Coating material with characteristics of efficiency, energy saving, heat shield, cooling and corrosion resistance

An anti-corrosion coating, high-efficiency and energy-saving technology, applied in coatings, epoxy coatings, reflective/signal coatings, etc., can solve the problems of limited reflective wavelength range, insufficient thermal insulation effect, and lack of far infrared rays. To achieve good thermal insulation effect, reduce surface temperature and internal ambient temperature, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

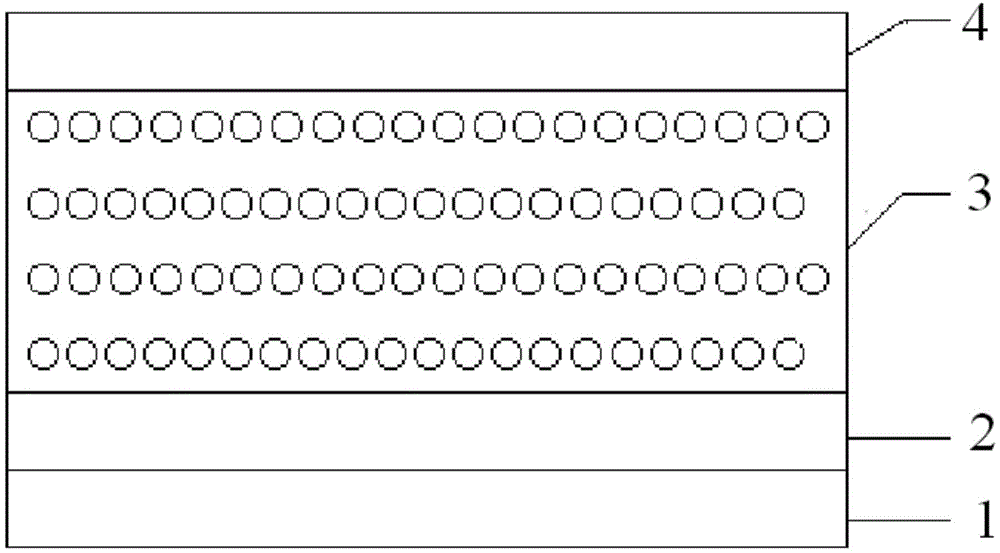

[0045] A high-efficiency energy-saving heat shielding and cooling anti-corrosion coating material, the structure coated on the substrate 1 is as follows figure 1 As shown, it is a three-layer composite material composed of anticorrosion bottom layer 2, heat insulation middle layer 3, and heat radiation surface layer 4. The thickness ratio of each layer is bottom layer: middle layer: surface layer is 1:4:0.8, and the total thickness range of the three-layer coating of the present invention is 0.4-0.8mm.

[0046] The bottom layer of the present invention is epoxy zinc-rich paint with respect to metal matrix, as the product inorganic epoxy zinc-rich primer H06-4 of Jiangsu Ao Dun Chemical Coatings Co., Ltd., as the product anti-alkali sealing bottom of Jiangsu Ao Dun Chemical Coatings Co., Ltd. Lacquer H53-51.

[0047] The components of the heat-insulating middle layer include the following compositions and parts by weight:

[0048] 1 epoxy resin E-44 35

[0049] 2 iron oxide ...

Embodiment 2

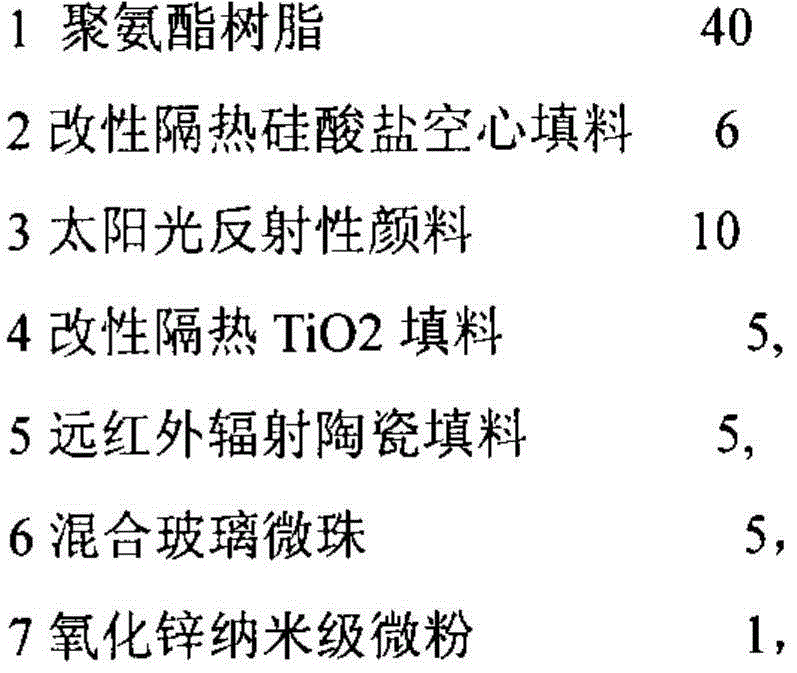

[0079] A high-efficiency energy-saving heat shielding and cooling anti-corrosion coating material is a three-layer composite material composed of an anti-corrosion bottom layer, a heat-insulating middle layer, and a heat-radiating surface layer. The thickness ratio of the anti-corrosion bottom layer, heat-insulating middle layer, and heat-radiating surface layer is 1:4 : 0.8. The total thickness of anti-corrosion bottom layer, heat insulation middle layer and heat radiation surface layer is 0.4mm. The anti-corrosion bottom layer is epoxy zinc-rich paint, the heat insulation middle layer is composed of three-component paint and curing agent in a weight ratio of 35:1, and the heat radiation surface layer is a composite surface layer with polyurethane resin as a film-forming material.

[0080] Wherein, the three-component coating of the heat-insulating middle layer includes the following components and contents in parts by weight:

[0081] A component: epoxy resin 100, additive ...

Embodiment 3

[0104] A high-efficiency energy-saving heat shielding and cooling anti-corrosion coating material, which is a three-layer composite material composed of an anti-corrosion bottom layer, a heat-insulating middle layer, and a heat-radiating surface layer. The thickness ratio of the anti-corrosion bottom layer, heat-insulating middle layer, and heat-radiating surface layer is 1:4 : 0.8. The total thickness of anti-corrosion bottom layer, heat insulation middle layer and heat radiation surface layer is 0.6mm.

[0105] The anti-corrosion bottom layer is epoxy zinc-rich paint, the heat insulation middle layer is composed of three-component paint and curing agent in a weight ratio of 40:1, and the heat radiation surface layer is a composite surface layer with polyurethane resin as a film-forming material.

[0106] The three-component coating for the heat-insulating middle layer includes the following components and parts by weight:

[0107] A component: epoxy resin 100, additive 80, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com