Patents

Literature

230results about How to "Increase recording capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic tape

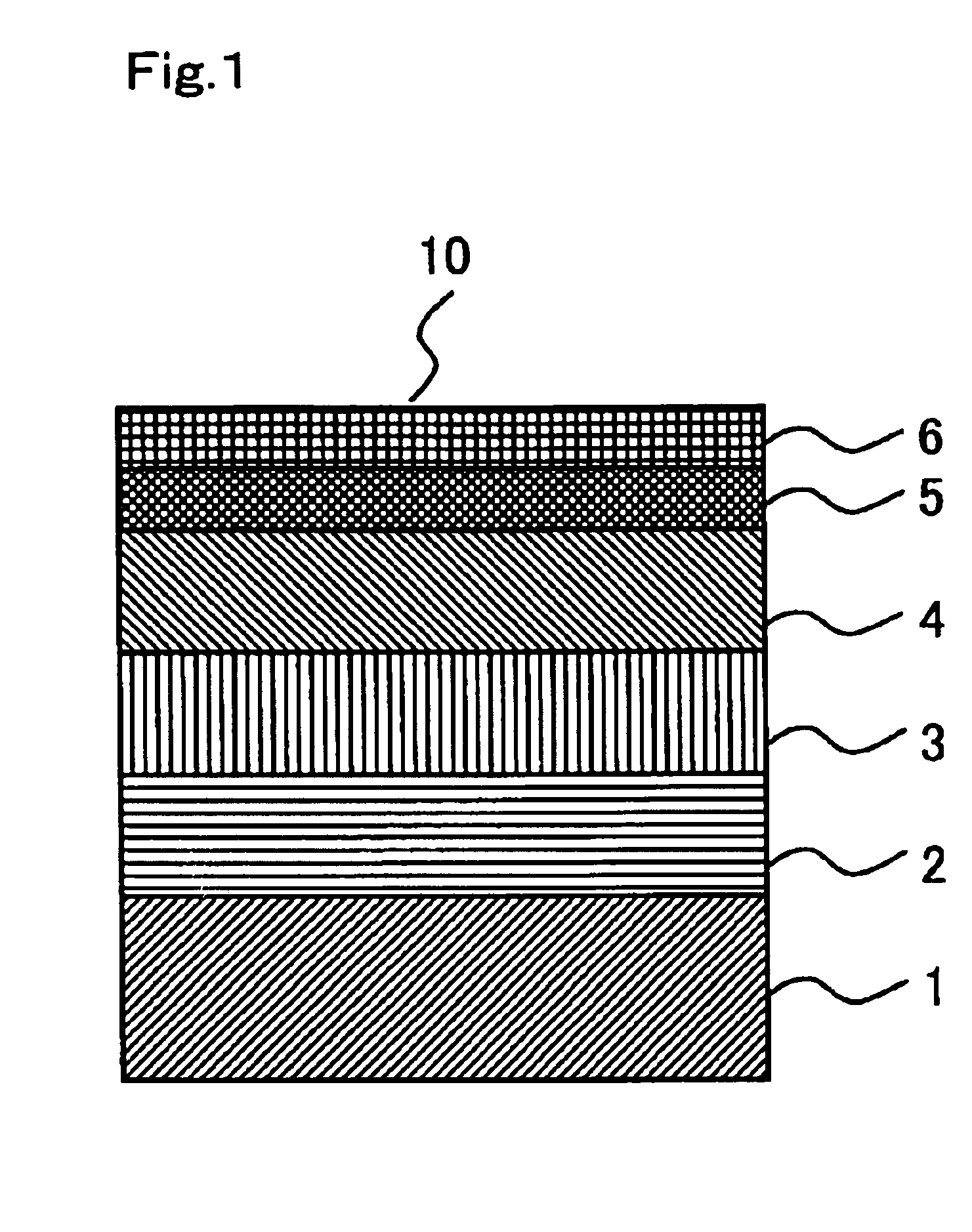

ActiveUS20160093322A1Reduce coefficient of frictionImprove noiseRecord information storageMagnetic recordingMagnetic tapeNon magnetic

The magnetic tape comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder, nonmagnetic powder, and binder, wherein a total thickness of the magnetic tape is less than or equal to 4.80 μm, and a coefficient of friction as measured on a base portion of a surface of the magnetic layer is less than or equal to 0.35.

Owner:FUJIFILM CORP

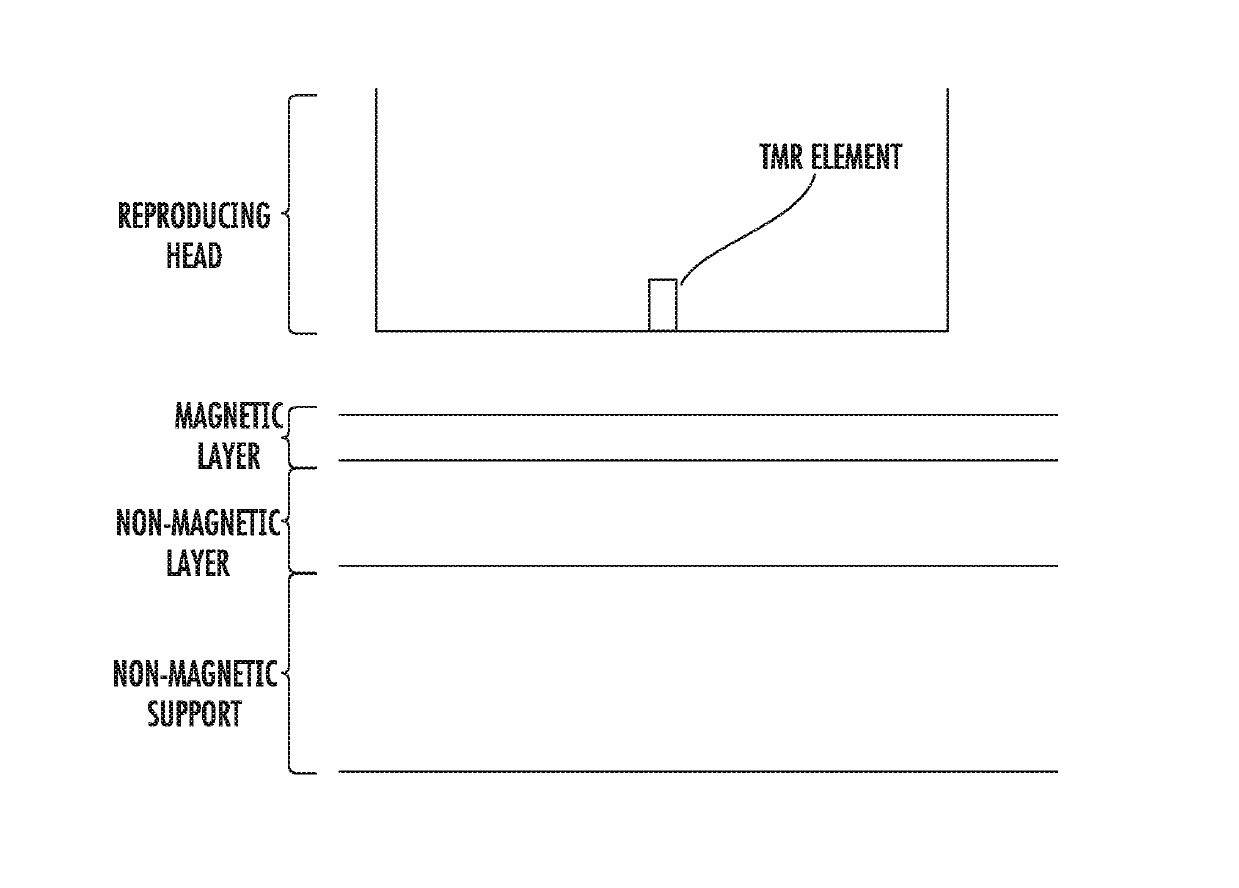

Magnetic tape device and head tracking servo method

ActiveUS20180286447A1Excellent sensitivityIncrease recording capacityMaterials with ironAlignment for track following on tapesMagnetic layerHead tracking

The magnetic tape device includes a magnetic tape and a TMR head (servo head), in which the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, an intensity ratio of a peak intensity Int(110) of a diffraction peak of a (110) plane with respect to a peak intensity Int(114) of a diffraction peak of a (114) plane of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, and a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS9837116B2Increase the number ofIncrease recording capacityAlignment for track following on tapesRecord information storageMagnetic tapeSurface roughness

Owner:FUJIFILM CORP

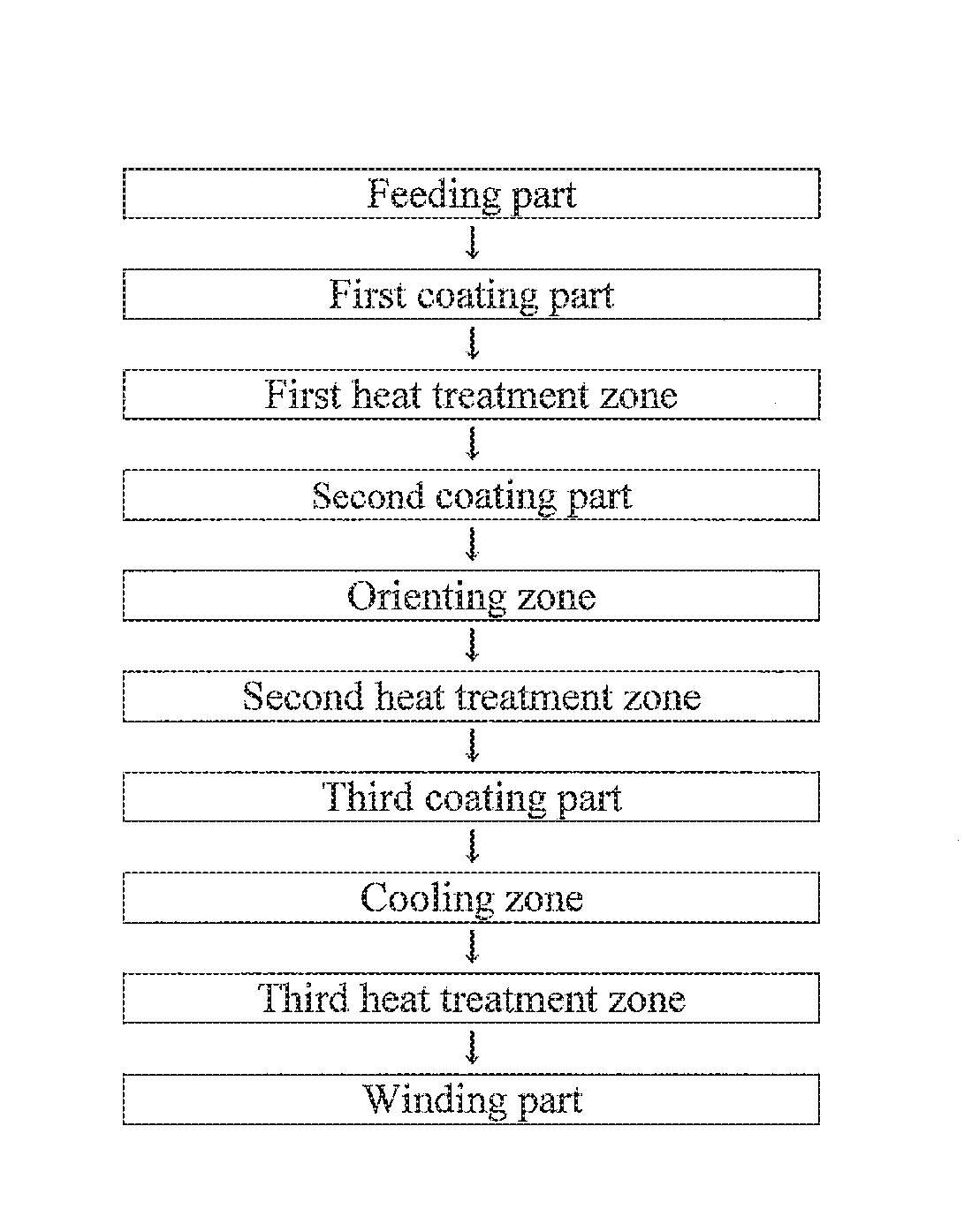

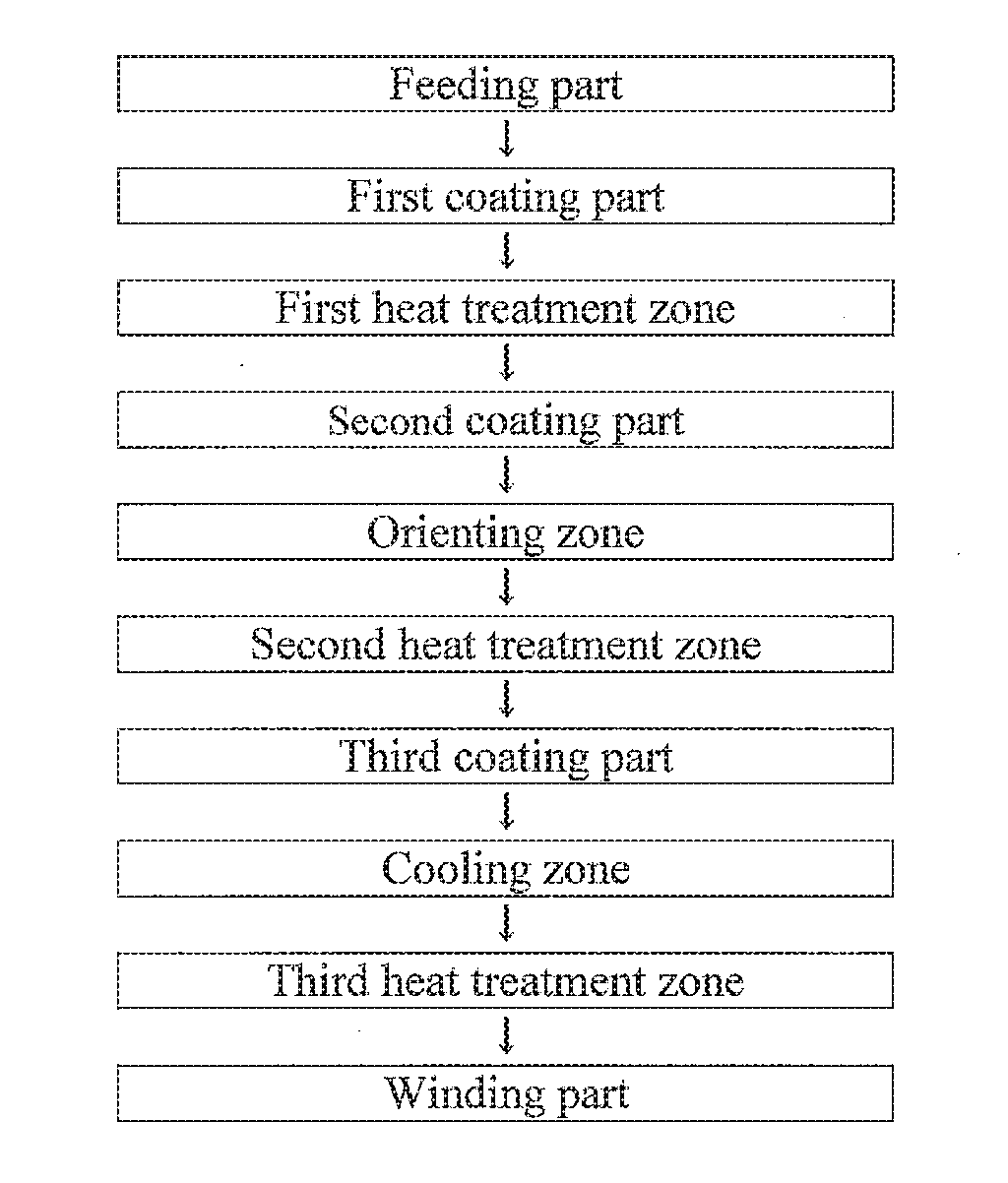

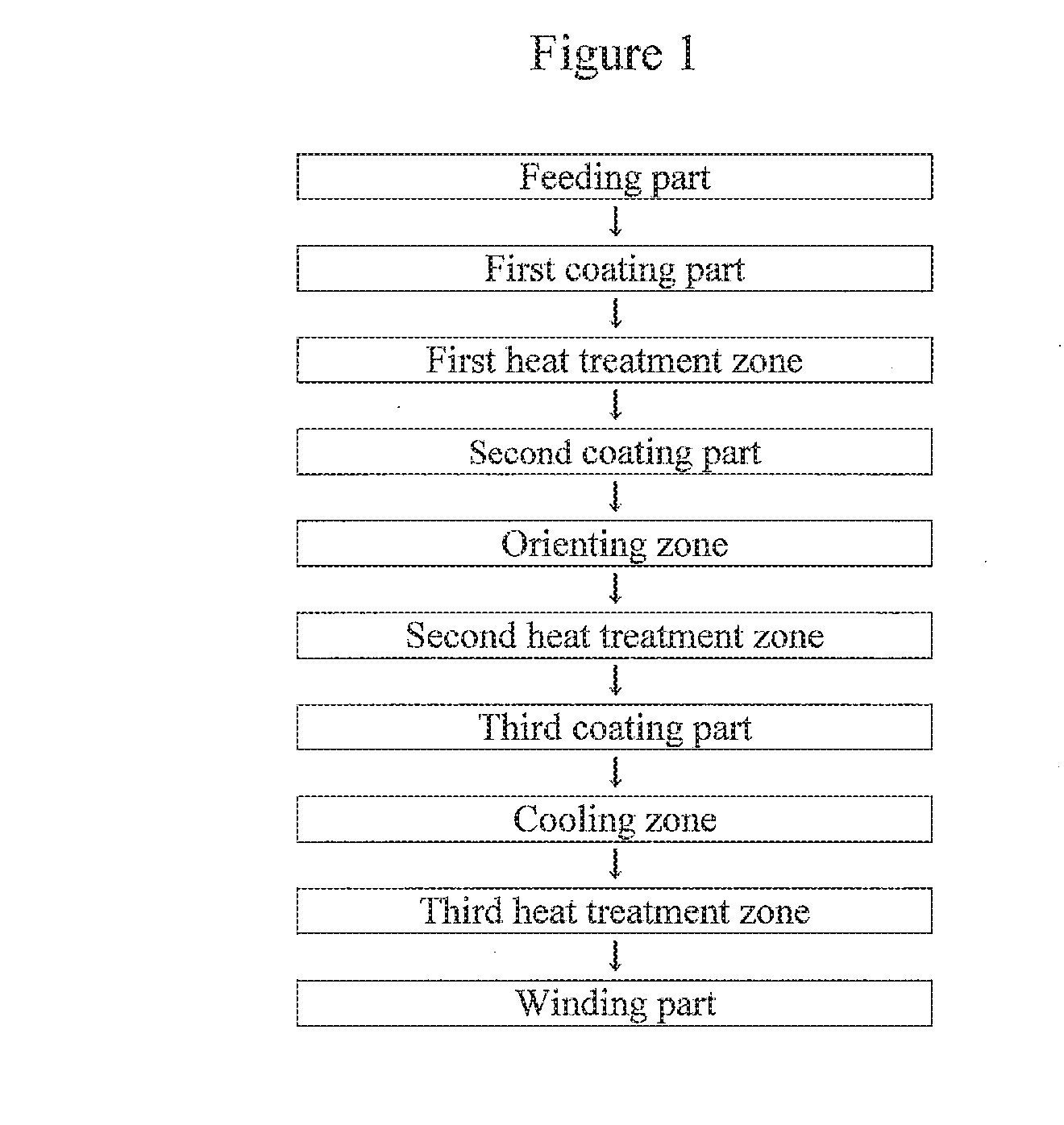

Magnetic tape and method of manufacturing the same

ActiveUS9711174B2Reduce thicknessIncrease recording capacityBase layers for recording layersTape carriersMagnetic tapeNon magnetic

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein a total thickness of the magnetic tape is less than or equal to 4.80 μm; at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; and a C—H derived carbon, C, concentration calculated from a C—H peak area ratio in a C1s spectrum obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on a surface on the magnetic layer side of the magnetic tape is greater than or equal to 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20170032812A1Increase the lengthReduce thicknessRecord information storageMaterials with non-metallic substancesMagnetic tapeNon magnetic

The magnetic tape has a magnetic layer containing ferromagnetic powder and binder on one surface of a nonmagnetic support, and has a backcoat layer containing nonmagnetic powder and binder on the other surface thereof, wherein the magnetic layer contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide; the backcoat layer has a thickness of less than or equal to 0.30 μm and contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide; a magnetic layer side C—H derived C concentration is greater than or equal to 45 atom %; and a backcoat layer side C—H derived C concentration is greater than or equal to 35 atom %.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180286449A1Improve signal-to-noise ratioIncrease recording capacityRecord information storageManufacture of flux-sensitive headsMagnetic tapeX-ray

The magnetic tape device includes a magnetic tape and a TMR head, in which the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, an intensity ratio of a peak intensity Int(110) of a diffraction peak of a (110) plane with respect to a peak intensity Int(114) of a diffraction peak of a (114) plane of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, and a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS10026430B2Improve noiseDeterioration of characteristicRecord information storageMagnetic recordingMagnetic tapeNon magnetic

The magnetic tape comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder, nonmagnetic powder, and binder, wherein a total thickness of the magnetic tape is less than or equal to 4.80 μm, and a coefficient of friction as measured on a base portion of a surface of the magnetic layer is less than or equal to 0.35.

Owner:FUJIFILM CORP

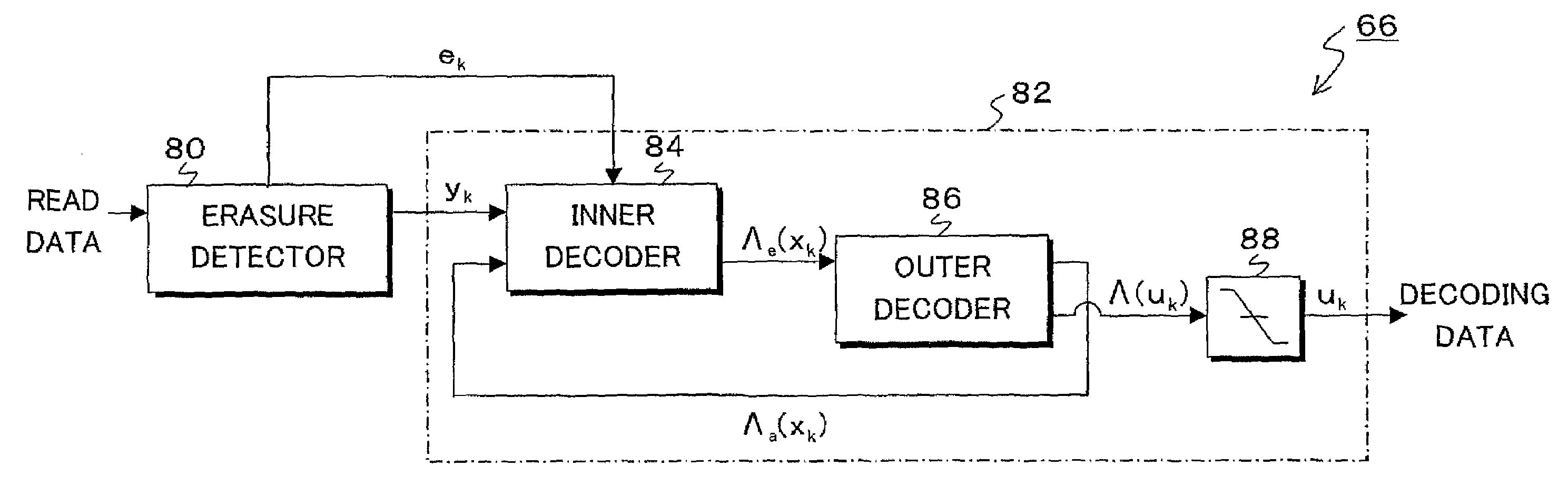

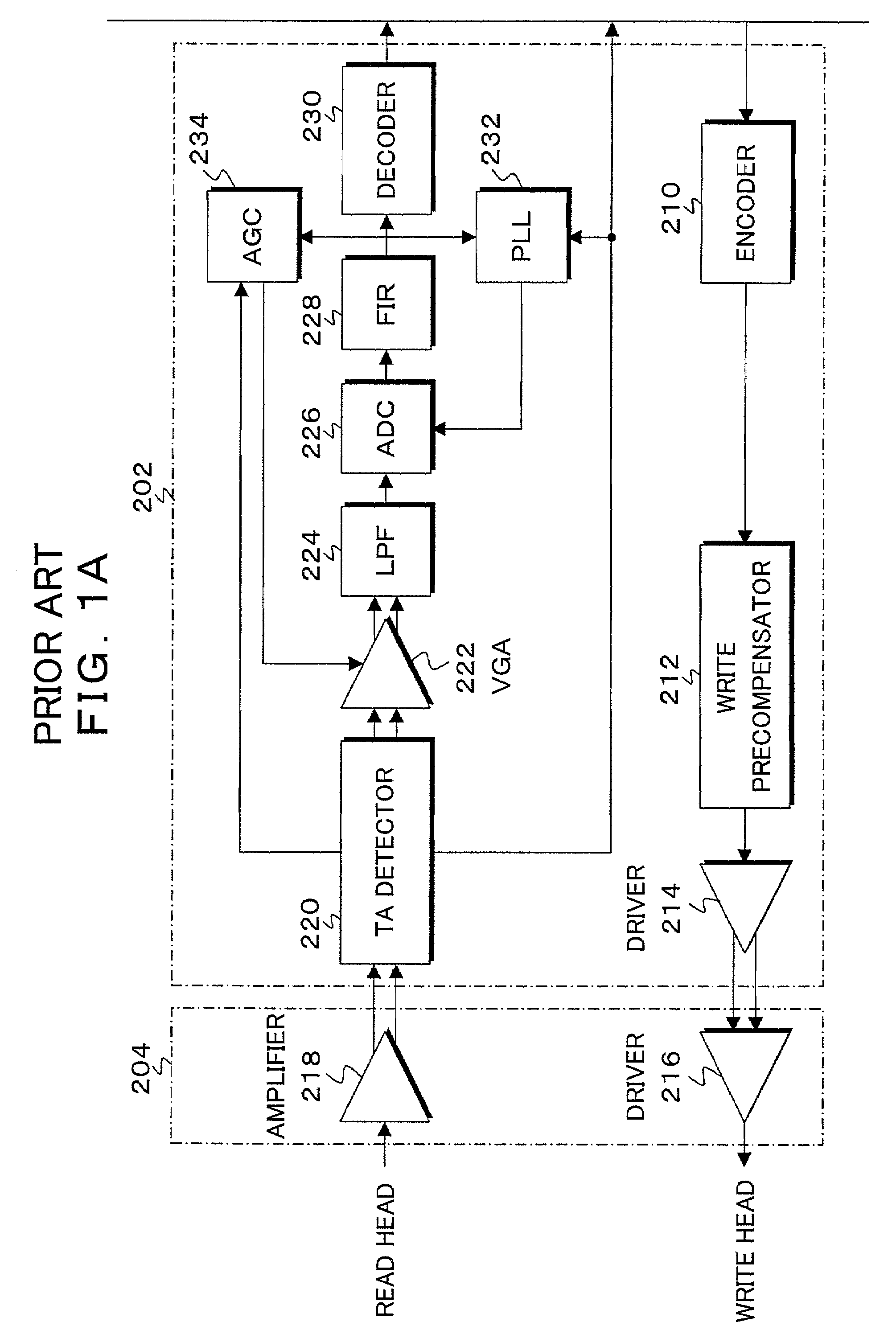

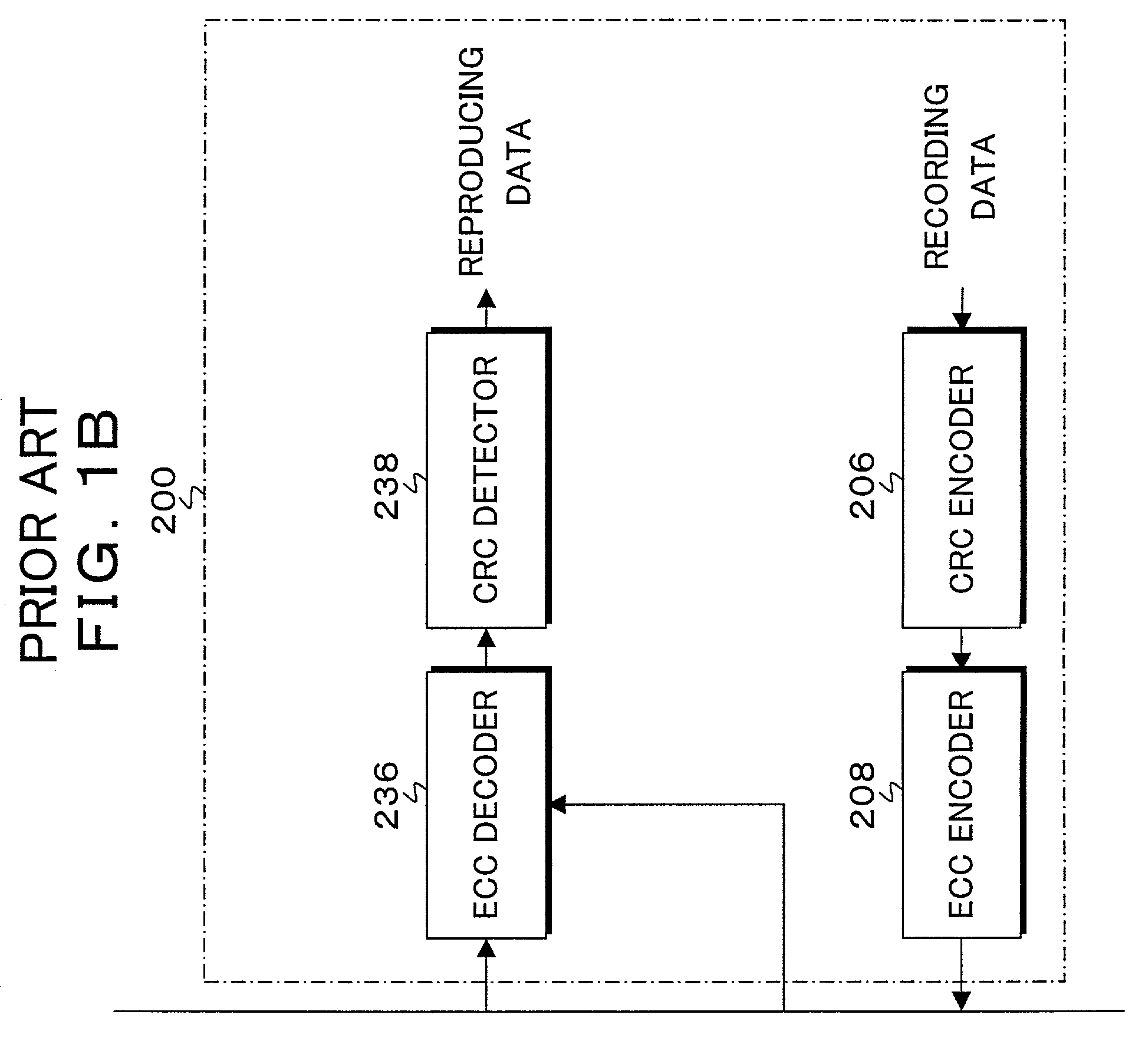

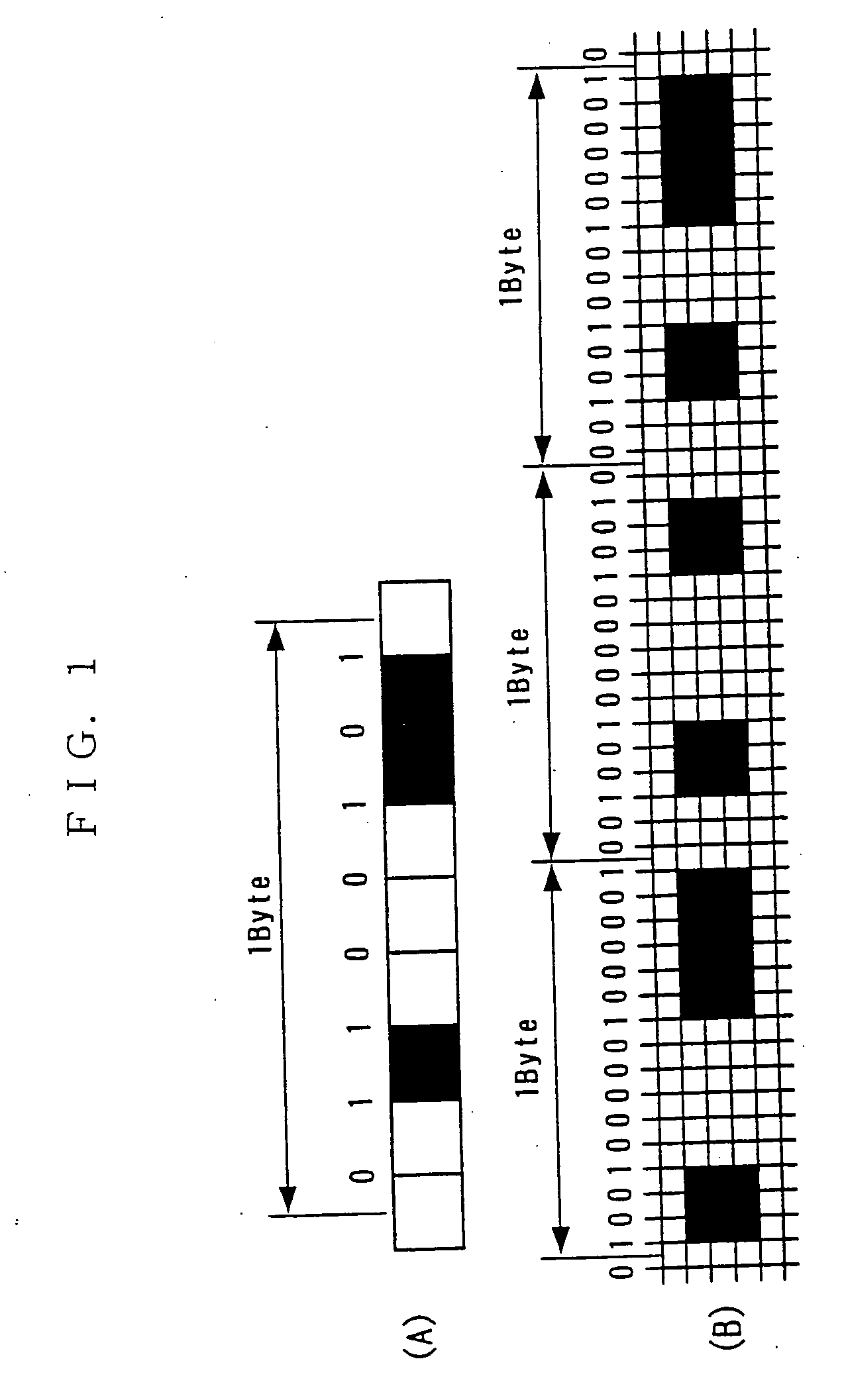

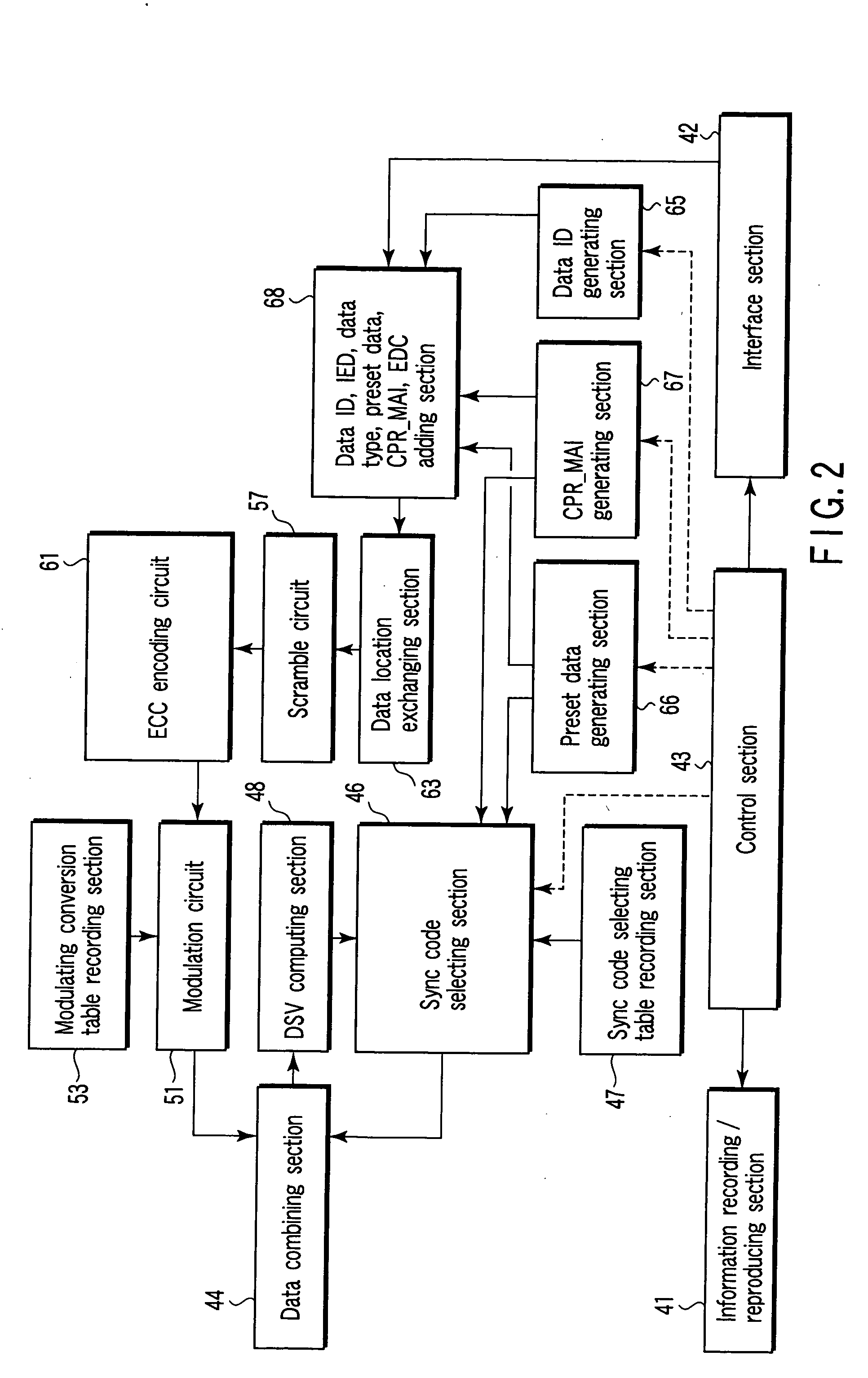

Recording and reproducing apparatus, signal decoding circuit, error correction method and iterative decoder

InactiveUS7237173B2Increase recording capacityIncrease the number ofData representation error detection/correctionModification of read/write signalsCorrection methodSignal decoding

A recording and reproducing apparatus having an ECC-less error correction function, includes an erasure detector generating an erasure flag indicating erasure of a read signal; and an iterative decoder having two soft-in / soft-out (SISO) decoders, i.e., an inner decoder and an outer decoder, and correcting the erasure by inputting the erasure flag ek into the inner decoder and performing erasure compensation in the inner decoder. As the erasure compensation in the inner decoder, channel information is masked while the erasure flag is on. The erasure of data due to a media defect is detected inside the iterative decoder, and the second erasure flag is inputted into the inner decoder to perform erasure compensation in the inner decoder.

Owner:FUJITSU LTD

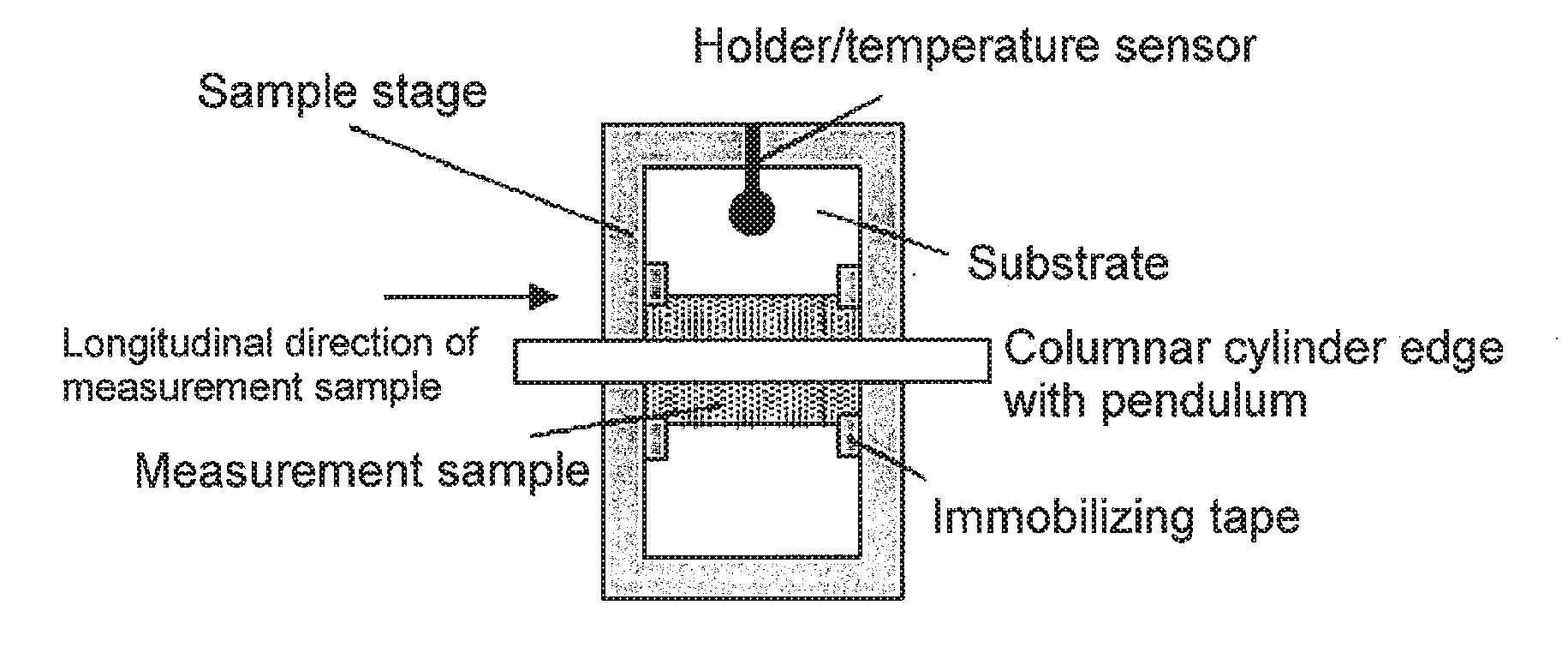

Magnetic tape and method of manufacturing the same

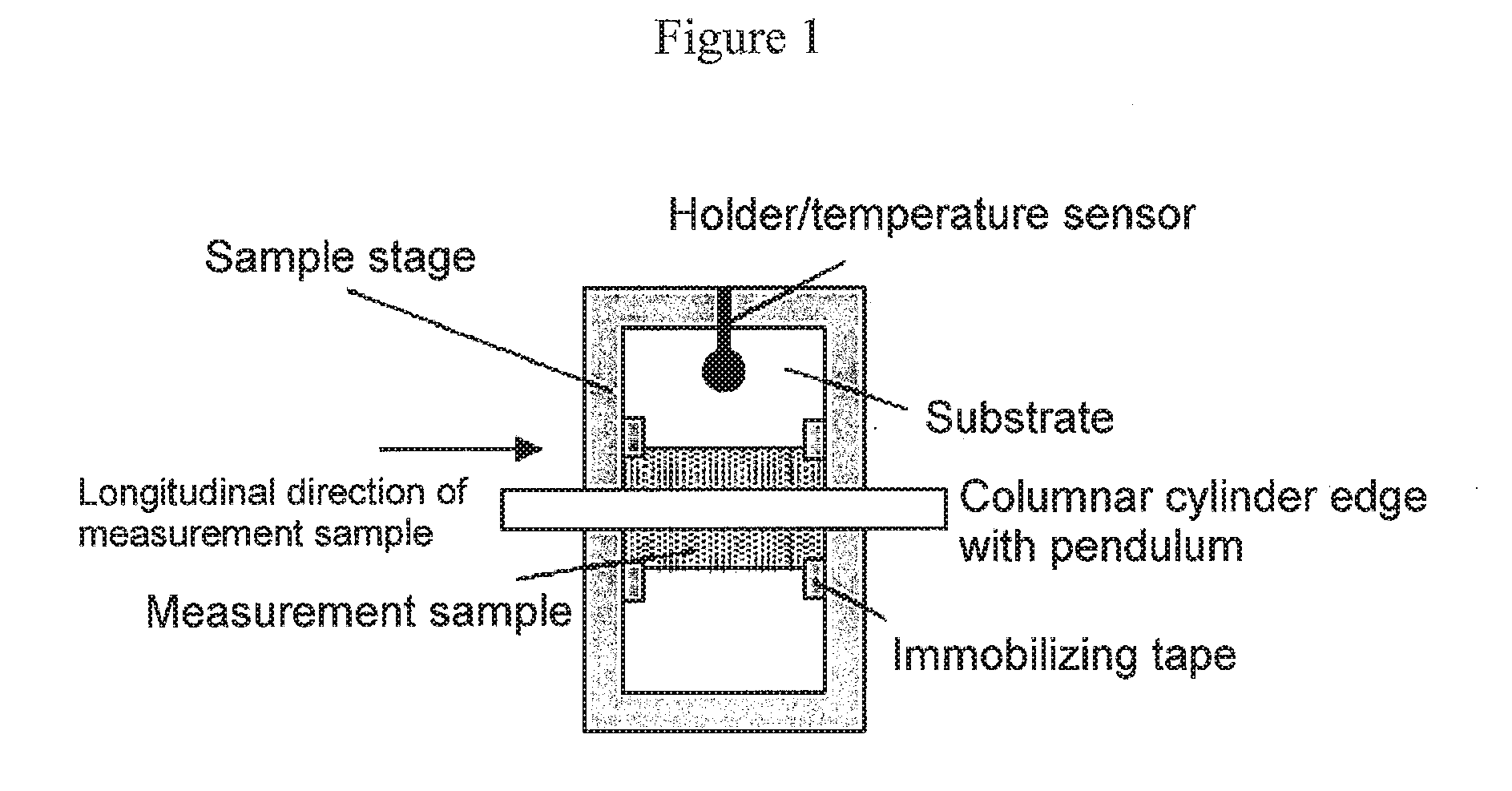

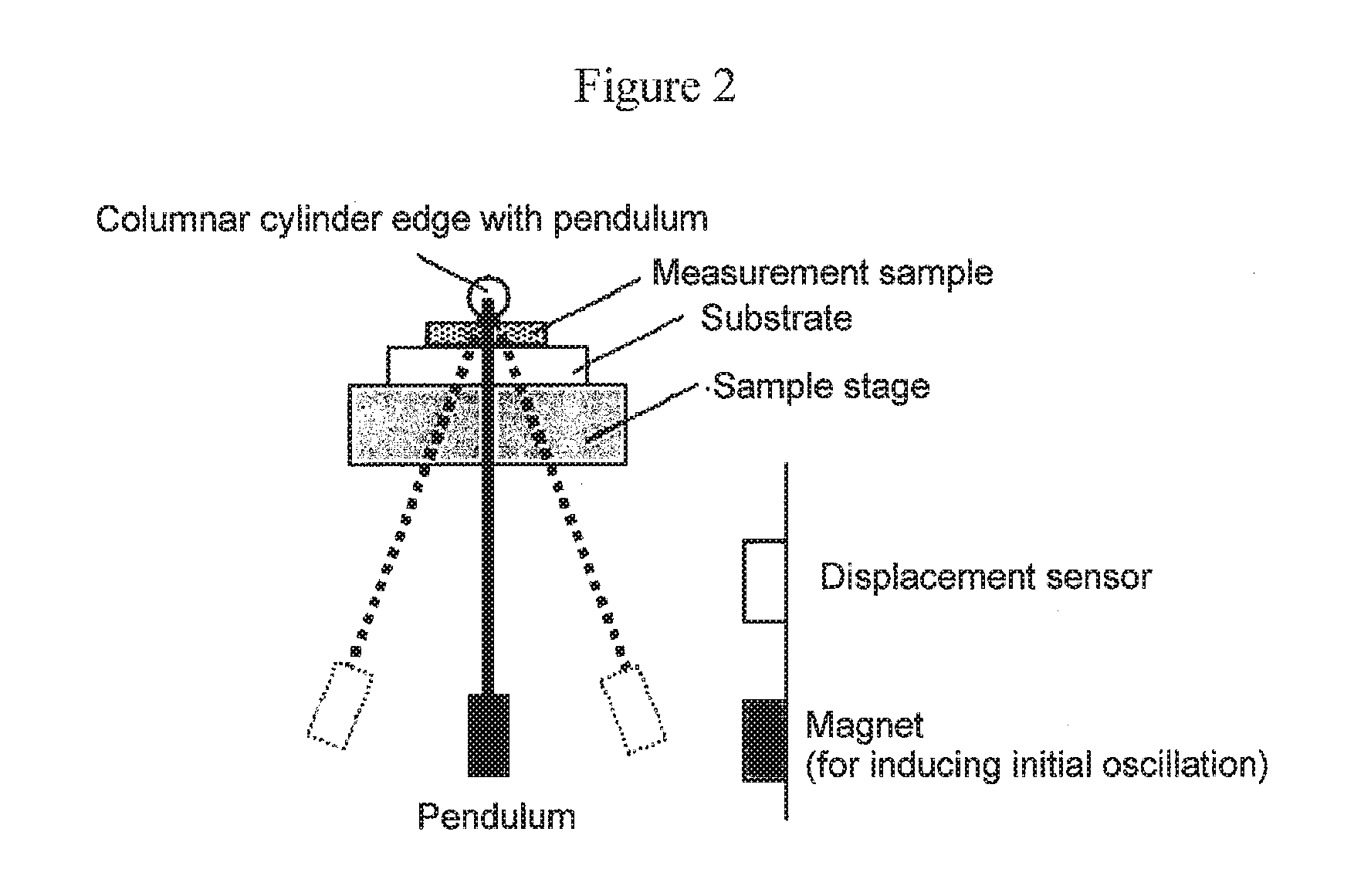

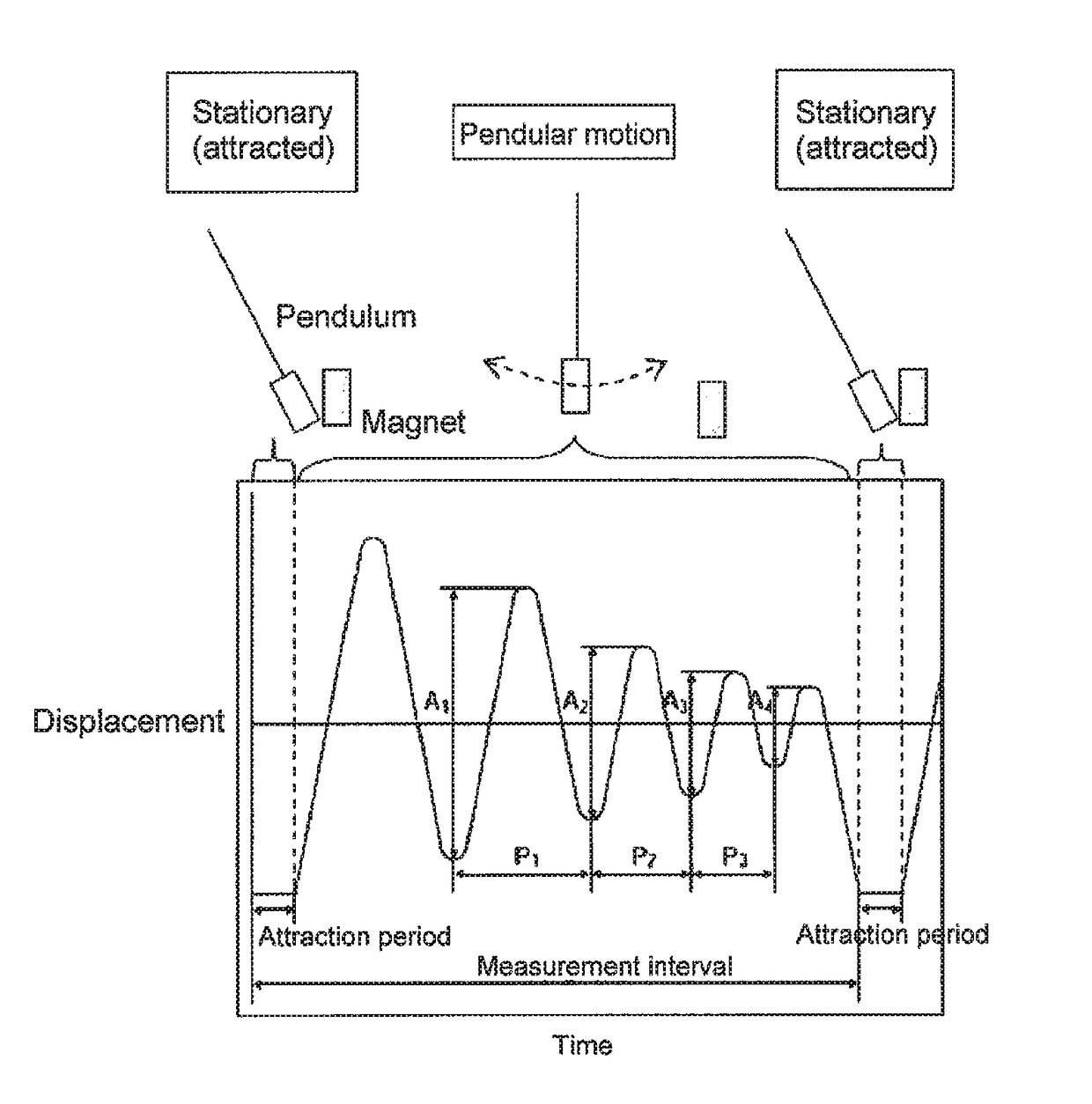

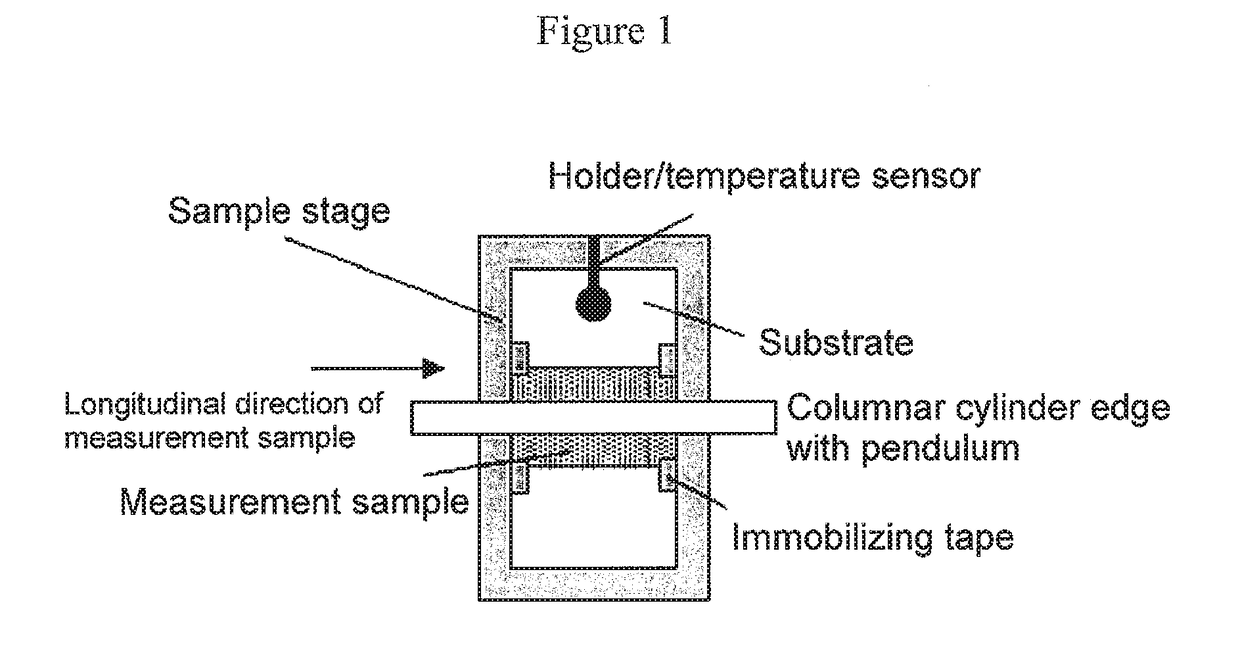

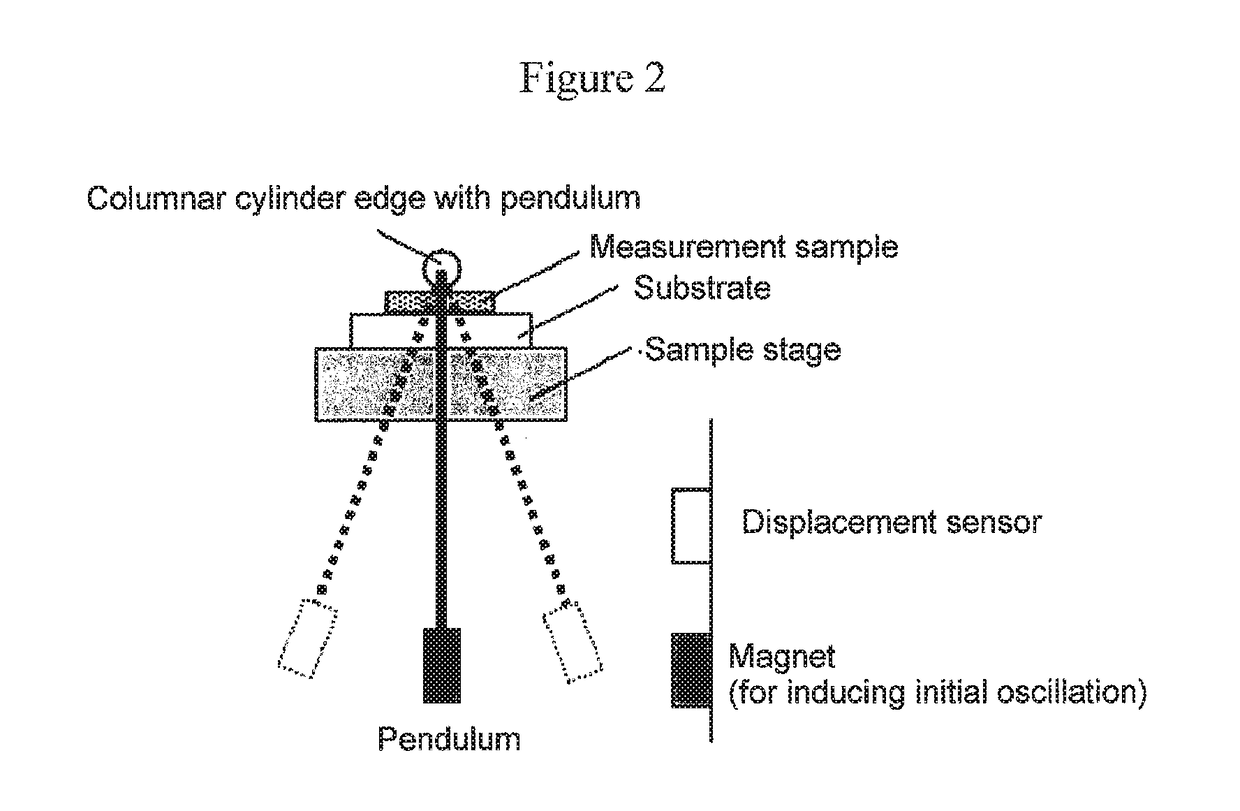

ActiveUS20170053671A1Increase recording capacityReduce thicknessTape carriersRecord information storageMagnetic tapeNon magnetic

The magnetic tape has a magnetic layer containing ferromagnetic powder and binder on the surface on one side of a nonmagnetic support and has a backcoat layer containing nonmagnetic powder and binder on the surface on the other side of the nonmagnetic support, wherein the backcoat layer is less than or equal to 0.30 μm in thickness; and the logarithmic decrement as determined by a pendulum viscoelasticity test on the surface on the backcoat layer side of the magnetic tape is less than or equal to 0.060.

Owner:FUJIFILM CORP

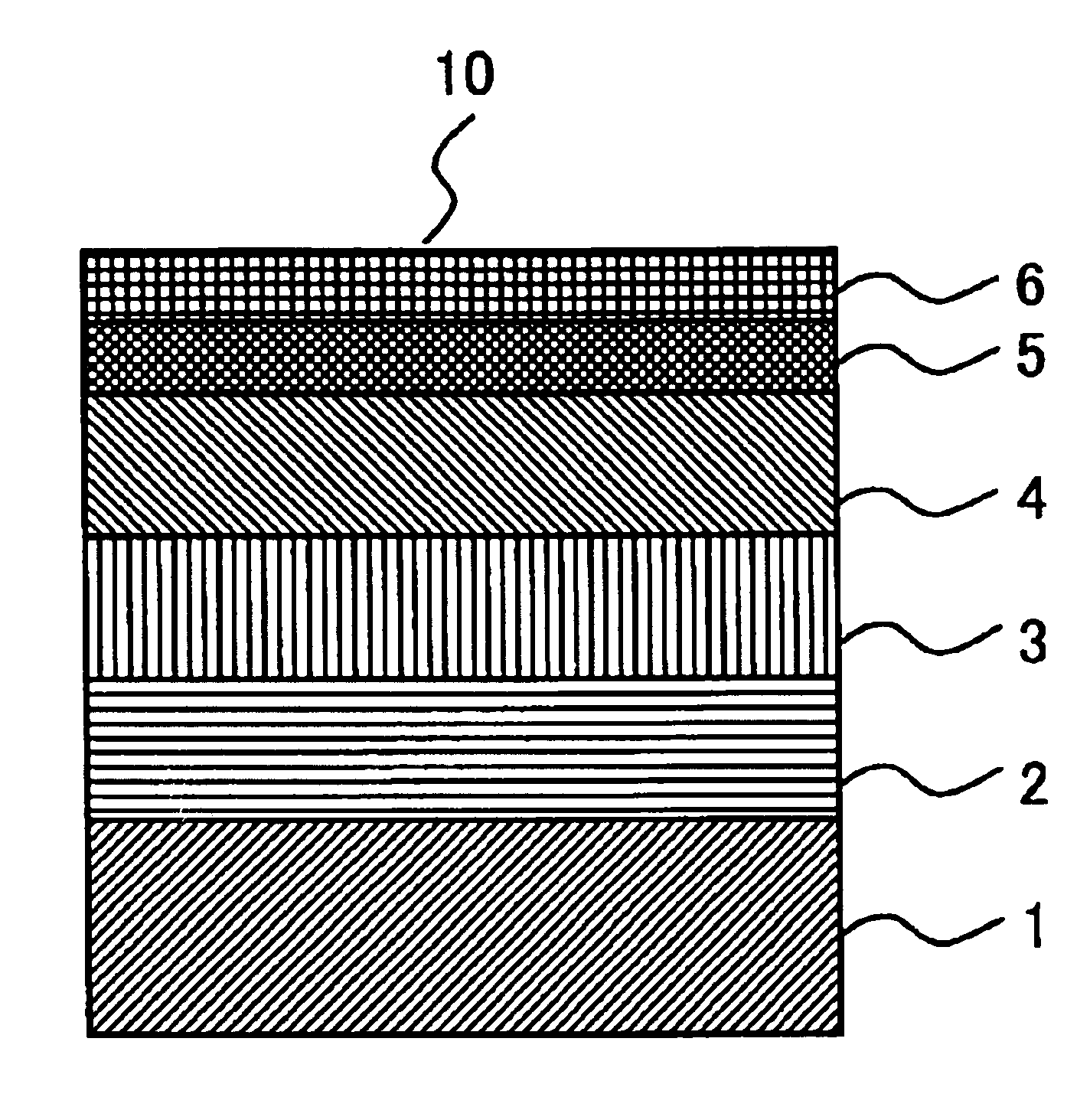

Magnetic tape

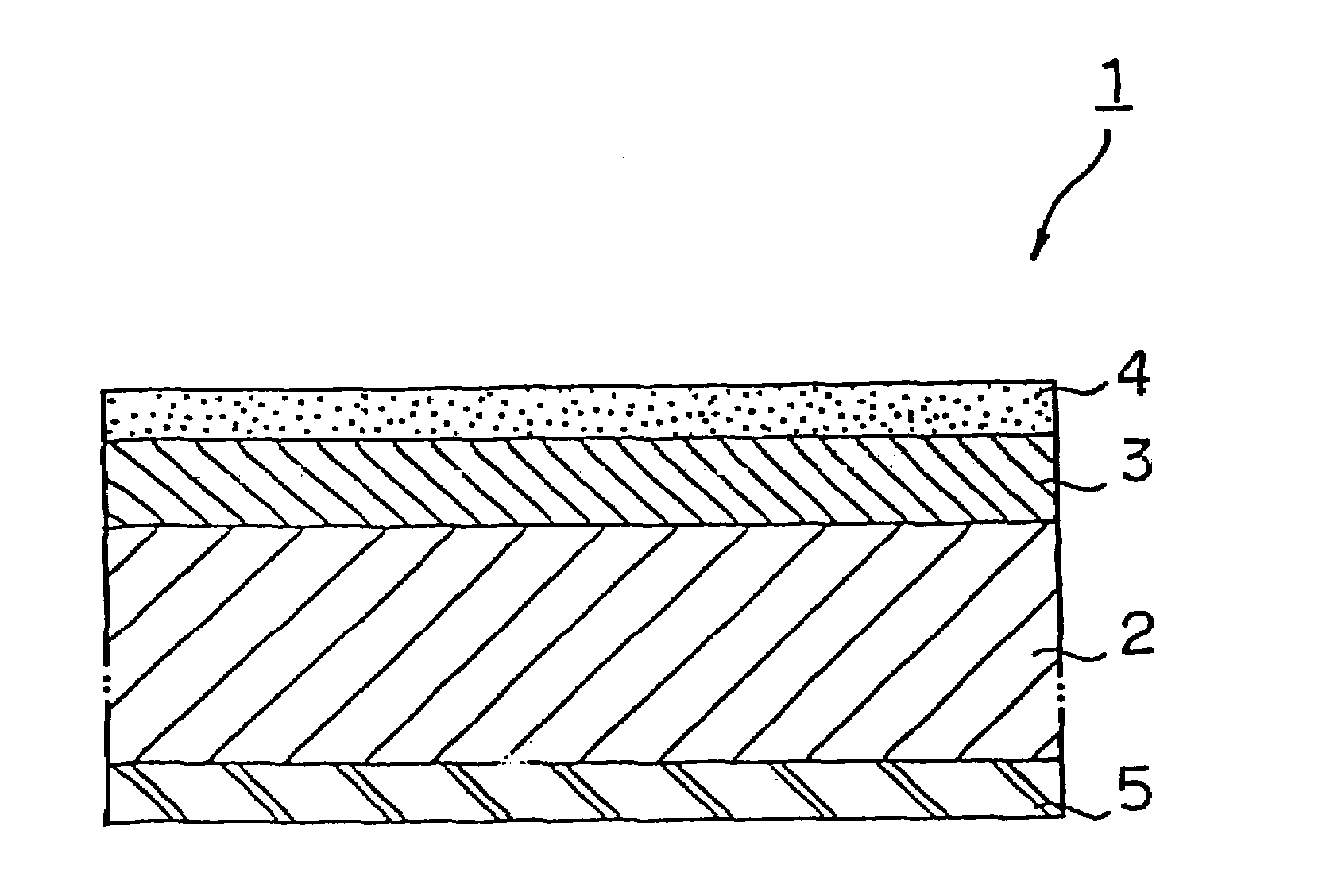

InactiveUS7255908B2Without reducing data areaReduce areaLayered productsAlignment for track following on tapesMagnetic tapeOxygen

A magnetic tape (1) characterized by having a backcoating layer (5) which comprises a binder and fine particles having been dispersed in the binder and being capable of irreversibly changing in color on oxidation reaction, and has a sufficient number of microvoids of sufficient size to supply sufficient oxygen to cause the oxidation reaction.

Owner:QUANTUM CORP

Magnetic tape and method of manufacturing the same

ActiveUS9704527B2Increase coefficient of frictionReduced stabilityRecord information storageMetals or alloysMagnetic tapeNon magnetic

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20160247530A1Improve running stabilityReduce coefficient of frictionRecord information storageMetals or alloysMagnetic tapeTotal thickness

The magnetic tape has on one surface of a nonmagnetic support a magnetic layer containing ferromagnetic powder and binder, and on the other surface of the nonmagnetic support, a backcoat layer containing nonmagnetic powder and binder, wherein the total thickness of the magnetic tape is less than or equal to 4.80 μm, the backcoat layer contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide, and a C—H derived carbon, C, concentration calculated from a C—H peak area ratio in a C1s spectrum obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on a surface on the backcoat layer side of the magnetic tape ranges from 35 to 60 atom %.

Owner:FUJIFILM CORP

Magnetic tape having controlled surface properties of the backcoat layer and method of manufacturing the same

ActiveUS10026435B2Increase recording capacityReduce thicknessTape carriersRecord information storageMagnetic tapeNon magnetic

The magnetic tape has a magnetic layer containing ferromagnetic powder and binder on the surface on one side of a nonmagnetic support and has a backcoat layer containing nonmagnetic powder and binder on the surface on the other side of the nonmagnetic support, wherein the backcoat layer is less than or equal to 0.30 μm in thickness; and the logarithmic decrement as determined by a pendulum viscoelasticity test on the surface on the backcoat layer side of the magnetic tape is less than or equal to 0.060.

Owner:FUJIFILM CORP

Magnetic tape, magnetic tape cartridge, and magnetic recording and reproducing device

ActiveUS20170178677A1Reduce thicknessIncrease recording capacityBase layers for recording layersTape carriersMagnetic tapeNon magnetic

The magnetic tape includes a nonmagnetic layer containing nonmagnetic powder and binder on a nonmagnetic support, and a magnetic layer containing ferromagnetic powder, abrasive, and binder on the nonmagnetic layer, wherein a thickness of the nonmagnetic layer is less than or equal to 0.50 μm, a coefficient of friction as measured on a base portion of a surface of the magnetic layer is less than or equal to 0.35, and ΔSFD in a longitudinal direction of the magnetic tape as calculated with Equation 1, ΔSFD=SFD25° C.−SFD−190° C., is greater than or equal to 0.50, wherein, in Equation 1, SFD25° C. denotes a SFD as measured in the longitudinal direction of the magnetic tape in an environment with a temperature of 25° C., and SFD−190° C. denotes a SFD as measured in the longitudinal direction of the magnetic tape in an environment with a temperature of −190° C.

Owner:FUJIFILM CORP

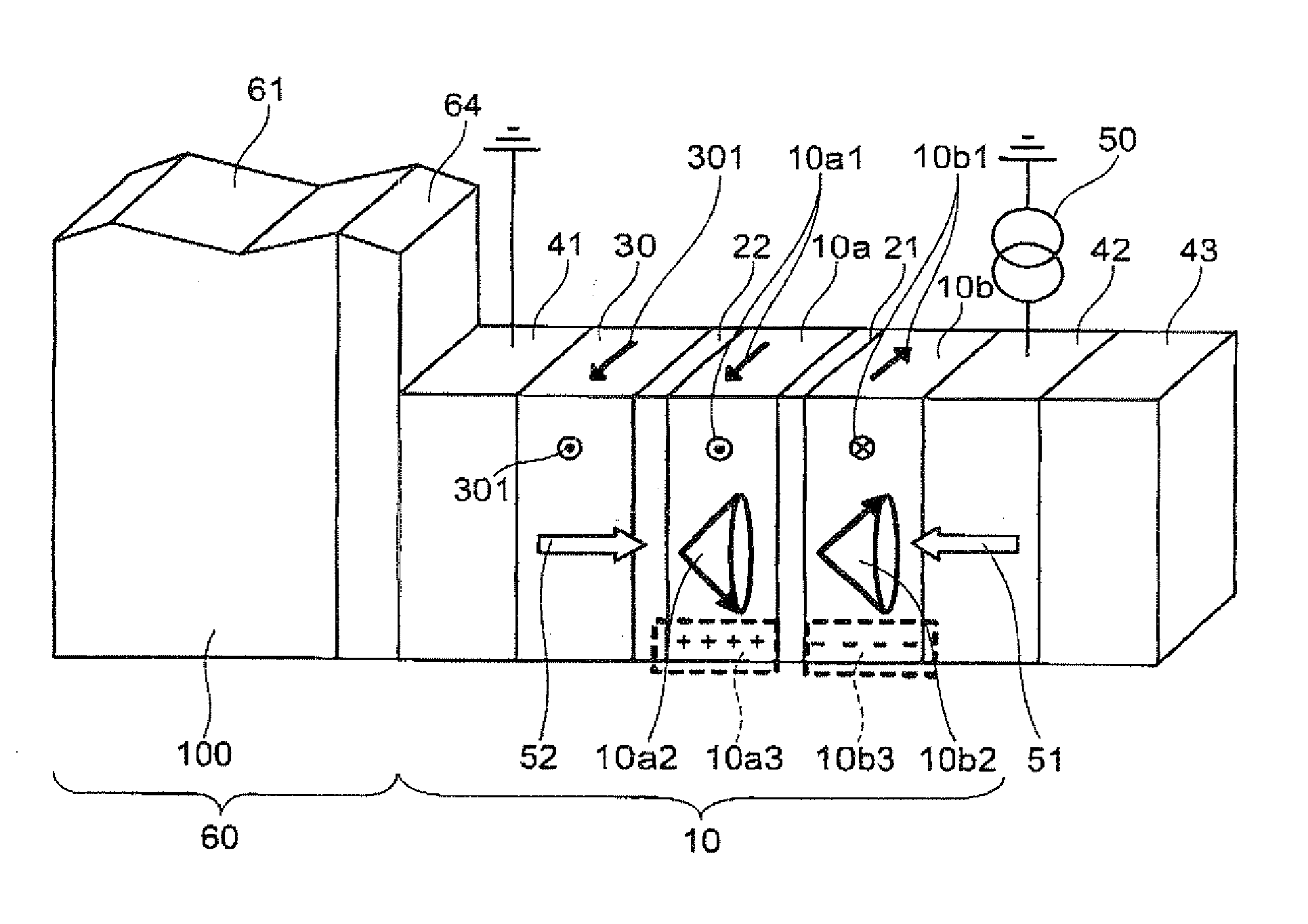

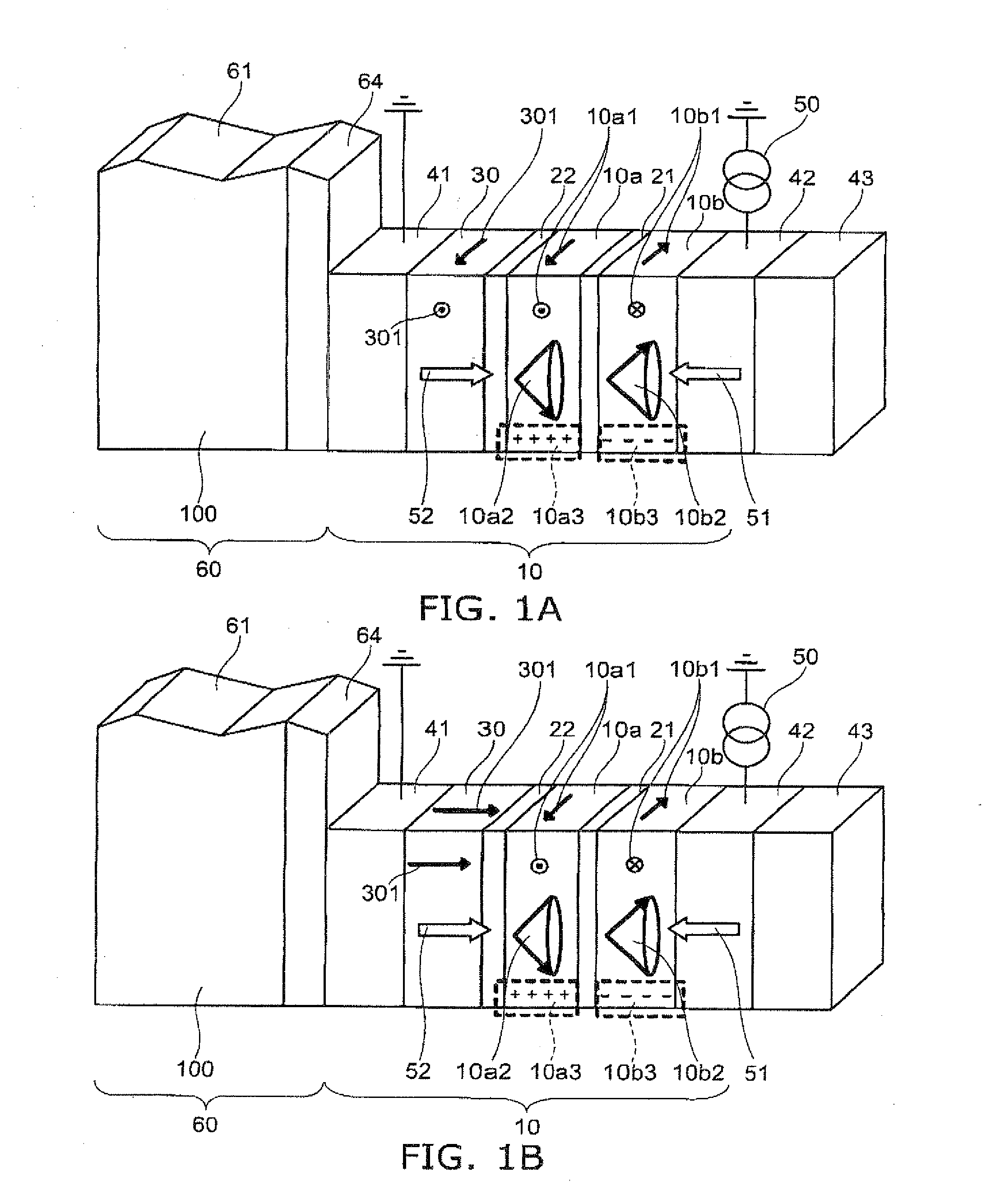

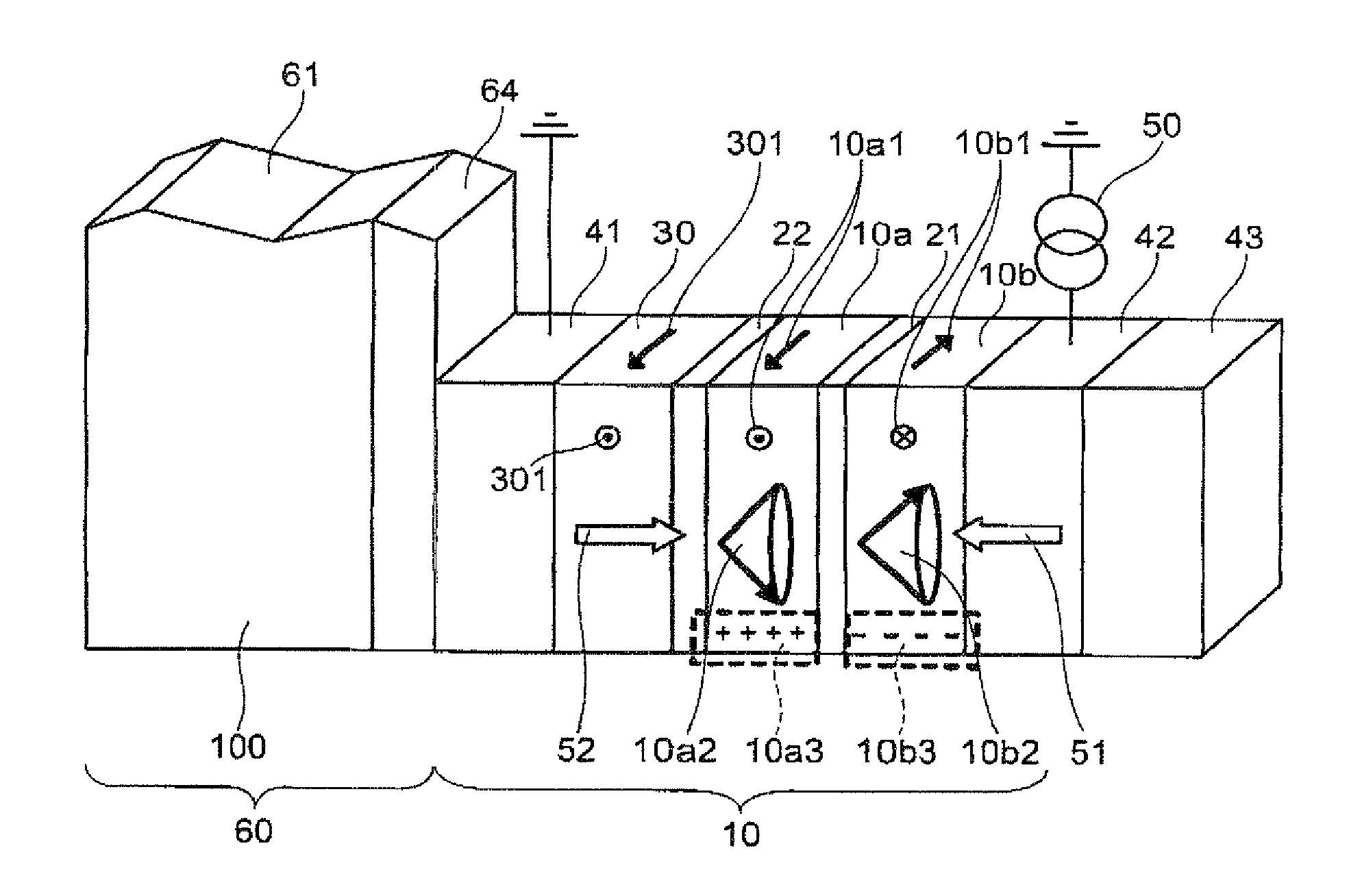

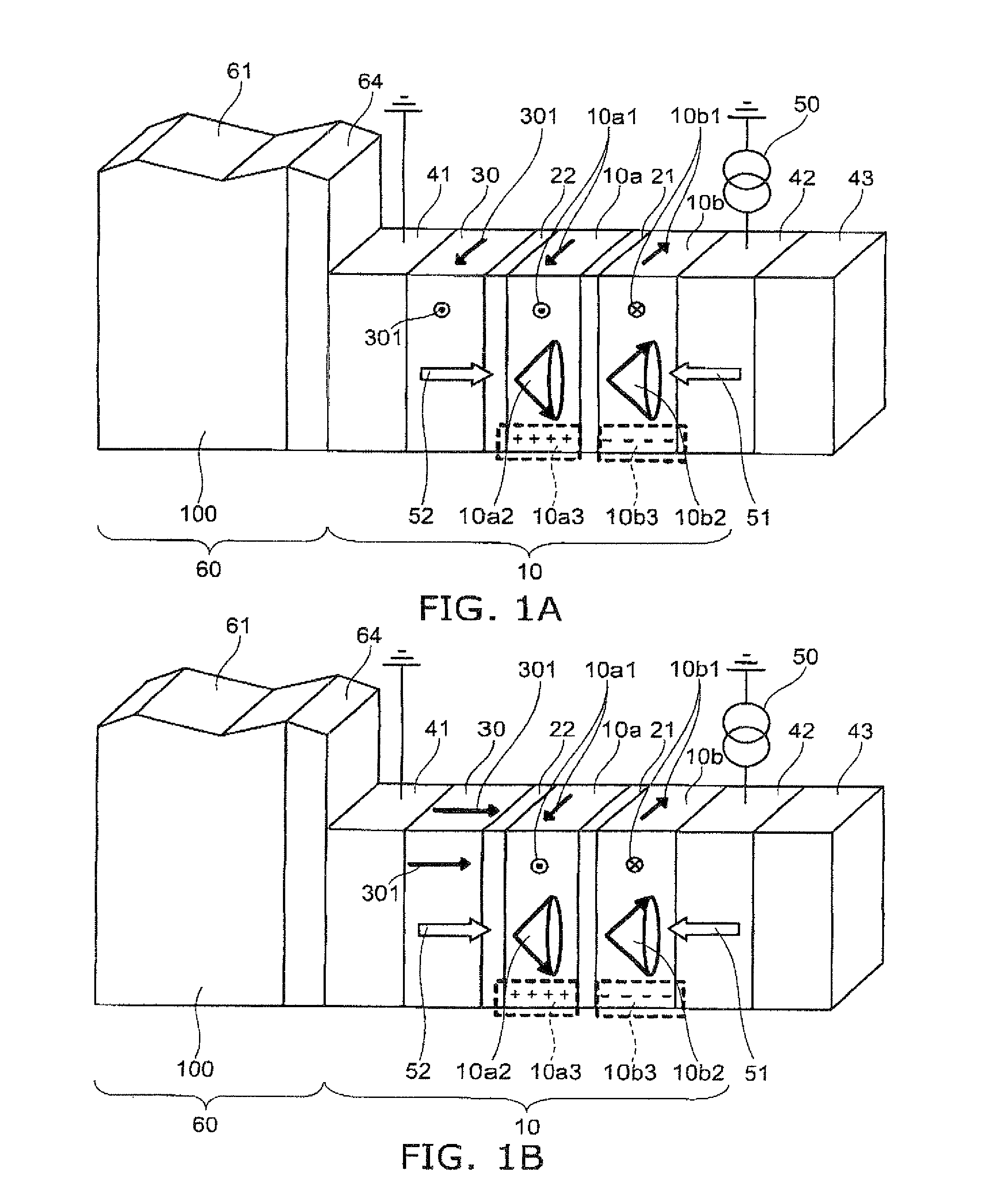

Magnetic device, magnetic recording head, and magnetic recording apparatus

ActiveUS20080268291A1Improve recording densityIncrease recording capacityRecord information storageManufacture of flux-sensitive headsMagnetizationNon magnetic

A magnetic device includes a first magnetic layer having at least one magnetic material layer, a second magnetic layer having at least one magnetic material layer, a first nonmagnetic layer provided between the first magnetic layer and the second magnetic layer, a third magnetic layer including a ferromagnetic material with a fixed magnetization direction, and a pair of electrodes. The pair of electrodes are operable to pass a current through a laminated body including the first and second magnetic layers, the nonmagnetic layer, and the third magnetic layer.

Owner:KK TOSHIBA

Magnetic tape

ActiveUS20170249965A1Increase recording capacityReduce thicknessBase layers for recording layersTape carriersMagnetic tapeMaterials science

The magnetic tape has a magnetic layer containing ferromagnetic powder and binder on one surface of a nonmagnetic support and has a backcoat layer containing nonmagnetic powder and binder on the other surface thereof, wherein the thickness of the backcoat layer is less than or equal to 0.20 μm, and the contact angle for 1-bromonaphthalene that is measured on the surface of the backcoat layer falls within a range of 10.0° to 30.0°.

Owner:FUJIFILM CORP

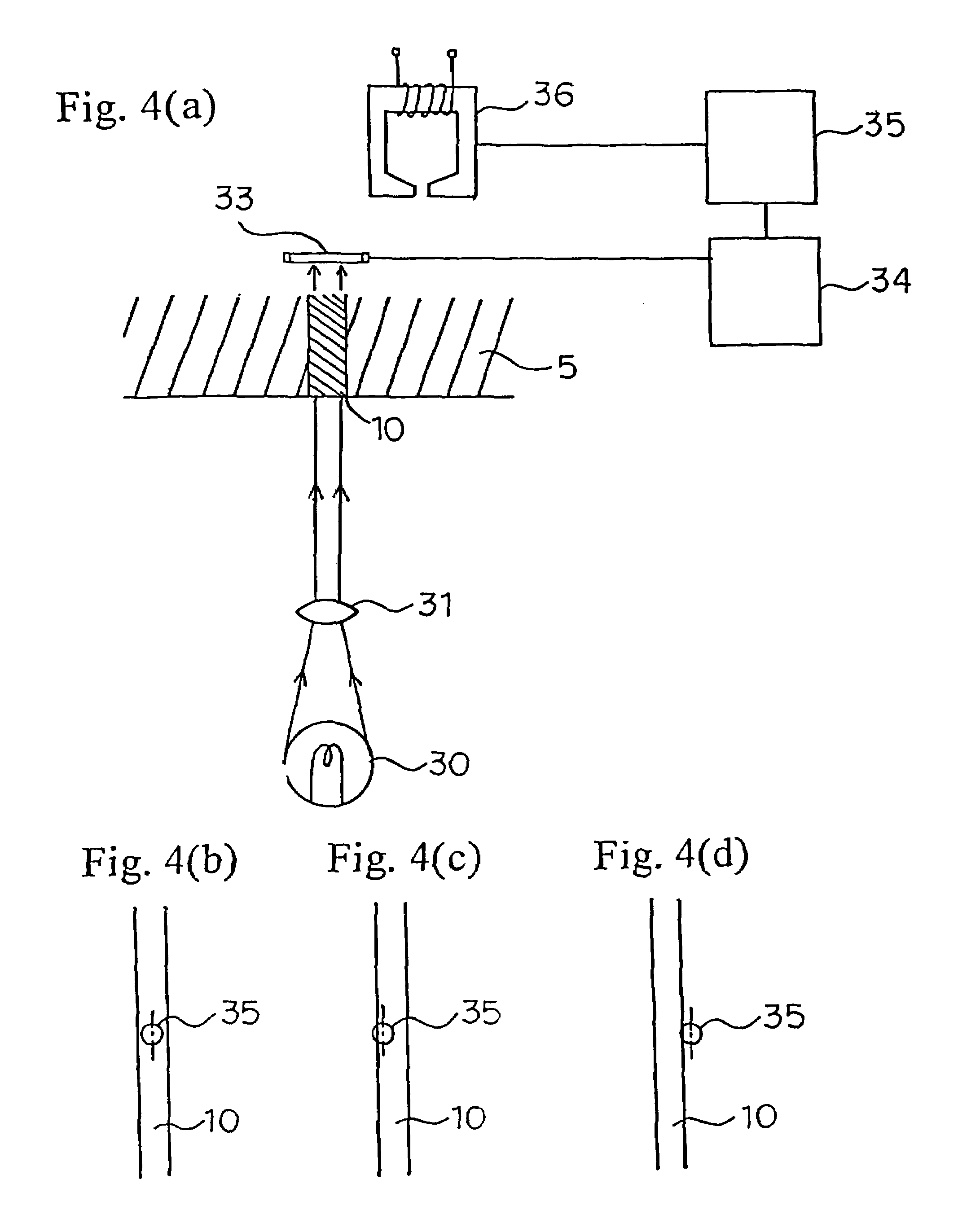

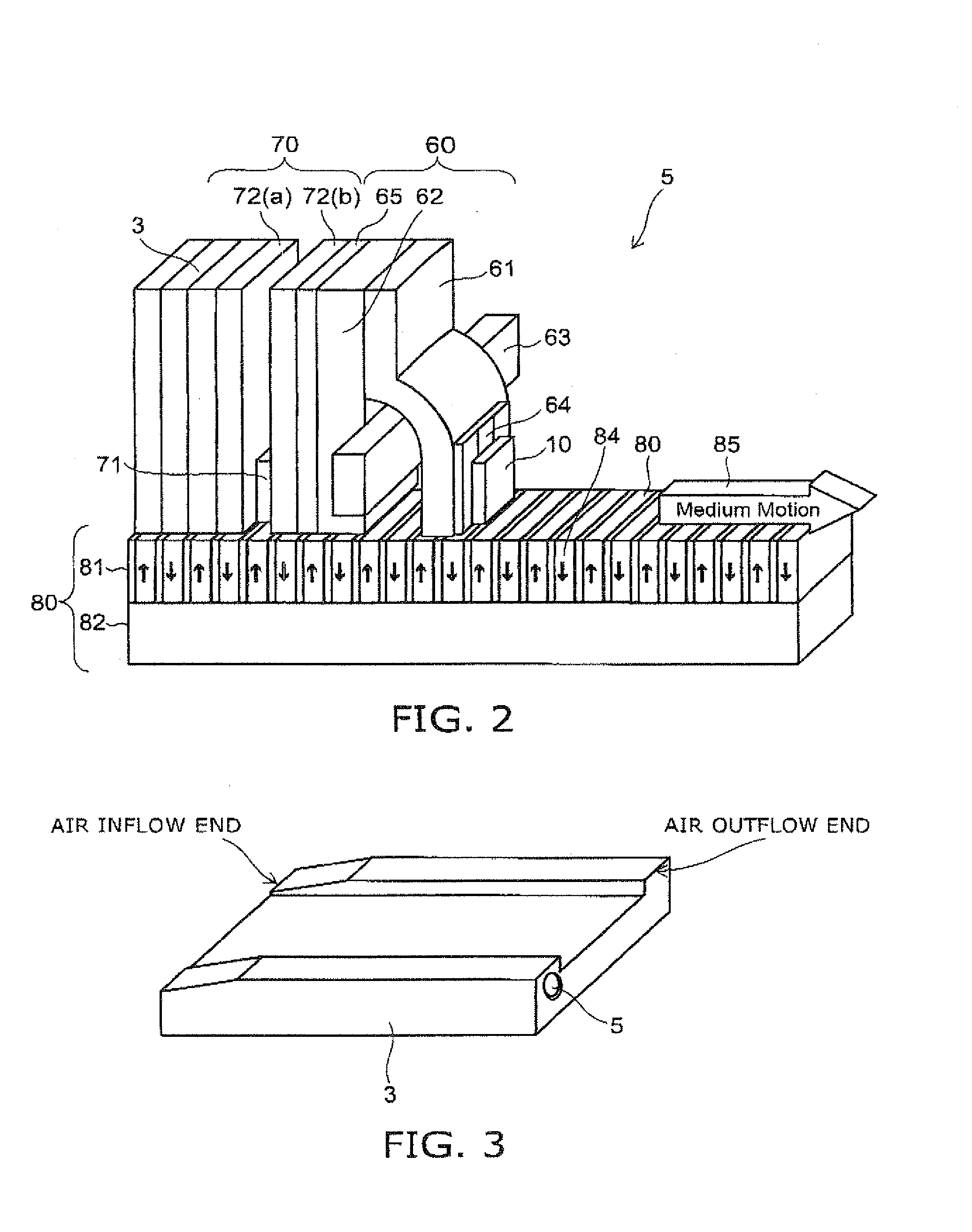

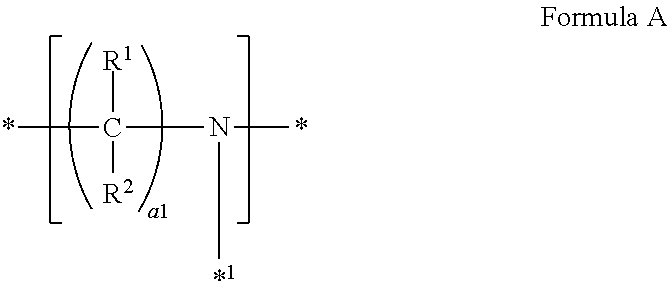

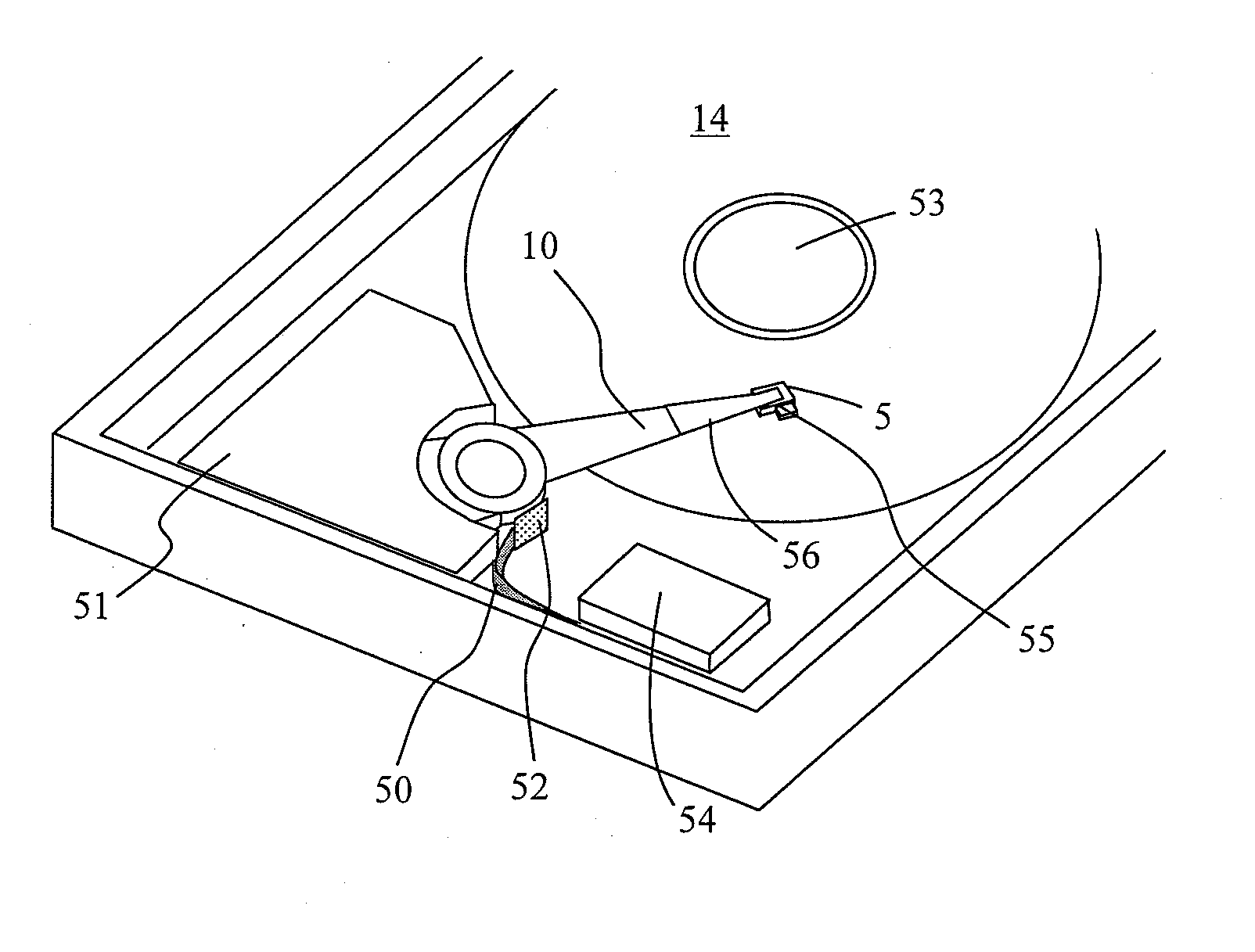

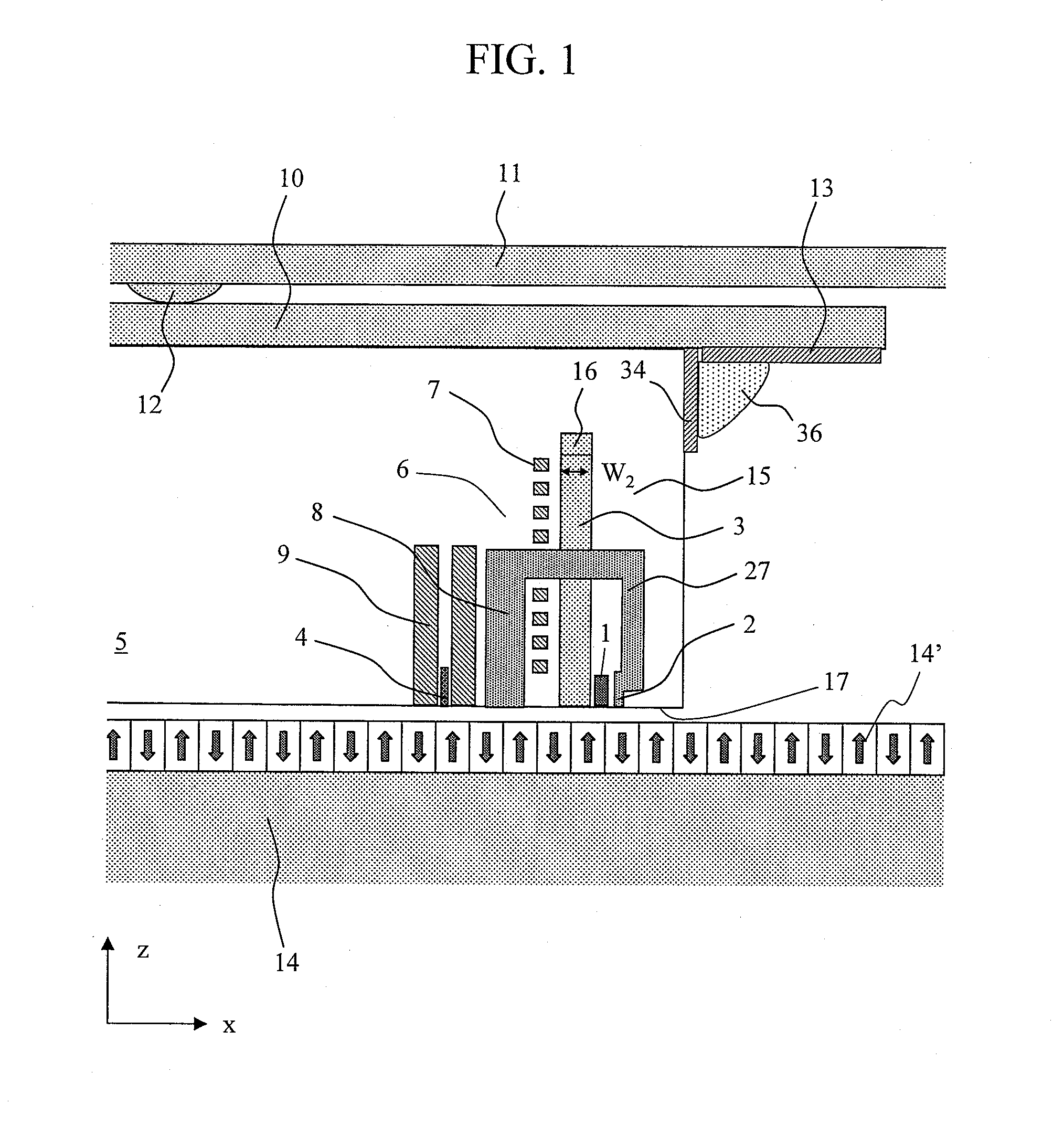

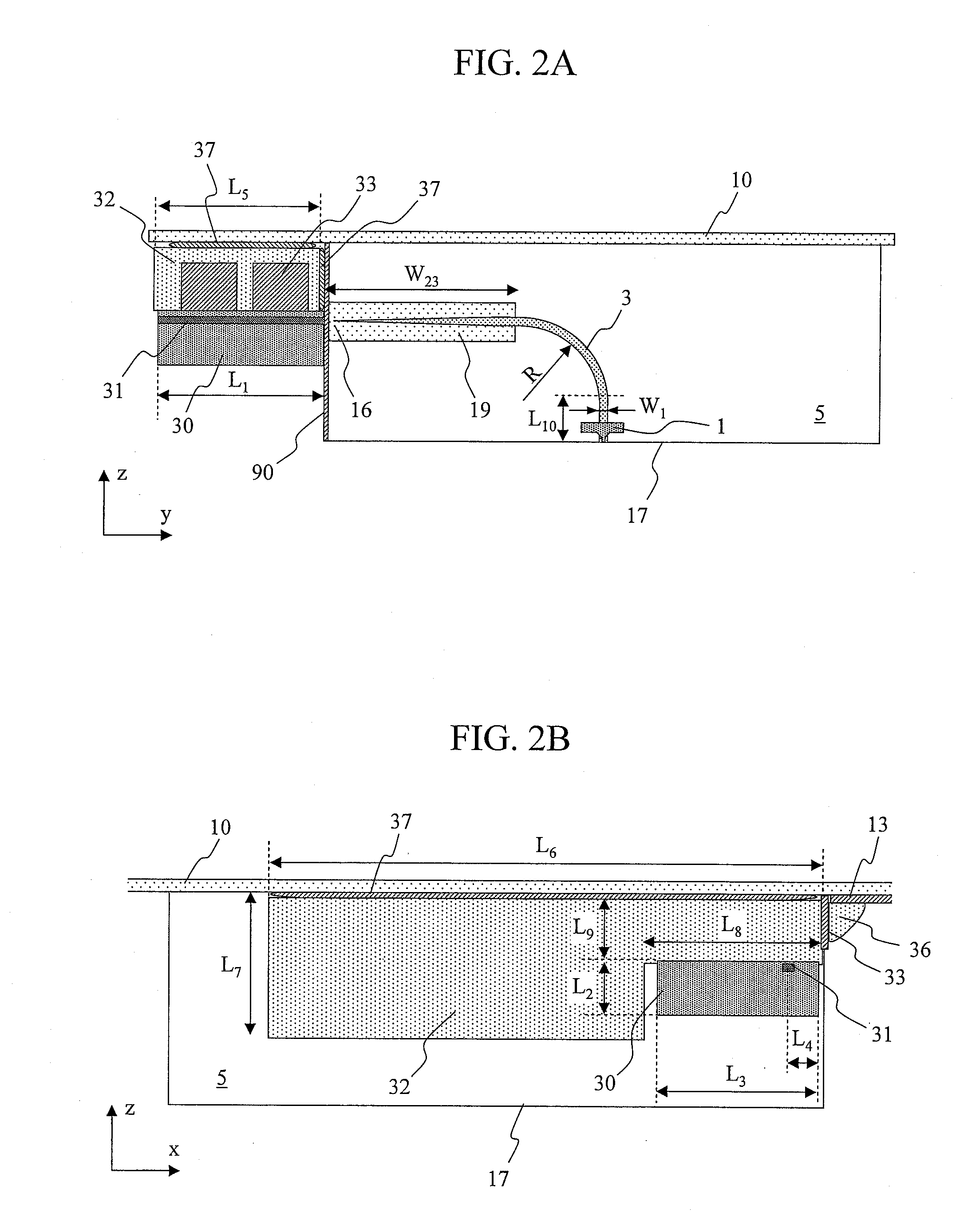

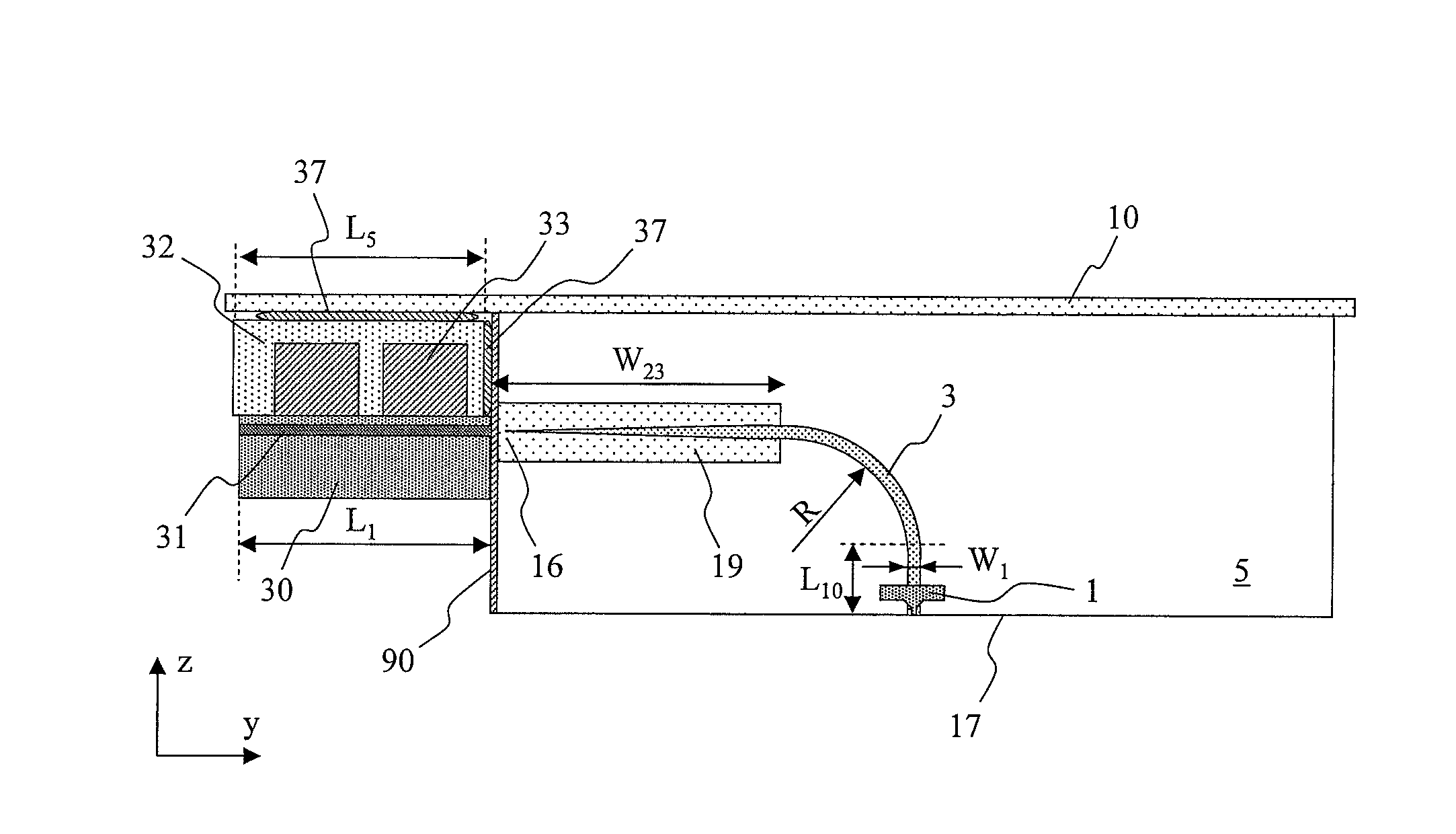

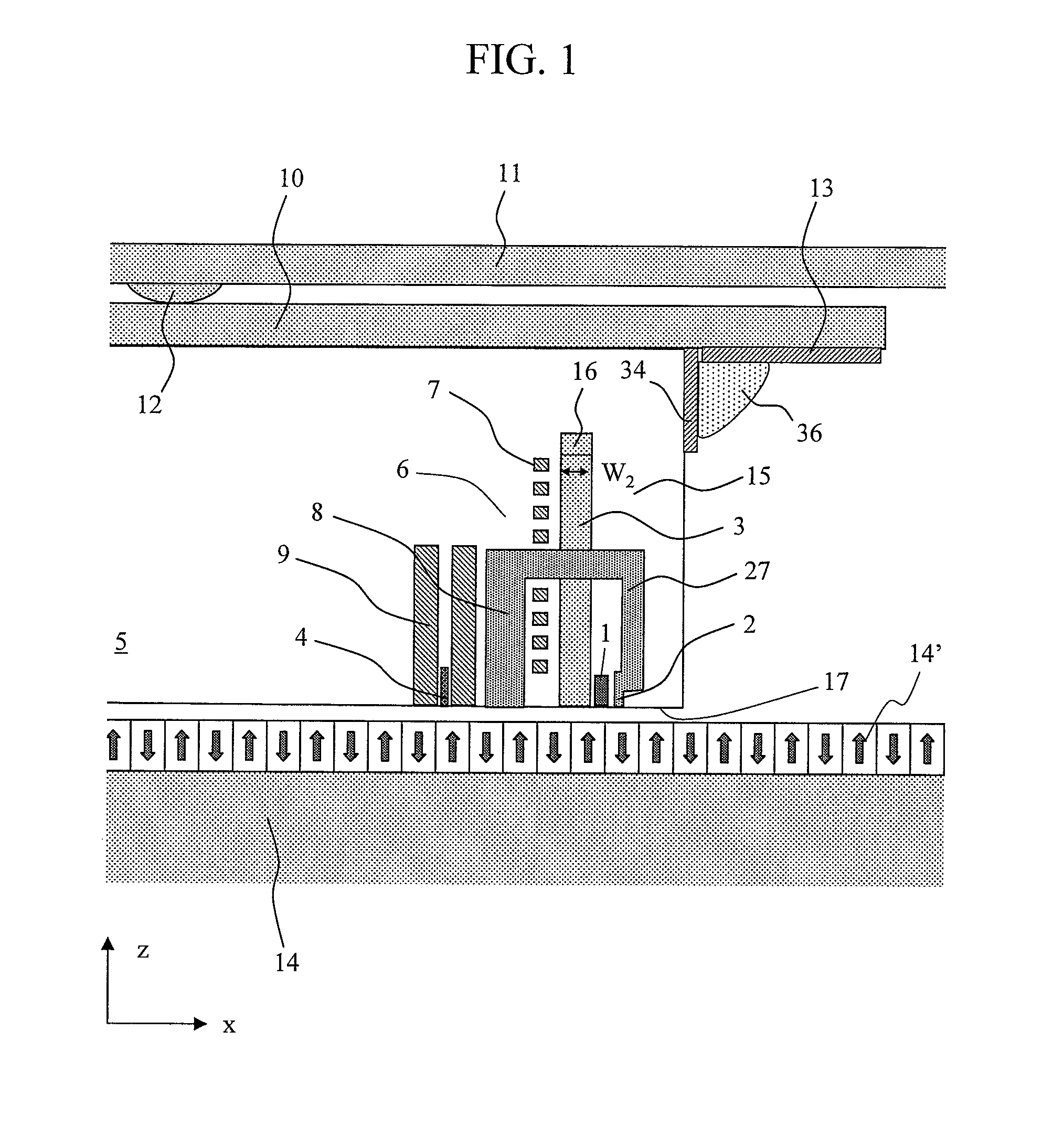

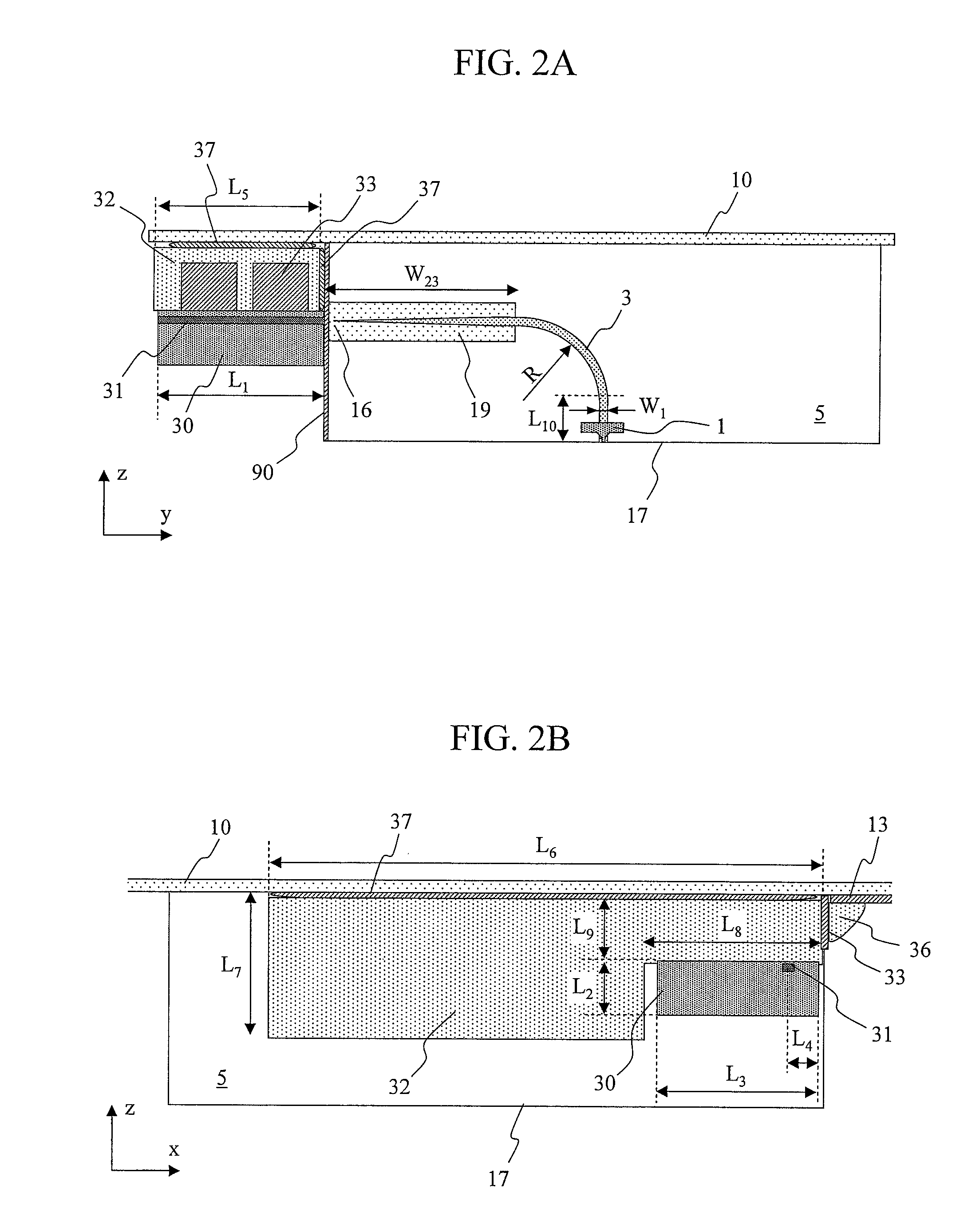

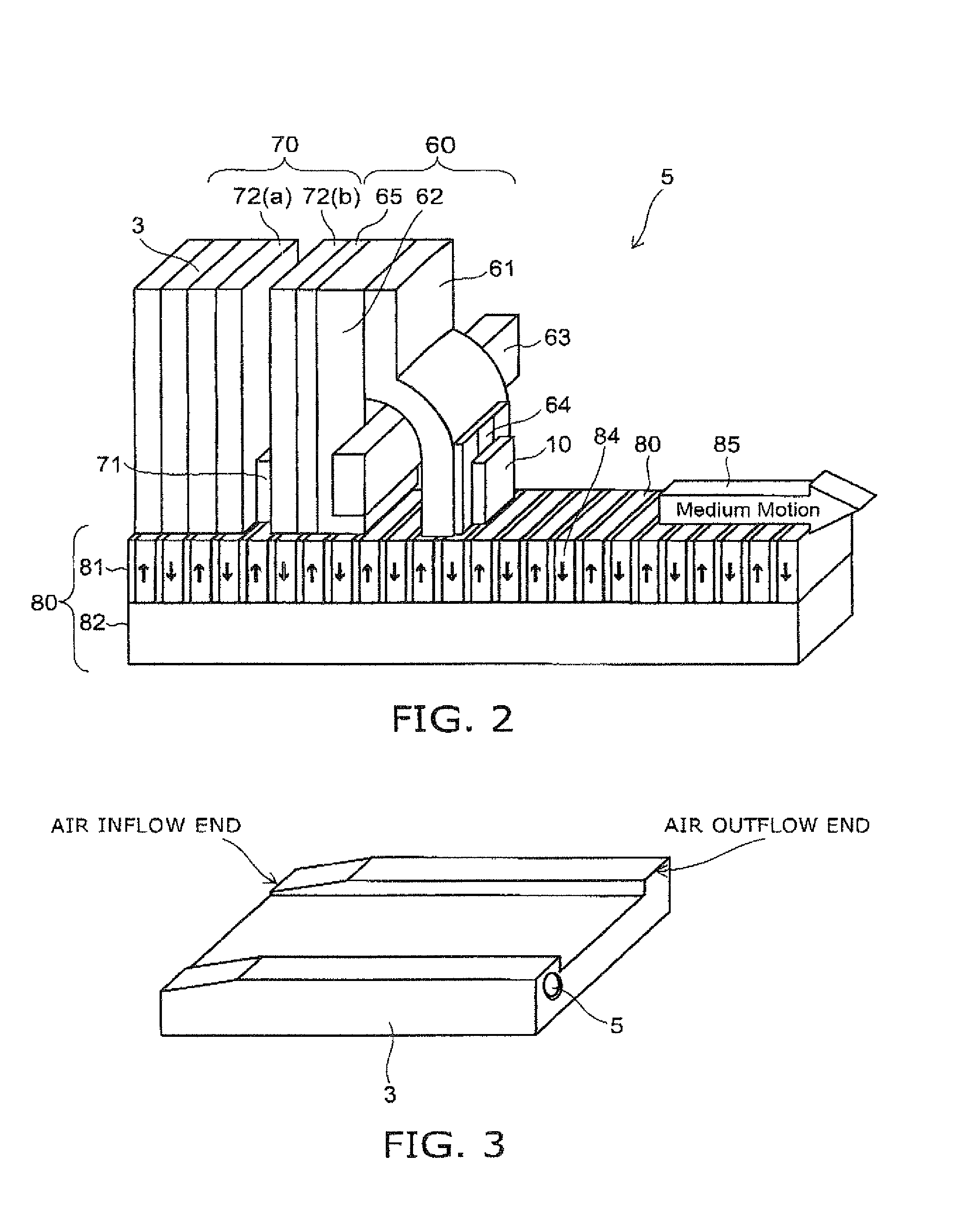

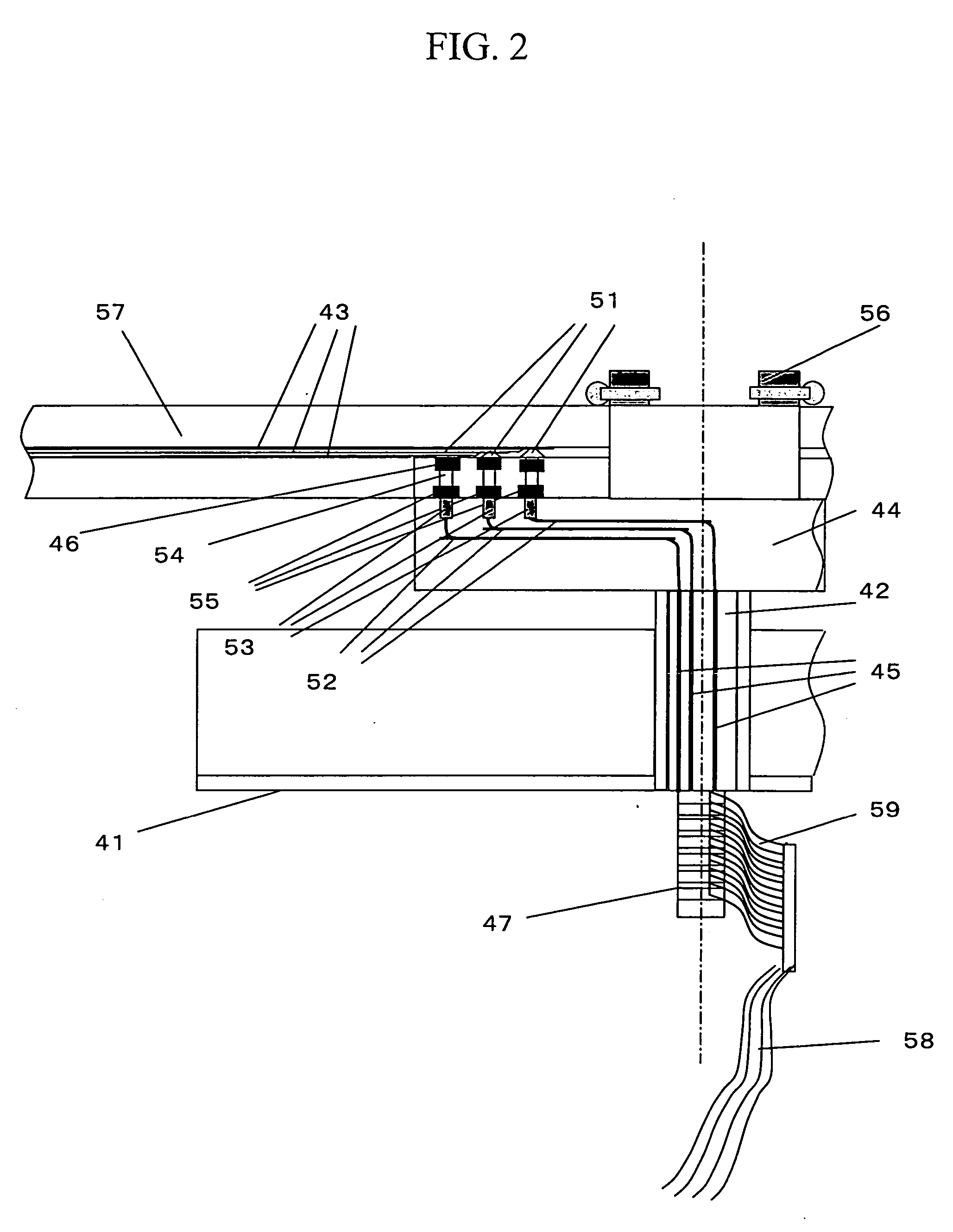

Head for thermal assisted magnetic recording device, and thermal assisted magnetic recording device

ActiveUS20110216635A1Increase head heightImprove floating stabilityCombination recordingRecord information storageHeat-assisted magnetic recordingEngineering

In a head for thermal assisted magnetic recording device, a semiconductor laser is mounted so that the total height of the head does not become larger and light power fluctuation due to wavelength fluctuation occurs less frequently. In addition, the rise in temperature of the mounted semiconductor laser is suppressed. A semiconductor laser is placed on a side surface which is different from surfaces on an inflow end side and a trailing side, of four side surfaces of a floating slider. An entrance of a waveguide is placed on the side surface of the floating slider, to thereby cause emitted light from the semiconductor laser to directly enter the waveguide. A curved line part or a reflective mirror is formed in the middle of the waveguide so that the light which has entered the waveguide travels toward an optical near-field generating element.

Owner:HITACHI LTD

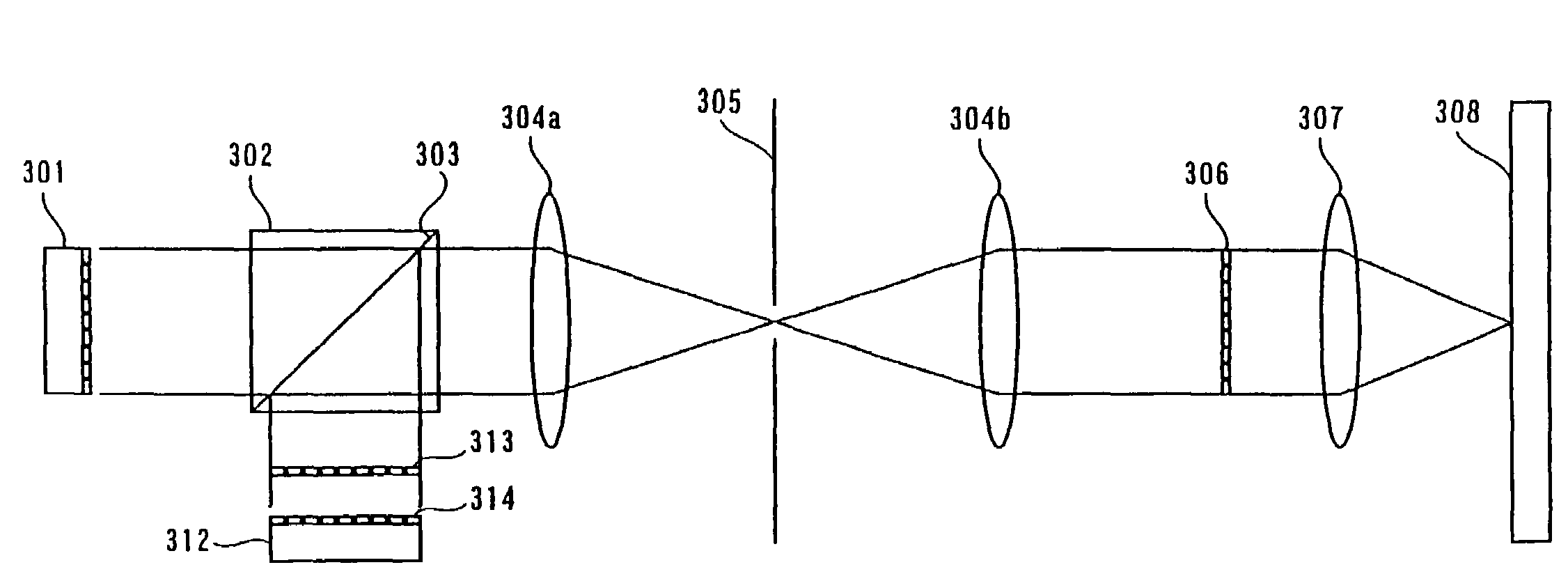

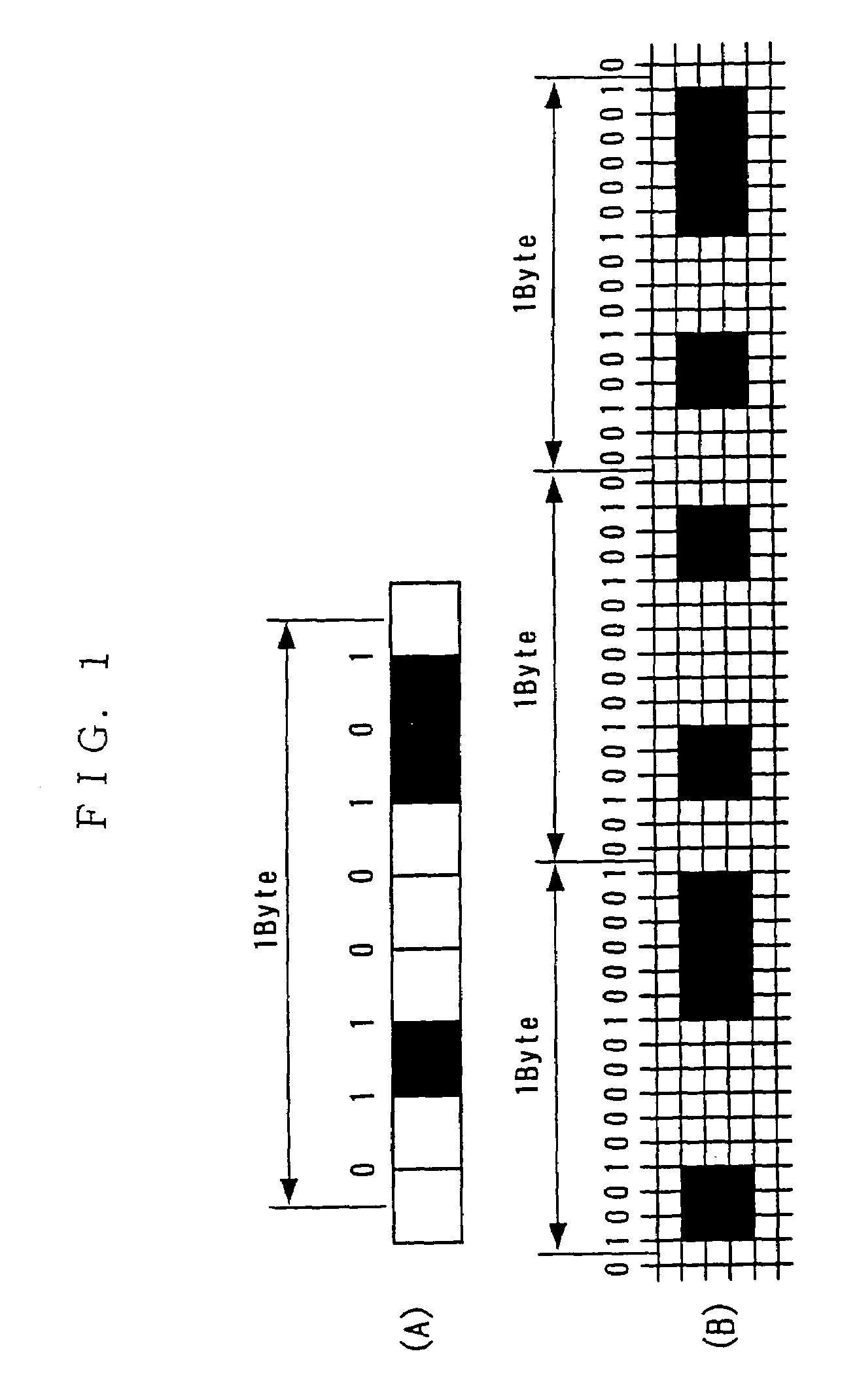

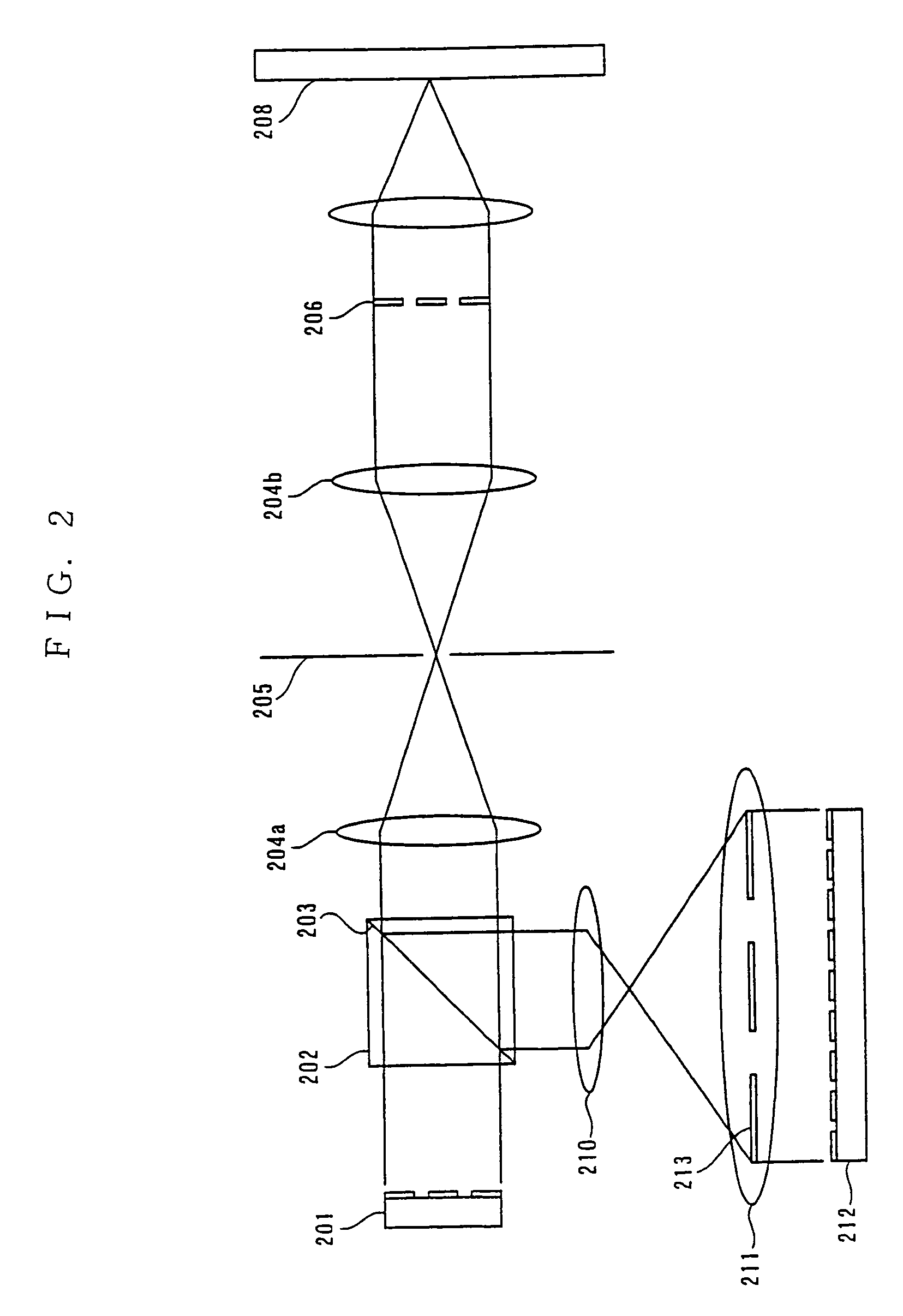

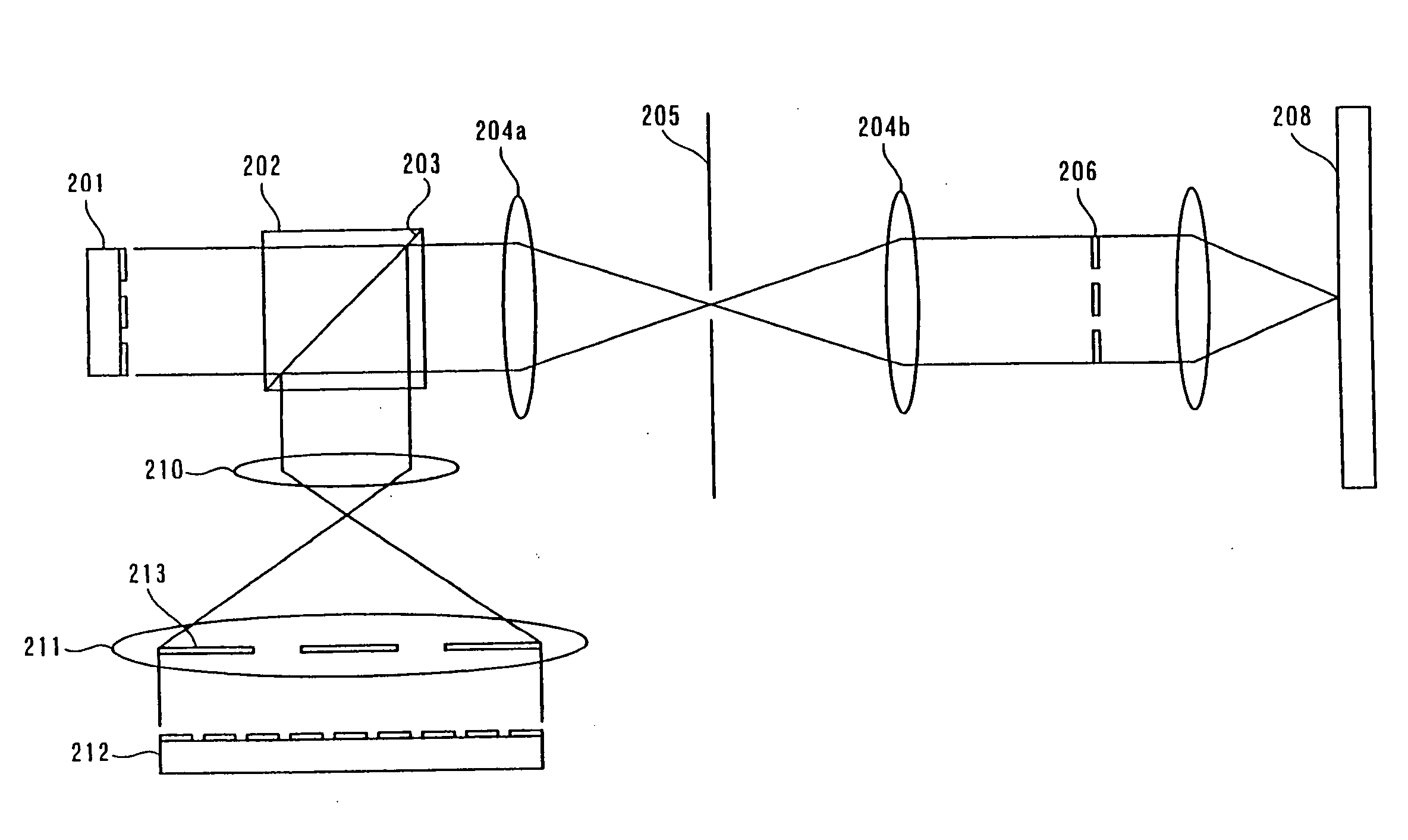

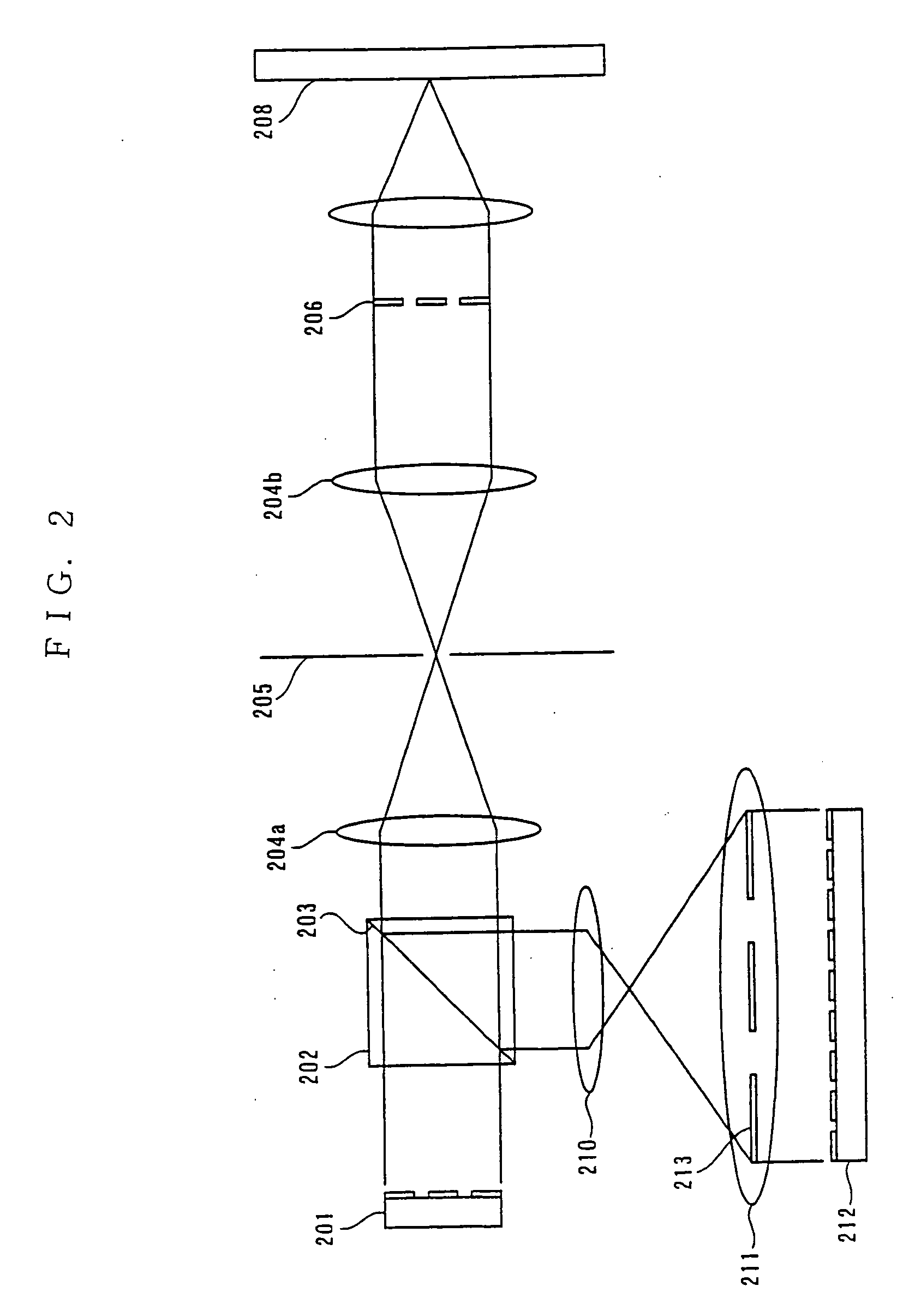

Information recording method, reproducing method, and recording/reproducing method utilizing holography

InactiveUS7321541B2Improve recording densityIncrease recording capacityRecord information storageDigital storageSpatial light modulatorRecording density

A method for recording information on a recording medium utilizing an interference pattern by interference between an information light modulated spatially with digital pattern information displayed on a spatial light modulator having multiple pixels and a reference light for recording. In order to provide a novel recording method capable of enhancing the recording density and the transfer rate furthermore, digital information to be recorded is represented by match / mismatch of the attributes of adjacent pixels in the spatial light modulator to produce digital pattern information.

Owner:OPTWARE

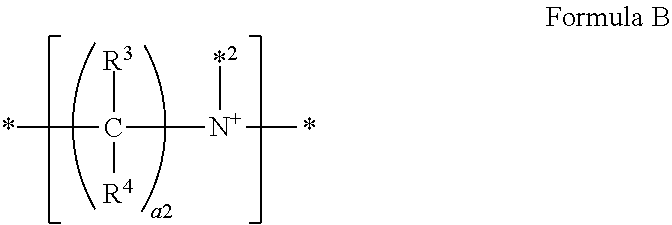

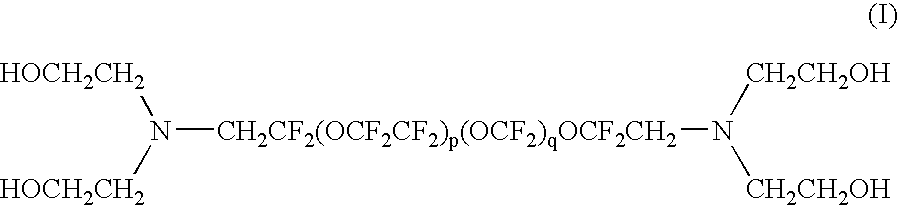

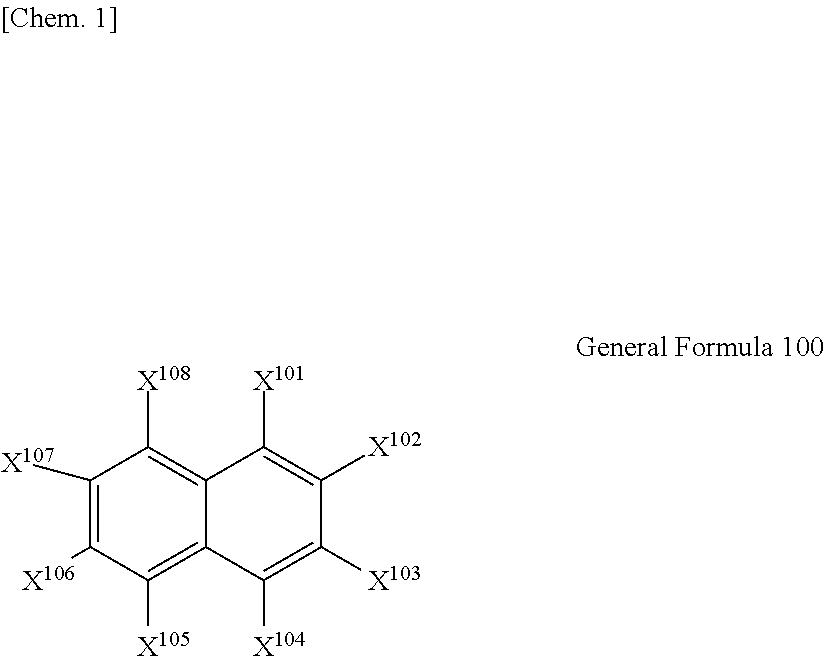

Magnetic recording disk and process for manufacture thereof

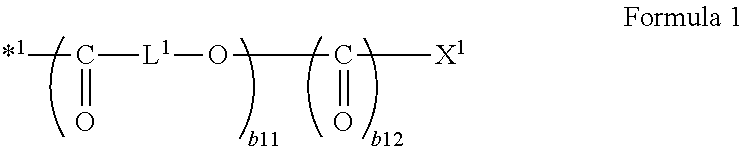

ActiveUS7045215B2Improve the lubrication effectImprove adhesionProtective coatings for layersSynthetic resin layered productsPerfluoropolyetherEther

A magnetic recording disk has a high-adhesion lubricant layer that permits an operation at an extremely low level of flying height of 12 nm or less without troubles and which is capable of preventing the migration at a high-speed rotation, and comprises a substrate, a magnetic layer formed on the substrate, a protective layer formed on the magnetic layer and a lubricant layer formed on the protective layer, the lubricant layer containing a compound (A) of the general formula (I), wherein each of p and q is an integer of 1 or more, anda compound (B) having a perfluoropolyether main chain having two end moieties each of which contains a carbon atom or an oxygen atom to which a hydroxyl-containing hydrocarbon group that optionally contains ether bond(s) is bonded, and a process for the manufacture thereof is provided.

Owner:WESTERN DIGITAL TECH INC

Information recording method, reproducing method, and recording reproducing method utilizing holography

InactiveUS20060050544A1Enhancement be weakenIncrease in number of pixelRecord information storageDigital storageRecording densityHolography

A method for recording information on a recording medium utilizing an interference pattern by interference between an information light modulated spatially with digital pattern information displayed on a spatial light modulator having multiple pixels and a reference light for recording. In order to provide a novel recording method capable of enhancing the recording density and the transfer rate furthermore, digital information to be recorded is represented by match / mismatch of the attributes of adjacent pixels in the spatial light modulator to produce digital pattern information.

Owner:OPTWARE

Head for thermal assisted magnetic recording device, and thermal assisted magnetic recording device

ActiveUS8243561B2Reduce in quantityIncrease recording capacityCombination recordingRecord information storageHeat-assisted magnetic recordingEngineering

In a head for thermal assisted magnetic recording device, a semiconductor laser is mounted so that the total height of the head does not become larger and light power fluctuation due to wavelength fluctuation occurs less frequently. In addition, the rise in temperature of the mounted semiconductor laser is suppressed. A semiconductor laser is placed on a side surface which is different from surfaces on an inflow end side and a trailing side, of four side surfaces of a floating slider. An entrance of a waveguide is placed on the side surface of the floating slider, to thereby cause emitted light from the semiconductor laser to directly enter the waveguide. A curved line part or a reflective mirror is formed in the middle of the waveguide so that the light which has entered the waveguide travels toward an optical near-field generating element.

Owner:HITACHI LTD

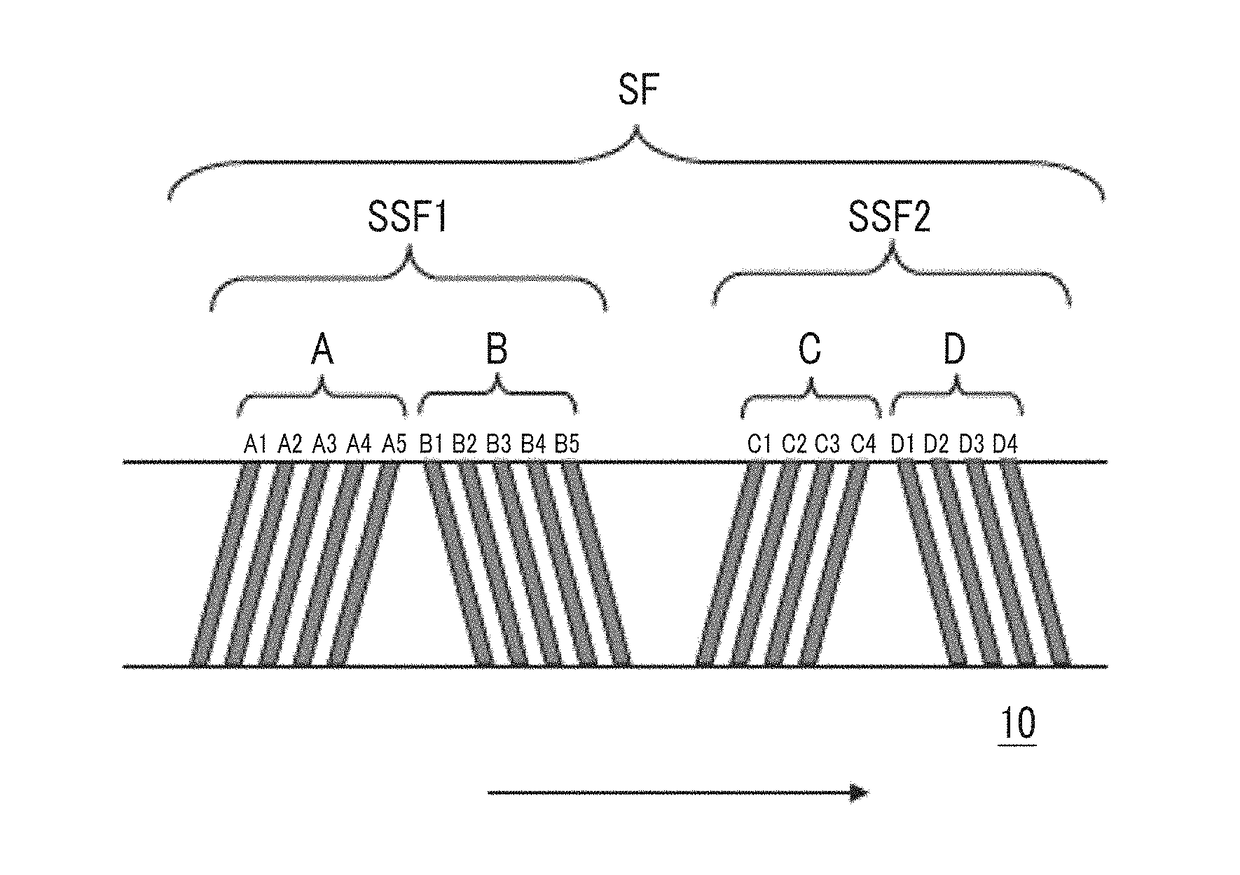

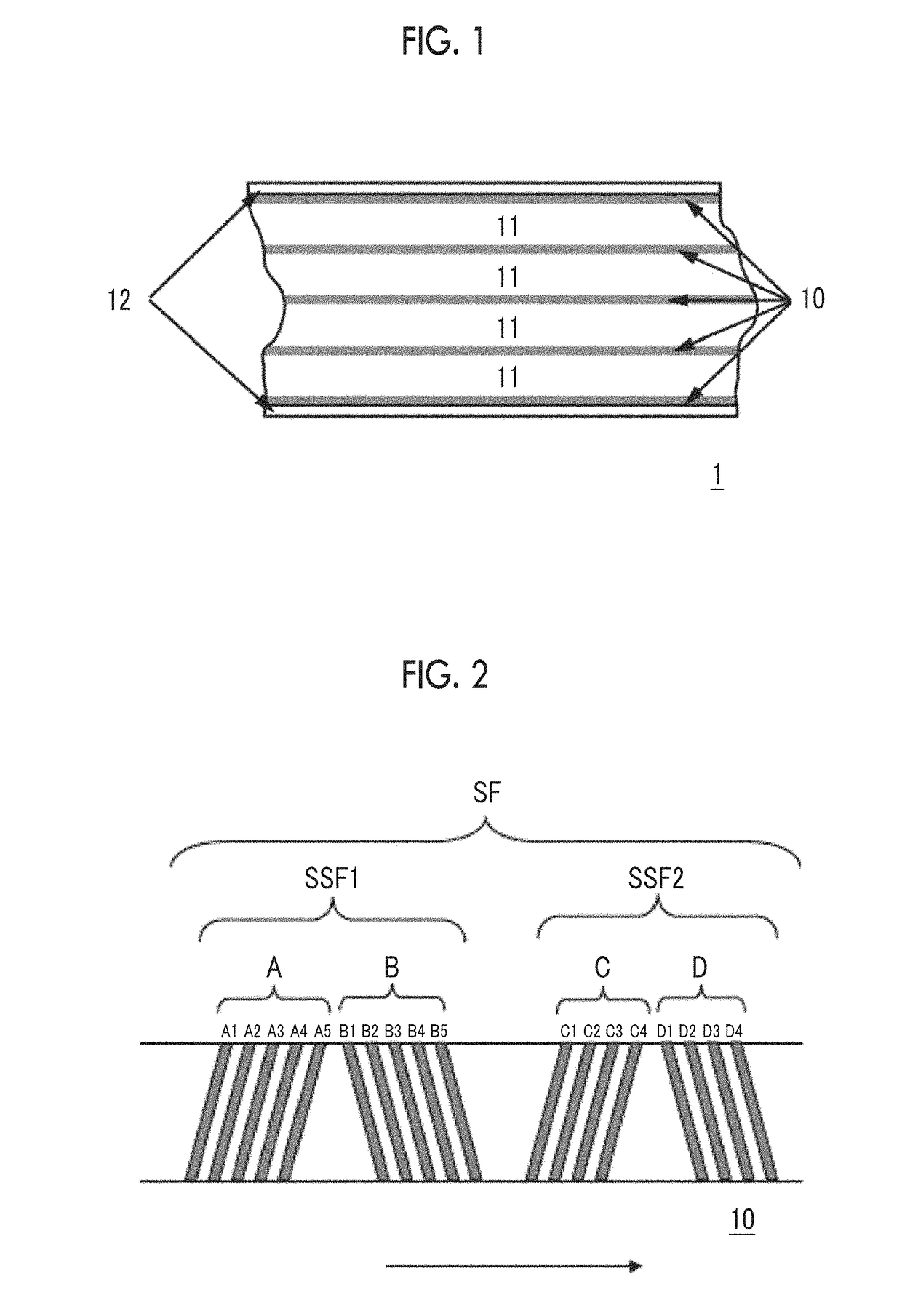

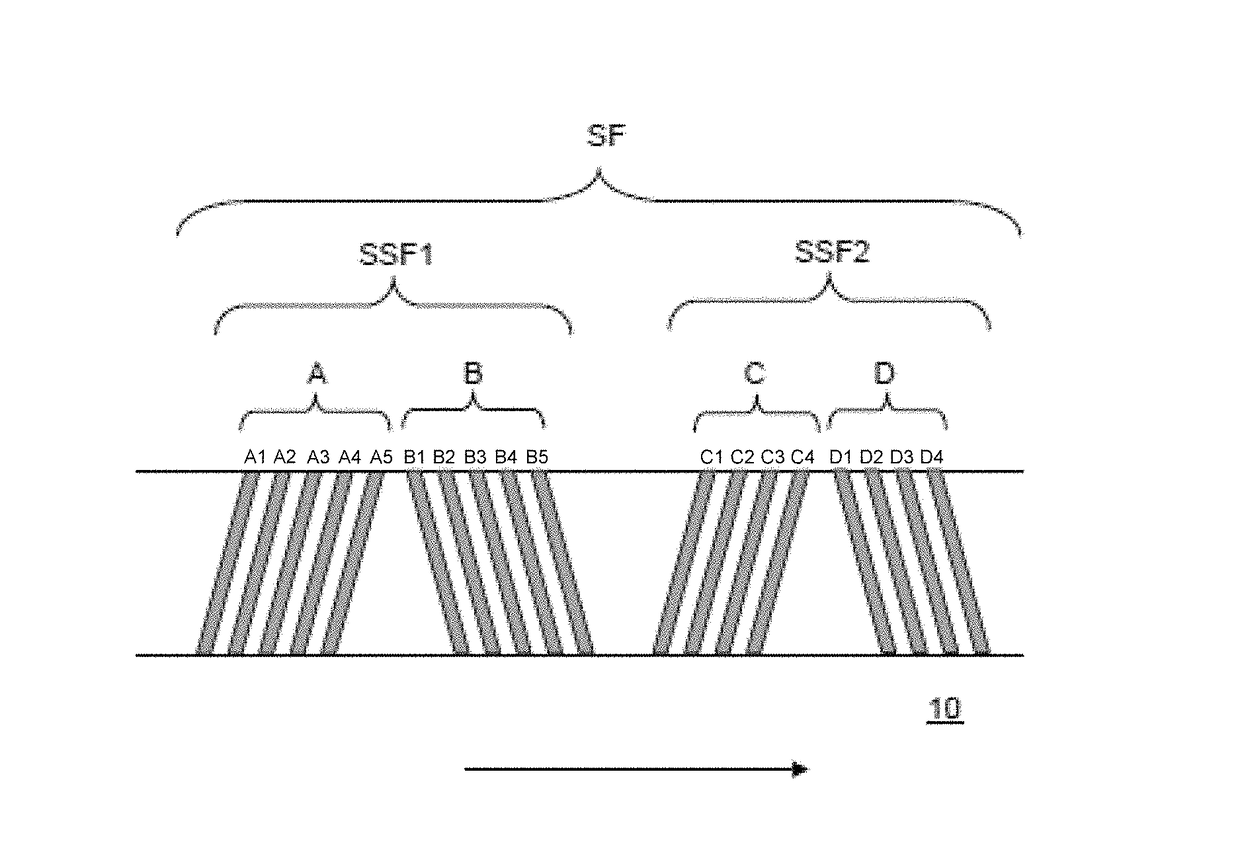

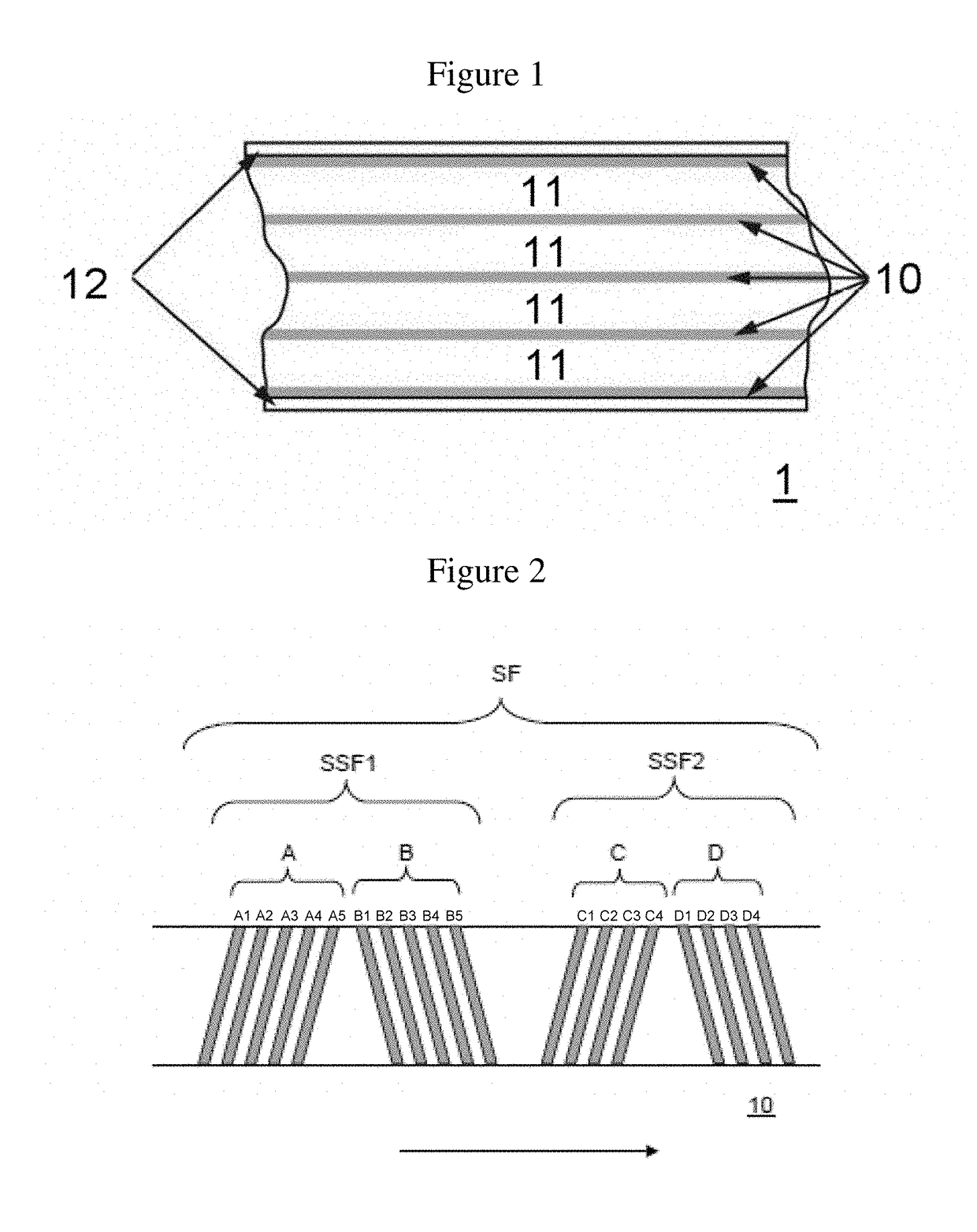

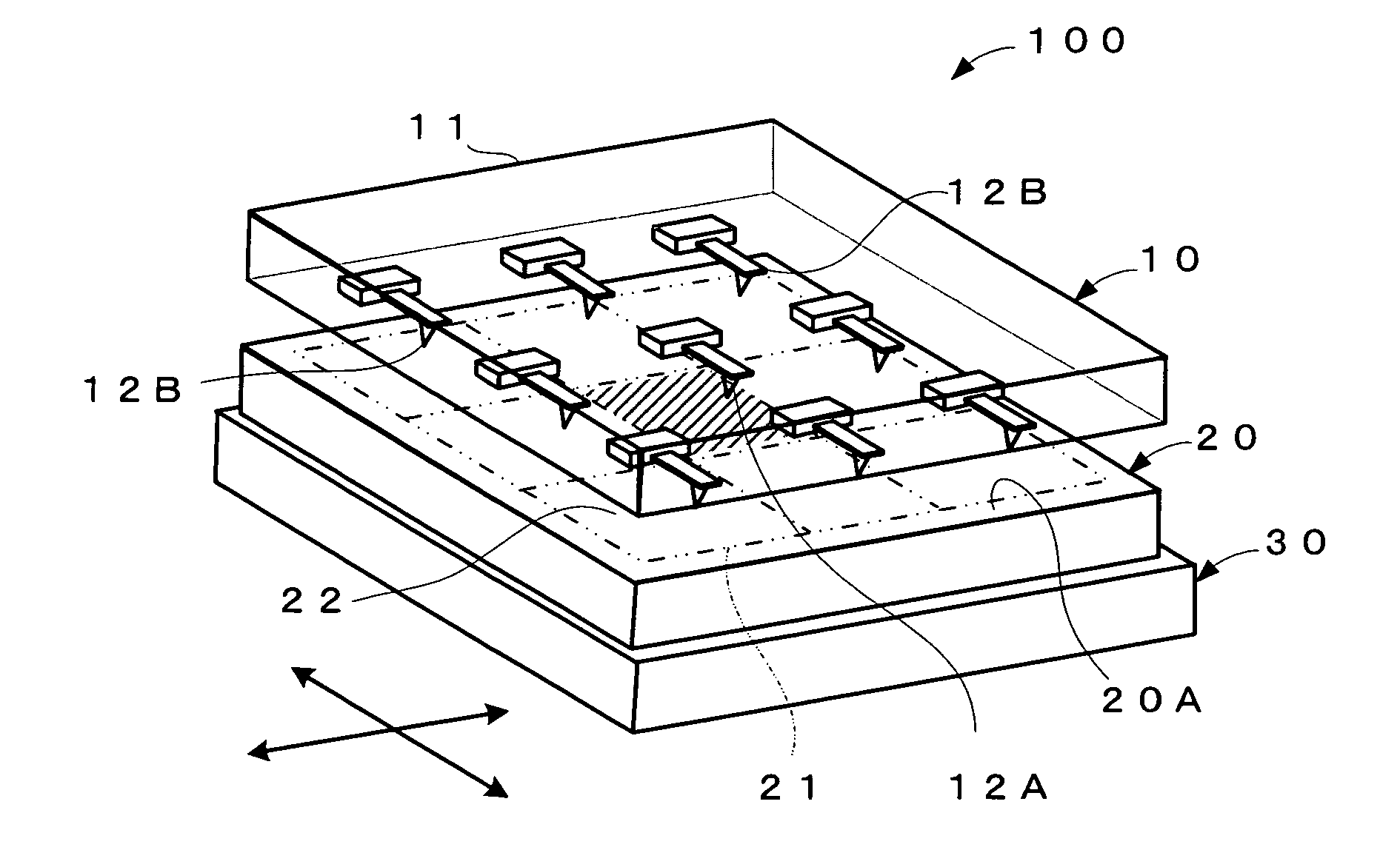

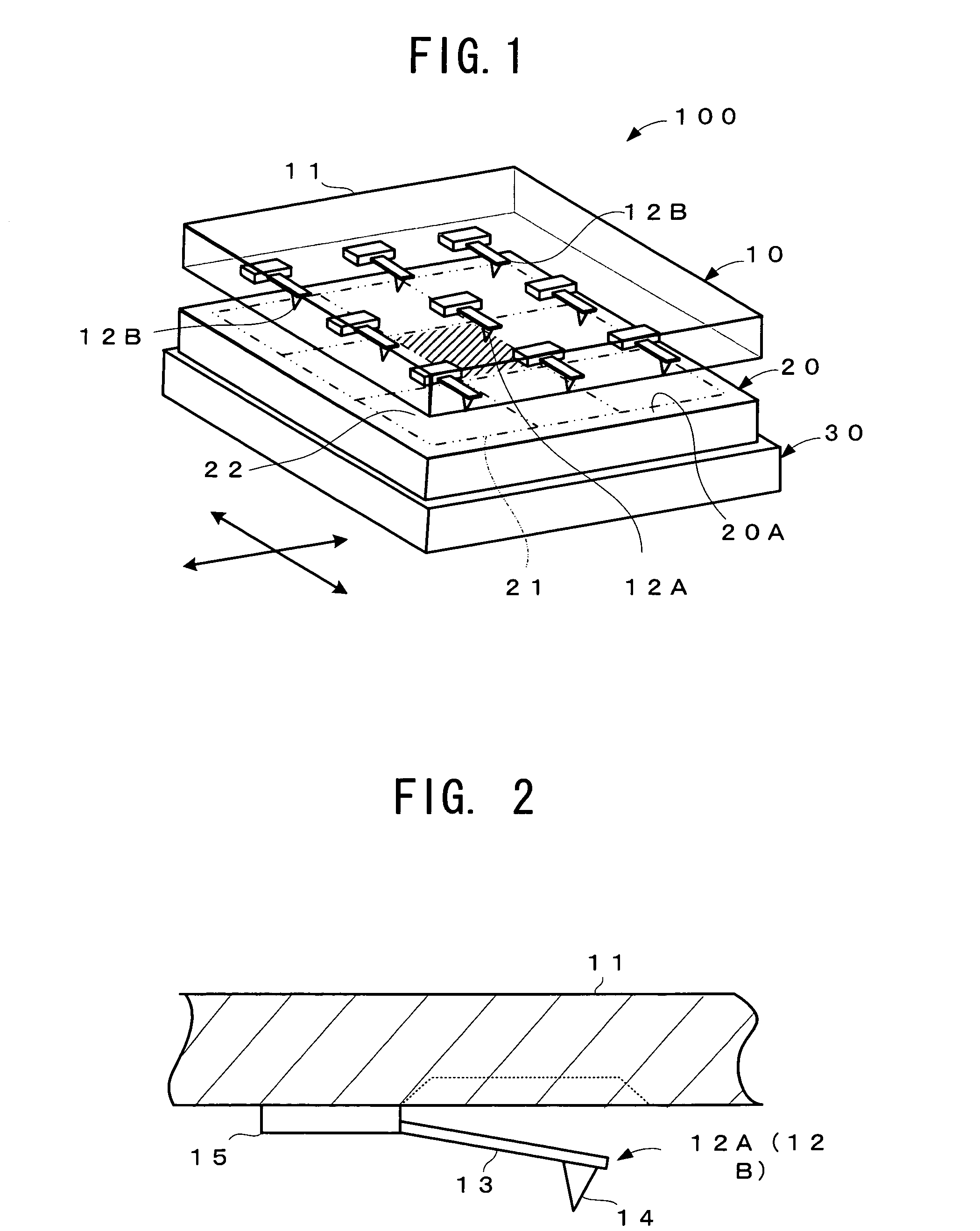

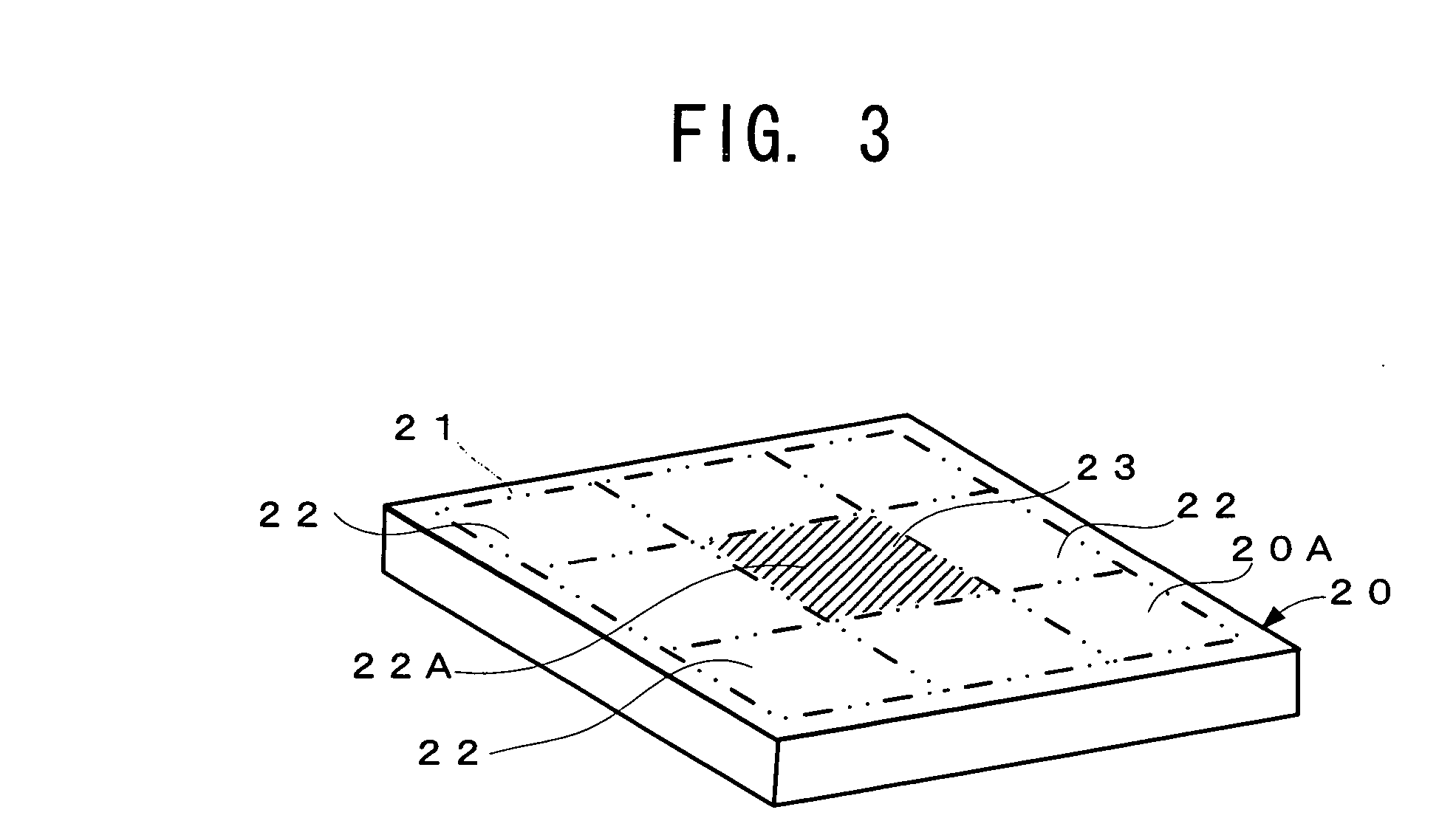

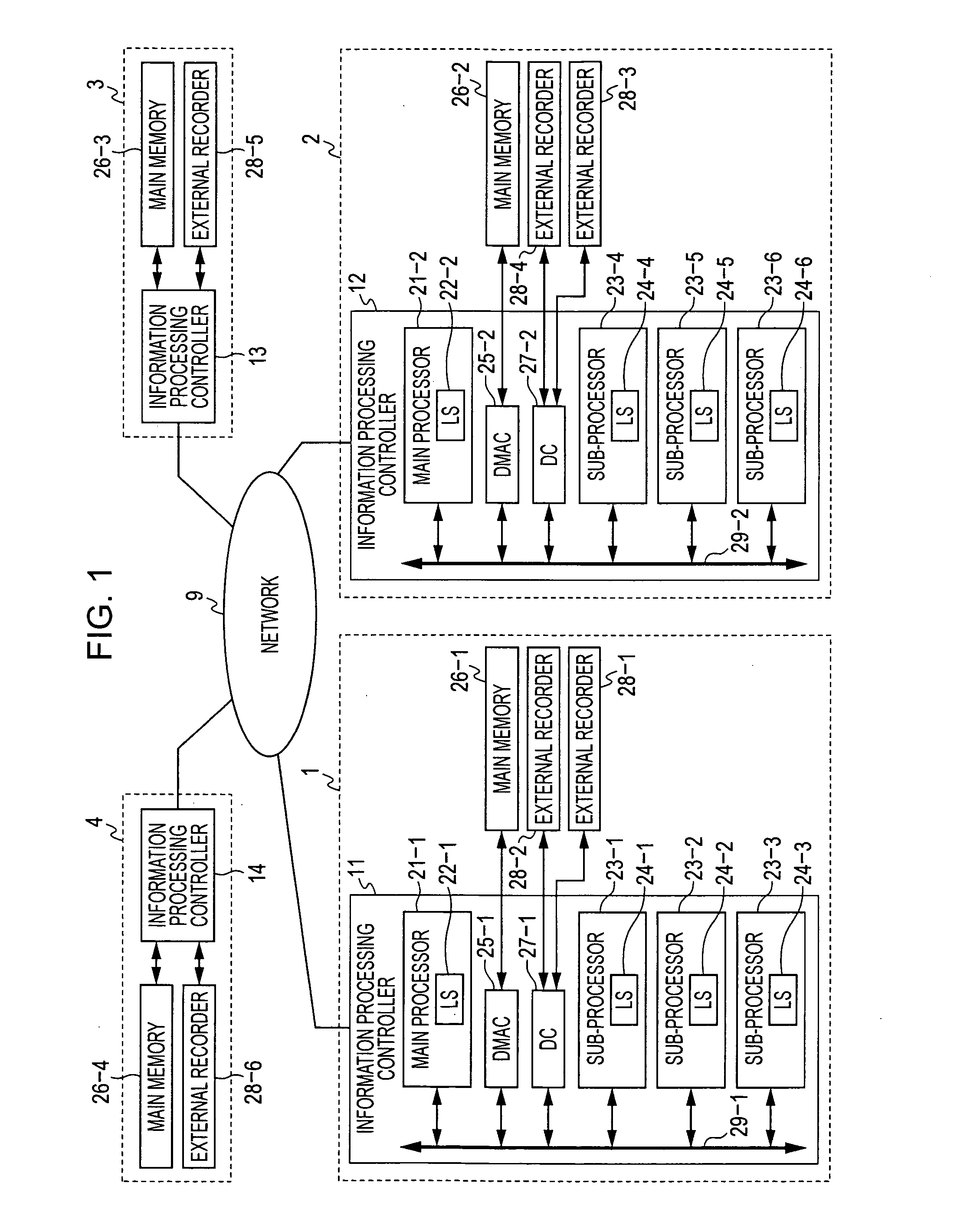

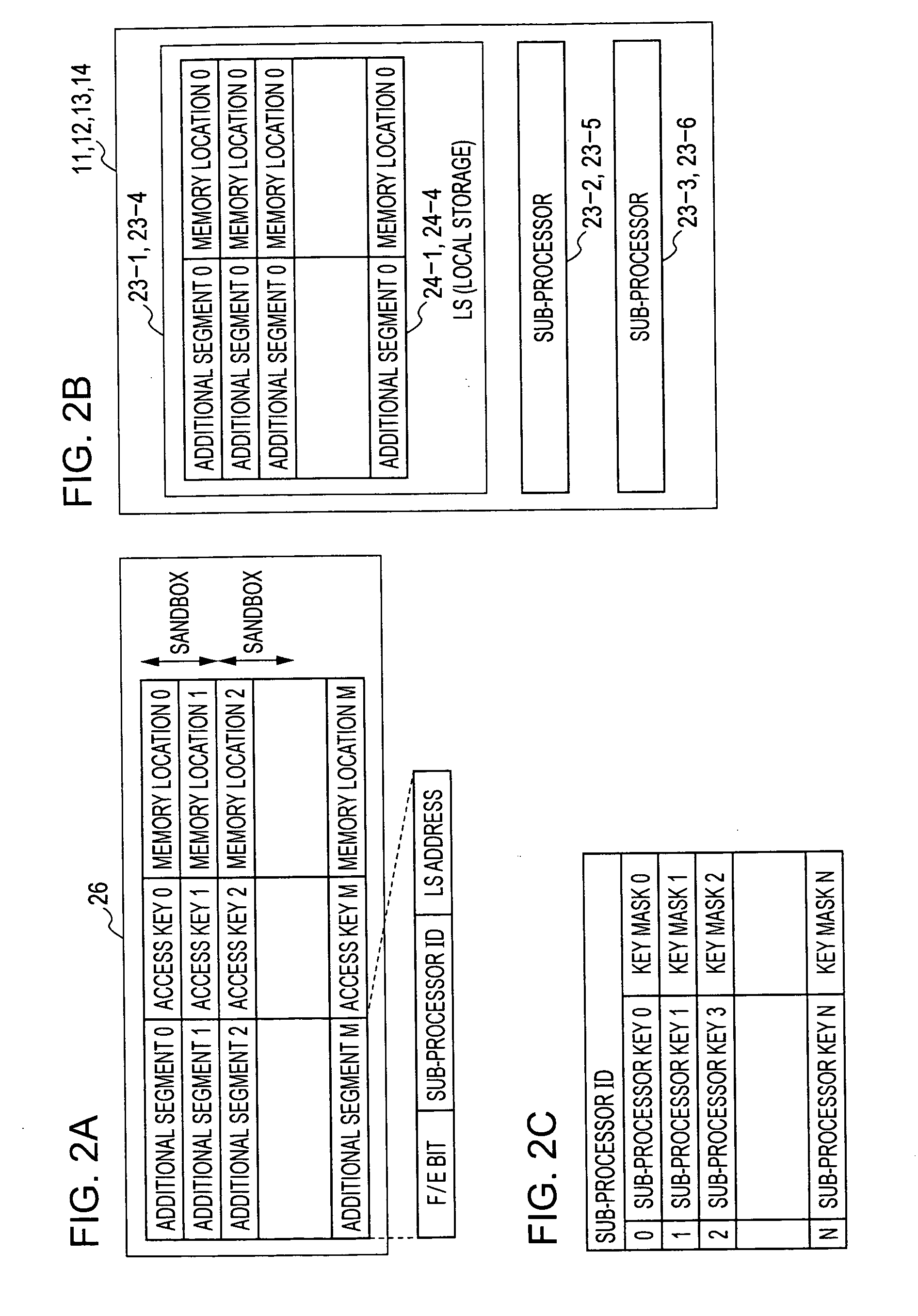

Data recording and reproducing device, data recording and reproducing method, and recording medium

InactiveUS20060182004A1Improve recording densityImprove reading resolutionNanoinformaticsRecord information storageData recordingCantilever

A position control area (76A) is partly formed in the recording area (75) of a recording medium (70) and position information is recorded only in the position control area (76A). To record data in the recording medium (70) by a head (60) having a plurality of cantilevers (62A), (62B), . . . , the position information is read by the cantilever (62E) corresponding to the position control area (76A) and, based on the position information, the positioning control or moving control of all the other cantilevers is performed.

Owner:PIONEER CORP

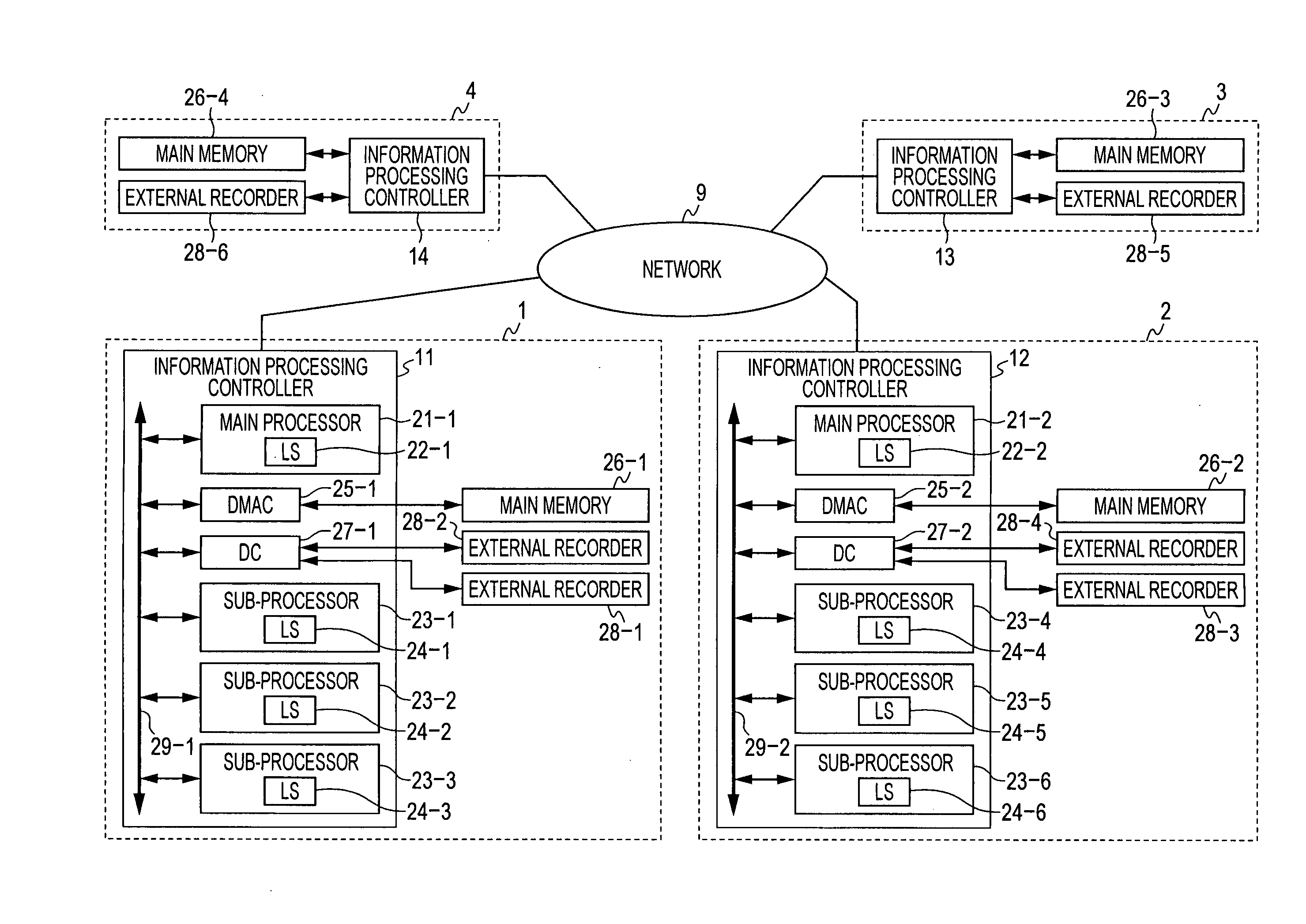

Content recording apparatus, content playback apparatus, content recording method, content playback method, and computer program

InactiveUS20060013566A1Increase the number ofIncrease recording capacityTelevision system detailsElectronic editing digitised analogue information signalsComputer networkComputer science

A content recording apparatus for communicating with a content playback apparatus via a network, includes a first receiver for receiving, from the content playback apparatus, information related to a content segment to be received by the content playback apparatus, the content segment being a portion of a single content, an attaching unit for attaching, to the content segment, a content identification identifying the content segment based on the received related information, a second receiver for receiving, from the content playback apparatus, the content segment received by the content playback apparatus, a recorder for recording the received content segment with both the content identification and the related information associated with the received content segment, and a synthesizer for synthesizing, into the single content, content segments having the same content identification.

Owner:SONY CORP

Magnetic tape, magnetic tape cartridge, and magnetic tape apparatus

ActiveUS20200126589A1Deterioration in electromagnetic conversionIncrease recording capacityMagnetic materials for record carriersRecord information storageZeta potentialIonogram

The magnetic tape includes a non-magnetic support; a non-magnetic layer including a non-magnetic powder and a binding agent on the non-magnetic support; and a magnetic layer including a ferromagnetic powder and a binding agent on the non-magnetic layer, in which a total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, an isoelectric point of a surface zeta potential of the magnetic layer is equal to or greater than 5.5, the magnetic layer includes an oxide abrasive, and an average particle diameter of the oxide abrasive obtained from a secondary ion image obtained by irradiating the surface of the magnetic layer with a focused ion beam is 0.04 μm to 0.08 μm.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS10403317B2Increase recording capacityHigh capacity)Magnetic materials for record carriersRecord information storageMagnetic tapeX-ray

The magnetic tape device includes a magnetic tape and a TMR head, in which the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, an intensity ratio of a peak intensity Int(110) of a diffraction peak of a (110) plane with respect to a peak intensity Int(114) of a diffraction peak of a (114) plane of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, and a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00.

Owner:FUJIFILM CORP

Magnetic tape having characterized magnetic layer, tape cartridge, and recording and reproducing device

ActiveUS10403319B2Reduce thicknessIncrease recording capacityRecord information storageTape carriersMagnetic tapeNon magnetic

The magnetic tape includes a nonmagnetic layer containing nonmagnetic powder and binder on a nonmagnetic support, and a magnetic layer containing ferromagnetic powder, abrasive, and binder on the nonmagnetic layer, wherein a thickness of the nonmagnetic layer is less than or equal to 0.50 μm, a coefficient of friction as measured on a base portion of a surface of the magnetic layer is less than or equal to 0.35, and ΔSFD in a longitudinal direction of the magnetic tape as calculated with Equation 1, ΔSFD=SFD25° C.−SFD−190° C., is greater than or equal to 0.50, wherein, in Equation 1, SFD25° C. denotes a SFD as measured in the longitudinal direction of the magnetic tape in an environment with a temperature of 25° C., and SFD−190° C. denotes a SFD as measured in the longitudinal direction of the magnetic tape in an environment with a temperature of −190° C.

Owner:FUJIFILM CORP

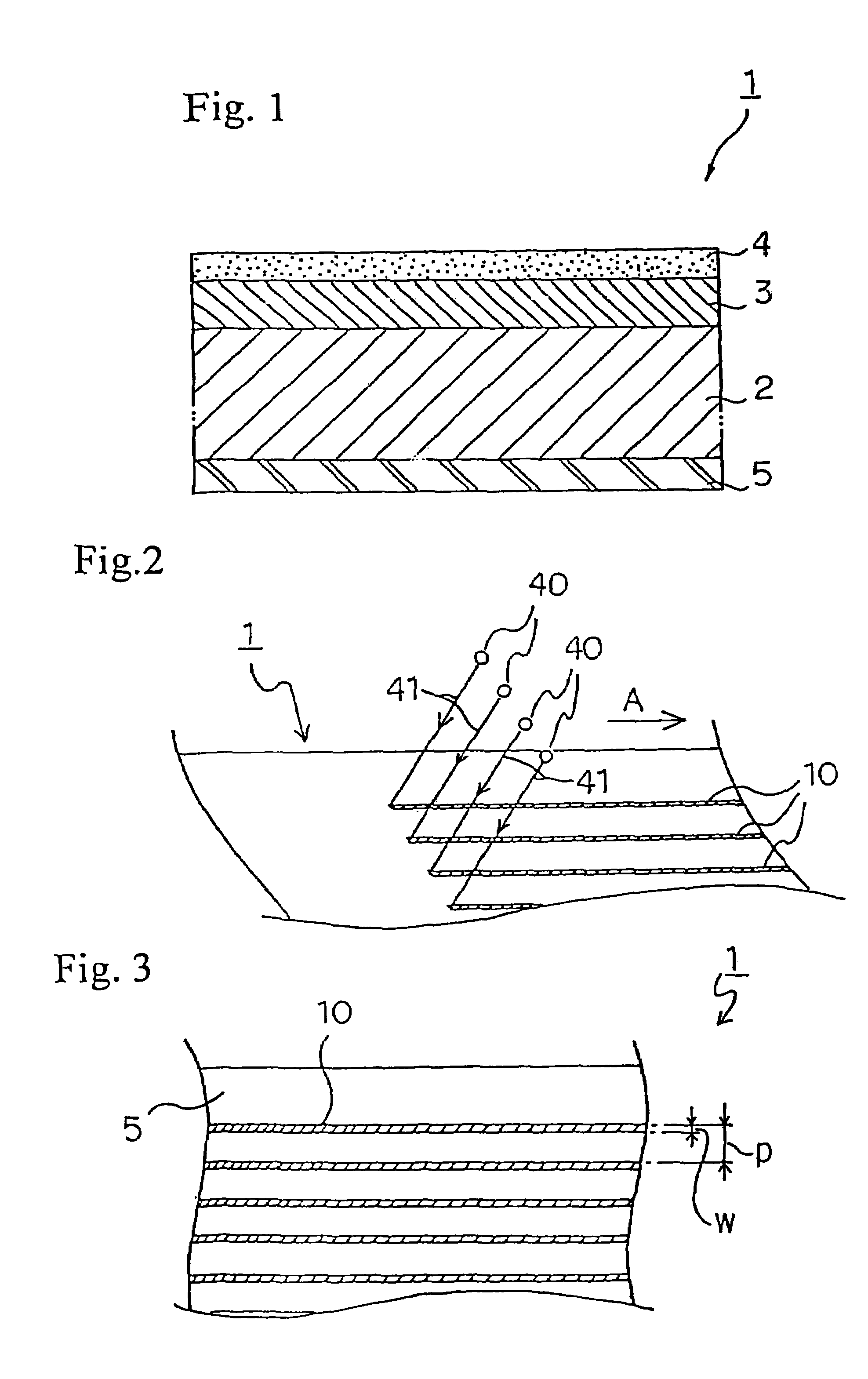

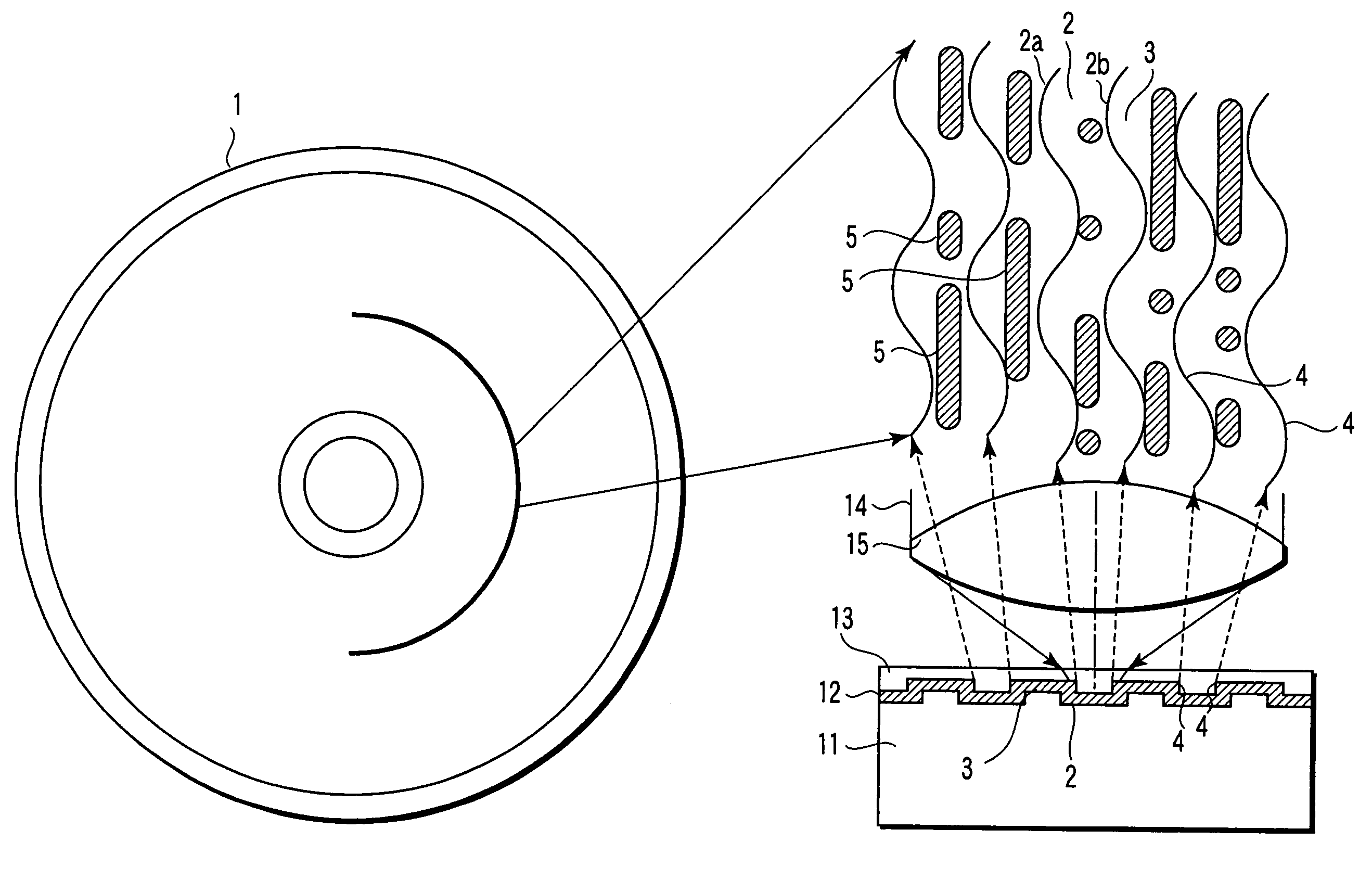

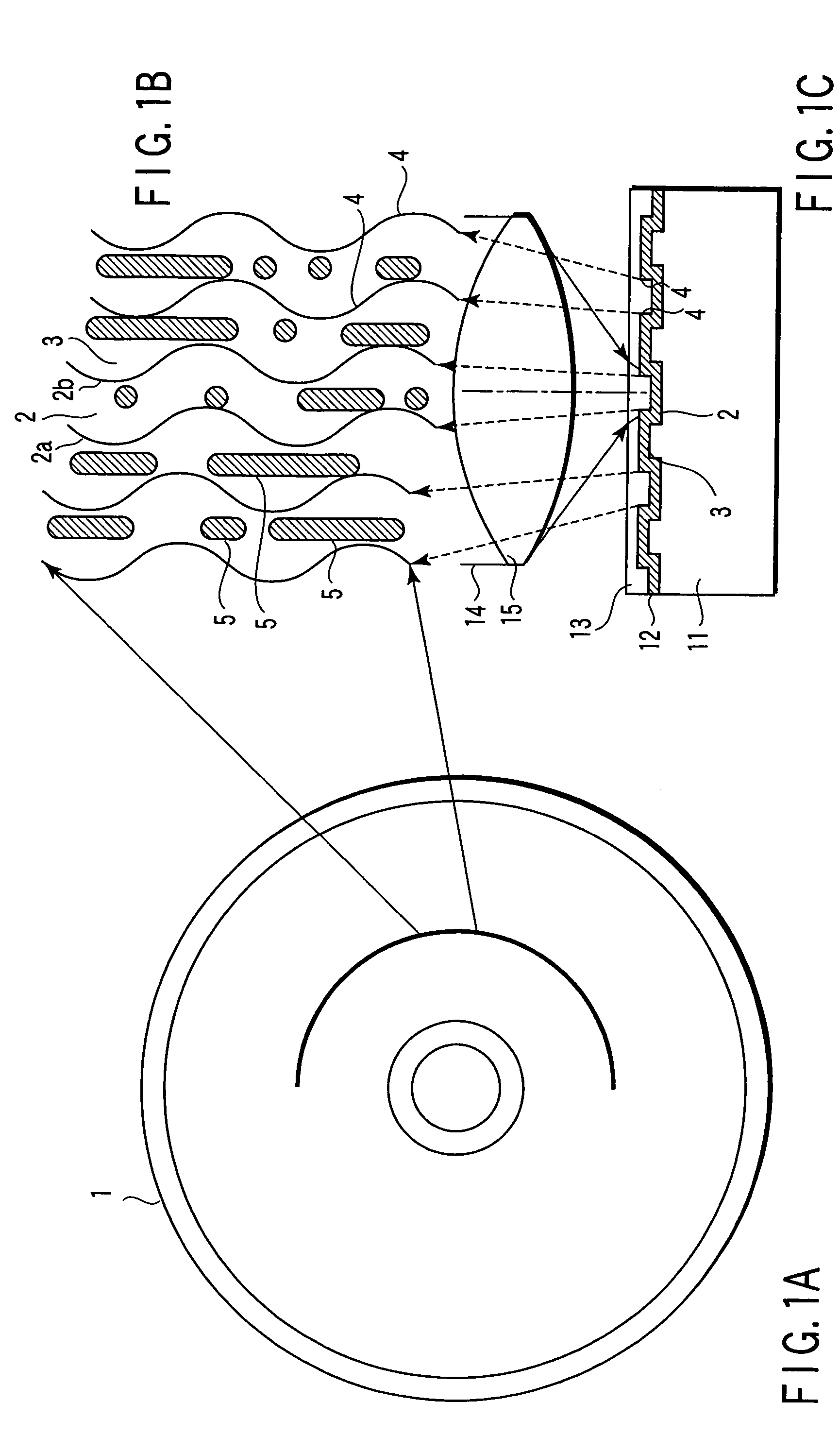

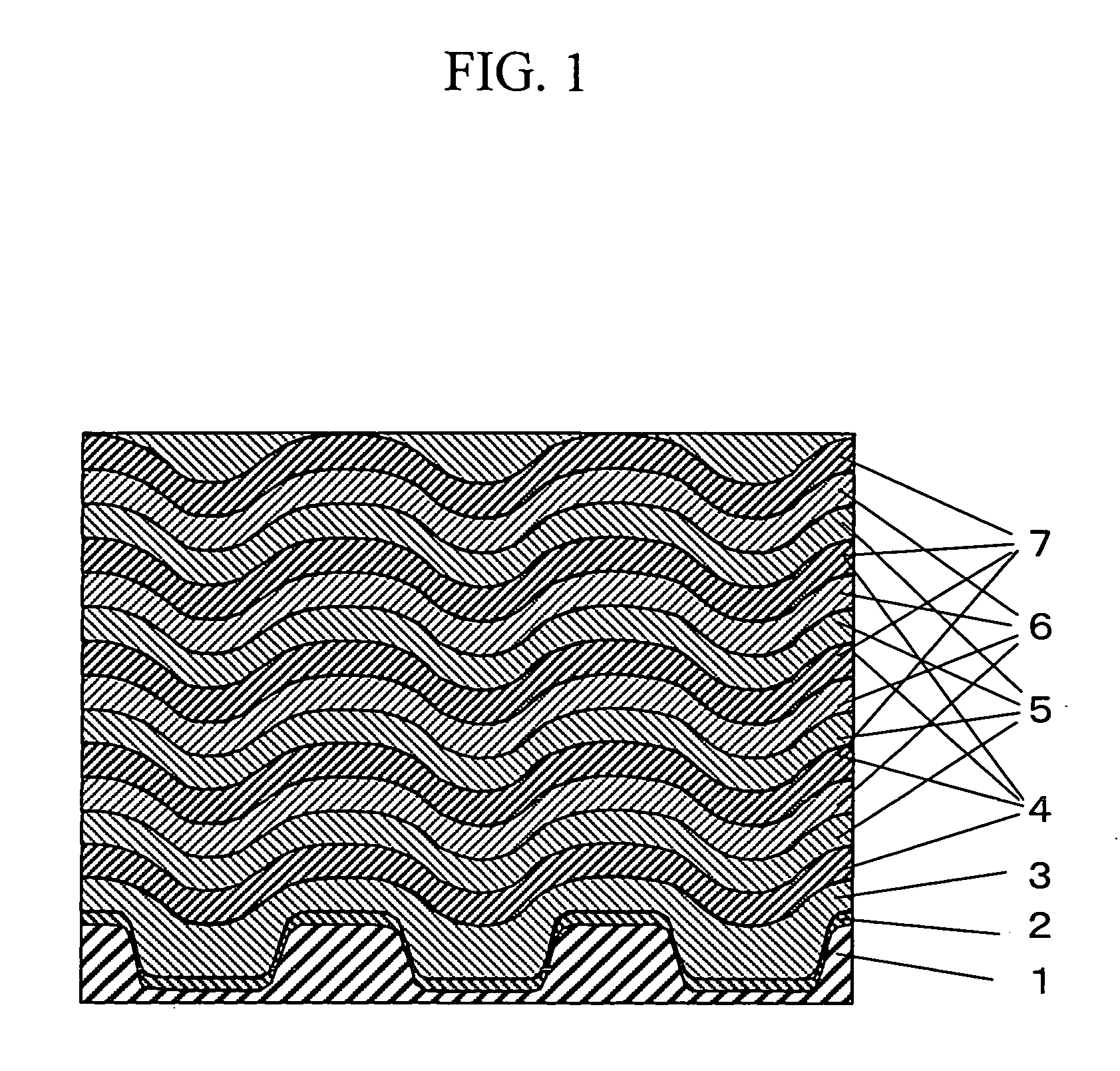

Information recording medium and information recording/ reproducing device and method

InactiveUS20050122890A1Increase recording capacityIncrease capacityRecord information storageDigital recordingEngineeringRecording media

An information storage medium (1) has tracks in which information is recorded. The tracks are formed as a groove section (2) and a land section (3). The groove section (2) has a synchronous structure in which wobbles (2a) and (2b) formed on both walls of the groove section (2) are not displaced from each other in the circumferential direction of the medium, and the land section (3) has an asynchronous structure in which wobbles formed on both sides of the land section (3) are displaced from each other. A good signal is reproduced from each of the groove and land sections.

Owner:KK TOSHIBA

Magnetic recording head

ActiveUS8264799B2Improve recording densityIncrease recording capacityRecord information storageManufacture of flux-sensitive headsPower flowMagnetization

A magnetic device includes a first magnetic layer having at least one magnetic material layer, a second magnetic layer having at least one magnetic material layer, a first nonmagnetic layer provided between the first magnetic layer and the second magnetic layer, a third magnetic layer including a ferromagnetic material with a fixed magnetization direction, and a pair of electrodes. The pair of electrodes are operable to pass a current through a laminated body including the first and second magnetic layers, the nonmagnetic layer, and the third magnetic layer.

Owner:KK TOSHIBA

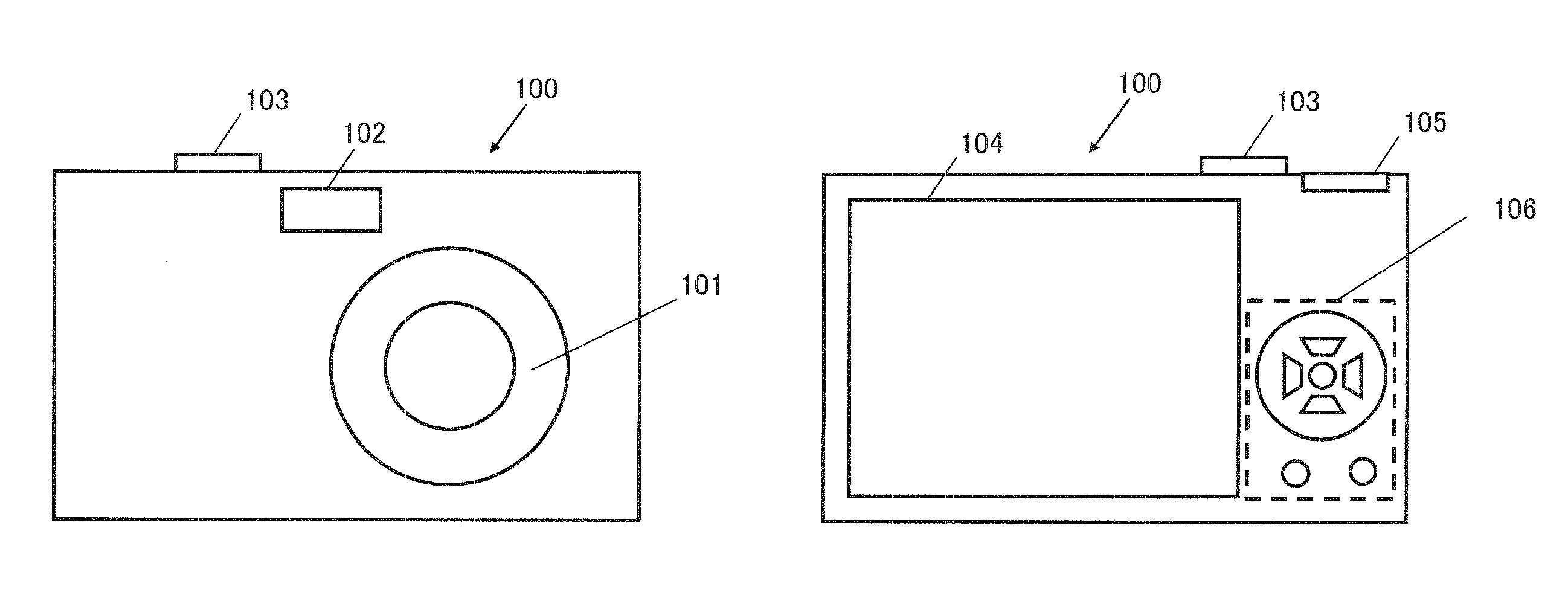

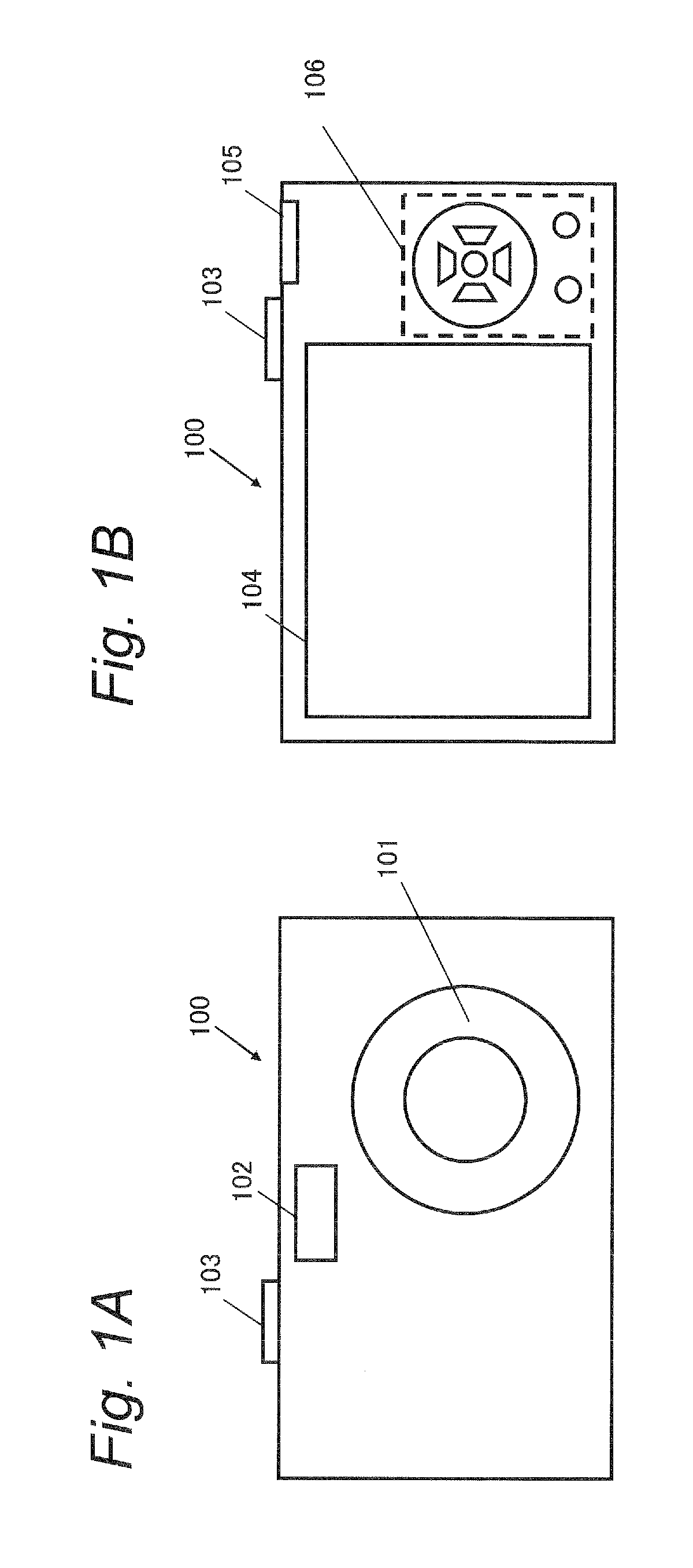

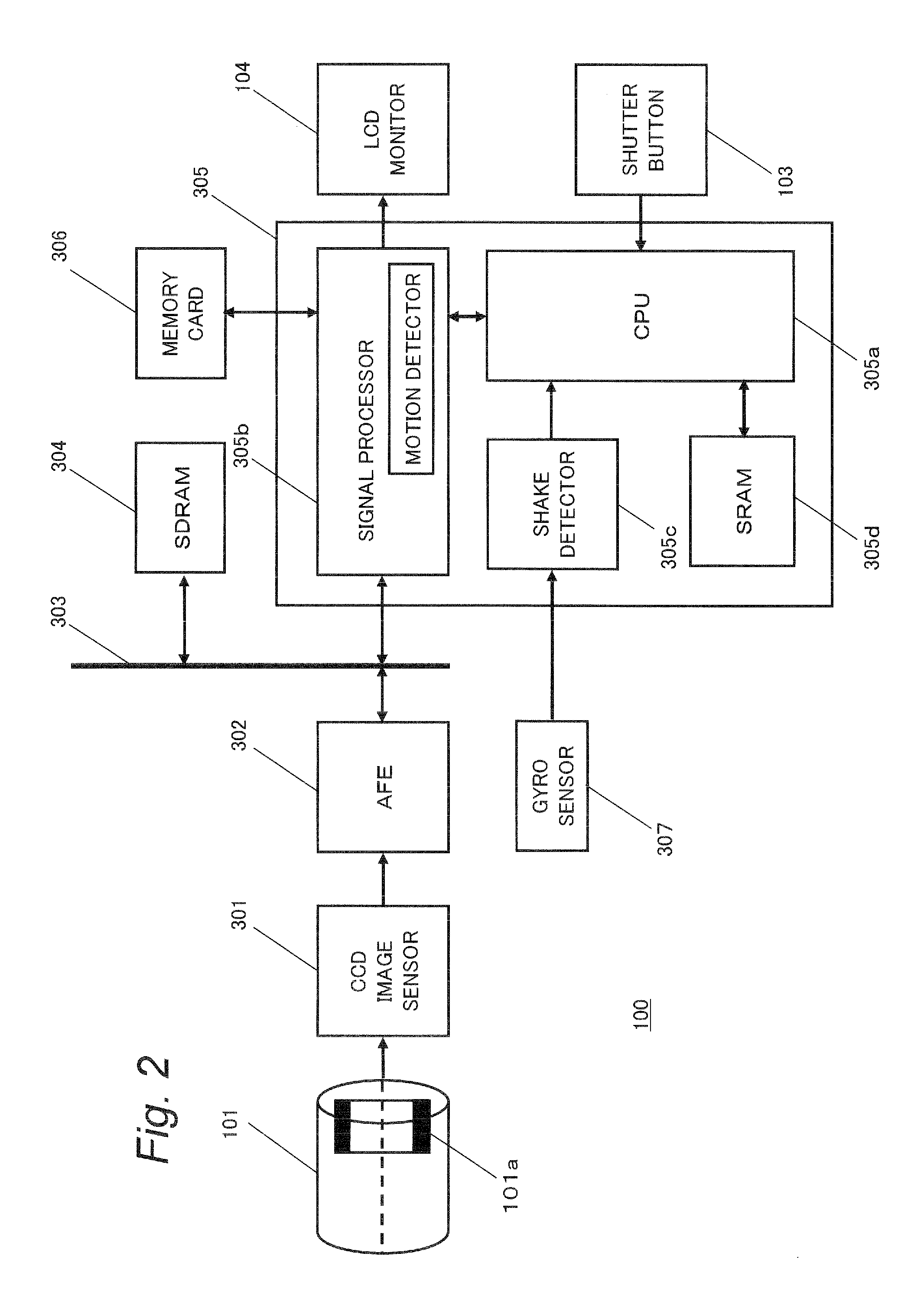

Imaging apparatus

InactiveUS20110279691A1Less catchEasy to captureTelevision system detailsPicture signal generatorsImaging equipmentImage signal

An imaging apparatus having a continuous shooting function includes an imaging unit configured to generate an image signal based on an optical signal of a subject, a storage unit configured to store an image file based on the image signal, a first detector configured to detect a motion of the imaging apparatus, and a controller configured to control a capturing interval of the imaging unit for capturing an image in a continuous shooting operation based on a detecting result of the first detector so that the capturing interval for a magnitude of the motion of the imaging apparatus which is larger than a predetermined value is shorter than the capturing interval for the magnitude of the motion of the imaging apparatus which is smaller than the predetermined value.

Owner:PANASONIC CORP

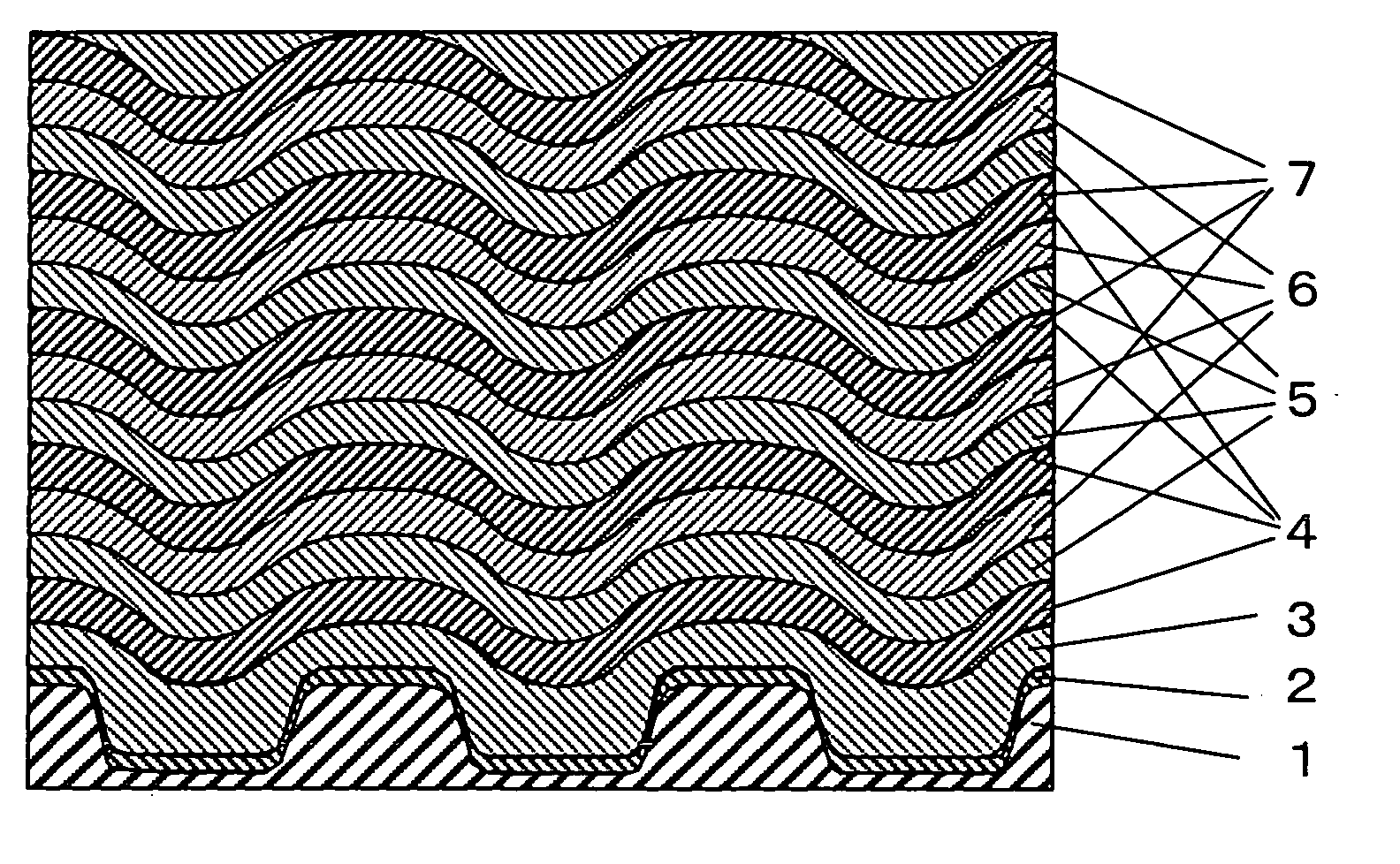

Information recording medium and manufacturing process

InactiveUS20050276211A1Ensure electrical connection reliabilityHigh speed recordingMechanical record carriersRecord information storageInformation layerOrganic film

An information recording medium and manufacturing method for high-speed and high density recording. An inorganic film is formed by sputtering while applying a bias voltage to shift the substrate voltage potential in the negative direction, or a laminated film is formed by applying energy after coating a substrate with an organic film, and the irregularities maintained even after the laminated film is formed, so that stable, high-capacity and high-speed recording can be attained by forming a multi-information-layer that still retains the irregularities.

Owner:HITACHT MAXELL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com