Patents

Literature

5569 results about "Gallium nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

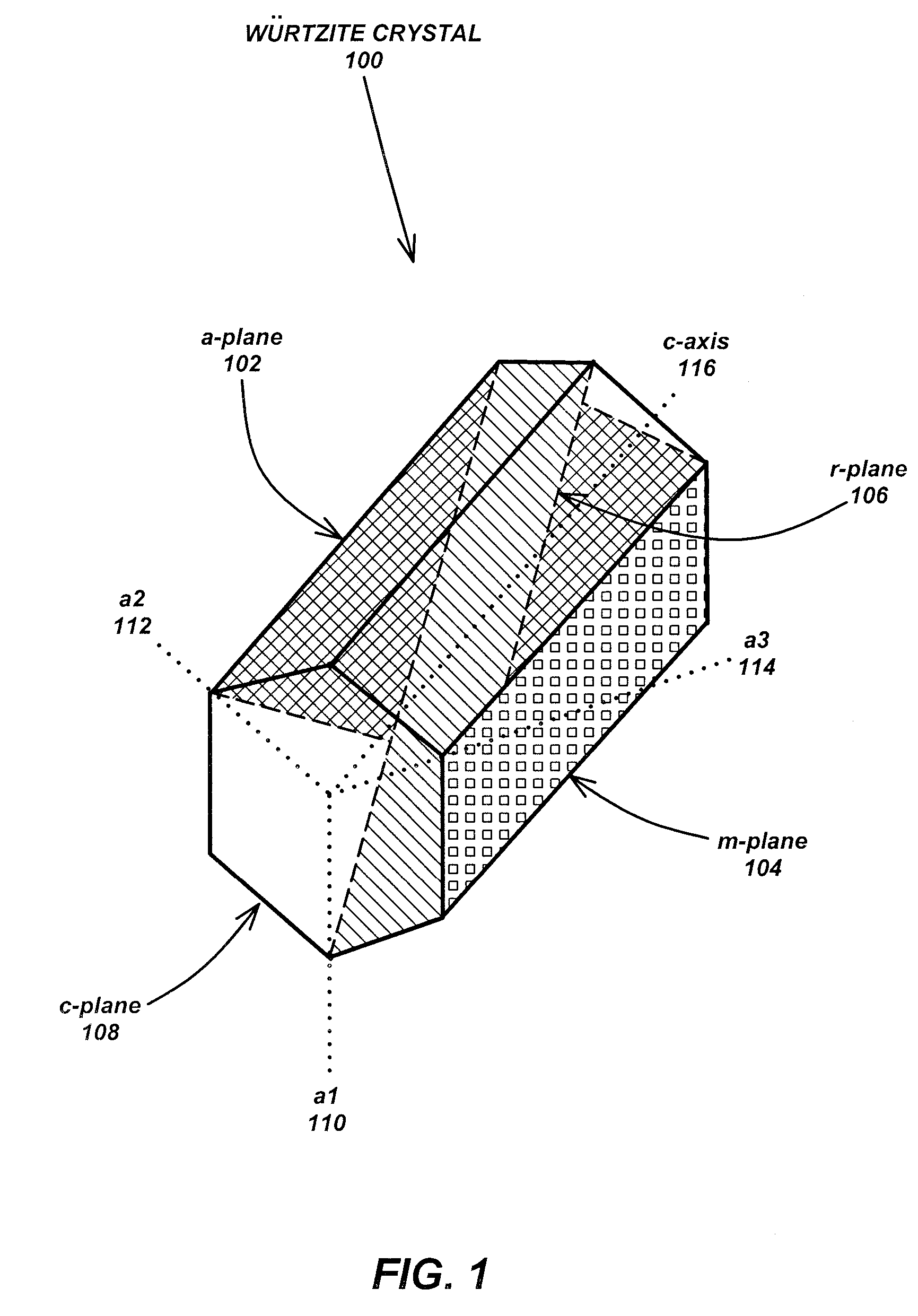

Gallium nitride (GaN) is a binary III/V direct bandgap semiconductor commonly used in light-emitting diodes since the 1990s. The compound is a very hard material that has a Wurtzite crystal structure. Its wide band gap of 3.4 eV affords it special properties for applications in optoelectronic, high-power and high-frequency devices. For example, GaN is the substrate which makes violet (405 nm) laser diodes possible, without use of nonlinear optical frequency-doubling.

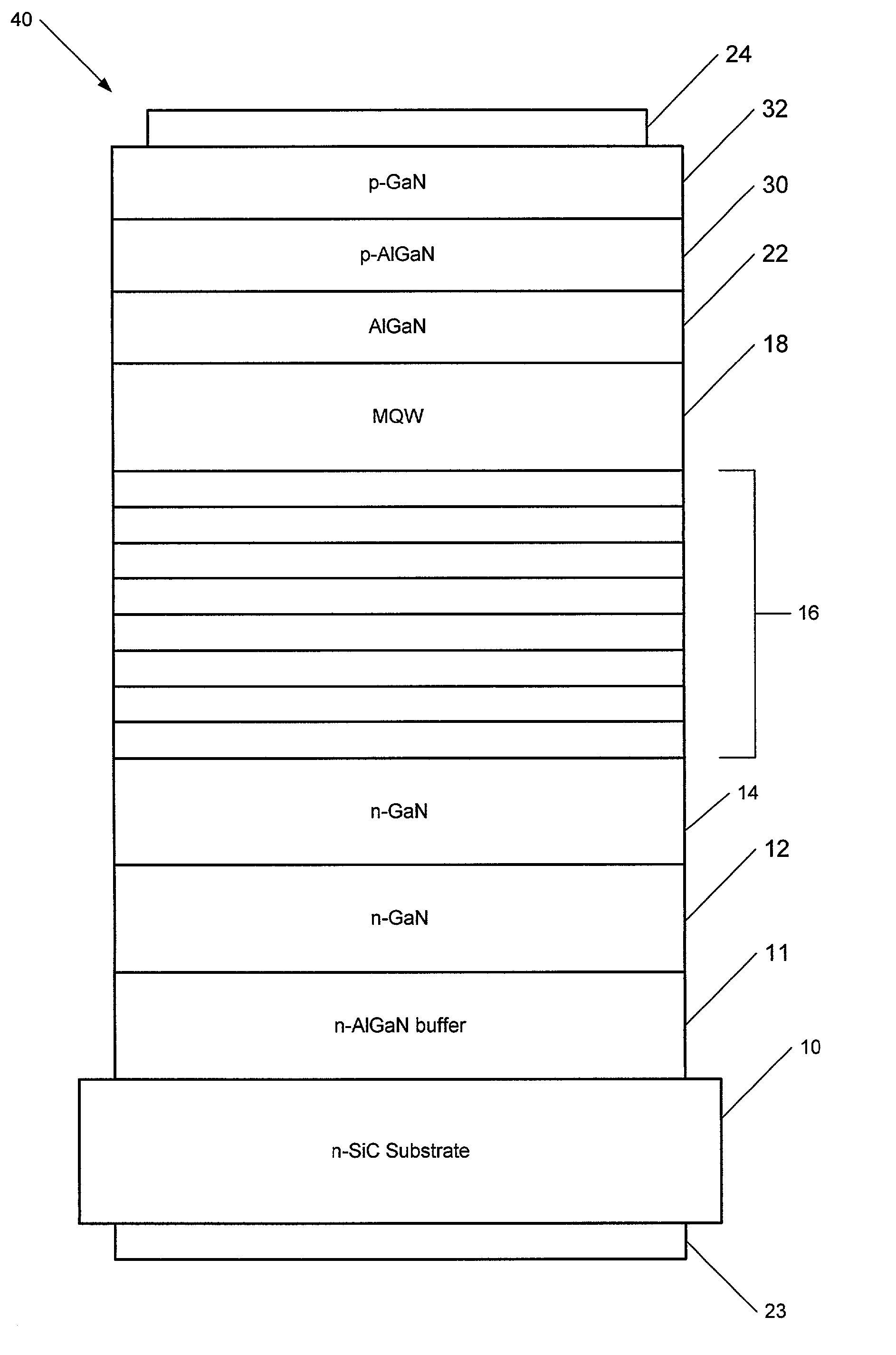

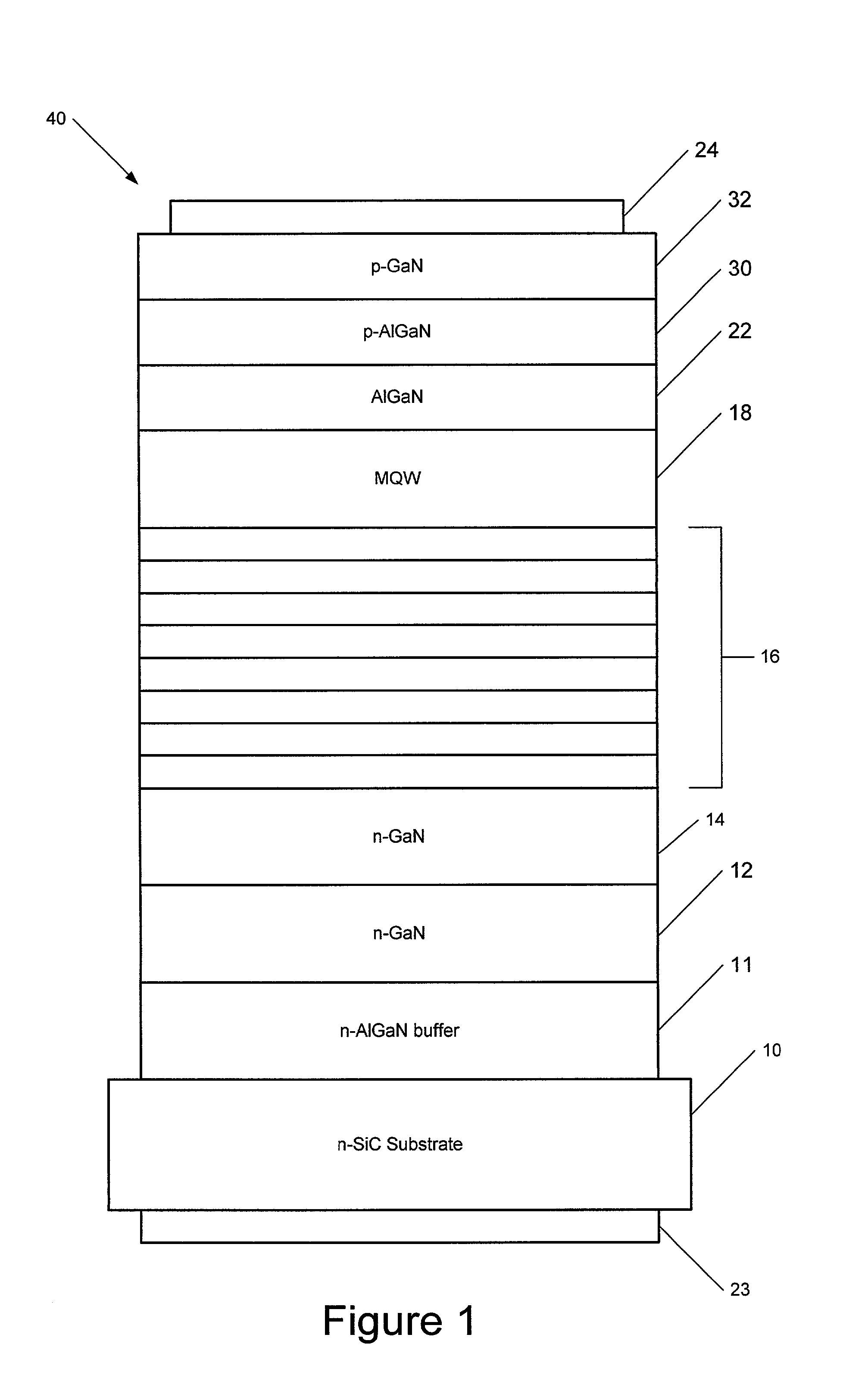

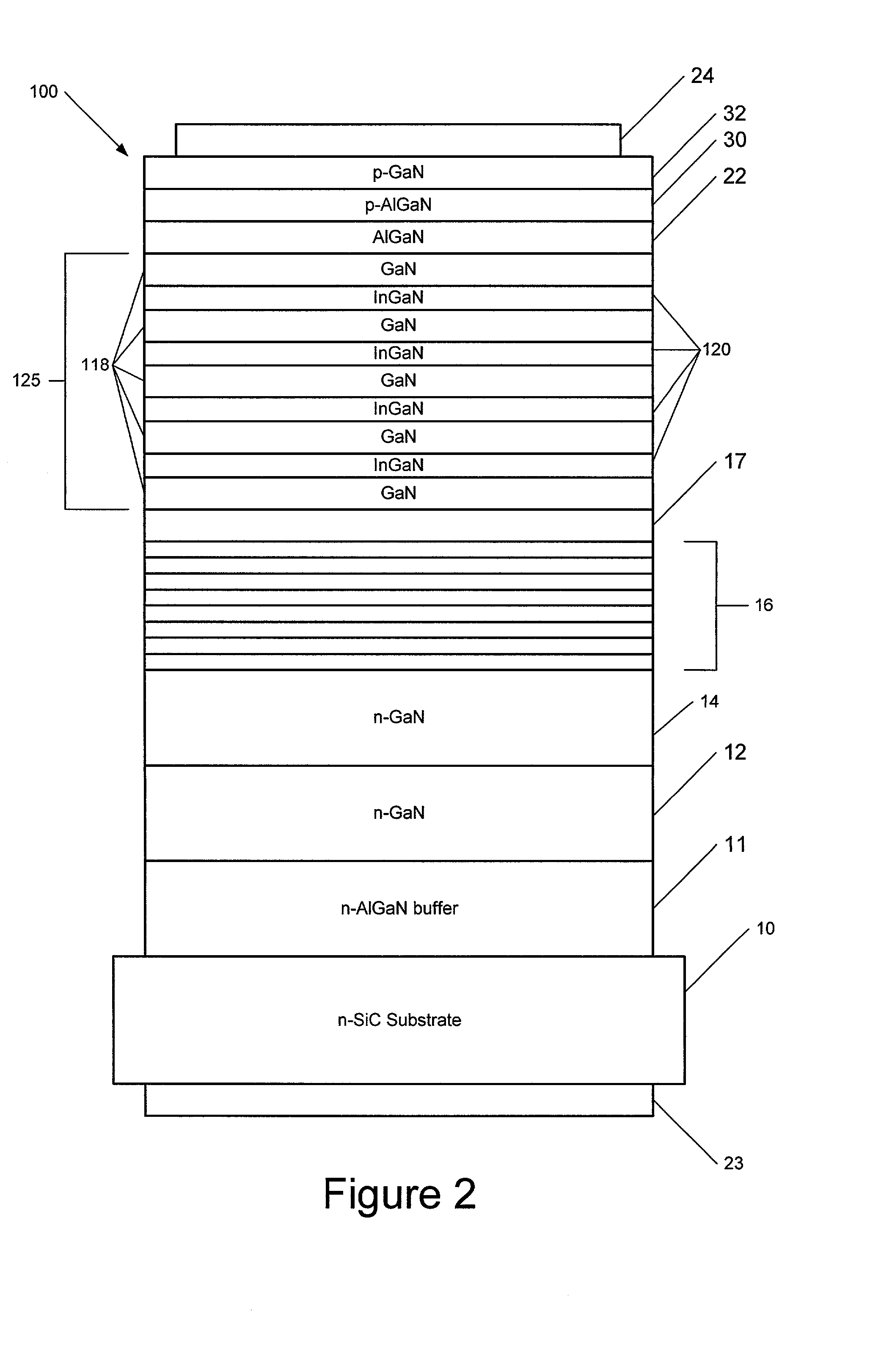

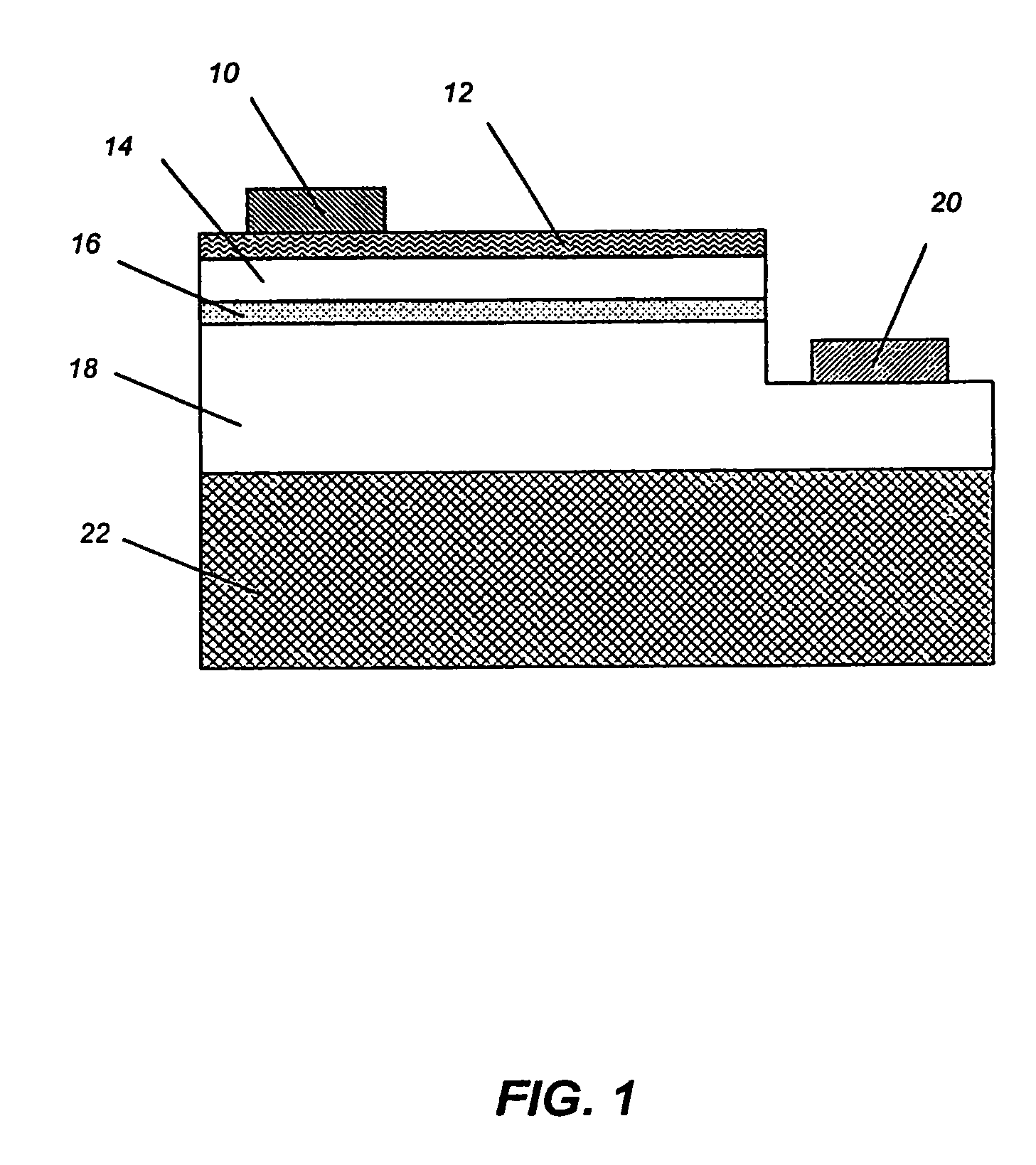

Group III nitride photonic devices on silicon carbide substrates with conductive buffer interlay structure

InactiveUS6201262B1Avoid crackingEasy to manufactureSemiconductor/solid-state device manufacturingSemiconductor devicesStress inducedStress relieving

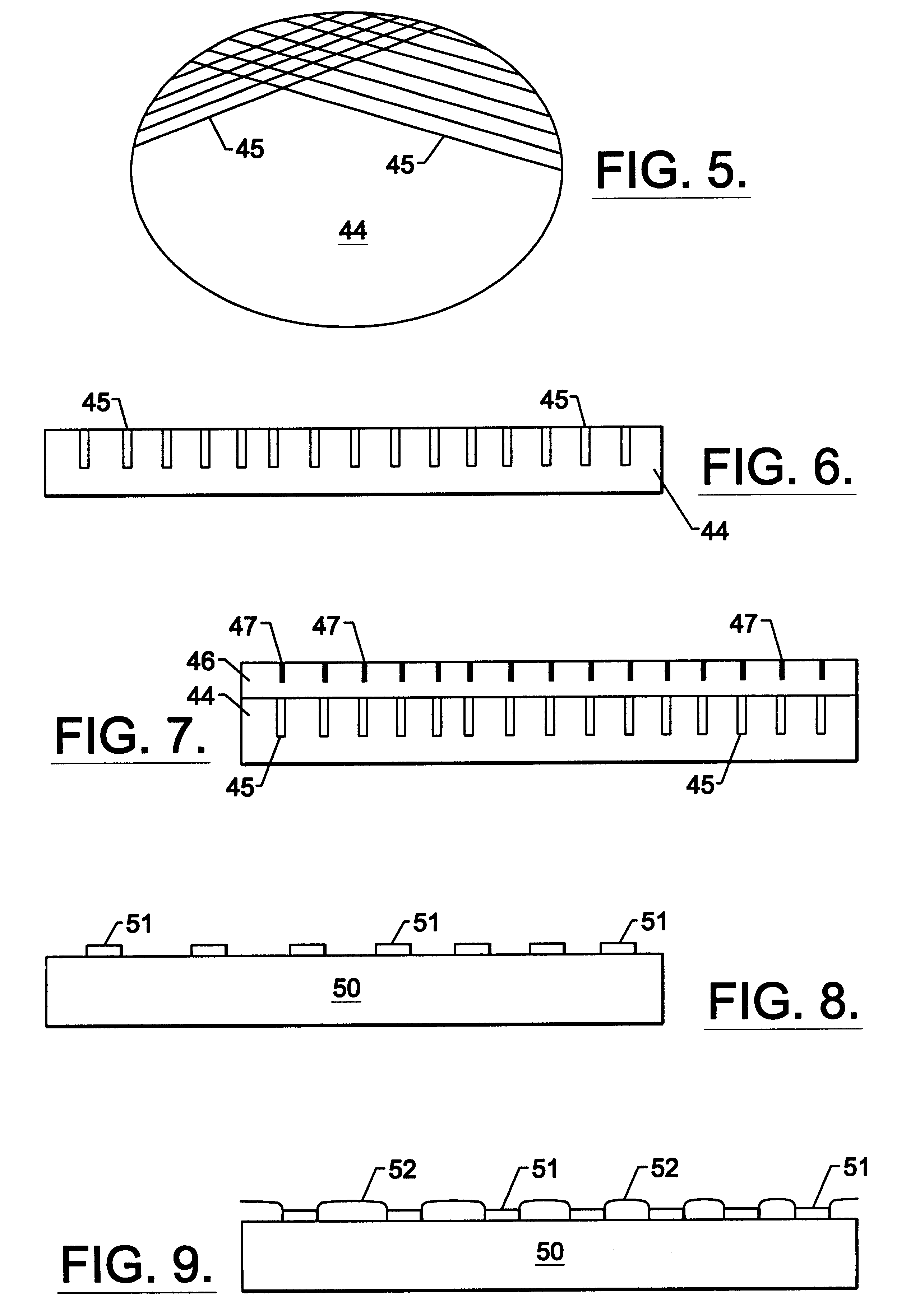

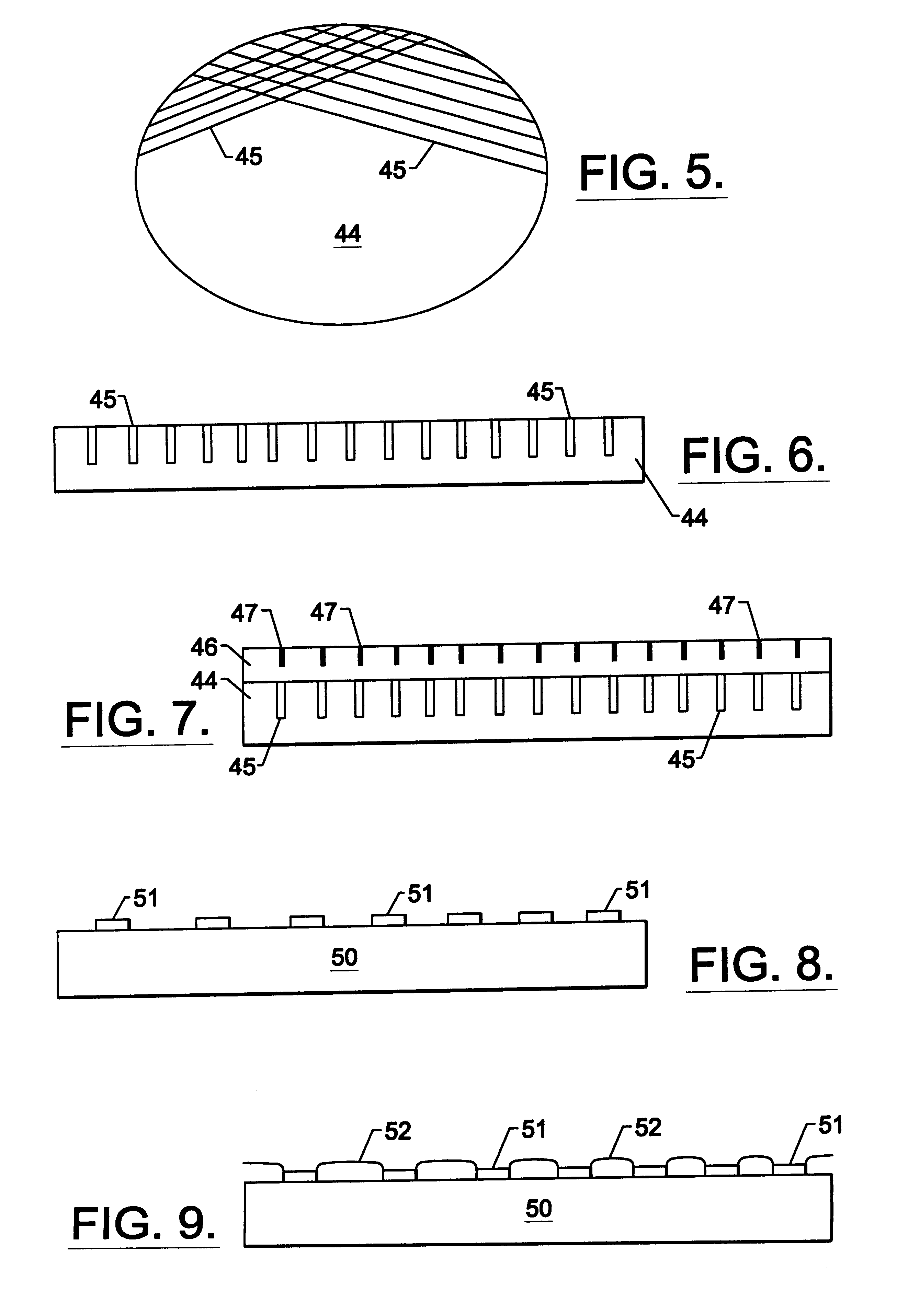

An optoelectronic device with a Group III Nitride active layer is disclosed that comprises a silicon carbide substrate; an optoelectronic diode with a Group III nitride active layer; a buffer structure selected from the group consisting of gallium nitride and indium gallium nitride between the silicon carbide substrate and the optoelectronic diode; and a stress-absorbing structure comprising a plurality of predetermined stress-relieving areas within the crystal structure of the buffer structure, so that stress-induced cracking that occurs in the buffer structure occurs at predetermined areas rather than elsewhere in the buffer structure.

Owner:CREE INC

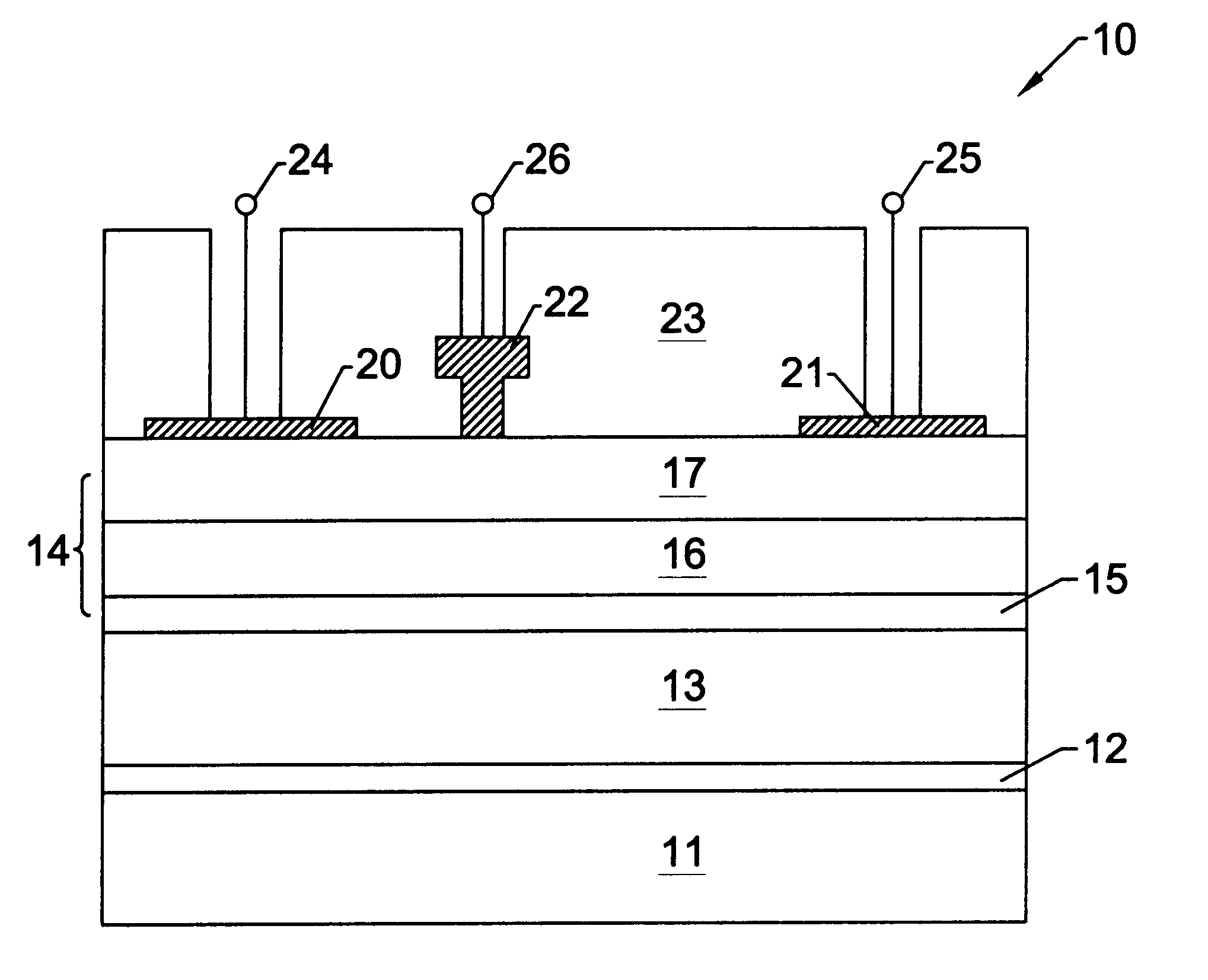

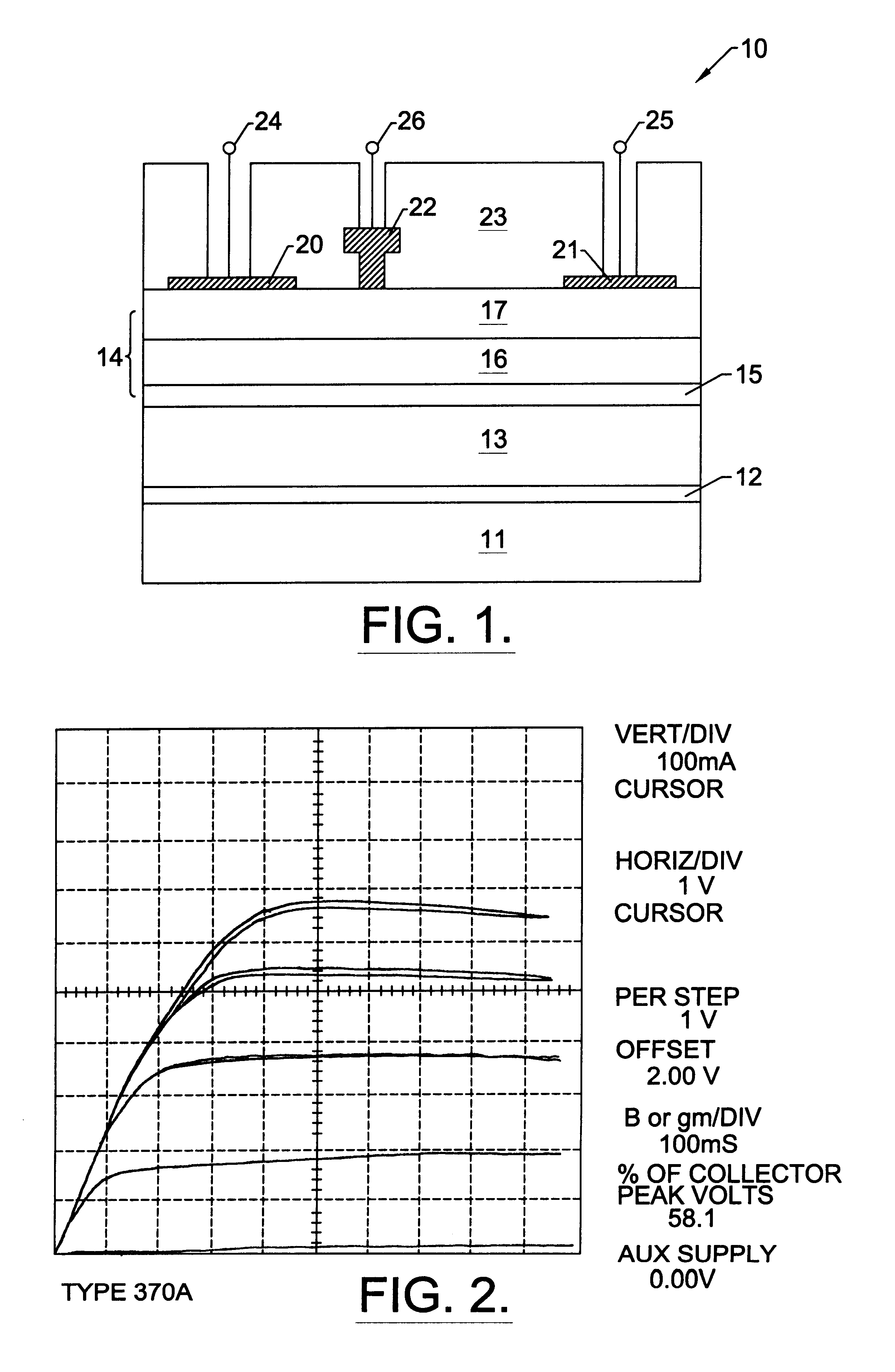

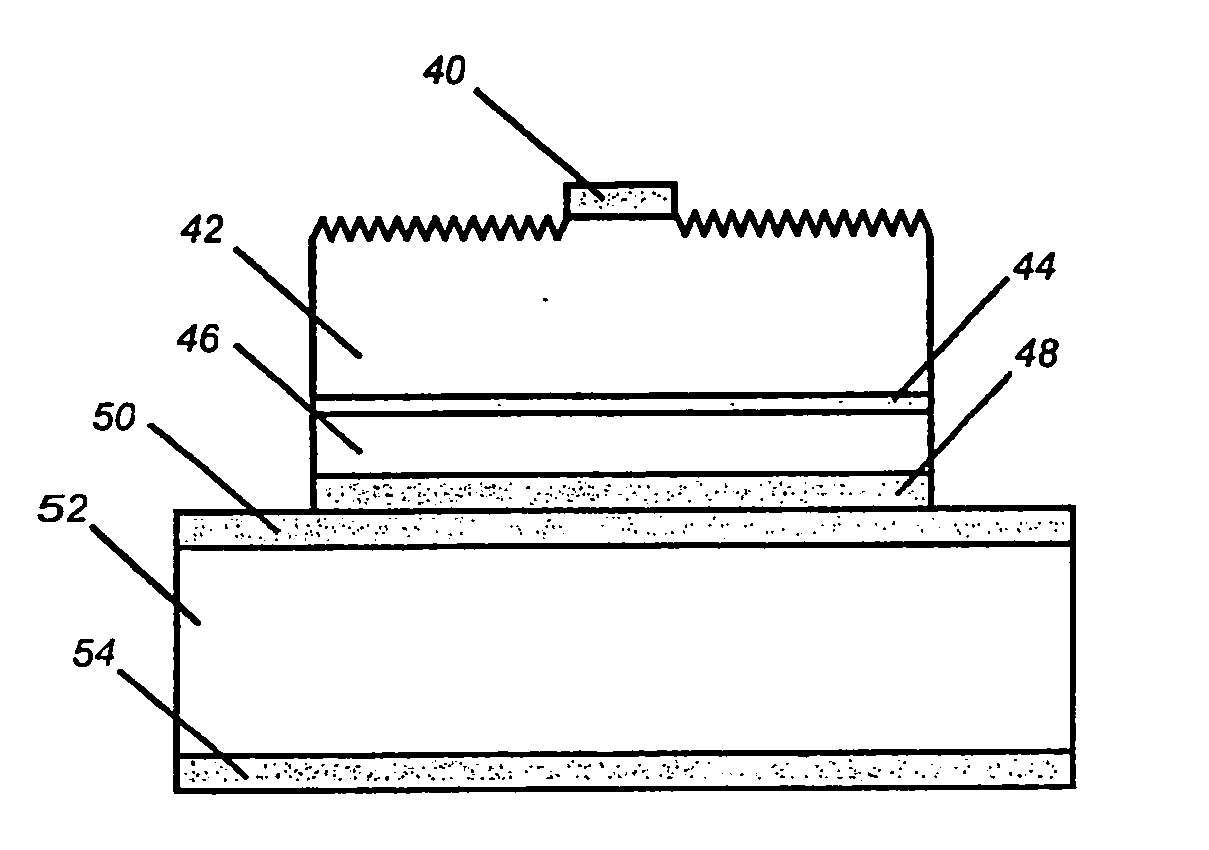

Nitride based transistors on semi-insulating silicon carbide substrates

InactiveUS6316793B1Quality improvementImprove thermal conductivitySemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideMaterials science

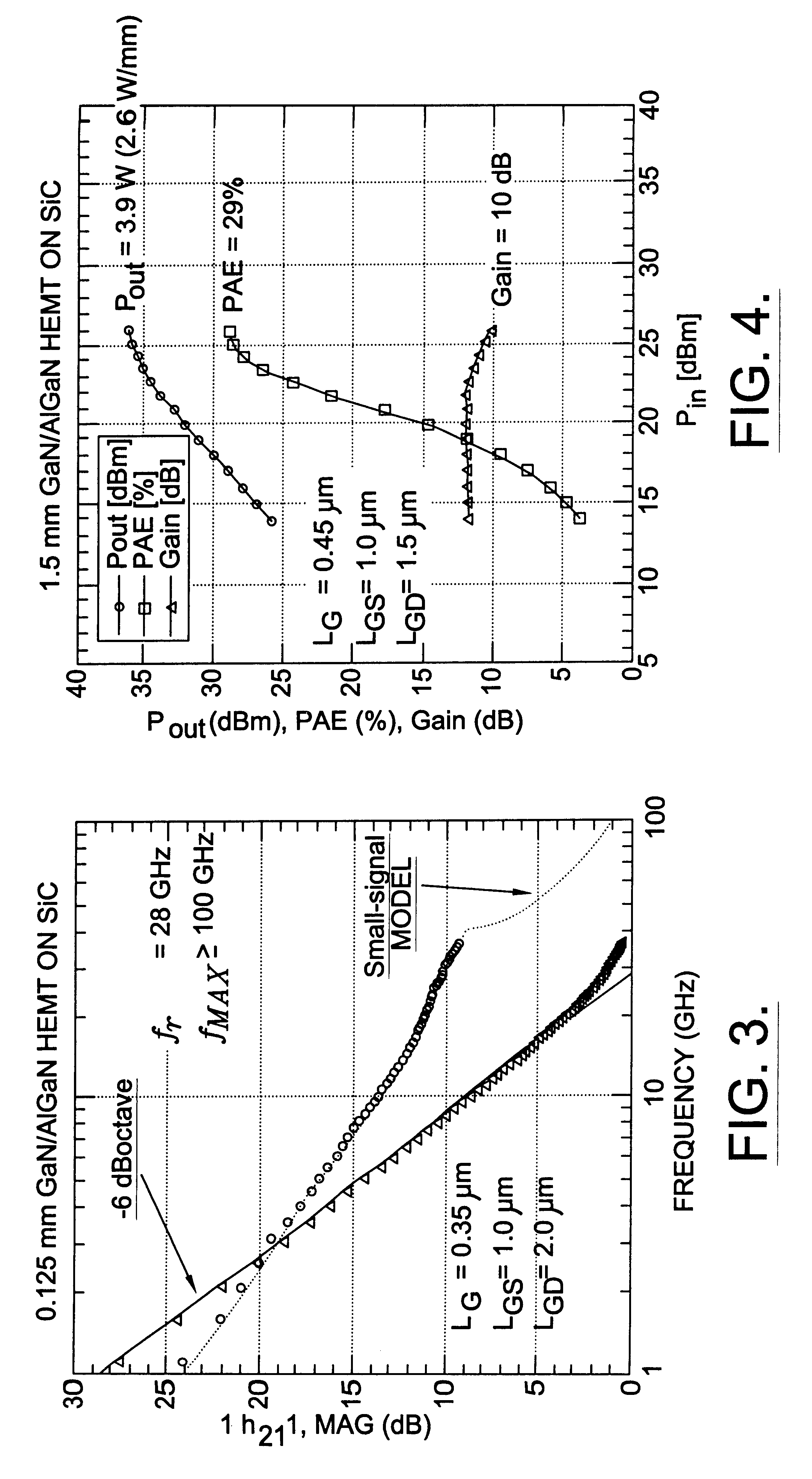

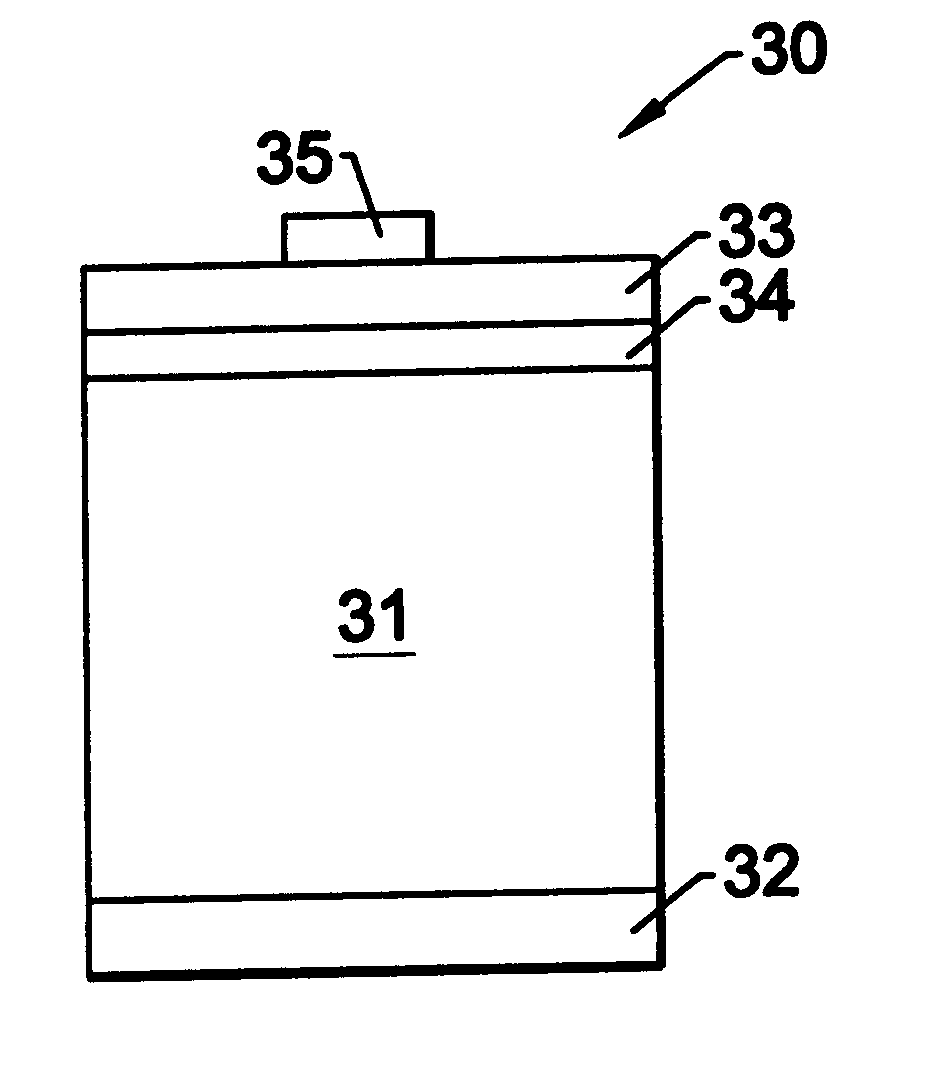

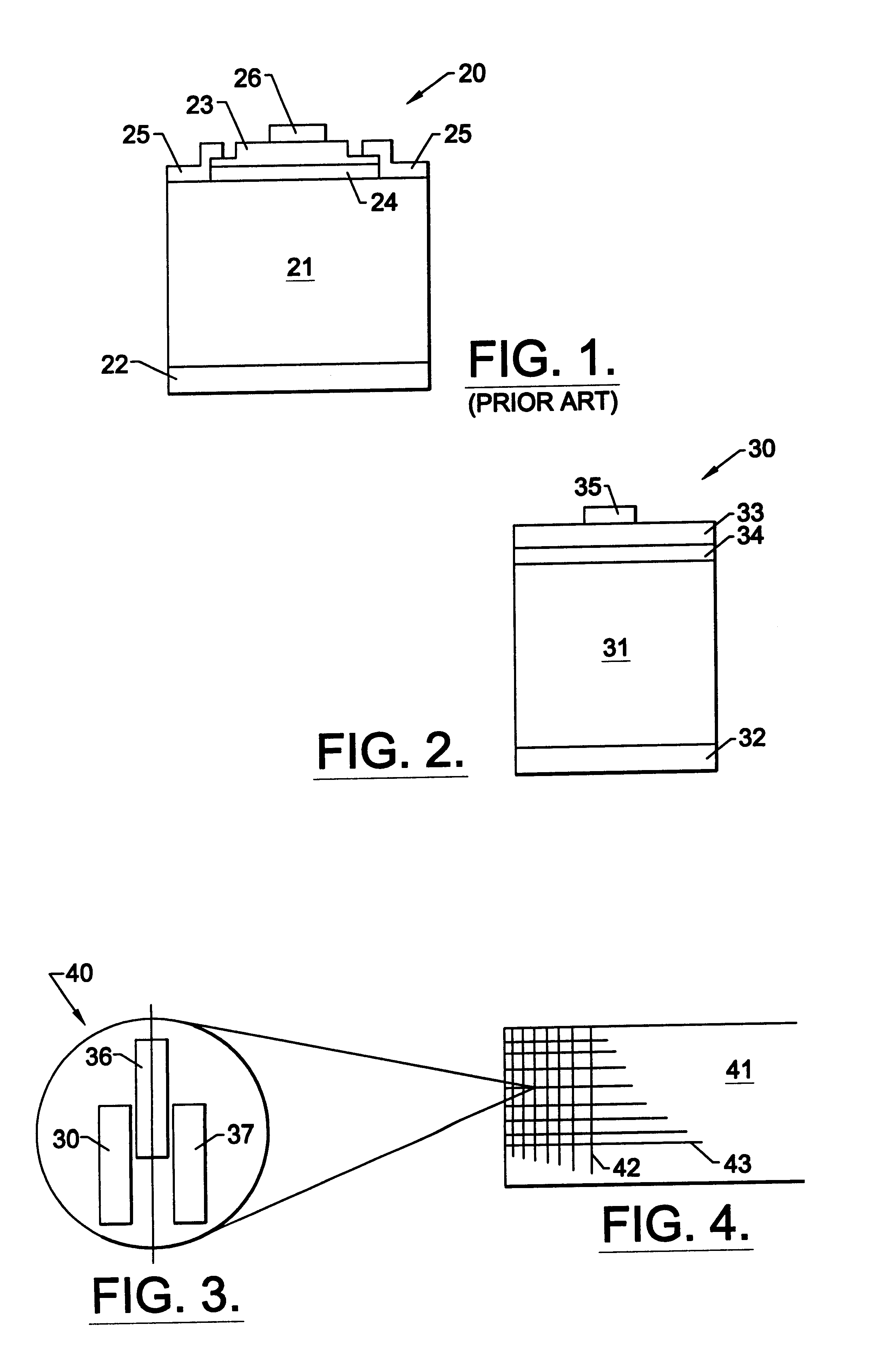

A high electron mobility transistor (HEMT) is disclosed that includes a semi-insulating silicon carbide substrate, an aluminum nitride buffer layer on the substrate, an insulating gallium nitride layer on the buffer layer, an active structure of aluminum gallium nitride on the gallium nitride layer, a passivation layer on the aluminum gallium nitride active structure, and respective source, drain and gate contacts to the aluminum gallium nitride active structure.

Owner:WOLFSPEED INC

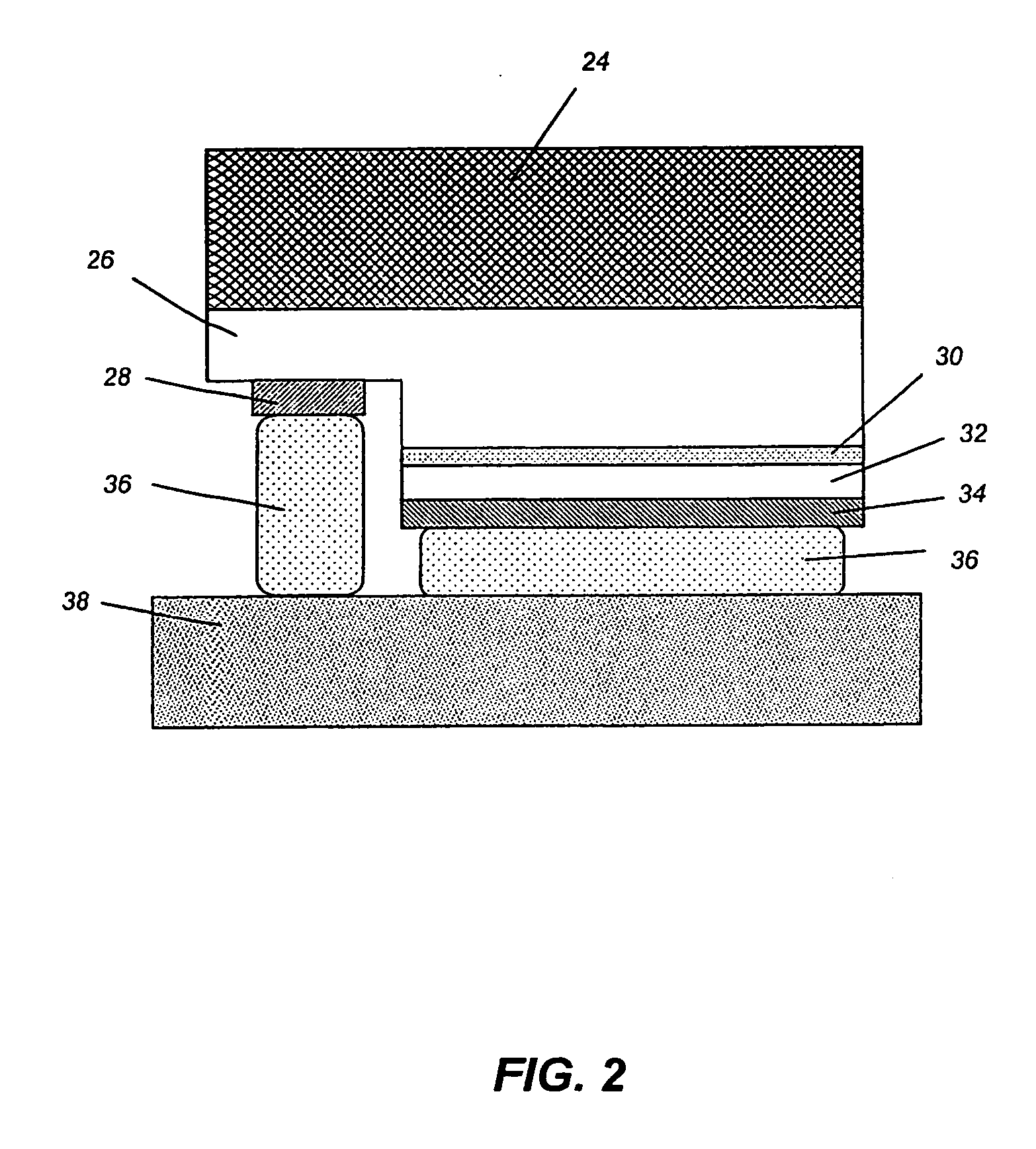

Group III nitride photonic devices on silicon carbide substrates with conductive buffer interlayer structure

InactiveUS6187606B1Avoid crackingMinimize and eliminate heterobarrierSemiconductor/solid-state device manufacturingSemiconductor devicesStress inducedStress relieving

An optoelectronic device with a Group III Nitride active layer is disclosed that comprises a silicon carbide substrate; an optoelectronic diode with a Group III nitride active layer; a buffer structure selected from the group consisting of gallium nitride and indium gallium nitride between the silicon carbide substrate and the optoelectronic diode; and a stress-absorbing structure comprising a plurality of predetermined stress-relieving areas within the crystal structure of the buffer structure, so that stress-induced cracking that occurs in the buffer structure occurs at predetermined areas rather than elsewhere in the buffer structure.

Owner:CREE INC

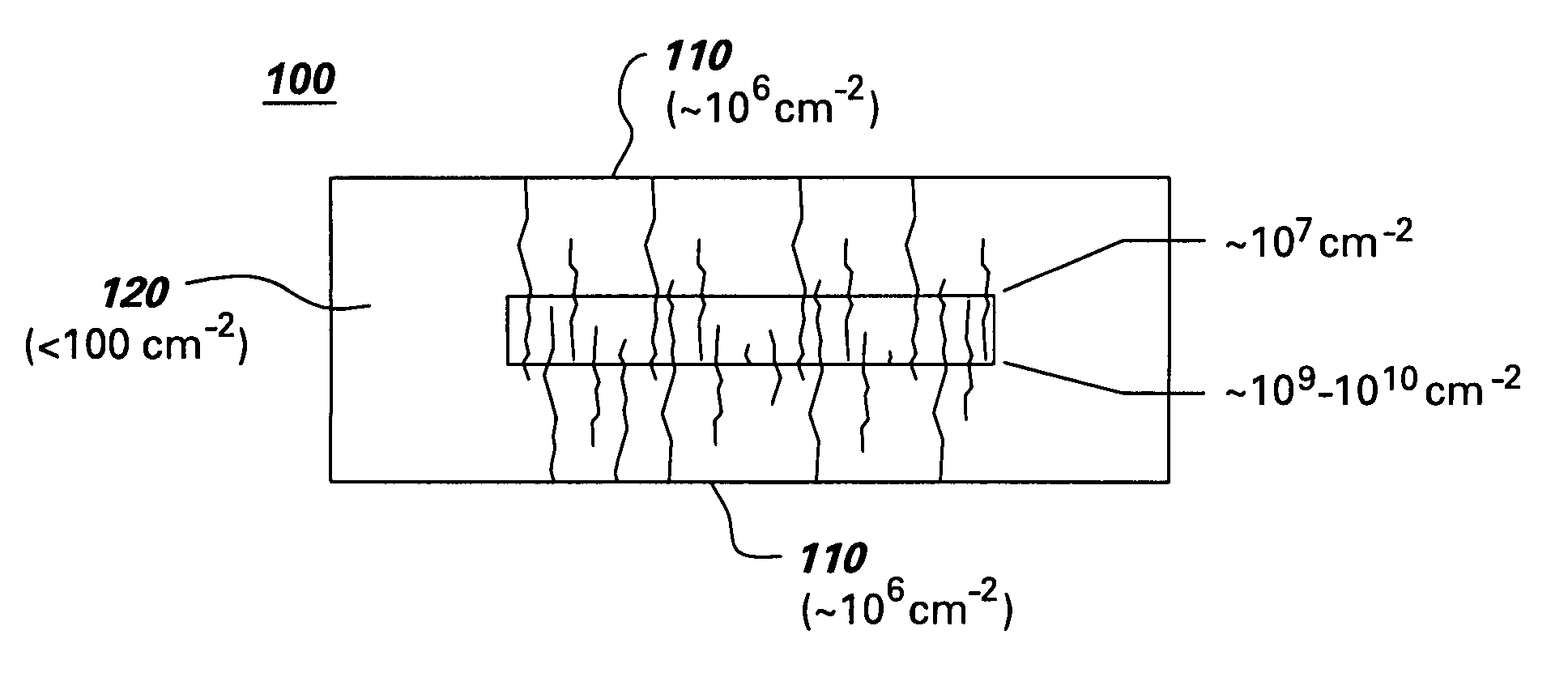

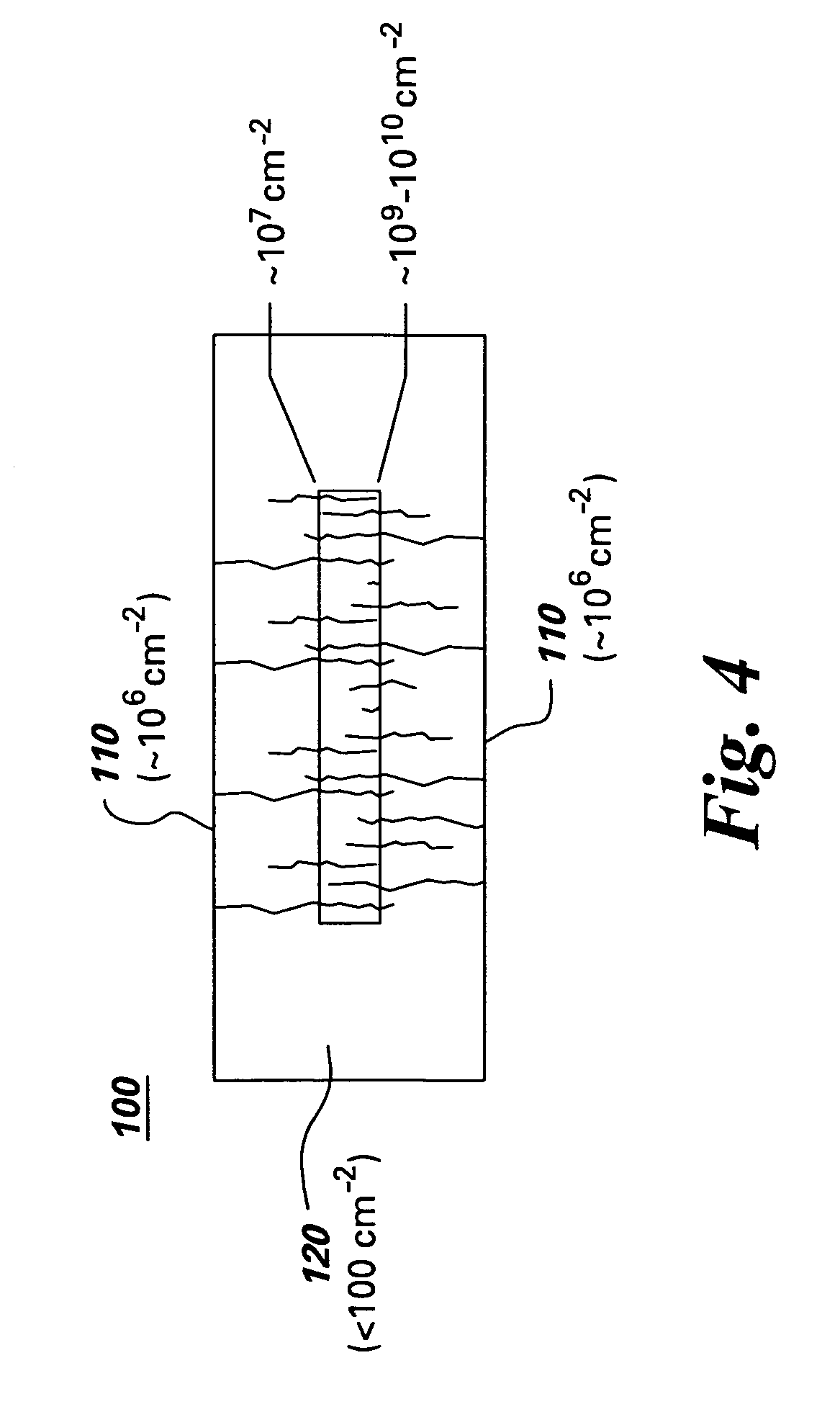

Homoepitaxial gallium-nitride-based light emitting device and method for producing

A light emitting device, such as a light emitting diode or a laser diode. The light emitting device comprises a light emitting semiconductor active region disposed on a substrate. The substrate comprises an optical absorption coefficient below about 100 cm−1 at wavelengths between 700 and 465 nm a GaN single crystal having a dislocation density of less than 104 per cm2 and an optical absorption coefficient below about 100 cm−1 at wavelengths between 700 and 465 nm. A method of making such a light emitting device is also provided.

Owner:SLT TECH +1

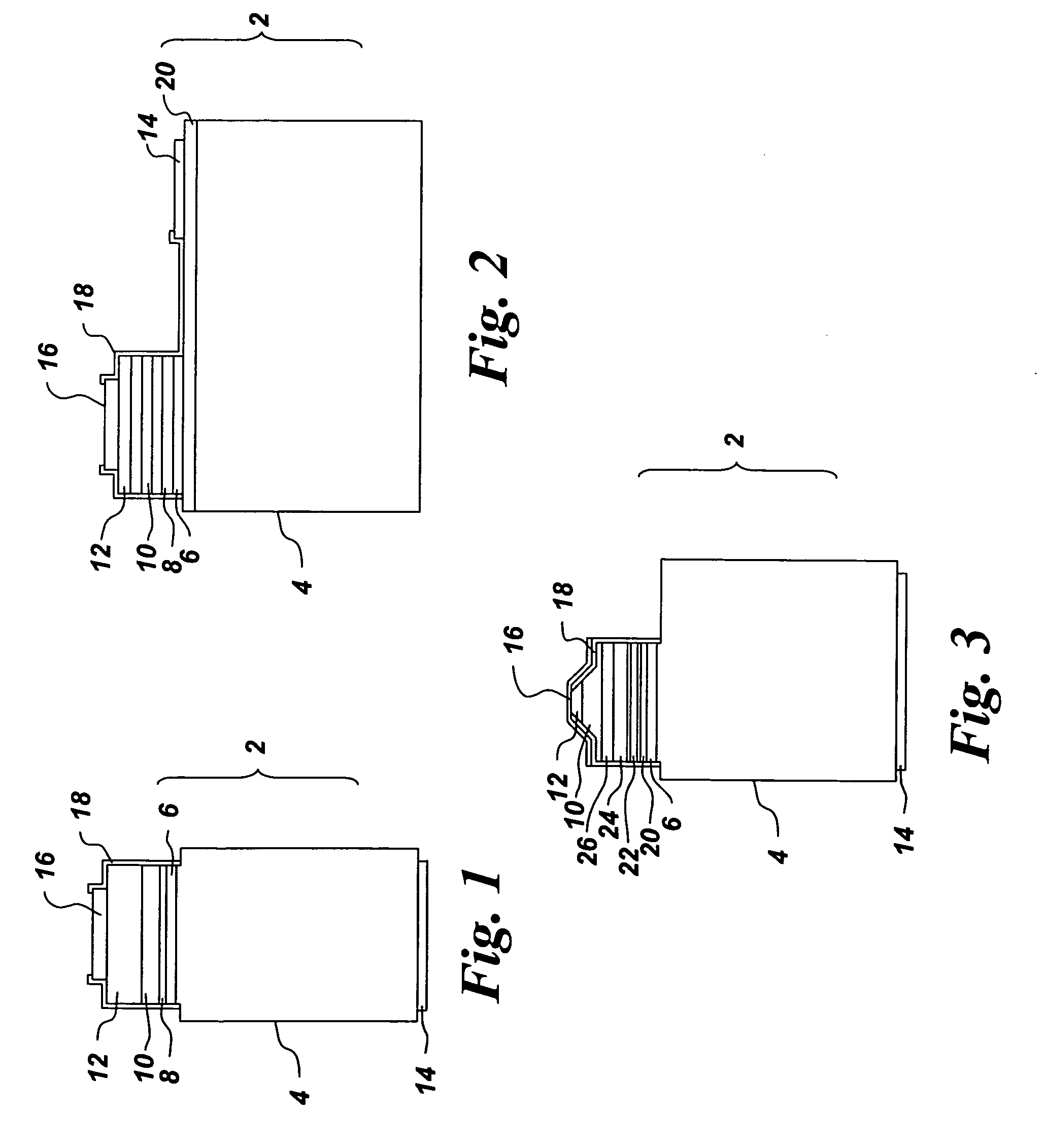

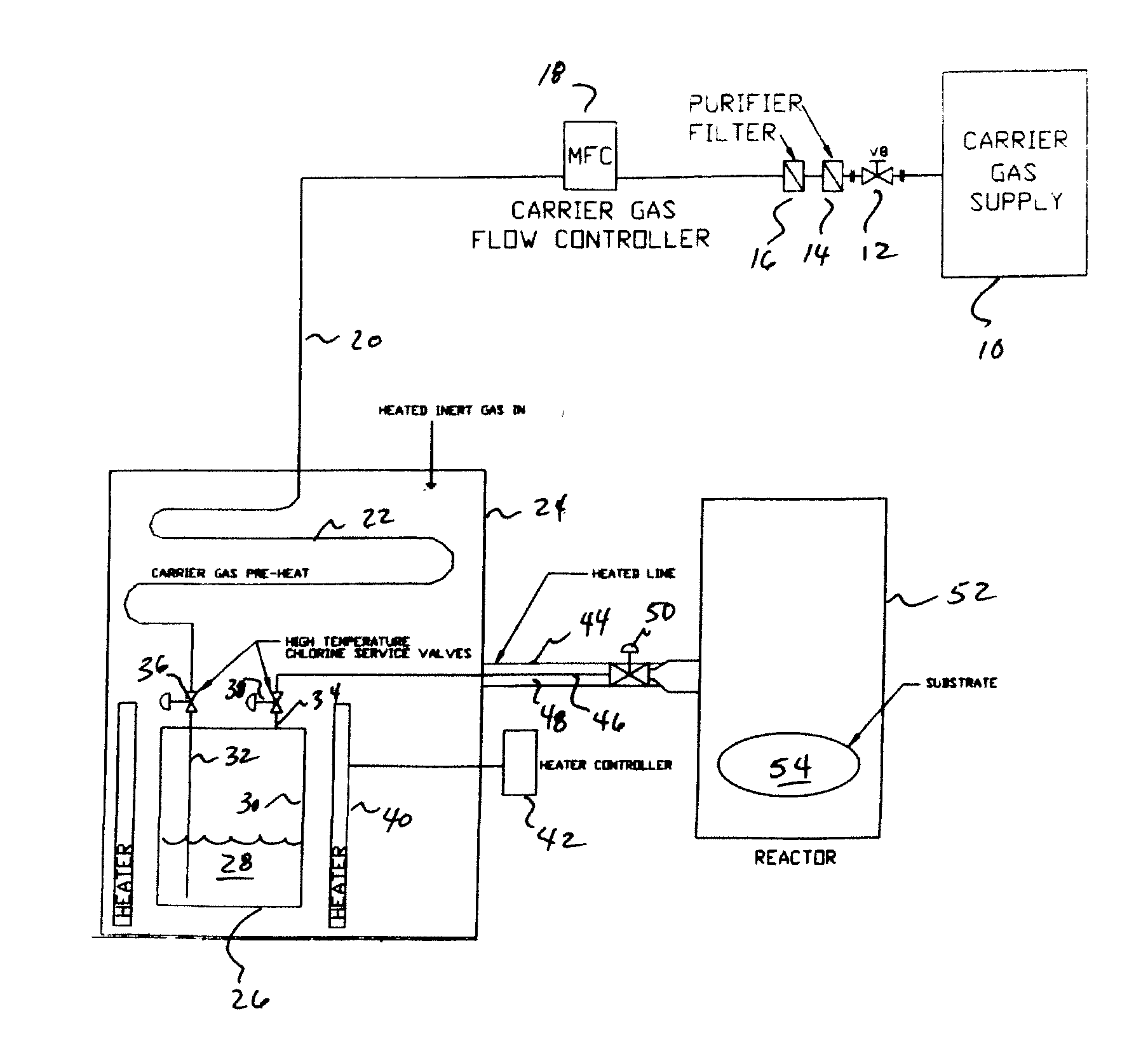

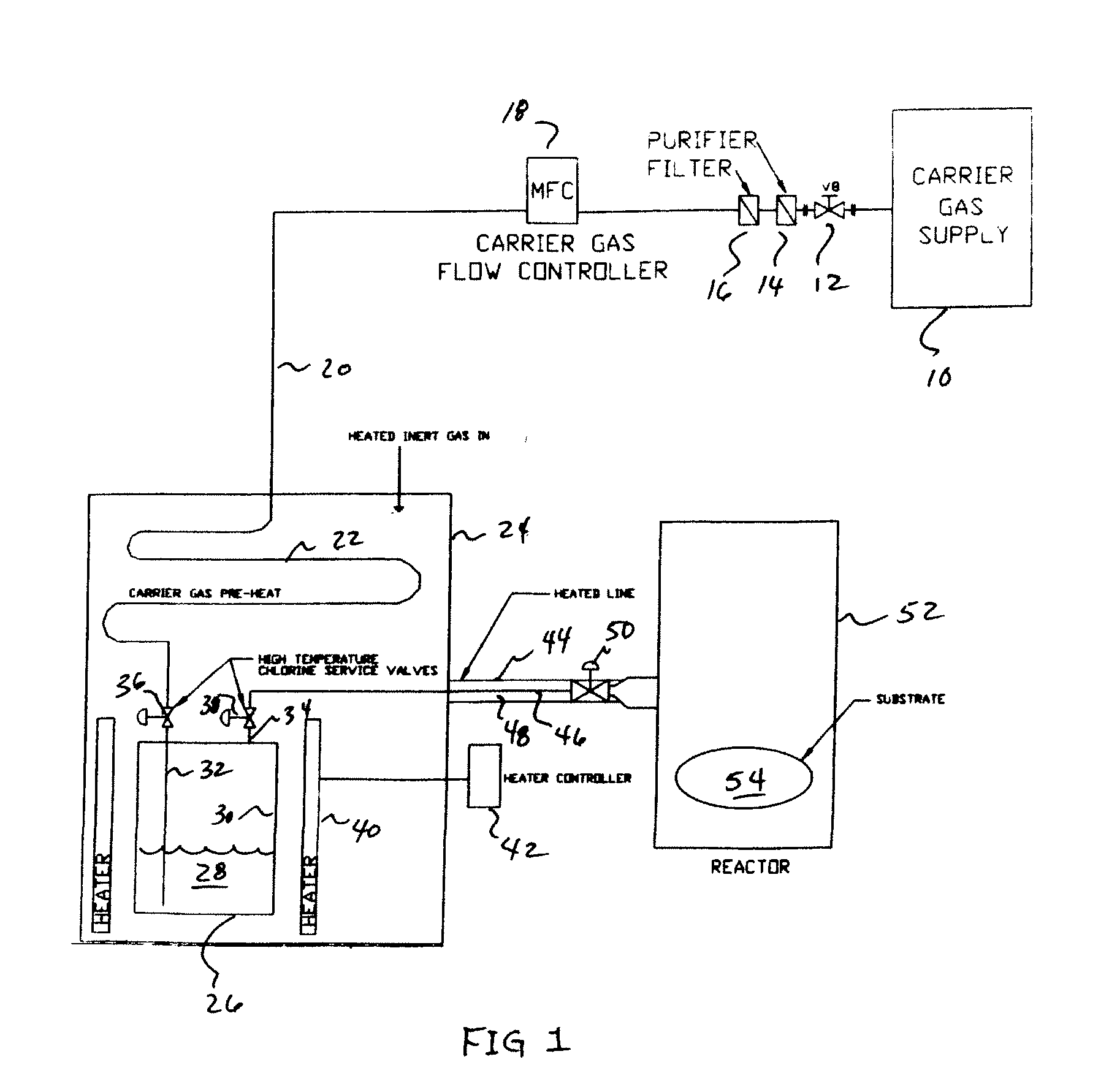

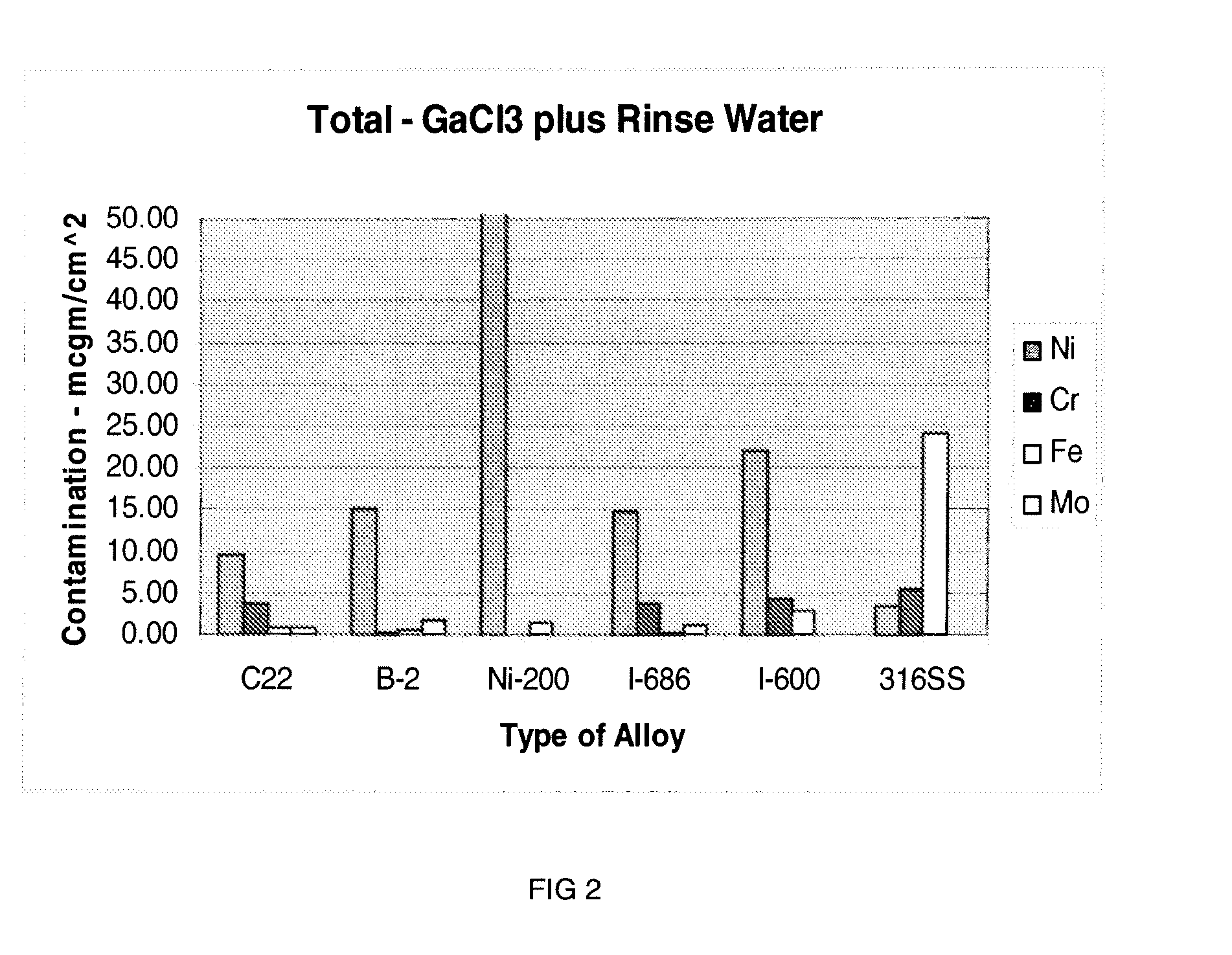

High Flow GaCl3 Delivery

InactiveUS20080018004A1Avoid insufficient heatingCarburetting airPolycrystalline material growthGas phaseReaction zone

The present invention is an apparatus for deliverying high purity gallium trichloride in the vapor phase to a gallium nitride reactor, comprising; a source of carrier gas at an elevated pressure; a purifier to remove moisture from the carrier gas; a heater capable of heating the carrier gas to at least 80° C.; a container having a supply of gallium trichloride, a valve controlled inlet for the carrier gas having a dip tube with an outlet below the level of the gallium trichloride, a valve controlled outlet for removing the carrier gas and entrained gallium trichloride; a heater capable of heating sufficient to melt the gallium trichloride; a delivery line connected to the valve controlled outlet for carrying the entrained gallium trichloride to a reaction zone for gallium nitride. A process is also described for the apparatus.

Owner:VERSUM MATERIALS US LLC

Group III nitride based light emitting diode structures with a quantum well and superlattice, group III nitride based quantum well structures and group III nitride based superlattice structures

InactiveUS6958497B2Semiconductor/solid-state device manufacturingNanoopticsDevice materialGallium nitride

A light emitting diode is provided having a Group III nitride based superlattice and a Group III nitride based active region on the superlattice. The active region has at least one quantum well structure. The quantum well structure includes a first Group III nitride based barrier layer, a Group III nitride based quantum well layer on the first barrier layer and a second Group III nitride based barrier layer. A Group III nitride based semiconductor device and methods of fabricating a Group III nitride based semiconductor device having an active region comprising at least one quantum well structure are provided. The quantum well structure includes a well support layer comprising a Group III nitride, a quantum well layer comprising a Group III nitride on the well support layer and a cap layer comprising a Group III nitride on the quantum well layer. A Group III nitride based semiconductor device is also provided that includes a gallium nitride based superlattice having at least two periods of alternating layers of InXGa1−XN and InYGa1−YN, where 0≦X<1 and 0≦Y<1 and X is not equal to Y. The semiconductor device may be a light emitting diode with a Group III nitride based active region. The active region may be a multiple quantum well active region.

Owner:CREELED INC

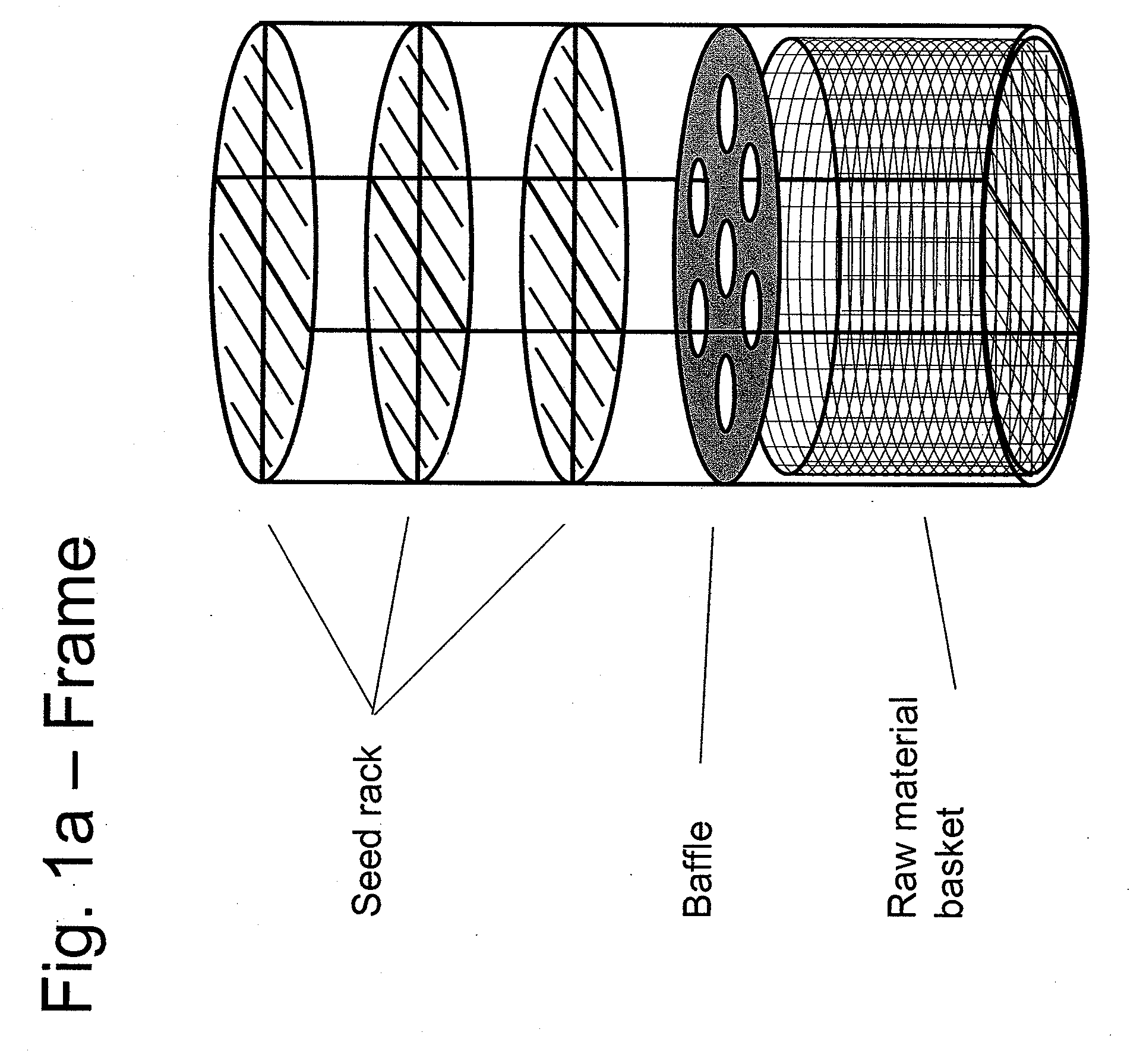

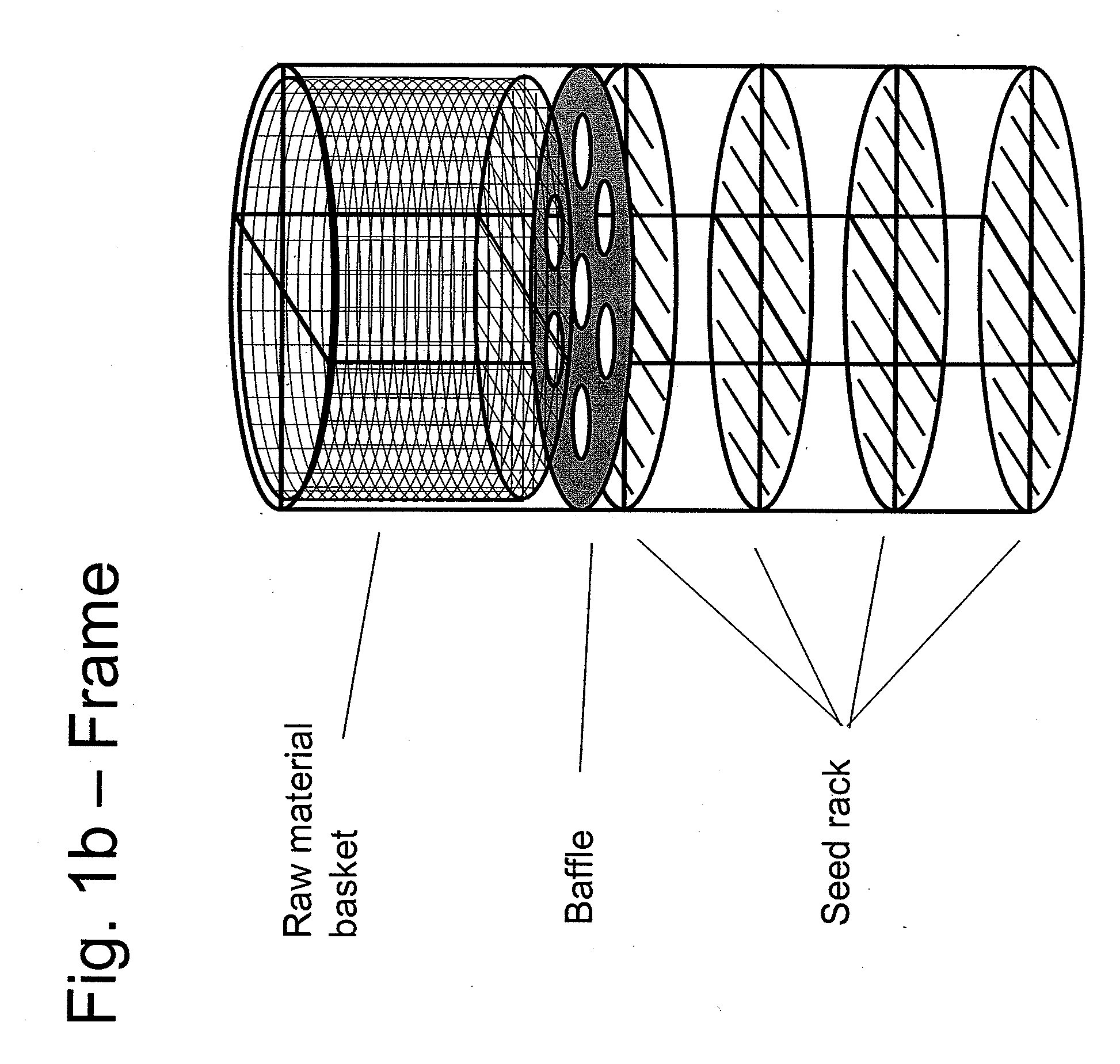

Resonant cavity light emitting devices and associated method

InactiveUS20060118799A1Increase probabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingResonant cavitySource material

A method may produce a resonant cavity light emitting device. A seed gallium nitride crystal and a source material in a nitrogen-containing superheated fluid may provide a medium for mass transport of gallium nitride precursors therebetween. A seed crystal surface may be prepared by applying a first thermal profile between the seed gallium nitride crystal and the source material. Gallium nitride material may be grown on the prepared surface of the seed gallium nitride crystal by applying a second thermal profile between the seed gallium nitride crystal and the source material while the seed gallium nitride crystal and the source material are in the nitrogen-containing superheated fluid. A stack of group III-nitride layers may be deposited on the single-crystal gallium nitride substrate. The stack may include a first mirror sub-stack and an active region adaptable for fabrication into one or more resonant cavity light emitting devices.

Owner:SORAA

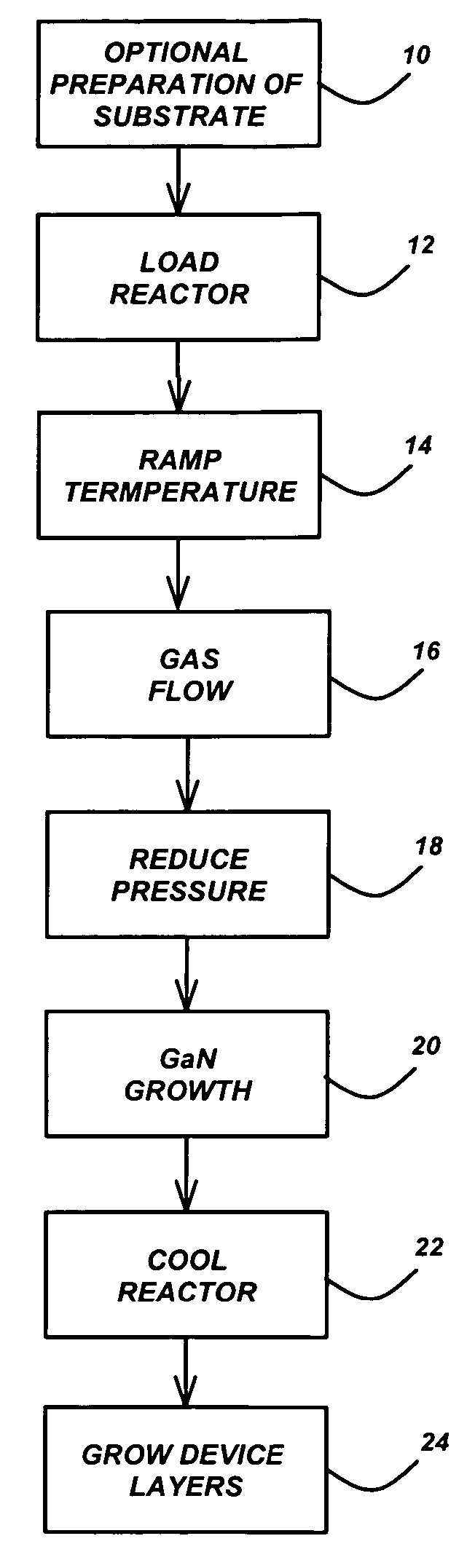

Formation of heteroepitaxial layers with rapid thermal processing to remove lattice dislocations

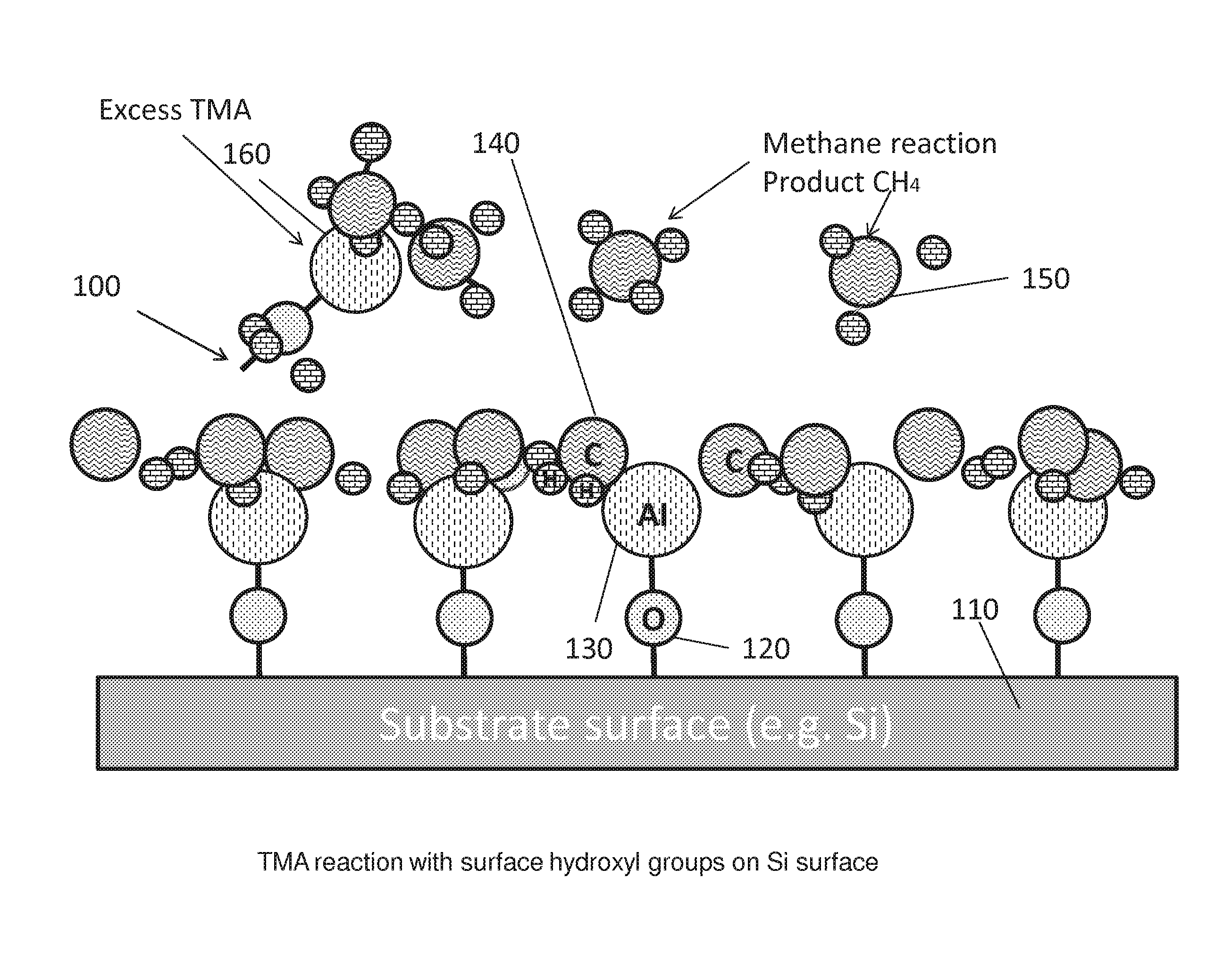

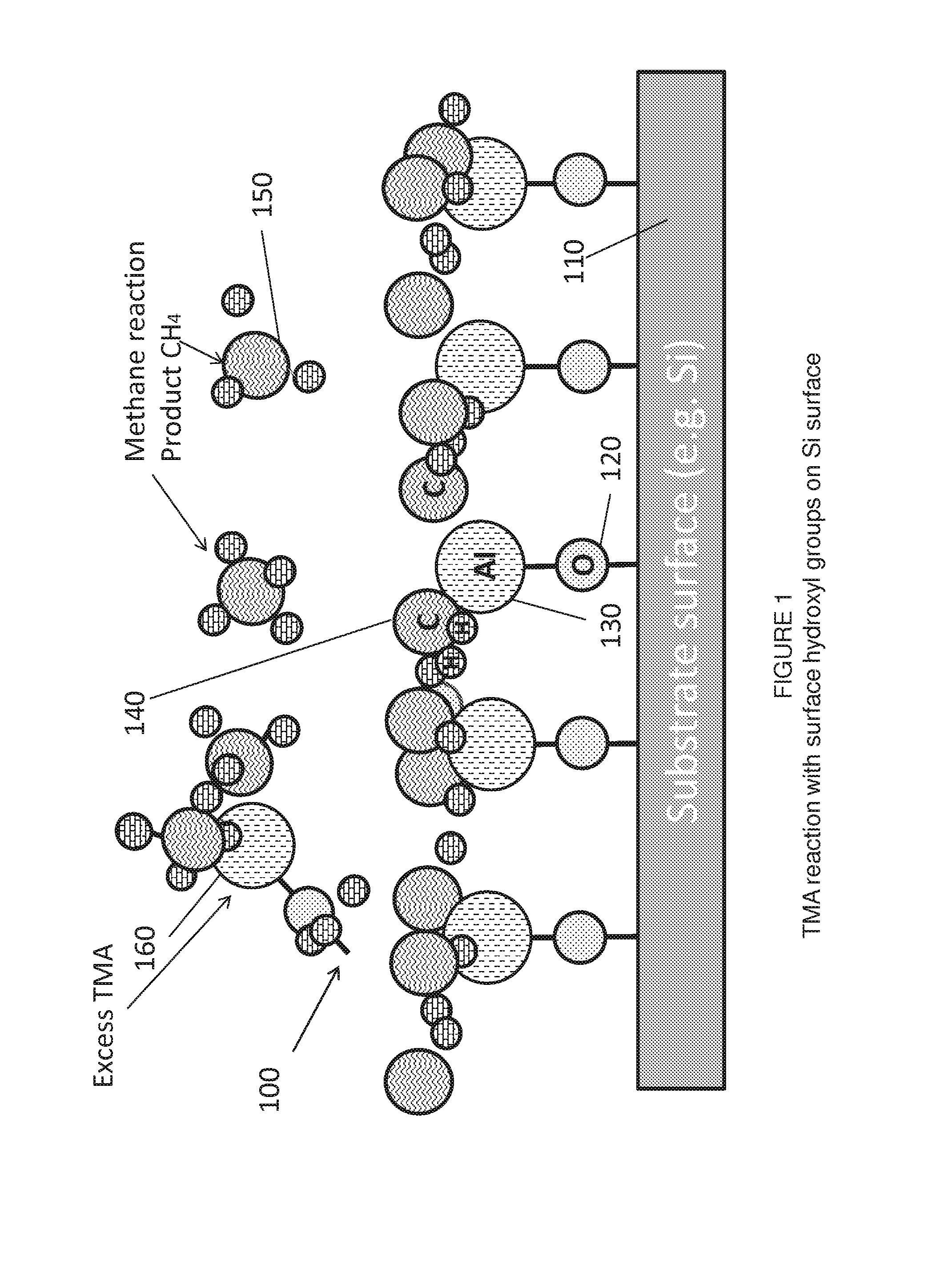

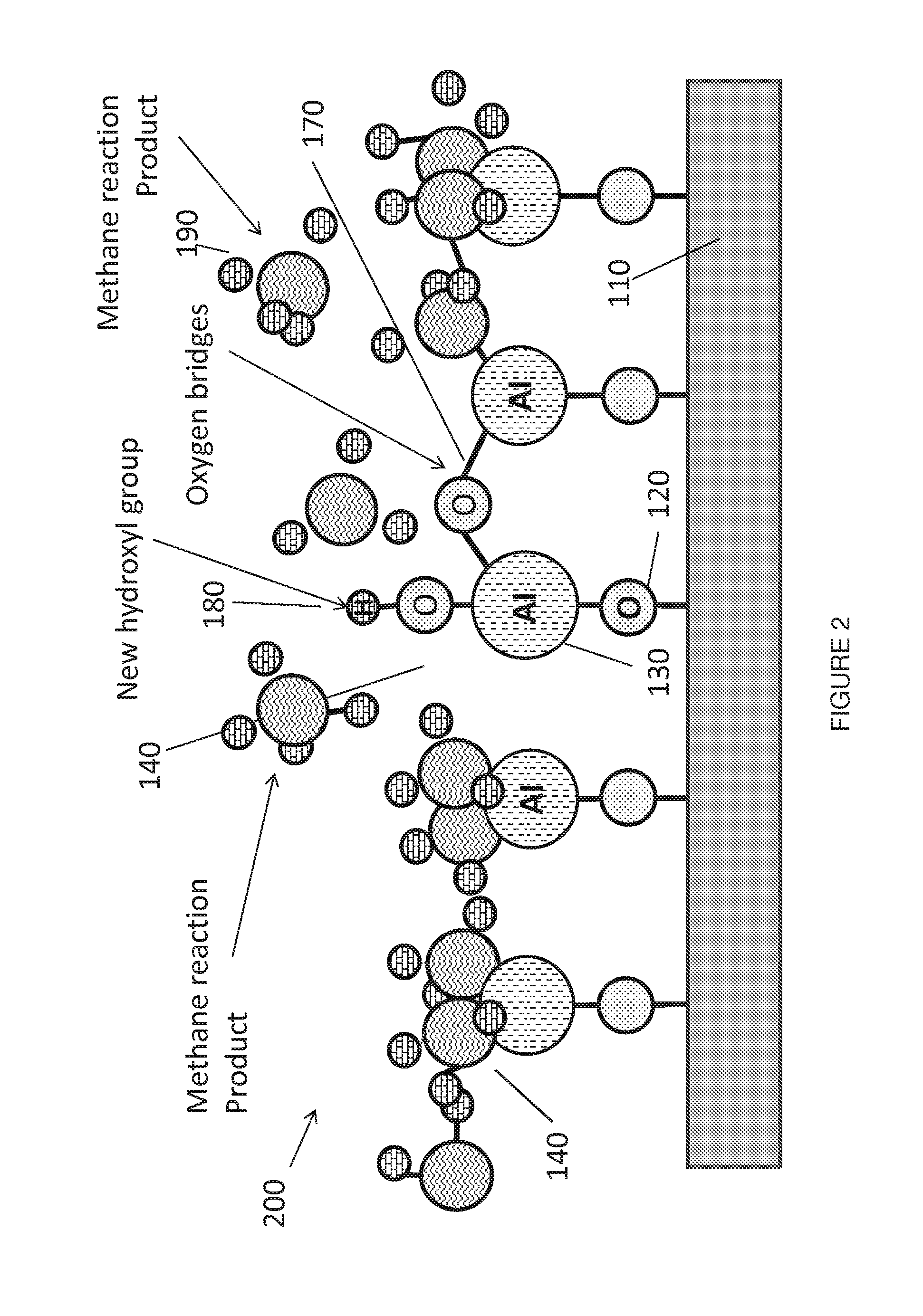

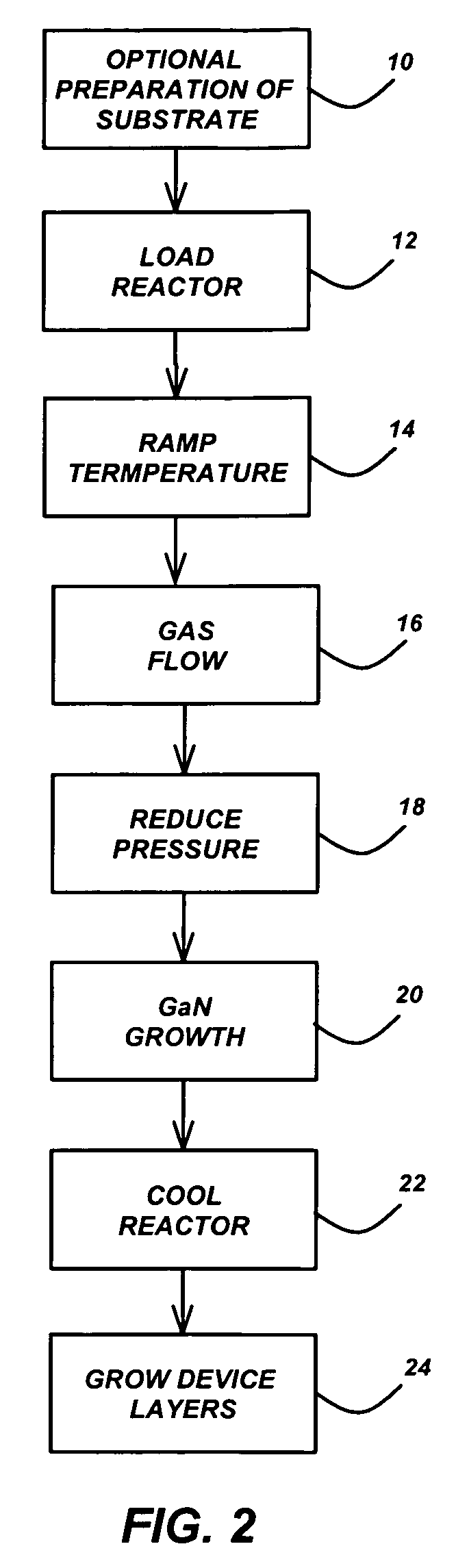

InactiveUS20160155629A1Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesReaction temperatureGallium nitride

Method and devices are disclosed for device manufacture of gallium nitride devices by growing a gallium nitride layer on a silicon substrate using Atomic Layer Deposition (ALD) followed by rapid thermal annealing. Gallium nitride is grown directly on silicon or on a barrier layer of aluminum nitride grown on the silicon substrate. One or both layers are thermally processed by rapid thermal annealing. Preferably the ALD process use a reaction temperature below 550° C. and preferable below 350° C. The rapid thermal annealing step raises the temperature of the coating surface to a temperature ranging from 550 to 1500° C. for less than 12 msec.

Owner:VEECO INSTR

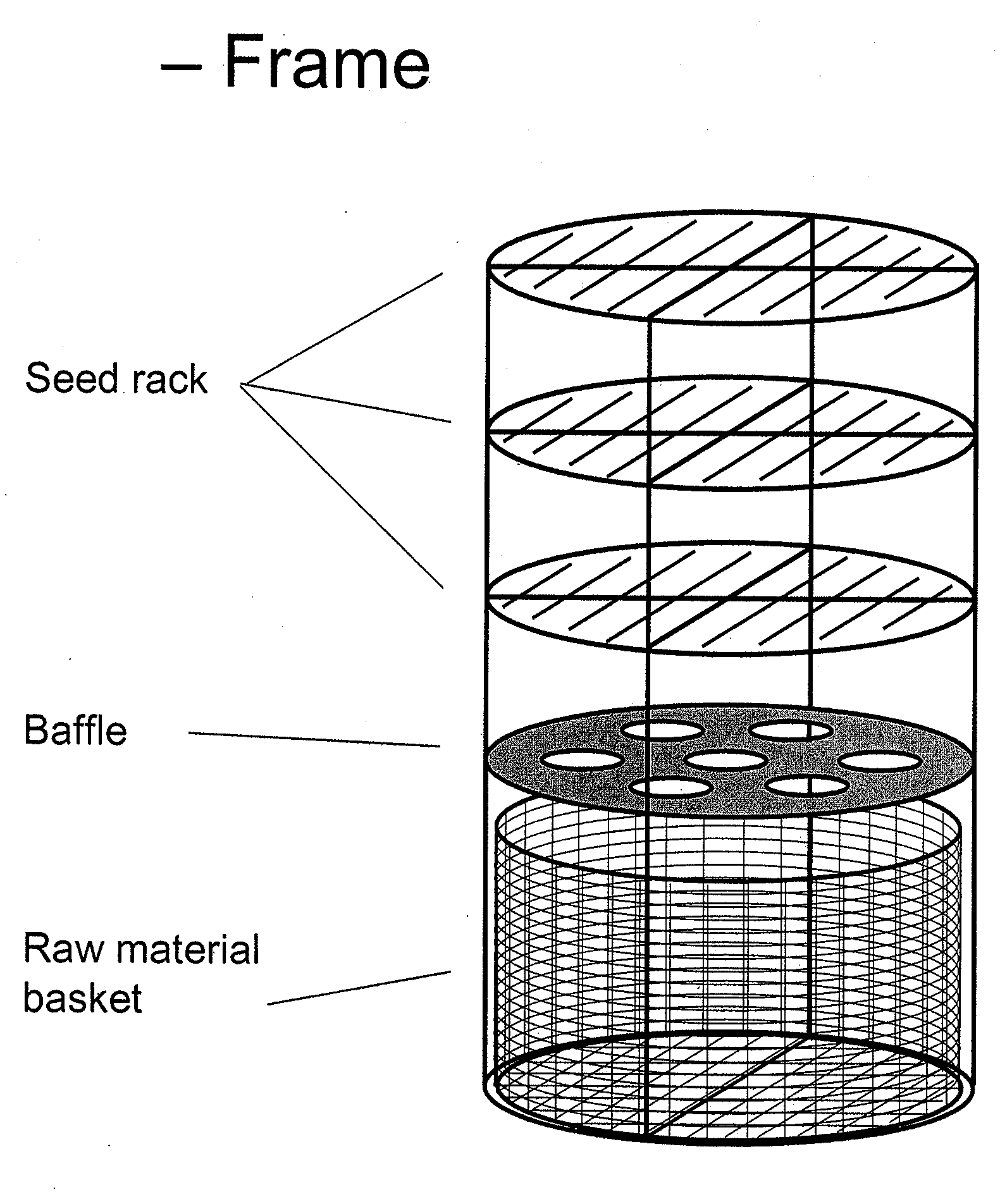

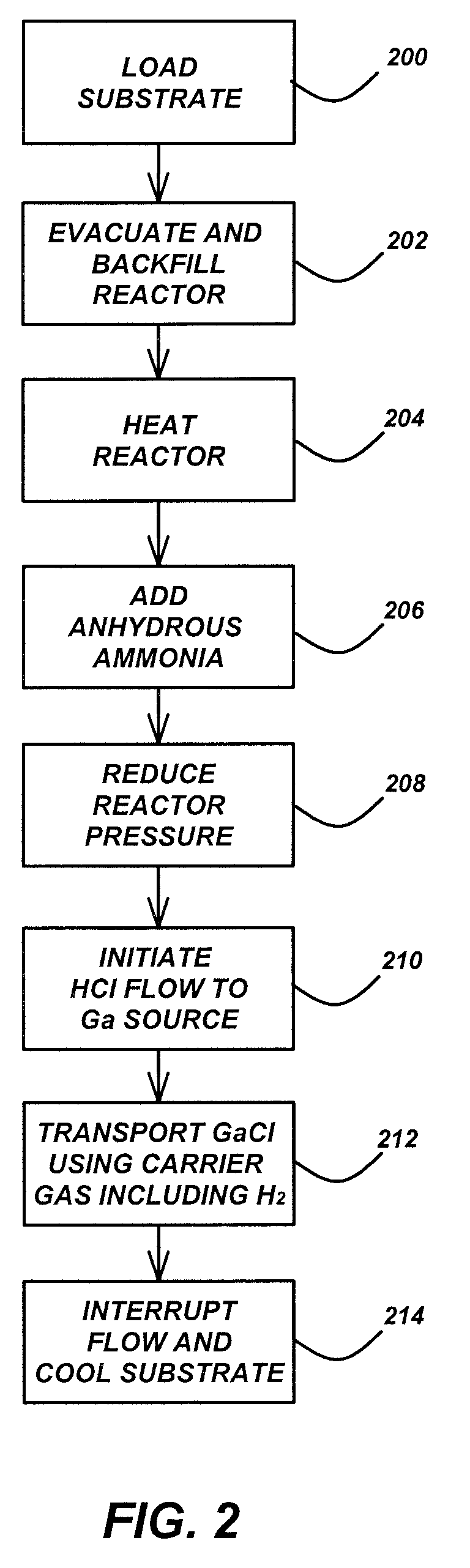

Process for large-scale ammonothermal manufacturing of gallium nitride boules

ActiveUS20100031875A1Cost-effectiveSimple and cost-effective to manufacturePolycrystalline material growthFrom normal temperature solutionsCost effectivenessEngineering

A method for large-scale manufacturing of gallium nitride boules. Large-area single crystal seed plates are suspended in a rack, placed in a large diameter autoclave or internally-heated high pressure apparatus along with ammonia and a mineralizer, and grown ammonothermally. The seed orientation and mounting geometry are chosen to provide efficient utilization of the seed plates and of the volume inside the autoclave or high pressure apparatus. The method is scalable up to very large volumes and is cost effective.

Owner:SLT TECH

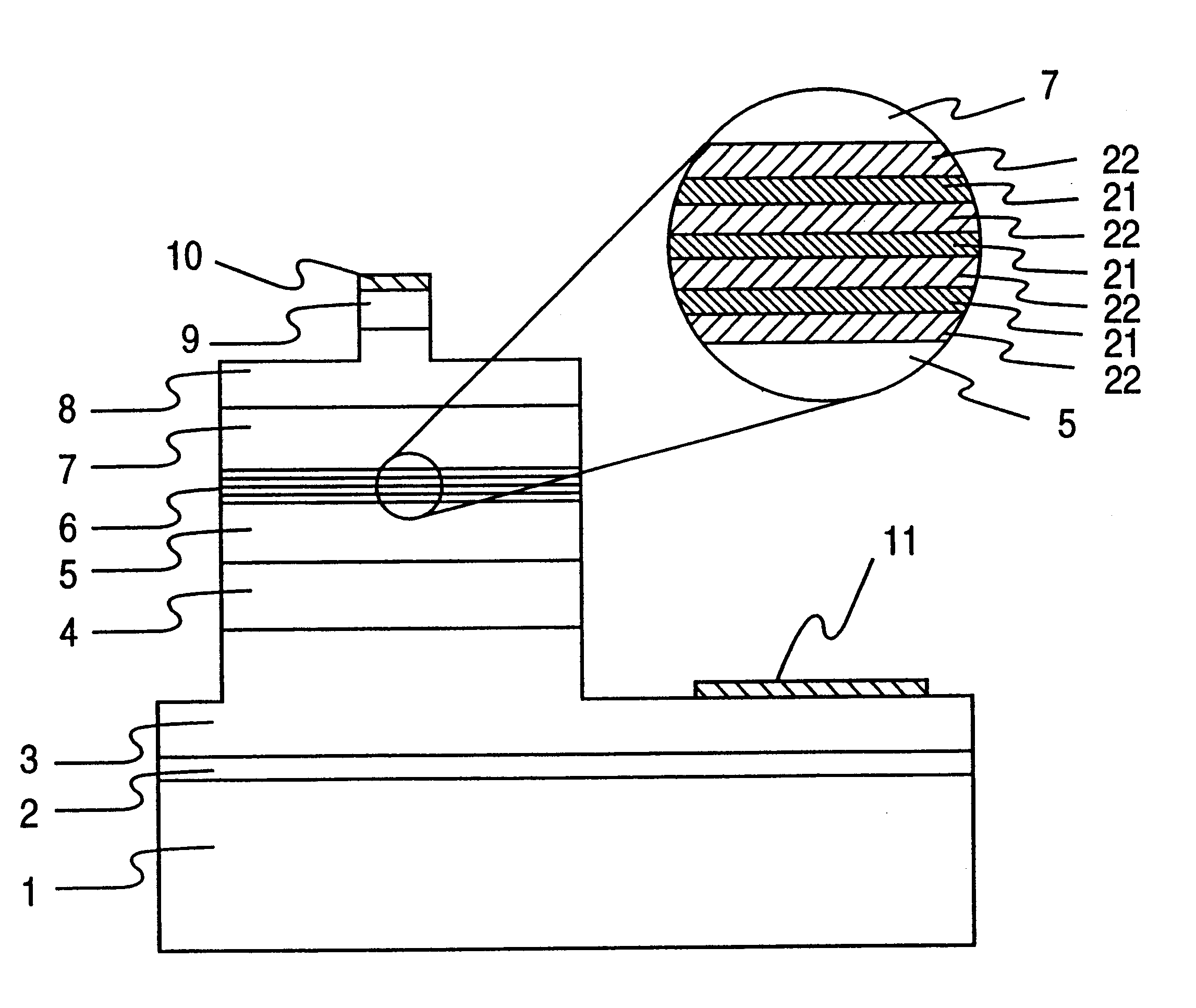

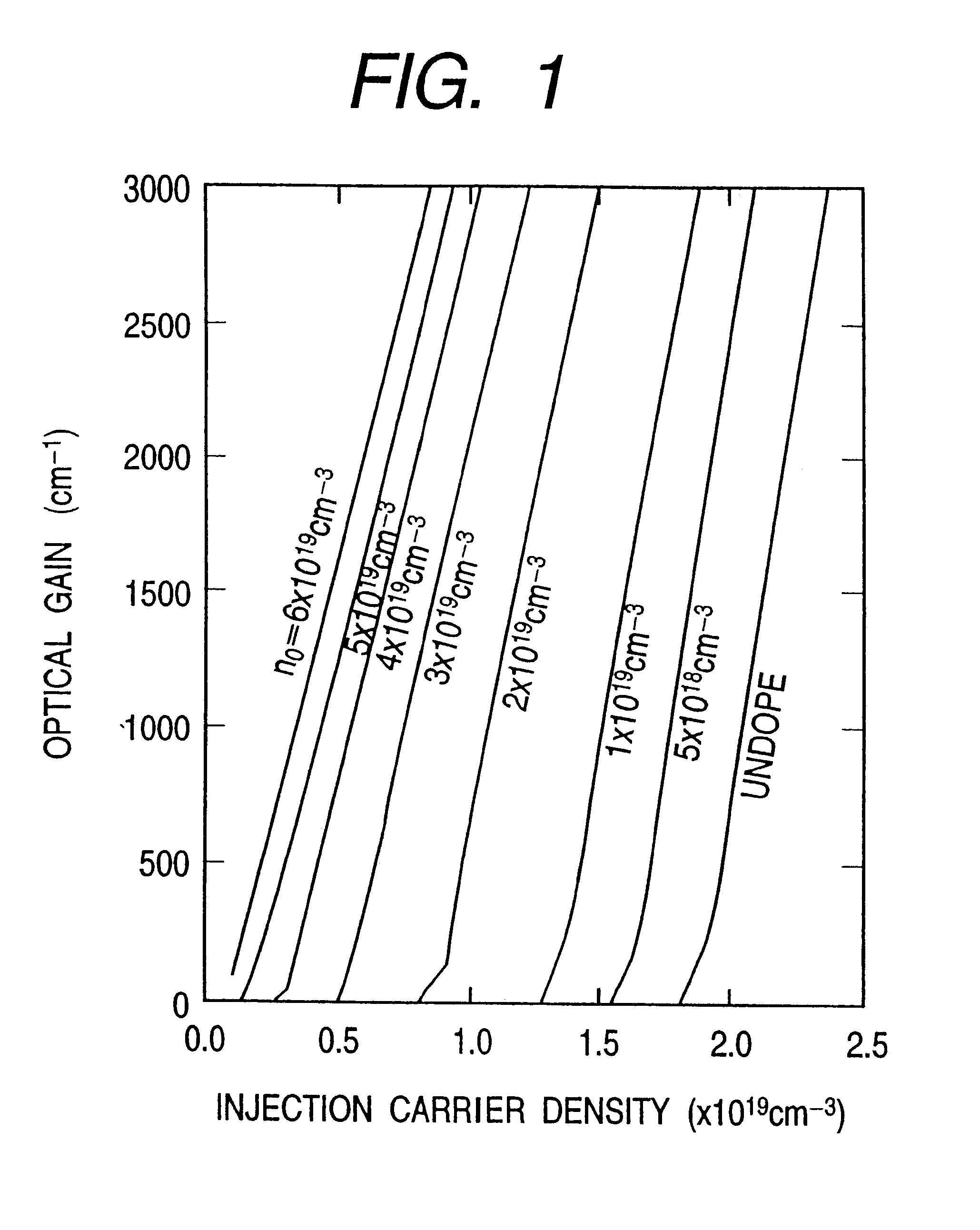

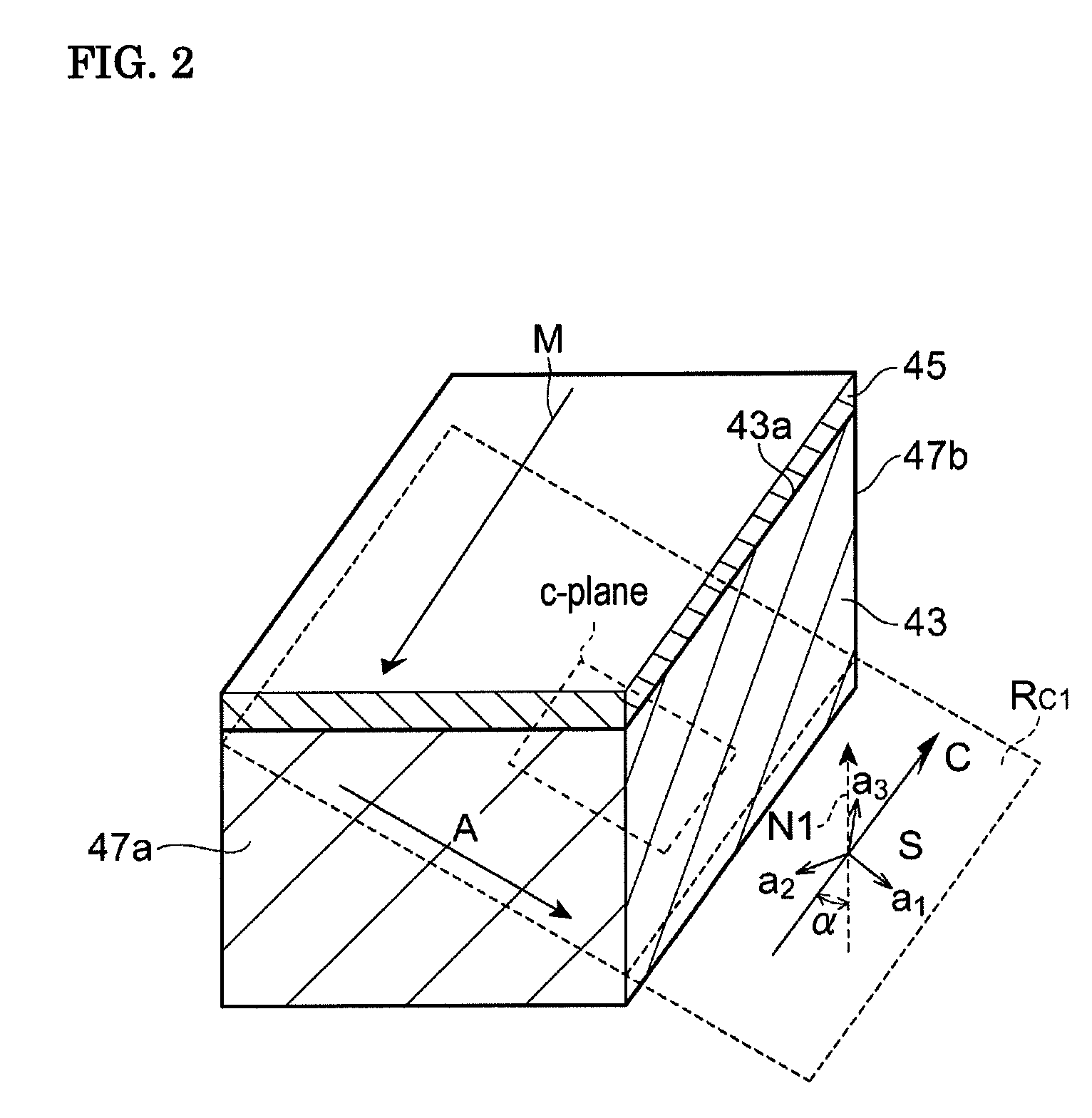

Optical information processing equipment and semiconductor light emitting device suitable therefor

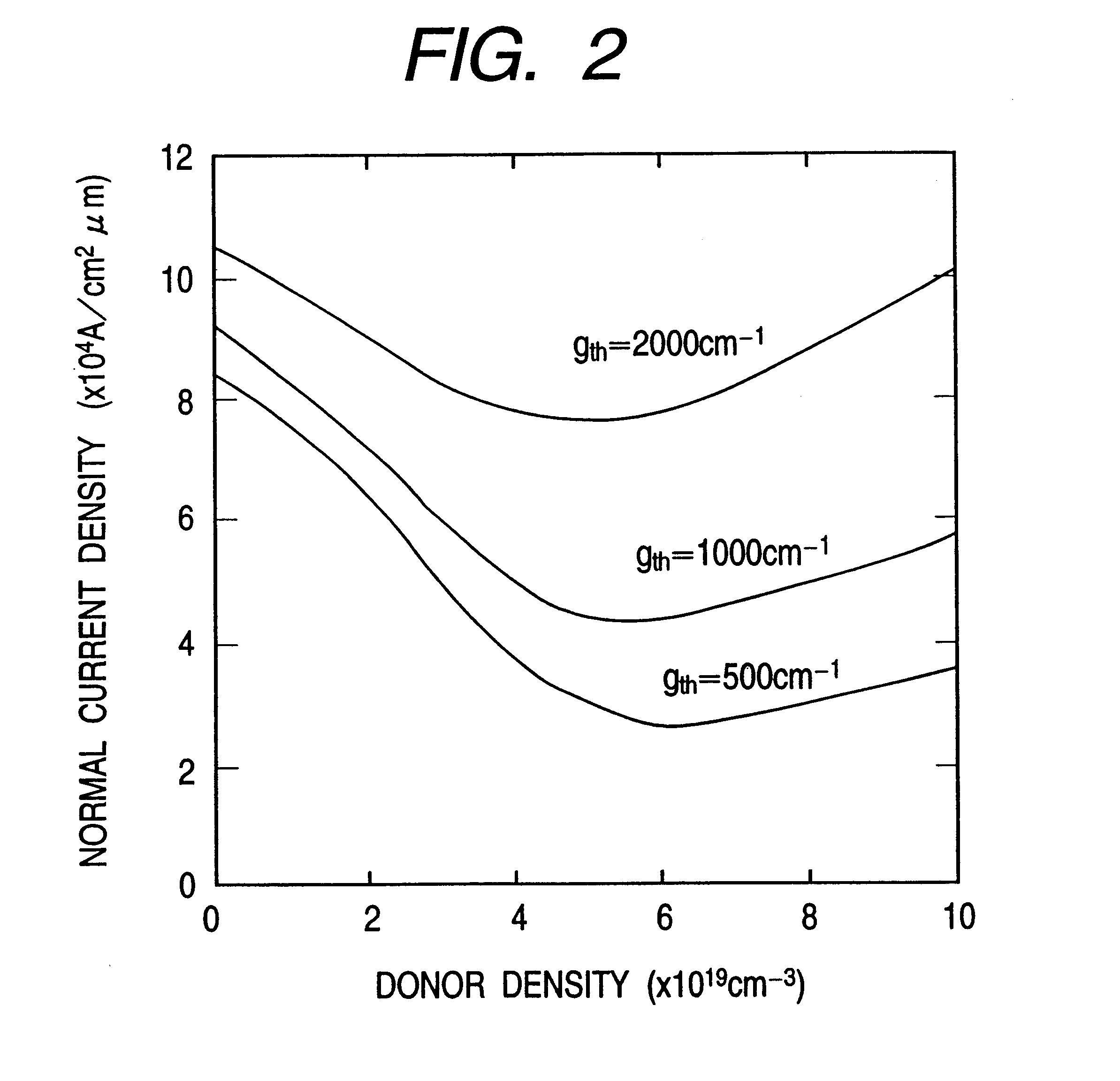

An information processor of a high reliability and a high recording density, and a blue color, blue-violet color and violet color based semiconductor light emitting device operable at a low threshold current density, used for the same, are provided. An optical information processor of a high reliability and a high recording density enables a moving picture, such as a high-definition television picture, to be recorded and reproduced satisfactorily. A barrier layer in a quantum-well active layer of a semiconductor light emitting device is doped with n-type impurities at a high density. Alternatively, the face orientation of a quantum-well active layer of a semiconductor light emitting device is a plane inclined from the (0001) plane, whereby the threshold current value of the semiconductor light emitting device can be decreased. The semiconductor light emitting device is typified by a gallium nitride based compound semiconductor laser device.

Owner:USHIO OPTO SEMICON

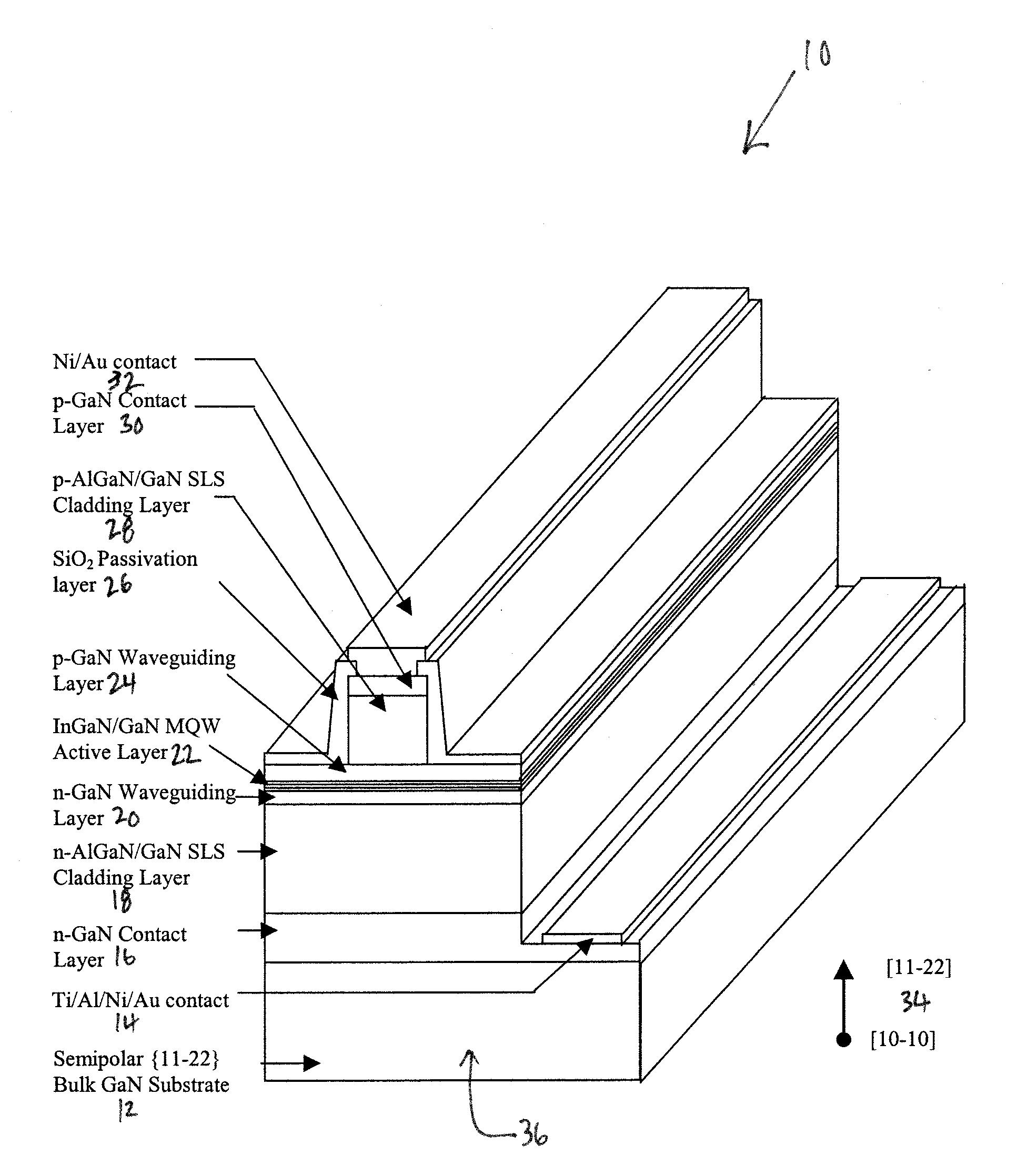

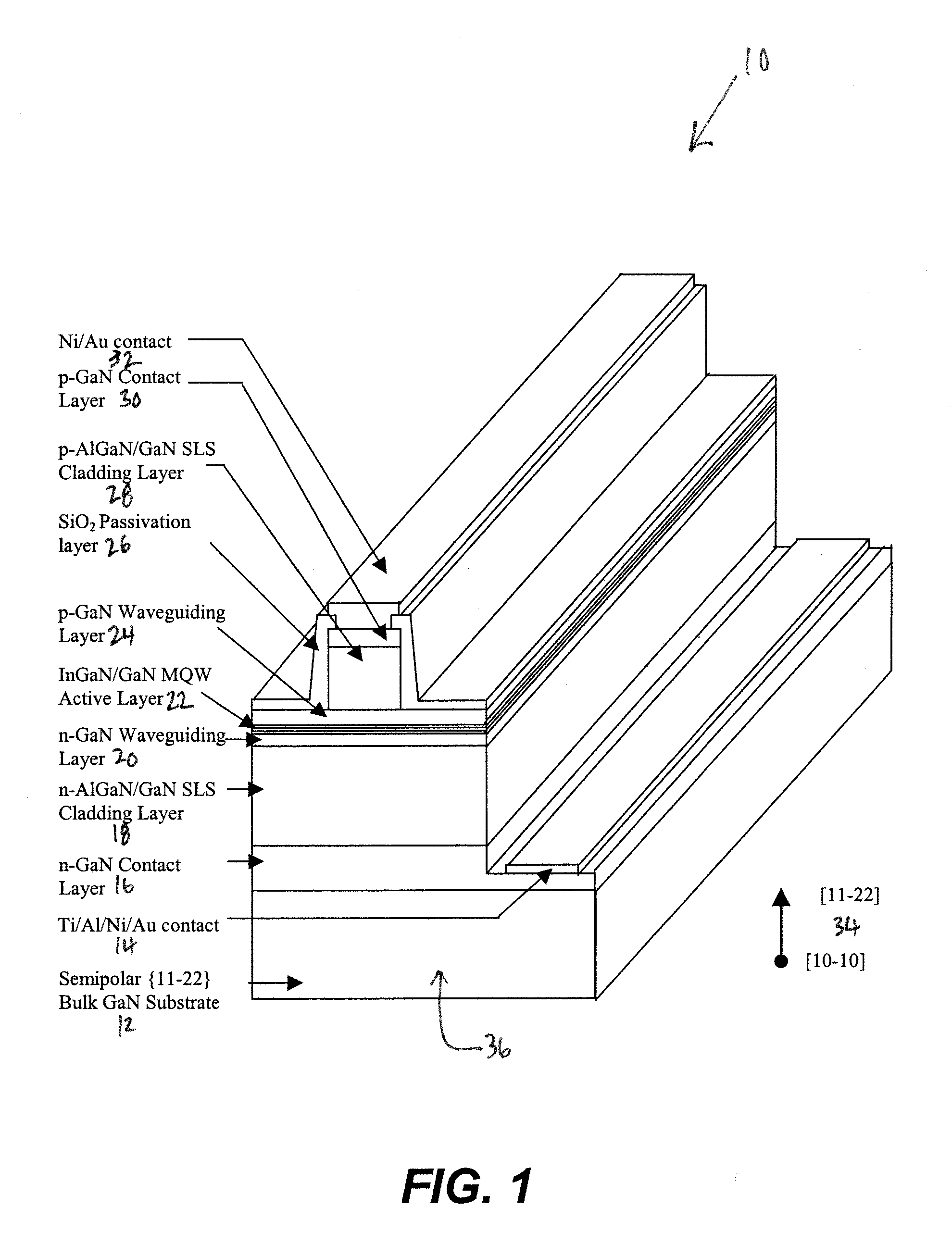

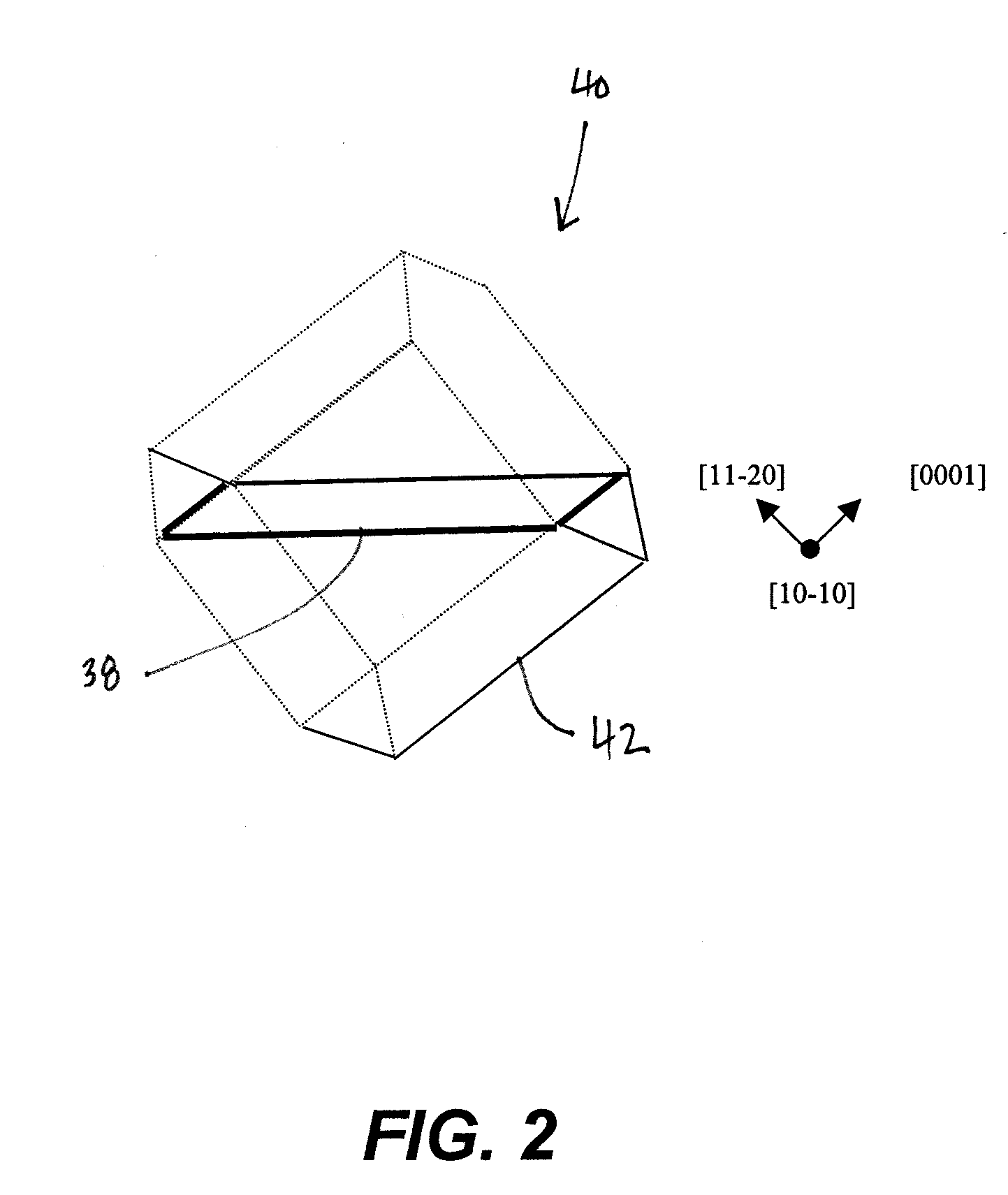

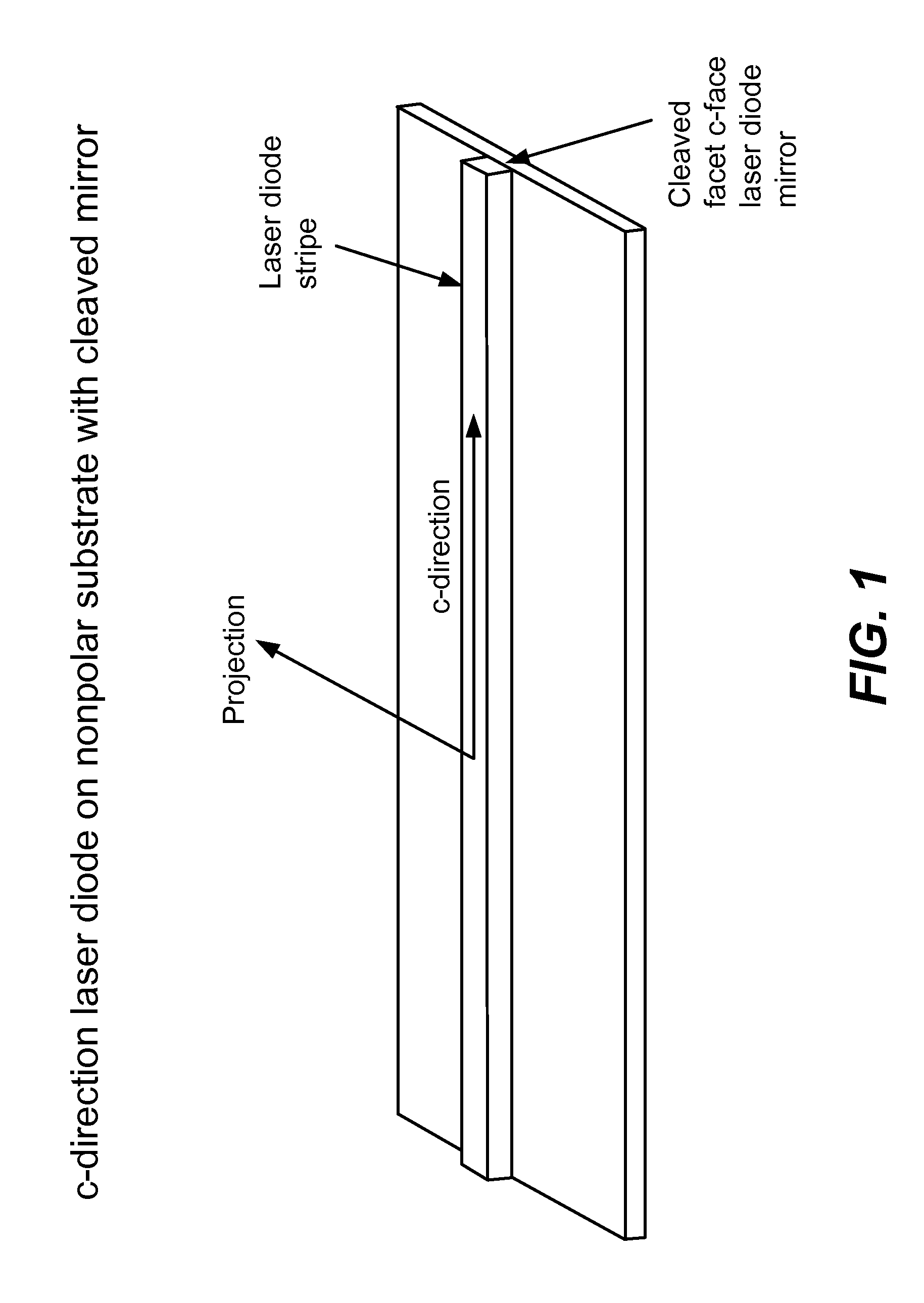

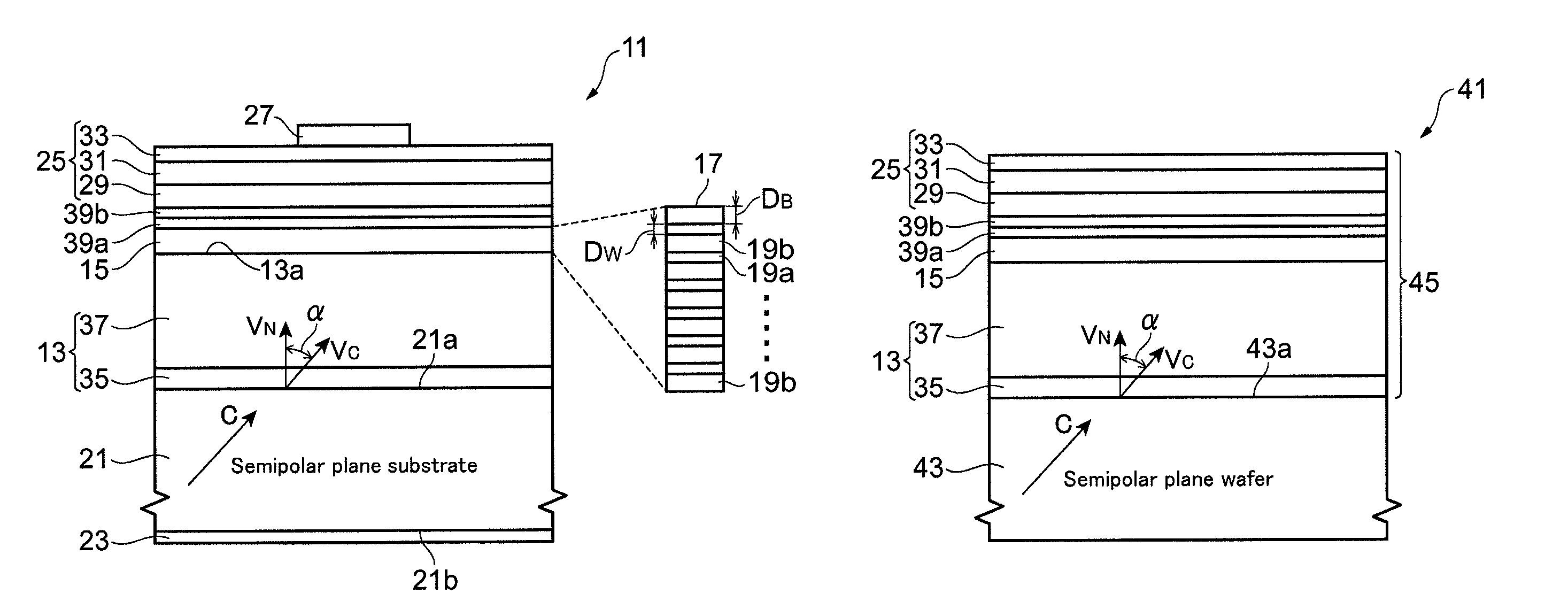

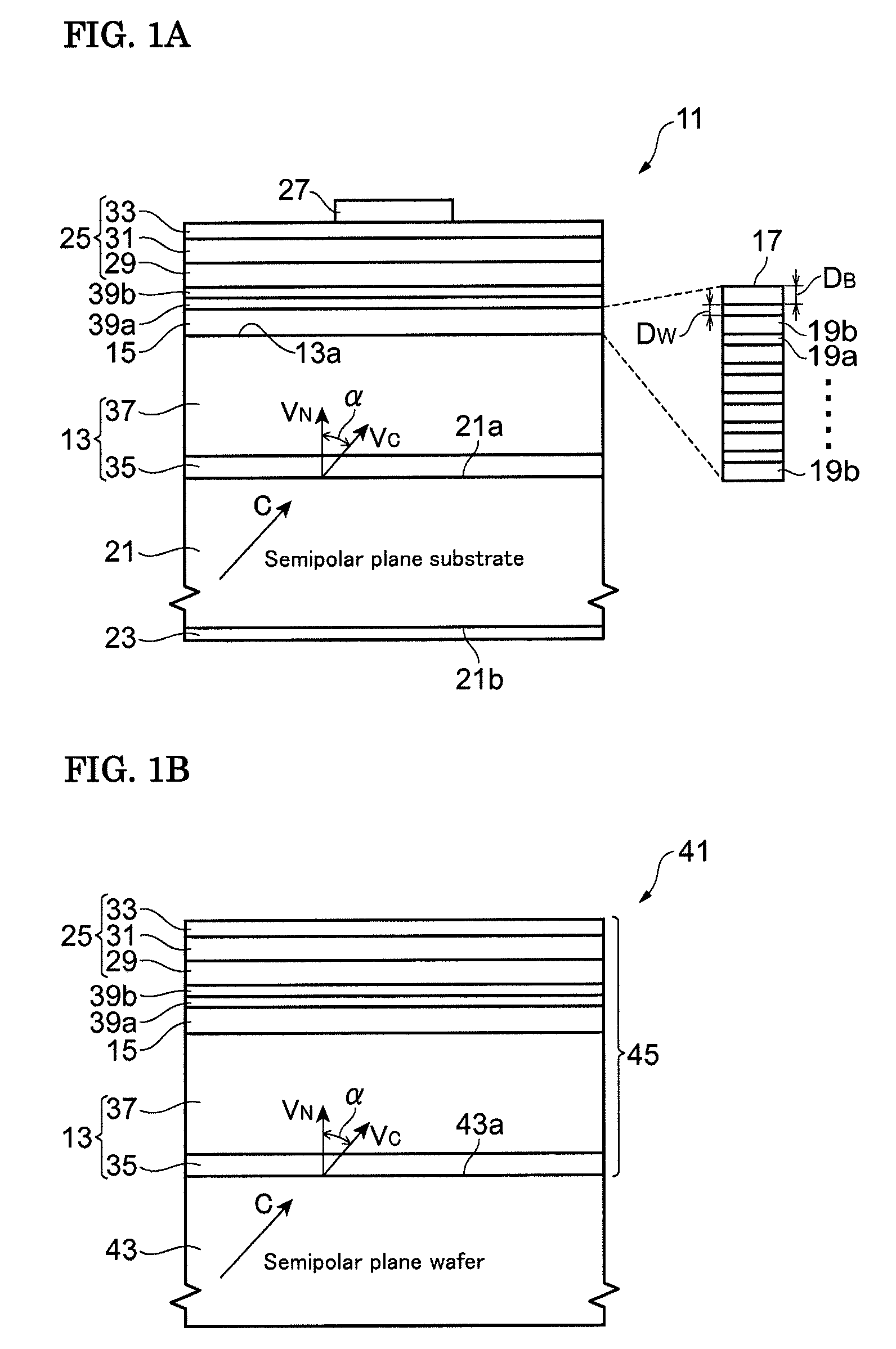

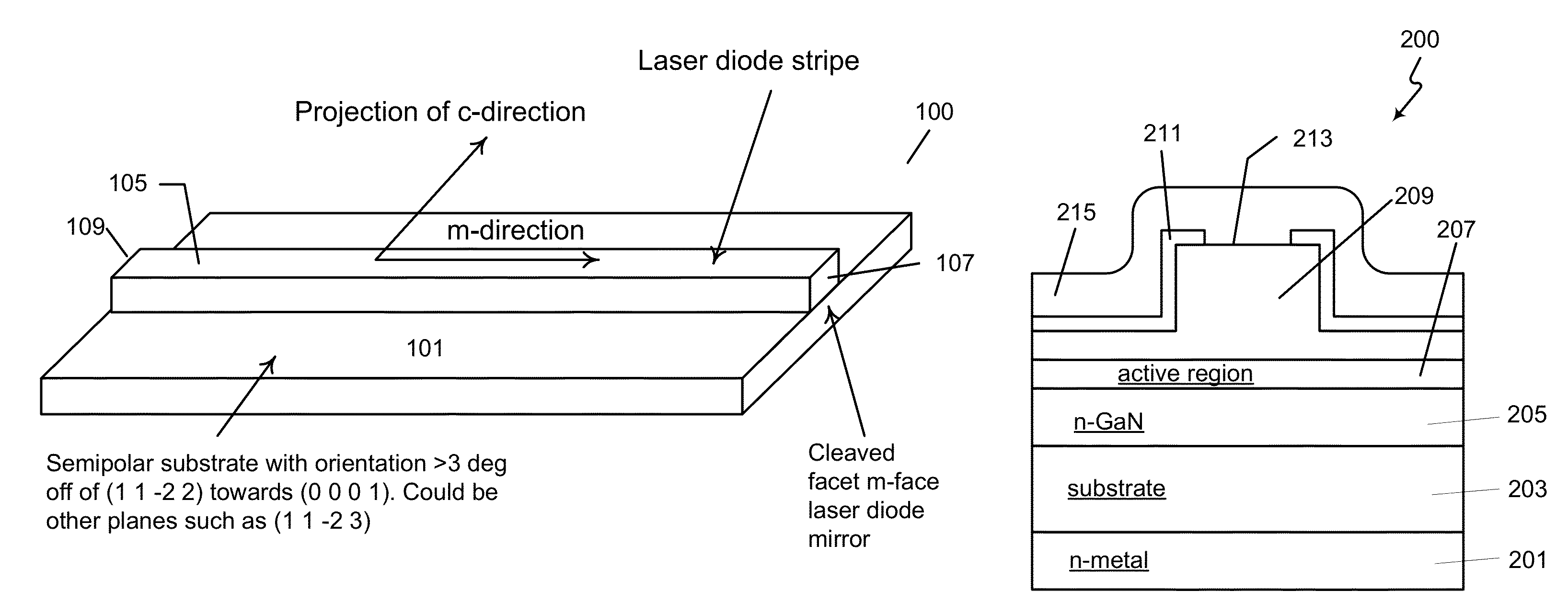

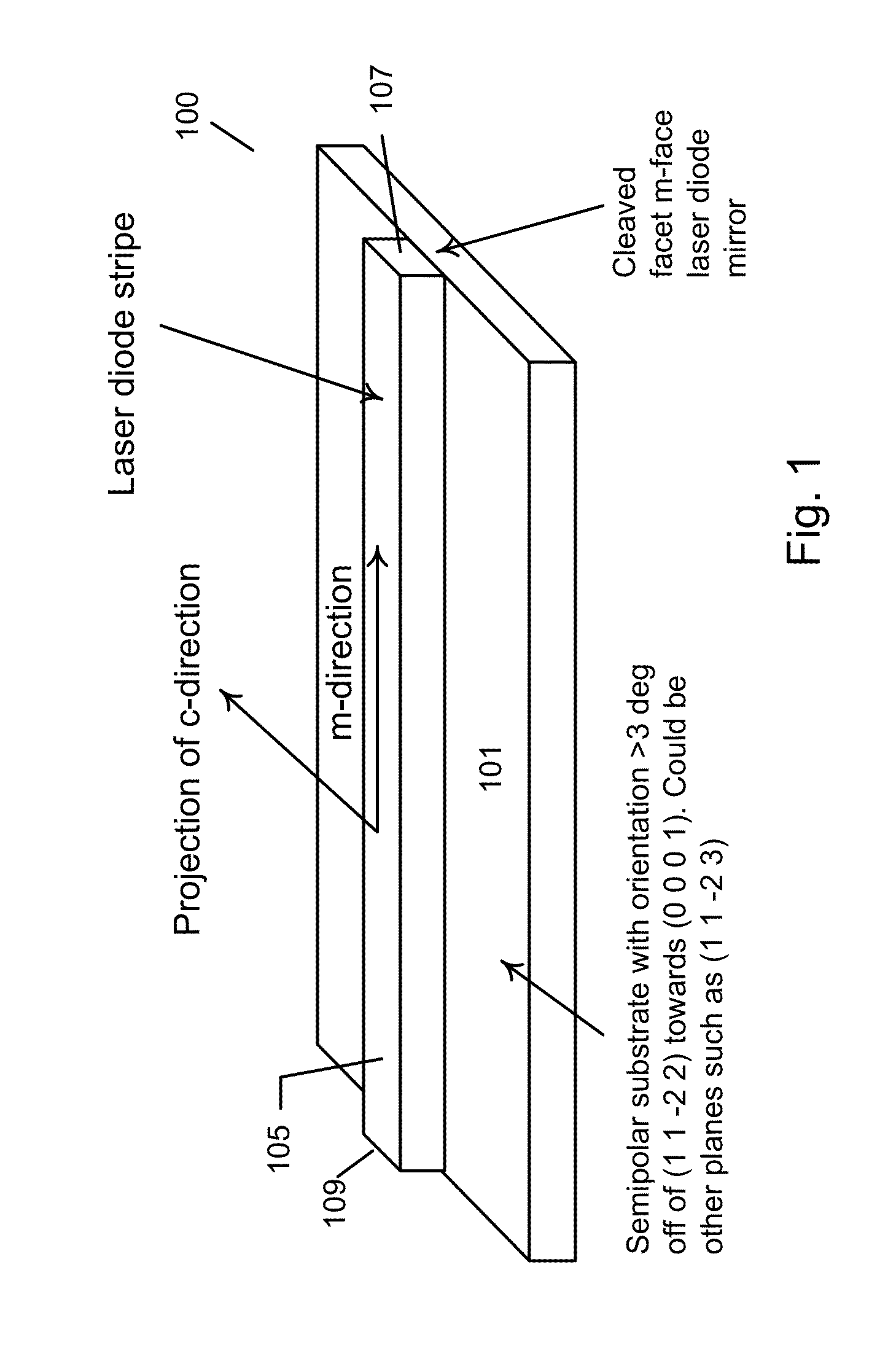

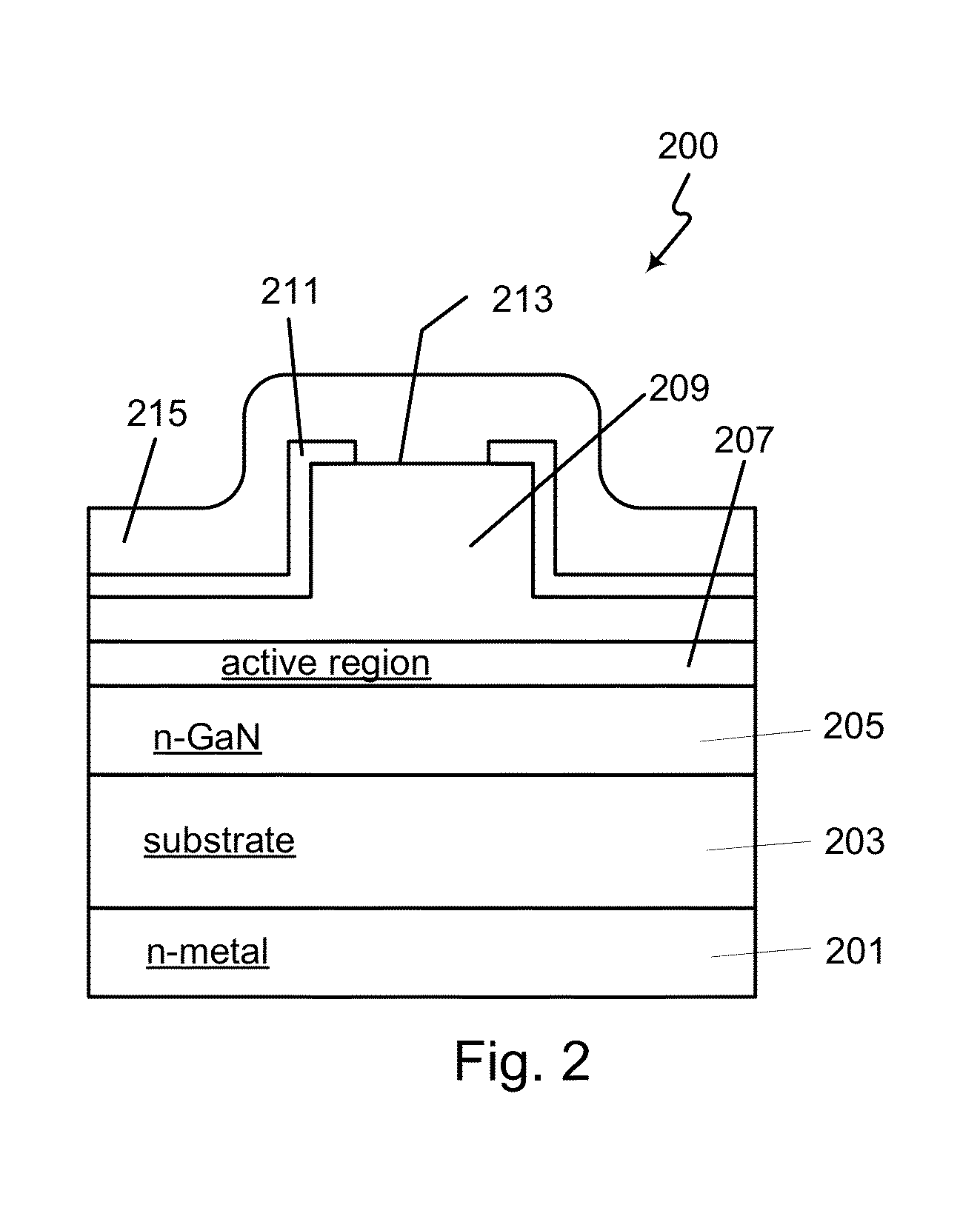

CLEAVED FACET (Ga,Al,In)N EDGE-EMITTING LASER DIODES GROWN ON SEMIPOLAR BULK GALLIUM NITRIDE SUBSTRATES

ActiveUS20080191223A1Optical wave guidanceSemiconductor/solid-state device manufacturingPlane orientationGallium nitride

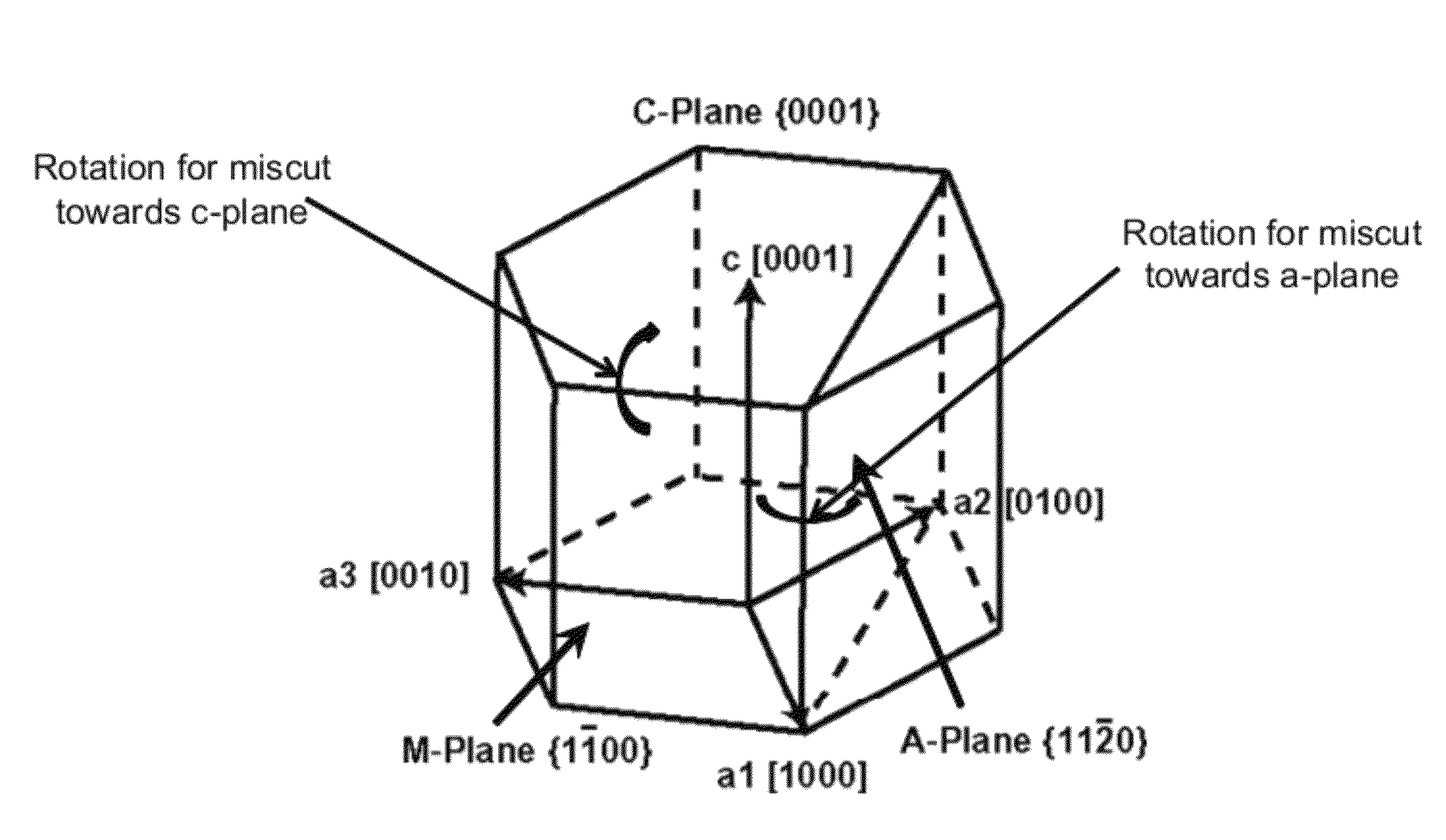

A III-nitride edge-emitting laser diode is formed on a surface of a III-nitride substrate having a semipolar orientation, wherein the III-nitride substrate is cleaved by creating a cleavage line along a direction substantially perpendicular to a nonpolar orientation of the III-nitride substrate, and then applying force along the cleavage line to create one or more cleaved facets of the III-nitride substrate, wherein the cleaved facets have an m-plane or a-plane orientation.

Owner:RGT UNIV OF CALIFORNIA

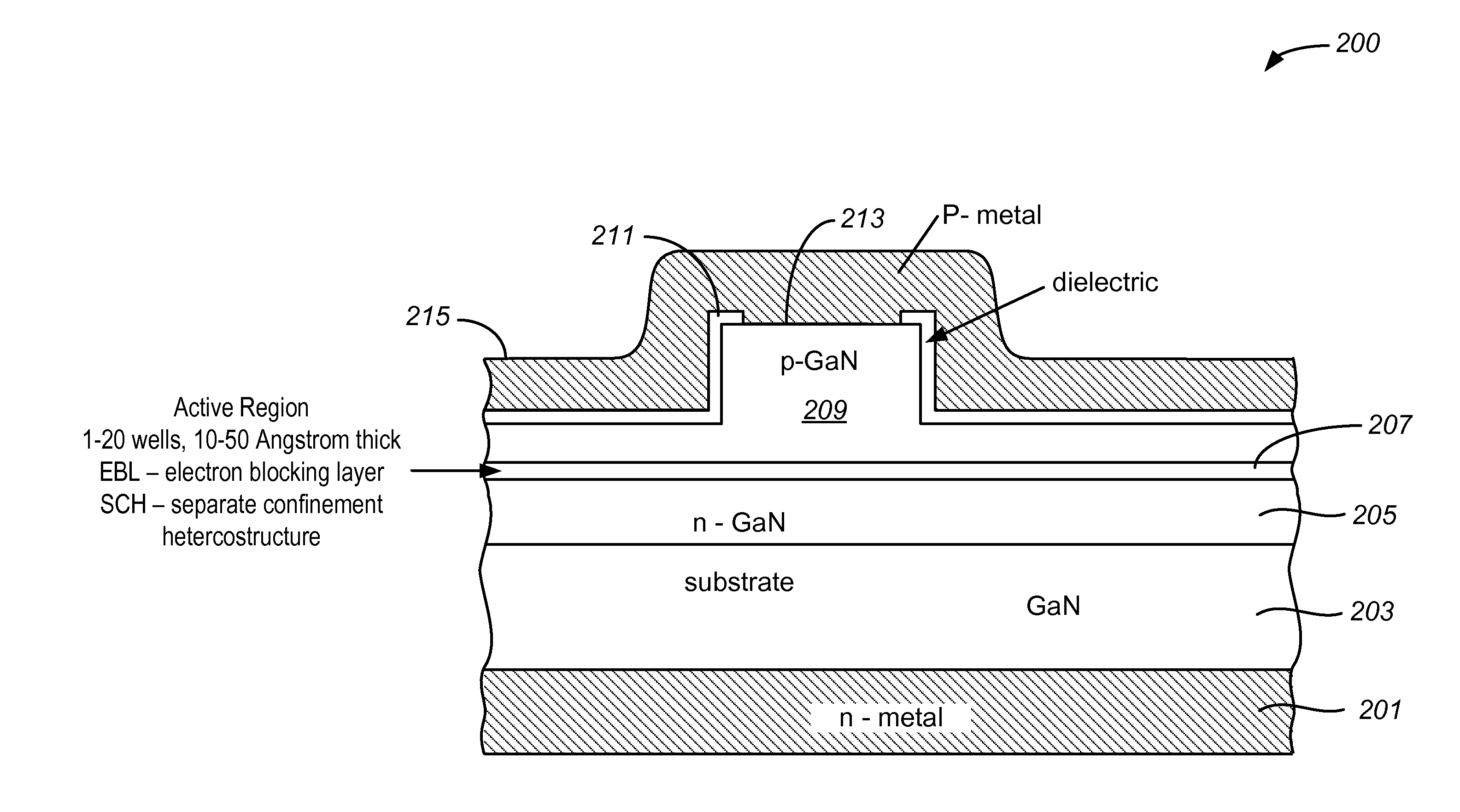

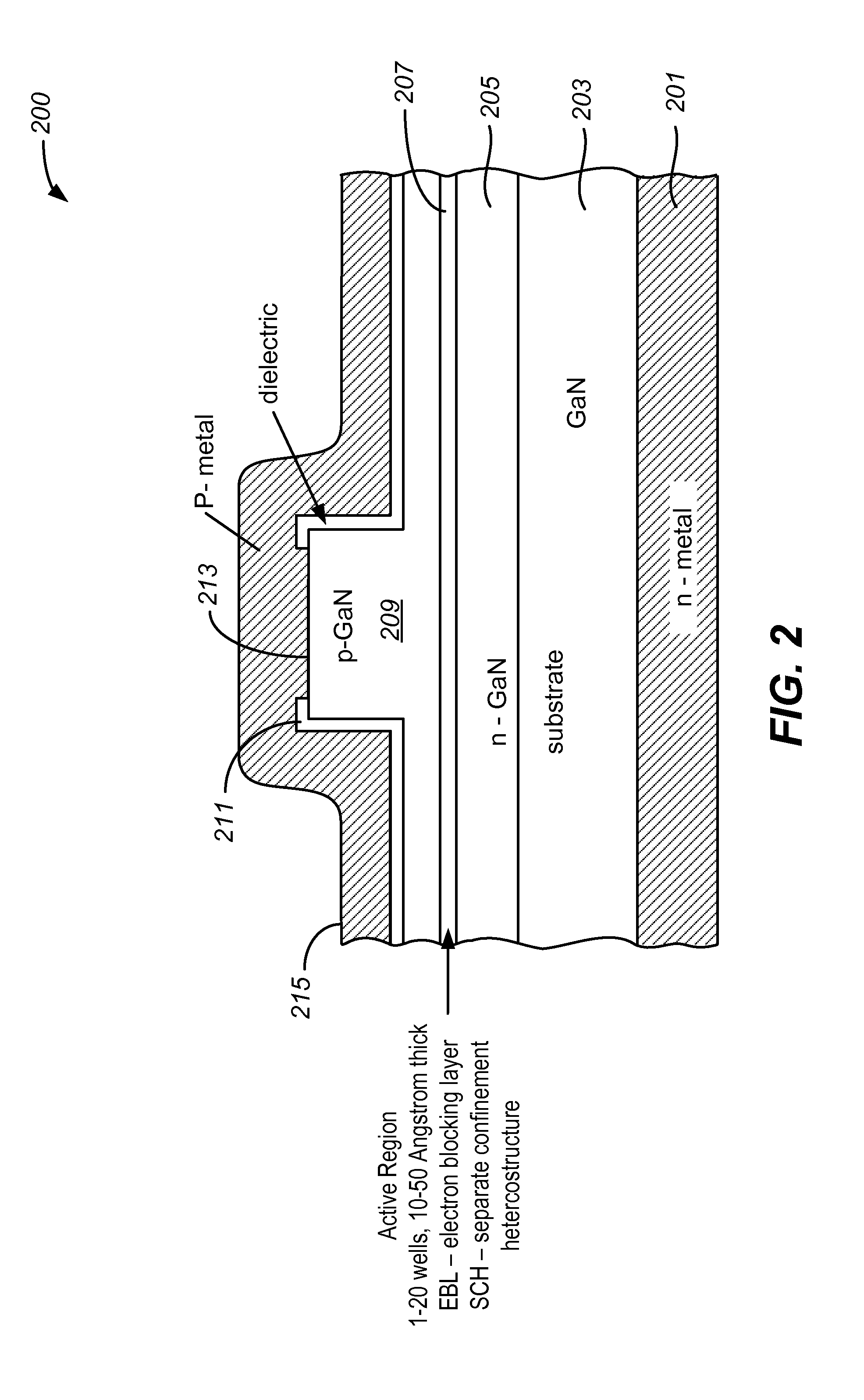

Optical Device Structure Using GaN Substrates for Laser Applications

ActiveUS20100316075A1Simple and cost-effectiveAchieve benefitsLaser detailsLaser optical resonator constructionGallium nitrideLaser application

An optical device includes a gallium nitride substrate member having an m-plane nonpolar crystalline surface region characterized by an orientation of about −2 degrees to about 2 degrees towards (000-1) and less than about 0.5 degrees towards (11-20). The device also has a laser stripe region formed overlying a portion of the m-plane nonpolar crystalline orientation surface region. A first cleaved c-face facet is provided on one end of the laser stripe region, and a second cleaved c-face facet is provided on the other end of the laser stripe region.

Owner:KYOCERA SLD LASER INC

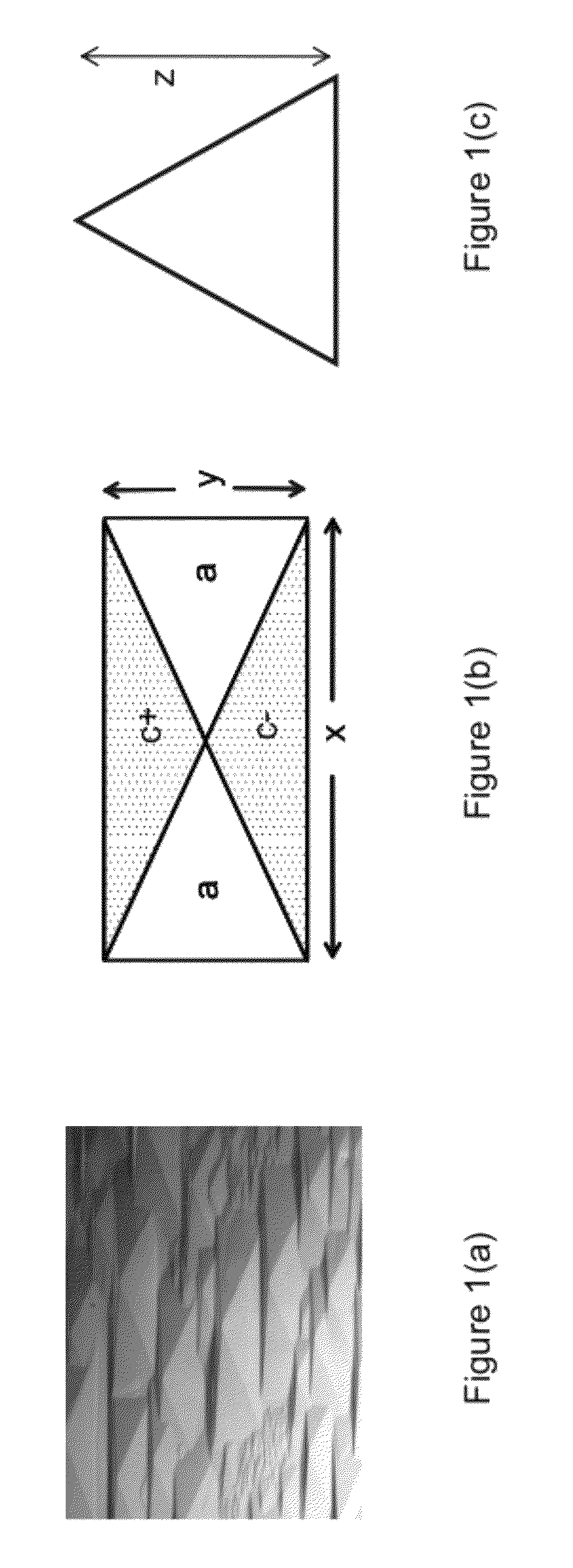

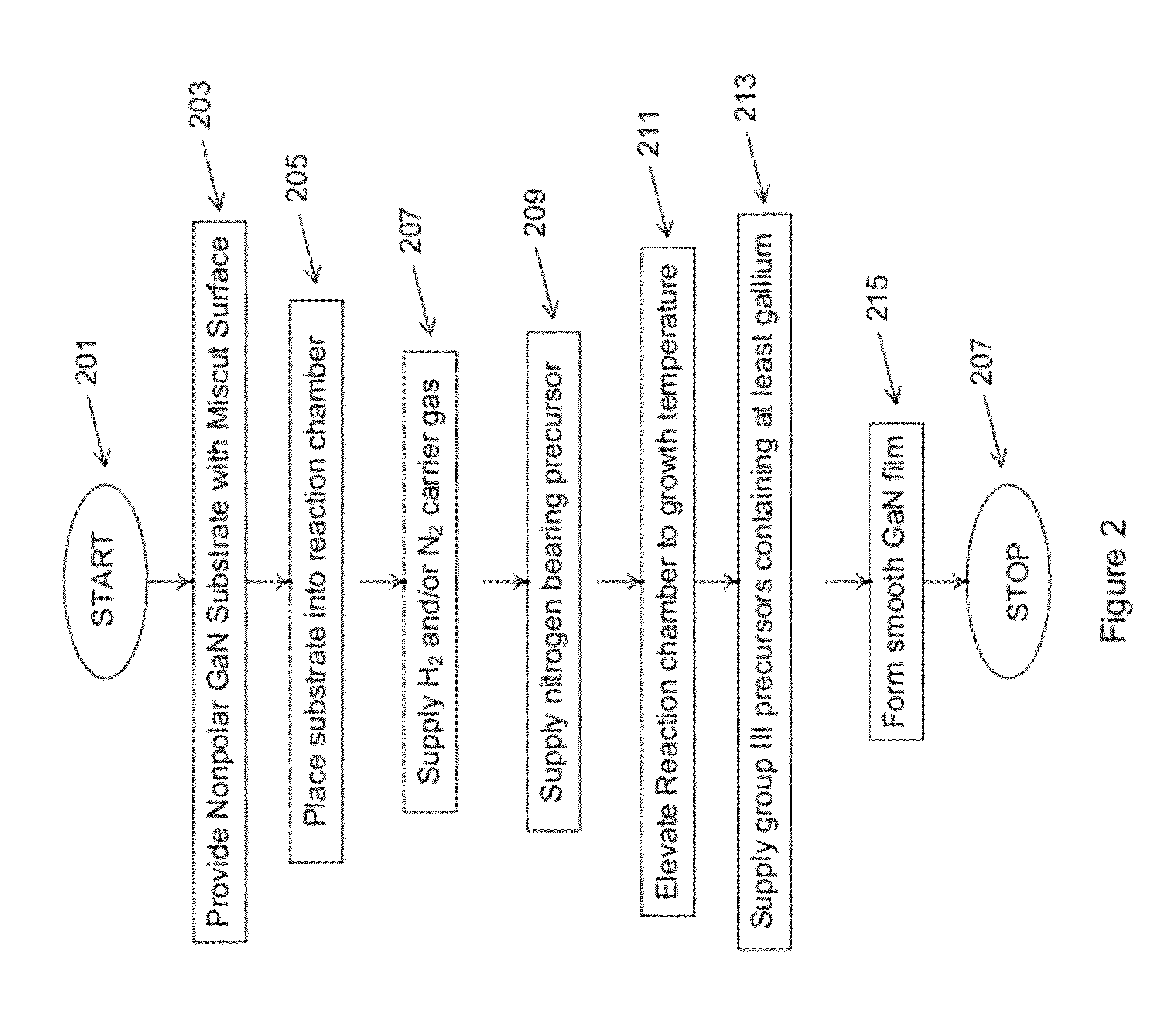

Method and surface morphology of non-polar gallium nitride containing substrates

ActiveUS8247887B1Improve device performanceCost-effective manufacturingPolycrystalline material growthFrom chemically reactive gasesGallium nitrideLaser

An optical device, e.g., LED, laser. The device includes a non-polar gallium nitride substrate member having a slightly off-axis non-polar oriented crystalline surface plane. In a specific embodiment, the slightly off-axis non-polar oriented crystalline surface plane is up to about −0.6 degrees in a c-plane direction, but can be others. In a specific embodiment, the present invention provides a gallium nitride containing epitaxial layer formed overlying the slightly off-axis non-polar oriented crystalline surface plane. In a specific embodiment, the device includes a surface region overlying the gallium nitride epitaxial layer that is substantially free of hillocks.

Owner:SLT TECH

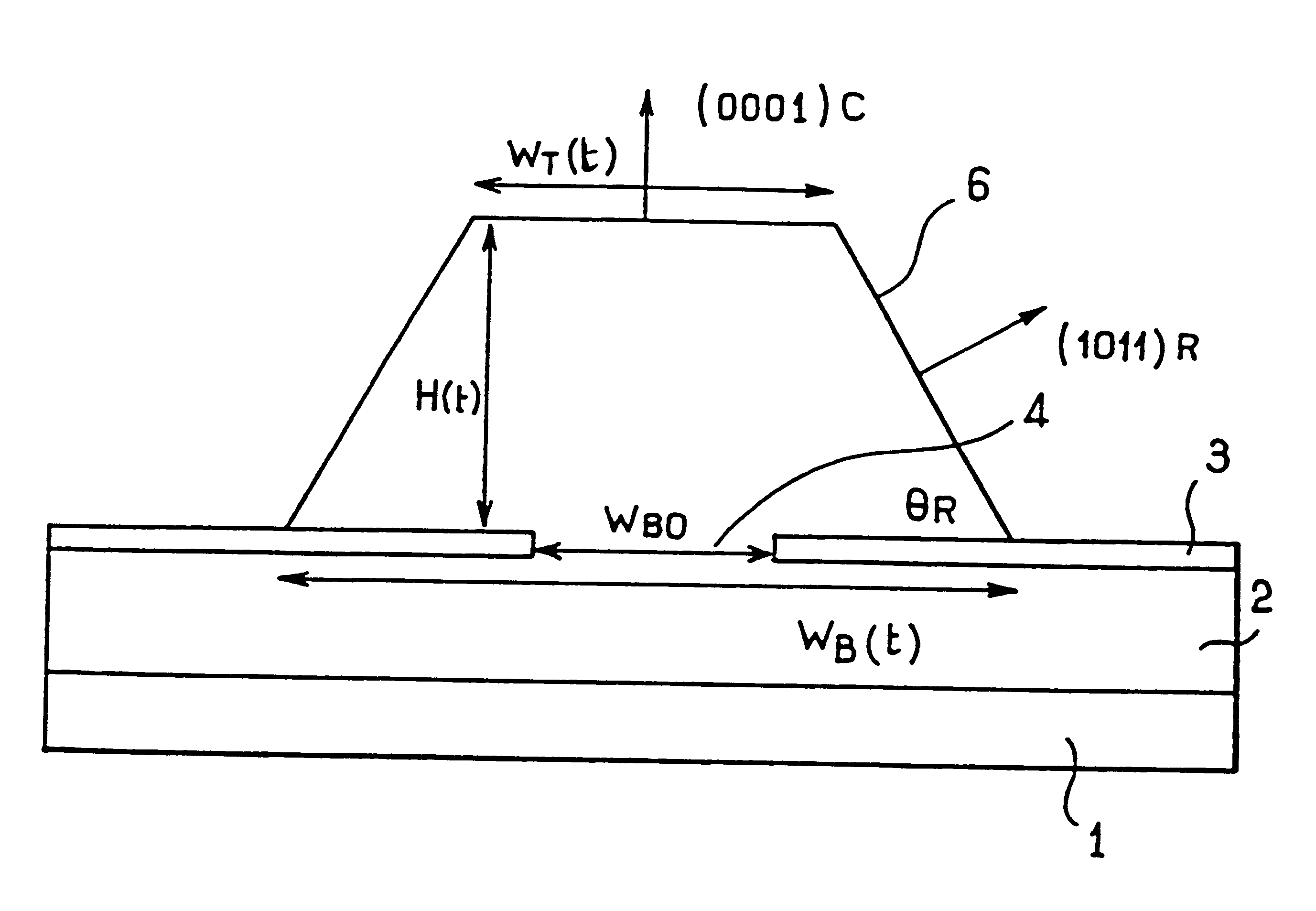

Technique for the growth of planar semi-polar gallium nitride

ActiveUS20060205199A1Reduce the impactReduce impactPolycrystalline material growthSemiconductor/solid-state device manufacturingSpinelGallium nitride

A method for growing planar, semi-polar nitride film on a miscut spinel substrate, in which a large area of the planar, semi-polar nitride film is parallel to the substrate's surface. The planar films and substrates are: (1) {10{overscore (1)}1} gallium nitride (GaN) grown on a {100} spinel substrate miscut in specific directions, (2) {10{overscore (1)}3} gallium nitride (GaN) grown on a {110} spinel substrate, (3) {11{overscore (2)}2} gallium nitride (GaN) grown on a {1{overscore (1)}00} sapphire substrate, and (4) {11{overscore (1)}3} gallium nitride (GaN) grown on a {1{overscore (1)}00} sapphire substrate

Owner:JAPAN SCI & TECH CORP

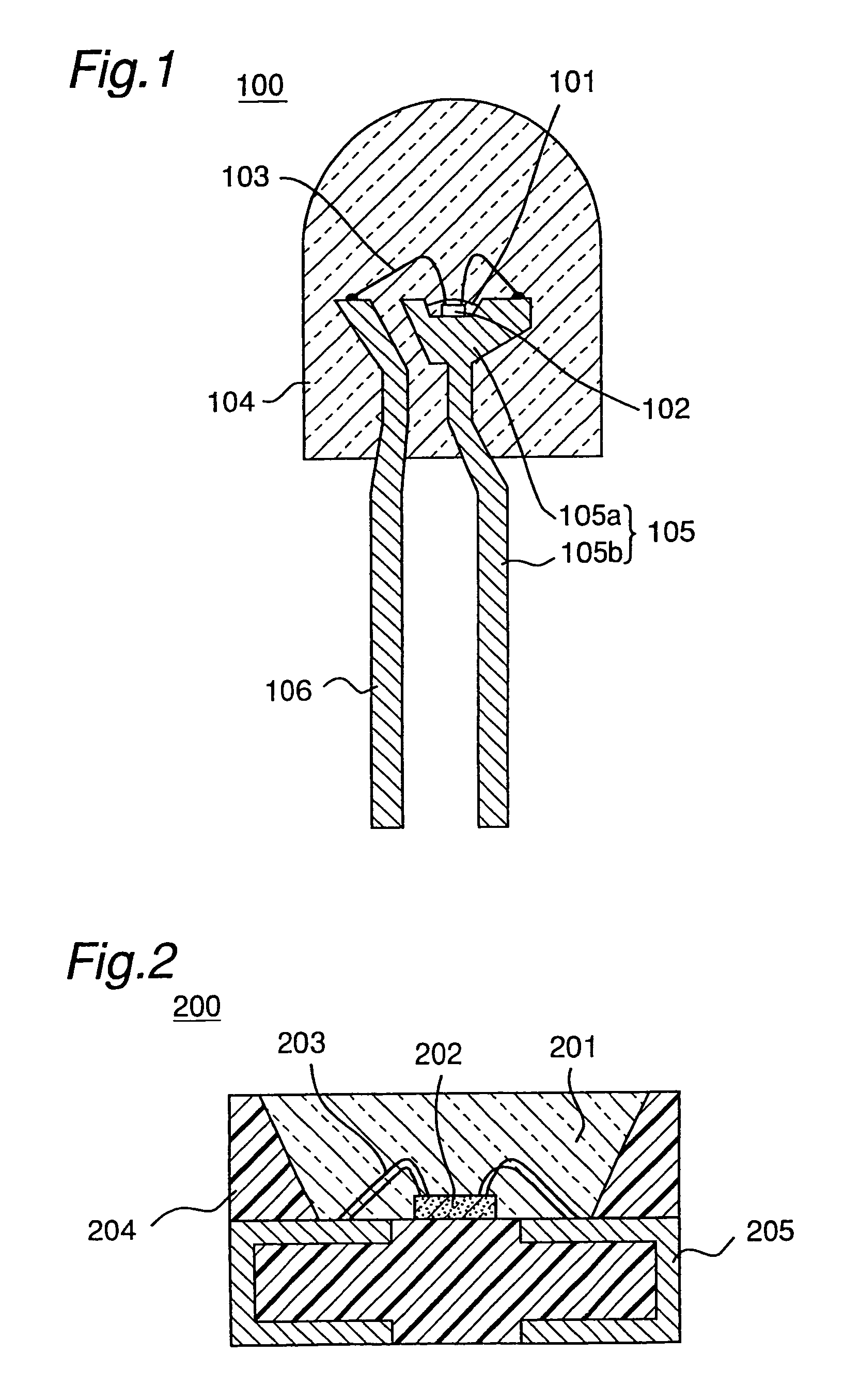

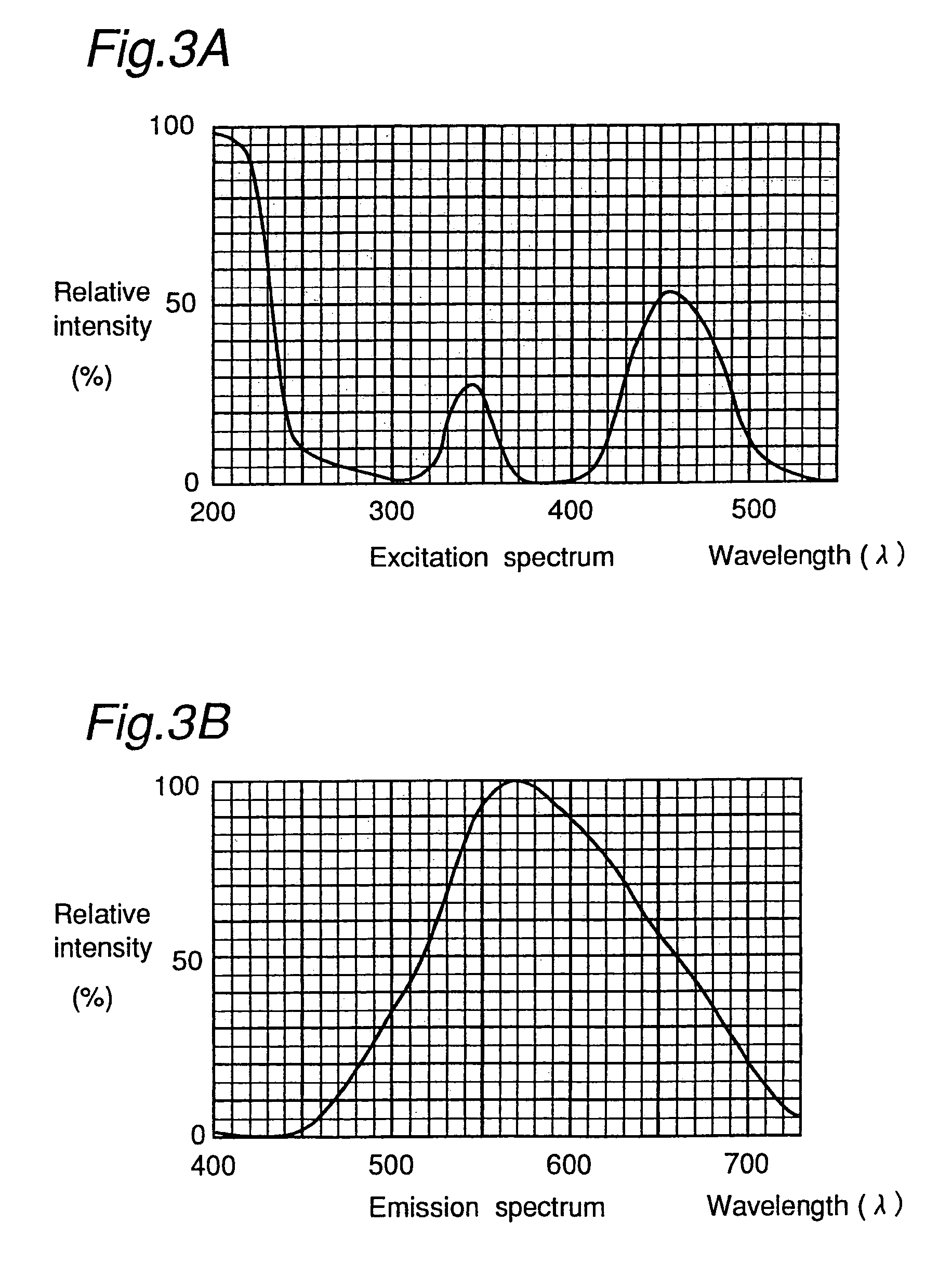

Light emitting device with blue light LED and phosphor components

InactiveUS7026756B2Low degree of deterioration in emission light intensityIncrease brightnessMechanical apparatusDischarge tube luminescnet screensIndiumPhosphor

A light emitting device includes a light emitting component having an active layer of a semiconductor and a phosphor capable of absorbing a part of light emitted from the light emitting component and emitting light of wavelength different from that of the absorbed light, wherein the light emitting component is a LED which has an active layer constituting a gallium nitride based semiconductor containing Indium and is capable of emitting a blue color light with a peak wavelength within the range from 420 to 490 nm. The phosphor is a garnet fluorescent material activated with cerium which is capable of absorbing a part of the blue color light and thereby emitting light having a broad emission spectrum with a peak wavelength existing around the range from 510 to 600 nm and a tail continuing into the region from 700 to 750 nm.

Owner:NICHIA CORP

Group-III nitride light-emitting device

ActiveUS7968864B2Piezoelectric field is reducedLow efficiencyThyristorSolid-state devicesQuantum wellLength wave

A group-III nitride light-emitting device is provided. An active layer having a quantum well structure is grown on a basal plane of a gallium nitride based semiconductor region. The quantum well structure is formed in such a way as to have an emission peak wavelength of 410 nm or more. The thickness of a well layer is 4 nm or more, and 10 nm or less. The well layer is composed of InXGa1-XN (0.15≦X<1, where X is a strained composition). The basal plane of the gallium nitride based semiconductor region is inclined at an inclination angle within the range of 15 degrees or more, and 85 degrees or less with reference to a {0001} plane or a {000-1} plane of a hexagonal system group III nitride. The basal plane in this range is a semipolar plane.

Owner:SUMITOMO ELECTRIC IND LTD

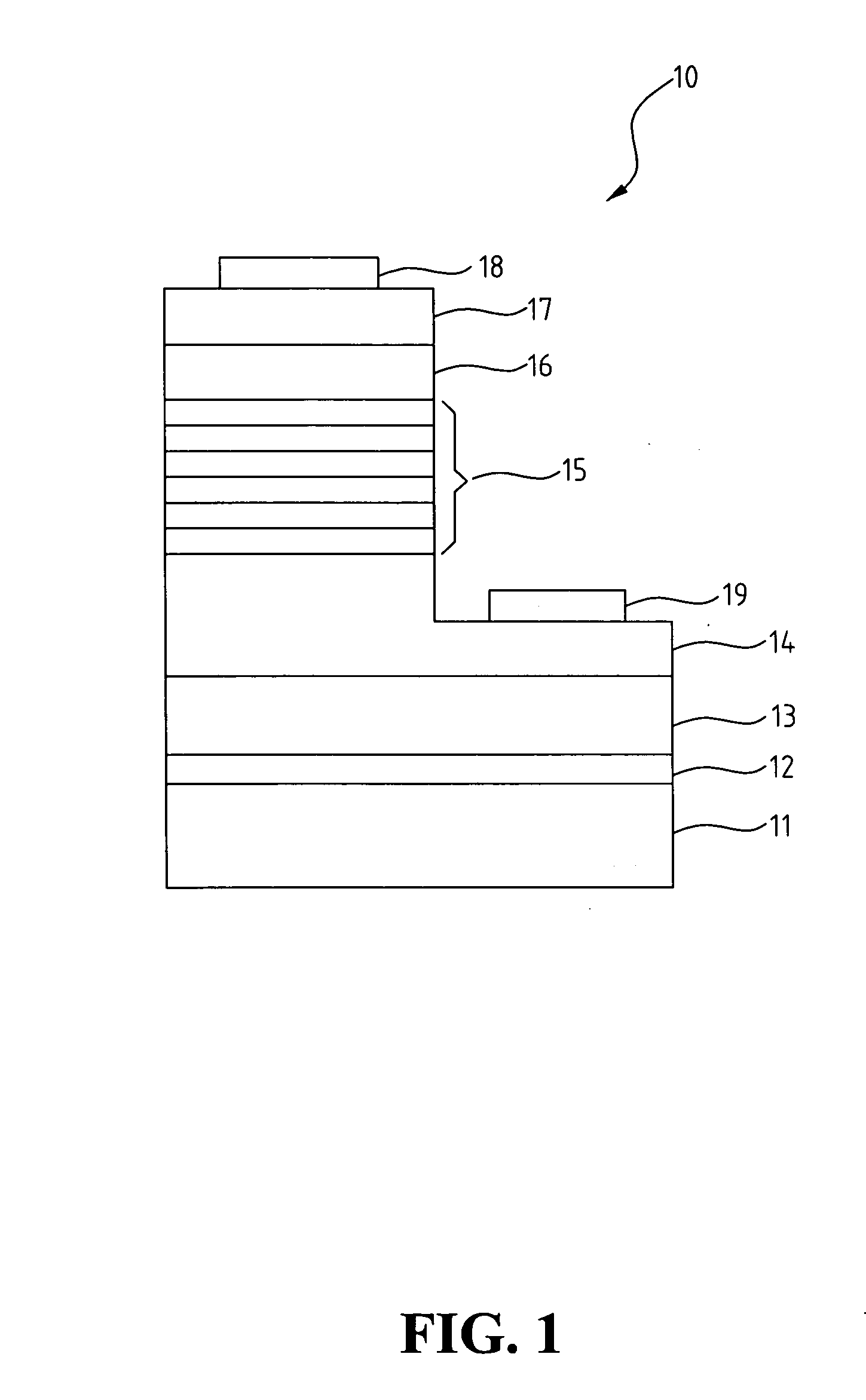

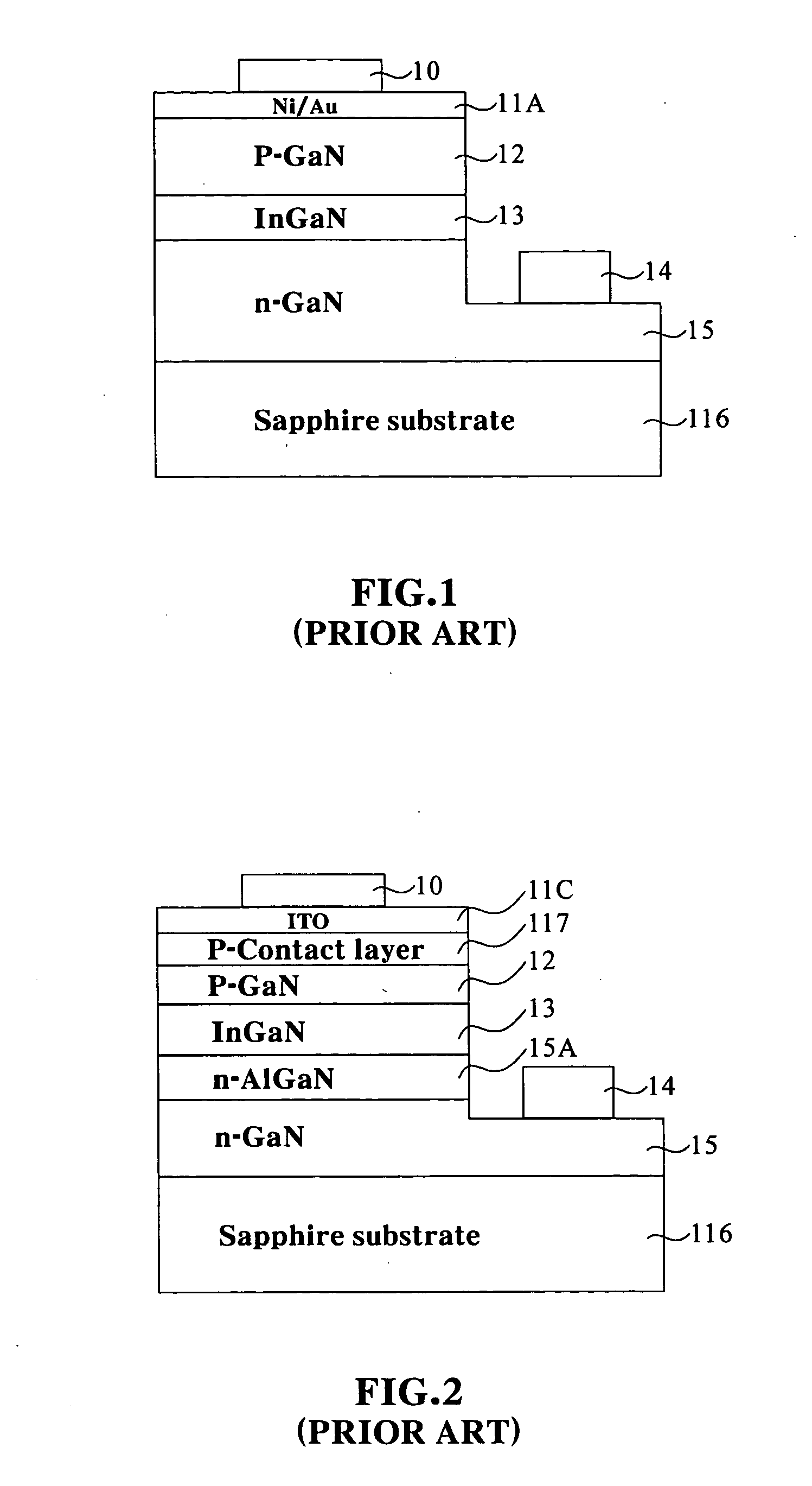

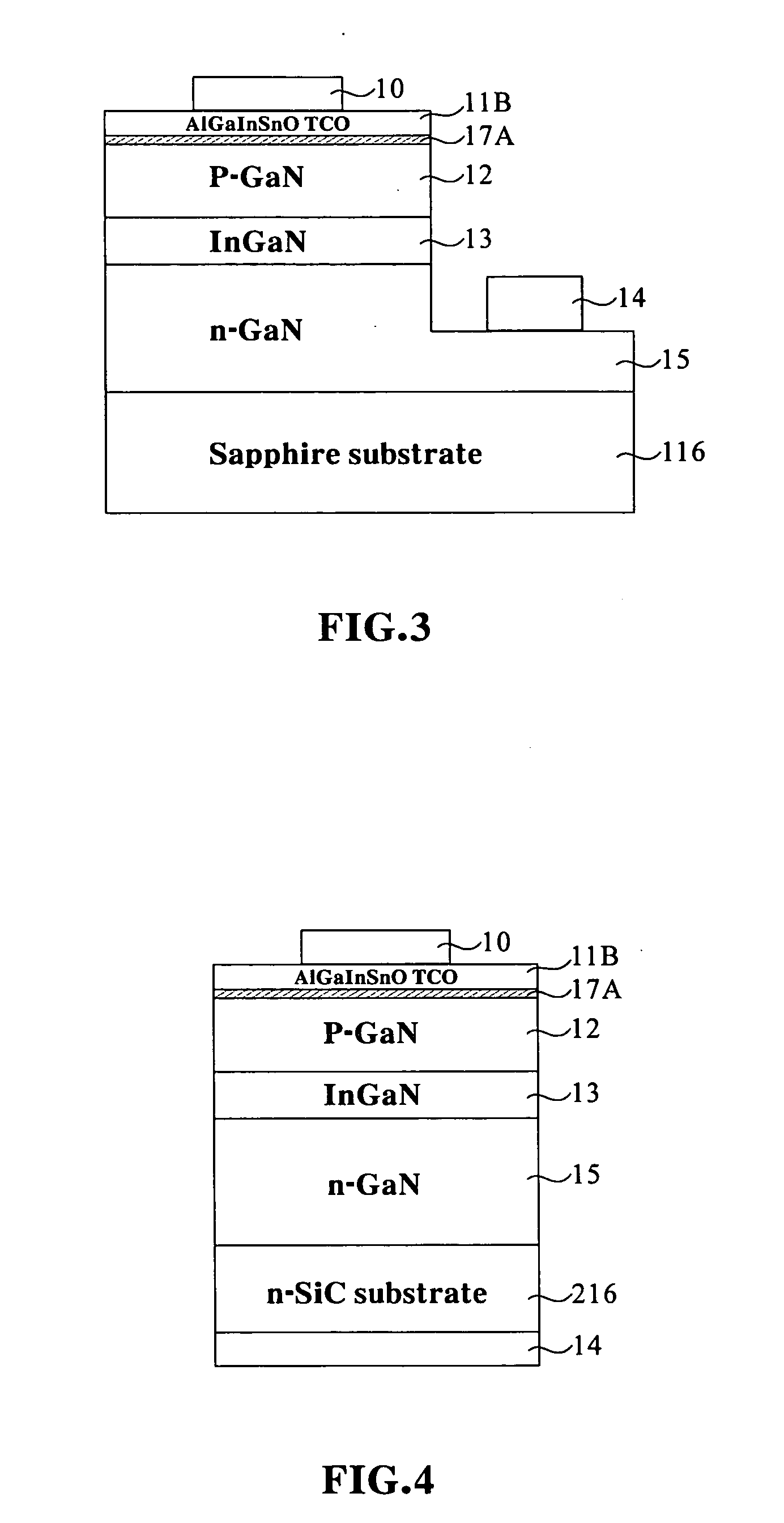

Gallium-nitride based light emitting diode structure with enhanced light illuminance

InactiveUS20060038193A1High light transmittanceConvenient lightingSemiconductor devicesIlluminanceQuantum well

Disclosed is a multi-quantum-well light emitting diode, which makes enormous adjustments and improvements over the conventional light emitting diode, and further utilizes a transparent contact layer of better transmittance efficiency, so as to significantly raise the illuminance of this light emitting diode and its light emission efficiency. The multi-quantum-well light emitting diode has a structure including: substrate, buffer layer, n-type gallium-nitride layer, active light-emitting-layer, p-type cladding layer, p-type contact layer, barrier buffer layer, transparent contact layer, and the n-type electrode layer.

Owner:FORMOSA EPITAXY INCORPORATION +1

Method for producing a gallium nitride epitaxial layer

InactiveUS6325850B1GaN crystal qualityImprove crystal qualityPolycrystalline material growthLaser detailsEtchingGallium nitride

The invention concerns a method for producing a gallium nitride (GaN) epitaxial layer characterised in that it consists in depositing on a substrate a dielectric layer acting as a mask and depositing on the masked gallium nitride, by epitaxial deposit, so as to induce the deposit of gallium nitride patterns and the anisotropic lateral growth of said patterns, the lateral growth being pursued until the different patterns coalesce. The deposit of the gallium nitride patterns can be carried out ex-situ by dielectric etching or in-situ by treating the substrate for coating it with a dielectric film whereof the thickness is of the order of one angstrom. The invention also concerns the gallium nitride layers obtained by said method.

Owner:SAINT GOBAIN CRISTAUX & DETECTEURS

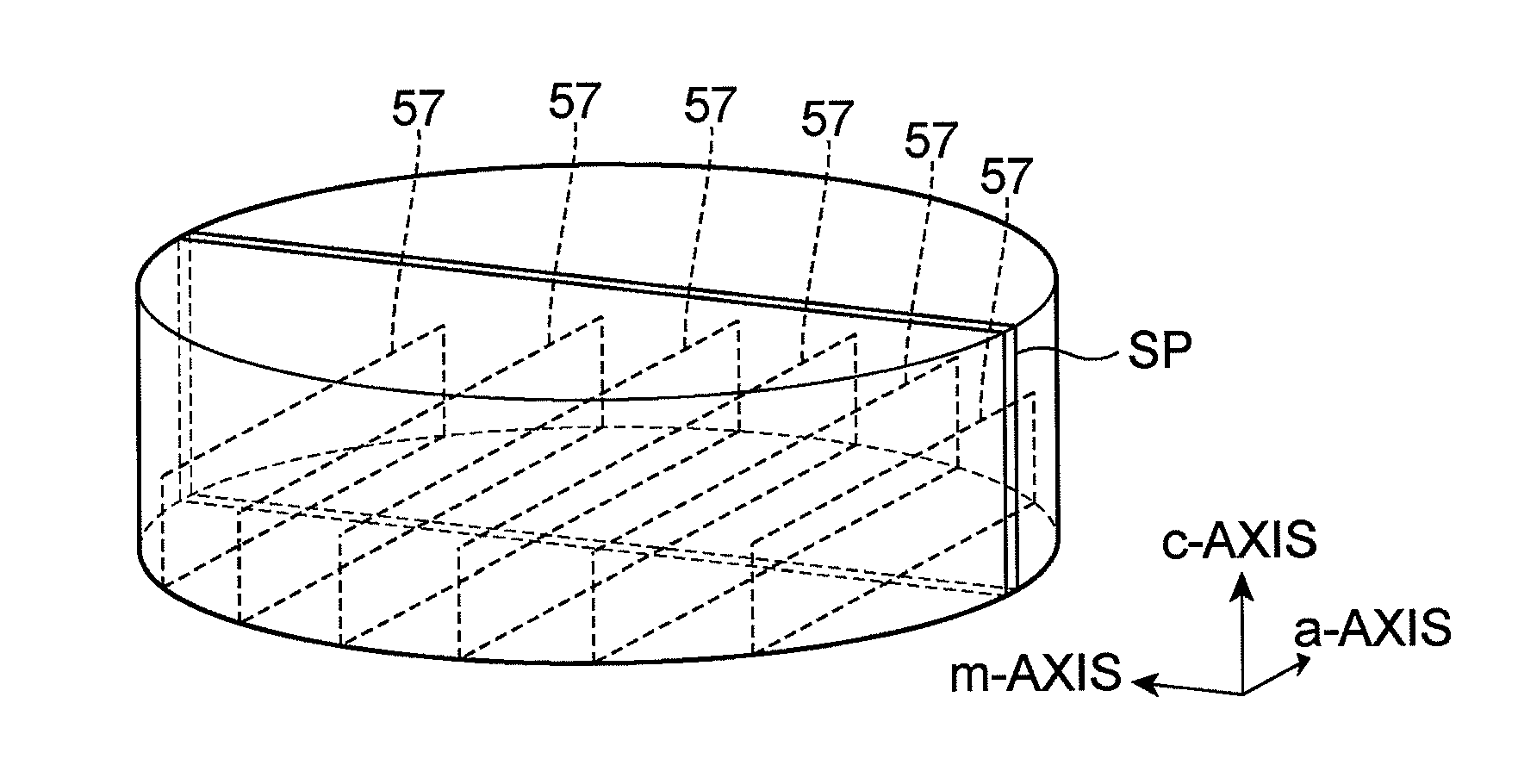

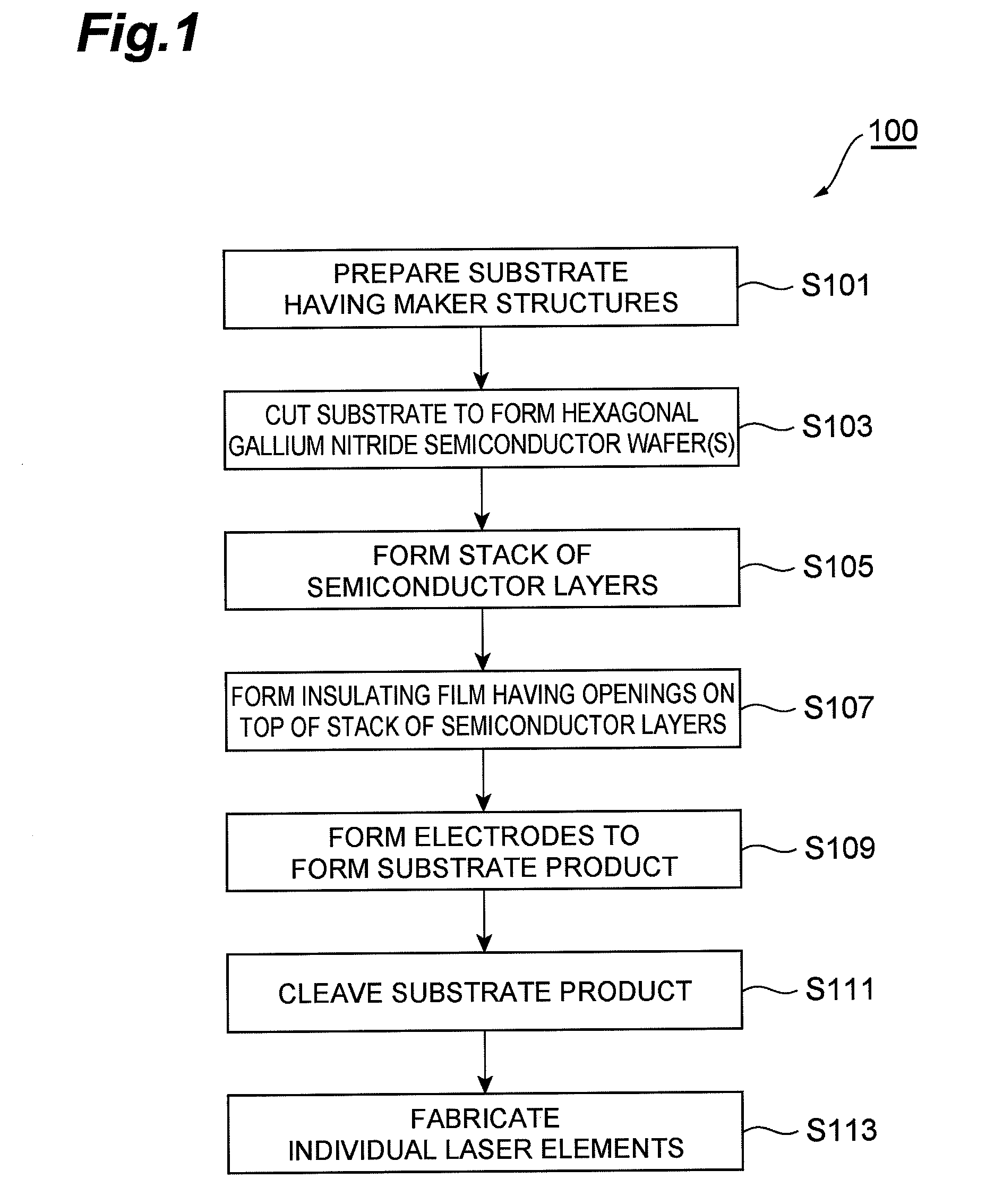

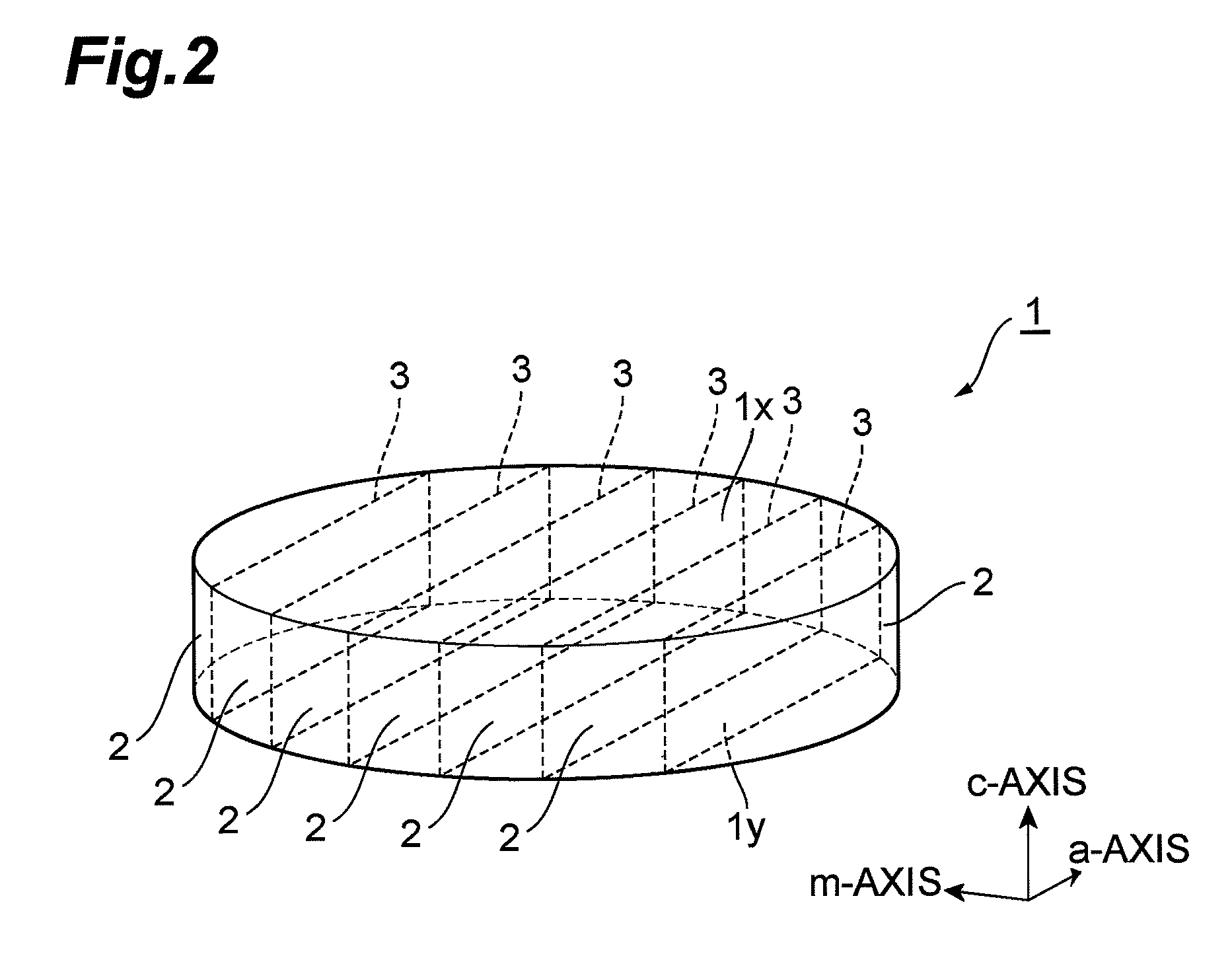

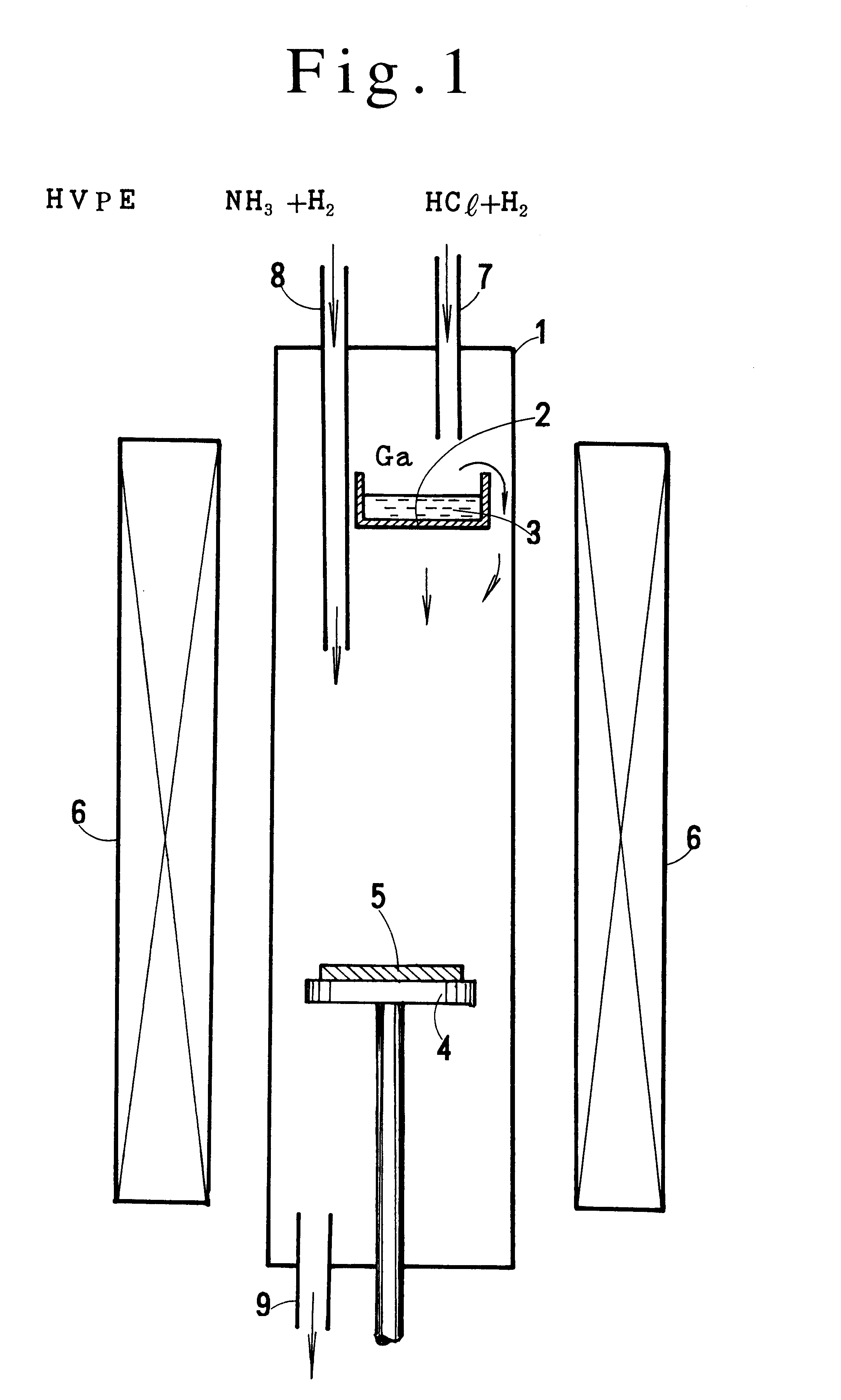

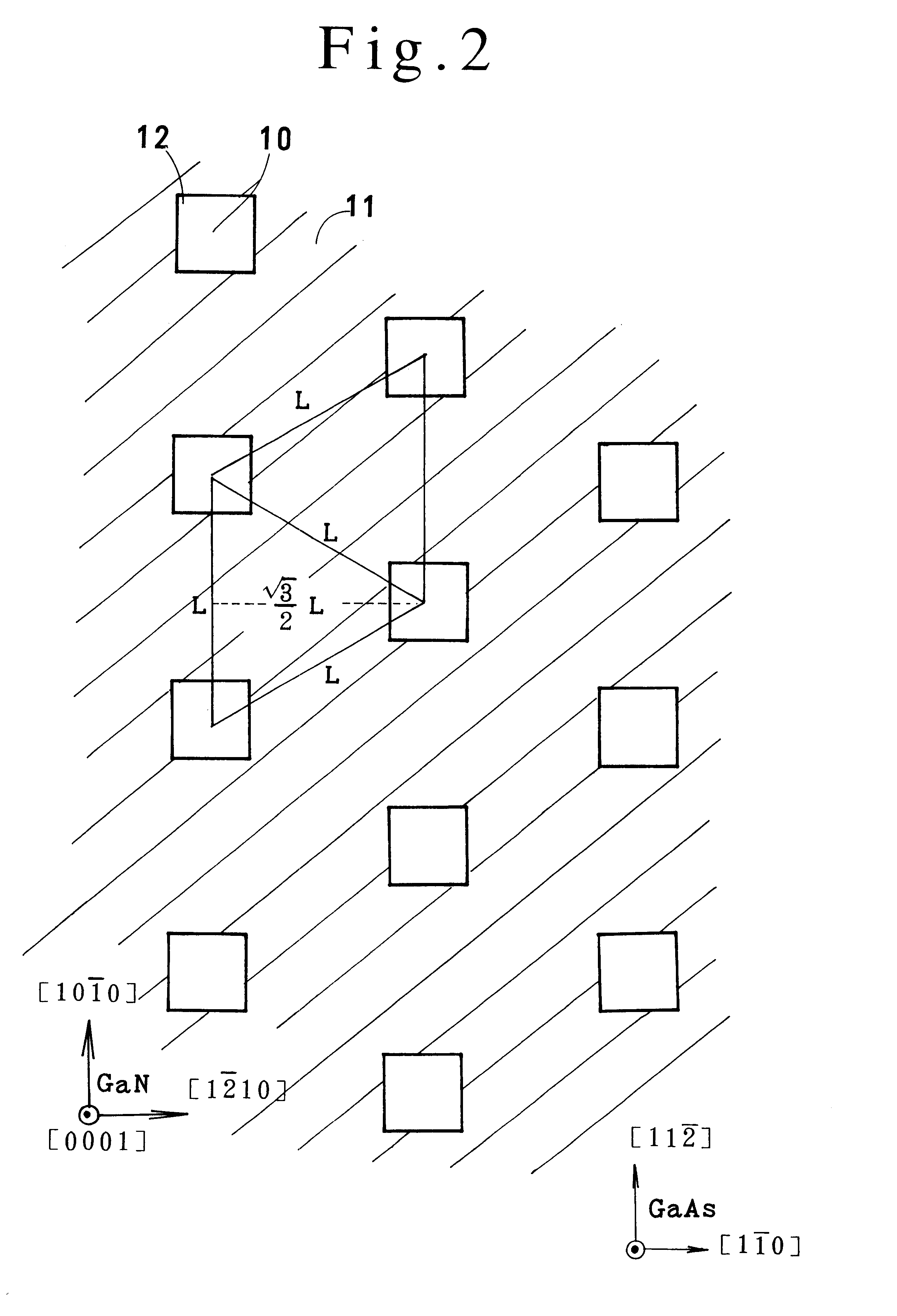

Method of fabricating nitride semiconductor laser

InactiveUS7939354B2Good orientationLarge caliberSemiconductor/solid-state device detailsSemiconductor laser structural detailsGallium nitrideNitride semiconductors

A method of fabricating a nitride semiconductor laser comprises preparing a substrate having a plurality of marker structures and a crystalline mass made of a hexagonal gallium nitride semiconductor. The primary and back surfaces of the substrate intersect with a predetermined axis extending in the direction of a c-axis of the hexagonal gallium nitride semiconductor. Each marker structure extends along a reference plane defined by the c-axis and an m-axis of the hexagonal gallium nitride semiconductor. The method comprises cutting the substrate along a cutting plane to form a wafer of hexagonal gallium nitride semiconductor, and the cutting plane intersects with the plurality of the marker structures. The wafer has a plurality of first markers, each of which extends from the primary surface to the back surface of the wafer, and each of the first markers comprises part of each of the marker structures. The primary surface of the wafer is semipolar or nonpolar. The method comprises growing a number of gallium nitride based semiconductor layers for a semiconductor laser. The method comprises cleaving the substrate product at a cleavage plane of the hexagonal gallium nitride semiconductor, after forming a substrate product in an electrode forming step.

Owner:SUMITOMO ELECTRIC IND LTD

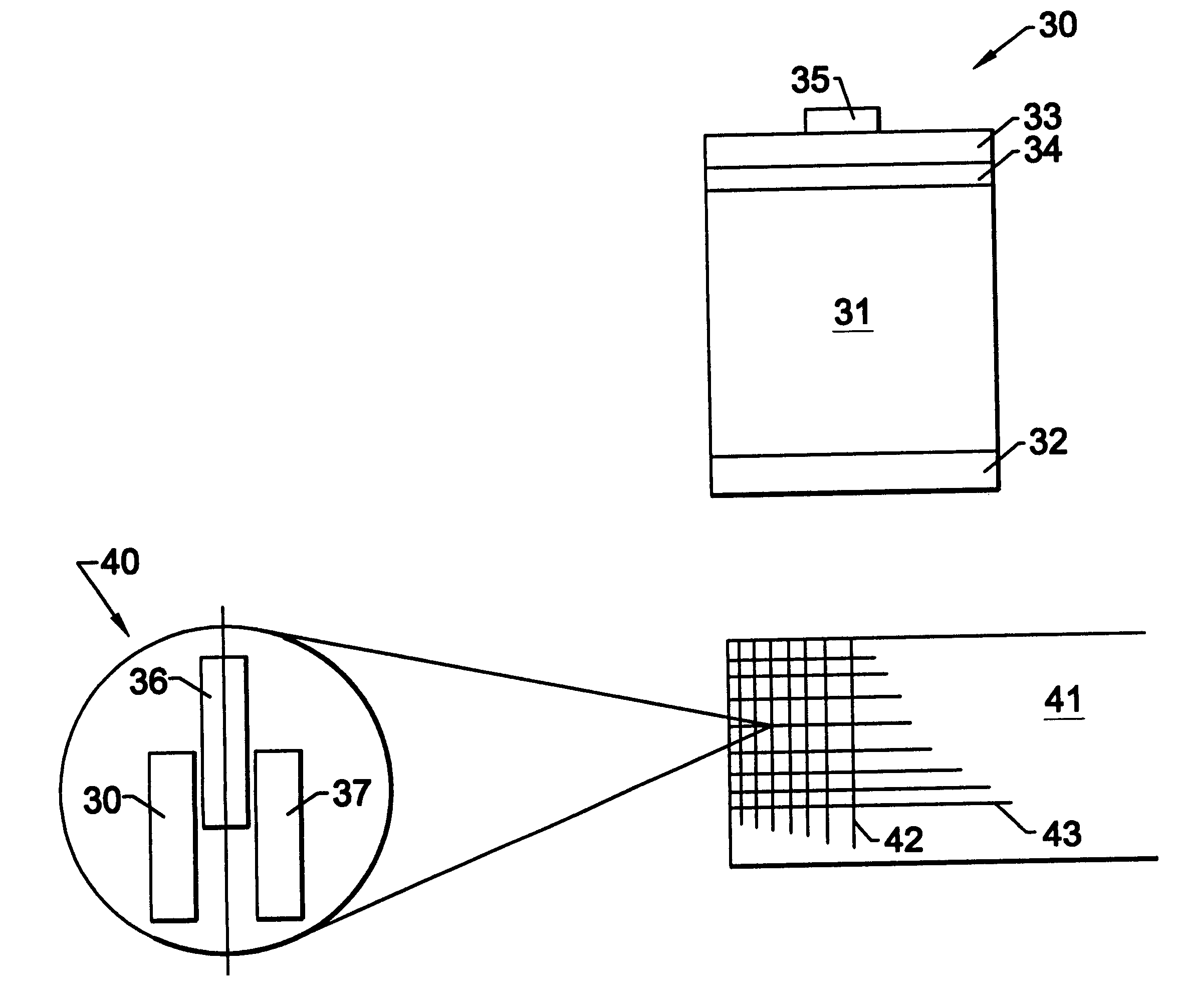

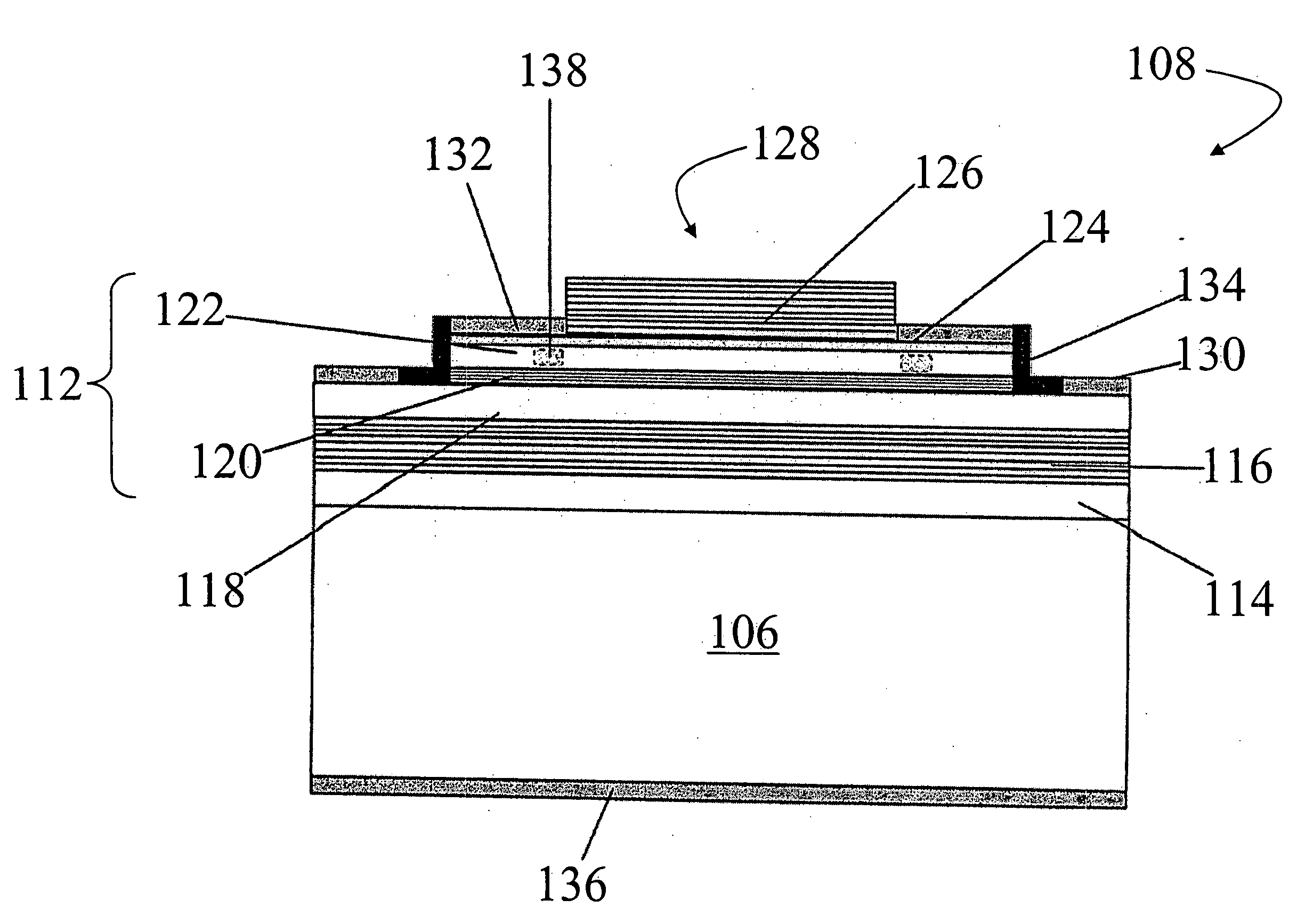

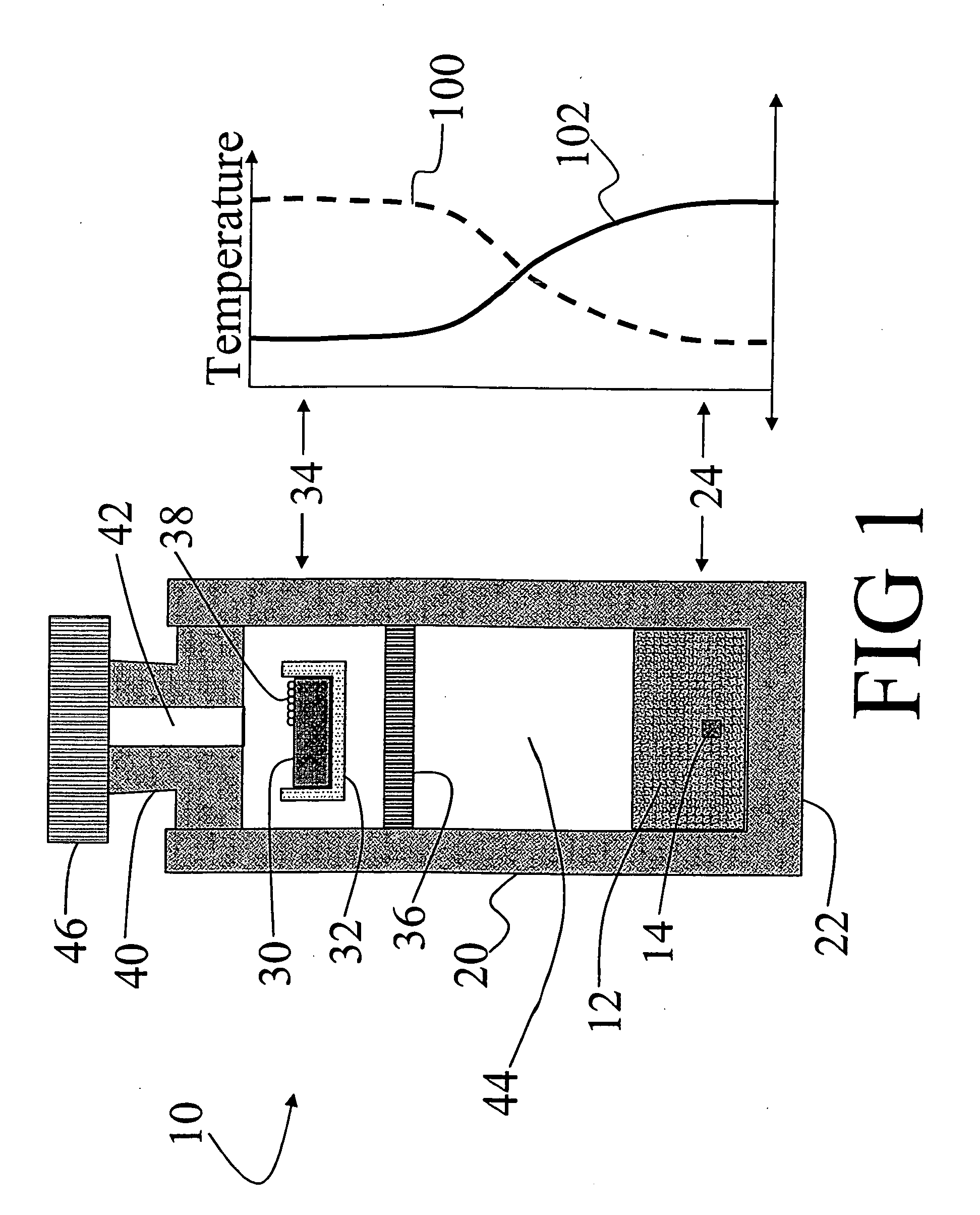

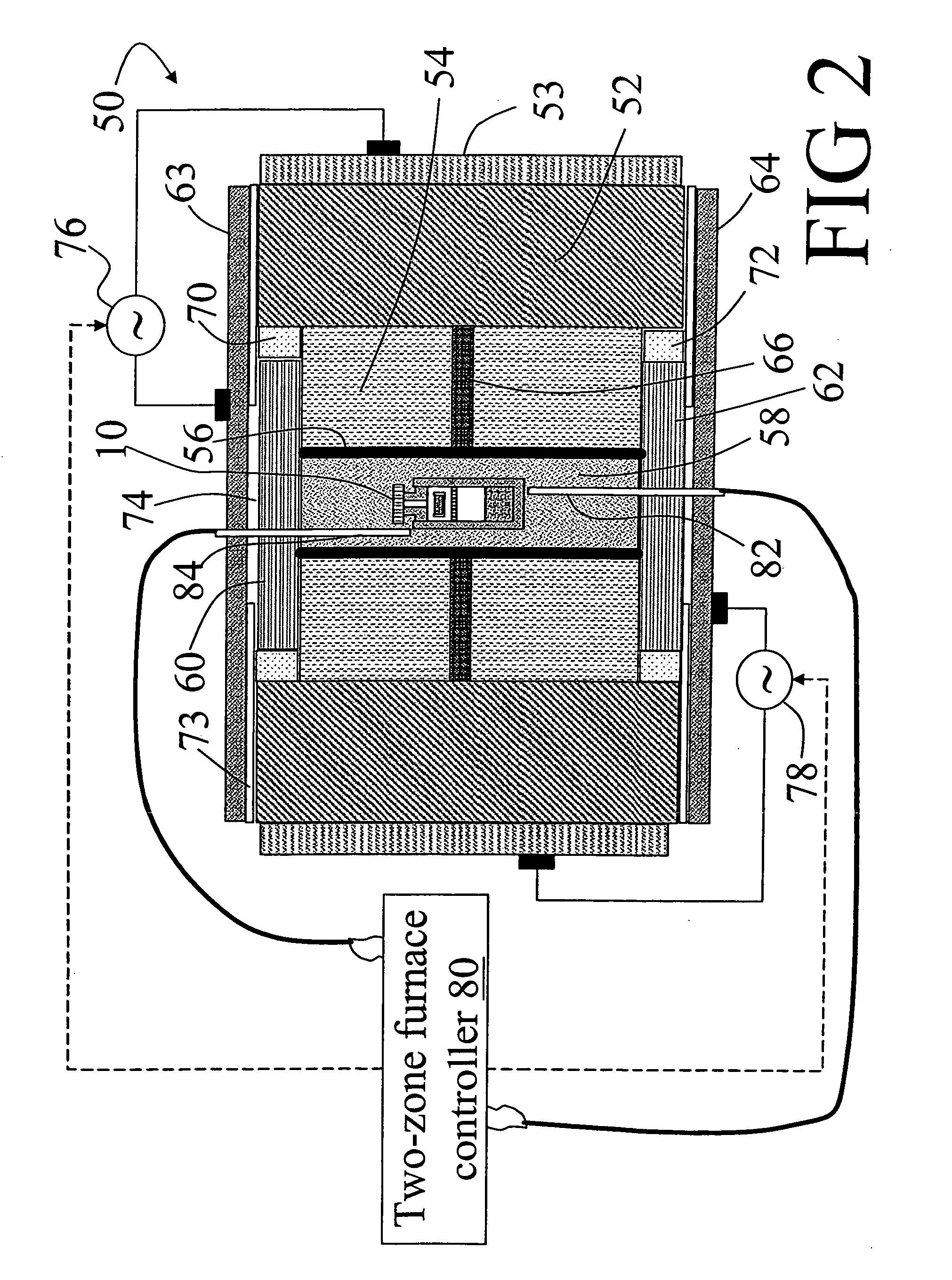

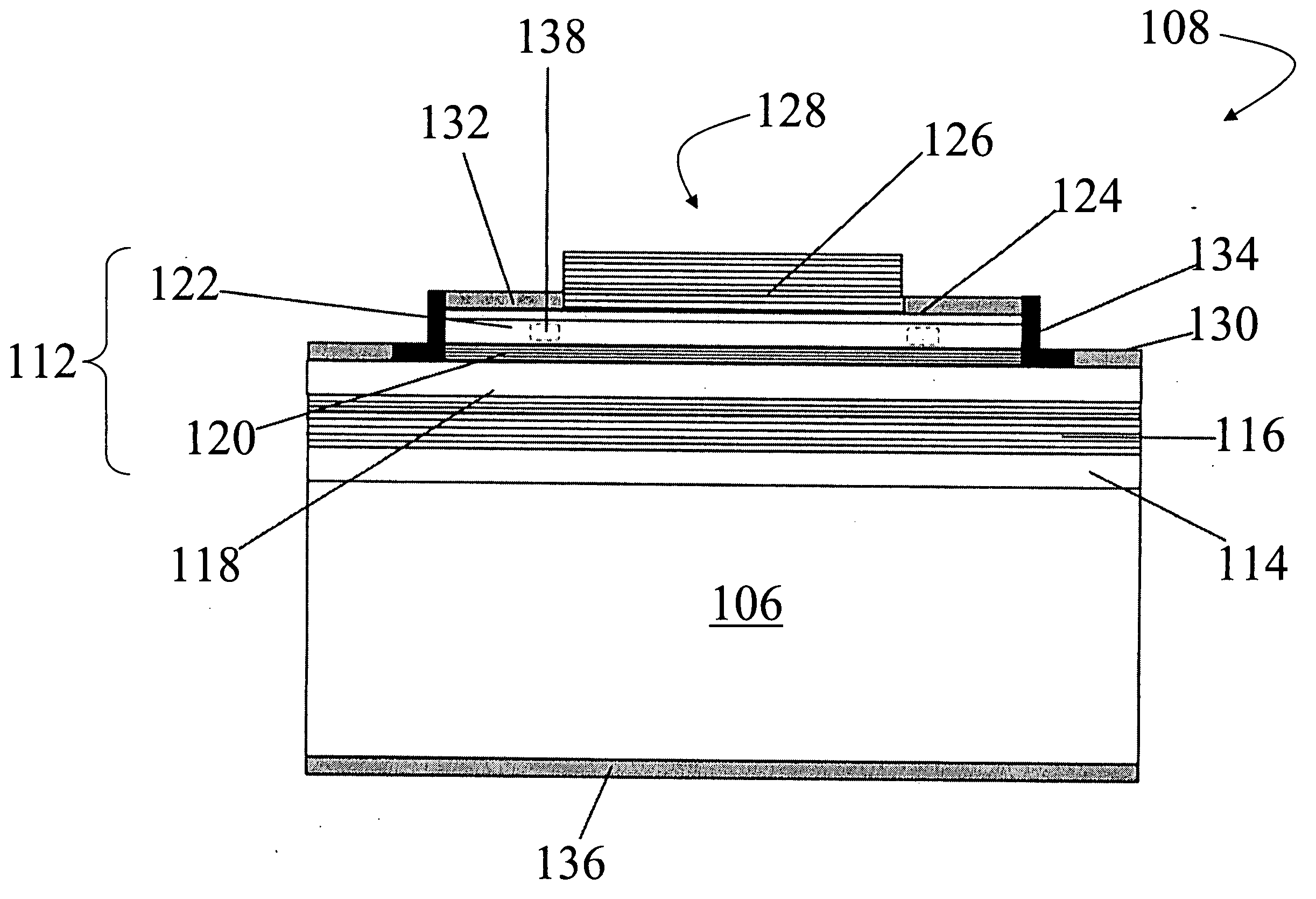

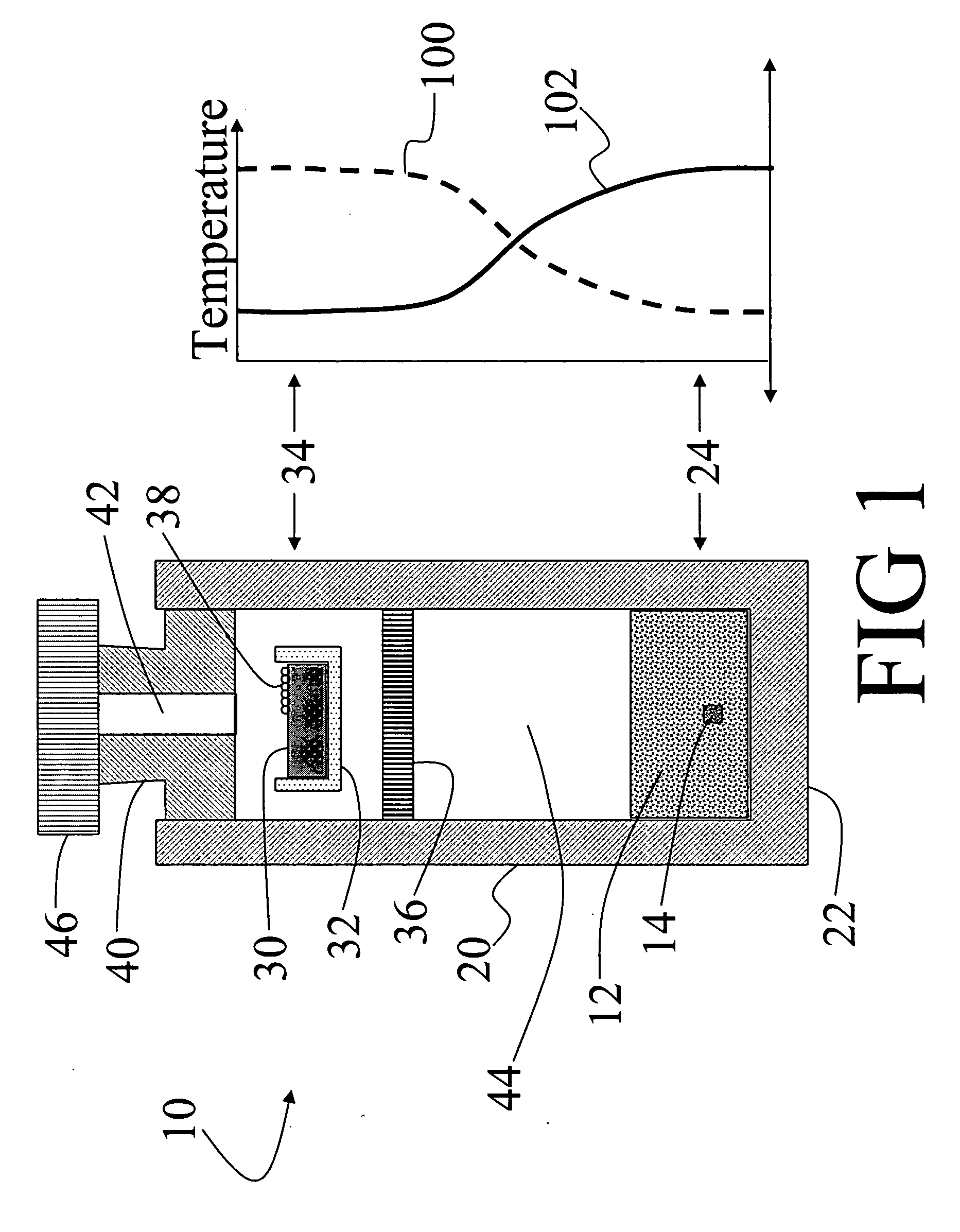

Group III-nitride based resonant cavity light emitting devices fabricated on single crystal gallium nitride substrates

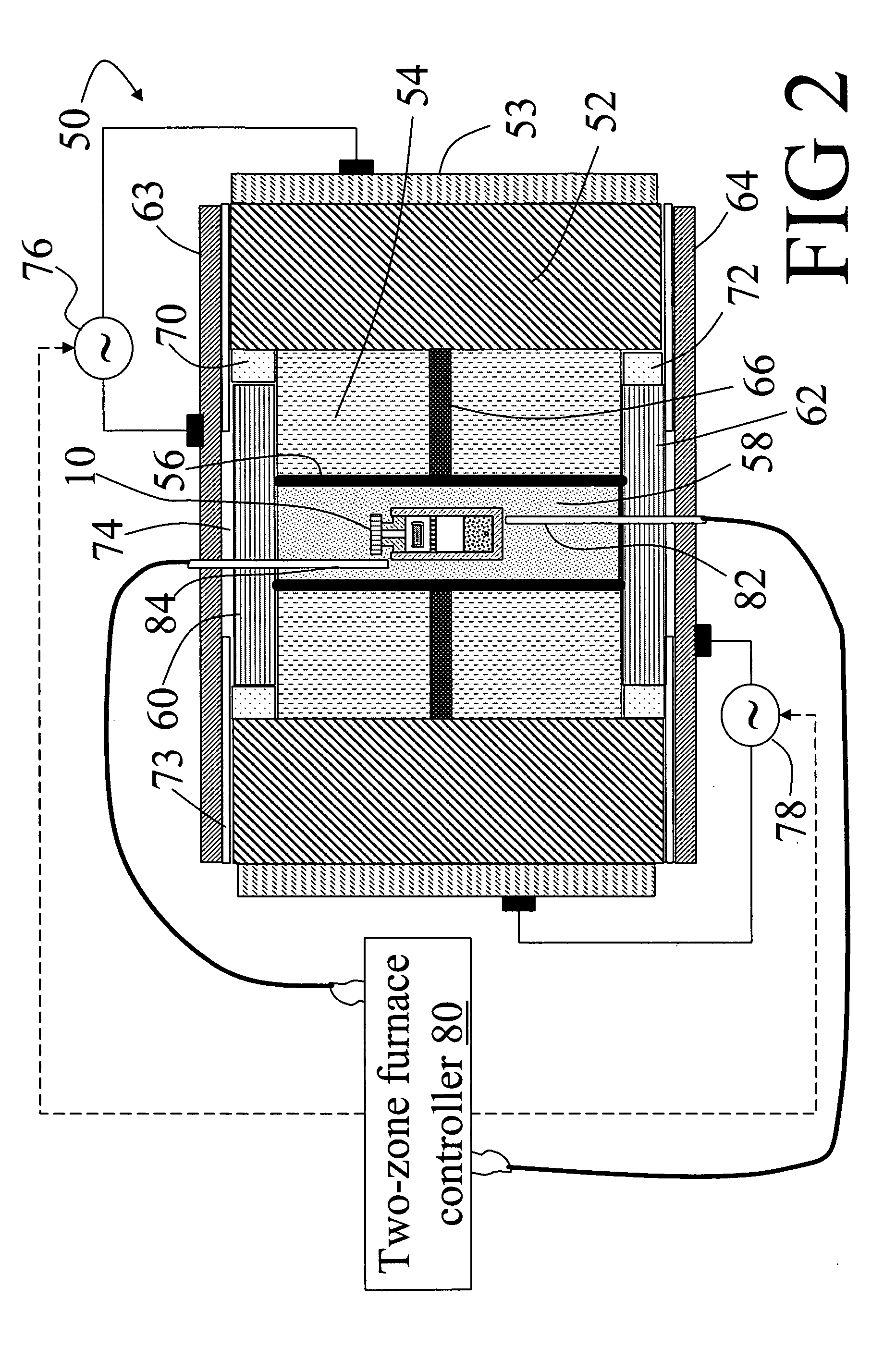

ActiveUS20050087753A1Increase probabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingResonant cavitySource material

In a method for producing a resonant cavity light emitting device, a seed gallium nitride crystal (14) and a source material (30) are arranged in a nitrogen-containing superheated fluid (44) disposed in a sealed container (10) disposed in a multiple-zone furnace (50). Gallium nitride material is grown on the seed gallium nitride crystal (14) to produce a single-crystal gallium nitride substrate (106, 106′). Said growing includes applying a temporally varying thermal gradient (100, 100′, 102, 102′) between the seed gallium nitride crystal (14) and the source material (30) to produce an increasing growth rate during at least a portion of the growing. A stack of group III-nitride layers (112) is deposited on the single-crystal gallium nitride substrate (106, 106′), including a first mirror sub-stack (116) and an active region (120) adapted for fabrication into one or more resonant cavity light emitting devices (108, 150, 160, 170, 180).

Owner:SLT TECH

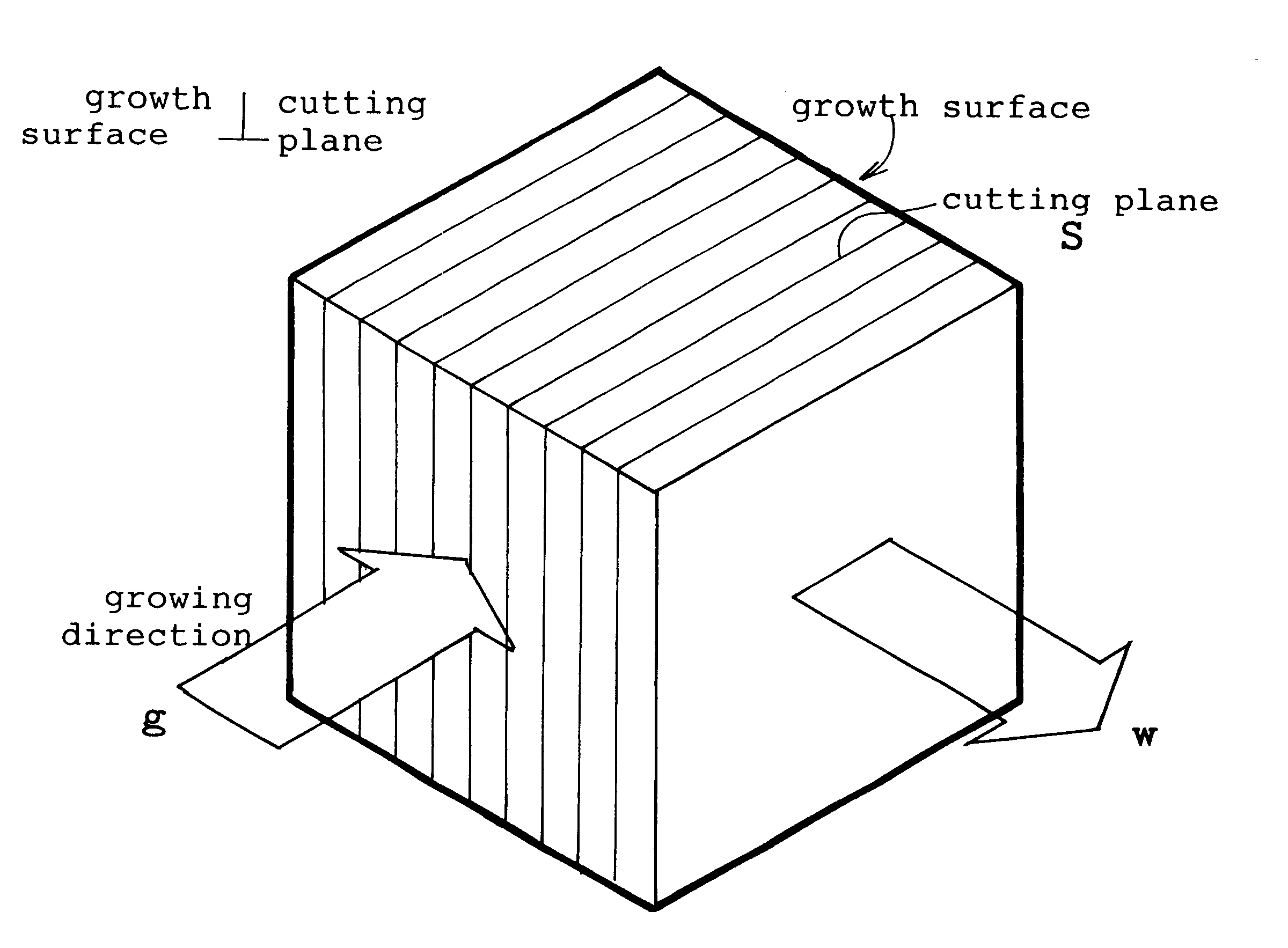

Method of producing a single crystal gallium nitride substrate and single crystal gallium nitride substrate

InactiveUS6468882B2Increase the number ofPolycrystalline material growthLaser detailsThreading dislocationsSingle crystal substrate

GaN single crystal substrates are produced by slicing a GaN single crystal ingot in the planes parallel to the growing direction. Penetration dislocations which have been generated in the growing direction extend mainly in the bulk of the GaN substrate. A few of the threading dislocations appear on the surface of the GaN substrate. GaN substrates of low-dislocation density are obtained.

Owner:SUMITOMO ELECTRIC IND LTD

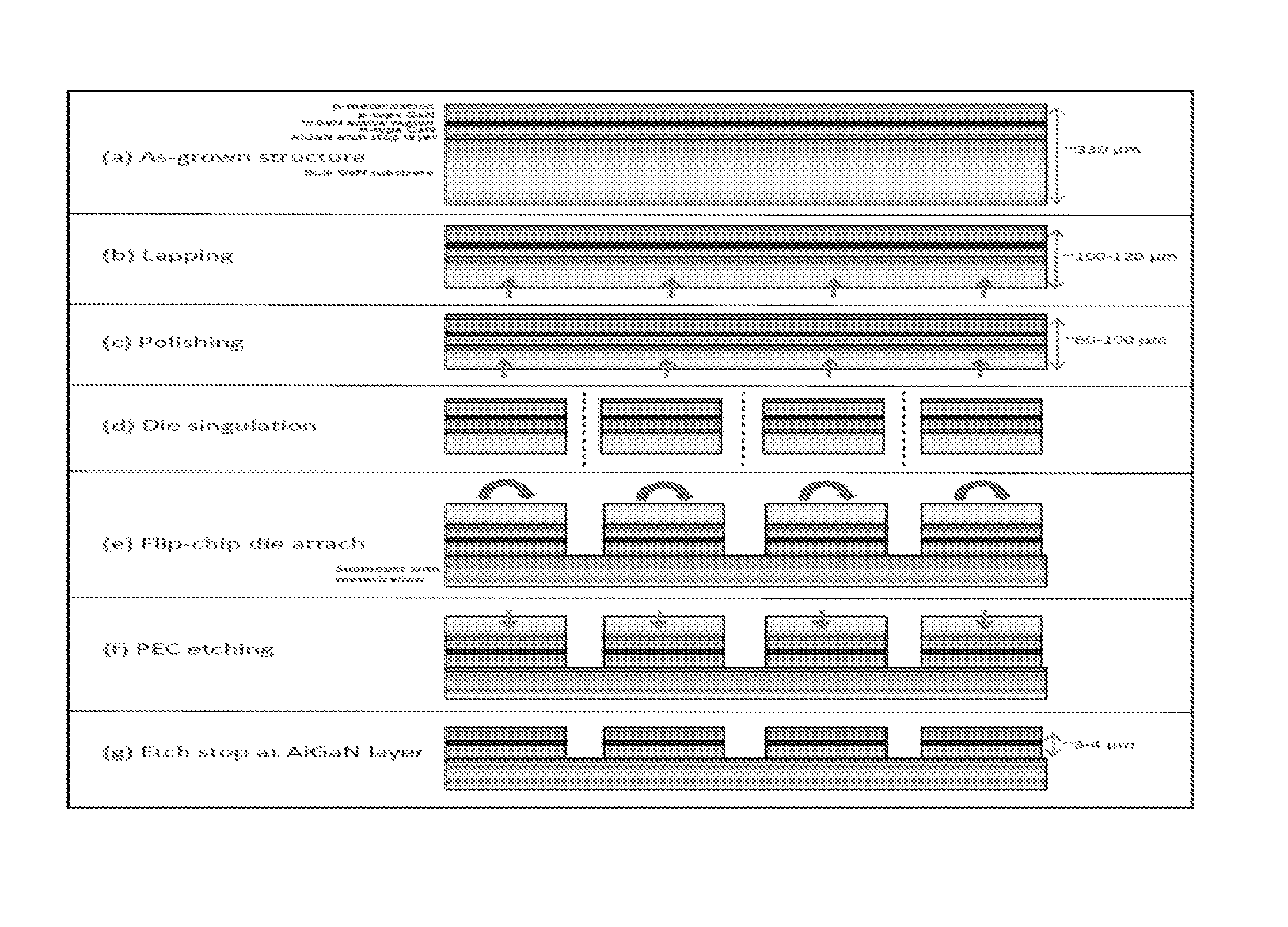

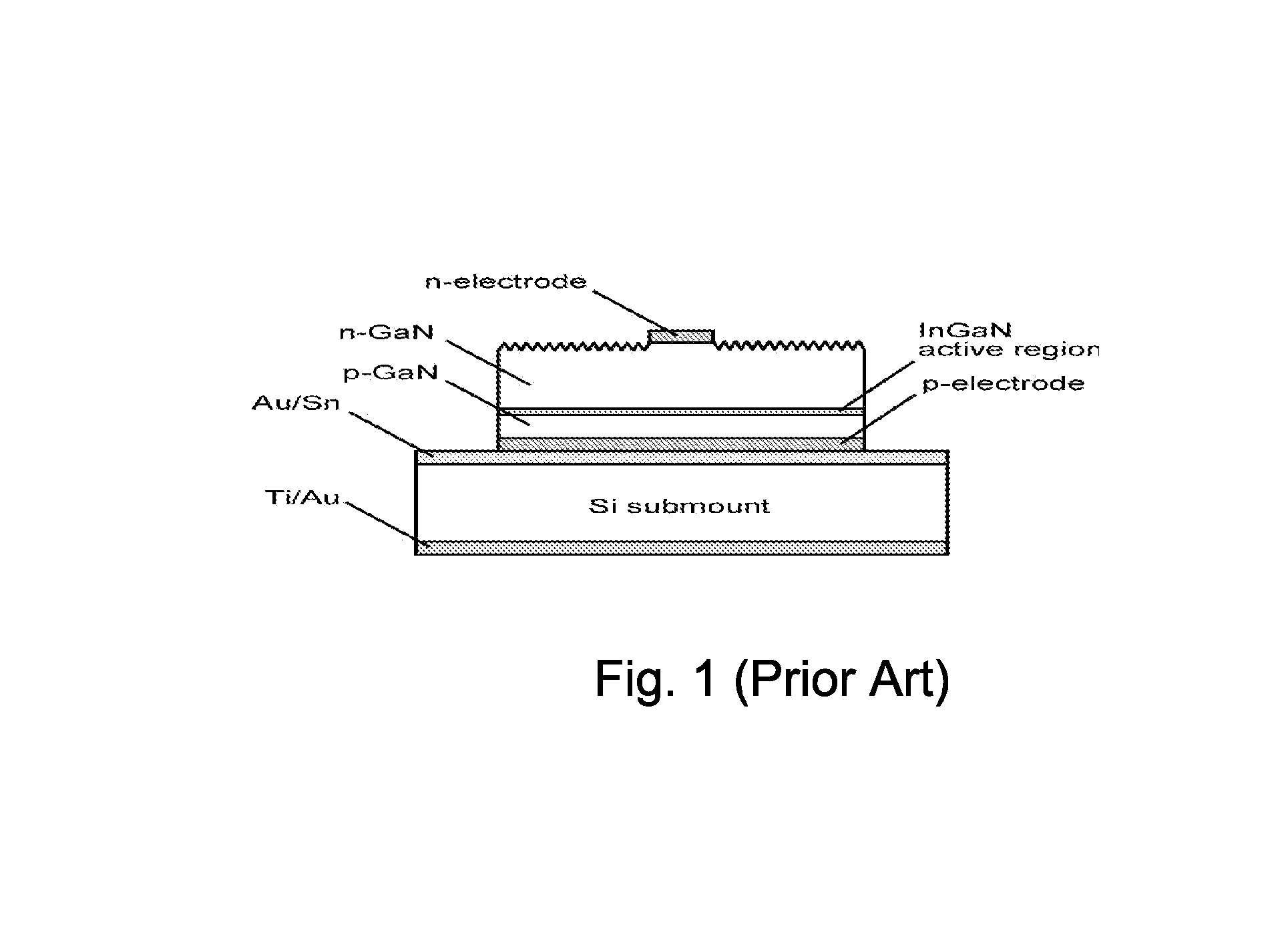

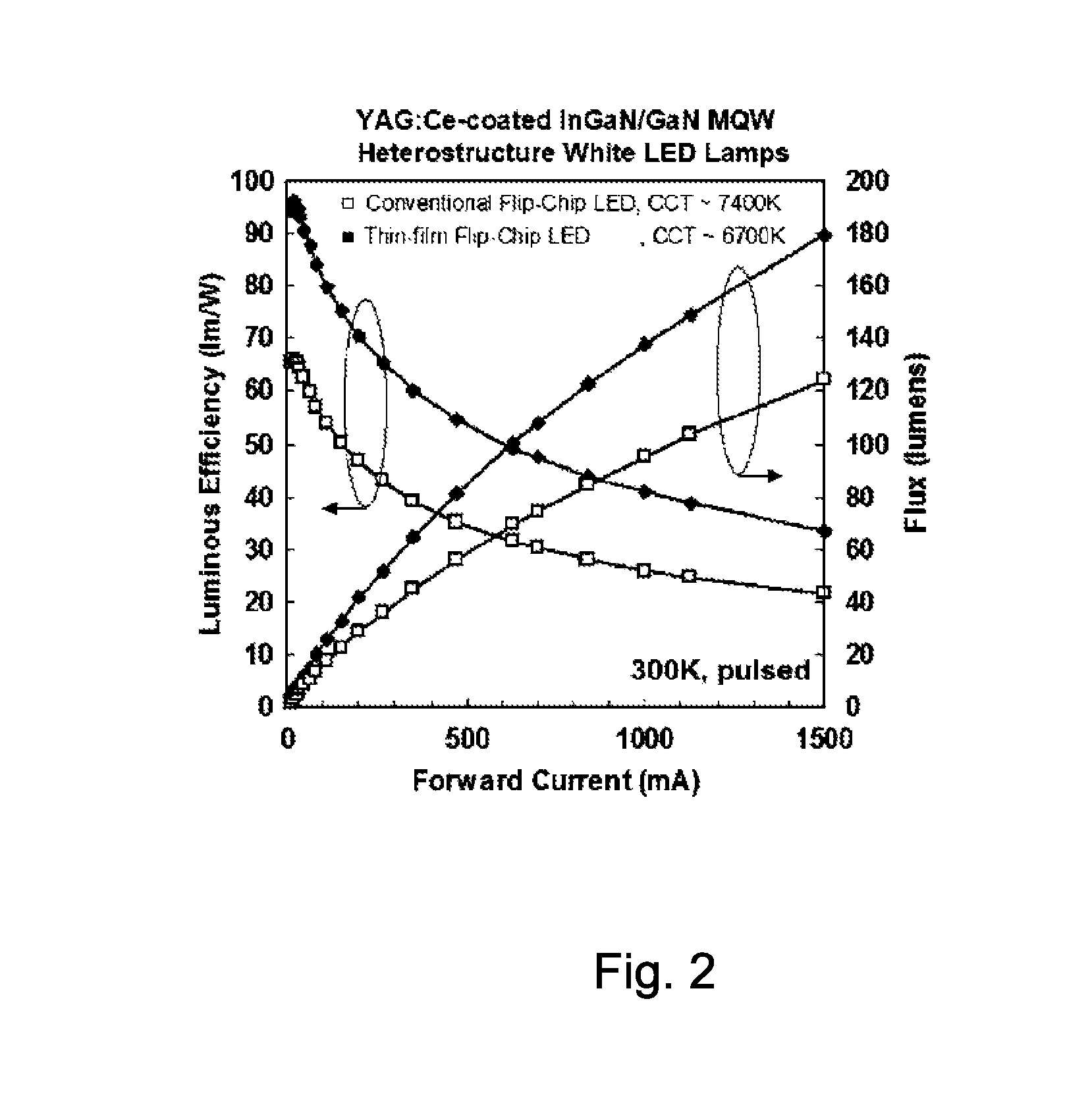

Method and structure for manufacture of light emitting diode devices using bulk GaN

ActiveUS8252662B1Minimize re-absorptionThickness minimizationSemiconductor/solid-state device manufacturingSemiconductor devicesCrystalline materialsGallium nitride

A method for manufacturing a plurality light emitting diodes includes providing a gallium nitride containing bulk crystalline substrate material configured in a non-polar or semi-polar crystallographic orientation, forming an etch stop layer, forming an n-type layer overlying the etch stop layer, forming an active region, a p-type layer, and forming a metallization. The method includes removing a thickness of material from the backside of the bulk gallium nitride containing substrate material. A plurality of individual LED devices are formed from at least a sandwich structure comprising portions of the metallization layer, the p-type layer, active layer, and the n-type layer. The LED devices are joined to a carrier structure. The method also includes subjecting the gallium nitride containing bulk crystalline substrate material to at least one etching process to selectively remove crystalline material underlying the etch stop layer, wherein the etch stop layer is exposed, and the etch stop layer remains substantially intact.

Owner:SLT TECH

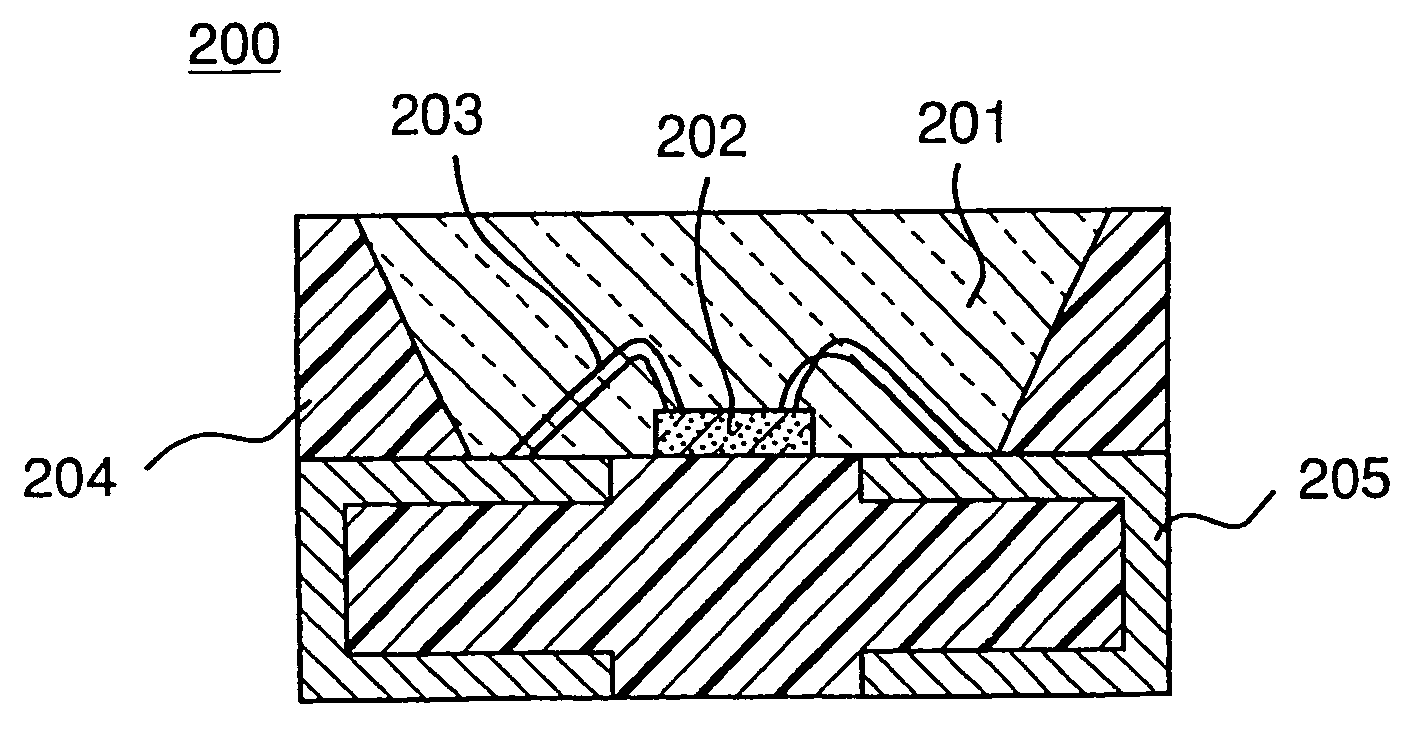

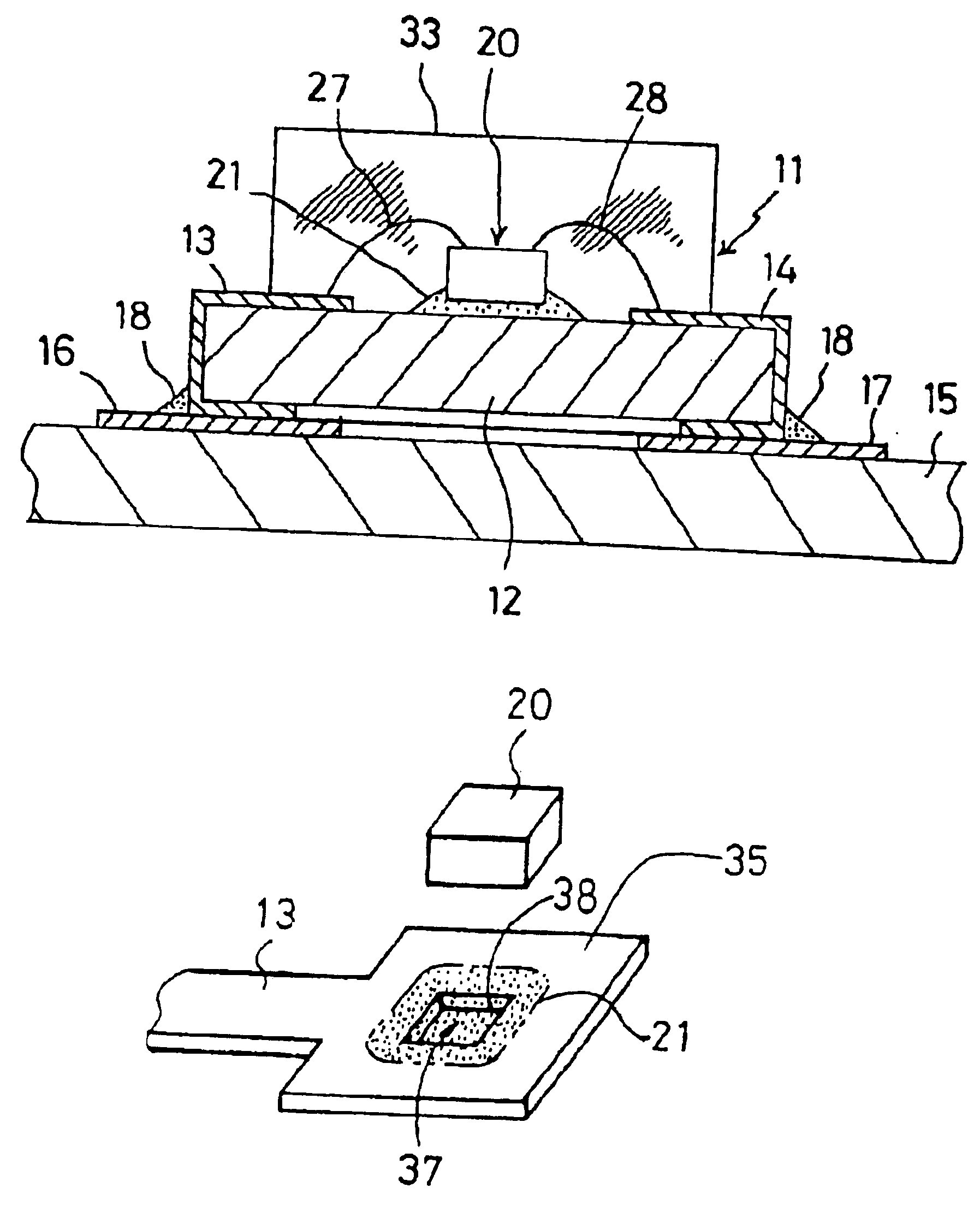

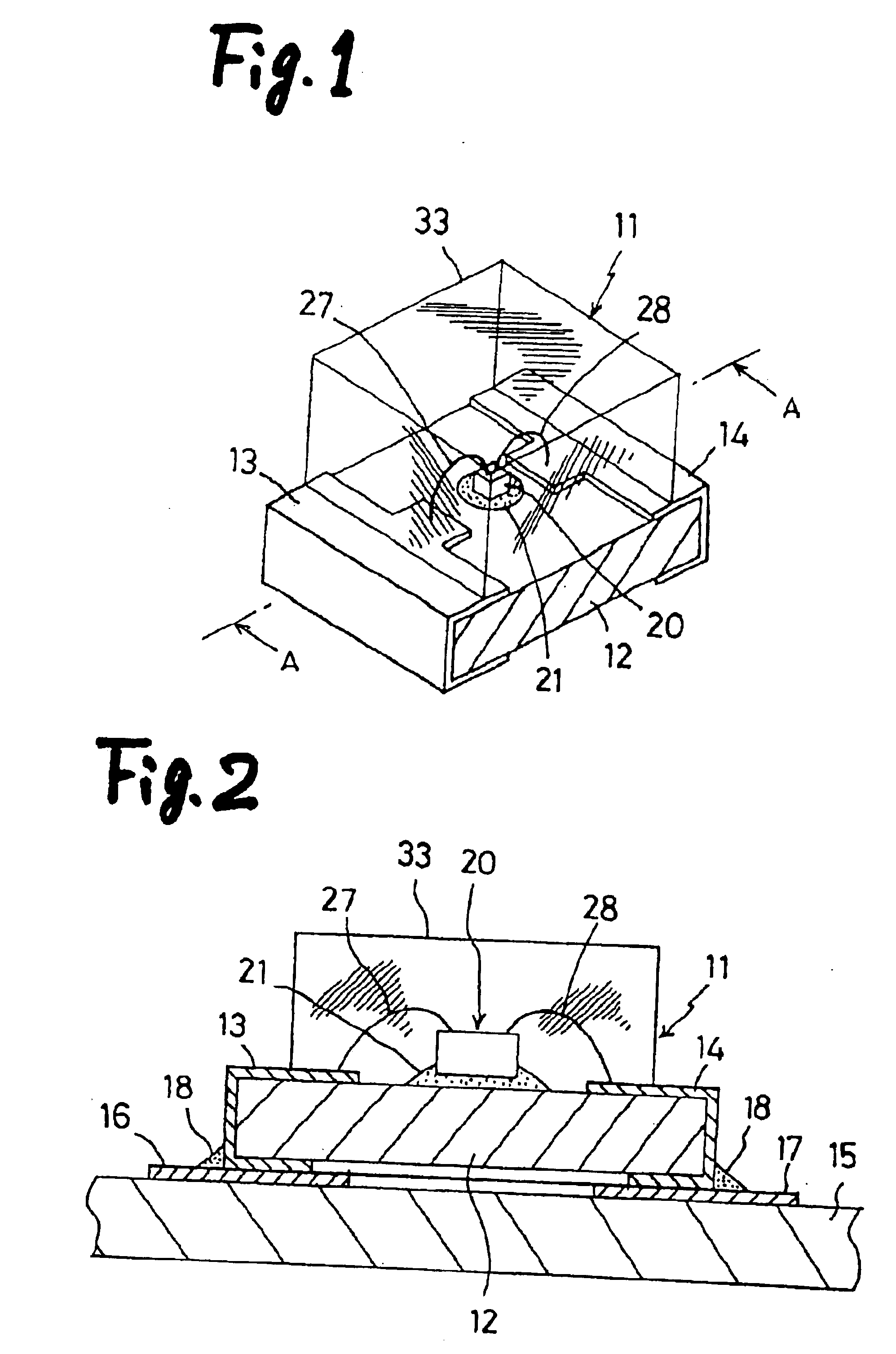

Light emitting diode

InactiveUS6914267B2Increase production capacityGood suitSolid-state devicesSemiconductor devicesElectrical conductorAdhesive

A light emitting diode comprising a light emitting diode element 20 mounted on a glass epoxy substrate 12, this light emitting diode element 20 being protected at its surface side by a resin seal member 33, in which: a light emitting diode element for blue luminescence, formed of gallium nitride type compound semiconductor is used as the above-mentioned light emitting diode element 20; and a fluorescent material containing layer 21 composed of a fluorescent material containing layer 21 composed of a fluorescent material dispersed into an adhesive is arranged on the back side of this light emitting diode element. On the back side of the light emitting diode element 20, blue luminescence is converted in wavelength to produce white luminescence of high intensity.

Owner:CITIZEN ELECTRONICS CO LTD

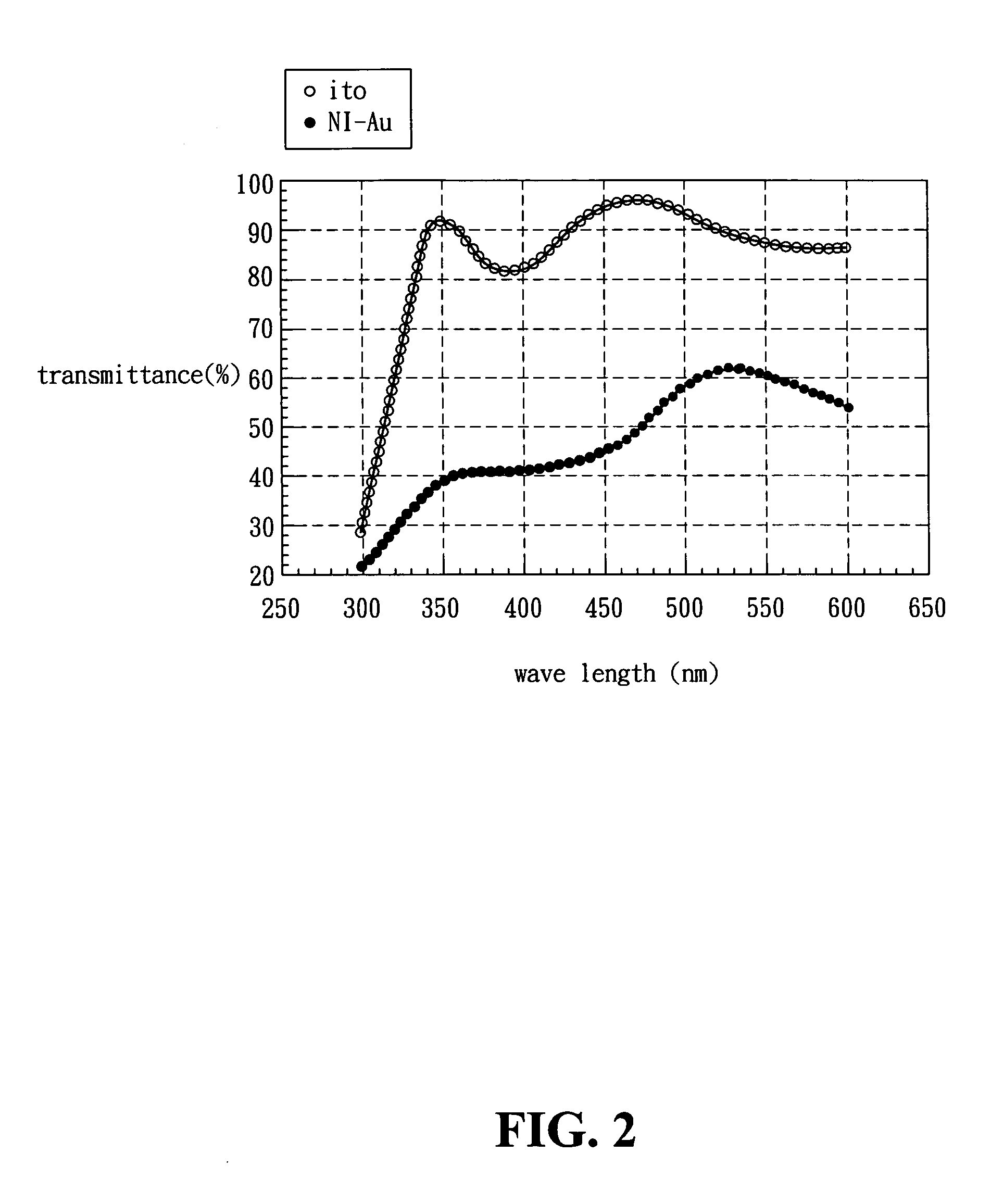

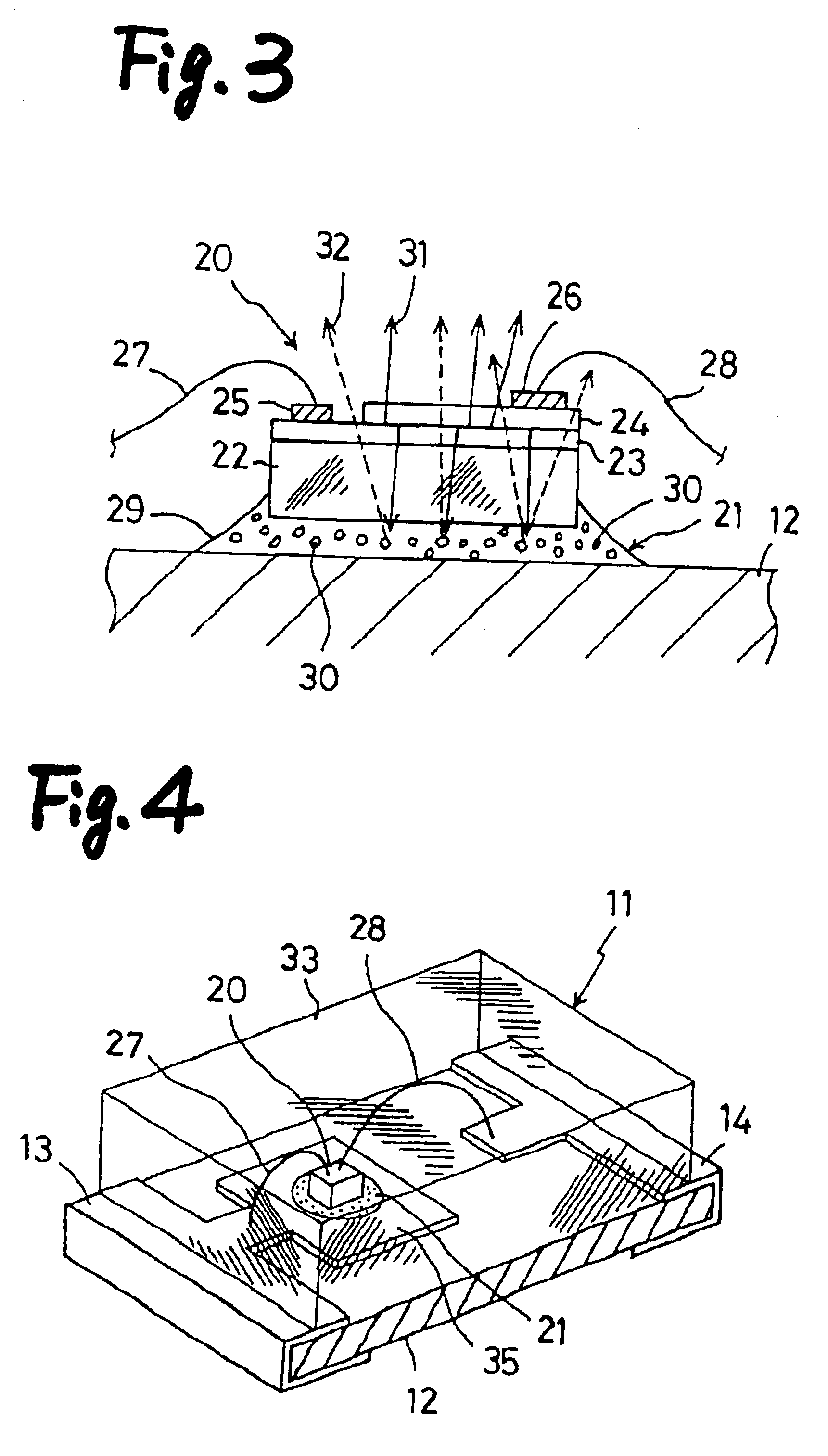

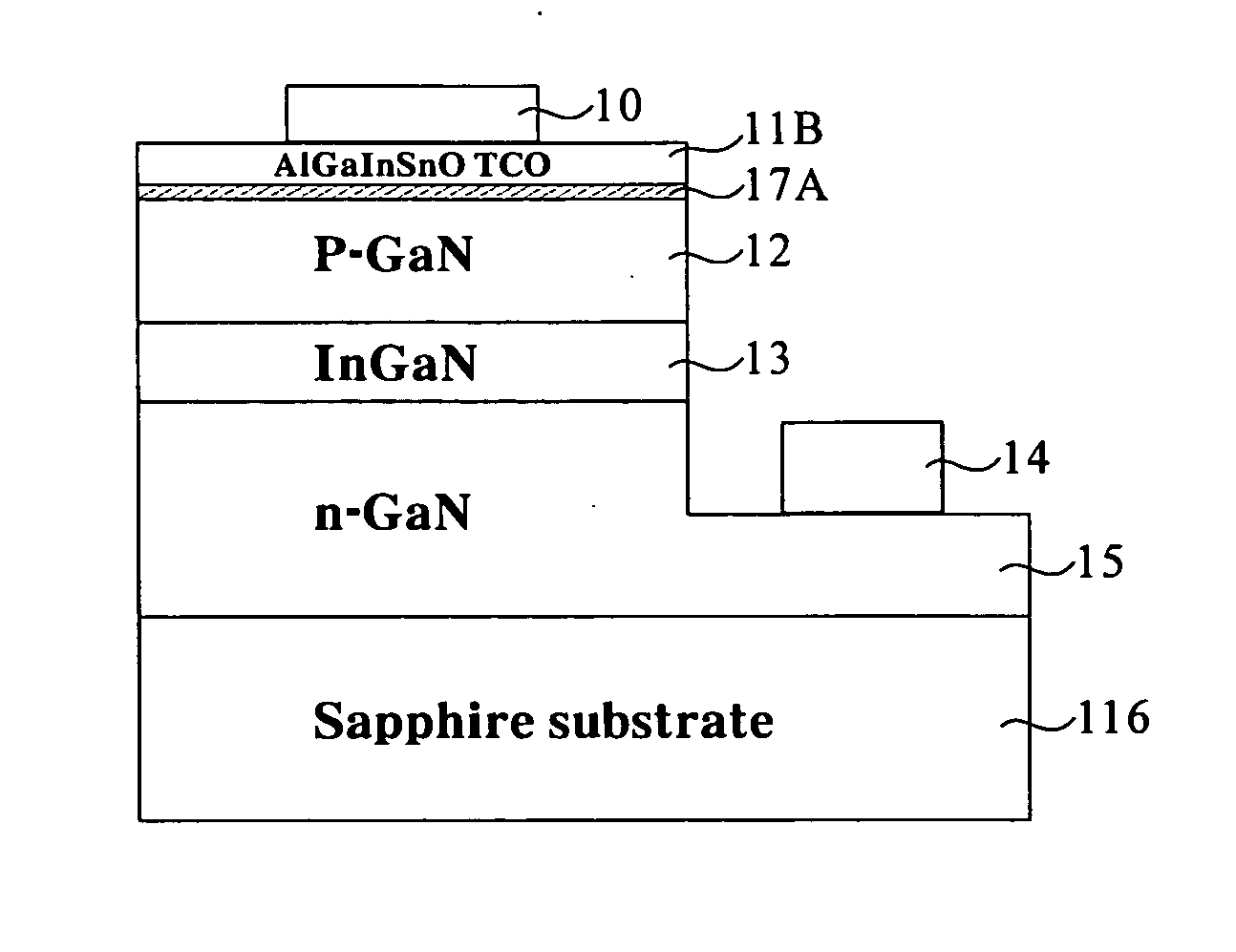

High brightness gallium nitride-based light emitting diode with transparent conducting oxide spreading layer

InactiveUS20050230701A1Reduce contact resistanceReduce the impactFibre treatmentSolid-state devicesOptical propertyGallium

A new transparent conducting oxide (TCO), which can be expressed as AlxGa3−x−yIn5+ySn2−zO16−2z; 0≦x<1, 0<y<3, 0≦z<2, has been used to improve the brightness and current spreading in GaN base LED process. The optical properties of this system are superior to regular Ni / Au transparent conducting layer in blue-green region, and the new Al2O3—Ga2O3—In2O3—SnO2 system is able to increase the brightness at 1.5˜2.5 time to compare to regular process. Furthermore, the new transparent conducting oxide thin film has the highest conductivity, which is better than the Ni / Au transparent conducting thin film.

Owner:ARIMA OPTOELECTRONICS

Optical device structure using miscut GaN substrates for laser applications

ActiveUS8422525B1Simple and cost-effectiveAchieve benefitsNanoopticsSemiconductor lasersLength waveGallium nitride

An optical device capable of emitting light having a wavelength ranging from about 490 to about 580 nanometers has a gallium nitride substrate with a semipolar crystalline surface region characterized by an orientation of greater than 3 degrees from (11-22) towards (0001) but less than about 50 degrees. A laser stripe formed on the substrate has a cavity orientation substantially parallel to the m-direction.

Owner:KYOCERA SLD LASER INC

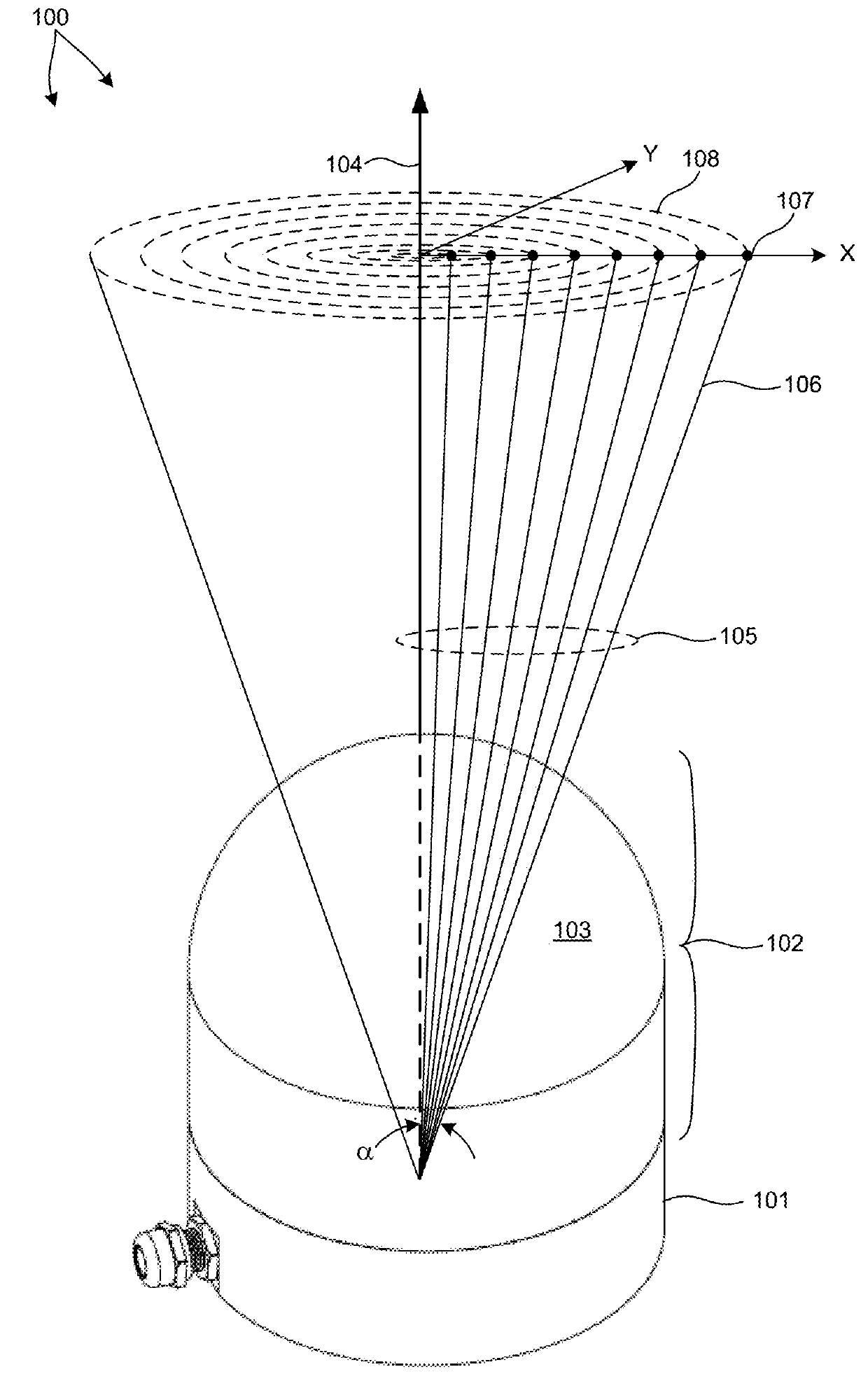

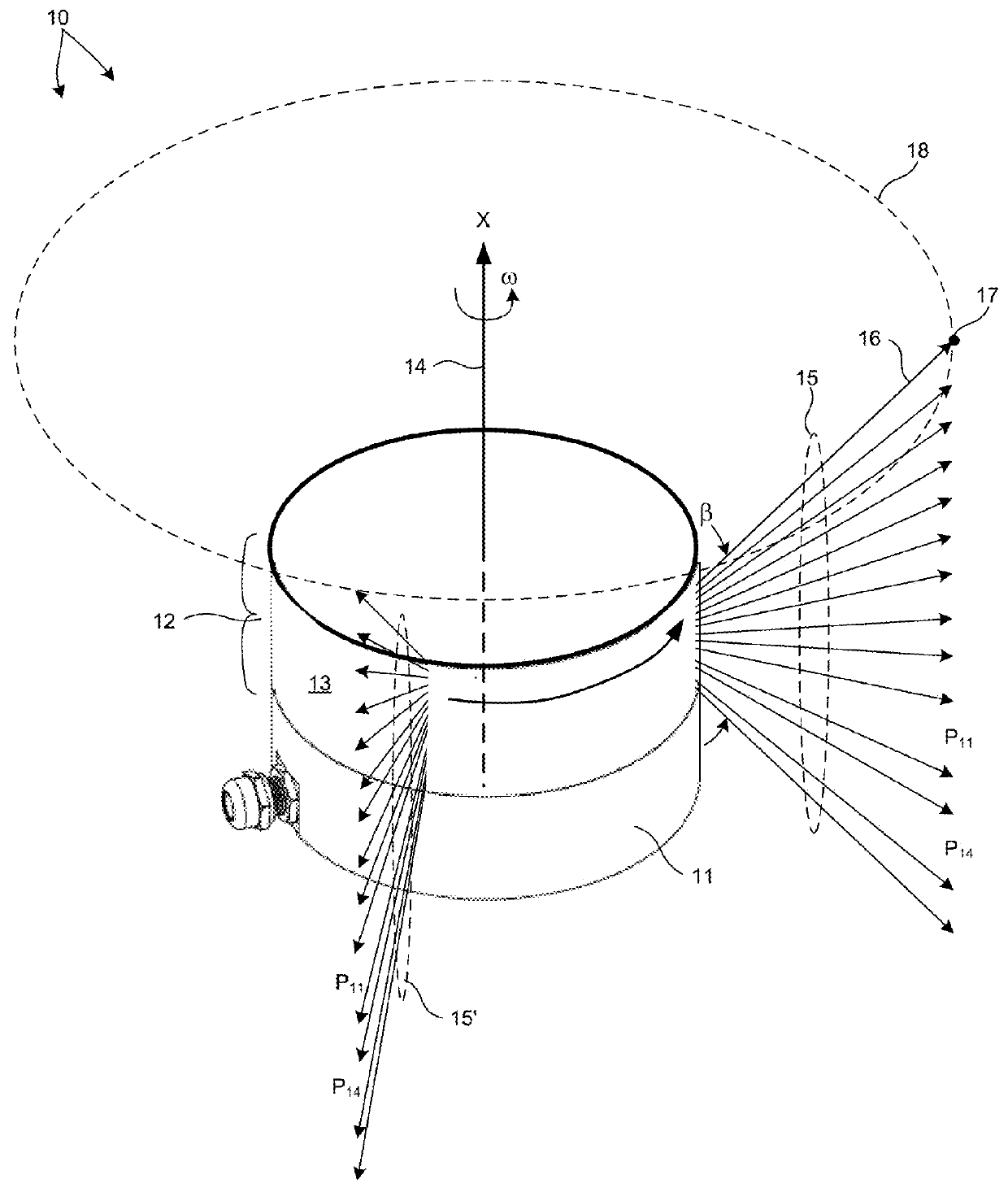

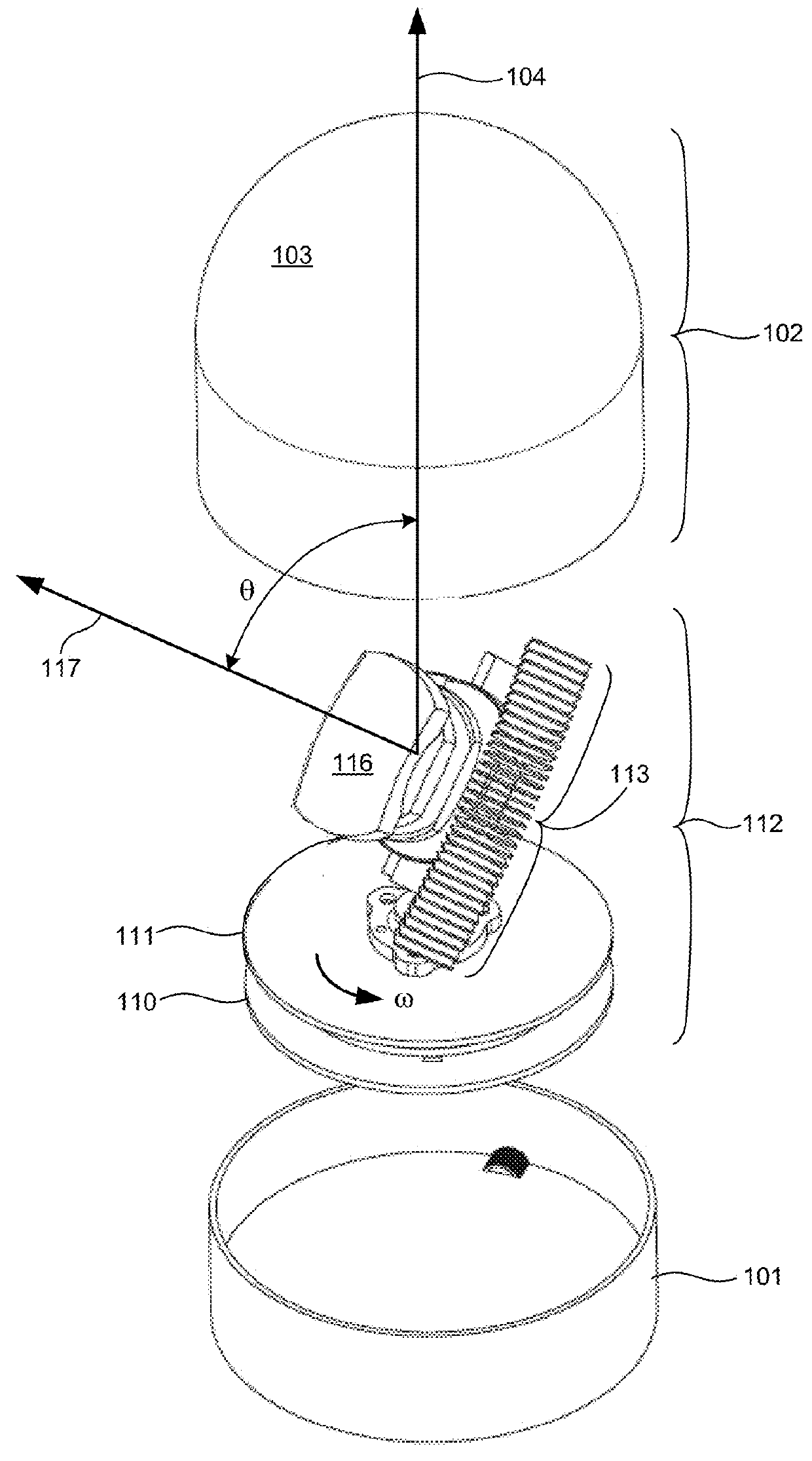

Integrated Illumination And Detection For LIDAR Based 3-D Imaging

ActiveUS20170269215A1Reduce lossesAvoid lostElectromagnetic wave reradiationMeasurement deviceBeam splitter

Methods and systems for performing three dimensional LIDAR measurements with a highly integrated LIDAR measurement device are described herein. In one aspect, the illumination source, detector, and illumination drive are integrated onto a single printed circuit board. In addition, in some embodiments, the associated control and signal conditioning electronics are also integrated onto the common printed circuit board. Furthermore, in some embodiments, the illumination drive and the illumination source are integrated onto a common Gallium Nitride substrate that is independently packaged and attached to the printed circuit board. In another aspect, the illumination light emitted from the illumination source and the return light directed toward the detector share a common optical path within the integrated LIDAR measurement device. In some embodiments, the return light is separated from the illumination light by a beam splitter. In some other embodiments, the optical design avoids losses associated with a beam splitter.

Owner:VELODYNE LIDAR USA INC

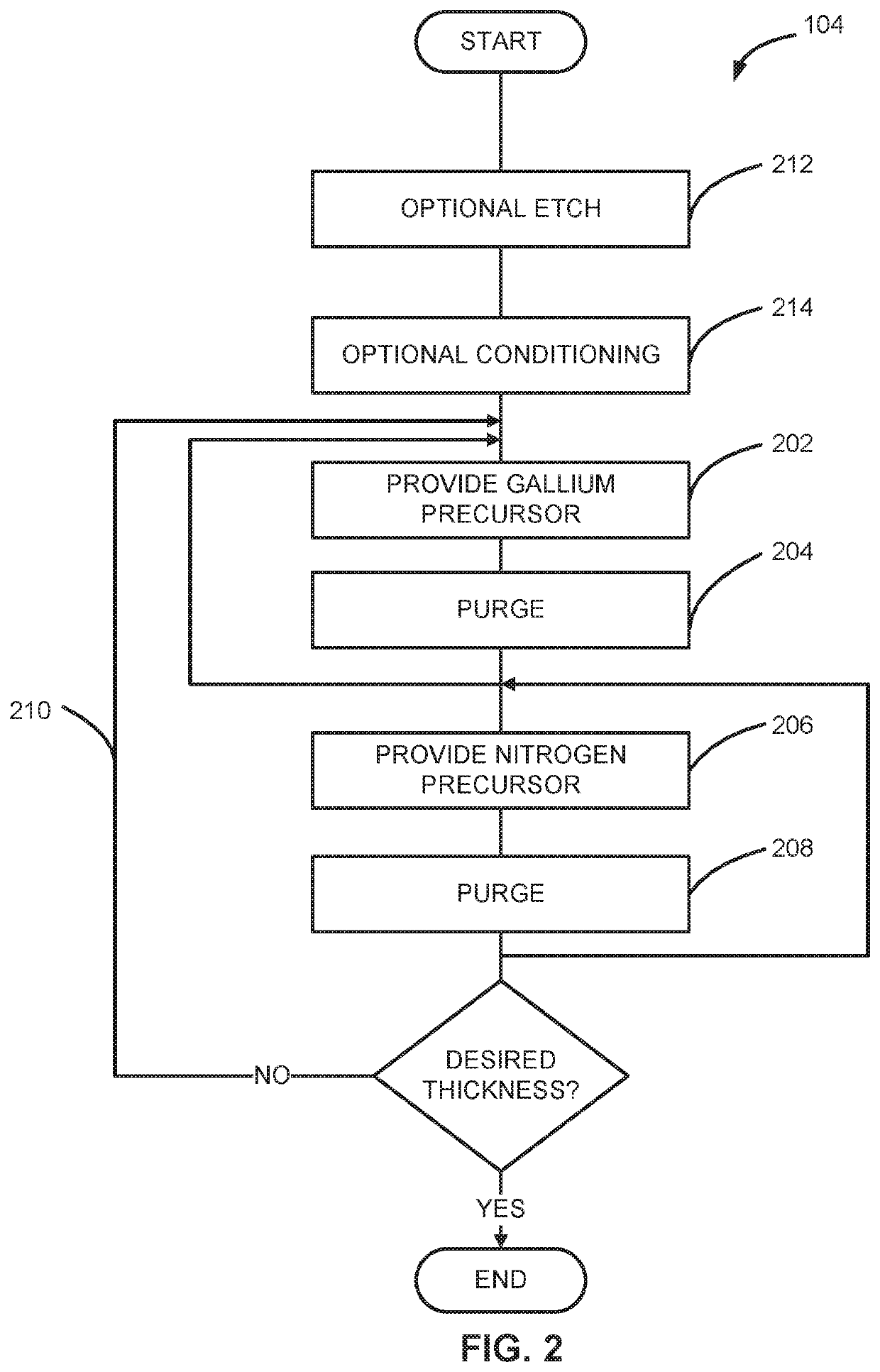

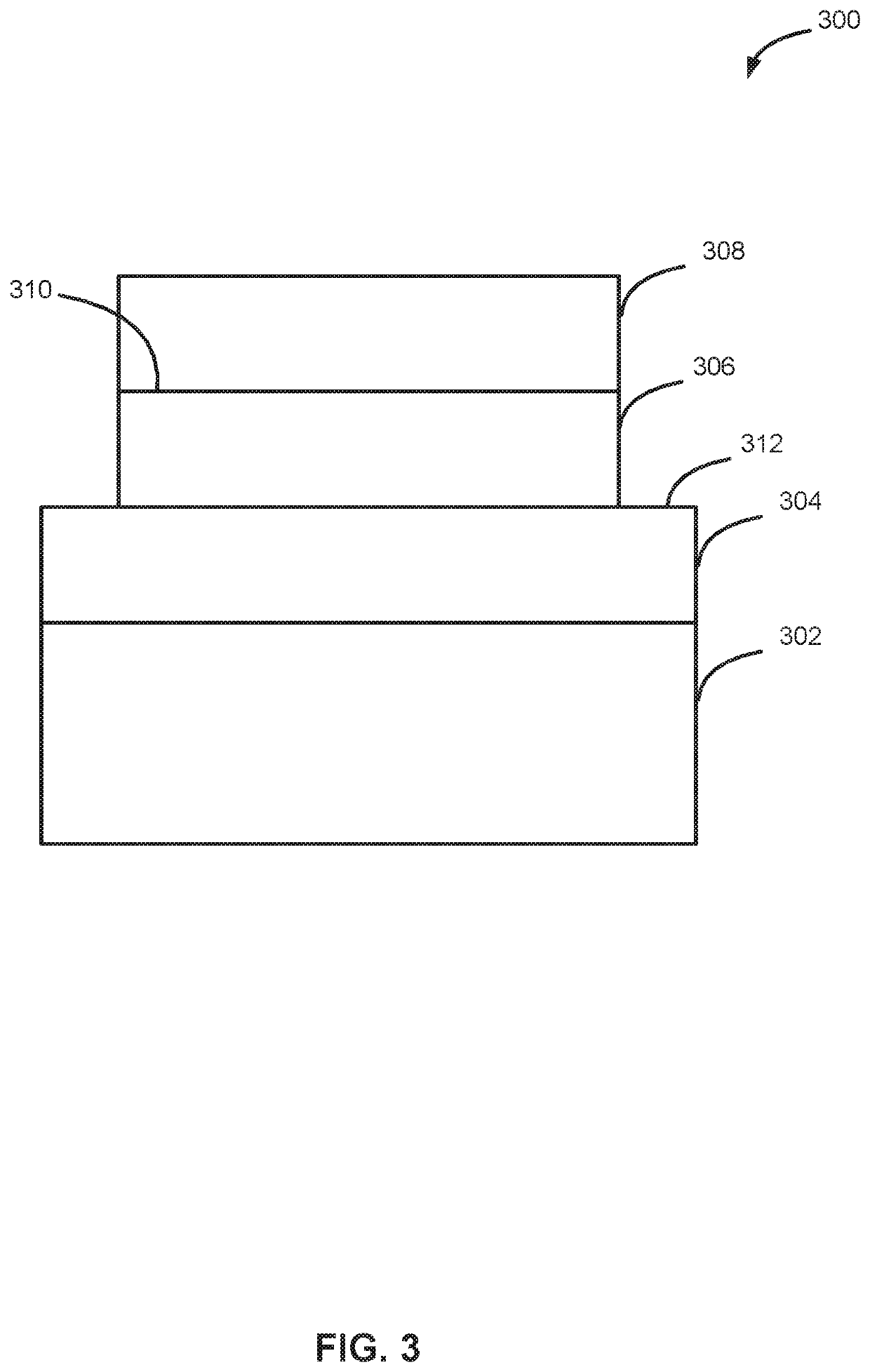

Method of forming a device structure using selective deposition of gallium nitride and system for same

ActiveUS20200194253A1Polycrystalline material growthSemiconductor/solid-state device manufacturingEngineeringSelective deposition

Owner:ASM IP HLDG BV

Highly efficient gallium nitride based light emitting diodes via surface roughening

ActiveUS20070121690A1Solid-state devicesSemiconductor/solid-state device manufacturingNitrogenLight reflection

A gallium nitride (GaN) based light emitting diode (LED), wherein light is extracted through a nitrogen face (N-face) (42) of the LED and a surface of the N-face (42) is roughened into one or more hexagonal shaped cones. The roughened surface reduces light reflections occurring repeatedly inside the LED, and thus extracts more light out of the LED. The surface of the N-face (42) is roughened by an anisotropic etching, which may comprise a dry etching or a photo-enhanced chemical (PEC) etching.

Owner:JAPAN SCI & TECH CORP

Single step pendeo-and lateral epitaxial overgrowth of group III-nitride epitaxial layers with group III-nitride buffer layer and resulting structures

InactiveUS20020022290A1Semiconductor laser structural detailsSemiconductor/solid-state device manufacturingSemiconductor structureGallium nitride

A method of fabricating a gallium nitride-based semiconductor structure on a substrate includes the steps of forming a mask having at least one opening therein directly on the substrate, growing a buffer layer through the opening, and growing a layer of gallium nitride upwardly from the buffer layer and laterally across the mask. During growth of the gallium nitride from the mask, the vertical and horizontal growth rates of the gallium nitride layer are maintained at rates sufficient to prevent polycrystalline material nucleating on said mask from interrupting the lateral growth of the gallium nitride layer. In an alternative embodiment, the method includes forming at least one raised portion defining adjacent trenches in the substrate and forming a mask on the substrate, the mask having at least one opening over the upper surface of the raised portion. A buffer layer may be grown from the upper surface of the raised portion. The gallium nitride layer is then grown laterally by pendeoepitaxy over the trenches.

Owner:CREE INC

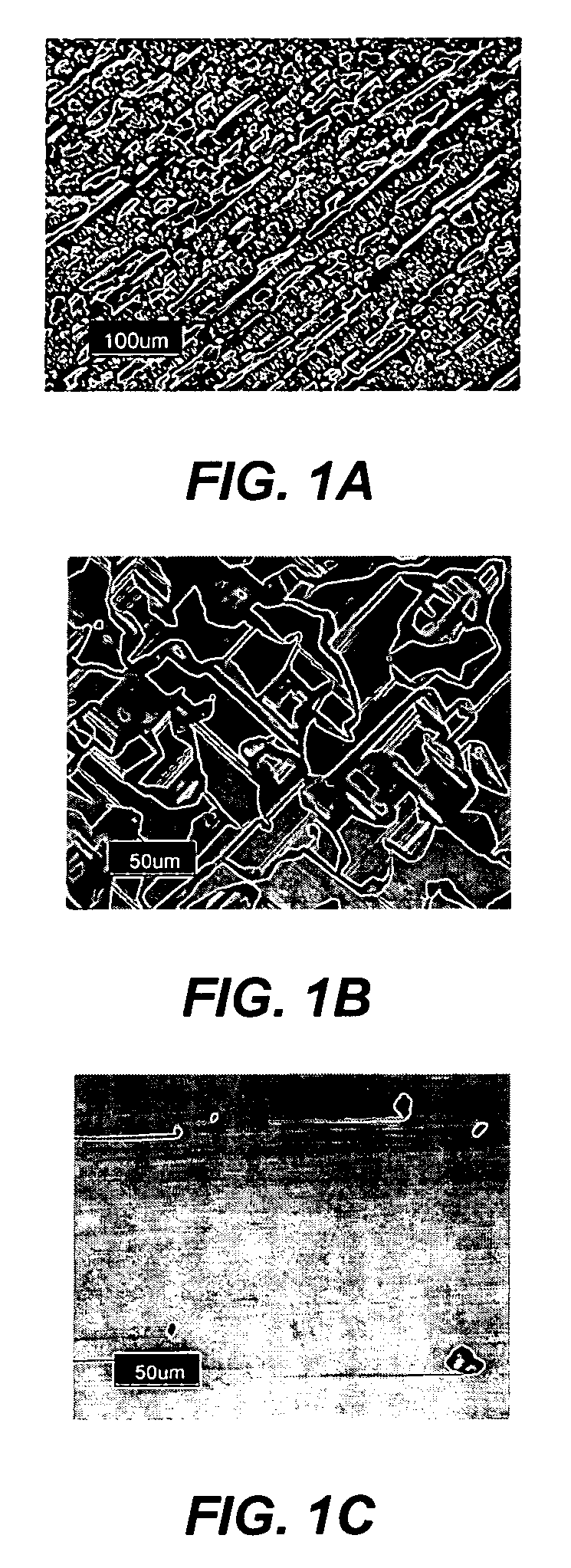

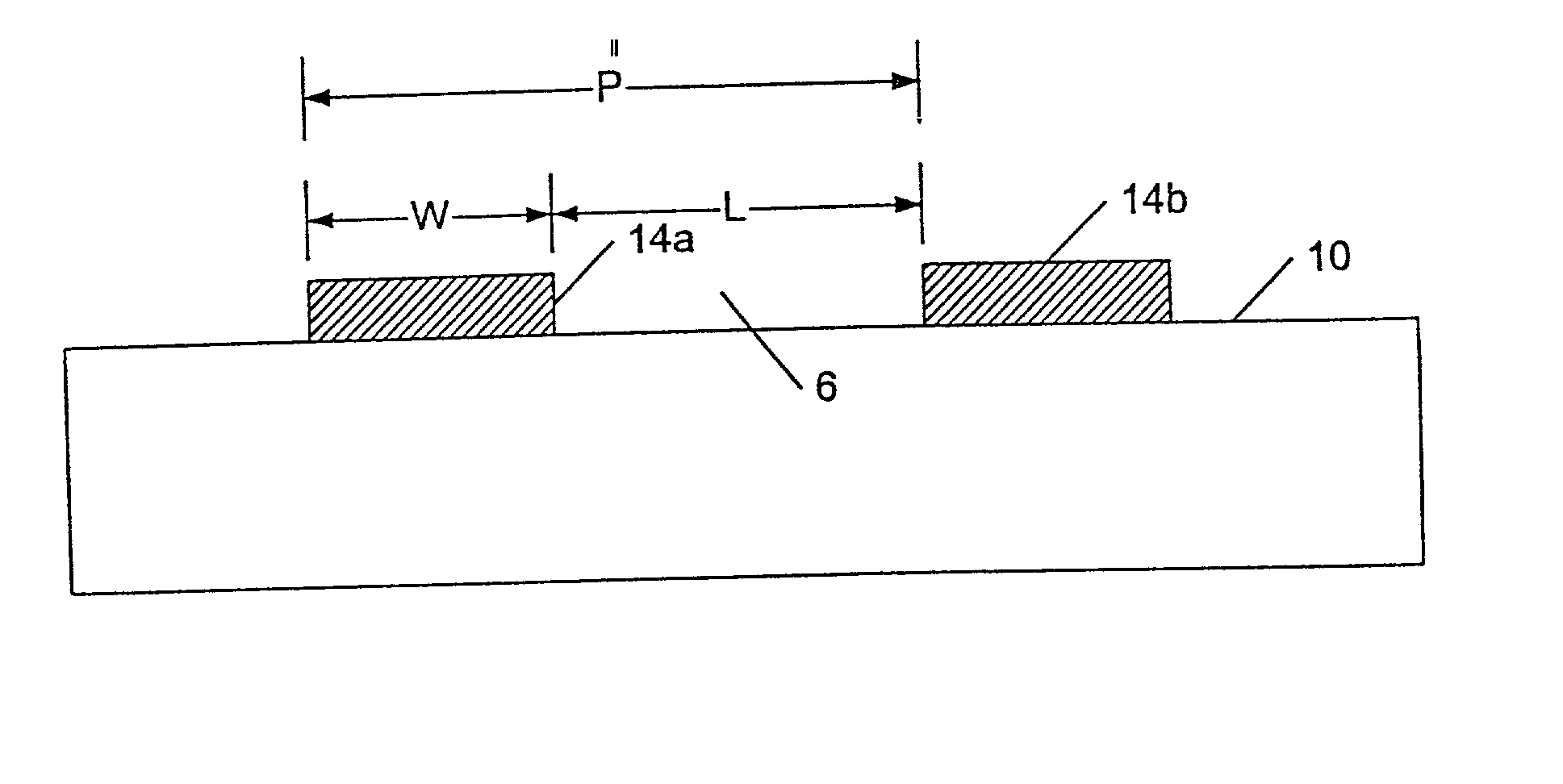

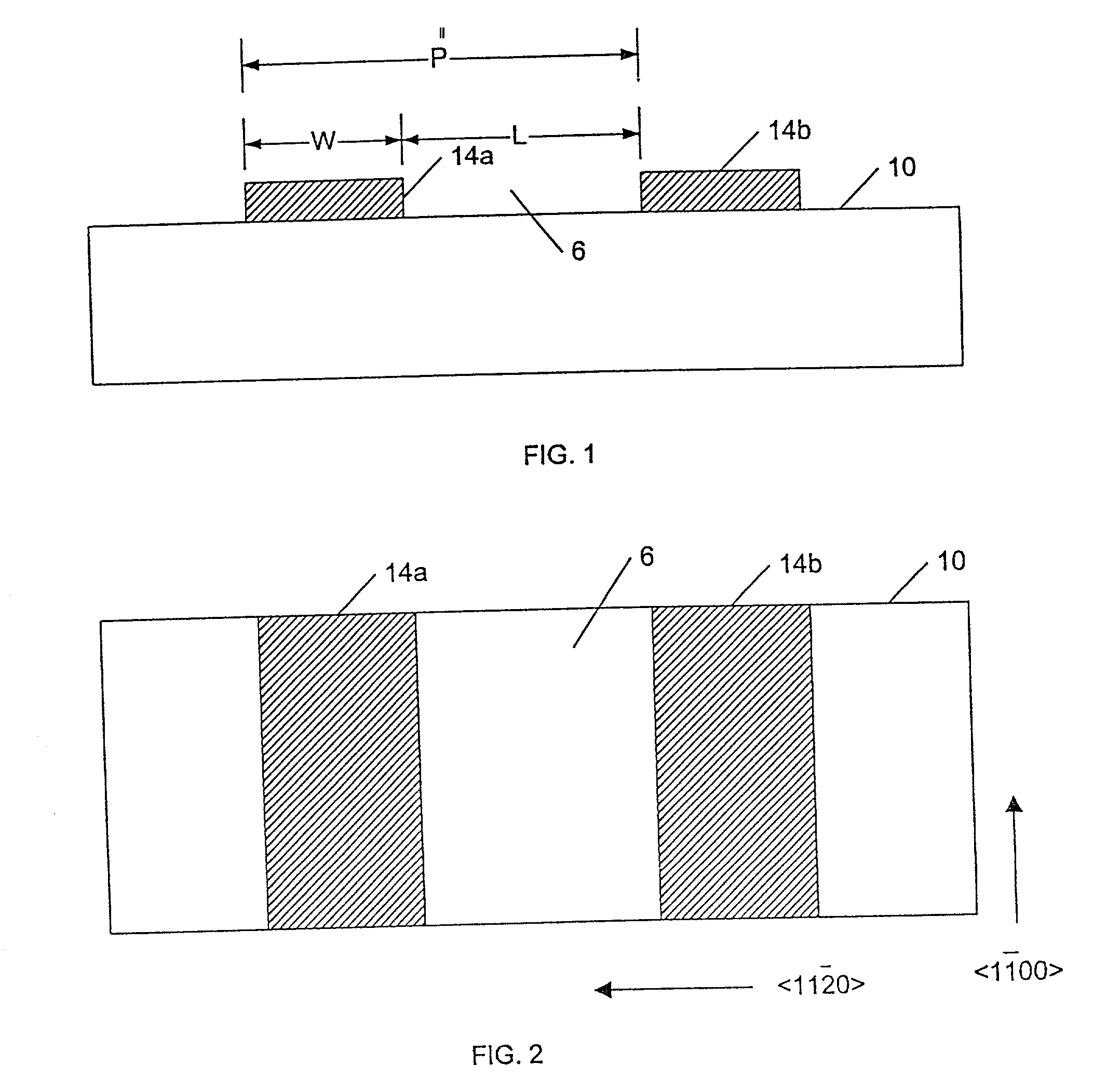

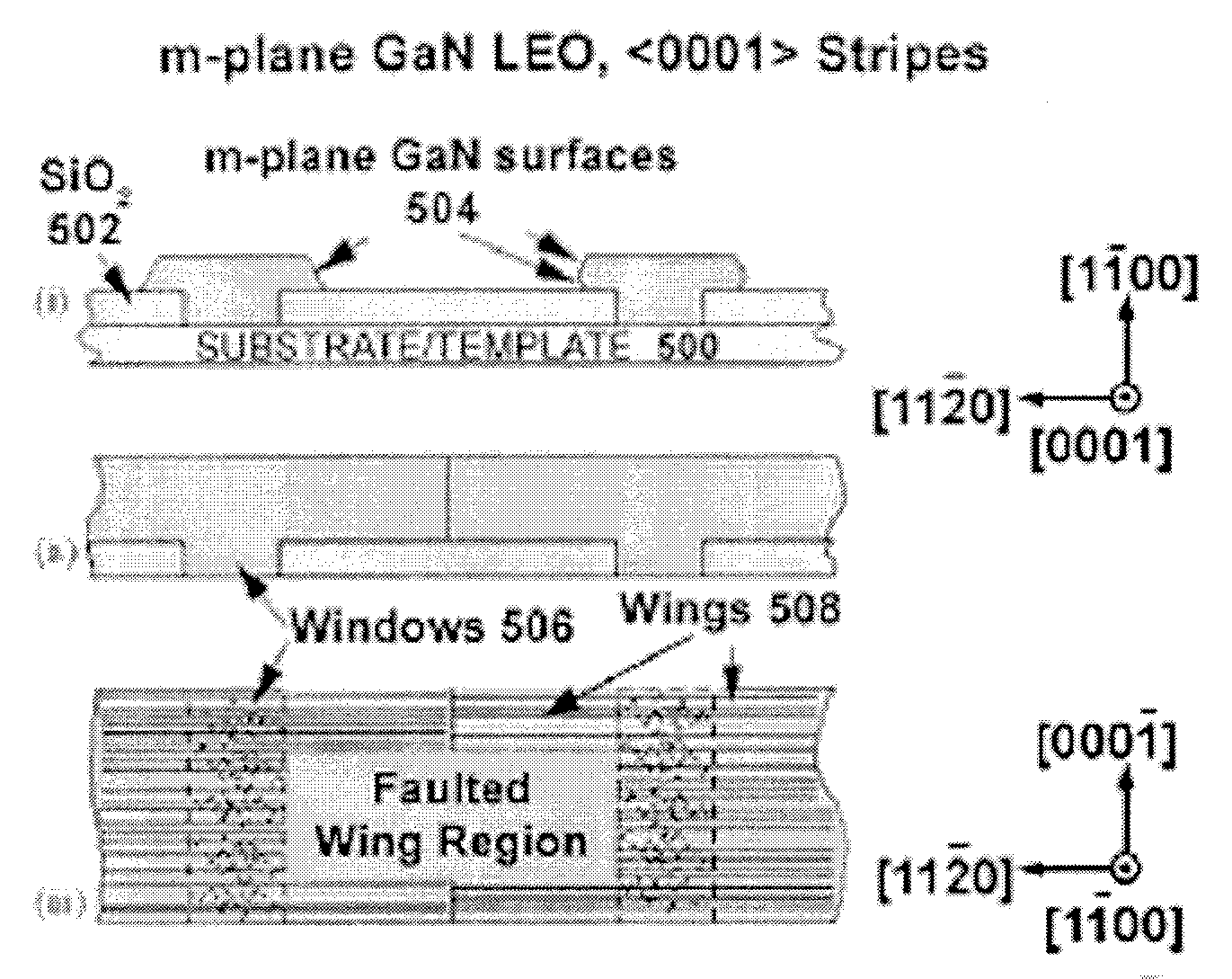

Growth of planar reduced dislocation density m-plane gallium nitride by hydride vapor phase epitaxy

ActiveUS20070184637A1Reduction in structural defect densityReduce defect densitySemiconductor/solid-state device manufacturingSemiconductor devicesLateral overgrowthVolumetric Mass Density

A method of growing highly planar, fully transparent and specular m-plane gallium nitride (GaN) films. The method provides for a significant reduction in structural defect densities via a lateral overgrowth technique. High quality, uniform, thick m-plane GaN films are produced for use as substrates for polarization-free device growth.

Owner:JAPAN SCI & TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com