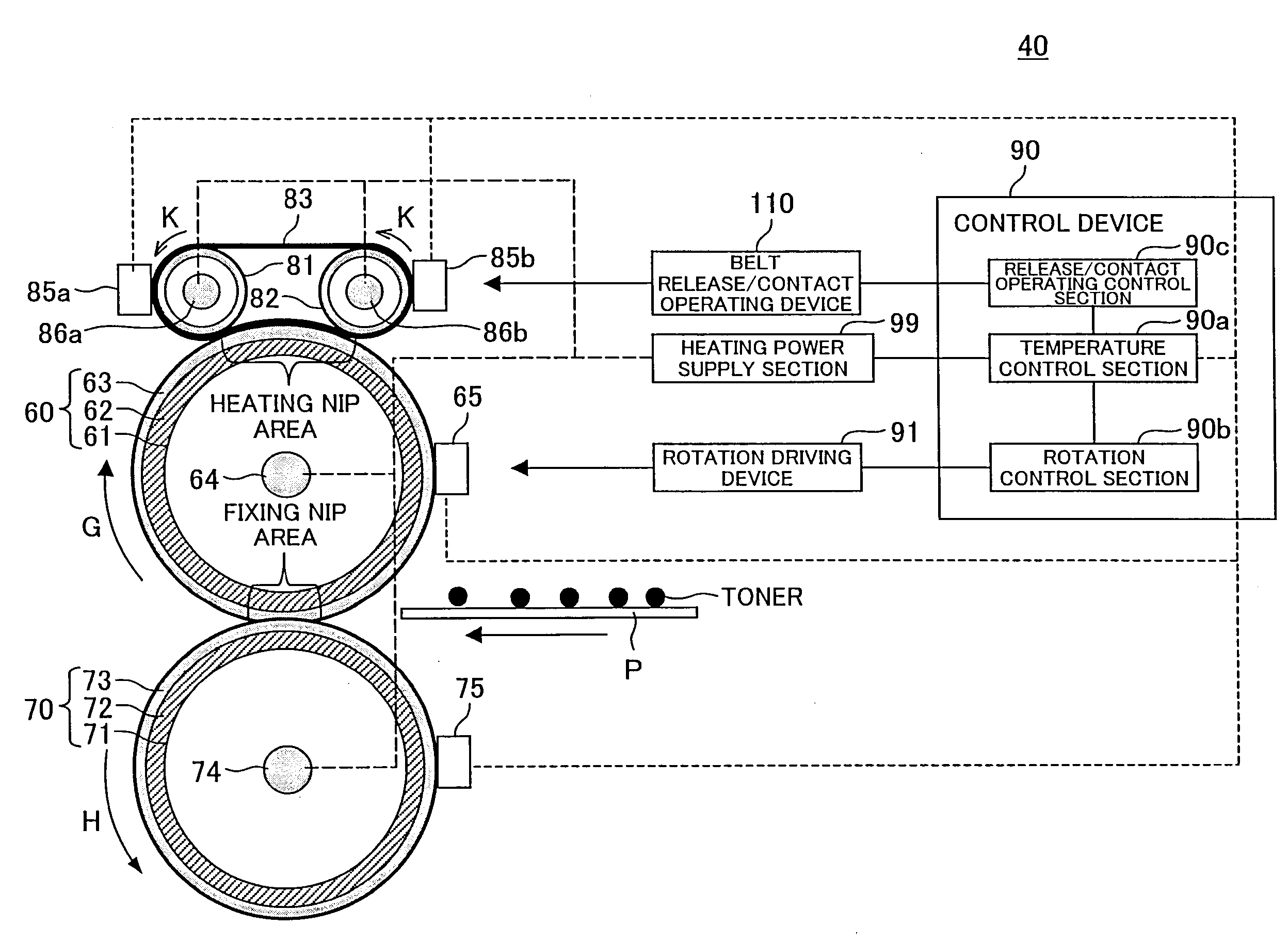

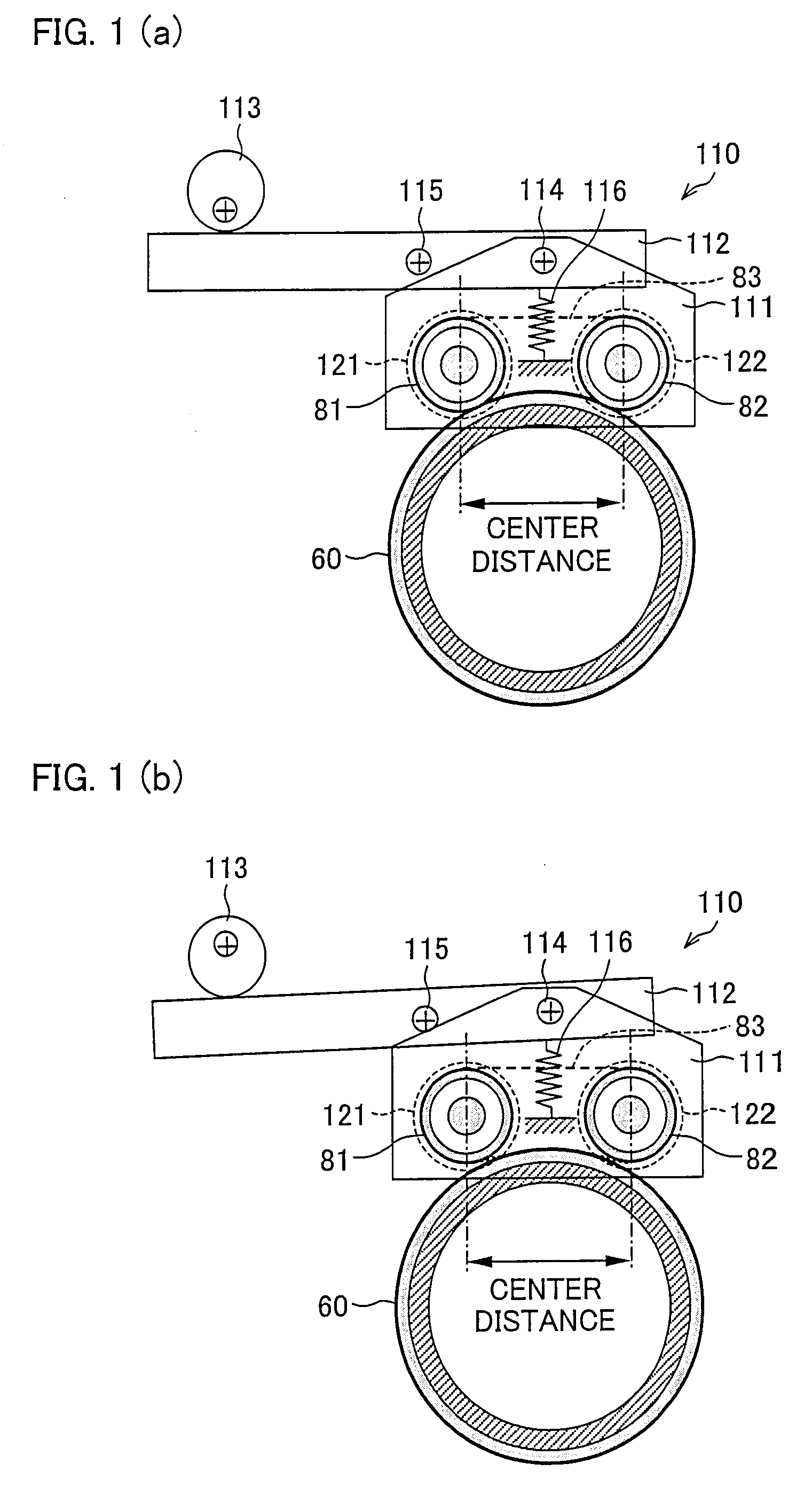

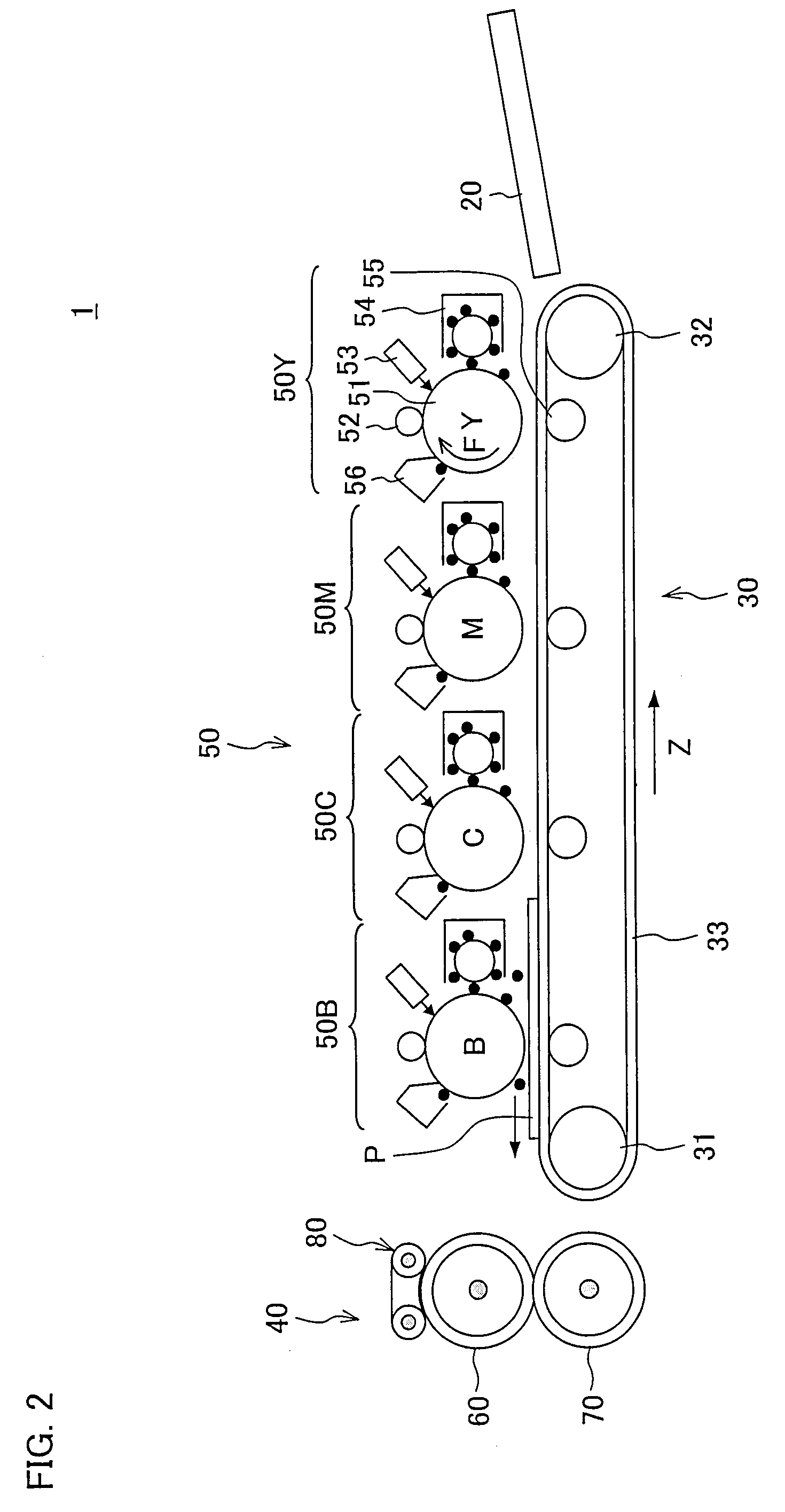

Fixing apparatus and image forming apparatus including the same

InactiveUS20070248389A1Increased durabilityLife safetyElectrographic process apparatusImage formationEngineering

Owner:SHARP KK

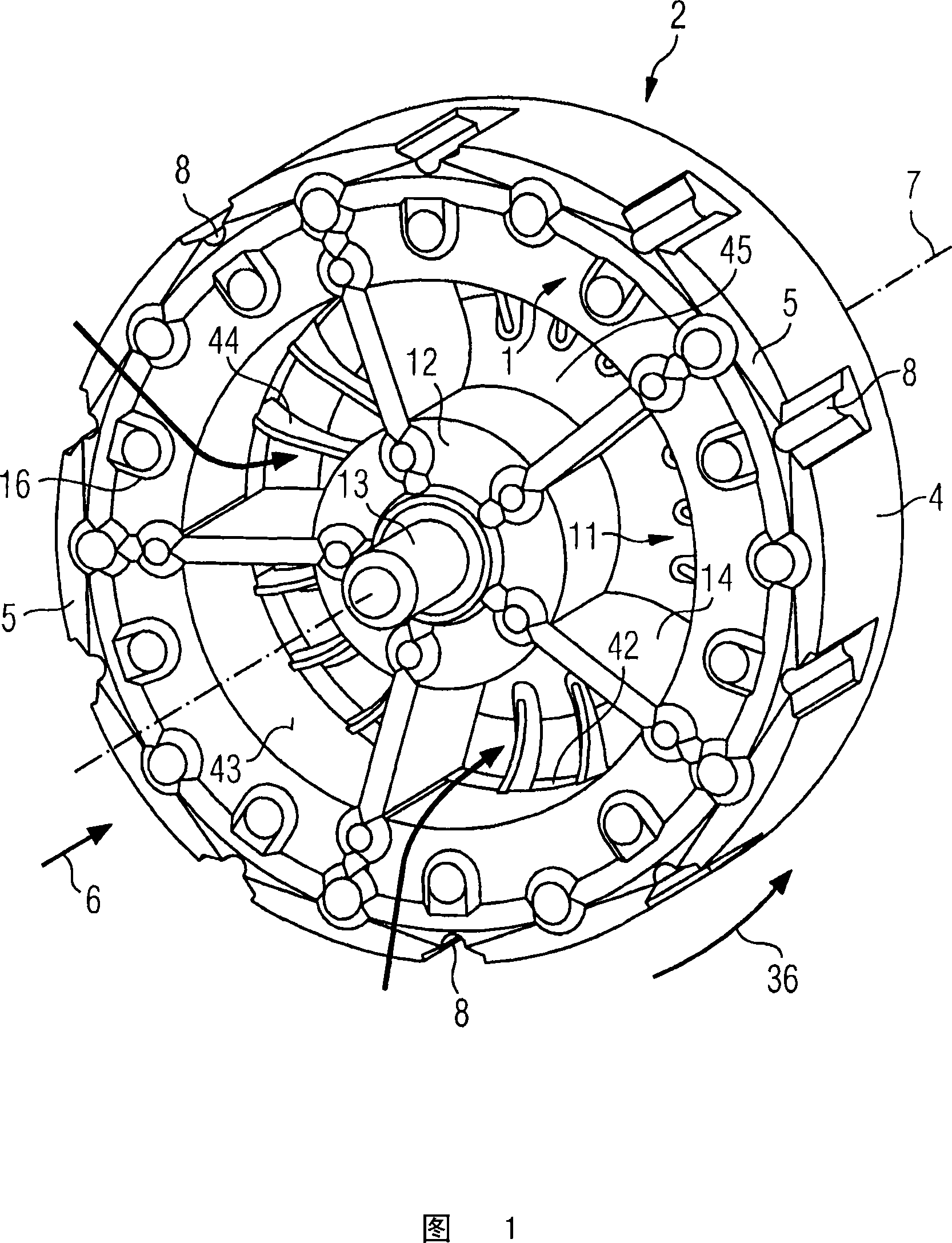

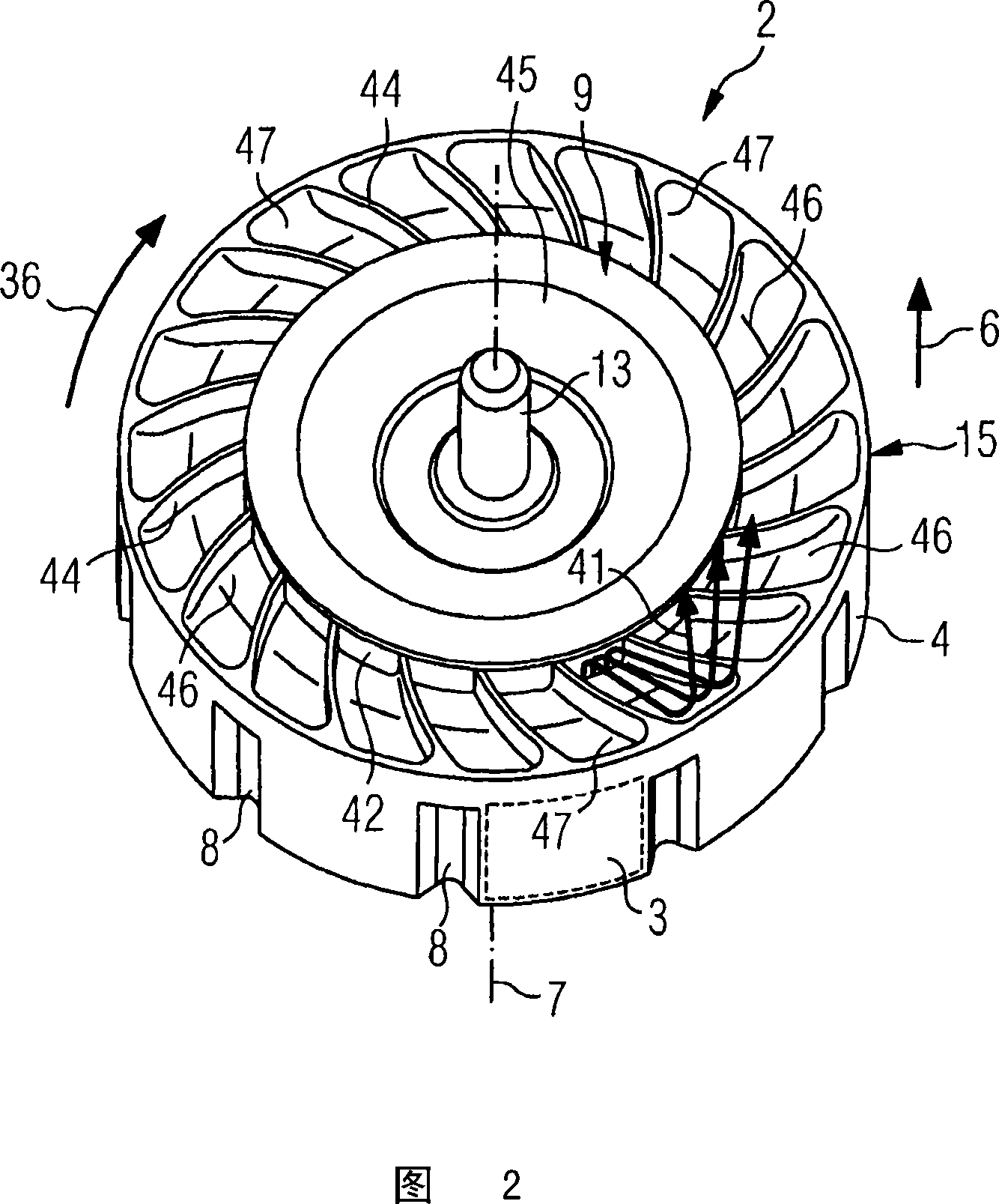

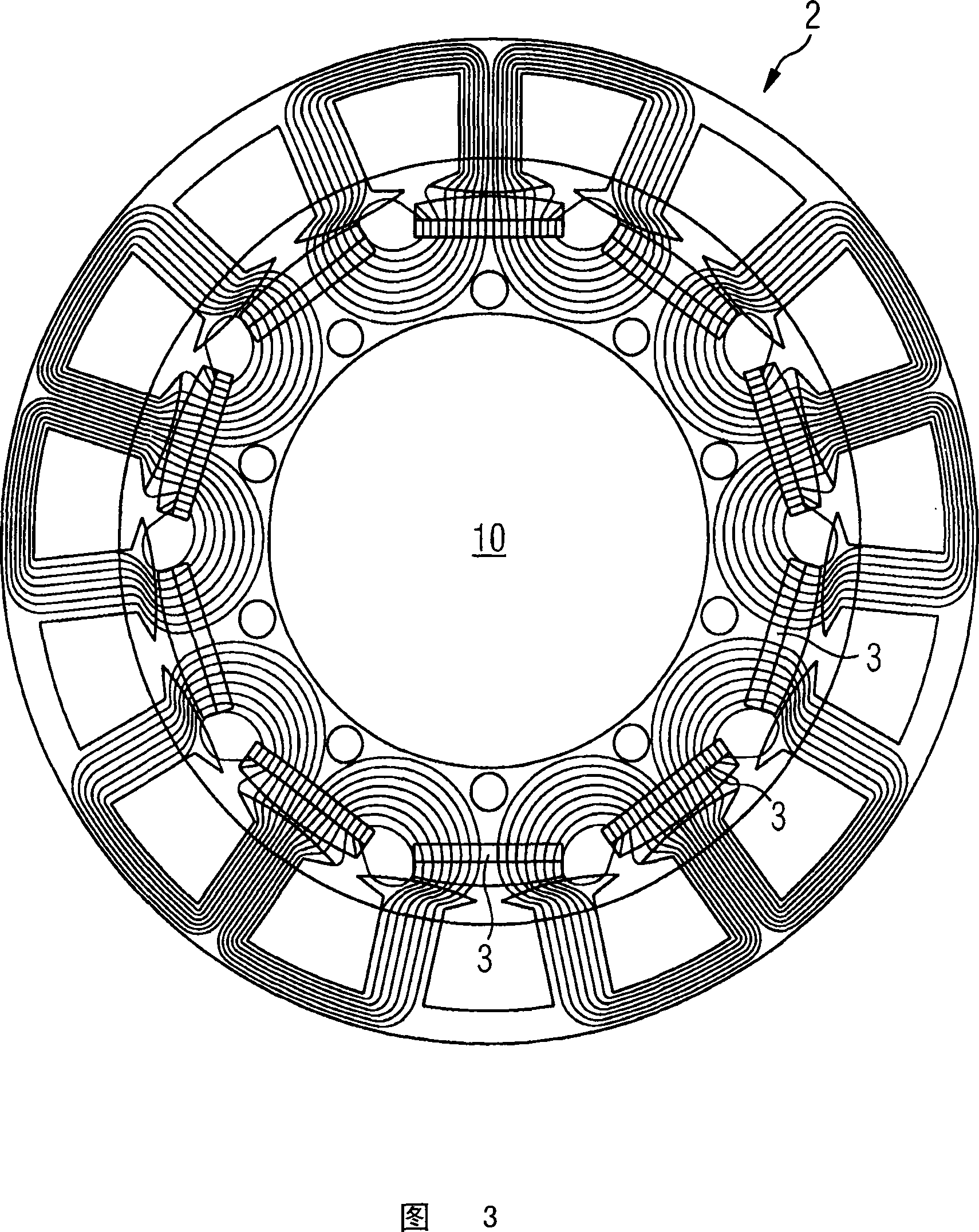

Electric machine

InactiveCN101171736AImprove cooling effectAvoid failureAssociation with control/drive circuitsMagnetic circuit rotating partsMagnetic tension forceElectric machine

The invention relates to an electric machine comprising a rotor and a stator as well as a method for cooling such a machine. In order to improve cooling of an electric machine, the inventive electric machine (18) comprises a rotor (2) that is excited by permanent magnets, a stator (38), magnets (3) which are arranged along the circumferential line of the rotor (2) in such a way that a magnetically non-effective zone (10) is created around the center of the rotor (2), at least one opening (11) in the magnetically non-effective zone (10) of the rotor (2) in order to embody an air flow path (41) through the rotor (2), said opening (11) extending substantially in an axial direction, and a fan (15, 56, 58, 59) which moves along with the rotor (2) and is used for embodying an air flow through the opening (11) of the rotor (2).

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

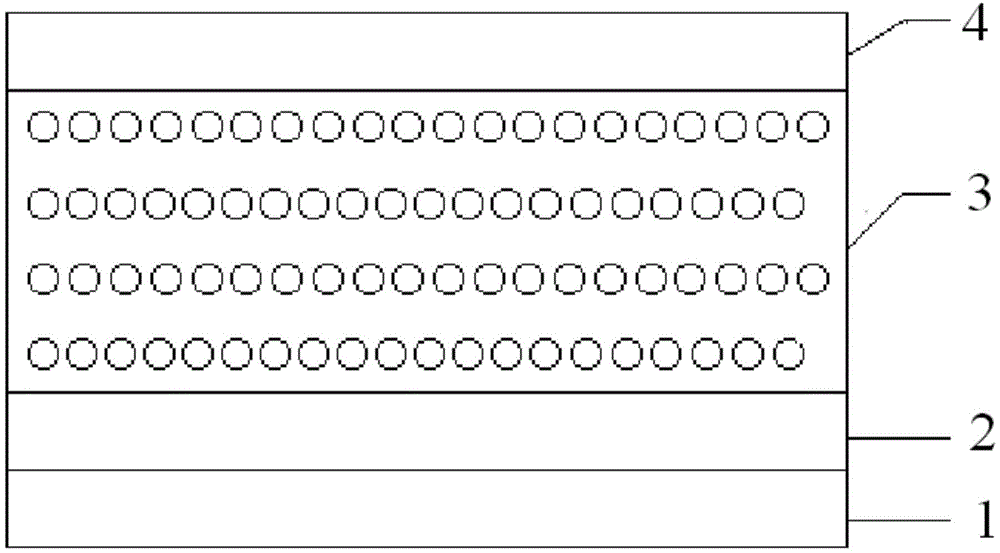

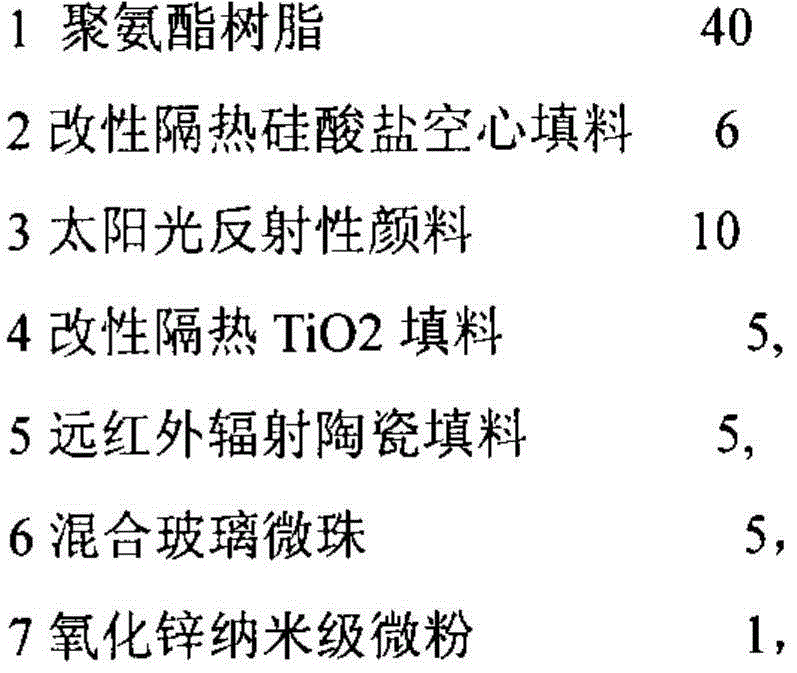

Coating material with characteristics of efficiency, energy saving, heat shield, cooling and corrosion resistance

InactiveCN104985891AImprove infrared reflectivityGood dispersionSynthetic resin layered productsPolyurea/polyurethane coatingsSurface layerThermal insulation

The present invention relates to a coating material with characteristics of efficiency, energy saving, heat shield, cooling and corrosion resistance, wherein the coating material is a three-layer composite material formed from a corrosion resistance bottom layer, a thermal insulation middle layer and a heat radiating surface layer, the corrosion resistance bottom layer is epoxy zinc-rich paint, the thermal insulation middle layer comprises a three-component coating material and a curing agent according to a weight ratio of 35-50:1, and the heat radiating surface layer is a composite surface layer adopting a polyurethane resin as a film forming substance. Compared with the coating material in the prior art, the coating material of the present invention integrates advantages of corrosion resistance, thermal barrier, heat reflection, and heat radiation.

Owner:德邦新材料有限公司 +1

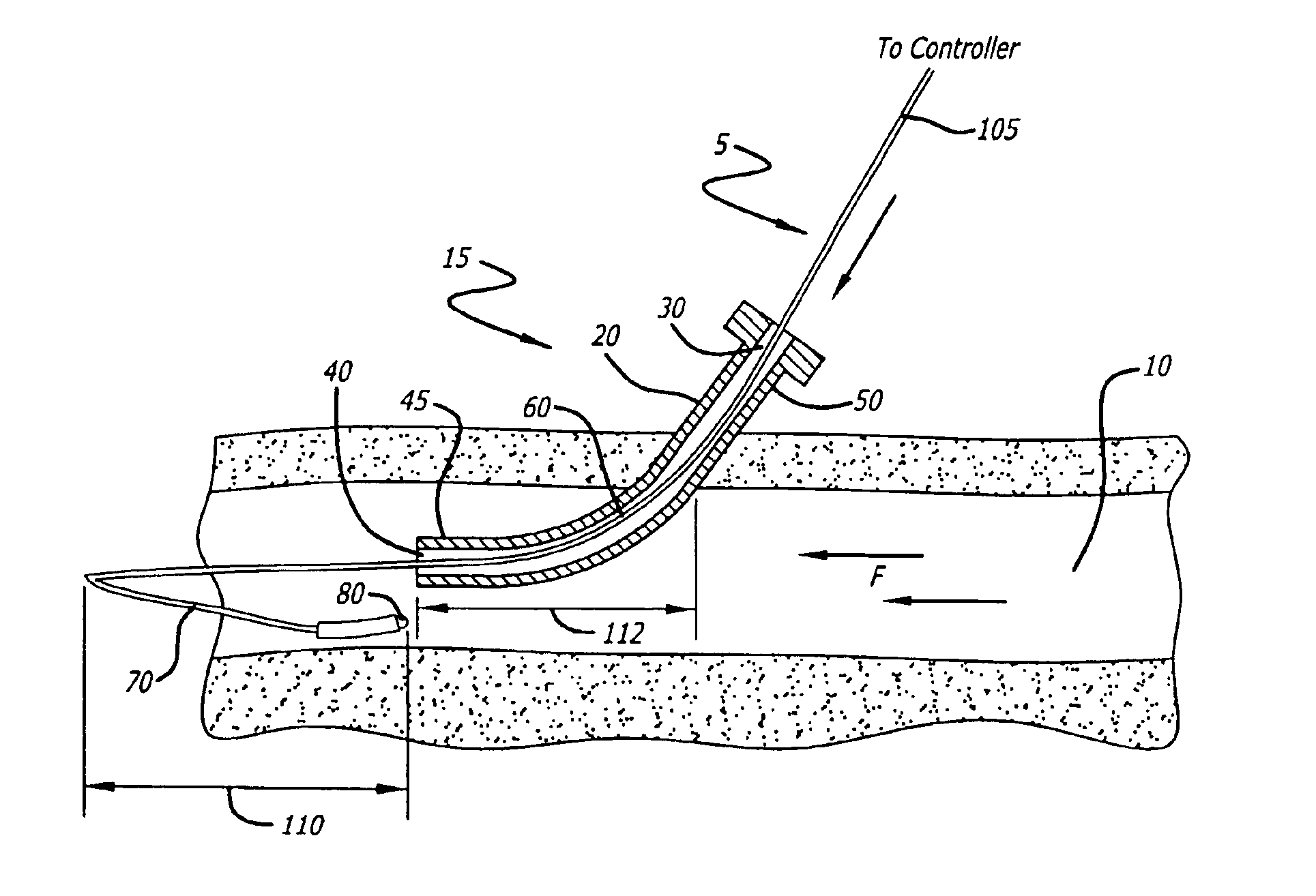

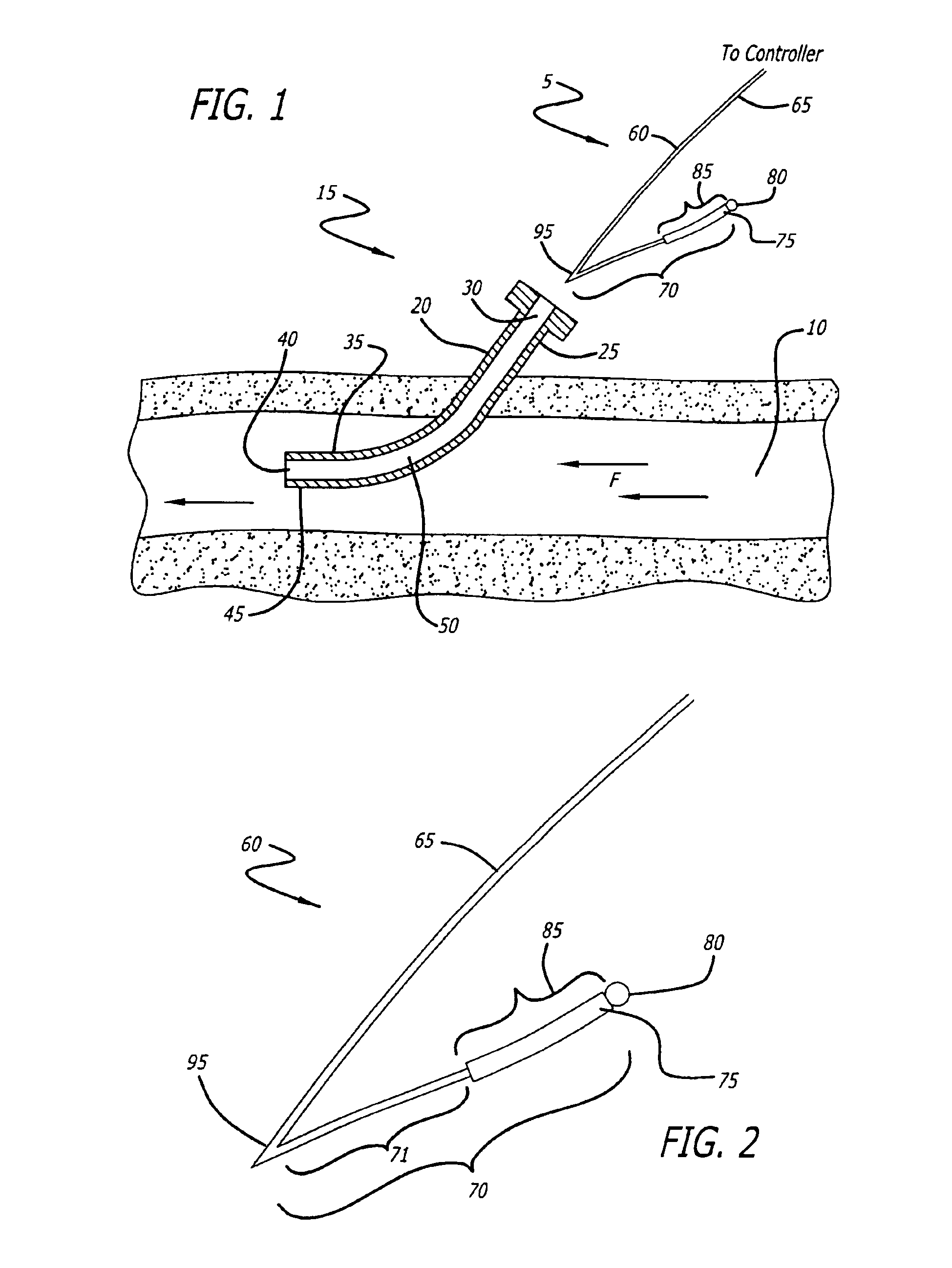

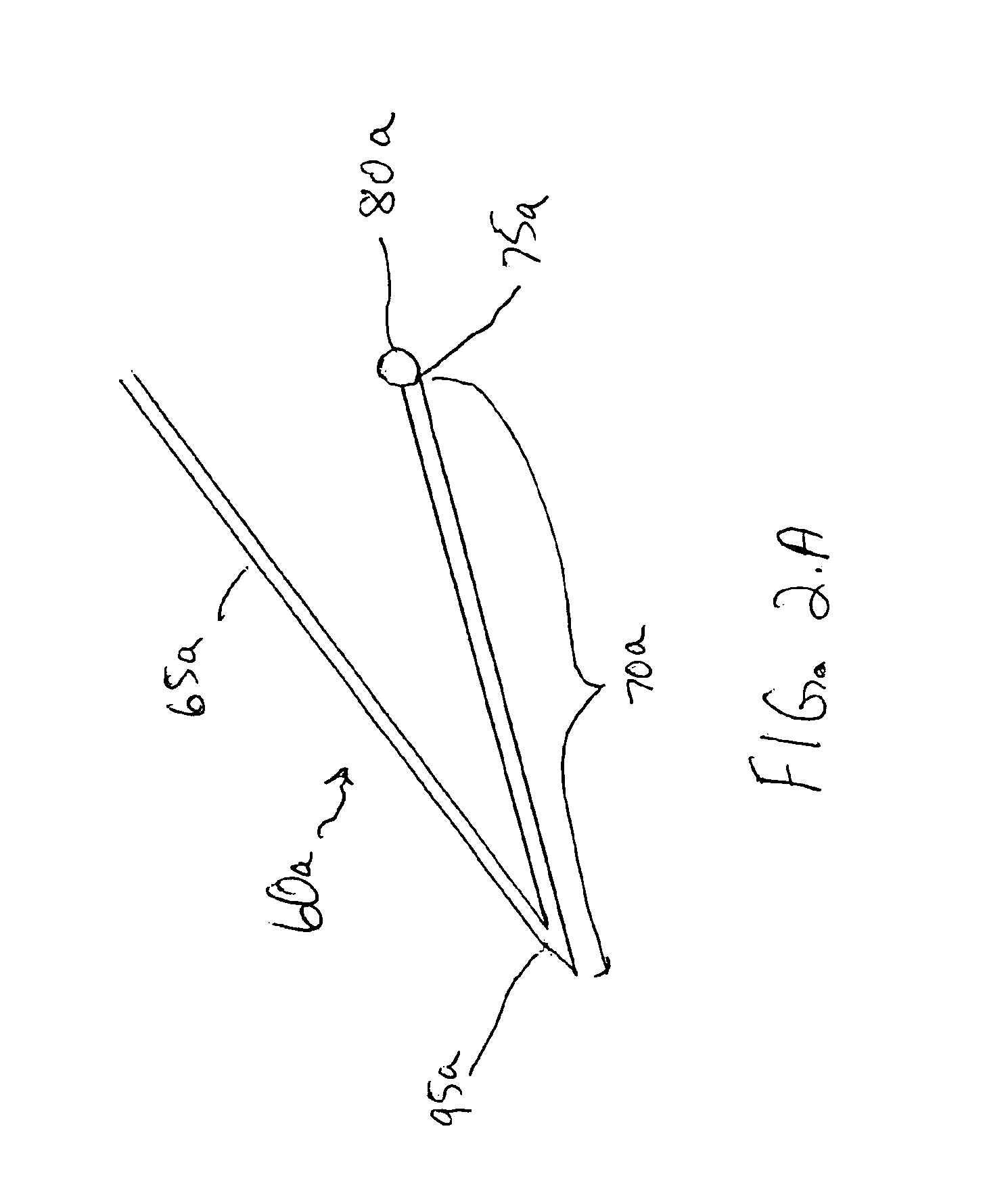

Temperature sensing system with retrograde sensor

InactiveUS6866638B2Promote withdrawalAvoid heat conductionThermometer detailsCatheterRadiologyInsertion point

A temperature sensing system and method for determining a patient's core body temperature by measuring the temperature of the patient's blood at a location in a vessel lumen retrograde of an insertion point of a temperature sensor or sensors into the vessel lumen.

Owner:ZOLL CIRCULATION

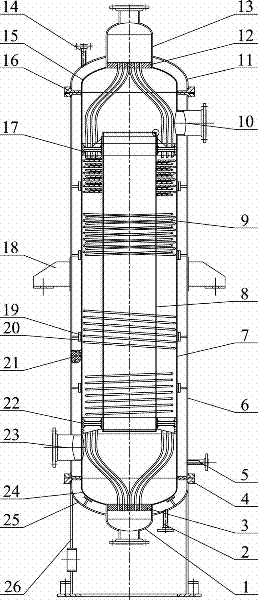

Single-flow low-temperature spiral winding tube type heat exchanger with vacuum heat-insulation effect

InactiveCN102564167AAvoid heat conductionHas low temperature heat transfer characteristicsStationary tubular conduit assembliesMathematical modelEngineering

A single-flow low-temperature spiral winding tube type heat exchanger with a vacuum heat-insulation effect mainly comprises a spiral winding tube bundle and a vacuum shell. A winding equation of a novel spiral tube bundle theory is applied, a mathematical model is built and applied to a numerical simulation process of a flow field, accordingly, a computation method of the tube bundle winding theory is obtained, and the spiral winding tube type heat exchanger is designed and manufactured. The vacuum heat-insulation technology is applied to the single-flow low-temperature spiral winding tube type heat exchanger, a vacuum structure consisting of an upper gland, a lower gland and a barrel which are independent from each other is adopted, and shortcomings that a traditional vacuum structure and a tube nest bundle are combined difficultly and inconvenient in manufacture, installation, detachment and maintenance and the like are overcome. The single-flow low-temperature spiral winding tube type heat exchanger is applicable to technical fields of gas purification and liquefaction separation including natural gas low-temperature liquefaction at the temperature of minus 161 DEG C, air low-temperature liquefaction separation at the temperature of minus 197 DEG C, low-temperature liquid-nitrogen washing at the temperature of minus 197 DEG C, low-temperature methanol washing at the temperature of minus 70 DEG C and the like, low-temperature heat exchange efficiency can be improved, and the single-flow low-temperature spiral winding tube type heat exchanger has the advantages that the single-flow low-temperature spiral winding tube type heat exchanger is compact in structure, heat transfer area of unit volume is large, heat expansion can be automatically compensated, the heat exchanger can be enlarged easily, the quantity of heat exchange equipment can be reduced, and the like.

Owner:张周卫

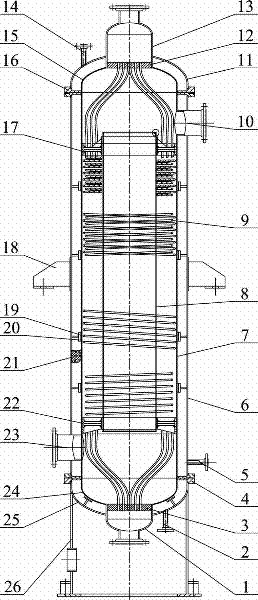

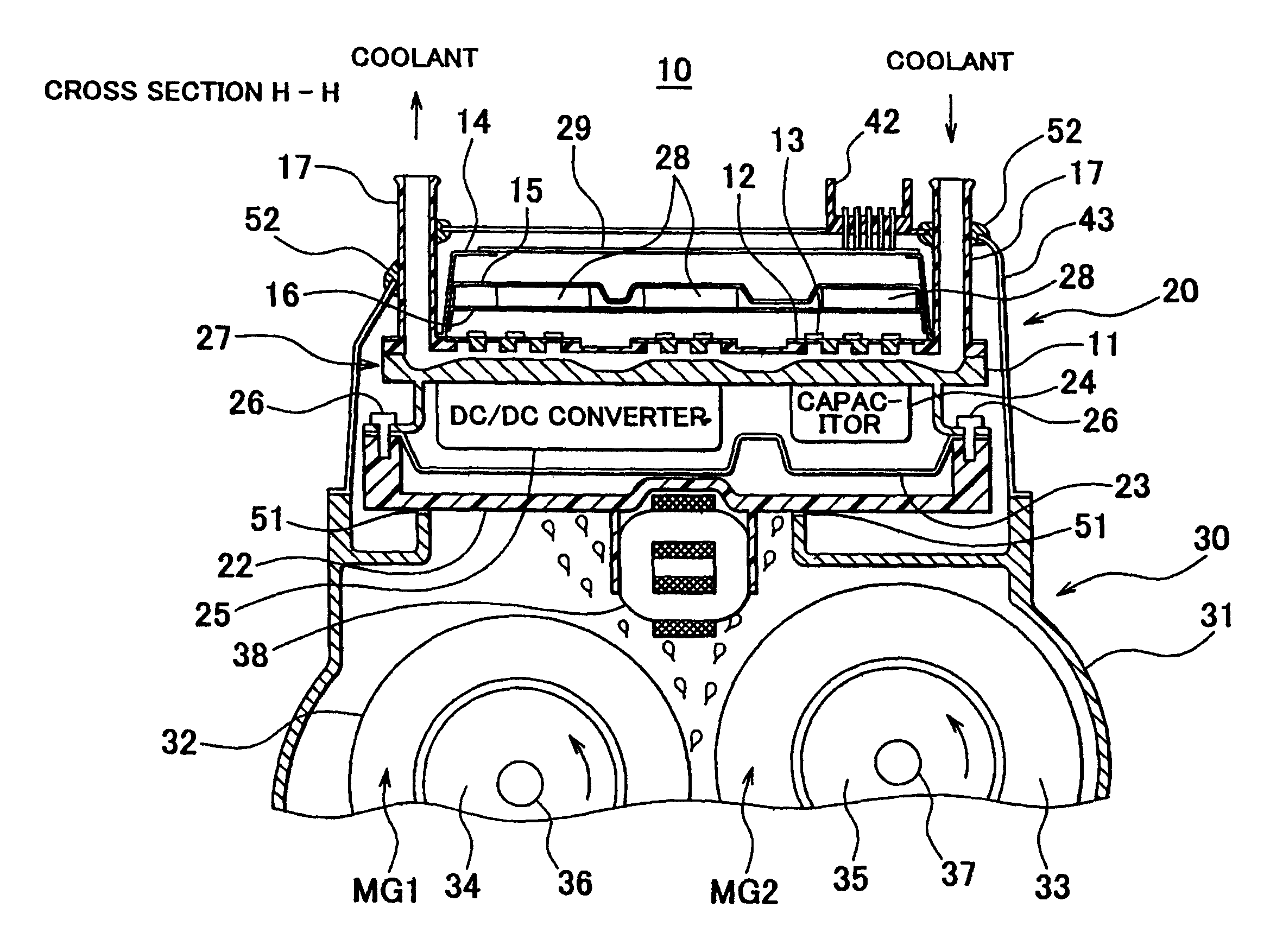

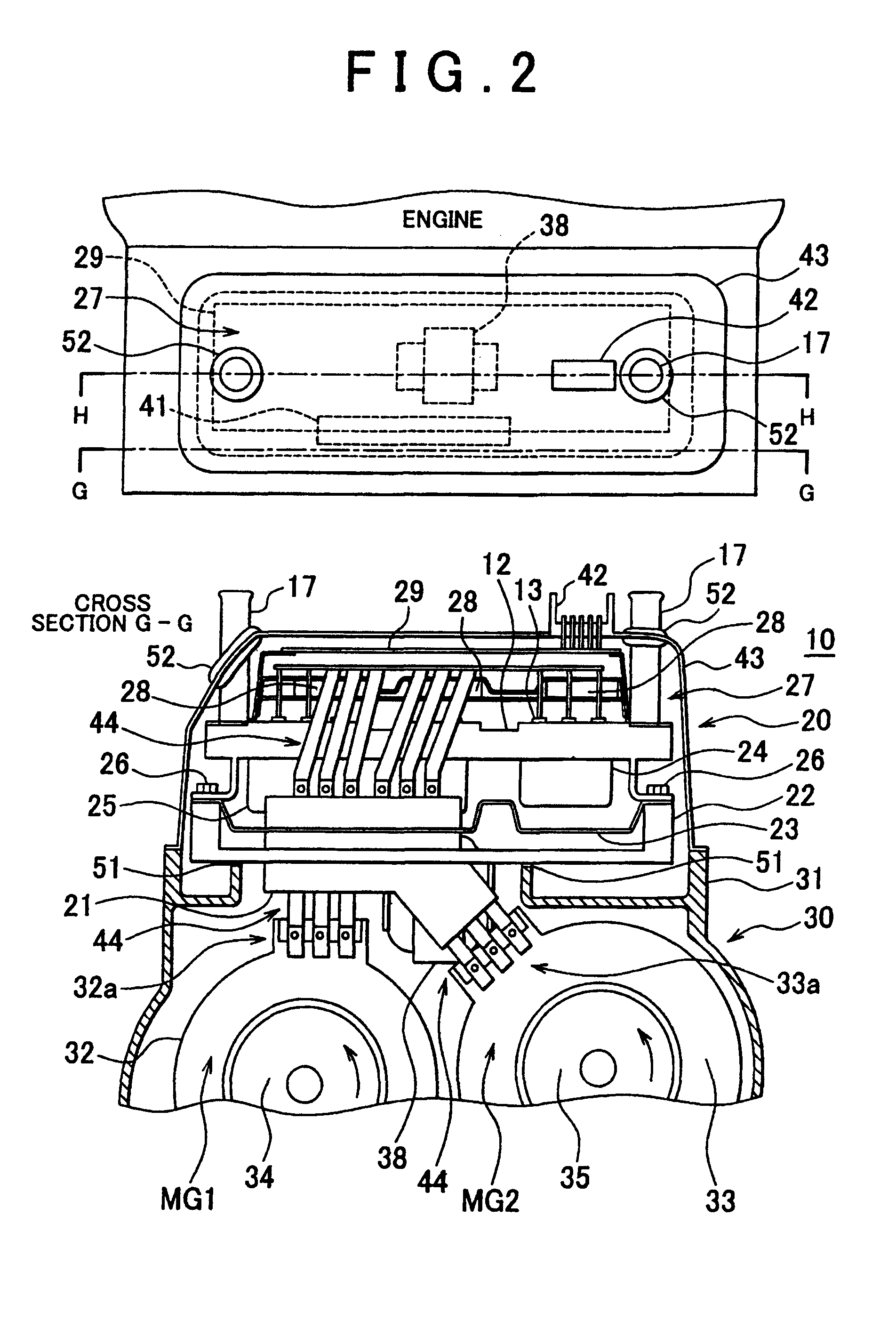

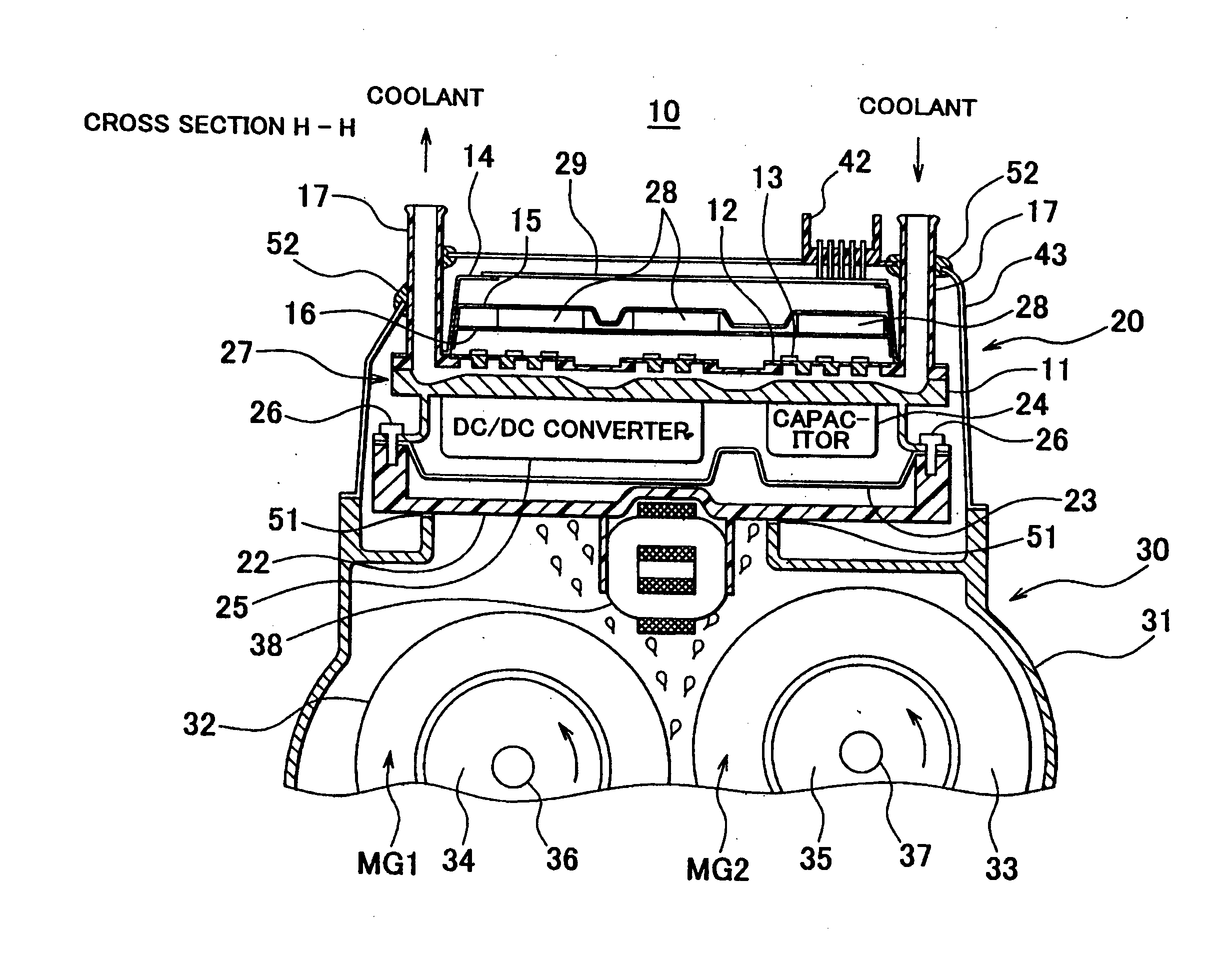

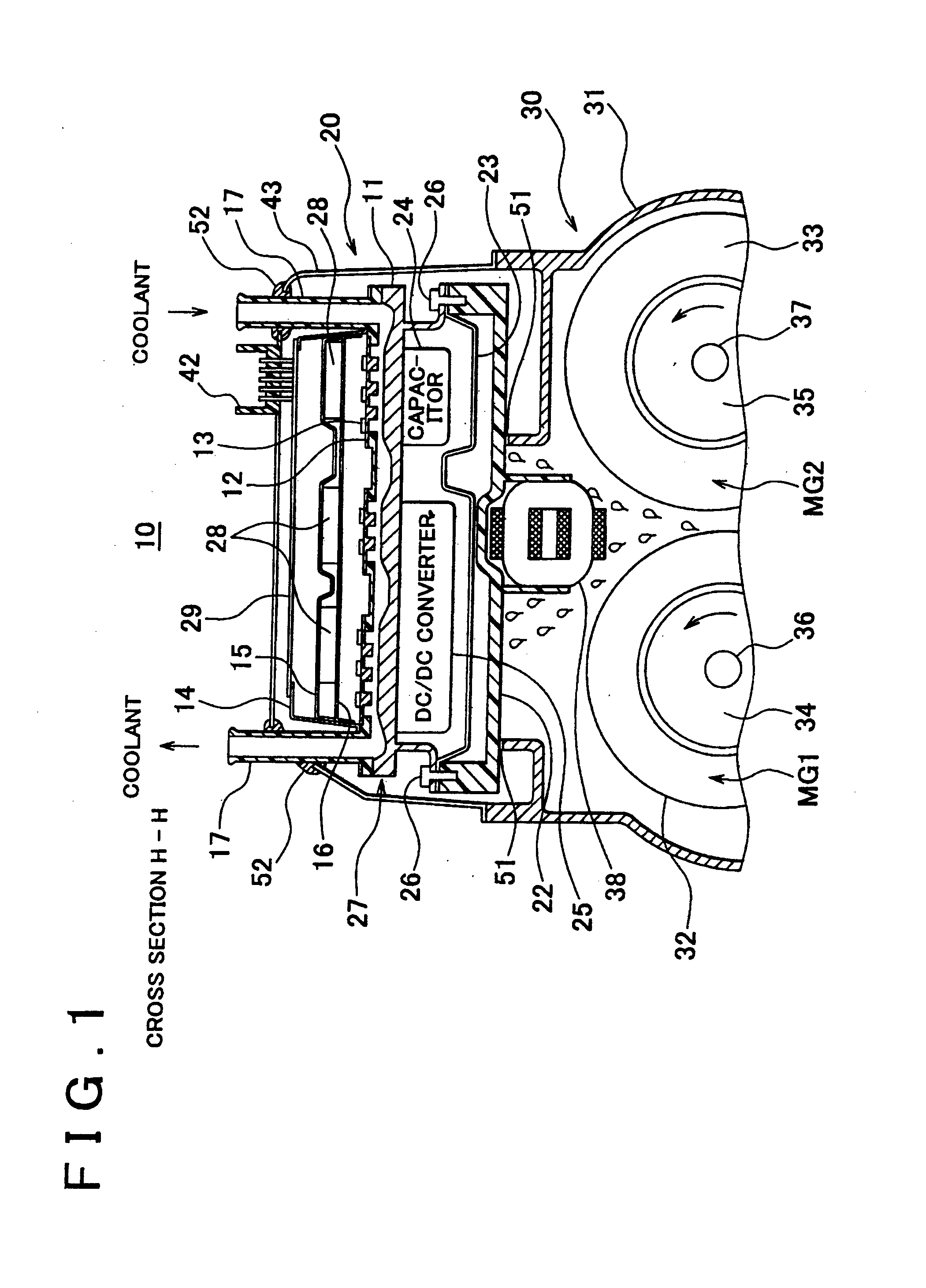

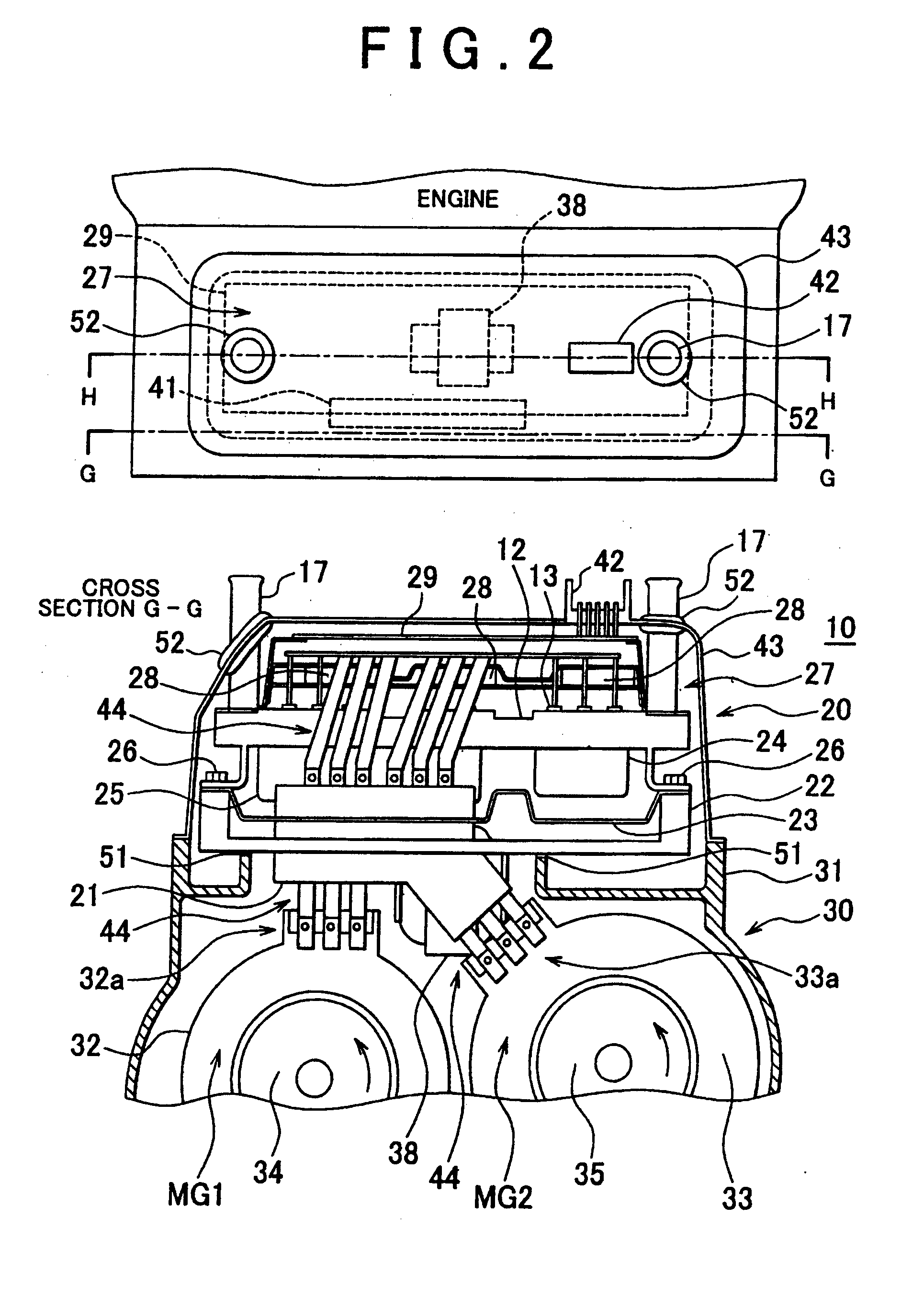

Power control unit

ActiveUS8875825B2Avoid heat conductionIncrease temperatureDomestic cooling apparatusLighting and heating apparatusElectric machineControl unit

A power control unit that controls a rotary electric machine that drives a vehicle, and that is mounted onto a motor case in which the rotary electric machine is housed, includes a fixed base that is made of resin; a cooler that is arranged on the fixed base and that includes a power module; and a control substrate that is arranged on the cooler. The fixed base inhibits conduction of heat from the motor case to the power control unit.

Owner:TOYOTA JIDOSHA KK +1

Power control unit

ActiveUS20140084719A1Cooling ability can be ensuredAvoid heat conductionElectric propulsion mountingVehicle sub-unit featuresElectric machineEngineering

A power control unit that controls a rotary electric machine that drives a vehicle, and that is mounted onto a motor case in which the rotary electric machine is housed, includes a fixed base that is made of resin; a cooler that is arranged on the fixed base and that includes a power module; and a control substrate that is arranged on the cooler. The fixed base inhibits conduction of heat from the motor case to the power control unit.

Owner:TOYOTA JIDOSHA KK +1

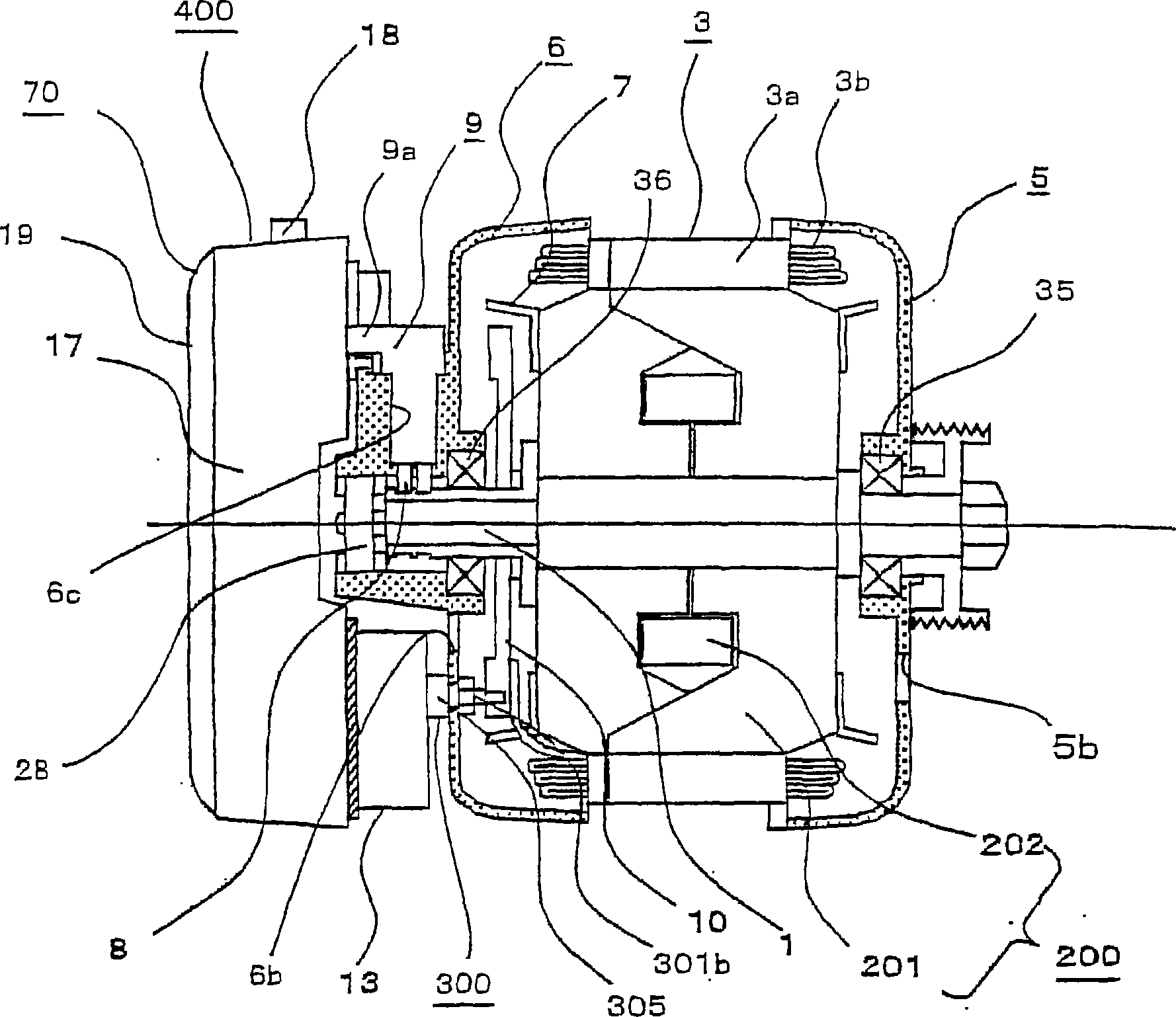

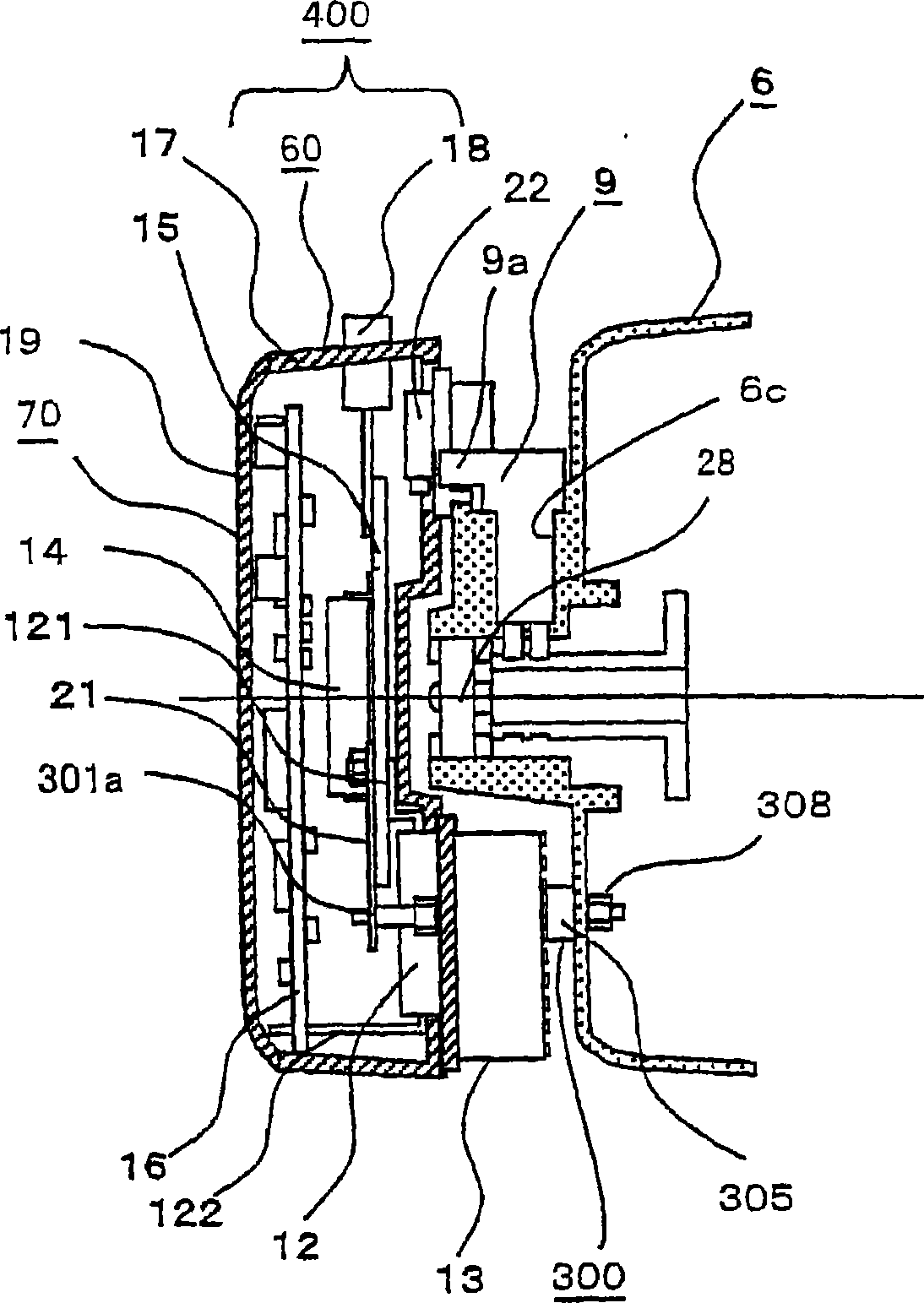

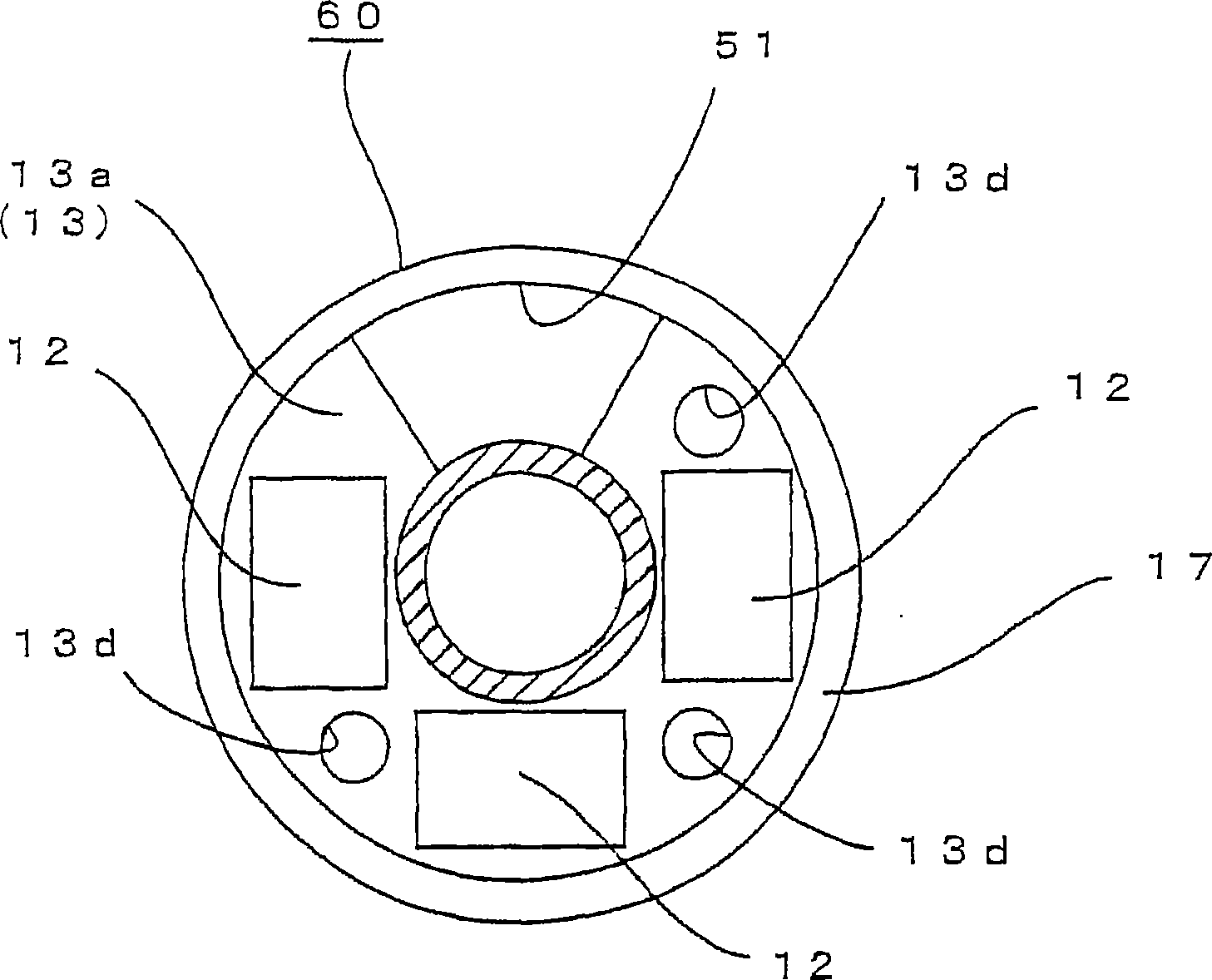

Rotating electric machine integral with control device

ActiveCN1906826AAvoid heat conductionCooling air cooling is effectiveCooling/ventillation arrangementSupports/enclosures/casingsElectric machineEngineering

The invention is intended to obtain a rotating electric machine with a built-in control device in which the control device is kept from receiving heat from a main body of the rotating electric machine and the control device can be cooled in a desirable fashion. A heat sink 13 on which switching devices 12 of a control device 400 are mounted is attached to a rear bracket 6 by means of conductive studs 300 with a particular spacing provided in a left-to-right direction of figure 2. The heat sink 13 is cooled by a flow of cooling air induced by an unillustrated fan. Since the control device 400 is attached to the rear bracket 6 of which temperature increases with the spacing provided therefrom, it is possible to suppress heat transfer from the rear bracket 6 and effectively cool the control device 400 through the heat sink 13.

Owner:MITSUBISHI ELECTRIC CORP

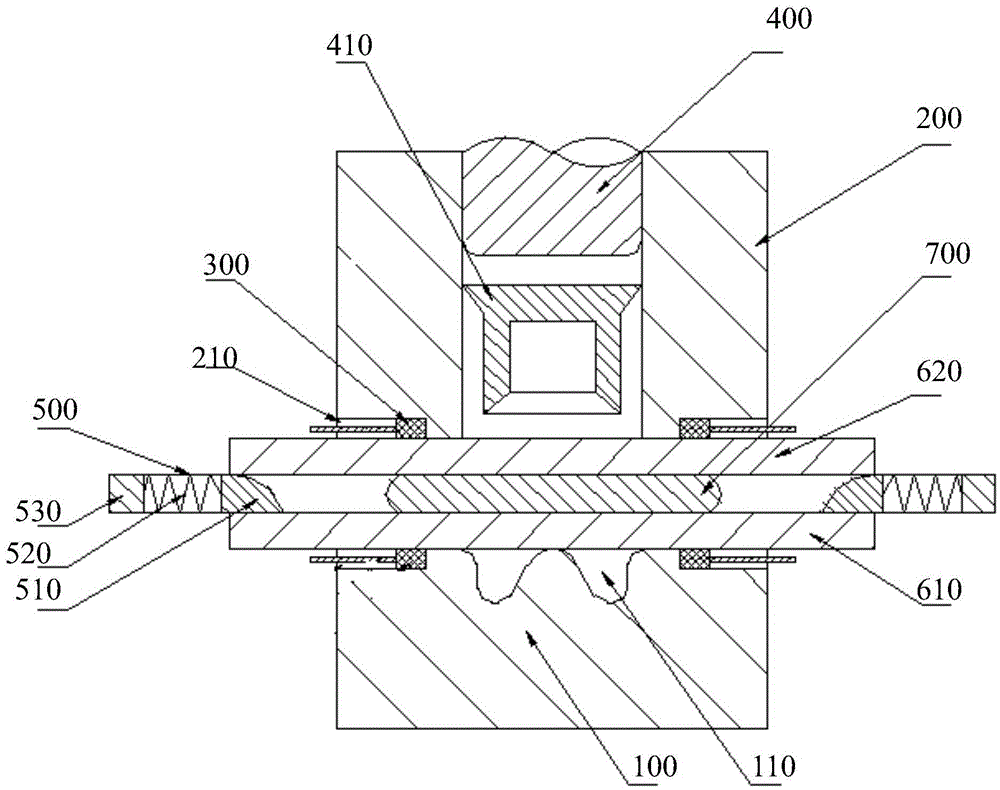

Self-punching bond-riveting connecting device and bond-riveting method

InactiveCN105458147ASelf-piercing riveting is possibleReduce intensityFurnace typesHeat treatment furnacesPunchingEngineering

A self-punching bond-riveting connecting device comprises a compound female die, a compound edge pressing ring, heat conduction electrodes and a punch, wherein an annular groove is formed in the compound female die, the compound edge pressing ring is opposite to the compound female die in the vertical direction, the compound edge pressing ring can move in the vertical direction and is used for pressing to-be-riveted pieces, the heat conduction electrodes are arranged at the bottom of the compound edge pressing ring and the upper portion of the compound female die and can heat the different to-be-riveted pieces independently, and the punch is a solid circular structural piece, is arranged in a central hole of the compound edge pressing ring and can slide up and down in the axial direction of the central hole. The expanding performance of super-strength steel nearby riveting points is greatly improved, and the problems that super-strength steel is difficult to deform and effective connectors can not be formed are solved. The invention further provides a self-punching bond-riveting connecting method. By precisely controlling the punching speed of the punch, the requirements for the strength of the rivet, the punch riveting capacity of the device and the rigidity of a C-shaped frame of a riveting gun are lowered, and production cost is reduced.

Owner:JILIN UNIV

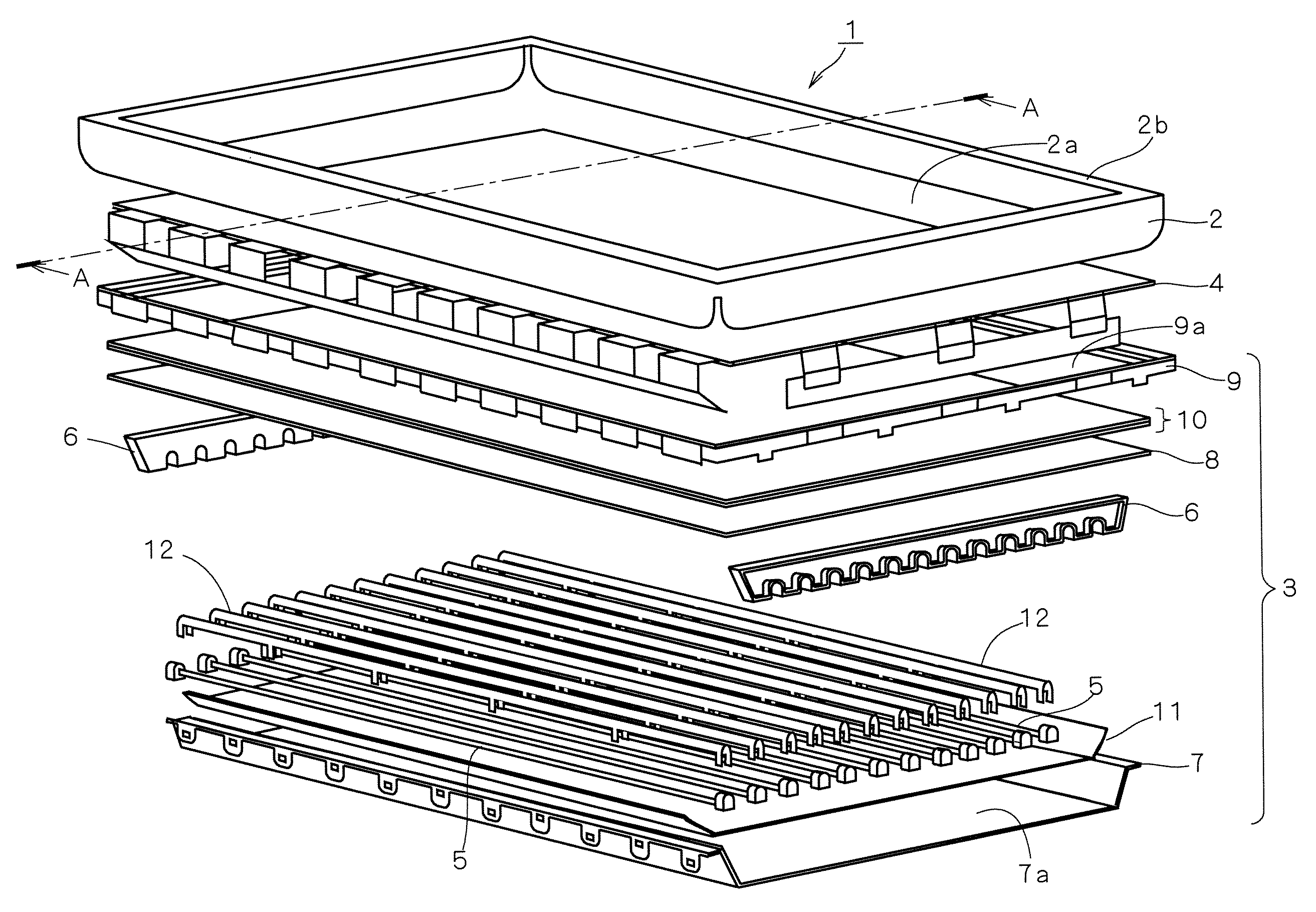

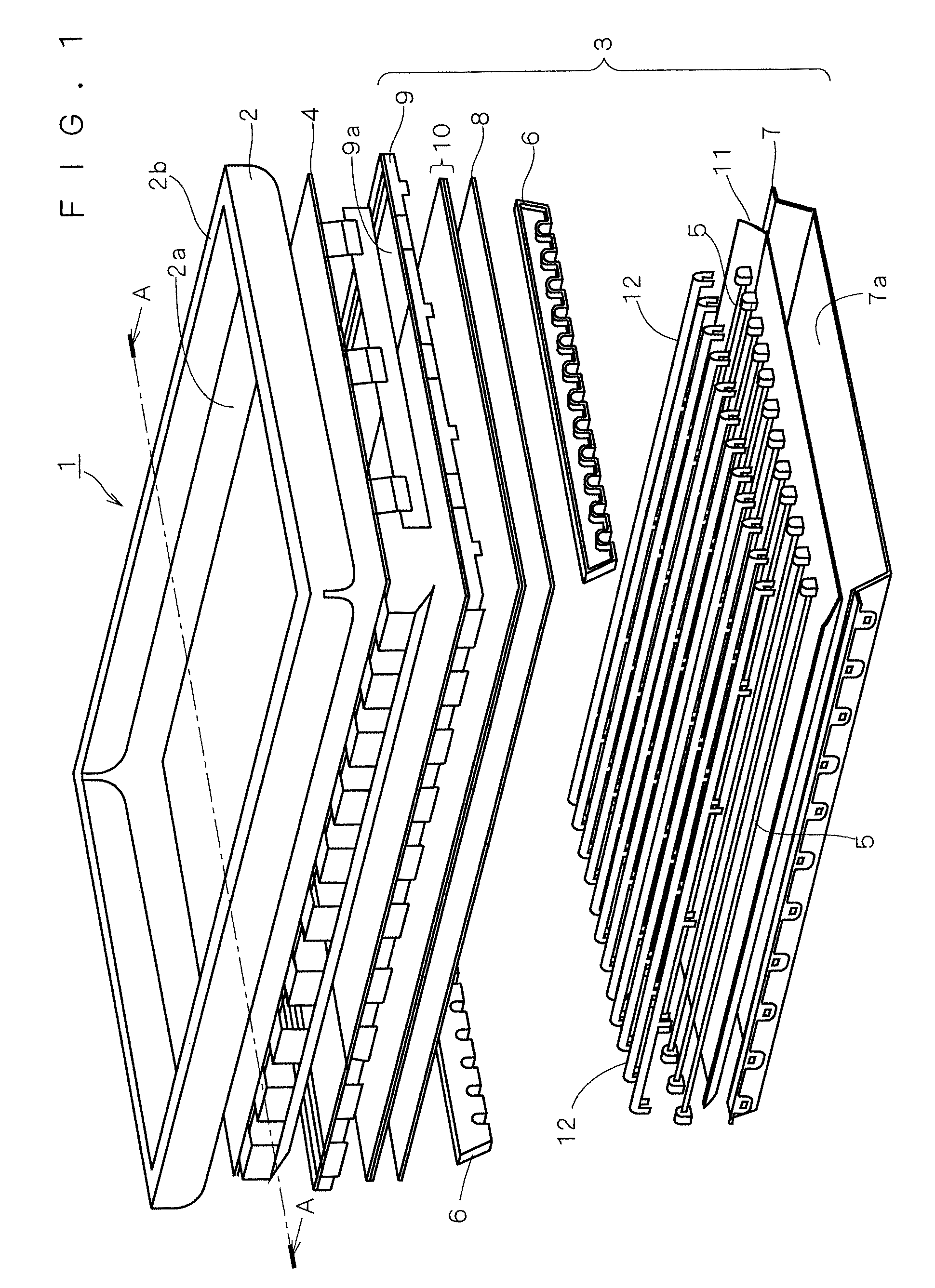

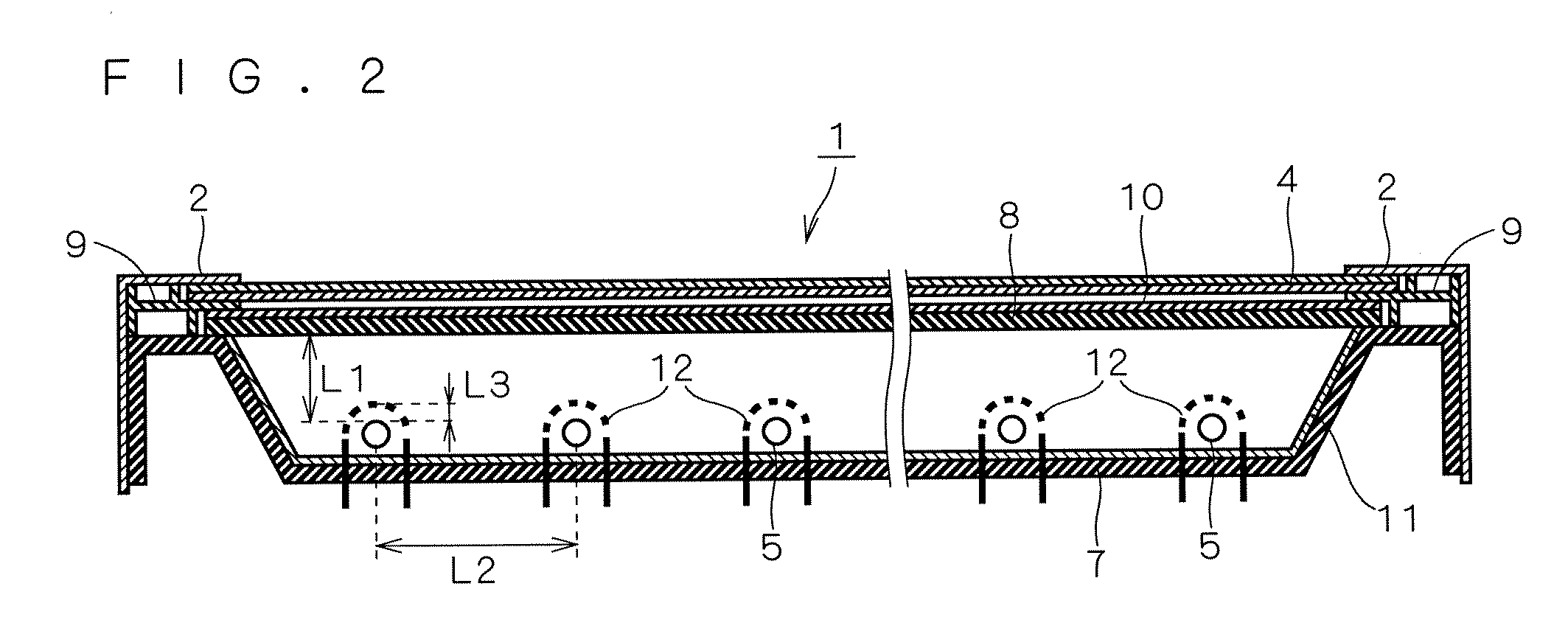

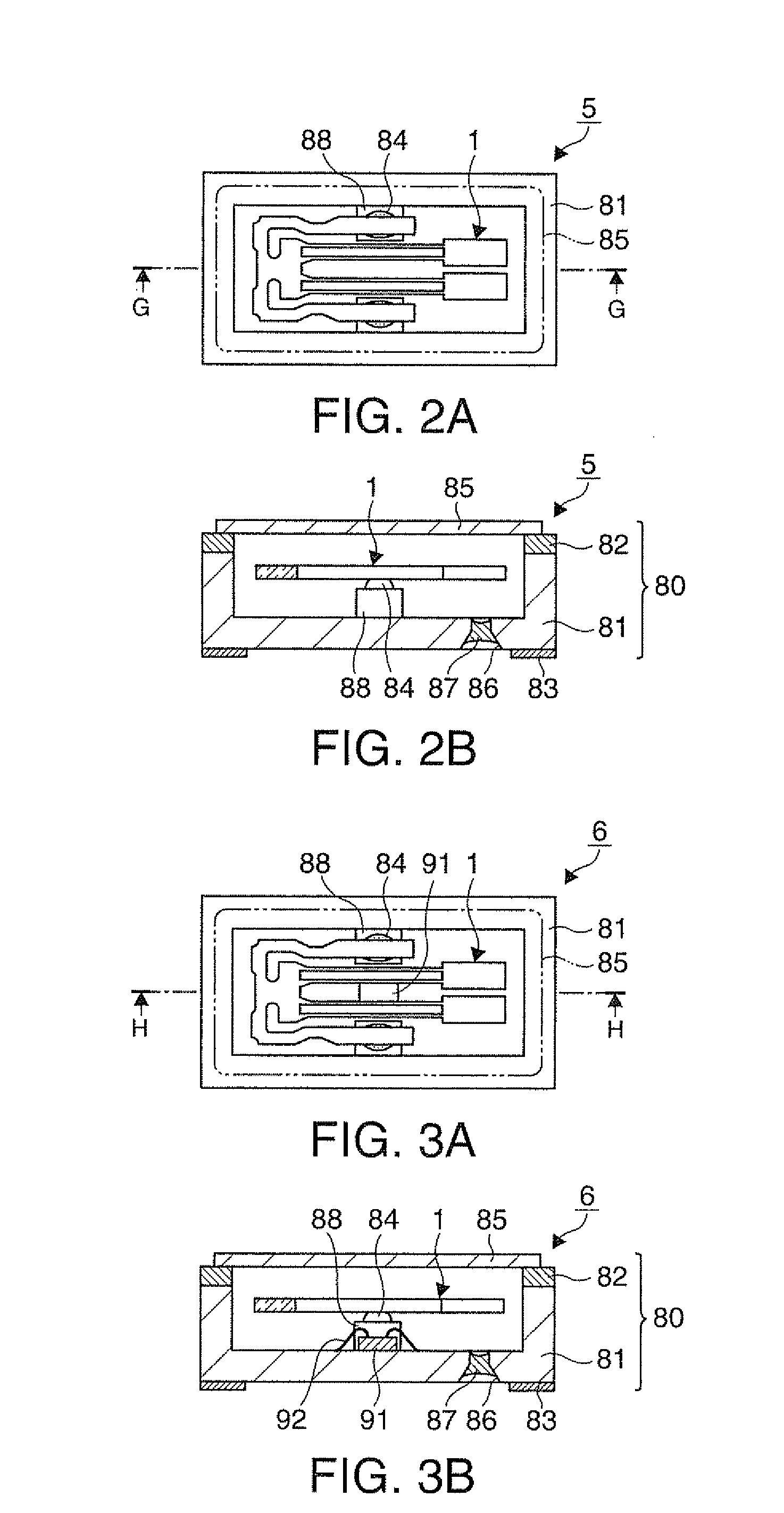

Plane light-source device

InactiveUS20080094831A1Suppress influence of heat and electromagnetic waveAvoid breakingNon-electric lightingPoint-like light sourceLiquid-crystal displayDrop impact

A plane light-source device having lamps disposed behind a diffuser is provided in which influences of heat and electromagnetic waves generated by the lamps are suppressed and the lamps are prevented from being broken on drop impact. A plane light-source device (a direct-type backlight) of a liquid-crystal display apparatus includes a plurality of lamps disposed side by side with a given pitch, a diffuser for diffusing light from the lamps, and metal covers disposed between the diffuser and the lamps. The metal covers each have a plurality of through holes, and they reflect light from the lamps at their respective surfaces that face the lamps.

Owner:MITSUBISHI ELECTRIC CORP

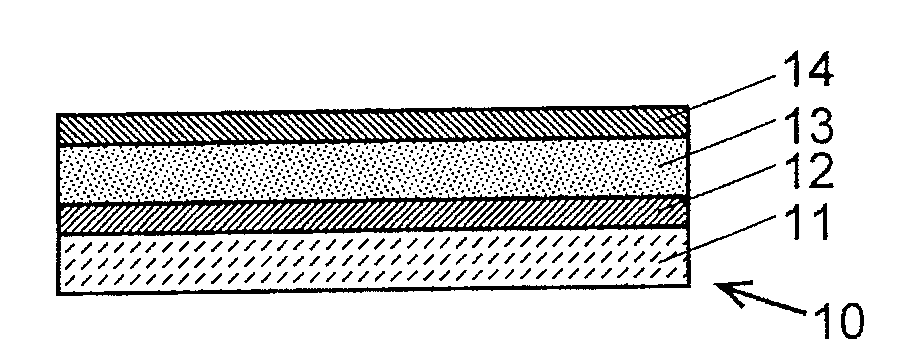

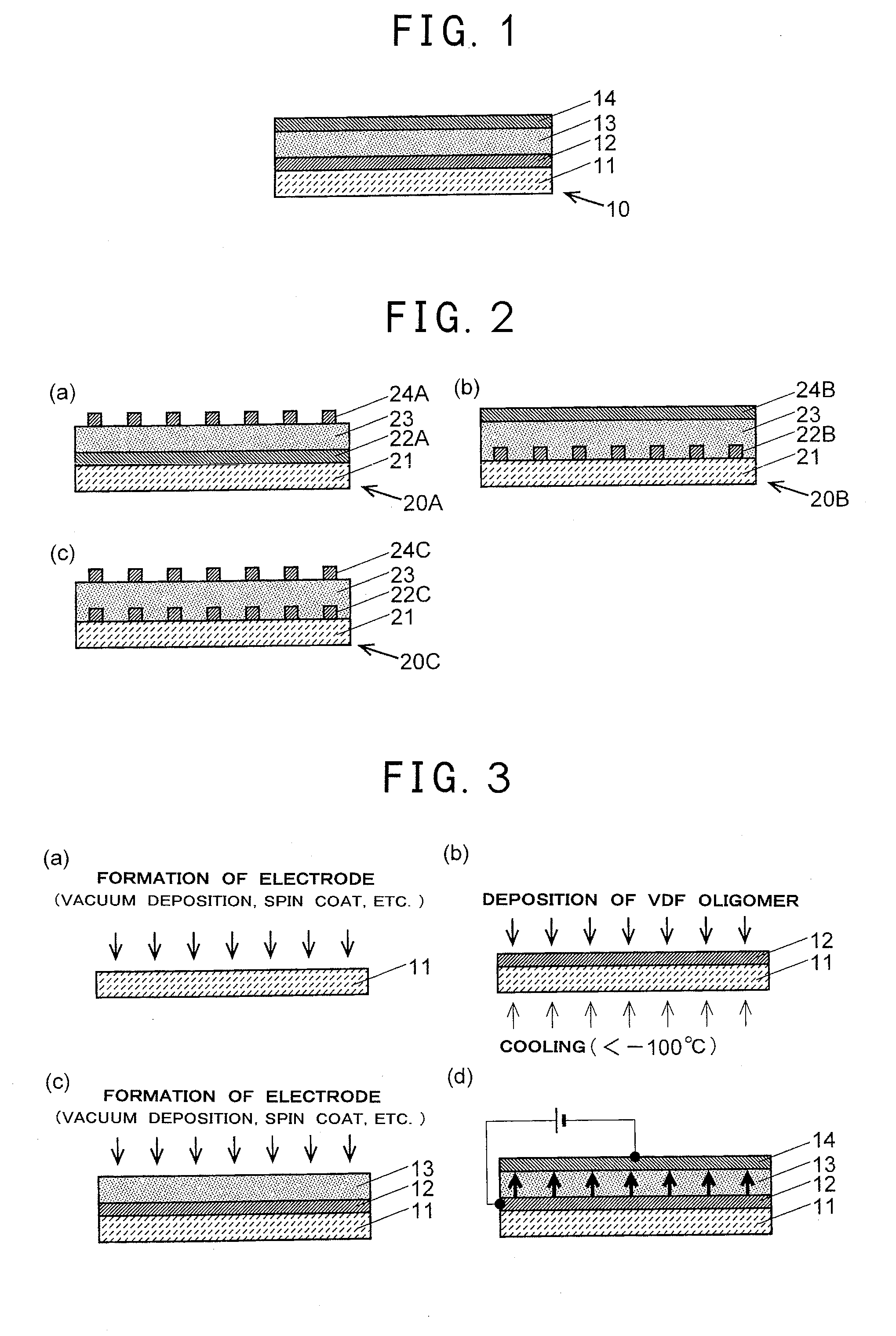

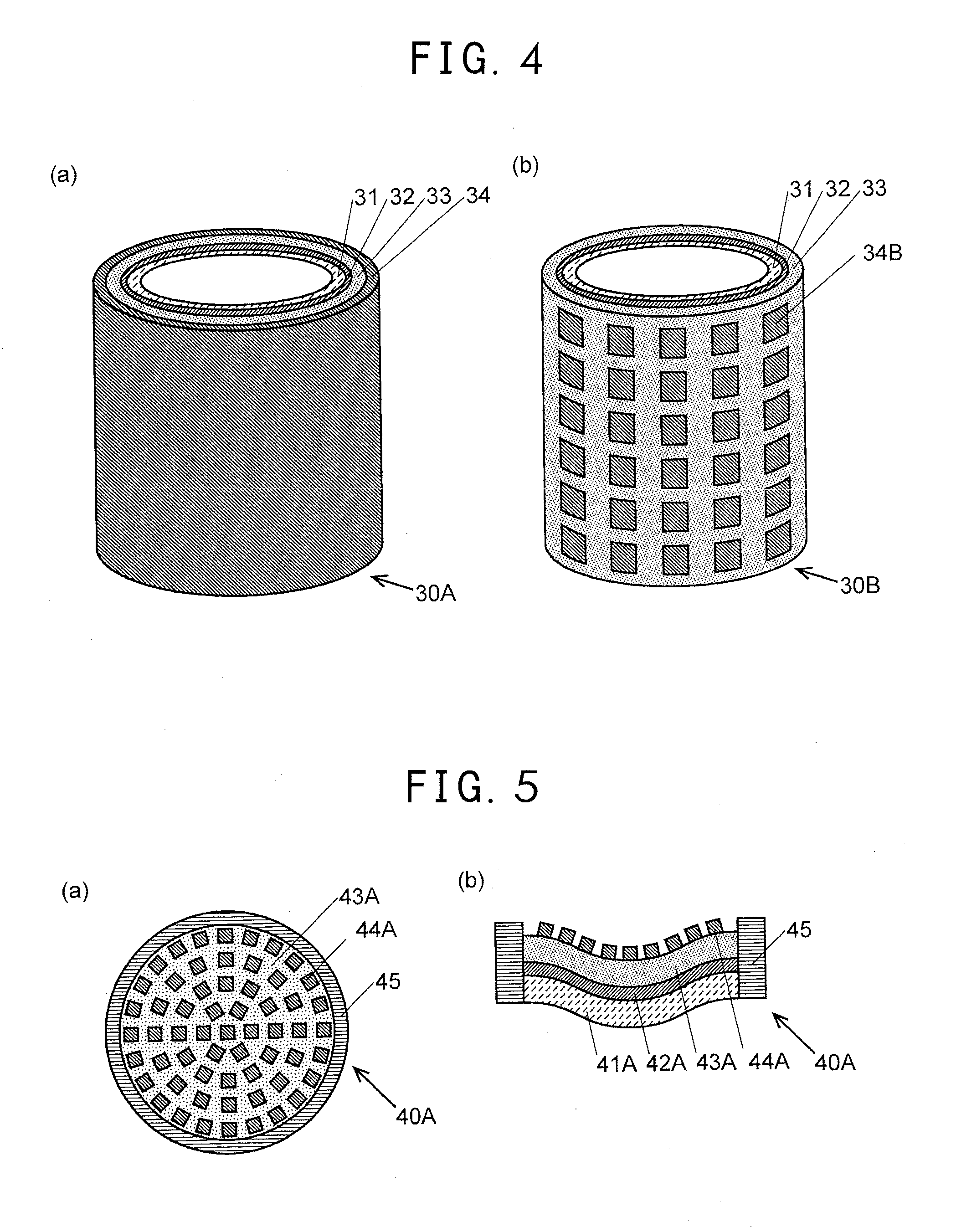

Pyroelectric infrared sensor

InactiveUS20090072143A1High sensitivityAvoid heat conductionMaterial analysis by optical meansPyrometry using electric radation detectorsPolyethylene terephthalateOligomer

There is provided a pyroelectric infrared sensor being capable of changing its shape and having high sensitivity. The sensor comprises the substrate 11 made of a polymer material such as polyimide or polyethylene terephthalate and having flexibility, the layer 13 comprising vinylidene fluoride (VDF), and the flexible electrodes 12 and 14 comprising an Al-deposited film and provided on and under the VDF oligomer layer 13. The pyroelectric infrared sensor of the present invention has flexibility as a whole due to flexibility of each component elements and can be formed into desired shapes. In addition, since a substrate made of a polymer material has heat capacity and heat conductivity lower than those of Si substrates used on conventional pyroelectric infrared sensors, sensitivity of the sensor can be increased.

Owner:DAIKIN IND LTD

Evaporative cooling device

ActiveCN101336358AAvoid heat conductionFree-cooling systemsStationary conduit assembliesHeat conductingEvaporation

Owner:OXYCOM BEHEER BV

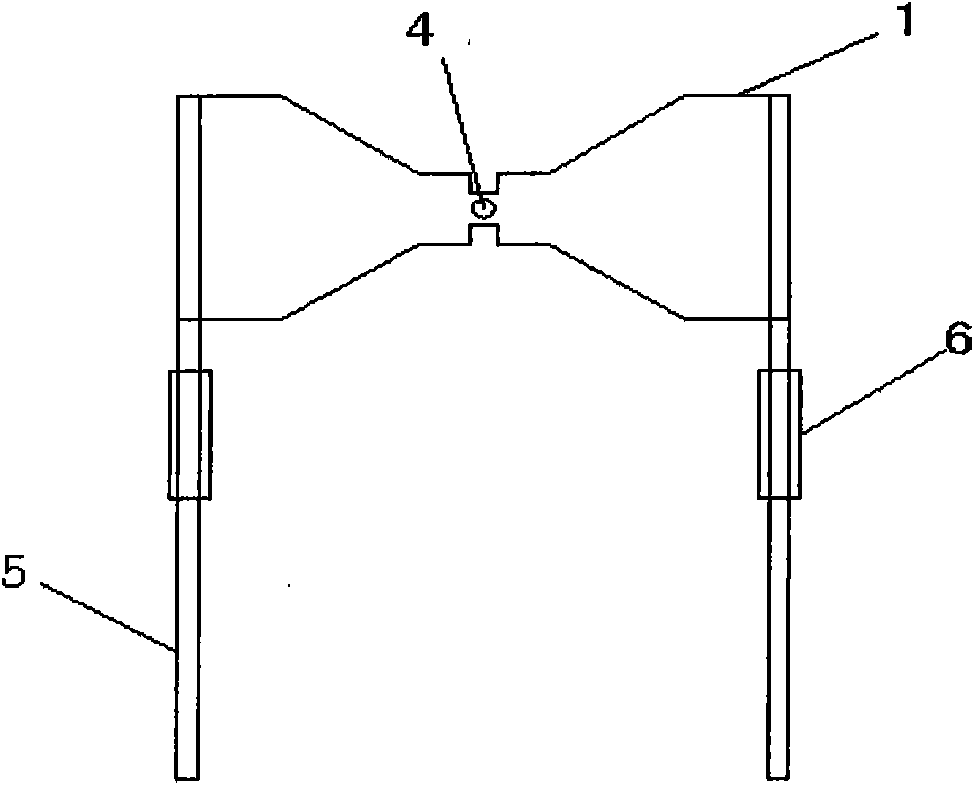

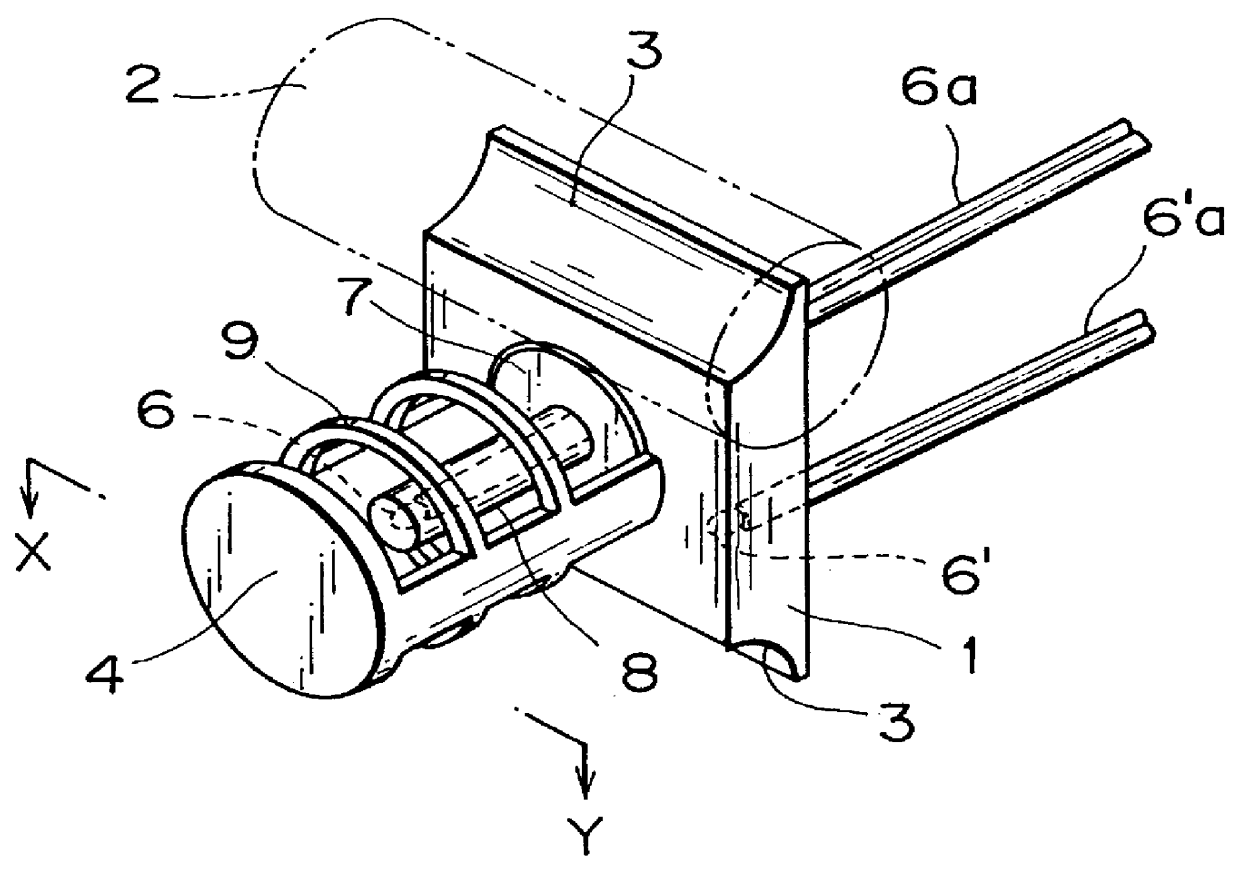

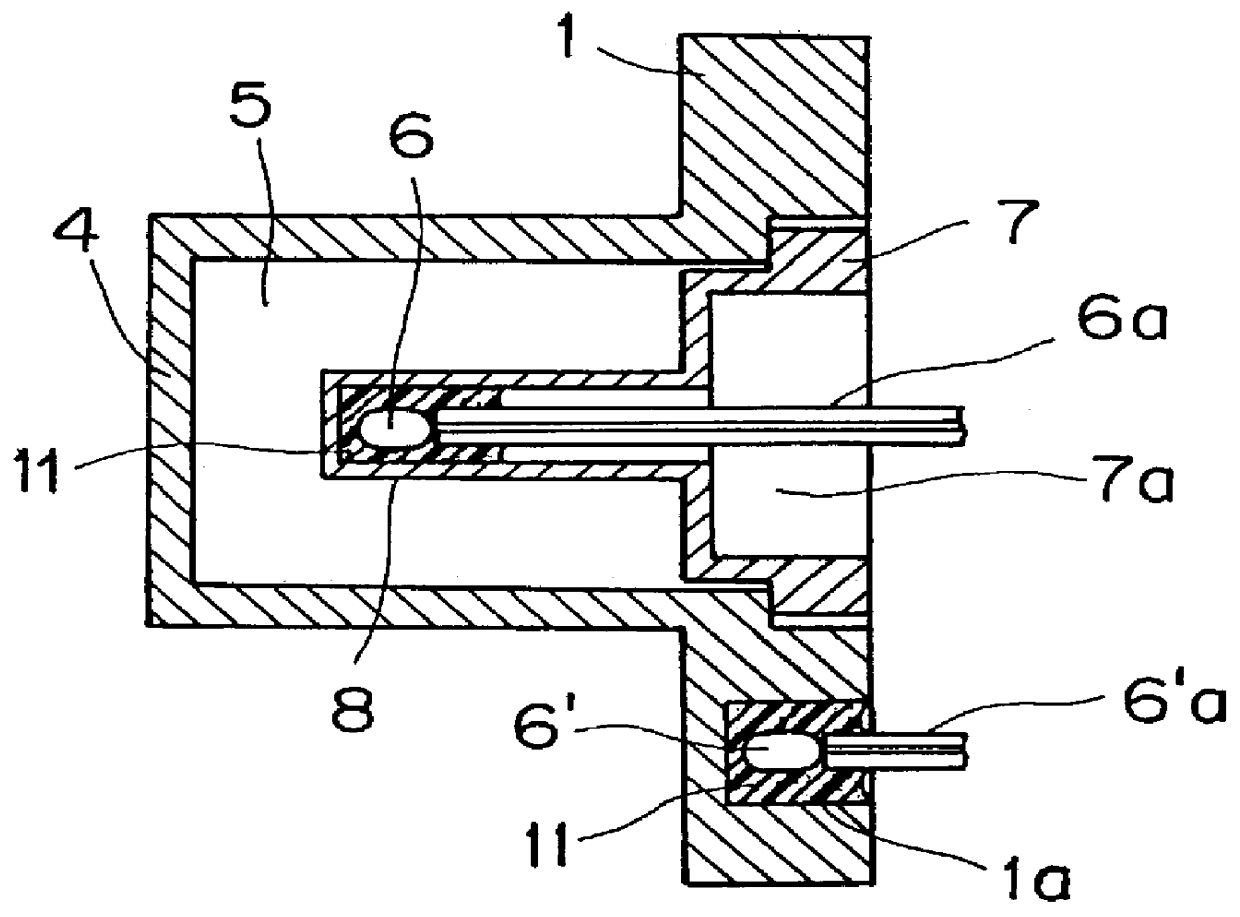

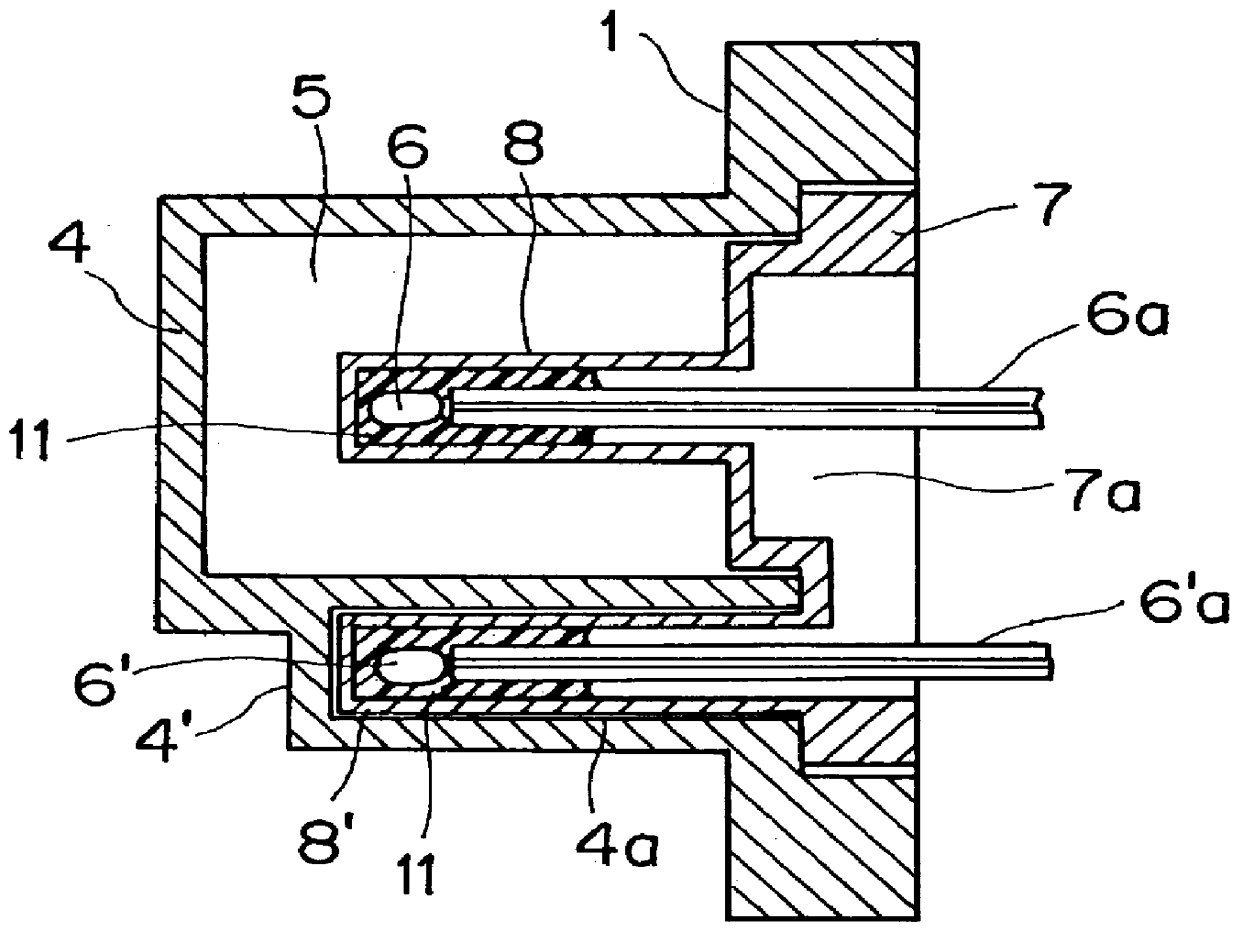

Frost formation detector

InactiveUS6092925AImprove reliabilityImprove performanceThermometer detailsLighting and heating apparatusFrostEngineering

PCT No. PCT / JP96 / 02451 Sec. 371 Date Aug. 6, 1998 Sec. 102(e) Date Aug. 6, 1998 PCT Filed Aug. 30, 1996 PCT Pub. No. WO97 / 29332 PCT Pub. Date Aug. 14, 1997A frost deposition detecting device is provided. This frost deposition detecting device comprises: a base member 1; a heat-conductive container 4 including a frosting portion provided to the base member 1; a thermally sensitive element 6' for detecting the temperature of the base member 1; a protection pipe 8 inserted into the base member 1 and disposed in the cavity formed inside the heat-conductive container; a heat insulator integrally formed with the protection pipe 8 to reduce heat conduction to the protection pipe 8; and another thermally sensitive element 6 secured in the protection pipe 8. With such frost deposition detecting device, highly accurate frost detecting performance and excellent durability in terms of water resistance and humidity resistance can be achieved.

Owner:ISHIZUKI ELECTRONICS

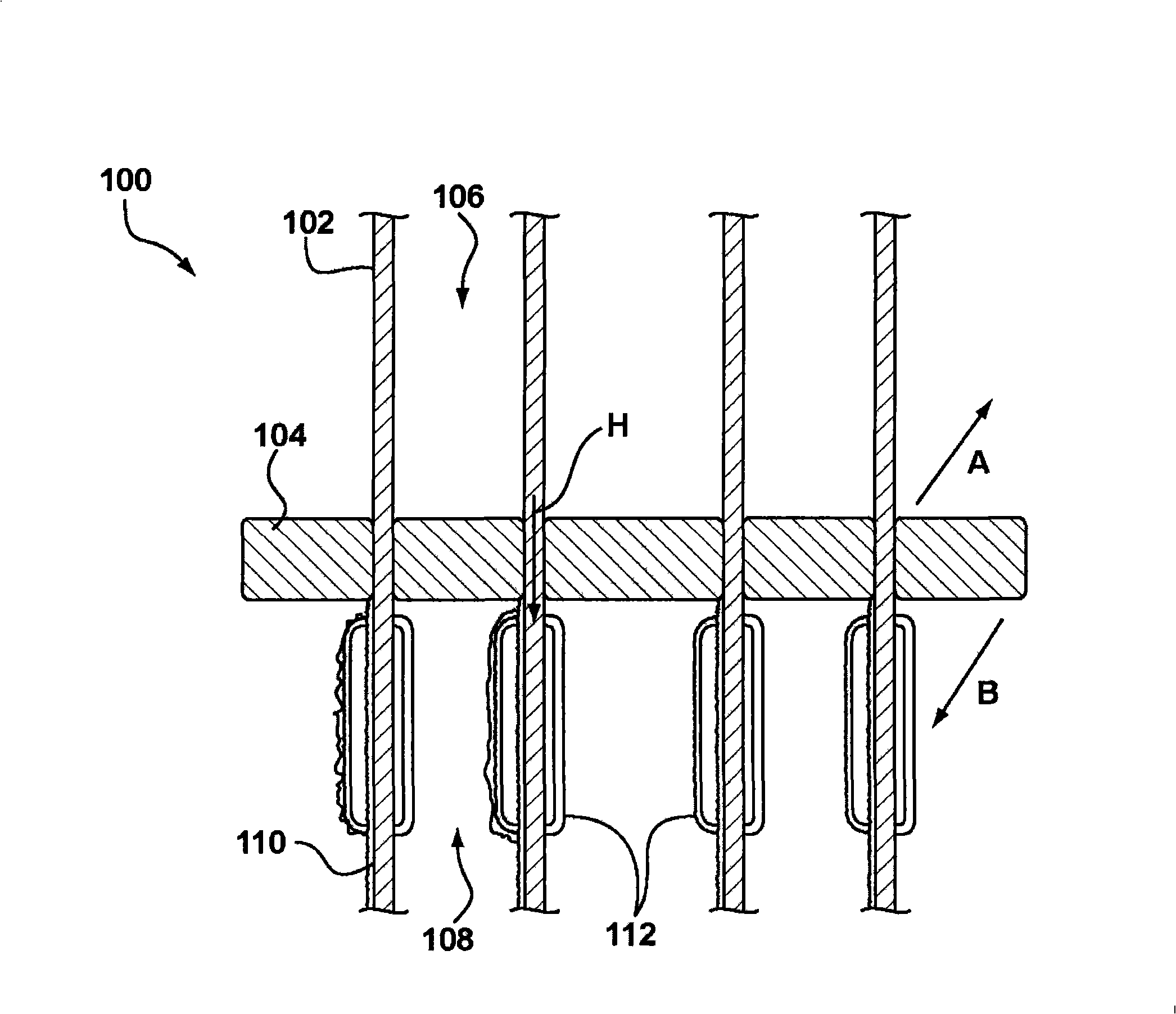

Thermal treatment apparatus

InactiveUS6623269B2Small heat lossAvoid heat conductionLining supportsGlass transportation apparatusThermal energyHeat losses

A thermal treatment apparatus has a plurality of thermal treatment chambers in which an object to be treated is thermally treated while being transported, and at least one pair of two adjacent thermal treatment chambers of which inside temperatures are different from each other. The thermal treatment chambers are connected through a thermal insulating structural member, whereby thermal conduction between the chambers, such as muffles, is prevented to reduce a heat loss caused in the thermal treatment apparatus. Therefore, input thermal energy which is necessary to carry out a predetermined thermal treatment is significantly reduced without affecting quality and yield of the object.

Owner:PANASONIC CORP

Laminated insulator of low-temperature thermal-insulative composite nanometer material

InactiveCN1895885AIncrease the average reflectanceReduce heat transferLaminationLamination apparatusCalcium silicatePolyester

A multi-layer heat isolator used as the low-temp heat-insulating surface layer of LNG ship or tank is prepared through plating zirconium oxide or zirconium oxide-aluminum oxide film on both surfaces of polyester or polyamide film by sol-gel method to form a reflecting screen, preparing the composite SiO2 aerogel-calcium silicate nanoparticles by sol-gel method, solvent replacing and surface modifying to obtain an isolating substance, and alternatively in-situ sticking to obtain a (3-50)-layer heat isolator (reflecting screen-isolating substance-reflecting screen-isolating substance).

Owner:上海暄能工程材料有限公司

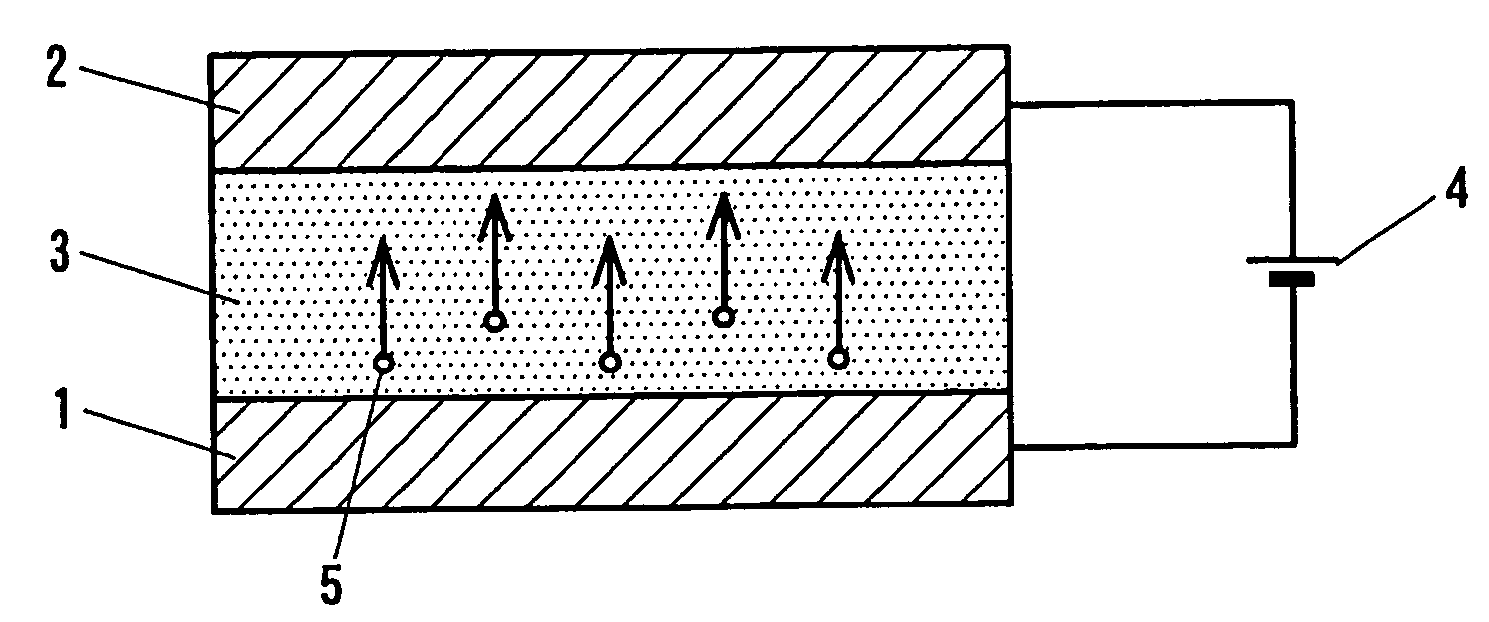

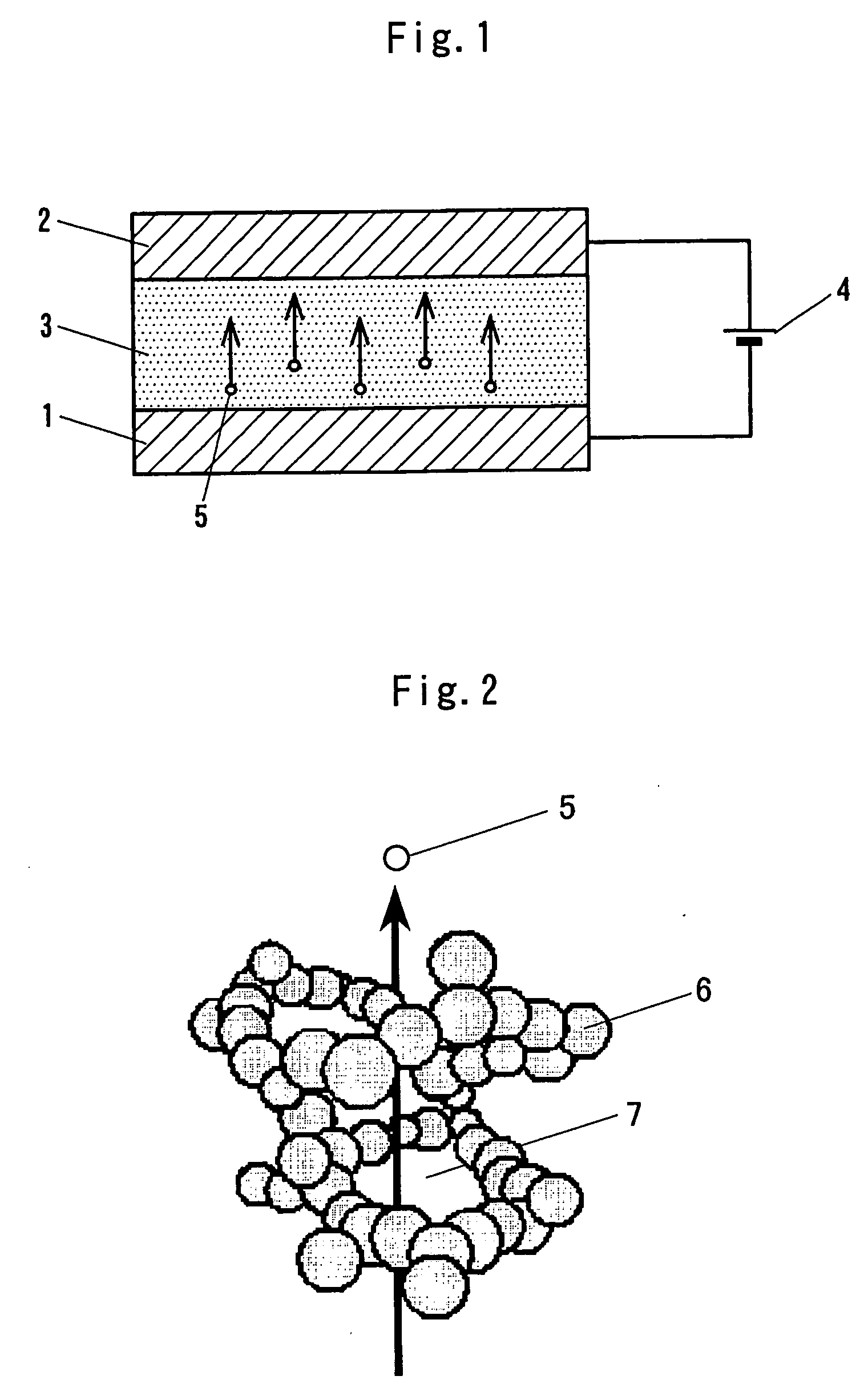

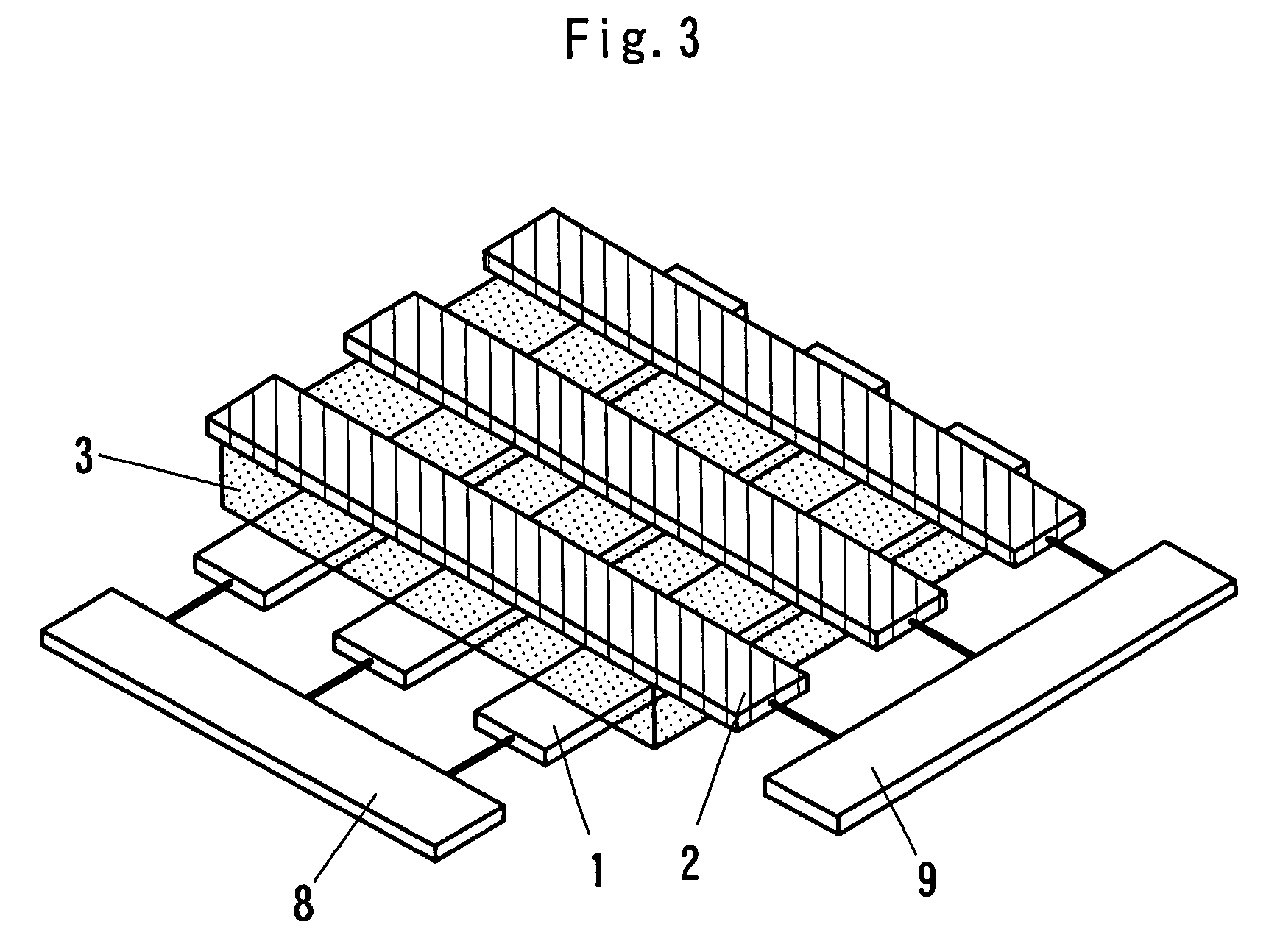

Thermoelectric transducer, a manufacturing method thereof, a cooling device using the same, and a method for controlling the cooling device

ActiveUS20050134167A1Easily formEffectively transfer electronDischarge tube luminescnet screensStatic indicating devicesSolid phasesElectric field

A thermoelectric transducer comprising an emitter (1) for emitting electrons according to the action of heat or an electric field, a collector (2) disposed so as to face the emitter (1) and collect electrons emitted from the emitter (1), and an electron transport layer (3) held between the emitter (1) and the collector (2) to serve as a region for transferring the electrons emitted from the emitter (1), the electron transport layer (3) being a porous body having a mixed structure of a vapor phase and a solid phase, the entire solid phase which composes the porous body being composed of an insulating material, and the electrons emitted from the emitter traveling in the vapor phase by applying an electric potential to the collector (2) that is higher than that applied to the emitter (1).

Owner:PANASONIC CORP

Resonator element, resonator, and oscillator

InactiveUS20120007685A1Improve the vibration effectAvoid heat conductionImpedence networksOscillations generatorsMechanical resonanceEngineering

A resonator element includes: at least one resonating arm extending, wherein the resonating arm has a mechanical resonance frequency which is higher than a thermal relaxation frequency thereof, the resonating arm has a groove portion, the groove portion includes a bottom portion, a first side surface that extends along the longitudinal direction of the resonating arm and comes into contact with the opened principal surface and the bottom portion, and a second side surface that faces the first side surface with the bottom portion disposed therebetween and comes into contact with the opened principal surface and the bottom portion, and the groove portion has a non-electrode region which extends from a part of the first side surface close to the bottom portion to a part of the second side surface close to the bottom portion and in which no electrode is provided.

Owner:SEIKO EPSON CORP

Method of treating surface of mold and mold having surface treated by said method

ActiveUS20150024660A1Good release effectEasy procedureFoundry mouldsFoundry coresElastomerAbrasive blasting

Provided is a method of treating a surface of a mold to achieve good demoldability and capable of preventing wearing of the mold by avoiding load concentration on one part of the surface of the mold. After a first blasting is performed on the surface of the mold to remove a hardened layer produced on the surface and / or to adjust the surface roughness, a second blasting is performed to create fine irregularities on the surface. Then, an elastic abrasive in which abrasive grains are carried on an elastic body, or a plate-like abrasive having a planar shape with a maximum length that is 1.5 to 100 times the thickness thereof, is ejected onto the surface of the mold at an inclined ejection angle such that the abrasive is caused to slide along the mold surface to flatten peaks of the irregularities created on the mold surface.

Owner:FUJI MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com