Laser boron doped selective emitter TOPCon structure cell and preparation method thereof

A selective and emitter technology, which is applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of deeper junction and lower surface doping concentration, and achieve the effect of increasing fill factor, improving conversion efficiency, and benefiting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

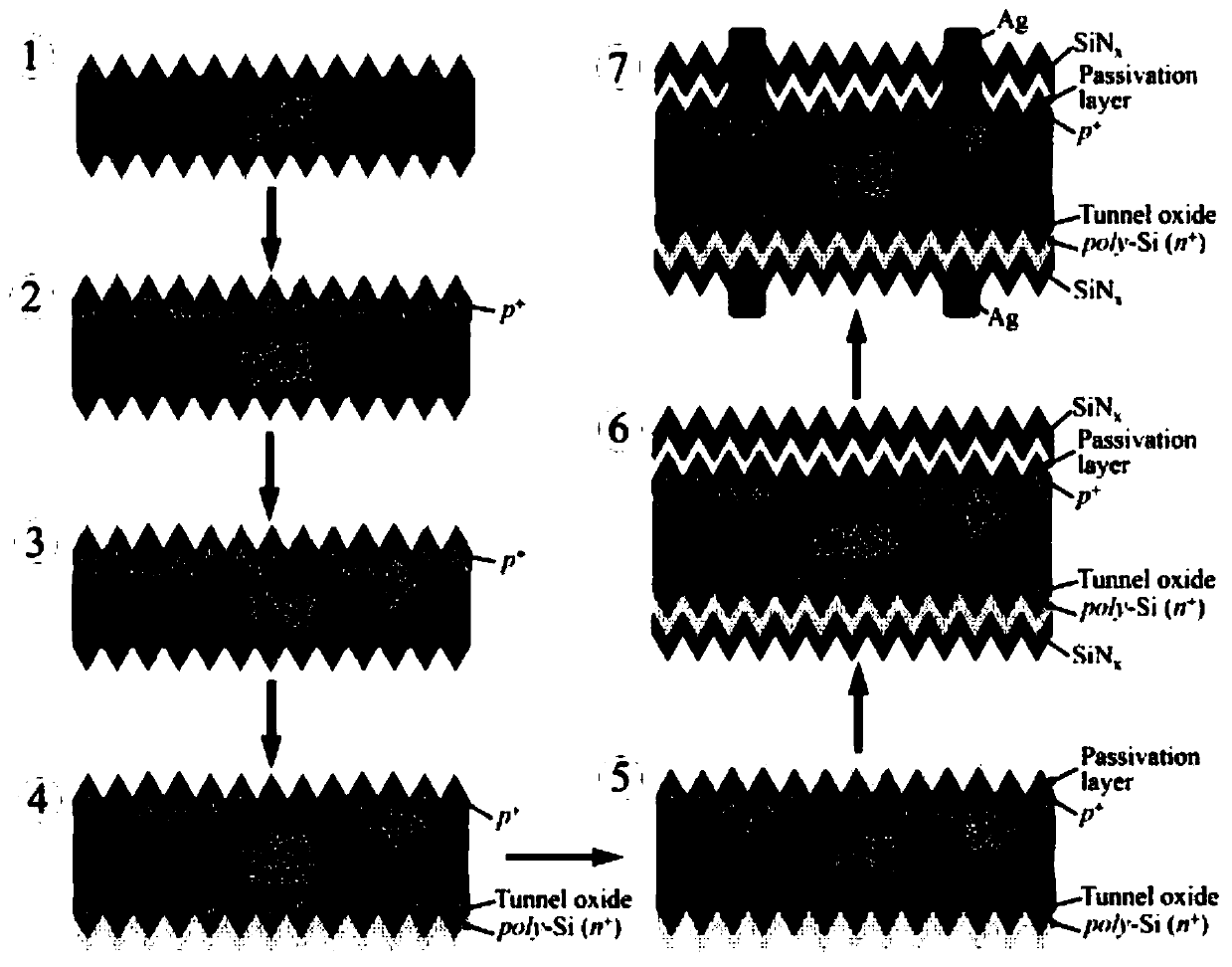

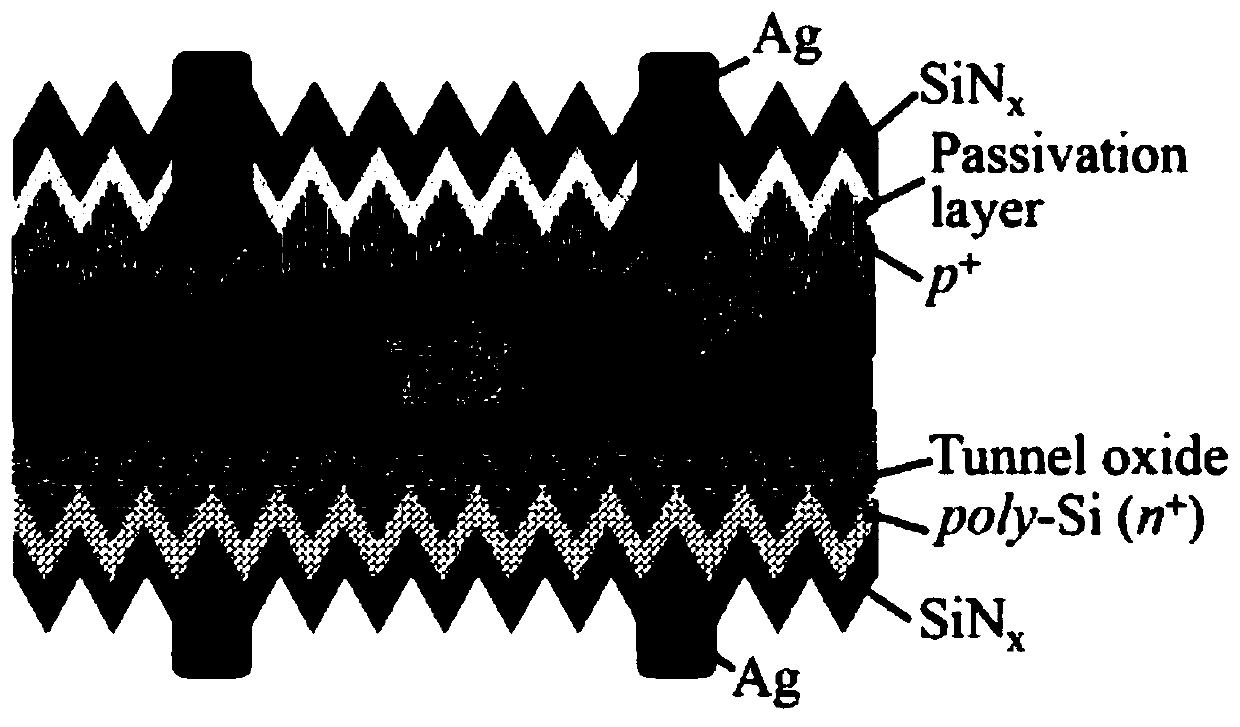

[0025] The preparation method of the laser boron doped selective emitter TOPCon solar cell of the present invention comprises the following steps, such as figure 1 Shown:

[0026] Ⅰ. Texturing and RCA cleaning of N-type silicon wafers;

[0027] Ⅱ. Carry out boron diffusion, where BBr 3 N 2 Flow rate 130sccm, push temperature: 900°C; push time: 2h, push to form P with high boron surface concentration ++ layer without oxidation process;

[0028] Ⅲ. Use 532nm green nanosecond Q-switched laser with power of 28W and scanning speed of 20m / s to dope the metal grid line area;

[0029] Ⅳ. After cleaning, put it back into the diffusion furnace for oxidation. The oxidation process parameters are: O 2 The flow rate is 30sccm, the oxidation temperature is 920°C; the oxidation time is 2h, so as to form a selective emitter;

[0030] Ⅴ. Removal of BSG and P on the back + Layer, prepare Tunnel oxide layer (tunnel oxide layer) and doped thin film silicon layer on the back;

[0031] Ⅵ. R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com