Solar energy cell with double-layer perovskite film structure and manufacturing method thereof

A double-layer perovskite and solar cell technology, applied in the field of solar cells, can solve the problems of high toxicity and impact of toluene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

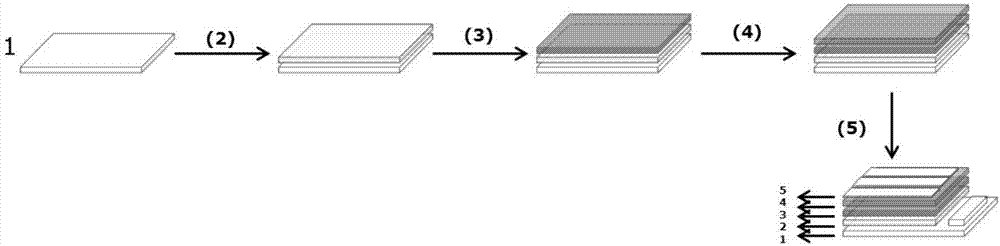

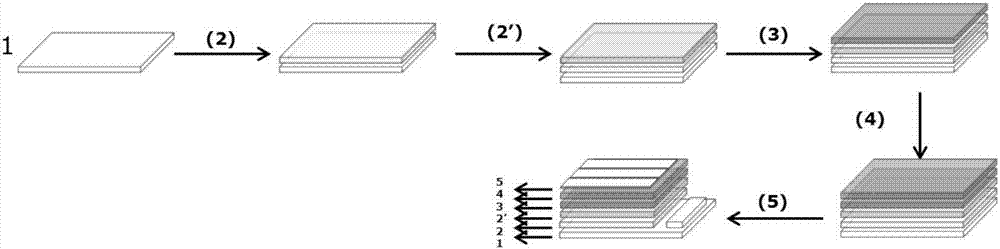

[0080] Such as figure 2 As shown, the preparation method of a solar cell with a double-layer perovskite film structure provided in this embodiment includes the following steps:

[0081] (1) The FTO transparent conductive glass is etched into the desired target pattern by laser, and then the etched conductive substrate is ultrasonically cleaned with conventional detergent aqueous solution, deionized water, acetone and isopropanol for 20 minutes, and then Blow dry with nitrogen to obtain a clean conductive substrate for later use;

[0082] (2) Treat the surface with plasma (plasma, using a conventional plasma cleaning machine) for 10 minutes before use to hydrophilize the surface, and put the electron transport material TiO 2 The sol-gel (is the isopropanol solution of two (acetylacetonato) diisopropyl titanate with a mass percentage of 75%, the solution is diluted in n-butanol at a dilution ratio of 1:10 by mass ) at a speed of 2000rpm, spin-coated for 30s, and spin-coated o...

Embodiment 2

[0090] (1) The FTO transparent conductive glass is etched into the desired target pattern by laser, and then the etched conductive substrate is ultrasonically cleaned with conventional detergent aqueous solution, deionized water, acetone and isopropanol for 20 minutes, and then Blow dry with nitrogen to obtain a clean conductive substrate for later use;

[0091] (2) Treat the surface with plasma (plasma, using a conventional plasma cleaning machine) for 10 minutes before use to hydrophilize the surface, and put the electron transport material TiO 2 The sol-gel (is the isopropanol solution of two (acetylacetonato) diisopropyl titanate with a mass percentage of 75%, the solution is diluted in n-butanol at a dilution ratio of 1:10 by mass ) at a speed of 2000rpm, spin-coated for 30s, and spin-coated on a glass substrate, TiO 2 The thickness is 20-50nm, baked at 125°C for 5 minutes, annealed at 450°C for 15-30 minutes to obtain an electron transport layer;

[0092] (2') After co...

Embodiment 3

[0100] Such as figure 1 As shown, the preparation method of a solar cell with a double-layer perovskite film structure provided in this embodiment includes the following steps:

[0101] (1) The FTO transparent conductive glass is etched into the required target pattern by laser, and then the etched conductive substrate is ultrasonically cleaned with cleaning agent aqueous solution, deionized water, acetone and isopropanol for 20 minutes respectively, and then Blow dry with nitrogen to obtain the conductive substrate for subsequent use;

[0102] (2) Treat the surface with plasma for 10 minutes before use to hydrophilize the surface, and the TiO 2 The sol-gel (the isopropanol solution of 75% di(acetylacetonato) titanate diisopropyl titanate diluted in n-butanol at a dilution ratio of 1:10 by mass percentage) was spin-coated at a speed of 2000rpm for 30s, spin-coat on a glass substrate with a thickness of 20-50nm, bake at 125°C for 5 minutes, and anneal at 500°C for 30 minutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com