Patents

Literature

1896results about "X-ray spectral distribution measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

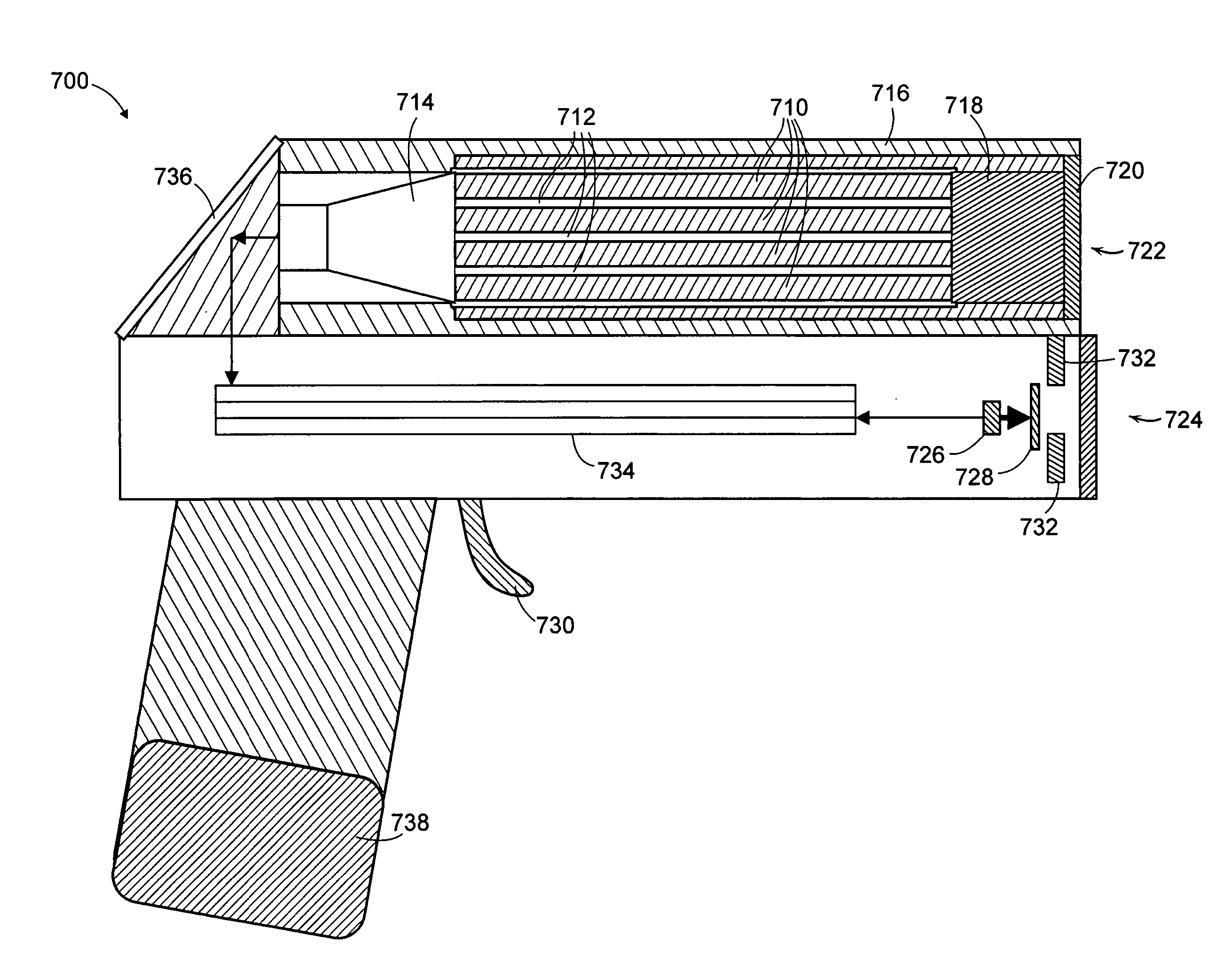

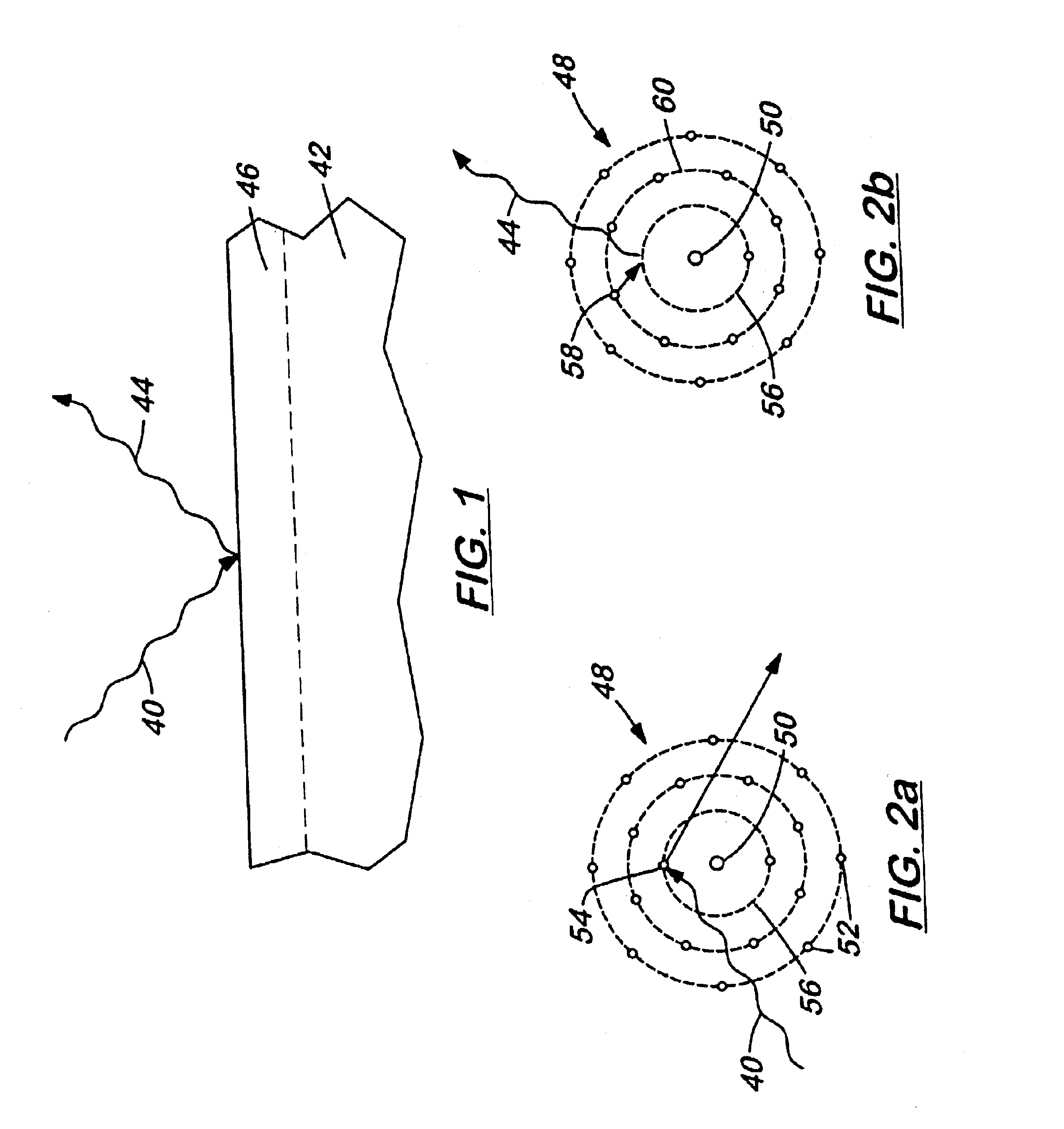

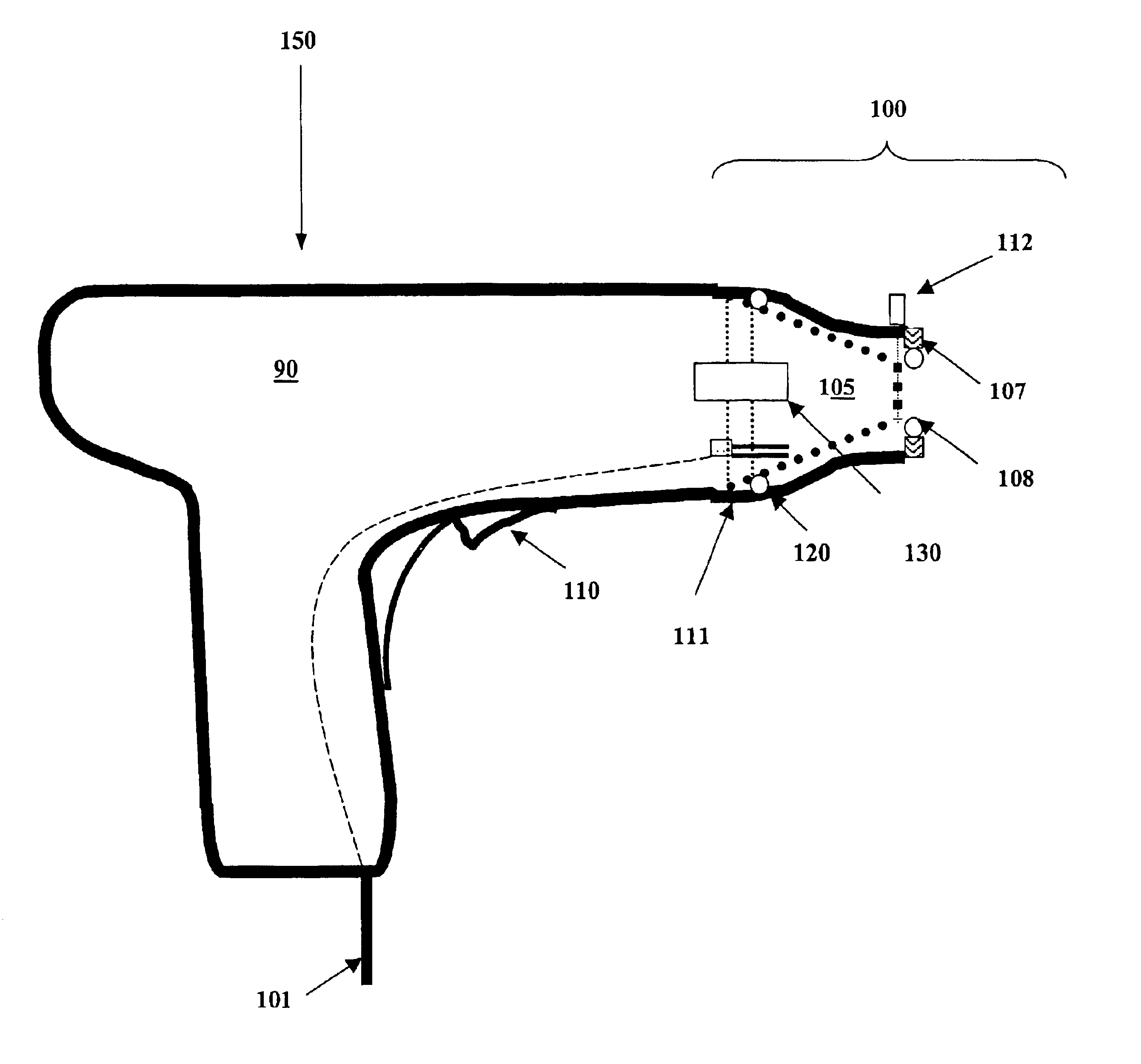

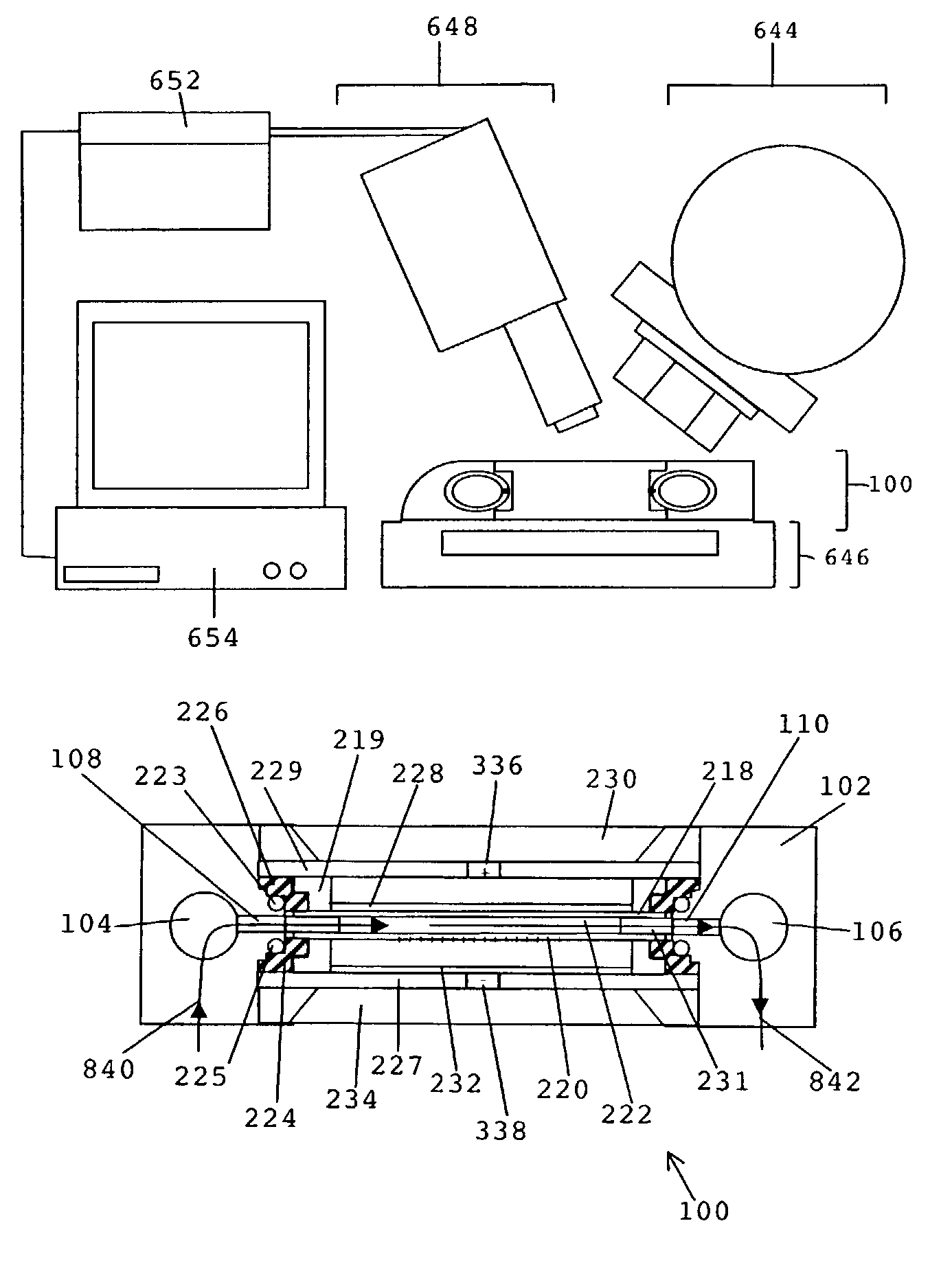

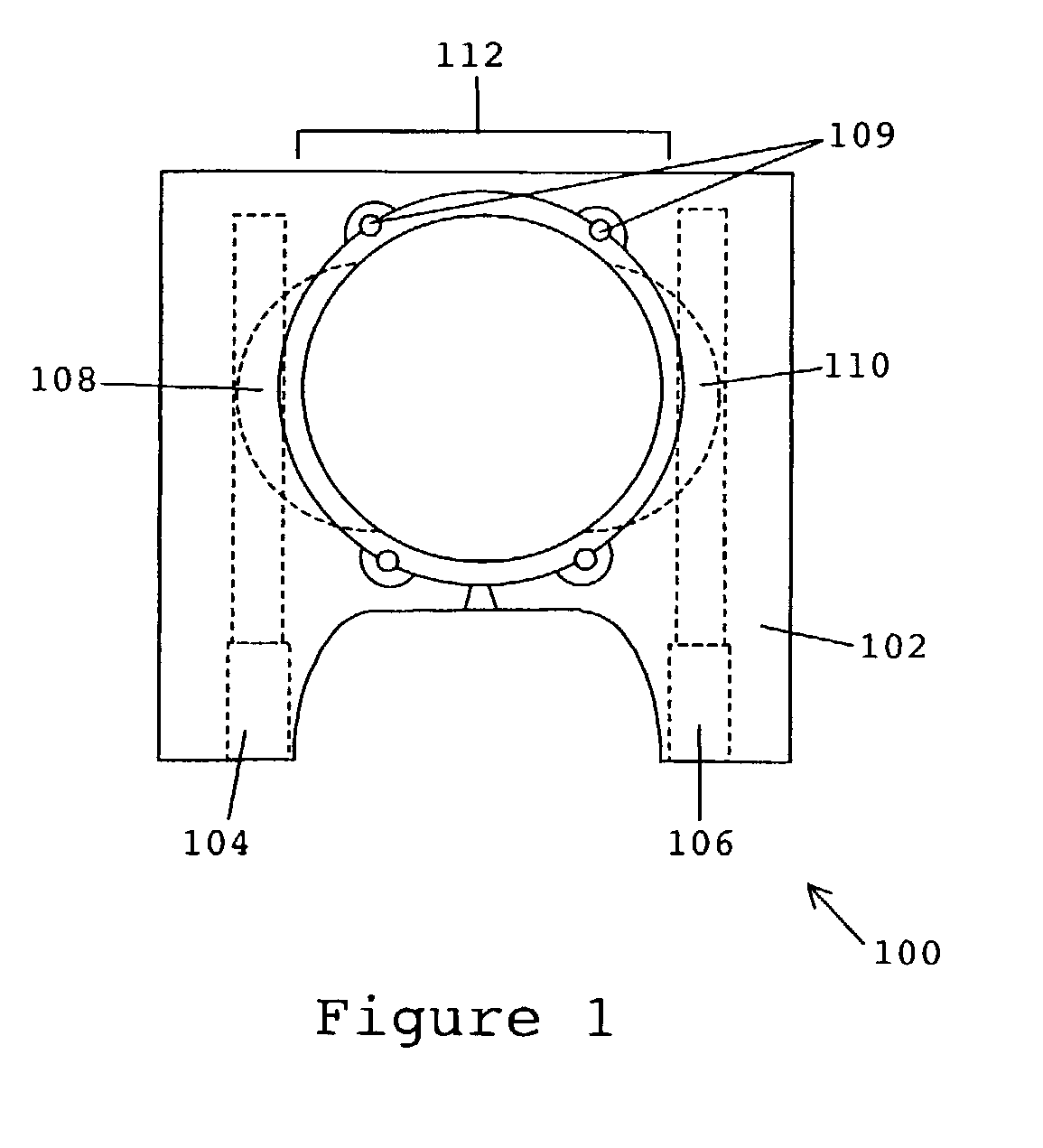

Fluoroscopic tracking and visualization system

InactiveUS6856827B2Quickly and accurately determineImprove accuracyX-ray spectral distribution measurementX-ray/infra-red processesDisplay deviceComputer vision

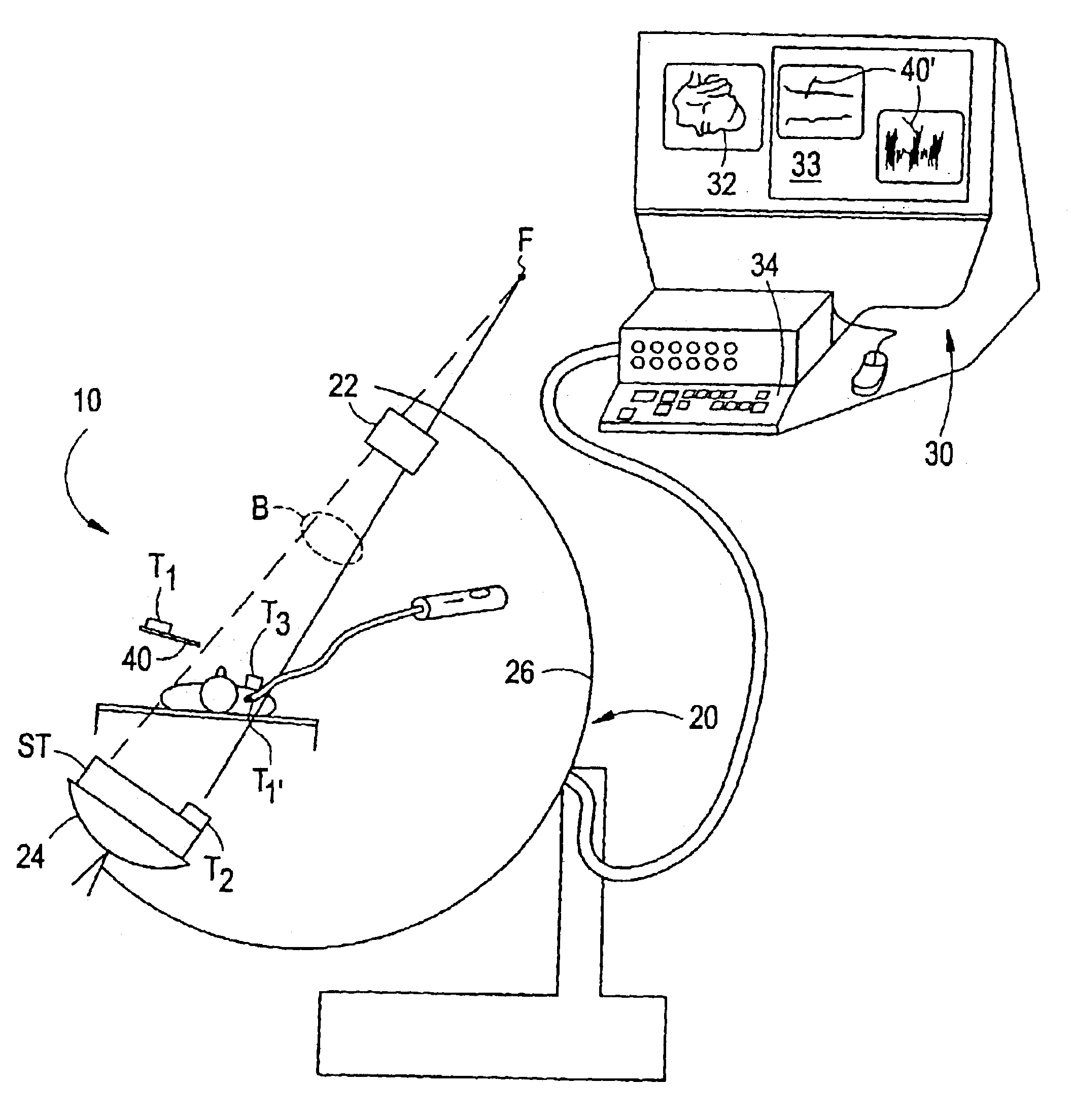

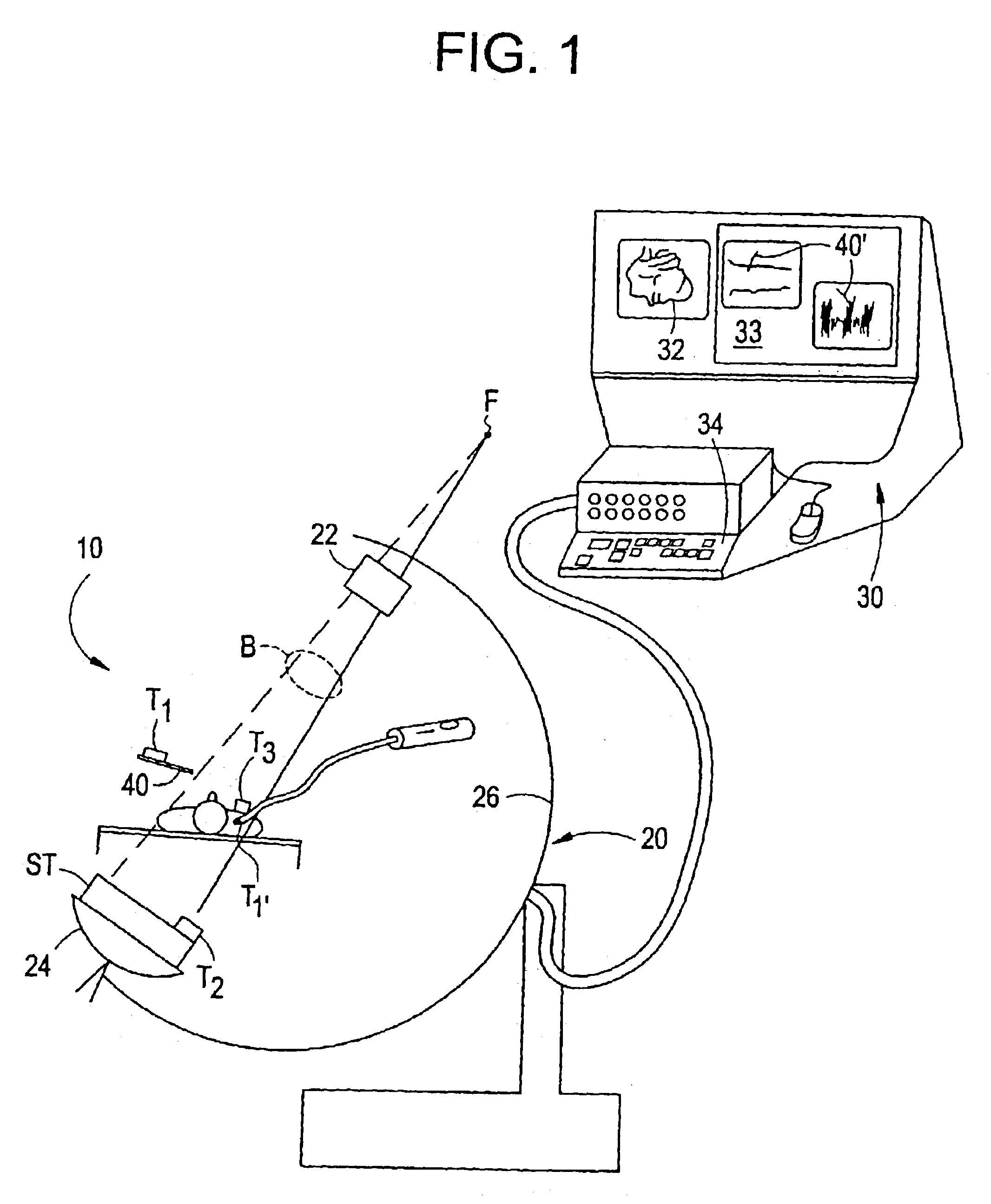

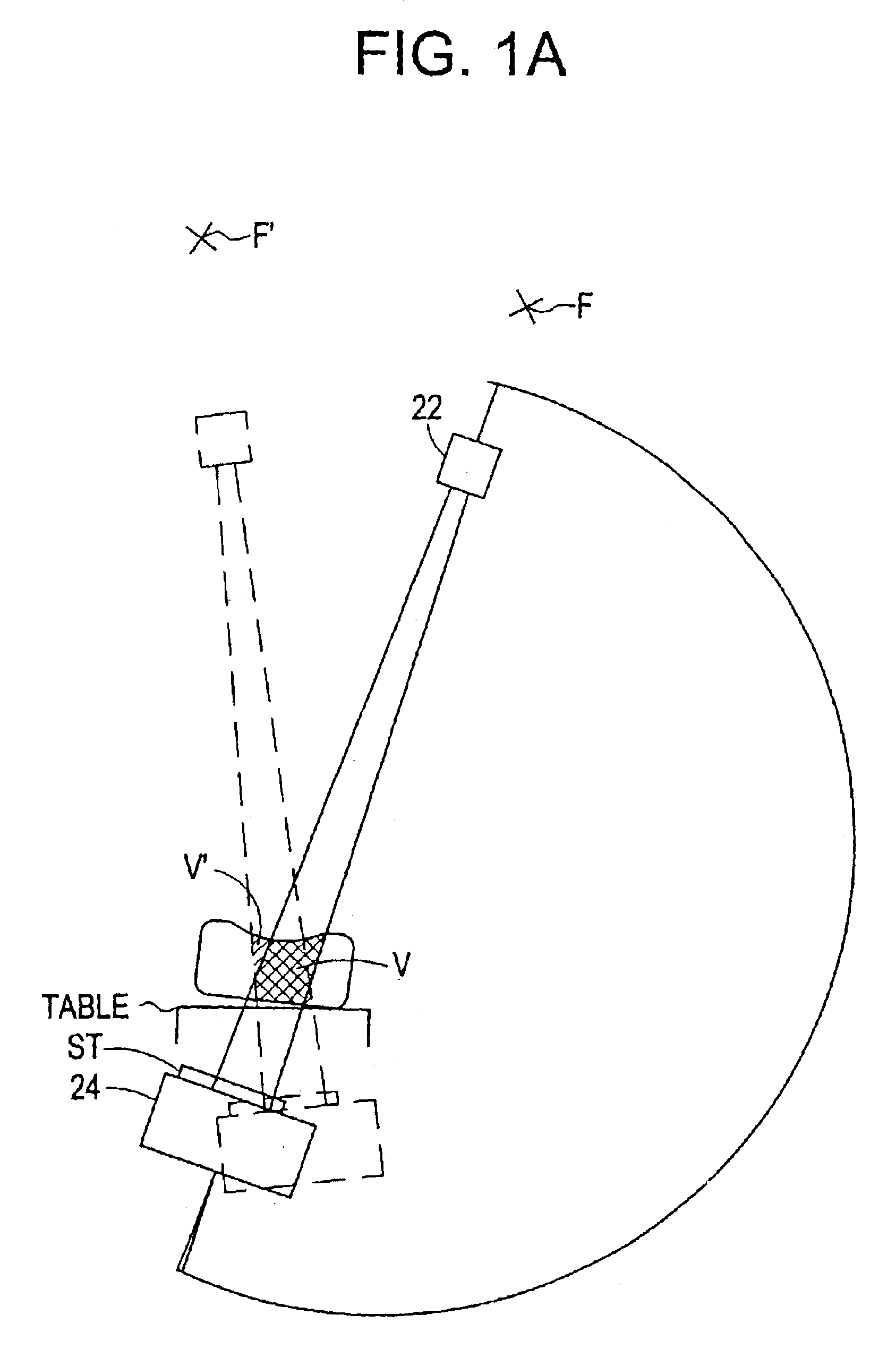

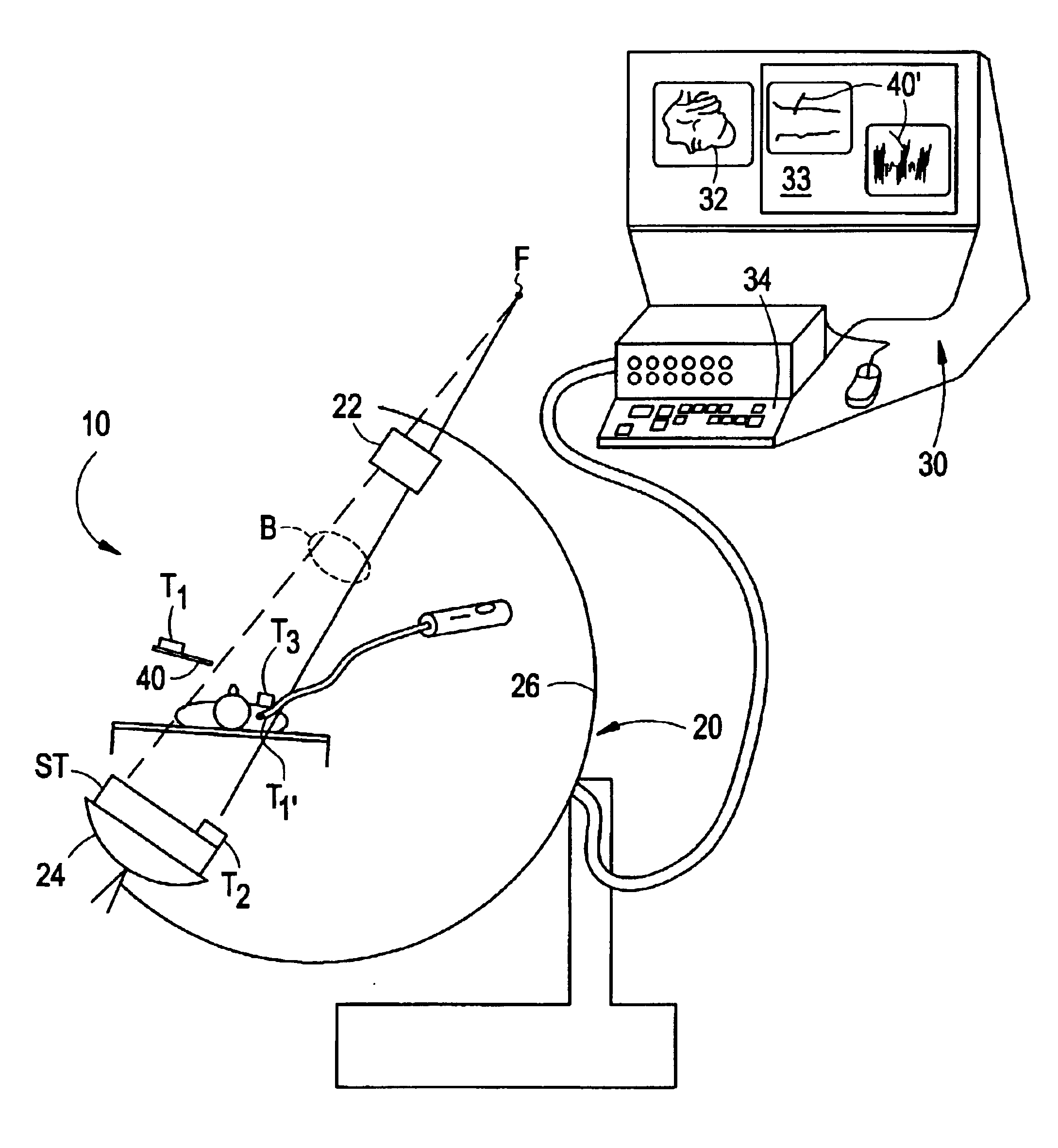

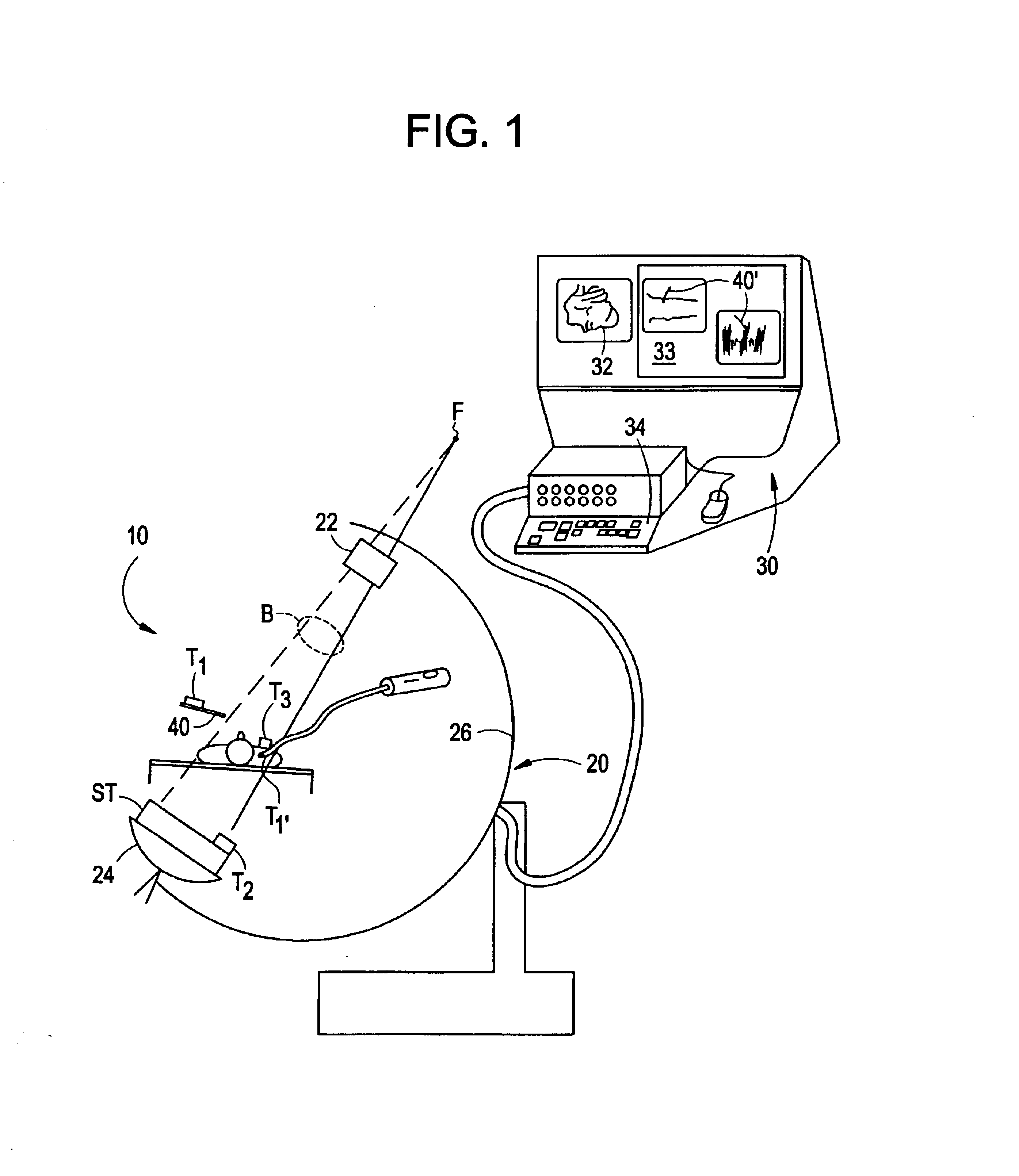

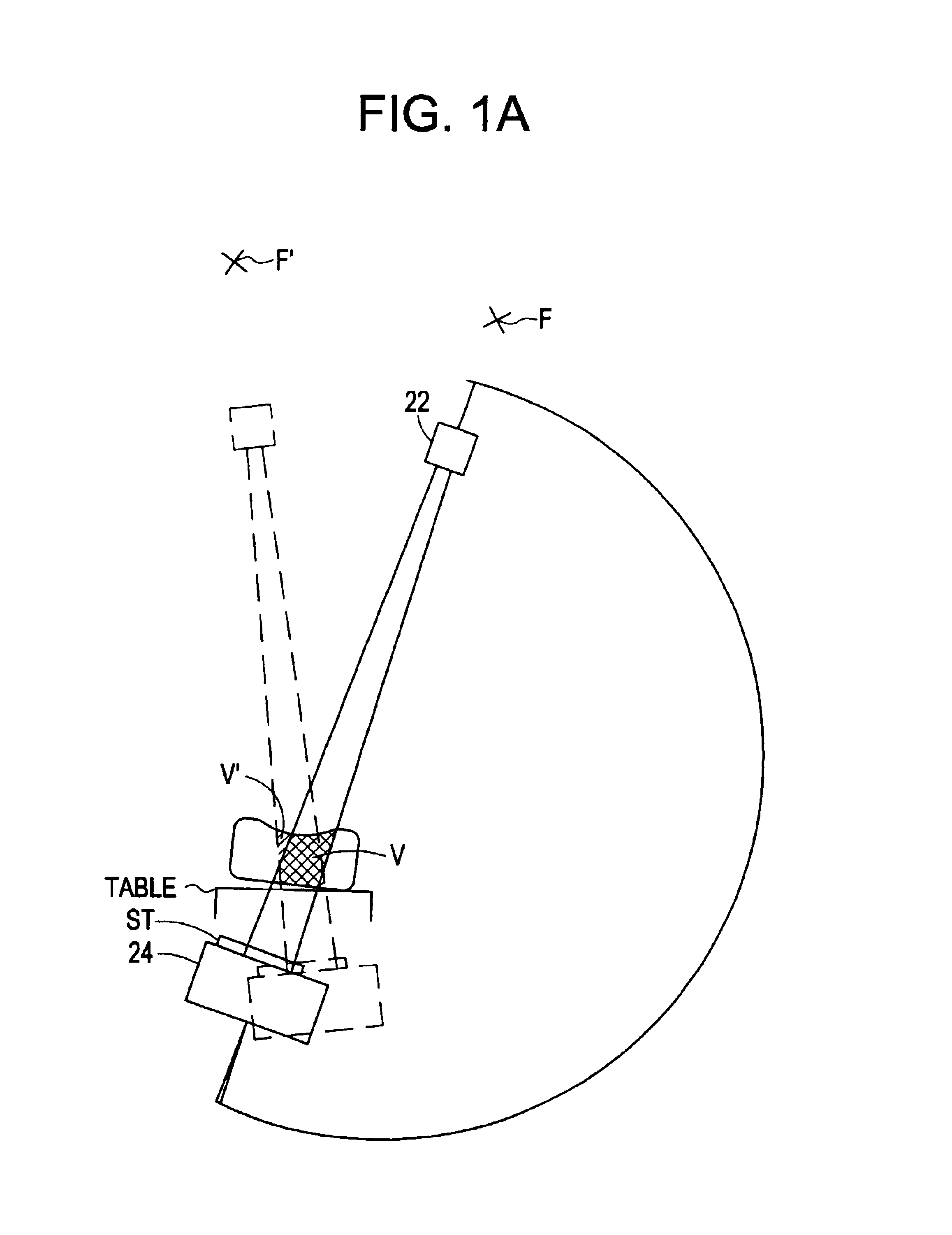

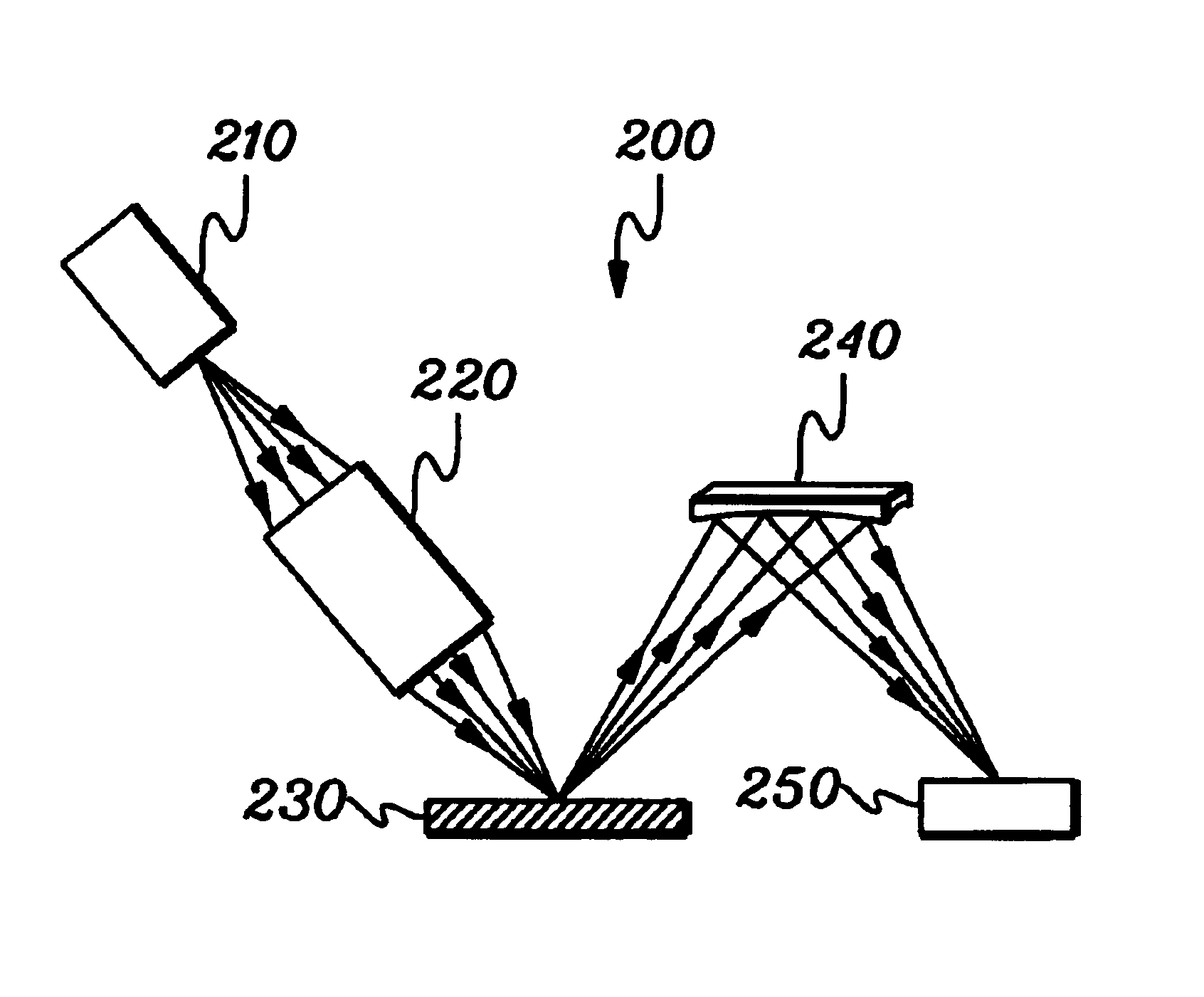

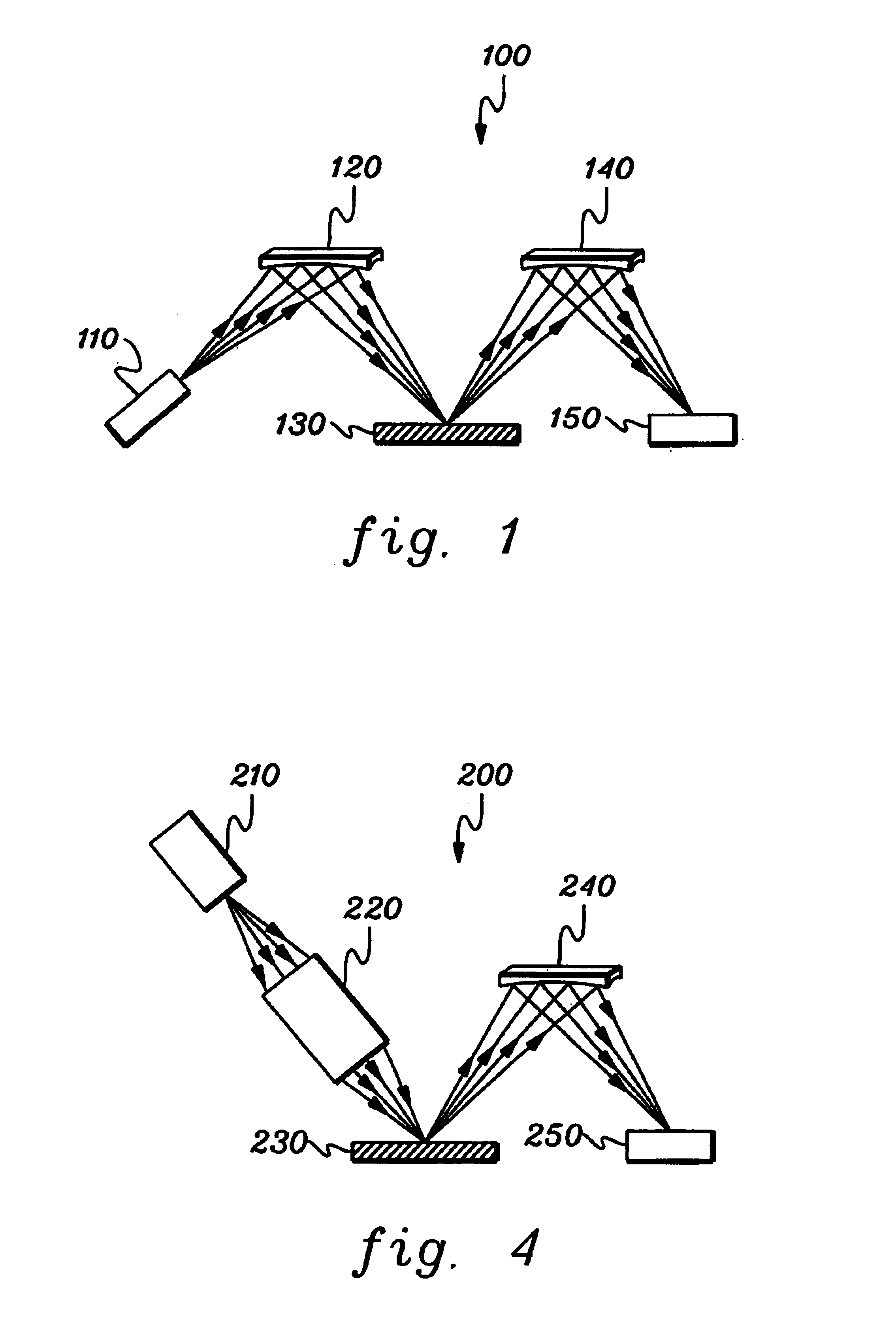

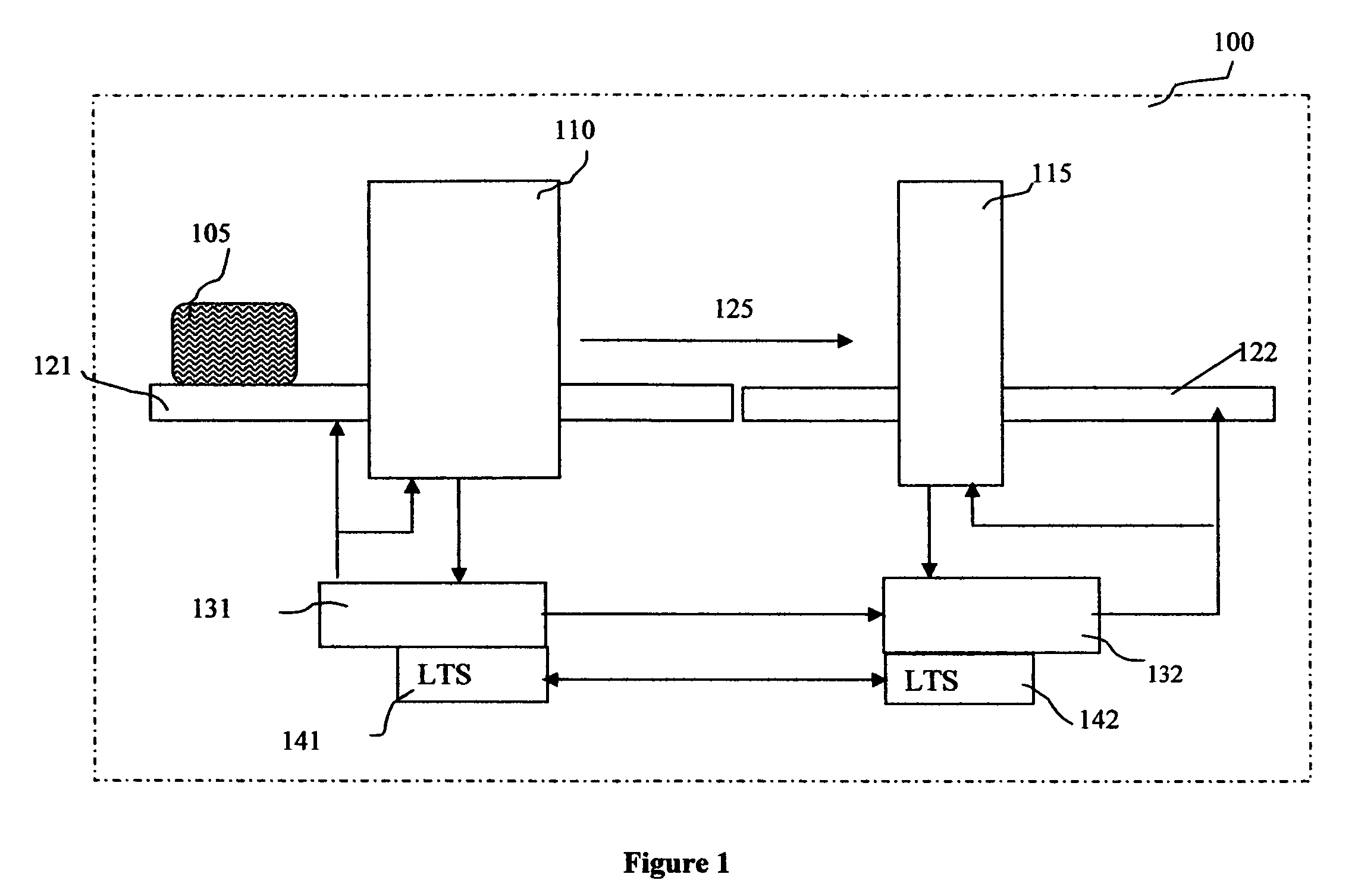

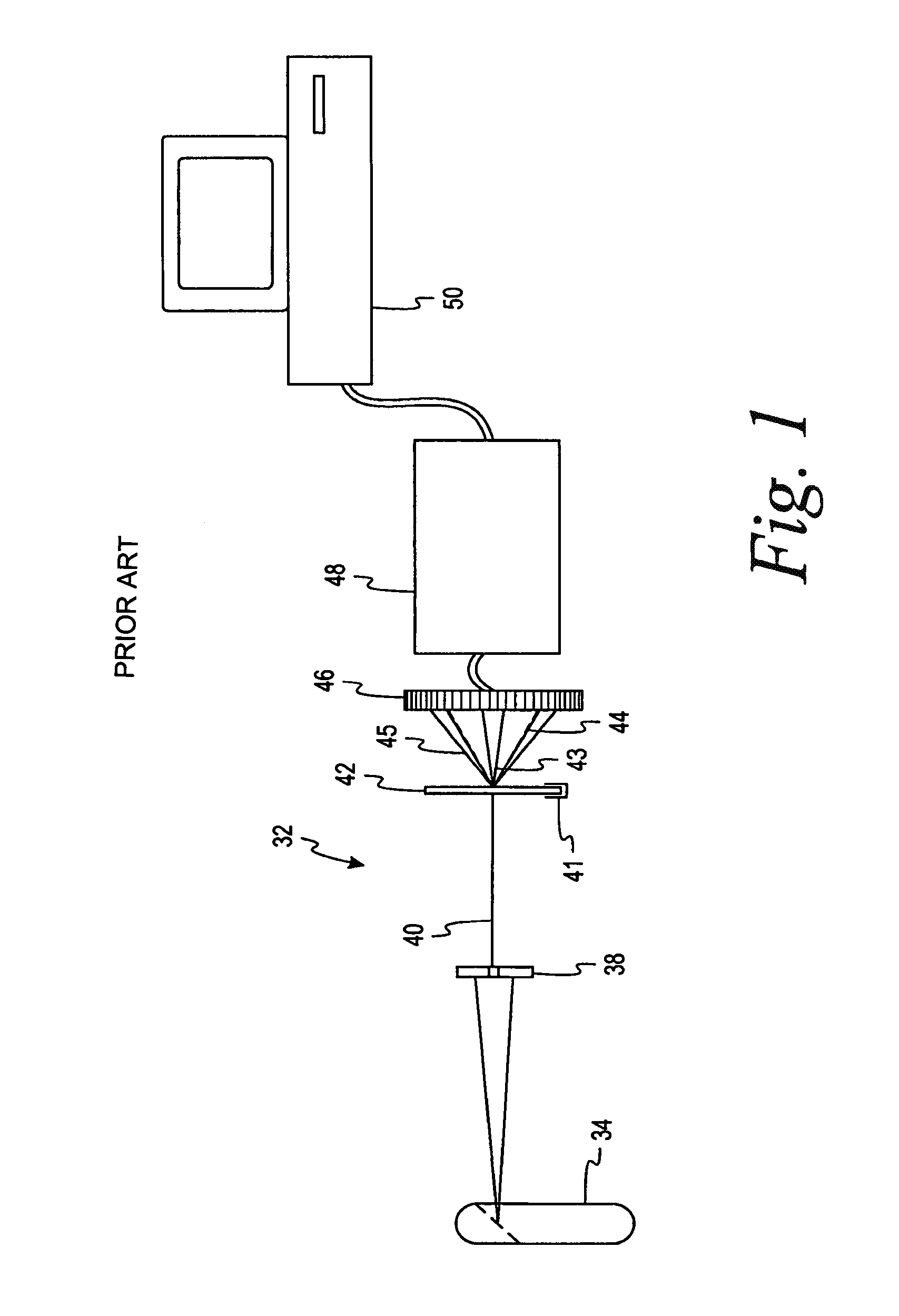

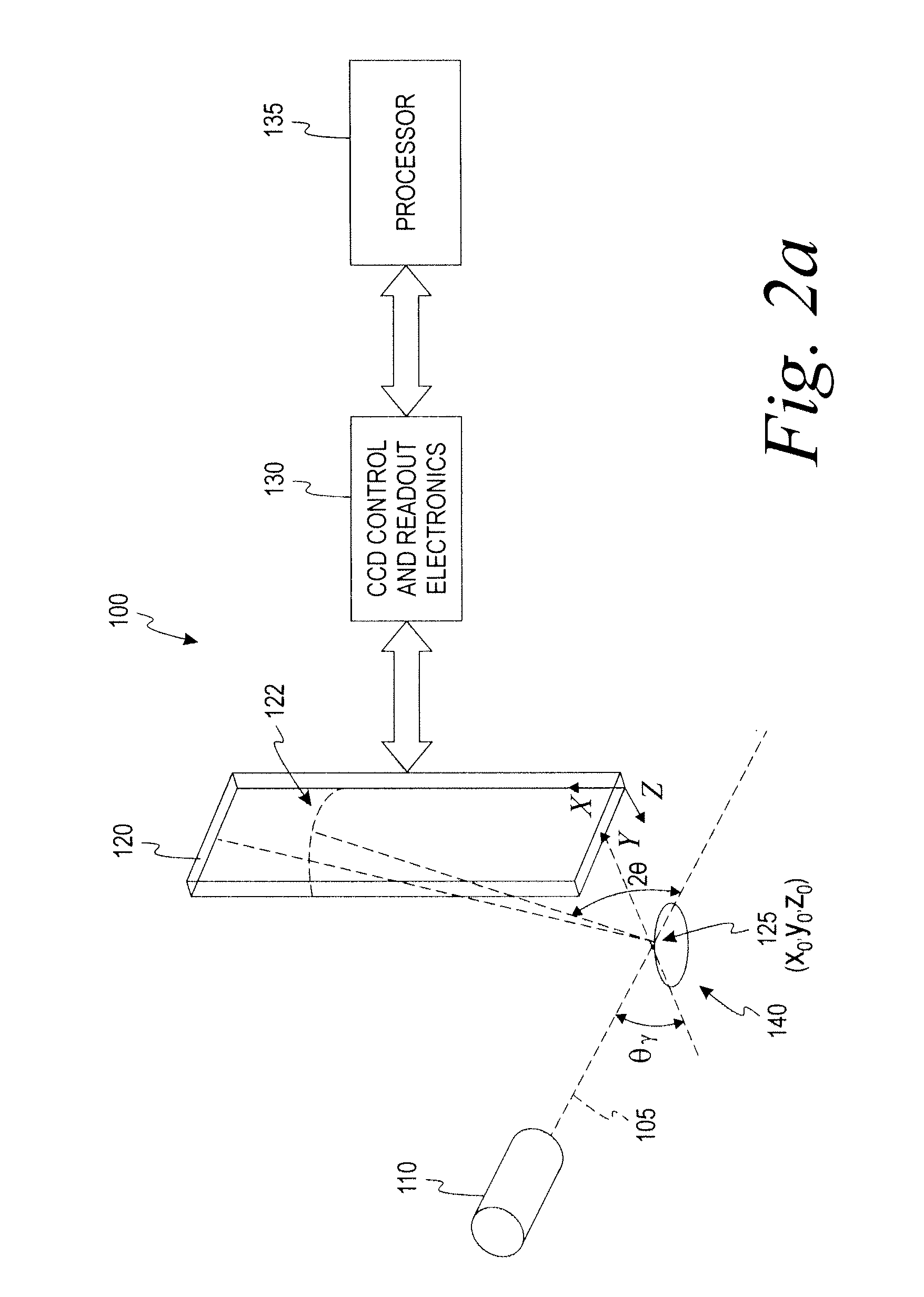

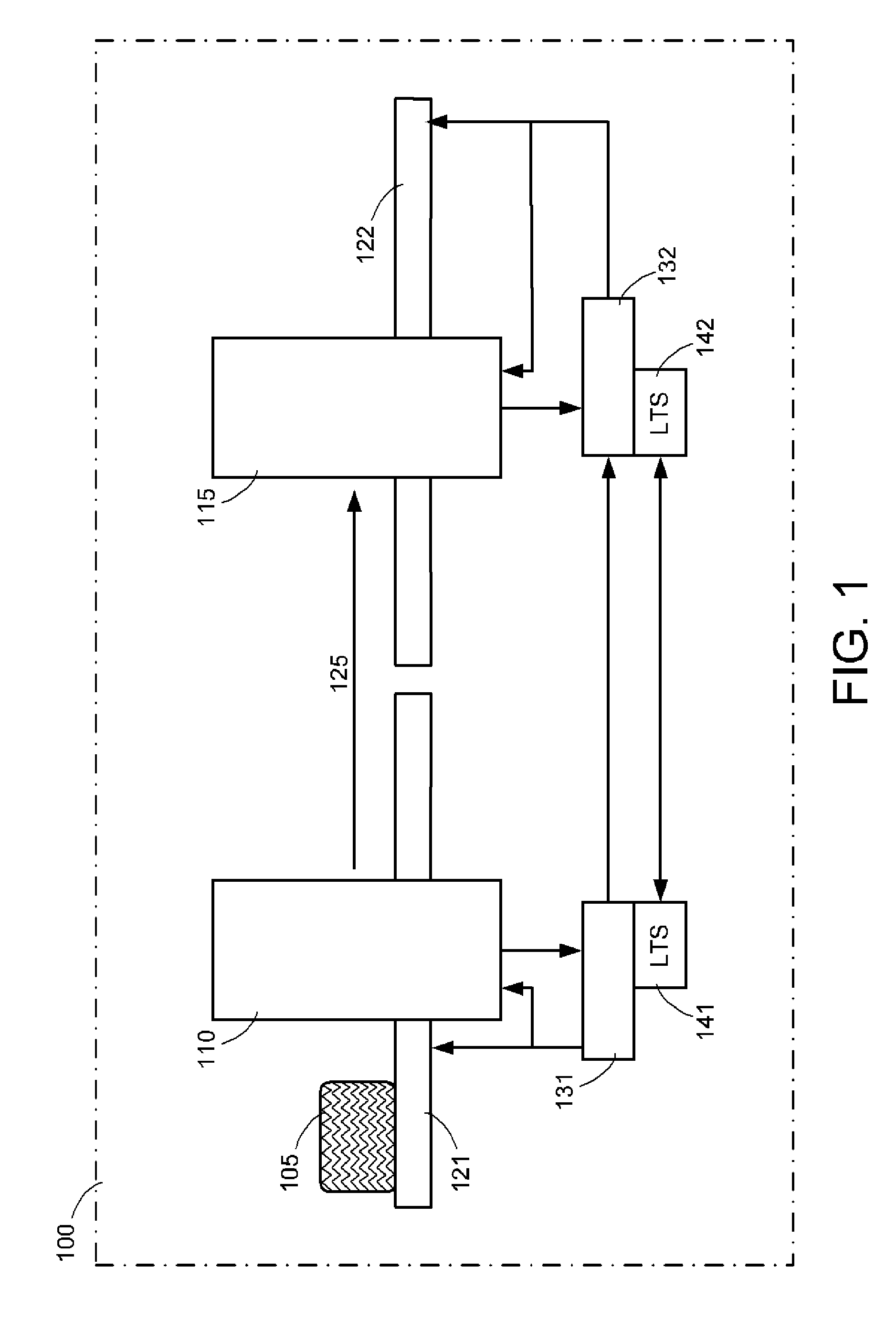

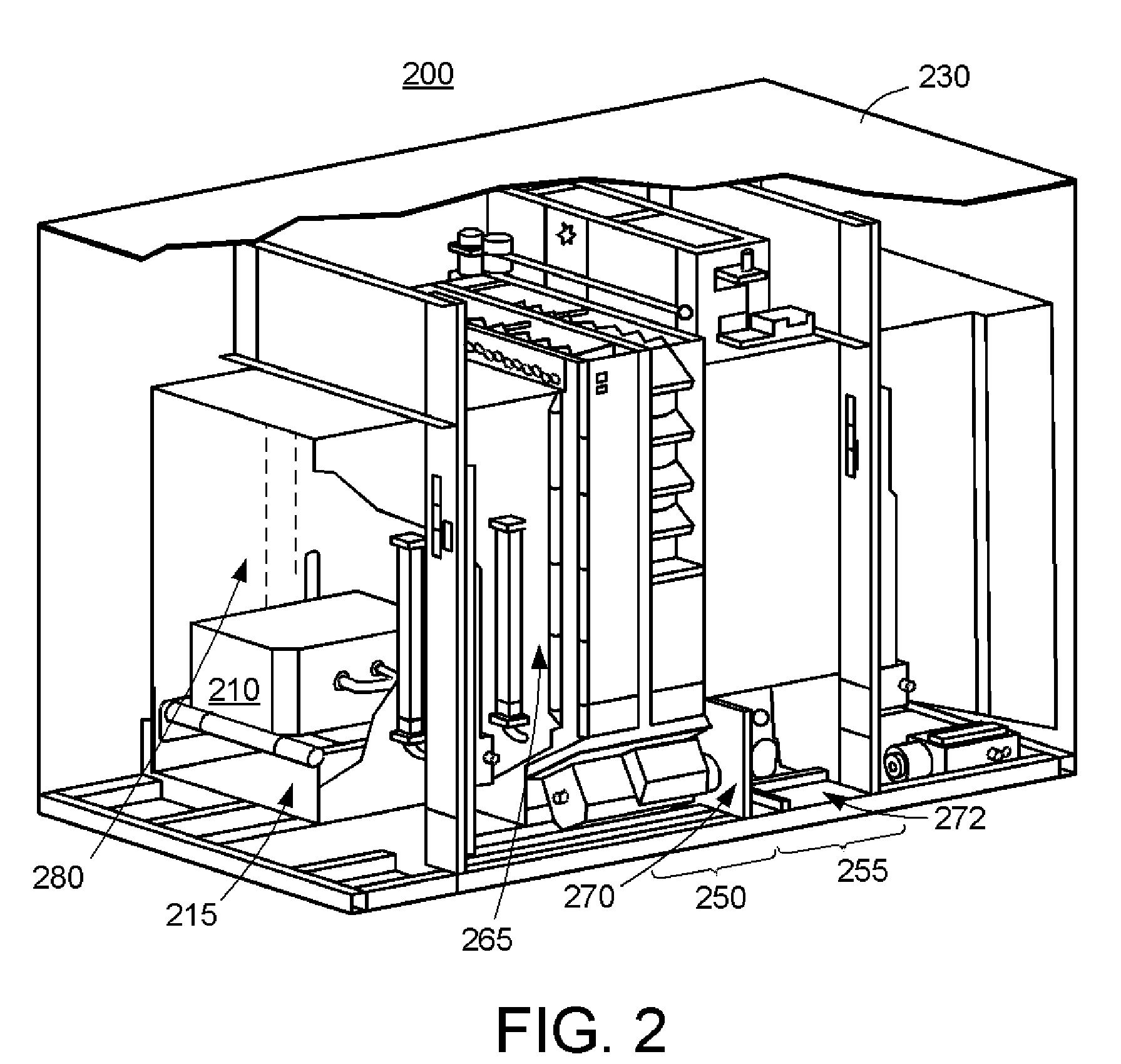

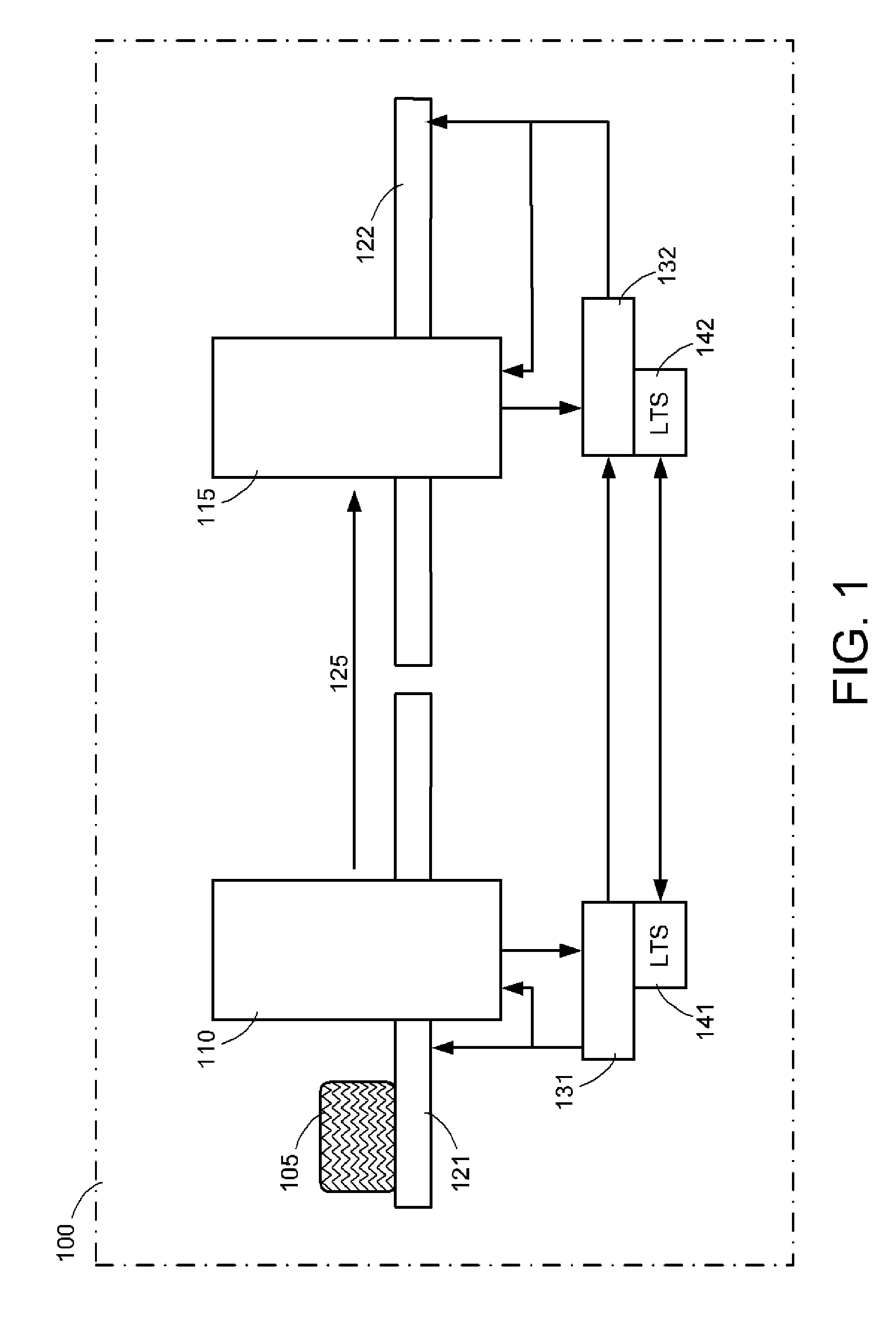

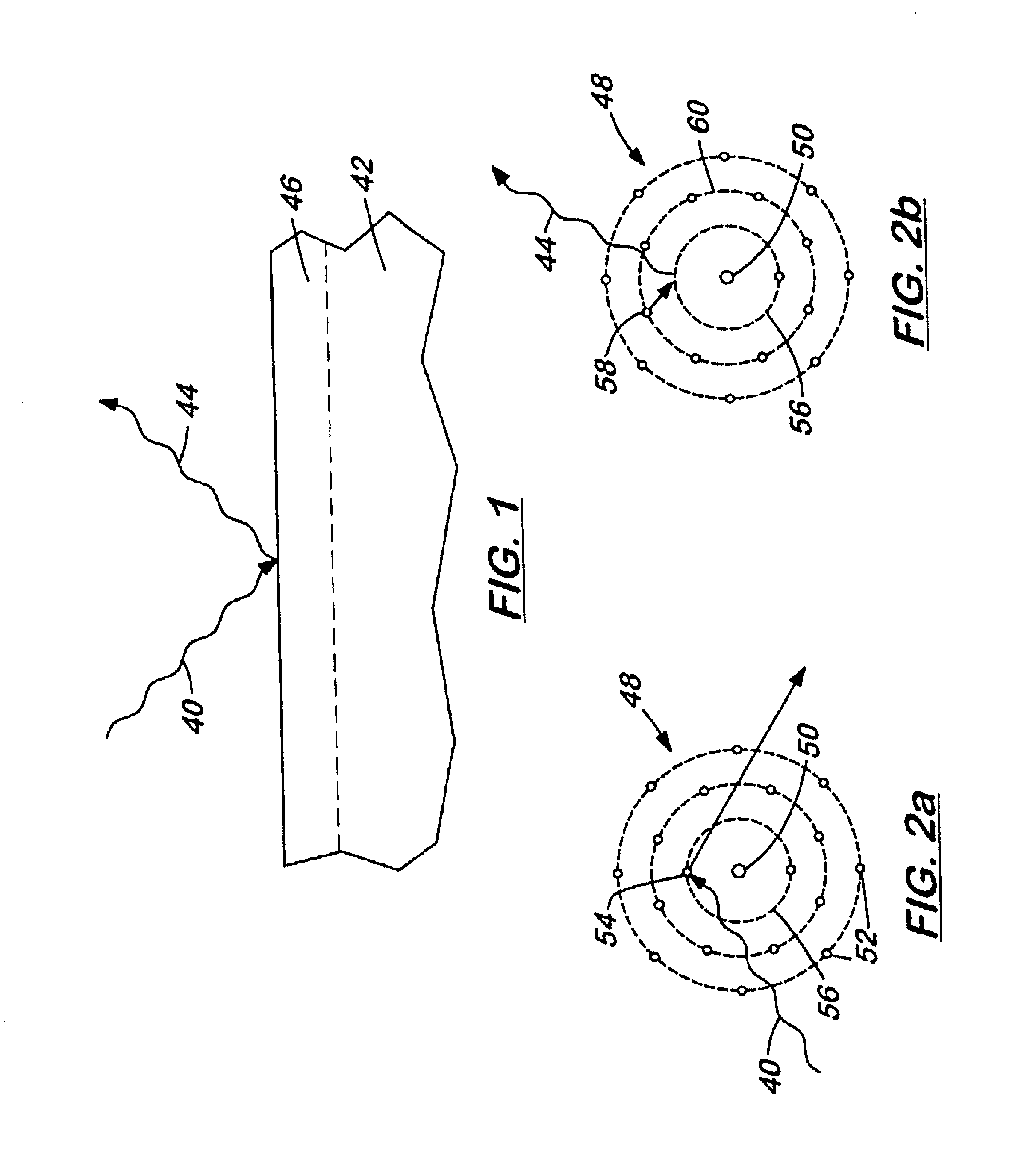

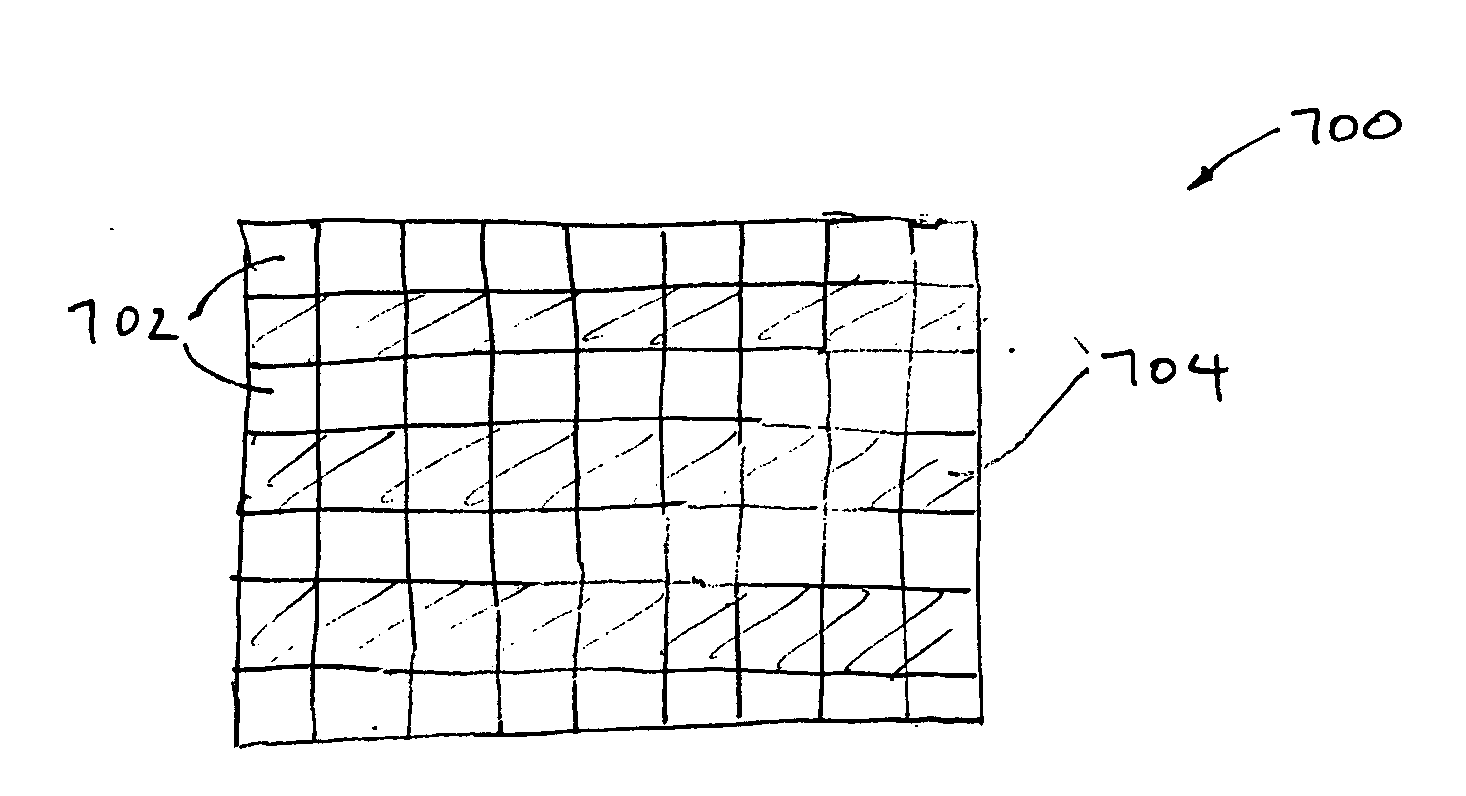

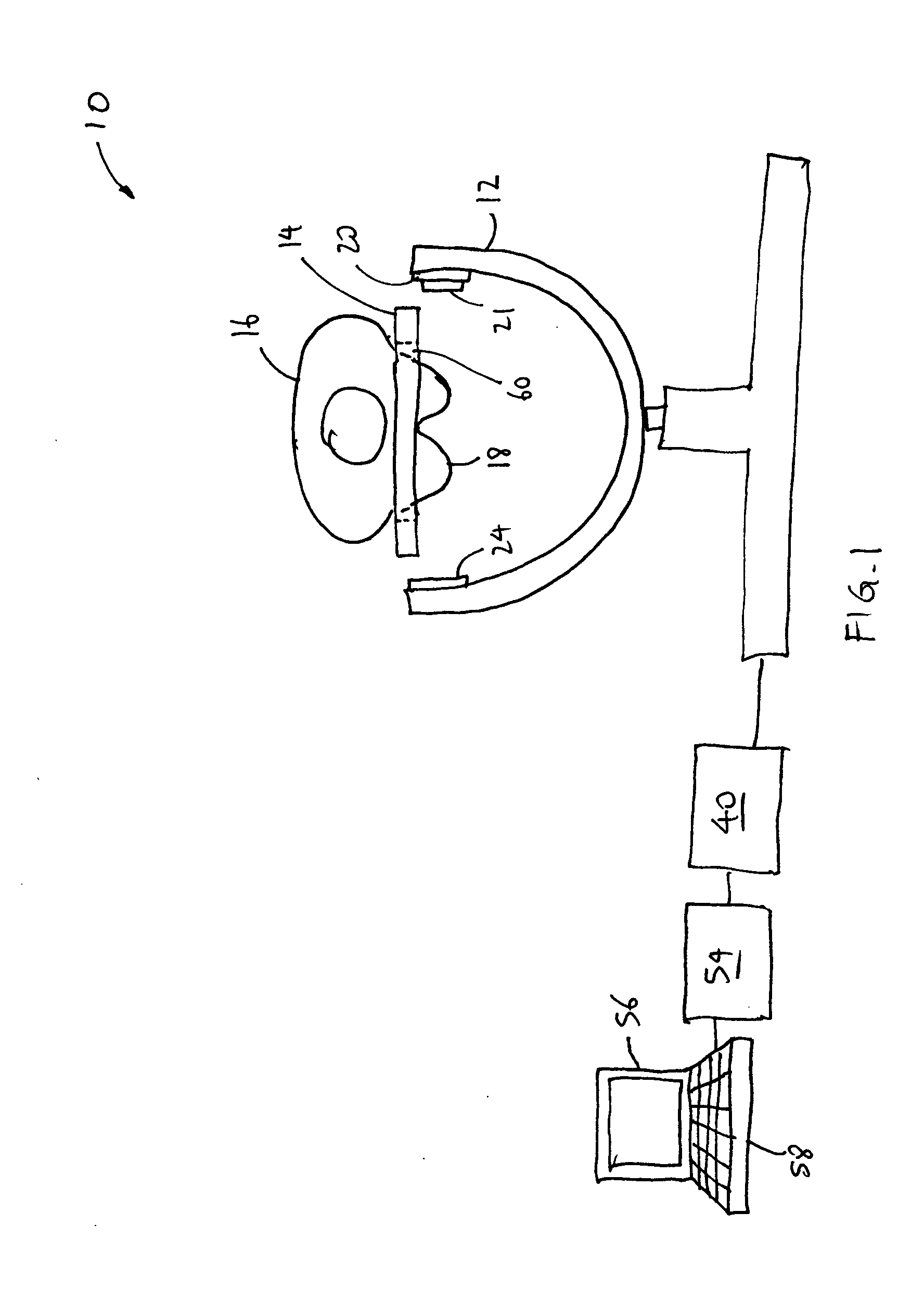

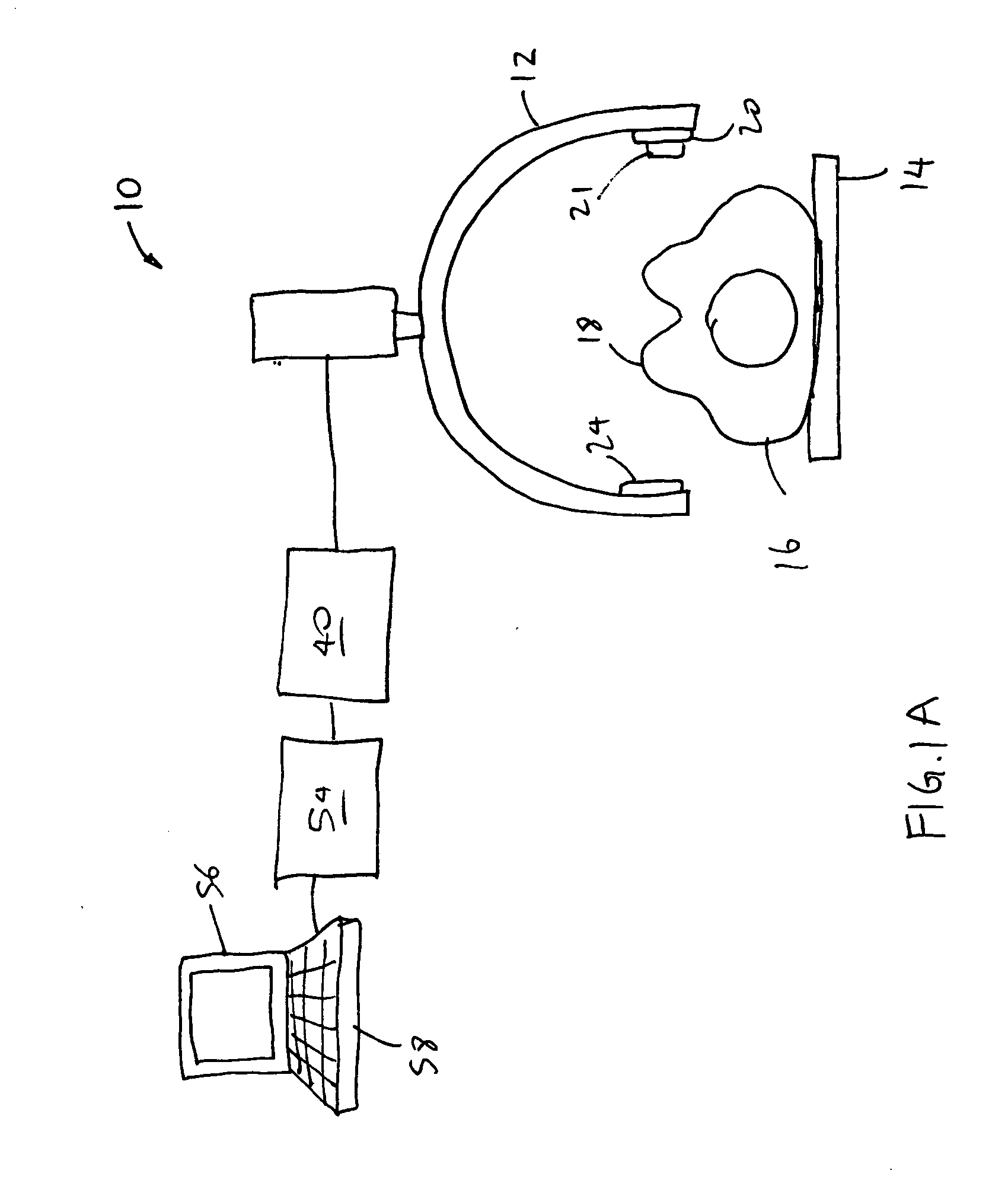

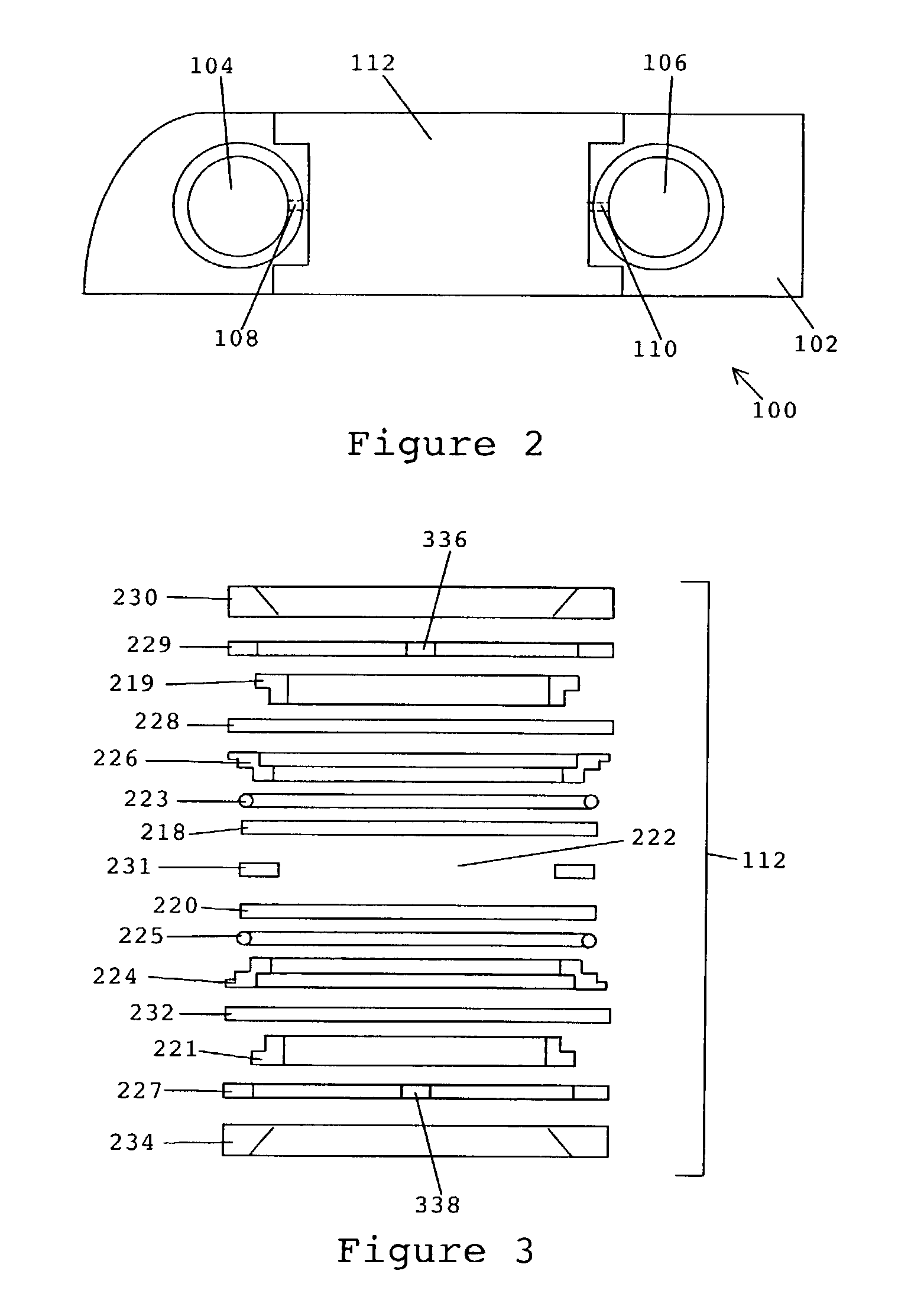

A system for surgical imaging and display of tissue structures of a patient, including a display and an image processor for displaying such images in coordination with a tool image to facilitate manipulation of the tool during the surgical procedure. The system is configured for use with a fluoroscope such that at least one image in the display is derived from the fluoroscope at the time of surgery. A fixture is affixed to an imaging side of the fluoroscope for providing patterns of an of array markers that are imaged in each fluoroscope image. A tracking assembly having a plurality of tracking elements is operative to determine positions of said fixture and the patient. One of the tracking elements is secured against motion with respect to the fixture so that determining a position of the tracking element determines a position of all the markers in a single measurement.

Owner:STRYKER EURO HLDG I LLC +1

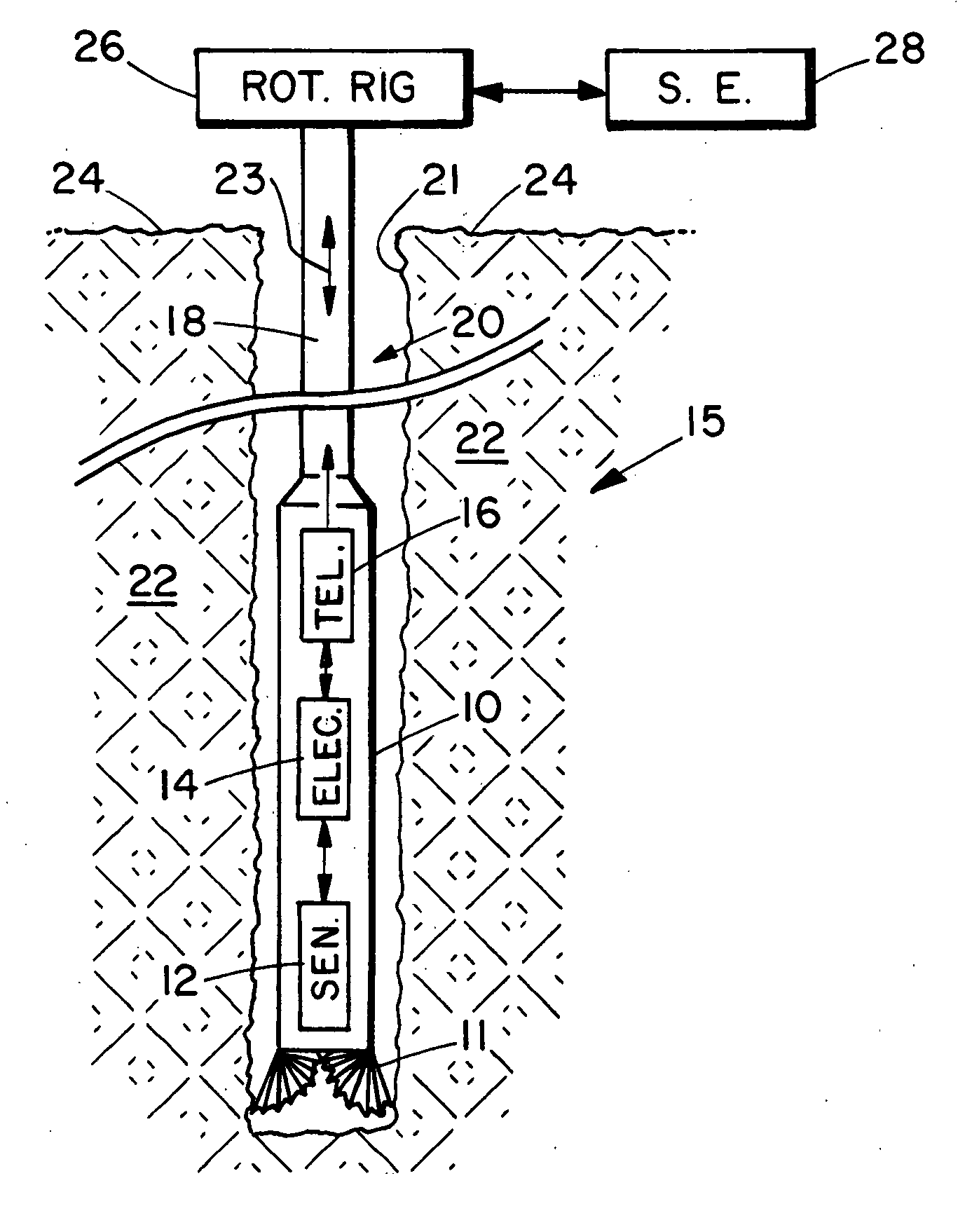

Fluoroscopic tracking and visualization system

InactiveUS6856826B2Quickly and accurately determineHigh position tracking accuracyX-ray spectral distribution measurementX-ray/infra-red processesPostural orientationComputer science

A method for surgical imaging and display including (i.) positioning a defined set of markers disposed in a pattern so as to be imaged in each pose or view of an imaging assembly, the set of markers being fixed in pre-determined positions in a rigid carrier, (ii.) securing a first tracking element against motion with respect to the rigid carrier so that determining a position of the first tracking element in a single measurement determines positions of all the markers of the set, and (iii.) identifying images of at least a subset of the markers in a first view.

Owner:STRYKER EURO HLDG I LLC +1

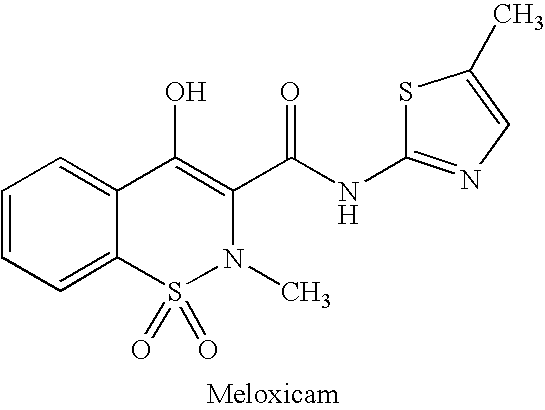

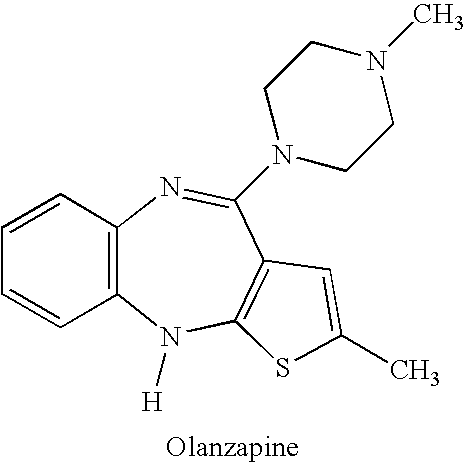

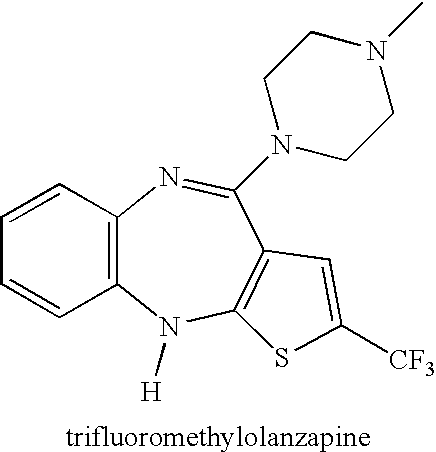

Advanced drug development and manufacturing

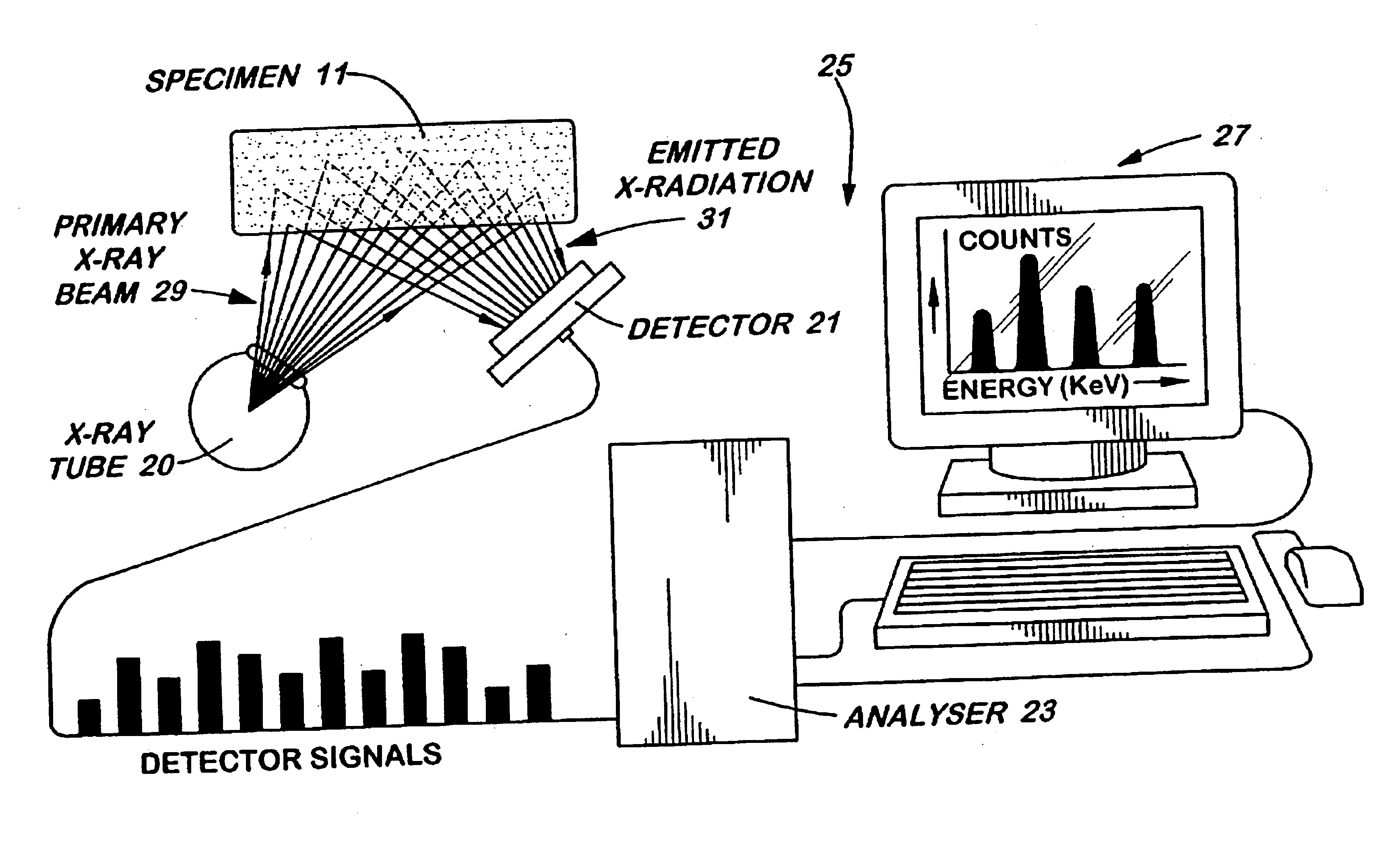

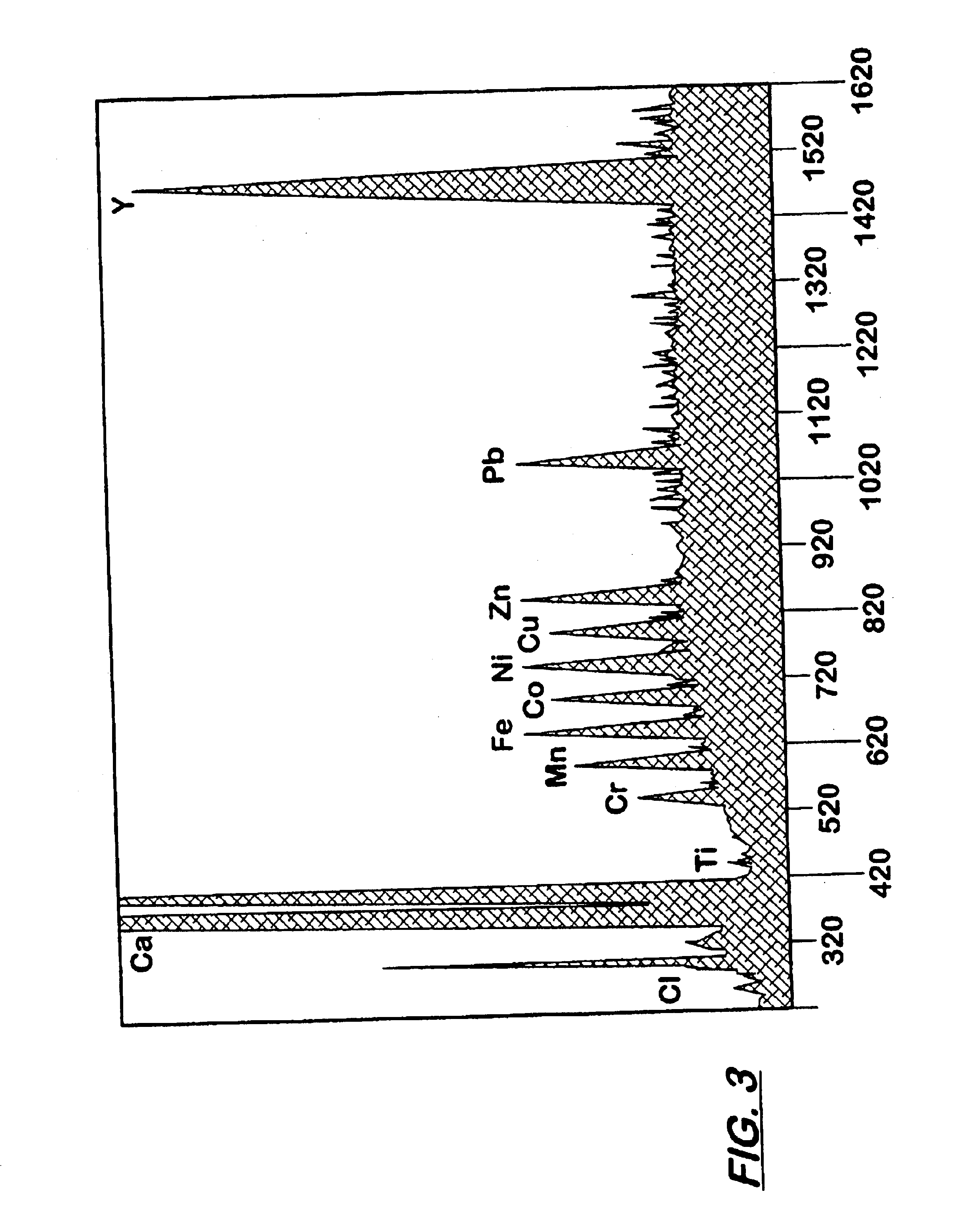

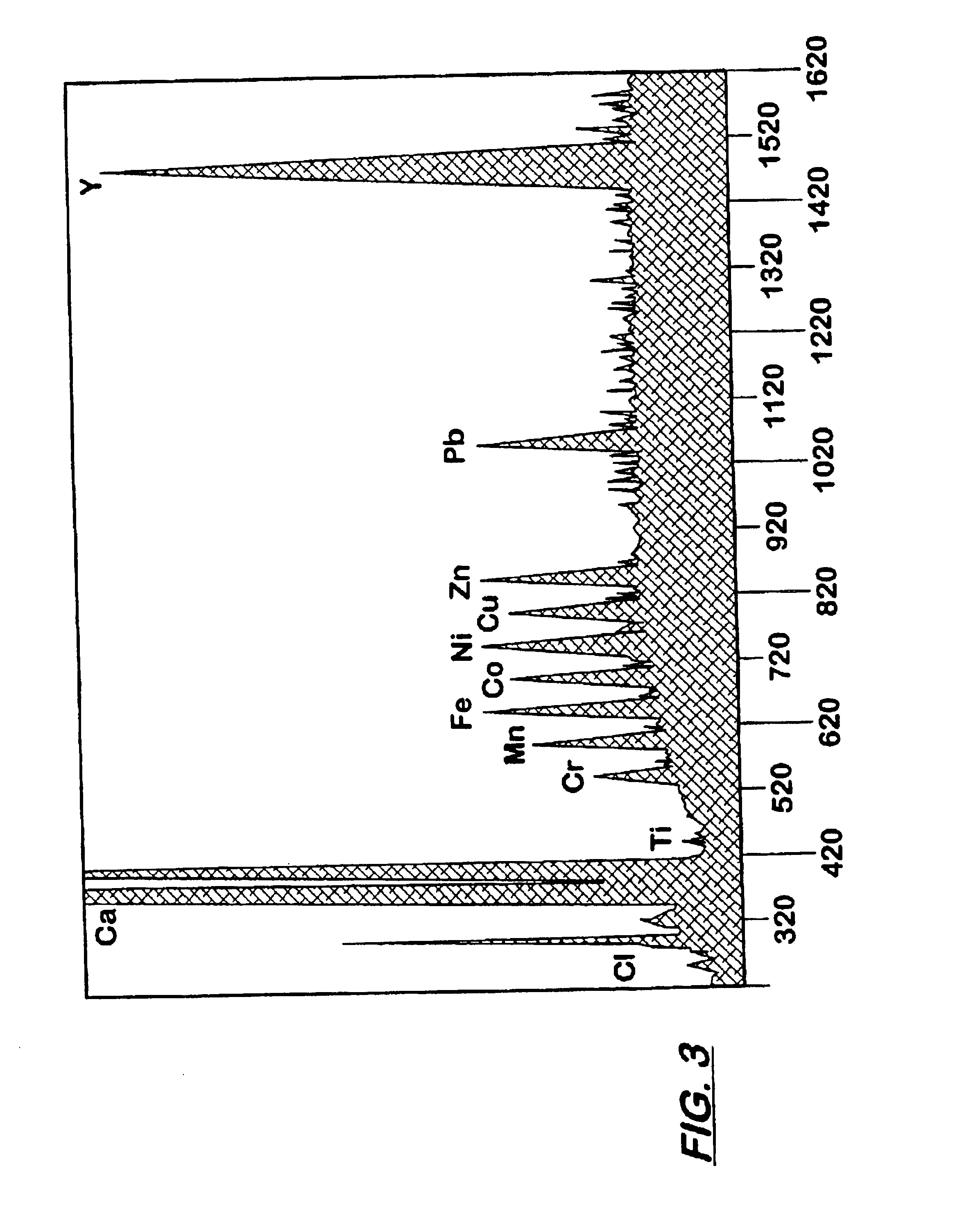

X-ray fluorescence (XRF) spectrometry has been used for detecting binding events and measuring binding selectivities between chemicals and receptors. XRF may also be used for estimating the therapeutic index of a chemical, for estimating the binding selectivity of a chemical versus chemical analogs, for measuring post-translational modifications of proteins, and for drug manufacturing.

Owner:RGT UNIV OF CALIFORNIA

Neutron and gamma ray monitor

InactiveUS20050023479A1Light weightMore selectiveX-ray spectral distribution measurementMeasurement with scintillation detectorsNeutron emissionX-ray

An apparatus for selective radiation detection includes a neutron detector that facilitates detection of neutron emitters, e.g. plutonium, and the like; a gamma ray detector that facilitates detection of gamma ray sources, e.g., uranium, and the like; and / or an X-ray analyzer that facilitates detection of materials that can shield radioactive sources, e.g., lead, and the like.

Owner:THERMO NITON ANALYZERS

Method for obtaining a picture of the internal structure of an object using x-ray radiation and device for the implementation thereof

InactiveUS6754304B1Improve accuracyReduce usageX-ray spectral distribution measurementHandling using diffraction/refraction/reflectionX-rayX ray dose

Owner:KUMAKHOV MURADIN ABUBEKIROVICH

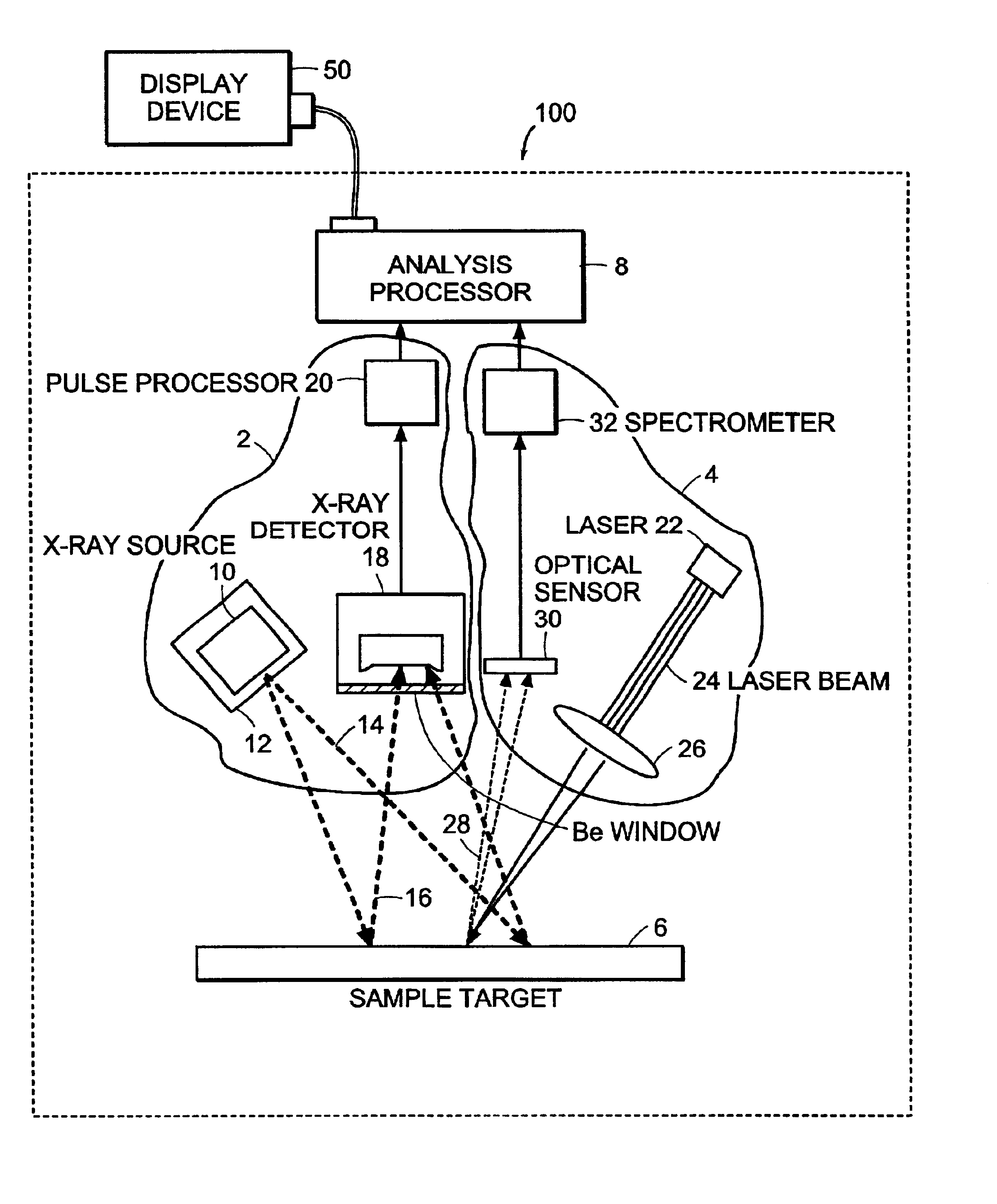

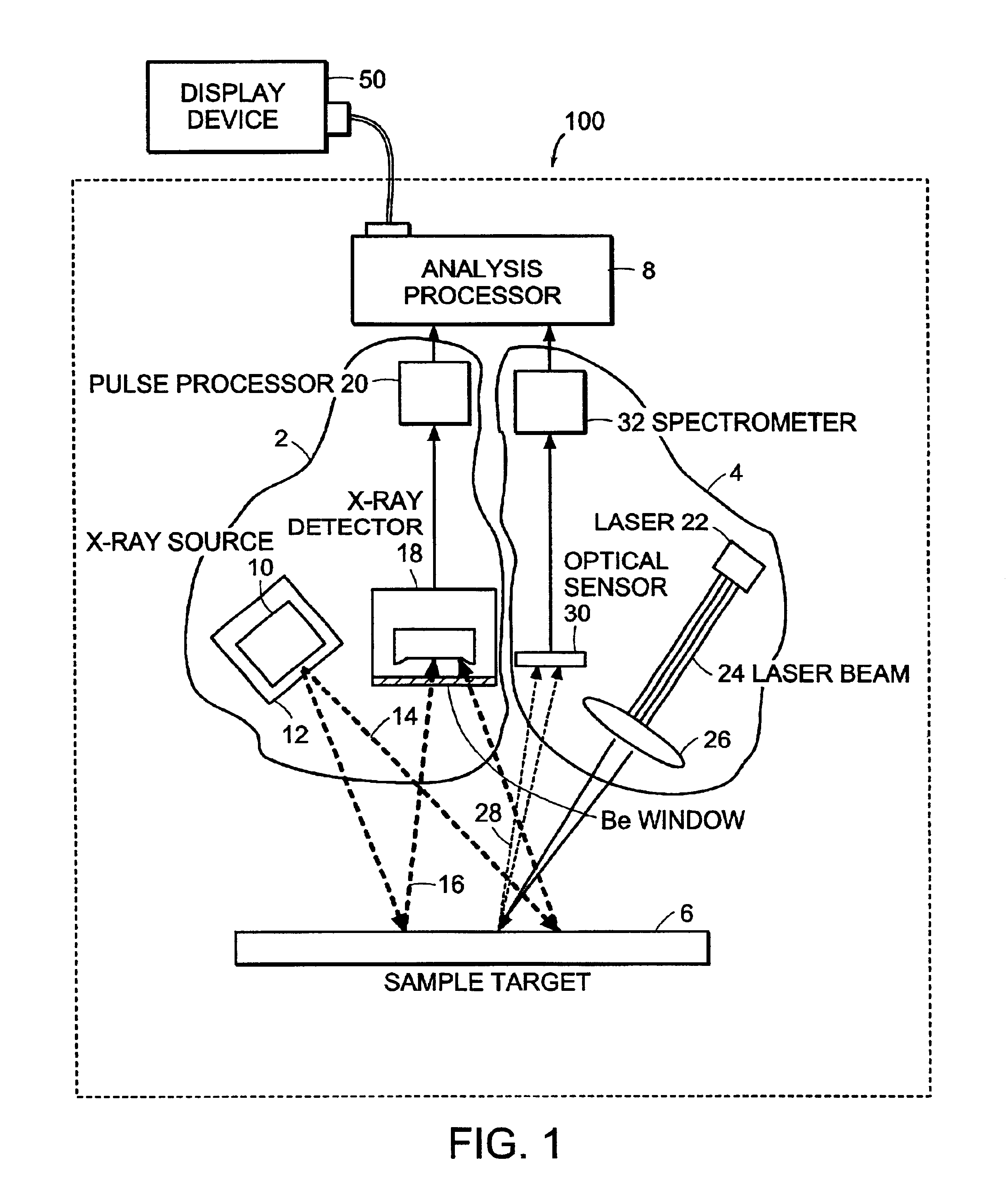

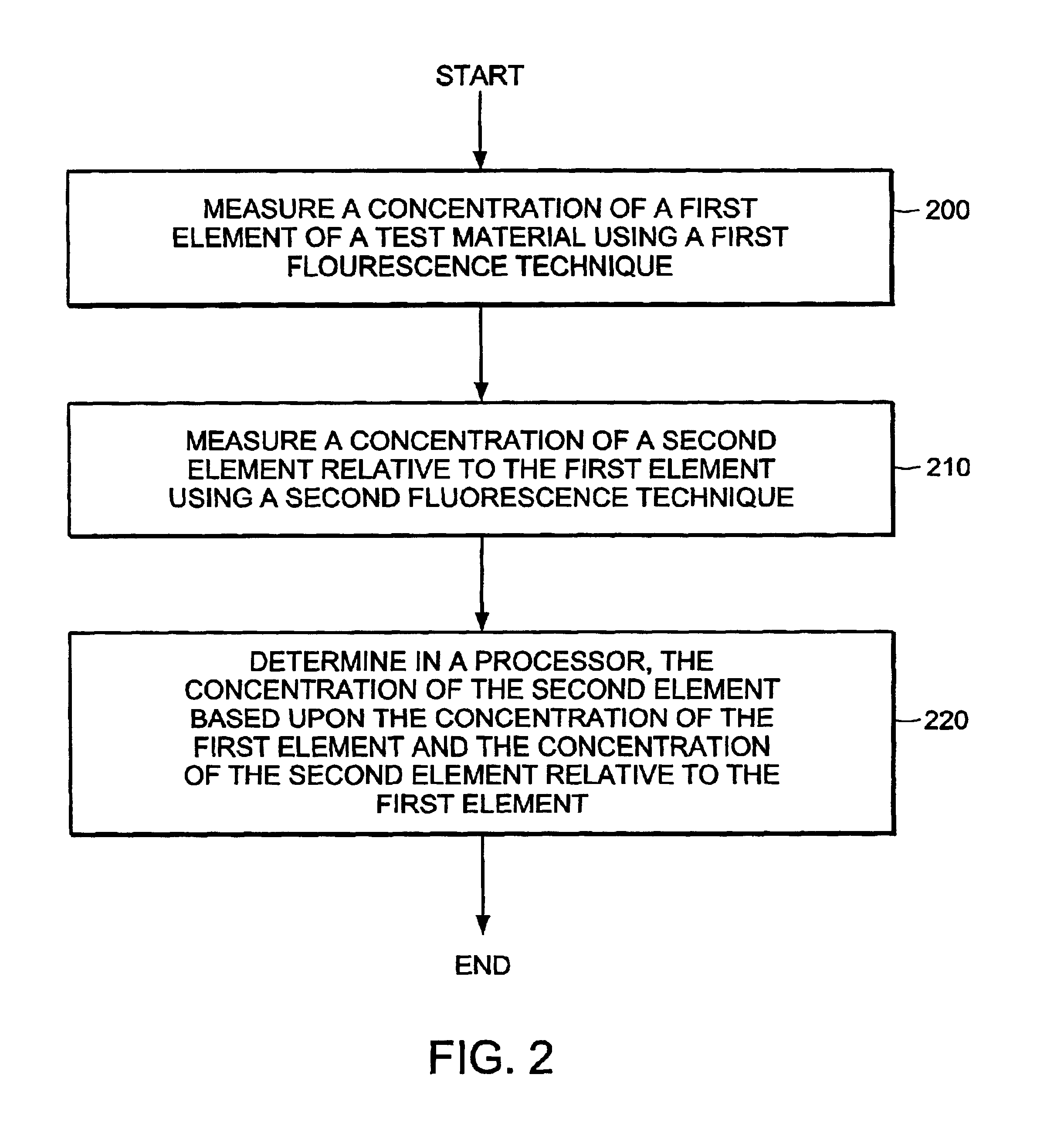

X-ray fluorescence combined with laser induced photon spectroscopy

A device and method for identifying the composition of a target sample. The target sample may be a matrix such as a metal alloy, a soil sample, or a work of art. The device includes an x-ray fluorescence detector that produces an x-ray signal output in response to the target sample. The device also includes an optical spectroscope that produces an optical signal output in response to the target sample. Further, a processor is included that analyzes and combines the x-ray signal output and the optical signal output to determine the composition of the test material. In one embodiment, the optical spectroscope is a laser induced photon fluorescence detector.

Owner:THERMO NITON ANALYZERS

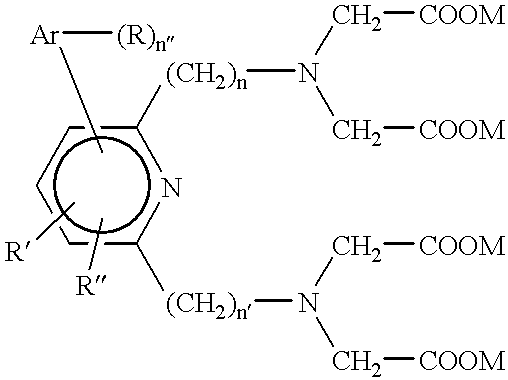

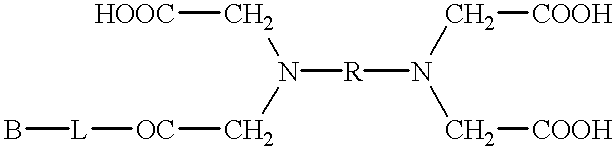

Homogeneous fluorassay methods employing fluorescent background rejection and water-soluble rare earth metal chelates

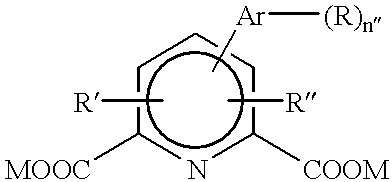

InactiveUS6242268B1High binding constantNon-metal conductorsGlass making apparatusHalf-lifeMetal chelate

Homogeneous assays for determining quantitatively the extent of a specific binding reaction can be carried out effectively on very dilute solutions using measurements of fluorescence if a fluorescence measurement scheme that is capable of rejecting short-lived background fluorescence is employed and if the fluorescent group being measured has the following properties: a. the group being measured must be a rare earth metal chelate complex combination; b. the chelate must be water-soluble; c. the complex combination must also be stable in extremely dilute aqueous solutions, that is, the measured chelate must have at least one ligand having a metal-to-ligand binding constant of at least about 1013M-1 or greater and it must have a fluorescent emission that is long-lived compared to the longest decay lifetime of ambient substances and have a half life of from 0.01 to 50 msec.

Owner:EG&G WALLAC

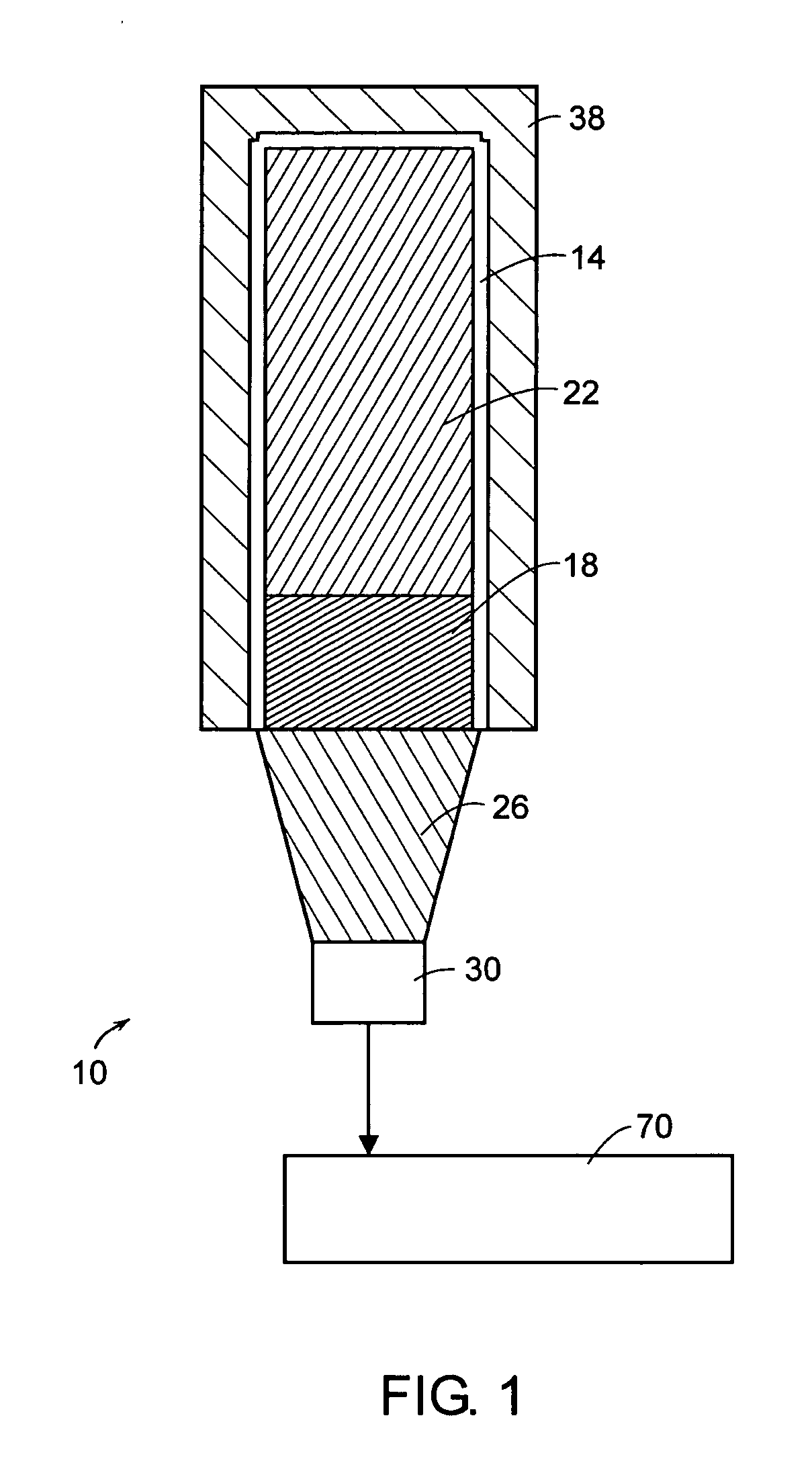

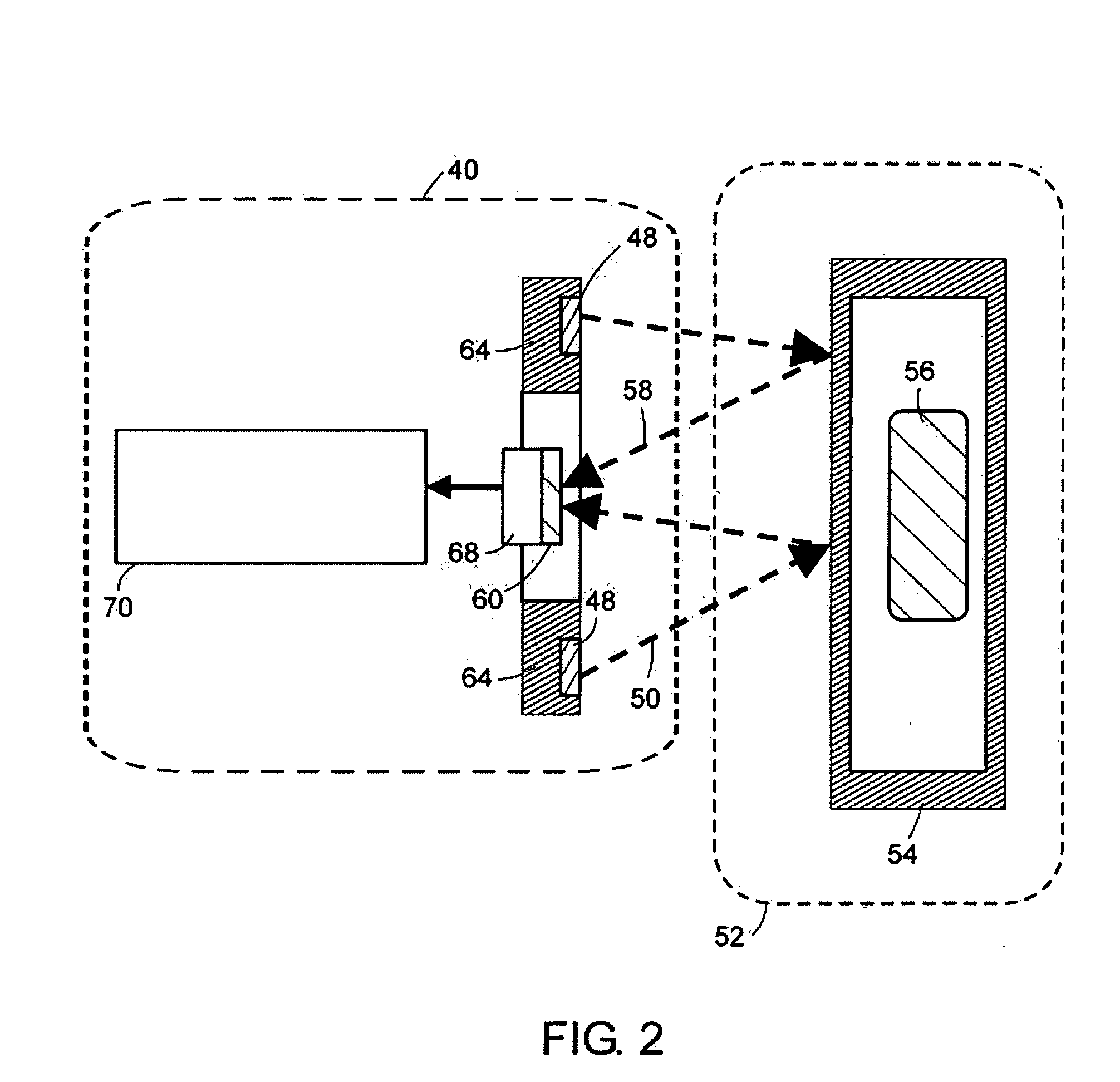

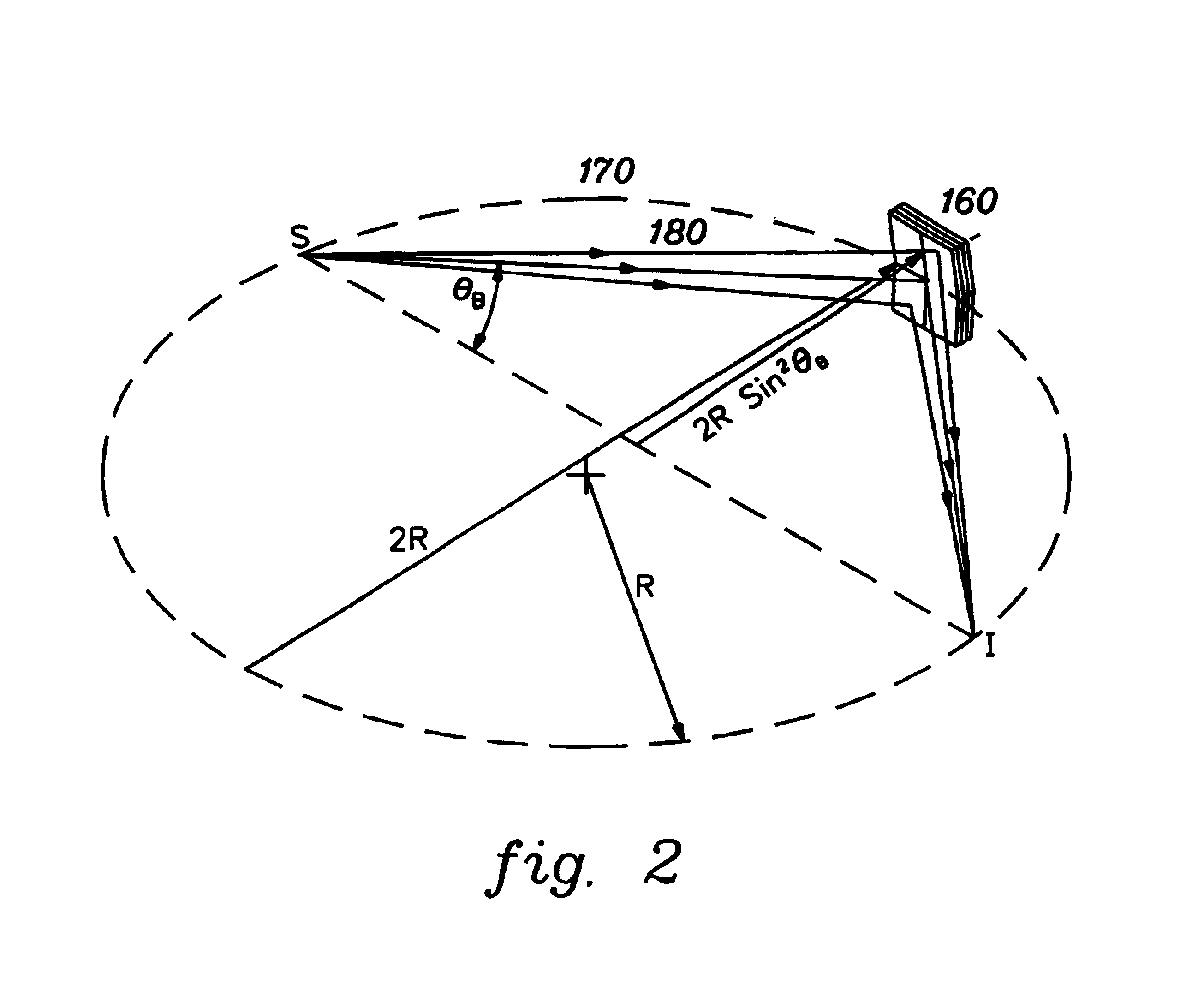

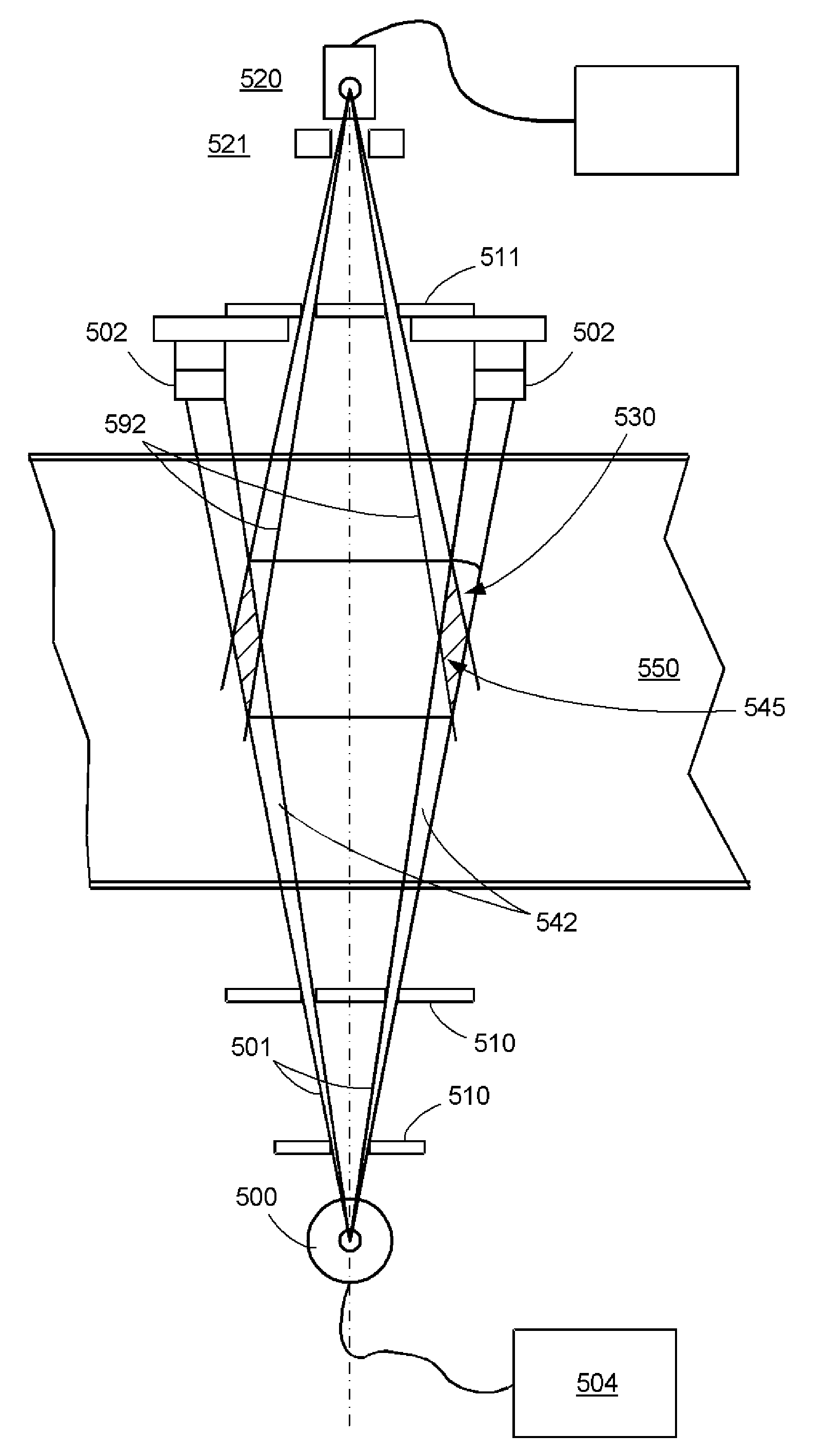

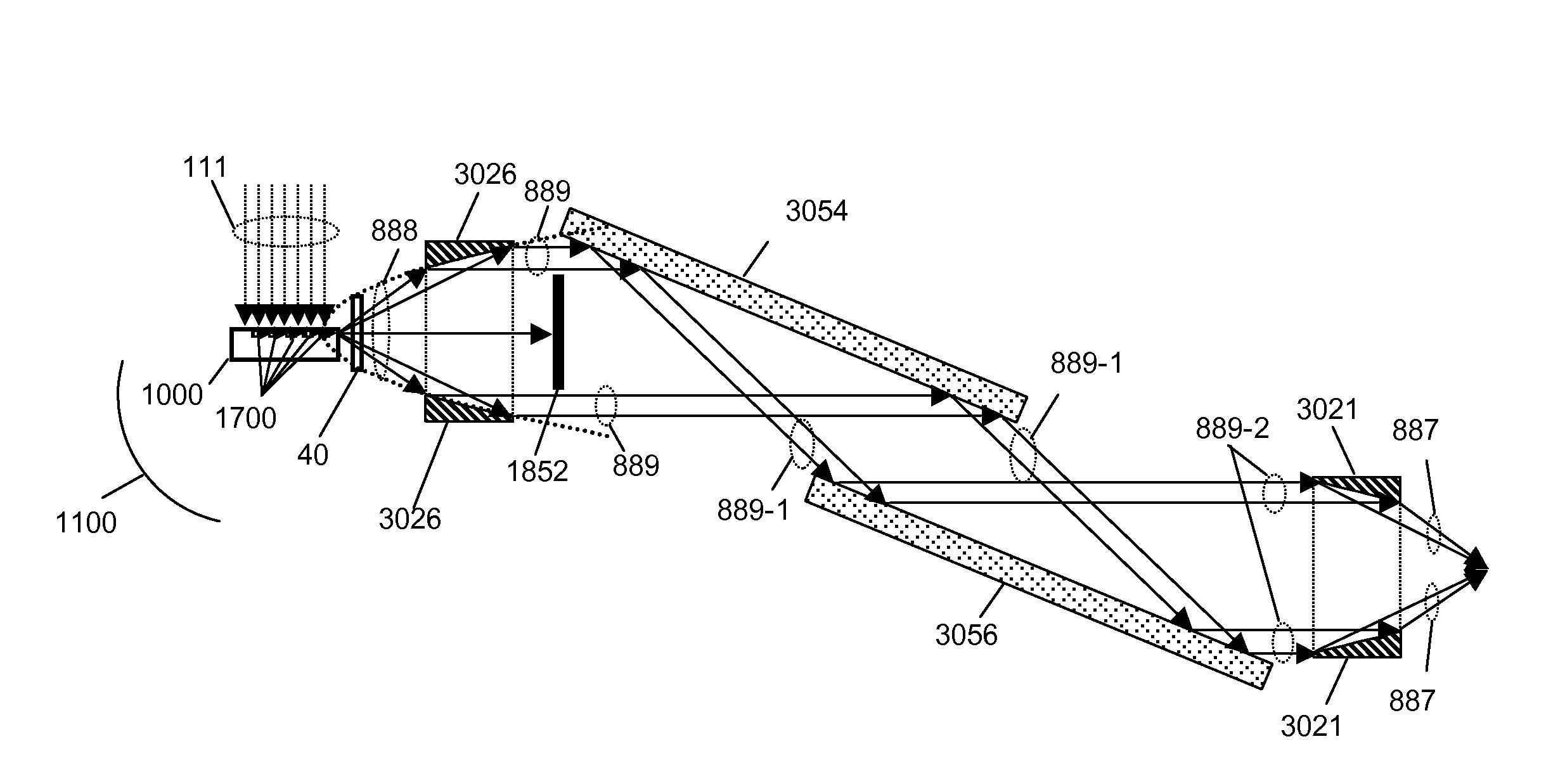

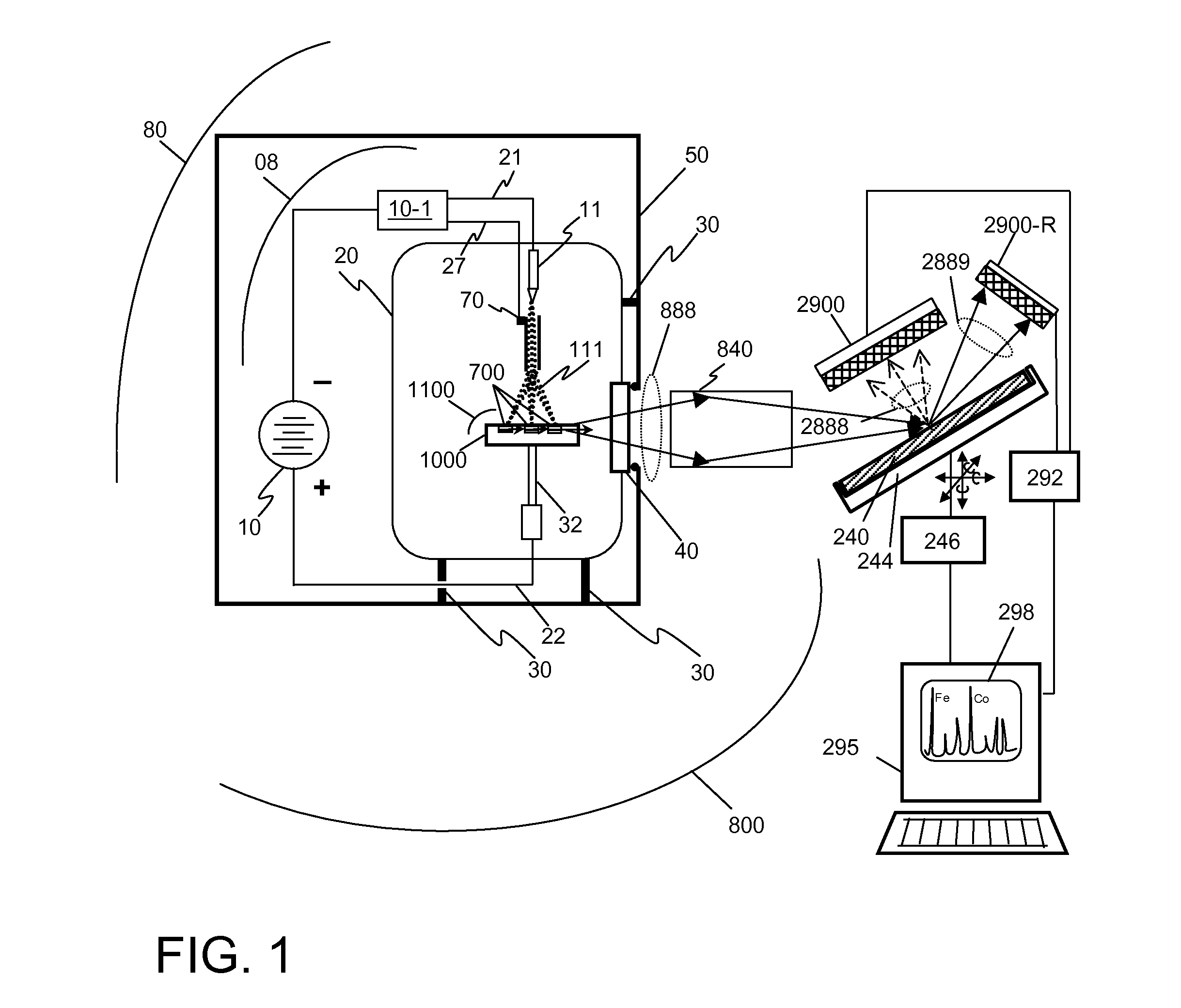

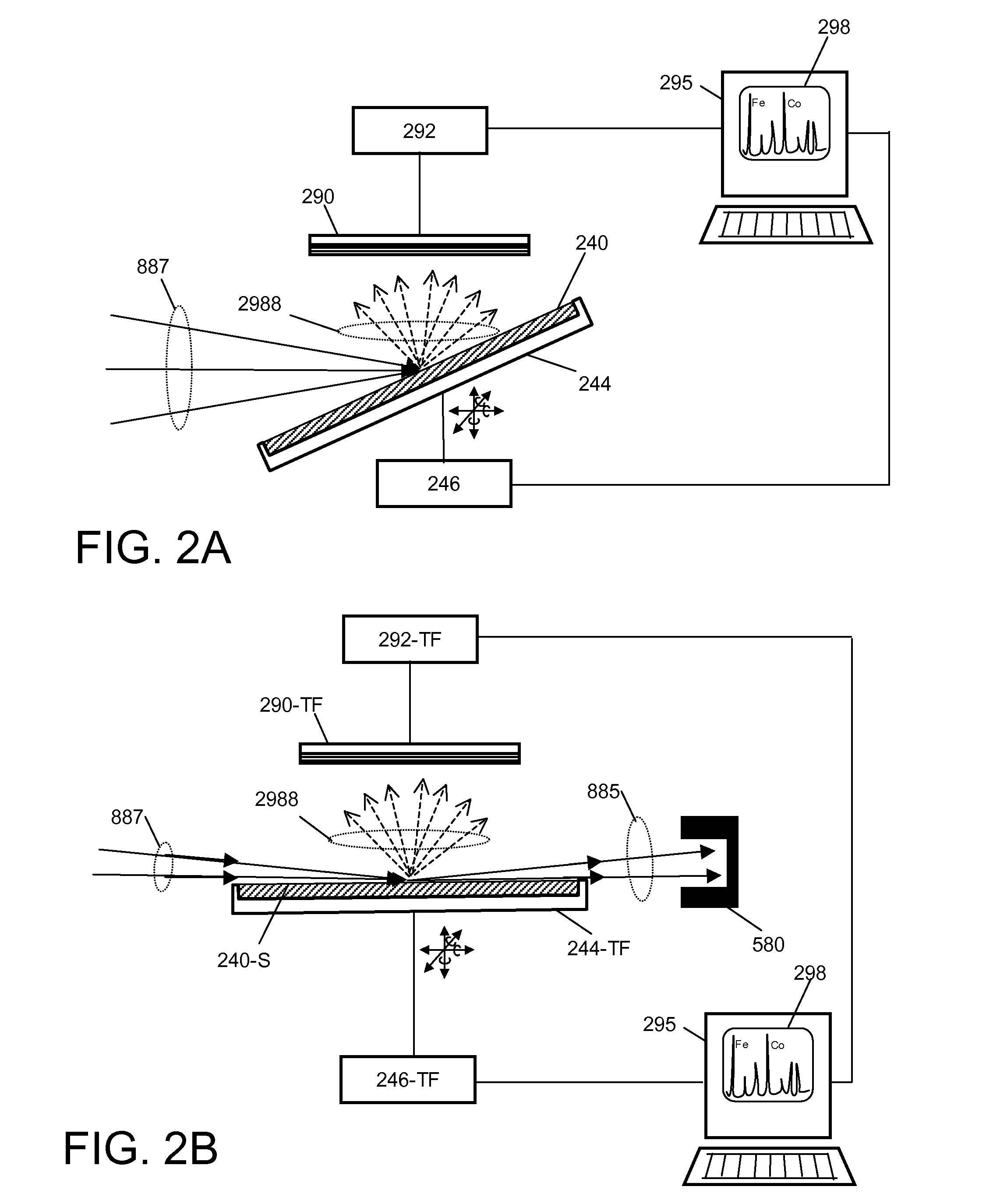

Wavelength dispersive XRF system using focusing optic for excitation and a focusing monochromator for collection

InactiveUS6934359B2Overcomes shortcomingX-ray/infra-red processesX-ray spectral distribution measurementSoft x rayAnalyte

X-ray fluorescence (XRF) spectroscopy systems and methods are provided. One system includes a source of x-ray radiation and an excitation optic disposed between the x-ray radiation source and the sample for collecting x-ray radiation from the source and focusing the x-ray radiation to a focal point on the sample to incite at least one analyte in the sample to fluoresce. The system further includes an x-ray fluorescence detector and a collection optic comprising a doubly curved diffracting optic disposed between the sample and the x-ray fluorescence detector for collecting x-ray fluorescence from the focal point on the sample and focusing the fluorescent x-rays towards the x-ray fluorescence detector.

Owner:X-RAY OPTICAL SYSTEM INC

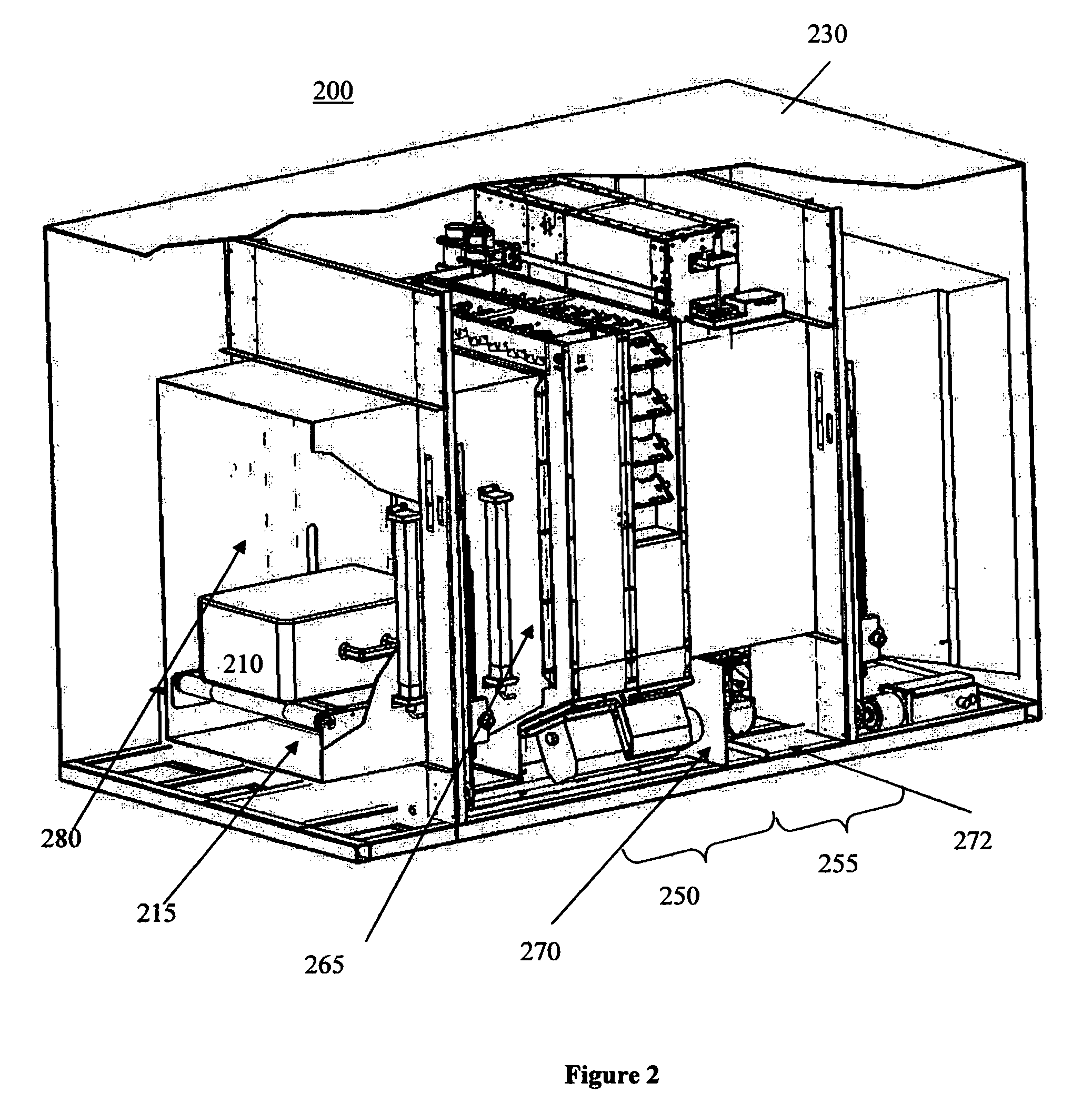

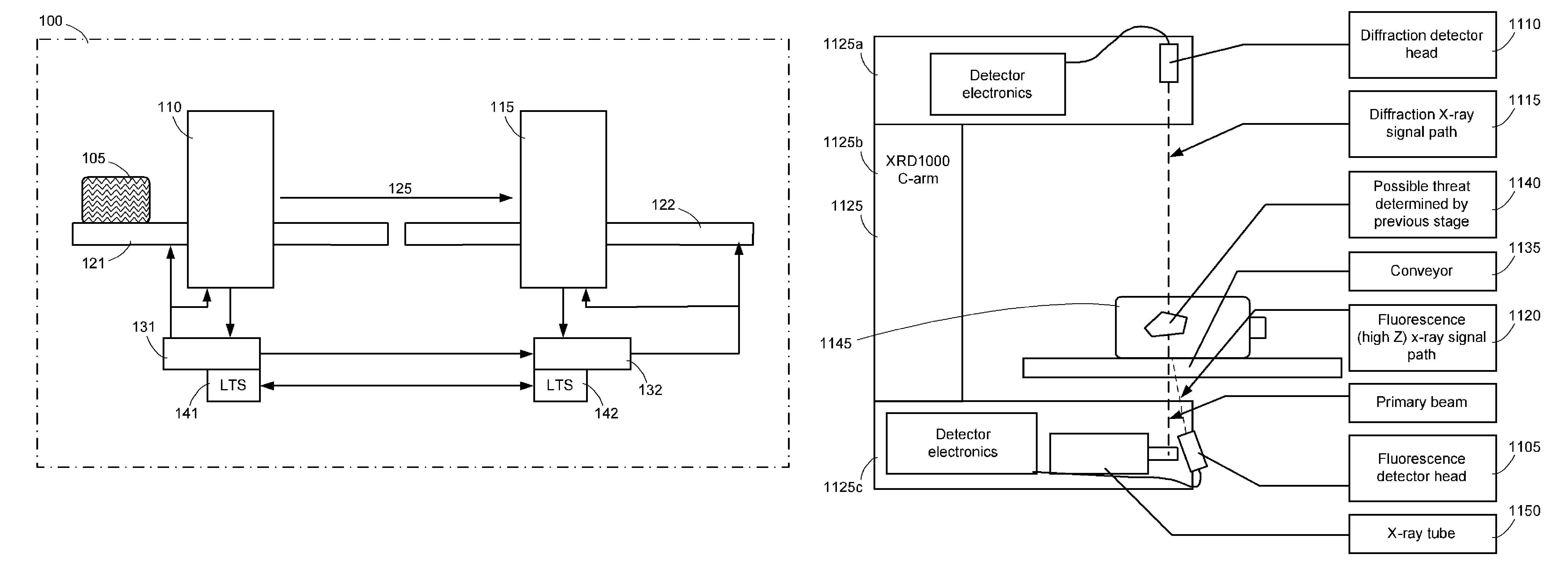

Methods and systems for rapid detection of concealed objects using fluorescence

InactiveUS20060098773A1True natureImprove throughputX-ray spectral distribution measurementMaterial analysis by transmitting radiationImaging processingFluorescence

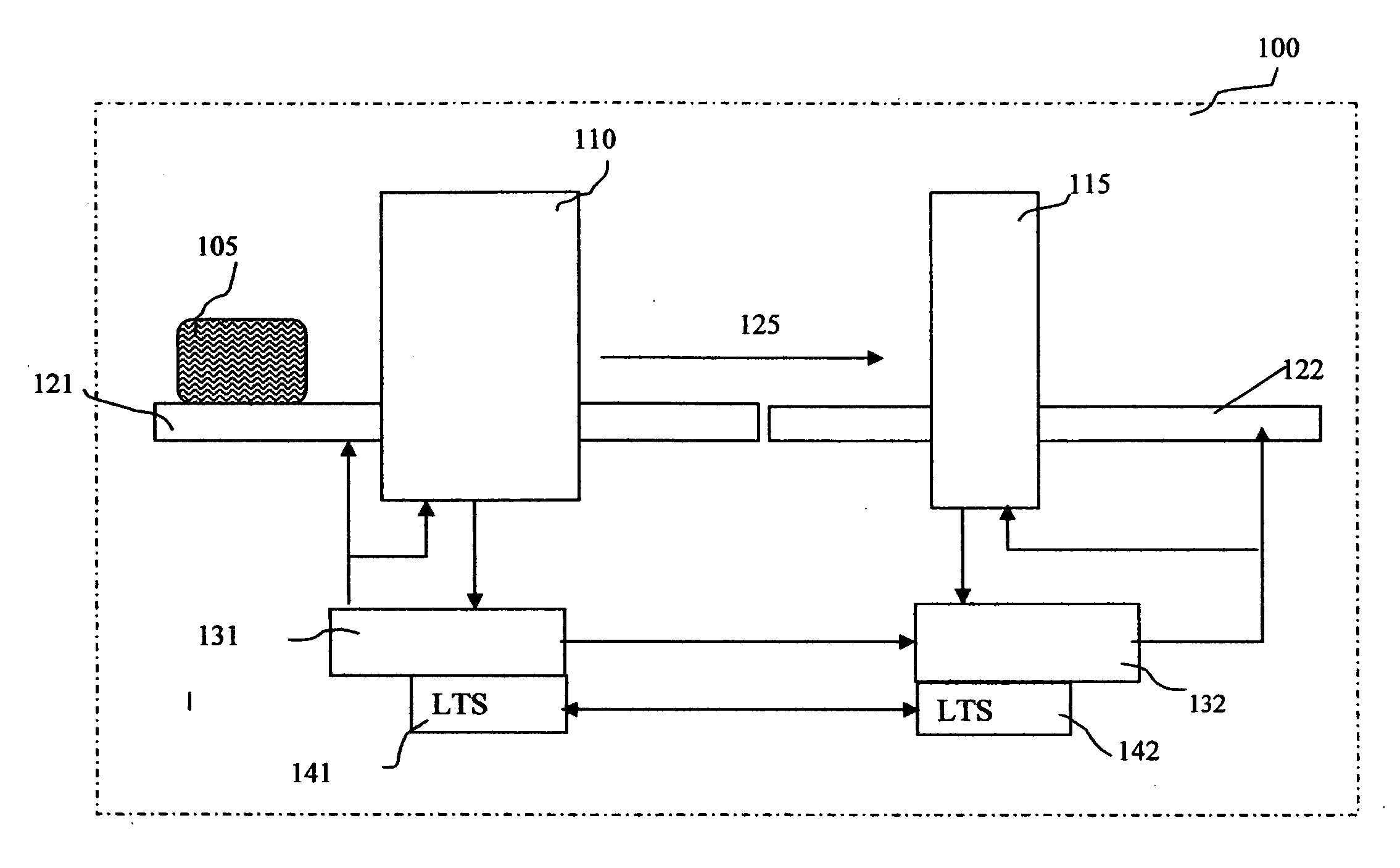

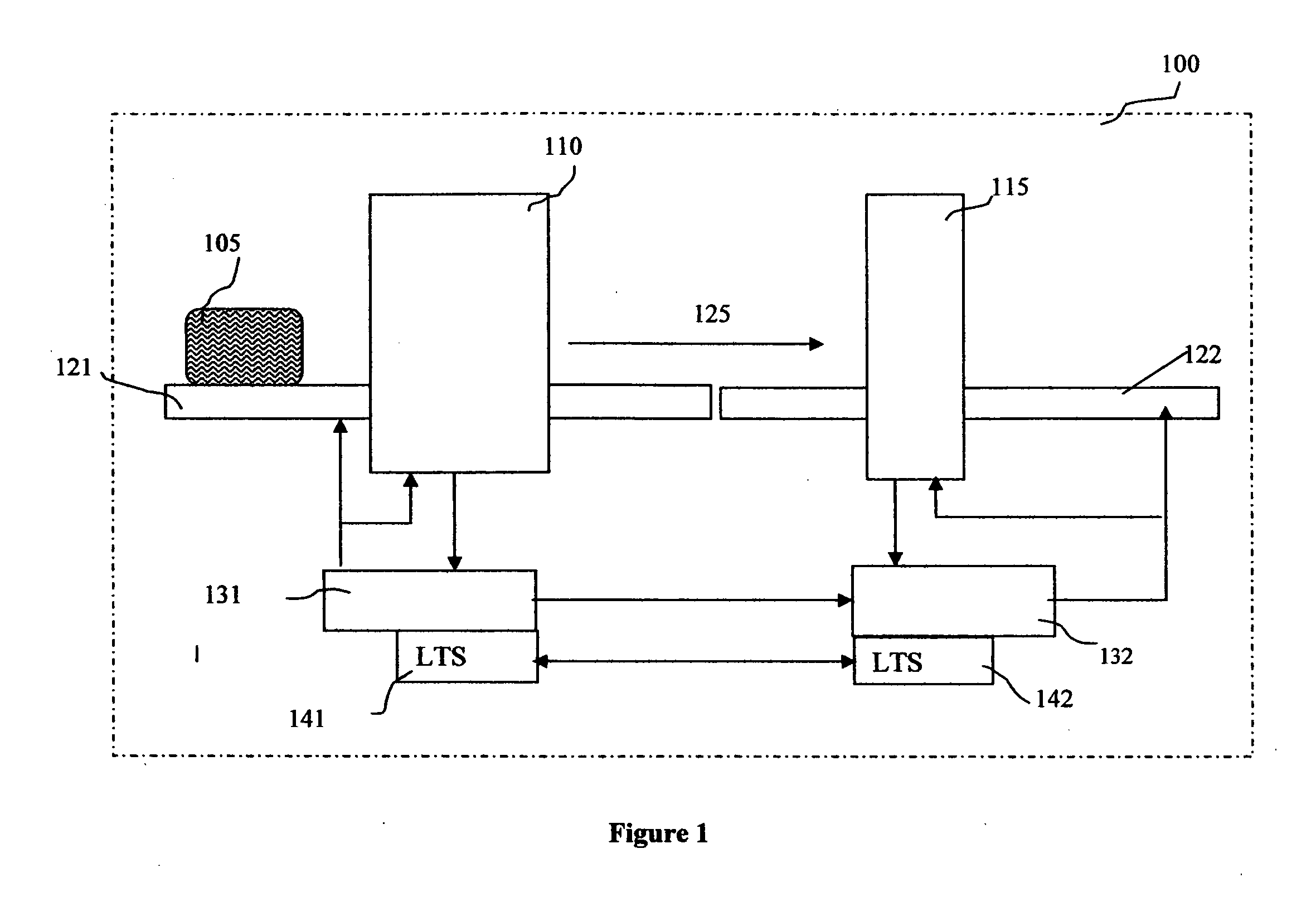

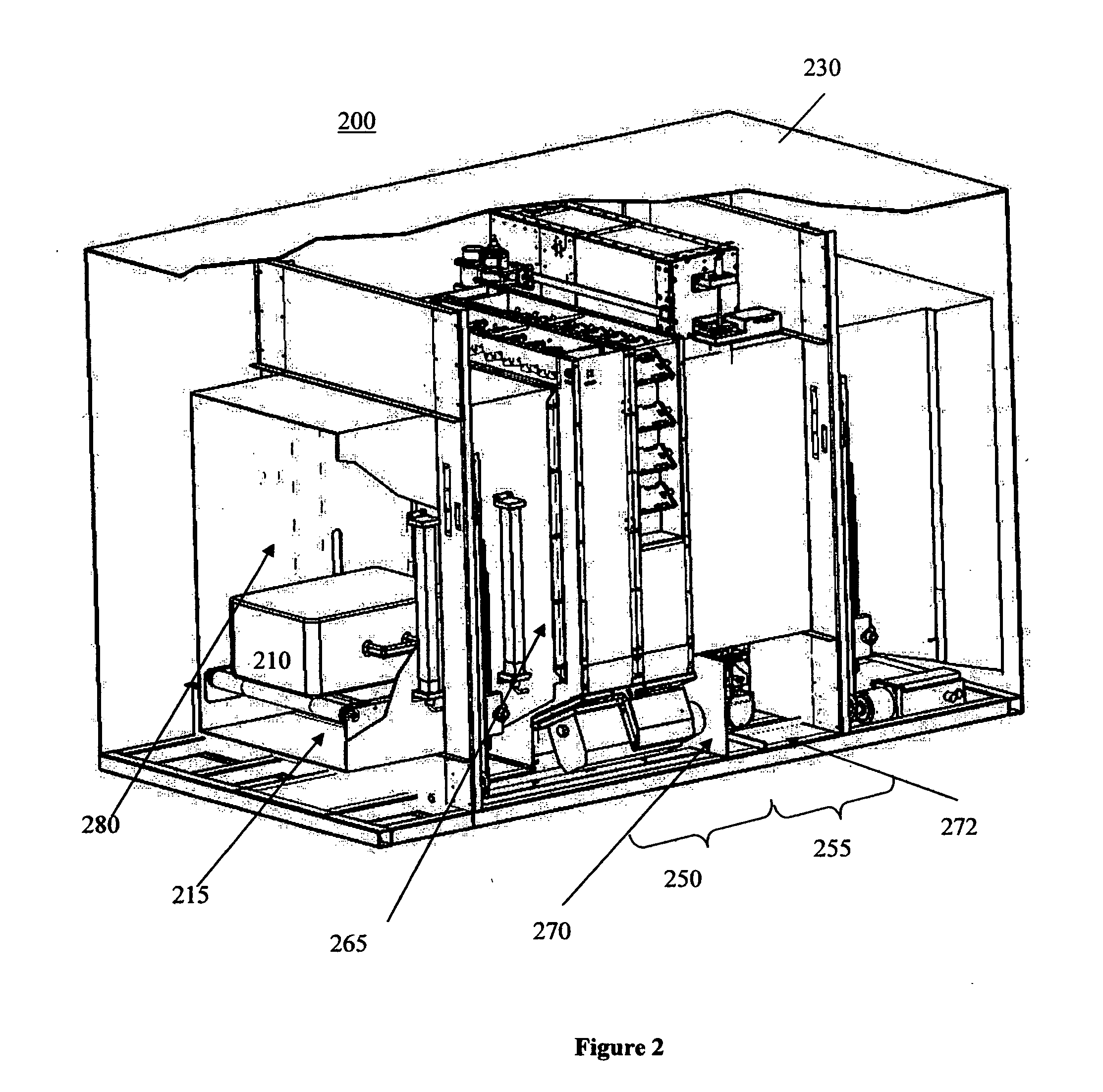

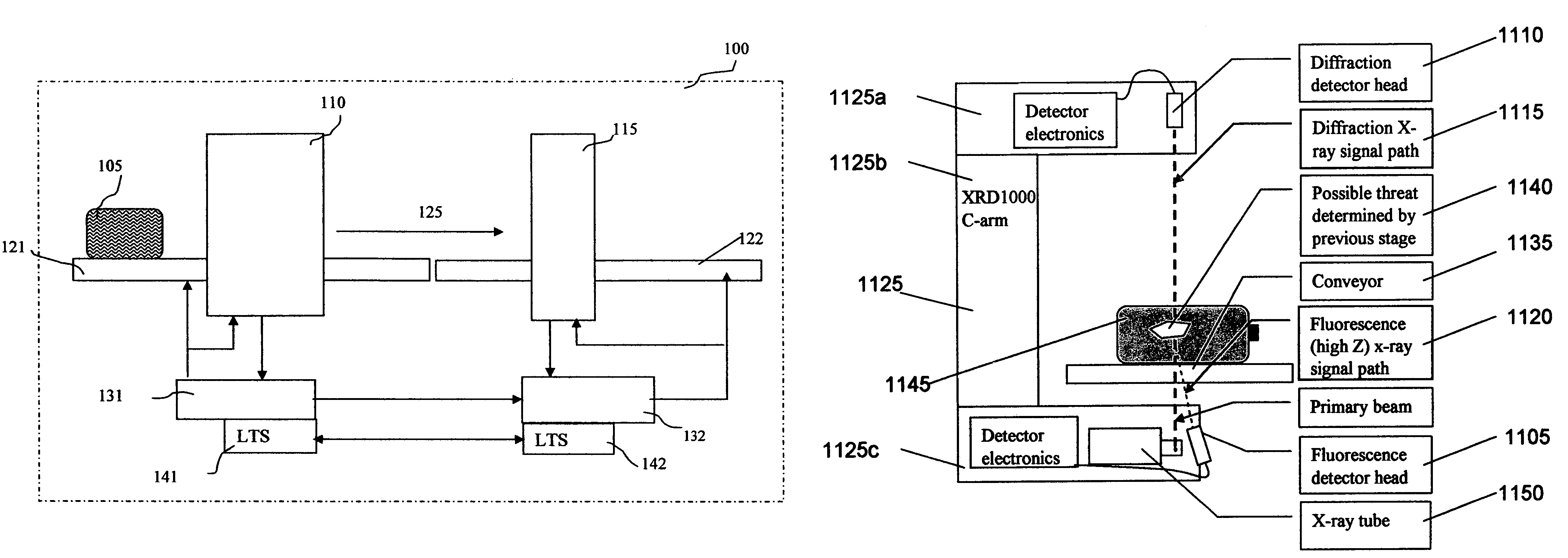

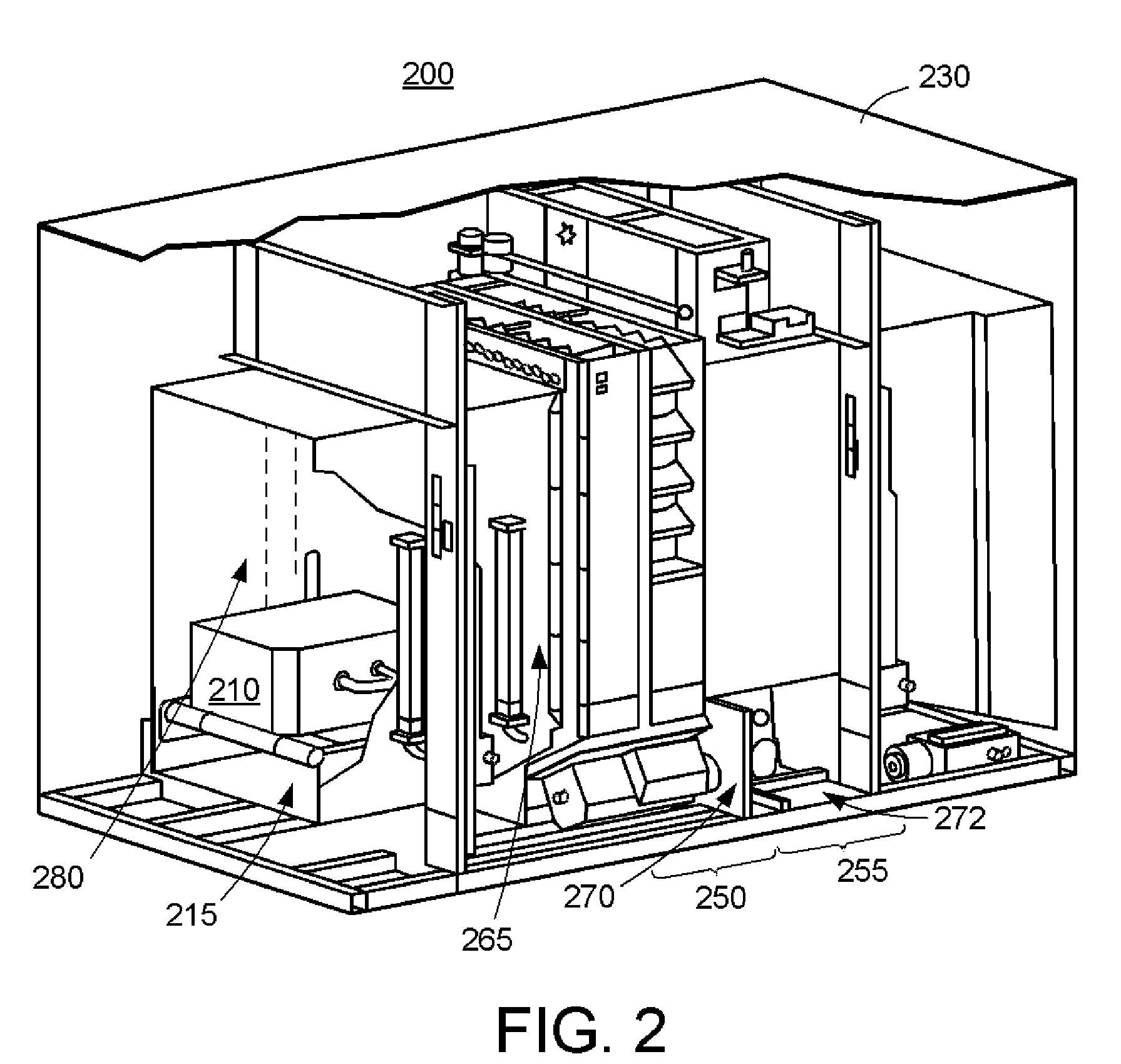

This invention is directed towards finding, locating, and confirming threat items and substances. The inspection system is designed to detect objects that are made from, but not limited to, special nuclear materials (“SNM”) and / or high atomic number materials. The system employs advanced image processing techniques to analyze images of an object under inspection (“OUI”), which includes, but is not limited to baggage, parcels, vehicles and cargo, and fluorescence detection.

Owner:RAPISCAN SYST INC (US)

Methods and systems for rapid detection of concealed objects using fluorescence

InactiveUS7366282B2True natureImprove throughputX-ray spectral distribution measurementMaterial analysis by transmitting radiationImaging processingSystems design

This invention is directed towards finding, locating, and confirming threat items and substances. The inspection system is designed to detect objects that are made from, but not limited to, special nuclear materials (“SNM”) and / or high atomic number materials. The system employs advanced image processing techniques to analyze images of an object under inspection (“OUI”), which includes, but is not limited to baggage, parcels, vehicles and cargo, and fluorescence detection.

Owner:RAPISCAN SYST INC (US)

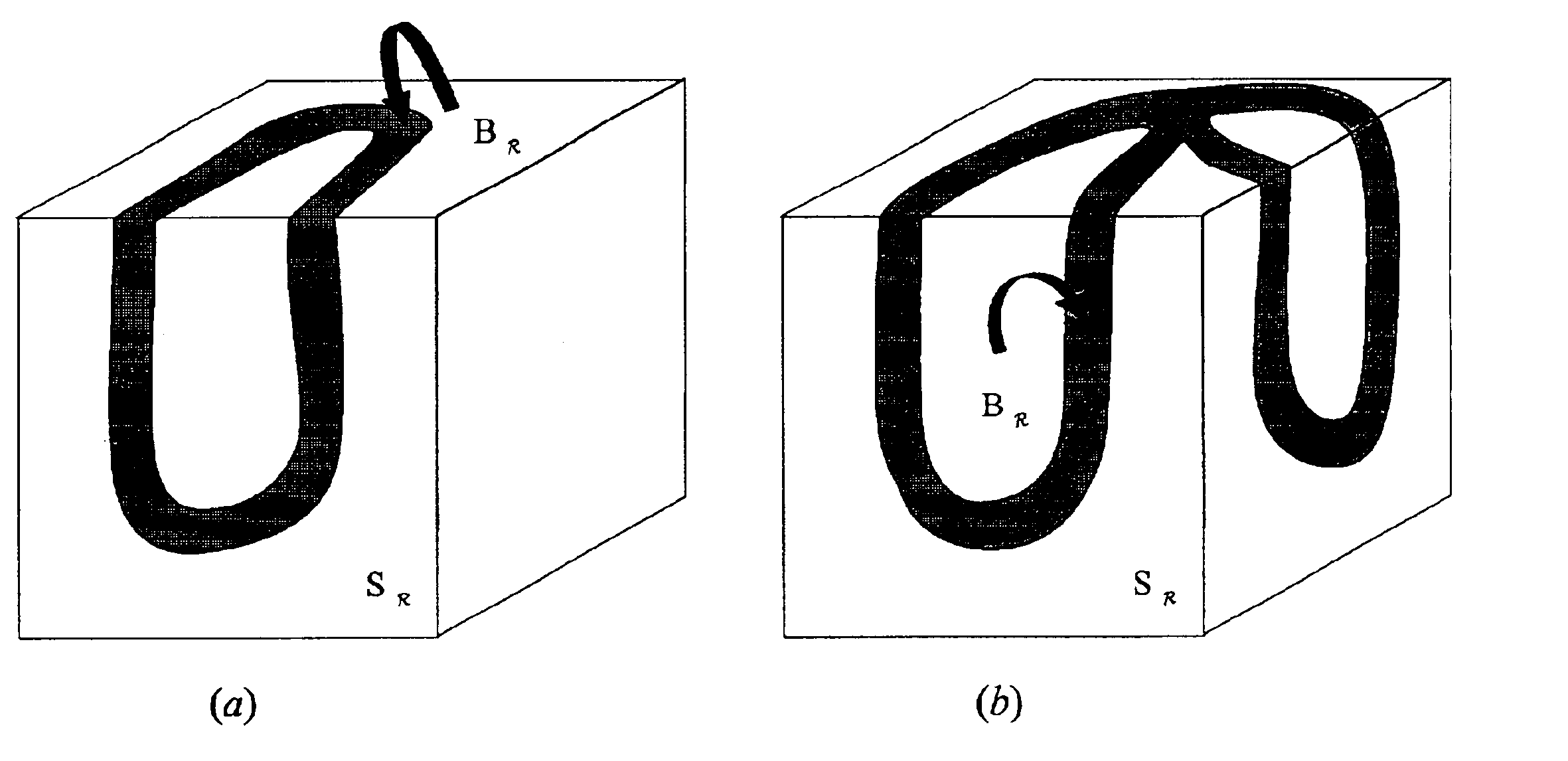

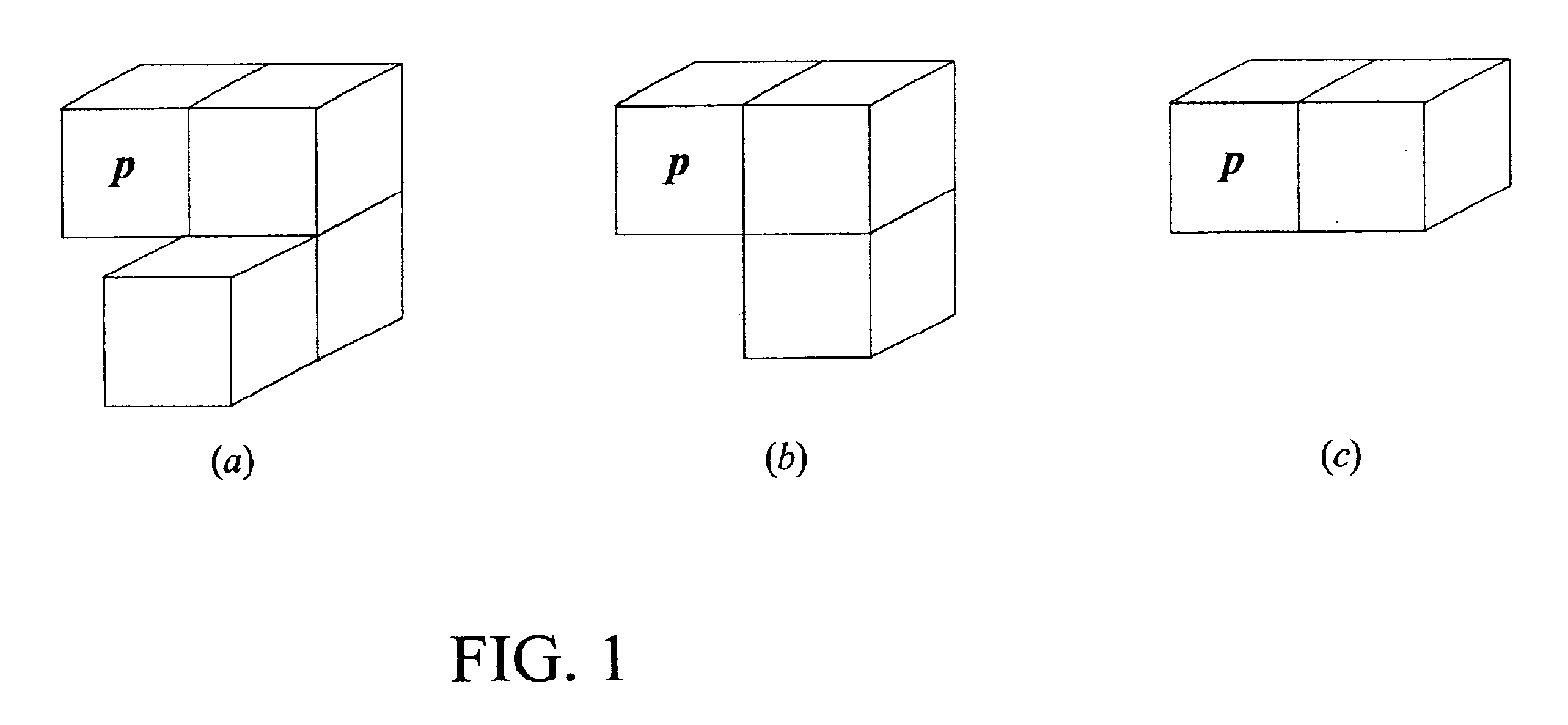

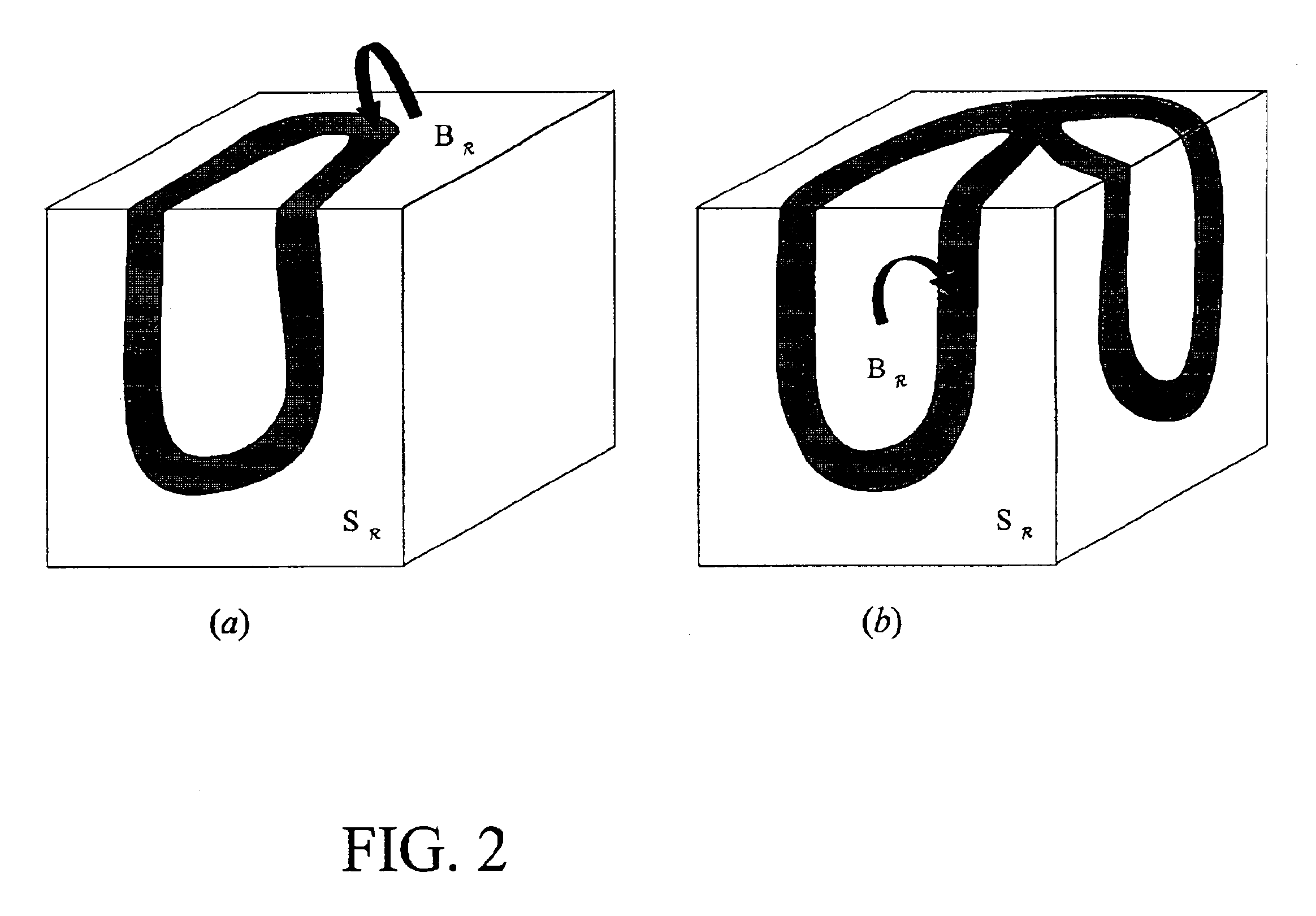

Digital topological analysis of trabecular bone MR images and prediction of osteoporosis fractures

The invention provides method, system and device for determining trabecular bone structure and strength by digital topological analysis, and offers, for the first time, a demonstration of superior associations between vertebral deformity and a number of architectural indices measured in the distal radius, thus permitting reliable and noninvasive detection and determination of the pathogenesis of osteoporosis. A preferred embodiment provides imaging in three dimension of a region of trabecular bone, after which the 3D image is converted into a skeletonized surface representation. Digital topological analysis is applied to the converted image, and each image voxel is identified and classified as a curve, a surface, or a junction; and then associated with microarchitectural indices of trabecular bone to quantitatively characterize the trabecular bone network. The invention is applicable in vivo, particularly on human subjects, or ex vivo.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

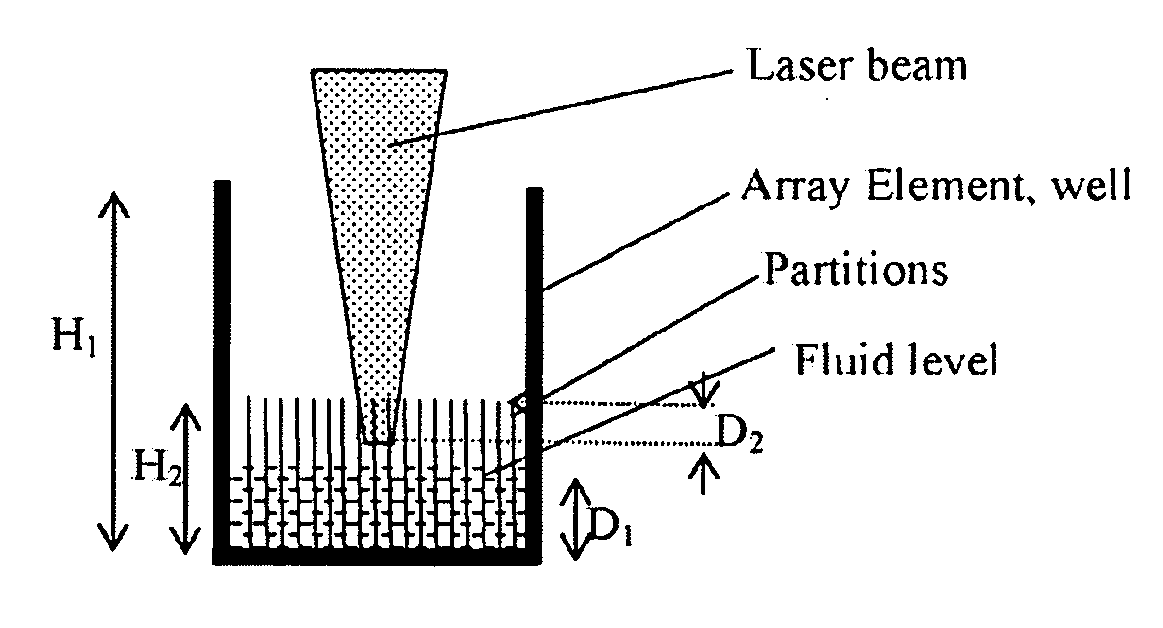

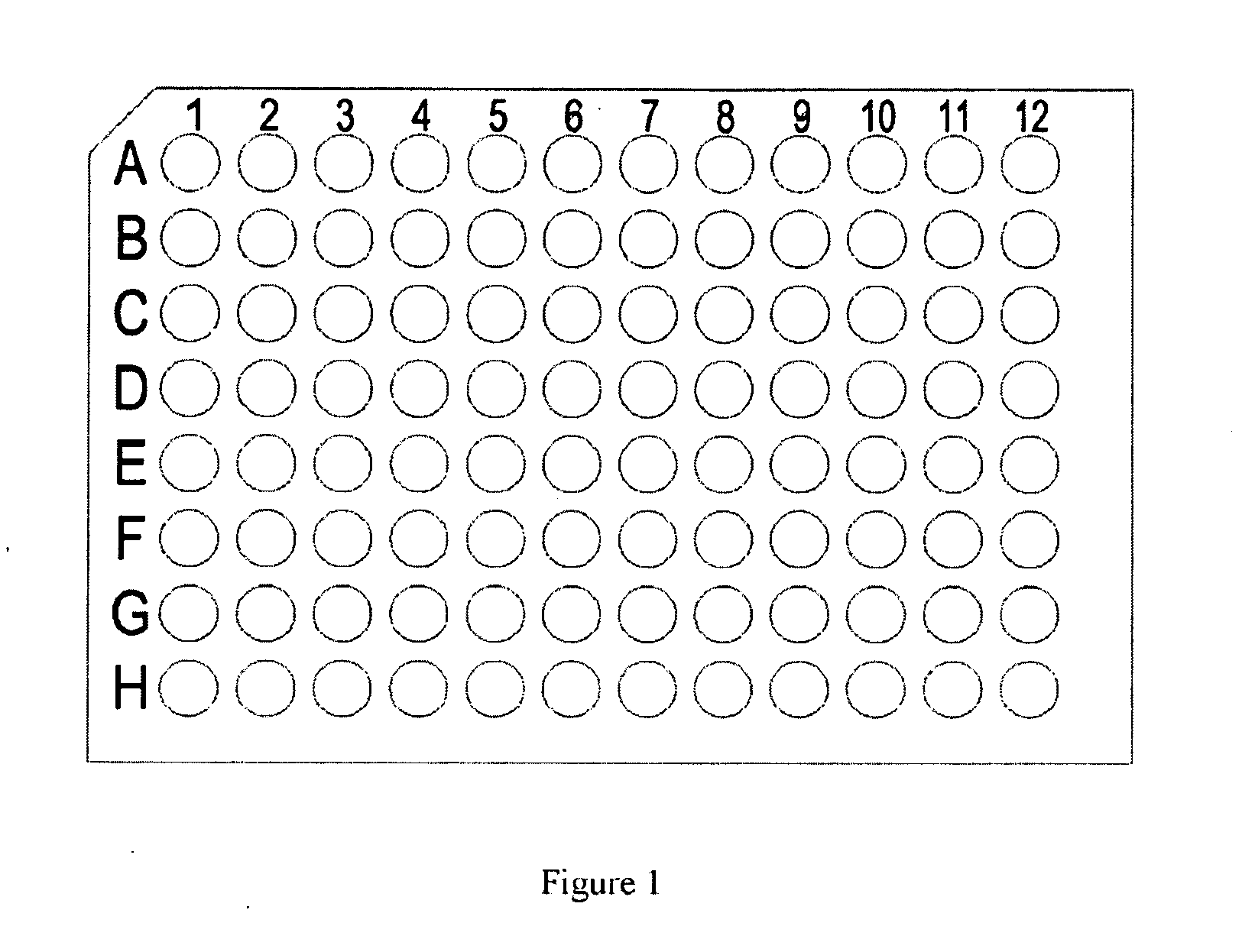

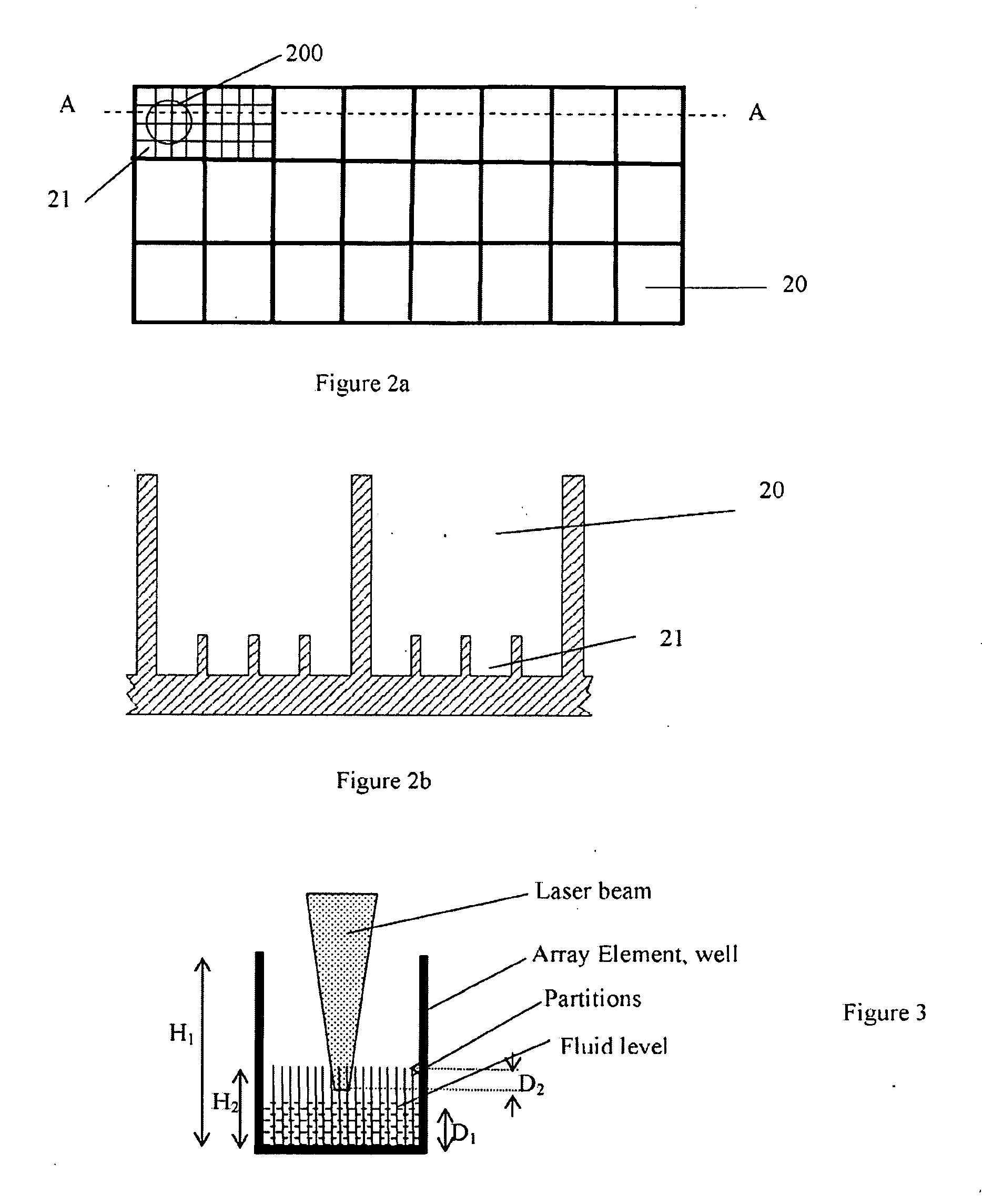

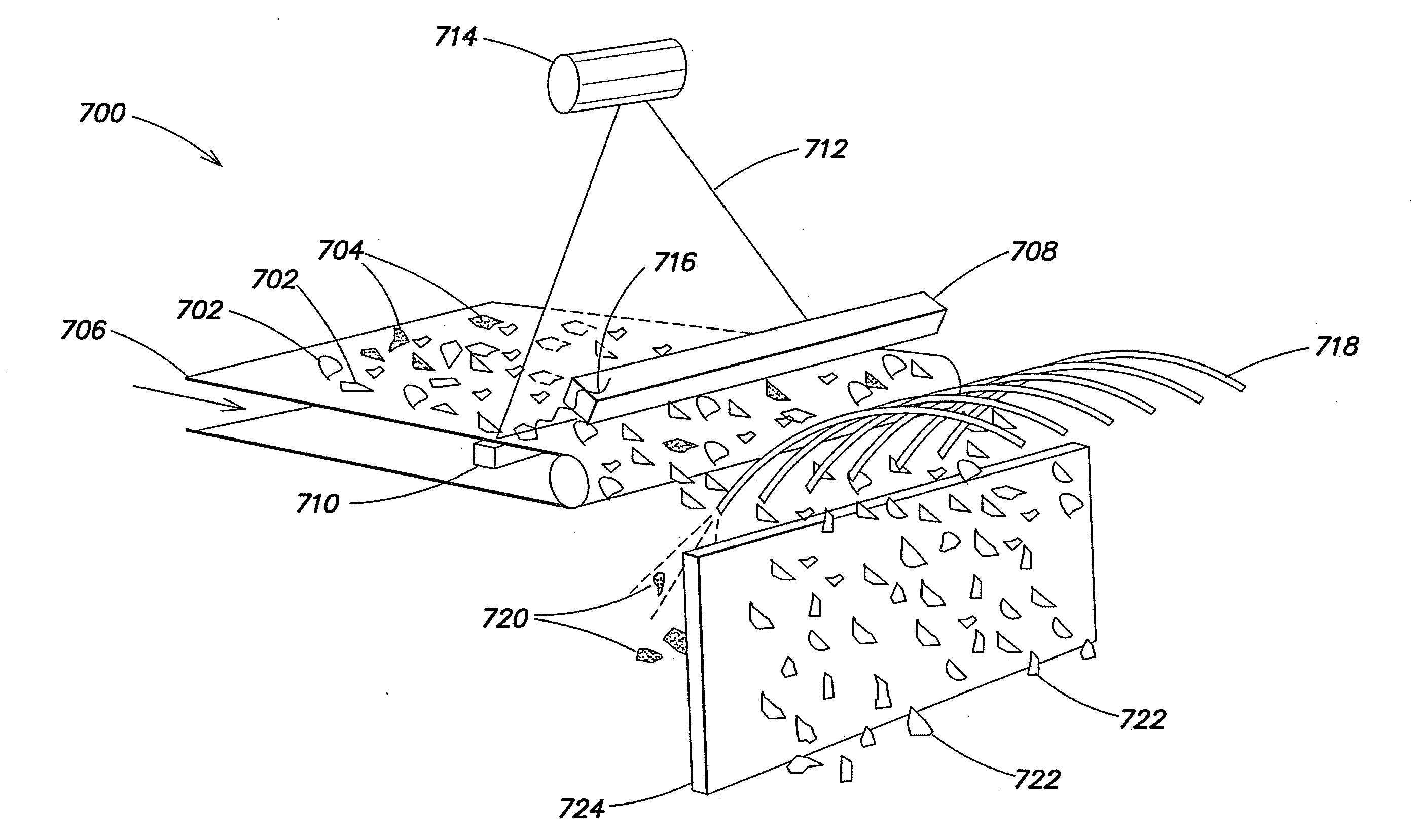

Analysis of arrays by laser induced breakdown spectroscopy

ActiveUS20090290151A1Improve throughputRadiation pyrometryX-ray spectral distribution measurementPhysicsLight spectrum

The present invention relates to the detection of materials using laser induced breakdown spectroscopy (LIBS). This invention discloses methods to draw the analyte of interest in a homogeneous matrix and subsequent analysis of these matrices, wherein the said matrices are preferably arranged in an array format. This invention is particularly applicable to analysis of Liquid samples arranged in an array format.

Owner:AJJER

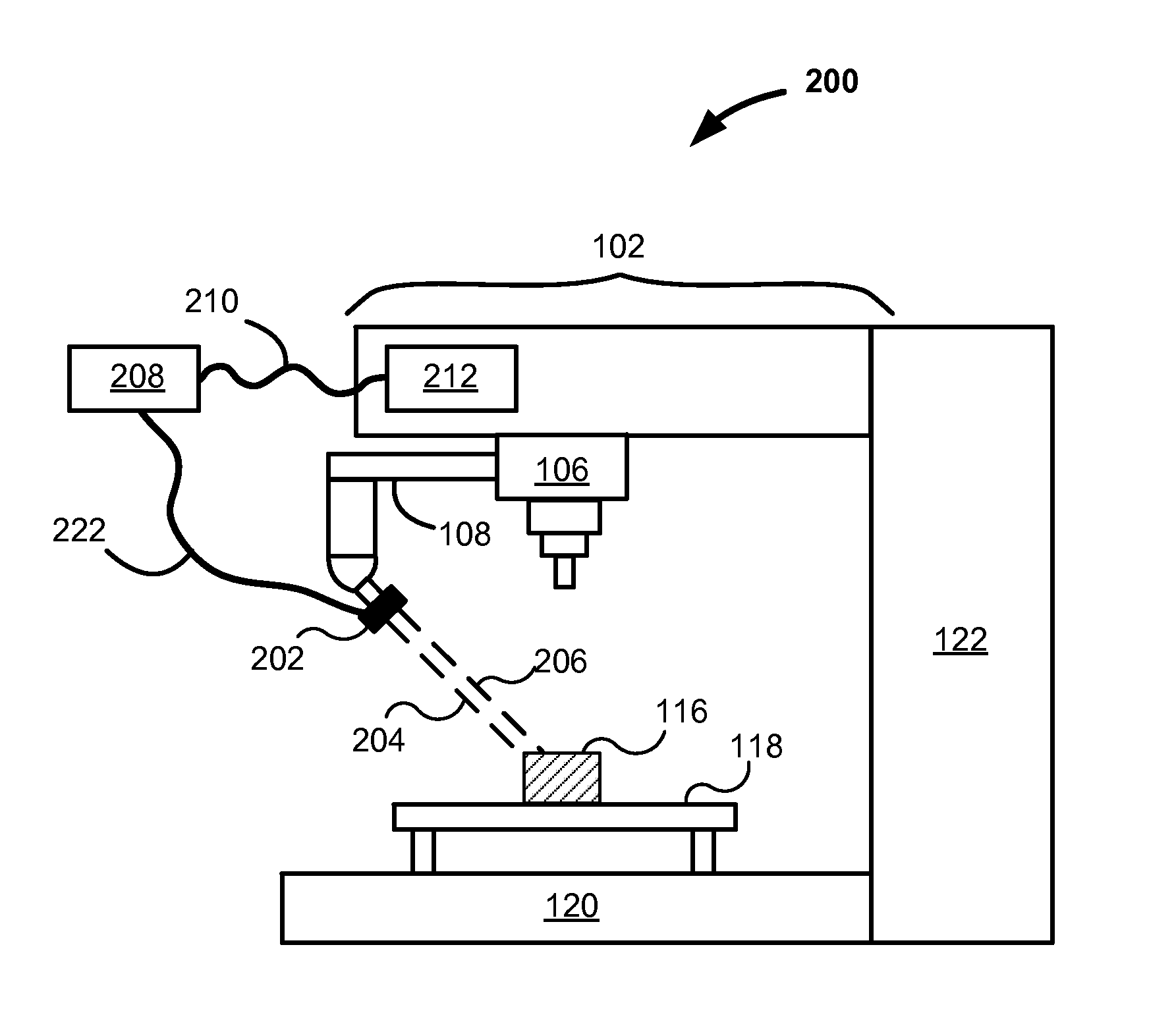

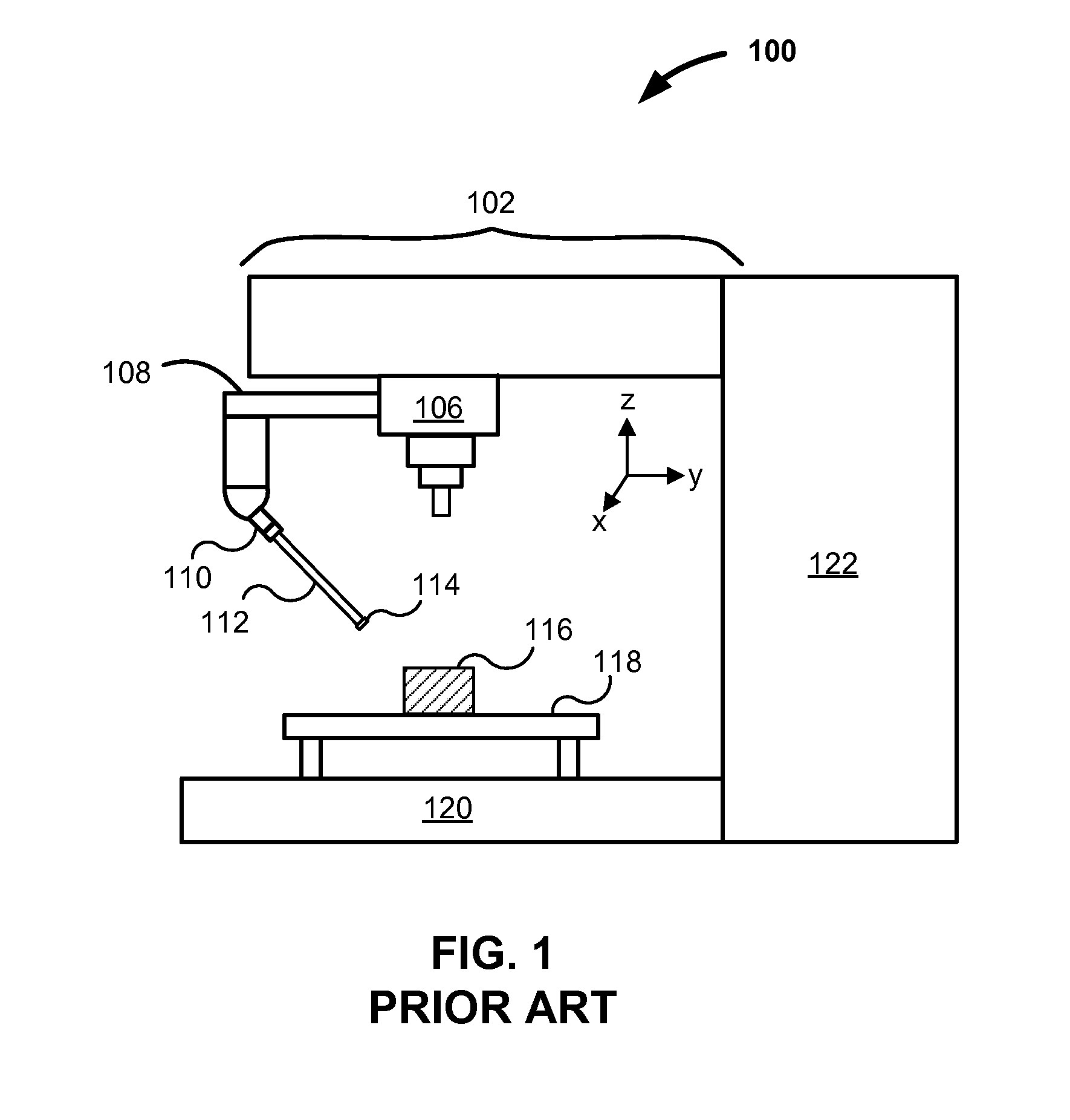

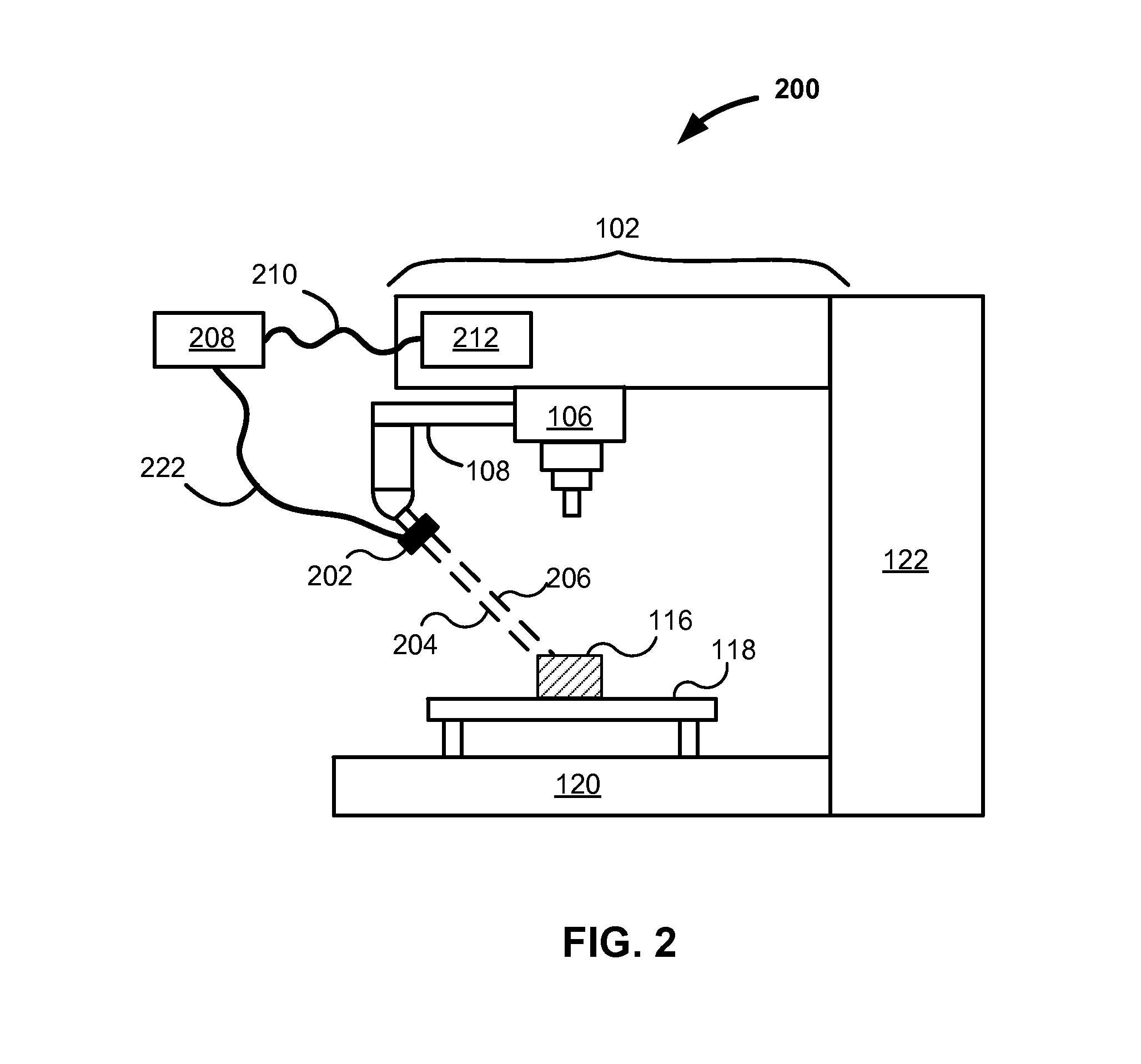

High Speed Metrology with Numerically Controlled Machines

ActiveUS20140157610A1Accurate verificationTight stack-up toleranceVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesNumerical controlMetrology

Systems, apparatuses and methods are described for integrating an electronic metrology sensor with precision production equipment such as computer numerically controlled (CNC) machines. For example, a laser distance measuring sensor is used. Measurements are taken at a relatively high sample rate and converted into a format compatible with other data generated or accepted by the CNC machine. Measurements from the sensor are synchronized with the position of the arm of the machine such as through the use of offsets. Processing yields a detailed and highly accurate three-dimensional map of a workpiece in the machine. Applicable metrology instruments include other near continuously reading non-destructive characterization instruments such as contact and non-contact dimensional, eddy current, ultra-sound, and X-Ray Fluorescence (XRF) sensors. Various uses of measurements include: multiple component matching, correction of machine drift, closed loop control of machines, and verification of product tolerances via substantially complete serialized dimensional quality control.

Owner:GRALE TECH

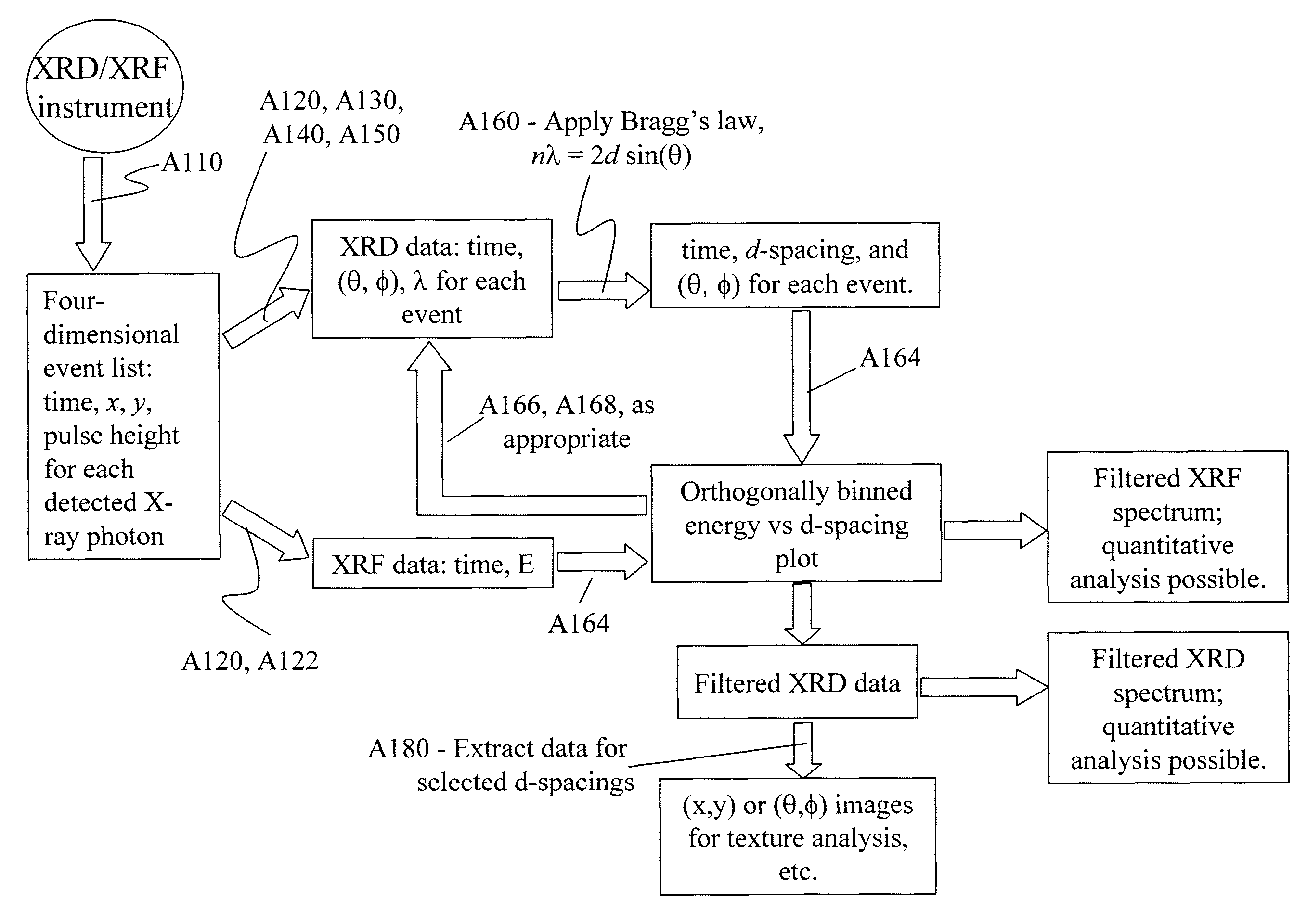

Instrument and method for X-ray diffraction, fluorescence, and crystal texture analysis without sample preparation

InactiveUS7796726B1Reduce power consumptionHigh sensitivityX-ray spectral distribution measurementMaterial analysis using radiation diffractionX-rayReflection geometry

An X-ray diffraction and X-ray fluorescence instrument for analyzing samples having no sample preparation includes a X-ray source configured to output a collimated X-ray beam comprising a continuum spectrum of X-rays to a predetermined coordinate and a photon-counting X-ray imaging spectrometer disposed to receive X-rays output from an unprepared sample disposed at the predetermined coordinate upon exposure of the unprepared sample to the collimated X-ray beam. The X-ray source and the photon-counting X-ray imaging spectrometer are arranged in a reflection geometry relative to the predetermined coordinate.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

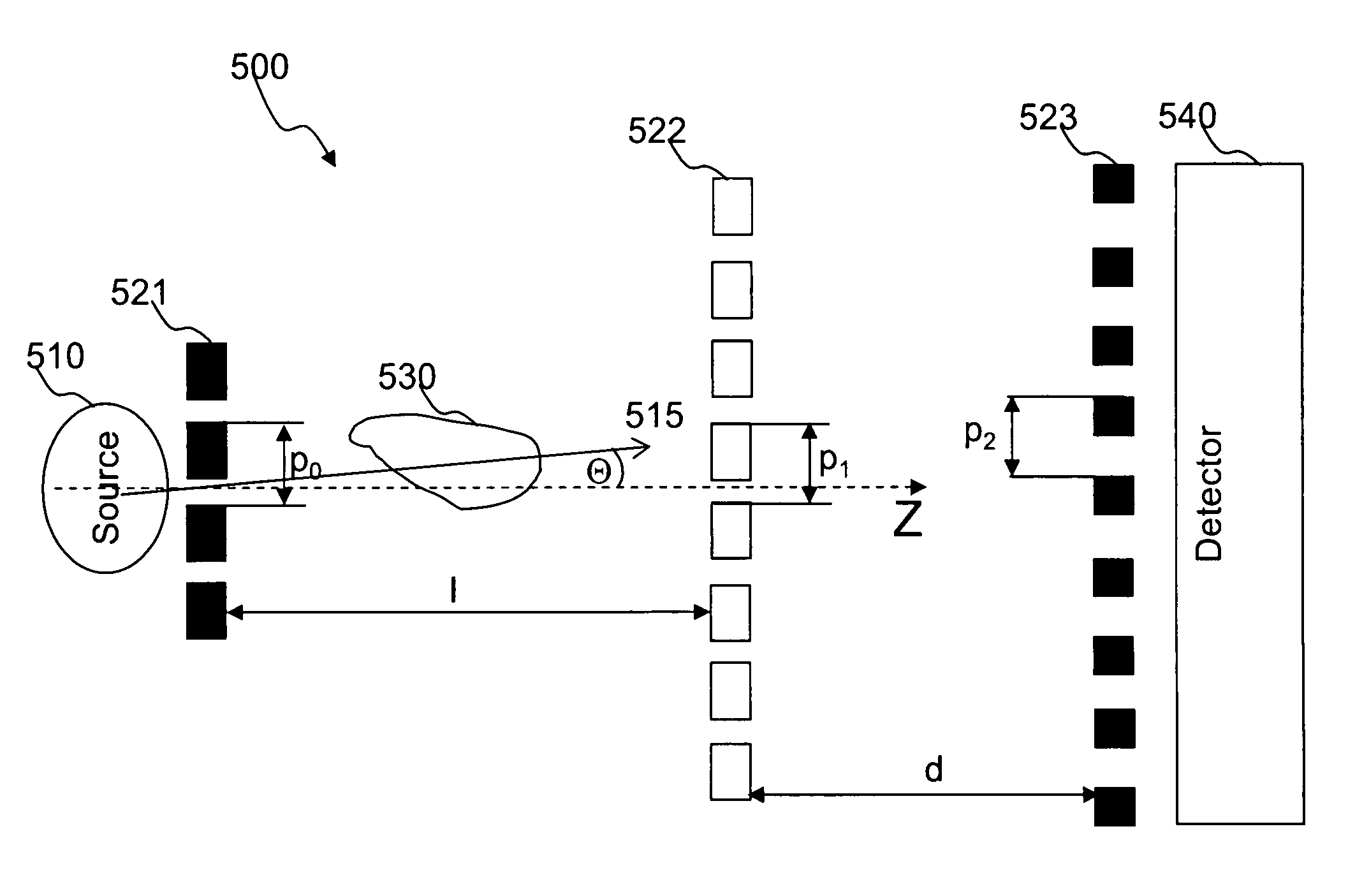

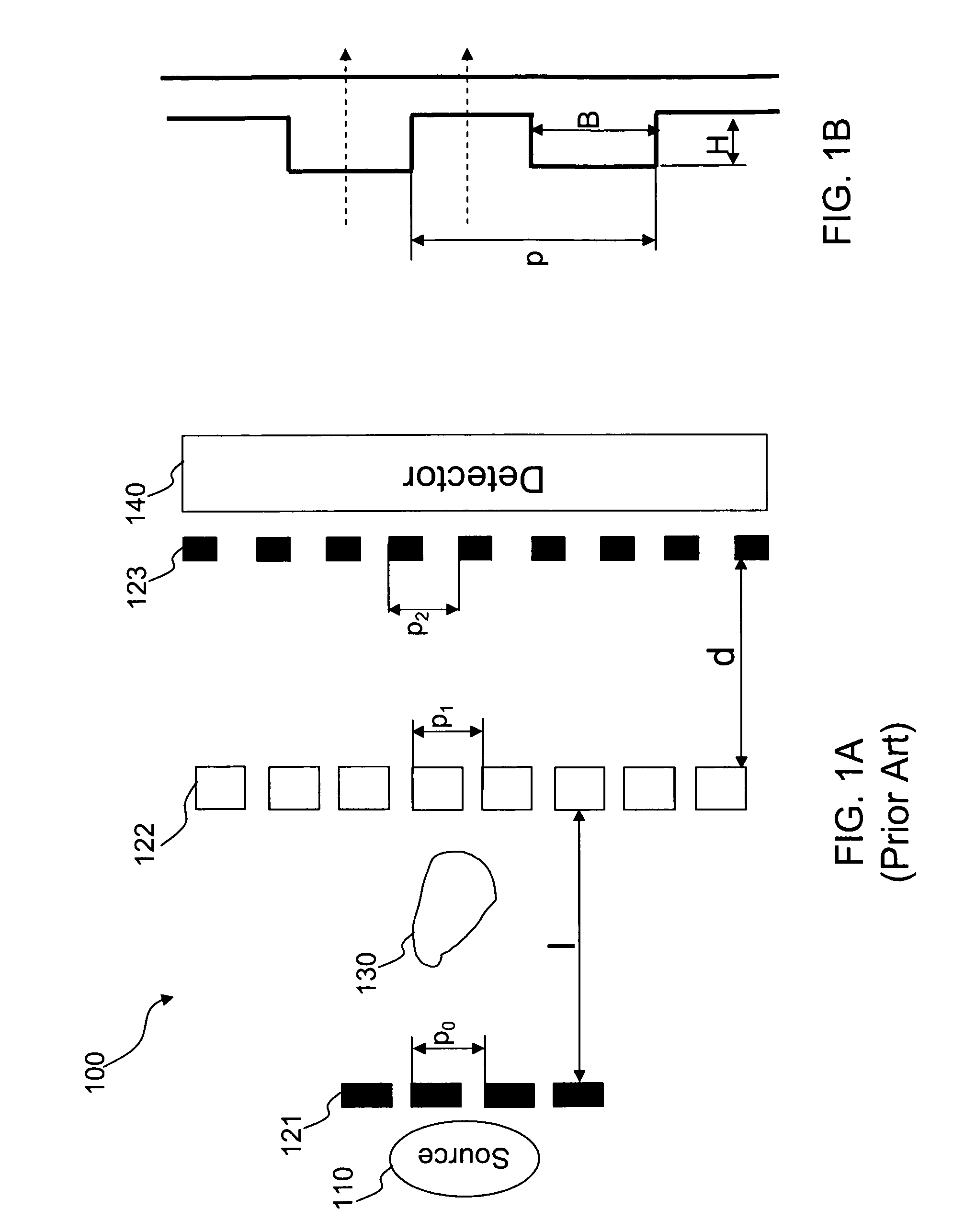

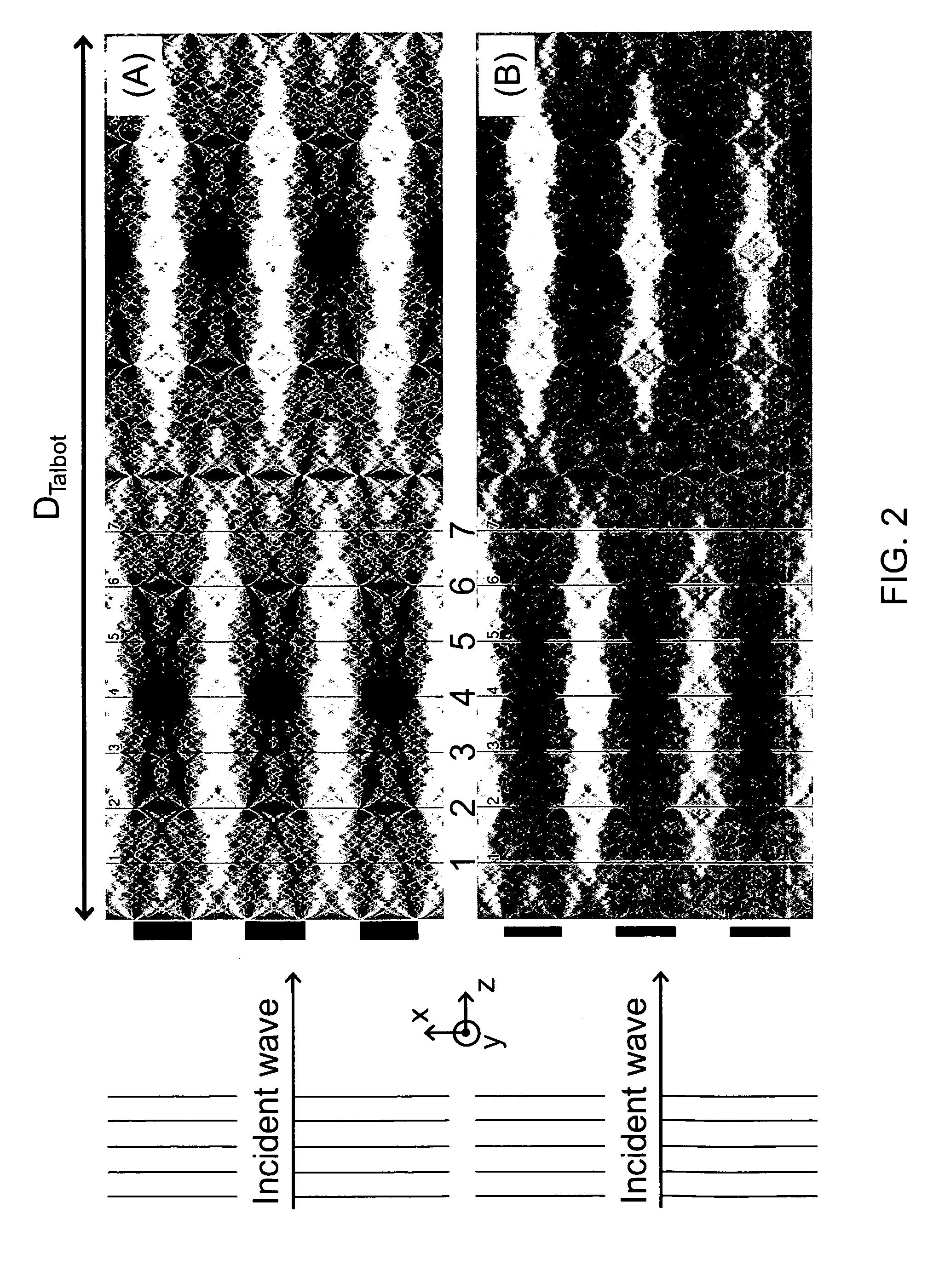

Interferometer device and method

The present invention discloses an interferometer device and method. In embodiments, the device comprises an electromagnetic radiation source emitting radiation having a first mean wavelength λLE; a phase grating having a first aspect ratio; an absorption grating having a second aspect ratio; and a detector. The electromagnetic radiation source, the phase grating, the absorption grating and the detector are radiatively coupled with each other. The absorption grating is positioned between the detector and the phase grating; the electromagnetic radiation source is positioned in front of the source grating; and wherein the phase grating is designed such to cause a phase shift that is smaller than π on the emitted radiation. Additional and alternative embodiments are specified and claimed.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

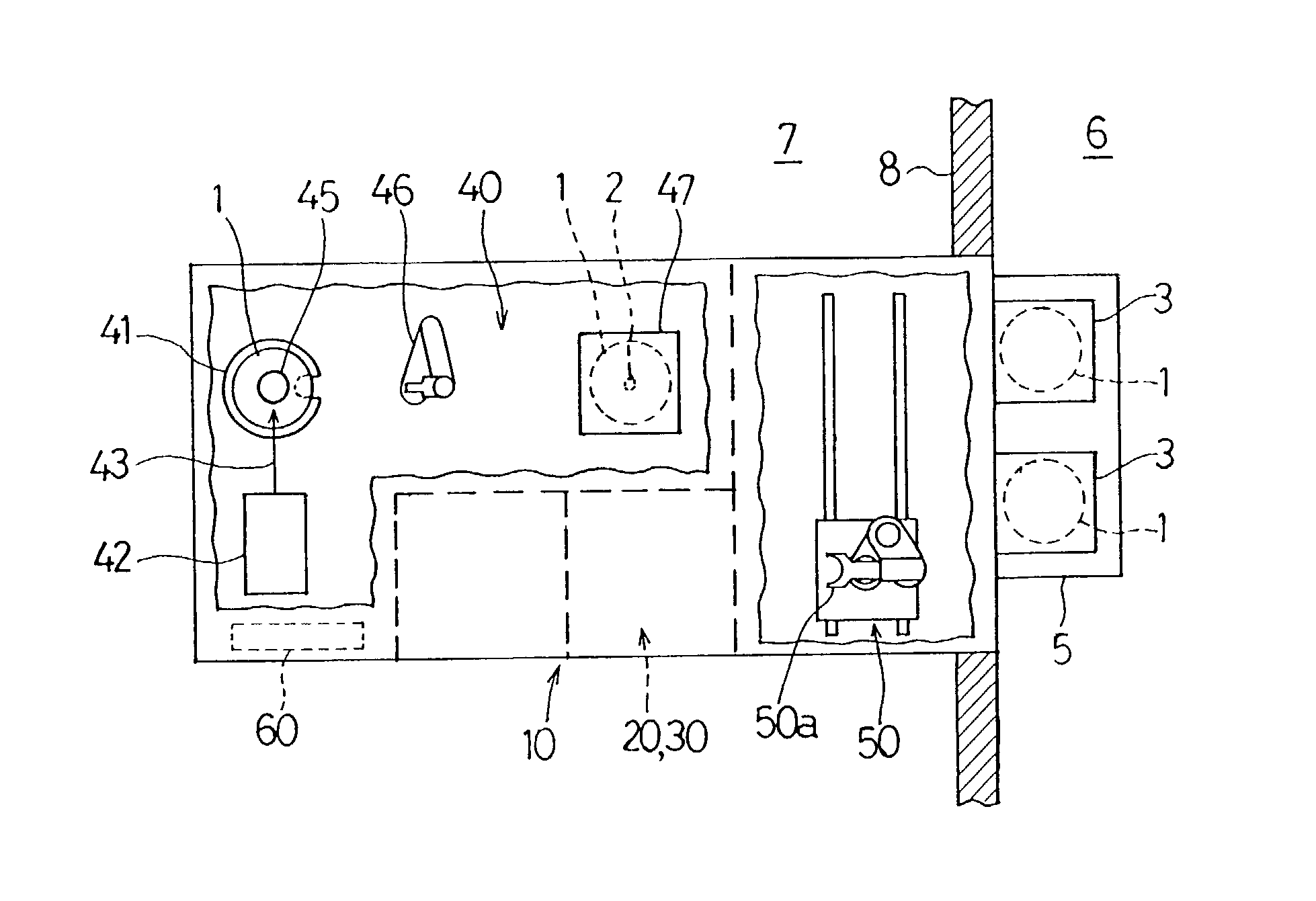

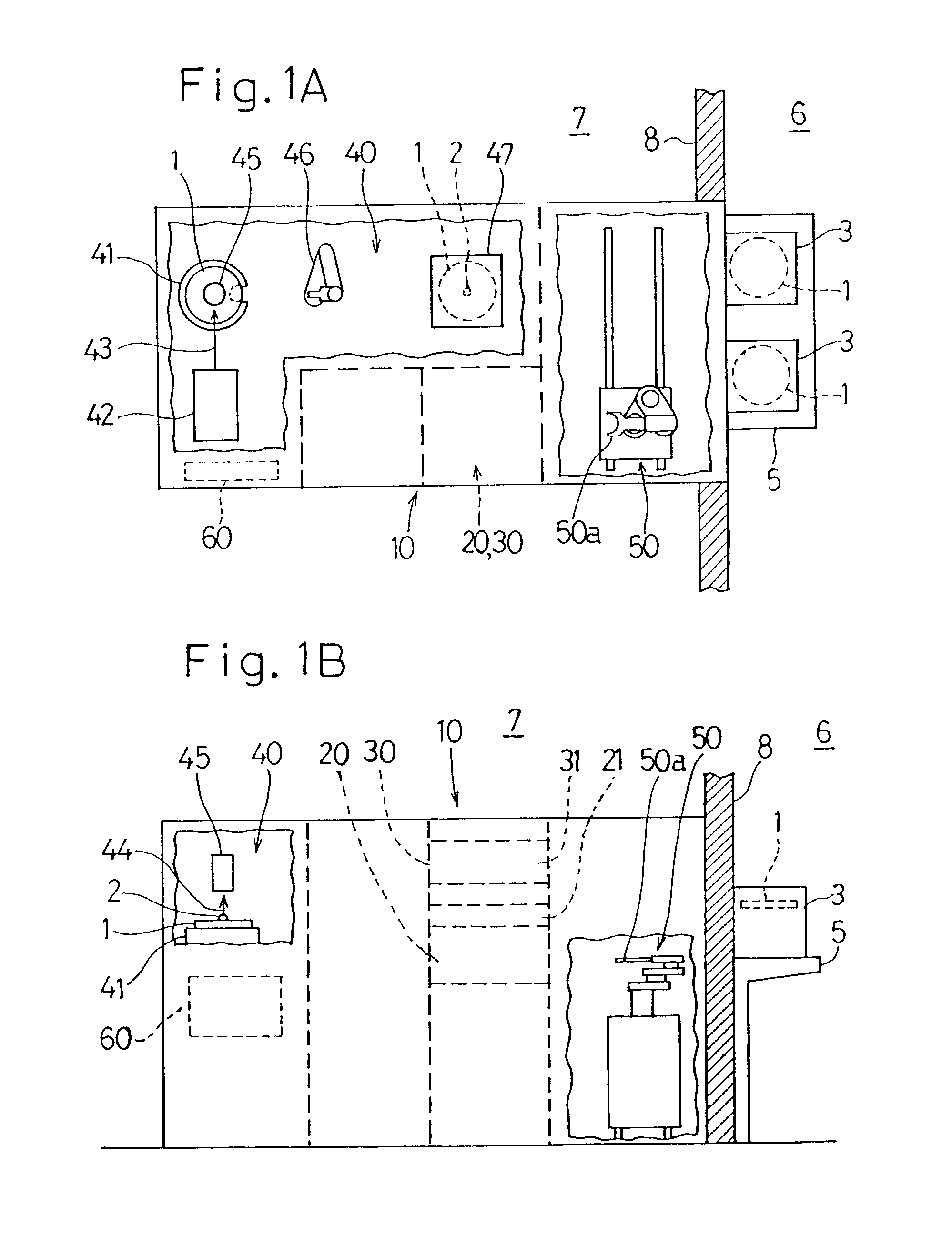

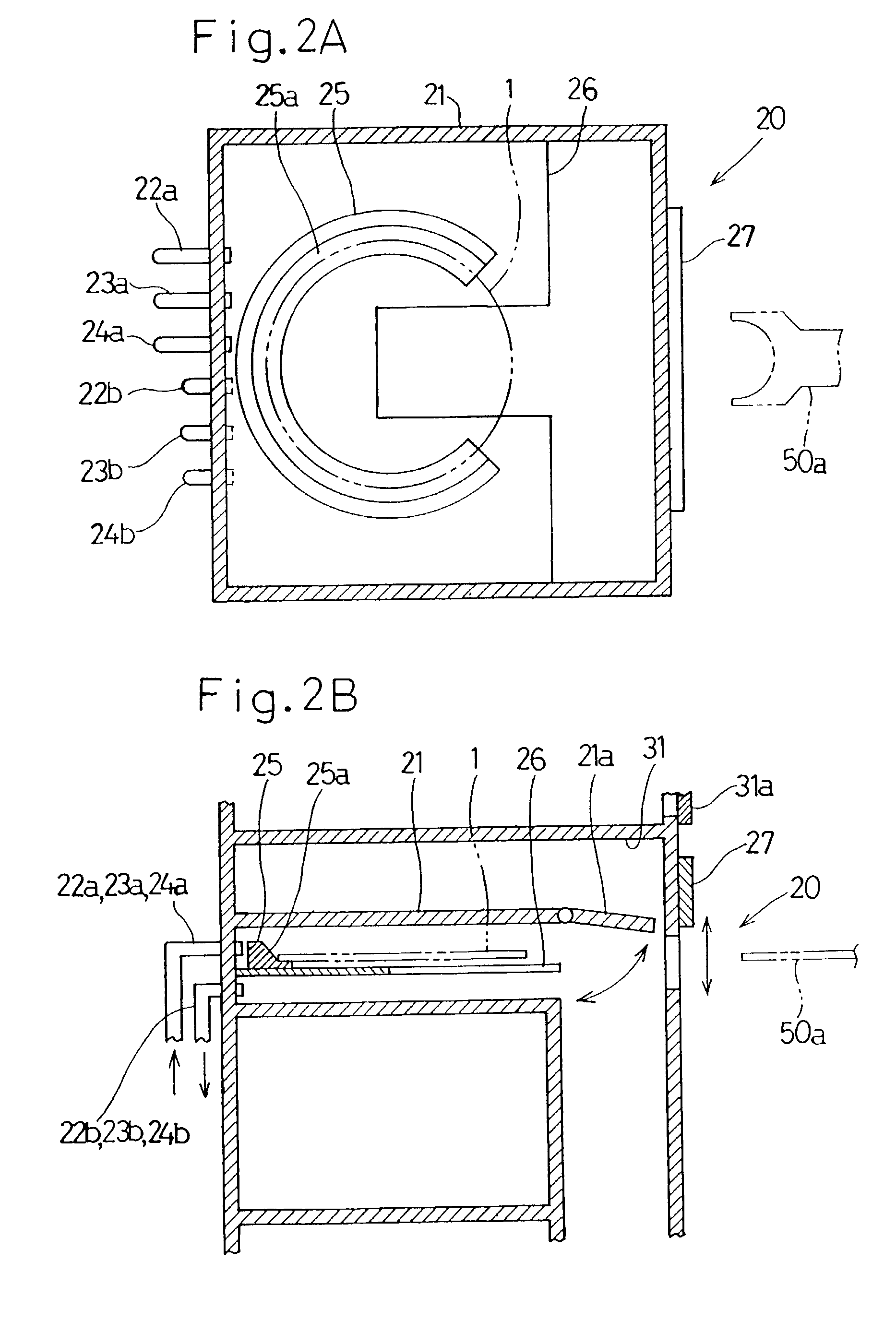

X-ray fluorescence spectrometric system and a program for use therein

InactiveUS20030043963A1Easy to operateLiquid surface applicatorsX-ray spectral distribution measurementFluorescence spectrometryPre treatment

An X-ray fluorescence spectrometric system includes a sample pre-treatment apparatus 10 for retaining on a surface of a substrate a substance to be measured that is found on the surface of the substrate, after such substance has been dissolved and subsequently dried, an X-ray fluorescence spectrometer 40, and a transport apparatus 50 for transporting the substrate from the sample pre-treatment apparatus towards the X-ray fluorescence spectrometer, which system as a whole is easy to operate. This spectrometric system also includes a control apparatus 50 for controlling the sample pre-treatment apparatus 10, the X-ray fluorescence spectrometer 40 and the transport apparatus 50 in a totalized fashion.

Owner:RIGAKU CORP

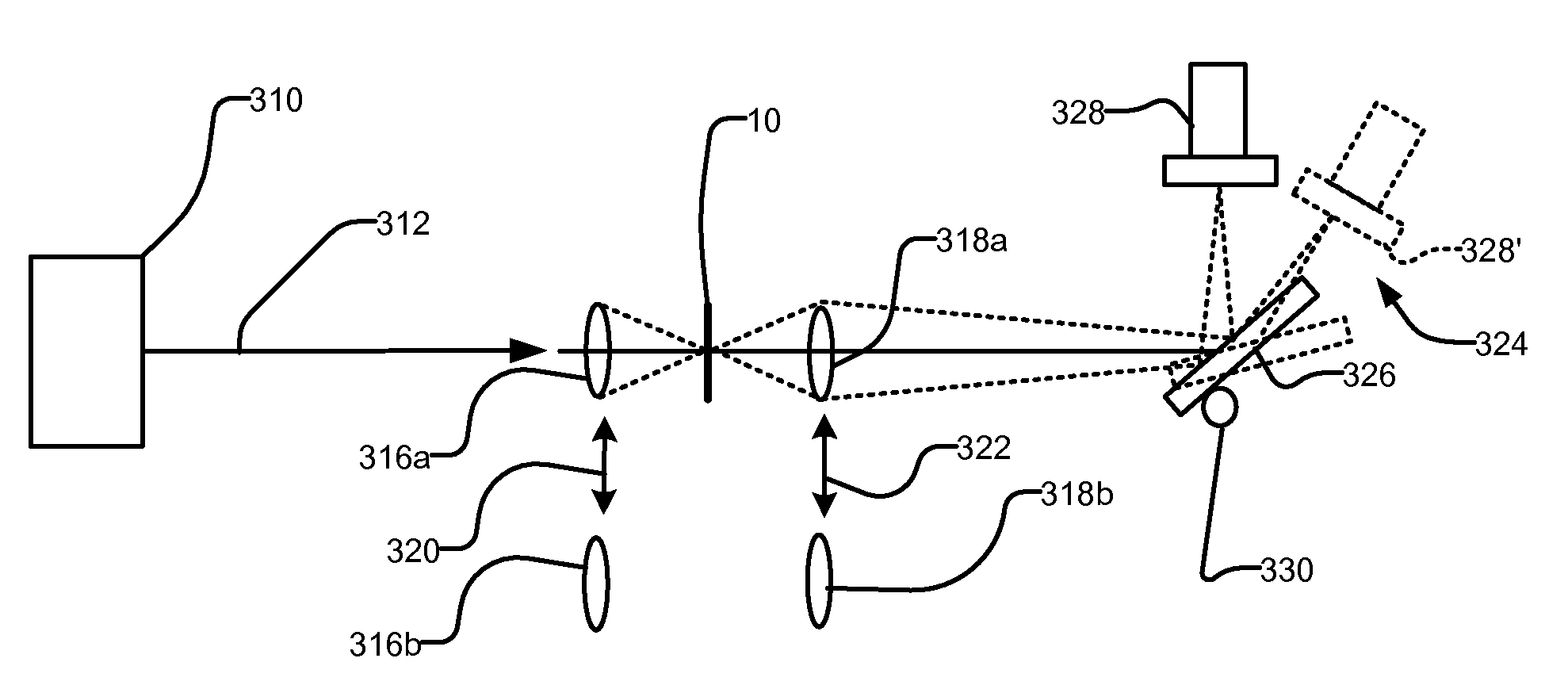

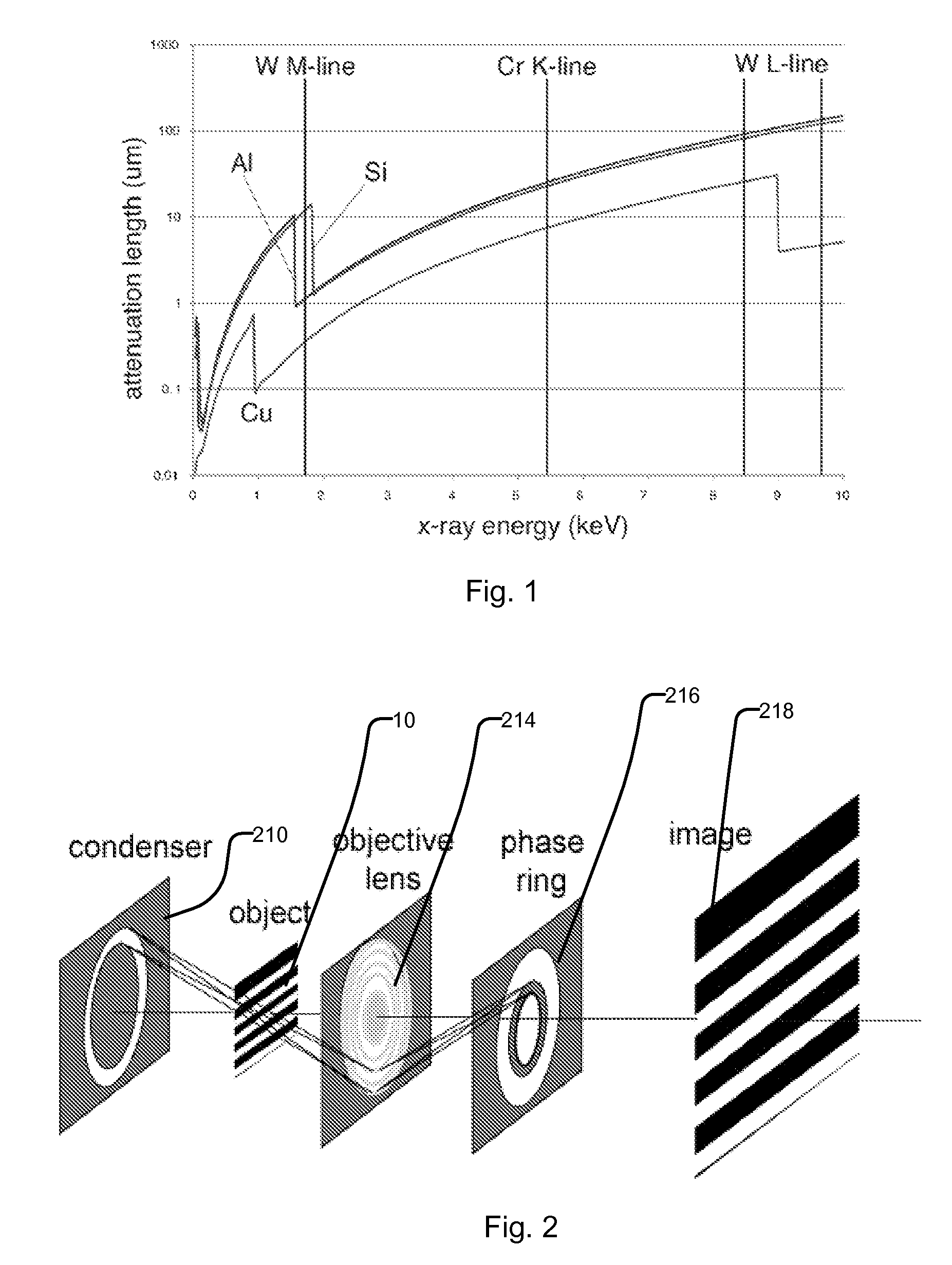

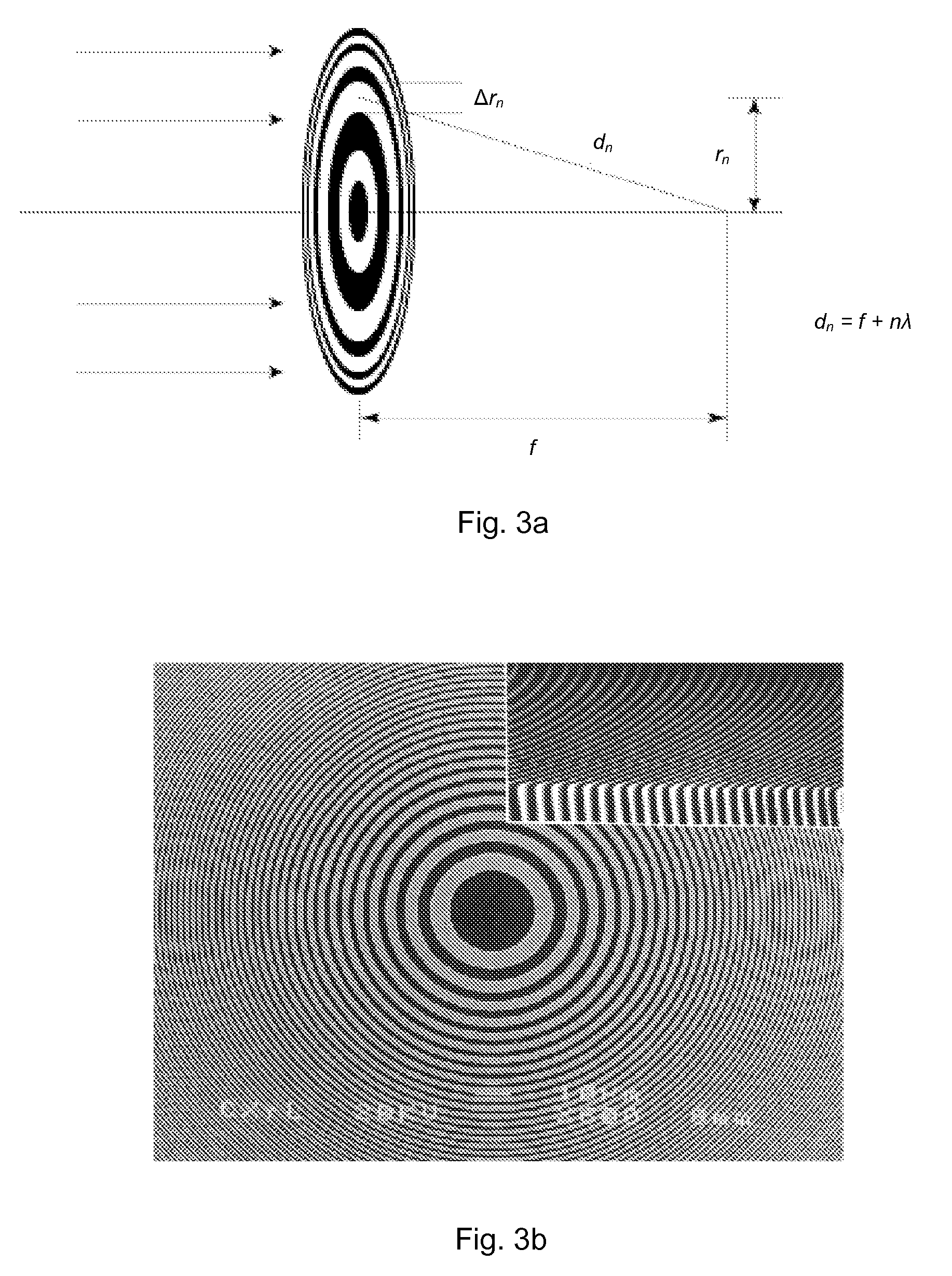

Optimized x-ray energy for high resolution imaging of integrated circuits structures

ActiveUS7394890B1Increase contrastImprove throughputImaging devicesX-ray spectral distribution measurementHigh resolution imagingX-ray

An x-ray imaging system uses particular emission lines that are optimized for imaging specific metallic structures in a semiconductor integrated circuit structures and optimized for the use with specific optical elements and scintillator materials. Such a system is distinguished from currently-existing x-ray imaging systems that primarily use the integral of all emission lines and the broad Bremstralung radiation. The disclosed system provides favorable imaging characteristics such as ability to enhance the contrast of certain materials in a sample, to use different contrast mechanisms in a single imaging system, and to increase the throughput of the system.

Owner:CARL ZEISS X RAY MICROSCOPY

Methods and systems for rapid detection of concealed objects using fluorescence

InactiveUS7856081B2True natureImprove throughputX-ray spectral distribution measurementMaterial analysis by transmitting radiationImaging processingSystems design

This invention is directed towards finding, locating, and confirming threat items and substances. The inspection system is designed to detect objects that are made from, but not limited to, special nuclear materials (“SNM”) and / or high atomic number materials. The system employs advanced image processing techniques to analyze images of an object under inspection (“OUI”), which includes, but is not limited to baggage, parcels, vehicles and cargo, and fluorescence detection.

Owner:RAPISCAN SYST INC (US)

Methods and Systems for Rapid Detection of Concealed Objects Using Fluorescence

InactiveUS20090010386A1True natureImprove throughputX-ray spectral distribution measurementMaterial analysis by transmitting radiationImaging processingSystems design

This invention is directed towards finding, locating, and confirming threat items and substances. The inspection system is designed to detect objects that are made from, but not limited to, special nuclear materials (“SNM”) and / or high atomic number materials. The system employs advanced image processing techniques to analyze images of an object under inspection (“OUI”), which includes, but is not limited to baggage, parcels, vehicles and cargo, and fluorescence detection.

Owner:RAPISCAN SYST INC (US)

Methods for identification and verification using digital equivalent data system

Apparatus and methods in which one or more elemental taggants that are extrinsically placed in an object are detected by x-ray fluorescence analysis to identify or authenticate the object are described. The taggant is manufactured as part of the object or the taggant is placed into a coating, packaging, label, or otherwise embedded onto the object for the purpose of later verifying the presence or absence of these elements by x-ray fluorescence. The taggant is then analyzed by XRF and the analysis is then converted into a 2D symbol format that can be used in various security and authentication applications. By using x-ray fluorescence analysis, the apparatus and methods of the invention are simple and easy to use, without the limitations experience by current anti-counterfeiting technologies.

Owner:NASA +1

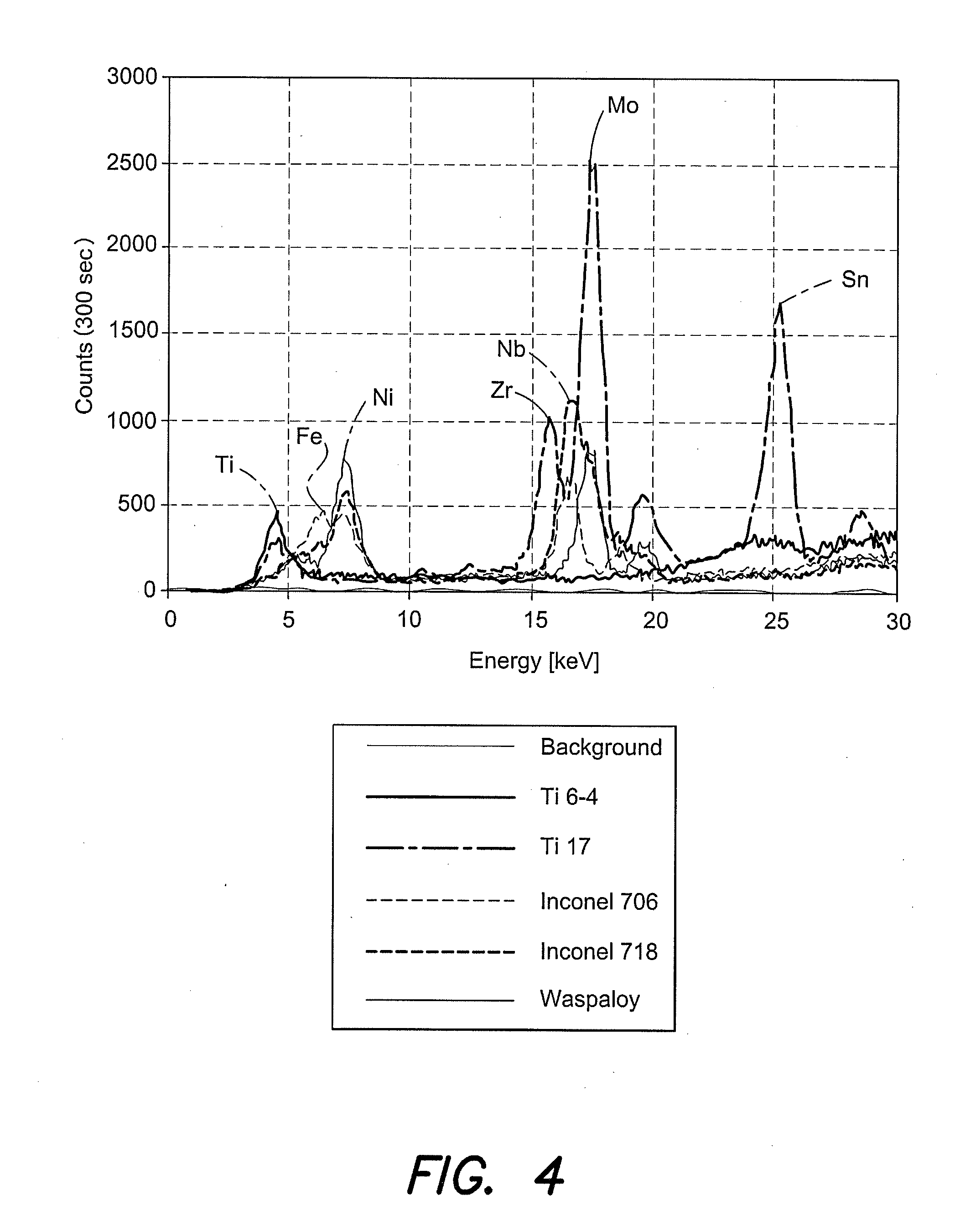

Material sorting technology

InactiveUS20130079918A1X-ray spectral distribution measurementDigital data processing detailsX-rayDetector array

Systems for sorting materials, such as those made of metal, are described. The systems may operate by irradiating the materials with x-rays and then detecting fluoresced x-rays, transmitted x-rays, or both. Detection of the fluoresced x-rays may be performed using an x-ray fluorescence detector array. The systems may be configured to provide high throughput sorting of small pieces of materials.

Owner:SPECSTREETCARET

Methods for identification and verification using vacuum XRF system

InactiveUS6909770B2Efficient use ofSmall atomic numberX-ray spectral distribution measurementMaterial analysis using wave/particle radiationSoft x rayX-ray

Apparatus and methods in which one or more elemental taggants that are intrinsically located in an object are detected by x-ray fluorescence analysis under vacuum conditions to identify or verify the object's elemental content for elements with lower atomic numbers. By using x-ray fluorescence analysis, the apparatus and methods of the invention are simple and easy to use, as well as provide detection by a non line-of-sight method to establish the origin of objects, as well as their point of manufacture, authenticity, verification, security, and the presence of impurities. The invention is extremely advantageous because it provides the capability to measure lower atomic number elements in the field with a portable instrument.

Owner:NASA +1

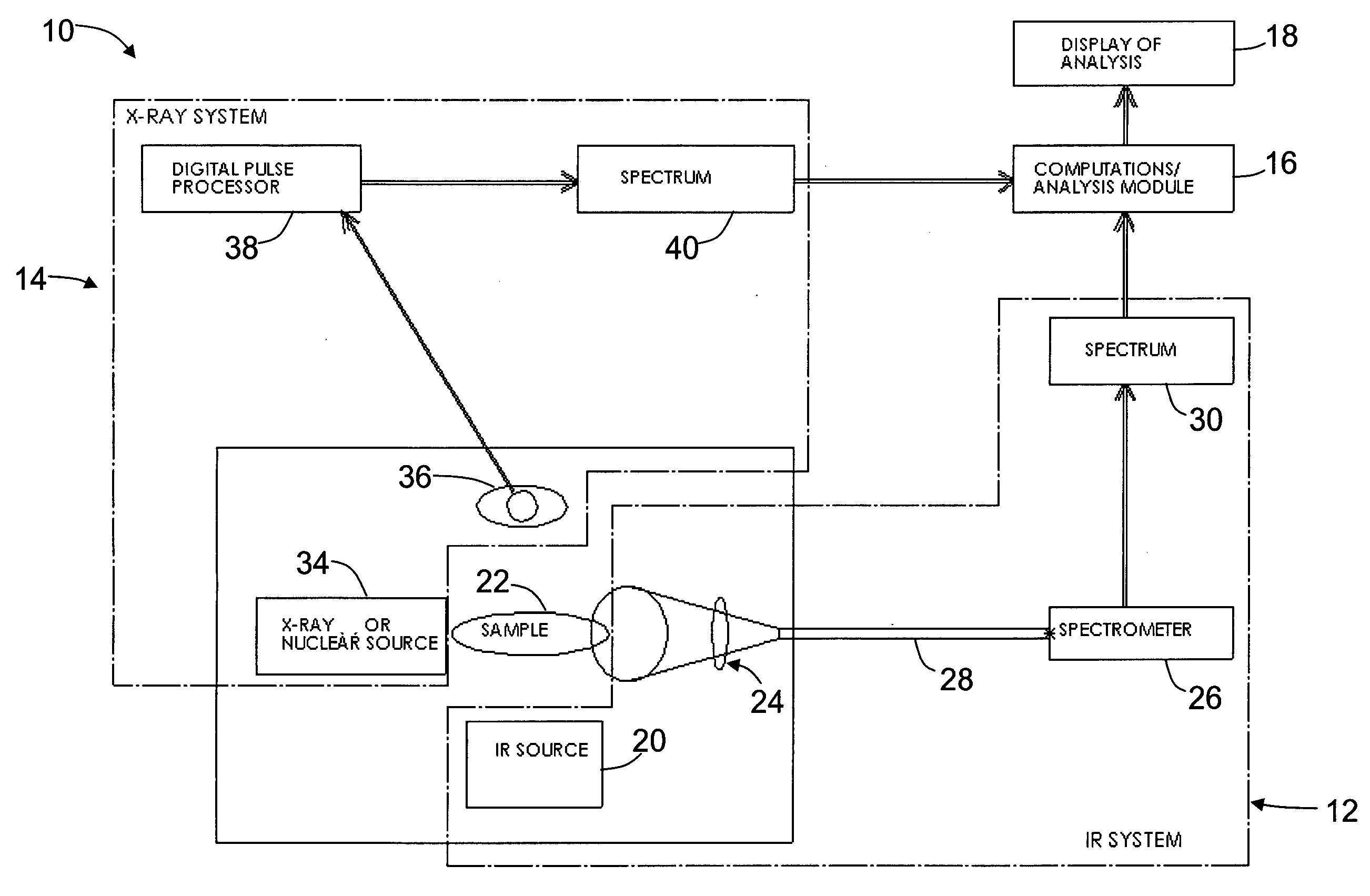

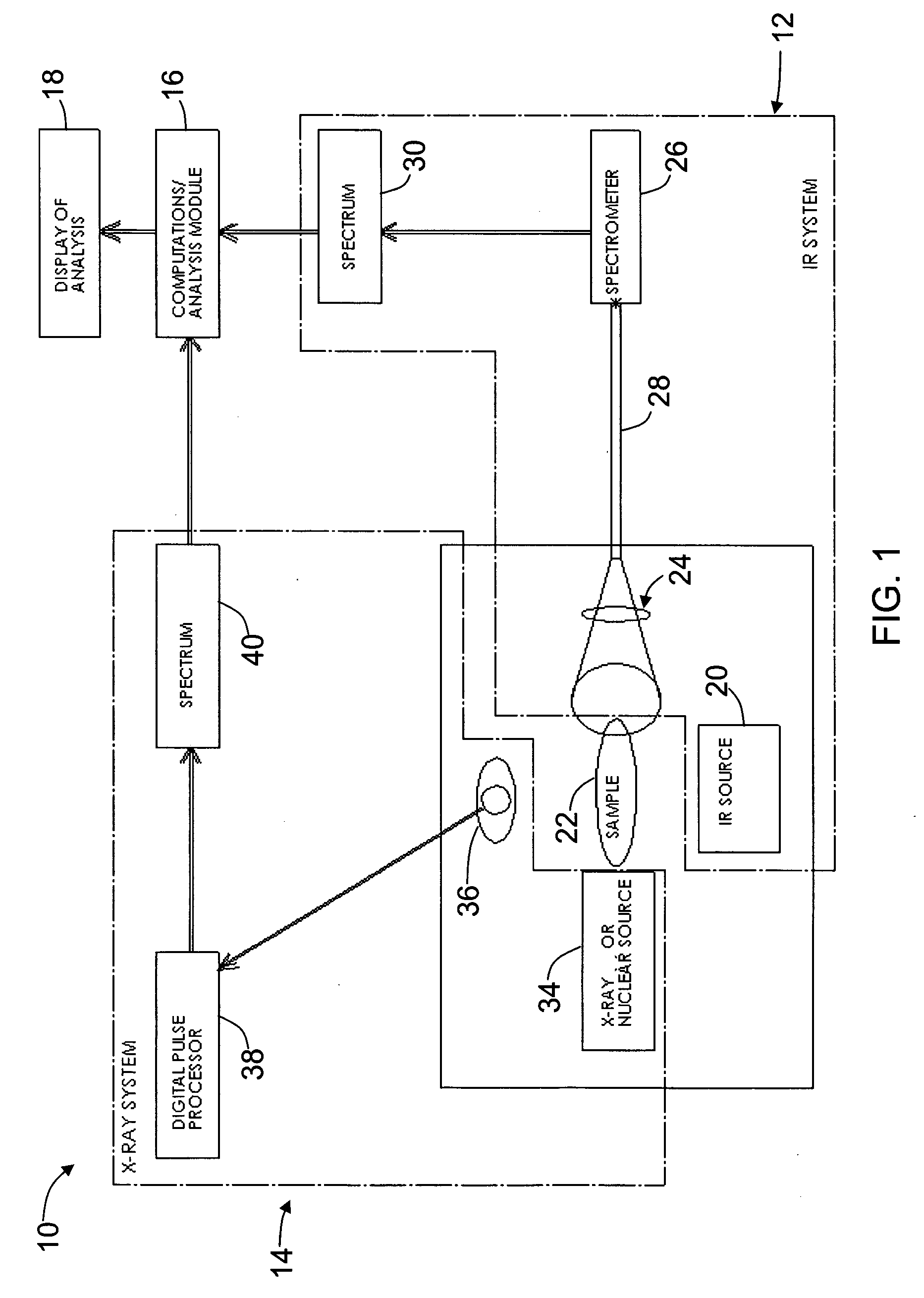

Methods and apparatus for improving the reliability and accuracy of identifying, analyzing and authenticating objects, including chemicals, using multiple spectroscopic techniques

InactiveUS20060086901A1Easy to identifyEasy to useRadiation pyrometryX-ray spectral distribution measurementDisplay deviceComputer science

An integrated apparatus capable of both molecular and elemental spectroscopic analysis includes, in an exemplary embodiment, a molecular spectroscopic analysis system, an elemental spectroscopic analysis system, and a computational and analysis module. The computational and analysis module is coupled to the molecular spectroscopic analysis system and to the elemental spectroscopic analysis system. The integrated apparatus also includes a display device coupled to the computational and analysis module.

Owner:PRICE L STEPHEN +3

Multi-energy radiation detector

InactiveUS20050082491A1X-ray spectral distribution measurementSolid-state devicesElectrical conductorDetector array

A radiation projection detector includes a conversion layer configured to generate light photons in response to a radiation, the conversion layer having a plurality of first conversion elements and a plurality of second conversion elements, and a photo detector array aligned with the conversion panel, wherein each of the first conversion elements has a first radiation conversion characteristic, and each of the second conversion elements has a second radiation conversion characteristic. A radiation projection detector includes a photoconductor layer configured to generate charges in response to radiation, the photoconductor layer having a plurality of first photoconductor elements and a plurality of second photoconductor elements, and a detector array aligned with the photoconductor layer, wherein each of the first photoconductor elements has a first charge generating characteristic, and each of the second photoconductor elements has a second charge generating characteristic.

Owner:VARIAN MEDICAL SYSTEMS

X-ray surface analysis and measurement apparatus

InactiveUS20150247811A1Wide choiceIncrease brightnessX-ray spectral distribution measurementMaterial analysis using wave/particle radiationDesign for XHigh energy

This disclosure presents systems for total reflection x-ray fluorescence measurements that have x-ray flux and x-ray flux density several orders of magnitude greater than existing x-ray technologies. These may therefore useful for applications such as trace element detection and / or for total-reflection fluorescence analysis.The higher brightness is achieved in part by using designs for x-ray targets that comprise a number of microstructures of one or more selected x-ray generating materials fabricated in close thermal contact with a substrate having high thermal conductivity. This allows for bombardment of the targets with higher electron density or higher energy electrons, which leads to greater x-ray brightness and therefore greater x-ray flux.The high brightness / high flux source may then be coupled to an x-ray reflecting optical system, which can focus the high flux x-rays to a spots that can be as small as one micron, leading to high flux density.

Owner:SIGRAY INC

Ionic pre-concentration XRF identification and analysis device, system and method

InactiveUS7016462B1High sensitivityHinder full rangeMaterial analysis using wave/particle radiationX-ray spectral distribution measurementCapacitanceX-ray

A device, system and method for detecting and measuring concentrations of elements in fluids comprises: flowing a fluid through a central flow interelectrode gap of an ionic preconcentration cell separating an upper high specific surface area electrode from a lower high specific surface area electrode of the ionic preconcentration cell by a predetermined interelectrode gap width; and applying a voltage differential between the upper high surface area electrode and the lower high surface area electrode while the fluid is flowing through the central flow interelectrode gap. As such, this cell that utilizes its inherent capacitance for double layer formation to extract ultra-trace levels of ionic contaminants from fluids in order to enhance detection by x-ray fluorescence analysis.

Owner:INTERSCI +1

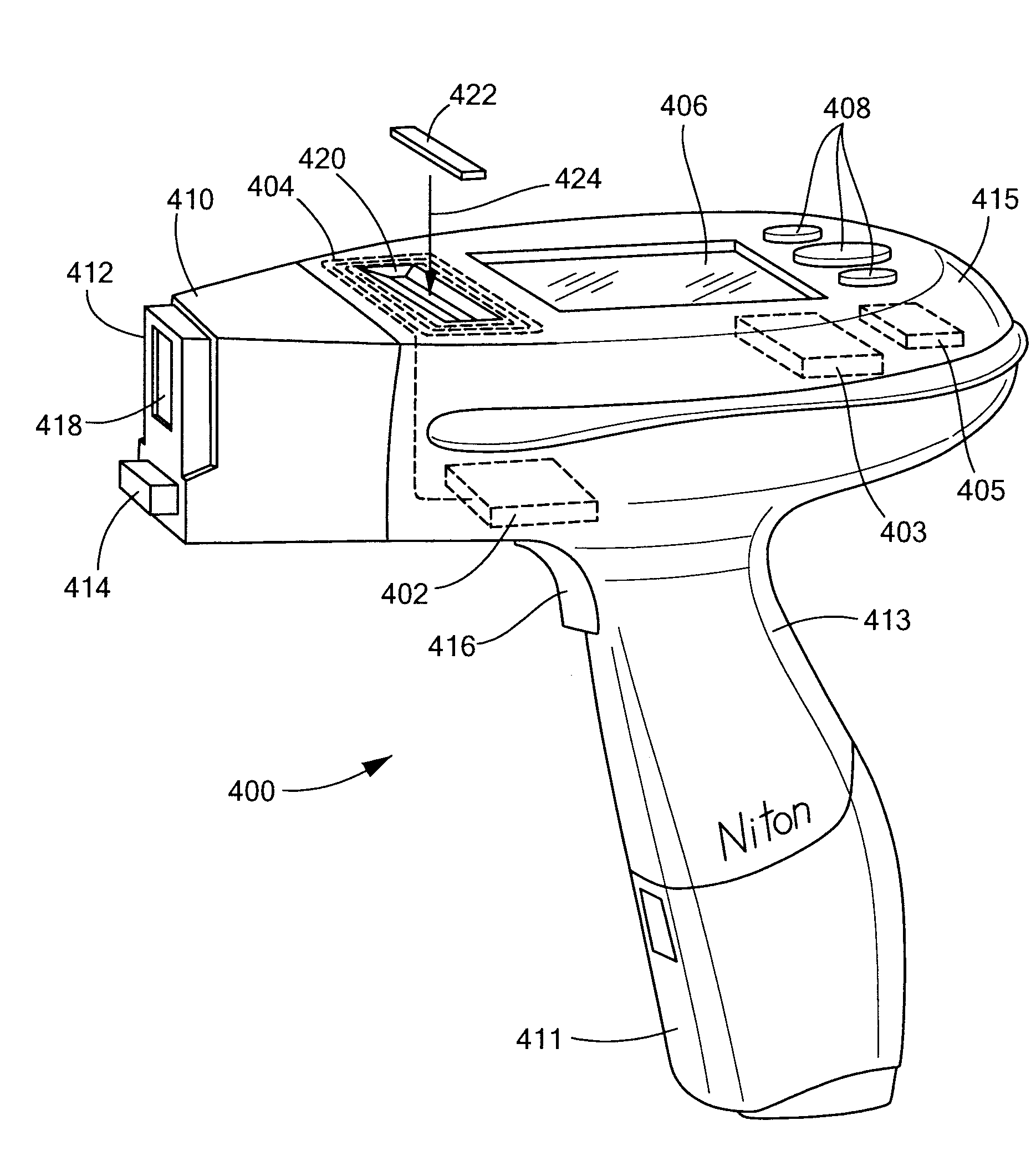

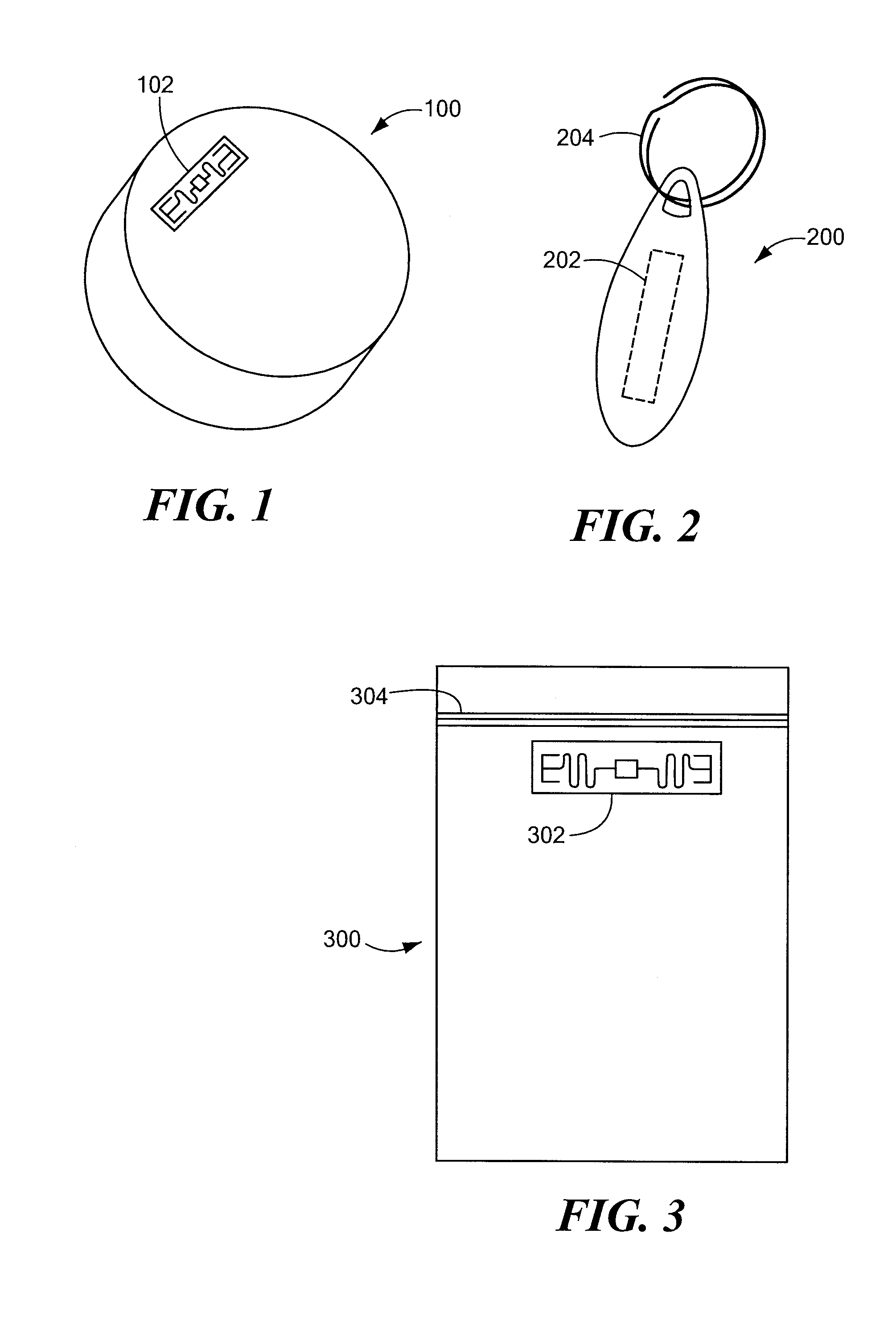

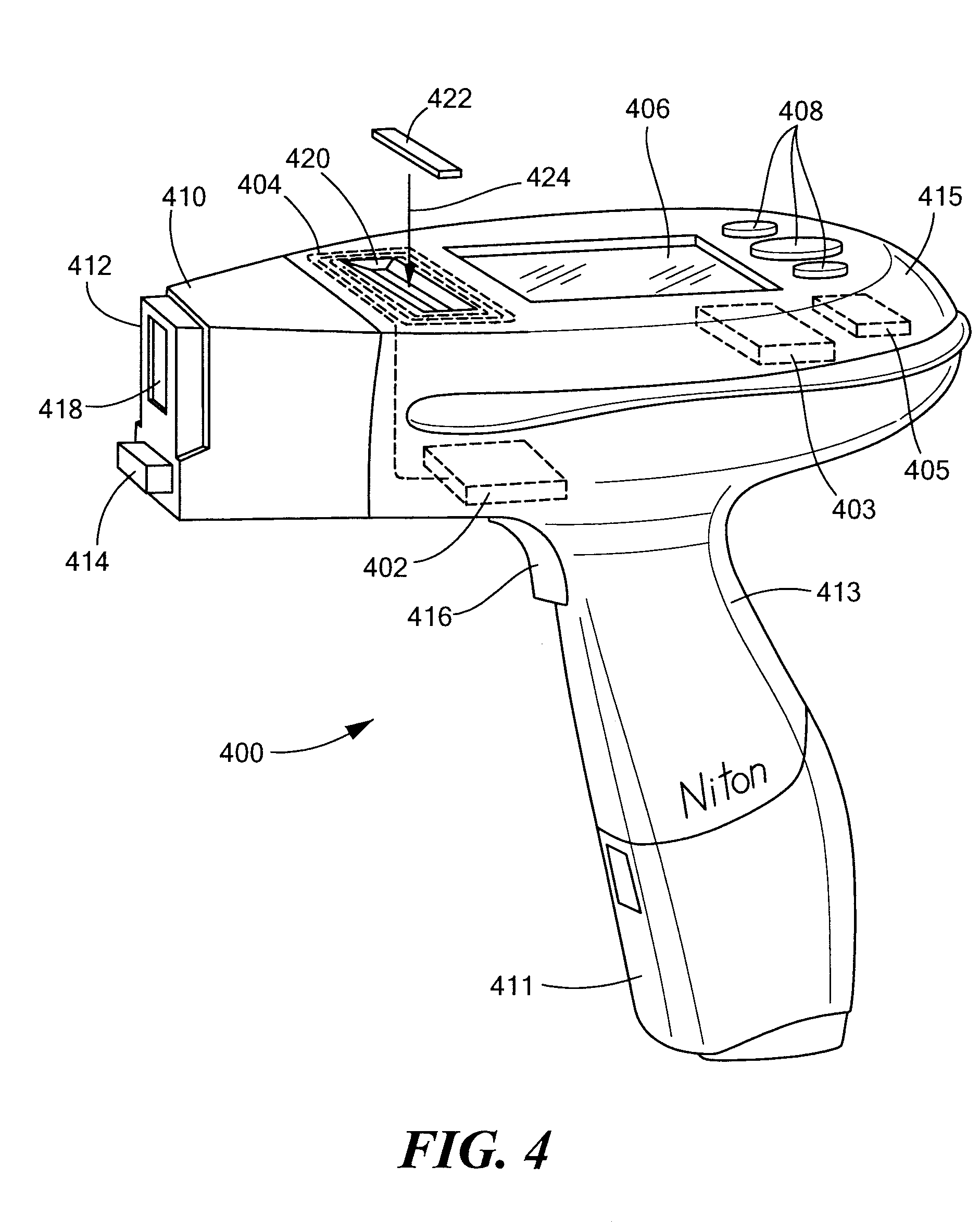

Contactless Memory Information Storage for Sample Analysis and Hand-Holdable Analyzer for Use Therewith

InactiveUS20090057422A1Radiation pyrometryX-ray spectral distribution measurementUser inputSelf-documenting

An analytical instrument stores and / or reads information related to a sample in a contactless memory, such as a passive or active radio-frequency identification (RF-ID) tag. The information may include information about: composition of the sample, one or more analytical instruments that were used to analyze the sample, operator(s) who used the instrument(s) to analyze the sample, user-entered data about the sample (such as an origin of the sample) or a combination thereof or the like. The memory may be attached to the sample or to a container, in which the sample is stored or transported. One or more copies of such a memory may be loosely stored with the sample, such as with soil in a plastic bag or a rail car. When the memory is attached to, or stored with, the sample, the sample becomes essentially self-documenting. Information about the sample, such as its composition or origin, may be read by a contactless memory reader, such as an RF-ID reader.

Owner:THERMO NITON ANALYZERS

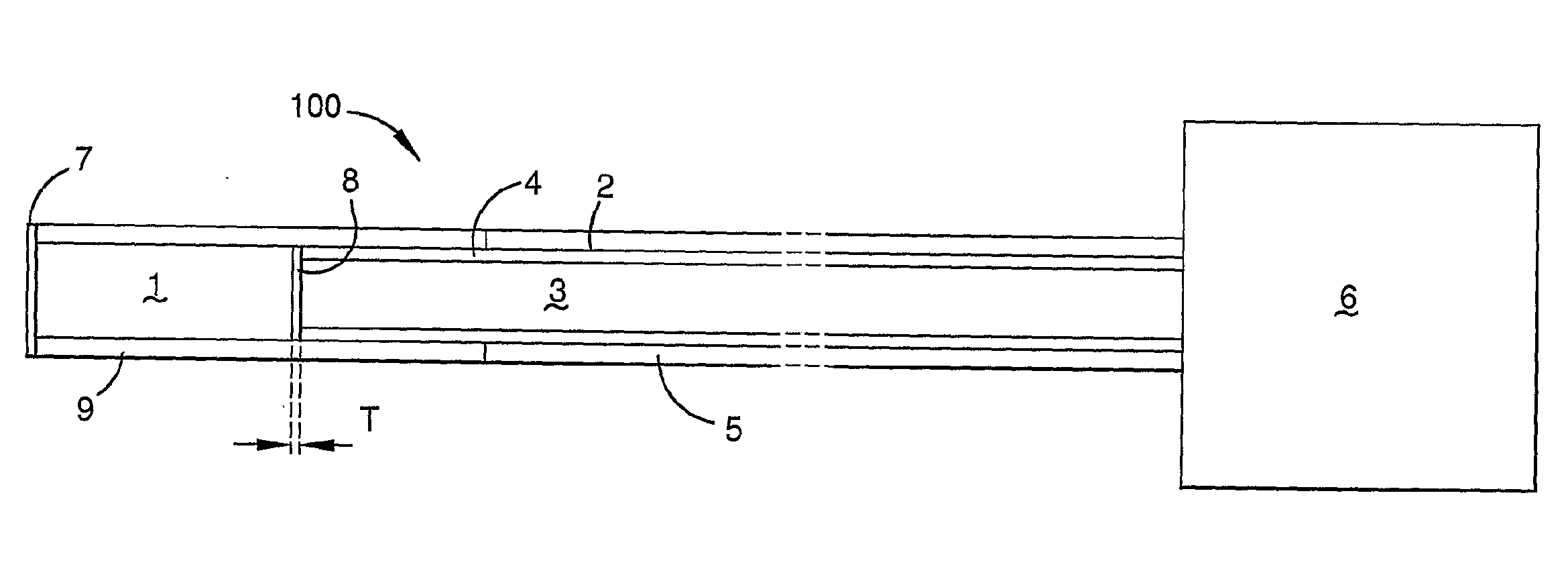

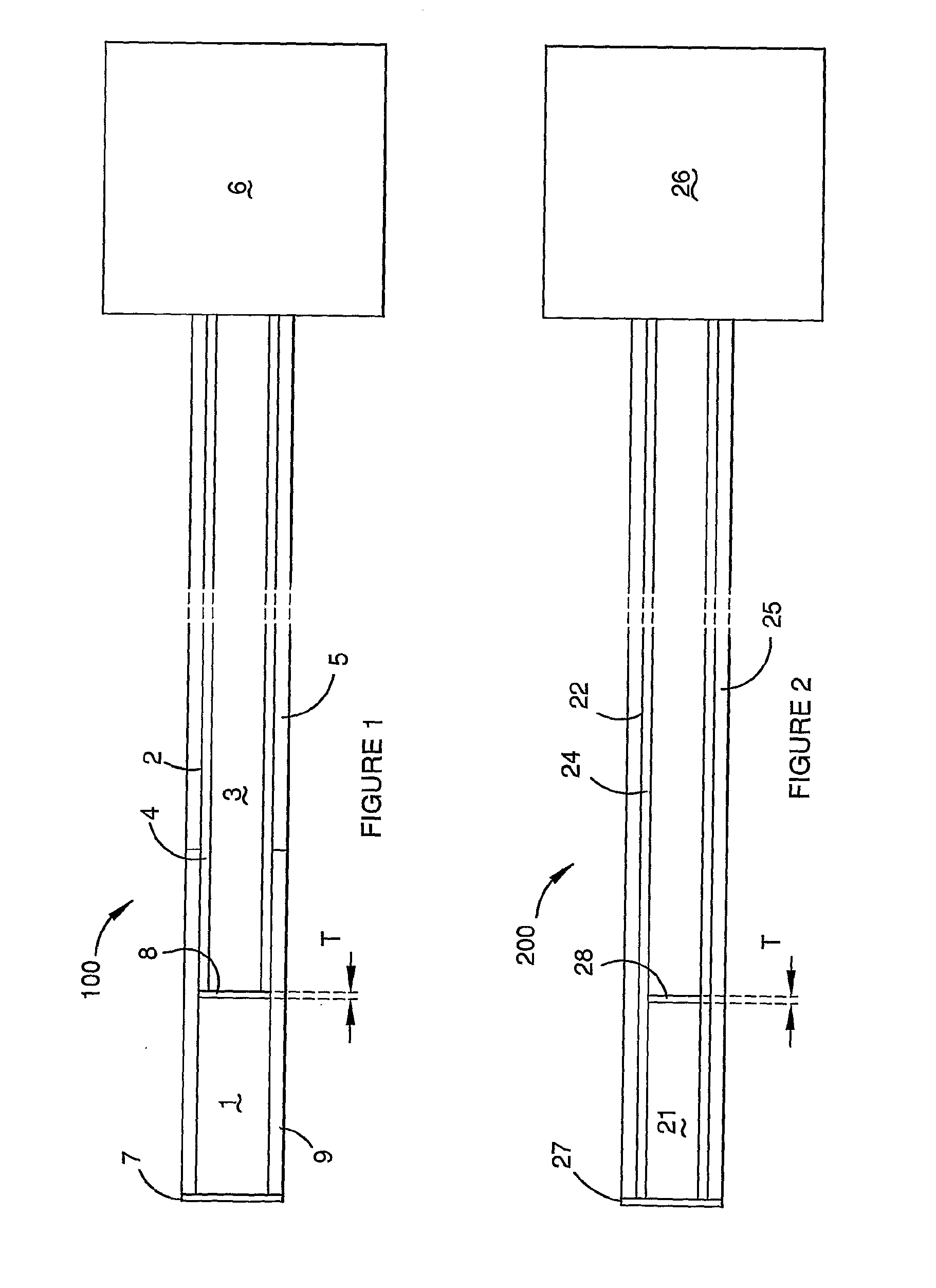

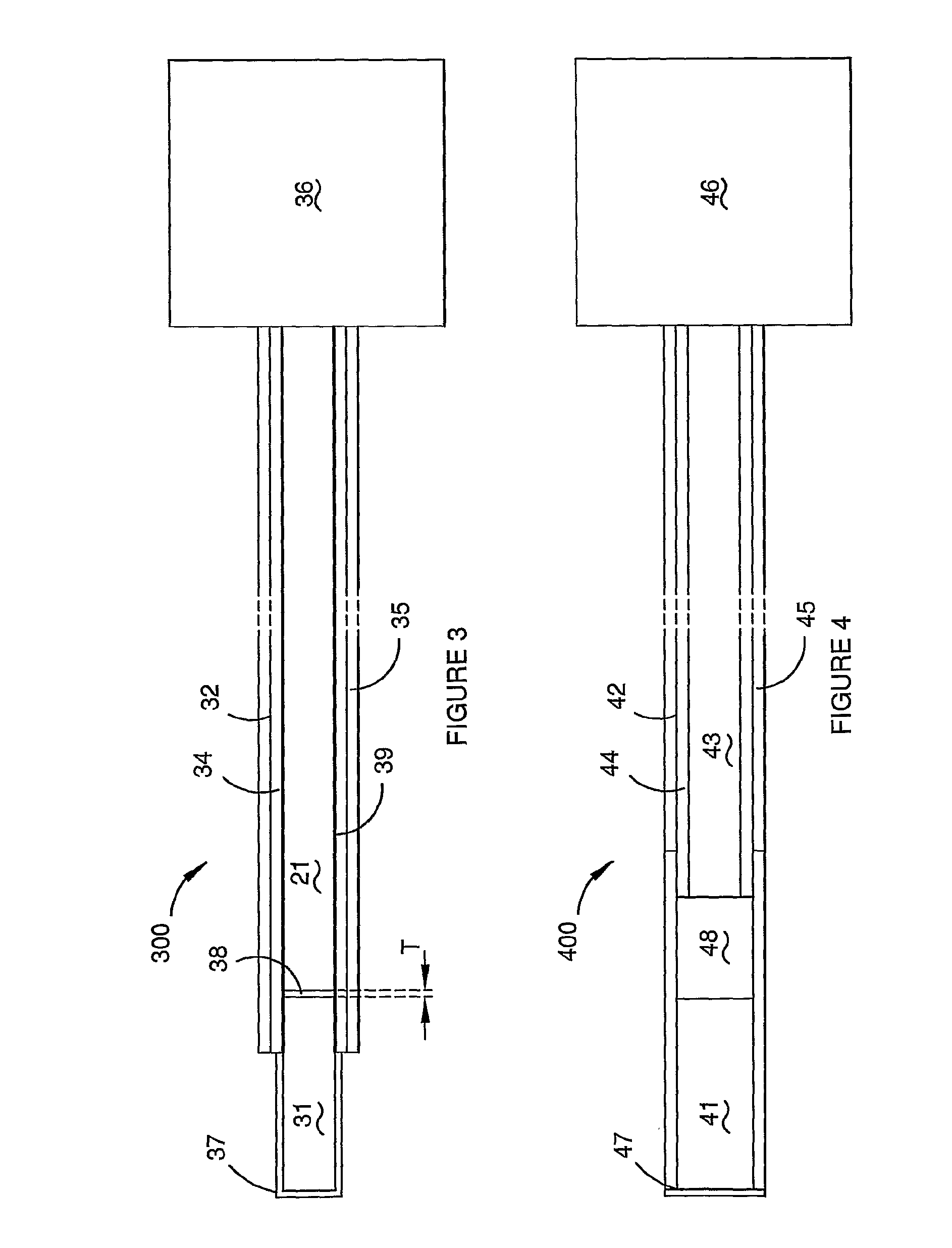

Fibre Optic Dosimeter

InactiveUS20090014665A1Reduces and prevents entryReduce and prevent detectionX-ray spectral distribution measurementElectrical apparatusDosimeterLight pipe

A dosimeter (100) for radiation fields is described. The dosimeter includes a scintillator (1) a light pipe (2) having a first end in optical communication with the scintillator (1) and a light detector (6). The light pipe (2) may have a hollow core (3) with a light reflective material about the periphery of the hollow core (3). The dosimeter (100) may further include a light source (61) that generates light for use as a calibrating signal for a measurement signal and / or for use to check the light pipe (2).

Owner:THE UNIV OF SYDNEY

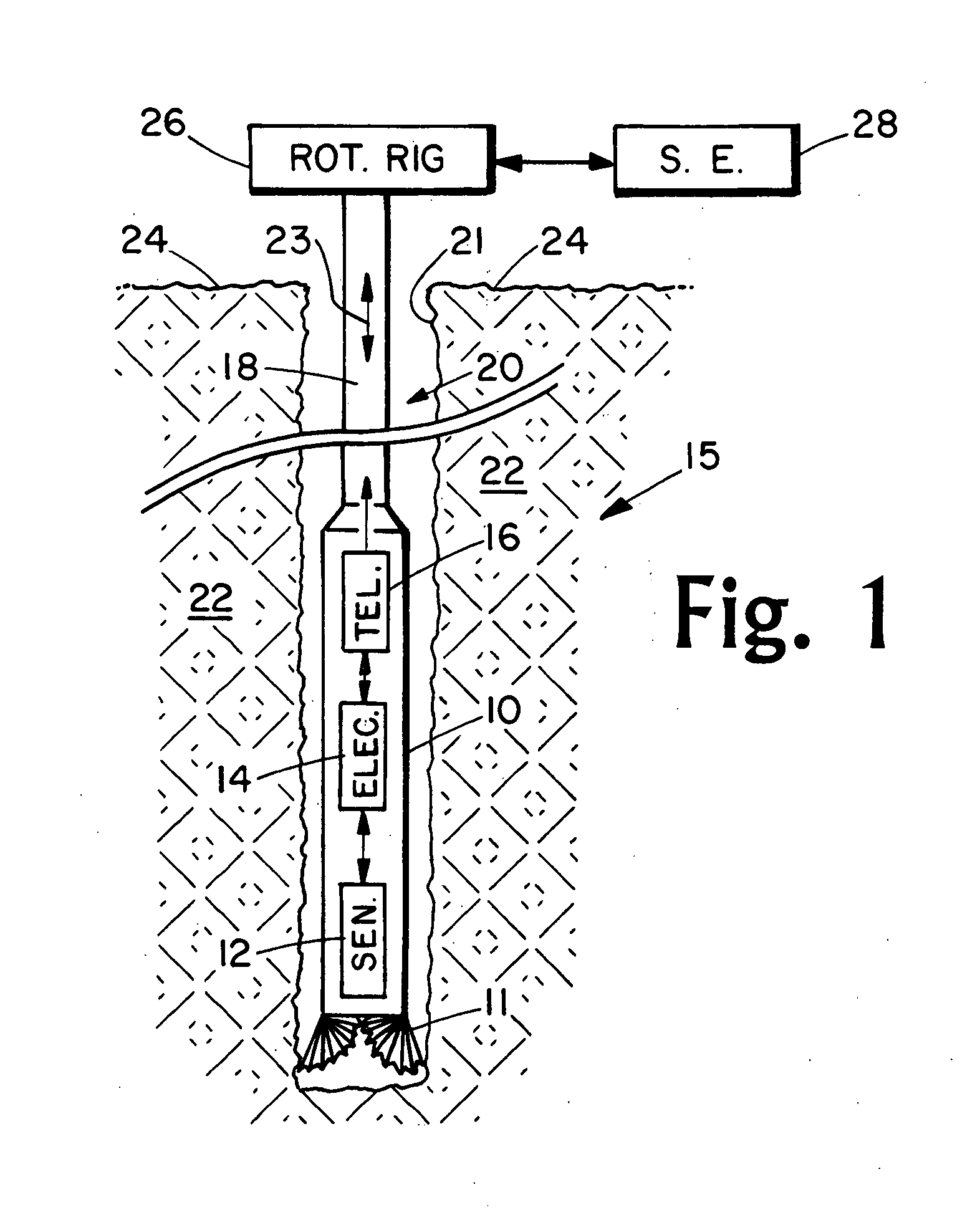

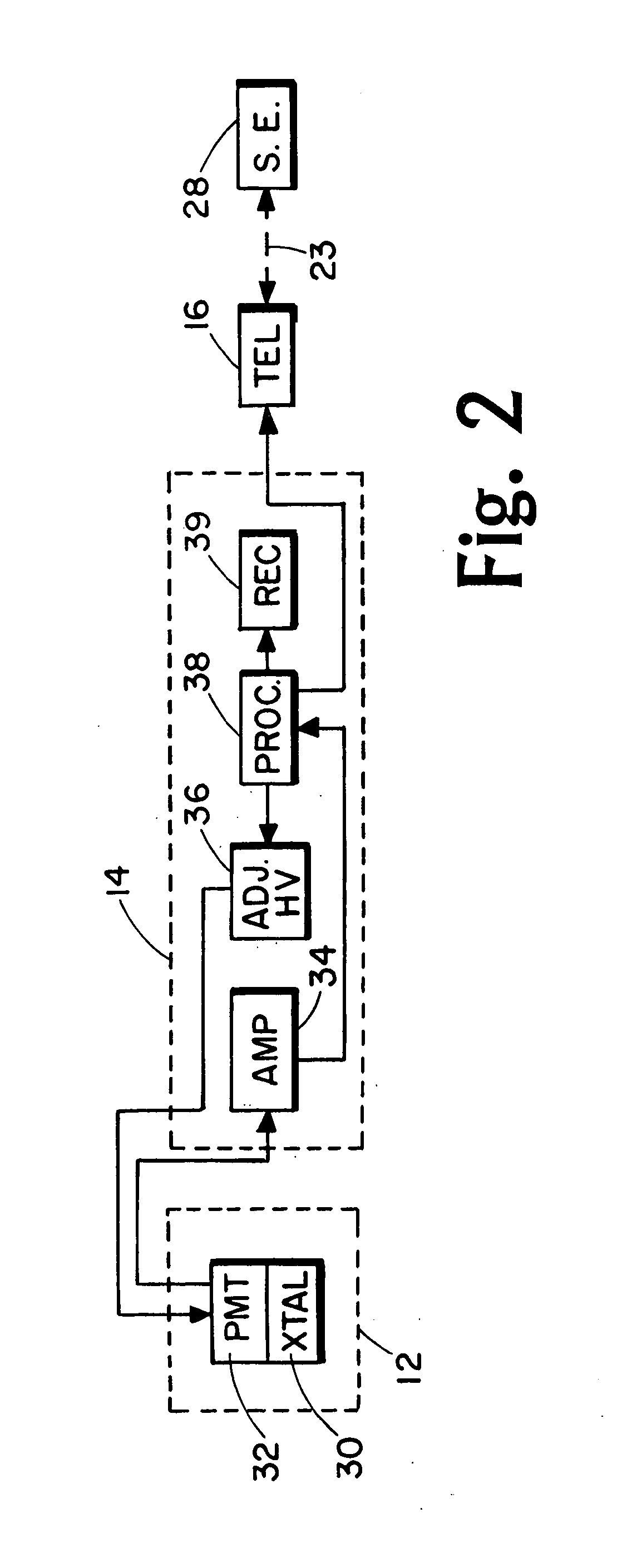

Gain stabilization apparatus and methods for spectraal gamma ray measurement systems

ActiveUS20060065824A1Minimize degradationMaximizing counting rateX-ray spectral distribution measurementConstructionsBiological activationAutomated control system

Owner:WEATHERFORD TECH HLDG LLC

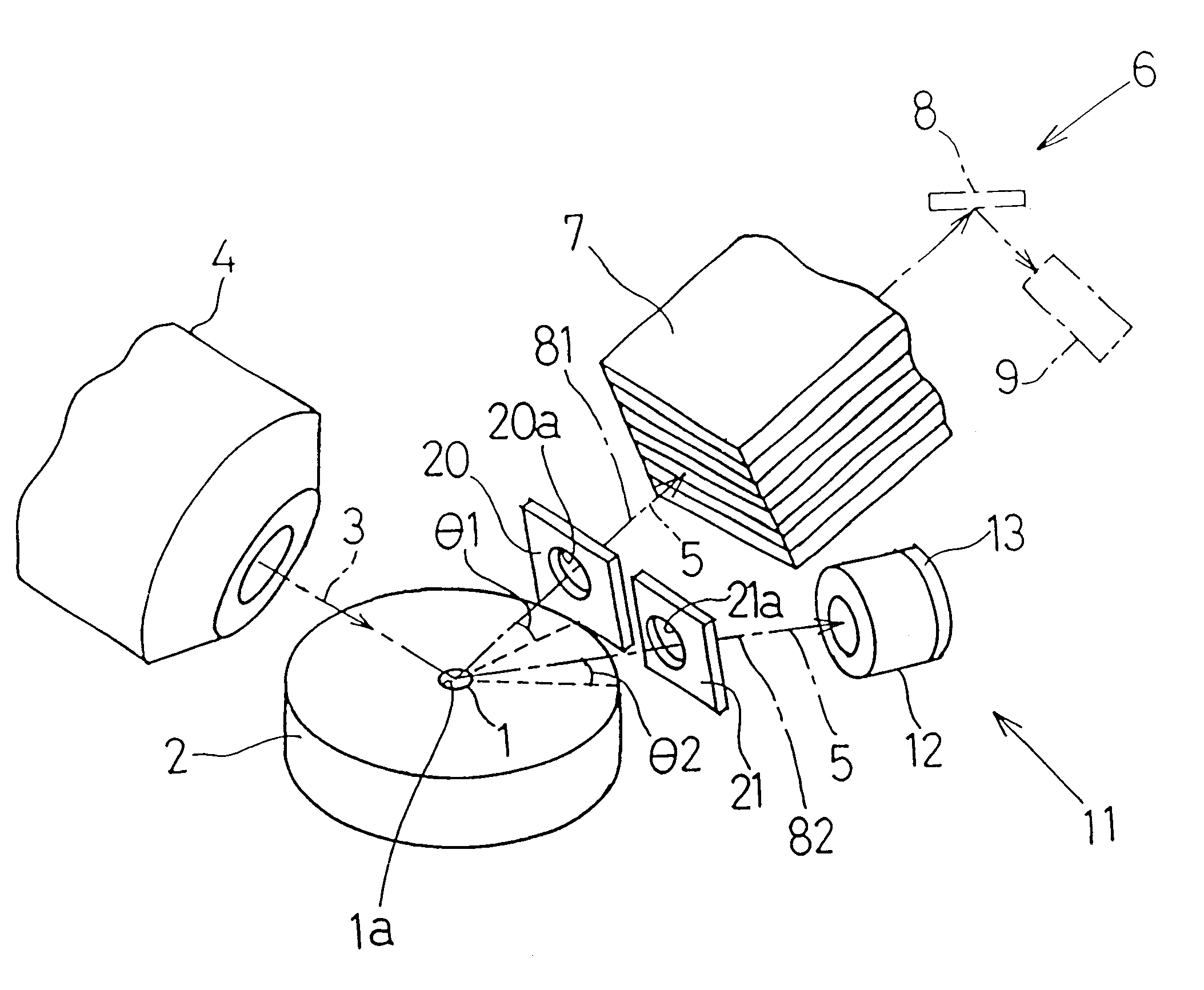

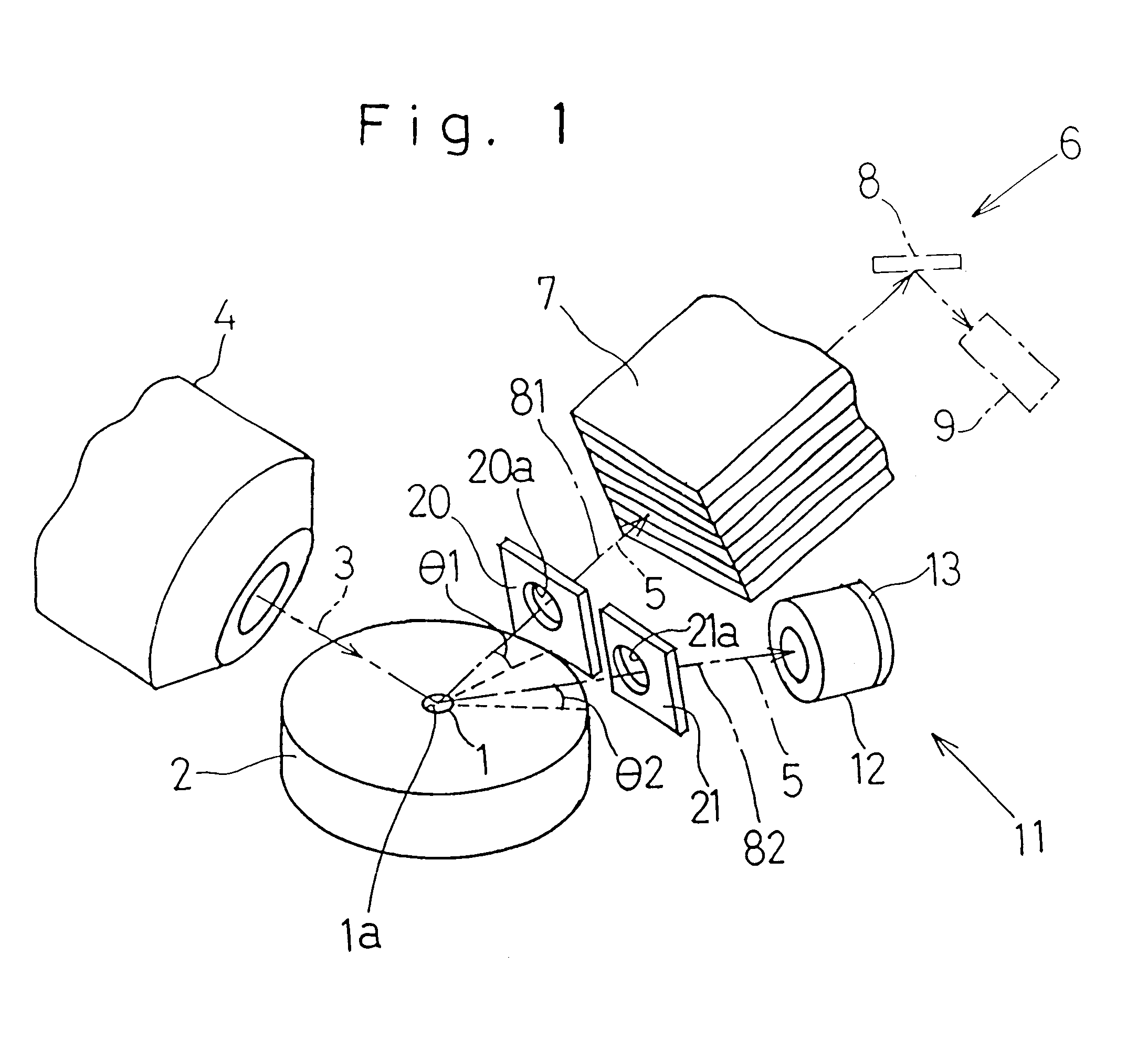

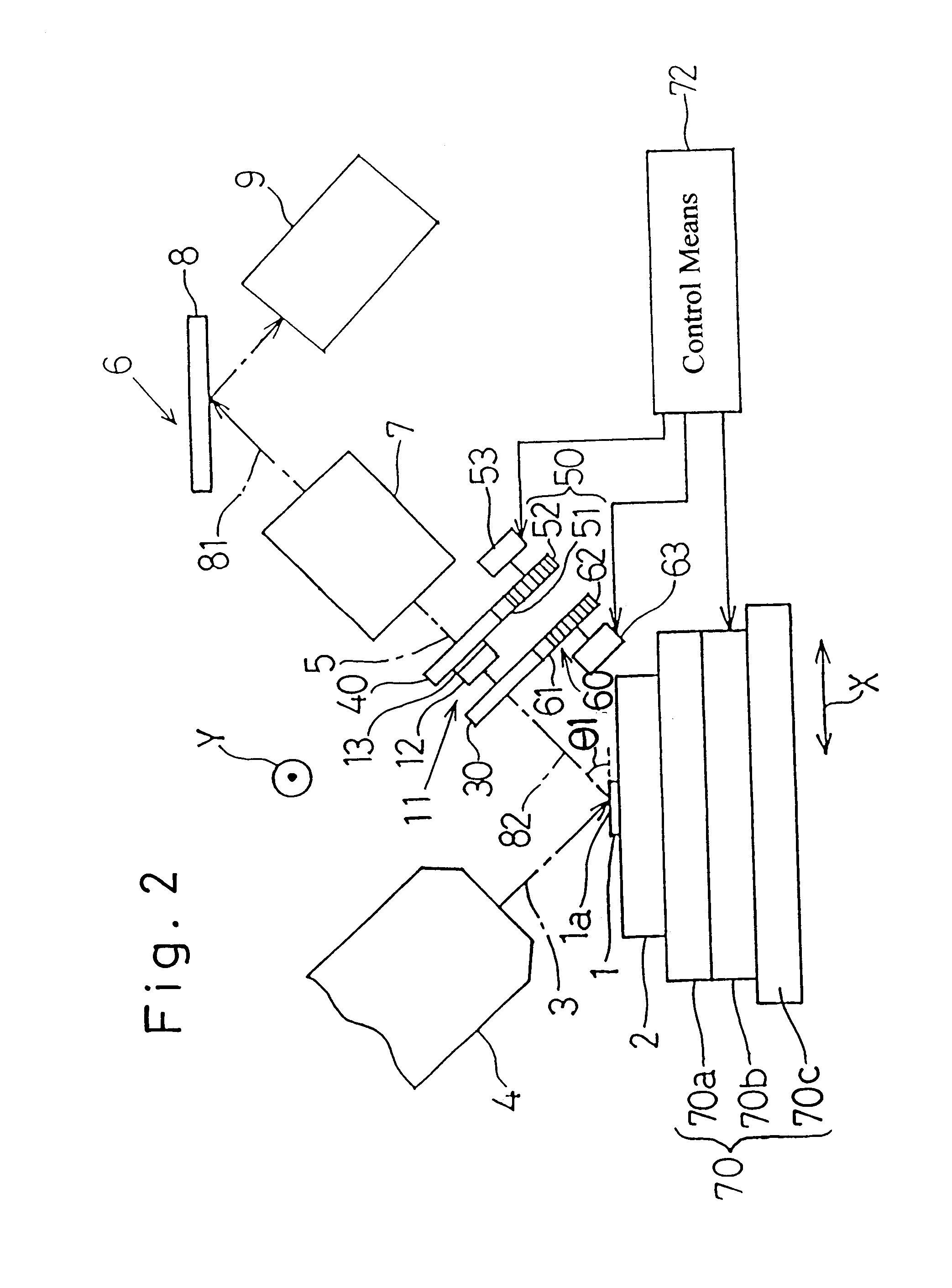

Fluorescent X-ray analyzer useable as wavelength dispersive type and energy dispersive type

InactiveUS6292532B1X-ray spectral distribution measurementUsing wave/particle radiation meansSoft x rayFluorescence

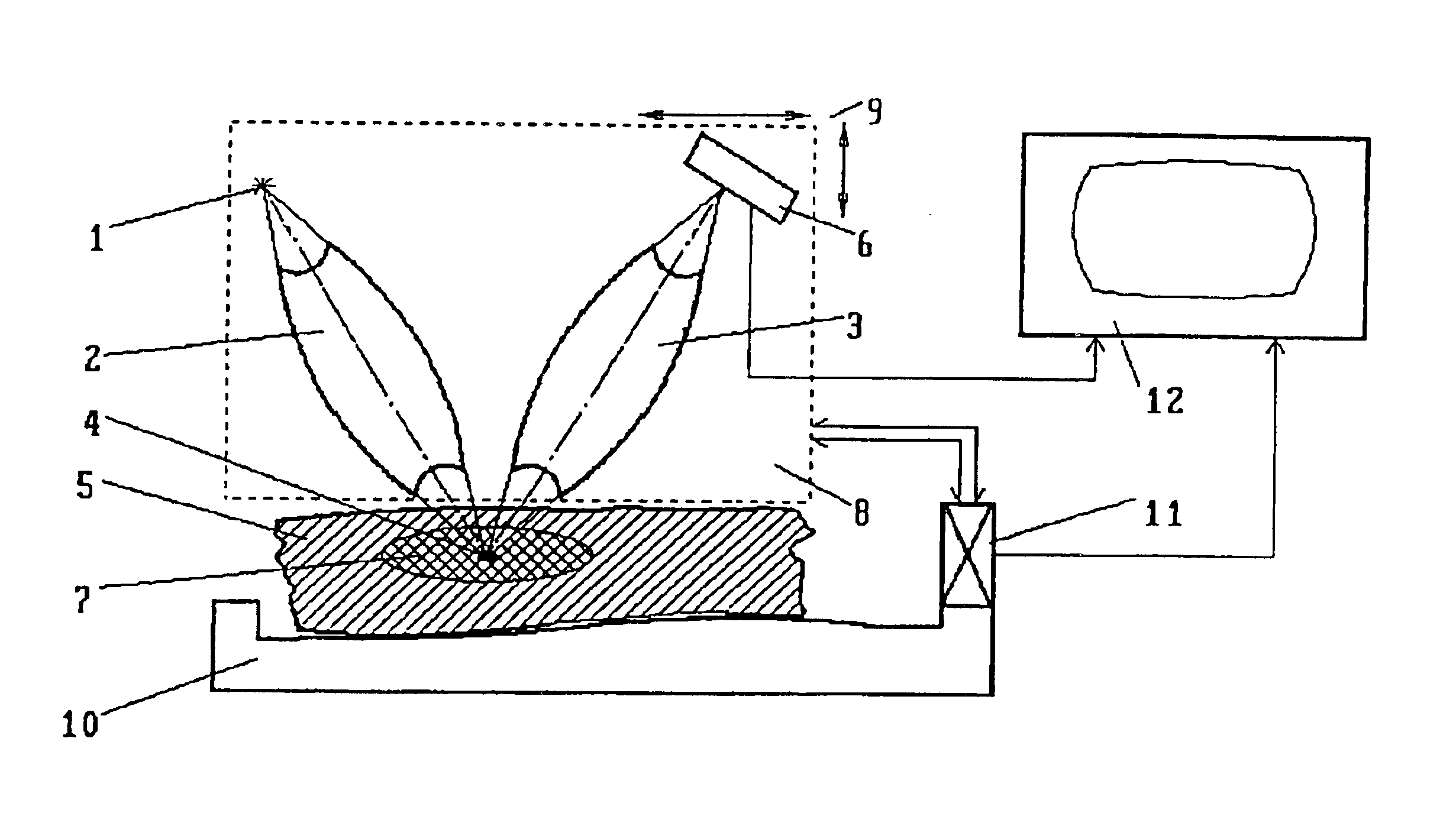

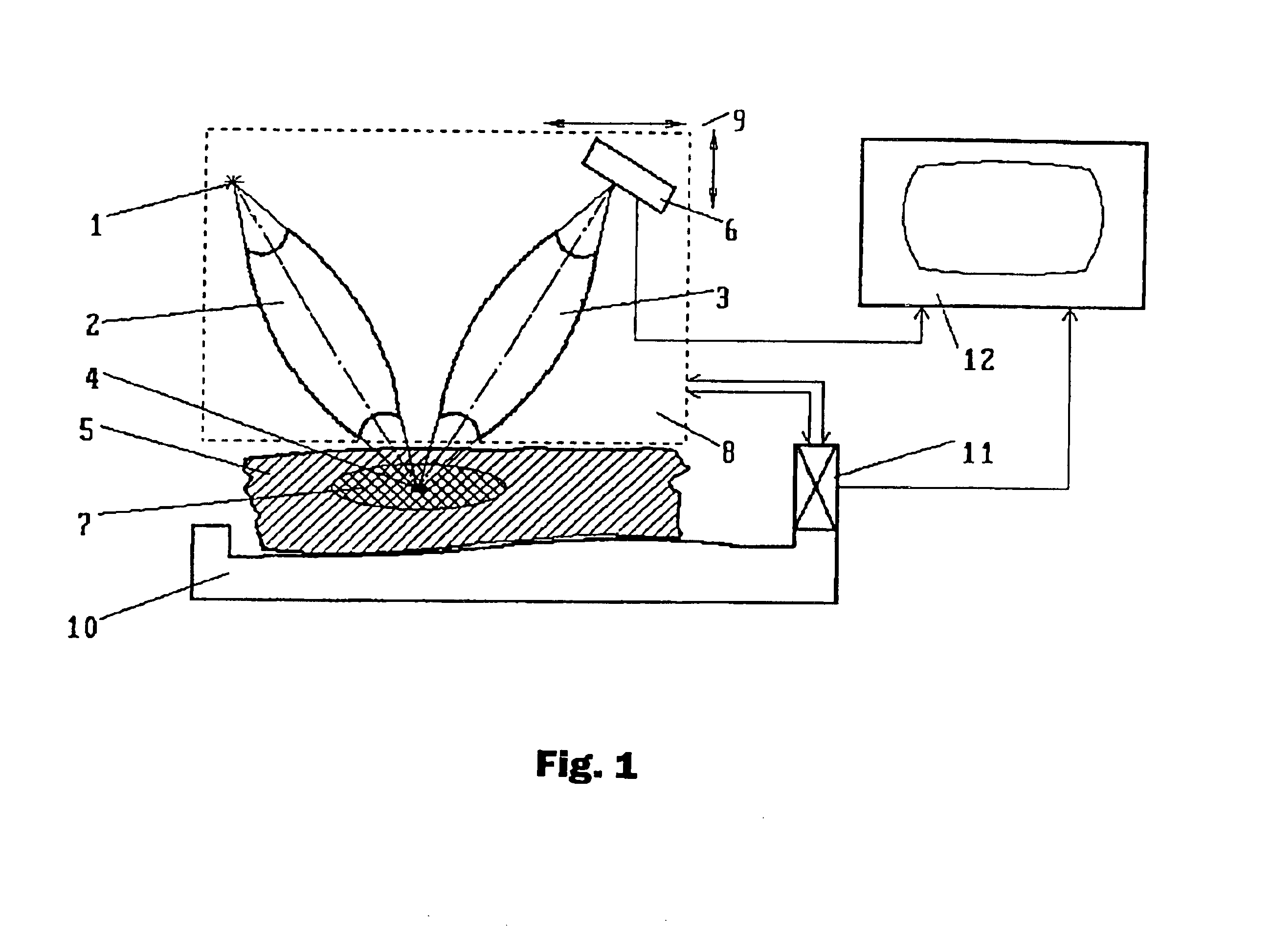

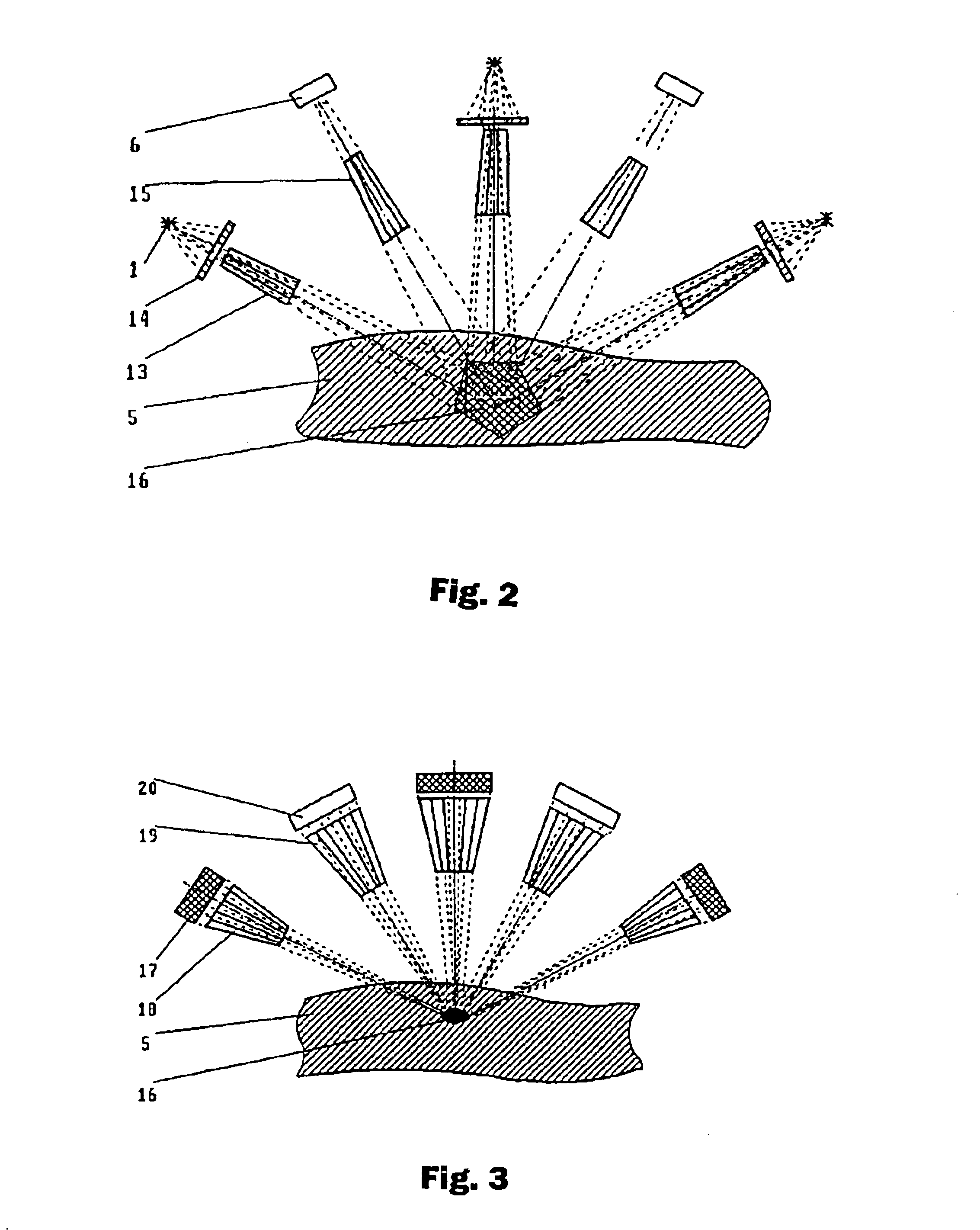

A fluorescent X-ray analyzing apparatus capable of being used as either a wavelength dispersive type or an energy dispersive type is provided, with which the analysis can be performed quickly and accurately. The fluorescent X-ray analyzing apparatus includes a detecting unit for detecting and analyzing fluorescent X-ray (5) emitted from at least one target area (1a) of a sample (1) to be analyzed as a result of excitation of such target area (1a) with a primary X-ray (3). The detecting unit includes a wavelength dispersive type detecting unit (6) including a spectroscope (8) and a first detector (9), and an energy dispersive type detecting unit (11) including a second detector (12) of an energy dispersive type. The angle theta1 formed between a first path (81) of travel of the fluorescent X-ray from the target area (1a) towards the spectroscope (8) and a surface of the sample (1) is equal to the angle theta2 formed between a second path (82) of travel of the fluorescent X-ray from the target area (1a) towards the second detector (12) of the energy dispersive type and a surface of the sample (1), but the second path (82) is shorter than the first path (81).

Owner:RIGAKU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com