Patents

Literature

641results about How to "Deterioration of characteristic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

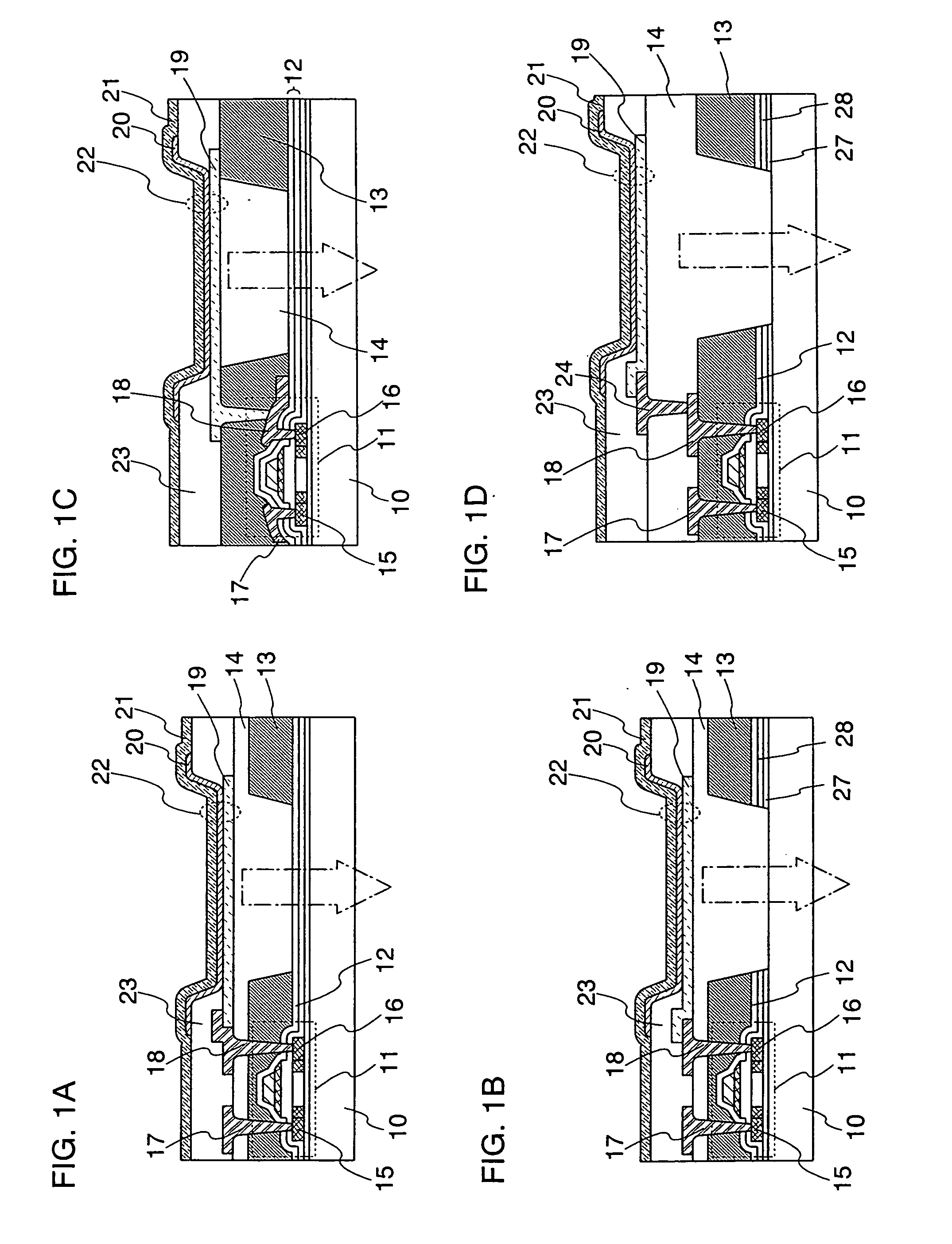

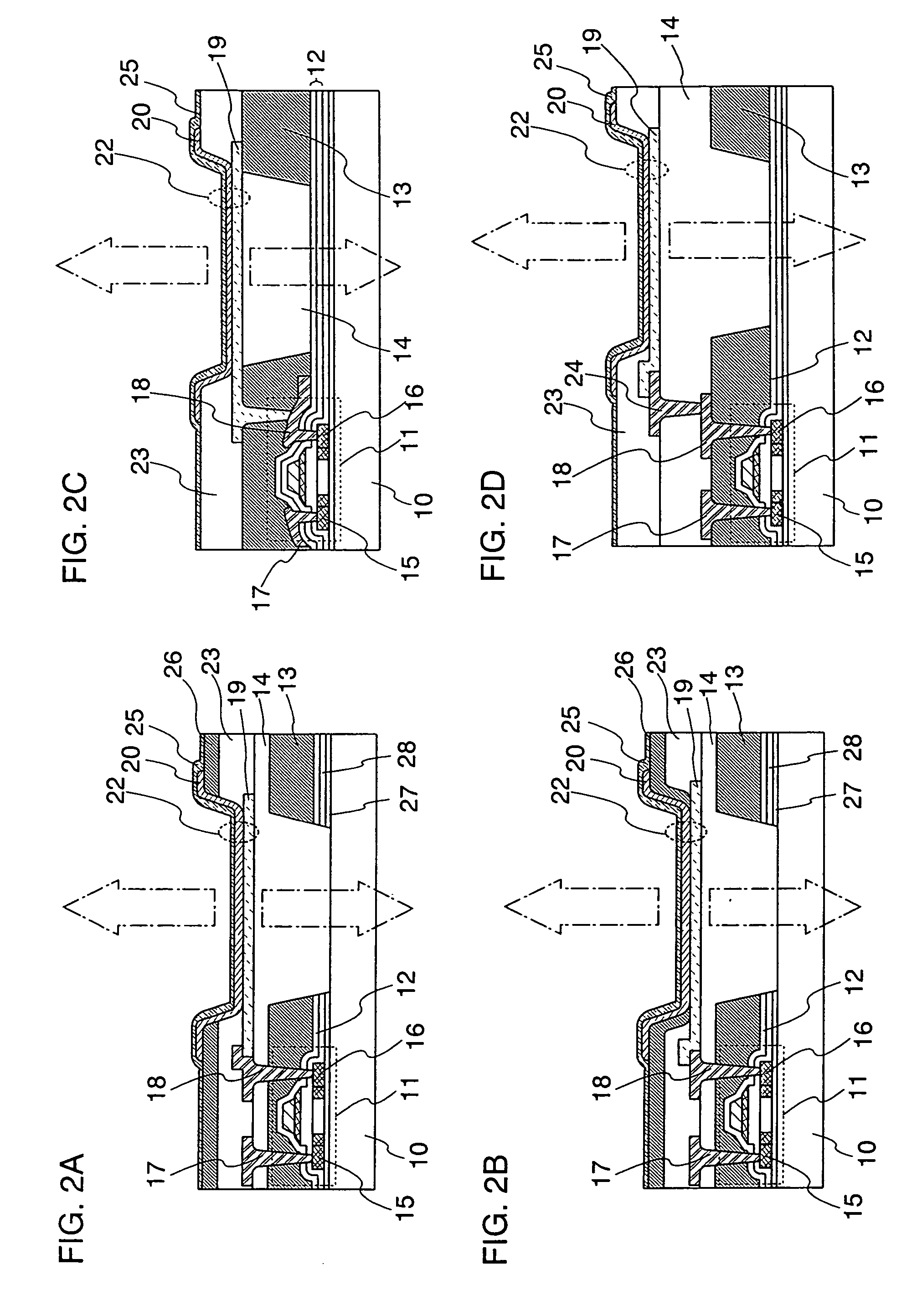

Emissive element and display device using such element

InactiveUS6246179B1Avoid it happening againLayer deterioratesDischarge tube luminescnet screensStatic indicating devicesDisplay deviceOptoelectronics

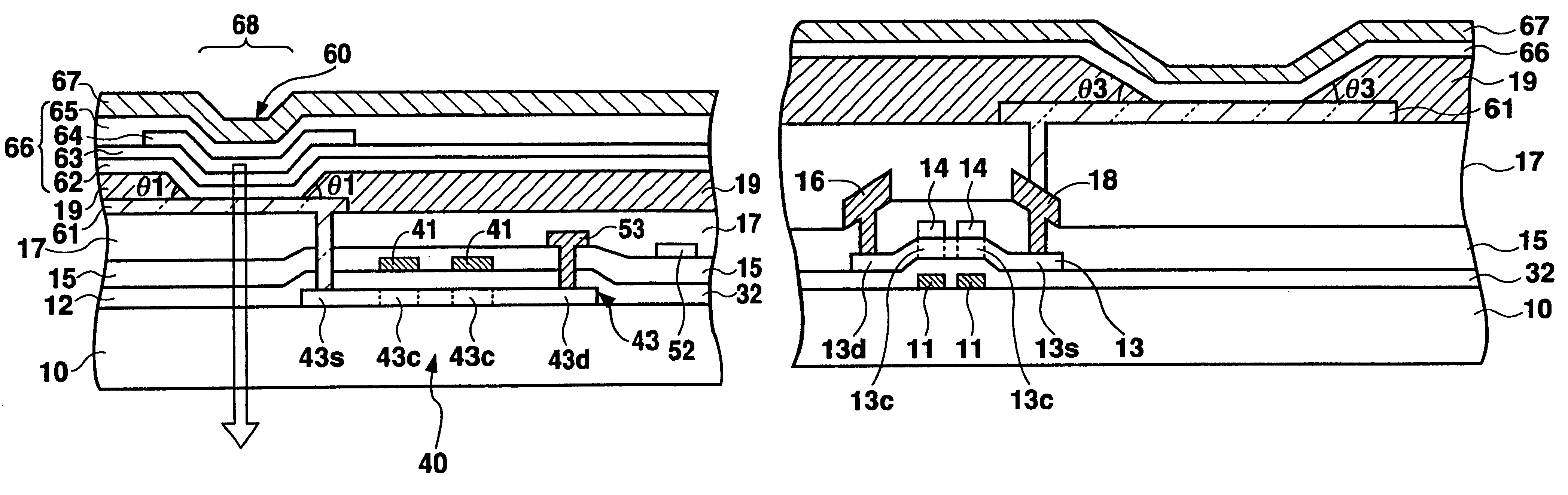

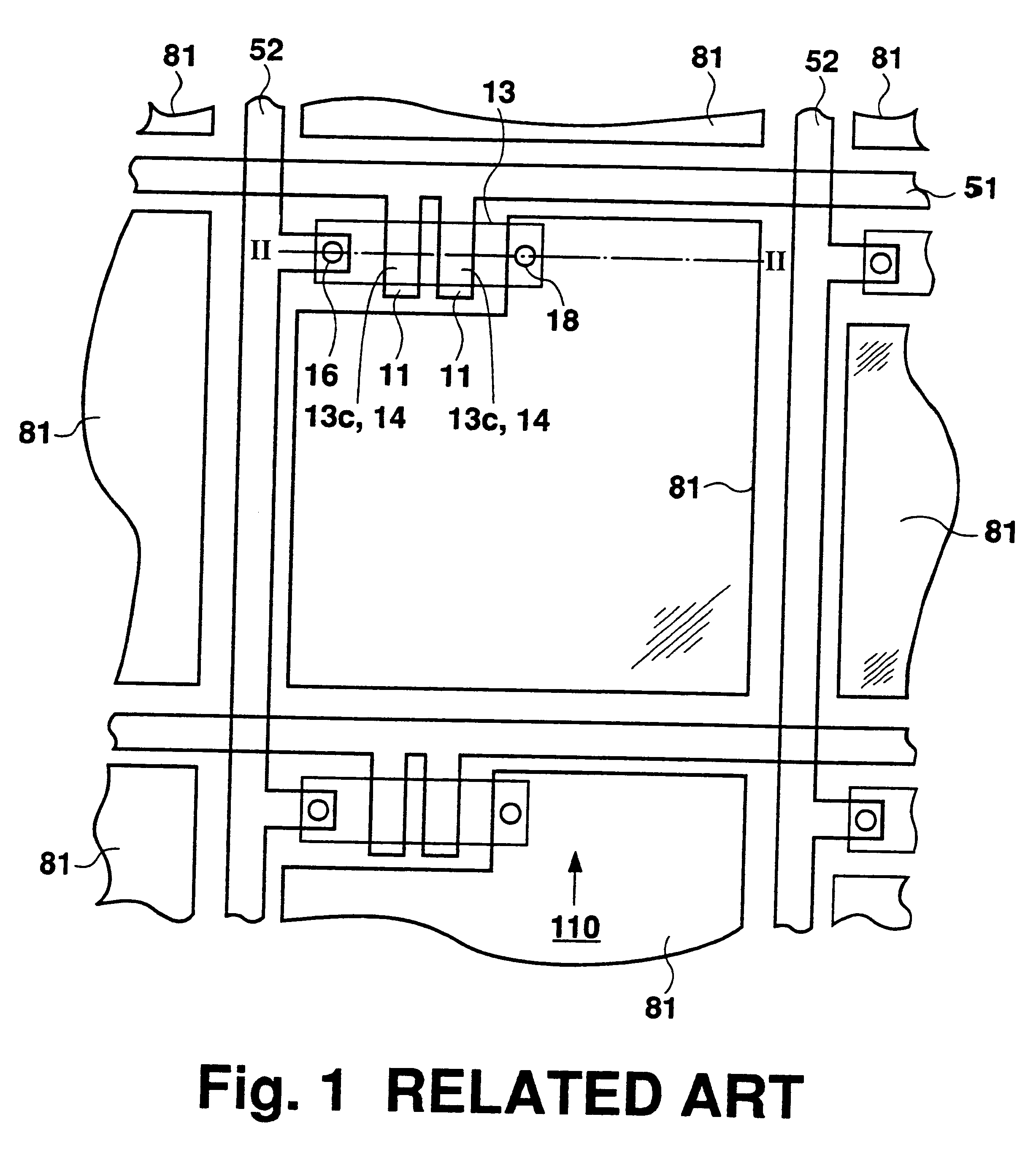

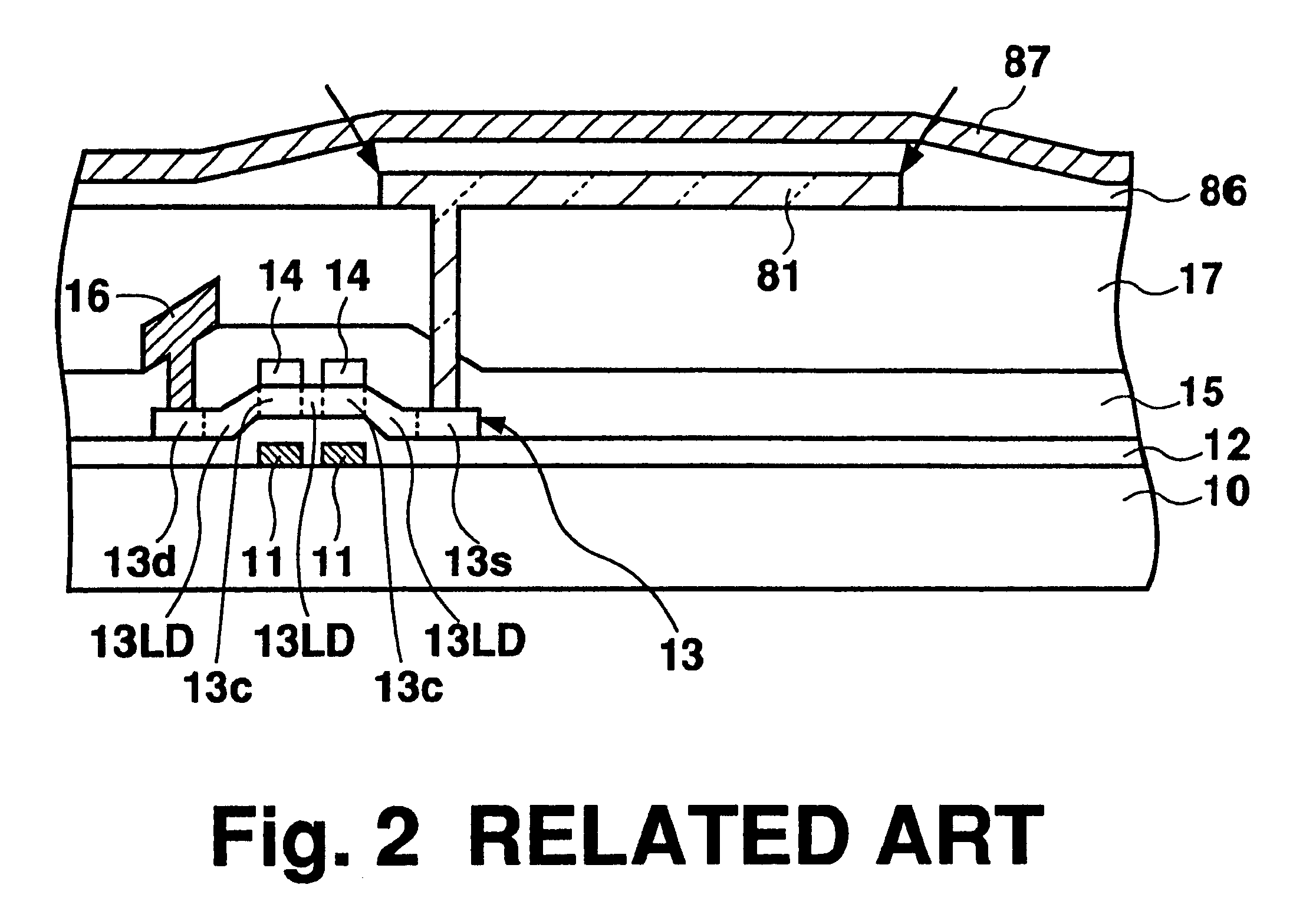

An EL element (60) comprises an anode (61), a cathode (67), and an emissive element layer (66) interposed between the two electrodes. A TFT is connected to the anode (61) at its source electrode (33s). The peripheral portion of the anode (61) and the entire region over the TFT are covered with a planarizing insulating film (17), and a part of the exposed portion of the anode (61) is connected to the emissive element layer (66). According to the above arrangement, it is possible to prevent disconnection of the emissive element layer (66) which may be caused by an uneven surface created by the thickness of the anode (61), and to avoid formation of a short circuit between the anode (61) and the cathode (67).

Owner:SANYO ELECTRIC CO LTD

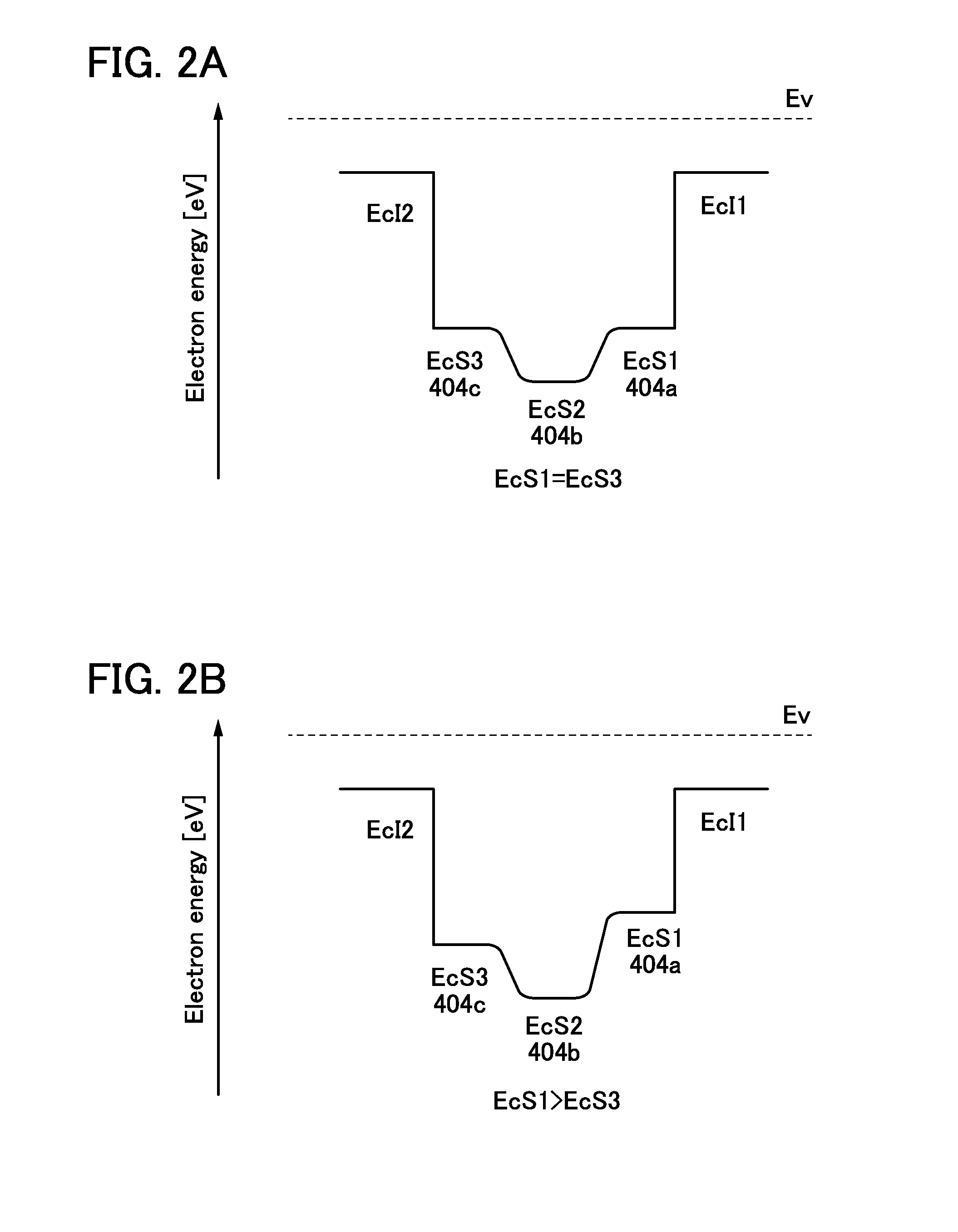

Liquid crystal display device

InactiveUS20080062112A1Deterioration in characteristic can be suppressedDeterioration of characteristicStatic indicating devicesSolid-state devicesLiquid-crystal displayTransistor

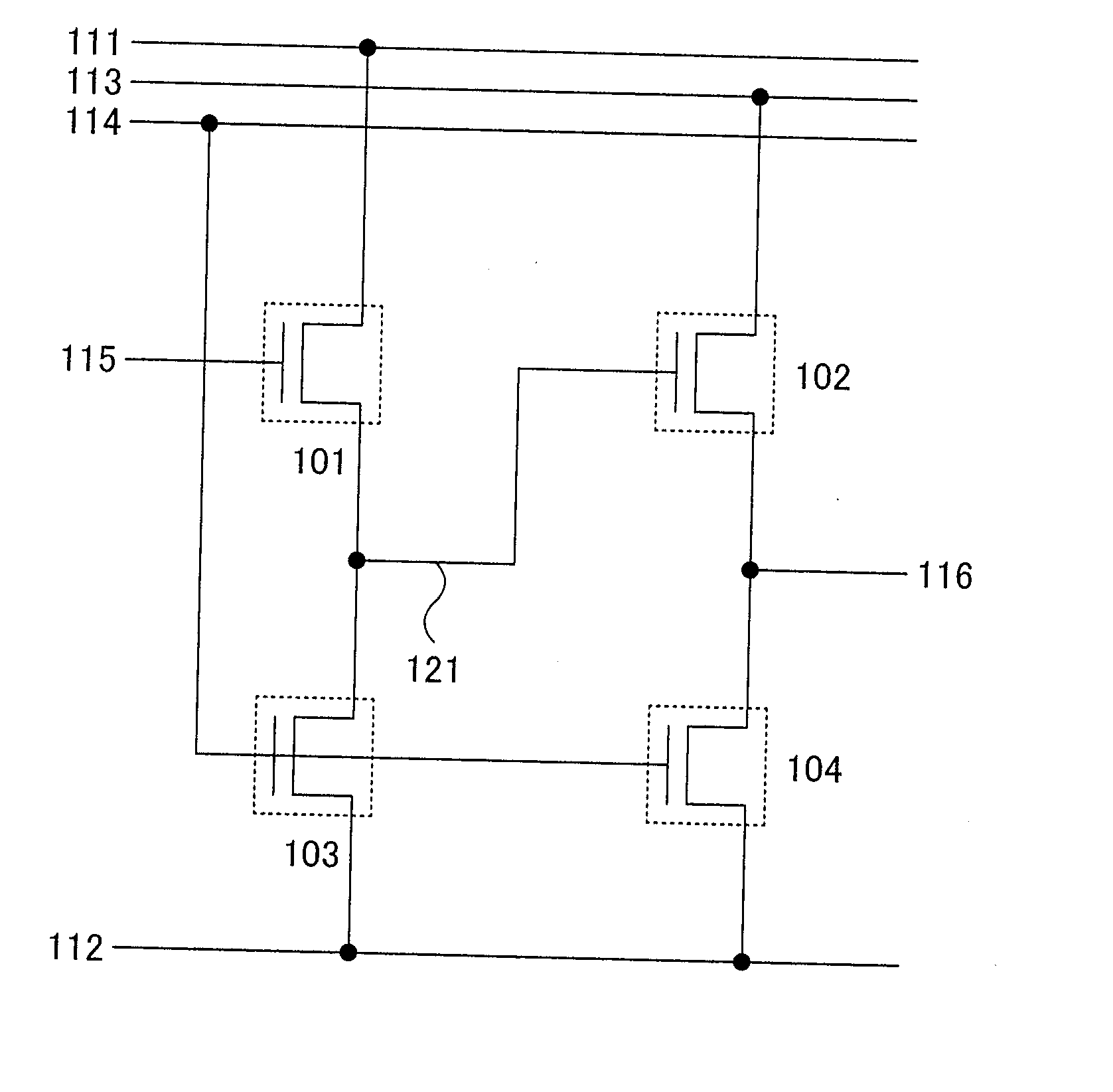

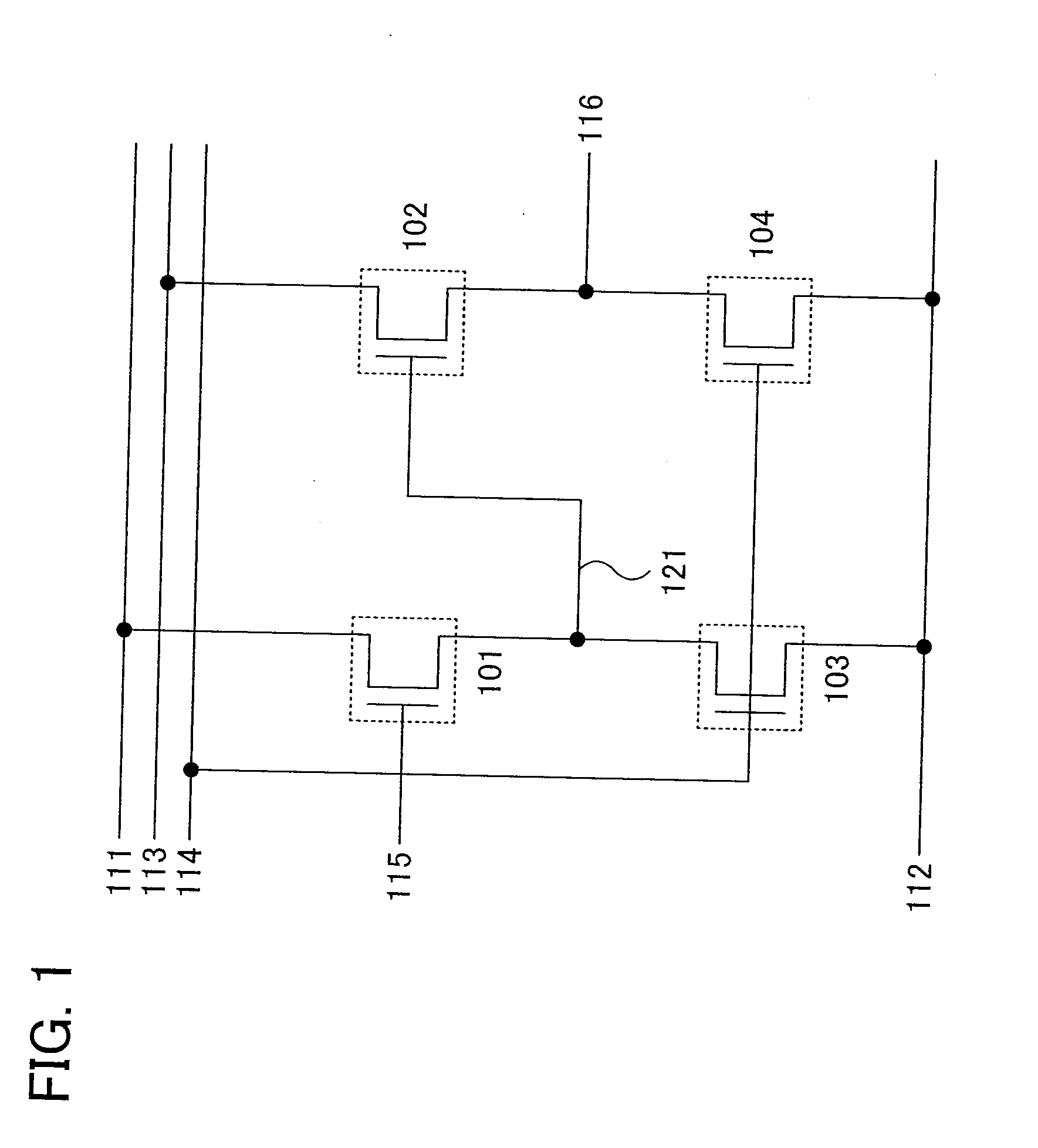

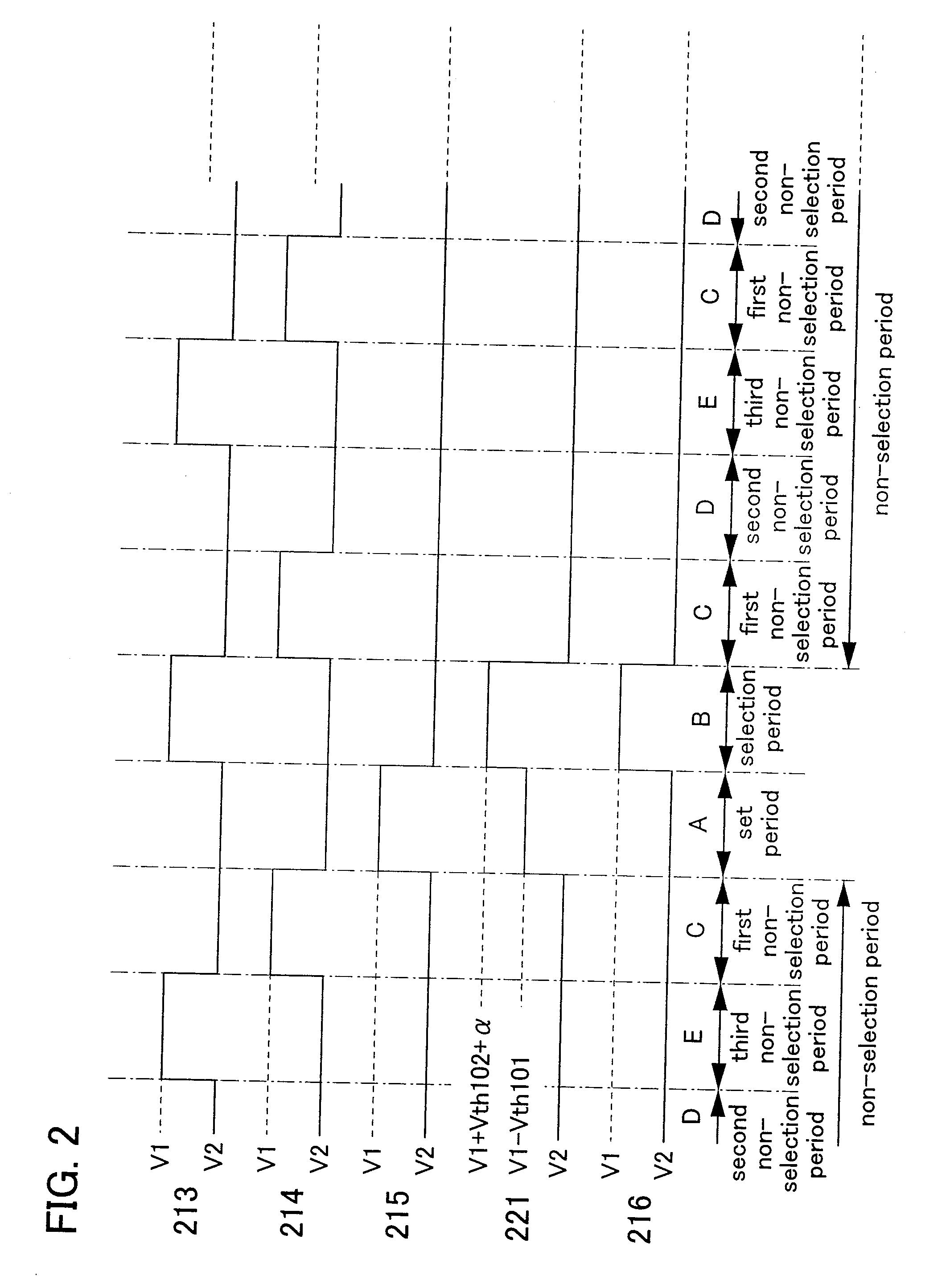

A first transistor, a second transistor, a third transistor, a fourth transistor are provided. In the first transistor, a first terminal is electrically connected to a first wiring; a second terminal is electrically connected to a gate terminal of the second transistor; a gate terminal is electrically connected to a fifth wiring. In the second transistor, a first terminal is electrically connected to a third wiring; a second terminal is electrically connected to a sixth wiring. In the third transistor, a first terminal is electrically connected to a second wiring; a second terminal is electrically connected to the gate terminal of the second transistor; a gate terminal is electrically connected to a fourth wiring. In the fourth transistor, a first terminal is electrically connected to the second wiring; a second terminal is electrically connected to the sixth wiring; a gate terminal is connected to the fourth wiring.

Owner:SEMICON ENERGY LAB CO LTD

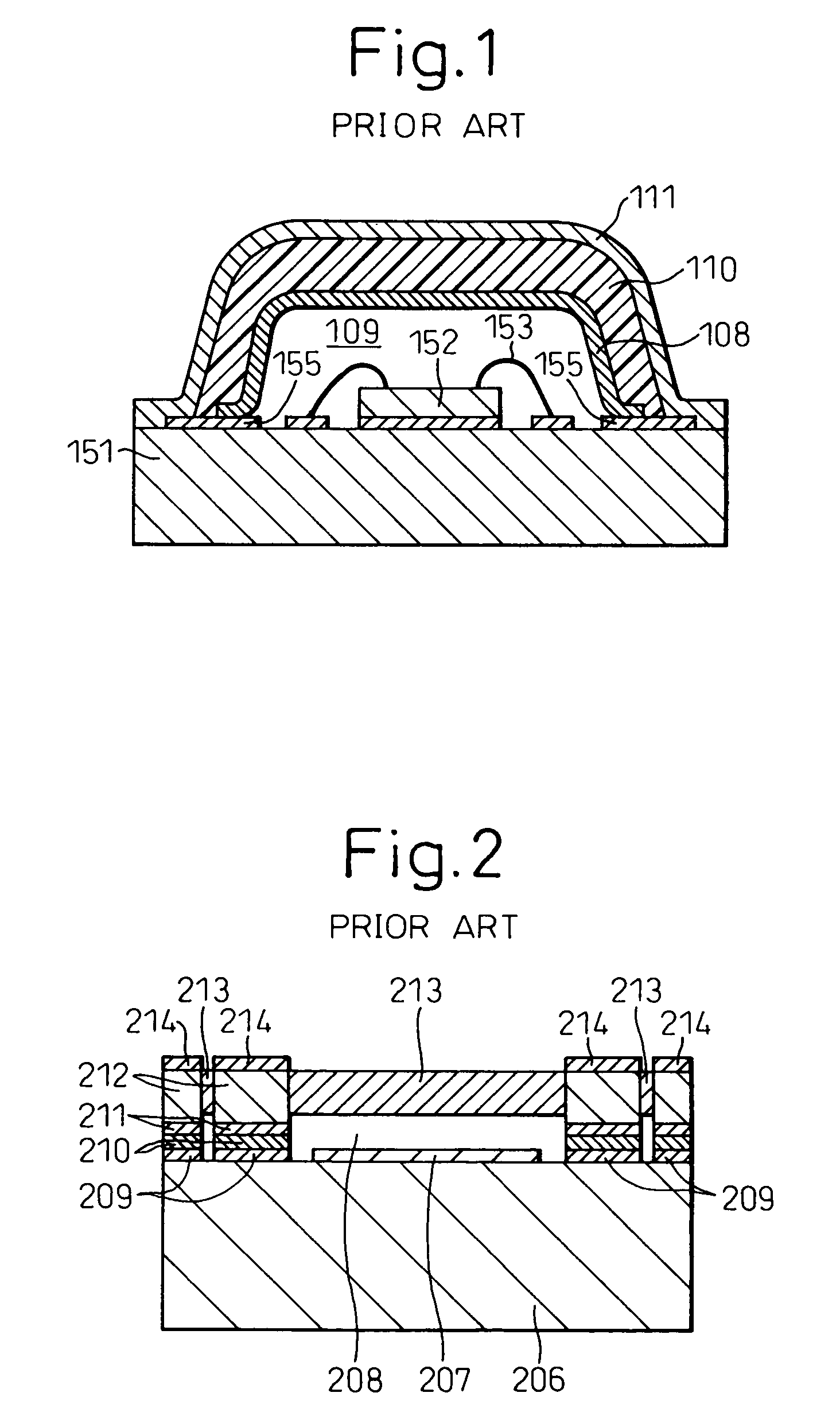

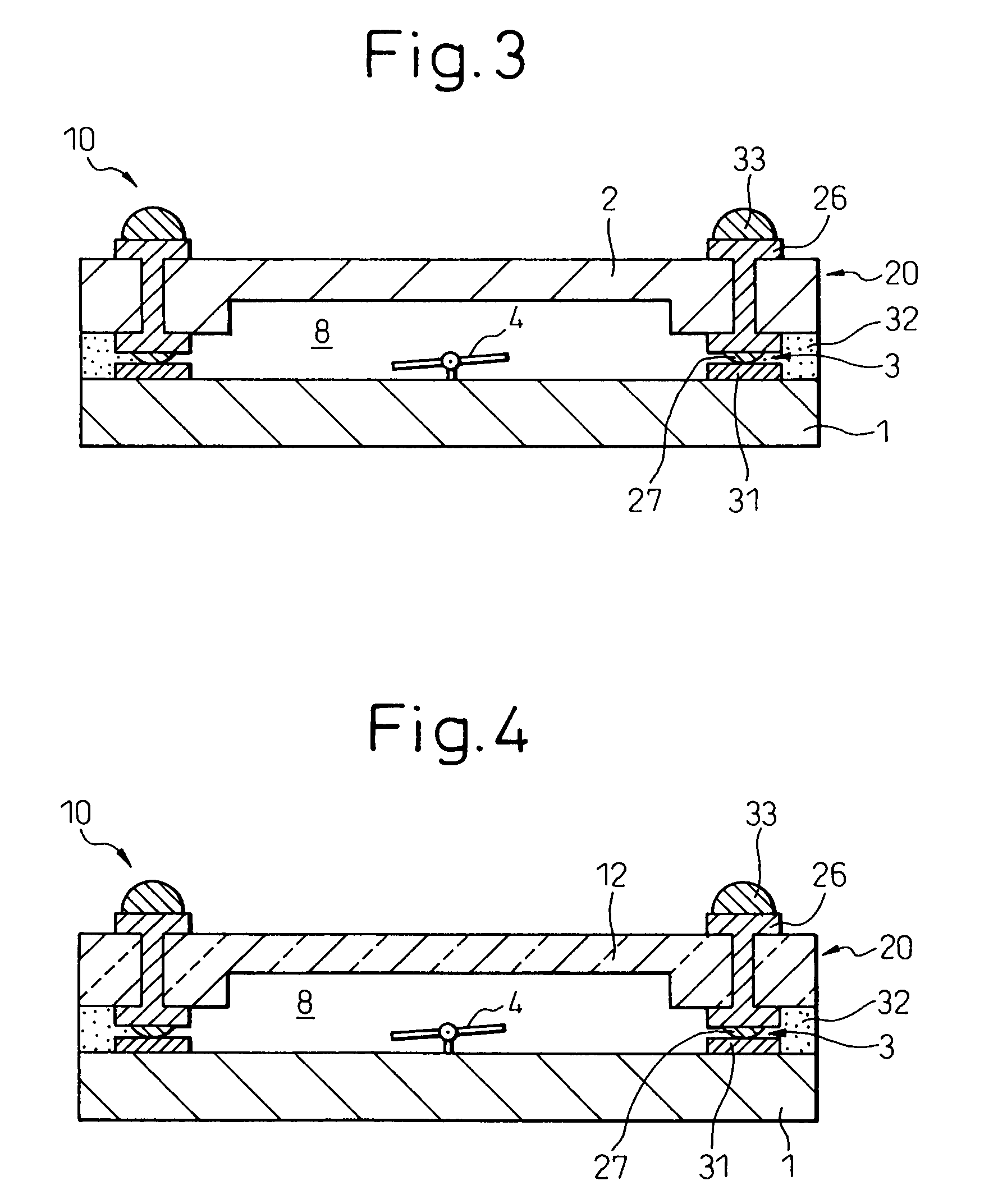

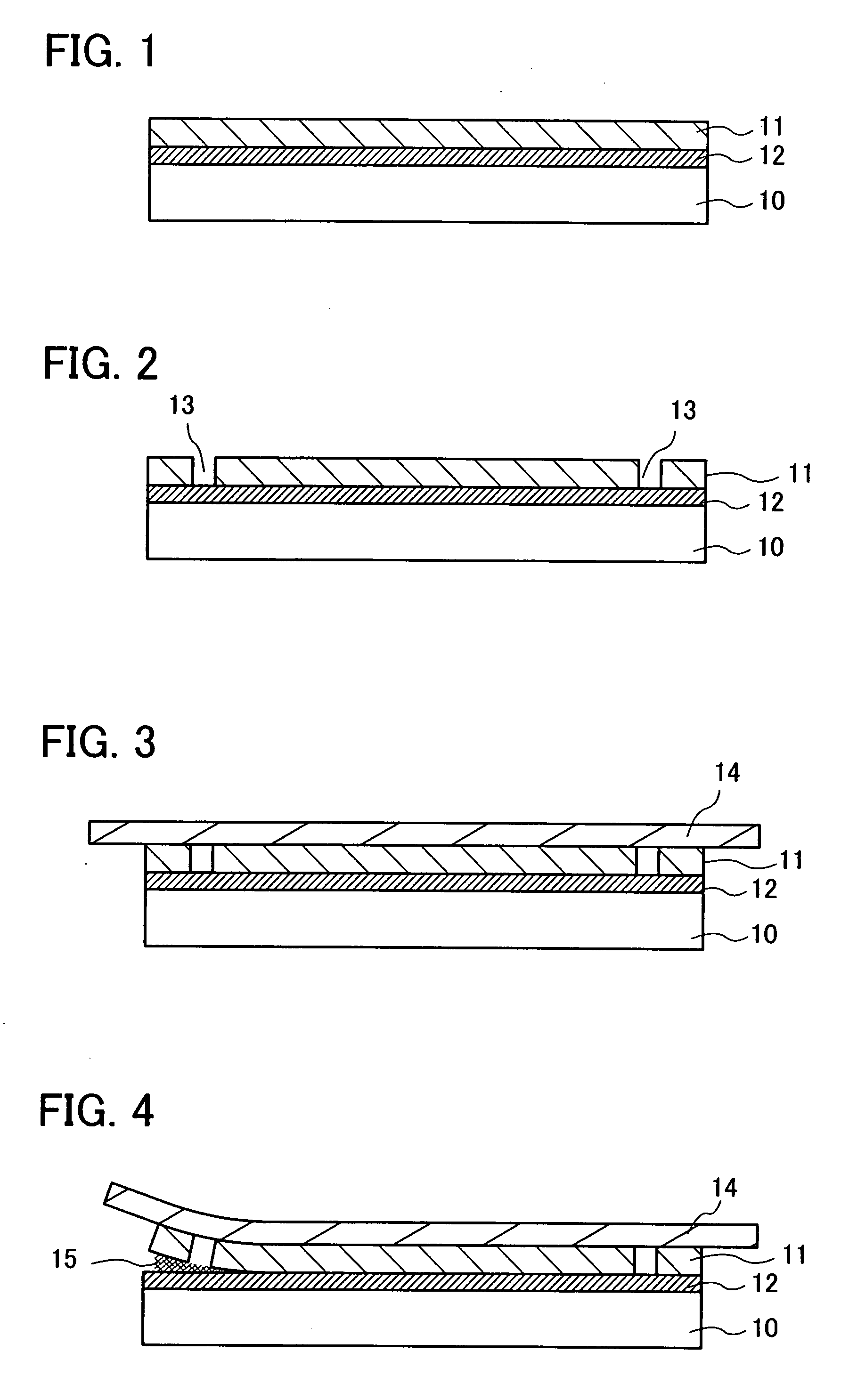

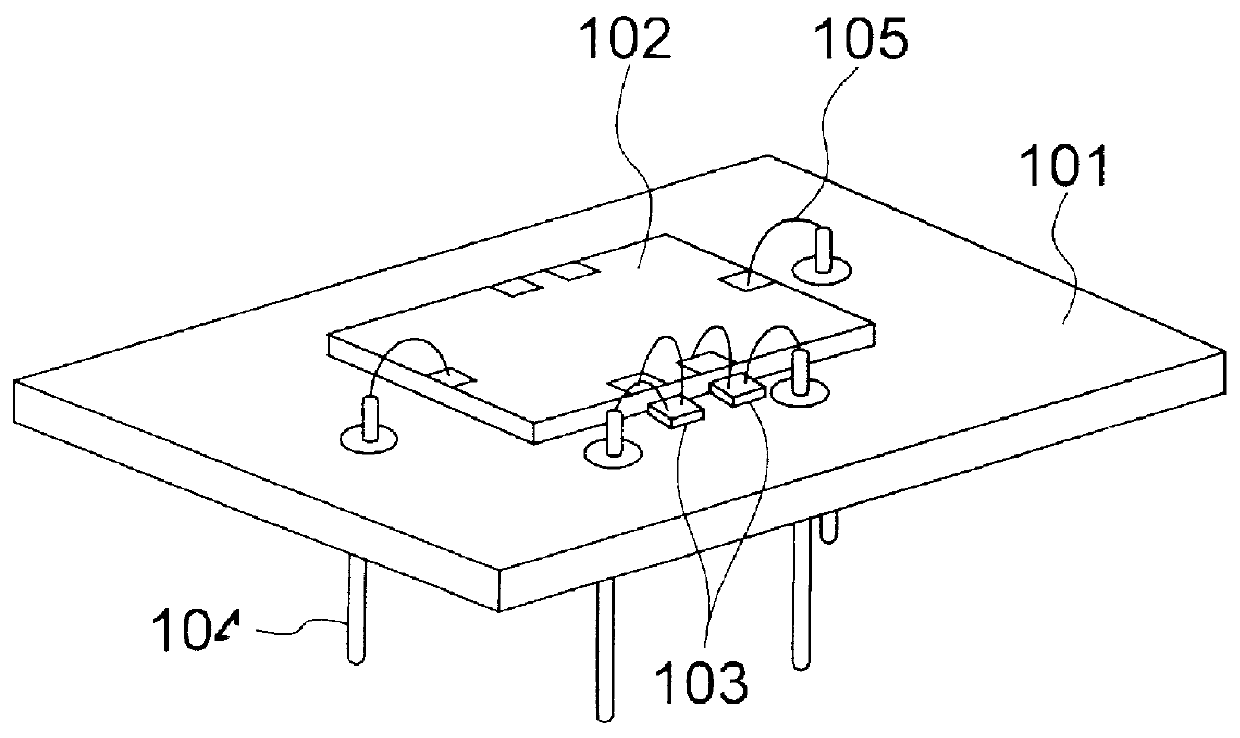

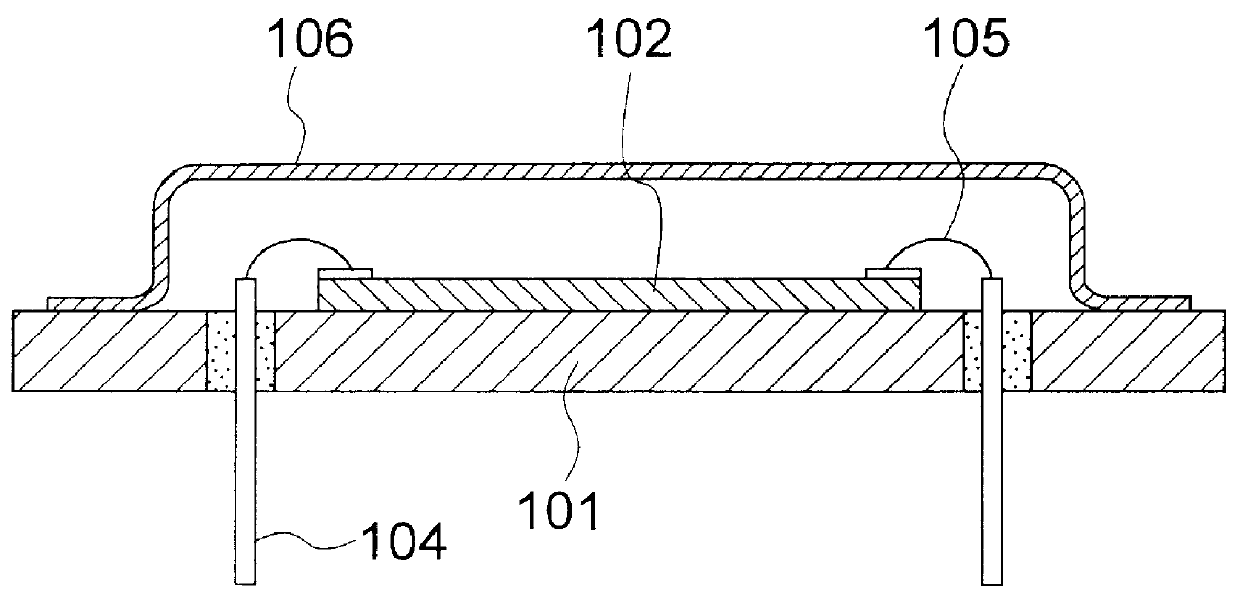

Electronic devices and its production methods

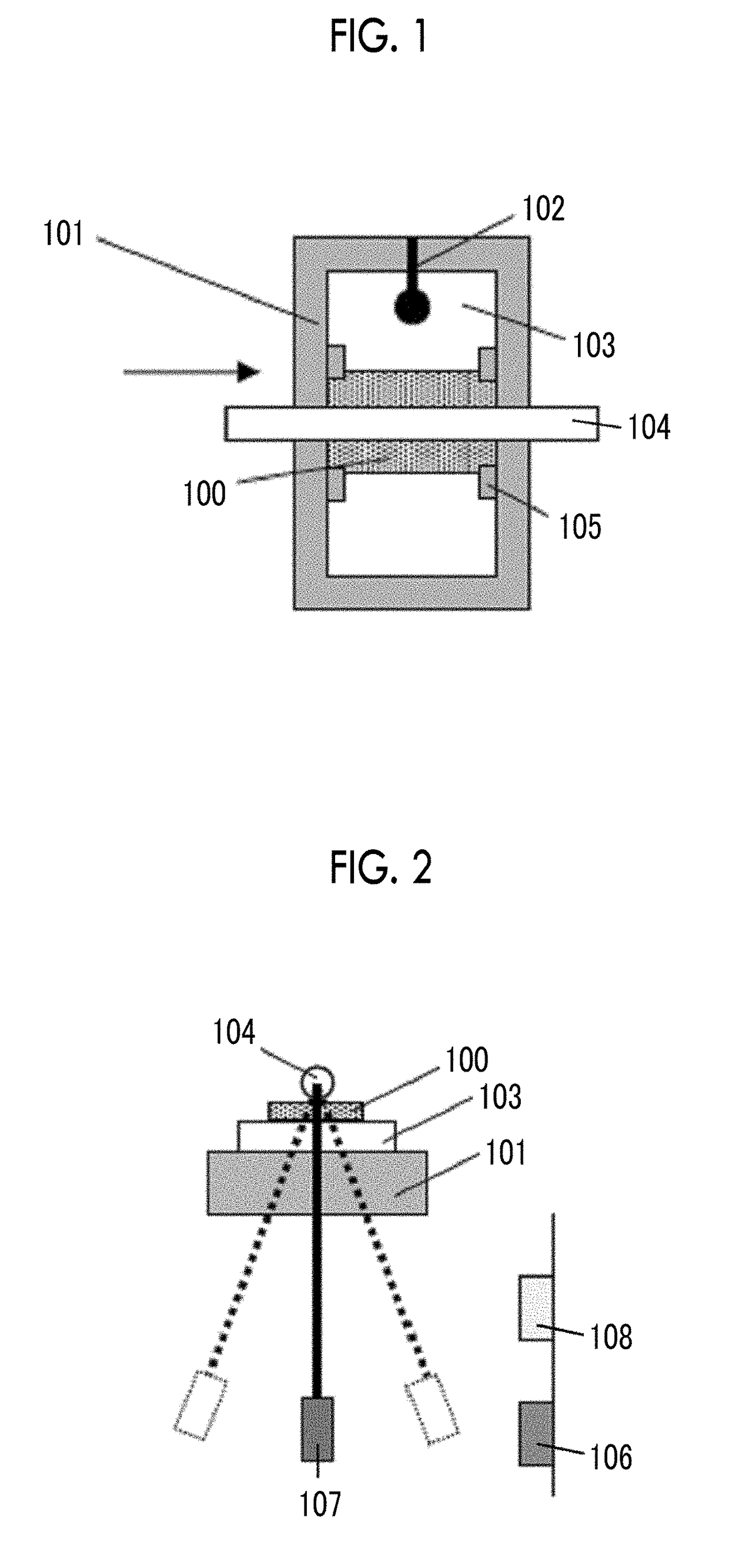

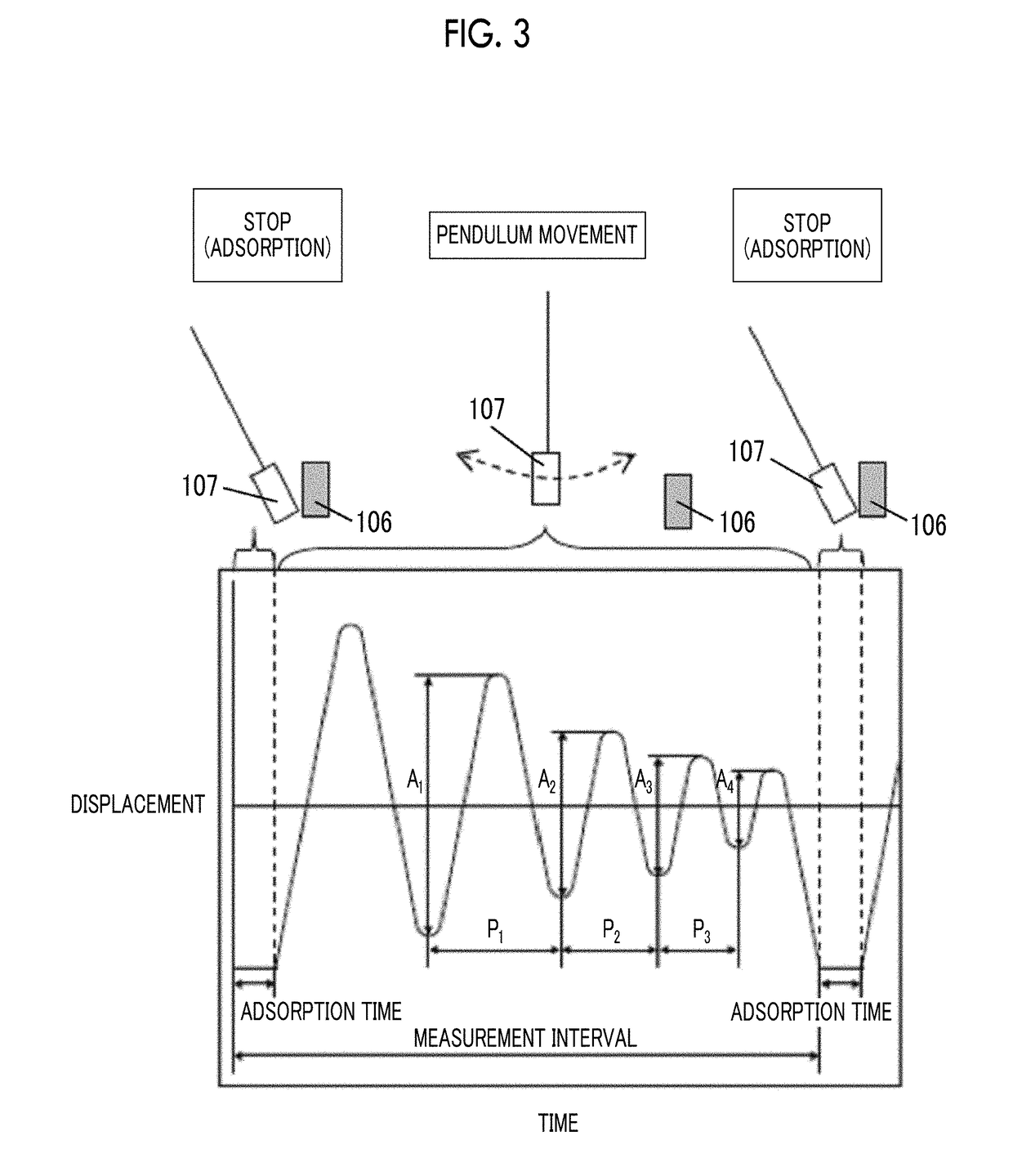

ActiveUS20050167795A1Deterioration of characteristicSmall and compactVolume/mass flow by thermal effectsFixed microstructural devicesSystem elementEngineering

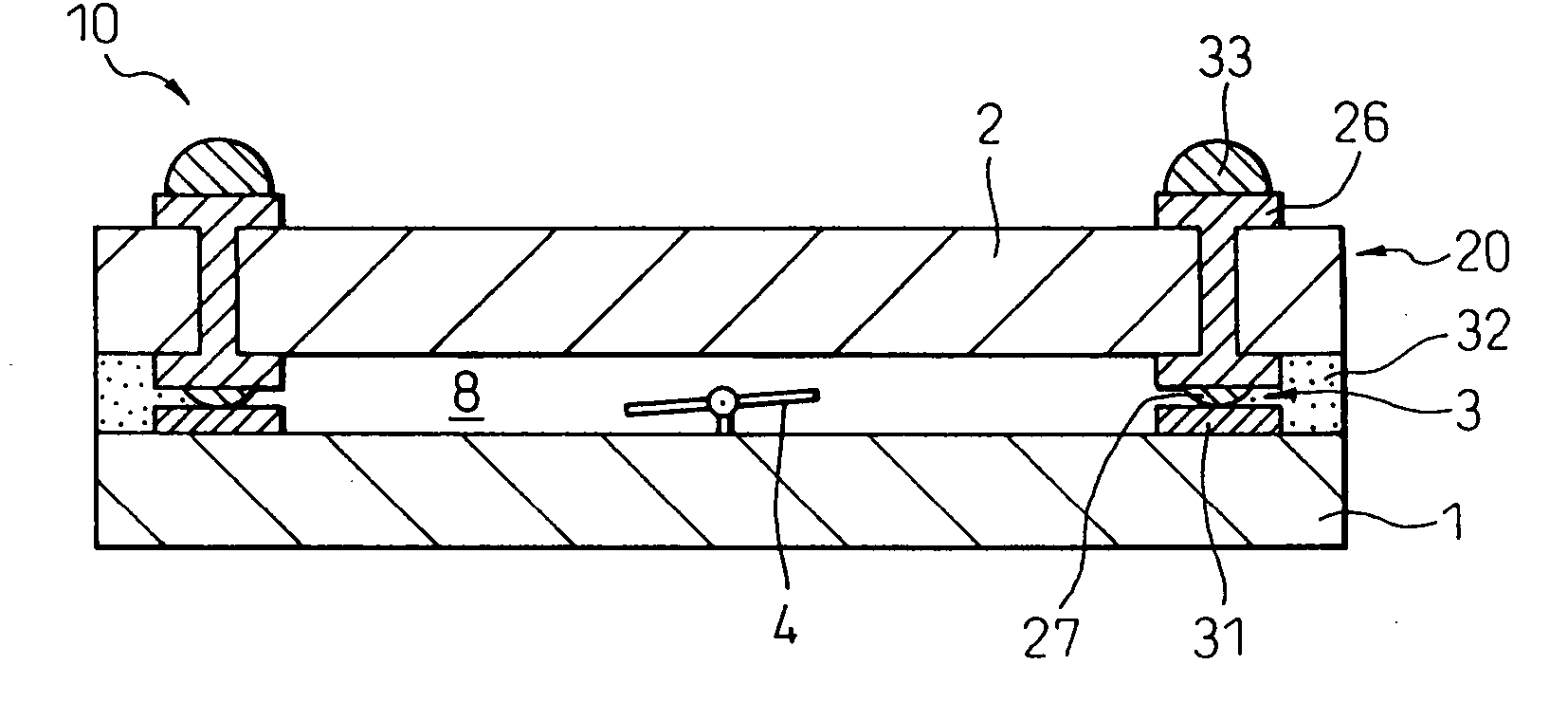

An electronic device having mounted thereon an MEMS element or other functional elements, in which a device body and lid define an element-carrying space, the element-carrying space is sealed air-tight by an ultrasonic bonded part bonding the device body and the lid, and the element-carrying space having arranged inside it a system element secured to the device body and / or the lid by flip-chip connection.

Owner:SHINKO ELECTRIC IND CO LTD

Electronic devices and its production methods

ActiveUS7456497B2Deterioration of characteristicSmall and compactFixed microstructural devicesVolume/mass flow by thermal effectsHermetic sealEngineering

An electronic device having mounted thereon an MEMS element or other functional elements, in which a device body and lid define an element-carrying space, the element-carrying space is sealed air-tight by an ultrasonic bonded part bonding the device body and the lid, and the element-carrying space having arranged inside it a system element secured to the device body and / or the lid by flip-chip connection.

Owner:SHINKO ELECTRIC IND CO LTD

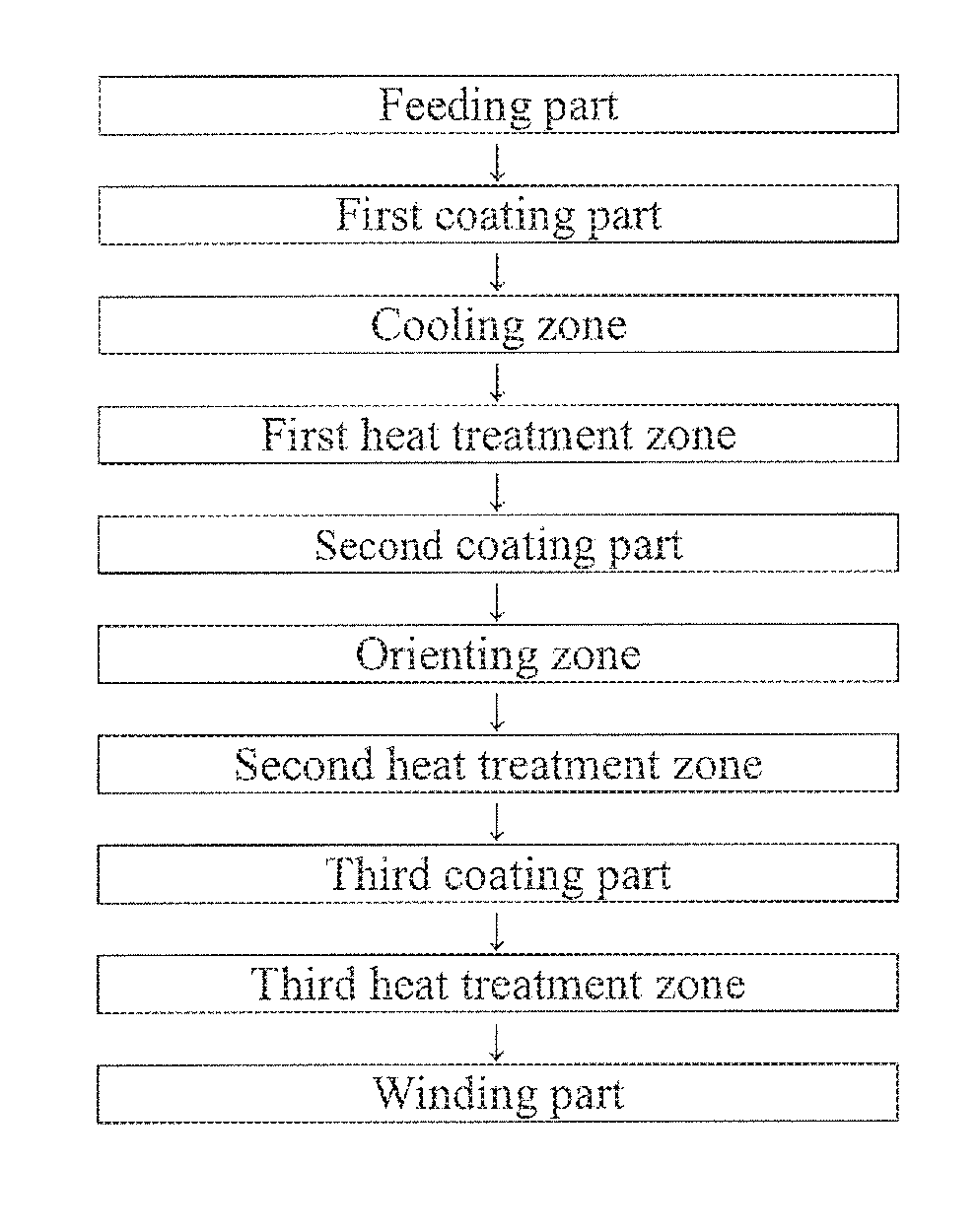

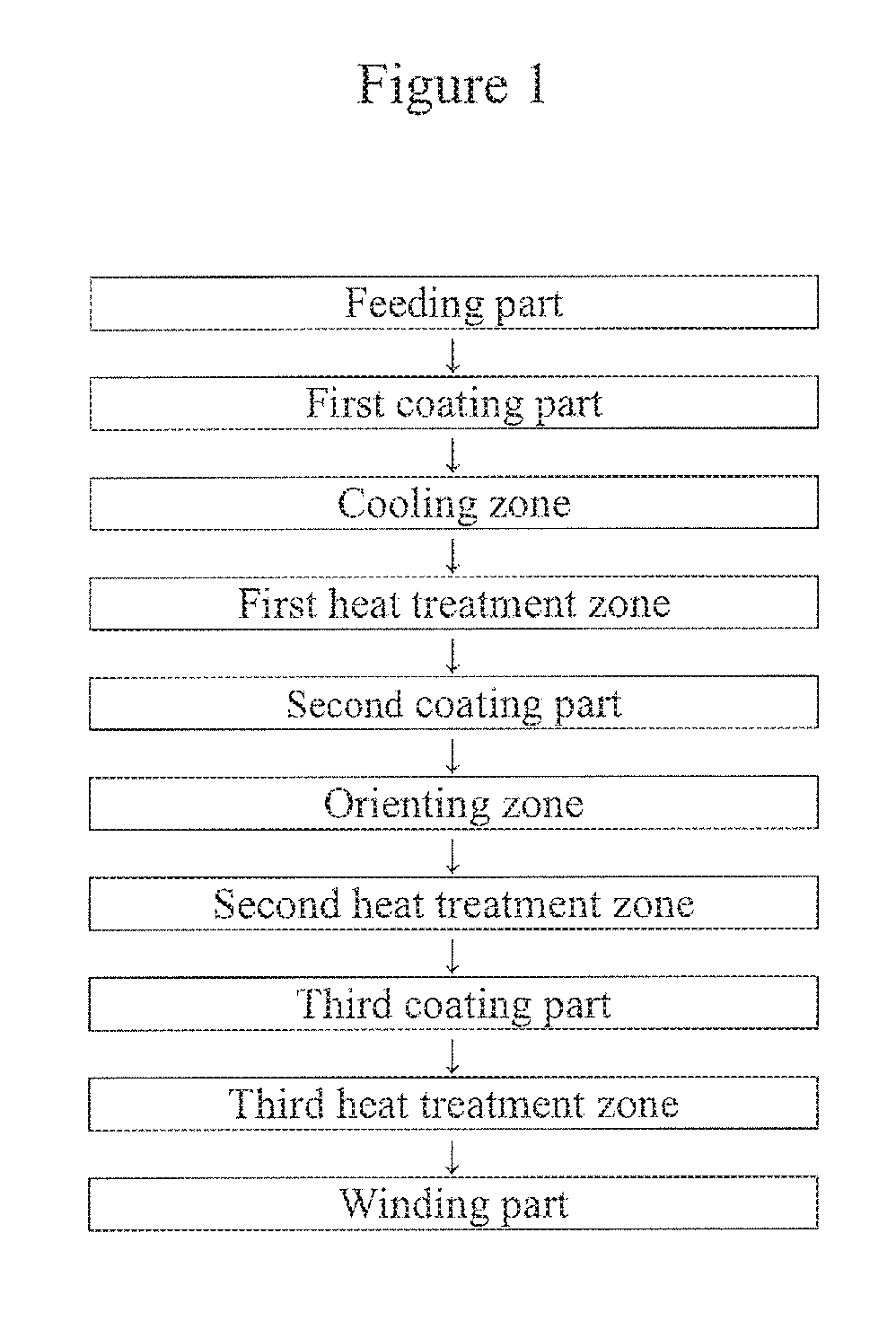

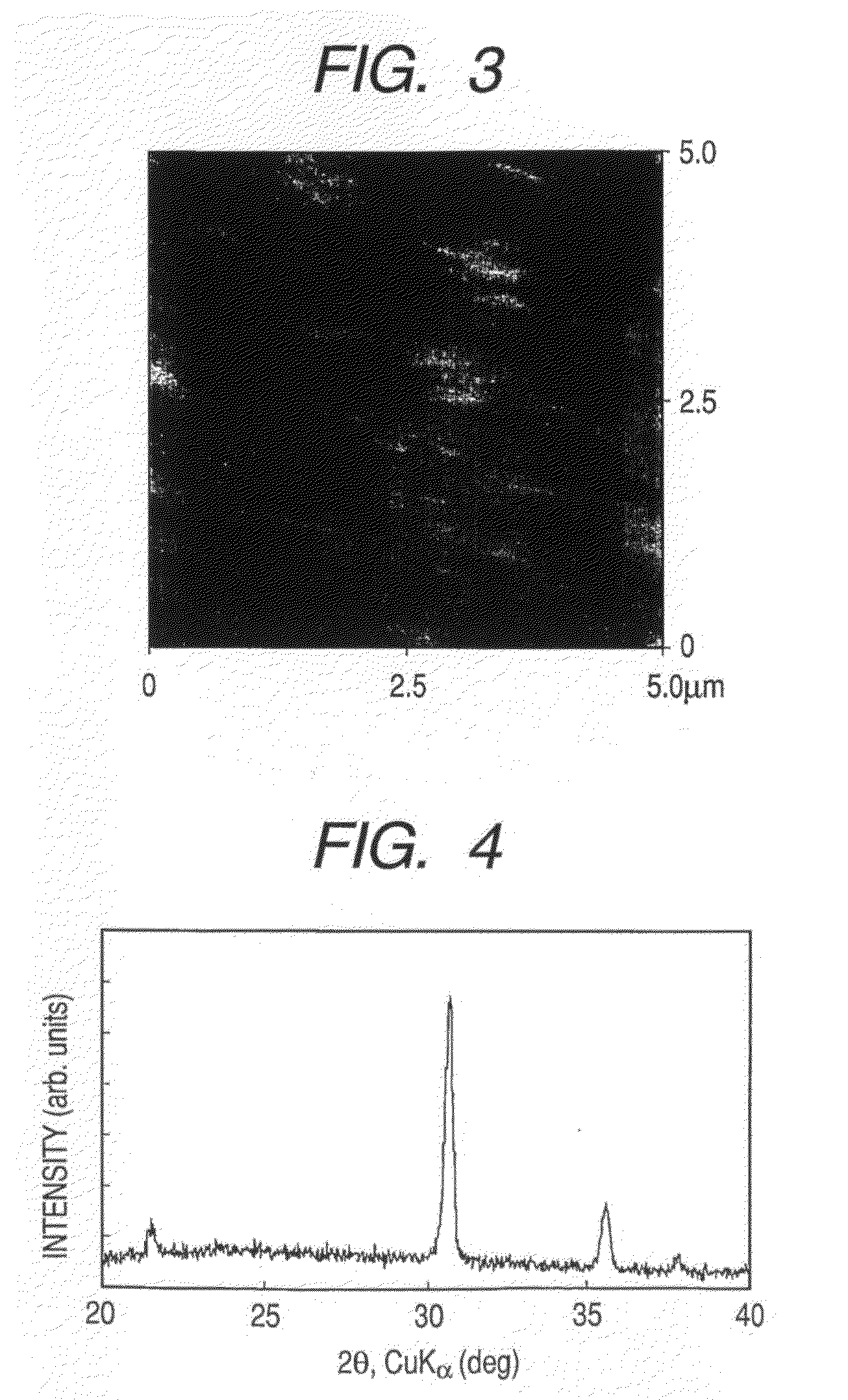

Magnetic tape, magnetic tape cartridge, magnetic recording and reproducing device, and method of manufacturing magnetic tape

ActiveUS20170178676A1Good electromagnetic characteristicShorten the timeBase layers for recording layersRecord information storagePeak areaMagnetic layer

The magnetic tape has a nonmagnetic layer containing nonmagnetic powder and binder on a nonmagnetic support, and a magnetic layer containing ferromagnetic powder and binder on the nonmagnetic layer; wherein the combined thickness of the nonmagnetic layer and the magnetic layer is less than or equal to 0.60 μm, the coefficient of friction as measured on the base portion of the surface of the magnetic layer is less than or equal to 0.35, at least the magnetic layer contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide, and a C—H derived carbon, C, concentration calculated from a C—H peak area ratio in a C1s spectrum obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on the surface of the magnetic layer is greater than or equal to 45 atom %.

Owner:FUJIFILM CORP

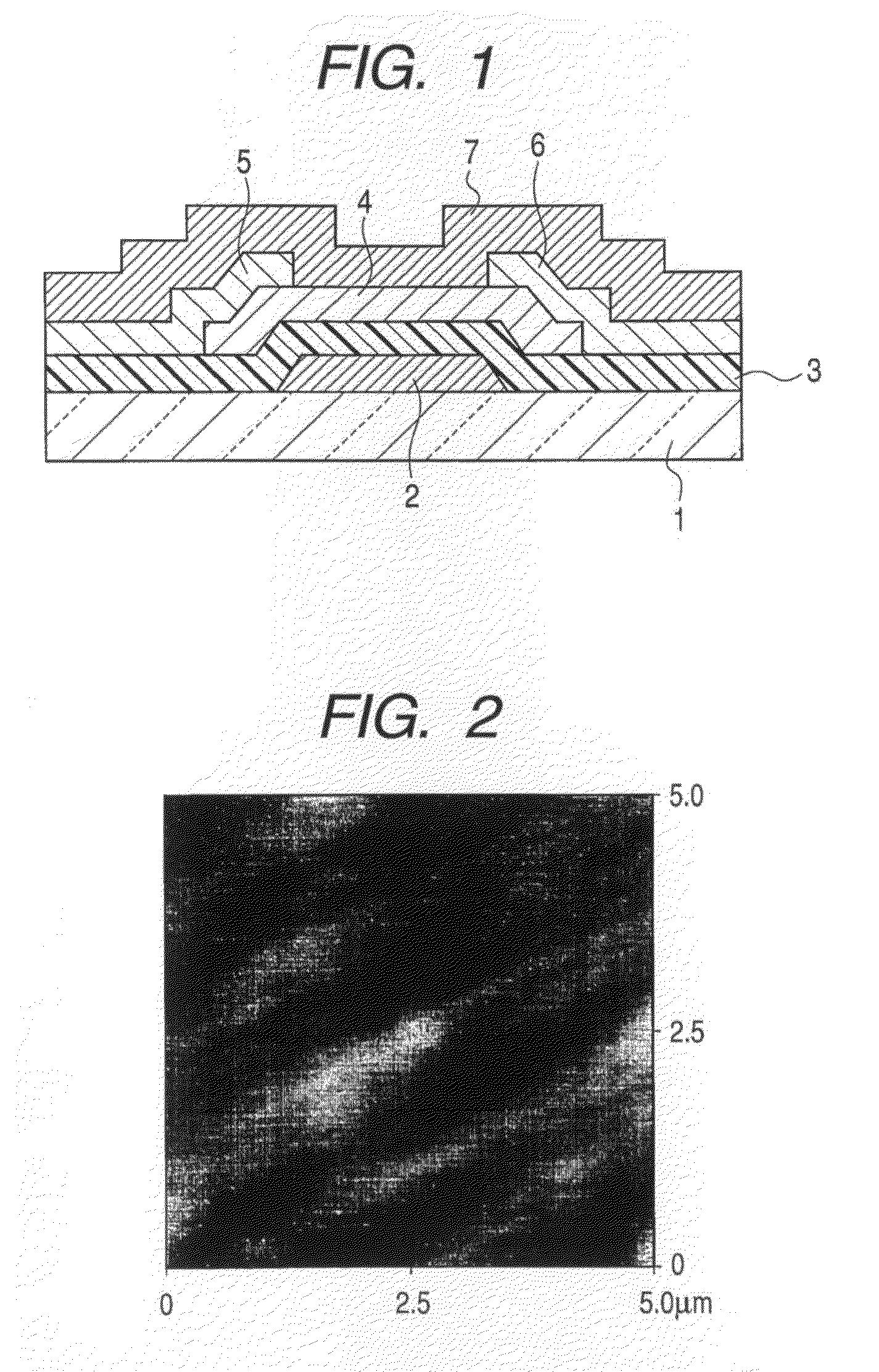

Magnetic tape

ActiveUS20180061446A1Deterioration of characteristicMagnetic materials for record carriersTape carriersConventional transmission electron microscopeScanning tunneling microscope

Provided is a magnetic tape in which the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes ferromagnetic hexagonal ferrite powder and an abrasive, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer by plane observation using a scanning electron microscope, with respect to the total area of the region is equal to or greater than 0.02% and less than 0.06%, and a tilt cos 0 of the ferromagnetic hexagonal ferrite powder with respect to a surface of the magnetic layer acquired by cross section observation performed by using a scanning transmission electron microscope is 0.85 to 1.00.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS10026430B2Improve noiseDeterioration of characteristicRecord information storageMagnetic recordingMagnetic tapeNon magnetic

The magnetic tape comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder, nonmagnetic powder, and binder, wherein a total thickness of the magnetic tape is less than or equal to 4.80 μm, and a coefficient of friction as measured on a base portion of a surface of the magnetic layer is less than or equal to 0.35.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20180286443A1Deterioration of characteristicMaterials with ironRecord information storageMagnetic tapeFull width at half maximum

The magnetic tape has the total thickness of a non-magnetic layer and a magnetic layer of 0.60 μm or smaller, the magnetic layer including an abrasive and fatty acid ester, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer with respect to the total area of the region, obtained by plane observation performed by using an SEM of 0.02% or greater and less than 0.06%, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape of greater than 0 nm and 7.0 nm or smaller, and a difference between spacings before and after the vacuum heating of greater than 0 nm and 8.0 nm or smaller.

Owner:FUJIFILM CORP

Electro-optical device

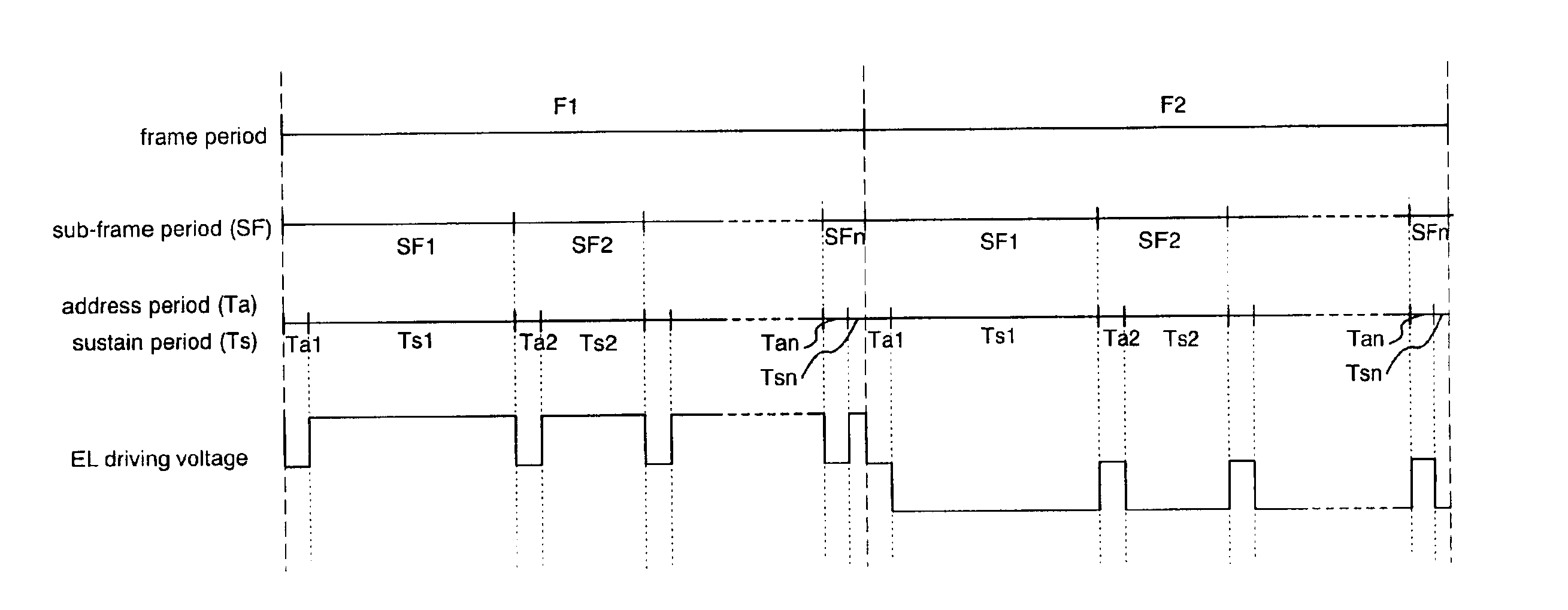

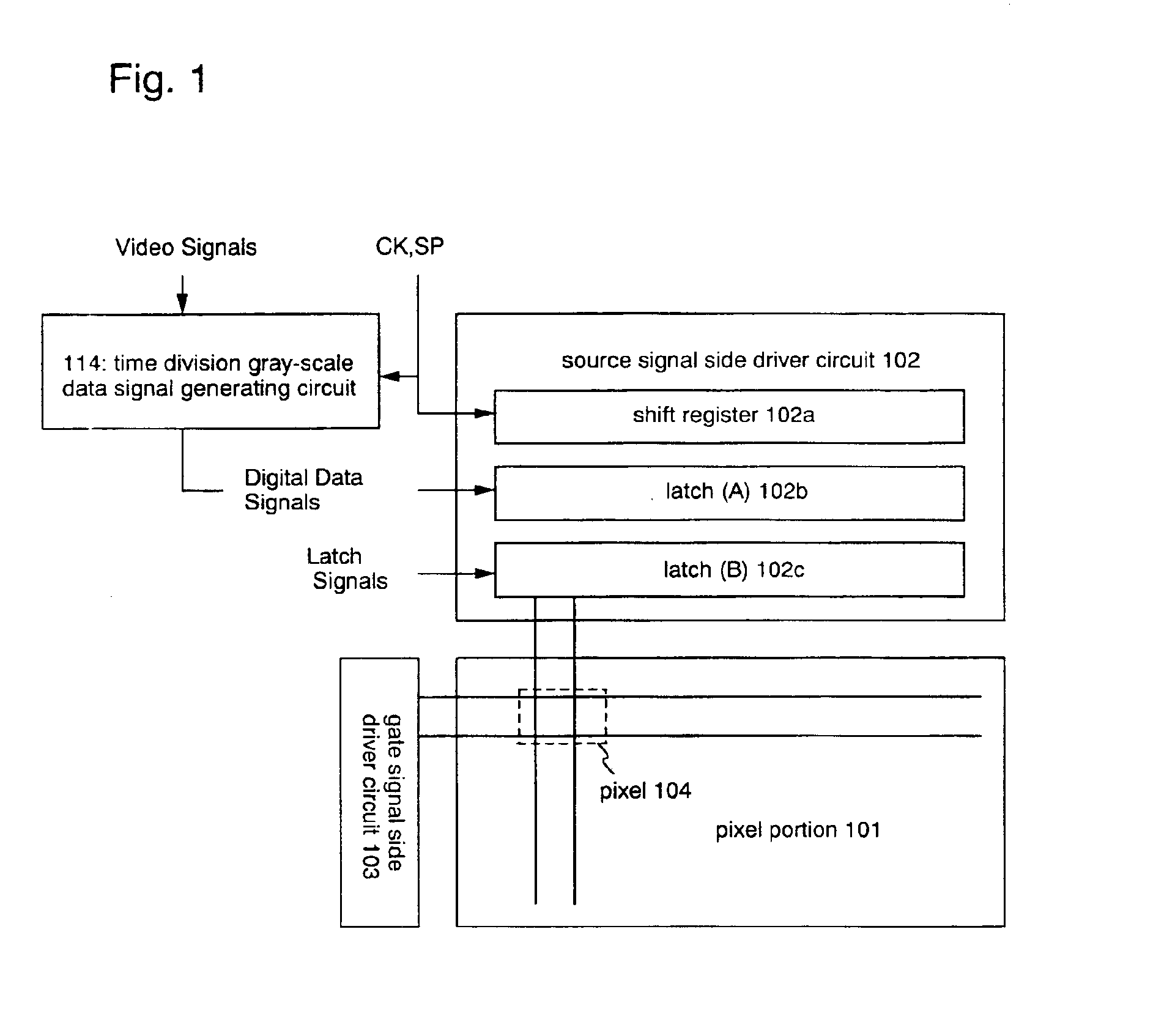

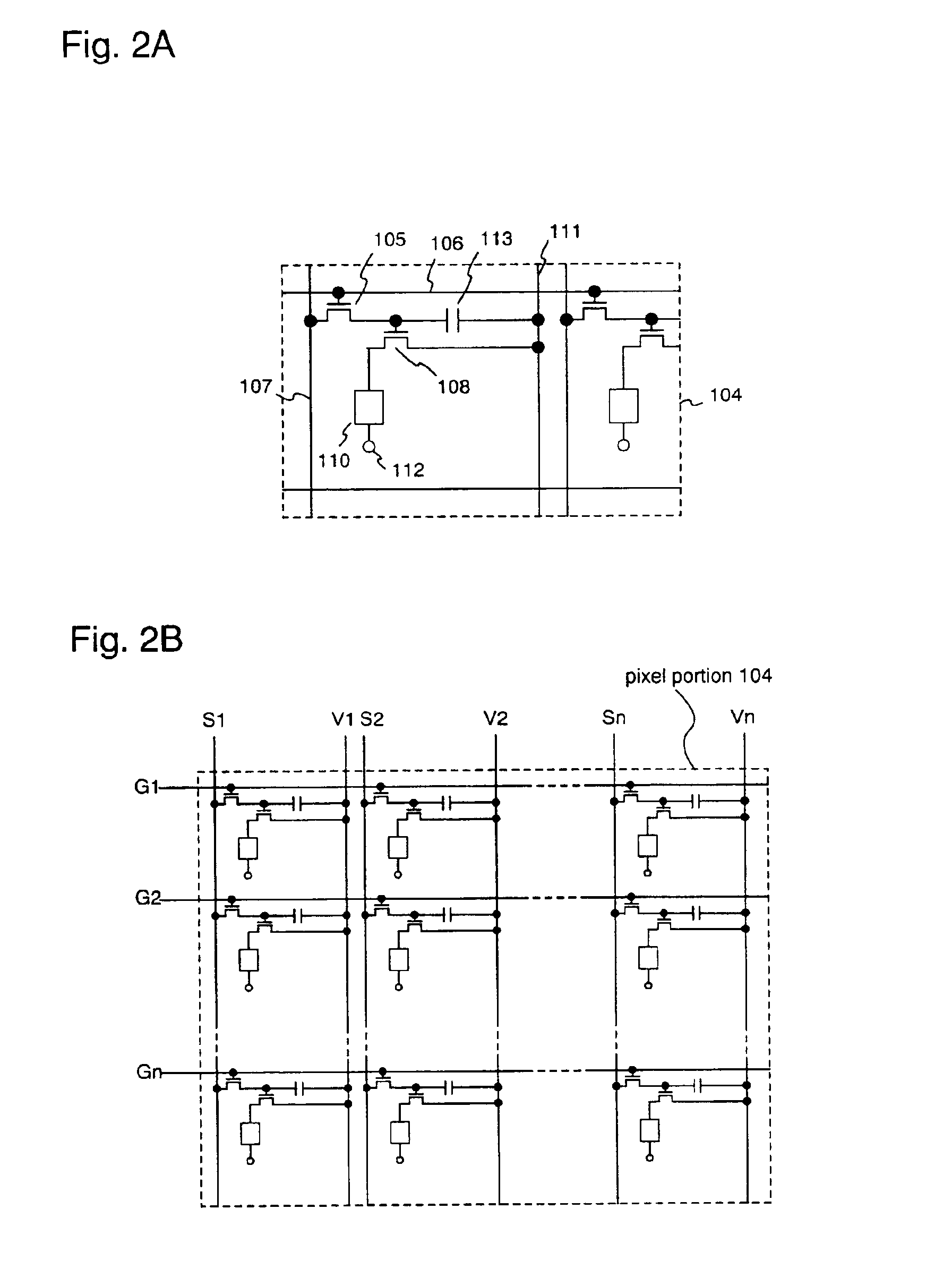

InactiveUS6872973B1Inhibit currentAvoid flickeringTelevision system detailsStatic indicating devicesEngineeringVoltage

An electro-optical device having a plurality of pixels including a plurality of EL elements, wherein the electro-optical device provides a gray scale display by controlling a period of time at which the plurality of the EL elements emit light in one frame period; the plurality of the EL elements have a first electrode and a second electrode; the first electrode is held at a constant potential; and a potential of the second electrode changes in such a manner that a polarity of an EL driving voltage, which is a difference between the potentials applied to the first and second electrodes, is inverted for each one frame period.

Owner:SEMICON ENERGY LAB CO LTD

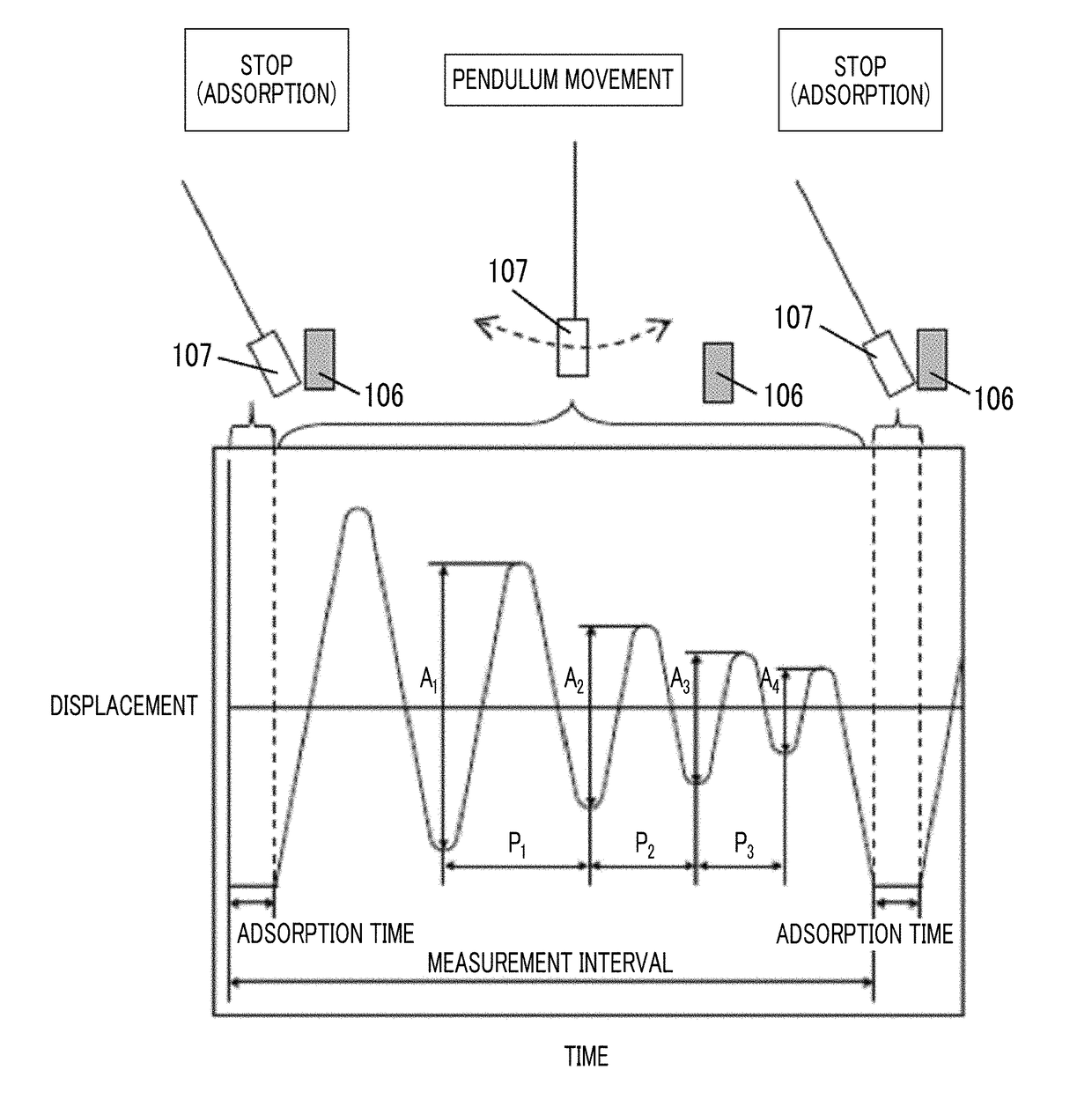

Magnetic tape

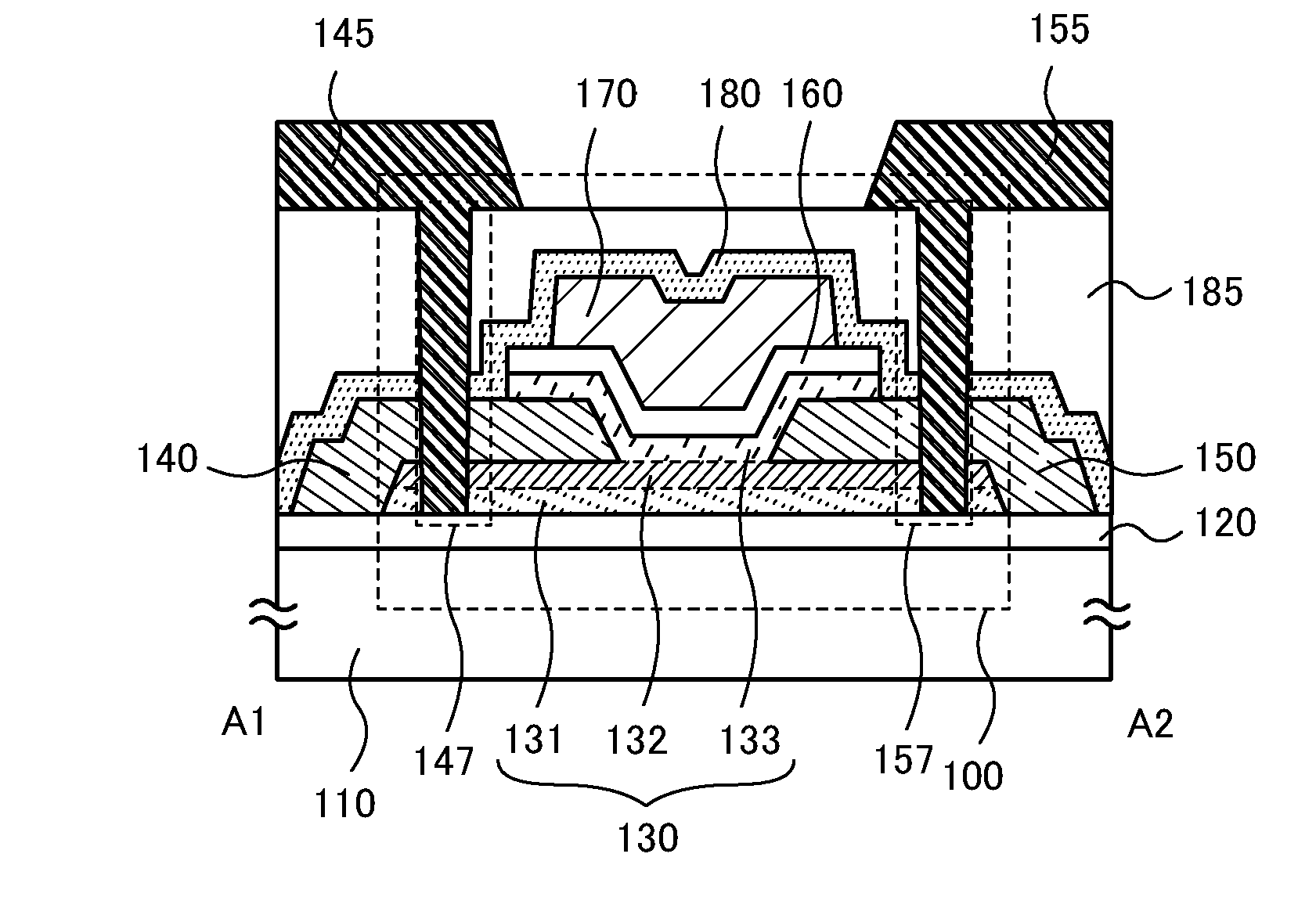

ActiveUS20180240495A1Deterioration of characteristicMaterials with ironRecord information storageScanning tunneling microscopeMagnetic tape

The magnetic tape includes a non-magnetic support; a non-magnetic layer including non-magnetic powder and a binding agent on the non-magnetic support; and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic layer, in which the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes an abrasive, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer with respect to the total area of the region, obtained by plane observation performed by using a scanning electron microscope is equal to or greater than 0.02% and less than 0.06%, and a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050.

Owner:FUJIFILM CORP

Semiconductor device

InactiveUS20140326992A1Reduce yieldEasy to integrateTransistorSolid-state devicesElectrical conductorMiniaturization

Provided is a semiconductor device that can be miniaturized in a simple process and that can prevent deterioration of electrical characteristics due to miniaturization. The semiconductor device includes an oxide semiconductor layer, a first conductor in contact with the oxide semiconductor layer, and an insulator in contact with the first conductor. Further, an opening portion is provided in the oxide semiconductor layer, the first conductor, and the insulator. In the opening portion, side surfaces of the oxide semiconductor layer, the first conductor, and the insulator are aligned, and the oxide semiconductor layer and the first conductor are electrically connected to a second conductor by side contact.

Owner:SEMICON ENERGY LAB CO LTD

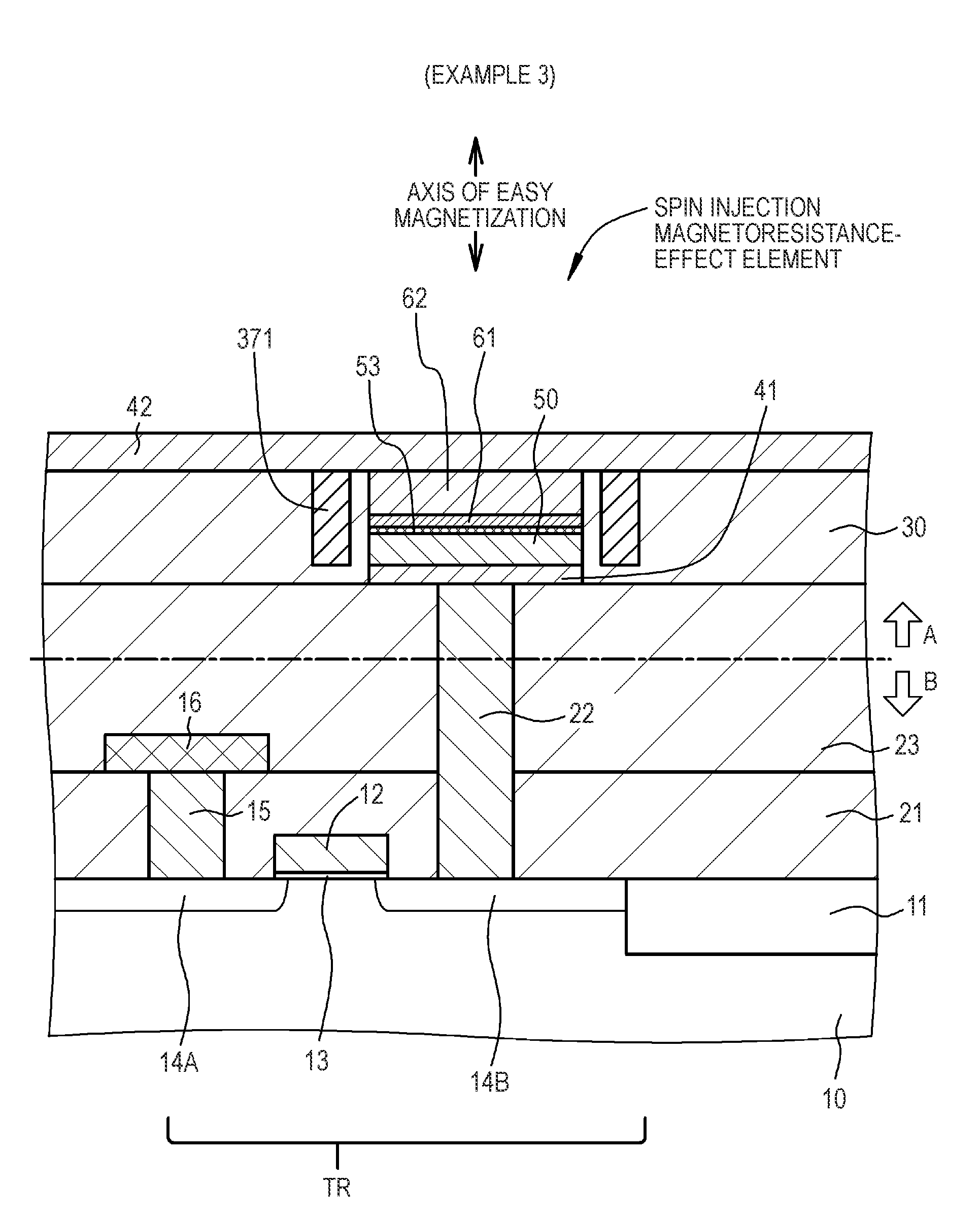

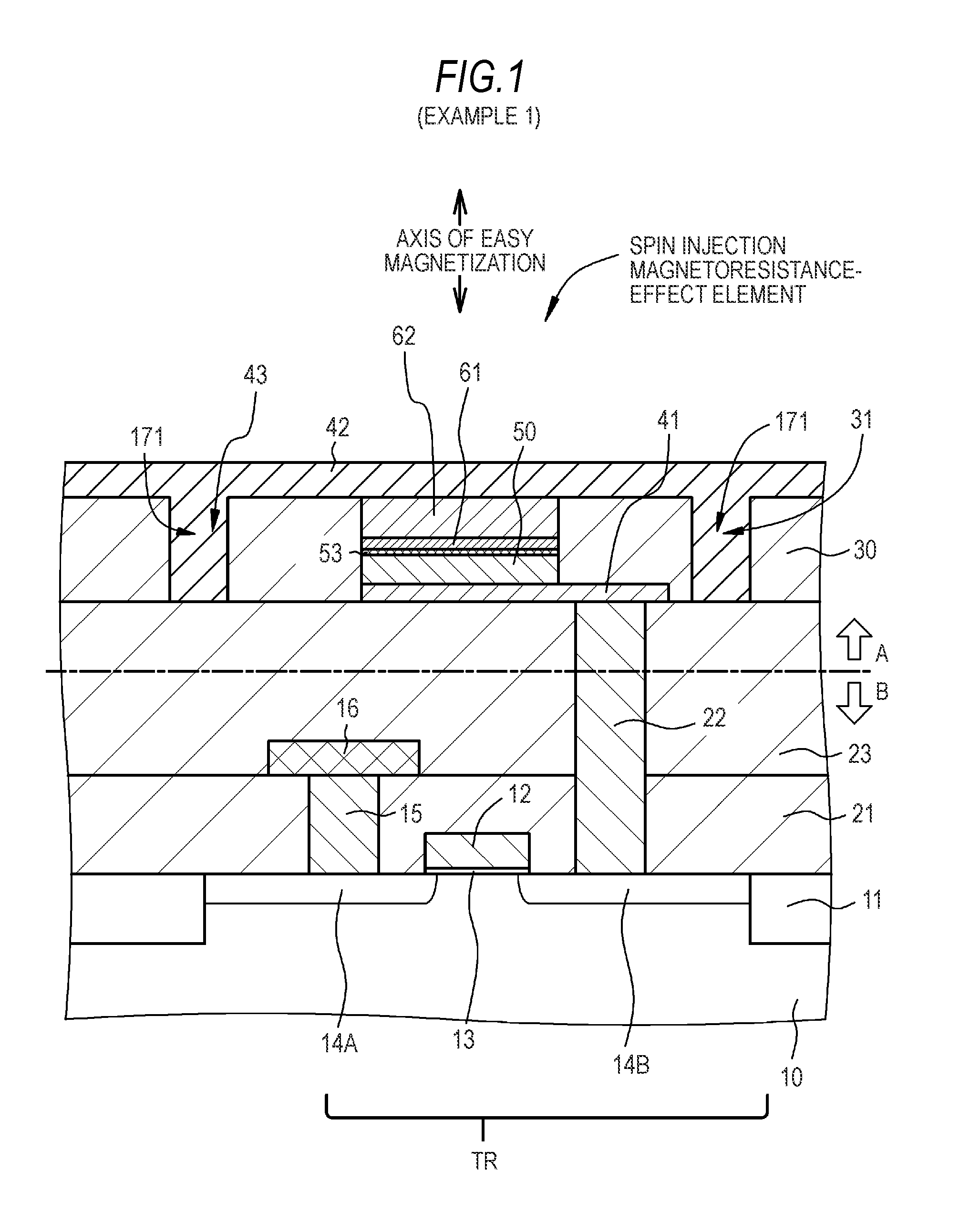

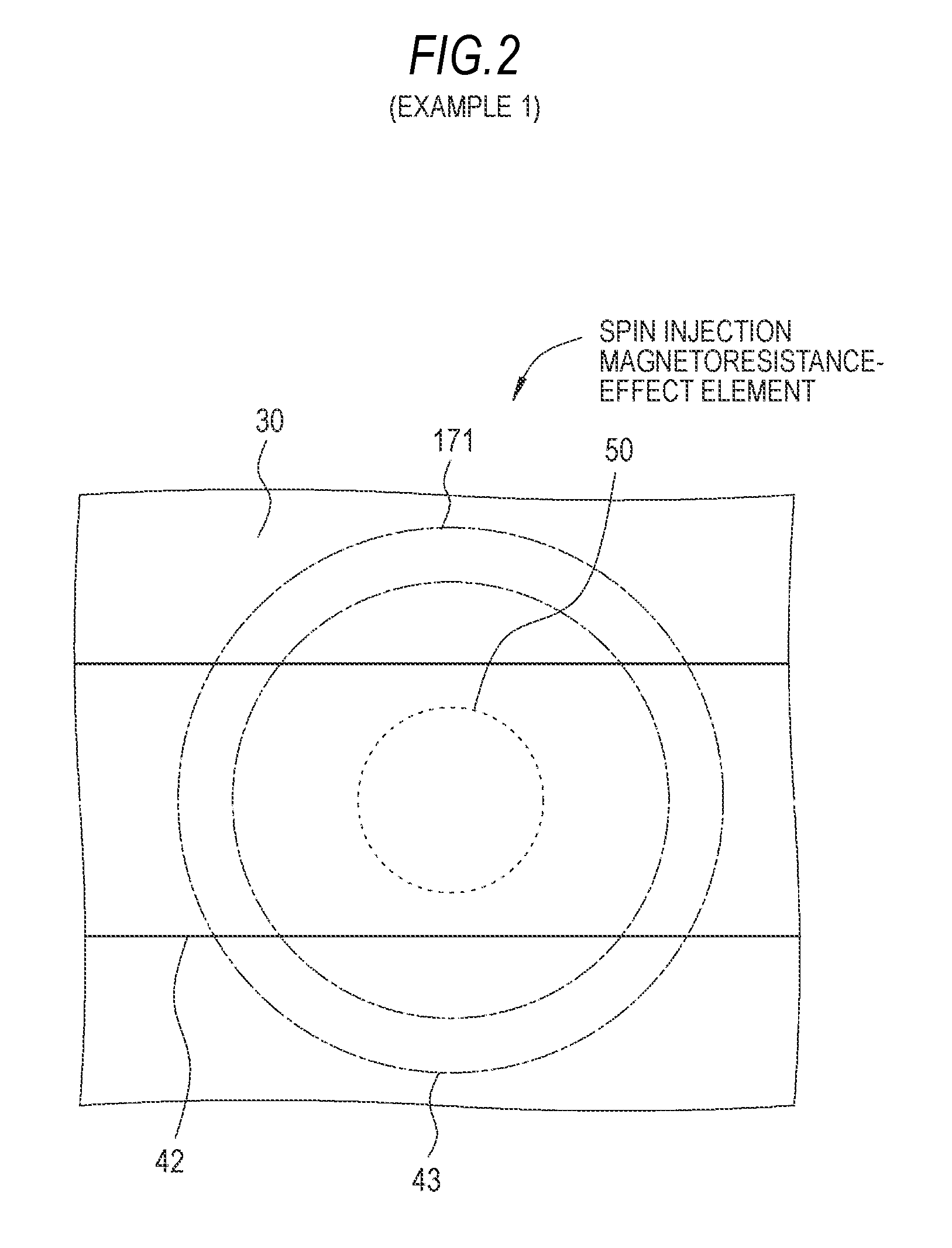

Nonvolatile magnetic memory device

InactiveUS20100176472A1Reduce polarizabilitySmall MRNanomagnetismGalvano-magnetic device detailsMagnetizationMagnetic memory

A nonvolatile magnetic memory device having a magnetoresistance-effect element includes: (A) a laminated structure having a recording layer in which an axis of easy magnetization is oriented in a perpendicular direction; (B) a first wiring line electrically connected to a lower part of the laminated structure; and (C) a second wiring line electrically connected to an upper part of the laminated structure, wherein a high Young's modulus region having a Young's modulus of a higher value than that of a Young's modulus of a material forming the recording layer is provided close to a side surface of the laminated structure.

Owner:SONY CORP

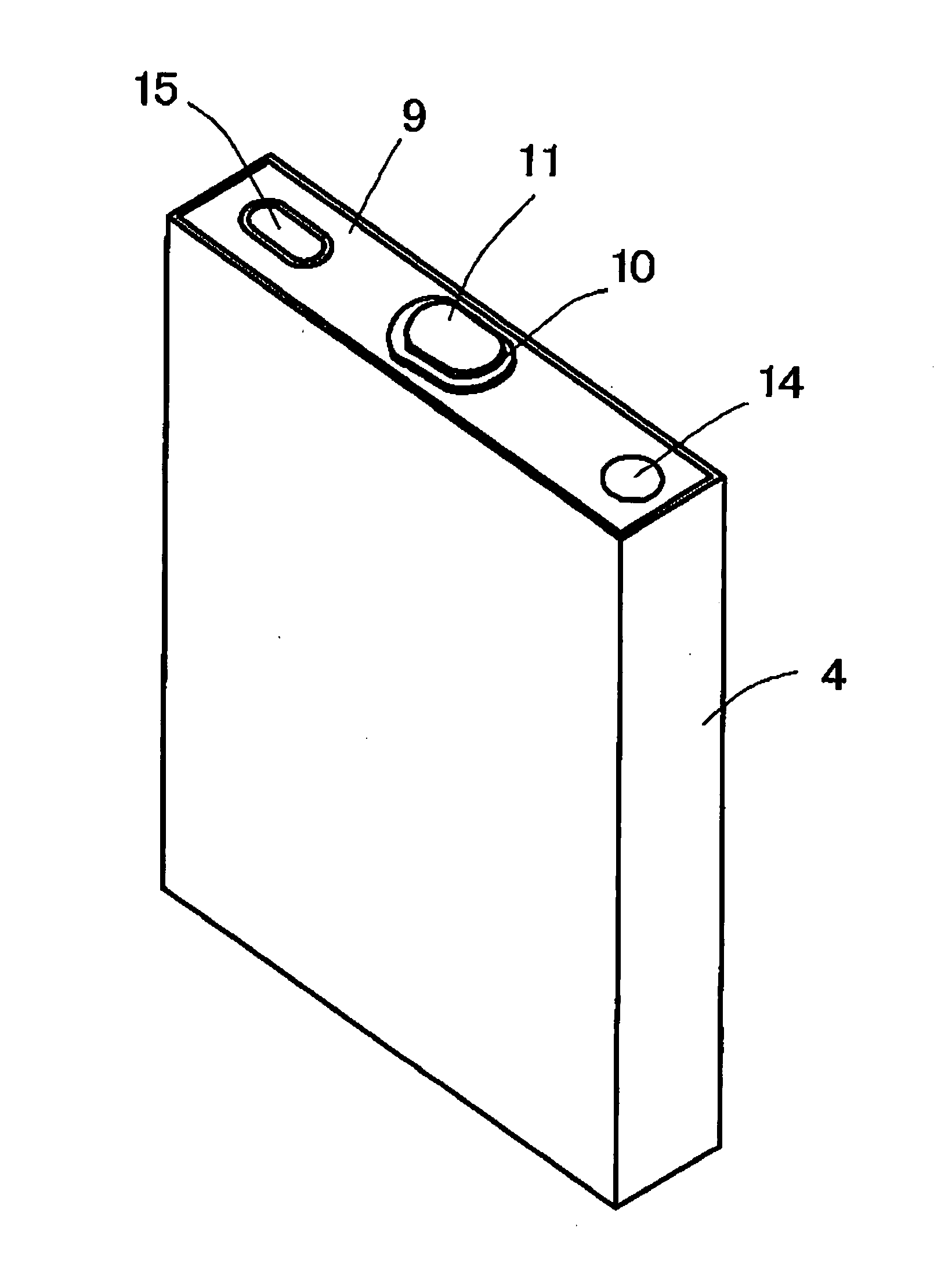

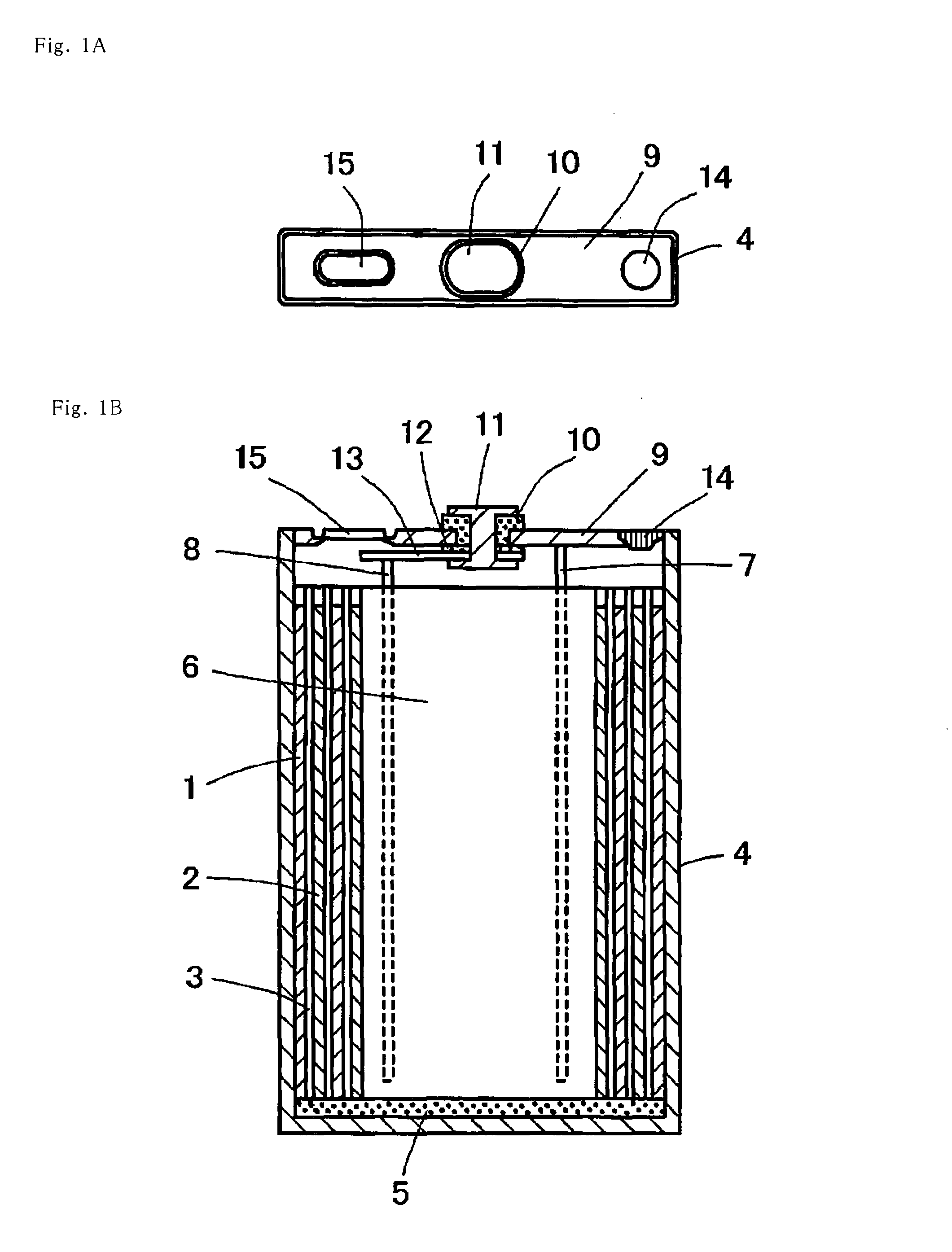

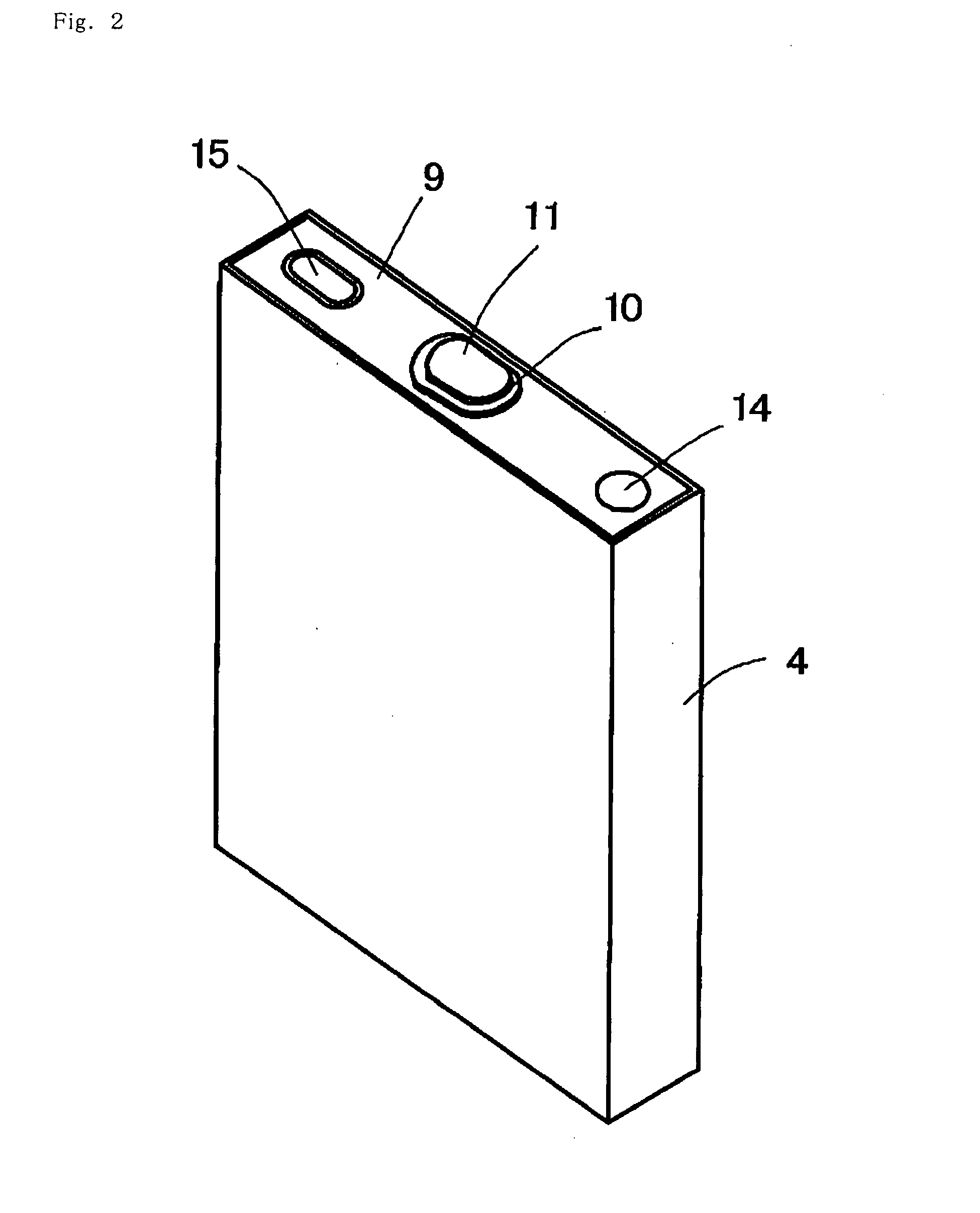

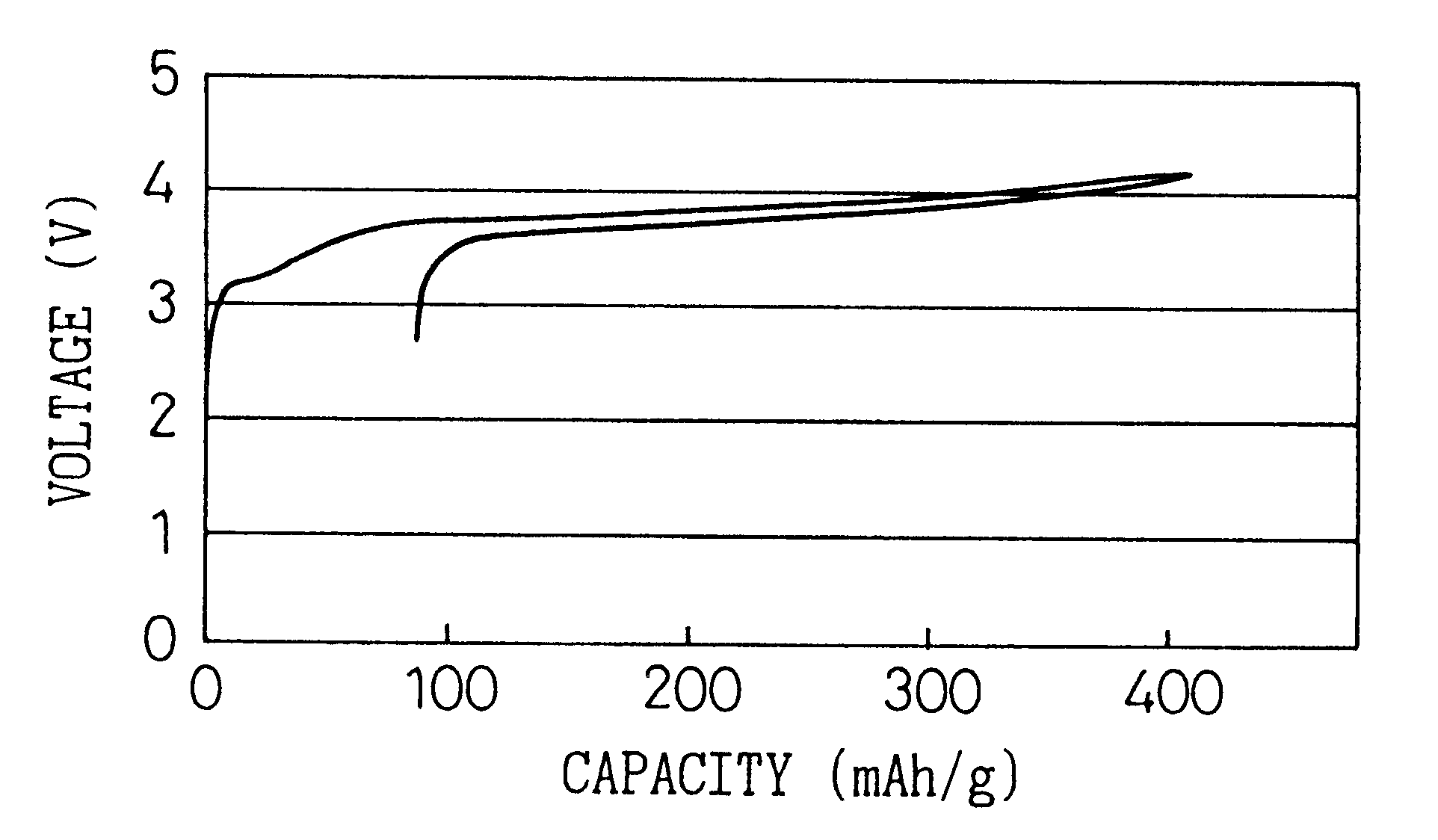

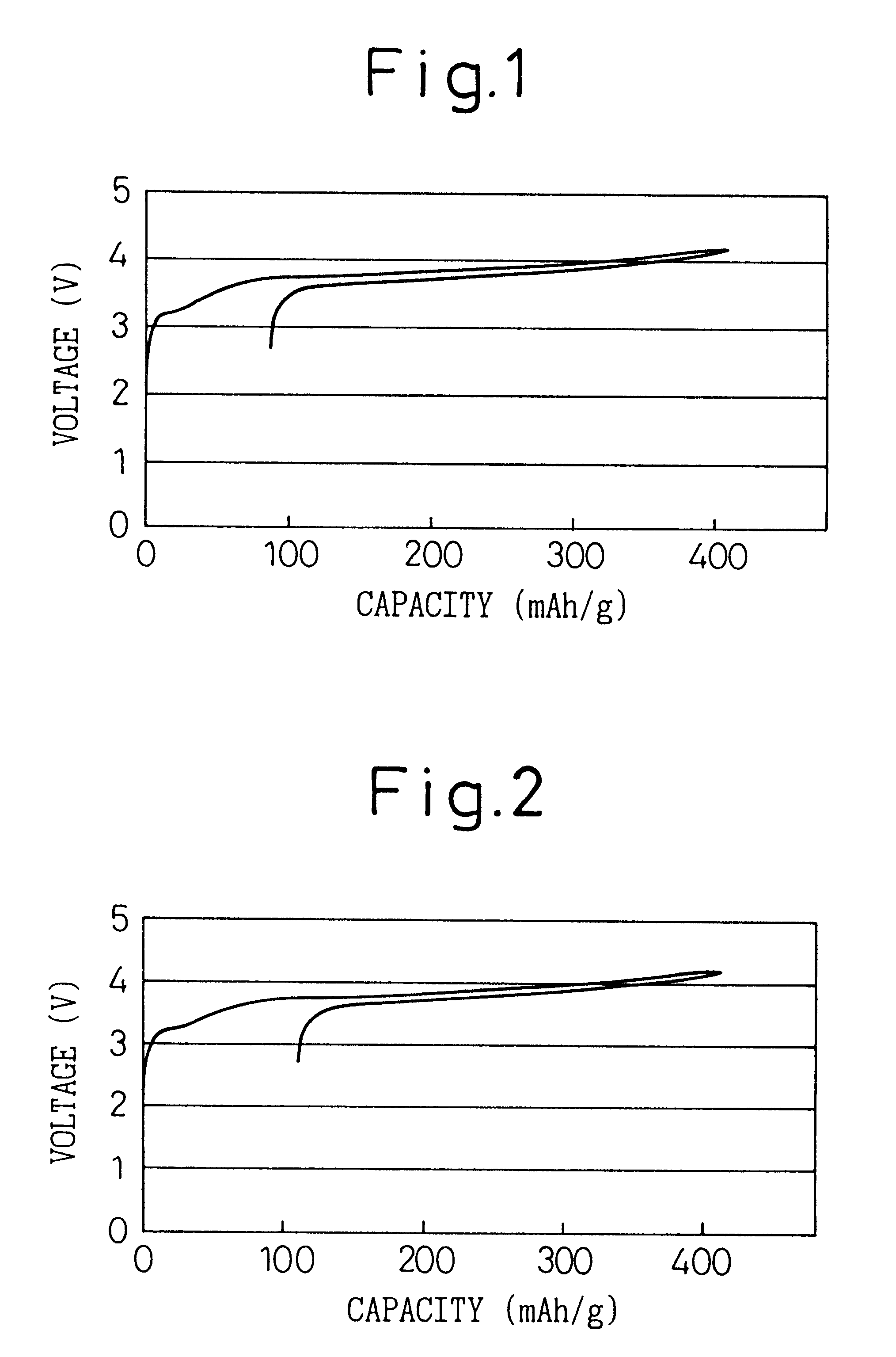

Nonaqueous secondary battery and method of using the same

ActiveUS20080102369A1Deterioration of characteristicDifficult to formFinal product manufactureActive material electrodesOxideMetal

A nonaqueous secondary battery having a positive electrode having a positive electrode mixture layer, a negative electrode, and a nonaqueous electrolyte, in which the positive electrode contains, as an active material, a lithium-containing transition metal oxide containing a metal element selected from the group consisting of Mg, Ti, Zr, Ge, Nb, Al and Sn, the positive electrode mixture layer has a density of 3.5 g / cm3 or larger, and the nonaqueous electrolyte contains a compound having two or more nitrile groups in the molecule

Owner:MAXELL HLDG LTD

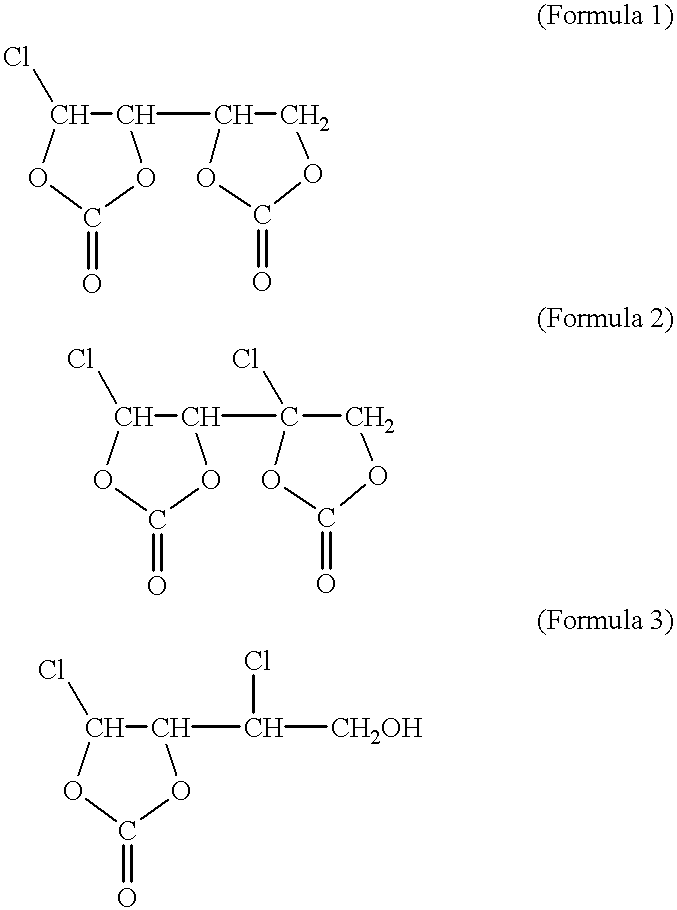

Non-aqueous electrolyte and lithium secondary battery using the same

InactiveUS6413678B1Satisfactory battery characteristicDeterioration of characteristicOrganic electrolyte cellsActive material electrodesPhysical chemistrySolvent

A non-aqueous electrolyte comprising a non-aqueous solvent and a lithium salt dissolved therein, and a cyclic carbonate, linear carbonate, and vinylene carbonate having a chlorine content of 100 ppm or less, and a lithium secondary battery using the same.

Owner:UBE IND LTD

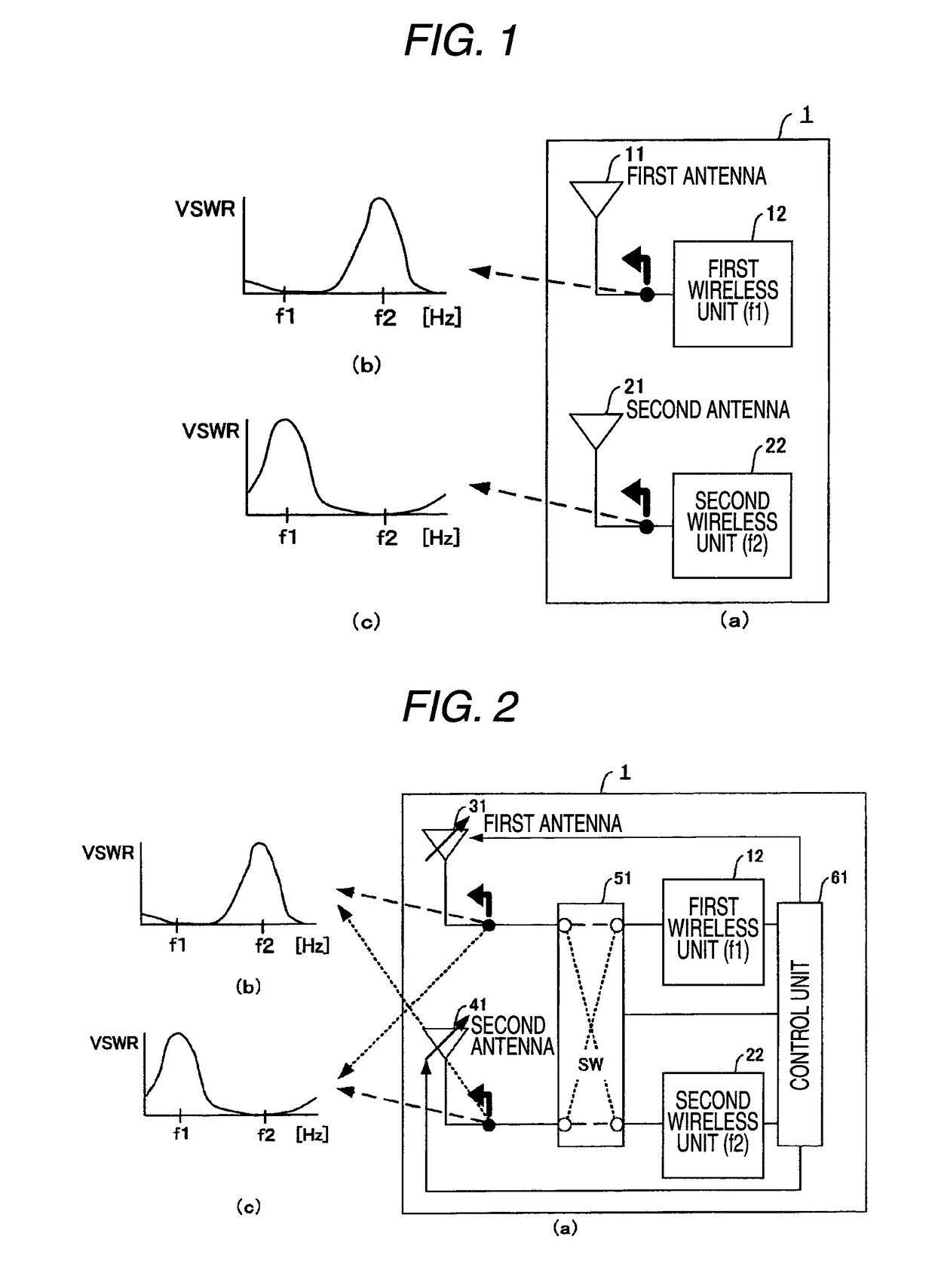

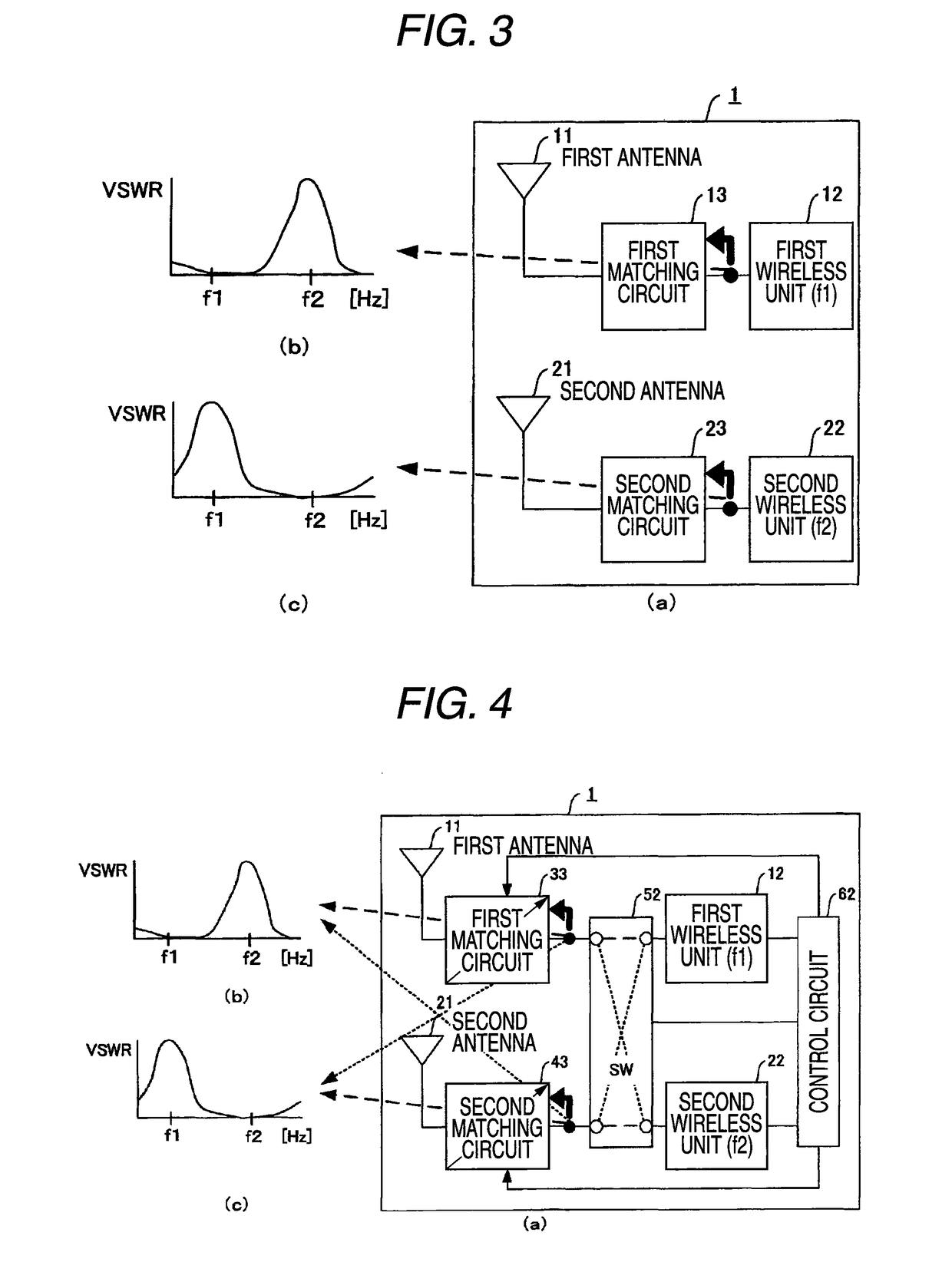

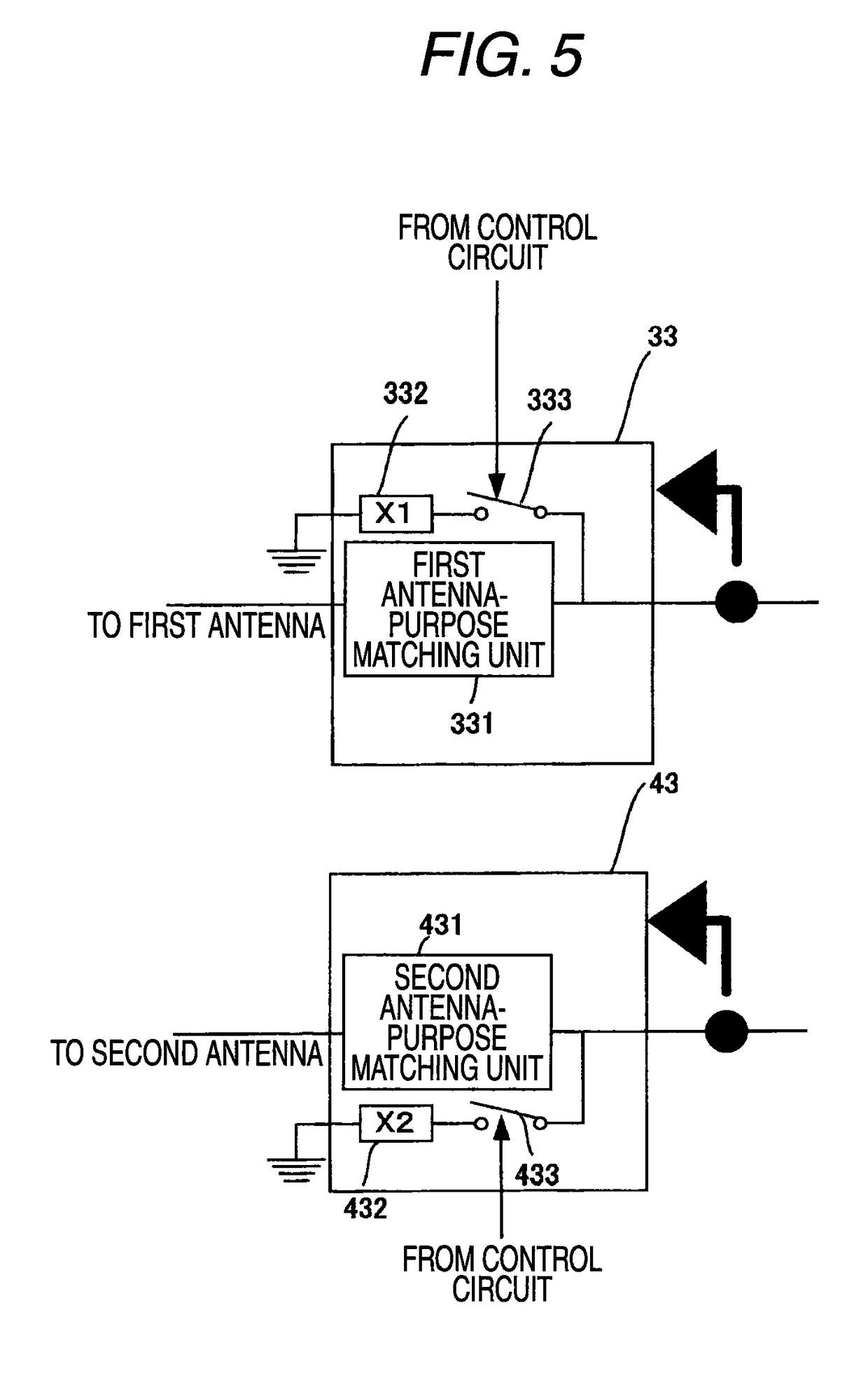

Portable terminal apparatus

InactiveUS7907094B2Deterioration of characteristicAntenna supports/mountingsRadio transmissionTerminal equipmentFrequency characteristic

Owner:PANASONIC CORP

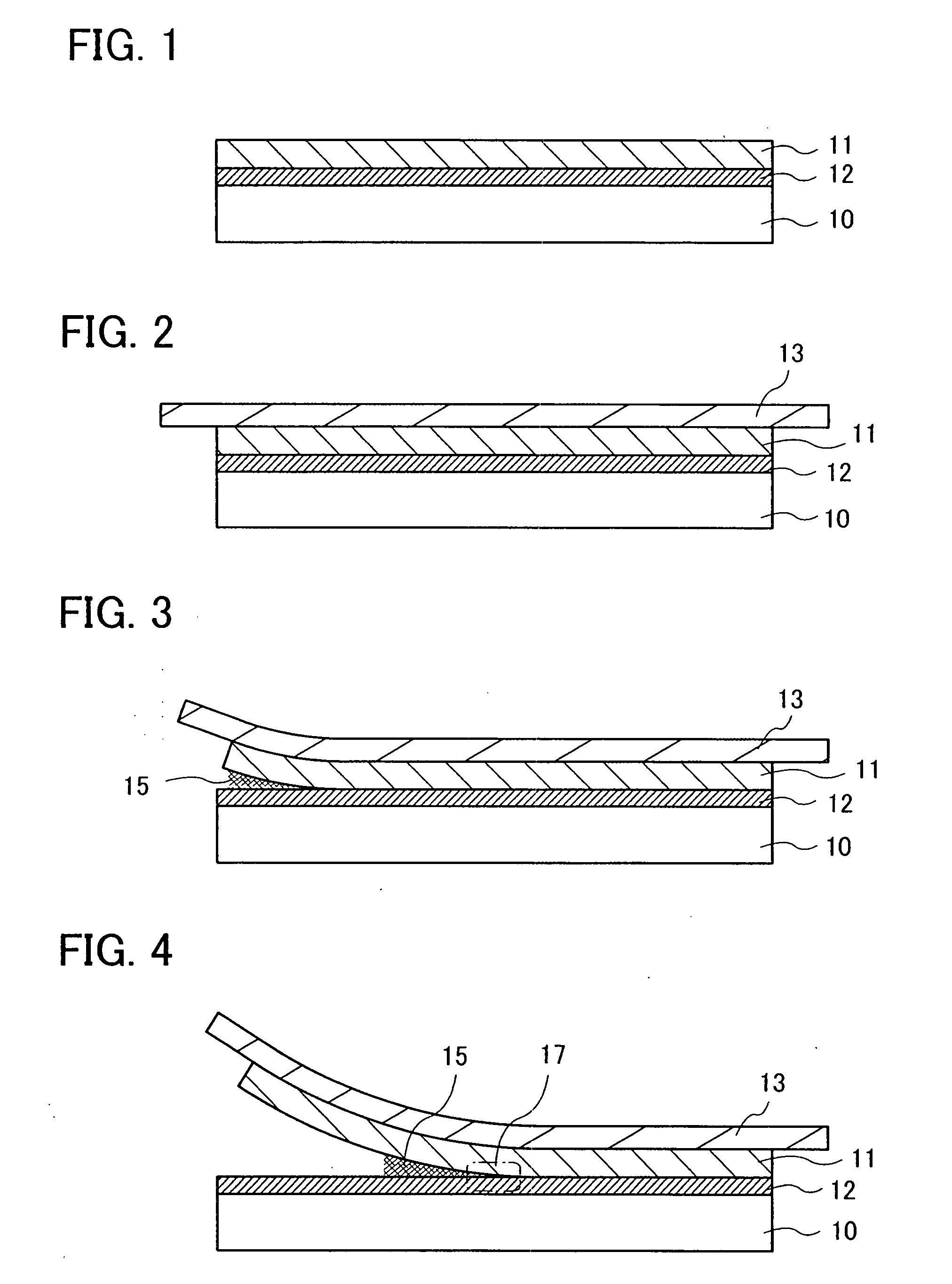

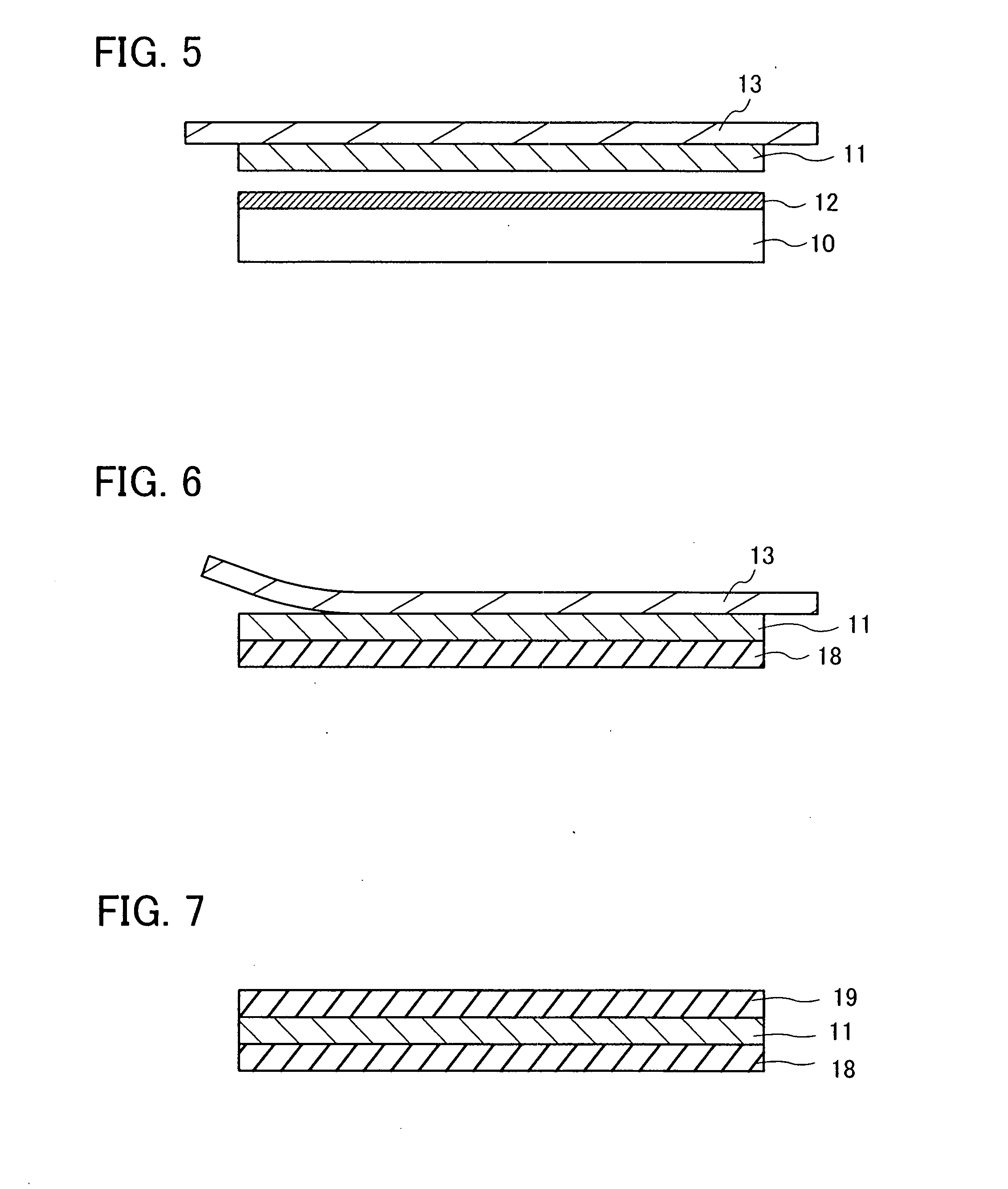

Method for manufacturing semiconductor device

ActiveUS20080132033A1Avoid destruction and characteristic deteriorationReduce surface resistanceSolid-state devicesSemiconductor/solid-state device manufacturingLiquid diffusionDevice material

An object is to suppress discharge due to static electricity generated by peeling, when an element formation layer including a semiconductor element is peeled from a substrate. Over the substrate, the release layer and the element formation layer are formed. The support base material which can be peeled later is fixed to the upper surface of the element formation layer. The element formation layer is transformed through the support base material, and peeling is generated at an interface between the element formation layer and the release layer. Peeling is performed while the liquid is being supplied so that the element formation layer and the release layer which appear sequentially by peeling are wetted with the liquid such as pure water. Electric charge generated on the surfaces of the element formation layer and the release layer can be diffused by the liquid, and discharge by peeling electrification can be eliminated.

Owner:SEMICON ENERGY LAB CO LTD

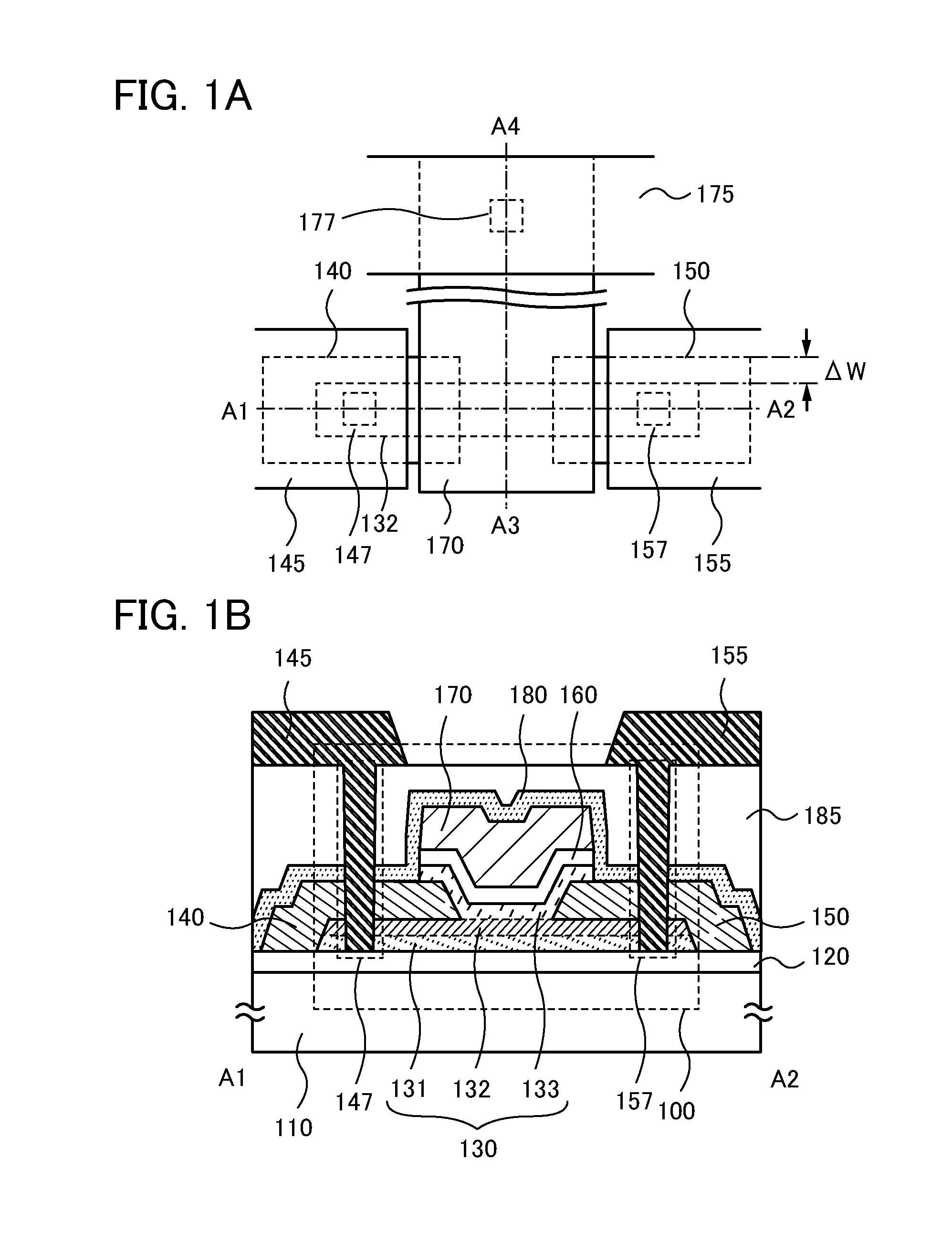

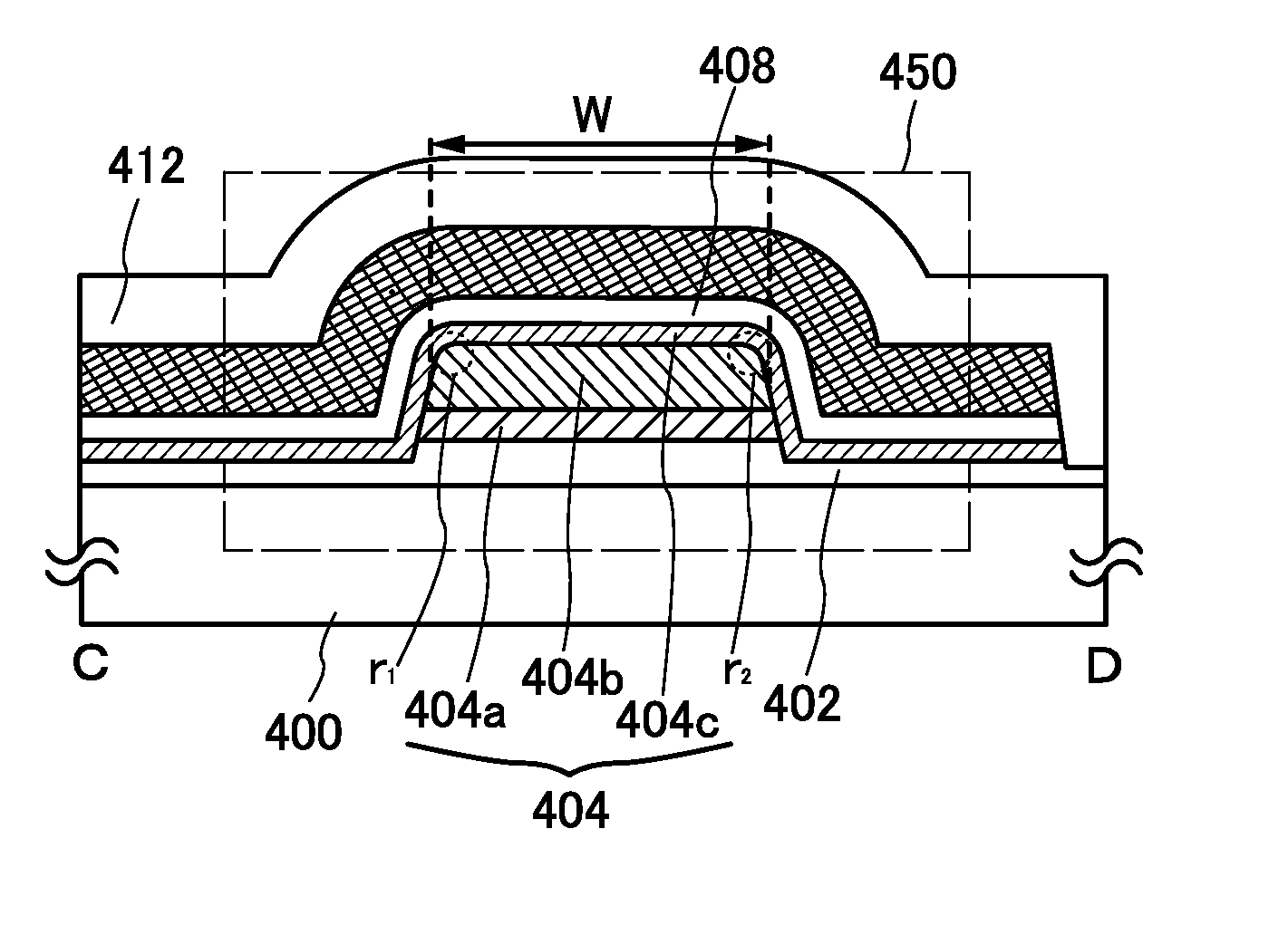

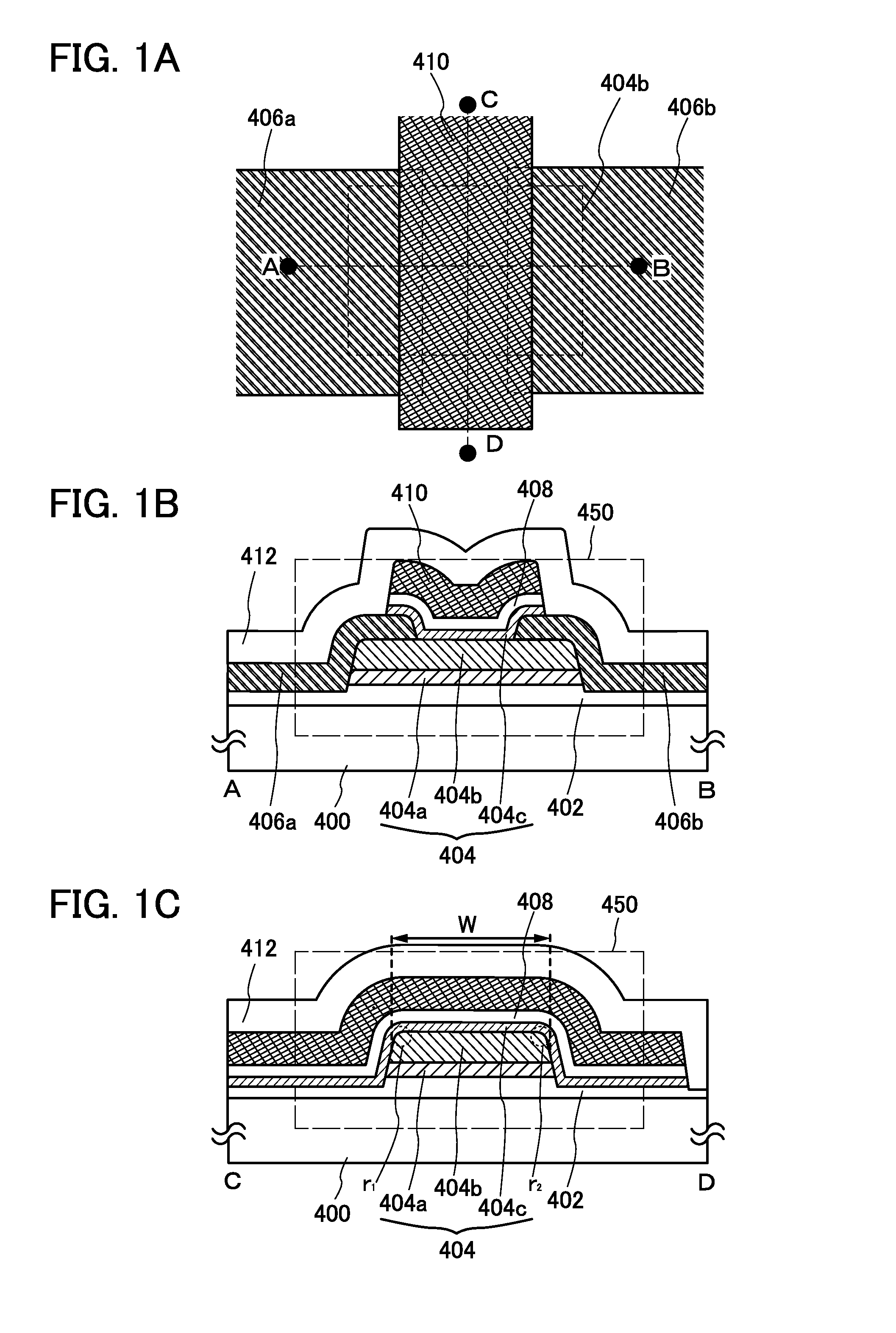

Semiconductor device

InactiveUS20140339544A1Easy to integrateReduce power consumptionTransistorSolid-state devicesSemiconductorSemiconductor device

Provided is a semiconductor device in which deterioration of electric characteristics which becomes more noticeable as the semiconductor device is miniaturized can be suppressed. The semiconductor device includes a first oxide film, an oxide semiconductor film over the first oxide film, a source electrode and a drain electrode in contact with the oxide semiconductor film, a second oxide film over the oxide semiconductor film, the source electrode, and the drain electrode, a gate insulating film over the second oxide film, and a gate electrode in contact with the gate insulating film. A top end portion of the oxide semiconductor film is curved when seen in a channel width direction.

Owner:SEMICON ENERGY LAB CO LTD

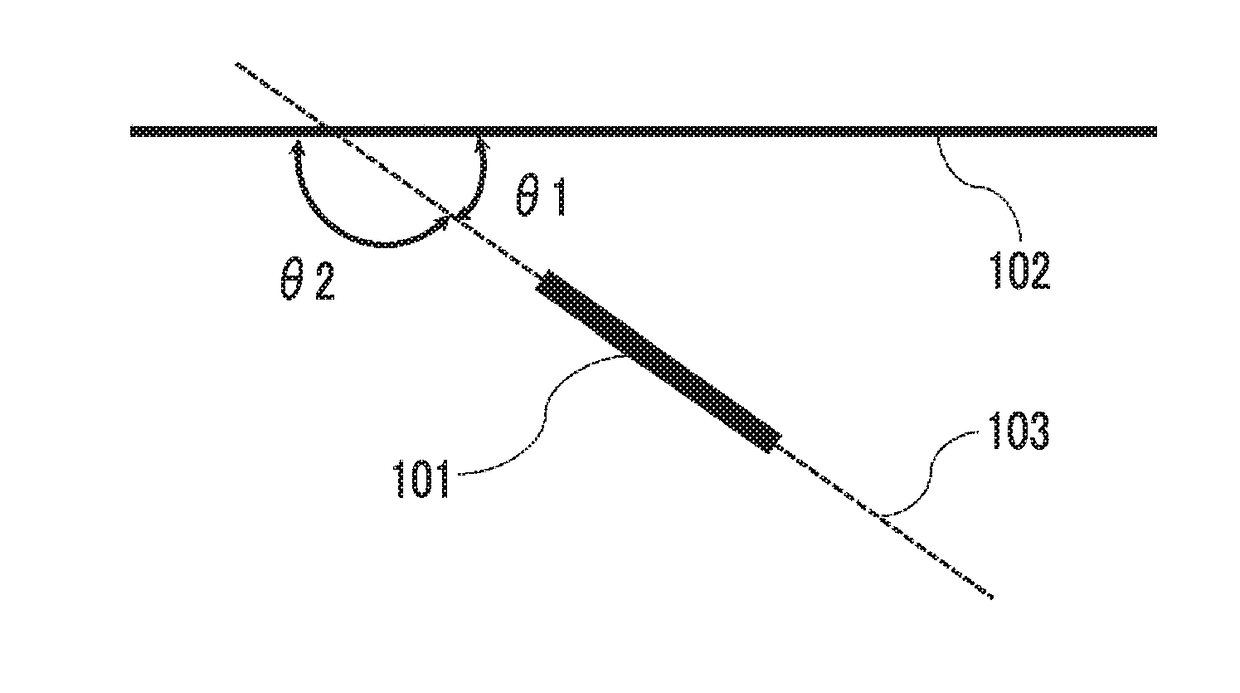

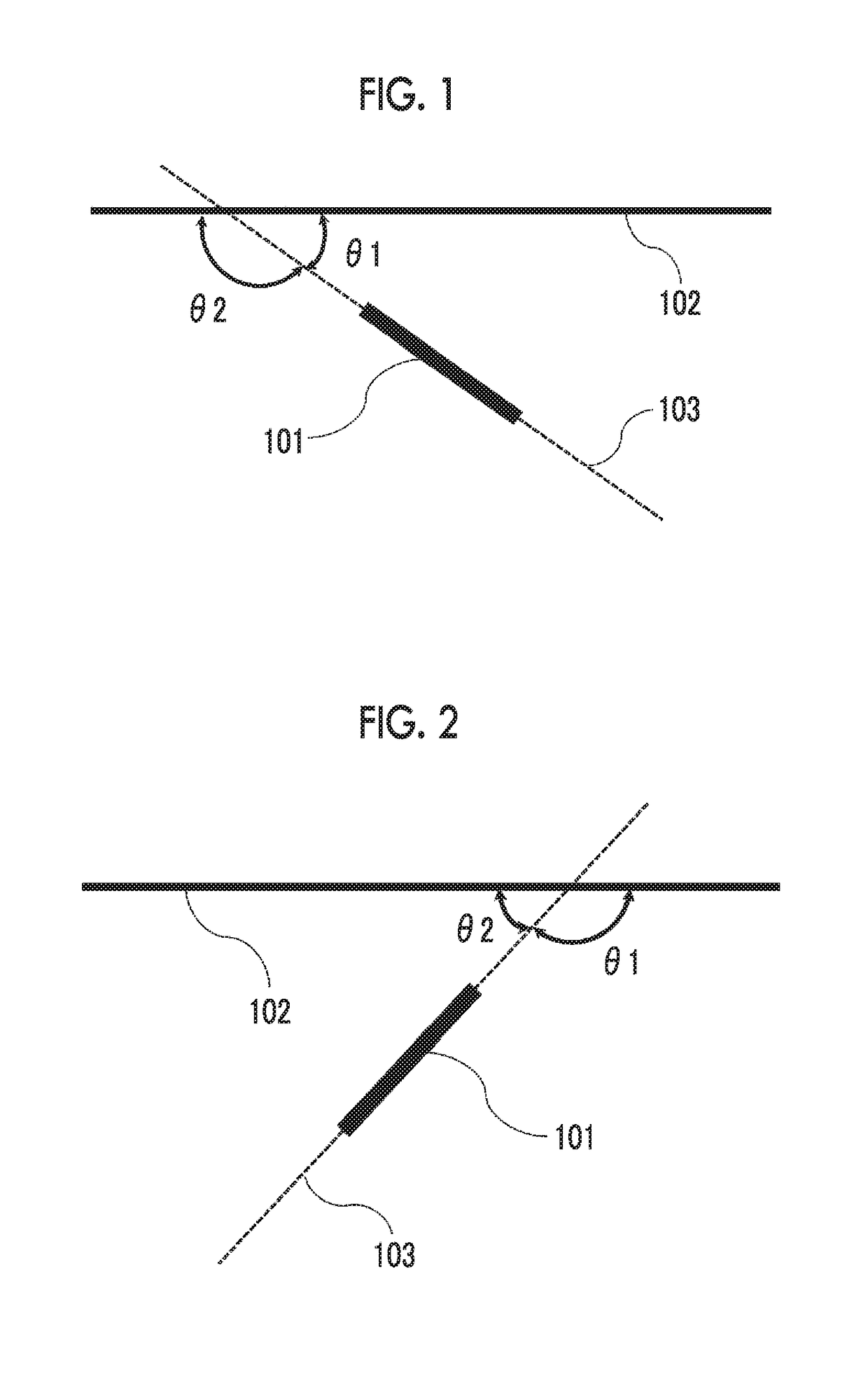

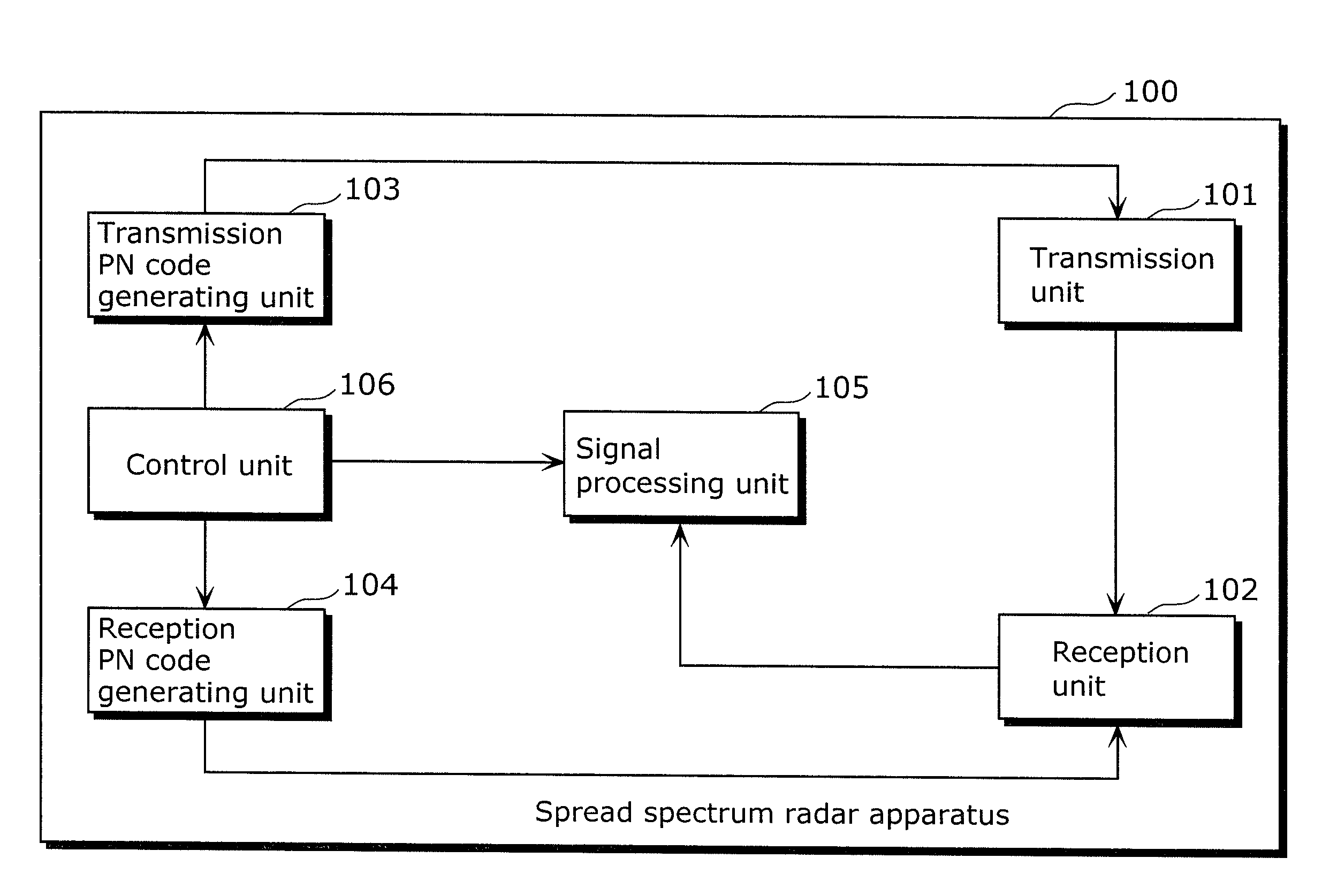

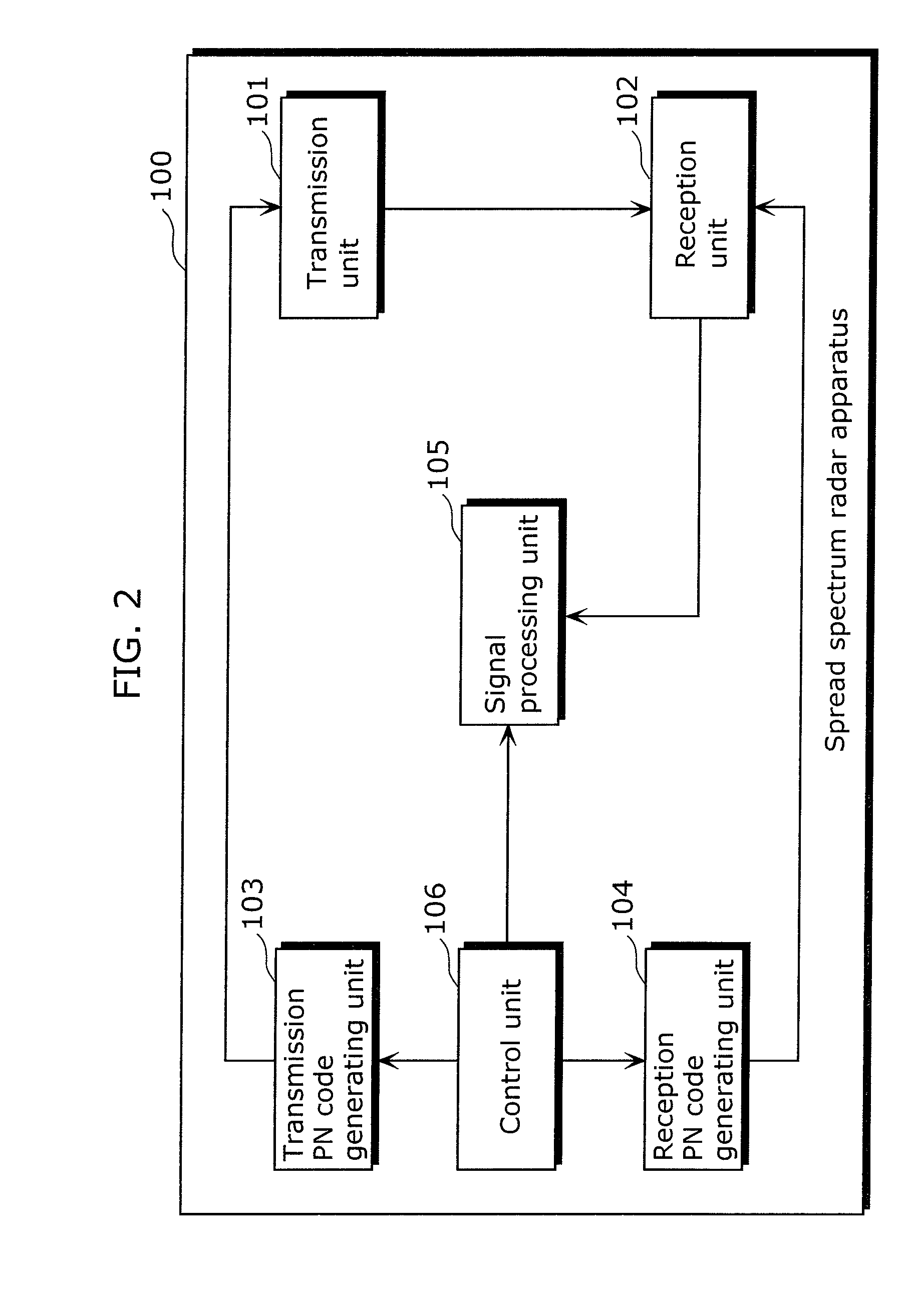

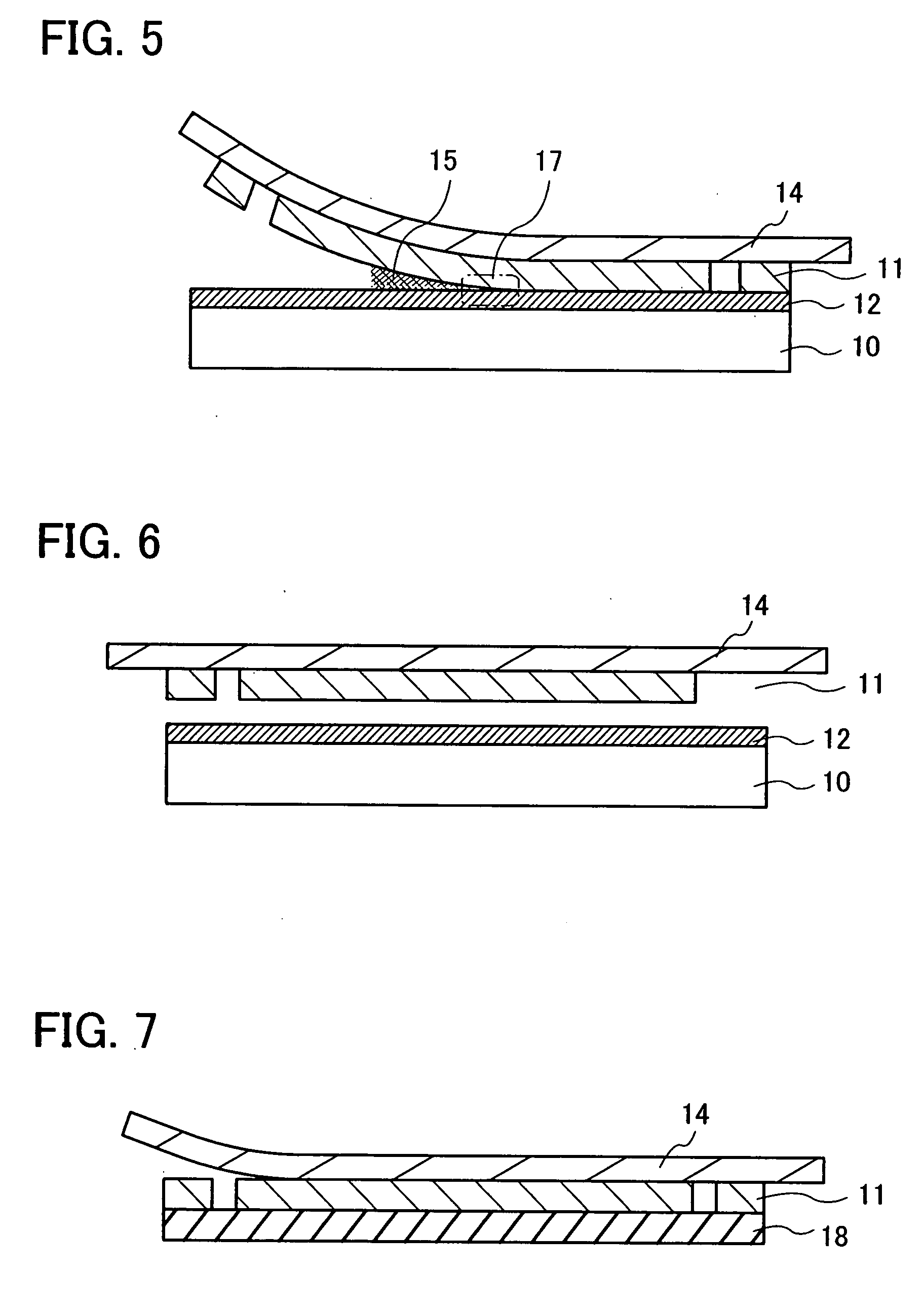

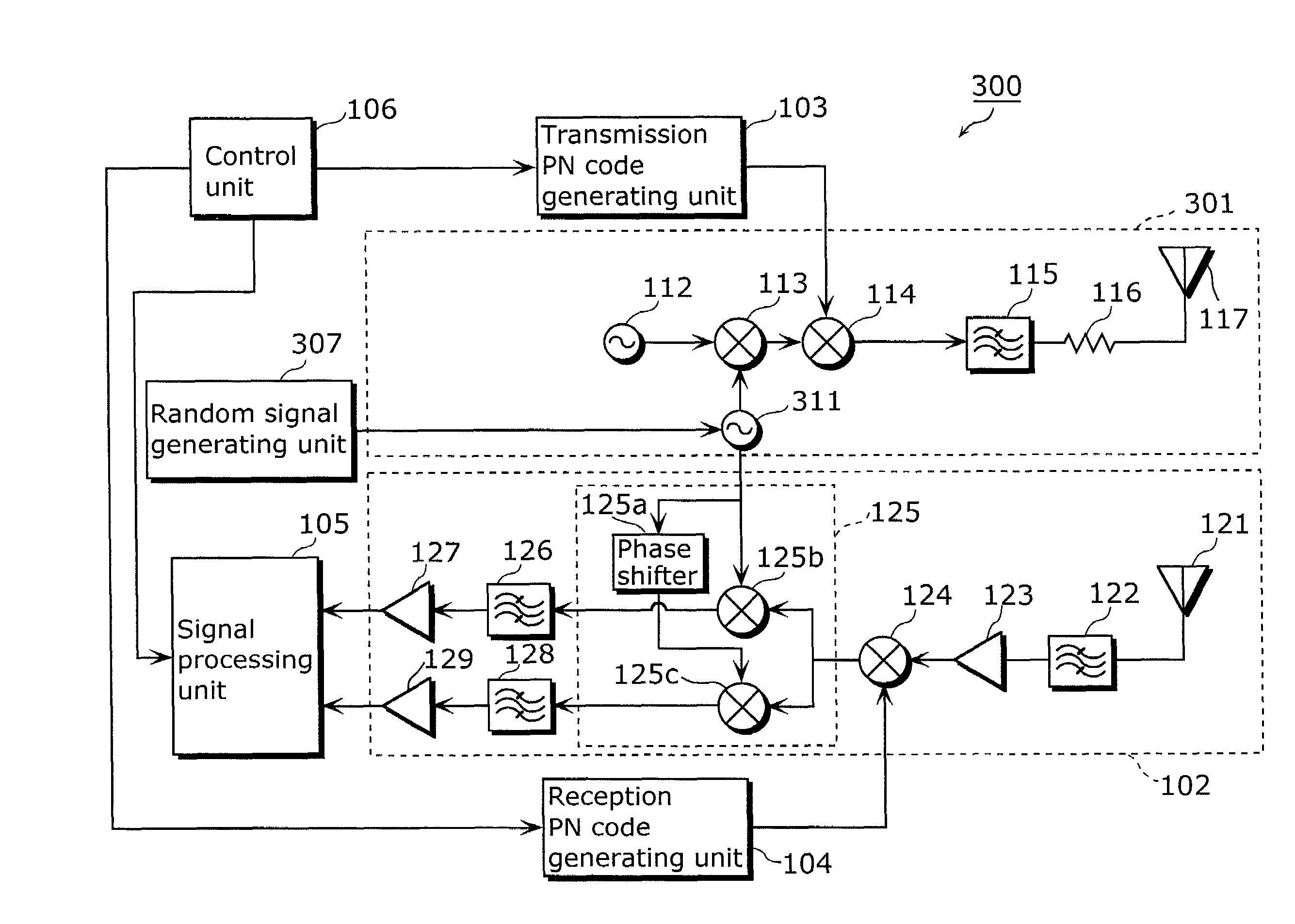

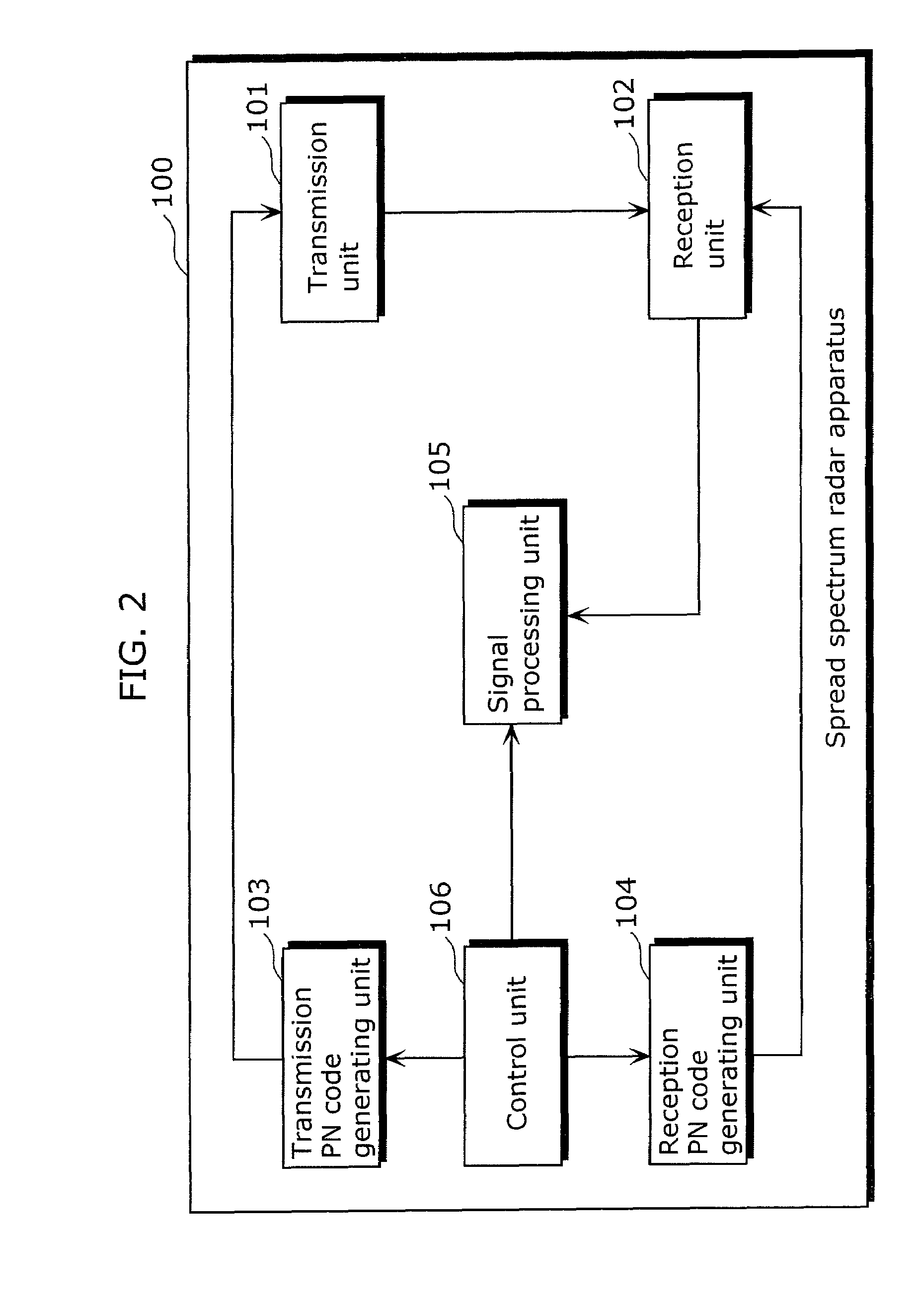

Spread spectrum radar apparatus

InactiveUS20090015464A1Wide detection rangeImprove performanceTransmissionRadio wave reradiation/reflectionPhysics

A spread spectrum radar apparatus includes: a transmission unit which generates a spread signal that is a spectrum-spread signal, using a first oscillator signal, a second oscillator signal, and a transmission PN code, and which emits the spread signal as a detection radio wave; and a reception unit which receives, as a reception signal, the detection radio wave reflected from an object, and which generates an intermediate frequency signal by despreading the reception signal based on the first oscillator signal and a reception PN code obtained by delaying the transmission PN code.

Owner:PANASONIC CORP

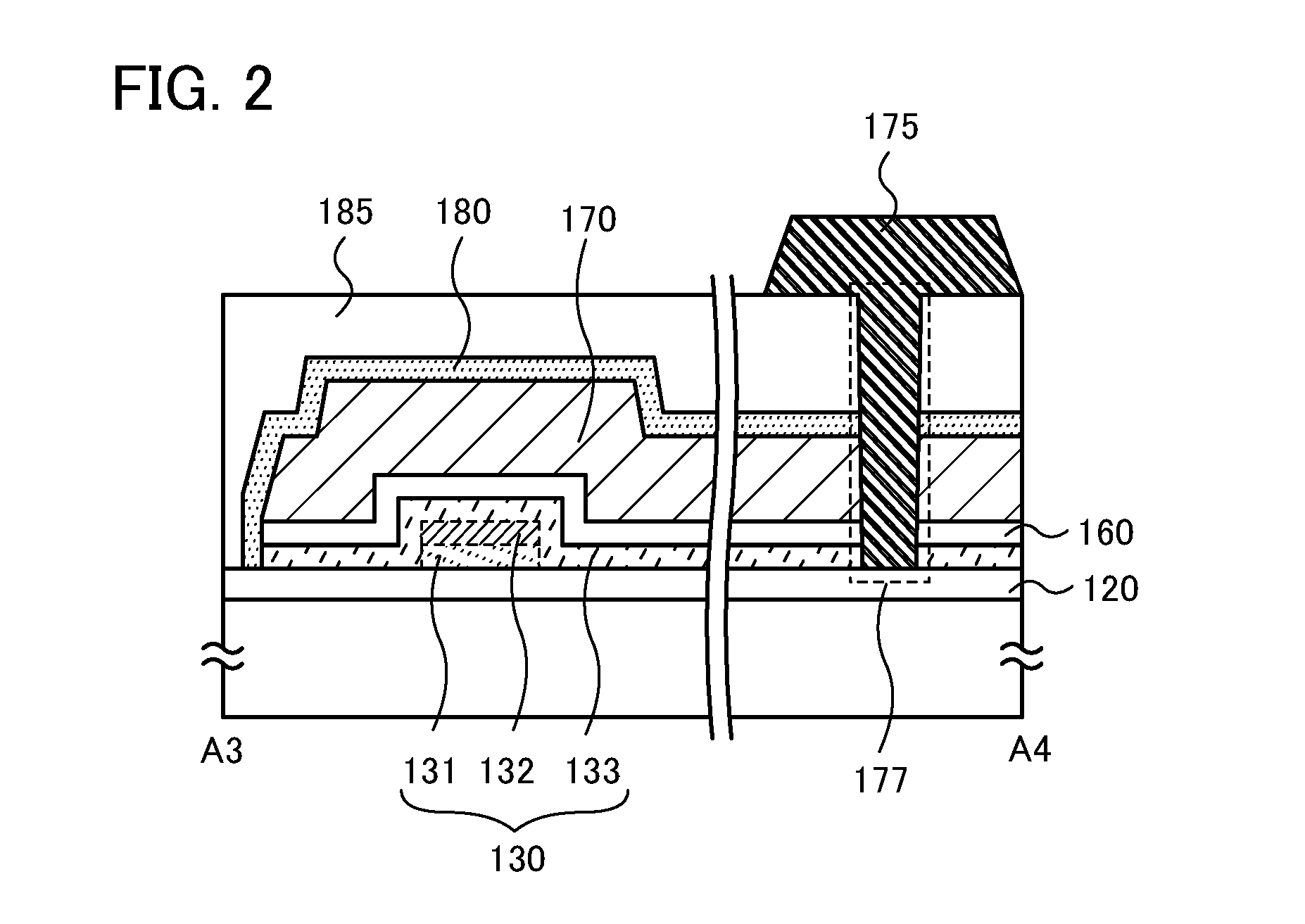

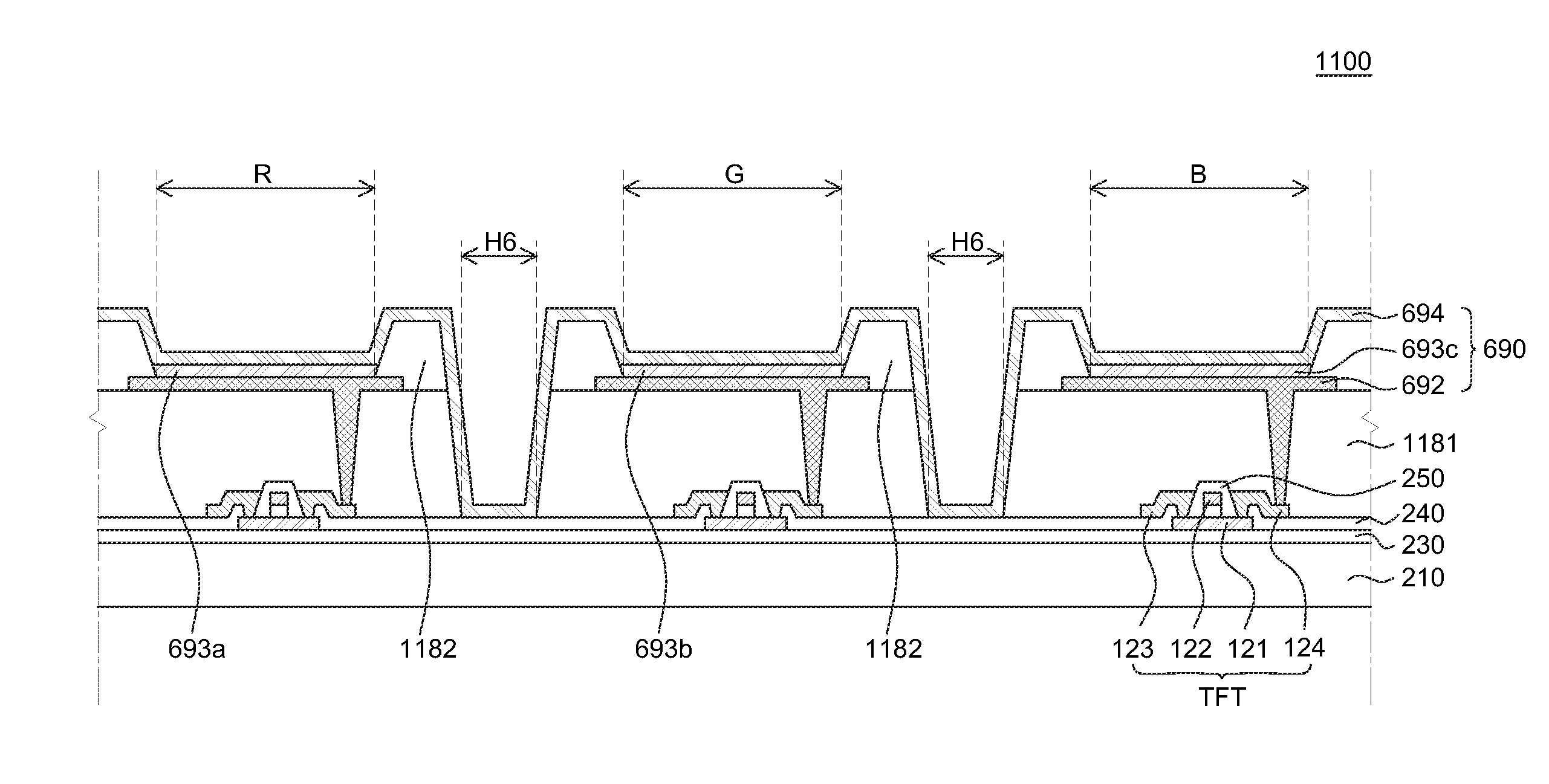

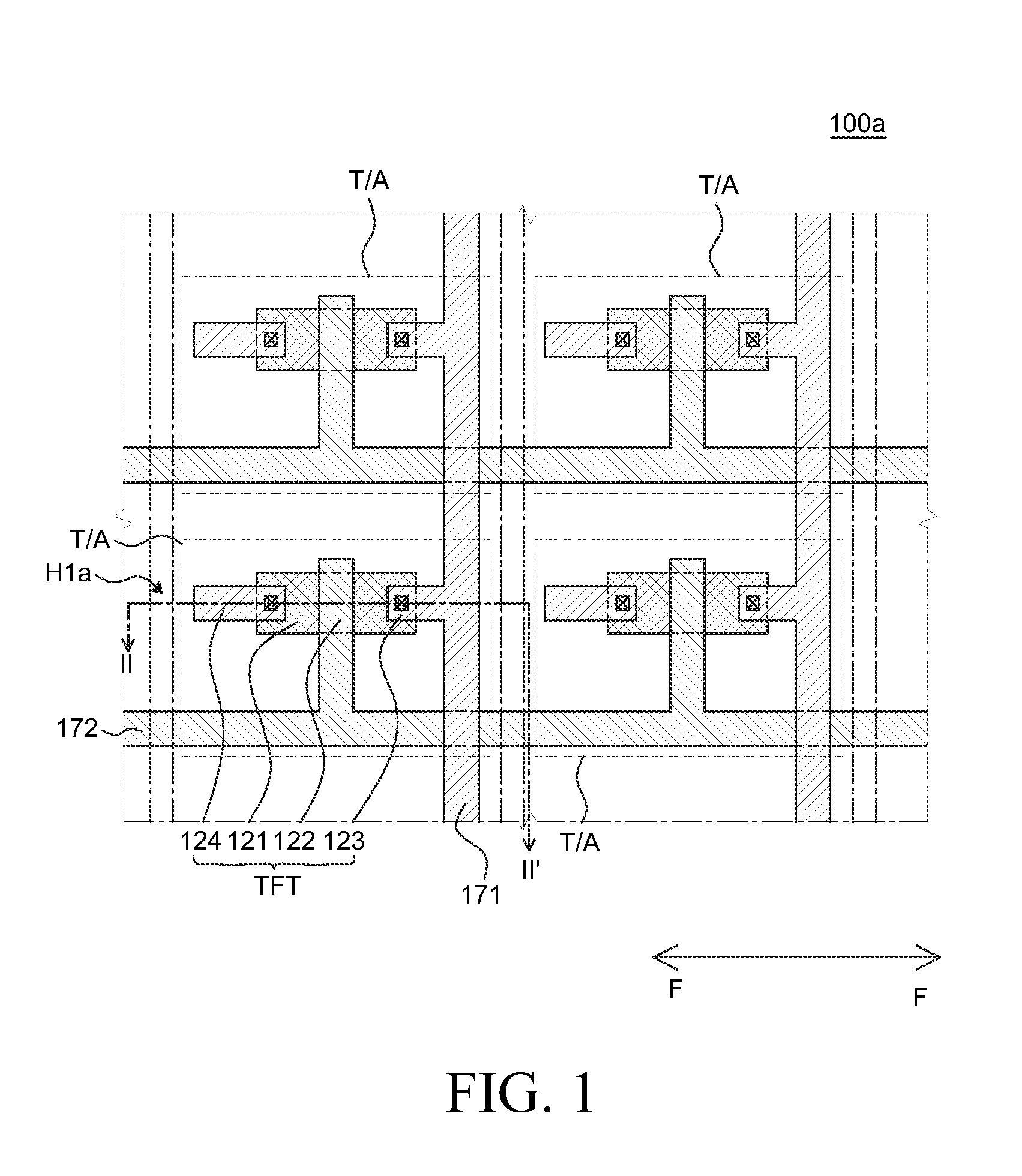

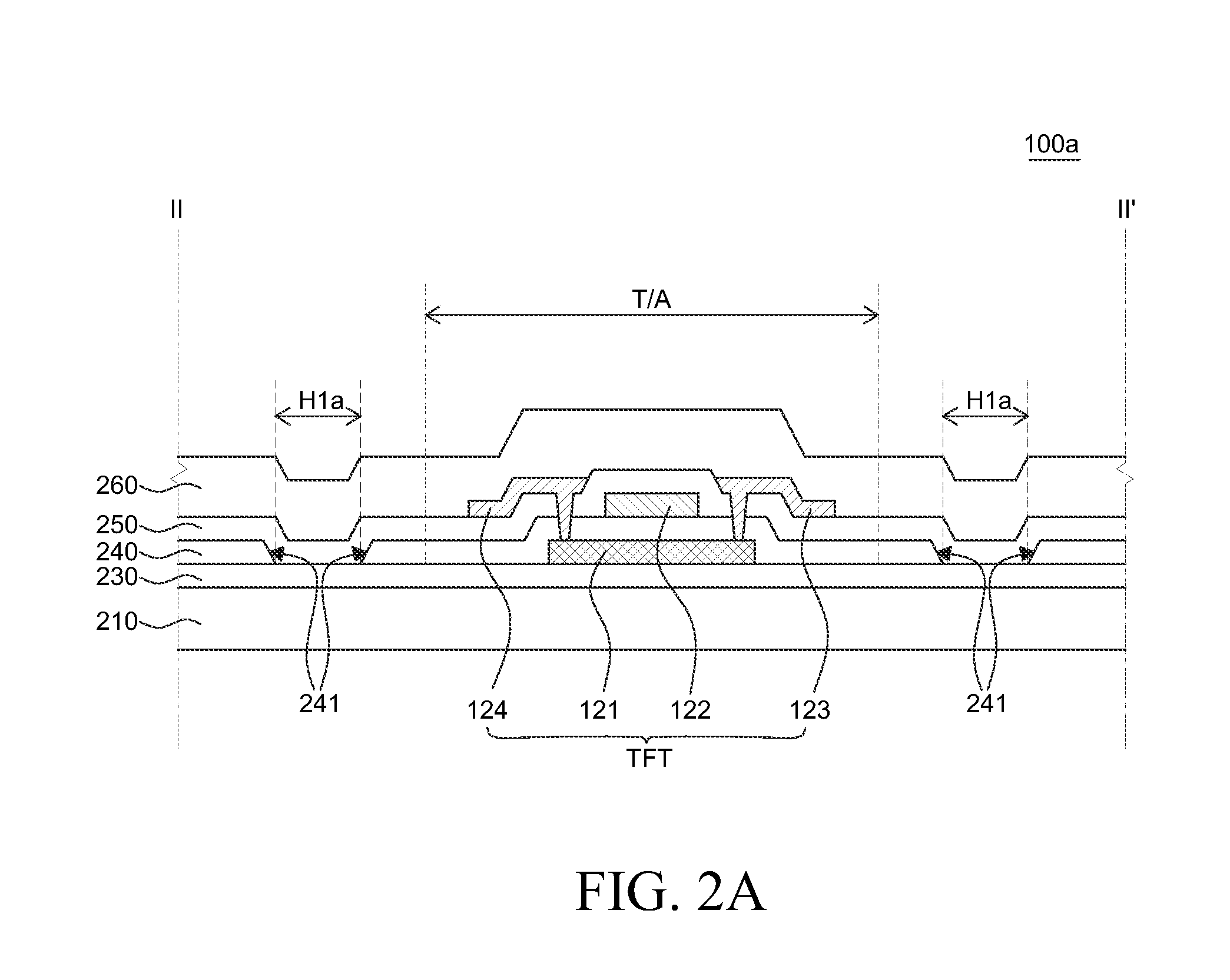

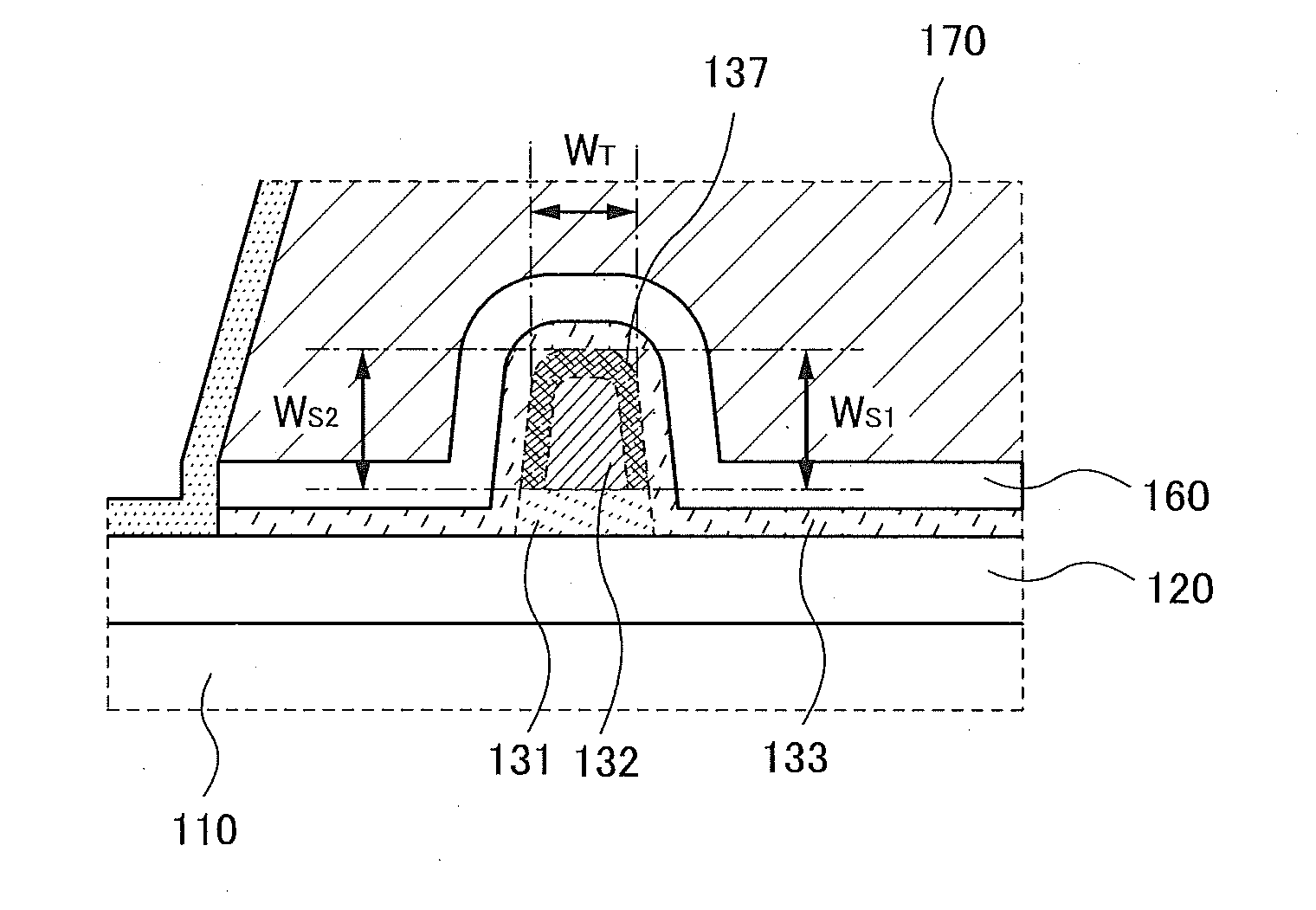

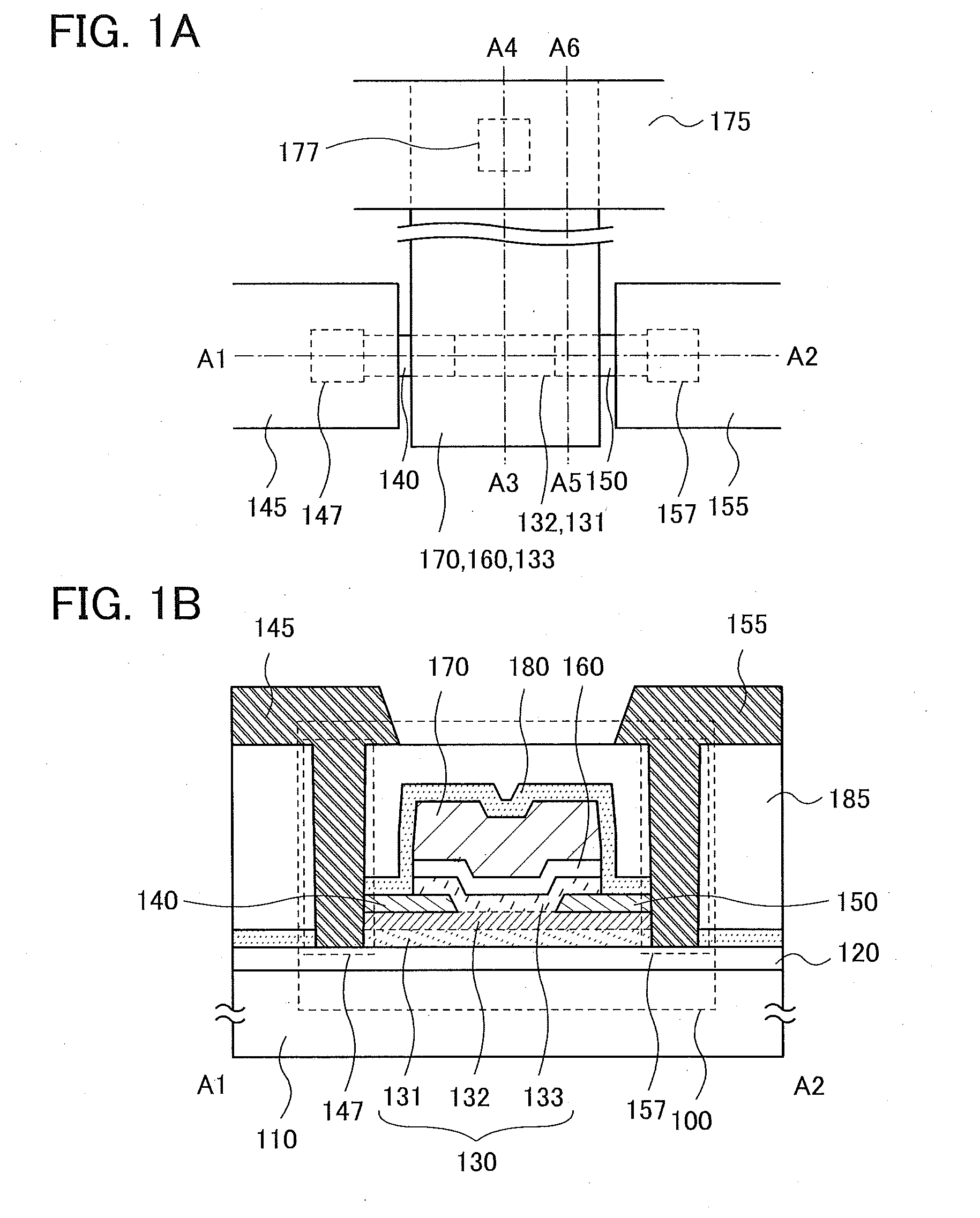

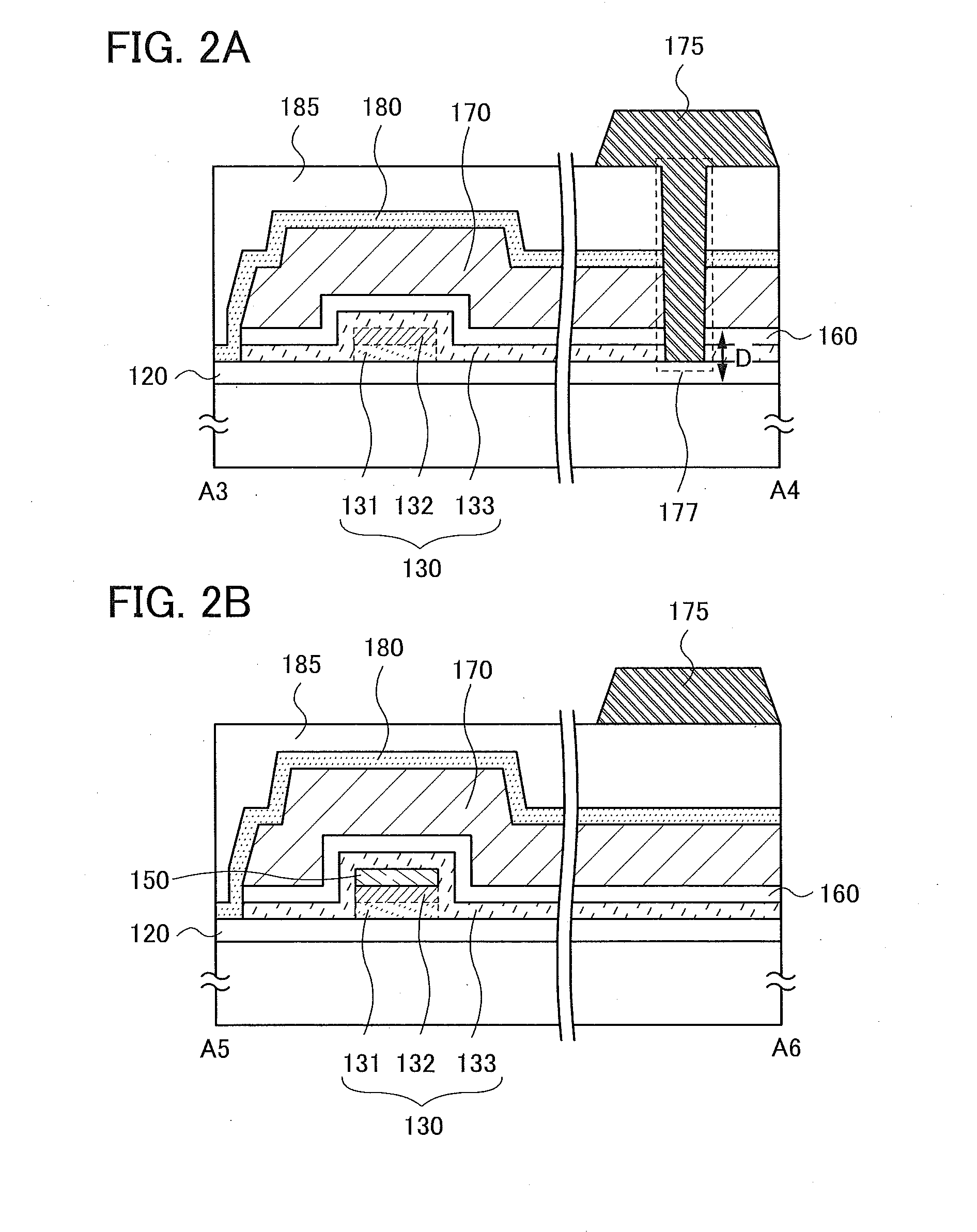

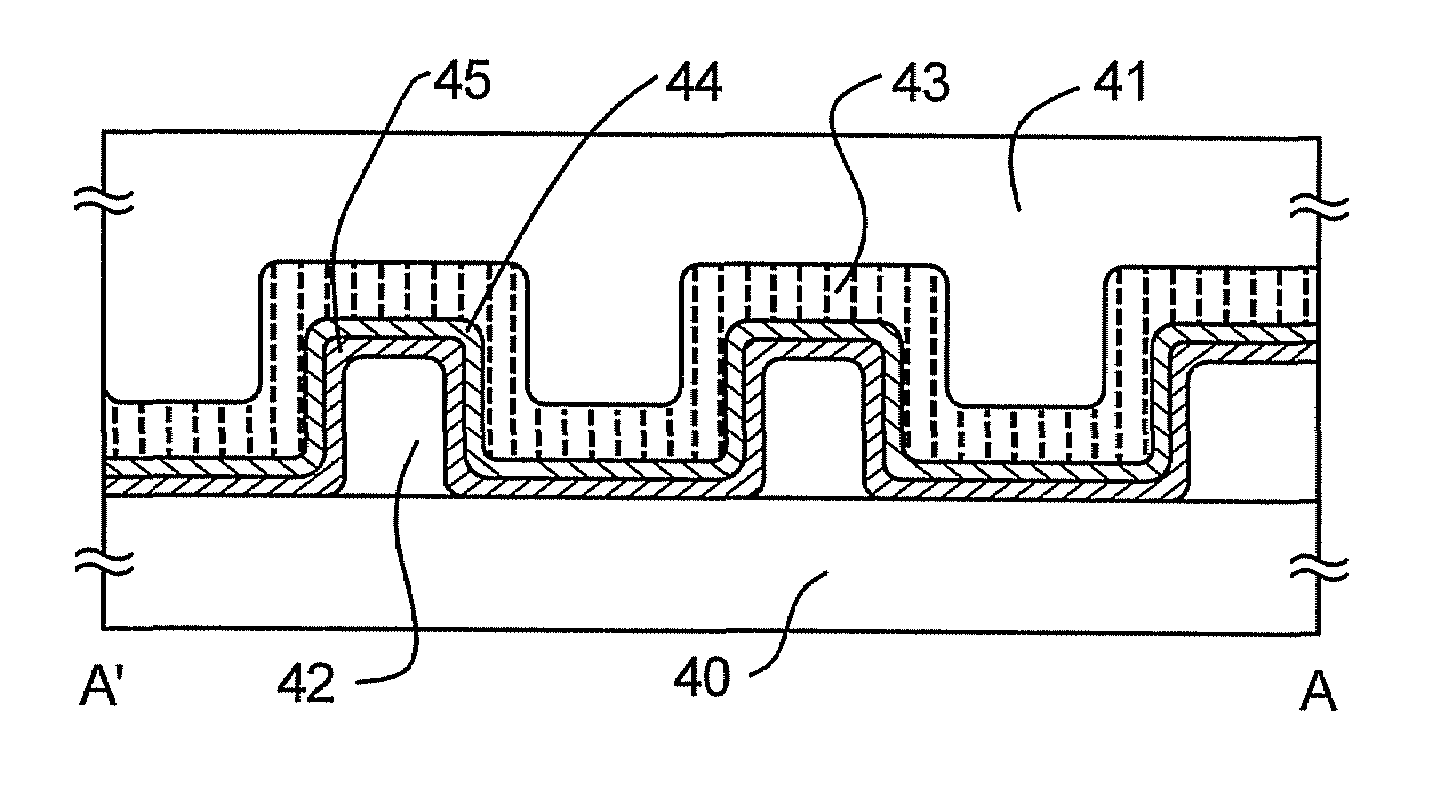

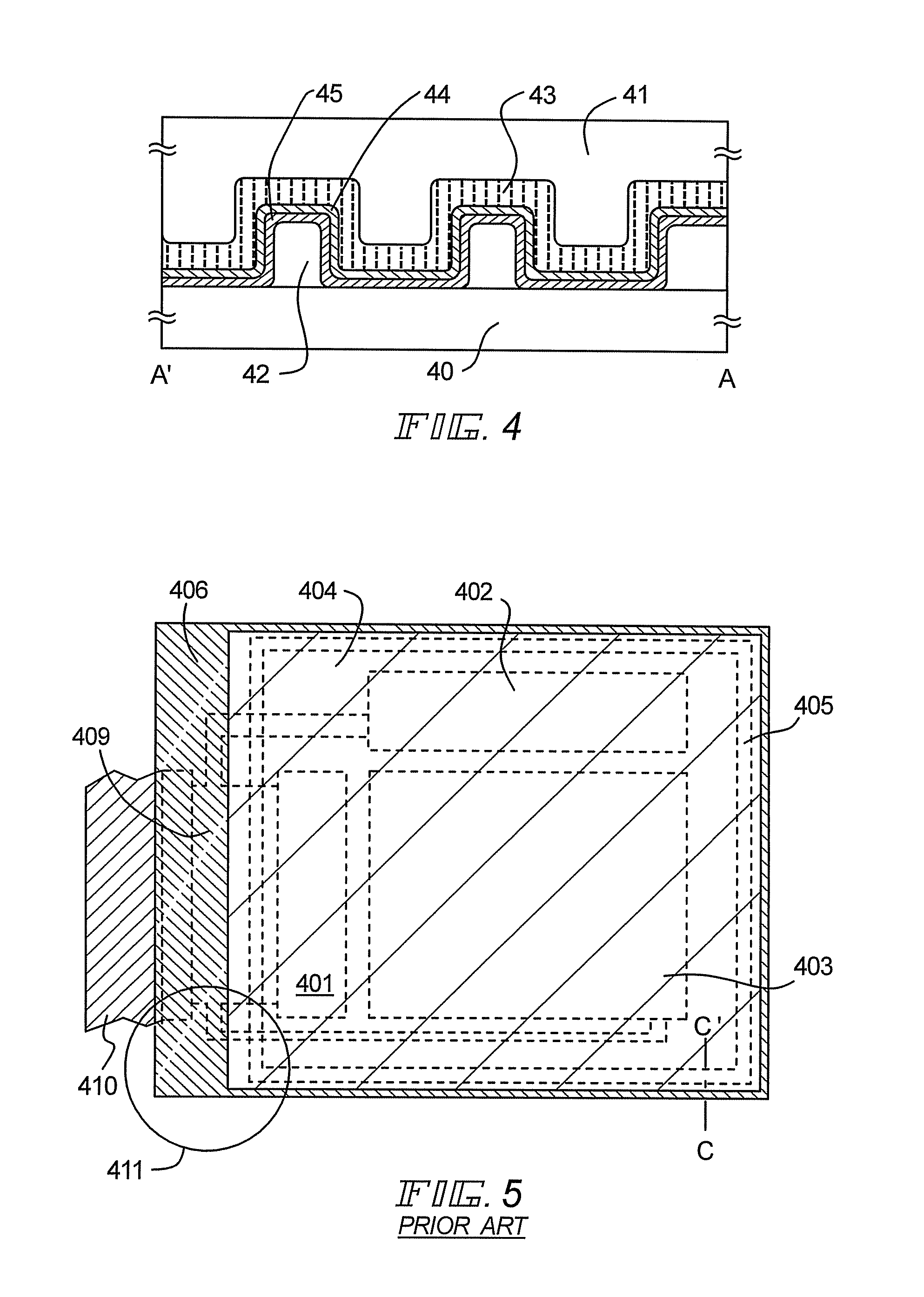

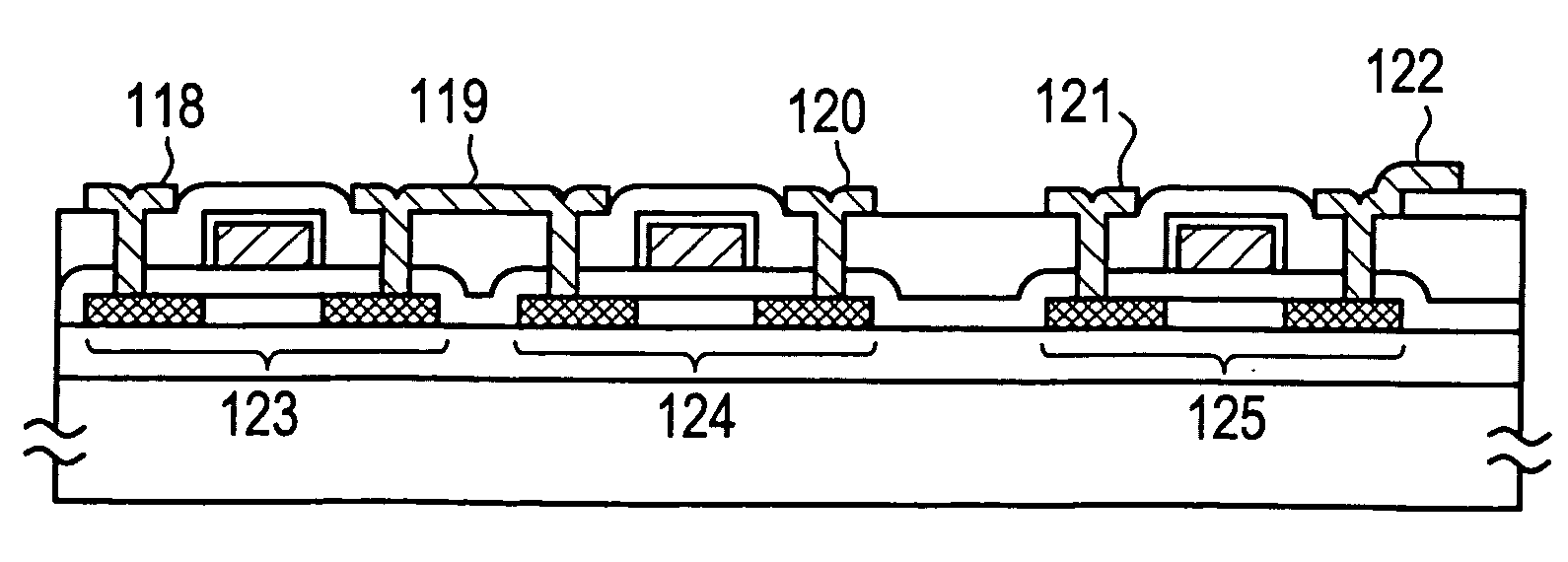

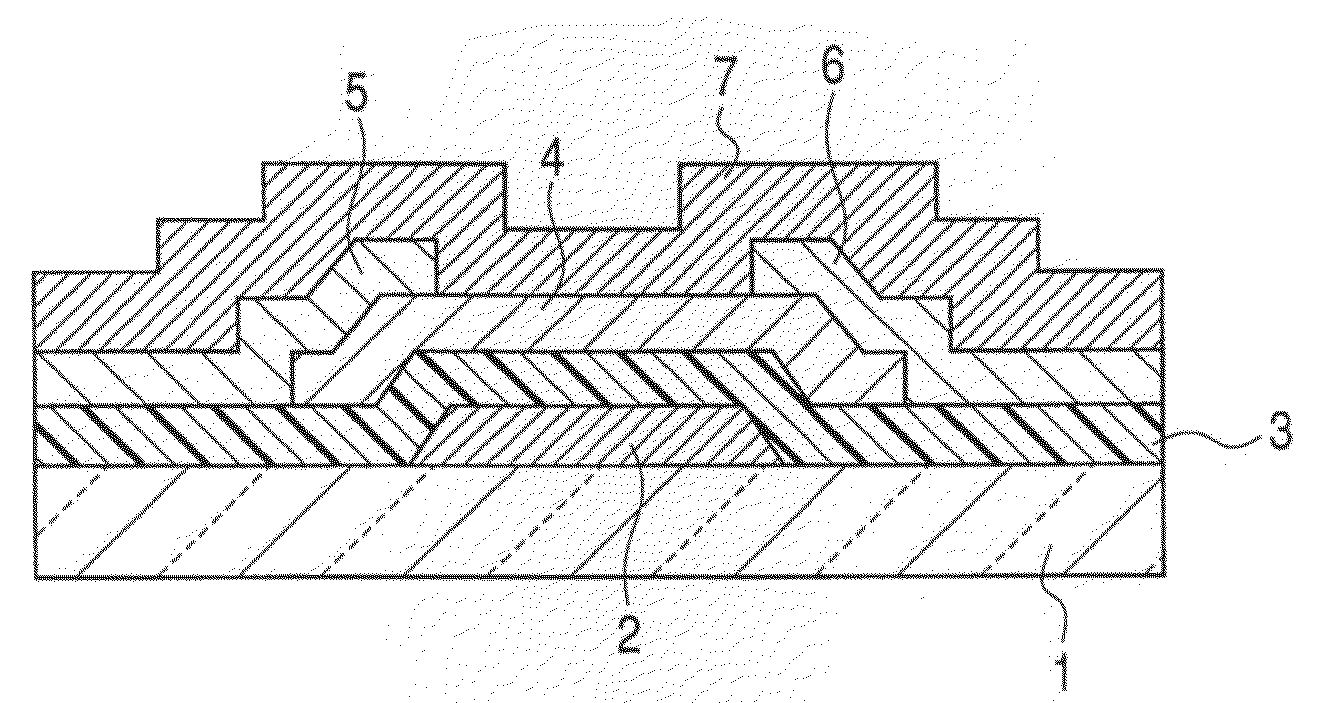

Flexible thin film transistor substrate and flexible organic light emitting display device

ActiveUS20160118451A1Minimize probabilitySuppress propagation of crackSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsInsulation layer

Provided are a flexible thin film transistor substrate and a flexible organic light emitting display device. The flexible thin film transistor substrate includes: a flexible substrate including at least one thin film transistor (TFT) area and having flexibility, an active layer disposed in the TFT area on the flexible substrate, a gate insulation layer disposed on the active layer, a gate electrode overlapping with the active layer on the gate insulation layer, an insulating interlayer disposed on the gate electrode, and a source electrode and a drain electrode disposed on the insulating interlayer and connected with the active layer, respectively. The gate insulation layer or the insulating interlayer includes at least one hole pattern configured to reduce bending stress.

Owner:LG DISPLAY CO LTD

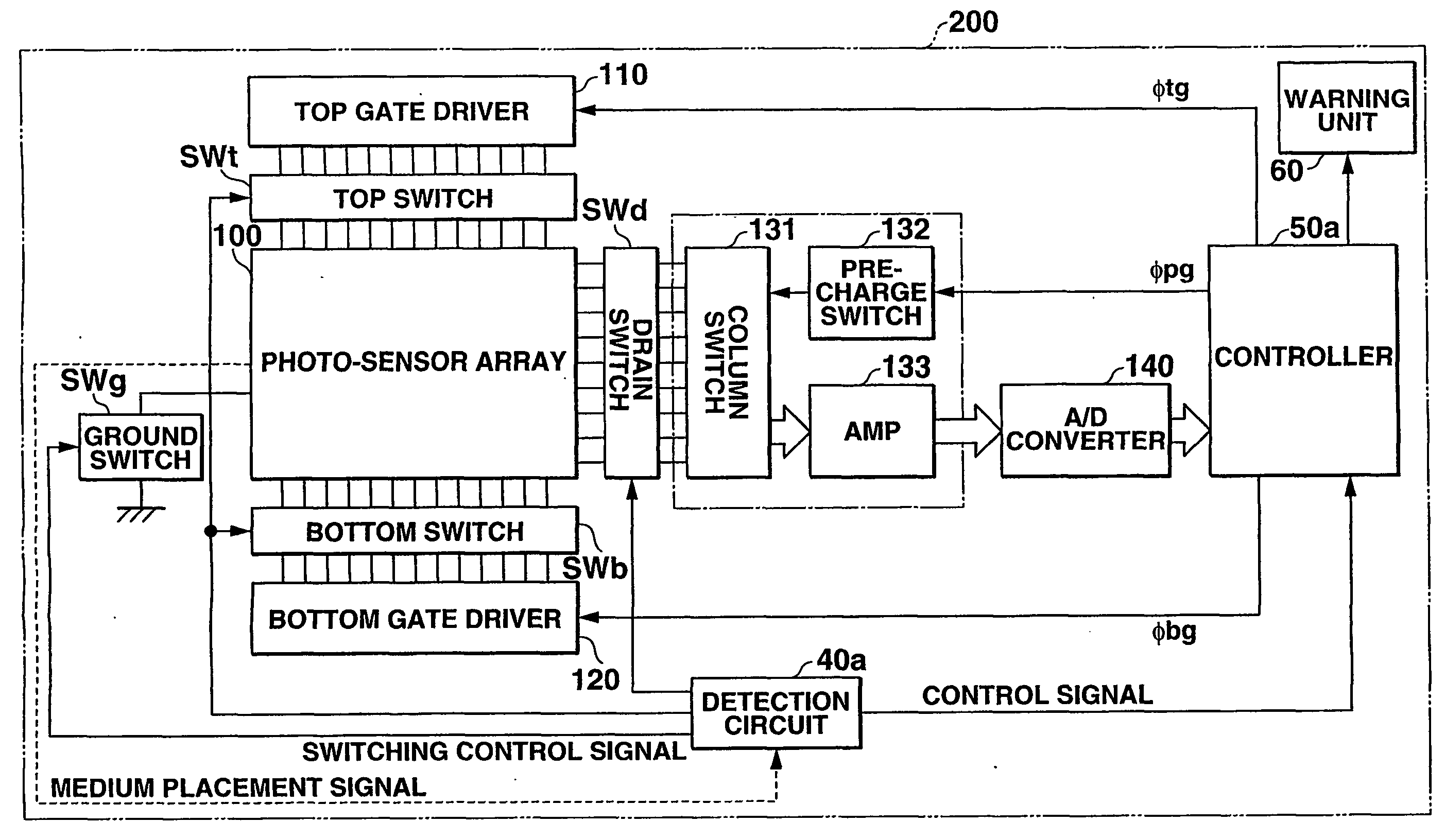

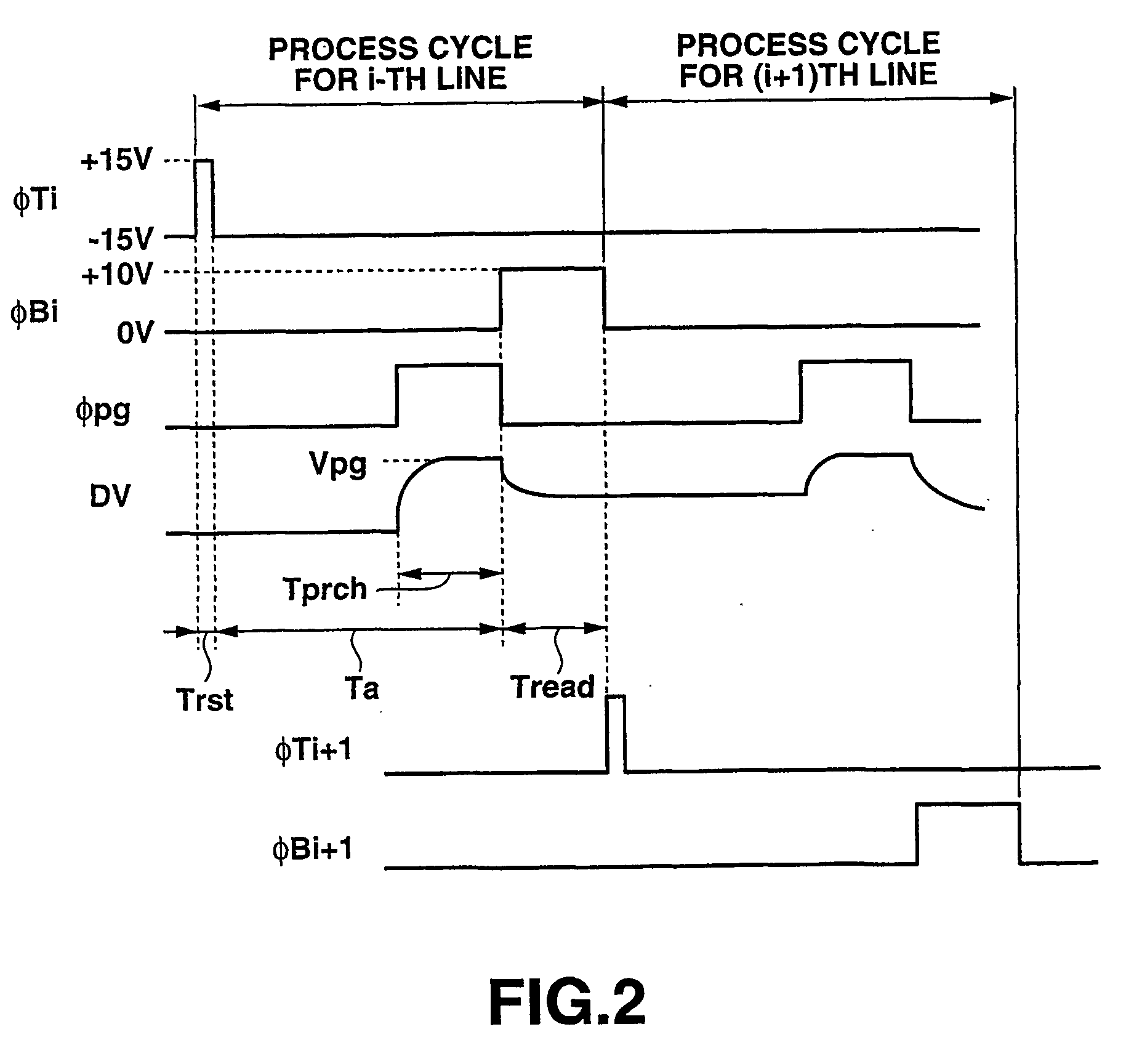

Image reading apparatus and drive control method therefor

InactiveUS20050141048A1Improve ease of useCharacteristicSolid-state devicesMaterial analysis by optical meansSensor arrayElectrical connection

There is provided an image reading apparatus which reads an image pattern of a medium placed on a detection surface of a sensor array (100). In a waiting state, electrical connection between the sensor array (100) and a drive controller (110, 120) is cut off, and whether a medium is placed on the detection surface or not is detected. When a medium is placed on the detection surface, the sensor array (100) and the drive controller (110, 120) are electrically connected and an image reading operation is started. In a case where the medium is separated from the detection surface during the image reading operation, the image reading operation is suspended and the image reading apparatus is set to the waiting state.

Owner:CASIO COMPUTER CO LTD

Semiconductor Device and Manufacturing Method Thereof

ActiveUS20140332800A1High densitySimple structureTransistorSolid-state devicesEngineeringSemiconductor

To provide a semiconductor device having a structure with which the device can be easily manufactured even if the size is decreased and which can suppress a decrease in electrical characteristics caused by the decrease in the size, and a manufacturing method thereof. A source electrode layer and a drain electrode layer are formed on an upper surface of an oxide semiconductor layer. A side surface of the oxide semiconductor layer and a side surface of the source electrode layer are provided on the same surface and are electrically connected to a first wiring. Further, a side surface of the oxide semiconductor layer and a side surface of the drain electrode layer are provided on the same surface and are electrically connected to a second wiring.

Owner:SEMICON ENERGY LAB CO LTD

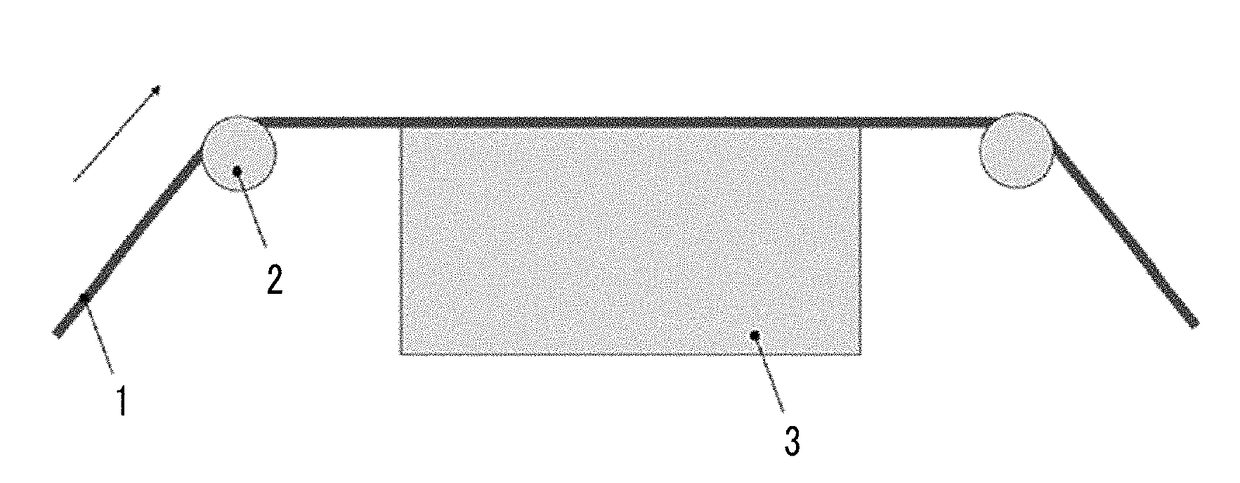

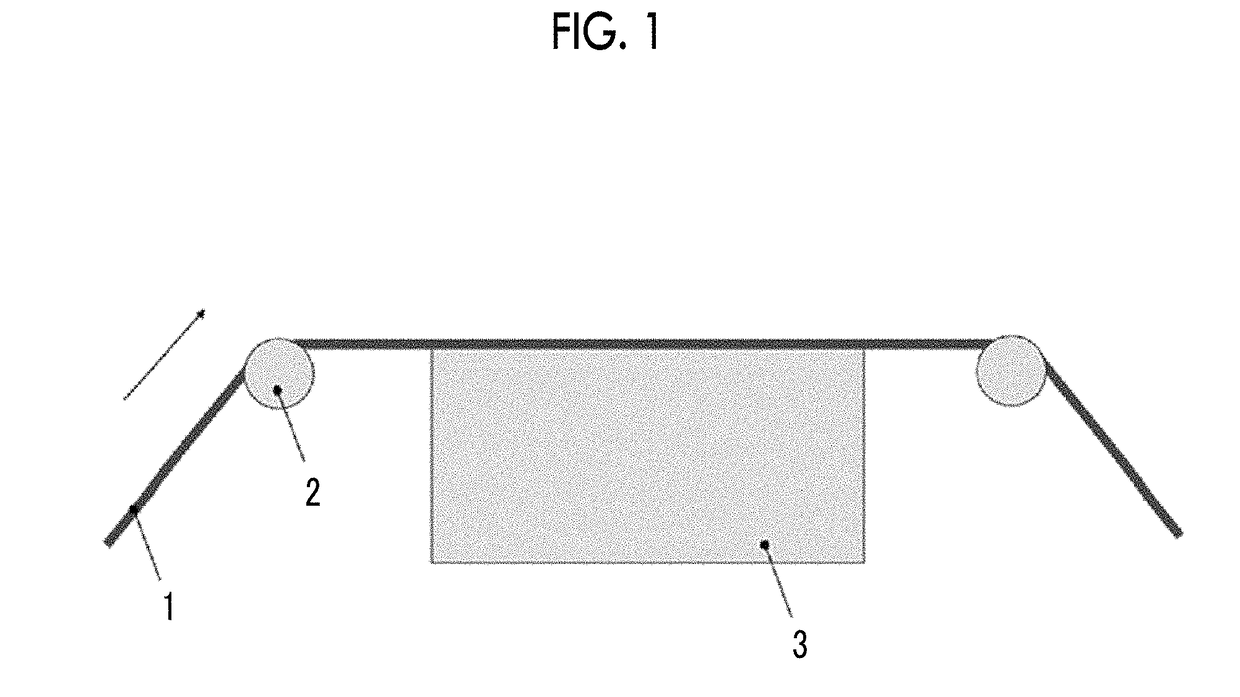

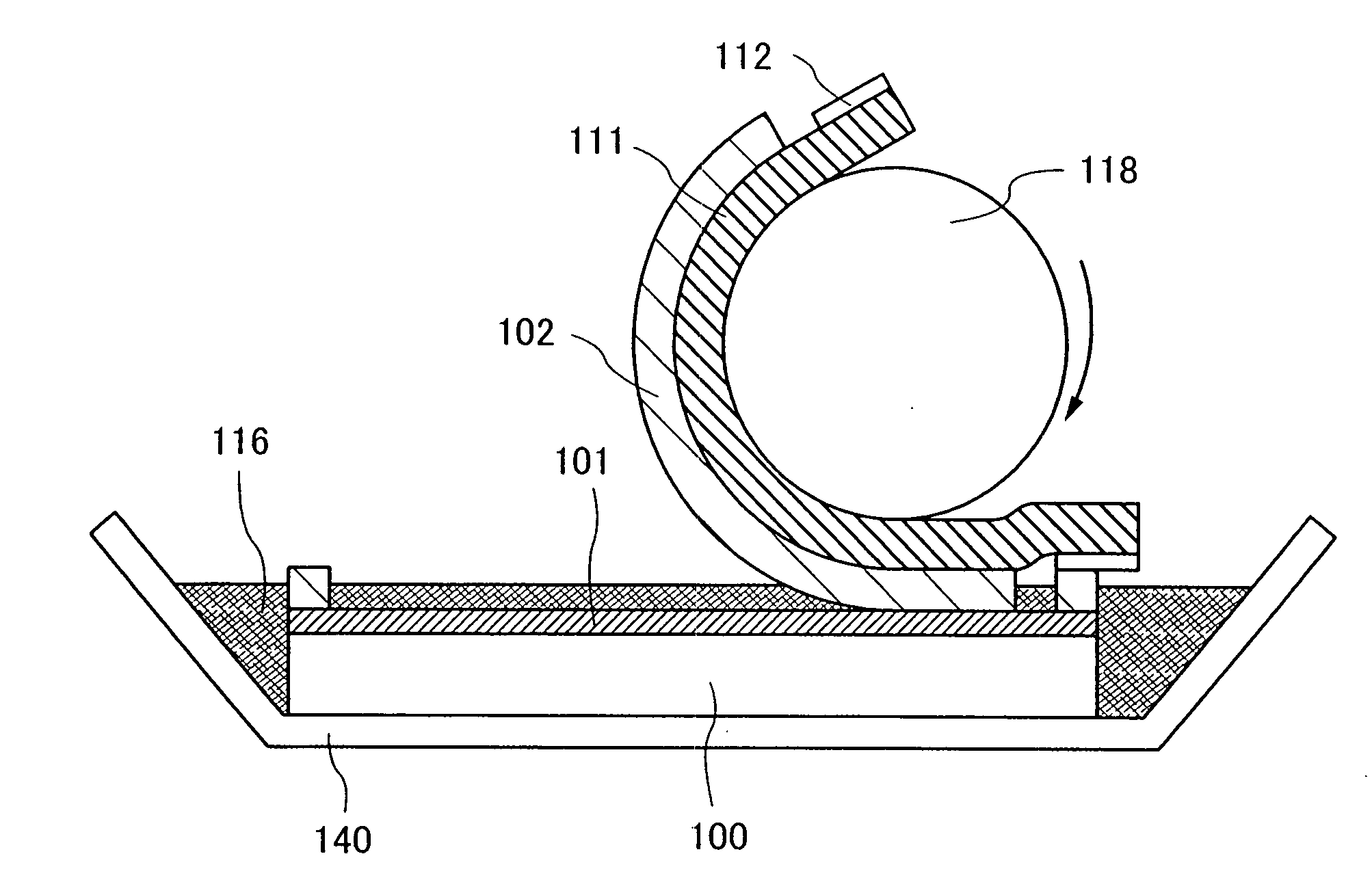

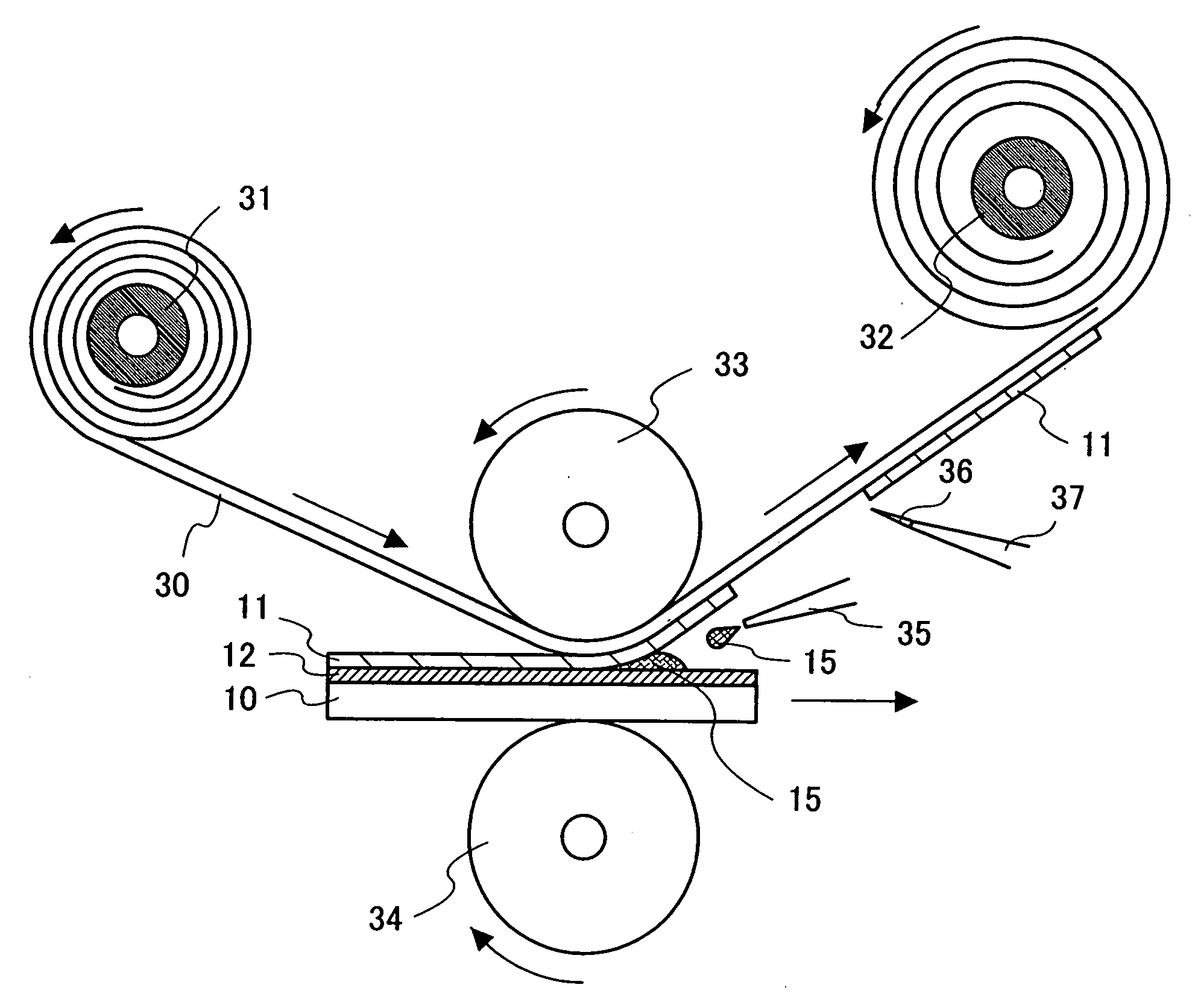

Peeling apparatus and manufacturing apparatus of semiconductor device

ActiveUS20080113486A1Decrease of electrical resistivityElectrical discharge be preventFinal product manufactureLayered productsEngineeringSemiconductor components

An object is to eliminate electric discharge due to static electricity generated by peeling when an element formation layer including a semiconductor element is peeled from a substrate used for manufacturing the semiconductor element. A substrate over which an element formation layer and a peeling layer are formed and a film are made to go through a gap between pressurization rollers. The film is attached to the element formation layer between the pressurization rollers. The film is bent along a curved surface of the pressurization roller on a side of the pressurization rollers, where the film is collected, and accordingly, peeling is generated between the element formation layer and the peeling layer and the element formation layer is transferred to the film. Liquid such as pure water is sequentially supplied by a nozzle to a gap between the element formation layer and the peeling layer, which is generated by peeling, so that electric charge generated on surfaces of the element formation layer and the peeling layer is diffused by the liquid.

Owner:SEMICON ENERGY LAB CO LTD

Spread spectrum radar apparatus

InactiveUS7642952B2Wide detection rangeImprove performanceTransmissionRadio wave reradiation/reflectionFrequency spectrumIntermediate frequency

A spread spectrum radar apparatus includes: a transmission unit which generates a spread signal that is a spectrum-spread signal, using a first oscillator signal, a second oscillator signal, and a transmission PN code, and which emits the spread signal as a detection radio wave; and a reception unit which receives, as a reception signal, the detection radio wave reflected from an object, and which generates an intermediate frequency signal by despreading the reception signal based on the first oscillator signal and a reception PN code obtained by delaying the transmission PN code.

Owner:PANASONIC CORP

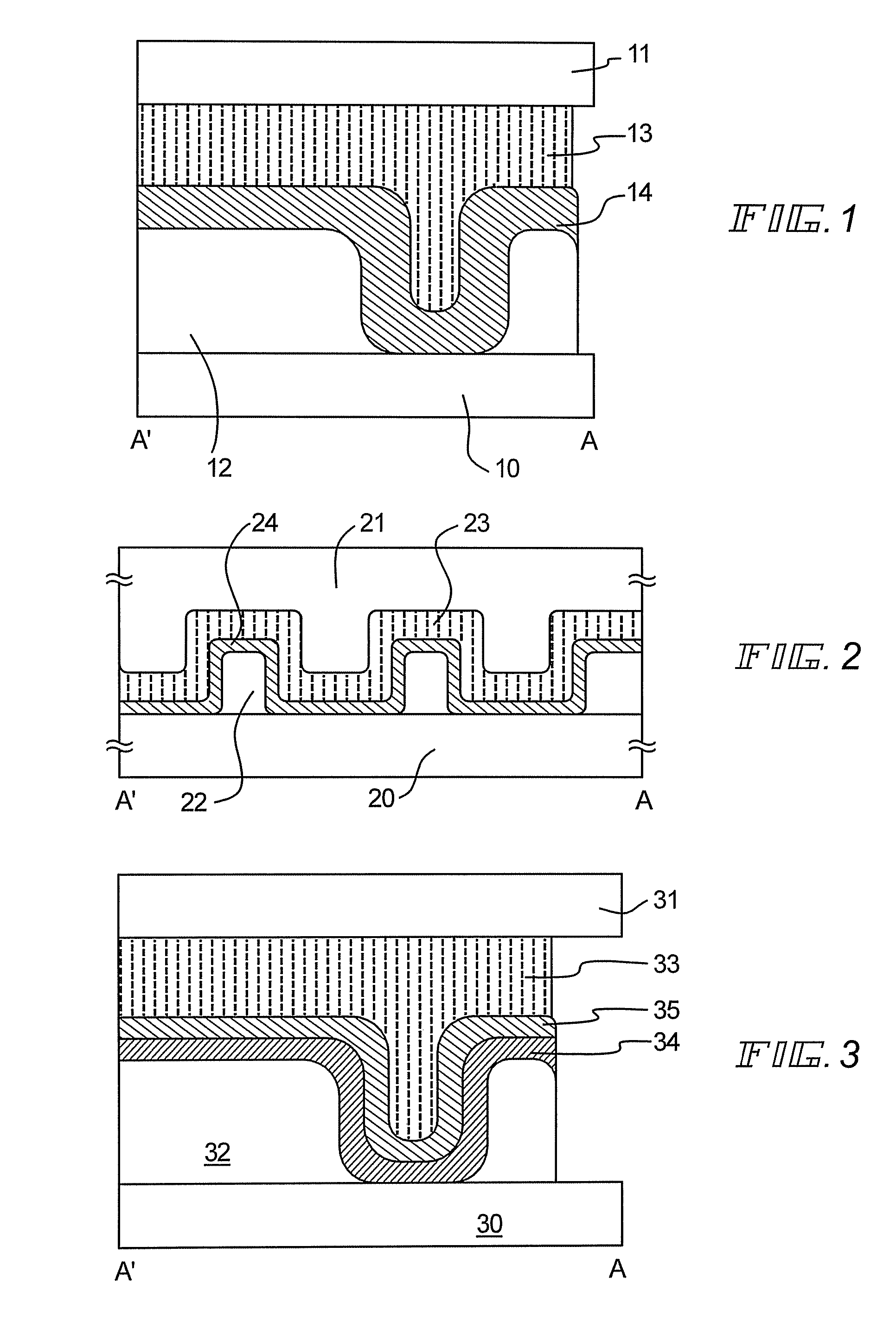

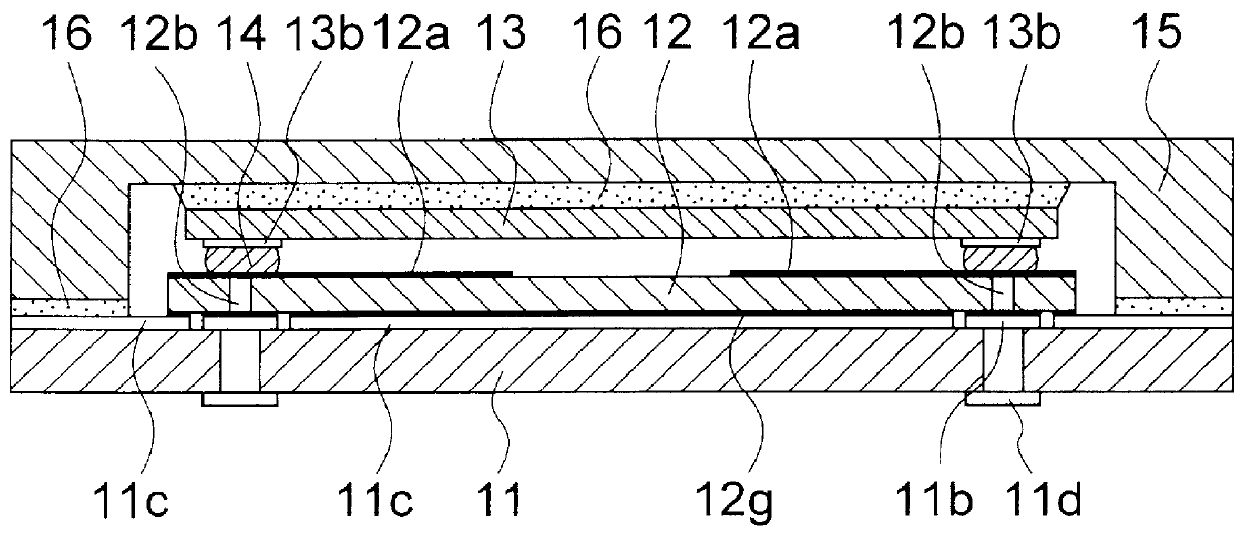

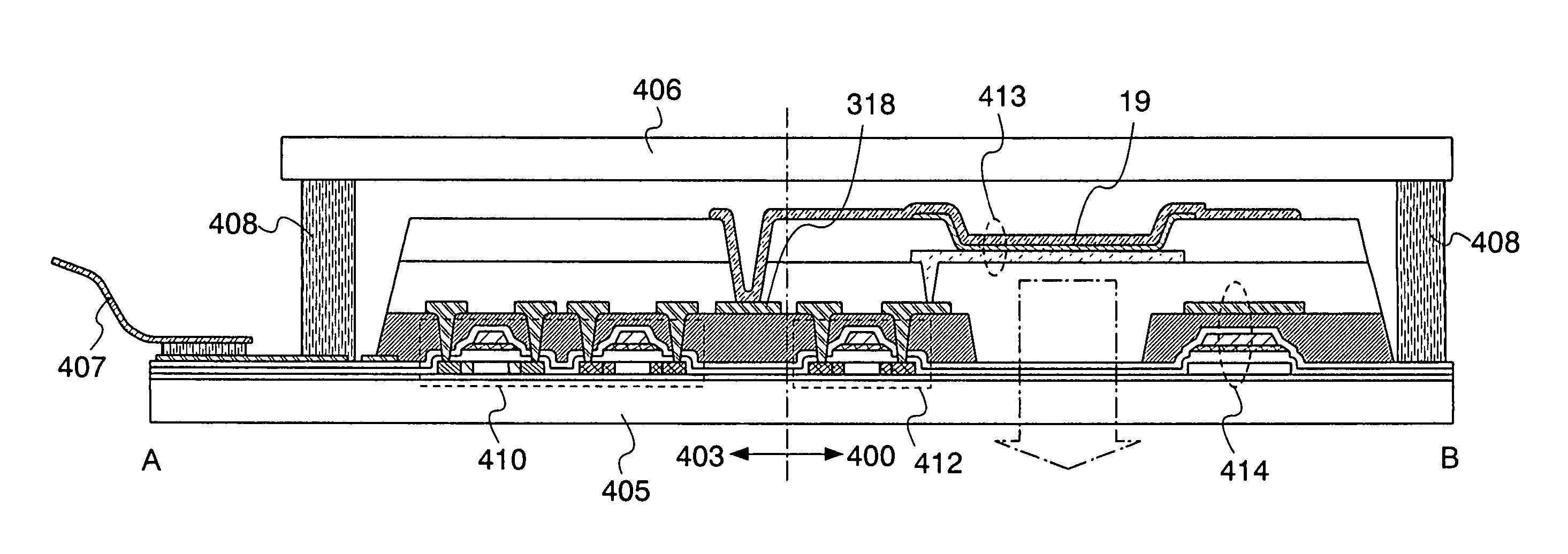

Display device and method of manufacturing thereof

InactiveUS7486368B2Prevent penetrationImprove reliabilitySemiconductor/solid-state device detailsElectroluminescent light sourcesTectorial membraneDisplay device

A novel display device with higher reliability having a structure of blocking moisture and oxygen, which deteriorate the characteristics of the display device, from penetrating through a sealing region and a method of manufacturing thereof is provided. According to the present invention, a display device and a method of manufacturing the same comprising: a display portion formed by aligning a light-emitting element using an organic light-emitting material between a pair of substrate, wherein the display portion is formed on an insulating layer formed on any one of the substrates, the pair of substrates is bonded to each other with a sealing material formed over the insulating layer while surrounding a periphery of the display portion, at least one layer of the insulating layer is made of an organic resin material, the periphery has a first region and a second region, the insulating layer in the first region has an opening covered with a protective film, the sealing material is formed in contact with the opening and the protective film, an outer edge portion of the insulating layer in the second region is covered with the protective film or the sealing material.

Owner:SEMICON ENERGY LAB CO LTD

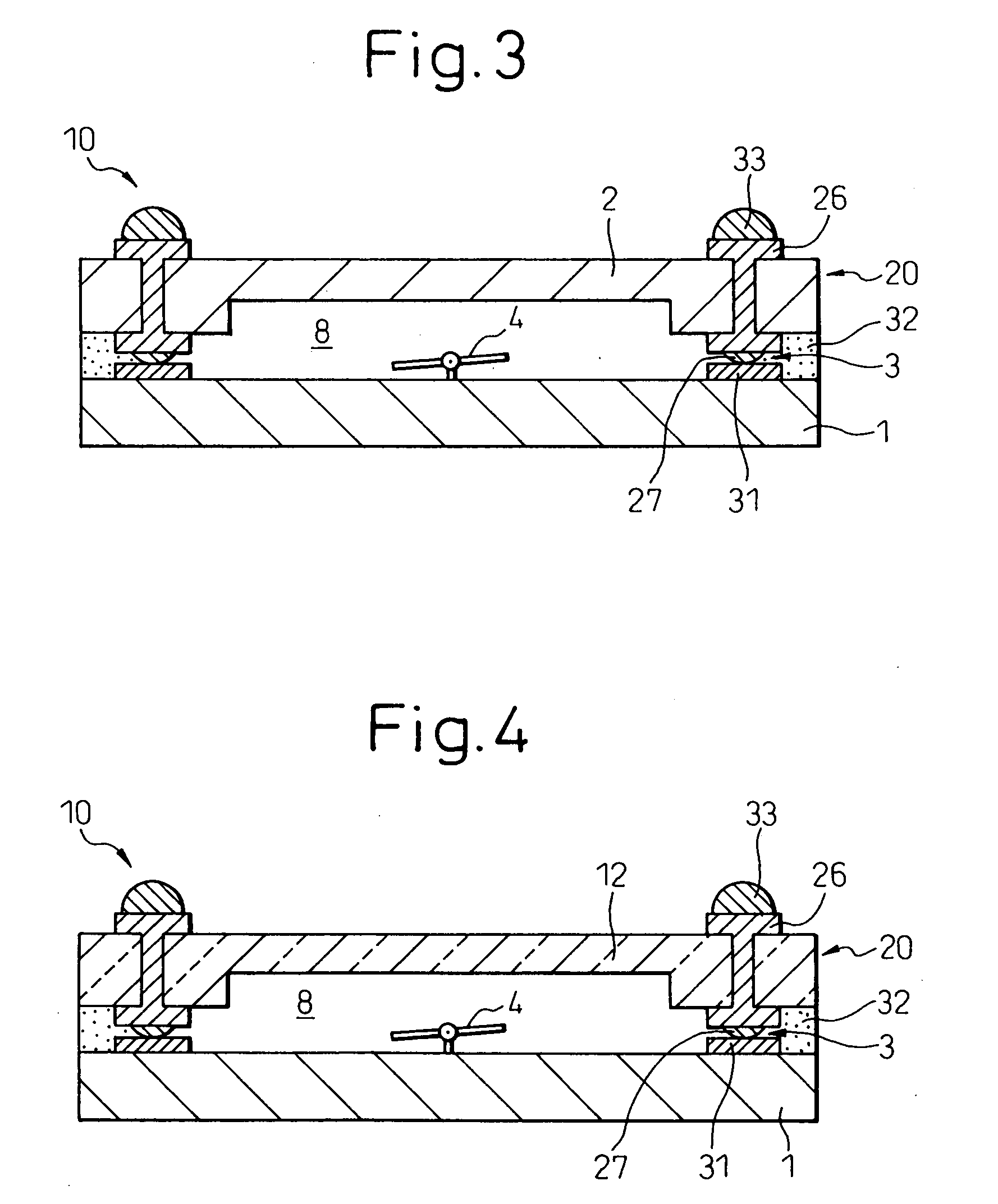

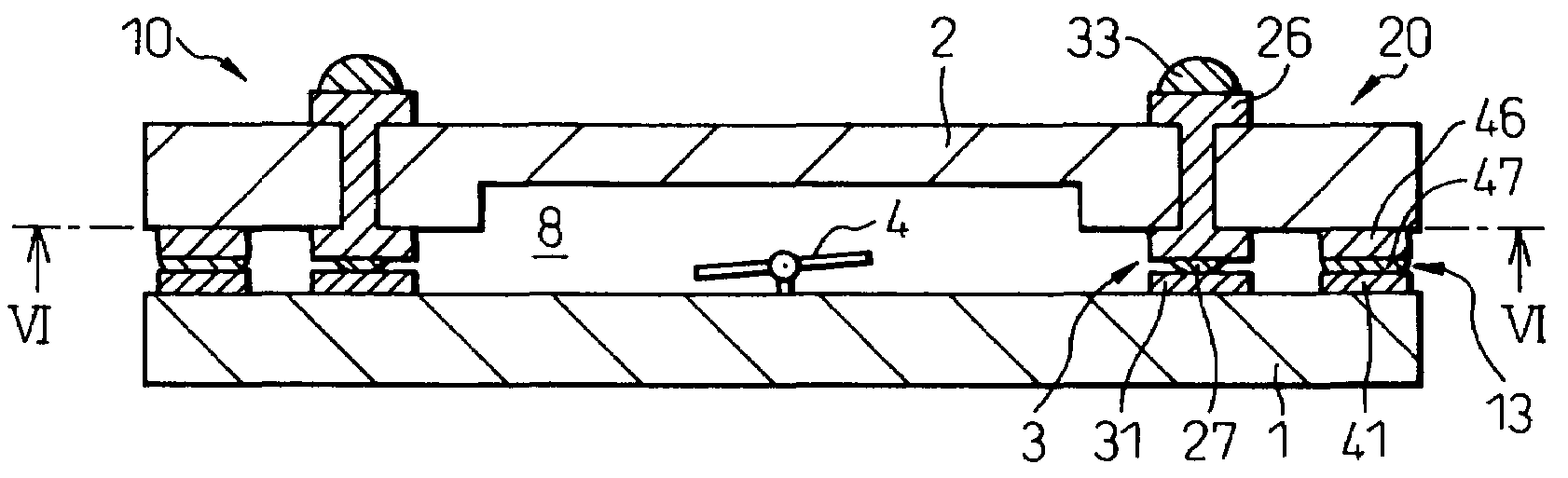

MMIC package

InactiveUS6124636AConnection lengthDeterioration of characteristicSemiconductor/solid-state device detailsSolid-state devicesEngineeringInterconnection

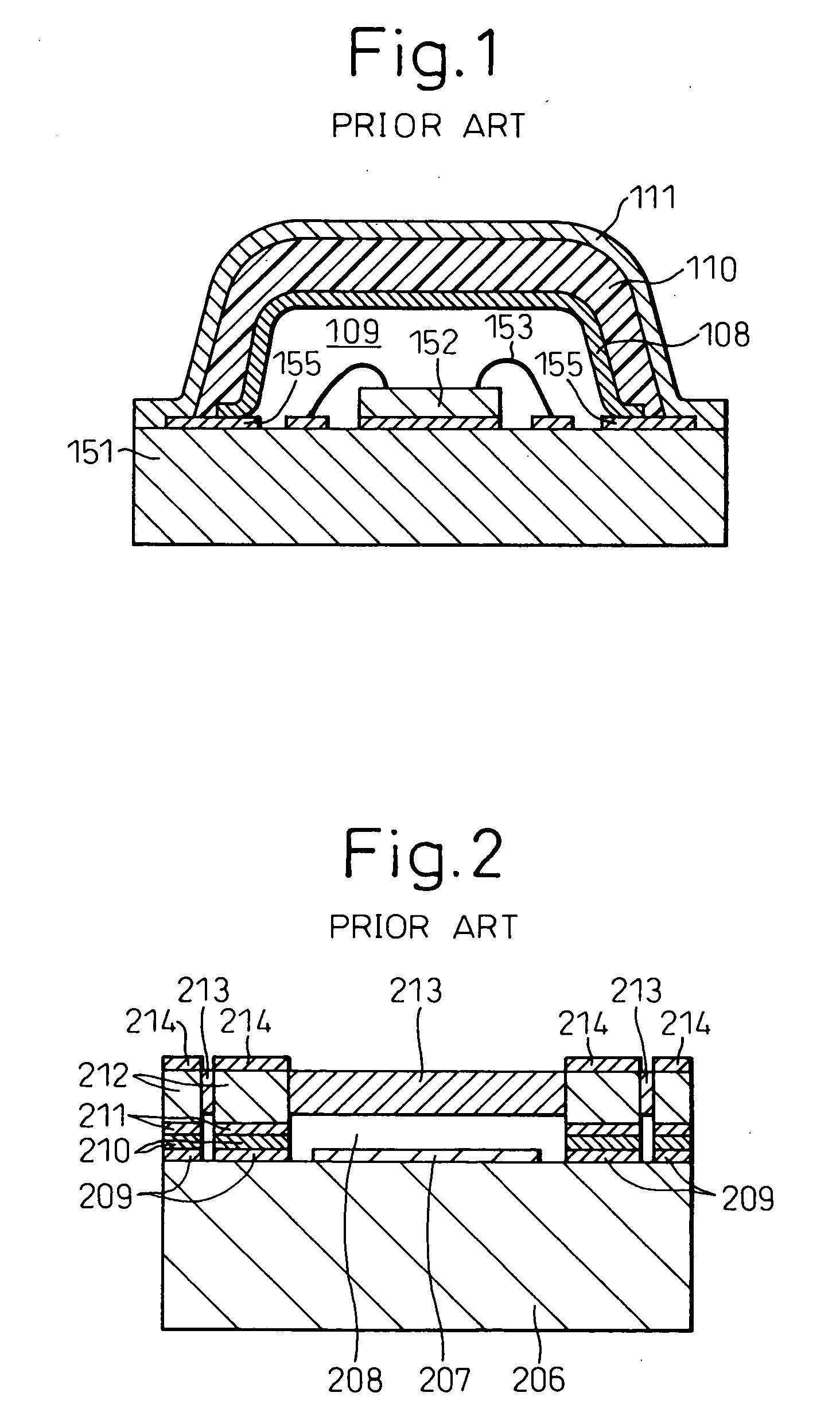

Disclosed herein is an MMIC package which comprises a base substrate, a composite capacitor substrate made of a ceramics plate mounted on the base substrate, an MMIC bare chip which functions as a high frequency semiconductor element and face-down bonded on the composite capacitor substrate, and an electroconductive covering which covers, together with the base substrate, the MMIC bare chip. In order to suppress the deterioration of the electrical characteristics of the above MMIC, the above components are so arranged that the interconnection length between the components is made to be minimum.

Owner:STMICROELECTRONICS SRL +1

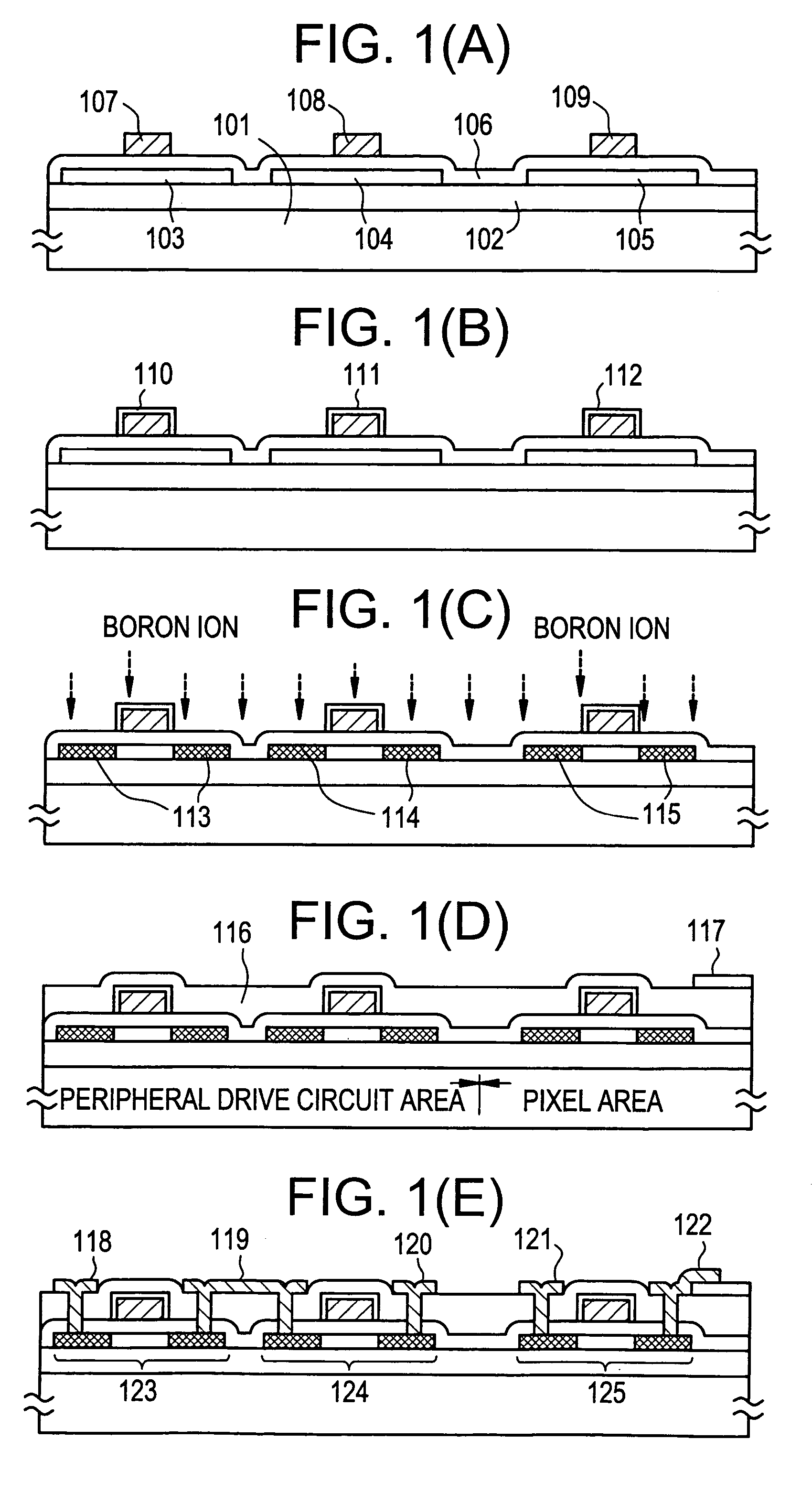

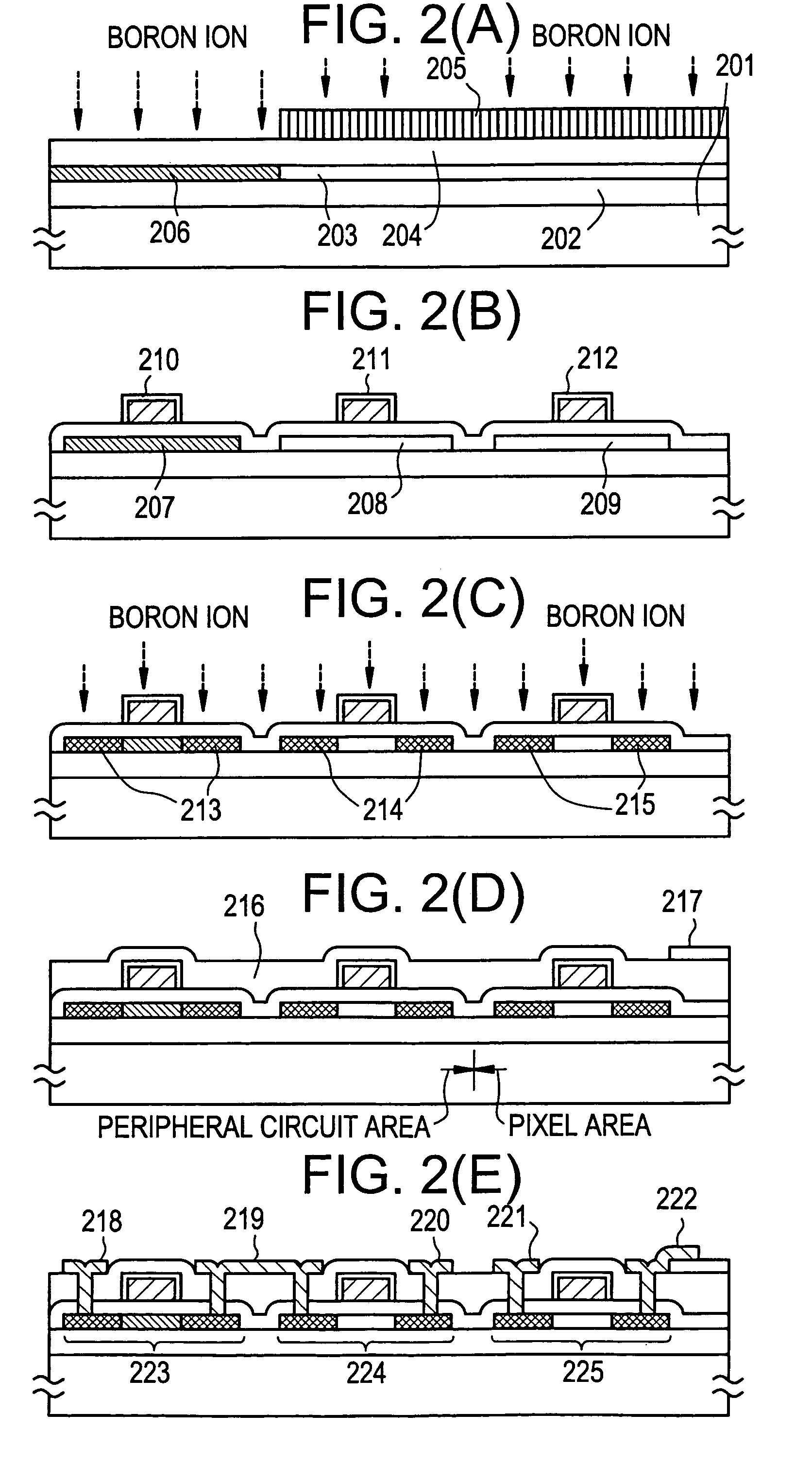

Semiconductor integrated circuit

InactiveUS7166862B2Improve featuresImprove reliabilityTransistorStatic indicating devicesActive matrixP channel

In a monolithic active matrix circuit that uses offset-gate TFTs in which the gate electrode is offset from the source and drain regions or TFTs whose gate insulating film is formed by vapor deposition, not only an active matrix circuit but also a drive circuit therefor is formed by using P-channel TFTs.

Owner:SEMICON ENERGY LAB CO LTD

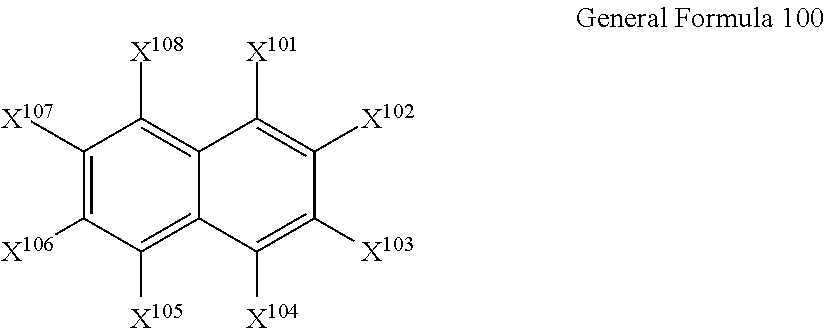

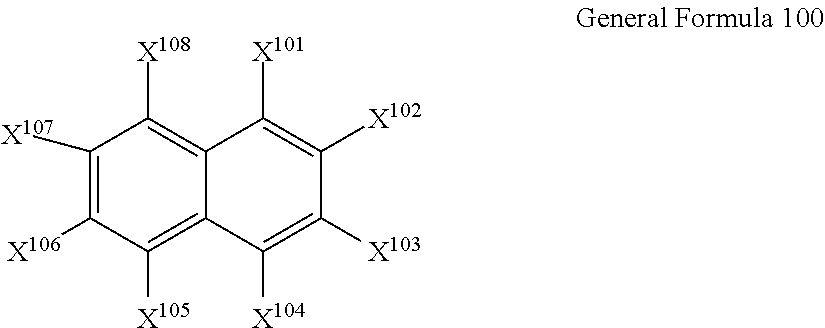

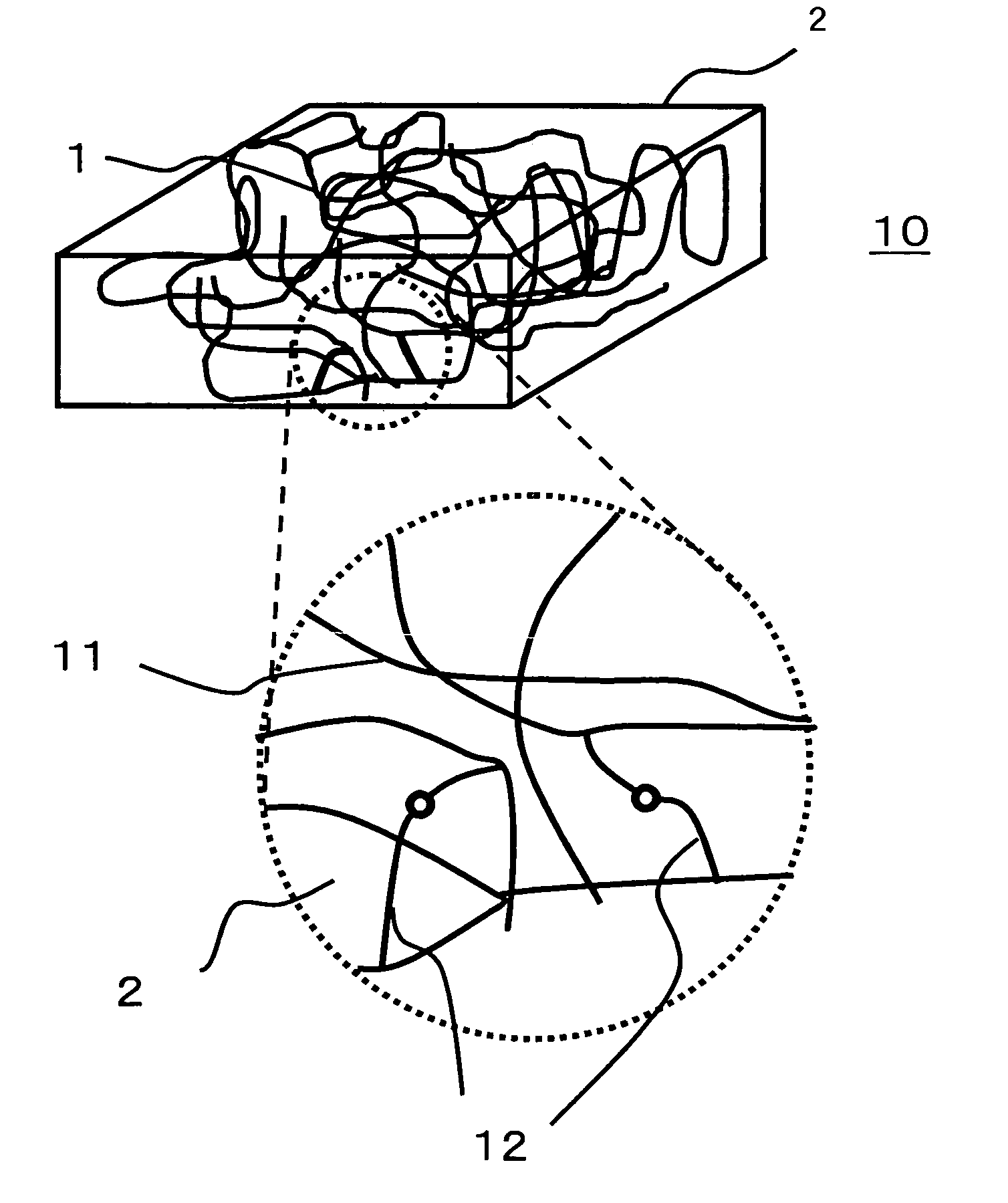

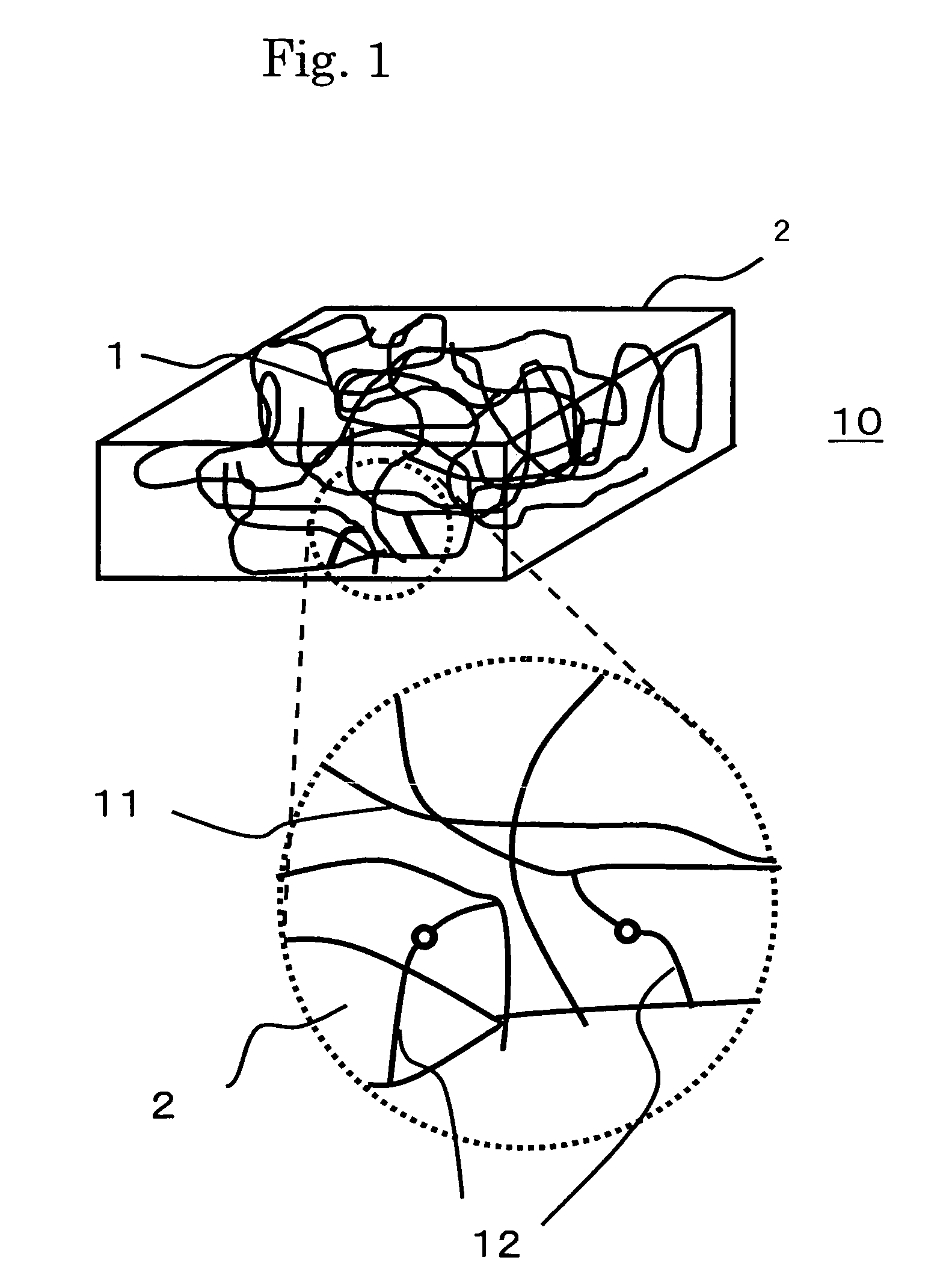

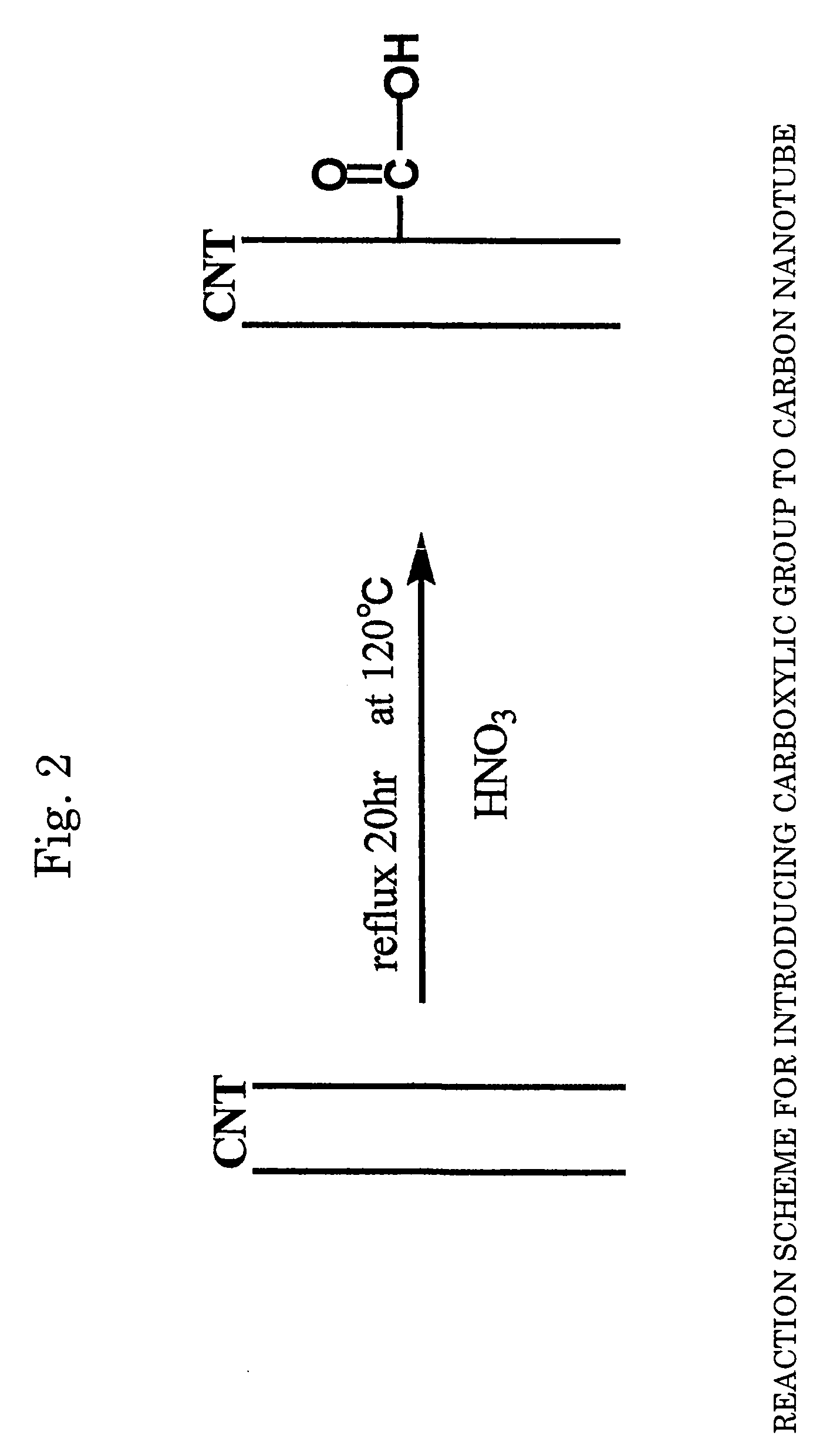

Composite and method of manufacturing the same

InactiveUS20050170169A1Improve conductivityDeterioration of characteristicMaterial nanotechnologyOrganic chemistryCross-linkNetwork structure

Provided is a nanotube-polymer composite which can effectively utilize characteristics of a carbon nanotube structure. The composite includes a carbon nanotube structure and a polymer, in which: the carbon nanotube structure has a network structure constructed by mutually cross-linking functional groups bonded to multiple carbon nanotubes through chemical bonding of the functional groups together; and the polymer is filled in the network structure. Also provided is a method of manufacturing a composite which includes the steps of: supplying a base body surface with a solution containing multiple carbon nanotubes to which multiple functional groups are bonded; mutually cross-linking the multiple carbon nanotubes through chemical bonding of the multiple functional groups together to construct a network structure constituting a carbon nanotube structure; impregnating the network structure with a polymer liquid forming a polymer; and combining the carbon nanotube structure and the polymer by curing the polymer liquid.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Display device

InactiveUS20050242713A1Avoid stray lightAvoid strayDischarge tube luminescnet screensElectroluminescent light sourcesRough surfaceDisplay device

When light generated in a light emitting layer of a display device is emitted through insulating films such as a planarizing film, an interlayer insulating film and a gate insulating film of a transistor, diffused reflection is caused due to slight-rough surfaces of the insulating films every time light passes through each insulating film. Accordingly, problems are caused in which stray light is caused, an outline of a pixel becomes indistinct, and a characteristic of the transistor is deteriorated. A display device according to the invention includes a transistor formed over a substrate, an insulating film with a light shielding property formed on the transistor, an opening for transmitting light therethrough formed in the insulating film with the light shielding property, and a light emitting element formed overlapping the opening.

Owner:SEMICON ENERGY LAB CO LTD

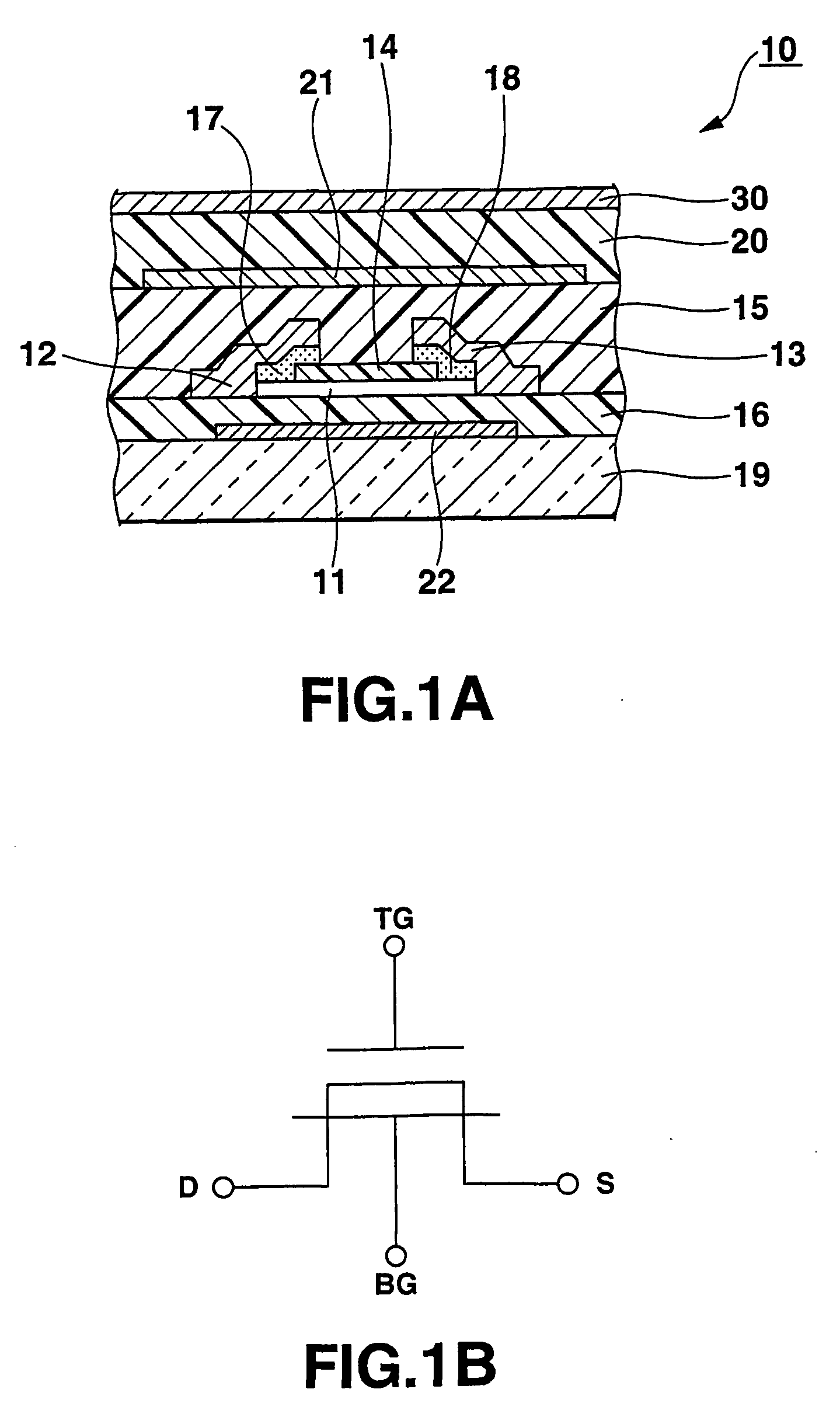

Thin-film transistor and process for its fabrication

ActiveUS20100059751A1Deterioration of characteristicUnevenness of on resistanceTransistorSemiconductor/solid-state device manufacturingBottom gateEngineering

A bottom gate type thin-film transistor constituted of at least a substrate, a gate electrode, a gate insulating layer, a semiconductor layer, a source electrode and a drain electrode. At an interface between the gate electrode and the gate insulating layer, the interface has a difference between hill tops and dale bottoms of unevenness in the vertical direction, of 30 nm or less.

Owner:CANON KK

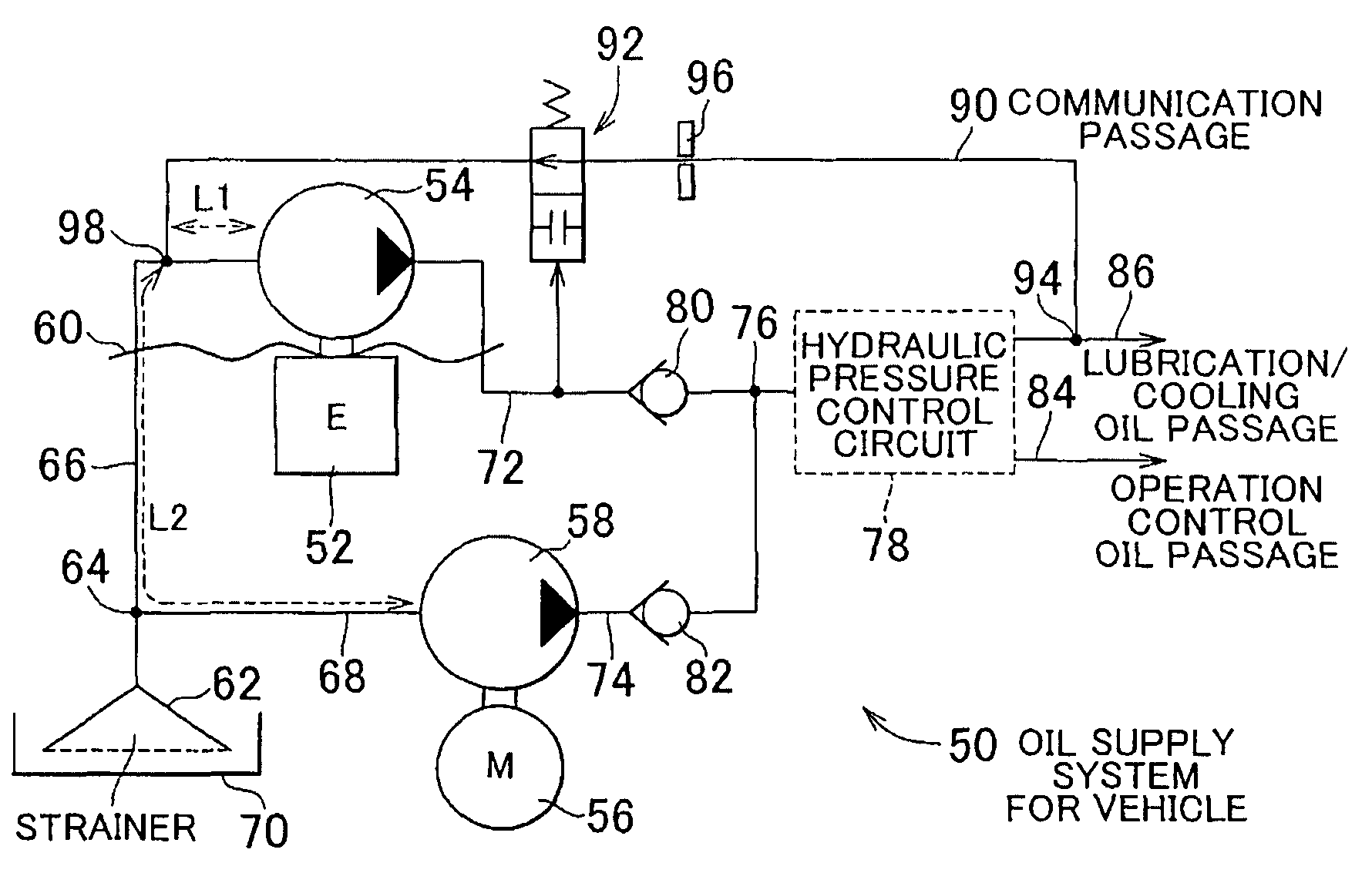

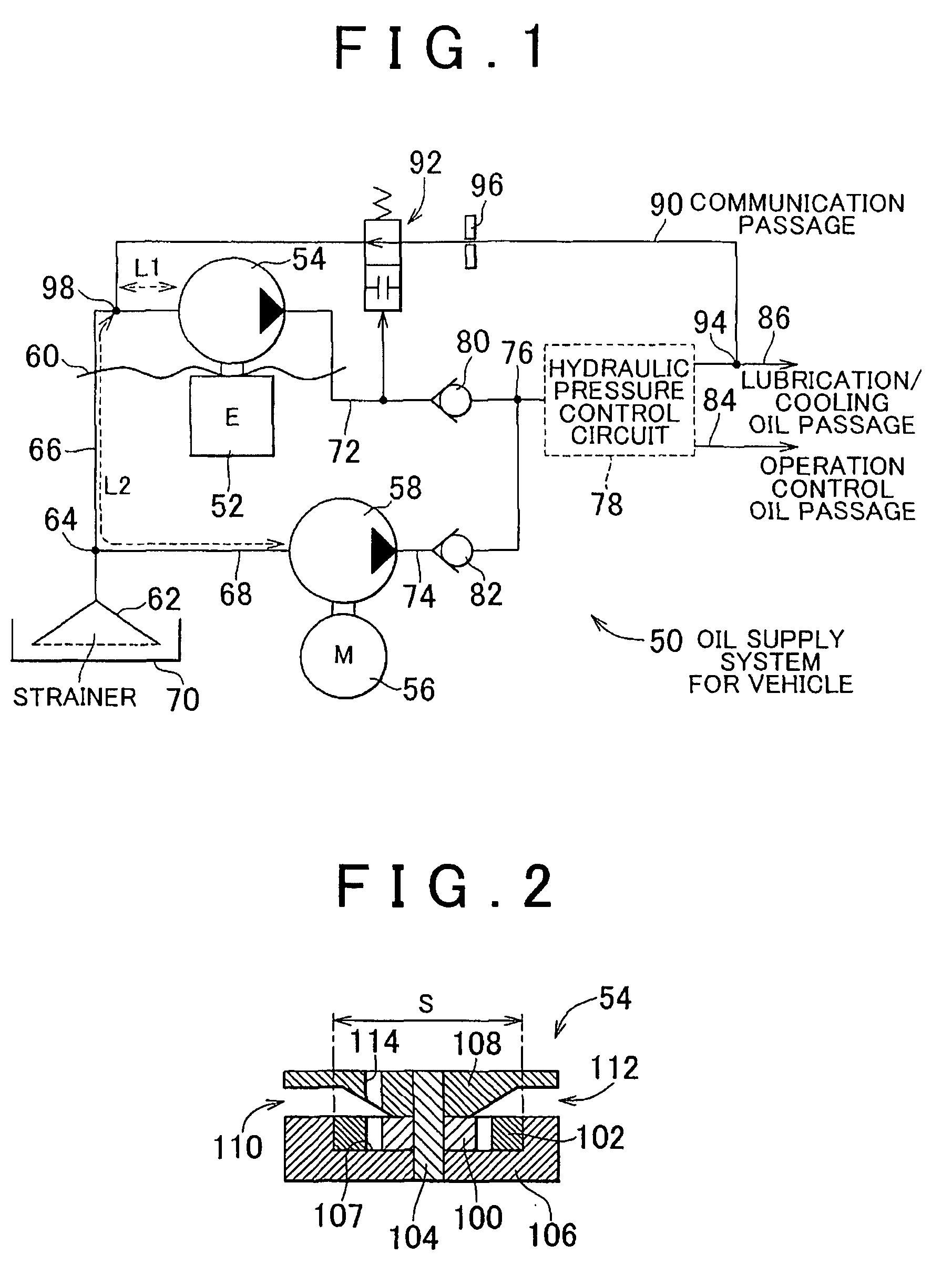

Oil supply system for vehicle

InactiveUS20080308355A1Deterioration of characteristicAvoid airGearboxesGear lubrication/coolingControl circuitLubrication

An oil supply system for a vehicle includes: a mechanical oil pump driven by an engine; an electric oil pump driven by an electric motor; a hydraulic pressure control circuit supplied with oil from the mechanical oil pump and the electric oil pump through an oil discharge passage for the mechanical oil pump and an oil discharge passage for the electric oil pump, which are connected to each other; a lubrication / cooling oil passage that is supplied with the oil from the hydraulic pressure control circuit; and a communication passage that provides communication between the lubrication / cooling oil passage and the mechanical oil pump. With this oil supply system, it is possible to prevent the electric oil pump from causing air-sucking noise, for example, in the motor-power cruise mode, and to improve the rising characteristics of the hydraulic pressure produced by the mechanical oil pump during startup of the engine.

Owner:TOYOTA JIDOSHA KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com