Patents

Literature

1777results about How to "Increase current density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

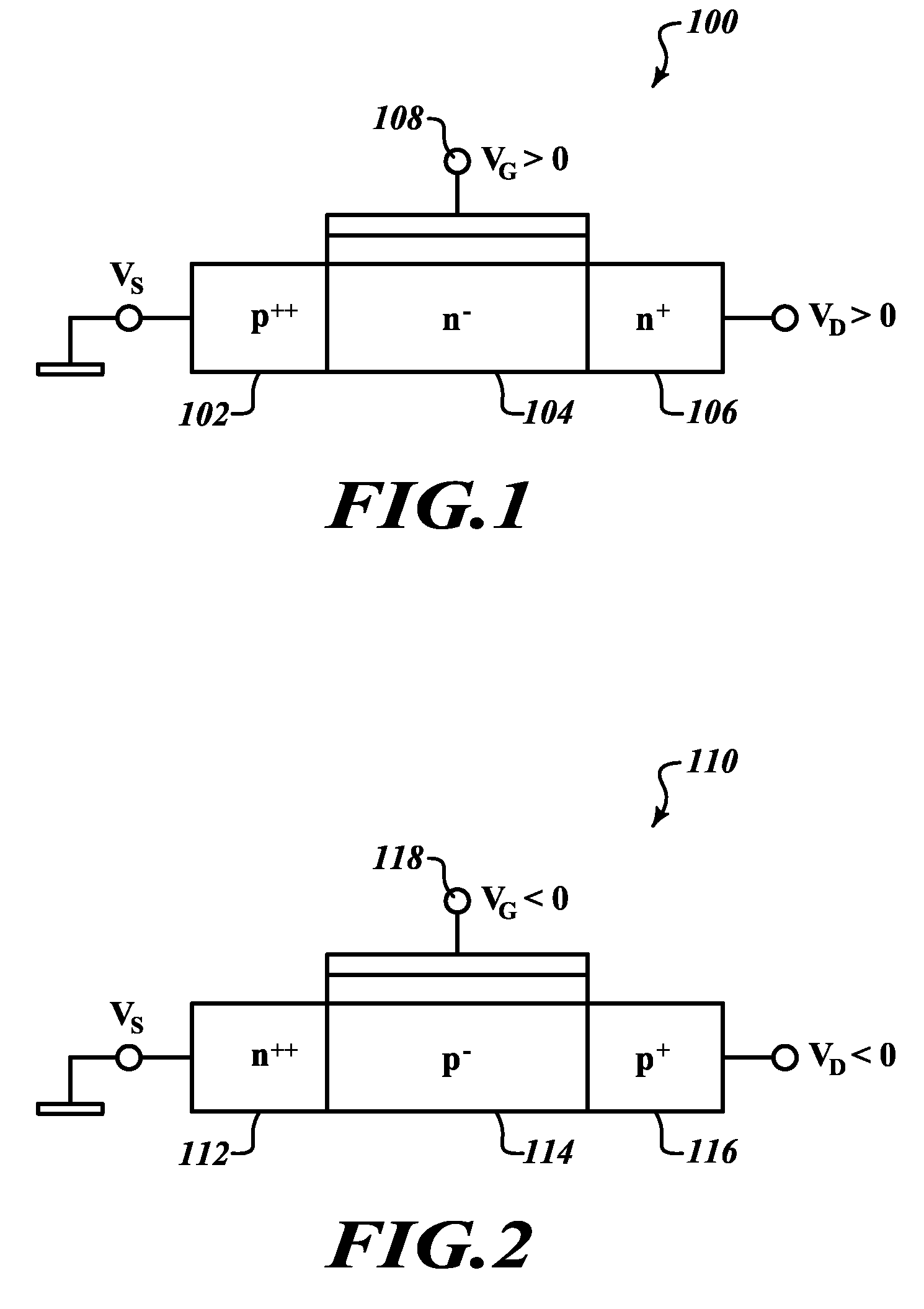

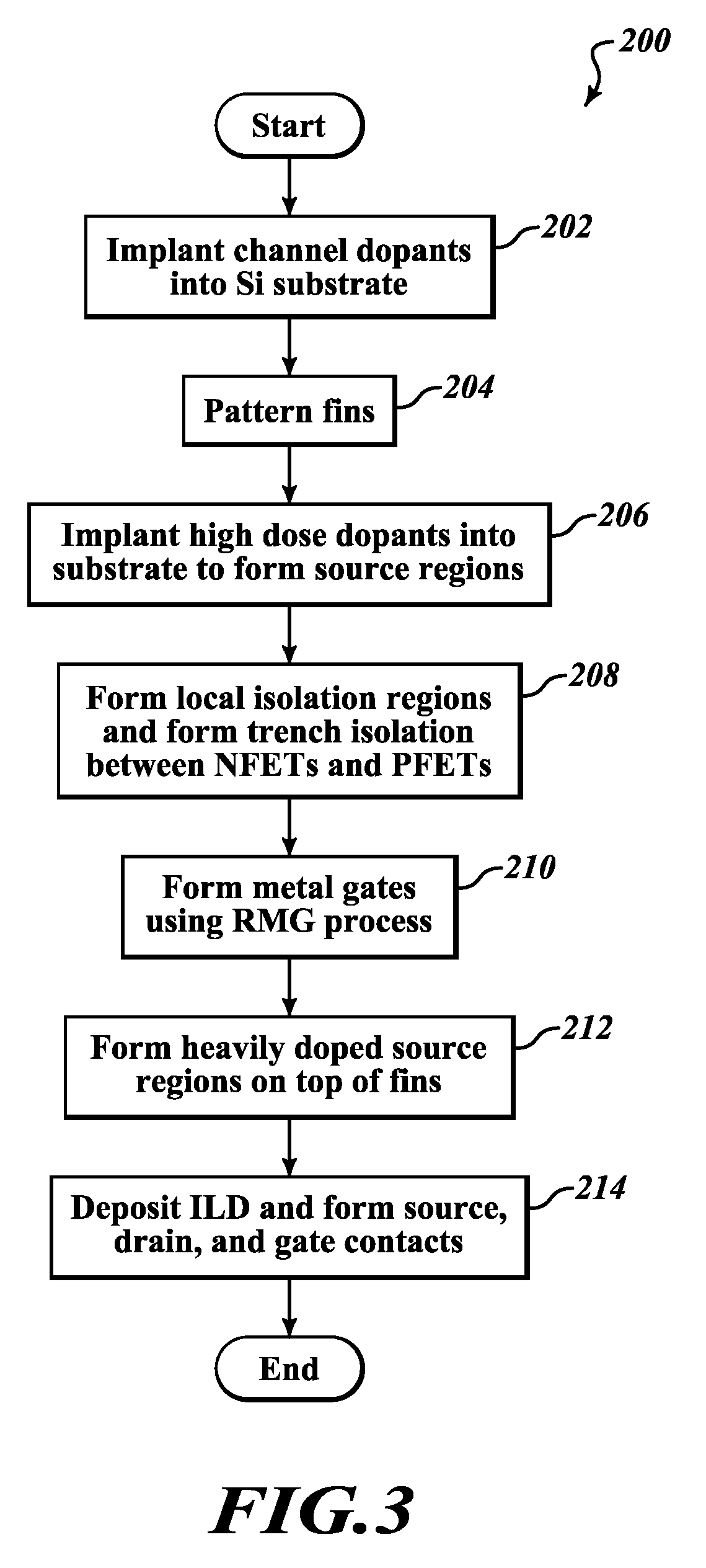

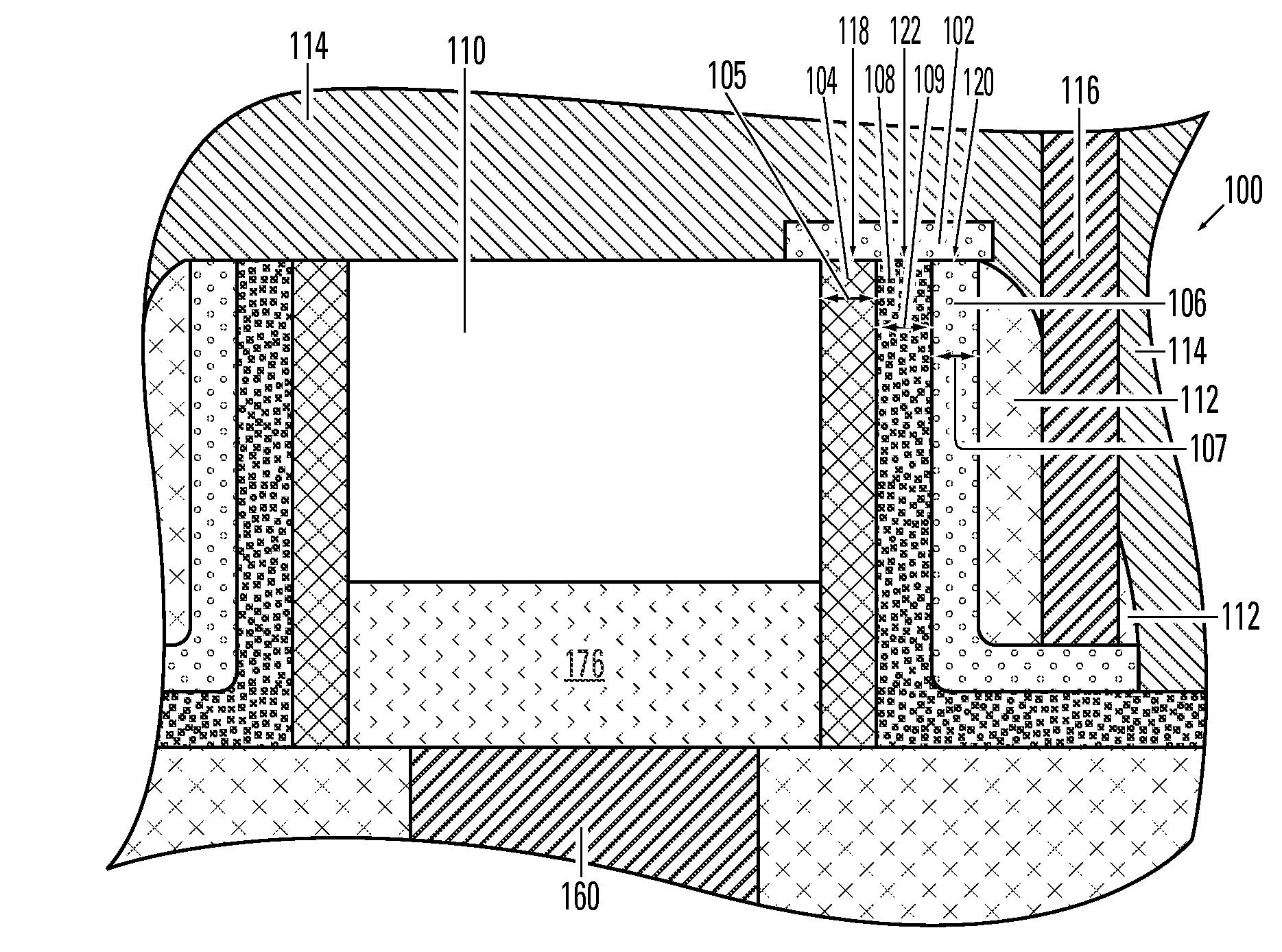

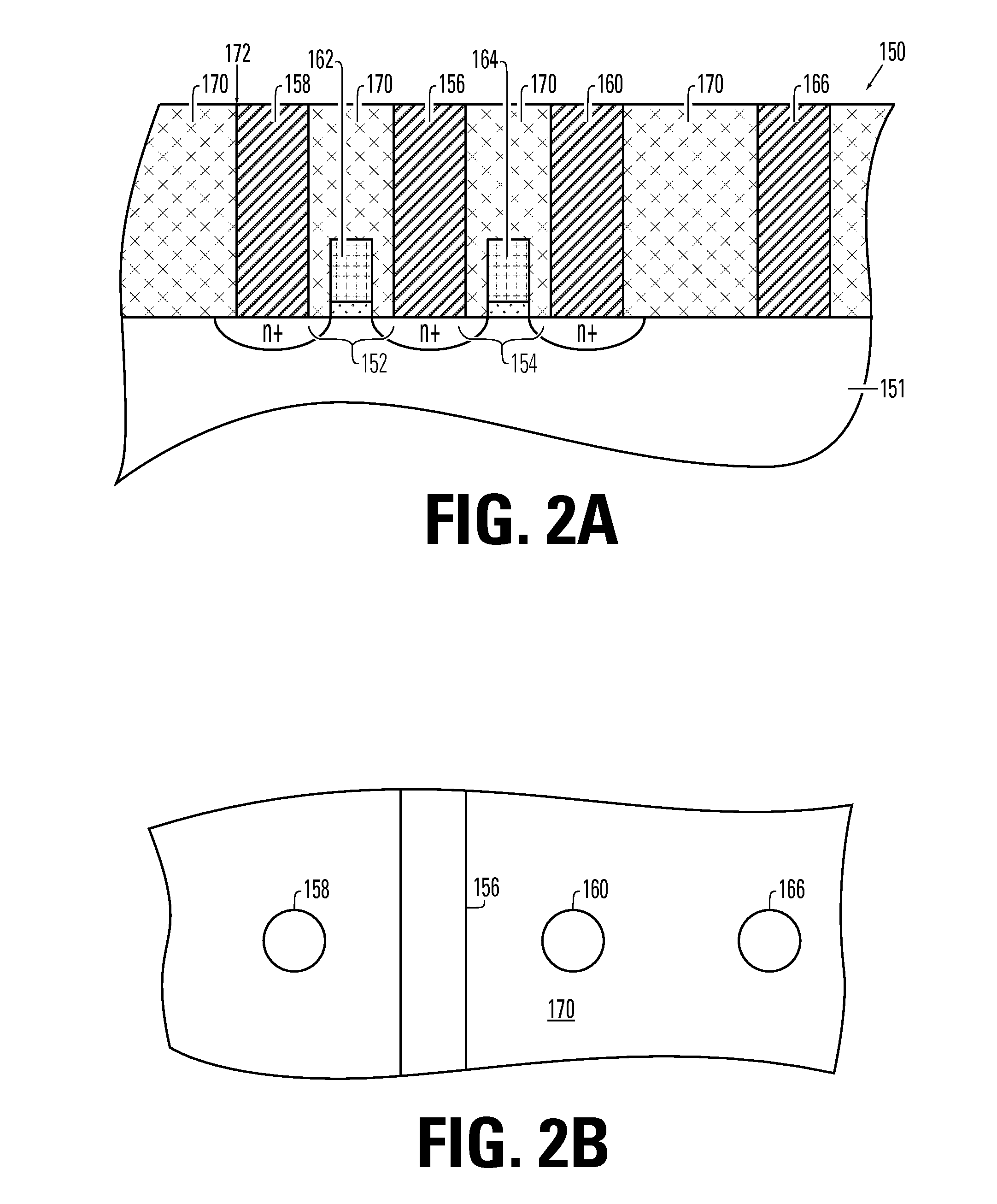

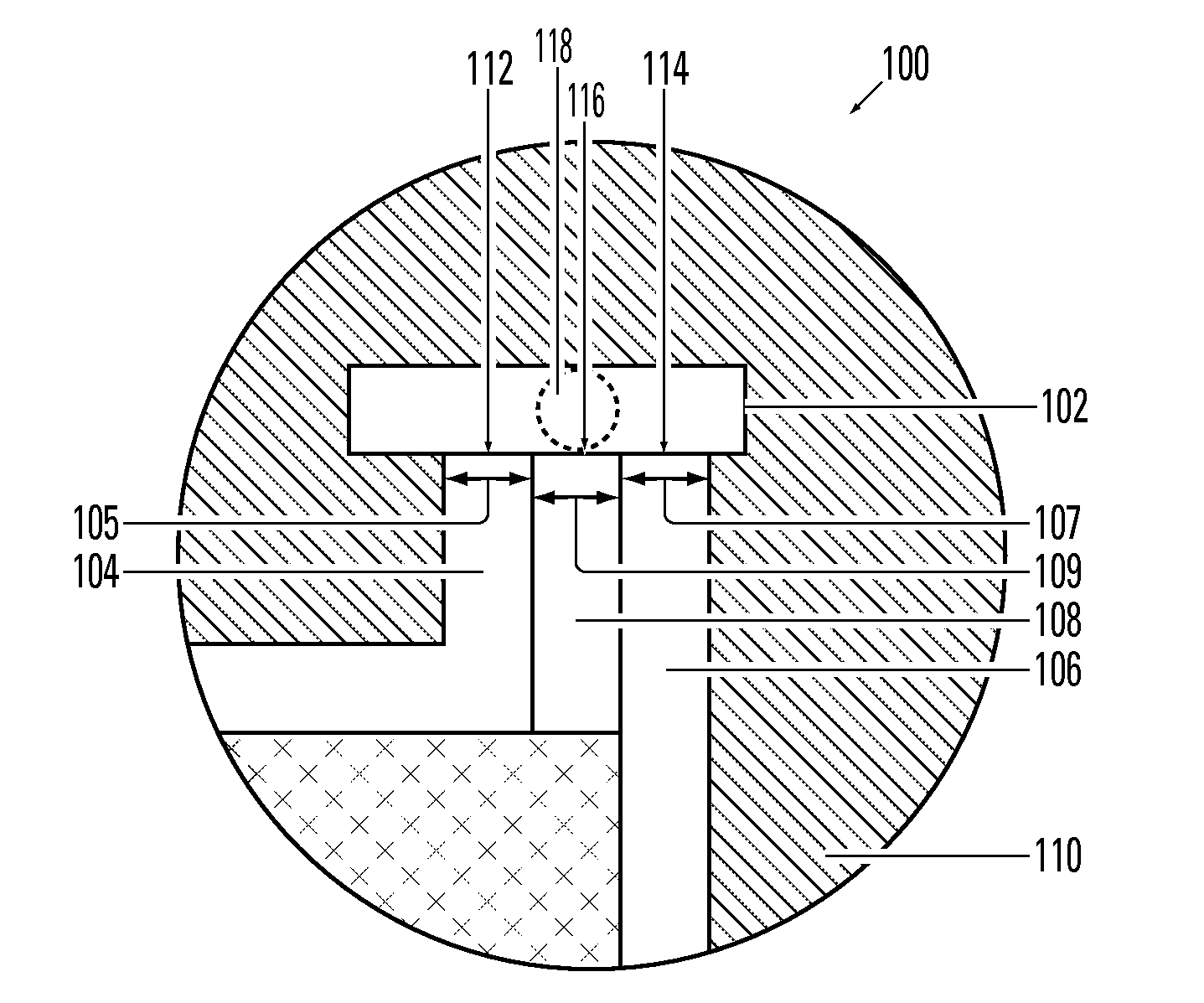

Vertical tunneling finfet

ActiveUS20160293756A1Increase current densityTransistorSemiconductor/solid-state device manufacturingHigh current densityCMOS

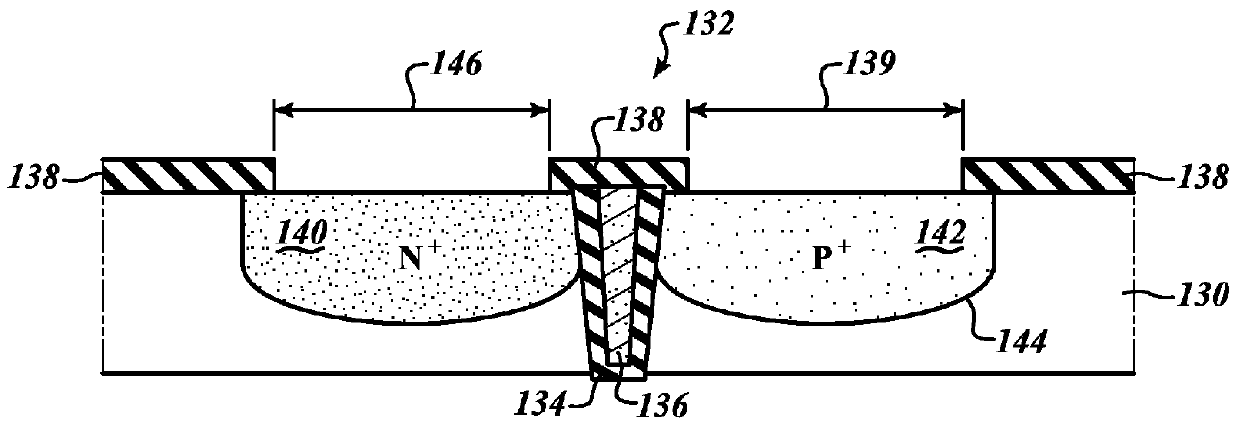

A tunneling transistor is implemented in silicon, using a FinFET device architecture. The tunneling FinFET has a non-planar, vertical, structure that extends out from the surface of a doped drain formed in a silicon substrate. The vertical structure includes a lightly doped fin defined by a subtractive etch process, and a heavily-doped source formed on top of the fin by epitaxial growth. The drain and channel have similar polarity, which is opposite that of the source. A gate abuts the channel region, capacitively controlling current flow through the channel from opposite sides. Source, drain, and gate terminals are all electrically accessible via front side contacts formed after completion of the device. Fabrication of the tunneling FinFET is compatible with conventional CMOS manufacturing processes, including replacement metal gate and self-aligned contact processes. Low-power operation allows the tunneling FinFET to provide a high current density compared with conventional planar devices.

Owner:STMICROELECTRONICS SRL

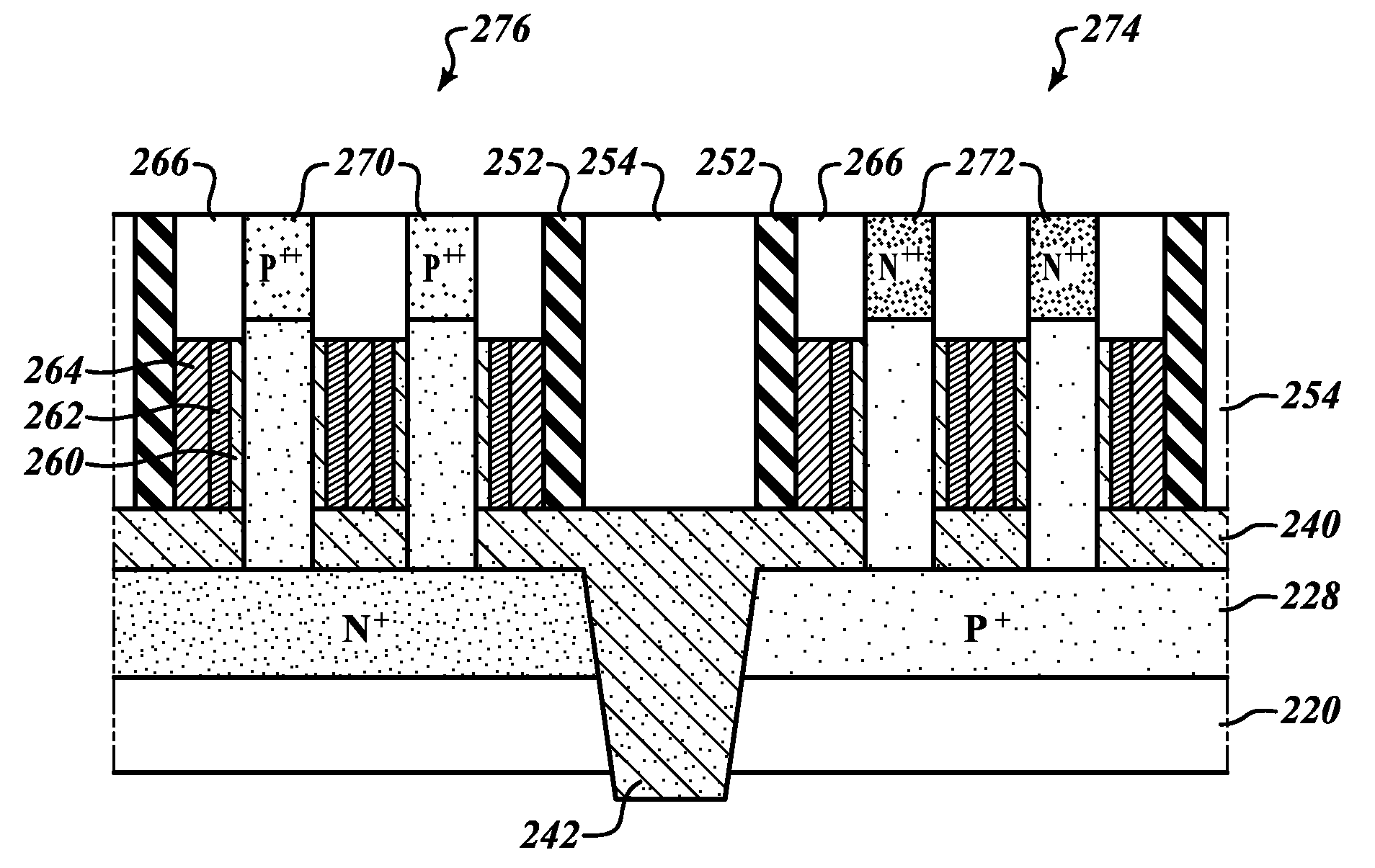

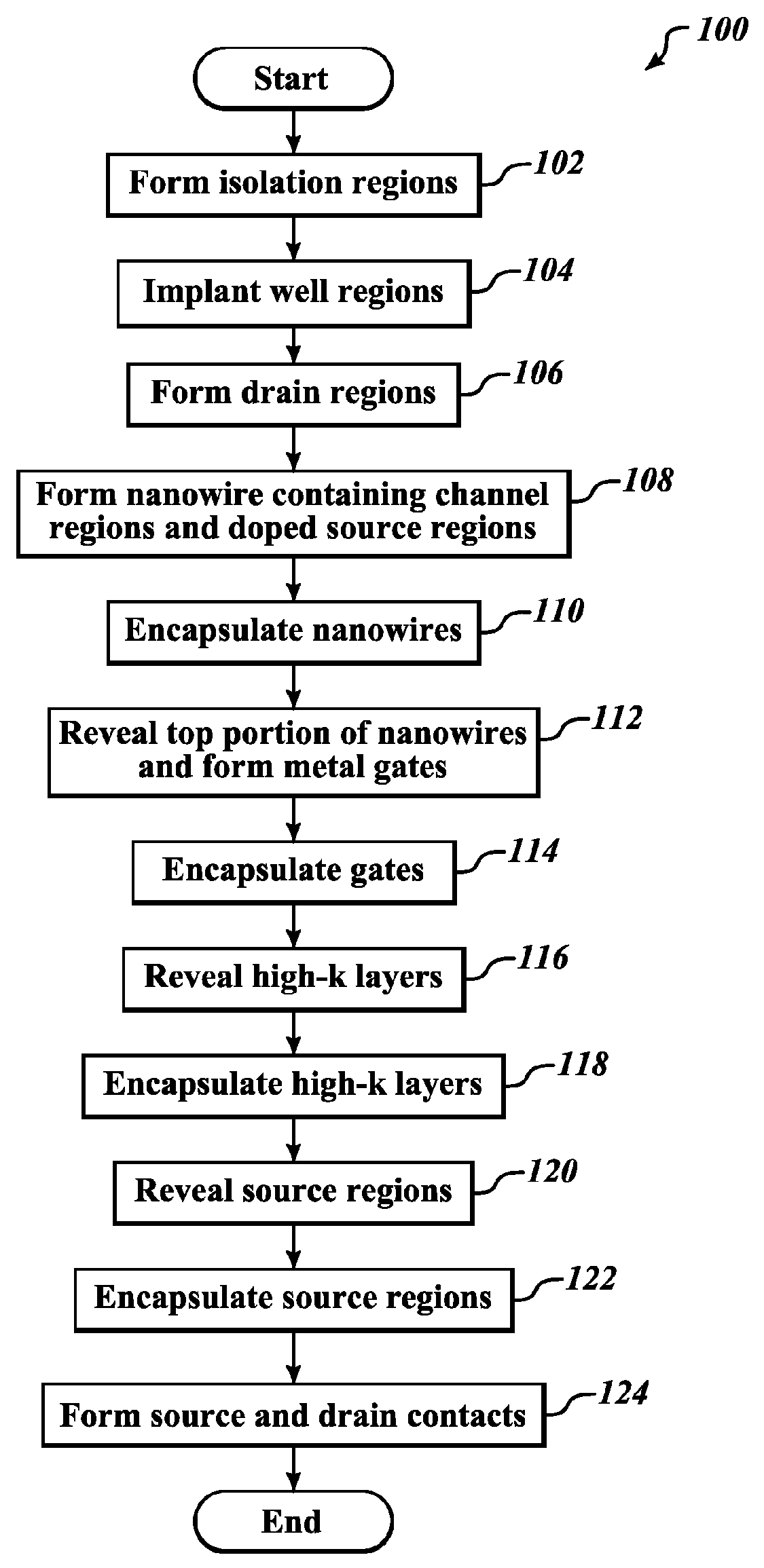

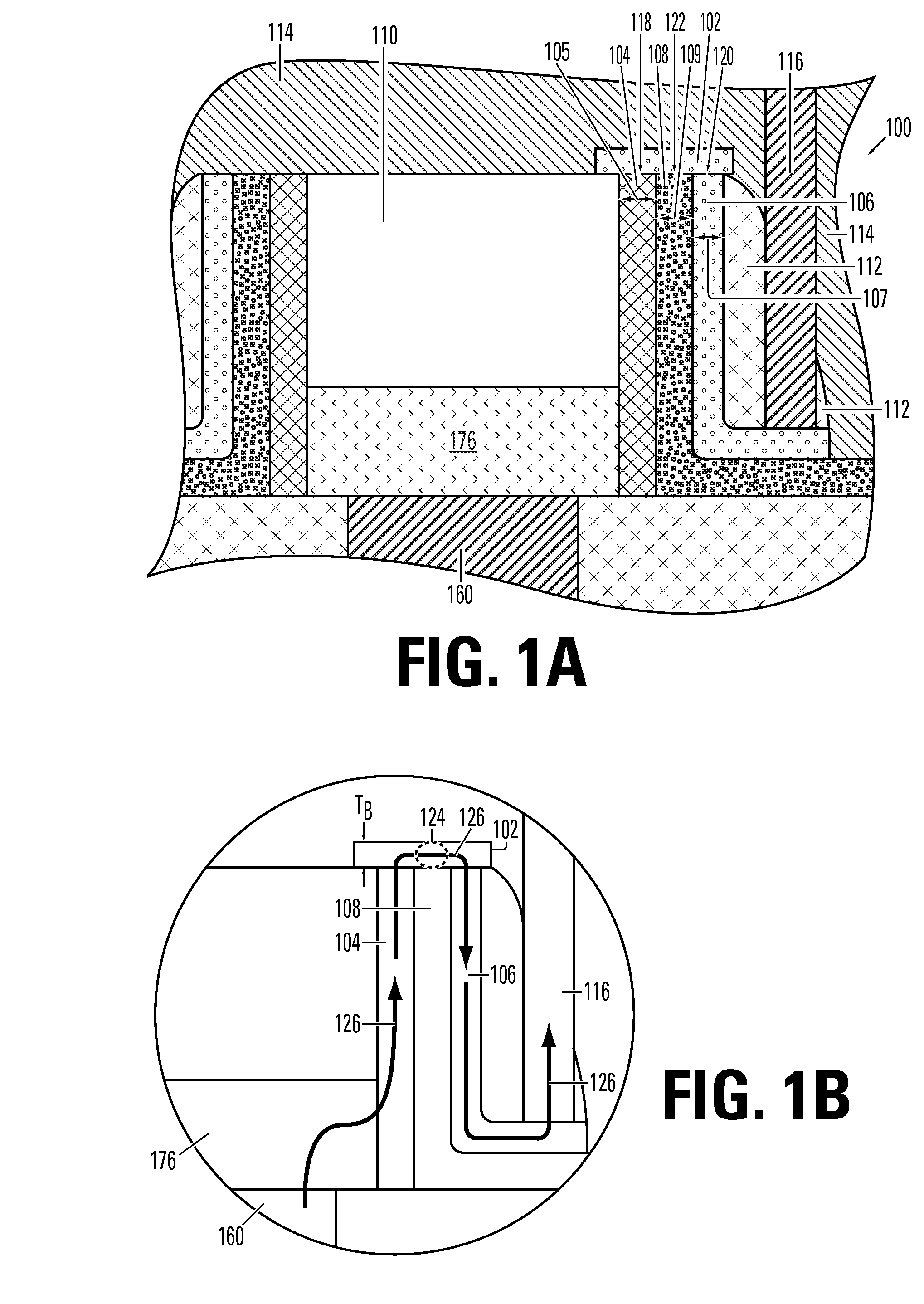

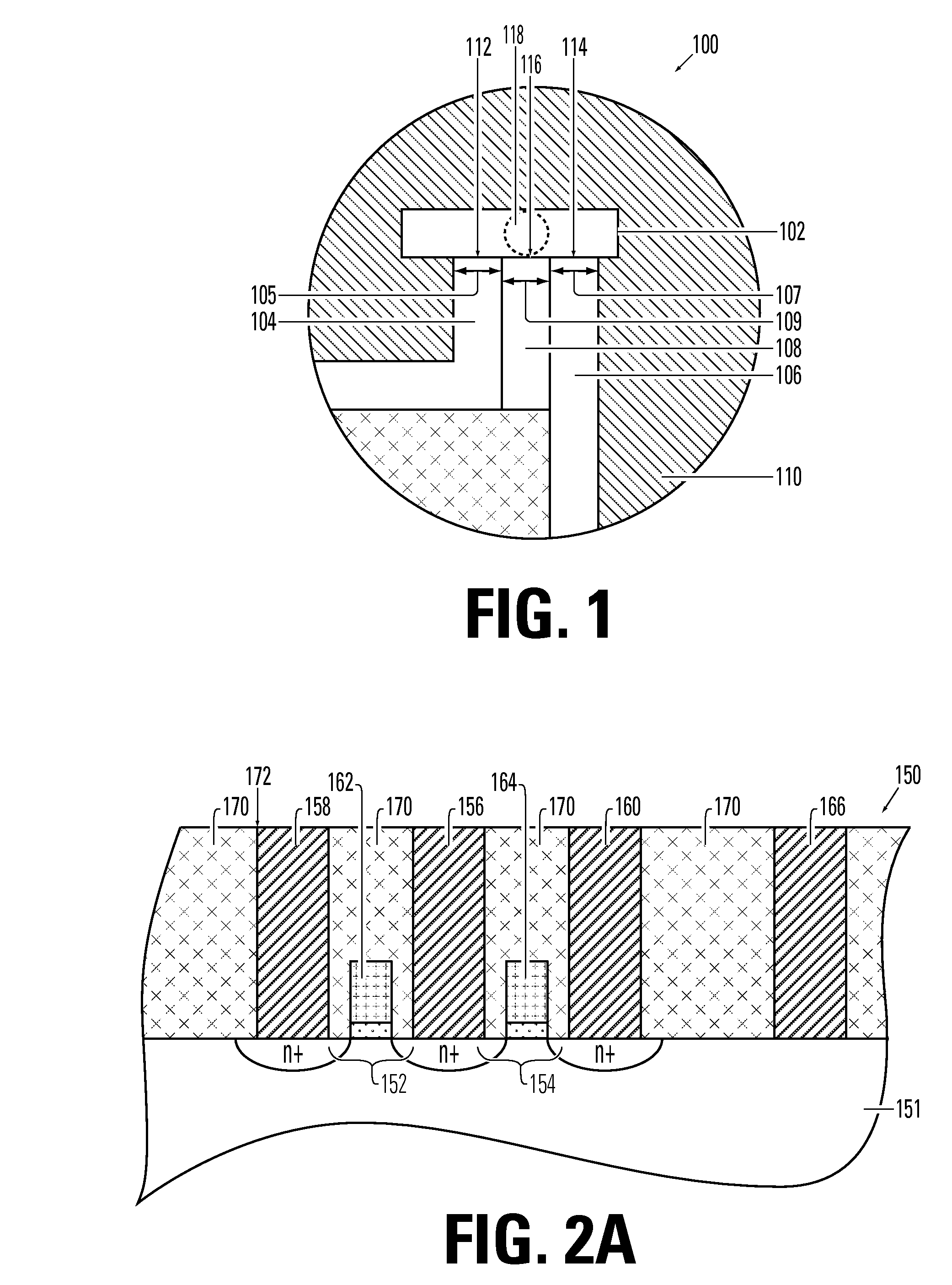

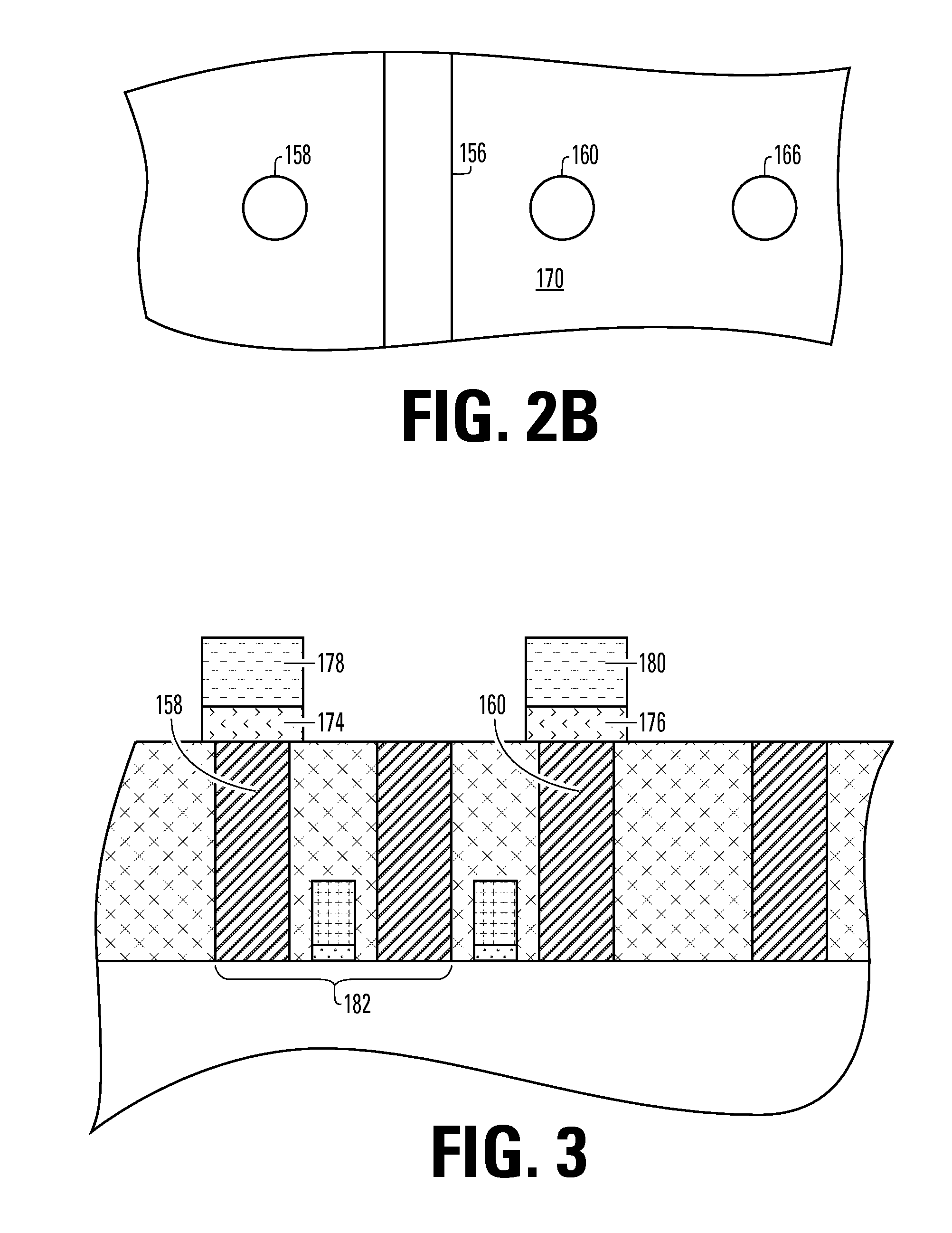

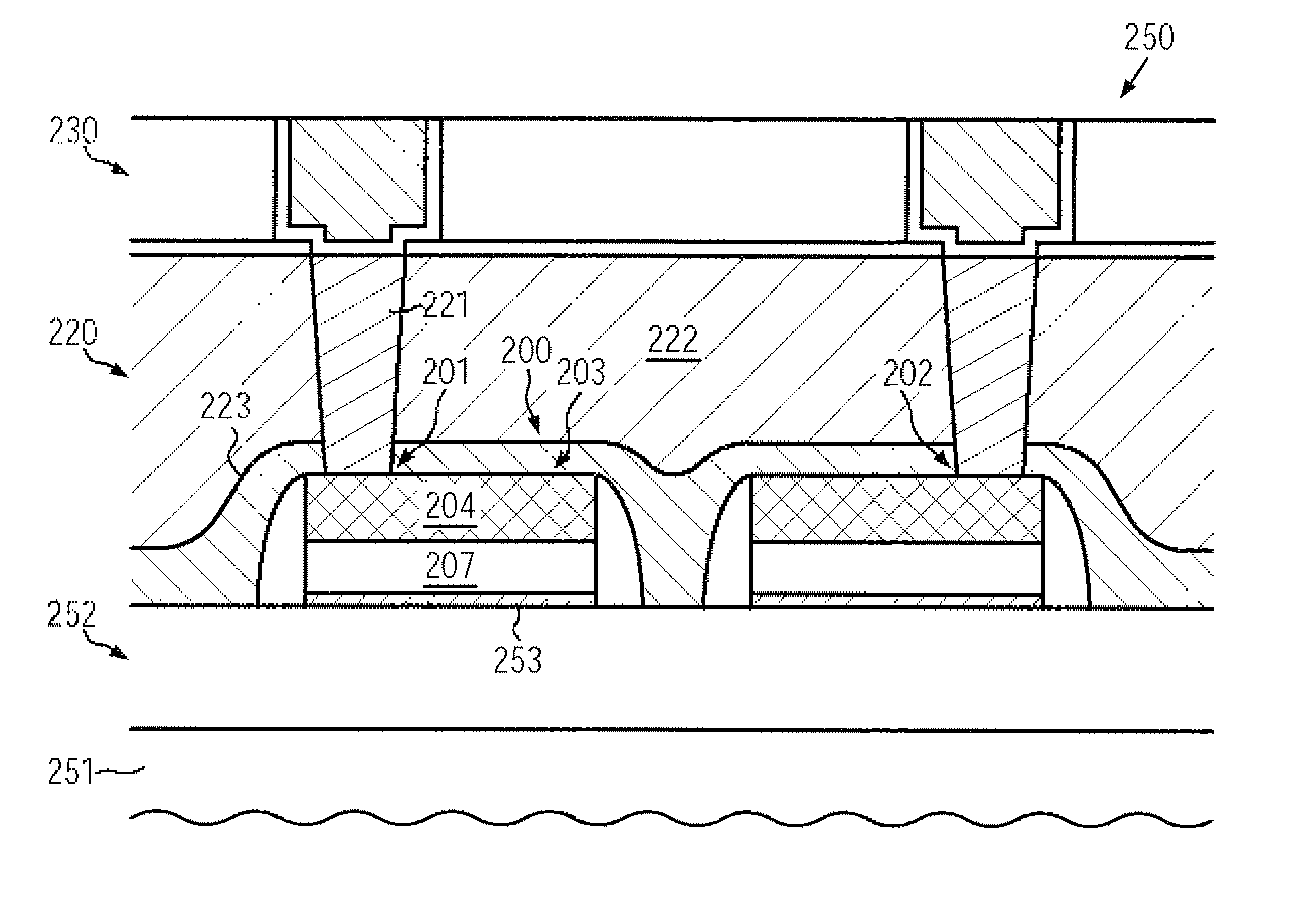

Vertical gate-all-around TFET

ActiveUS9385195B1Reduce contact resistanceImprove reliabilityTransistorNanoinformaticsElectrical resistance and conductanceEngineering

A vertical tunneling FET (TFET) provides low-power, high-speed switching performance for transistors having critical dimensions below 7 nm. The vertical TFET uses a gate-all-around (GAA) device architecture having a cylindrical structure that extends above the surface of a doped well formed in a silicon substrate. The cylindrical structure includes a lower drain region, a channel, and an upper source region, which are grown epitaxially from the doped well. The channel is made of intrinsic silicon, while the source and drain regions are doped in-situ. An annular gate surrounds the channel, capacitively controlling current flow through the channel from all sides. The source is electrically accessible via a front side contact, while the drain is accessed via a backside contact that provides low contact resistance and also serves as a heat sink. Reliability of vertical TFET integrated circuits is enhanced by coupling the vertical TFETs to electrostatic discharge (ESD) diodes.

Owner:STMICROELECTRONICS INT NV

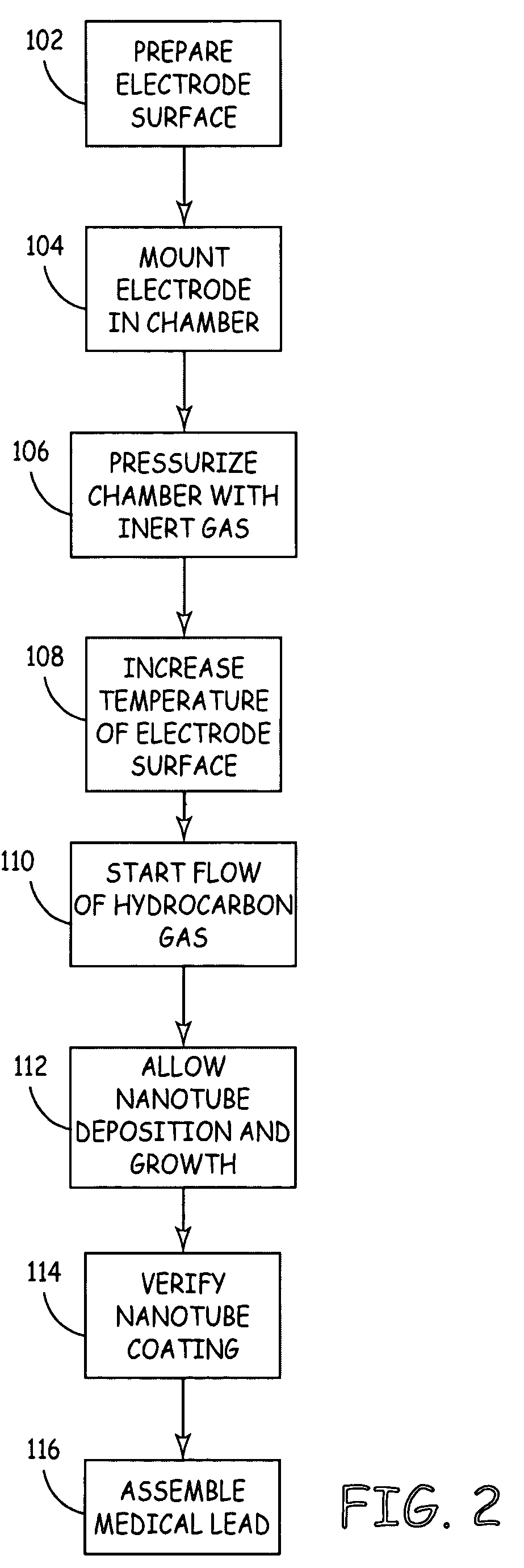

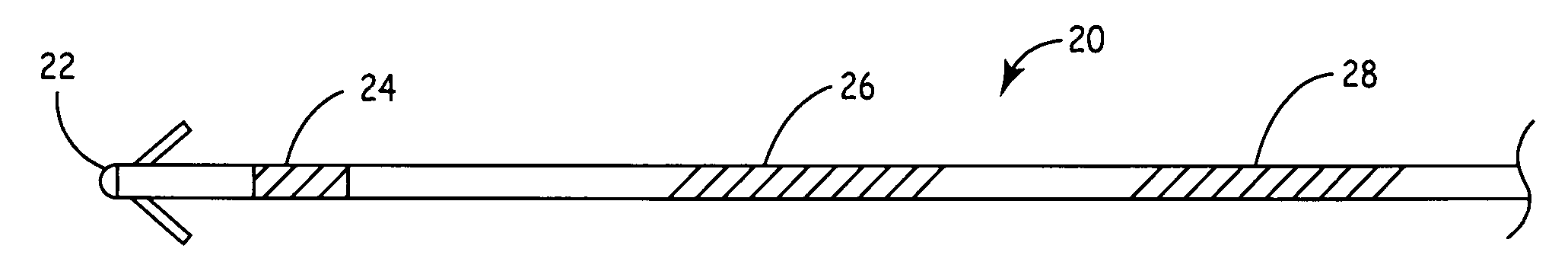

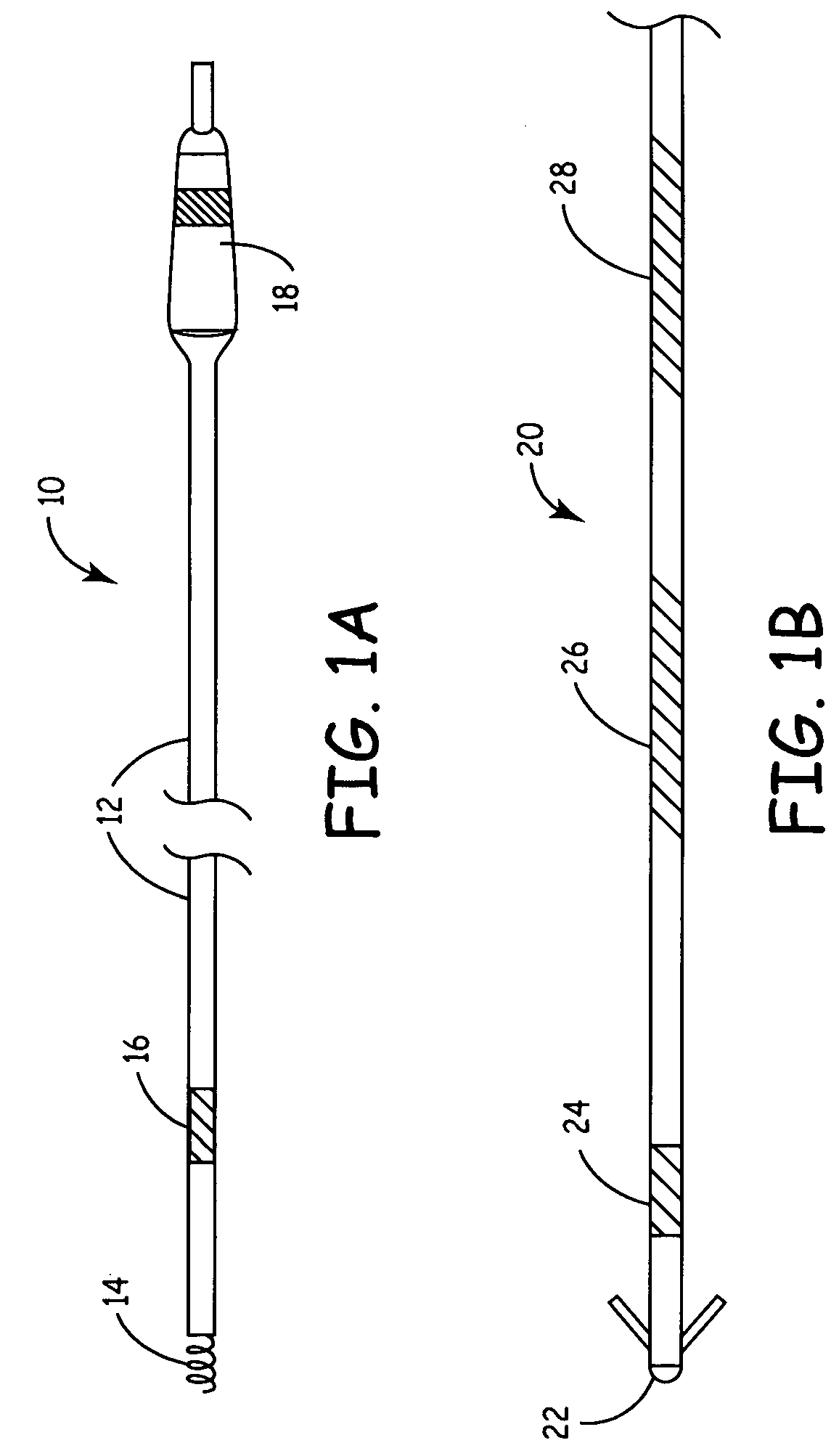

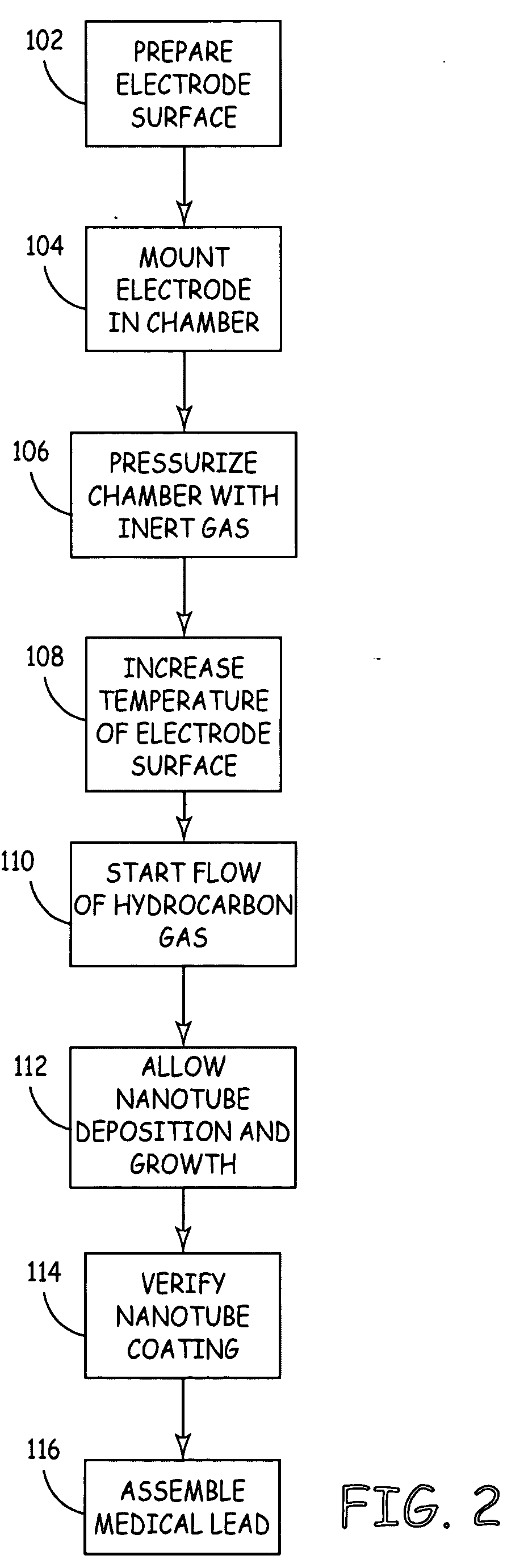

Medical devices incorporating carbon nanotube material and methods of fabricating same

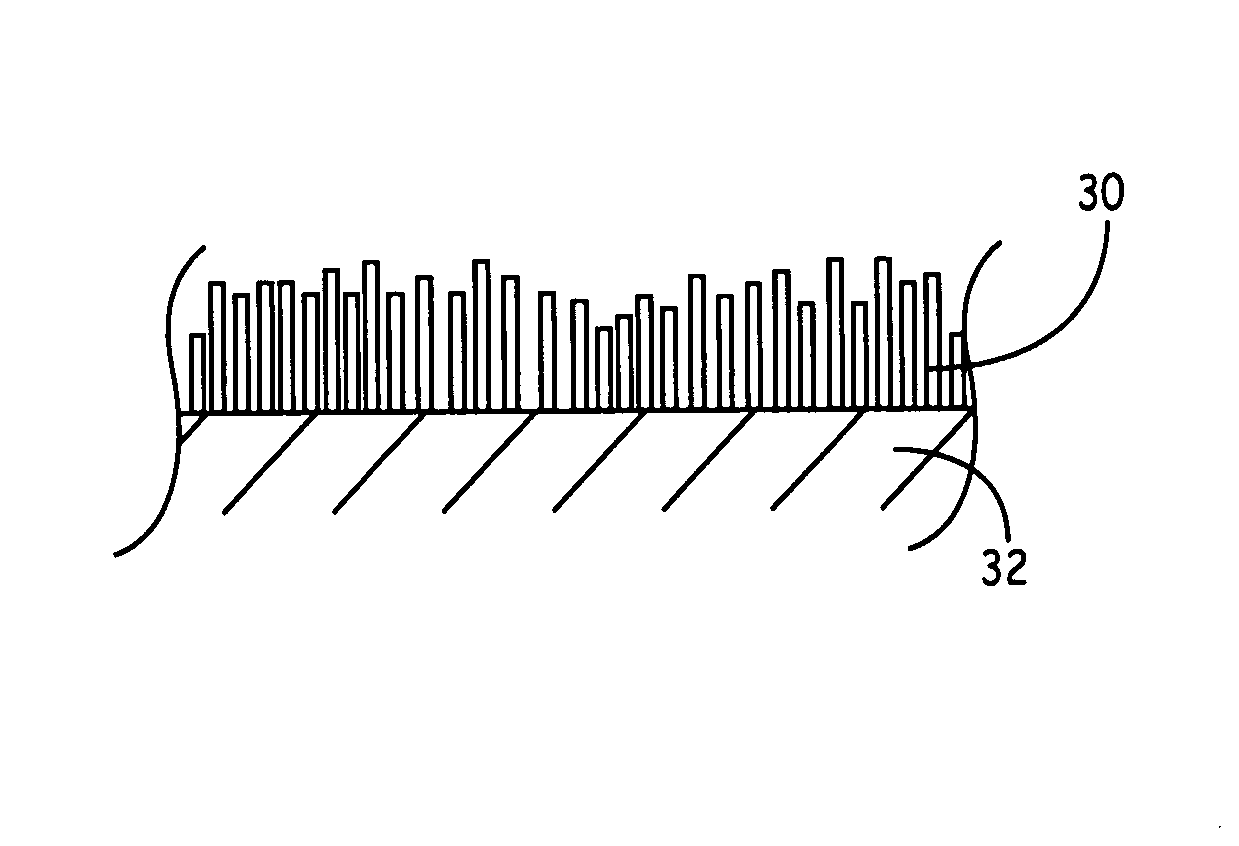

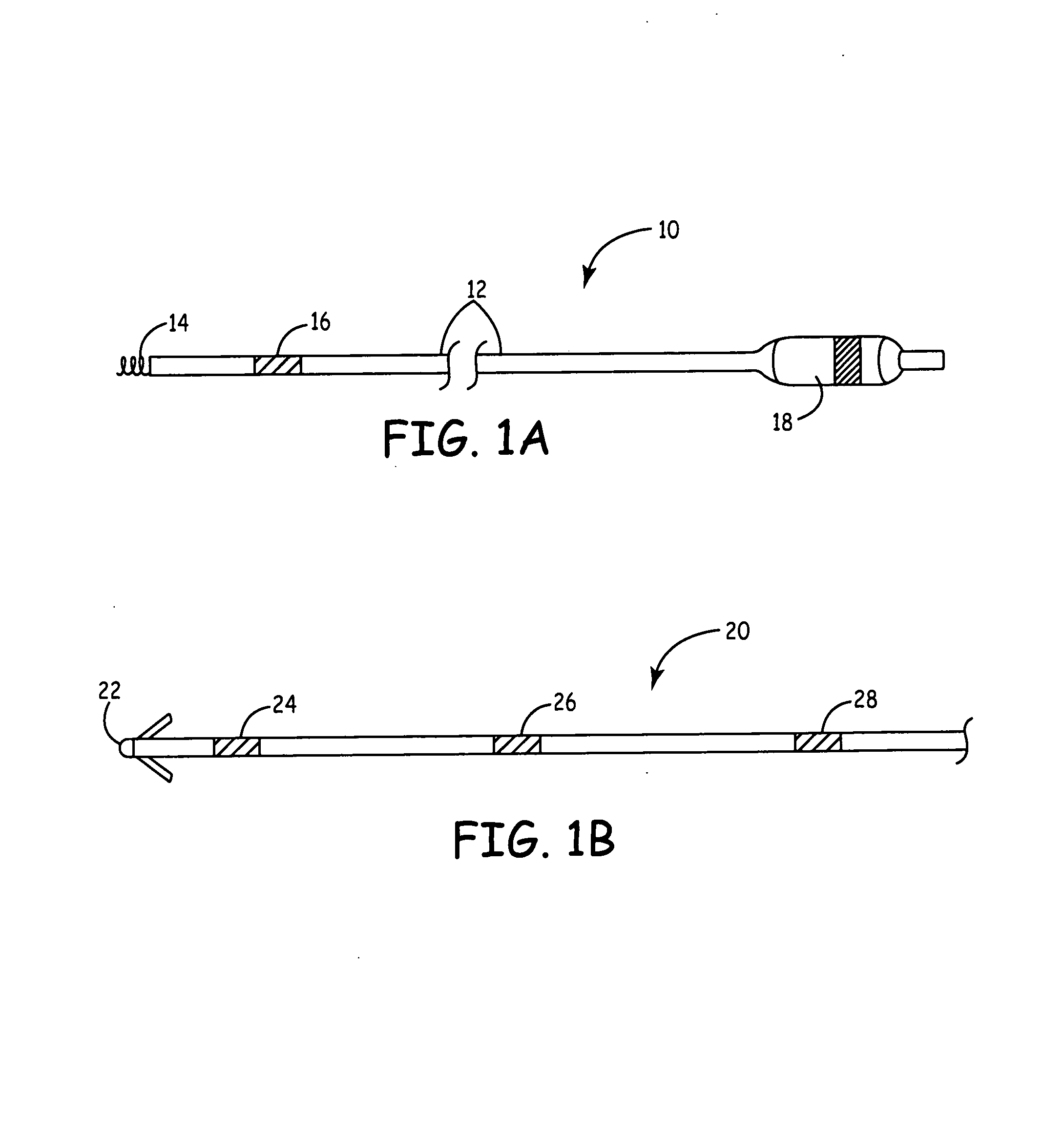

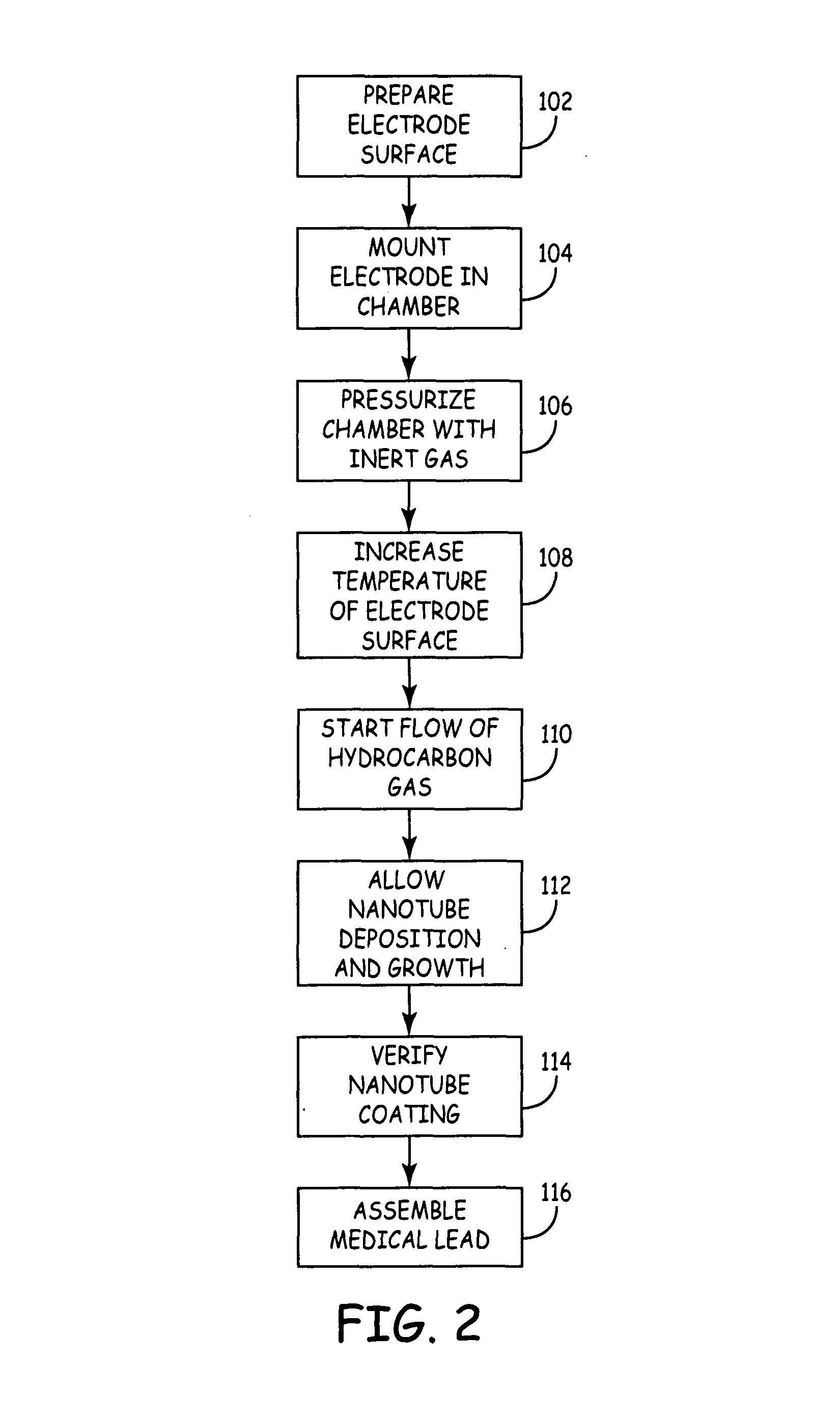

InactiveUS7596415B2High strengthStable stateNanotechTransvascular endocardial electrodesMuscle tissueCarbon nanotube

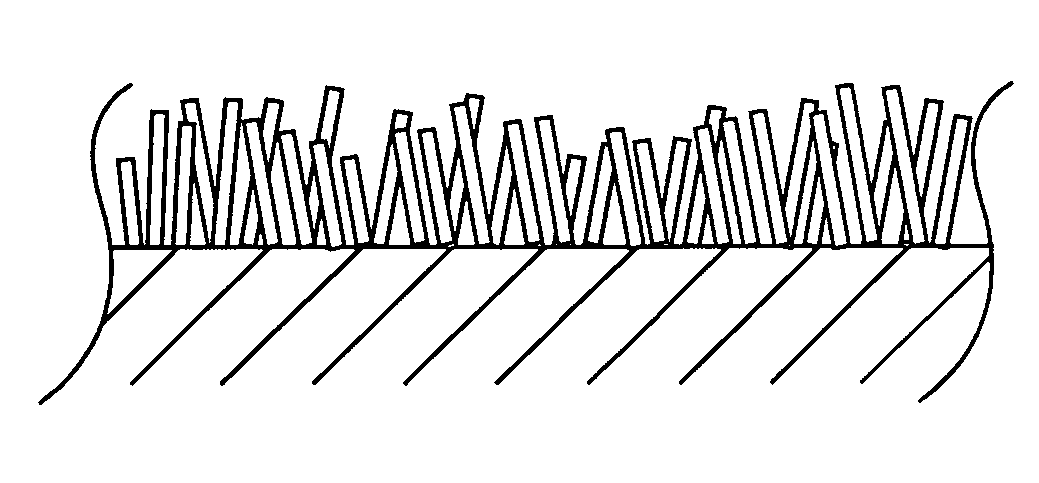

The present invention relates generally to medical devices; in particular and without limitation, to unique electrodes and / or electrical lead assemblies for stimulating cardiac tissue, muscle tissue, neurological tissue, brain tissue and / or organ tissue; to electrophysiology mapping and ablation catheters for monitoring and selectively altering physiologic conduction pathways; and, wherein said electrodes, lead assemblies and catheters optionally include fluid irrigation conduit(s) for providing therapeutic and / or performance enhancing materials to adjacent biological tissue, and wherein each said device is coupled to or incorporates nanostructure or materials therein. The present invention also provides methods for fabricating, deploying, and operating such medical devices.

Owner:MEDTRONIC INC

Medical devices incorporating carbon nanotube material and methods of fabricating same

InactiveUS20050203604A1High strengthStable stateNanotechTransvascular endocardial electrodesMuscle tissueCarbon nanotube

The present invention relates generally to medical devices; in particular and without limitation, to unique electrodes and / or electrical lead assemblies for stimulating cardiac tissue, muscle tissue, neurological tissue, brain tissue and / or organ tissue; to electrophysiology mapping and ablation catheters for monitoring and selectively altering physiologic conduction pathways; and, wherein said electrodes, lead assemblies and catheters optionally include fluid irrigation conduit(s) for providing therapeutic and / or performance enhancing materials to adjacent biological tissue, and wherein each said device is coupled to or incorporates nanostructure or materials therein. The present invention also provides methods for fabricating, deploying, and operating such medical devices.

Owner:MEDTRONIC INC

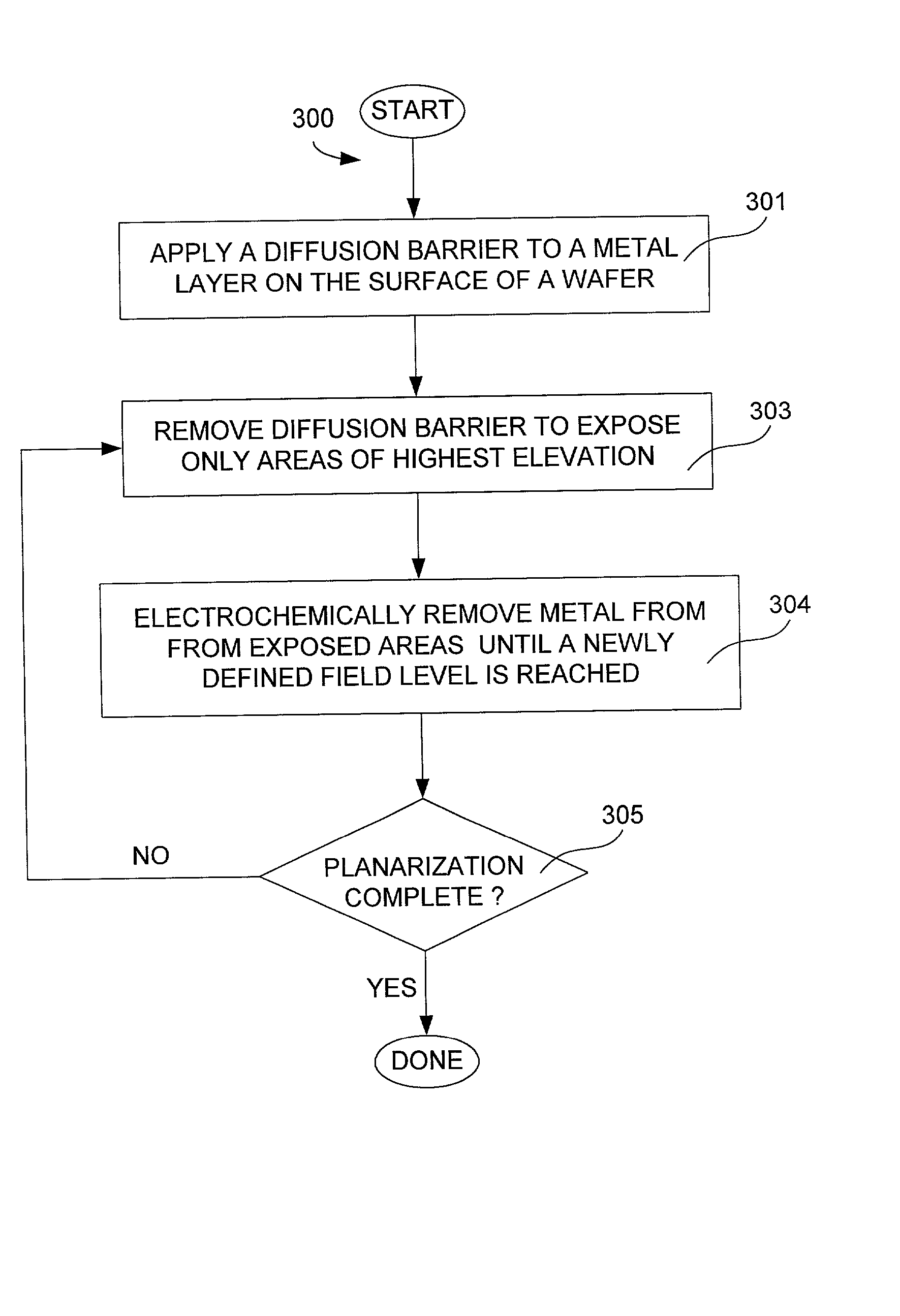

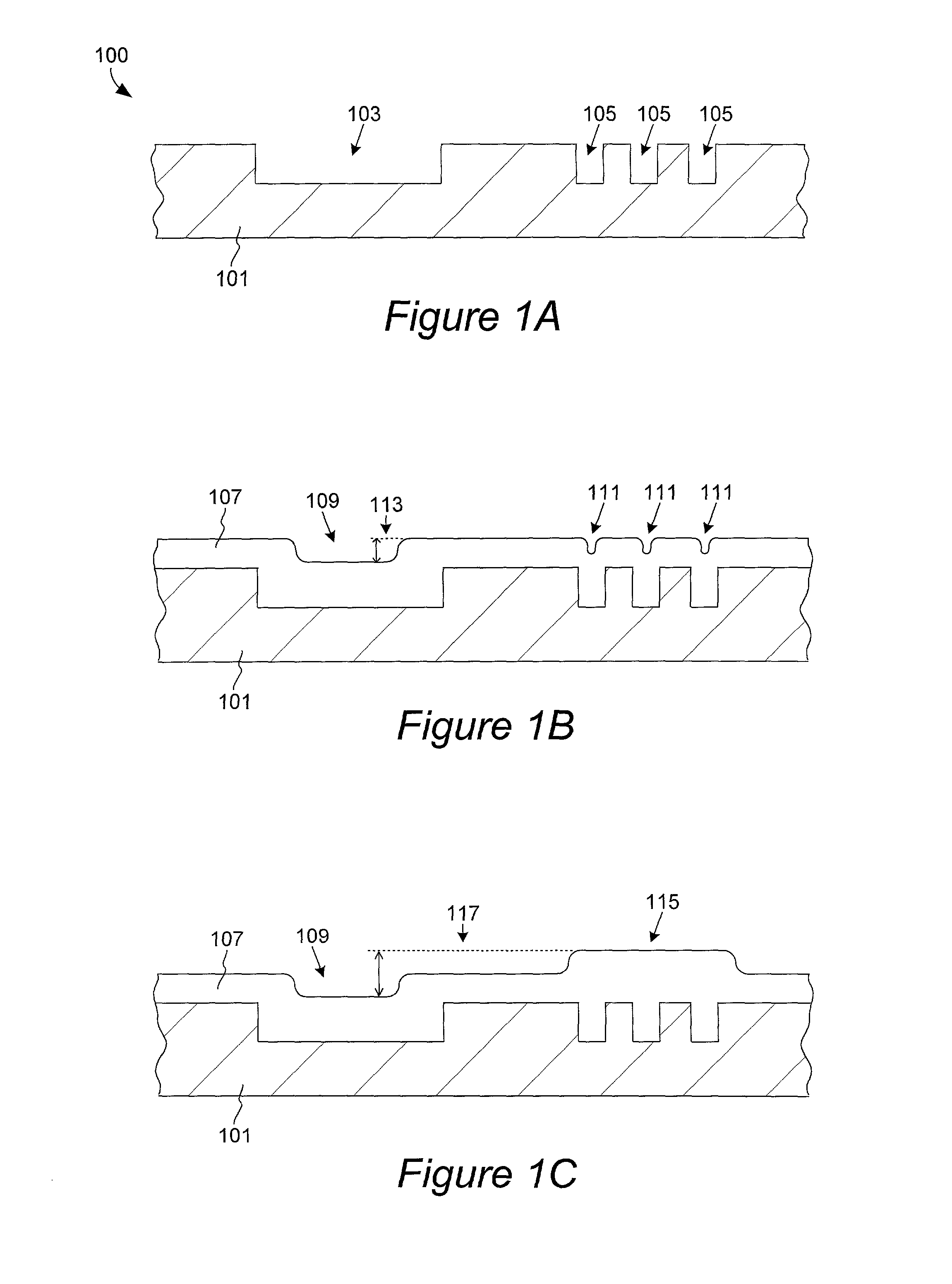

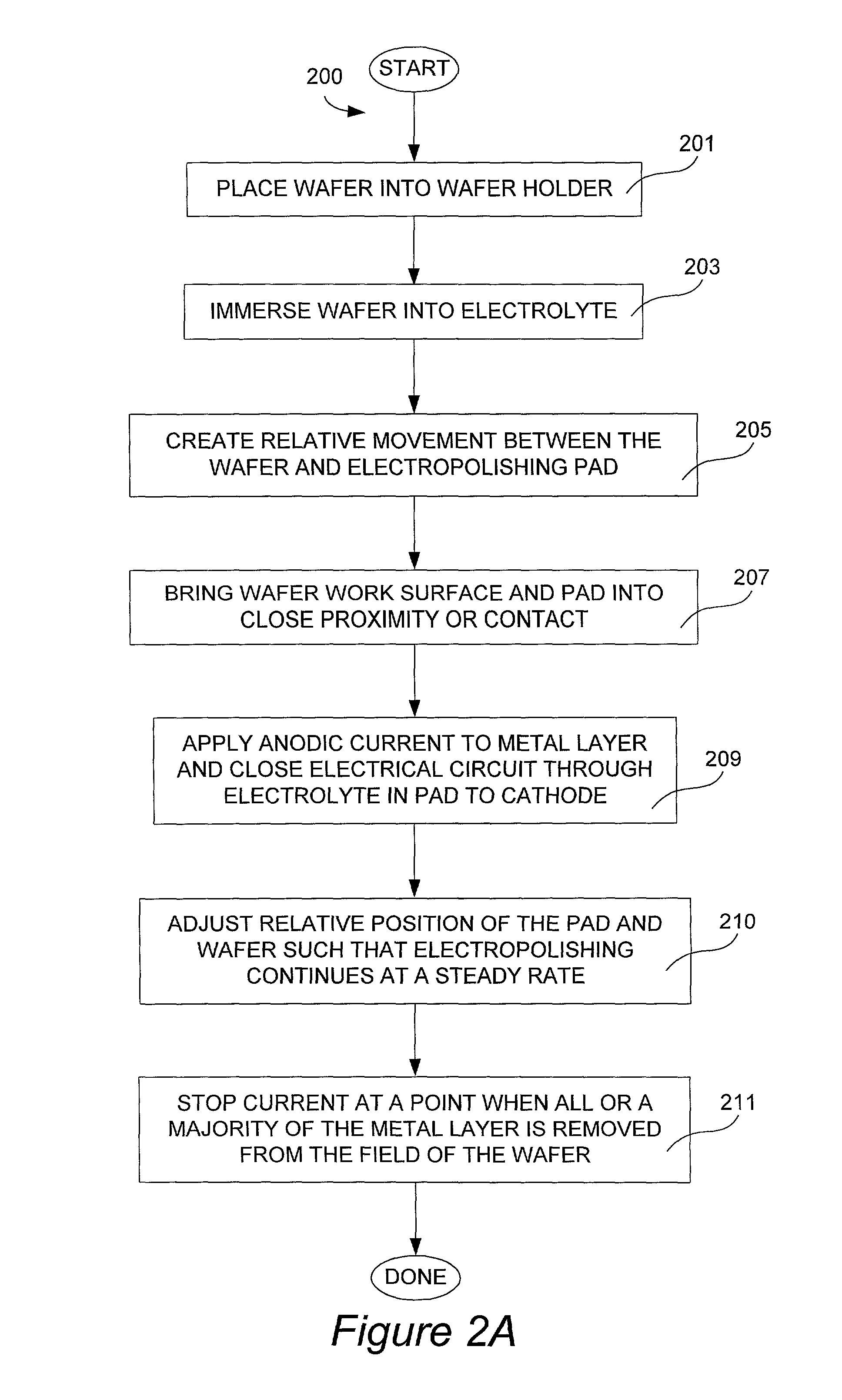

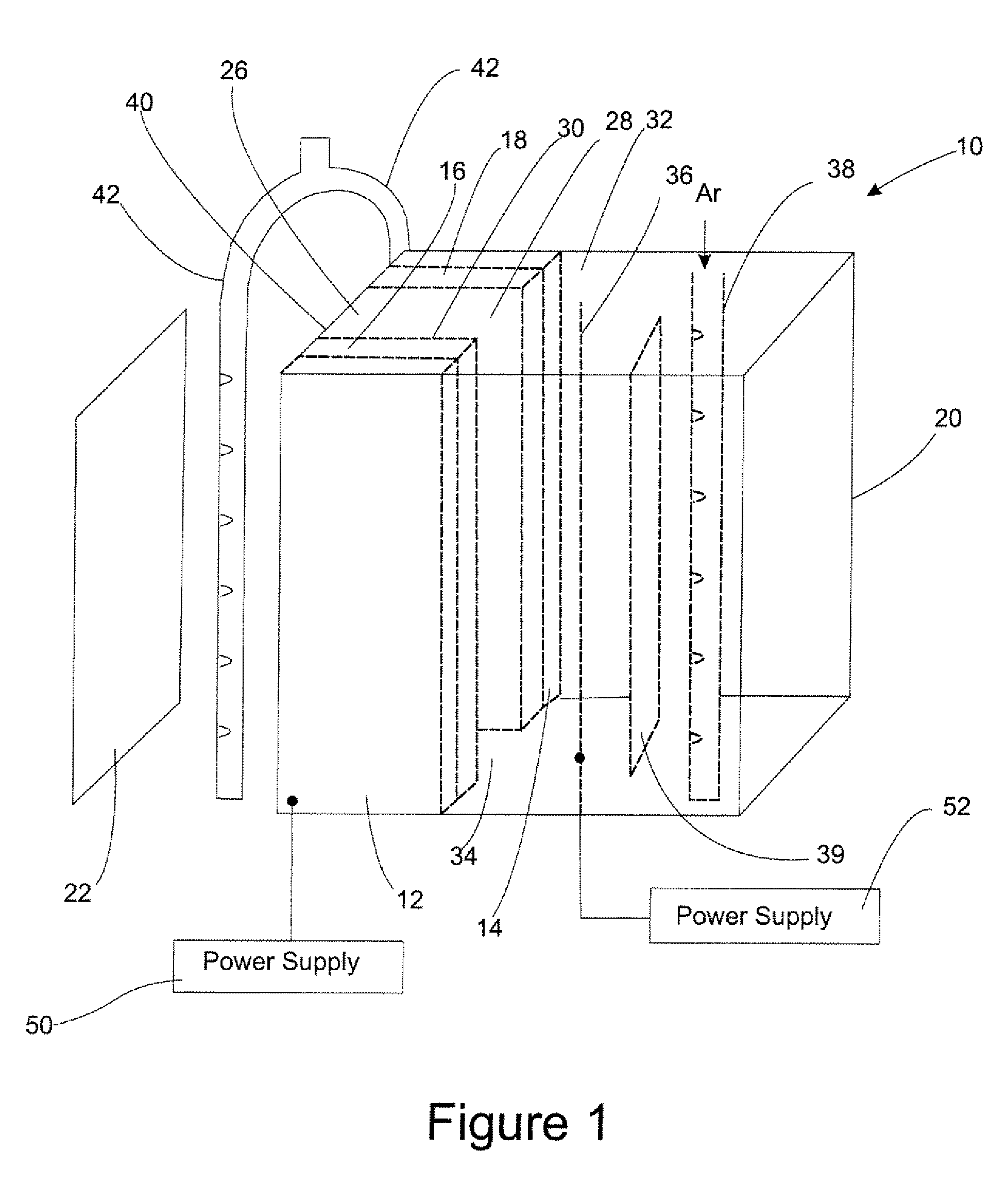

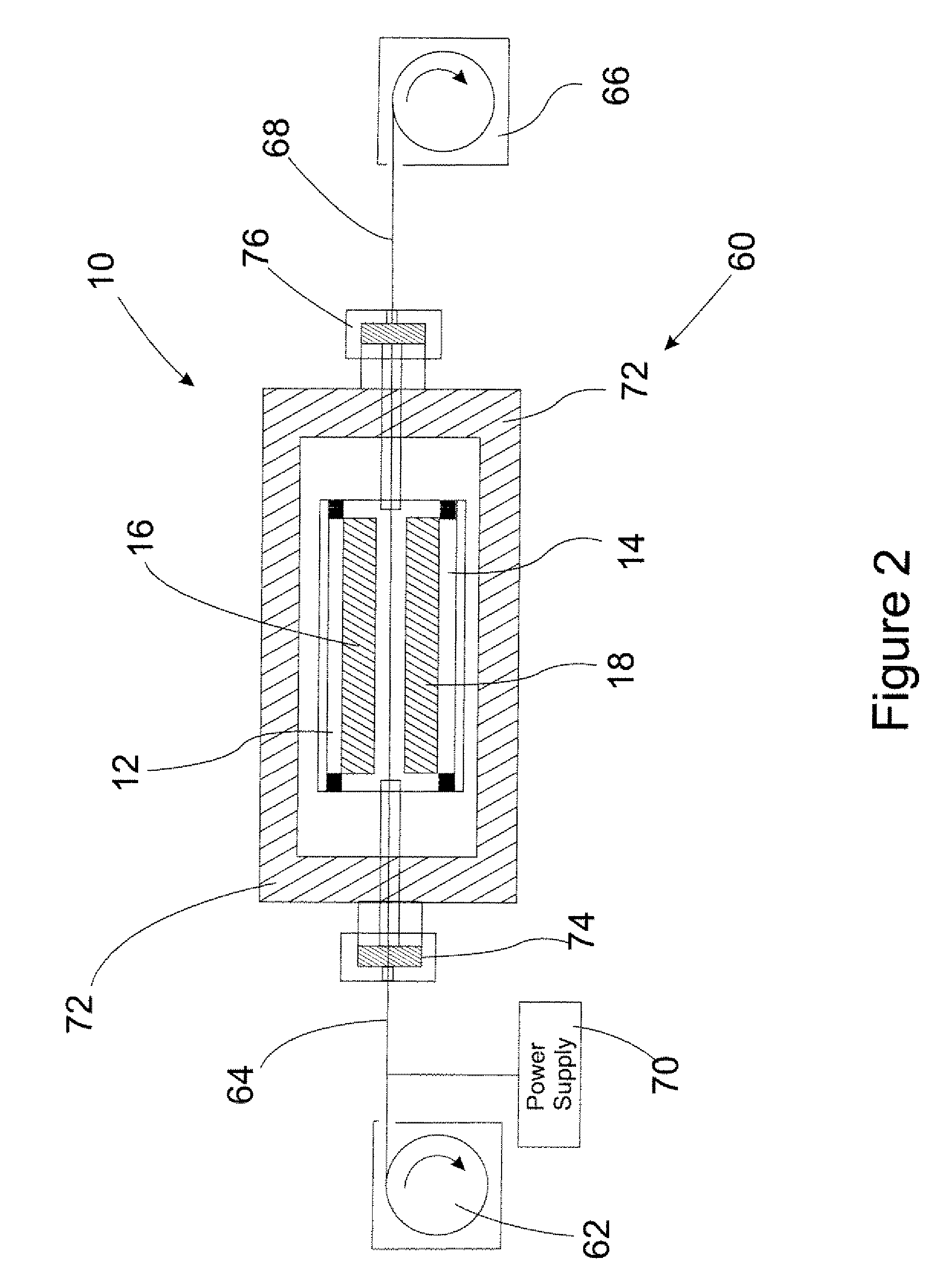

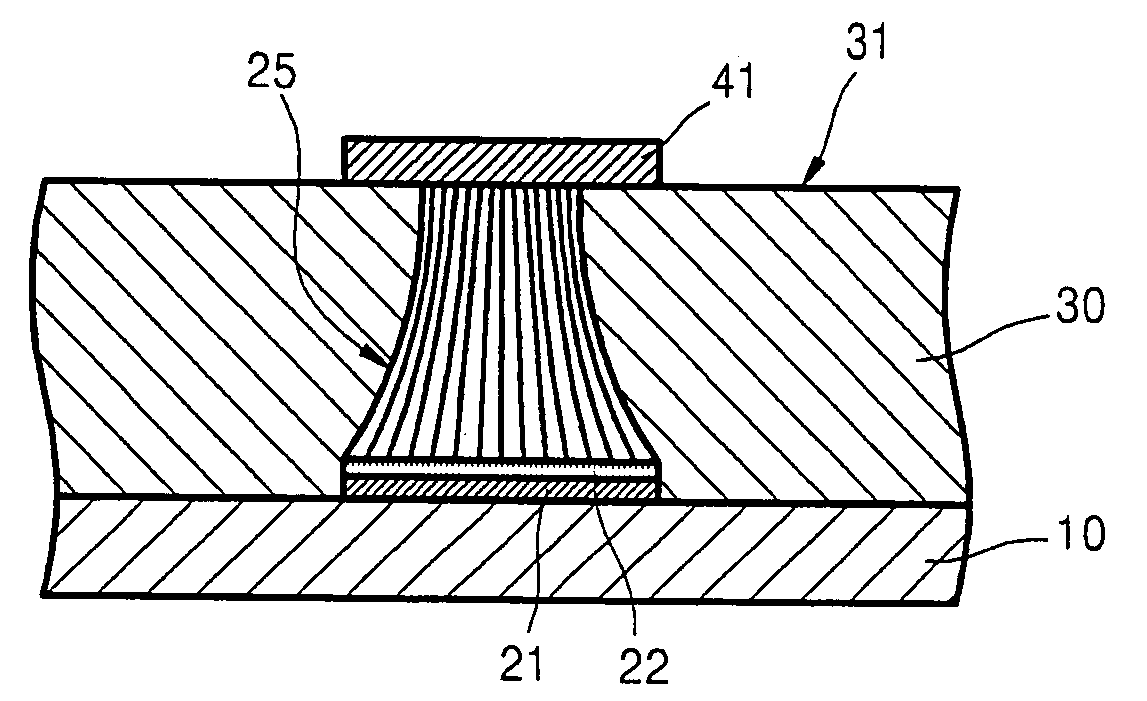

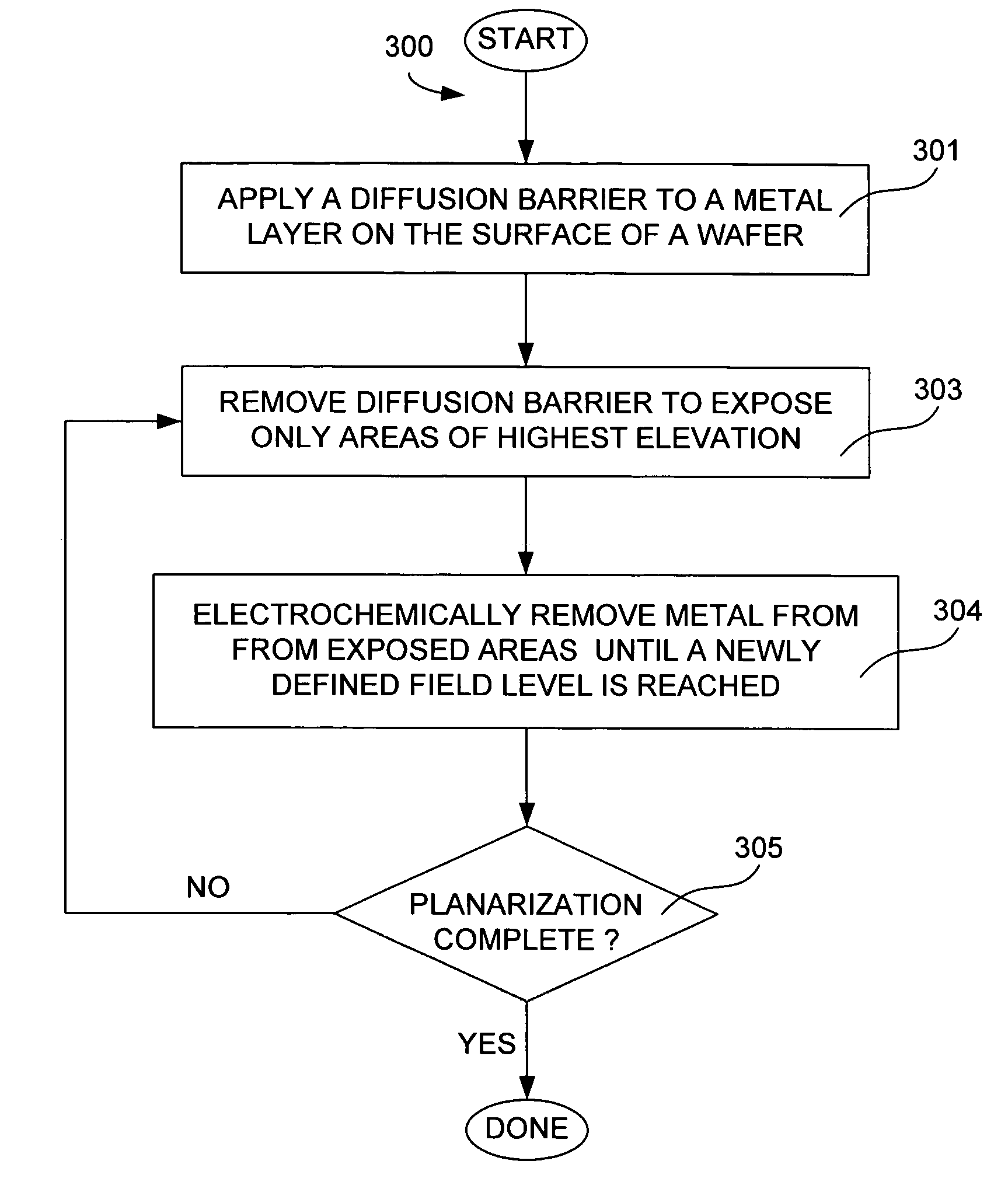

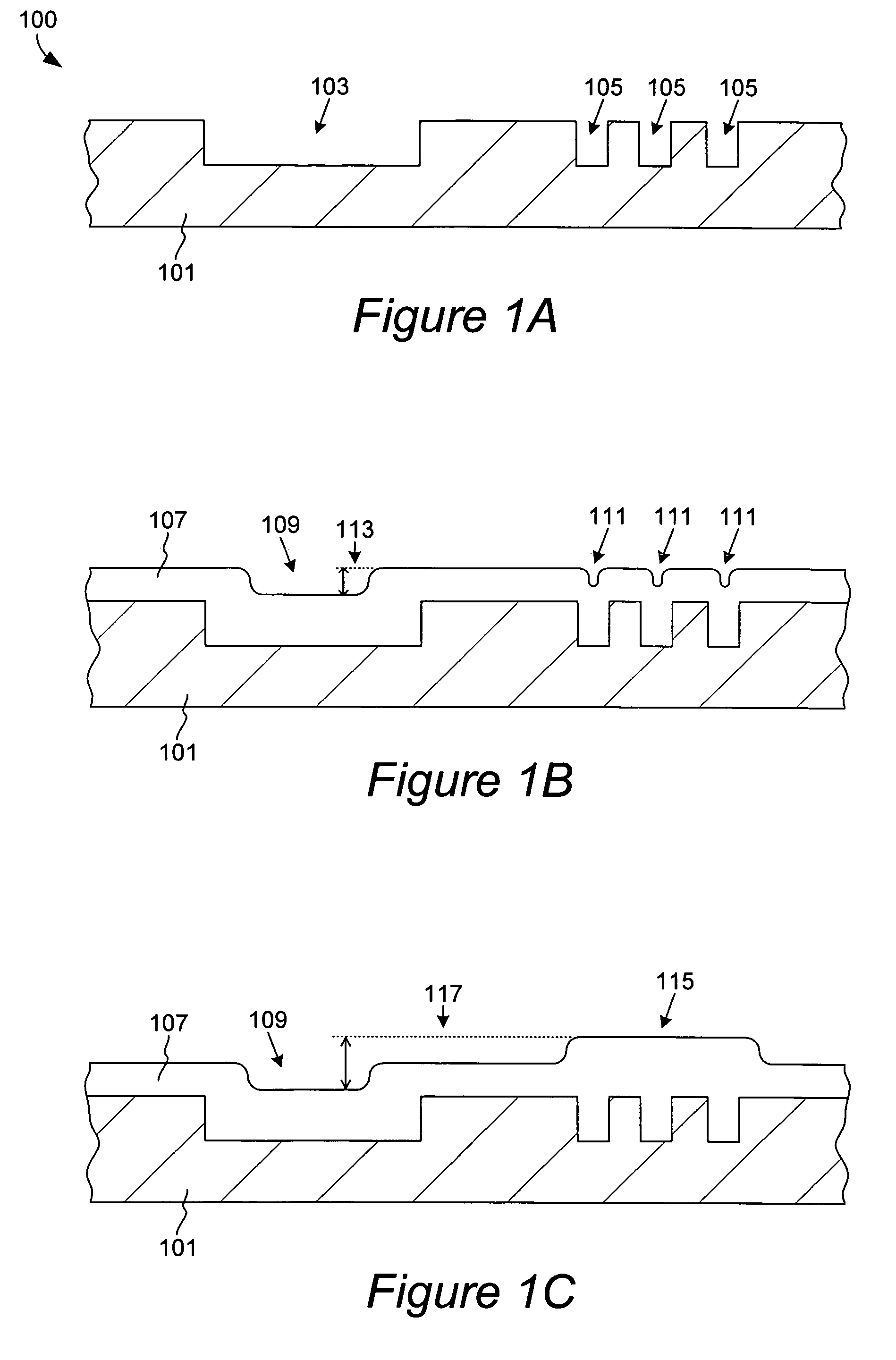

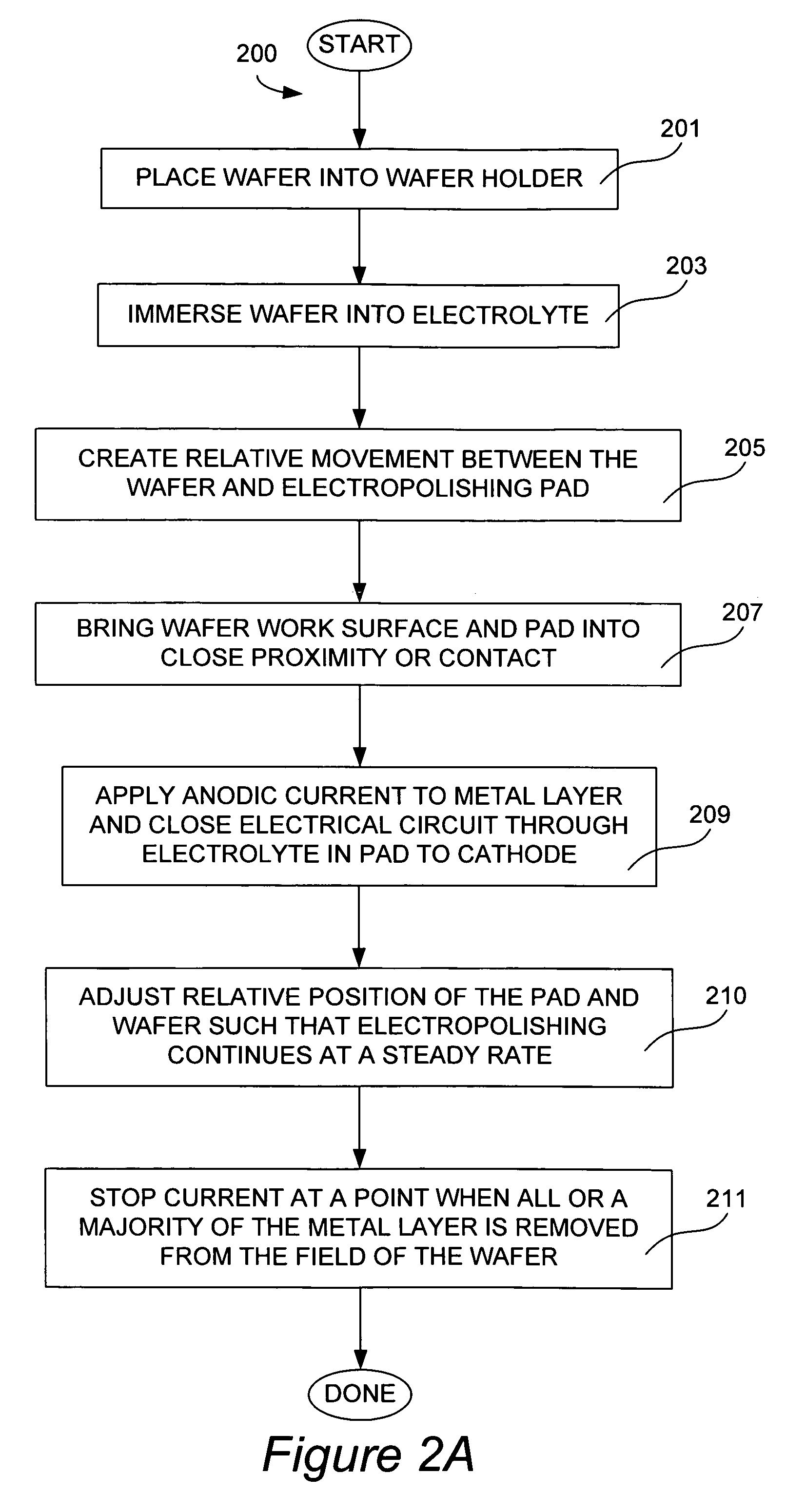

Method and apparatus for uniform electropolishing of damascene ic structures by selective agitation

InactiveUS20020074238A1Small apertureSufficiently porousElectrolysis componentsSemiconductor/solid-state device manufacturingElectricityElectrolysis

The present invention pertains to apparatus and methods for planarization of metal surfaces having both recessed and raised features, over a large range of feature sizes. The invention accomplishes this by increasing the fluid agitation in raised regions with respect to recessed regions. That is, the agitation of the electropolishing bath fluid is agitated or exchanged as a function of elevation on the metal film profile. The higher the elevation, the greater the movement or exchange rate of bath fluid. In preferred methods of the invention, this agitation is achieved through the use of a microporous electropolishing pad that moves over (either near or in contact with) the surface of the wafer during the electropolishing process. Thus, methods of the invention are electropolishing methods, which in some cases include mechanical polishing elements.

Owner:NOVELLUS SYSTEMS

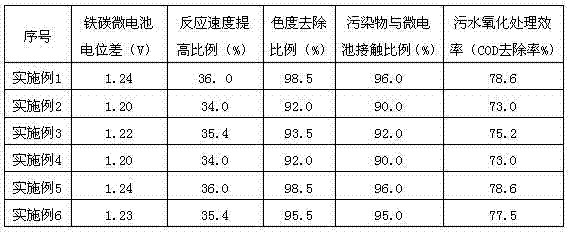

Multi-component oxidation micro-electrolytic filler and preparation method thereof

ActiveCN102276021AIncrease contact areaAvoid separationWater/sewage treatment by sorptionActivated carbonIron powder

The invention belongs to the technical field of environmental engineering wastewater treatment, and particularly relates to multi-component oxidized micro-electrolysis filler and a preparation method thereof. The multi-component oxidized micro-electrolysis filler is mainly prepared from the following components in percentage by mass: 50-60% of iron, 20-30% of activated carbon, 12-15% of adhesive and 3-5% of catalyst through mixing, wherein iron is iron scrap or iron powder with particle size not more than 80 mesh; and activated carbon is in a powder and has particle size not more than 100 mesh. The preparation method of the multi-component oxidized micro-electrolysis filler comprises uniformly mixing iron, activated carbon, the adhesive and the catalyst according to the ratio, adding water, stirring and aging, then carrying out extrusion molding to obtain molded filler, demolding to obtain a filler blank, after naturally drying, drying, sintering in the absence of air, and cooling thefiller blank to obtain the multi-component oxidized electrolysis filler. According to the invention, the hardening, dead pool, stoppage and other practical problems existing in the use of the traditional micro-electrolysis fillers are solved.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

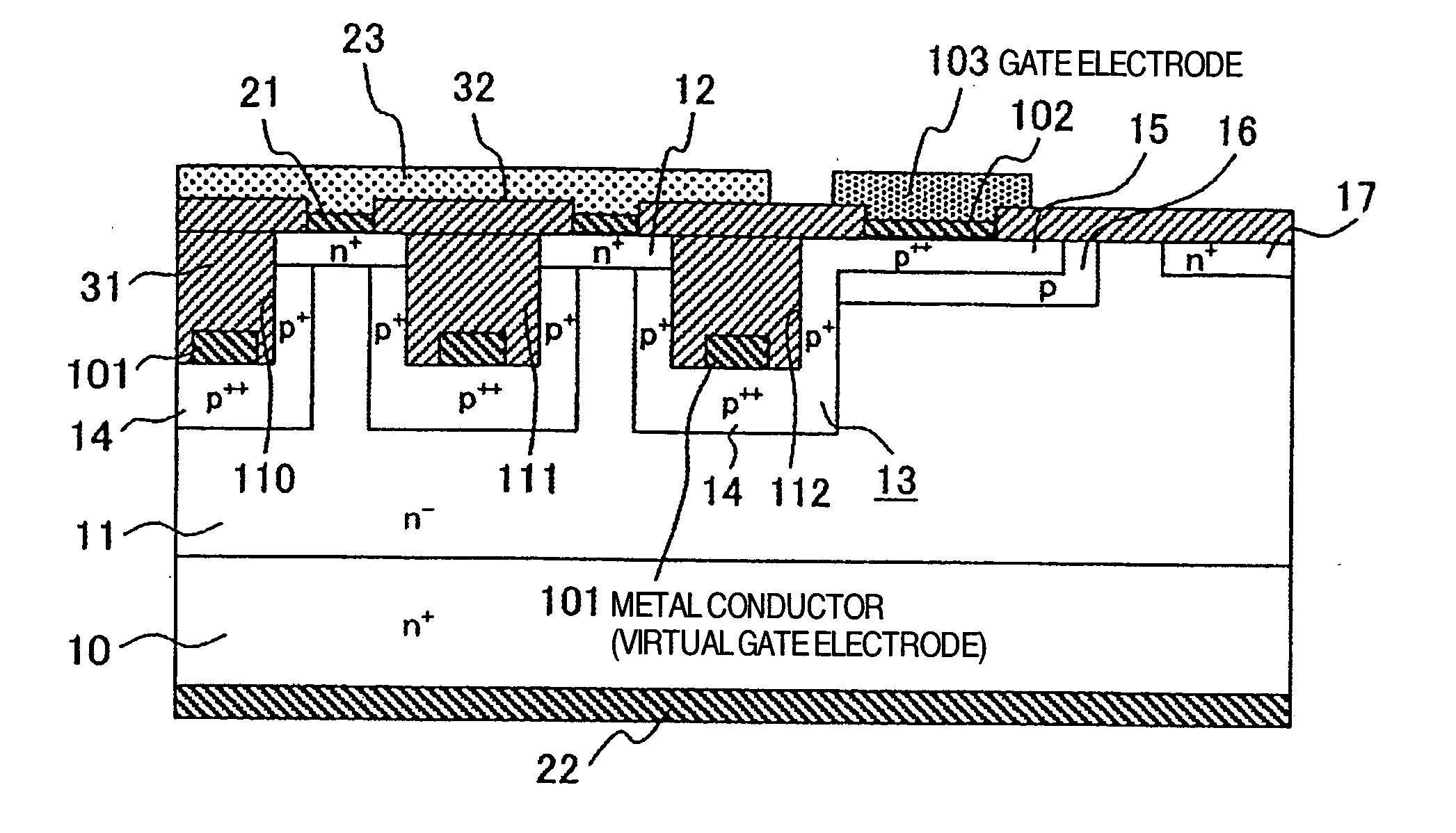

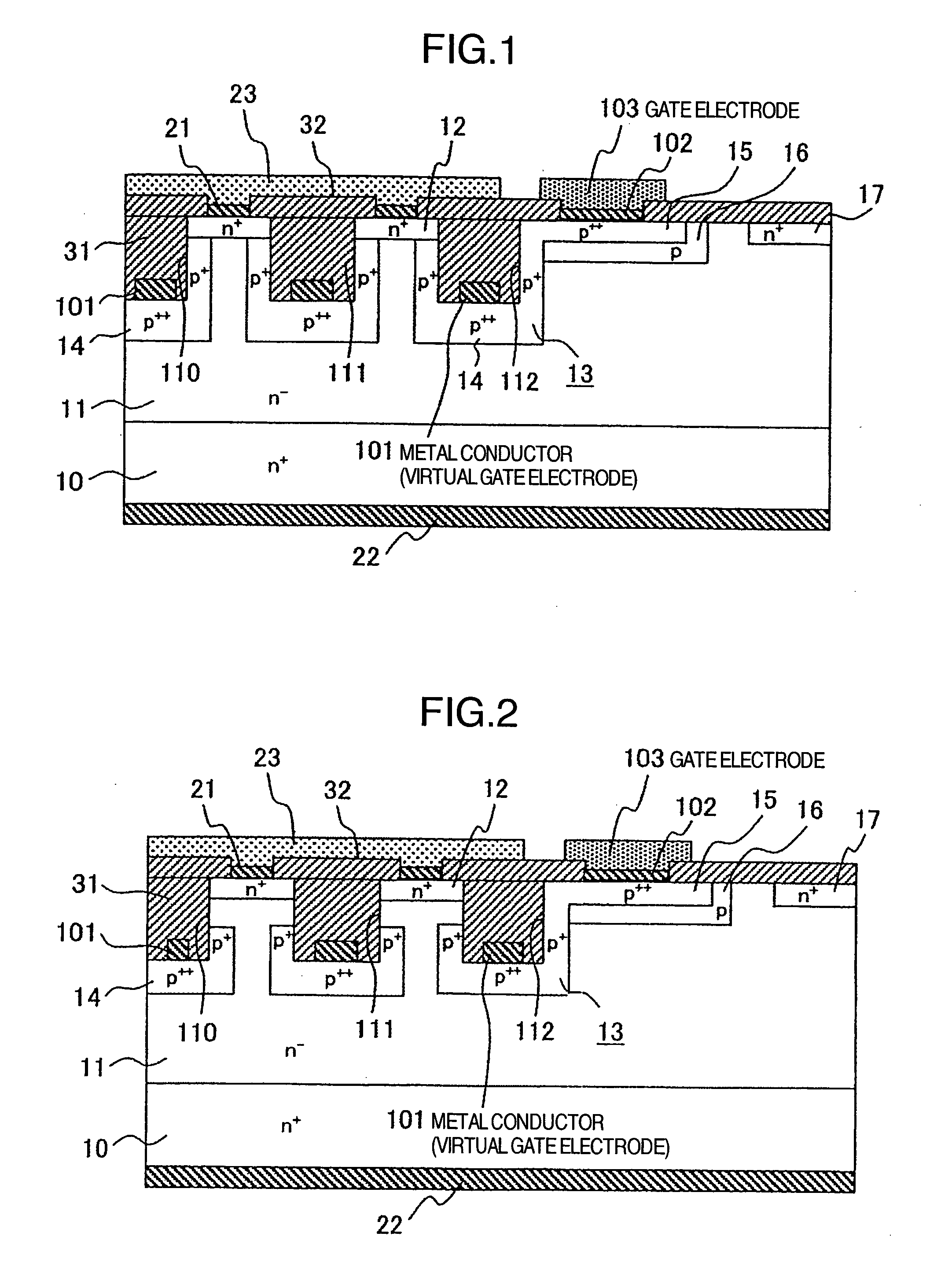

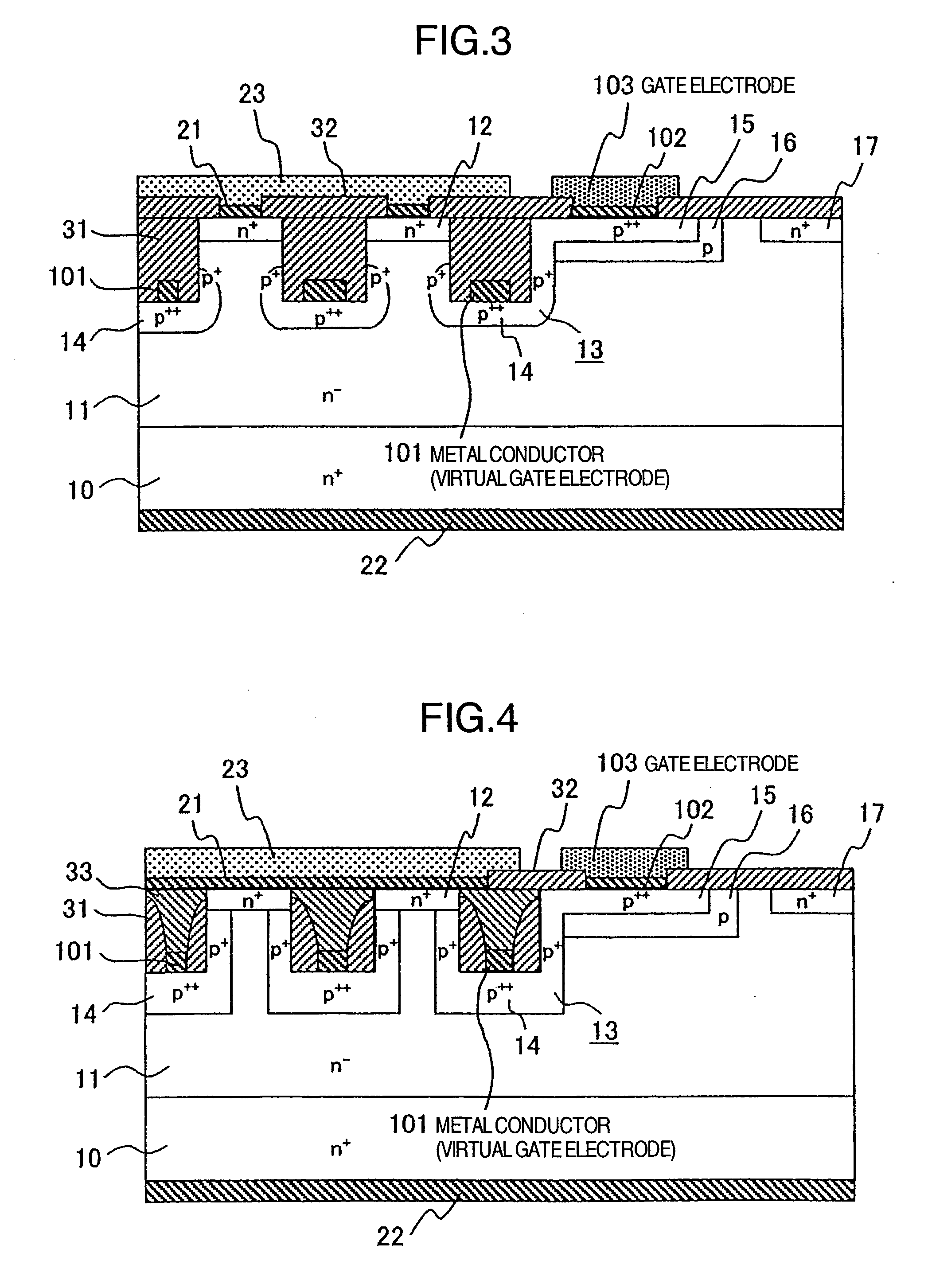

Semiconductor devices

InactiveUS20060060884A1Increase current densityLower gate resistanceThyristorElectrical conductorDevice material

A silicon carbide semiconductor device such as JFET, SIT and the like is provided for accomplishing a reduction in on-resistance and high-speed switching operations. In the JFET or SIT which turns on / off a current with a depletion layer extending in a channel between a gate region formed along trench grooves, a gate contact layer and a gate electrode, which can be supplied with voltages from the outside, are formed on one surface of a semiconductor substrate or on the bottom of the trench groove. A metal conductor (virtual gate electrode) is formed in ohmic contact with a p++ contact layer of the gate region on the bottom of the trench grooves independently of the gate electrode. The virtual gate electrode is electrically isolated from the gate electrode and an external wire.

Owner:DENSO CORP +1

Resistor random access memory cell with l-shaped electrode

ActiveUS20070278529A1Improve insulation performanceIncrease current densitySemiconductor/solid-state device detailsSolid-state devicesRandom access memoryEngineering

A phase change random access memory PCRAM device is described suitable for use in large-scale integrated circuits. An exemplary memory device has a pipe-shaped first electrode formed from a first electrode layer on a sidewall of a sidewall support structure. A sidewall spacer insulating member is formed from a first oxide layer and a second, “L-shaped,” electrode is formed on the insulating member. An electrical contact is connected to the horizontal portion of the second electrode. A bridge of memory material extends from a top surface of the first electrode to a top surface of the second electrode across a top surface of the sidewall spacer insulating member.

Owner:MACRONIX INT CO LTD

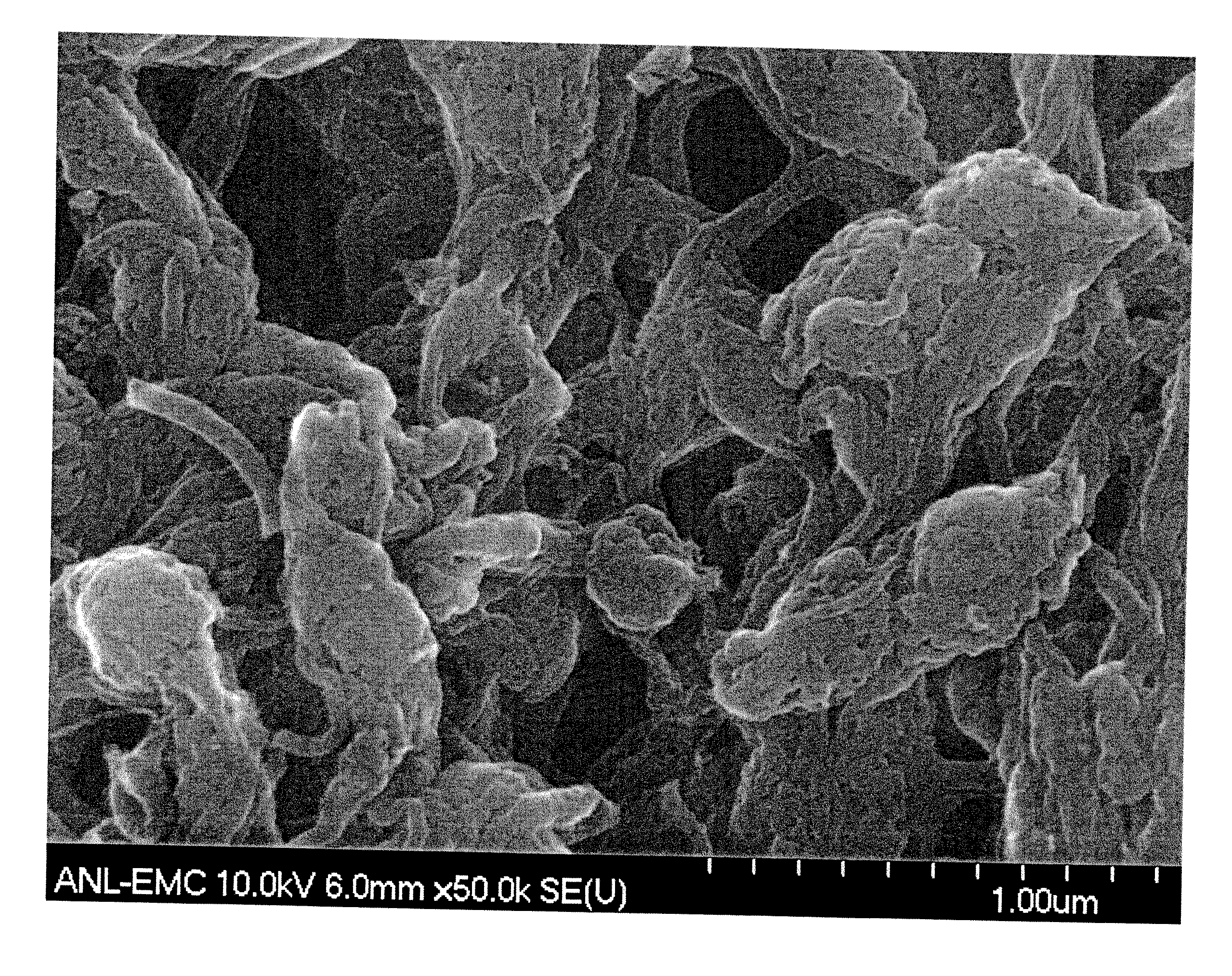

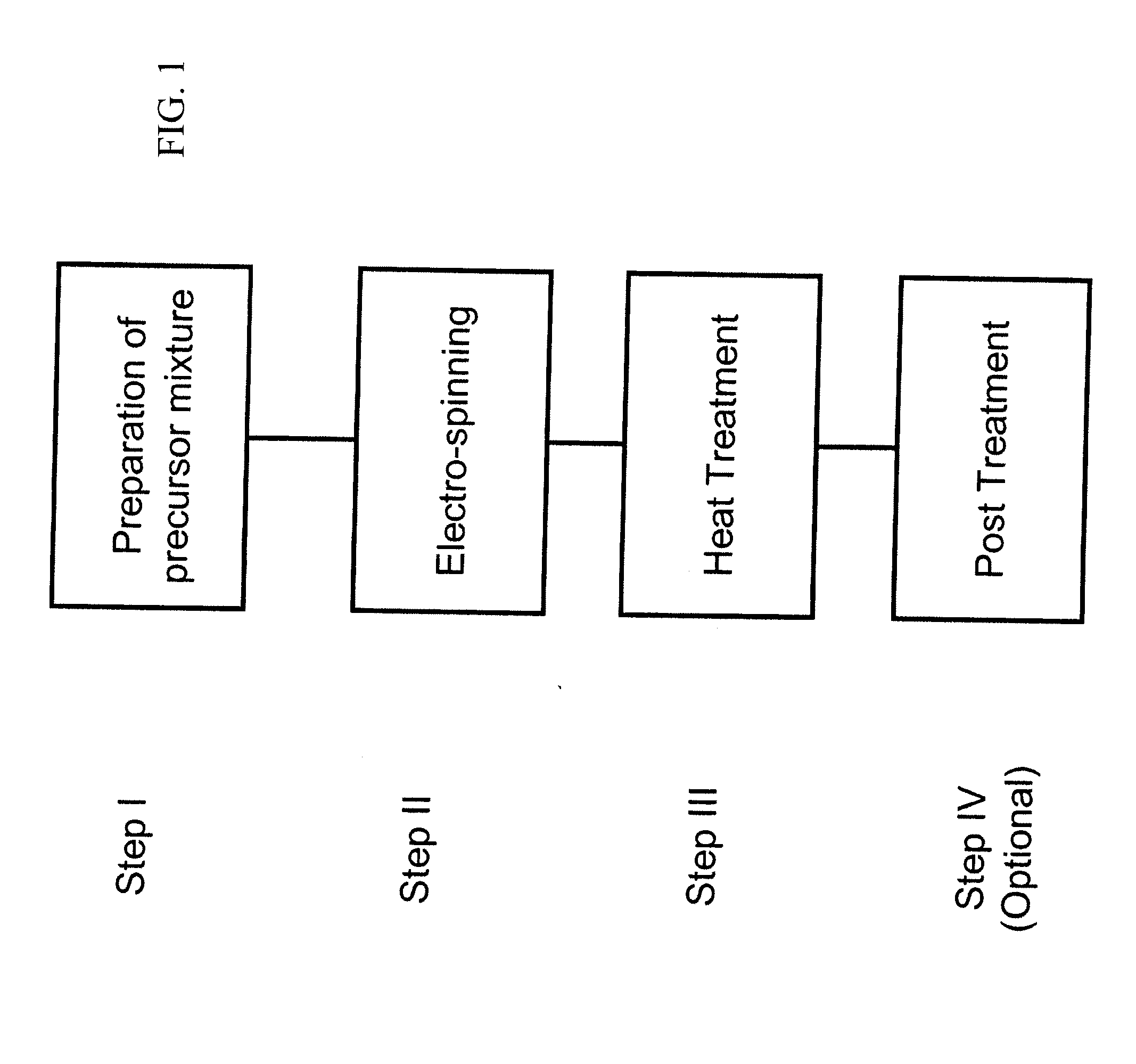

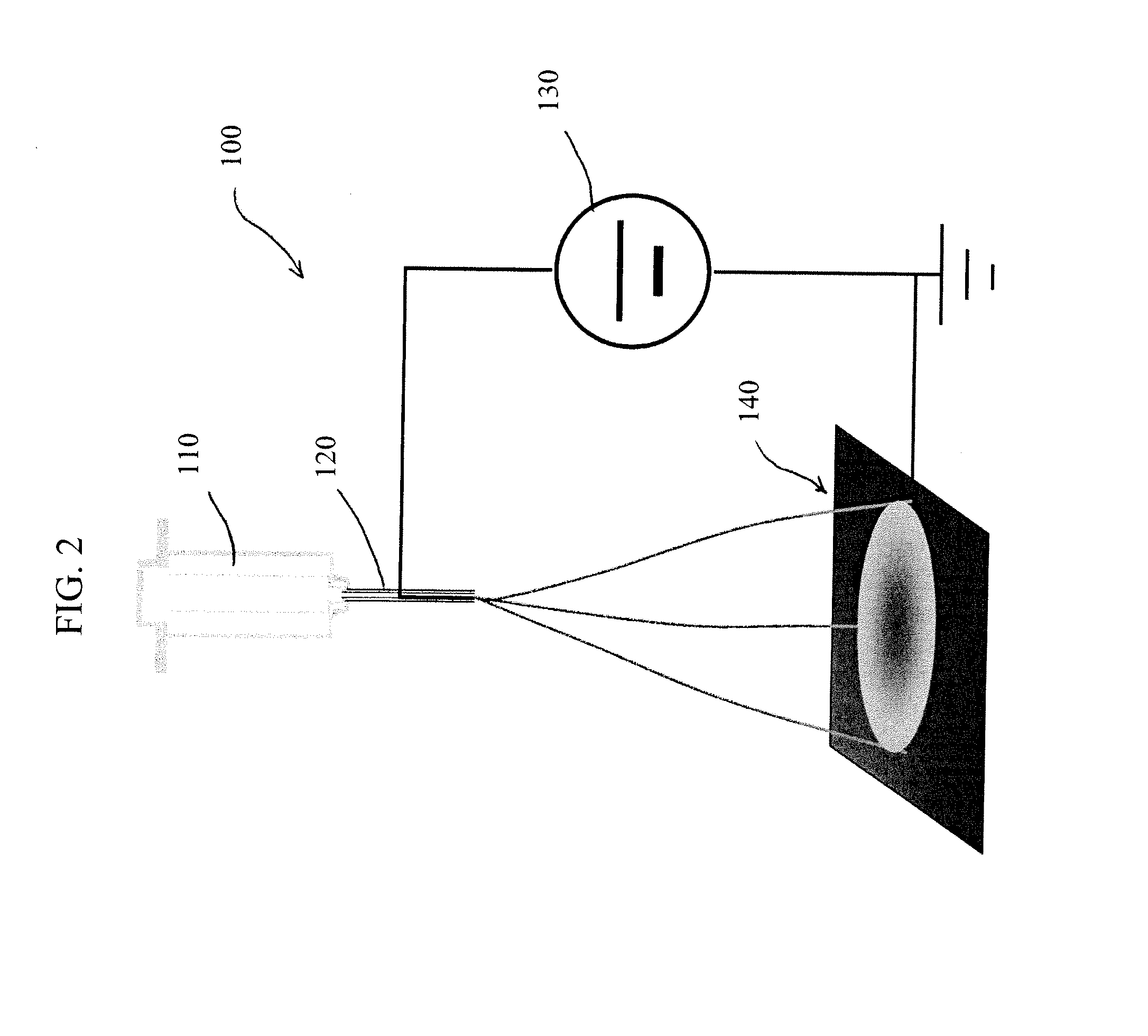

Nanofibrous electrocatalysts

ActiveUS20140093790A1Promoting mass transportImproves thermalMaterial nanotechnologyFuel and secondary cellsNanofiberMetal

A nanofibrous catalyst and method of manufacture. A precursor solution of a transition metal based material is formed into a plurality of interconnected nanofibers by electro-spinning the precursor solution with the nanofibers converted to a catalytically active material by a heat treatment. Selected subsequent treatments can enhance catalytic activity.

Owner:UCHICAGO ARGONNE LLC

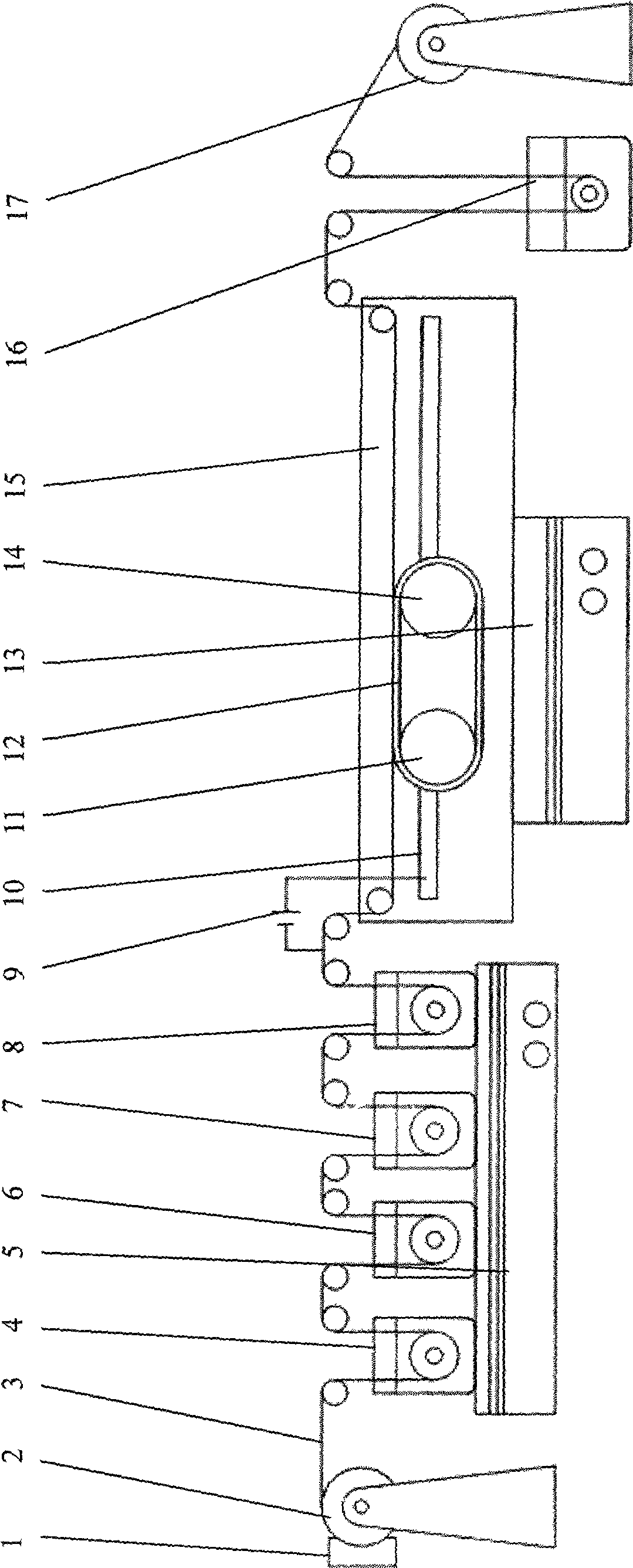

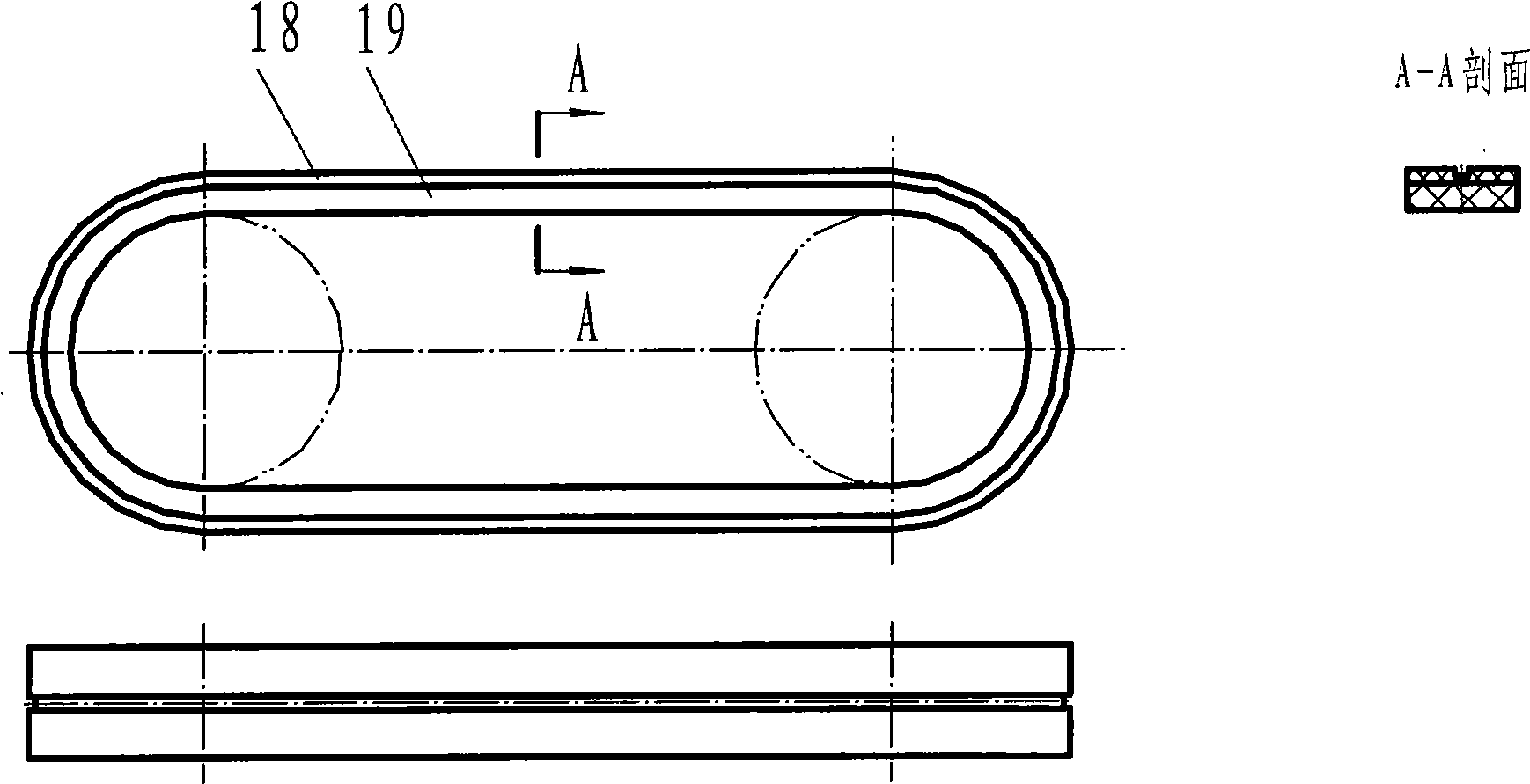

A method for manufacturing electroplating diamond wire saw

InactiveCN101531035AIncrease the concentration of nickel ionsIncrease current densityFine working devicesStone-like material working toolsDiamond wire sawElectroplating

The invention relates to a method for manufacturing electroplating diamond wire saw. The invention has main features as follows: firstly, winding the metal lines on a string releasing wheel, continuous operating the metal lines, completing the fore treatment, pre-plating, sanding and thickening procedures, and finally winding the metal lines on a string receiving wheel to complete the electroplating process, wherein, the pre-plating, sanding and thickening procedures are completed in a same electroplating bath; sanding is completed by annular feather belt subsequent rotated in the electroplating bath; the diamond grinding medium in the plating solution is suspended in the plating solution under the mixing function, and naturally depositing on the annular feather belt; and the linear velocity passing through the annular feather belt and the metal lines of the annular feather belt are identical, so the diamond grinding medium on the metal lines and the annular feather belt has a definite relative still time, to ensure sanding time. The invention uses annular feather belt to perform sanding, improves sanding efficiency, improves the manufacturing efficiency of electroplating diamond wire saw and reduces the manufacturing costs.

Owner:QINGDAO UNIV OF SCI & TECH

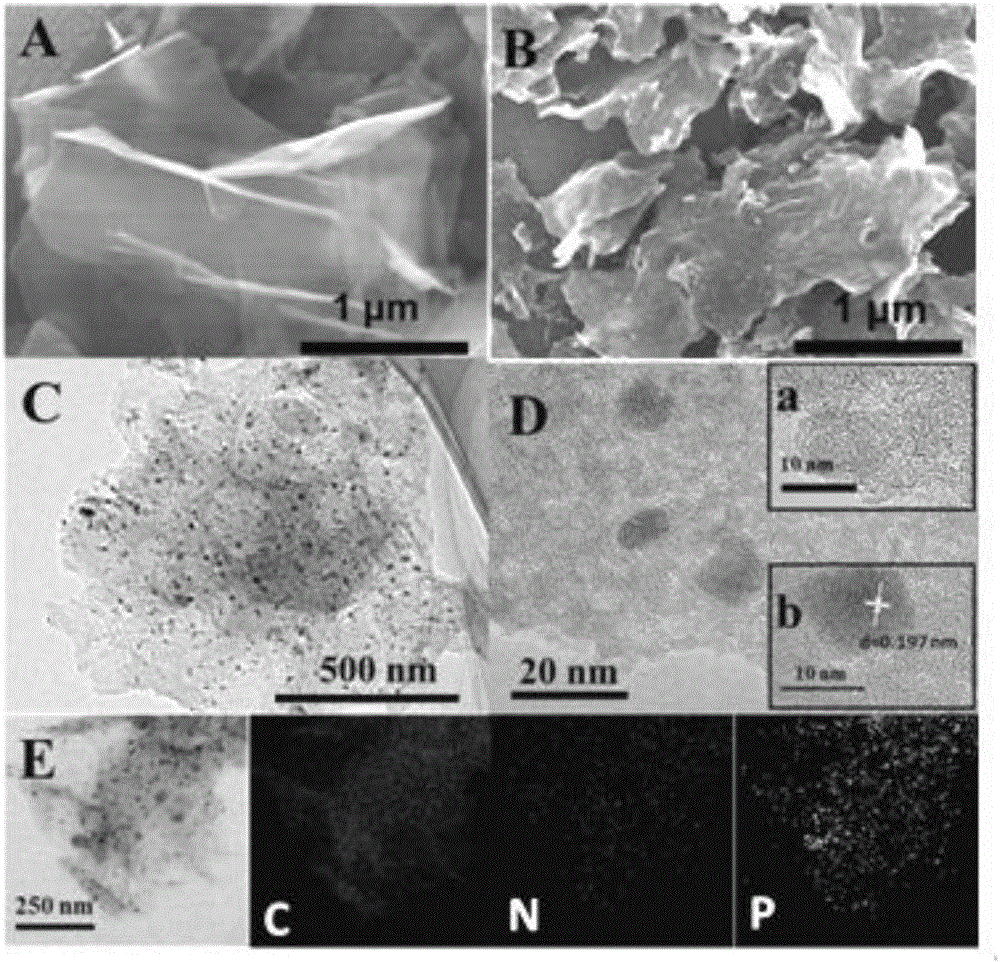

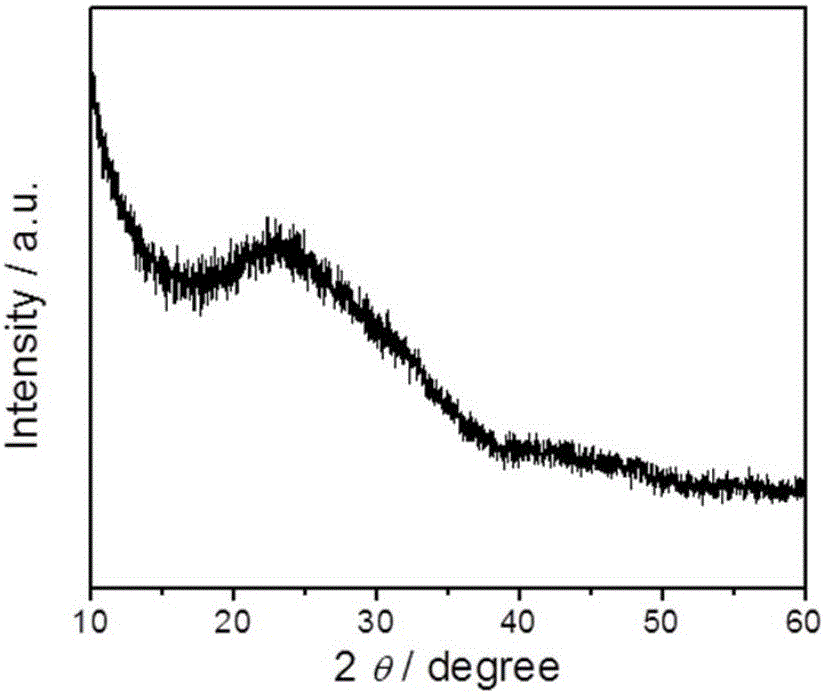

Preparation method of nitrogen-phosphorus co-doped carbon nanosheet and application of preparation method

ActiveCN105762376APositive onset potentialIncrease current densityMaterial nanotechnologyCell electrodesHigh current densityElectron transfer reactions

The invention discloses a preparation method of a nitrogen-phosphorus co-doped carbon nanosheet and application of the preparation method.Nitrogen-phosphorus co-doped carbon nanosheet catalyst material is prepared by: calcining at high temperature, template-free one-step self-assembled precursors: melamine and phytic acid.Oxygen reduction tests show that prepared N-P / CNS-1000 shows corrected initial potential and higher current density, represents four-electron transfer reaction, can match with commercial Pt / C and shows both excellent ethanol resistance and long-range stability in alkali solutions.

Owner:QINGDAO UNIV

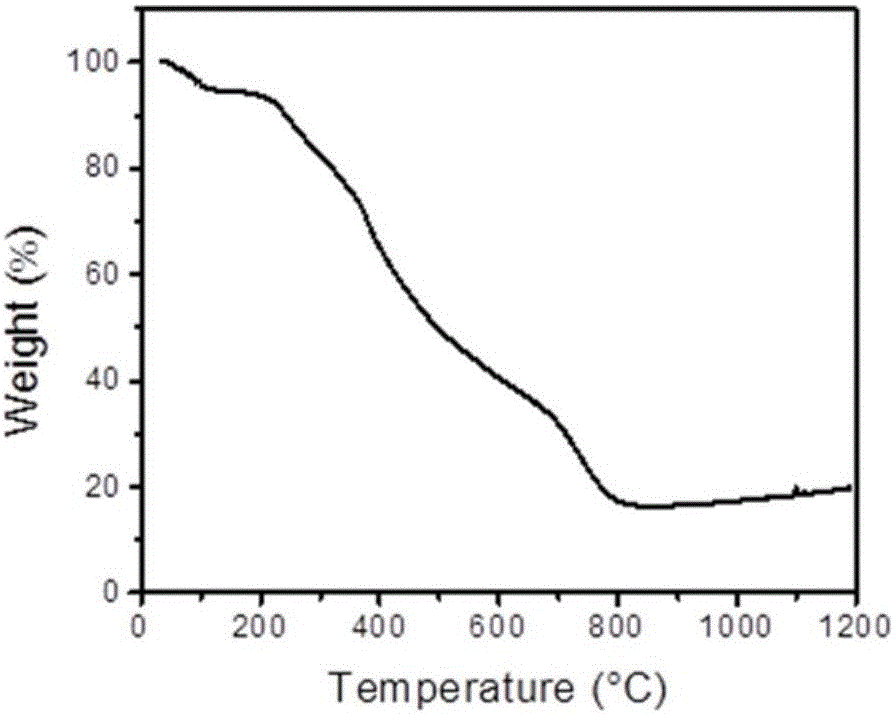

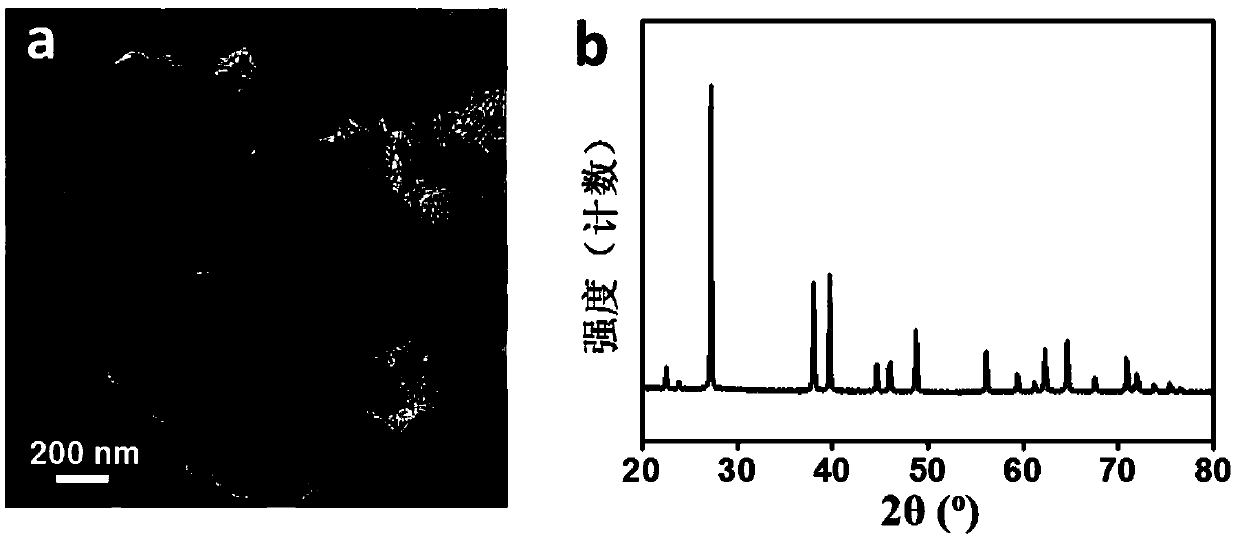

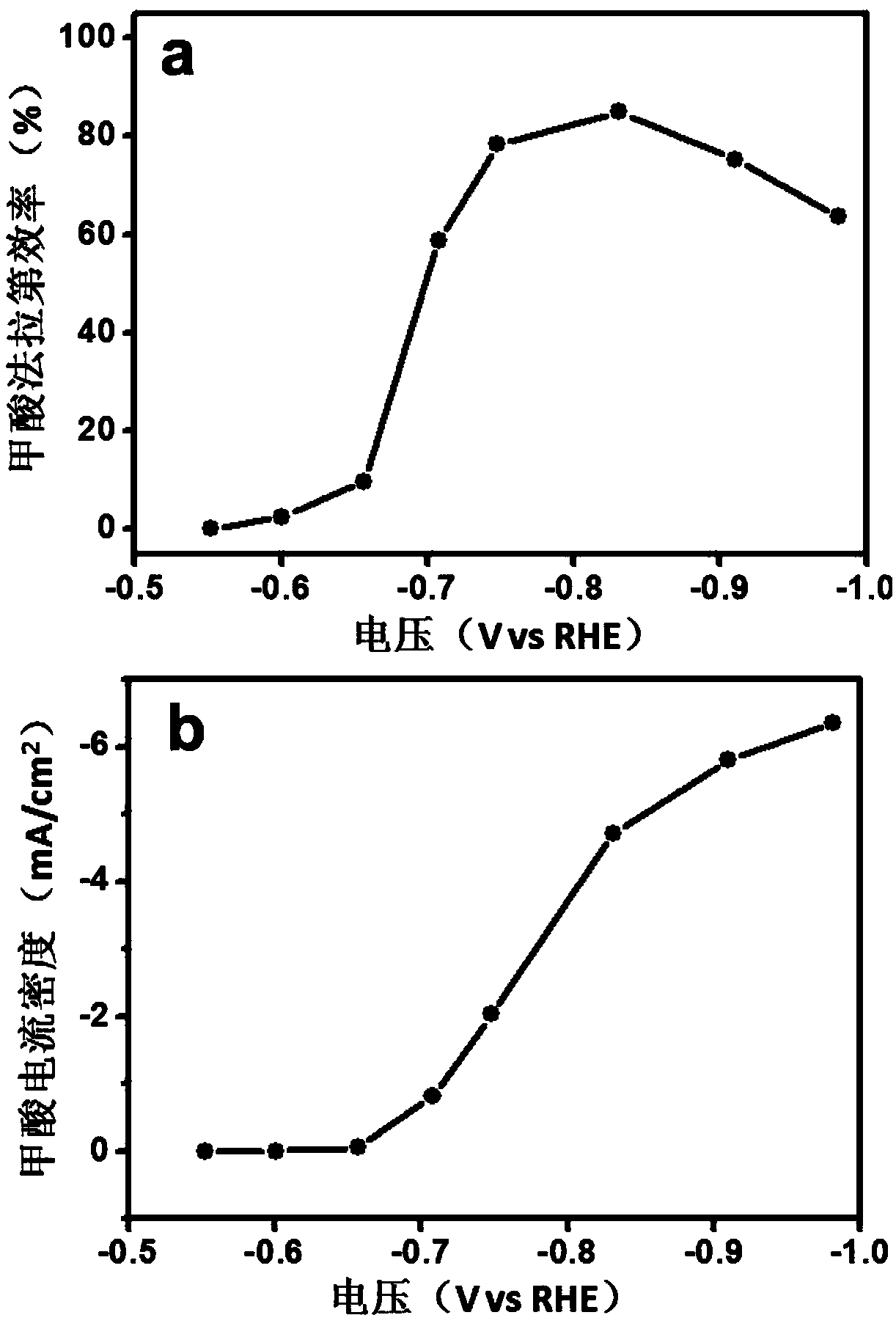

Bismuth-based catalyst for electrocatalytic CO2 reduction to form formic acid and preparation method and application thereof

ActiveCN109518222AImprove efficiencyIncrease current densityElectrolytic organic productionElectrodesResource utilizationNanostructure

The invention provides a bismuth-based catalyst for electrocatalytic CO2 reduction to form formic acid and a preparation method and application of the bismuth-based catalyst. In a water phase system,the bismuth catalyst has the characteristic of electrocatalytic CO2 reduction, and is superior to similar formic acid producing electrode materials in activity and selectivity. Compared with bulk bismuth metal, the bismuth-based catalyst with a nanometer structure is larger in specific surface area and has rich surface chemical reaction sites, specific exposed crystal faces and diversified size effects, thereby being better in catalytic activity as shown in an electrocatalytic CO2 reduction system. The nanometer-bismuth-based catalyst is environmentally friendly, low in cost, efficient and stable, the conversion efficiency of electrocatalytic CO2 reduction to form the formic acid through the nanometer-bismuth-based catalyst can be up to more than 98%, and the nanometer-bismuth-based catalyst has important practical significance for environmental protection and resource utilization.

Owner:SUZHOU UNIV

Resistor random access memory cell with reduced active area and reduced contact areas

ActiveUS20070281420A1Improve insulation performanceIncrease current densitySolid-state devicesSemiconductor/solid-state device manufacturingRandom access memoryEngineering

A memory device has a sidewall insulating member with a sidewall insulating member length according to a first spacer layer thickness. A first electrode formed from a second spacer layer having a first electrode length according to a thickness of a second spacer layer and a second electrode formed from the second spacer layer having a second electrode length according to the thickness of the second spacer layer are formed on sidewalls of the sidewall insulating member. A bridge of memory material having a bridge width extends from a top surface of the first electrode to a top surface of the second electrode across a top surface of the sidewall insulating member, wherein the bridge comprises memory material.

Owner:MACRONIX INT CO LTD

Method of making an electroplated interconnection wire of a composite of metal and carbon nanotubes

InactiveUS20070056855A1Increase current densityDegrade electromigration resistanceElectrolytic coatingsPrinted circuit manufactureOrganic solventCarbon nanotube

Method of making an electroplated interconnection wire of a composite of metal and carbon nanotubes is disclosed, including electroplating a substrate having a conductive baseline on a surface thereof in an electroplating bath containing a metal ion and carbon nanotubes, so that an electroplated interconnection wire of a composite of the metal and carbon nanotubes is formed on the conductive baseline. Alternatively, a method of the present invention includes preparing a dispersion of carbon nanotubes dispersed in an organic solvent, printing a baseline with the dispersion on a surface of a substrate, evaporating the organic solvent to obtain a conductive baseline, and electroplating the surface in an electroplating bath containing a metal ion, so that an electroplated interconnection wire of a composite of the metal and carbon nanotubes is formed on the conductive baseline.

Owner:IND TECH RES INST

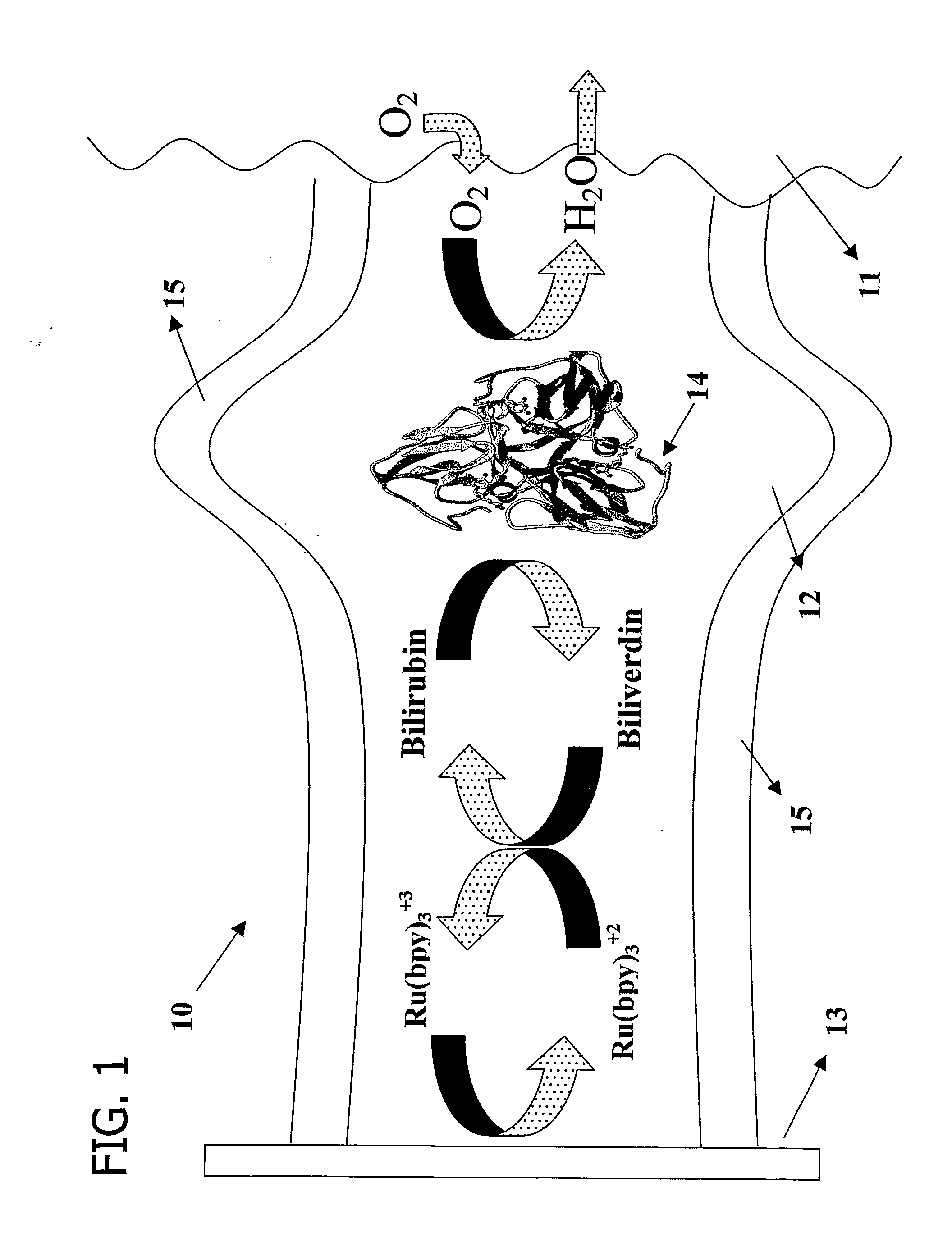

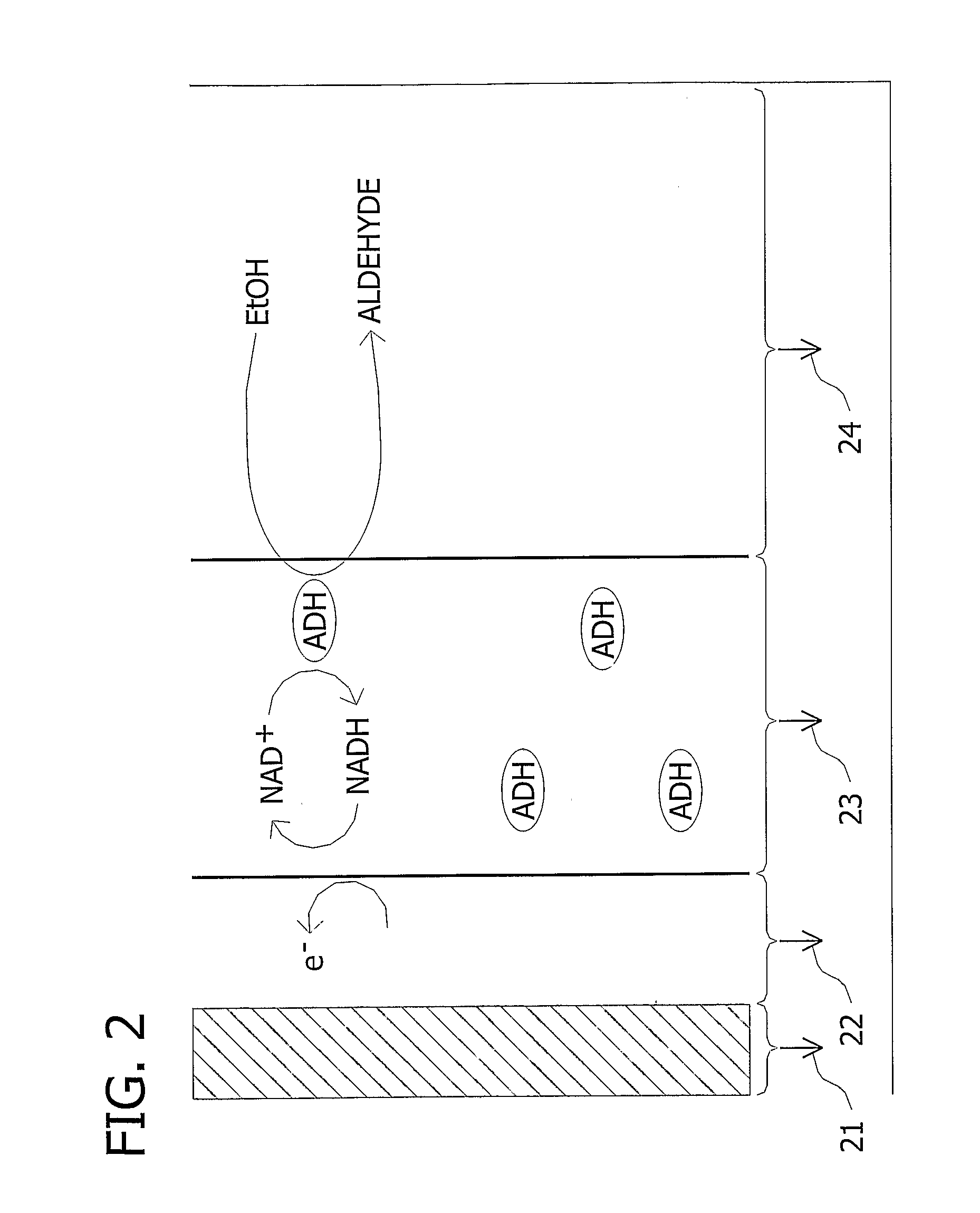

Microfluidic Biofuel Cell

InactiveUS20070287034A1Great current densityIncrease current densityElectrolysis componentsActive material electrodesChemical physicsFuel cells

Microfluidic biofuel cells comprising a bioanode and / or a biocathode are formed using microfluidic principles and soft lithography. The enzymes utilized in the redox reactions at the bioanode and / or the biocathode are stabilized in a micellar or inverted micellar structure. The biofuel cell is used to produce high power densities.

Owner:SAINT LOUIS UNIVERSITY

Medical devices incorporating carbon nanotube material and methods of fabricating same

InactiveUS7844347B2High strengthStable stateSpinal electrodesTransvascular endocardial electrodesMuscle tissueNanotube

Unique electrodes and / or electrical lead assemblies are provided for stimulating cardiac tissue, muscle tissue, neurological tissue, brain tissue and / or organ tissue; to electrophysiology mapping and ablation catheters for monitoring and selectively altering physiologic conduction pathways. The electrodes, lead assemblies and catheters optionally include fluid irrigation conduit(s) for providing therapeutic and / or performance enhancing materials to adjacent biological tissue. Each device is coupled to or incorporates nanotube structures or materials therein. Methods for fabricating, deploying, and operating such medical devices are also provided.

Owner:MEDTRONIC INC

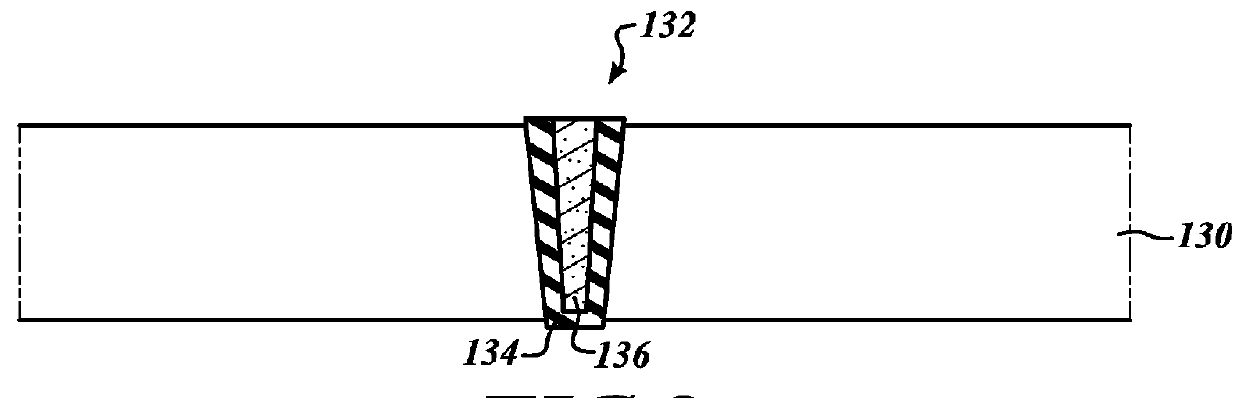

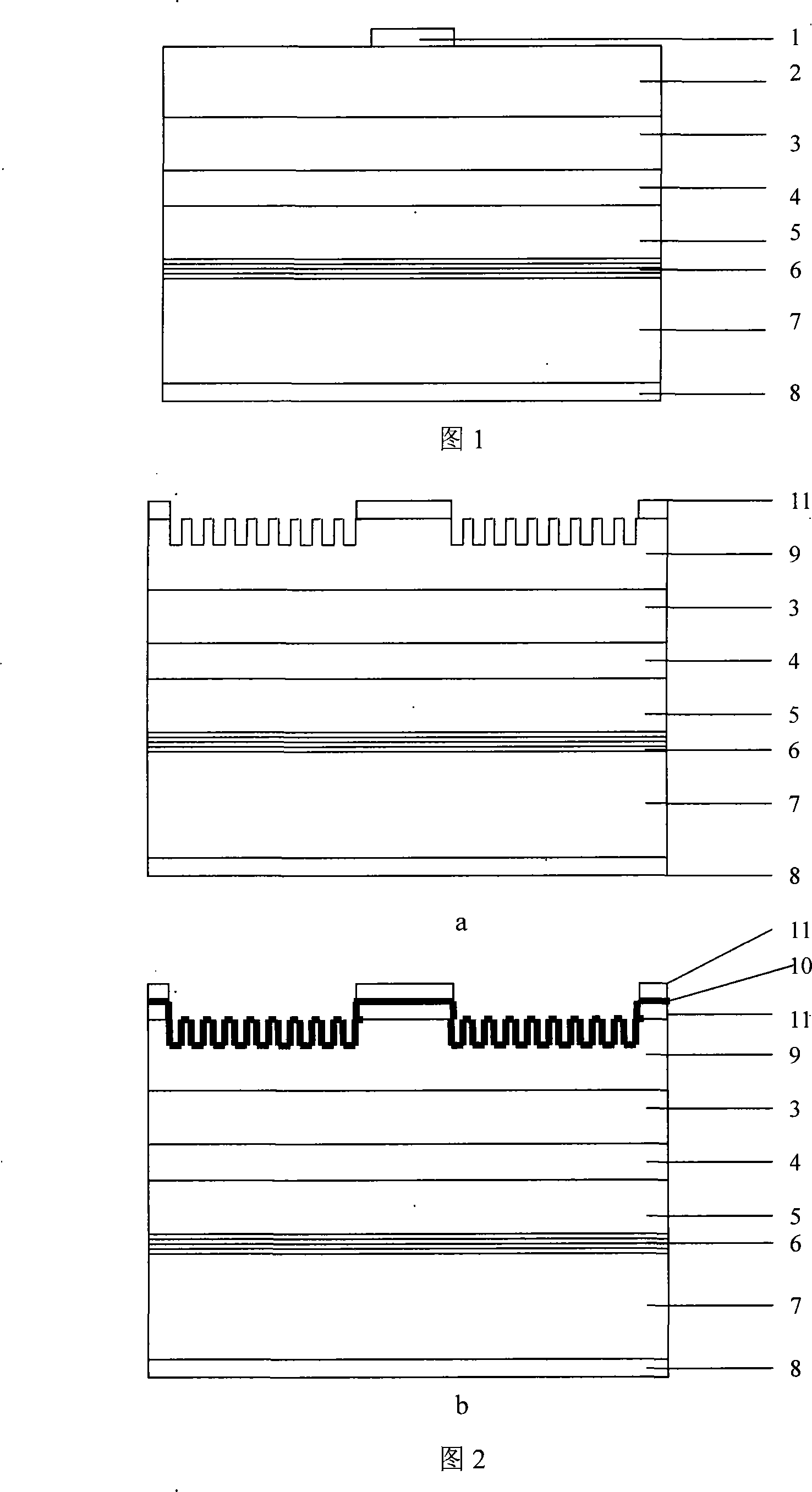

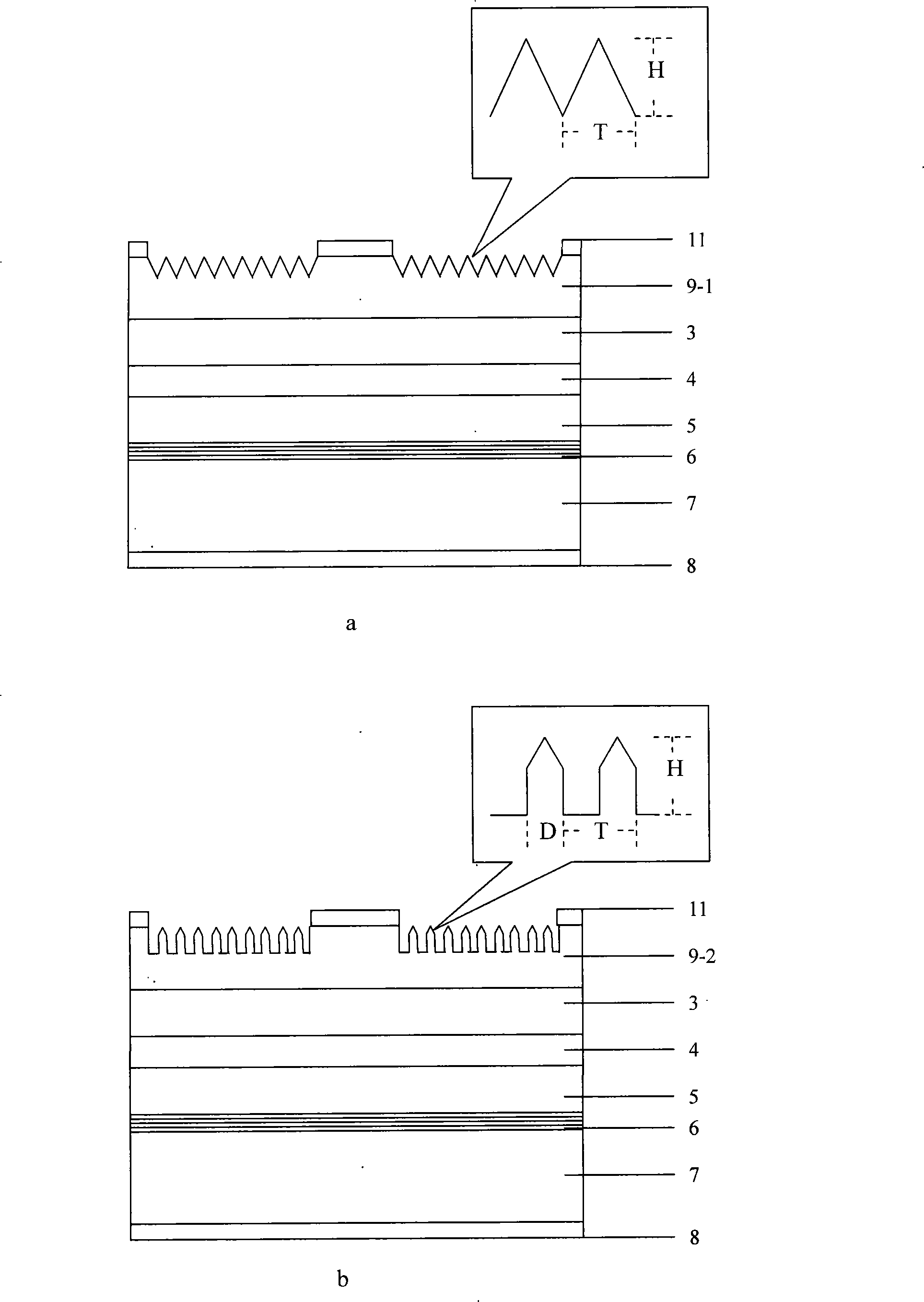

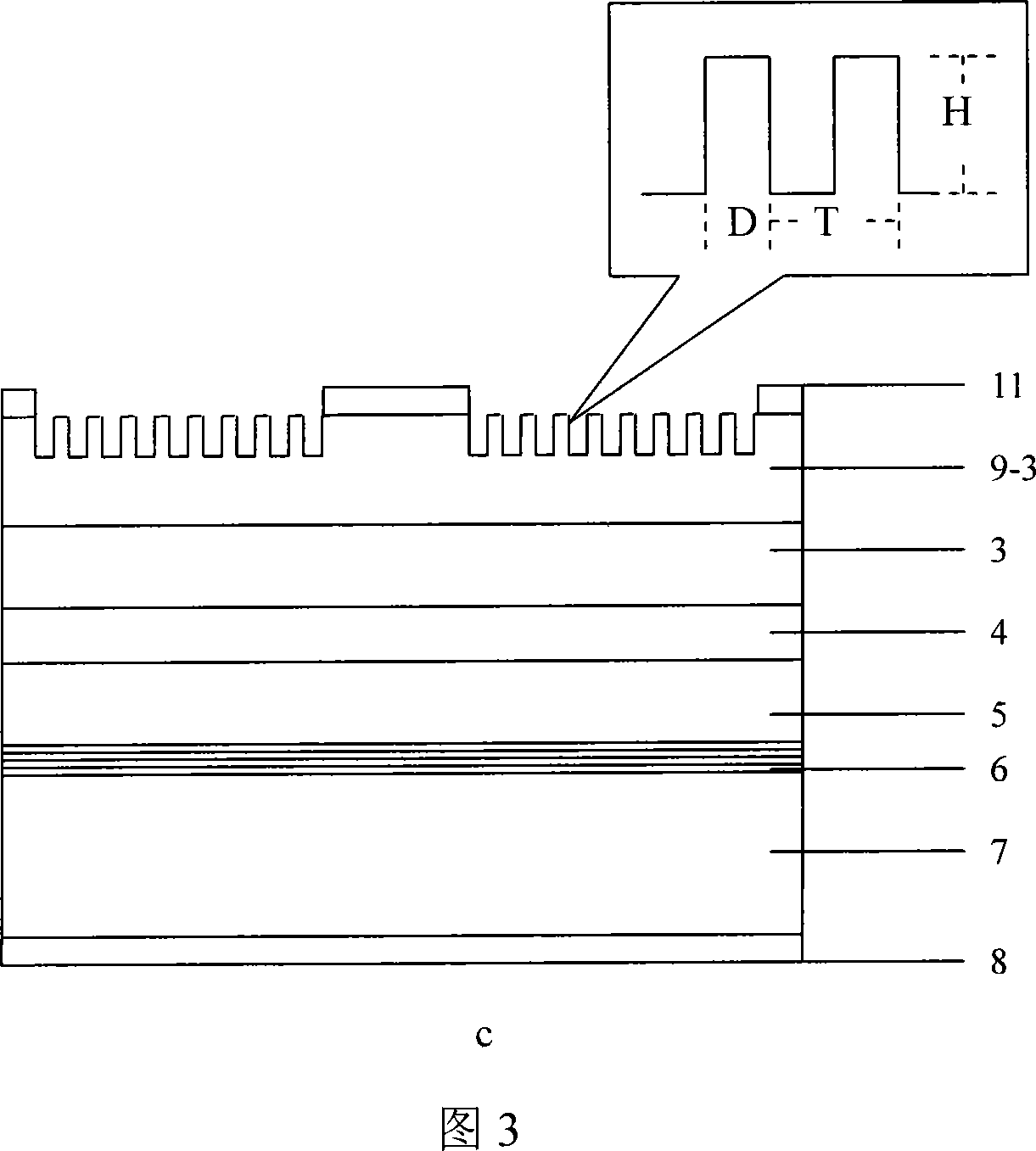

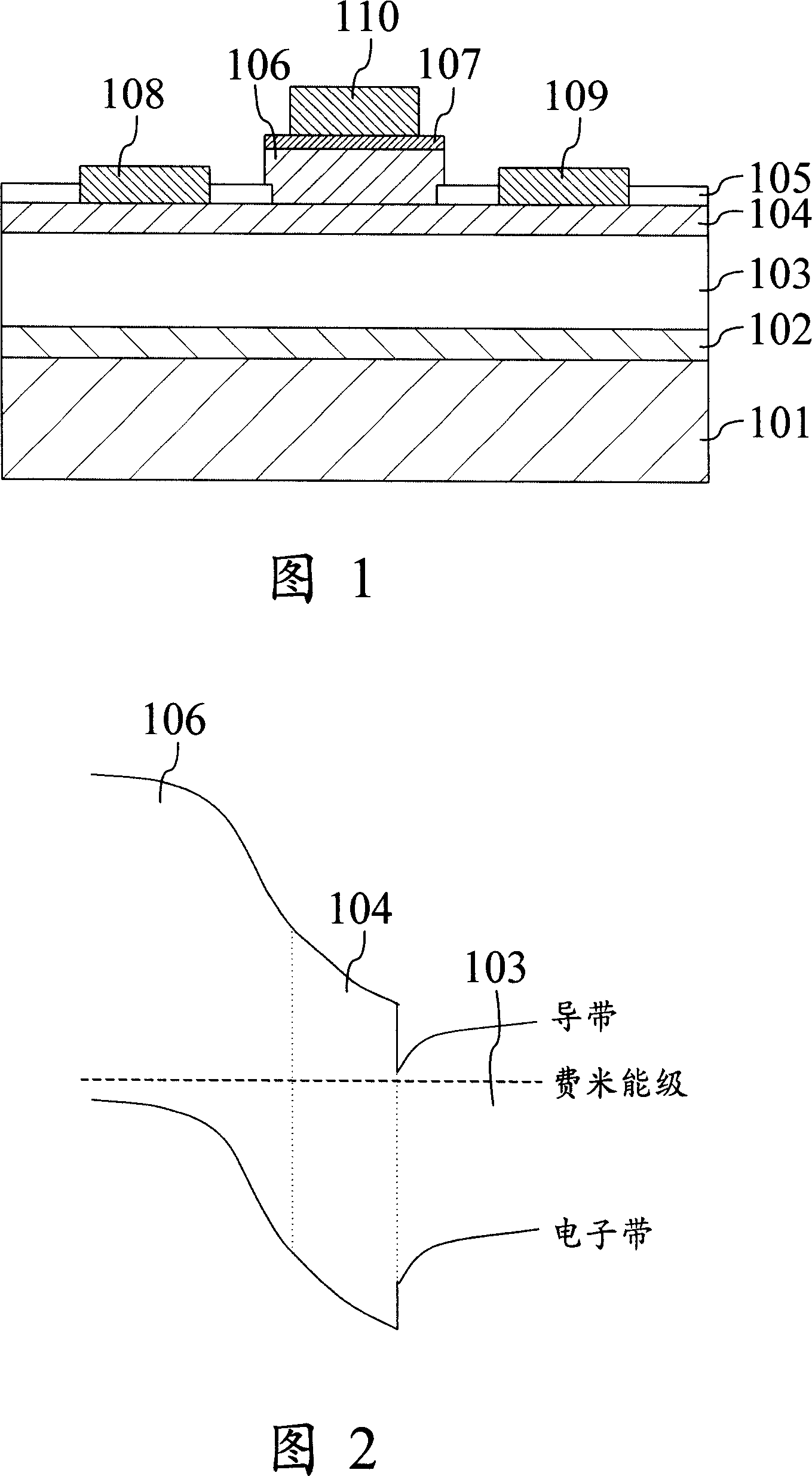

Emitting surface semiconductor LED with nanostructure and its preparing process

InactiveCN101159307AReduce reflectionLarge luminous areaSemiconductor devicesLight reflexManufacturing technology

The invention relates to the technical field of semiconductor photoelectronic device manufacturing, in particular to a semiconductor light emitting diode (LED) with a nanometer light emitting surface. The inventive method comprises growing a dielectric layer (12) and a metal layer (13) on a GaP layer (2) of the conventional LED, and sequentially using the metal layer (13) as a mask to etch the dielectric layer (12) and the parts outside a P type electrode (11) on the upper surface of the GaP layer (2) to obtain the LED with the nanometer light emitting surface. The method also comprises coating a layer of indium tin oxide (ITO) conducting film (10) on the nanometer light emitting surface and the upper surface of the P-type electrode (11), and preparing a P-type electrode (11) with the same structure on the P-type electrode (11) coated with the ITO conducting film (10). The invention reduces light reflex, improves device performance, and can be used in various semiconductor LEDs. Meanwhile, the invention has the advantages of simple process, low cost, and applicability to batch production.

Owner:BEIJING UNIV OF TECH

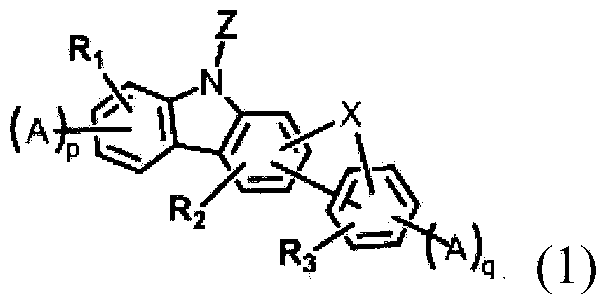

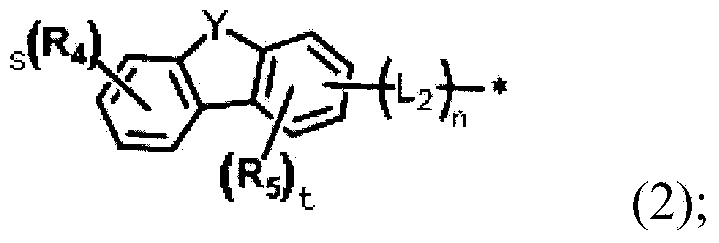

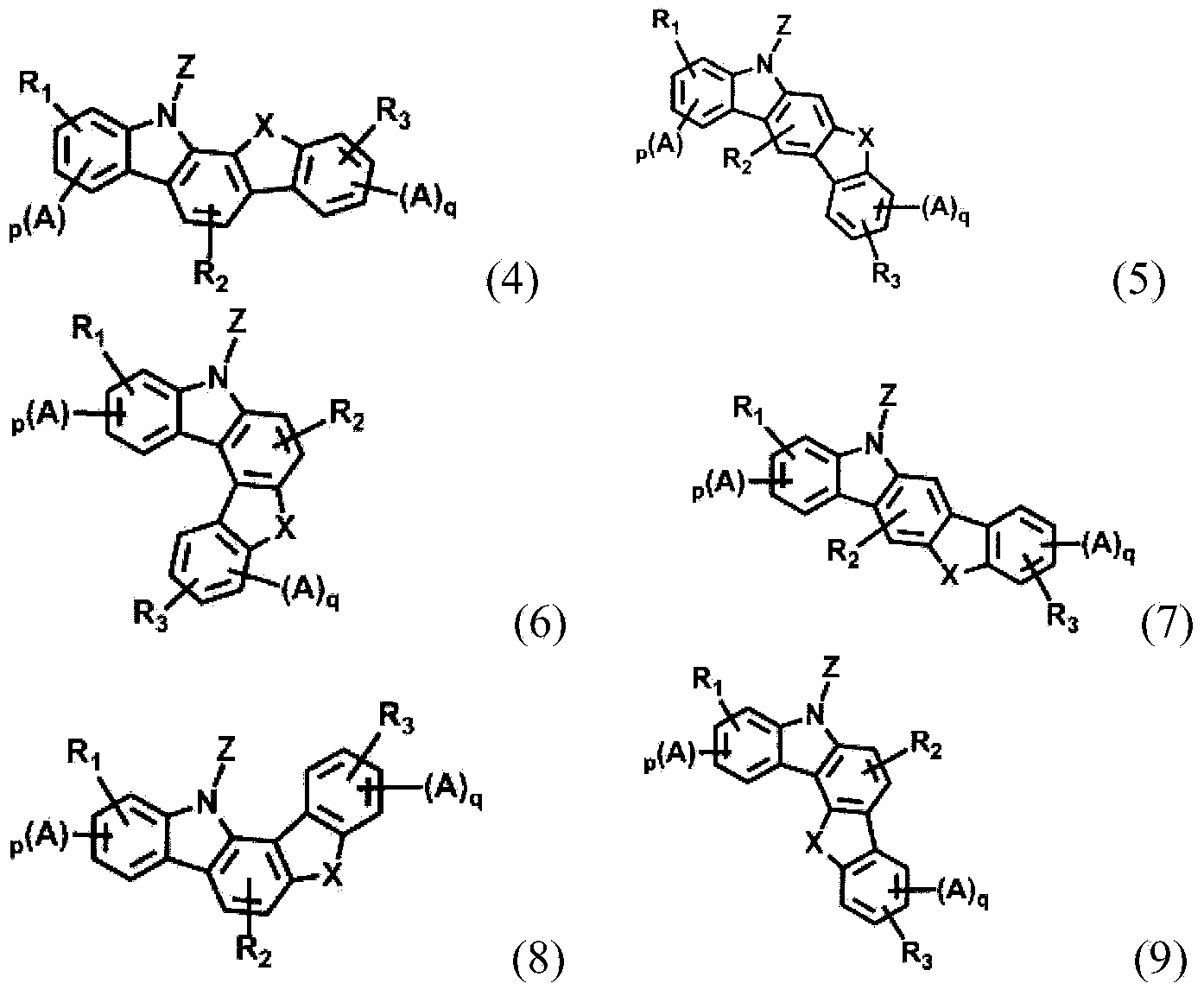

Novel organic electroluminescent compounds and organic electroluminescent device comprising the same

InactiveCN104271700AImprove luminous efficiencyExtend working lifeGroup 4/14 element organic compoundsElectroluminescent light sourcesOrganic electroluminescenceOrganic chemistry

The present invention relates to novel organic electroluminescent compounds and an organic electroluminescent device containing the same. The organic electroluminescent compounds according to the present invention can be used as a phosphorescent host material, a hole transport material, or a mixed host material; have a good hole transport ability; prevent crystallization in the production of the device; are suitable for forming a layer; and improve the current density of the device thereby reducing the driving voltage of the device.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

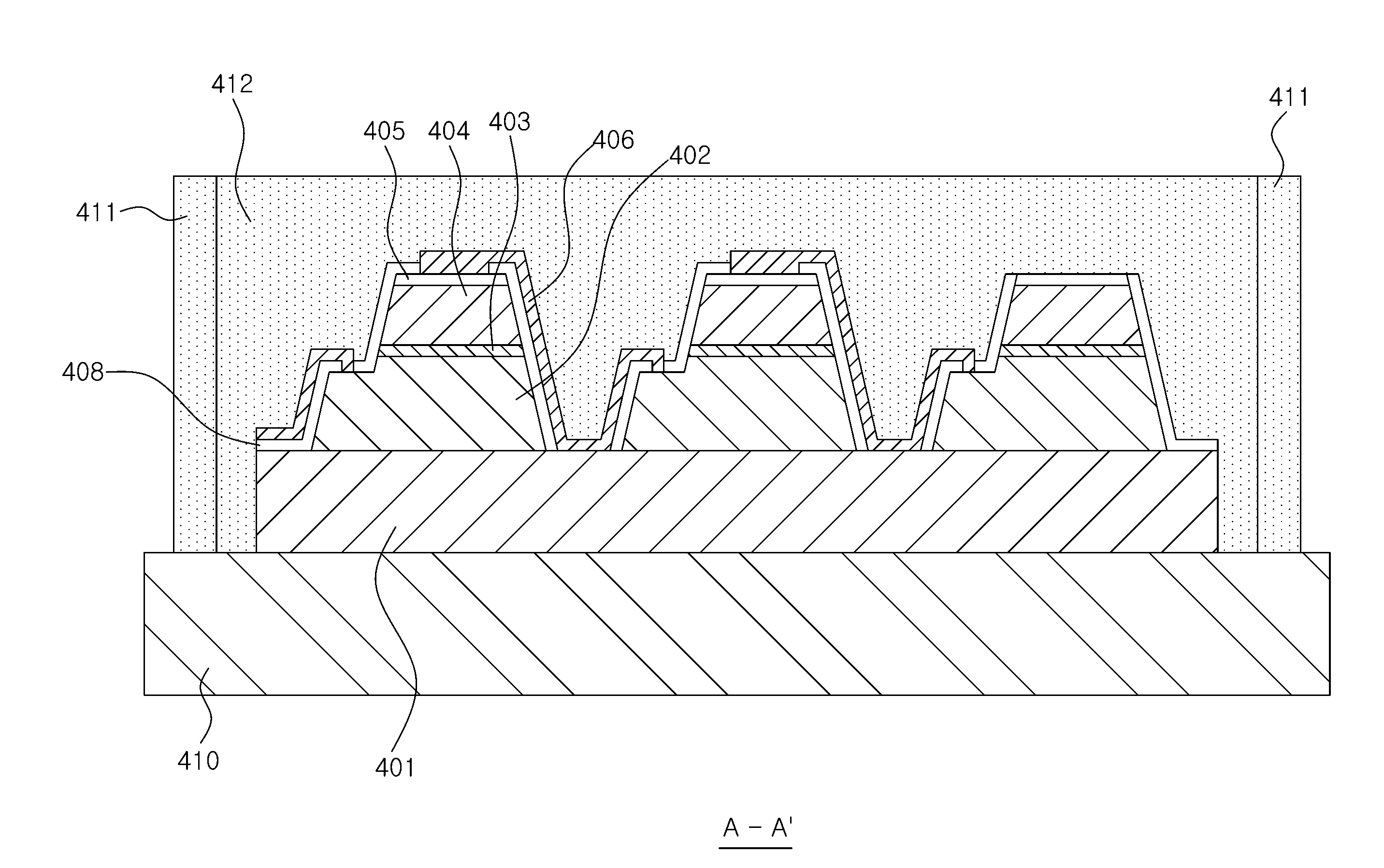

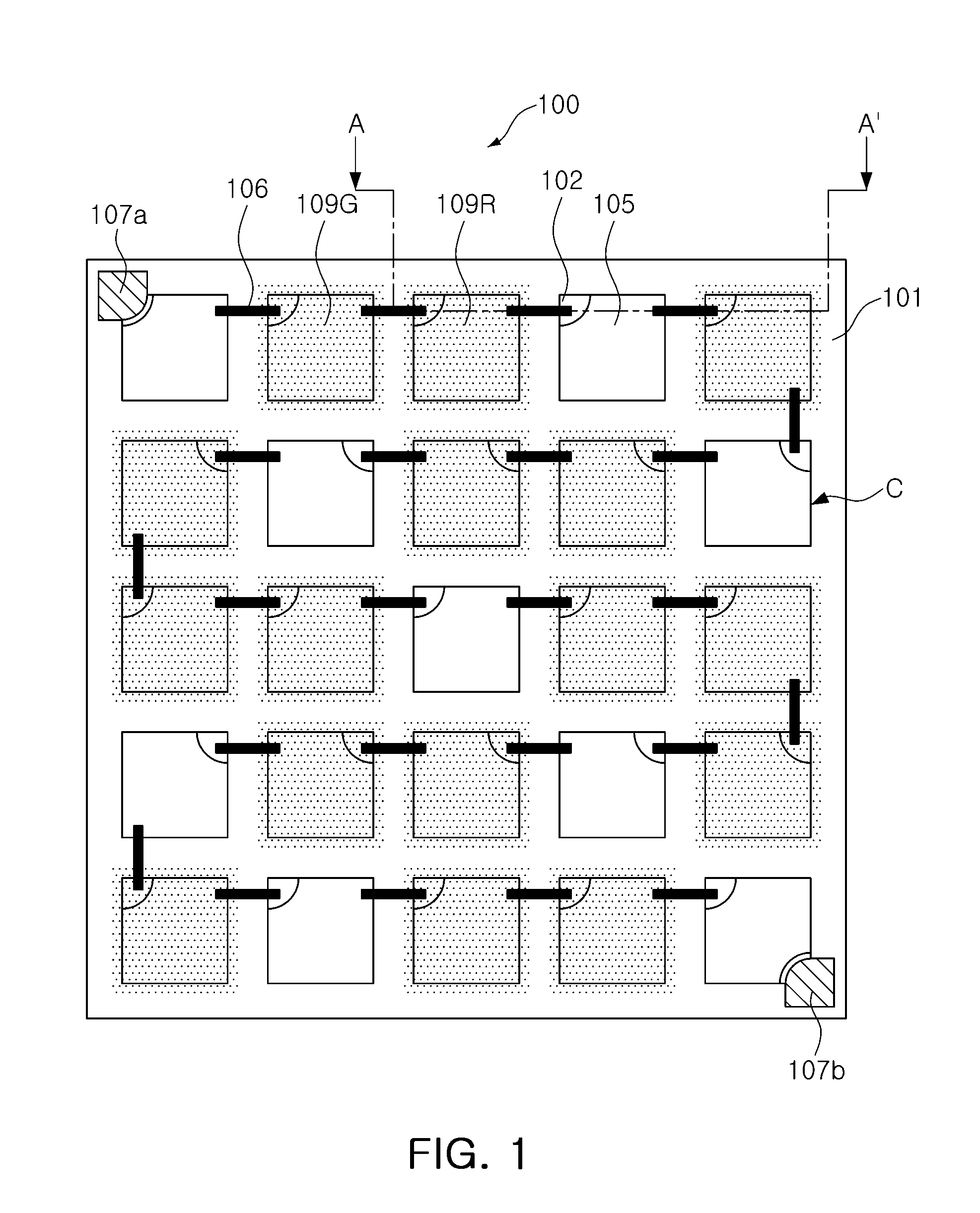

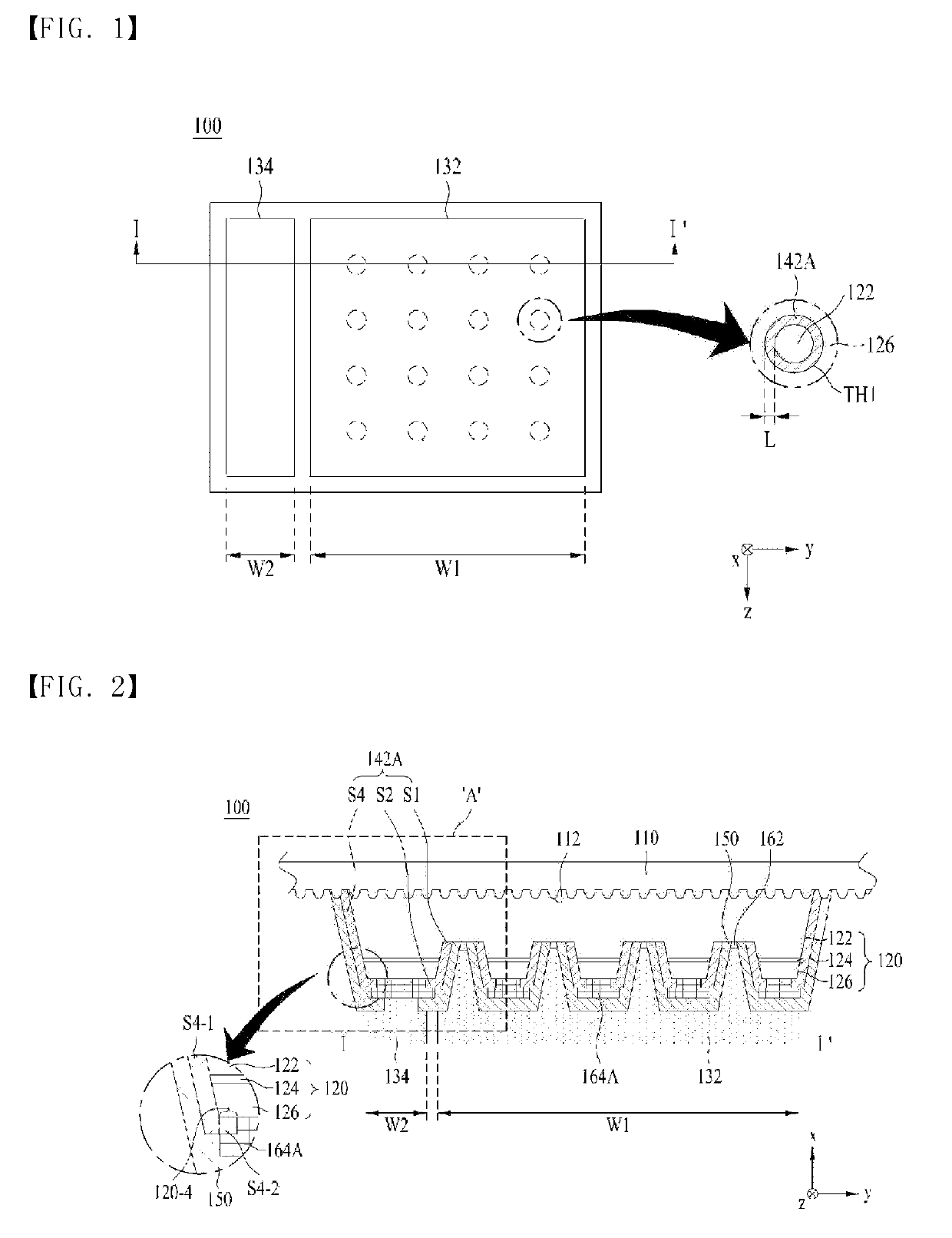

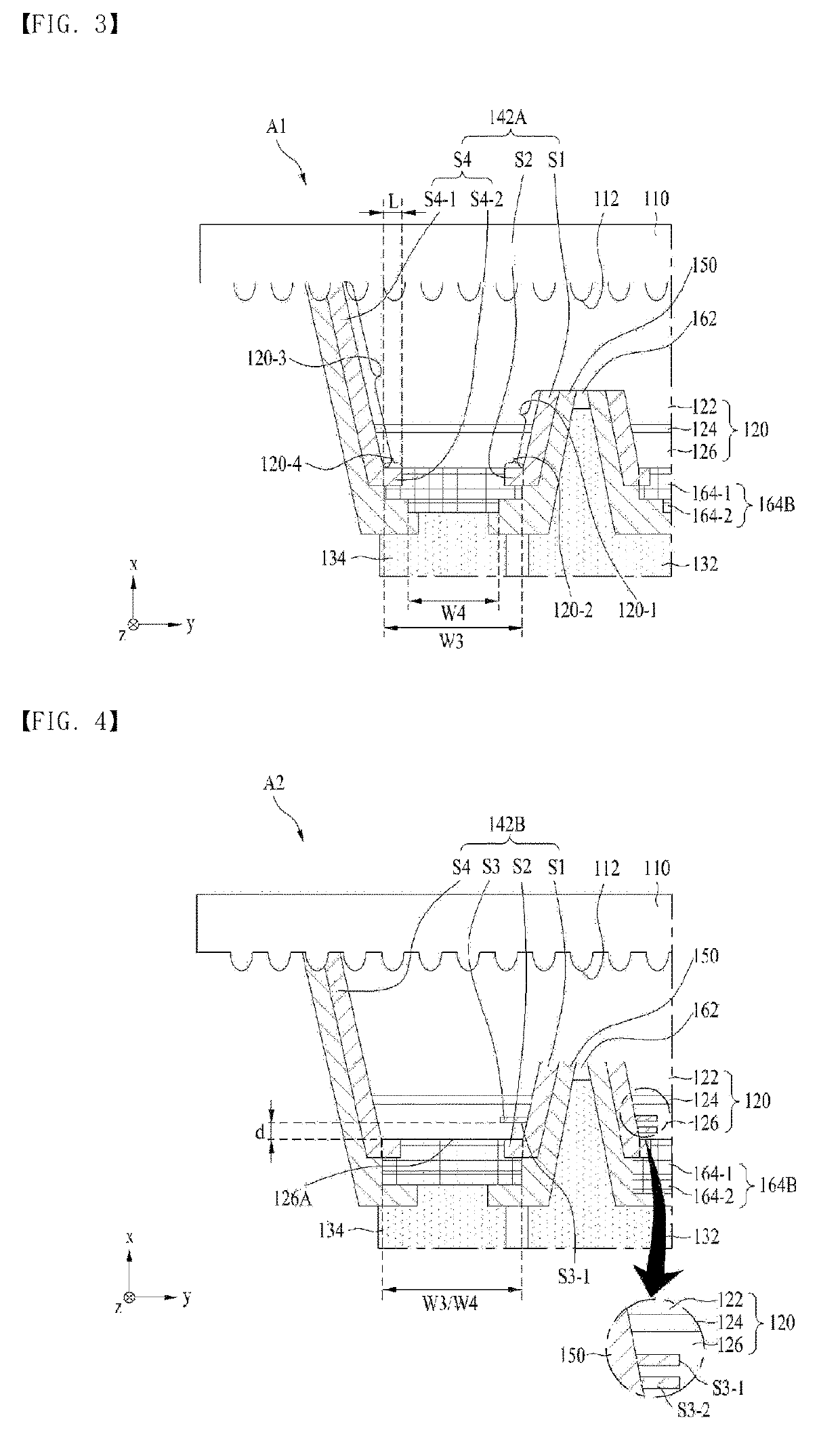

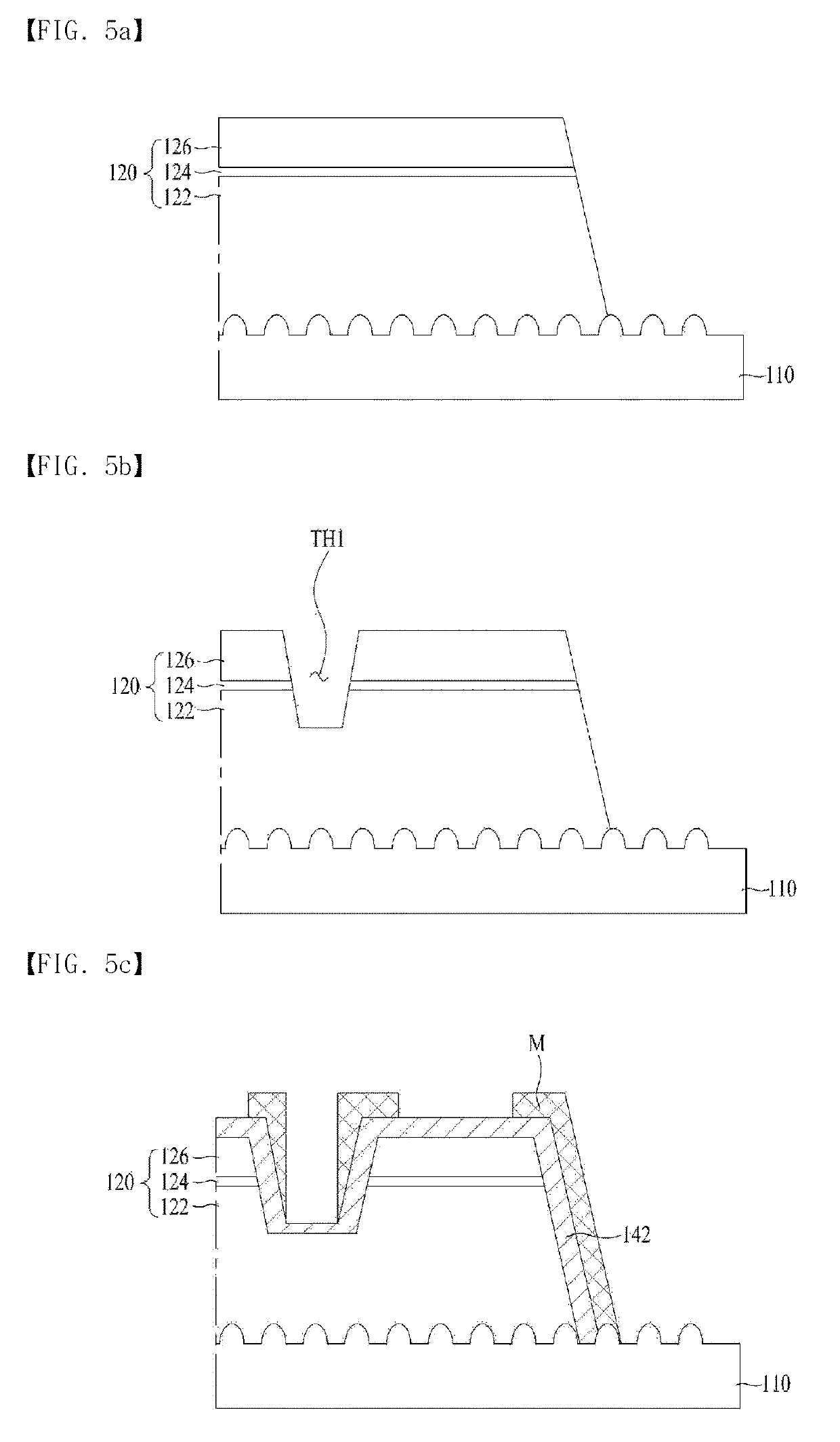

Semiconductor light emitting device having multi-cell array and method for manufacturing the same

InactiveUS20110210351A1Improve lighting efficiencyIncrease current densityDischarge tube luminescnet screensLighting support devicesInterconnectionGreen-light

A semiconductor light emitting device includes: a substrate; a plurality of light emitting cells arranged on the substrate, each of the light emitting cells including a first-conductivity-type semiconductor layer, a second-conductivity-type semiconductor layer, and an active layer disposed therebetween to emit blue light; an interconnection structure electrically connecting at least one of the first-conductivity-type semiconductor layer and the second-conductivity-type semiconductor layer of the light emitting cell to at least one of the first-conductivity-type semiconductor layer and the second-conductivity-type semiconductor layer of another light emitting cell; and a light conversion part formed in at least a portion of a light emitting region defined by the plurality of light emitting cells, the light conversion part including at least one of a red light conversion part having a red light conversion material and a green light conversion part having a green light conversion material.

Owner:SAMSUNG ELECTRONICS CO LTD

Efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing and preparation method thereof

ActiveCN104761024ANo compactionHyperactive stateWater/sewage treatmentHigh current densityElectrolysis

The invention discloses efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing and a preparation method thereof. The packing is prepared from the following raw materials in parts by weight: 45-65 parts of pure iron powder, 10-25 parts of cast iron powder, 2-8 parts of graphite powder, 5-15 parts of active carbon powder, 2-10 parts of copper powder, 2-10 parts of manganese powder, 2-10 parts of aluminum powder, 2-10 parts of fine wood bits, 1-6 parts of sodium silicate, 1-6 parts of sodium borate, 2-6 parts of pyrite dust and 5-15 parts of an adhesive. The efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing disclosed by the invention is prepared by taking heterogeneous metal alloy with high potential difference as a catalyst and using a high-temperature micropore roasting technology and has the characteristics of heterogeneous metal and ferric-carbon integration, micropore framework type alloy structure, large specific surface area, low density, strong activity, high current density and the like; organic wastewater is treated so that COD, ammonia nitrogen and total phosphorus can be efficiently removed, the chroma can be reduced, the biodegradability can be improved, the treatment effect is extremely stable, and the phenomena of packing passivating, hardening and the like caused in the operation process can be avoided.

Owner:HUBEI QUANSHENG ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

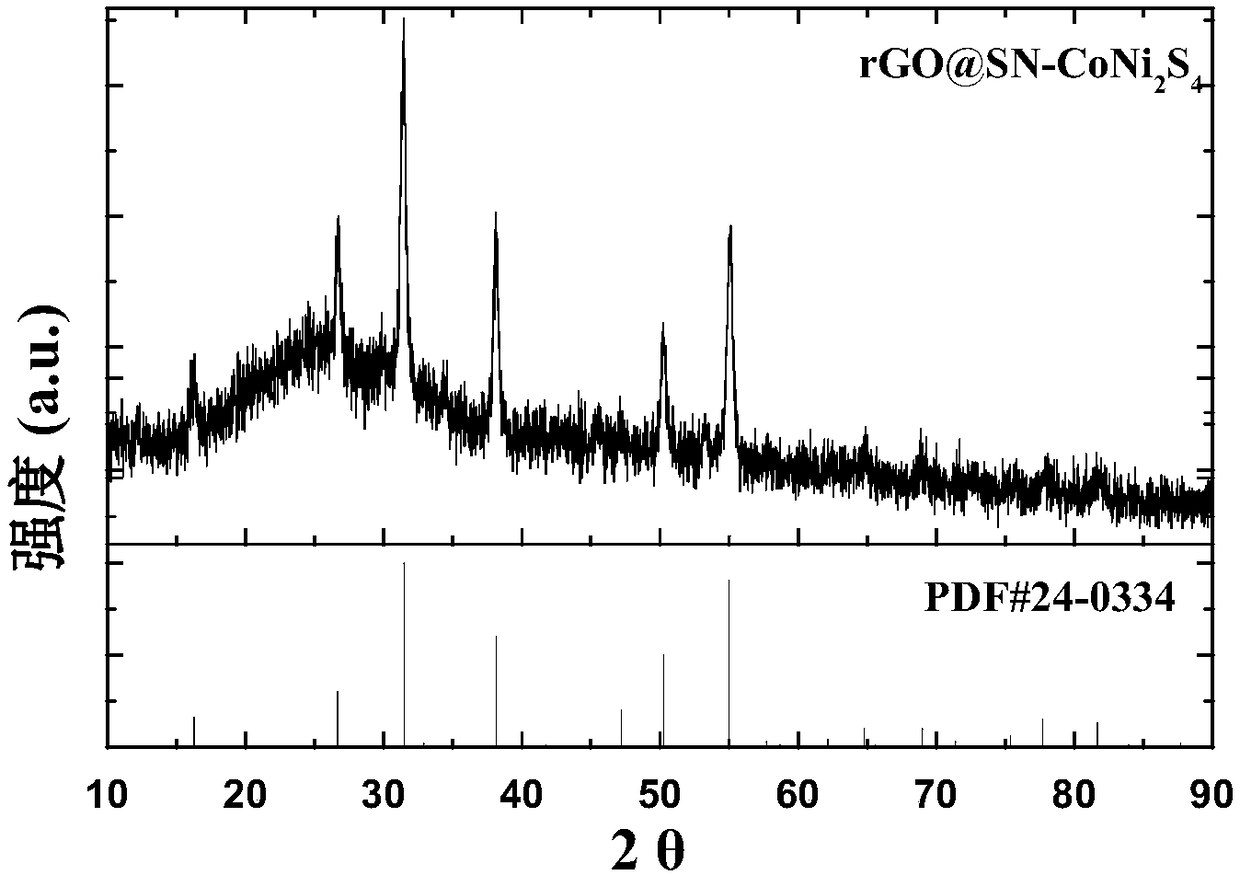

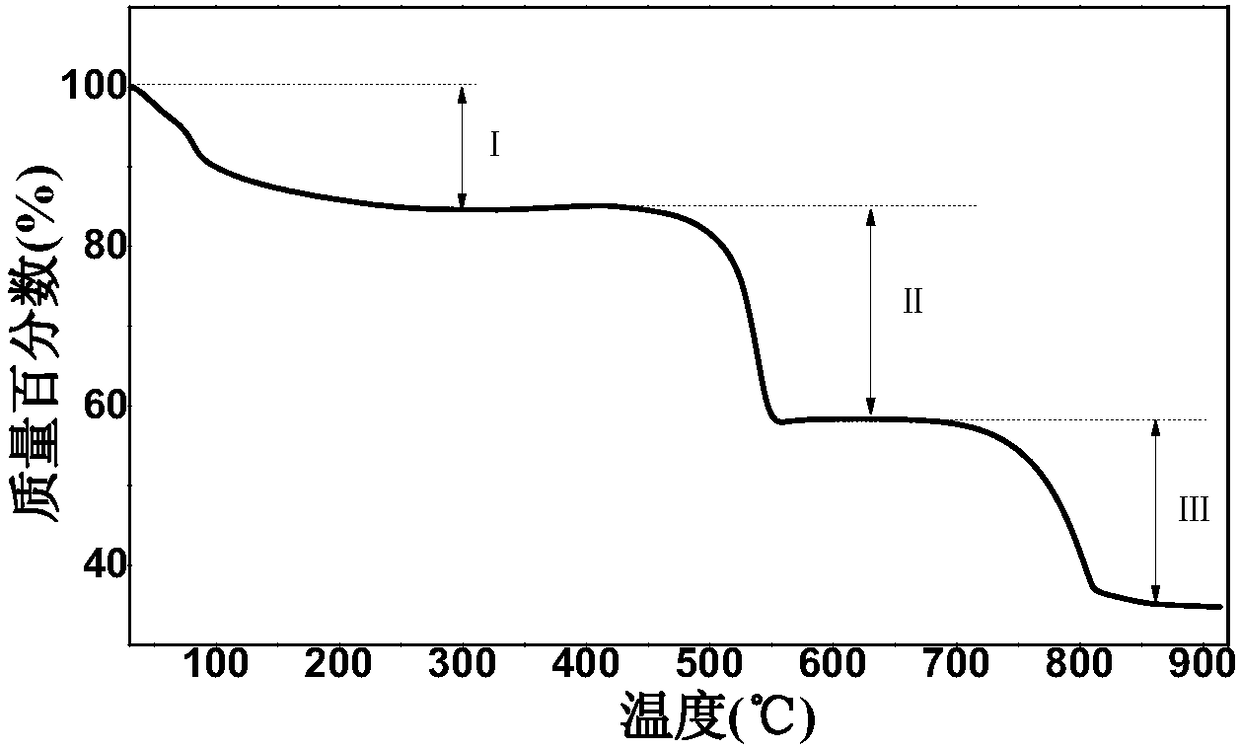

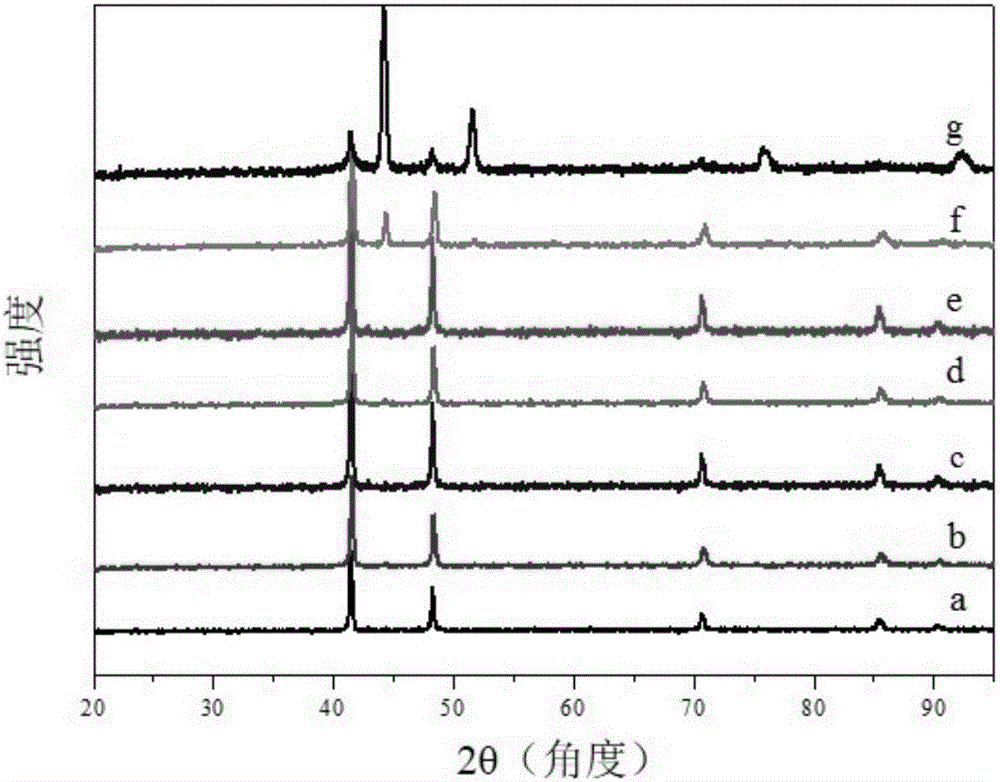

Sulfur and nitrogen codoping graphene loaded vulcanized cobalt and nickel catalytic material and preparation and application

The invention belongs to the field of electrochemical materials, and discloses a sulfur and nitrogen codoping graphene loaded vulcanized cobalt and nickel catalytic material and preparation and application. A metal cobalt source, a nickel source and thiourea are dissolved in a solvent, a mixture is subjected to ultrasonic stirring and mixing, later, ammonium hydroxide is added dropwise, a mixtureis stirred and mixed, then, graphene oxide is added, a mixture is subjected to ultrasonic stirring and mixing and then subjected to hydro-thermal treatment, next, centrifugal washing and freeze dryingare carried out, and a graphene loaded vulcanized cobalt and nickel composite material is obtained; and then, in a nitrogen atmosphere, calcination treatment is carried out, graphene oxide is furtherreduced to obtain the sulfur and nitrogen codoping graphene loaded vulcanized cobalt and nickel catalytic material. The synthetic method is simple, the cost is low, the energy consumption is relatively low, environmental friendliness is achieved, and the obtained product has good electrical conductivity and electrochemical catalysis performance and is suitable for actual application of a water cracked cathode and anode catalytic material.

Owner:SOUTH CHINA UNIV OF TECH

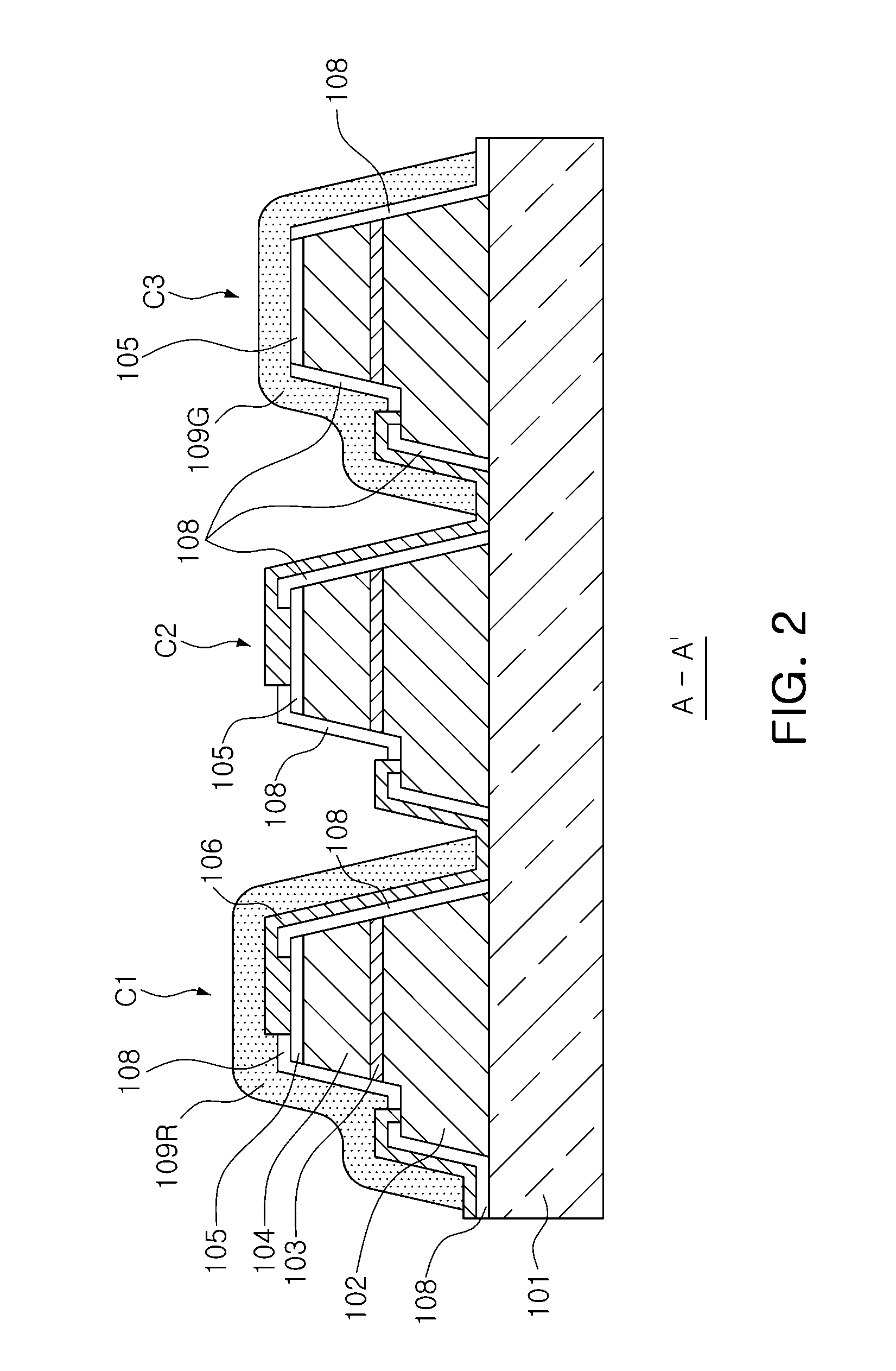

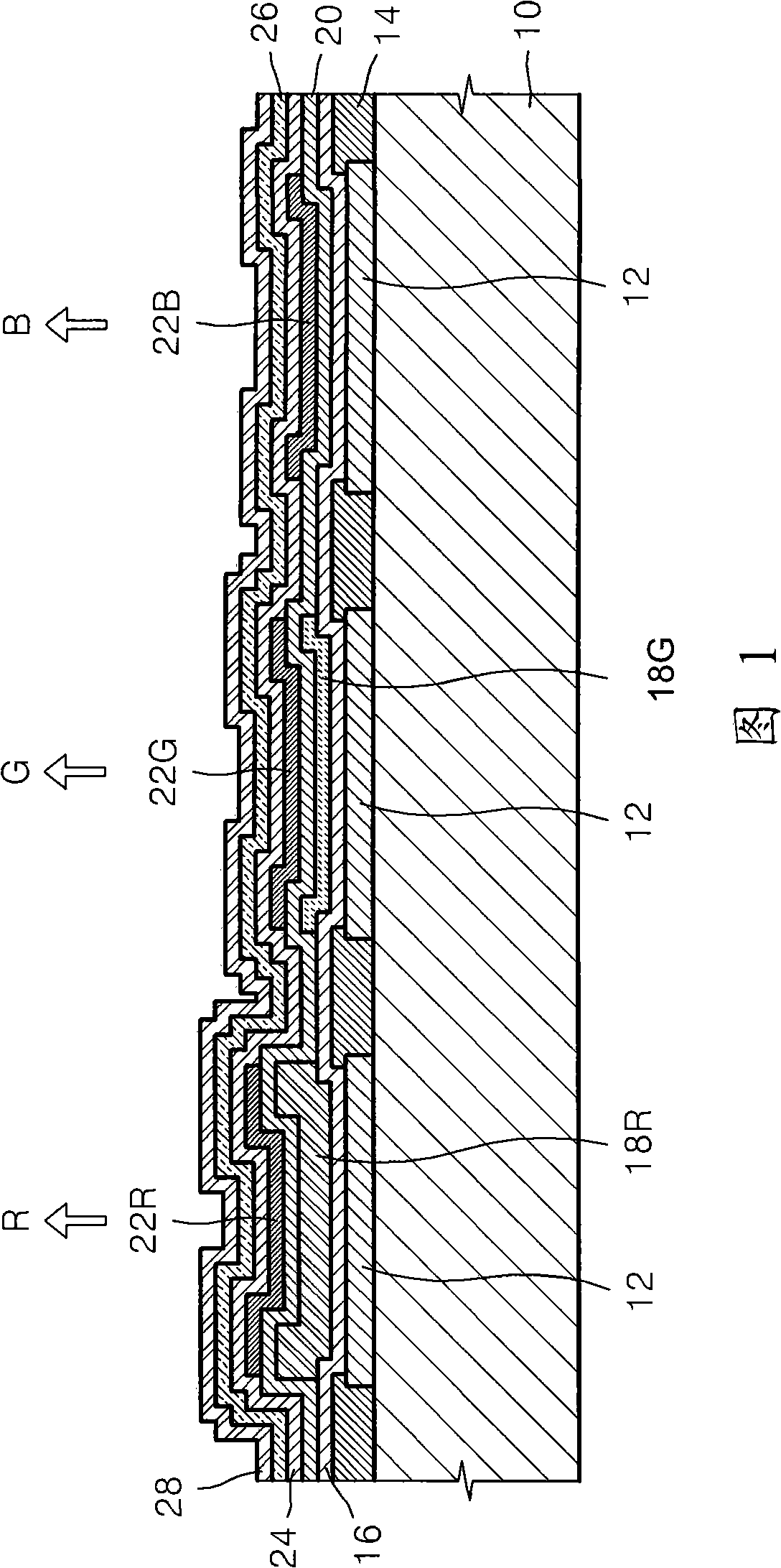

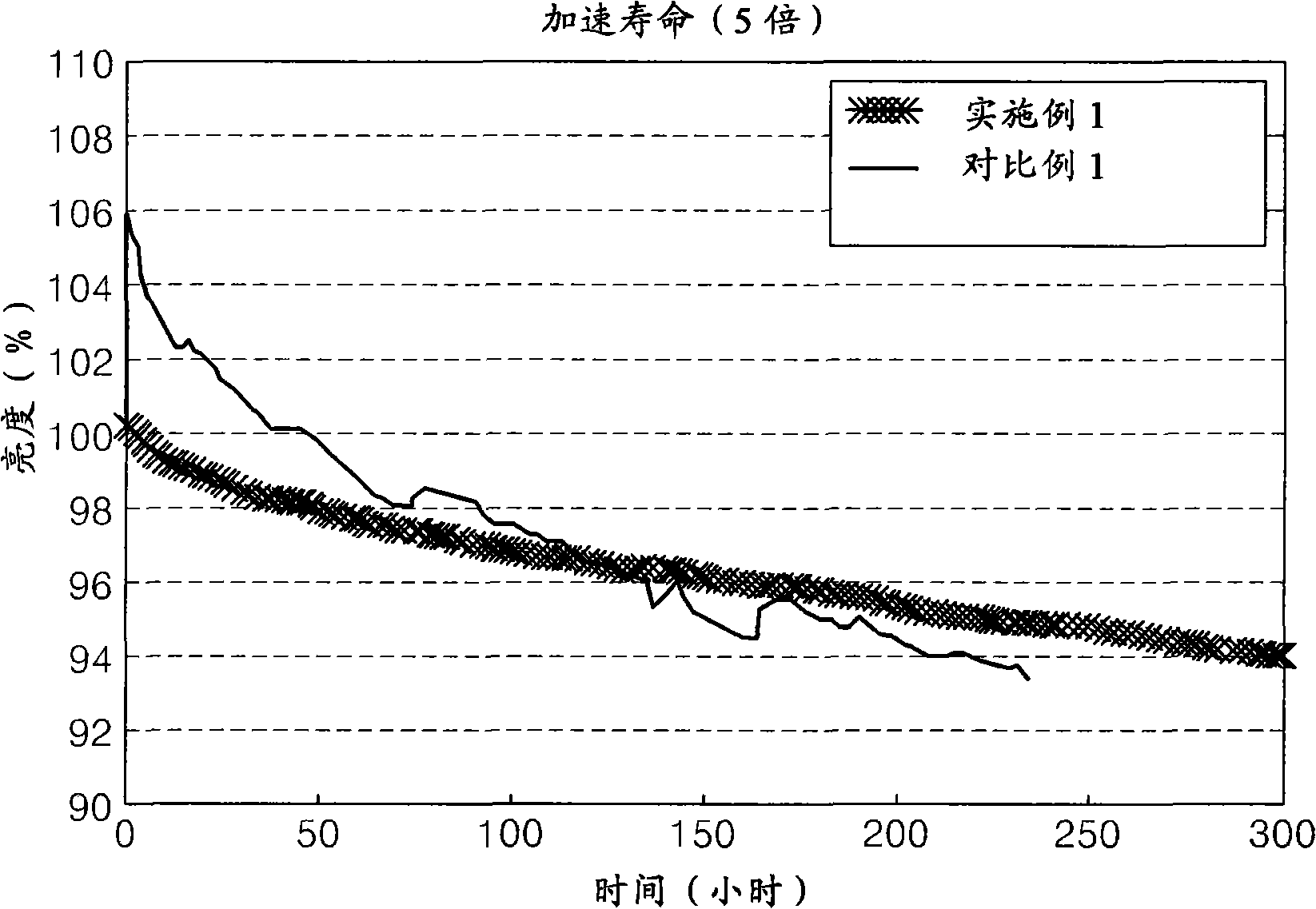

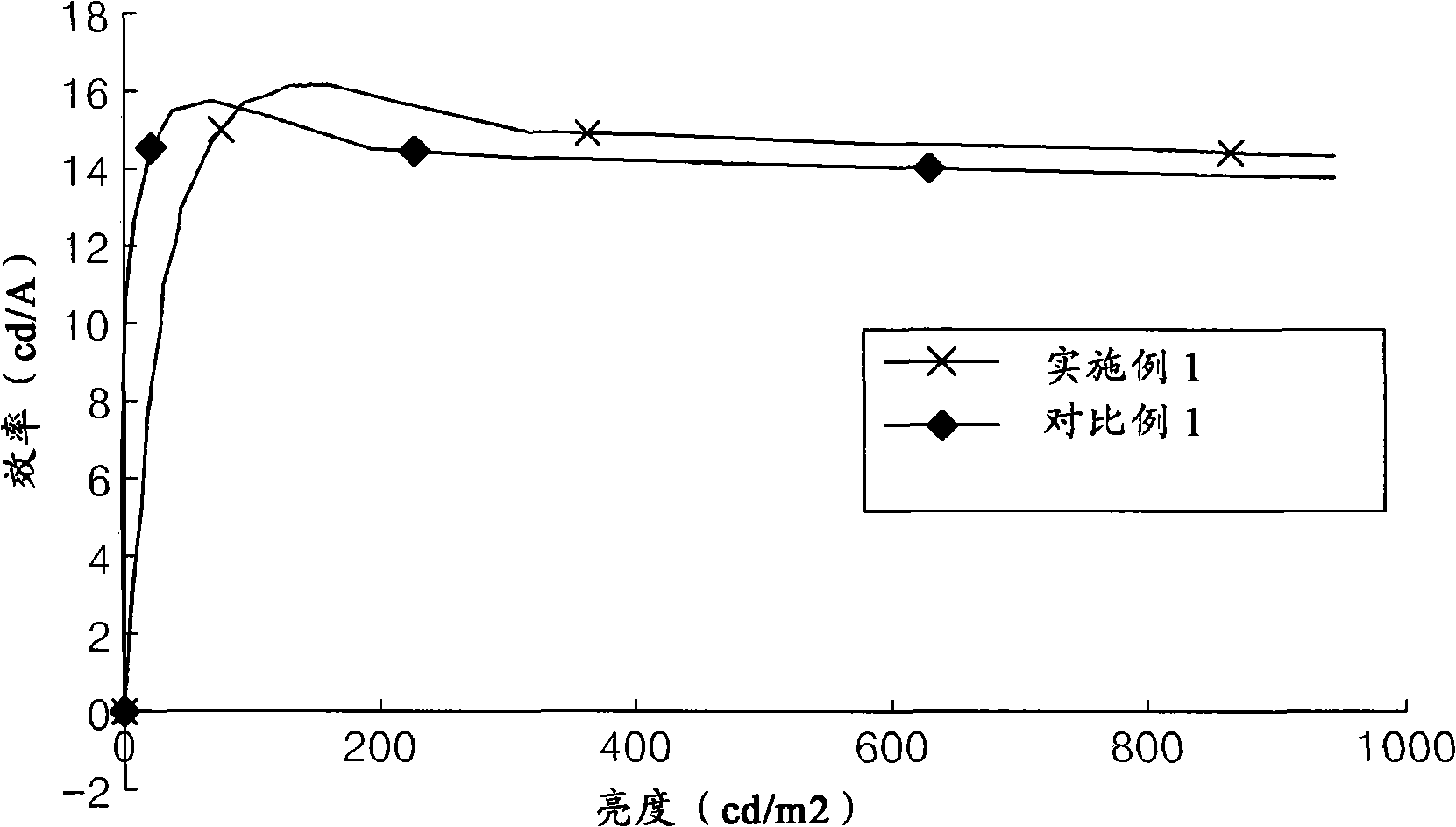

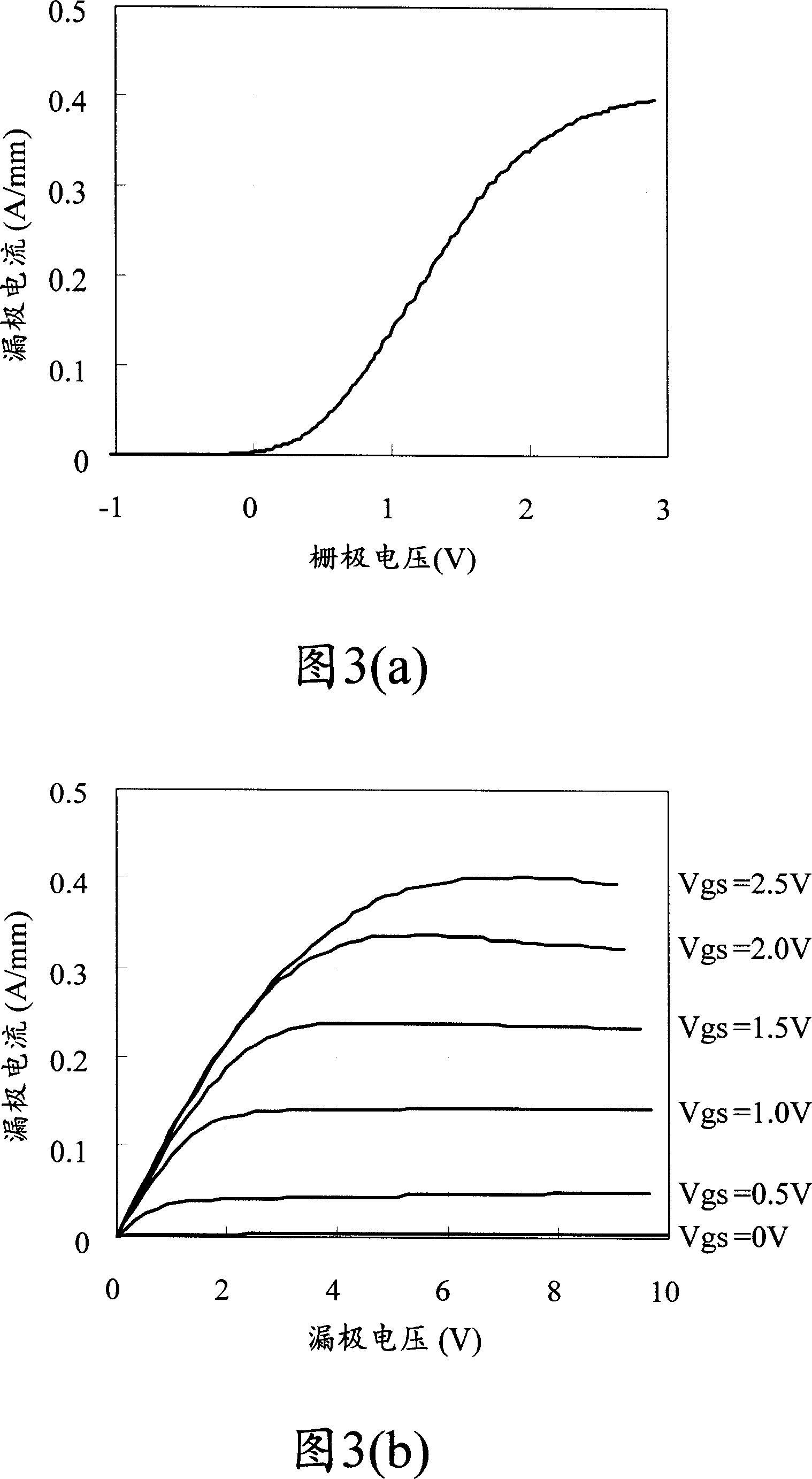

Organic light emitting device

ActiveCN101308863ALower turn-on voltageIncrease current densityElectroluminescent light sourcesSolid-state devicesHigh current densityOrganic layer

Organic light emitting devices (OLEDs) are provided. An exemplary OLED includes a substrate, a first electrode, a second electrode, and an organic layer between the first and second electrodes having a hole injection layer and an emissive layer. The emissive layer includes red, green and blue emissive layers. The organic layer further includes an auxiliary layer selected from a first auxiliary layer between the hole injection layer and the red emissive layer for adjusting the resonance cycle of red light, a second auxiliary layer between the hole injection layer and the green emissive layer for adjusting the resonance cycle of green light, and combinations thereof. The material of the auxiliary layer is different from the material of the hole injection layer. The organic light emitting device has low turn-on voltage, high current density, high luminance, high current efficiency, high power, long life-time, and excellent color purity.

Owner:SAMSUNG DISPLAY CO LTD

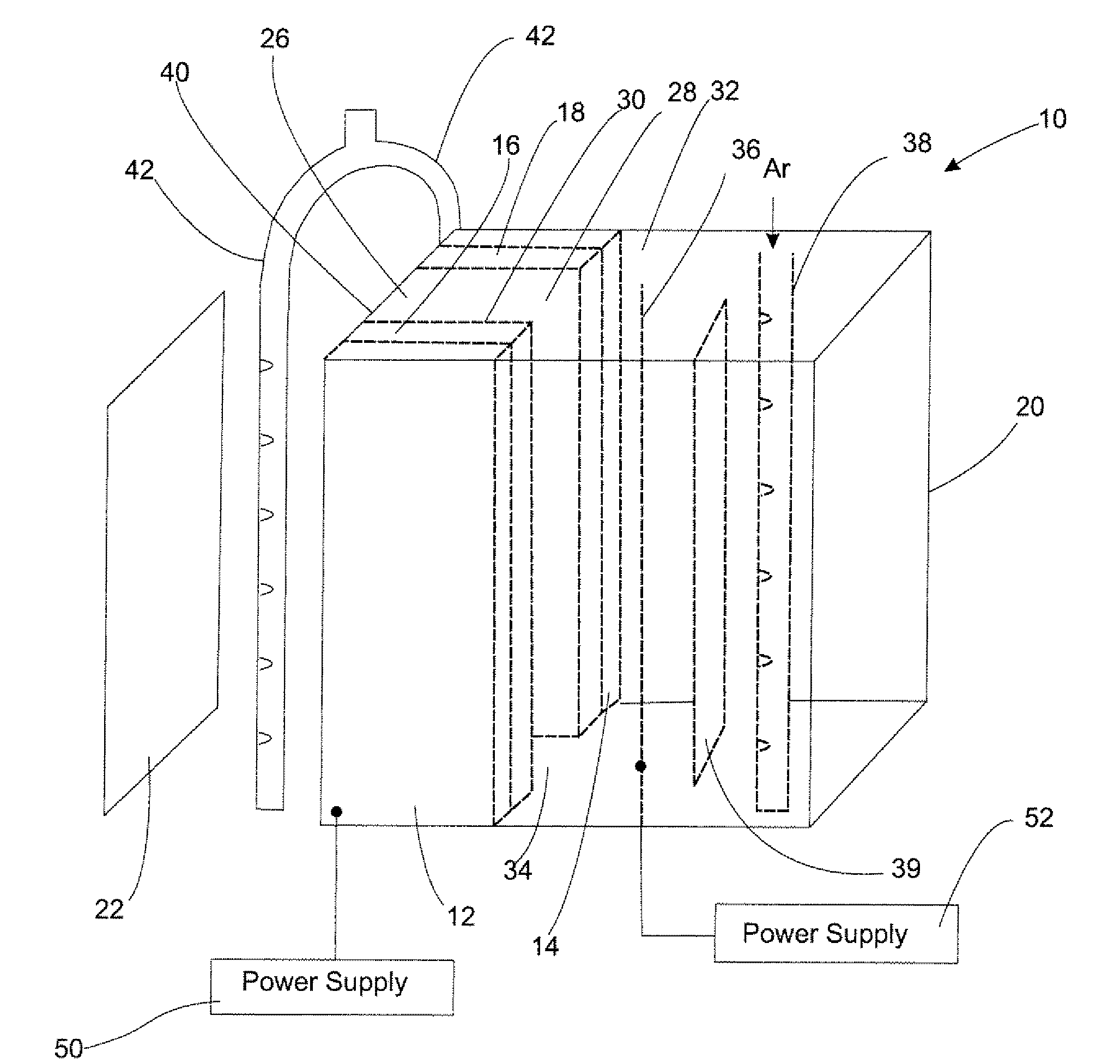

Sputtered transparent conductive films

InactiveUS20060118406A1Readily availableAvoid difficult choicesCellsVacuum evaporation coatingDopantSputtering

A hollow cathode sputtering apparatus and related method for introducing dopants into a sputtered coating is provided. The method utilizes a sputter reactor which includes a cathode channel that allows a gas stream to flow therein and a flow exit end from which gases may flow out of and towards a substrate to be coated. The cathode channel as used in the invention is defined by a channel defining surface that includes at least one target material. The sputter reactor further includes a dopant target positioned to provide dopant atoms to the gas stream when the gas stream is flowed through the cathode channel.

Owner:NEW MILLENNIUM SOLAR EQUIP CORP

Light emitting device package and lighting apparatus

ActiveUS10381519B2Increase current densityImproved current spreadingSemiconductor devicesLight equipmentInsulation layer

A light emitting device package, according to an embodiment, includes: a substrate; a light emitting structure that is disposed below the substrate and includes a first conductive type semiconductor layer, an active layer, and a second conductive type semiconductor layer; a first bonding pad connected with the first conductive type semiconductor layer while being embedded in a through-hole exposed the first conductive type semiconductor layer by passing through the active layer and the second conductive type semiconductor layer; a second bonding pad that is disposed below the second conductive type semiconductor layer while being spaced apart from the first bonding pad and is connected with the second conductive type semiconductor layer; a first insulation layer disposed on the lateral portion of the light emitting structure in the through-hole and on the lower inner edge of the light emitting structure; and a second insulation layer disposed between the first insulation layer and the first bonding pad in the through-hole.

Owner:SUZHOU LEKIN SEMICON CO LTD

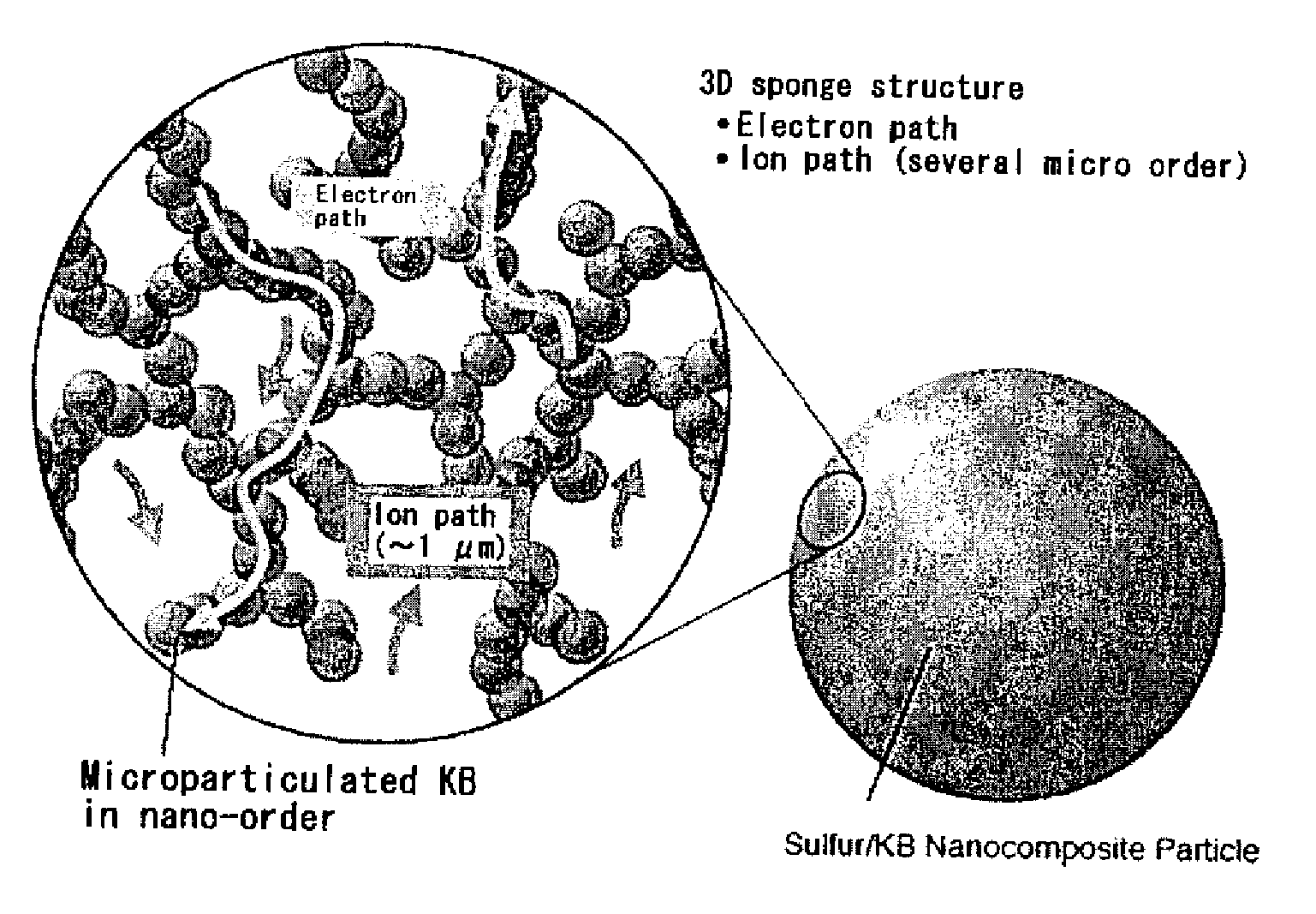

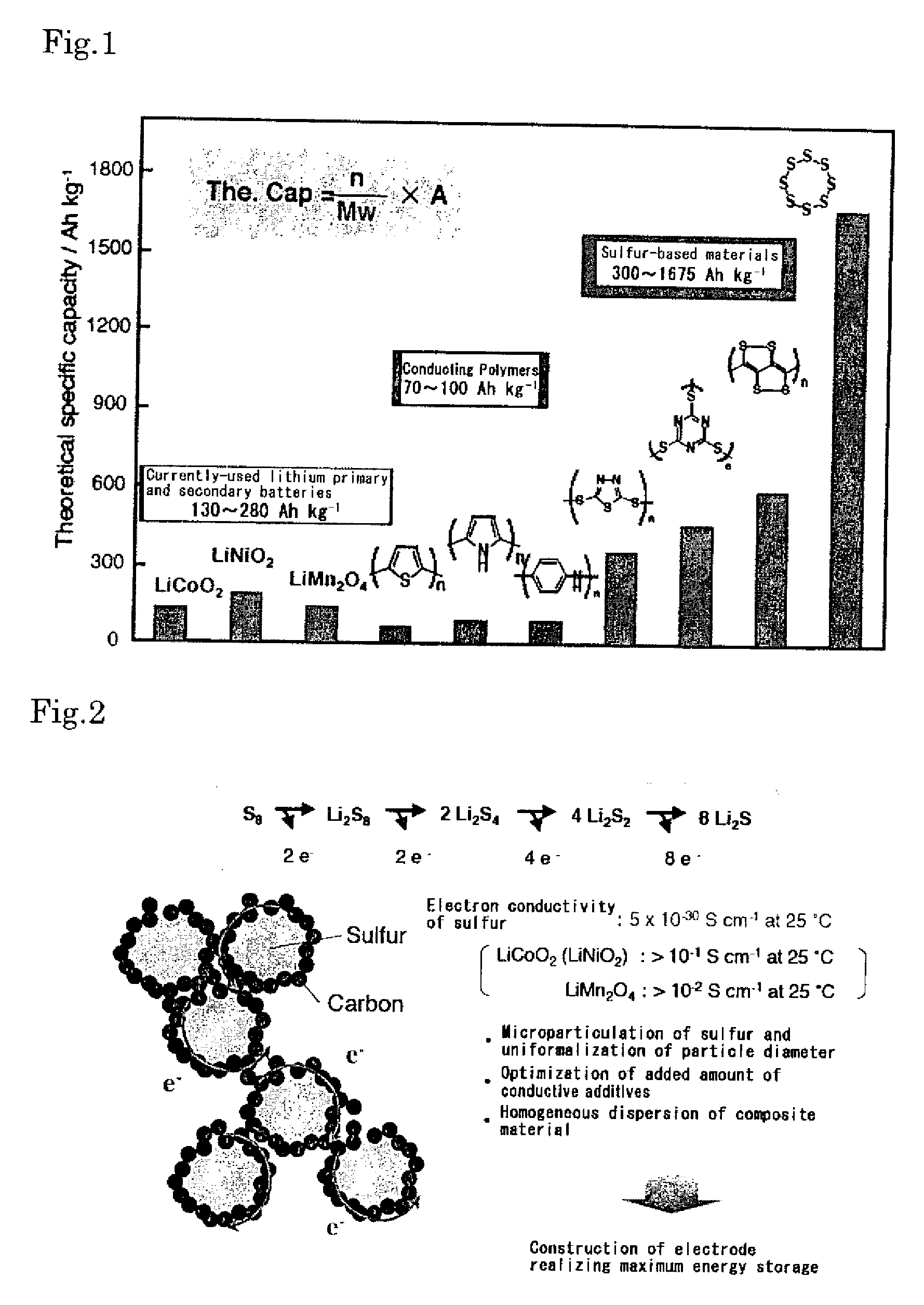

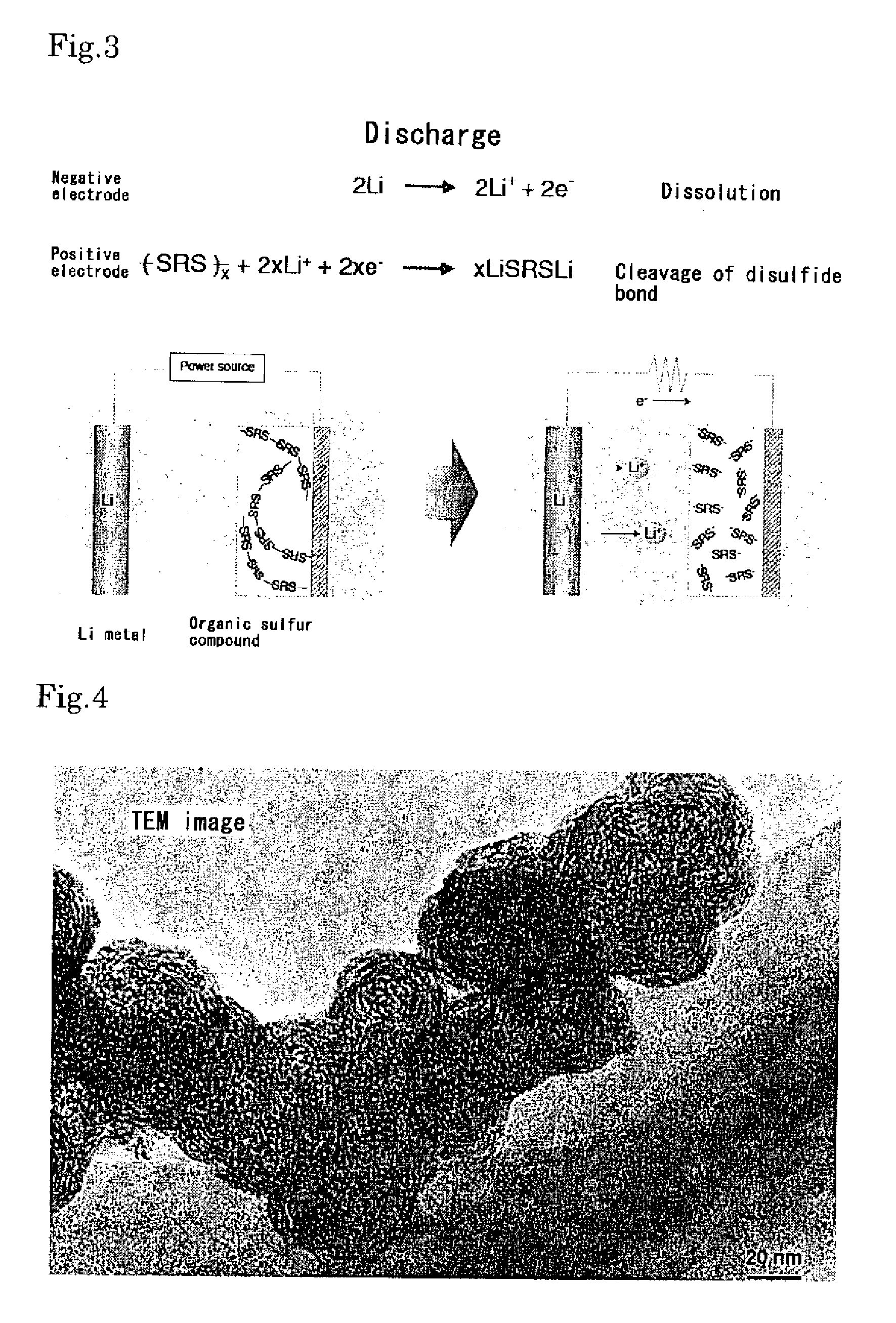

Battery Positive Electrode Material Containing Sulfur and /or Sulfur Compound having S-S Bond, and Process for Producing the Same

InactiveUS20070287060A1Increase densityHigh operating voltagePrimary cellsActive material electrodesHigh energyConductive materials

A positive electrode material that contains sulfur of high capacitance density as an active material without containing any large amount of conduction aid, namely, a positive electrode material for a battery of high energy density. There is provided a battery positive electrode material comprising a composite of conductive substance and sulfur and / or a sulfur compound having S—S bond, wherein there is disposed a composite microparticle layer having microparticles of conductive material cut into particles of sulfur and / or a sulfur compound having S—S bond. Further, there is provided a process for producing a battery positive electrode material, comprising conducting mechanofusion between particles of sulfur and / or above-mentioned sulfur compound as a raw material and microparticles of conductive material so as to obtain a composite material having a composite microparticle layer wherein the above microparticles are cut into the above particles.

Owner:AOI ELECTRONICS CO LTD +1

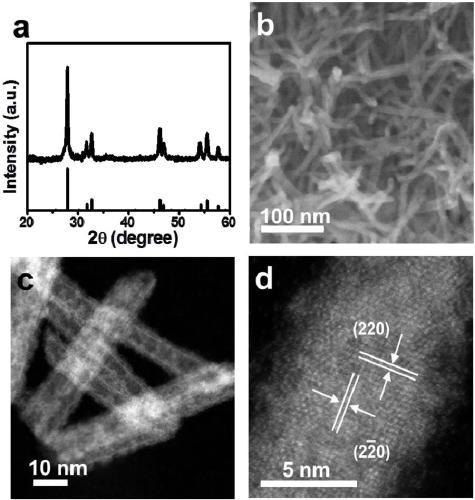

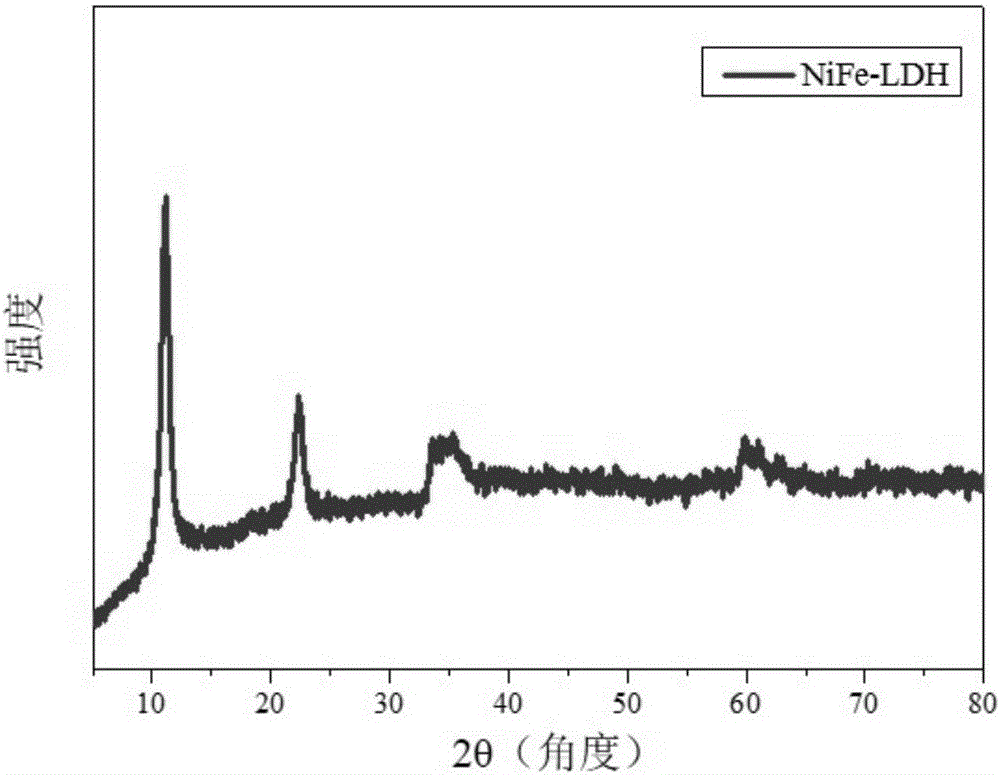

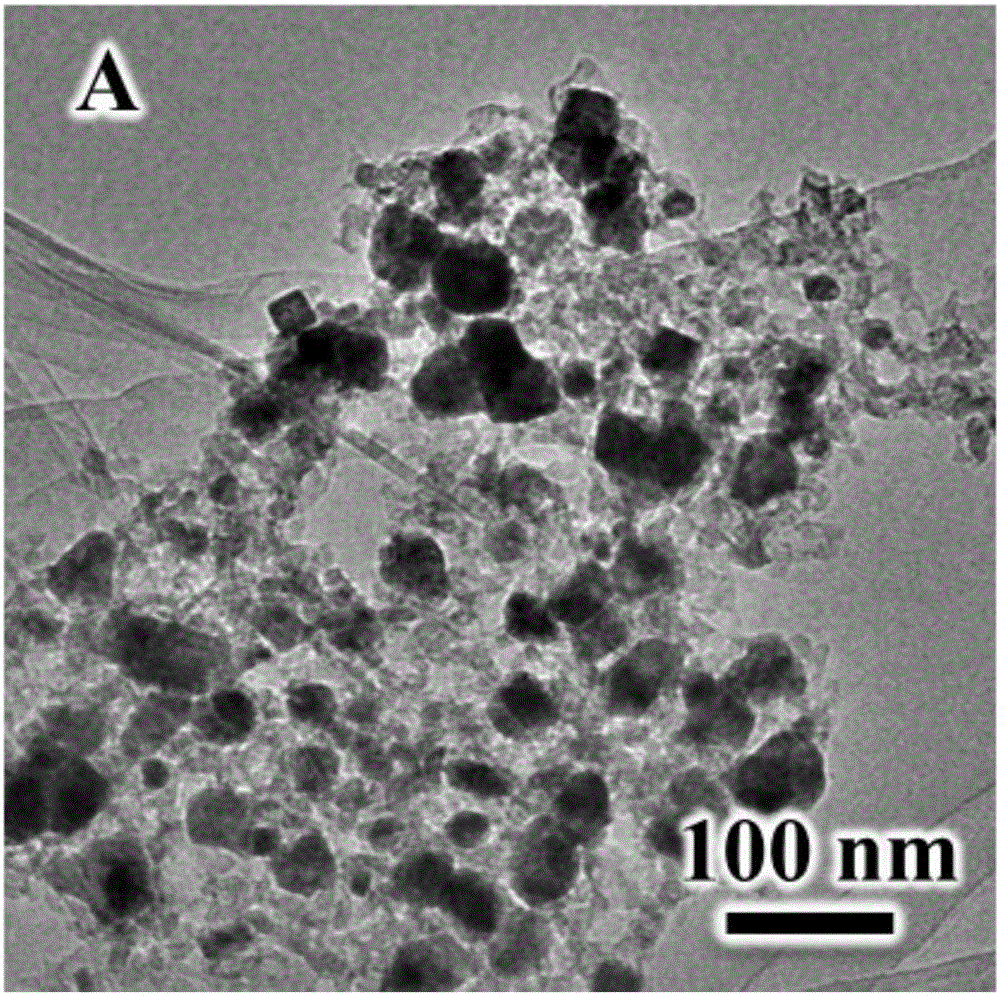

High-performance ultrathin nitride electro-catalyst with functions of producing hydrogen and oxygen by means of electrochemically totally decomposing water, method for synthesizing high-performance ultrathin nitride electro-catalyst and application thereof

ActiveCN105148971AIncrease current densityLower overpotentialMaterial nanotechnologyPhysical/chemical process catalystsDecompositionSynthesis methods

The invention discloses a high-performance ultrathin nitride electro-catalyst with functions of producing hydrogen and oxygen by means of electrochemically totally decomposing water, a method for synthesizing the high-performance ultrathin nitrite electro-catalyst and application thereof. A chemical formula of the high-performance ultrathin nitride electro-catalyst is (Fe<X>Ni<1-X>)<4>N, and the x is larger than 0 and is smaller than 1. The nitrite electro-catalyst is of an ultrathin nanometer plate structure, the size of the nitrite electro-catalyst is 50-100nm, and the thickness of the nitrite electro-catalyst is 1.5-3nm. The method includes synthesizing NiFe hydrotalcite precursors at first; nitriding the NiFe hydrotalcite precursors at high temperatures under the protection of ammonia gas to obtain end products. The high-performance ultrathin nitride electro-catalyst, the method and the application have the advantages that series of nitrite have large specific surface areas, are good in electron conductance and are excellent in performance during electro-catalytic water total-decomposition reaction, limiting currents are higher than limiting currents of Pt / C during electro-catalytic hydrogen evolution reaction (HER), and the performance of the nitride in various aspects are superior to the performance of corresponding oxide NiFe-MMO during oxygen evolution reaction (OER); the electro-catalyst is low in cost, easy and convenient to operate, simple in process and excellent in catalytic performance, and fundamental application research on materials in the field of electro-catalysis can be provided.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

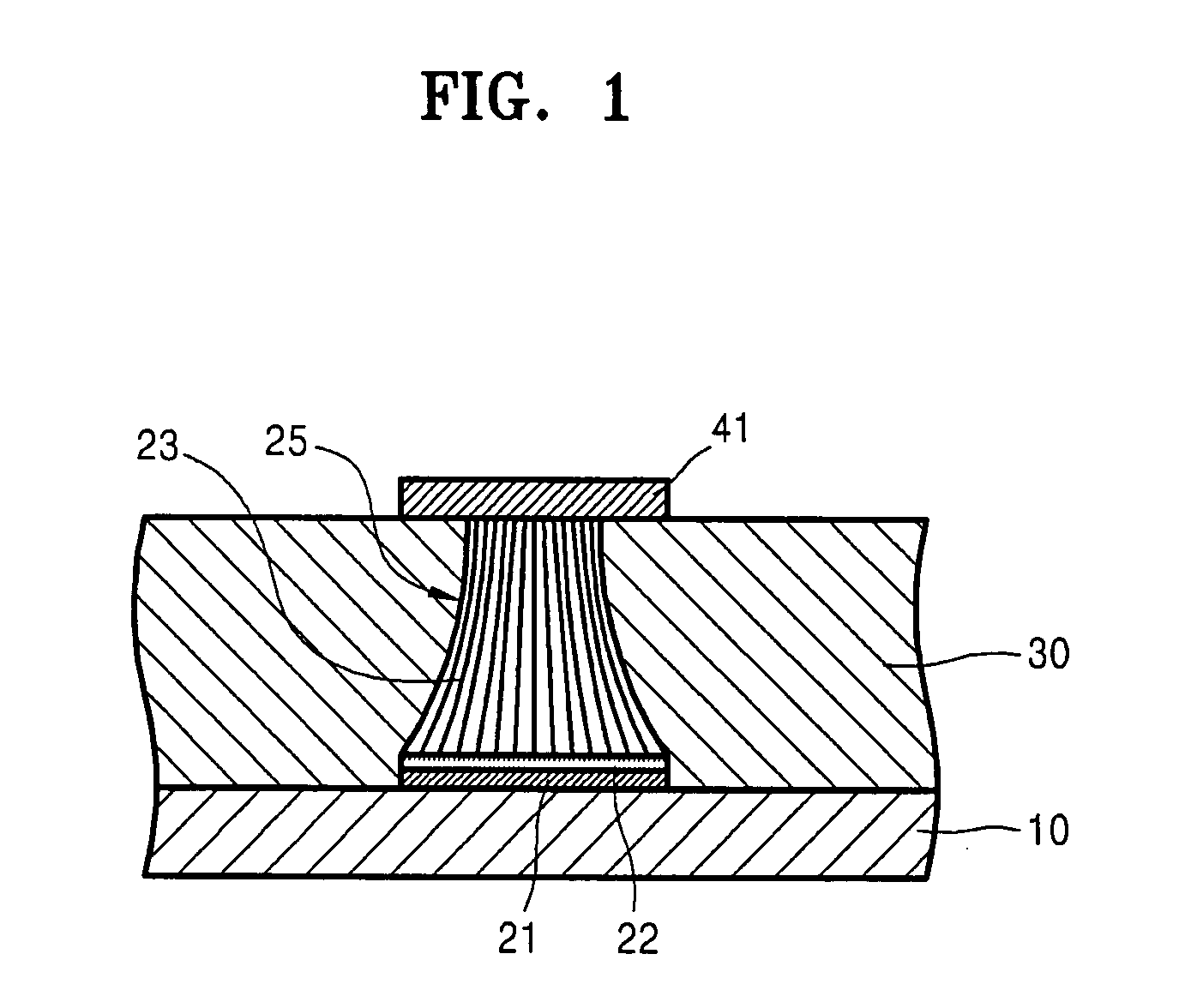

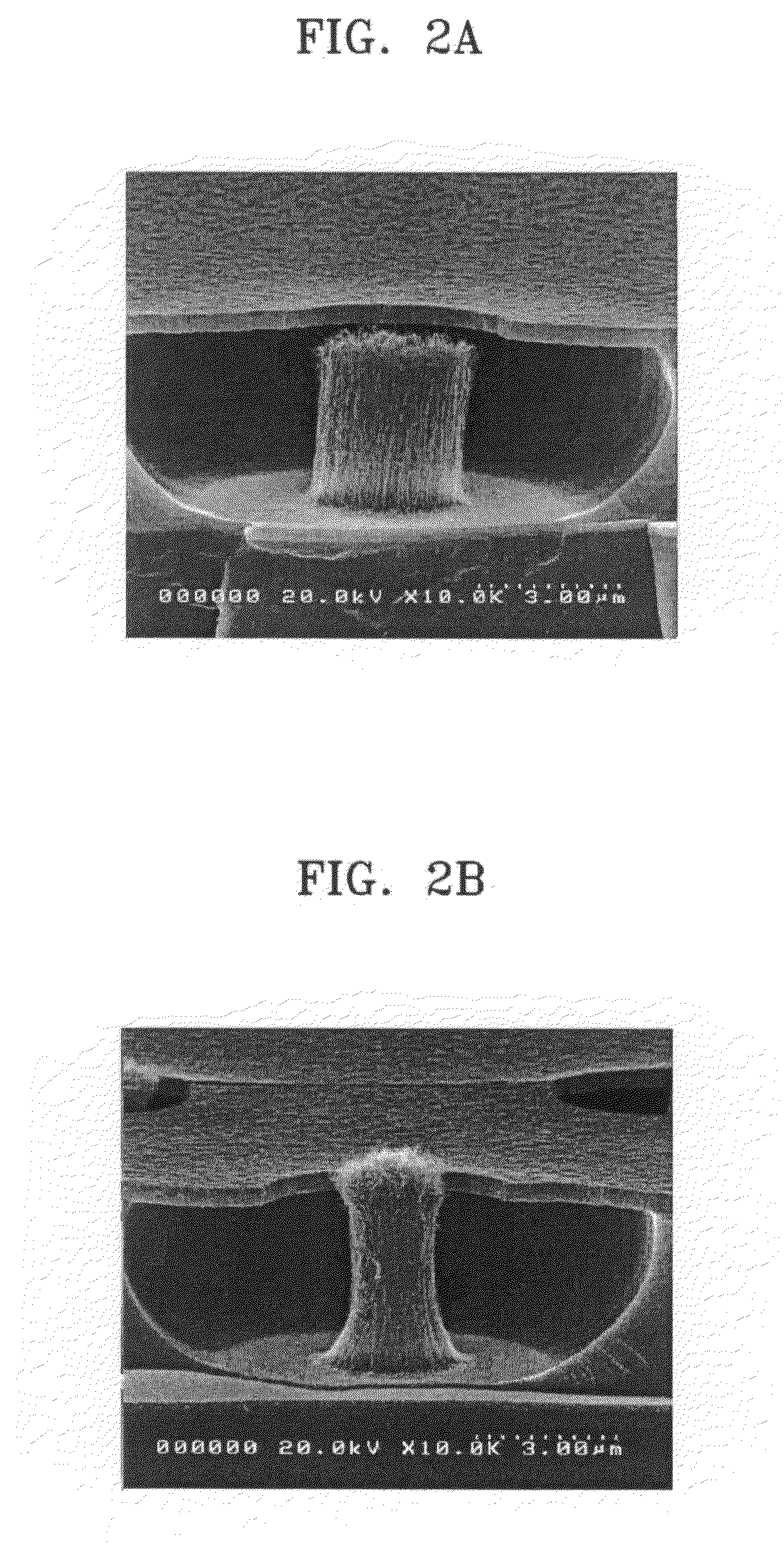

Interlayer wiring of semiconductor device using carbon nanotube and method of manufacturing the same

InactiveUS20080211101A1Lower resistanceIncrease current densityMaterial nanotechnologySemiconductor/solid-state device detailsDielectricHigh density

Provided is an interlayer wiring structure of a semiconductor device using carbon nanotubes, and a method of manufacturing the interlayer wiring structure. The interlayer wiring structure is a carbon nanotube bundle that connects a first electrode to a second electrode. The carbon nanotube bundle includes a plurality of carbon nanotubes grown from a catalyst layer that is formed on a first electrode. The carbon nanotube bundle is made in a manner that a portion of the carbon nanotube bundle close to the second electrode has higher density of carbon nanotubes than another portion of the carbon nanotube bundle close to the first electrode. The carbon nanotube bundle is surrounded by an interlayer dielectric. In one embodiment of a method of manufacturing the carbon nanotube interlayer wire, liquid droplets are distributed between the carbon nanotubes to induce surface tension between the carbon nanotubes. The surface tension makes the carbon nanotube bundle maintain higher density of carbon nanotubes in a portion close to the second electrode.

Owner:SAMSUNG SDI CO LTD

Method and apparatus for uniform electropolishing of damascene IC structures by selective agitation

InactiveUS7531079B1Small apertureSufficiently porousElectrolysis componentsSemiconductor/solid-state device manufacturingBiomedical engineeringLarge range

The present invention pertains to apparatus and methods for planarization of metal surfaces having both recessed and raised features, over a large range of feature sizes. The invention accomplishes this by increasing the fluid agitation in raised regions with respect to recessed regions. That is, the agitation of the electropolishing bath fluid is agitated or exchanged as a function of elevation on the metal film profile. The higher the elevation, the greater the movement or exchange rate of bath fluid. In preferred methods of the invention, this agitation is achieved through the use of a microporous electropolishing pad that moves over (either near or in contact with) the surface of the wafer during the electropolishing process. Thus, methods of the invention are electropolishing methods, which in some cases include mechanical polishing elements.

Owner:NOVELLUS SYSTEMS

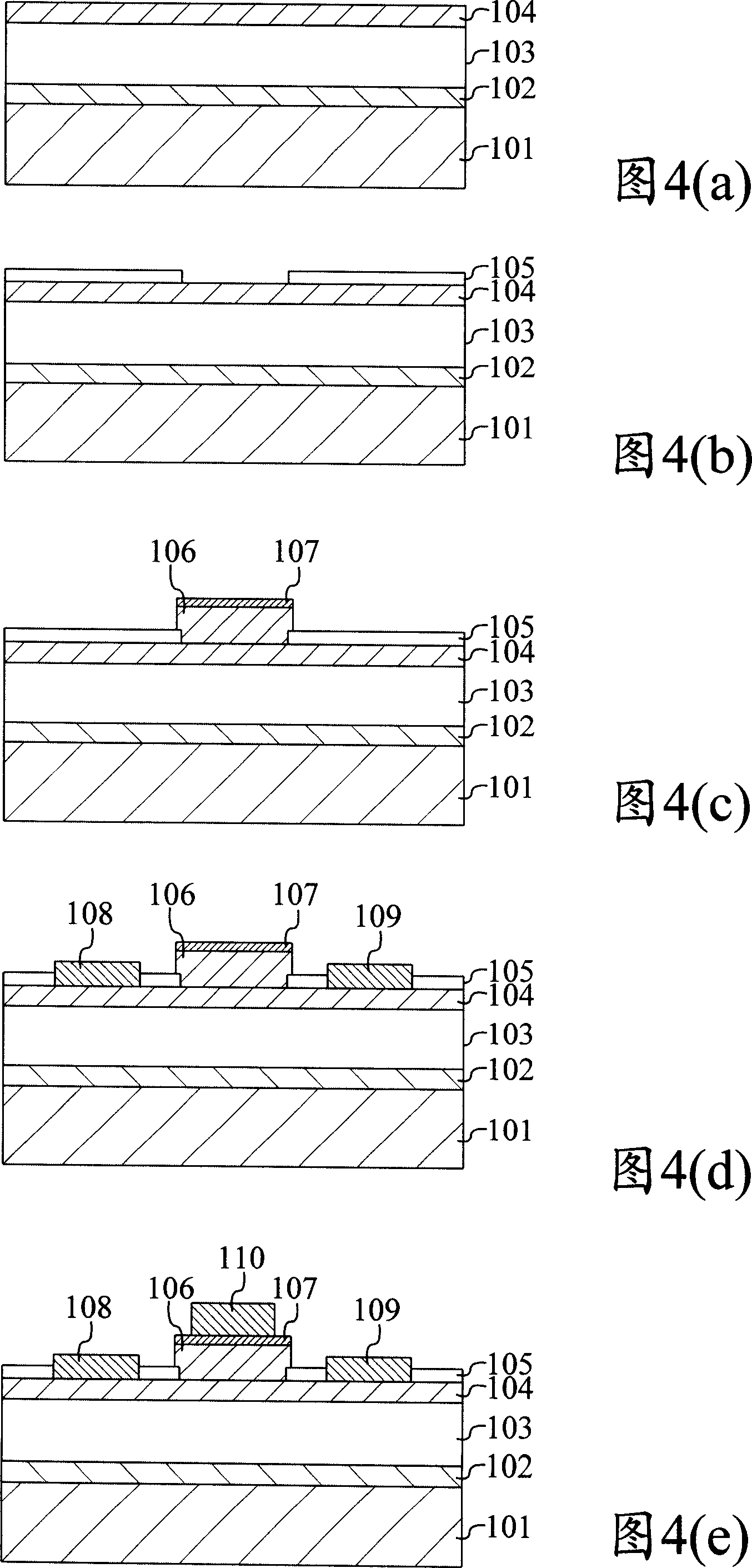

Nitride semiconductor device and method for manufacturing same

InactiveCN101022128ASuppression of thickness deviationIncrease current densitySemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationGallium nitride

Owner:PANASONIC CORP

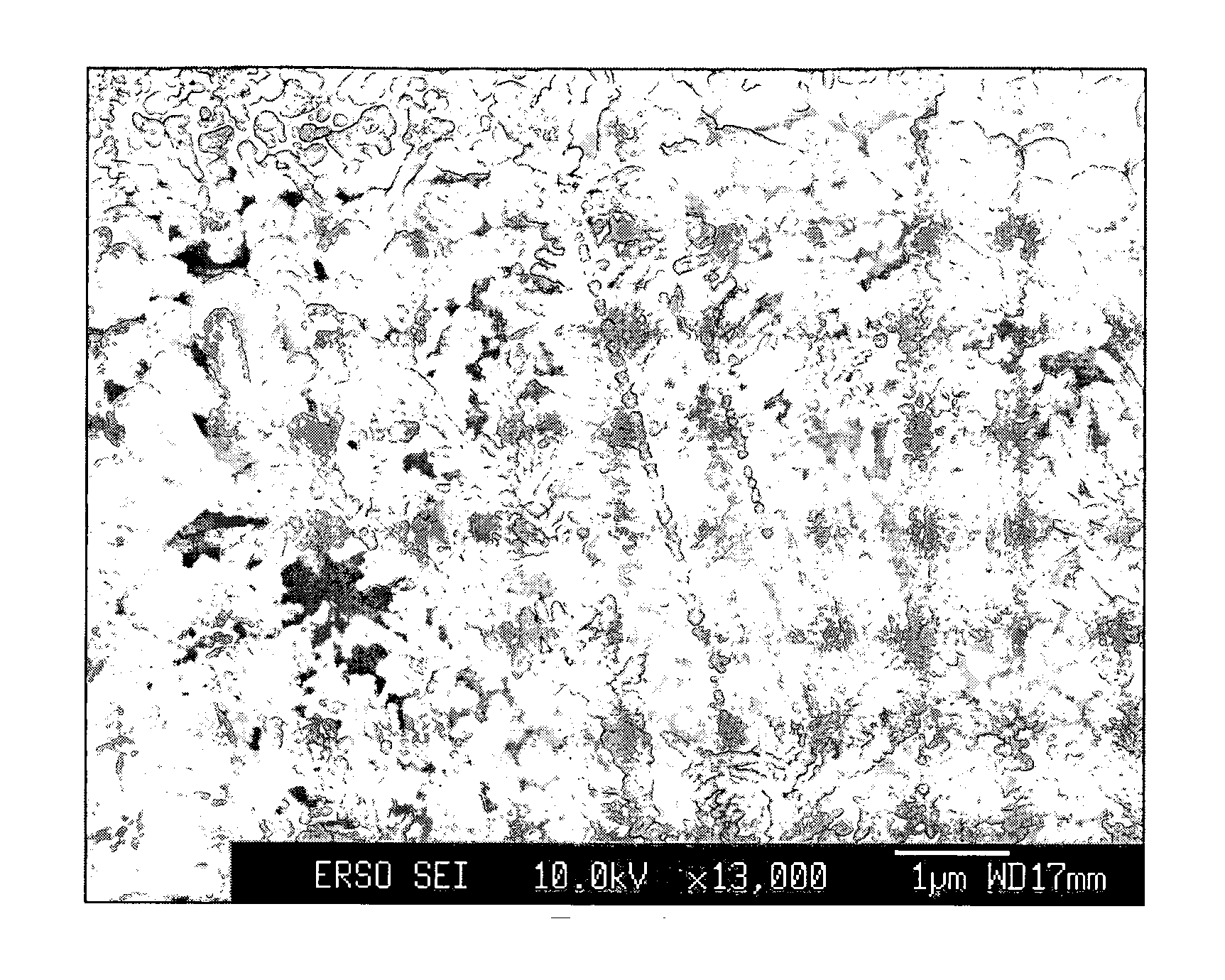

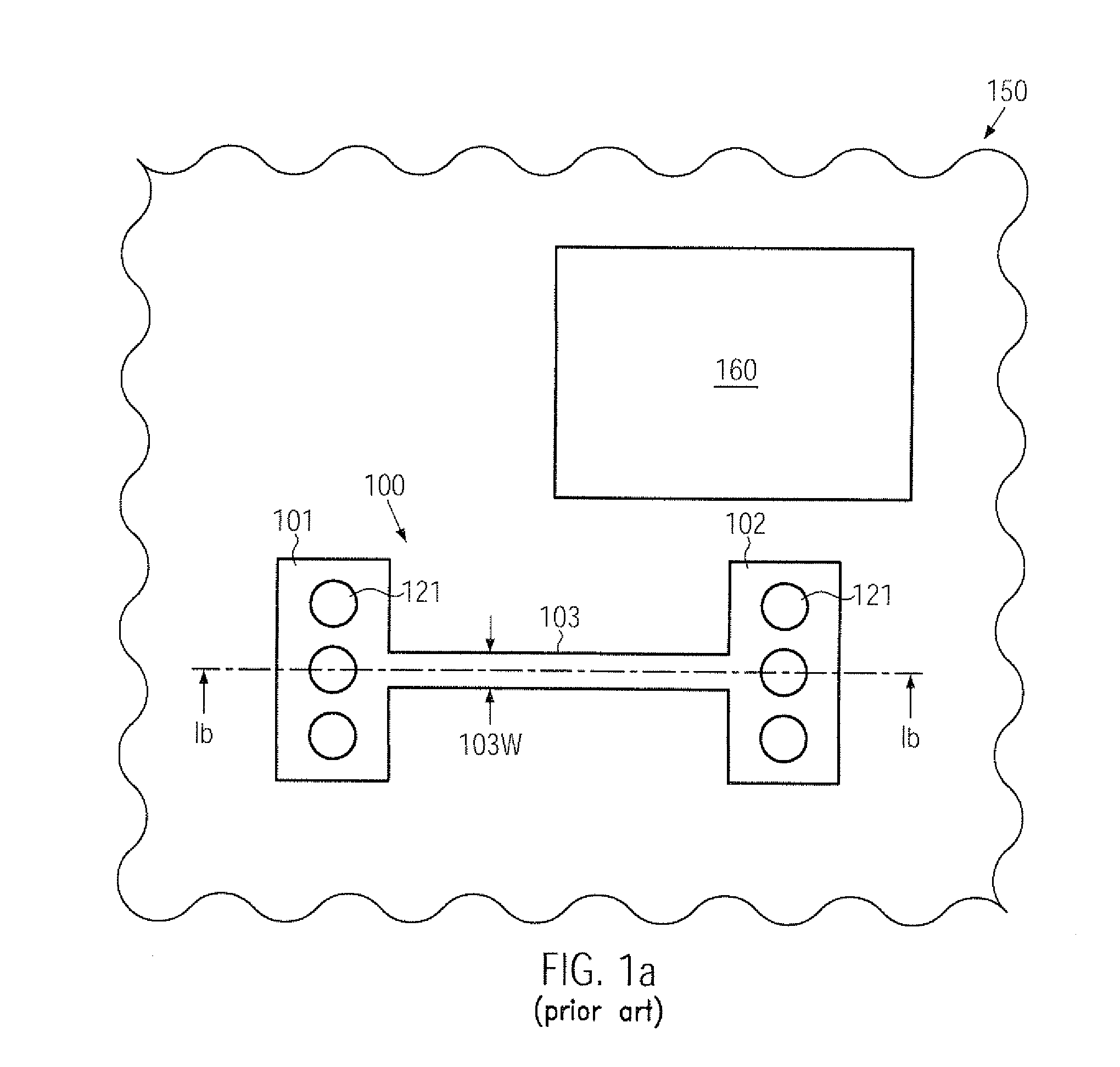

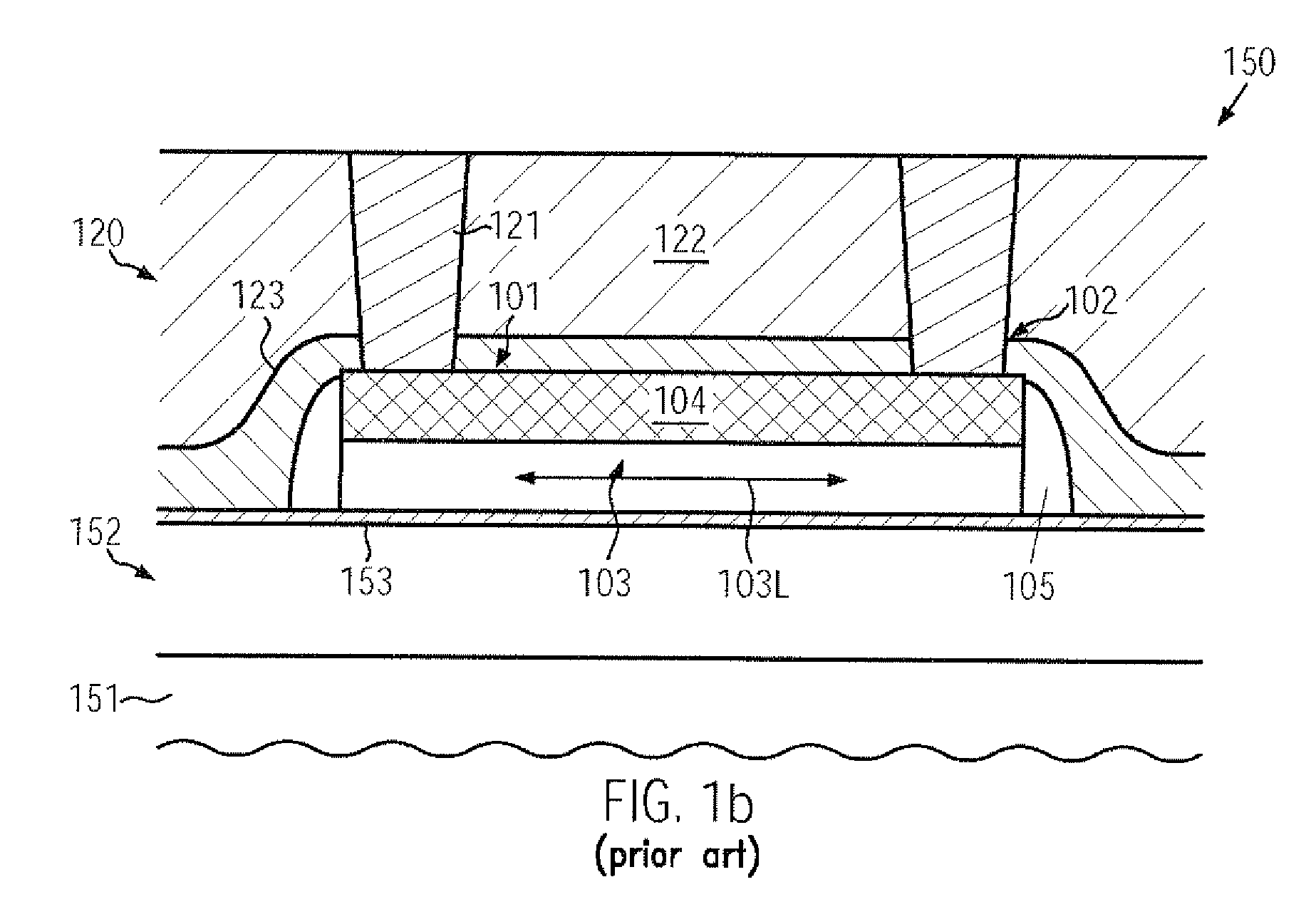

SEMICONDUCTOR DEVICE COMPRISING eFUSES OF ENHANCED PROGRAMMING EFFICIENCY

ActiveUS20100107403A1Increase current densityImprove toleranceFuse device manufactureSemiconductor/solid-state device detailsLinear configurationSemiconductor

In sophisticated integrated circuits, an electronic fuse may be formed such that an increased sensitivity to electromigration may be accomplished by including at least one region of increased current density. This may be accomplished by forming a corresponding fuse region as a non-linear configuration, wherein at corresponding connection portions of linear segments, the desired enhanced current crowding may occur during the application of the programming voltage. Hence, increased reliability and more space-efficient layout of the electronic fuses may be accomplished.

Owner:GLOBALFOUNDRIES US INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com