Patents

Literature

597 results about "Scanning tunneling microscope" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Scanning Tunneling Microscope (STM) is an instrument for imaging surfaces at the atomic level. Its development in 1981 earned its inventors, Gerd Binnig and Heinrich Rohrer (at IBM Zürich), the Nobel Prize in Physics in 1986. For an STM, good resolution is considered to be 0.1 nm lateral resolution and 0.01 nm (10 pm) depth resolution. With this resolution, individual atoms within materials are routinely imaged and manipulated. The STM can be used not only in ultra-high vacuum but also in air, water, and various other liquid or gas ambients, and at temperatures ranging from near zero kelvin to over 1000 °C.

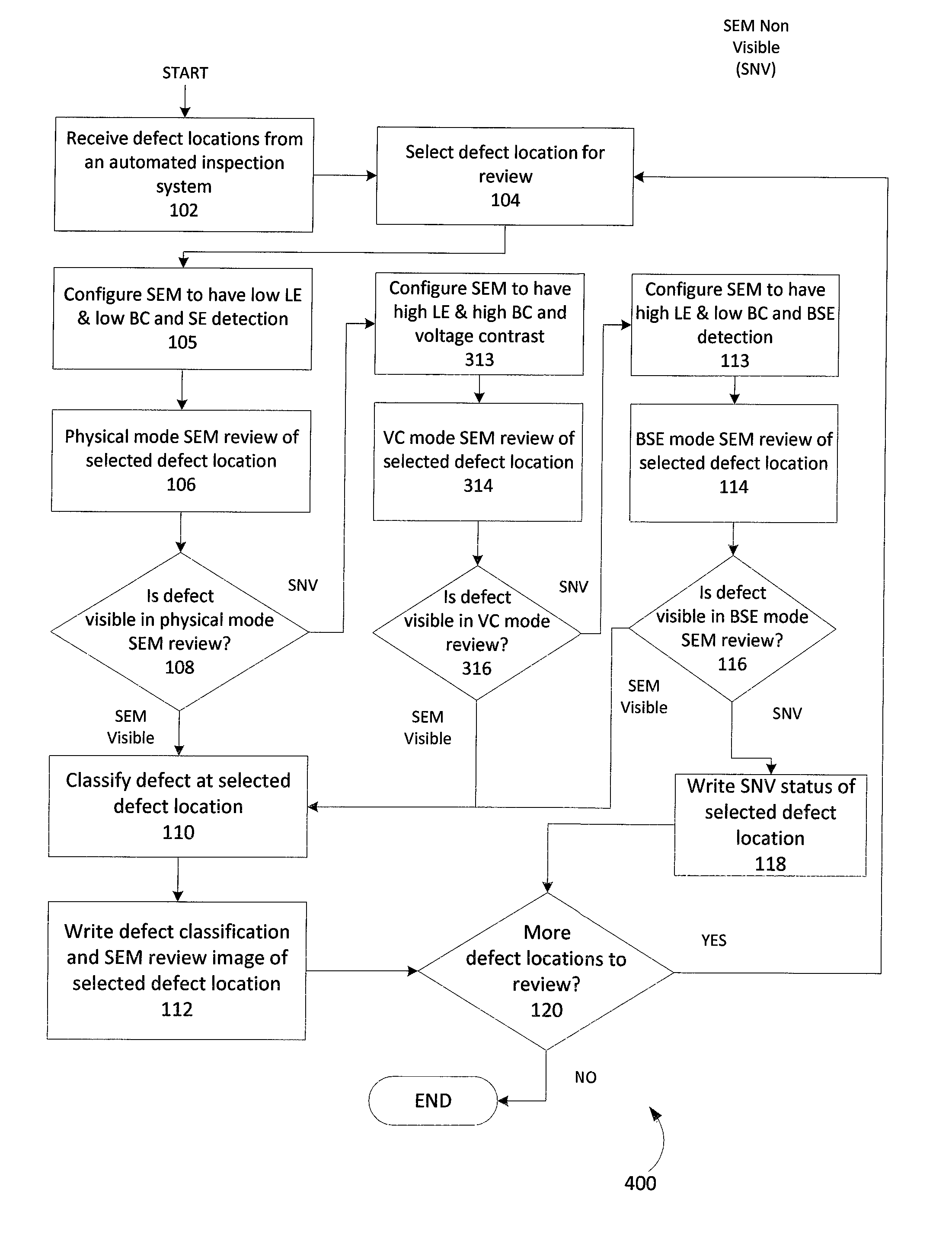

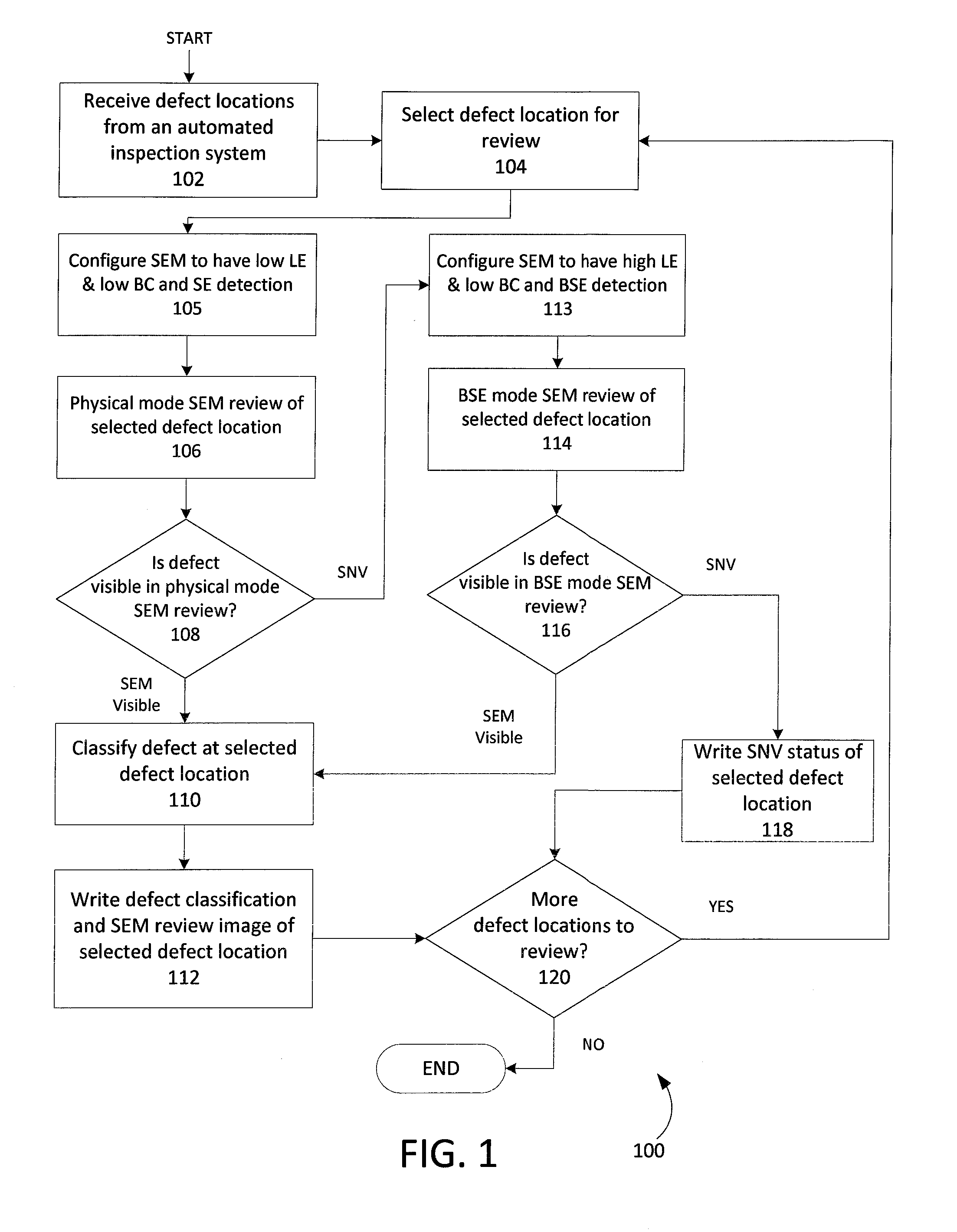

Methods and apparatus to review defects using scanning electron microscope with multiple electron beam configurations

ActiveUS8716662B1Material analysis using wave/particle radiationElectric discharge tubesScanning tunneling microscopeElectron

One embodiment relates to a method of reviewing defects using a scanning electron microscope (SEM). A defect location having a defect for review is selected, and the SEM is configured to be in a first imaging configuration. The selected defect location is imaged using the SEM to generate a first SEM image of the selected defect location. A determination is made as to whether the defect is visible or non-visible in the first SEM image. If the defect is non-visible in the first SEM image, then the SEM is configured to be into a second imaging configuration, the selected defect location is imaged using the SEM to generate a second SEM image of the selected defect location, and a further determination is made as to whether the defect is visible or non-visible in the second SEM image. Other embodiments, aspects and features are also disclosed.

Owner:KLA TENCOR TECH CORP

Magnetic tape

ActiveUS20180061446A1Deterioration of characteristicMagnetic materials for record carriersTape carriersConventional transmission electron microscopeScanning tunneling microscope

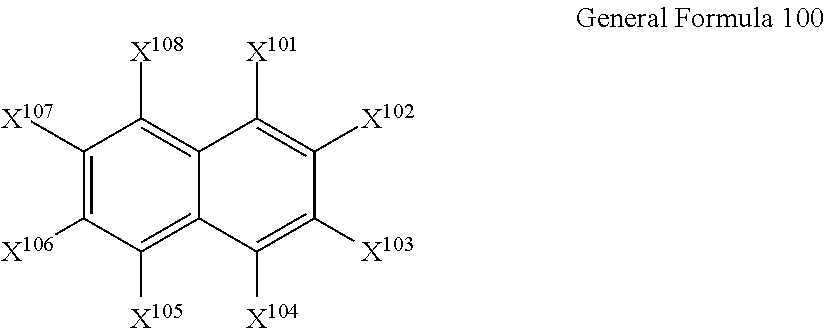

Provided is a magnetic tape in which the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes ferromagnetic hexagonal ferrite powder and an abrasive, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer by plane observation using a scanning electron microscope, with respect to the total area of the region is equal to or greater than 0.02% and less than 0.06%, and a tilt cos 0 of the ferromagnetic hexagonal ferrite powder with respect to a surface of the magnetic layer acquired by cross section observation performed by using a scanning transmission electron microscope is 0.85 to 1.00.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20180240495A1Deterioration of characteristicMaterials with ironRecord information storageScanning tunneling microscopeMagnetic tape

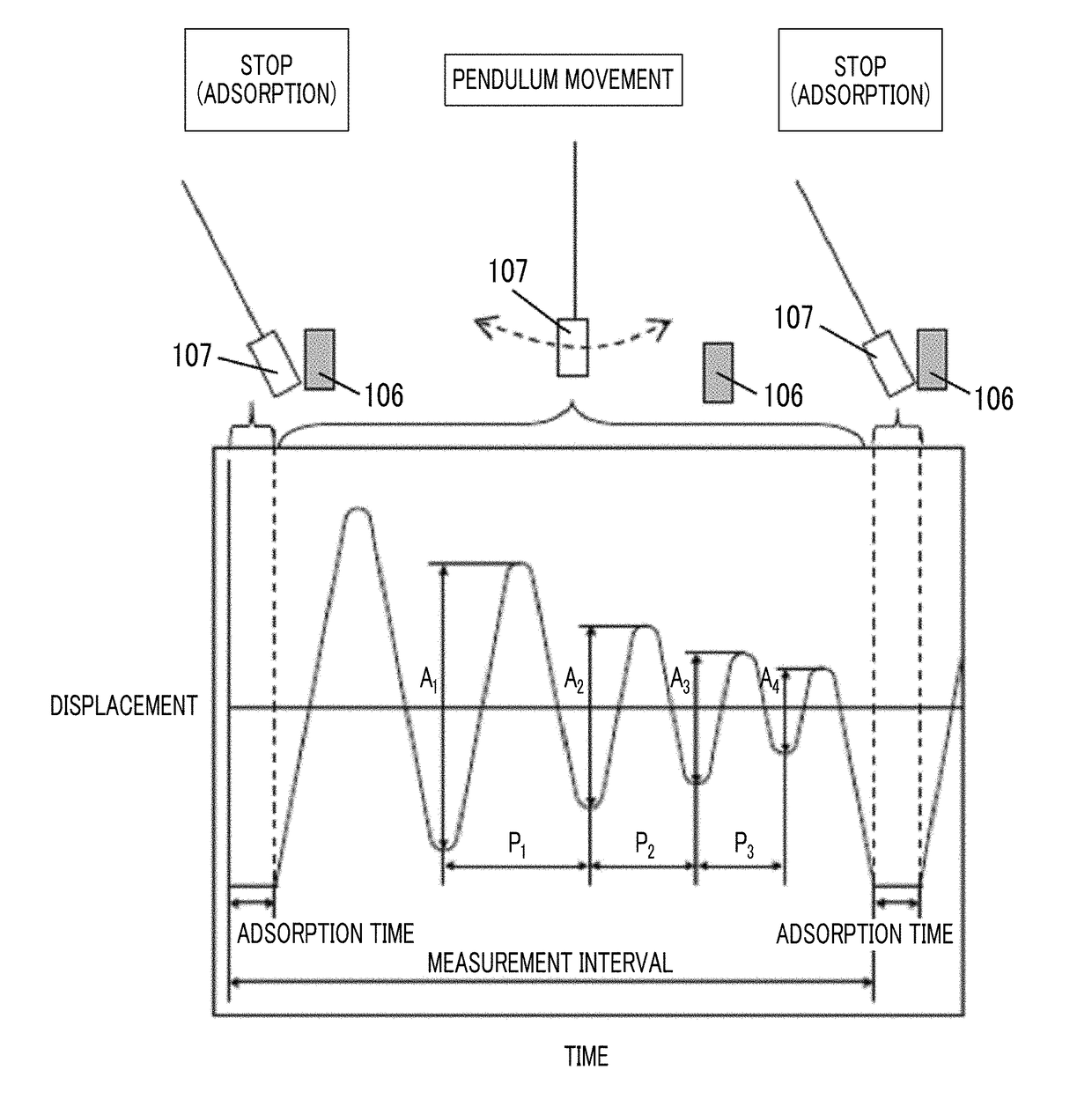

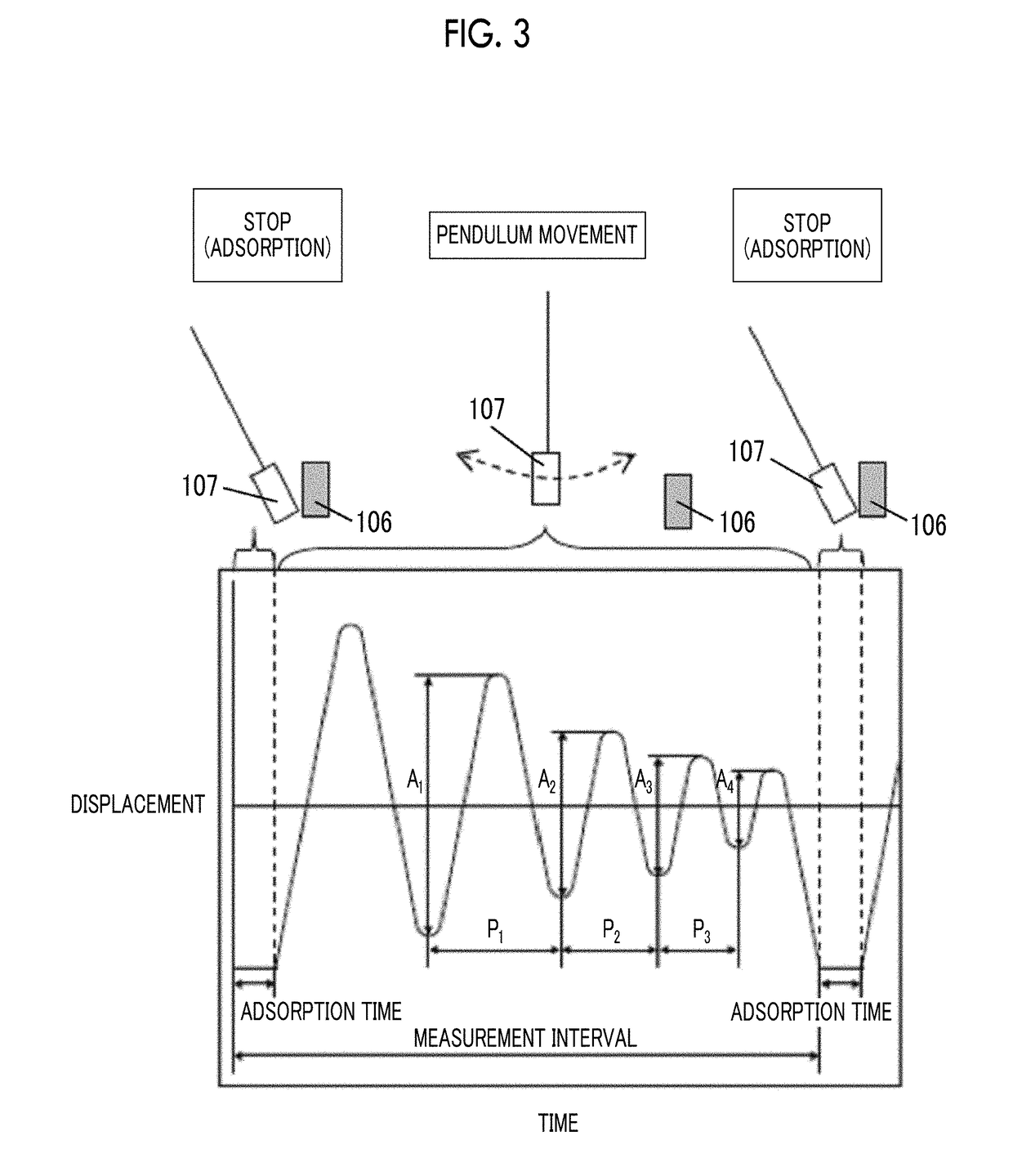

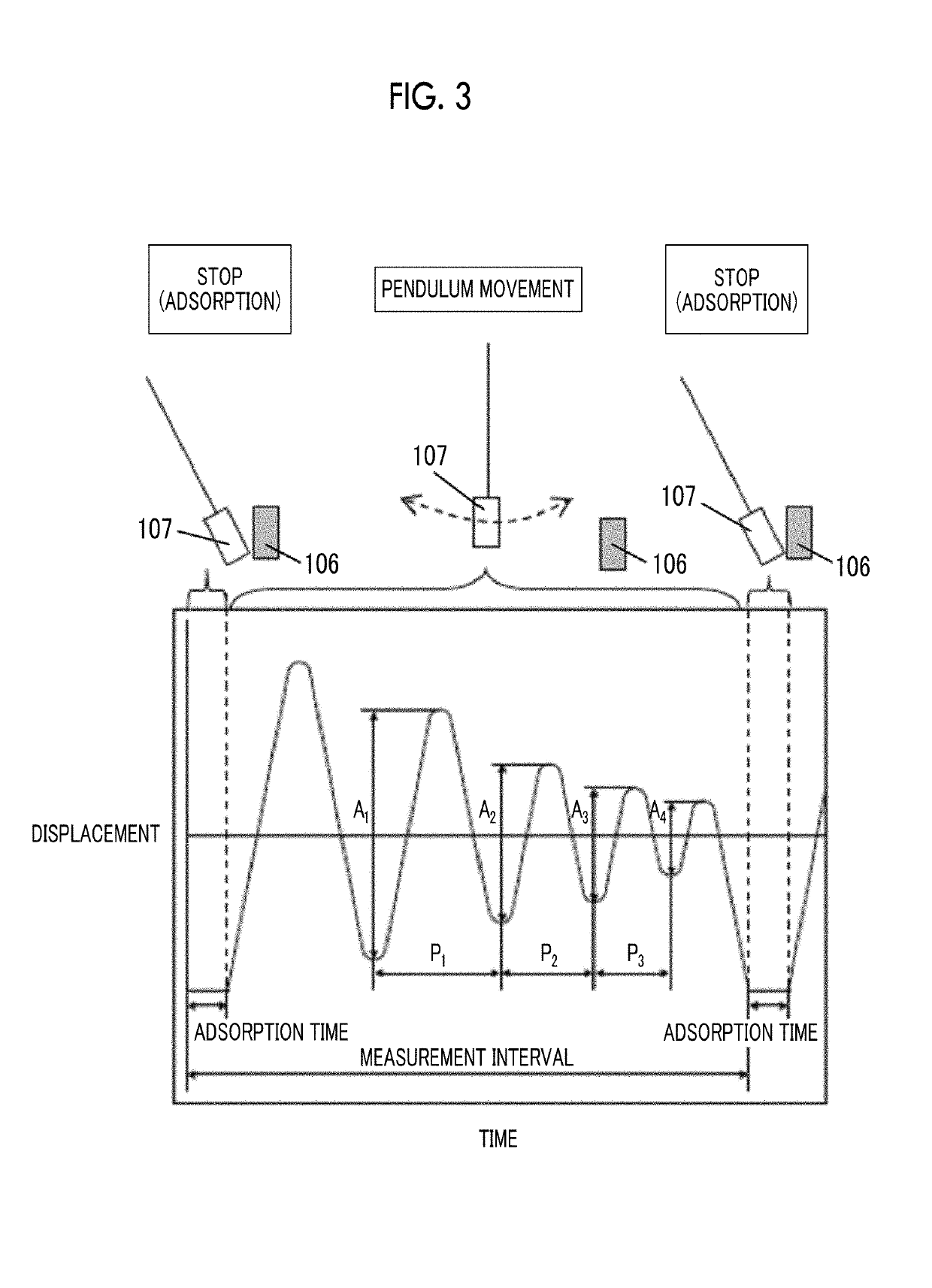

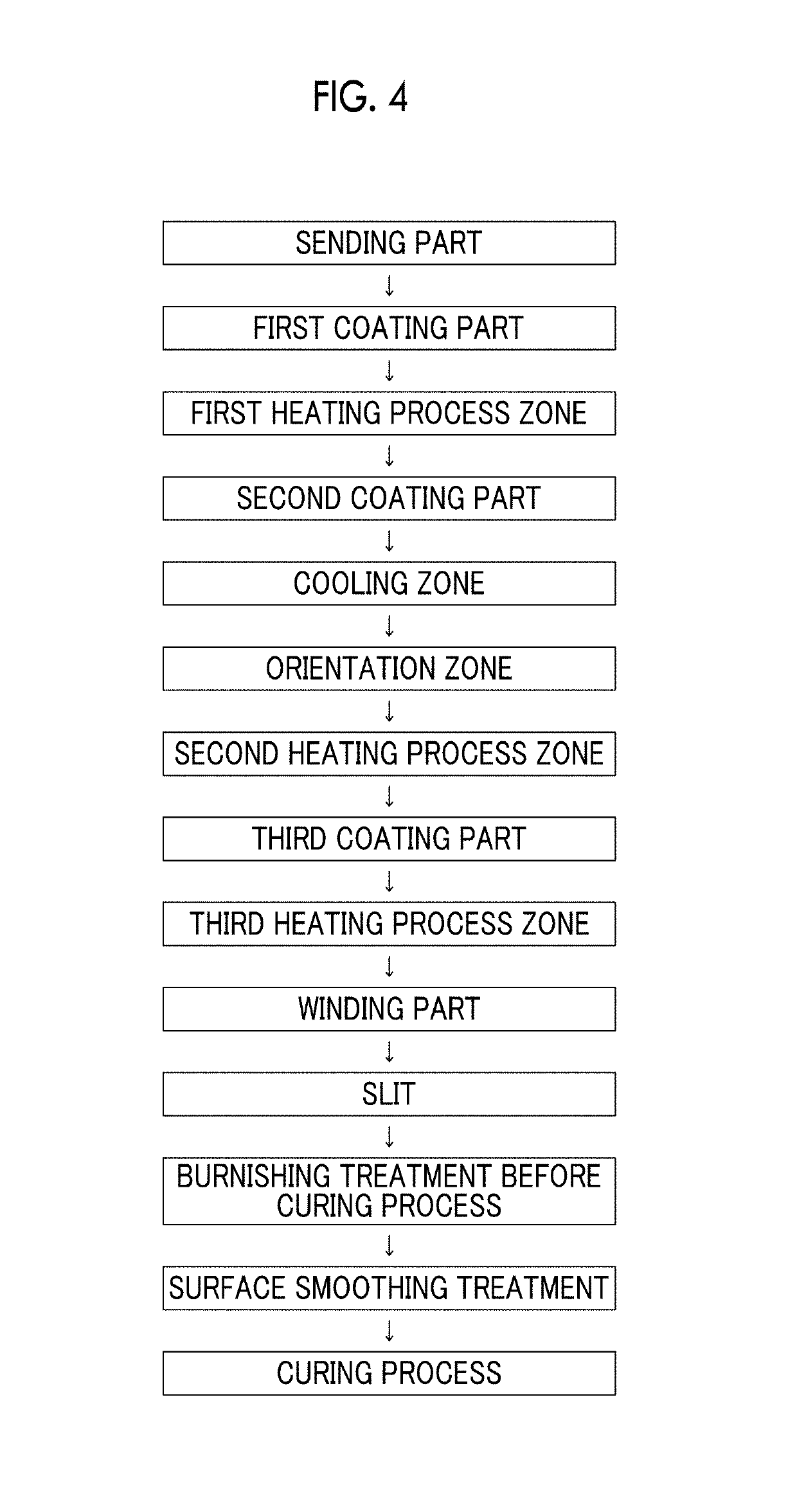

The magnetic tape includes a non-magnetic support; a non-magnetic layer including non-magnetic powder and a binding agent on the non-magnetic support; and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic layer, in which the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes an abrasive, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer with respect to the total area of the region, obtained by plane observation performed by using a scanning electron microscope is equal to or greater than 0.02% and less than 0.06%, and a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050.

Owner:FUJIFILM CORP

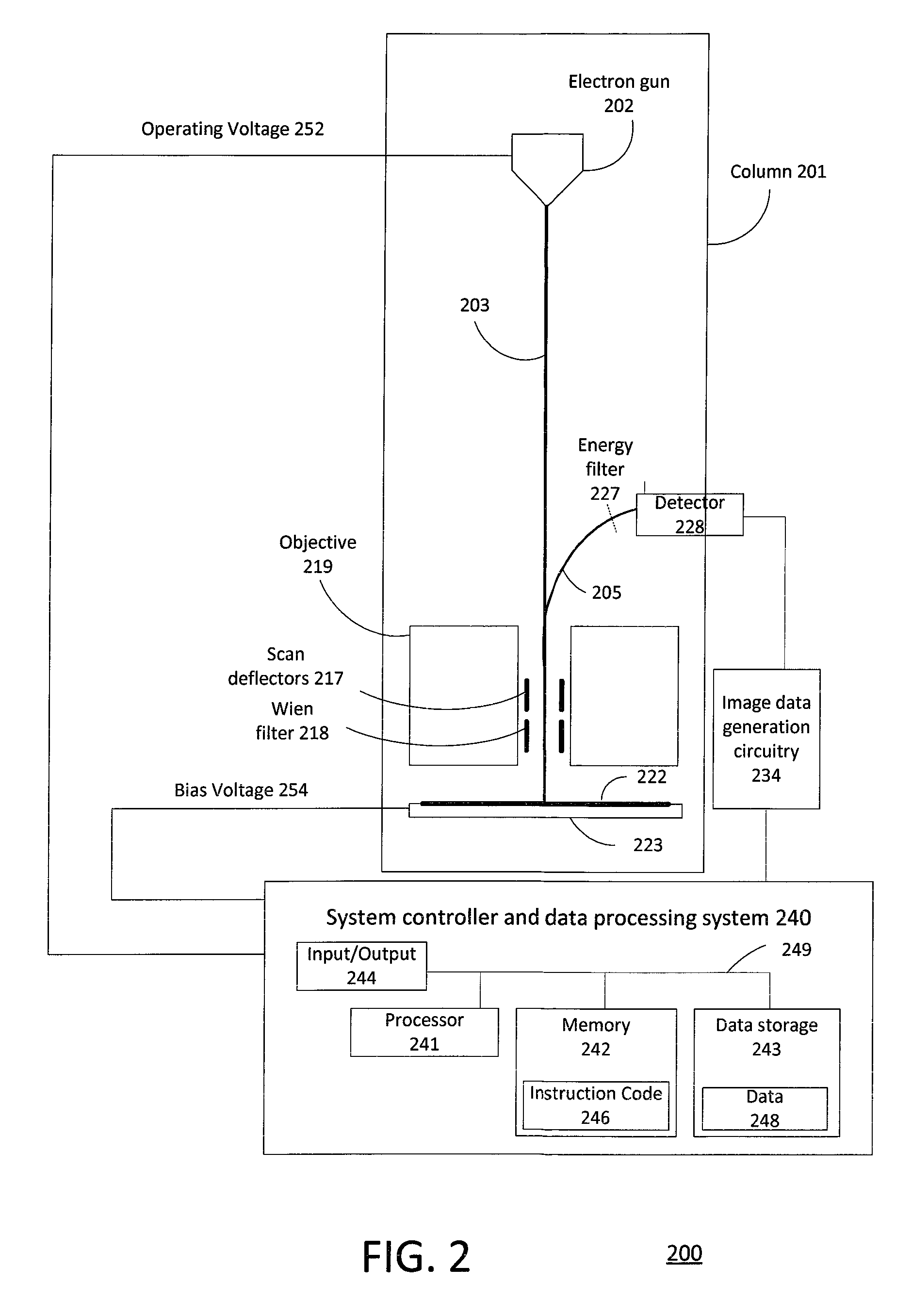

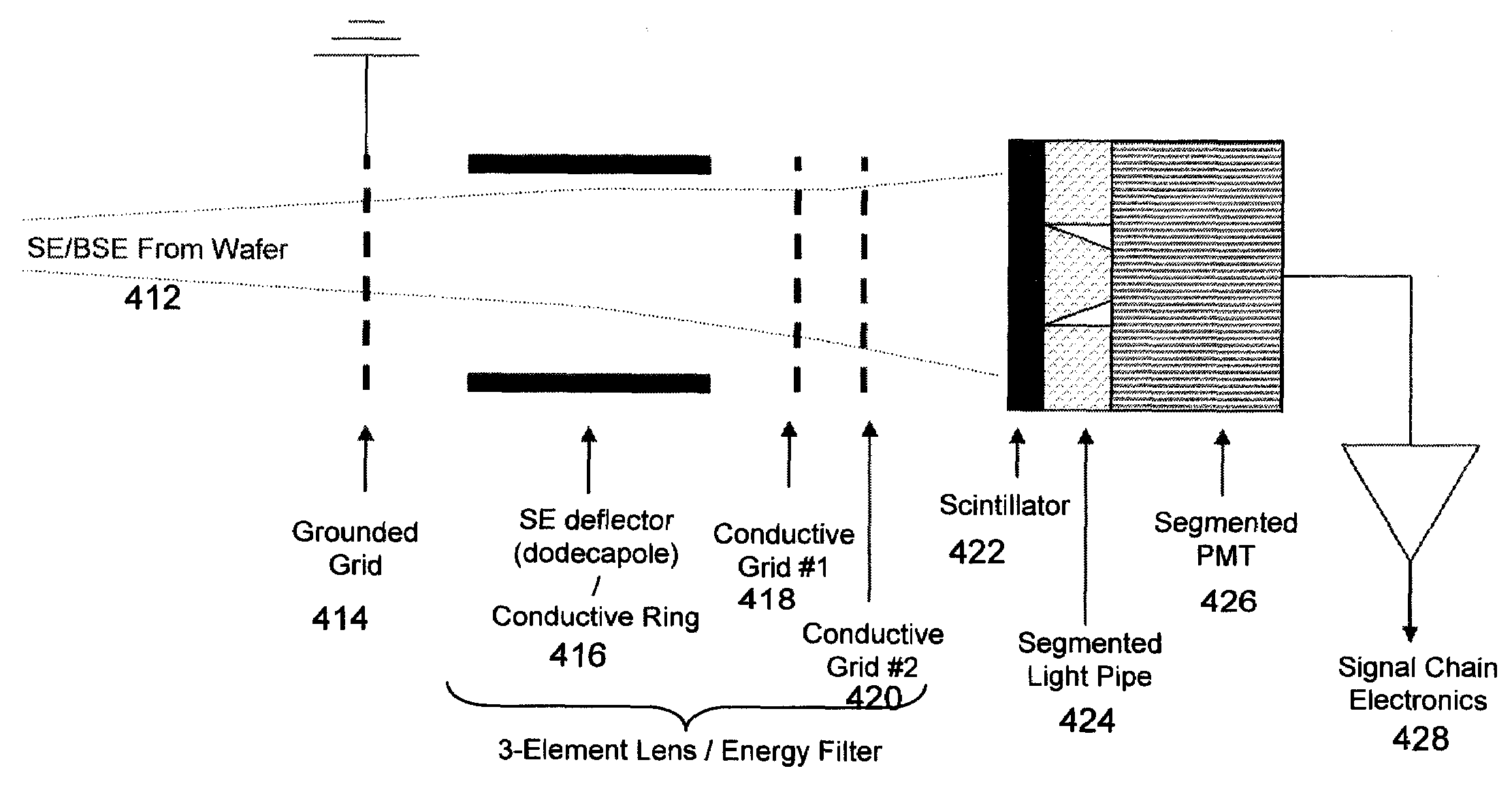

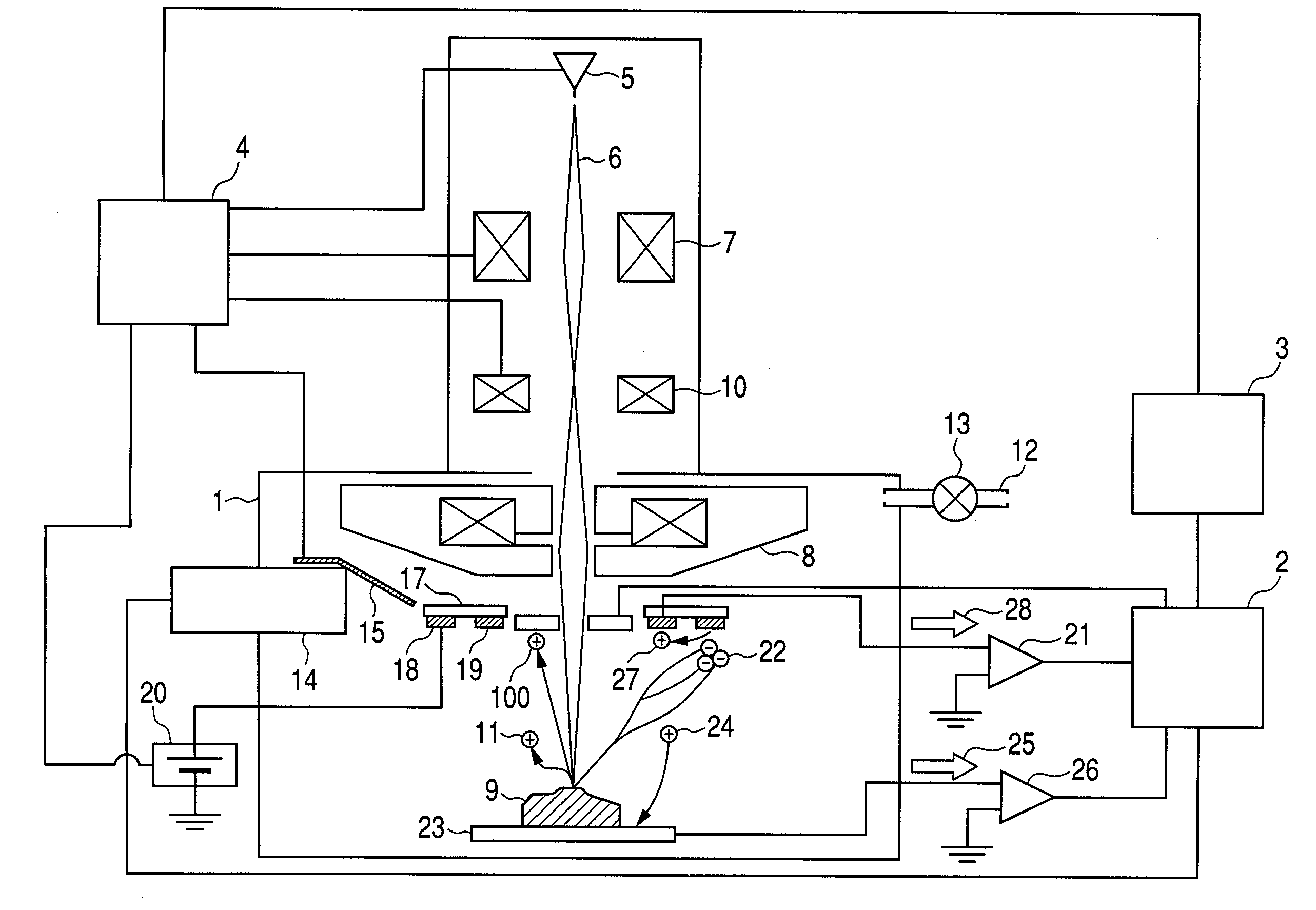

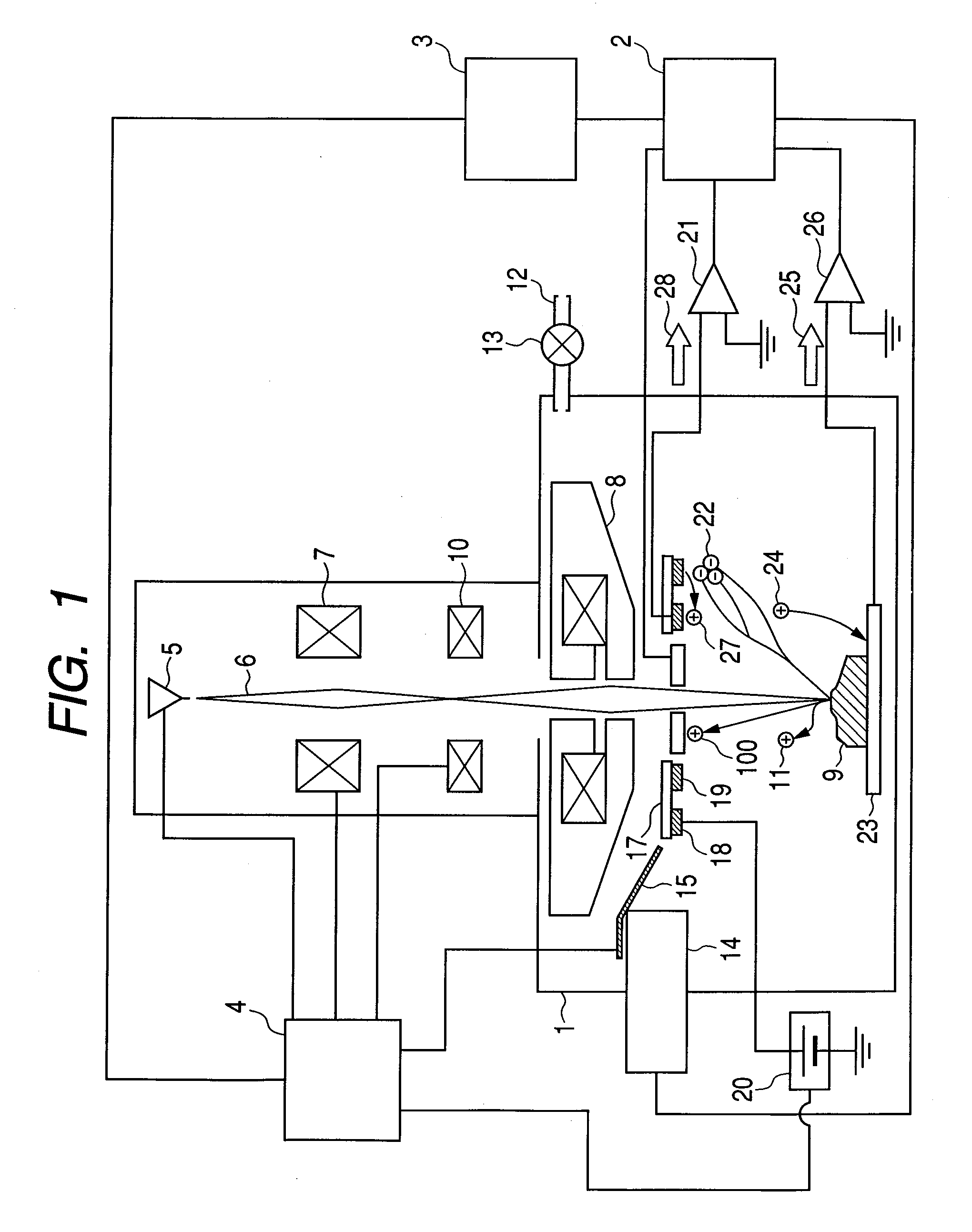

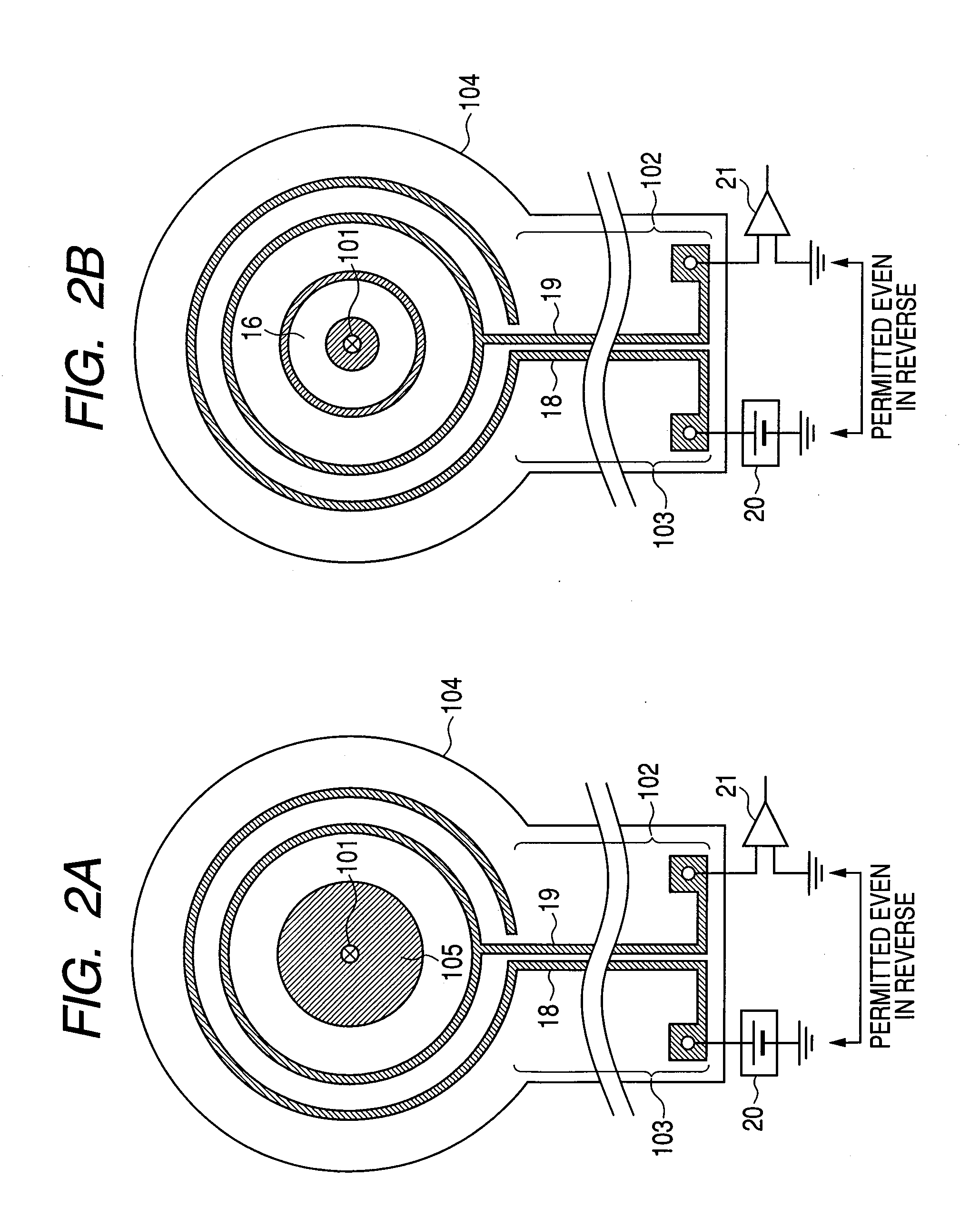

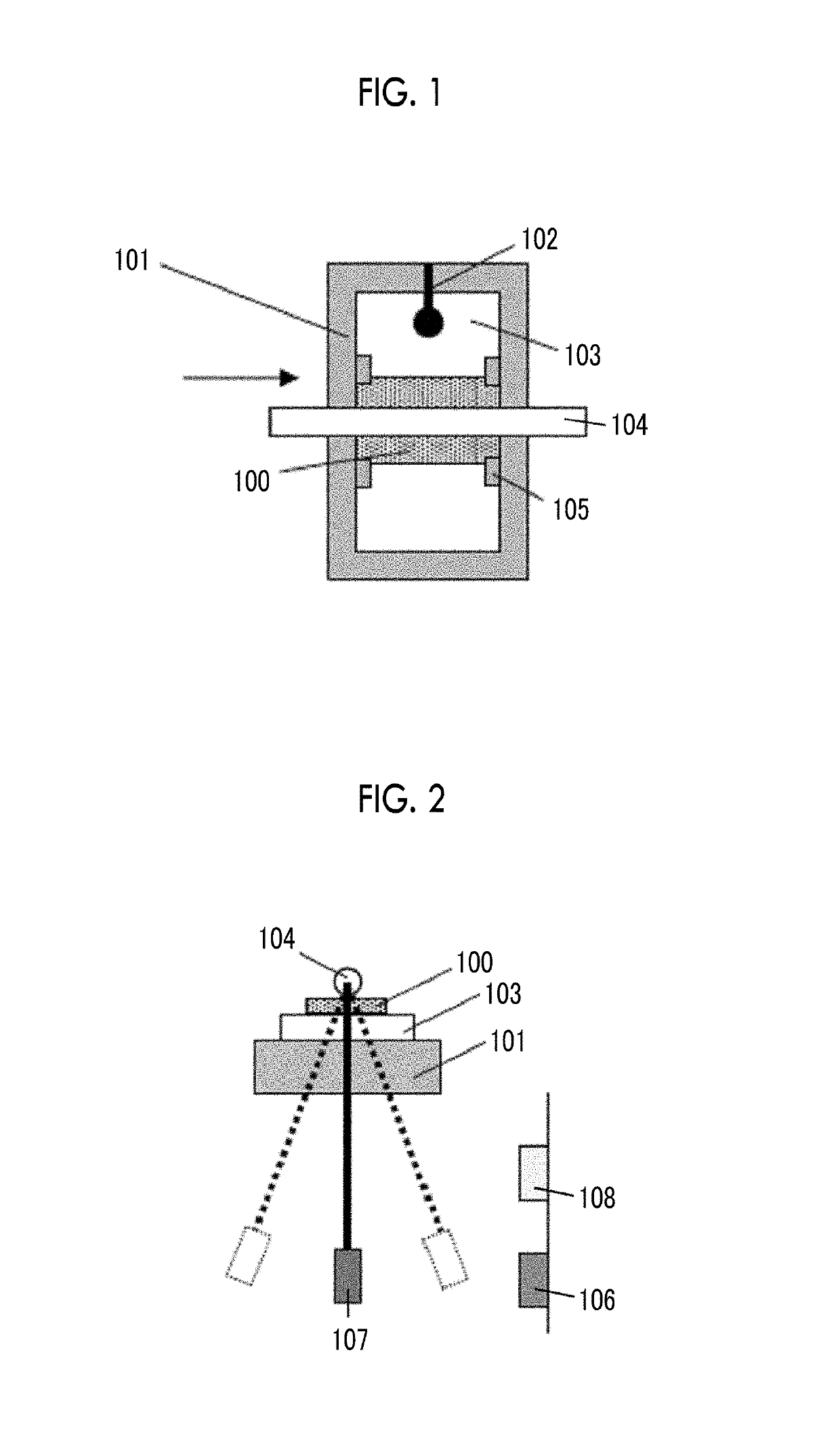

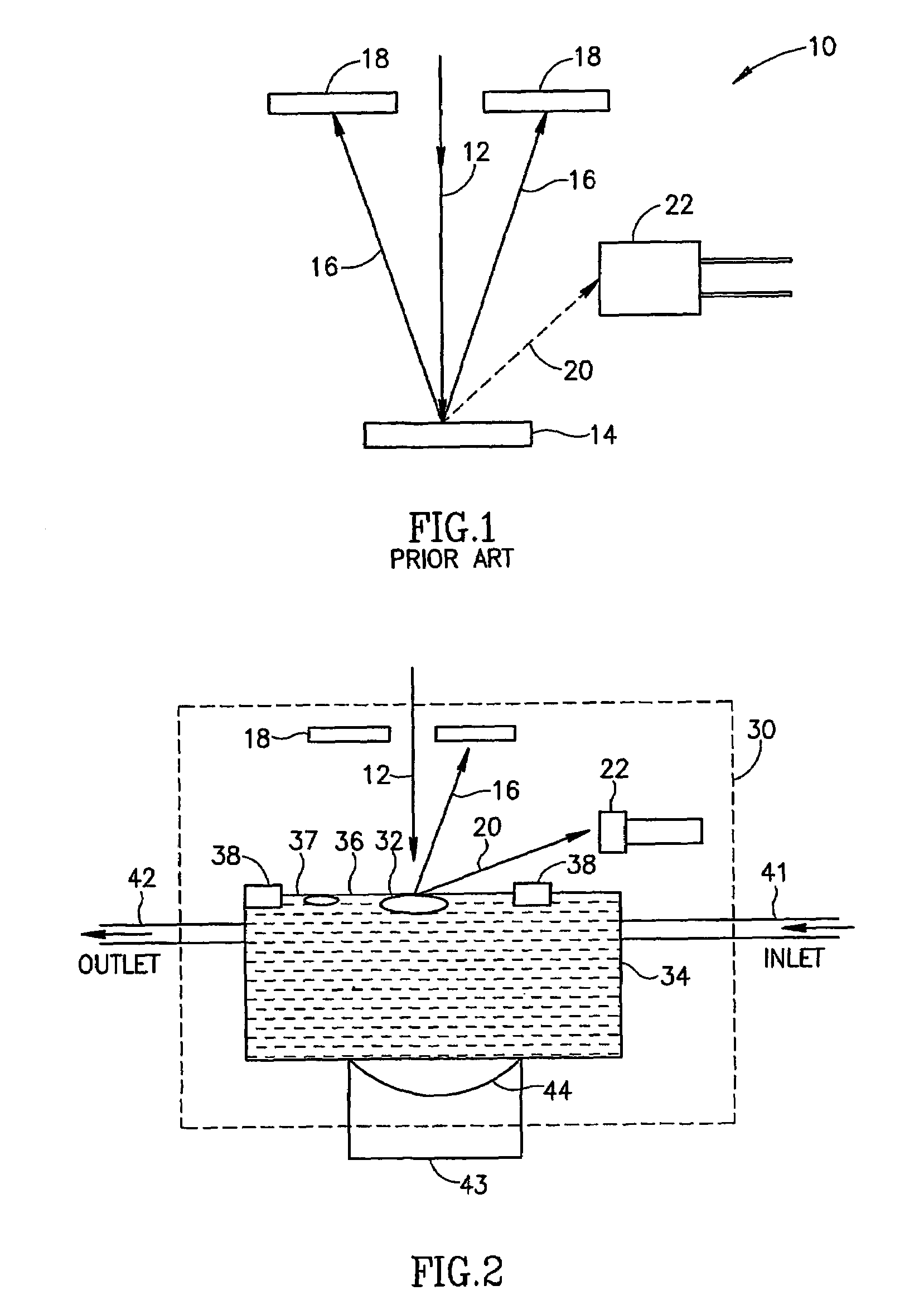

Apparatus and method for obtaining topographical dark-field images in a scanning electron microscope

ActiveUS7714287B1Thermometer detailsStability-of-path spectrometersScanning tunneling microscopeImage contrast

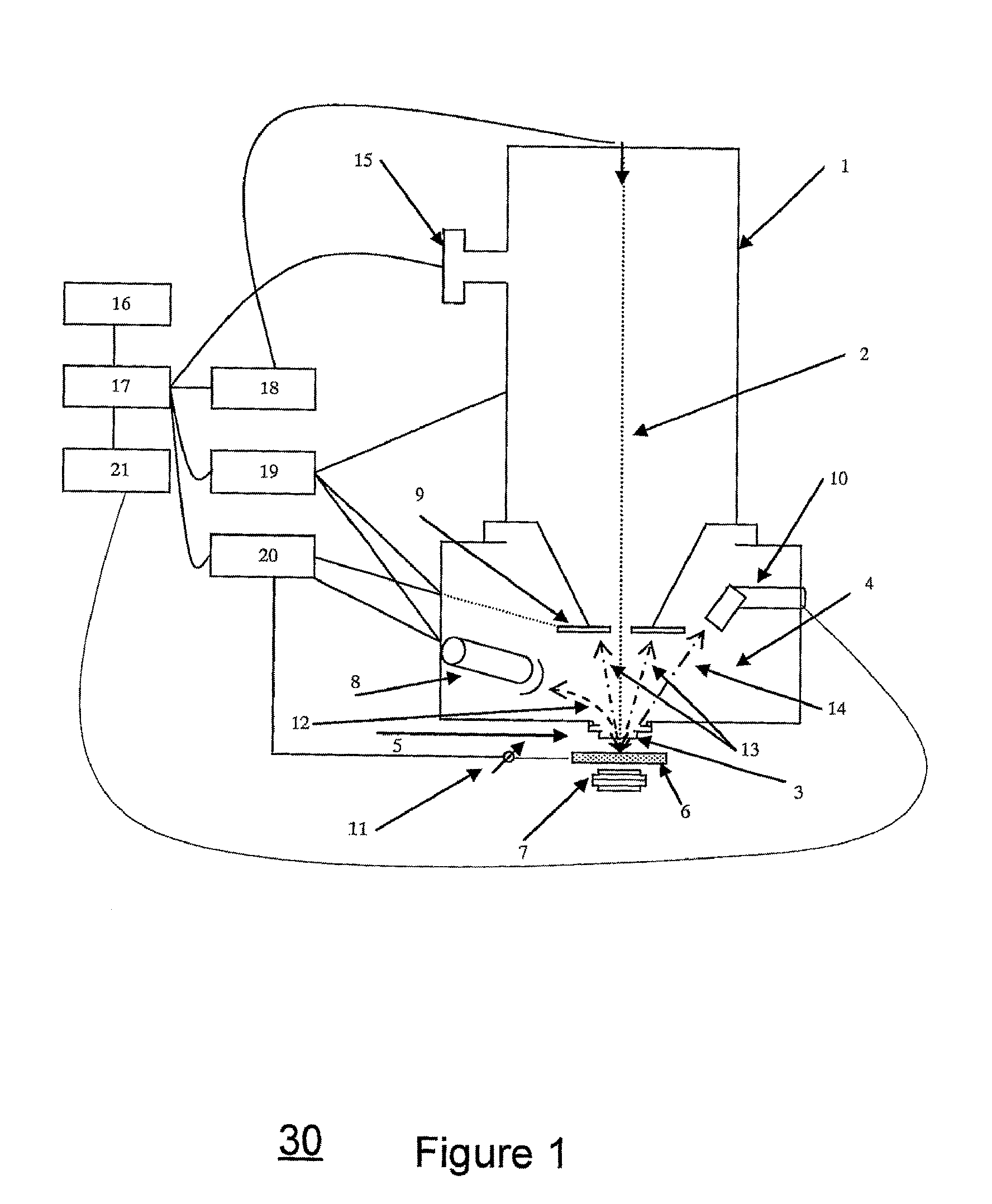

An electron beam apparatus is configured for dark field imaging of a substrate surface. Dark field is defined as an operational mode where the image contrast is sensitive to topographical features on the surface. A source generates a primary electron beam, and scan deflectors are configured to deflect the primary electron beam so as to scan the primary electron beam over the substrate surface whereby secondary and / or backscattered electrons are emitted from the substrate surface, said emitted electrons forming a scattered electron beam. A beam separator is configured to separate the scattered electron beam from the primary electron beam. The apparatus includes a cooperative arrangement which includes at least a ring-like element, a first grid, and a second grid. The ring-like element and the first and second grids each comprises conductive material. A segmented detector assembly is positioned to receive the scattered electron beam after the scattered electron beam passes through the cooperative arrangement. Other embodiments, aspects and features are also disclosed. The apparatus is configured to yield good topographical contrast, high signal to noise ratio, and to accommodate a variety of scattered beam properties that result from different primary beam and scan geometry settings.

Owner:KLA TENCOR TECH CORP

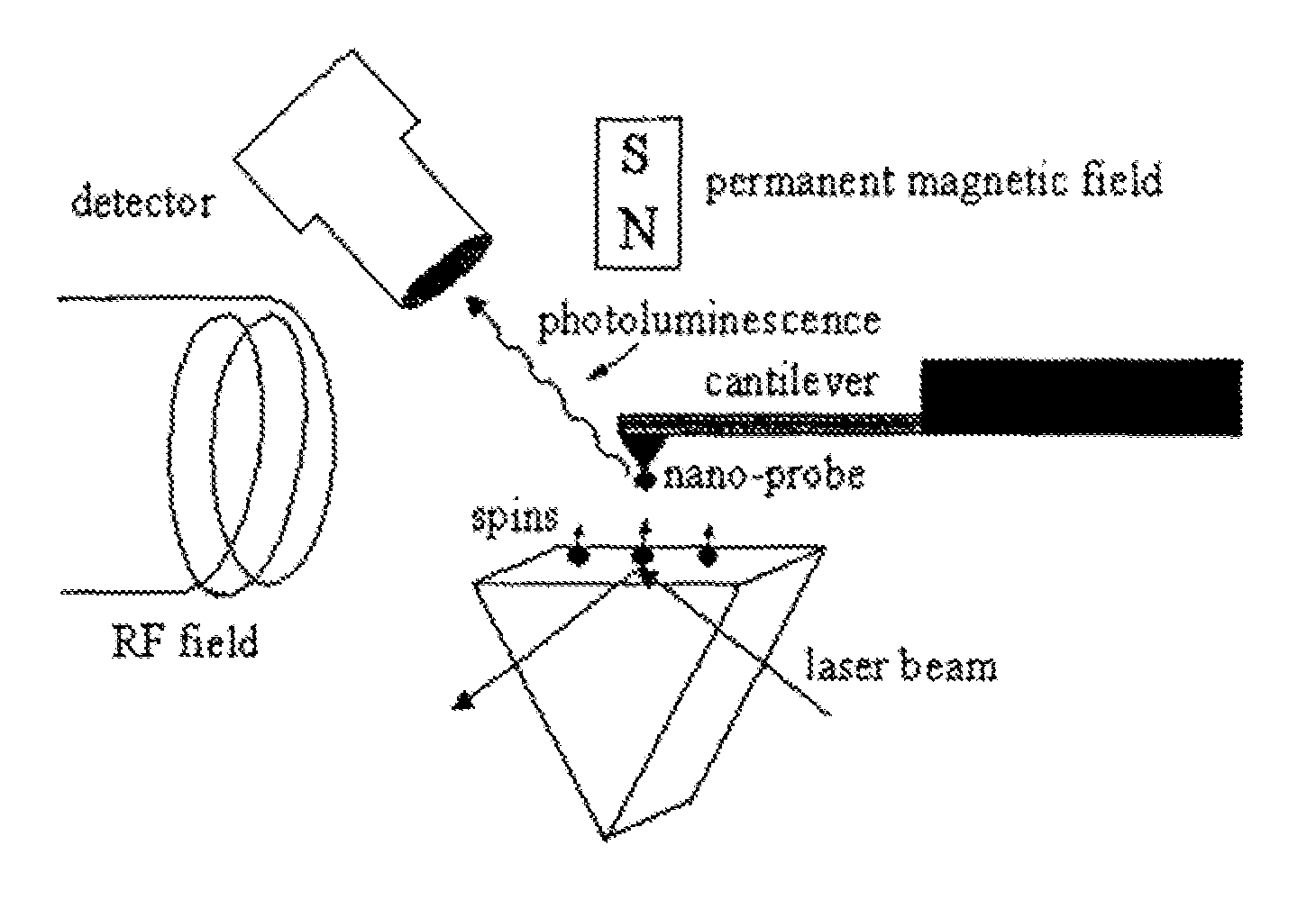

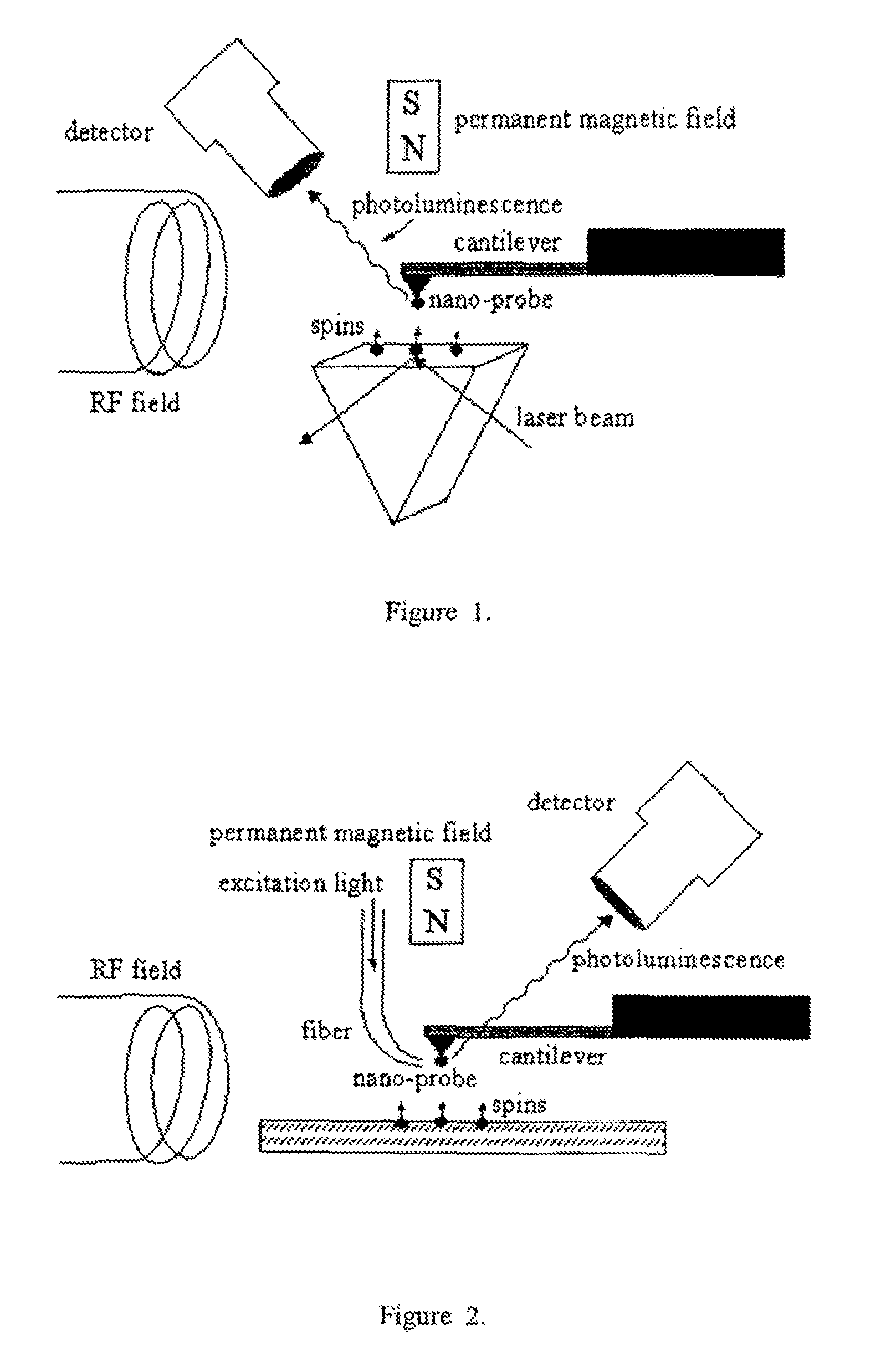

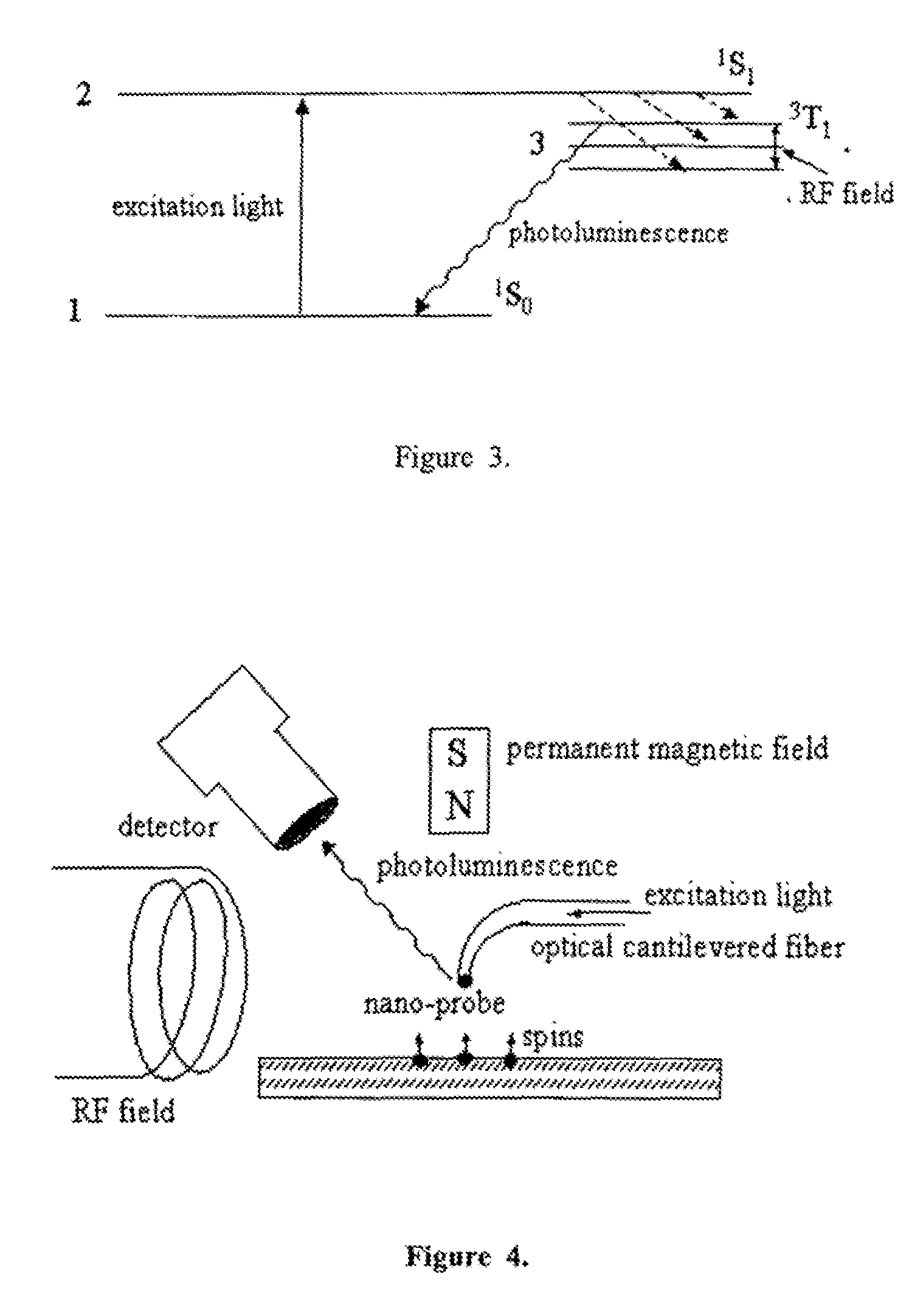

Spin microscope based on optically detected magnetic resonance

InactiveUS7608820B1NanomagnetismMaterial analysis using wave/particle radiationMagnetic force microscopePhotoluminescence

The invention relates to scanning magnetic microscope which has a photoluminescent nanoprobe implanted in the tip apex of an atomic force microscope (AFM), a scanning tunneling microscope (STM) or a near-field scanning optical microscope (NSOM) and exhibits optically detected magnetic resonance (ODMR) in the vicinity of unpaired electron spins or nuclear magnetic moments in the sample material. The described spin microscope has demonstrated nanoscale lateral resolution and single spin sensitivity for the AFM and STM embodiments.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

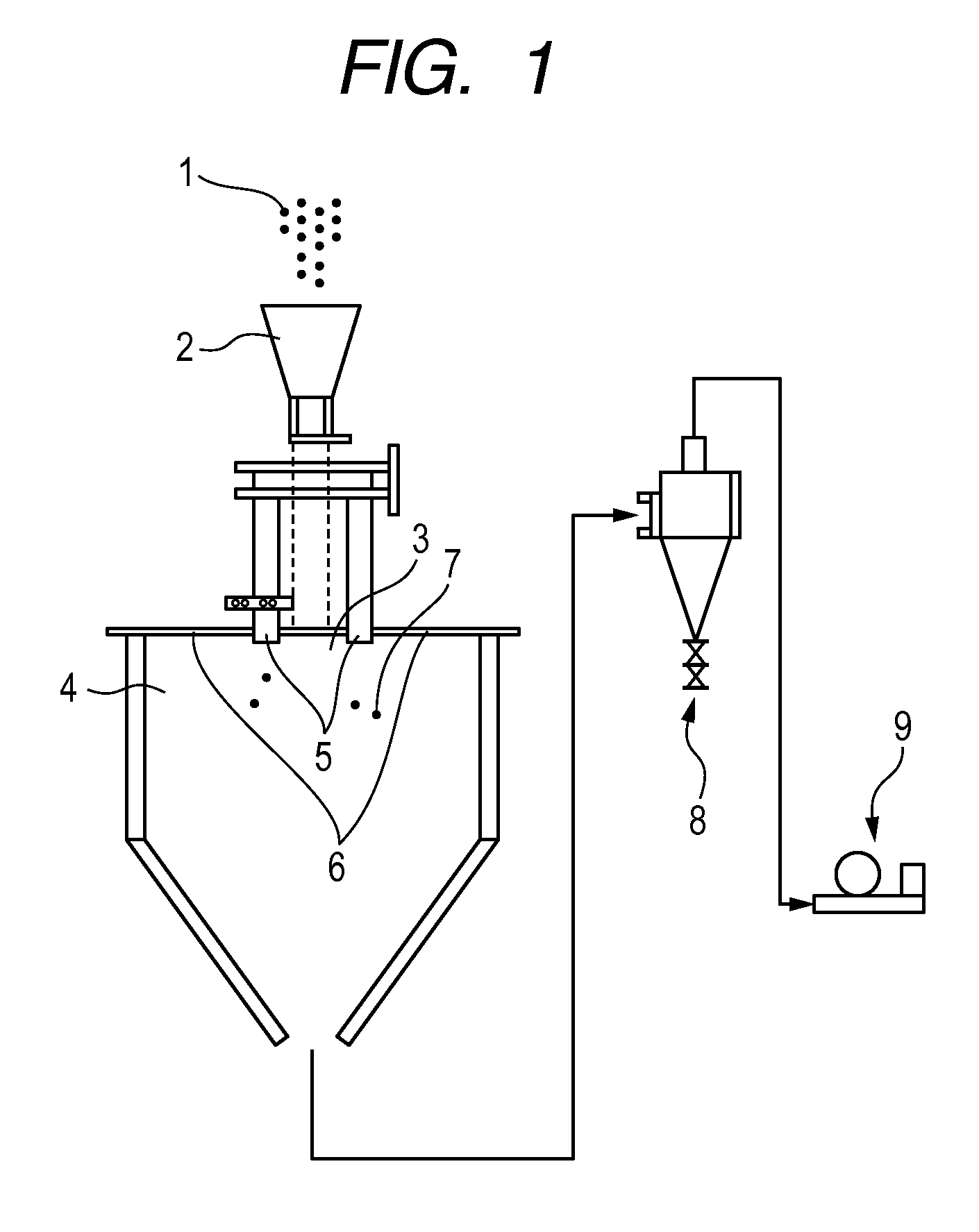

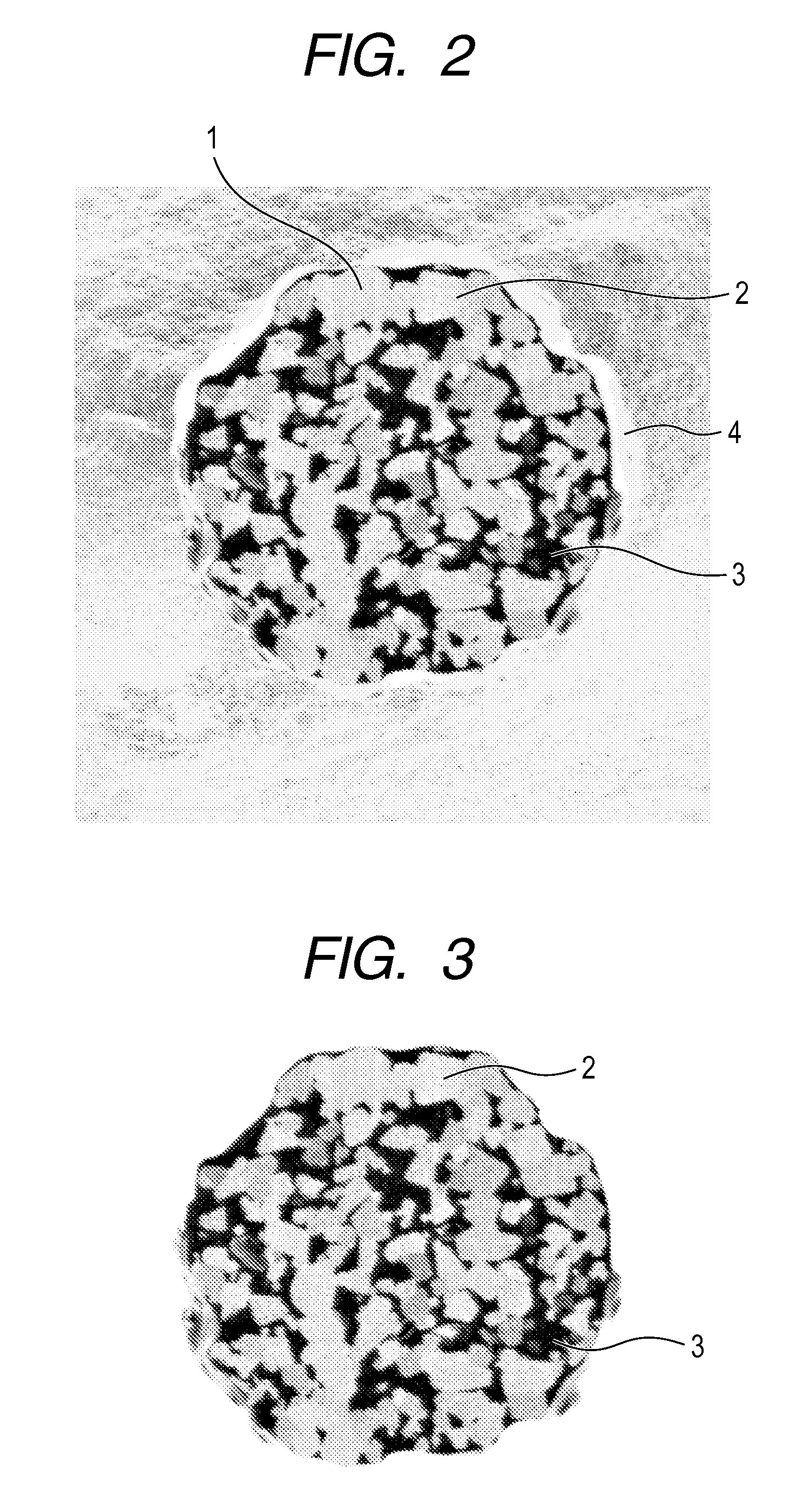

Magnetic carrier and two-component developer

ActiveUS7939233B2Reduce variationDevelopersScanning tunneling microscopeScanning electron microscope

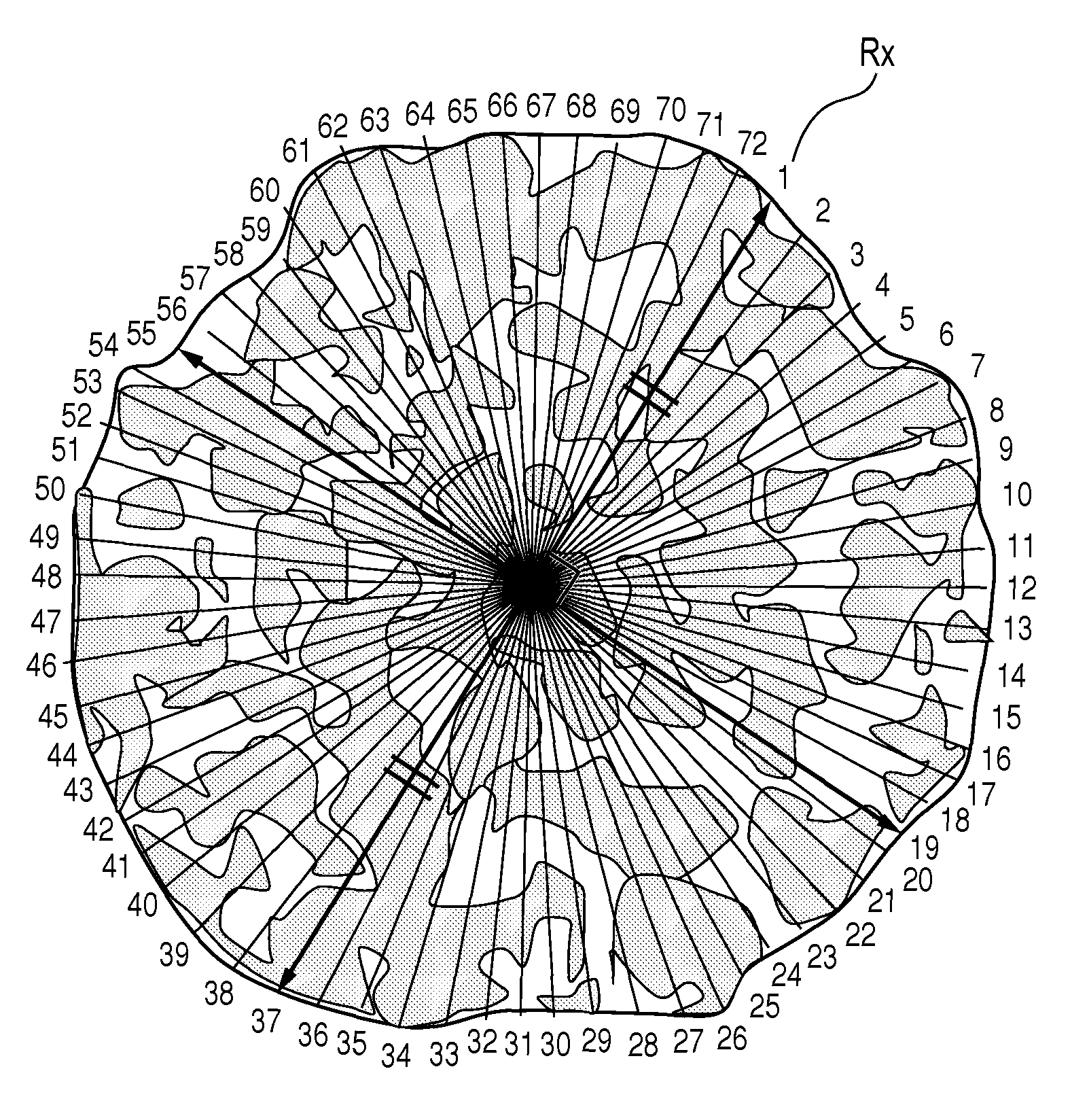

A magnetic carrier and a two-component developer are provided which have remedied blank areas, fog after leaving, carrier sticking during running, and image density variations before and after running. The magnetic carrier has magnetic carrier particles having at least porous magnetic core particles and a resin. The magnetic carrier particles satisfying the specific conditions (a), (b) and (c) where, in a reflected electron image of cross sections of the magnetic carrier particles as photographed with a scanning electron microscope, straight lines that divide a cross section of a magnetic carrier particle into 72 at intervals of 5° are drawn from a reference point of the cross section thereof toward the surface of the magnetic carrier particle; the magnetic carrier particles being contained in an amount of 60% by number or more.

Owner:CANON KK

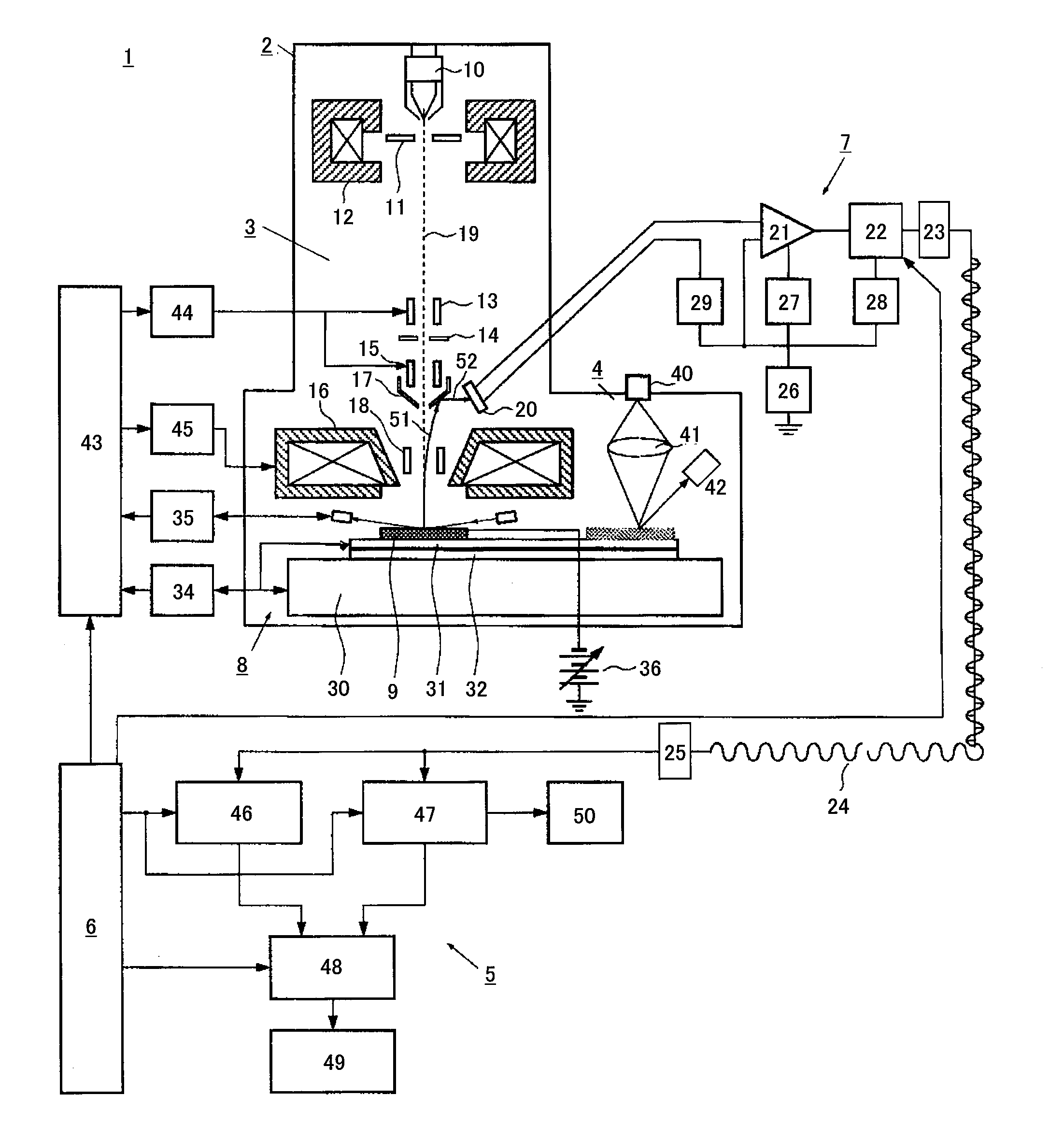

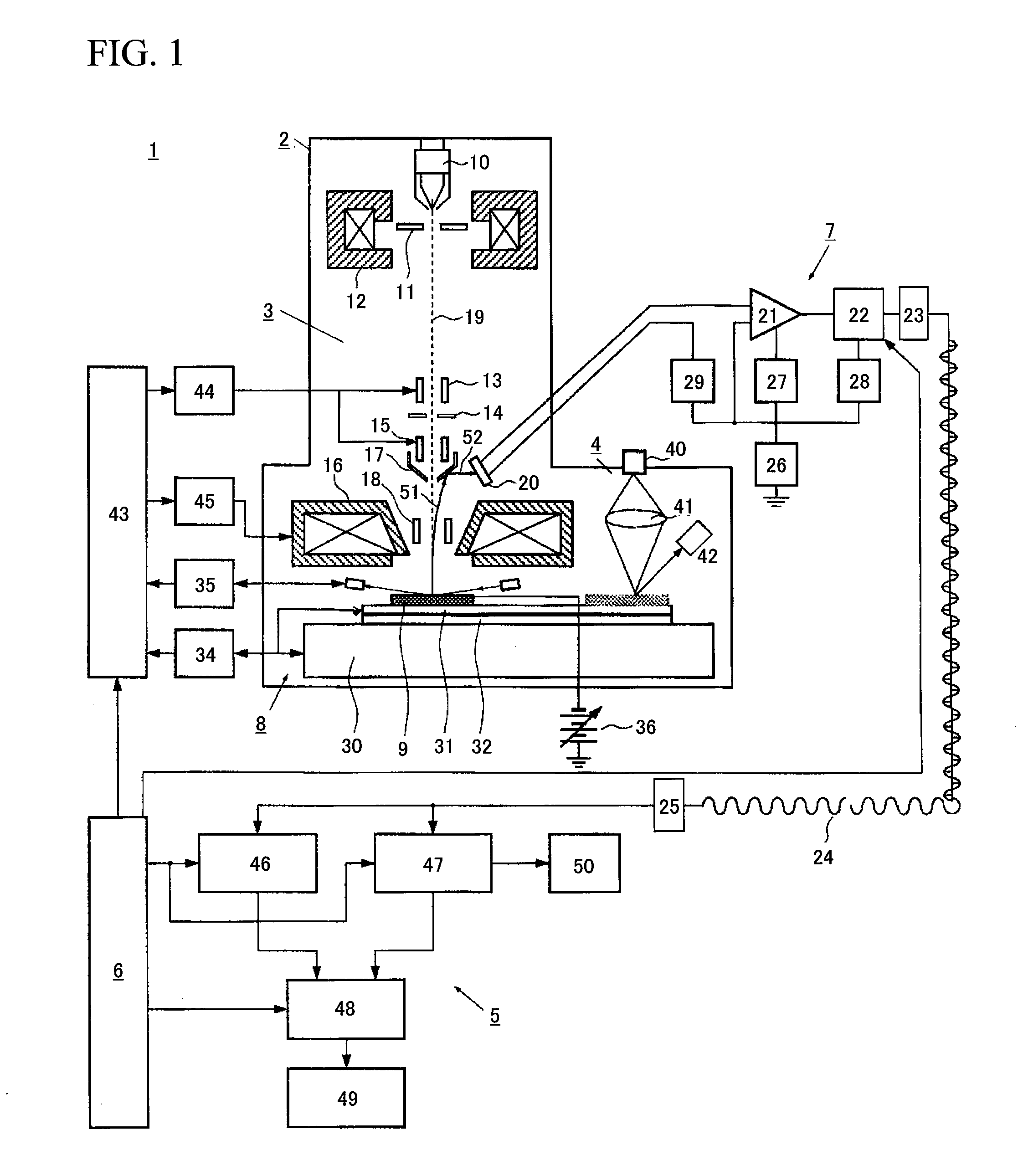

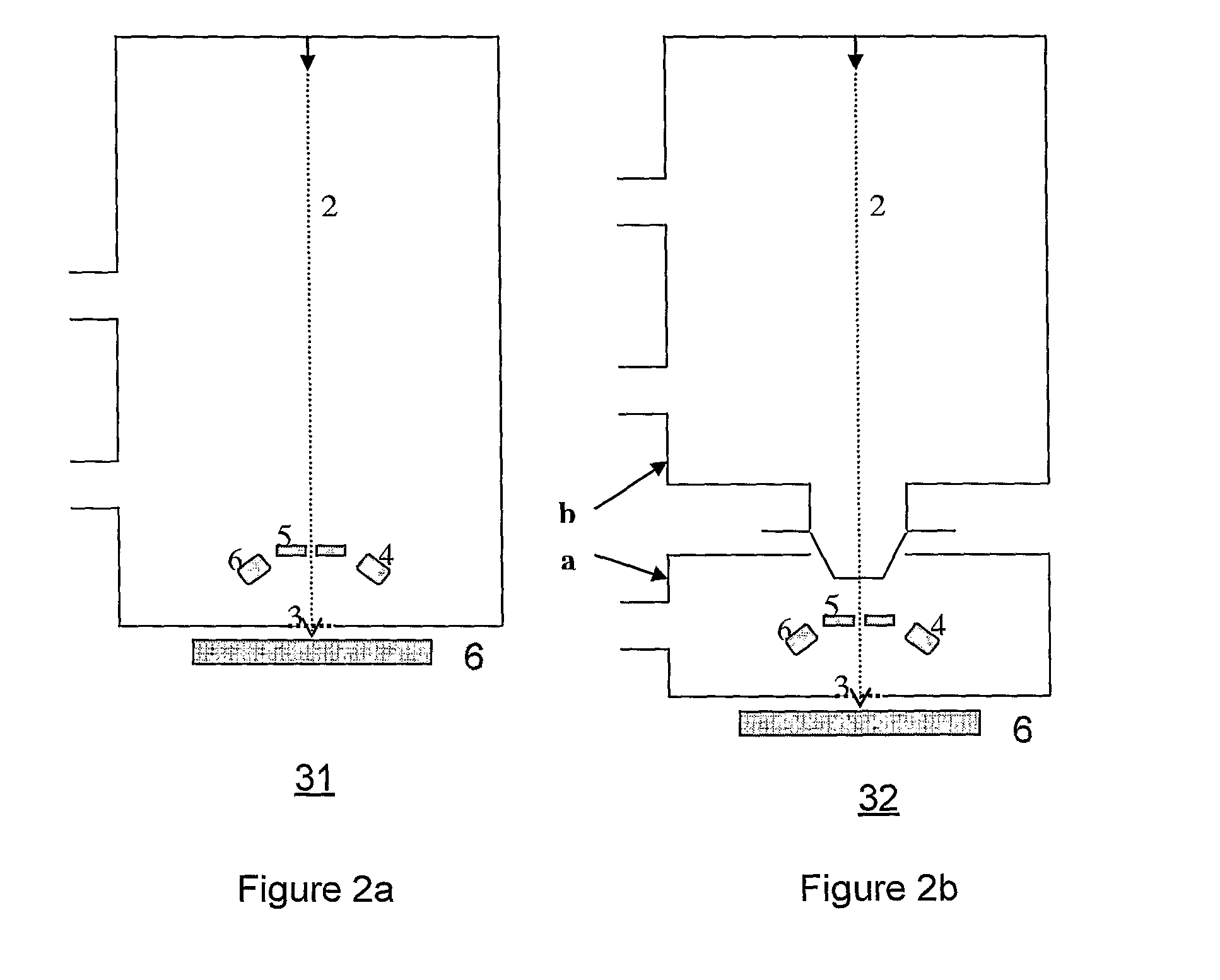

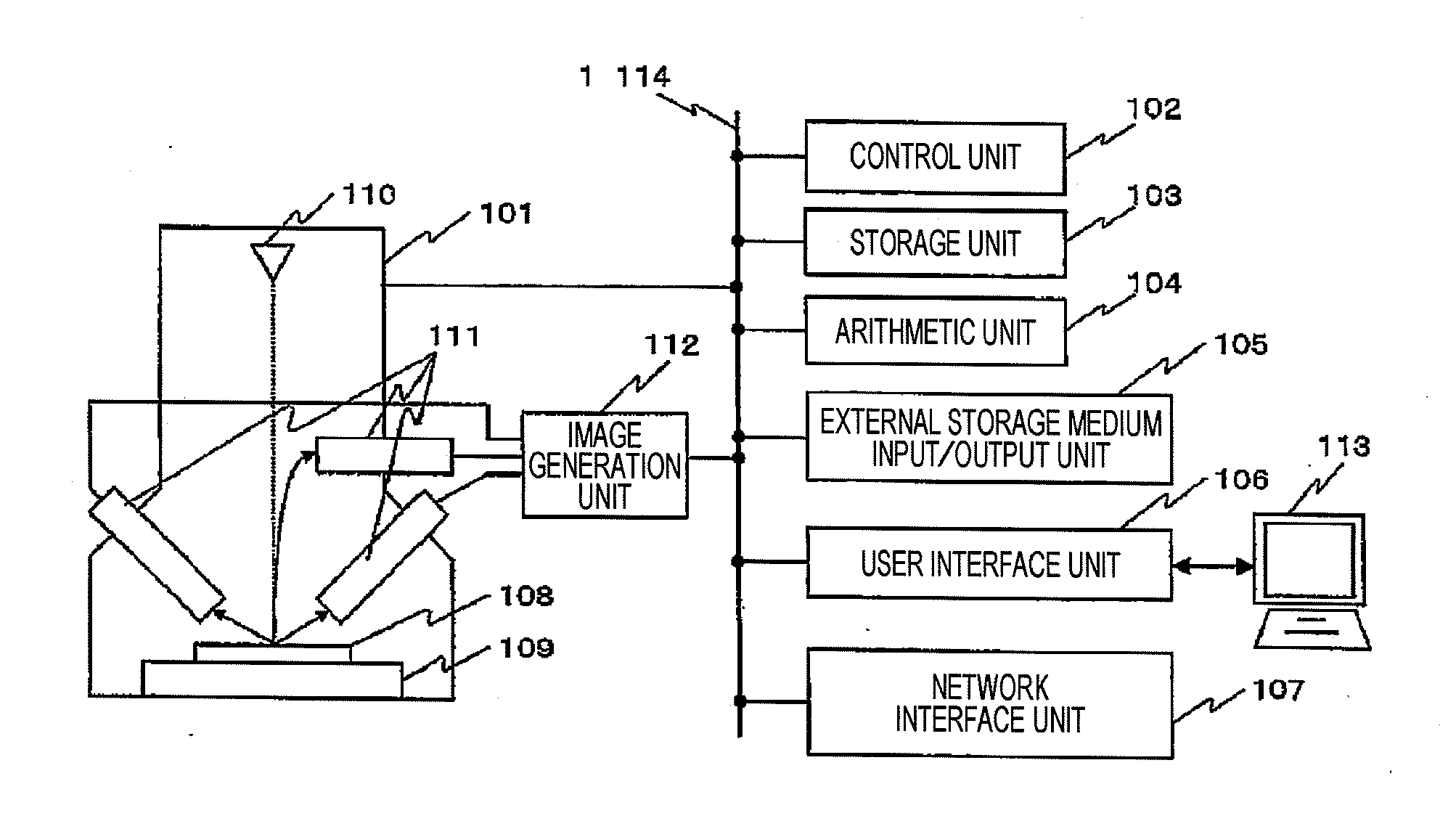

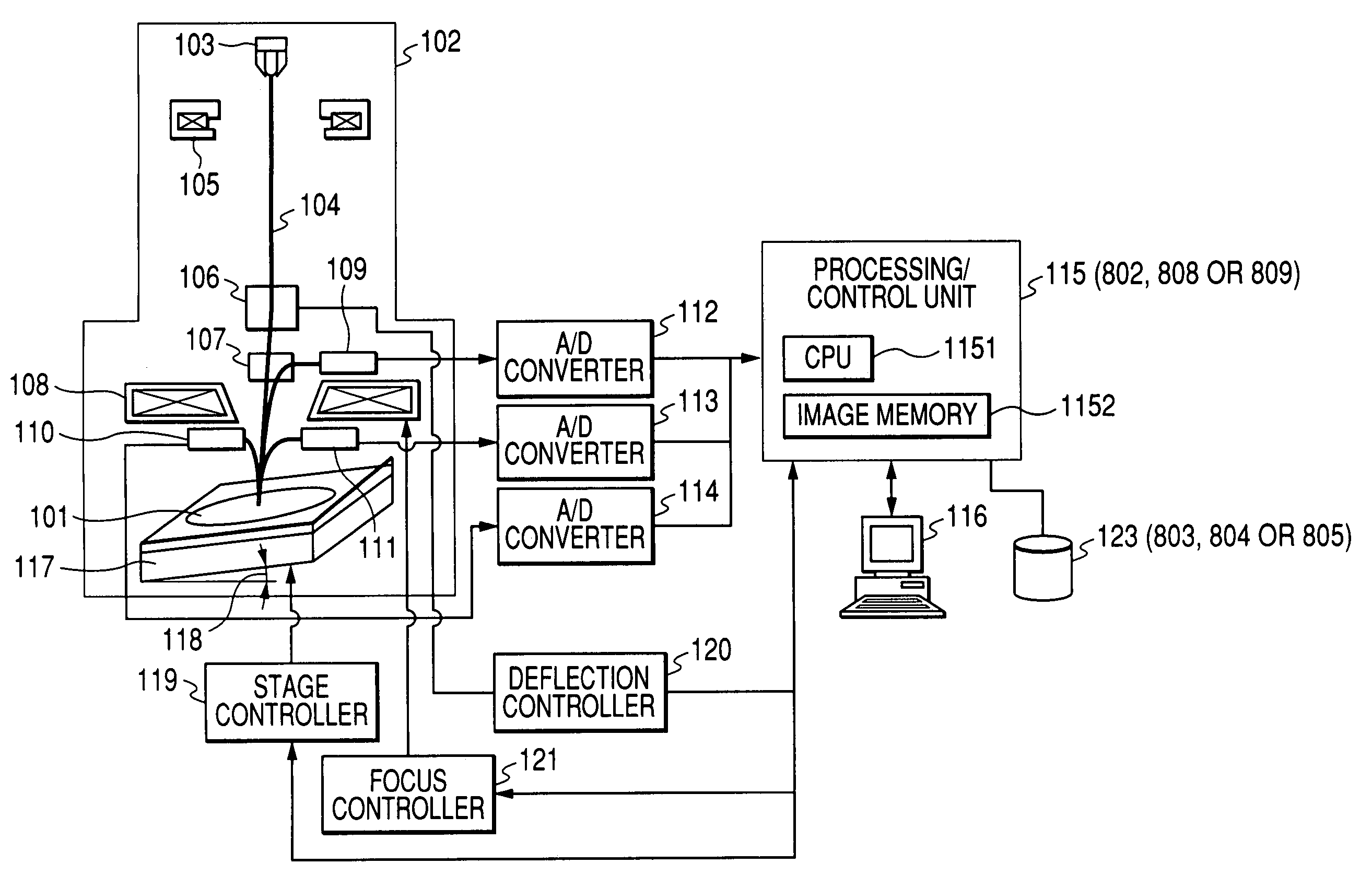

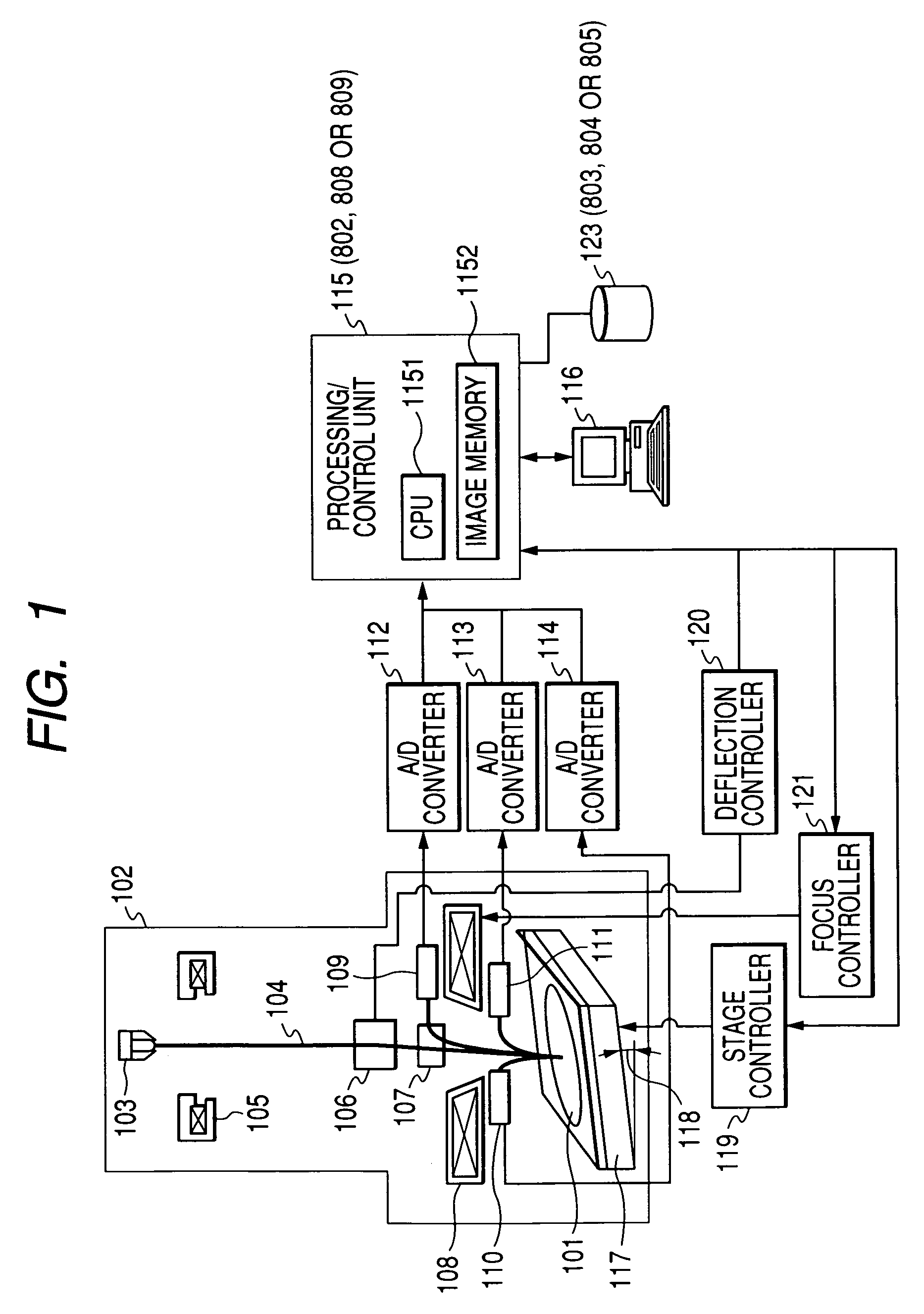

Apparatus for inspecting a substrate, a method of inspecting a substrate, a scanning electron microscope, and a method of producing an image using a scanning electron microscope

InactiveUS20090309022A1Excellent substrate inspectionSensitive defect detecting capabilityStability-of-path spectrometersMaterial analysis using wave/particle radiationScanning tunneling microscopeScanning electron microscope

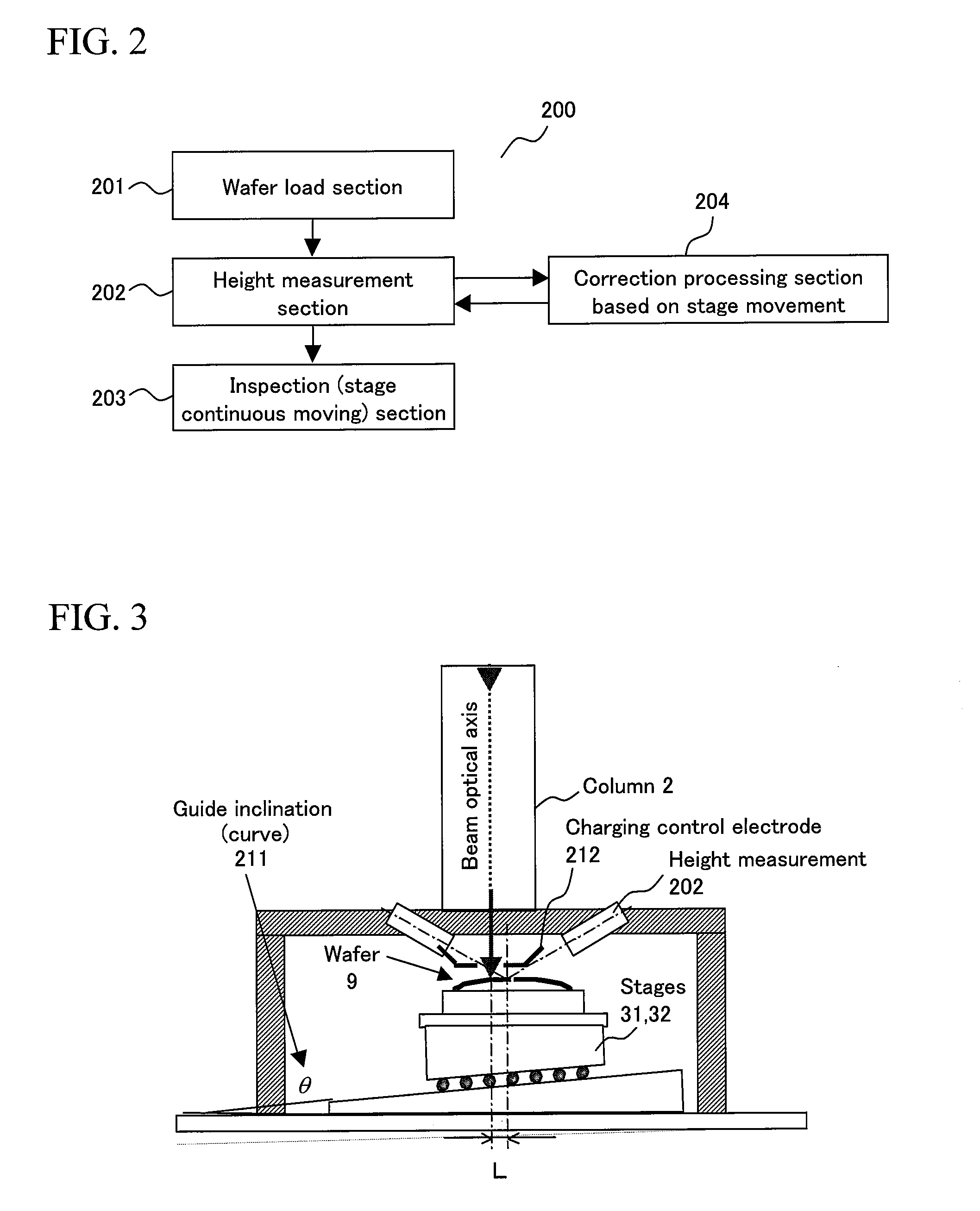

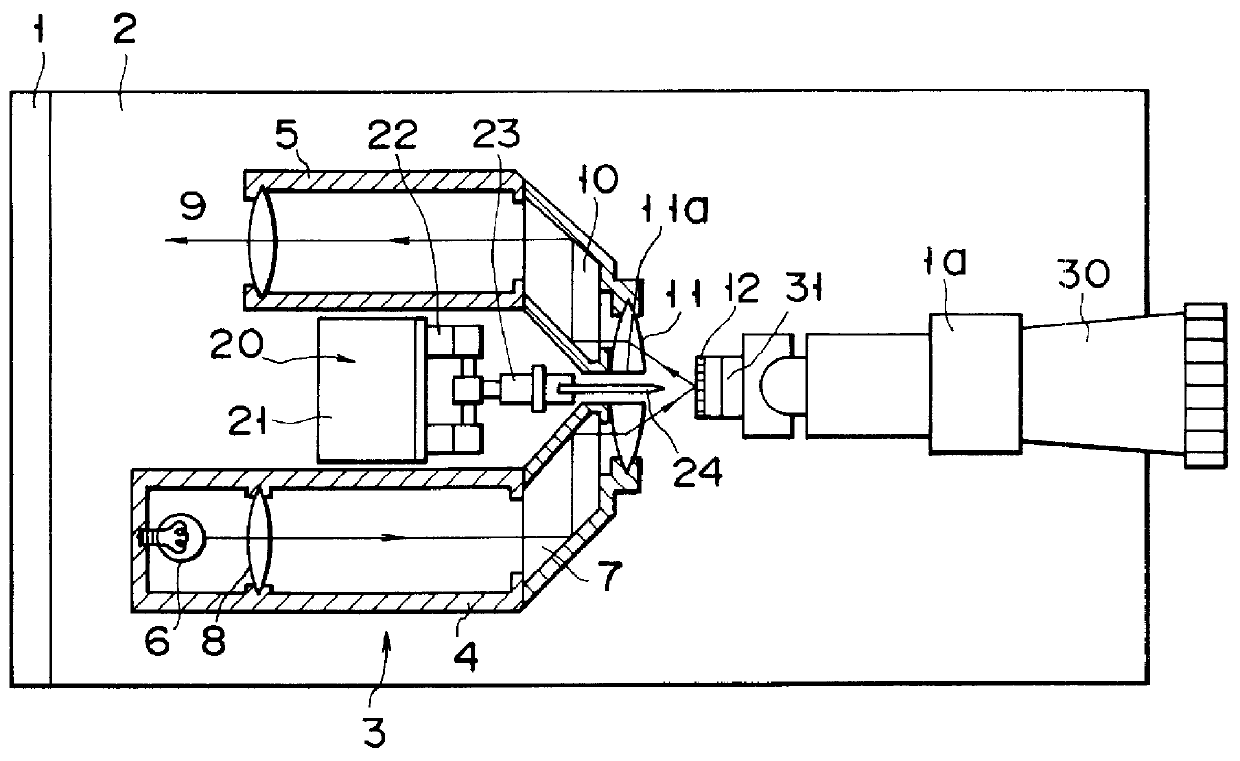

An object of the present invention provides an inspection apparatus and an inspection method which use an electron beam image to accurately detect a defect that is difficult to detect in an optical image, the apparatus and method also enabling prevention of a possible decrease in focus accuracy of an inspection image which affect the defect detection. To accomplish the object, the present invention includes a height measurement section which measures height of the electron beam irradiation position on the substrate after the substrate is loaded onto a movable stage, a height correction processing section which corrects the measured height, and a control section which adjusts a focus of the electron beam according to the height corrected by the height correction processing section, wherein a stage position set when the height measurement section measures the height differs from a stage position set when the substrate is irradiated with the electron beam, and the height correction processing section corrects a possible deviation in height resulting from movement from the stage position for the height measurement to the stage position for the electron beam irradiation.

Owner:HITACHI HIGH-TECH CORP

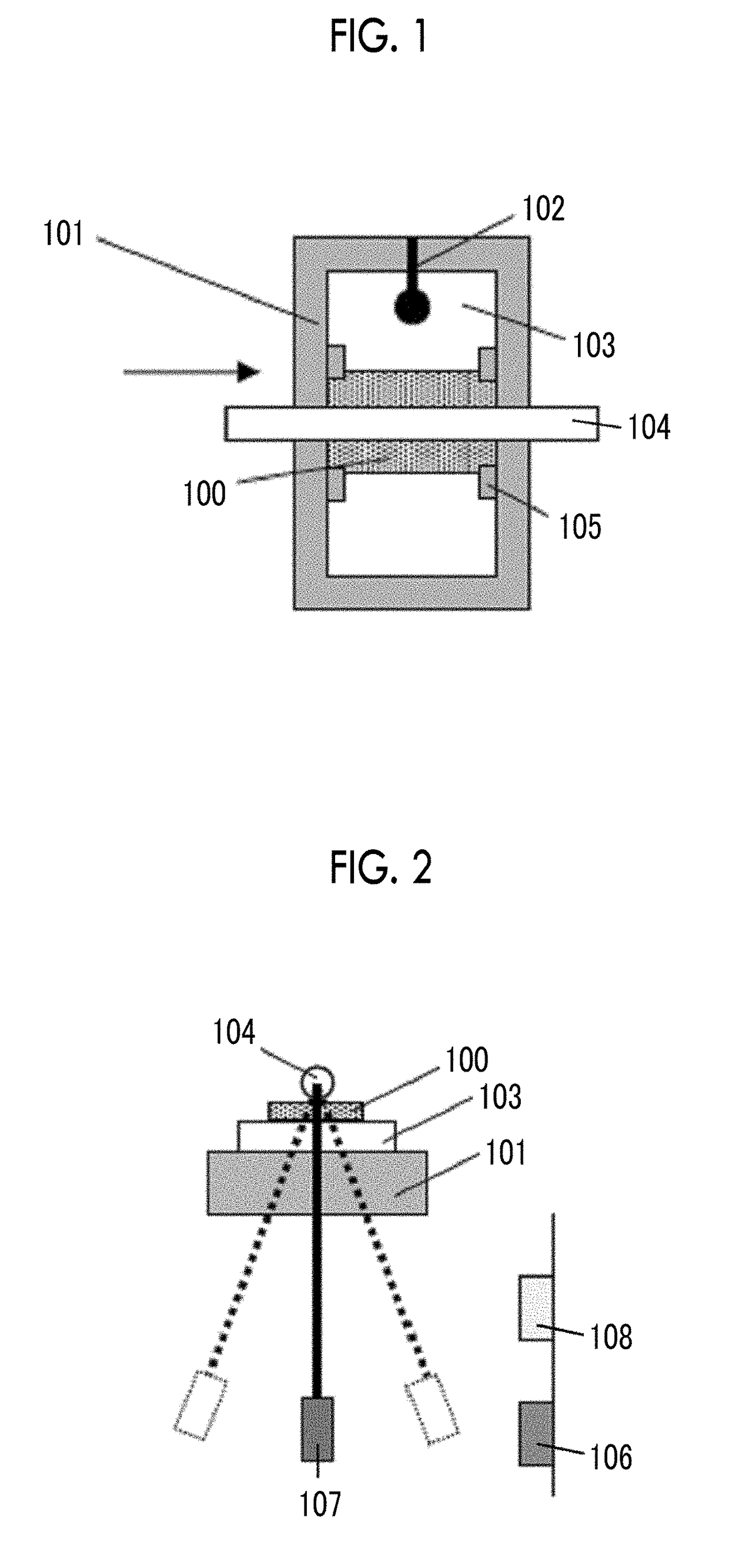

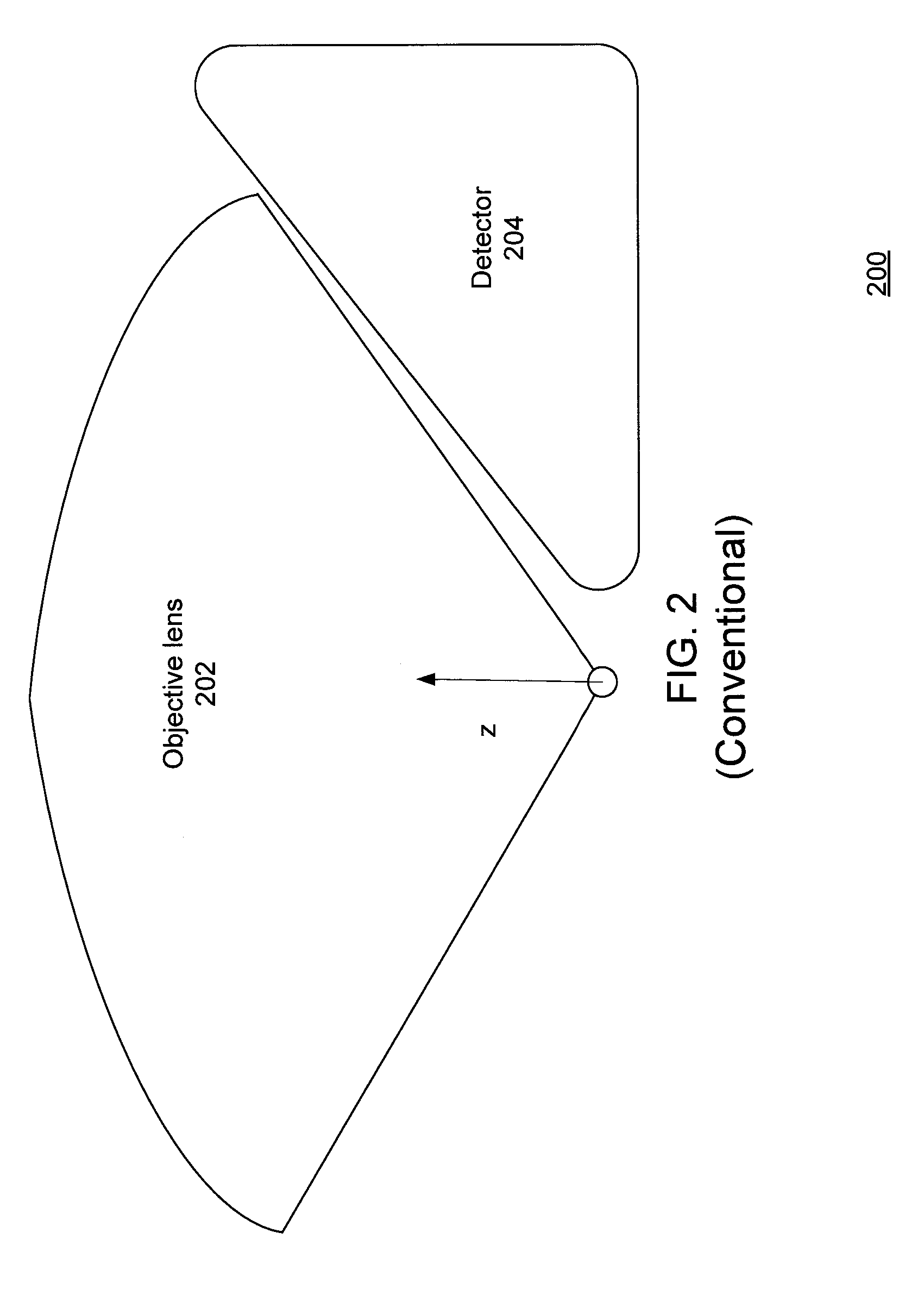

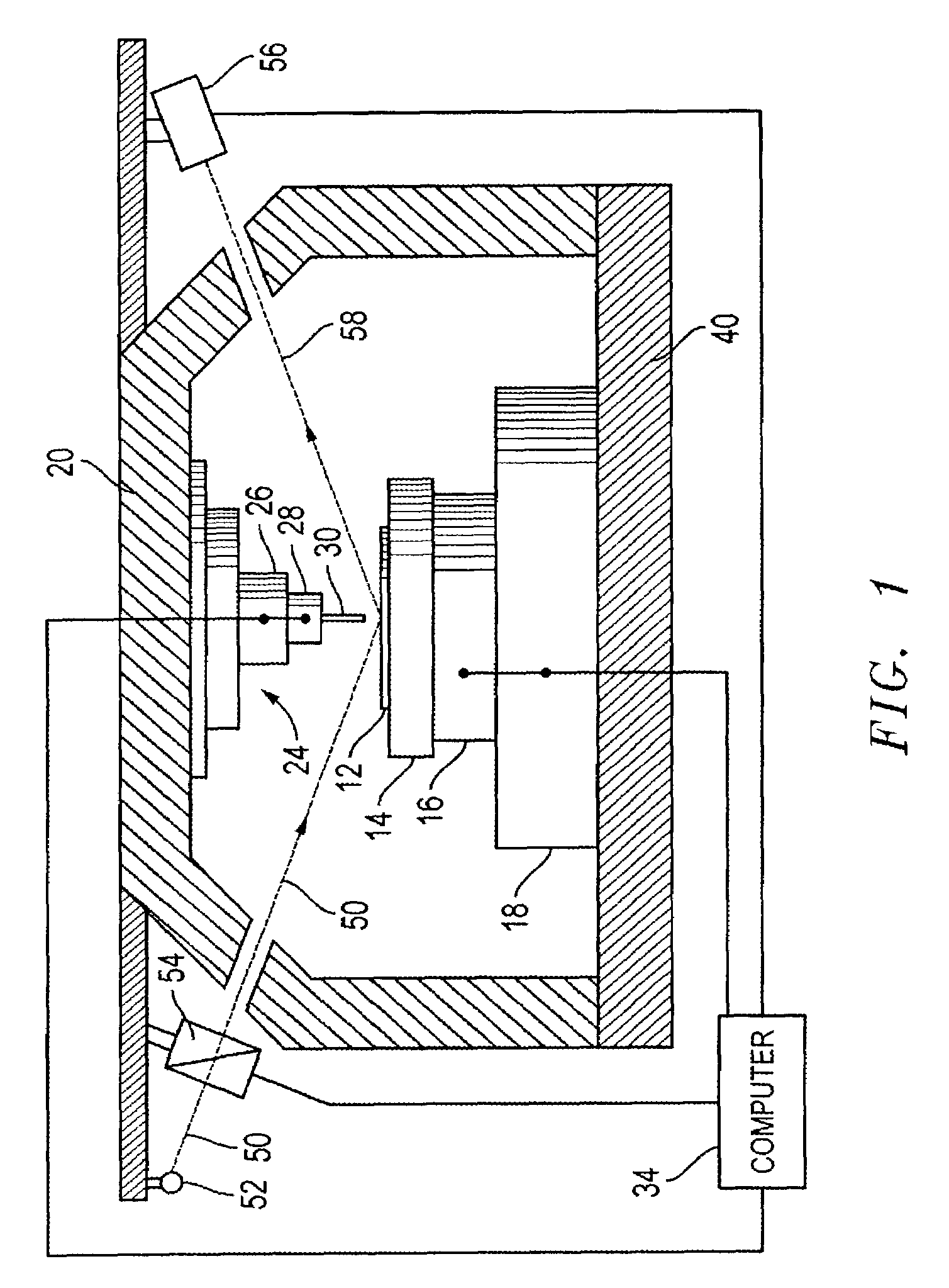

Scanning tunnel microscope

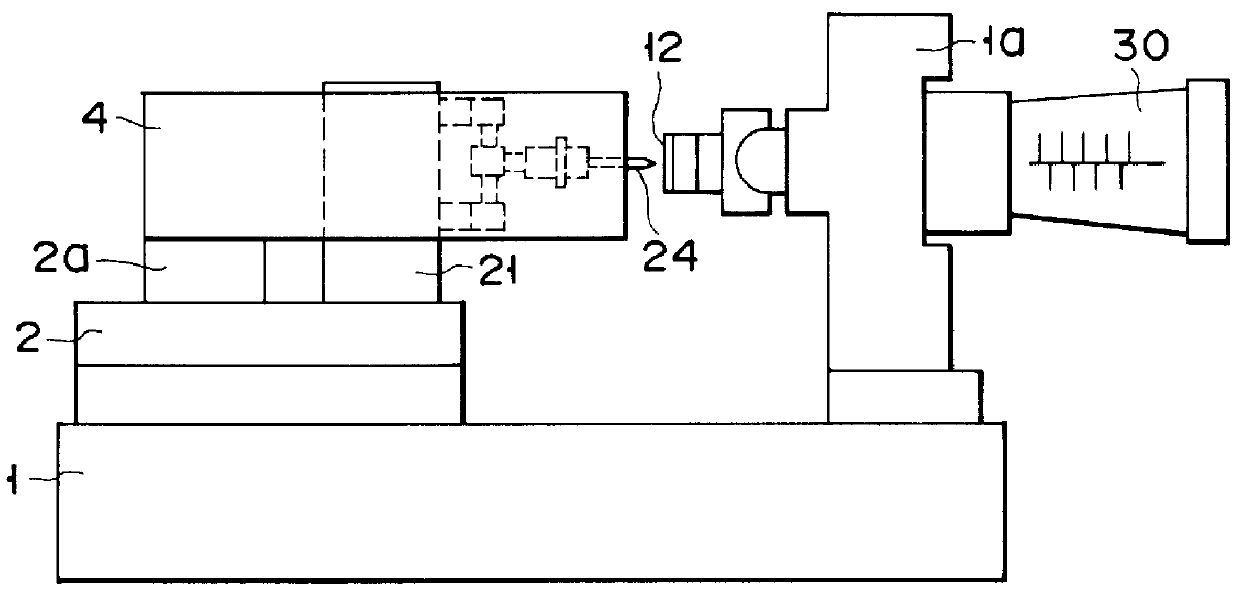

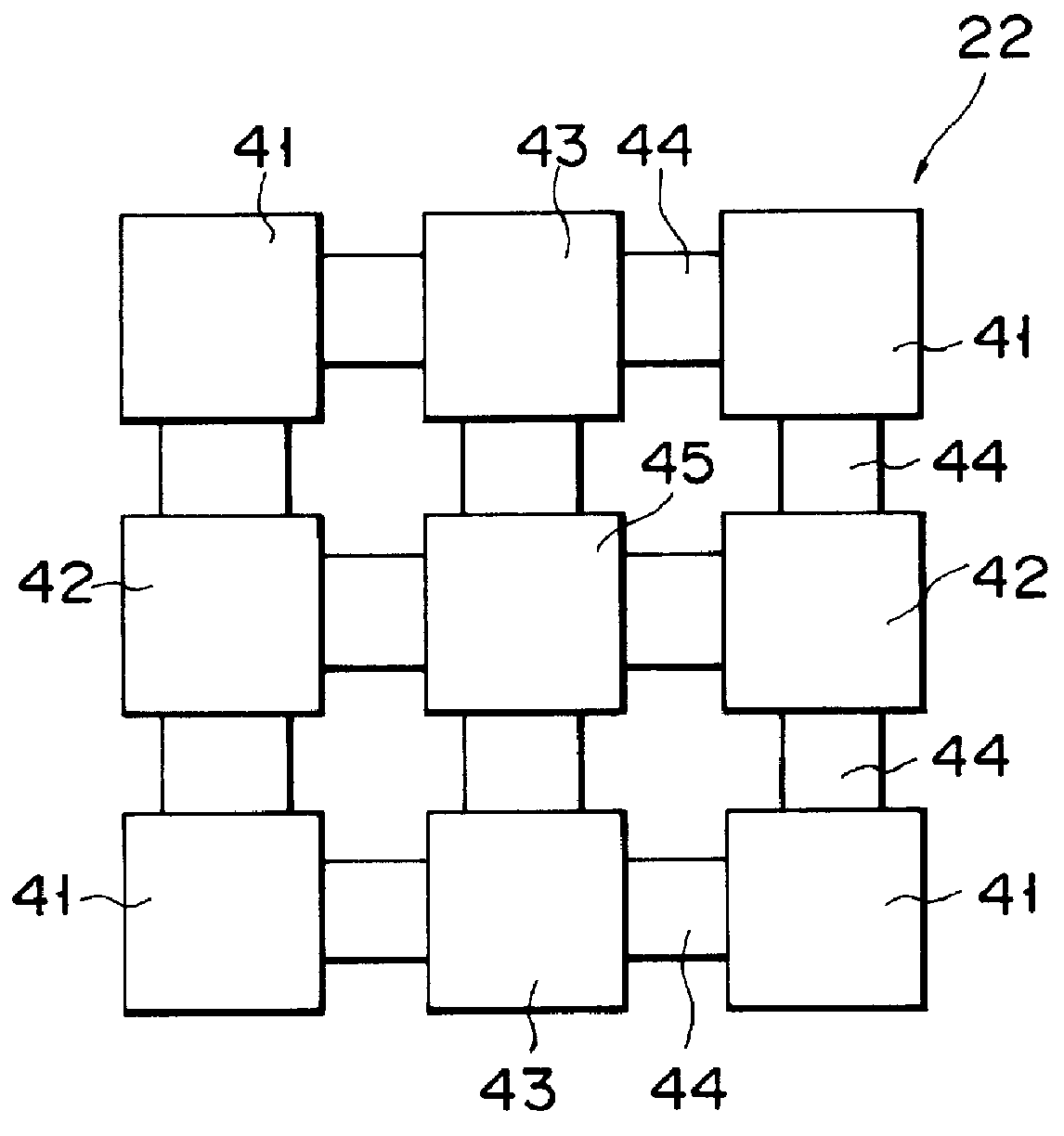

PCT No. PCT / JP88 / 00804 Sec. 371 Date Feb. 5, 1990 Sec. 102(e) Date Feb. 5, 1990 PCT Filed Aug. 12, 1988 PCT Pub. No. WO89 / 01603 PCT Pub. Date Feb. 23, 1989A scanning tunnel microscope is arranged by a combination of an optical microscope and a tunnel scanning unit. The scanning tunnel unit includes a probe held to be spaced apart from a sample placed on a sample table by a predetermined interval in an axial direction, and an actuator for axially moving the sample table and the probe to a tunnel region and relatively and three-dimensionally driving the sample table and the probe. An objective lens and the probe are arranged such that the axis of the probe of the scanning tunnel unit is aligned with an optical axis of the objective lens of the optical microscope. The sample and the probe are axially moved and brought into the tunnel region, and the sample is scanned in its surface direction while the sample and the probe are finely moved in the axial direction and a tunnel current is kept constant, thereby performing an STM observation of an observation surface of the sample. The objective lens of the optical microscope is axially moved to obtain an in-focus state, and the field of the STM observation surface is observed as an optical microscopic image through an eyepiece lens.

Owner:OLYMPUS OPTICAL CO LTD

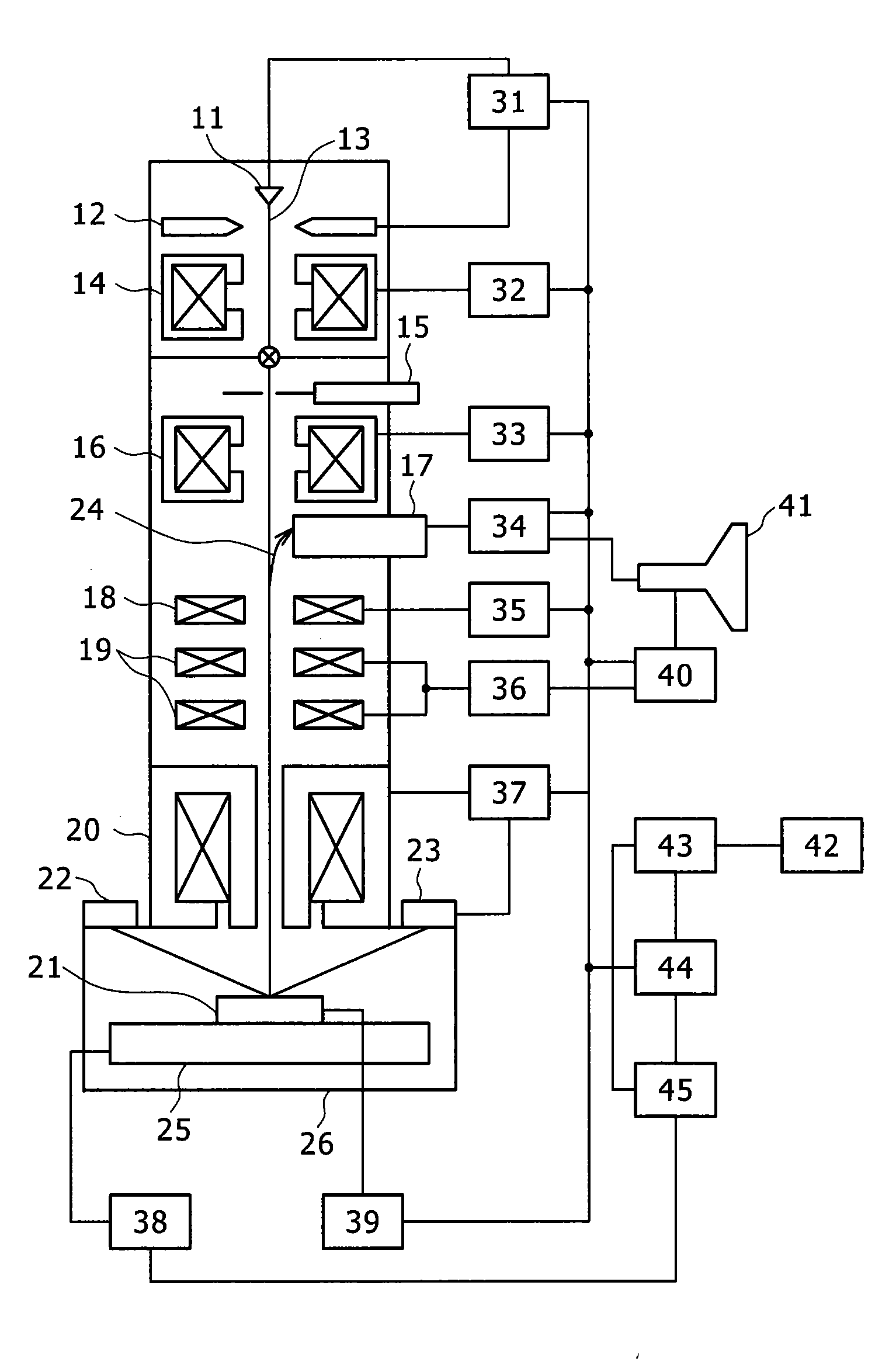

Scanning electron microscope

InactiveUS20090230304A1Low costSave spaceThermometer detailsMaterial analysis using wave/particle radiationScanning tunneling microscopeScanning electron microscope

In a VP-SEM that uses gas multiplication induced within a low-vacuum sample chamber and uses a method of detecting a positive displacement current, a secondary electron detector for the VP-SEM that responds at high speed, which can acquire a TV-Scan rate image at a low cost while saving a space is provided. A secondary electron detector is formed by forming the electron supplying electrode and the detection electrode on the flexible thin film type substrate such as a polyimide film, etc., by an etching method. Thereby, the space can be saved while realizing low cost due to mass production. Further, the ion horizontally moving with respect to the surface of the secondary electron detector is detected and the ion moving in a vertical direction returned to the sample holder is not detected, making it possible to realize a high-speed response.

Owner:HITACHI HIGH-TECH CORP

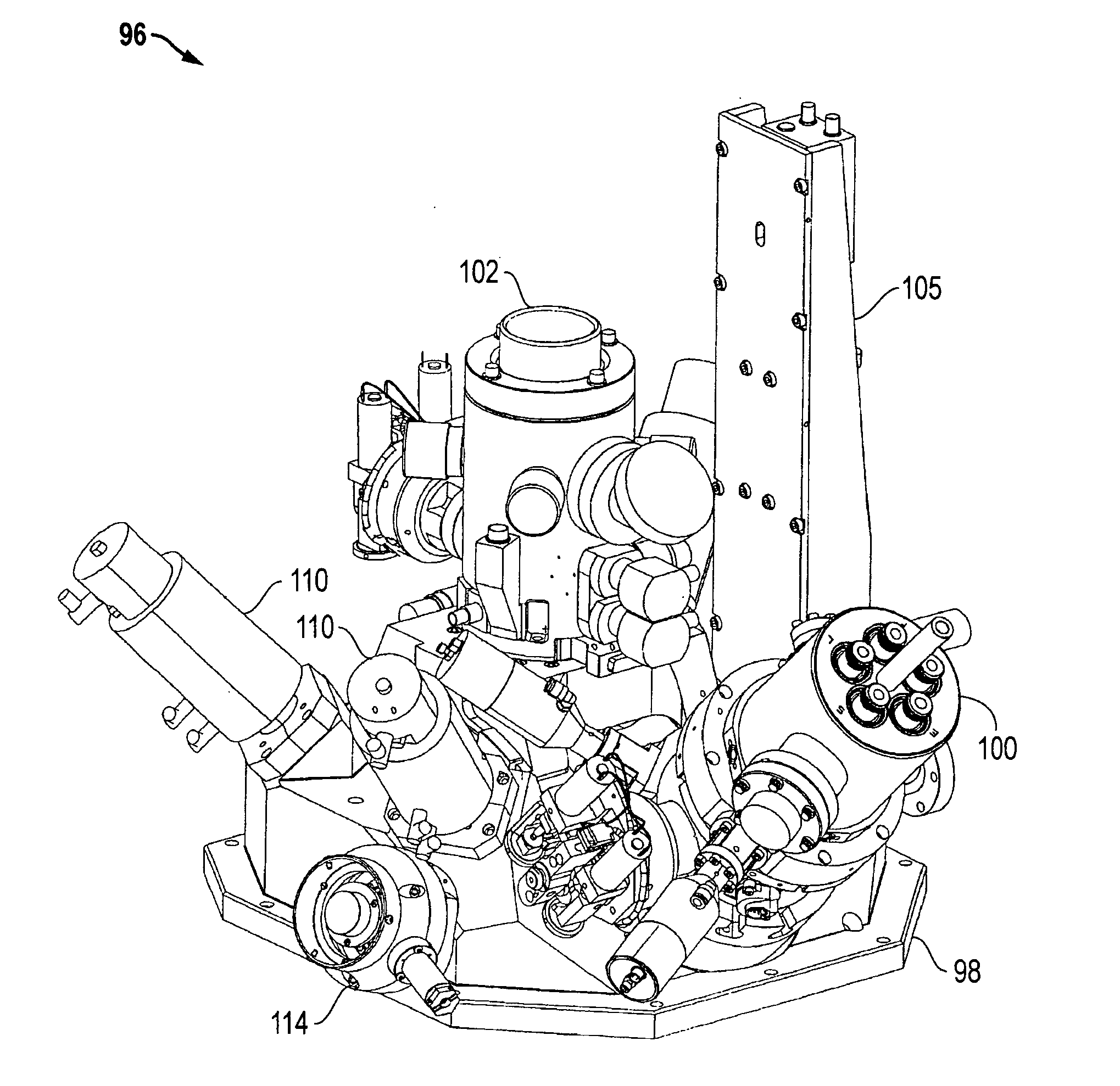

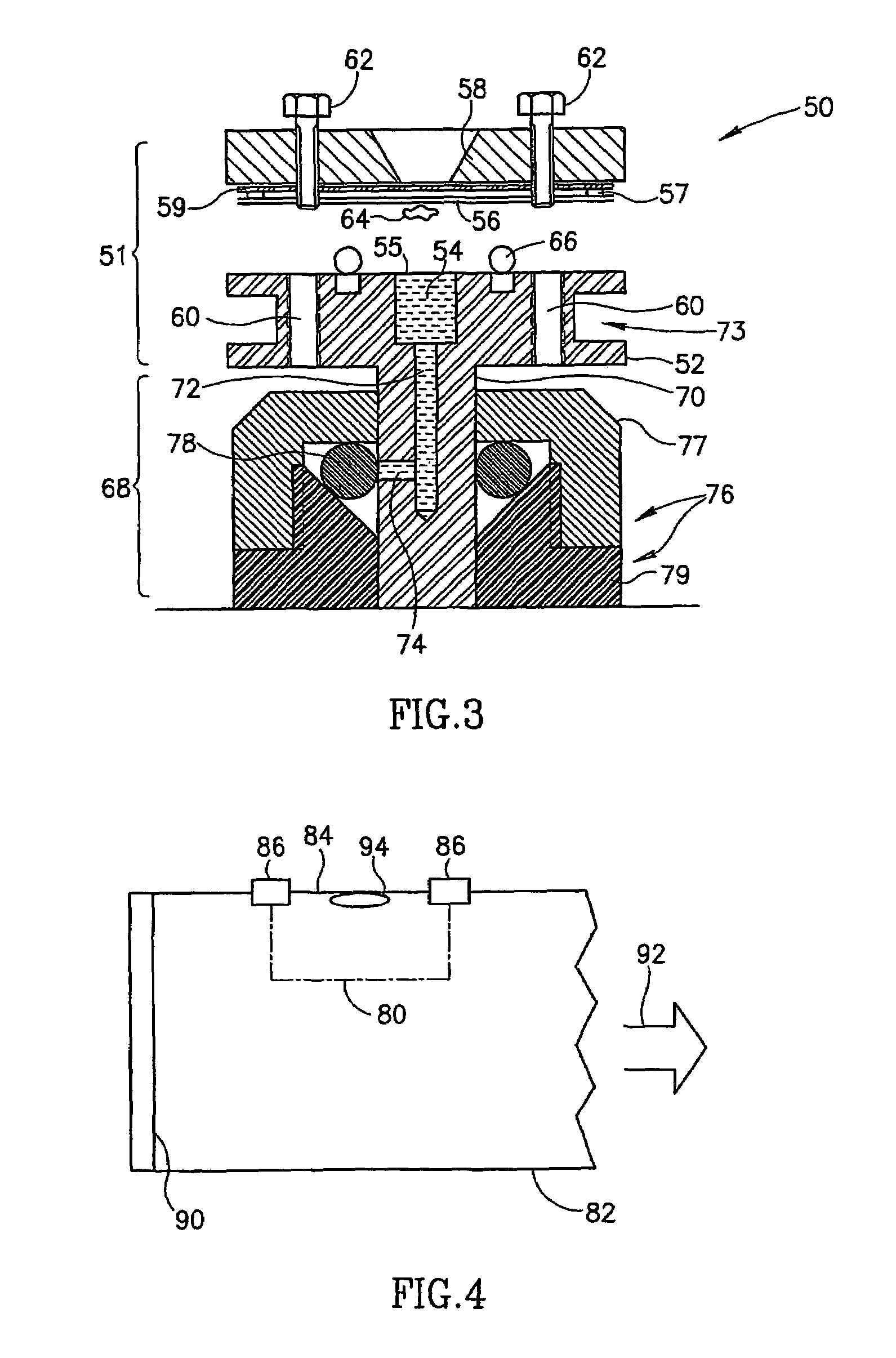

Dual beam system

ActiveUS20050035291A1Remove blurEasy to collectThermometer detailsMaterial analysis using wave/particle radiationDual beamScanning tunneling microscope

A dual beam system includes an ion beam system and a scanning electron microscope with a magnetic objective lens. The ion beam system is adapted to operate optimally in the presence of the magnetic field from the SEM objective lens, so that the objective lens is not turned off during operation of the ion beam. An optional secondary particle detector and an optional charge neutralization flood gun are adapted to operate in the presence of the magnetic field. The magnetic objective lens is designed to have a constant heat signature, regardless of the strength of magnetic field being produced, so that the system does not need time to stabilize when the magnetic field is changed.

Owner:FEI CO

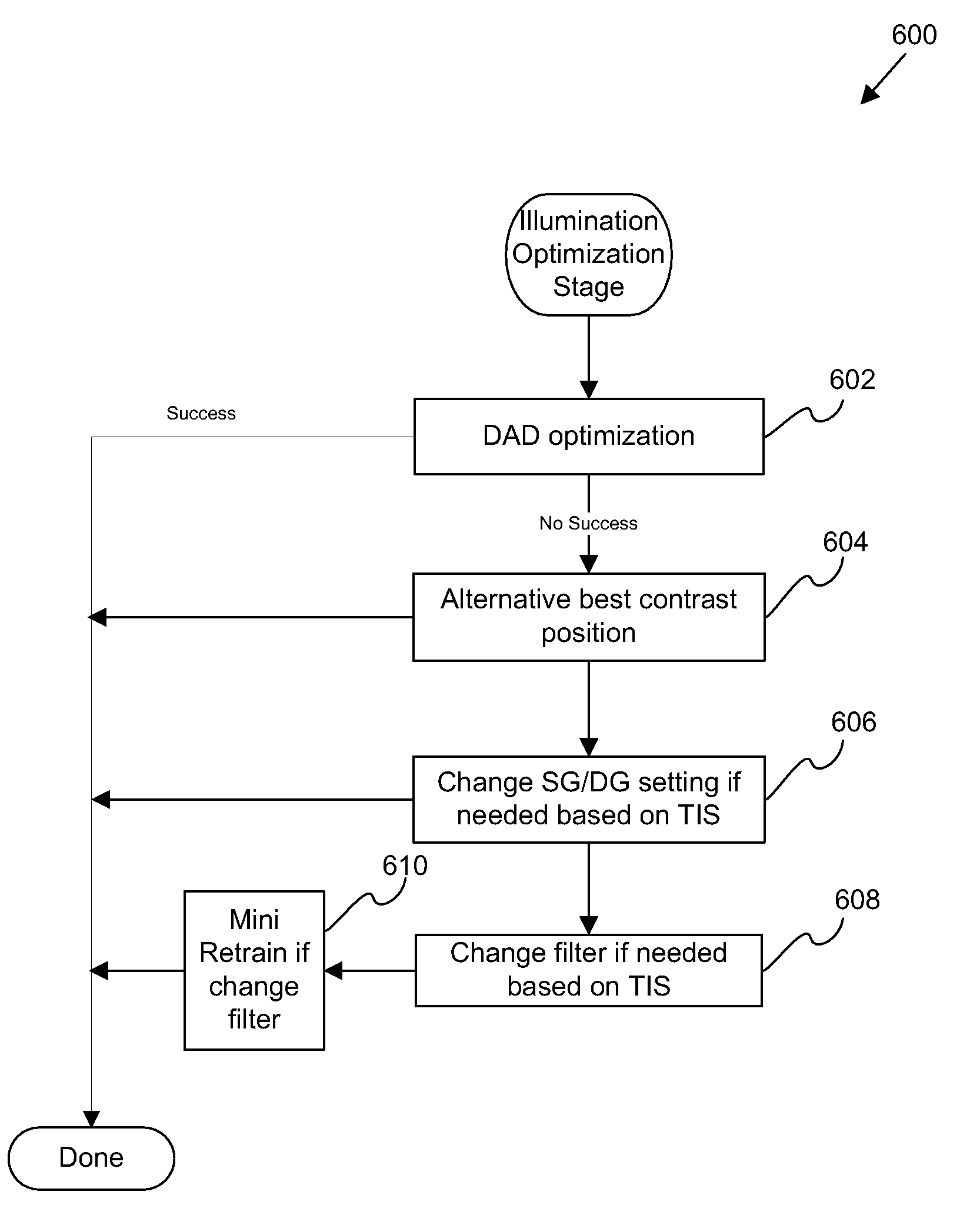

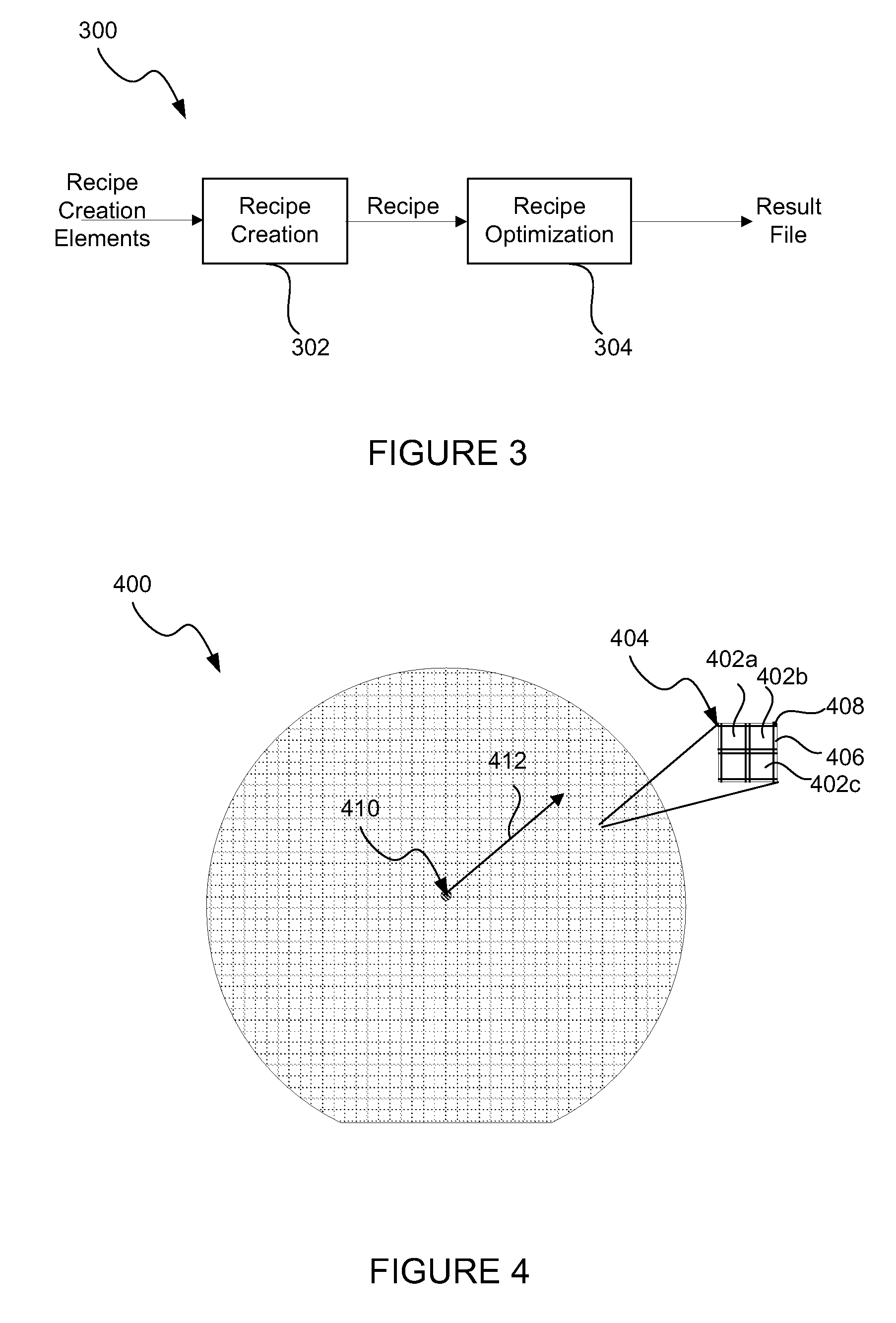

Waferless recipe optimization

ActiveUS20080094639A1Minimal human interventionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsMetrologyScanning tunneling microscope

Disclosed are apparatus and methods for optimizing a metrology tool, such as an optical or scanning electron microscope so that minimum human intervention is achievable during the optimization. In general, a set of specifications and an initial input data are initially provided for a particular target. The specifications provide limits for characteristics of images that are to be measured by the metrology tool. The metrology tool is then automatically optimized for measuring the particular target so as to meet one or more of the provided specifications without further significant human intervention with respect to the metrology tool. In one aspect, the input data provided prior to the automated optimization procedure includes a plurality of target locations and a synthetic image of the particular target.

Owner:KLA TENCOR CORP

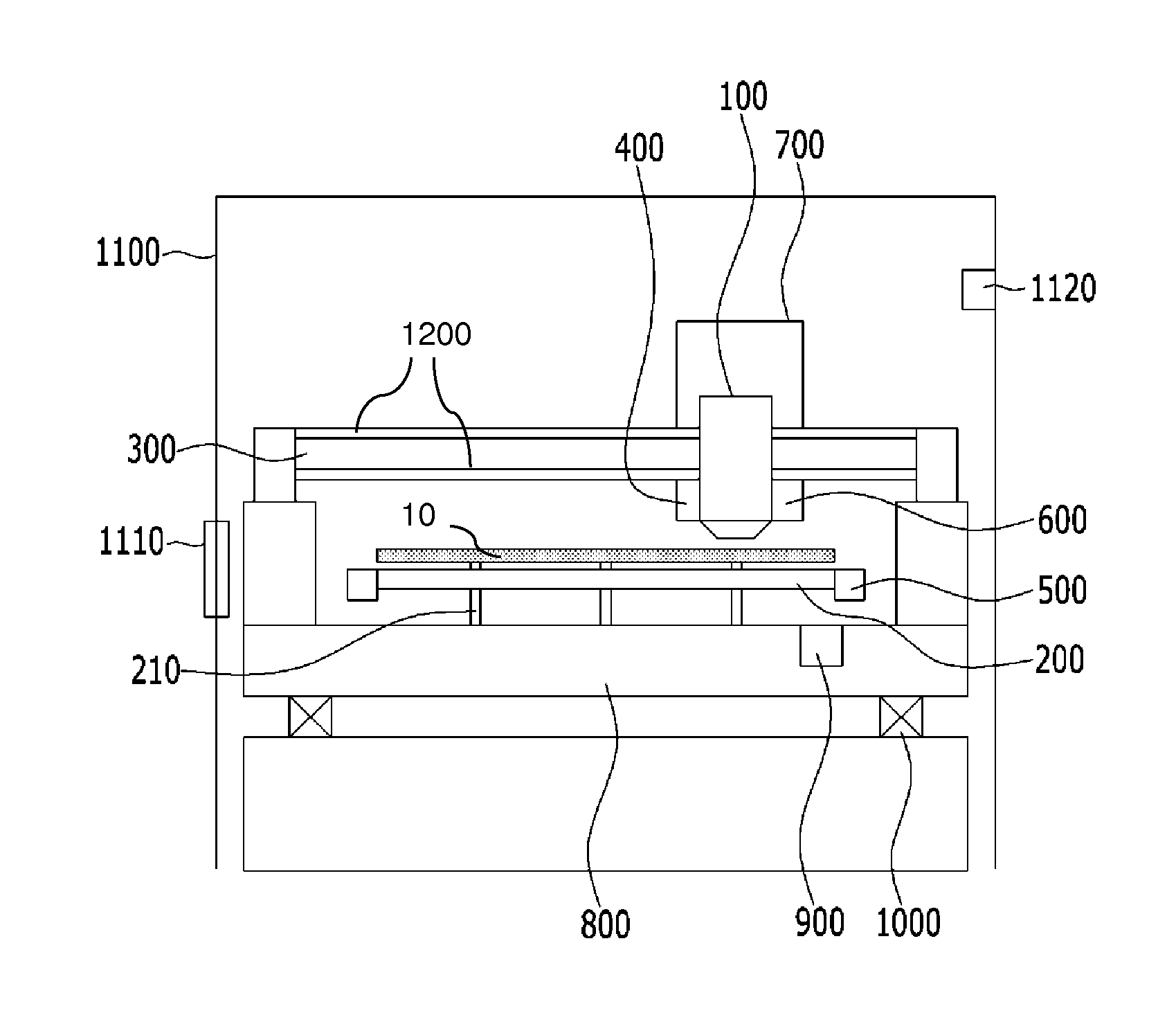

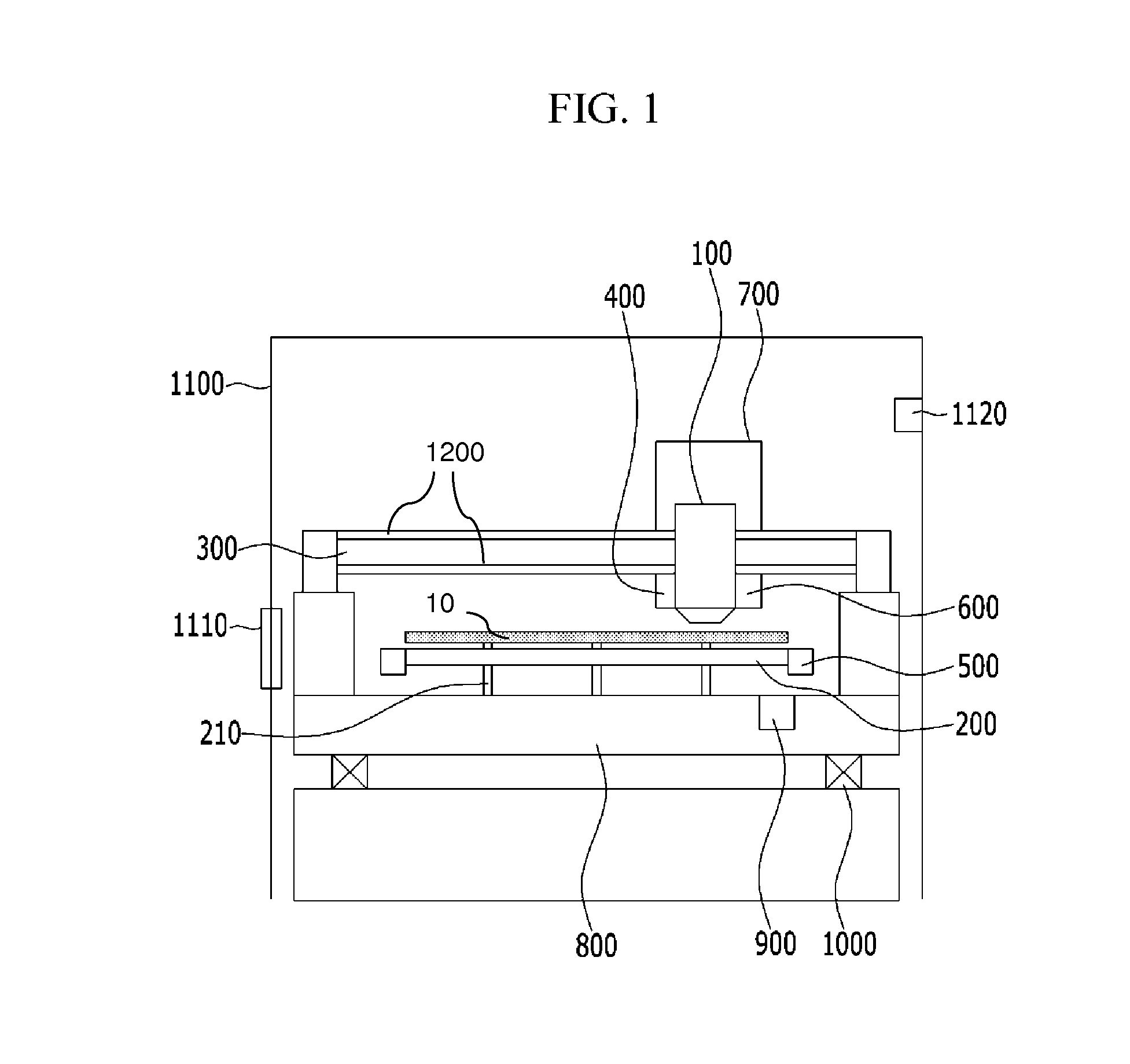

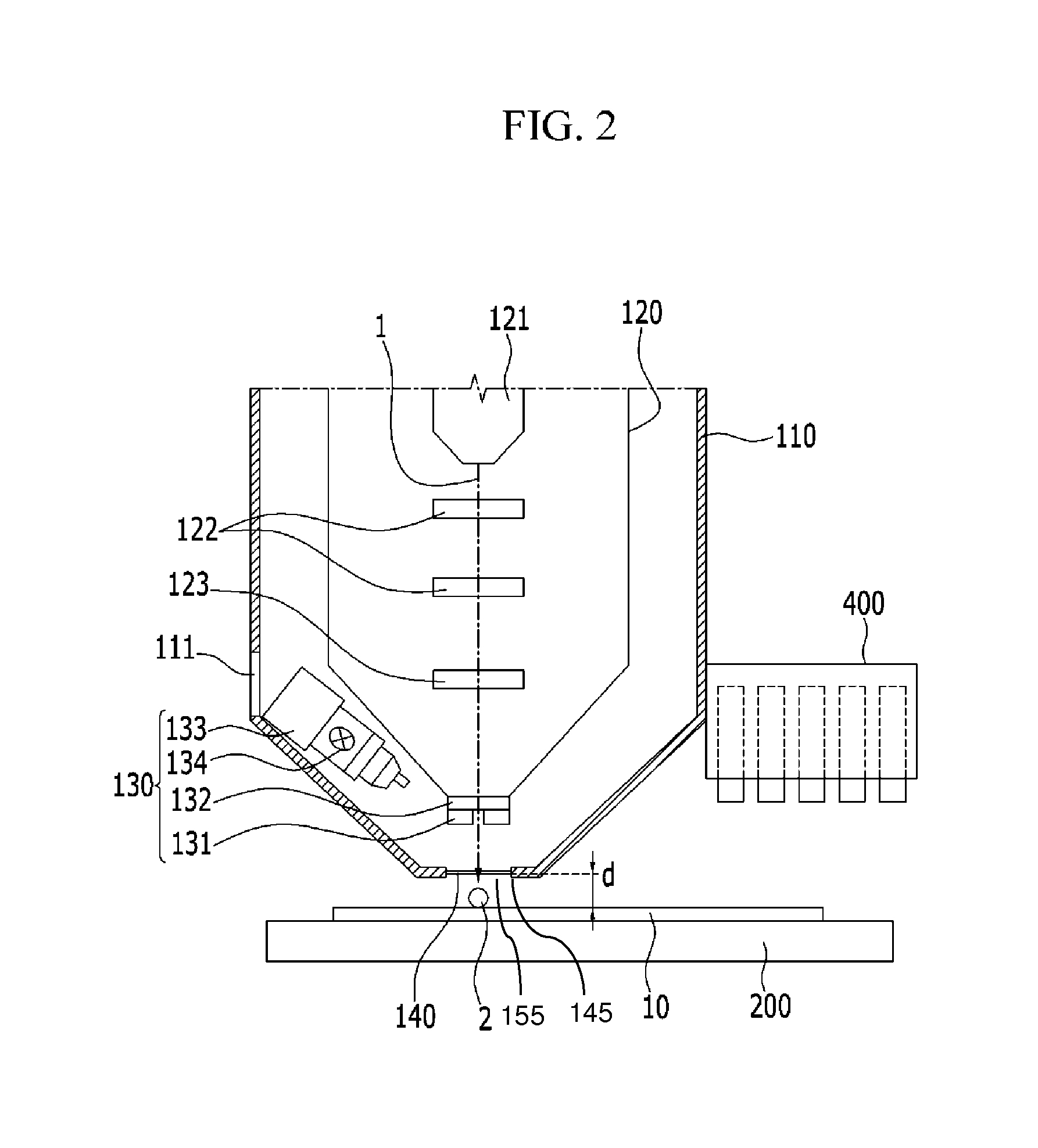

Inspection system using scanning electron microscope

ActiveUS20130320211A1Low costIncrease productionMaterial analysis using wave/particle radiationElectric discharge tubesScanning tunneling microscopeLarge size

An inspection system using a scanning electron microscope includes a scanning electron microscope chamber inspecting an object to be inspected by using an electron beam and maintaining a vacuum condition, a stage positioned below the scanning electron microscope chamber to be separated therefrom and mounted with the object to be inspected, and a transverse guide transferring the scanning electron microscope chamber on the stage. Atmospheric conditions are maintained between the scanning electron microscope chamber and the object to be inspected. Accordingly, object to be inspected a large size of an object to be inspected may be inspected without damage to the object to be inspected such that a cost reduction and a yield improvement may be realized.

Owner:SAMSUNG DISPLAY CO LTD

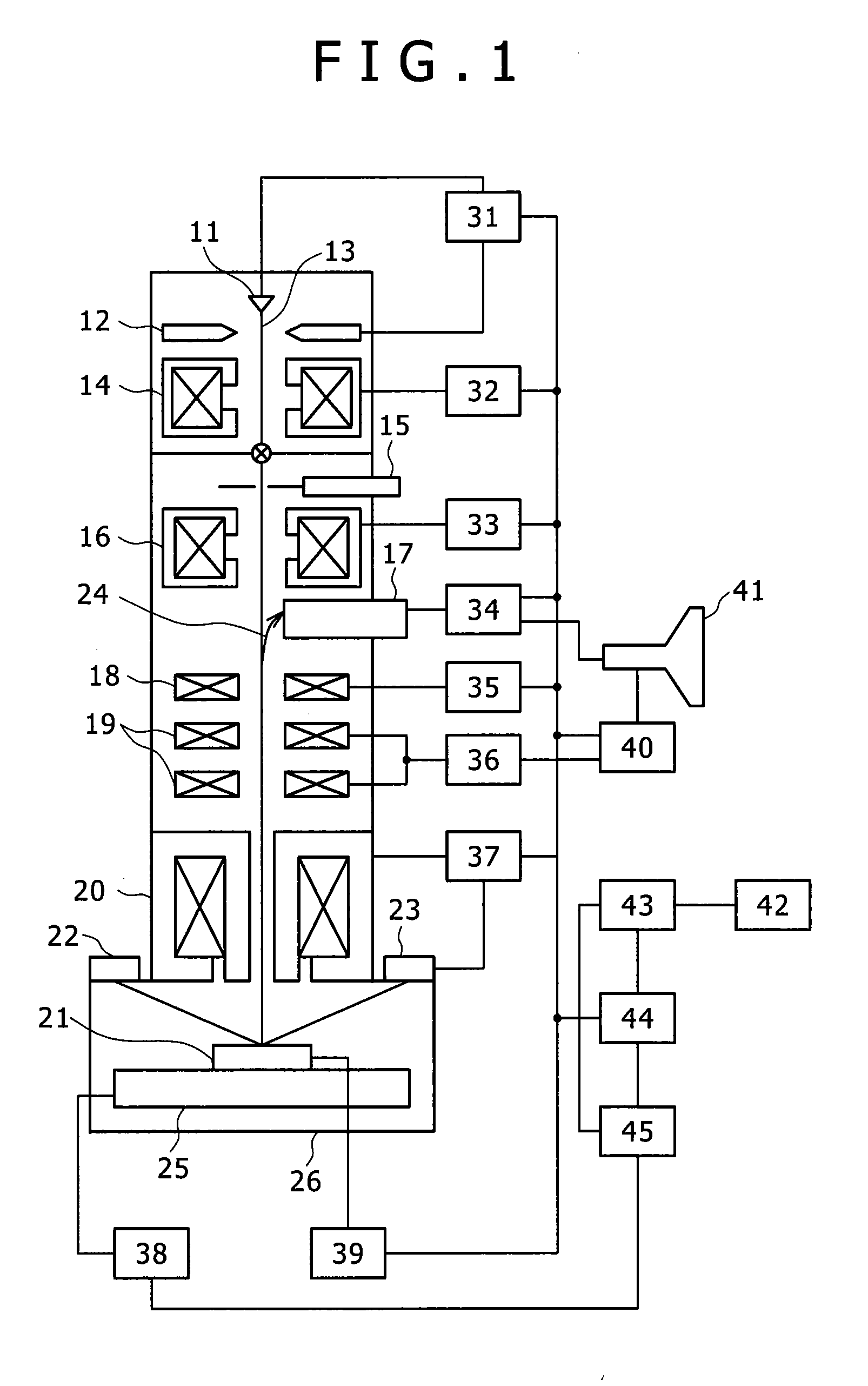

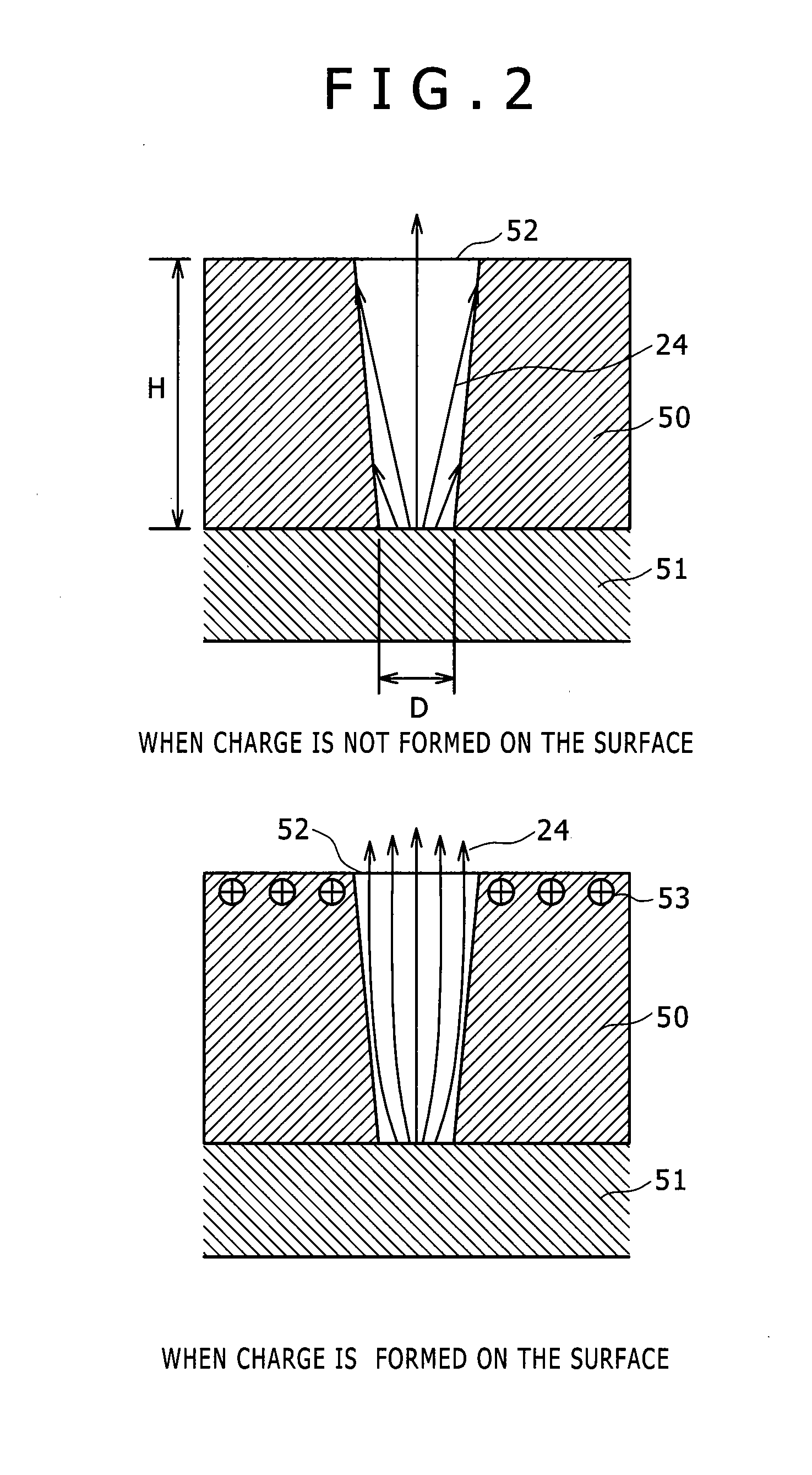

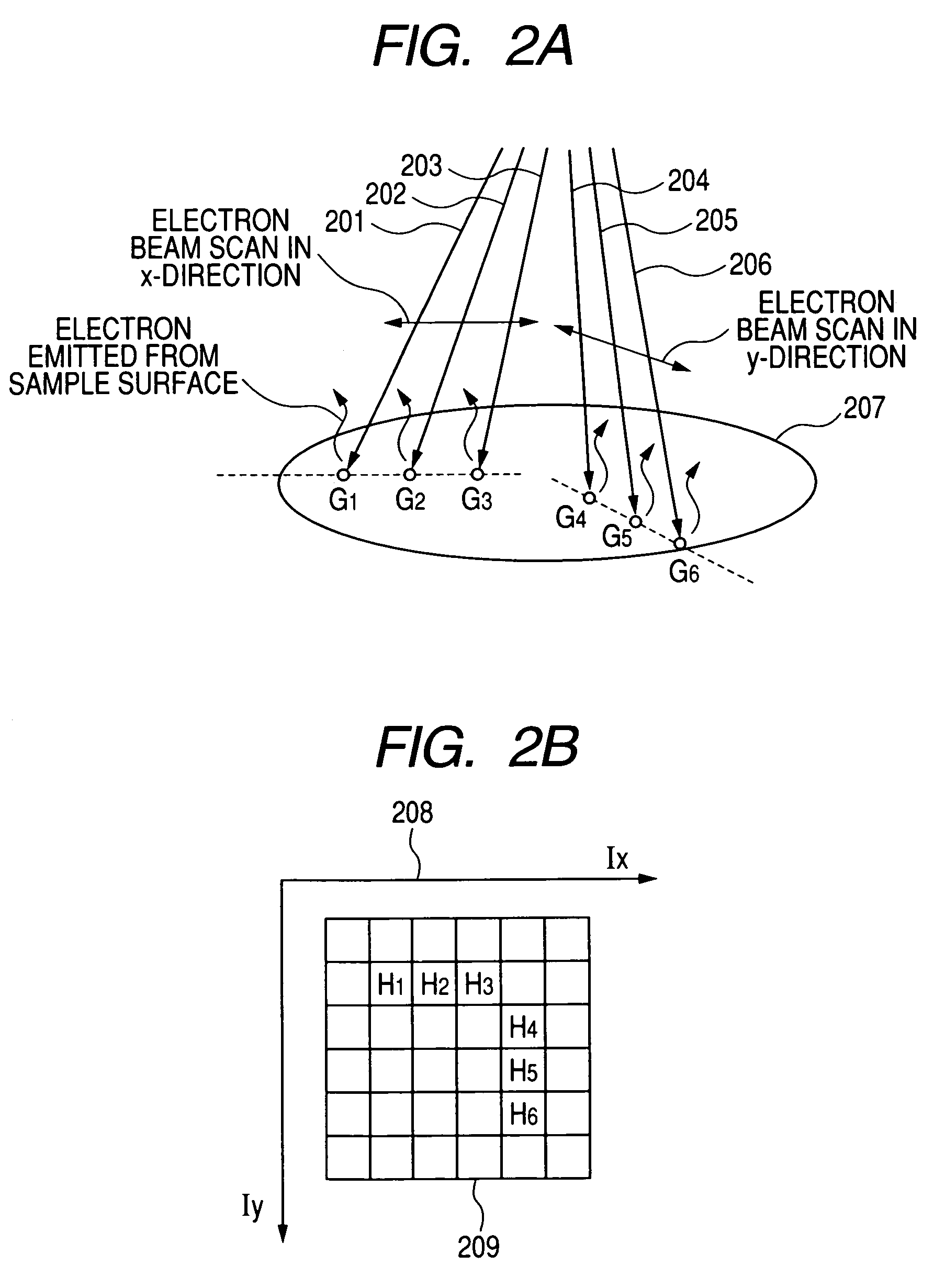

Method for inspecting and measuring sample and scanning electron microscope

ActiveUS20090084954A1Improve spatial resolutionInhibition of variationMaterial analysis using wave/particle radiationElectric discharge tubesScanning tunneling microscopeBeam diameter

As an aspect for realizing accurate observation, inspection, or measurement of the contact hole with large aspect ratio, a method and a device to scan a second electron beam after scanning a first electron beam to a sample to charge the sample are proposed wherein the beam diameter of the first electron beam is made larger than the beam diameter of the second electron beam.

Owner:HITACHI HIGH-TECH CORP

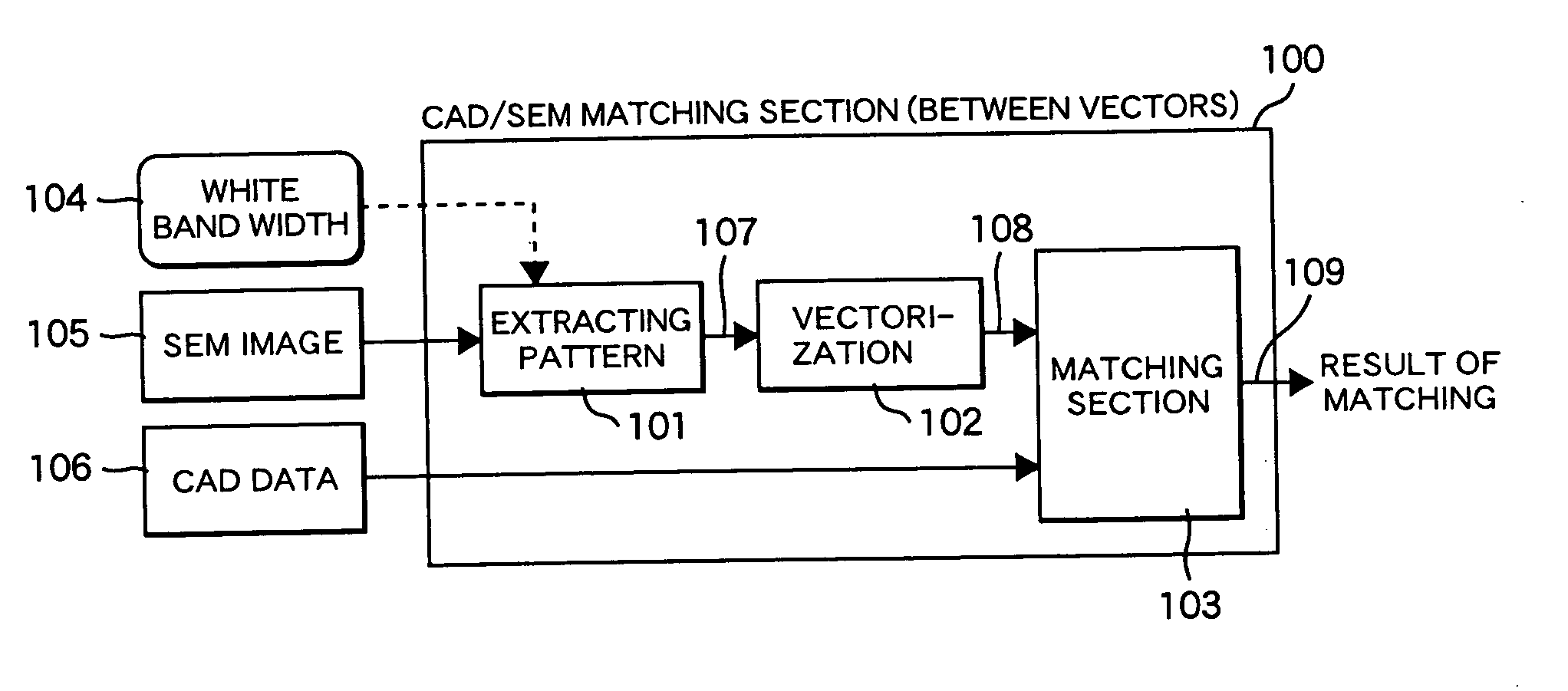

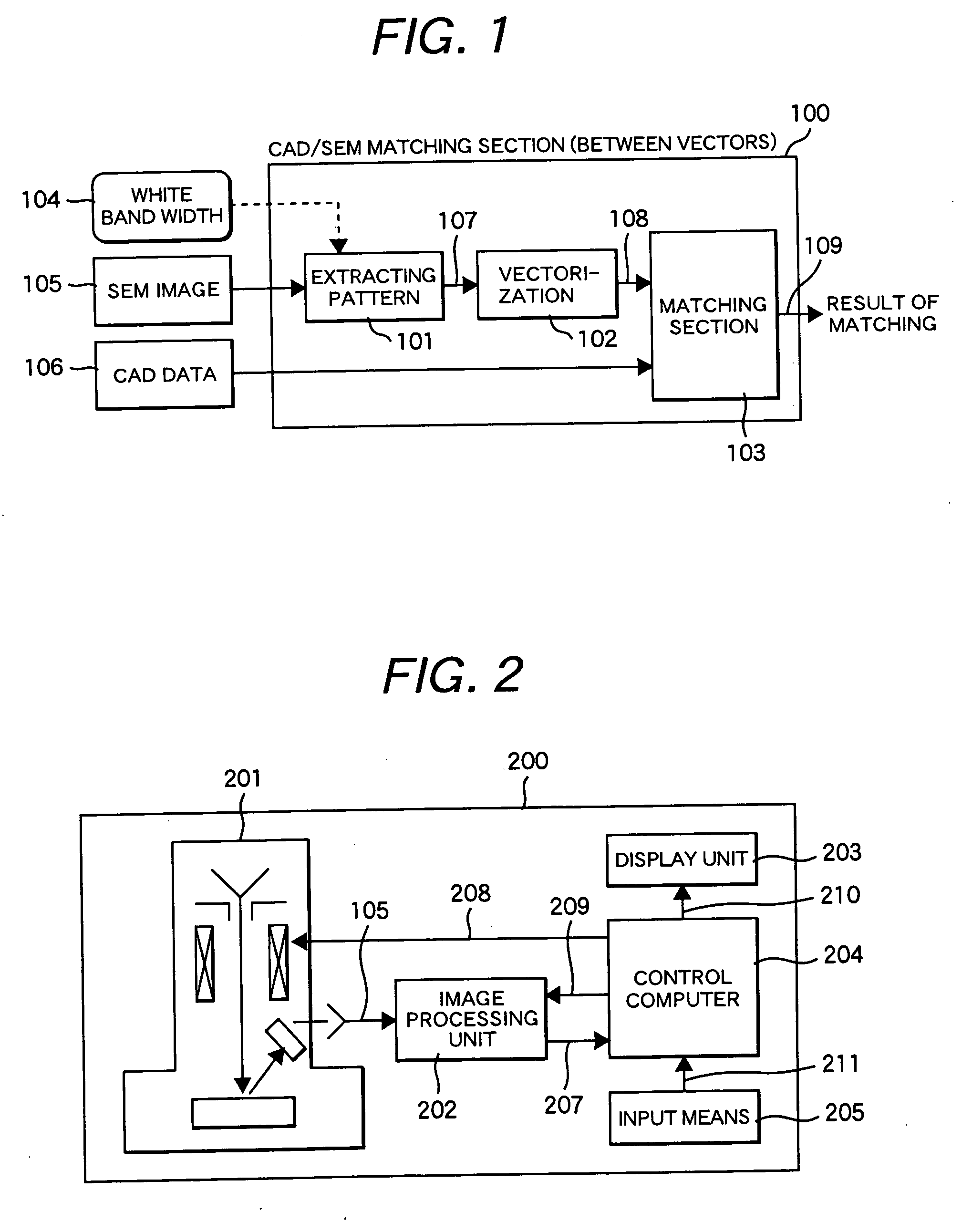

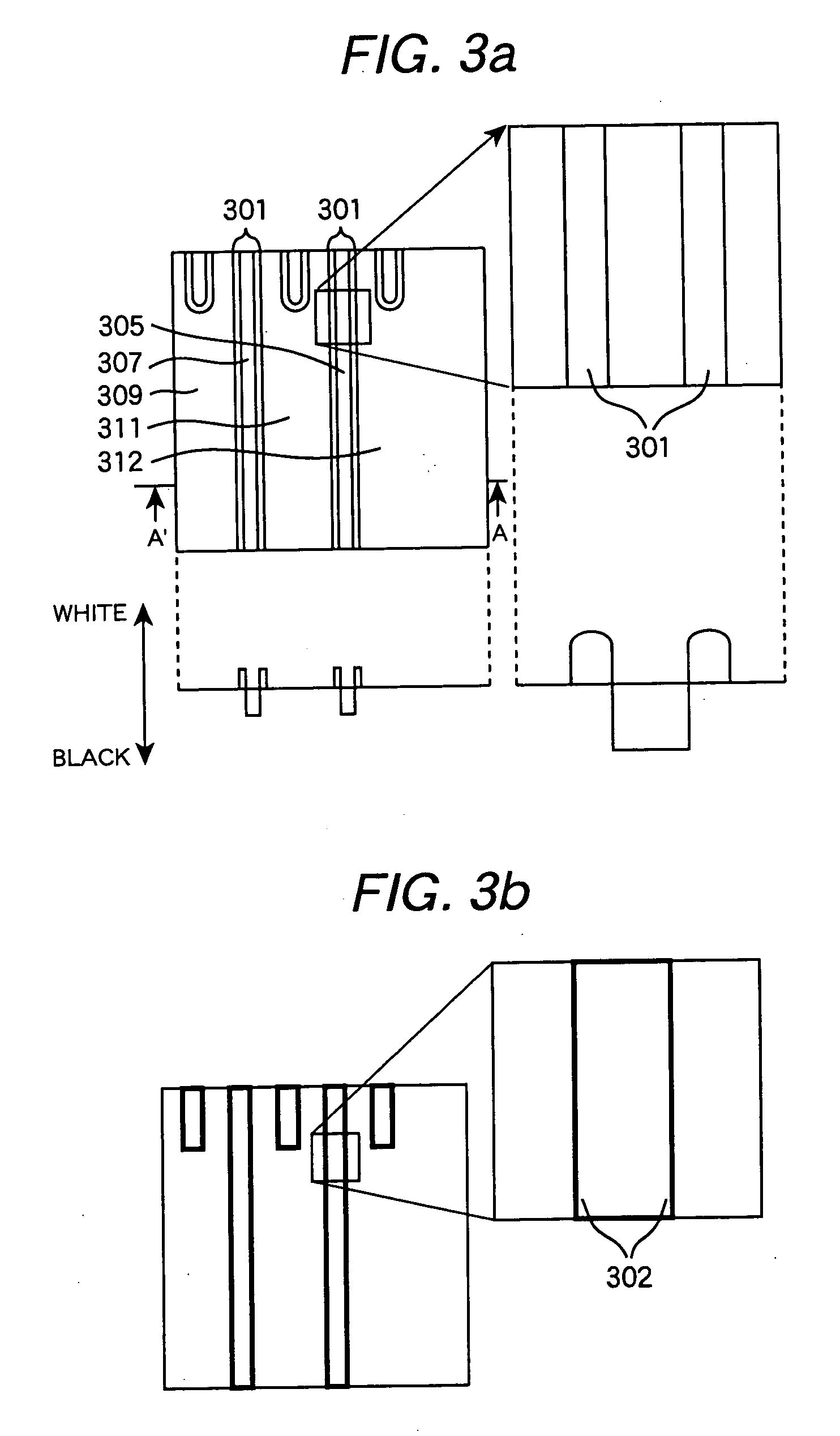

Pattern matching apparatus and scanning electron microscope using the same

ActiveUS20060045326A1Accurate isolationAccurate extractionImage enhancementImage analysisPattern matchingScanning tunneling microscope

A pattern matching apparatus comprising: means for storing photographed image data of a semiconductor device; means for storing CAD data of said semiconductor device; an information input means for inputting information on the white band width contained in said image data; a pattern extracting means for extracting a pattern on the semiconductor device from said image data by using the white band width information; and a matching means for matching said pattern with the CAD data.

Owner:HITACHI HIGH-TECH CORP

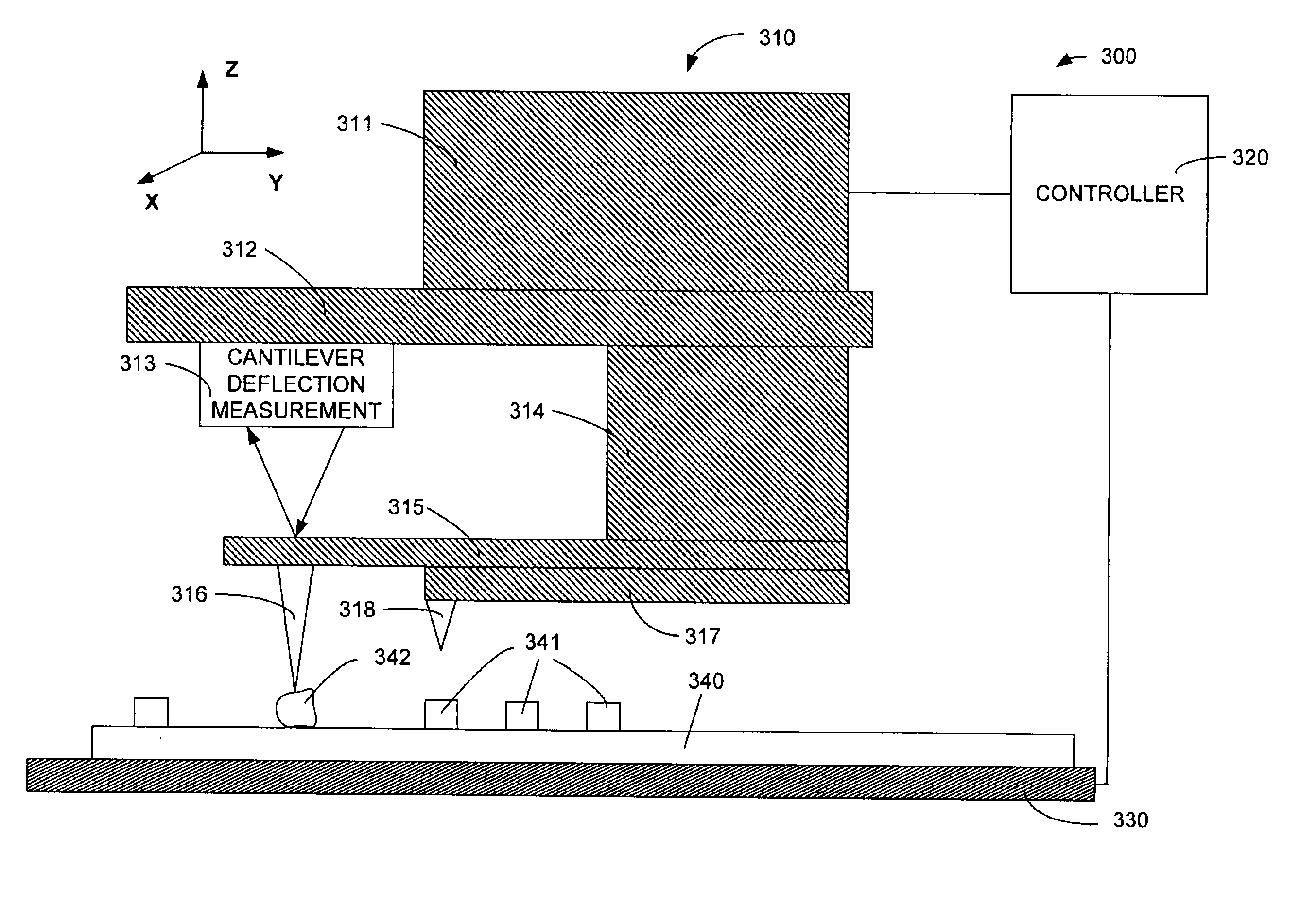

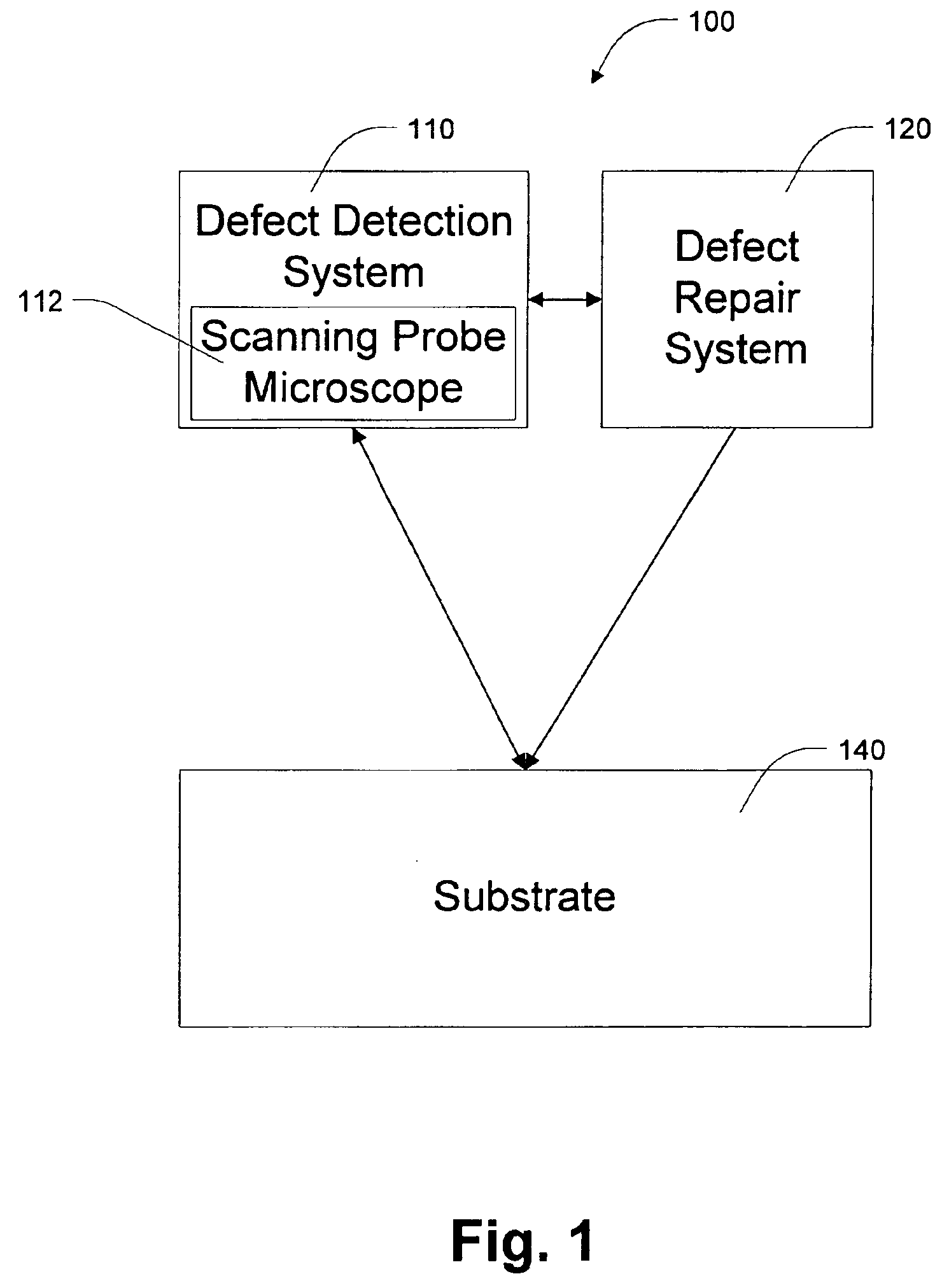

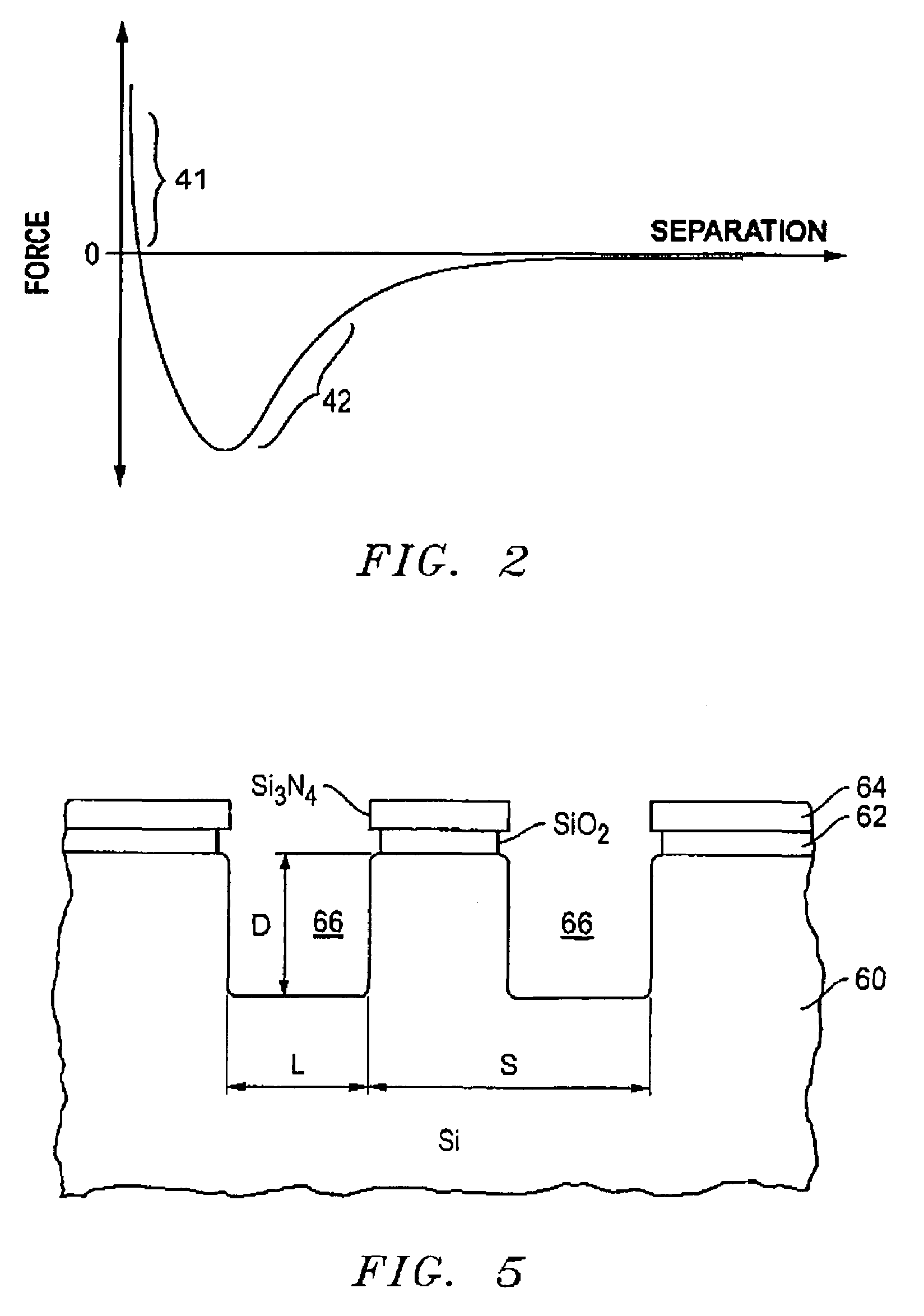

Use of scanning probe microscope for defect detection and repair

InactiveUS6884999B1Accurate correctionPrecise correction of defectsNanotechMaterial analysis using wave/particle radiationScanning tunneling microscopeScanning electron microscope

The present invention provides a system and method for detecting and repairing defects in semiconductor devices. According to the invention, defects are located using a scanning probe microscope, such as an atomic force microscope or a scanning tunneling microscope, and repaired at locations determined by the scanning probe microscope. The microscope itself, and in particular the detection tip, may be employed to remove the defects. For example, the tip may be used to machine away the defect, to apply an electric field to oxidize the defect, and / or to heat the defect causing it to burn or vaporize. By combining precise defect location capabilities of a scanning probe microscope with defect removal, the invention permits very precise correction of defects such as excess material and foreign particles on semiconductor substrates.

Owner:GLOBALFOUNDRIES INC

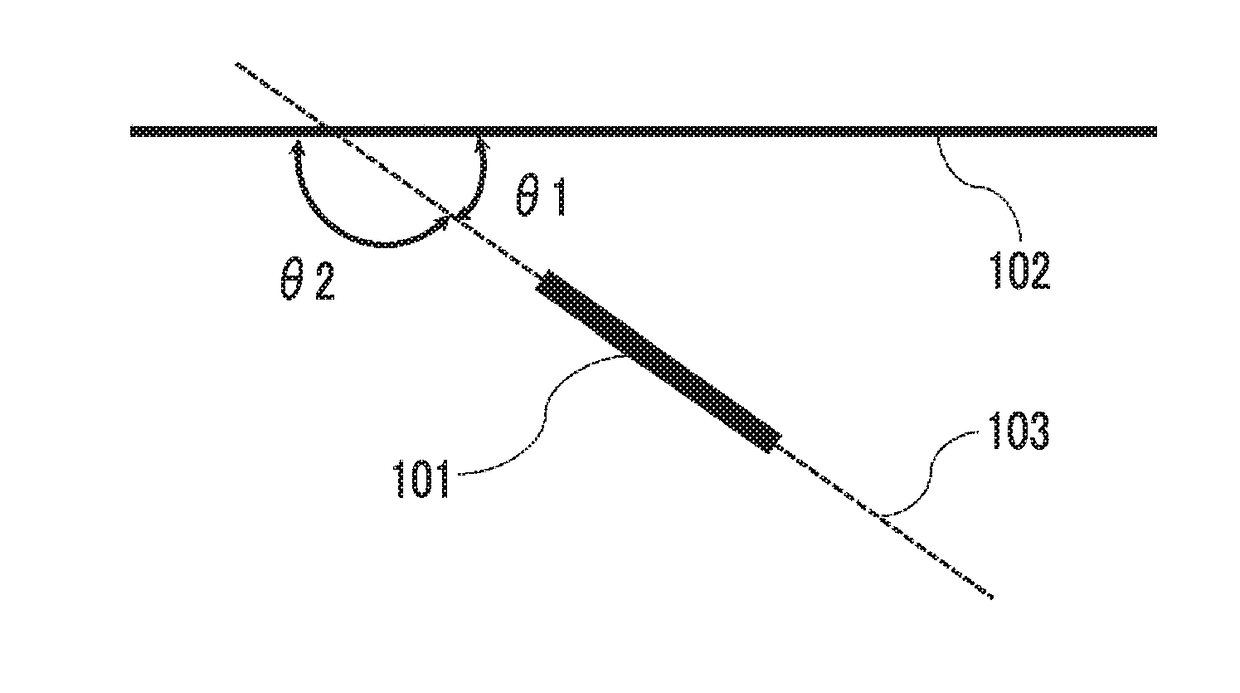

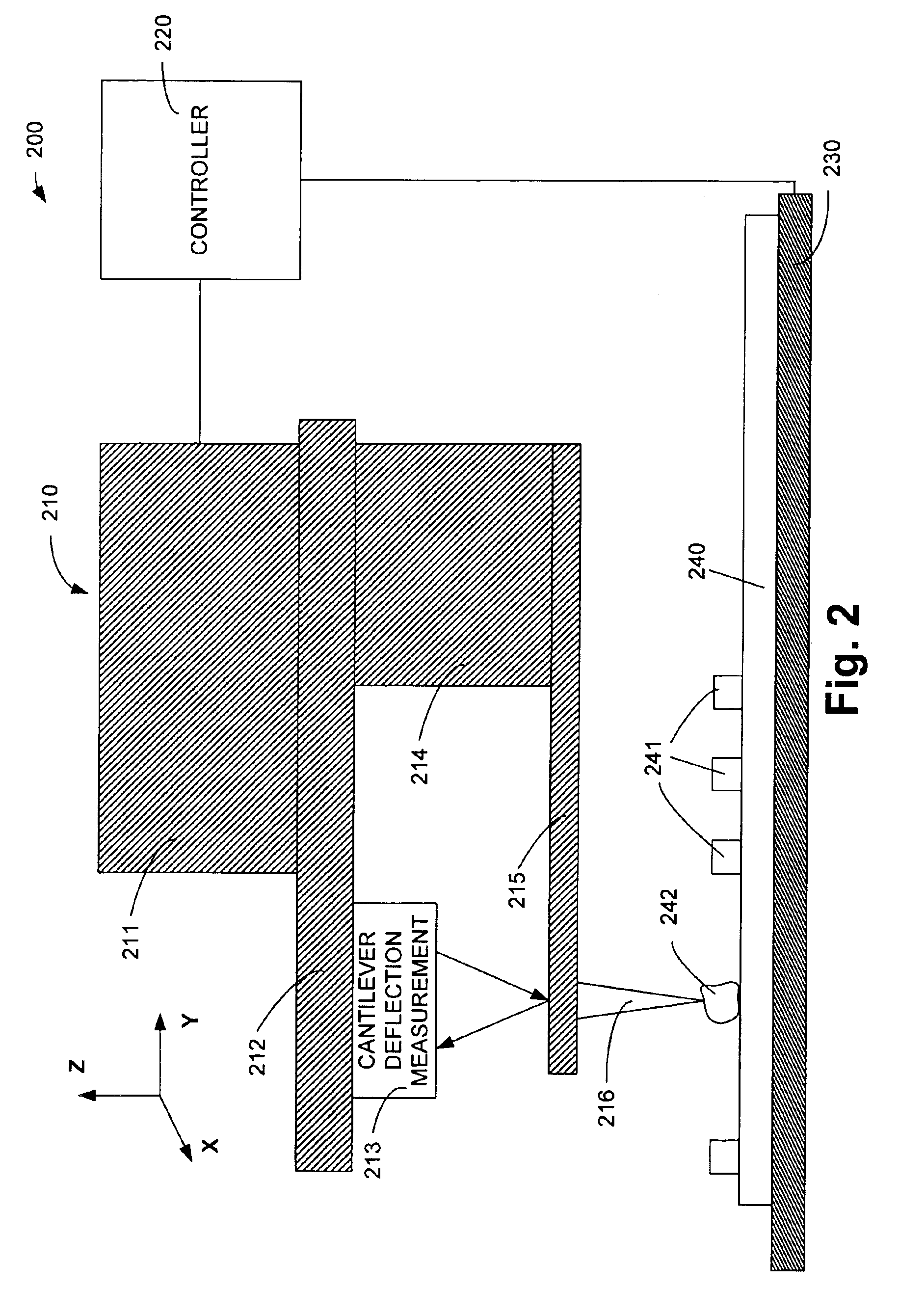

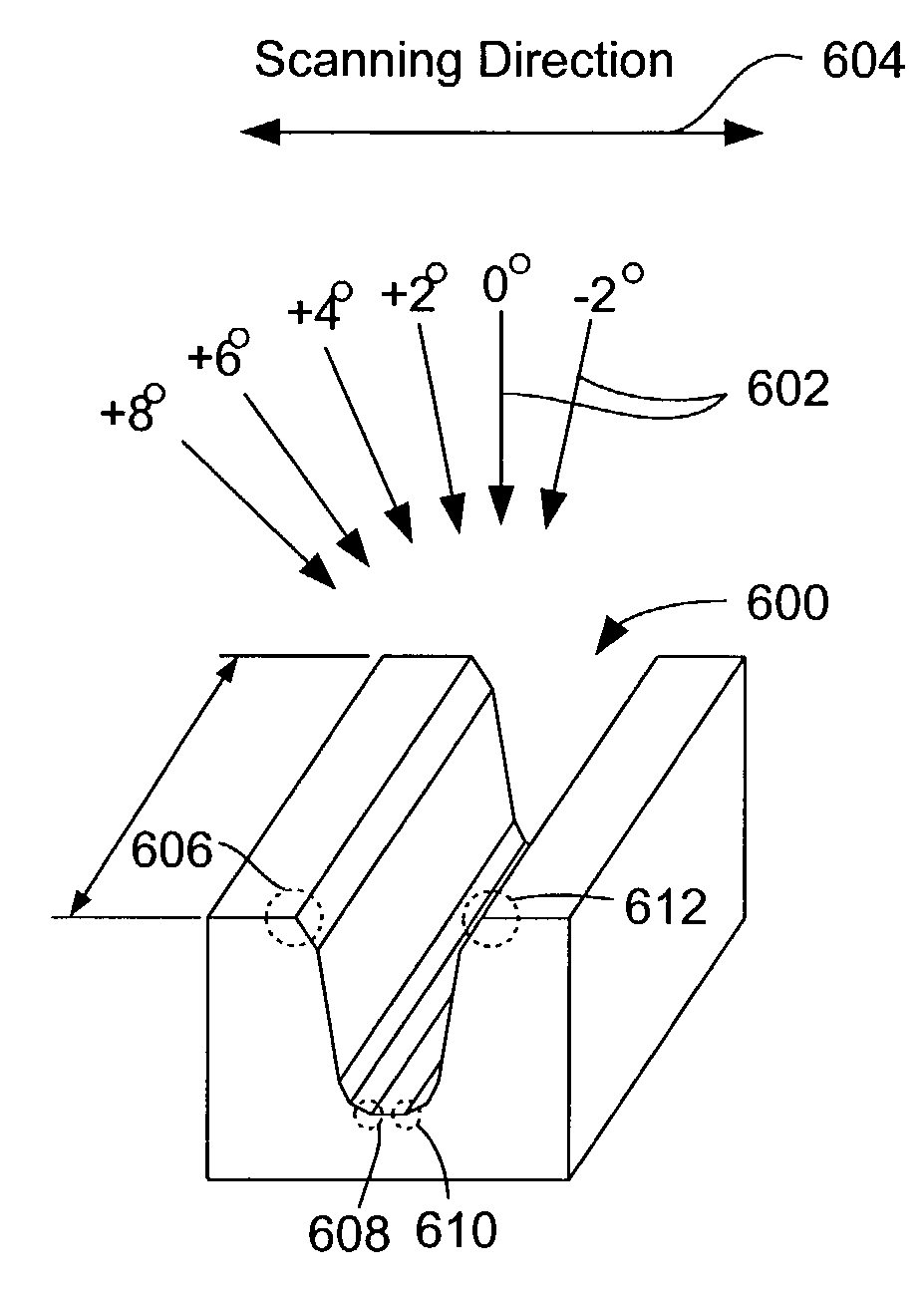

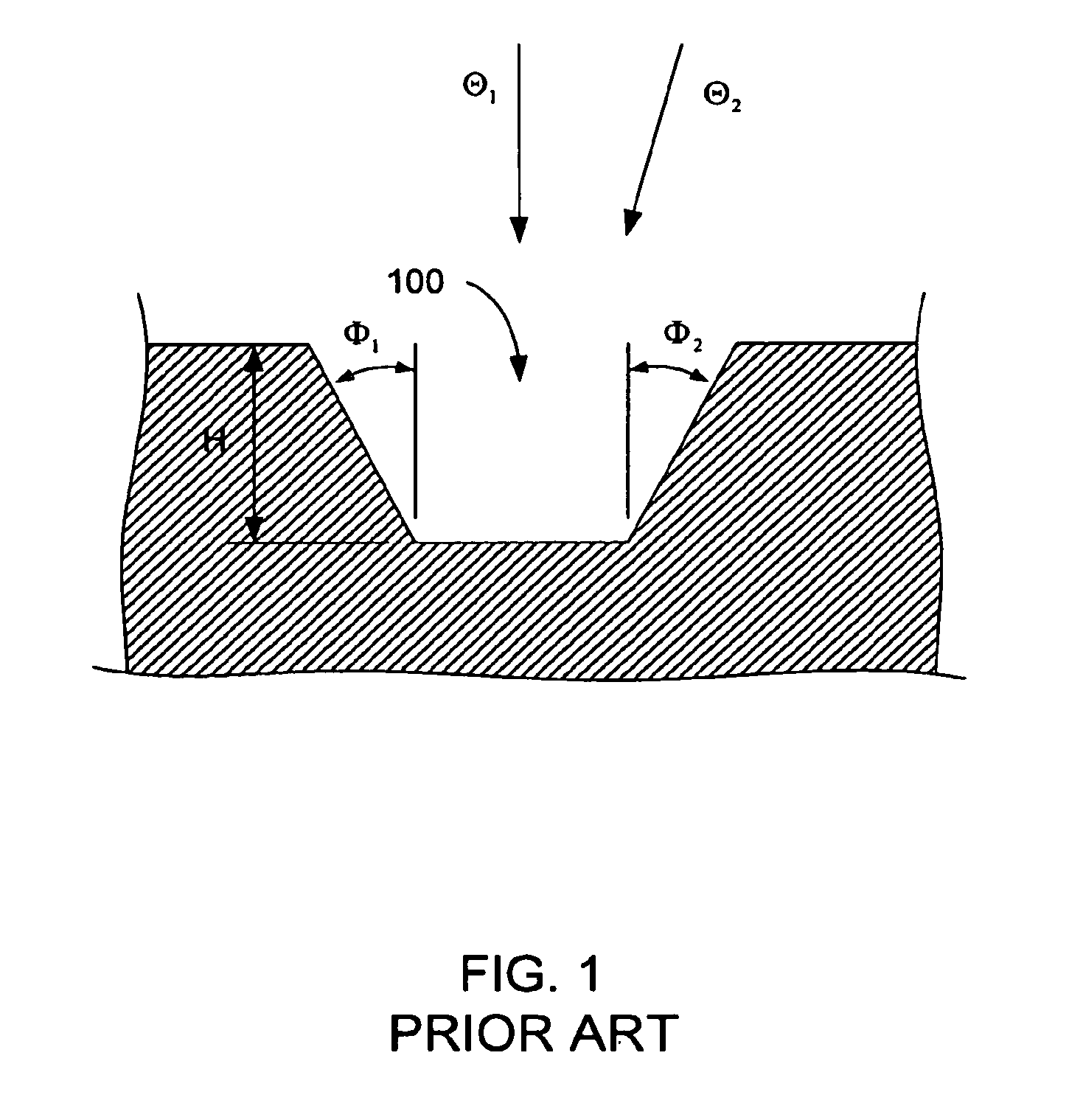

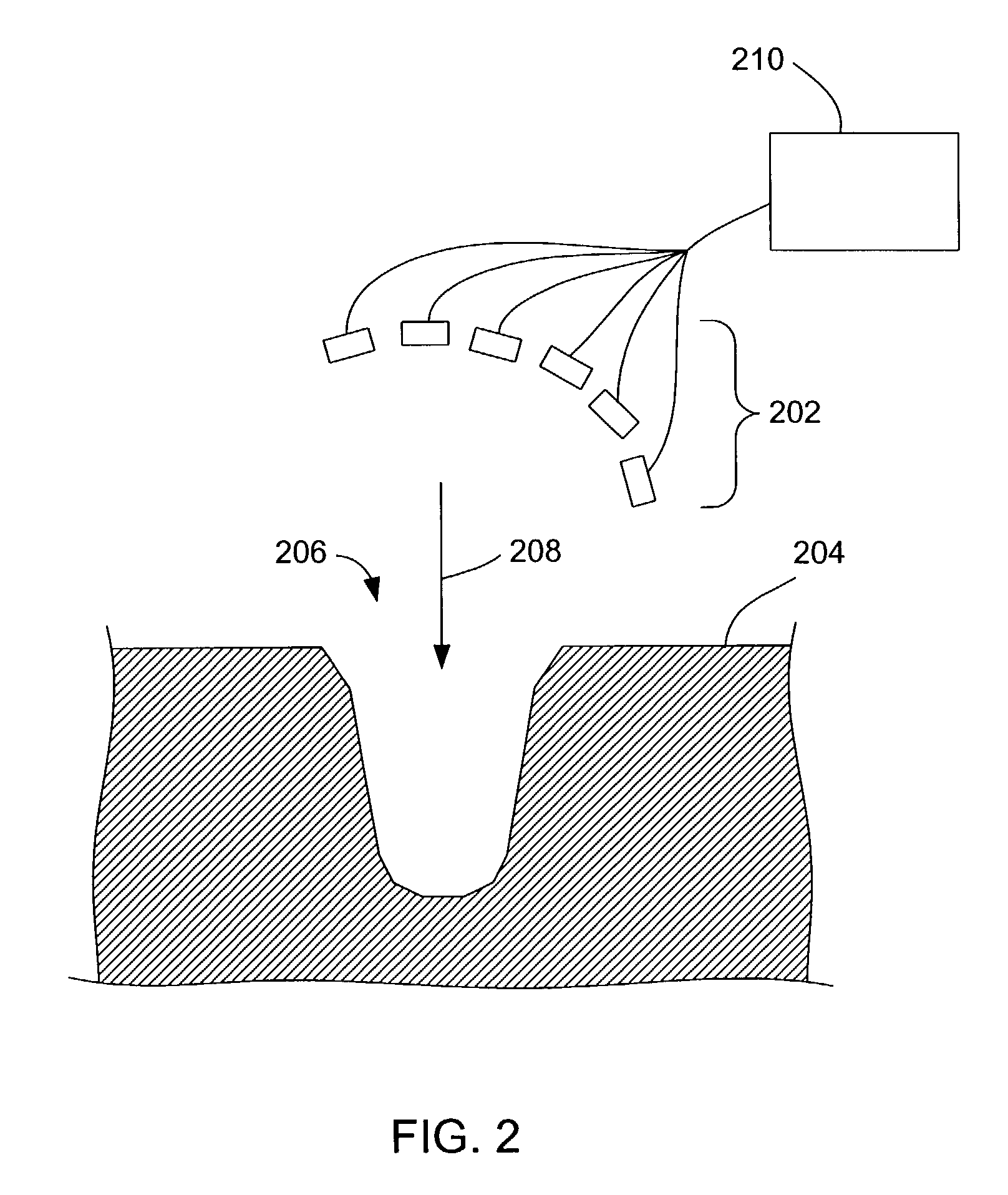

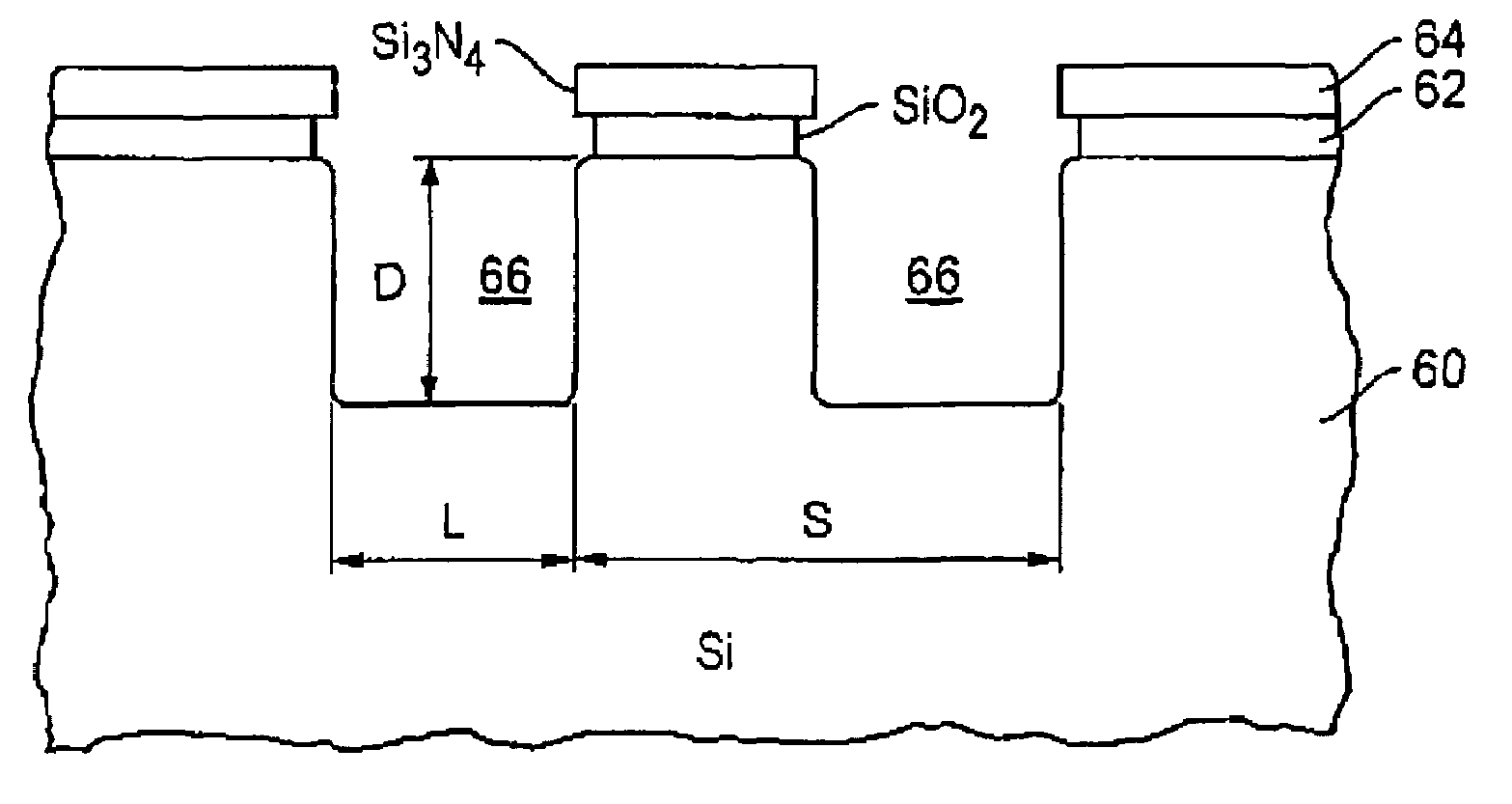

SEM profile and surface reconstruction using multiple data sets

InactiveUS6930308B1Accurate estimateMaterial analysis using wave/particle radiationElectric discharge tubesData setScanning tunneling microscope

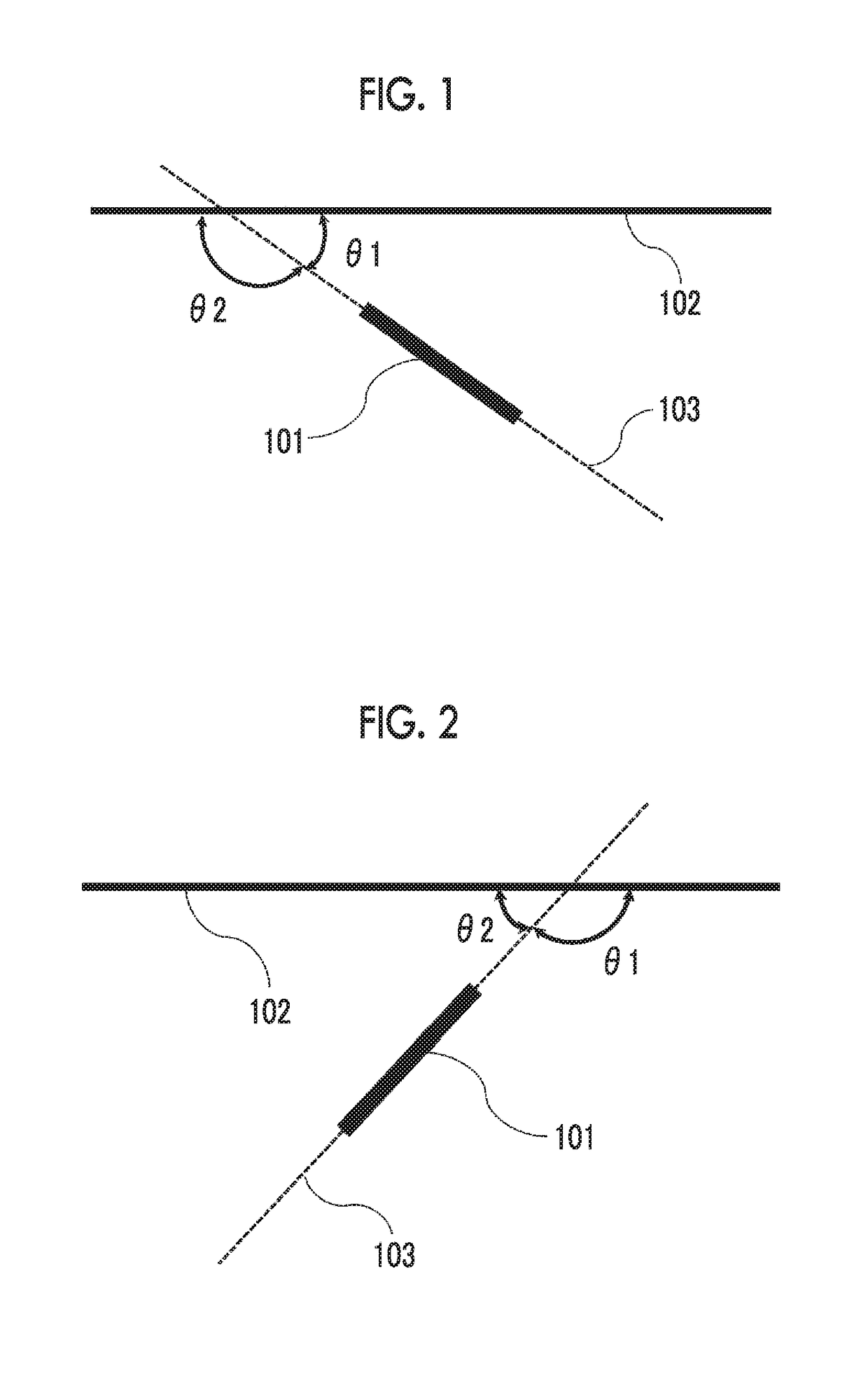

A highly accurate technique for inspecting semiconductor devices is described. The technique involves utilizing multiple sets of measurement data obtained by a scanning electron microscope (SEM) to determine the dimensional parameters of a semiconductor device. The SEM collects each set of data from a different angular orientation with respect to the device. The dimensional parameters of the semiconductor device are determined by analyzing the relationship between the SEM inspection angle and the collected data sets. Various configurations of an SEM can be used to implement this invention. For instance an electron beam inspection system of the present invention can have at least two sets of deflectors for guiding the electron beam, a swiveling specimen stage, and / or a set of detectors set about the specimen at different angular orientations.

Owner:KLA TENCOR TECH CORP

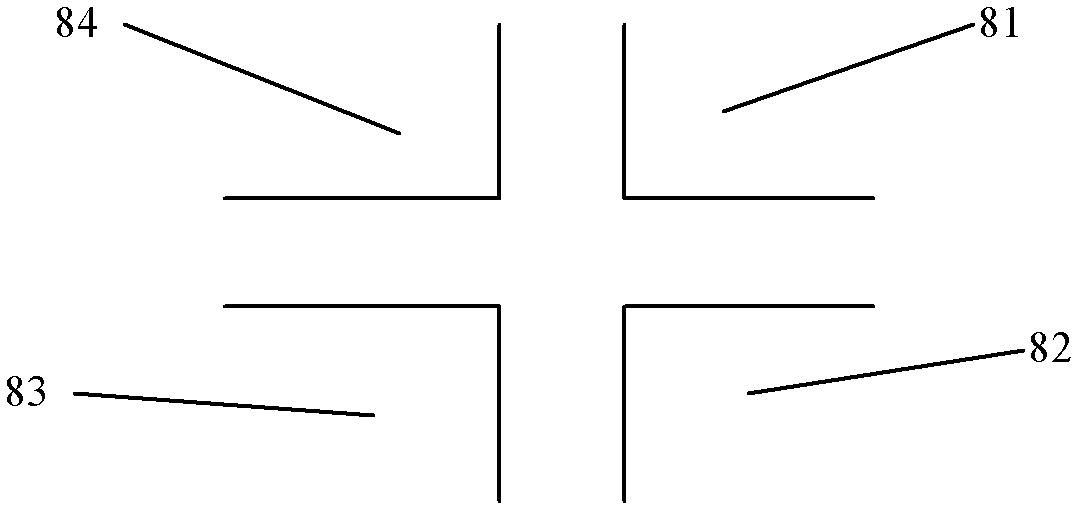

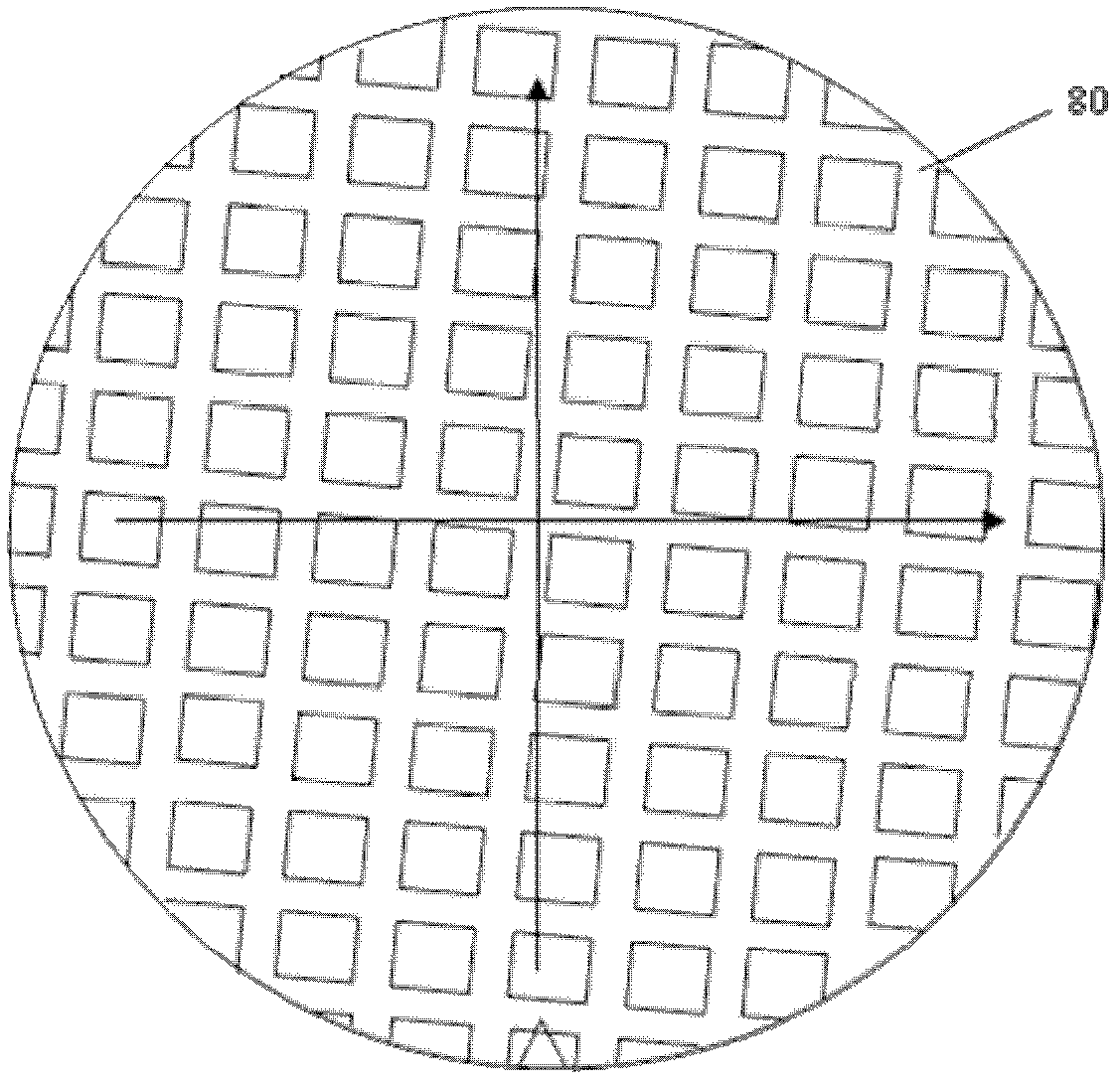

Detection method of scanning electron microscope

ActiveCN102435629AQuick snapAccurate captureMaterial analysis by measuring secondary emissionScanning tunneling microscopeDisplay device

The invention relates to a detection method of a scanning electron microscope. The detection method can be used for detecting the defect of a wafer provided with a plurality of chips, and comprises the steps of: importing a file of the wafer with a defect; putting the wafer to be detected on an objective table of the scanning electron microscope; setting a corner of a certain chip arranged on the wafer to be detected as an initial position; correcting the position of the wafer to be detected; obtaining the offset value of the levels of the wafers arranged at the central parts of cavities of two machine types; selecting the chip to be detected, and correcting the coordinate of the corner of the chip in a defect scanning machine according to the offset value of the levels of the wafers; leading the corner of the chip to be moved to the center of the image of a display device in a state of amplifying the image, and obtaining the offset value of the levels of the chips arranged at the central parts of the cavities of the two machine types; obtaining the corrected coordinate of the defect based on the offset value of the levels of the wafers and the offset value of the levels of the chips; and according to the corrected coordinate of the defect, leading the defect to be detected to be positioned under an electron gun of the defect scanning machine, and therefore, the feature of the defect can be rapidly and accurately caught.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Magnetic tape having characterized magnetic layer

ActiveUS10482913B2Deterioration of characteristicMaterials with ironTape carriersScanning tunneling microscopeMagnetic tape

A magnetic tape includes a non-magnetic support; a non-magnetic layer including non-magnetic powder and a binding agent on the non-magnetic support; and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic layer. The total thickness of the non-magnetic layer and the magnetic layer is less than or equal to 0.60 μm. The magnetic layer includes an abrasive, and the percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer with respect to the total area of the region, obtained by plane observation performed by using a scanning electron microscope, is greater than or equal to 0.02% and less than 0.06%. Also, the logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is less than or equal to 0.050.

Owner:FUJIFILM CORP

Interface, a method for observing an object within a non-vacuum environment and a scanning electron microscope

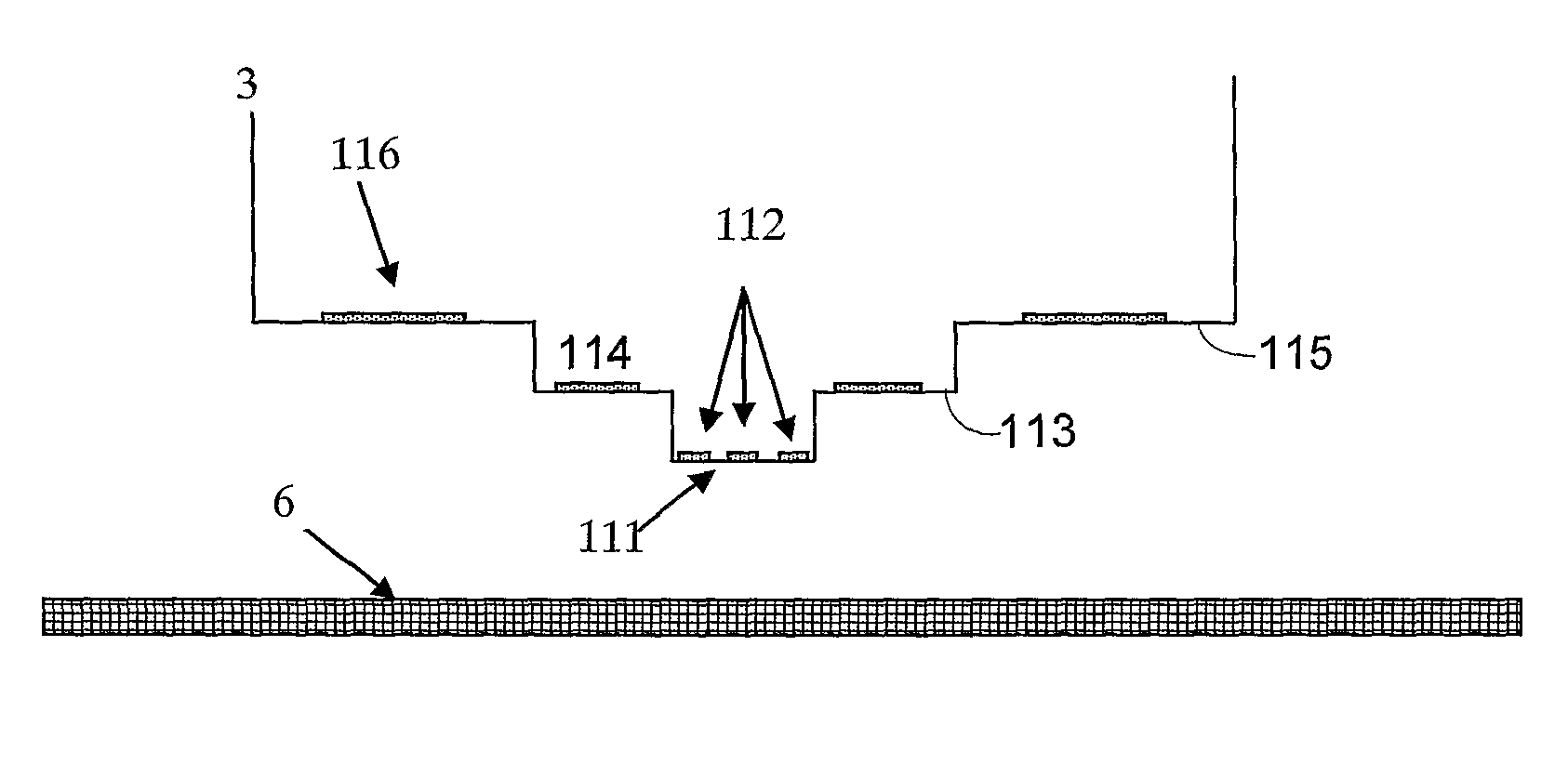

ActiveUS8164057B2Easy to detectHigh resolution imageEngine sealsMaterial analysis using wave/particle radiationScanning tunneling microscopeThin membrane

An interface, a scanning electron microscope and a method for observing an object that is positioned in a non-vacuum environment. The method includes: passing at least one electron beam that is generated in a vacuum environment through at least one aperture out of an aperture array and through at least one ultra thin membrane that seals the at least one aperture; wherein the at least one electron beam is directed towards the object; wherein the at least one ultra thin membrane withstands a pressure difference between the vacuum environment and the non-vacuum environment; and detecting particles generated in response to an interaction between the at least one electron beam and the object.

Owner:B NANO

Device and method for the examination of samples in a non-vacuum environment using a scanning electron microscope

InactiveUS6992300B2Minimum distanceHigh inspectionMaterial analysis using wave/particle radiationElectric discharge tubesScanning tunneling microscopeLiving cell

A chamber suitable for use with a scanning electron microscope. The chamber comprises at least one aperture sealed with a membrane. The membrane is adapted to withstand a vacuum, and is transparent to electrons and the interior of the chamber is isolated from said vacuum. The chamber is useful for allowing wet samples including living cells to be viewed under an electron microscope.

Owner:EL MUL TECH +1

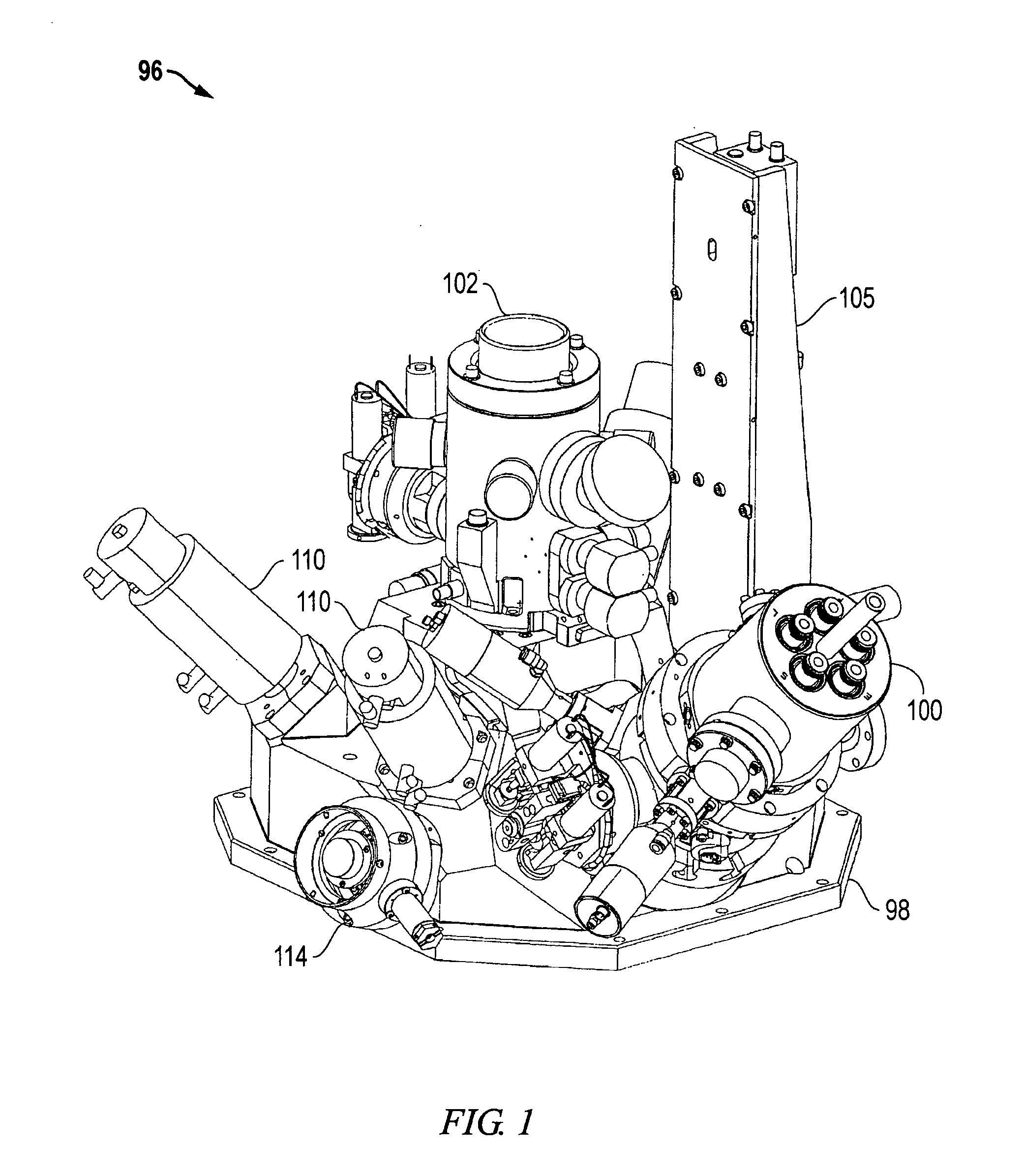

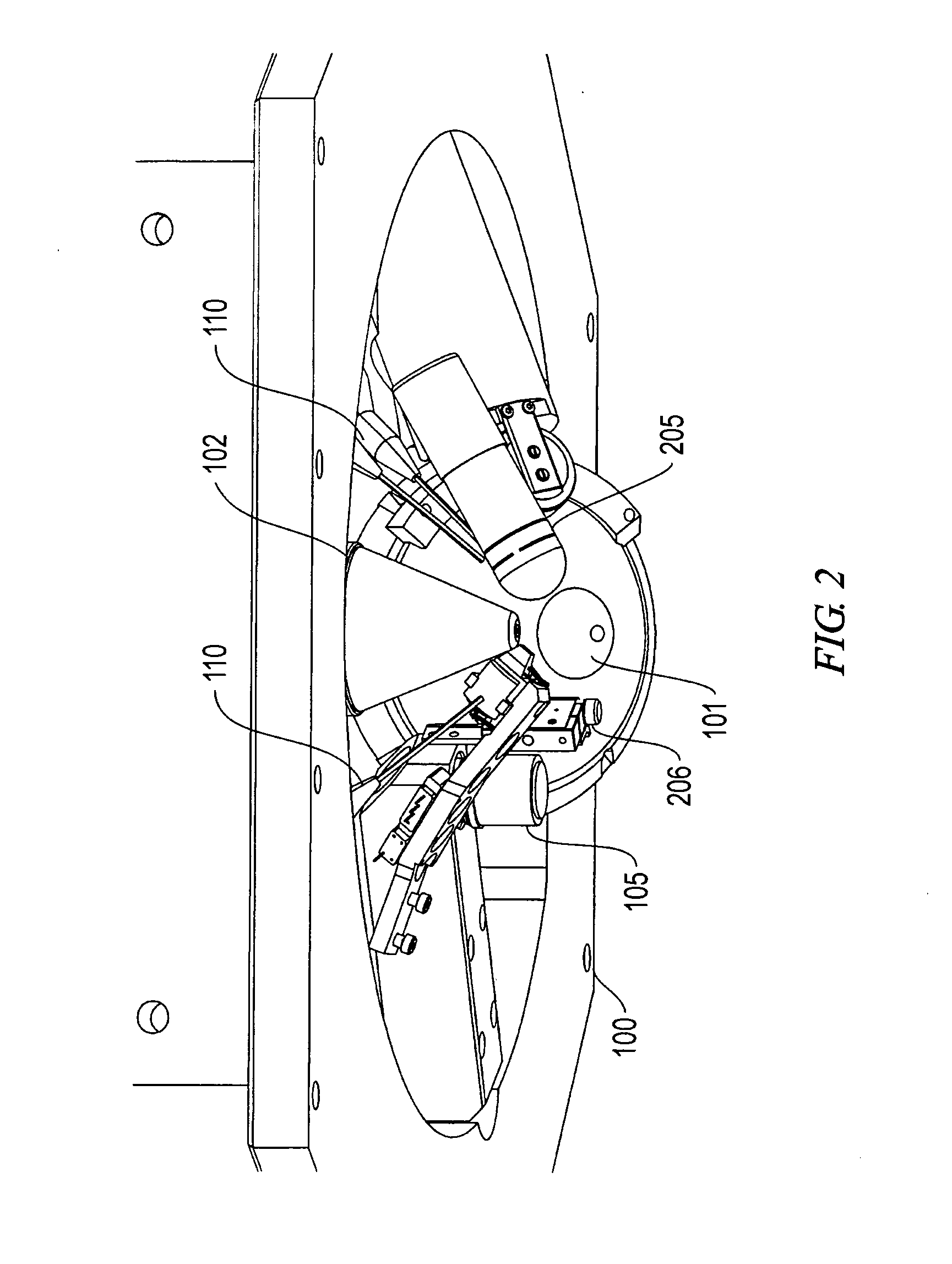

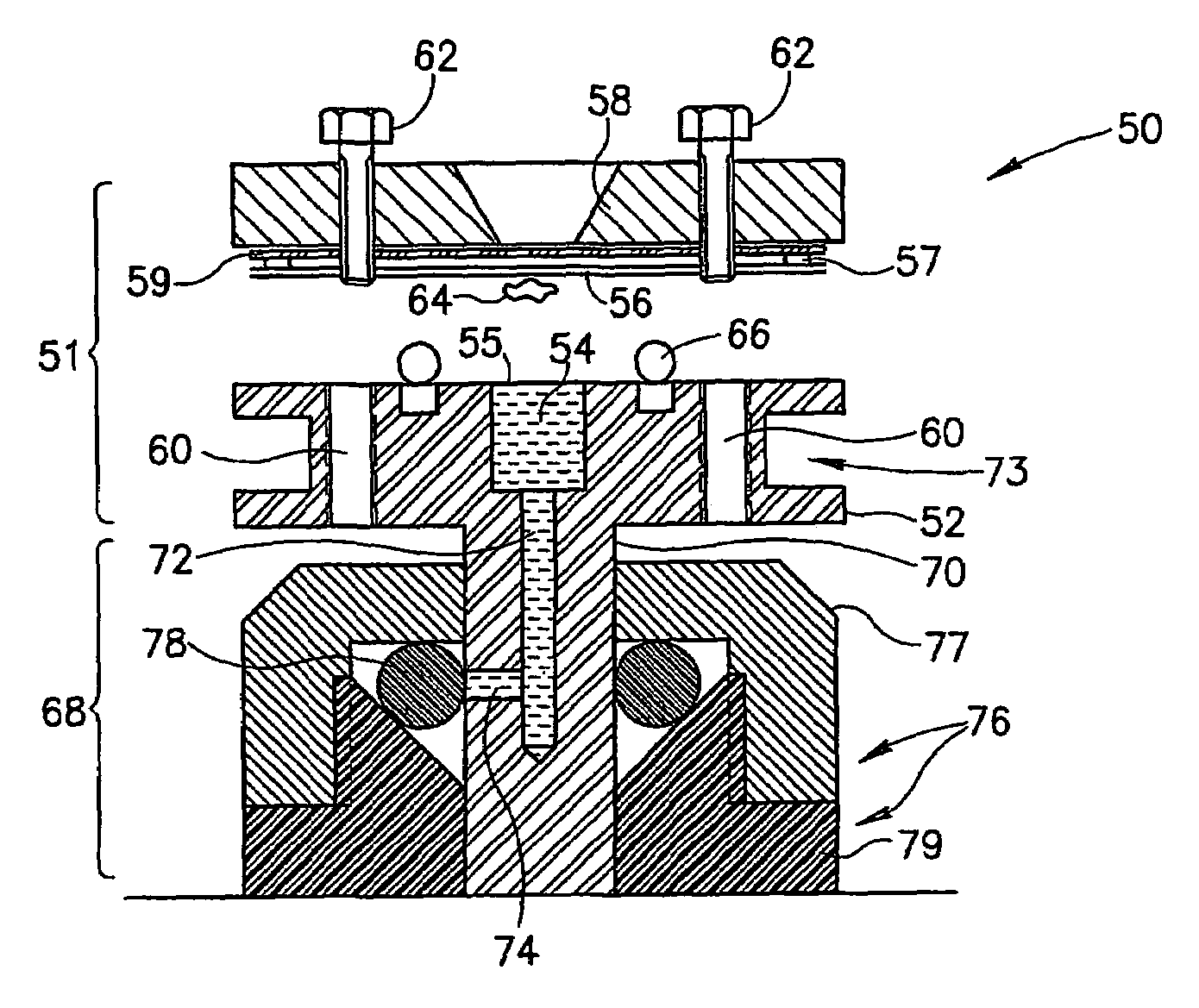

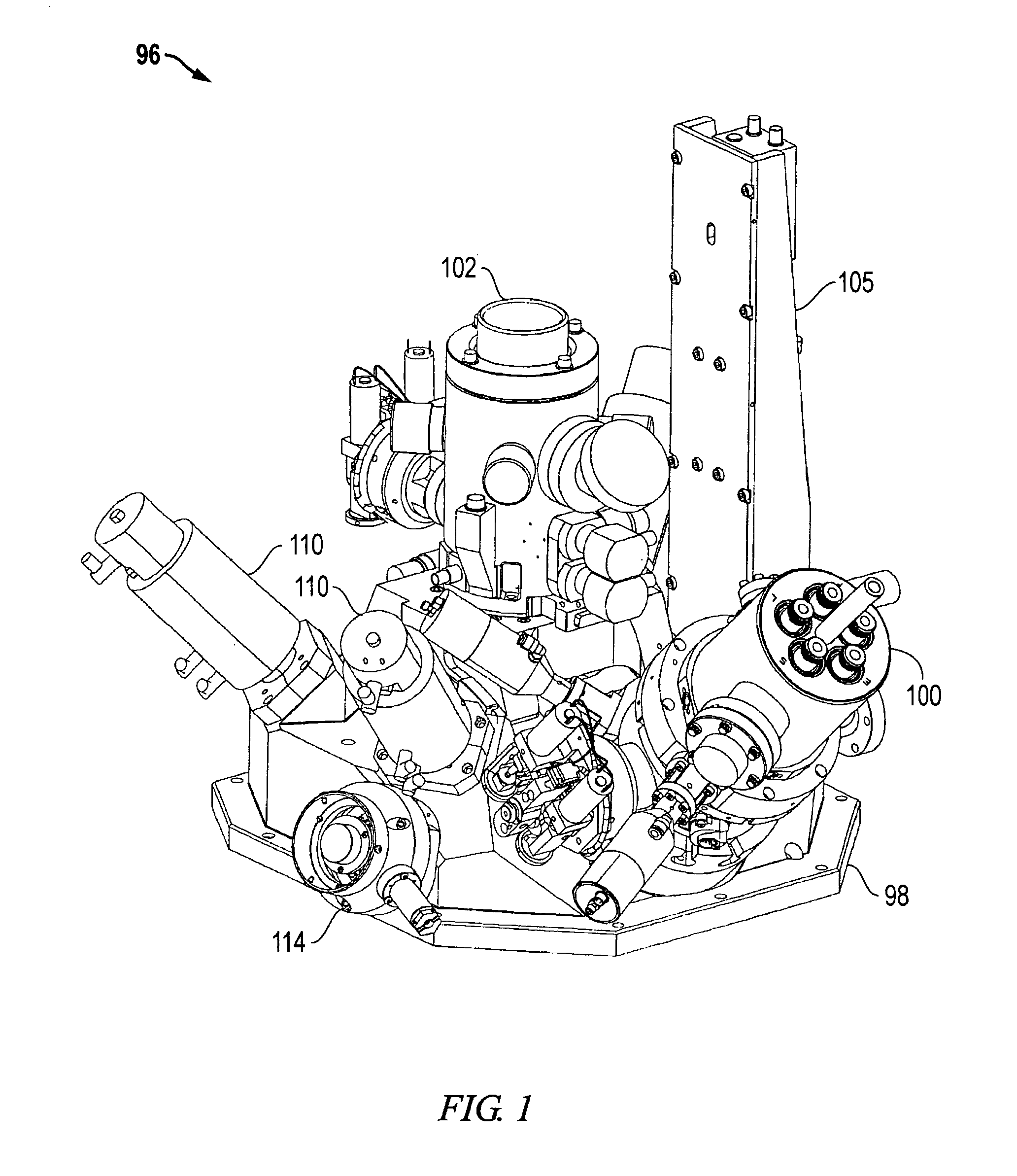

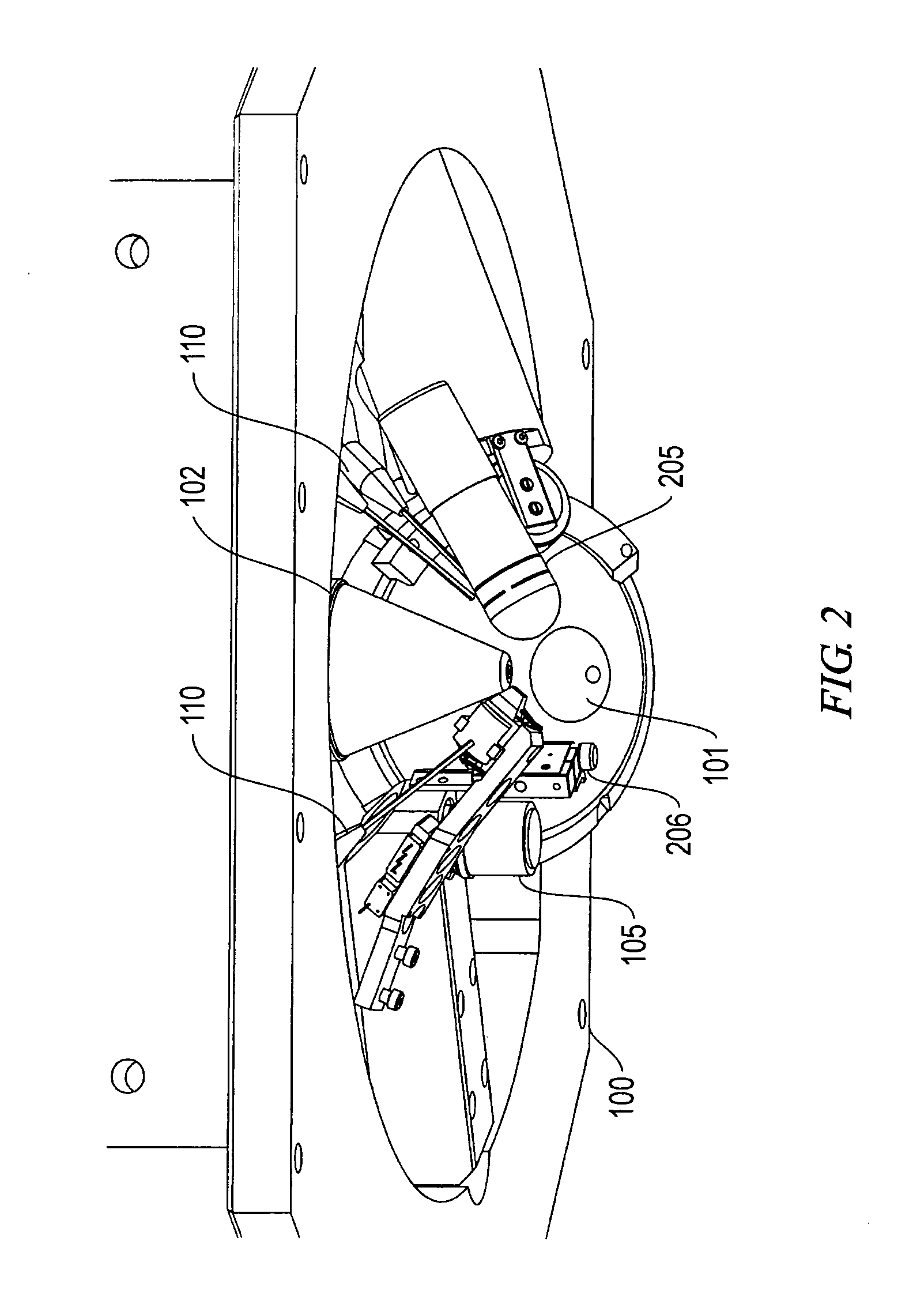

Dual beam system

ActiveUS7161159B2Remove blurEasy to collectThermometer detailsMaterial analysis using wave/particle radiationScanning tunneling microscopeDual beam

A dual beam system includes an ion beam system and a scanning electron microscope with a magnetic objective lens. The ion beam system is adapted to operate optimally in the presence of the magnetic field from the SEM objective lens, so that the objective lens is not turned off during operation of the ion beam. An optional secondary particle detector and an optional charge neutralization flood gun are adapted to operate in the presence of the magnetic field. The magnetic objective lens is designed to have a constant heat signature, regardless of the strength of magnetic field being produced, so that the system does not need time to stabilize when the magnetic field is changed.

Owner:FEI CO

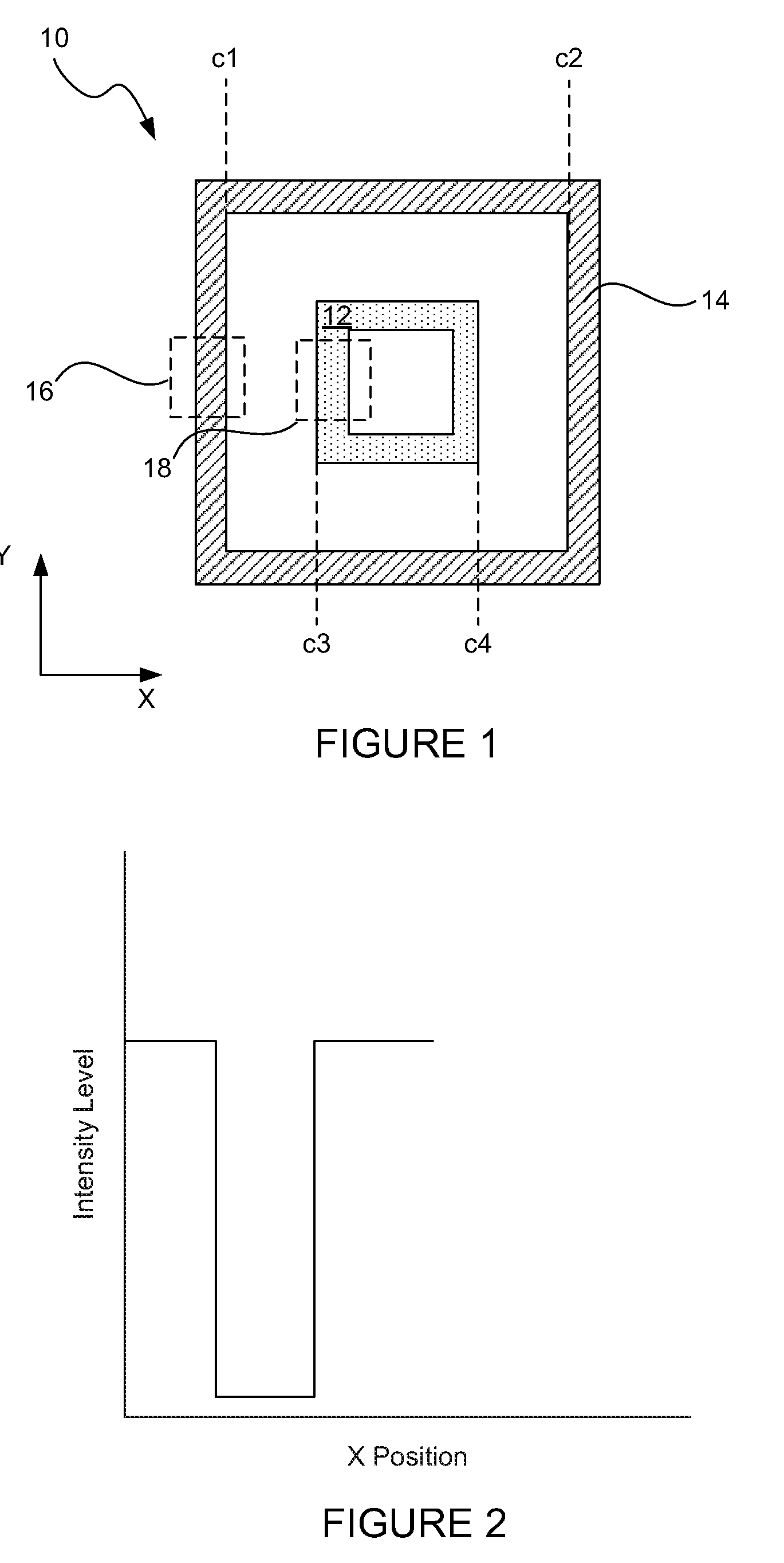

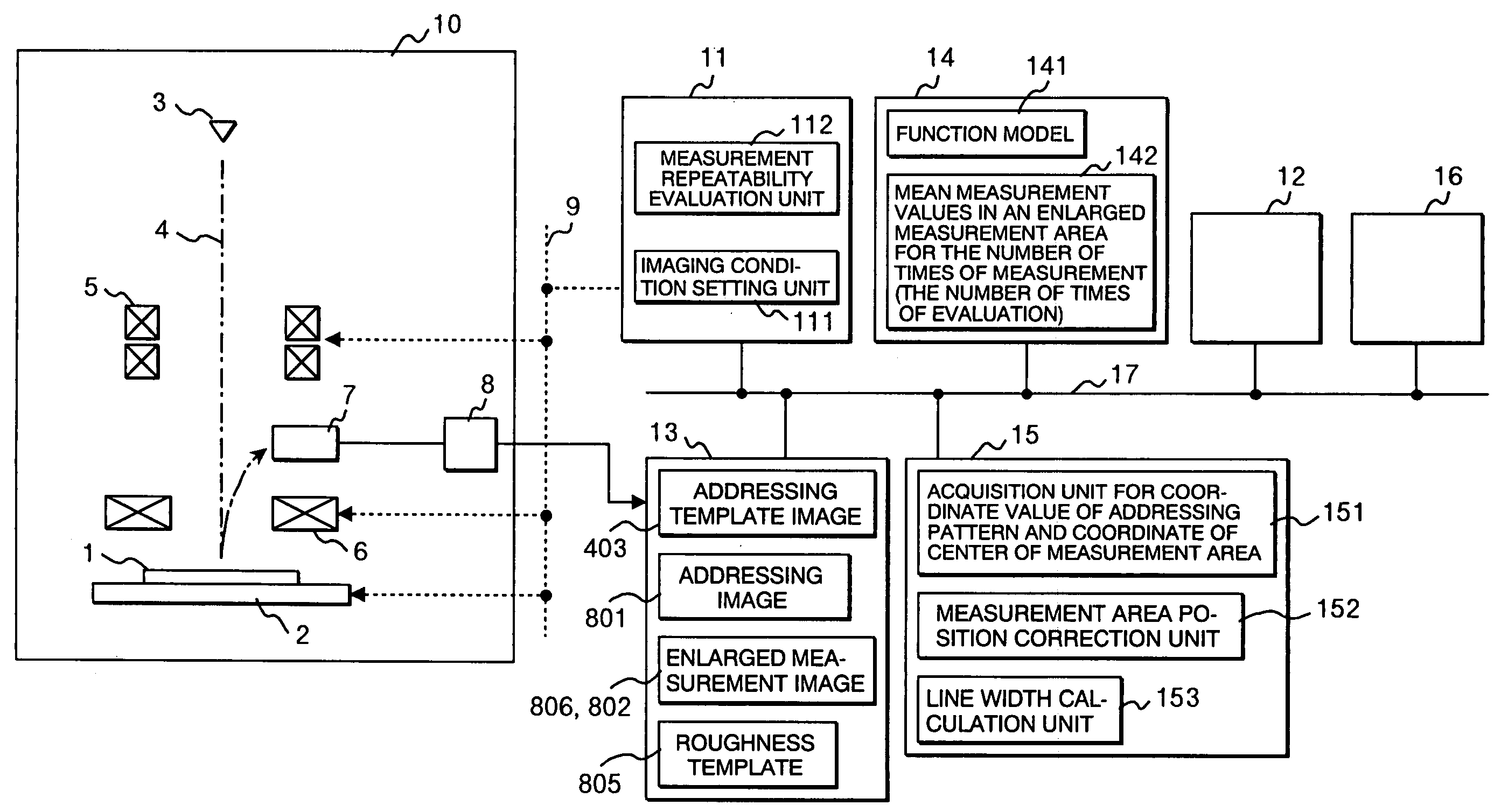

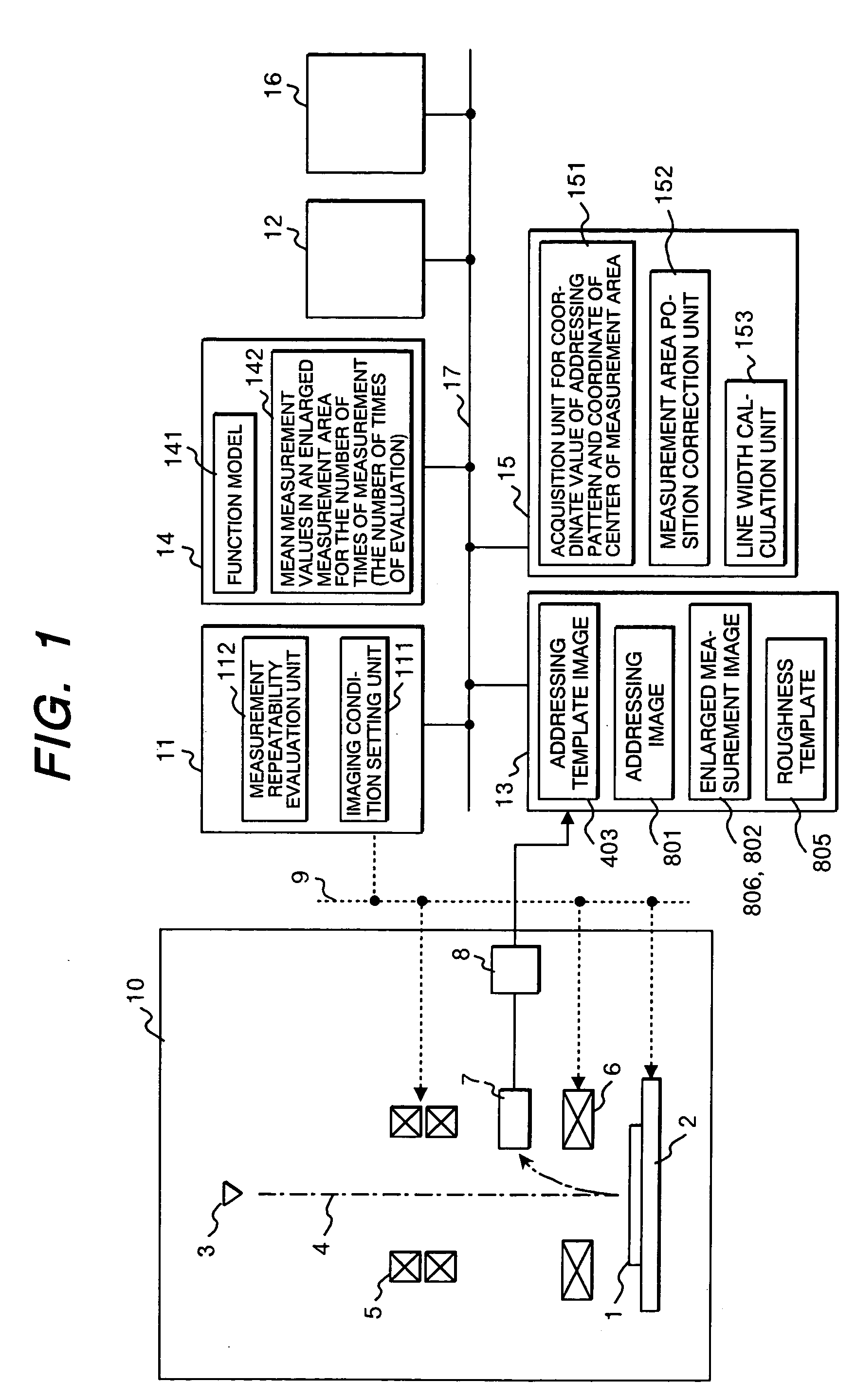

Method for measuring overlay and measuring apparatus, scanning electron microscope, and GUI

ActiveUS20140375793A1Easy to measureImage enhancementImage analysisMeasurement deviceScanning tunneling microscope

A method for measuring overlay at a semiconductor device on which circuit patterns are formed by a plurality of exposure processes is characterized in including an image capturing step for capturing images of a plurality of areas of the semiconductor device, a reference image setting step for setting a reference image based on a plurality of the images captured in the image capturing step, a difference quantifying step for quantifying a difference between the reference image set in the reference image setting step and the plurality of images captured in the image capturing step, and an overlay calculating step for calculating the overlay based on the difference quantified in the difference quantifying step.

Owner:HITACHI HIGH-TECH CORP

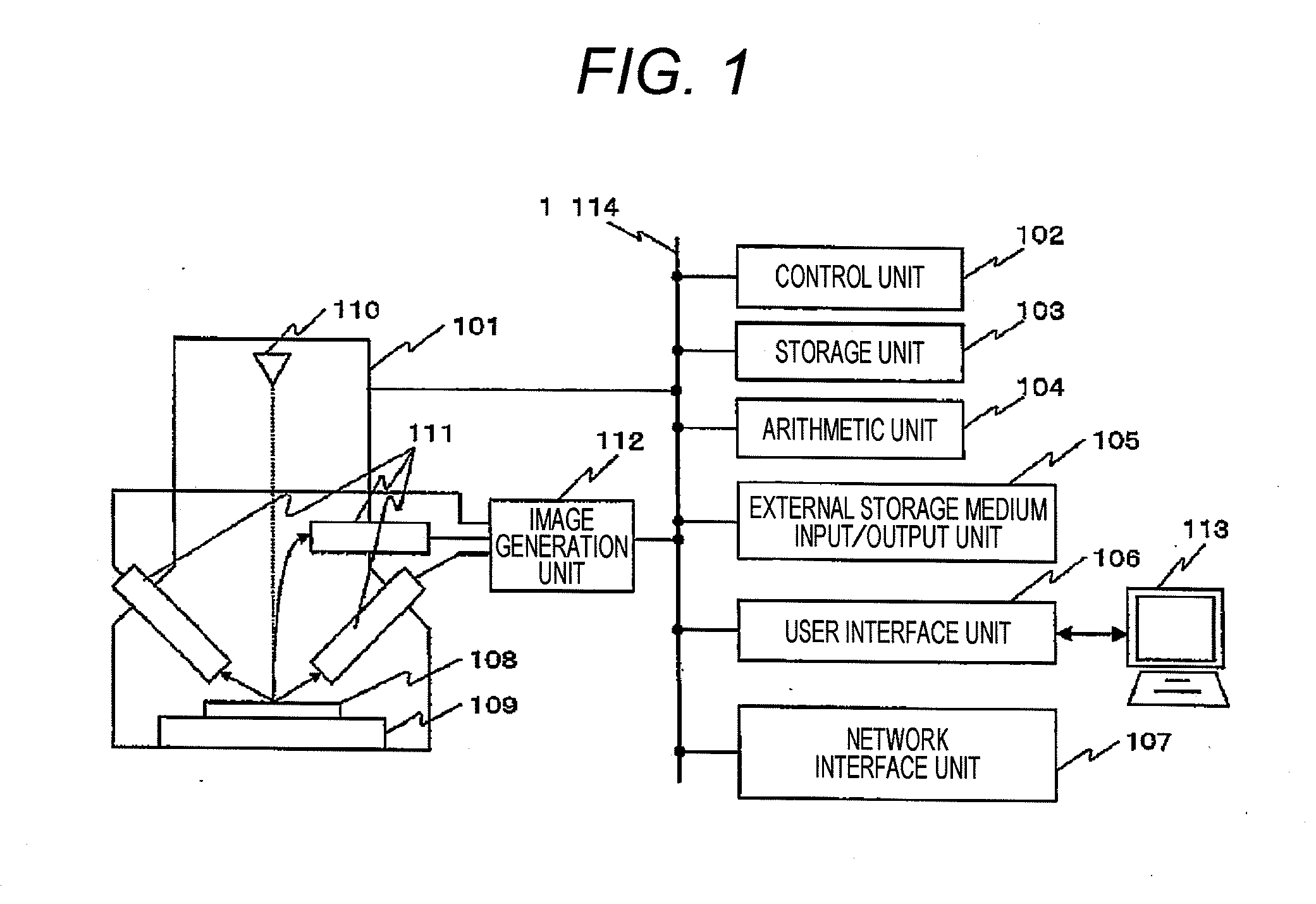

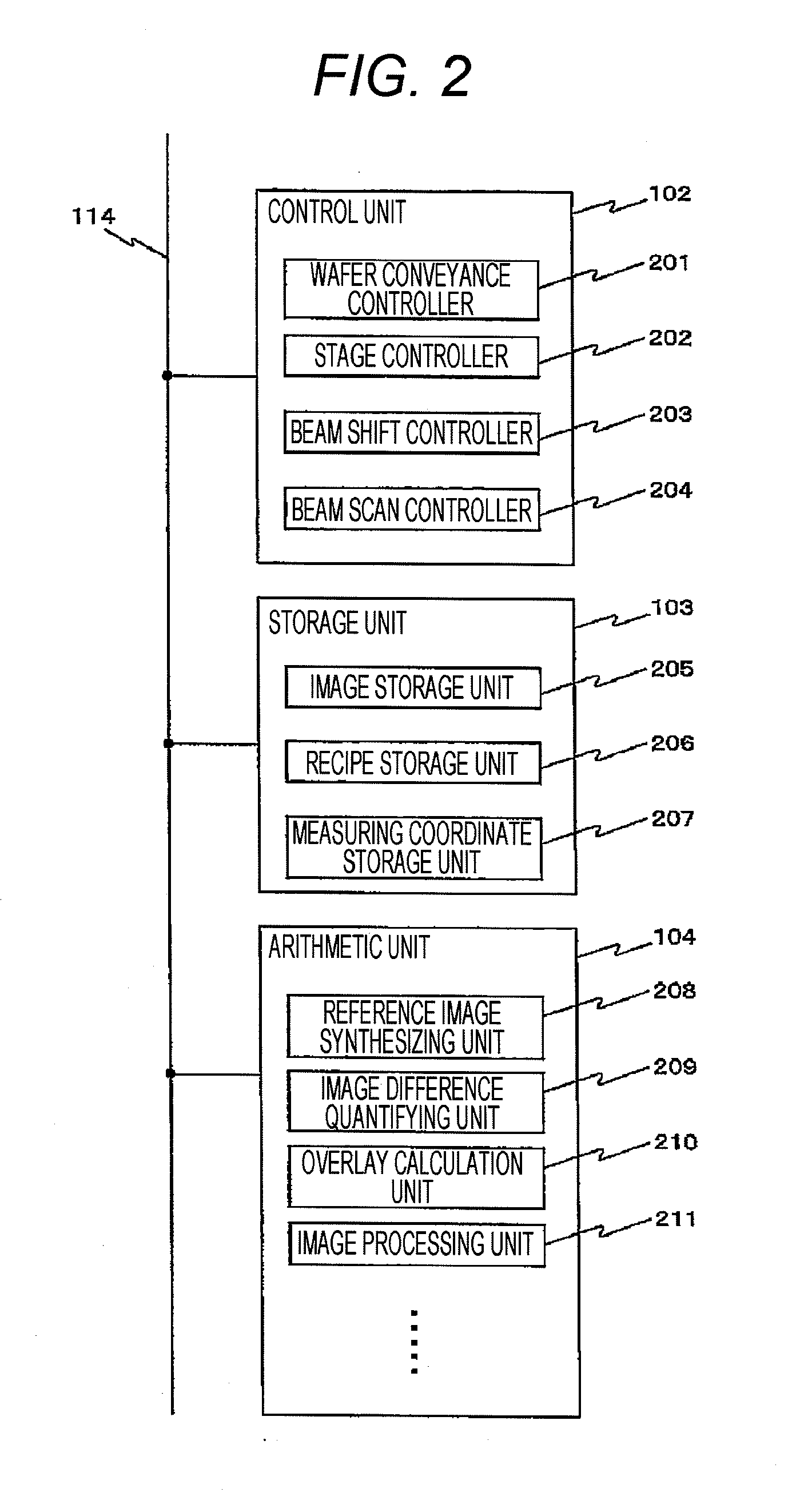

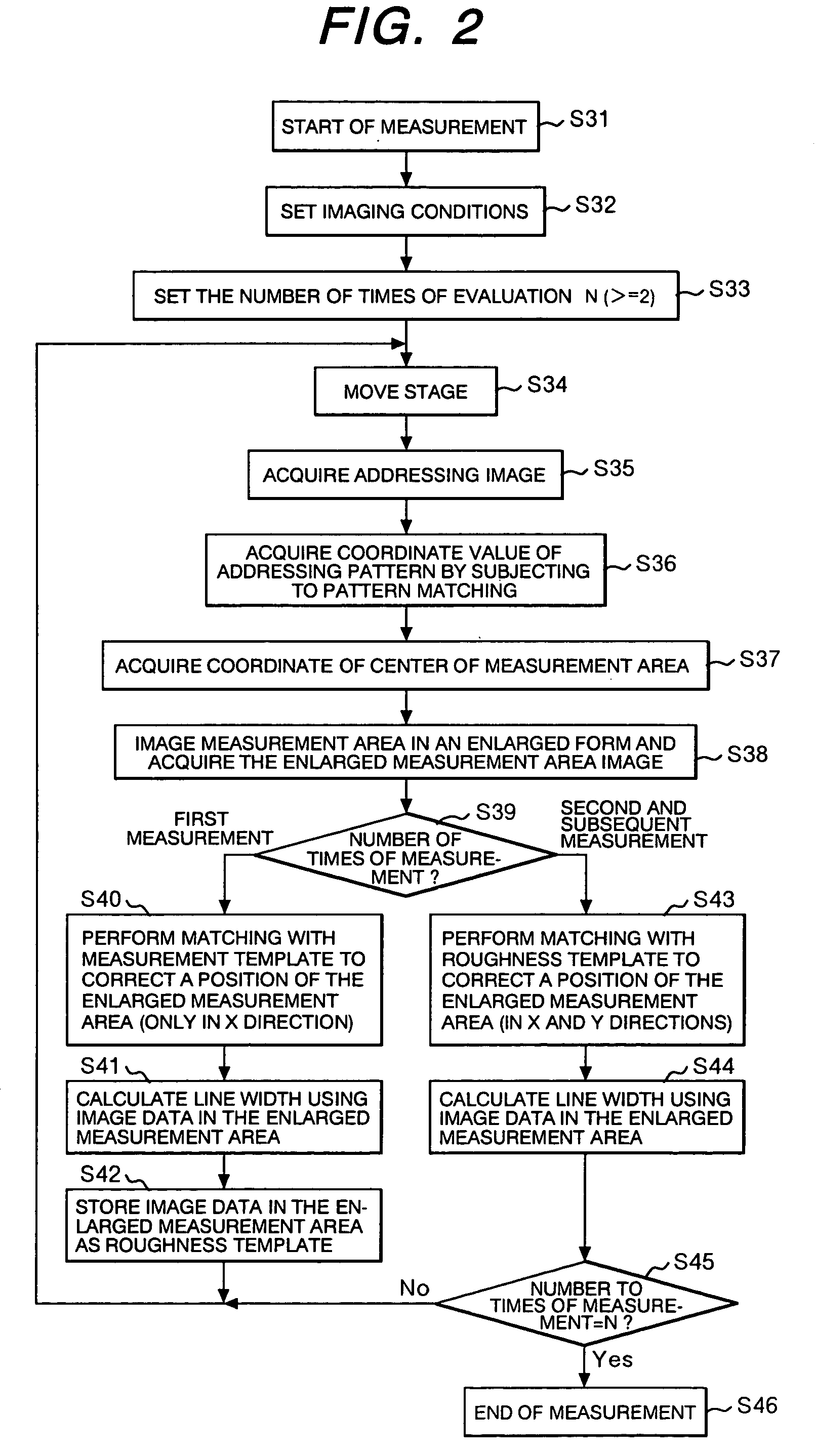

Scanning electron microscope and a method for evaluating accuracy of repeated measurement using the same

InactiveUS20050205780A1Eliminate measurement errorsHigh precisionMaterial analysis using wave/particle radiationElectric discharge tubesScanning tunneling microscopePattern matching

The present invention relates to a CDSEM (scanning electron microscope) capable of evaluating and presenting the measurement repeatability as a tool with a high degree of accuracy without being influenced by fluctuations in micro-minute shape that tend to increase with the microminiaturization of semiconductor patterns, and to a method for evaluating accuracy of repeated measurement using the scanning electron microscope. There is provided a function whereby when measuring a plurality of times the same part to be measured, by making use of a micro-minute pattern shape such as the roughness included in the pattern, pattern matching with a roughness template image is performed to correct two-dimensional deviation in position of the part to be measured on an enlarged measurement image acquired, and then an enlarged measurement area image is extracted and acquired. This makes it possible to eliminate variation in measurements caused by the micro-minute pattern shape.

Owner:HITACHI HIGH-TECH CORP

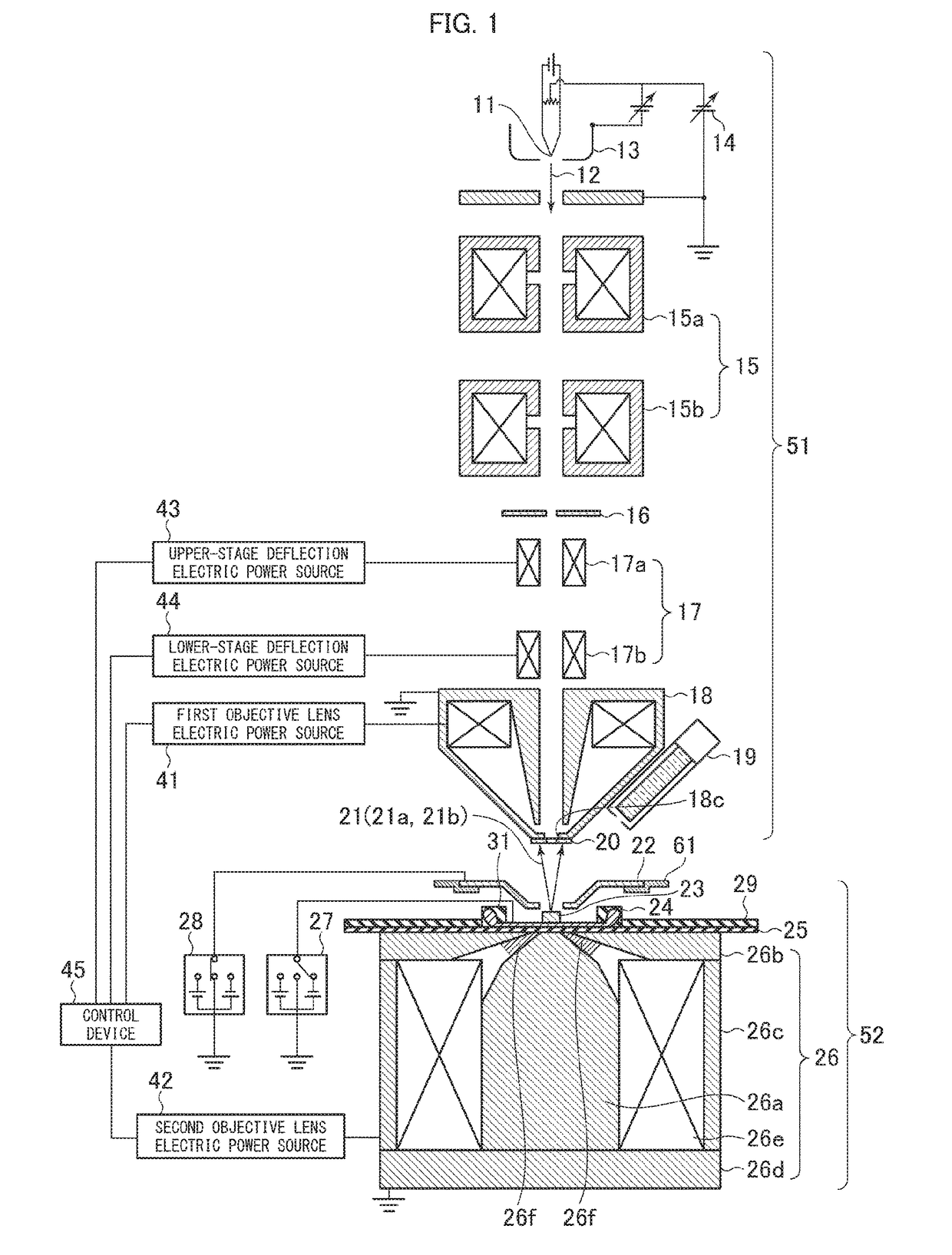

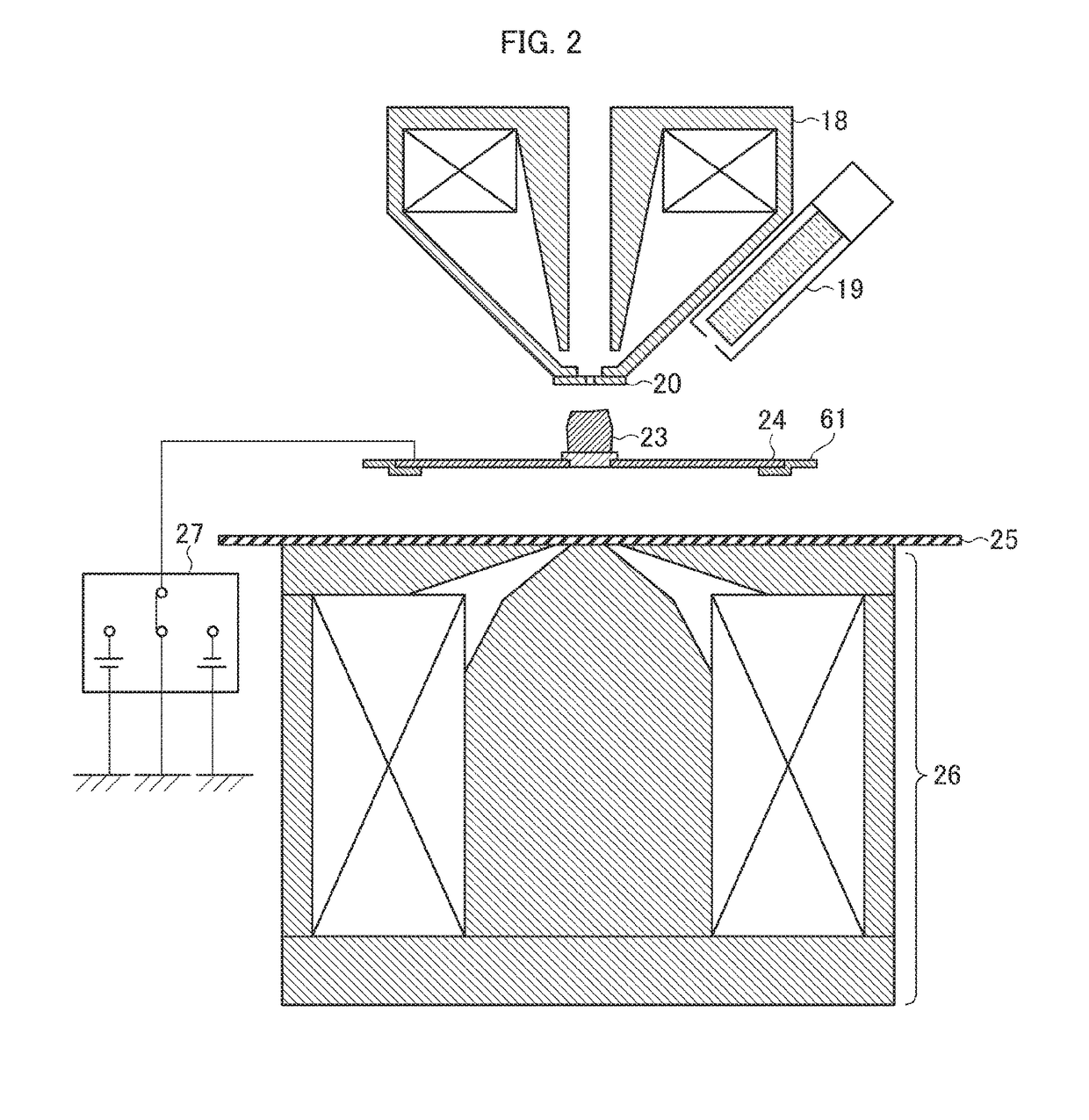

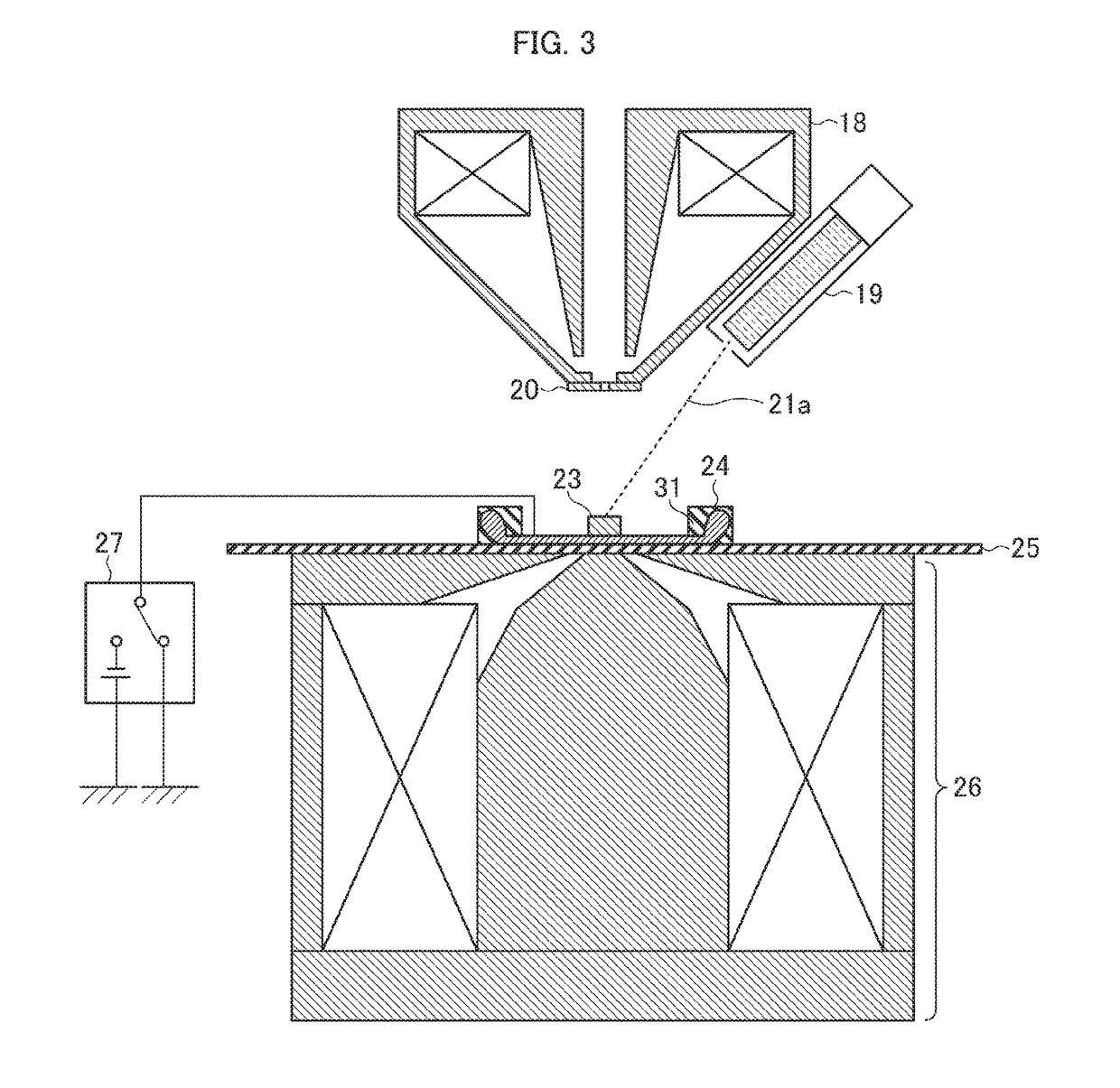

Charged particle beam device and scanning electron microscope

ActiveUS20180358199A1Improve performanceElectric discharge tubesScanning tunneling microscopeParticle beam

A charged particle beam device includes: a charged particle source configured to emit a charged particle beam; an acceleration electric power source connected to the charged particle source and configured to accelerate the charged particle beam; a second objective lens configured to focus the charged particle beam onto a sample; and a second detector. The second objective lens is positioned on the opposite side of the sample from where the charged particle beam is incident on the sample. The second detector is configured to receive at least one of: an electromagnetic wave that the sample emits upon receiving the charged particle beam, and an electromagnetic wave that the sample reflects upon receiving the charged particle beam. The second detector carries out a detection of the received electromagnetic wave(s).

Owner:MATSUSADA PRECISION

Method and apparatus for arranging recipe of scanning electron microscope and apparatus for evaluating shape of semiconductor device pattern

InactiveUS7365322B2Increase speedQuickly accommodate changeMaterial analysis using wave/particle radiationElectric discharge tubesScanning tunneling microscopeScanning electron microscope

In order to provide an imaging-recipe arranging or creating apparatus and method adapted so that selection rules for automatic arrangement of an imaging recipe can be optimized by teaching in a SEM apparatus or the like, the imaging-recipe arranging or creating apparatus in this invention that arranges an imaging recipe for SEM-observing a semiconductor pattern using a scanning electron microscope includes a database that receives and stores layout information of the above semiconductor pattern in a low-magnification field, and an imaging-recipe arranging unit which, on the basis of the database-stored semiconductor pattern layout information, arranges the imaging recipe automatically in accordance with the automatic arrangement algorithm that includes teaching-optimized selection rules for selecting an imaging point(s).

Owner:HITACHI HIGH-TECH CORP

Integrated measuring instrument

InactiveUS6986280B2Improve accuracyImprove efficiencySemiconductor/solid-state device testing/measurementScattering properties measurementsFast measurementMeasuring instrument

A surface analyzing system including in one system both an integrating optical instrument, such as a scatterometer, and individual-feature-measuring instrument, such as a scanning probe microscope or a beam imaging system, for example, a scanning electron microscope. In a preferred embodiment, the two instruments are capable of characterizing a wafer held on a common stage. The stage may be movable a predetermined displacement to allow the same area of the wafer to be characterized by a scatterometer at one position of the stage and to be characterized by the scanning probe microscope or beam imaging system. The scatterometer can rapidly measure wafers to indicate whether a problem exists, and the scanning probe microscope can perform detailed measurements on wafers flagged by the scatterometer.

Owner:FEI CO

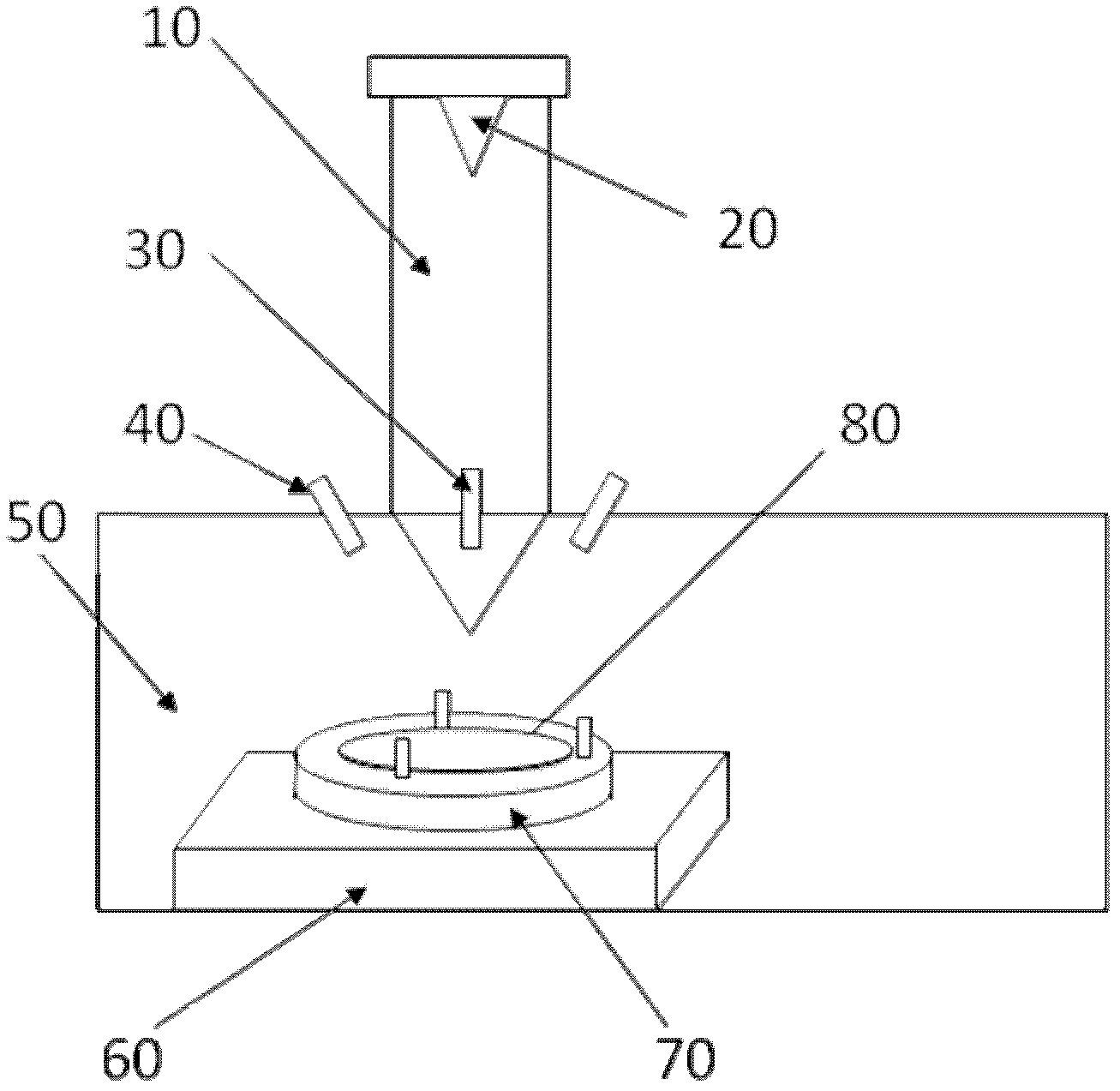

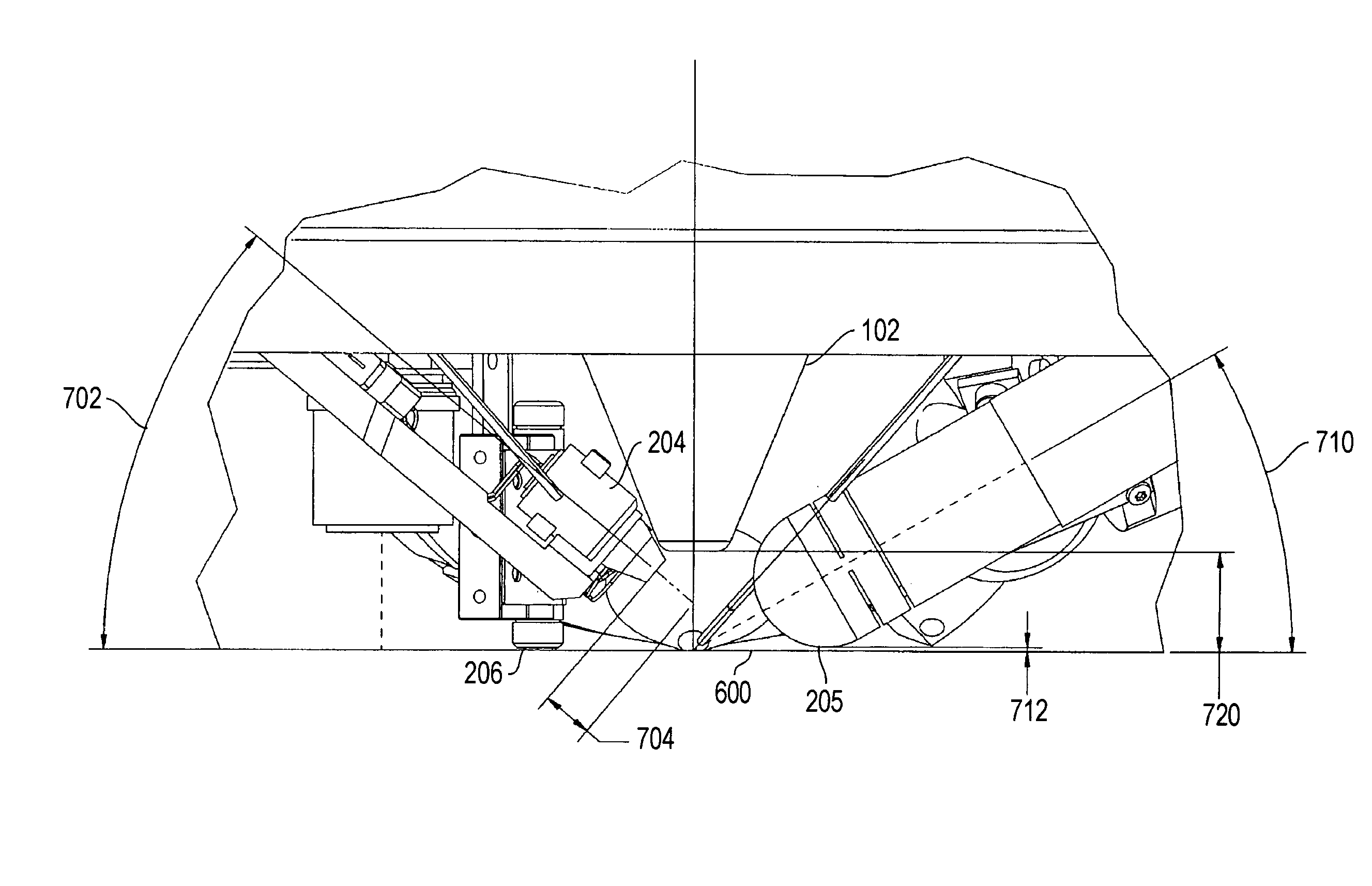

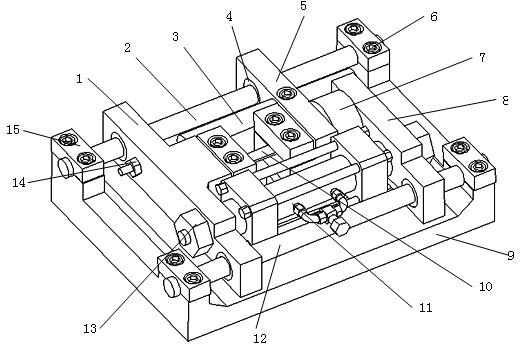

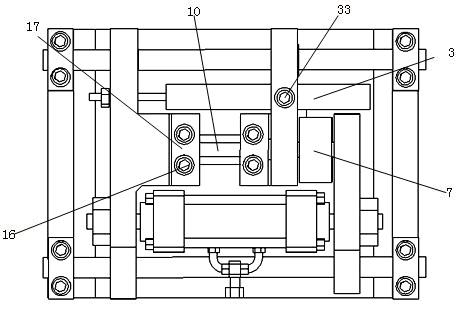

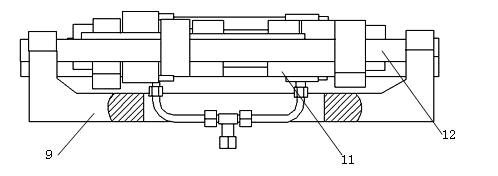

Hydraulic-driving mode based in situ tensile/compression testing platform under scanning electron microscope

InactiveCN102435493AGood structural compatibilityImprove compatibilityStrength propertiesElectromechanicsScanning tunneling microscope

The invention relates to a hydraulic-driving mode based in-situ tensile / compression testing platform under a scanning electron microscope, and belongs to the field of electromechanics. The hydraulic-driving mode based in-situ tensile / compression testing platform under the scanning electron microscope comprises a hydraulic driving unit consisting of a hydraulic cylinder, an oil tank, an oil filter, a motor, a hydraulic pump, an overflow valve, a throttle valve and an electro-hydraulic servo valve, a load / displacement signal detection and control unit consisting of a displacement sensor and a pull and pressure sensor, and a clamping and supporting unit consisting of light bars, fixture body supporting racks, base linear bearings, pressure plates, a force sensor supporting rack and a specimen. The hydraulic-driving mode based in-situ tensile / compression testing platform under the scanning electron microscope has the advantages of small volume, compact structure, large output load, continuously variable transmission loading, and good structural compatibility with a microscopic imaging system with an open space structure, such as an optical microscope, a Raman spectrometer and an X-ray diffractometer and the like, and also can used for deep study on the micro-mechanical behavior and the deformation and damage mechanism of the specimen with a centimeter-level characteristic size under the action of tensile / compression loads by combination with the instruments.

Owner:JILIN UNIV

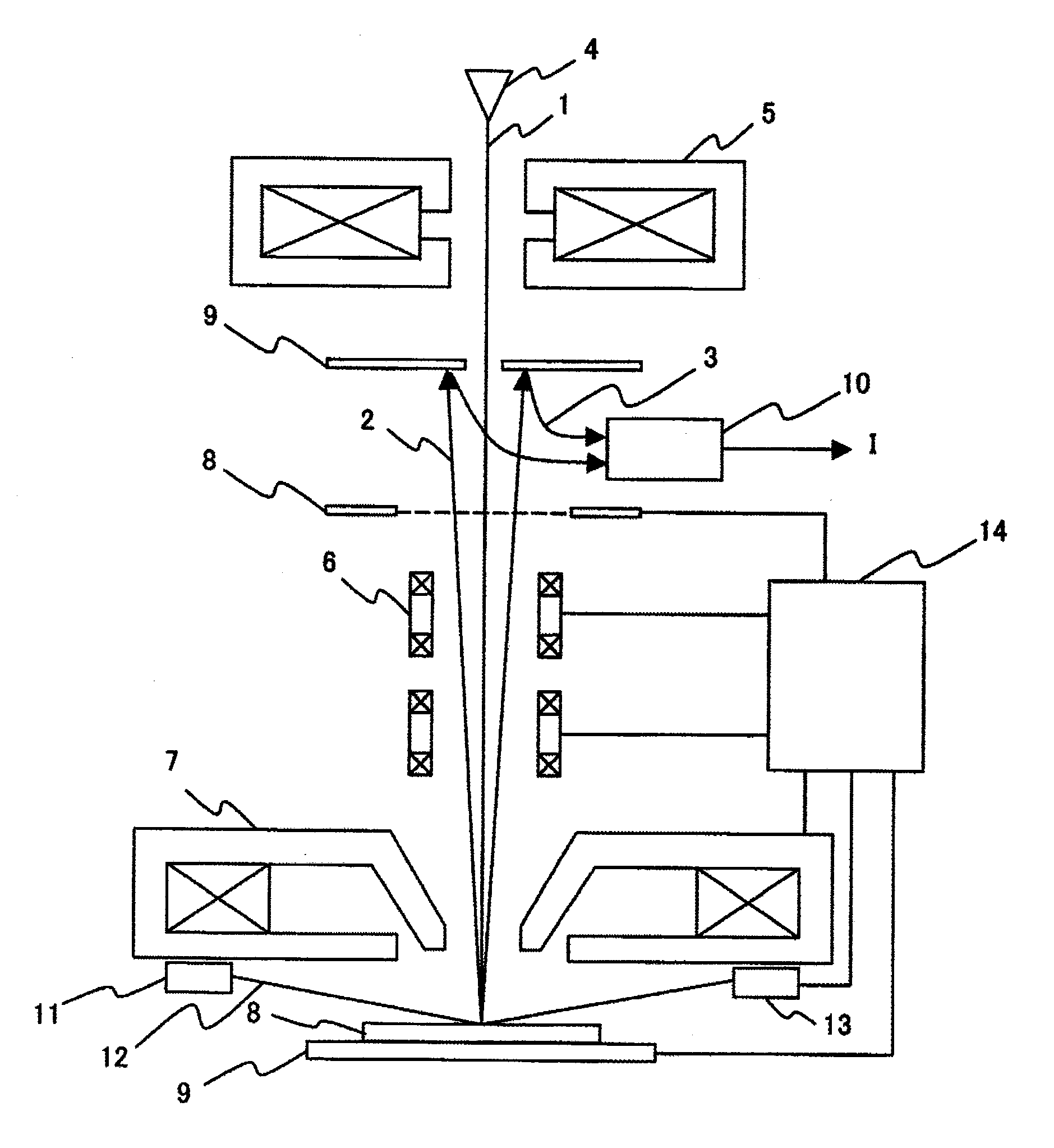

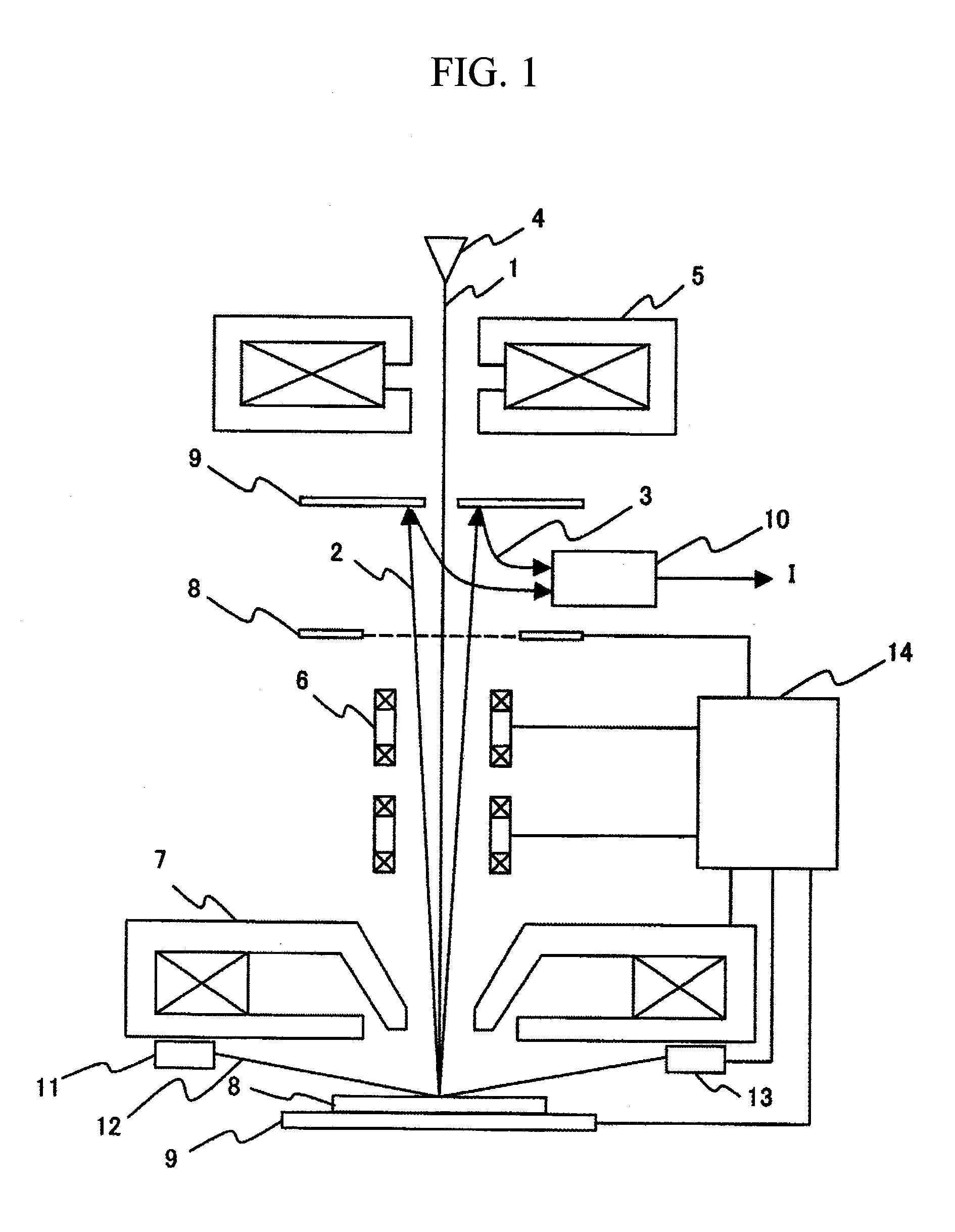

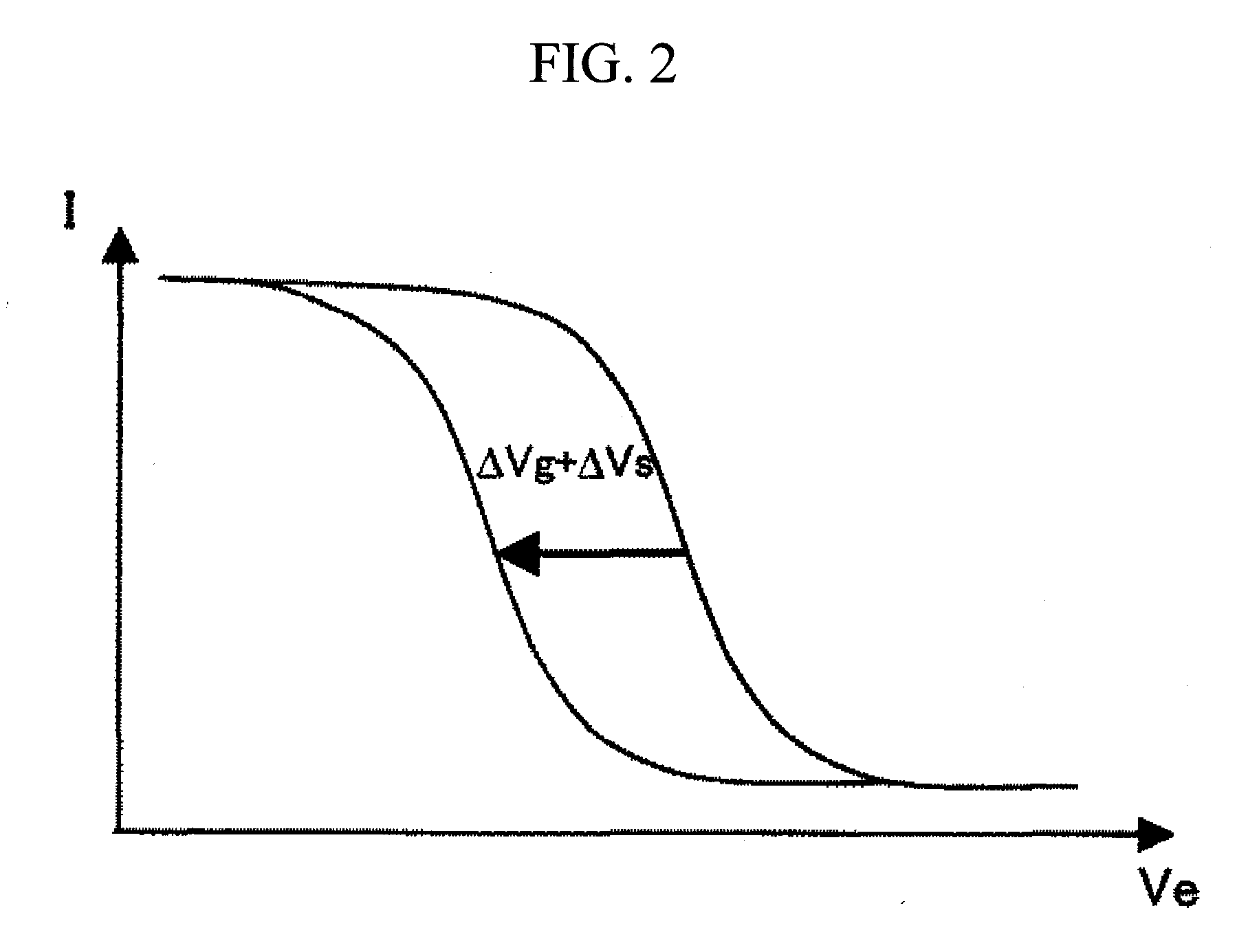

Electrostatic Charge Measurement Method, Focus Adjustment Method, And Scanning Electron Microscope

ActiveUS20080203298A1The right amountSuppressing error in amountMaterial analysis using wave/particle radiationPhotoelectric discharge tubesScanning tunneling microscopeBeam scanning

The present invention aims to provide a method and a device of capable of suppressing error in electrostatic charge amount or defocus on the basis of electrostatic charge storage due to electron beam scanning when measuring the electrostatic charge amount of the sample or a focus adjustment amount by scanning the electron beam.In order to achieve the above object, according to one aspect of the present invention, an electrostatic charge measurement method, a focus adjustment method, or a scanning electron microscope for measuring an electrostatic charge amount or controlling an application voltage to the sample by changing the application voltage to the energy filter while moving the scanning location of the electron beam on the sample is proposed.

Owner:HITACHI HIGH-TECH CORP

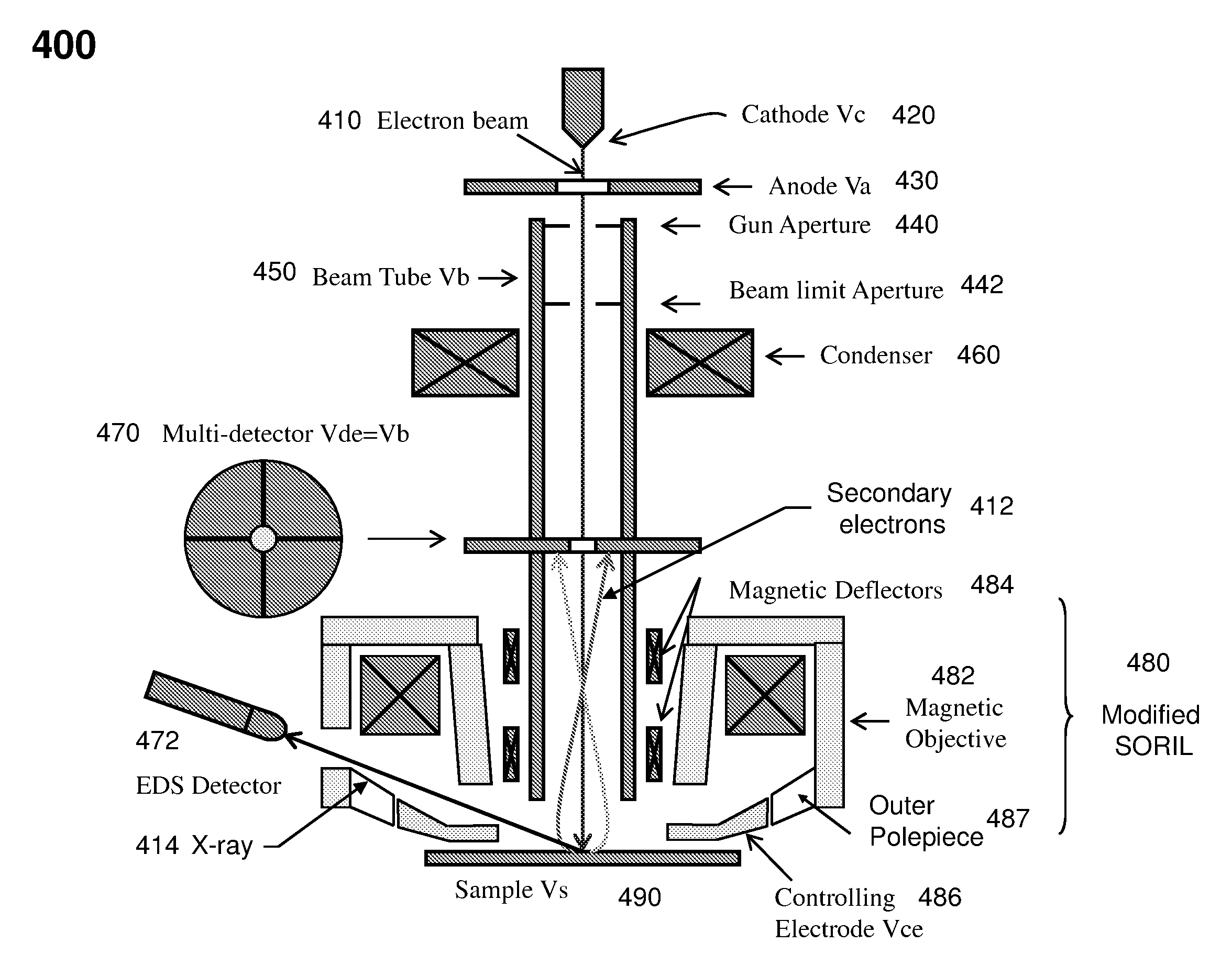

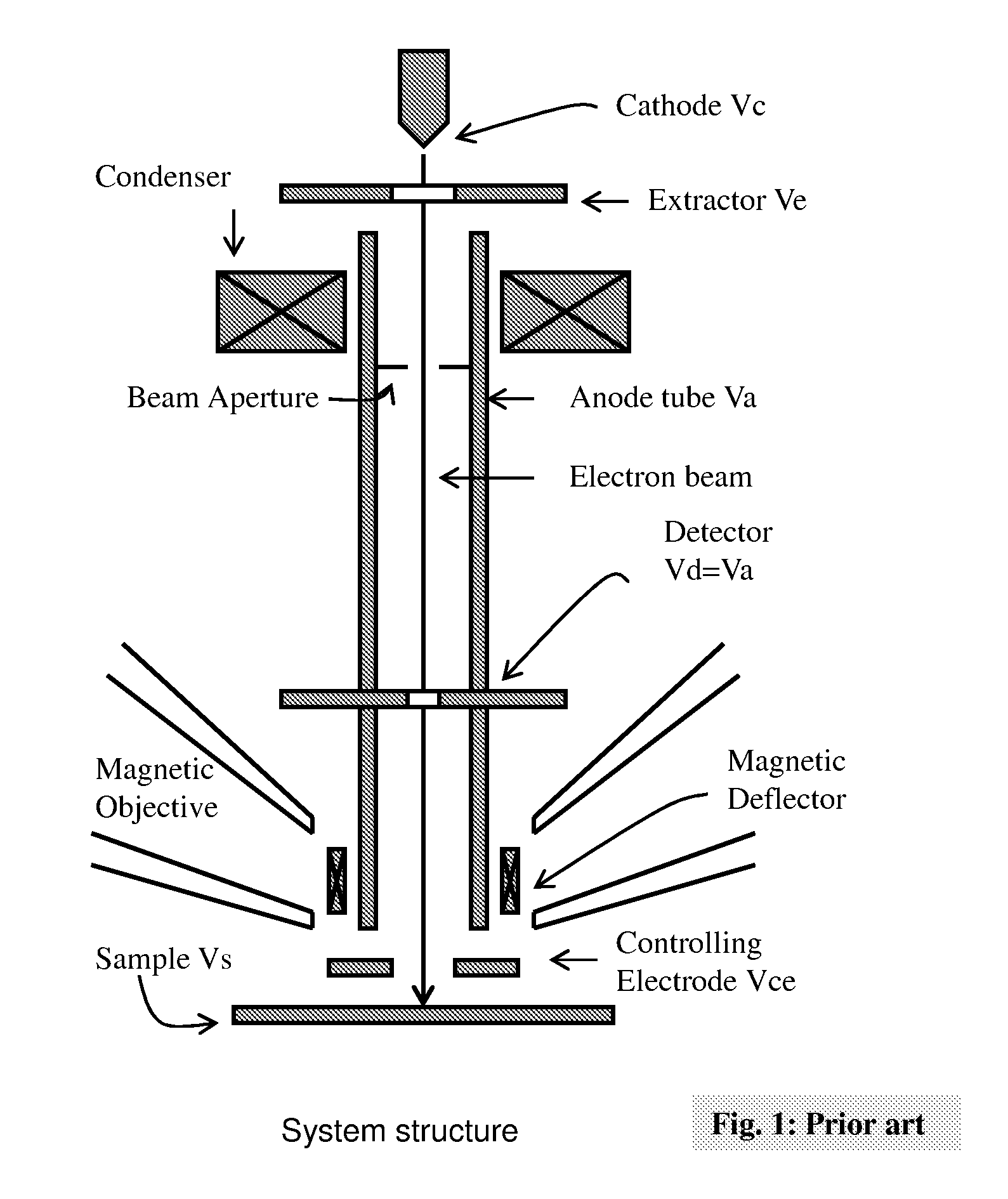

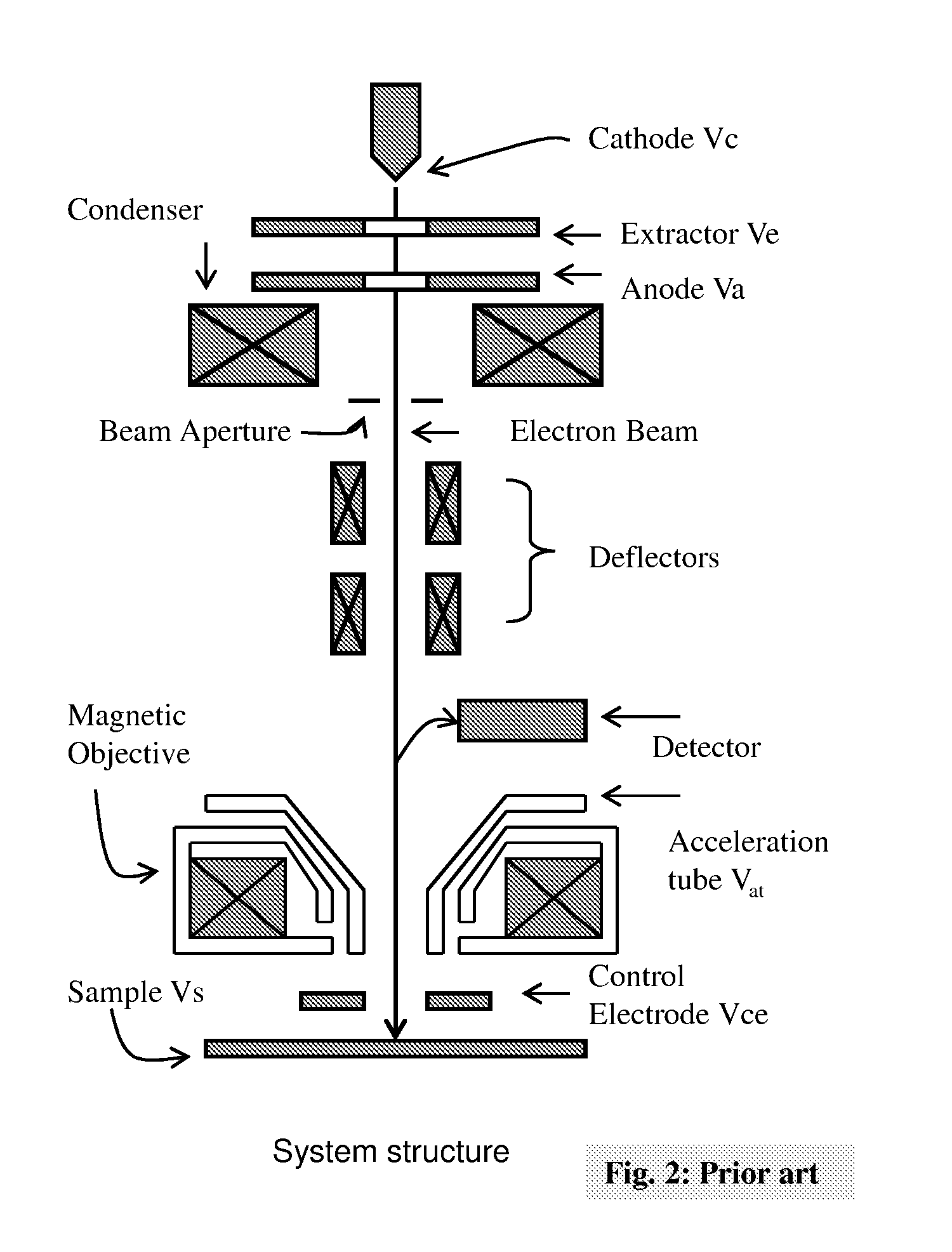

Electron beam apparatus

InactiveUS7960697B2Improve imaging resolutionIncrease intensityThermometer detailsMaterial analysis using wave/particle radiationScanning tunneling microscopeScanning electron microscope

The present invention relates to a charged particle beam apparatus which employs a scanning electron microscope for sample inspection and defect review.The present invent provides solution of improving imaging resolution by utilizing a field emission cathode tip with a large tip radius, applying a large accelerating voltage across ground potential between the cathode and anode, positioning the beam limit aperture before condenser lens, utilizing condenser lens excitation current to optimize image resolution, applying a high tube bias to shorten electron travel time, adopting and modifying SORIL objective lens to ameliorate aberration at large field of view and under electric drifting and reduce the urgency of water cooling objective lens while operating material analysis.The present invent provides solution of improving throughput by utilizing fast scanning ability of SORIL and providing a large voltage difference between sample and detectors.

Owner:ASML NETHERLANDS BV

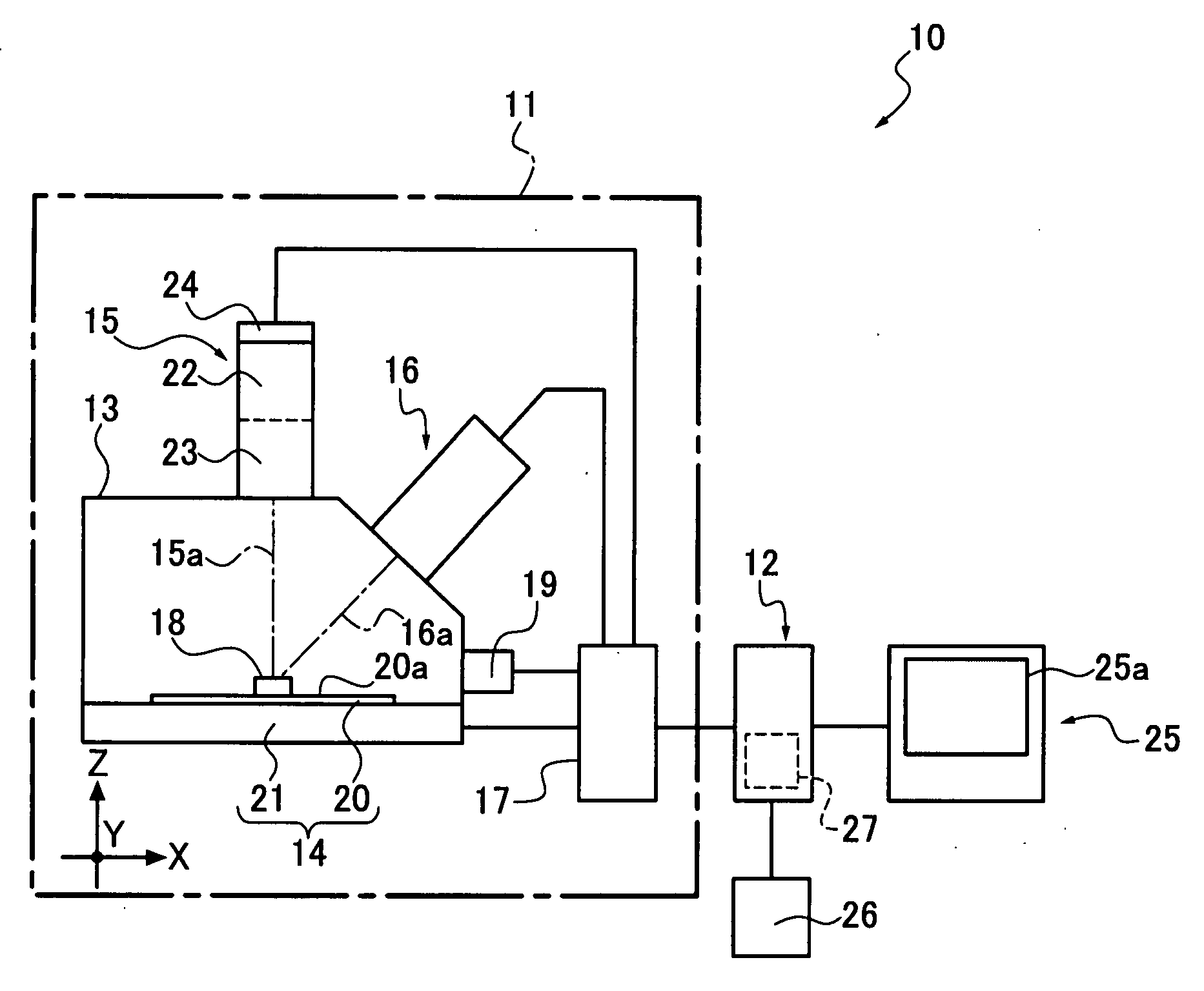

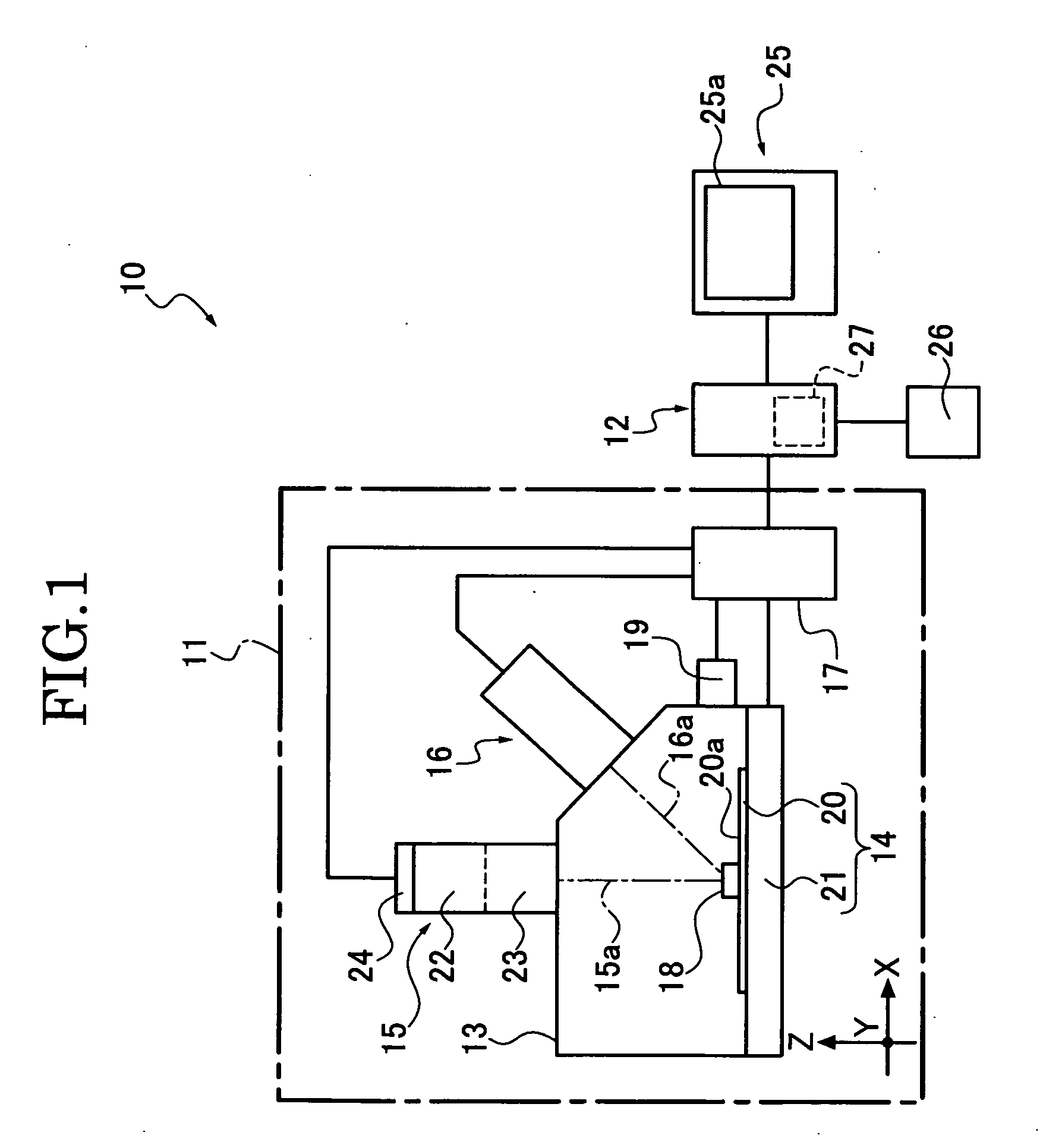

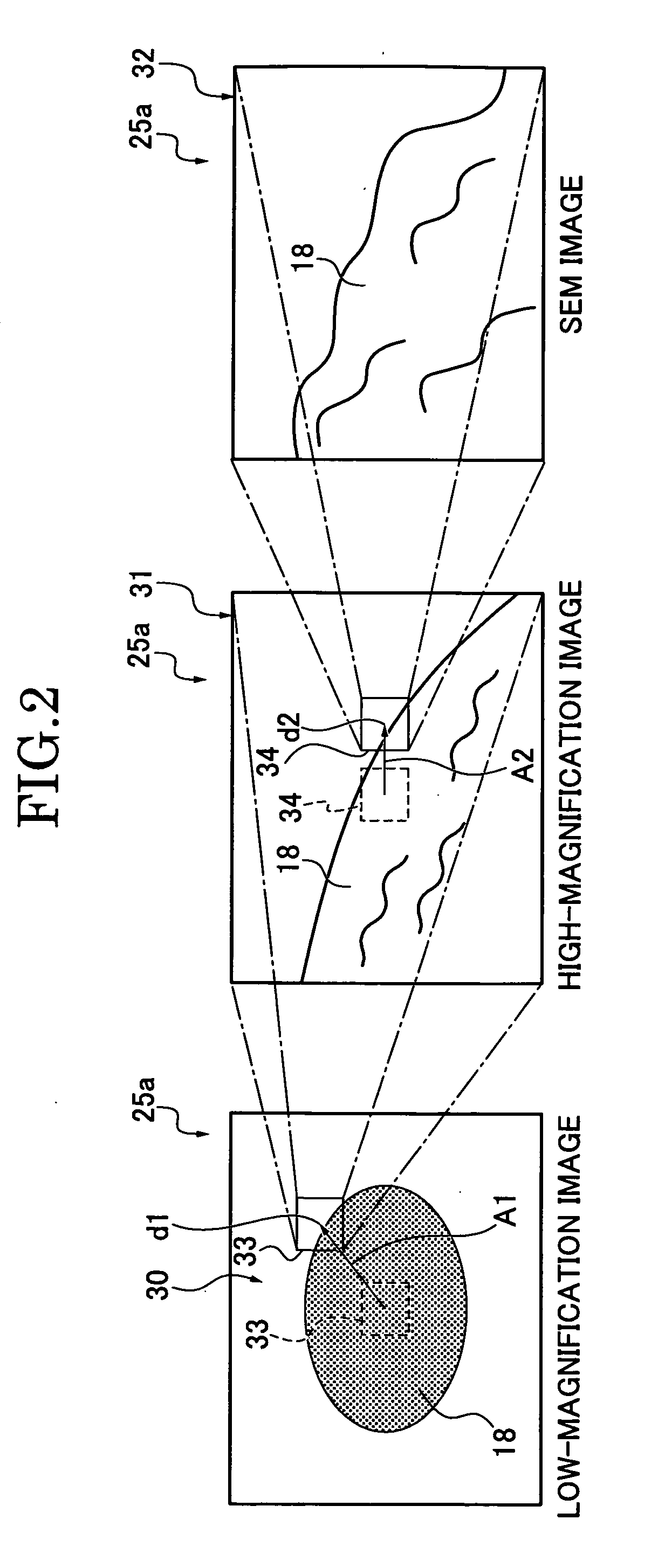

Complex type microscopic device

InactiveUS20100091362A1Accurate observationMaterial analysis using wave/particle radiationElectric discharge tubesMicroscopic imageComplex type

A complex type microscopic device includes a slider unit moving a stage, an optical microscope, a scanning electron microscope with an electron axis intersecting with an optical axis of the optical microscope, an optical measurement / observation unit having a magnification between those of the scanning electron microscope and the optical microscope and co-using an objective lens with the optical microscope, and a control unit controlling the entire device, and a display unit having a display screen. During display of a low-magnification optical microscopic image, the control unit controls the display unit to display, on the image, a representation to designate an area to be observed at a magnification of the optical measurement / observation unit, and to display, on the image, another representation to designate an area to be observed at a magnification of the scanning electron microscope during display of a high-magnification optical microscopic image.

Owner:HORIBA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com