Patents

Literature

193 results about "Surface concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

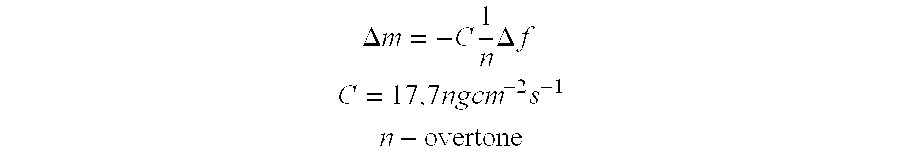

The surface excess concentration Γ is the area-related concentration of a surfactant at the surface or interface. It has the unit mol/m 2. Background. Due to the adsorption of a surfactant at the surface or interface, the surfactant concentration at this surface is very much higher than that of the volume phase.

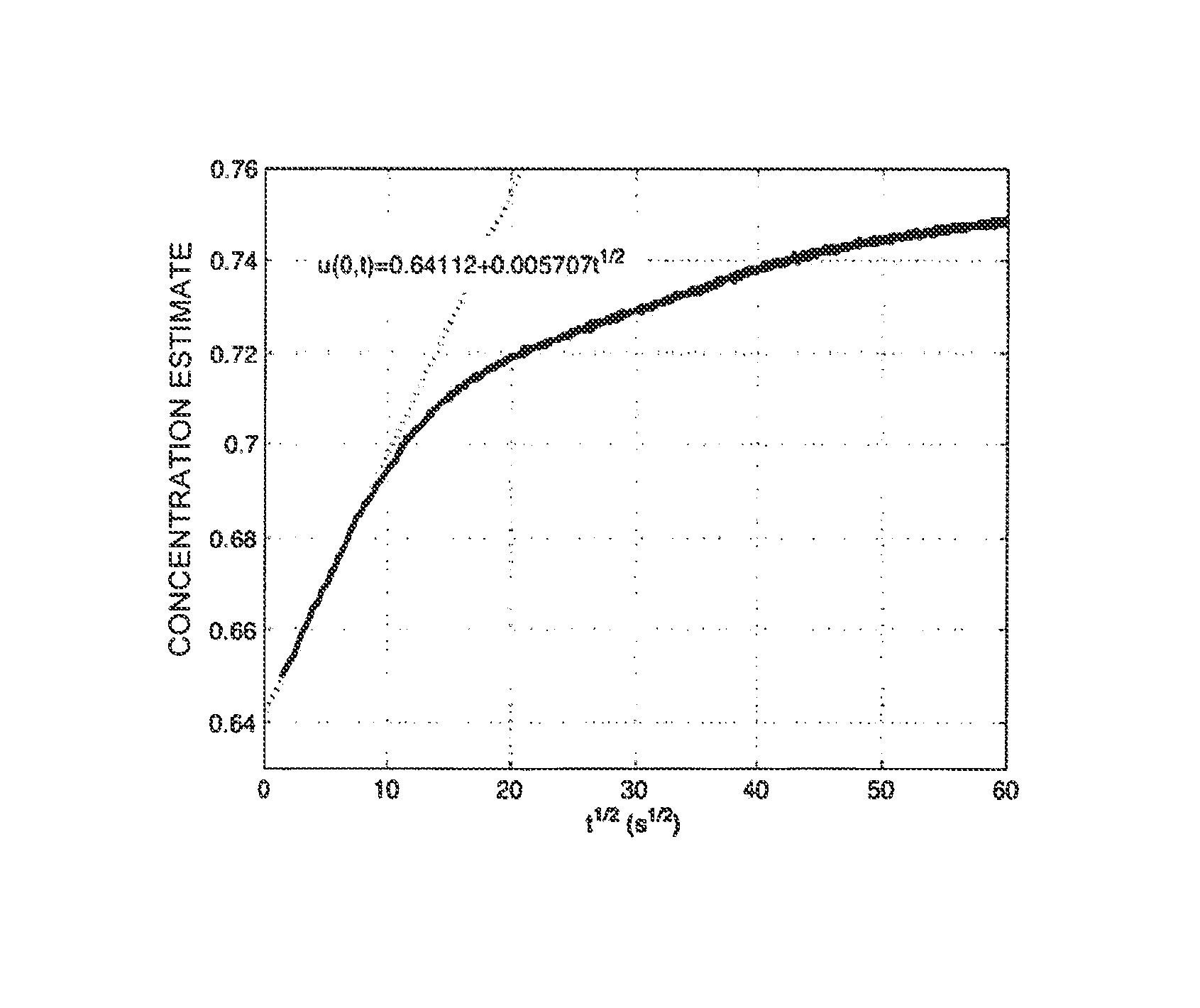

Diffusion-limited adaptive battery charging

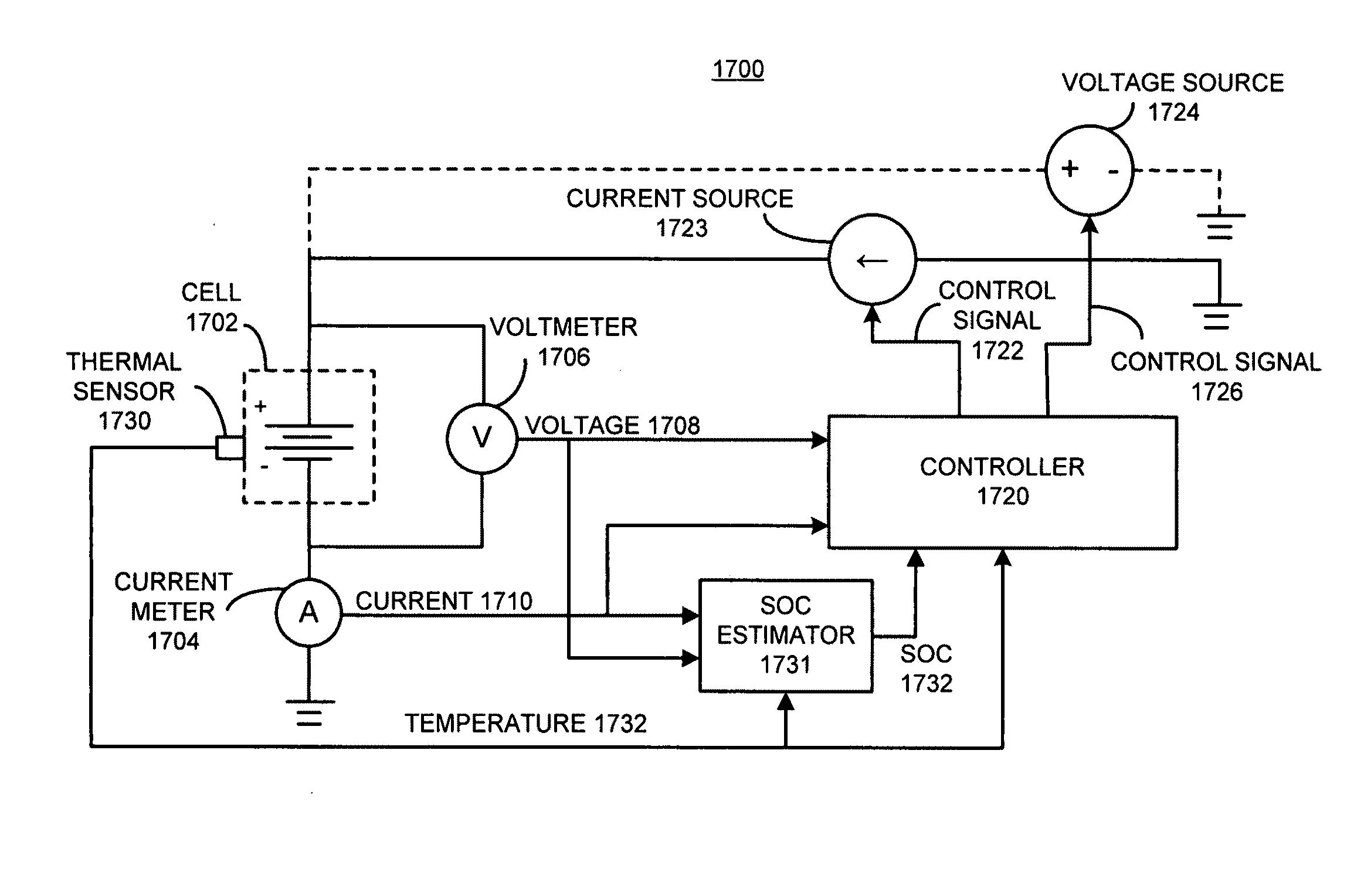

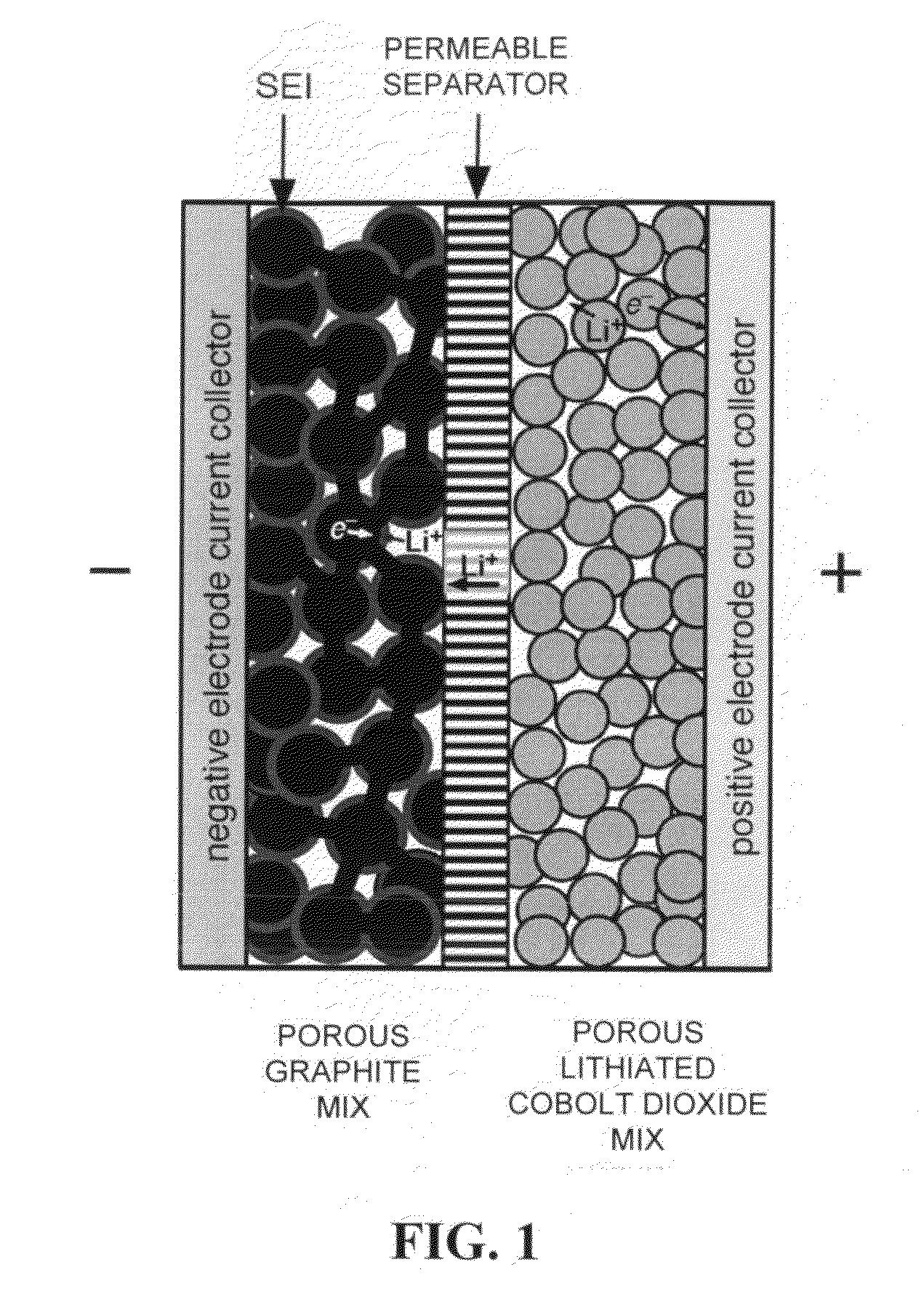

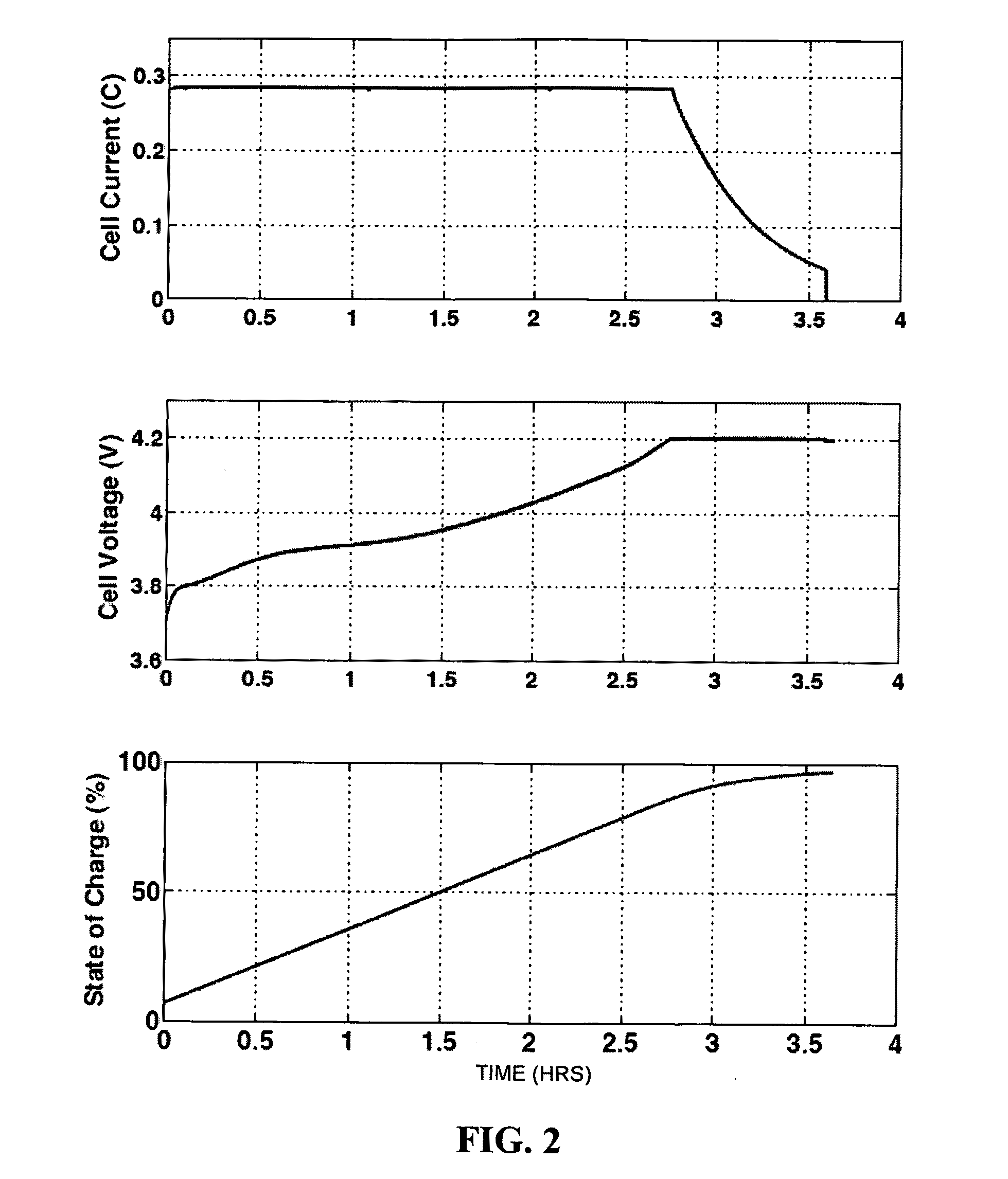

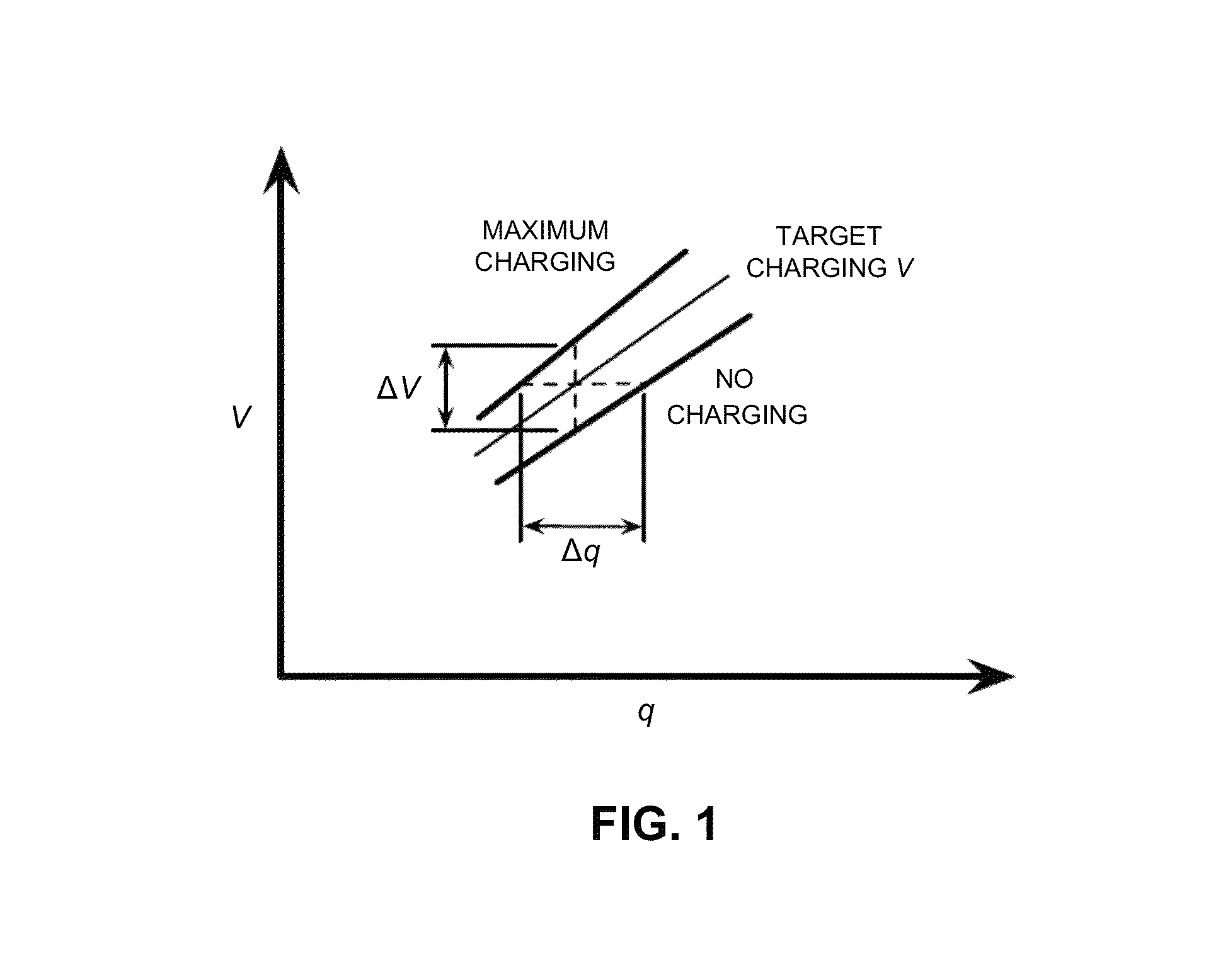

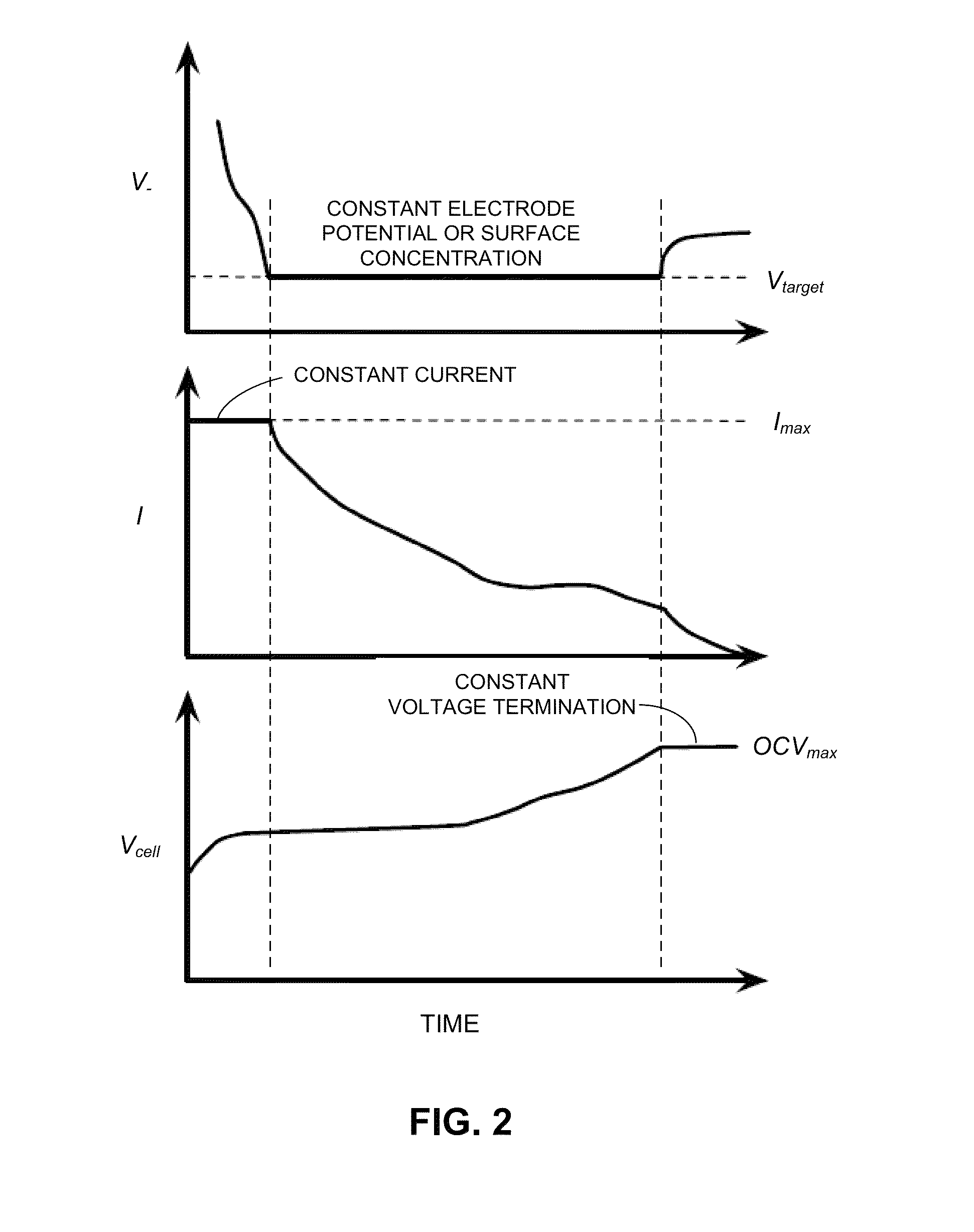

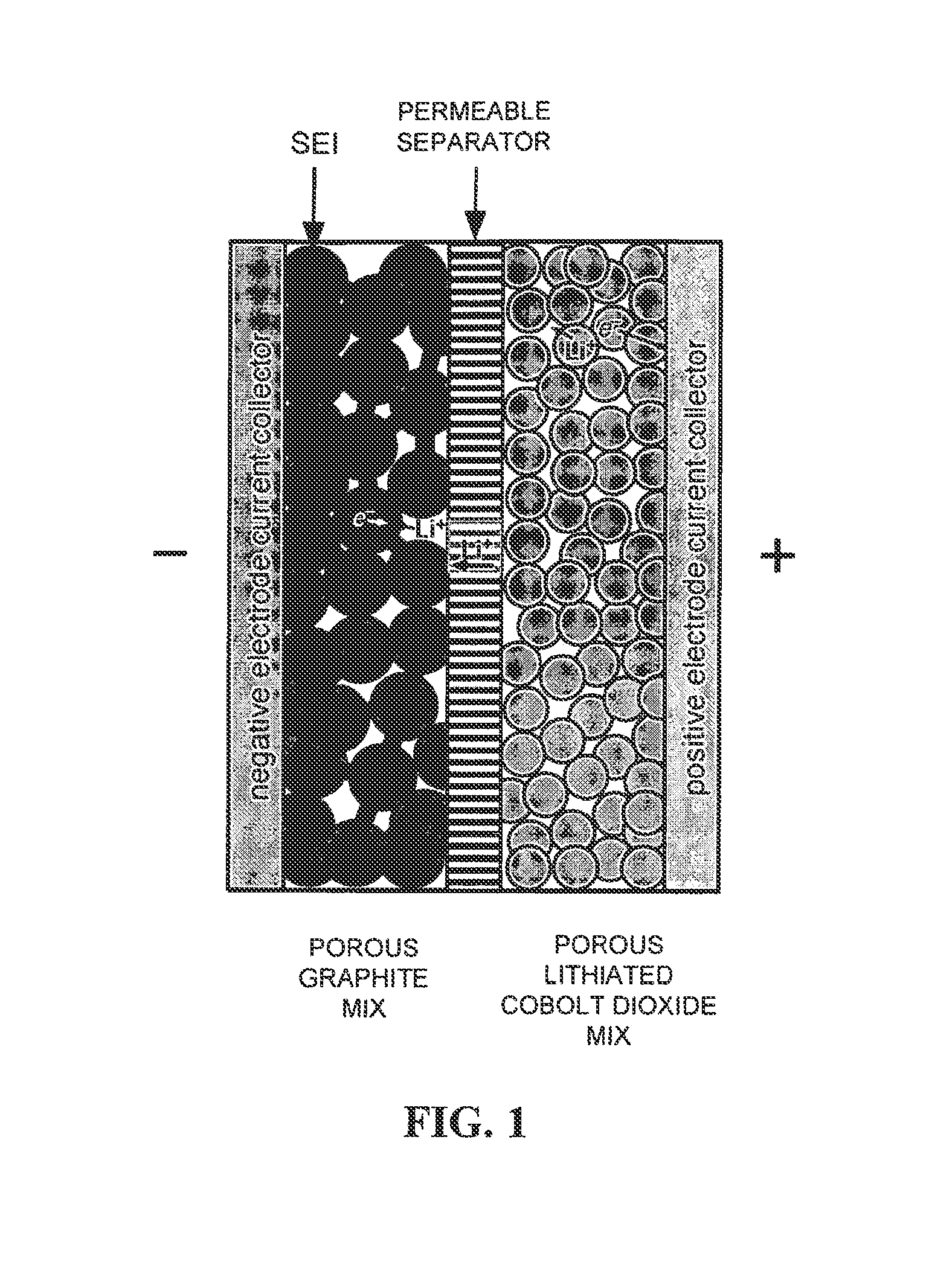

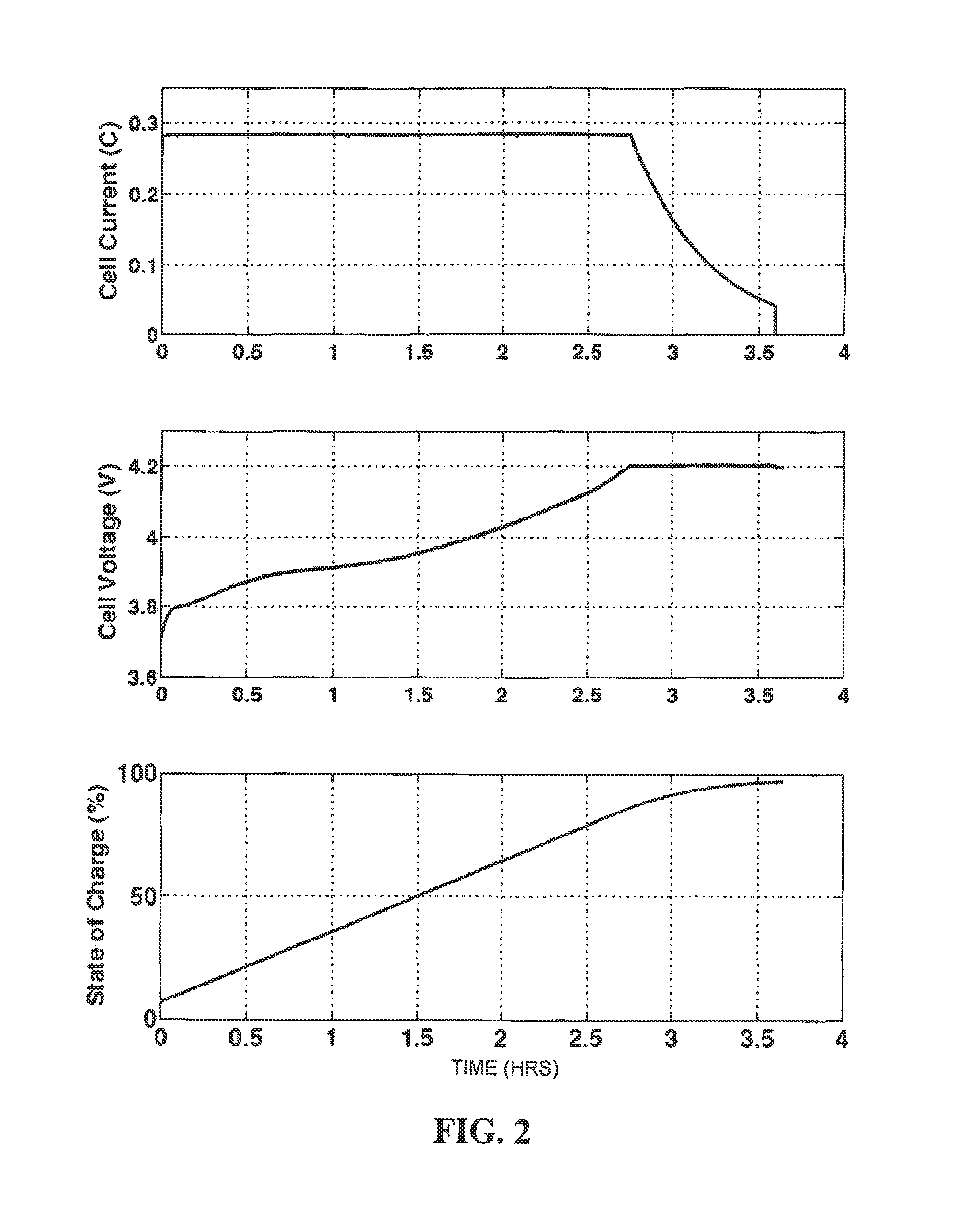

ActiveUS20090256528A1Acceleration measurementSecondary cells charging/dischargingSurface concentrationCharge current

Some embodiments of the present invention provide a system that adaptively charges a battery, wherein the battery is a lithium-ion battery which includes a transport-limiting electrode governed by diffusion, an electrolyte separator and a non-transport-limiting electrode. During operation, the system determines a lithium surface concentration at an interface between the transport-limiting electrode and the electrolyte separator based on a diffusion time for lithium in the transport-limiting electrode. Next, the system calculates a charging current or a charging voltage for the battery based on the determined lithium surface concentration. Finally, the system applies the charging current or the charging voltage to the battery.

Owner:APPLE INC

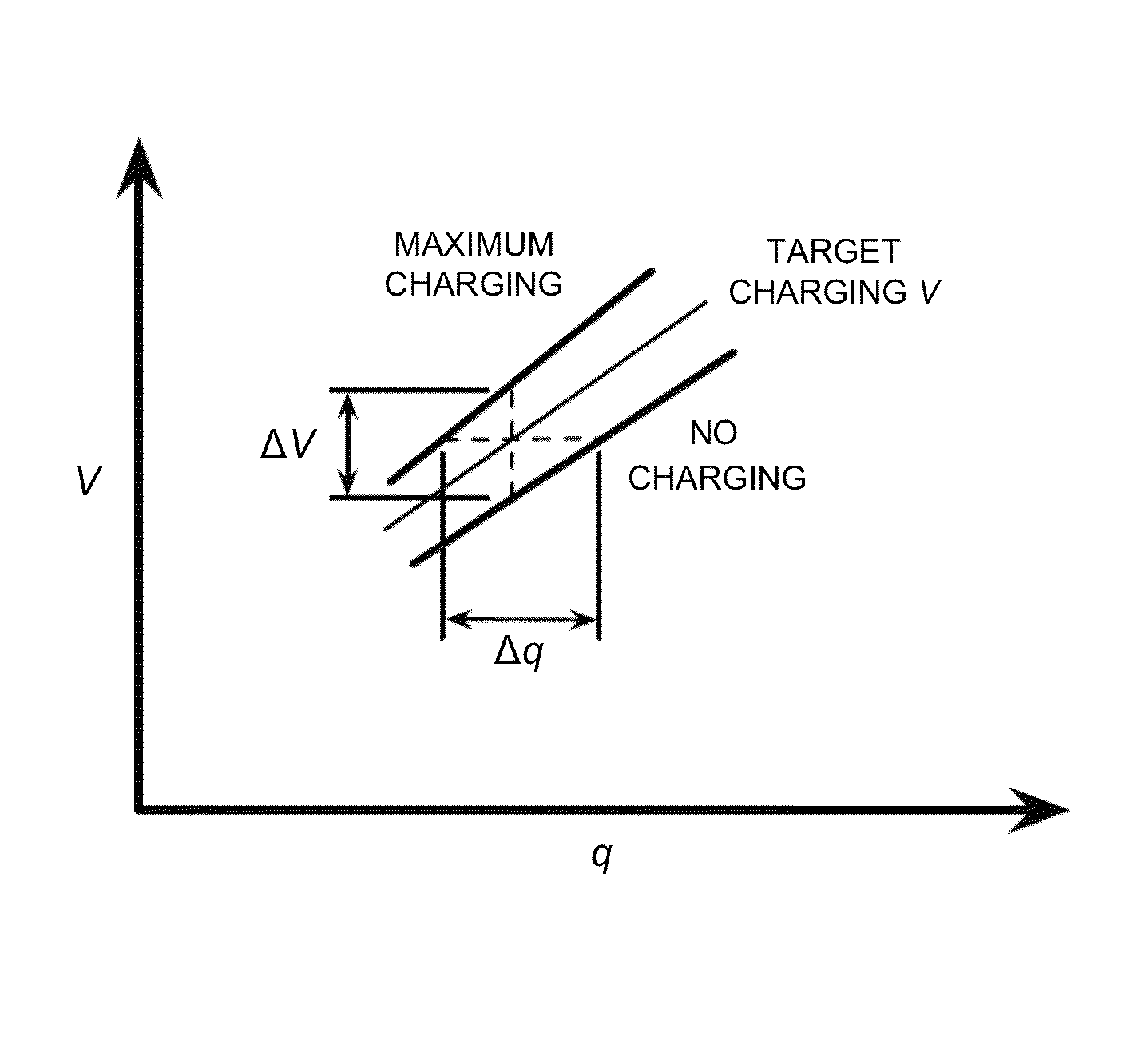

Controlling battery charging based on current, voltage and temperature

Some embodiments of the present invention provide a system that charges a lithium-ion battery. During operation, the system monitors: a current through the battery, a voltage of the battery, and a temperature of the battery. Next, the system uses the monitored current, voltage and temperature to control a charging process for the battery. In some embodiments, controlling the charging process involves: inferring electrode lithium surface concentrations for the battery from the monitored current, voltage and temperature; and applying the charging current and / or the charging voltage in a manner that maintains the inferred electrode lithium surface concentrations for the battery within set limits.

Owner:APPLE INC

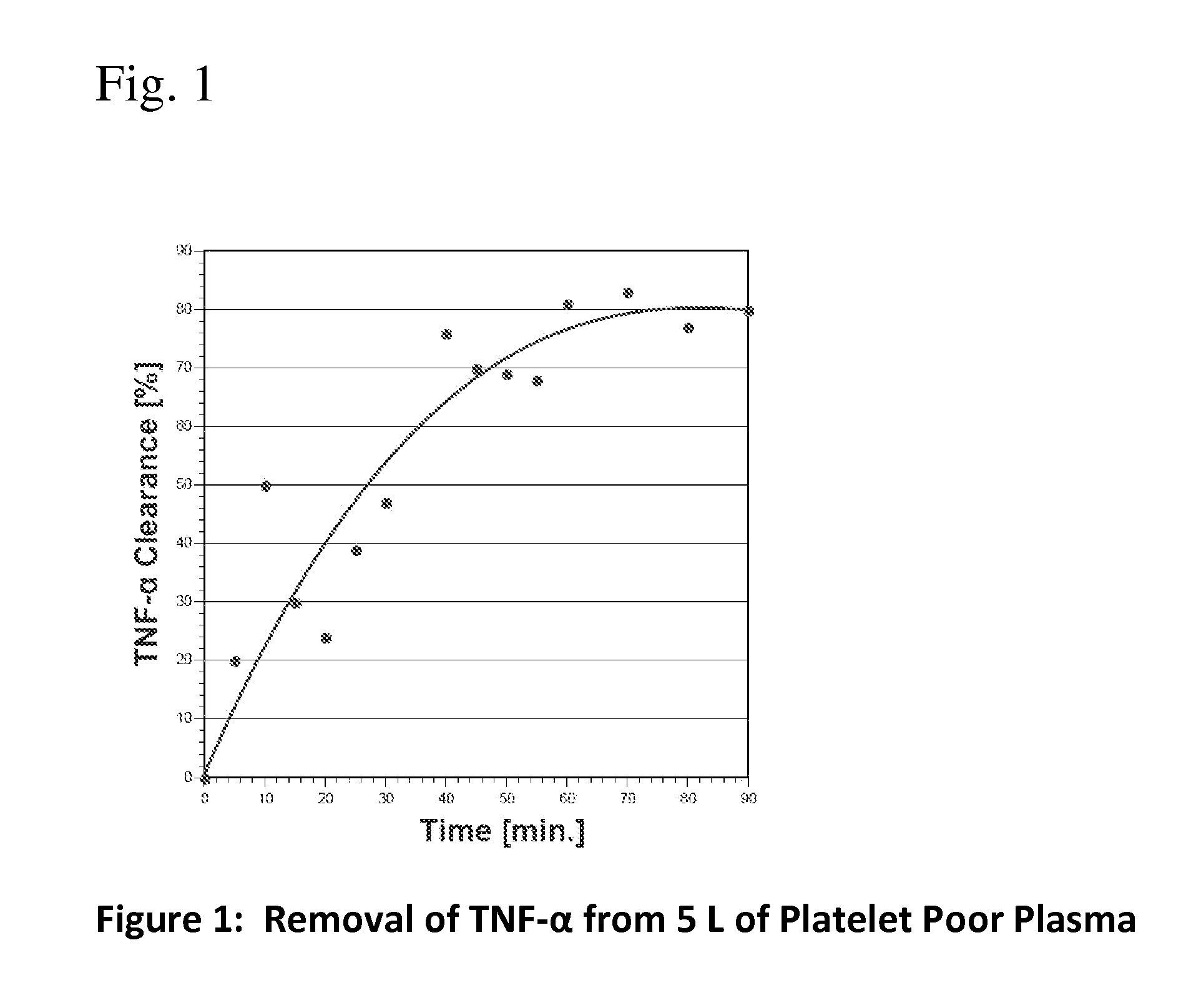

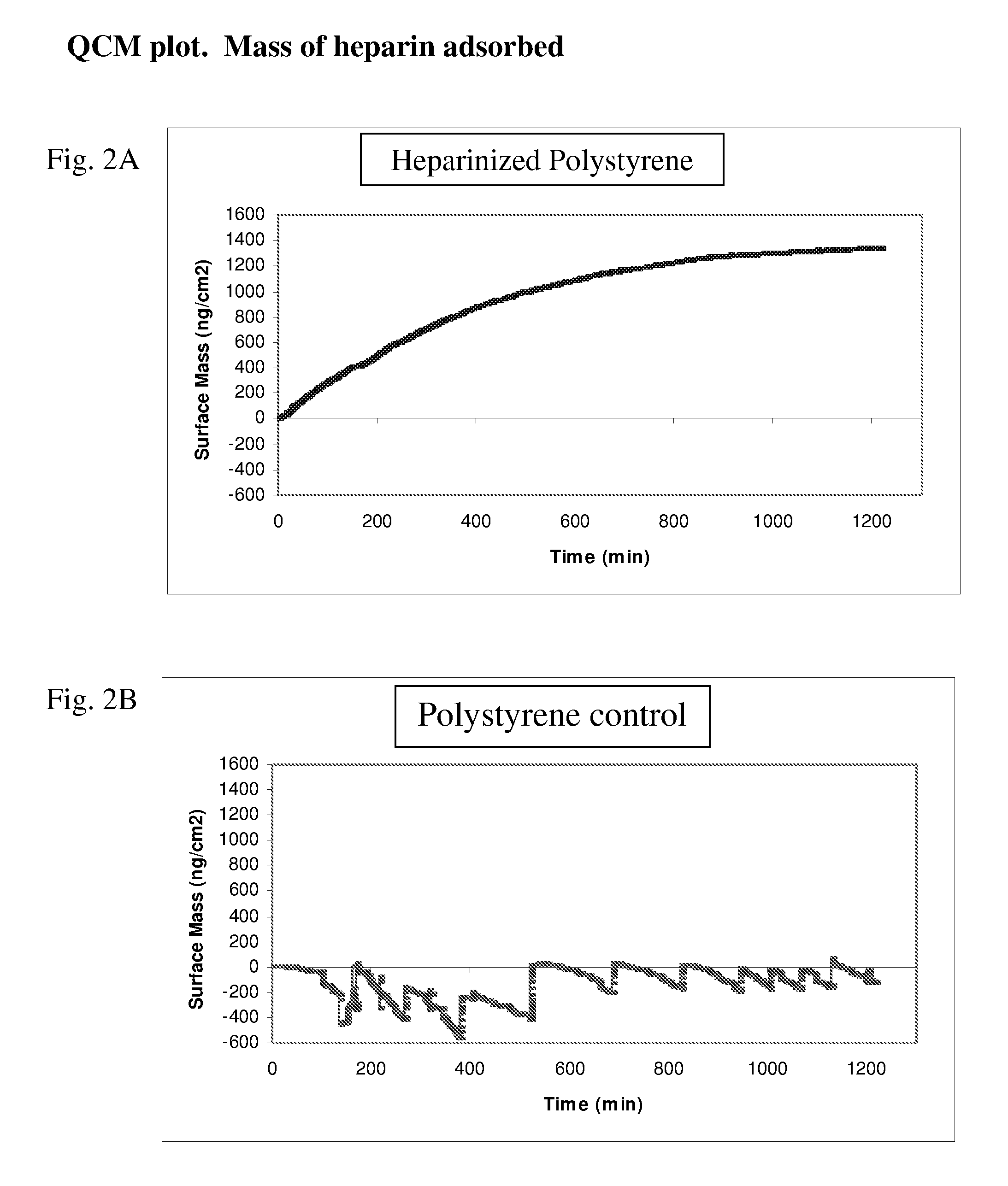

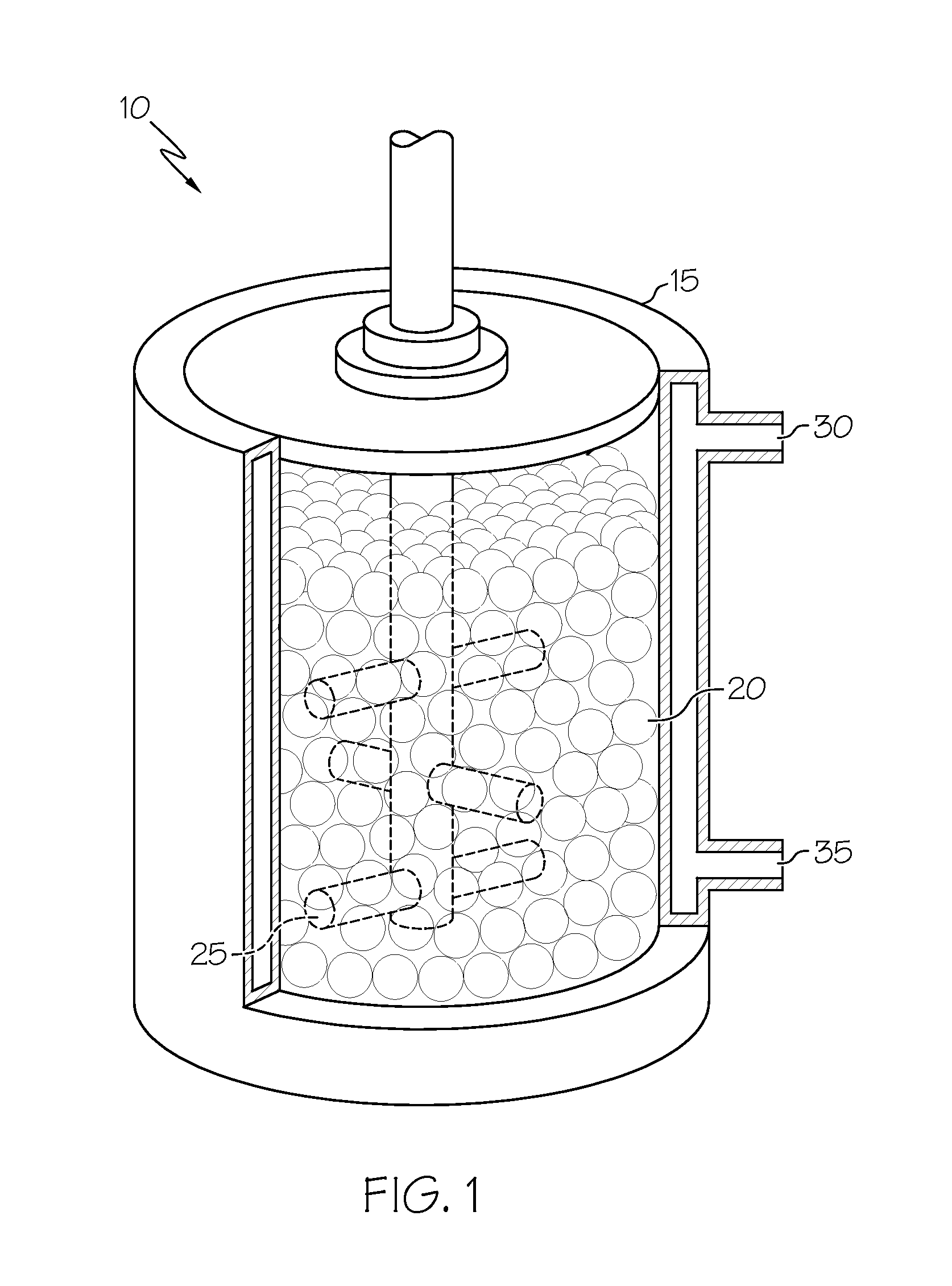

Method for removing cytokines from blood with surface immobilized polysaccharides

ActiveUS20110184377A1Lessen and eliminate spreadPrevent diseaseAntibacterial agentsSalicyclic acid active ingredientsPorous substrateSurface concentration

The present invention is directed to a method for removing cytokines and / or pathogens from blood or blood serum (blood) by contacting the blood with a solid, essentially non micro-porous substrate which has been surface treated with heparin, heparan sulfate and / or other molecules or chemical groups (the adsorbent media or media) having a binding affinity for the cytokine or pathogen(s) to be removed (the adsorbates), and wherein the size of the interstitial channels within said media is balanced with the amount of media surface area and the surface concentration of binding sites on the media in order to provide adequate adsorptive capacity while also allowing relatively high flow rates of blood through the adsorbent media.

Owner:EXTHERA MEDICAL

Porous Hybrid Monolith Materials With Organic Groups Removed From the Surface

InactiveUS20070215547A1High bonded phase surface concentrationReduce decreaseIon-exchange process apparatusOther chemical processesChromatographic separationSurface concentration

A material for chromatographic separations, processes for its preparation, and separation devices containing the chromatographic material. In particular, porous inorganic / organic hybrid monoliths are provided with a decreased concentration of surface organic groups, and have improved pH stability, improved chromatographic separation performance, and improved packed bed stability. These monoliths may be surface modified resulting in higher bonded phase surface concentrations and have enhanced stability at low pH.

Owner:WATERS TECH CORP

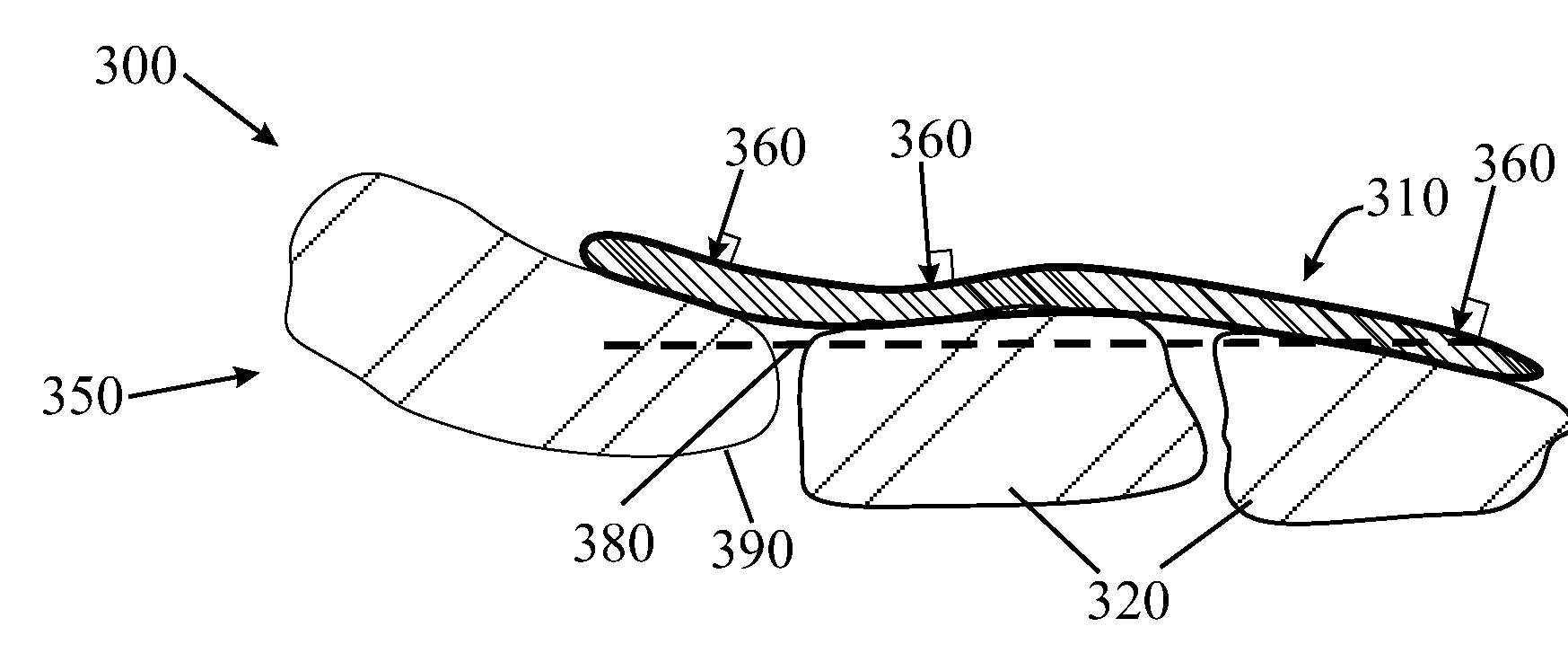

Ink film constructions

An ink film construction comprising: (a) a printing substrate; and (b) at least one ink film, fixedly adhered to a top surface of the printing substrate, the ink film having an upper film surface distal to the top surface of the substrate, wherein a surface concentration of nitrogen at the upper film surface exceeds a bulk concentration of nitrogen within the film, the bulk concentration measured at a depth of at least 30 nanometers below the upper film surface, and wherein a ratio of the surface concentration to the bulk concentration is at least 1.1 to 1.

Owner:LANDA

Doped precipitated silica

InactiveUS7070749B2Non-fibrous pulp additionNatural cellulose pulp/paperSurface concentrationPapermaking

Foreign-atom-doped precipitated silicas having a BET surface area of more than 300 m2 / g and a maximum surface concentration of the foreign atoms of 0.05 mmol / m2, to a process for preparing them and to the use of the resulting precipitated silicas in papermaking.

Owner:EVONIK DEGUSSA GMBH

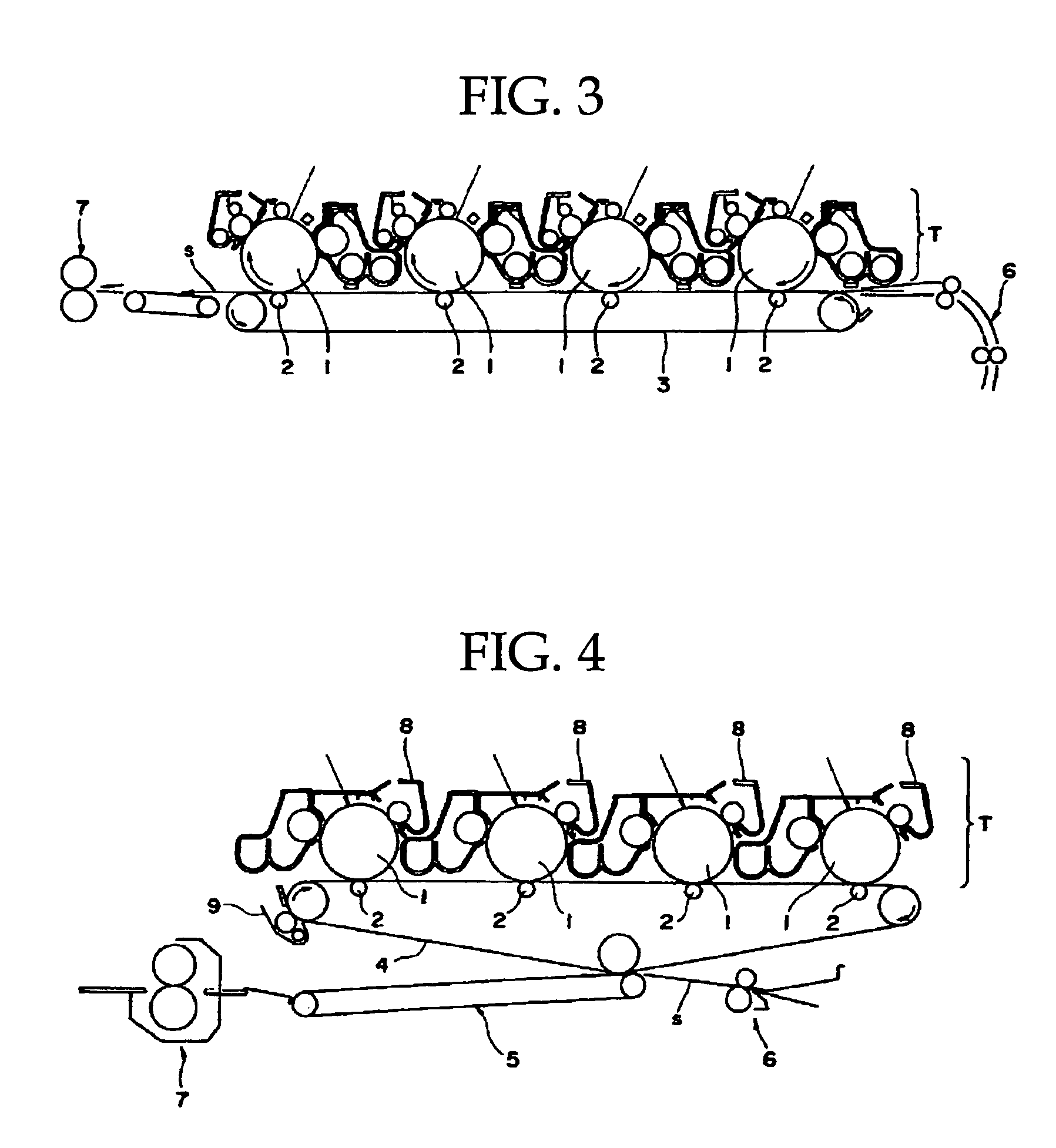

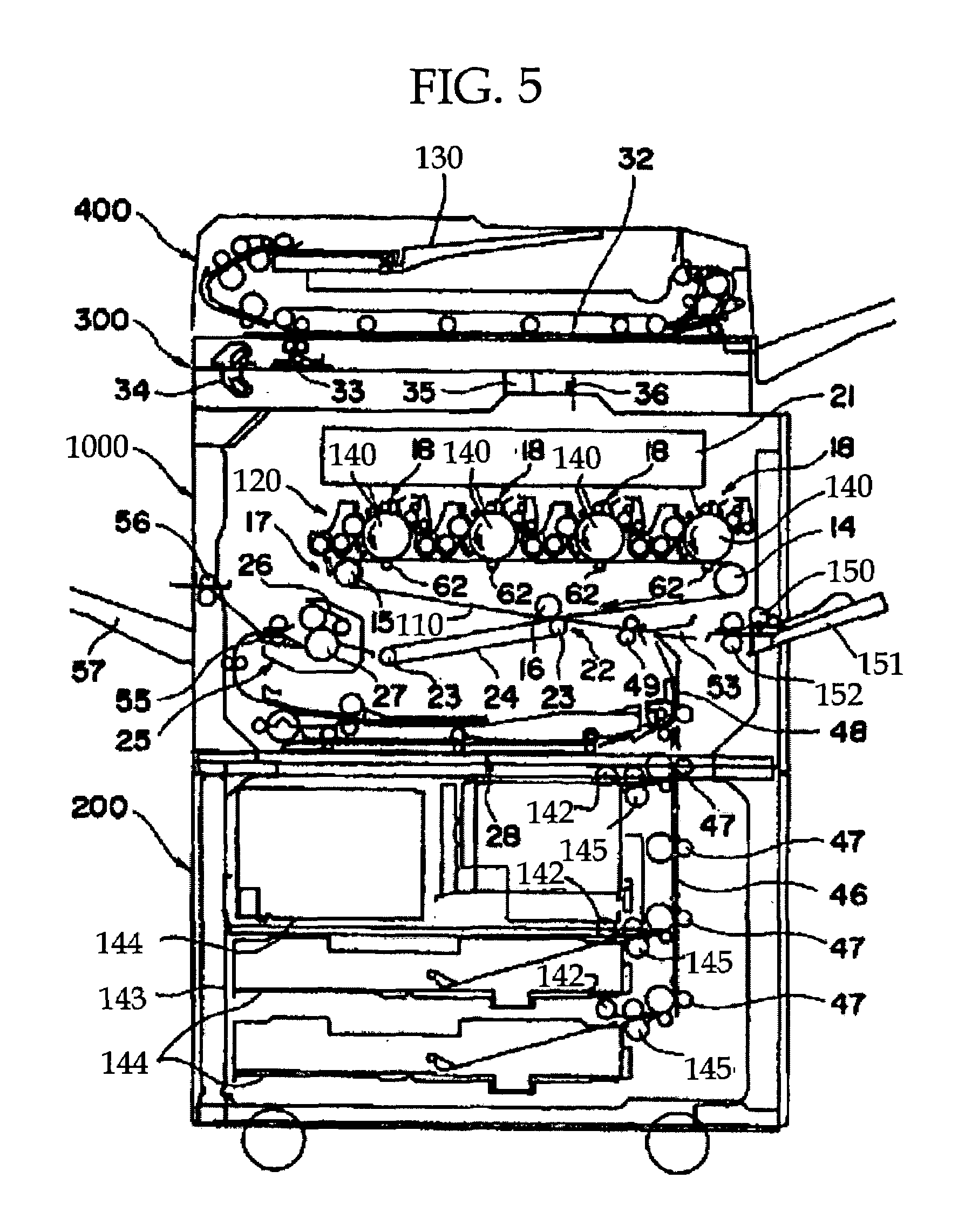

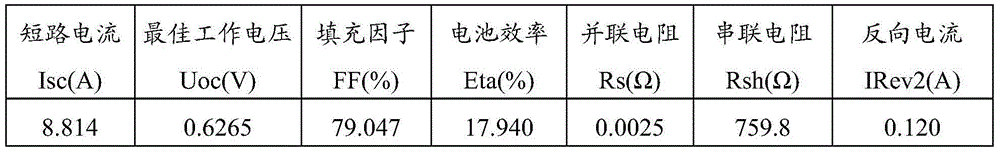

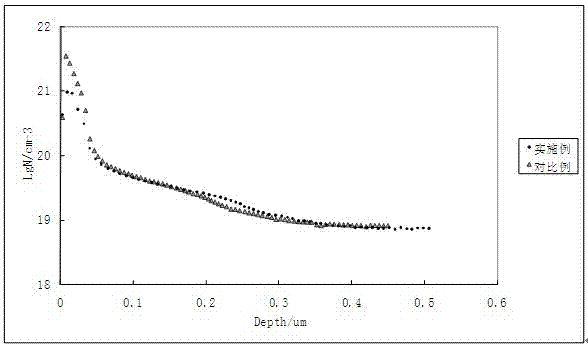

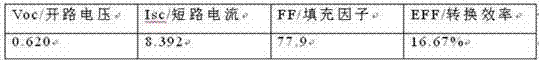

Technology for manufacturing selective emitter junction solar cell by printed phosphorous source one-step diffusion method

ActiveCN101937940ARealize the structureGood diffusion uniformity controlFinal product manufactureSemiconductor devicesDiffusion methodsScreen printing

The invention relates to technology for manufacturing a selective emitter junction solar cell by a printed phosphorous source one-step diffusion method. The method comprises the following steps of: cleaning and texturing a silicon wafer, performing screen printing of phosphorous-containing nano Si slurry, drying at the temperature of between 200 and 350 DEG C for about 20 minutes, and removing the solvent to obtain a phosphorous-containing oxidation layer with the thickness of 30 to 100nm; implementing BOE and RCA cleaning to remove 70 percent of surface phosphorous slurry before diffusion; putting the silicon wafer into a diffusion furnace, adding a POCL3 air source, heating to between 800 and 1,000 DEG C, forming re-diffusion at a grid line of the phosphorous-containing nano slurry on the silicon wafer to form a higher surface concentration-heavily doped region, and forming a shallow diffusion region in other areas. By adopting the screen printing of the phosphorous-containing nano slurry, the phosphorous-containing nano slurry is heated at high temperature for diffusion, forms the heavily doped region at a contact position with the grid line and forms a lightly doped region in other areas. The technology has the efficiency of over 18.5 percent on the premise of better controlling the diffusion uniformity.

Owner:TRINA SOLAR CO LTD

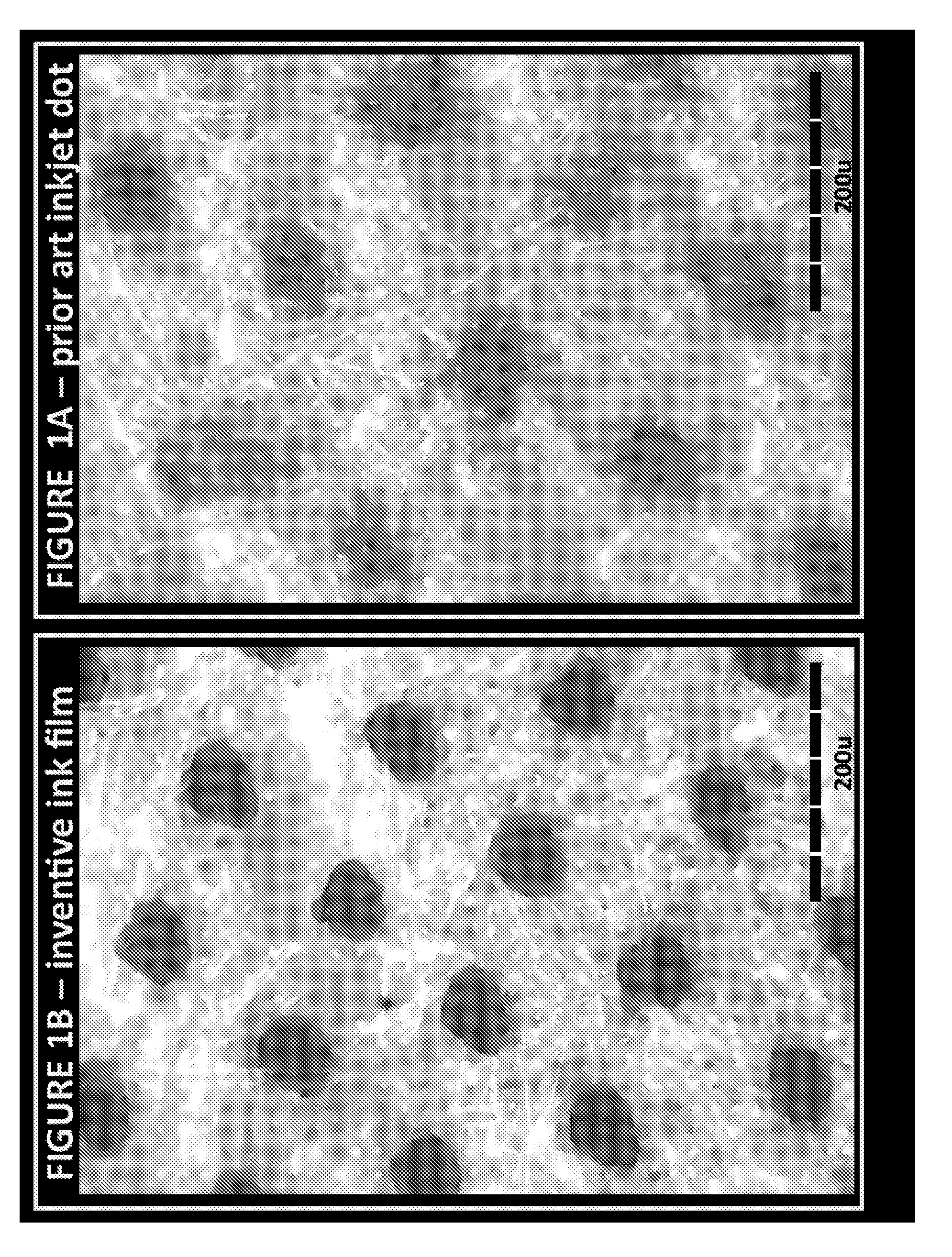

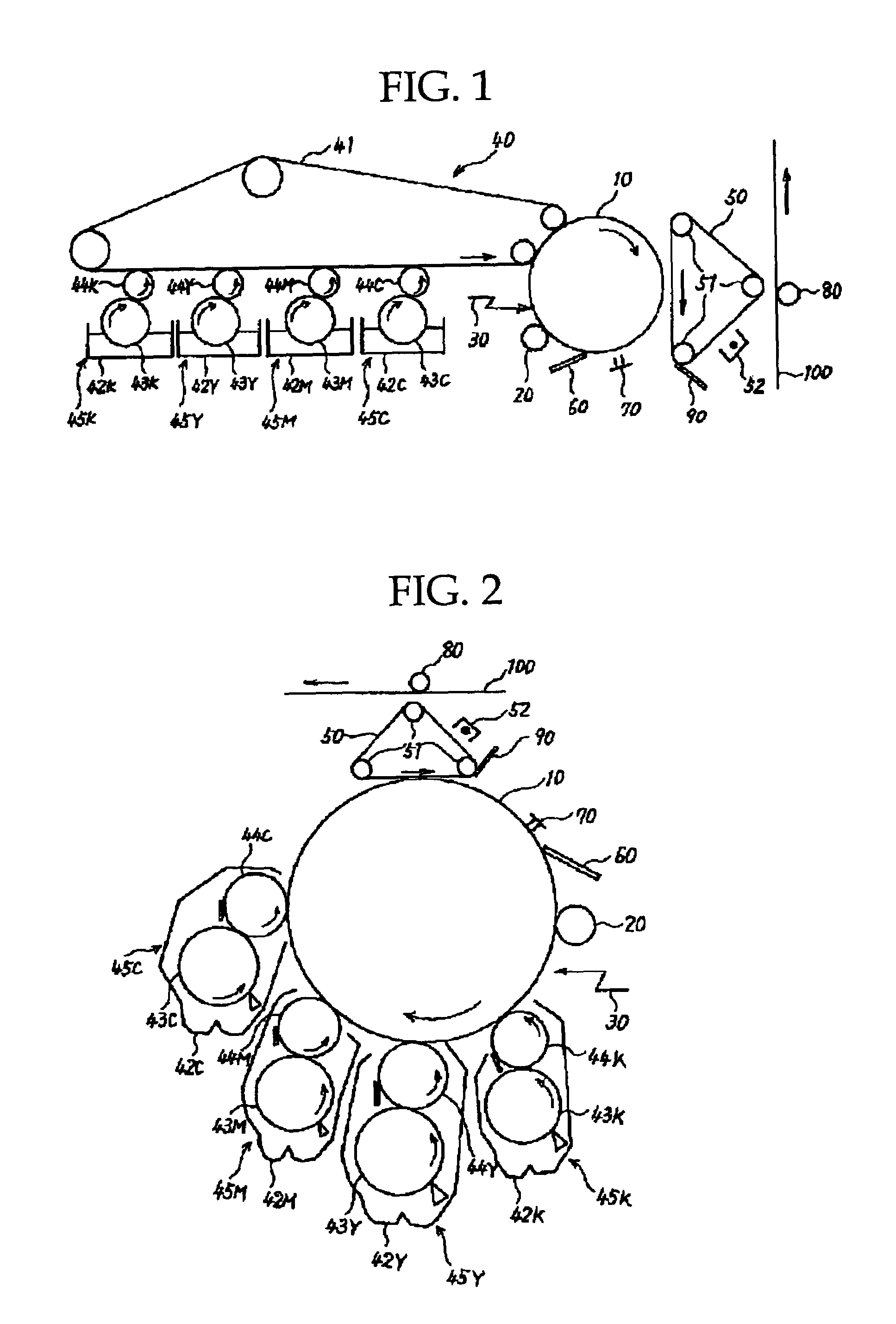

Toner for developing electrostatic image, developer, process for forming image, and image forming apparatus

InactiveUS7163773B2High hardnessOffset resisDevelopersElectrographic processes using charge patternSurface concentrationNitrogen

Spherical toners having excellent fusibility are disclosed. The toners are fusible at low temperatures and are excellent in preservability and therefore charge properties, flowability, and transferability do not deteriorate. The toners contain a colorant and a nitrogen-containing polyester resin, in which the concentration of nitrogen at the surface of toner particles is higher than the concentration of nitrogen of the entire particles. The ratio of the surface concentration to the overall concentration is from 1.2 to 10. Additionally, the nitrogen-containing resin is preferably a polyester resin modified by urea bonds. Also, it is preferred that the toner particles are substantially spherical having an average sphericity E of from 0.90 to 0.99.

Owner:RICOH KK

Method for diffusing high sheet resistance of solar cells

ActiveCN102097524AReduce errorsImprove life expectancyFinal product manufactureSemiconductor devicesSurface concentrationSolar cell

The invention relates to a method for diffusing high sheet resistance of solar cells. The method is characterized by texturing the surface of a solar crystal silicon wafer, sending the silicon wafer to a diffusion furnace for high sheet resistance diffusion and then carrying out subsequent solar cell processes. The method has the following advantages: (1) superior sheet resistance uniformity can be still maintained when high sheet resistance is diffused; (2) through introducing TCA or TCE during pre-oxidation, oxidation can be sped up, the substrate fault number can be reduced and the minority carrier lifetime of the substrate silicon can be prolonged; (3) dead layers can be well avoided through oxide layers; and (4) surface concentration and junction depth topography of diffusion can be well controlled through low-temperature pre-deposition and high-temperature junction propelling forming.

Owner:TRINA SOLAR CO LTD

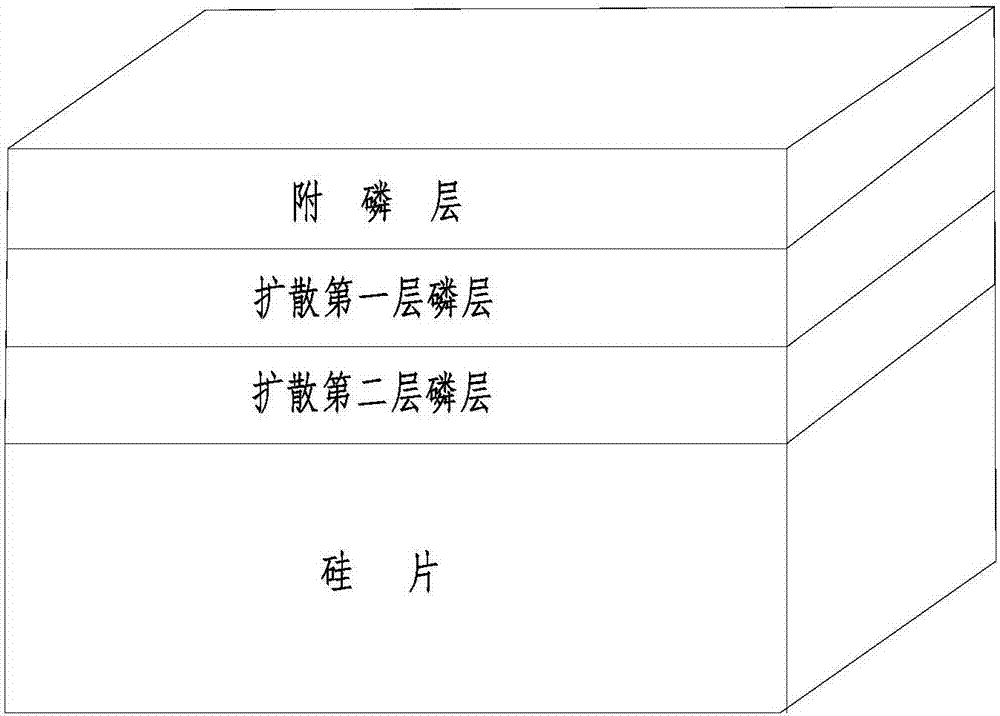

Diffusion process of silicon-wafer laser doping SE

InactiveCN107394012AIncrease contactSolve the problem of insufficient PSG concentration for laser ablationFinal product manufactureSemiconductor/solid-state device manufacturingOhmic contactSurface concentration

The invention relates to a diffusion process of a silicon-wafer laser doping SE. According to the process, after formation of a diffusion first phosphorus layer and a diffusion second phosphorus layer on a surface of a silicon wafer, phosphorus attachment layer deposition processing is carried out to form a phosphorus attachment layer on the surface of the silicon after diffusion. With the phosphorus attachment layer, a problem of insufficient PSG concentration of laser ablation is solved; the phosphorus attachment layer is easy to remove during the follow-up phosphorus washing and removing process and thus the low-surface-concentration lightly-doped region is kept at the emitter, so that problems of poor ohmic contact and packing factor reduction caused by low PSG concentration during laser doping are solved.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

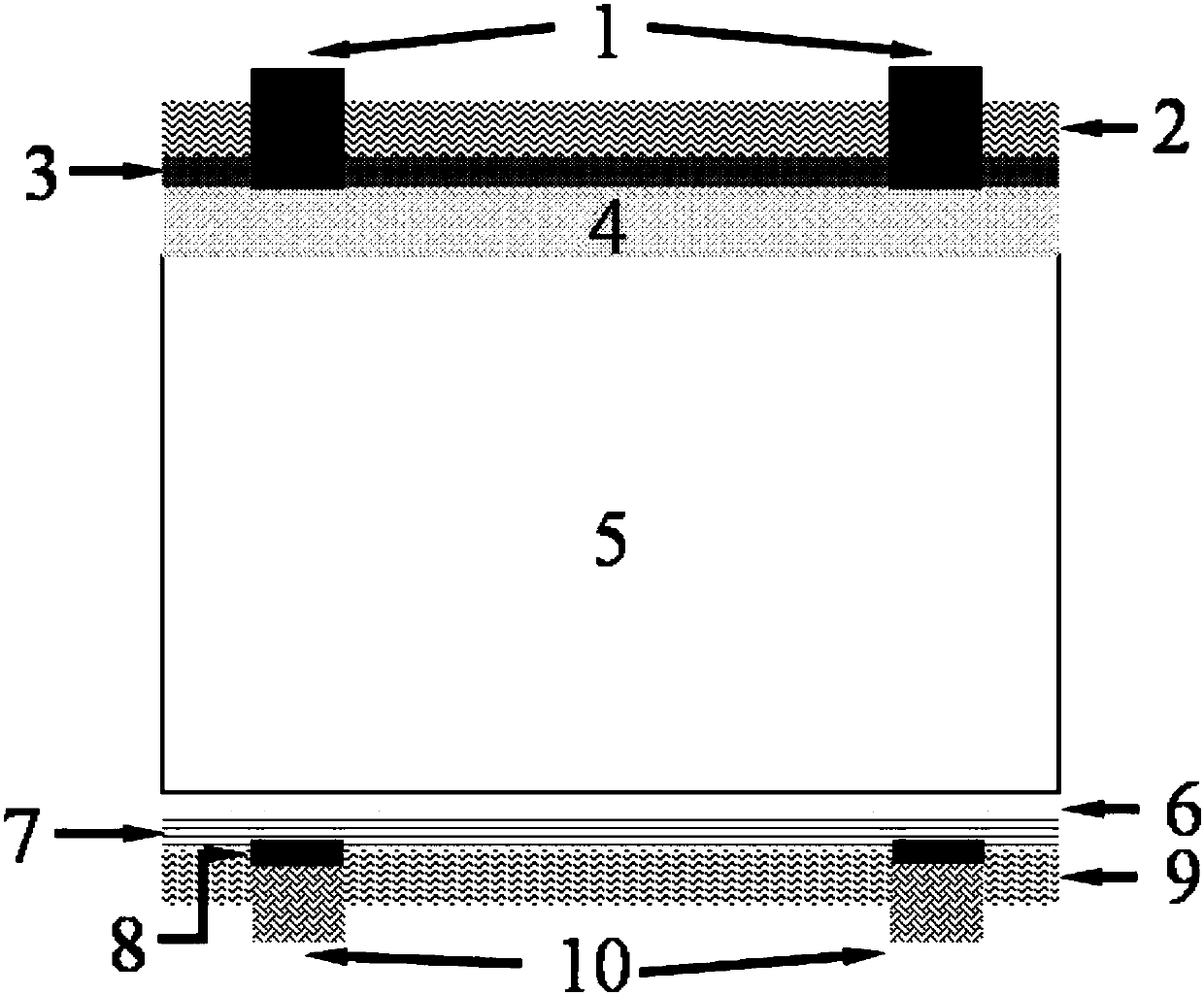

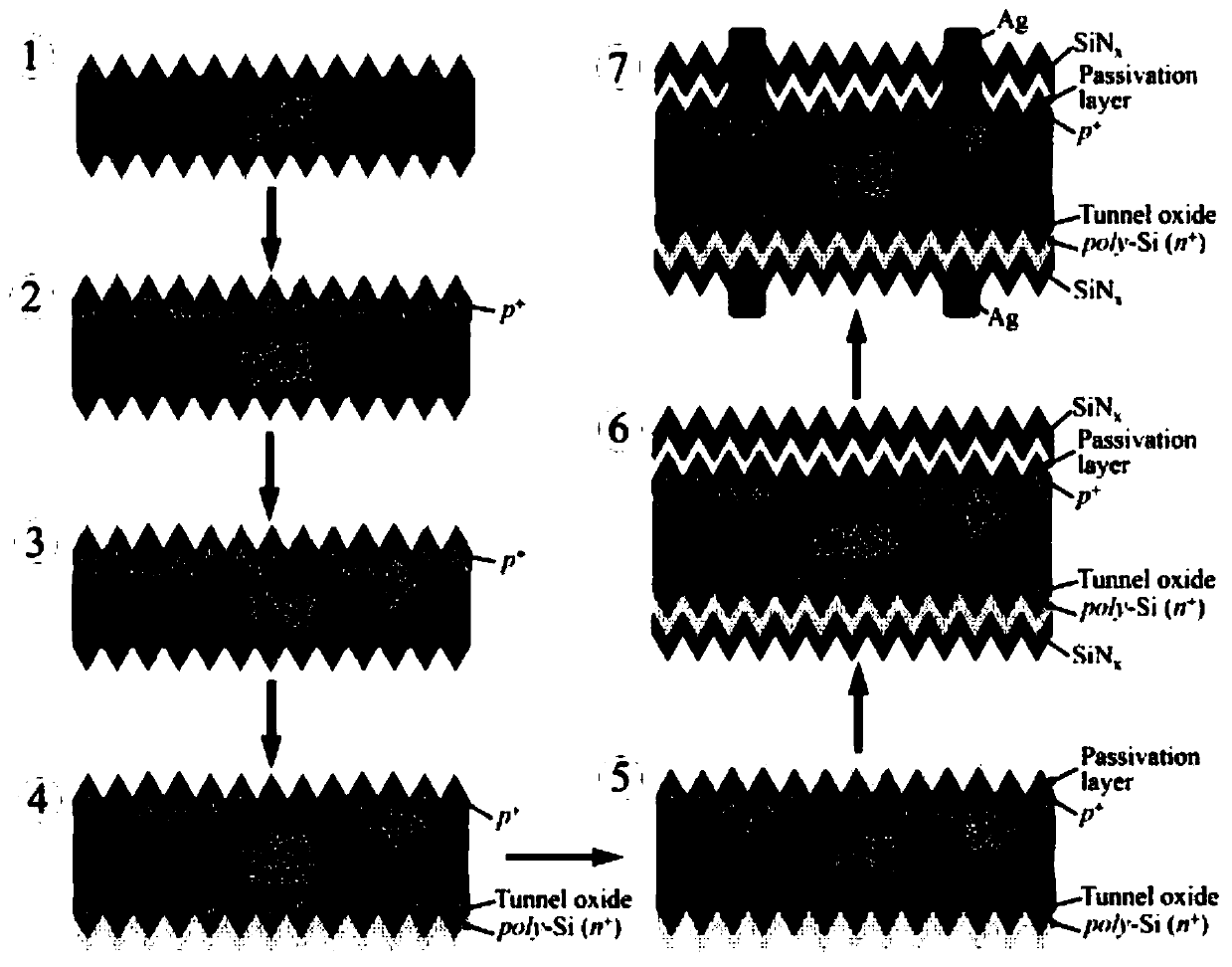

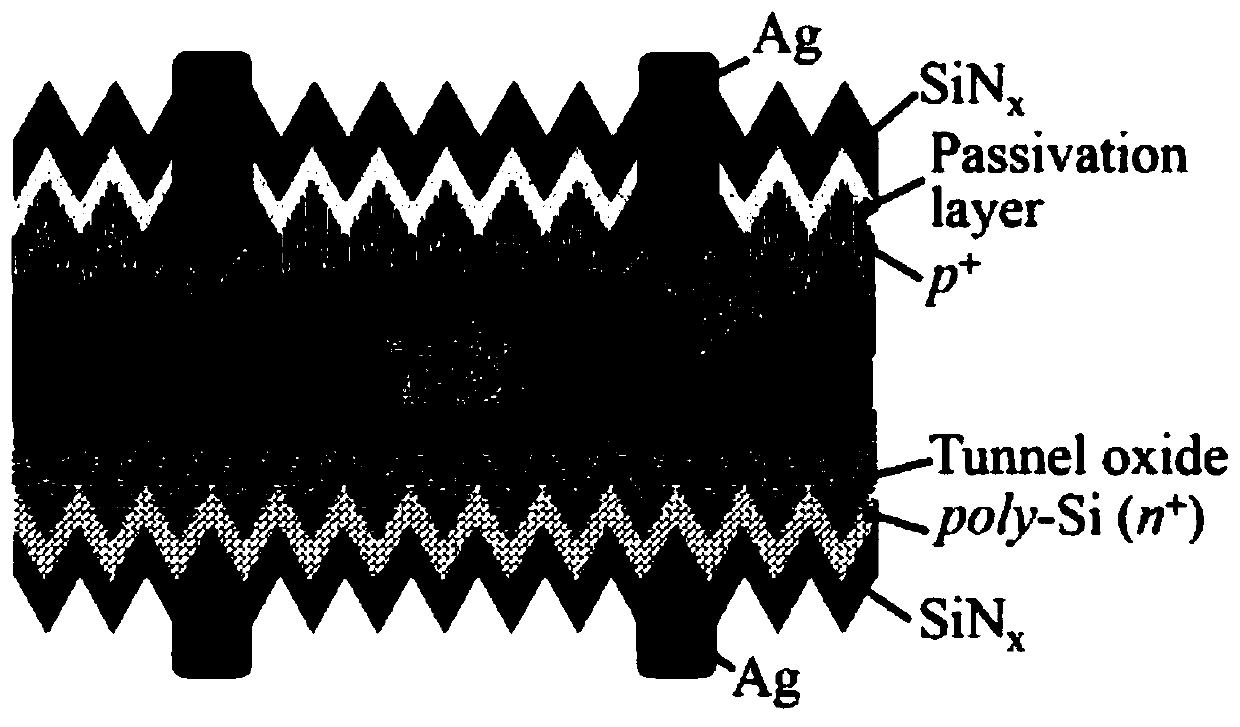

Preparation method of improved type back surface tunnel oxidization and passivation contact efficient battery

InactiveCN107845692AIncrease the open circuit voltageHigh process feasibilityFinal product manufactureSemiconductor devicesSurface concentrationElectricity

The invention relates to a preparation method of an improved type back surface tunnel oxidization and passivation contact efficient battery. The preparation method comprises the steps of performing texturing after a silicon wafer damage layer is removed; next, forming a low surface concentration B doped P<+> emitting junction; after performing edge insulating and back surface polishing, enabling ultra-thin tunnel oxide layer SiO<2> and P-doped polysilicon layer to be grown on the back surface of a silicon wafer; depositing an aluminium oxide layer on the surface of the P<+> emitting junction;enabling a hydrogenated amorphous silicon nitride passivated antireflection layer to be grown on the front surface of the silicon wafer; forming partial heavy doping on the back surface of the siliconwafer by adopting a laser doping or wet etching method; enabling the hydrogenated amorphous silicon nitride passivated antireflection layer to be grown on the back surface of the silicon wafer; and finally, printing Ag / Al paste on the front surface of the silicon wafer, and printing Ag paste on the back surface. By adoption of the layer of the ultra-thin tunnel oxide layer SiO<2>, one layer of phosphorus P-doped silicon layer and the P-doped region partial heavy doping, the metal-semiconductor surface compounding on the back surface can be greatly lowered; and the preparation method has the most obvious advantage of capability of greatly improving electrical performance on the basis of compatibility with the conventional battery manufacturing process.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

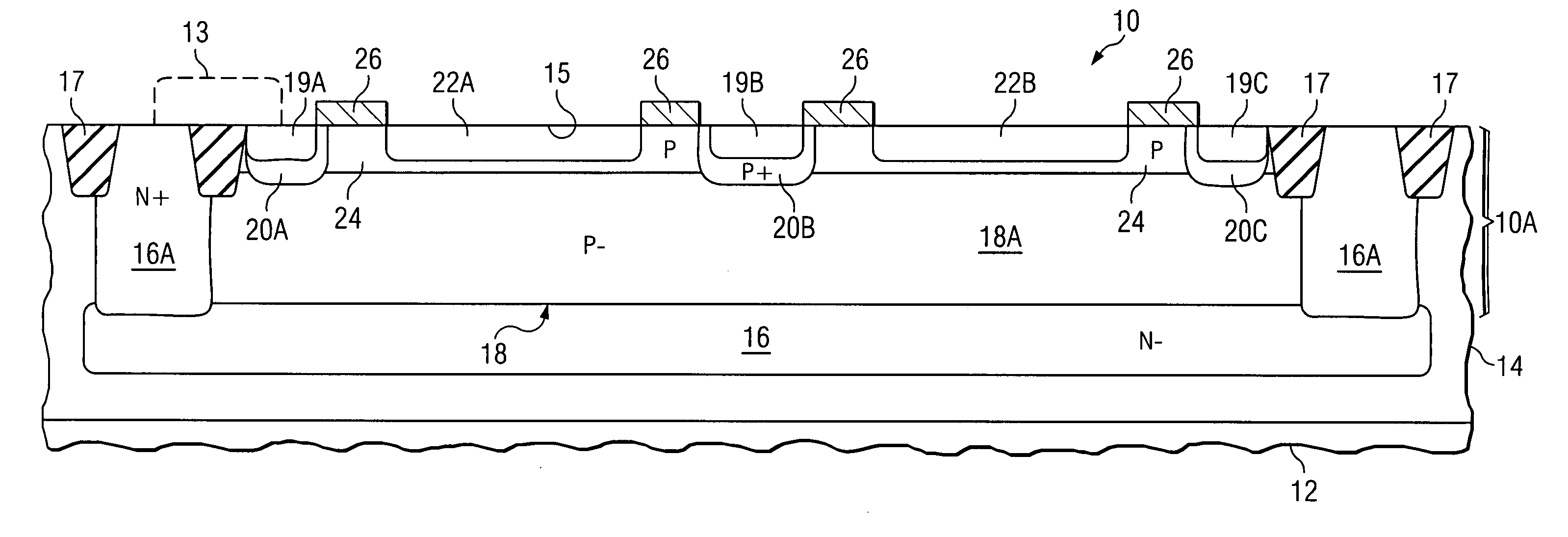

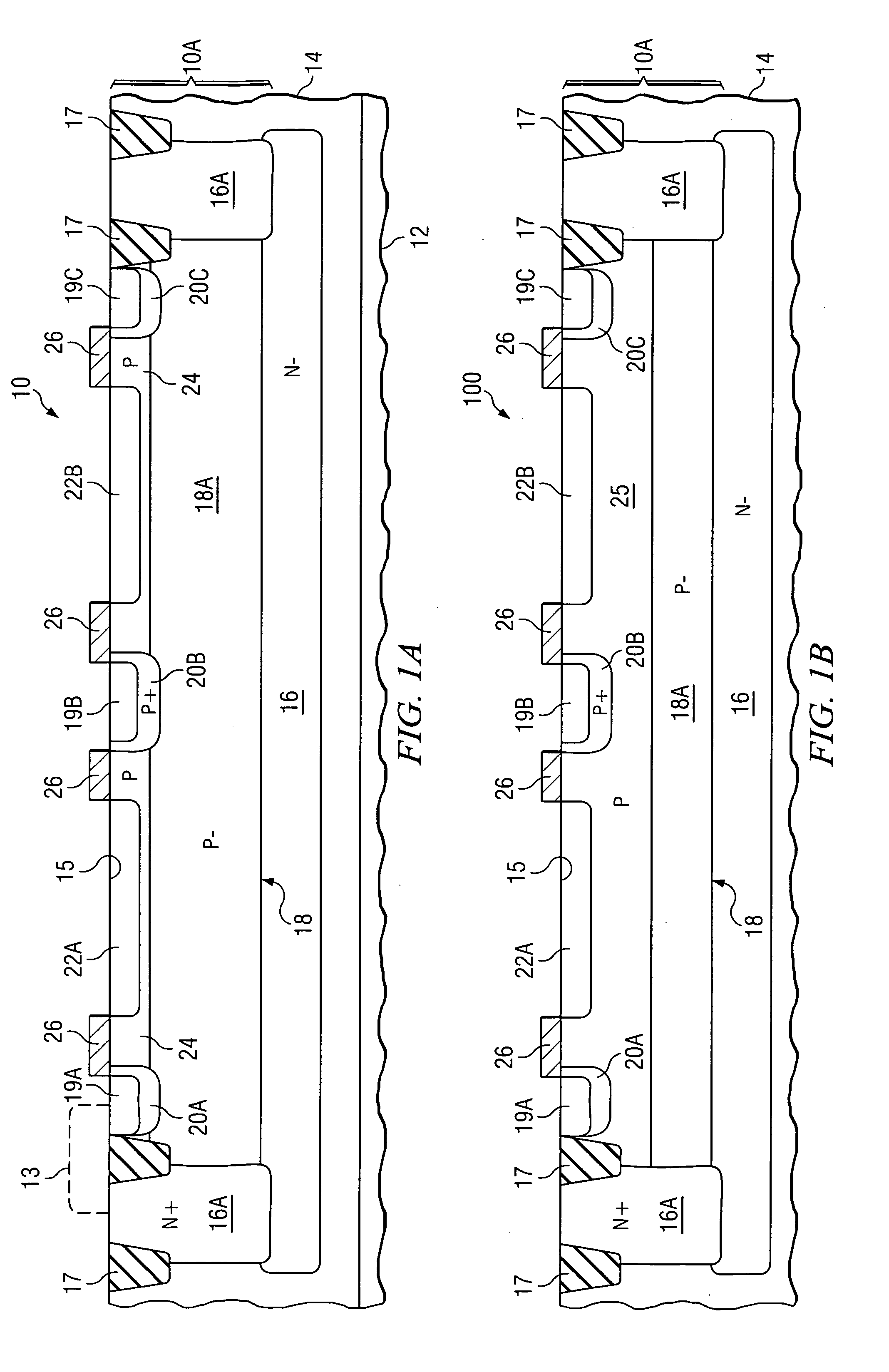

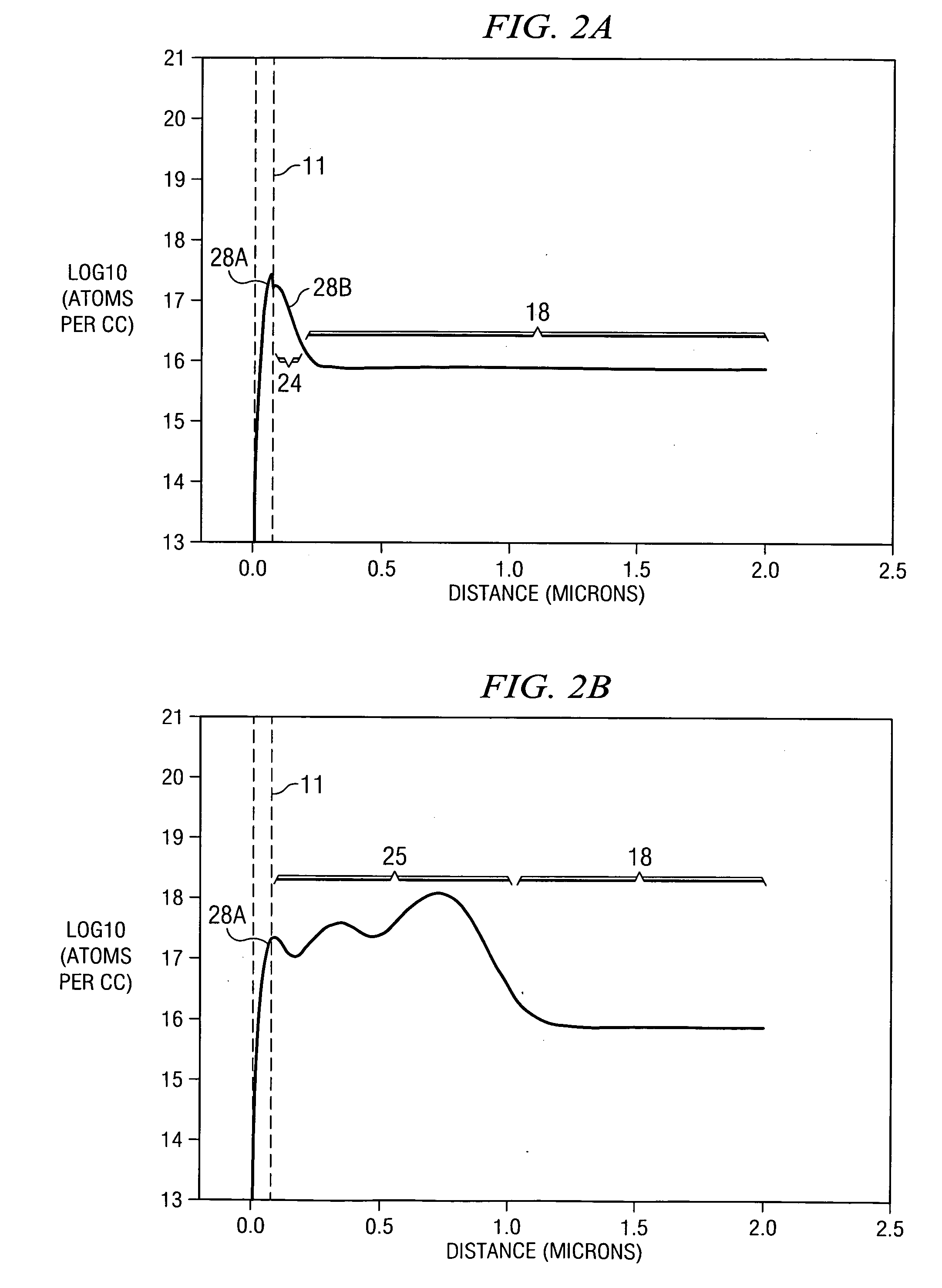

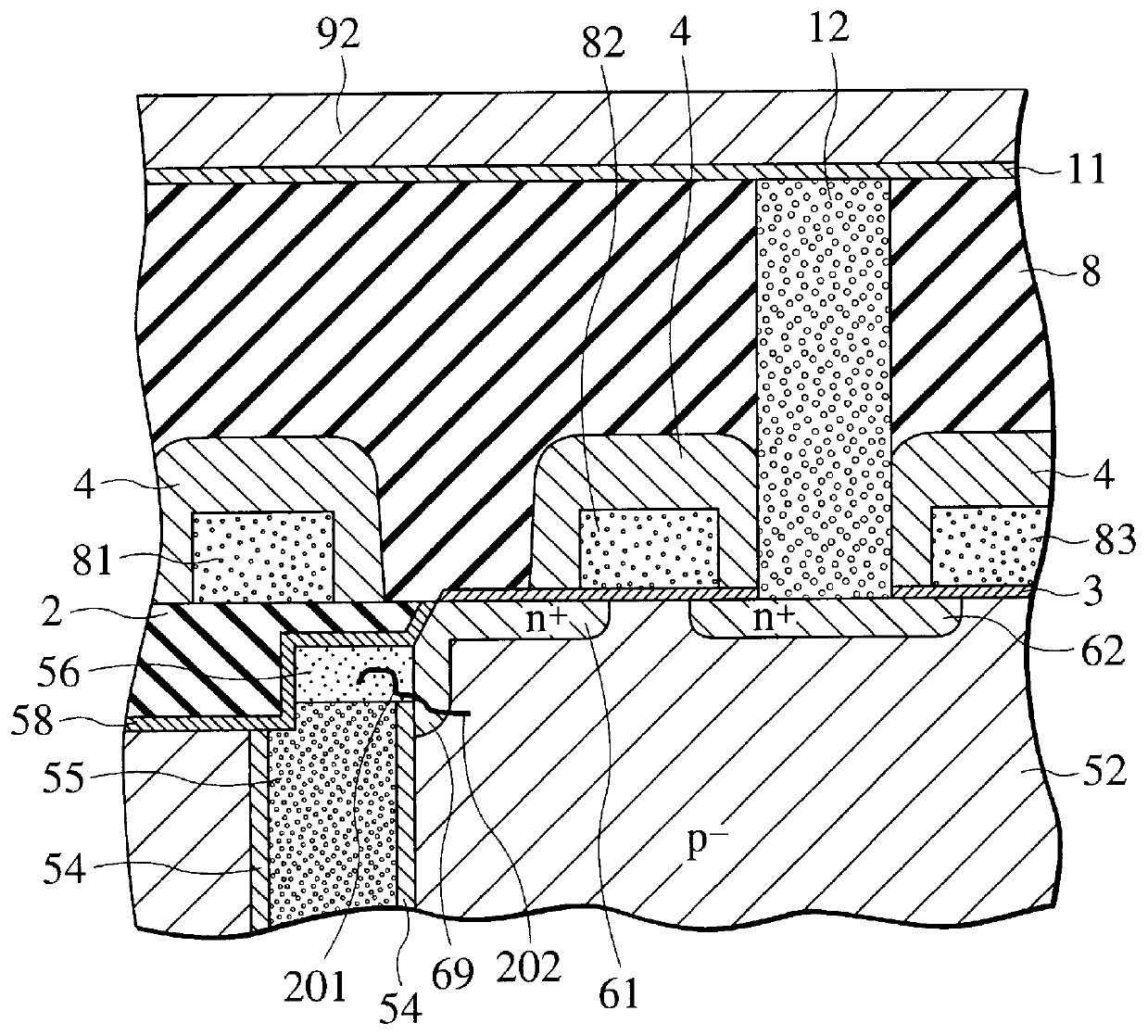

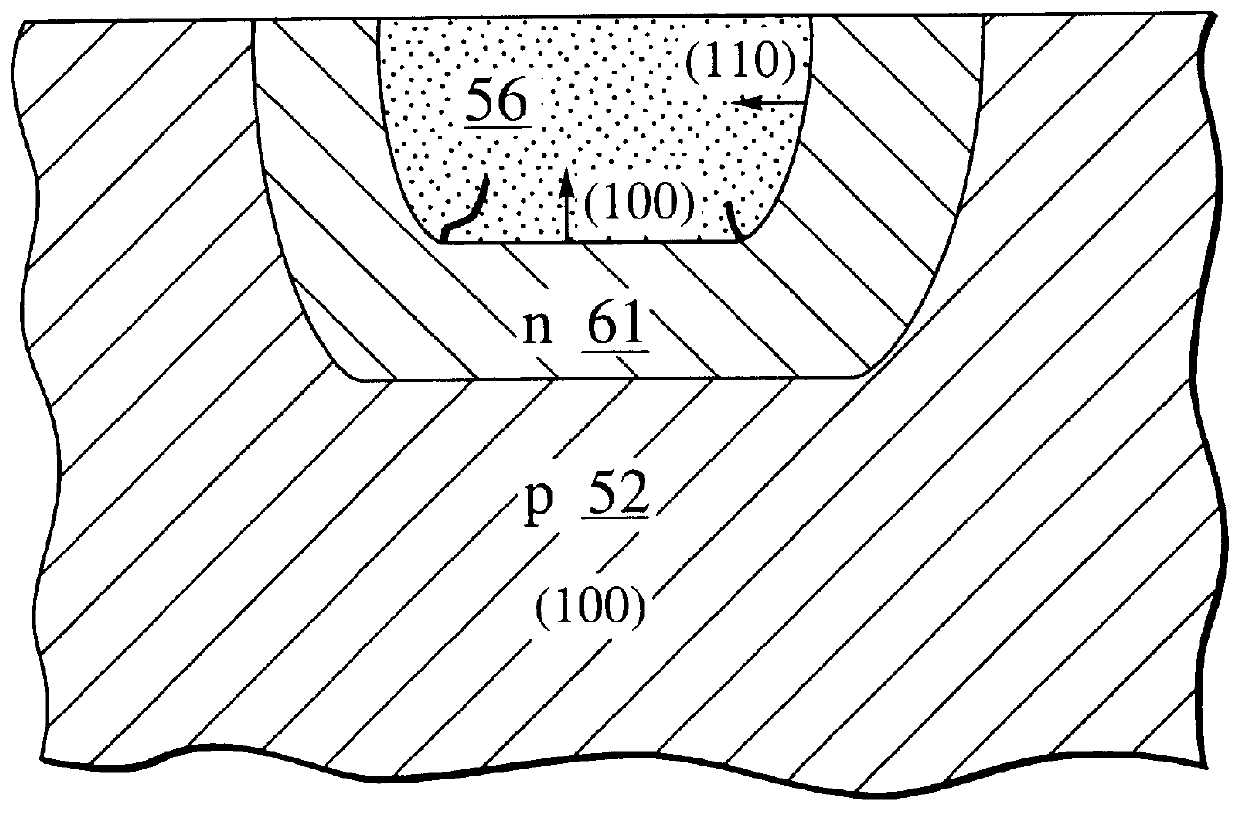

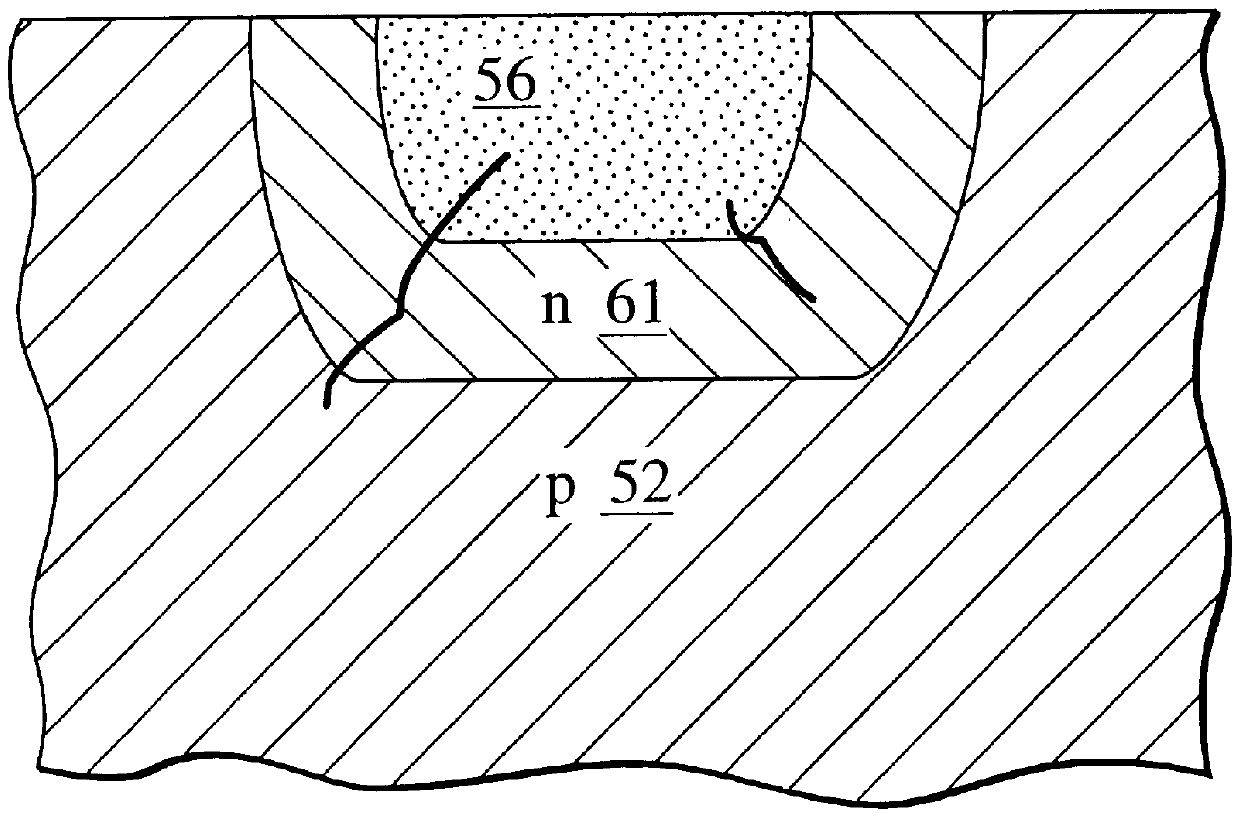

Method and Schottky diode structure for avoiding intrinsic NPM transistor operation

InactiveUS20070052057A1Avoid unnecessary operationsUndesired operationSolid-state devicesDiodeMetal silicideParasitic bipolar transistor

A Schottky diode includes an isolation region of a first conductivity type and an anode region of a second conductivity type isolated by the isolation region, the anode region including a lightly doped deep anode region of the second conductivity type and an increased dopant region of the second conductivity type, the increased dopant region including a shallow surface dopant spike region of the second conductivity type at a surface of the anode region. A heavily doped anode contact region of the second conductivity type electrically contacts the anode region, and a metal silicide cathode region is disposed in the surface dopant spike region. The peak dopant surface concentration is high enough to produce a predetermined saturation current density. The dopant concentration in the increased dopant region is sufficiently high to suppress the current gain of a parasitic bipolar transistor enough to adequately suppress operation of the parasitic bipolar transistor.

Owner:TEXAS INSTR INC

Diffusion-limited adaptive battery charging

ActiveUS8754611B2Acceleration measurementSecondary cells charging/dischargingSurface concentrationCharge current

Some embodiments of the present invention provide a system that adaptively charges a battery, wherein the battery is a lithium-ion battery which includes a transport-limiting electrode governed by diffusion, an electrolyte separator and a non-transport-limiting electrode. During operation, the system determines a lithium surface concentration at an interface between the transport-limiting electrode and the electrolyte separator based on a diffusion time for lithium in the transport-limiting electrode. Next, the system calculates a charging current or a charging voltage for the battery based on the determined lithium surface concentration. Finally, the system applies the charging current or the charging voltage to the battery.

Owner:APPLE INC

Semiconductor device and manufacturing method thereof

A semiconductor device provided with a thin film of 0.1 nm to 2 nm in thickness, having a crystal structure different from that of a conductor and a semiconductor region, between the conductor and the semiconductor region. When the semiconductor region is made of single crystal silicon and the conductor region is made of amorphous silicon or poly silicon, the oxygen surface concentration of the thin film is equal to or higher than 1x1015 cm-2 and equal to or lower than 4x1015 cm-2 in one case, that of oxygen is equal to or higher than 1x1015 cm-2 and equal to or lower than 2x1015 cm-2 and that of nitrogen is equal to or higher than 1x1015 cm-2 and equal to or lower than 4x1015 cm-2 in the other case. The presence of the thin film prevents the epitaxial growth from starting from the interface between the conductor and the semiconductor region and reduces the crystal defect formation and growth near the interface.

Owner:KK TOSHIBA

Laser boron doped selective emitter TOPCon structure cell and preparation method thereof

ActiveCN110299422AIncrease the open circuit voltageImprove fill factorFinal product manufacturePhotovoltaic energy generationSurface concentrationScreen printing

The invention discloses a laser boron doped selective emitter TOPCon structure cell and a preparation method thereof. The method comprises the following steps: cleaning and texturing an n-type siliconwafer; during boron diffusion, promoting the formation of a P++ layer with high boron surface concentration without an oxidation process; promoting the doping in a grid line region by laser; after cleaning, putting the n-type silicon wafer back to a diffusion furnace for oxidization to form a selective emitter; removing BSG and a P+ layer on the back, and preparing a tunneling oxide layer and a doped film silicon layer on the back; removing the polycrystalline silicon produced by roll plating on the front and the BSG obtained in step II, and depositing a passivation layer and a SiNx antireflection film on both sides; and screen-printing a double-sided electrode. The preparation method of the invention can not only improve the open circuit voltage of the cell, but also improve the fillingfactor of the cell and finally improve the conversion efficiency of the Topcon solar cell.

Owner:TRINA SOLAR CO LTD +1

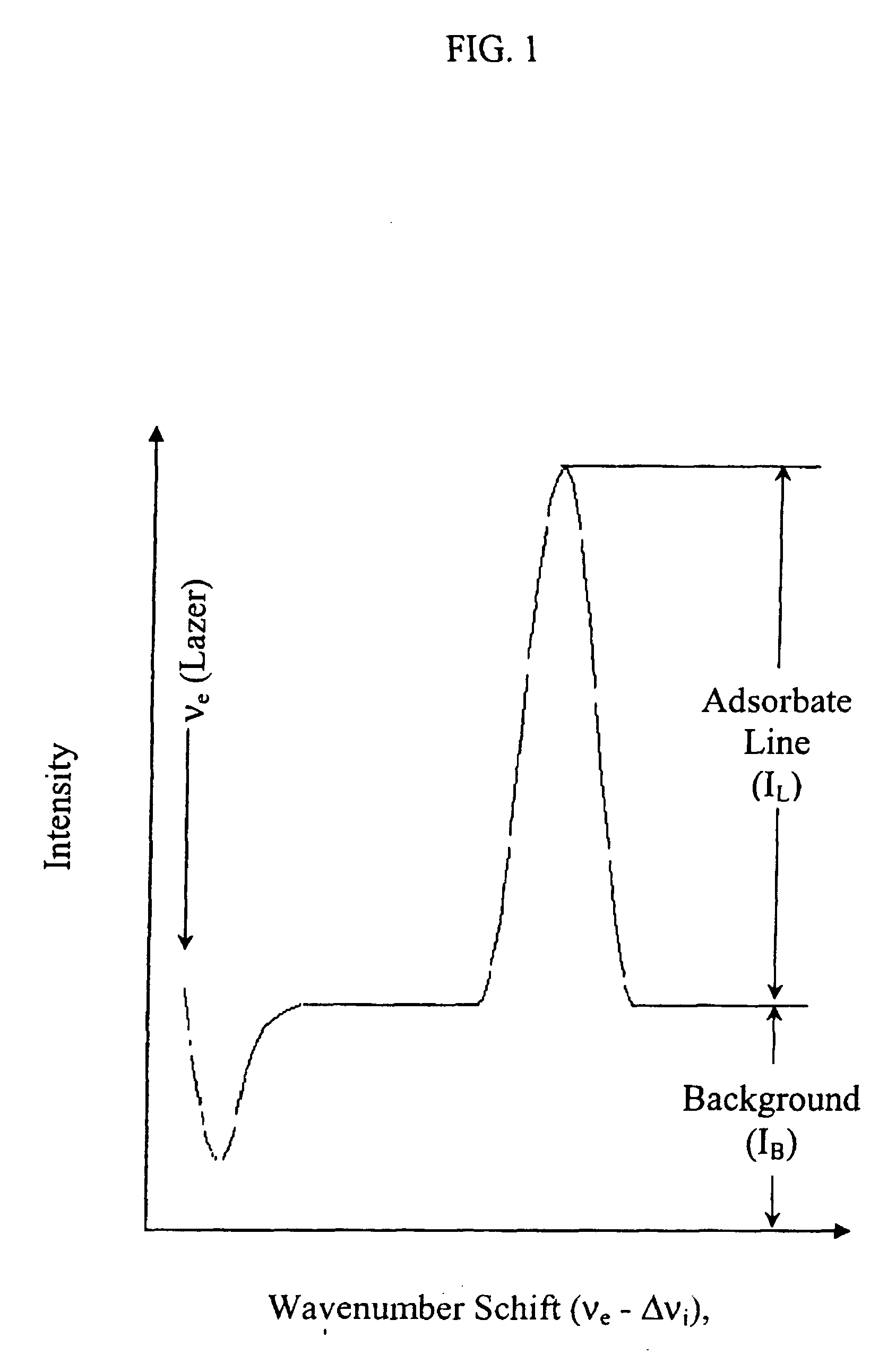

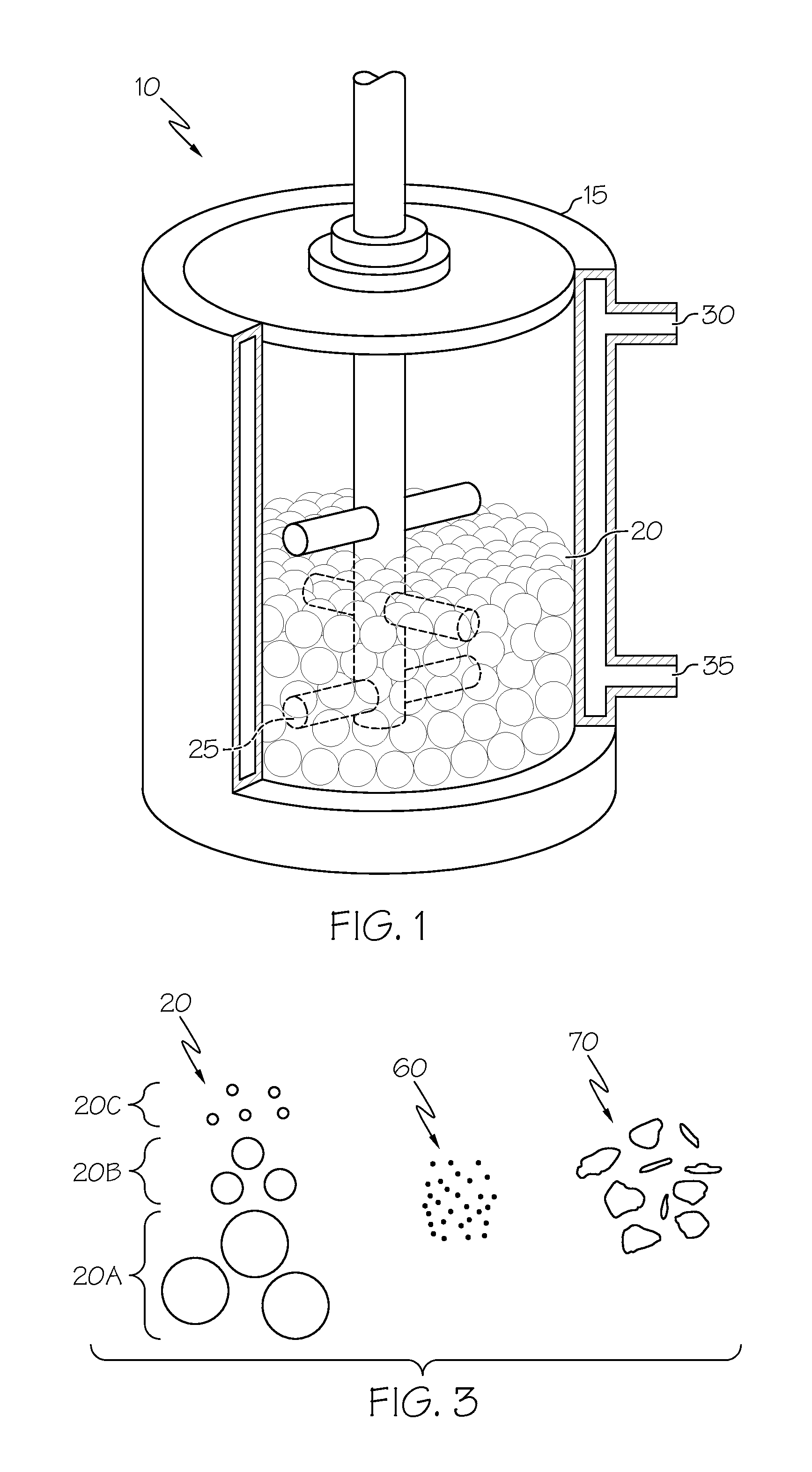

Method and apparatus for detection and quantitation of impurities in electrolytic solutions

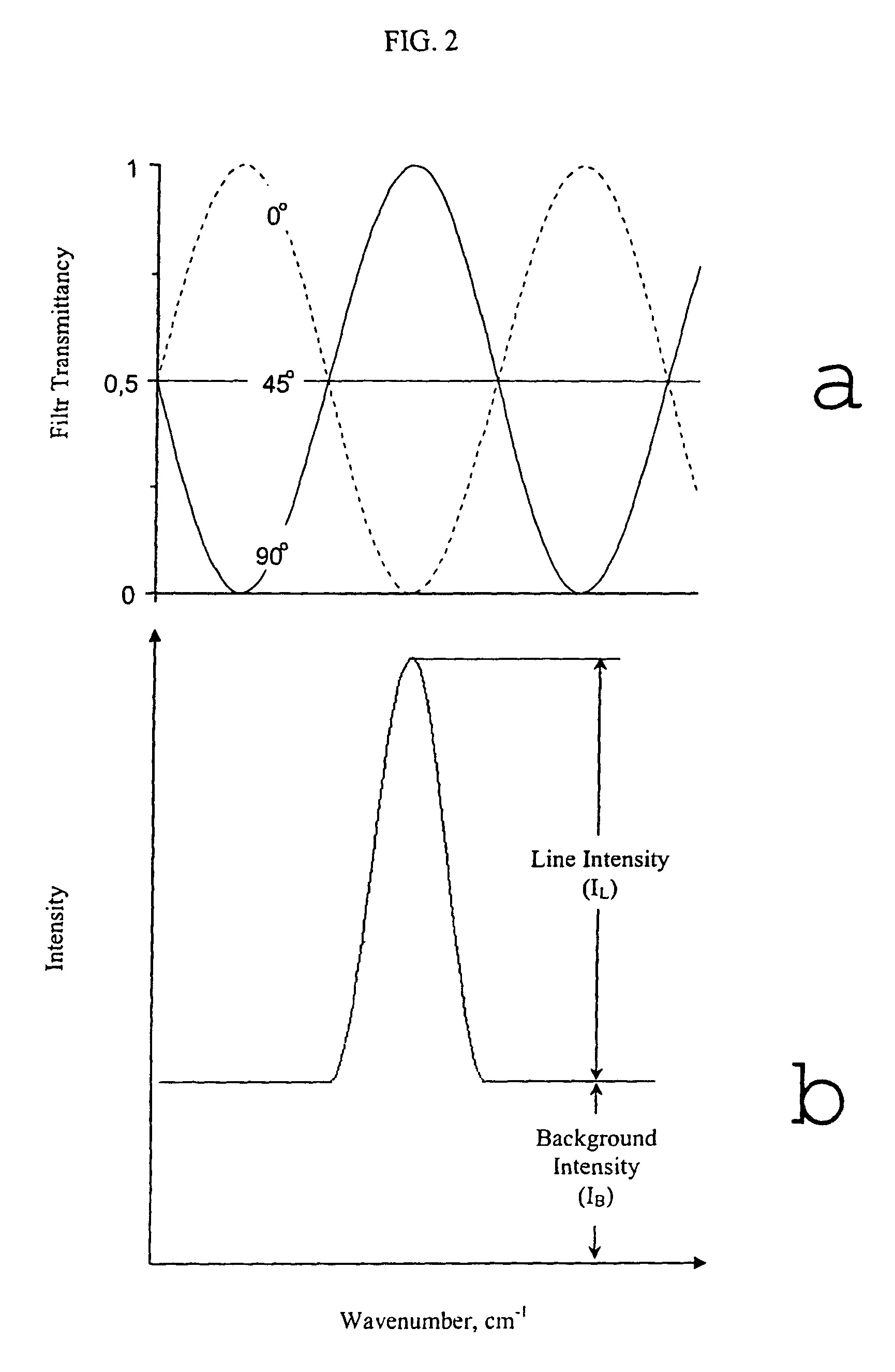

InactiveUS20050079630A1Intuitive evaluationReliable assessmentRaman scatteringBiological testingSurface concentrationAnalyte

Analytes are detected and / or quantified in electrolytic solutions suing Surface Enhanced Raman Scattering spectroscopy (SERS) by adsorbing the analyte on the surface of an active metal electrode placed into an electrolytic solution being analyzed and which provide periodic regeneration or modulation of surface concentration of SERS-active sites. As this occurs, the ambiguity of the measured values of the analyte signal, which is caused by instability of the surface activity of the sensor, is eliminated by optically normalizing to the total SERS signal determined by active metal adatoms.

Owner:FETISOV IGOR V

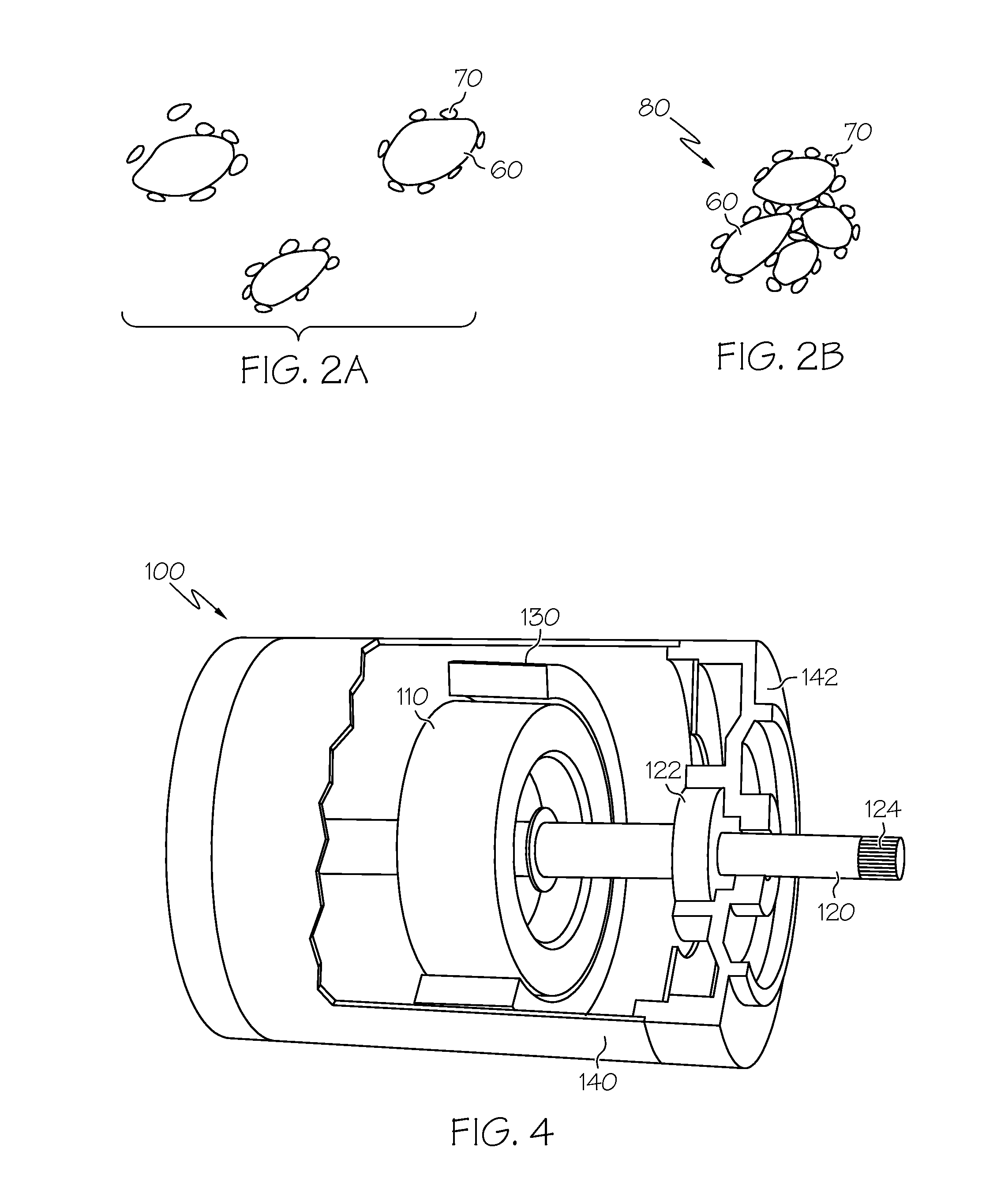

Method of making Nd-Fe-B sintered magnets with Dy or Tb

Owner:GM GLOBAL TECH OPERATIONS LLC

Method of making nd-fe-b sintered magnets with dy or tb

ActiveUS20120182102A1Transportation and packagingMetal-working apparatusSurface concentrationSintered magnets

A method of making a permanent magnet is described. In one embodiment, the method includes providing a first alloy powder having a desired composition, the alloy powder containing neodymium, iron, and boron; coating the first alloy powder with dysprosium, dysprosium alloy. terbium, or terbium alloy so that the first alloy powder has a surface concentration of dysprosium, terbium, or both in excess of a bulk concentration of dysprosium, terbium, or both; and forming the permanent magnet from the coated alloy powder using a powder metallurgy process, the permanent magnet having a non-uniform distribution of dysprosium, terbium, or both therein. Permanent magnets are also described.

Owner:GM GLOBAL TECH OPERATIONS LLC

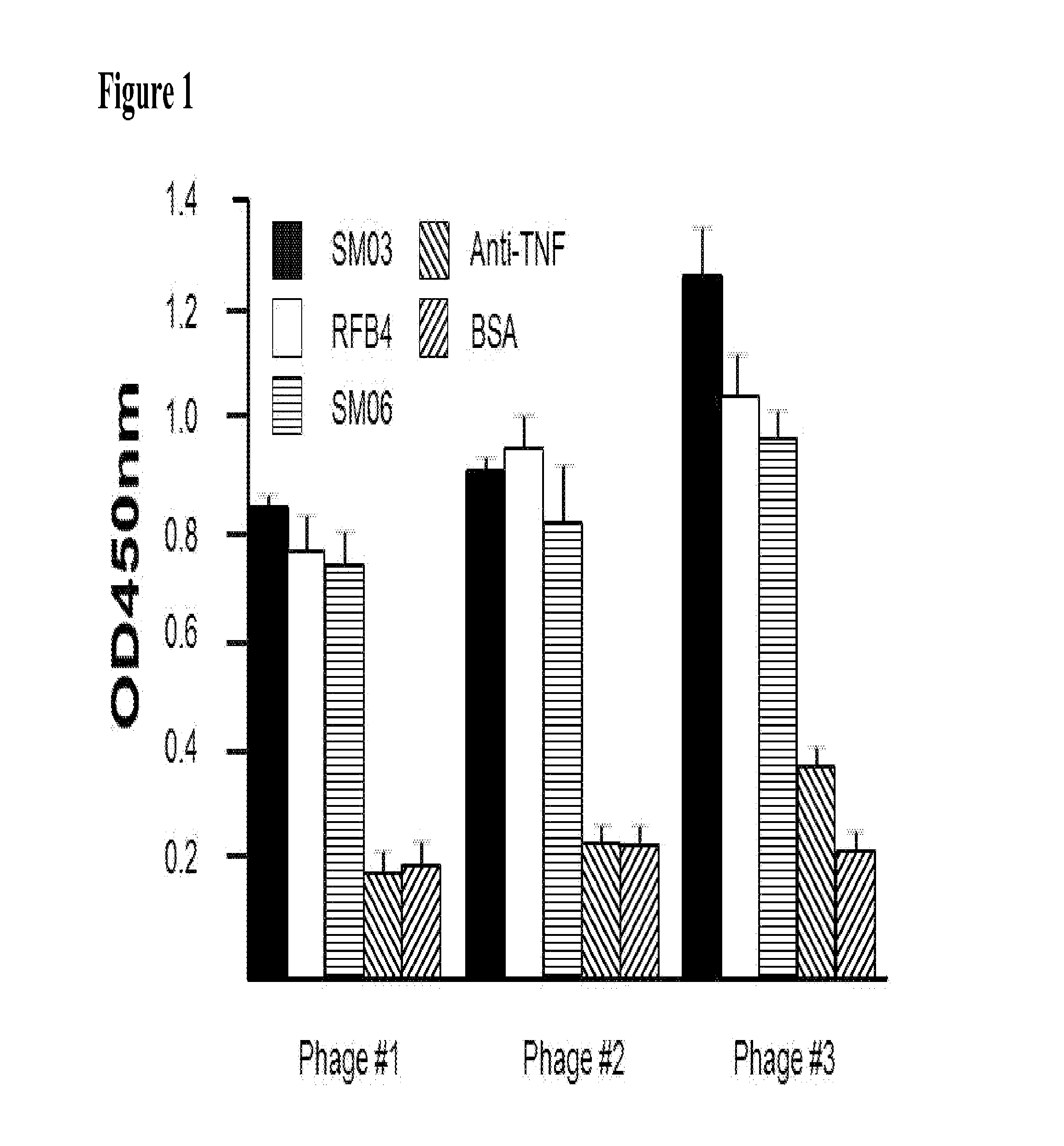

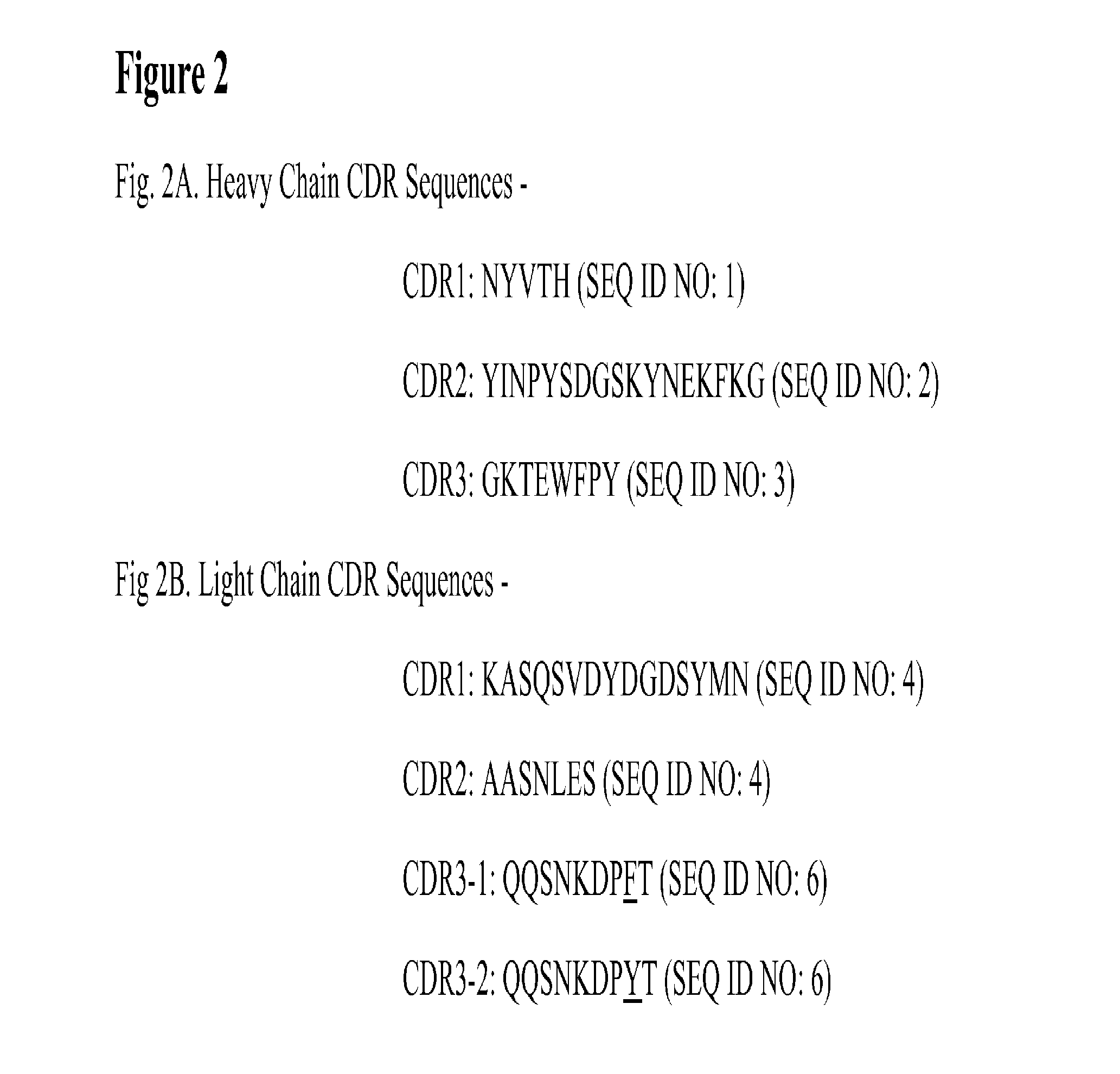

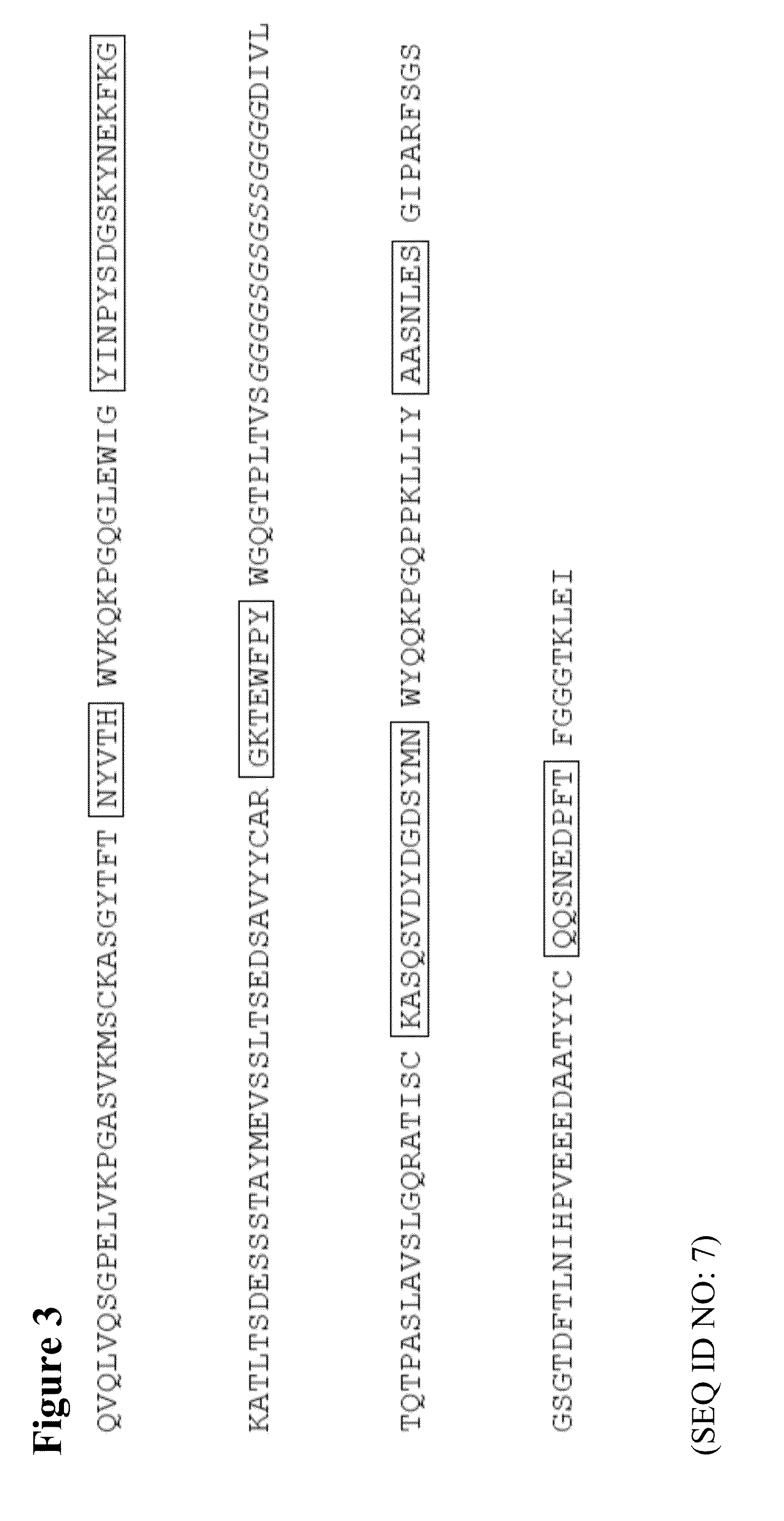

Anti-cd22 Anti-idiotypic antibodies and uses thereof

ActiveUS20150175711A1Not applyBiological material analysisArtificial cell constructsComplement-dependent cytotoxicityAntibody fragments

The present invention describes the generation of an anti-idiotype single-chain Fv (scFv) antibody specific for the murine (RFB4), chimeric (SM03) and humanized (SM06) versions of an anti-CD22 antibody (the anti-CD22 antibodies). The present invention further describes the construction of a murine IgG2a / kappa immunoglobulin carrying the variable region sequences of the anti-idiotype scFv sequences. Additionally, the present invention provides a cell line capable of producing an anti-idiotype murine antibody specific for the anti-CD22 antibodies. The present invention is directed against a method for identifying and evaluating the activities and concentration of the anti-CD22 antibodies. Additionally, the present invention provides a method for evaluating serum concentration of the anti-CD22 antibodies that are being used clinically. The present invention is also directed against a method to detect HAMA, HACA and HAHA responses in patients treated with the anti-CD22 antibodies. Specifically, the present invention is directed against the establishment of a cell line expressing surface concentration of the antibody of the invention; the said cell line expressing surface anti-idiotype antibodies or antibody fragments will be used as the target cell line for evaluating the functional activities of the anti-CD22 antibodies via complement dependent cytotoxicity (CDC) and / or antibody dependent cell cytotoxicity (ADCC) activities.

Owner:SINOMAB BIOSCI

P diffusion method of silicon wafer and preparation method of solar cell

ActiveCN104409339AImprove square resistance uniformityImprove conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingSurface concentrationDiffusion methods

The invention provides a P diffusion method of a silicon wafer; a textured silicon wafer is subjected to P diffusion; in the P diffusion process, the steps of increasing the temperature for the first time, depositing for the first time, propelling for the first time, increasing the temperature for the second time, depositing for the second time, propelling for the second time, increasing the temperature for the third time, depositing for the third time, propelling for the third time, decreasing the temperature and absorbing impurities are carried out in sequence; by means of the depositing processes, the propelling processes and the impurity-absorbing processes step by step, the sheet resistance uniformity of the silicon wafer containing a PN junction is increased; the surface concentration and the junction depth are reduced; therefore, the conversion efficiency of the solar cell is effectively increased; furthermore, the method provided by the method is incapable of increasing existing production of production lines, and has better economic benefits.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

Diffusion method used for crystalline silicon solar battery

InactiveCN102157606AHigh gettering capacityIncrease short circuit currentFinal product manufactureDiffusion/dopingDiffusion methodsSurface concentration

The invention discloses a diffusion method used for a crystalline silicon solar battery. The method comprises the following steps of: (1) placing a silicon wafer into a diffusion furnace; rising the temperature from 780-810 DEG C to 840-860 DEG C; and simultaneously introducing POCL3+O2+N2 for 12 to 14 minutes; (2) simultaneously introducing O2+N2 when rising the temperature in the diffusion furnace to 840-860 DEG C and keeping the constant temperature for 2 to 5 minutes; simultaneously introducing the POCL3+O2+N2 for 8 to 12 minutes when rising the temperature from 840-860 DEG C to 870-890 DEG C; reducing the temperature from 870-890 DEG C to 800 DEG C; introducing the O2+N2 in the process of reducing the temperature; stabilizing for 2 minutes at the temperature of 800 DEG C; and introducing the POCL3+O2+N2; and (3) taking the silicon wafer out of the diffusion furnace. In the method, both the requirements on the doping concentration of an emitting region and the surface concentration of the emitting region in diffusion can be met at the same time; a gettering effect is good; and the distribution of a doping curve is more reasonable.

Owner:BAODING GUANGWEI GREEN ENERGY TECH CO LTD

Phosphorus diffusion method for preparing silicon solar battery

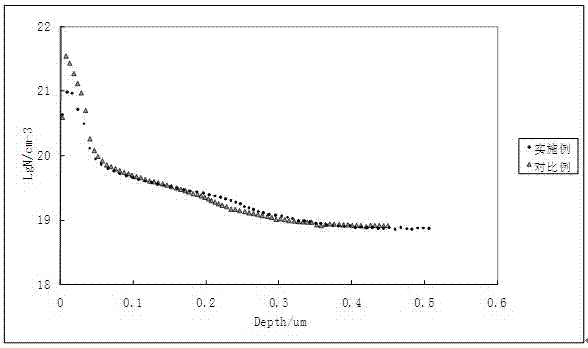

ActiveCN102522449ALow saturated vapor pressureHigh trafficFinal product manufactureSemiconductor/solid-state device manufacturingFurnace temperatureSilicon solar cell

The invention discloses a phosphorus diffusion method of a silicon solar battery. The phosphorus diffusion method comprises the following steps: (1) placing a silicon wafer to be treated in a diffusion furnace and heating to 780-810 DEG C; (2) heating to 810-870 DEG C, and after the temperature is stable, introducing nitrogen carrying a phosphorus source and dry oxygen at the same time so as to carry out constant-source diffusion, wherein the flow of the nitrogen carrying a phosphorus source is 1-1.7L / min, the dry oxygen flow is 0.4-0.7L / min, the phosphorus source is phosphorus oxychloride, and the temperature of the phosphorus source is constant at 12-20 DEG C, so the surface concentration of phosphorus impurities on the surface of the silicon wafer is (1.0e+21)-(1.3e+21)cm<-3>; (3) keeping the diffusion furnace temperature and the dry oxygen flow unchanged, stopping introducing the nitrogen carrying a phosphorus source, and carrying out oxygen limited-source diffusion; and (4) cooling, and pulling out a quartz boat, thus finishing the diffusion process. The phosphorus diffusion method disclosed by the invention can be used for reducing the surface concentration of the phosphorus impurities on the surface of the silicon wafer, reducing the surface minority carrier recombination rate and improving the photoelectric conversion efficiency. Compared with an existing phosphorus diffusion process, the phosphorus diffusion method disclosed by the invention has the advantages that the absolute value of the increase of the photoelectric conversion efficiency of the obtained solar battery is 0.1%, and an unexpected technical effect can be achieved.

Owner:CSI CELLS CO LTD +1

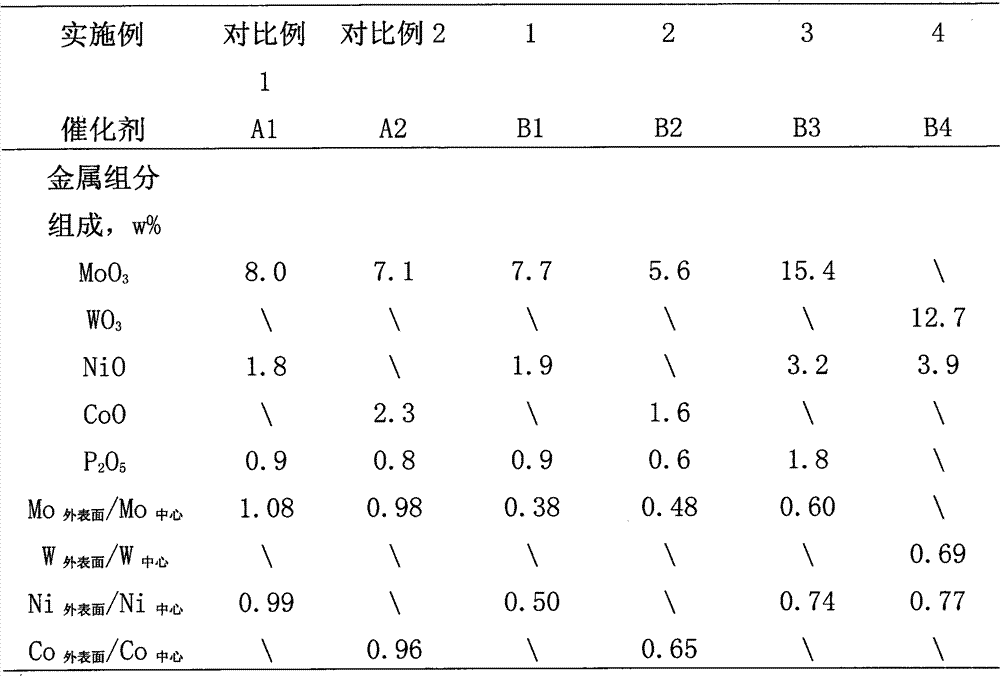

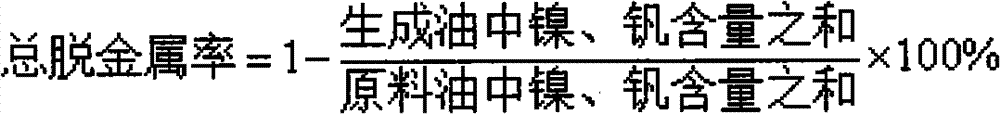

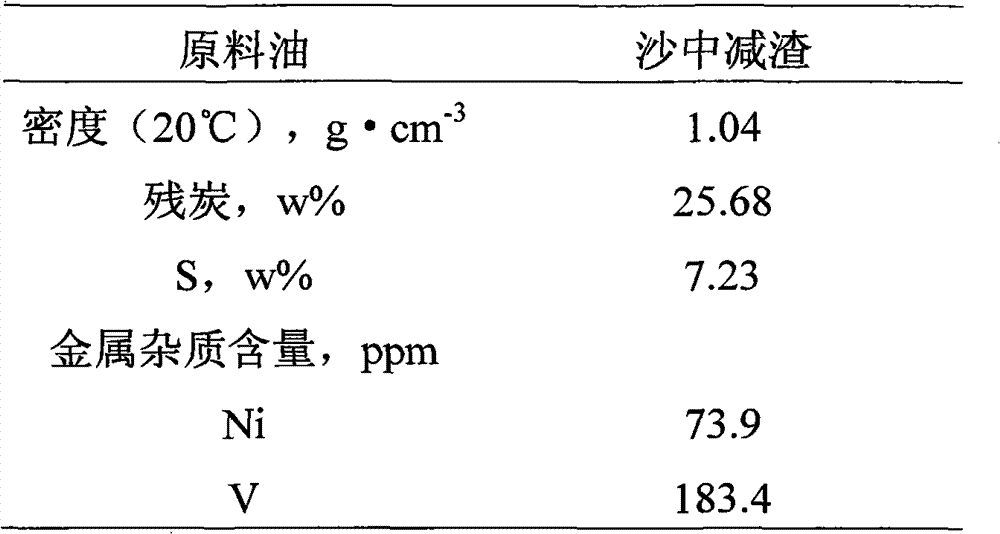

Active metal component nonuniformly distributed hydrogenation catalyst and its preparation

ActiveCN102764665AExcellent heavy oil hydrodemetallization performanceGood metal toleranceMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsSurface concentrationPresent method

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for diffusing silicon solar cell adopting selective emitter junction realized through double diffusion

InactiveCN102097523AGuaranteed concentrationImprovement of uneven square resistanceFinal product manufactureSemiconductor devicesDiffusionSurface concentration

The invention relates to the technical field of silicon solar cells, in particular to a process for diffusing a silicon solar cell adopting a selective emitter junction realized through double diffusion. The process comprises the following steps: placing a cleaned silicon wafer into a furnace, raising the temperature and introducing oxygen, nitrogen and phosphorus oxychloride into the furnace to carry out diffusion; and stopping introducing phosphorus oxychloride, continuing introducing oxygen and nitrogen and distributing after raising the temperature. The process has the following beneficial effects: the general condition of non-uniform sheet resistance is greatly improved under the condition of low surface concentration; the problem of ensuring low surface concentration of the silicon wafer while ensuring good sheet resistance uniformity in the low-concentration doped diffusion process is solved; the lightly-doped diffusion process has the following requirements: the surface concentration is 1E20-5E20Atom / cm2 and the junction depth is 0.2-0.35mu m; the sheet resistance uniformity is about 15% by adopting the general diffusion processes, but the sheet resistance uniformity is within 8% by adopting the technical scheme adopted by the invention; and through verification, the electrical performance yield of the solar cell plate is improved from 95% to 99.5%.

Owner:TRINA SOLAR CO LTD

Method of making nd-fe-b sintered magnets with reduced dysprosium or terbium

ActiveUS20130084204A1Low usageTransportation and packagingMetal-working apparatusSurface concentrationMetallurgy

A method of making a permanent magnet and a permanent magnet. The method includes providing combining a core material and a surface material so that the surface concentration of dysprosium, terbium, or both in the surface material is high while simultaneously keeping the bulk concentration of dysprosium, terbium, or both low. From this, the magnet has a non-uniform distribution of dysprosium, terbium or both. Varying approaches to preparing the combined core and surface materials may be used to ensure that the surface powder effectively wraps around the core powder as a way to achieve the high surface concentration and low bulk concentration. In one form, the core material may be made from a neodymium-iron-boron permanent magnet precursor material.

Owner:GM GLOBAL TECH OPERATIONS LLC

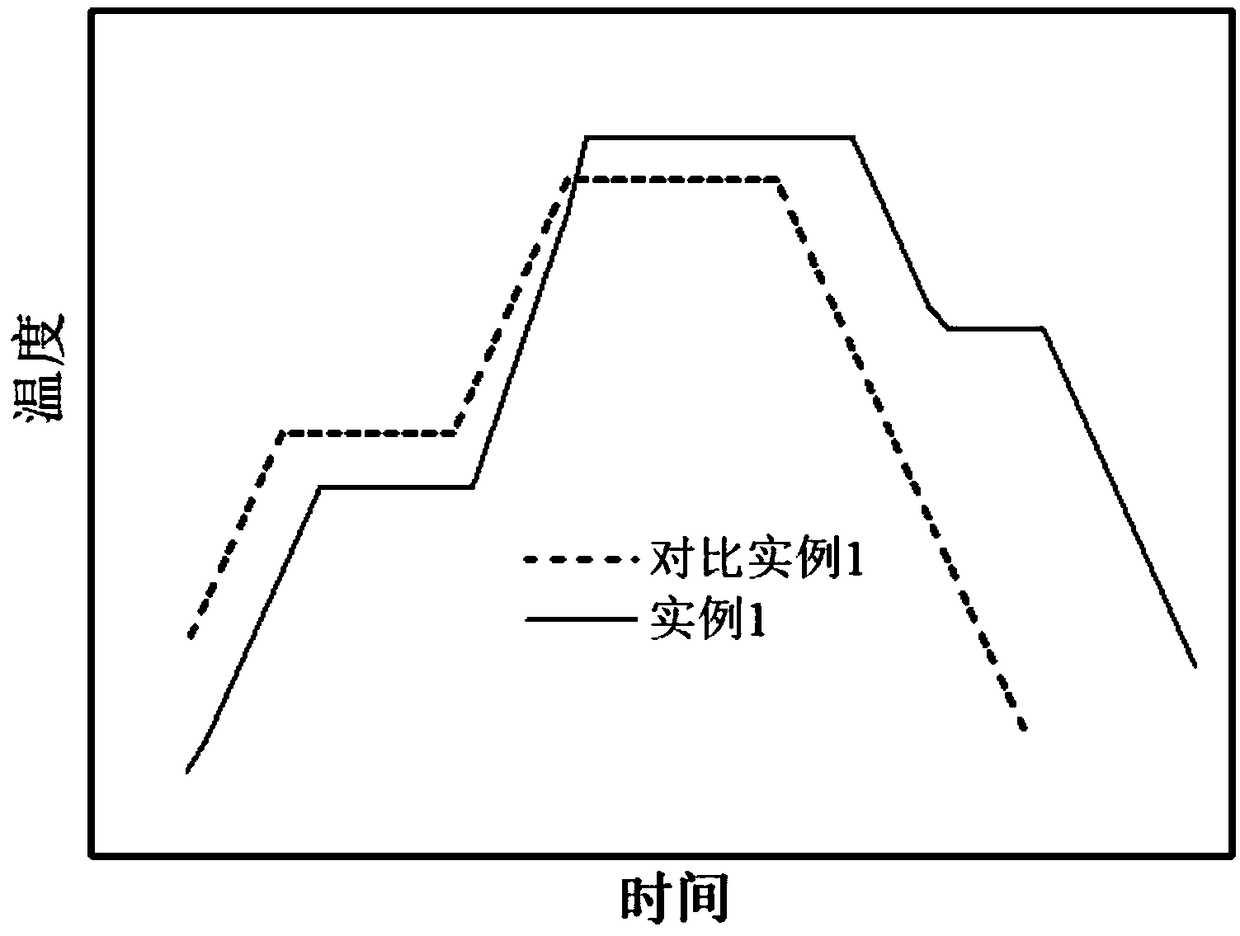

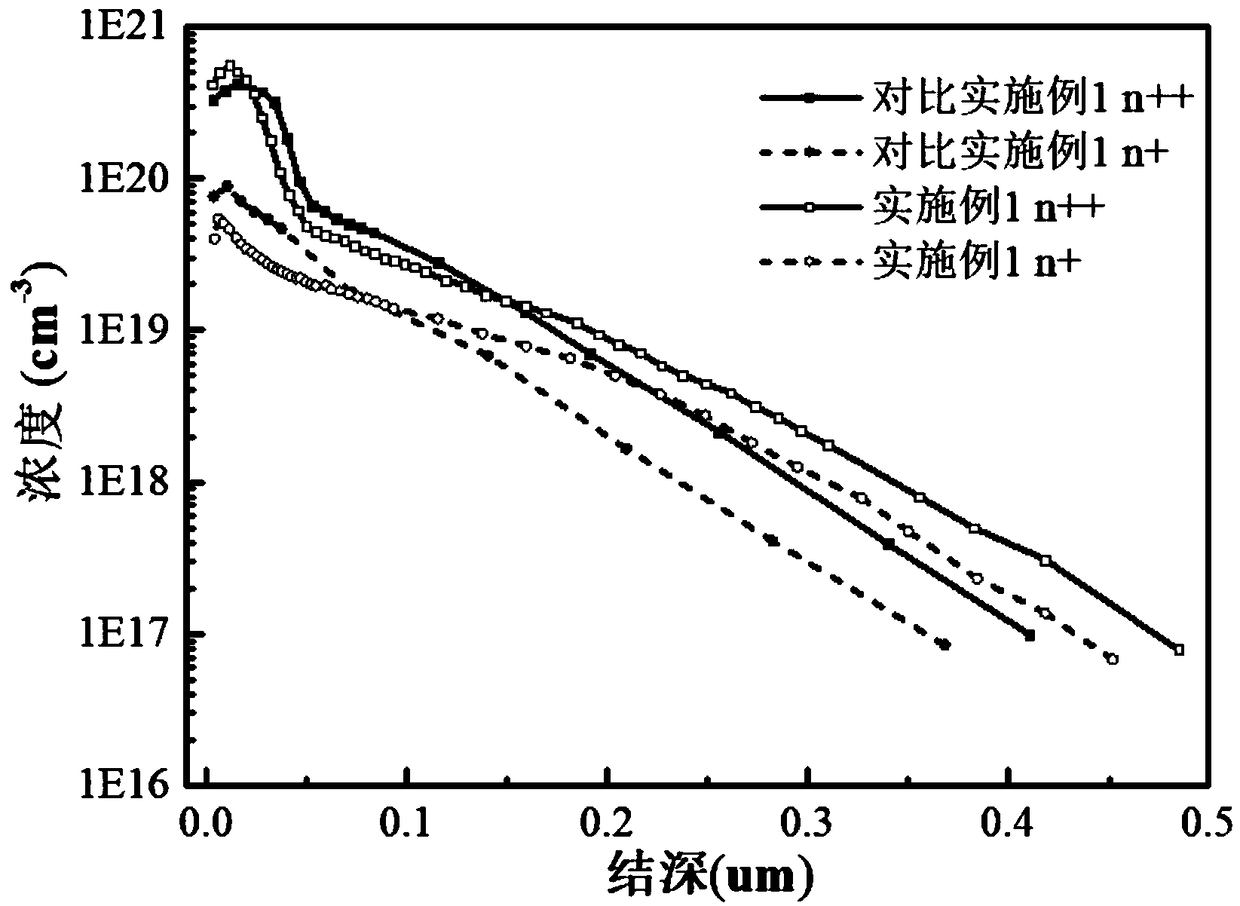

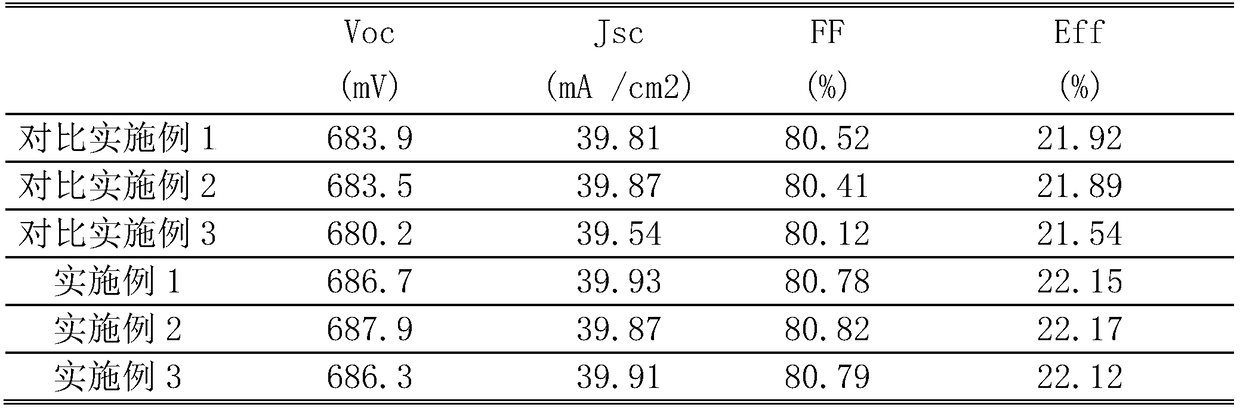

A step-by-step phosphorus doping method for high-efficiency and low-cost crystalline silicon batteries

ActiveCN109166794AIncrease the open circuit voltageReduce concentrationFinal product manufactureSemiconductor/solid-state device manufacturingHigh concentrationHigh surface

The invention belongs to the technical field of solar cell manufacturing, and relates to a step-by-step phosphorus doping method of a high-efficiency and low-cost crystal silicon cell, namely a primary depletion diffusion combined with secondary high-concentration shallow layer diffusion and back etching method. By controlling the flow of oxygen, A low-temperature low-phosphorus source depositionis carry out for that first time on a p-type silicon substrate by nitrogen flow rate and phosphorus oxychloride flow rate, After a long time of high temperature propulsion, the phosphorus in the phosphor-silicate glass is exhausted, and the low surface concentration layer n + is realized. The second time, the phosphor-free glass is deposited on the phosphor-silicate glass, and the high surface concentration layer n + + is pushed to form a very thin high concentration layer, which can be quickly etched off by means of back etching. The method can accurately control the phosphorus doping distribution in different regions independently to ensure that the non-electrode region has low doping concentration and low recombination current so as to ensure higher open-circuit voltage. The electrode region has high doping concentration, which forms good ohmic contact with the metal electrode and ensures that the filling factor is not lost, so as to improve the photoelectric conversion performanceof the battery as a whole.

Owner:CHANGZHOU UNIV +1

Diffusion technology of crystalline silicon solar cell

ActiveCN101707226AAverage non-uniformity dropIncreased average photoelectric conversion efficiencyFinal product manufactureSemiconductor devicesSurface concentrationP–n junction

The invention discloses a new diffusion technology of the crystalline silicon solar cell. The diffusion technology mainly refers to a technology which divides the source step into the following steps based on the original technology: low temperature prediffusion, step-ramp-temperature elevation diffusion and high temperature diffusion. The technology can significantly enhance the uniformity of the diffusion, well control the depth and surface concentration of the PN junction and increase the photoelectric conversion efficiency of the crystalline silicon solar cell. The new diffusion technology can be edited easily which only needs to modify the original technological parameters so as to facilitate the operation. The technology is applicable to industrialized production, does not affect the production progress and can be used in large-scale production lines of the solar cell.

Owner:湖南红太阳新能源科技有限公司

Quick diffusion annealing method

InactiveCN106653598AImprove conversion efficiencyIncrease surface concentrationFinal product manufactureSemiconductor/solid-state device manufacturingP–n junctionPre deposition

The invention discloses a quick diffusion annealing method. A primary source introduction and pre-deposition process is carried out at below 800 DEG C. After deposition, aerobic heating advance is carried out, and the temperature can rise up to 840-880 DEG C. A PN node advanced at the moment is deep. Then, an aerobic cooling process is carried out, and the temperature drops to 810-850 DEG C. Secondary source introduction is carried out, which is a key step for quick annealing. After that, the furnace door is half-opened immediately, a large amount of nitrogen is introduced, and quick cooling and annealing are carried out. The lattice is repaired to a certain degree, but the phosphorus source still needs certain advance time. Thus, the furnace door is closed slowly, and the temperature goes back to a constant state. The beneficial effects of the method are as follows: through secondary source introduction, the surface concentration is increased, and the filling factor is improved; through lattice repair, thermal damage is reduced, the open-circuit voltage and short-circuit current are improved, and the conversion efficiency of cells is improved; and through quick cooling, the total process time is reduced, the process efficiency is improved, and the production capacity is increased.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

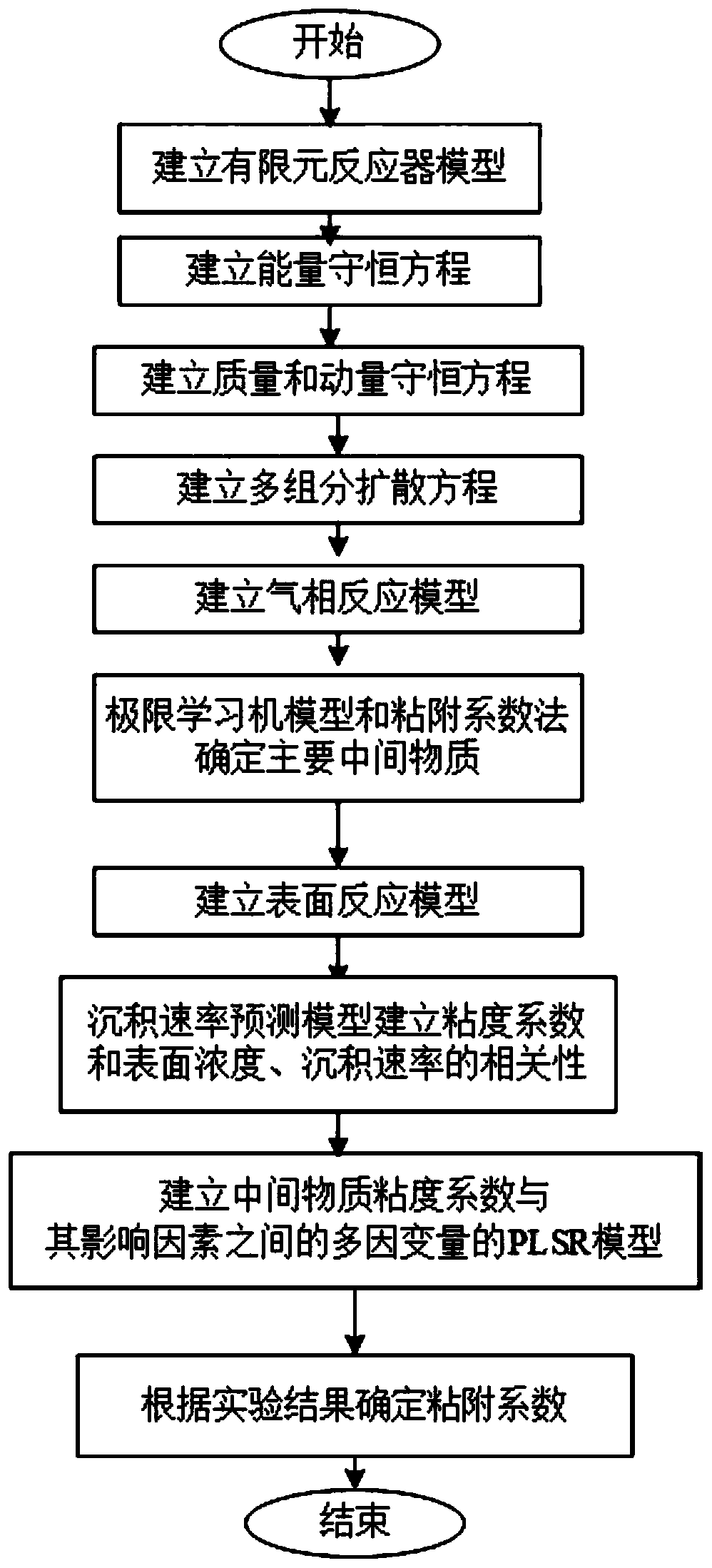

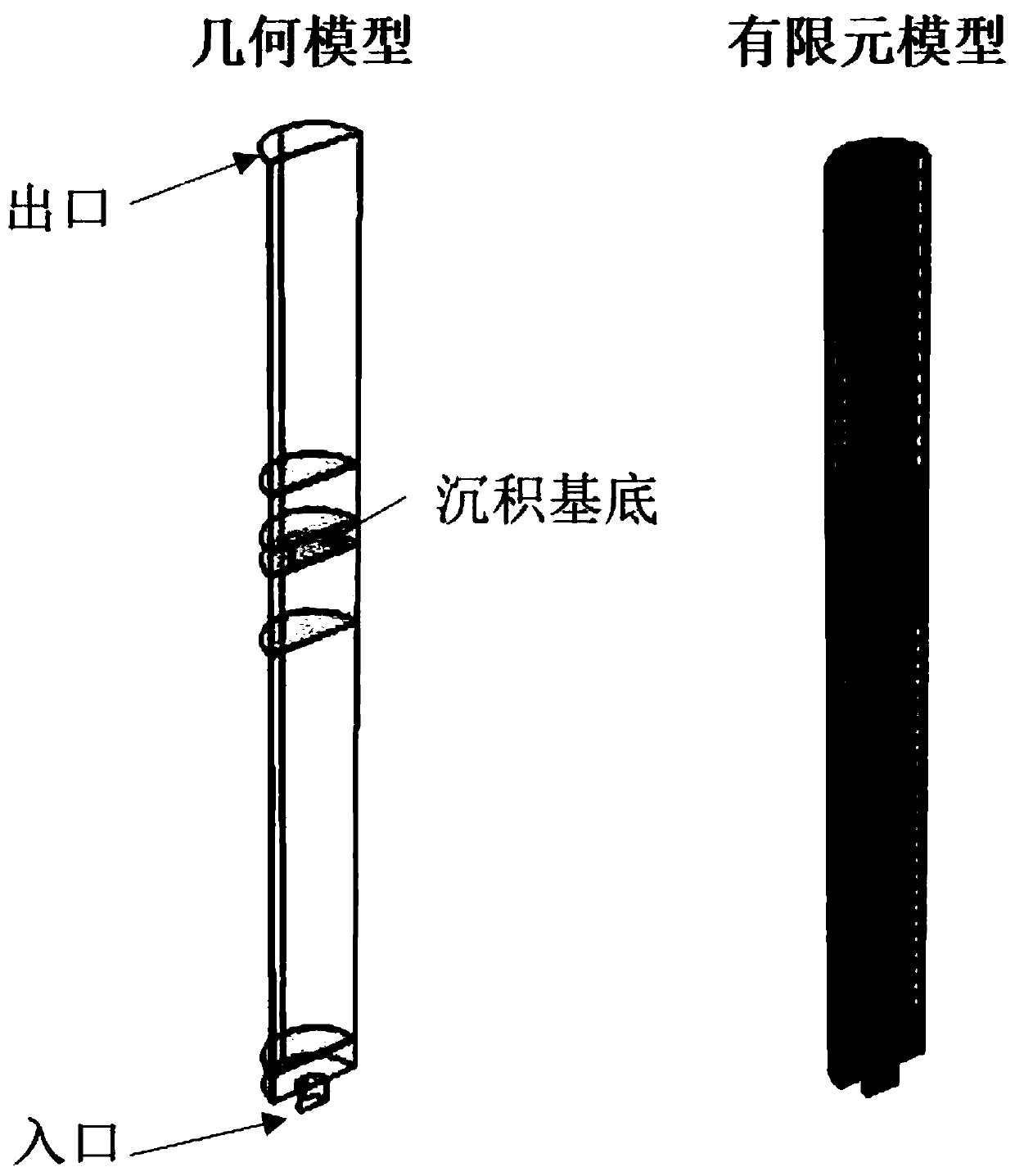

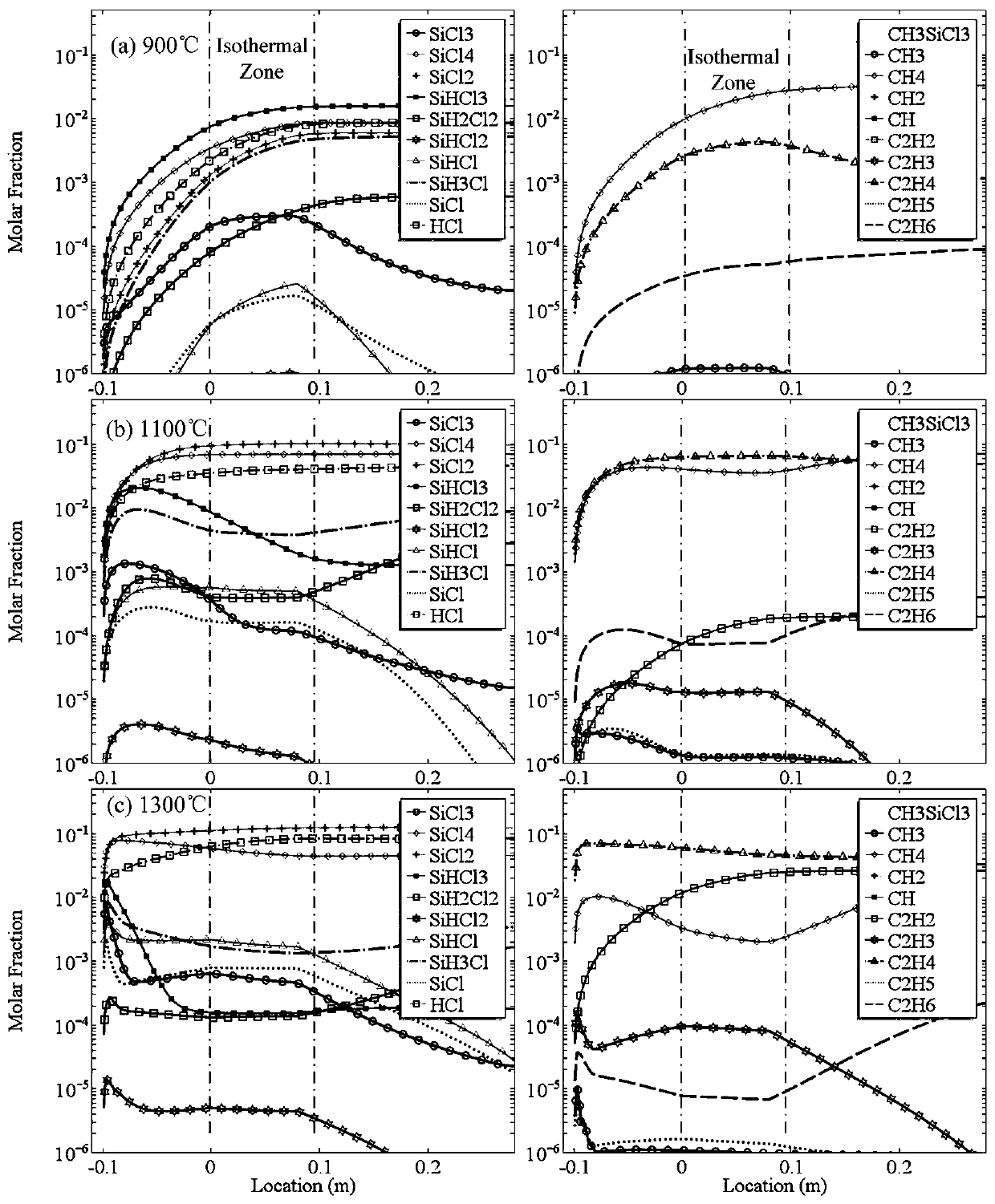

Chemical vapor deposition rate prediction method

ActiveCN110598255AAccurate calculation of viscosity coefficientUniversalChemical property predictionChemical machine learningLearning machineGas phase

The invention discloses a chemical vapor deposition rate prediction method, and particularly relates to the field of chemical process research. The chemical vapor deposition rate prediction method comprises the following steps: building a finite element reactor model; establishing an energy conservation equation; establishing a mass conservation equation and a momentum conservation equation; establishing a multi-component diffusion equation; establishing a gas phase reaction model; determining main intermediate substances by an extreme learning machine model and an adhesion coefficient method;establishing a surface reaction model; establishing correlation between the viscosity coefficient and the surface concentration as well as the deposition rate by the deposition rate prediction model;establishing a multi-dependent-variable PLSR model between the viscosity coefficient of the intermediate substance and the influence factor of the intermediate substance; and determining an adhesioncoefficient according to an experimental result. According to the chemical vapor deposition rate prediction method, the simulation technology of machine learning and computational fluid mechanics is combined, and the dependence of model parameters on human experience is greatly reduced, and the important mesophase and the viscosity coefficient can be accurately determined through a small number ofexperiments, and the technical effects of high prediction result accuracy and high reliability are achieved.

Owner:SOUTH CHINA UNIV OF TECH

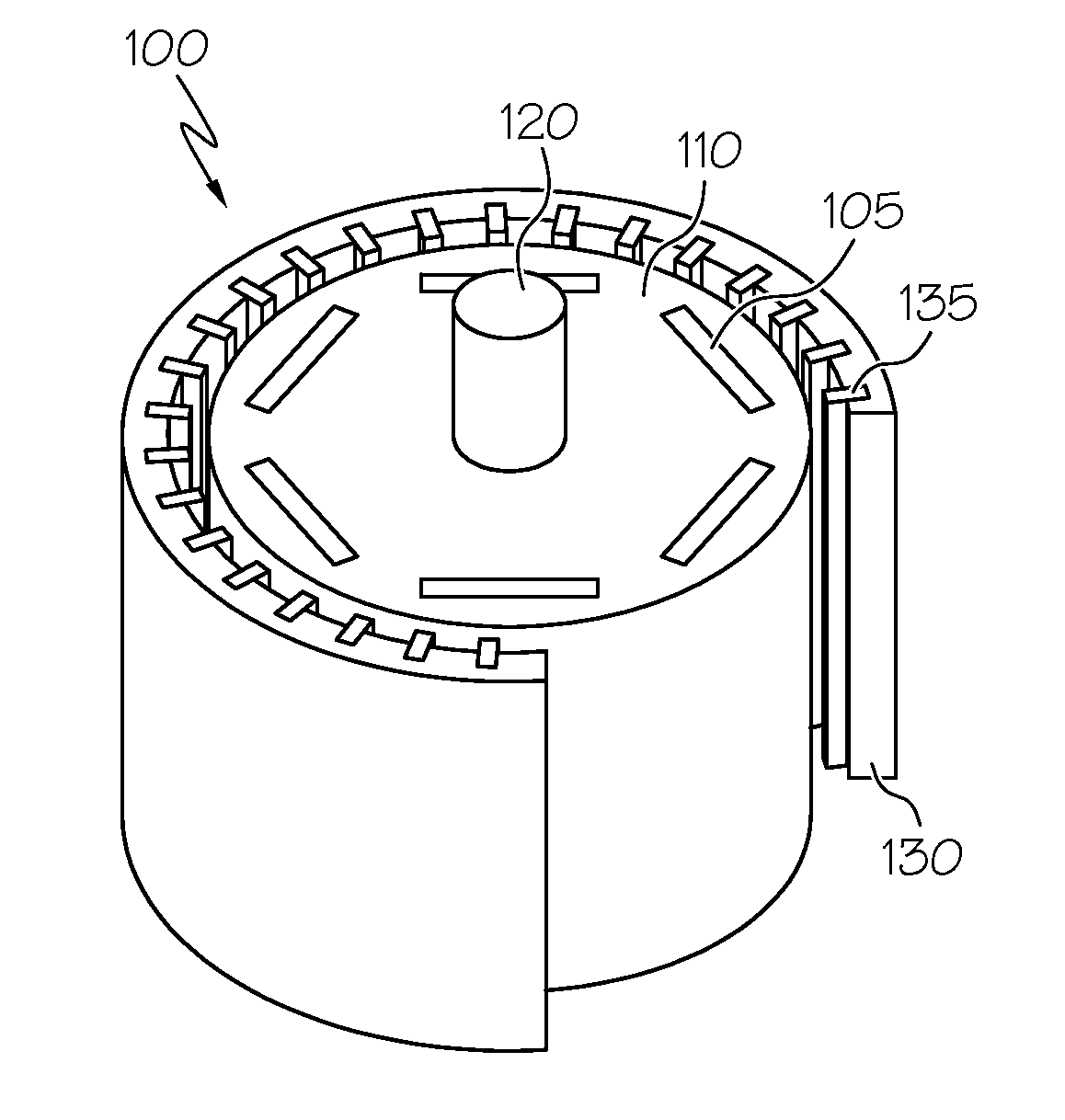

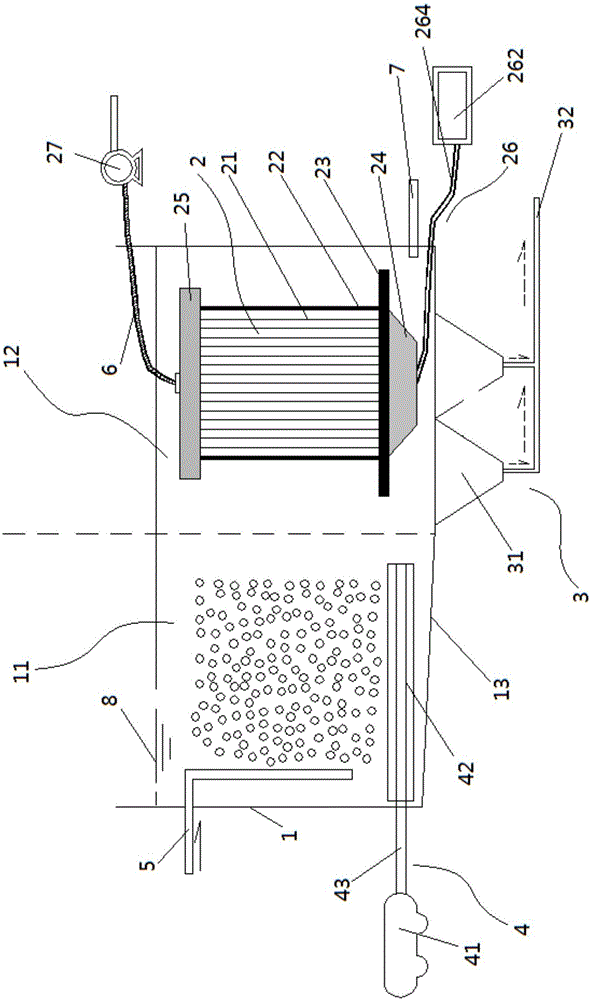

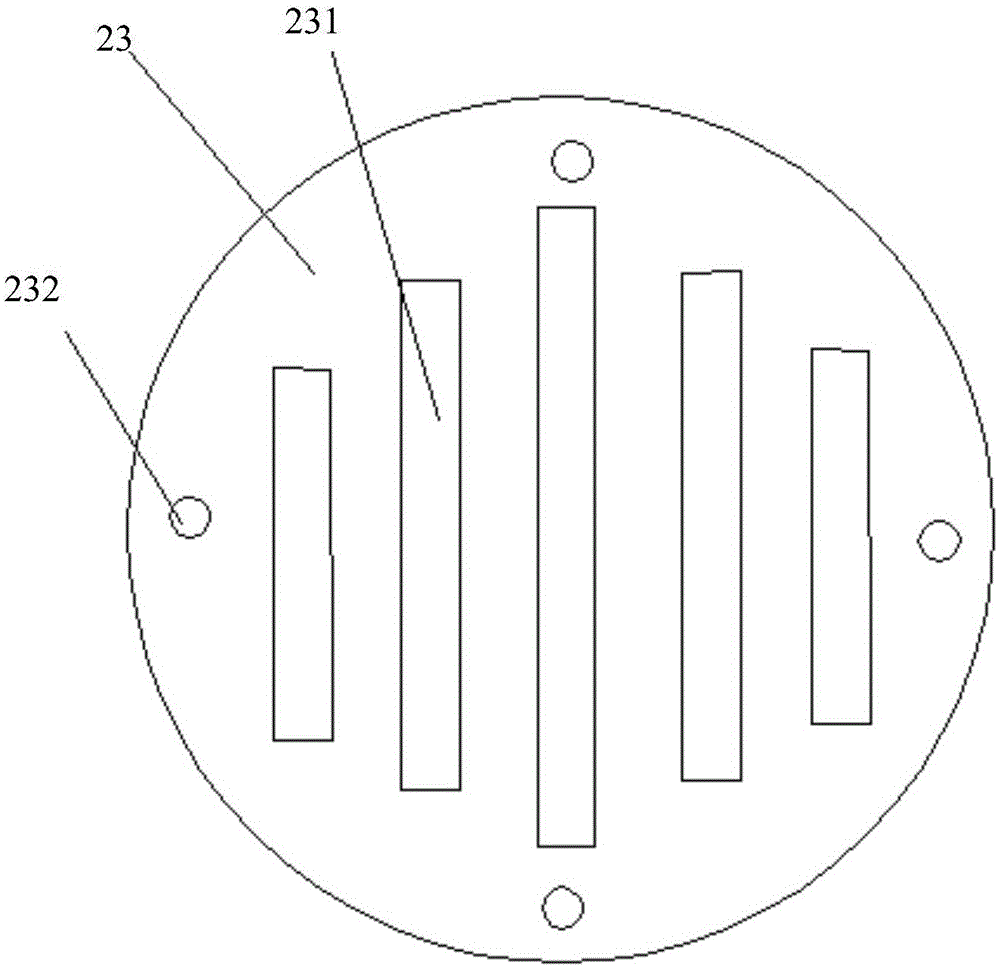

Reciprocating rotary type membrane bioreactor

ActiveCN105129974AReduce interactionImprove retention efficiencySustainable biological treatmentBiological water/sewage treatmentSurface concentrationPolarization phenomenon

The invention discloses a reciprocating rotary type membrane bioreactor which comprises a sewage treatment pond, a membrane separation device, a sludge discharge device, an aeration device, a water inlet pipe and a water outlet pipe. The membrane separation device is arranged in the sewage treatment pond, and a power driving assembly which drives the membrane separation device to conduct reciprocating rotation movement is installed on the lower portion of the membrane separation device. Due to the fact that the membrane separation device conducts the reciprocating rotation movement under the action of the power driving assembly, the surface concentration polarization phenomenon of a membrane separation assembly is significantly reduced, the membrane flux is kept stable, the service life of the membrane assembly is prolonged, and the sewage treatment efficiency is improved. Meanwhile, rejuvenation of the membrane assembly is conducted by rotating the membrane assembly in a rapid and reciprocating mode, traditional cleaning processes of adding chemical drugs or water or gas or the like are not needed, operation is easy, and the consumption of energy resources is greatly reduced.

Owner:BEIJING SINORICHEN ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com