Patents

Literature

537 results about "Polycrystalline material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycrystalline materials are made of crystallites. A crystallite is a small or even microscopic crystal which forms, for example, during the cooling of many materials. The orientation of crystallites can be random with no preferred direction, called random texture, or directed, possibly due to growth and processing conditions.

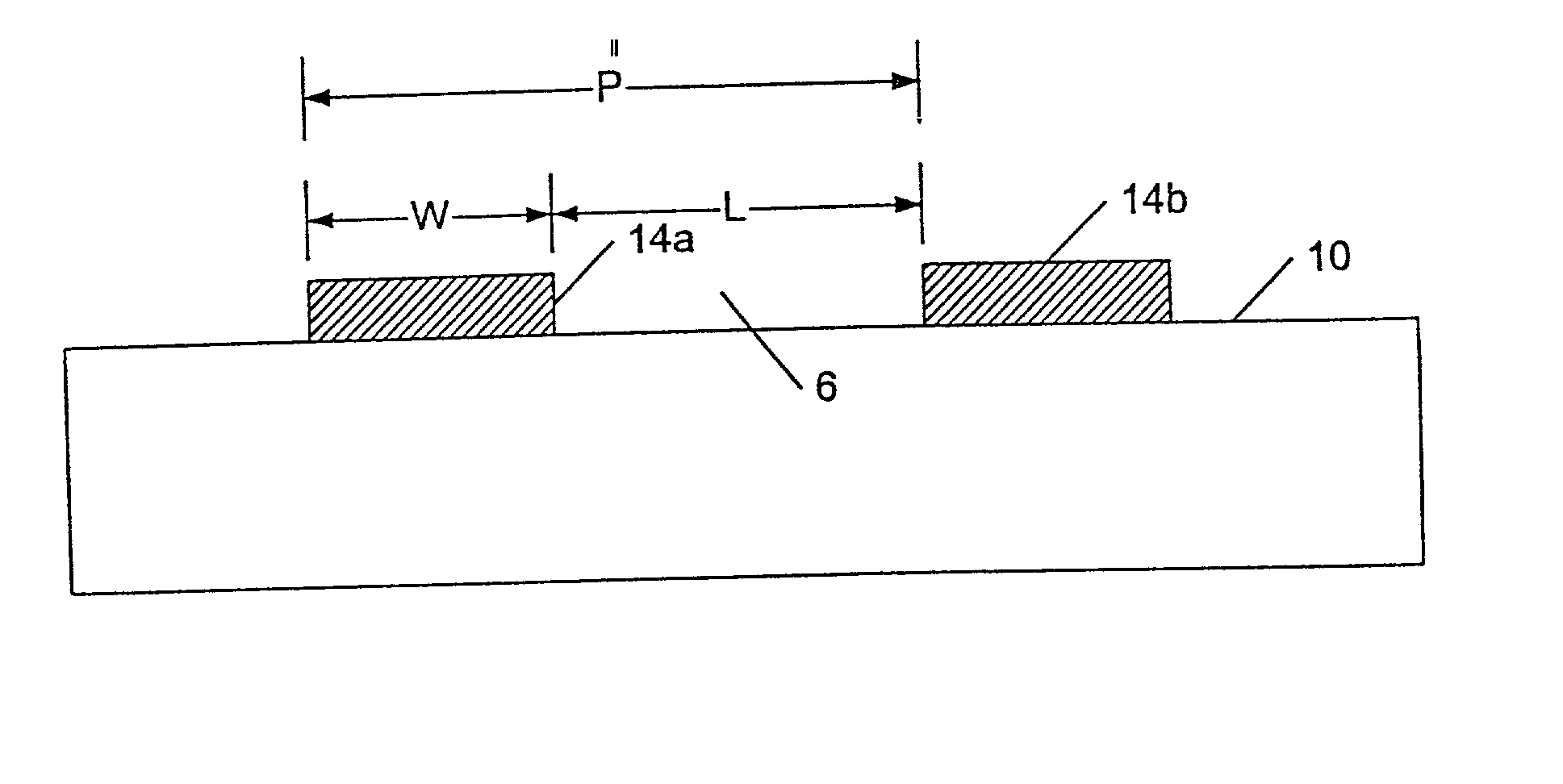

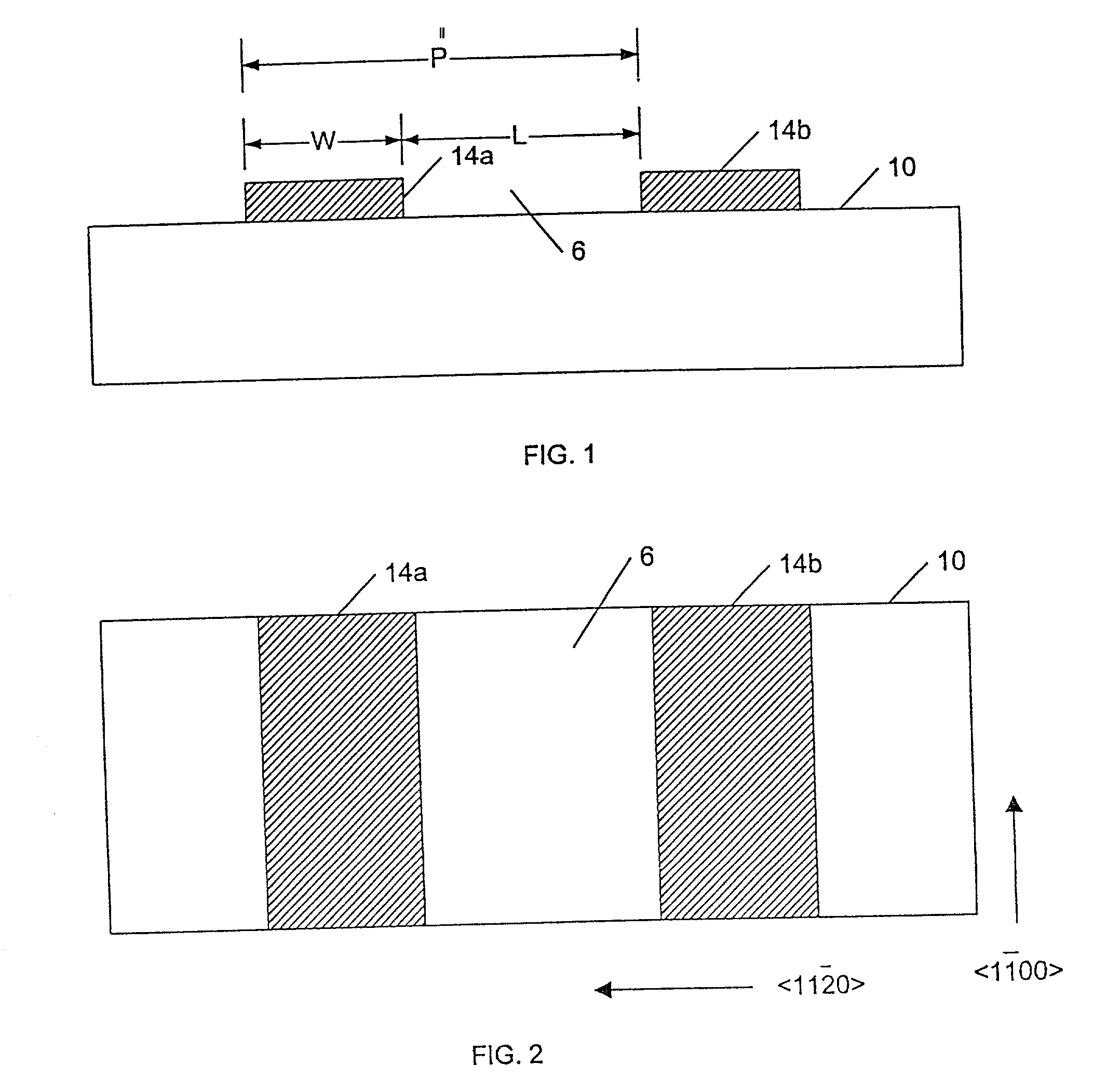

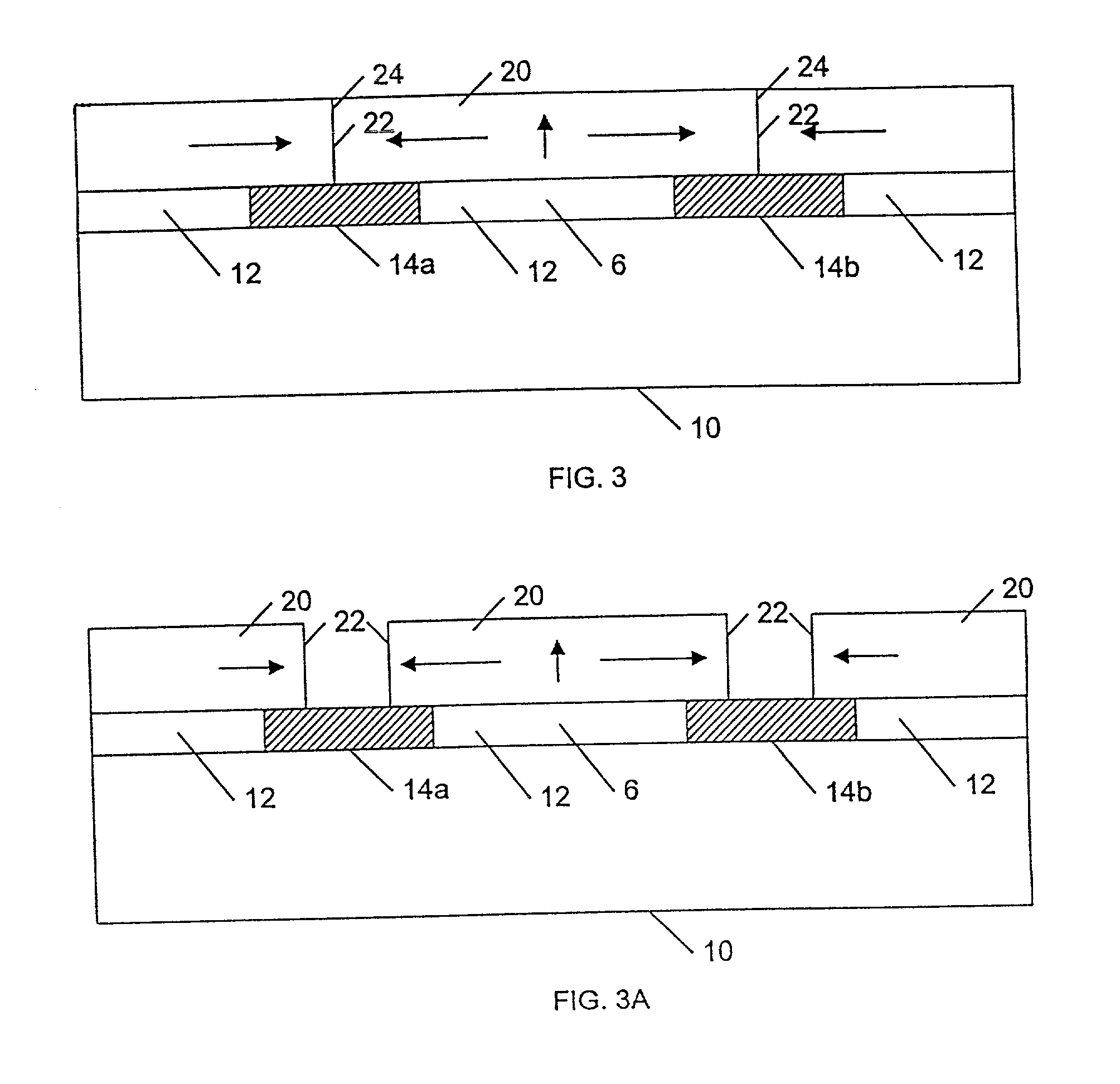

Single step pendeo-and lateral epitaxial overgrowth of group III-nitride epitaxial layers with group III-nitride buffer layer and resulting structures

InactiveUS20020022290A1Semiconductor laser structural detailsSemiconductor/solid-state device manufacturingSemiconductor structureGallium nitride

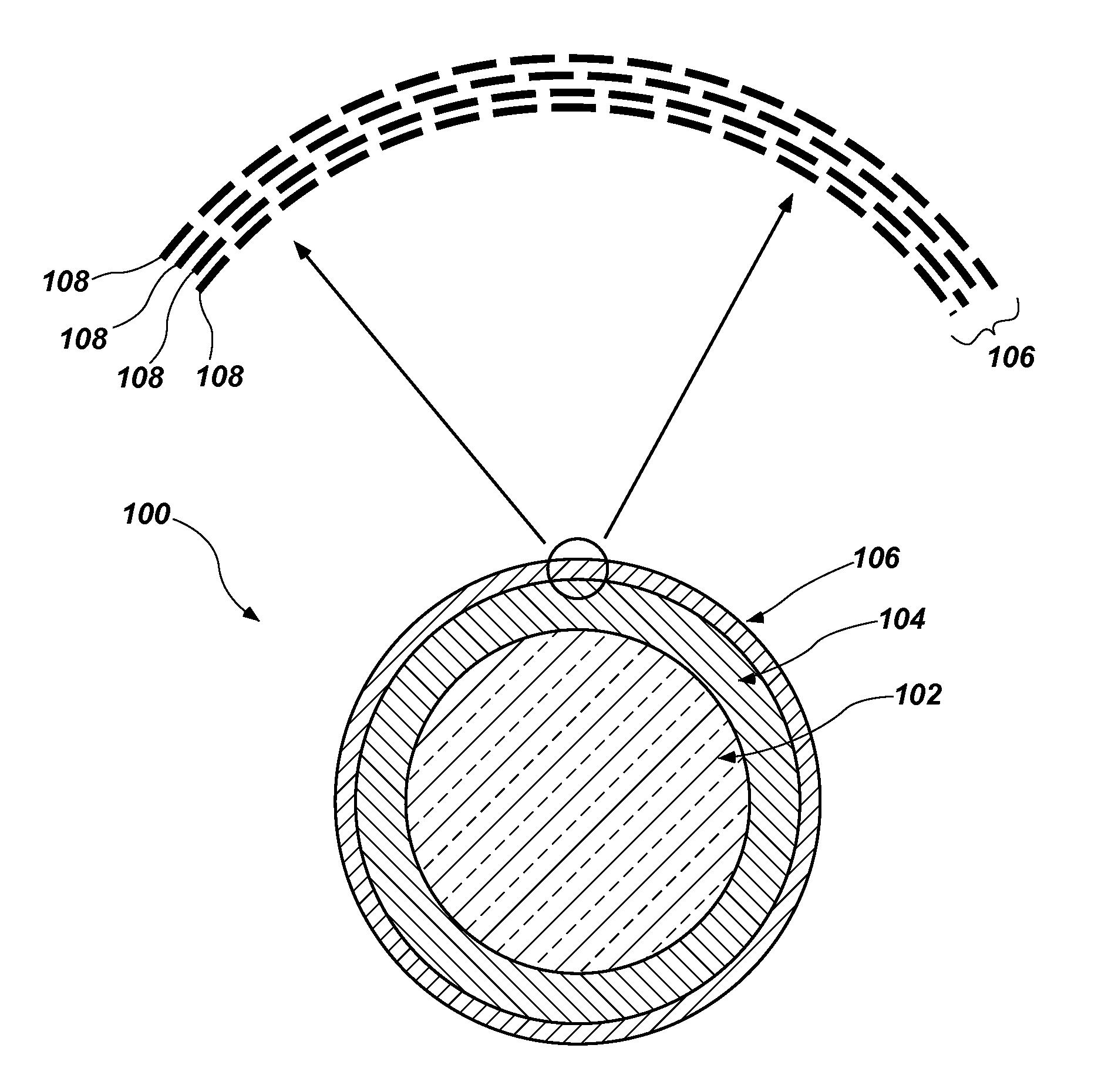

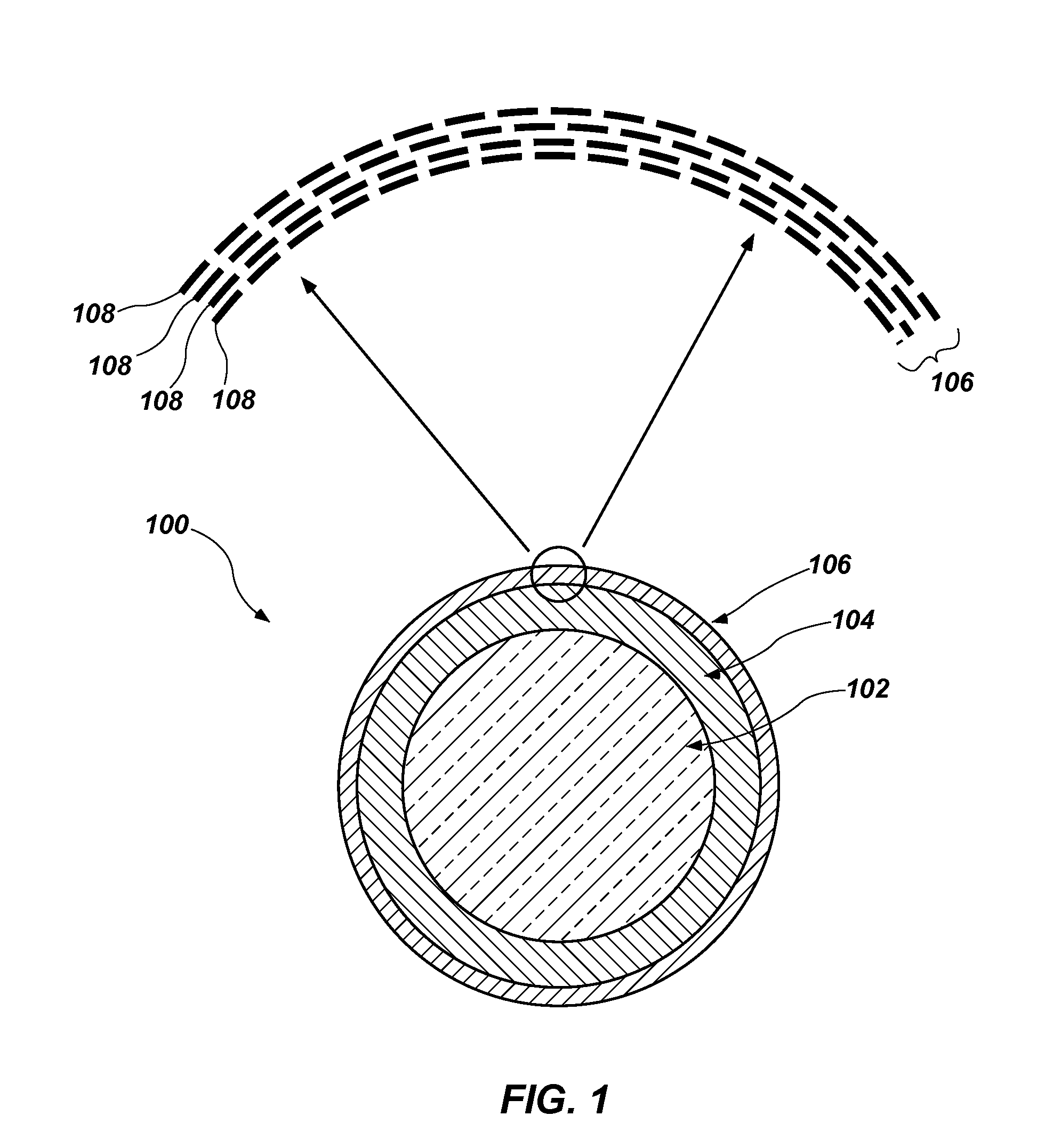

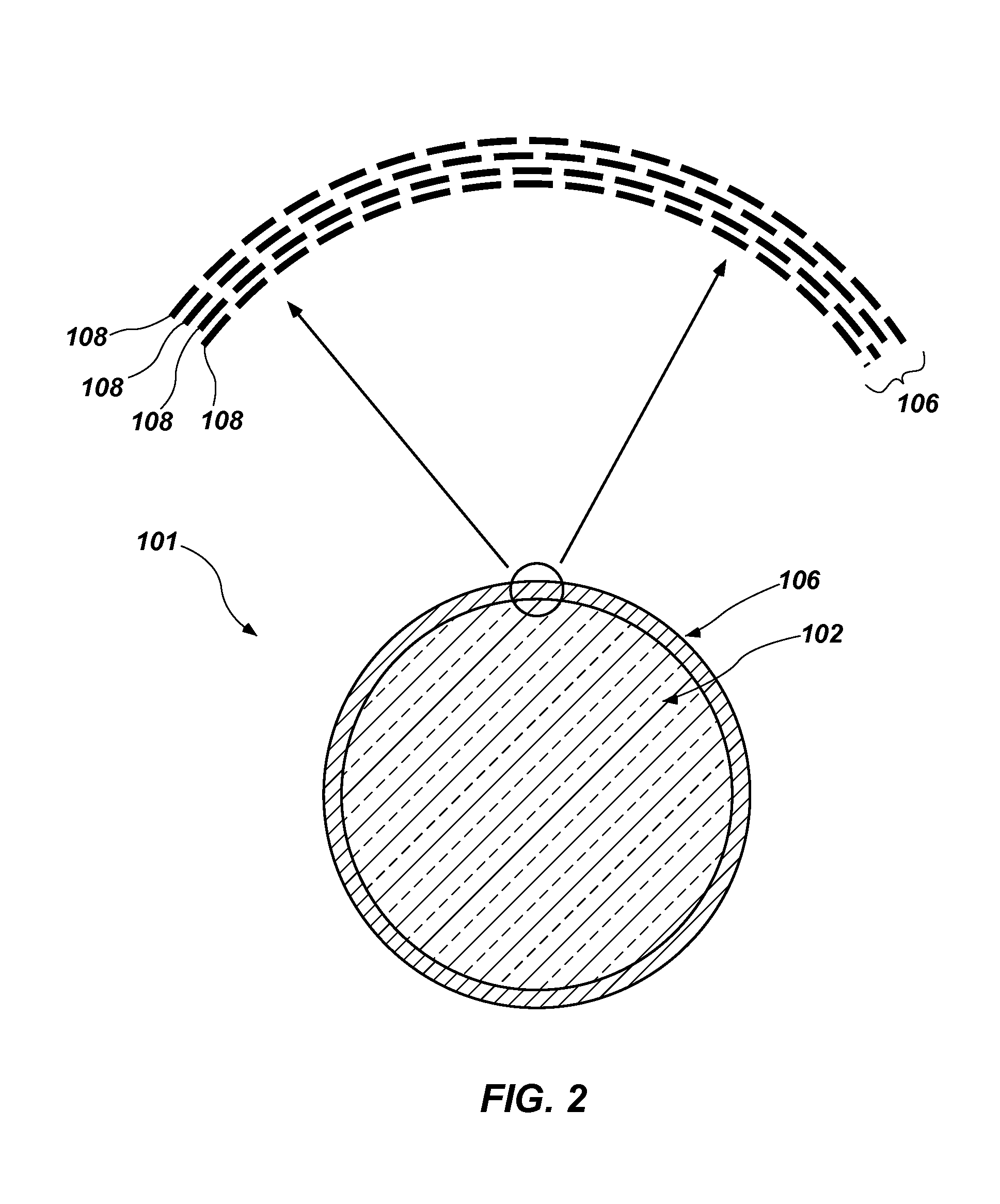

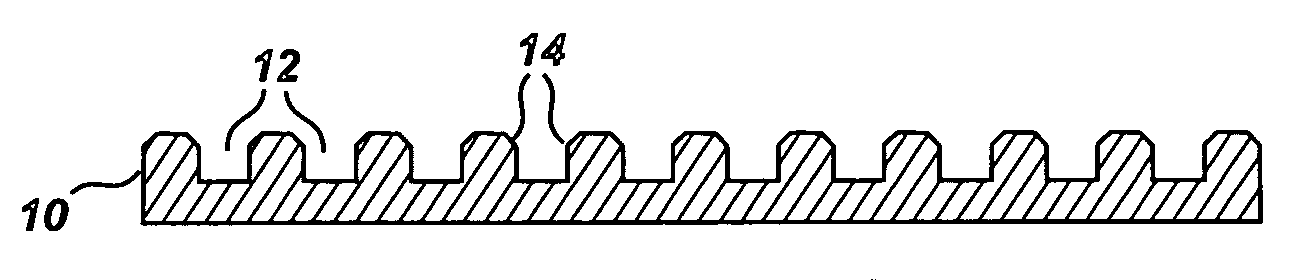

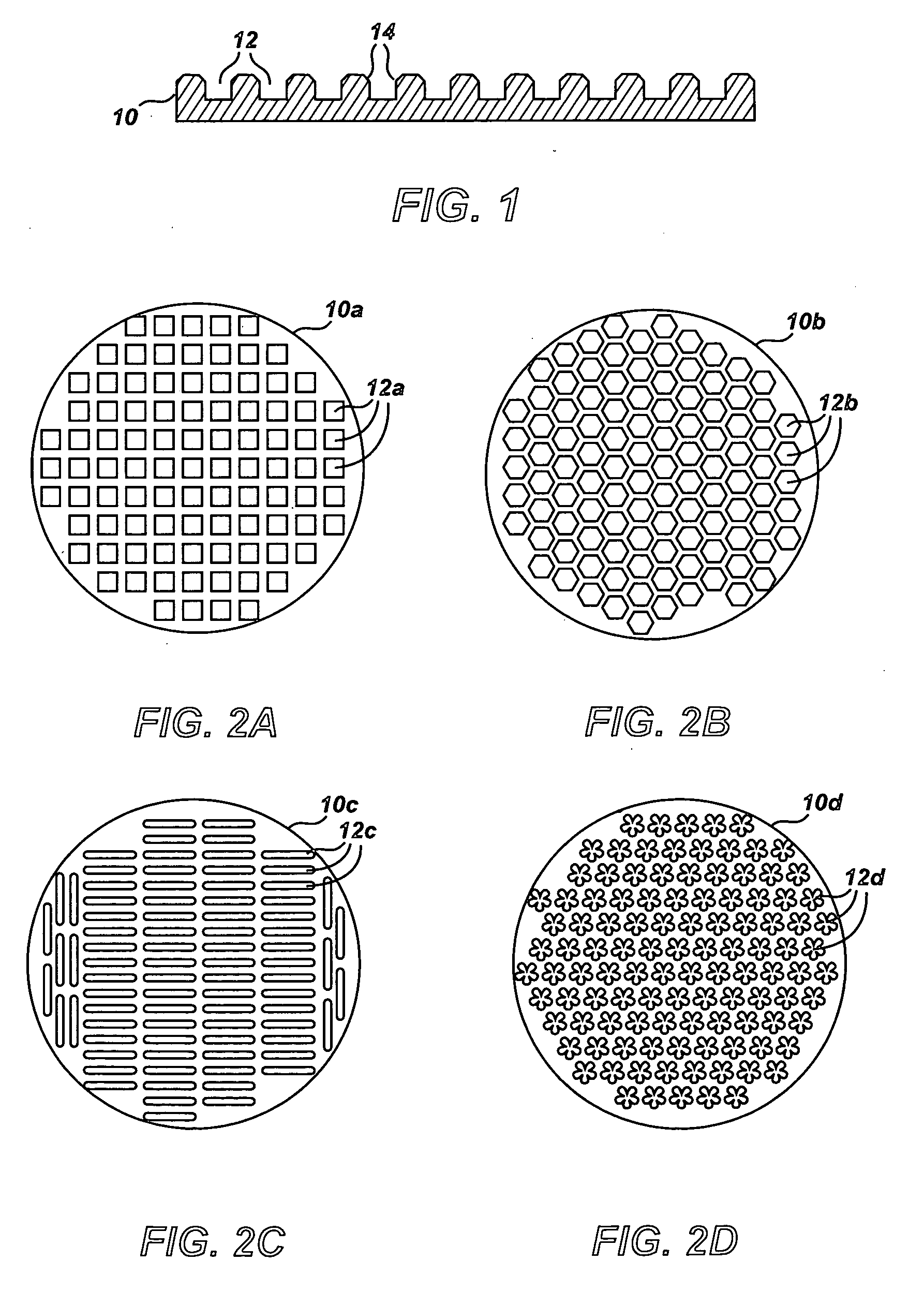

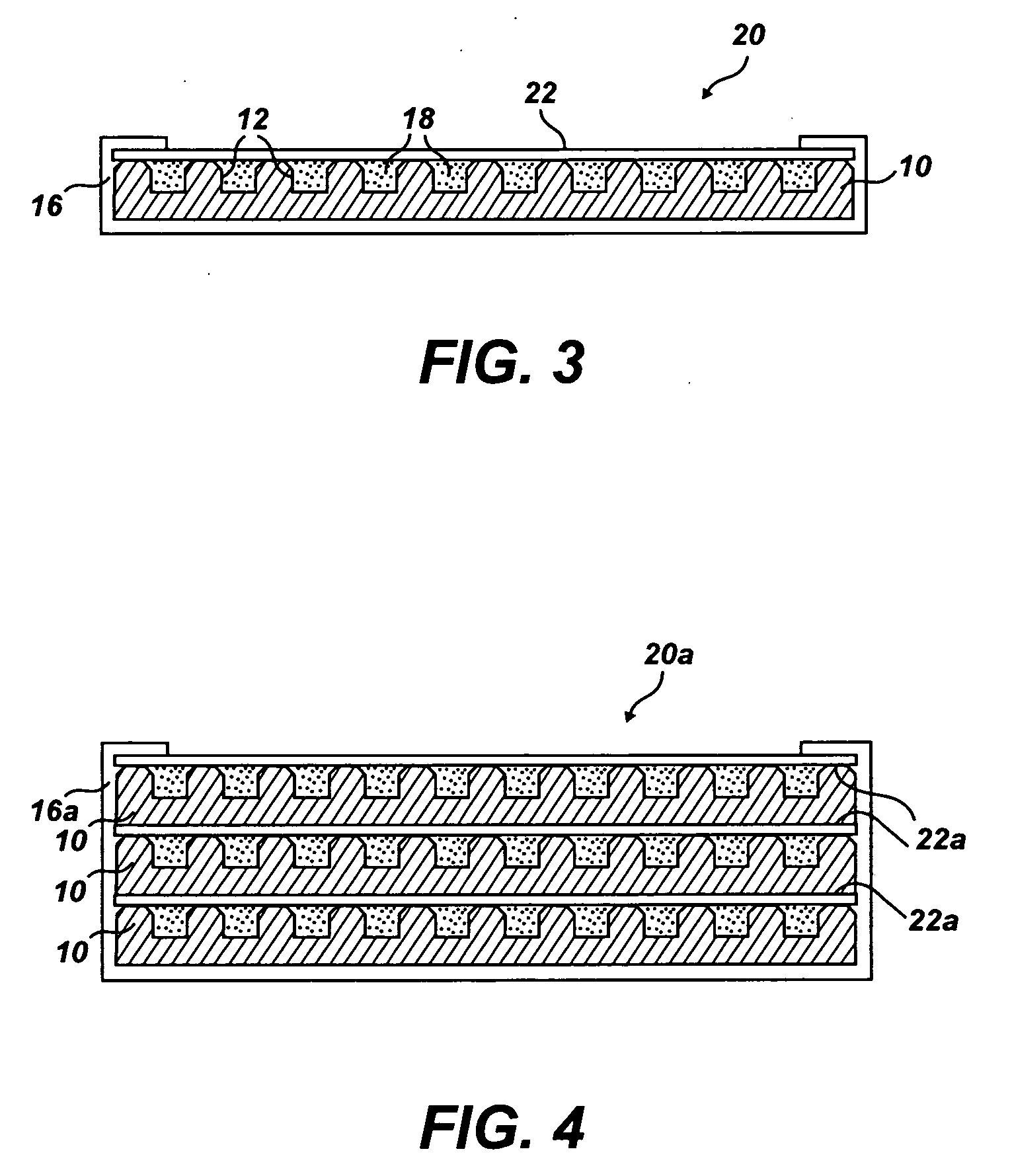

A method of fabricating a gallium nitride-based semiconductor structure on a substrate includes the steps of forming a mask having at least one opening therein directly on the substrate, growing a buffer layer through the opening, and growing a layer of gallium nitride upwardly from the buffer layer and laterally across the mask. During growth of the gallium nitride from the mask, the vertical and horizontal growth rates of the gallium nitride layer are maintained at rates sufficient to prevent polycrystalline material nucleating on said mask from interrupting the lateral growth of the gallium nitride layer. In an alternative embodiment, the method includes forming at least one raised portion defining adjacent trenches in the substrate and forming a mask on the substrate, the mask having at least one opening over the upper surface of the raised portion. A buffer layer may be grown from the upper surface of the raised portion. The gallium nitride layer is then grown laterally by pendeoepitaxy over the trenches.

Owner:CREE INC

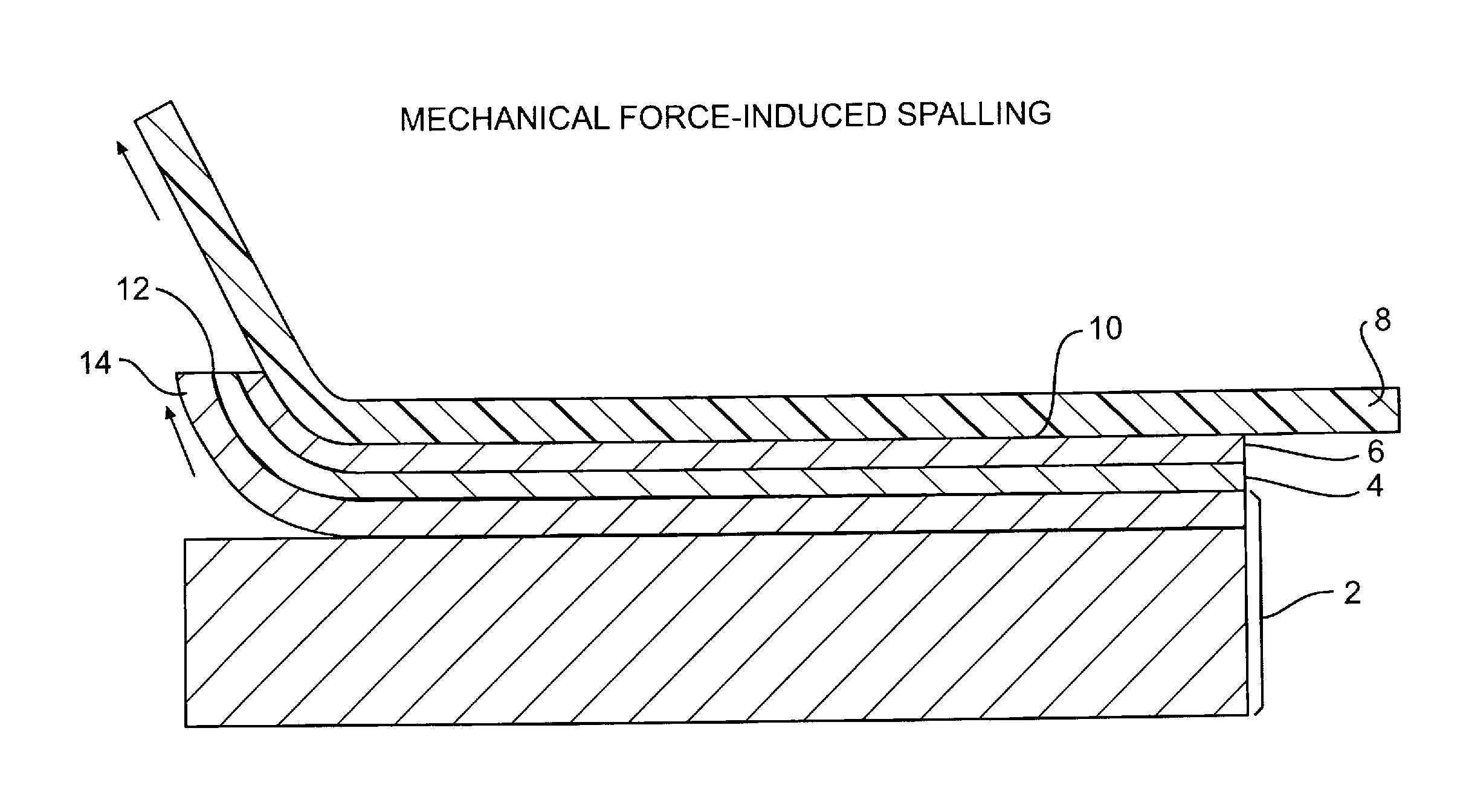

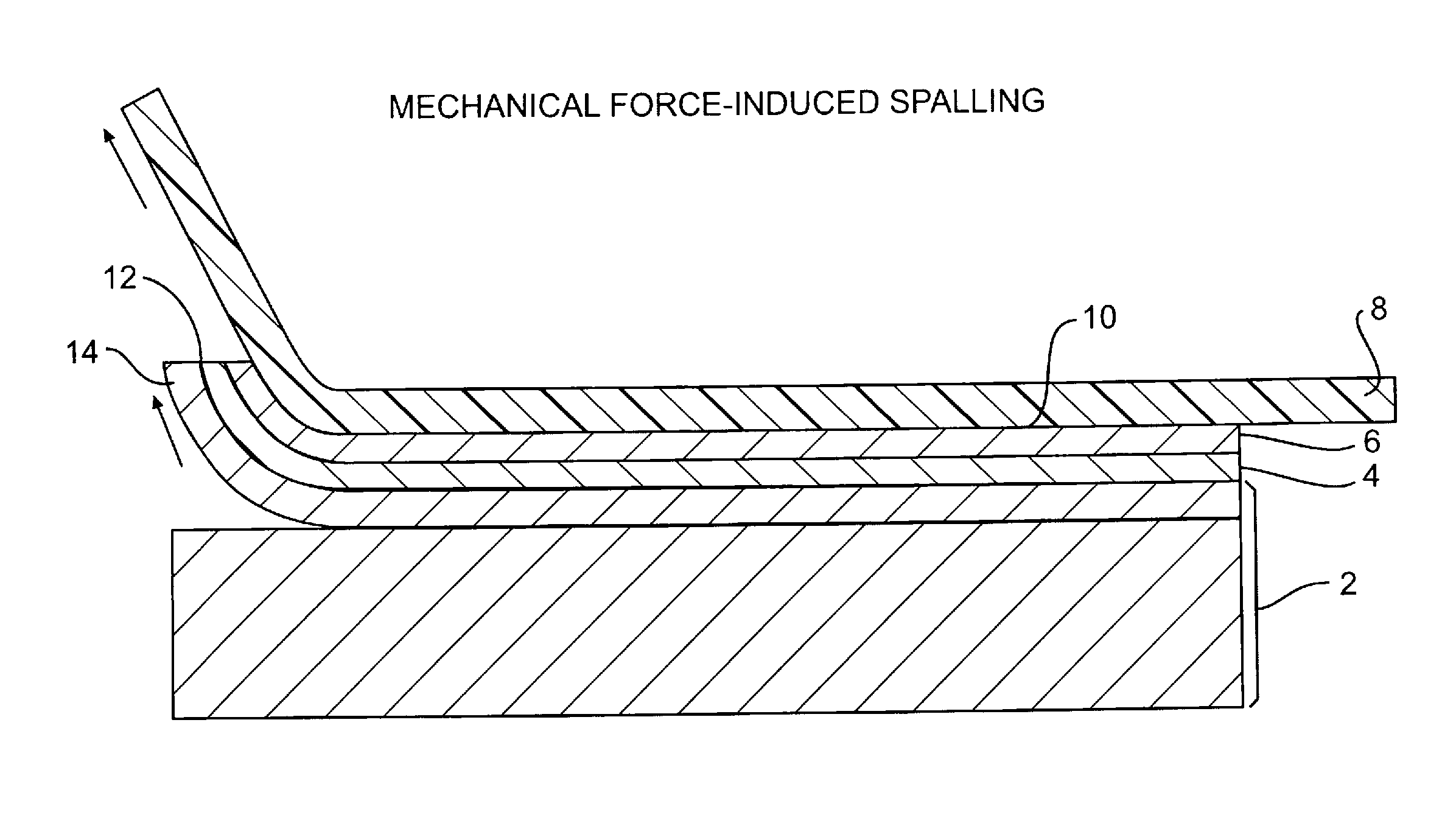

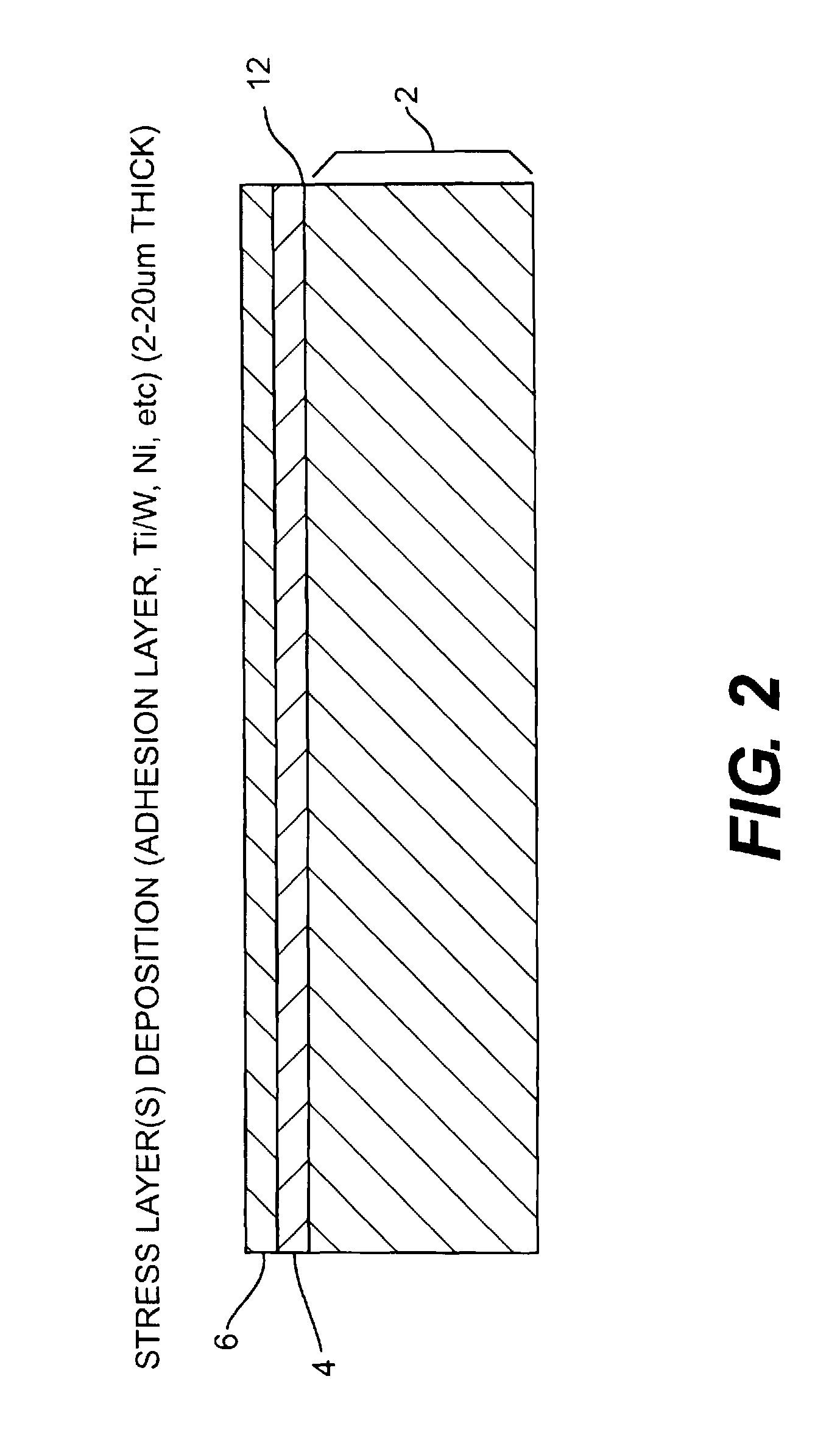

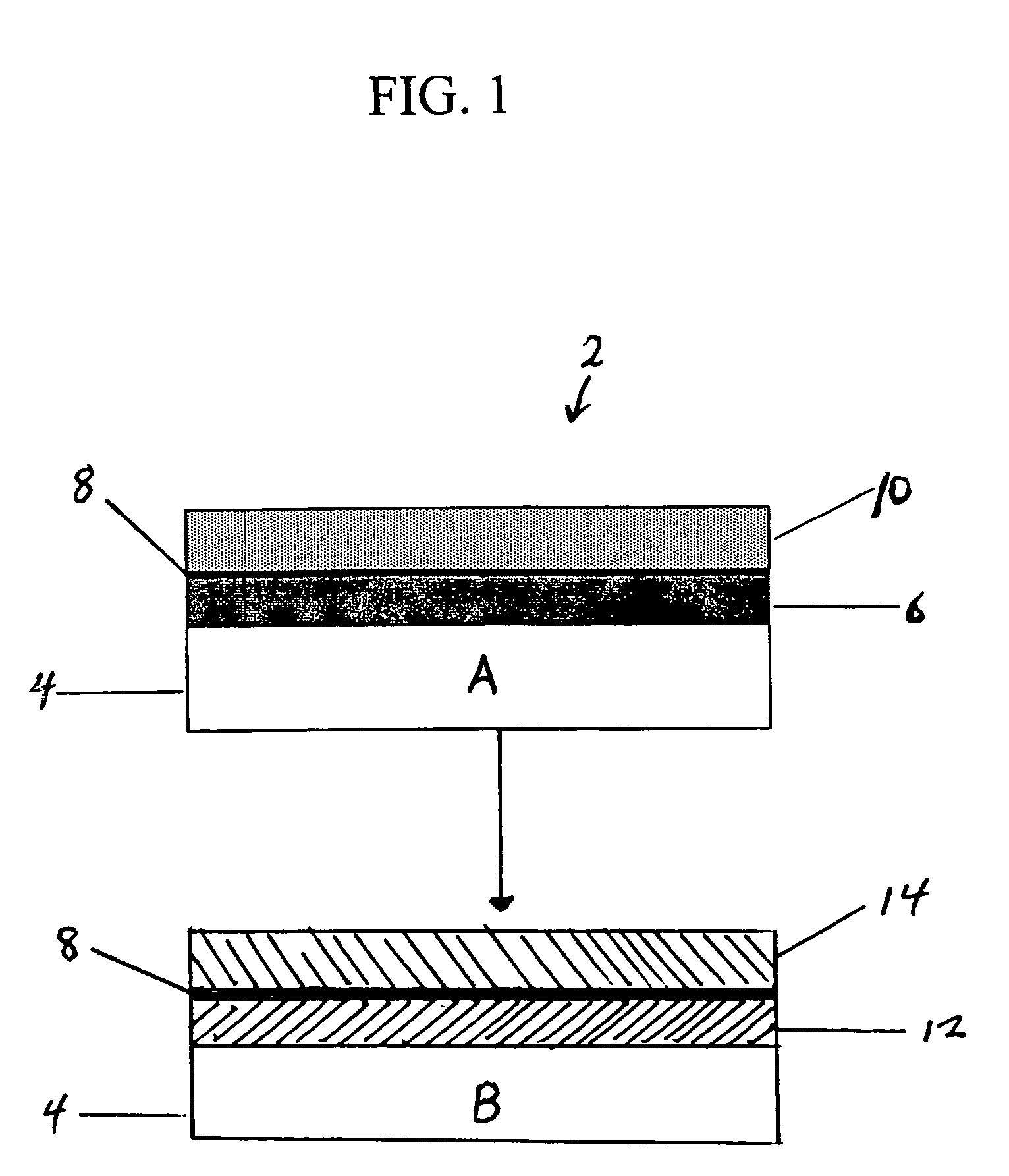

Thin substrate fabrication using stress-induced substrate spalling

ActiveUS20100311250A1Increase cost per Watt valueImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingStress inducedActive solar

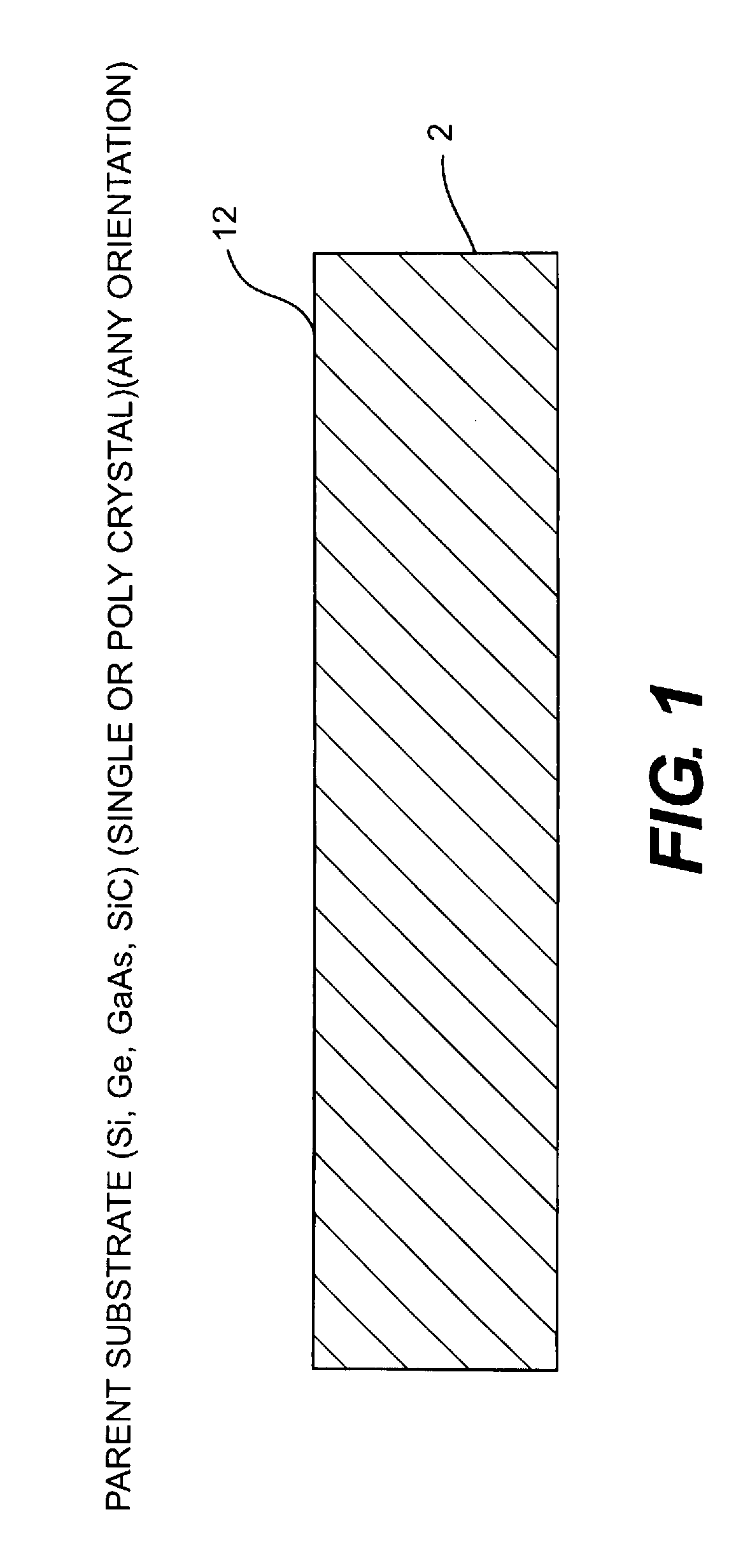

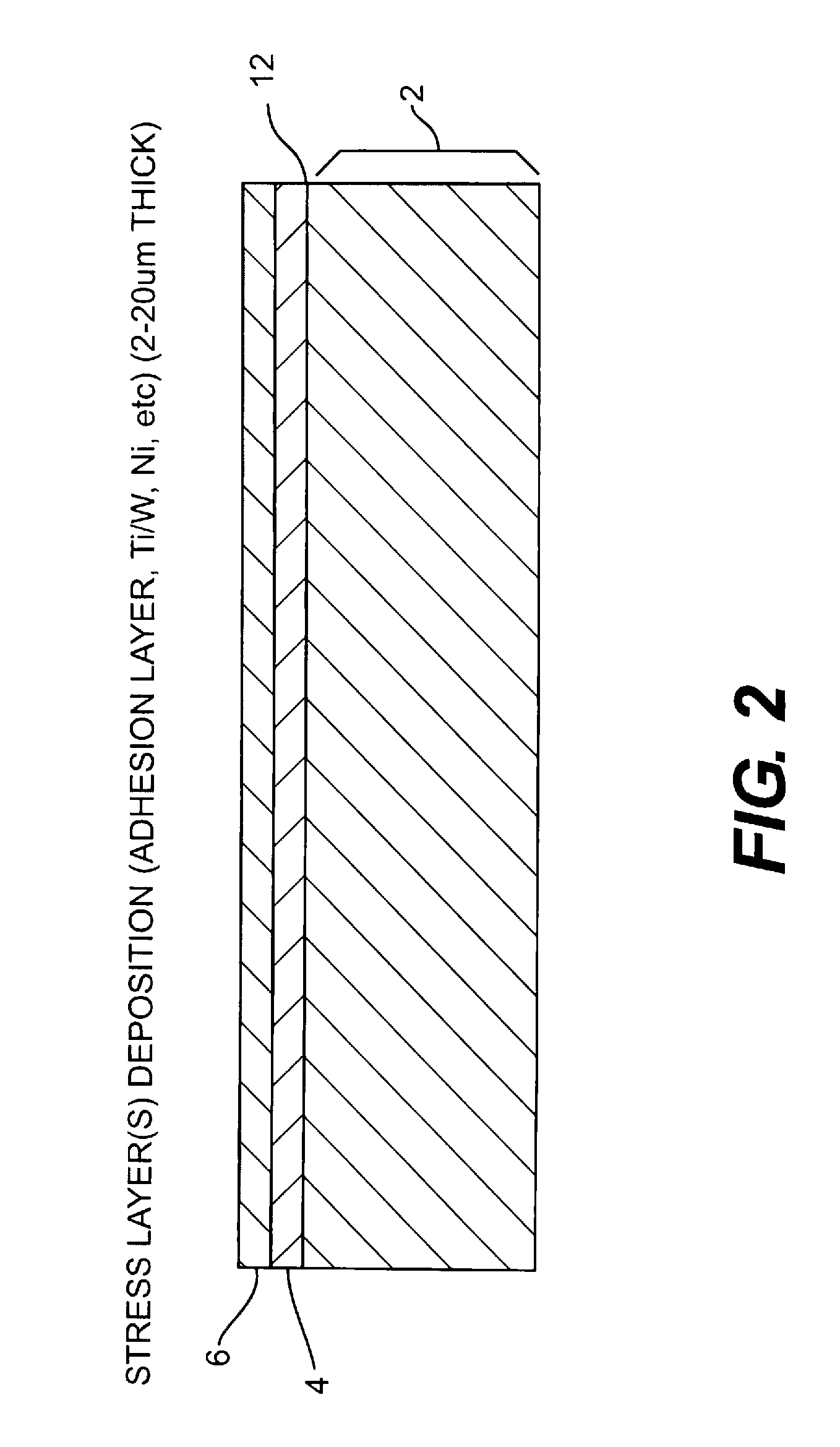

A method for manufacturing a thin film direct bandgap semiconductor active solar cell device comprises providing a source substrate having a surface and disposing on the surface a stress layer having a stress layer surface area in contact with and bonded to the surface of the source substrate. Operatively associating a handle foil with the stress layer and applying force to the handle foil separates the stress layer from the source substrate, and leaves a portion of the source substrate on the stress layer surface substantially corresponding to the area in contact with the surface of the source substrate. The portion is less thick than the source layer. The stress layer thickness is below that which results in spontaneous spalling of the source substrate. The source substrate may comprise an inorganic single crystal or polycrystalline material such as Si, Ge, GaAs, SiC, sapphire, or GaN. In one embodiment the stress layer comprises a flexible material.

Owner:GLOBALFOUNDRIES US INC

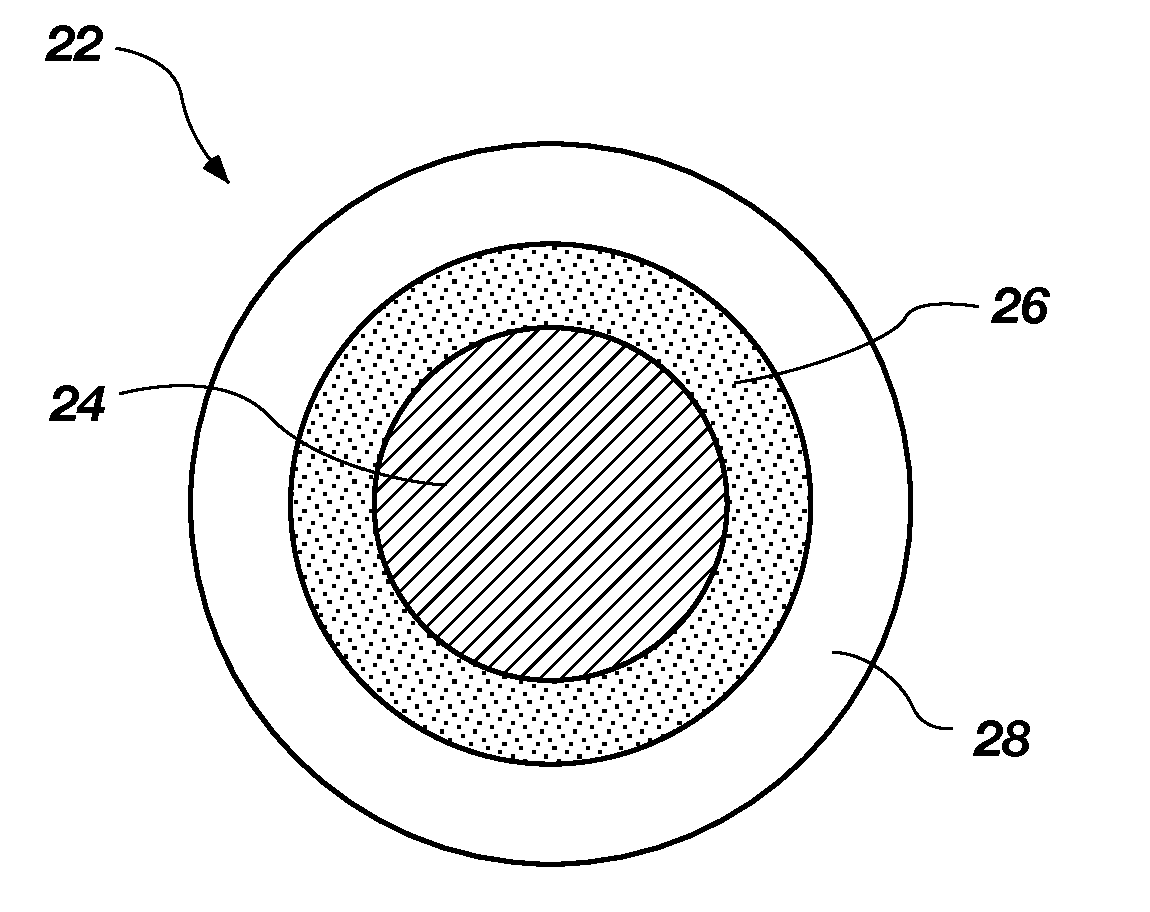

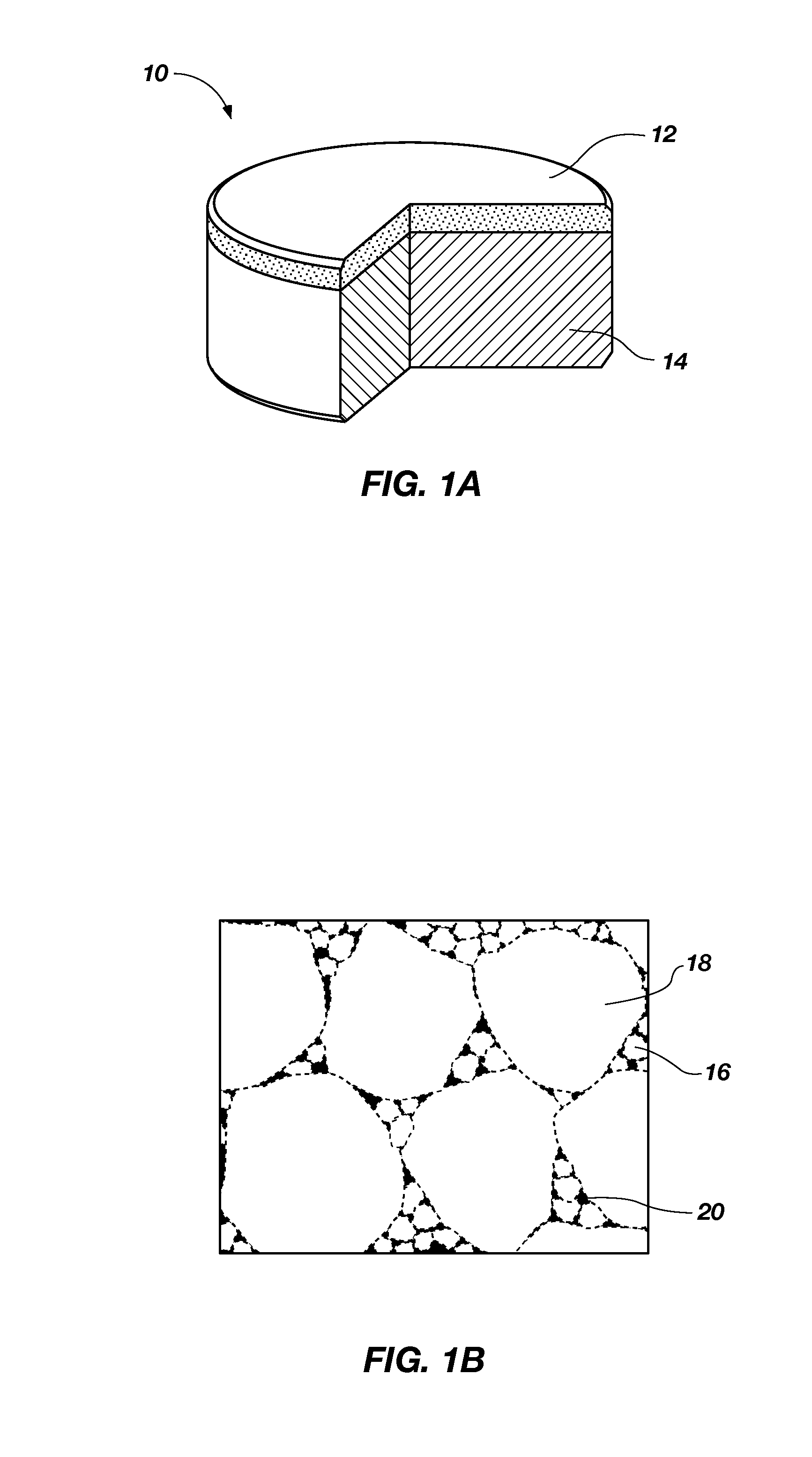

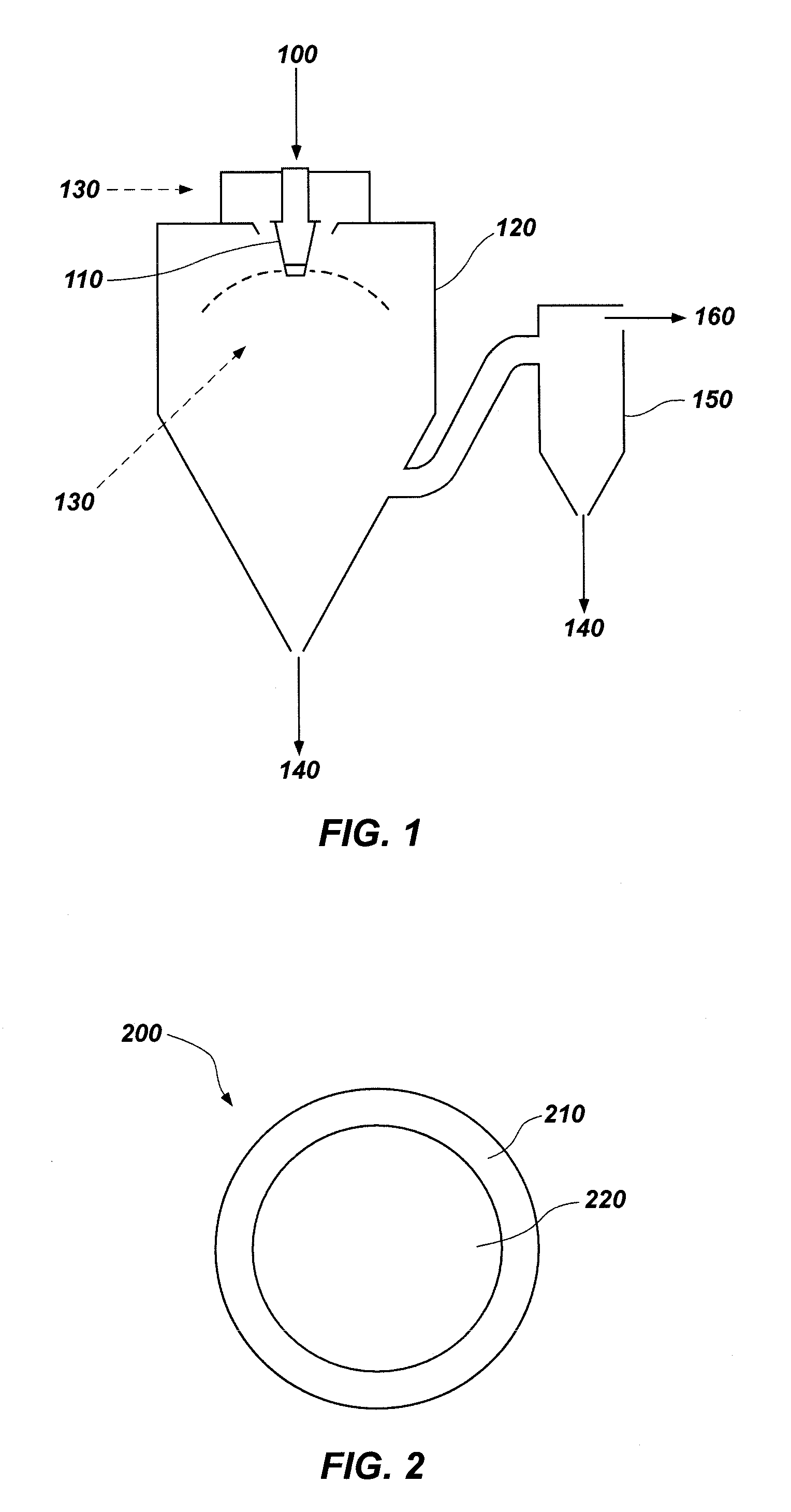

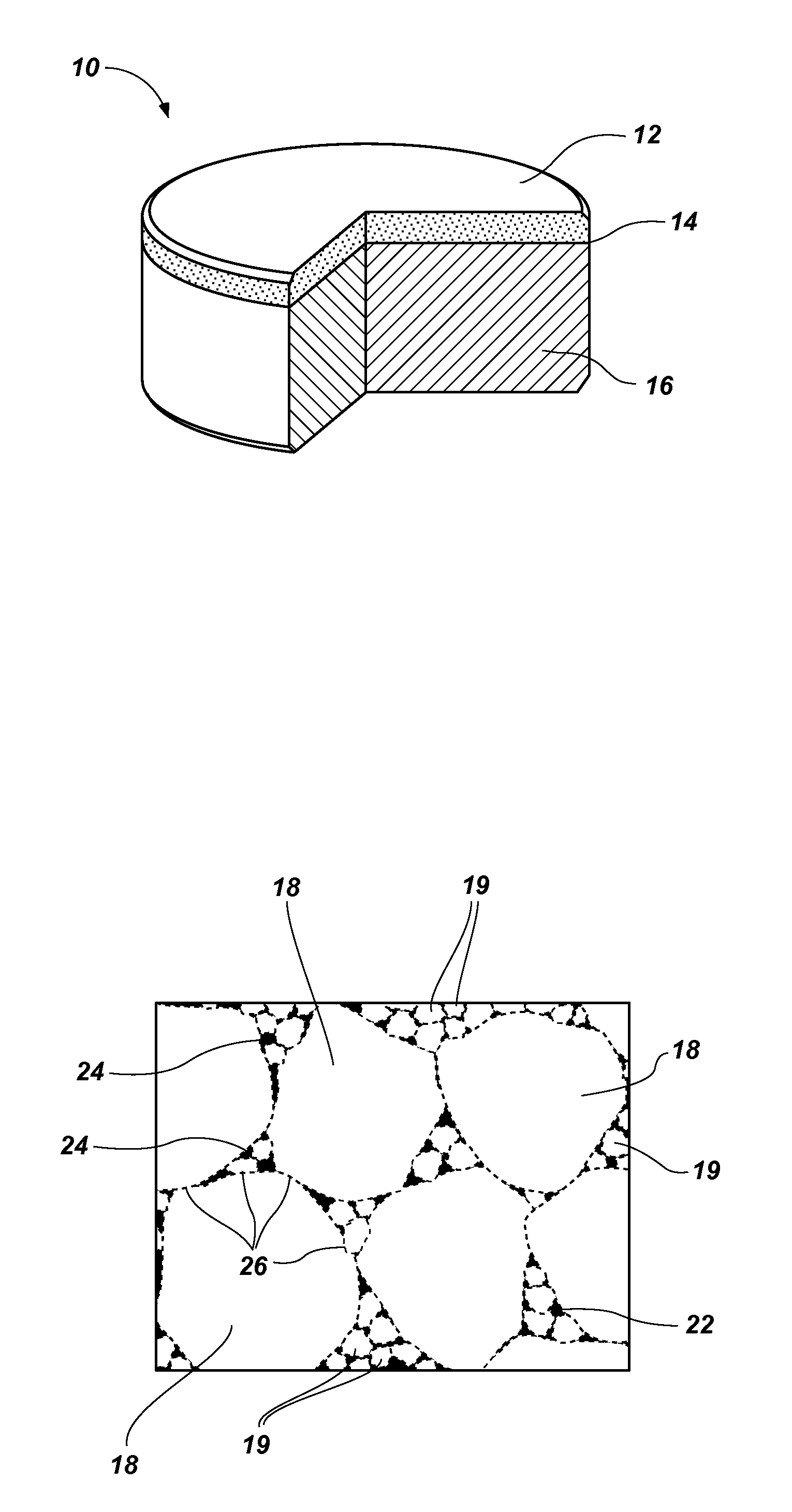

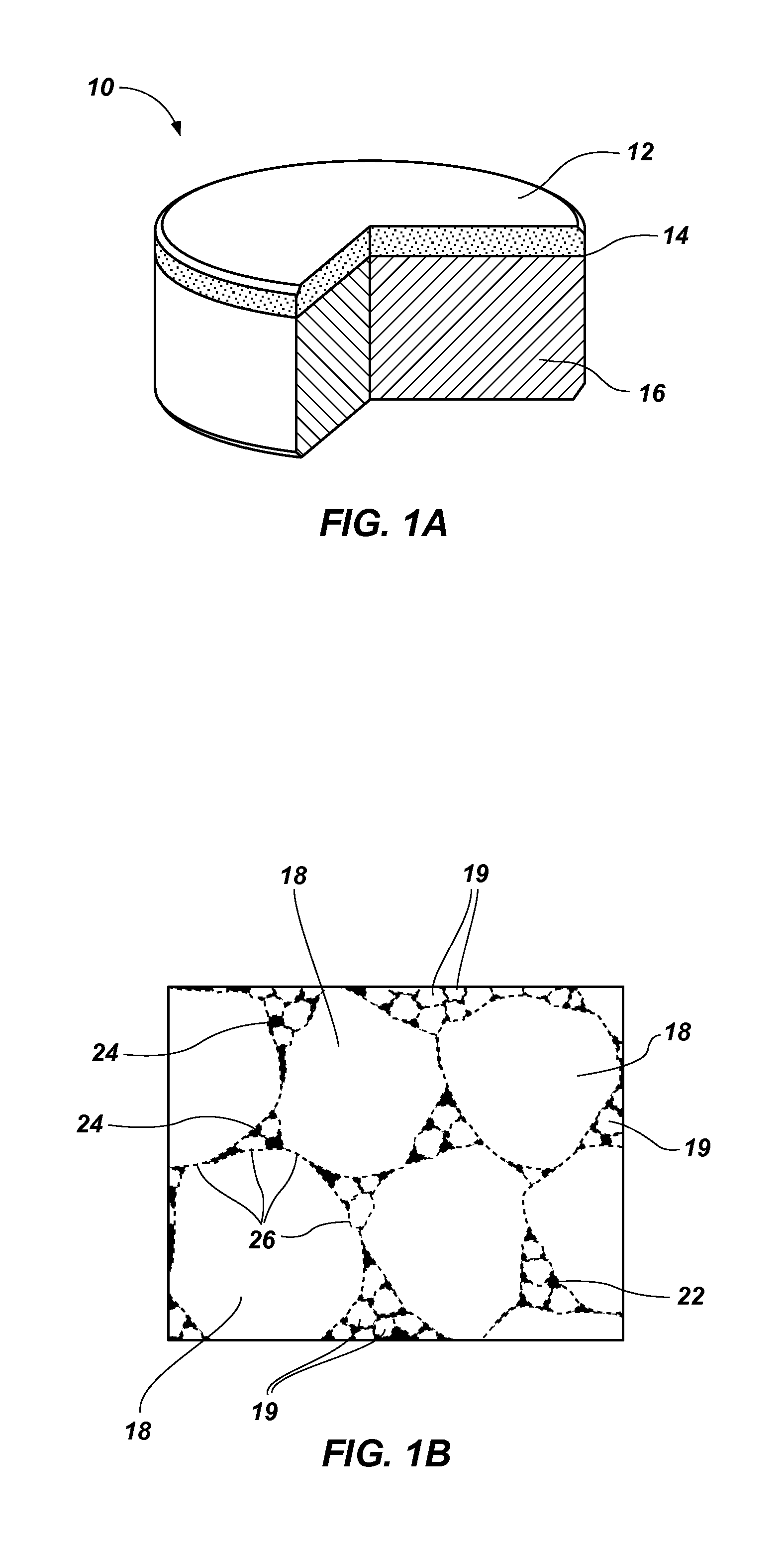

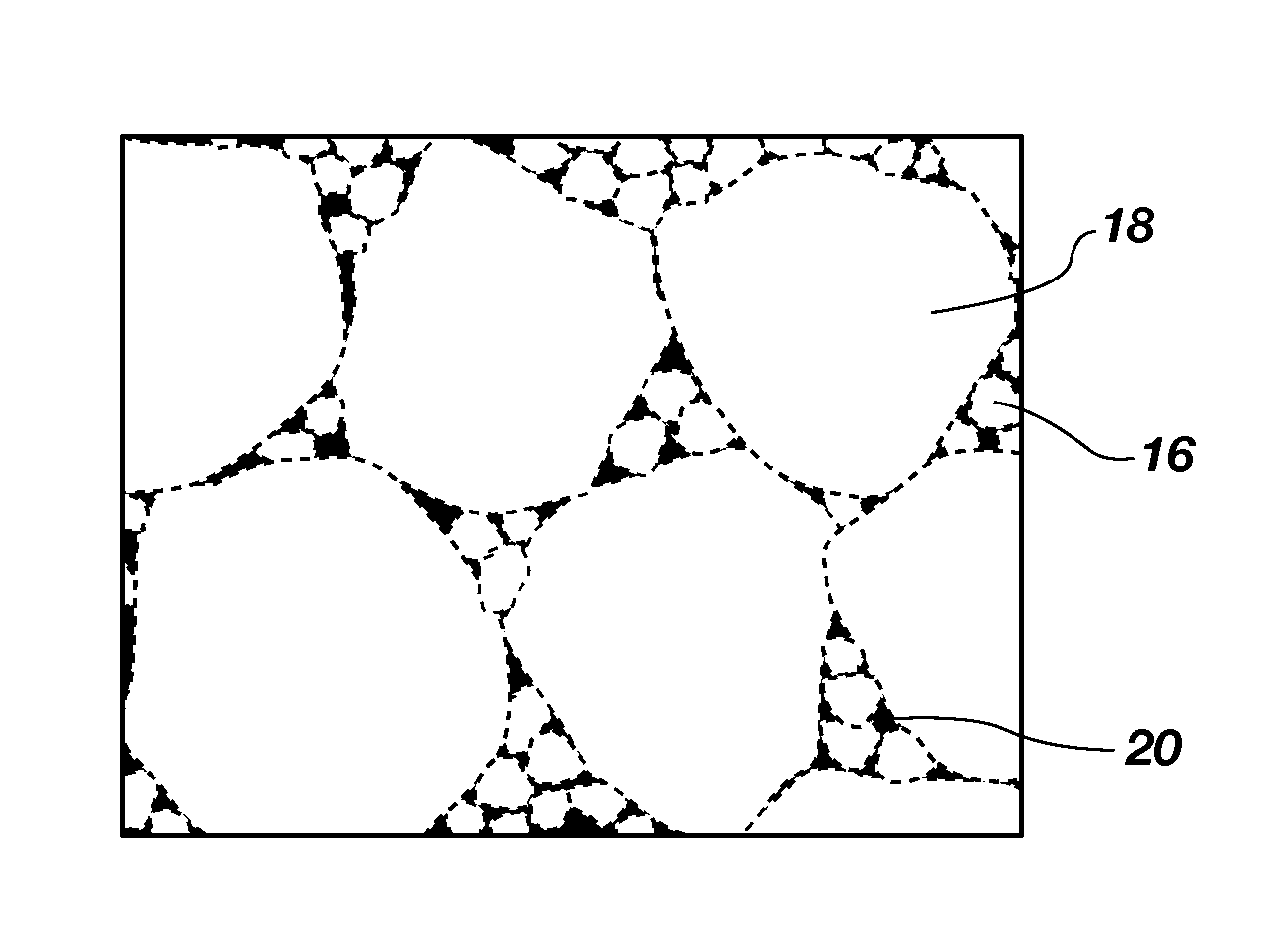

Polycrystalline compacts including in-situ nucleated grains, earth-boring tools including such compacts, and methods of forming such compacts and tools

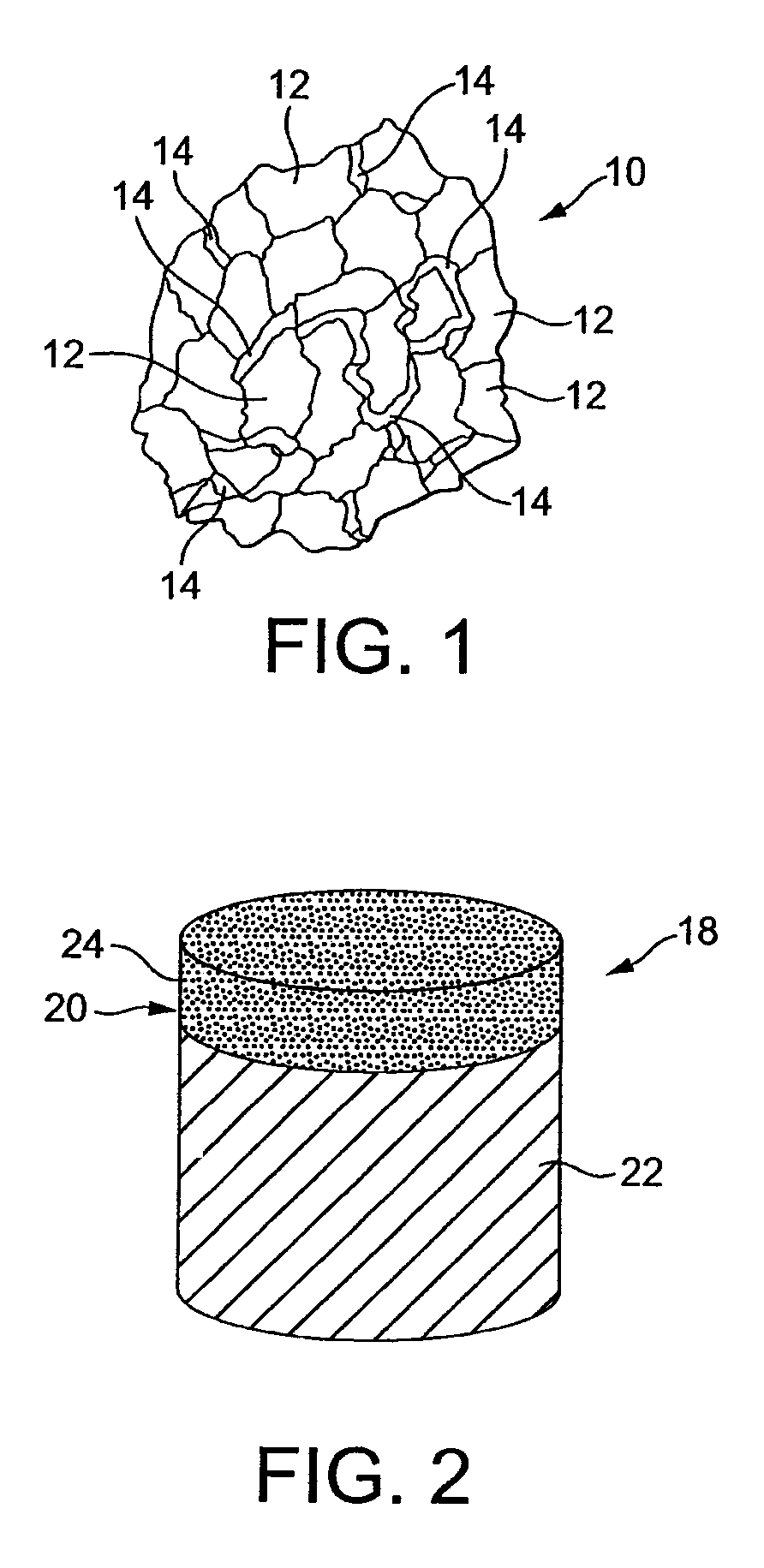

Polycrystalline compacts include hard polycrystalline materials comprising in situ nucleated smaller grains of hard material interspersed and inter-bonded with larger grains of hard material. The average size of the larger grains may be at least about 250 times greater than the average size of the in situ nucleated smaller grains. Methods of forming polycrystalline compacts include nucleating and catalyzing the formation of smaller grains of hard material in the presence of larger grains of hard material, and catalyzing the formation of inter-granular bonds between the grains of hard material. For example, nucleation particles may be mixed with larger diamond grains, a carbon source, and a catalyst. The mixture may be subjected to high temperature and high pressure to form in smaller diamond grains using the nucleation particles, the carbon source, and the catalyst, and to catalyze formation of diamond-to-diamond bonds between the smaller and larger diamond grains.

Owner:BAKER HUGHES INC

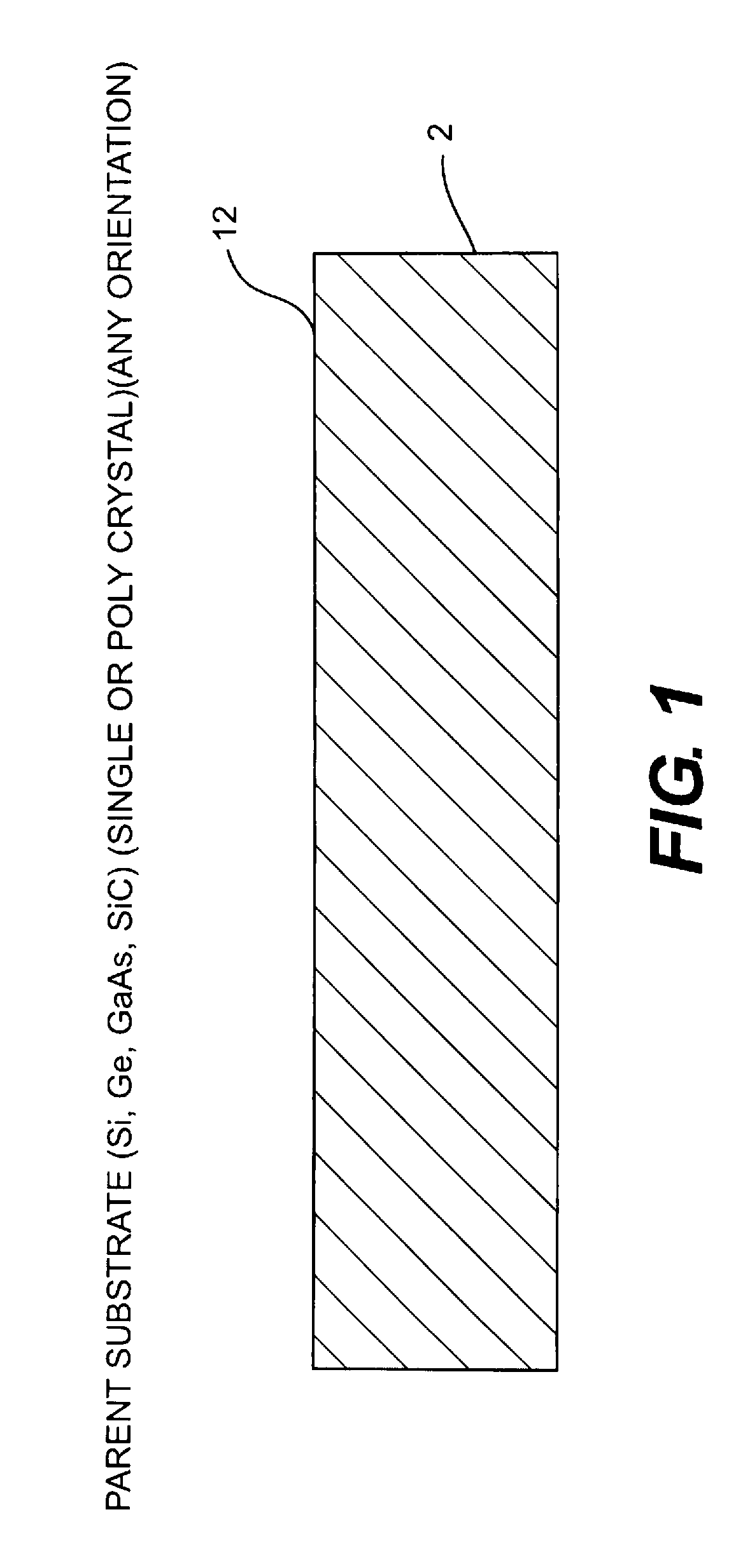

ß-Ga2o3 single crystal growing method, thin-film single crystal growing method, Ga2o3 light-emitting device, and its manufacturing method

InactiveUS20060150891A1Trend downHigh crystallinityPolycrystalline material growthBy zone-melting liquidsDopantInfrared

Owner:WASEDA UNIV

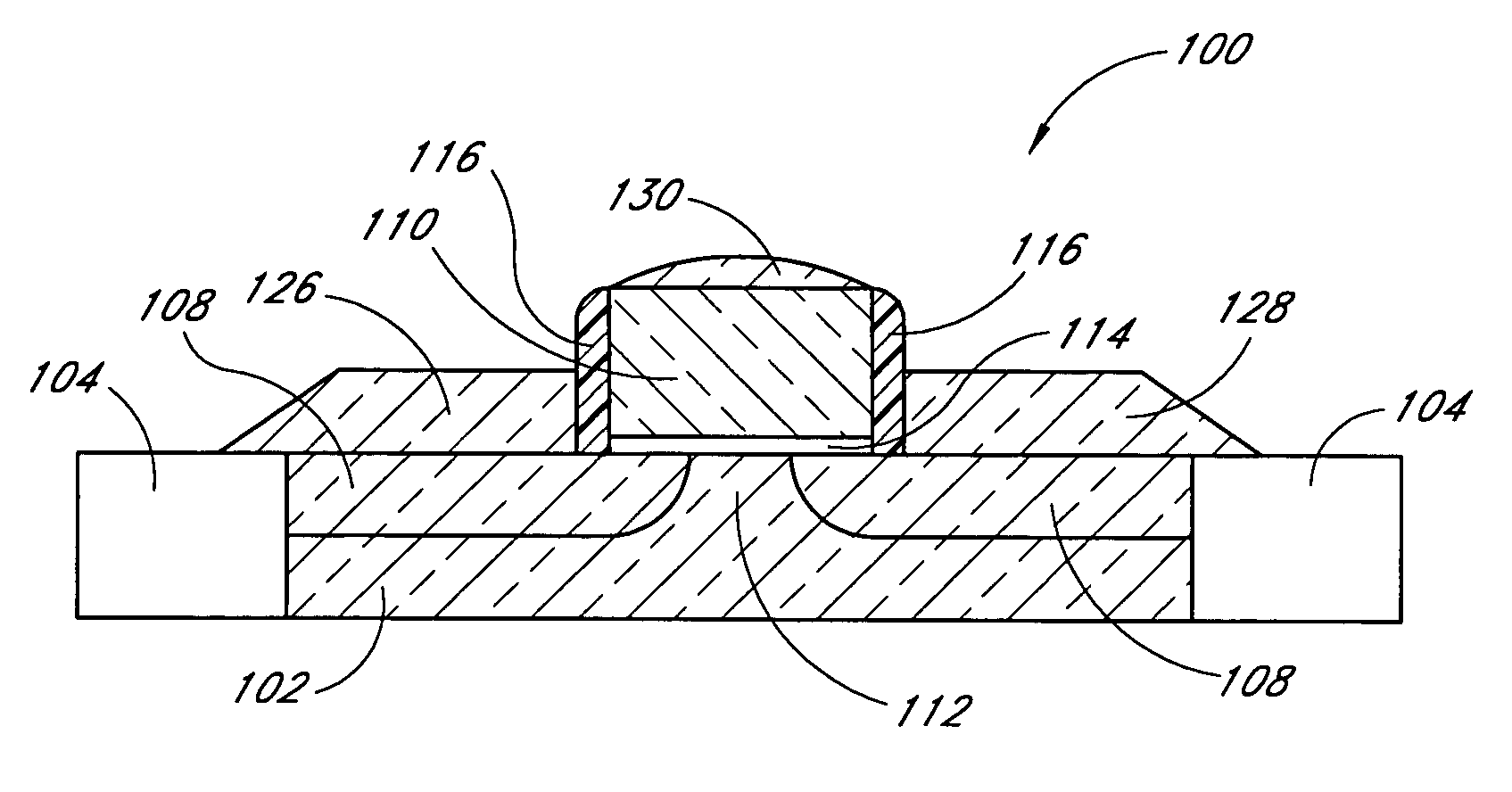

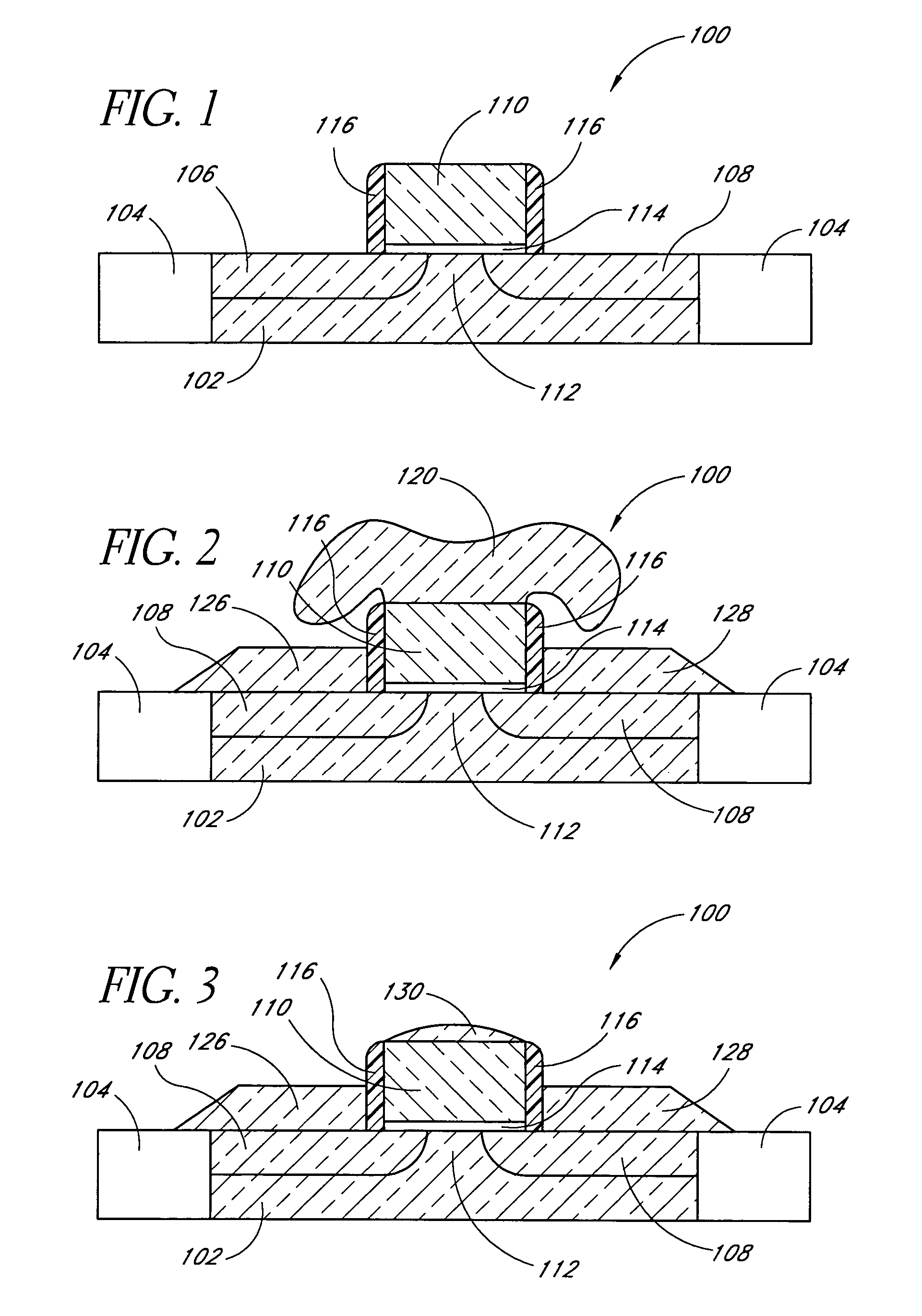

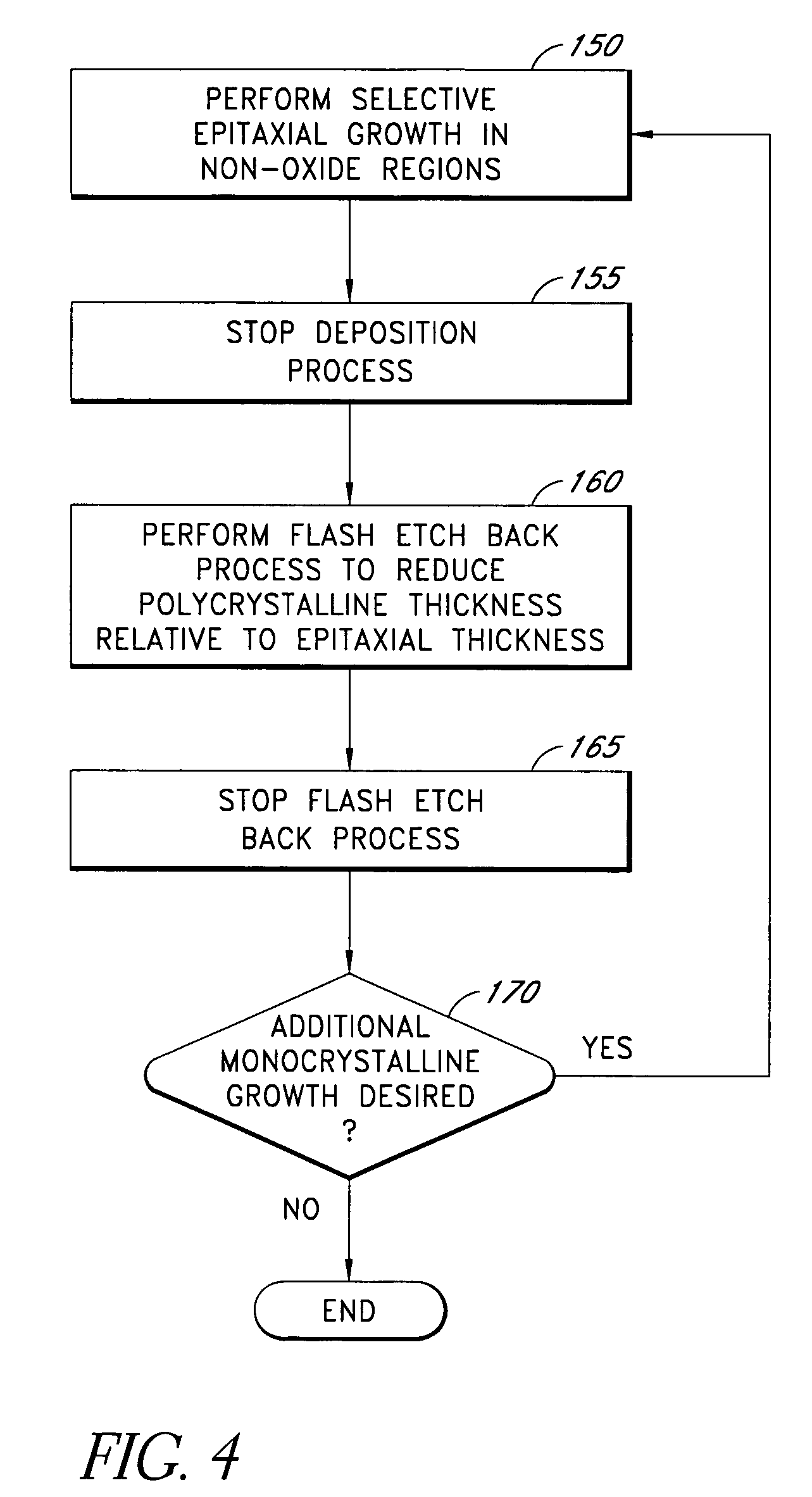

Enhanced selectivity for epitaxial deposition

ActiveUS6998305B2Increase activity areaFrom solid stateSemiconductor/solid-state device manufacturingElectronic componentDeposition process

A method of forming an electronic component having elevated active areas is disclosed. The method comprises providing a semiconductor substrate in a processing chamber. The semiconductor substrate has disposed thereon a polycrystalline silicon gate and exposed active areas. The method further comprises performing a deposition process in which a silicon-source gas is supplied into the processing chamber to cause polycrystalline growth on the gate and epitaxial deposition on the active areas. The method further comprises performing a flash etch back process in which polycrystalline material is etched from the gate at a first etching rate and the epitaxial layer is etched from the active areas at a second etching rate. The first etching rate is faster than the second etching rate. The deposition process and the flash etch back process can be repeated cyclically, if desired. In certain other embodiments, the deposition process is a selective epitaxial deposition process, wherein growth occurs in non-oxide regions, but not in oxide regions.

Owner:ASM IP HLDG BV

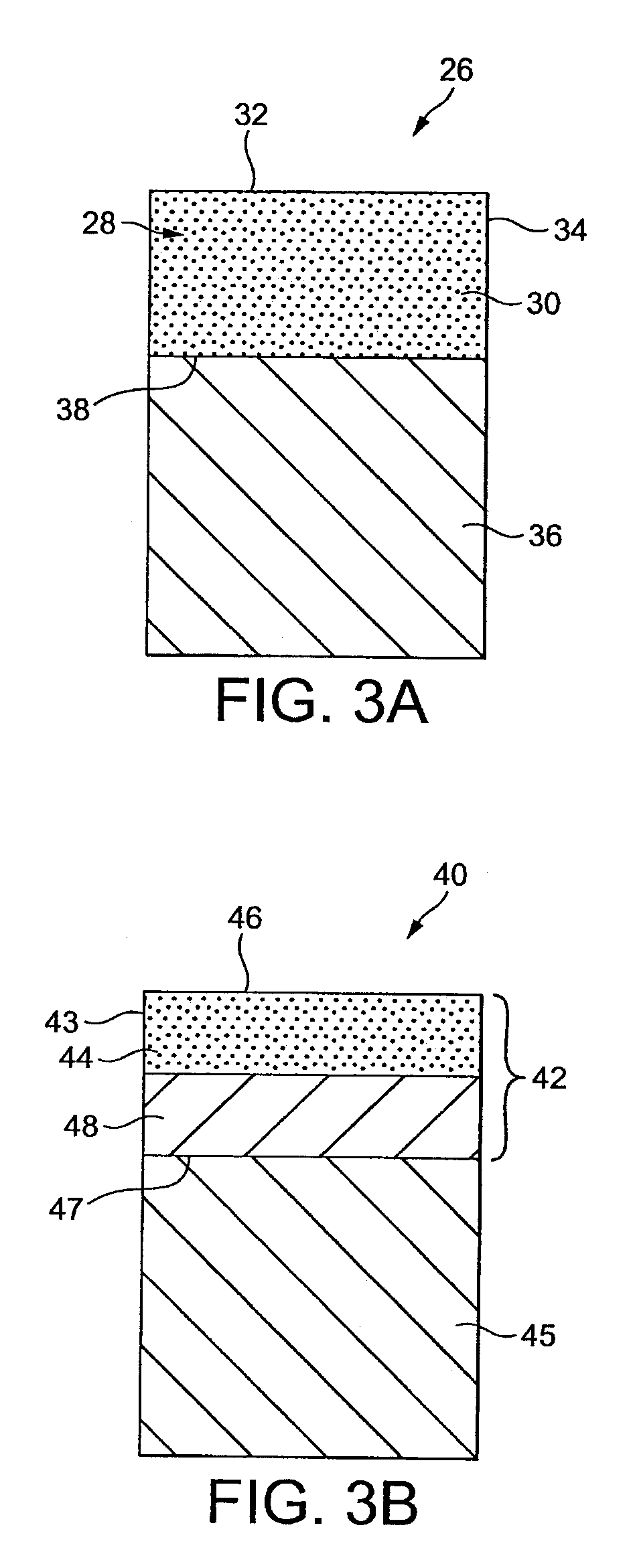

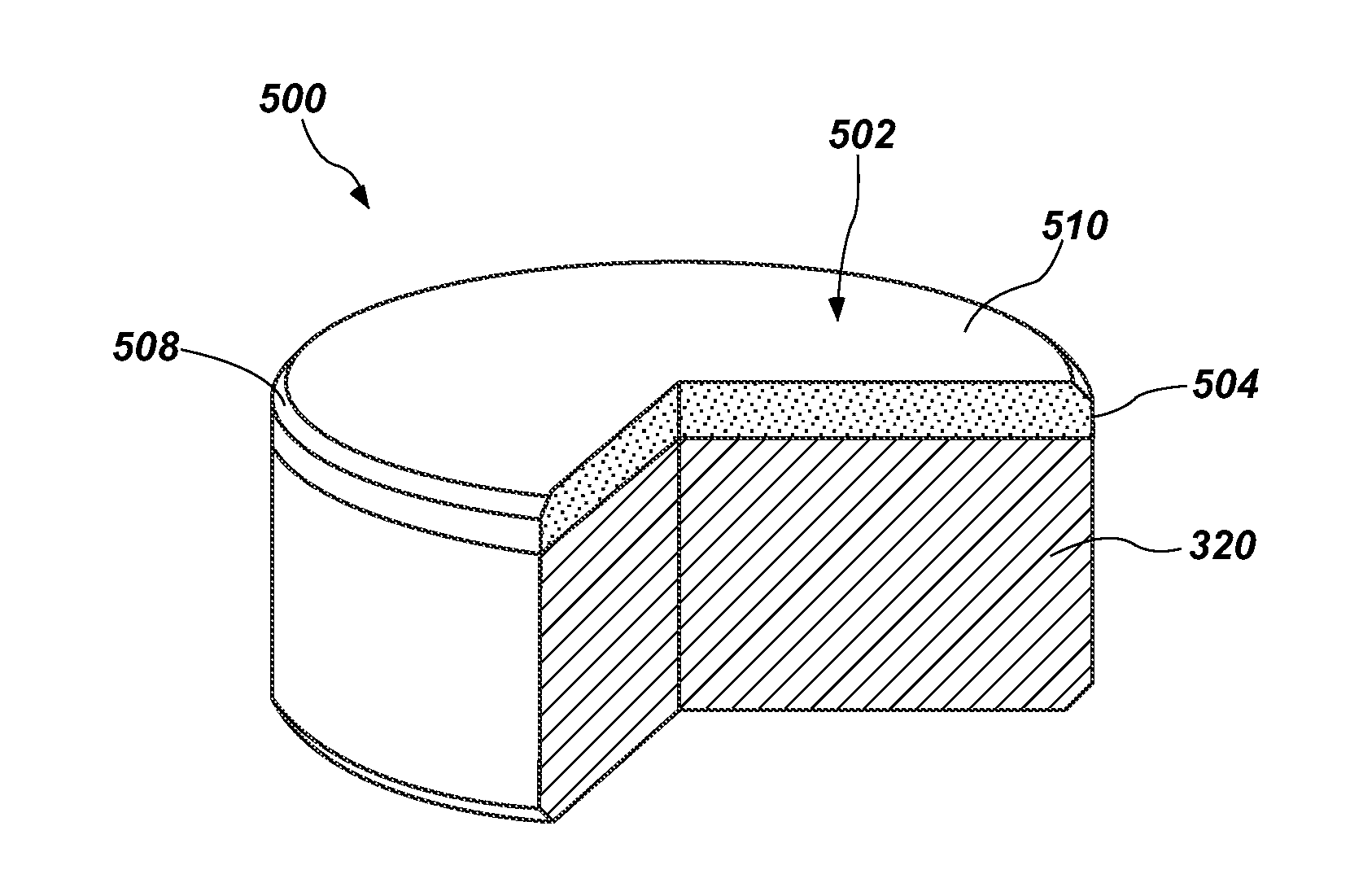

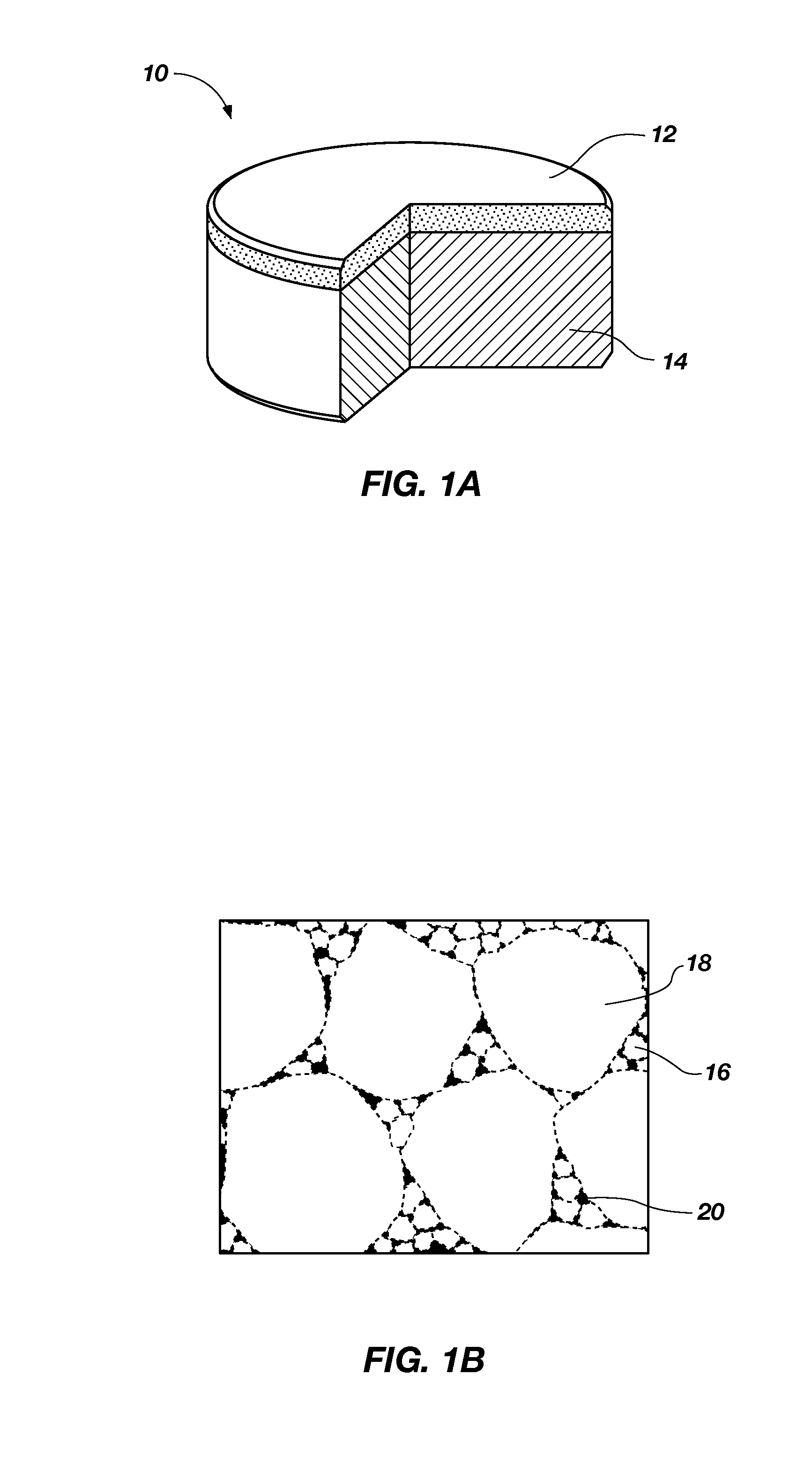

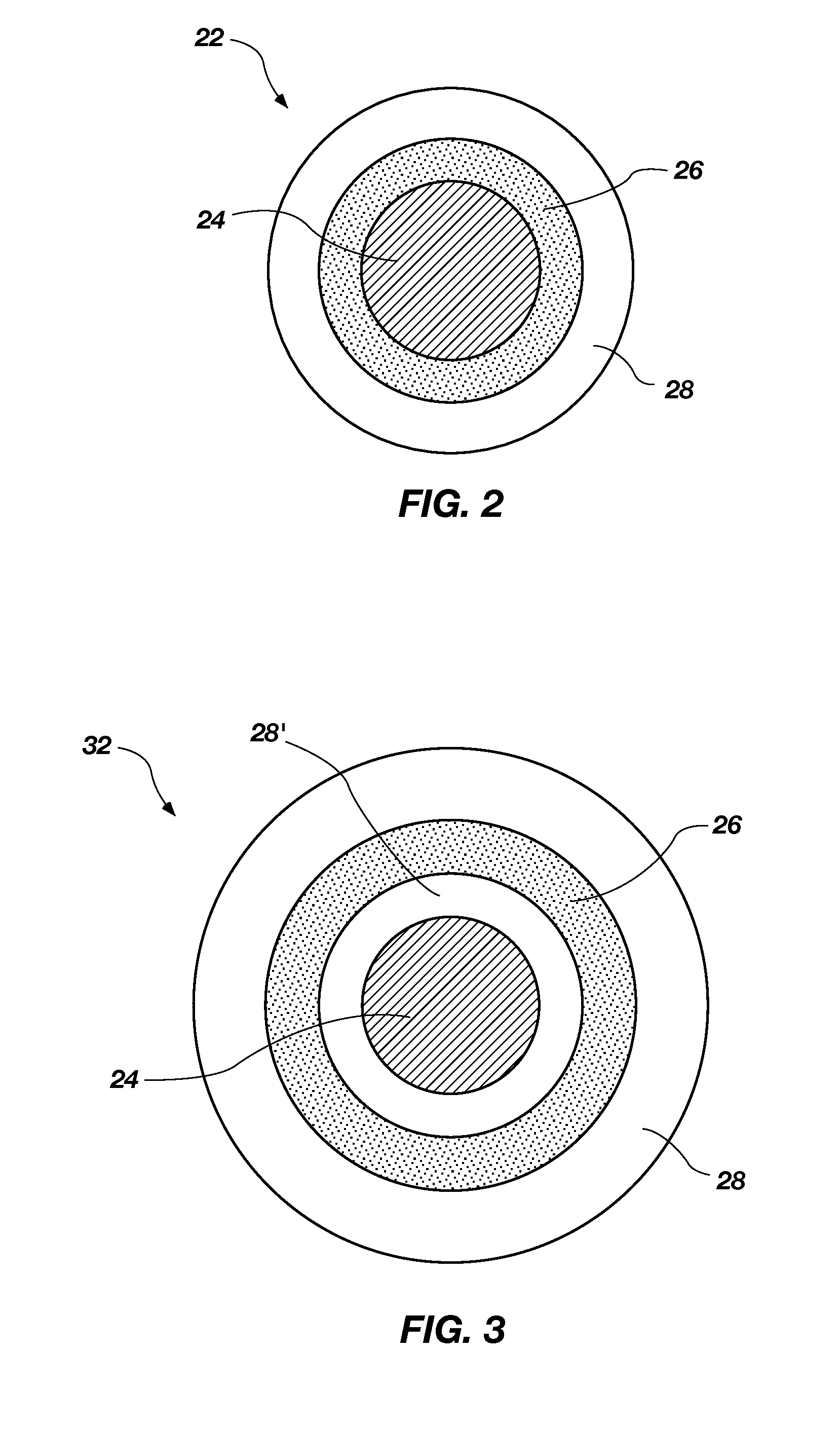

Thermally stable ultra-hard polycrystalline materials and compacts

Thermally stable ultra-hard polycrystalline materials and compacts comprise an ultra-hard polycrystalline body that wholly or partially comprises one or more thermally stable ultra-hard polycrystalline region. A substrate can be attached to the body. The thermally stable ultra-hard polycrystalline region can be positioned along all or a portion of an outside surface of the body, or can be positioned beneath a body surface. The thermally stable ultra-hard polycrystalline region can be provided in the form of a single element or in the form of a number of elements. The thermally stable ultra-hard polycrystalline region can be formed from precursor material, such as diamond and / or cubic boron nitride, with an alkali metal catalyst material. The mixture can be sintered by high pressure / high temperature process.

Owner:SMITH INT INC

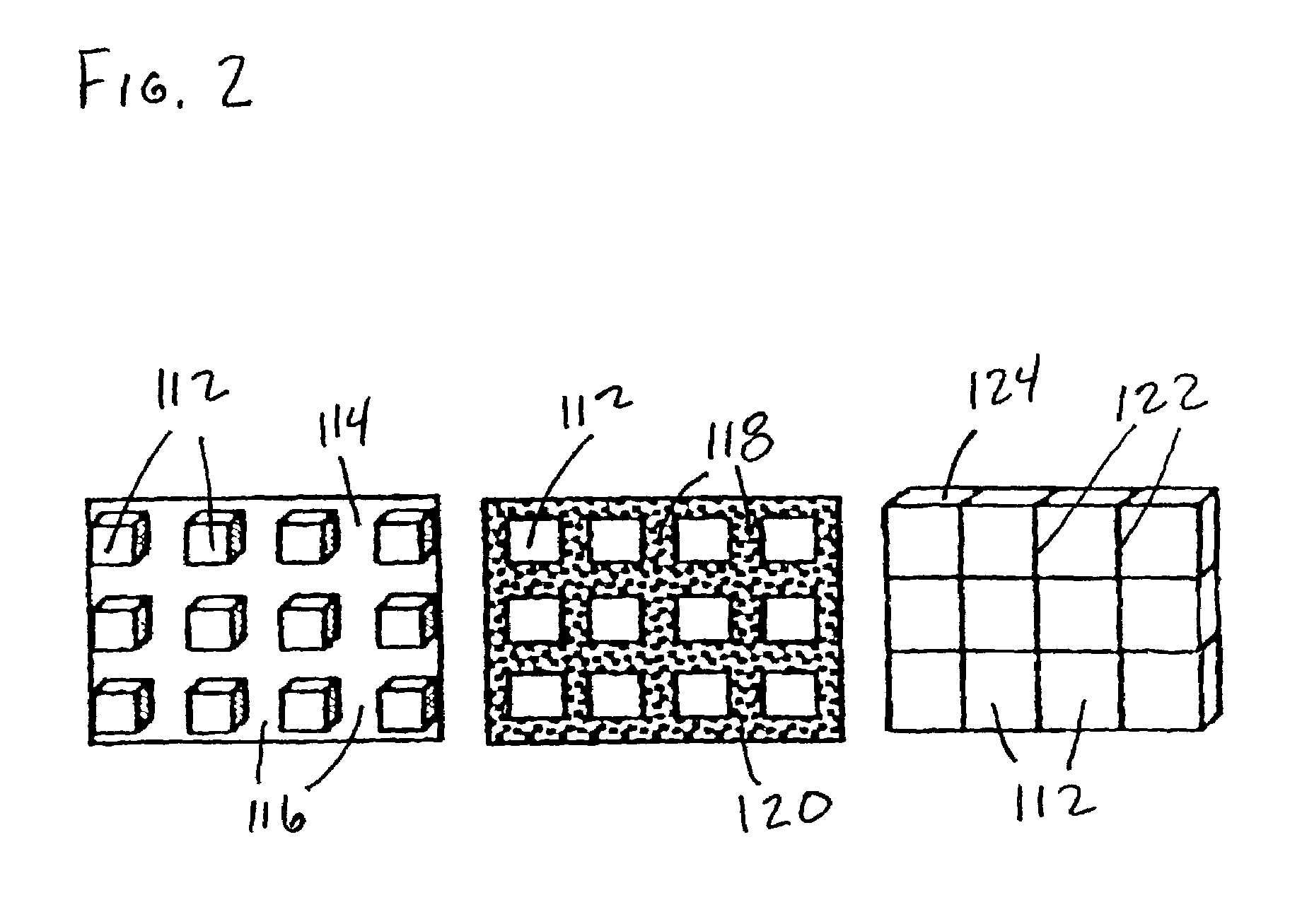

Single-crystal-like materials

InactiveUS7022303B2Improve fracture toughnessReadily apparentMagnesium fluoridesCalcium/strontium/barium fluoridesMetallurgySingle crystal

Polycrystalline materials of macroscopic size exhibiting Single-Crystal-Like properties are formed from a plurality of Single-Crystal Particles, having Self-Aligning morphologies and optionally ling morphology, bonded together and aligned along at least one, and up to three, crystallographic directions.

Owner:RUTGERS THE STATE UNIV

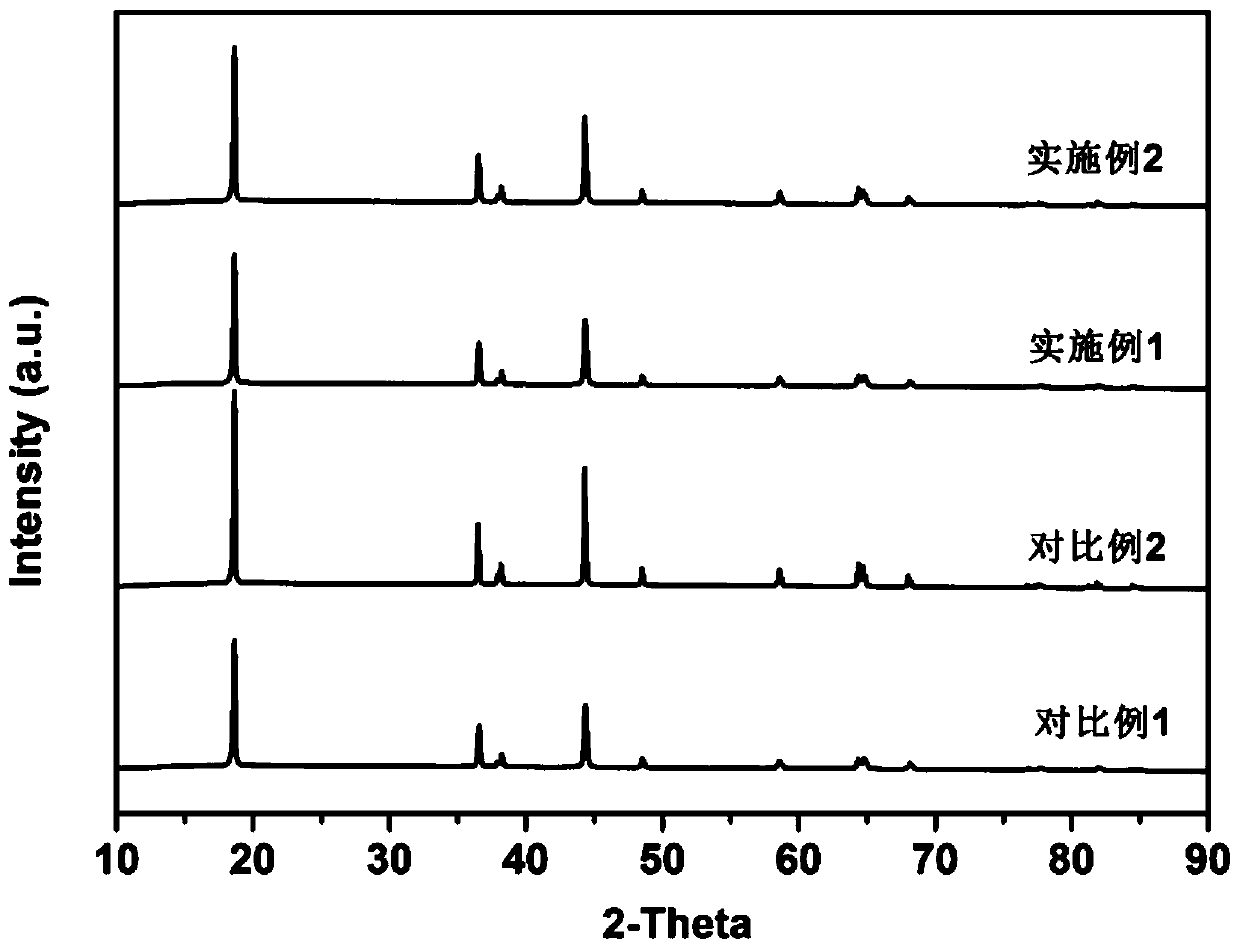

Graded high-nickel ternary anode material, and preparation method and application thereof

InactiveCN109888235AImprove compactionImprove cycle stabilityCell electrodesSecondary cellsSingle crystalMixed materials

The invention discloses a graded high-nickel ternary anode material, and a preparation method and an application thereof. The graded high-nickel ternary anode material is prepared by the following method: 1) mixing a high-nickel polycrystalline precursor with anhydrous LiOH and a doping additive, performing sintering, mixing the obtained product with a coating additive, and performing sintering toobtain a high-nickel polycrystalline material; 2) mixing a ternary monocrystalline silicon precursor with a lithium source and the doping additive, performing sintering, mixing the obtained product with the coating additive, and performing sintering to obtain a ternary monocrystalline silicon material; and 3) mixing the high-nickel polycrystalline material with the ternary monocrystalline siliconmaterial, or mixing the mixed material with the coating additive, and then performing sintering. The invention further discloses an application of the graded high-nickel ternary anode material in lithium batteries. The graded material prepared by the method provided by the invention has higher compaction and cycle stability than the single polycrystalline material, has higher capacity than the single monocrystalline silicon, and the gas production and service life problems of the battery can be effectively improved after the grading modification.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

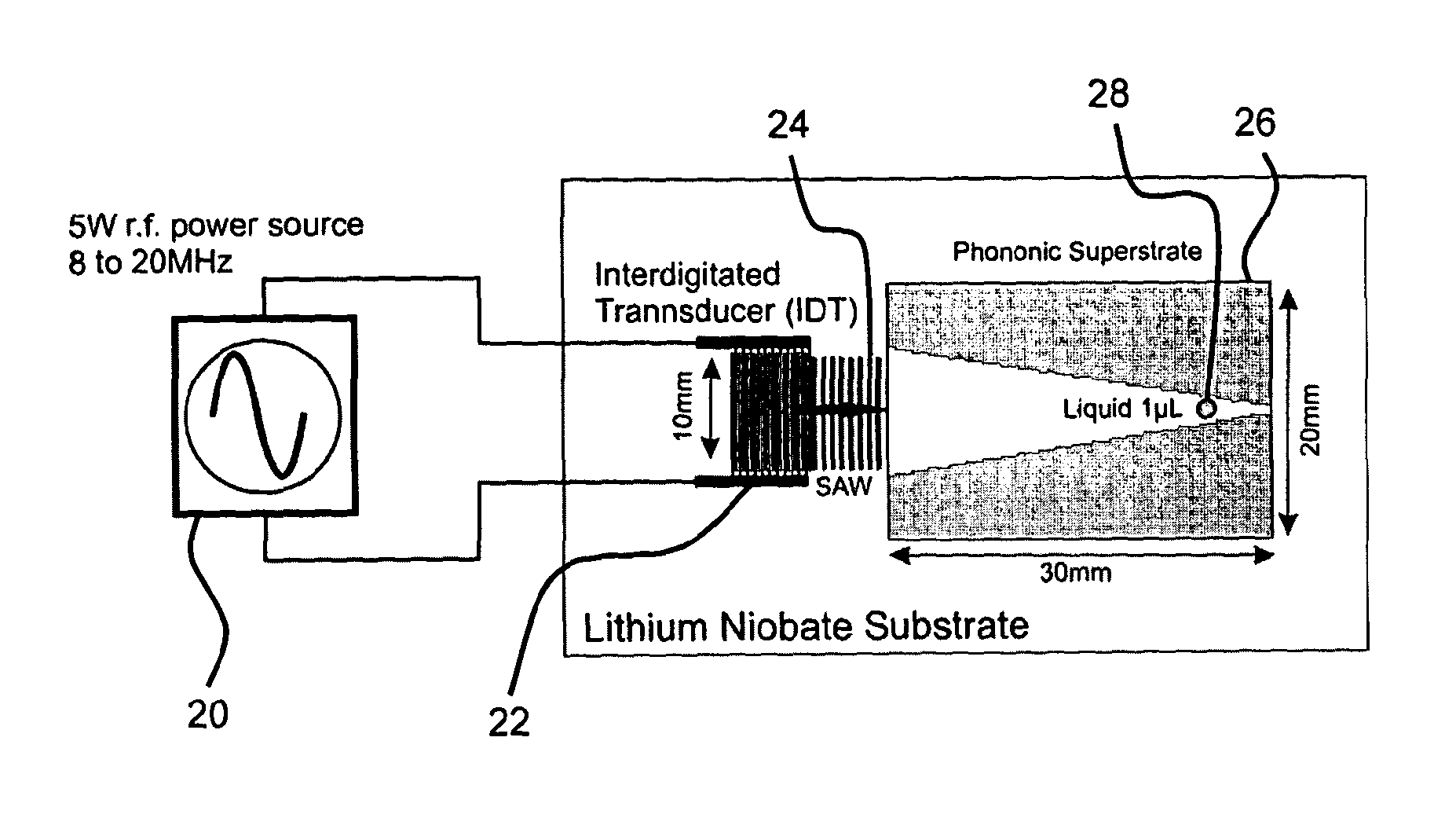

Fluidics Apparatus for Surface Acoustic Wave Manipulation of Fluid Samples, Use of Fluidics Apparatus and Process for the Manufacture of Fluidics Apparatus

ActiveUS20130330247A1Cost-effectiveEfficient preparationElectrolysis componentsVolume/mass flow measurementFluidicsTransducer

A fluidics apparatus for manipulation of at least one fluid sample is disclosed. A manipulation surface locates the fluid sample. A surface acoustic wave (SAW) generation material layer is provided. This is a polycrystalline material, textured polycrystalline material, biaxially textured polycrystalline material, microcrystalline material, nanocrystalline material, amorphous material or composite material. A transducer electrode structure arranged at the SAW generation material layer provides SAWs at the manipulation surface for interaction with the fluid sample. The manipulation surface has a phononic structure, for affecting the transmission, distribution and / or behaviour of SAWs at the manipulation surface. The apparatus is typically manufactured by reel-to-reel processes, to reduce the unit cost to a level at which the apparatus can be considered to be disposable after a single use.

Owner:THE UNIV COURT OF THE UNIV OF GLASGOW

Thin substrate fabrication using stress-induced substrate spalling

ActiveUS8247261B2Increase valueImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingStress inducedSingle crystal

A method for manufacturing a thin film direct bandgap semiconductor active solar cell device comprises providing a source substrate having a surface and disposing on the surface a stress layer having a stress layer surface area in contact with and bonded to the surface of the source substrate. Operatively associating a handle foil with the stress layer and applying force to the handle foil separates the stress layer from the source substrate, and leaves a portion of the source substrate on the stress layer surface substantially corresponding to the area in contact with the surface of the source substrate. The portion is less thick than the source layer. The stress layer thickness is below that which results in spontaneous spalling of the source substrate. The source substrate may comprise an inorganic single crystal or polycrystalline material such as Si, Ge, GaAs, SiC, sapphire, or GaN. In one embodiment the stress layer comprises a flexible material.

Owner:GLOBALFOUNDRIES U S INC

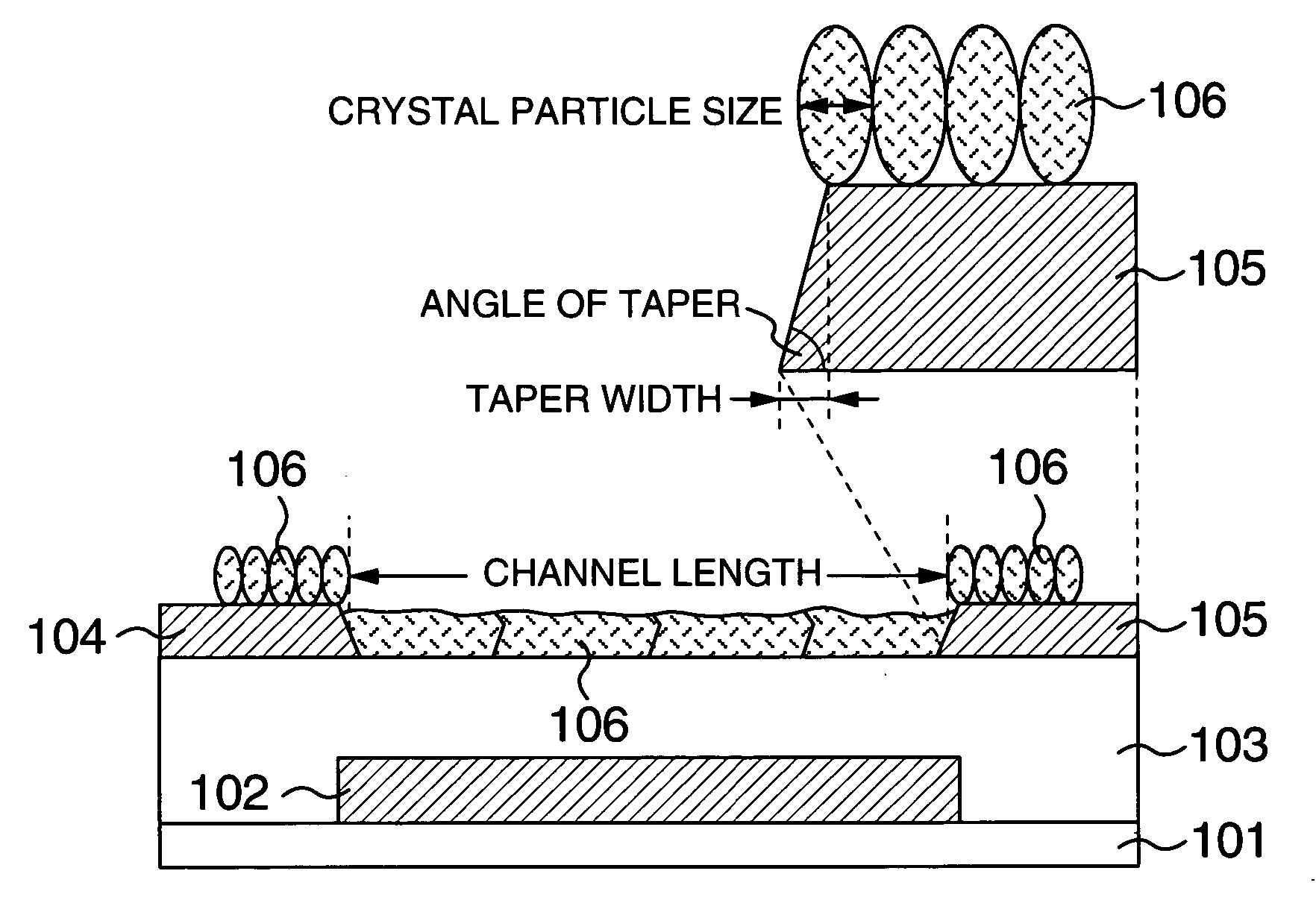

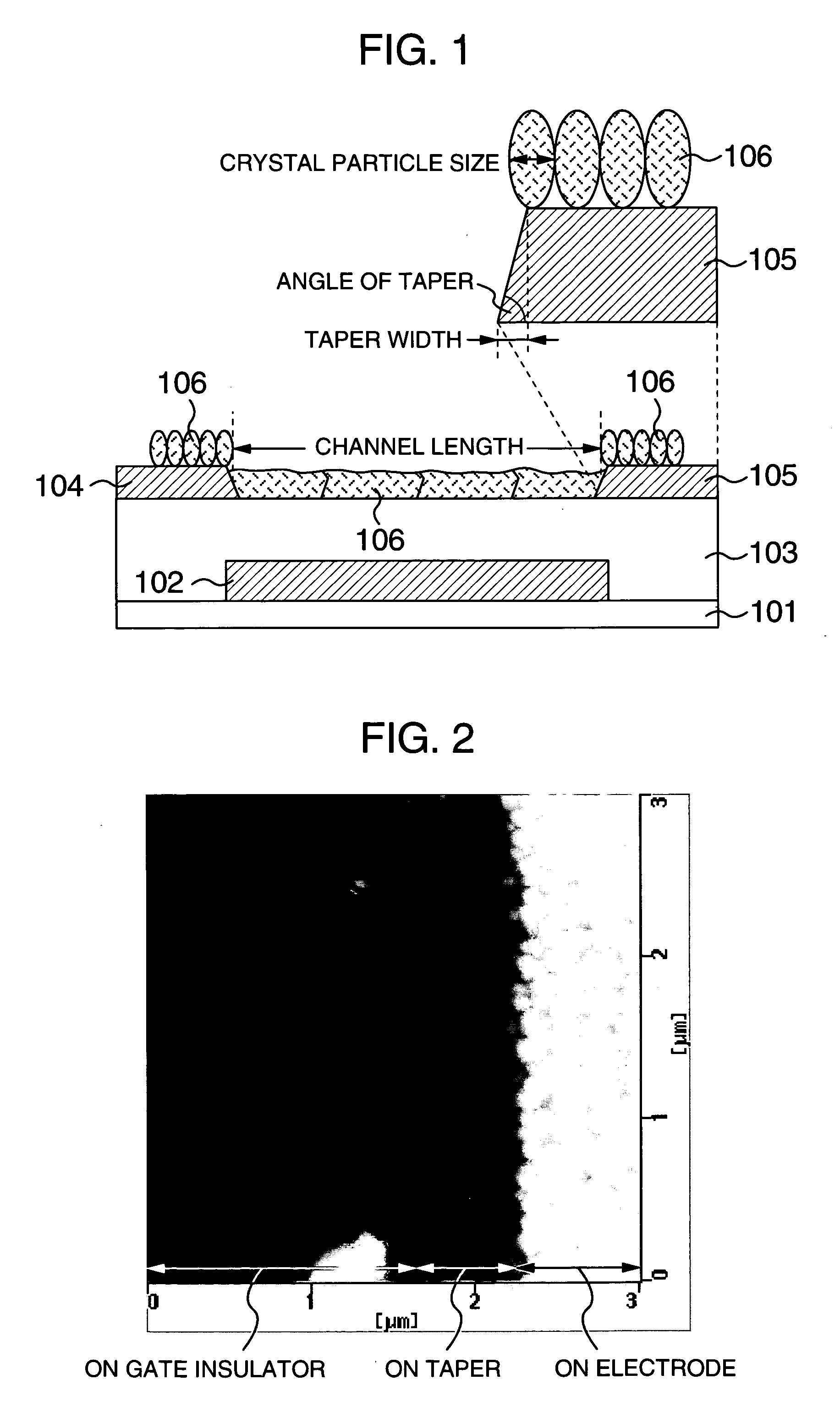

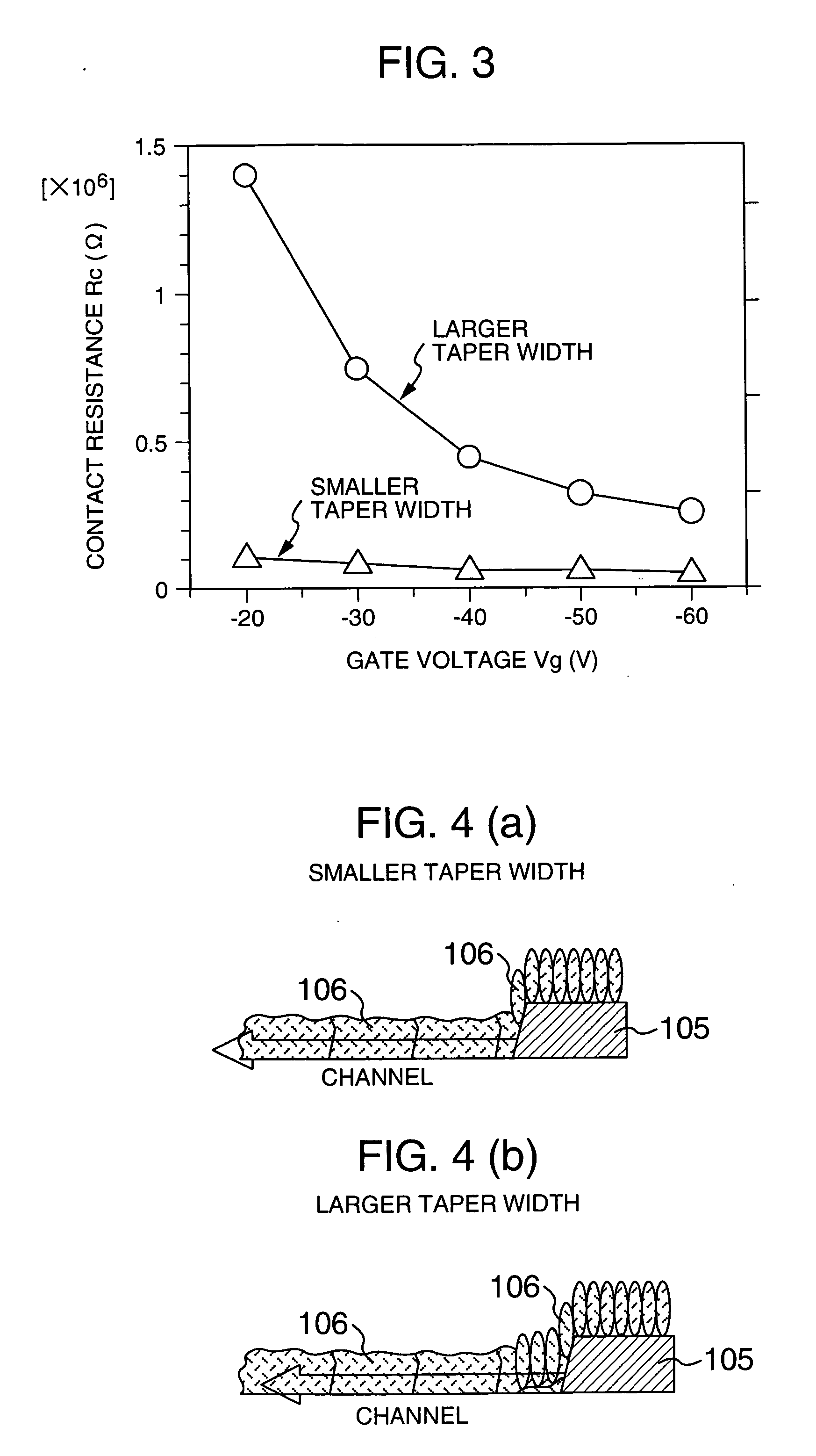

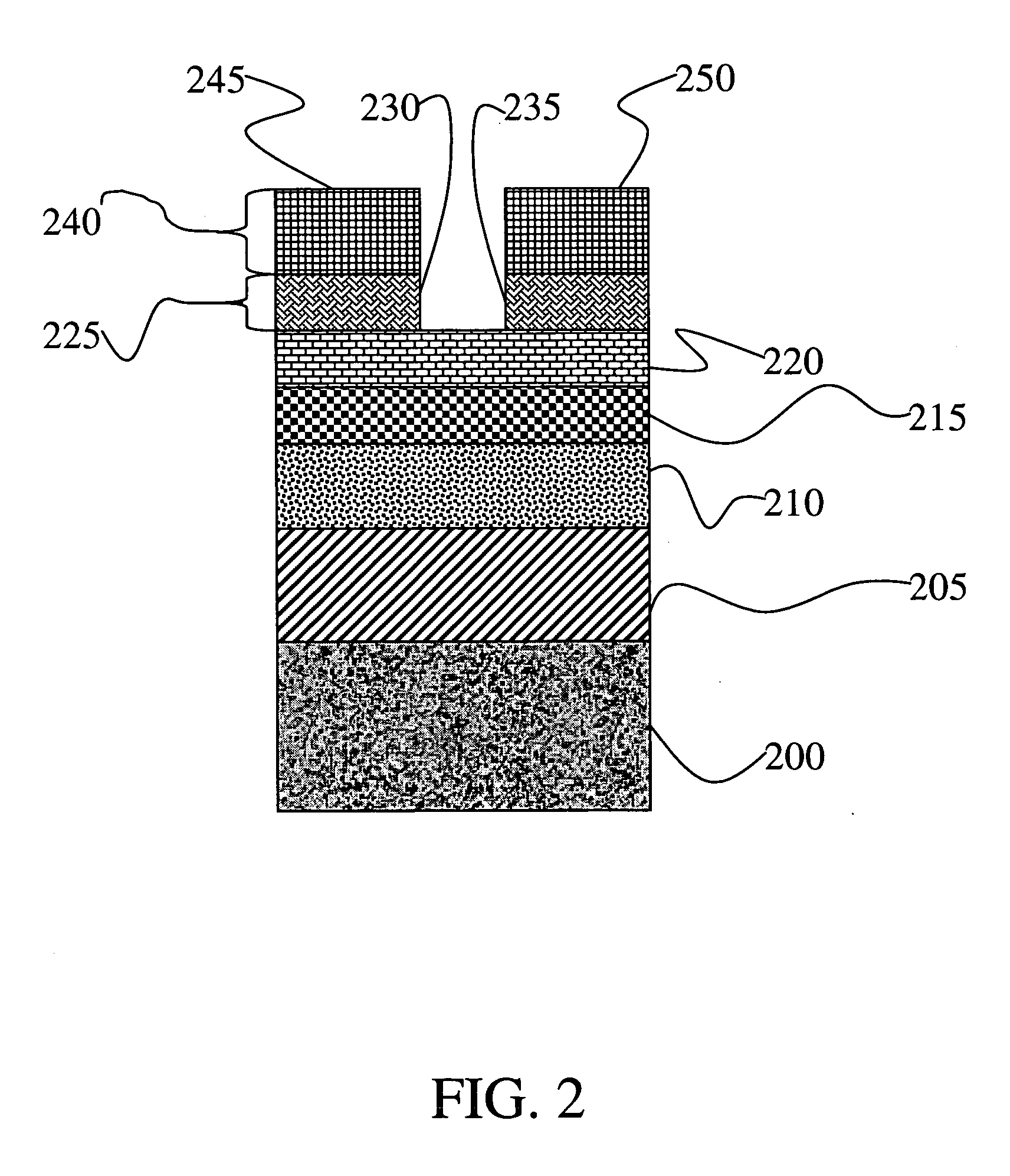

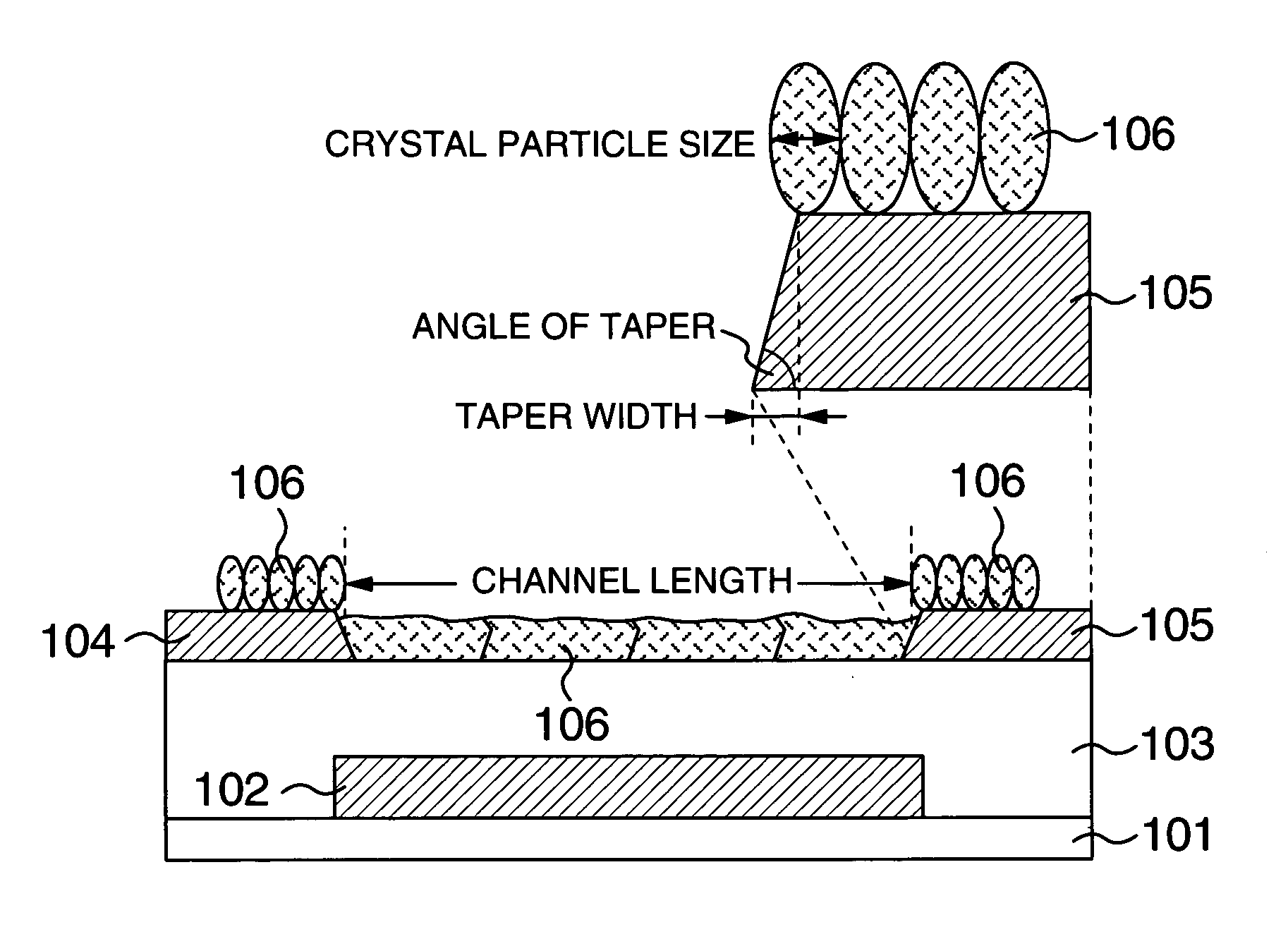

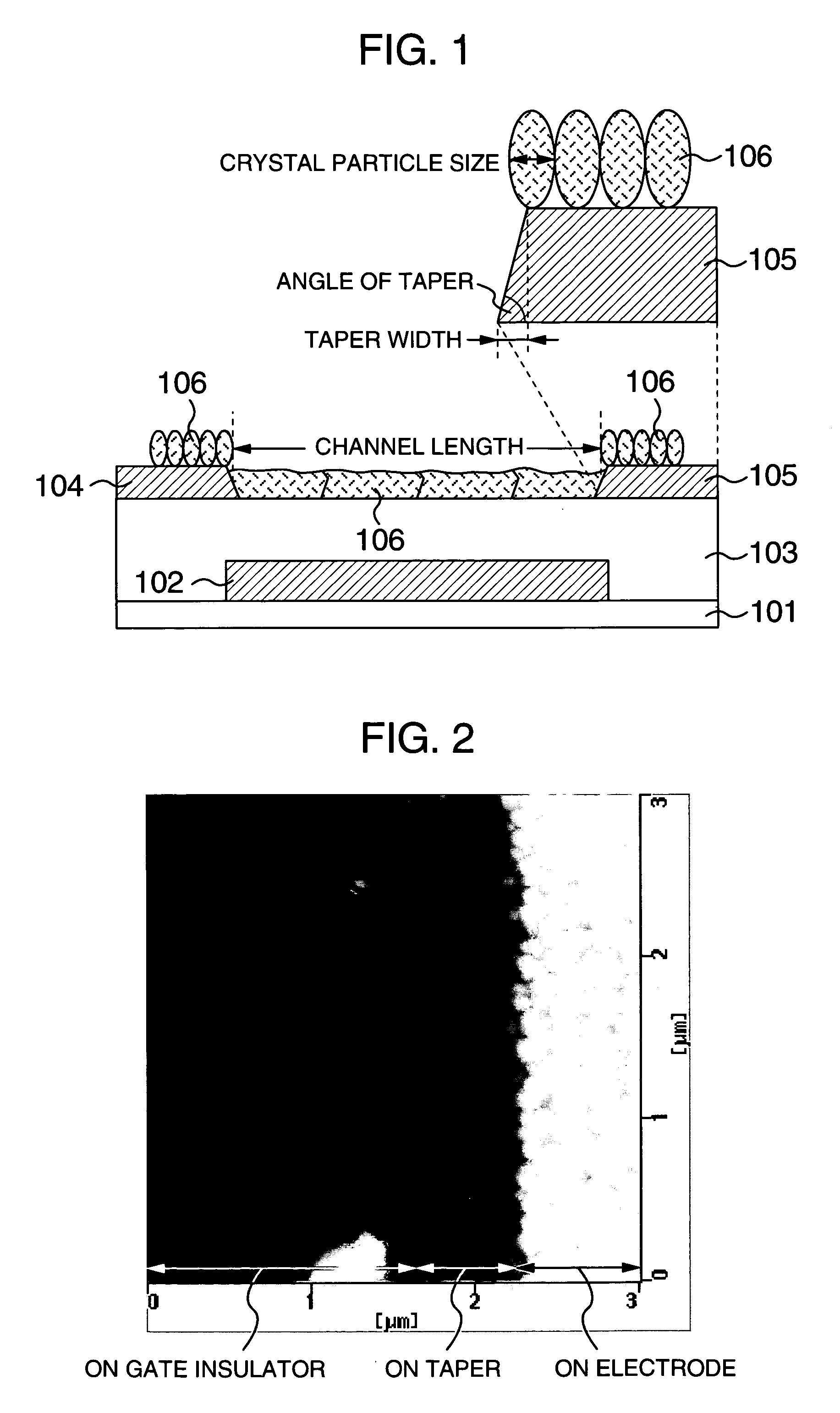

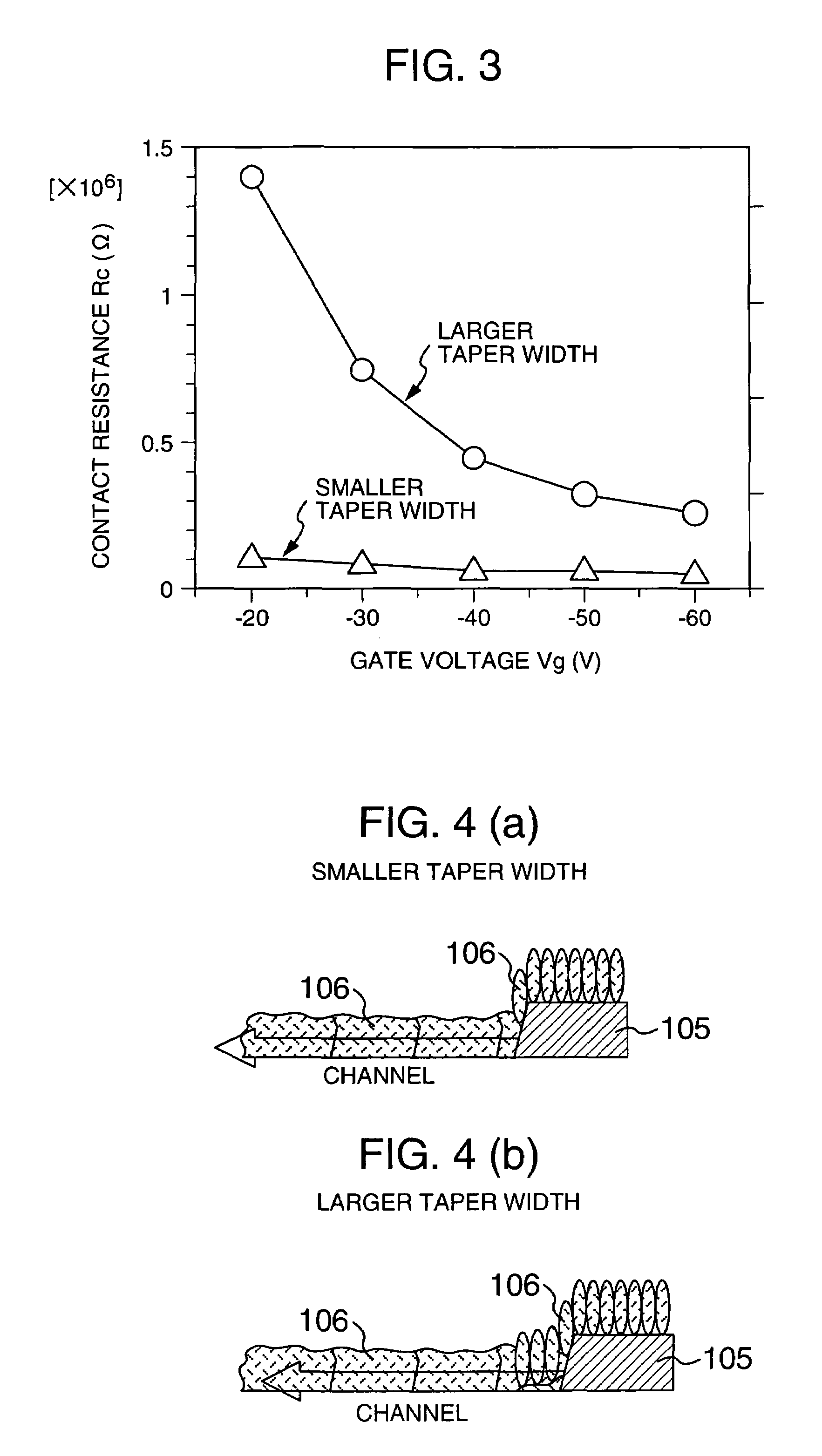

Semiconductor device and manufacturing method thereof

InactiveUS20050056897A1Reduce contact resistanceIncrease volumeTransistorSemiconductor/solid-state device detailsSimple Organic CompoundsDevice material

An object of the present invention is to provide a semiconductor device such as a display device, ID tag, sensor or the like at low cost by using a bottom contact type organic TFT as a switching element. In the present invention, the semiconductor layer of the bottom contact type organic TFT is formed of a polycrystalline material, and the taper width of each of the source and drain electrodes of the TFT in the direction of the channel length is smaller than the average particle size of semiconductor crystals grown on the source and drain electrodes. Alternatively, the side on the channel side of each of the source and drain electrodes of the bottom contact type organic TFT is formed so as to be convex upward with respect to the substrate surface. Alternatively, an organic compound layer different from the semiconductor layer of the bottom contact type organic TFT is made present between each of the source and drain electrodes of the bottom contact type organic TFT and said semiconductor layer, in a thickness of not more than 10 Å and not less than 1 Å.

Owner:HITACHI LTD

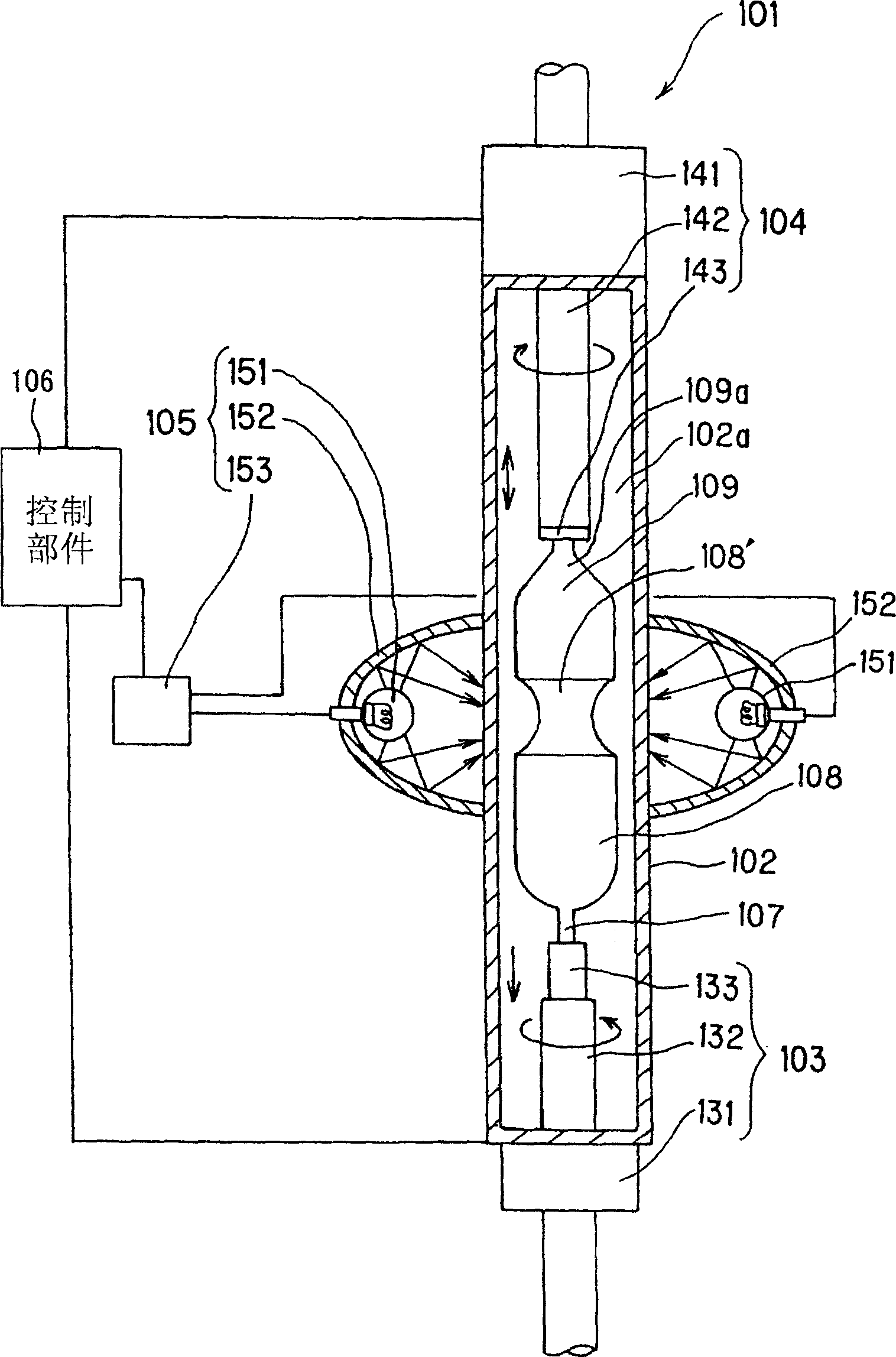

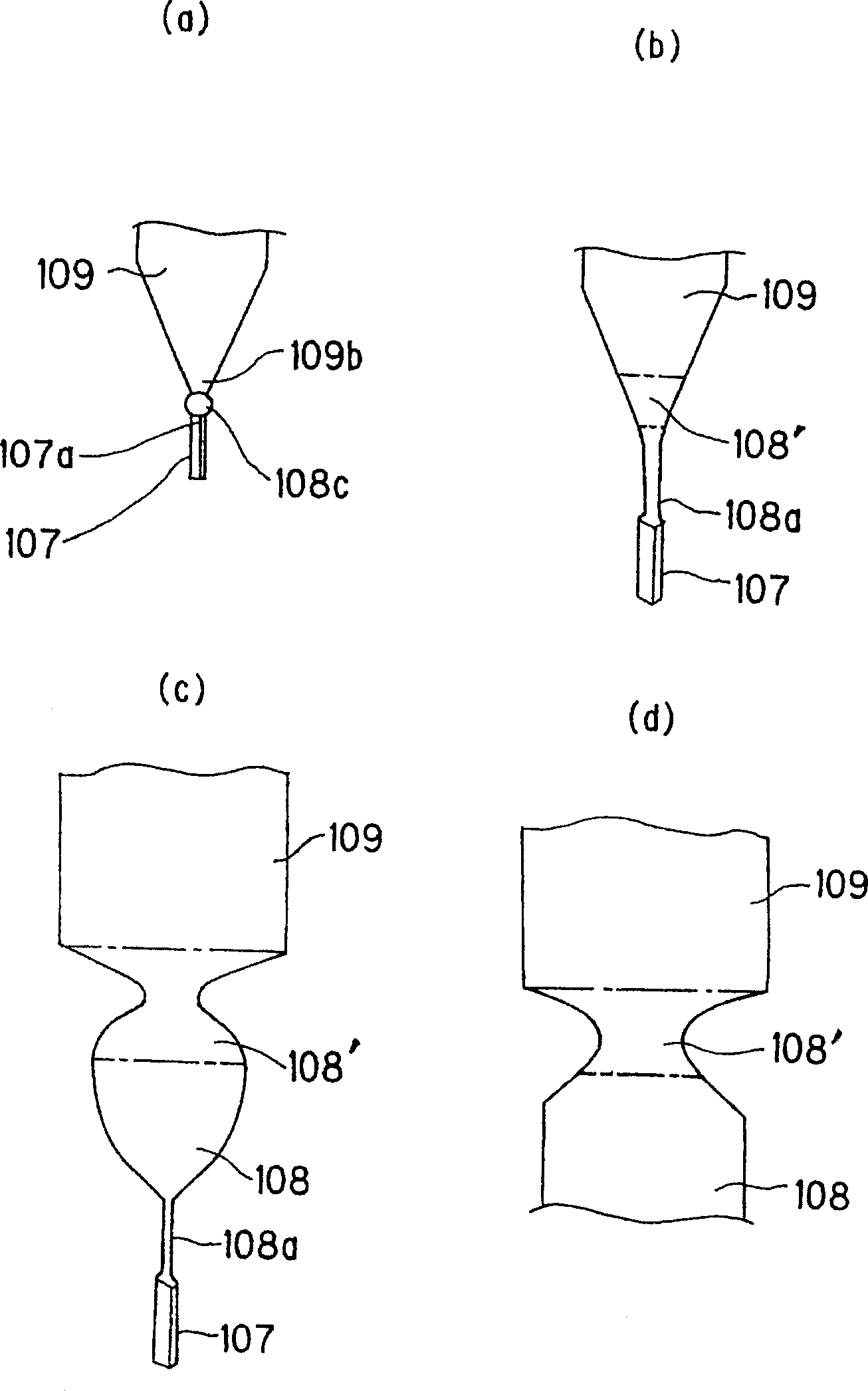

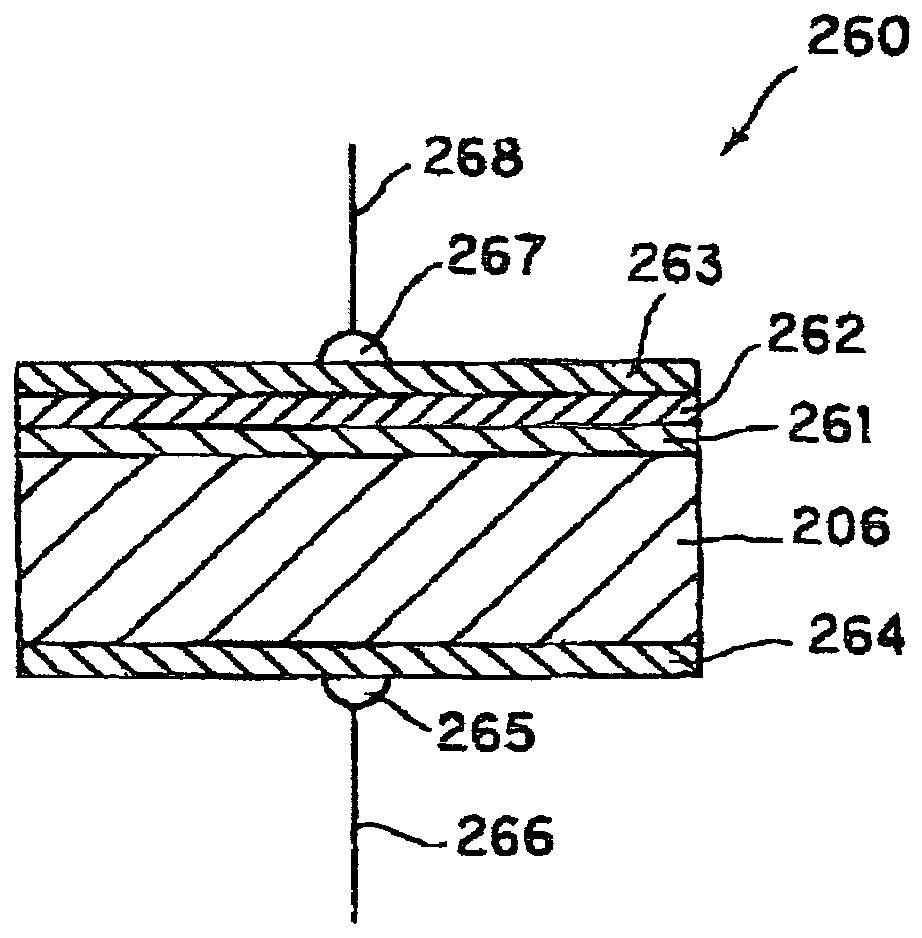

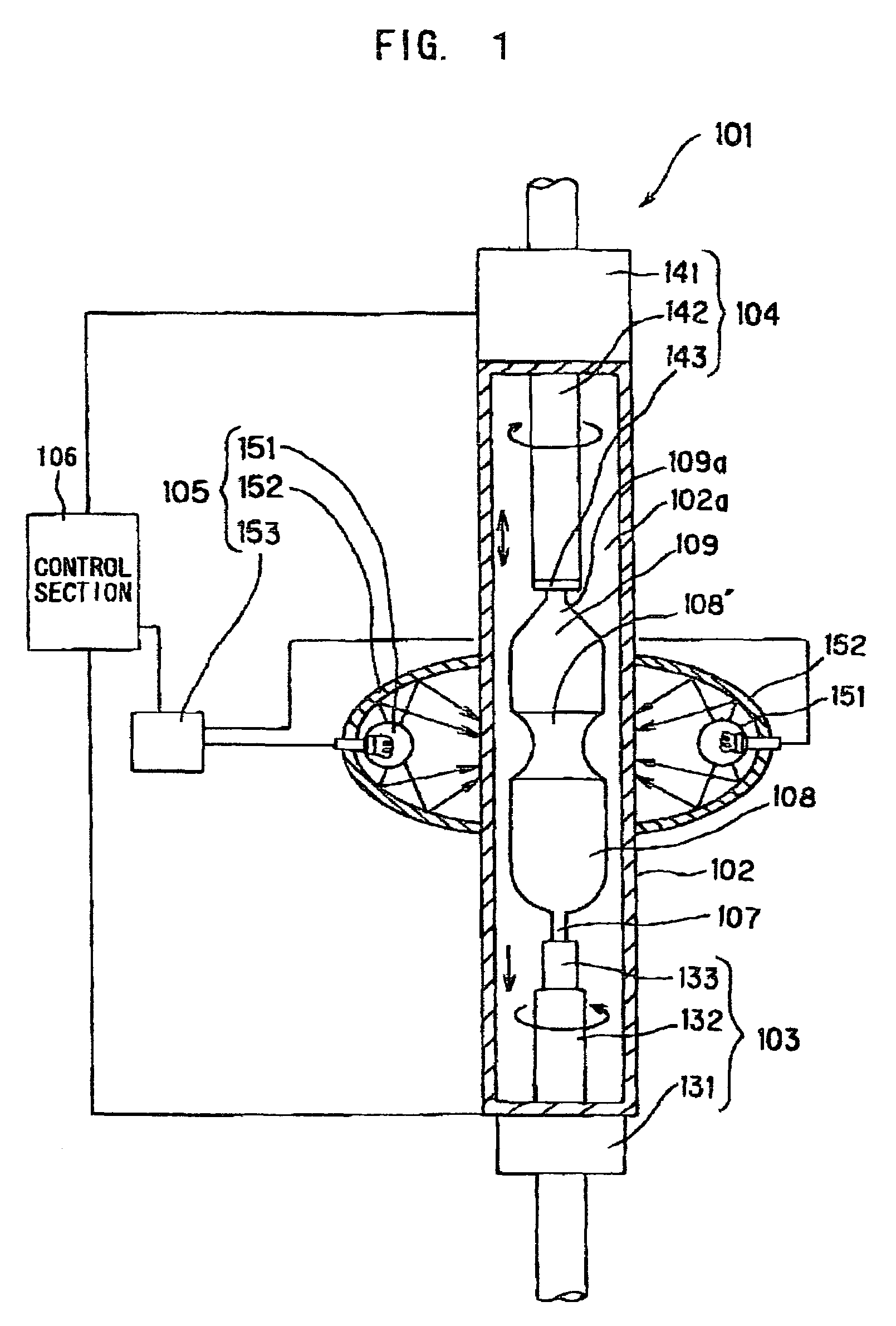

B-ga2o3 single crystal growing method, thin-film single crystal growing method, ga2o3 light-emitting device, and its manufacturing method

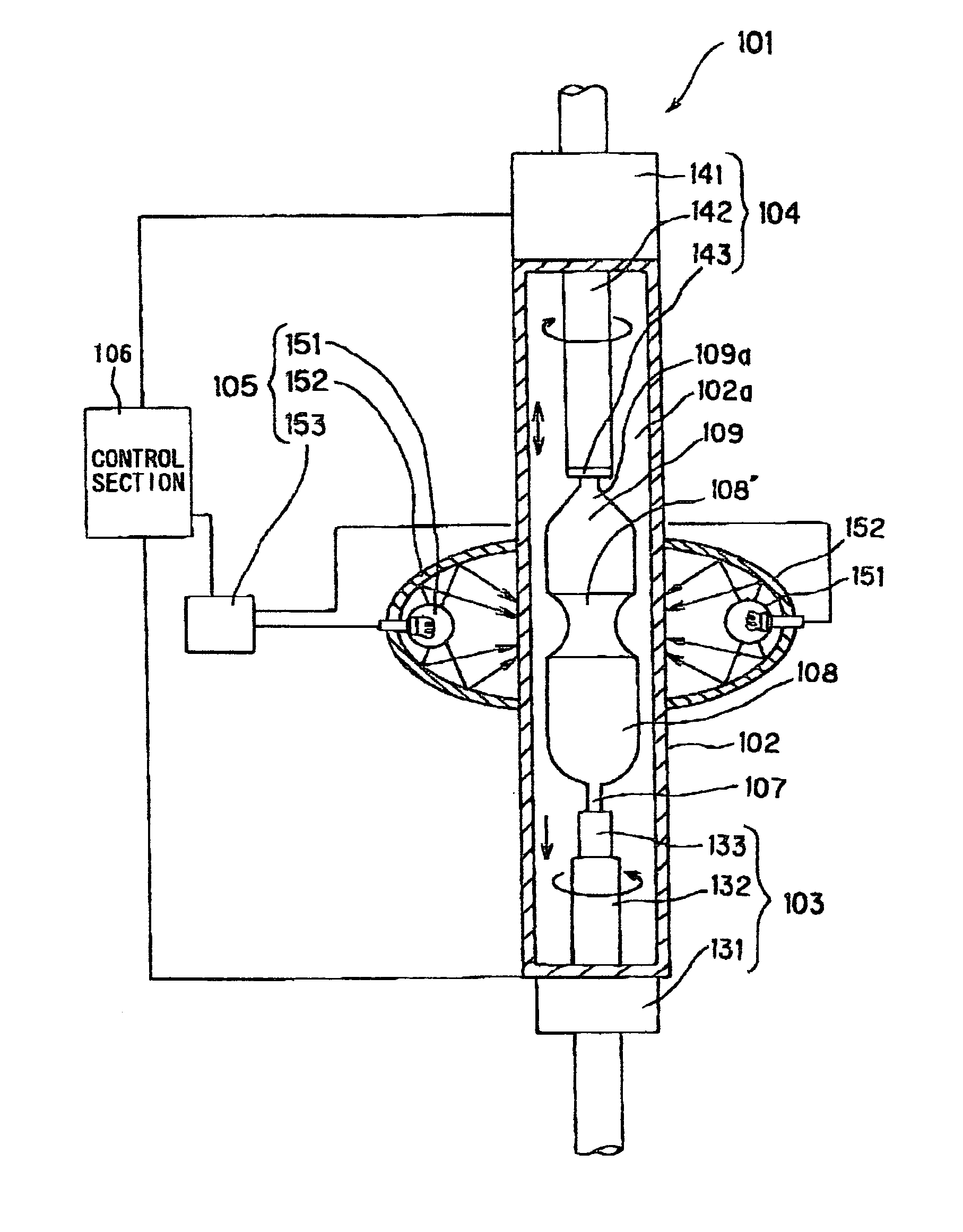

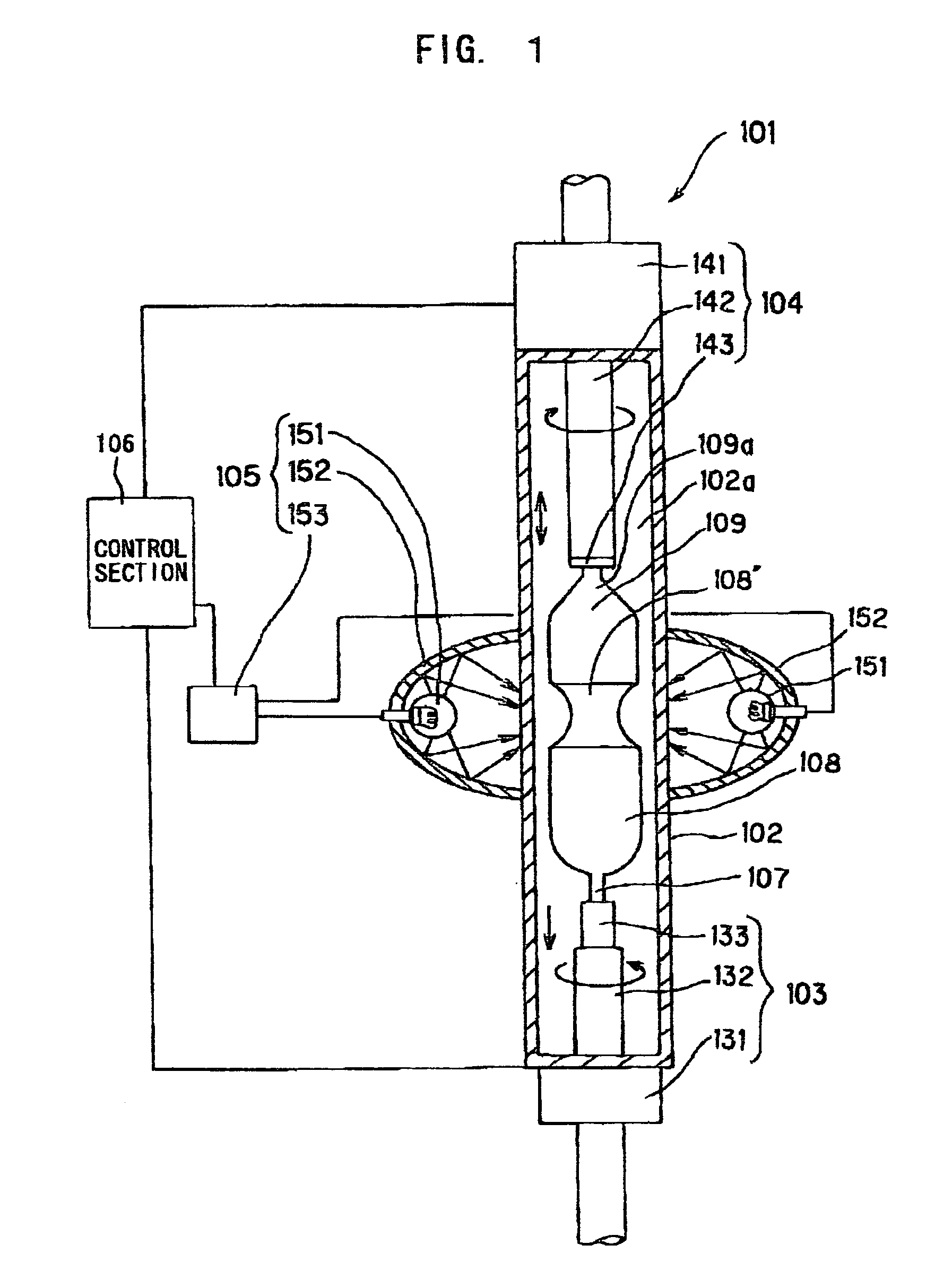

PROBLEM TO BE SOLVED: To provide a method for growing a β-f-based single crystal which is less prone to be cracked even when it is worked into a large size and high quality substrate or the like. ŽSOLUTION: The β-Ga<SB>2< / SB>O<SB>3< / SB>single crystal 8 is allowed to grow in one orientation selected from a-axis <100> orientation, b-axis <010> orientation, and the orientation inclined by 13.7°, determined crystallographically, from c-axis toward a-axis and having an angle of 90° with respect to a-axis by heating a seed crystal 7 and a polycrystalline base material 9 while rotating the crystal 7 and the base material 9 mutually in the opposite directions by using an infrared heating single crystal manufacturing device 1. Ž

Owner:WASEDA UNIV

β-Ga2O3 single crystal growing method, thin-film single crystal growing method, Ga2O3 light-emitting device, and its manufacturing method

InactiveUS7393411B2Trend downImprove machinabilityPolycrystalline material growthBy zone-melting liquidsInfraredDopant

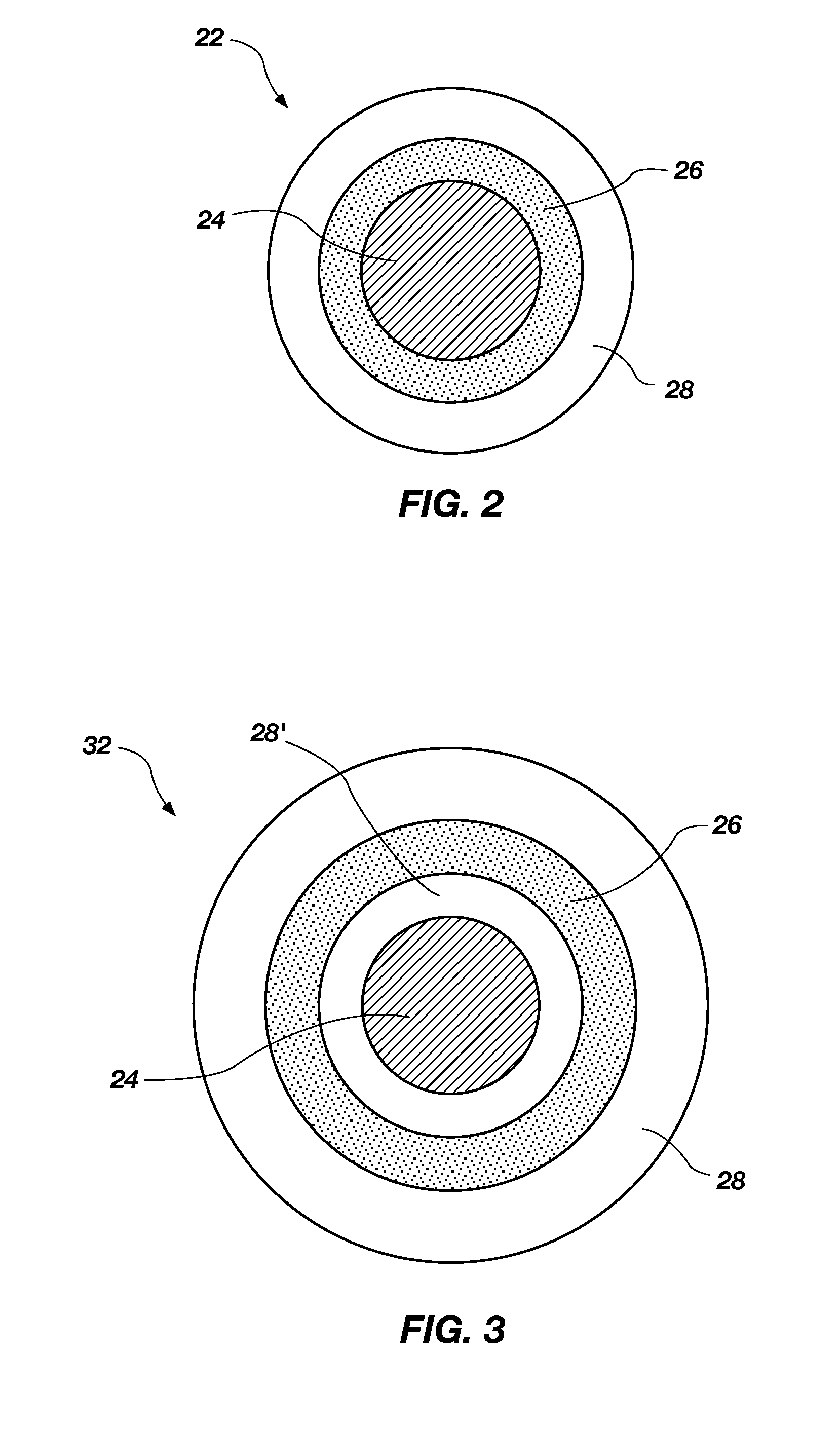

A method for growing a β-Ga2O3 single crystal hardly cracking and having a weakened twinning tendency and an improved crystallinity, a method for growing a thin-film single crystal with high quality, a GazO3 light-emitting device capable of emitting a light in the ultraviolet region, and its manufacturing method are disclosed. In an infrared-heating single crystal manufacturing system, a seed crystal and polycrystalline material are rotated in mutually opposite directions and heated, and a β-Ga2O3 single crystal is grown in one direction selected from among the a-axis <100> direction, the b-axis <010> direction, and the c-axis <001> direction. A thin film of a β-Ga2O3 single crystal is formed by PLD. A laser beam is applied to a target to excite atoms constituting the target Ga atoms are released from the target by thermal and photochemical actions. The free Ga atoms are bonded to radicals in the atmosphere in the chamber. Thus, a thin film of a β-Ga2O3 single crystal is grown on a substrate of a β-Ga2O3 single crystal A light-emitting device comprises an n-type substrate produced by doping a β-Ga2O3 single crystal with an n-type dopant and a p-type layer produced by doping the β-Ga2O3 single crystal with a p-type dopant and junctioned to the top of the n-type substrate. The light-emitting device emits a light from the junction portion.

Owner:WASEDA UNIV

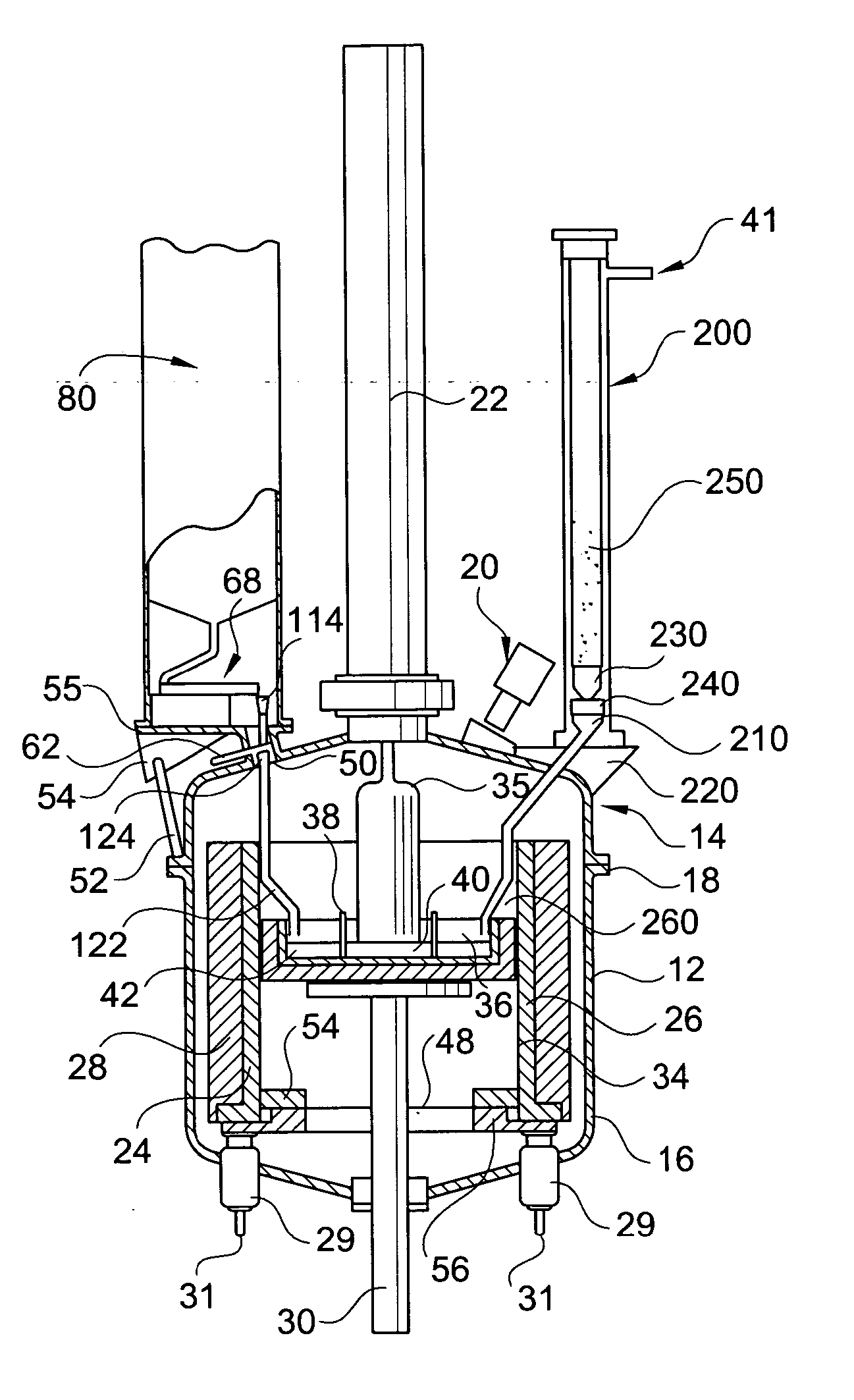

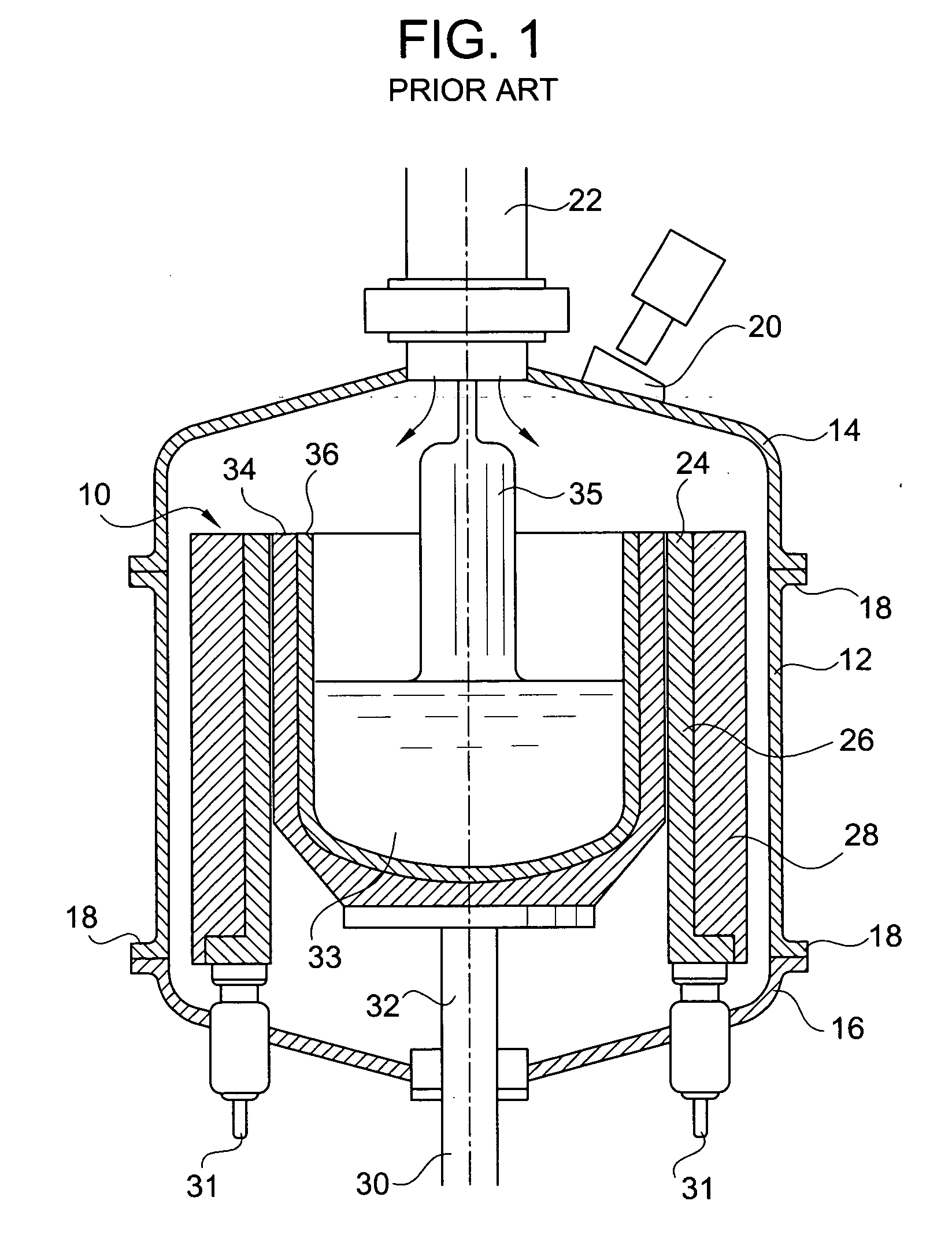

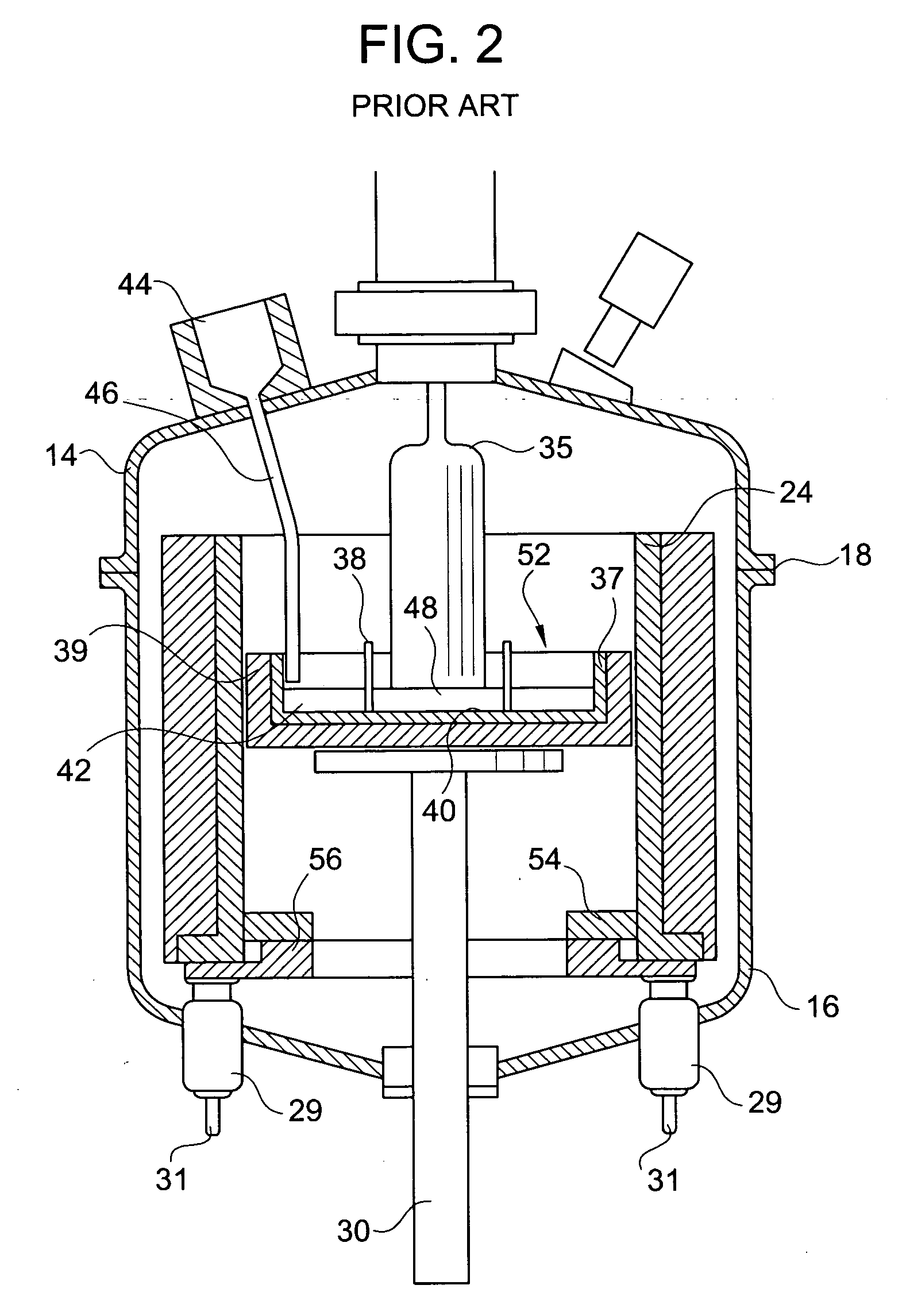

Method and apparatus to produce single crystal ingot of uniform axial resistivity

A method for producing a single crystal ingot includes steps of providing a first amount of polycrystalline material and a first amount of dopant material to form a first mixture having a first dopant concentration in a process furnace, increasing a temperature of the first mixture to provide a molten first mixture, providing a seed material to the molten first mixture, withdrawing the seed from the molten first mixture by a first distance to form a boule having a first length, providing a second amount of the polycrystalline material and a second amount of the dopant material to the molten first mixture to provide a molten second mixture having the first dopant concentration, withdrawing the first length of the boule from the molten second mixture by a second distance to form the boule having a second length, and removing the boule from the molten second mixture to form the single crystal ingot of uniform axial resistivity.

Owner:REXOR

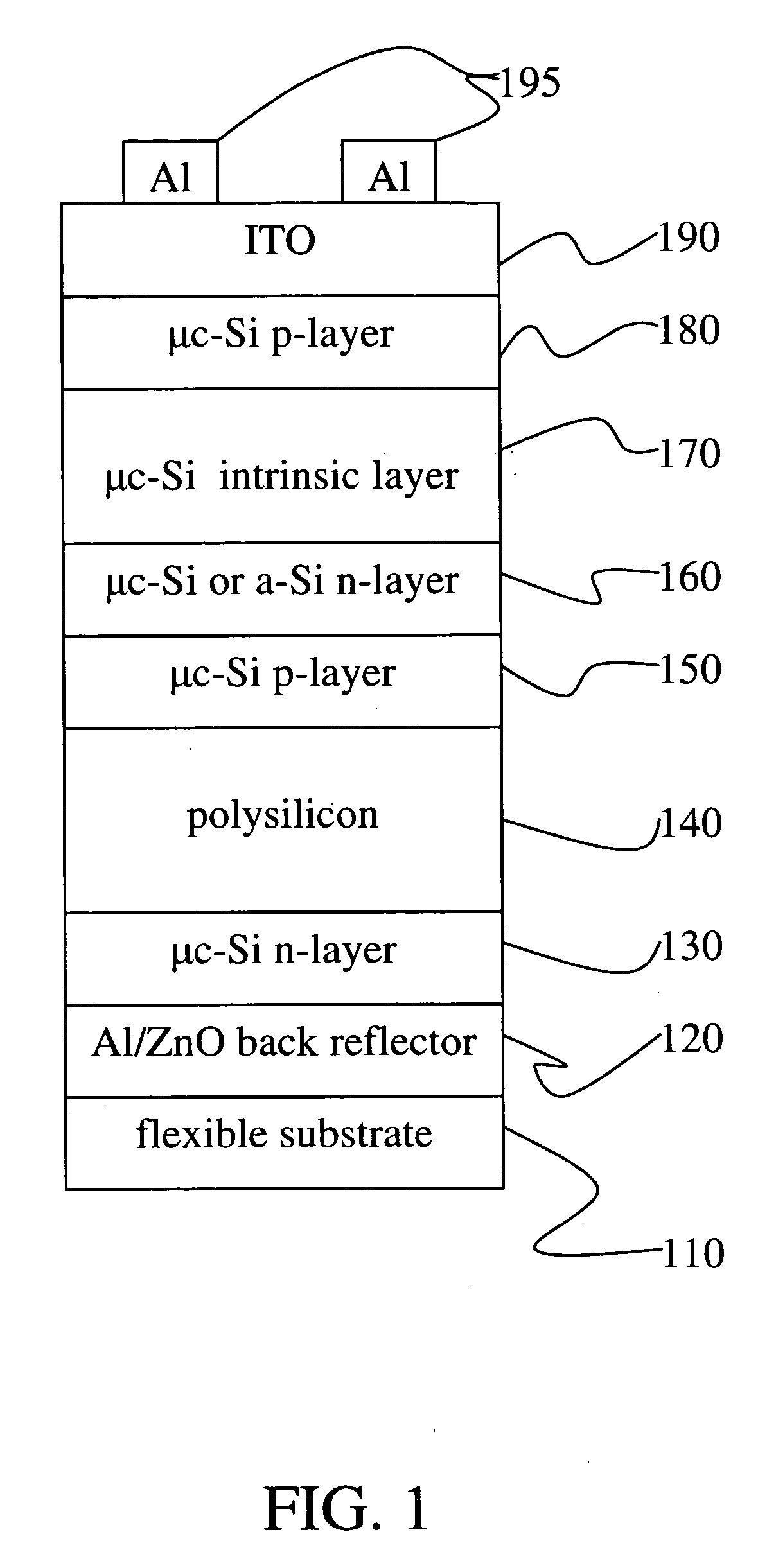

Deposition methods for the formation of polycrystalline materials on mobile substrates

InactiveUS20060024442A1Solid-state devicesChemical vapor deposition coatingHydrogenMicrocrystalline silicon

A deposition apparatus and method for continuously depositing a polycrystalline material such as polysilicon or polycrystalline SiGe layer on a mobile discrete or continuous web substrate. The apparatus includes a pay-out unit for dispensing a discrete or continuous web substrate and a deposition unit that receives the discrete or continuous web substrate and deposits a series of one or more thin film layers thereon in a series of one or more deposition or processing chambers. In a preferred embodiment, polysilicon is formed by first depositing a layer of amorphous or microcrystalline silicon using PECVD and transforming said layer to polysilicon through heating or annealing with one or more lasers, lamps, furnaces or other heat sources. Laser annealing utilizing a pulsed excimer is a preferred embodiment. By controlling the processing temperature, temperature distribution within a layer of amorphous or microcrystalline silicon etc., the instant deposition apparatus affords control over the grain size of polysilicon. Passivation of polysilicon occur through treatment with a hydrogen plasma. Layers of polycrystalline SiGe may similarly be formed. The instant deposition apparatus provides for the continuous deposition of electronic devices and structures that include a layer of a polycrystalline material such as polysilicon and / or polycrystalline SiGe. Representative devices include photovoltaic devices and thin film transistors. The instant deposition apparatus also provides for the continuous deposition of chalcogenide switching or memory materials alone or in combination with other metal, insulating, and / or semiconducting layers.

Owner:OVSHINSKY STANFORD R

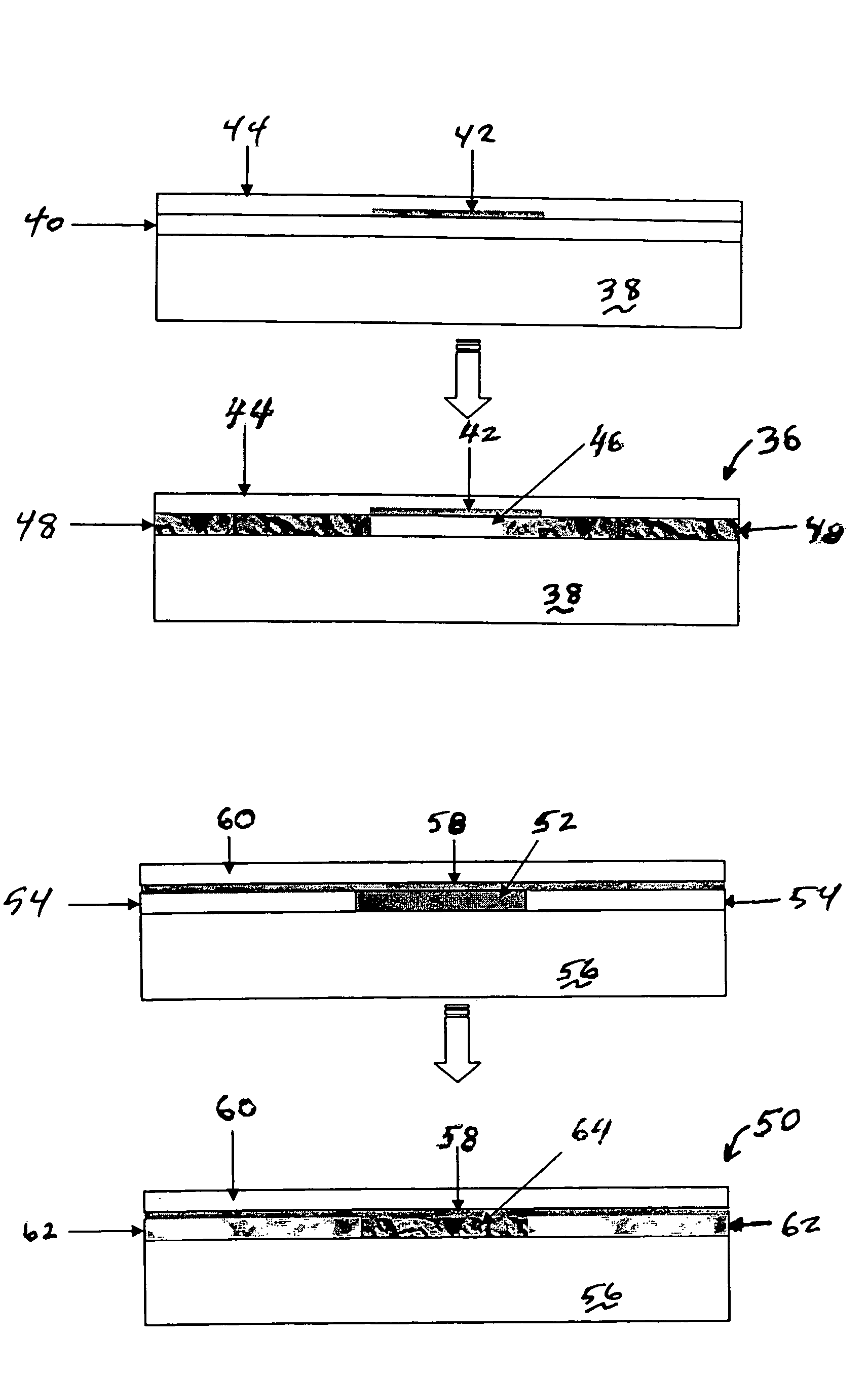

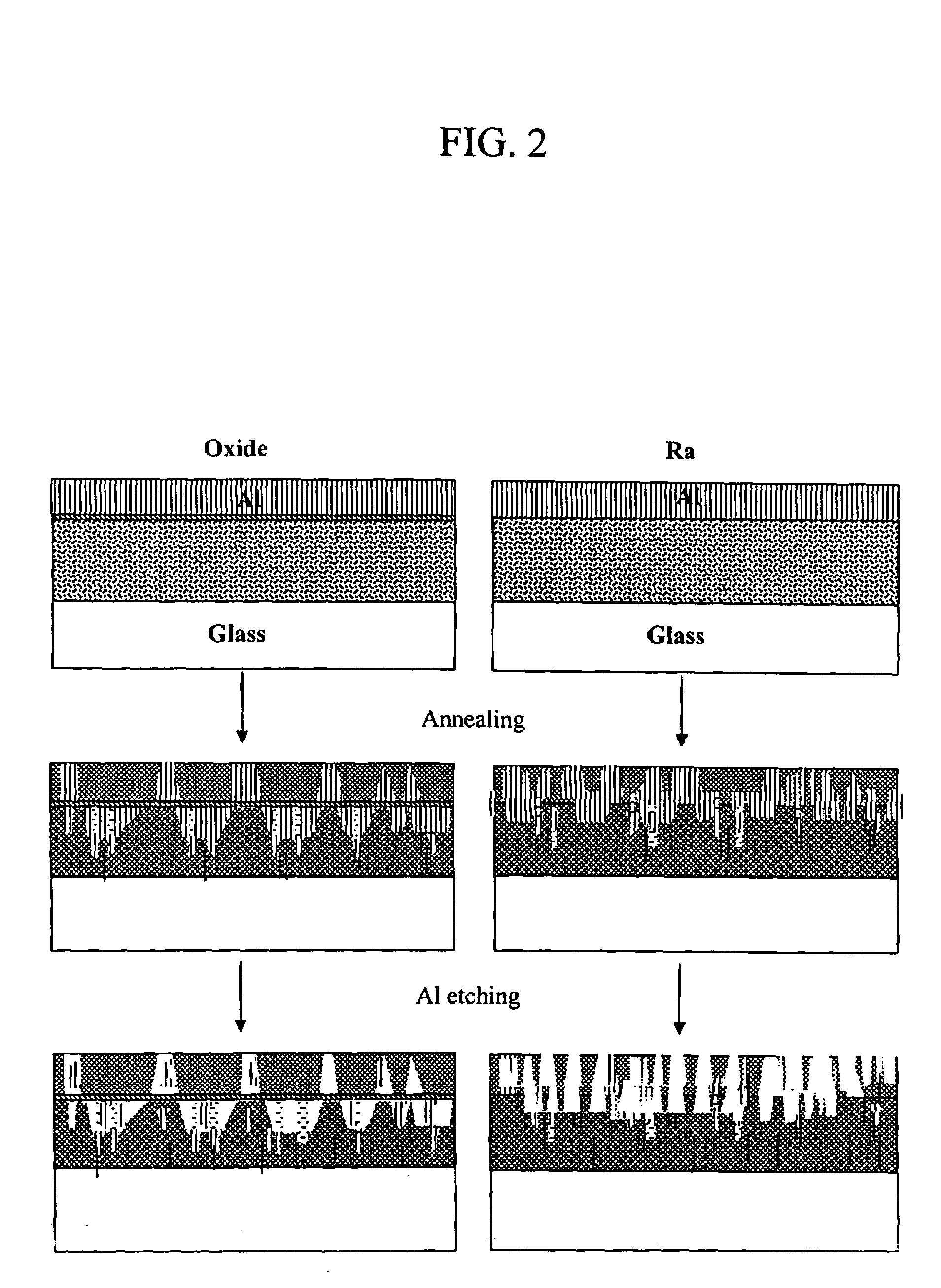

Low temperature production of large-grain polycrystalline semiconductors

InactiveUS7202143B1Final product manufactureSemiconductor/solid-state device manufacturingSolar cellSilicon dioxide

An oxide or nitride layer is provided on an amorphous semiconductor layer prior to performing metal-induced crystallization of the semiconductor layer. The oxide or nitride layer facilitates conversion of the amorphous material into large grain polycrystalline material. Hence, a native silicon dioxide layer provided on hydrogenated amorphous silicon (a-Si:H), followed by deposited Al permits induced crystallization at temperatures far below the solid phase crystallization temperature of a-Si. Solar cells and thin film transistors can be prepared using this method.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

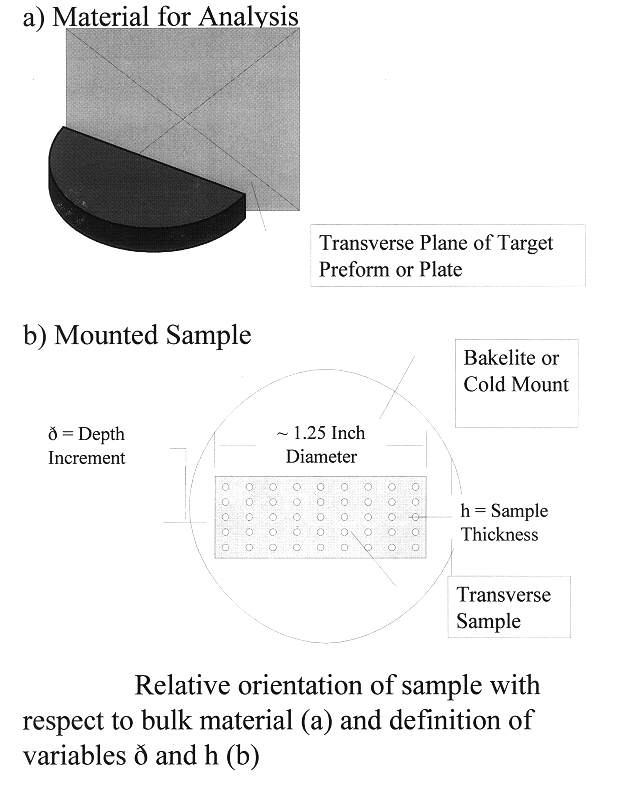

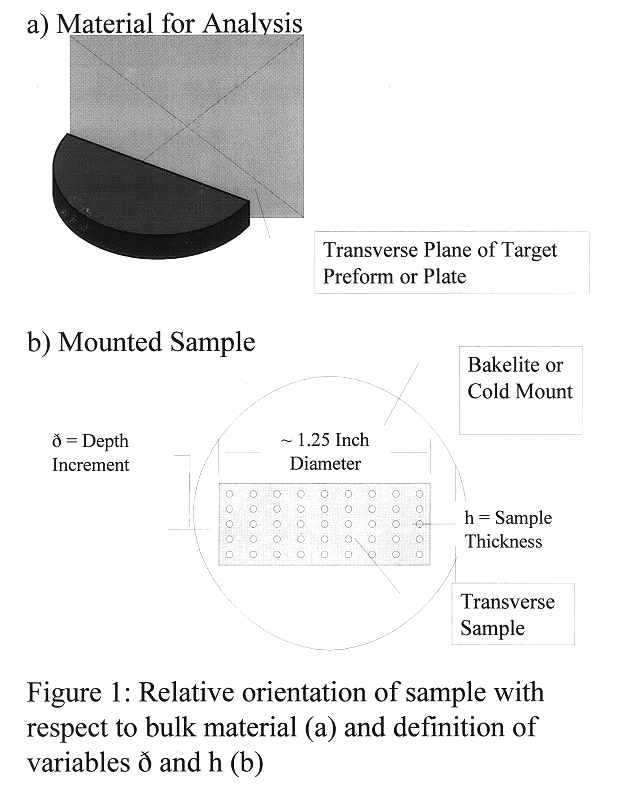

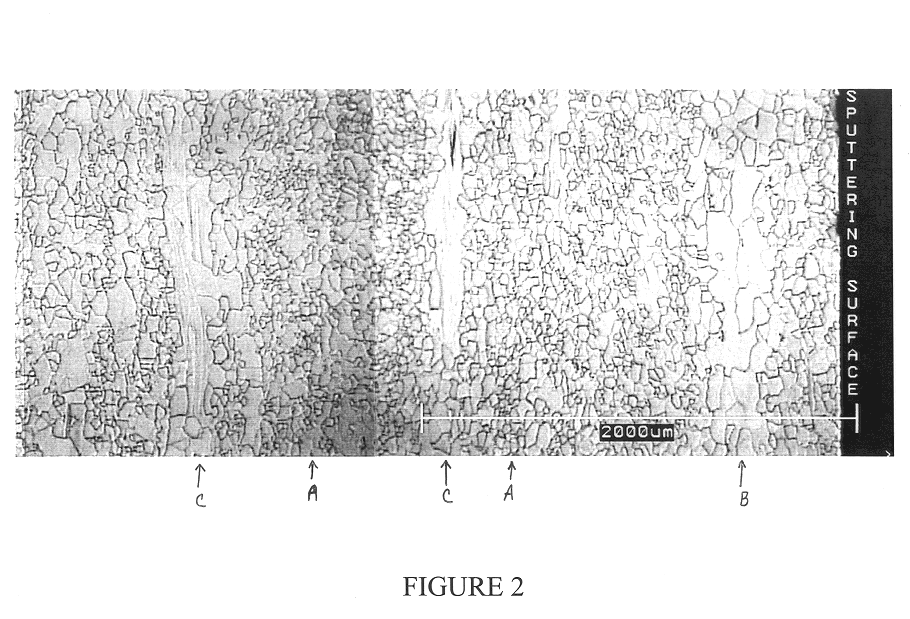

Method for quantifying the texture homogeneity of a polycrystalline material

InactiveUS6462339B1Desirable performanceUndesirable performanceElectric discharge tubesVacuum evaporation coatingTexture gradientPolycrystalline material

A method for quantifying the texture homogeneity of a polycrystalline material is described. The method involves selecting a reference pole orientation; scanning in increments a cross-section of the polycrystalline material having a thickness with scanning orientation imaging microscopy or other measuring technique to obtain actual pole orientations of a multiplicity of grains throughout the cross-section of the polycrystalline material. The orientation differences between the reference pole orientation and actual pole orientations of a multiplicity of grains is then determined. A value of misorientation from the reference pole orientation at each grain measured throughout the thickness is then assigned. The average misorientation of each measured increment throughout the thickness is then determined. A texture gradient and / or texture banding can then be obtained by determining the first and / or second derivative, respectively, of the average misorientation of each measured increment through the thickness of the sample used for evaluation. A method to predict the sputtering efficiency of a target is also described as well as a system for quantifying the texture homogeneity of a polycrystalline material.

Owner:CABOT CORP

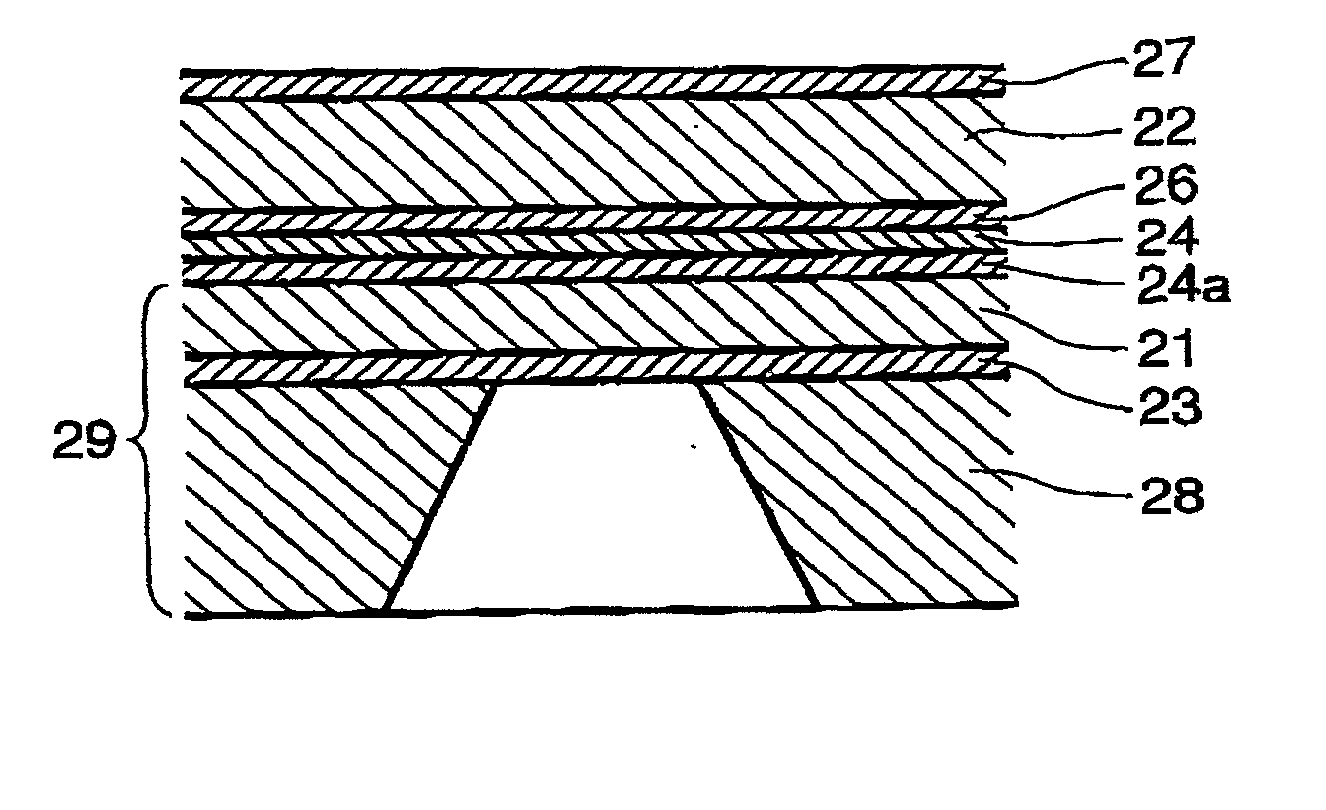

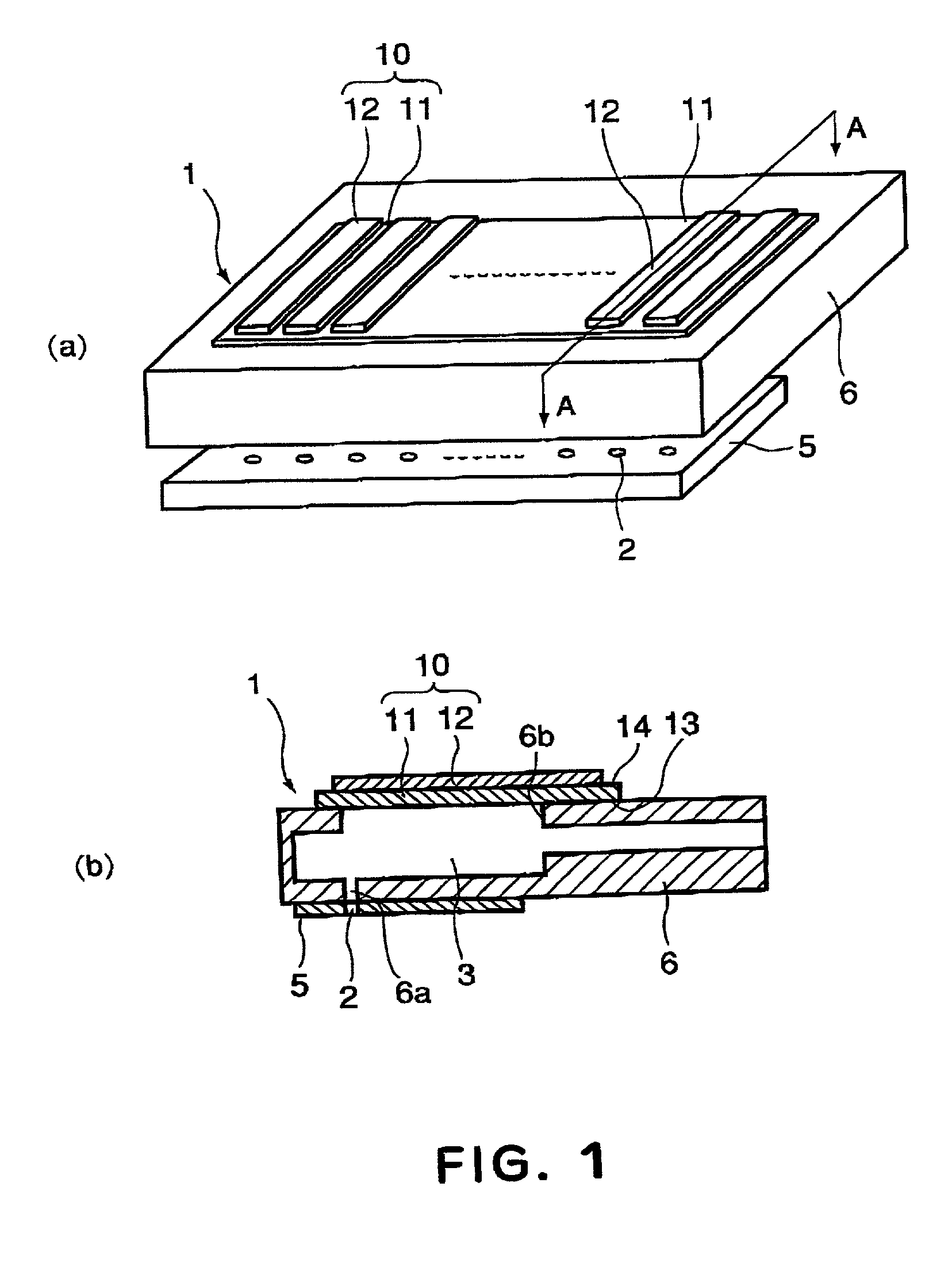

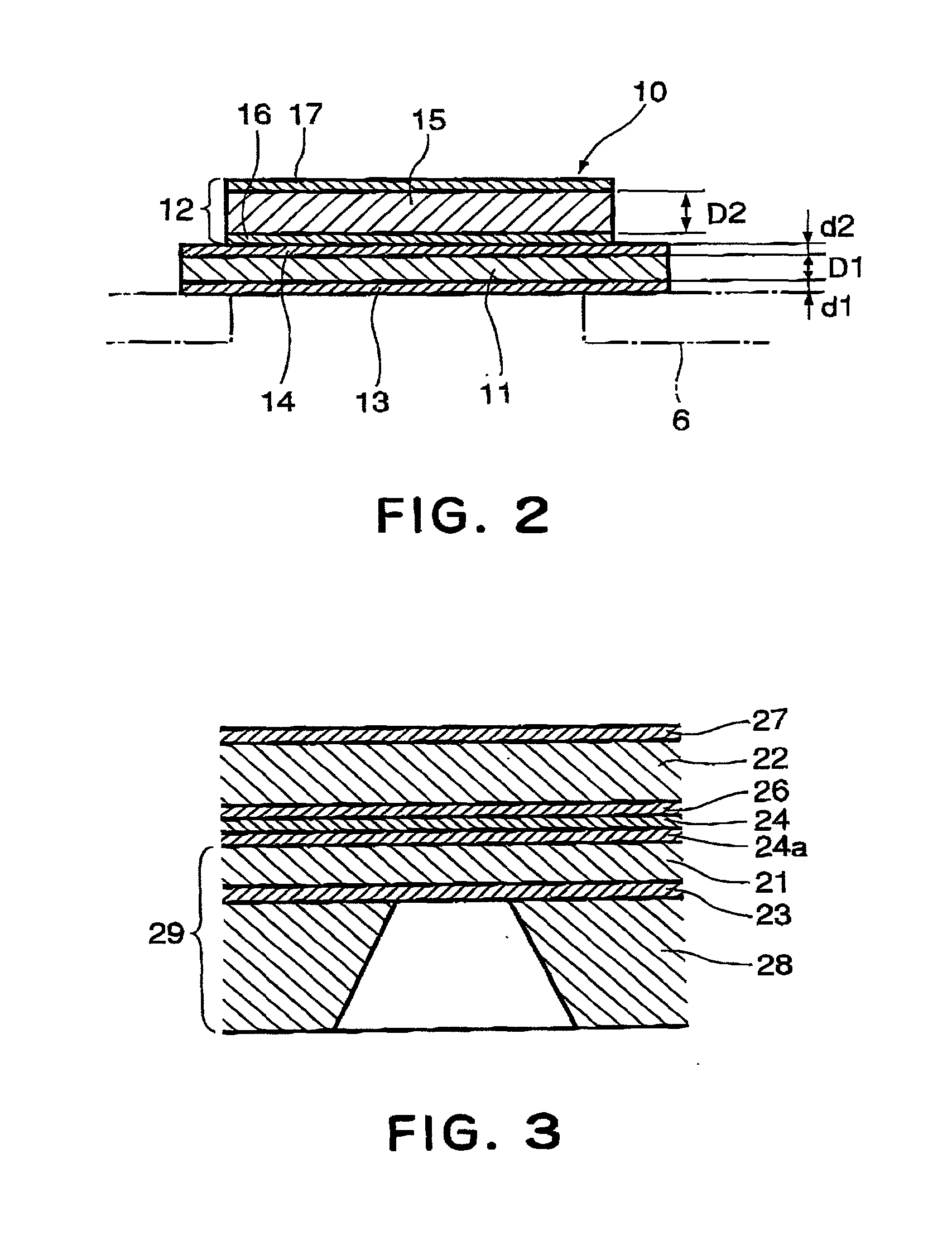

Piezoelectric structure, liquid ejecting head and manufacturing method therefor

InactiveUS20020140320A1Durable devices can be providedMaintain strengthPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesLiquid jetSingle crystal

A piezoelectric structure includes a vibrational plate; a piezoelectric film; the vibrational plate including a layer of a monocrystal material, a polycrystal material, a monocrystal material doped with an element which is different from an element constituting the monocrystal material, or a polycrystal material doped with an element which is different from an element constituting the polycrystal materials, and oxide layers sandwiching the aforementioned layer, the piezoelectric film has a single orientation crystal or monocrystal structure.

Owner:CANON KK +1

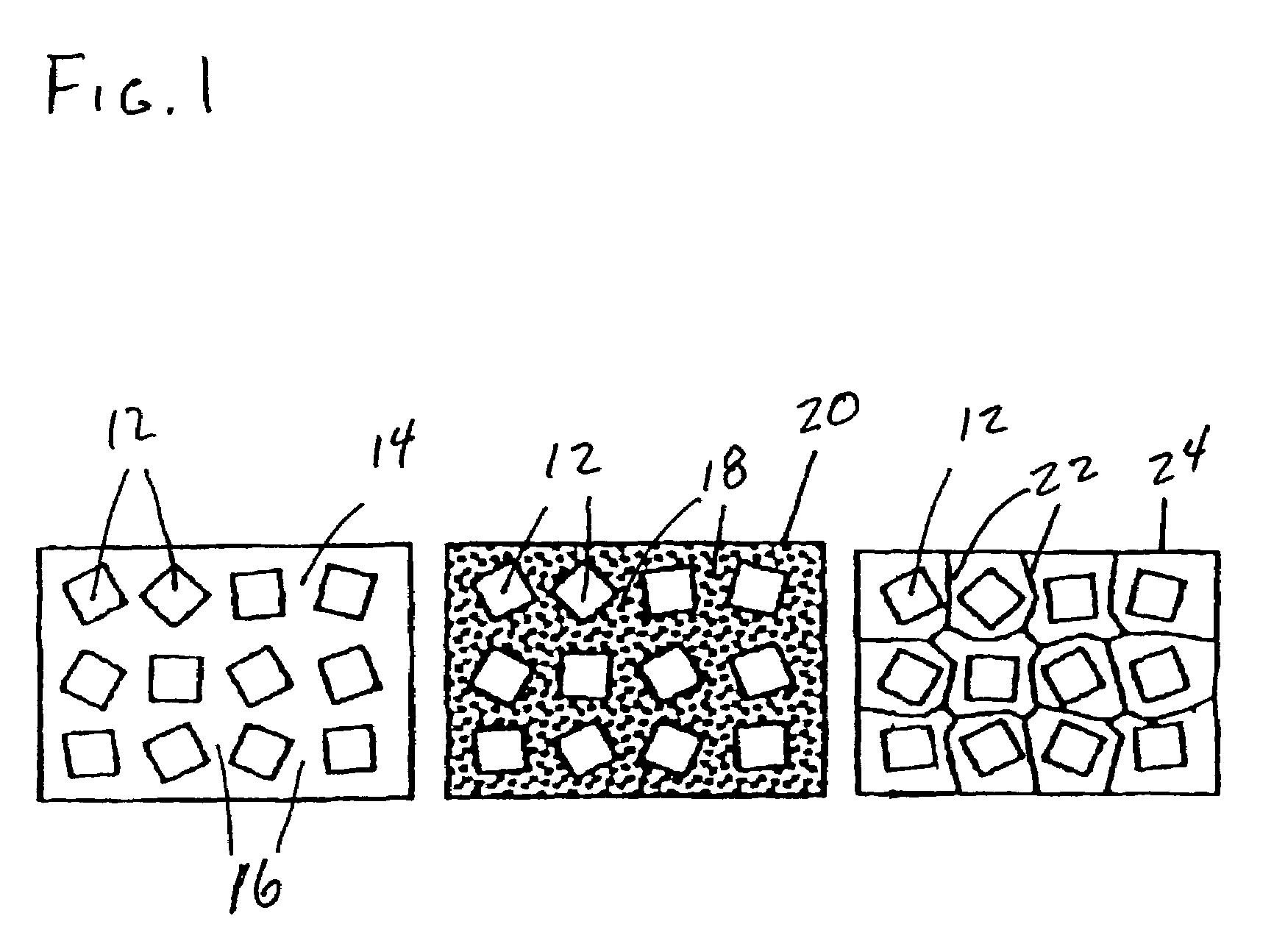

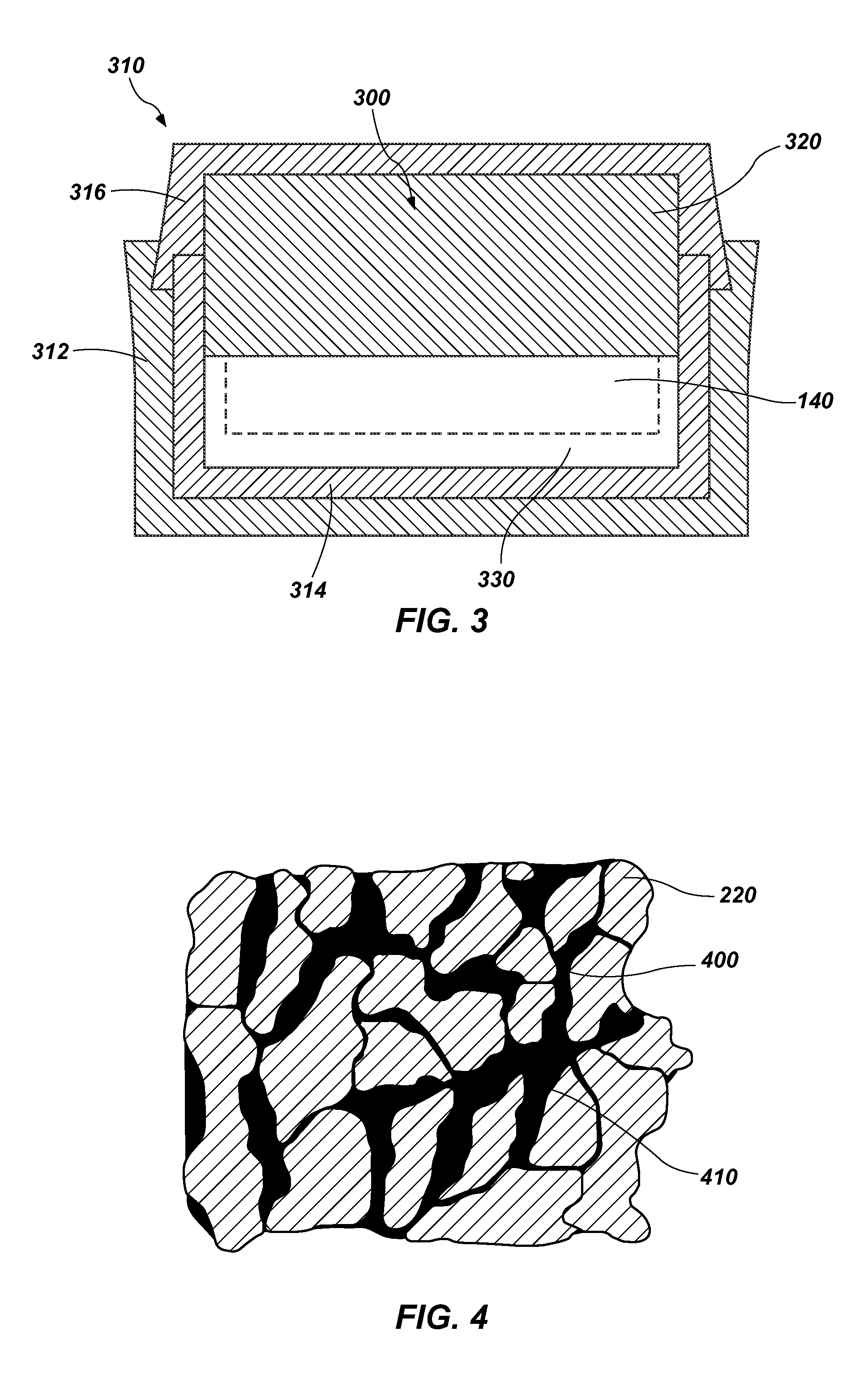

Graphene-coated diamond particles, compositions and intermediate structures comprising same, and methods of forming graphene-coated diamond particles and polycrystalline compacts

InactiveUS20120102843A1Pigmenting treatmentLiquid surface applicatorsCvd grapheneIntermediate structure

Coated diamond particles have solid diamond cores and at least one graphene layer. Methods of forming coated diamond particles include coating diamond particles with a charged species and coating the diamond particles with a graphene layer. A composition includes a substance and a plurality of coated diamond particles dispersed within the substance. An intermediate structure includes a hard polycrystalline material comprising a first plurality of diamond particles and a second plurality of diamond particles. The first plurality of diamond particles and the second plurality of diamond particles are interspersed. A method of forming a polycrystalline compact includes catalyzing the fox of inter-granular bonds between adjacent particles of a plurality of diamond particles having at least one graphene layer.

Owner:BAKER HUGHES INC

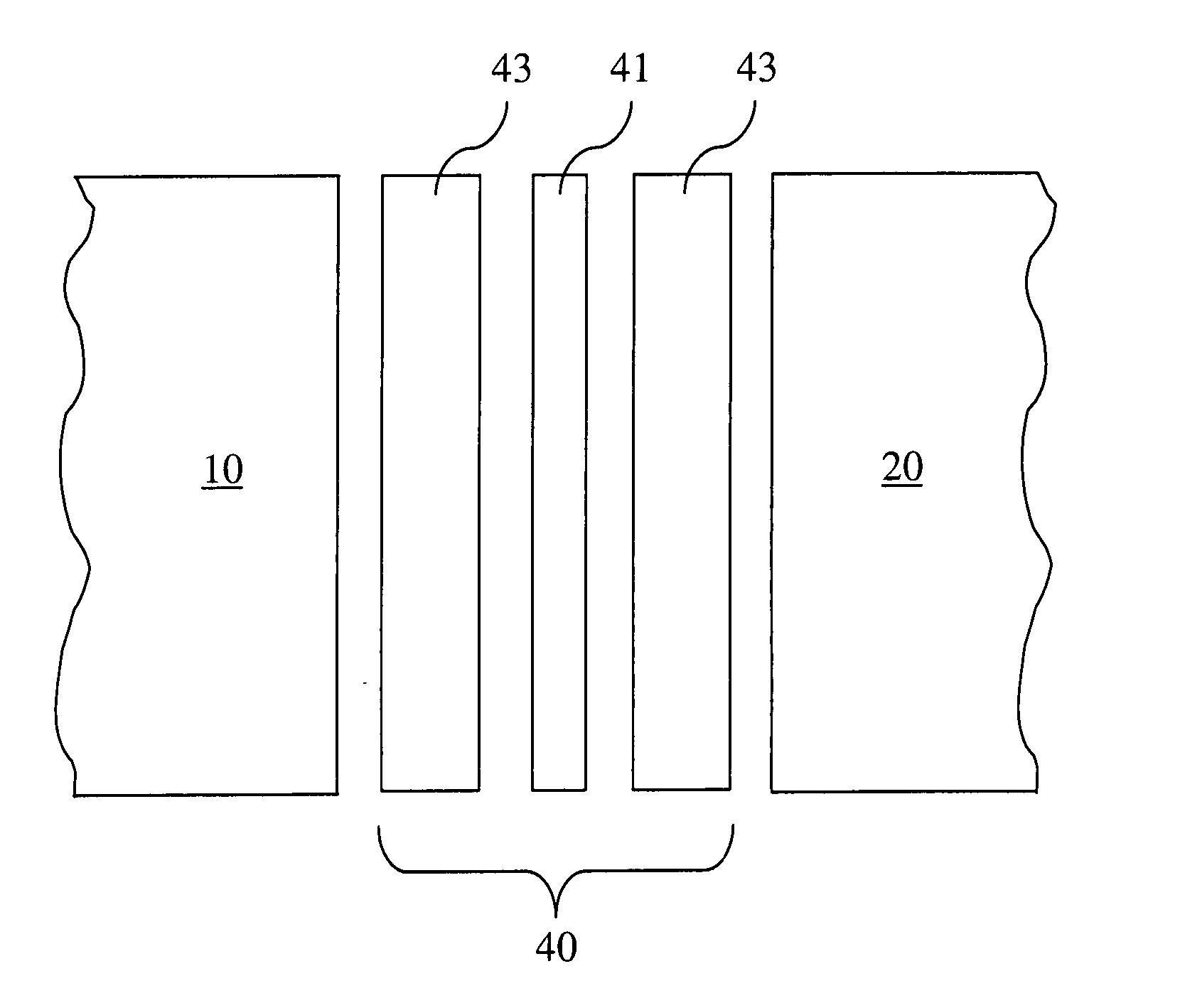

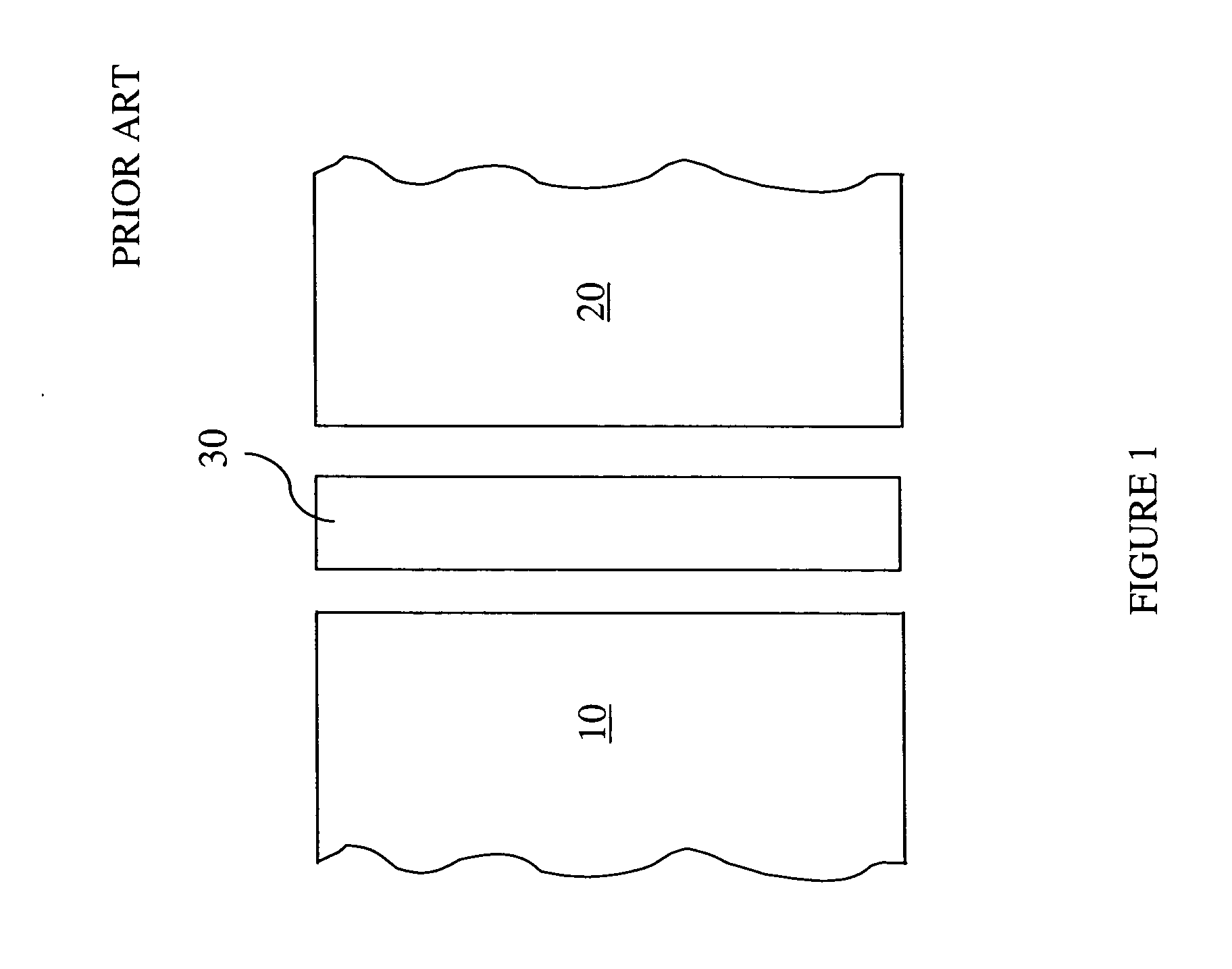

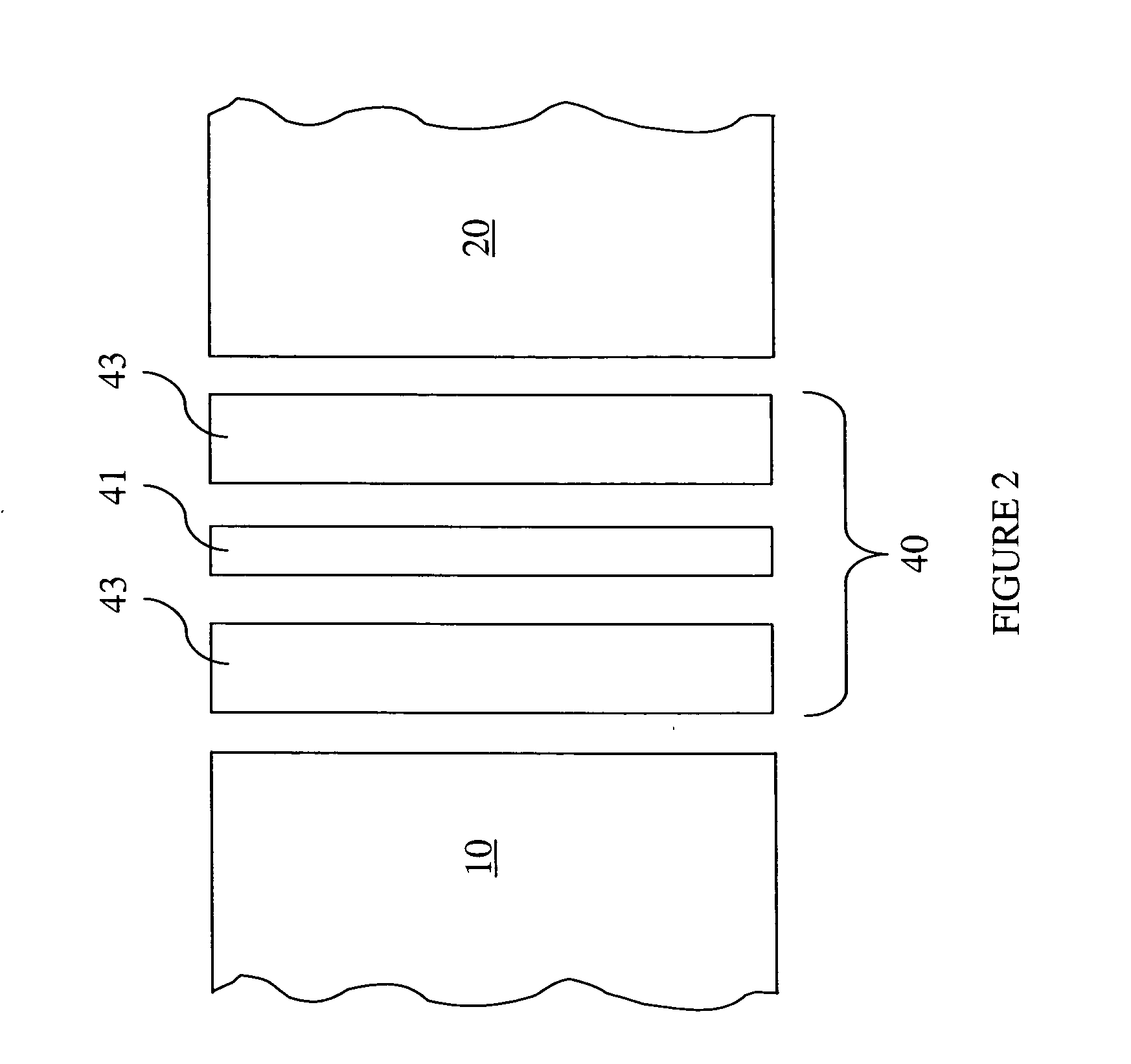

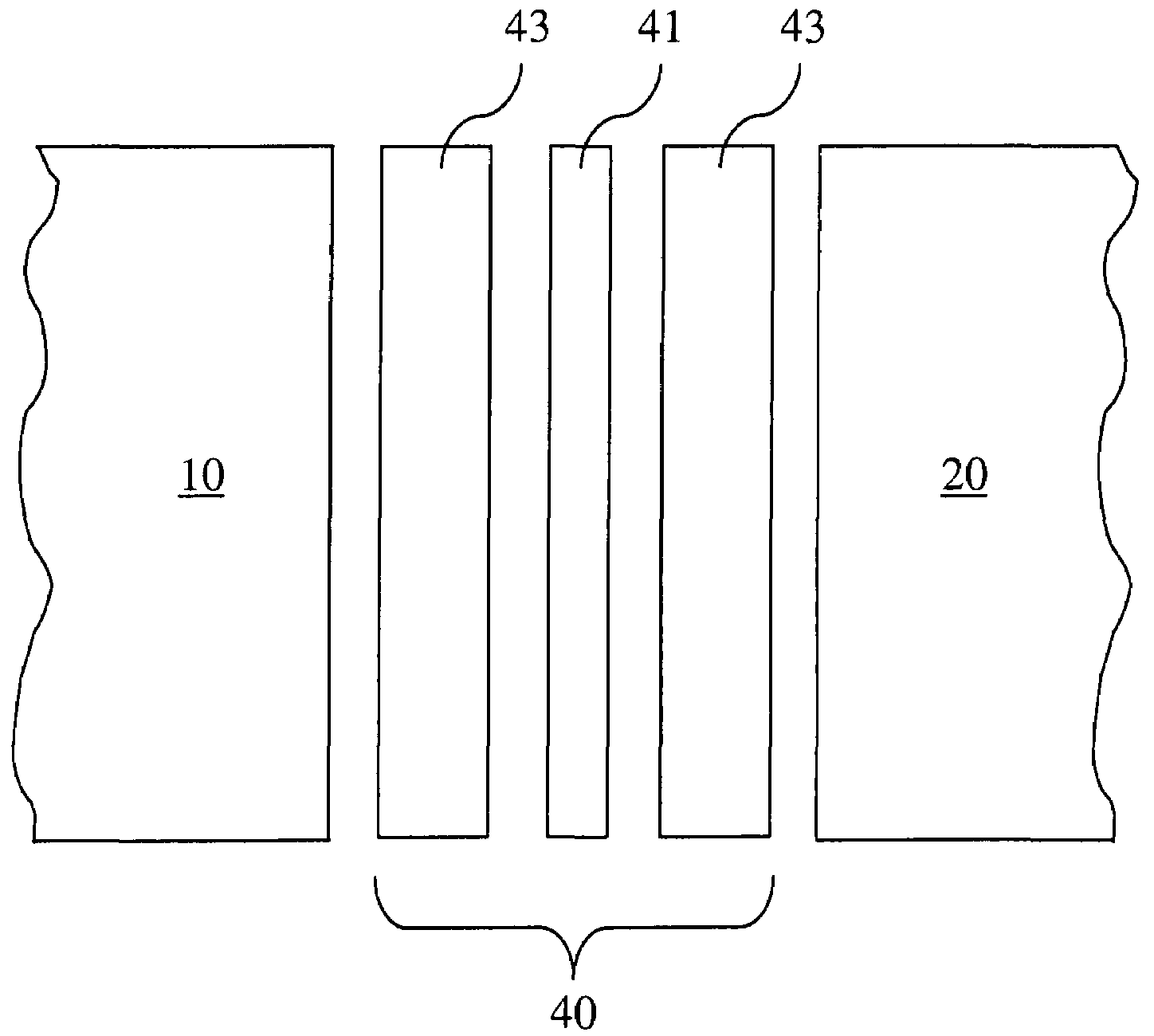

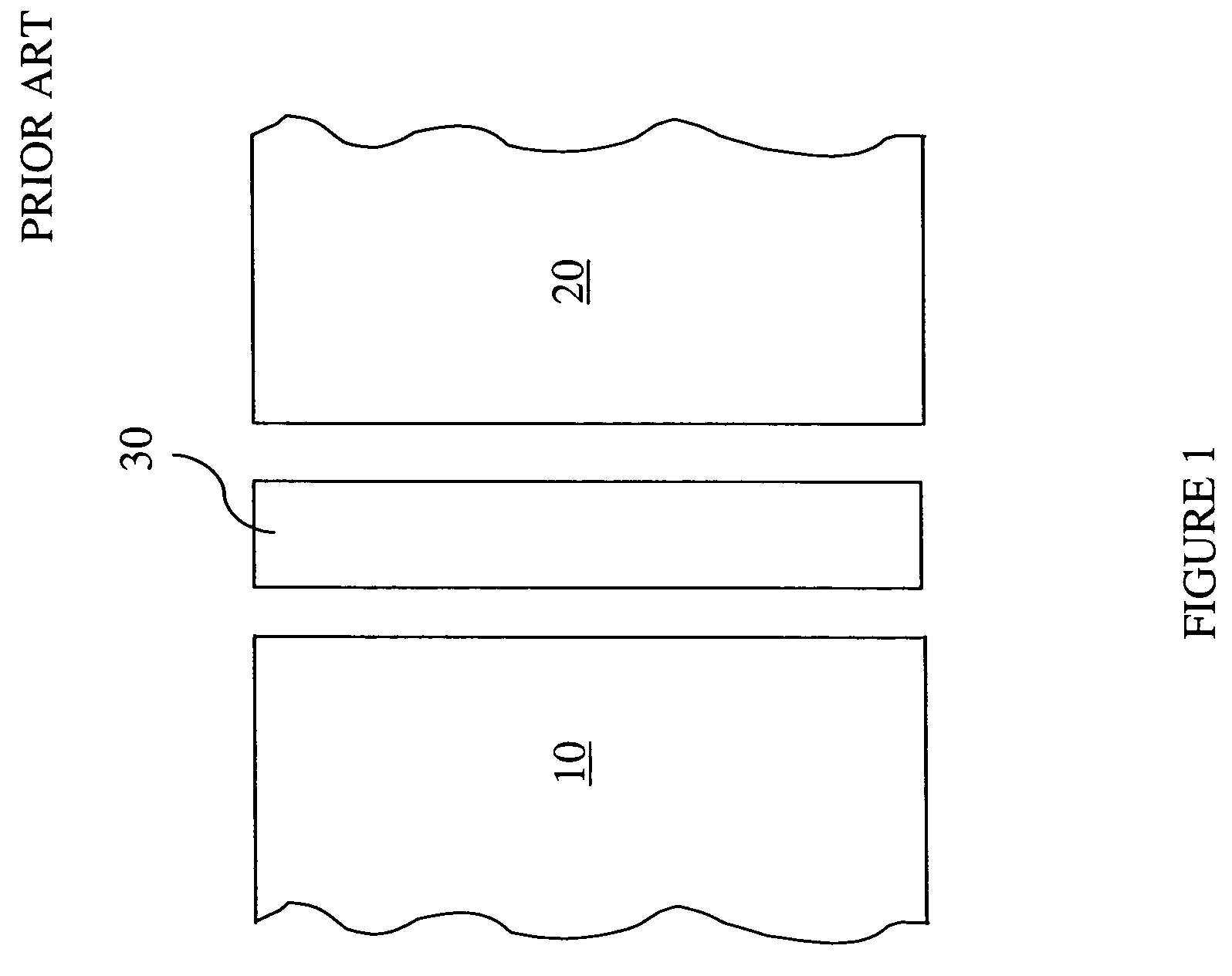

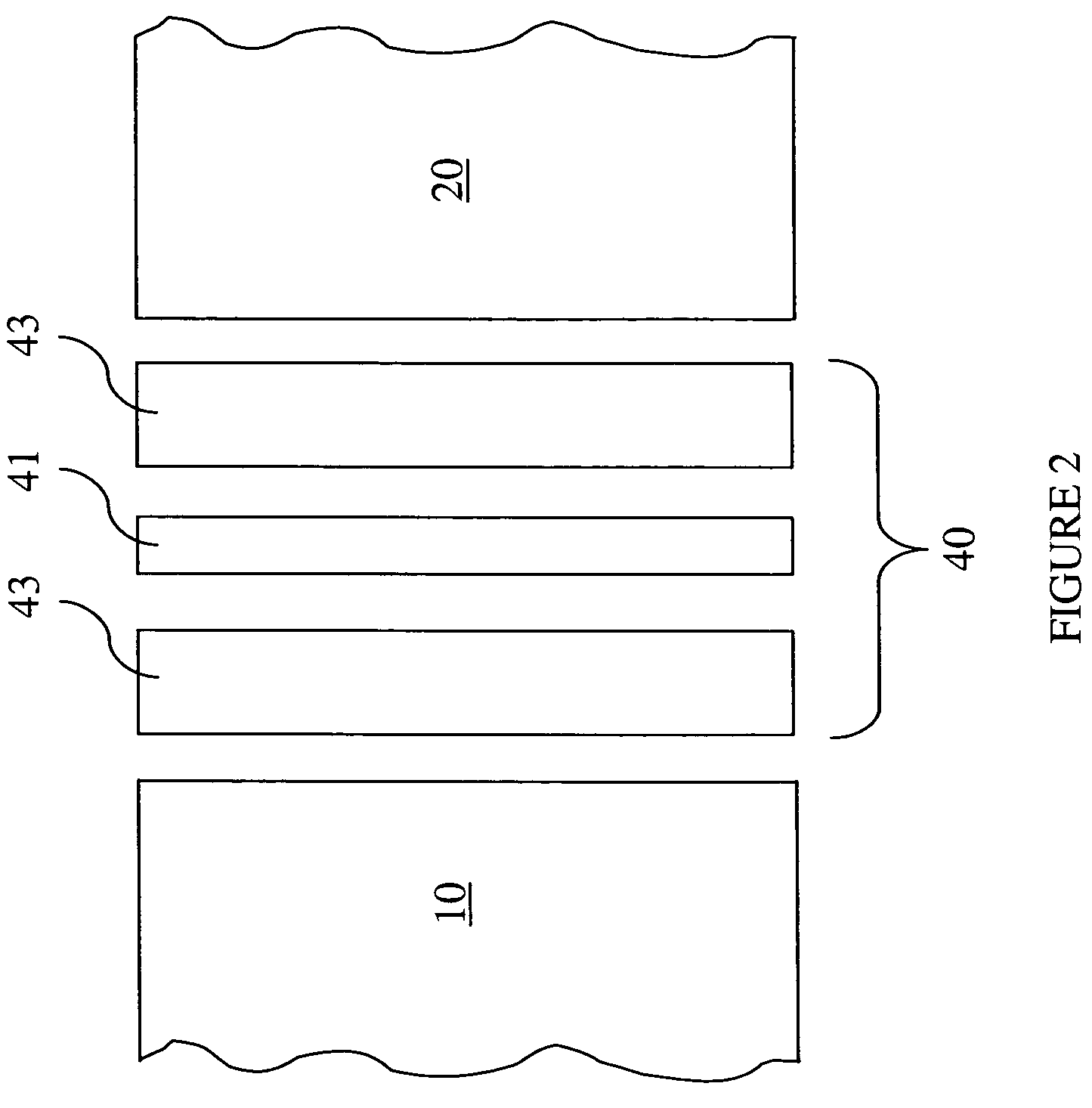

Transient liquid phase bonding using sandwich interlayers

ActiveUS20060071056A1Strong and more bondFiner microstructuresTurbinesWelding/cutting media/materialsEngineeringSingle crystal

Systems and methods for transient liquid phase bonding are described herein. Embodiments of these systems and methods utilize sandwich interlayers to produce stronger, more homogeneous bonds than currently possible. These sandwich interlayers comprise a middle bonding layer sandwiched between two outer bonding layers. The middle bonding layer comprises a different composition, and may even comprise a different form, than the outer bonding layers. In embodiments, these sandwich interlayers may be used to join a single crystal material to a polycrystalline material to make a gas turbine engine component, such as an integrally bladed rotor.

Owner:RAYTHEON TECH CORP

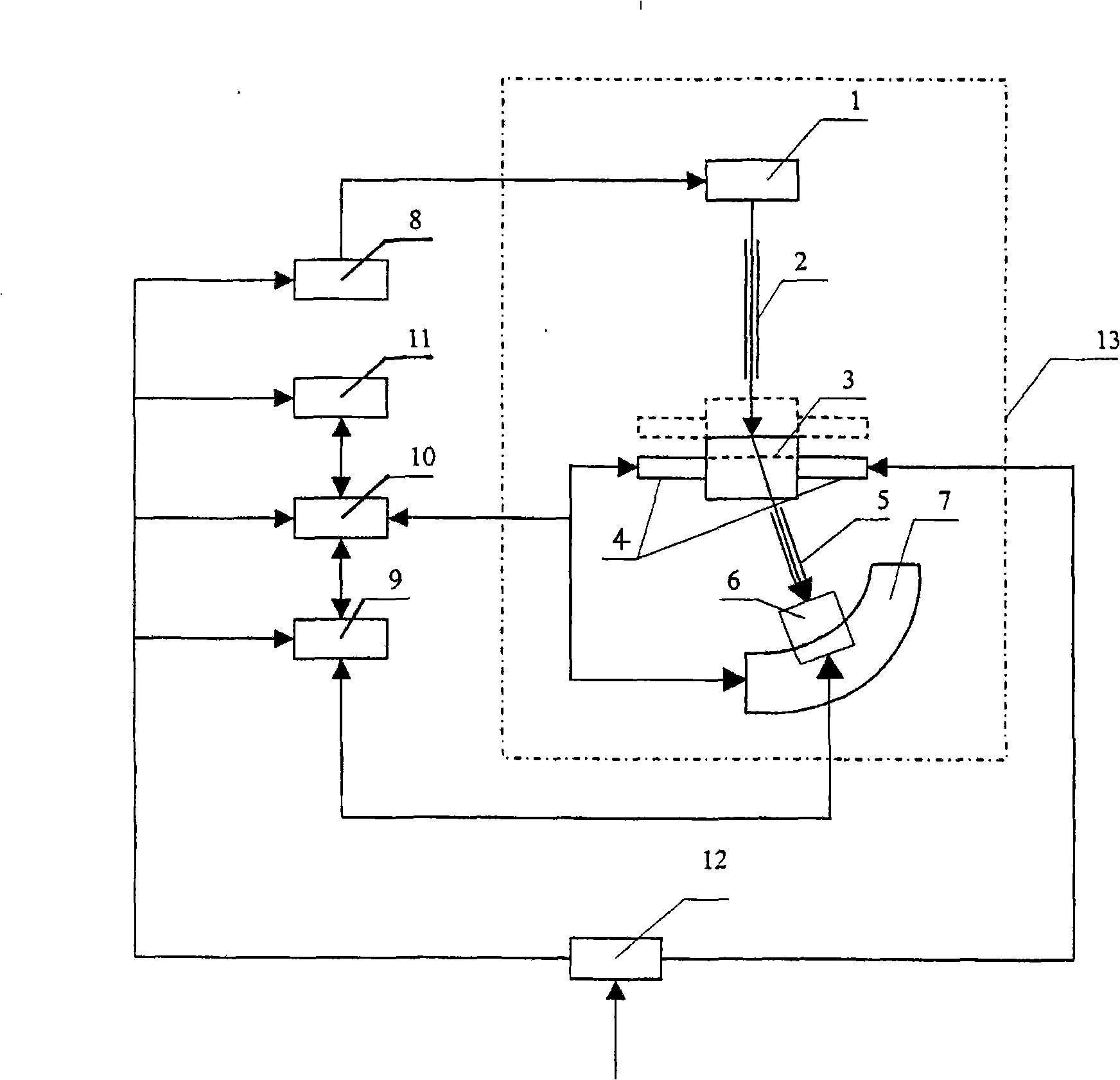

Nondestructive inspection method and device for internal defect of workpieces by x-ray diffraction x scan

InactiveCN101358938AImprove spatial resolutionMaterial analysis by transmitting radiationX-raySingle crystal

The present invention relates to a nondestructive testing method of X-ray diffraction which is used for detecting the internal defect of a workpiece which is made of crystal material (including single-crystal materials and polycrystalline materials) or material which contains atoms arranged in sequence along the one-dimensional space, and a device thereof, in particular suitable for detecting the internal defect of the workpiece made of material which consists of atoms of low atomic number. The method adopts the nondestructive test to get the intensity distribution map of diffraction of materials in all internal parts of the tested workpiece; then the nondestructive test is adopted to analyze the internal defect, the defect type and distribution of the tested workpiece. The X-ray tube radiation of easily available heavy metal anode target, which can be industrialized and practically applied, can be used in the rapid nondestructive test of the internal defect and the defect type of aluminum and magnesium workpieces which have a thickness of a plurality of millimeters; and the spatial resolution is superior to the existing X-ray detection machine and X-ray CT.

Owner:SOUTHWEST TECH & ENG INST

Methods of forming polycrystalline compacts, cutting elements and earth-boring tools

InactiveUS20120211284A1Pigmenting treatmentDrill bitsUltimate tensile strengthPolycrystalline material

Methods of forming a polycrystalline compact using at least one metal salt as a sintering aid. Such methods may include forming a mixture of the at least one metal salt and a plurality of grains of hard material and sintering the mixture to form a hard polycrystalline material. During sintering, the metal salt may melt or react with another compound to form a liquid that acts as a lubricant to promote rearrangement and packing of the grains of hard material. The metal salt may, thus, enable formation of hard polycrystalline material having increased density, abrasion resistance, or strength. The metal salt may also act as a getter to remove impurities (e.g., catalyst material) during sintering. The methods may also be employed to faun cutting elements and earth-boring tools.

Owner:BAKER HUGHES INC

Transient liquid phase bonding using sandwich interlayers

ActiveUS7565996B2Strong and more bondFiner microstructuresTurbinesWelding/cutting media/materialsEngineeringSingle crystal

Systems and methods for transient liquid phase bonding are described herein. Embodiments of these systems and methods utilize sandwich interlayers to produce stronger, more homogeneous bonds than currently possible. These sandwich interlayers have a middle bonding layer sandwiched between two outer bonding layers. The middle bonding layer is a different composition, and may even be a different form, than the outer bonding layers. In embodiments, these sandwich interlayers may be used to join a single crystal material to a polycrystalline material to make a gas turbine engine component, such as an integrally bladed rotor.

Owner:RTX CORP

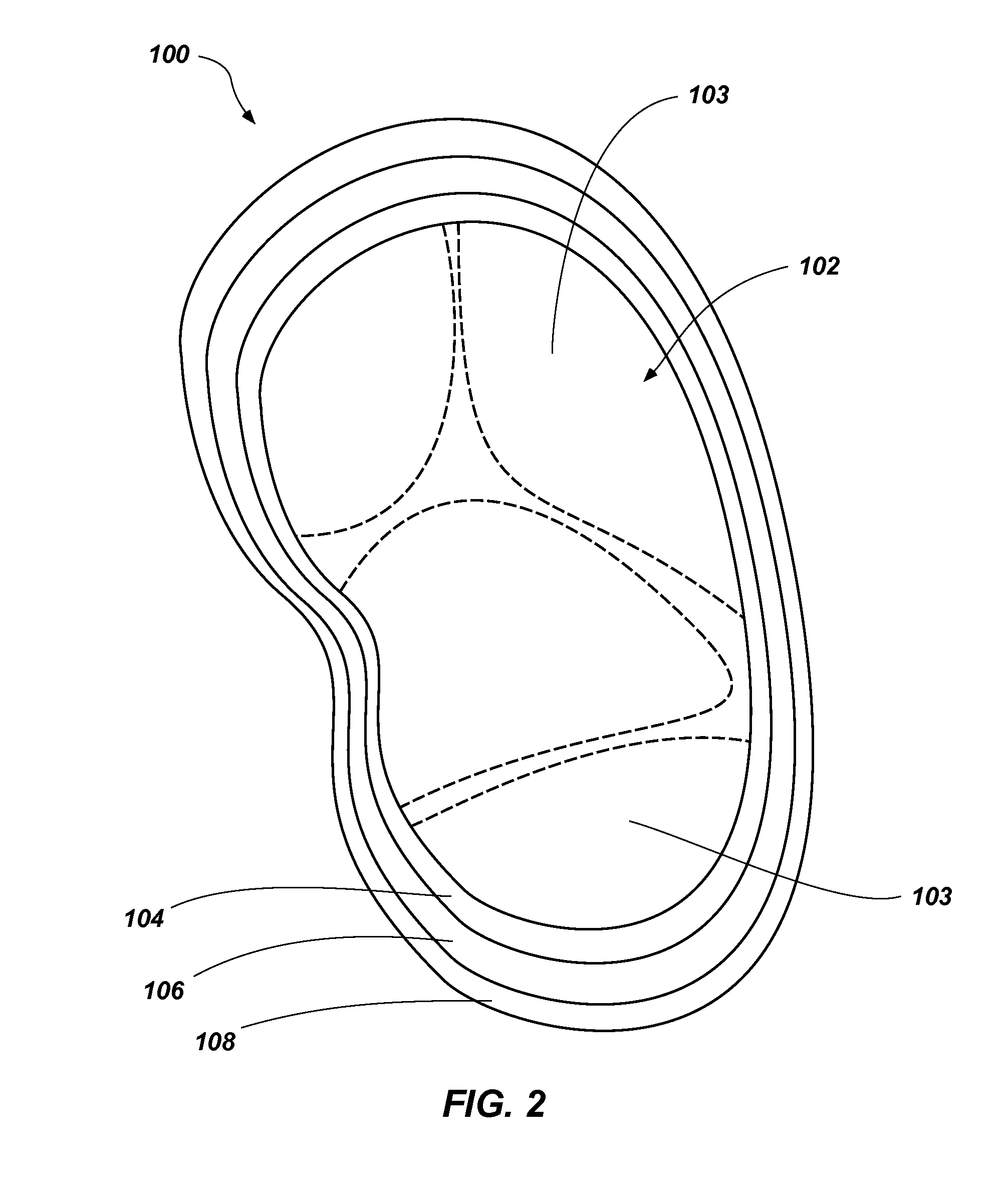

Polycrystalline compacts including nanoparticulate inclusions, cutting elements and earth-boring tools including such compacts, and methods of forming same

Polycrystalline compacts include non-catalytic, non-carbide-forming particles in interstitial spaces between interbonded grains of hard material in a polycrystalline hard material. Cutting elements and earth-boring tools include such polycrystalline compacts. Methods of forming polycrystalline compacts include forming a polycrystalline material including a hard material and a plurality of particles comprising a non-catalytic, non-carbide-forming material. Methods of forming cutting elements include infiltrating interstitial spaces between interbonded grains of hard material in a polycrystalline material with a plurality of non-catalytic, non-carbide-forming particles.

Owner:BAKER HUGHES INC

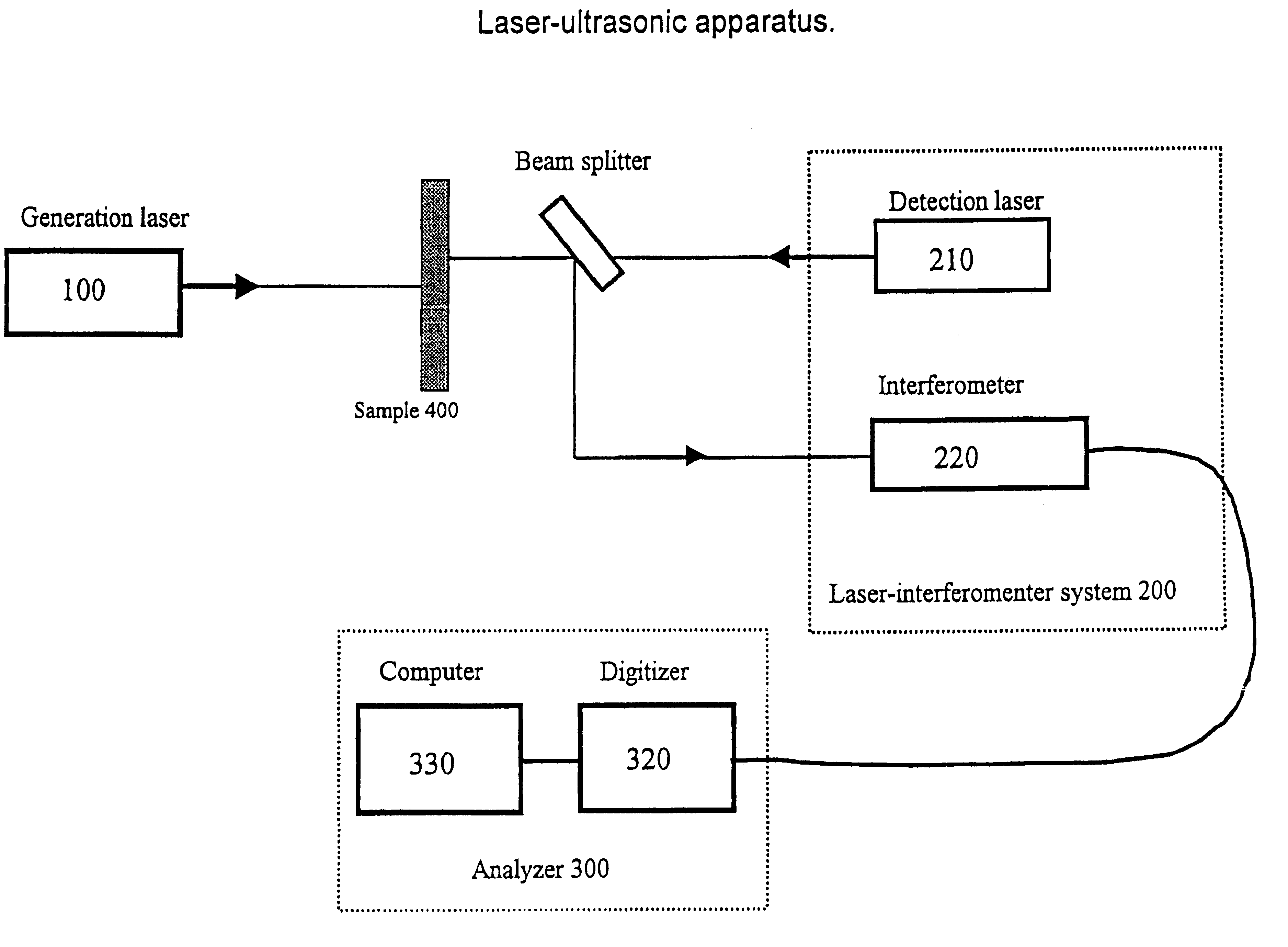

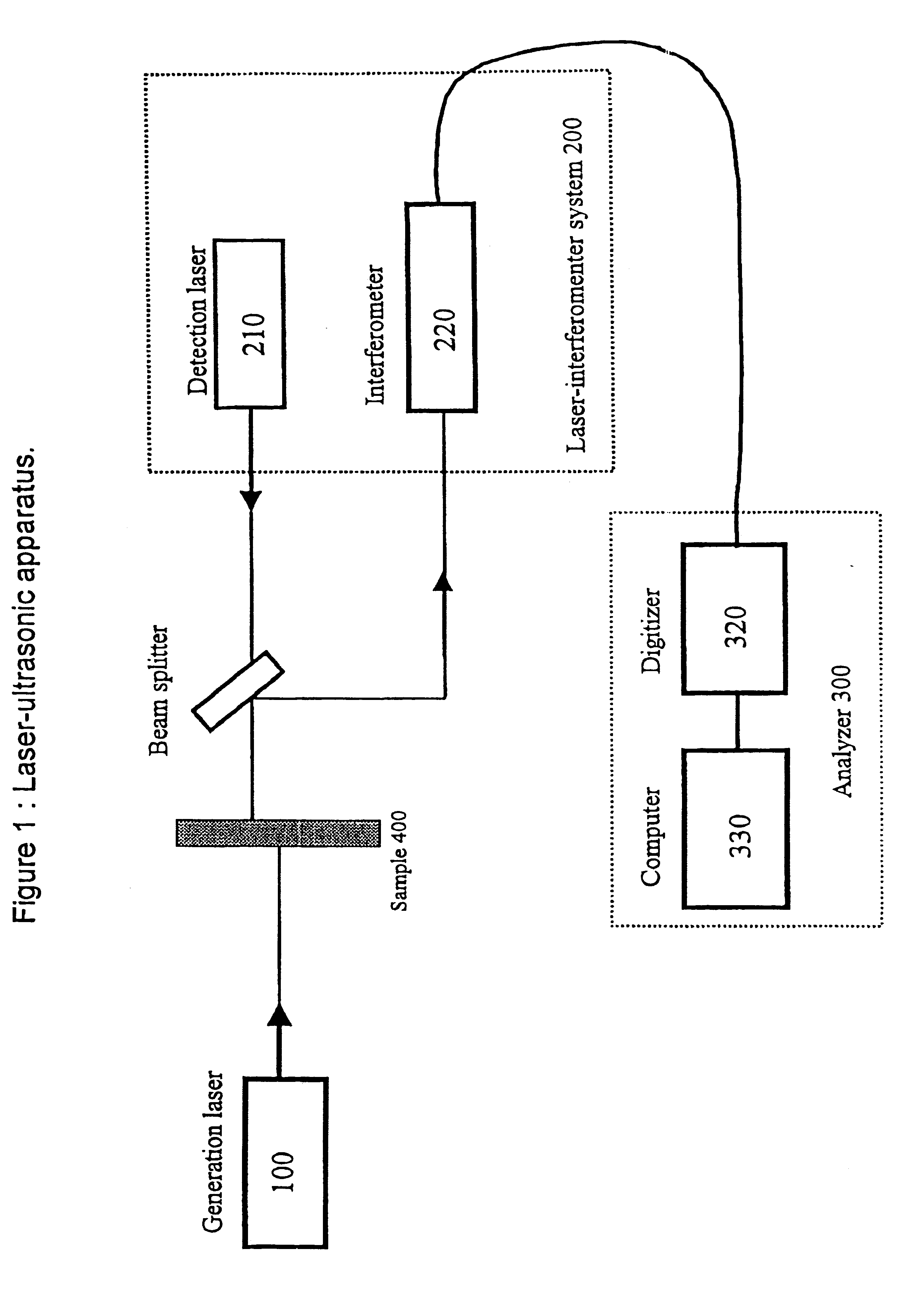

Apparatus and method for evaluating the physical properties of a sample using ultrasonics

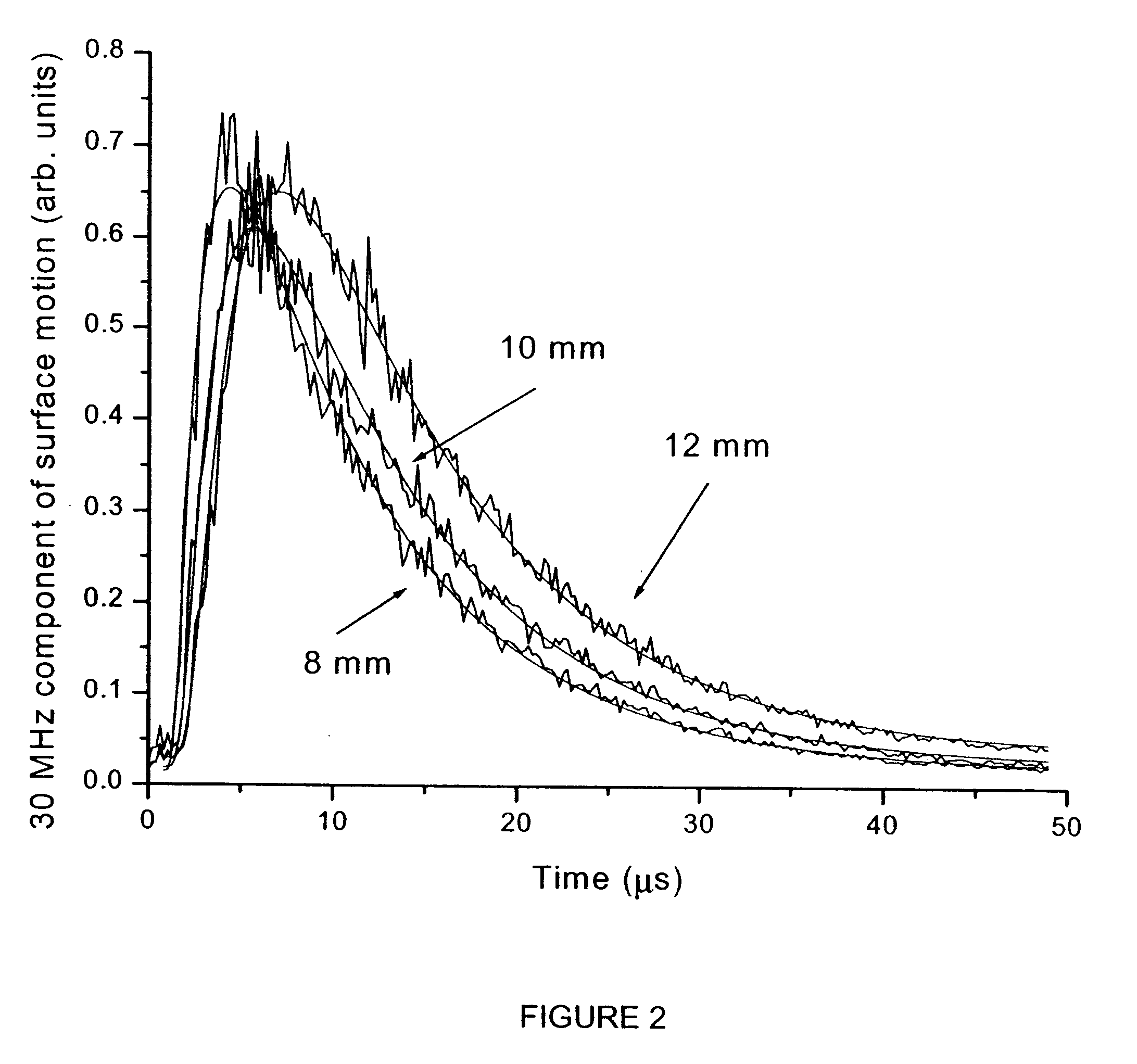

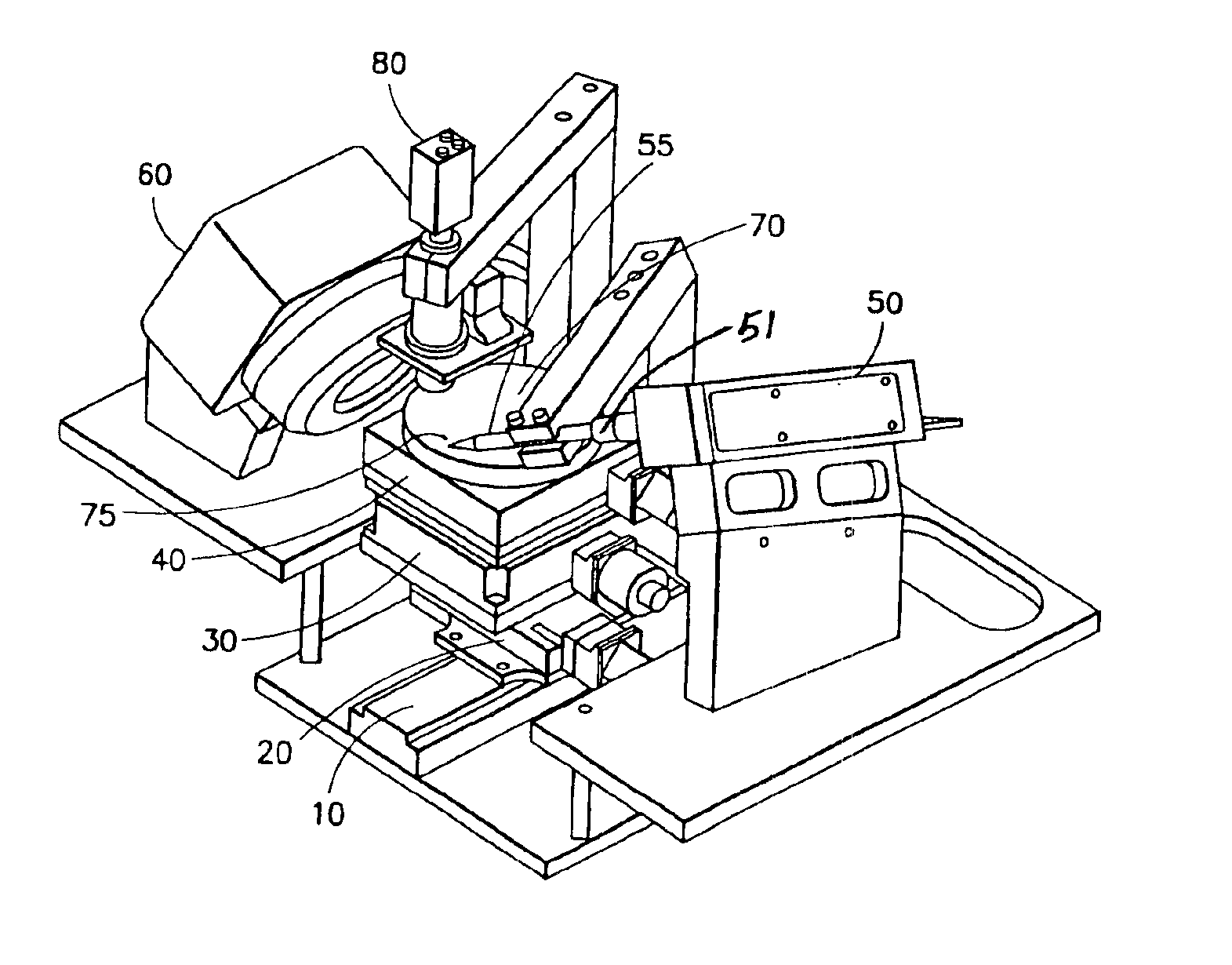

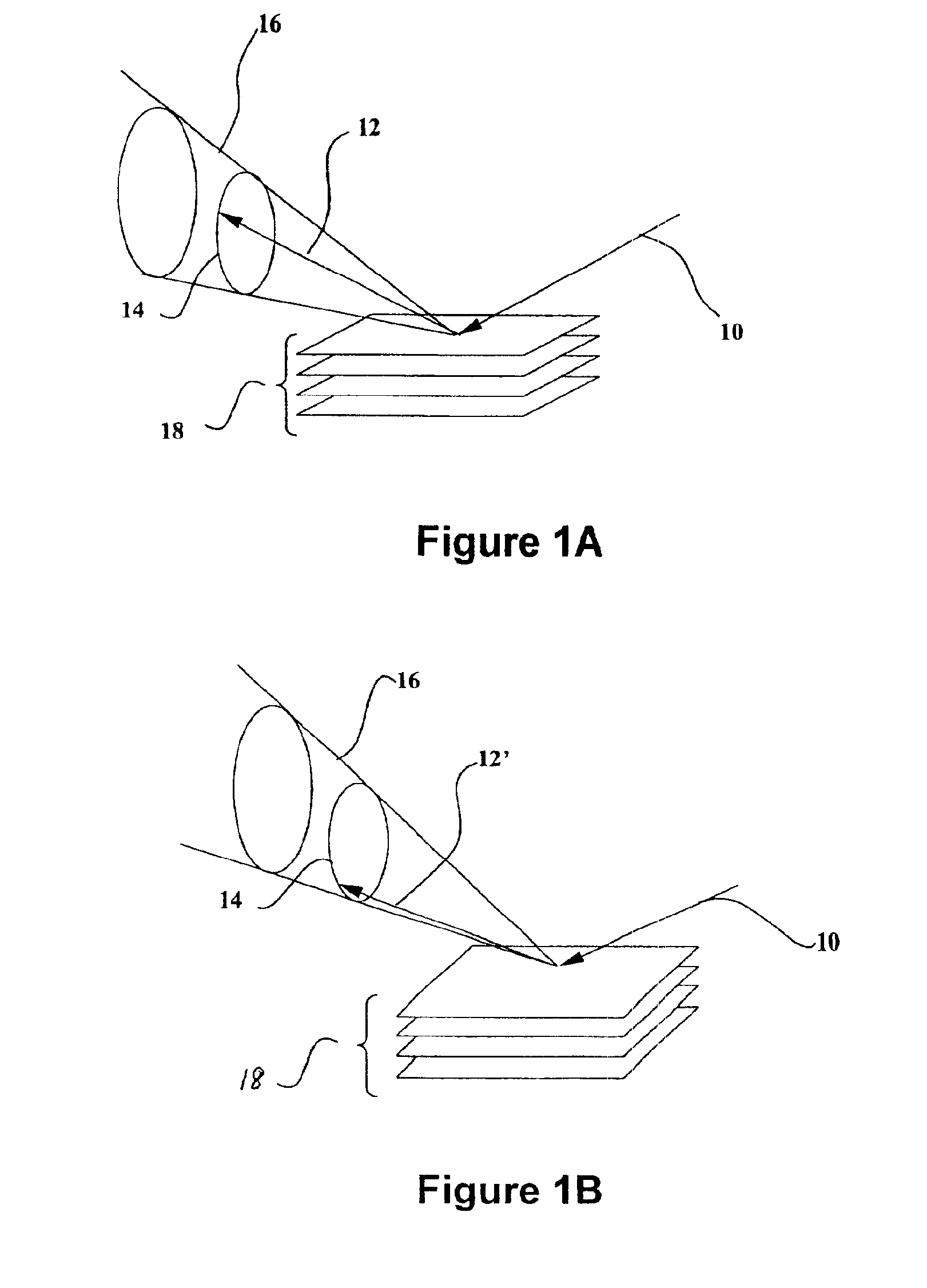

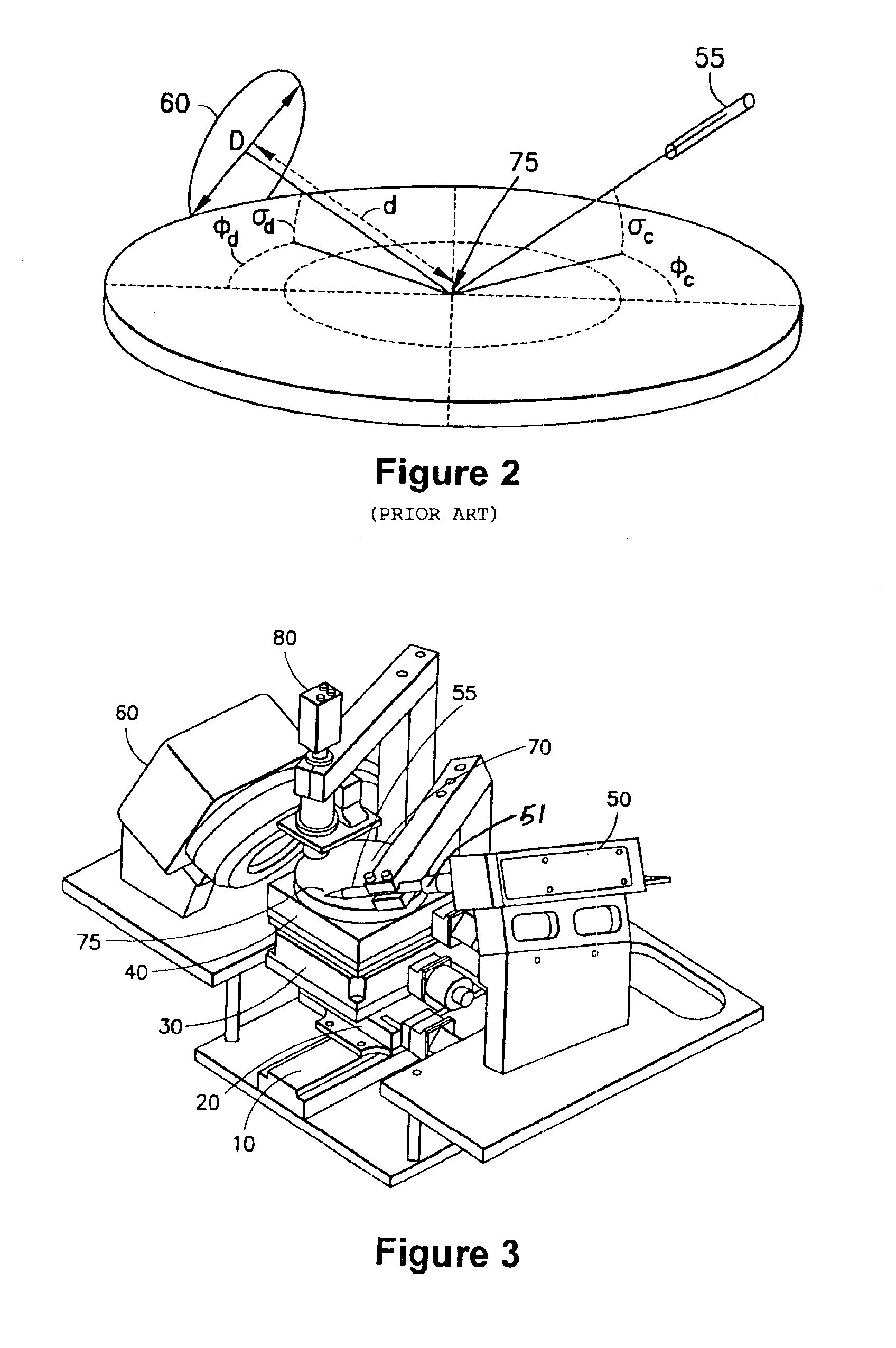

InactiveUS6532821B2Reduce in quantityNumber of measurements of the ultrasound fieldVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesDiffusionMathematical model

A method is disclosed for evaluating the physical properties of a sample, for example, the grain size in a polycrystalline material. An ultrasound field is generated in a local region of the sample with a non-contact source, such as a pulsed laser, such that the generated ultrasound diffuses away from said local region. After waiting until the generated ultrasound field has reached a diffusion regime, the resulting ultrasound field is measured with a non-contact detector. Parameters are adjusted in a mathematical model describing the predicted behaviour of the ultrasound field in the diffusion regime to fit the detected ultrasound field to the mathematical model. In this way, parameters dependent on the physical properties of the sample, such as the diffusion coefficient and absorption coefficient, can be derived. The grain size, for example, can be estimated from these parameters preferably by calibrating the diffusion coefficient to grain size.

Owner:NAT RES COUNCIL OF CANADA

Method and apparatus for rapid grain size analysis of polycrystalline materials

InactiveUS6882739B2Remove background noiseEliminate DiffractionMaterial analysis by optical meansCharacter and pattern recognitionHighly skilledX-ray

An apparatus and method for performing rapid grain size analysis on a textured polycrystalline material, by generating average grain size and grain size distribution data from x-ray diffraction data of such material. Raw diffraction data is obtained by capturing a plurality of diffraction arcs within a single data capture frame. The raw diffraction data is digitally registered; (3) and the registered diffraction data is filtered to remove background noise, exclude diffraction overlaps or truncations, and compensate for biased data obtained from regions of highly preferred orientations. Average grain size and grain size distribution data are then correlated with the filtered diffraction data. The apparatus for acquiring raw diffraction data includes a collimated x-ray source having means for adjusting beam size and divergence of the x-ray generated, a 2-dimensional area detector for registering diffracted x-ray, and a sample motion assembly for moving the sample in the sample plane. The resulting system is fast, accurate, amenable to automation, and does not require highly skilled personnel to operate.

Owner:NOVA MEASURING INSTR LTD

Semiconductor device and manufacturing method thereof

InactiveUS7081641B2Amount of electric current of a bottom-contact type organic TFTReduce contact resistanceTransistorSemiconductor/solid-state device detailsSemiconductor packageDisplay device

Owner:HITACHI LTD

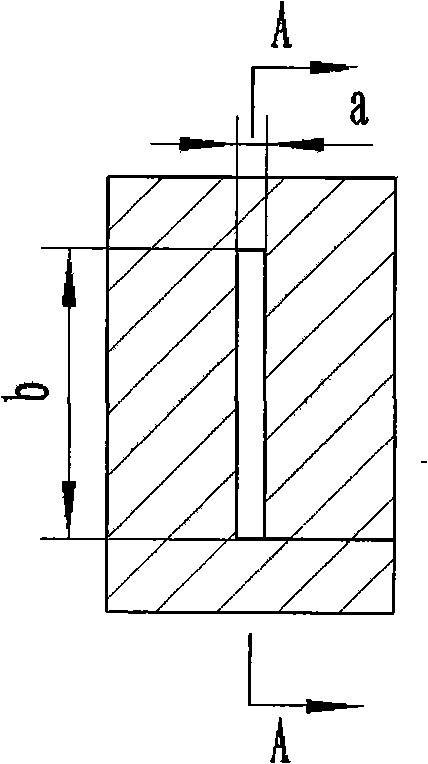

Method for manufacturing ultra-hard composite blade

The invention discloses a method for manufacturing a super-hard composite cutting blade. Firstly, carbide alloy or high-speed steel sheets prepared to be a base body of the cutting blade is cut into the needed size and shape. Secondly, the cutting tip portion is cut down, and the lateral surface of base body is manufactured with curve lines. Thirdly, the manufactured and formed base body of the cutting blade is placed inside a corresponding sintering mold, super-hard materials and composite powder are added into the missing cutting tip portion, and the super-hard materials and composite powder are transformed into super-hard polycrystalline materials and are fixedly combined with the base body of the cutting blade after being sintered under high temperature and high pressure. Fourthly, the super-hard polycrystalline cutting blade is made through the procedures of abrasive fabrication and blade-opening. The invention resolves problems of un-solid welding, easy peeling and high manufacture cost of an integral tool-holder super-hard cutter of the existing super-hard composite cutting blade. The invention not only increases the rigidity of the composite super-hard cutters, but also greatly reduces the using amount of super-hard material powder, and lowers the manufacture cost.

Owner:FUNIK ULTRAHARD MATERIAL

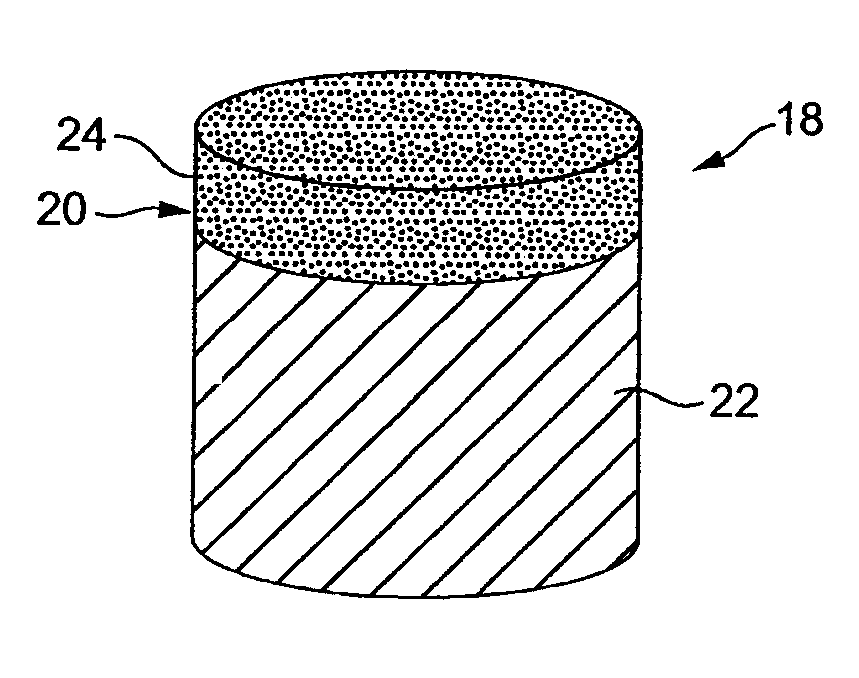

Polycrystalline compacts including in-situ nucleated grains, earth-boring tools including such compacts, and methods of forming such compacts and tools

Polycrystalline compacts include hard polycrystalline materials comprising in situ nucleated smaller grains of hard material interspersed and inter-bonded with larger grains of hard material. The average size of the larger grains may be at least about 250 times greater than the average size of the in situ nucleated smaller grains. Methods of forming polycrystalline compacts include nucleating and catalyzing the formation of smaller grains of hard material in the presence of larger grains of hard material, and catalyzing the formation of inter-granular bonds between the grains of hard material. For example, nucleation particles may be mixed with larger diamond grains, a carbon source, and a catalyst. The mixture may be subjected to high temperature and high pressure to form smaller diamond grains using the nucleation particles, the carbon source, and the catalyst, and to catalyze formation of diamond-to-diamond bonds between the smaller and larger diamond grains.

Owner:BAKER HUGHES HLDG LLC

Shaped thermally stable polycrystalline material and associated methods of manufacture

InactiveUS20060272571A1Tailored strengthGood self-cutting behaviorPigmenting treatmentPolycrystalline material growthPolycrystalline diamondThermal stability

A new industrial thermally stable polycrystalline diamond (TSP) is disclosed and described as a replacement of natural as well as synthetic diamond grit in concrete cutting, grinding, polishing, and surface-set grinding or core bit drilling applications. Conventional diamond is too strong and brittle for self-sharpening and polishing and has a lower thermal stability inferior to the industrial standard for high temperature tool segment bonding. TSP grits can be tailor-made having unique properties as well as an engineered shape of grits over naturally or synthetically produced diamond grits. The TSP grits have a high thermal stability of up to 1200° C. and are self-sharpening. Further, economical production of coarse TSP grit size up to 1-2 mm from 50 / 60 mesh size in almost any preferred shape such as blocky, round, hexagonal, thin elongated, spherical, needle like, and any desirable tailor-made shaped etc can be realized. The use of a partition member during production of the TSP grits allows for the effective manufacturing of desired shaped grits as compared to laborious and ineffective low yield crushing of TSP material. Advantageously, the process time can also be exceptionally shorter than conventional HPHT processes.

Owner:ADICO ASIA POLYDIAMOND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com