Patents

Literature

51 results about "Binding selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Binding selectivity is defined with respect to the binding of ligands to a substrate forming a complex. Binding selectivity describes how a ligand may bind more preferentially to one receptor than another. A selectivity coefficient is the equilibrium constant for the reaction of displacement by one ligand of another ligand in a complex with the substrate. Binding selectivity is of major importance in biochemistry and in chemical separation processes.

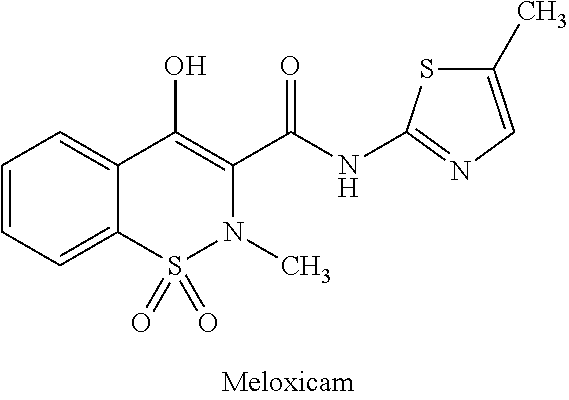

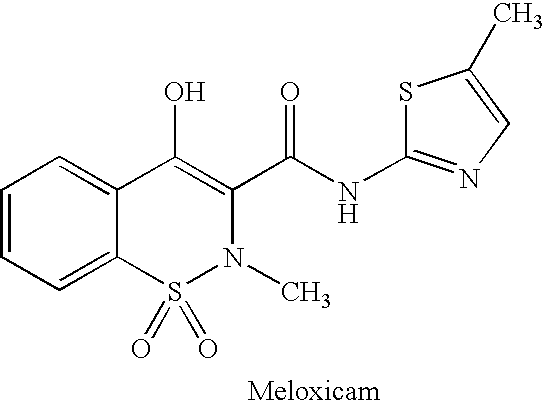

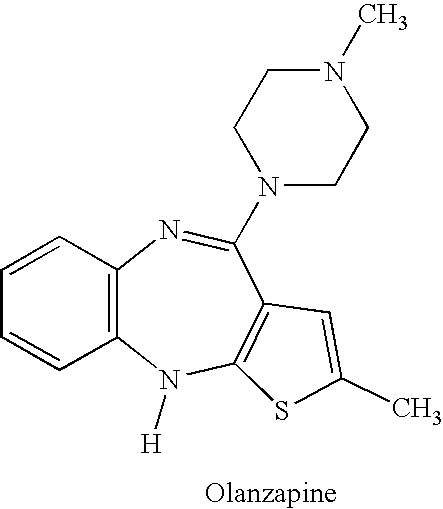

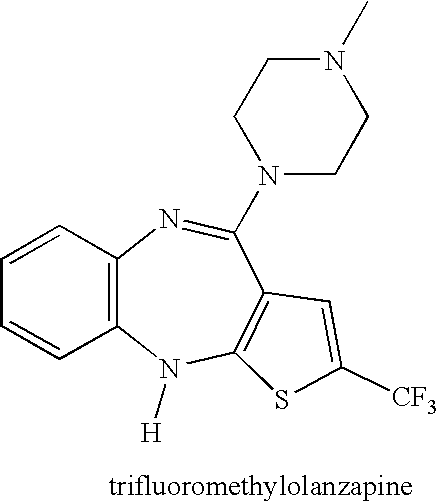

Advanced drug development and manufacturing

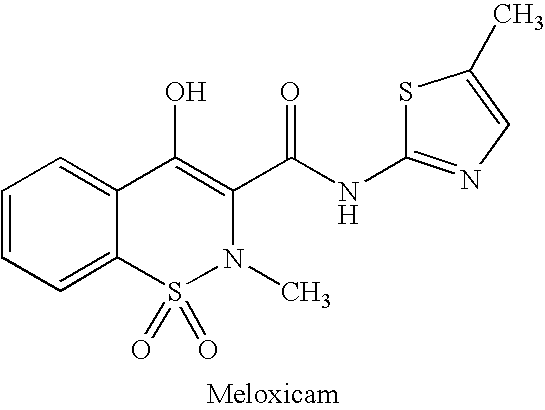

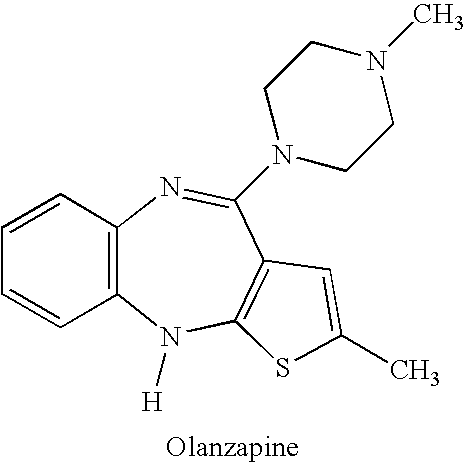

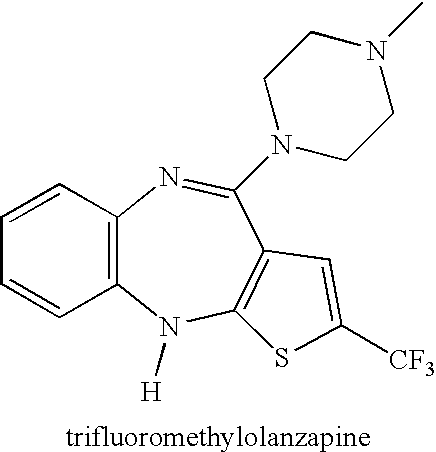

X-ray fluorescence (XRF) spectrometry has been used for detecting binding events and measuring binding selectivities between chemicals and receptors. XRF may also be used for estimating the therapeutic index of a chemical, for estimating the binding selectivity of a chemical versus chemical analogs, for measuring post-translational modifications of proteins, and for drug manufacturing.

Owner:RGT UNIV OF CALIFORNIA

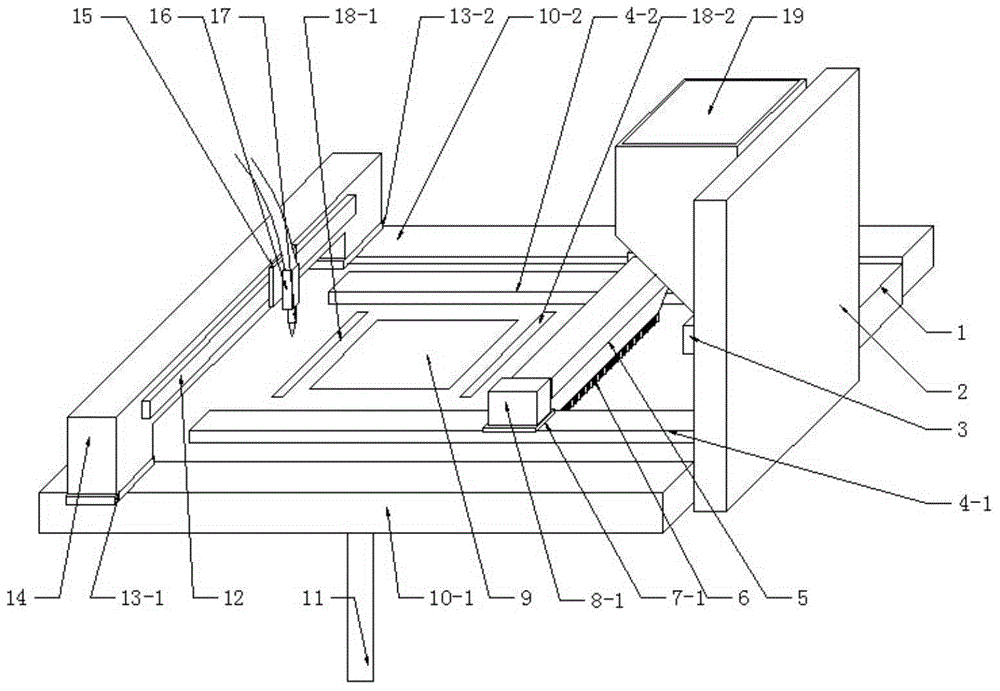

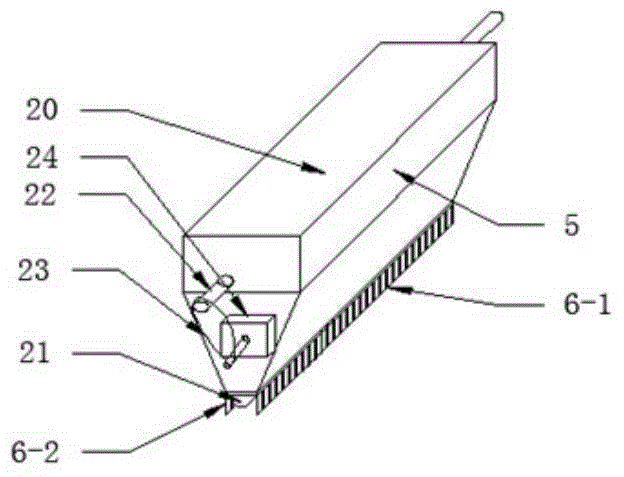

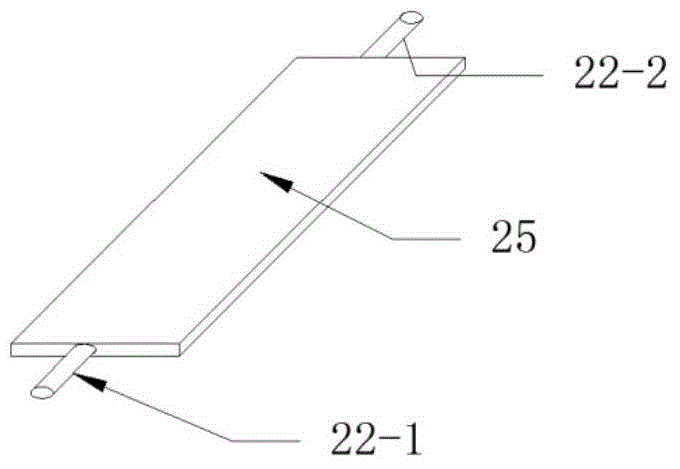

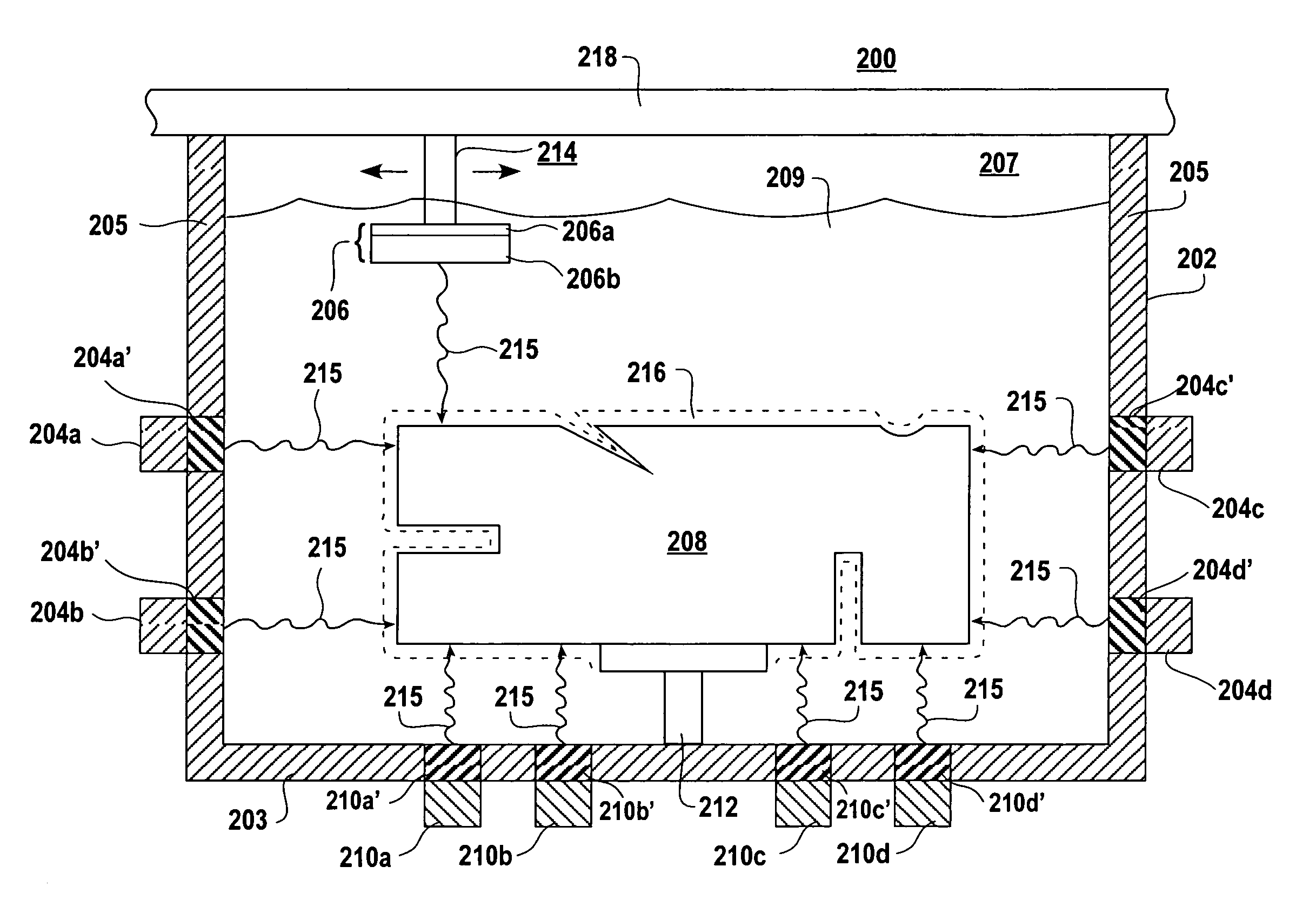

Selective laser melting powder sending and laying device used for compounding of different types of powder

ActiveCN105562687ASolve recycling difficultiesReduce consumptionIncreasing energy efficiencySelective laser meltingMetallurgy

The invention discloses a selective laser melting powder sending and laying device used for compounding of different types of powder. The selective laser melting powder sending and laying device comprises a worktable, a forming cylinder, a powder spraying device and a powder laying device. The upper surface of the forming cylinder is arranged on the worktable. The powder spraying device and the powder laying device are arranged on the two sides of the forming cylinder. The powder spraying device is characterized in that powder spraying electric guide rails, a support, a nozzle electric guide rail and a nozzle are included; the nozzle is arranged on the nozzle electric guide rail; the nozzle electric guide rail is arranged on the powder spraying electric guide rails through the support; and the powder spraying electric guide rails are fixed to the worktable. The powder laying device comprises a powder hopper, a powder scraping electric guide rail and a supporting frame; the powder hopper is arranged on the powder scraping electric guide rail through the supporting frame; and the powder scraping electric guide rail is fixed to the worktable. According to the selective laser melting powder sending and laying device used for compounding of different types of powder, the selective laser melting technology and the laser cladding coaxial powder sending technology are combined, and the purposes of effectively recovering powder during compound additive manufacturing of gradient materials and forming parts with complex gradients in any direction are achieved.

Owner:NANJING UNIV OF SCI & TECH

Biological materials and uses thereof

InactiveUS20060193849A1Minimal impactInfluence the stability of the whole scFv moleculeAntibody ingredientsImmunoglobulinsAntibody fragmentsAntigen binding

A modified antibody molecule which selectively binds to a specific target, the antibody molecule being modified at at least one amino acid residue that determines antigen binding selectivity and / or affinity, characterised in that the modified antibody molecule exhibits a greater stability than an unmodified parent antibody molecule which selectively binds to the target. Also described are nucleotide sequences encoding, vectors, host cells and composition containing and uses of such antibodies, antibody fragments or antibody derivatives.

Owner:ANTISOMA LTD +1

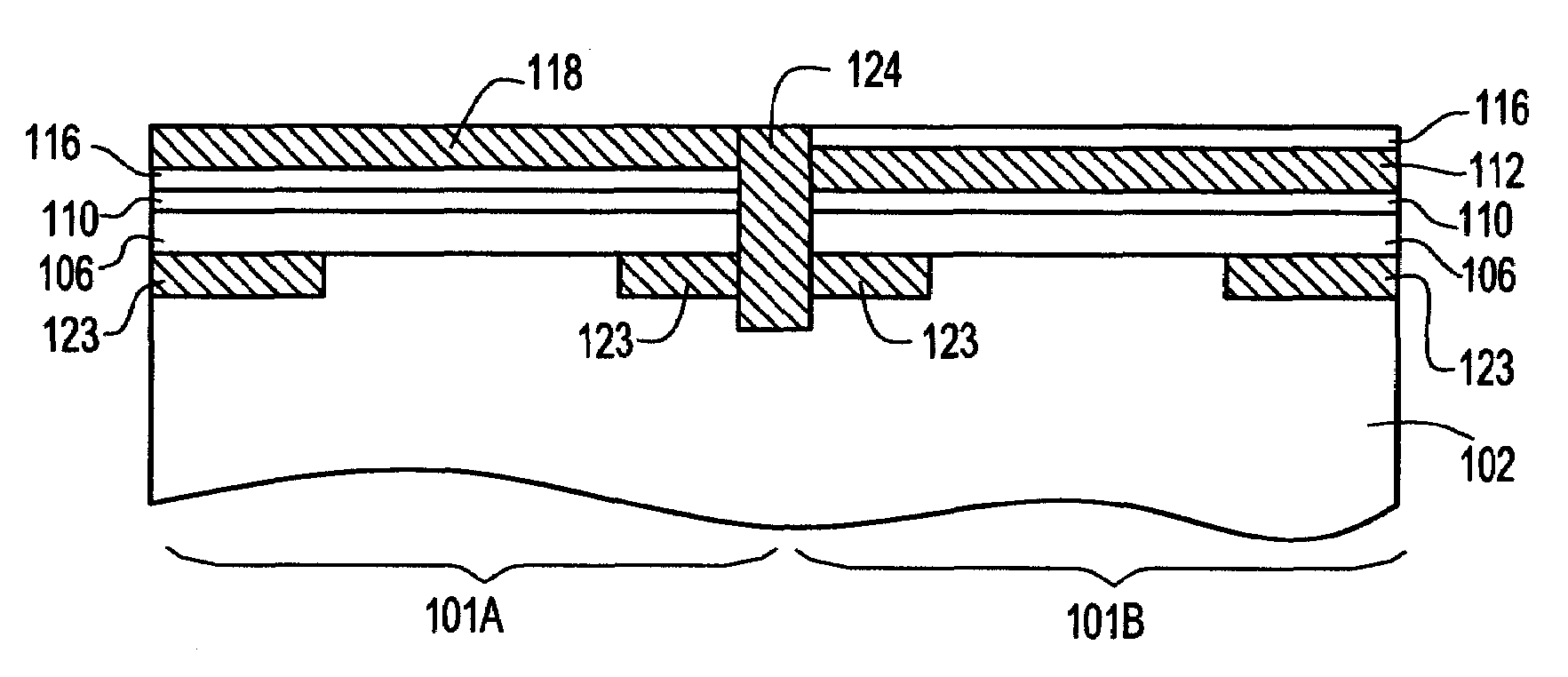

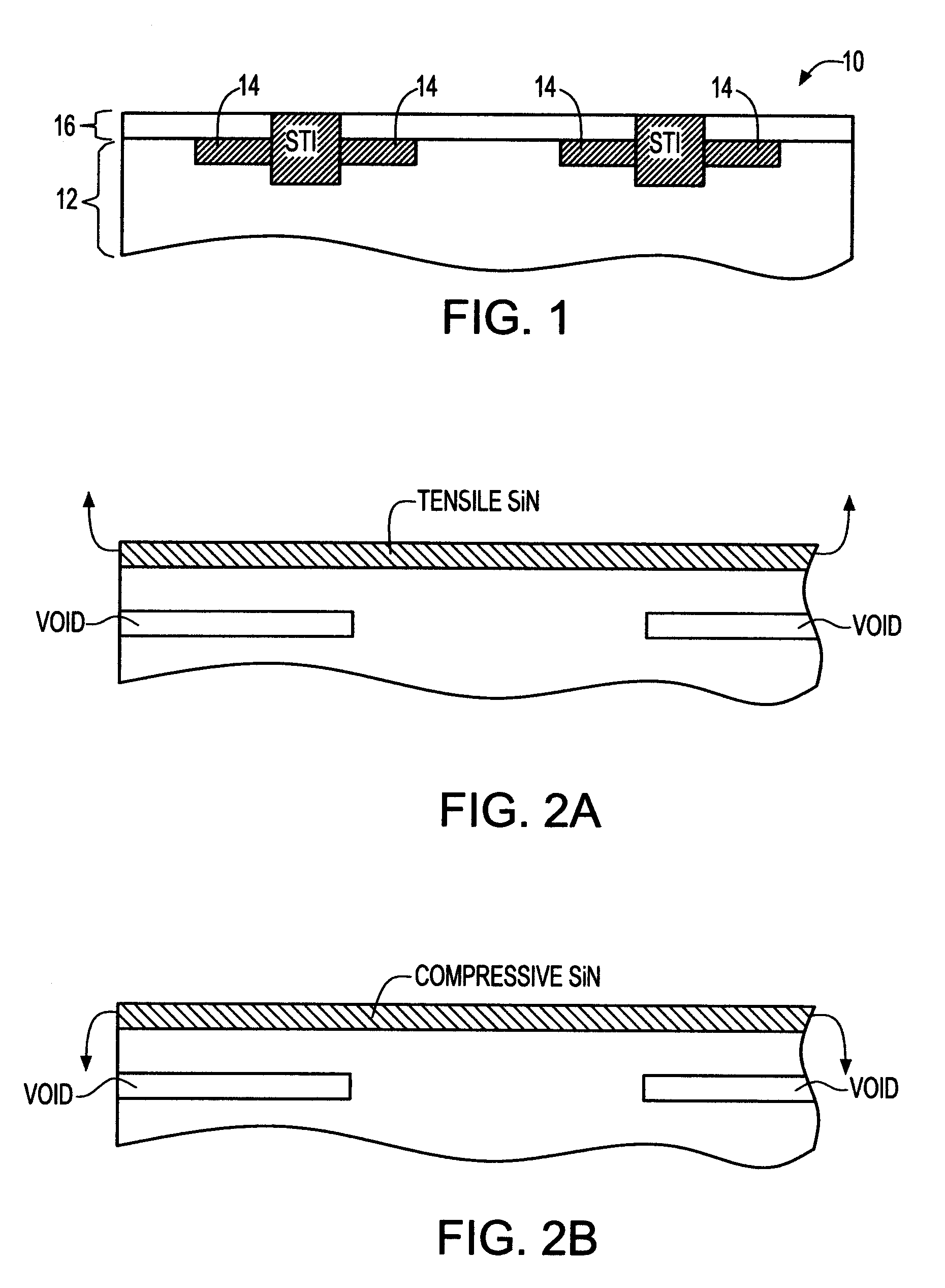

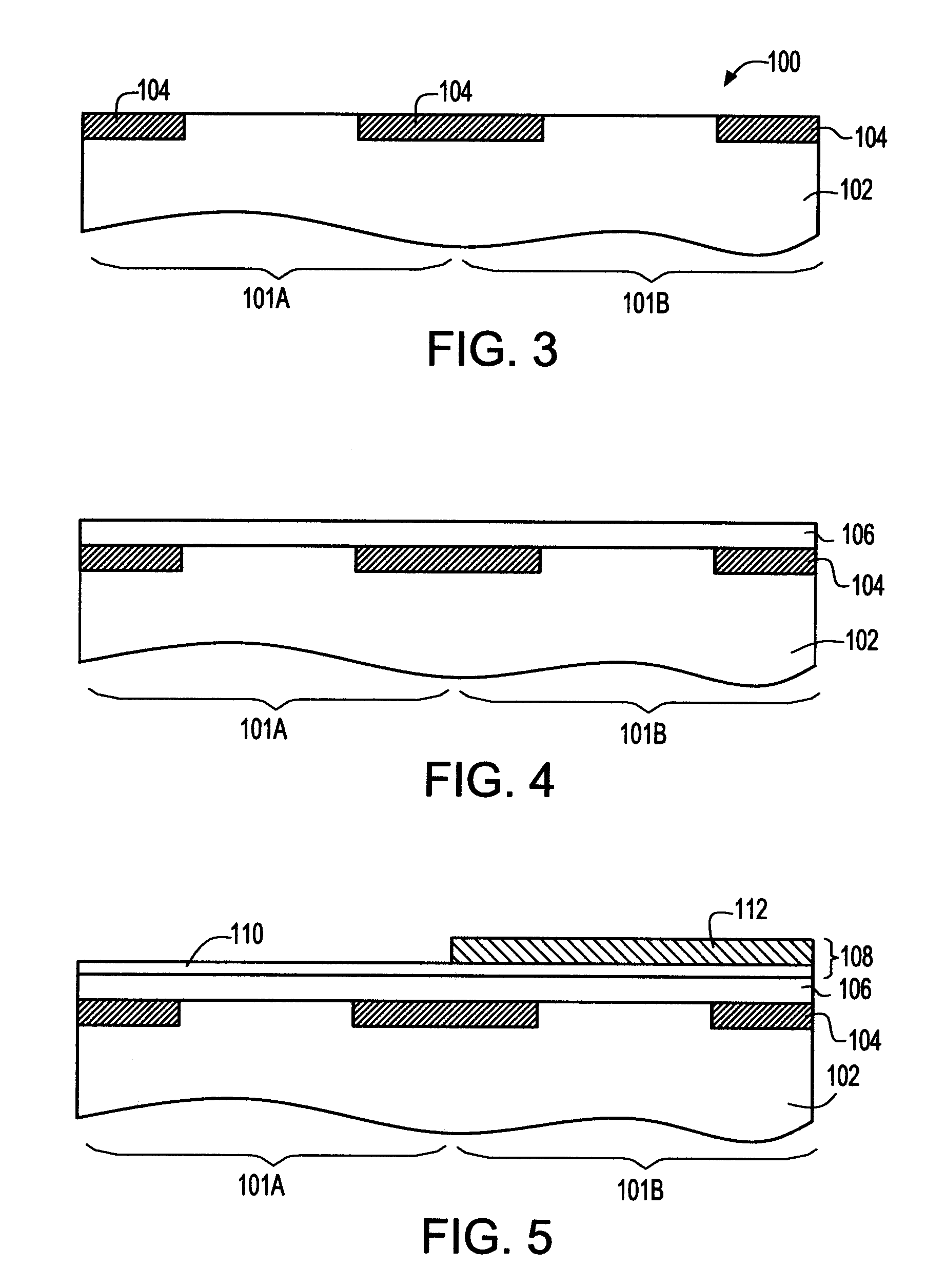

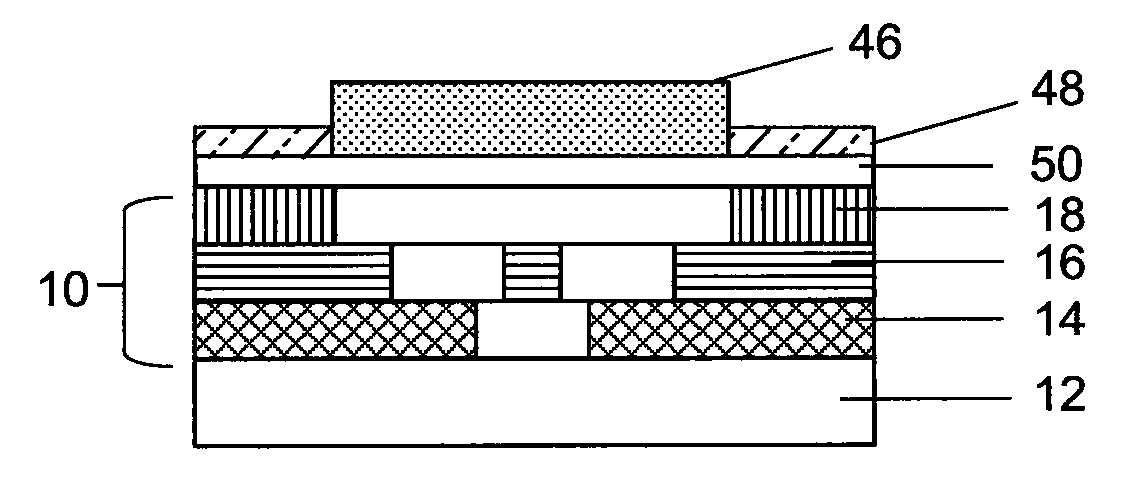

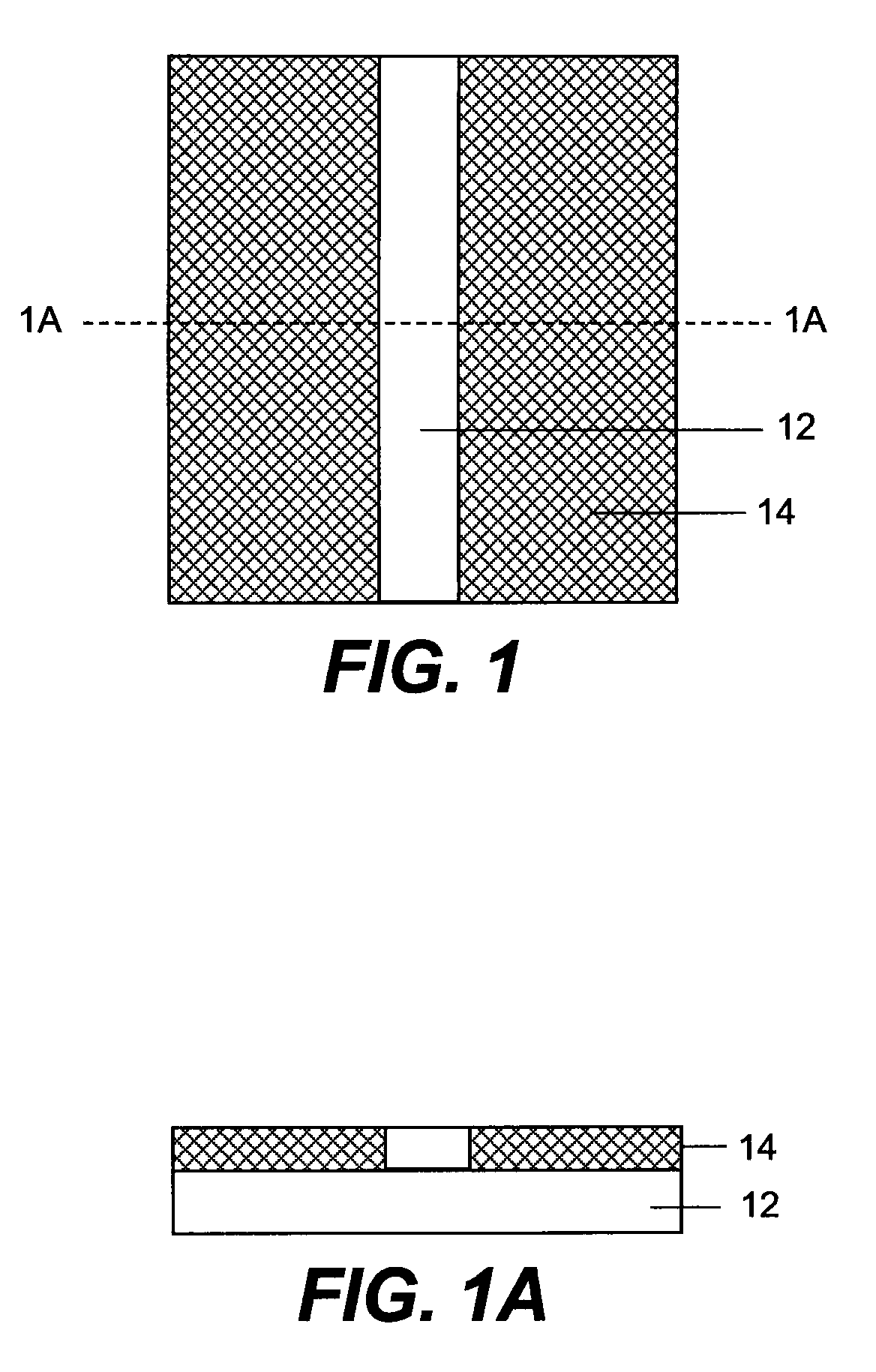

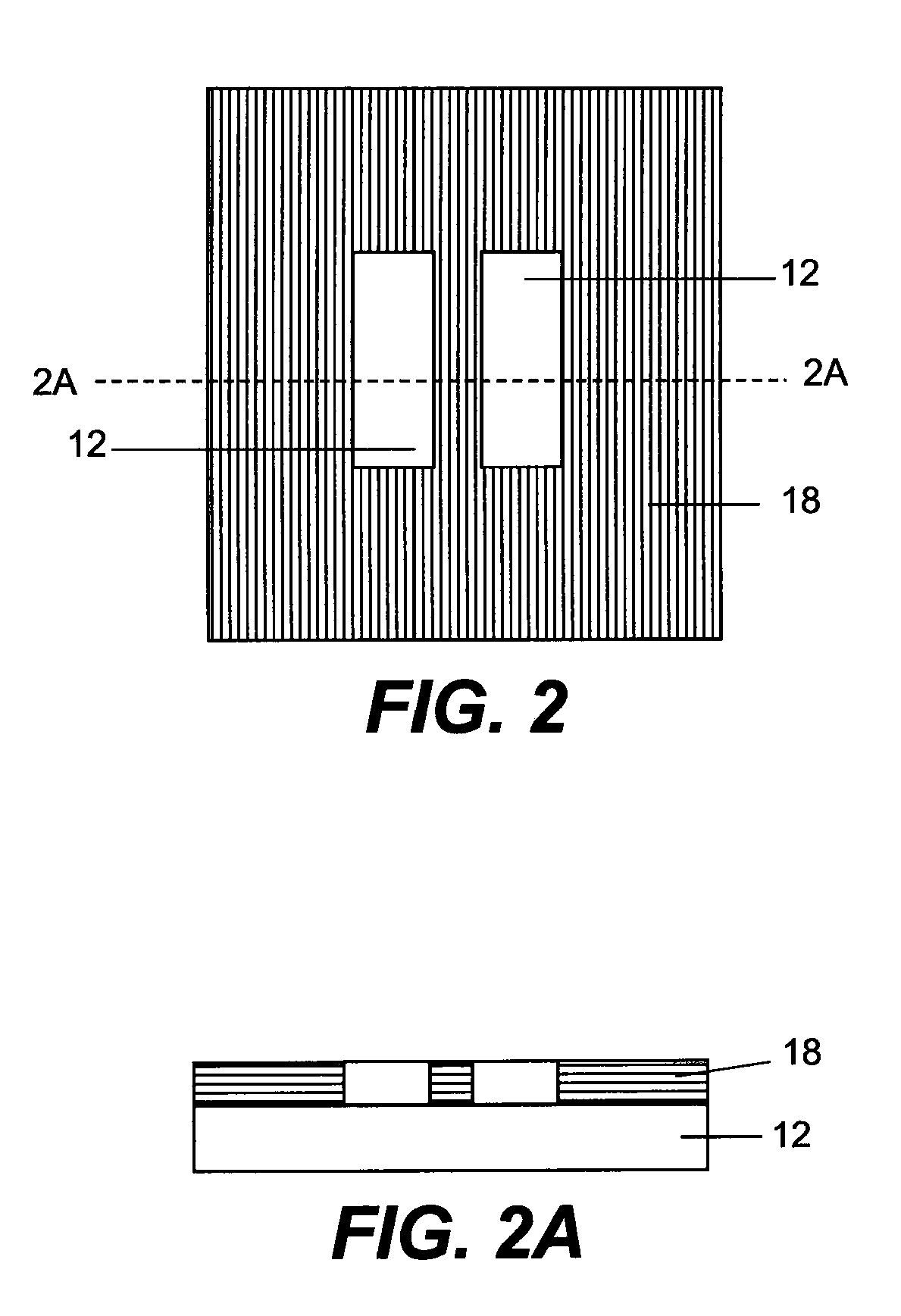

Stress engineering using dual pad nitride with selective SOI device architecture

ActiveUS7202513B1Increase valueSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorMaterials science

A method for engineering stress in the channels of MOS transistors of different conductivity using highly stressed nitride films in combination with selective semiconductor-on-insulator (SOI) device architecture is described. A method of using compressive and tensile nitride films in the shallow trench isolation (STI) process is described. High values of stress are achieved when the method is applied to a selective SOI architecture.

Owner:GLOBALFOUNDRIES U S INC

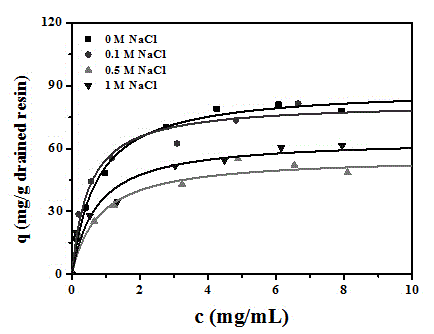

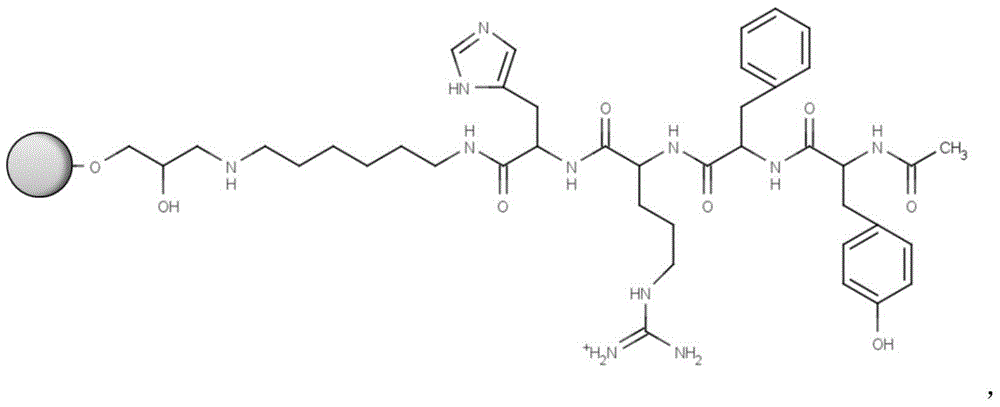

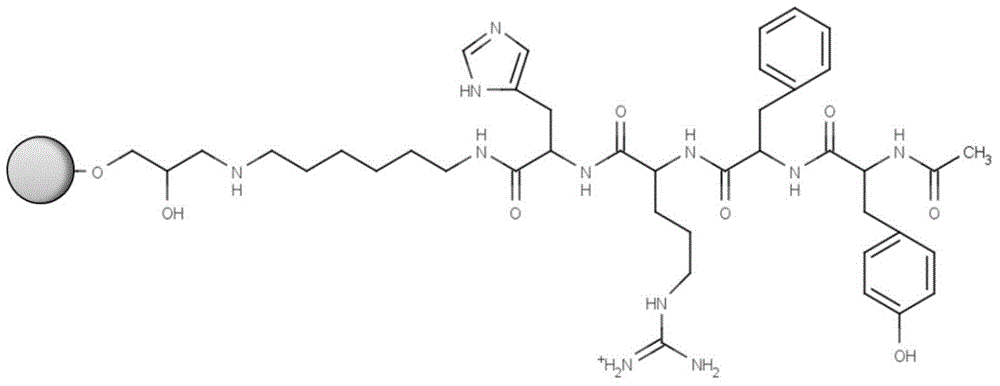

Affinity chromatography medium employing tetrapeptide as functional ligand and preparation method of affinity chromatography medium

ActiveCN104645949AHigh affinityGood choiceOther chemical processesSolid sorbent liquid separationSodium acetateAcetic anhydride

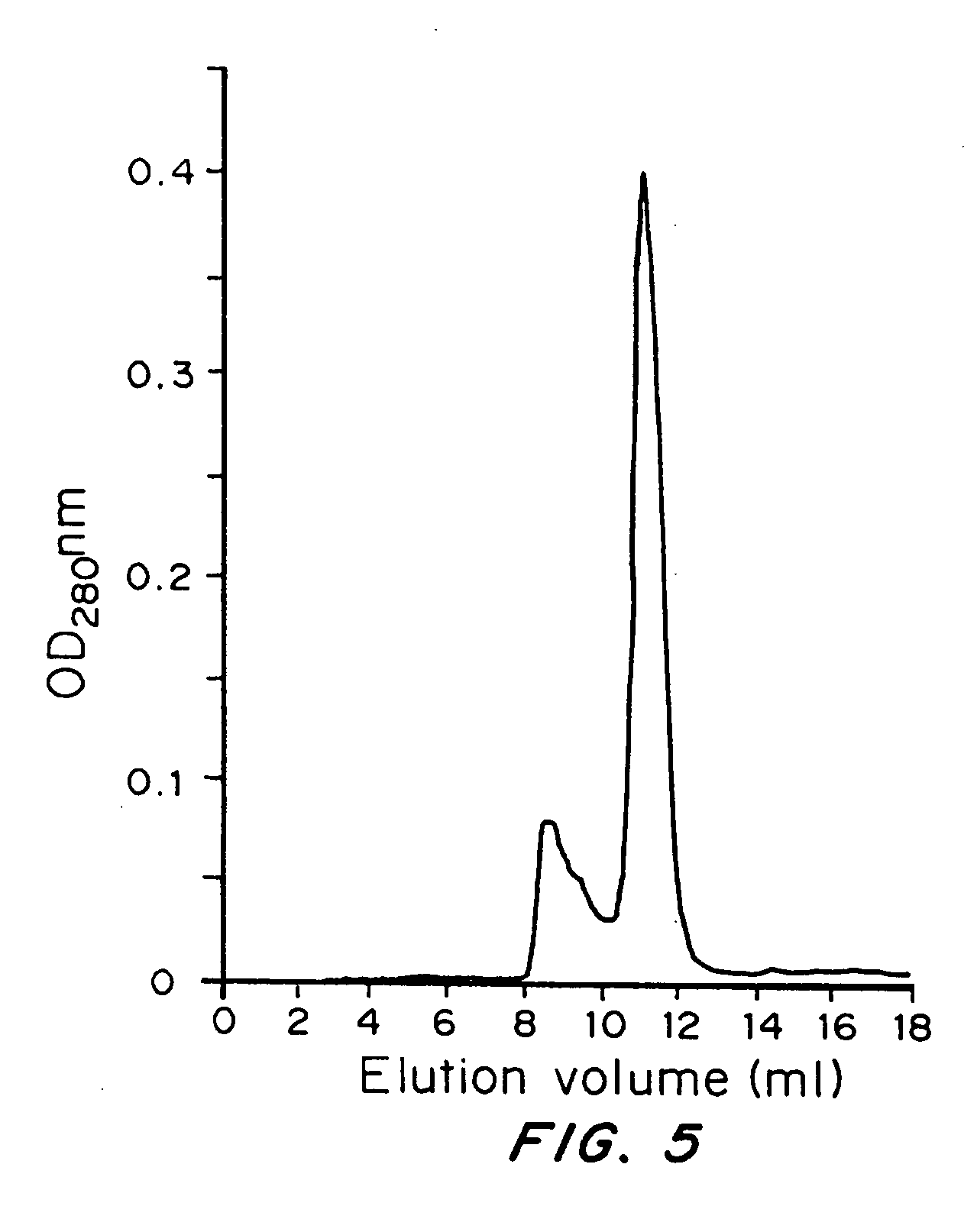

The invention discloses an affinity chromatography medium employing tetrapeptide as a functional ligand and a preparation method of the affinity chromatography medium. The method comprises the following steps: adding dry matrix and allyl bromide to a dimethyl sulfoxide solution, activating, and reacting activating matrix with N-bromo succinimide; enabling bromo alcoholized matrix to react with hexamethylendiamine to obtain amino activating matrix; sequentially washing with deionized water, absolute ethyl alcohol and anhydrous N,N-dimethyl formamide, adding an N,N-dimethyl formamide solution containing tetrapeptide, 2-(7-azobenzotriazole)-N,N,N',N'-te-tramethyluronium hexafluorophosphate and N,N-diisopropylethylamine, and coupling a tetrapeptide ligand; and putting a medium coupled to tetrapeptide in a mixed liquid of sodium acetate and acetic anhydride to obtain the affinity chromatography medium employing tetrapeptide as the functional ligand. According to the novel chromatography medium developed by the method, a functional group is tetrapeptide composed of tyrosine, phenylalanine, arginine and histidine, and is designed on the basis of a protein A binding site of an antibody Fc segment; the antibody binding selectivity is greatly improved; and the affinity chromatography medium can be applied to efficient separation of an antibody.

Owner:ZHEJIANG UNIV

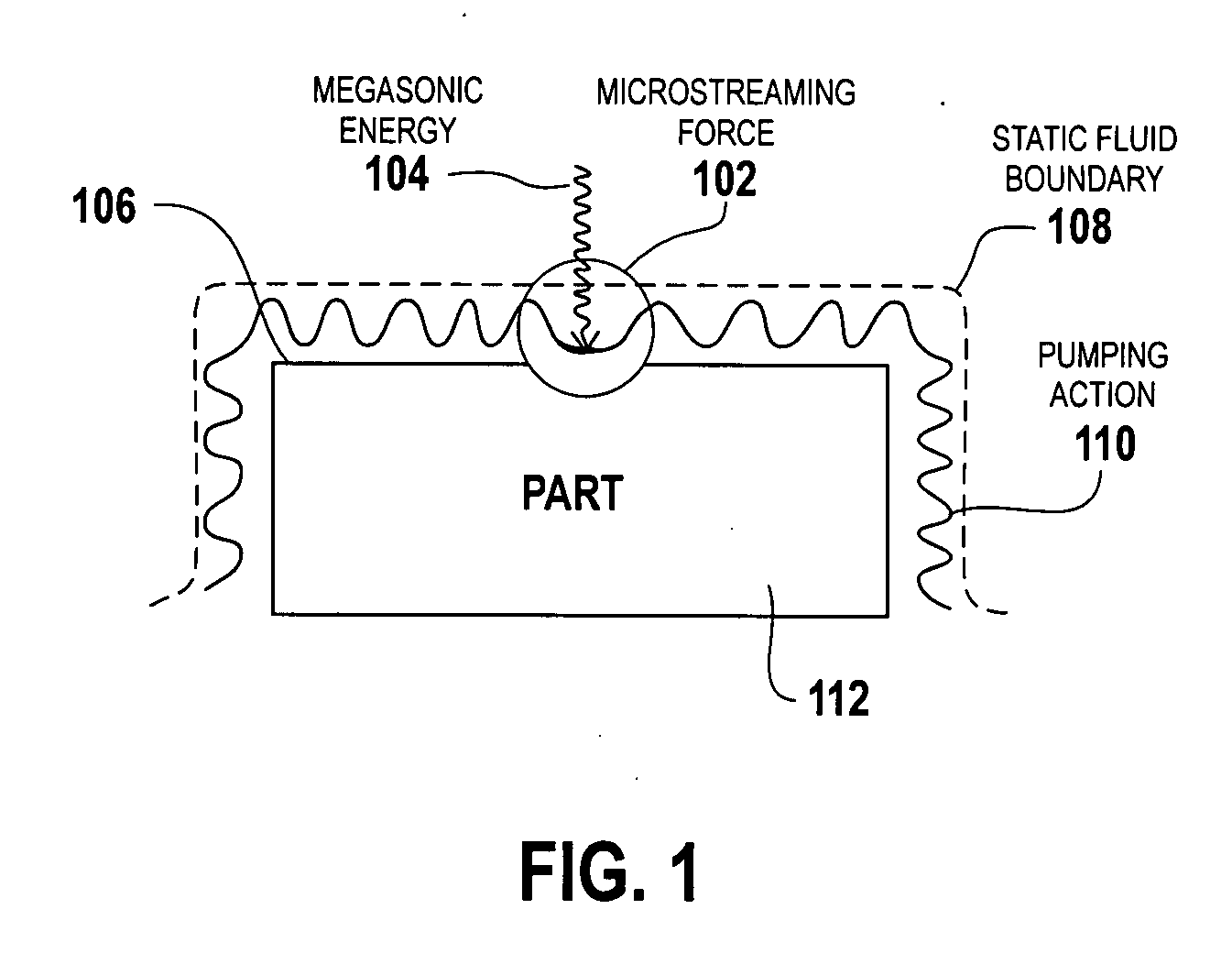

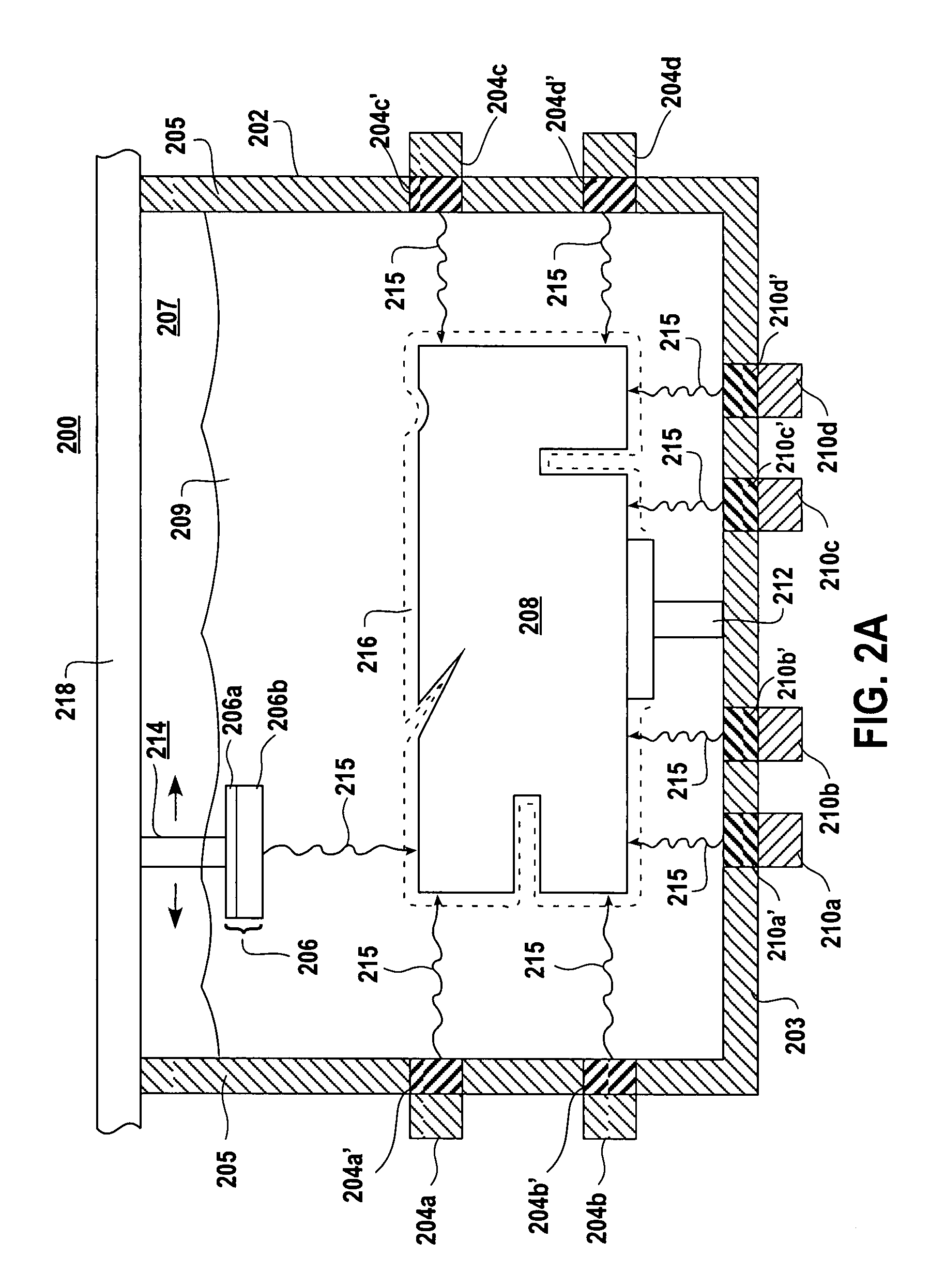

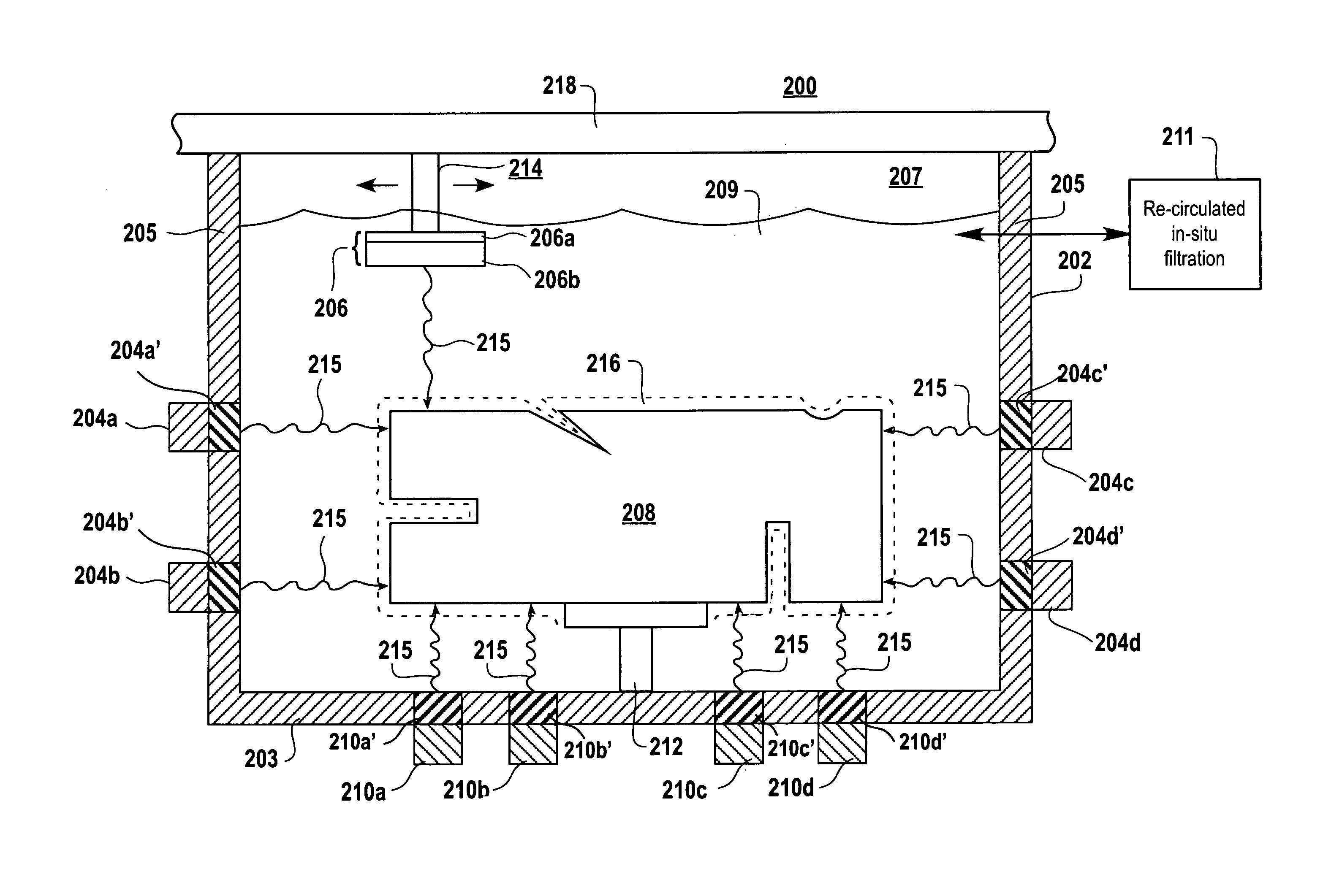

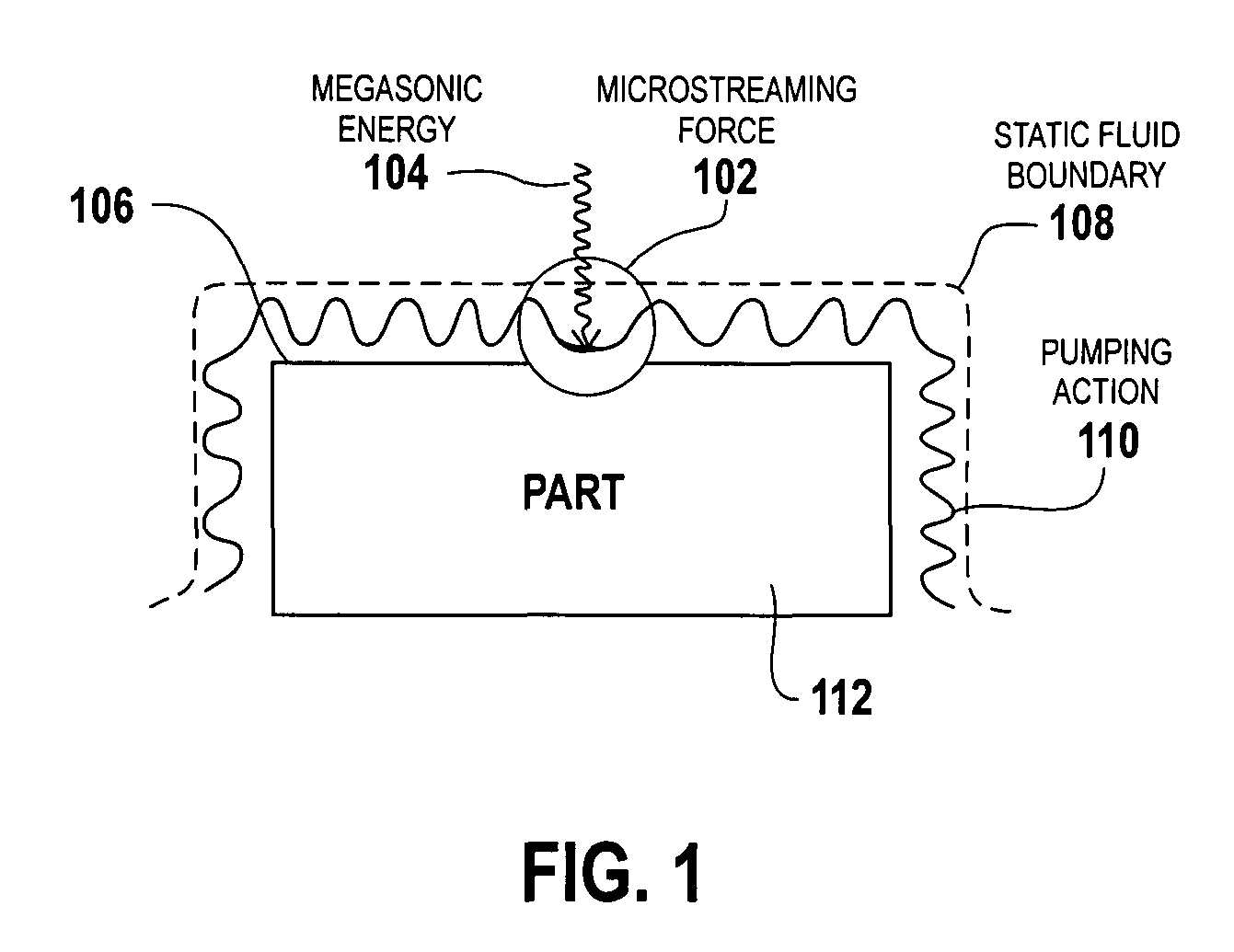

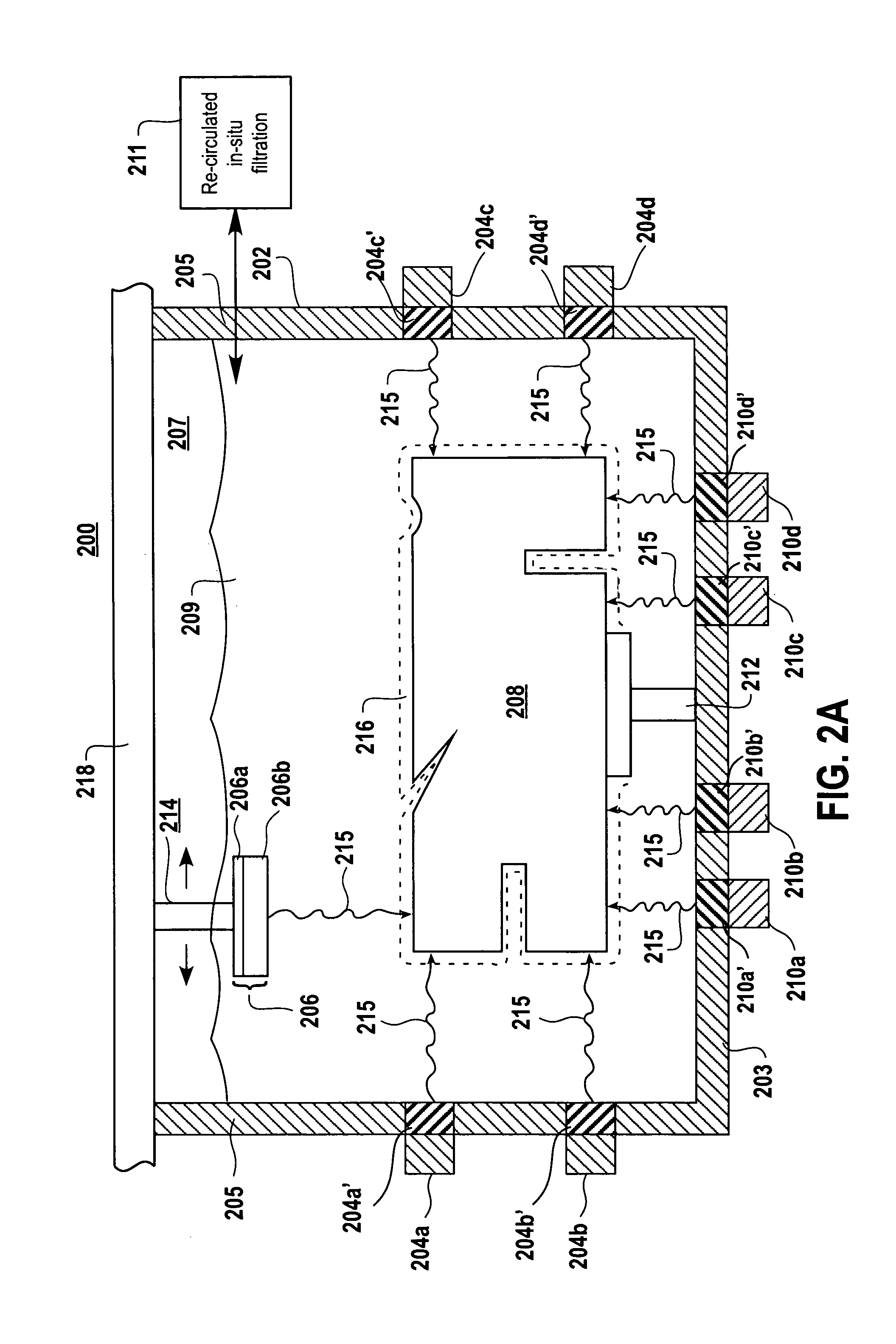

Megasonic precision cleaning of semiconductor process equipment components and parts

ActiveUS20080142055A1Precision cleaningImprove performanceElectrostatic cleaningSemiconductor/solid-state device manufacturingParticulatesProcess equipment

Methods and apparatus are provided for using various megasonic apparatus including megasonic tanks, scanning megasonic plates, megasonic jets, and megasonic sweeping beams etc., in combination with selective chemistries to remove sub-micron particulate contaminants from the surfaces of the processing equipment used in semiconductor, medical, or any other processing environments.

Owner:LAM RES CORP

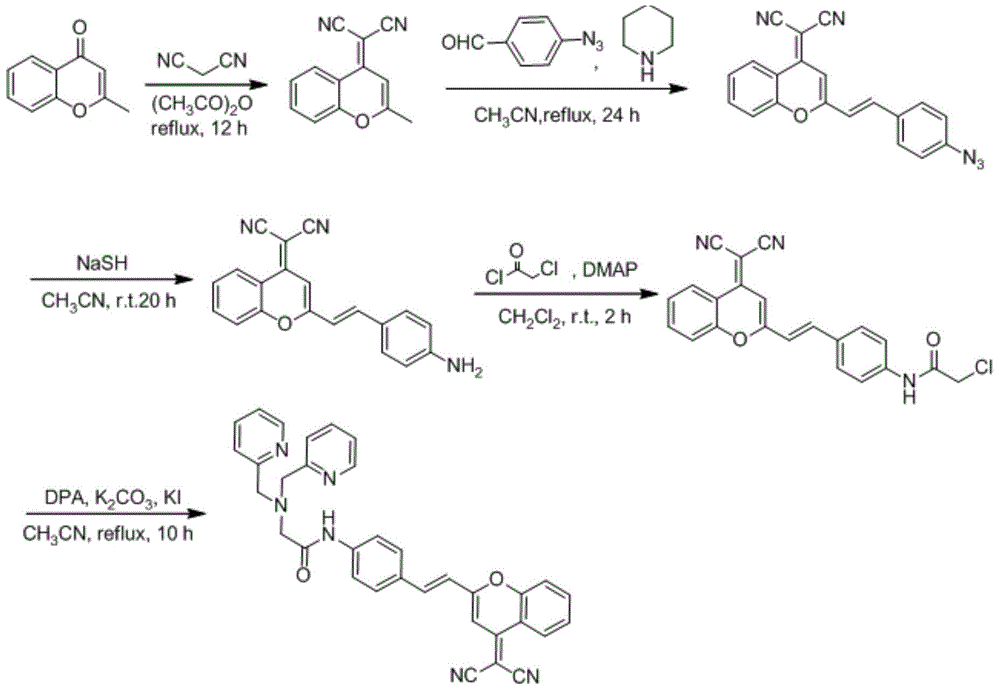

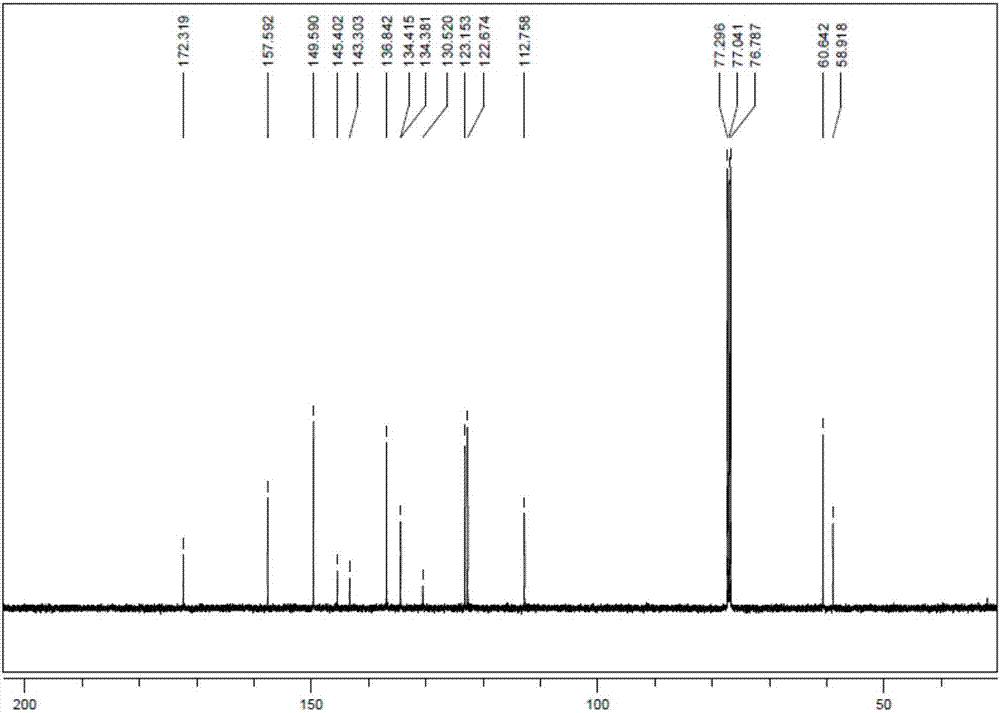

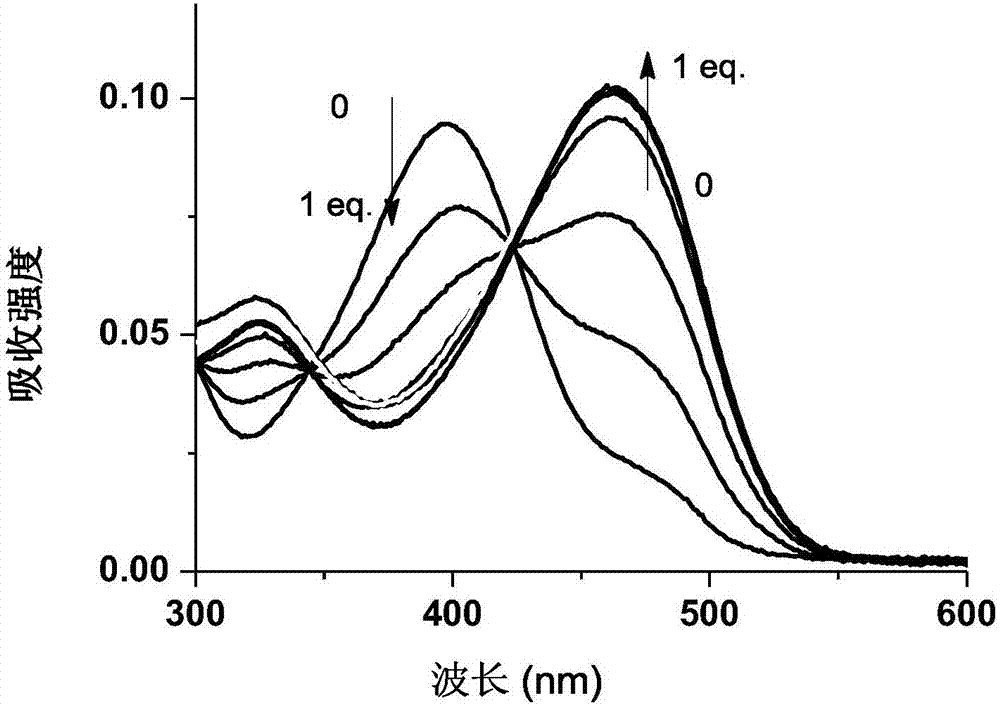

Ratio-type variant receptor mercury ion fluorescent probe and its preparation method and use

InactiveCN104804724AQuick responseImprove responsivenessOrganic chemistryFluorescence/phosphorescenceCadmium CationChemical stability

The invention discloses a ratio-type variant receptor mercury ion fluorescent probe and its preparation method and use. The ratio-type variant receptor mercury ion fluorescent probe has the advantages of simple synthesis processes, good light stability, the largest emission wavelength of 550nm and good chemical stability under neutral conditions. Through amide functional group tautomerism, the receptor has a deformation capability of combination of an imidic acid isomer and mercury ions and combination of an amide isomer structure and other metal ions so that the receptor has mercury ion specific combination selectivity. The probe with the mercury ion produces fluorescence spectrum red shift to 633nm and the fluorescence spectrum is enhanced by 9 times. After bonding to other metal ions especially such as congener zinc ion and cadmium ions, the probe has no obvious fluorescence change and has mercury ion specific fluorescence signal selectivity. The probe realizes mercury ion specific ratio identification, can be used in detection of mercury ions in cells and has a wide application prospect in detection of mercury ions in other organisms and environments.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

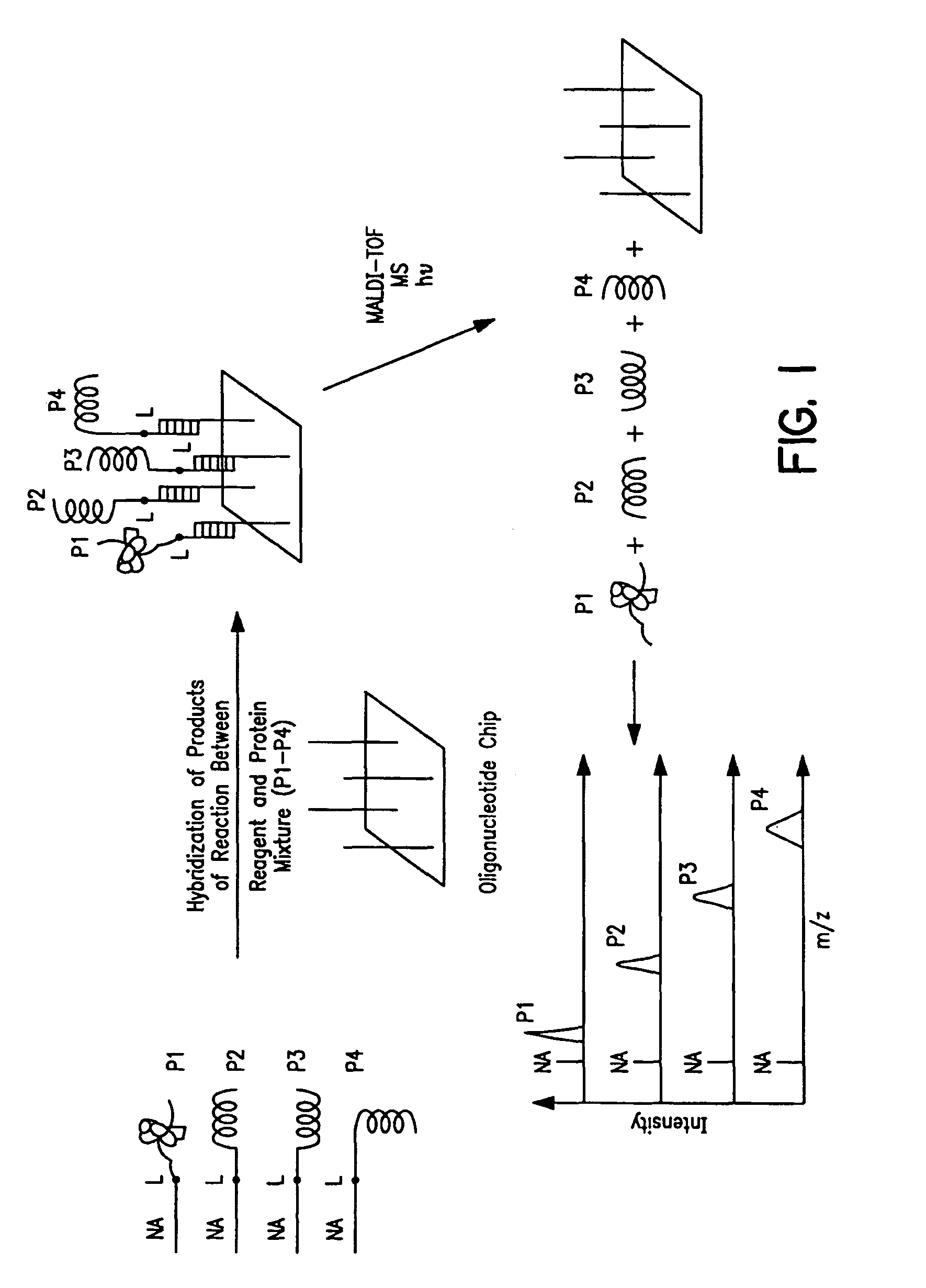

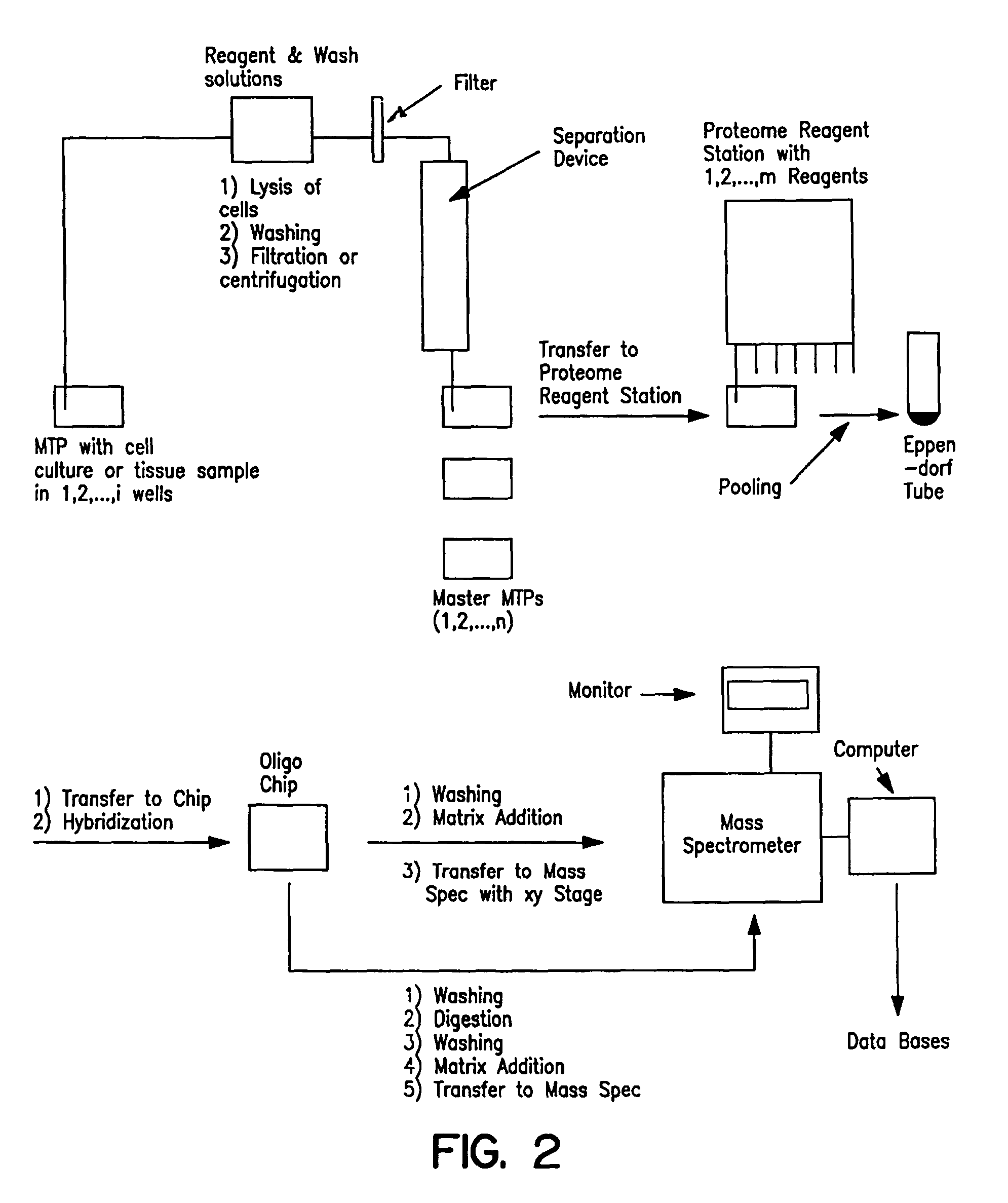

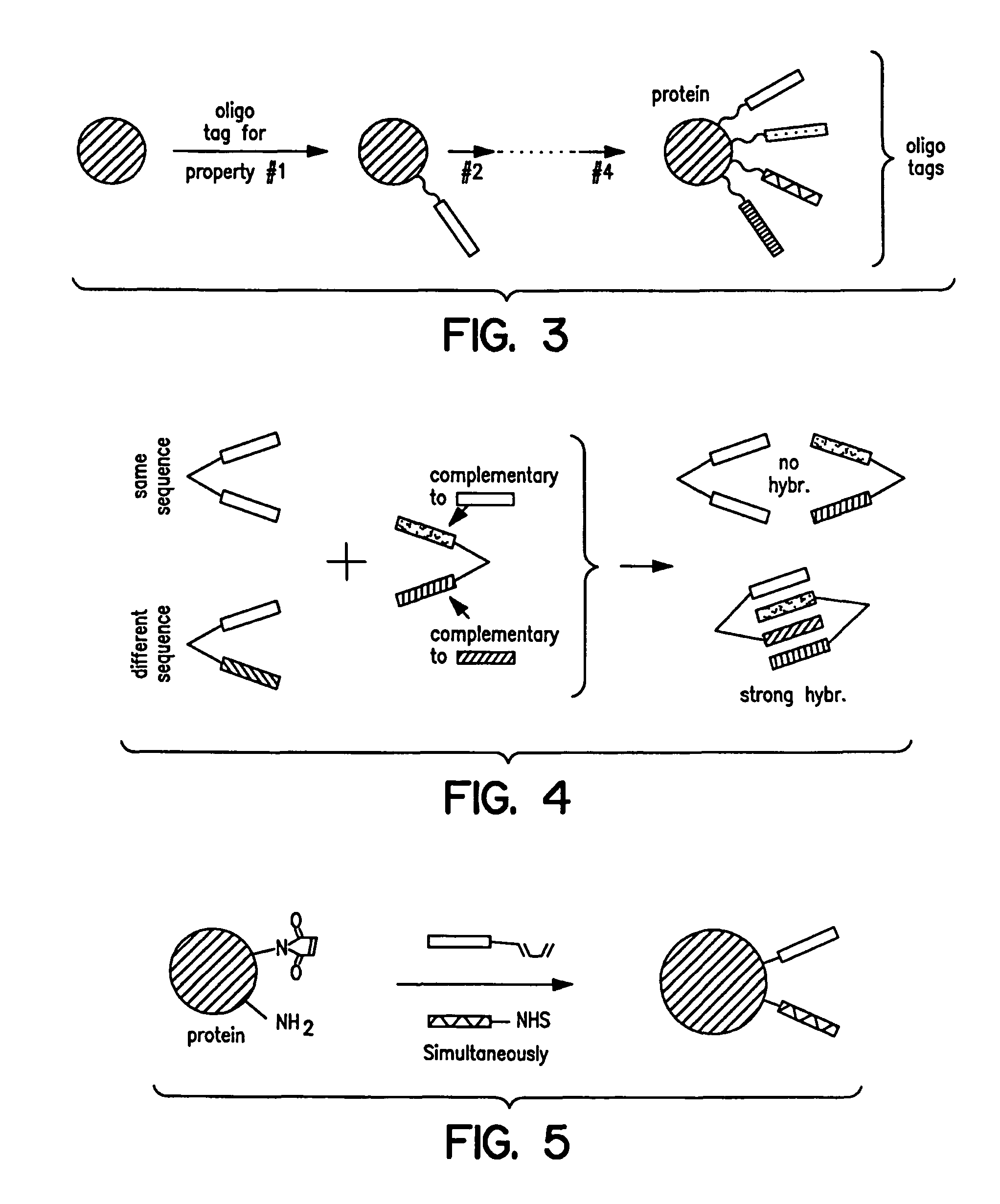

Capture compounds, collections thereof and methods for analyzing the proteome and complex compositions

InactiveUS8569481B2Effective treatmentEffective therapyPeptide librariesPeptide/protein ingredientsAmino acid side chainComplex protein

Capture compounds and collections thereof and methods using the compounds for the analysis of biomolecules are provided. In particular, collections, compounds and methods are provided for analyzing complex protein mixtures, such as the proteome. The compounds are multifunctional reagents that provide for the separation and isolation of complex protein mixtures. Each compound has the formula:wherein: Z is a trityl derivative; X, the reactivity function, covalently binds to amino acid side chains of proteins; Y, the selectivity function, modulates binding of X to the amino acid side chains in proteins such that X binds to fewer proteins when Y is present than in its absence; and Q permits separation or immobilization of the capture compound. Automated systems for performing the methods also are provided.

Owner:IONIS PHARMA INC

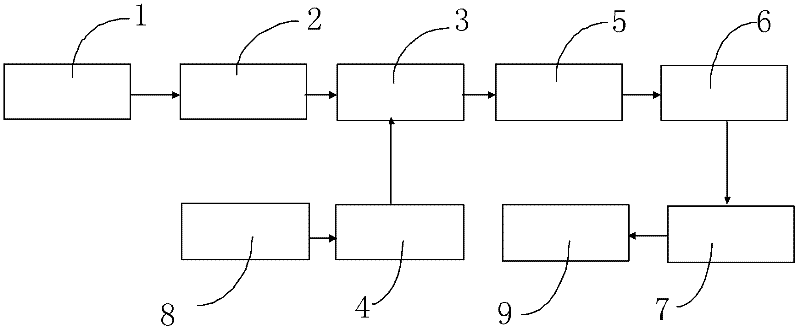

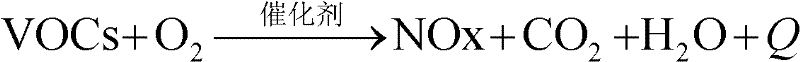

Purification equipment and treatment process for tail gas from acrylonitrile absorption tower

InactiveCN102233231AReduce excess oxygenSafe and stable operationDispersed particle separationAir filterAcrylonitrile

The invention discloses purification equipment for tail gas from an acrylonitrile absorption tower. The purification equipment comprises a gas-liquid separator for separating the tail gas from the acrylonitrile absorption tower, an air filter for mixing fresh air and the tail gas, an oxygen supply fan and a heat exchanger for heat exchange of mixed gas of the tail gas and the air; the heat exchanger is circularly communicated with a catalytic reactor, and the mixed gas produced after catalytic oxidation reaction is introduced from the top of a denitration reactor through the heat exchanger; the bottom of the denitration reactor is communicated with a waste heat boiler for recycling heat; and a chimney for exhausting the purified tail gas is arranged at the exhaust port of the waste heat boiler. Through the technical scheme, the purification equipment has the following advantages that: by taking the measures of combining a catalytic oxidation system and a selective catalytic reduction denitration system, adopting segmental heat receiving in the catalytic oxidation reactor, reducing redundant oxygen quantity or adopting segmental combustion, operational stability and safety are ensured, and the organic substances and the nitrogen oxides in the treated tail gas accord with the national discharge standards.

Owner:SHANGHAI NORMAL UNIVERSITY

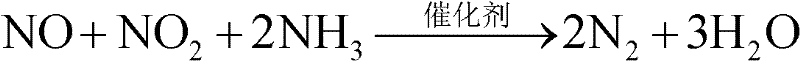

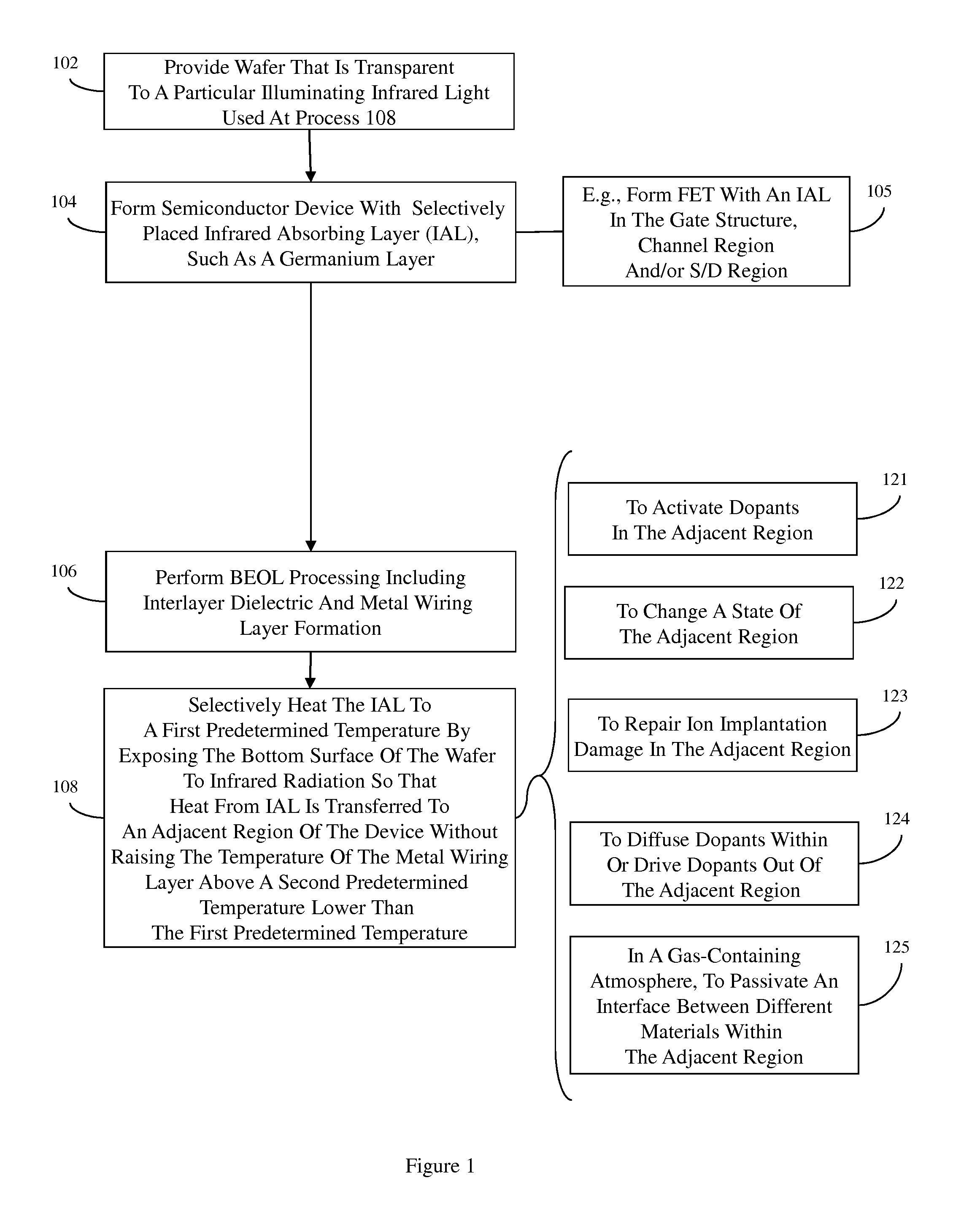

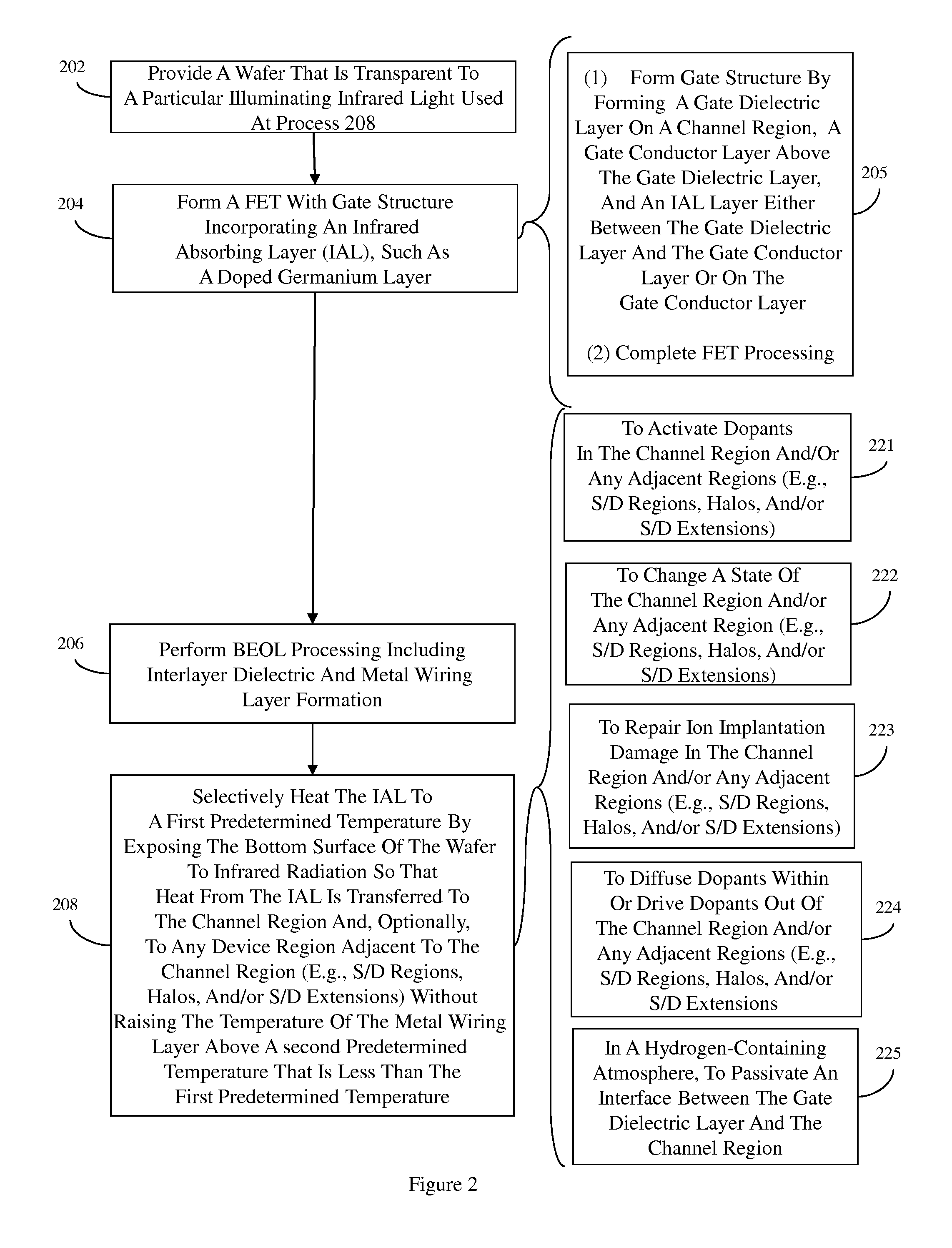

Semiconductor wafer processing method that allows device regions to be selectively annealed following back end of the line (BEOL) metal wiring layer formation

InactiveUS8021950B1TransistorSemiconductor/solid-state device manufacturingState variationLength wave

Disclosed are embodiments of a semiconductor wafer processing method that allow device regions to be selectively annealed following back end of the line (BEOL) metal wiring formation without degrading wiring layer reliability. In the embodiments, a semiconductor device is formed adjacent to the top surface of a wafer such that it incorporates a selectively placed infrared absorbing layer (IAL). Then, following BEOL metal wiring formation, the bottom surface of the wafer is exposed to an infrared light having a wavelength that is transparent to the wafer. The infrared light is absorbed by and, thereby heats up the IAL to a first predetermined temperature (e.g., a dopant activation temperature, a temperature required for a state change, etc.). The resulting heat is transferred from the IAL to an adjacent region of the semiconductor device without raising the temperature of the metal wiring above a second predetermined temperature (e.g., a temperature that could degrade the metal wiring) that is lower than the first predetermined temperature.

Owner:ULTRATECH INT INC

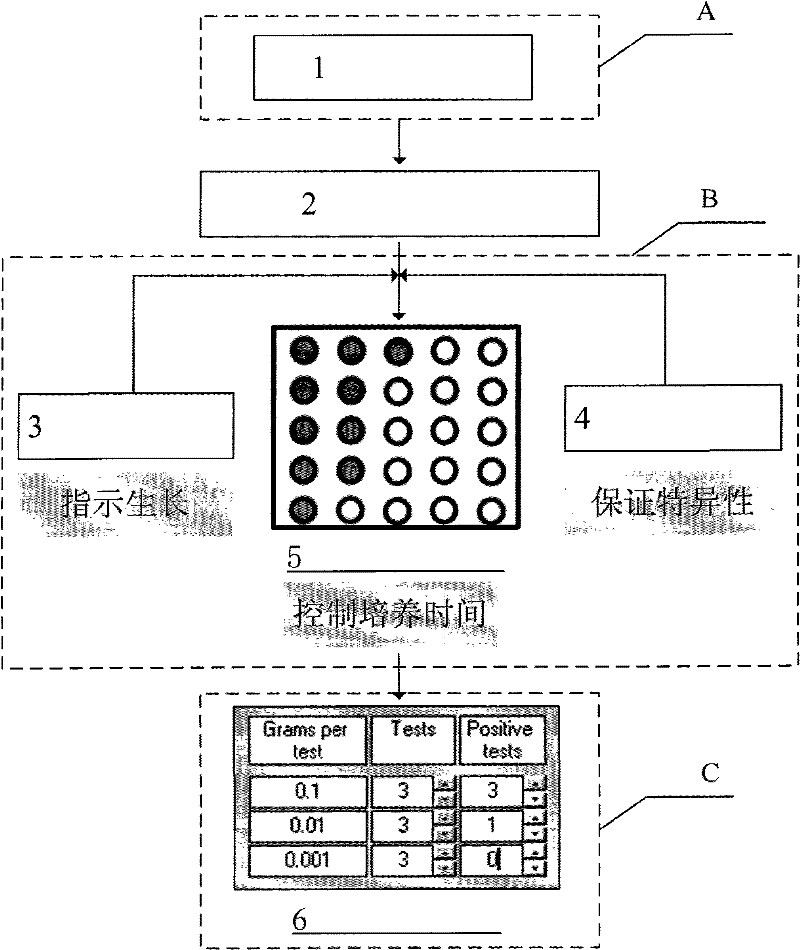

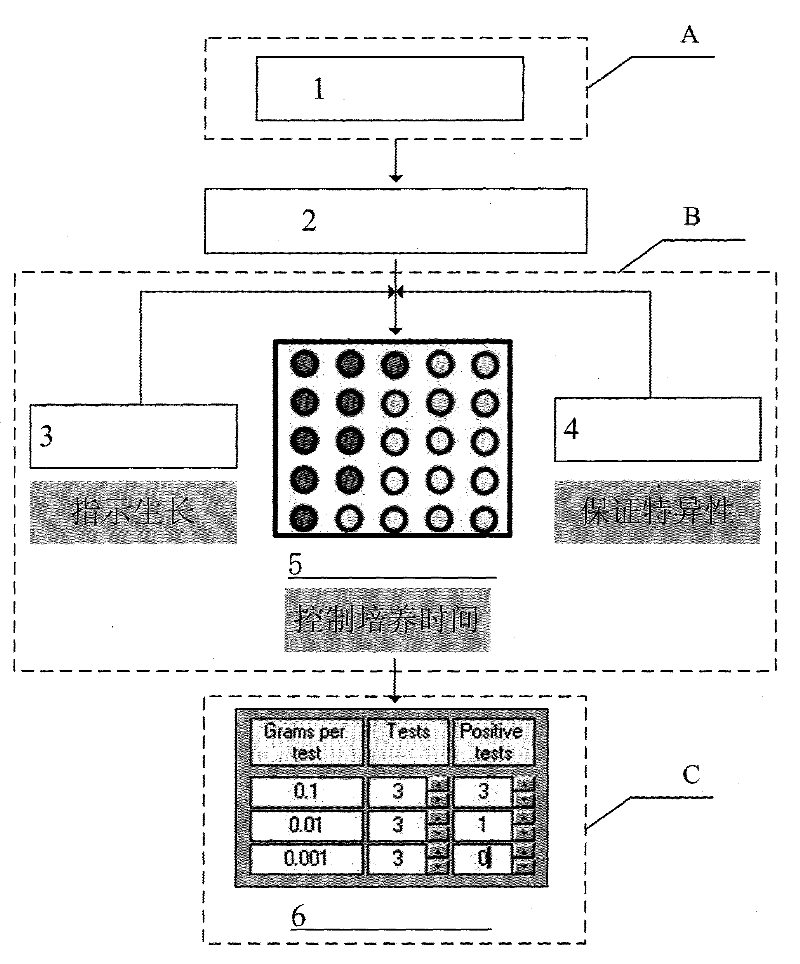

Detection method for obligate hydrocarbon oxidizing bacteria

ActiveCN102453746AEasy to operateShort training periodMicrobiological testing/measurementColor changesShort terms

The invention discloses a detection method for obligate hydrocarbon oxidizing bacteria, belonging to the technical field of microorganism detection methods. The detection method comprises the following steps of: suspending and diluting a soil sample with a basic culture medium; performing short-term culturing in combination with a selective culture carbon source and an oxidation reduction indicating dye for 3-5 days; and computing the quantity of obligate hydrocarbon oxidizing bacteria in the soil sample according to the color change of an airtight culture tube through a computer program. A detection technology for obligate hydrocarbon oxidizing bacteria disclosed by the invention has the advantages of simple operating process, economic efficiency, practicability, quickly-obtained result in a short period of time, high specificity, capability of effectively shielding the interference of other bacteria on counting and simple and accurate counting process, and is suitable for large-scale industrial exploration measurement with a large sample quantity.

Owner:CHINA PETROLEUM & CHEM CORP +1

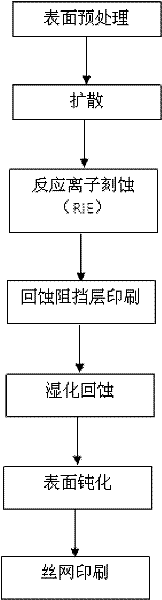

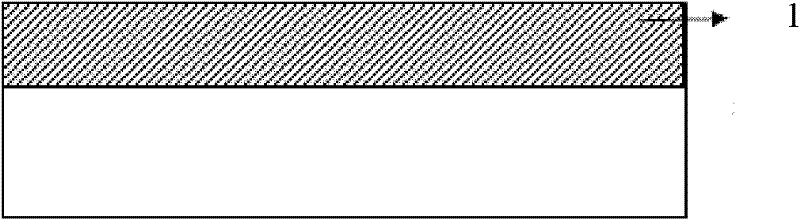

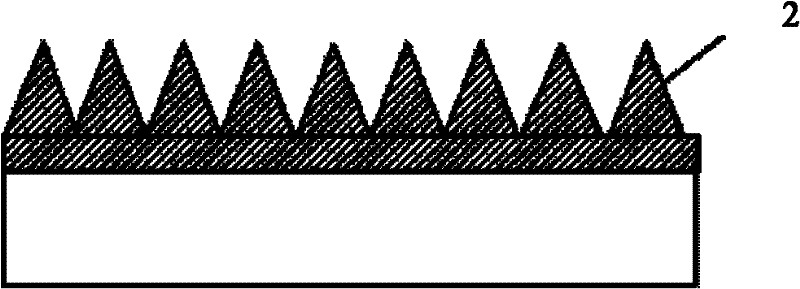

Selective emitter electrode solar battery manufacturing process combined with reactive ion etching (RIE)

InactiveCN102315317AResolve uneven diffusionImprove shortwave responseFinal product manufactureSemiconductor devicesOptoelectronicsSolar battery

The invention relates to the solar battery manufacturing method field, especially relates to a selective emitter electrode solar battery manufacturing process combined with a reactive ion etching (RIE). The method comprises the following steps that: after a surface is pretreated, a silicon chip diffuses so as to form a diffusion layer; a tiny suede is formed on a surface of the silicon chip through etching the reactive ion on the diffusion layer; a barrier layer is printed; a heavily doped region and a low doped region is formed after etching back through a local wet method; finally, an electrode is printed in the heavily doped region; sintering is performed and preparation of a cell sheet is completed. By using the technology provided in the invention, a problem of non-uniform diffusion caused by the RIE can be solved. Simultaneously, a diffusion selectivity emitter electrode technology is combined so as to raise short wave response, further increase light absorption and obtain high photoelectric conversion efficiency.

Owner:TRINA SOLAR CO LTD

Megasonic precision cleaning of semiconductor process equipment components and parts

ActiveUS8327861B2Precision cleaningImprove performanceSemiconductor/solid-state device manufacturingElectrostatic cleaningParticulatesProcess equipment

Methods and apparatus are provided for using various megasonic apparatus including megasonic tanks, scanning megasonic plates, megasonic jets, and megasonic sweeping beams etc., in combination with selective chemistries to remove sub-micron particulate contaminants from the surfaces of the processing equipment used in semiconductor, medical, or any other processing environments.

Owner:LAM RES CORP

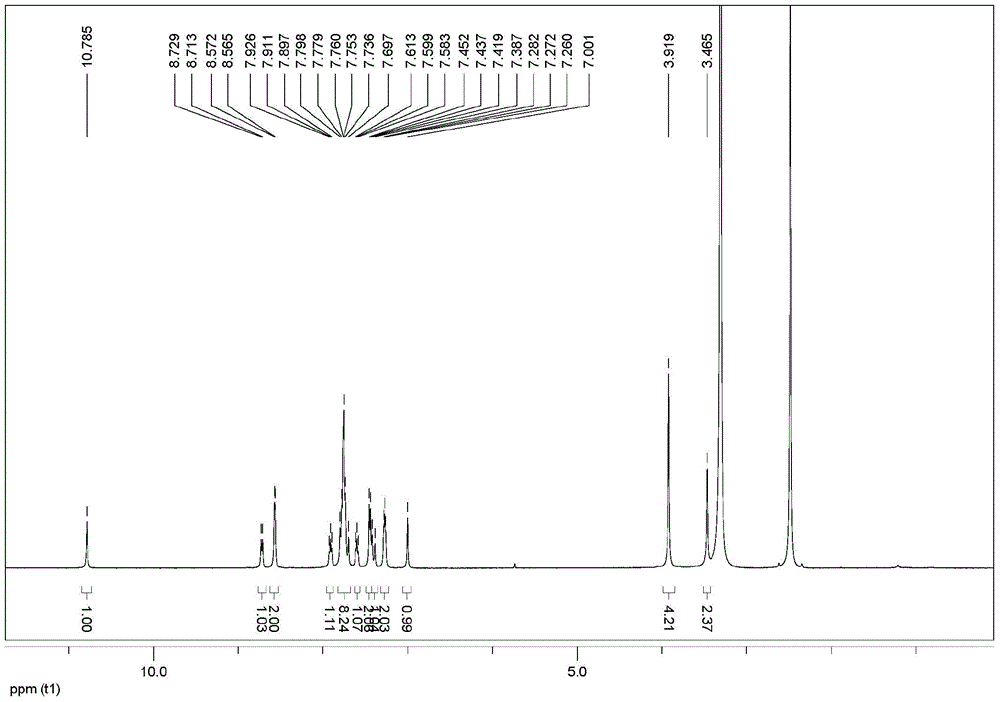

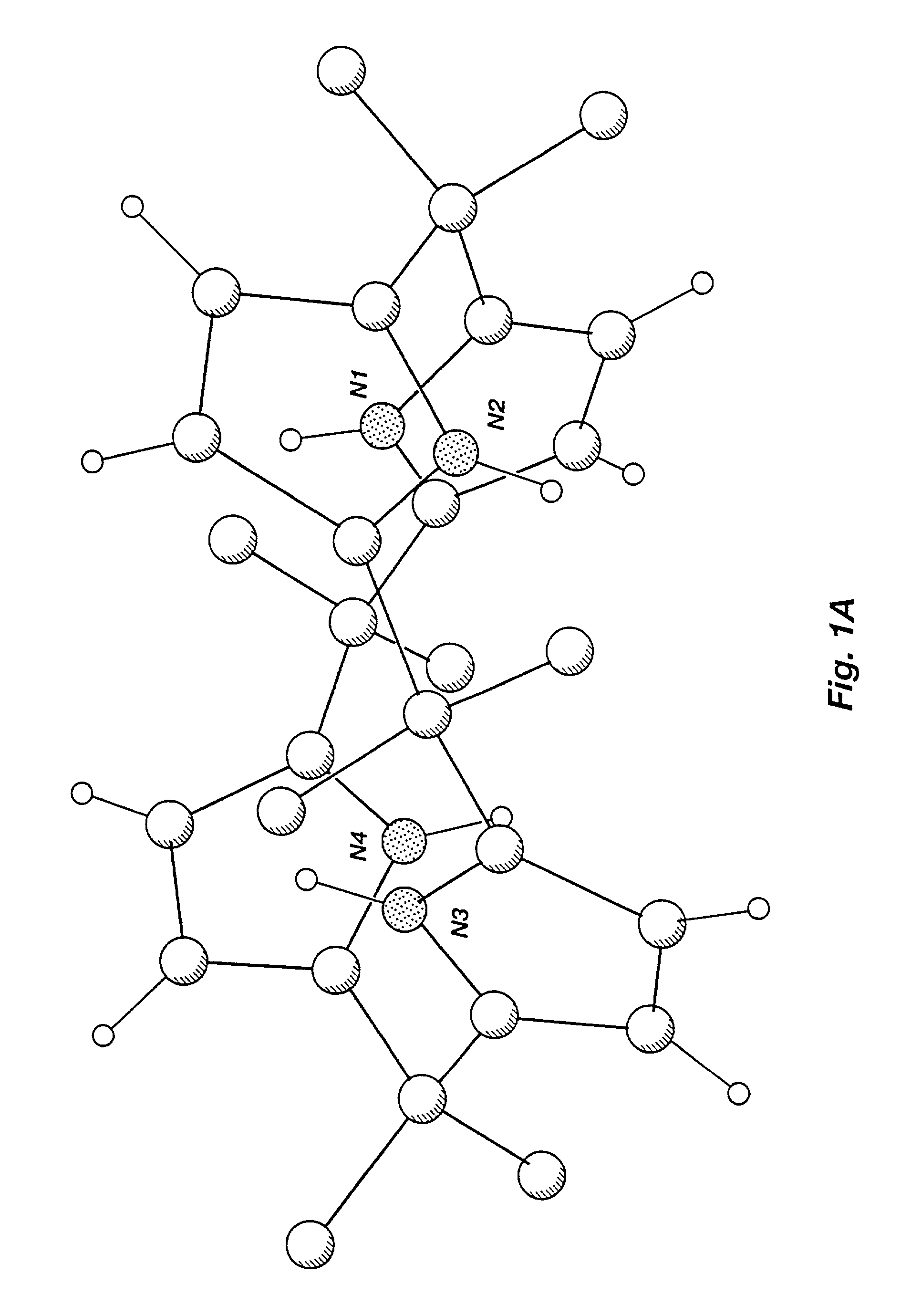

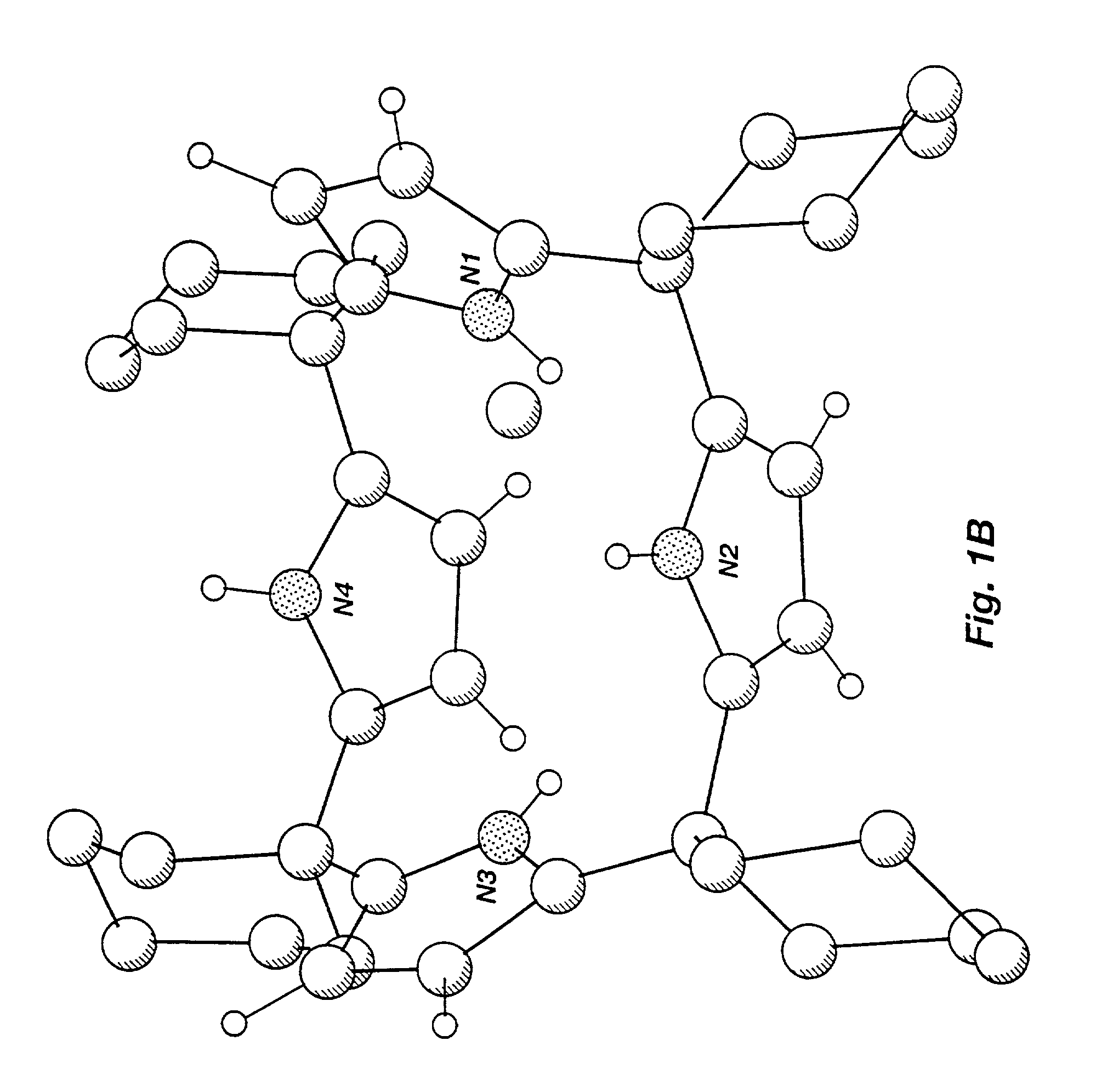

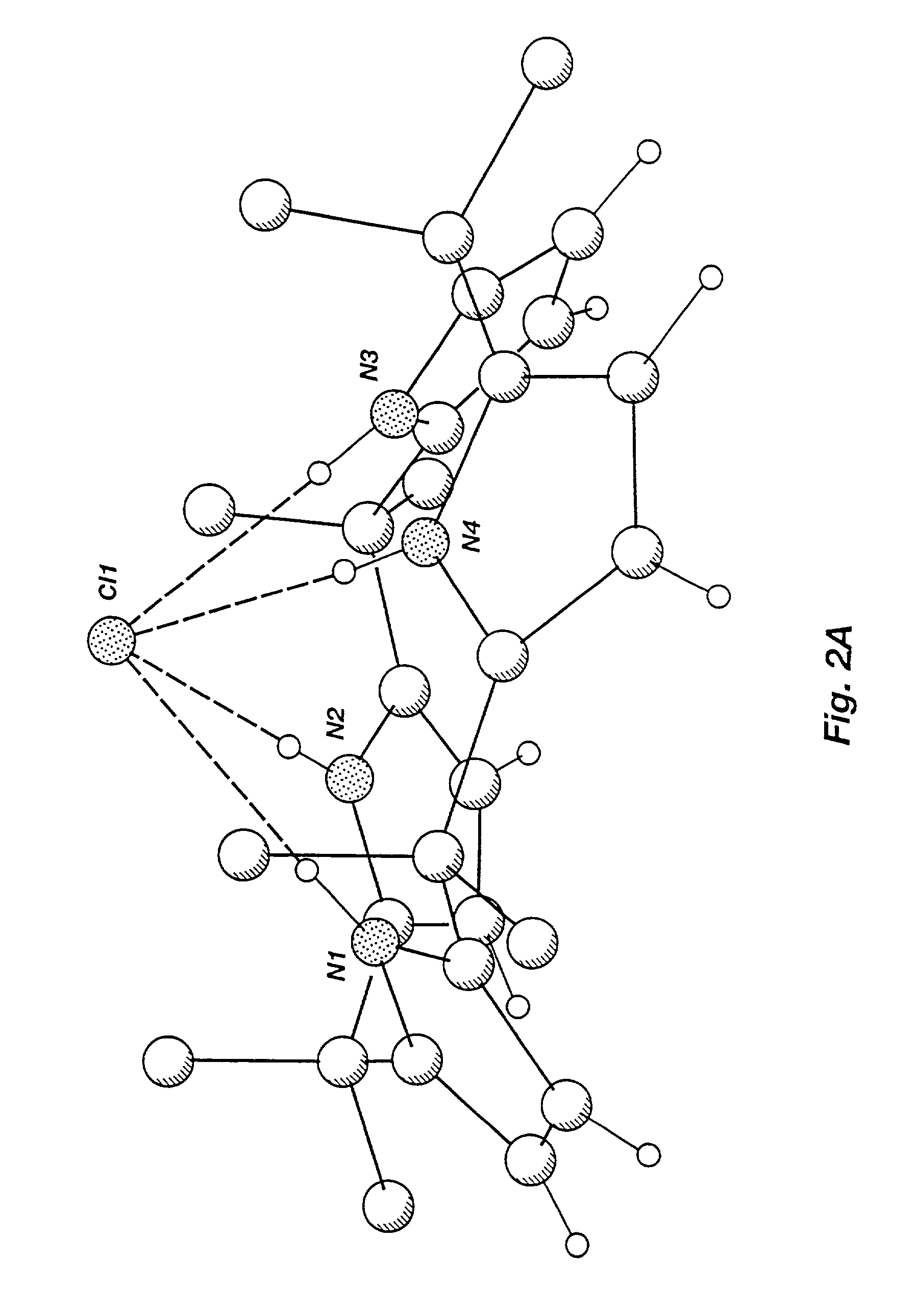

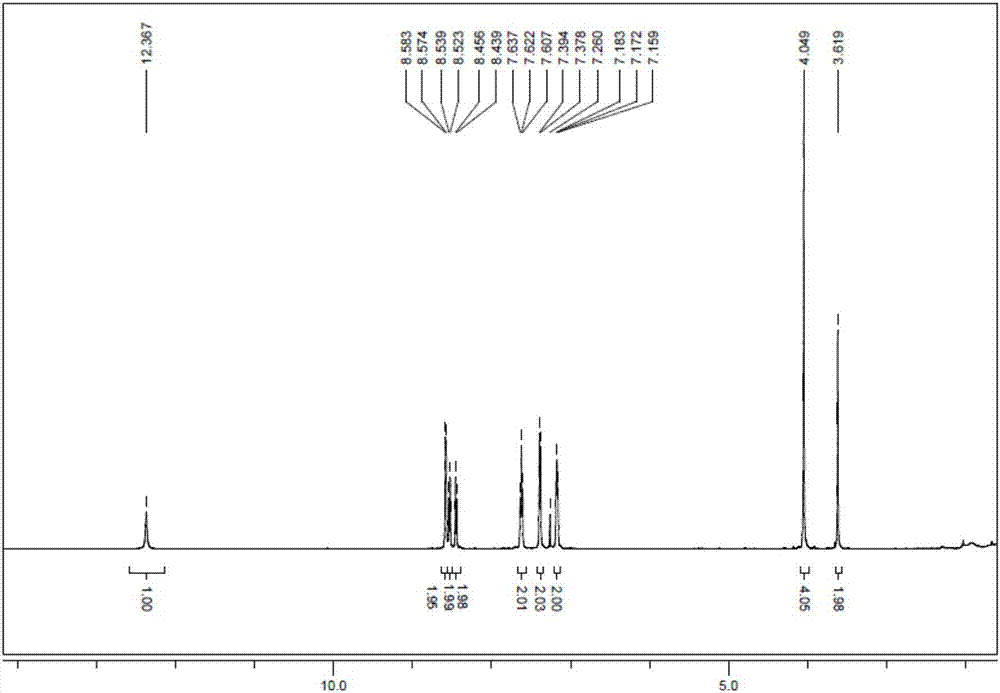

Halogenated calixpyrroles and uses thereof

InactiveUS7041819B2Improve bindingPreferential bindingComponent separationSolid sorbent liquid separationFluorescencePyridine

The present invention provides halogenated calixpyrrole, calixpyridinopyrrole, and calixpyridine macrocycles having 4–12 pyrrolic rings with greater stability, enhanced anion and neutral molecule binding affinity, and different binding selectivites as compared to their non-halogenated congeners as judged from 1H NMR, 19F NMR and fluorescence emission spectroscopic analyses.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

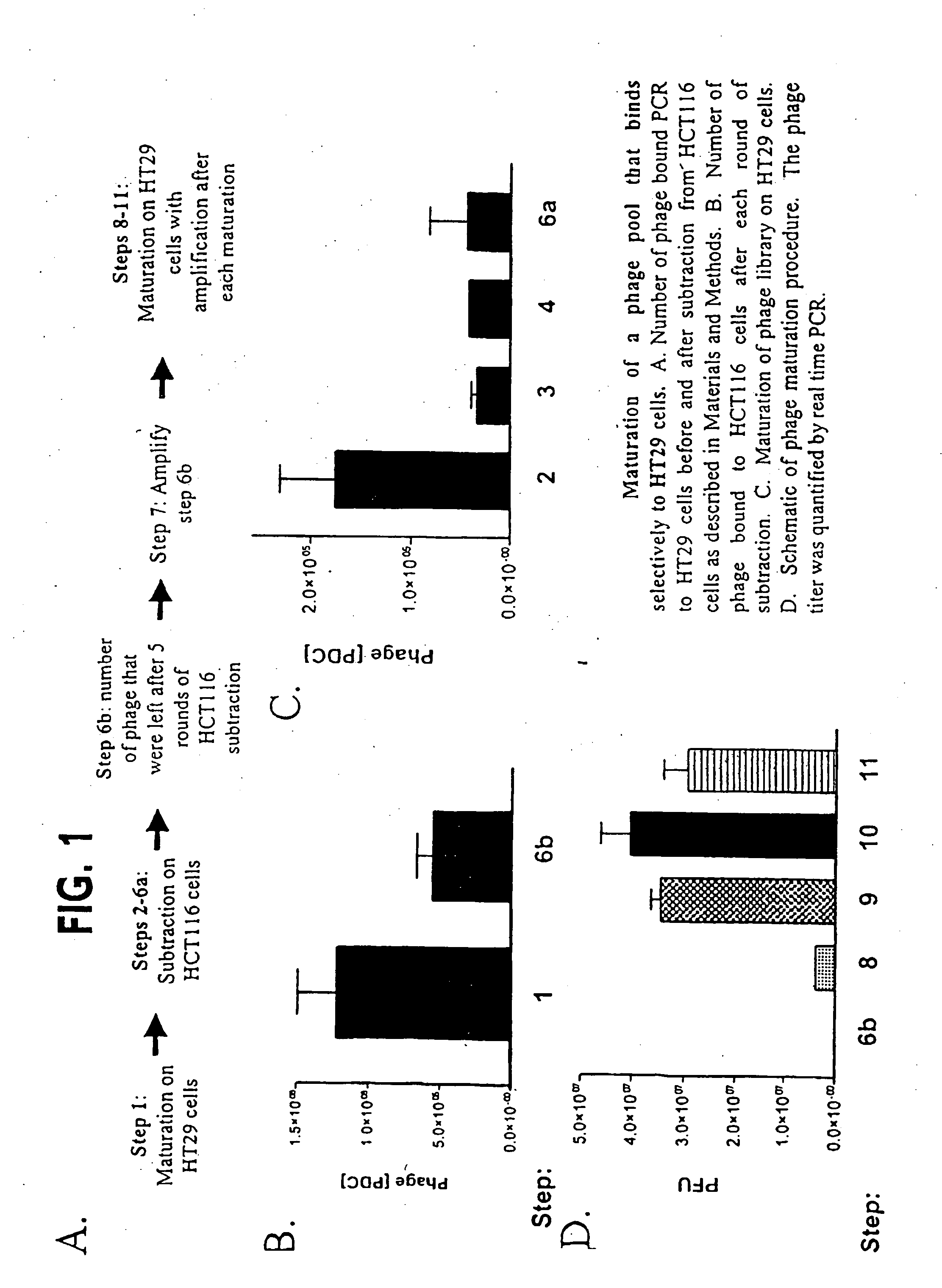

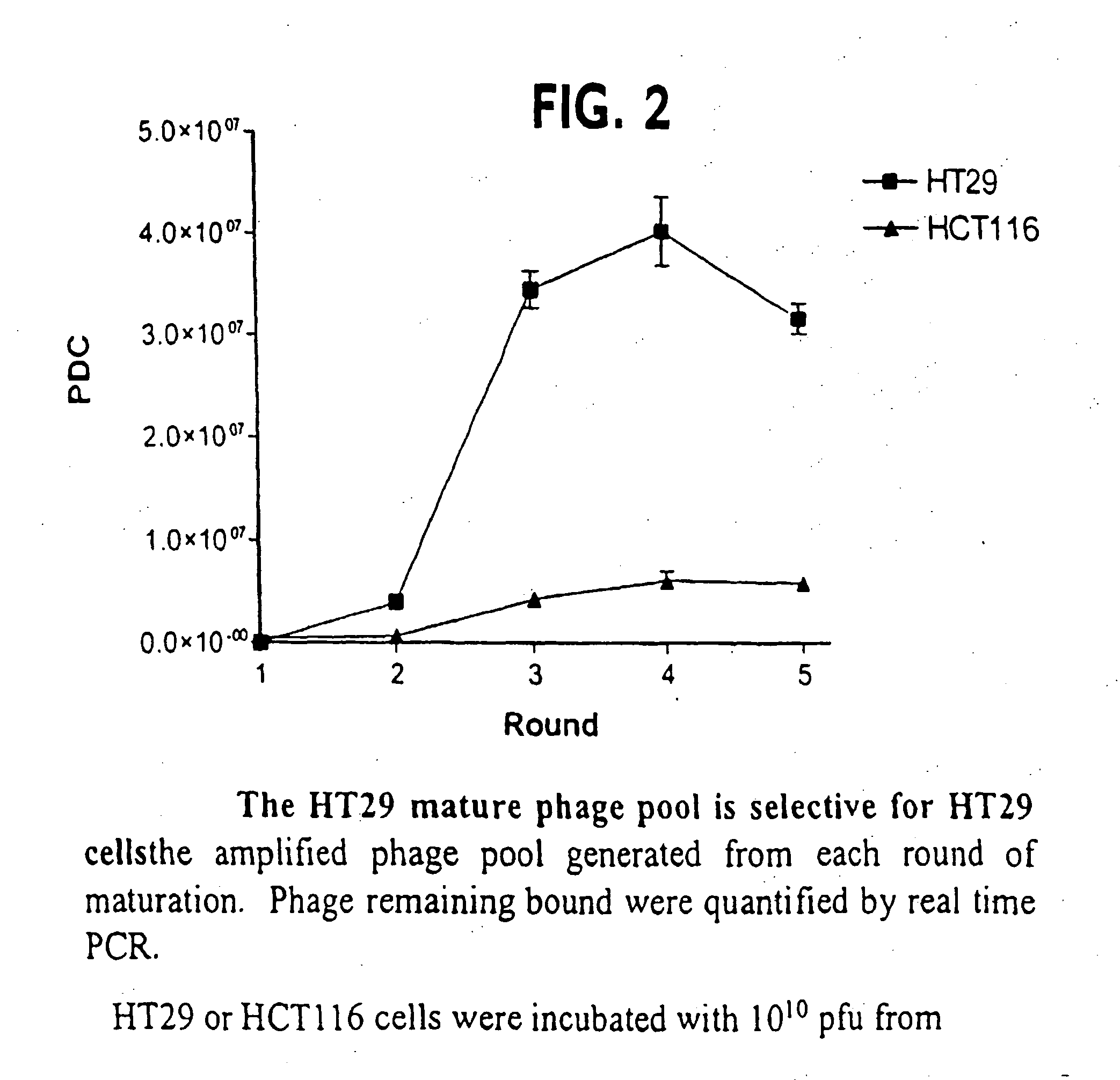

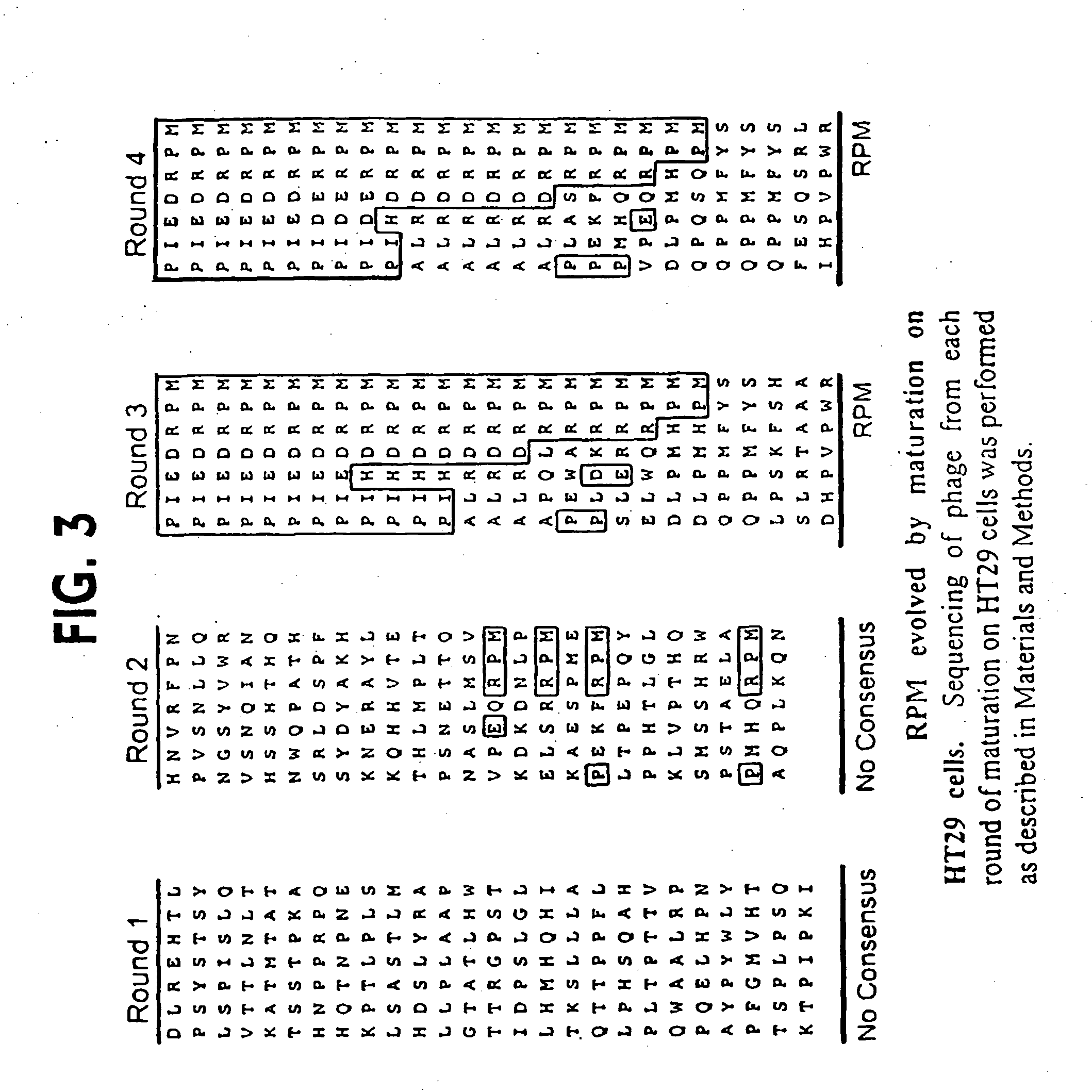

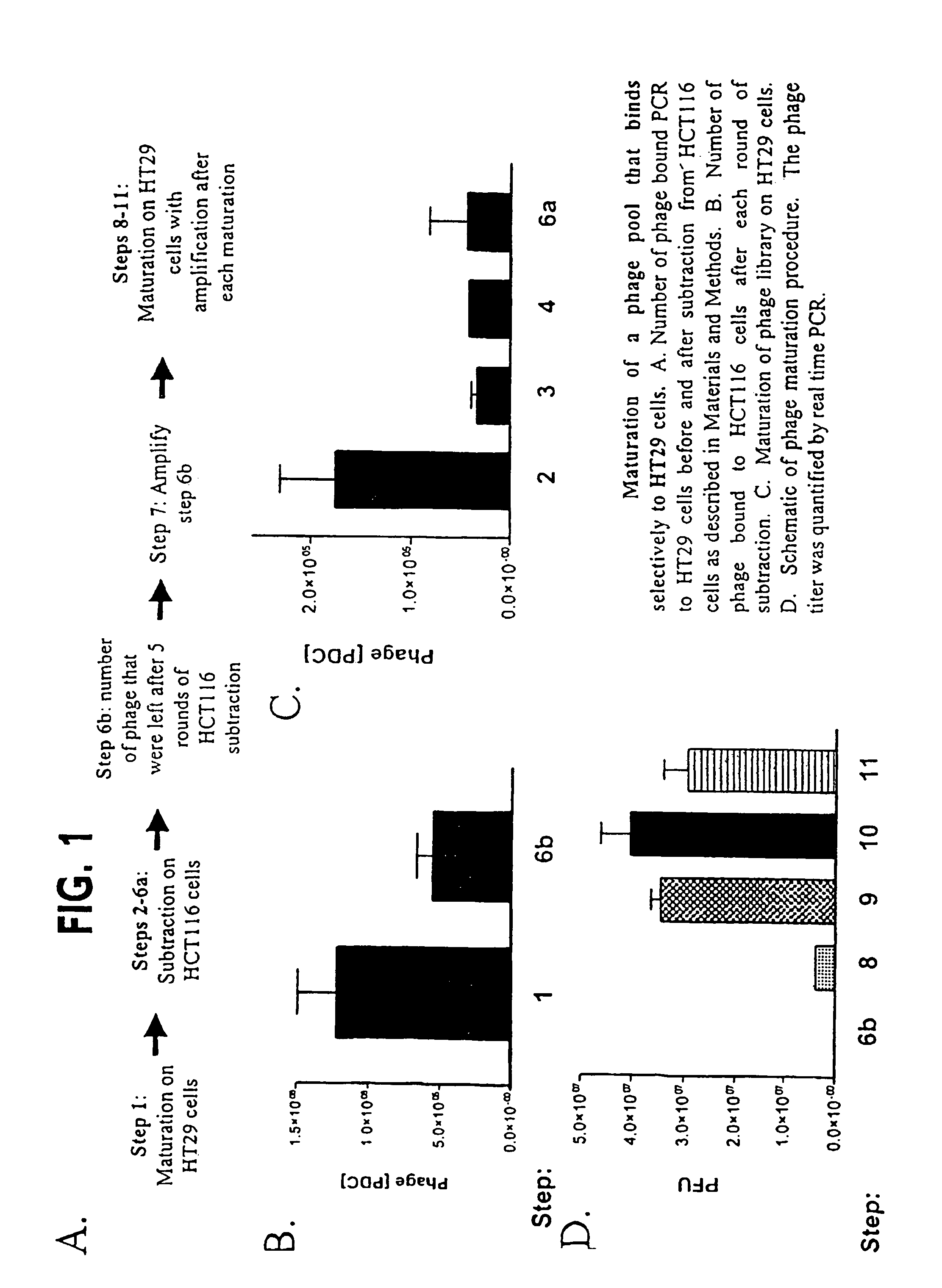

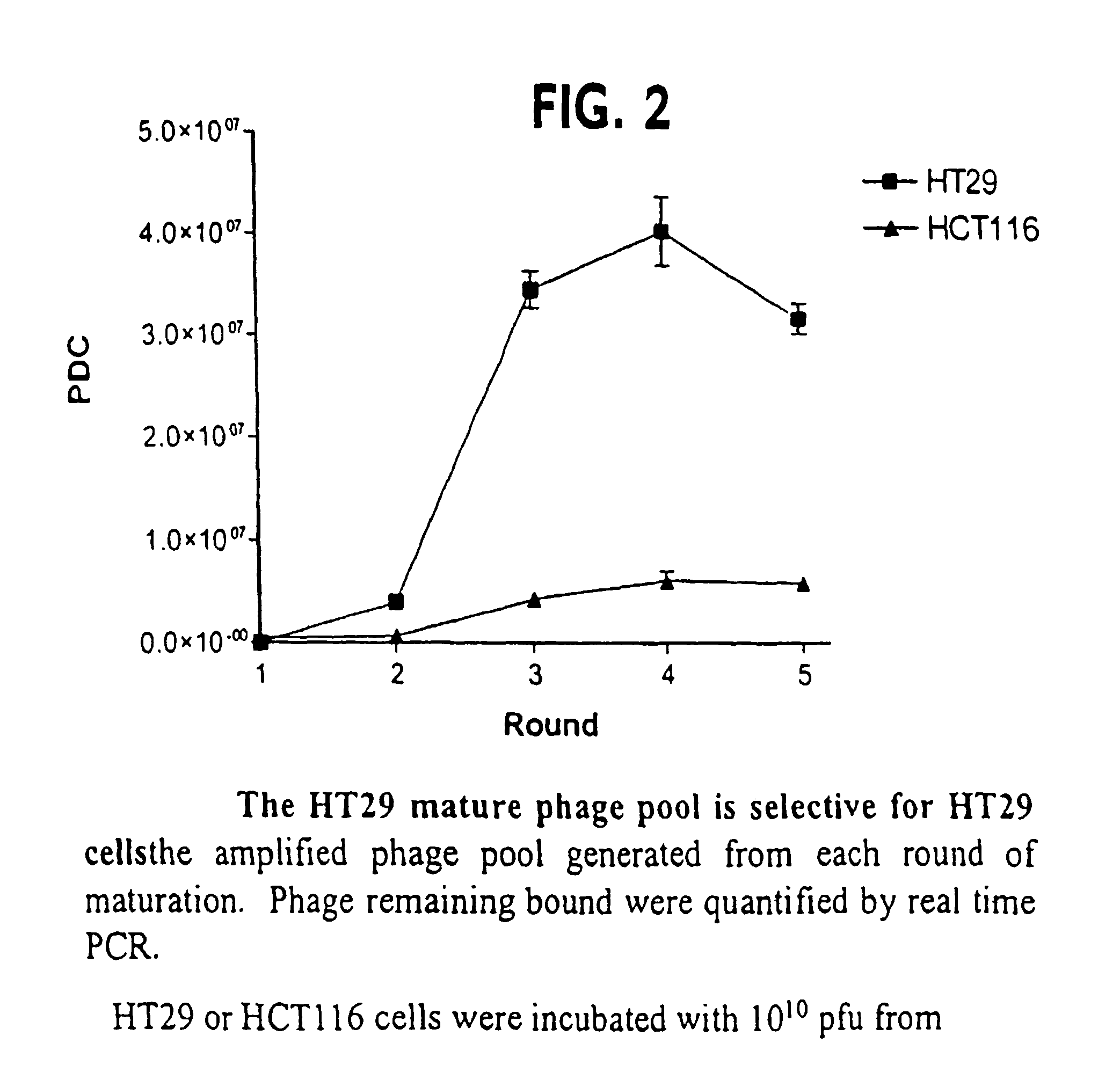

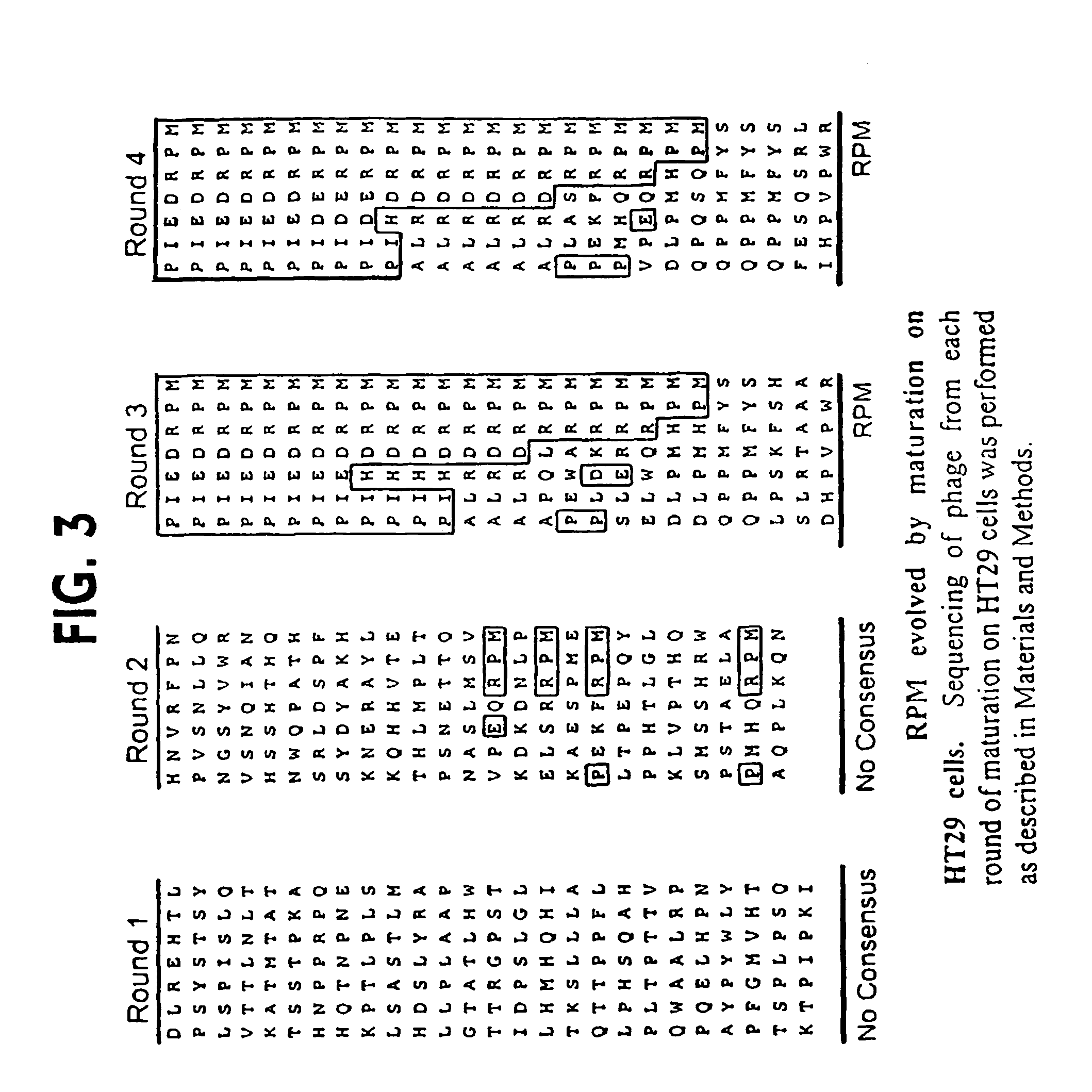

Colon tumor specific binding peptides

InactiveUS20060058228A1Low immunogenicityCompound screeningApoptosis detectionBinding peptideBiology

Phage display was used to screen peptide libraries that distinguish between well-differentiated (HCT116) and poorly-differentiated colon carcinoma cells (HT29). The screening protocol used selection and subtraction on intact, viable cells, resulting in phage libraries exhibiting high binding selectivity for the poorly-differentiated HT29 cells. A nine amino acid, disulfide-constrained peptide (RPM) was identified that selectively bound and was internalized into colon cancer cells. The peptide may be used to detect colon cancer cells and also may be used to selectively deliver therapeutic agents to the cells.

Owner:UNIV OF UTAH RES FOUND

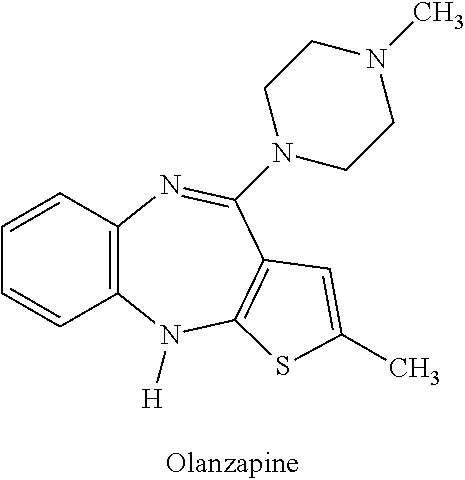

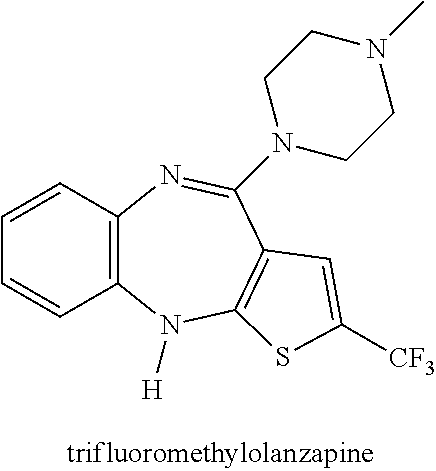

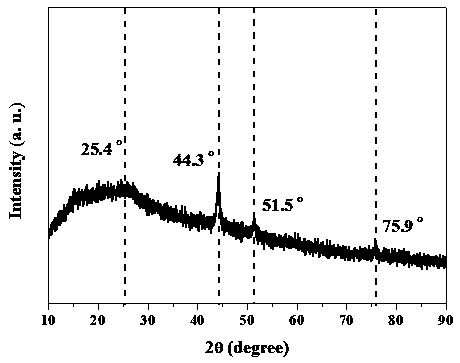

Advanced Drug Development and Manufacturing

InactiveUS20150309021A1Compound screeningApoptosis detectionDrug developmentReceptor for activated C kinase 1

X-ray fluorescence (XRF) spectrometry has been used for detecting binding events and measuring binding selectivities between chemicals and receptors. XRF may also be used for estimating the therapeutic index of a chemical. For estimating the binding selectivities of a chemical versus chemical analogs, for measuring post translational modification of proteins, and for drug manufacturing.

Owner:ICAGEN LLC

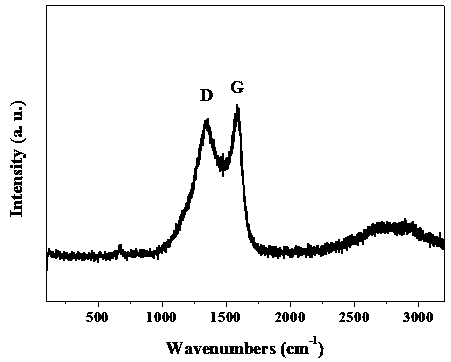

Nitrogen-doped carbon-inlaid non-noble metal catalyst and preparation method and application thereof

ActiveCN108704654ALow priceEasy to manufacturePhysical/chemical process catalystsHydrogen productionSilica nanoparticlesDecomposition

The invention discloses a nitrogen-doped carbon-inlaid non-noble metal catalyst and a preparation method and application thereof. A non-noble metal organic complex and a compound of silicon dioxide are taken as precursors, and the catalyst for efficient decomposition of ammonia-borane into hydrogen by the aid of high temperature thermal decomposition and in combination with a selective etching strategy. The preparation method includes: dispersing the non-noble metal organic complex and commercial silica nanoparticles in an ethanol-chloroform two-phase solvent system and removing the solvent byspin evaporation to obtain composite nanopowder; putting the composite nanopowder in a tube furnace, raising the temperature to 700-1000DEG C under the protection of insert gas and keeping the constant temperature for 1-6 hours; repeatedly treating obtained black solid in a dilute alkali solution for 12-24 hours at the temperature of 50DEG C, and performing bleaching, washing and drying to obtainthe target catalyst. The catalyst shows excellent catalytic properties, resistance to poisioning / inactivation and cycling stability in the catalytic hydrolysis of ammonia-borane to produce hydrogen;the method has the advantages that the raw materials are easy to obtain, preparation period is short, and batch production can be realized.

Owner:山西佳翔瑞科技有限公司

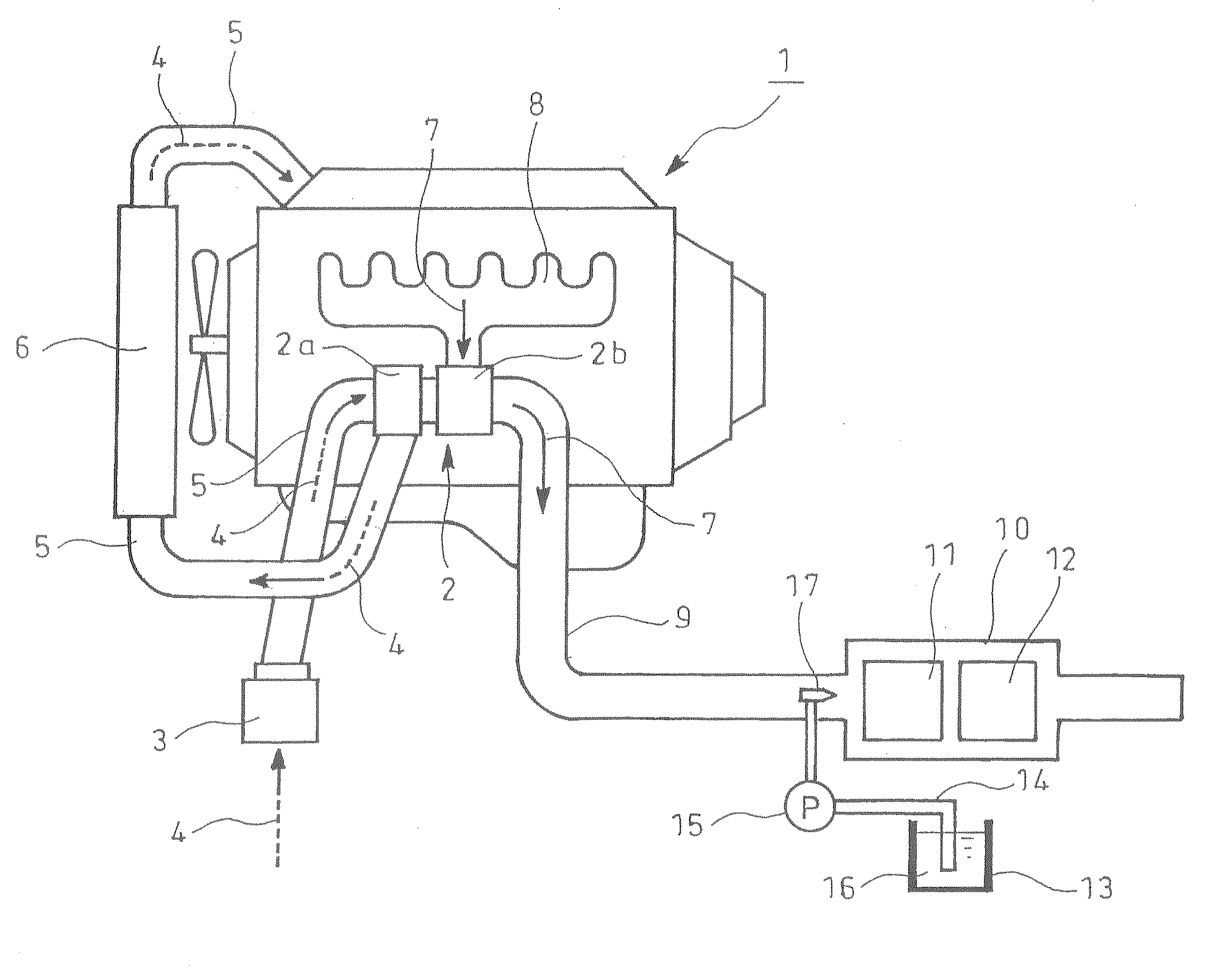

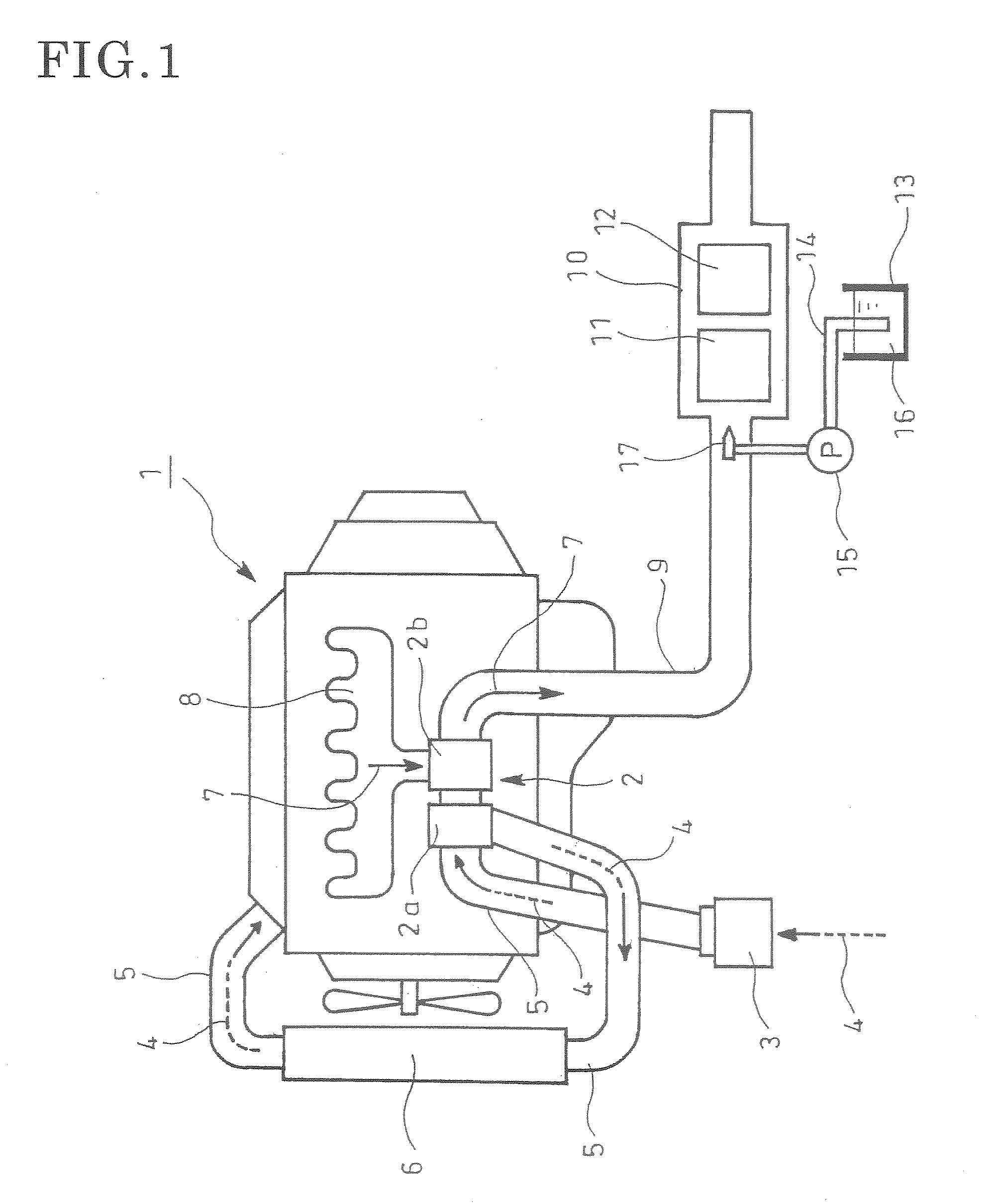

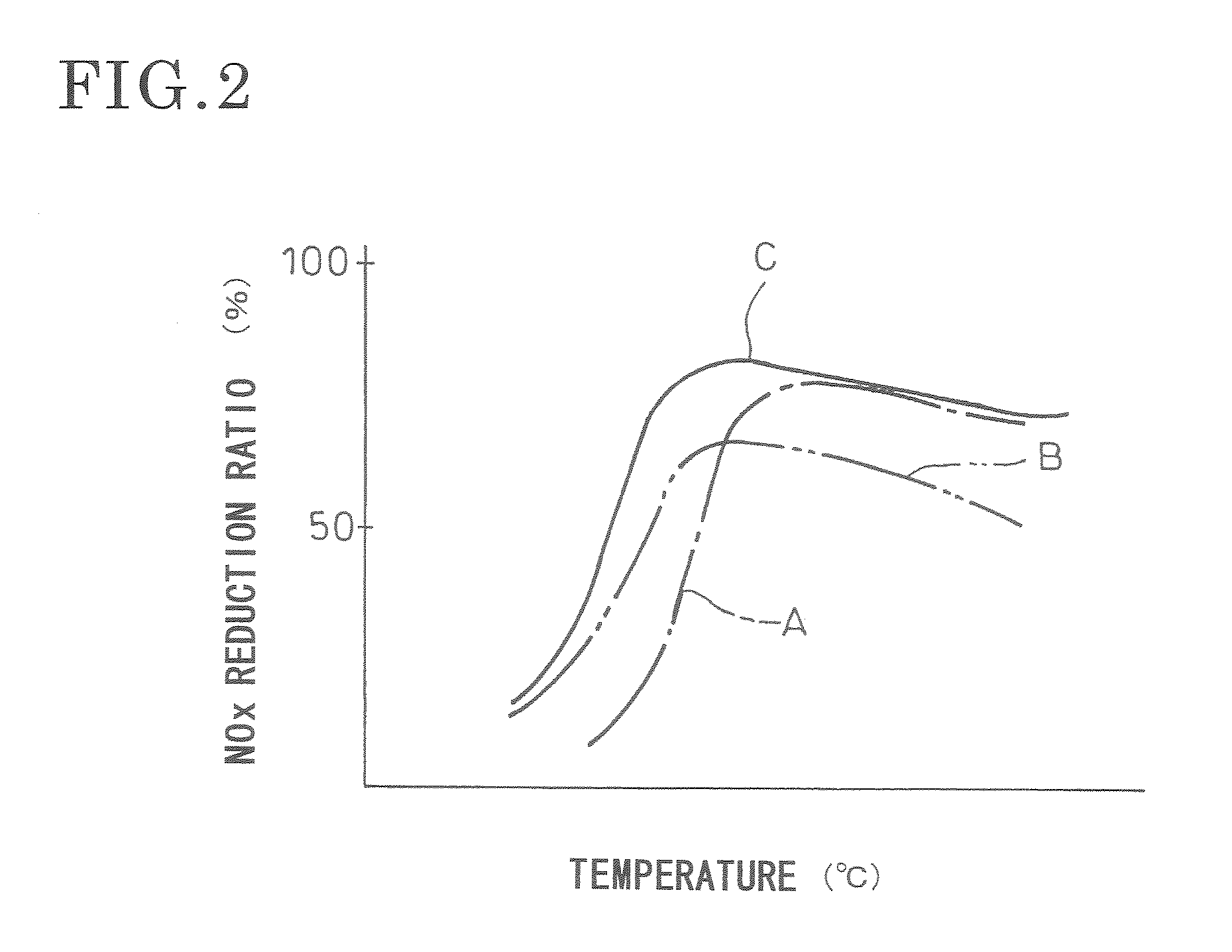

Exhaust Gas Purifier

Active temperature areas of selective reduction catalysts are expanded more than ever before so as to obtain high NOx reduction ratio in a larger exhaust temperature range. Disclosed is an exhaust emission control device with selective reduction catalyst incorporated in an exhaust pipe 9, the catalyst having enhanced reaction selectivity so as to selectively react NOx with ammonia even in the presence of oxygen, urea water 16 being added as reducing agent upstream of the catalyst by urea water adding means (urea water tank 13, urea water supply pipe 14, supply pump 15 and injection nozzle 17) so as to reduce and purify NOx. The catalyst comprises two or high- and low-temperature-active catalysts 11 and 12 with different active temperature areas. The catalysts are arranged in series in such a manner that the catalysts 11 and 12 with relatively high and low active temperature areas are positioned upstream and downstream, respectively.

Owner:HINO MOTORS LTD

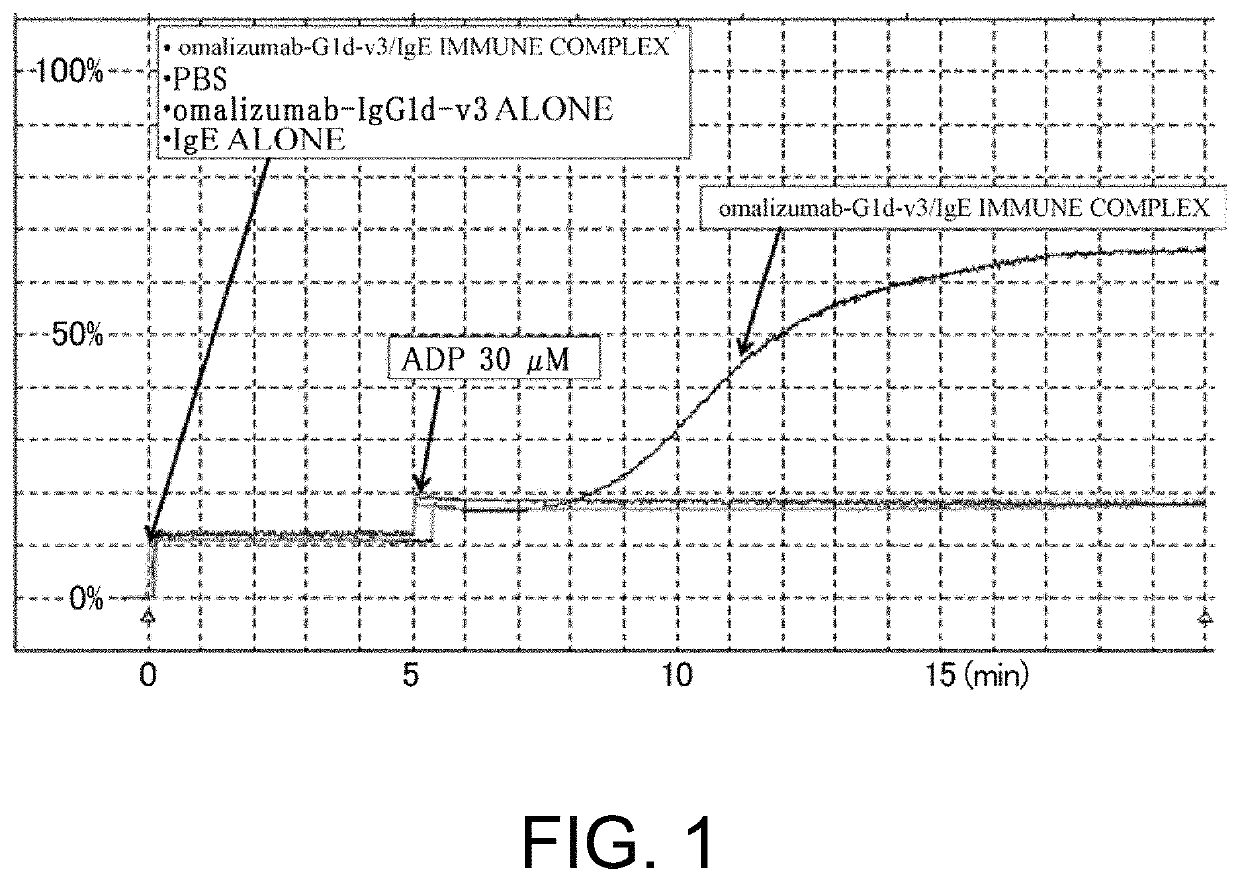

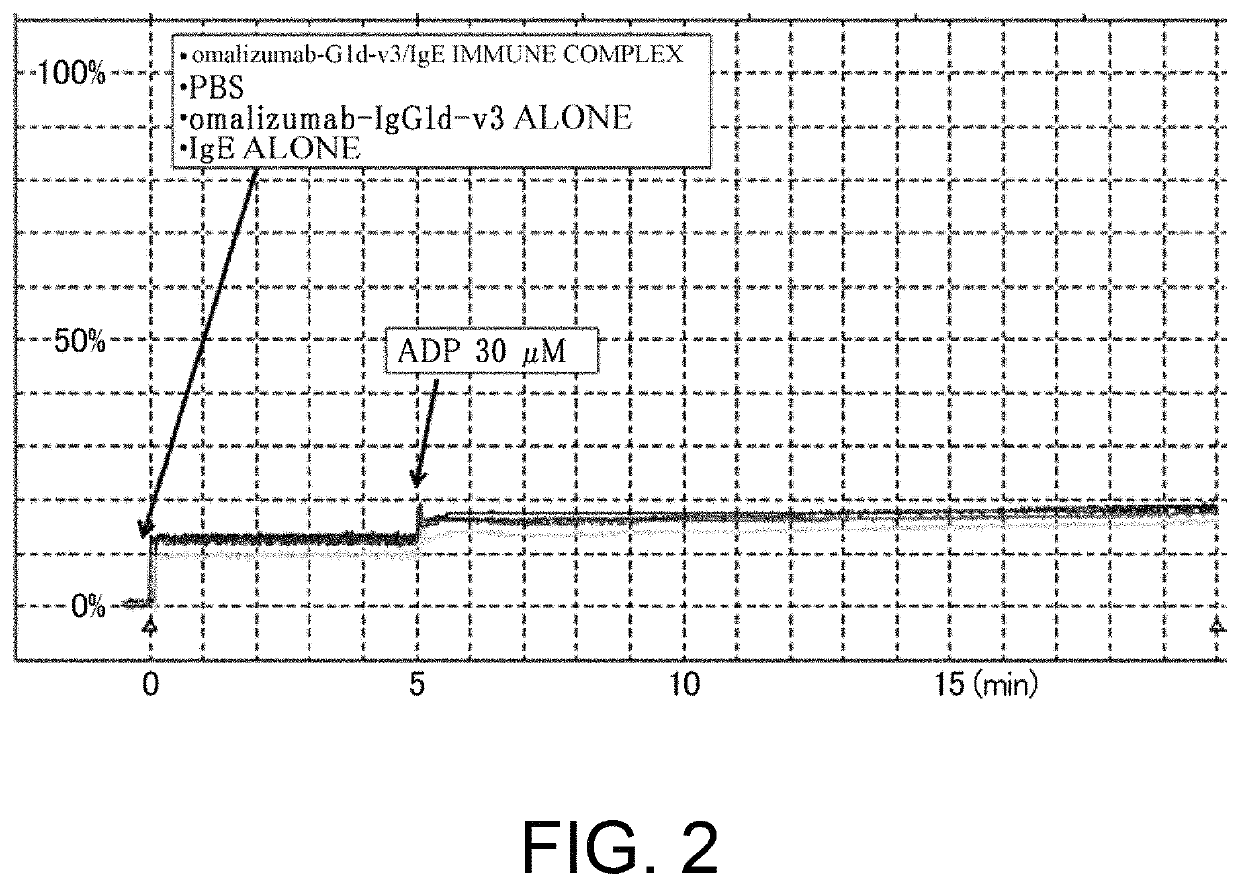

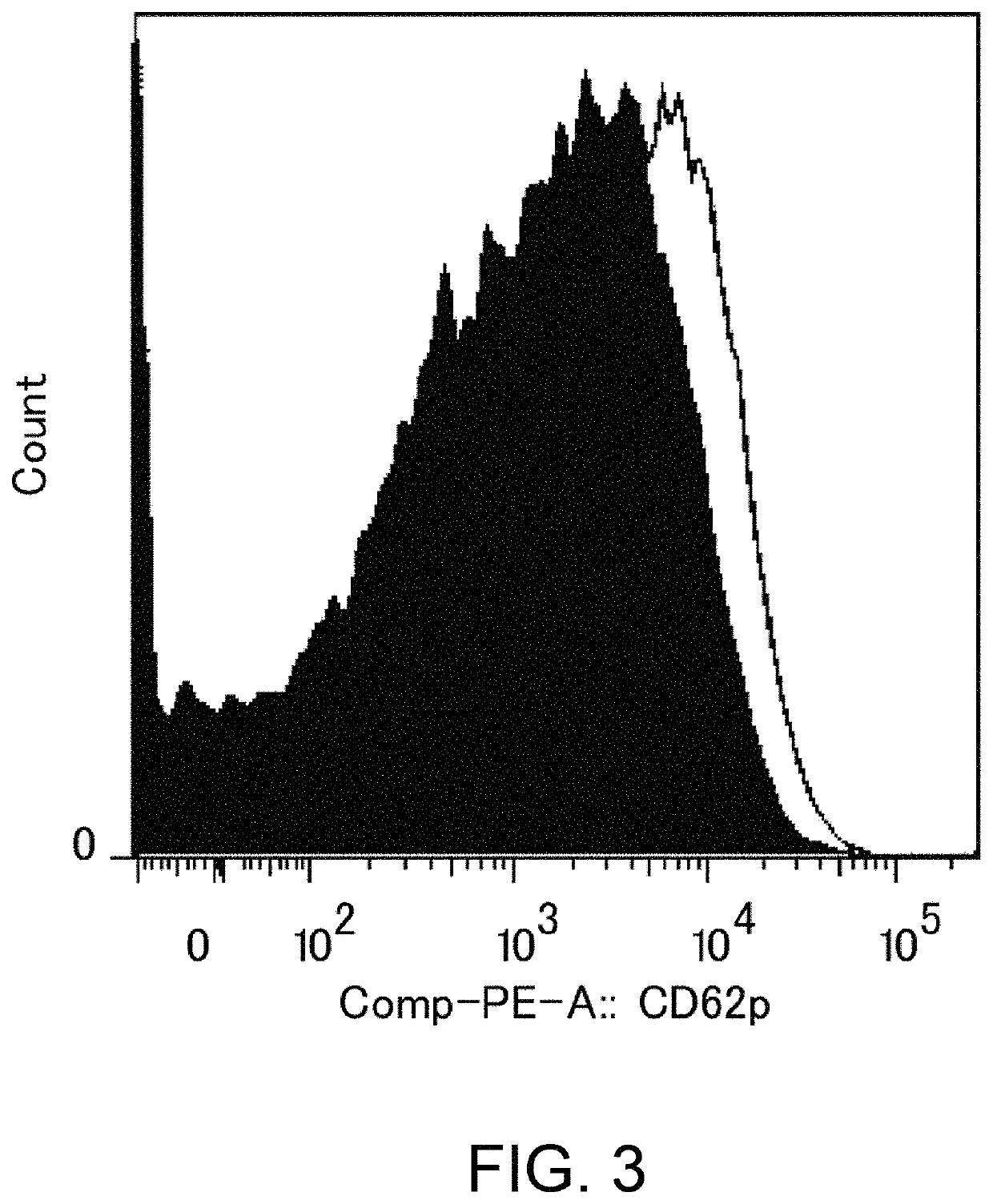

FcgammaRIIB-specific Fc region variant

ActiveUS10919953B2Enhanced signalEasy to eliminateAntibody mimetics/scaffoldsAntipyreticDiseasePharmaceutical drug

An objective of the present invention is to provide an Fc region variant with enhanced FcγRIIb-binding activity, and / or enhanced binding selectivity to FcγRIIb compared to FcγRIIa (type R), as compared to those of a polypeptide containing an Fe region to which an amino acid alteration(s) has not been introduced; a polypeptide which includes the Fc region variant; a pharmaceutical composition containing the polypeptide; preventing therapeutic or preventive agent for immunological inflammatory diseases that includes the pharmaceutical composition; a production method thereof; and a method of enhancing FcγRIIb-binding activity and also enhancing binding selectivity to FcγRIIb compared to FcγRIIa (type R).It was found that a polypeptide containing an antibody Fc region variant that contains an amino acid sequence in which an amino-acid alteration at position 238 (EU numbering) is combined with other specific amino-acid alterations enhances FcγRIIb-binding activity, and / or enhances binding selectivity to FcγRIIb compared to FcγRIIa (type R).

Owner:CHUGAI PHARMA CO LTD

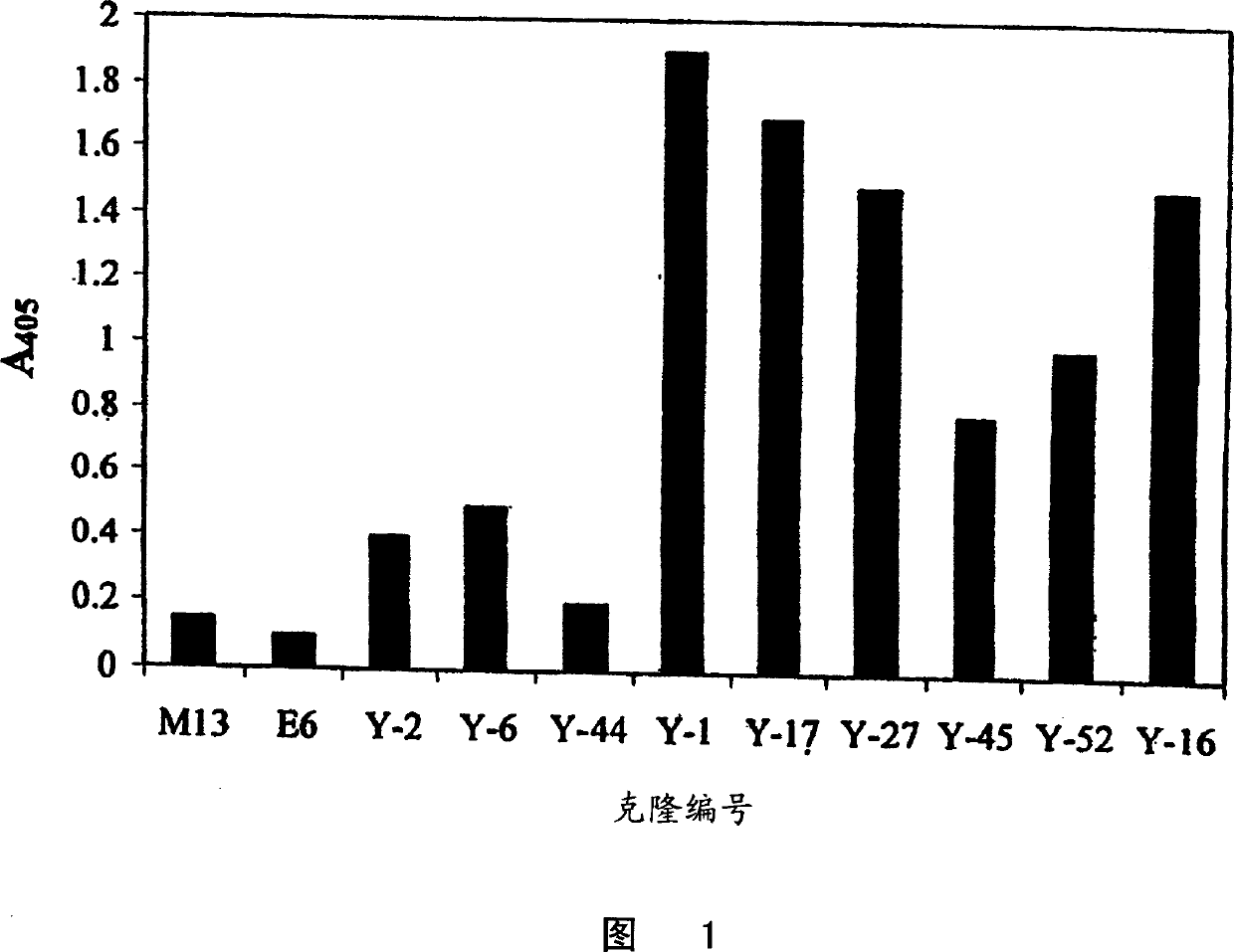

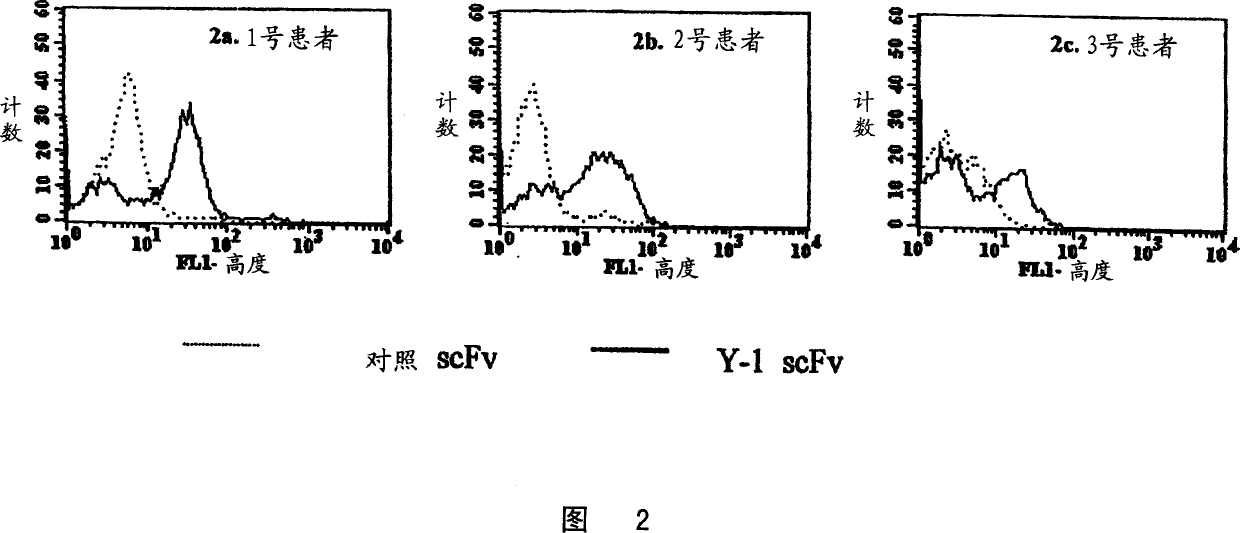

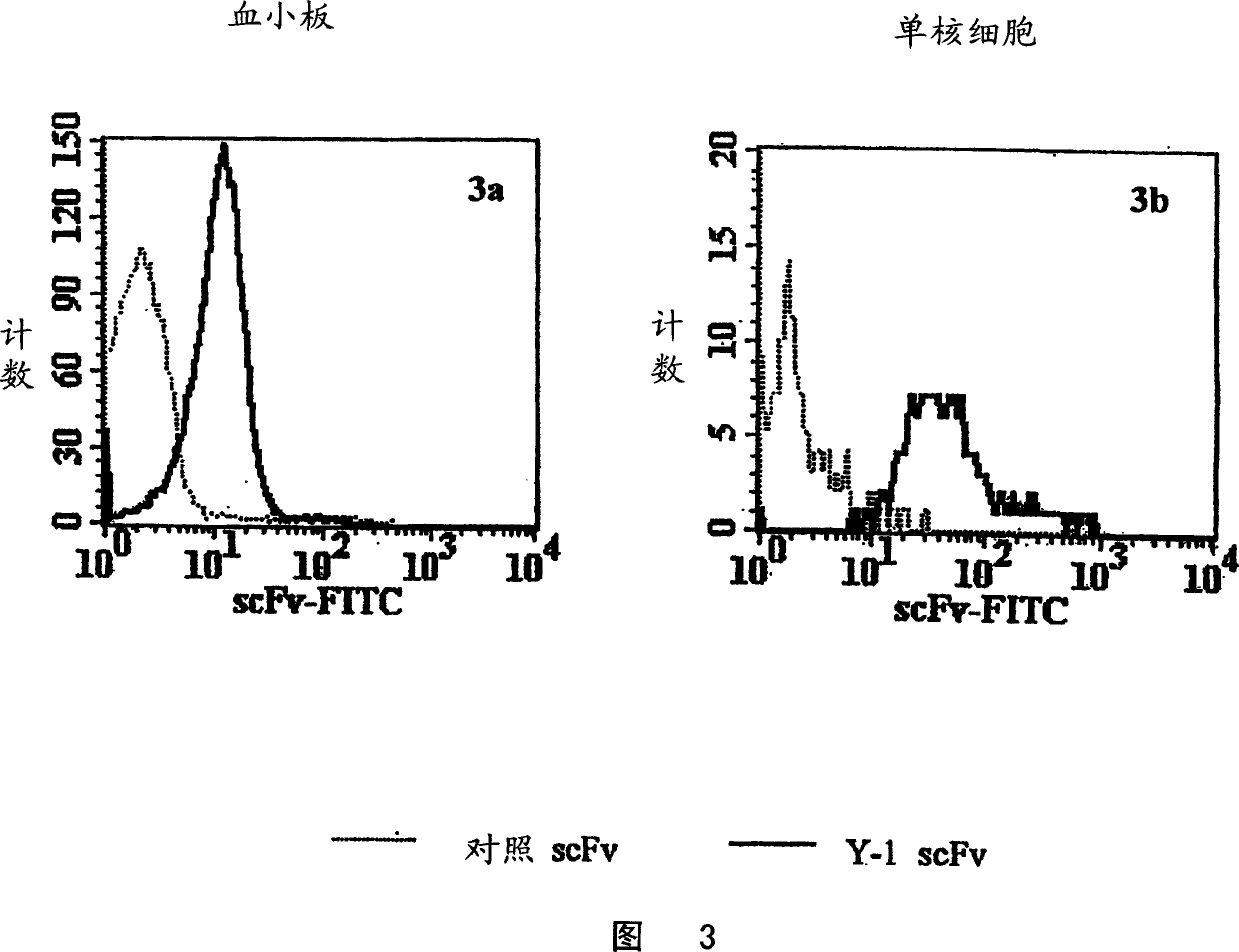

Specific human antibodies for selective cancer therapy

The present invention relates to a peptide or polypeptide comprising an Fv molecule, a construct thereof, a fragment of both, or a construct of a fragment, which has enhanced binding characteristics to favor selective and / or Or specifically bind to target cells, wherein the binding selectivity or specificity is mainly determined by the first hypervariable region, and wherein the Fv is scFv or dsFv, and optionally has one or more markers. Said enhanced binding is to a substantially exposed and / or overexpressed binding site on or within the target comprising a cell that is substantially Other cells that do not present and / or do not express the binding site are more favorable for binding. The invention also relates to methods for isolating said peptides and polypeptides from phage display libraries, and to nucleic acid molecules encoding them. The present invention provides pharmaceutical compositions comprising said peptides or polypeptides, and kits for the diagnosis and treatment of diseases, preferably cancer, most preferably acute myeloid leukemia.

Owner:BIO TECH GENERAL CORP

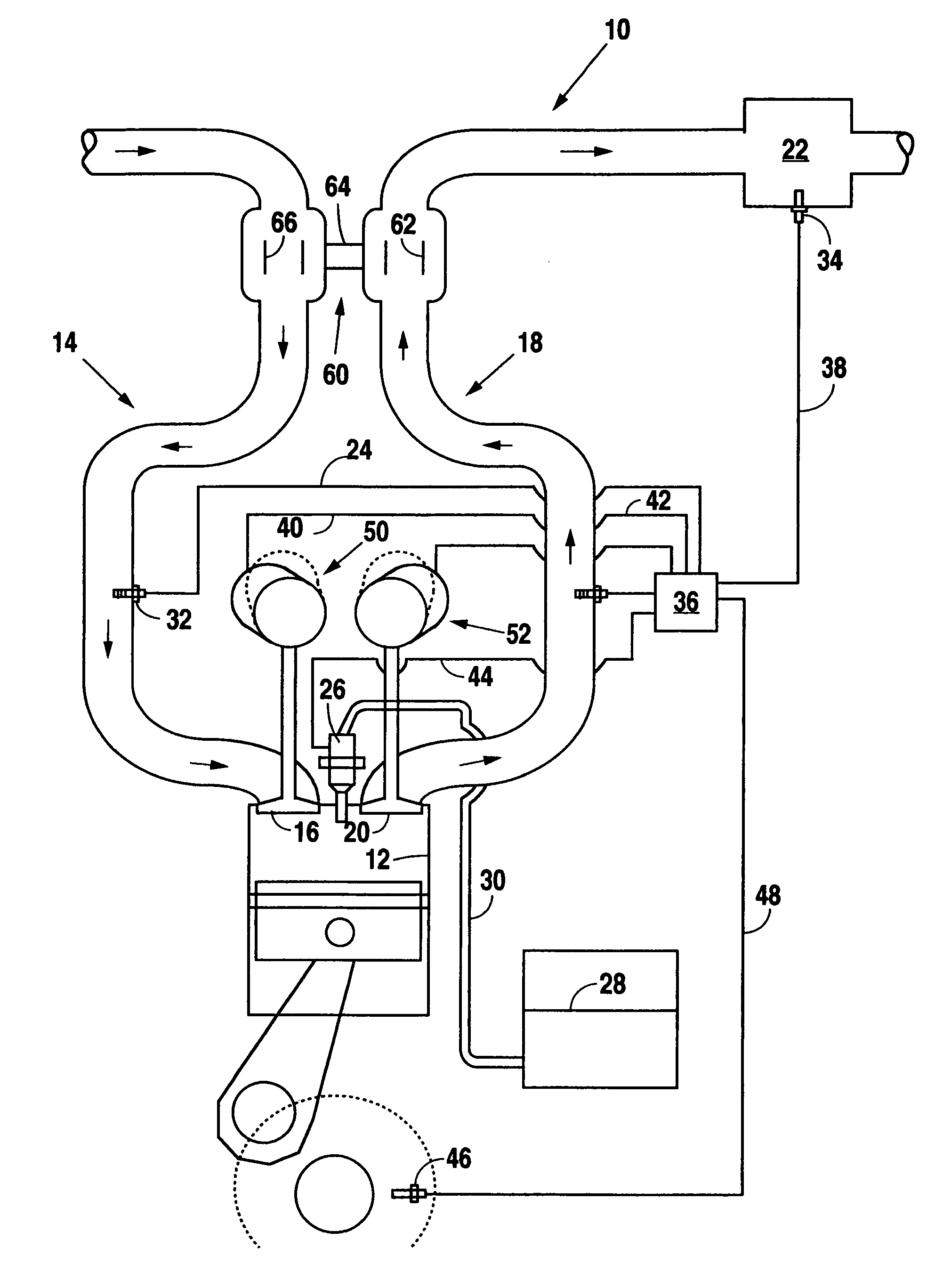

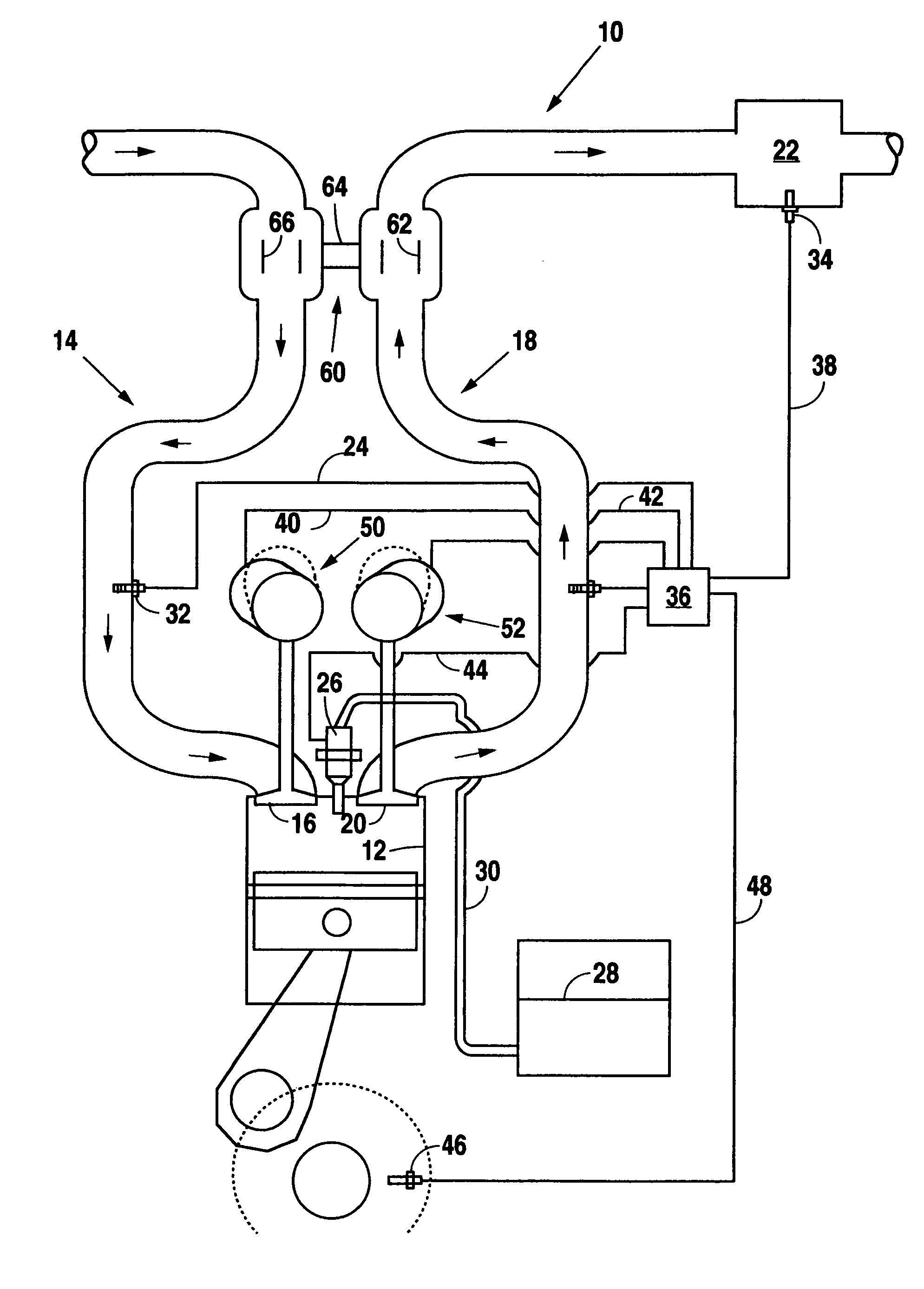

Method for controlling exhaust gas temperature and space velocity during regeneration to protect temperature sensitive diesel engine components and aftertreatment devices

A method for controlling the temperature and / or space velocity of exhaust gas provides control of the maximum temperature of the exhaust gas to prevent thermal damage to the Diesel engine components and associated aftertreatment devices during regeneration of the aftertreatment devices. The method includes controlling intake and / or exhaust valve opening timing and duration, either singly or in combination with selective individual cylinder cutout, in response to sensed engine operating parameters.

Owner:SOUTHWEST RES INST

Method for conduction high polymer pattern sedimentation on surface of plastic

InactiveCN1912190AReduce usageAvoid emissionsLiquid/solution decomposition chemical coatingChemical platingPolymer science

The invention relates to a pattering deposition method conducting high polymer on plastic surface. It combines selectivity photochemistry decorating and selectivity area chemical plating to make metal electrode on the plastic surface, adopts electrochemical oxidation to realize pattering deposition of the conducing high polymer on the metal electrode. This can effectively remove residue reagent, improve sample performance, avoid a great number of acid waste water discharging to protect the environment, and ensure the security of the operator.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

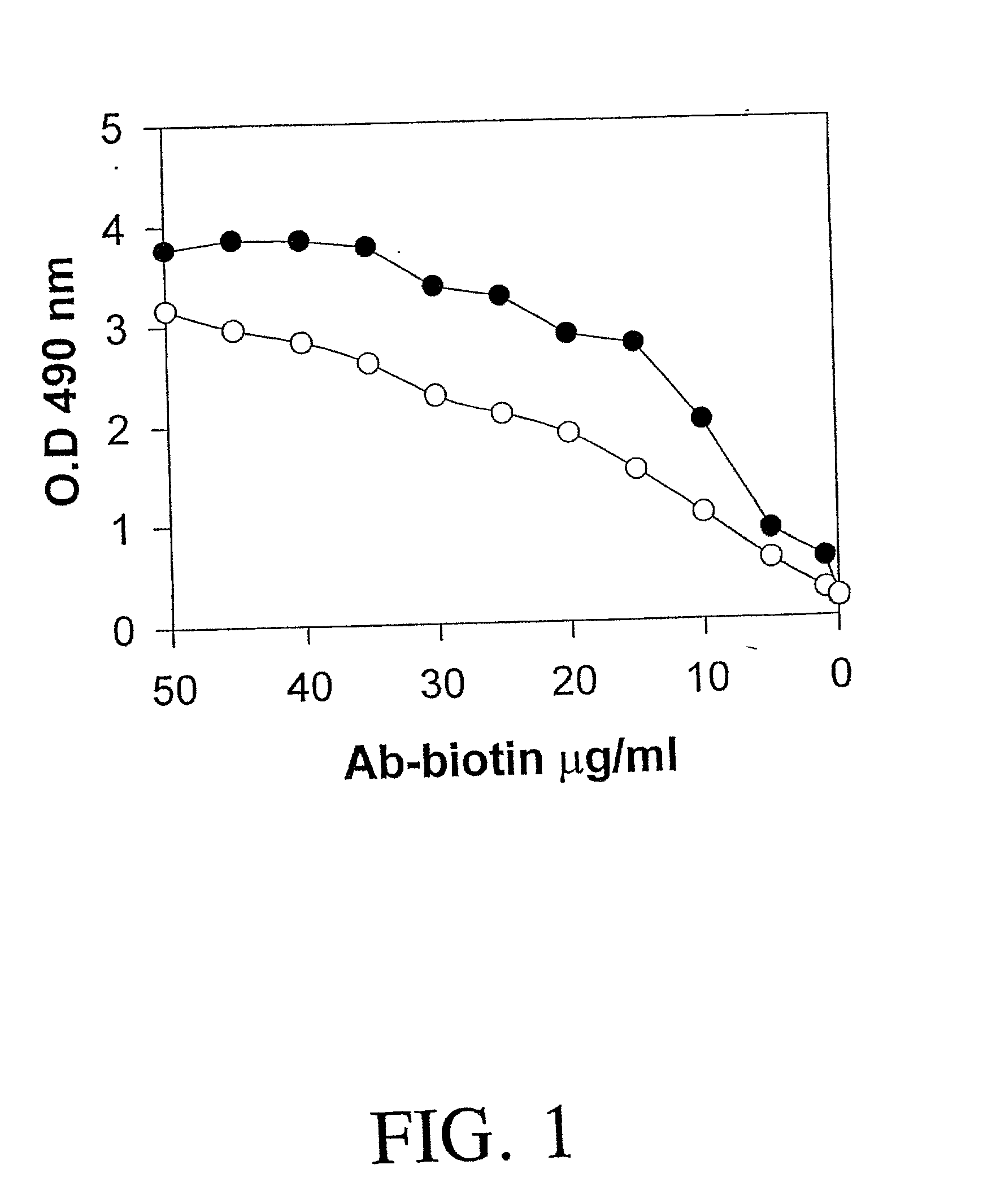

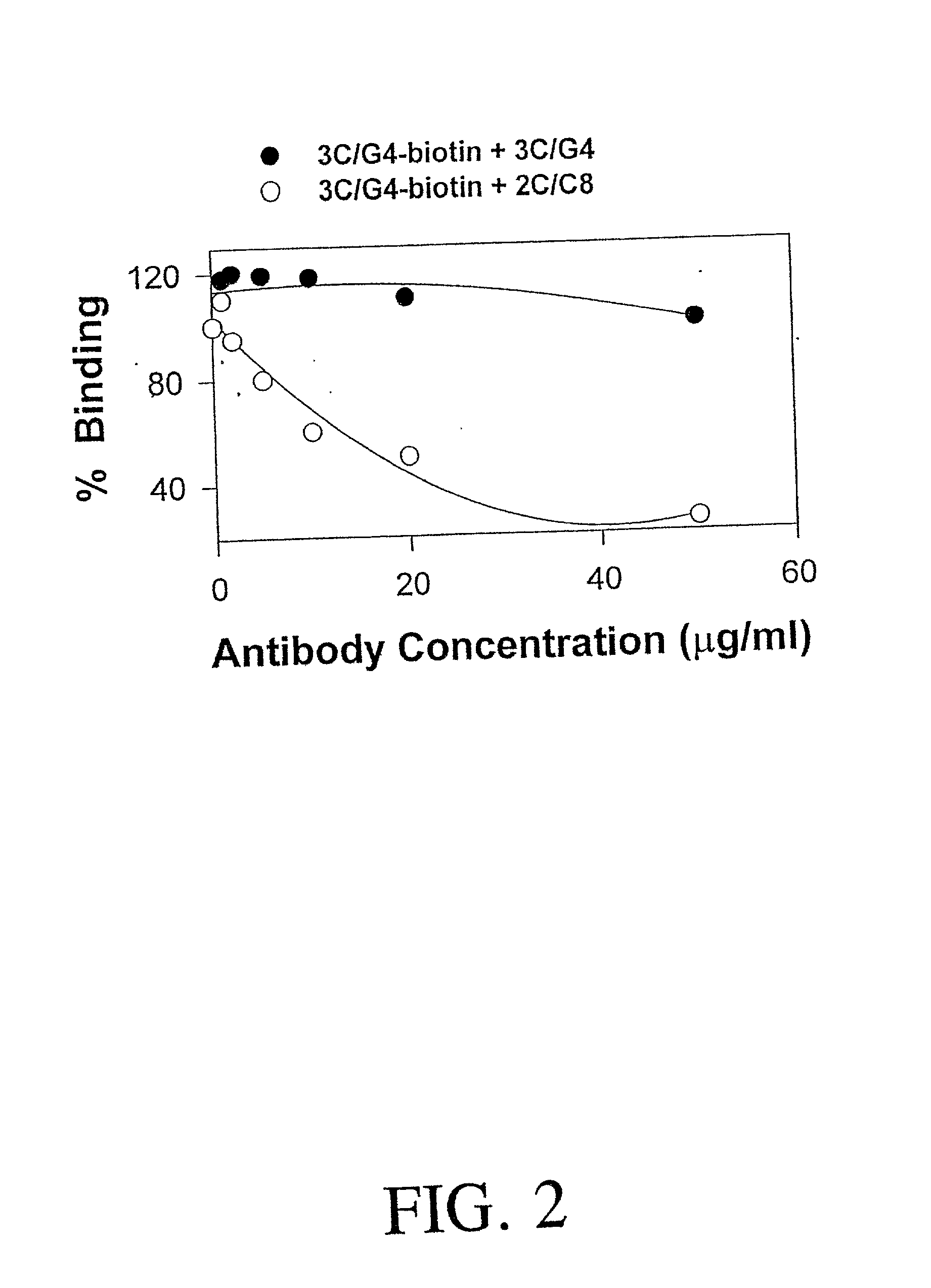

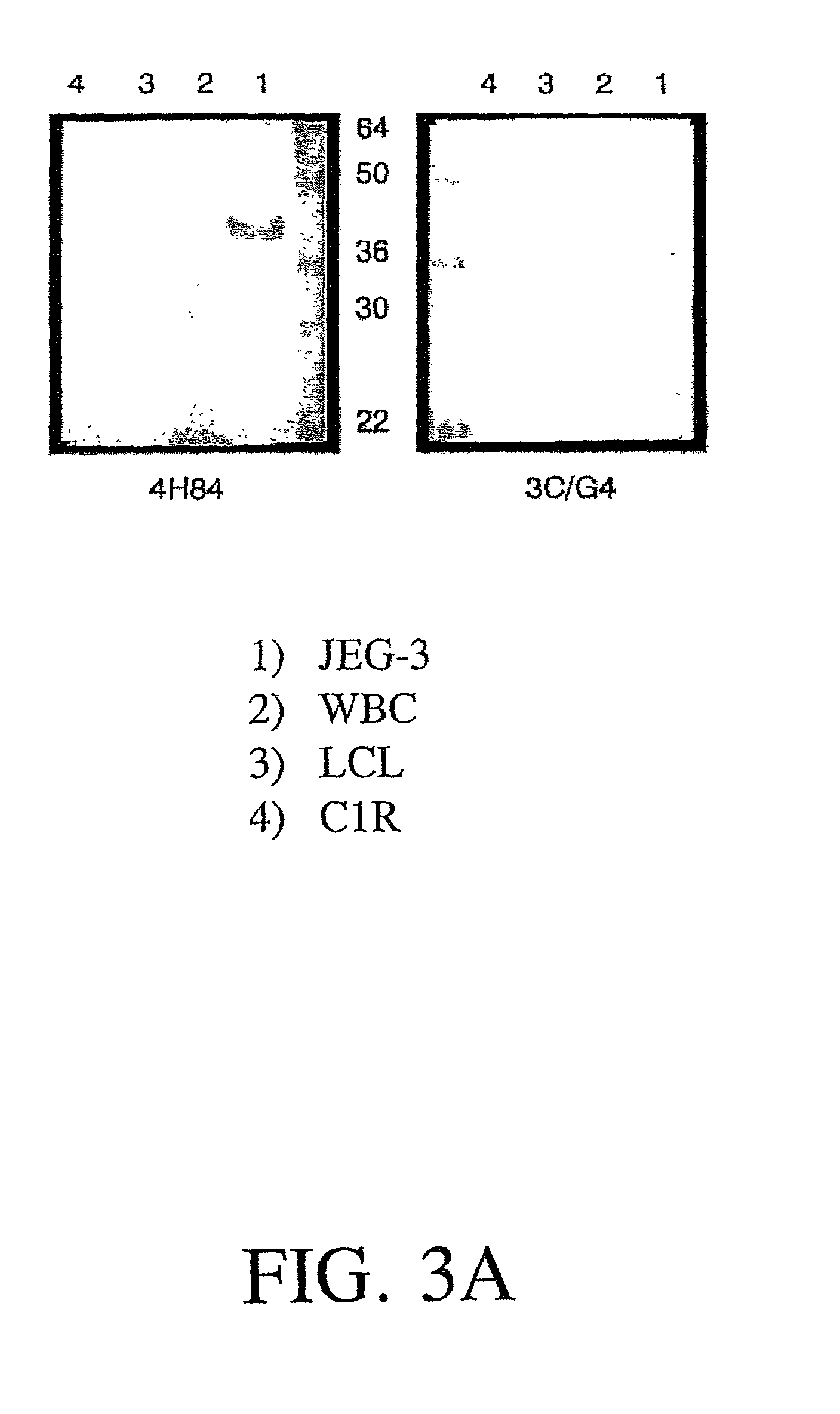

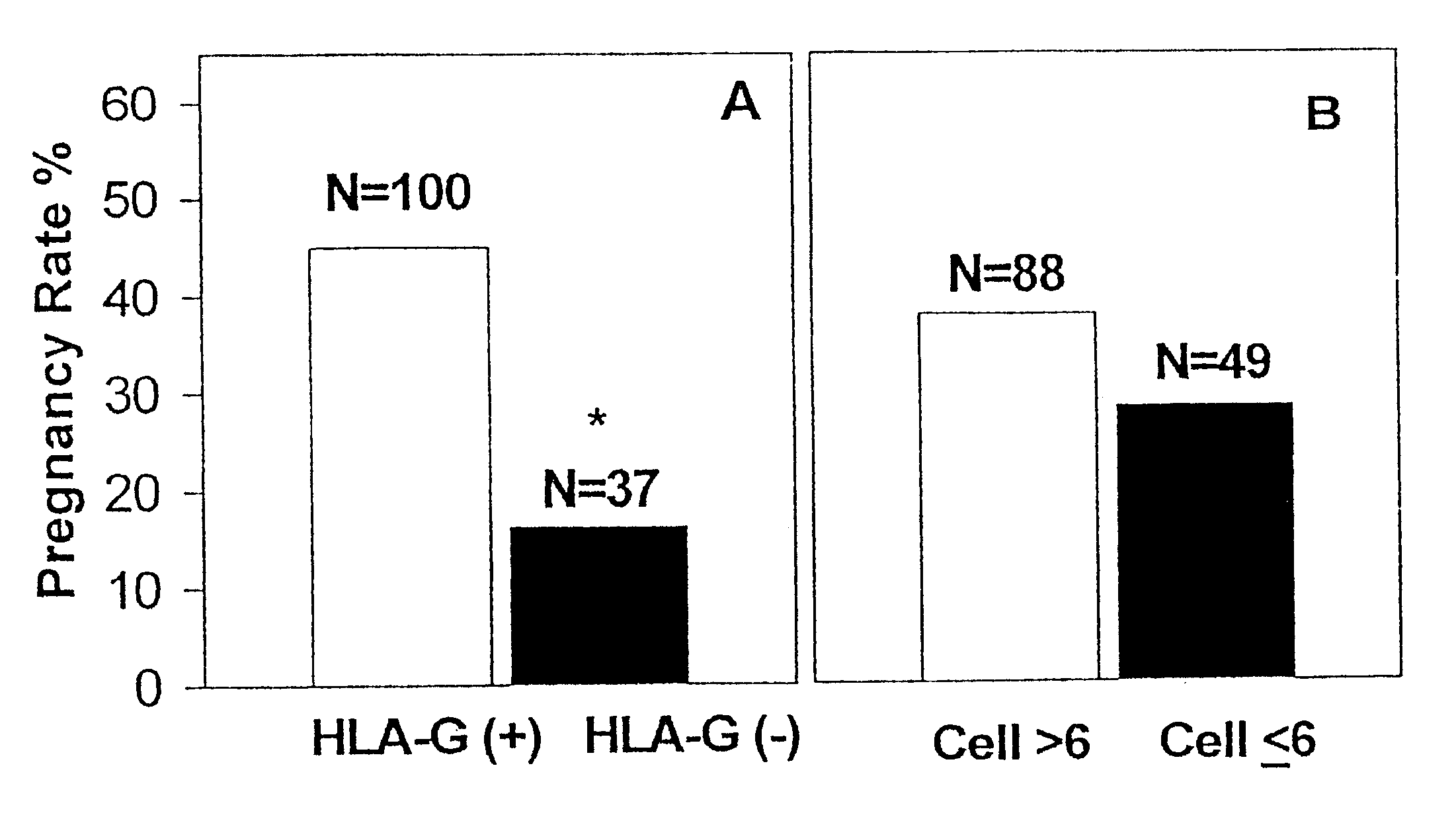

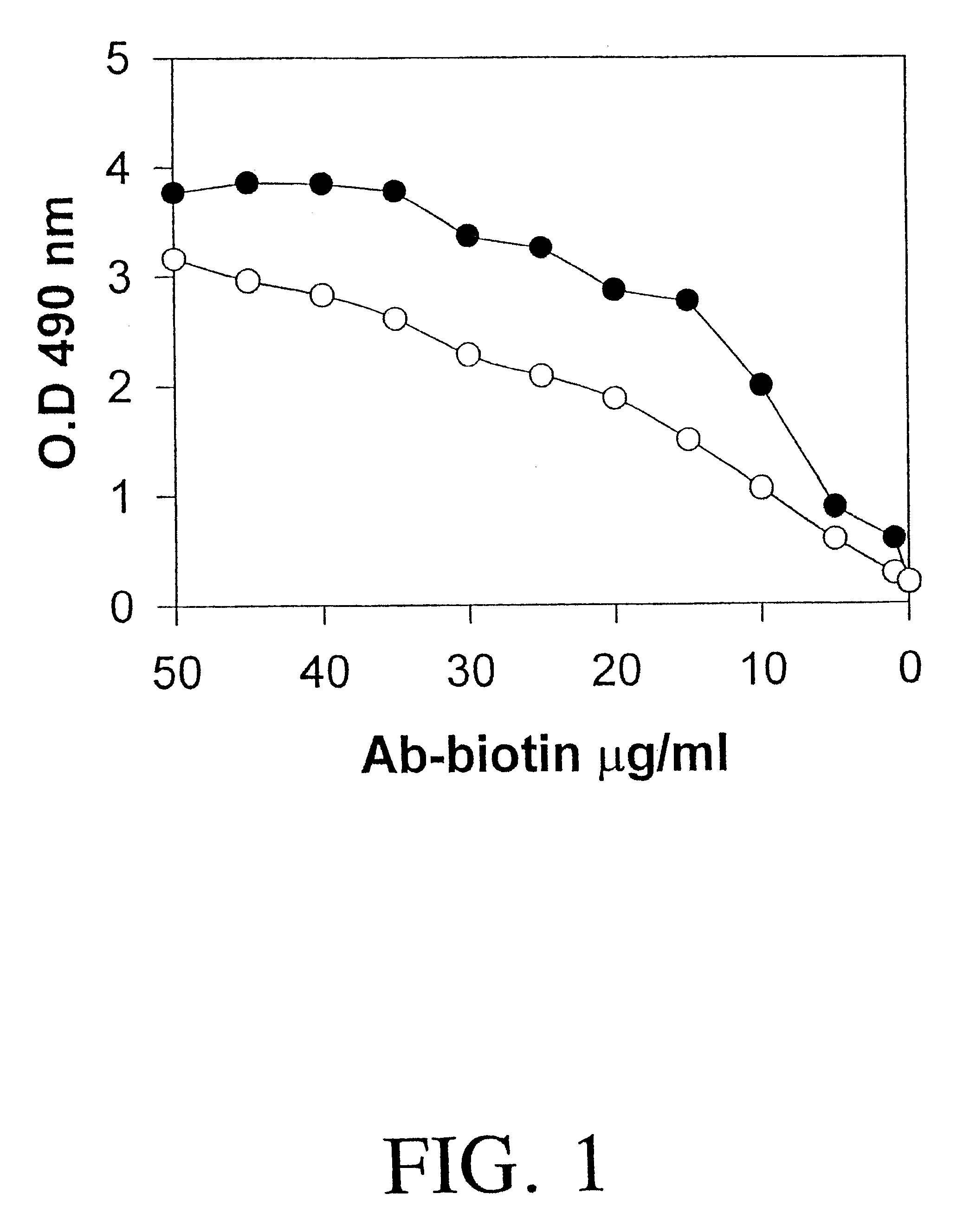

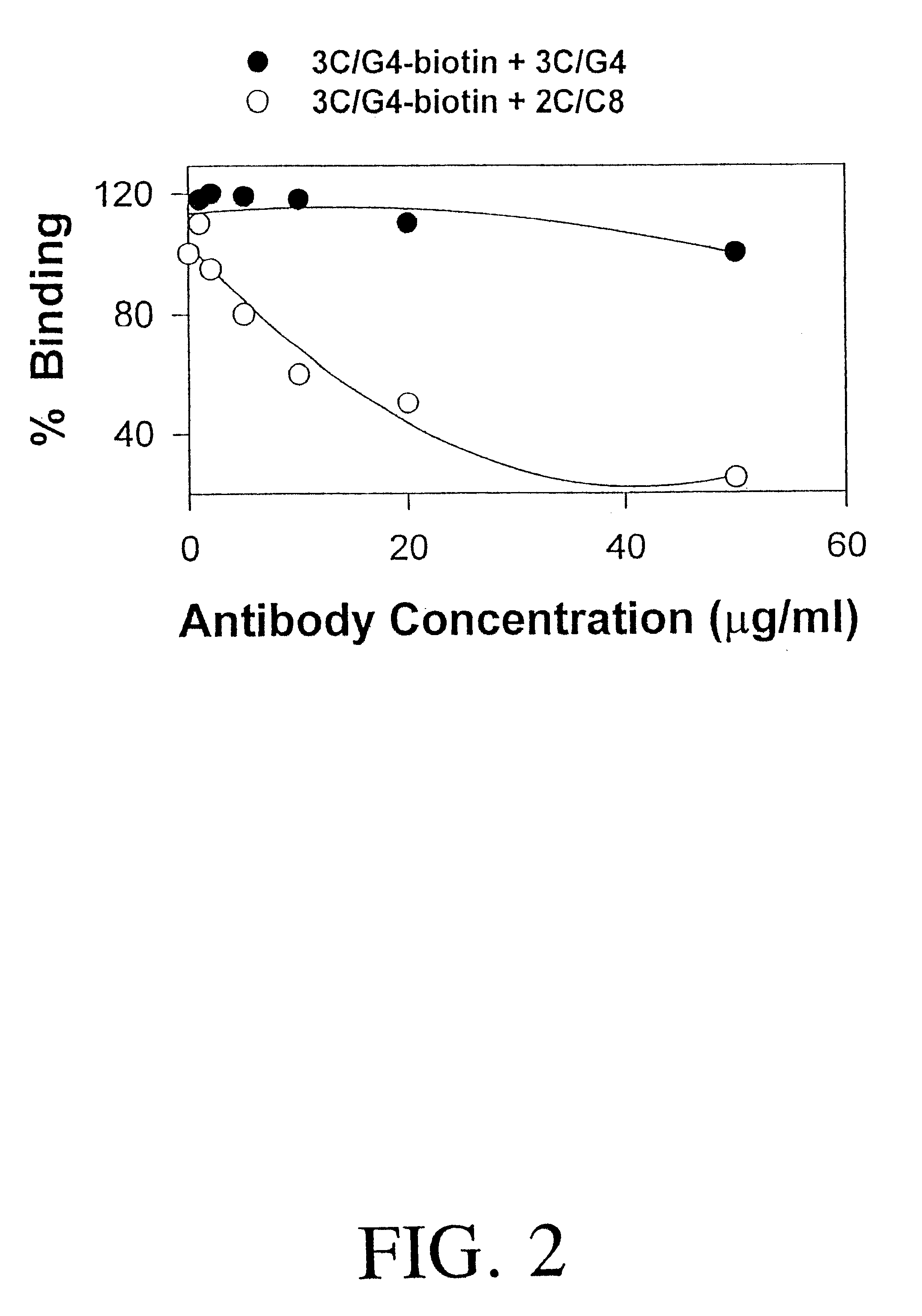

Detection of HLA-G

InactiveUS20020015973A1Raise the possibilityFast quantitative measurementAnimal cellsImmunoglobulins against cell receptors/antigens/surface-determinantsClinical settingsHLA-G

The present invention relates to the detection of HLA-G. Antibodies to both soluble and membrane bound HLA-G are disclosed. Exemplary antibodies include 2C / C8, 3C / G4, and 4H84. 2C / C8 and 4H84 antibodies bind to the same region of HLA-G, which is a different region than that bound by 3C / G4. Methods of detection and diagnosis are disclosed as well as kits, including a miniaturized assay suitable for a clinical setting. Further, a method of selecting an embryos for in vitro fertilization is disclosed. A sandwich ELISA test is provided using two antibodies that bind to HLA-G at different regions. The HLA-G test according to the invention is over 1000 times more selective in binding to HLA-G than to antigens HLA-A2, HLA-B4, HLA-C, or mixed WBC preparations.

Owner:LIBRACH CLIFFORD L +1

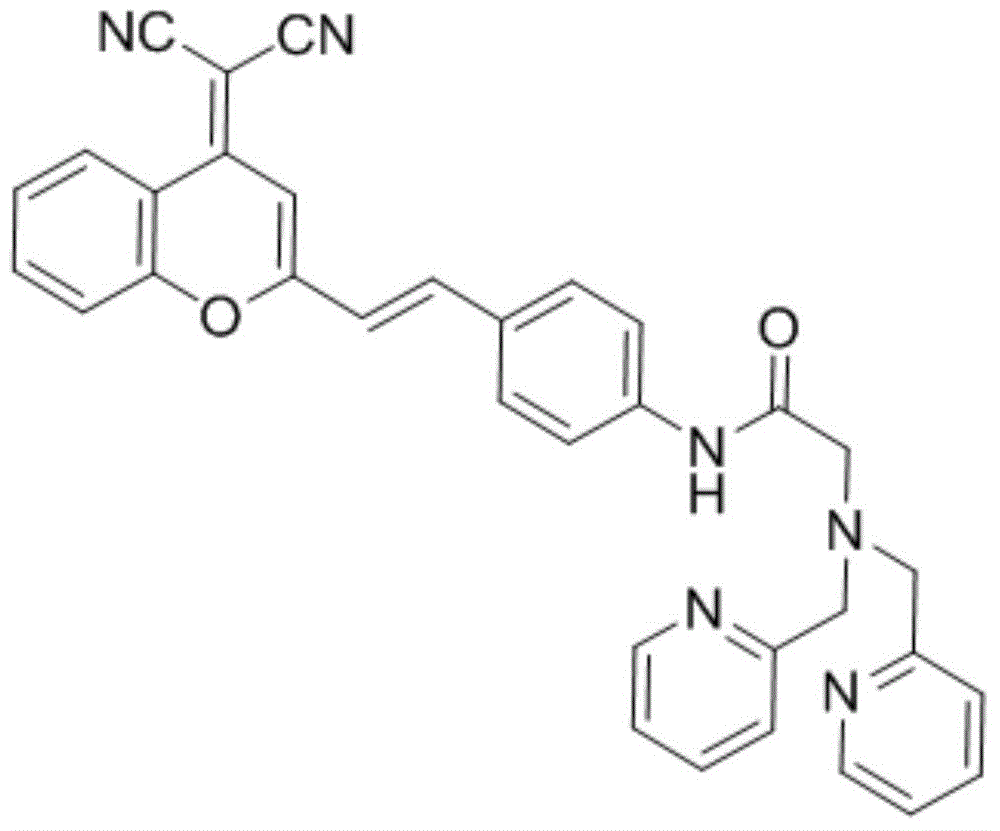

Cadmium ion fluorescence probe, preparation method and applications thereof

InactiveCN107501252AQuick responseImprove solubilityOrganic chemistryFluorescence/phosphorescenceFluorophoreMetal

The present invention provides a cadmium ion fluorescence probe, a preparation method and applications thereof. According to the present invention, the probe has specific binding selectivity and fluorescence response to cadmium ions; 4-amno-7-nirobenzoxadiazole is used as a fluorophore and amide DPA is used as a receptor in the probe, and the acceptor can have the variation ability through the tautomerism of the amide functional group, wherein the isomer of the imidic acid binds the cadmium ions, and the structure of the amide isomer binds other metal ions so as to provide the specific binding selectivity to the cadmium ions; and the unique identification on the cadmium ions by the probe is achieved, the obtained probe can be used for detecting the cadmium ions in cells, and can further be used for the cadmium ion detection in other organisms and environments due to the wide pH value working range.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Detection of HLA-G

InactiveUS6613538B2Easy accessImprove the level ofAnimal cellsImmunoglobulins against cell receptors/antigens/surface-determinantsClinical settingsHLA-G

The present invention relates to the detection of HLA-G. Antibodies to both soluble and membrane bound HLA-G are disclosed. Exemplary antibodies include 2C / C8, 3C / G4, and 4H84. 2C / C8 and 4H84 antibodies bind to the same region of HLA-G, which is a different region than that bound by 3C / G4. Methods of detection and diagnosis are disclosed as well as kits, including a miniaturized assay suitable for a clinical setting. Further, a method of selecting an embryos for in vitro fertilization is disclosed. A sandwich ELISA test is provided using two antibodies that bind to HLA-G at different regions. The HLA-G test according to the invention is over 1000 times more selective in binding to HLA-G than to antigens HLA-A2, HLA-B4, HLA-C, or mixed WBC preparations.

Owner:LIBRACH CLIFFORD L +1

Colon tumor specific binding peptides

Phage display was used to screen peptide libraries that distinguish between well-differentiated (HCT116) and poorly-differentiated colon carcinoma cells (HT29). The screening protocol used selection and subtraction on intact, viable cells, resulting in phage libraries exhibiting high binding selectivity for the poorly-differentiated HT29 cells. A nine amino acid, disulfide-constrained peptide (RPM) was identified that selectively bound and was internalized into colon cancer cells. The peptide may be used to detect colon cancer cells and also may be used to selectively deliver therapeutic agents to the cells.

Owner:UNIV OF UTAH RES FOUND

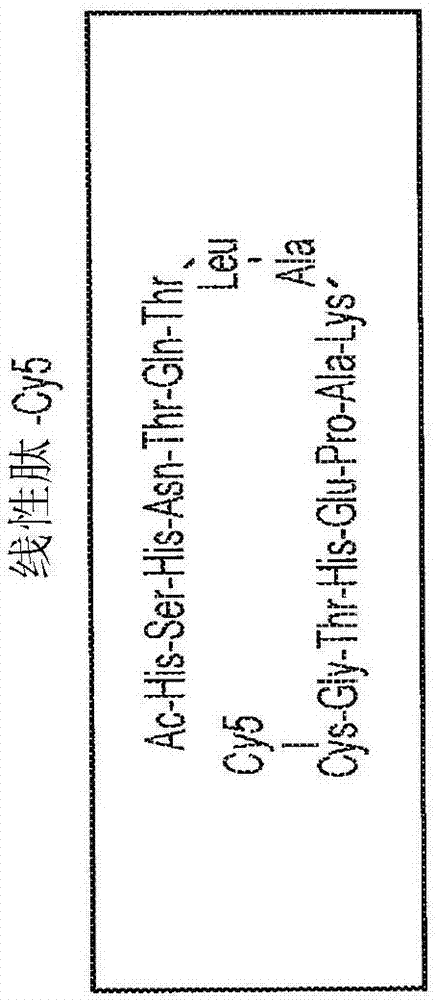

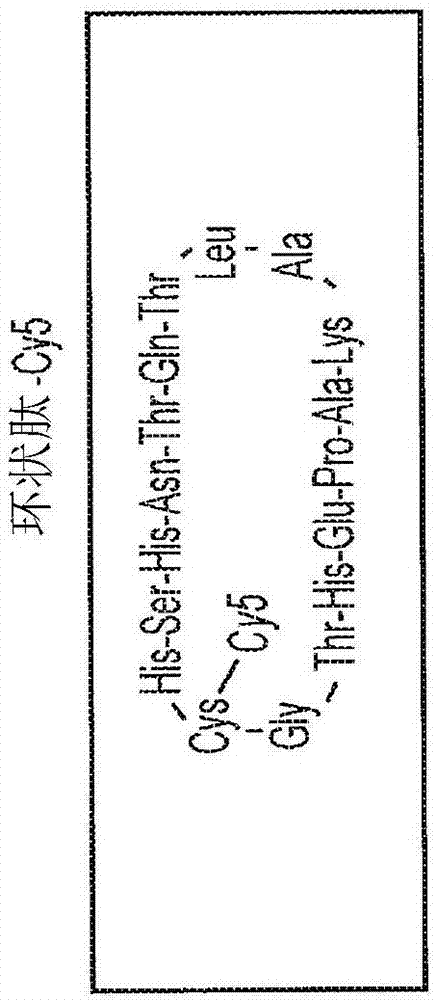

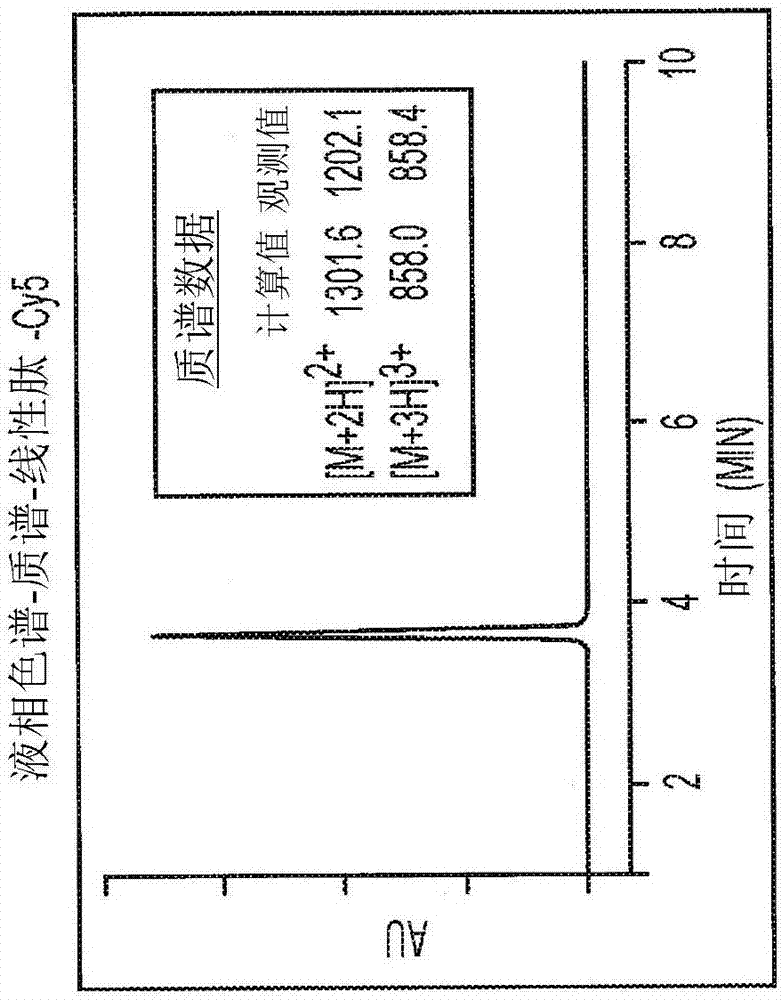

Cyclic peptides with enhanced nerve-binding selectivity, nanoparticles bound with said cyclic peptides, and use of same for real-time in vivo nerve tissue imaging

Described herein are cyclic peptides, nanoparticles bound with cyclic peptides, and methods for using said cyclic peptides and / or said nanoparticles bound with cyclic peptides for intraoperative nerve tissue imaging.

Owner:MEMORIAL SLOAN KETTERING CANCER CENT +1

Colored mask combined with selective area deposition

InactiveUS8129098B2Reduce in quantityDifficult to selectPhoto-taking processesSolid-state devicesBinding selectivityPhysics

Owner:EASTMAN KODAK CO

Drug development and manufacturing

InactiveUS9157875B2Material analysis using wave/particle radiationRadiation applicationsPost translationalDrug development

X-ray fluorescence (XRF) spectrometry has been used for detecting binding events and measuring binding selectivities between chemicals and receptors. XRF may also be used for estimating the therapeutic index of a chemical, for estimating the binding selectivity of a chemical versus chemical analogs, for measuring post-translational modifications of proteins, and for drug manufacturing.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

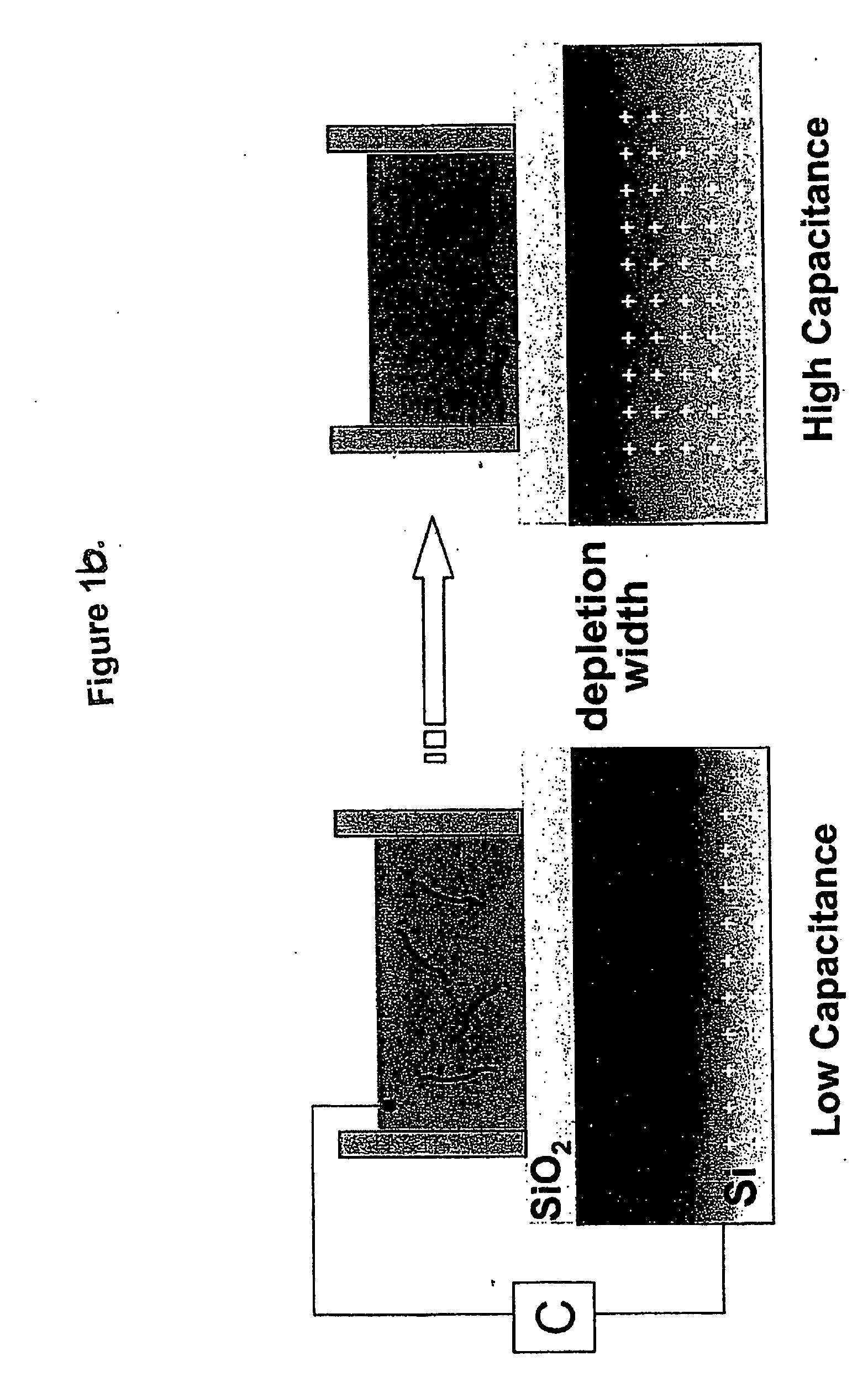

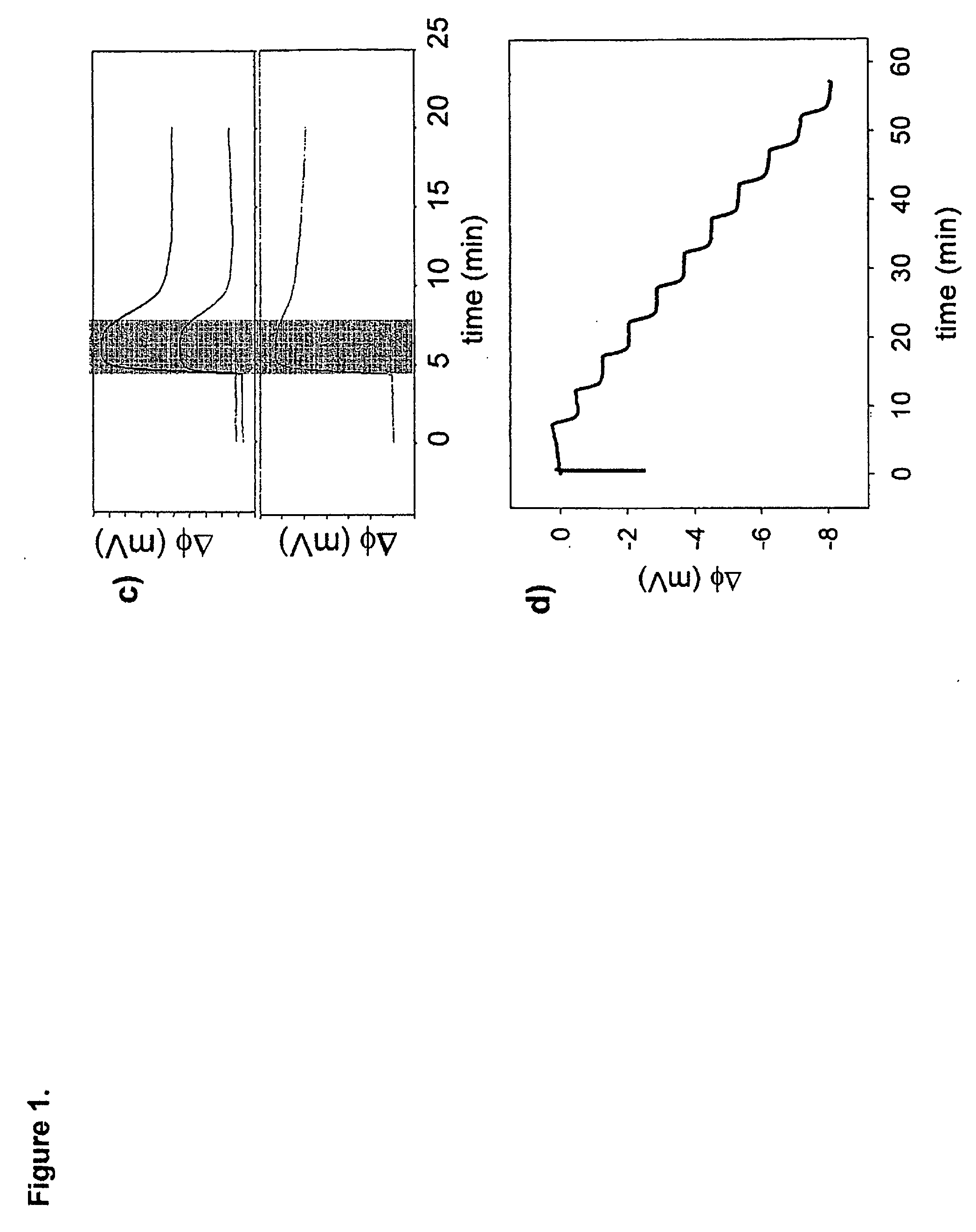

Monitoring heparin by microelectronic devices

InactiveUS20070212786A1Microbiological testing/measurementBiological material analysisCapacitanceEngineering

In one aspect, the present invention provides a device and method for real-time, direct detection of heparin in buffer and in serum comprising a microfluidic field-effect device as an affinity biosensor. The sensor is based on an electrolyte-insulator-silicon structure, and is manufactured by a standard high-yield silicon microfabrication process. The binding of heparin to the sensor surface induces a change in the insulator-electrolyte surface potential, which is measured as a change in sensor capacitance. To ensure the binding selectivity, protamine and antithrombin III are used as affinity probes.

Owner:MANALIS SCOTT +6

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com