Patents

Literature

673 results about "Dual beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

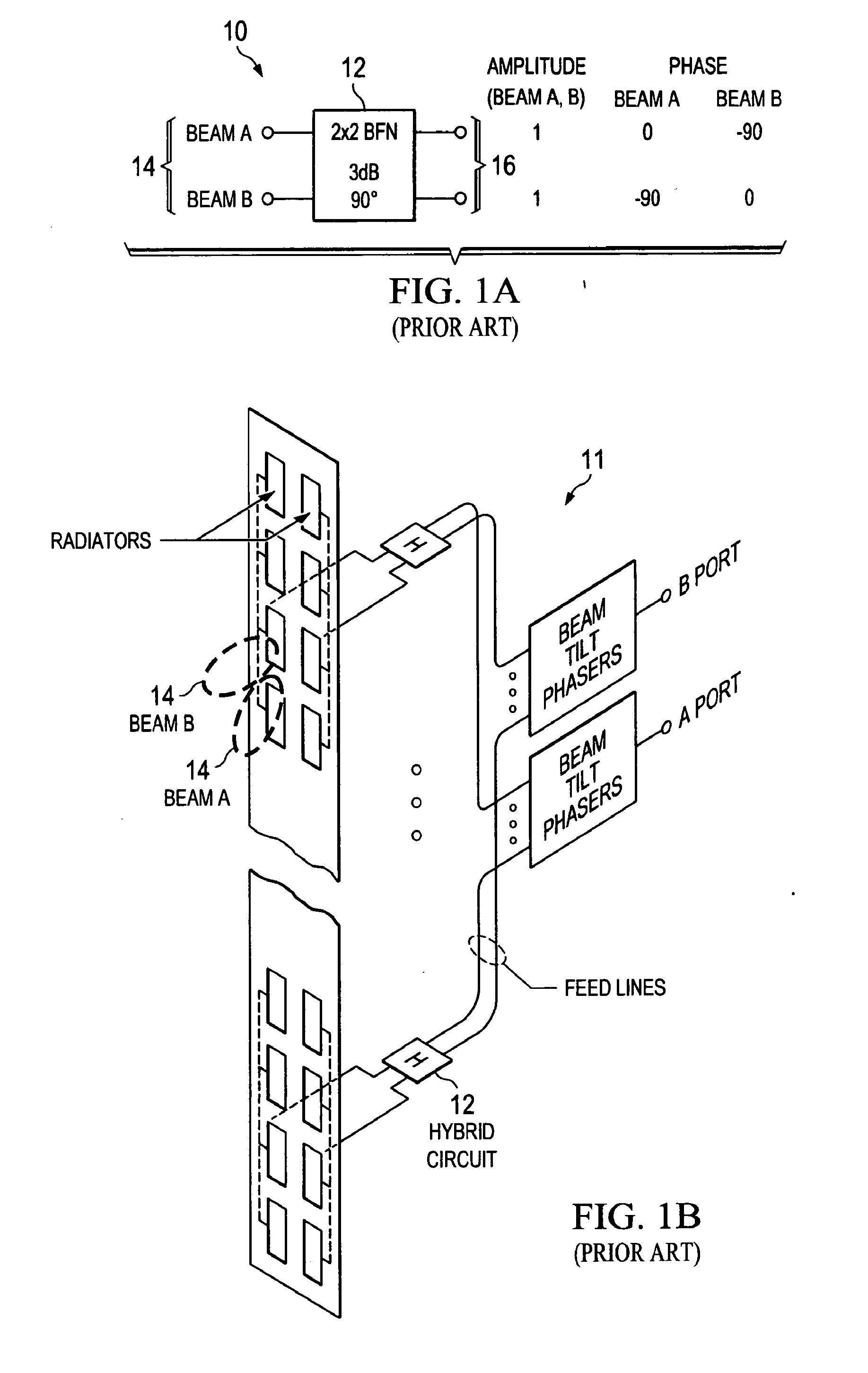

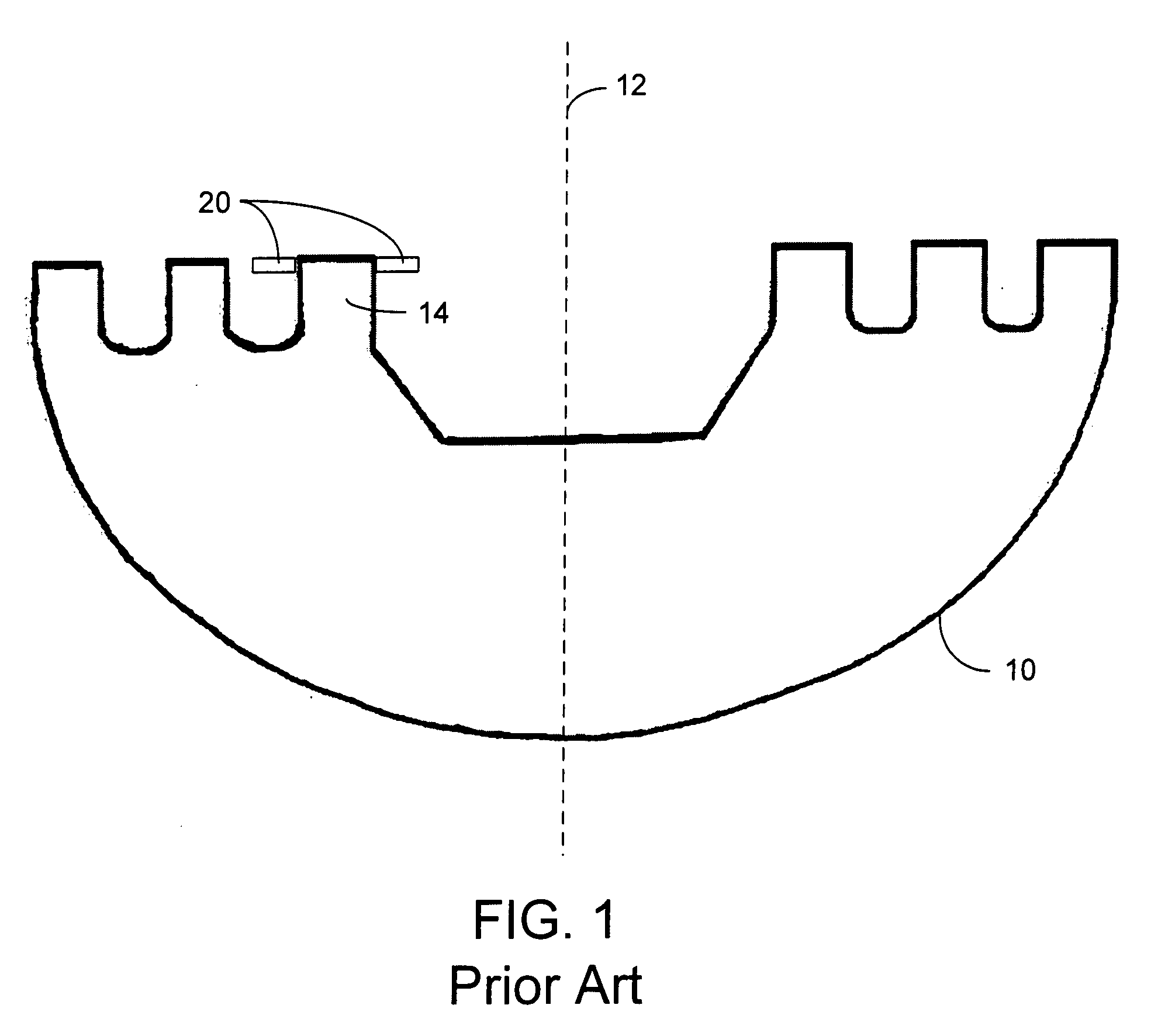

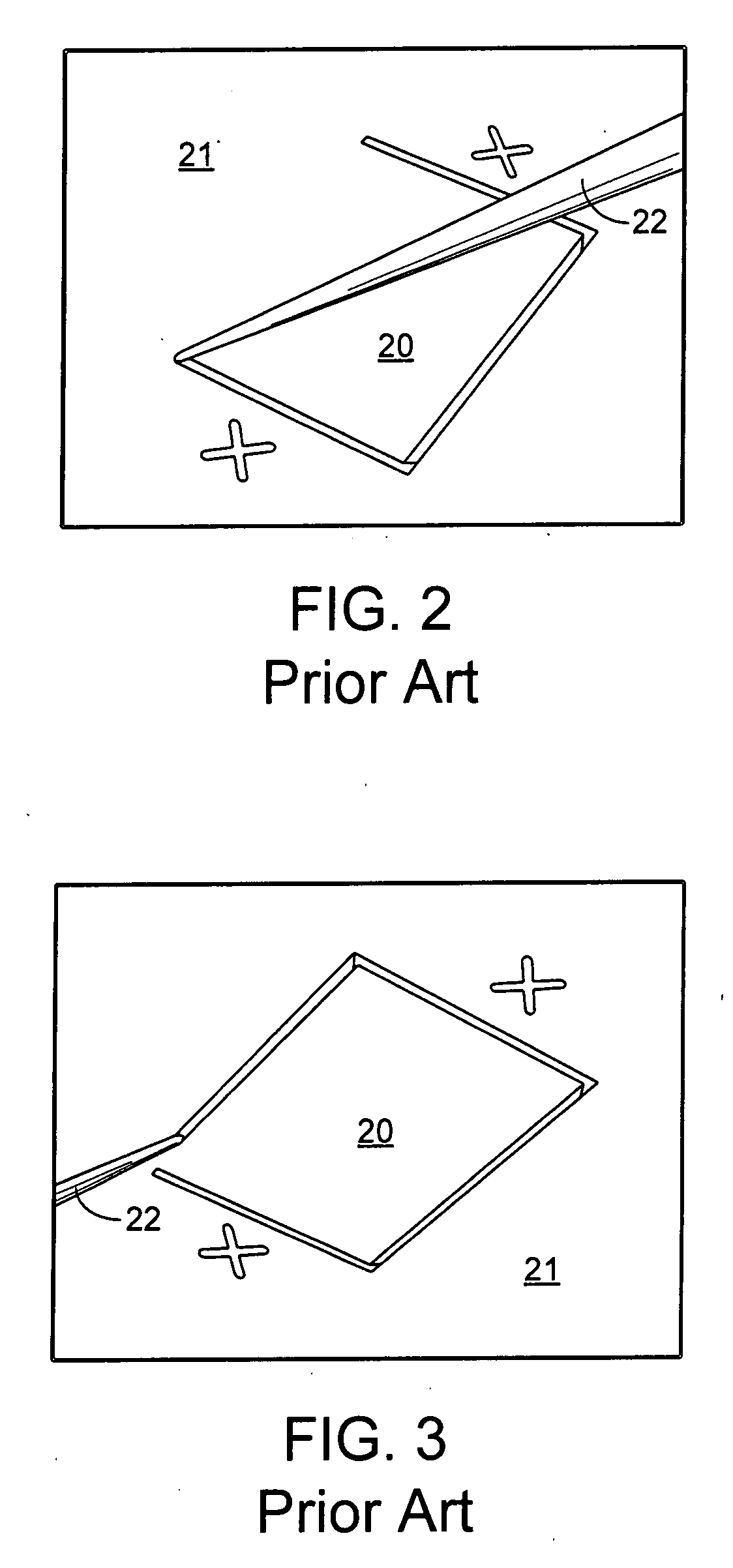

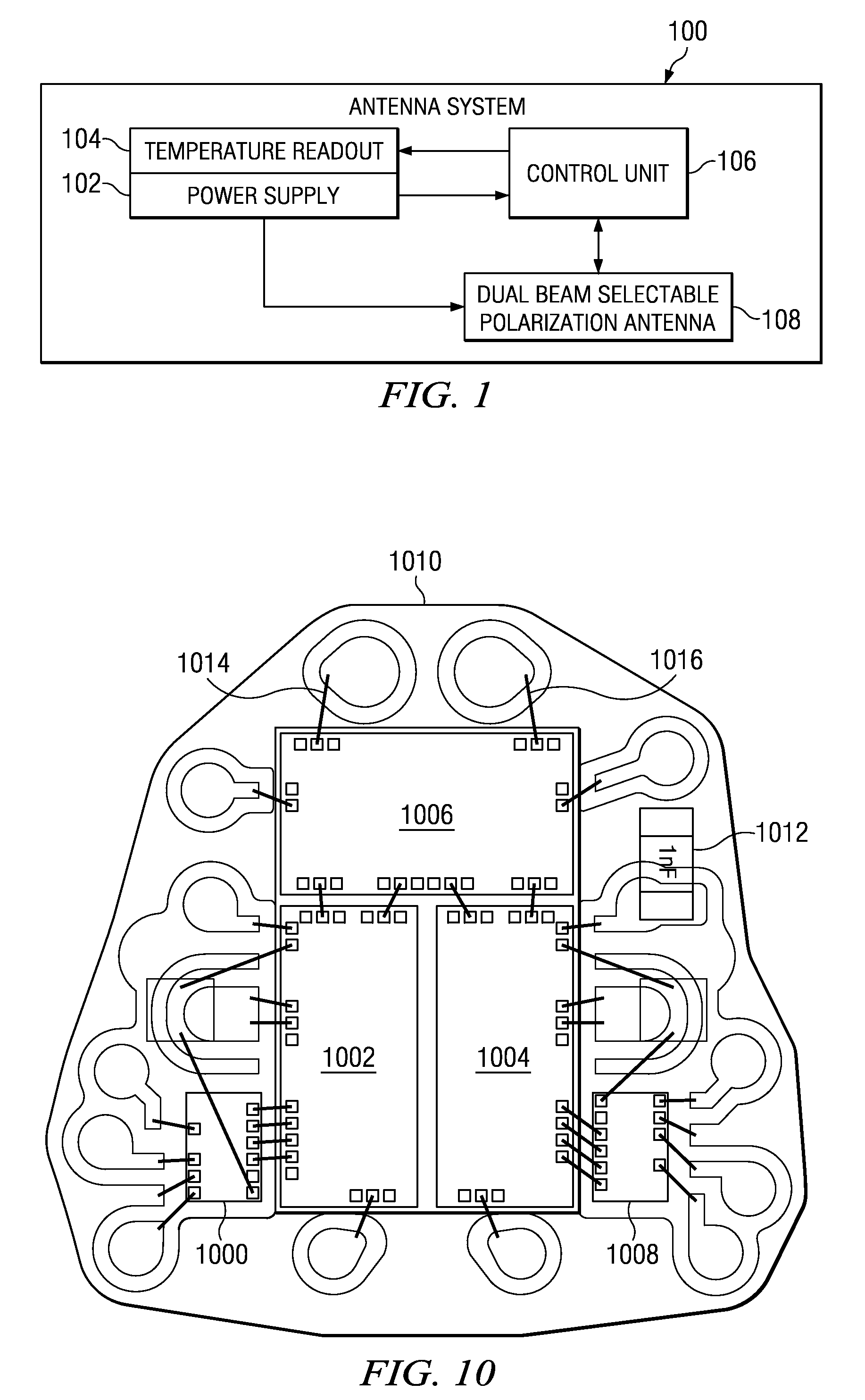

Electronically agile dual beam antenna system

InactiveUS6768456B1Reduce needSimple and reliable processAntenna adaptation in movable bodiesIndividually energised antenna arraysDual beamMulti beam

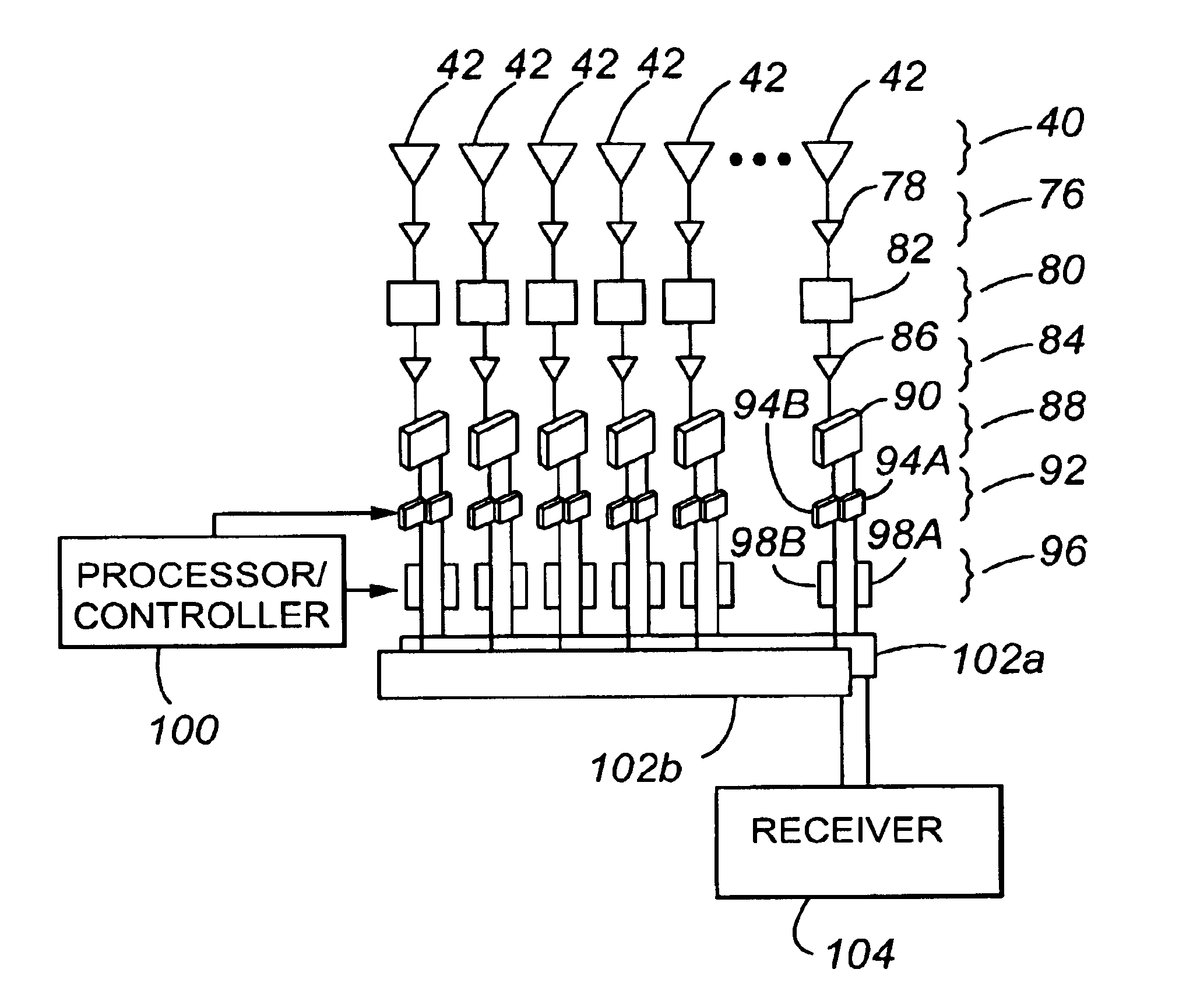

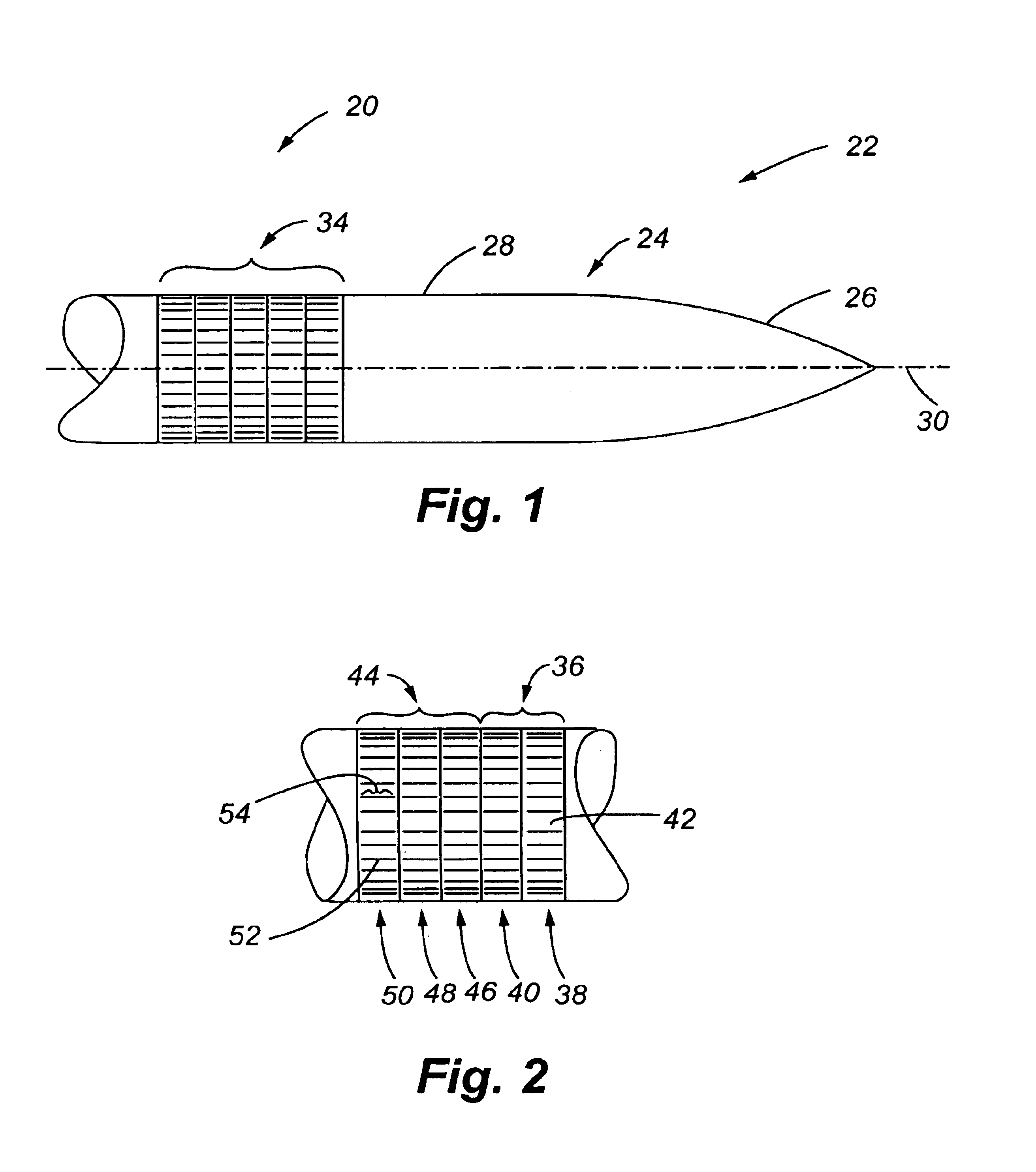

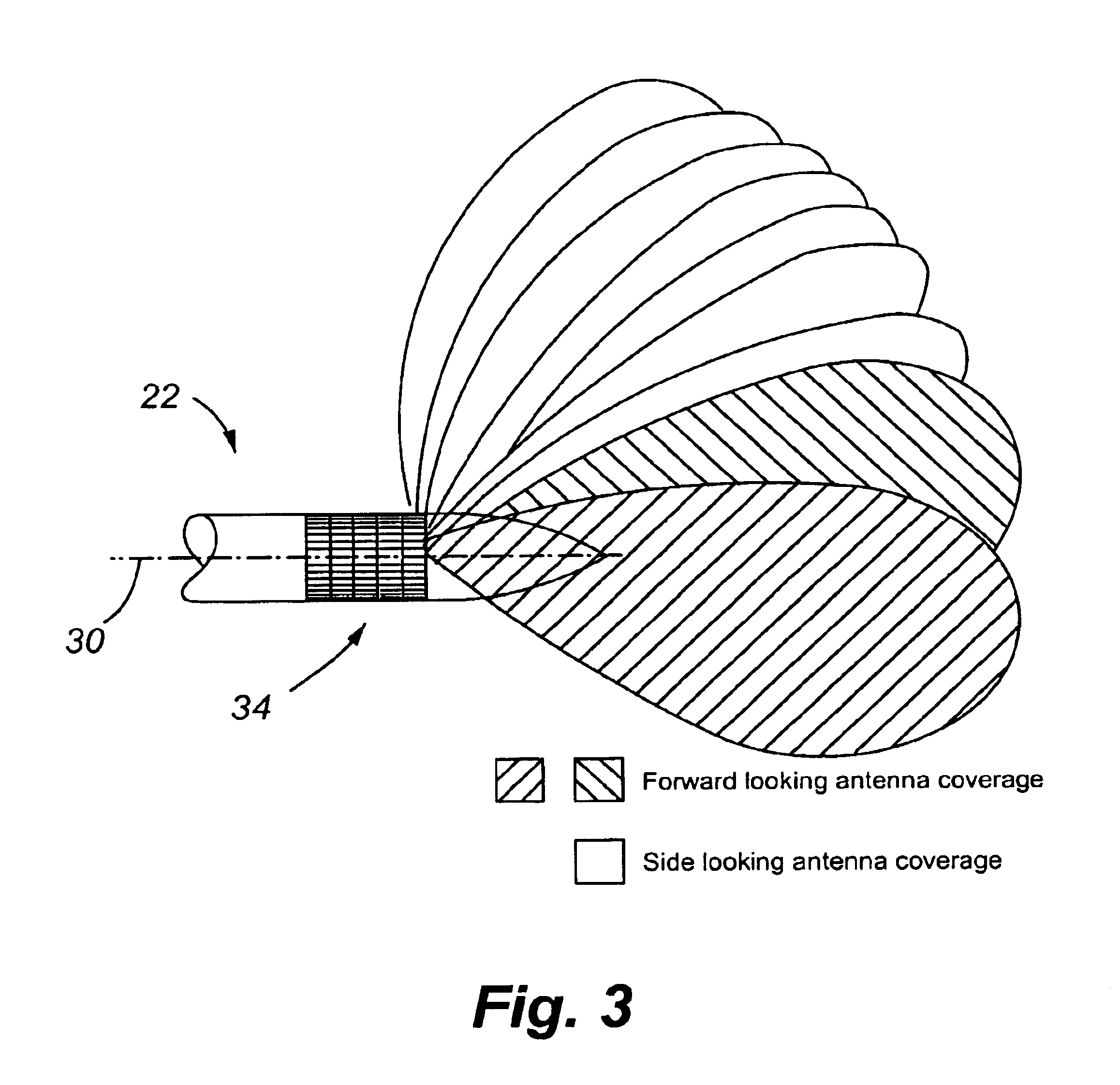

The present invention provides an improved antenna system that, in one embodiment, includes an antenna array comprised of a plurality of elements, each of which is capable of providing a signal. Also included in the improved antenna system is a multi-beam beamformer for producing two spatially independent overlapping beams from the signals provided by two different subsets of the antenna array. The phase of the two beams is compared to realize an interferometer that can provide high or fine resolution data on the position of an object relative to the antenna system. The amplitude of the two beams can also be compared to obtain coarse data on the position of the object. The beamformer includes a switching network for selecting which elements of the antenna array form the two subsets. This permits, for example, the position of the beams to moved, the baseline of the two beams to be varied, and / or the beam width of the beams to be altered. To reduce adverse aerodynamic effects in certain applications, the antenna array is located conformal to the exterior surface of the body on which the array is mounted. Further, to reduce temperature related problems associated with high speed movement of the body on which the array is located, the array is located on the side of the body, as opposed to the front of the body. The side location also provides space for other types of sensors that are preferably located adjacent to the front surface of the body.

Owner:BALL AEROSPACE & TECHNOLOGIES

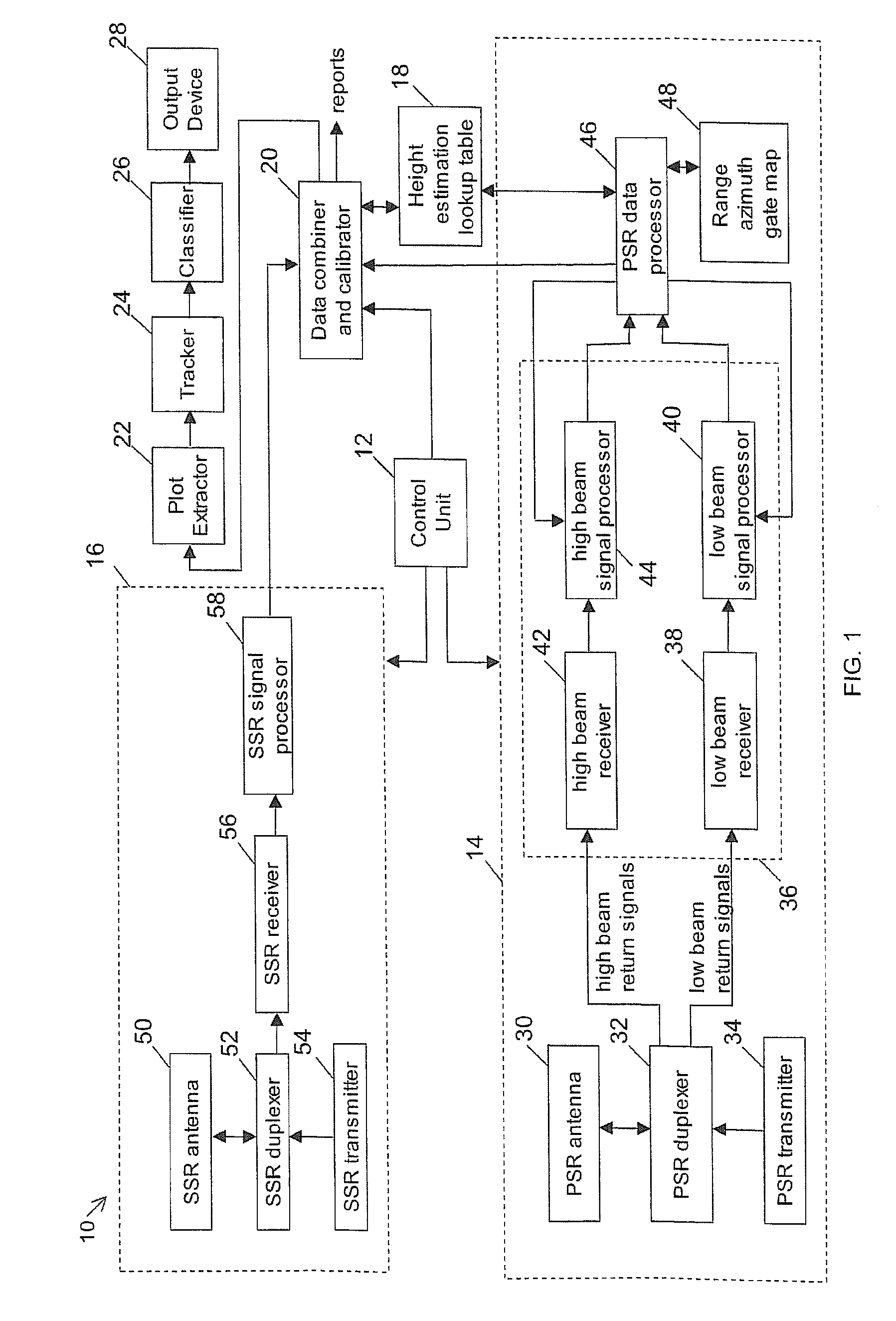

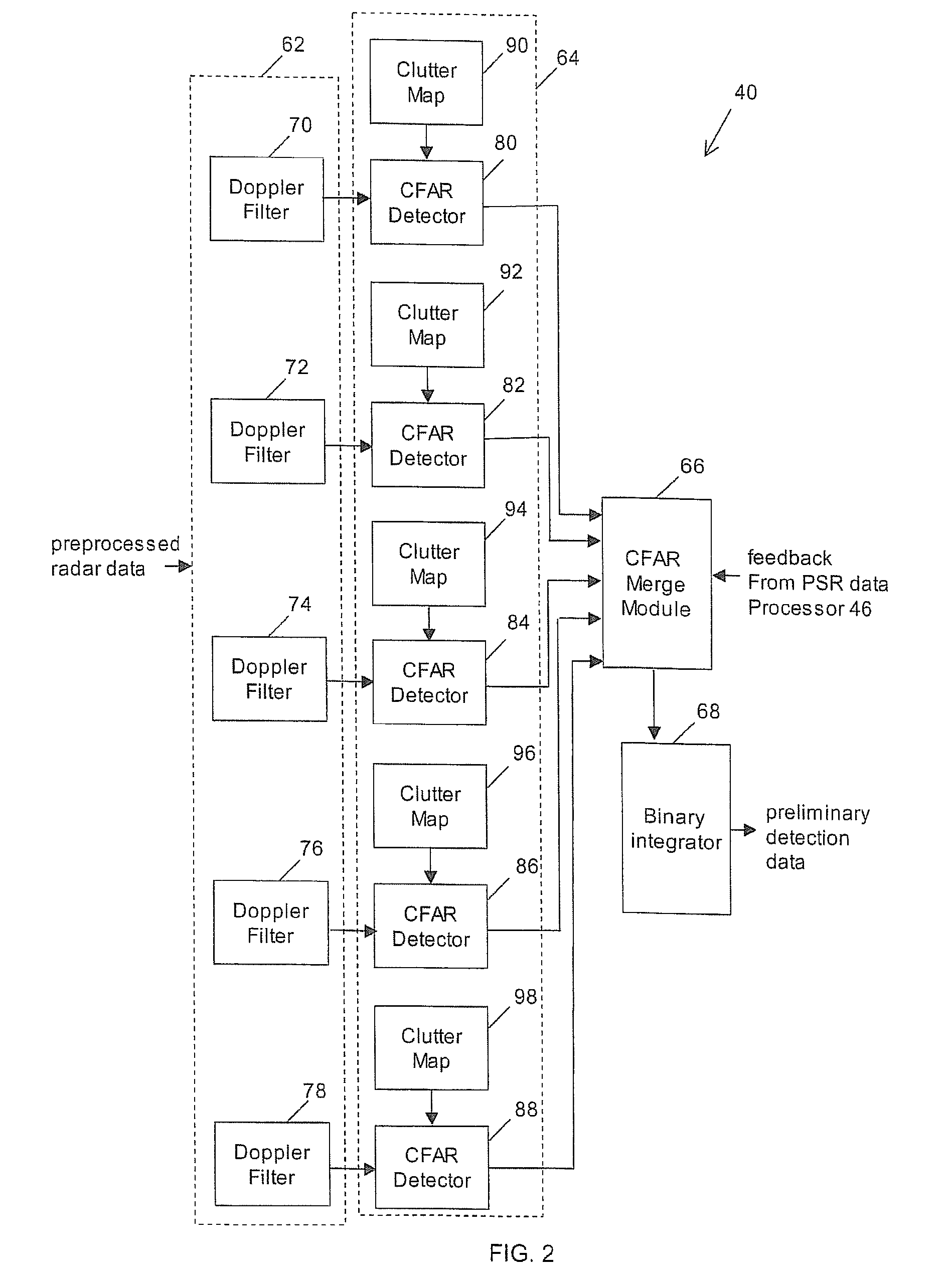

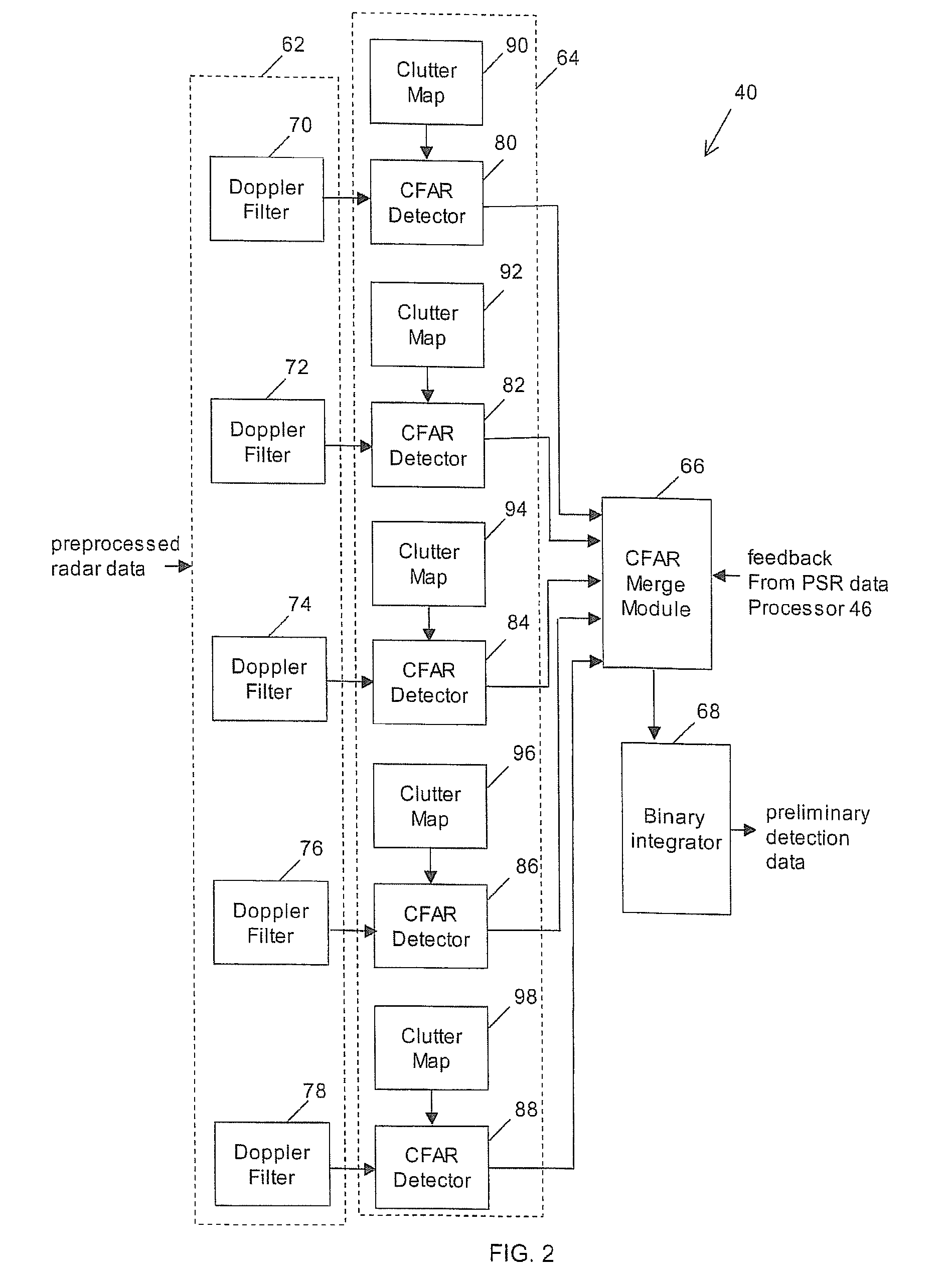

Dual beam radar system

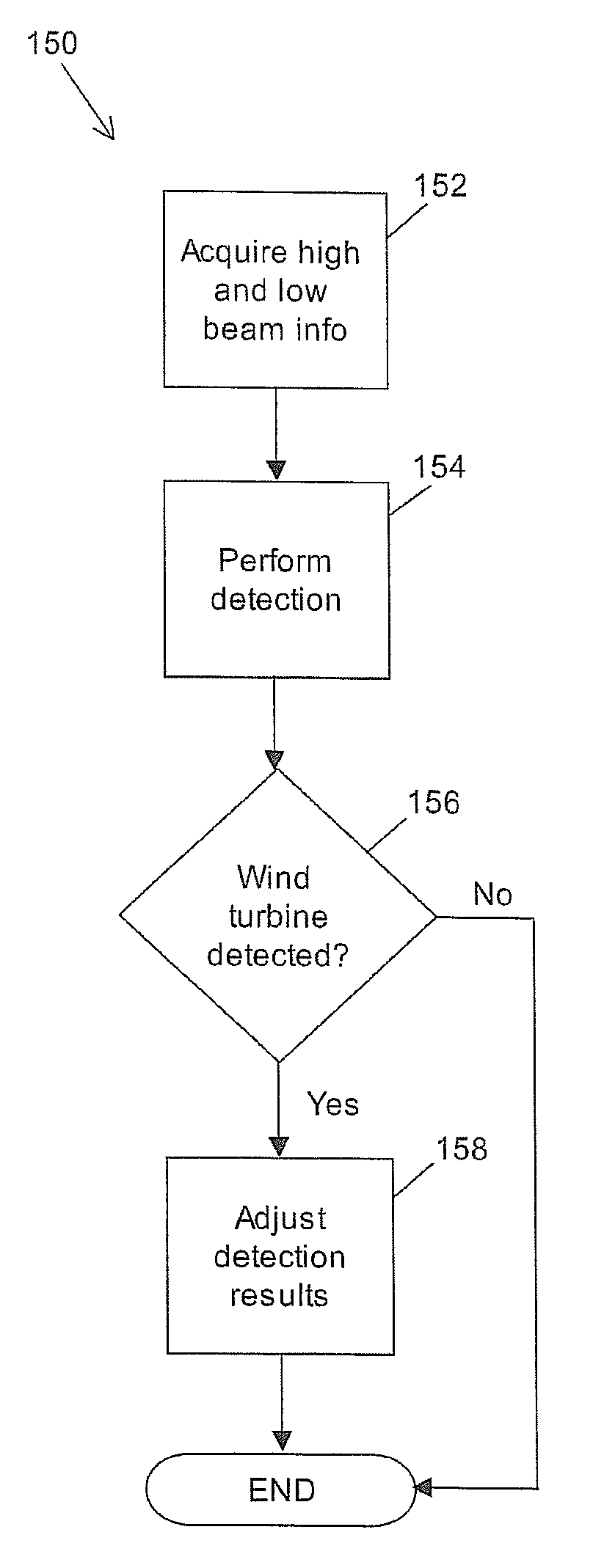

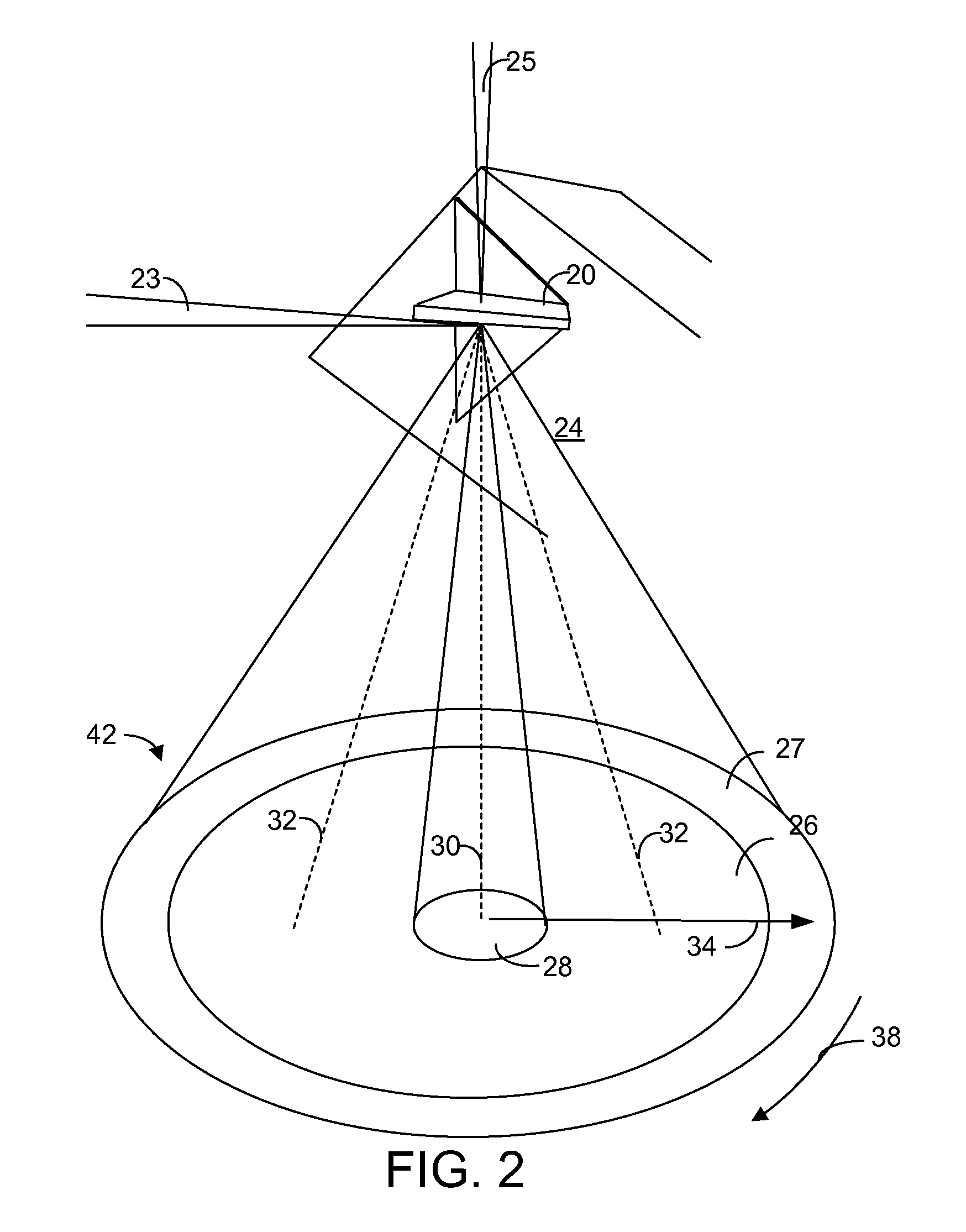

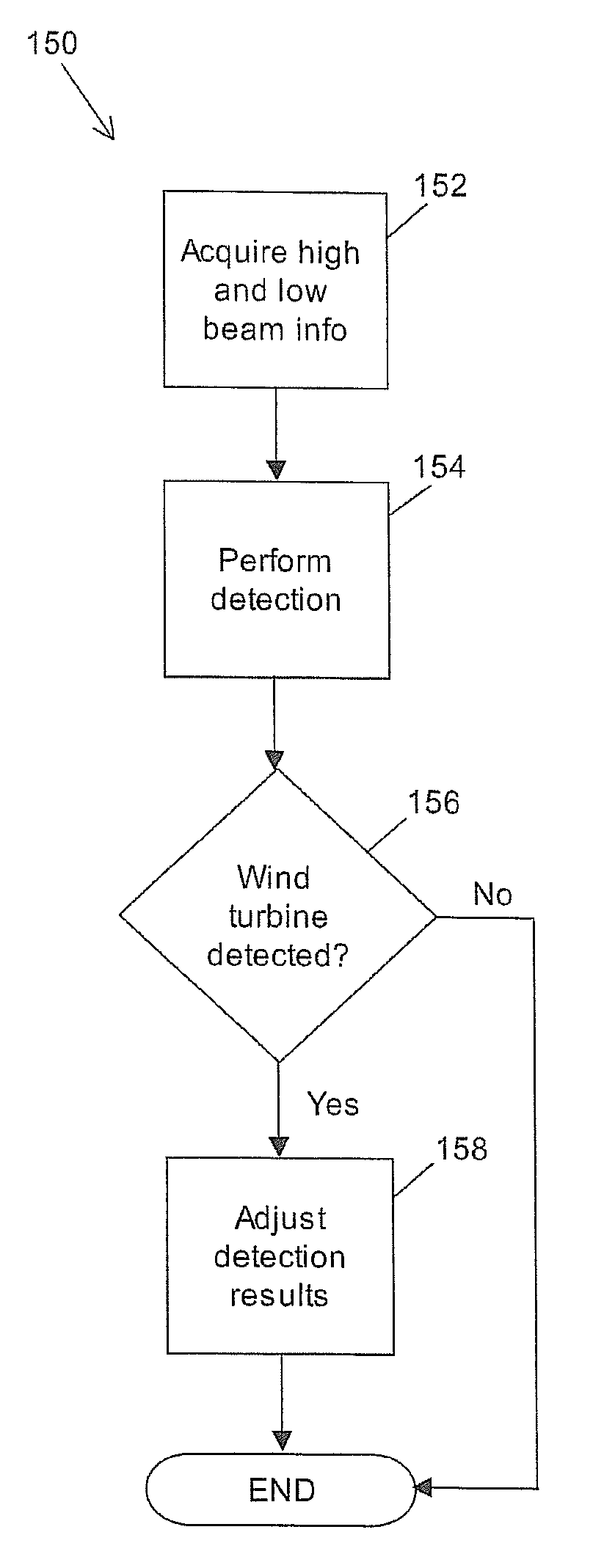

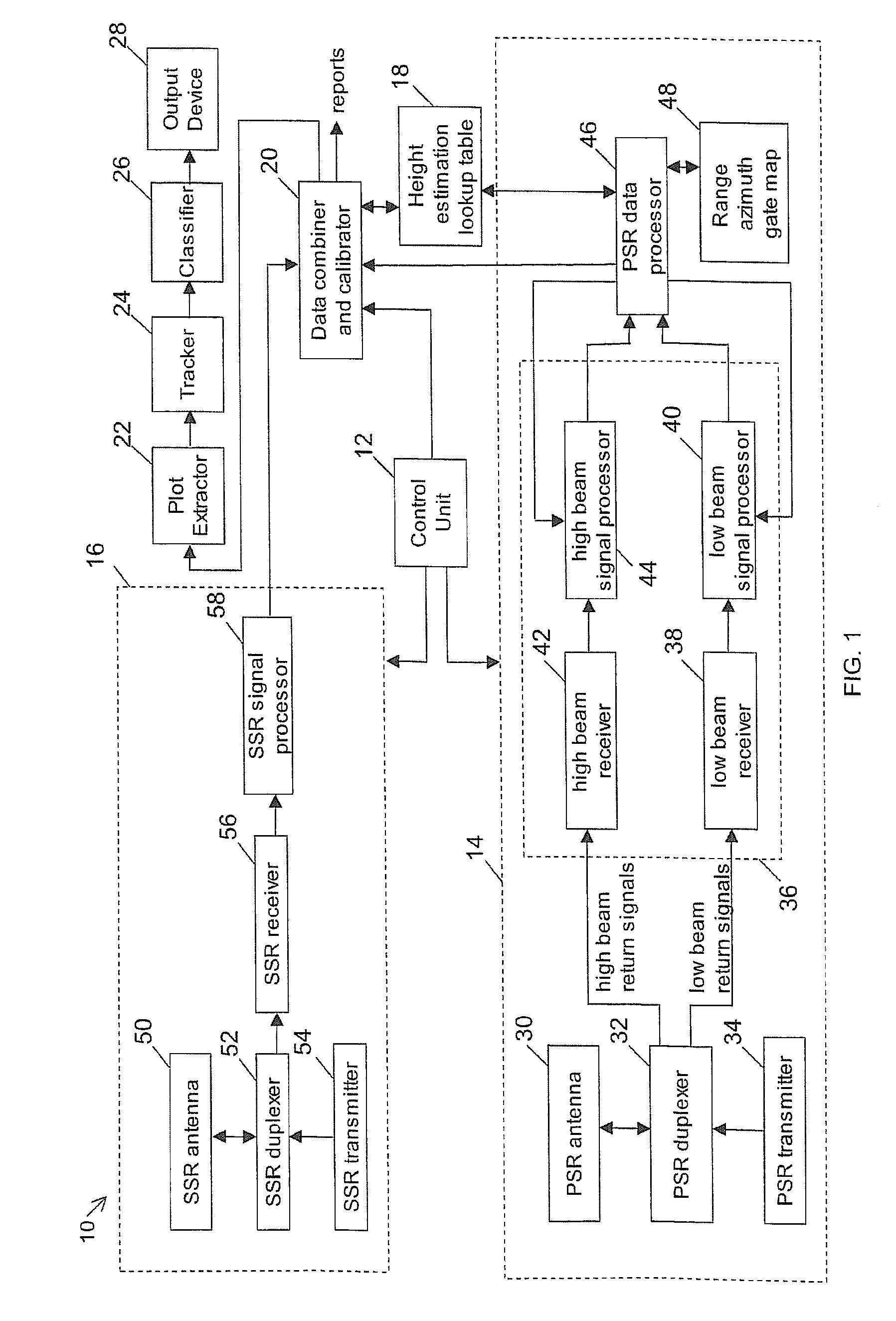

Various embodiments are described herein relating to a radar system and associated methods for detecting targets in the presence of certain types of clutter. The radar system generally comprises hardware operatively configured to obtain first and second sets of radar return signals concurrently, first circuitry operatively configured to detect targets in the first and second sets of radar return signals, and second circuitry operatively configured to identify detected targets due to clutter.

Owner:RAYTHEON CANADA LTD

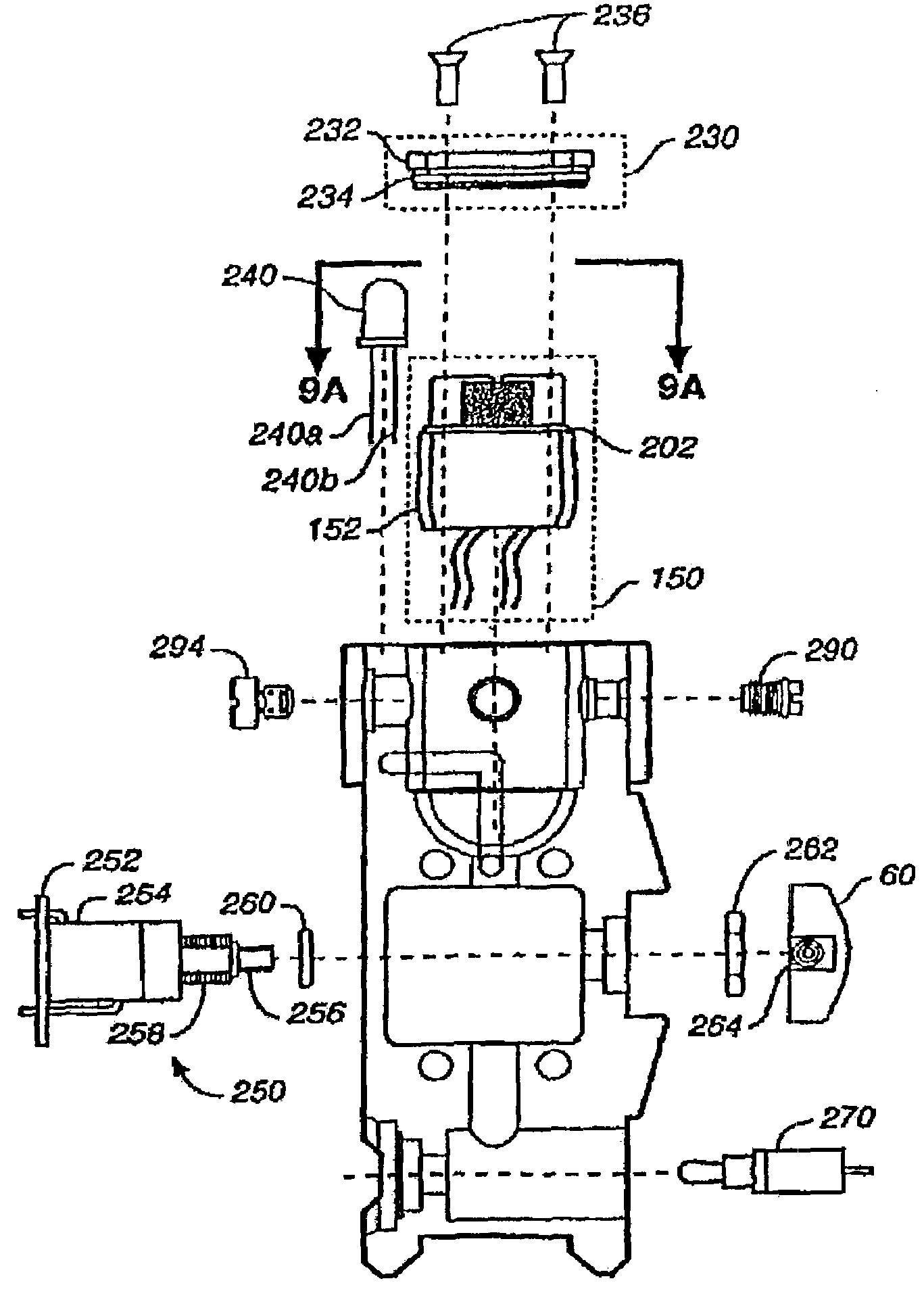

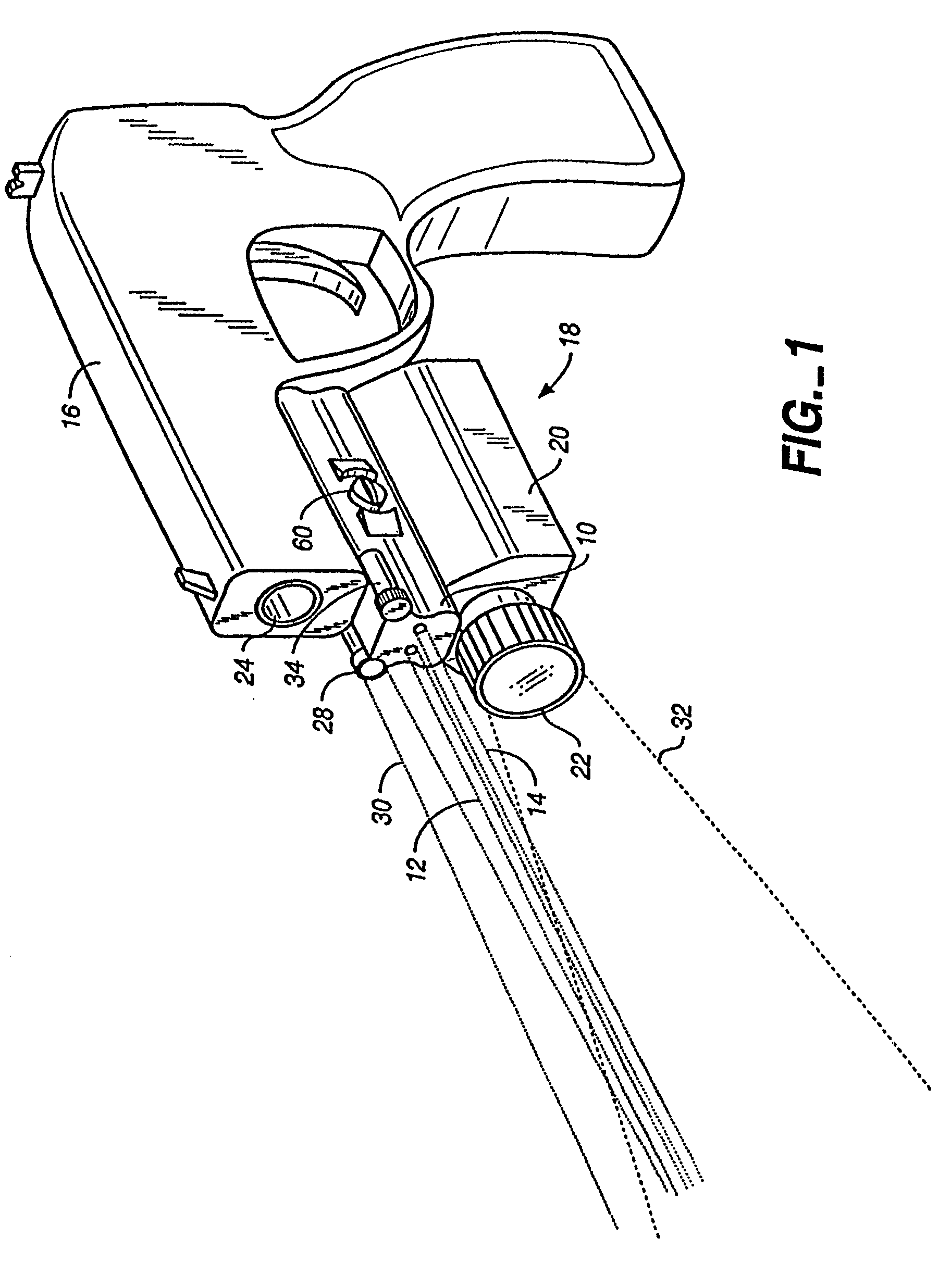

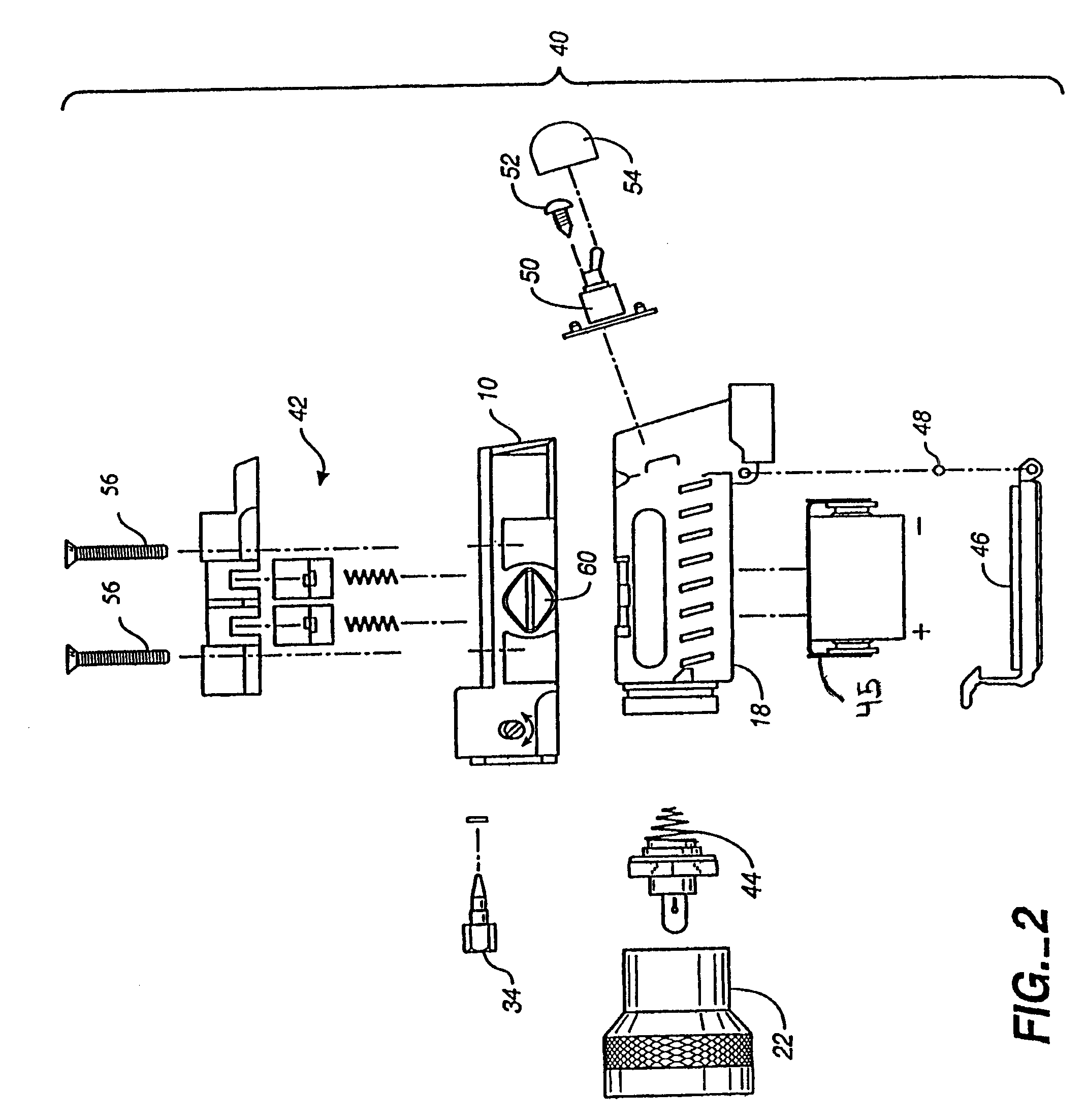

Dual beam laser module

A dual beam laser aiming module for a firearm has a dual-laser alignment housing with a first IR laser assembly in a first cavity and that provides a first beam axis. A second visible laser assembly is adjustably located in a second cavity to provide a second beam having an axis parallel to the first beam axis. A housing for the dual-laser alignment housing is adapted to be fixed to the firearm. The dual-laser alignment housing has a rounded exterior surface that interfaces with a corresponding rounded surface in the interior of the cavity of the laser housing. The dual-laser alignment housing is adjustably pivoted with respect to the laser housing with a four-point laser alignment mechanism to align the parallel first and second axes further in parallel to a centerline of a barrel of the firearm.

Owner:STEINER EOPTICS INC

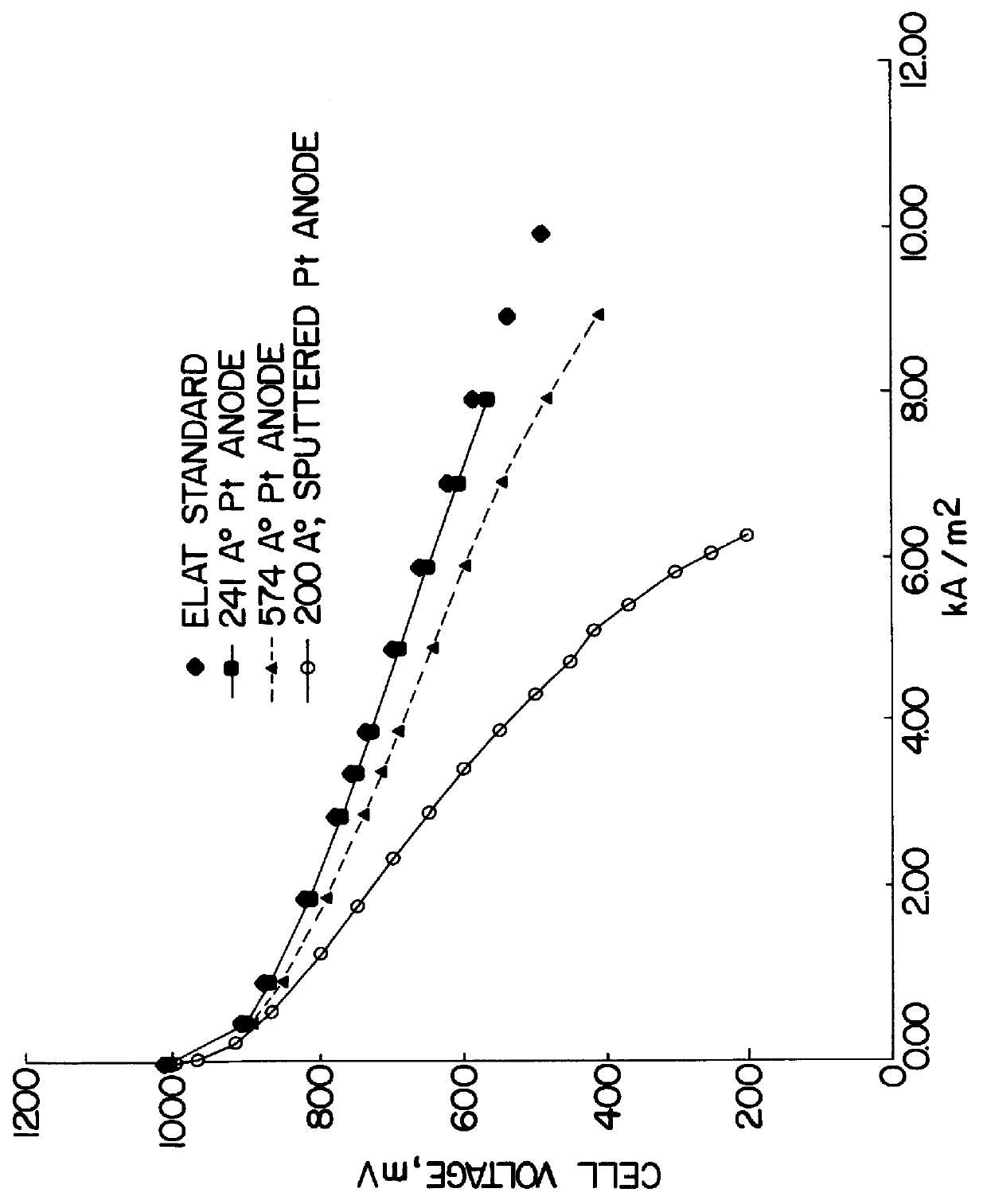

Method of forming robust metal, metal oxide, and metal alloy layers on ion-conductive polymer membranes

InactiveUS6077621AShort development timeLow costFinal product manufactureVacuum evaporation coatingConductive polymerElectron bunches

The invention is to a dual beam process for providing an ion-conducting membrane with a thin metal or metal-oxide film. The process includes the cleaning of a membrane surface with a low energy electron beam followed by the deposition of the metal or metal-oxide film by a high energy electron beam of ions.

Owner:BASF FUEL CELL

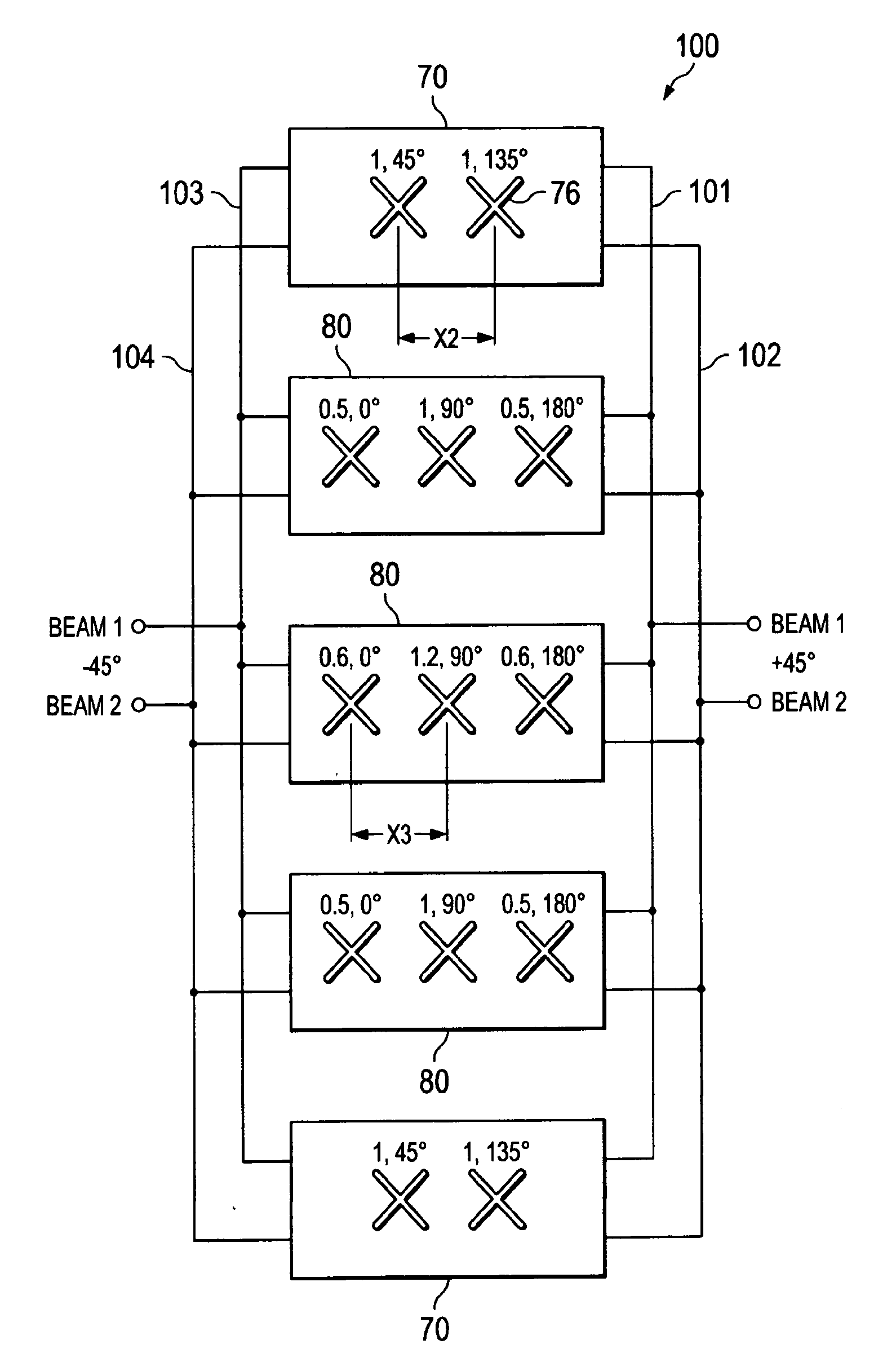

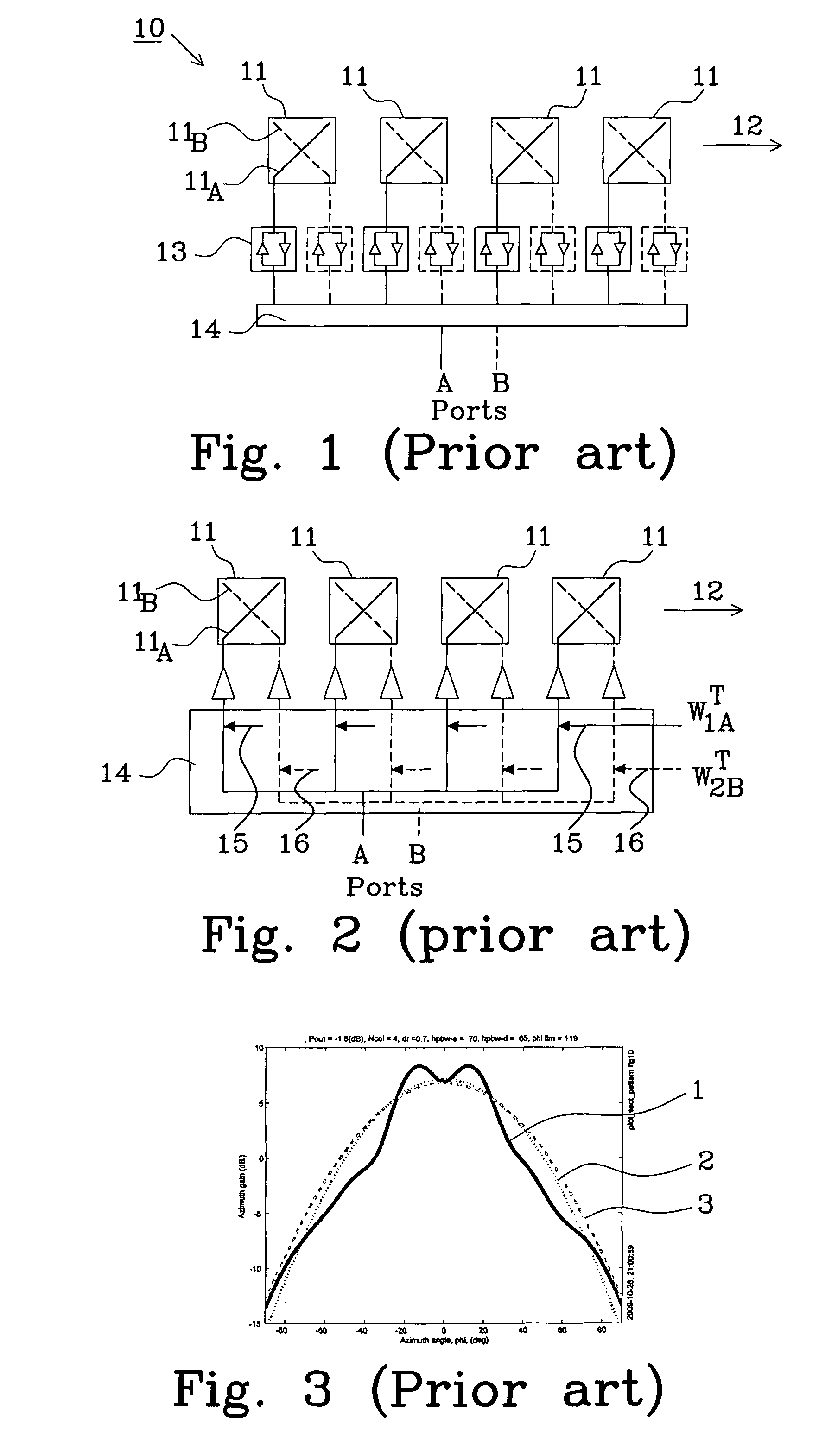

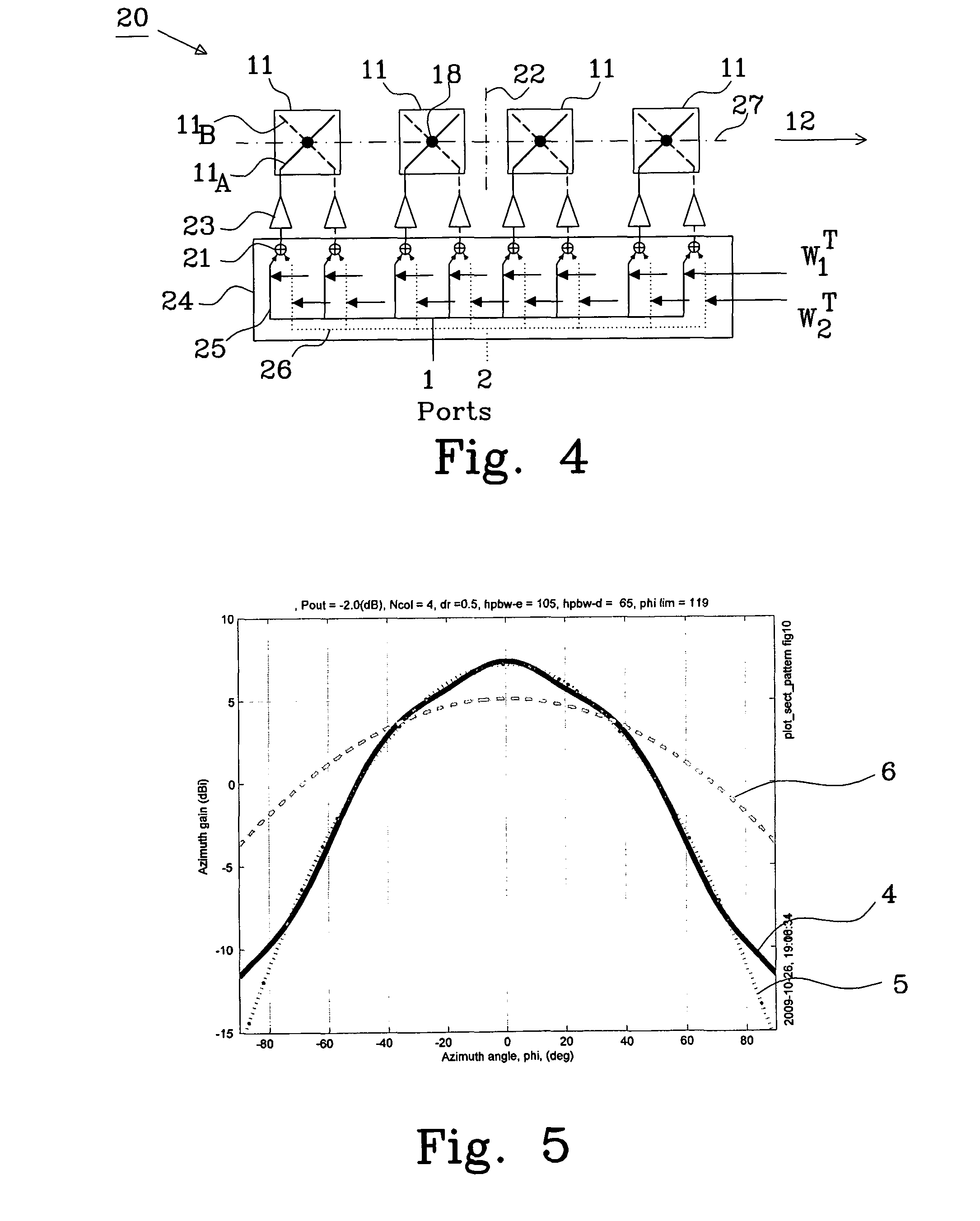

Dual-Beam Sector Antenna and Array

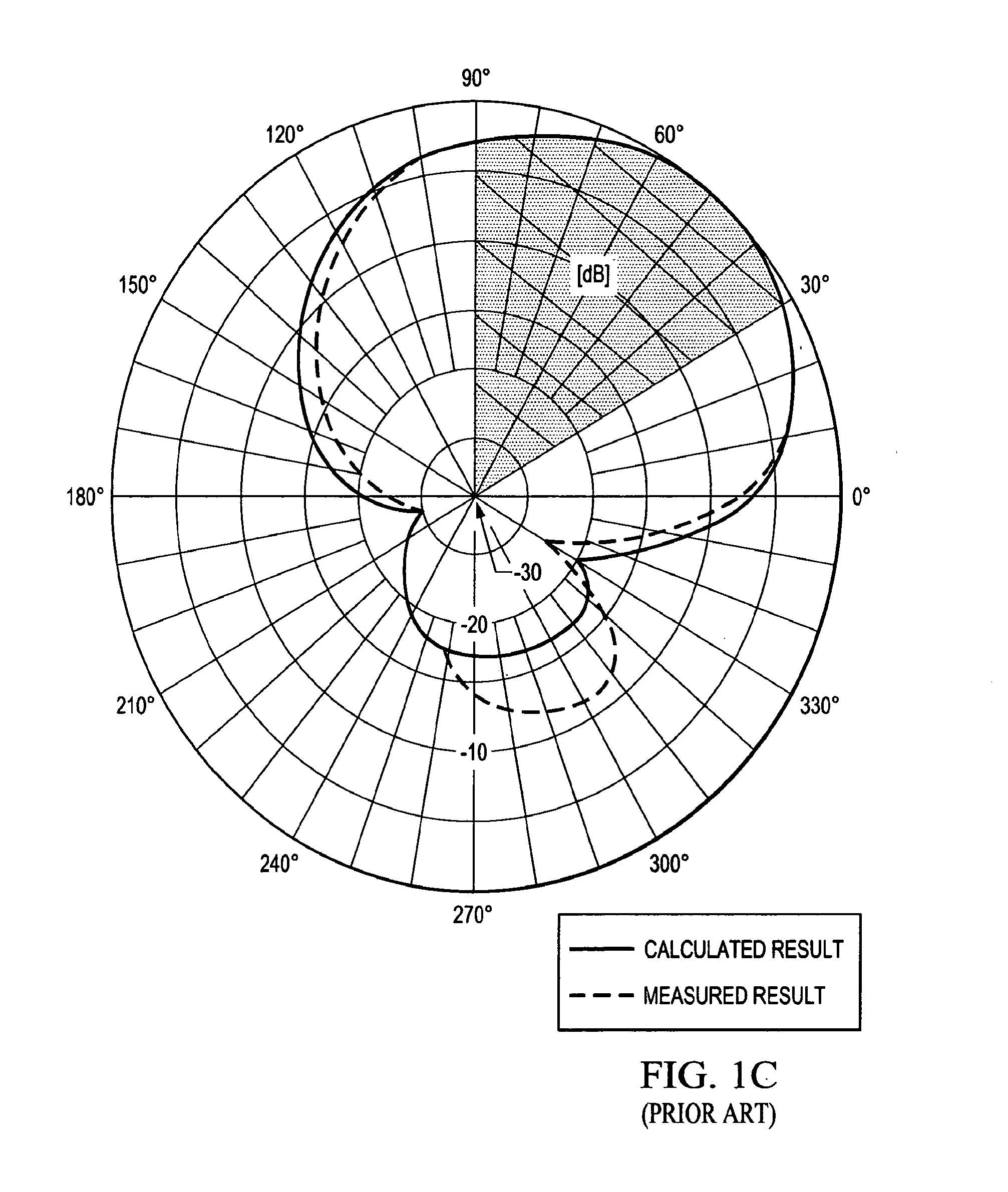

ActiveUS20110205119A1Less interferenceBetter cell efficiencyAntenna supports/mountingsIndividually energised antenna arraysDual beamSide lobe

A low sidelobe beam forming method and dual-beam antenna schematic are disclosed, which may preferably be used for 3-sector and 6-sector cellular communication system. Complete antenna combines 2-, 3- or -4 columns dual-beam sub-arrays (modules) with improved beam-forming network (BFN). The modules may be used as part of an array, or as an independent 2-beam antenna. By integrating different types of modules to form a complete array, the present invention provides an improved dual-beam antenna with improved azimuth sidelobe suppression in a wide frequency band of operation, with improved coverage of a desired cellular sector and with less interference being created with other cells. Advantageously, a better cell efficiency is realized with up to 95% of the radiated power being directed in a desired cellular sector.

Owner:COMMSCOPE TECH LLC

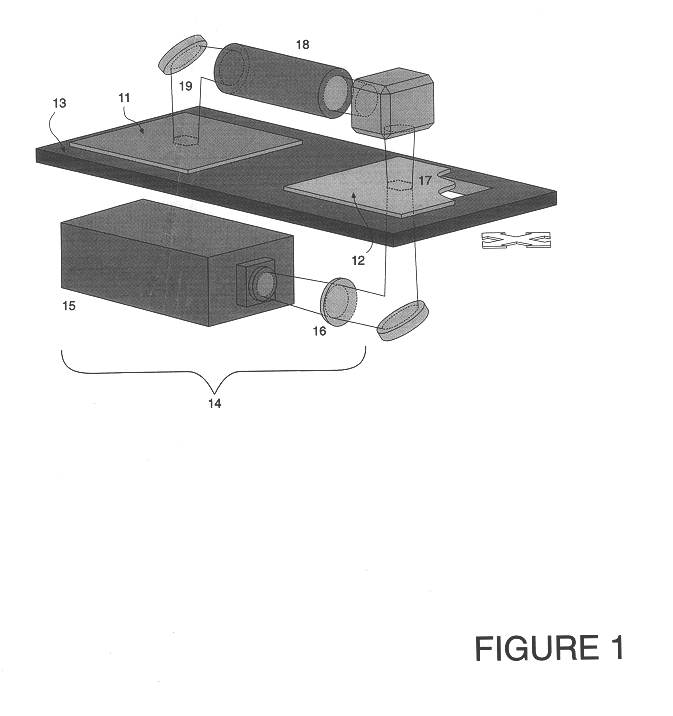

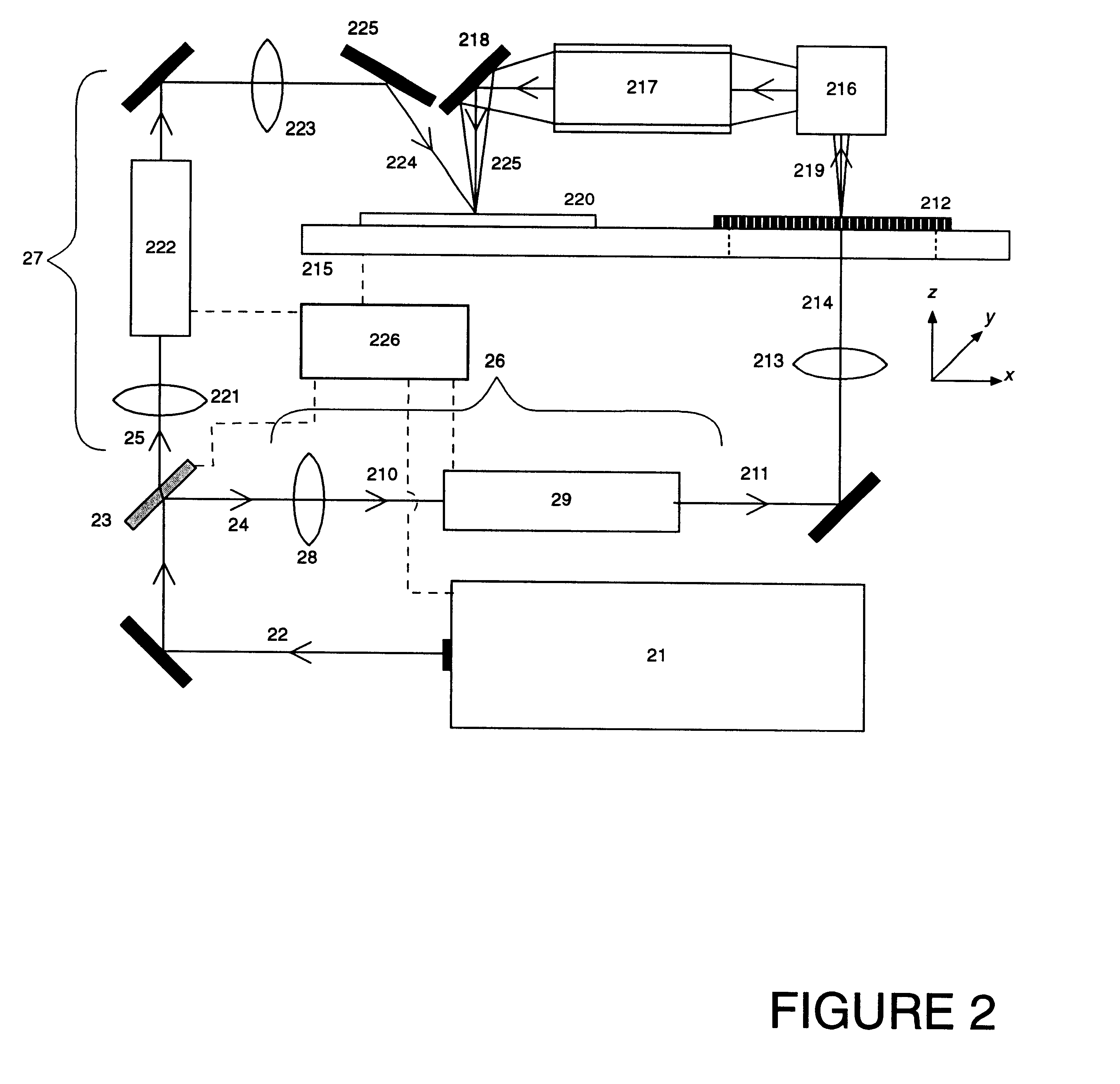

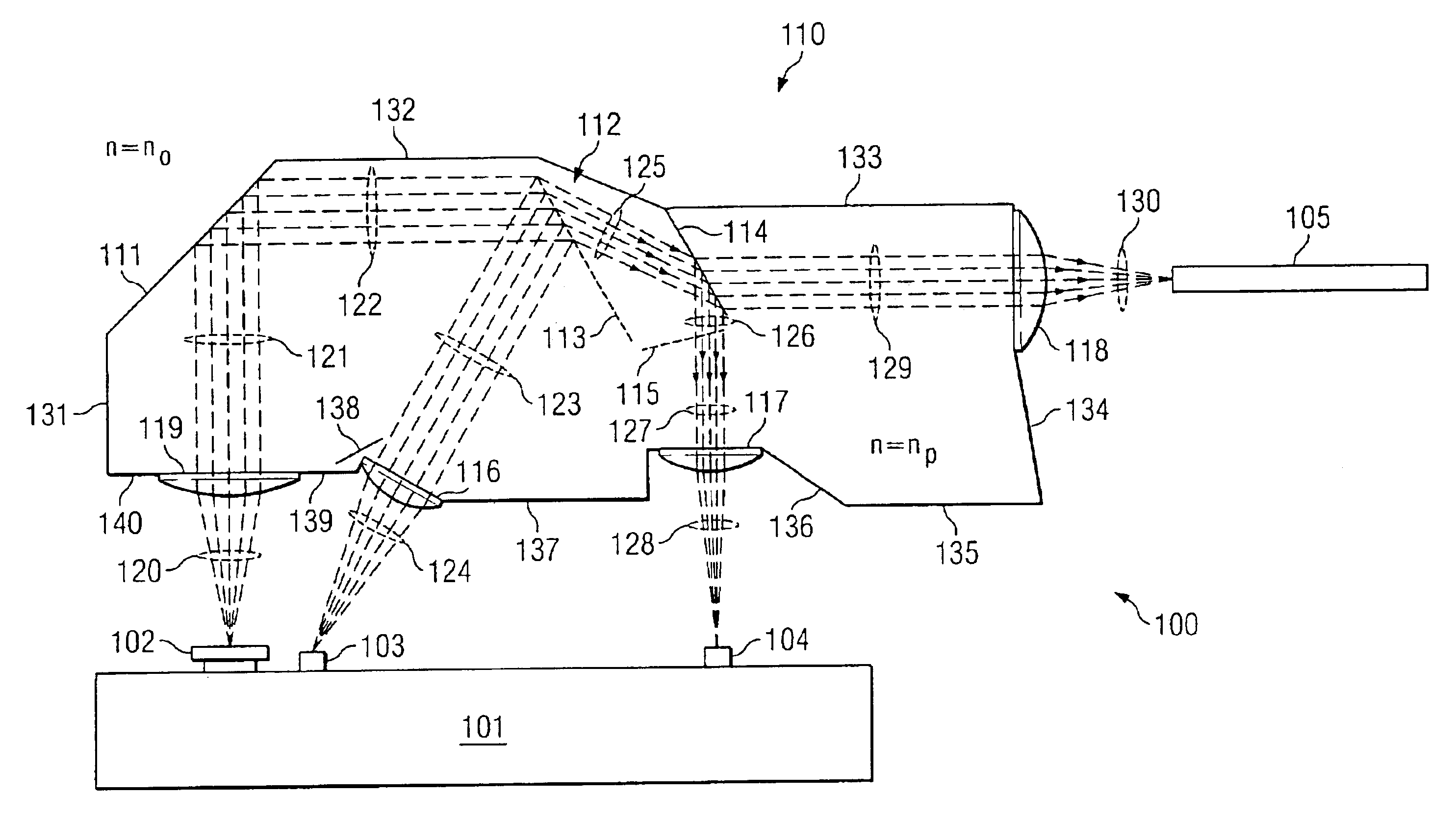

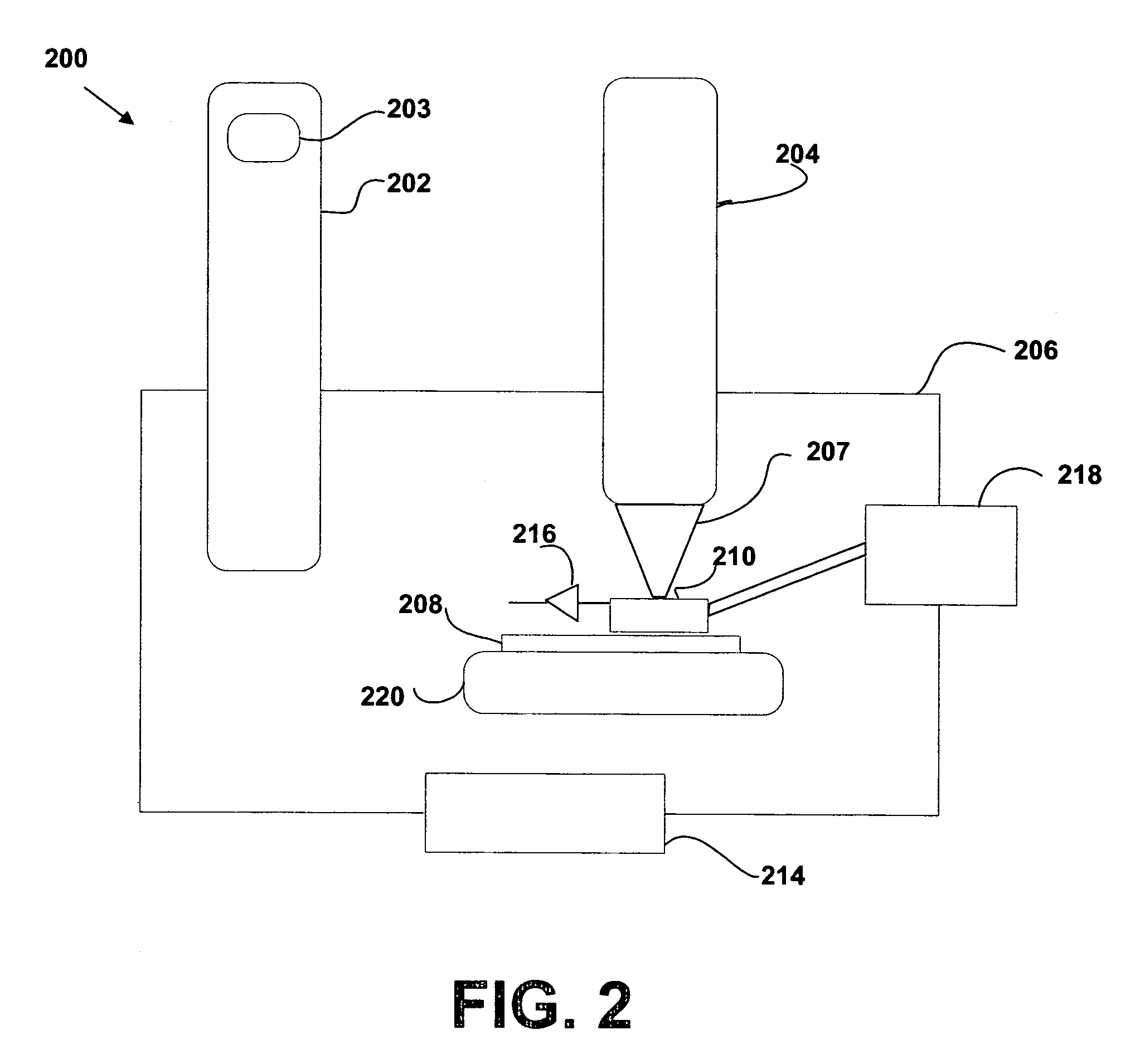

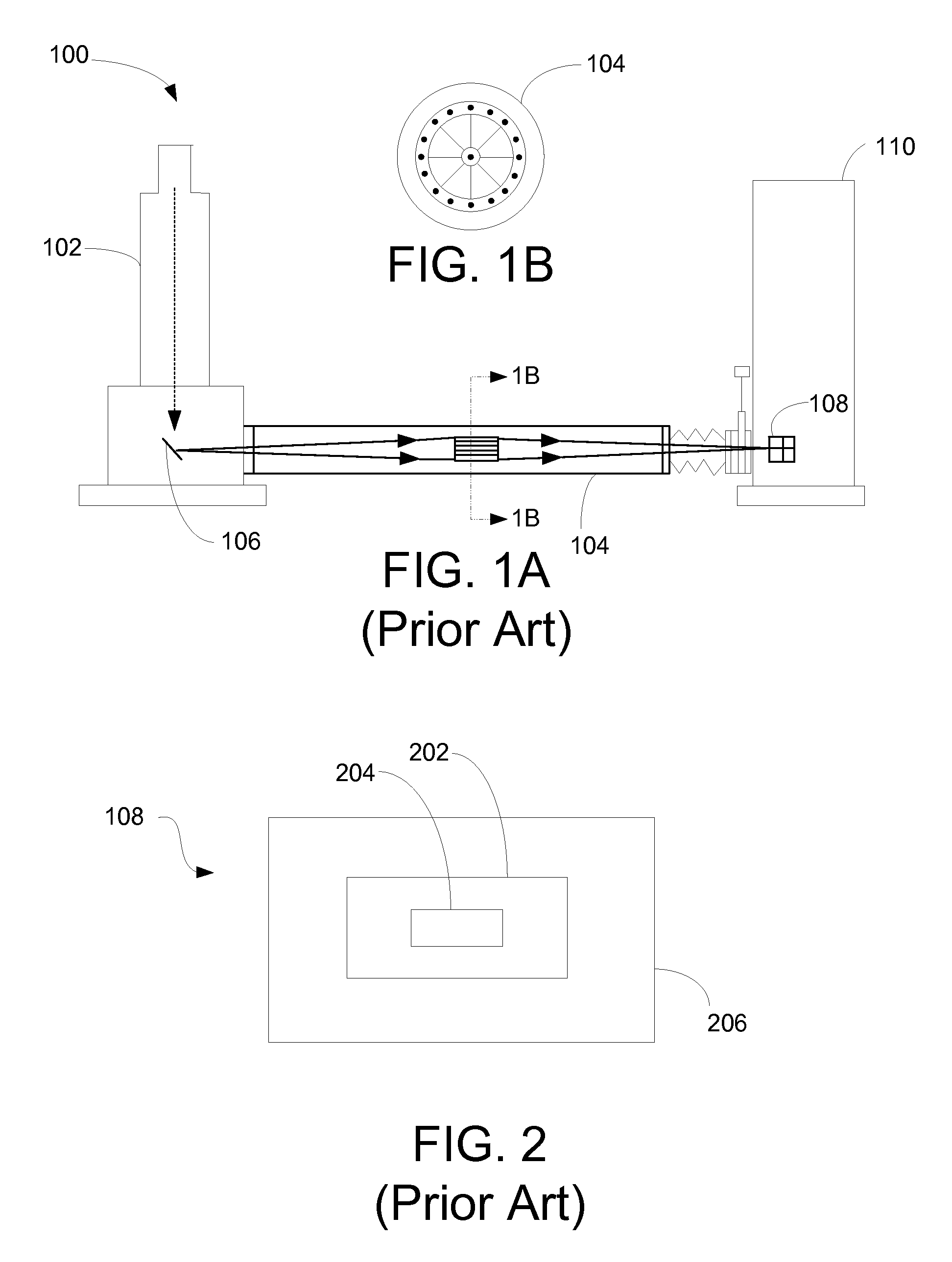

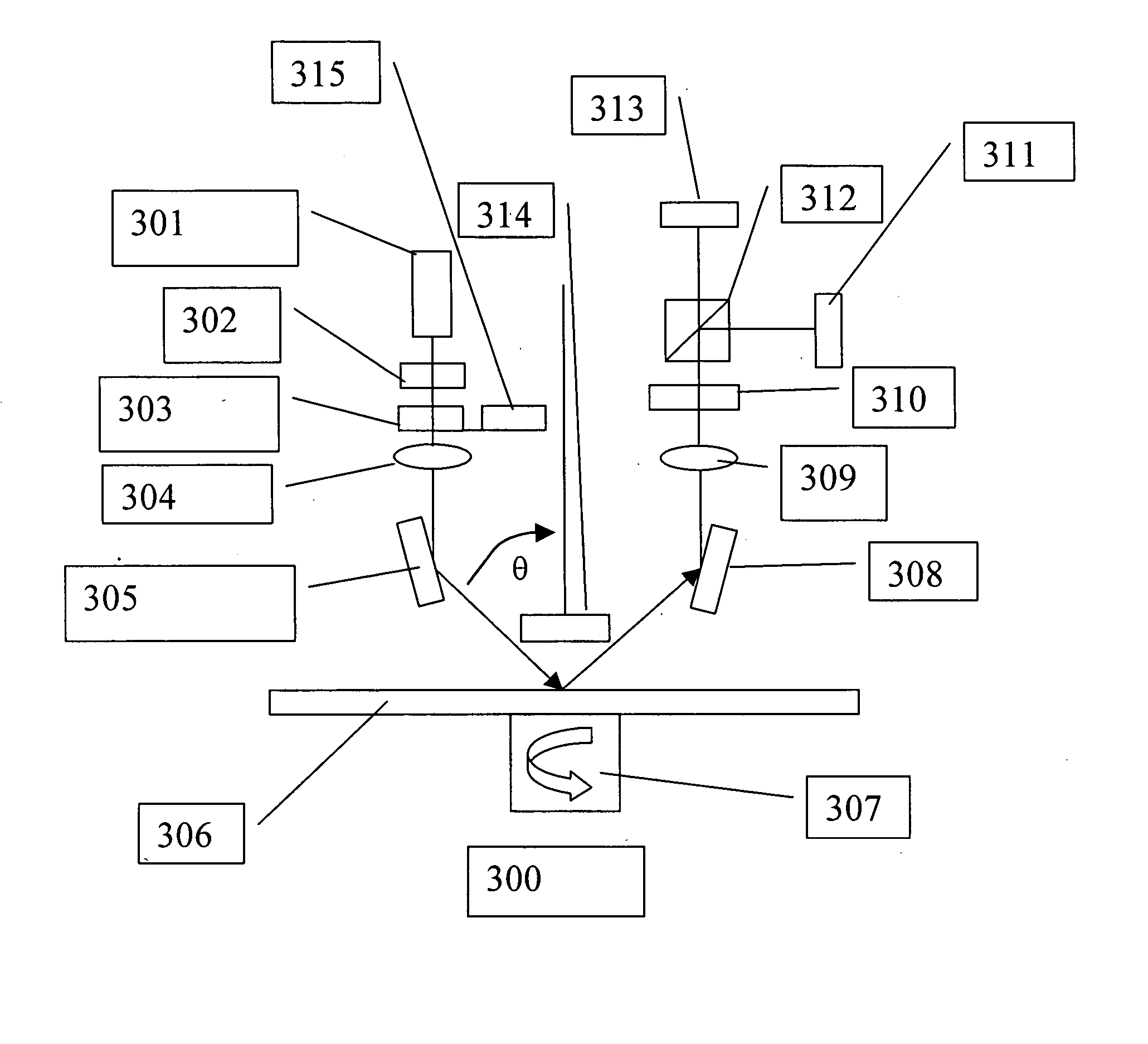

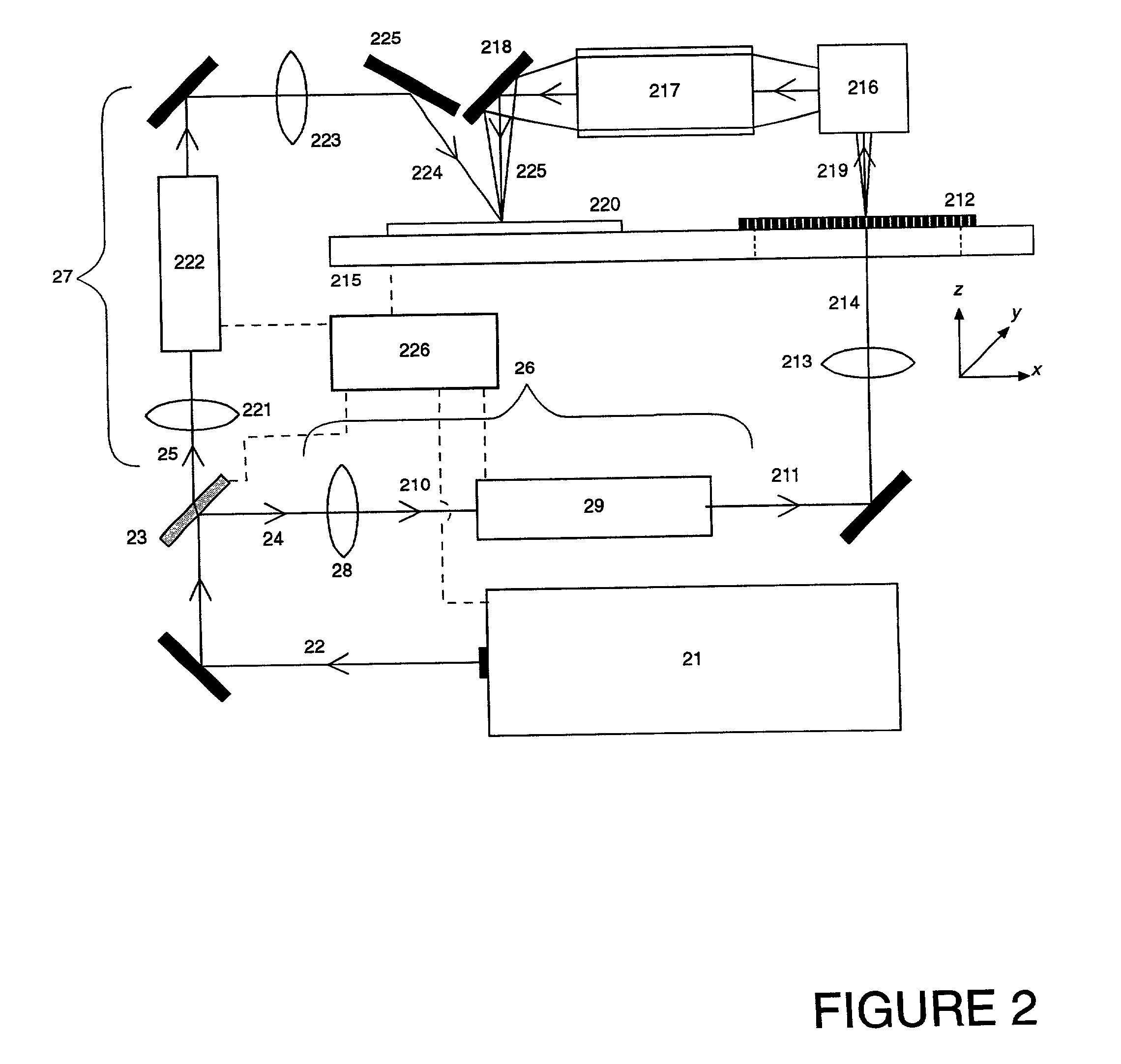

Dual-beam materials-processing system

InactiveUS6621044B2Improve throughputProlong lifePhotomechanical exposure apparatusLight therapyDual beamLight beam

Apparatus and method for patterned sequential lateral solidification of a substrate surface, avoiding the need for demagnification to avoid mask damage from fluence sufficient to overcome the threshold for sequential lateral solidification, while using the high throughput of a common stage presenting both 1:1 mask and substrate simultaneously for patterning. The radiation source provides imaging beam and non-imaging beam, each of fluence below the threshold of sequential lateral solidification, but with aggregate fluence above the threshold. The imaging beam path includes a relatively delicate 1:1 mask and 1:1 projection subsystem, with optical elements including a final fold mirror proximate to the substrate surface, put the below-threshold mask pattern on the substrate surface. The non-imaging beam bypasses the delicate elements of imaging beam path, passing through or around the final fold mirror, to impinge on the substrate surface at the same location. Where the radiation patterns of the masked imaging beam and non-imaging beam coincide, their aggregate fluence exceeds the threshold for sequential lateral solidification. The dual selection provides pattern without damage to delicate optical elements.

Owner:ANVIK CORP

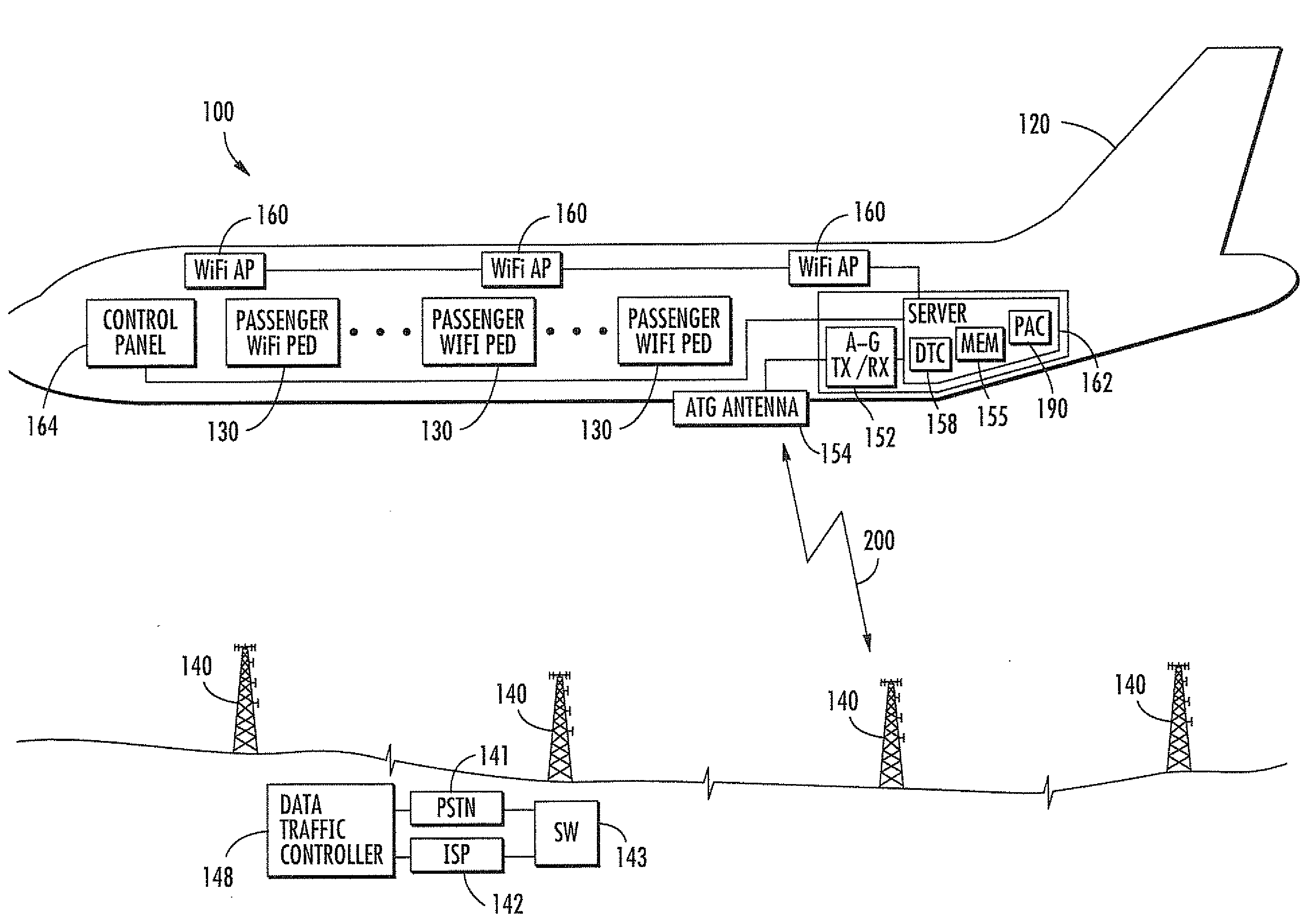

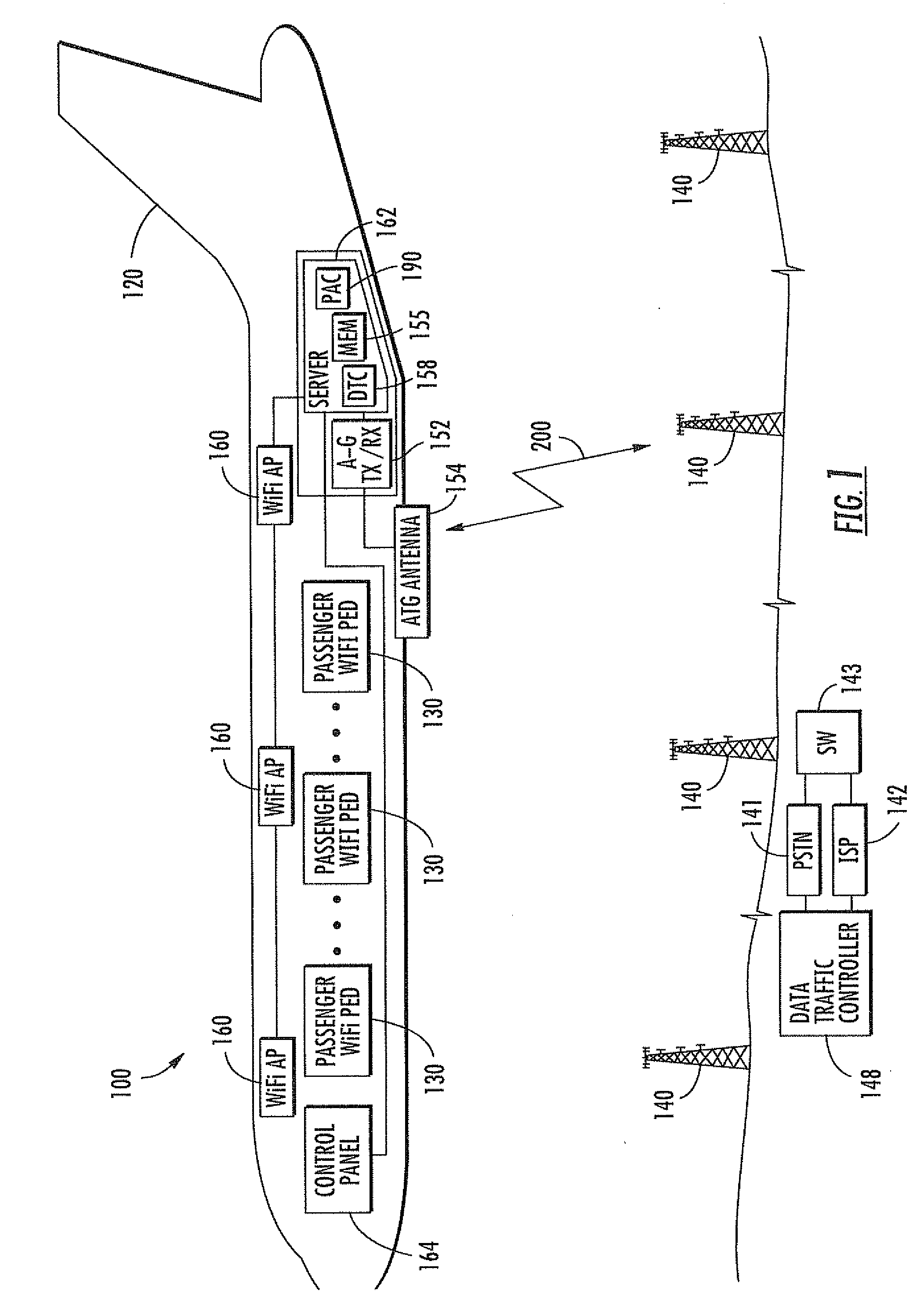

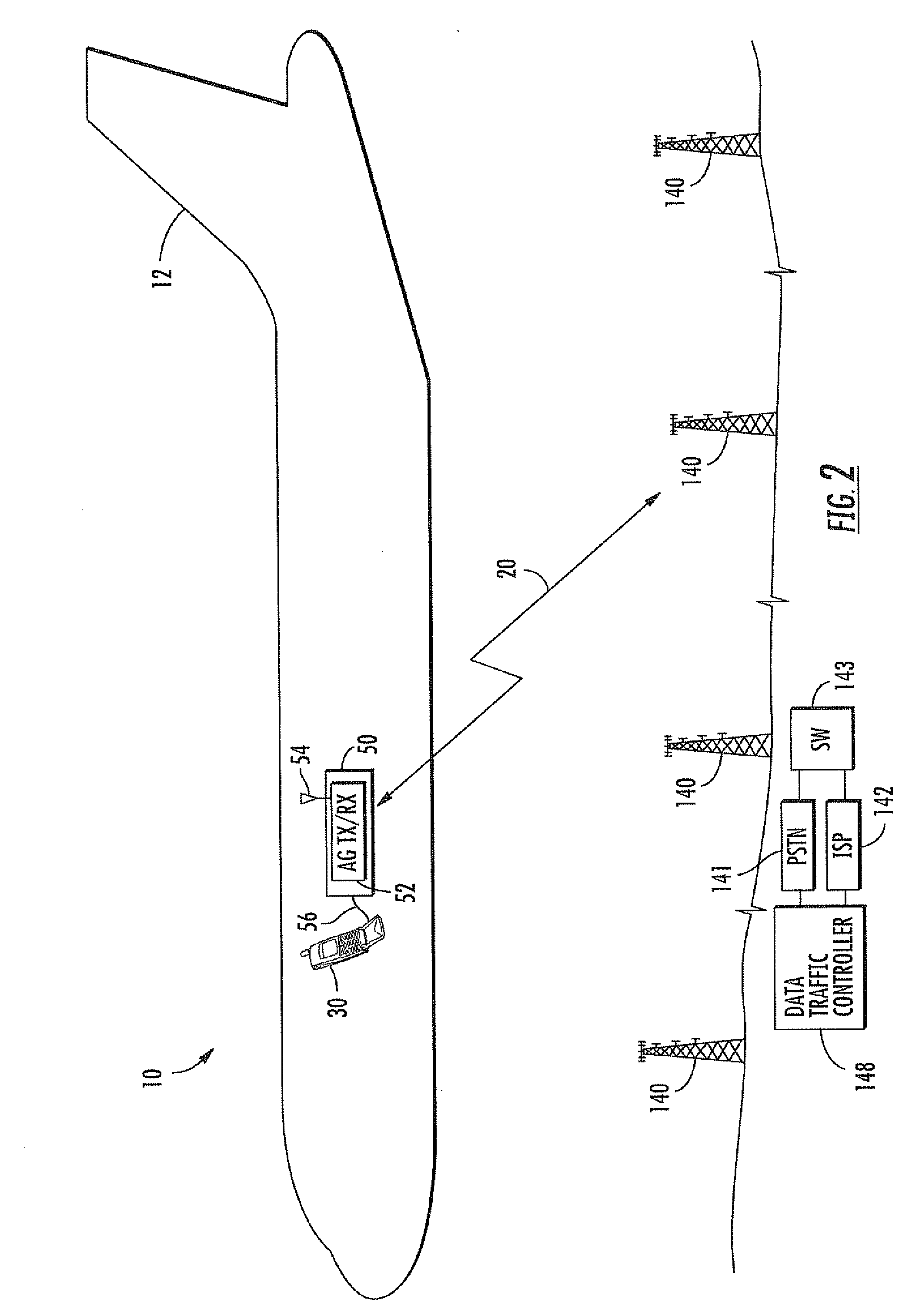

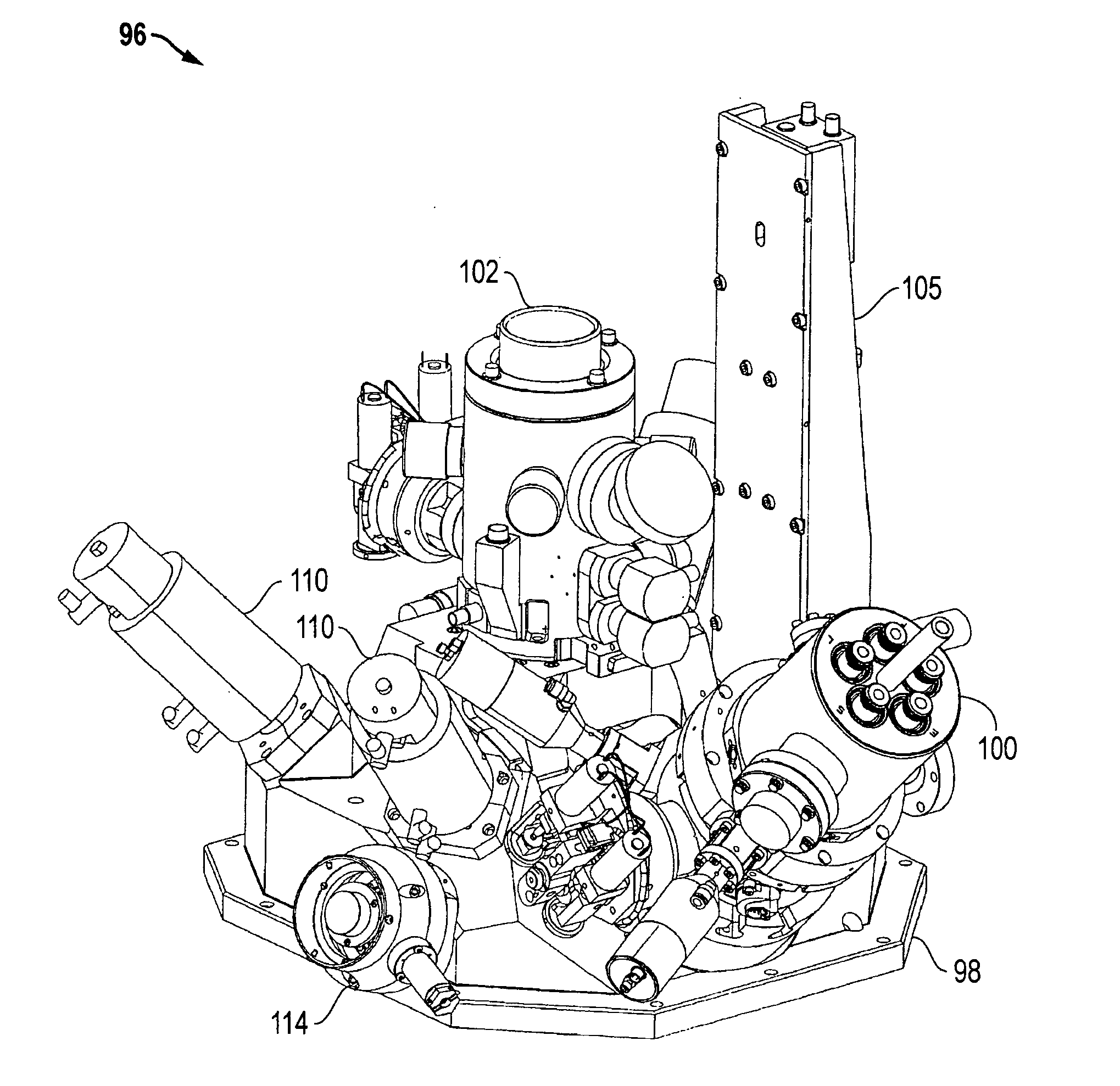

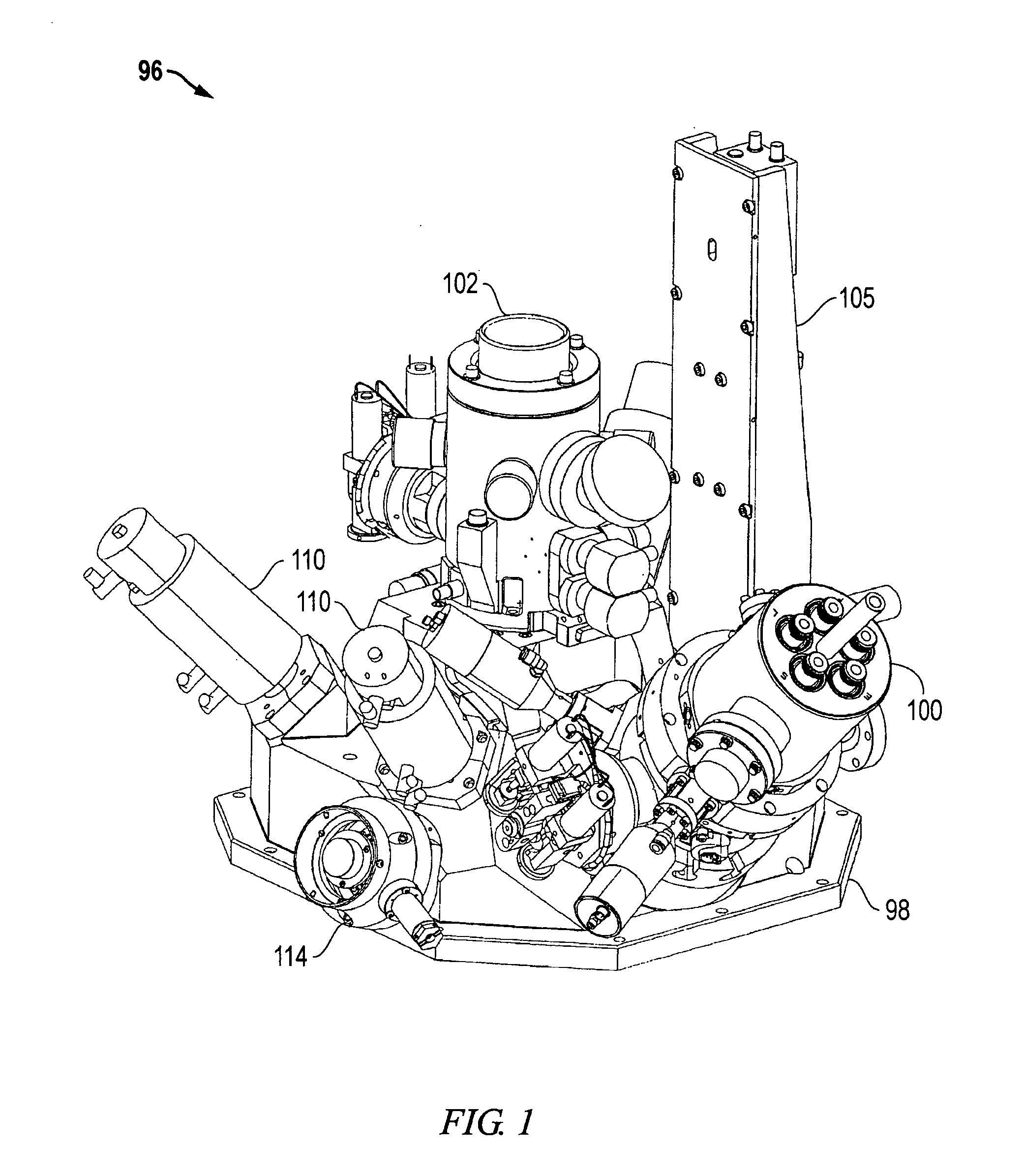

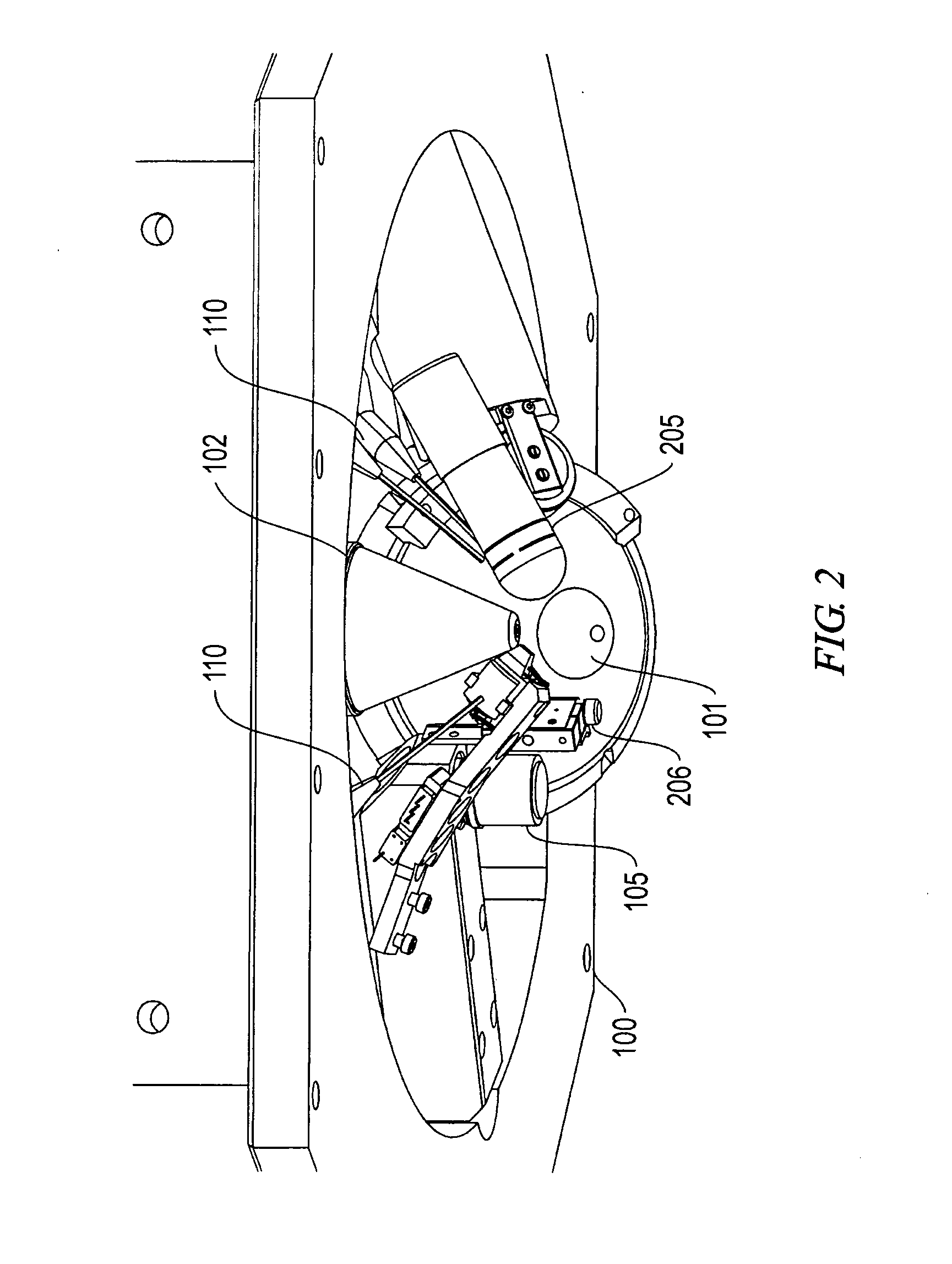

Aircraft in-flight entertainment system having a dual-beam antenna and associated methods

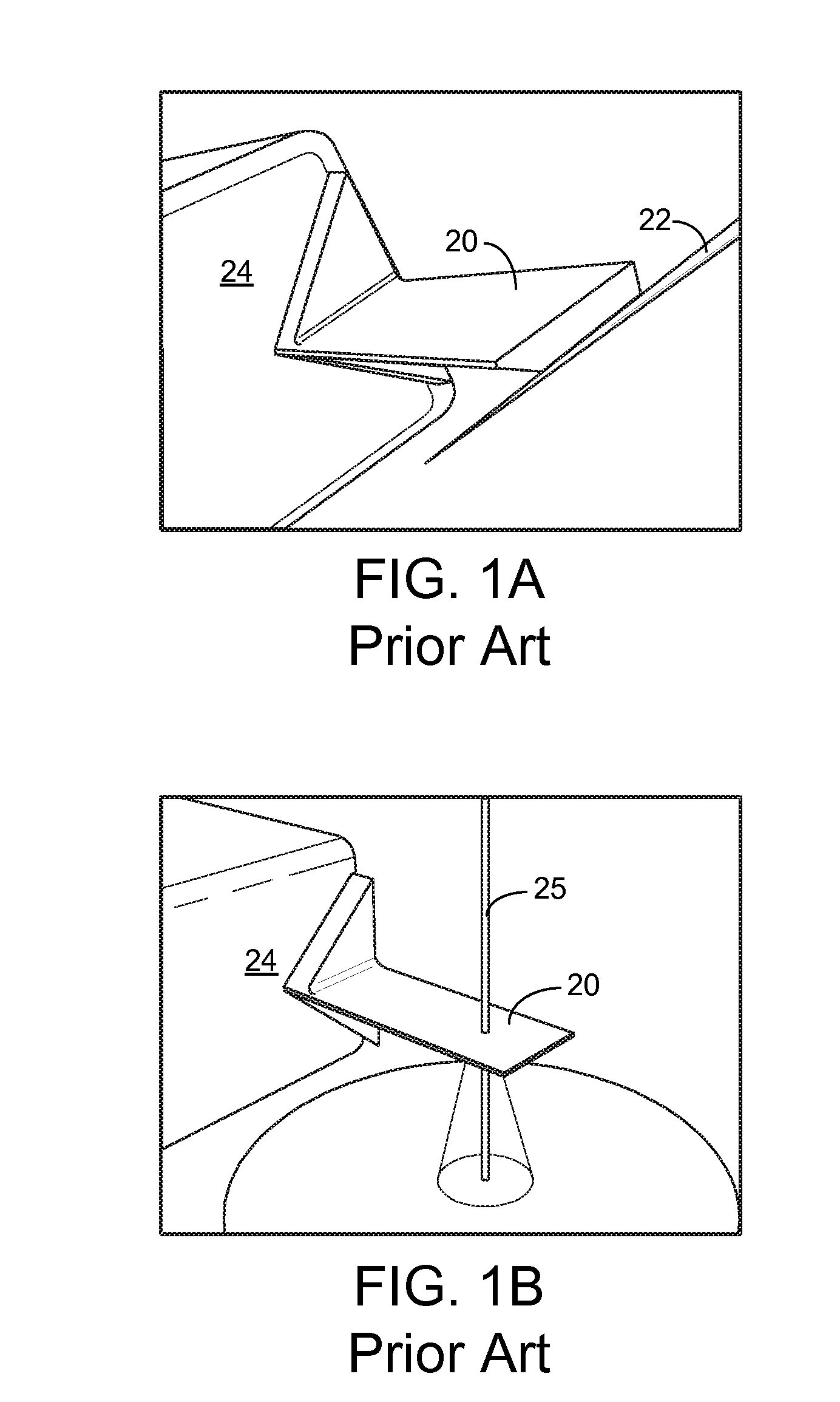

An aircraft in-flight entertainment (IFE) system for an aircraft includes a radome to be carried by the aircraft, and a dual-beam satellite antenna and at least one positioner coupled thereto to be carried by the aircraft and protected by the radome. The dual-beam satellite antenna is to generate dual antenna beams for television programming and Internet data from respective spaced apart satellites. The dual-beam satellite antenna includes a first aperture for receiving the television programming, and a second aperture adjacent the first aperture for receiving the Internet data. A television programming distribution system is to be carried by the aircraft and coupled to the dual-beam satellite antenna to provide television programming within the aircraft. At least one access point is to be carried by the aircraft and coupled to the dual-beam 0satellite antenna to provide a wireless local area network (WLAN) within the aircraft for the Internet data.

Owner:LIVETV

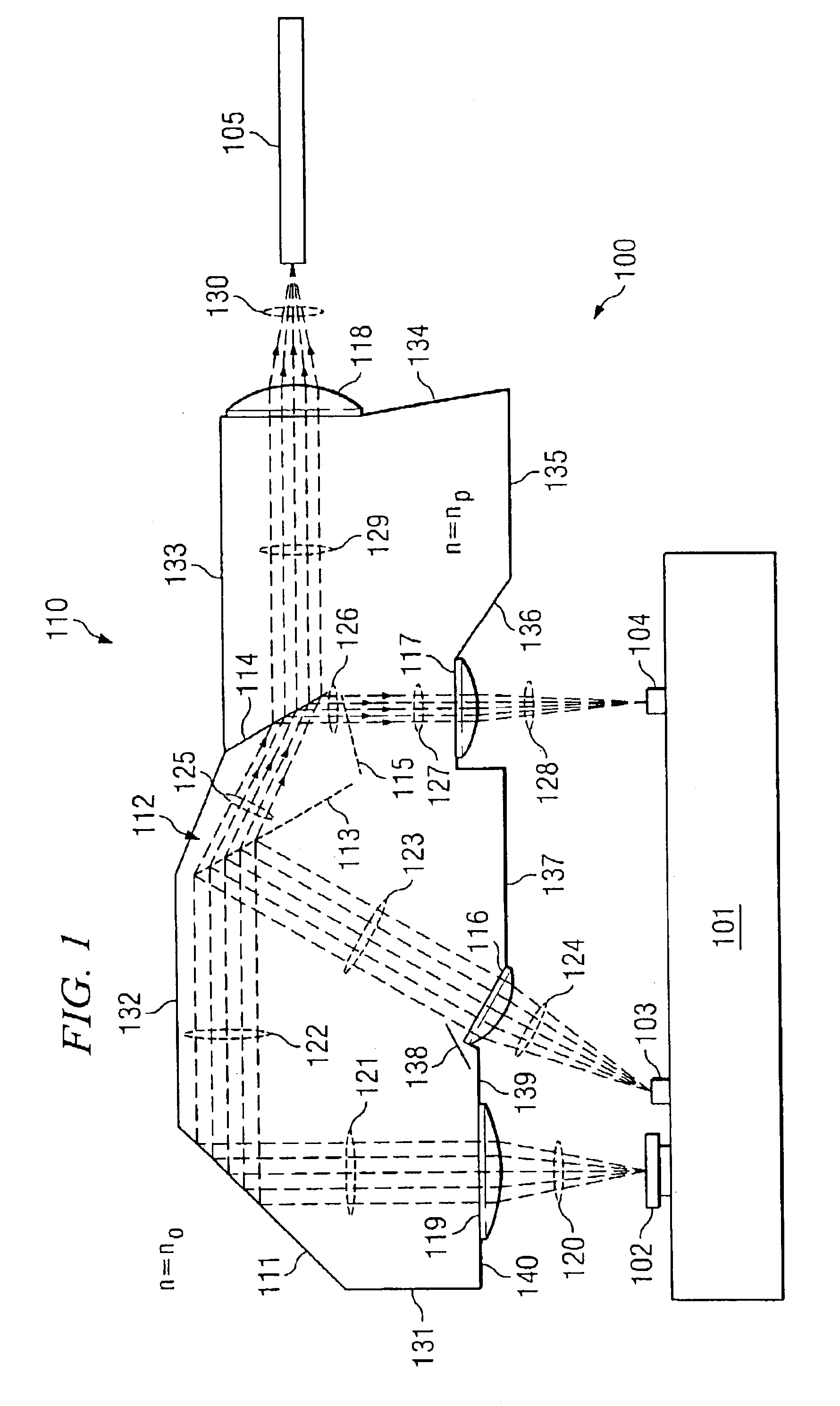

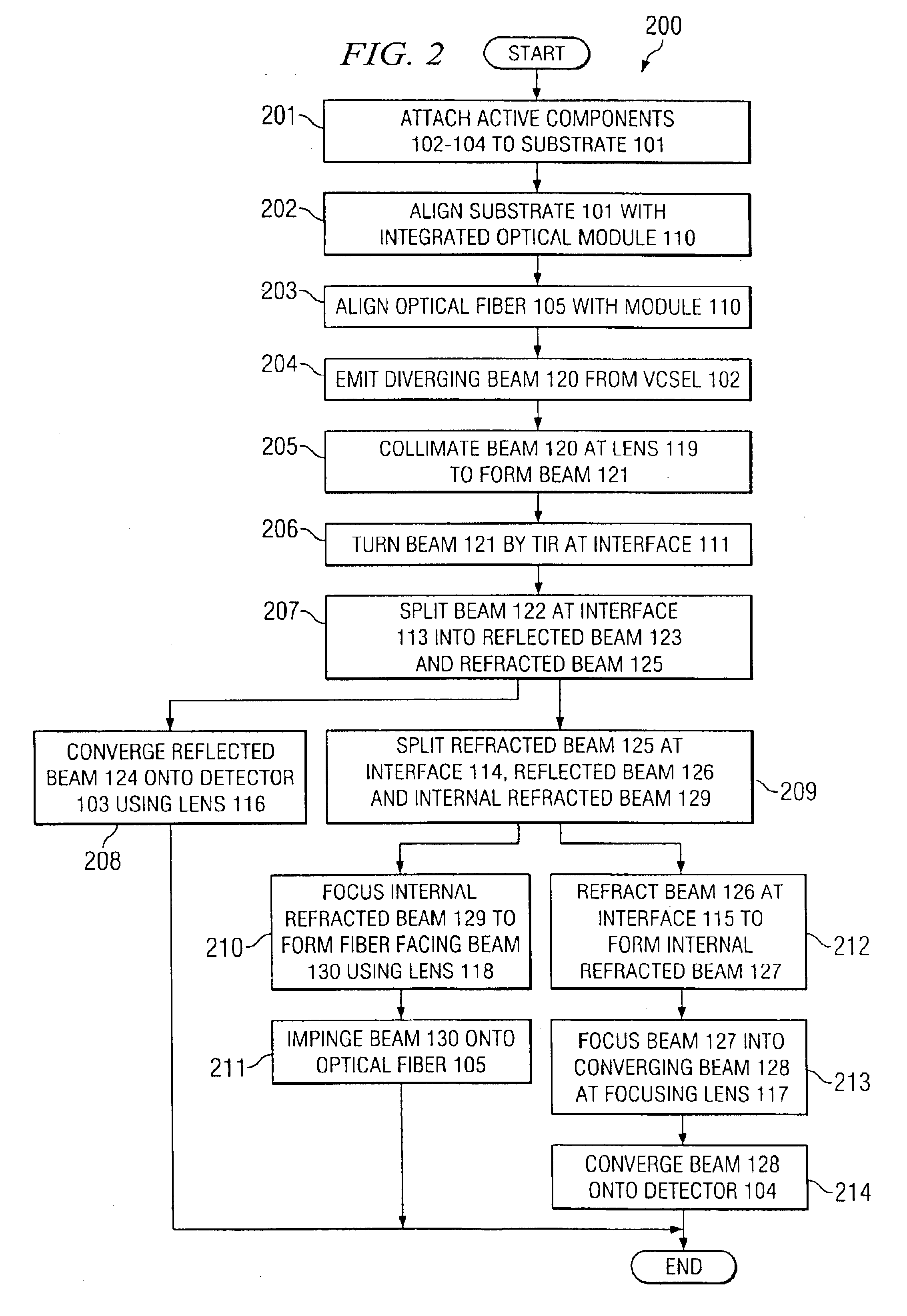

Small form factor all-polymer optical device with integrated dual beam path based on total internal reflection optical turn

InactiveUS6888988B2Low costUse minimizedCoupling light guidesNon-linear opticsTotal internal reflectionOptical Module

A monolithic optical module of injection-molded high temperature polymeric resin combines an optical turn of typically 90 degrees together with dual or triple beam paths. No additional piece parts are necessary for achieving the optical turn, since this occurs by total internal reflection (TIR), and no additional piece parts are necessary for dual monitoring, which is realized by means of an air-gap functioning as a dual beam-splitter plate. The monolithic optical module further includes integrally surfaces for accurate alignment of the module with external optical elements, and can additionally include integral optical elements, for example lenses and thin film coatings.

Owner:AVAGO TECH INT SALES PTE LTD

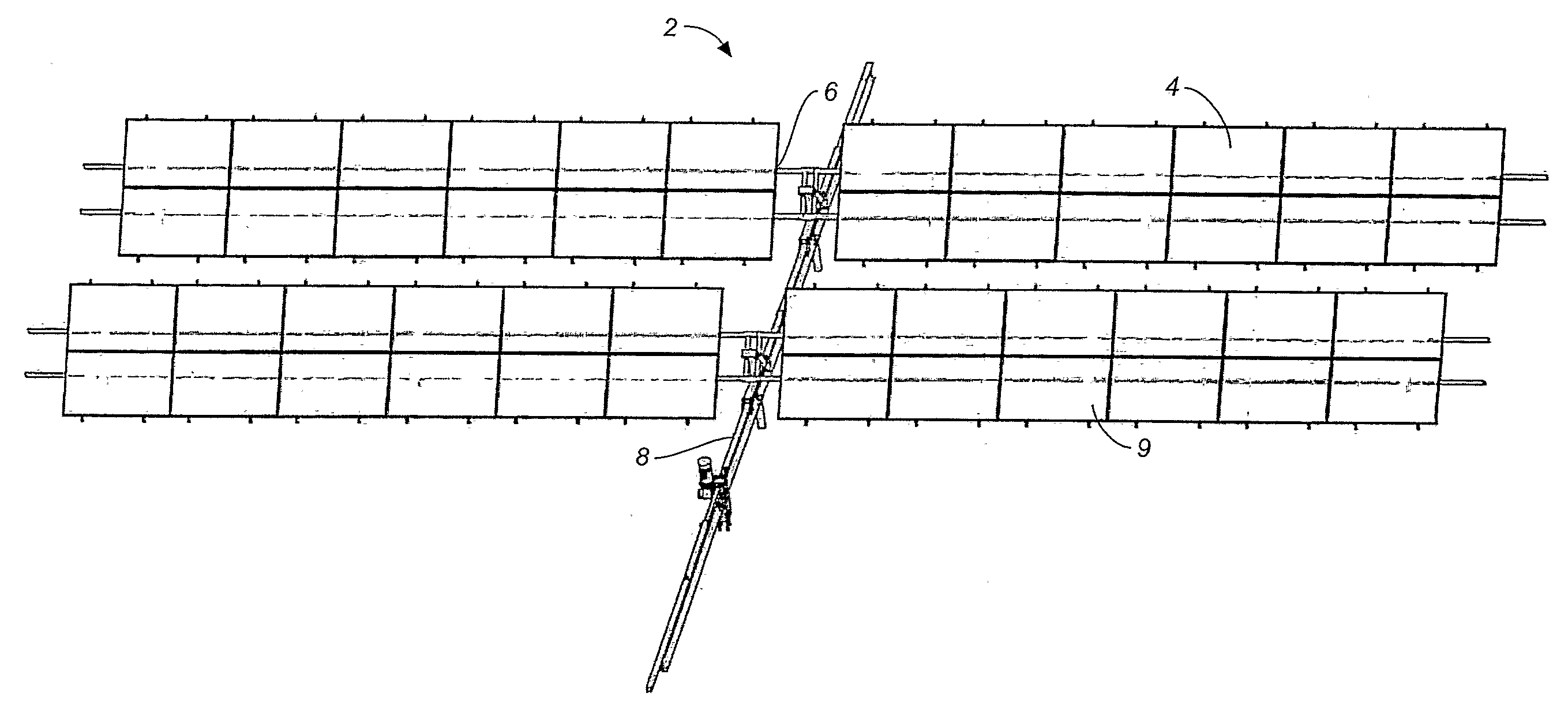

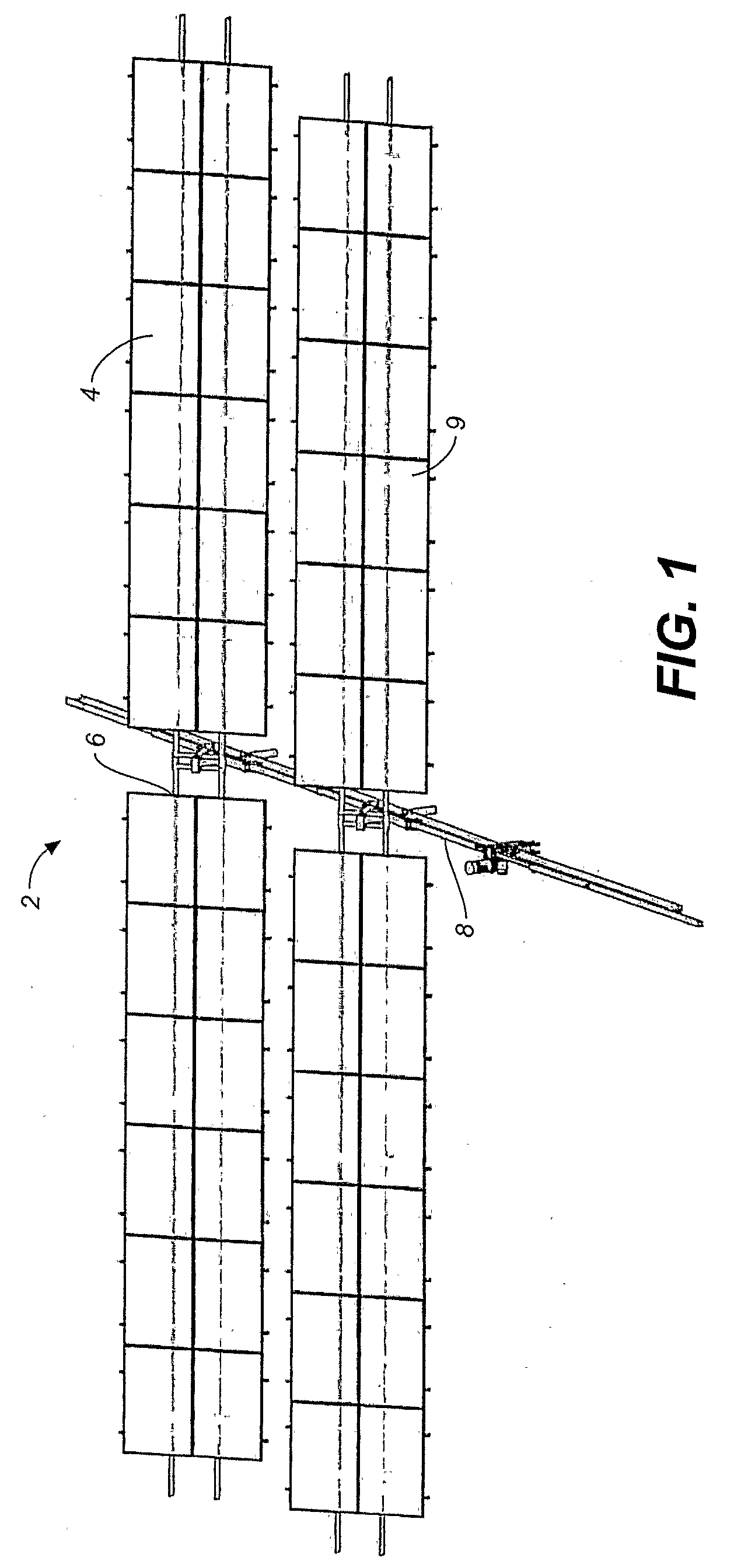

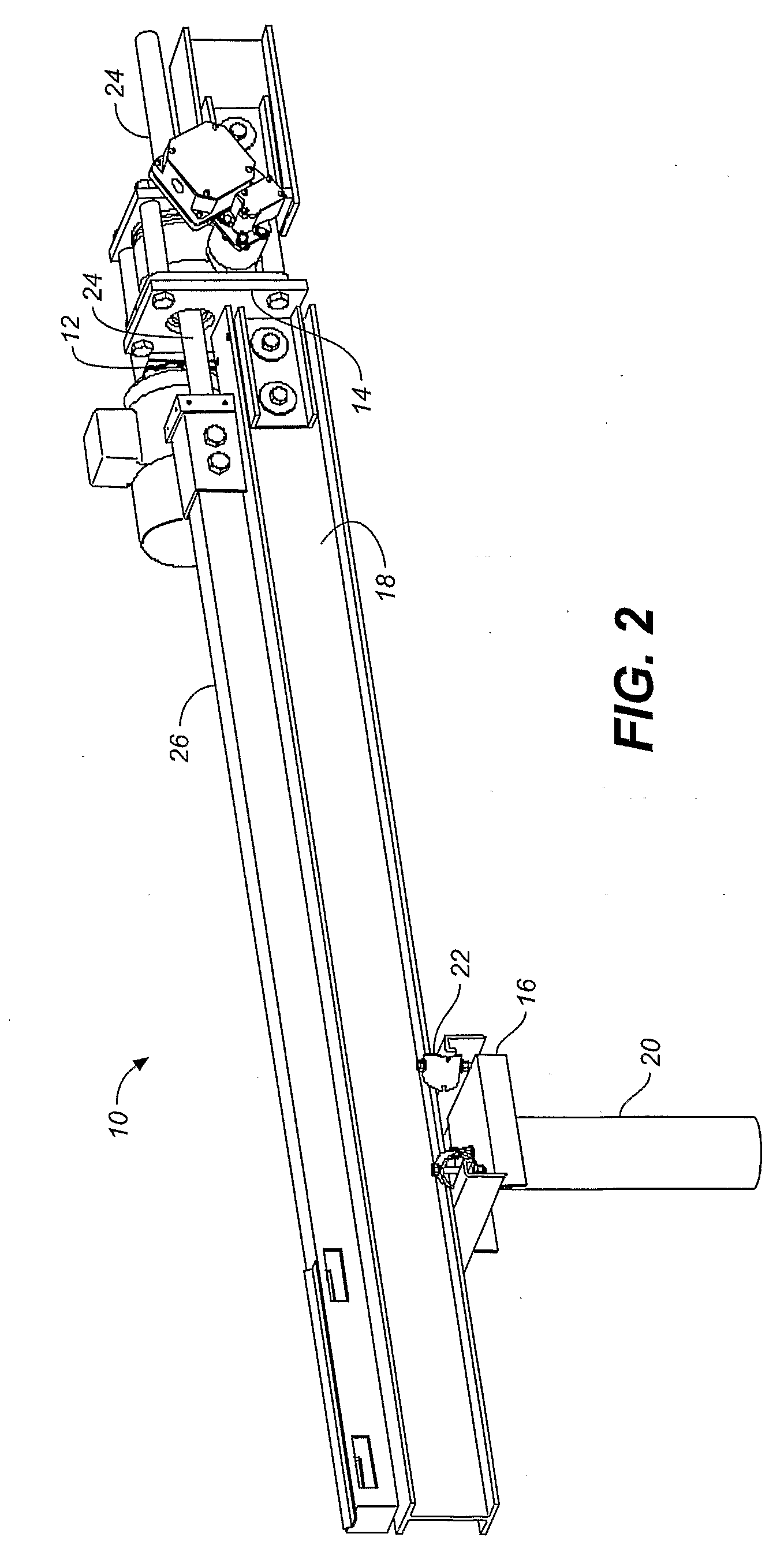

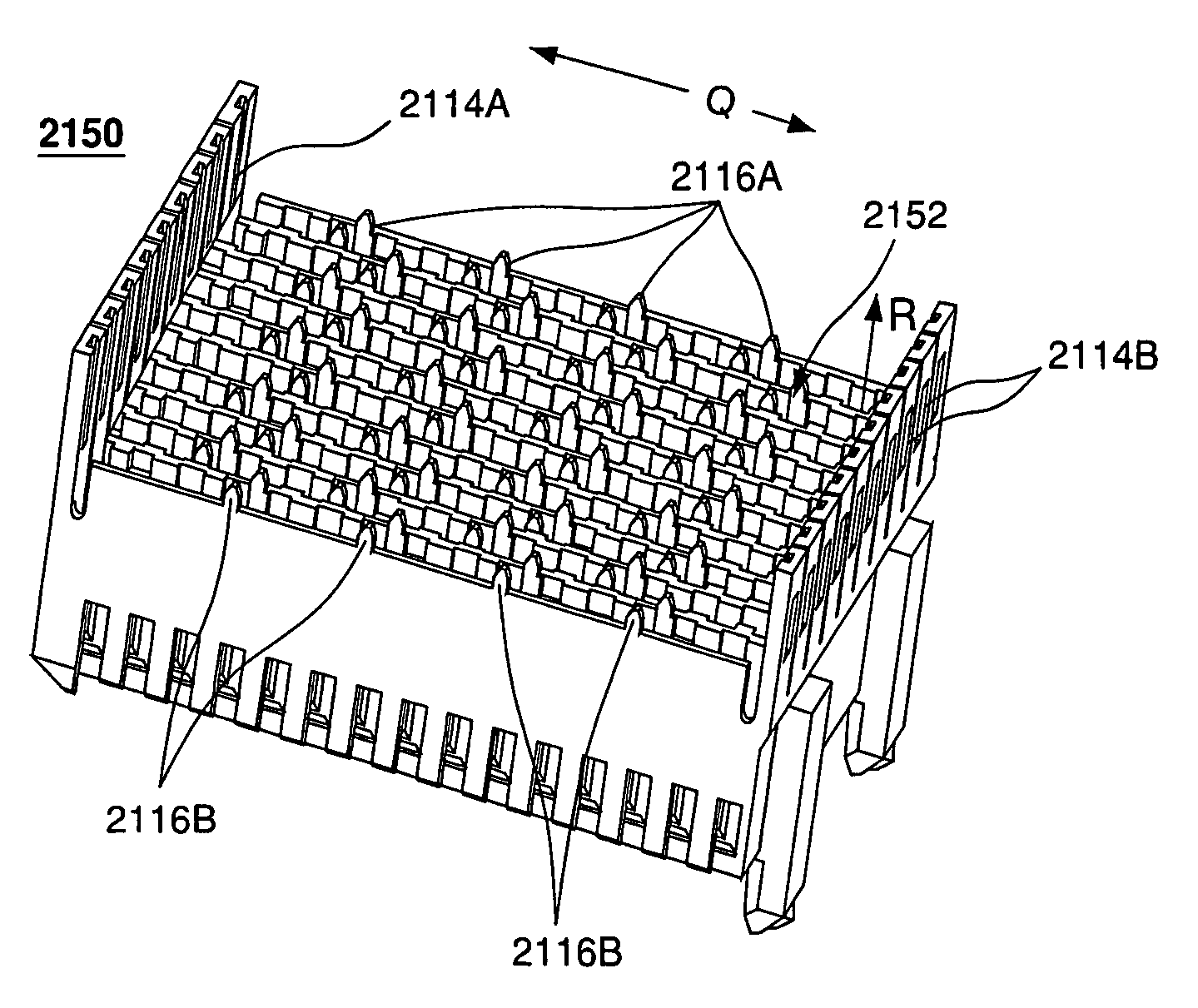

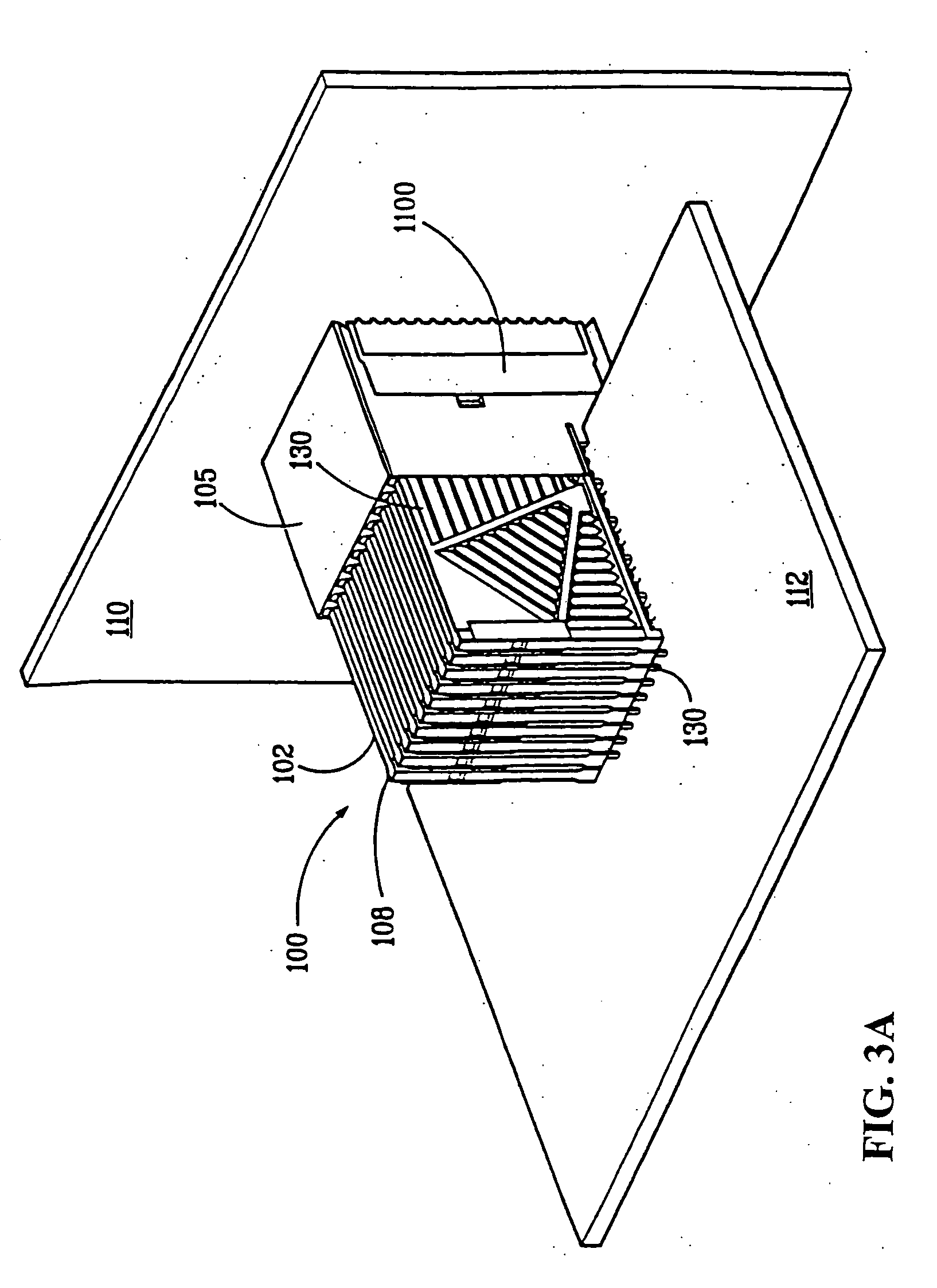

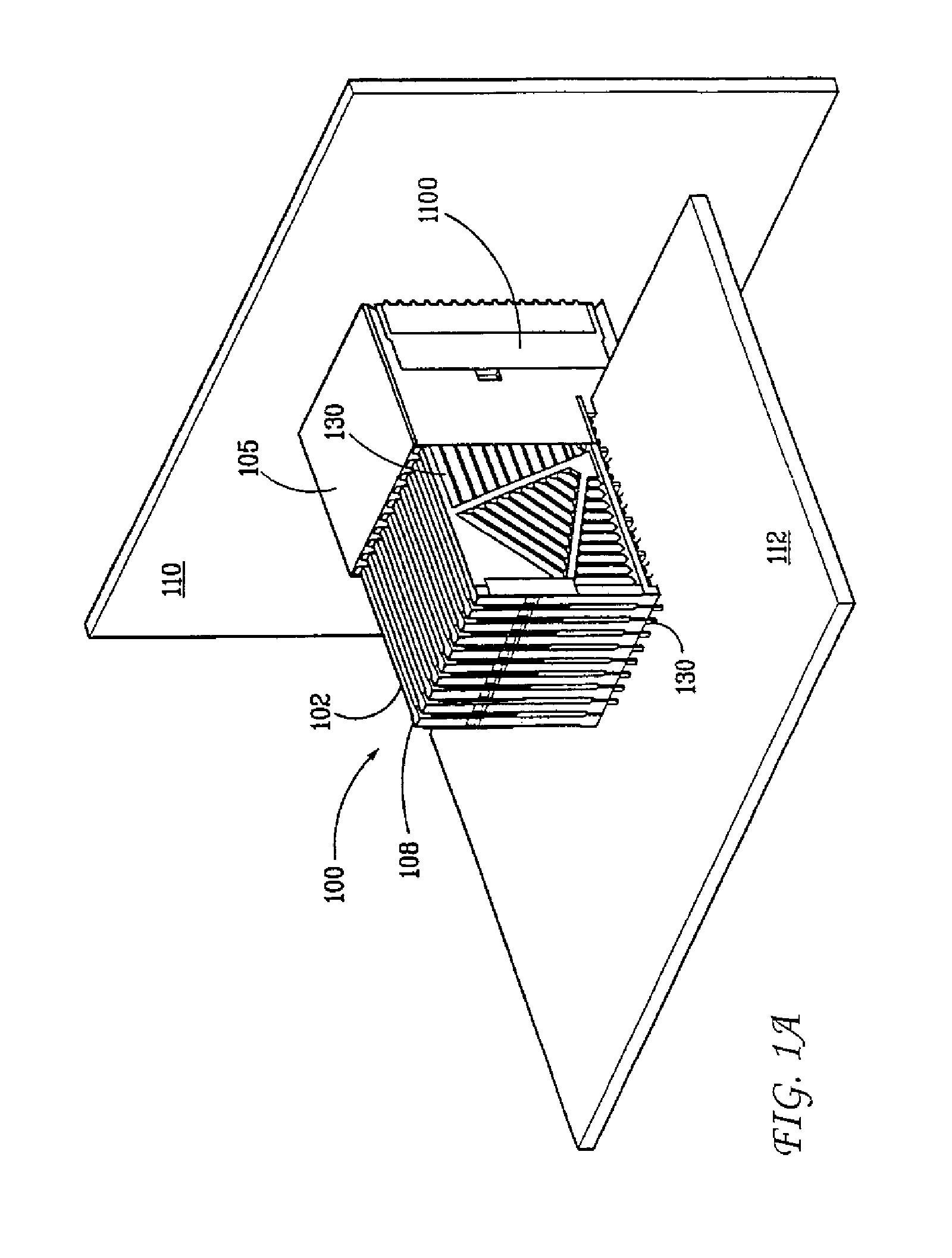

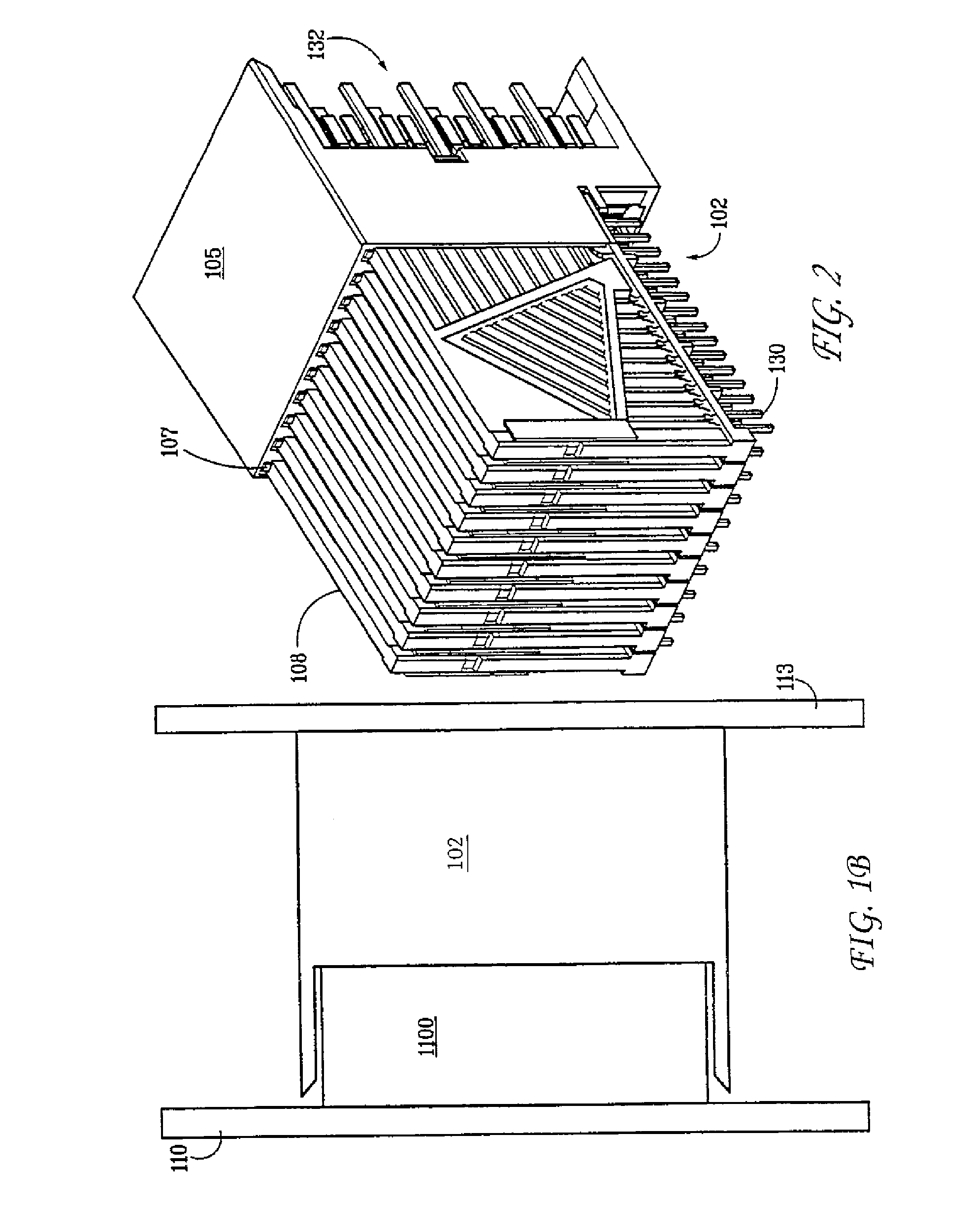

Solar Panel Array Sun Tracking System

InactiveUS20080251115A1Eliminates large side loadReduce the force requiredPhotovoltaic supportsSolar heating energyDual beamEngineering

A solar panel tracking system that can simultaneously rotate large arrays of solar panels position in multiple rows utilizing a single drive system. The drive system comprises a single actuation device that drives multiple rotational translation stages at each solar array row for tilting the panels to the correct position. A dual beam structure within each row insure appropriate panel support during rotation and provide the framework for simplified installation and maintenance.

Owner:THOMPSON TECH IND

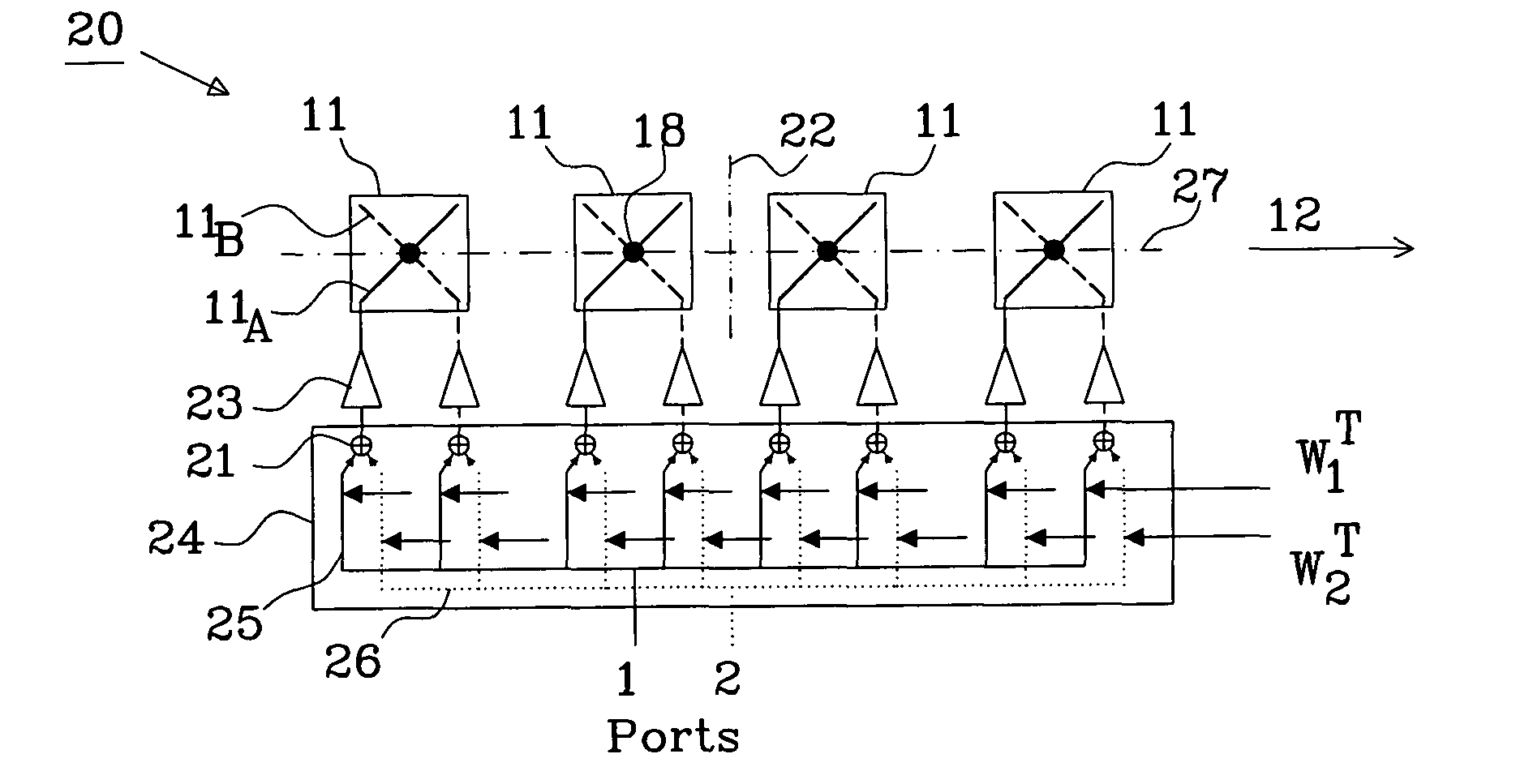

Method of designing weight vectors for a dual beam antenna with orthogonal polarizations

ActiveUS20120212372A1Improved antenna radiation propertyImprove matchPolarisation/directional diversityIndividually energised antenna arraysDual beamLight beam

The present invention relates to a method of generating two beams, having orthogonal polarizations, covering a selected area using an antenna (20) comprising multiple dual-polarized array elements (11). Each dual-polarized array element having a first phase centre (18) associated with a first polarization and a second phase centre (18) associated with a second polarization. The method comprises: designing a first weight matrix having a first non-zero weight vector for the first polarization and a second non-zero weight vector for the second polarization, calculating a second weight matrix based on the weight vectors of the first weight matrix, and applying the first and second weight matrix to the dual-polarized array elements to generate a second beam covering the selected area.

Owner:TELEFON AB LM ERICSSON (PUBL)

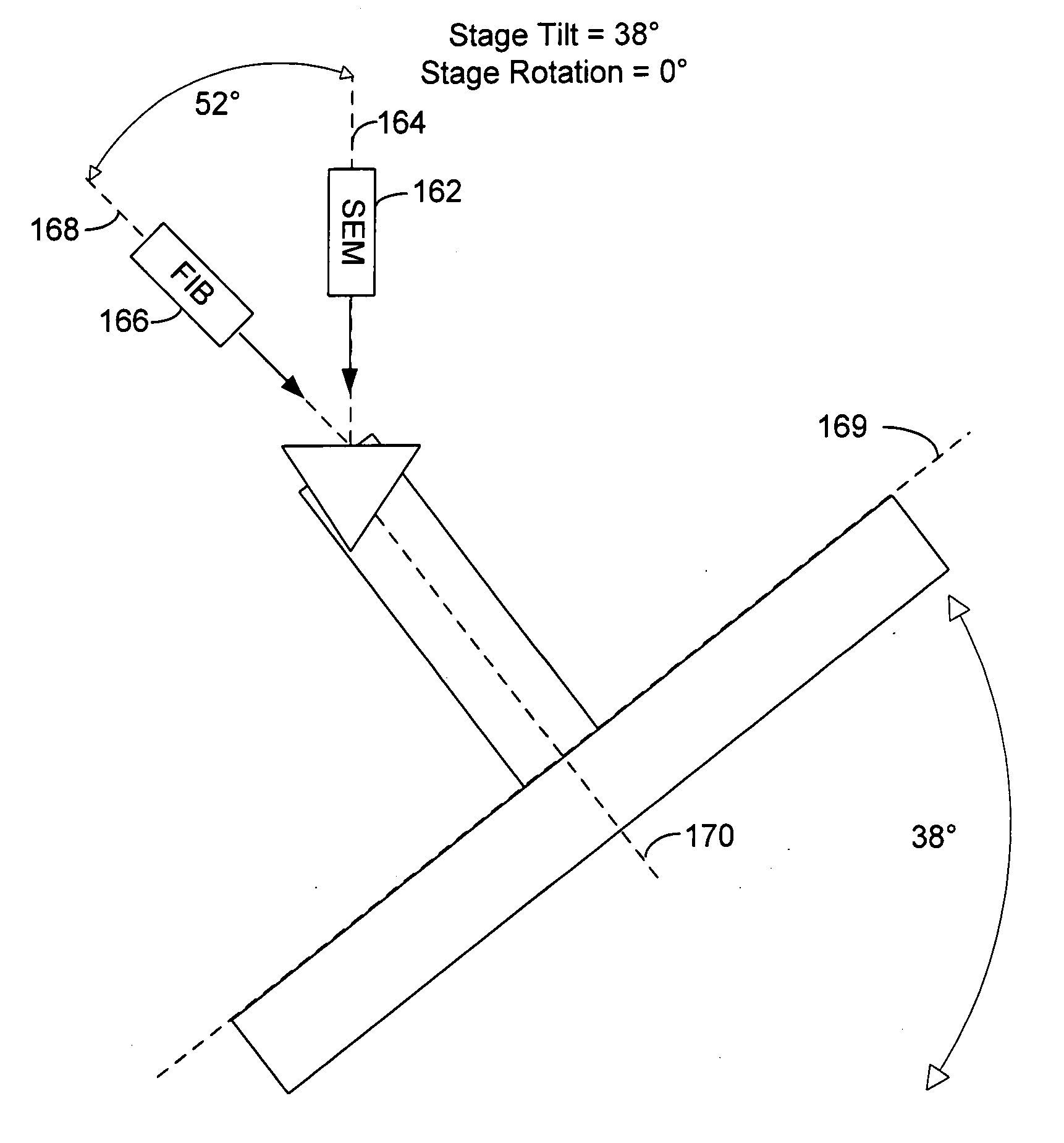

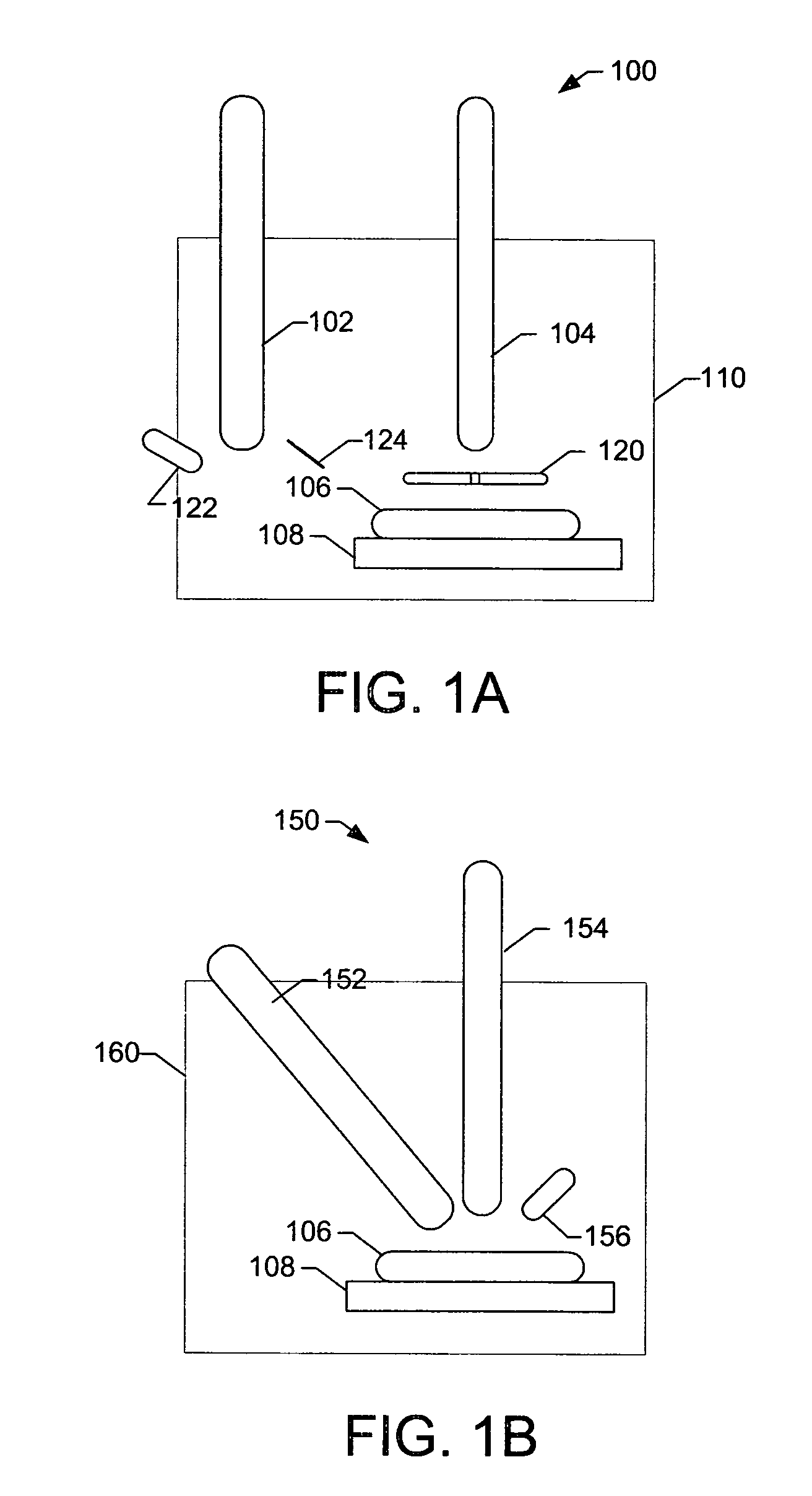

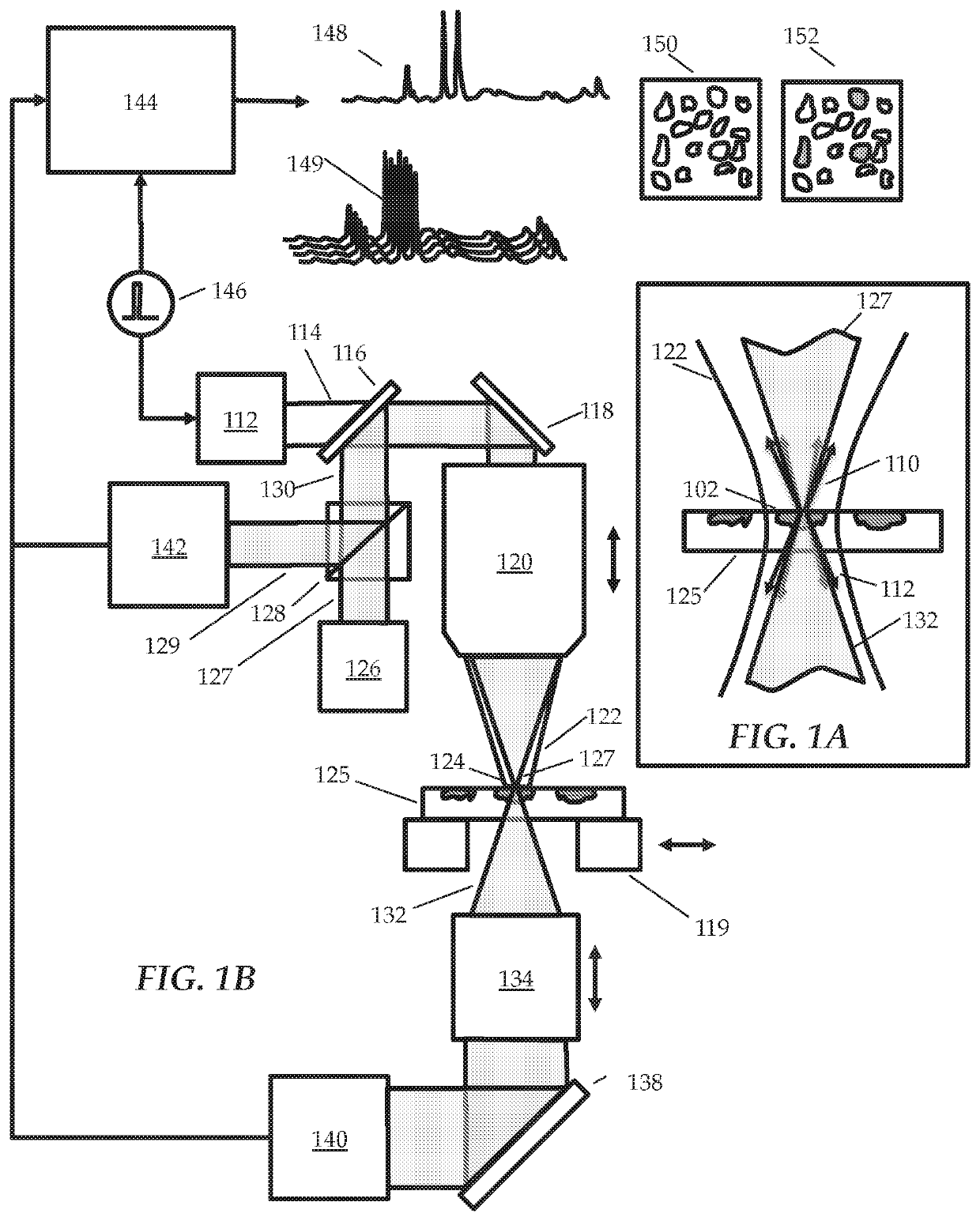

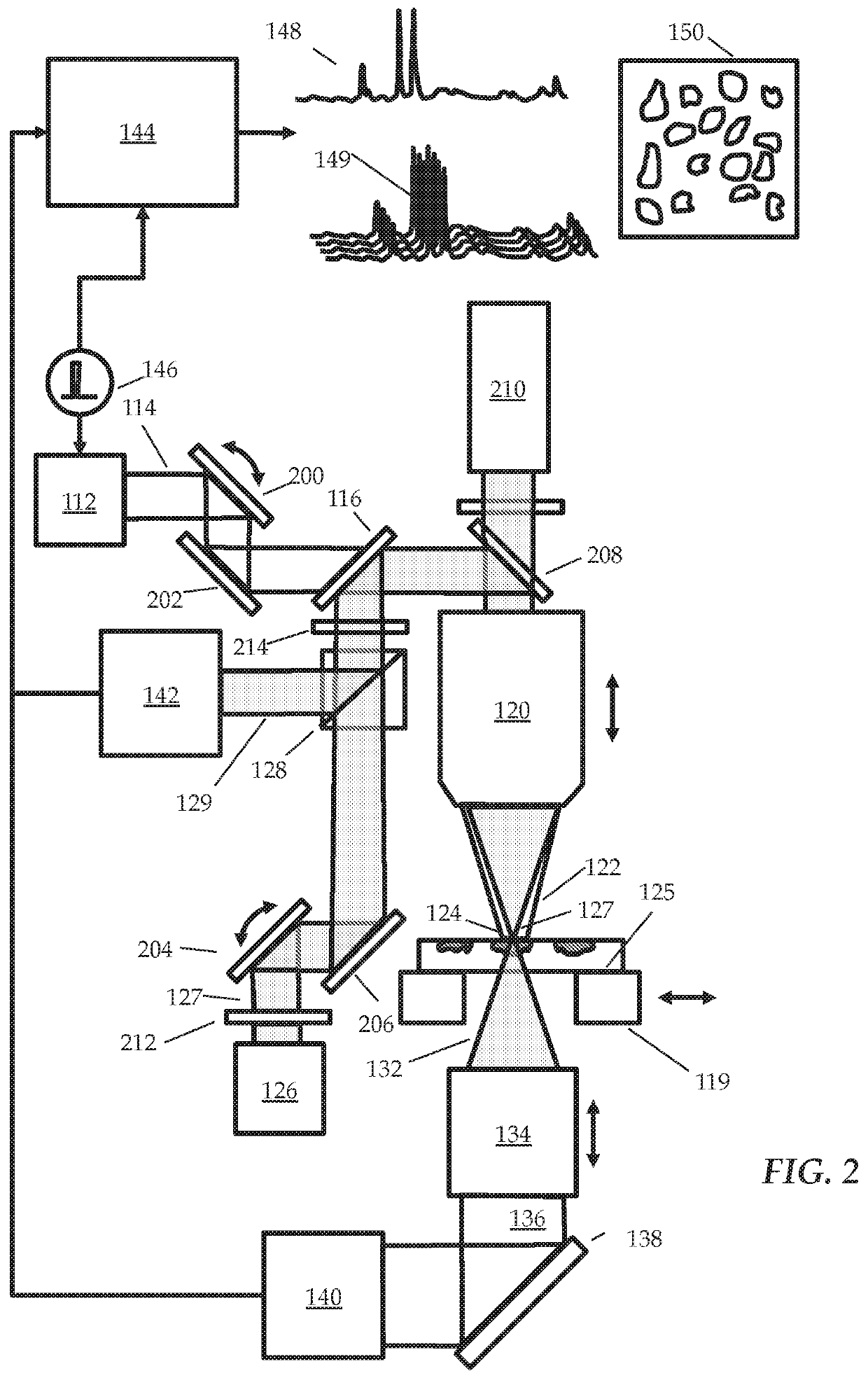

In-situ STEM sample preparation

ActiveUS20080296498A1Simple methodMaterial analysis using wave/particle radiationElectric discharge tubesDual beamAnalysis method

A method for STEM sample preparation and analysis that can be used in a FIB-STEM system without a flip stage. The method allows a dual beam FIB / STEM system with a typical tilt stage having a maximum tilt of approximately 60 to be used to extract a STEM sample to from a substrate, mount the sample onto a TEM sample holder, thin the sample using FIB milling, and rotate the sample so that the sample face is perpendicular to a vertical electron column for STEM imaging.

Owner:FEI COMPANY

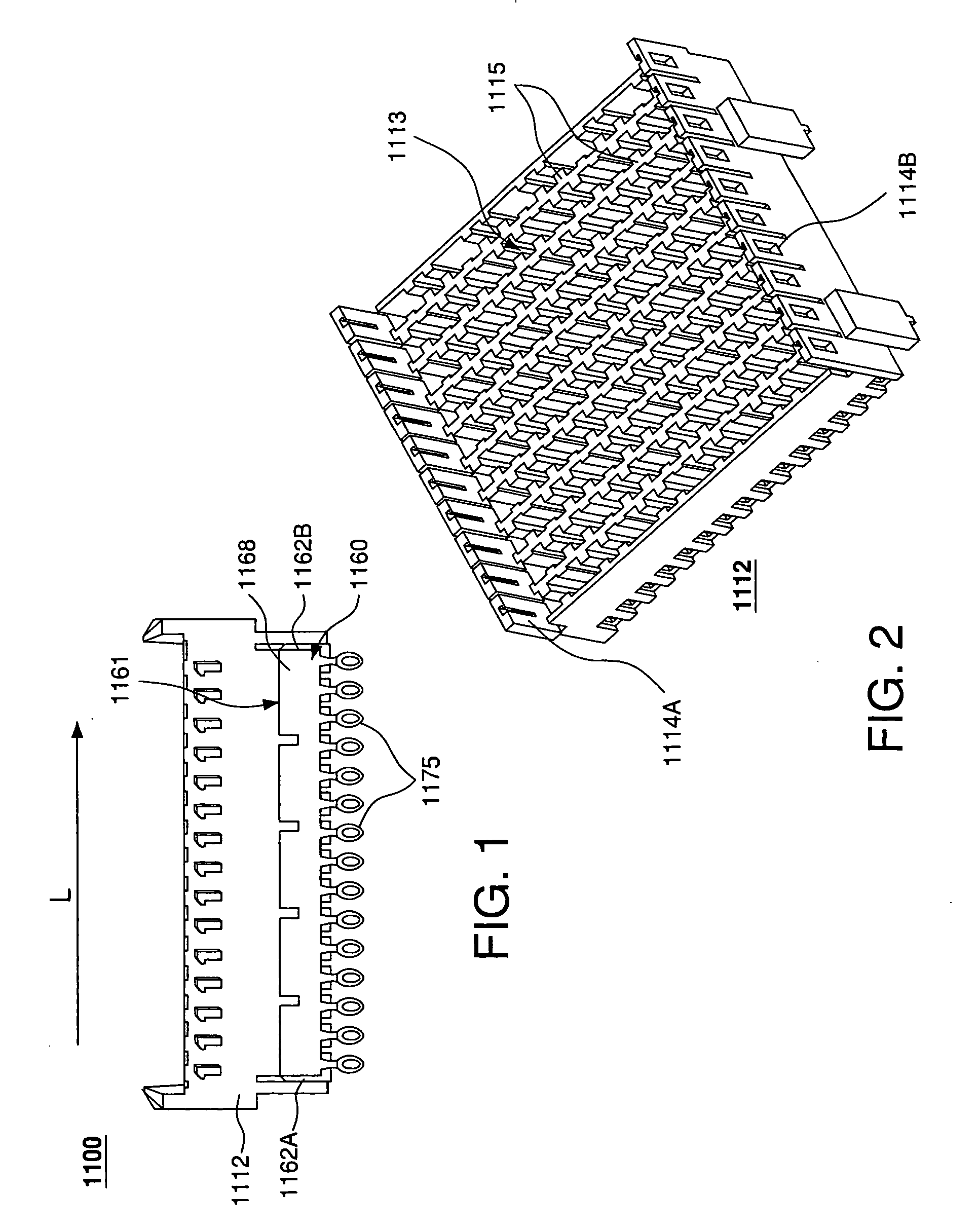

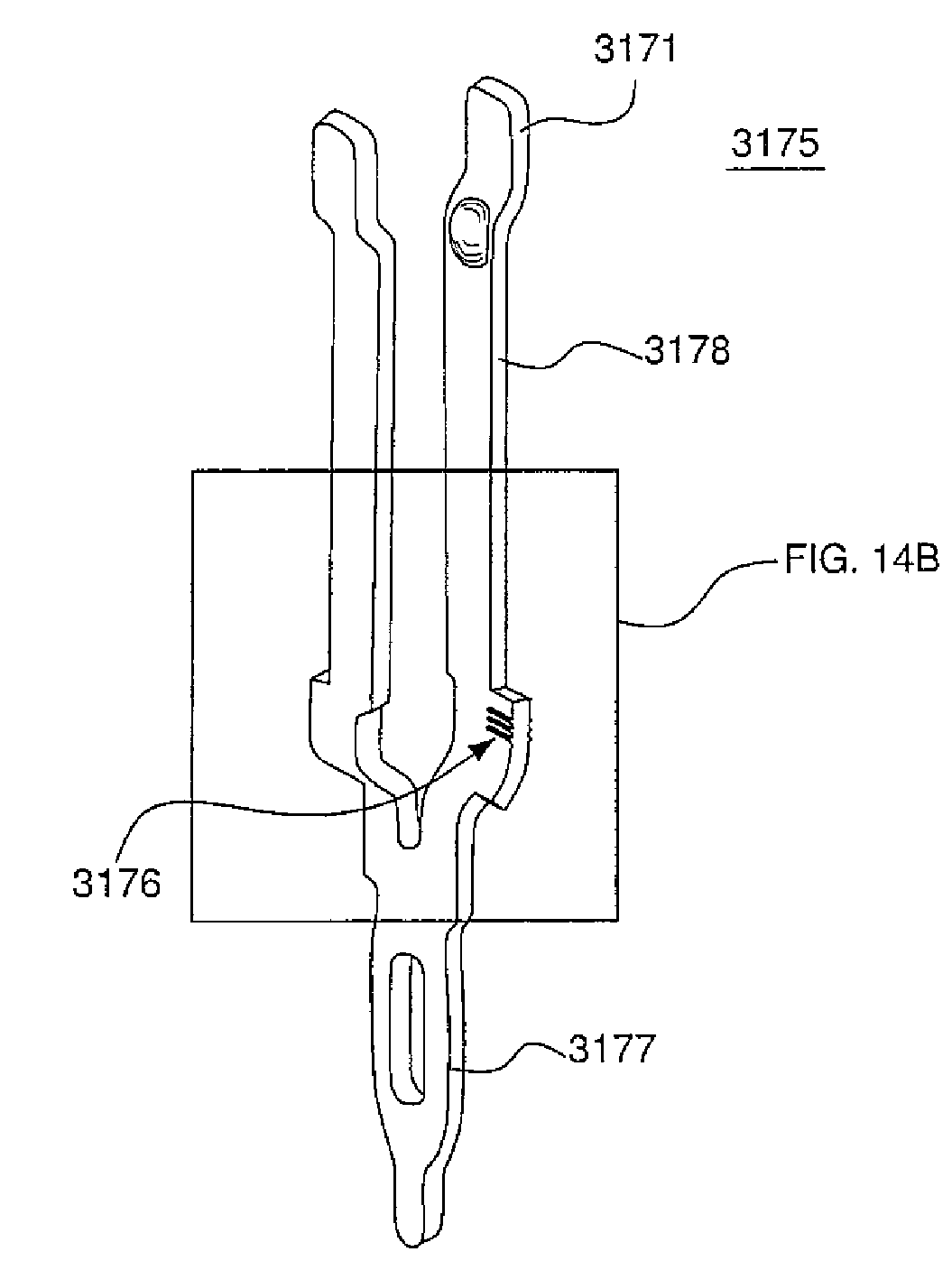

Electrical connector housing alignment feature

ActiveUS20070004287A1Minimize movementMinimize shear stressEngagement/disengagement of coupling partsIncorrect coupling preventionGround contactDual beam

An electrical connector receptacle housing is provided that includes protrusions in the housing's contact assembly receiving area. The location of each protrusion corresponds to a location of a well formed in a contact assembly between dual beams of ground contacts. When the contact block is received in the housing, each protrusion is received in a corresponding well. The protrusions may be sized to provide a snug fit as the contact block is received in the receptacle housing. The protrusions thus help minimize the movement of the contact block.

Owner:FCI AMERICAS TECH LLC

High Throughput TEM Preparation Processes and Hardware for Backside Thinning of Cross-Sectional View Lamella

ActiveUS20130248354A1Easy to useElectric discharge tubesPreparing sample for investigationDual beamLight beam

A method for TEM sample preparation and analysis that can be used in a FIB-SEM system without re-welds, unloads, user handling of the lamella, or a motorized flip stage. The method allows a dual beam FIB-SEM system with a typical tilt stage to be used to extract a sample to from a substrate, mount the sample onto a TEM sample holder capable of tilting, thin the sample using FIB milling, and rotate the sample so that the sample face is perpendicular to an electron column for STEM imaging.

Owner:FEI COMPANY

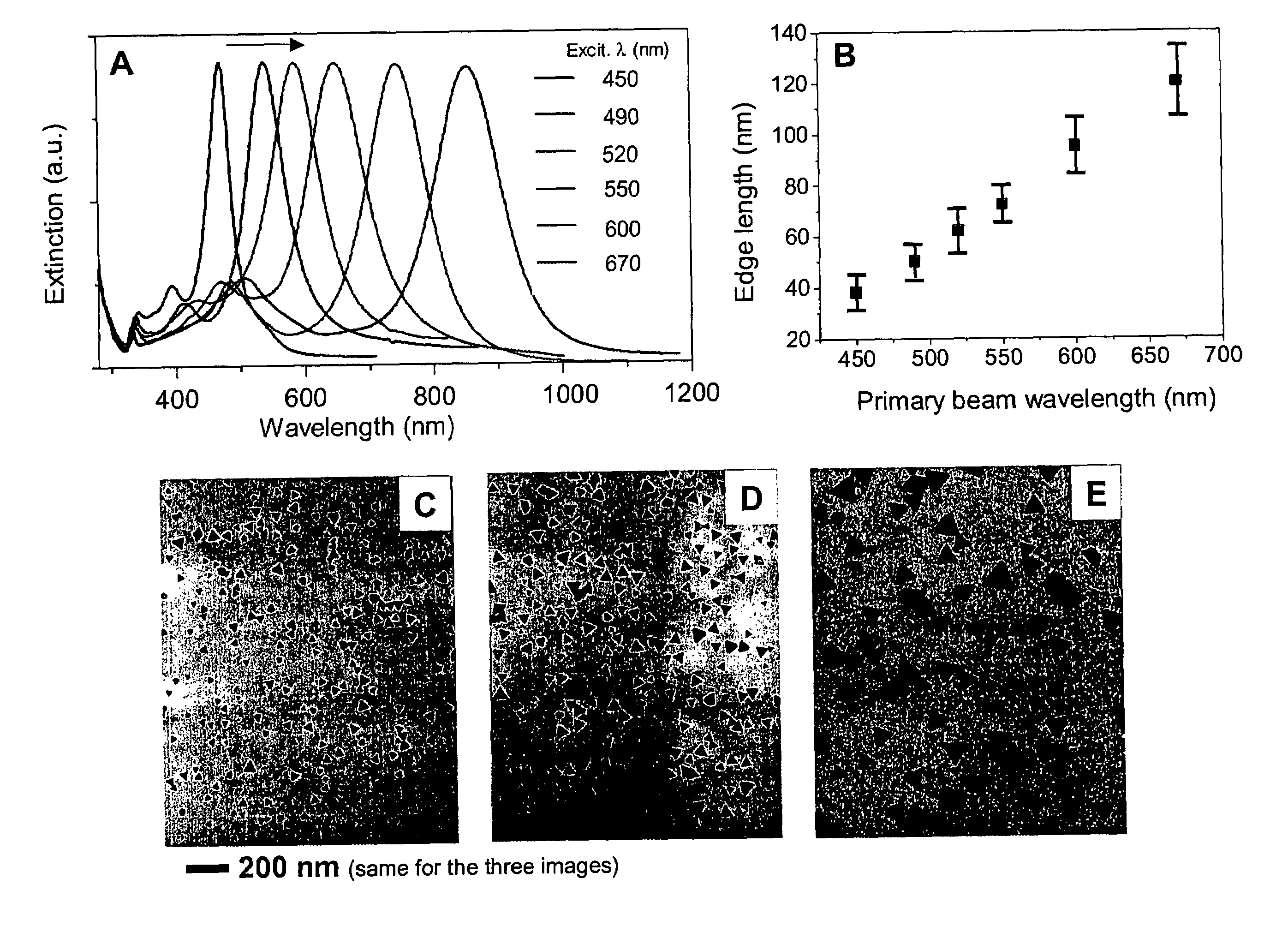

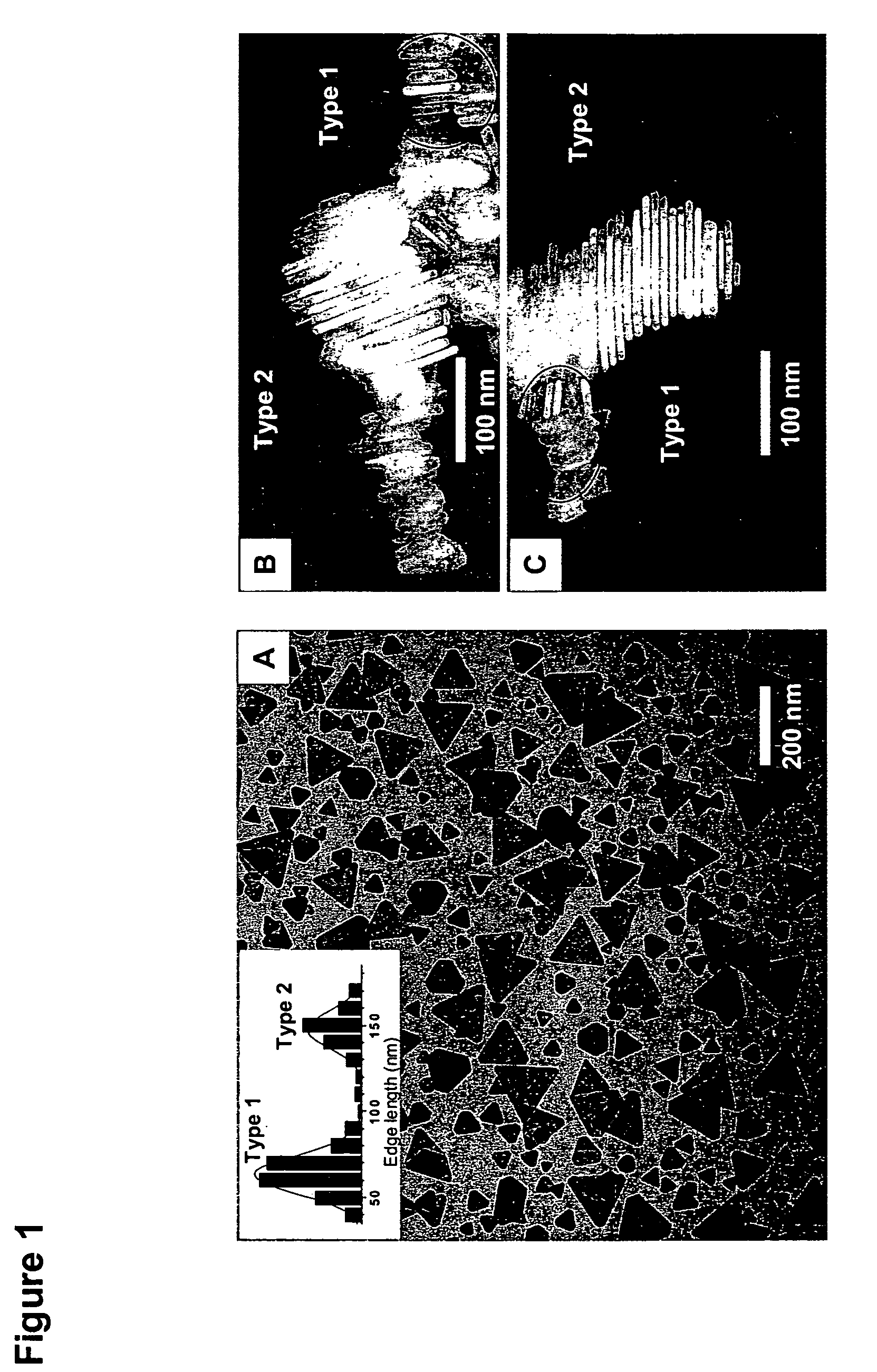

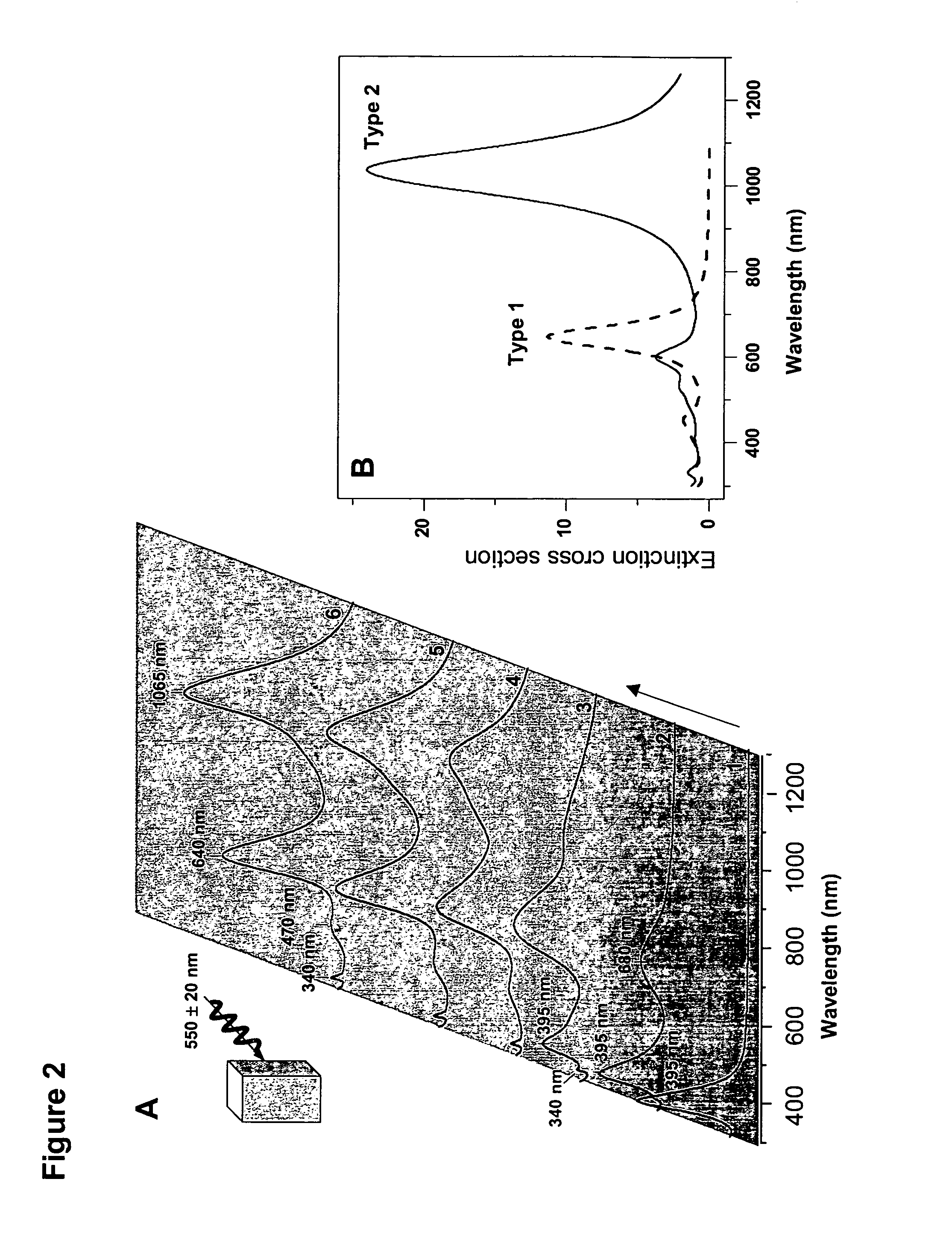

Methods of controlling nanoparticle growth

The invention provides new types of plasmon-driven growth mechanism for silver nanostructures involving the fusion of triangular nanoprisms. This mechanism, which is plasmon excitation-driven and highly cooperative, produces bimodal particle size distributions. In these methods, the growth process can be selectively switched between bimodal and unimodal distributions using dual beam illumination of the nanoparticles. This type of cooperative photo-control over nanostructure growth enables synthesis of monodisperse nanoprisms with a preselected edge length in the 30–120 nm range simply by using one beam to turn off bimodal growth and the other (varied over the 450–700 nm range) for controlling particle size.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

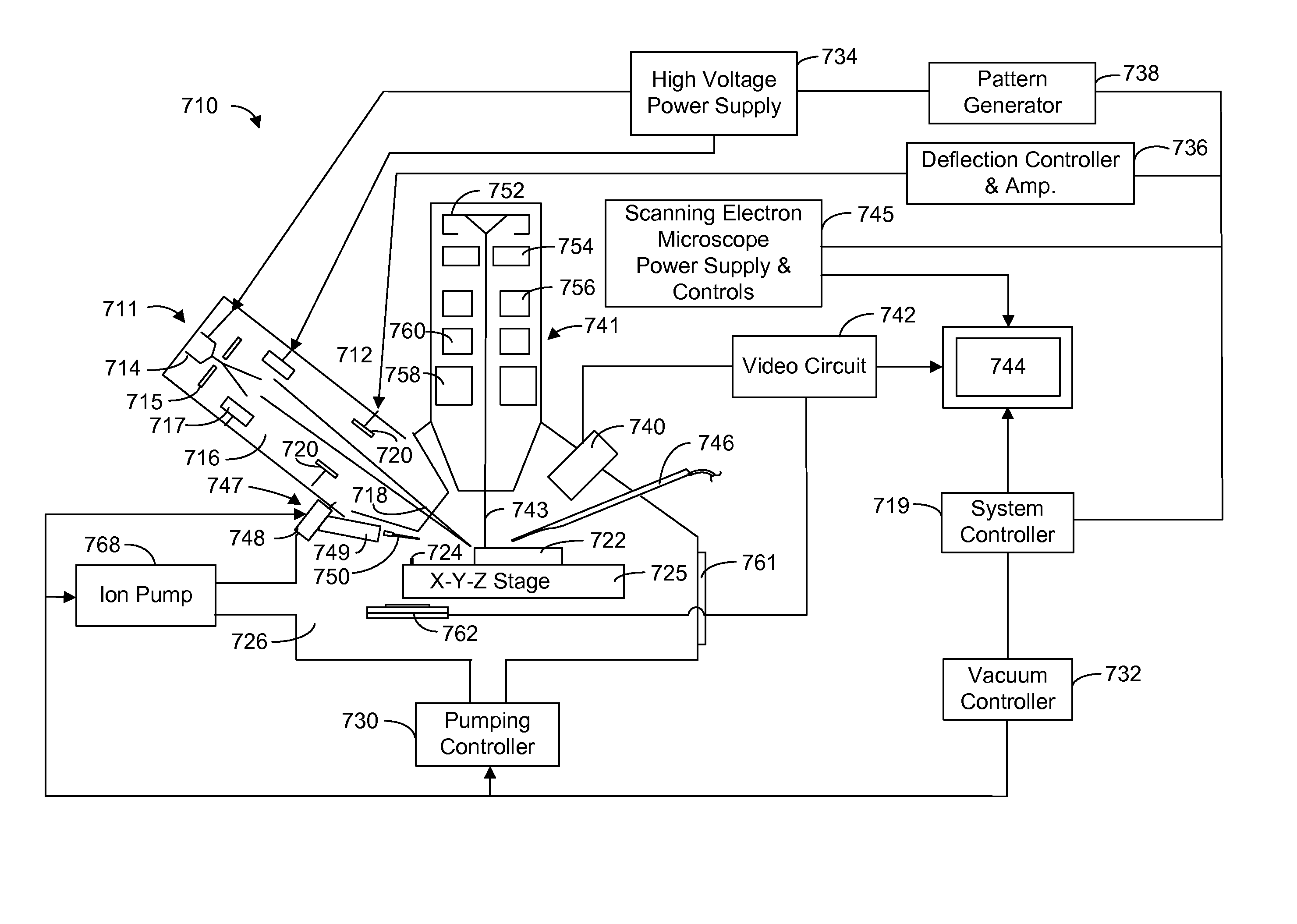

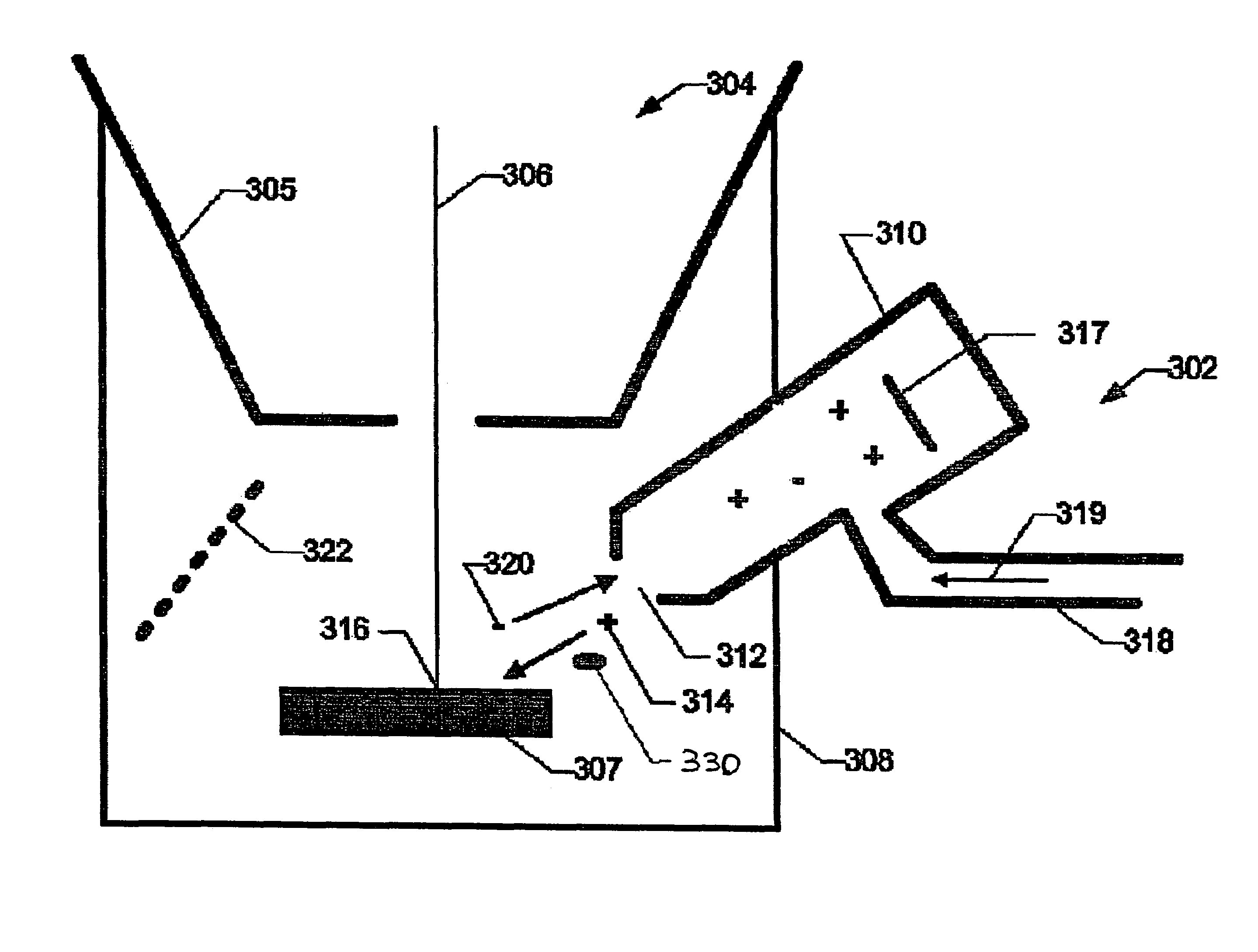

Charged particle beam system

InactiveUS6979822B1Reduce air pressureShorten the timeThermometer detailsStability-of-path spectrometersDual beamSignal generator

A charged particle beam system uses an ion generator for charge neutralization. In some embodiments, the ion generator is configured to maintain an adequate gas pressure at the ion generator to generate ions, but a reduced pressure in the remainder of the vacuum chamber, so that another column can operate in the chamber either simultaneously or after an evacuation process that is much shorter than a process that would be required to evacuate the chamber from the full pressure required at the ion generator. The invention is particularly useful for repair of photolithography masks in a dual beam system.

Owner:FEI CO

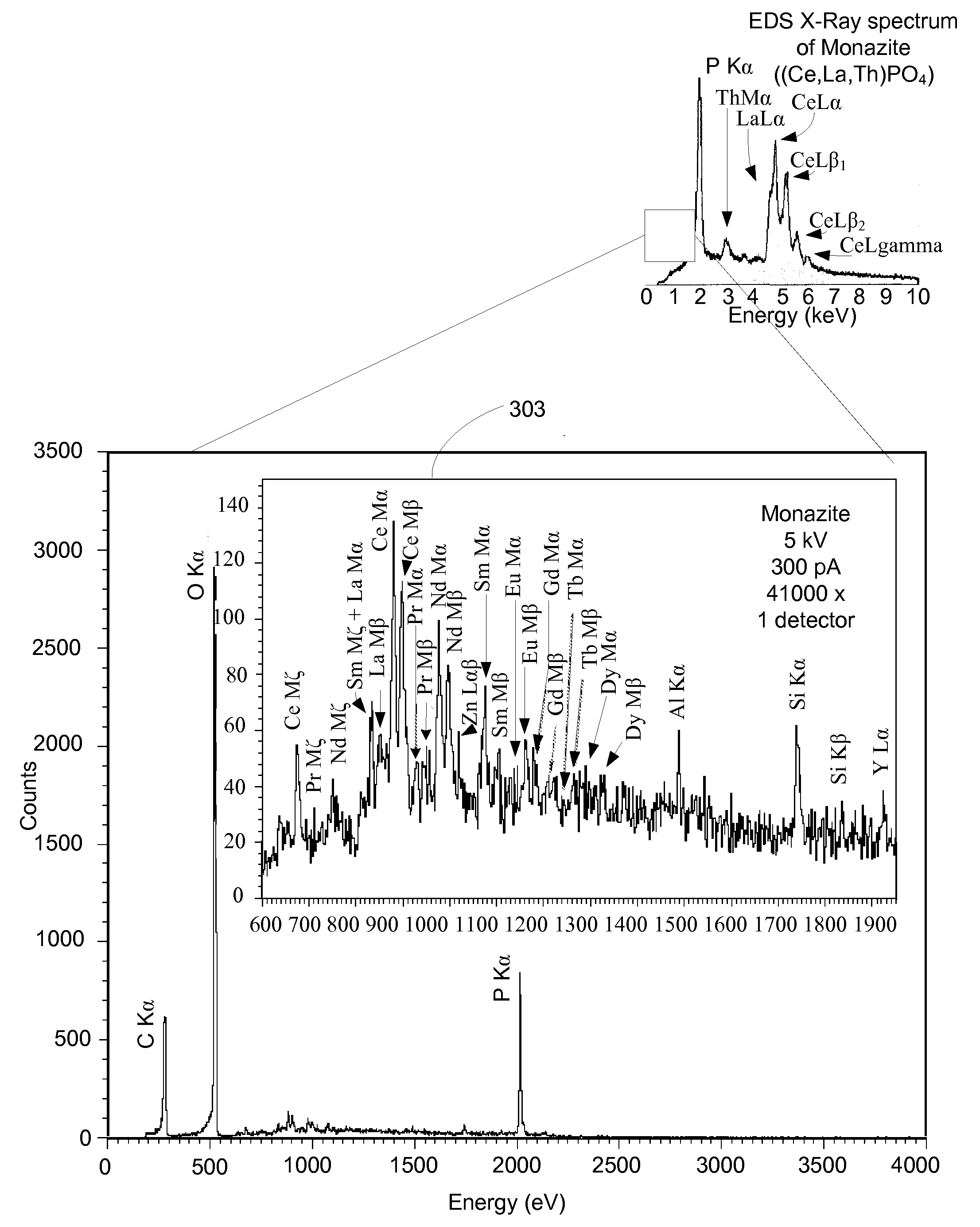

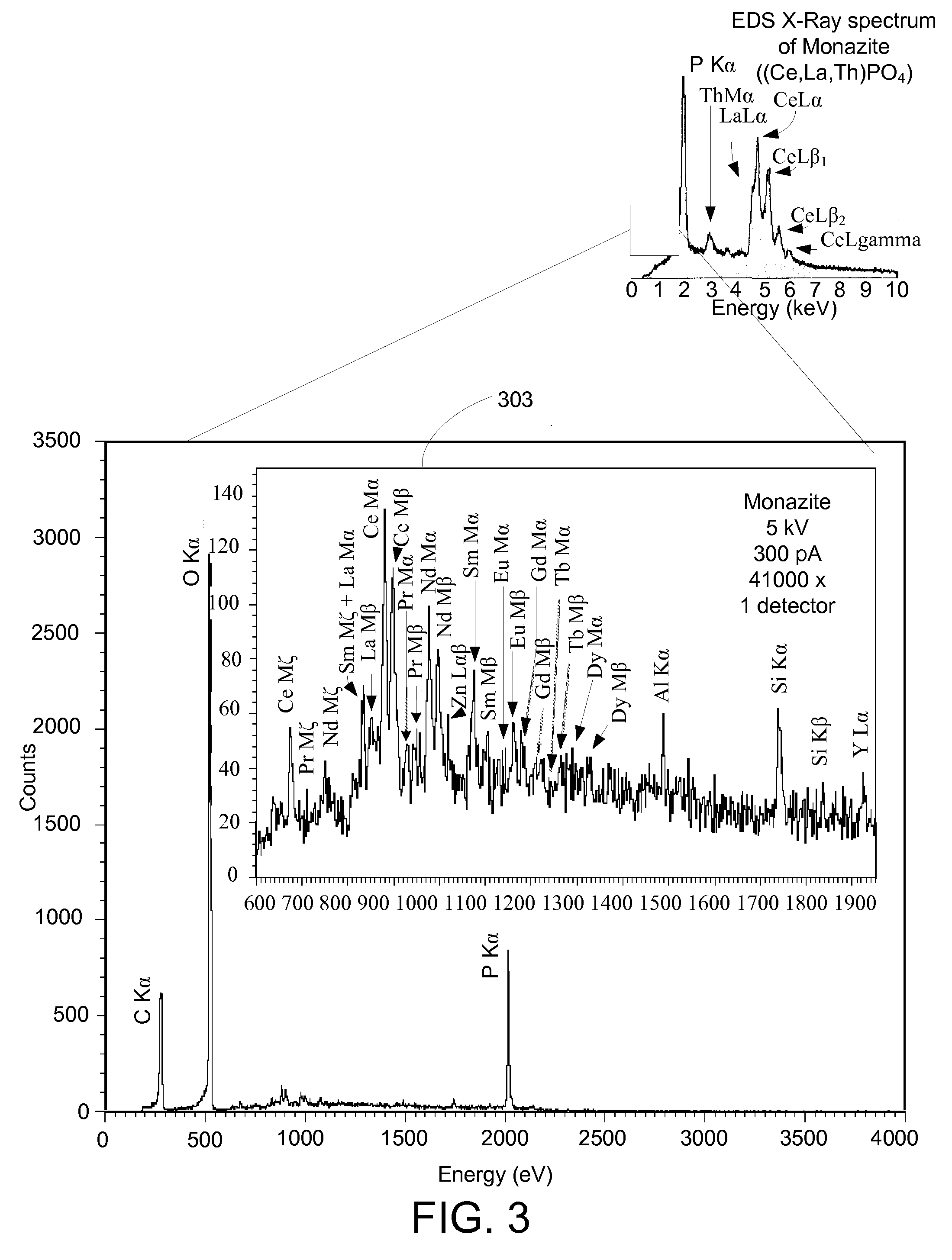

Microcalorimetry for x-ray spectroscopy

ActiveUS20110064191A1High resolution mappingSolve the lack of resolutionThermometer detailsX-ray spectral distribution measurementBeam energySpectrometer

An improved microcalorimeter-type energy dispersive x-ray spectrometer provides sufficient energy resolution and throughput for practical high spatial resolution x-ray mapping of a sample at low electron beam energies. When used with a dual beam system that provides the capability to etch a layer from the sample, the system can be used for three-dimensional x-ray mapping. A preferred system uses an x-ray optic having a wide-angle opening to increase the fraction of x-rays leaving the sample that impinge on the detector and multiple detectors to avoid pulse pile up.

Owner:FEI CO

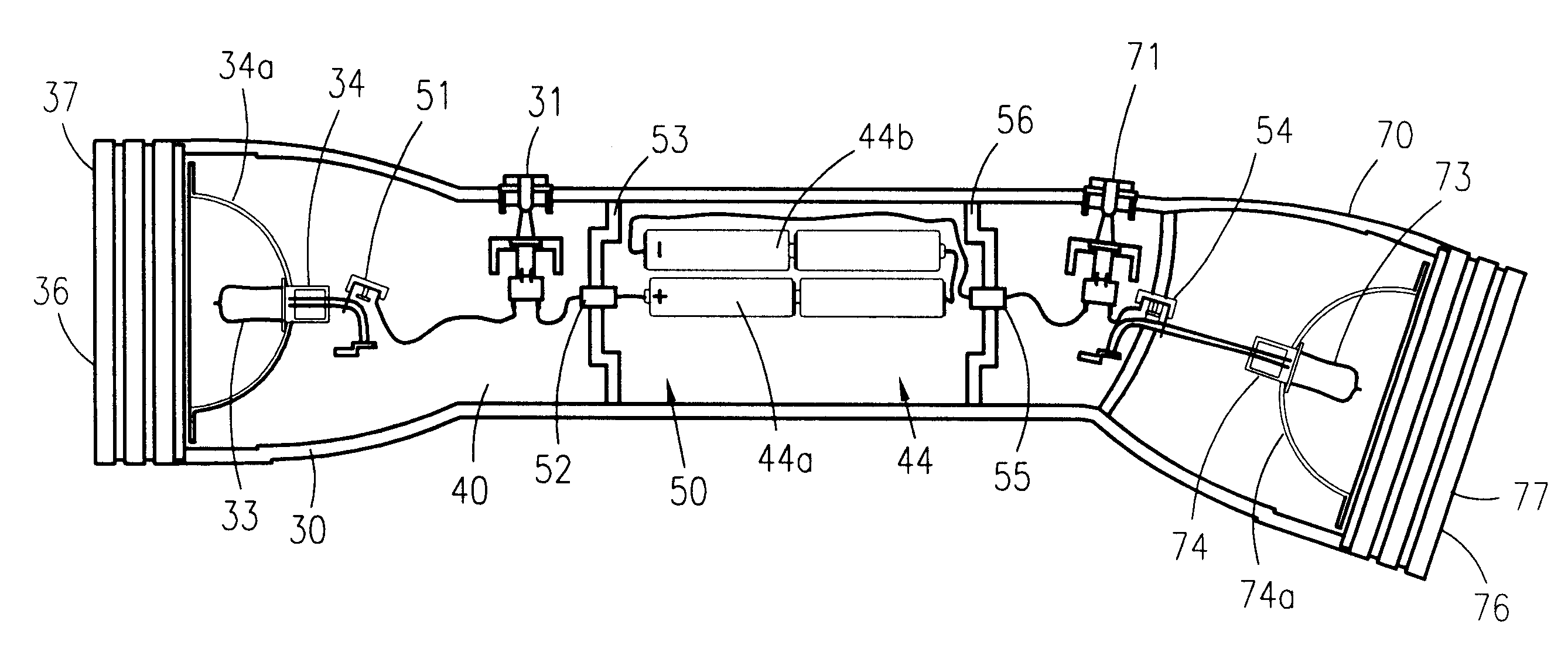

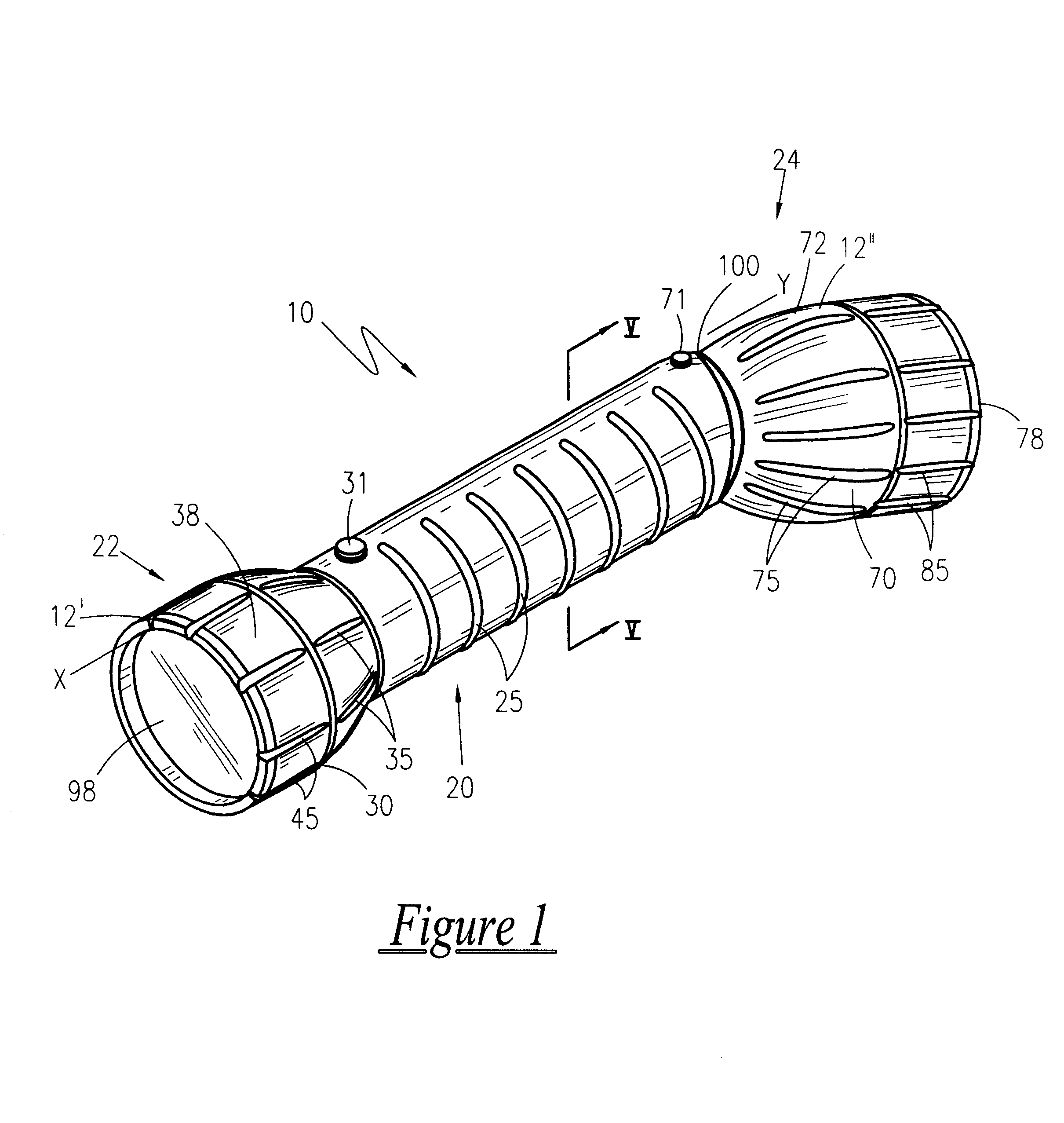

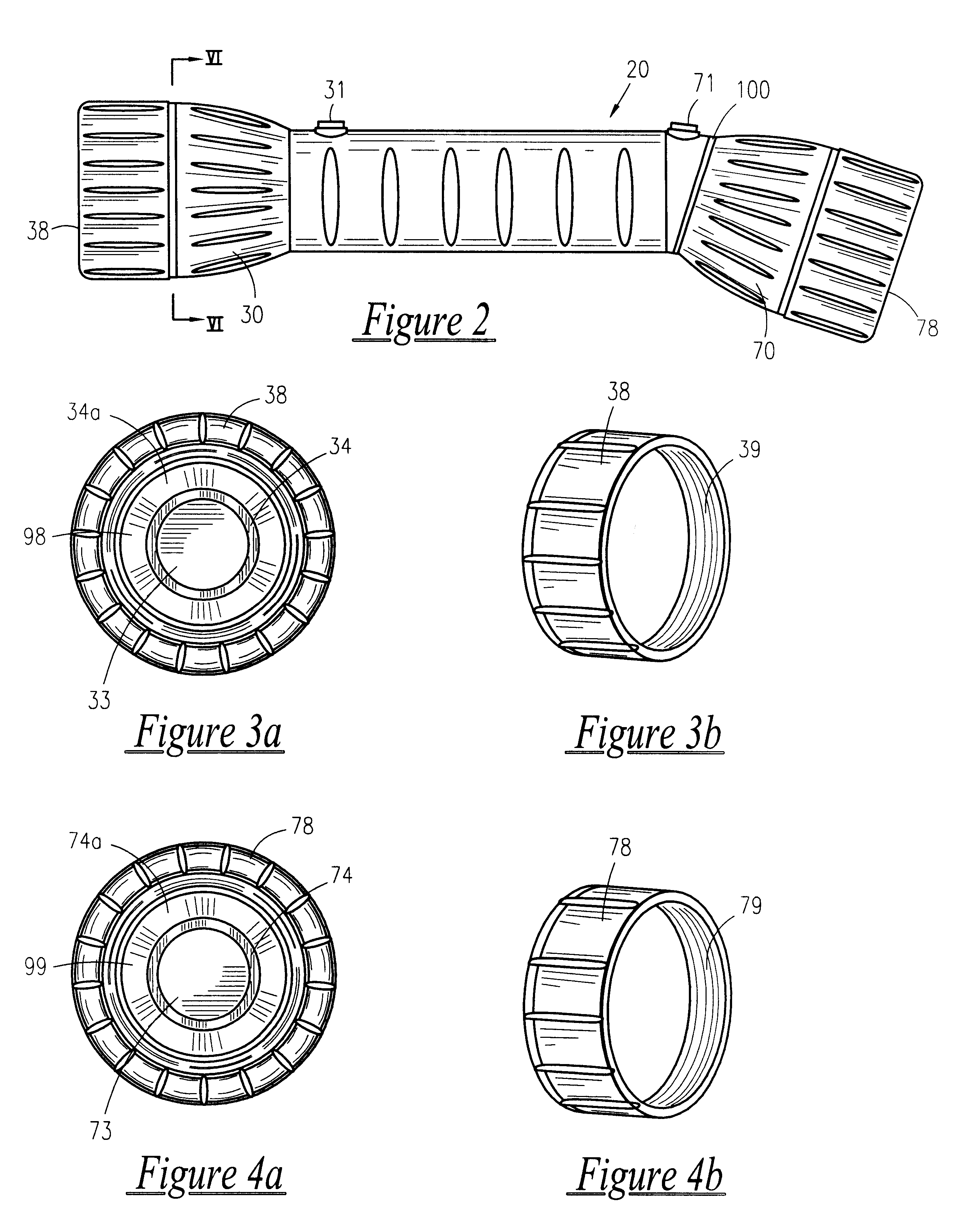

Dual-beam light assembly with adjustable posterior head

A dual-beam light assembly with adjustable posterior head provides a single lighting device for providing ample light for at least two persons walking in single file in an environment devoid of light. The dual-beam light assembly with adjustable posterior head has a pair of opposed, axially oriented, light emitting heads separated by a circular, hollow barrel which houses internal components. Flashlight bulbs are wired in a parallel circuit arrangement with the only common circuit elements being the power source. Two independent switches are provided to allow the flashlight bulbs to operate independently of one another. The barrel is made of high-impact plastic. A posterior end of the barrel includes a pivot assembly allowing for selective pivotal adjustment of the second light-emitting head to a plurality of specific angular settings.

Owner:WILLIAMS WILSON

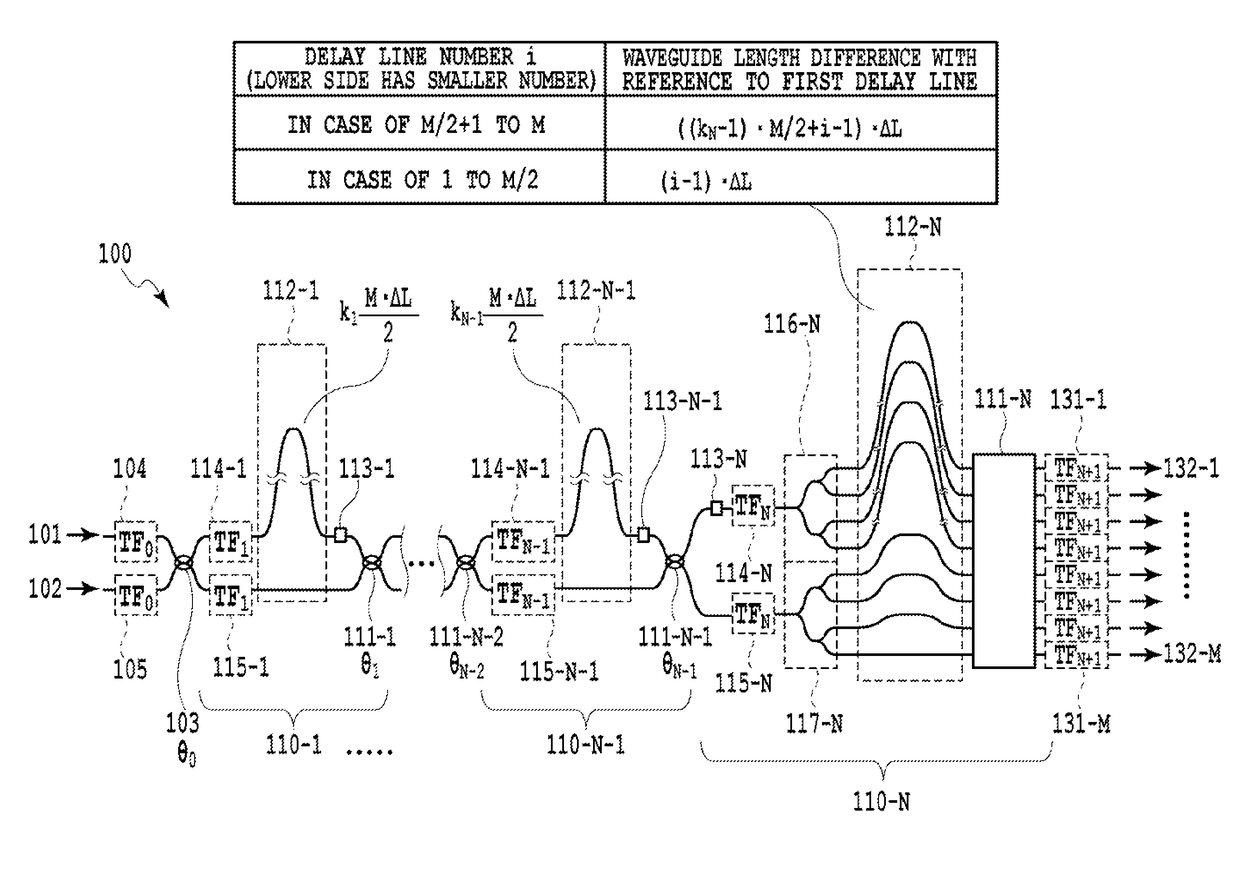

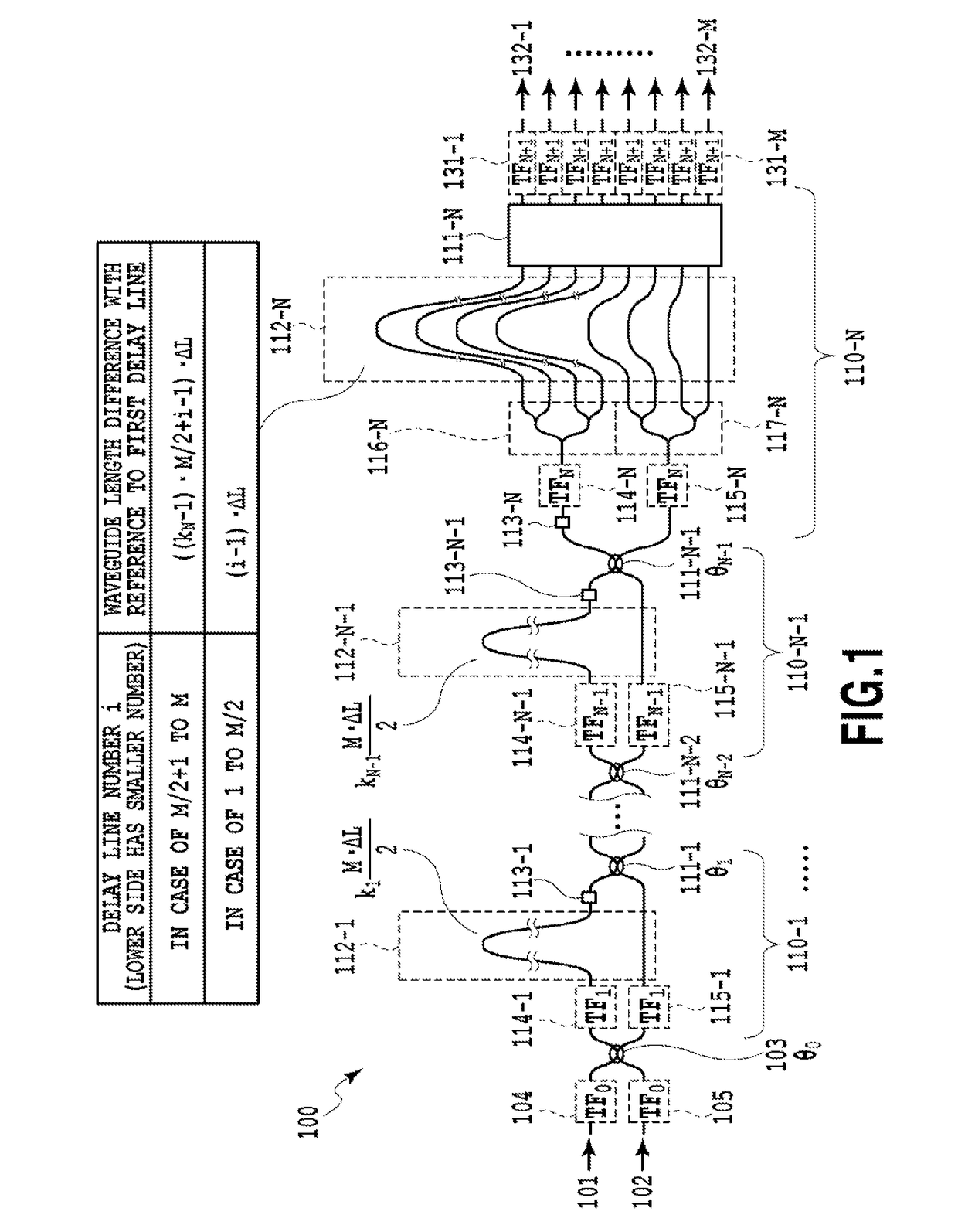

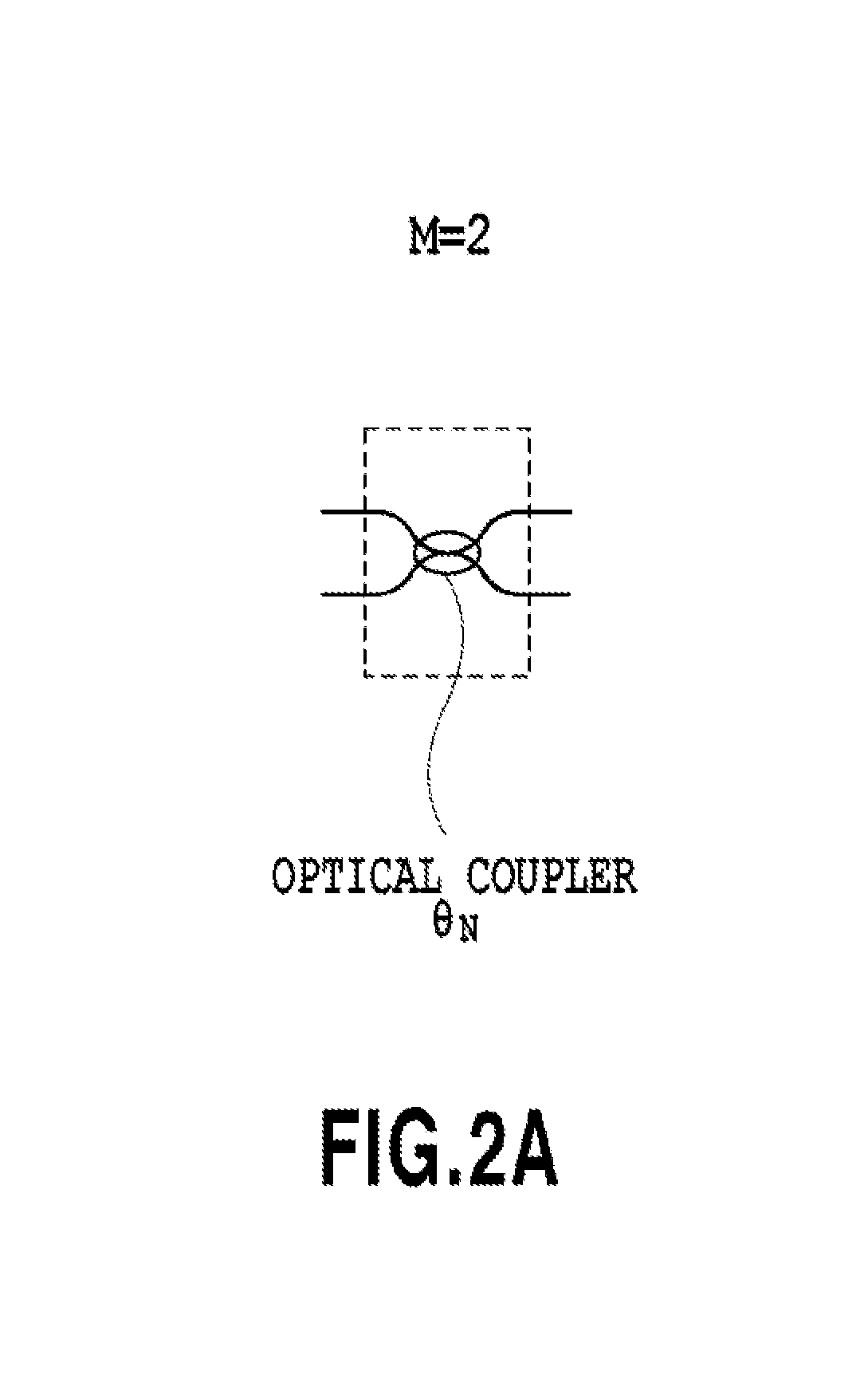

Multi-stage interferometer circuit with waveform shaping function

ActiveUS20180034555A1Device sizeSmall device sizeOptical multiplexElectromagnetic receiversOptical couplerPhysics

A multi-stage interferometer circuit of the present invention includes: a multiplexing port; (N-1) stages of lattice type two-beam interferometers, wherein each stage includes a two-beam delay circuit having a path length difference of an integral multiple of M·Δ L / 2, and wherein the two-beam delay circuit of the lattice type two-beam interferometer of the first stage is connected to the multiplexing port; an M-beam interferometer including: two sets of 1×(M / 2) optical couplers connected to the first optical coupler of the lattice type two-beam interferometer at the final stage; an M-array delay circuit, each delay circuit of which has a delay length different from each other by ΔL; and M×M optical couplers; and M demultiplexing ports, wherein one or more transversal filters are arranged inside the multi-stage interferometer circuit so that the light guided between the demultiplexing port and the multiplexing ports passes therethrough at least once.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

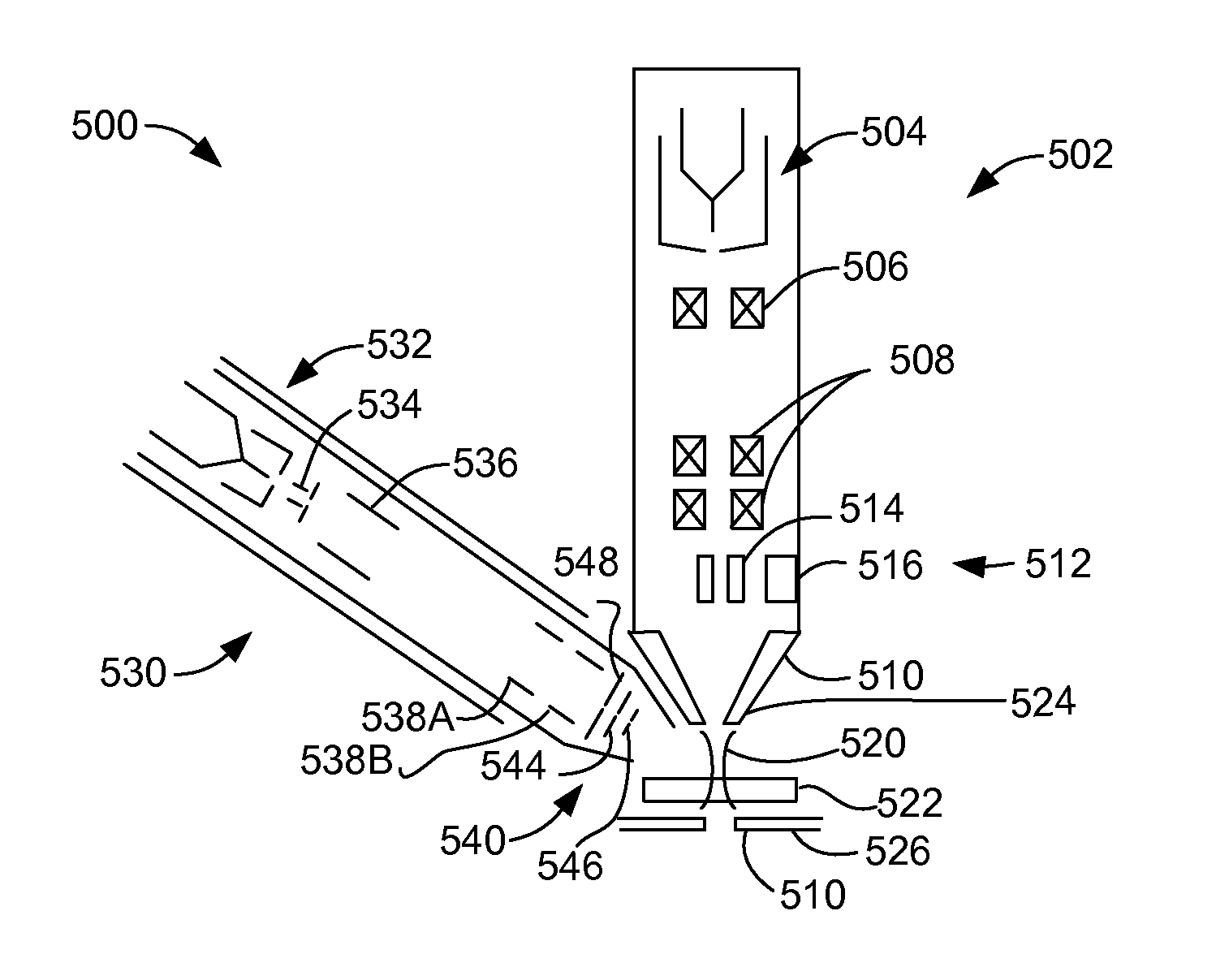

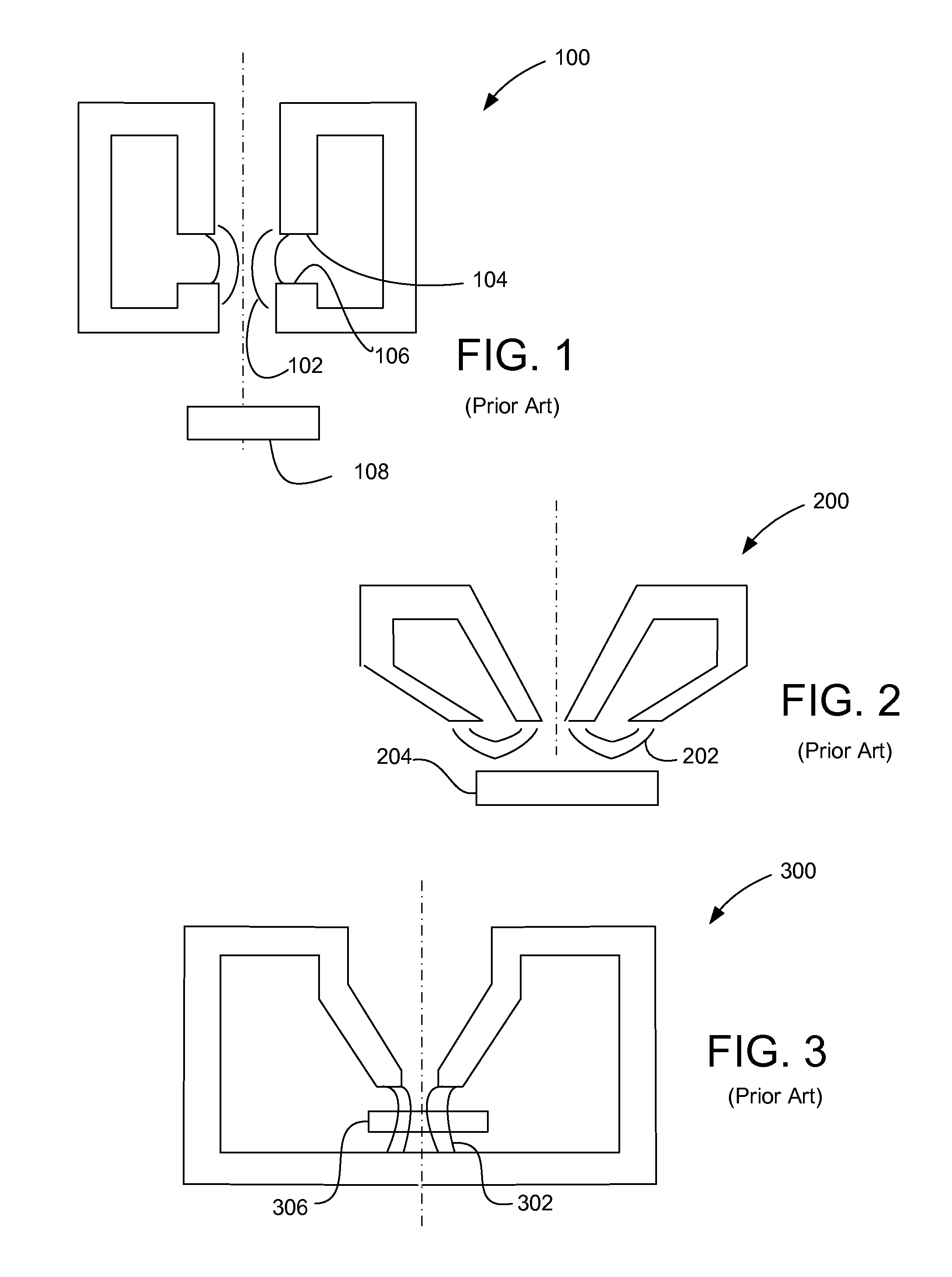

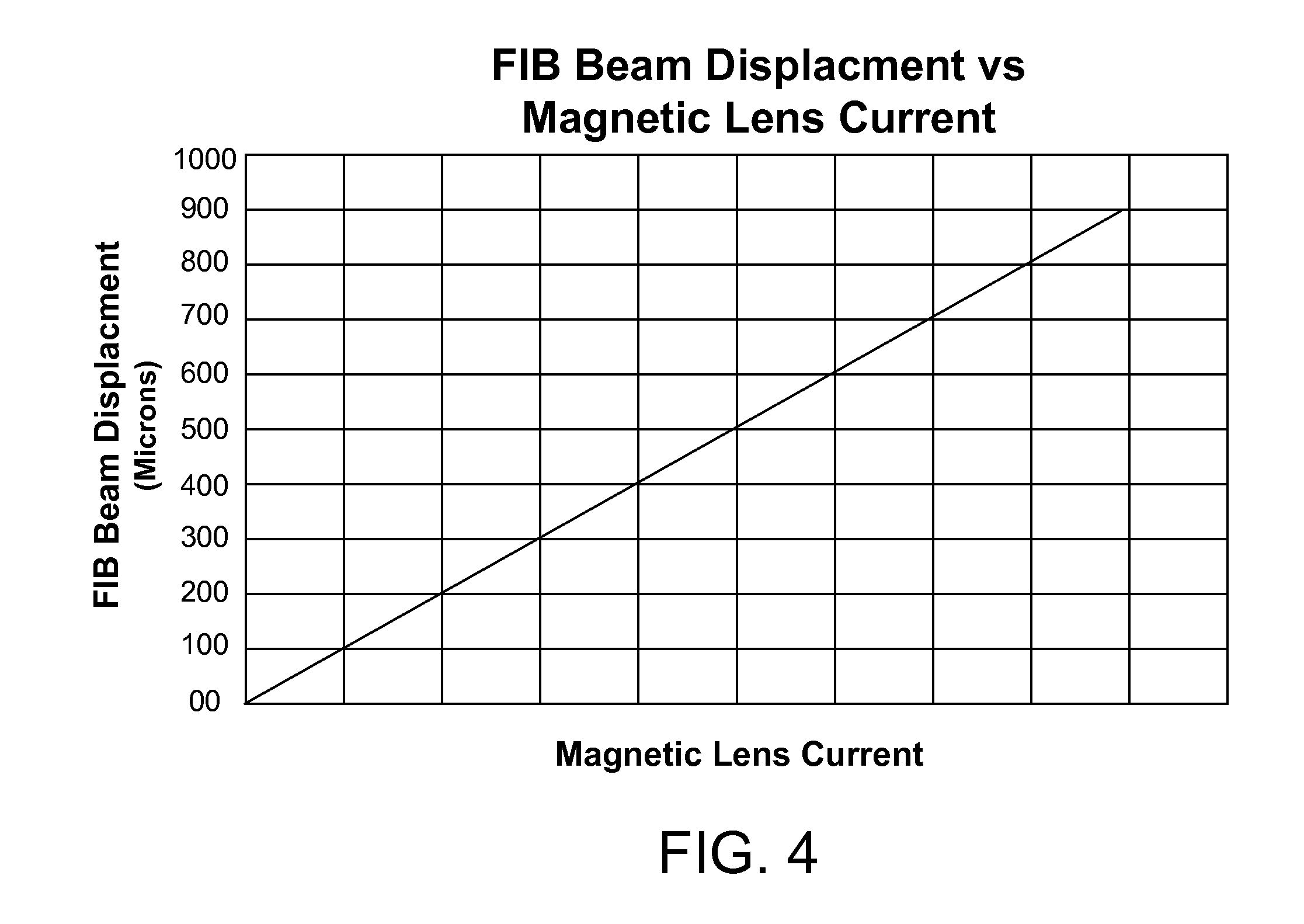

Dual beam system

ActiveUS20100301211A1Simple operating systemThermometer detailsMaterial analysis using wave/particle radiationDual beamImage resolution

A dual beam system provides for operation of a focused ion beam in the presence of a magnetic field from an ultra-high resolution electron lens. The ion beam is deflected to compensate for the presence of the magnetic field.

Owner:FEI CO

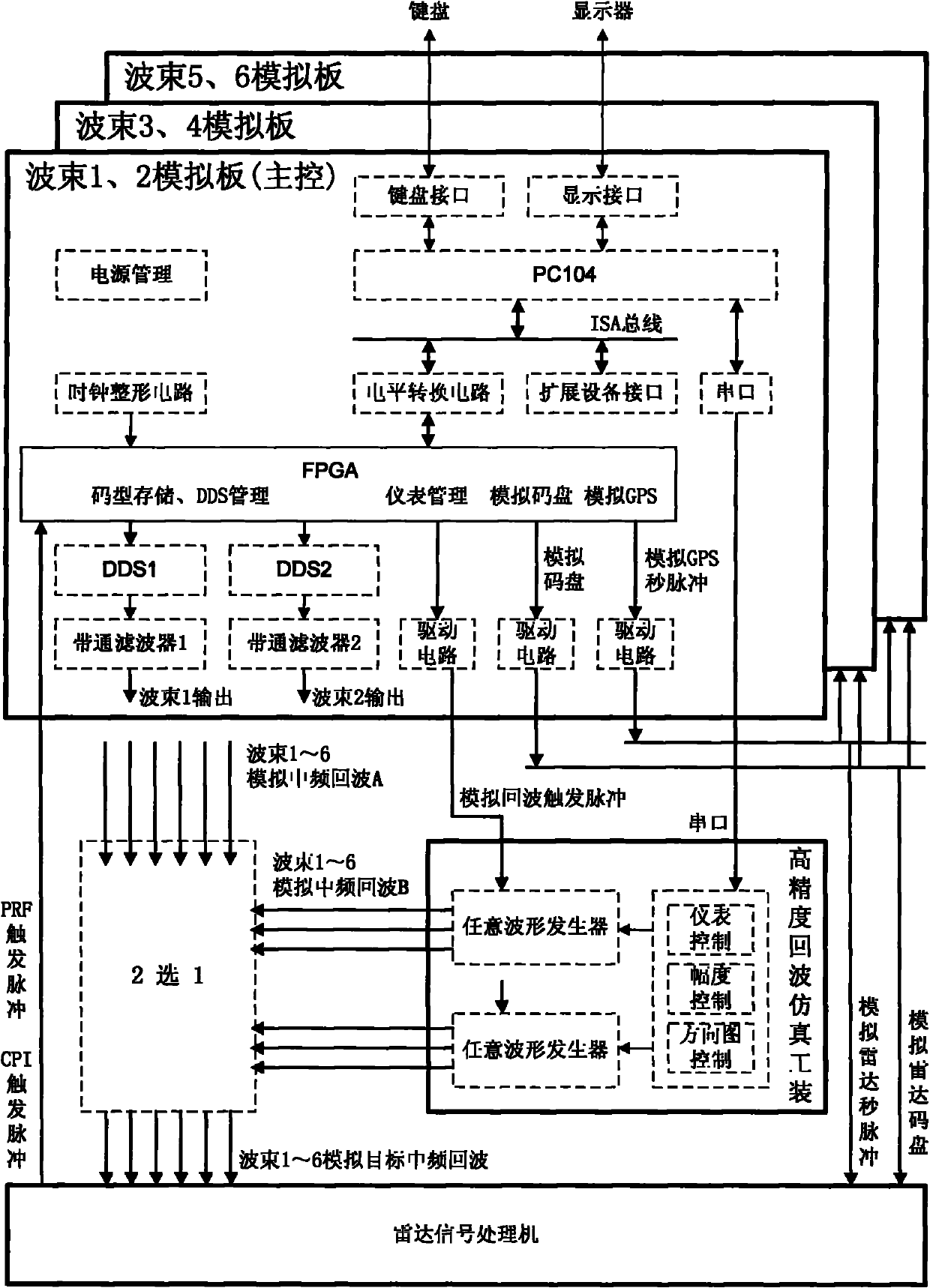

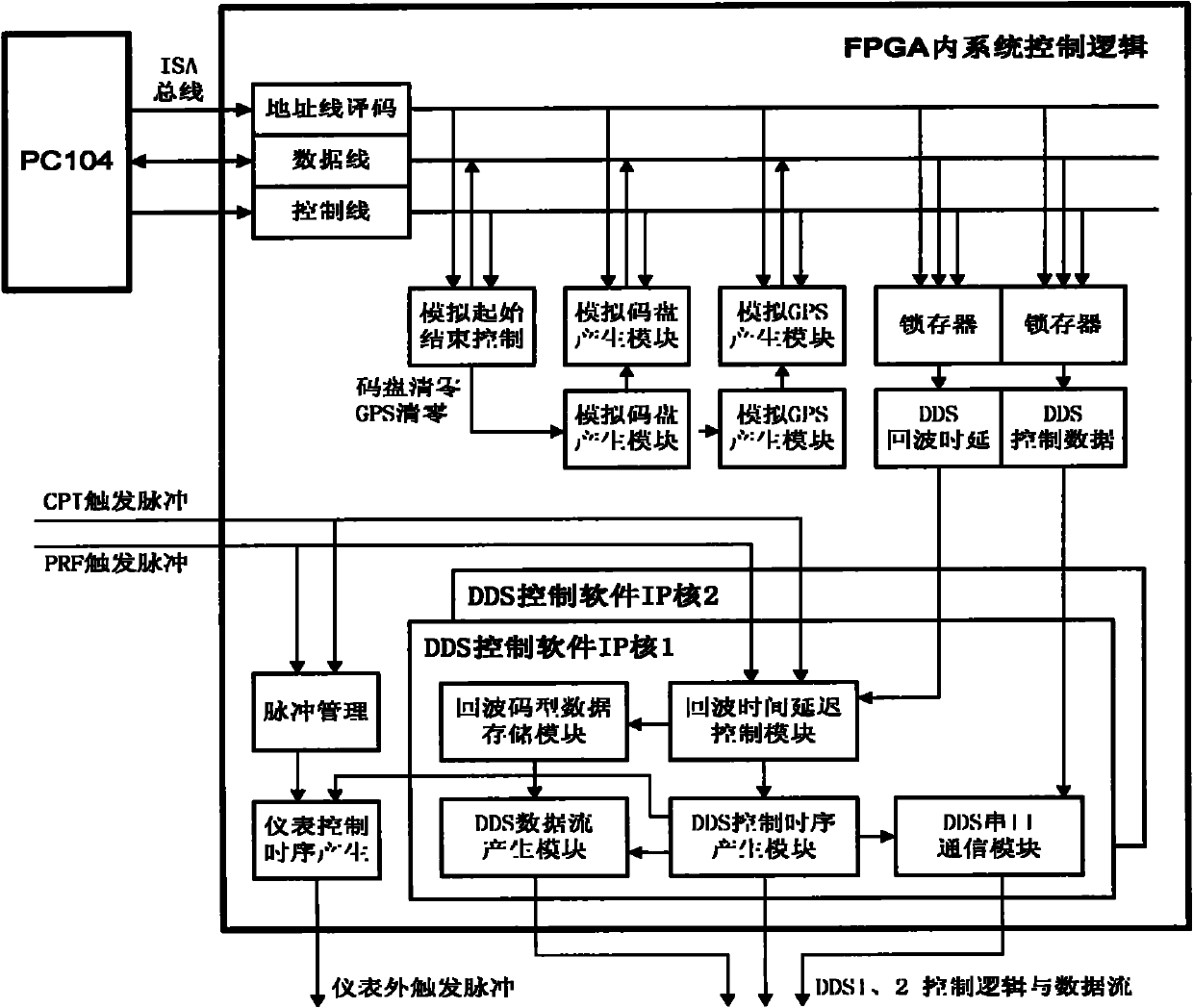

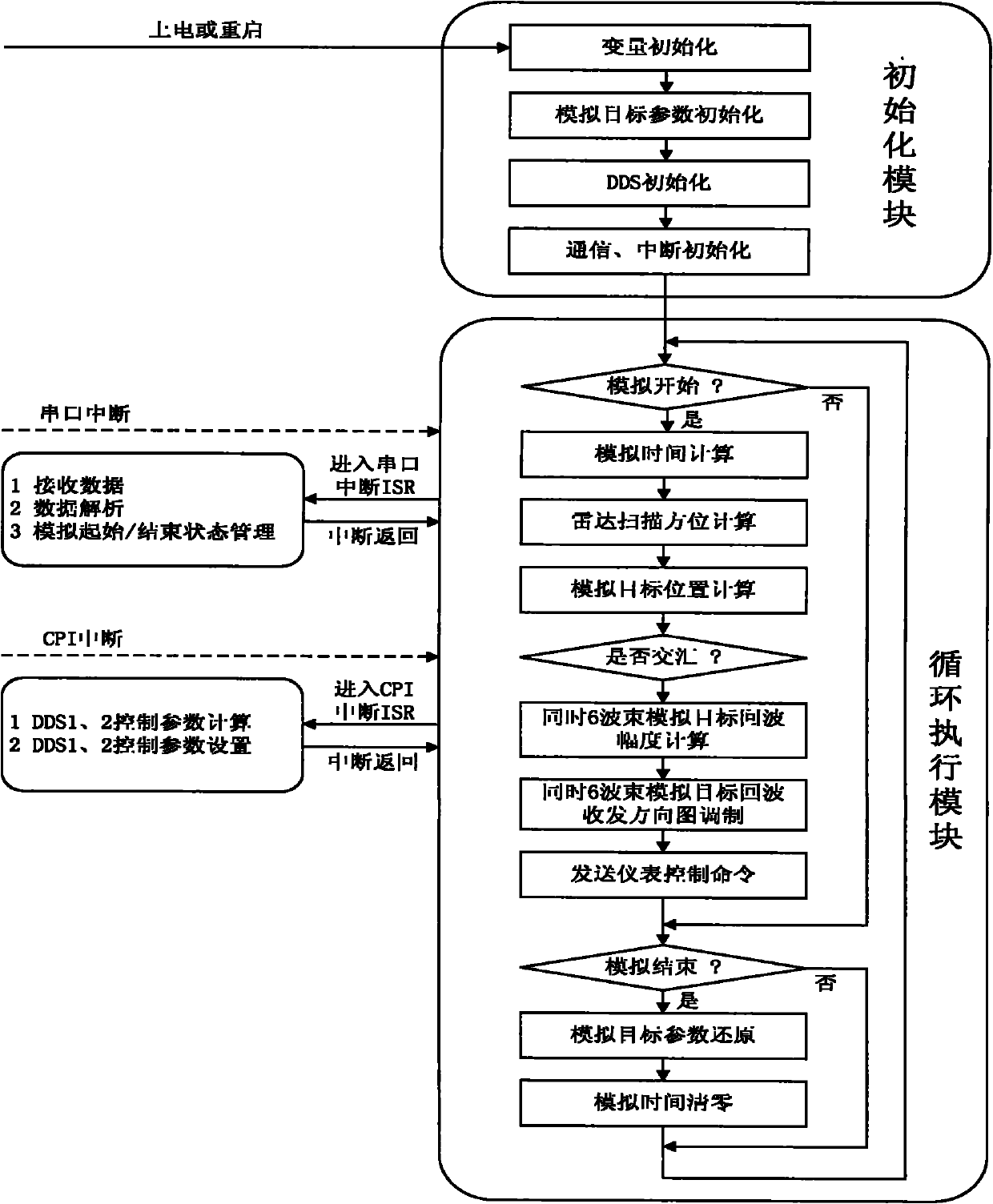

Radar target intermediate frequency (IR) echo simulation system based on multi-beam amplitude-comparison angle measurement and control method thereof

InactiveCN102023293AEasy to controlDensity controllableWave based measurement systemsIntermediate frequencyRadar signal processing

The invention relates to a radar target intermediate frequency (IR) echo simulation system based on multi-beam amplitude-comparison angle measurement and a control method thereof, relating to the field of radar target echo simulation. The system comprises three target echo simulation boards and an arbitrary waveform generator instrument fixture, wherein the echo simulation boards are designed with a computer module PC104, a field programmable gate array (FPGA), direct digital synthesis (DDS) technique and a simulation circuit as cores; and the arbitrary waveform generator instrument fixture is designed with instrument programming control as the core. According to the invention, simultaneous 6-channel simulated target IR echo simulation of the radar of the multi-beam amplitude-comparison angle measurement system is realized, parameters of the simulated target echo such as distance, delay, echo amplitude, Doppler shift, pattern, direction pattern modulation, noise superposition and the like can be controlled, single-channel switching and output of dual-beam echo is realized, and the test use requirement of the radar signal processor of the system is met. In the invention, the arbitrary waveform generator instrument frock is utilized, thus improving the amplitude precision of the output echo signals; and the control program in the FPGA in the target echo simulation boards is designed by the soft IP core, thus providing convenience for hardware transplanting and clipping.

Owner:中国兵器工业第二0六研究所

Dual beam system

ActiveUS20050035291A1Remove blurEasy to collectThermometer detailsMaterial analysis using wave/particle radiationDual beamScanning tunneling microscope

A dual beam system includes an ion beam system and a scanning electron microscope with a magnetic objective lens. The ion beam system is adapted to operate optimally in the presence of the magnetic field from the SEM objective lens, so that the objective lens is not turned off during operation of the ion beam. An optional secondary particle detector and an optional charge neutralization flood gun are adapted to operate in the presence of the magnetic field. The magnetic objective lens is designed to have a constant heat signature, regardless of the strength of magnetic field being produced, so that the system does not need time to stabilize when the magnetic field is changed.

Owner:FEI CO

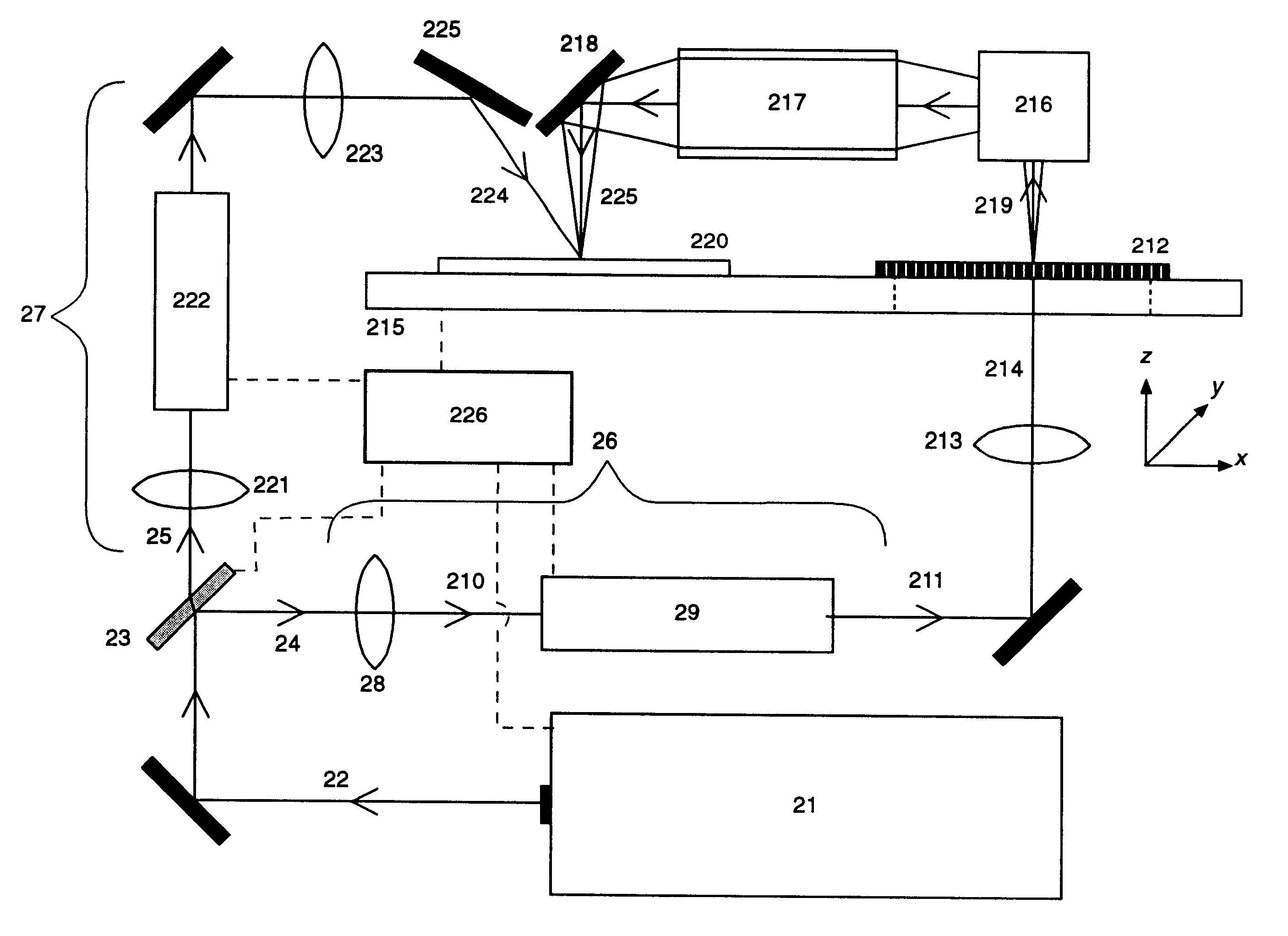

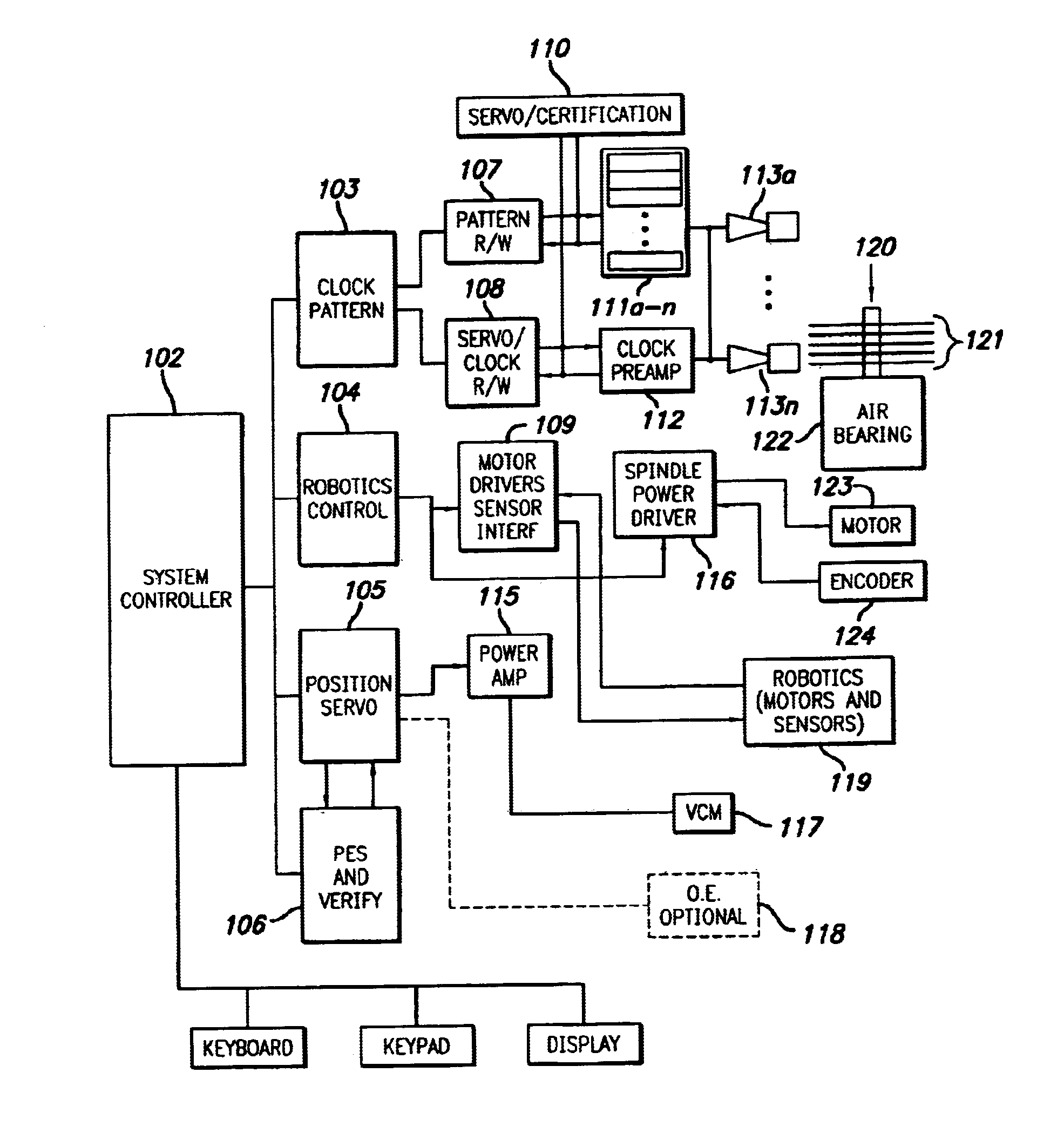

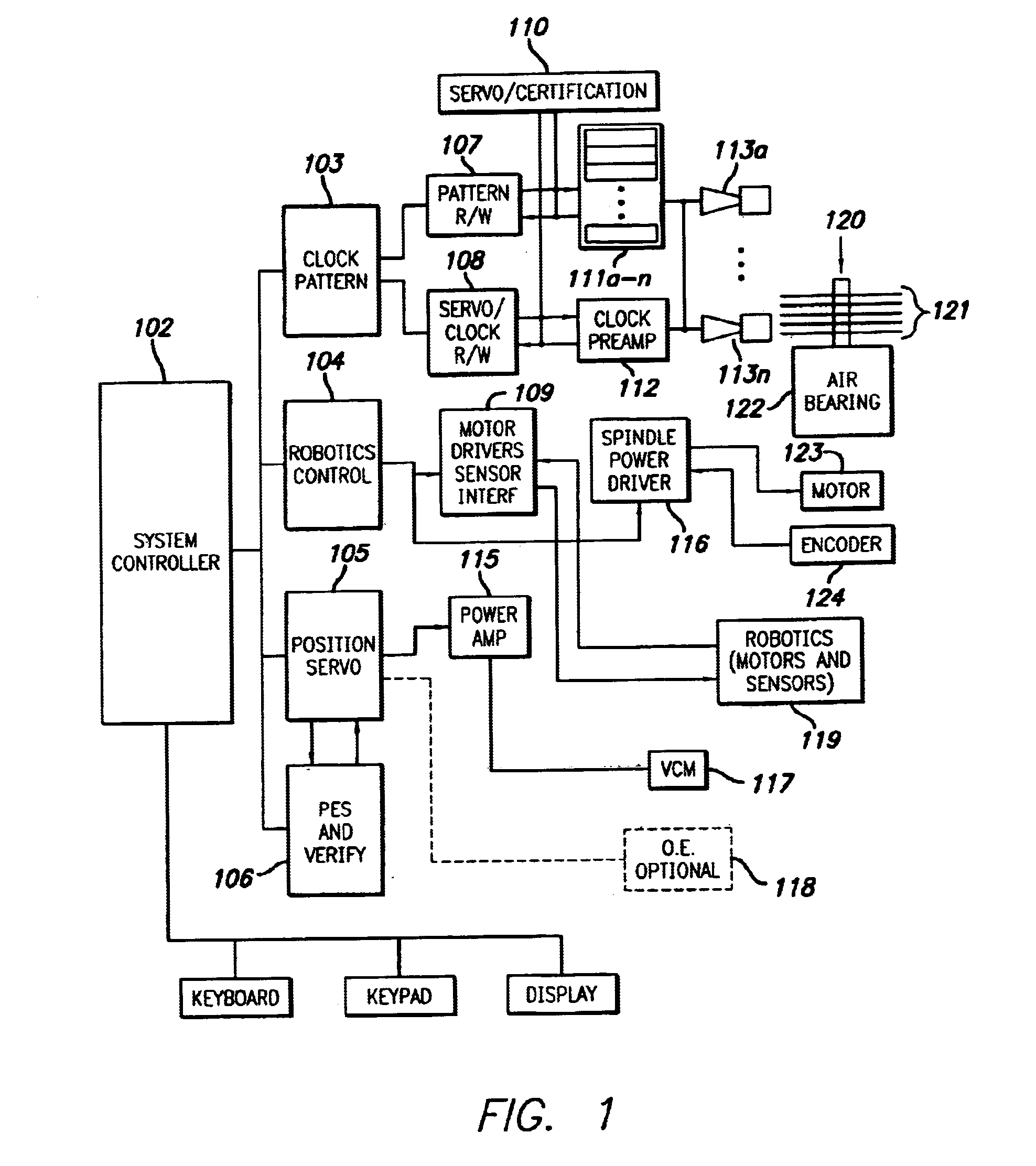

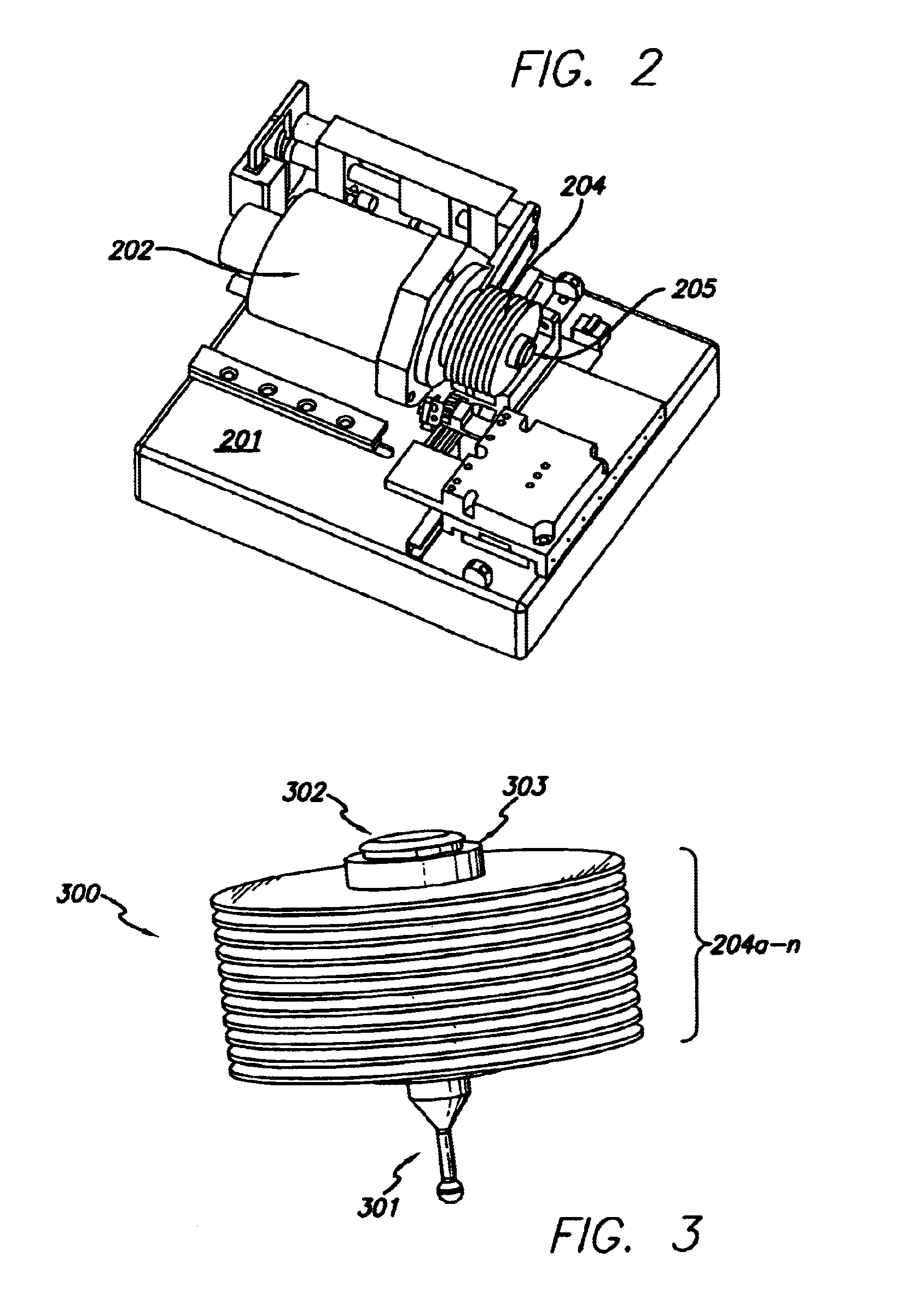

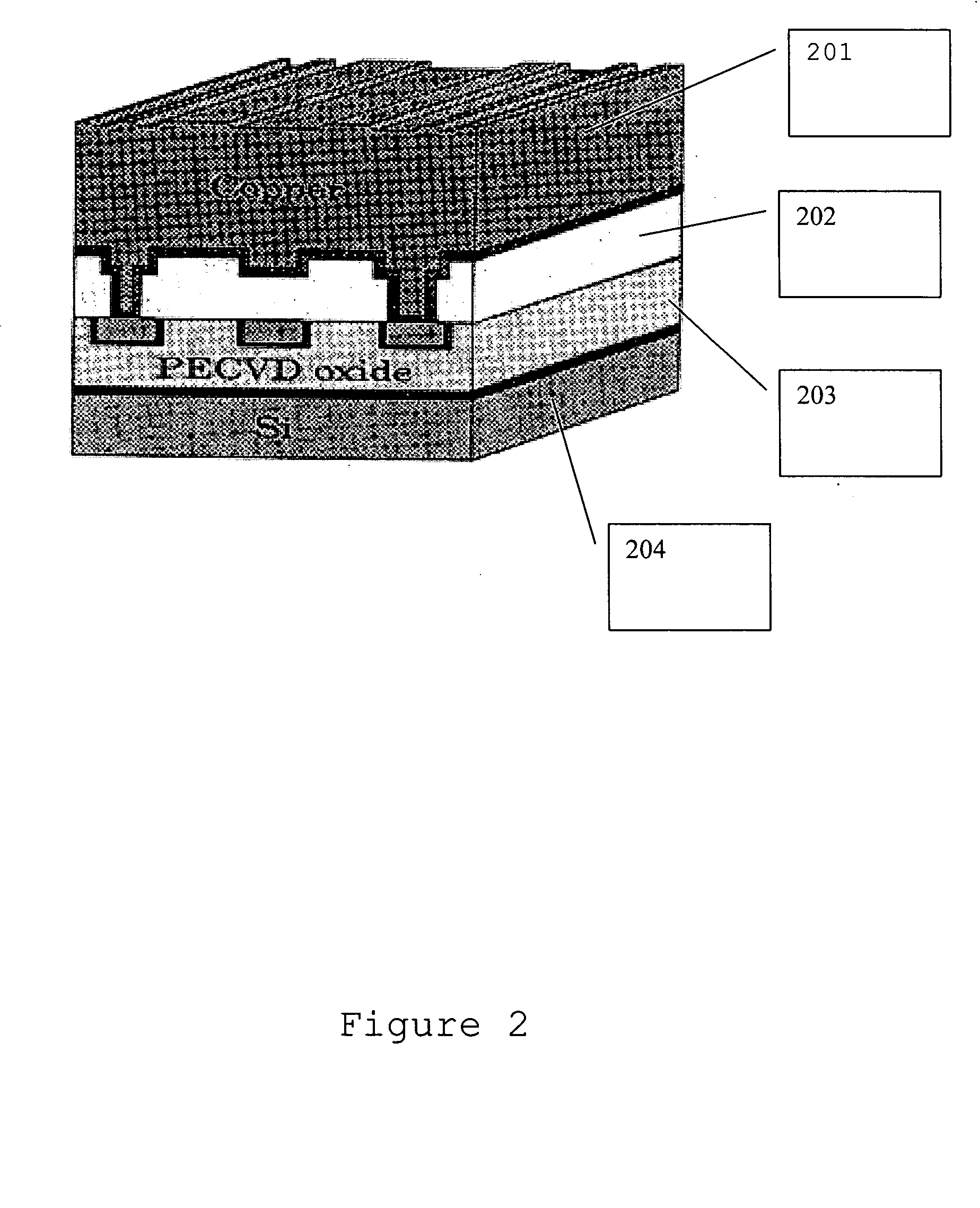

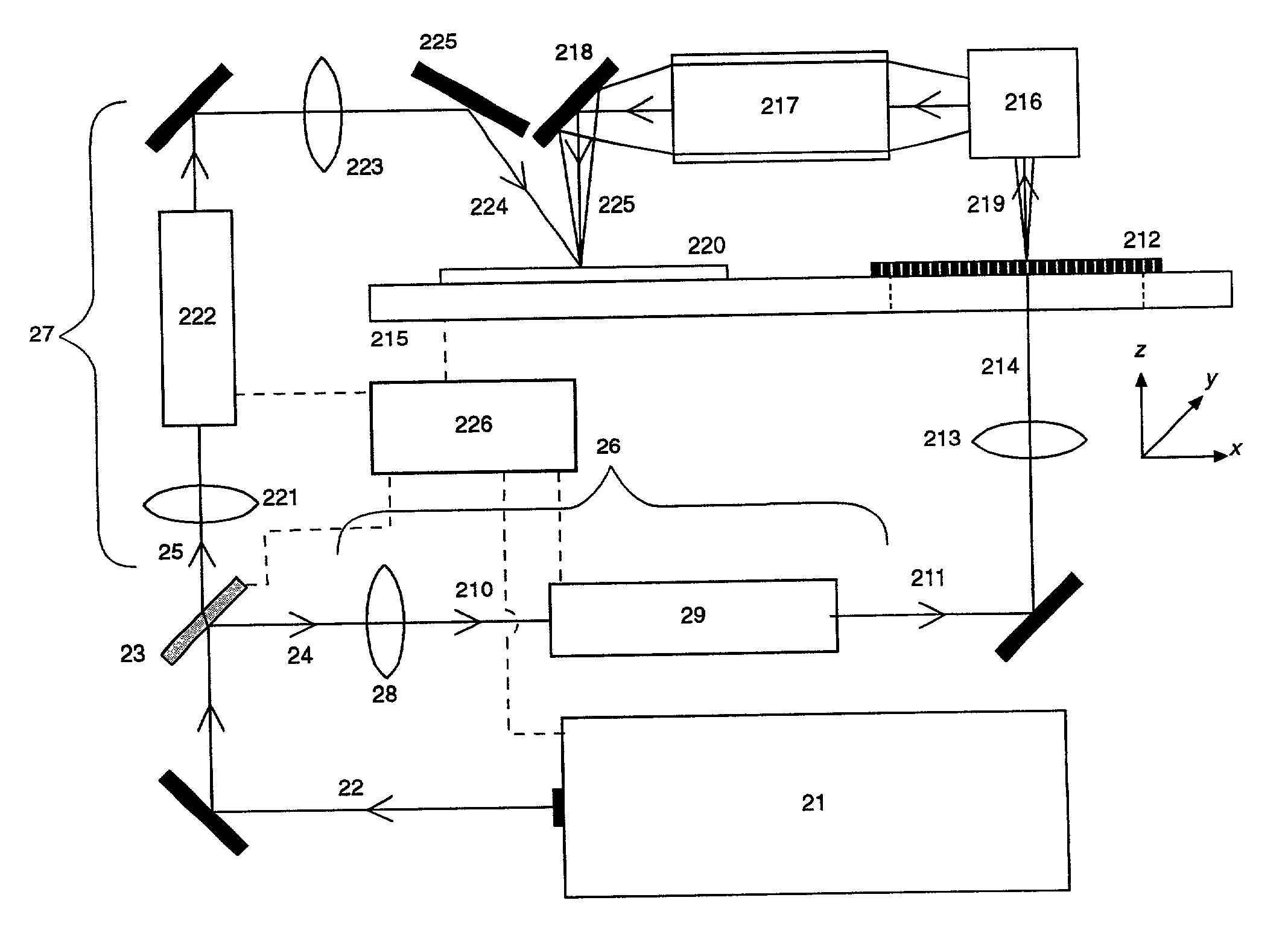

Media servowriting system

InactiveUS6977791B2Tight interfaceMinimize the possibilityDriving/moving recording headsUndesired vibrations/sounds insulation/absorptionDual beamLight beam

A system and methods for efficiently performing media writing functions is disclosed. The system and methods include: detecting media movement with respect to a base and heads during reading and writing, and moving the heads in response; using an interferometer, such as a dual beam differential interferometer, to dynamically monitor disk position and address perceived errors; and minimizing repeatable and non repeatable runout error by writing data, such as servo bursts, in multiple revolutions to average adverse runout conditions. The present system has the ability to use an interferometer to enhance media certification and perform on line, in situ monitoring of the media, and includes shrouding, head mounting, disk biasing, and related mechanical aspects beneficial to media writing.

Owner:KLA TENCOR TECH CORP

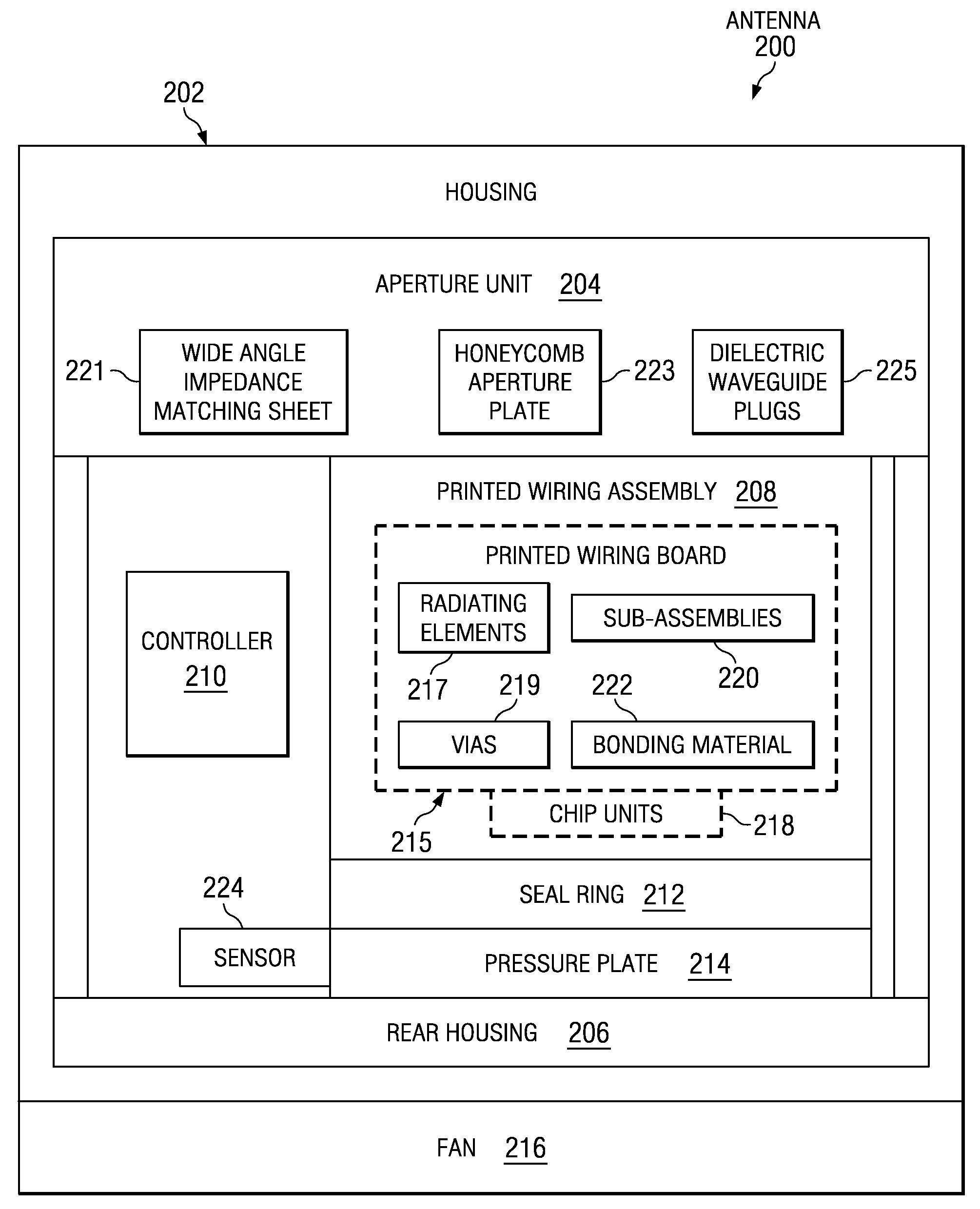

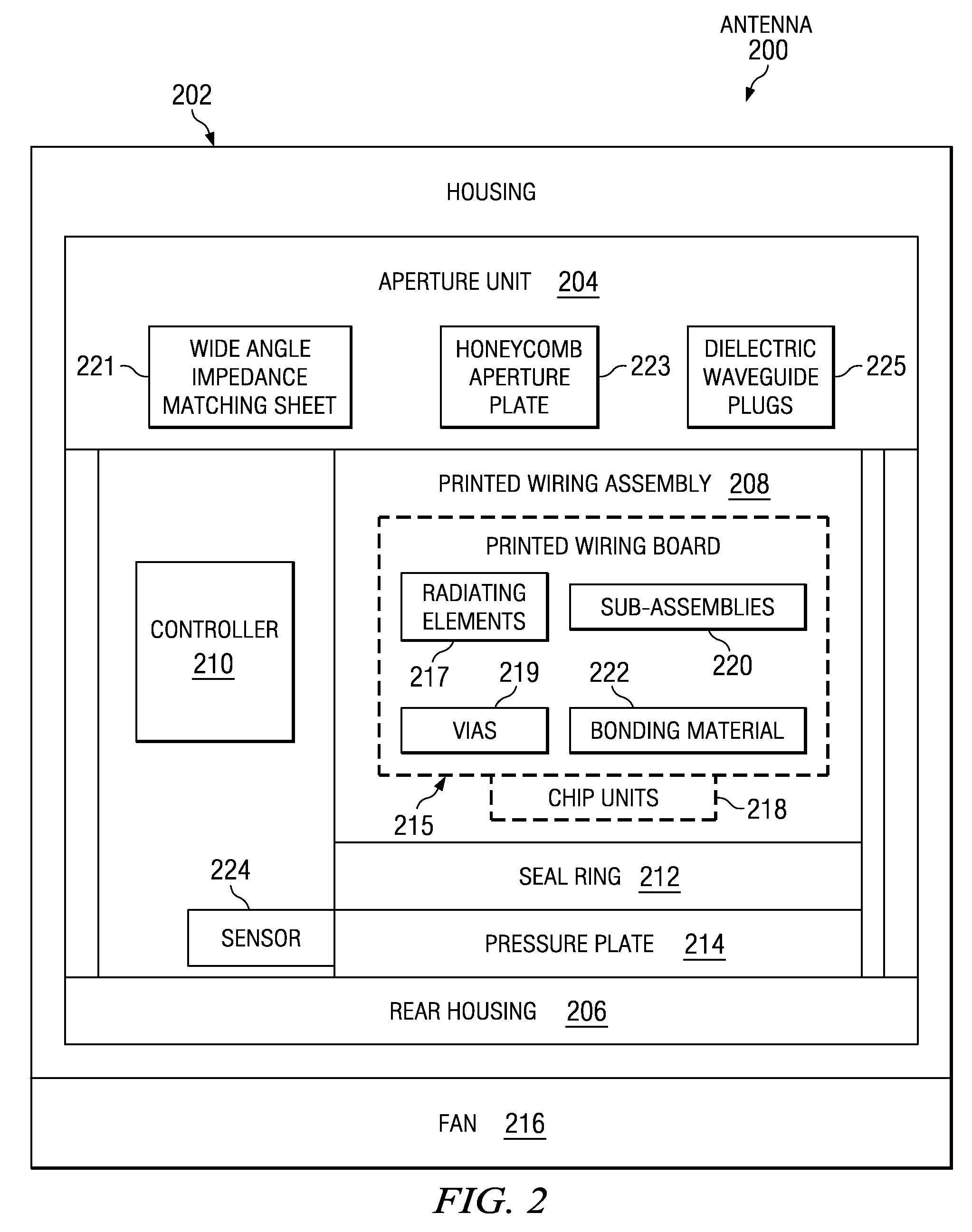

Dual beam dual selectable polarization antenna

A dual beam dual-selectable-polarization phased array antenna comprises an aperture unit, a printed wiring board, radiating elements, chip units, a pressure plate, and a rear housing unit. The printed wiring board has sub assemblies bonded to each other with a bonding material providing both mechanical and electrical connection. The printed wiring board is connected to the aperture unit. The radiating elements are formed on the printed wiring board. The chip units are mounted on the printed wiring board. The chip units include circuits capable of controlling radio frequency signals radiated by the radiating elements to form dual beams with independently selectable polarization. The pressure plate is connected to the aperture unit. The aperture unit is connected to the rear housing unit such that the aperture unit covers the rear housing unit.

Owner:THE BOEING CO

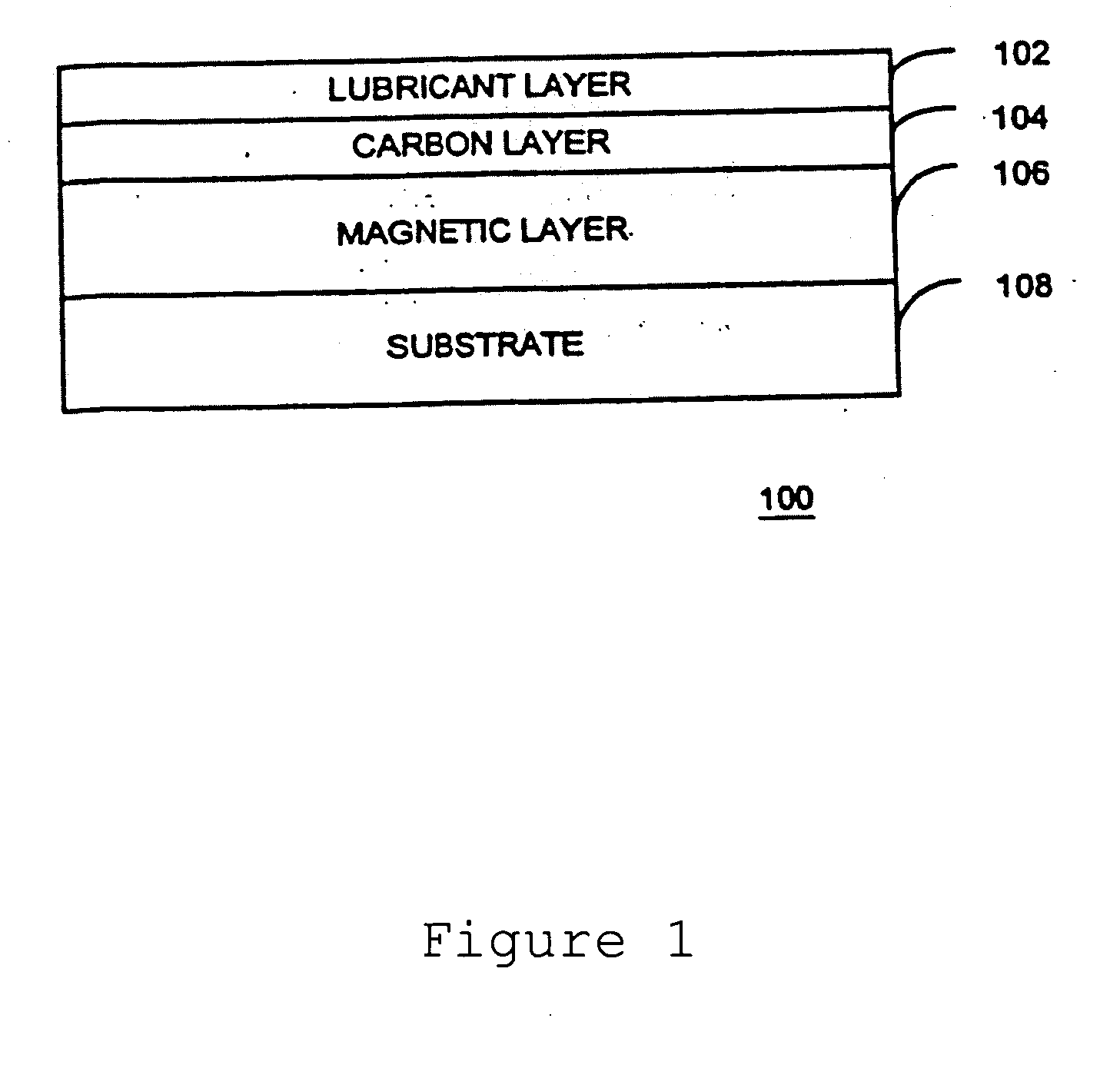

Method of detecting and classifying scratches, particles and pits on thin film disks or wafers

InactiveUS20050057747A1Semiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationDual beamLight beam

Scratches, pits and particles which are smaller or larger than the beam size may be measured and identified by a dual beam technique. This invention uses a pair of orthogonally oriented laser beams, one in the radial and one in the circumferential direction. The scattered light from radial and circumferential beams allows the detection and classification of particles, pits and scratches.

Owner:MEEKS STEVEN W

Dual-beam materials-processing system

InactiveUS20020130279A1Improve throughputProlonging of mask lifePhotometryPhotomechanical exposure apparatusDual beamLight beam

Apparatus and method for patterned sequential lateral solidification of a substrate surface, avoiding the need for demagnification to avoid mask damage from fluence sufficient to overcome the threshold for sequential lateral solidification, while using the high throughput of a common stage presenting both 1:1 mask and substrate simultaneously for patterning. The radiation source provides imaging beam and non-imaging beam, each of fluence below the threshold of sequential lateral solidification, but with aggregate fluence above the threshold. The imaging beam path includes a relatively delicate 1:1 mask and 1:1 projection subsystem, with optical elements including a final fold mirror proximate to the substrate surface, put the below-threshold mask pattern on the substrate surface. The non-imaging beam bypasses the delicate elements of imaging beam path, passing through or around the final fold mirror, to impinge on the substrate surface at the same location. Where the radiation patterns of the masked imaging beam and non-imaging beam coincide, their aggregate fluence exceeds the threshold for sequential lateral solidification. The dual selection provides pattern without damage to delicate optical elements.

Owner:ANVIK CORP

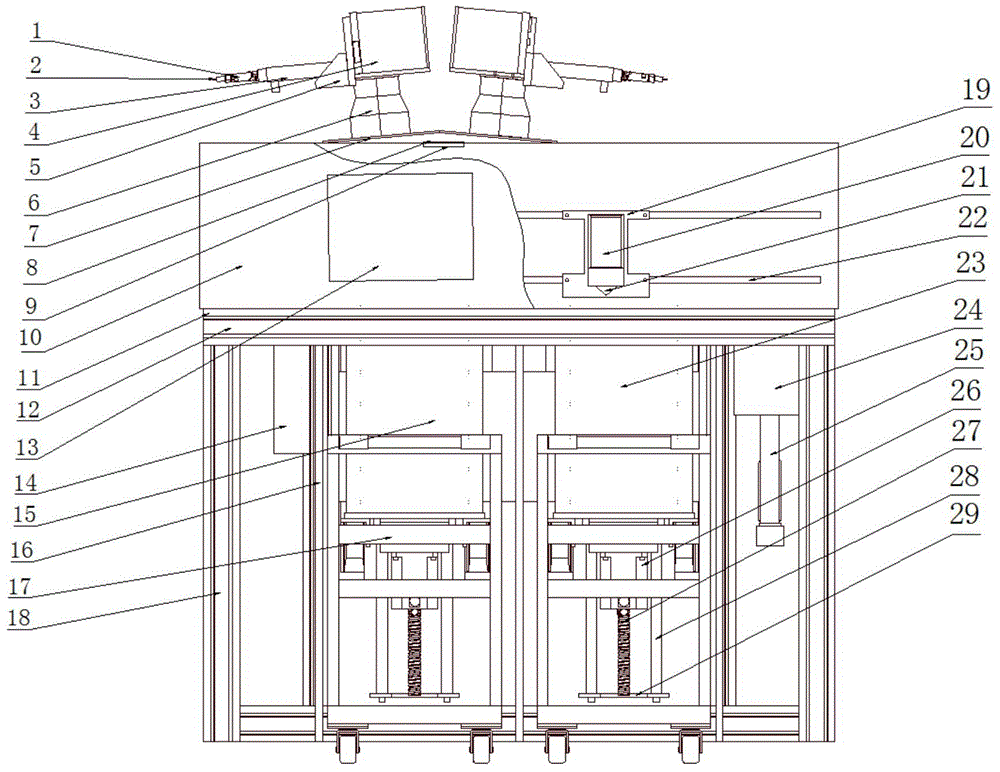

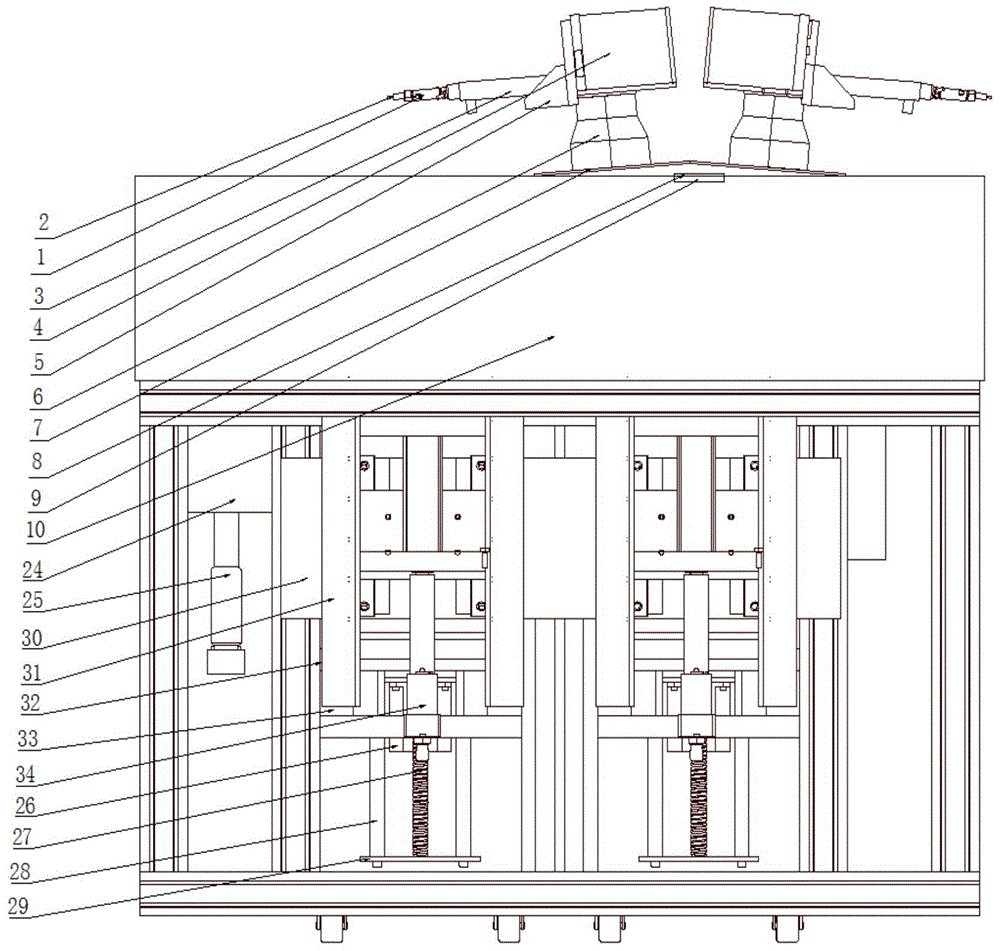

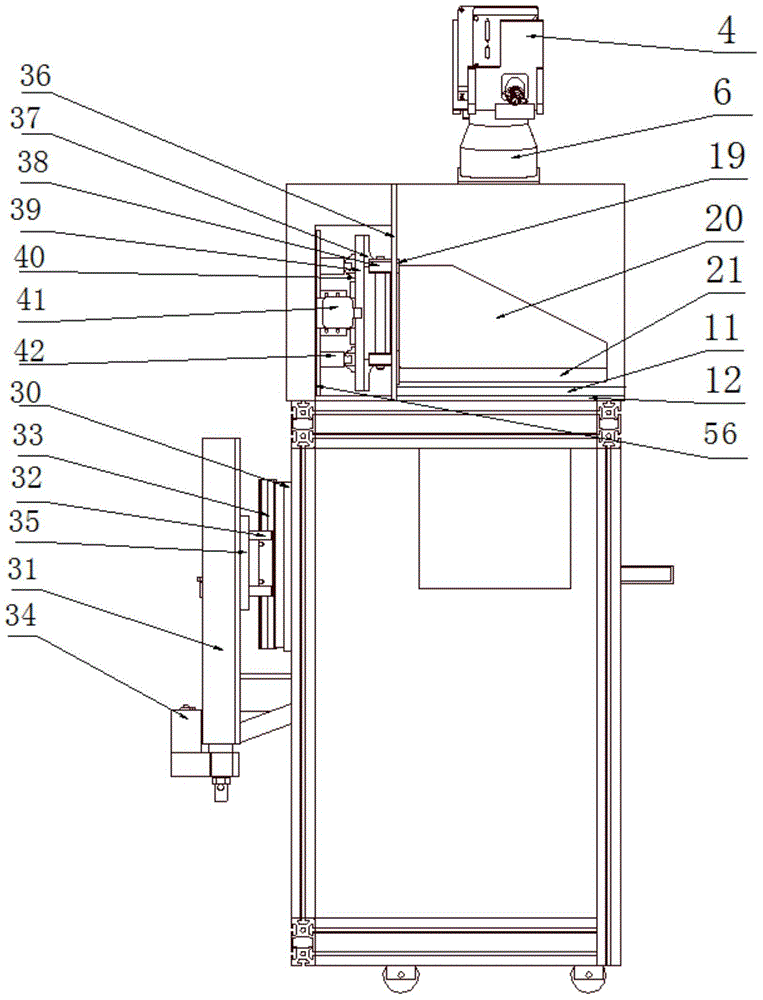

Dual-beam laser selective melting and moulding equipment with exchangeable powder cylinder

ActiveCN105039970AEasy to replaceImprove absorption rateMetallic material coating processesDual beamLight beam

The invention discloses dual-beam laser selective melting and moulding equipment with an exchangeable powder cylinder. The equipment comprises two optical systems, a frame, a workbench plate, a powder feeding cylinder, a powder storage cylinder, a moulding cylinder, a powder returning cylinder, a moulding cavity, and two first driving mechanisms, which are used to respectively drive the moulding cylinder and powder feeding cylinder to move up and down. The workbench plate is fixed on the frame, the moulding cavity is fixed on the upper surface of the workbench plate, and the powder returning cylinder, the moulding cylinder, the powder feeding cylinder, and powder storage cylinder are fixed on the lower surface of the workbench plate from left to right in sequence. A scraper is arranged in the moulding cavity, and a second driving mechanism is arranged on the frame. A substrate is arranged in the powder feeding cylinder, a substrate is arranged in the moulding cylinder, the lower ends of the powder feeding cylinder and the moulding cylinder are both provided with a cylinder end cover, and the substrates are connected to a first piston system. A second piston system is arranged in the powder storage cylinder. The provided equipment has a high moulding efficiency and is capable of effectively reducing the deformation and cracking of members.

Owner:XI AN JIAOTONG UNIV

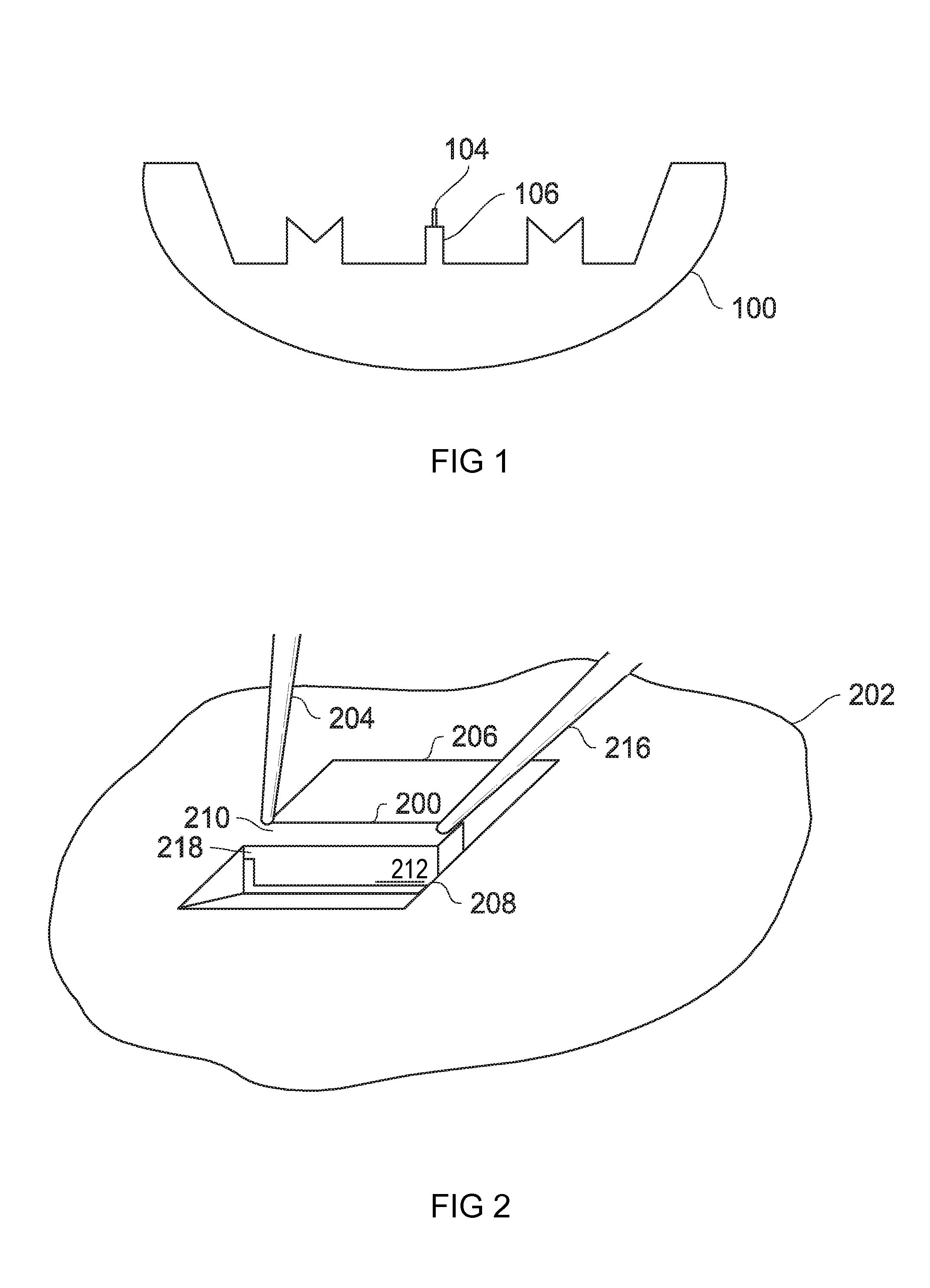

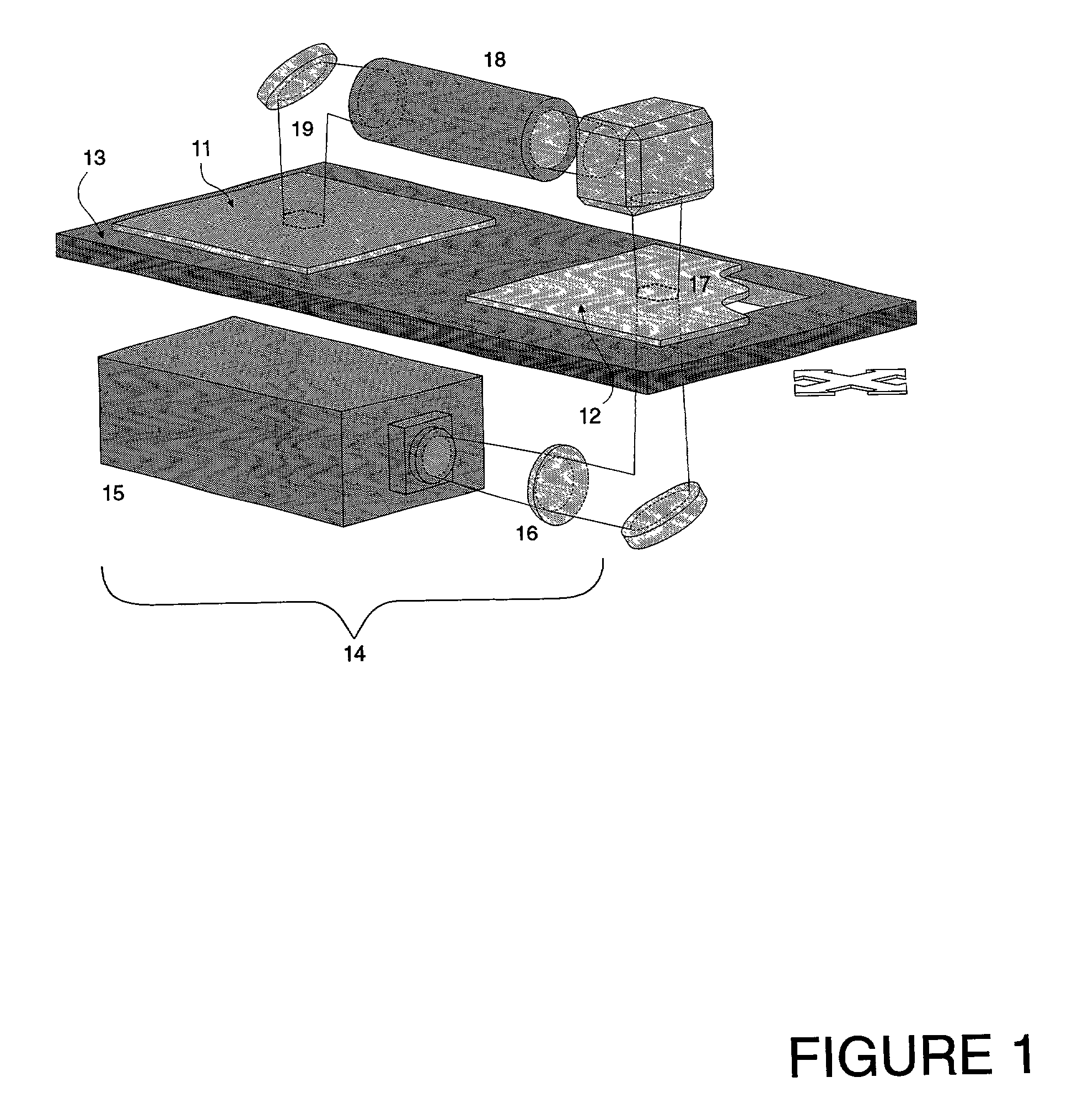

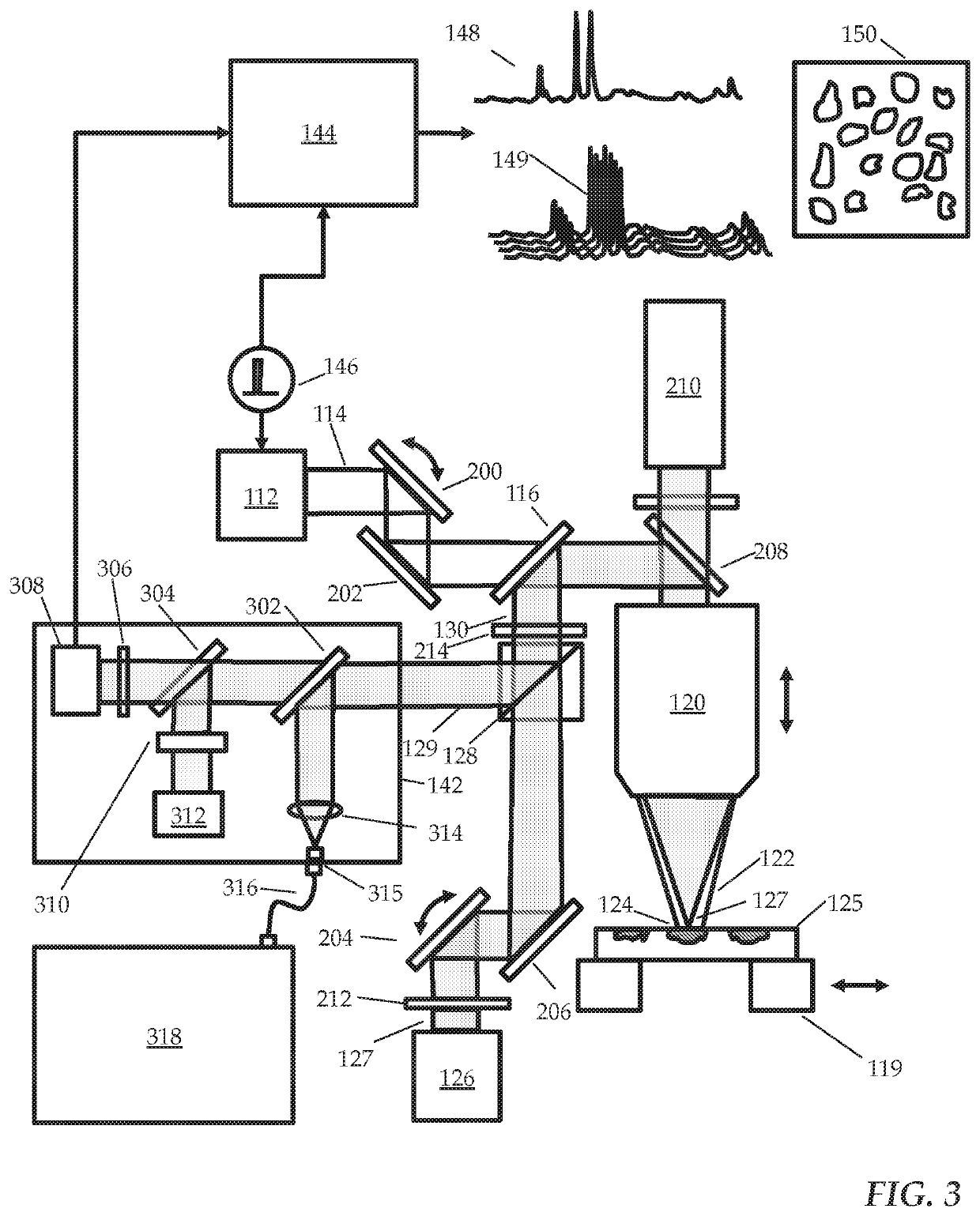

Method and apparatus for enhanced photo-thermal imaging and spectroscopy

ActiveUS20200025677A1Avoid strayRaman/scattering spectroscopyRadiation pyrometryFluorescenceMaterials science

System for performing chemical spectroscopy on samples from the scale of nanometers to millimeters or more with a multifunctional platform combining analytical and imaging techniques including dual beam photo-thermal spectroscopy with confocal microscopy, Raman spectroscopy, fluorescence detection, various vacuum analytical techniques and / or mass spectrometry. In embodiments described herein, the light beams of a dual-beam system are used for heating and sensing.

Owner:PHOTOTHERMAL SPECTROSCOPY CORP

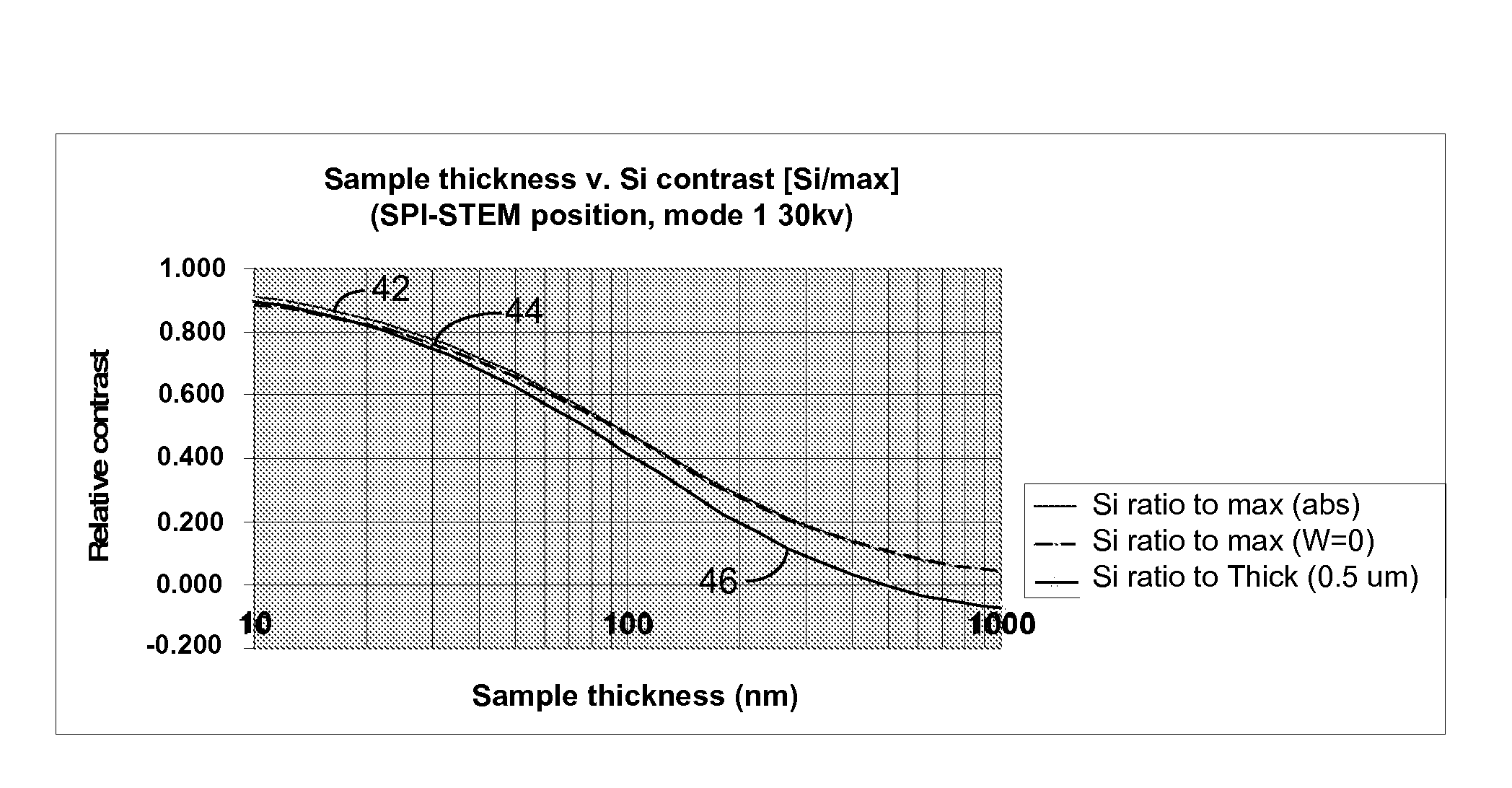

Measurement and endpointing of sample thickness

ActiveUS20100116977A1Simple methodImprove throughputSamplingScanning probe techniquesDirect feedbackDual beam

An improved method for TEM sample creation. The use of a SEM-STEM detector in the dual-beam FIB / SEM allows a sample to be thinned using the FIB, while the STEM signal is used to monitor sample thickness. A preferred embodiment of the present invention can measure the thickness of or create S / TEM samples by using a precise endpoint detection method that is reproducible and suitable for automation. Preferred embodiments also enable automatic endpointing during TEM lamella creation and provide users with direct feedback on sample thickness during manual thinning. Preferred embodiments of the present invention thus provide improved methods for endpointing sample thinning and methods to partially or fully automate endpointing to increase throughput and reproducibility of TEM sample creation.

Owner:FEI CO

Dual beam radar system

Owner:RAYTHEON CANADA LTD

Electrical connector with load bearing features

InactiveUS7270573B2Prevent movementElectrically conductive connectionsSecuring/insulating coupling contact membersDual beamElectrical connector

Owner:FCI AMERICAS TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com