Patents

Literature

3527 results about "Total thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

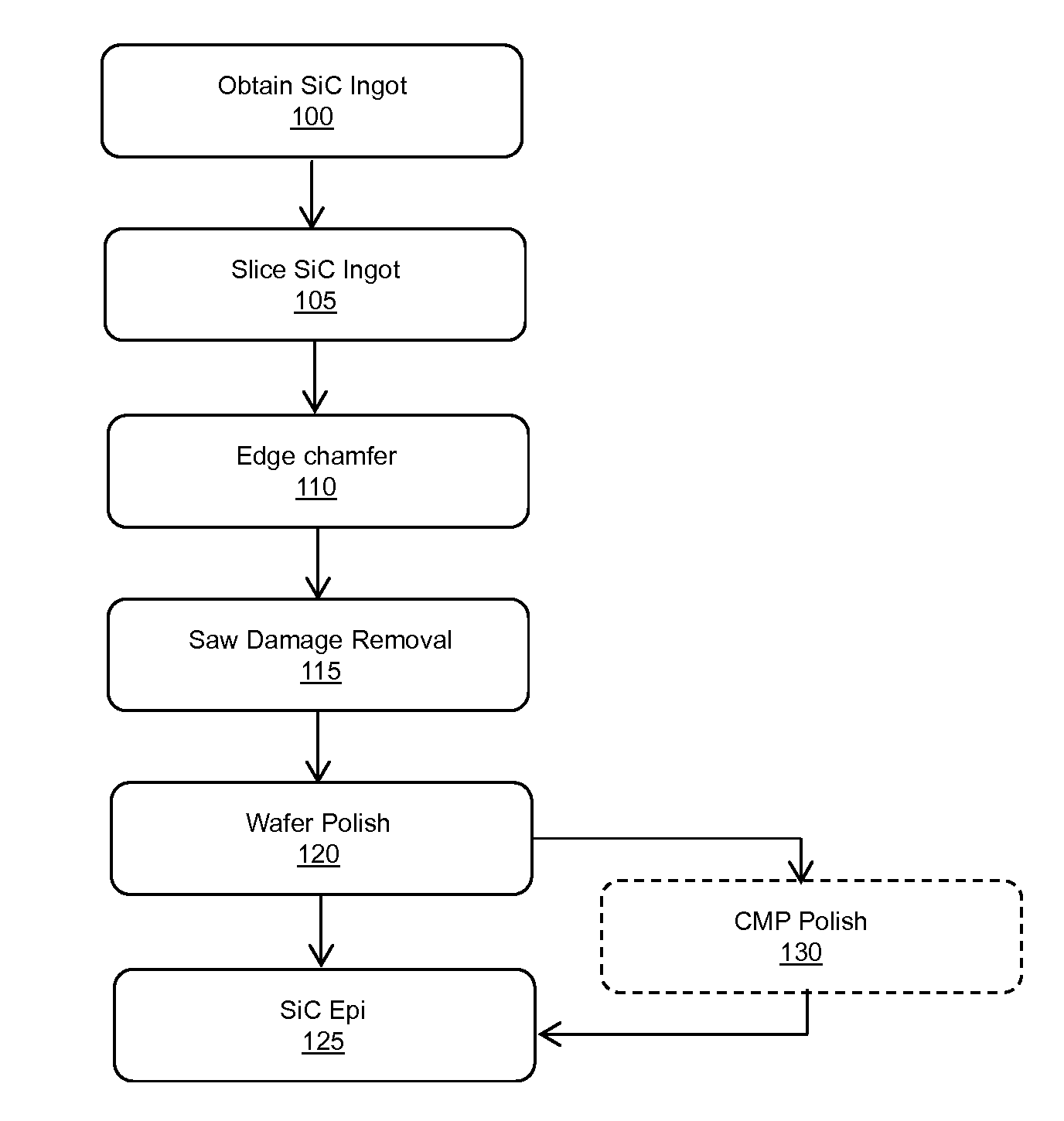

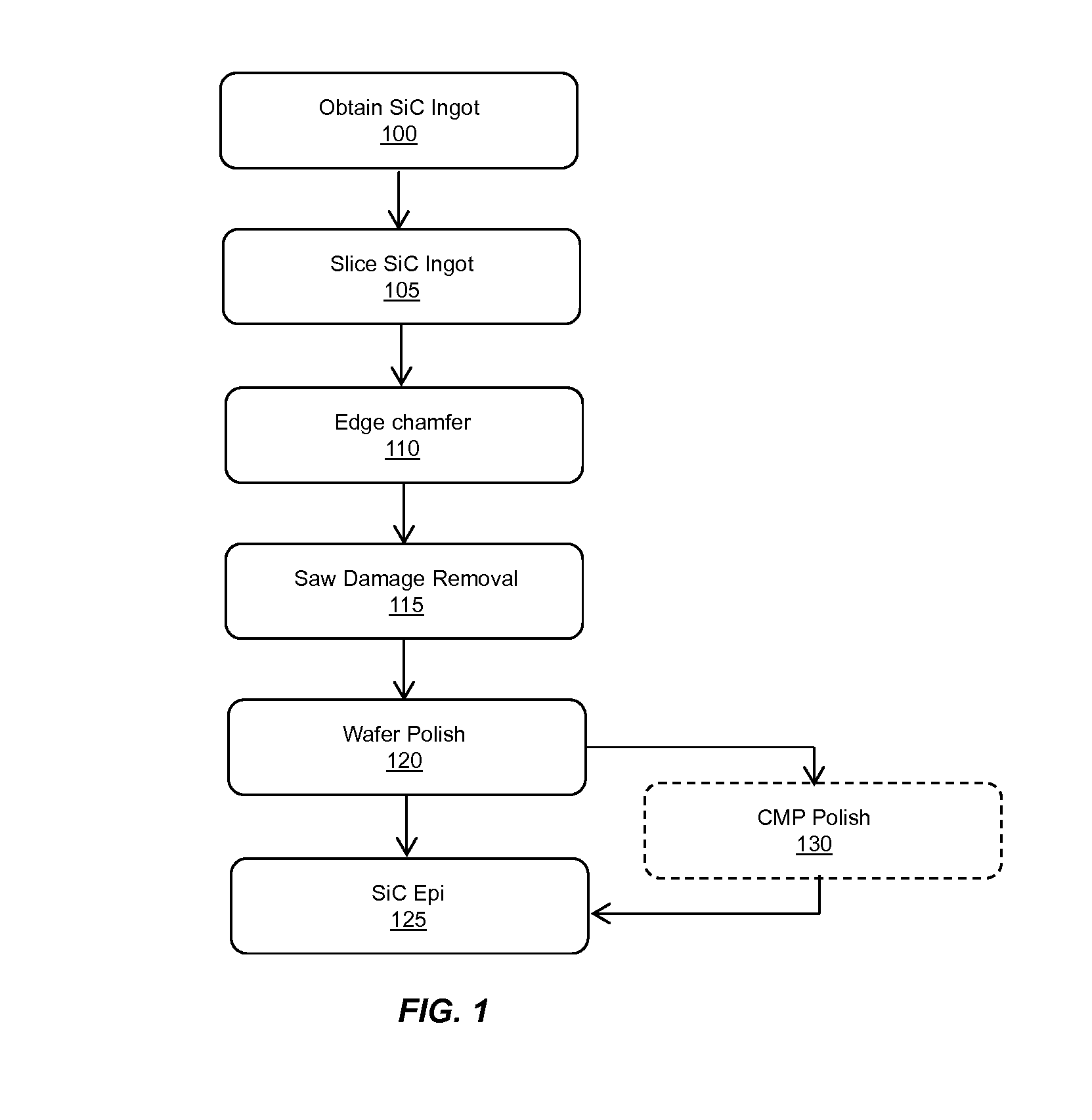

Flat sic semiconductor substrate

ActiveUS20140117380A1Efficient polishingImprove performanceEdge grinding machinesPolycrystalline material growthCrystallographyWafering

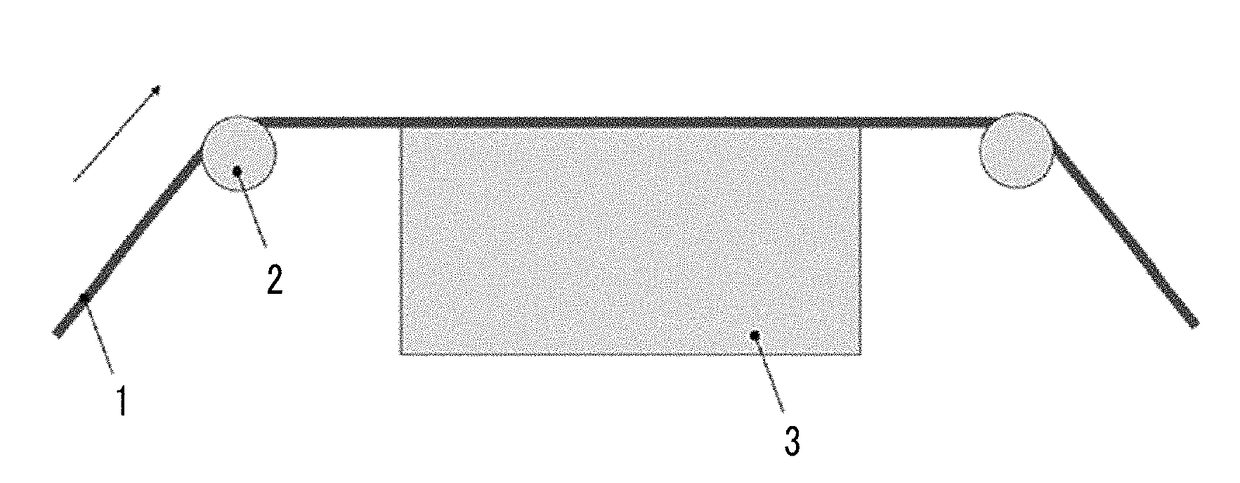

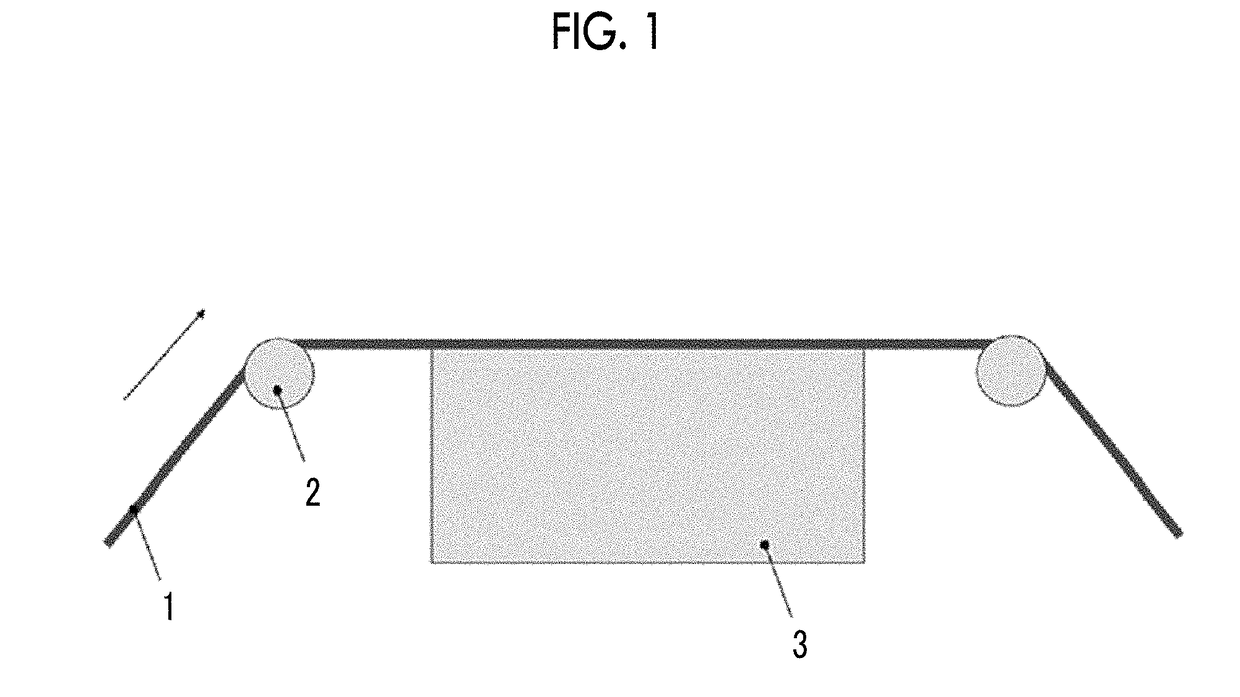

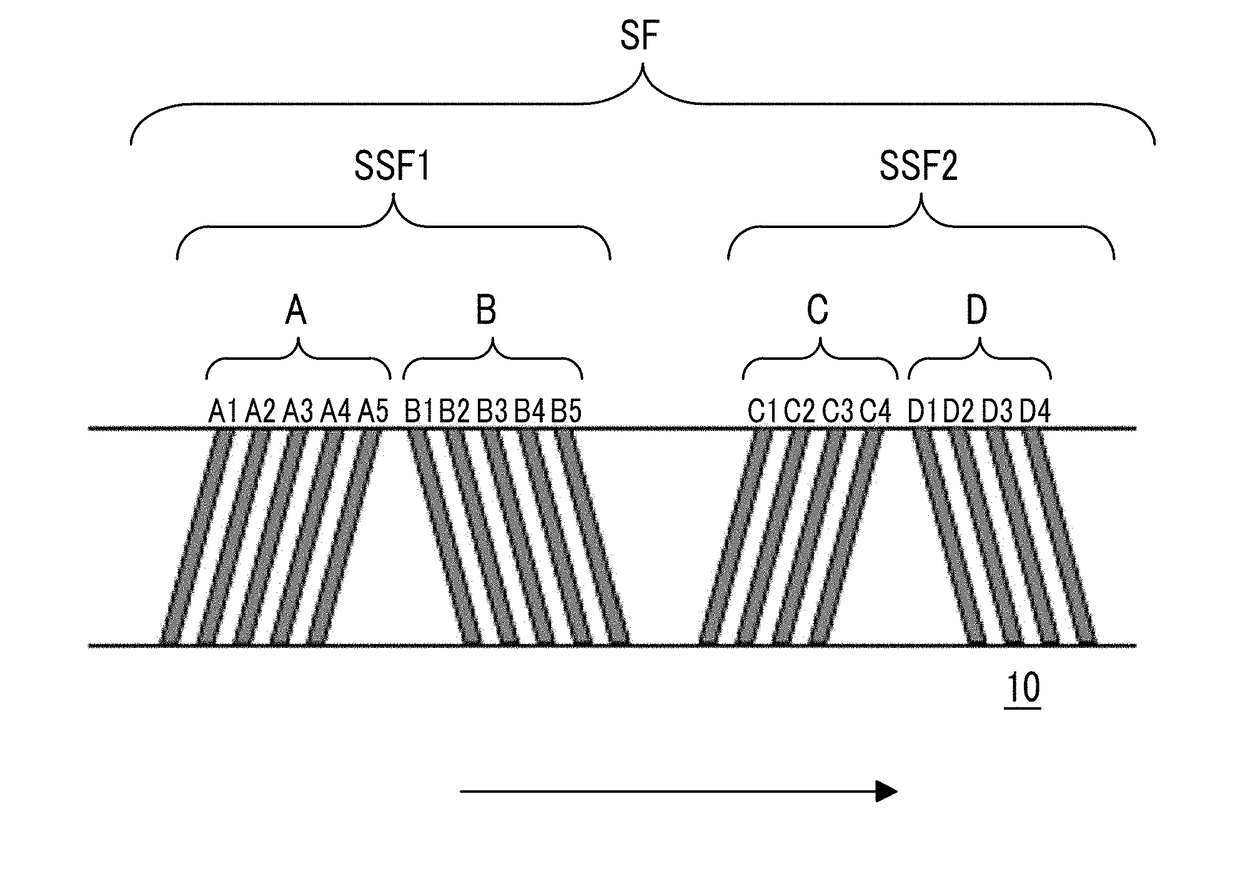

Methods for manufacturing silicon carbide wafers having superior specifications for bow, warp, total thickness variation (TTV), local thickness variation (LTV), and site front side least squares focal plane range (SFQR). The resulting SiC wafer has a mirror-like surface that is fit for epitaxial deposition of SiC. The specifications for bow, warp, total thickness variation (TTV), local thickness variation (LTV), and site front side least squares focal plane range (SFQR) of the wafer are preserved following the addition of the epitaxy layer.

Owner:SK SILTRON CSS LLC

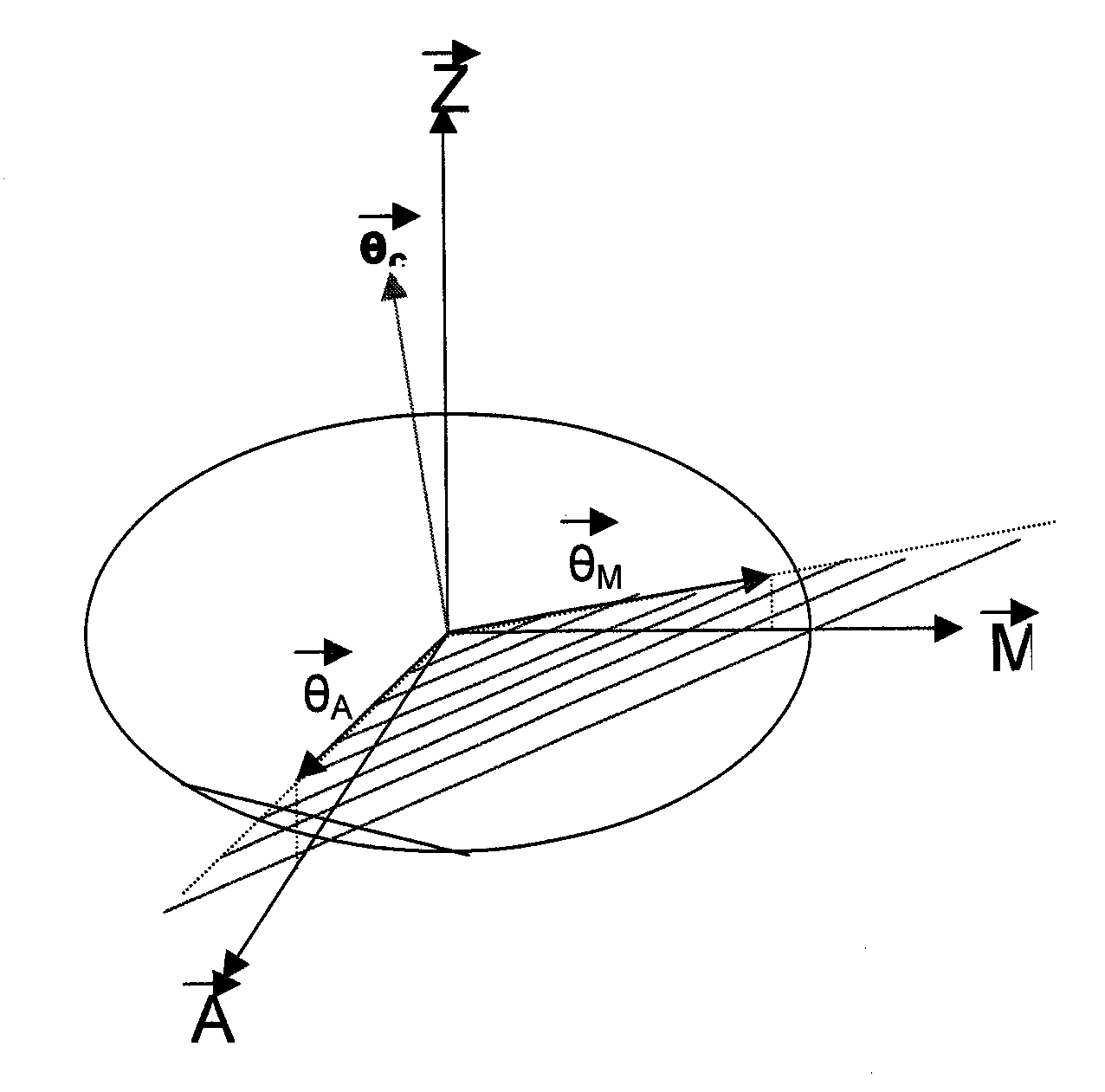

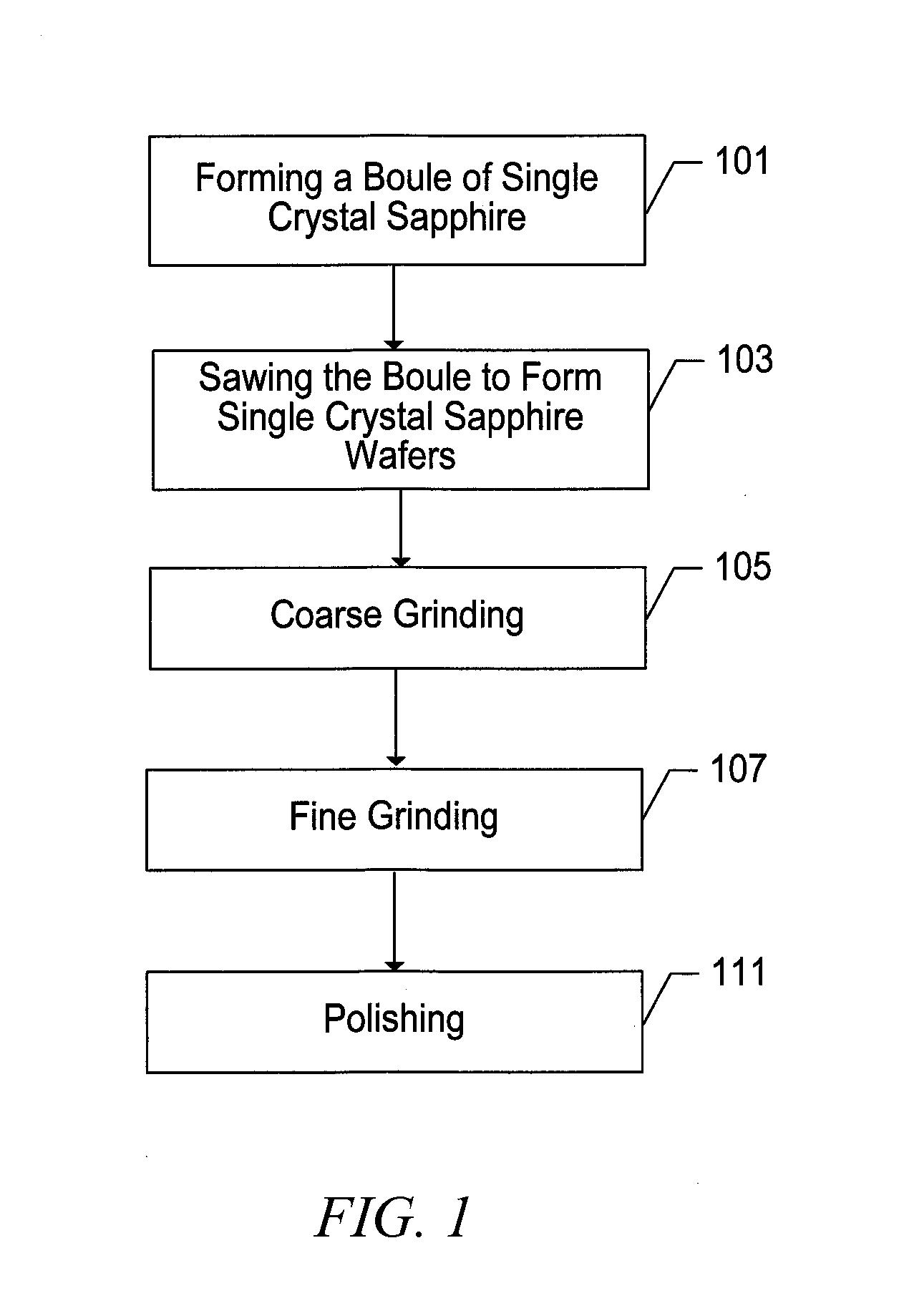

Sapphire substrates and methods of making same

InactiveUS20080164578A1Polycrystalline material growthFine working devicesPlane orientationTotal thickness

A sapphire substrate includes a generally planar surface having a crystallographic orientation selected from the group consisting of a-plane, r-plane, m-plane, and c-plane orientations, and having a nTTV of not greater than about 0.037 μm / cm2, wherein nTTV is total thickness variation normalized for surface area of the generally planar surface, the substrate having a diameter not less than about 9.0 cm.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

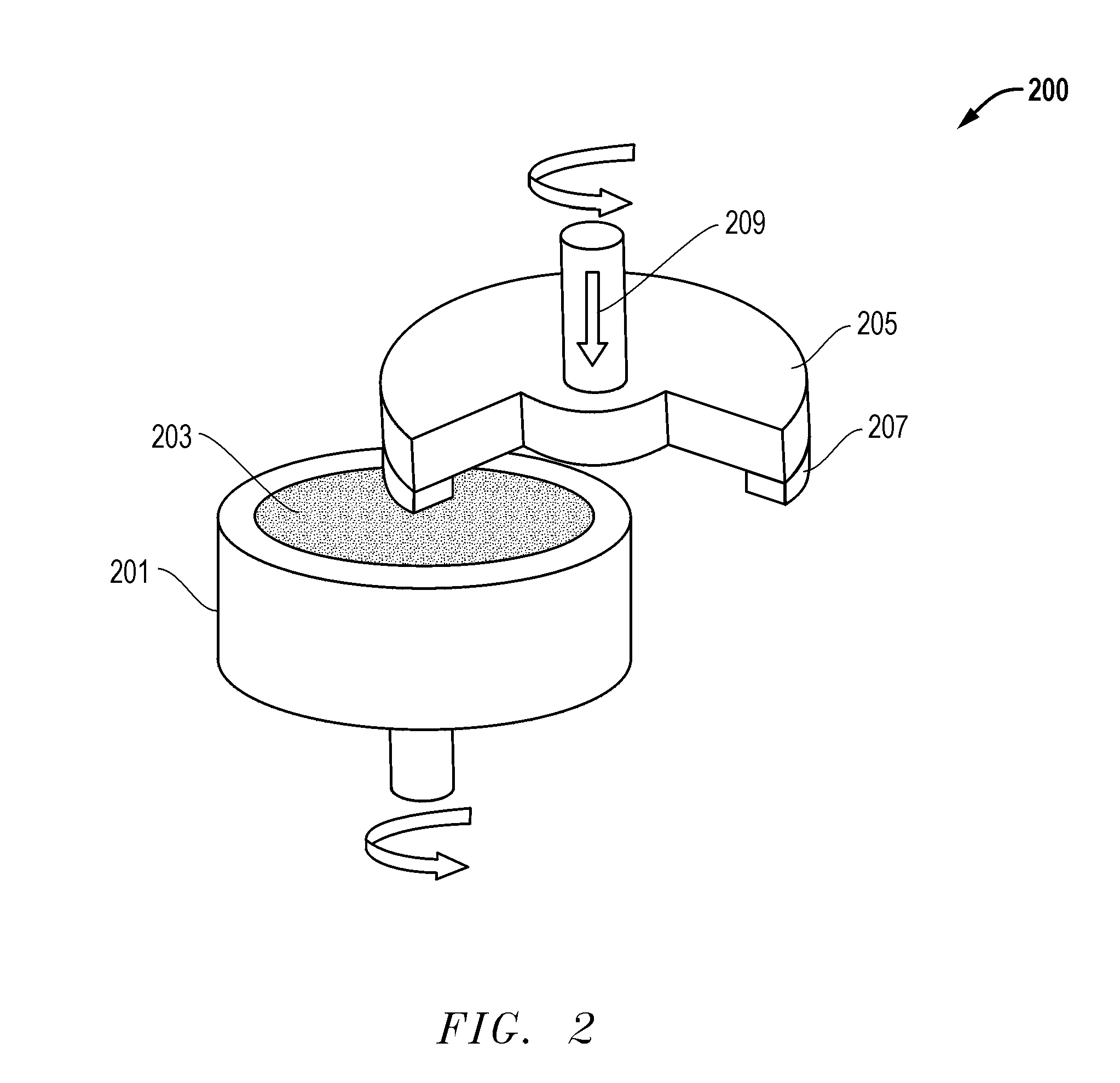

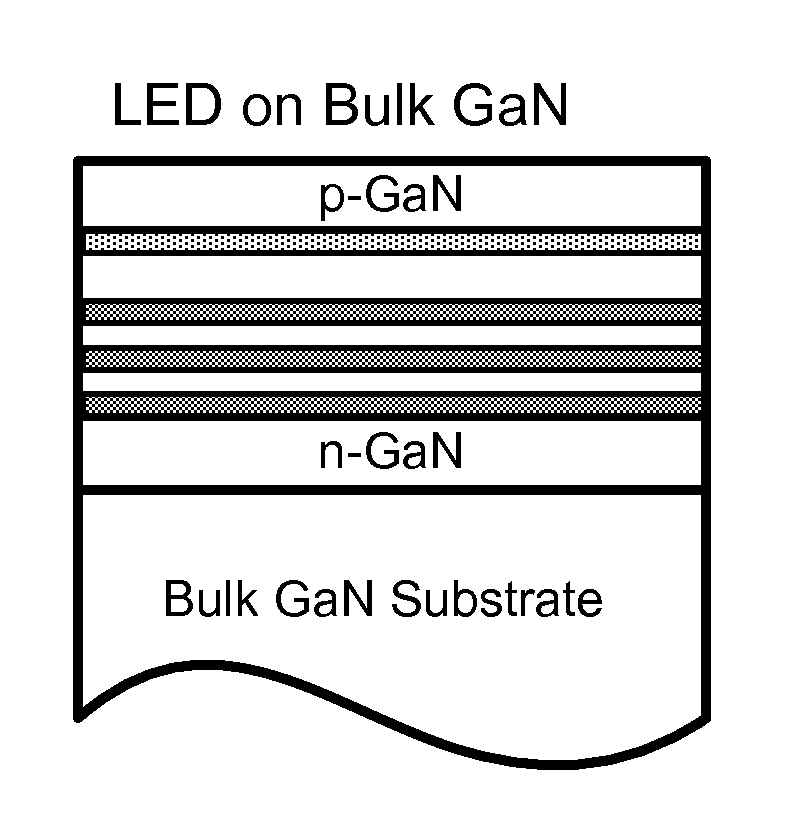

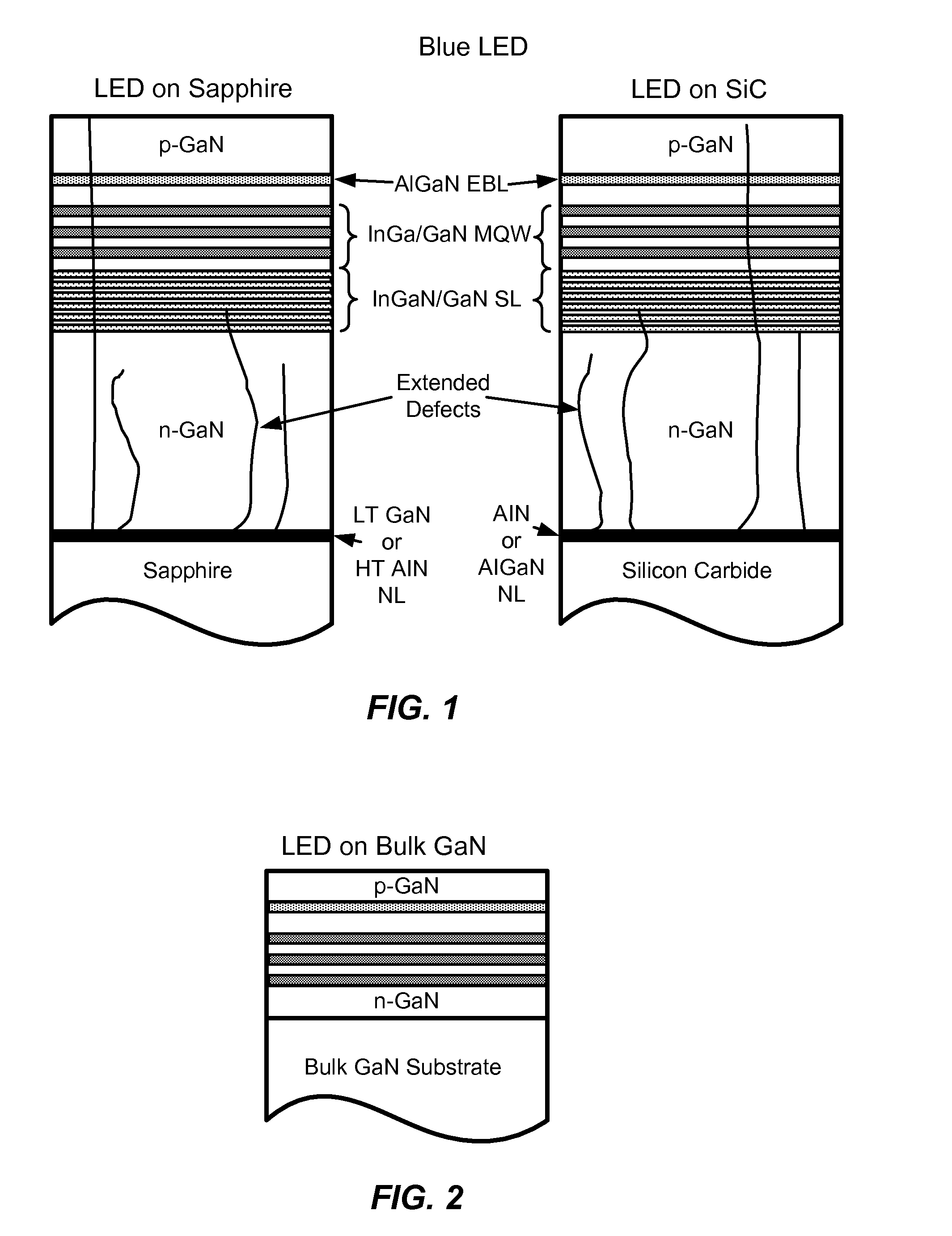

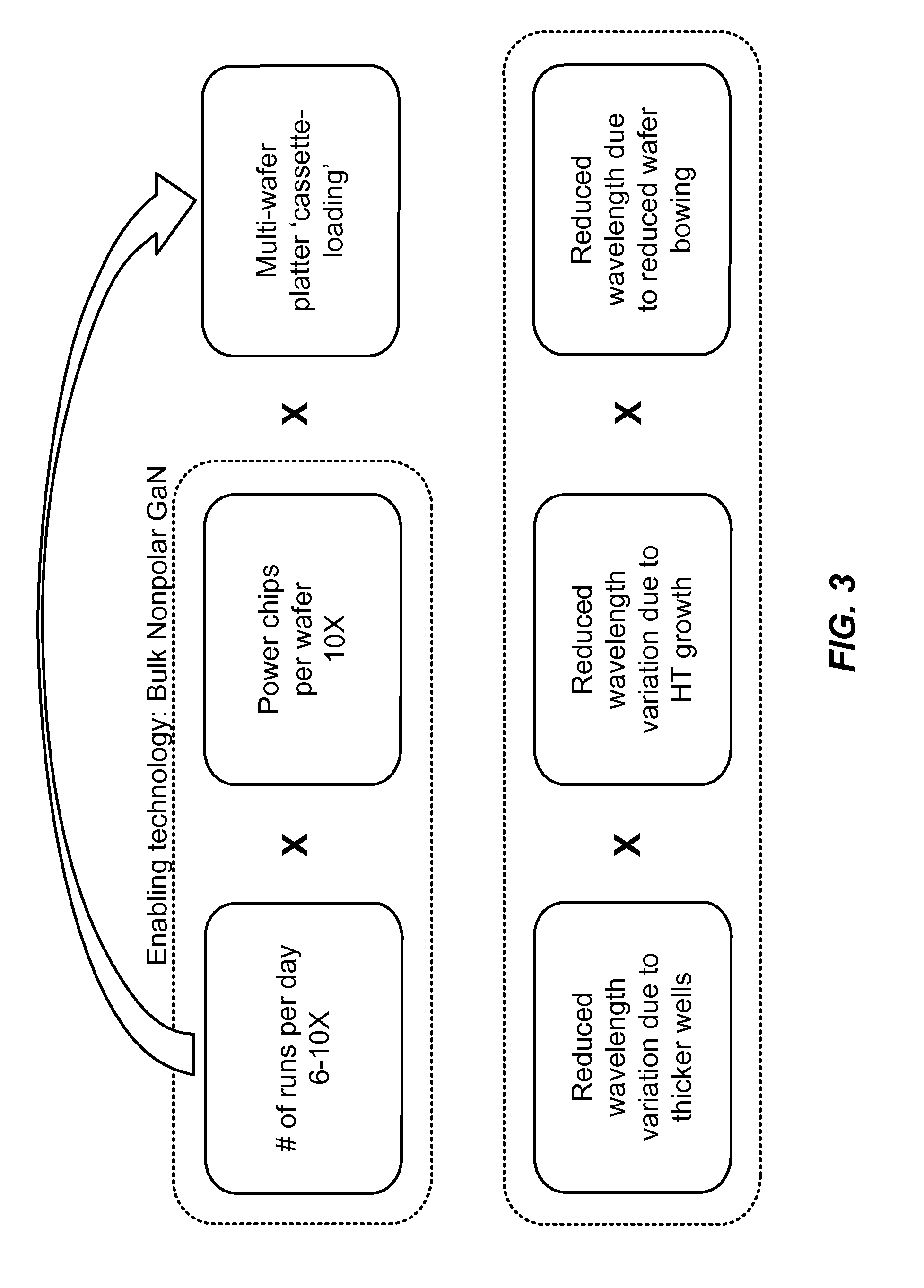

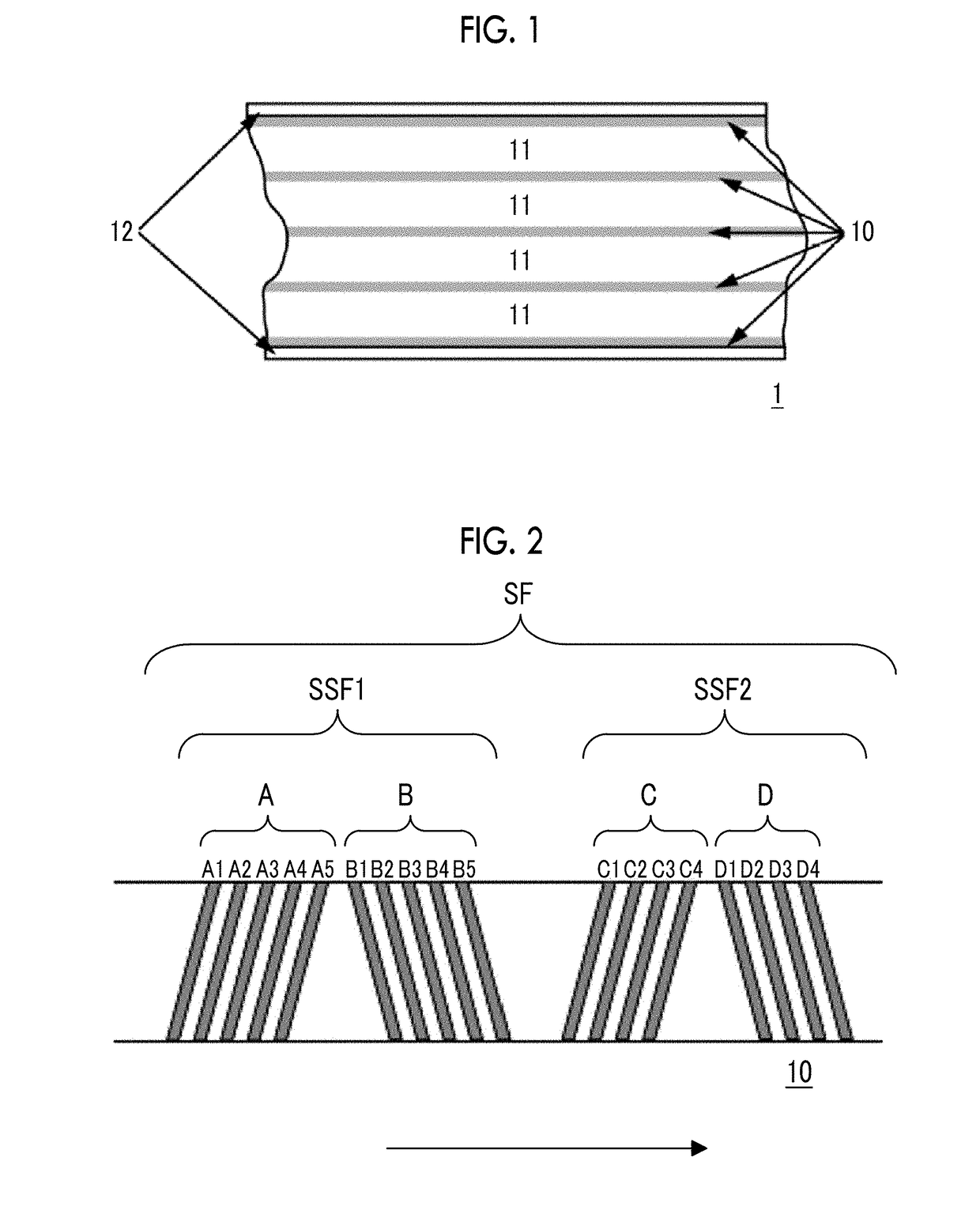

Rapid Growth Method and Structures for Gallium and Nitrogen Containing Ultra-Thin Epitaxial Structures for Devices

InactiveUS20110056429A1Quick upgradeReduce processing timePolycrystalline material growthSemiconductor/solid-state device manufacturingEpitaxial materialNitrogen

A method for rapid growth of gallium and nitrogen containing material is described. The method includes providing a bulk gallium and nitrogen containing substrate. A first epitaxial material of first thickness is formed over the substrate, preferably with a pseudomorphical process. The method also forms a second epitaxial layer over the first to create a stacked structure. The stacked structure consists of a total thickness of less than about 2 microns.

Owner:SORAA

Multilayered coated cutting tool

The present invention relates to a cutting tool comprising a body of sintered cemented carbide or cermet, ceramic or high speed steel on which at least one of the functioning parts of the surface of the body, a thin, adherent, hard and wear resistant coating is applied. The coating comprises a laminar, multilayered structure of refractory compounds in polycrystalline, non-repetitive form, MX / NX / MX / NX where the alternating layers MX and NX are metal nitrides or carbides with the metal elements M and N selected from the group consisting of Ti, Nb, Hf, V, Ta, Mo, Zr, Cr, Al and W. The sequence of individual layer thicknesses is essentially aperiodic throughout the entire multilayered structure, and layer thicknesses are larger than 0.1 nanometer but smaller than 30 nanometer, preferably smaller than 20 nanometer. The total thickness of said multilayered coating is larger than 0.5 mu m but smaller than 20 mu m.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

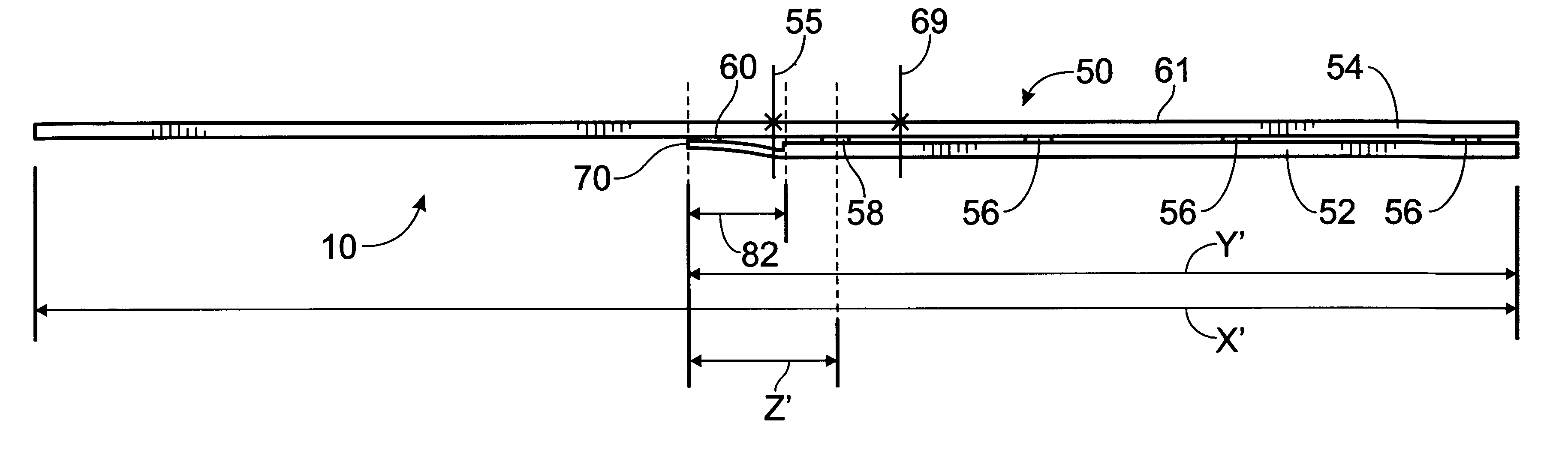

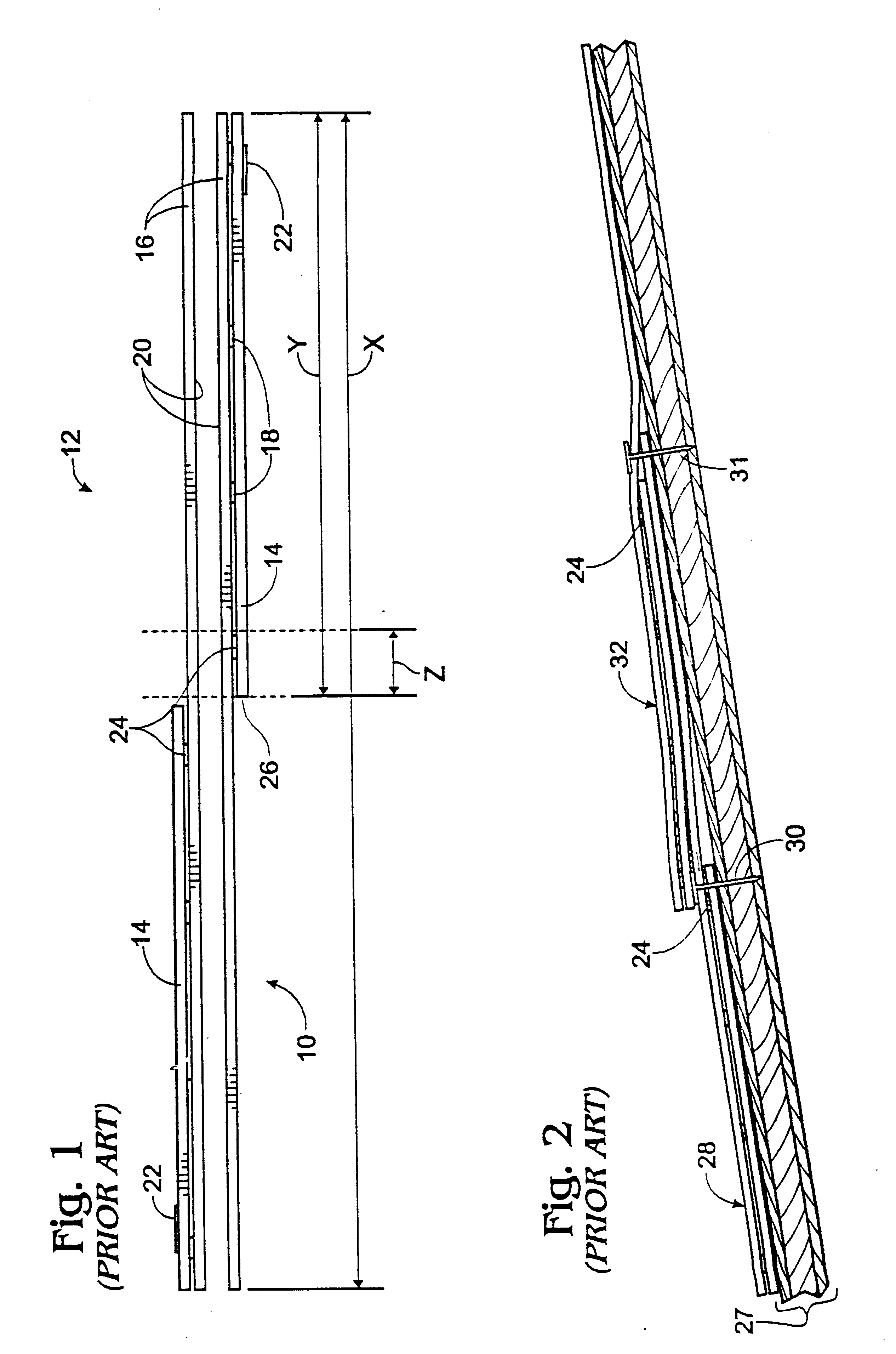

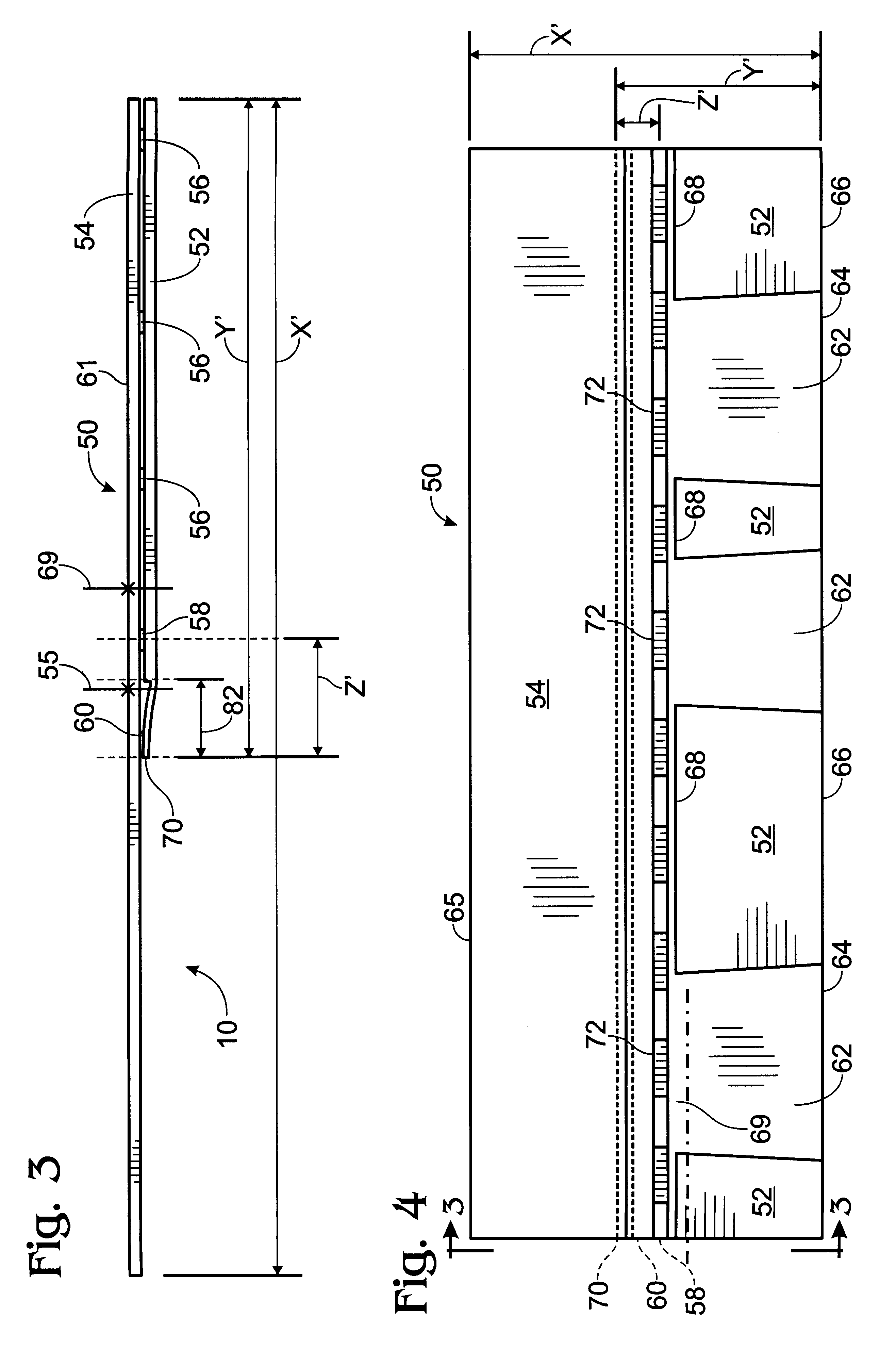

Laminated shingle

Laminated shingles are manufactured from roll stock roofing material that is wider than that used to make similar laminated shingles. The roll stock includes longitudinal edge strips having a reduced thickness. The roll stock is cut into strips of tabbed top sheets and backing sheets. The strips of material used for the backing sheets are at once wider than commonly used in the industry, and include the longitudinal edge strips of reduced-thickness material. Because the backing sheet is wider two rain seal strips are laid down on the backing sheet prior to being laminated to the tabbed top sheet. The backing sheets are laminated to the tabbed top sheets with the longitudinal edges aligned. The wider backing sheet provides a substantially wider nail zone. In addition, since it allows for a second rain seal strip, provides somewhat more protection against leakage. The portion of the backing sheet that comprises the added width is relatively thinner than the remaining portions of the sheet. Paired shingles may therefore be oriented adjacent one another in opposite directions and stacked and bundled. The total thickness of the stack will be the same throughout the stack, so the stack of shingles is flat.

Owner:HERBERT MALARKEY ROOFING

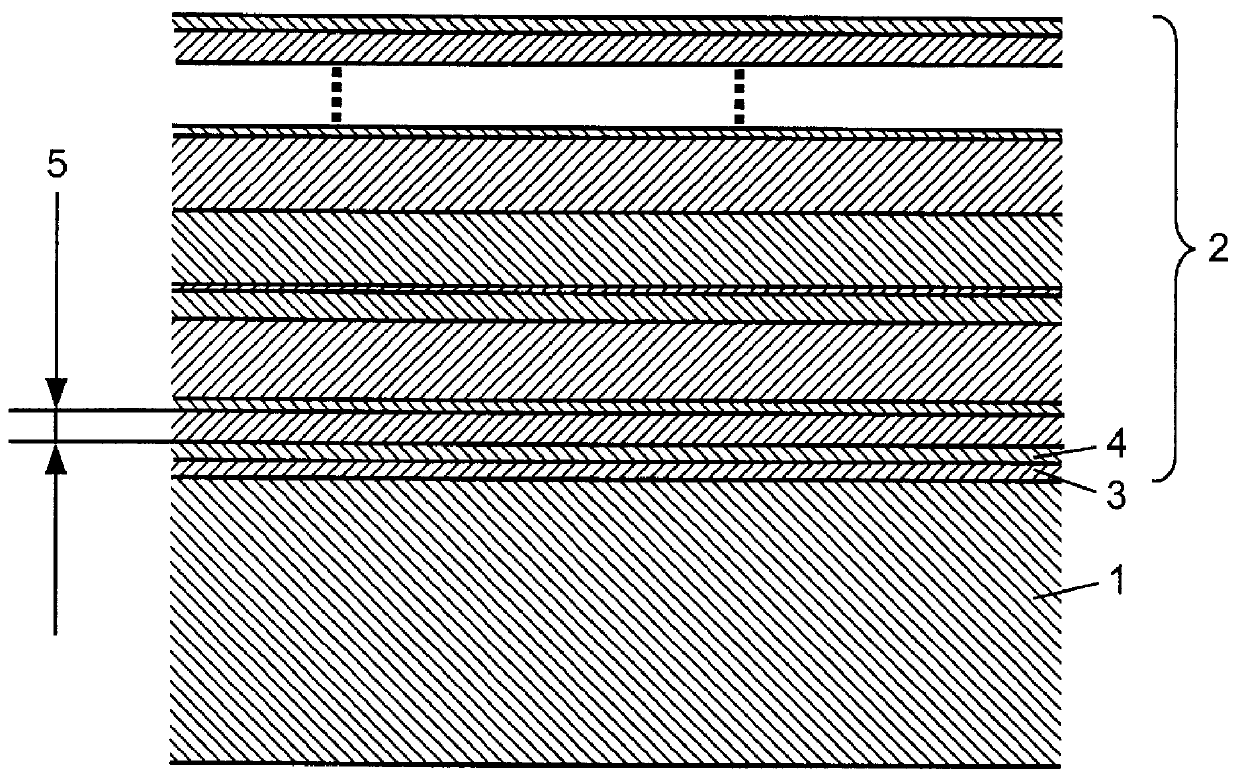

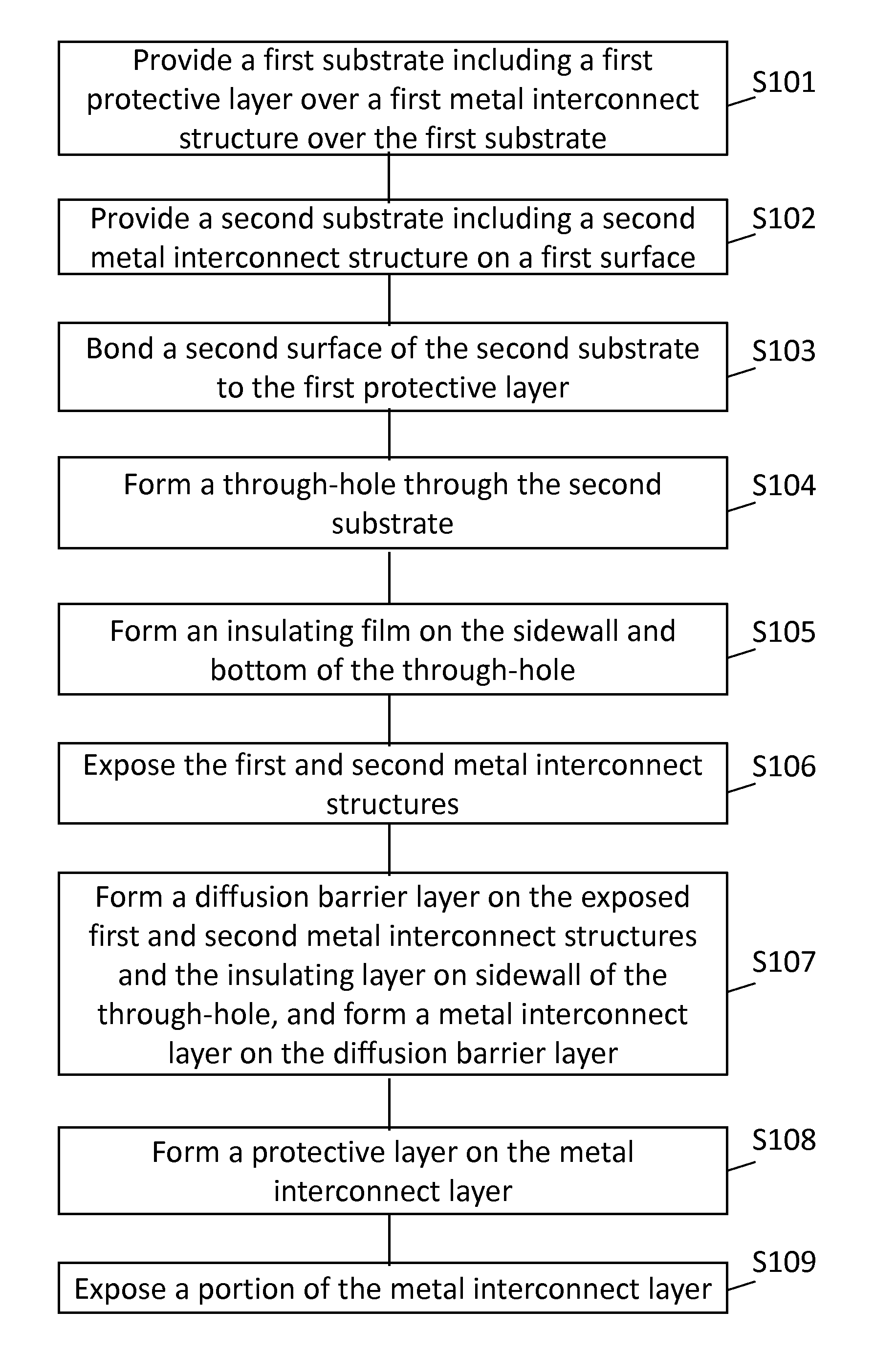

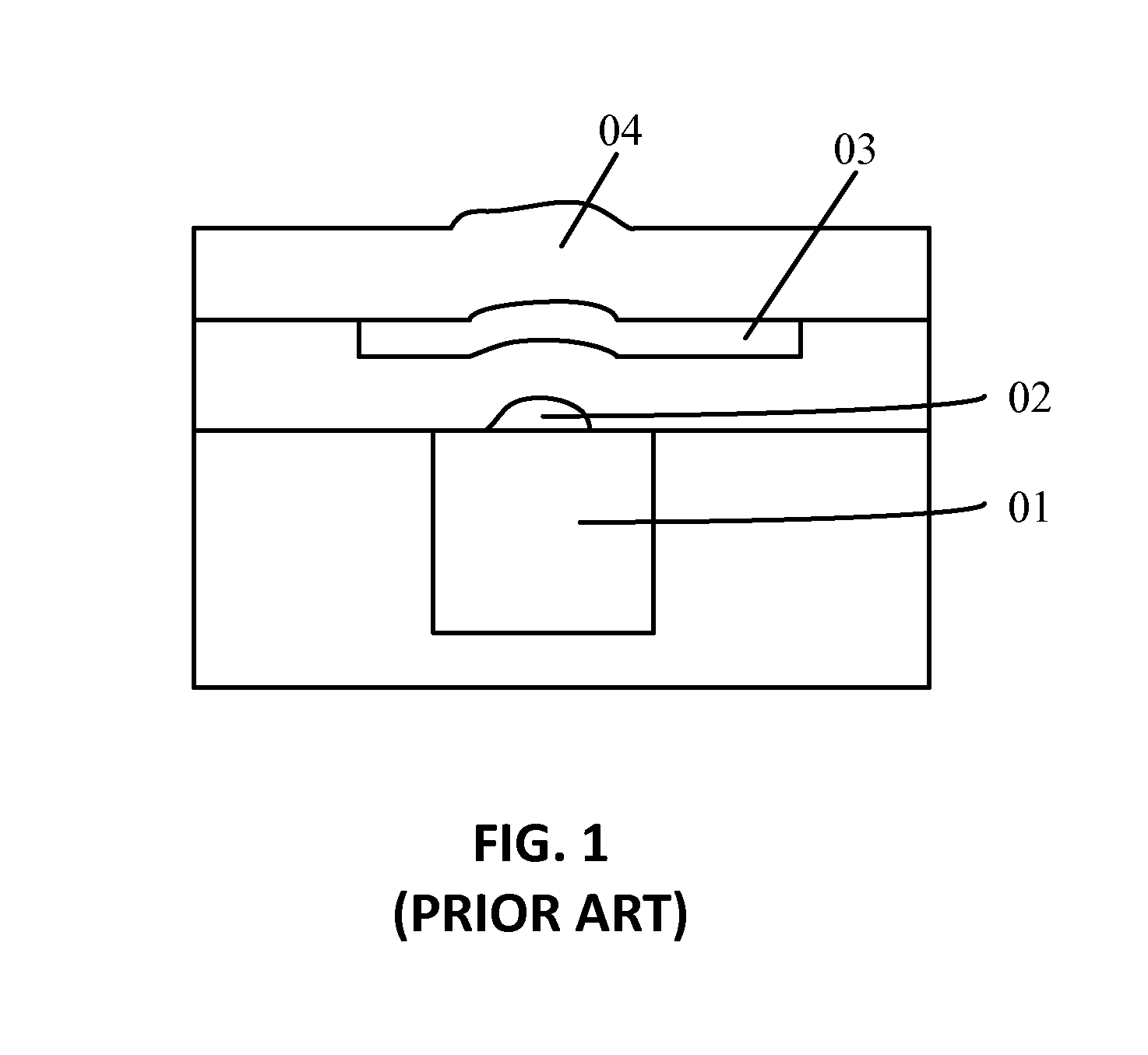

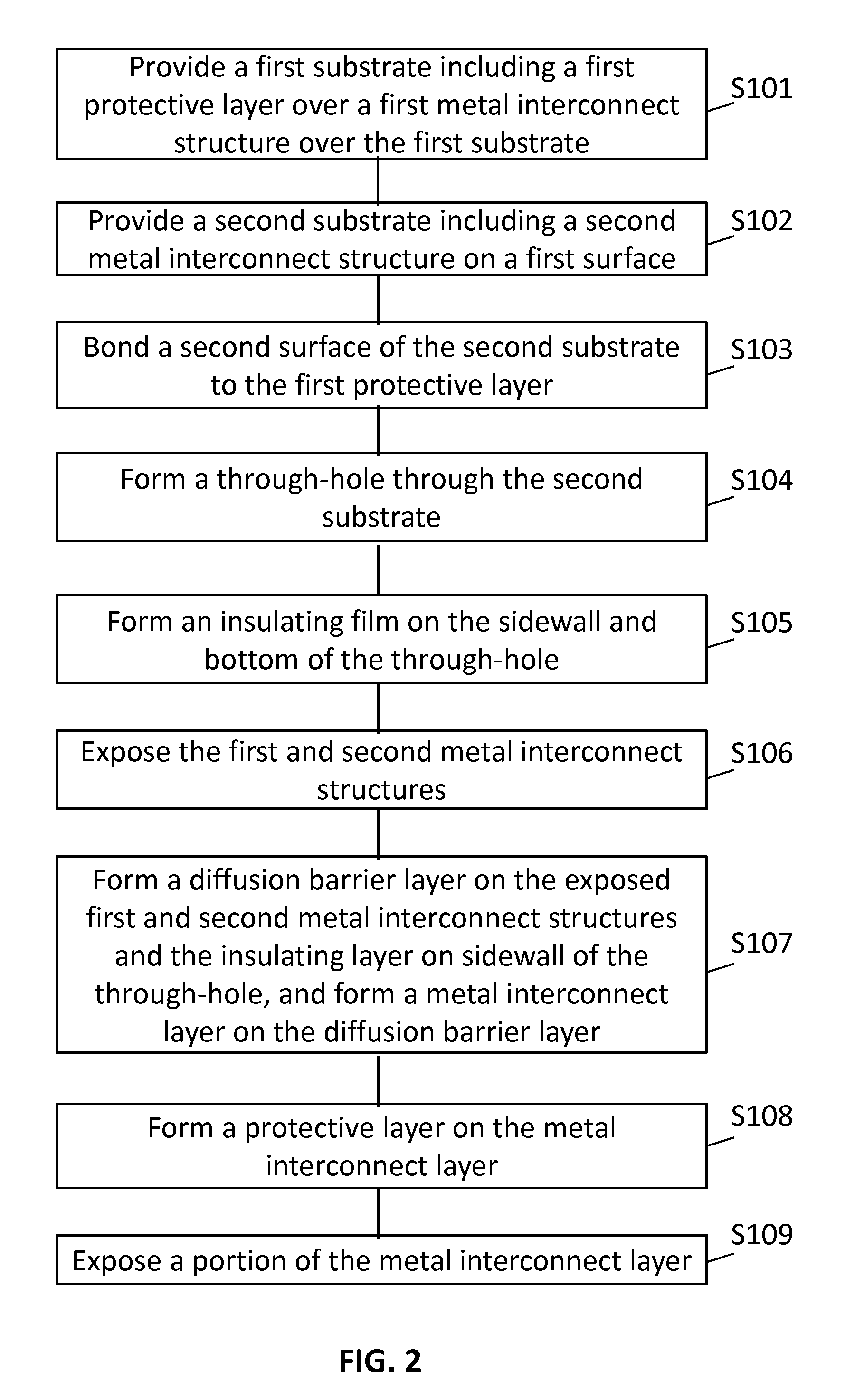

IC device including package structure and method of forming the same

ActiveUS20140015136A1Semiconductor/solid-state device detailsSolid-state devicesMetal interconnectEngineering

Various embodiments provide semiconductor devices including a package structure and methods of forming the semiconductor devices. In one embodiment, the package structure can include a through-hole at least partially filled by one or more layers of material(s) to form a through-hole interconnect between semiconductor devices in the package structure. The through-hole can be filled by an insulating layer, a diffusion barrier layer, a metal interconnect layer, and / or a protective layer having a total thickness from the sidewall of the through-hole of less than or equal to the radius of the through-hole.

Owner:SEMICON MFG INT (SHANGHAI) CORP

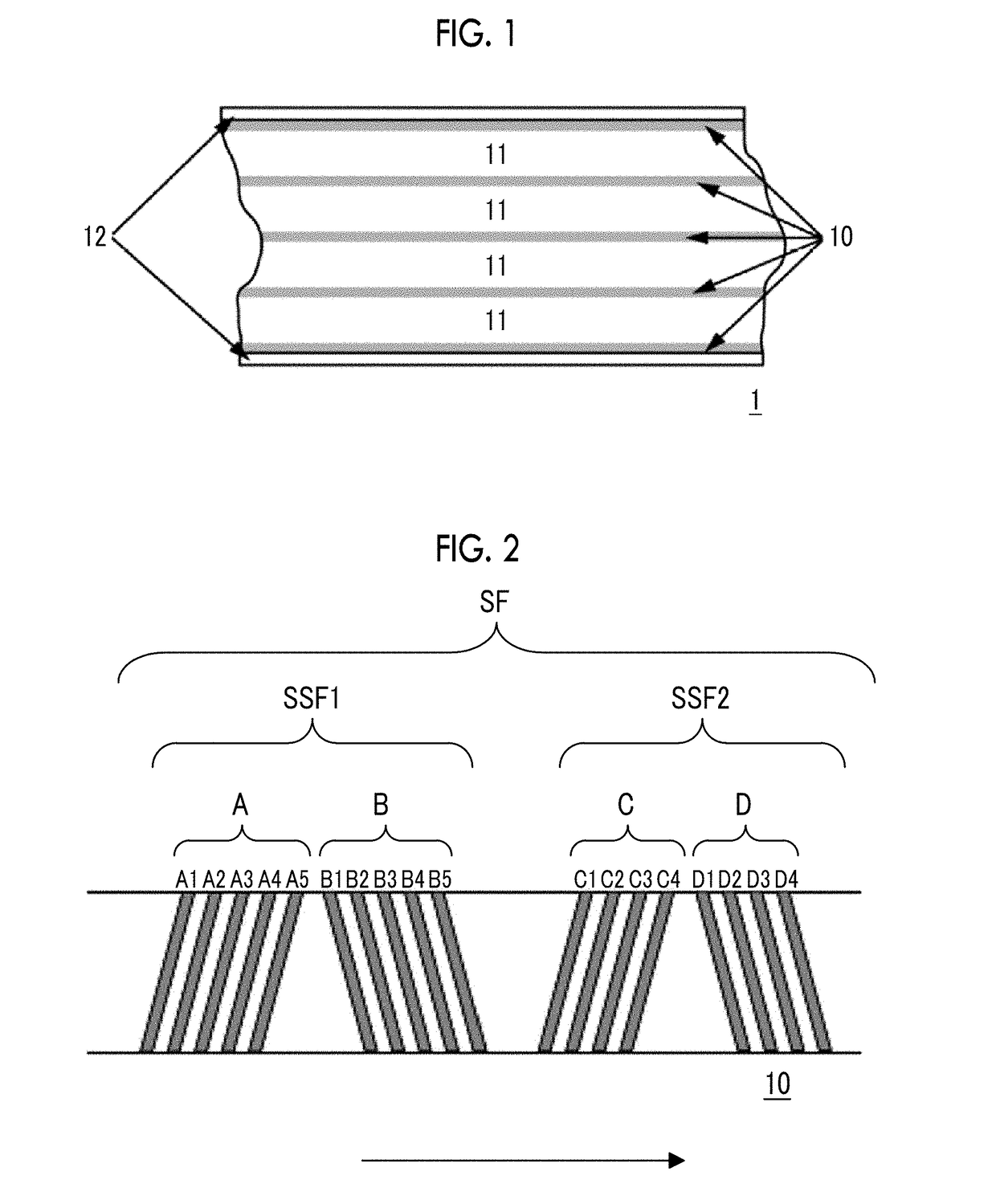

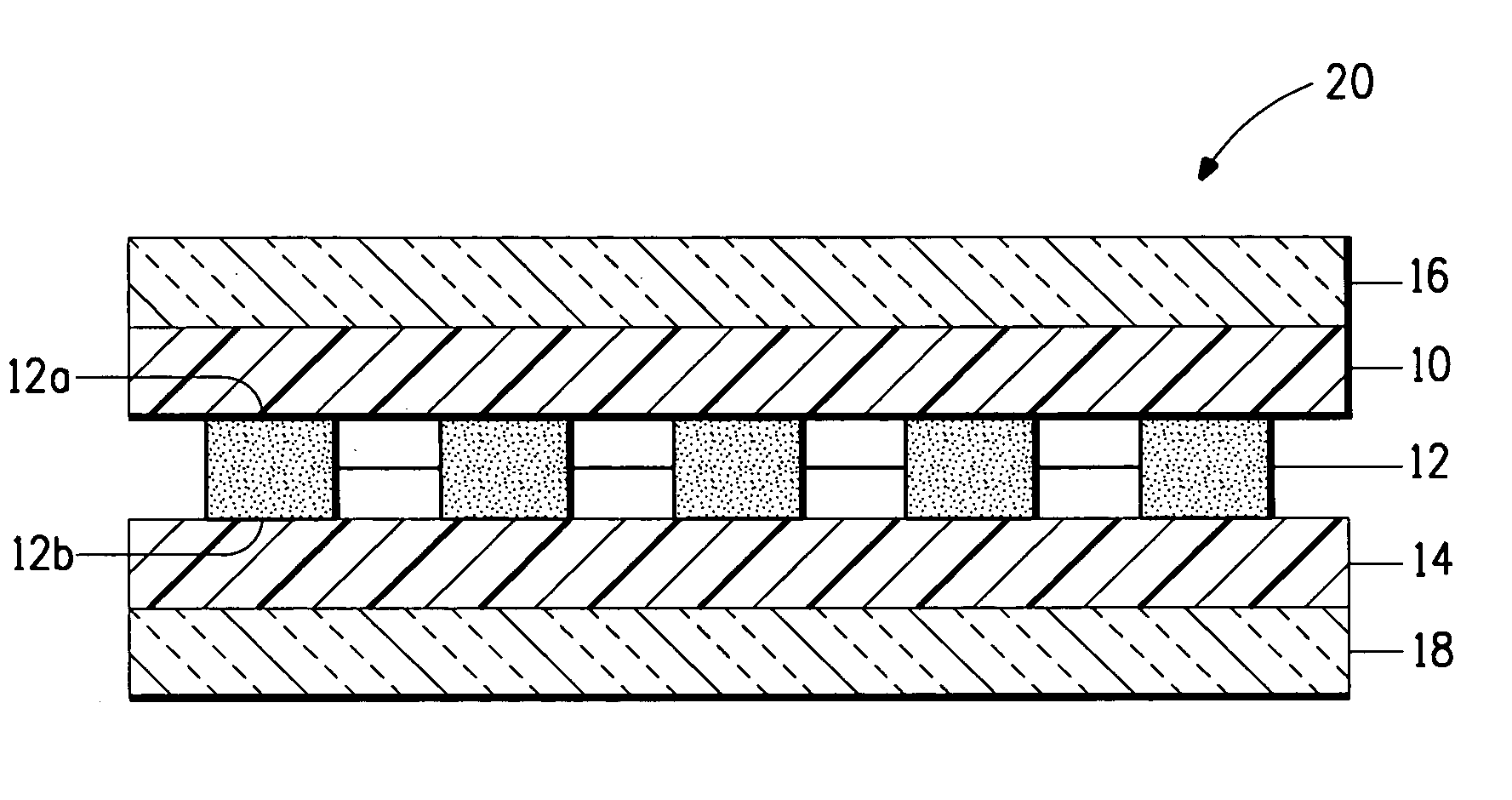

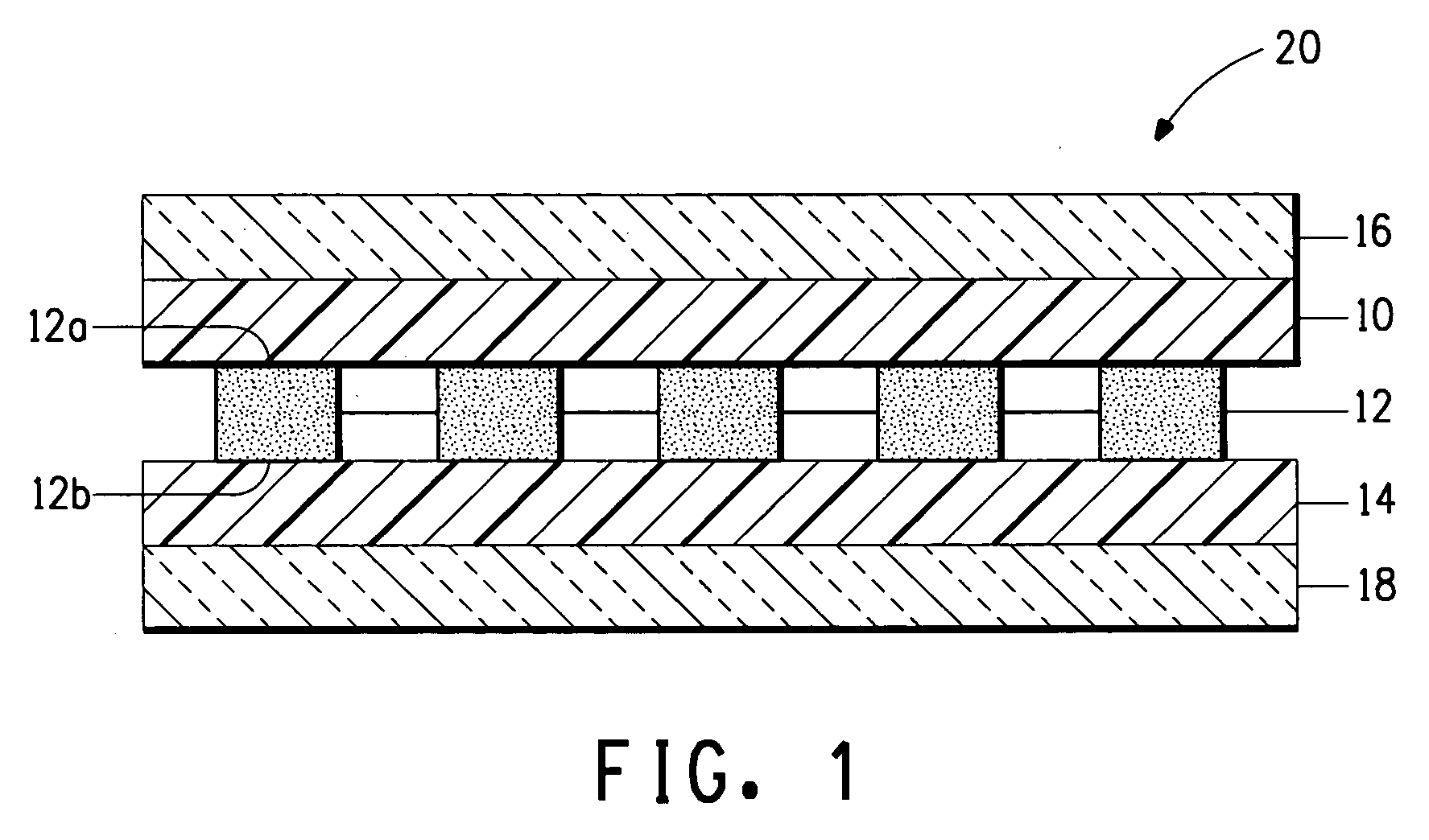

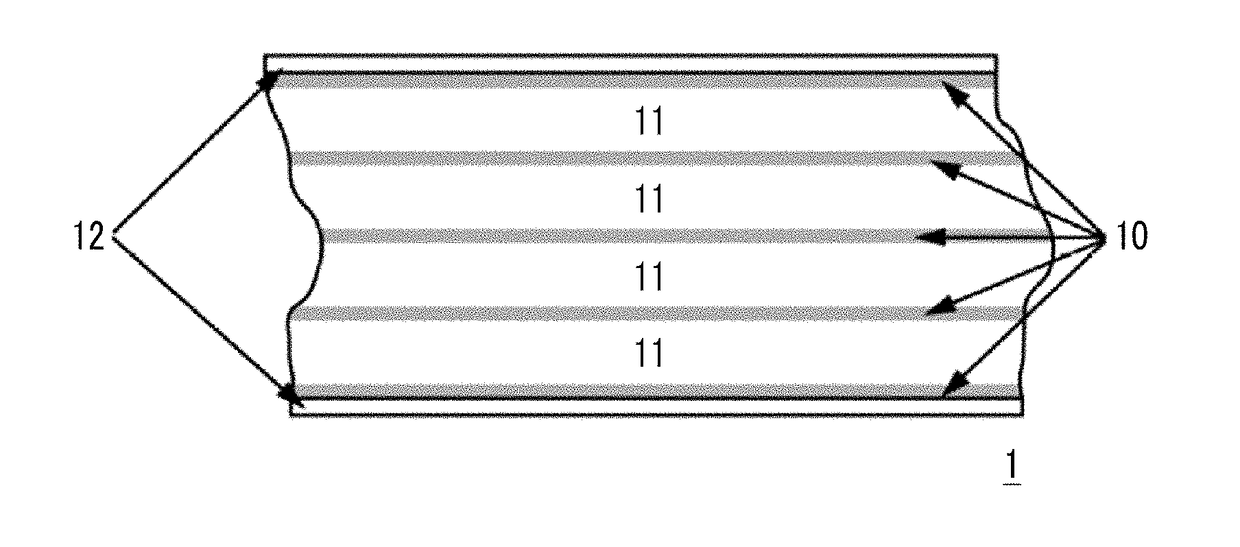

Magnetic tape

ActiveUS20160093322A1Reduce coefficient of frictionImprove noiseRecord information storageMagnetic recordingMagnetic tapeNon magnetic

The magnetic tape comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder, nonmagnetic powder, and binder, wherein a total thickness of the magnetic tape is less than or equal to 4.80 μm, and a coefficient of friction as measured on a base portion of a surface of the magnetic layer is less than or equal to 0.35.

Owner:FUJIFILM CORP

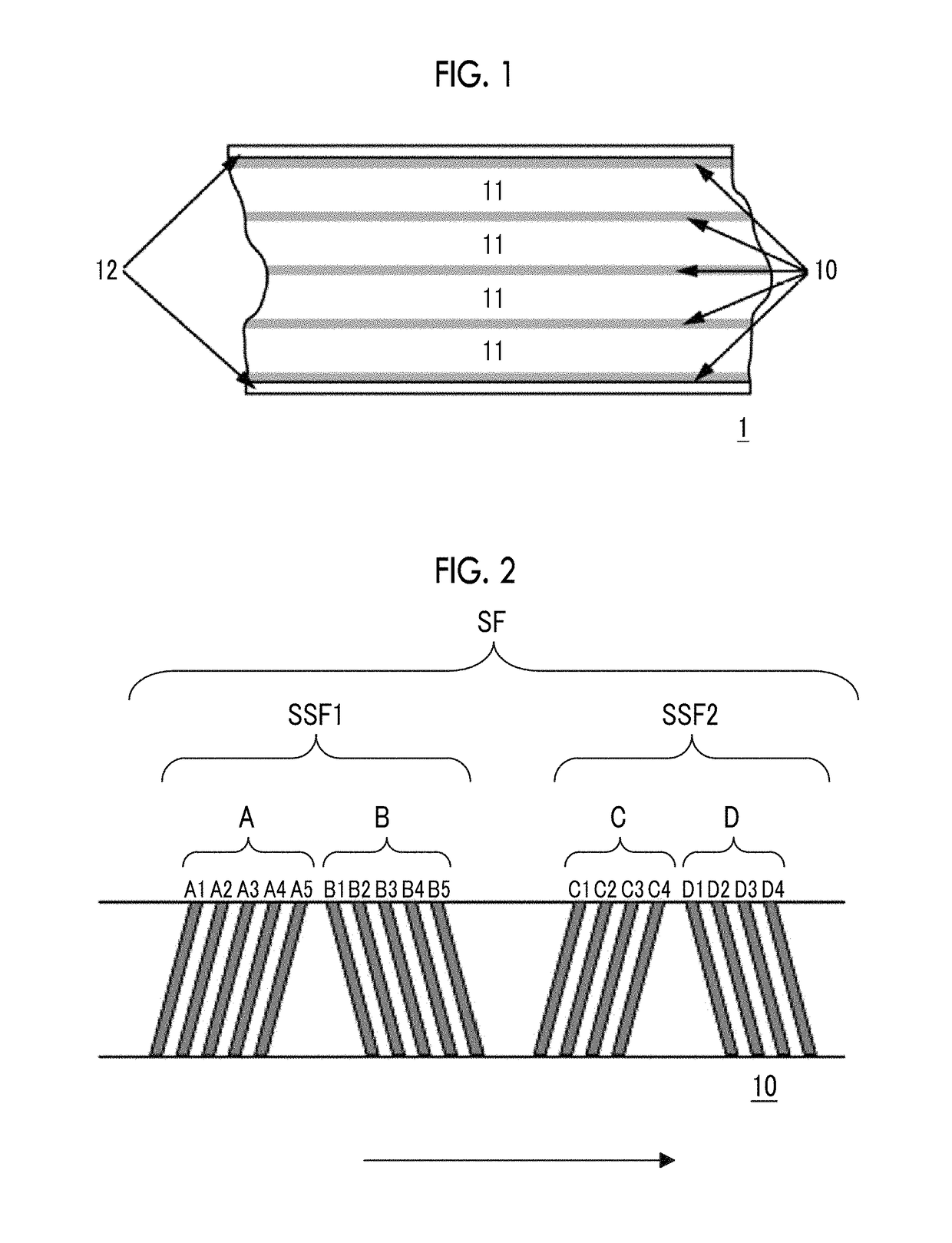

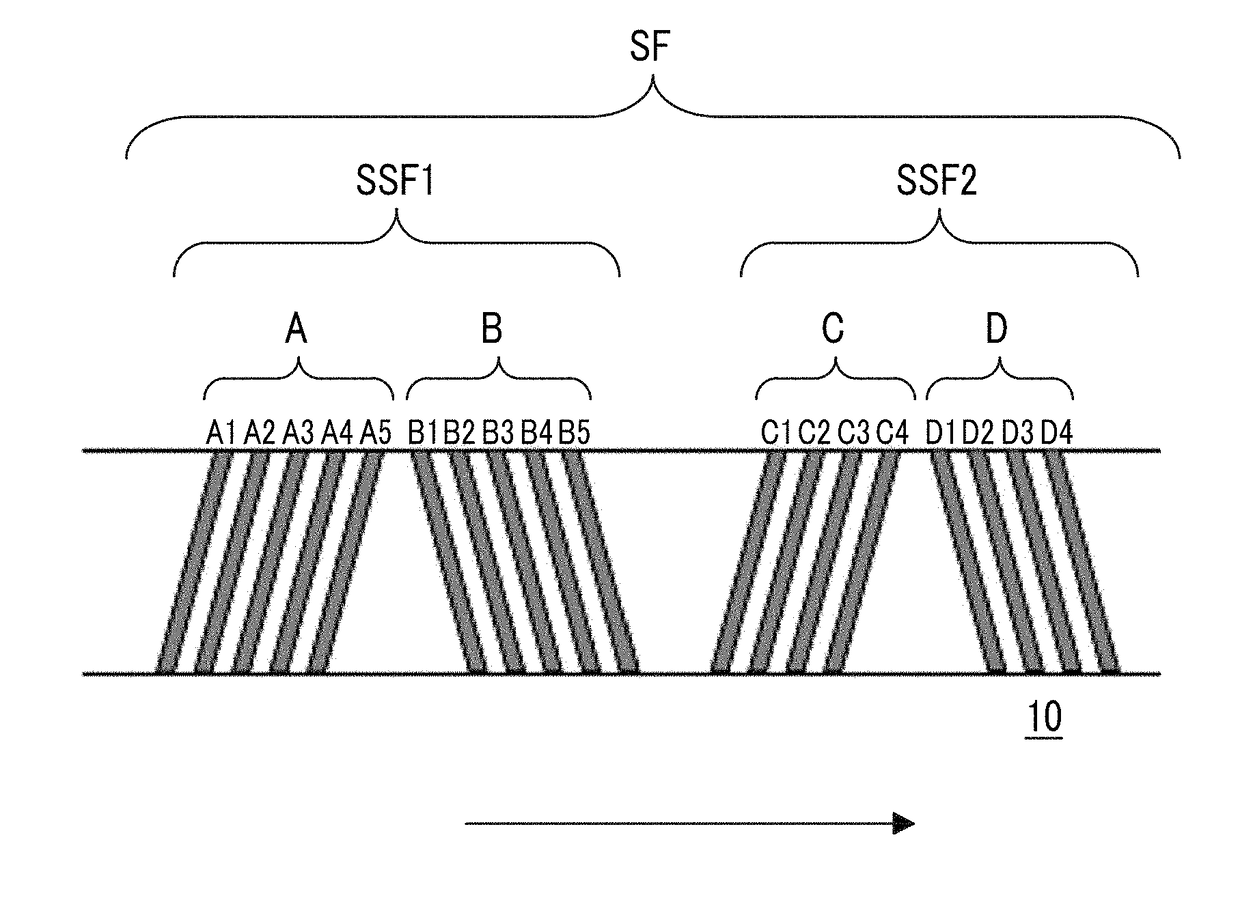

Magnetic tape and magnetic tape device

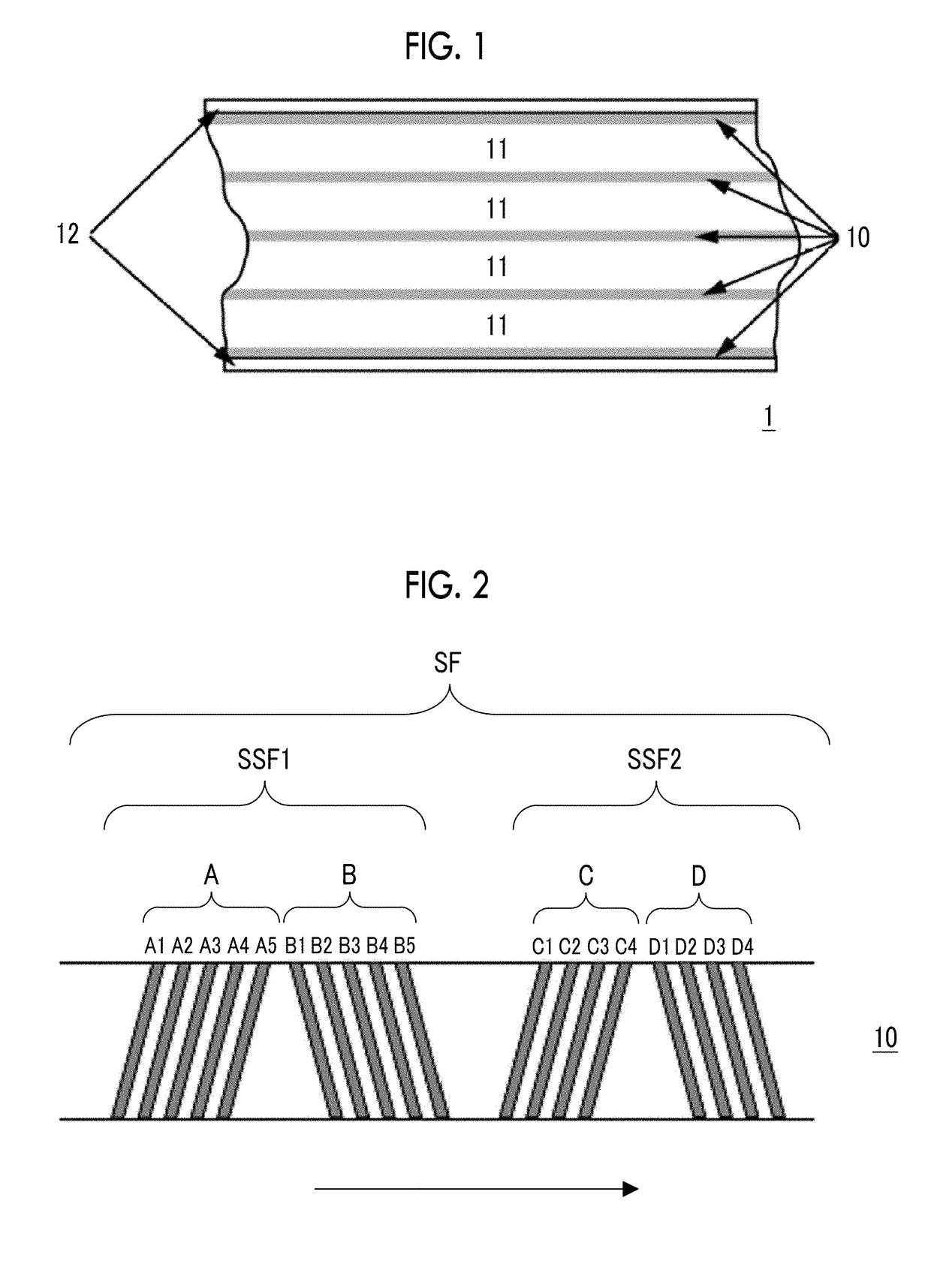

ActiveUS20170372740A1Improve accuracyAccurate informationBase layers for recording layersAlignment for track following on tapesMagnetic tapeFull width at half maximum

Provided is a magnetic tape in which the total thickness is equal to or smaller than 5.30 μm, the magnetic layer includes a timing-based servo pattern, a magnetic layer surface Ra is equal to or smaller than 1.8 nm, the magnetic layer includes fatty acid ester, a full width at half maximum of spacing distribution measured by optical interferometry regarding the surface of the magnetic layer before performing vacuum heating with respect to the magnetic tape is greater than 0 nm and equal to or smaller than 7.0 nm, a full width at half maximum of spacing distribution measured after performing the vacuum heating is greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between a spacing measured after performing the vacuum heating and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

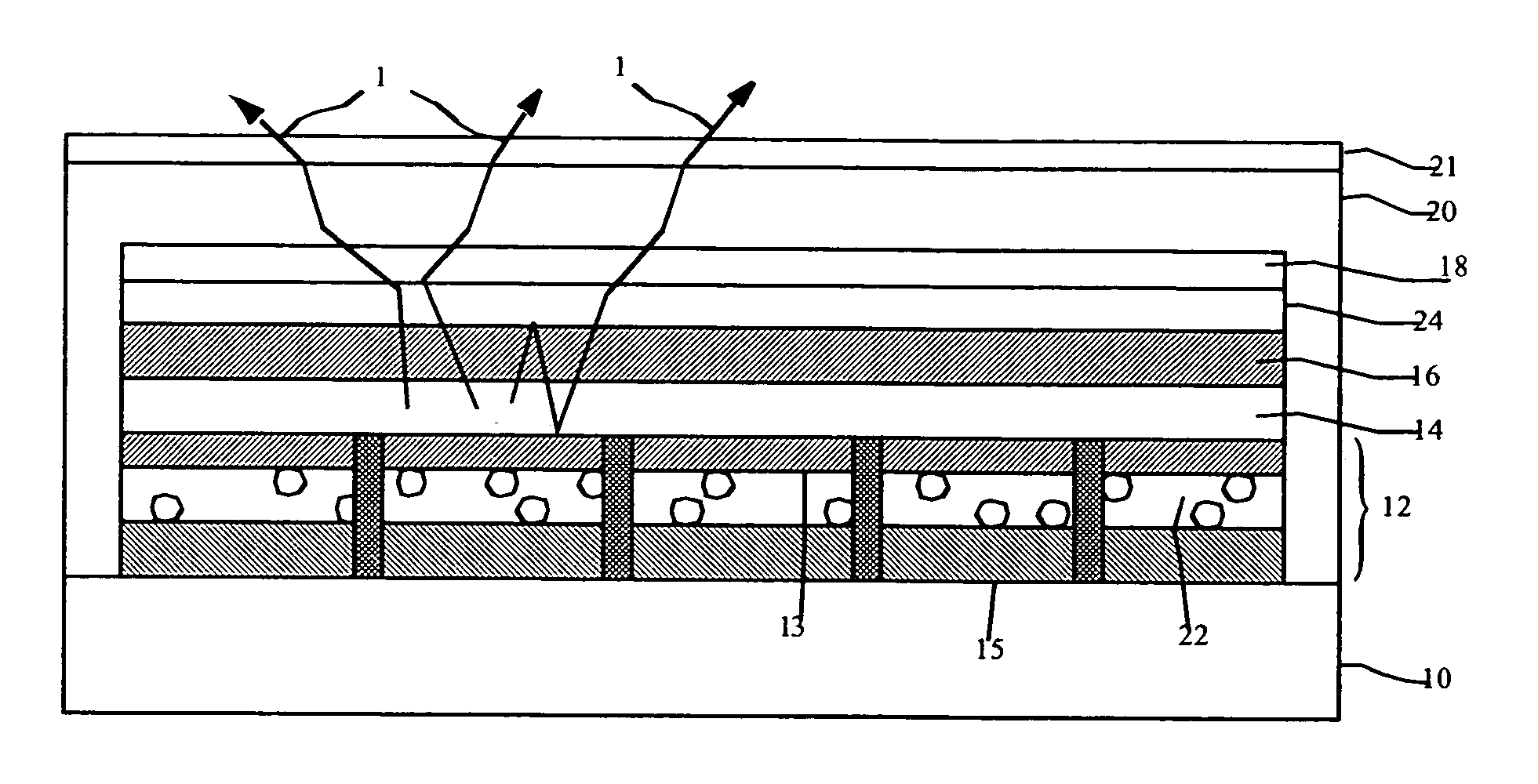

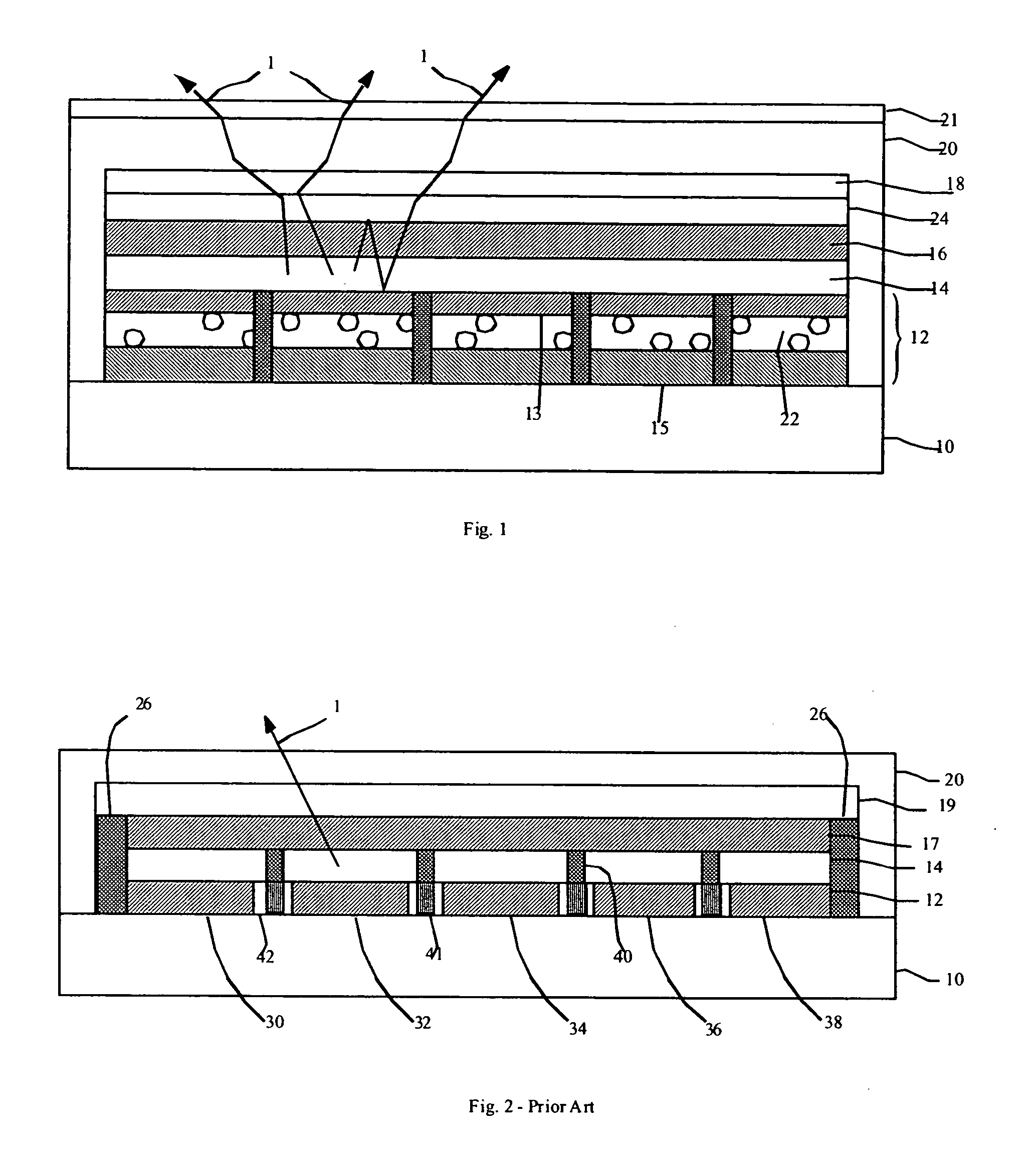

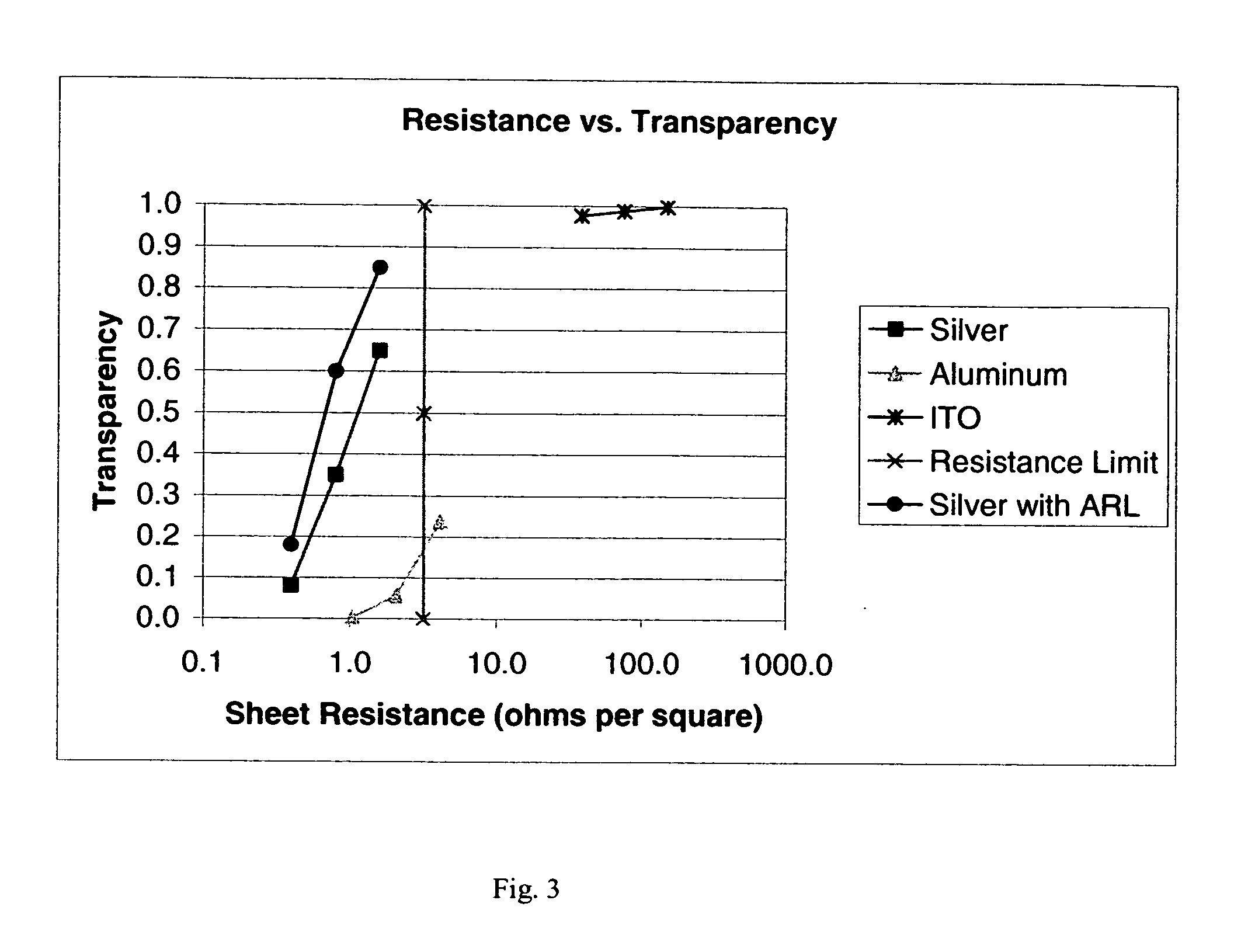

OLED device with improved light output

InactiveUS20060250084A1High transparencyDecrease in light absorbanceDischarge tube luminescnet screensElectroluminescent light sourcesAbsorbanceTotal thickness

An organic light-emitting diode (OLED) device is described, comprising: a) a substrate; b) an OLED formed over the substrate comprising a first electrode, a partially transparent second electrode through which light from the OLED is emitted, and at least one layer of organic light-emitting material disposed between the first electrode and partially transparent second electrode; and c) an encapsulating layer deposited on the partially transparent second electrode, wherein the encapsulating layer comprises one or more component layers, and wherein the encapsulating layer and the partially transparent second electrode combined have a transparency greater than the transparency of the partially transparent second electrode in the absence of the encapsulating layer, or wherein the encapsulating layer and the partially transparent second electrode combined have an absorbance less than the absorbance of the partially transparent second electrode in the absence of the encapsulating layer. To provide adequate encapsulation, in accordance with various embodiments of the invention at least one component layer of the encapsulating layer is deposited by atomic layer deposition, or the total thickness of encapsulating layer is at least about 150 nm. In a preferred embodiment, both such features are incorporated.

Owner:EASTMAN KODAK CO

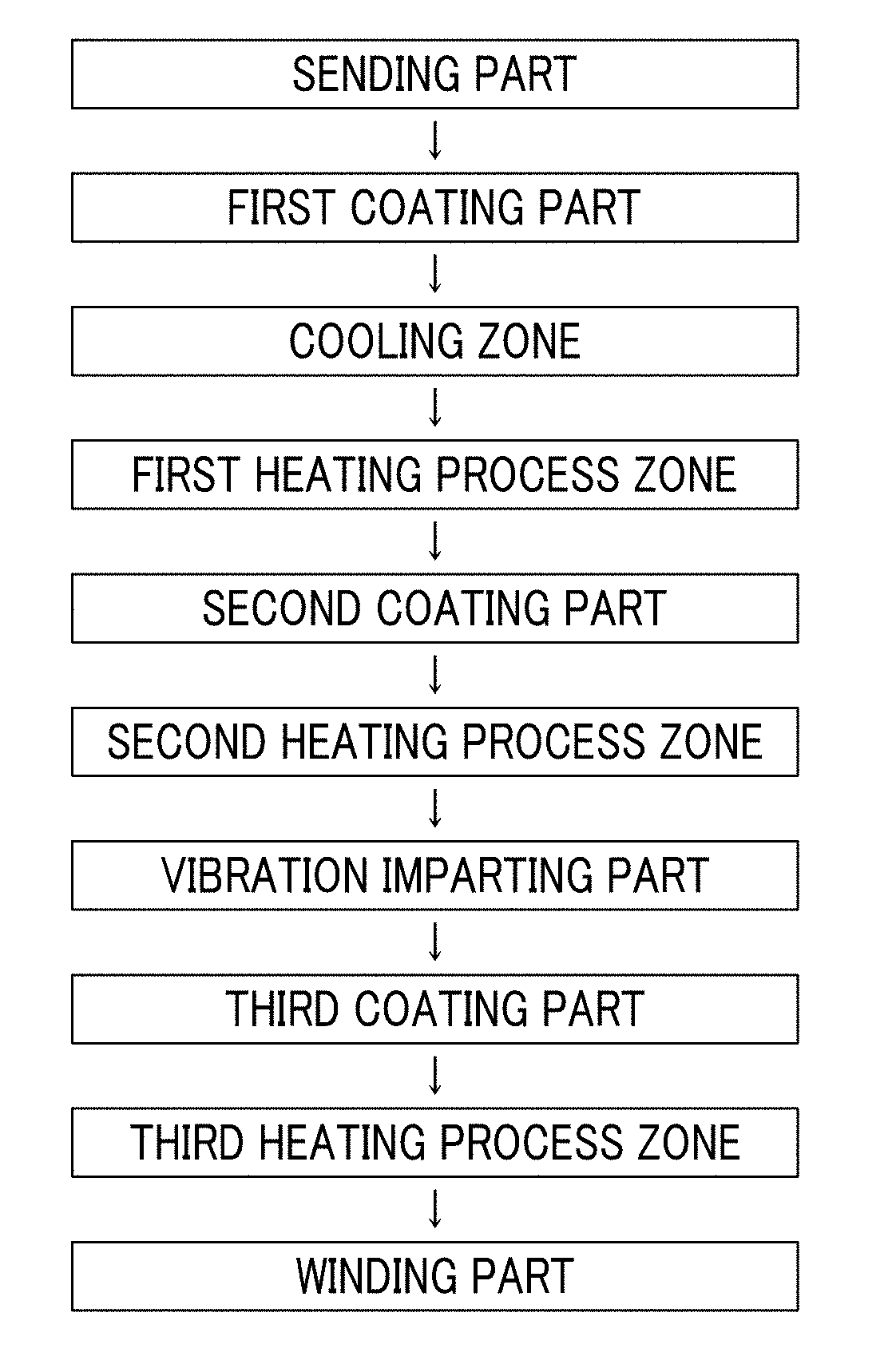

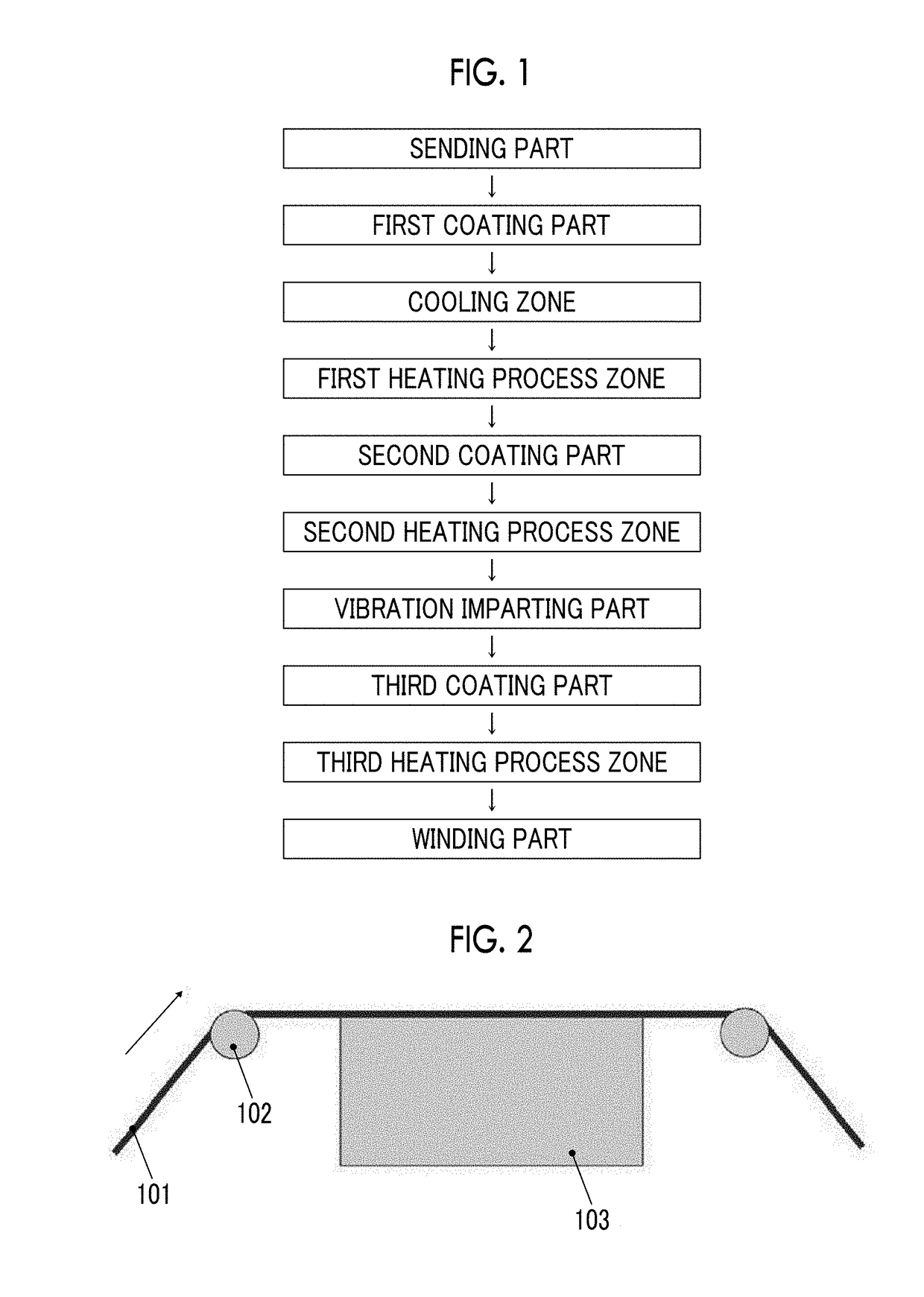

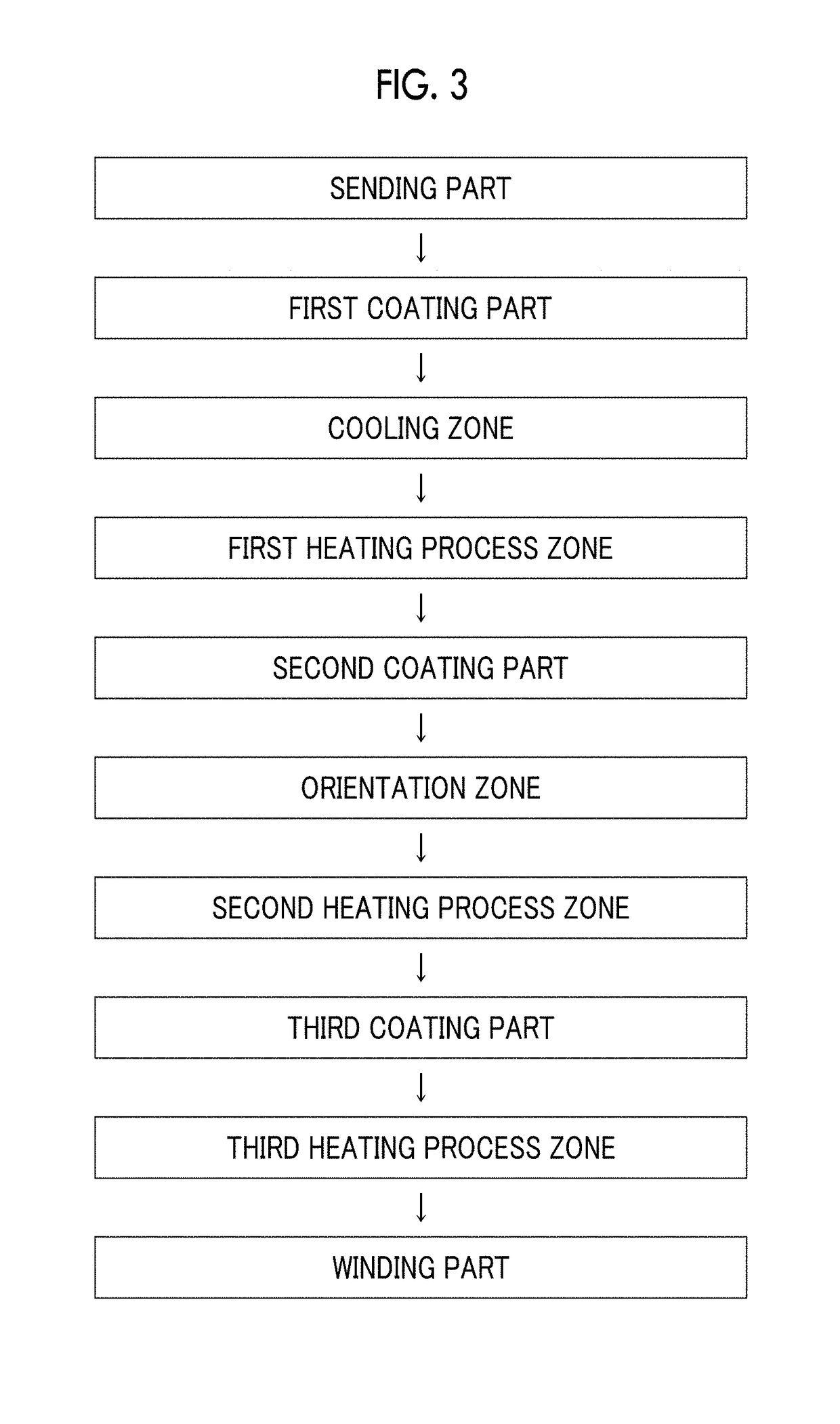

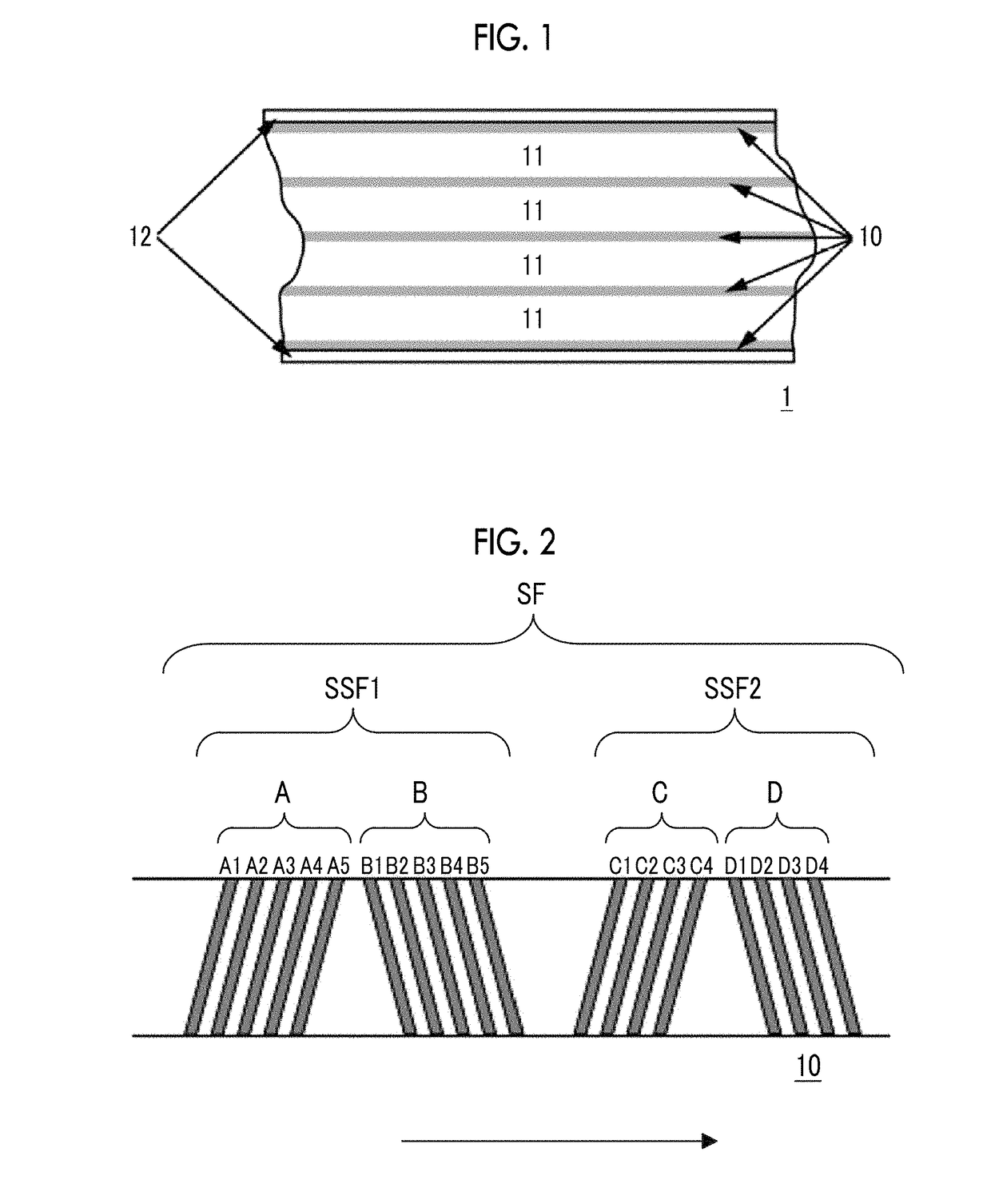

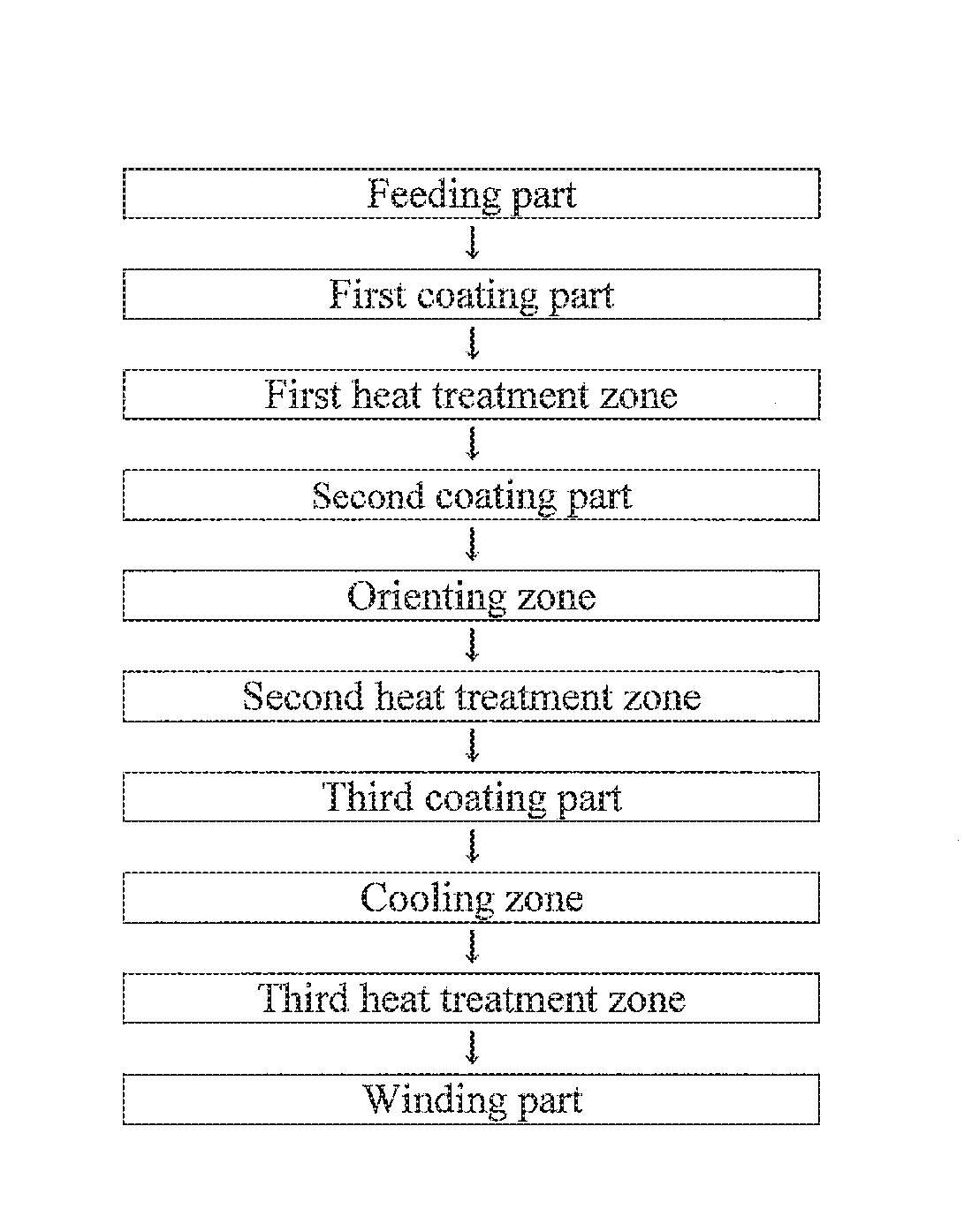

Magnetic tape and method of manufacturing the same

ActiveUS9711174B2Reduce thicknessIncrease recording capacityBase layers for recording layersTape carriersMagnetic tapeNon magnetic

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein a total thickness of the magnetic tape is less than or equal to 4.80 μm; at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; and a C—H derived carbon, C, concentration calculated from a C—H peak area ratio in a C1s spectrum obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on a surface on the magnetic layer side of the magnetic tape is greater than or equal to 45 atom %.

Owner:FUJIFILM CORP

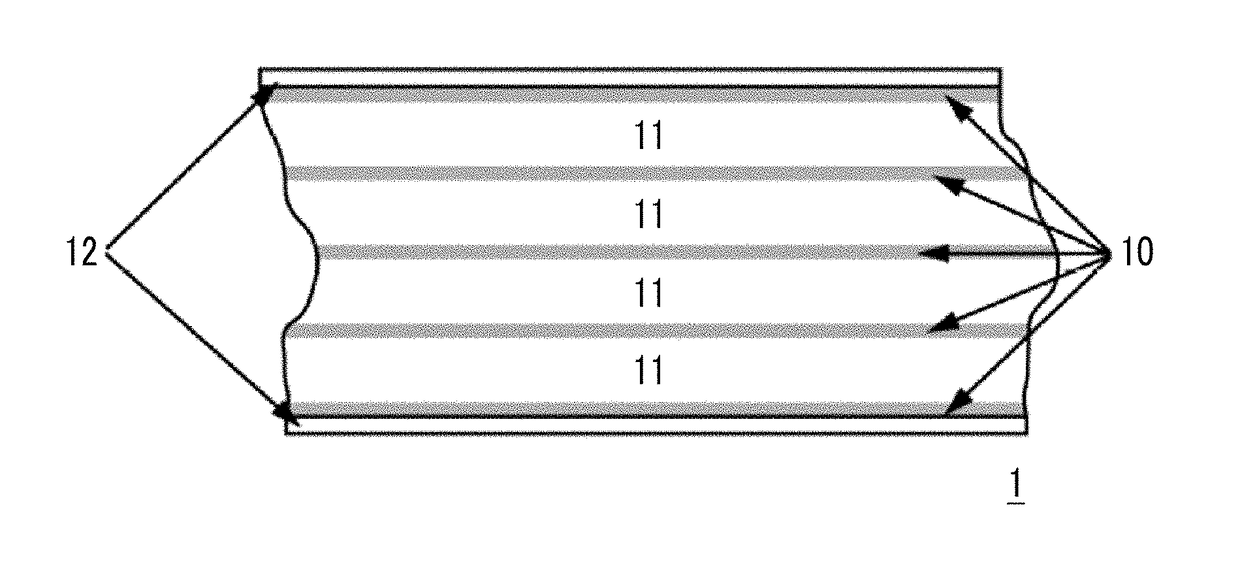

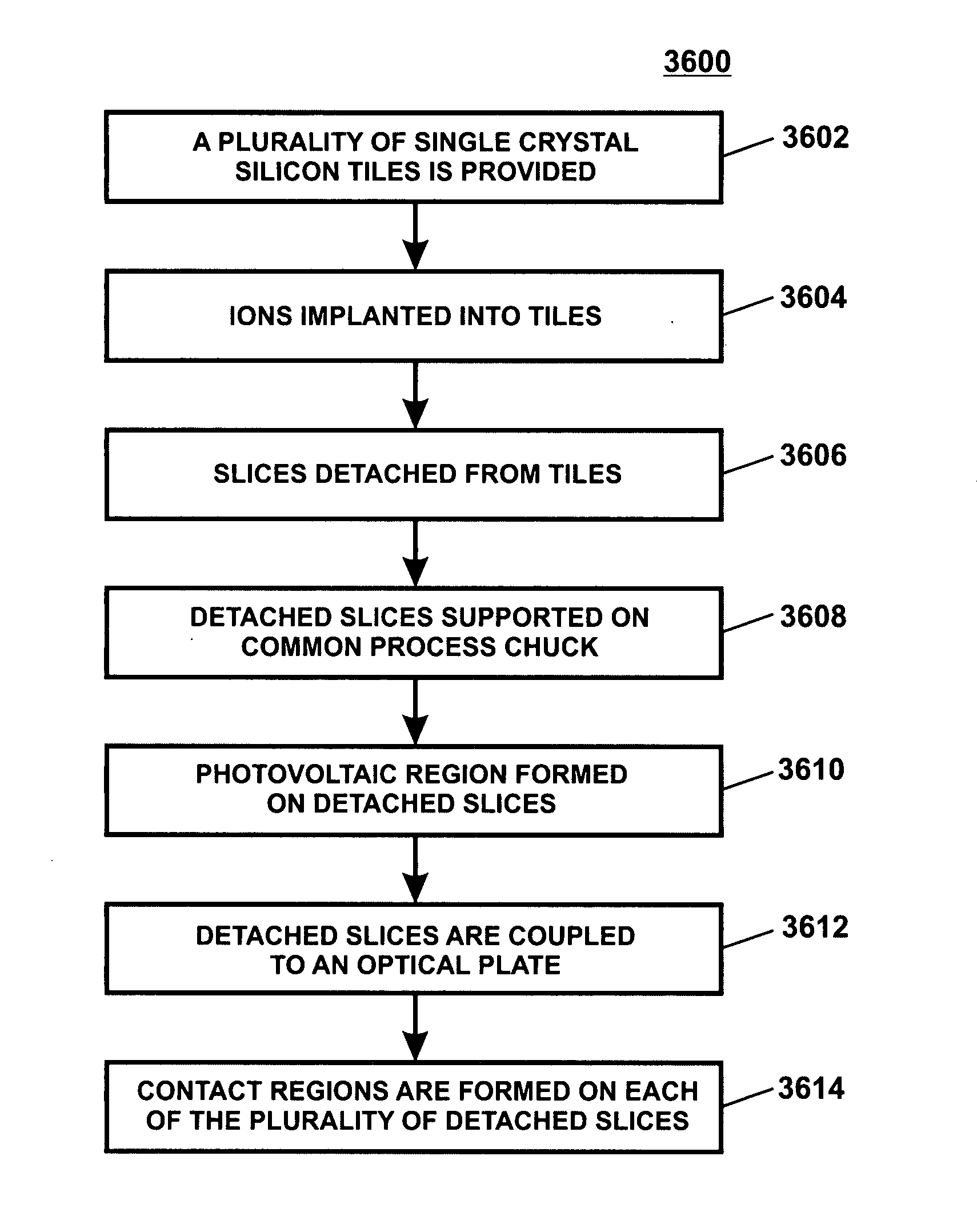

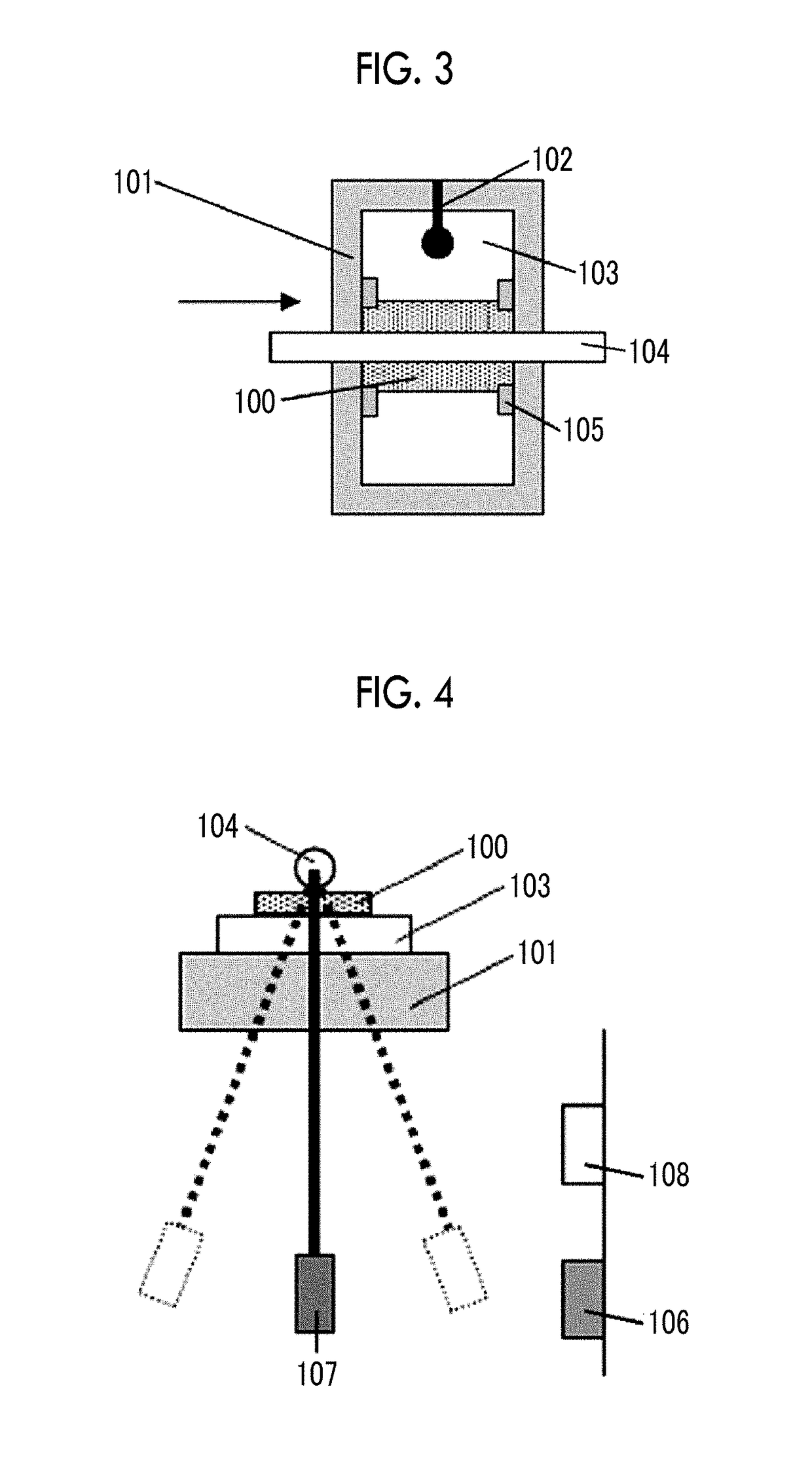

Method and structure for fabricating solar cells using a layer transfer process

InactiveUS20080160661A1Quality improvementEfficient powerSemiconductor/solid-state device manufacturingSemiconductor devicesMechanical pressureSolar cell

A reusable silicon substrate device for use with layer transfer process. The device has a reusable substrate having a surface region, a cleave region, and a total thickness of material. The total thickness of material is at least N times greater than a first thickness of material to be removed. In a specific embodiment, the first thickness of material to be removed is between the surface region and the cleave region, whereupon N is an integer greater than about ten. The device also has a chuck member adapted to hold a handle substrate member in place. The chuck member is configured to hold the handle substrate in manner to facilitate bonding the handle substrate to the first thickness of material to be removed. In a preferred embodiment, the device has a mechanical pressure device operably coupled to the chuck member. The mechanical pressure device is adapted to provide a force to cause bonding of the handle substrate to the first thickness of material to be removed.

Owner:SILICON GENERAL CORPORATION

Magnetic tape

ActiveUS20170372739A1Improve running stabilityBase layers for recording layersRecord information storageMagnetic tapeFull width at half maximum

Provided is a magnetic tape with the total thickness of a non-magnetic and magnetic layers is equal to or smaller than 0.60 μm, a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra by ESCA on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the magnetic layer before and after vacuum heating with respect to the magnetic tape are respectively greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between a spacing measured after the vacuum heating and a spacing measured before the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170372744A1Restrain output decreaseImprove accuracyBase layers for recording layersAlignment for track following on tapesMagnetic tapeFull width at half maximum

Provided is a magnetic tape in which the total thickness of a non-magnetic layer and a magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes a timing-based servo pattern, the magnetic layer includes fatty acid ester, a full width at half maximum of spacing distribution measured by optical interferometry regarding the surface of the magnetic layer before performing vacuum heating with respect to the magnetic tape is greater than 0 nm and equal to or smaller than 7.0 nm, a full width at half maximum of spacing distribution measured after performing the vacuum heating is greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between a spacing measured after performing the vacuum heating and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170372742A1Restrain output decreaseImprove accuracyBase layers for recording layersAlignment for track following on tapesMagnetic tapeElectron microscope

The magnetic tape includes a non-magnetic support; a non-magnetic layer including non-magnetic powder and a binder on the non-magnetic support; and a magnetic layer including ferromagnetic powder and a binder on the non-magnetic layer, in which the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes a timing-based servo pattern, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, the magnetic layer includes an abrasive, and a tilt cos η of the ferromagnetic hexagonal ferrite powder with respect to a surface of the magnetic layer acquired by cross section observation performed by using a scanning transmission electron microscope is 0.85 to 1.00.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20180061446A1Deterioration of characteristicMagnetic materials for record carriersTape carriersConventional transmission electron microscopeScanning tunneling microscope

Provided is a magnetic tape in which the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes ferromagnetic hexagonal ferrite powder and an abrasive, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer by plane observation using a scanning electron microscope, with respect to the total area of the region is equal to or greater than 0.02% and less than 0.06%, and a tilt cos 0 of the ferromagnetic hexagonal ferrite powder with respect to a surface of the magnetic layer acquired by cross section observation performed by using a scanning transmission electron microscope is 0.85 to 1.00.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170372736A1Improve surface smoothnessDefect signalAlignment for track following on tapesTape carriersMagnetic tapeSurface roughness

The magnetic tape includes a non-magnetic support; and a magnetic layer including ferromagnetic powder and a binder on the non-magnetic support, in which the total thickness of the magnetic tape is equal to or smaller than 5.30 μm, the magnetic layer includes a timing-based servo pattern, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 1.8 nm, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, the magnetic layer includes an abrasive, and a tilt cos θ of the ferromagnetic hexagonal ferrite powder with respect to a surface of the magnetic layer acquired by cross section observation performed by using a scanning transmission electron microscope is 0.85 to 1.00.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS10026430B2Improve noiseDeterioration of characteristicRecord information storageMagnetic recordingMagnetic tapeNon magnetic

The magnetic tape comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder, nonmagnetic powder, and binder, wherein a total thickness of the magnetic tape is less than or equal to 4.80 μm, and a coefficient of friction as measured on a base portion of a surface of the magnetic layer is less than or equal to 0.35.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20180286443A1Deterioration of characteristicMaterials with ironRecord information storageMagnetic tapeFull width at half maximum

The magnetic tape has the total thickness of a non-magnetic layer and a magnetic layer of 0.60 μm or smaller, the magnetic layer including an abrasive and fatty acid ester, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer with respect to the total area of the region, obtained by plane observation performed by using an SEM of 0.02% or greater and less than 0.06%, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape of greater than 0 nm and 7.0 nm or smaller, and a difference between spacings before and after the vacuum heating of greater than 0 nm and 8.0 nm or smaller.

Owner:FUJIFILM CORP

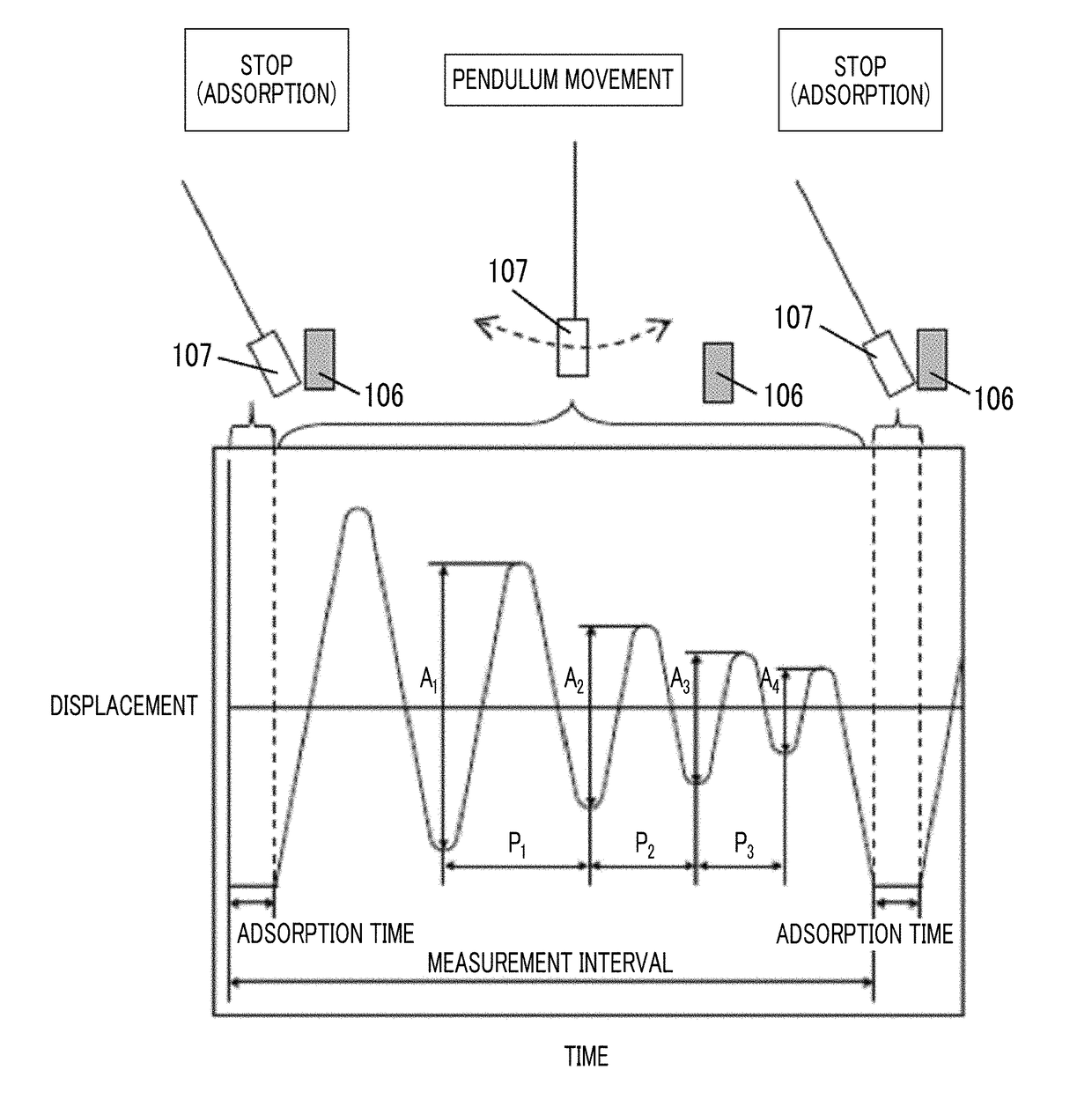

Magnetic tape and magnetic tape device

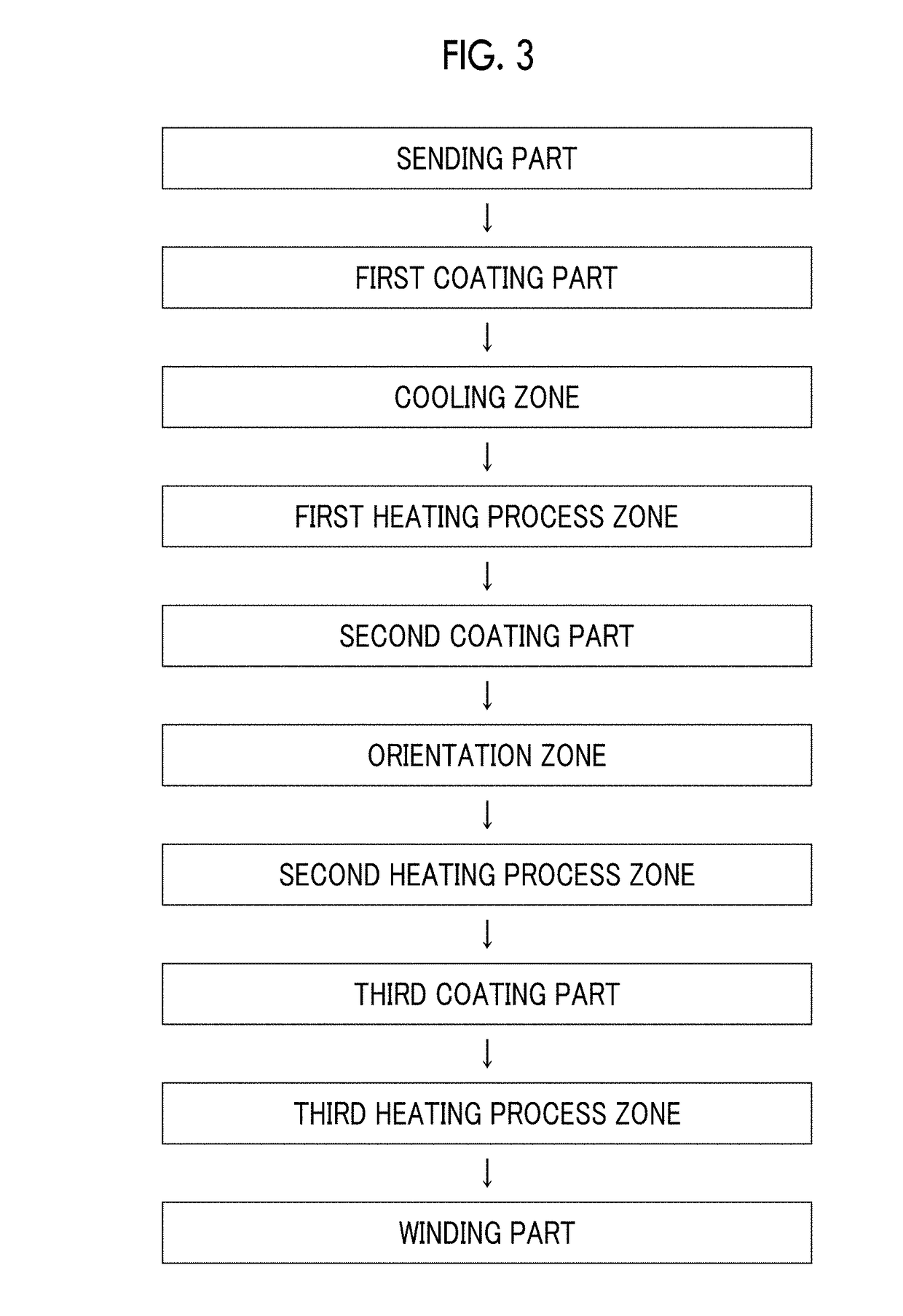

ActiveUS20170372727A1Restrain output decreaseImprove accuracyAlignment for track following on tapesRecord information storageMagnetic tapeNon magnetic

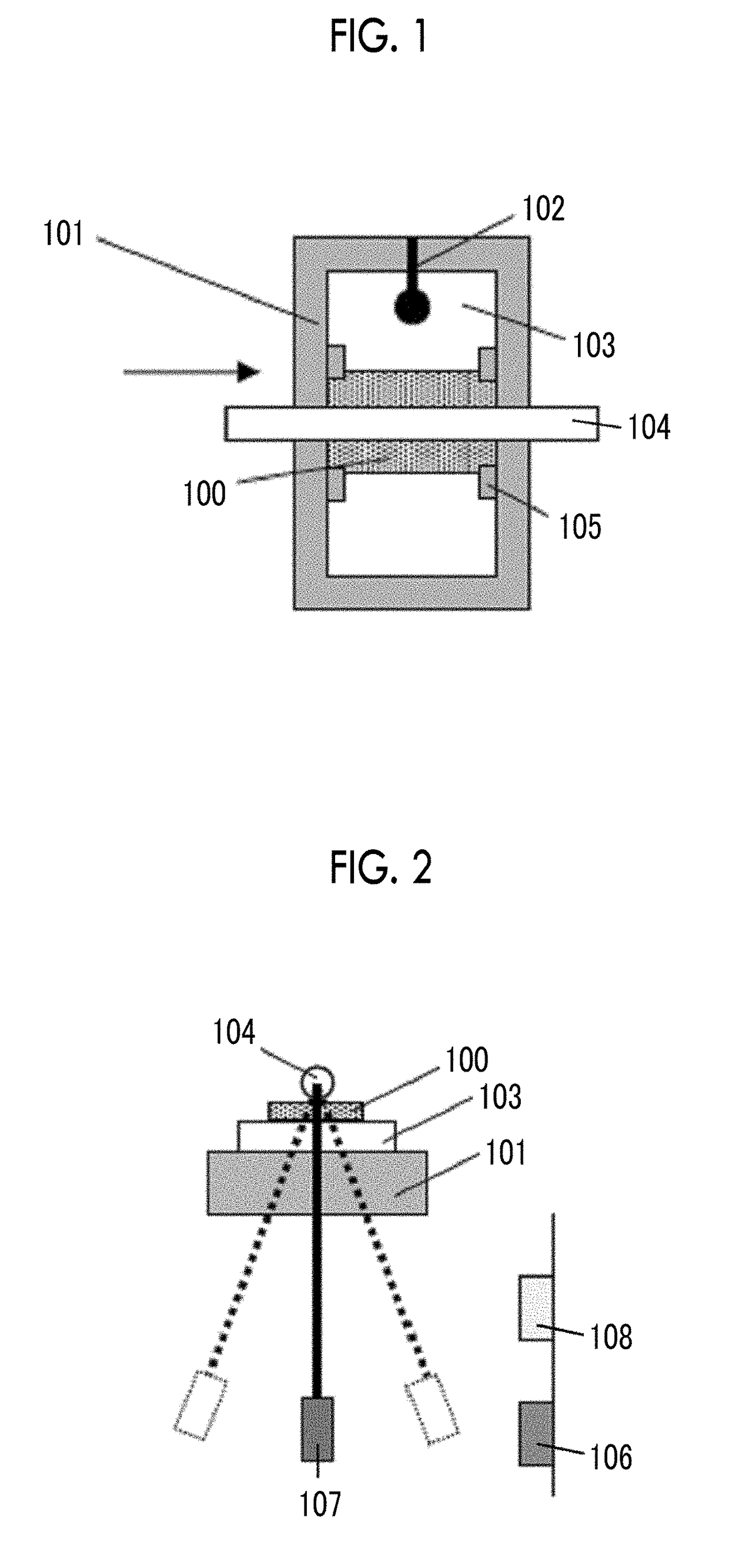

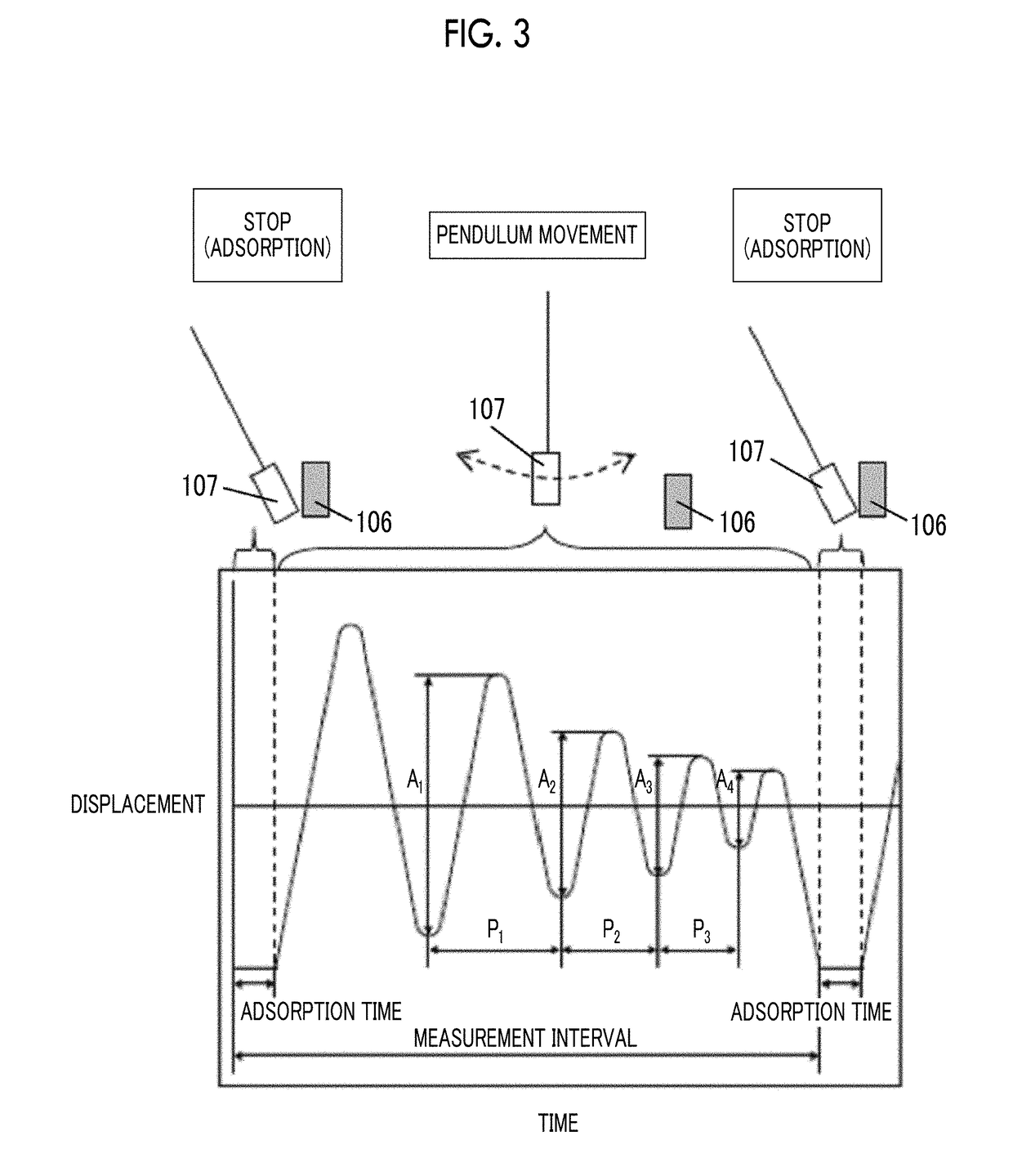

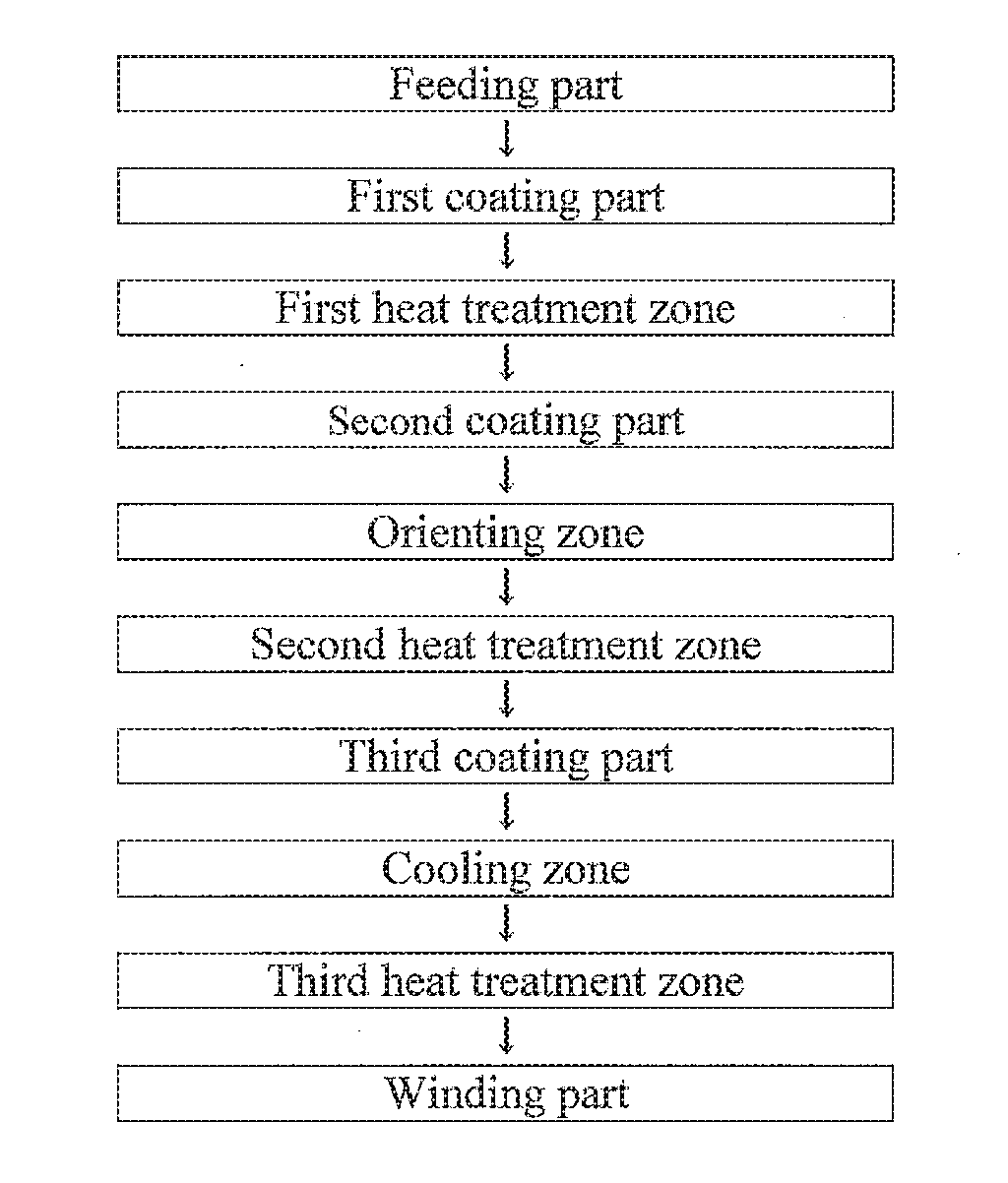

The magnetic tape includes a non-magnetic support; a non-magnetic layer including non-magnetic powder and a binder on the non-magnetic support; and a magnetic layer including ferromagnetic powder and a binder on the non-magnetic layer, in which the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes a timing-based servo pattern, and logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050.

Owner:FUJIFILM CORP

Solar cell encapsulant layers with enhanced stability and adhesion

The present invention provides a solar cell module comprising at least one encapsulant layer which has 1) a total thickness of from about 0.1 to about 20 mils and 2) at least one surface layer made of ionomers containing a finite amount of polymerized residues of α-olefins and from about 18 to about 25 wt % of polymerized residues of α,β-ethylenically unsaturated carboxylic acids. The present invention also provides a process of manufacturing the solar cell module.

Owner:DOW GLOBAL TECH LLC

Magnetic tape and magnetic tape device

ActiveUS20170372743A1Restrain output decreaseImprove accuracyBase layers for recording layersAlignment for track following on tapesMagnetic tapeX-ray

The magnetic tape includes a non-magnetic layer including non-magnetic powder and a binder on a non-magnetic support; and a magnetic layer including ferromagnetic powder and a binder on the non-magnetic layer, the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes a timing-based servo pattern, one or more components selected from the group consisting of fatty acid and fatty acid amide are at least included in the magnetic layer, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170372726A1Improve surface smoothnessReduce frequencyAlignment for track following on tapesRecord information storageMagnetic tapeX-ray

The magnetic tape includes a magnetic layer having ferromagnetic powder and a binder on a non-magnetic support, in which a total thickness of the magnetic tape is equal to or smaller than 5.30 μm, the magnetic layer includes a timing-based servo pattern, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 1.8 nm, one or more components selected from the group consisting of fatty acid and fatty acid amide are included in the magnetic layer, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS9704527B2Increase coefficient of frictionReduced stabilityRecord information storageMetals or alloysMagnetic tapeNon magnetic

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20180240495A1Deterioration of characteristicMaterials with ironRecord information storageScanning tunneling microscopeMagnetic tape

The magnetic tape includes a non-magnetic support; a non-magnetic layer including non-magnetic powder and a binding agent on the non-magnetic support; and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic layer, in which the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes an abrasive, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer with respect to the total area of the region, obtained by plane observation performed by using a scanning electron microscope is equal to or greater than 0.02% and less than 0.06%, and a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050.

Owner:FUJIFILM CORP

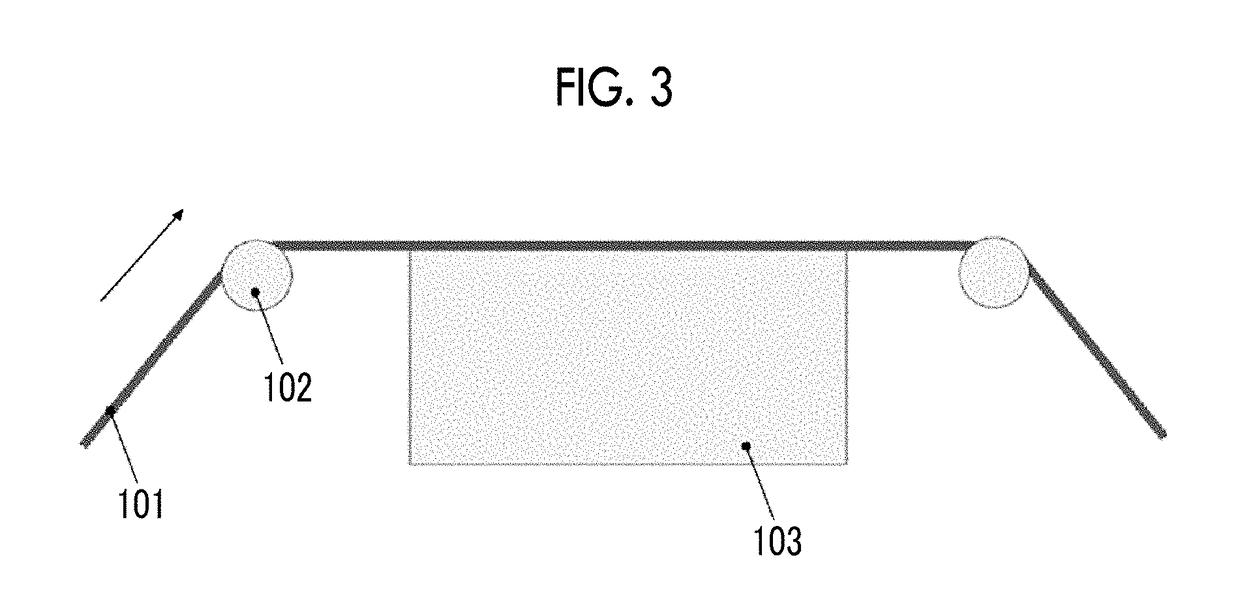

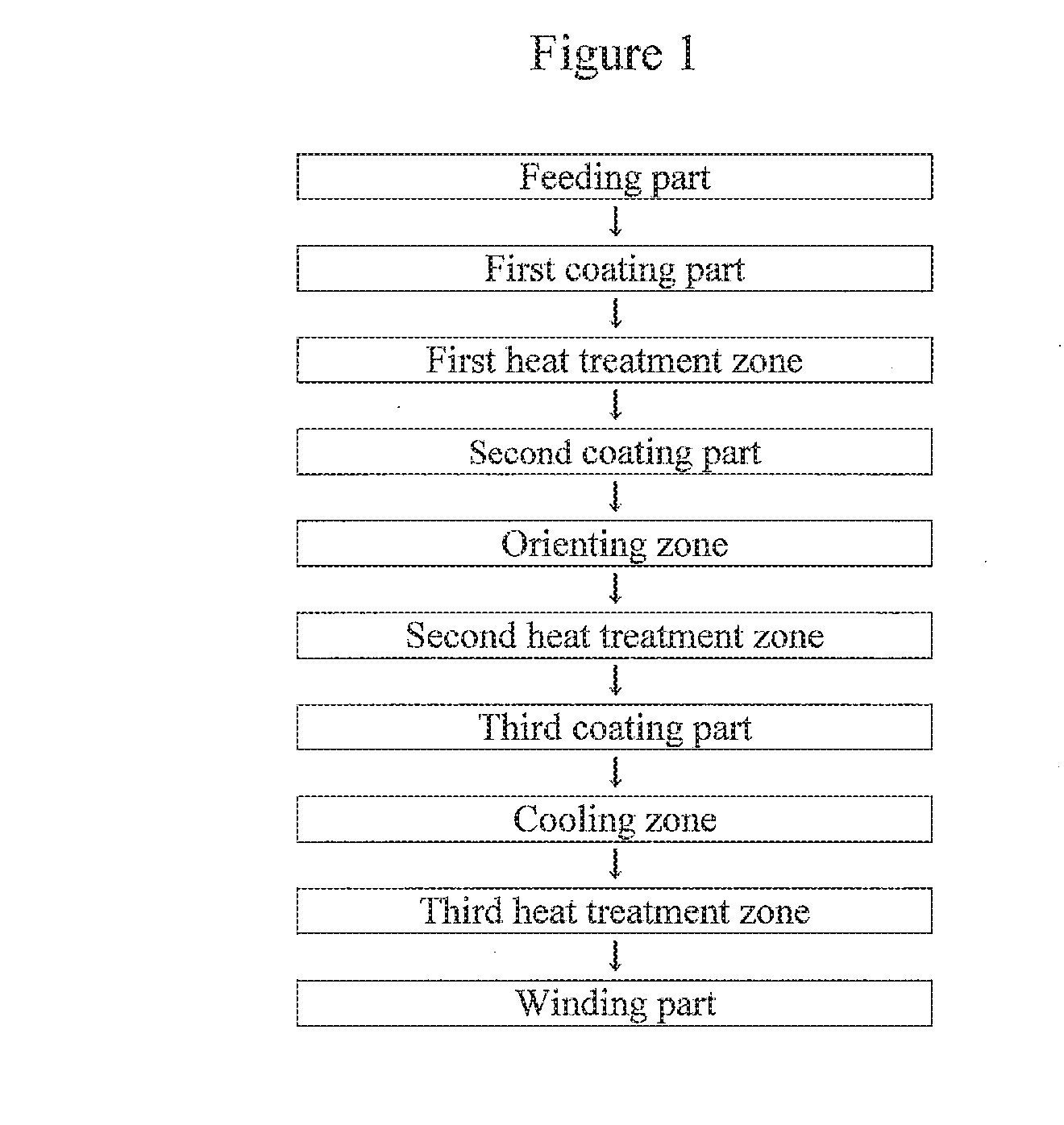

Magnetic tape and method of manufacturing the same

ActiveUS20160247530A1Improve running stabilityReduce coefficient of frictionRecord information storageMetals or alloysMagnetic tapeTotal thickness

The magnetic tape has on one surface of a nonmagnetic support a magnetic layer containing ferromagnetic powder and binder, and on the other surface of the nonmagnetic support, a backcoat layer containing nonmagnetic powder and binder, wherein the total thickness of the magnetic tape is less than or equal to 4.80 μm, the backcoat layer contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide, and a C—H derived carbon, C, concentration calculated from a C—H peak area ratio in a C1s spectrum obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on a surface on the backcoat layer side of the magnetic tape ranges from 35 to 60 atom %.

Owner:FUJIFILM CORP

Laminated shingle

InactiveUS6397546B1Roof covering using tiles/slatesLamination ancillary operationsEngineeringTotal thickness

Laminated shingles are manufactured from roll stock roofing material that is wider than that used to make similar laminated shingles. The roll stock includes longitudinal edge strips having a reduced thickness. The roll stock is cut into strips of tabbed top sheets and backing sheets. The strips of material used for the backing sheets are at once wider than commonly used in the industry, and include the longitudinal edge strips of reduced-thickness material. Because the backing sheet is wider two rain seal strips are laid down on the backing sheet prior to being laminated to the tabbed top sheet. The backing sheets are laminated to the tabbed top sheets with the longitudinal edges aligned. The wider backing sheet provides a substantially wider nail zone. In addition, since it allows for a second rain seal strip, provides somewhat more protection against leakage. The portion of the backing sheet that comprises the added width is relatively thinner than the remaining portions of the sheet. Paired shingles may therefore be oriented adjacent one another in opposite directions and stacked and bundled. The total thickness of the stack will be the same throughout the stack, so the stack of shingles is flat.

Owner:HERBERT MALARKEY ROOFING

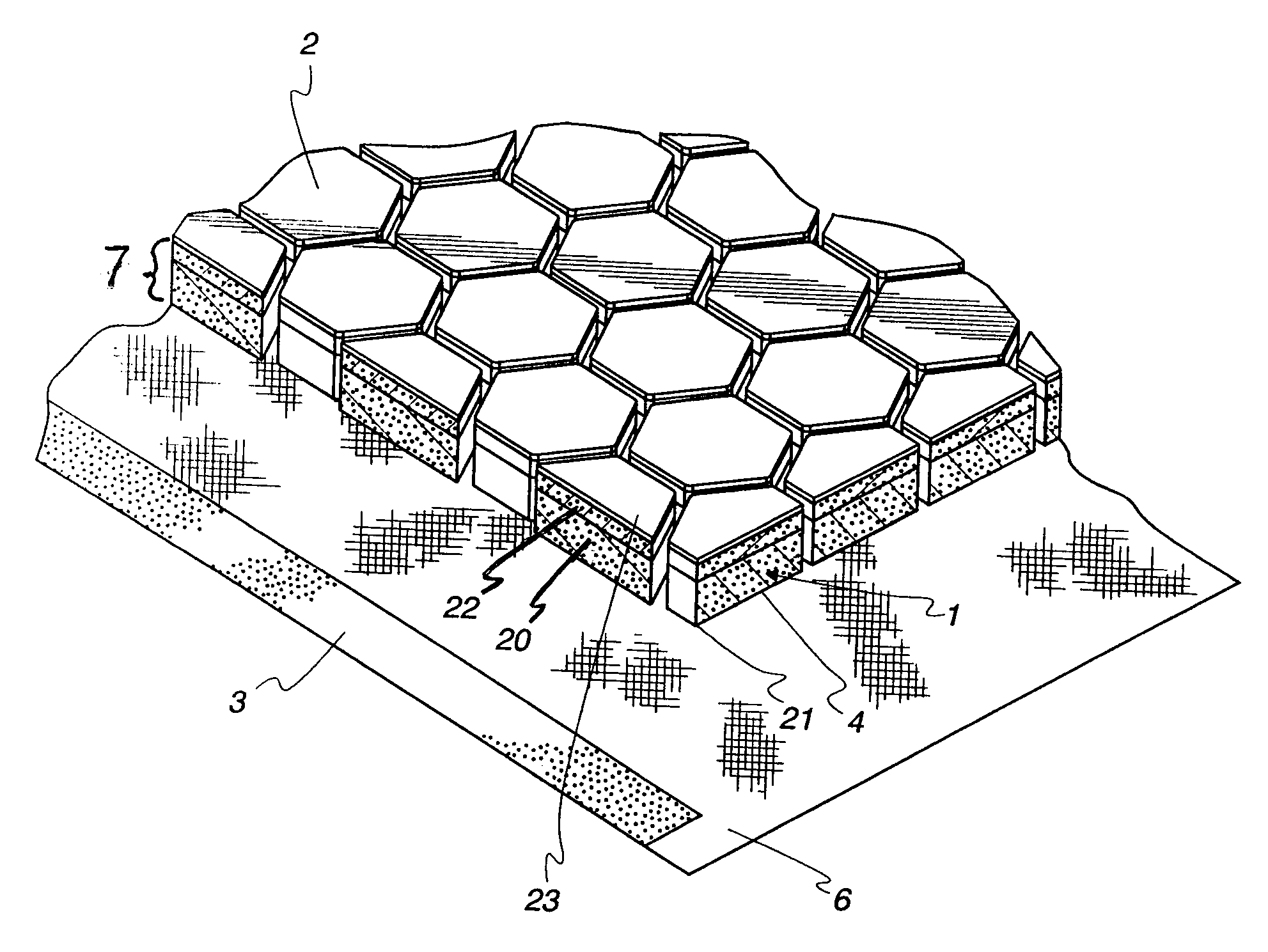

Flexible Material and Method of Manufacturing the Flexible Material

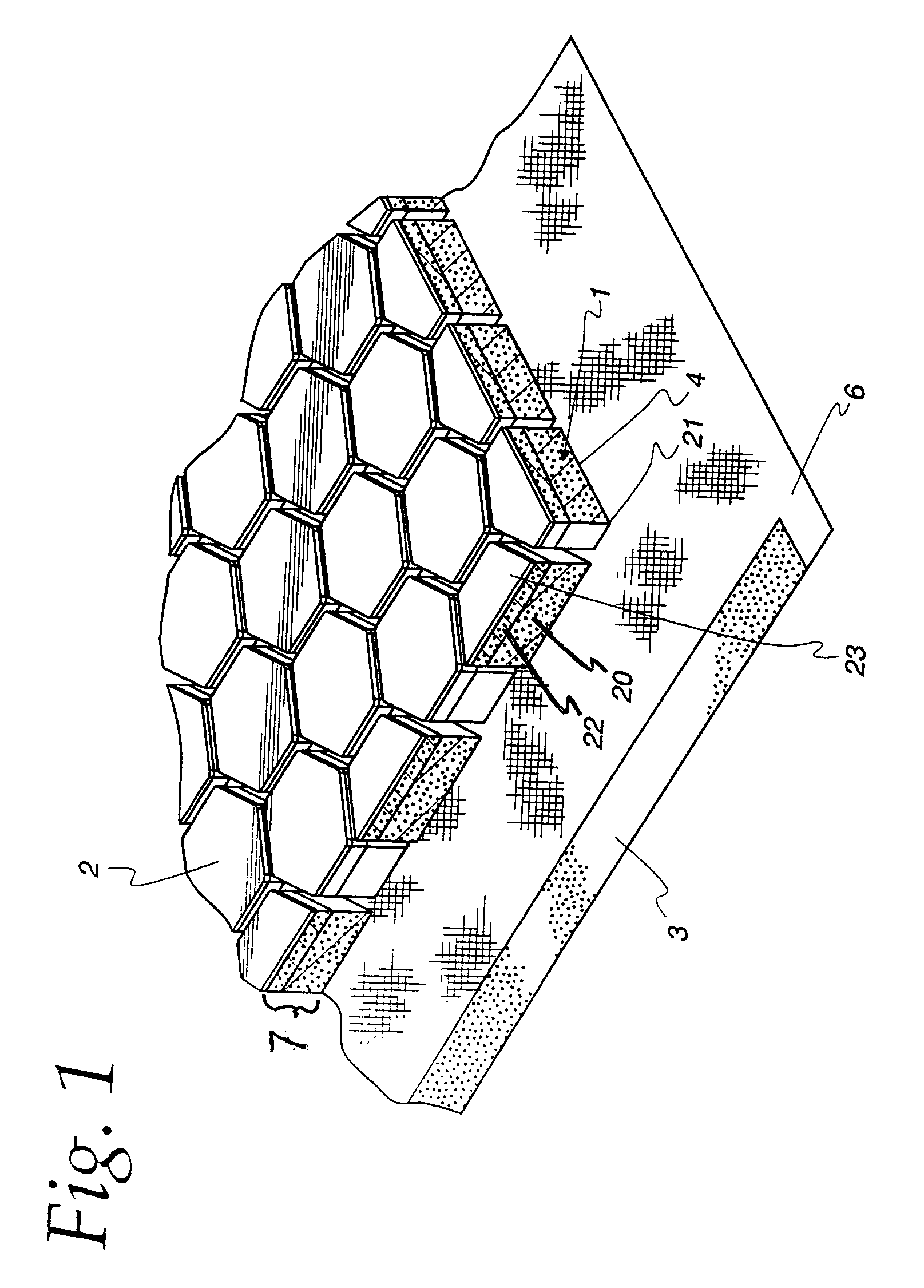

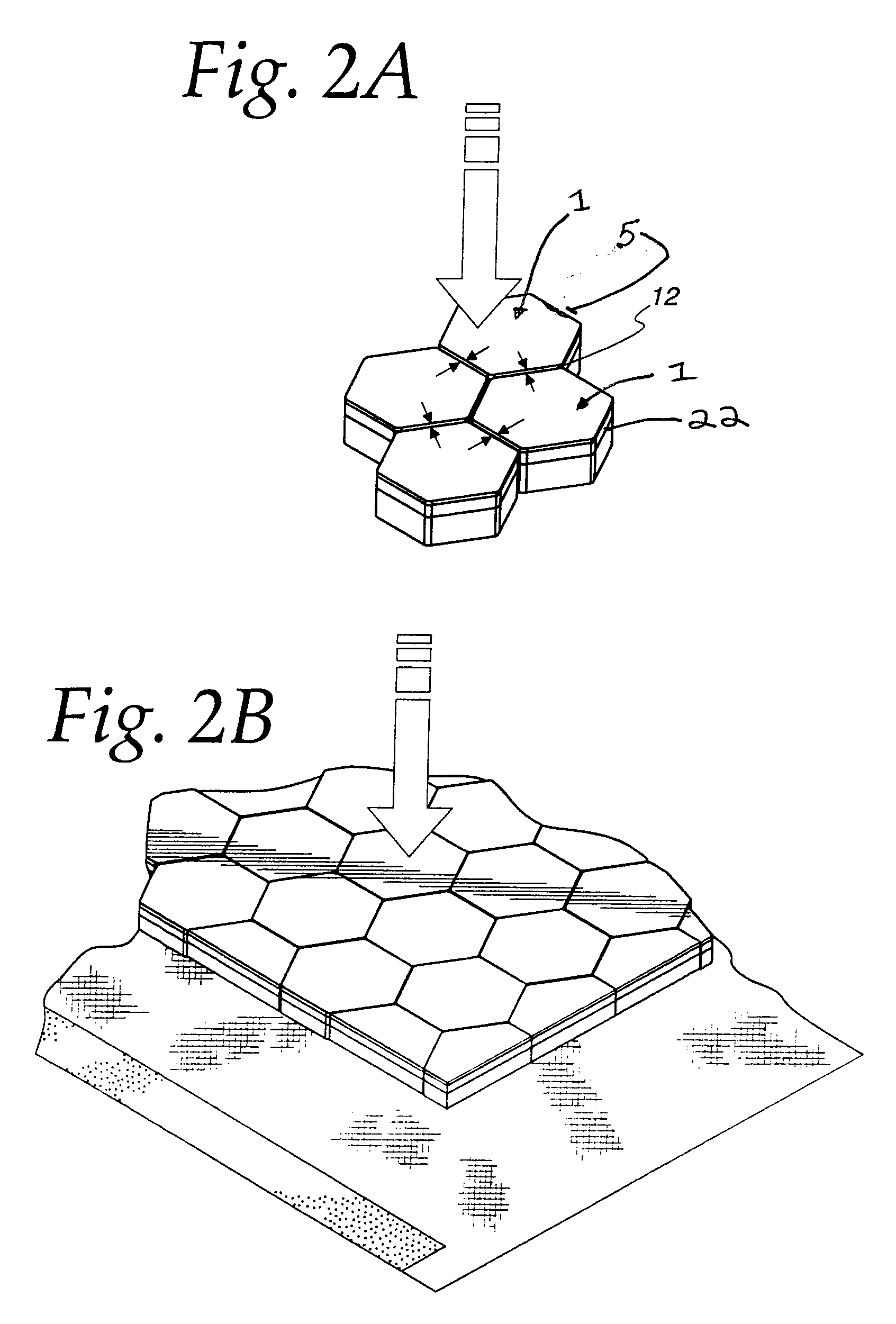

InactiveUS20080113143A1Dissipates blowReduce the impactProtective equipmentLayered productsCompressibilityEngineering

A flexible protective padding material is described and comprises an array of resilient multilayered elements or blocks which have generally planar top and bottom surfaces and each of which have at least two layers which include a first layer bonded to an outer second layer. The total compressibility of each element with the at least two layers, the spacing between the elements and the total thickness of the elements provides the elements with the ability to compress such that at least one side wall of each of adjacent elements move together and touch each other to provide a joined outer surface of elements which dissipates a blow to the protective padding.

Owner:STIRLING MOLDINGS

Magnetic tape and magnetic tape device

ActiveUS20190027177A1Improve surface smoothnessGeneration frequency can be reducedMaterials with ironAlignment for track following on tapesIn planeX-ray

The magnetic tape includes a magnetic layer including ferromagnetic powder and a binding agent, in which a magnetic tape total thickness is equal to or smaller than 5.30 μm, the magnetic layer has a servo pattern, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 1.8 nm, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, an intensity ratio of a peak intensity of a diffraction peak of a (110) plane with respect to a peak intensity of a diffraction peak of a (114) plane of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, and a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00, and a magnetic tape device including this magnetic tape.

Owner:FUJIFILM CORP

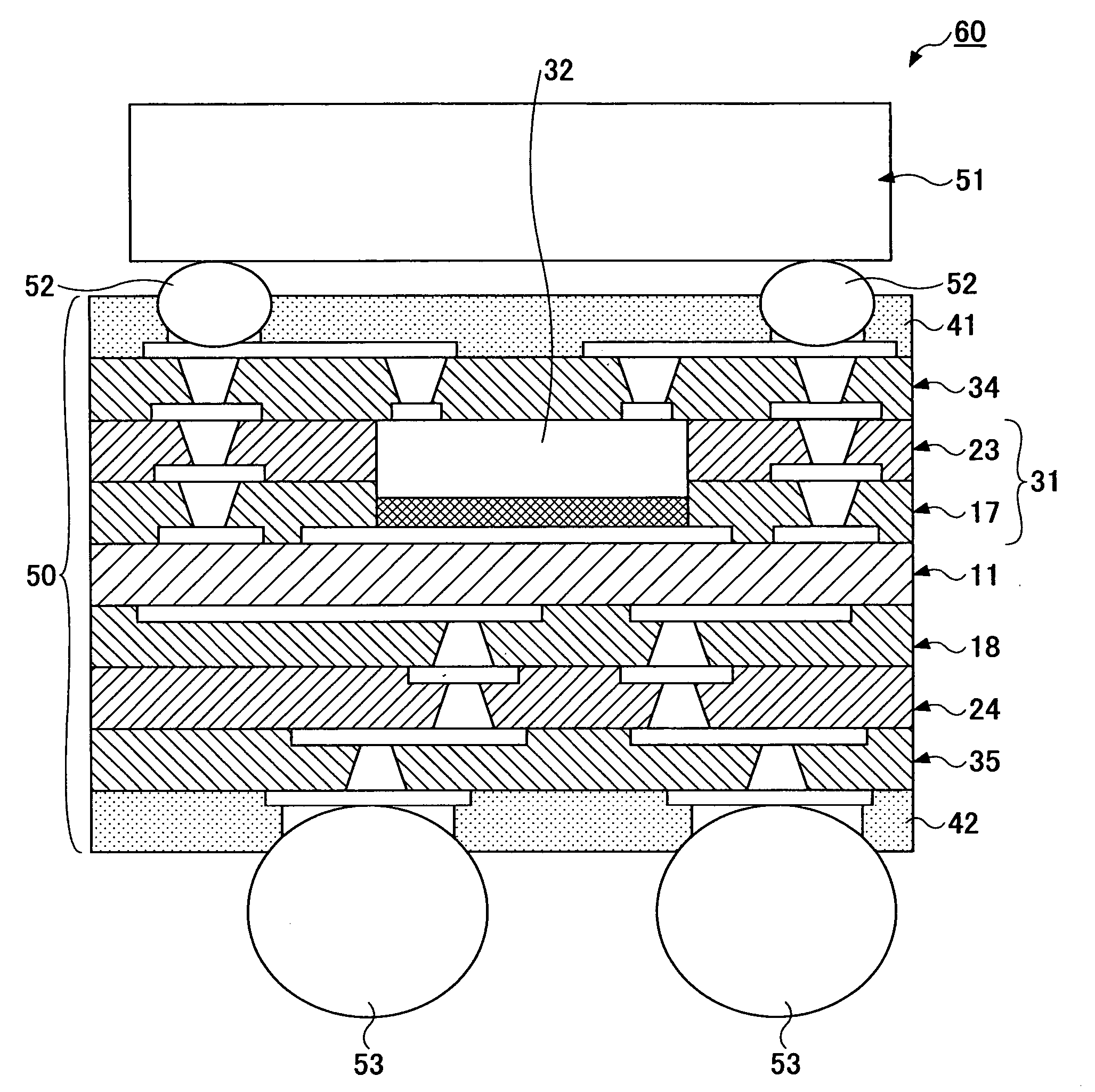

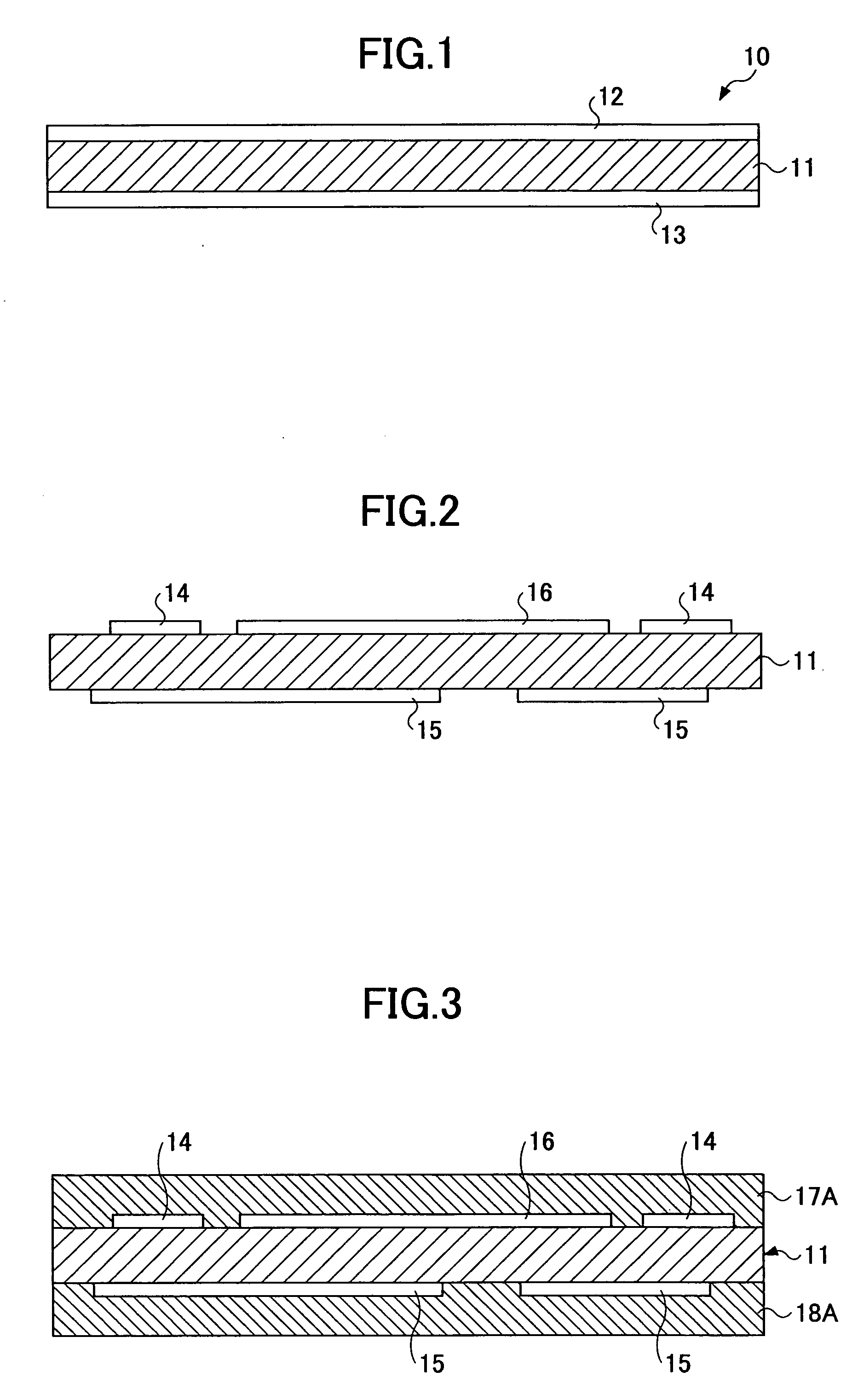

Method for fabricating an electronic component embedded substrate

InactiveUS20060003495A1Easily and inexpensively embeddedSemiconductor/solid-state device detailsSolid-state devicesElectronic componentTotal thickness

A method for fabricating an electronic component embedded substrate including an electronic component that is embedded within a buildup layer is disclosed. The method includes a first buildup layer lamination step of laminating plural first buildup layers on a core substrate such that the total thickness of the first buildup layers corresponds to the thickness of the electronic component; a cavity formation step of forming a cavity for accommodating the electronic component at the laminated first buildup layers; an accommodating step of accommodating the electronic component within the cavity; and a second buildup layer lamination step of laminating a second buildup layer on the first buildup layers and the electronic component.

Owner:SHINKO ELECTRIC IND CO LTD

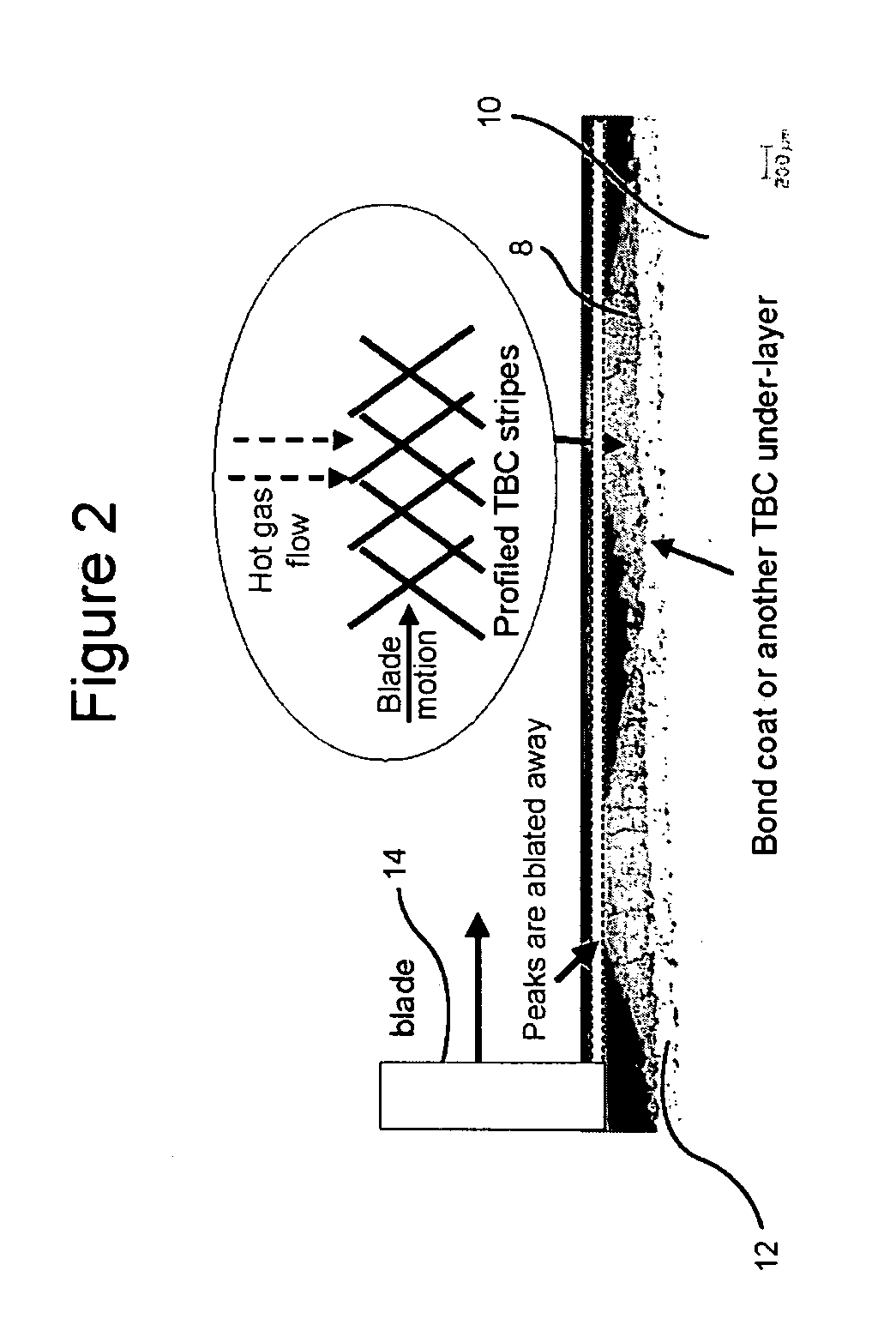

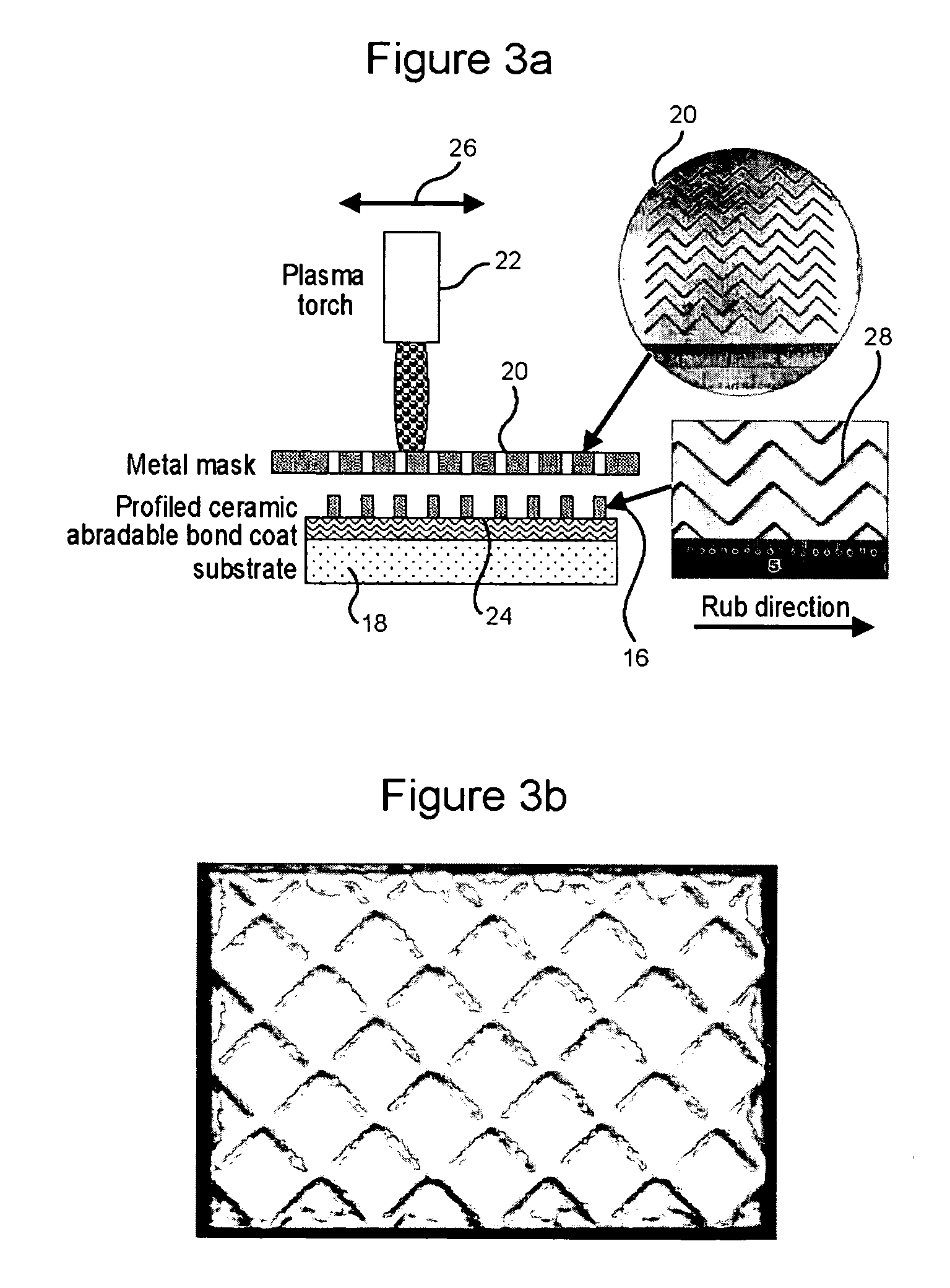

7FAstage 1 abradable coatings and method for making same

InactiveUS20050003172A1Minimal wearReduce gas leakageMolten spray coatingEngine manufactureLeading edgeGrid pattern

A method of applying a profiled abradable coating onto a substrate in which an abradable ceramic coating composition is applied to a metal substrate using one or more coating application techniques to produce a defined ceramic pattern without requiring a separate web or grid to be brazed onto the substrate. The invention is particularly designed to withstand the higher operating temperatures encountered with the stage 1 section of 7FA+e gas turbines to allow for increased coating life without significant deterioration in structural or functional integrity. Typically, the grid pattern coating begins approximately 0.431″ after the leading edge of the shroud, and ends approximately 1.60″ before the trailing edge of the shroud. In the case of diamond-shaped patterns, the grid pattern will be about 0.28″ long and 0.28″ wide, with an overall thickness of about 0.46.″ The coatings thus provide the required levels of abradability and leakage performance and may be applied as a chevron or diamond pattern with the shape oriented such that the diagonals run perpendicular and parallel to the sides of the shroud.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com