Patents

Literature

56results about How to "Improve shortwave response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

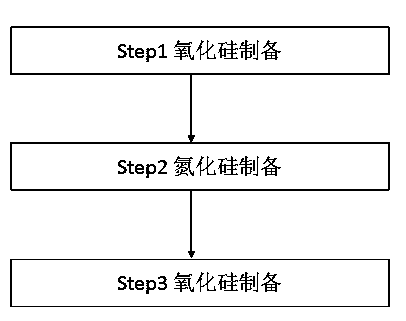

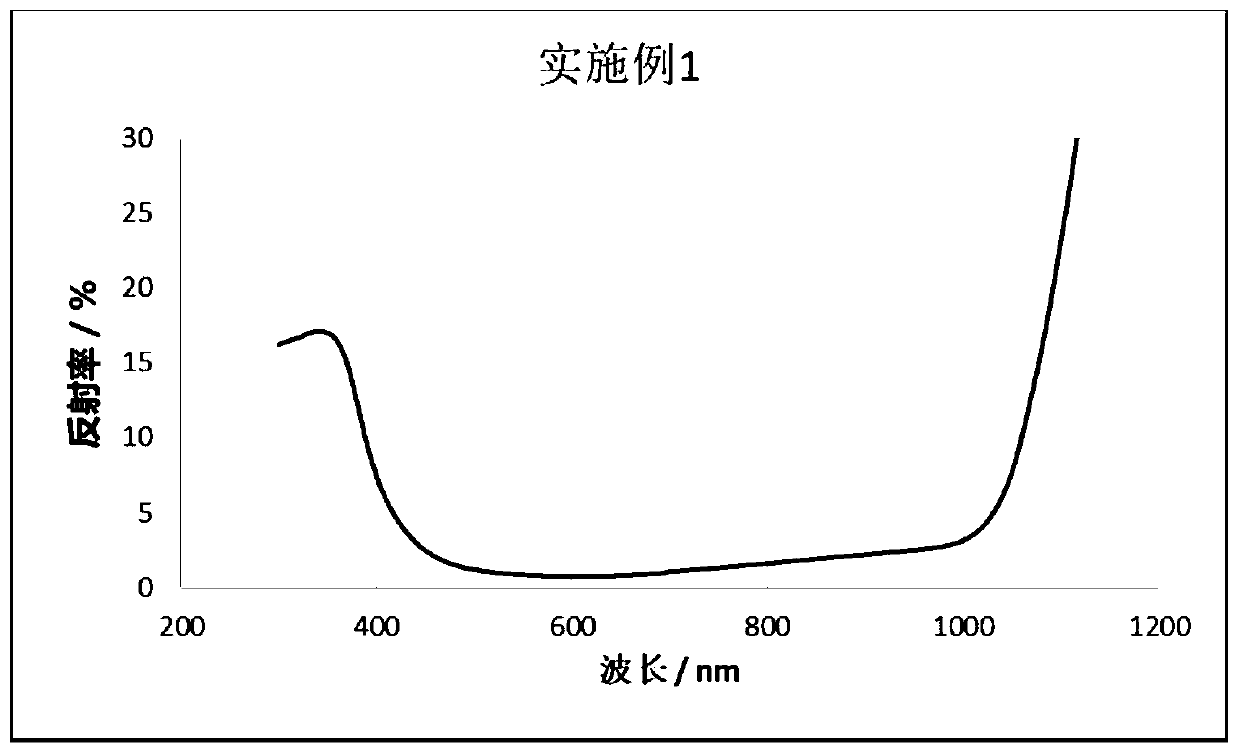

Solar cell passivation antireflection film and preparation technology and method thereof

InactiveCN103094366AReduce reflectivityImprove photoelectric conversion efficiencyFinal product manufactureChemical vapor deposition coatingPower flowRefractive index

The invention discloses a solar cell passivation antireflection film and a preparation technology and a method of the solar cell passivation antireflection film. The preparation technology and the method utilize a plasma enhanced chemical vapor deposition (PECVD), a layer of silicon dioxide film is deposited on the surface of a silicon slice, then a silicon nitride layer with high refractive index is deposited on the prepared silicon dioxide film, and finally a silicon nitride layer with low refractive index is deposited on the silicon nitride layer with high refractive index. The technology and the method have the advantages of being convenient to operate, low in operation cost, good in passivation and good in antireflection performance for the cell surface. The passivation antireflection film prepared by the technology can obviously improve the open circuit voltage, short circuit current and the cell efficiency of the solar cell, compared with a traditional single-layer or double-layer silicon nitride film.

Owner:SUN YAT SEN UNIV

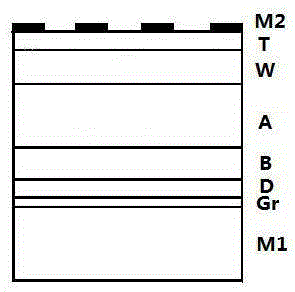

Phosphorus diffusion method of crystalline silicon solar cell

ActiveCN106057980AControl concentrationConcentration Control Concurrent Reduction of Phosphorus Doping Concentration Gradients in the BodyFinal product manufactureSemiconductor/solid-state device manufacturingConcentration gradientOxygen

The present invention discloses a phosphorus diffusion method of a crystalline silicon solar cell. The method comprises the steps of (1) entering into a boat, (2) adjusting temperature to be below 800 DEG C, introducing nitrogen carrying phosphorus source and dry oxygen, and forming a silicon dioxide layer containing phosphorus, (3) carrying out low temperature diffusion, (4) raising the temperature in a furnace and pushing with the rise of the temperature, (5) carrying out first time of high temperature diffusion, (6) raising the temperature in the furnace and pushing with the rise of the temperature, (7) carrying out second time of high temperature diffusion, (8) reducing the temperature in the furnace and pushing with the decrease of the temperature, and (9) reducing the temperature and going out of the boat, and completing a diffusion process. According to the method, an oxidation gettering effect is enhanced and the concentration gradient of the phosphorus doping is controlled, the separation and collection of carriers are facilitated, the open circuit voltage is raised, the temperature difference in a cooling process is controlled, and a crystal boundary gettering effect is enhanced.

Owner:CSI CELLS CO LTD +1

Oxide-metal multilayer film back contact crystalline silicon solar cell and preparation method thereof

ActiveCN105789342ALow costThe process steps are simpleFinal product manufacturePhotovoltaic energy generationMetal electrodesCrystalline silicon

The invention discloses an oxide-metal multilayer film back contact crystalline silicon solar cell, which comprises a crystalline silicon wafer, wherein passivation layers are arranged on the front surface and the back surface of the crystalline silicon wafer; the passivation layer on the back surface is provided with an emitter, an emitter metal electrode and a base metal electrode; the emitter comprises a first oxide thin film, a metal film and a second oxide thin film; the first oxide thin film or the second oxide thin film is a WO3 thin film, an NiO thin film or a V2O5 thin film; and the metal thin film is an Ag thin film, an Au thin film, a Pd thin film, a Cu thin film, an Ni thin film, an Mo thin film, a W thin film or an Al thin film. The surface of the cell is not shielded by a metal grid line; the raw materials do not include inflammable, explosive or toxic materials and are friendly to environment; expensive devices of a photoetching device, a laser device and the like and a complicated technological process are not needed in the overall preparation process; and the crystalline silicon solar cell disclosed by the invention is free of a high temperature, simple in processing step and suitable for large-scale production, does not need to use a transparent conductive thin film, is low in cost and has a wide application prospect.

Owner:江苏润阳悦达光伏科技有限公司

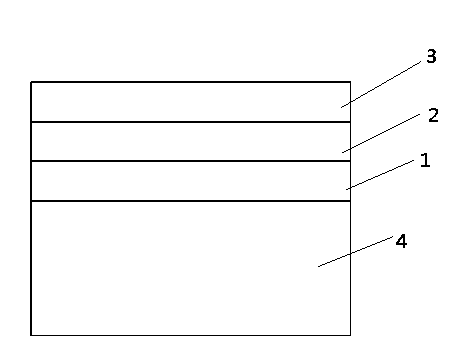

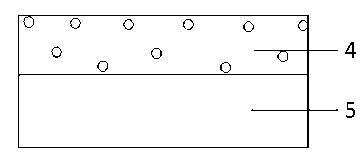

Crystalline silicon battery surface passive film and manufacturing method thereof

InactiveCN103996720AHigh relative permittivityDecrease the density of surface statesFinal product manufactureSemiconductor devicesCrystallographyCharge carrier

The invention discloses a crystalline silicon battery surface passive film and a manufacturing method of the crystalline silicon battery surface passive film. The crystalline silicon battery surface passive film comprises a first silicon oxide film, a silicon nitride film and a second silicon oxide film. The silicon nitride film is deposited on the first silicon oxide film. The second silicon oxide film is deposited on the silicon oxide film. The thickness d1 of the first silicon oxide film is 10 nm-30 nm. The thickness d2 of the silicon nitride film is 30 nm-50 nm. The thickness d3 of the second silicon oxide film is 25 nm-50 nm. The probability of light full reflection is substantially increased, and namely more light enters a silicon wafer, so that more charge carriers are generated, and battery efficiency is improved.

Owner:ALTUSVIA ENERGY TAICANG

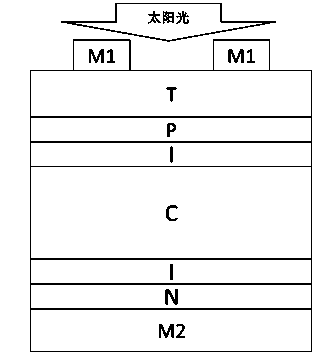

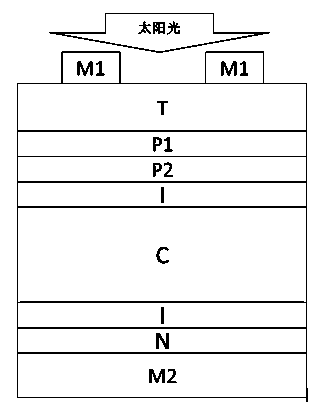

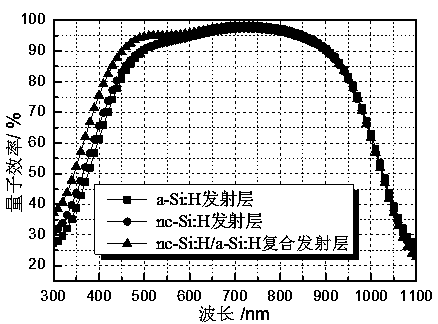

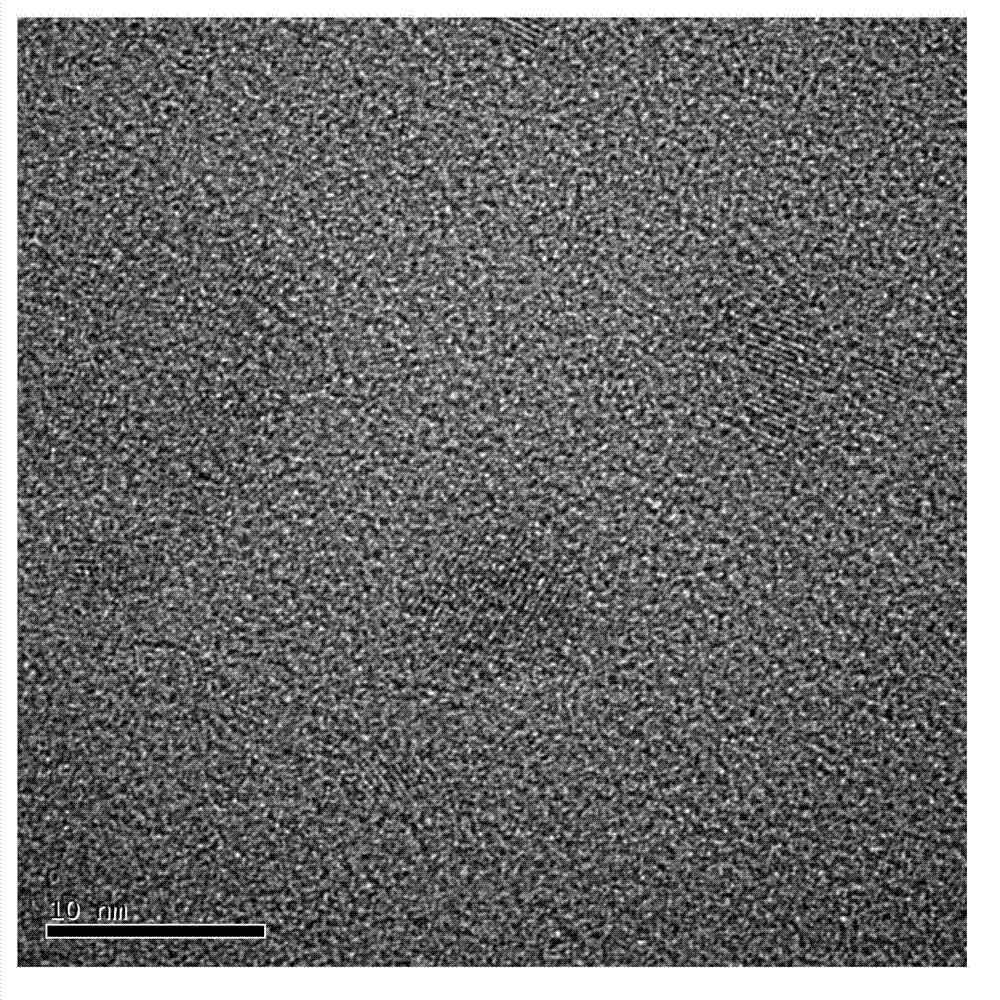

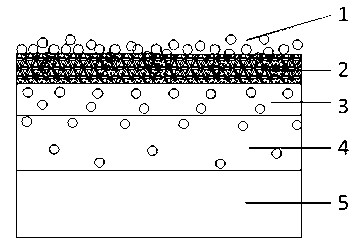

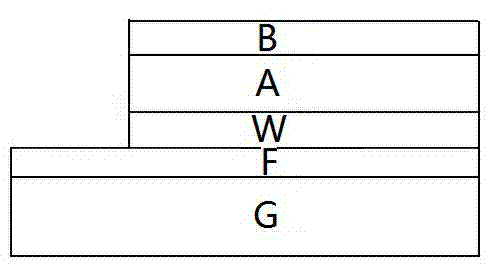

Method for preparing silicon heterojunction solar cell containing composite emission layer

ActiveCN103915523AReduced series resistanceReduce absorptionFinal product manufacturePhotovoltaic energy generationNanocrystalline siliconCrystalline silicon

The invention provides a method for preparing a silicon heterojunction solar cell containing a composite emission layer. The method includes the steps that an amorphous silicon back field N is deposited on one face of a substrate C on which a double-faced intrinsic amorphous silicon passivation layer I is deposited, an amorphous silicon layer P2 with the uniform structure is prepared on the face opposite to the amorphous silicon back field N under the conditions that doping concentration, hydrogen dilution and power density are low, a nanocrystalline silicon layer P1 with the uniform structure is prepared under the conditions that the doping concentration, the hydrogen dilution and the power density are improved, and an amorphous silicon / nanocrystalline silicon composite structure formed by the two silicon films serves as the emission layer of the silicon heterojunction solar cell. Materials have the advantages of being high in transmittance and conductivity through the structure, on the basis, the passivation effect of the surface of crystalline silicon can be improved, short wave response and output characteristics of the cell are improved, and the method for preparing the silicon heterojunction solar cell is simple and easy to carry out.

Owner:捷造科技(宁波)有限公司

Solar cell multi-layer anti-reflection grading film and preparation method thereof

PendingCN110391304ALow refractive indexHigh refractive indexFinal product manufactureChemical vapor deposition coatingRefractive indexSilicon oxide

The invention discloses a solar cell multi-layer anti-reflection grading film and a preparation method thereof. The solar cell multi-layer anti-reflection grading film comprises a first silicon nitride film, a second silicon nitride film, a first silicon oxynitride film, a second silicon oxynitride film and a silicon oxide film which are arranged in order from bottom to top, and the refractive index of each film is reduced layer by layer from bottom to top. The solar cell multi-layer anti-reflection grading film is formed by the two layers of silicon nitride films, the two layers of oxynitridefilms and a layer of the silicon oxide film, the refractive index of each film is reduced layer by layer, the problem is solved that the difference of the refractive indexes between the current silicon nitride films is large to cause the light loss due to optical mismatch, the whole refractive index of the front surface of the solar cell is lower, the light absorption is increased, and the conversion efficiency of the solar cell is improved; and moreover, the refractive index of the silicon nitride film at the inner layer is large, the silicon nitride film has an excellent passivation effectto further enhance the short-wave response of the solar cell and improve the anti-PID performance of the solar cell.

Owner:TIANJIN AIKO SOLAR ENERGY TECH CO LTD

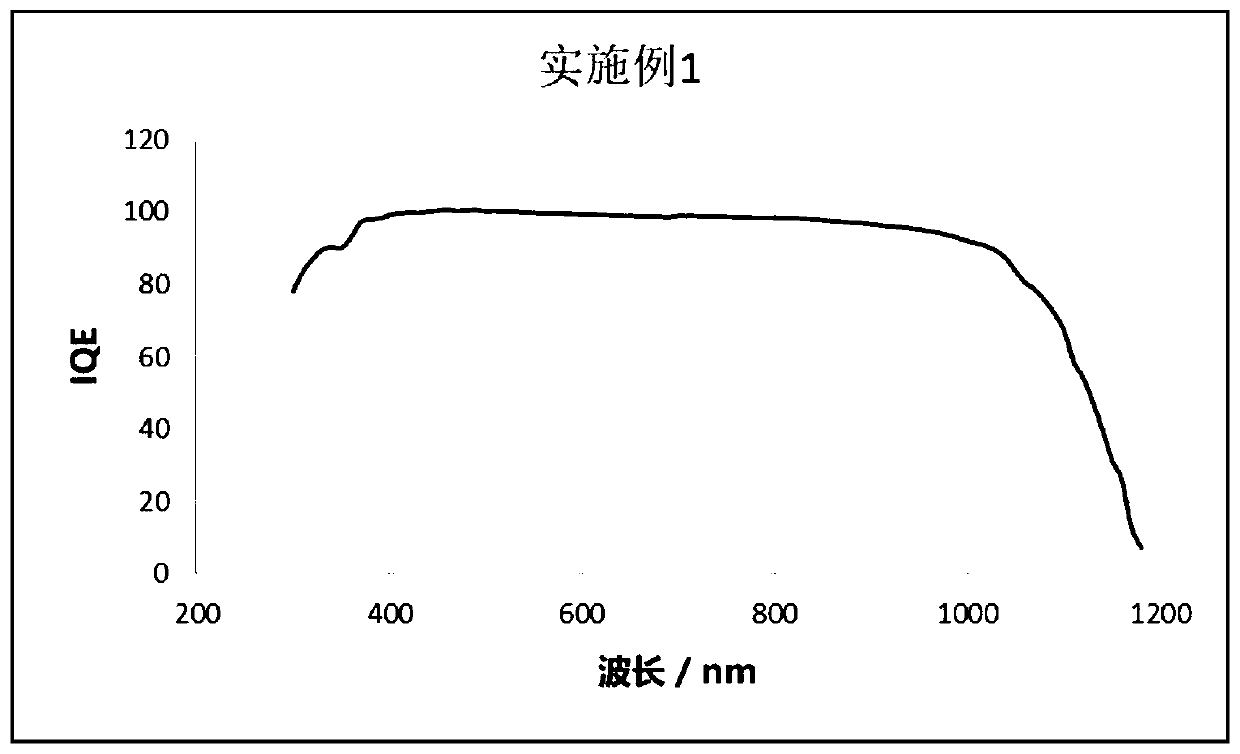

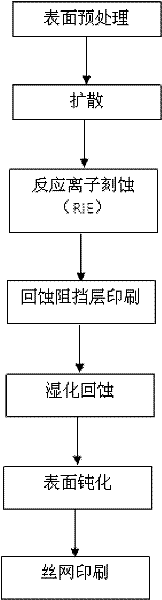

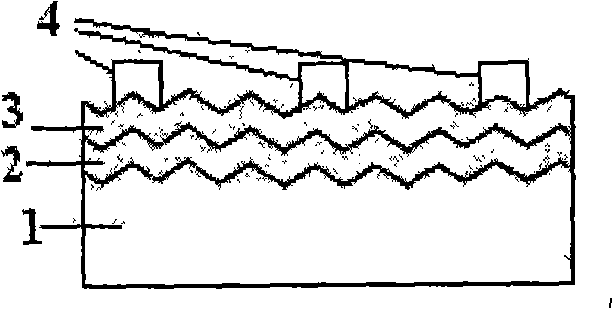

Selective emitter electrode solar battery manufacturing process combined with reactive ion etching (RIE)

InactiveCN102315317AResolve uneven diffusionImprove shortwave responseFinal product manufactureSemiconductor devicesOptoelectronicsSolar battery

The invention relates to the solar battery manufacturing method field, especially relates to a selective emitter electrode solar battery manufacturing process combined with a reactive ion etching (RIE). The method comprises the following steps that: after a surface is pretreated, a silicon chip diffuses so as to form a diffusion layer; a tiny suede is formed on a surface of the silicon chip through etching the reactive ion on the diffusion layer; a barrier layer is printed; a heavily doped region and a low doped region is formed after etching back through a local wet method; finally, an electrode is printed in the heavily doped region; sintering is performed and preparation of a cell sheet is completed. By using the technology provided in the invention, a problem of non-uniform diffusion caused by the RIE can be solved. Simultaneously, a diffusion selectivity emitter electrode technology is combined so as to raise short wave response, further increase light absorption and obtain high photoelectric conversion efficiency.

Owner:TRINA SOLAR CO LTD

Method for passivating crystal silicon P-type surface

InactiveCN102110742AAvoid it happening againGood passivation effectFinal product manufactureSemiconductor devicesThin layerEngineering

The invention discloses a method for passivating a crystal silicon P-type surface. The method comprises the following steps of: removing the borosilicate glass from the surface of an N-type crystal silicon wafer subjected to boron diffusion and cleaning the surface; generating a thin SiO2 layer on the cleaned silicon wafer surface; depositing a SiNx layer on the surface of the generated SiO2 thin layer by a plasma enhanced chemical vapor deposition (PECVD) method. The method provided by the invention is suitable for industrialization production and has characteristics of simple heat treatment process, good anti-reflection effect and good passivation quality.

Owner:ALTUSVIA ENERGY TAICANG

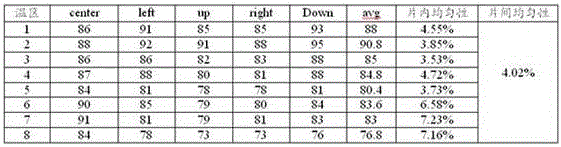

Phosphorus gettering technology for silicon chips

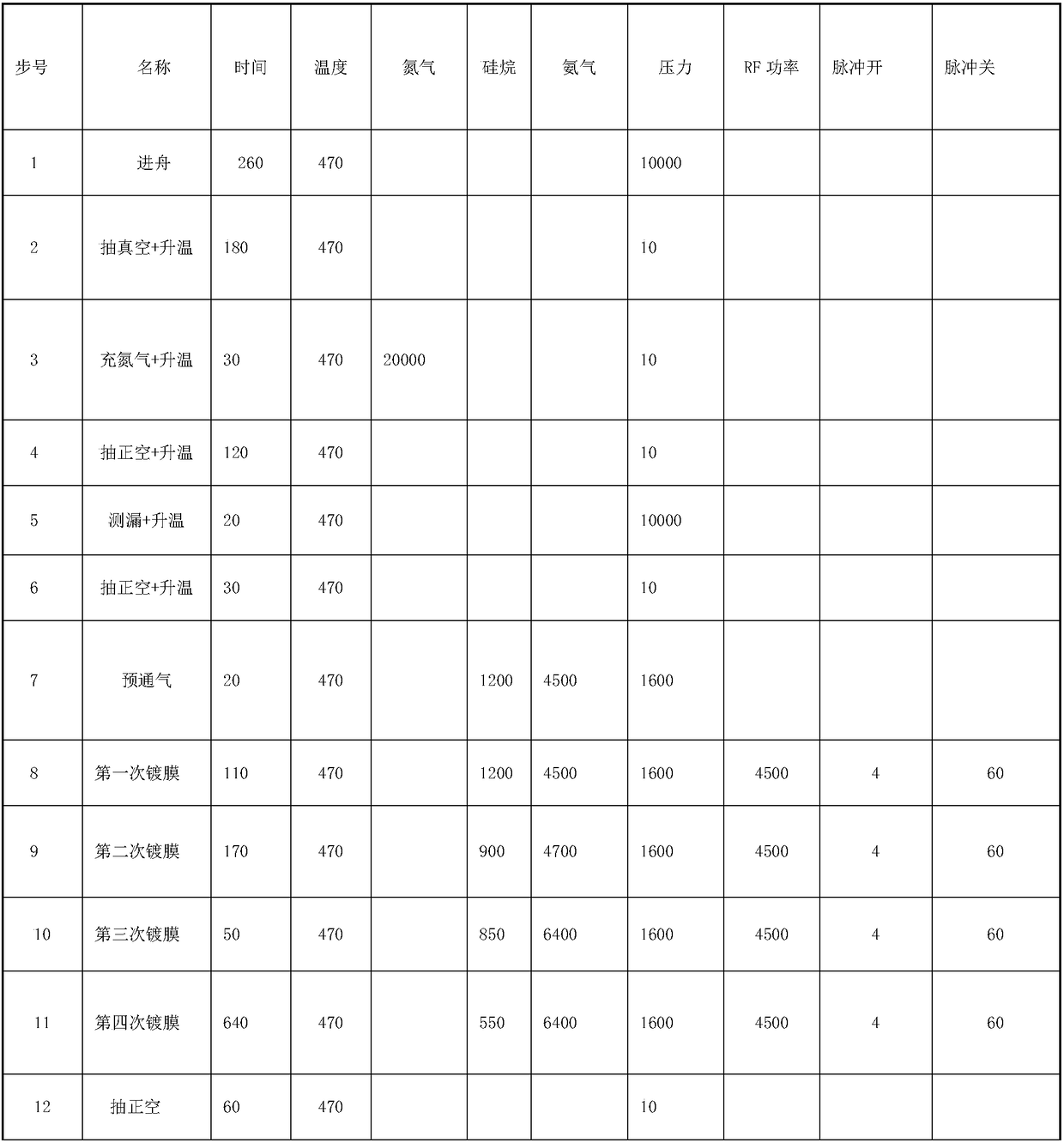

InactiveCN105185870AReduce the "dead layerImprove shortwave responseFinal product manufactureSemiconductor/solid-state device manufacturingSilicon chipNitrogen gas

The invention relates to a phosphorus gettering technology for silicon chips, belonging to the technical field of photovoltaic. The phosphorus gettering technology for silicon chips comprises the steps: putting silicon chips through cleaning and texturing in a diffusion furnace, letting nitrogen, oxygen and phosphorous oxychloride into the diffusion furnace, and diffusing under the high temperature; performing three times of deposition for the diffusion, performing propulsion of a certain time after every time of deposition, and then cooling the chips to the normal temperature, wherein the average transition efficiency of a cell is improved by 0.2% after completing the processes, such as etching, PECVD and silk screen sintering according to the normal processes of the cell.

Owner:JIANGXI UNIEX NEW ENERGY CO LTD

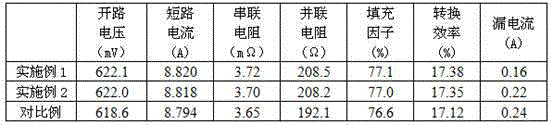

Diffusion technology for phosphorus slurry of selective emitter crystalline silicon solar cell

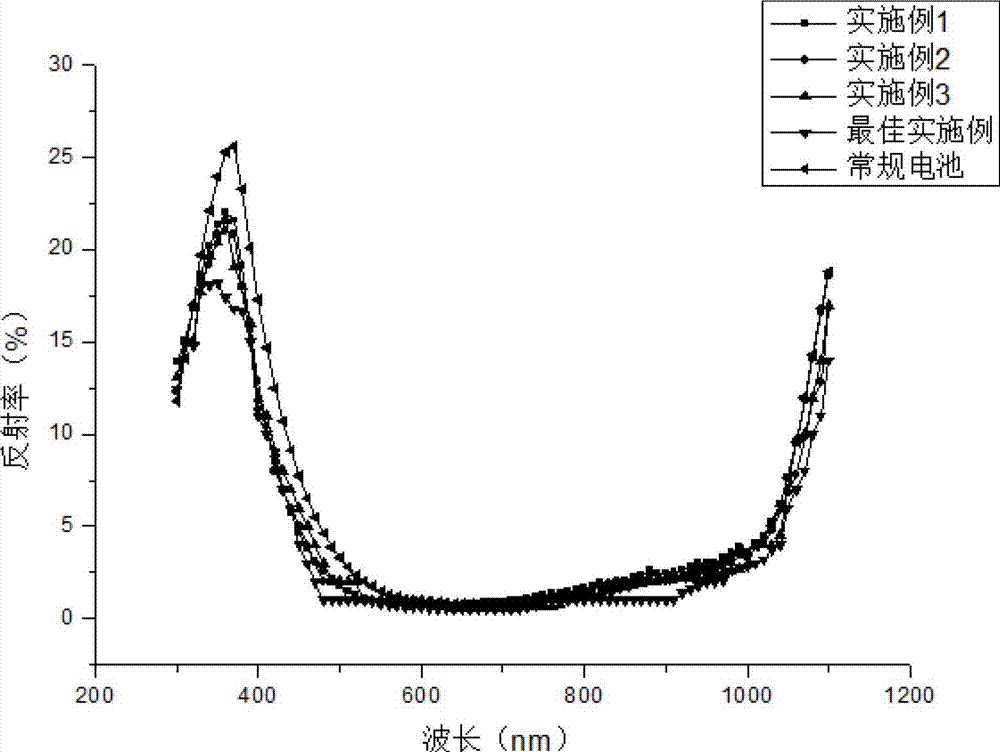

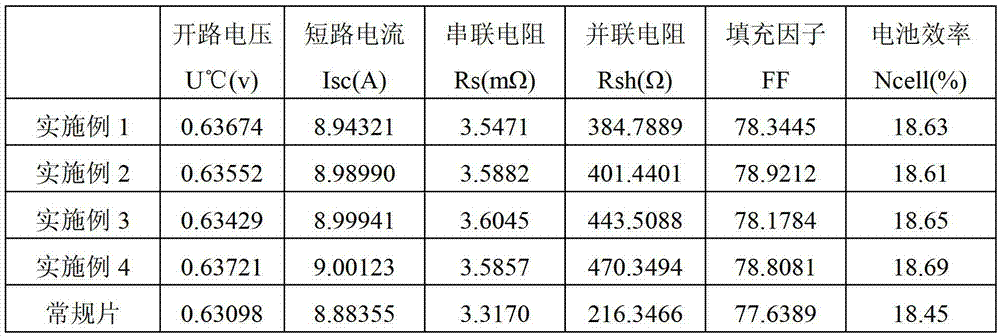

ActiveCN102732967AImprove shortwave responseImprove photoelectric conversion efficiencyFinal product manufactureDiffusion/dopingDiffusionFill factor

The invention relates to a diffusion technology for phosphorus slurry of a selective emitter crystalline silicon solar cell. According to the invention, relevant parameters of diffusion processing steps are adjusted, and a proper diffusion manner for phosphorus slurry of a selective emitter crystalline silicon solar cell is found out, so obvious heavily-doped zones and slightly-doped zones are generated, which enables short wave response of light to be enhanced and short-circuit current, open-circuit voltage and fill factors to be well improved, thereby improving photoelectric conversion efficiency.

Owner:JIANGXI UNIEX NEW ENERGY CO LTD

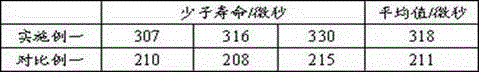

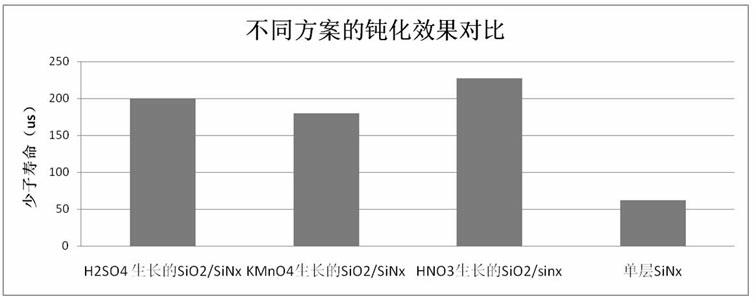

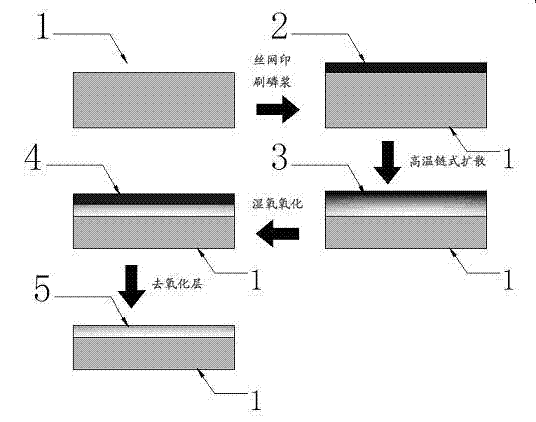

Chained diffusion process for solar cell

InactiveCN102881767AExtend your lifeImprove conversion efficiencyFinal product manufactureDiffusion/dopingSurface concentrationWater vapor

The invention discloses a chained diffusion process for a solar cell. The chained diffusion process is to remove a highly-doped area on a diffused surface and improve the minority carrier lifetime of a diffused silicon wafer by growing a thick oxidation layer on the surface of a silicon wafer subjected to chained diffusion and washing off the oxidation layer, and comprises the following steps: making a reaction between steam and the diffused surface of the silicon wafer at a high temperature to quickly grow the thick oxidation layer in a short time; and finally, removing the oxidation layer. The chained diffusion process avoids the phenomenon that the ordinary diffusion process cannot avoid generating a 'dead layer', further reduces the surface concentration, improves the minority carrier lifetime and the conversion efficiency of the cell, and reduces the production cost of the solar cell.

Owner:TIANWEI NEW ENERGY HLDG

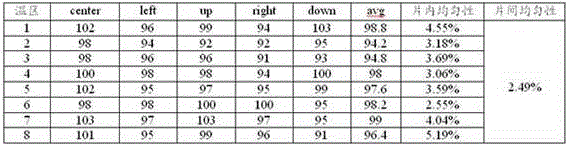

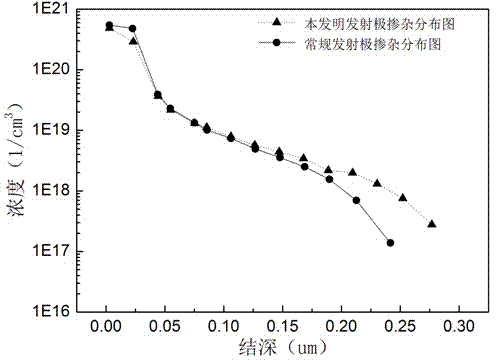

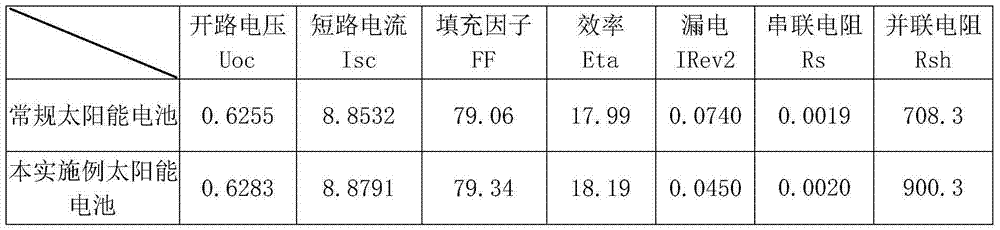

Solar cell emitter doping distribution method

ActiveCN104716232ALow surface doping concentrationImprove shortwave responseFinal product manufacturePhotovoltaic energy generationSheet resistanceDistribution method

The invention discloses a solar cell emitter doping distribution method. The solar cell emitter doping distribution method includes the steps of pre-oxidation, two times of source communication diffusion and two times of junction pushing for cooling and boat discharging. solar cell emitter doping distribution is realized through multiple times of source communication and multiple times of junction pushing, the time, temperature and source communication amount of multiple times of diffusion and the time and temperature of multiple times of junction pushing are adjusted, a solar cell emitter is made to have a lower surface doping concentration, and therefore the influences of a 'dead layer' are obviously weakened, and the short wave response of a solar cell is improved. The process of multiple times of source communication and multiple times of junction pushing further improves the doping concentration in a silicon wafer body, the silicon wafer surface doping concentration and the doping concentration inside the silicon wafer body are uniform, diffusion uniformity is good, and therefore the diffusion sheet resistance uniformity is improved. The process of multiple times of junction pushing improves the junction depth and increases blue light response of the solar cell, and finally the purpose of improving the conversion efficiency of the crystalline silicon solar cell is realized.

Owner:CECEP SOLAR ENERGY TECH (ZHENJIANG) CO LTD

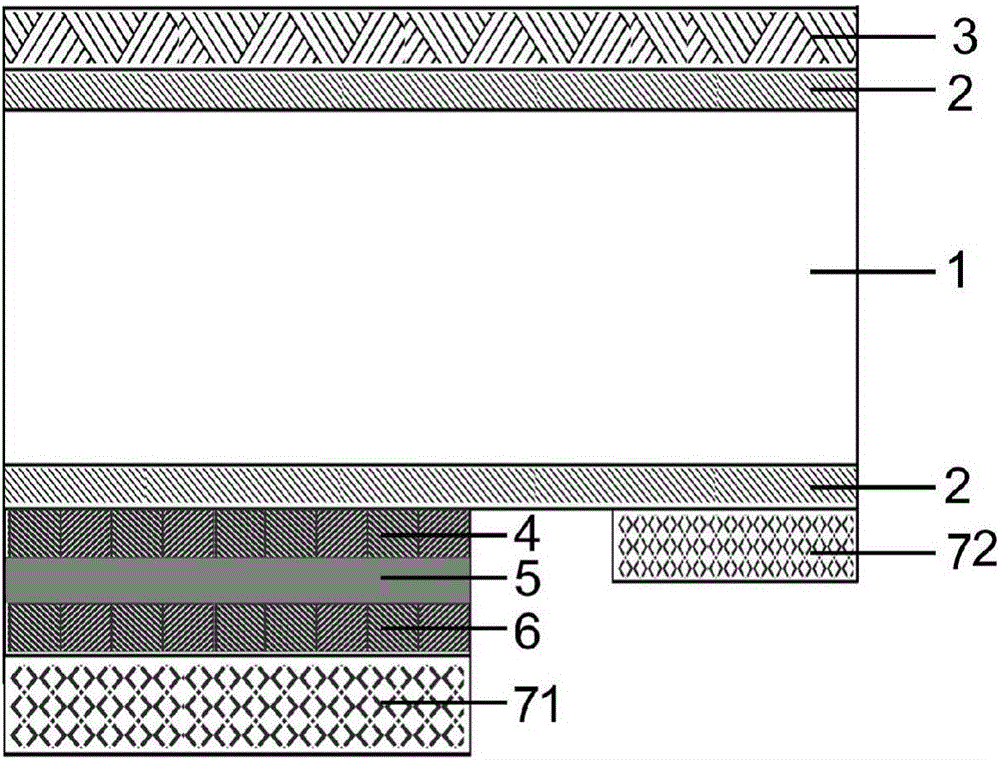

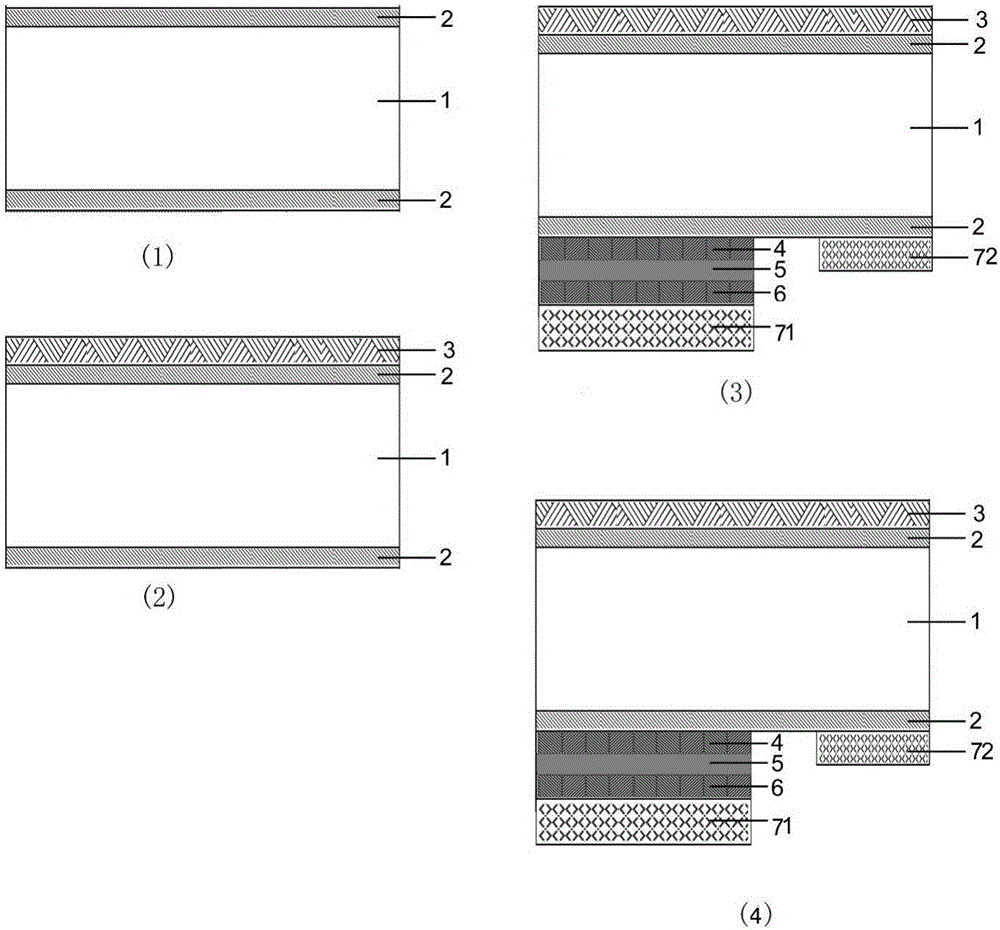

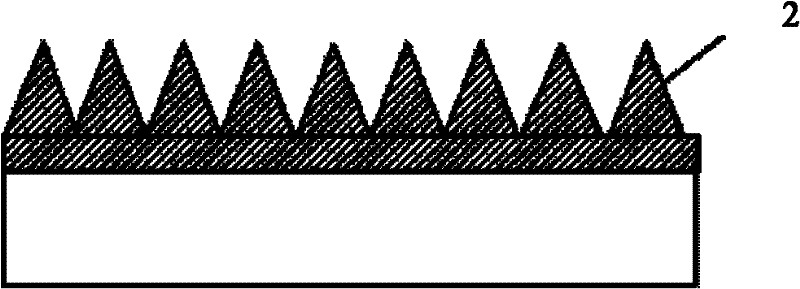

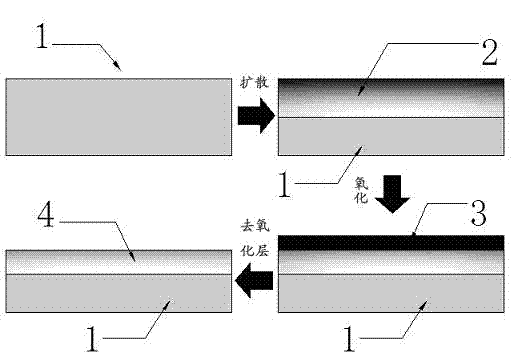

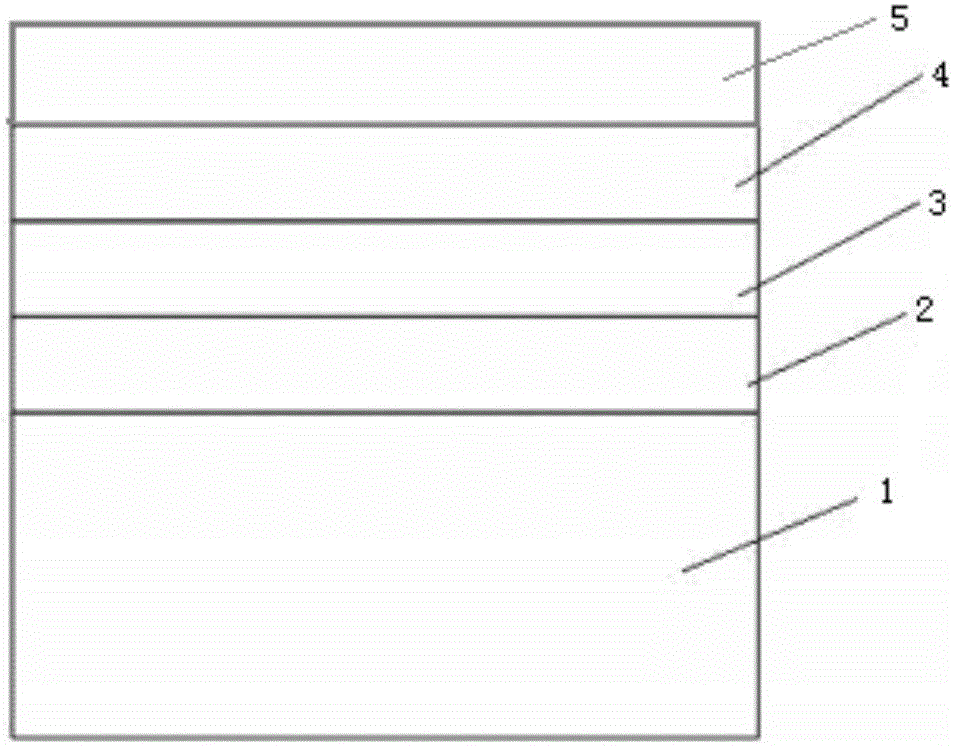

Process for manufacturing emitter of solar cell

InactiveCN102881766AExtend your lifeImprove conversion efficiencyFinal product manufactureSemiconductor devicesSurface concentrationP–n junction

The invention discloses a process for manufacturing an emitter of a solar cell, which comprises the following steps: step A, manufacturing a PN junction on the surface of a matrix silicon wafer (1) by a diffusion process to form a surface impurity distribution layer (2); step B, oxidizing the surface impurity distribution layer (2) obtained in step A to quickly grow an oxidation layer (3) distributed uniformly on the surface of the surface impurity distribution layer (2); and step C, removing the oxidation layer (3) in step B. The process avoids the phenomenon that the ordinary diffusion process cannot avoid generating a 'dead layer', further reduces the surface concentration, improves the minority carrier lifetime and the conversion efficiency of the cell, and reduces the production cost of the solar cell.

Owner:TIANWEI NEW ENERGY HLDG

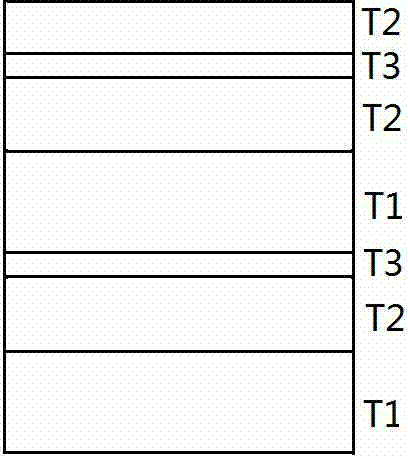

P-type amorphous silicon carbon-nanoparticle silicon multi-quantum well window layer material

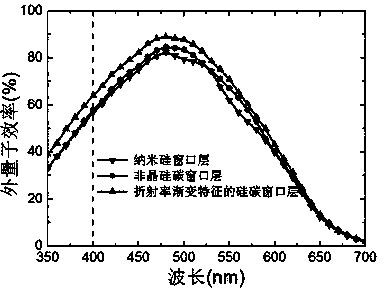

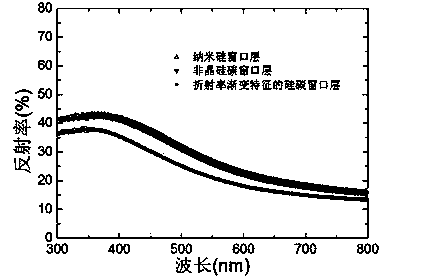

InactiveCN102903767AEnhanced built-in electric fieldIncrease the open circuit voltagePhotovoltaic energy generationSemiconductor devicesSilicon thin filmMaterials science

The invention discloses a p-type amorphous silicon carbon-nanoparticle silicon multi-quantum well window layer material. The p-type amorphous silicon carbon-nanoparticle silicon multi-quantum well window layer material is a multilayer material which is prepared by using a cascading deposition method and formed by alternately growing broadband gap amorphous silicon carbon thin films and narrowband gap p-type nanoparticle silicon thin films, wherein the thickness of each amorphous silicon carbon thin film is between 2 nm and 8 nm; the thickness of each p-type nanoparticle silicon thin film is between 2 nm and 8 nm; by repeated deposition, a p-type amorphous silicon carbon-nanoparticle silicon multi-quantum well material of which the total thickness is between 20 nm and 50 nm is formed; and the p-type amorphous silicon carbon-nanoparticle silicon multi-quantum well window layer material is applicable to a silicon-based thin film solar cell. The p-type amorphous silicon carbon-nanoparticle silicon multi-quantum well window layer material has the advantages that an optical band gap can reach 2.0 to 3.7 eV, and electric conductivity can reach 0.1 to 5.0 S / cm; and the material is applicable to the silicon-based thin film solar cell, so the open-circuit voltage of the cell can be remarkably improved, the optical absorption loss of a window layer is reduced, the short wave response and short-circuit current density of the cell are improved, and photoelectric conversion efficiency is improved.

Owner:NANKAI UNIV

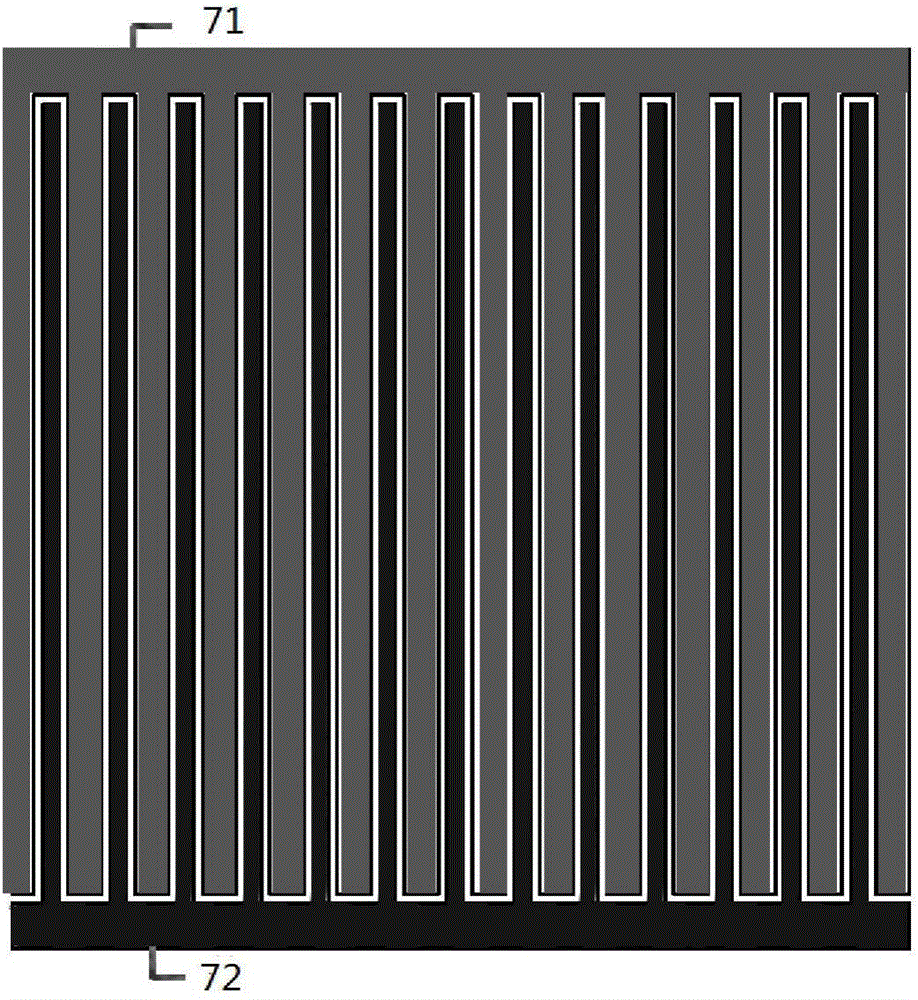

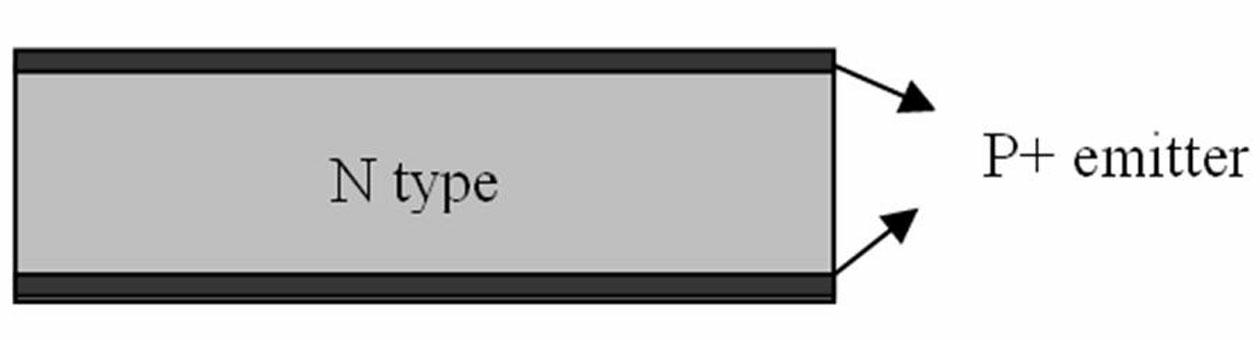

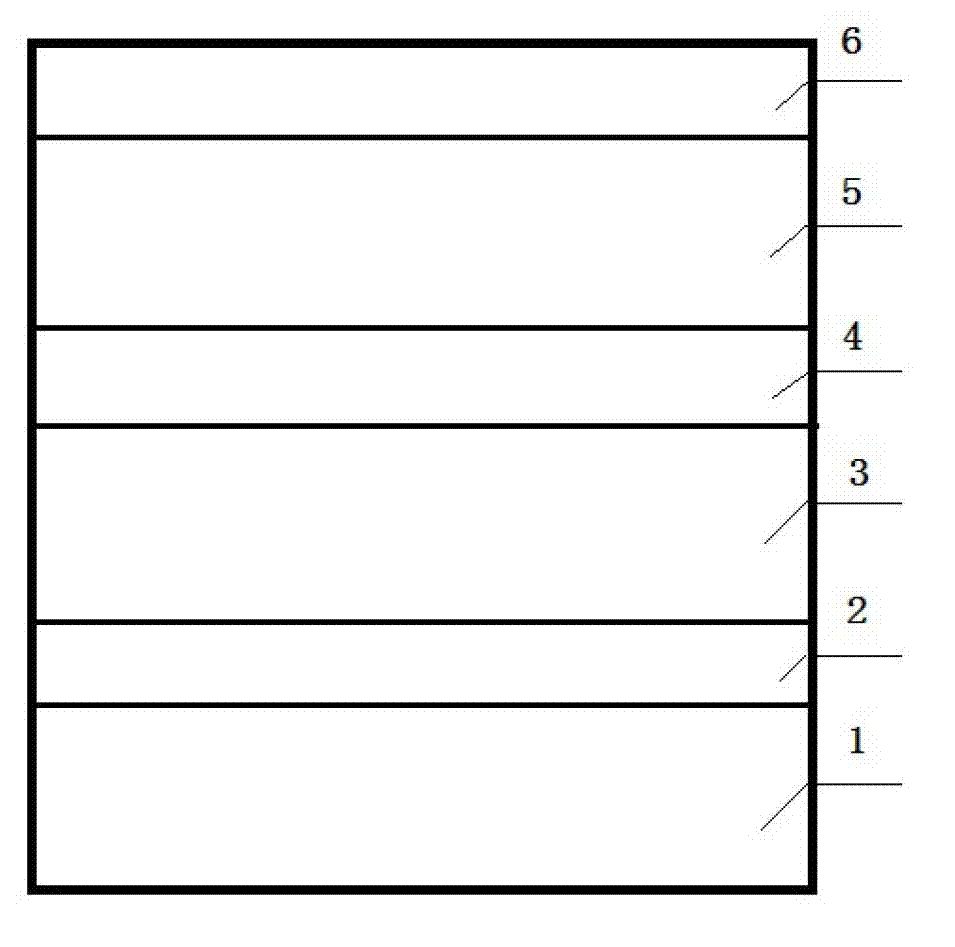

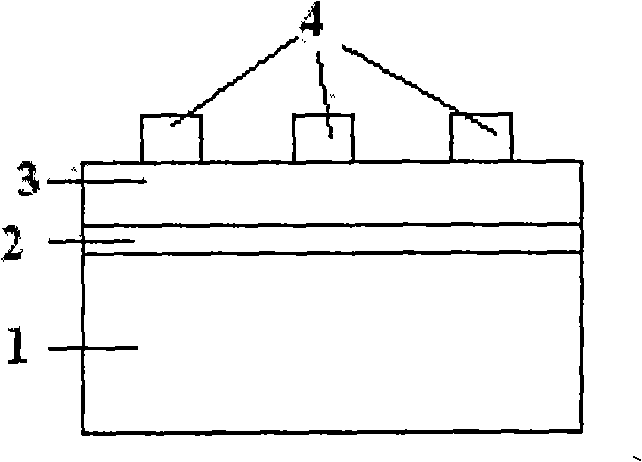

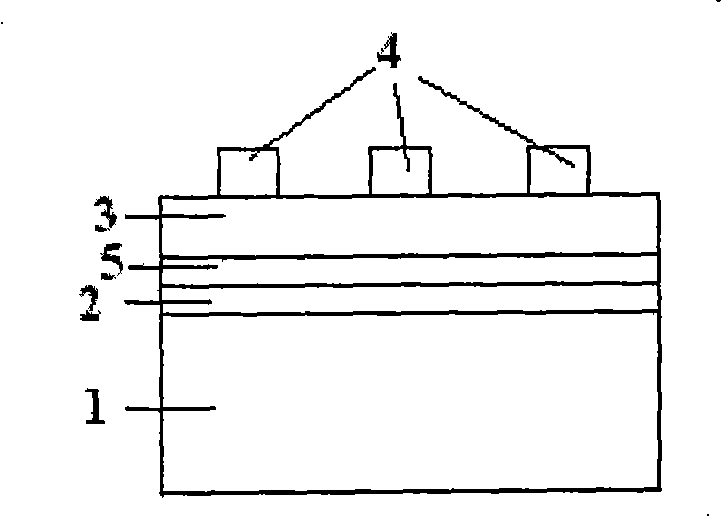

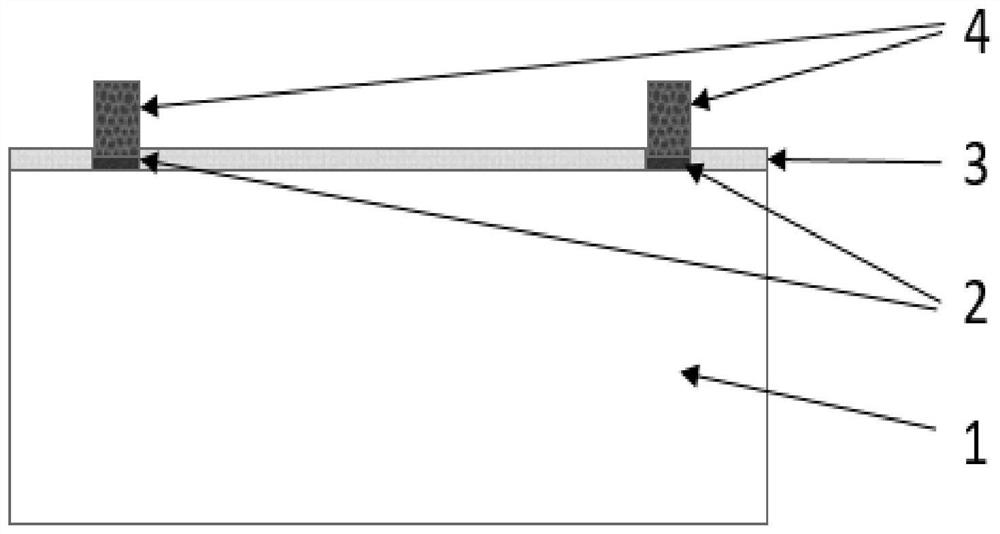

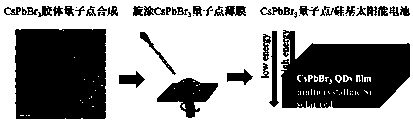

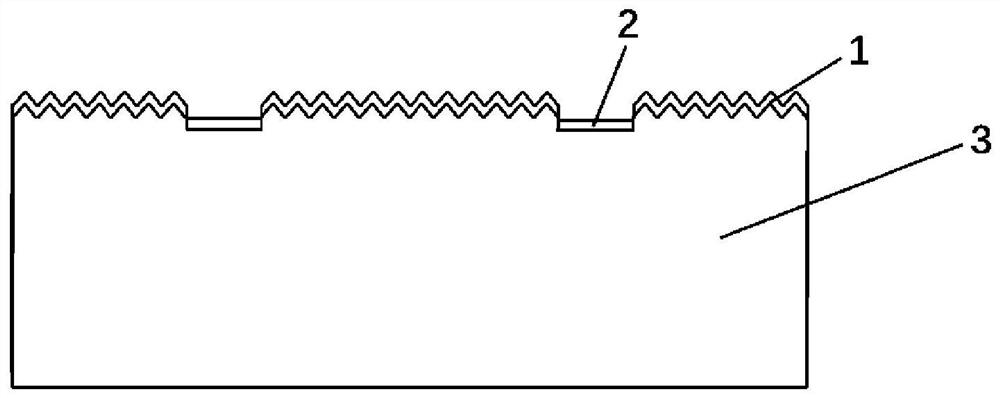

Emitter electrode structure capable of improving crystal silicon solar battery shortwave response

ActiveCN101325225AImprove shortwave responseEnhanced emitter structurePhotovoltaic energy generationSemiconductor devicesDopantCrystalline silicon

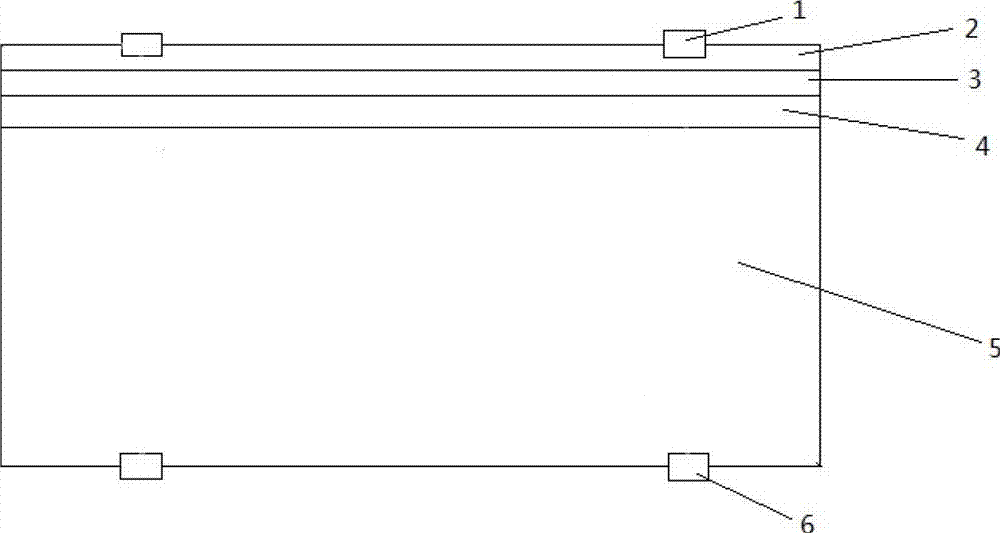

An emitter structure for improving shortwave response of crystalline silicon solar cells sequentially comprises a doped crystalline silicon substrate (1); a crystalline silicon layer (2), which is prepared on the crystalline silicon substrate (1) and has an opposite dopant type to the dopant of the crystalline silicon substrate (1); a transparent conducting electrode layer (3) prepared on the crystalline silicon layer (2); and a metal grid line (4) prepared on the transparent conducting electrode layer (3).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Preparation process of shallow junction solar battery

InactiveCN102969402AImprove shortwave responseIncrease the open circuit voltageFinal product manufactureSemiconductor devicesPhysicsSheet resistance

The invention discloses a preparation process of a shallow junction solar battery. The preparation process of the shallow junction solar battery comprises the following steps: a. cleaning a silicon wafer, removing a damaged layer, and making herbs into wool; b. spraying phosphoric acid on the surface of the silicon wafer; c. putting the silicon wafer into a chain-type diffusion furnace, and diffusing; d. removing phosphorosilicate glass for the diffused silicon wafer and etching a surface dead layer; e. depositing silicon nitride on the surface of an emitting electrode and passivating an antireflection layer; f. carrying out silk-screen printing on a back electrode and a positive surface electrode or electroplating the positive surface electrode; and g. sintering, testing and sorting. The preparation process of the shallow junction solar battery guarantees that sheet resistance is distributed uniformly based on a shallow junction, has much low saturation current density of the emitting electrode, improves the short-wave response of the solar battery obviously, and improves the open circuit voltage and short circuit voltage of the solar battery.

Owner:泰州德通电气有限公司

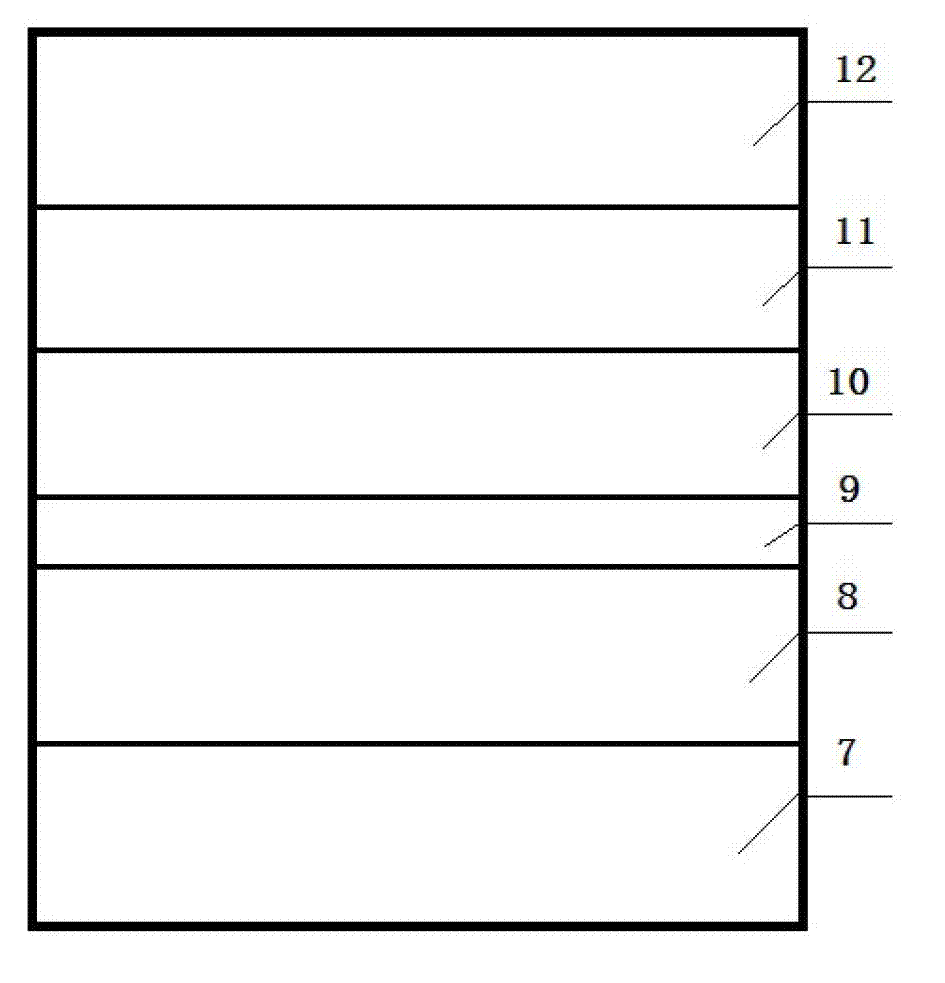

Multilayer passivation film of crystalline-silicon battery and manufacturing method thereof

InactiveCN106409926ADecrease the density of surface statesImprove shortwave responseFinal product manufacturePhotovoltaic energy generationCrystalline siliconSilicon oxide

The invention discloses a multilayer passivation film of a crystalline-silicon battery and a manufacturing method thereof. The multilayer passivation film comprises a first silicon oxide film, a silicon nitride film, a second silicon oxide film and a silicon oxynitride film. The silicon nitride film is deposited on the first silicon oxide film; the second silicon oxide film is deposited on the silicon nitride film; and the silicon oxynitride film is deposited on the second silicon oxide film. The thickness of the first silicon oxide film is 5 to 9 nm, the thickness of the silicon nitride film is 60 to 90 nm, the thickness of the second silicon oxide film is 10 to 20nm, and the thickness of the silicon oxynitride film is 15 to 30nm. According to the invention, the probability of total reflection of light is improved substantially and thus more light enters a silicon wafer to generate more carriers, so that the battery efficiency is enhanced.

Owner:庞倩桃

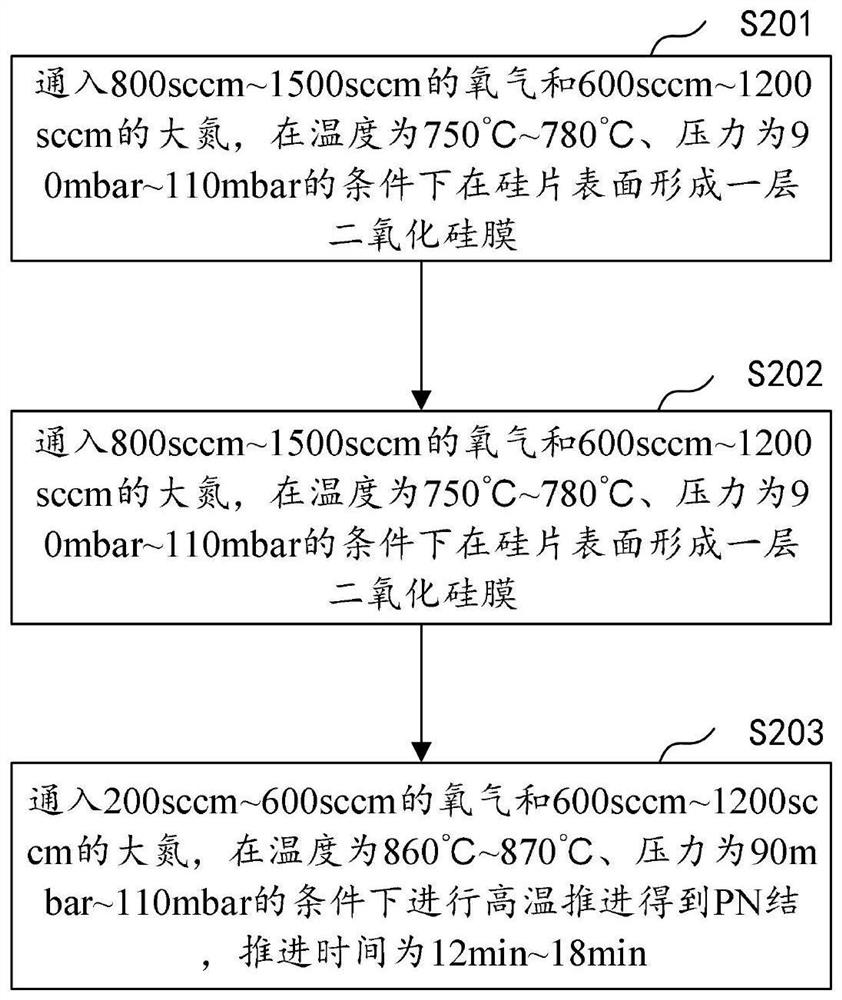

Low-pressure oxidization process for crystalline silicon small-textured structure

InactiveCN107681022ASolving Surface Passivation ProblemsExtend your lifeFinal product manufacturePhotovoltaic energy generationCrystalline siliconShort Waves

The invention discloses a low-pressure oxidization process for a crystalline silicon small-textured structure. The low-pressure oxidization process is carried out on a crystalline silicon wafer with the textured dimension of 0.1-2[mu]m to generate a layer of uniform SiO<2> layer on the surface of the crystalline silicon small-textured structure, so that the surface recombination rate is lowered, the minority carrier lifetime is prolonged, the problem of surface passivation of the crystalline silicon small-textured structure is solved, the surface doping concentration of an emitter can be lowered, the problem of overhigh surface doping concentration of the small-textured structure can be solved, the influence from "dead layer" can be weakened obviously, and the short-wave response of the battery can be improved; meanwhile, the oxidization process is performed in a low-pressure state, so that gas stability and uniformity and environment cleanliness in a diffusion furnace tube can be improved, the sheet resistance uniformity after oxidization is greatly improved and the battery efficiency is improved; and meanwhile, the problem of abnormal appearance of the silicon wafer surface in normal-pressure oxidization can be solved, the number of the abnormal white spots and the like on the silicon wafer surface can be obviously reduced, and the battery product quality is improved effectively.

Owner:CECEP SOLAR ENERGY TECH (ZHENJIANG) CO LTD

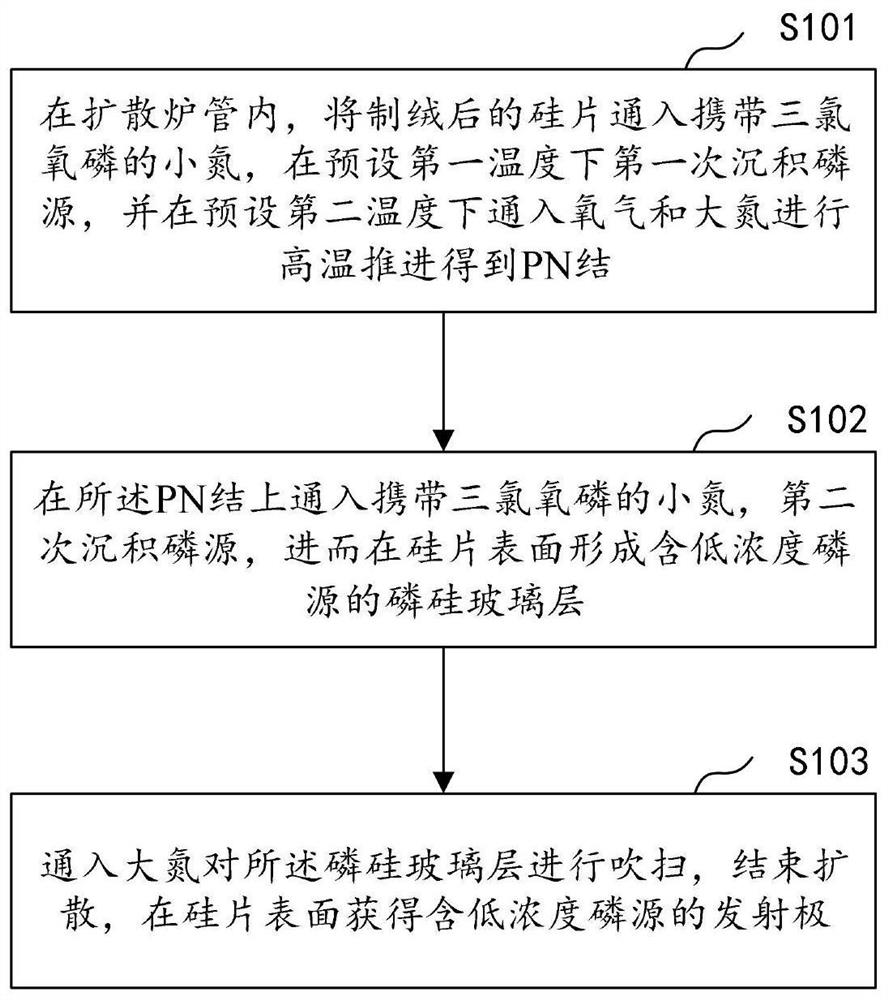

Diffusion process of solar cell, preparation method of solar cell and silicon wafer

PendingCN113437182AImprove conversion efficiencyReduce surface concentrationPolycrystalline material growthAfter-treatment detailsChemical physicsPhysical chemistry

The invention discloses a diffusion process of a solar cell, a preparation method of the solar cell and a silicon wafer, and the diffusion process comprises the steps: introducing small nitrogen carrying phosphorus oxychloride into the textured silicon wafer in a diffusion furnace tube, depositing a phosphorus source at a first temperature, and introducing oxygen and large nitrogen at a second temperature for high-temperature propulsion to obtain a PN junction; introducing small nitrogen carrying phosphorus oxychloride, secondarily depositing a phosphorus source, and further forming a phosphorosilicate glass layer containing a low-concentration phosphorus source on the surface of the silicon wafer; and introducing atmospheric nitrogen to purge, ending diffusion, and obtaining an emitter containing the low-concentration phosphorus source on the surface of the silicon wafer. According to the method, a two-step source deposition mode is adopted, phosphorus oxychloride is deposited in a low-temperature environment, the surface concentration of a silicon wafer can be fully reduced, meanwhile, the uniformity of PN junctions is guaranteed by controlling the gas flow ratio of large nitrogen, oxygen and small nitrogen deposited by a phosphorus source, and the conversion efficiency of a solar cell can be effectively improved.

Owner:CSG PVTECH +1

Phosphorus gettering process of silicon chips

InactiveCN104300040AImprove uniformityImprove average conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingEtchingNitrogen gas

The invention relates to a phosphorus gettering process of silicon chips, and belongs to the field of photovoltaic technologies. The phosphorus gettering process comprises the steps of putting sueded silicon chips into a diffusion furnace, supplying nitrogen, phosphorus oxychloride and oxygen, heating and carrying out diffusion. The diffusion is carried out by three stages which are a first step of diffusion, a second step of diffusion and annealing, and the silicon chips are cooled to the room temperature after deposition. According to the invention, heavily doped dead layers can be effectively decreased, and the average minority carrier lifetime of the silicon chips is greatly prolonged; and after the processes including etching, PECVD, silk screen sintering and the like are finished according to the normal process of a cell piece, the average transformation efficiency of the made cell piece is further improved, and the cell piece has better electrical performance parameters.

Owner:无锡尚品太阳能电力科技有限公司

Manufacturing method of N-type battery boron expansion SE structure

PendingCN113948374AImprove shortwave responseReduce contact resistanceFinal product manufactureSemiconductor/solid-state device manufacturingScreen printingMetallic electrode

The invention provides a manufacturing method of an N-type battery boron diffusion SE structure. A method of manufacturing a lightly doped region by high-temperature diffusion and manufacturing a heavily doped region by matching with laser slotting and boron paste printing is adopted to form the N-type battery boron diffusion SE structure. Due to the fact that laser slotting and boron paste printing patterns of the heavily-doped area are consistent with silk-screen printing patterns, the cell front face structure enables the non-printing area to be lightly-doped high-sheet-resistance, short-wave response of light rays is improved, meanwhile, the silk-screen printing area is heavily-doped low-sheet-resistance, and contact resistance of a front metal electrode is reduced, so the short-circuit current, the open-circuit voltage and the fill factor are well improved, and the conversion efficiency is improved.

Owner:普乐新能源科技(泰兴)有限公司

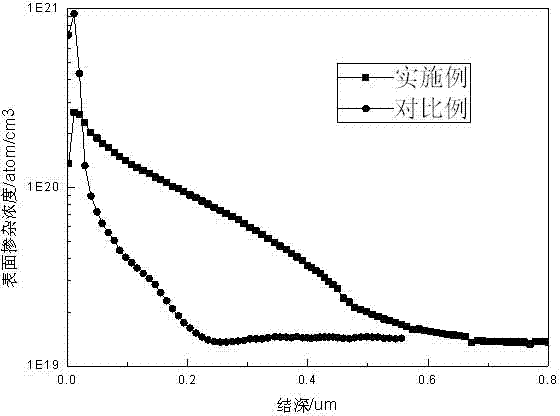

Crystal wafer and diffusion method thereof

ActiveCN102737964AReduced Auger RecombinationExtend your lifeSemiconductor/solid-state device manufacturingSemiconductor devicesDiffusion methodsHigh surface

The invention discloses a diffusion method of a crystal wafer, which comprises the following steps that (1) the crystal wafer is made into wool and cleaned; (2) constant source diffusion is carried out, the atmosphere in a furnace comprises nitrogen, oxygen and pure nitrogen which carry diffusion sources, and the flow of the nitrogen, the oxygen and the pure nitrogen which carry the diffusion sources remains unchanged during a diffusion process; (3) impurity glass is removed, and cleaning is carried out; (4) limited source diffusion is carried out, only the nitrogen and the oxygen are fed in during the diffusion process, and the flow of the nitrogen and the oxygen remains unchanged; (5) diffusion is over, and the wafer is taken out; the surface doping concentration of the wafer is 1*1020atom / cm<3> to 5*1020atom / cm<3>; and the depth of a PN junction is 0.5mum to 1mum. According to the diffusion method, the 'dead-layer' effect caused by high surface doping concentration is effectively reduced, the auger recombination of surface photon-generated carrier is reduced, and the minority carrier lifetime is prolonged.

Owner:CSI CELLS CO LTD +1

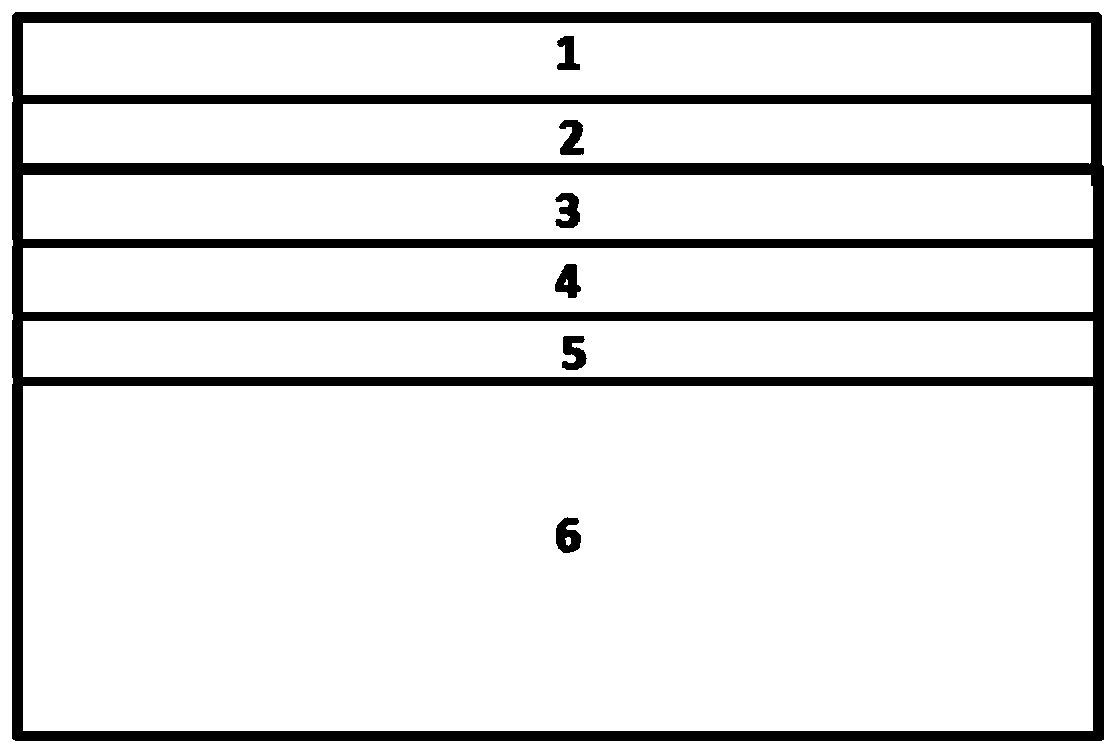

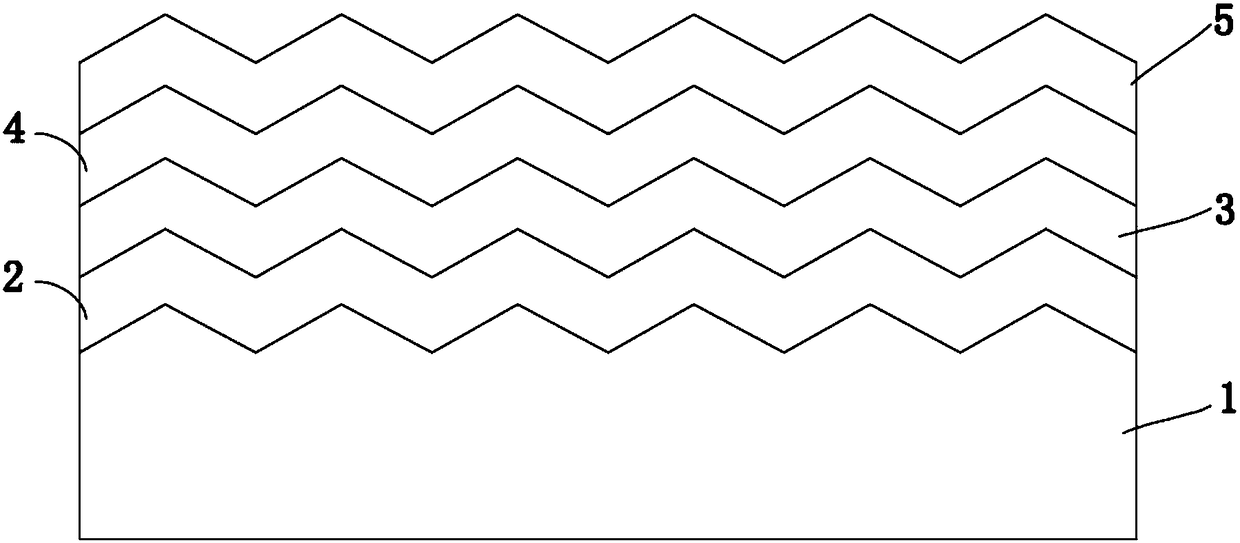

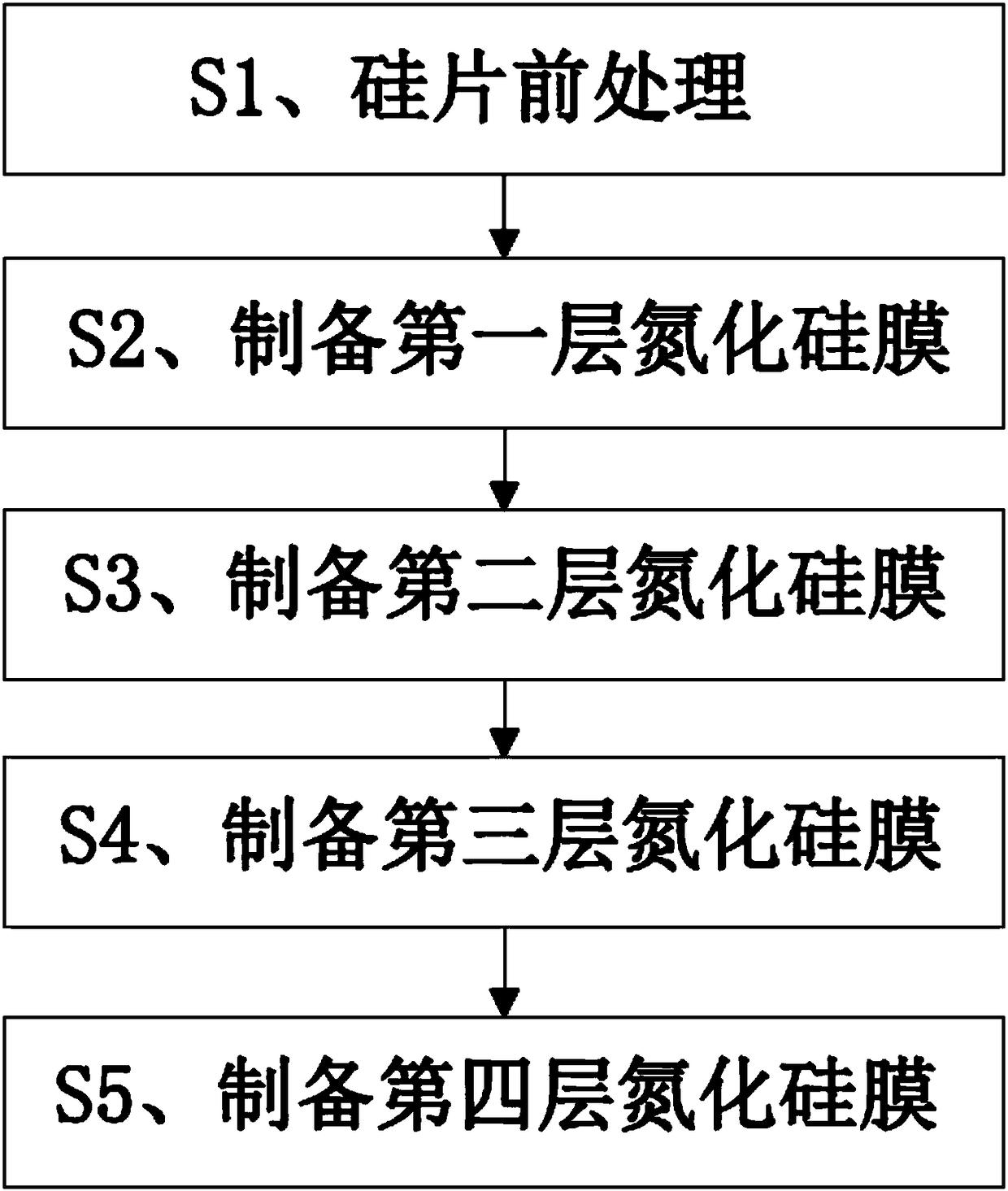

Front film layer structure capable of improving conversion efficiency of PERC battery and preparation method

ActiveCN108110066AGood refractive indexGood shortwave responsePhotovoltaic energy generationSemiconductor devicesRefractive indexEnergy conversion efficiency

The invention discloses a front film layer structure capable of improving the conversion efficiency of a PERC battery. The front film layer structure comprises a silicon wafer, wherein the thickness of a first silicon nitride film is 10+ / -2nm and the refractive index is 2.67+ / -0.05; the thickness of a second silicon nitride film is 15+ / -2nm and the refractive index is 1.91+ / -0.05; the thickness ofa third silicon nitride film is 5+ / -2nm and the refractive index is 1.33+ / -0.05; and the thickness of a fourth silicon nitride film is 50+ / -3nm and the refractive index is 0.86+ / -0.05. The inventionfurther discloses a preparation method used for preparing the front film layer structure capable of improving the conversion efficiency of the PERC battery. The method comprises the following steps of(S1) silicon wafer pretreatment; (S2) preparation of the first silicon nitride film; (S3) preparation of the second silicon nitride film; (S4) preparation of the third silicon nitride film; and (S5)preparation of the fourth silicon nitride film. According to the film layer structure, short-wave response of the battery can be improved, light absorption of the battery can be improved, short-circuit current of the battery is increased, improvement of the photoelectric conversion efficiency of the battery is finally achieved and the target of improving the efficiency is achieved.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

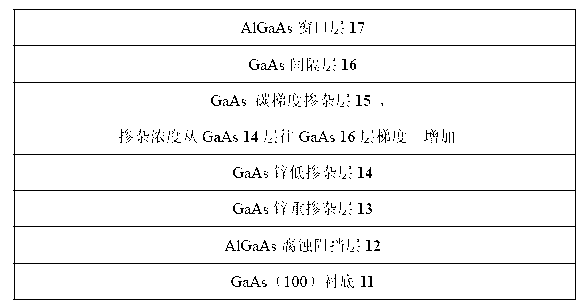

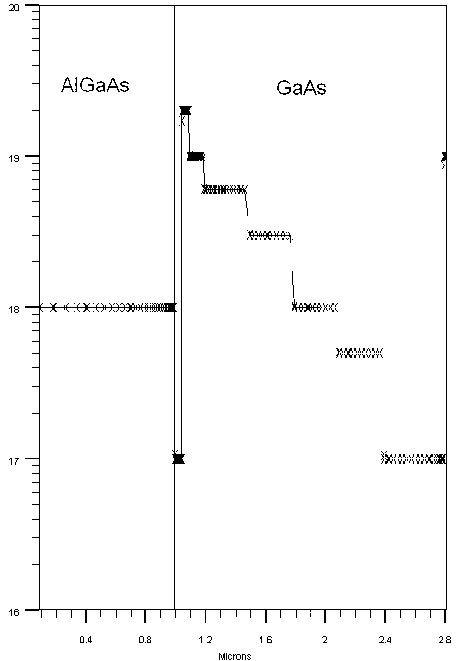

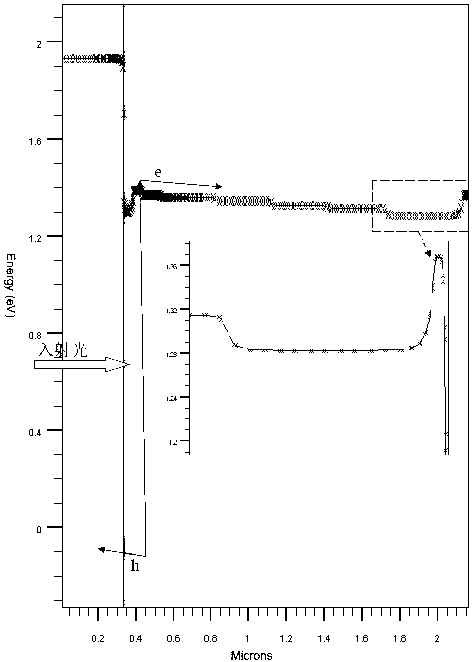

Variable doping structure of transmission-type photoelectric cathode material for enhancing thermal stability

ActiveCN103123885AReduce the rate of minority carrier recombinationImprove thermal stabilityPhoto-emissive cathodesPhotocathodeHeat stability

The invention discloses a variable doping structure of a transmission-type photoelectric cathode material for enhancing thermal stability. An AlGaAs corrosion barrier layer, a GaAs zinc heavy doping layer, a GaAs zinc light doping layer, a GaAs carbon gradient doping layer, a GaAs spacer layer and an AlGaAs window layer are arranged sequentially upwards on a GaAs100 substrate material layer. The variable doping structure of the transmission-type photoelectric cathode material for enhancing the thermal stability has the advantages of: enhancing short wave response of a transmission-type GaAs or InGaAs photoelectric cathode and improving the thermal stability during the photoelectric cathode technical process as the carbon doping and variable doping technologies are adopted; reducing a caesiated exhaustion region and increasing an escaping probability of photon-generated carriers as the variable doping comprehensively adopts zinc and carbon doping, and a caesiated surface adopts the zinc heavy doping; reducing a recombination rate of minority carriers of the interface as the interface of the window layer adopts the carbon light doping; and optimizing a high-performance photoelectric cathode as the carbon variable doping is adopted between an interface of the window layer and the zinc heavy doping layer to form a built-in electric field with good thermal stability.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Silicon carbon window layer film with refractive index gradient characteristics and application

InactiveCN104362183AEnhanced built-in electric fieldIncrease the open circuit voltageFinal product manufactureChemical vapor deposition coatingRefractive indexThin membrane

The invention discloses a silicon carbon window layer film with refractive index gradient characteristics and application. The carbon content of the film ranges from 30% to 80%, low discharge power density adjacent to the intrinsic layer is adopted, and the discharge power density is increased gradually with the increase of the thickness of the film according to a formula that P (t) = P0 + A*t, the P is the discharge power, the P0 is the initial power density, the A is a linear rate, the t is the discharge time, discharge power density longitudinal gradient change is implemented finally, and the change of the refractive index at the 400nm wavelength ranges from 2.8 to 2.2; the film is applied to silicon film solar batteries. The film has the advantages that the optical band gap of material ranges from 2.0 to 3.7eV, the electrical conductivity ranges from 0.1 to 5.0 omega*cm, the window layer optical loss is reduced effectively, the filling factors, open circuit voltage and short wave response speed of a solar battery can be increased significantly, and the photoelectric conversion efficiency is improved finally.

Owner:NANKAI UNIV

Technology for preparing emitting electrode without dead layer by adopting alkaline method and texturization

InactiveCN102623556AImprove performanceRemove low square resistanceFinal product manufactureSemiconductor devicesSilicon solar cellCrystalline silicon

The invention belongs to the technical field of manufacturing of crystal silicon solar cells, and in particular relates to a technology for preparing an emitting electrode without a dead layer by adopting an alkaline method and texturization. The emitting electrode without the dead layer and excellent performance is prepared by adopting a diffusion and texturization method; and by the technology, a dead layer emitting electrode region on the surface of a cell sheet can be effectively removed, the short wave response of the solar cell is improved, dark current is reduced, the open-circuit voltage of the cell sheet is effectively improved, and industrialized production is facilitated.

Owner:山东力诺太阳能电力股份有限公司

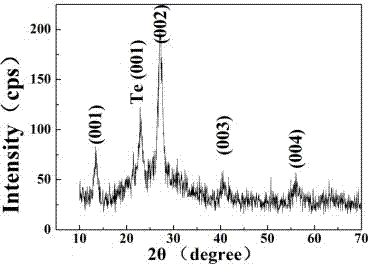

Flexible cadmium telluride solar cell with graphene insertion layer

ActiveCN105355674AImprove mobilityEfficient separationPhotovoltaic energy generationSemiconductor devicesMaterials sciencePhotochemistry

The invention discloses a flexible cadmium telluride solar cell with a graphene insertion layer. With nickel foil as a substrate and graphene as the insertion layer, the nickel foil and the graphene are arranged on the substrate; and a doped layer and a barrier layer are fabricated behind the insertion layer to form a back contact layer of the flexible cadmium telluride solar cell. Meanwhile, a ZnO-based transparent conductive composite thin film is adopted by a front contact layer; and a copper-free structural design and a copper-free technological treatment process are adopted by the solar cell, so that the photoelectric conversion efficiency of the flexible solar cell can be greatly improved; the long-term stability of a device is improved; and the structural design of the device and the selection of the back contact layer are well compatible to the technological process. In addition, due to the self-support characteristics of the graphene insertion layer, the graphene can be stripped from the metal substrate as an independent transparent cell, and can also be transplanted to a bottom cell to fabricate an efficient laminated cell.

Owner:SICHUAN UNIV

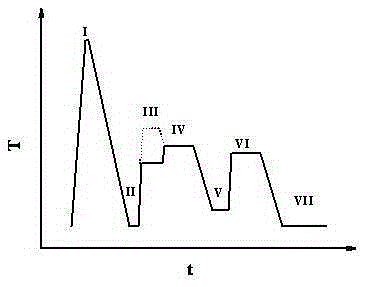

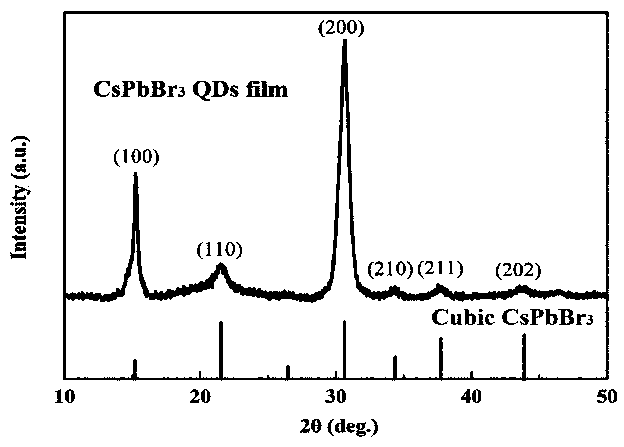

CsPbBr3 quantum dot-silicon based composite structure solar cell

InactiveCN109950330ALarge absorption cross sectionImprove light absorptionPhotovoltaic energy generationSemiconductor devicesFluorescenceWave response

The invention relates to a CsPbBr3 quantum dot-silicon based composite structure solar cell in the field of solar cells. The solar cell comprises a silicon-based solar cell and a CsPbBr3 quantum dot film coated on the surface of the silicon cell, and the thickness of the CsPbBr3 quantum dot film is 20-25nm. According to the CsPbBr3 quantum dot-silicon based composite structure solar cell, the CsPbBr3 quantum dot film is prepared in the surface of the silicon based solar cell in a spin coating method to form the CsPbBr3 quantum dot-silicon based composite structure solar cell, a fluorescence downward transfer layer is formed in the surface of the silicon based solar cell, compared with a traditional II-VI family compound quantum dot downward transfer material, the CsPbBr3 quantum dots havethe advantages of large absorption cross section and high absorptivity, the short wave response and photovoltaic characteristic of the cell can be enhanced by spin-coating a single film, adverse influence of increasing the serial connection resistance due to the fact that the downward transfer layer is too thick can be avoided, a film forming parameter is controllable, the surface reflectivity ofthe composite structure cell is reduced, short wave response is improved, long wave response is increased, the short-circuit current is increased, and the photovoltaic conversion efficiency of the cell is improved.

Owner:YANGZHOU UNIV

Preparation method of selective doping structure of solar cell

PendingCN112701192AReduced series resistanceImprove fill factorFinal product manufacturePhotovoltaic energy generationLaser processingPhysical chemistry

The invention belongs to the technical field of solar cells, and relates to a preparation method of a selective doping structure of a solar cell; the method comprises the following steps: step 1, pretreating the surface of a silicon wafer, and depositing a poly layer containing a doping source on the surface of the pretreated silicon wafer; step 2, carrying out laser processing on a part of the surface of the poly layer to form a heavily doped region; step 3, annealing the silicon wafer to form a lightly doped region in a non-laser-treated region on the surface of the poly layer, and introducing O2-containing gas in the annealing treatment process to oxidize the poly layer into a BSG / PSG layer; and step 4, cleaning the silicon wafer to remove the BSG / PSG layer so as to obtain the selective doping structure of the solar cell. According to the preparation method, the doping amounts of the lightly doped region and the heavily doped region of the selective doping structure can be accurately controlled, the preparation process and structure can be simplified, and the preparation efficiency is improved.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

Cadmium telluride solar cell with Te-Ti-Cu pre-set layer

InactiveCN104124290AAchieve ohmic contactInhibited DiffusionPhotovoltaic energy generationSemiconductor devicesOhmic contactContact layer

A cadmium telluride solar cell with a Te-Ti-Cu pre-set layer utilizes the pre-set Te-Ti-Cu layer of a periodic structure, and the pre-set Te-Ti-Cu layer is arranged on the back surface of an absorption layer of the cadmium telluride solar cell to be used as a back contact layer and a back electrode material of the cadmium telluride solar cell. The cadmium telluride solar cell with the Te-Ti-Cu pre-set layer can restrain copper diffusion on the material configuration and material property, eliminate the negative impact brought by copper diffusion, realize ohmic contact, avoid chemical corrosion and alone deposition of other metals as electrodes, reduce device production processes, enhance the photoelectric conversion efficiency of the solar cell and improve the long-term stability of devices.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com