Patents

Literature

122 results about "Misorientation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

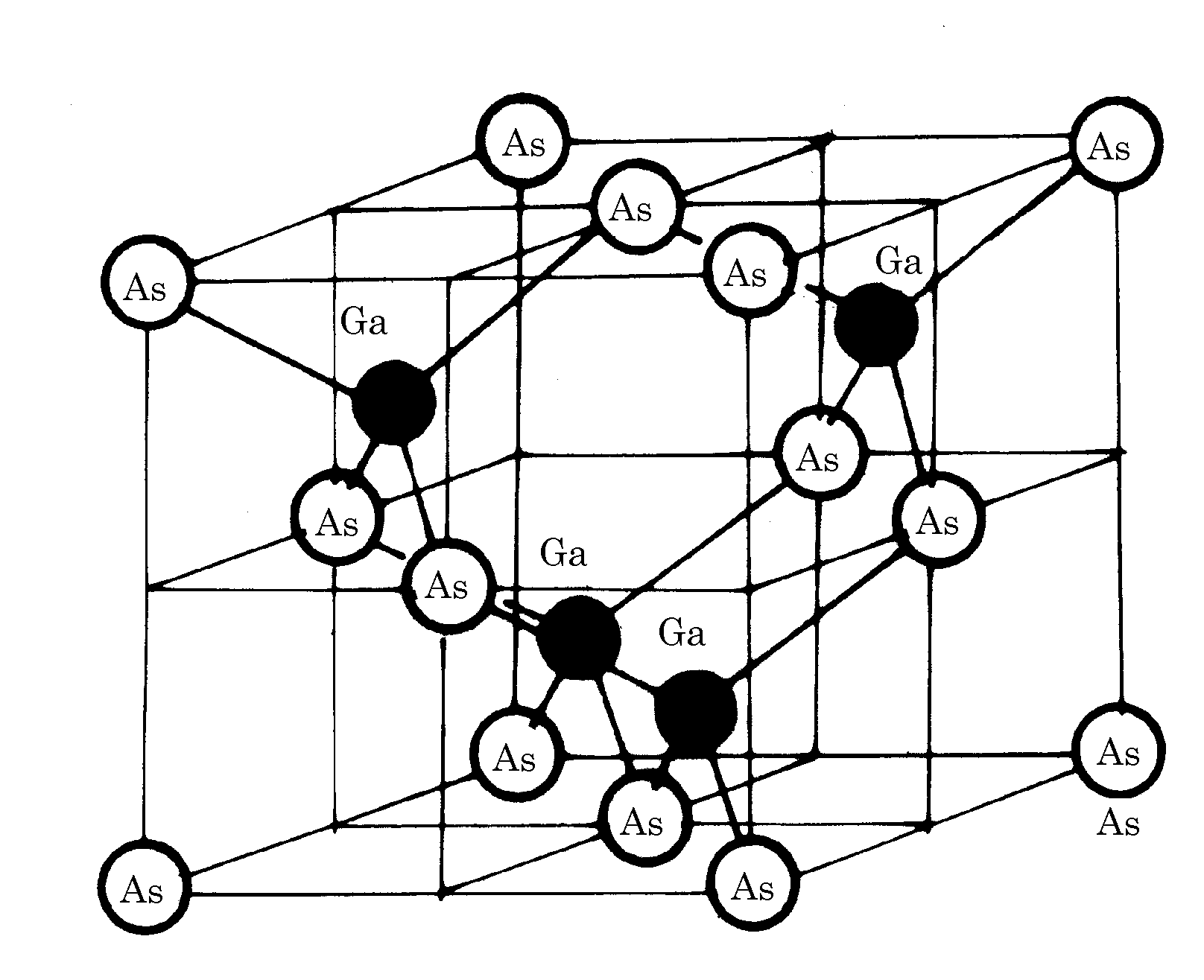

Misorientation is the difference in crystallographic orientation between two crystallites in a polycrystalline material. In crystalline materials, the orientation of a crystallite is defined by a transformation from a sample reference frame (i.e. defined by the direction of a rolling or extrusion process and two orthogonal directions) to the local reference frame of the crystalline lattice, as defined by the basis of the unit cell.

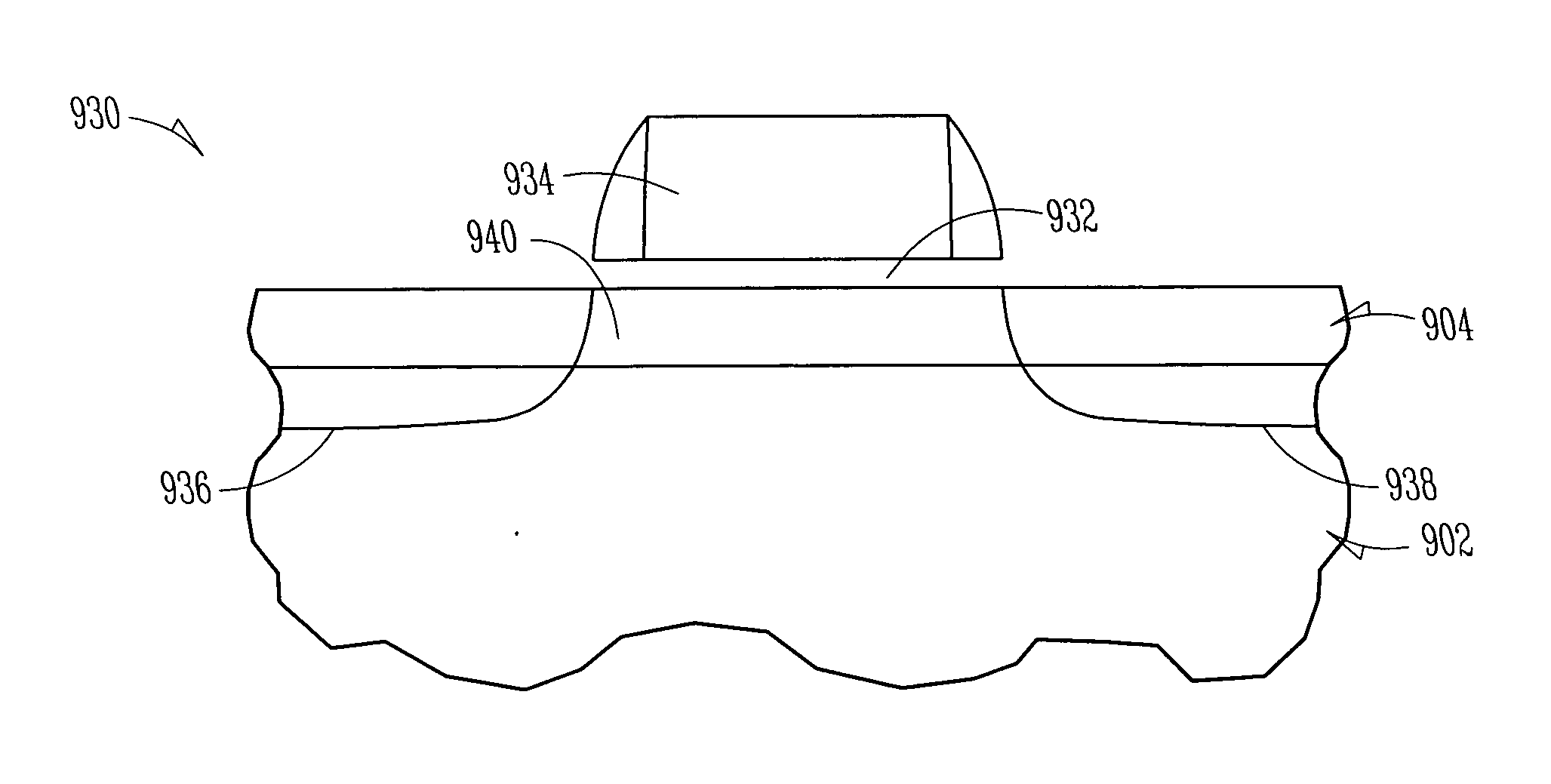

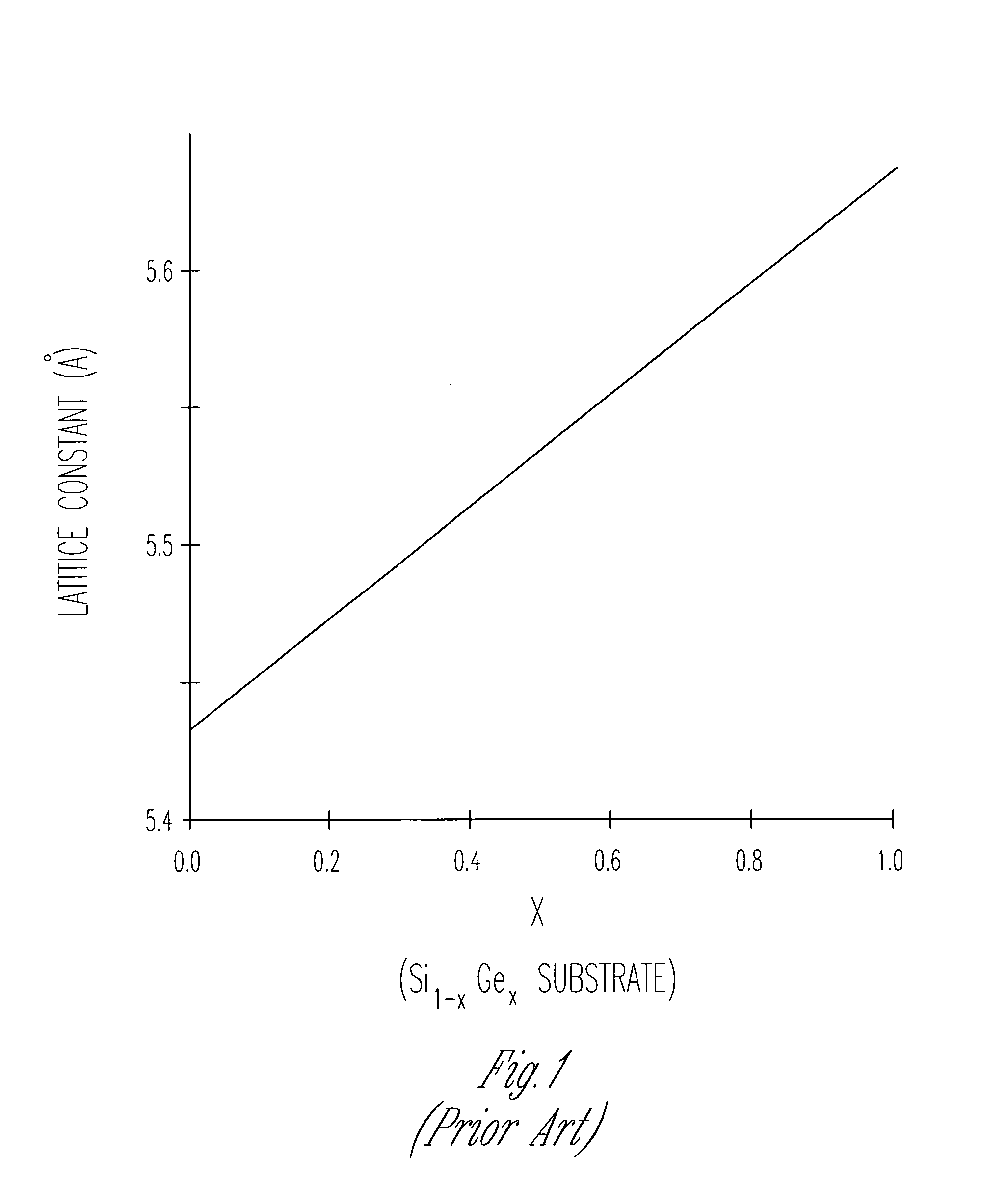

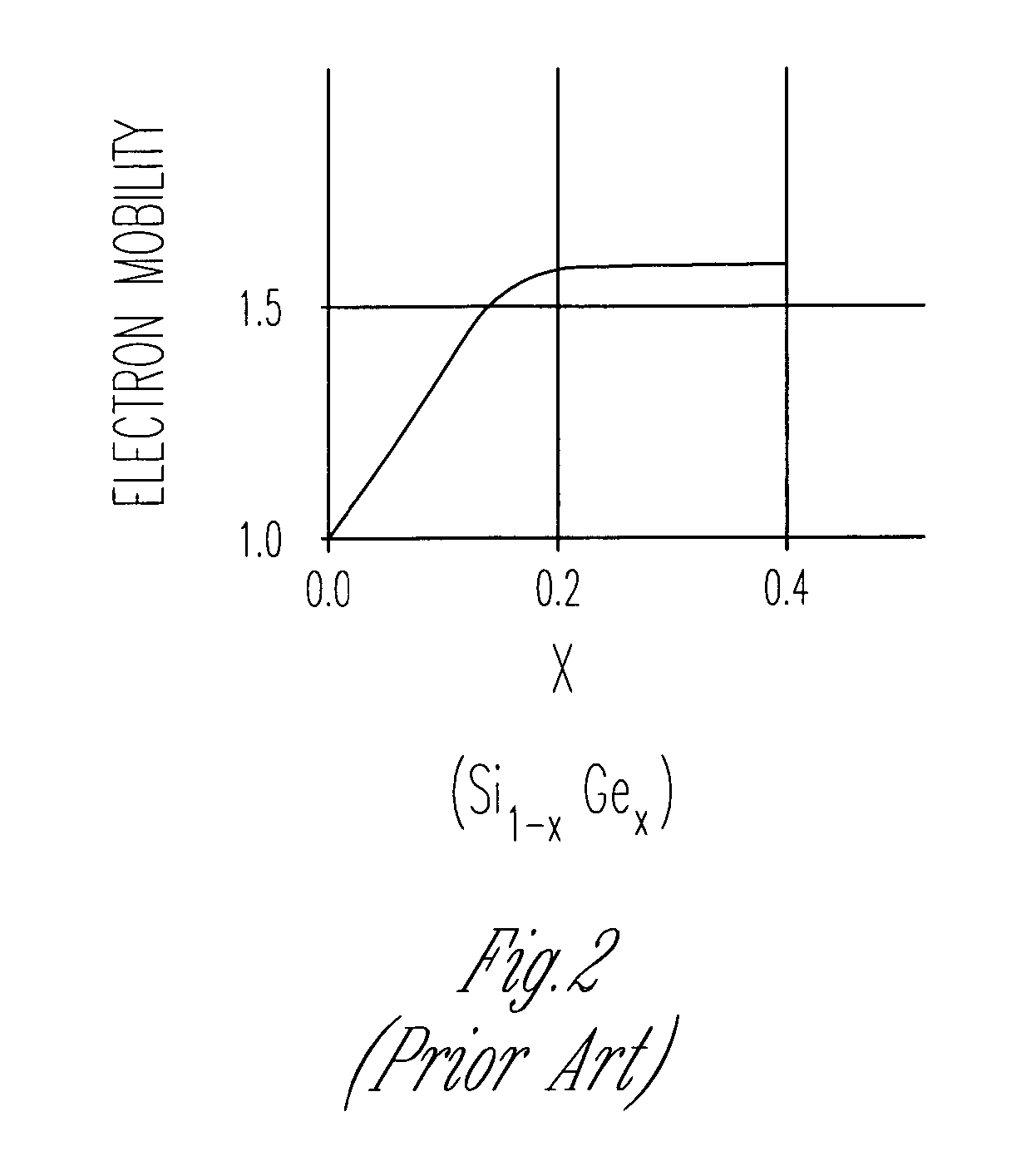

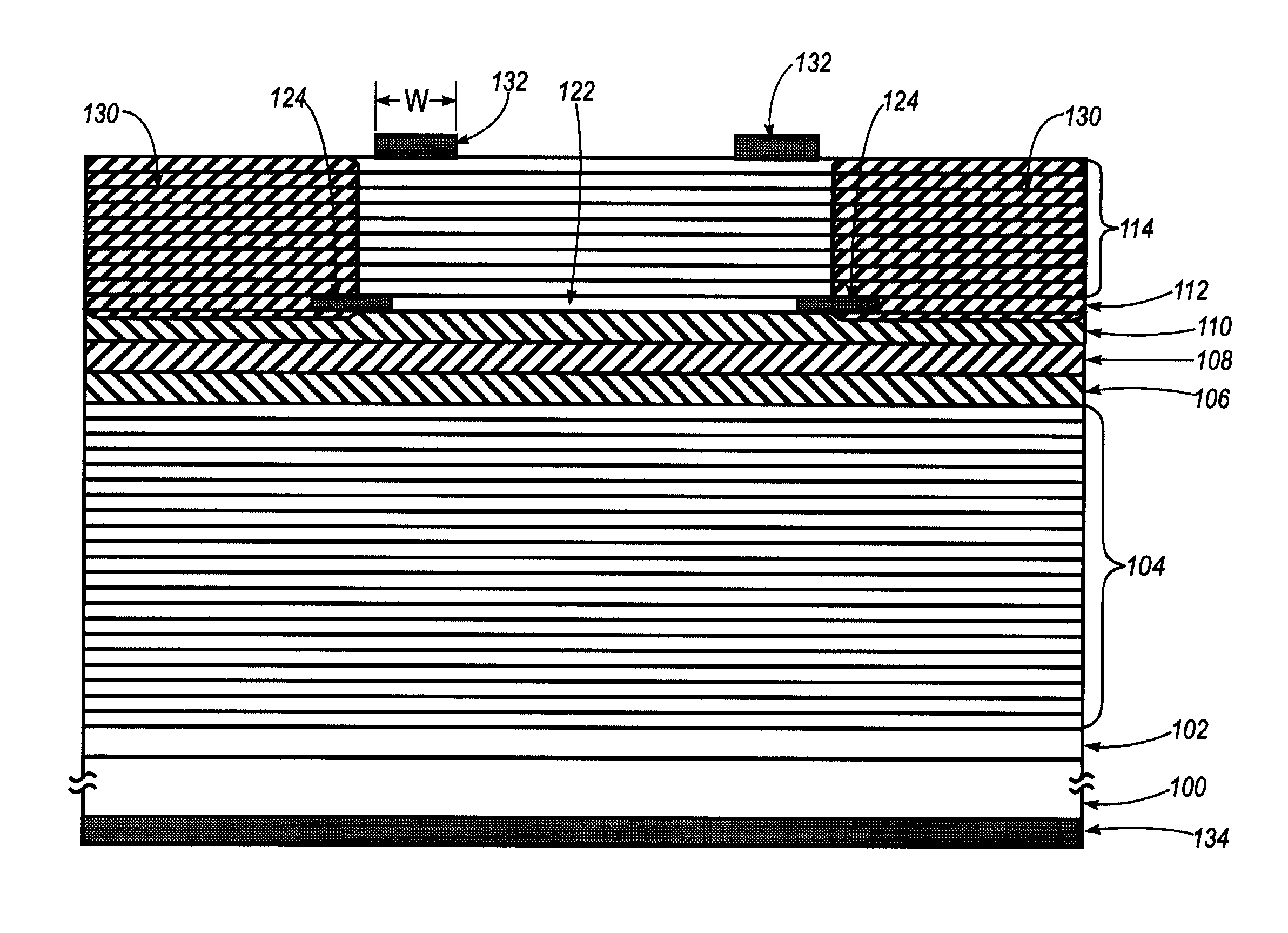

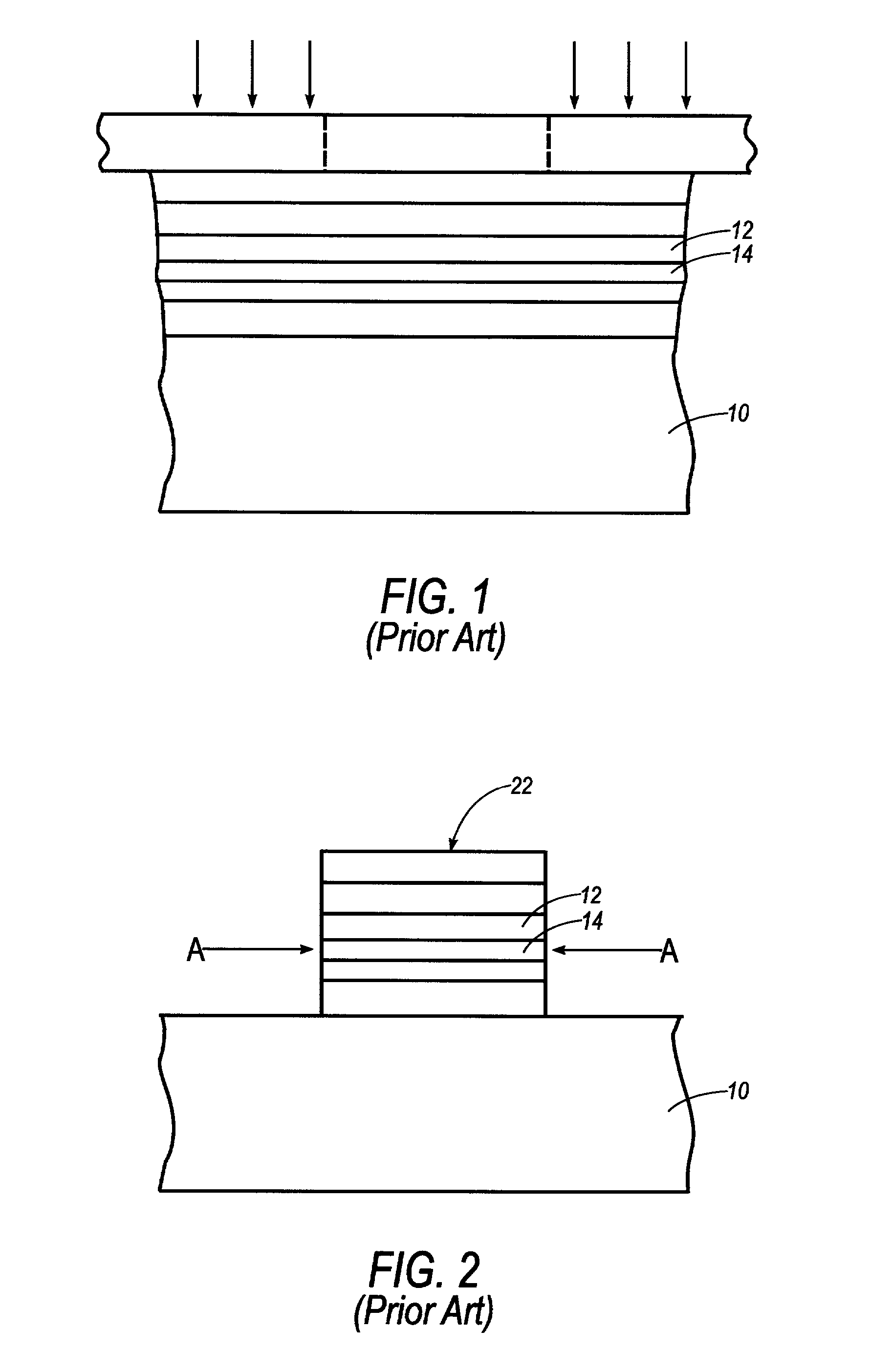

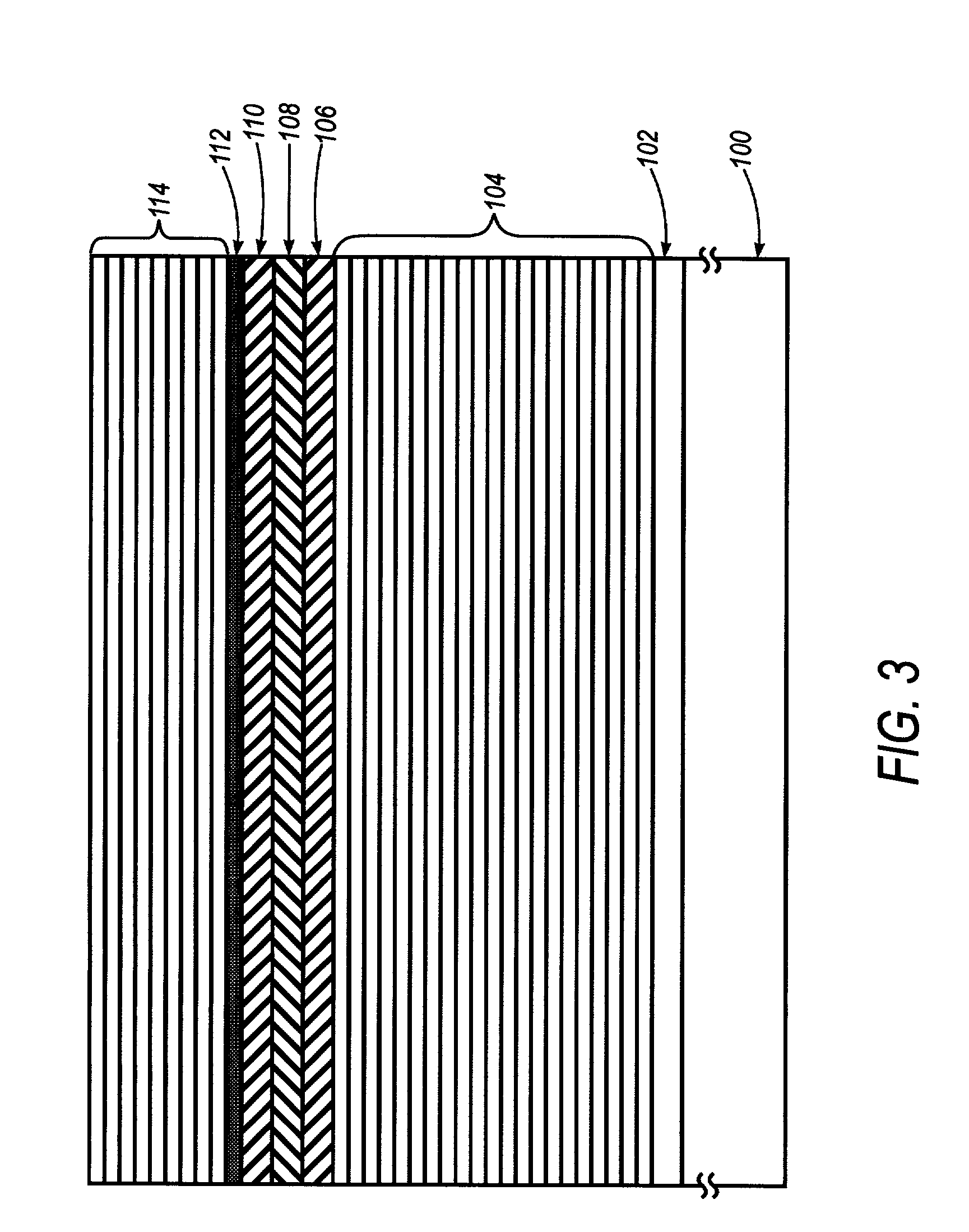

Strained semiconductor by wafer bonding with misorientation

InactiveUS20050023529A1Solid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureBiaxial strain

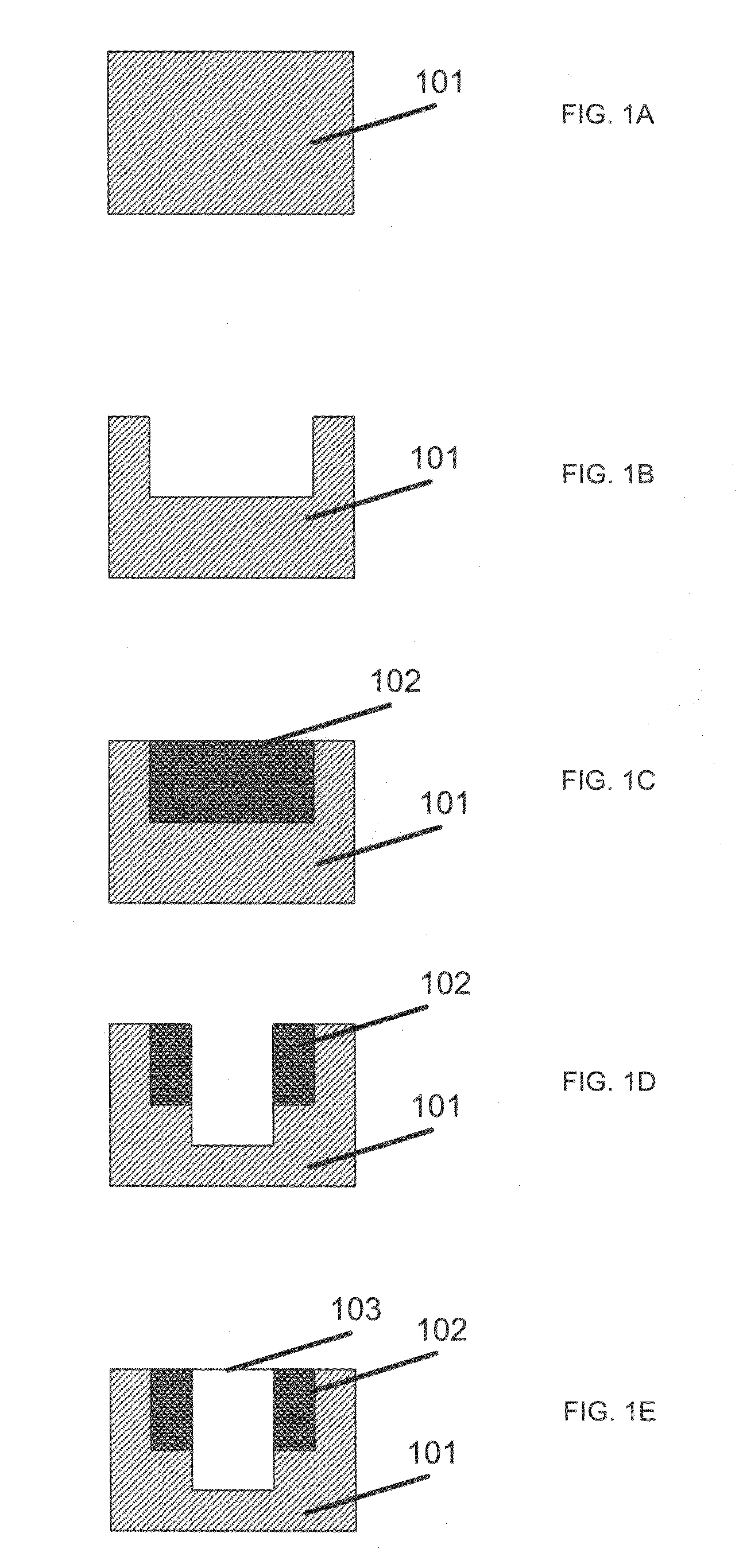

One aspect of the present invention relates to a method for forming a strained semiconductor structure. In various embodiments, at least two strong bonding regions are defined for a desired bond between a crystalline semiconductor membrane and a crystalline semiconductor substrate. The two strong bonding regions are separated by a weak bonding region. The membrane is bonded to the substrate at a predetermined misorientation. The membrane is pinned to the substrate in the strong bonding regions. The predetermined misorientation provides the membrane in the weak bonding region with a desired strain. In various embodiments, the membrane is bonded to the substrate at a predetermined twist angle to biaxially strain the membrane in the weak bonding region. In various embodiments, the membrane is bonded to the substrate at a predetermined tilt angle to uniaxially strain the membrane in the weak bonding region. Other aspects are provided herein.

Owner:MICRON TECH INC

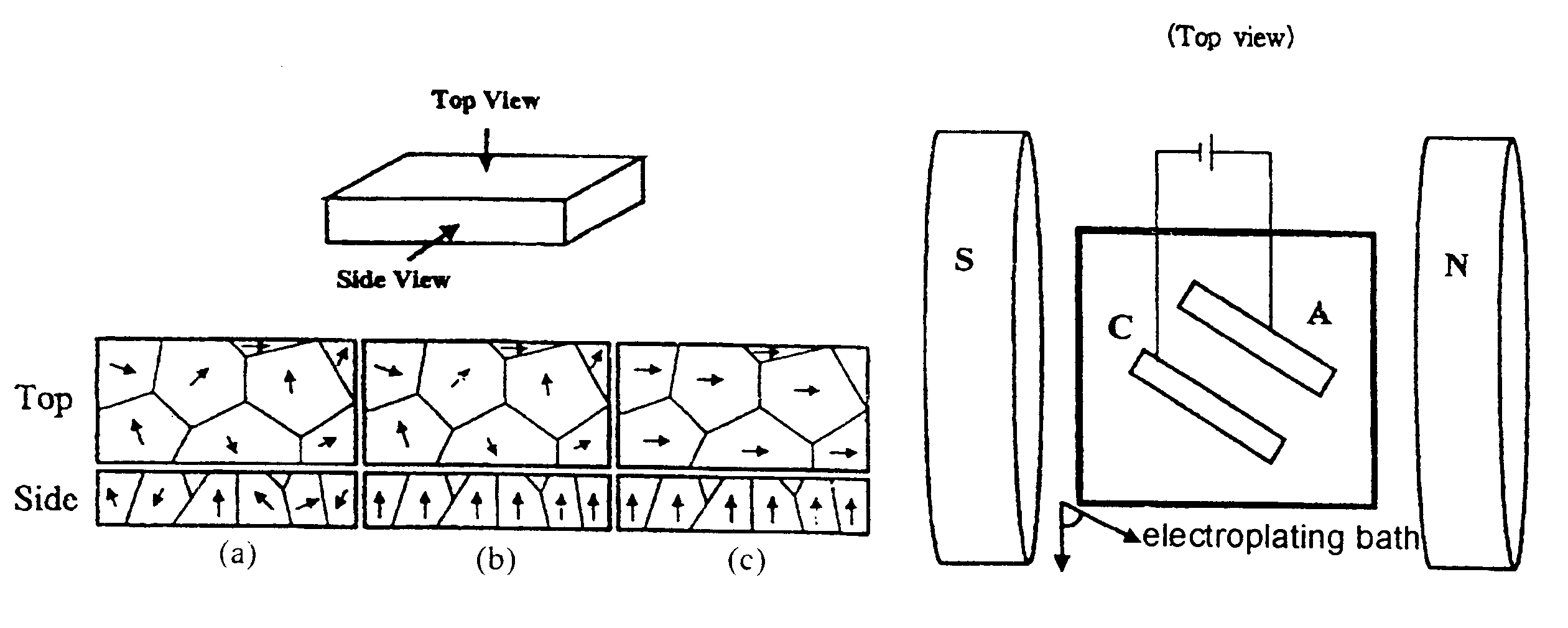

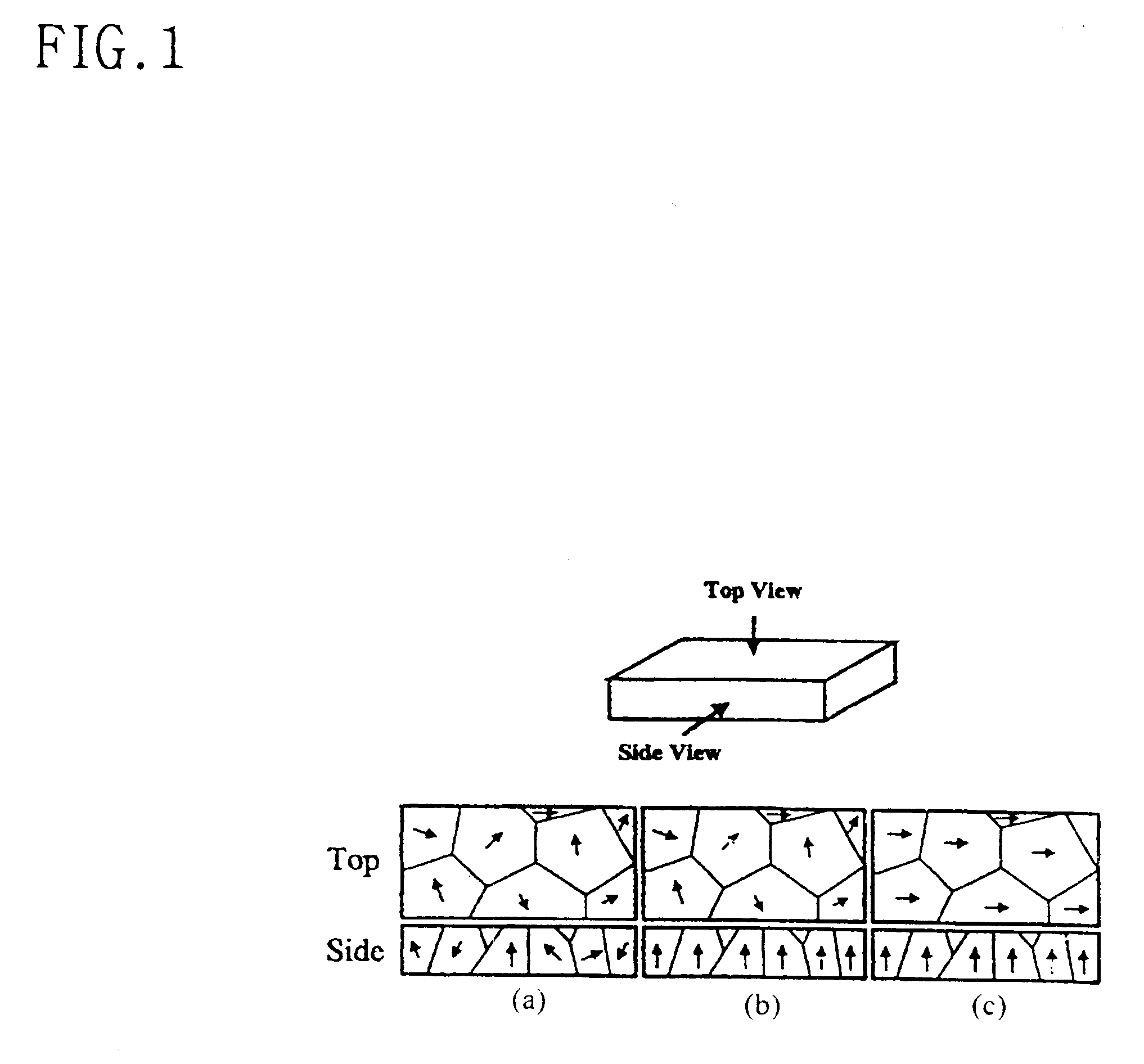

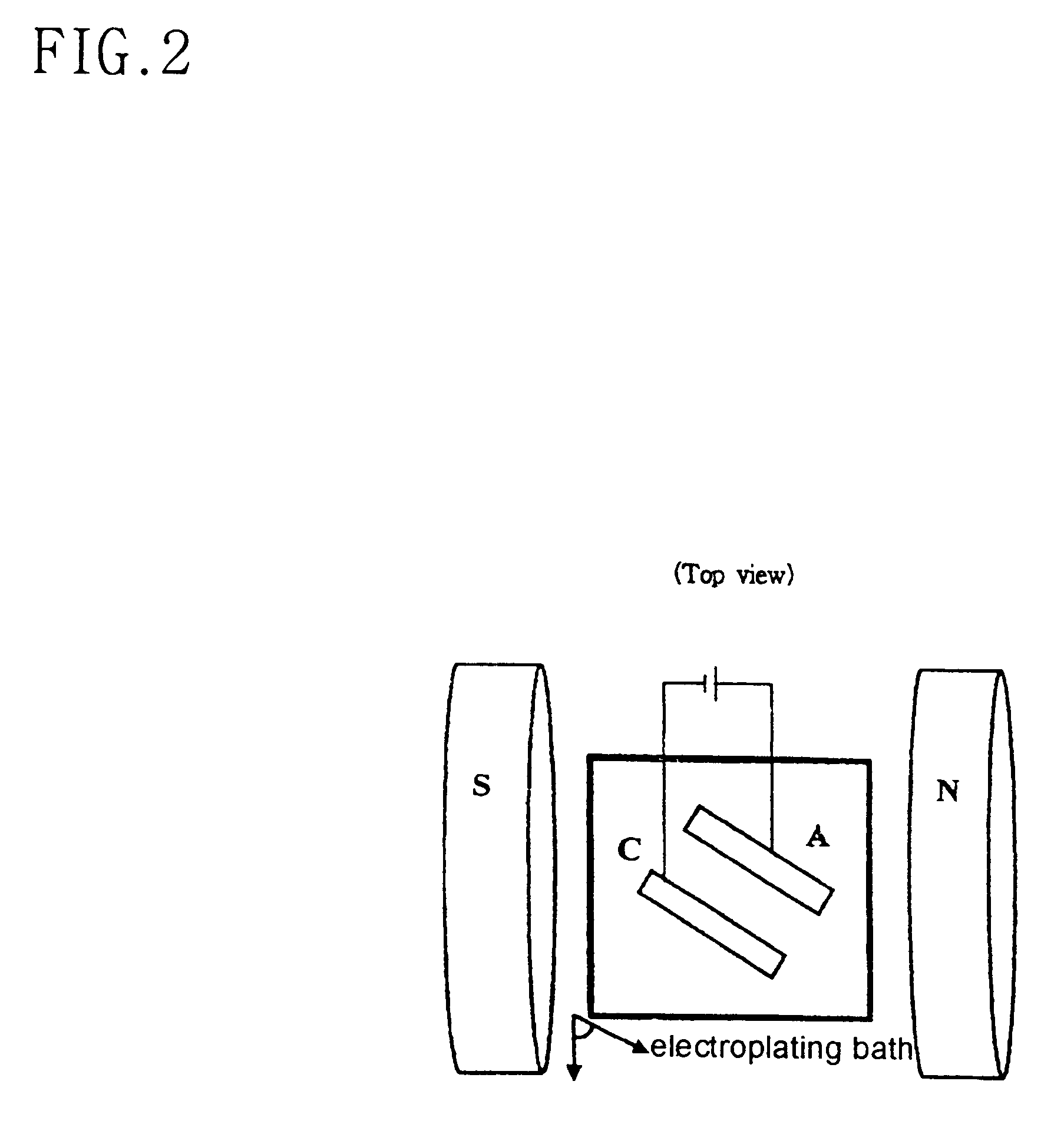

Electroplating process for preparing a Ni layer of biaxial texture

Disclosed is an Ni-plated layer of biaxial texture, which is formed by electroplating. In the Ni-plated layer,peaks measured on a theta-rocking curve have a FWHM of 7° or less in terms of the misorientation on the c-axis; and peaks measured on phi-scan have a FWHM of 21° or less in terms of the misorientation on the plane formed by the a-axis and the b-axis. Also, a process of electroplating a Ni layer are disclosed. The process comprises forming a Ni-plated layer of biaxial texture under a magnetic field by electroplating and subjecting the Ni-plated layer to thermal treatment to develop the biaxial texture. This electroplating process is expected to give a significant contribution to the development of the electroplating technology and to replace the vacuum deposition used for the preparation of thin film magnetic materials or thin film piezoelectric materials.

Owner:KOREA INST OF MASCH & MATERIALS

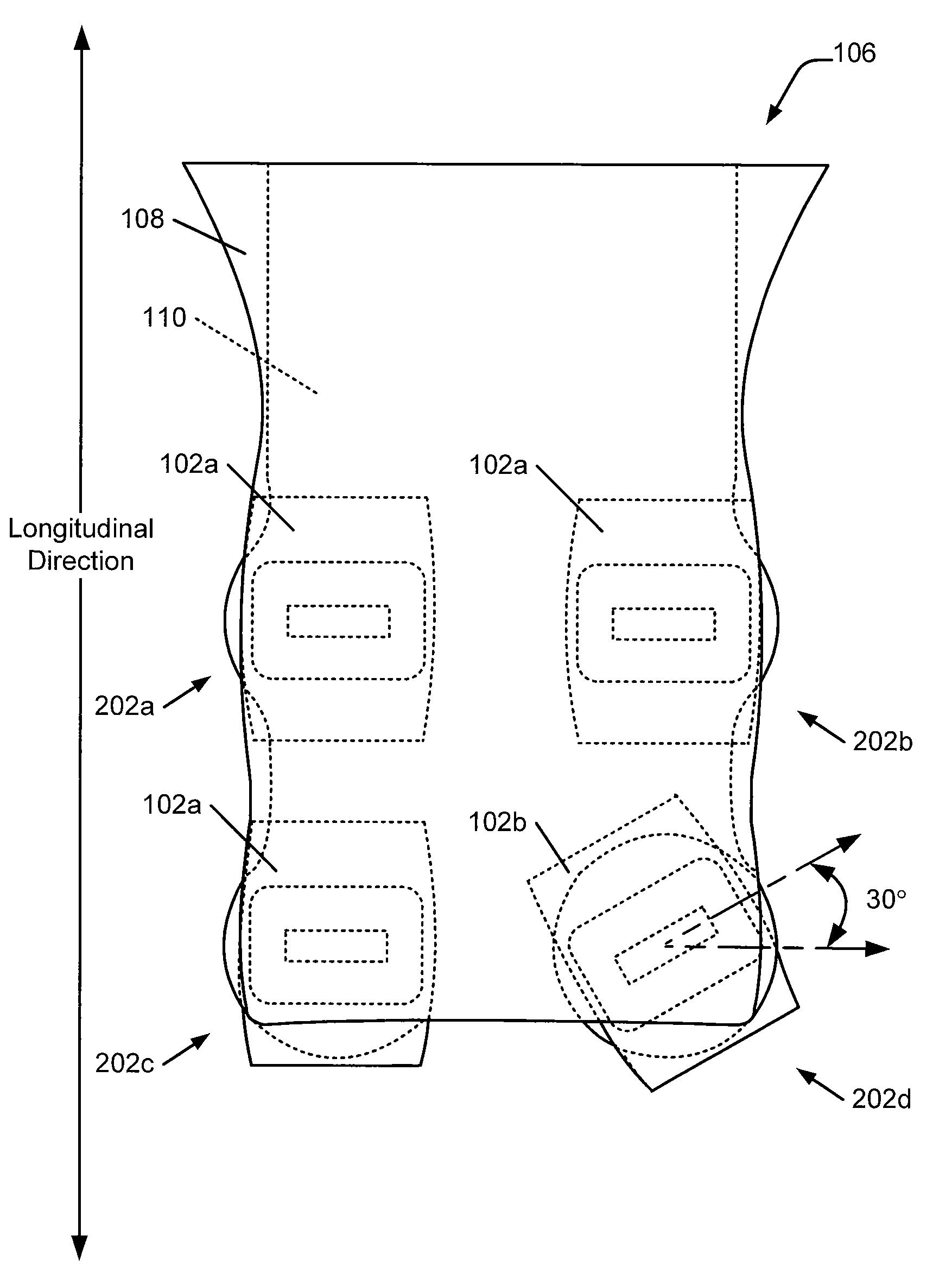

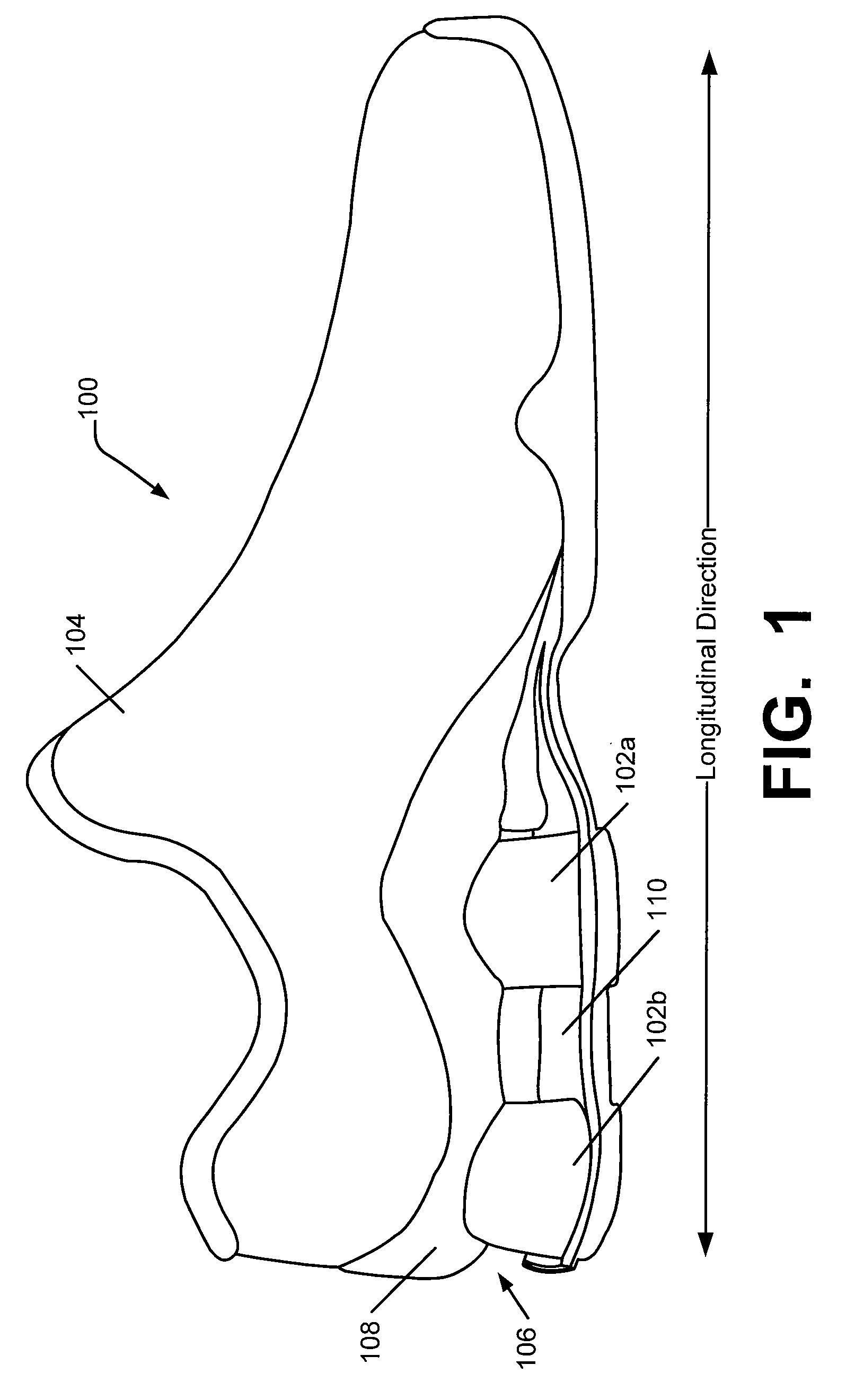

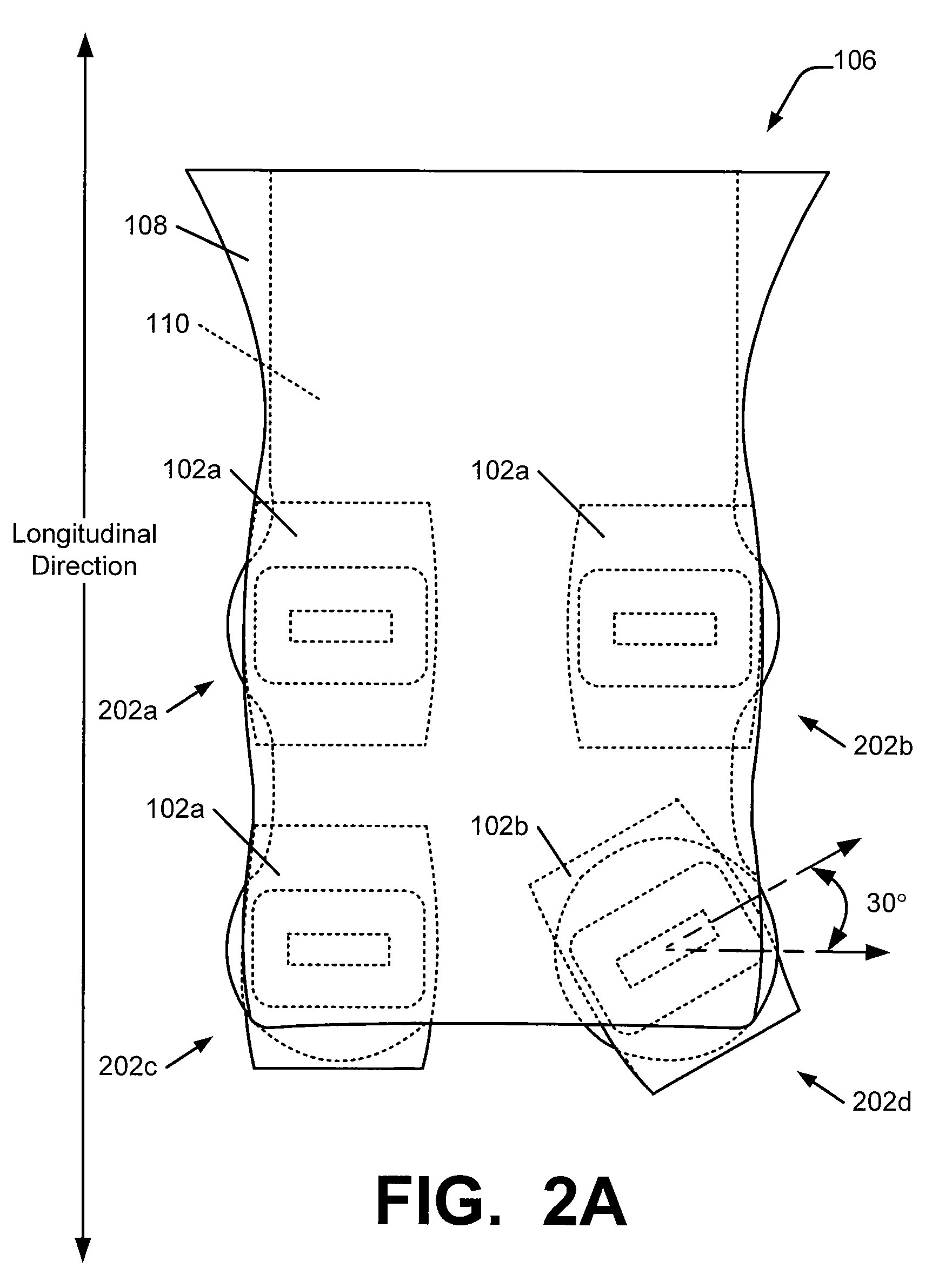

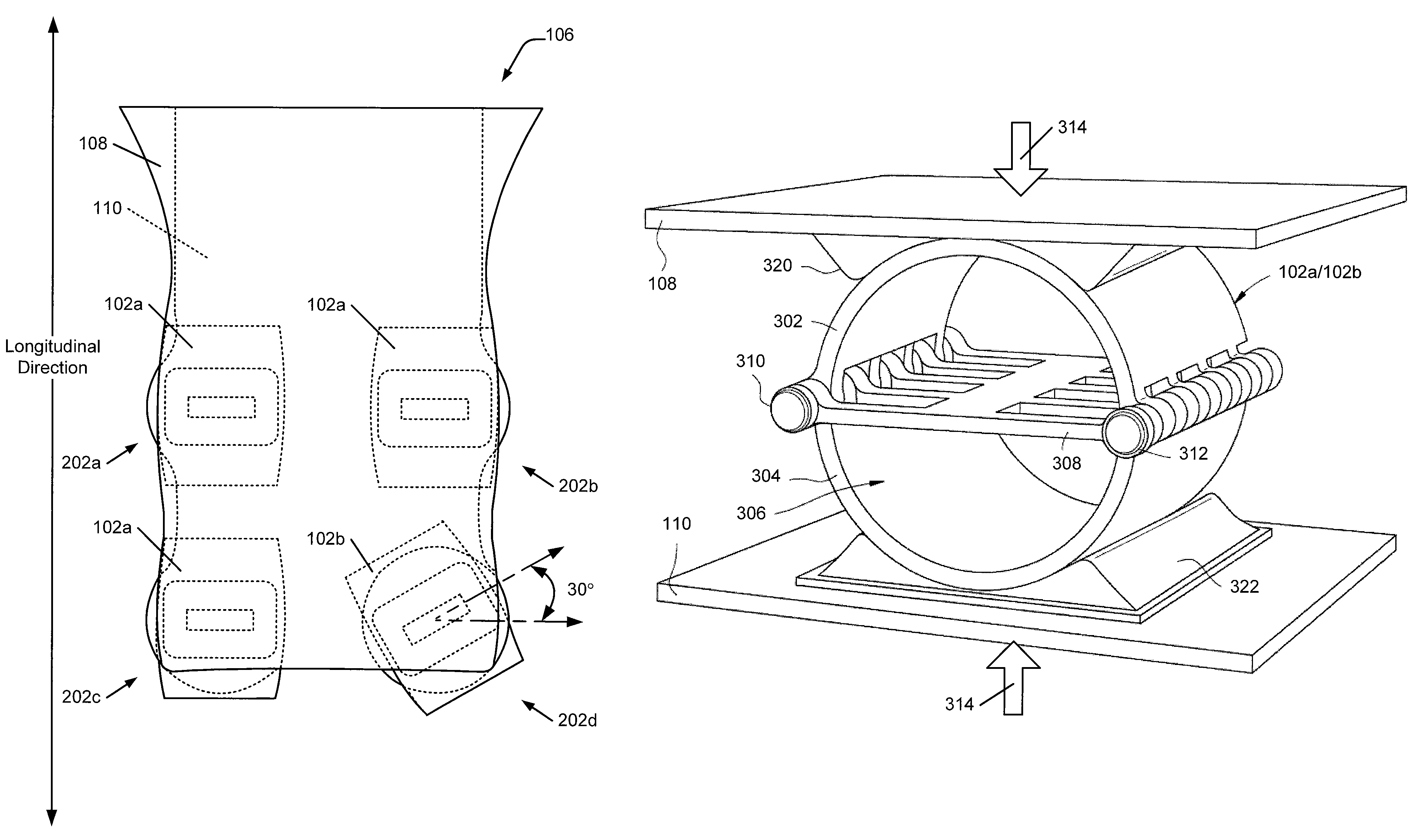

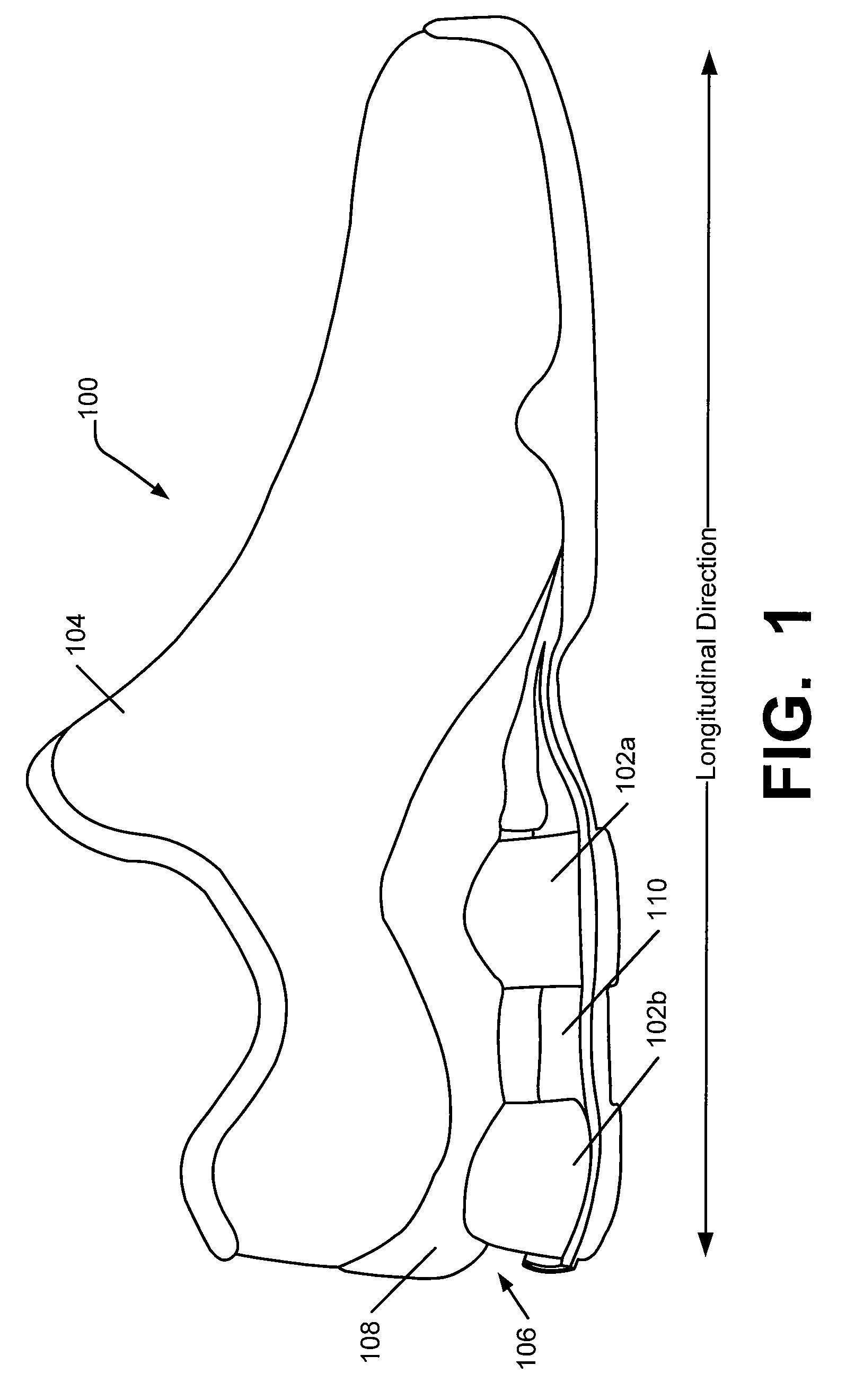

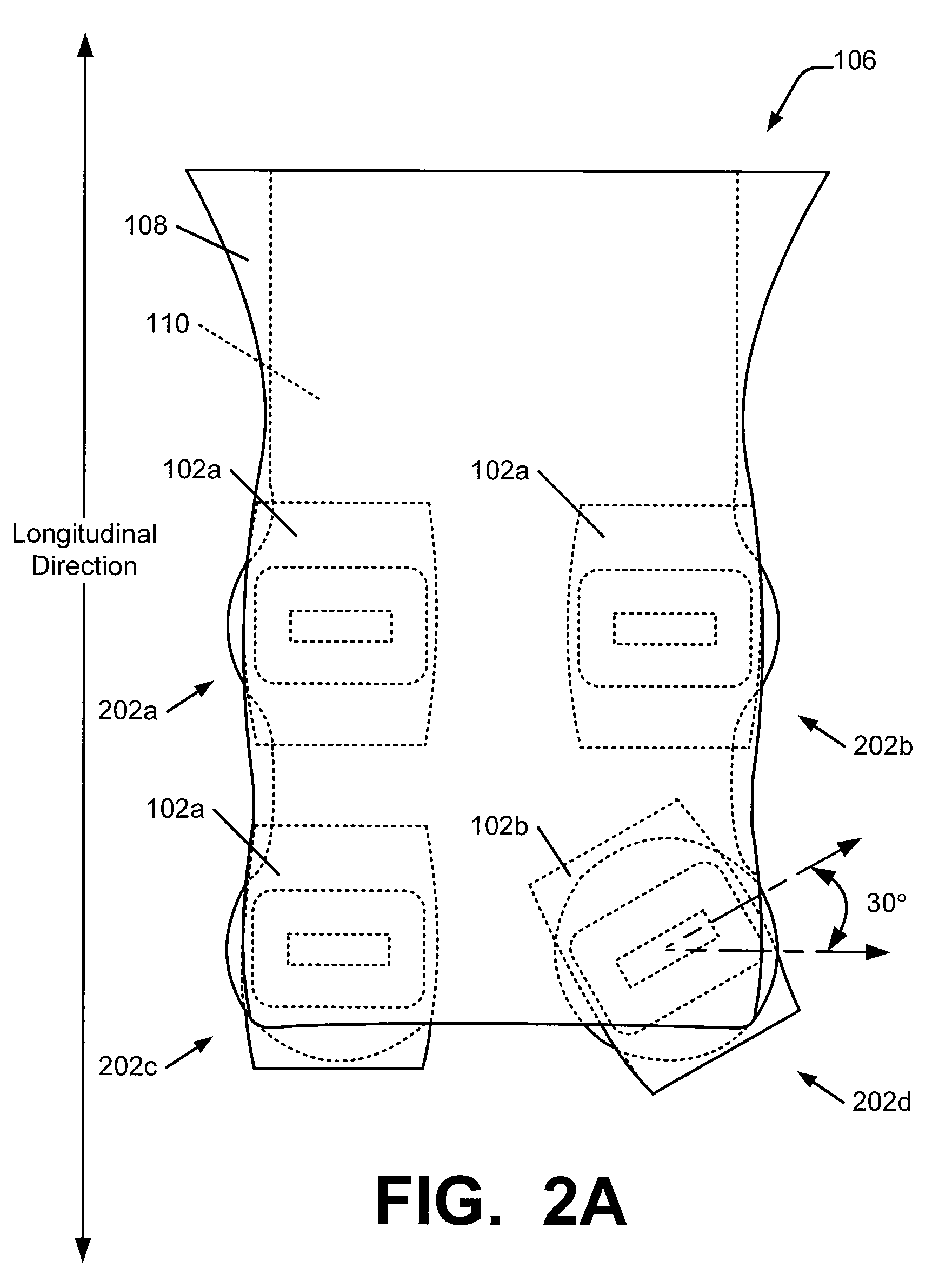

Articles of footwear and other foot-receiving devices including differently oriented impact-attenuation elements

ActiveUS20080016719A1Reduce or eliminate misorientation of the foot, and the fatigue and/or strainSolesHeelsUltrasound attenuationStep cycle

Impact-attenuation systems, e.g., for use in footwear, can help control foot positioning during a step cycle, e.g., to help reduce or eliminate misorientation of the foot, and the fatigue and / or strain that may result from such misorientation. Articles of footwear including such impact-attenuation systems may include: (a) an upper member; and (b) a sole structure engaged with the upper member. The sole structure may include: (i) a first impact-attenuating member located in a heel portion of the foot-supporting member, and (ii) a second, separate impact-attenuating member located at a rear, lateral heel portion. The second impact-attenuating member may be arranged at a different orientation with respect to the longitudinal direction as compared to the first orientation. Impact-attenuation systems having the characteristics described above, as well as methods of making and using products containing such systems, also are described.

Owner:NIKE INC

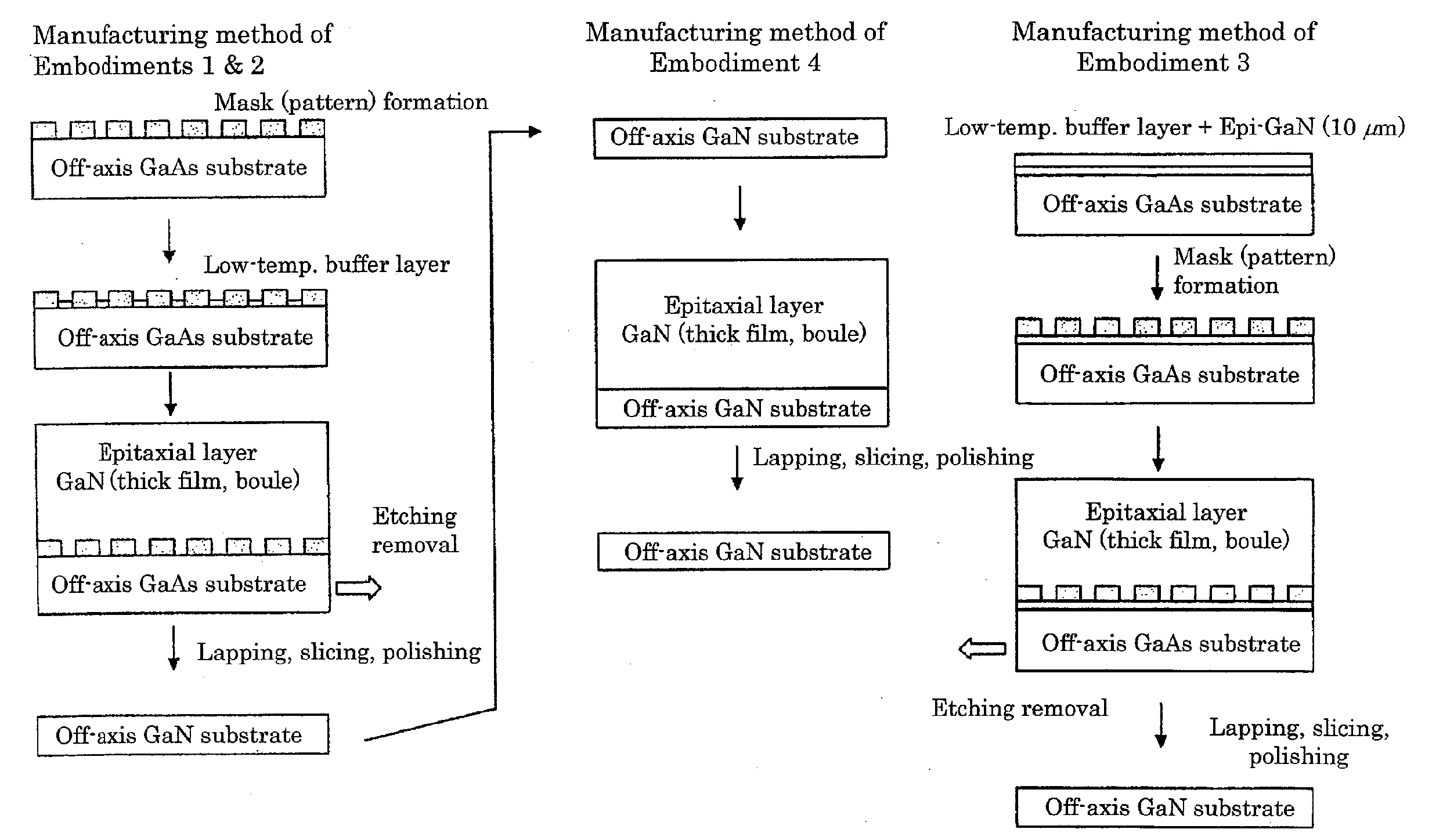

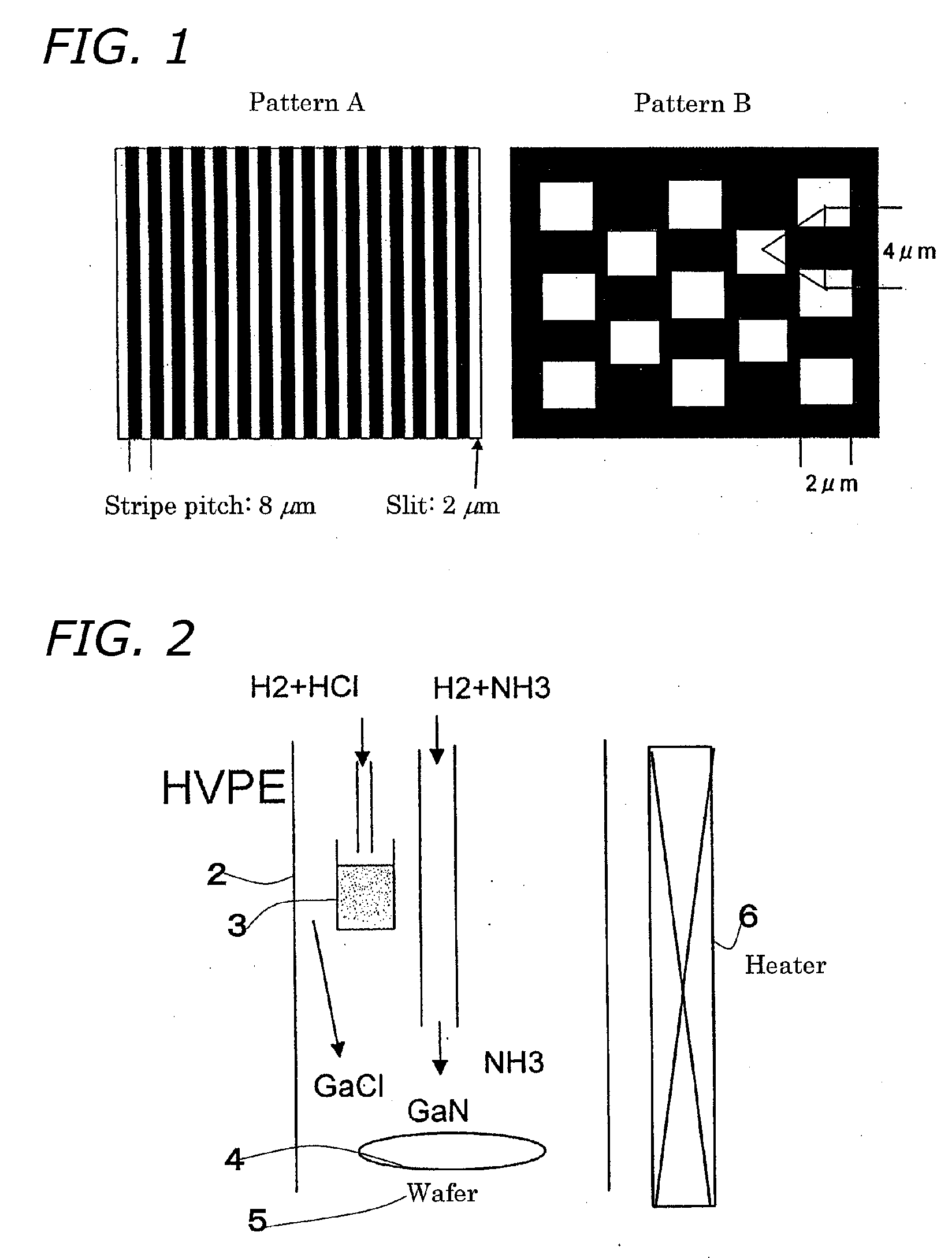

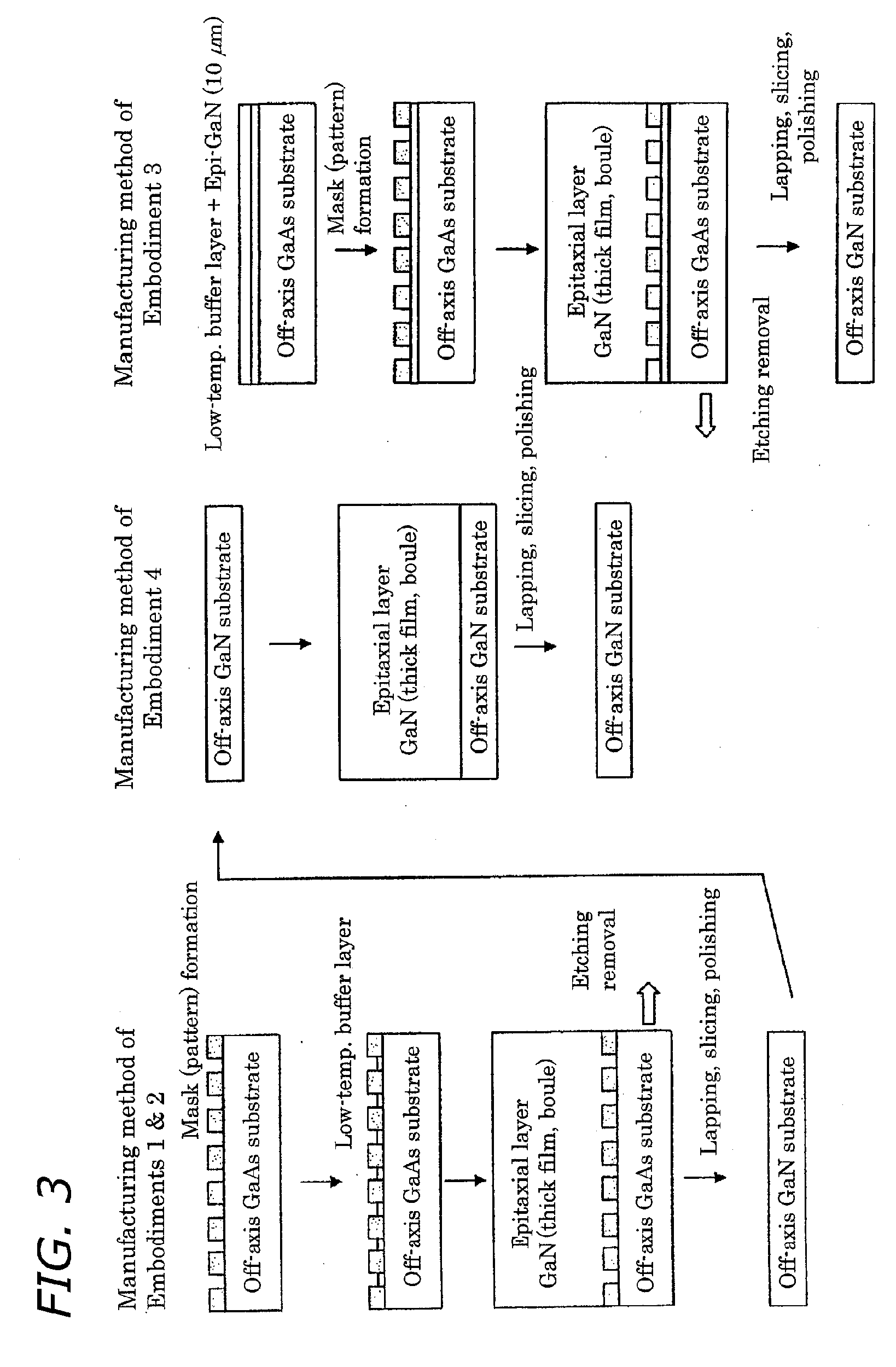

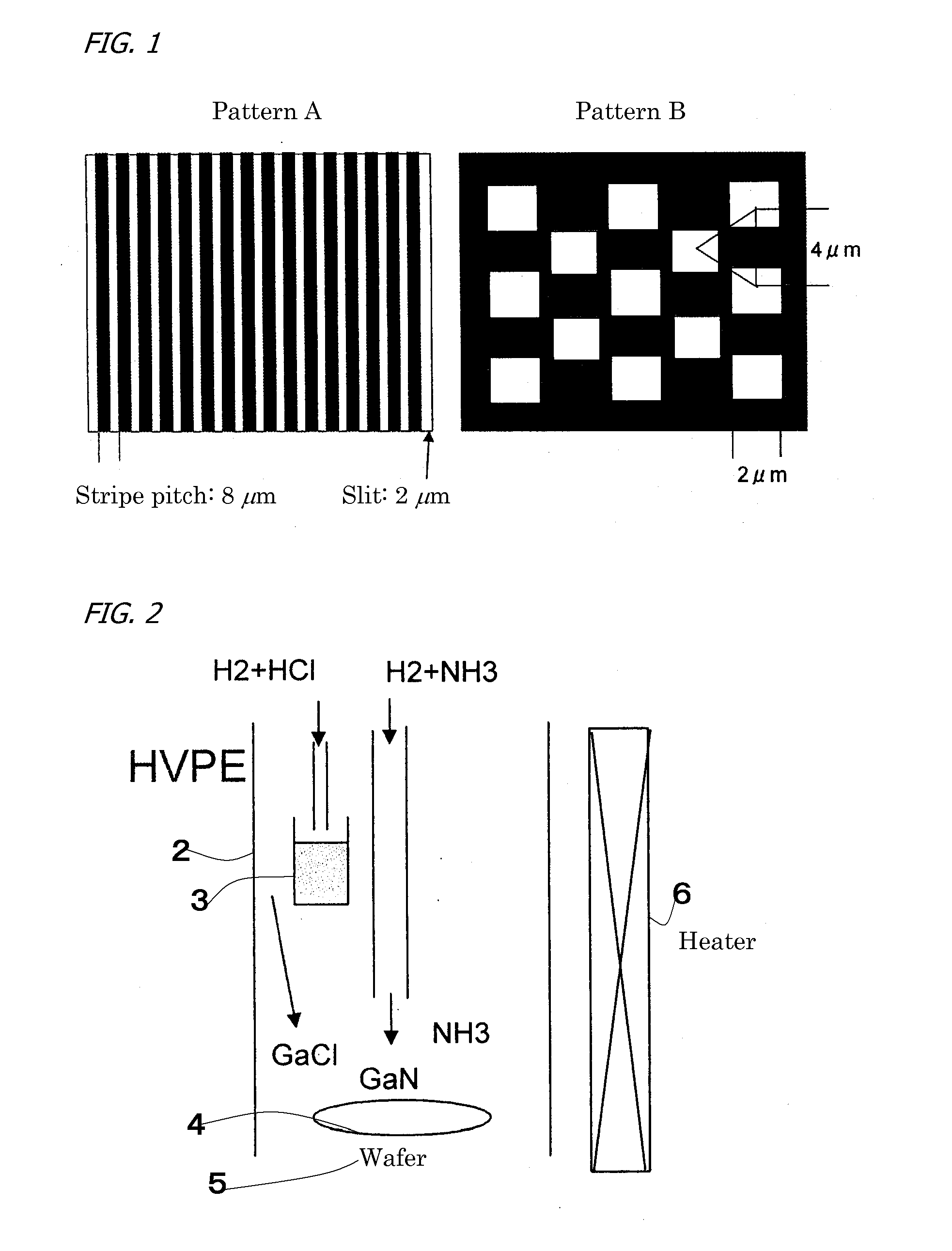

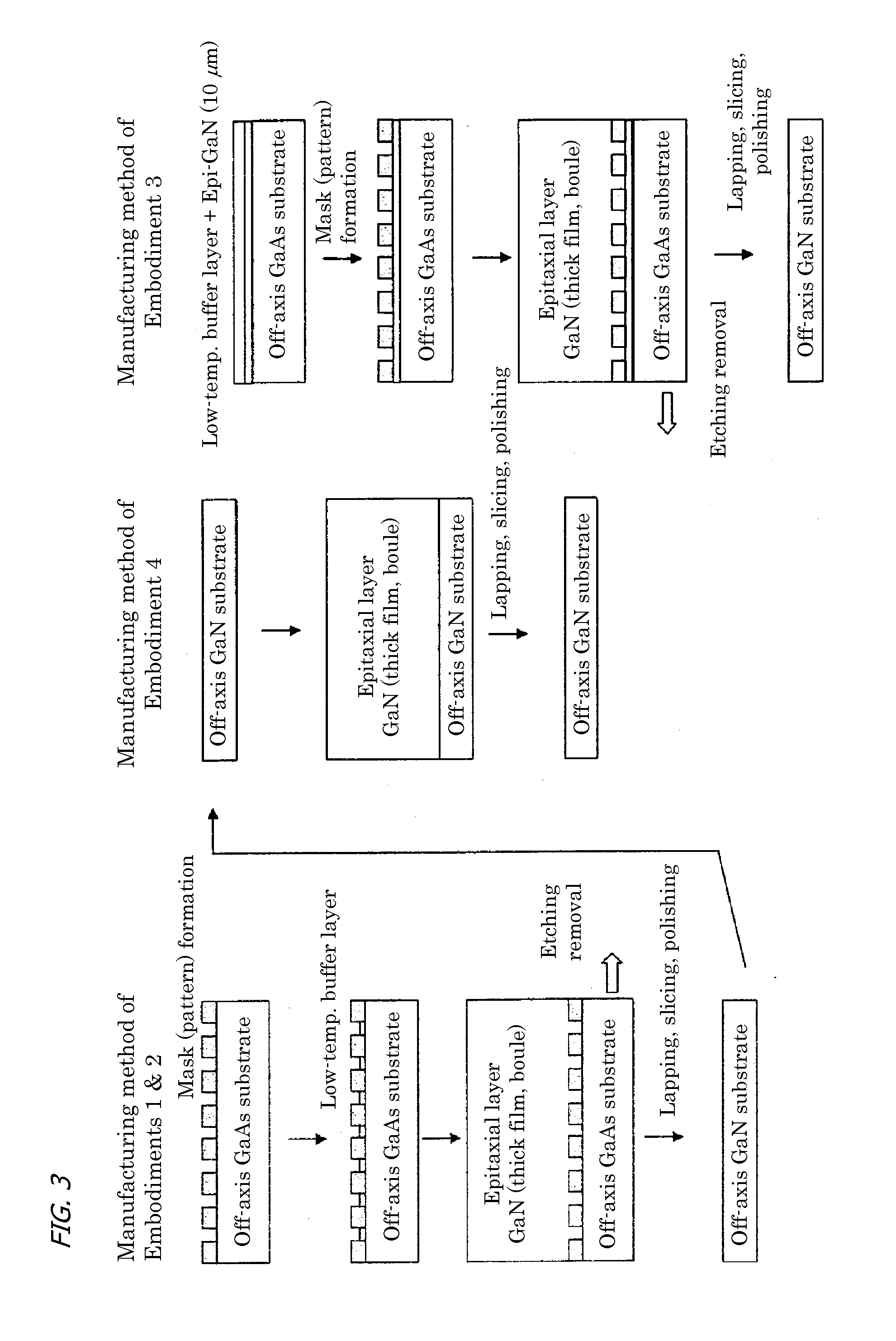

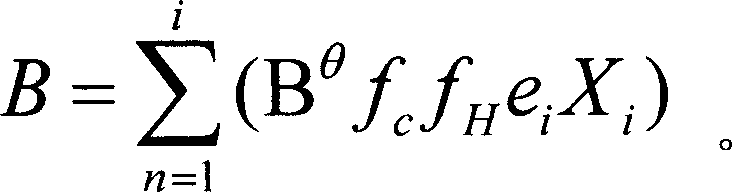

Method of Manufacturing Single-Crystal GaN Substrate, and Single-Crystal GaN Substrate

InactiveUS20050208687A1Polycrystalline material growthNon-mechanical controlsGas phaseSingle crystal substrate

Manufacture at lower cost of off-axis GaN single-crystal freestanding substrates having a crystal orientation that is displaced from (0001) instead of (0001) exact. With an off-axis (111) GaAs wafer as a starting substrate, GaN is vapor-deposited onto the starting substrate, which grows GaN crystal that is inclined at the same off-axis angle and in the same direction as is the starting substrate. Misoriented freestanding GaN substrates may be manufactured, utilizing a misoriented (111) GaAs baseplate as a starting substrate, by forming onto the starting substrate a mask having a plurality of apertures, depositing through the mask a GaN single-crystal layer, and then removing the starting substrate. The manufacture of GaN crystal having a misorientation of 0.1° to 25° is made possible.

Owner:SUMITOMO ELECTRIC IND LTD

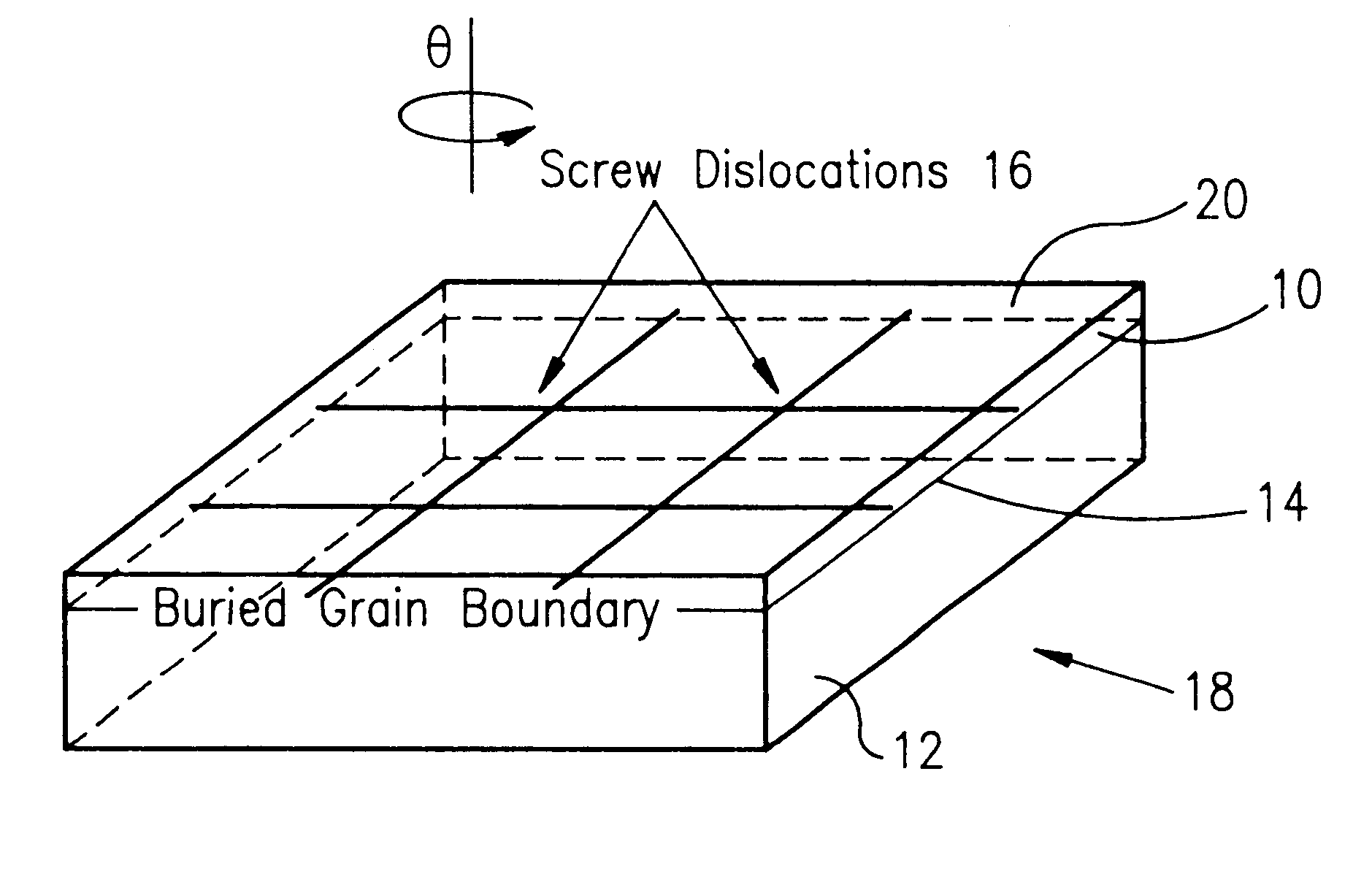

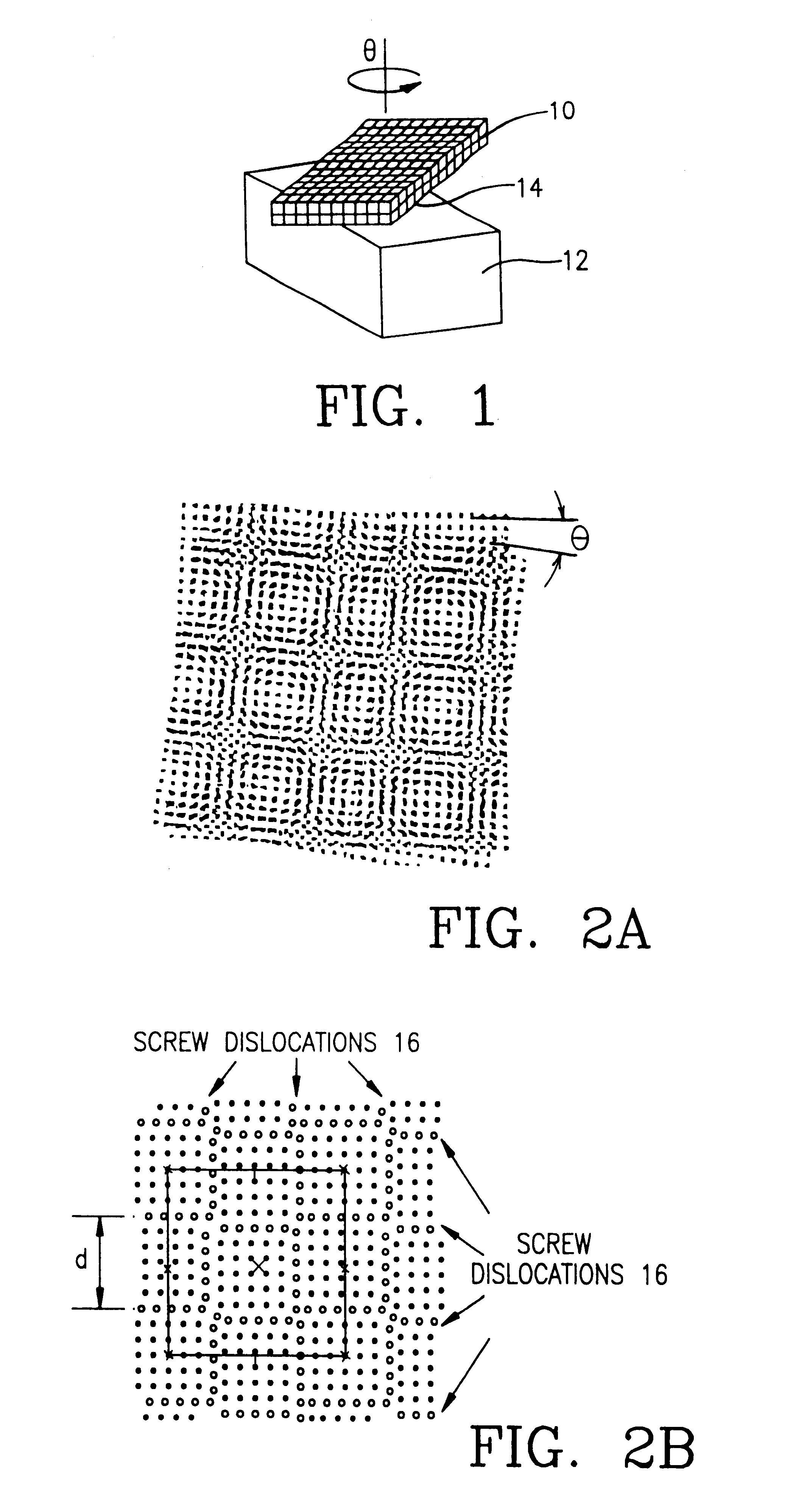

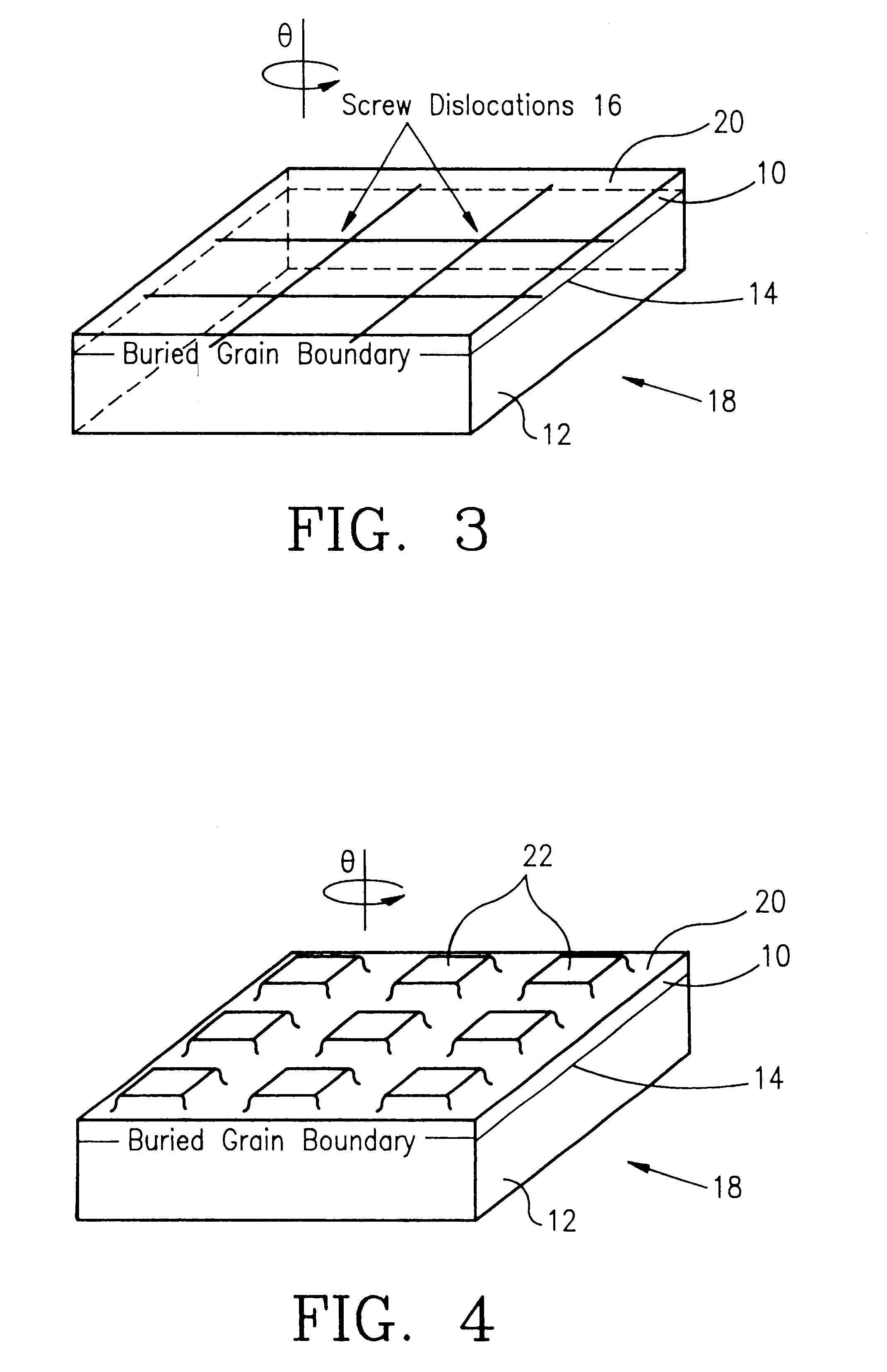

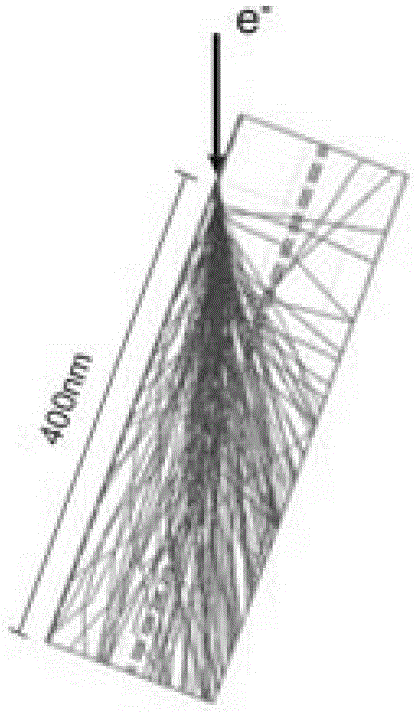

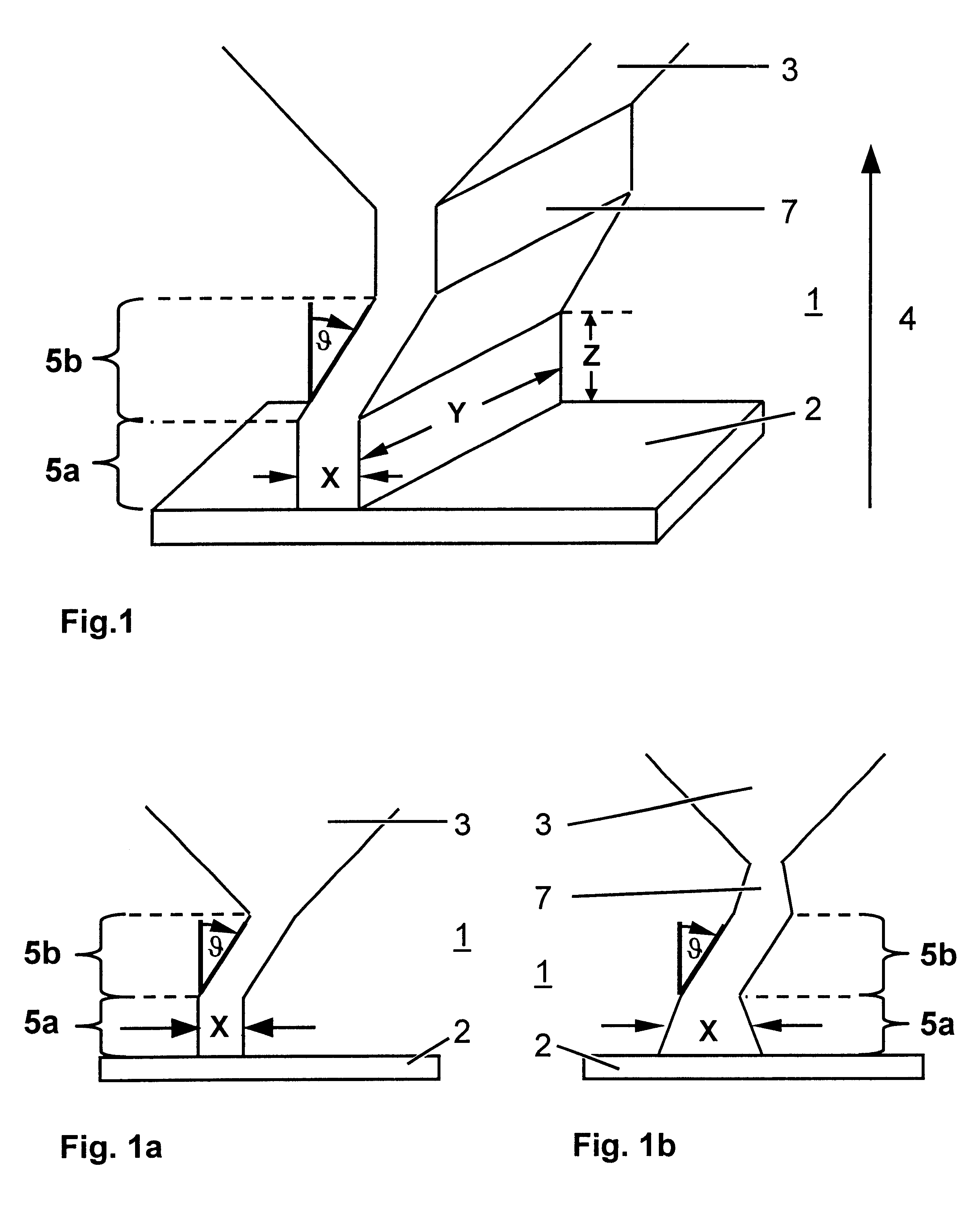

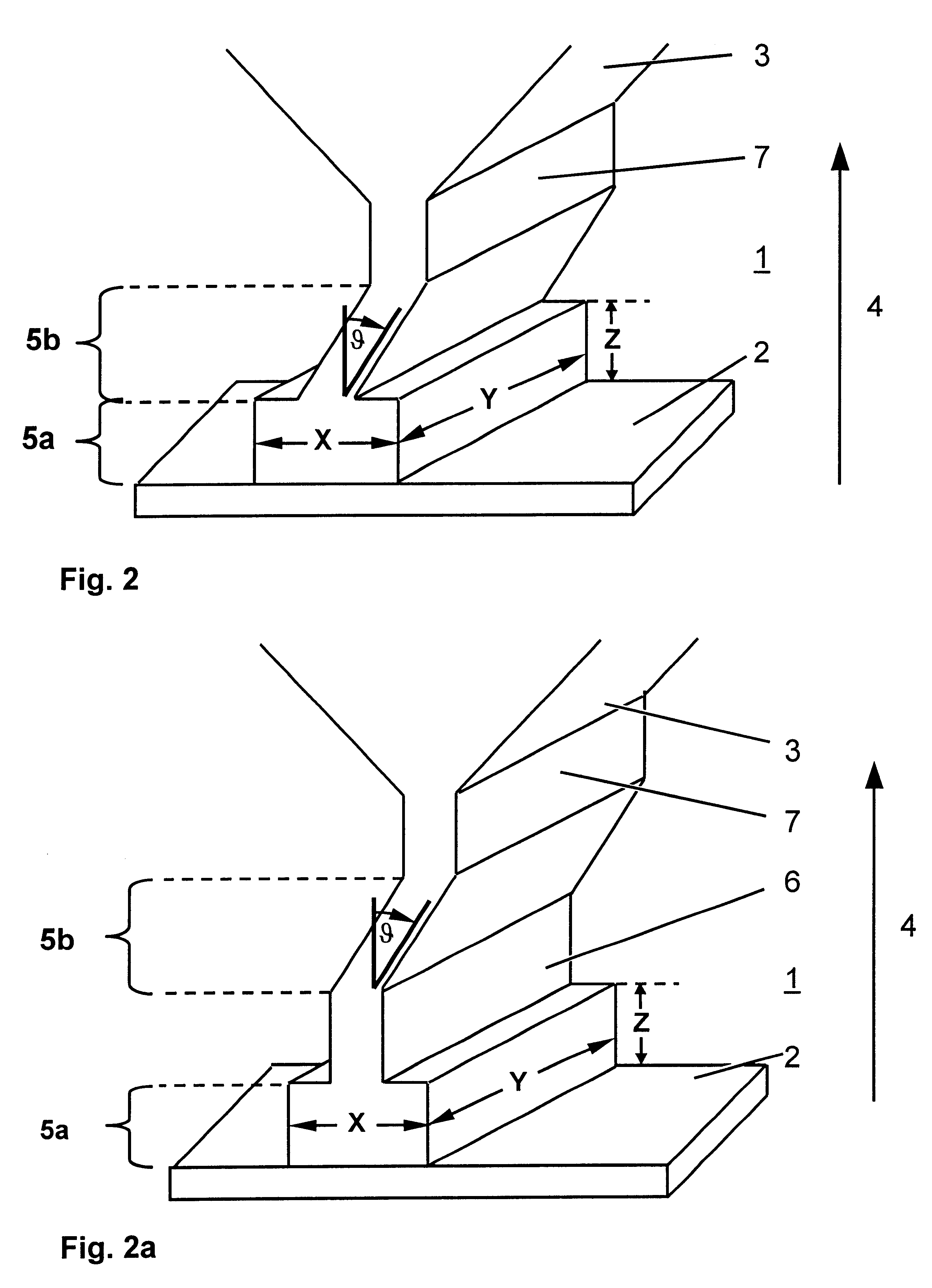

Fabrication of periodic surface structures with nanometer-scale spacings

The periodic stress and strain fields produced by a pure twist grain boundary between two single crystals bonded together in the form of a bicrystal are used to fabricate a two-dimensional surface topography with controllable, nanometer-scale feature spacings (e.g., from 50 nanometers down to 1.5 nanometers). The spacing of the features is controlled by the misorientation angle used during crystal bonding. One of the crystals is selected to be thin, on the order of 5-100 nanometers. A buried periodic array of screw dislocations is formed at the twist grain boundary. To bring the buried periodicity to the surface, the thin single crystal is etched to reveal an array of raised elements, such as pyramids, that have nanometer-scale dimensions. The process can be employed with numerous materials, such as gold, silicon and sapphire. In addition, the process can be used with different materials for each crystal such that a periodic array of misfit dislocations is formed at the interface between the two crystals.

Owner:CORNELL RES FOUNDATION INC

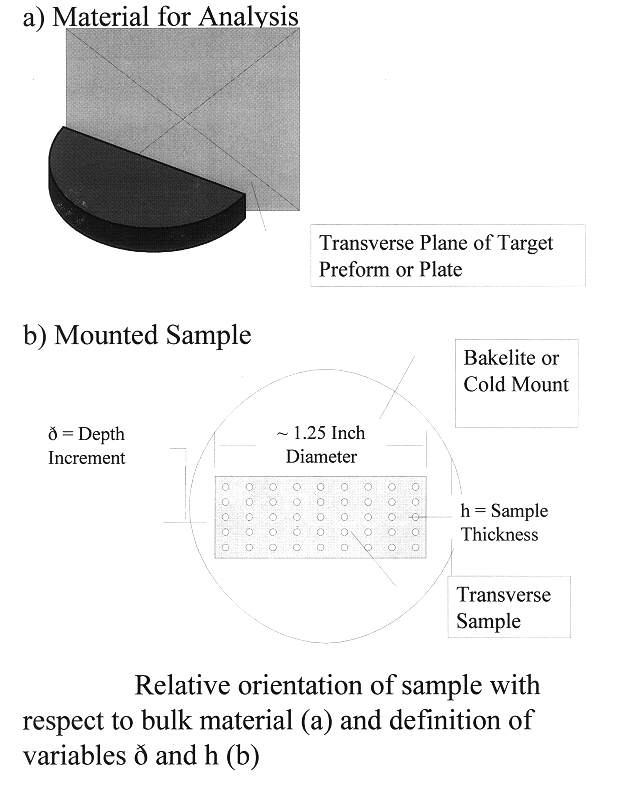

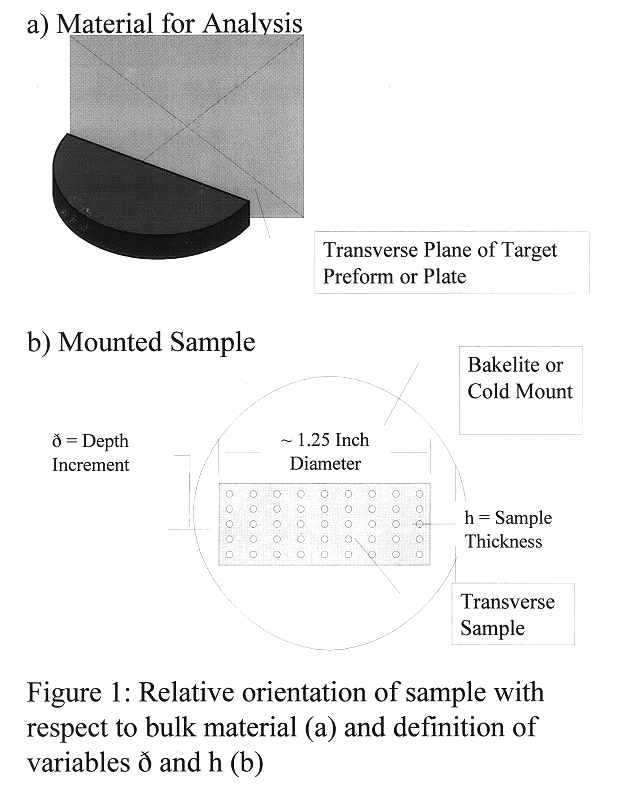

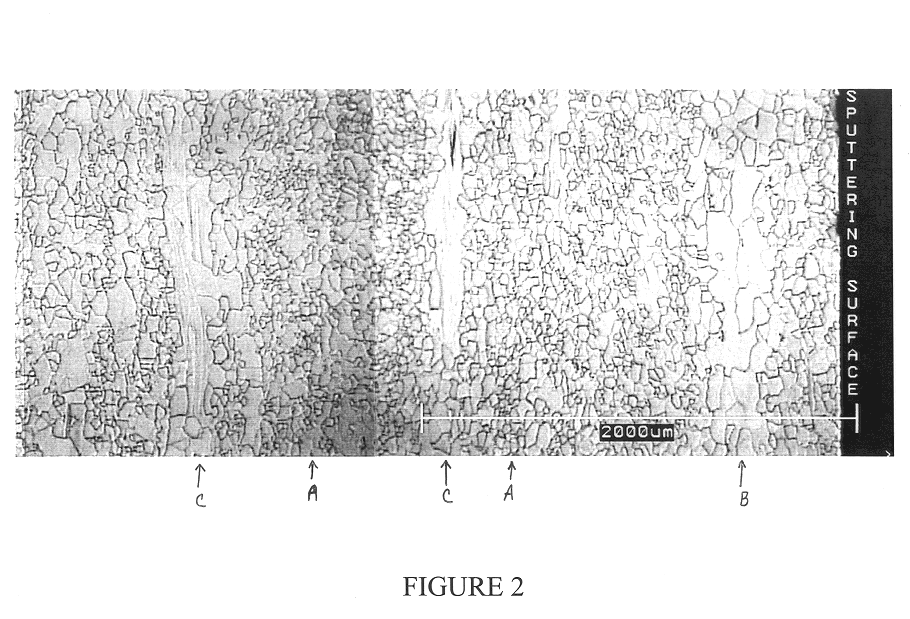

Method for quantifying the texture homogeneity of a polycrystalline material

InactiveUS6462339B1Desirable performanceUndesirable performanceElectric discharge tubesVacuum evaporation coatingTexture gradientPolycrystalline material

A method for quantifying the texture homogeneity of a polycrystalline material is described. The method involves selecting a reference pole orientation; scanning in increments a cross-section of the polycrystalline material having a thickness with scanning orientation imaging microscopy or other measuring technique to obtain actual pole orientations of a multiplicity of grains throughout the cross-section of the polycrystalline material. The orientation differences between the reference pole orientation and actual pole orientations of a multiplicity of grains is then determined. A value of misorientation from the reference pole orientation at each grain measured throughout the thickness is then assigned. The average misorientation of each measured increment throughout the thickness is then determined. A texture gradient and / or texture banding can then be obtained by determining the first and / or second derivative, respectively, of the average misorientation of each measured increment through the thickness of the sample used for evaluation. A method to predict the sputtering efficiency of a target is also described as well as a system for quantifying the texture homogeneity of a polycrystalline material.

Owner:CABOT CORP

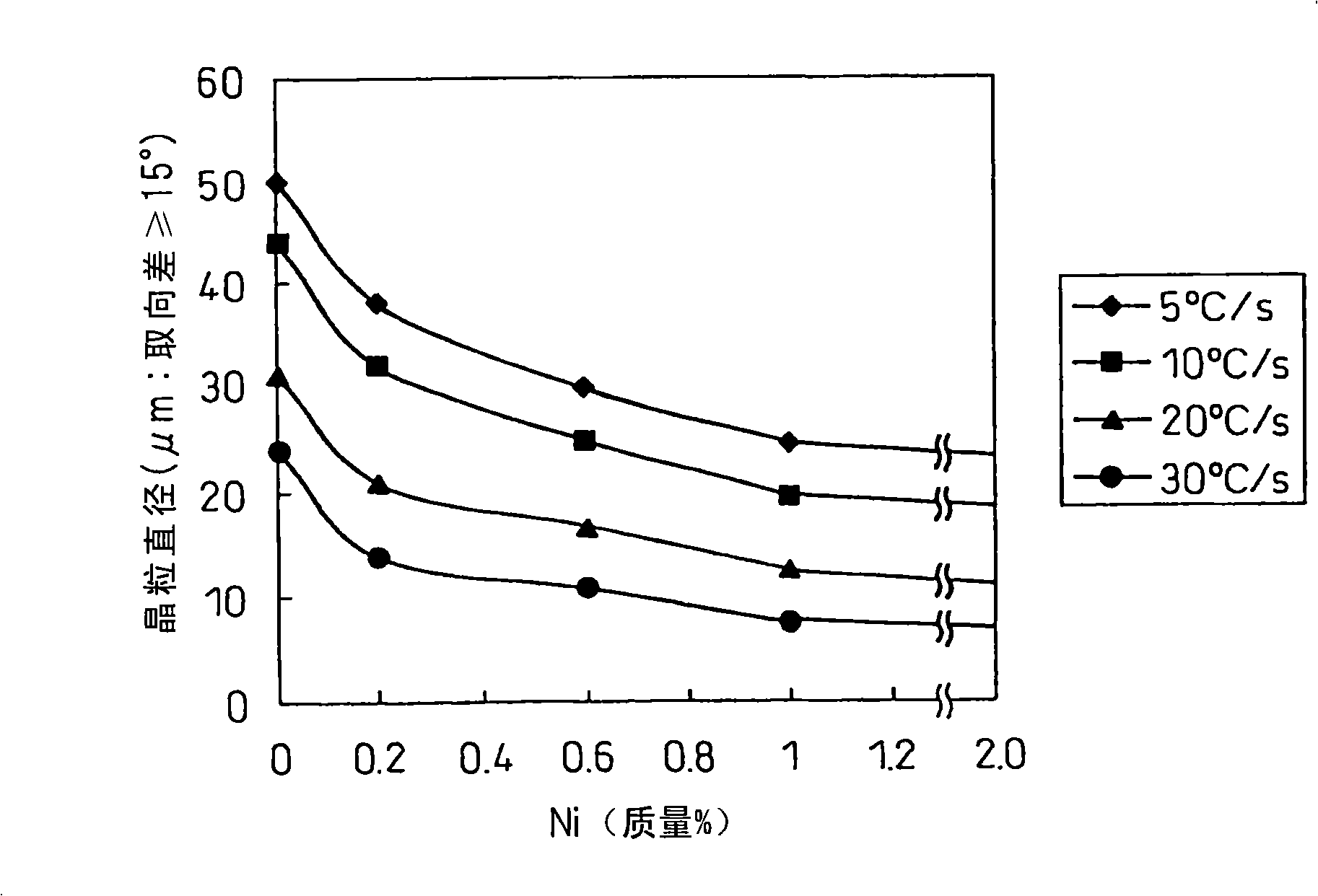

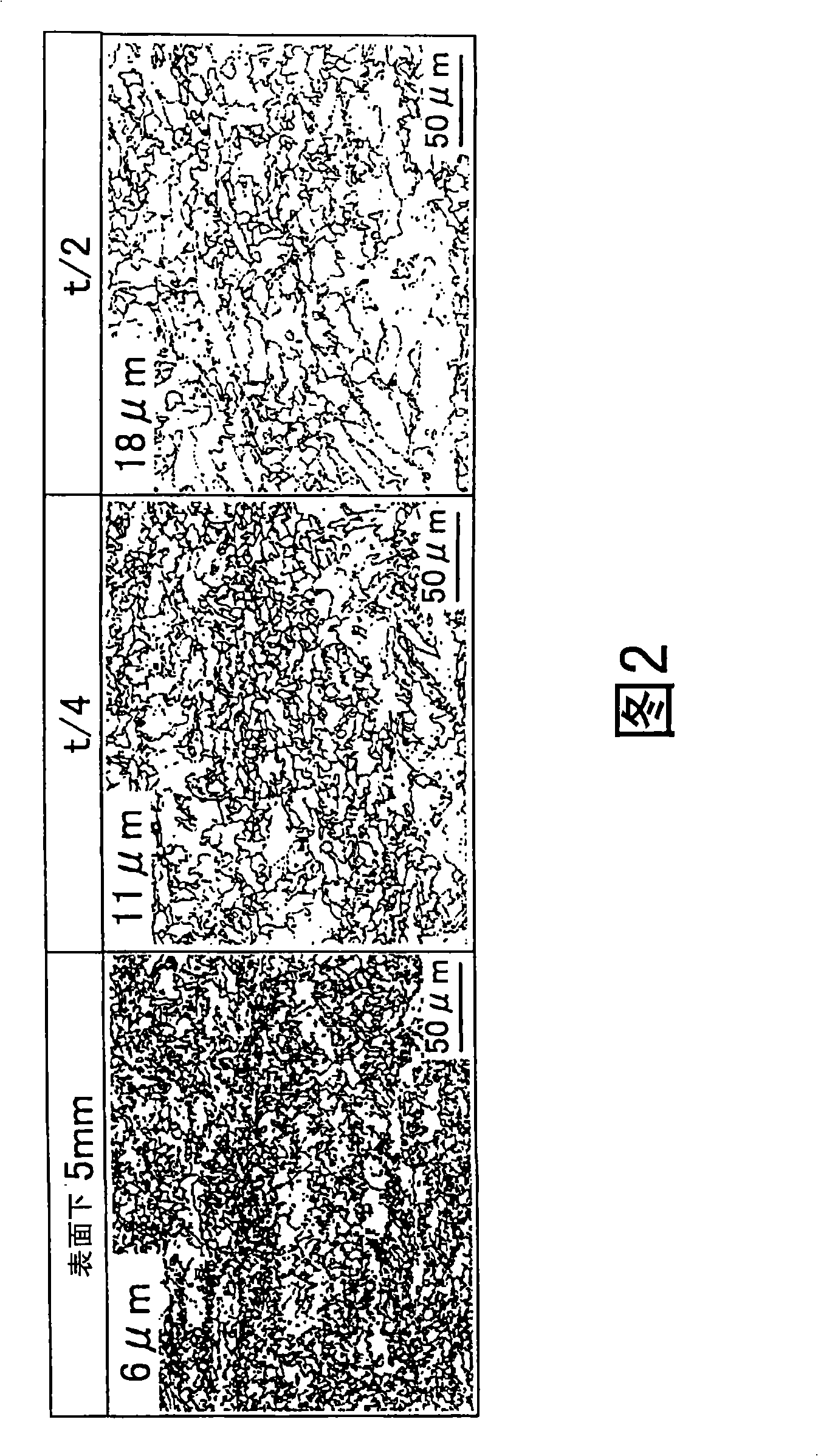

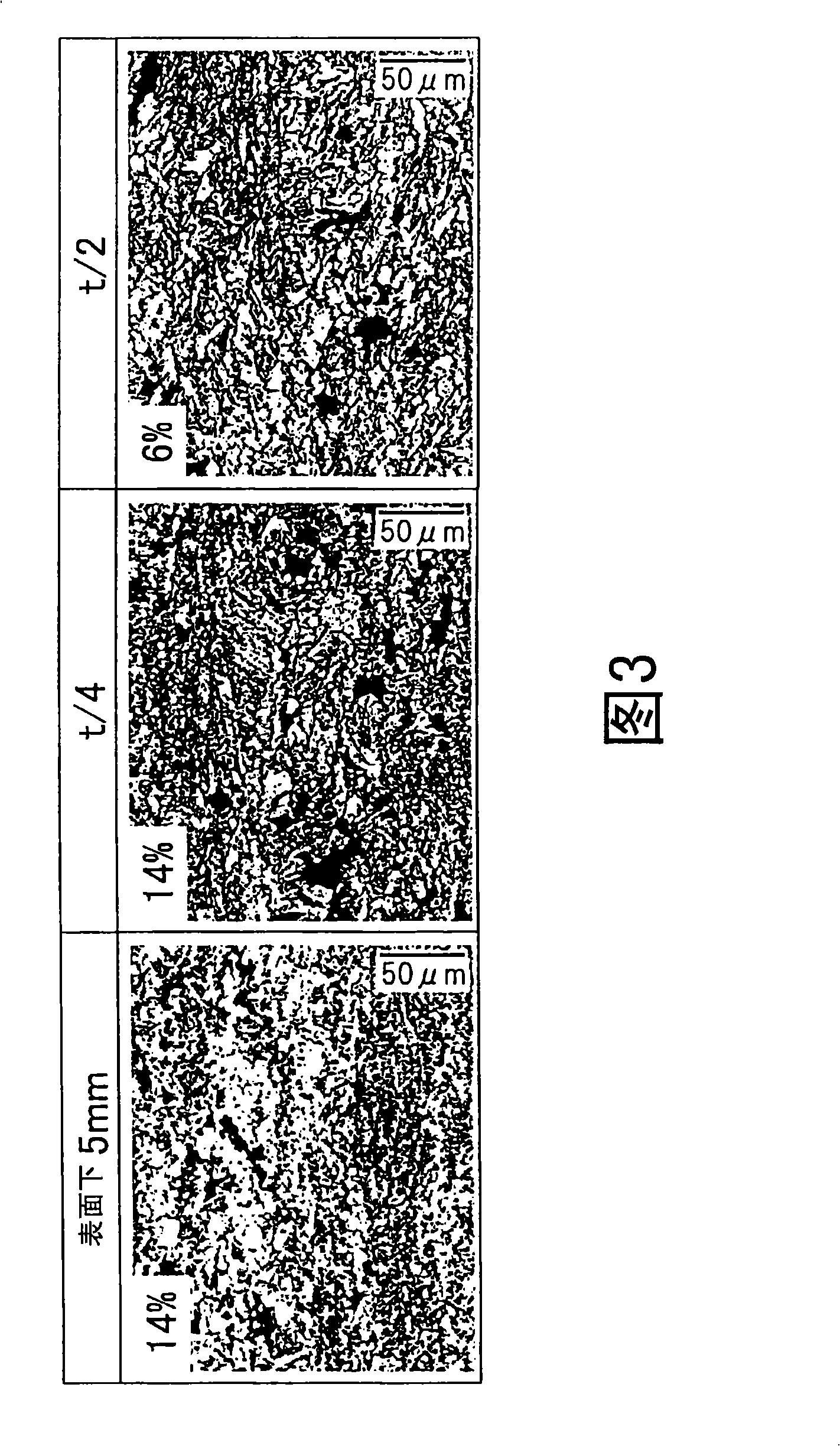

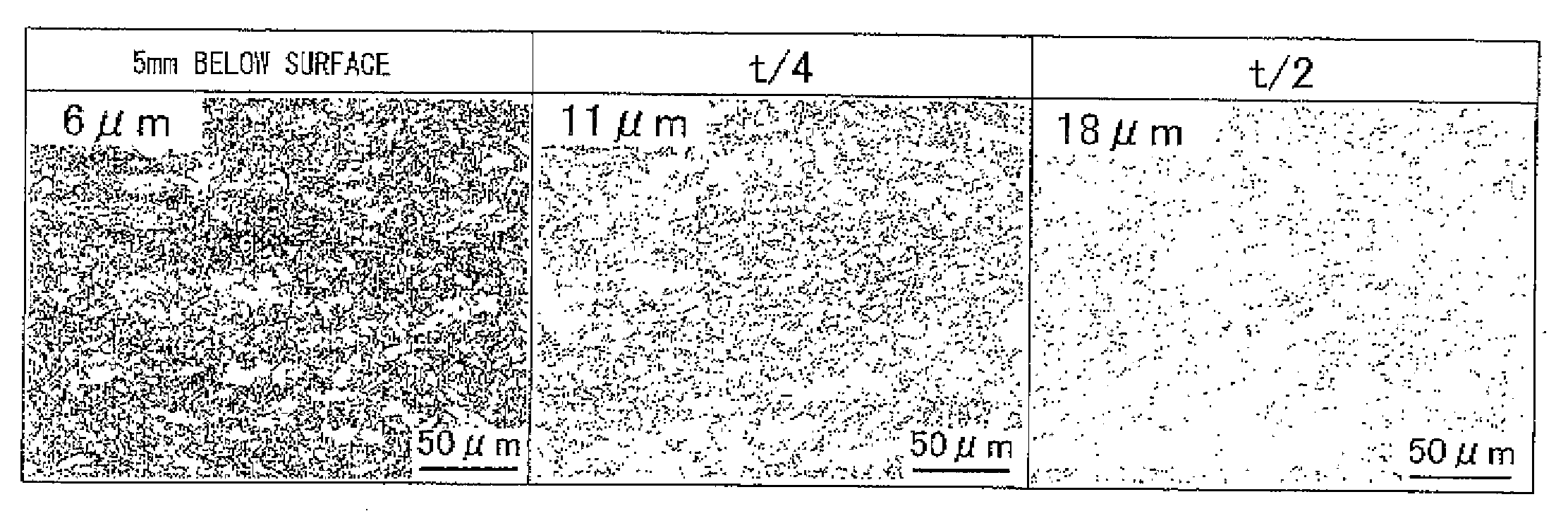

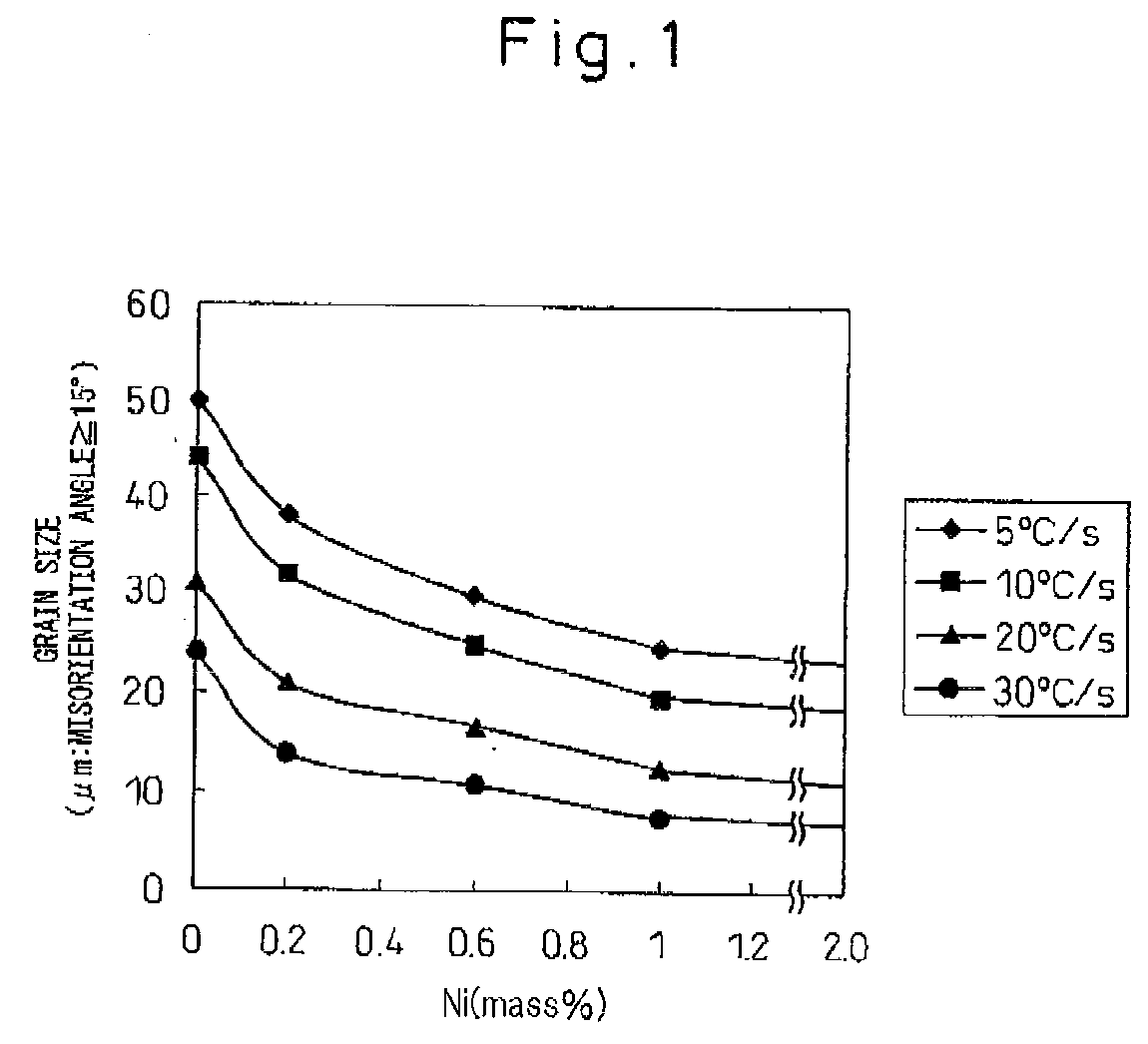

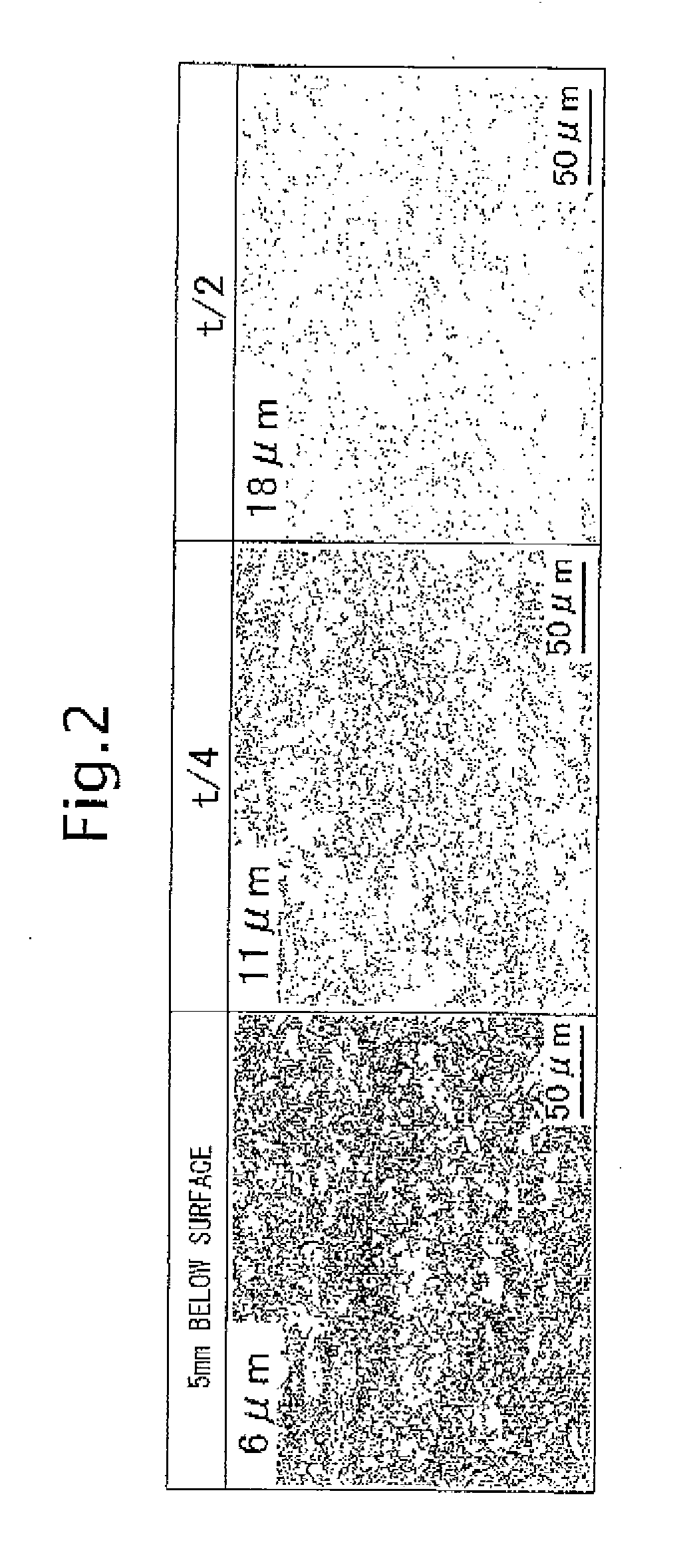

High-strength steel plate with superior crack arrestability

ActiveCN101341269AImprove crack arrest performanceHigh strengthThin material handlingHigh intensityPearlite

The present invention provides high strength thick steel plate superior in crack arrestability, high in strength, free of deterioration of HAZ toughness, and free of anisotropy, that steel plate containing, by mass%, C: 0.03 to 0.15%, Si: 0.1 to 0.5%, Mn: 0.5 to 2.0%, P: 0.02%, S: 0.01%, Al: 0.001 to 0.1%, Ti: 0.005 to 0.02%, Ni: 0.15 to 2%, and N: 0.001 to 0.008% and having a balance of iron and unavoidable impurities as chemical components, having a microstructure of a ferrite and / or pearlite structure with bainite as a matrix phase, and having an average circle equivalent diameter of crystal grains with a crystal misorientation angle of 15 DEG or more of 15 [mu]m or less in the regions of 10% of plate thickness from the front and rear surfaces and of 40 [mu]m or less in the other region including the center part of plate thickness.

Owner:NIPPON STEEL CORP

Method and structure for eliminating polarization instability in laterally - oxidized VCSELs

InactiveUS20050158902A1Sufficient polarization selectivityPolarization selectivity can be improvedOptical wave guidanceLaser detailsInstabilityOptoelectronics

The polarization instability inherent in laterally-oxidized VCSELs may be mitigated by employing an appropriately-shaped device aperture, a misoriented substrate, one or more cavities or employing the shaped device aperture together with a misoriented substrate and / or cavities. The laterally-oxidized VCSELs are able to operate in a single polarization mode throughout the entire light output power versus intensity curve. Combining the use of misoriented substrates with a device design that has an asymmetric aperture that reinforces the polarization mode favored by the substrate further improves polarization selectivity. Other device designs, however, can also be combined with substrate misorientation to strengthen polarization selectivity.

Owner:XEROX CORP

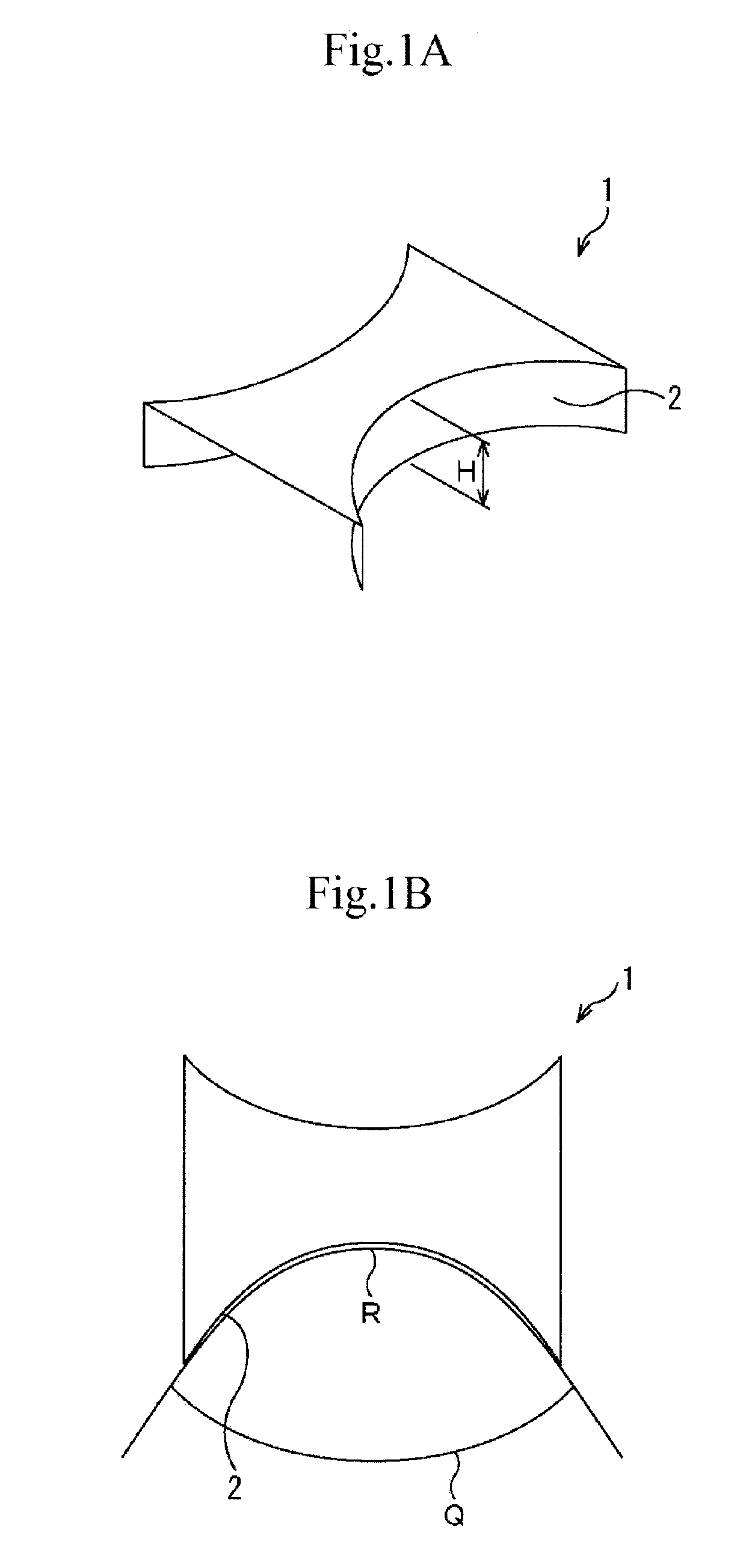

Intraocular lenses with high contrast haptics, materials, and methods

Intraocular lenses with high contrast haptics, materials and methods for making optical blanks and lenses, and methods of use are disclosed and claimed. Such lenses may provide easily recognizable visual cues that may be used to detect and correct misorientation of lenses prior to and during use.

Owner:CHU MILTON W

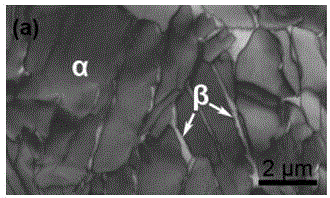

Hot-rolled steel sheet

ActiveUS20160017465A1High elongationExcellent hole expandabilityFurnace typesHeat treatment furnacesMisorientationHot rolled

A hot-rolled steel sheet includes a specified chemical composition and includes a steel structure represented by an area ratio of ferrite being 5% to 50%, an area ratio of bainite composed of an aggregate of bainitic ferrite whose grain average misorientation is 0.4° to 3° being 50% to 90%, and a total area ratio of martensite, pearlite, and retained austenite being 5% or less.

Owner:NIPPON STEEL CORP

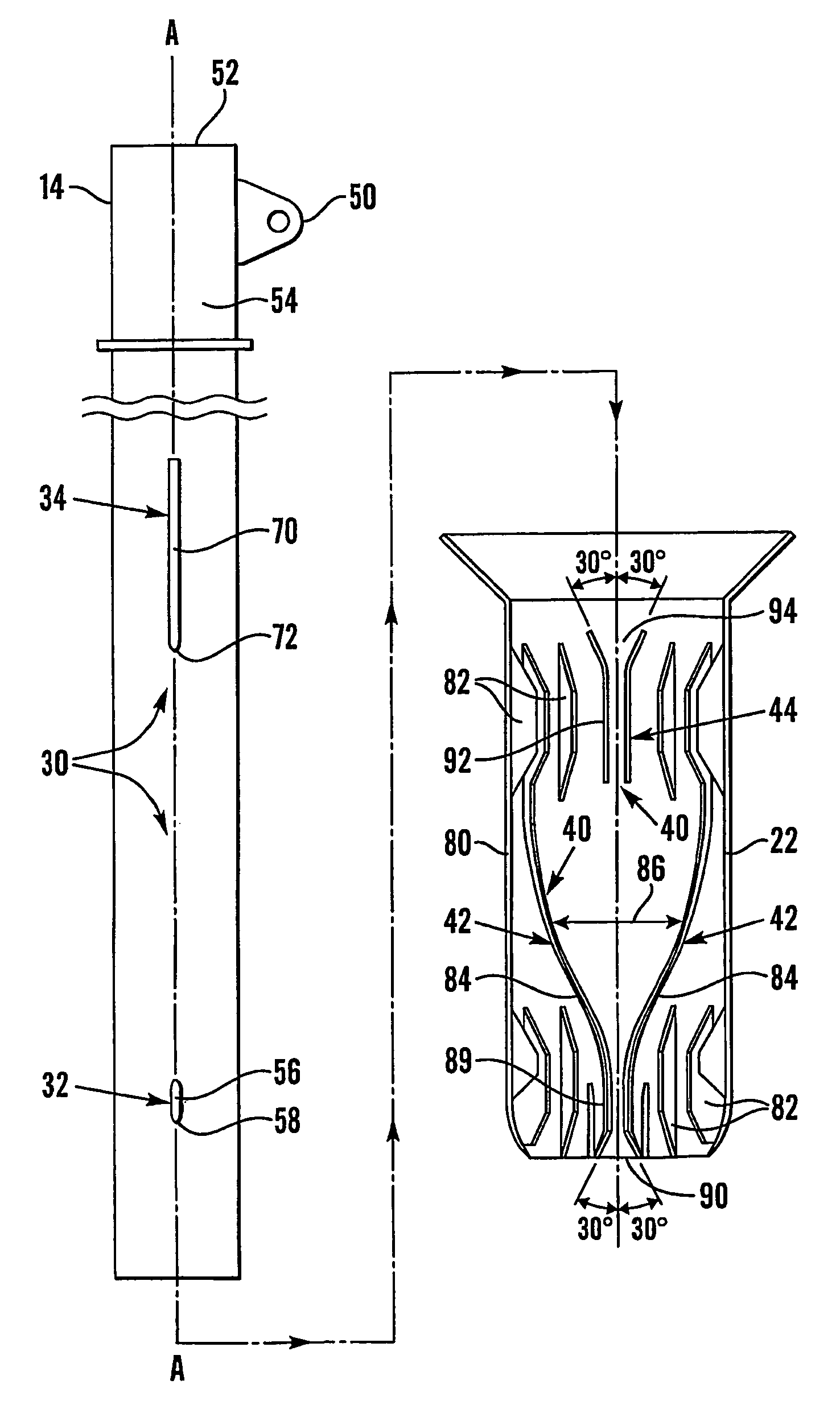

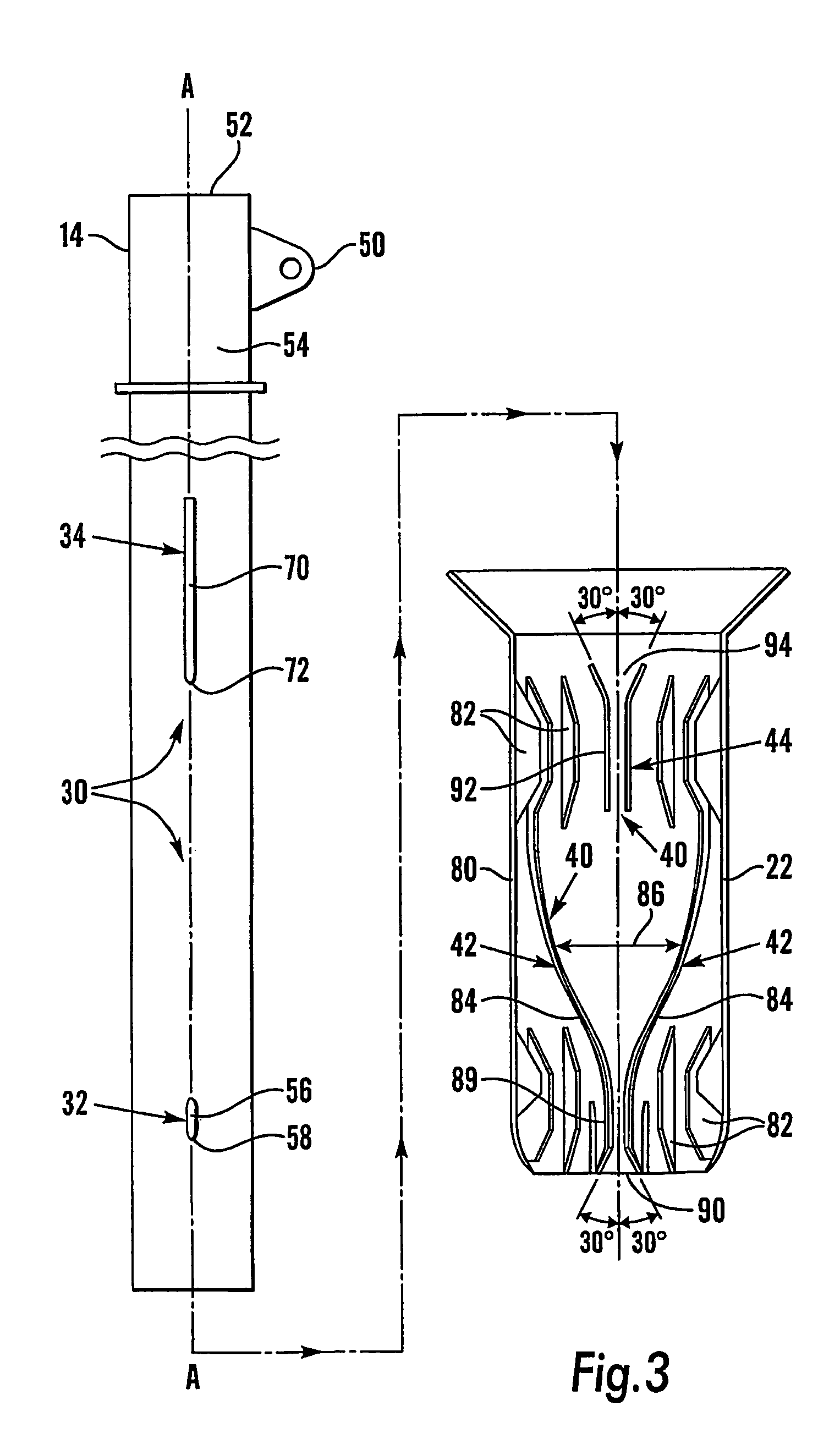

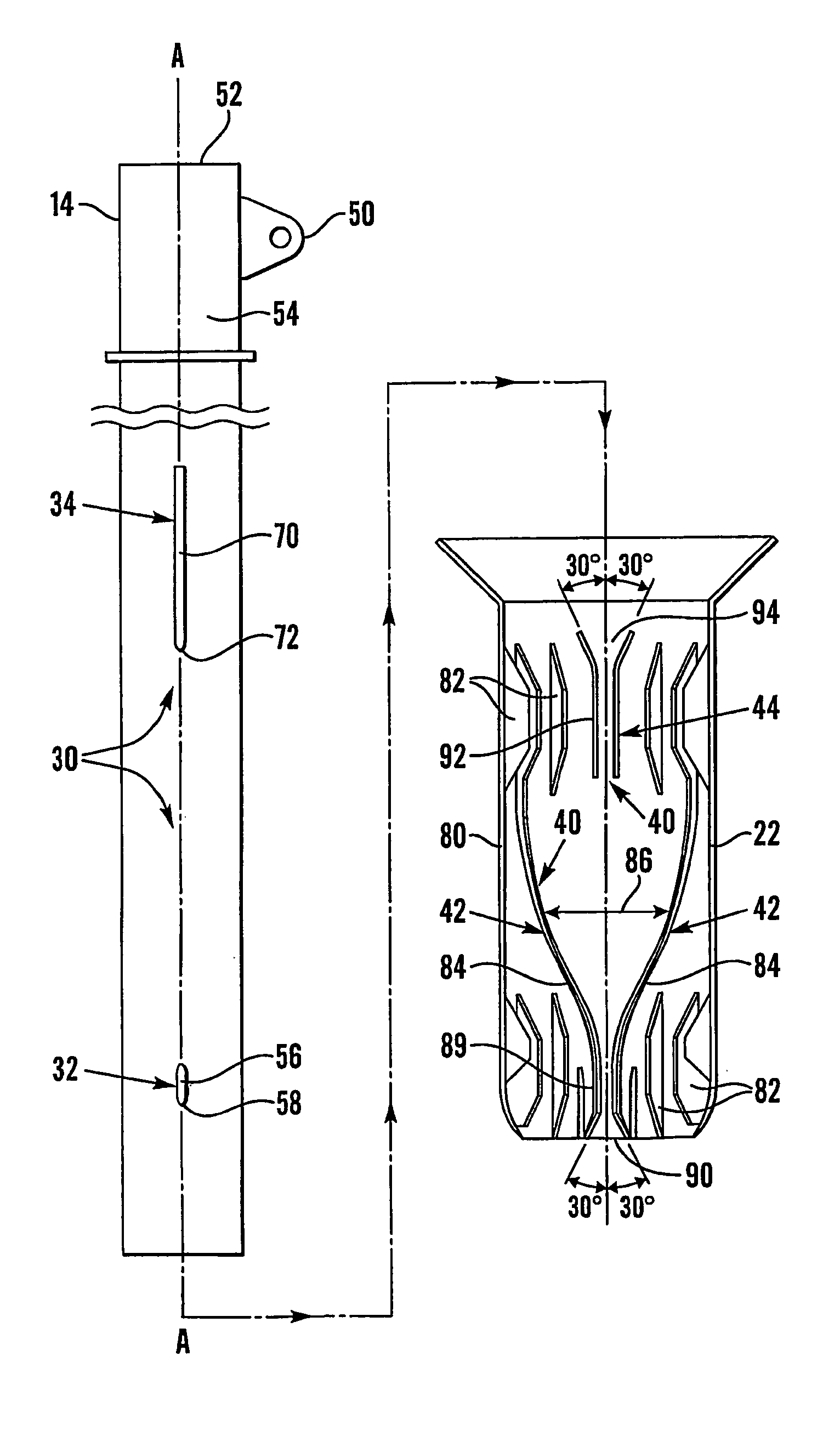

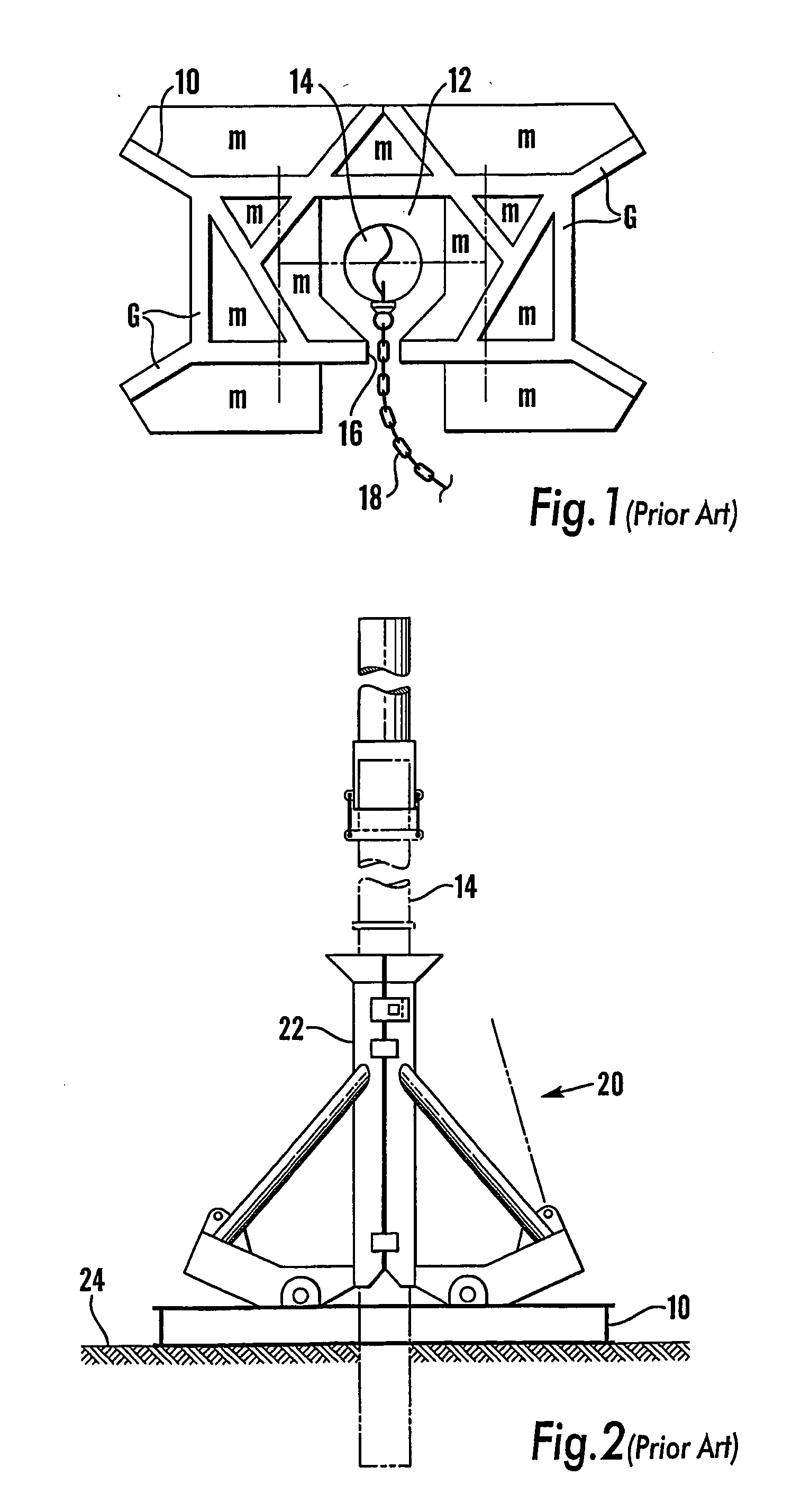

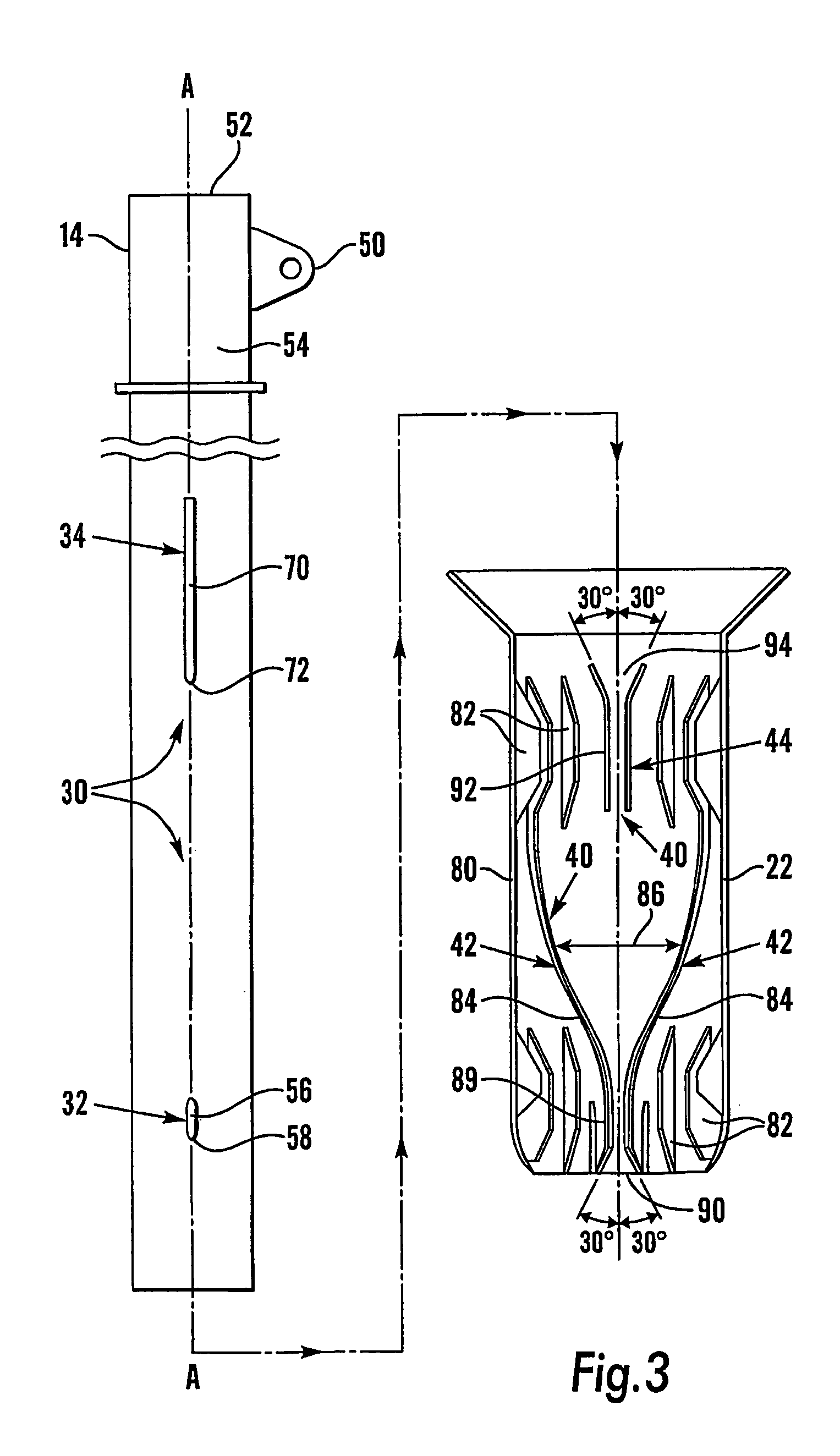

Pile driving system and pile for engagement with said system

A system for controlling pile orientation comprises a pile (14) and a pile guide (20) for supporting the pile as it is driven into a substrate, the pile guide comprising a base frame (10) and a pile guide member (22) mounted on the base frame. The pile (14) and the pile guide member (22) have slidaby interengaging profiles (30, 40) comprising first and second parts (32, 42), which are configured to axially rotate the pile to correct any misorientation relative to the pile guide as the parts slide past each other, and third and fourth parts (34, 44), which are configured to maintain a predetermined orientation of the pile relative to the pile guide once any misorientation has been corrected by interengagement of the first and second parts.

Owner:IHC HOLLAND NV

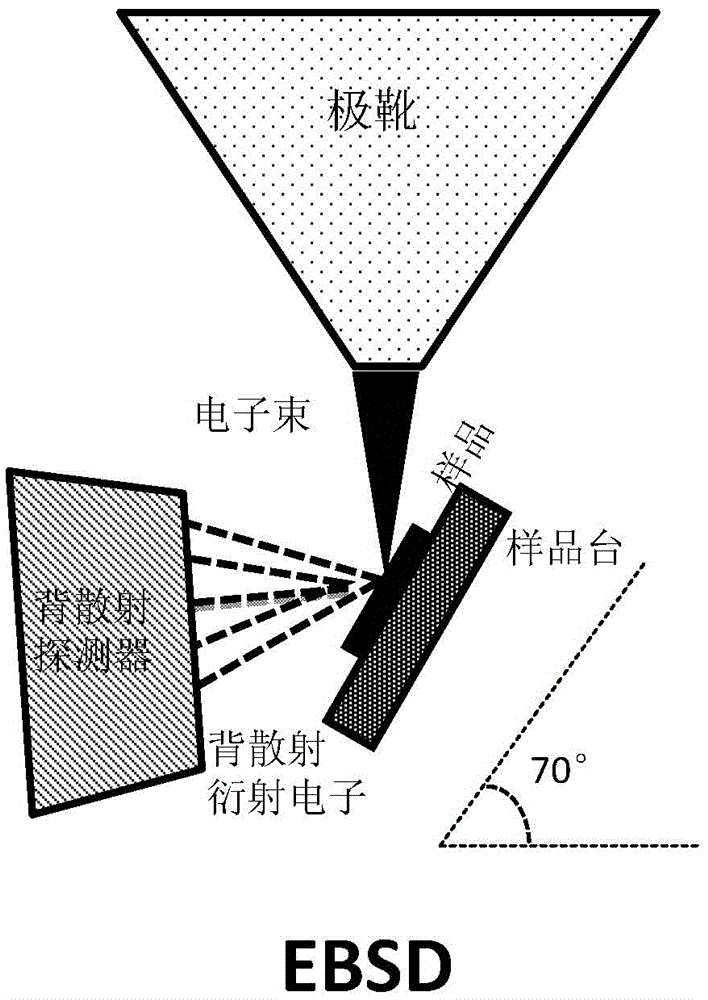

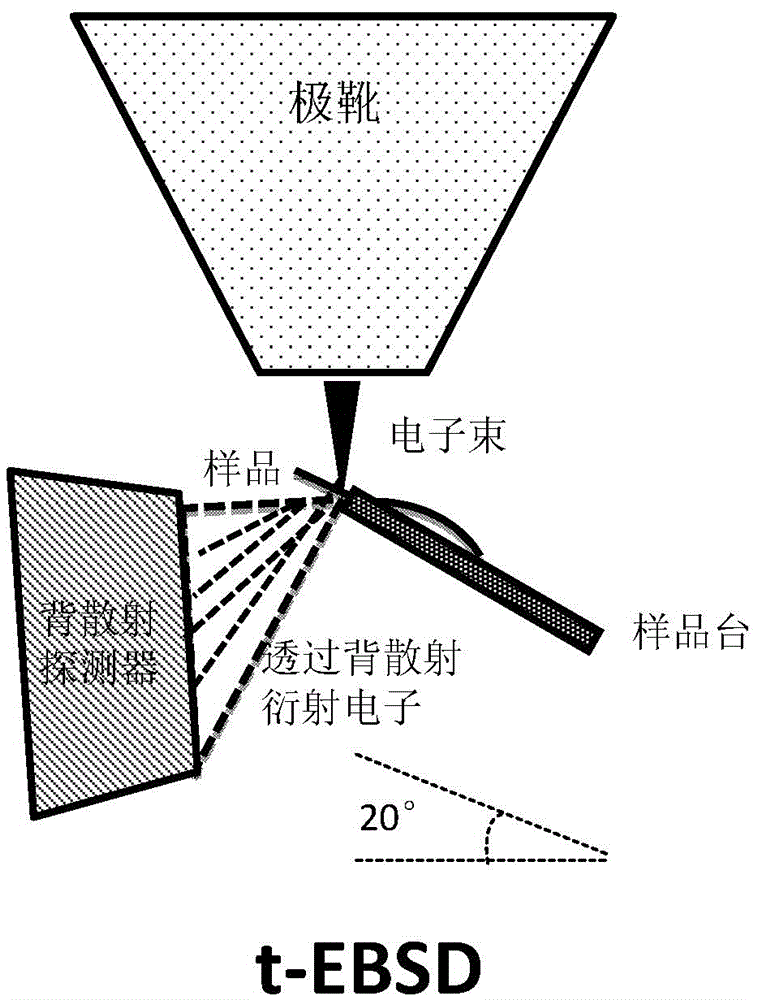

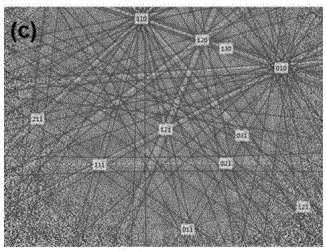

SEM transmission electron Kikuchi diffraction apparatus and analytical method

InactiveCN105651792AImprove spatial resolutionShorten working distanceNanoparticle analysisParticle size analysisCrystal twinningNanoscopic scale

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Articles of footwear and other foot-receiving devices including differently oriented impact-attenuation elements

ActiveUS8261469B2Reduce or eliminate misorientation of the foot, and the fatigue and/or strainSolesHeelsUltrasound attenuationStep cycle

Impact-attenuation systems, e.g., for use in footwear, can help control foot positioning during a step cycle, e.g., to help reduce or eliminate misorientation of the foot, and the fatigue and / or strain that may result from such misorientation. Articles of footwear including such impact-attenuation systems may include: (a) an upper member; and (b) a sole structure engaged with the upper member. The sole structure may include: (i) a first impact-attenuating member located in a heel portion of the foot-supporting member, and (ii) a second, separate impact-attenuating member located at a rear, lateral heel portion. The second impact-attenuating member may be arranged at a different orientation with respect to the longitudinal direction as compared to the first orientation. Impact-attenuation systems having the characteristics described above, as well as methods of making and using products containing such systems, also are described.

Owner:NIKE INC

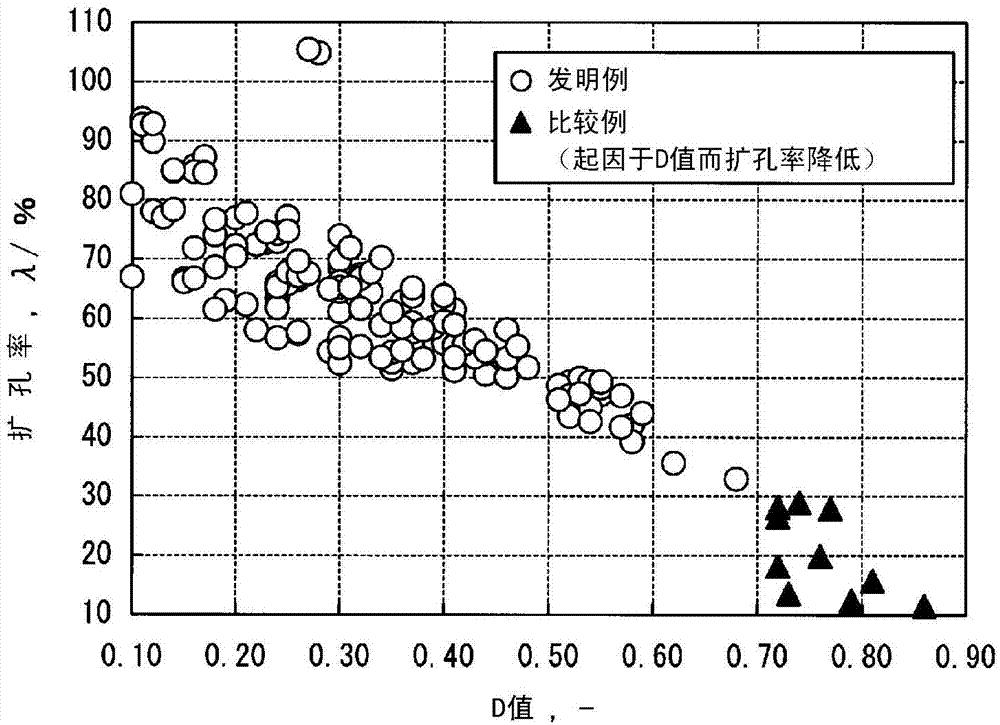

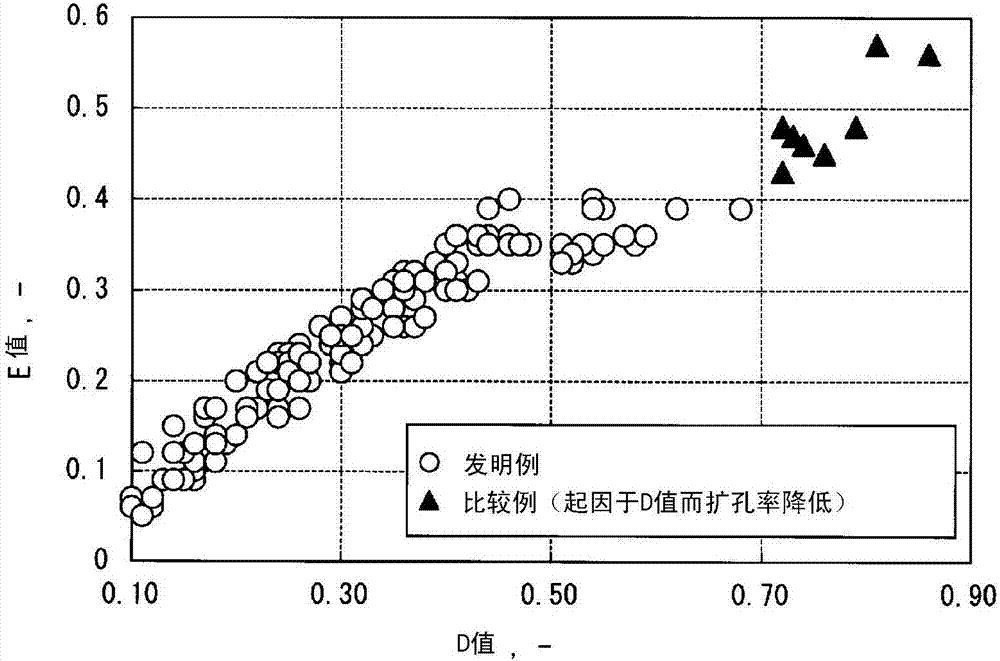

Cold-rolled steel sheet and method for manufacturing same

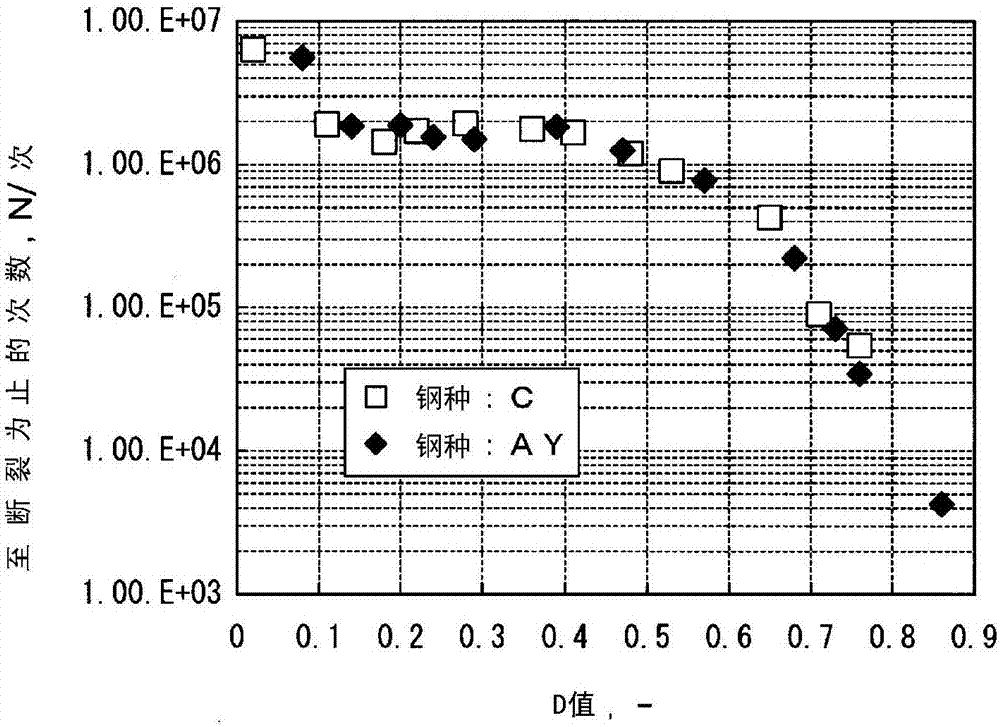

ActiveCN107429369AExcellent punching fatigue propertiesHigh elongationHot-dipping/immersion processesFurnace typesChemical compositionMartensite

This cold-rolled steel sheet has a predetermined chemical composition, and has a metallographic structure containing, by area fraction, 40.0% to below 60.0% of polygonal ferrite, 30.0% or more of bainitic ferrite, 10.0-25.0% of retained austenite, and 15.0% or less of martensite. In the retained austenite, the proportion of retained austenite having an aspect ratio of 2.0 or less, a major axis length of 1.0 microns or less, and a minor axis length of 1.0 microns or less is 80.0% or more. In the bainitic ferrite, the proportion of bainitic ferrite which has an aspect ratio of 1.7 or less, and in which the average crystallographic misorientation is 0.5 degrees to below 3.0 degrees in a region surrounded by grain boundaries having a crystallographic misorientation of 15 degrees or more, is 80.0% or more. The connectivity D value between the martensite, the bainitic ferrite, and the retained austenite is 0.70 or less.

Owner:NIPPON STEEL CORP

Pile driving system and pile for engagement with said system

A system for controlling pile orientation comprises a pile (14) and a pile guide (20) for supporting the pile as it is driven into a substrate, the pile guide comprising a base frame (10) and a pile guide member (22) mounted on the base frame. The pile (14) and the pile guide member (22) have slidaby interengaging profiles (30, 40) comprising first and second parts (32, 42), which are configured to axially rotate the pile to correct any misorientation relative to the pile guide as the parts slide past each other, and third and fourth parts (34, 44), which are configured to maintain a predetermined orientation of the pile relative to the pile guide once any misorientation has been corrected by interengagement of the first and second parts.

Owner:IHC HOLLAND NV

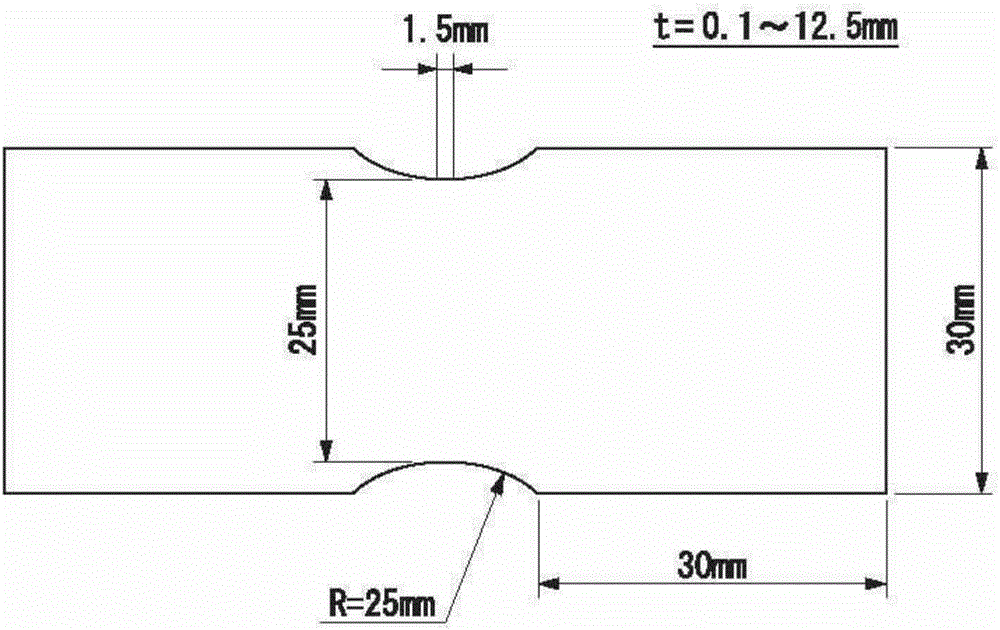

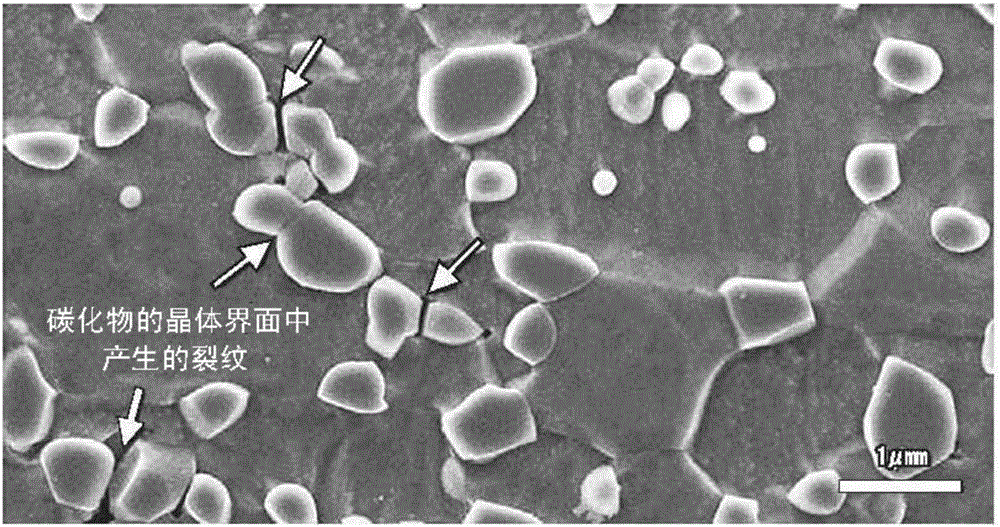

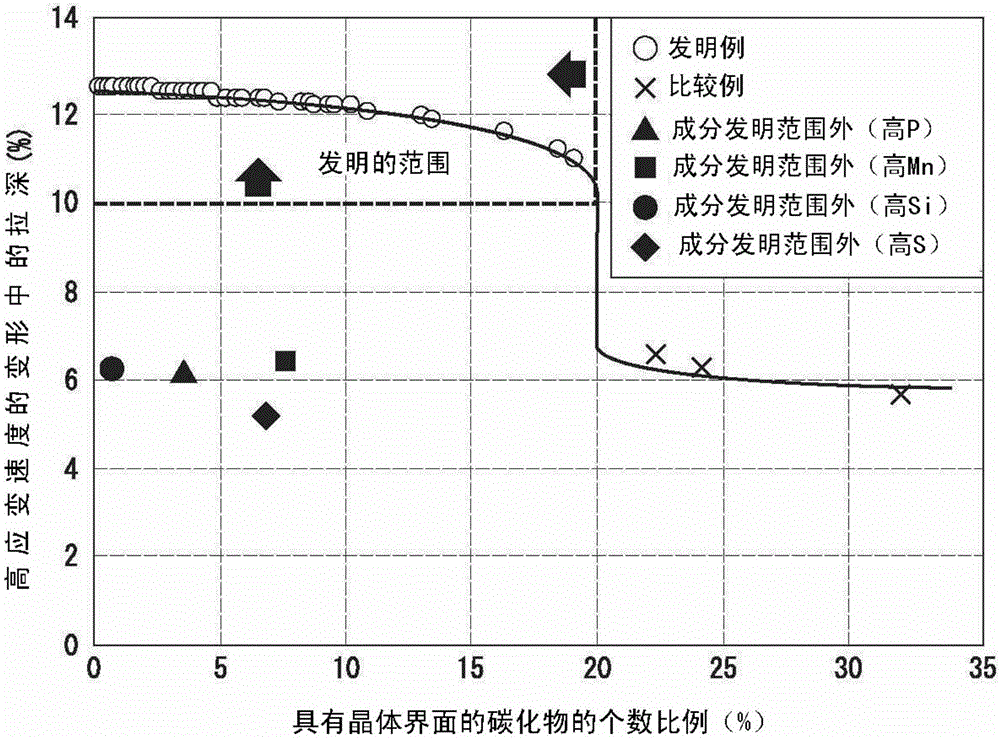

Medium-/high-carbon steel sheet and method for manufacturing same

The medium- / high-carbon steel sheet according to one aspect of the present invention is a steel sheet containing, in mass%, C: 0.10-1.50%, Si: 0.01-1.00%, Mn: 0.01-3.00 mass%, P: 0.0001-0.1000%, and S: 0.001-0.1000%, with the remainder having components comprising Fe and impurities, wherein the total volume fraction of martensite, bainite, pearlite, and residual austenite is 5% or less, the remainder being a composition of ferrite and carbide; the spheroidizing ratio of the carbide particles is 70 to 99%, inclusive; and the number of carbide particles that include crystal interface misorientation of 5 degrees or greater, expressed as a proportion of the carbide particles, is 20% or less with respect to the total number of carbide particles.

Owner:NIPPON STEEL CORP

Method for preparation of double-phase zirconium alloy EBSD sample by electrolytic polishing

InactiveCN106556532AHigh surface finishExtensive sources of raw materialsPreparing sample for investigationMaterial analysis using radiation diffractionElectrolysisDouble phase

Owner:CHONGQING UNIV OF TECH

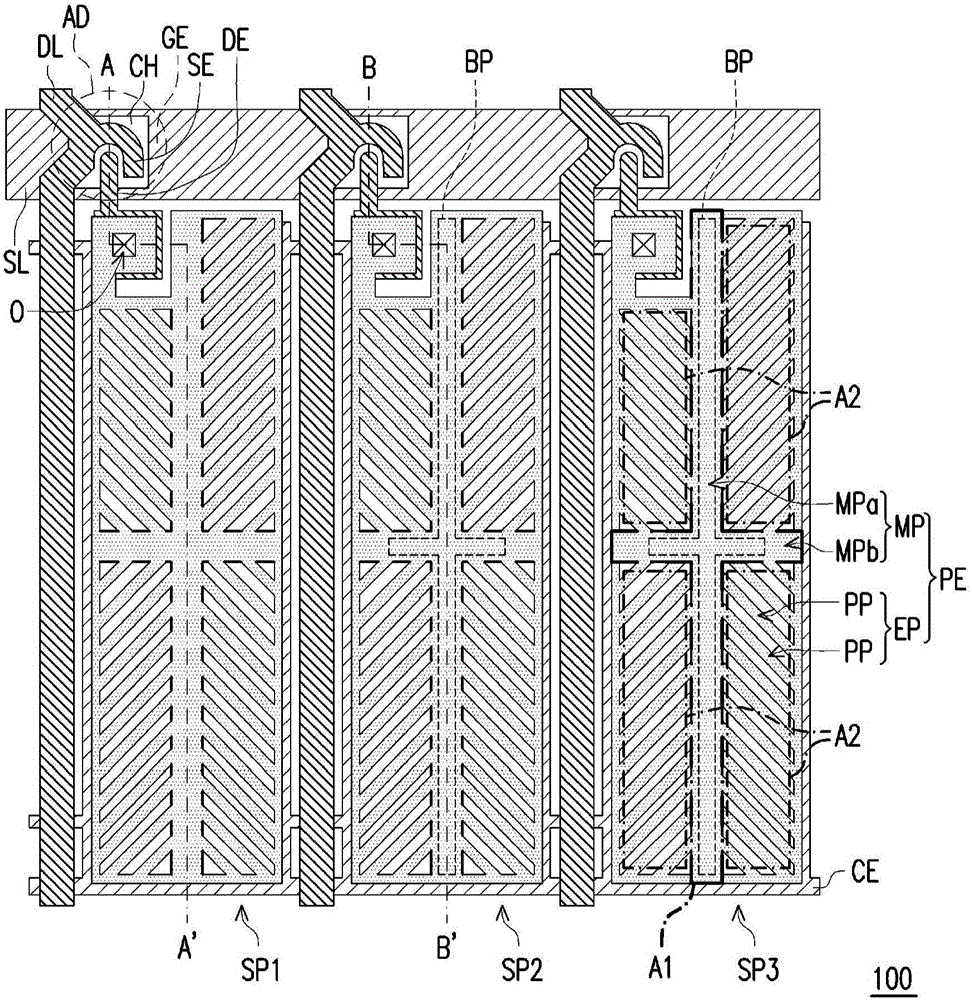

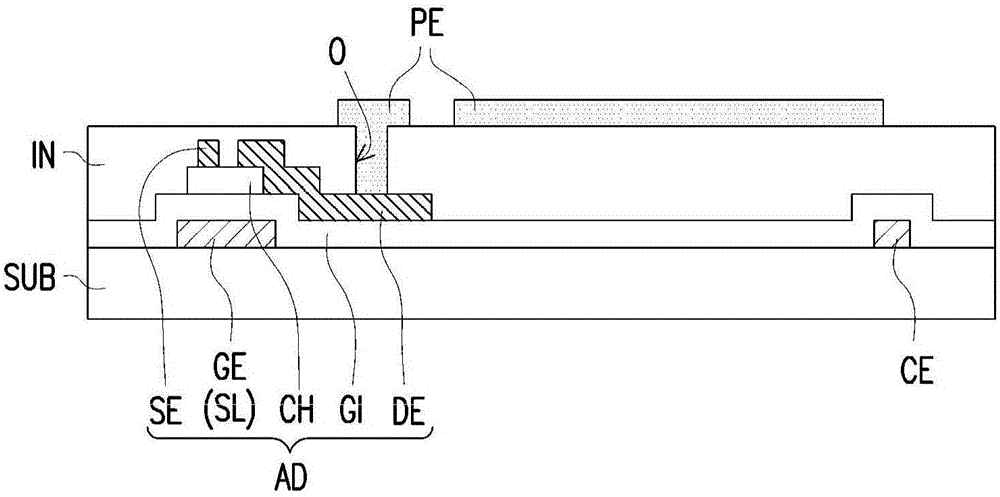

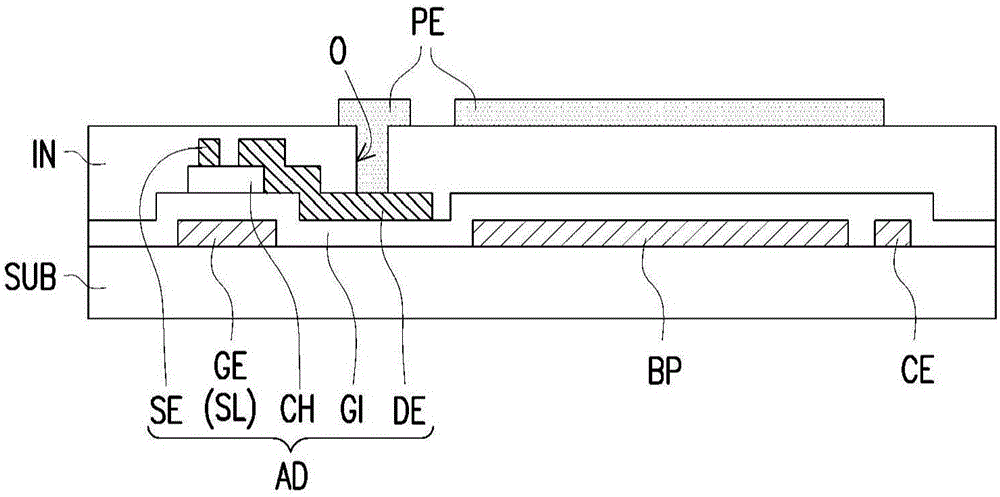

Pixel structure

The invention relates to a pixel structure, which comprises a plurality of sub-pixels arranged in an array. Each of the sub-pixels comprises an active component and a pixel electrode electrically connected with the active component. Each of the pixel electrodes separately defines misorientation regions and a plurality of display region separated by the misorientation regions, wherein only a part of the sub-pixels further comprises shading patterns corresponding to the misorientation regions.

Owner:AU OPTRONICS CORP

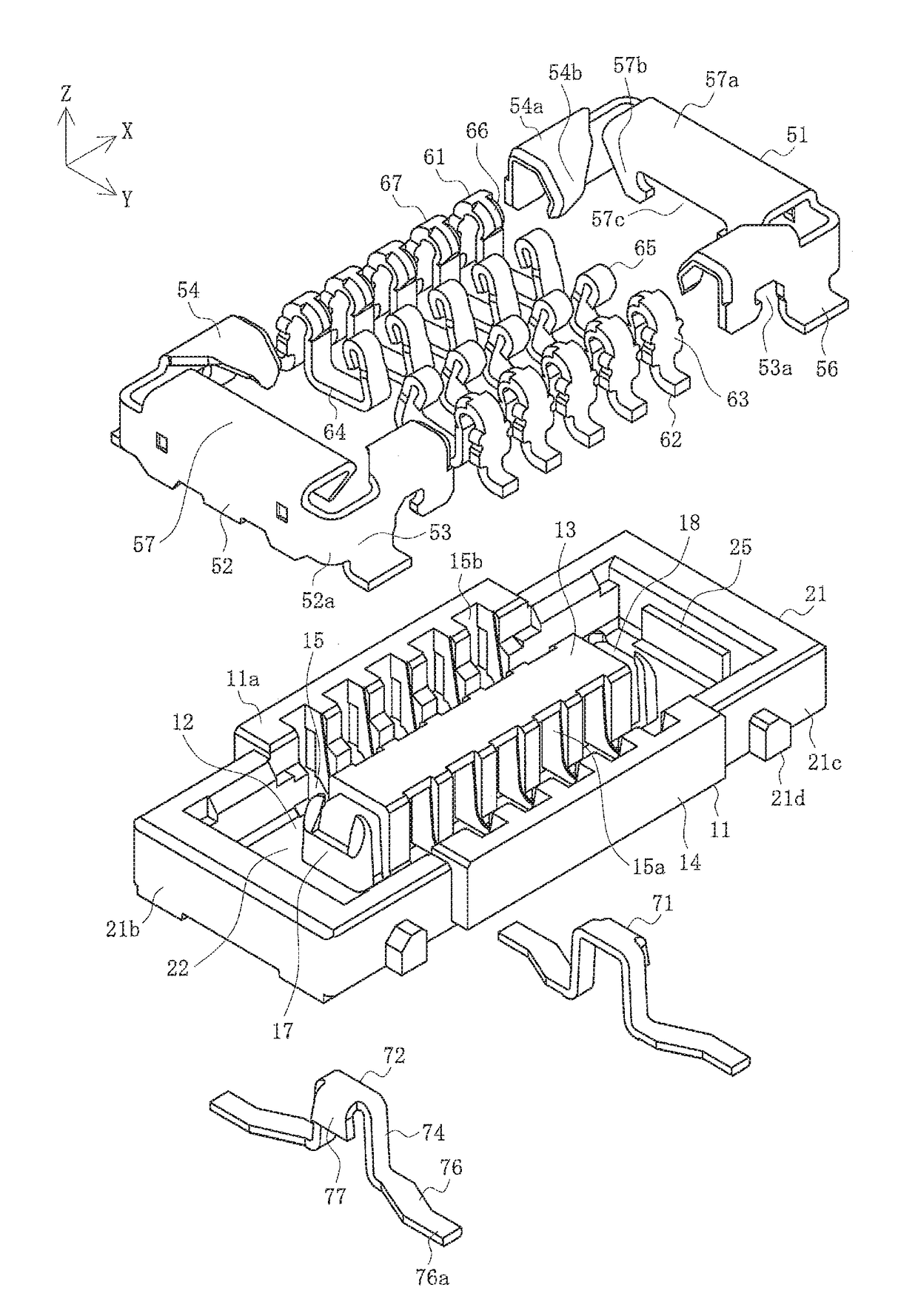

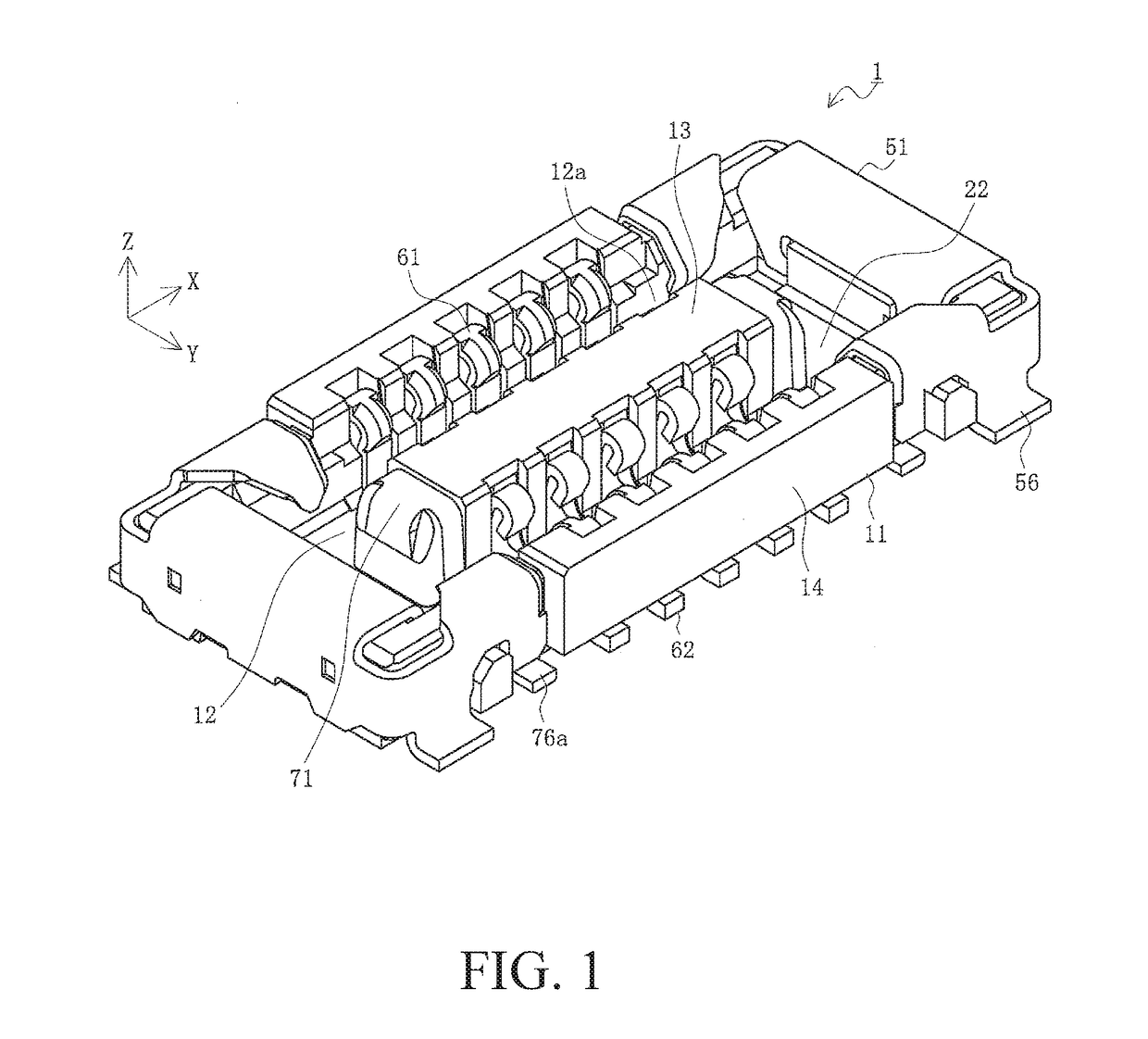

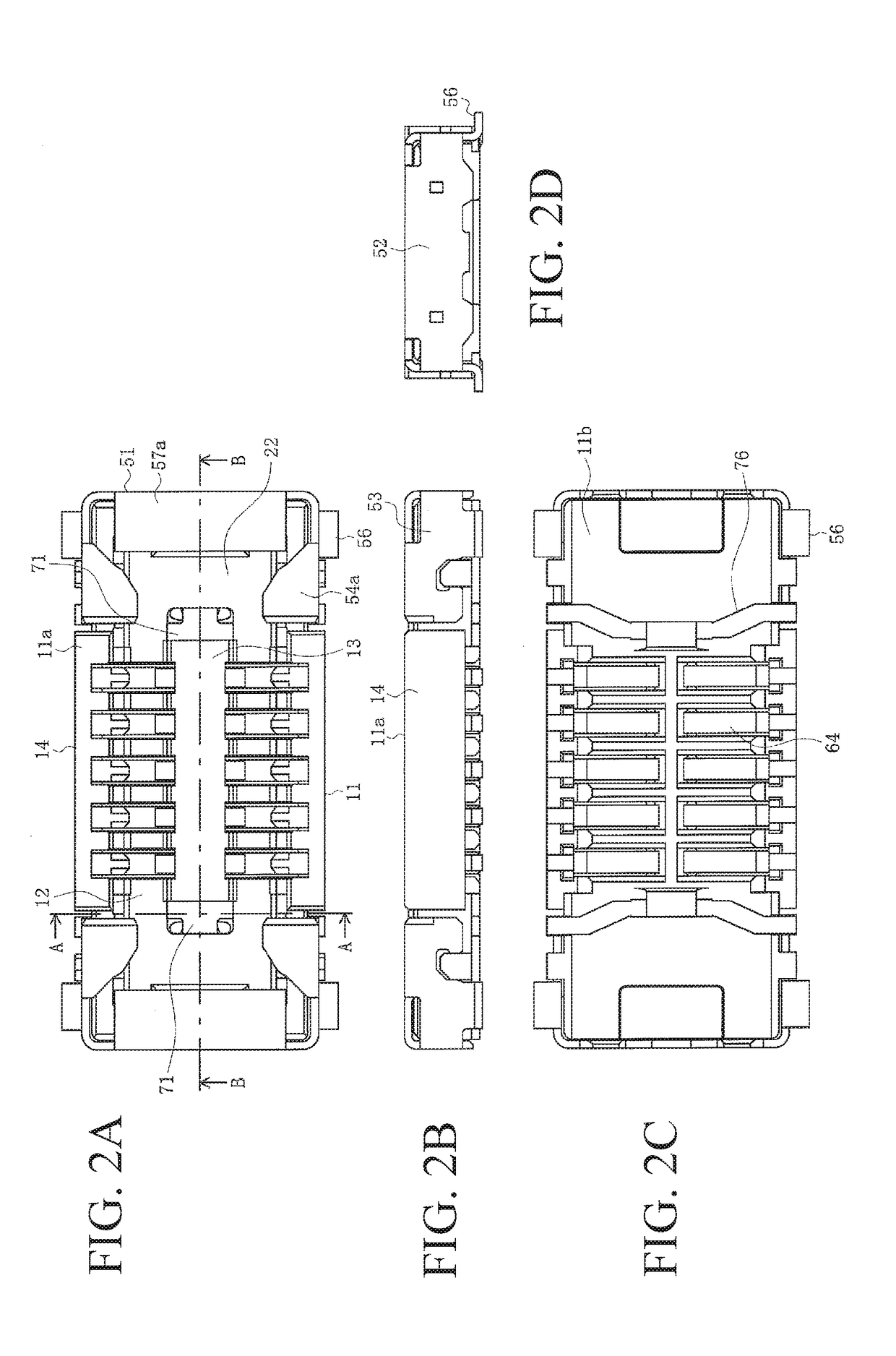

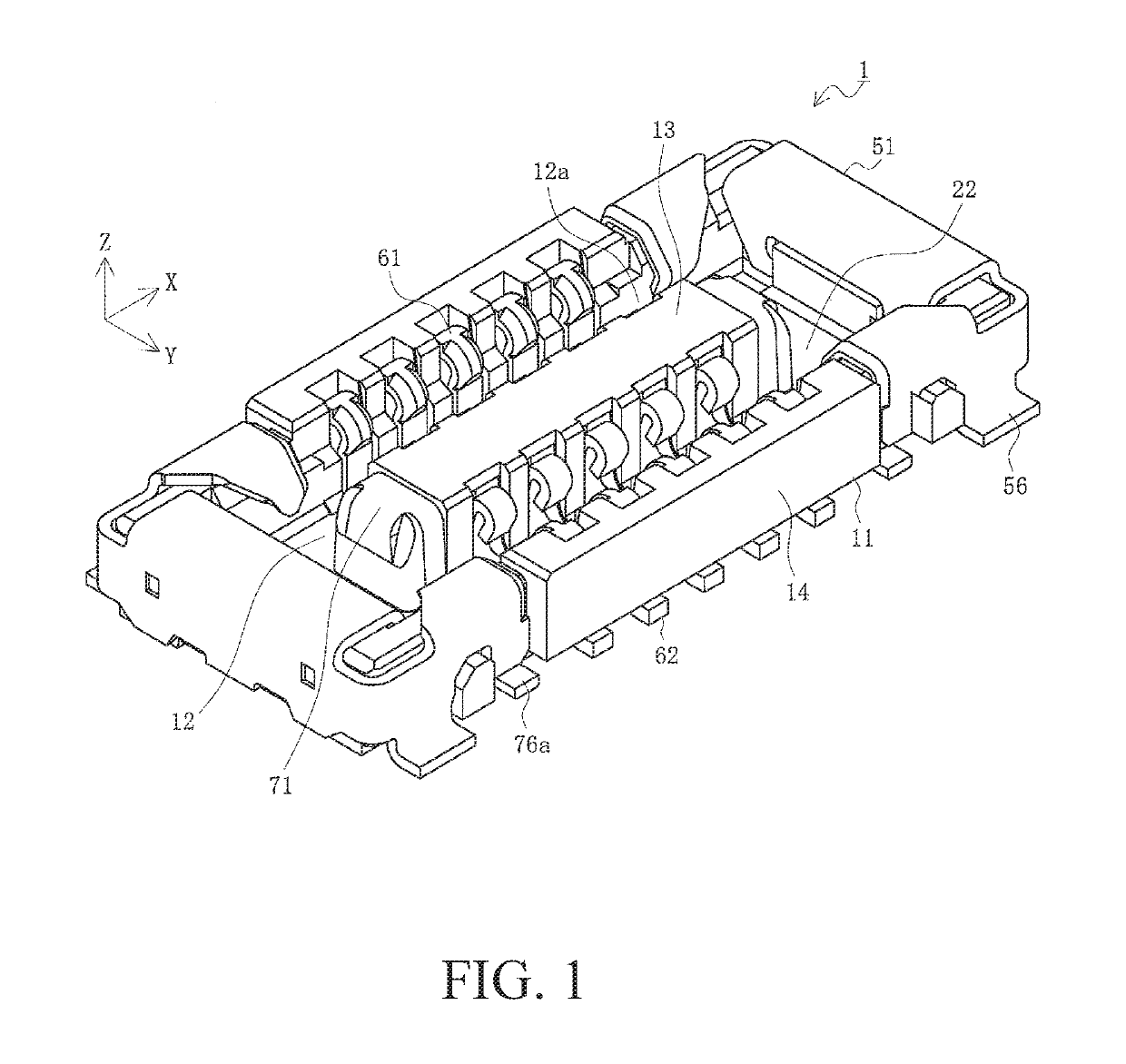

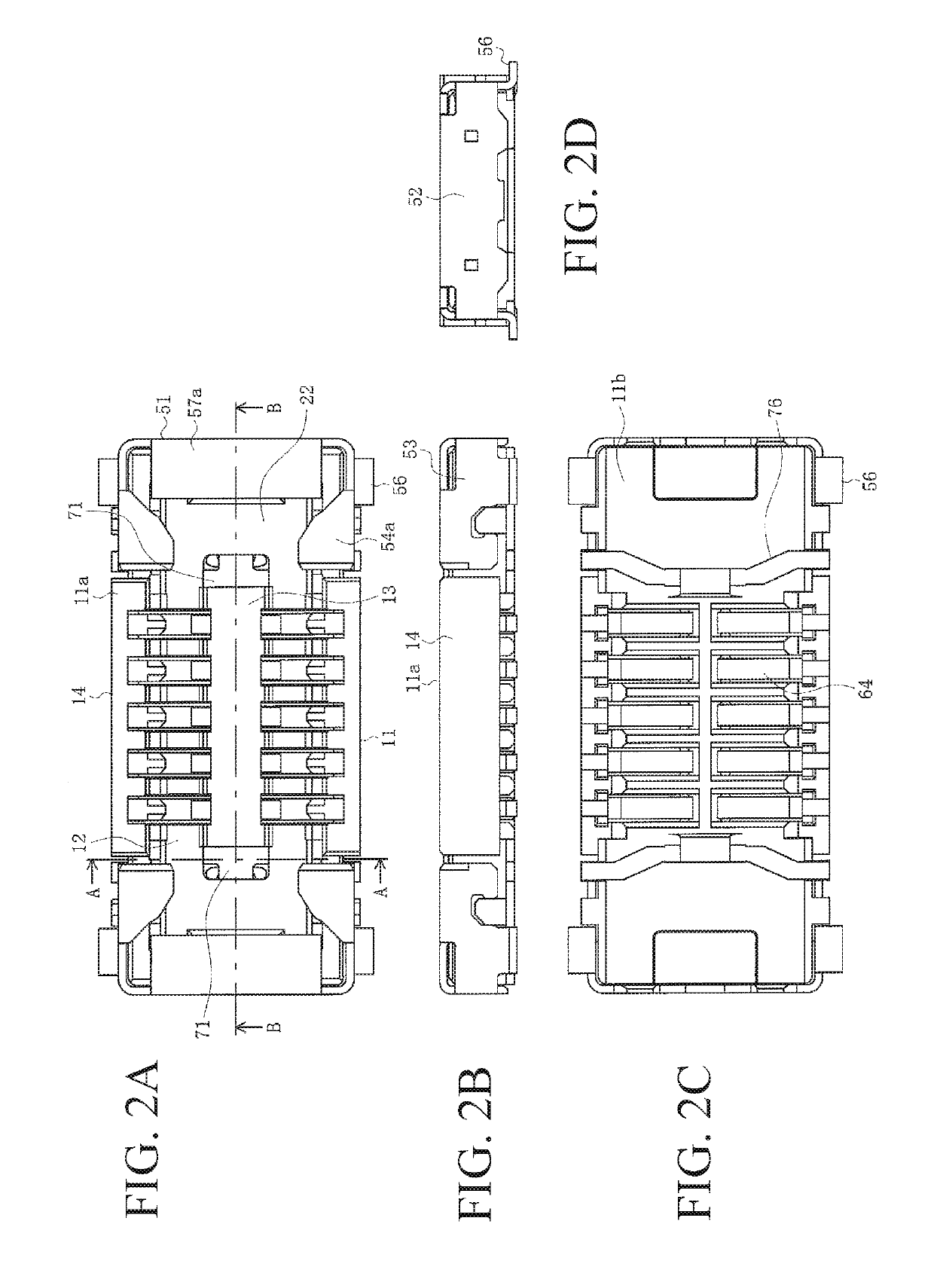

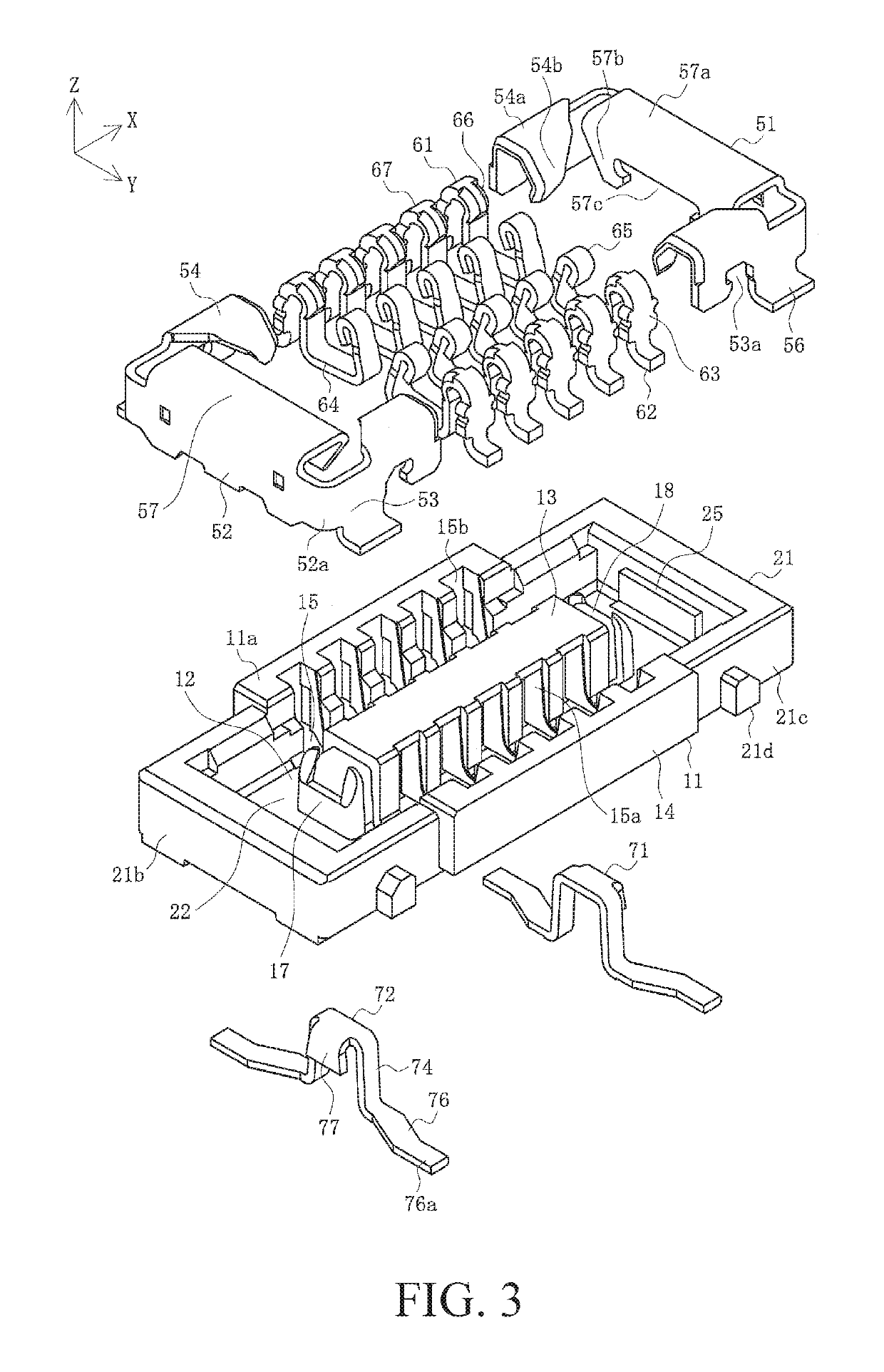

Connector

ActiveUS20180331444A1Improve reliabilityIncorrect coupling preventionCoupling contact membersMating connectionLeft direction

High reliability is achieved with a protected state guaranteed for housings with reinforcing brackets being rigid to be free from displacement and misorientation. A connector includes: a connector body; a terminal installed in the connector body; and a reinforcing bracket fit to the connector body. The connector body includes a recess in which a mating connector body of a mating connector fits, and an insular part that is in the recess and fits in a groove part of the mating connector body. The reinforcing bracket includes an inner reinforcing bracket fit to an insular end part that is an end portion of the insular part in a longitudinal direction. The inner reinforcing bracket includes a body part that is disposed on an upper surface of the insular end part, an end plate that is connected to the body part and is disposed on an end surface of the insular end part, a pair of side plates that are connected to right and left ends of the body part and are disposed on right and left side surfaces of the insular end part, and a pair of connecting legs that are each connected to a lower end of a corresponding one of the side plates and extend outward in a right and left direction of the connector body.

Owner:MOLEX INC

High strength thick steel plate superior in crack arrestability

InactiveUS20090092515A1Improve crack arrest performanceHigh strengthLayered productsThin material handlingChemical compositionEquivalent weight

The present invention provides high strength thick steel plate superior in crack arrestability high in strength, free of deterioration of HAZ toughness, and free of anisotropy, that steel plate containing, by mass %, C: 0.03 to 0.15%, Si: 0.1 to 0.5%, Mn: 0.5 to 2.0%, P: ≦0.02%, S: ≦0.01%, Al: 0.001 to 0.1%, Ti: 0.005 to 0.02%, Ni: 0.15 to 2%, and N: 0.001 to 0.008% and having a balance of iron and unavoidable impurities as chemical components, having a microstructure of a ferrite and / or pearlite structure with bainite as a matrix phase, and having an average circle equivalent diameter of crystal grains with a crystal misorientation angle of 15° or more of 15 μm or less in the regions of 10% of plate thickness from the front and rear surfaces and of 40 μm or less in the other region including the center part of plate thickness.

Owner:NIPPON STEEL CORP

Measurement method for effective grain size of structural steel with complex microstructure

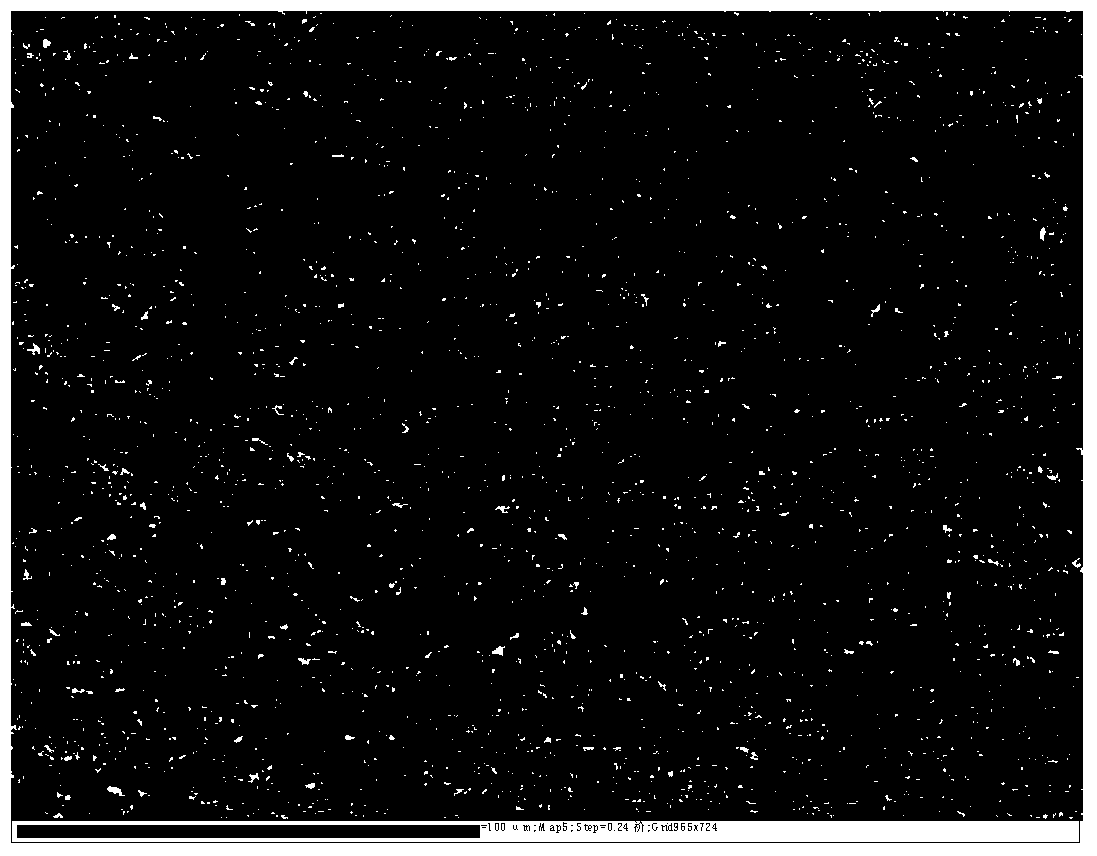

ActiveCN103529065ASolve measurement problemsEfficient measurementMaterial analysis using radiation diffractionMisorientationMicrostructure

The invention relates to a measurement method for the effective grain size of structural steel with a complex microstructure. The method comprises the following steps: acquiring a crystal diffraction pattern by using EBSD; measuring misorientation of crystal boundaries through the diffraction pattern and drafting a misorientation distribution curve chart; calculating threshold values of an effective grain size based on the misorientation distribution curve chart; and measuring transversal or longitudinal space between misorientation of the threshold values of the effective grain size and subjecting space data to statistical treatment so as to obtain average space between misorientation of average threshold values, wherein the average space is the effective grain size of a measured material. According to the invention, misorientation between crystal grains is used as a standard for measurement of the effective grain size, a prediction method for the threshold values of the effective grain size is brought forward, and it is convenient to formulate the threshold values of the effective grain size according to specific conditions of the material.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

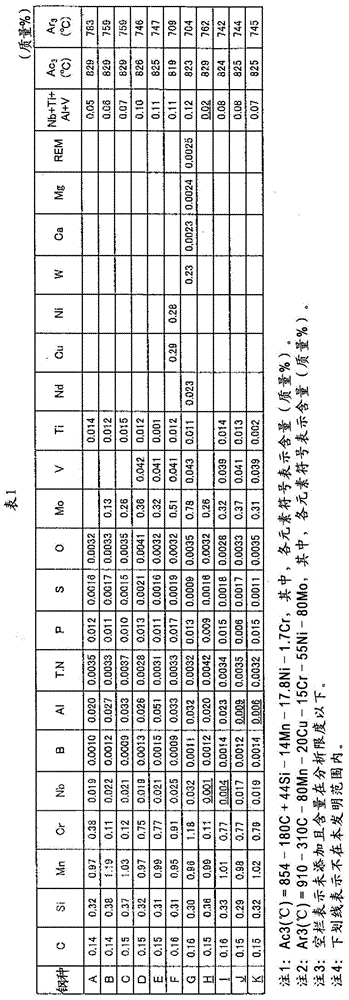

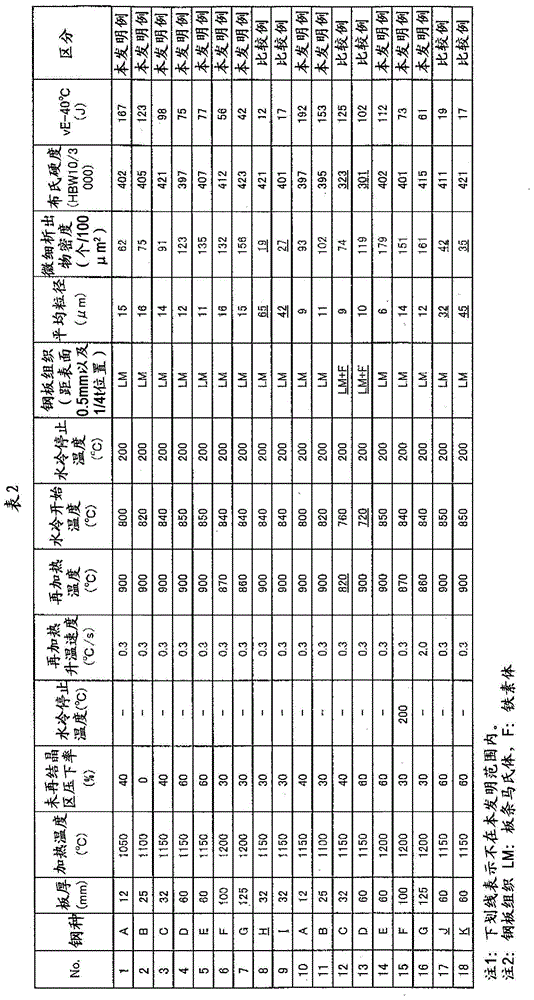

Abrasion resistant steel plate having low-temperature toughness, and manufacturing method therefor

ActiveCN105102656AImprove low temperature toughnessFurnace typesHeat treatment furnacesRare-earth elementHardness

Owner:JFE STEEL CORP

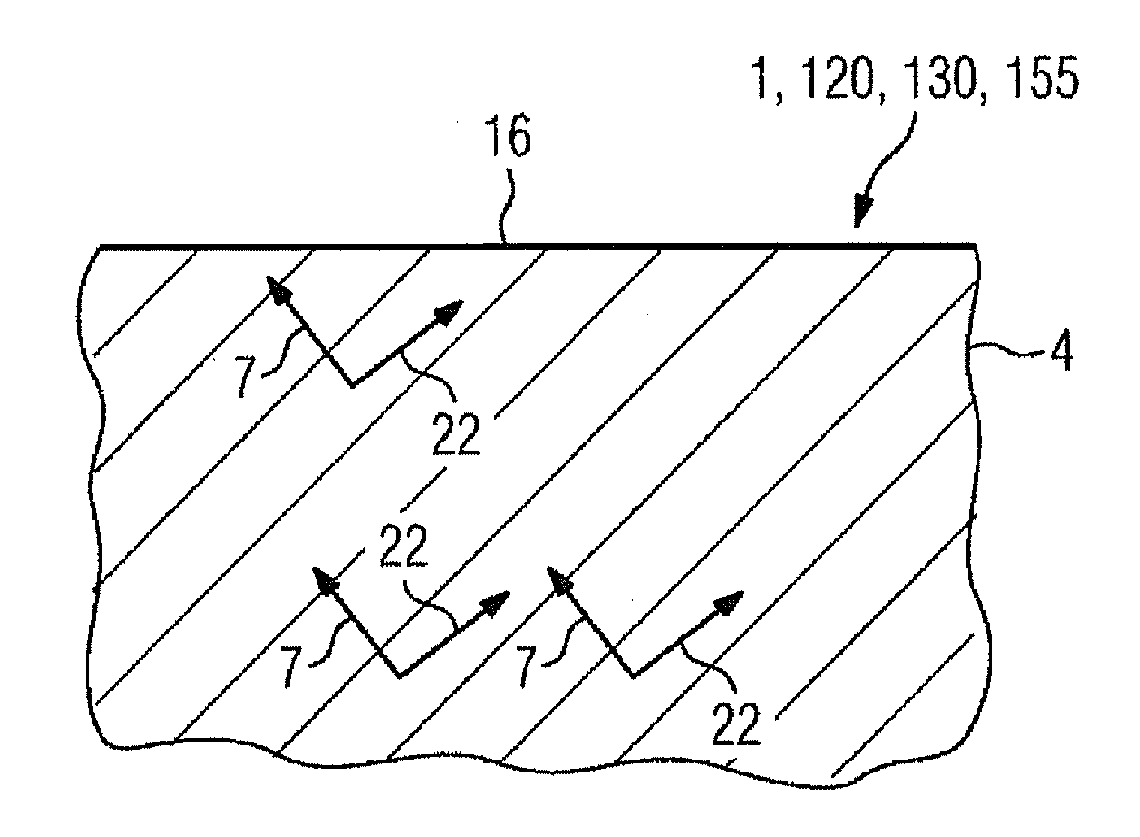

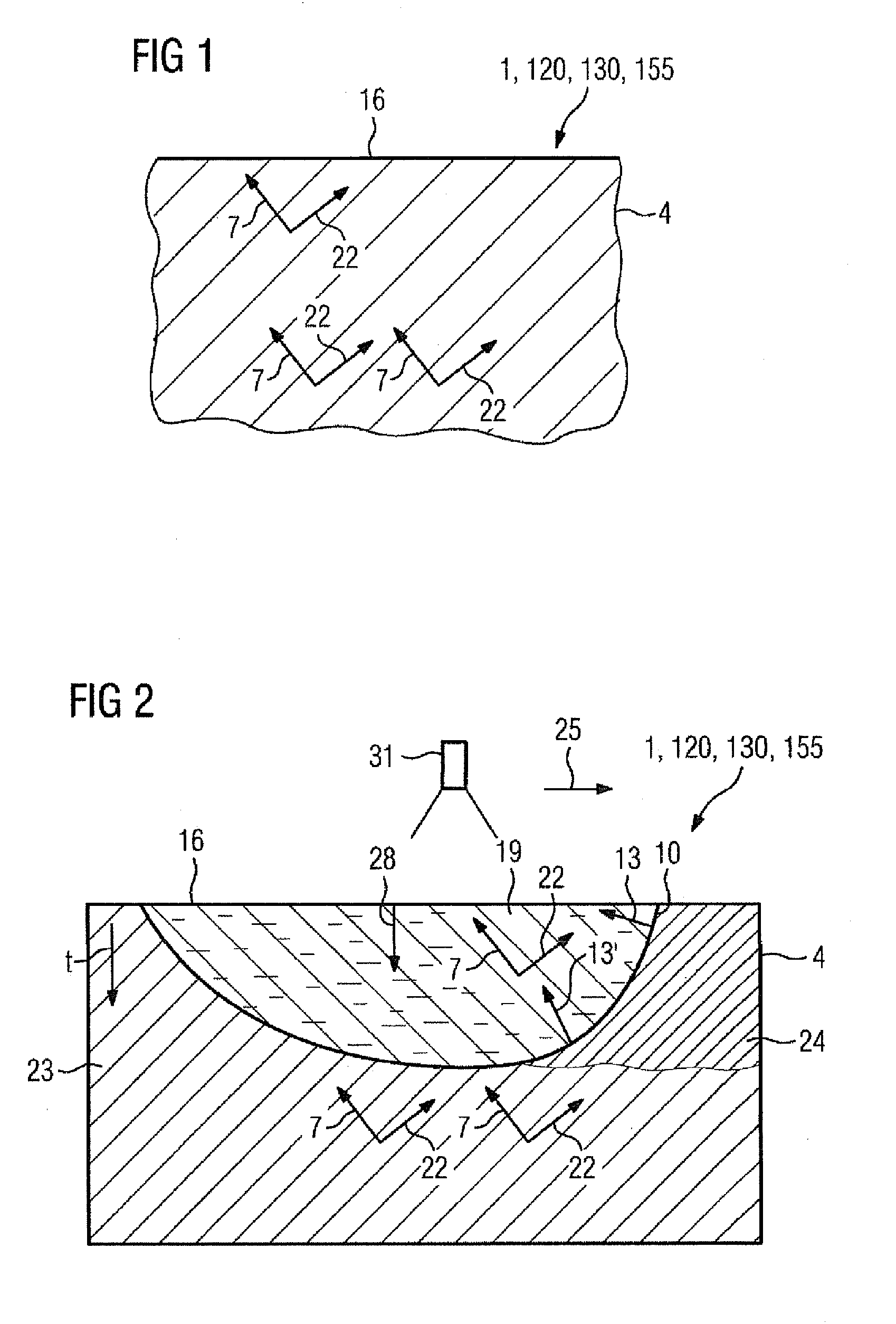

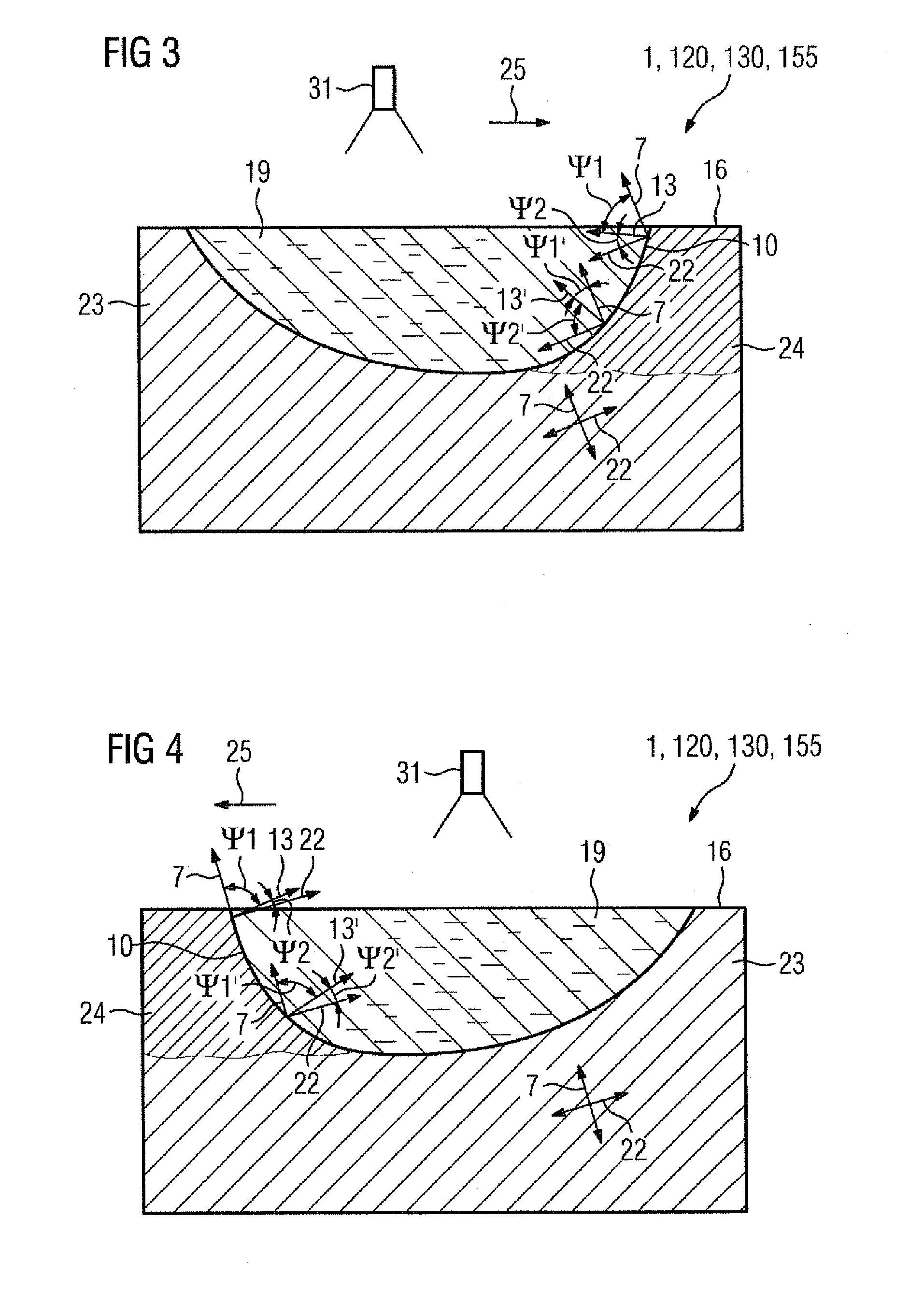

Method for Welding Depending on a Preferred Direction of the Substrate

Welding repairs are often carried out on directionally solidified components that nevertheless do not possess the desired crystallographic surface alignment, which reduces mechanical strength. The method provided selects the direction of travel depending on the crystallographically preferred direction of the substrate such that no more misorientations occur. A laser beam may be used for remelting.

Owner:SIEMENS AG +1

Single-Crystal GaN Substrate

InactiveUS20080219910A1Polycrystalline material growthNitrogen-metal/silicon/boron binary compoundsCrystal orientationSingle crystal

Owner:SUMITOMO ELECTRIC IND LTD

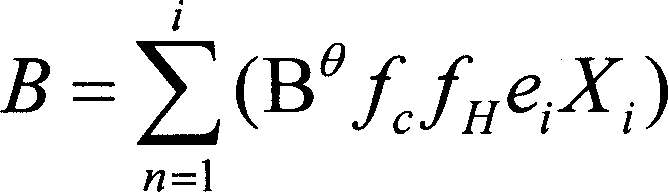

Electrical grade sheet electro-magnetism performance measurement method

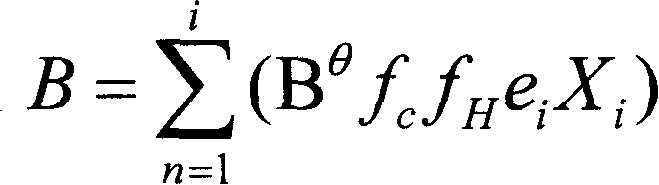

InactiveCN101210947AGood process improvementMagnetic Full ResponseElectrical testingMagnetic property measurementsCrystal orientationEpstein frame

The invention discloses a method of measuring electromagnetic performance of electric steel plates, which is characterized in that the method measures three Euler angles of each sample point orientation in an EBSD system and occupied proportion X of each identical or similar orientation, combining with conjectured coefficient of thickness fH, composition fc and influential factor (e) of misorientation on performance, applies these factors to modify the measuring on the basis of pure iron performance B, which is applicable for small quantity of samples that cannot be measured by Epstein frame, manifesting performance of each micro area of the sample and enabling good effect for the process improvement of the material with the same composition. In addition, the invention provides statistical calculation of crystal orientation of each orientation (100) in the measuring of non-oriented silicon steel, completely reflecting the general magnetic property of steel plates.

Owner:ANGANG STEEL CO LTD

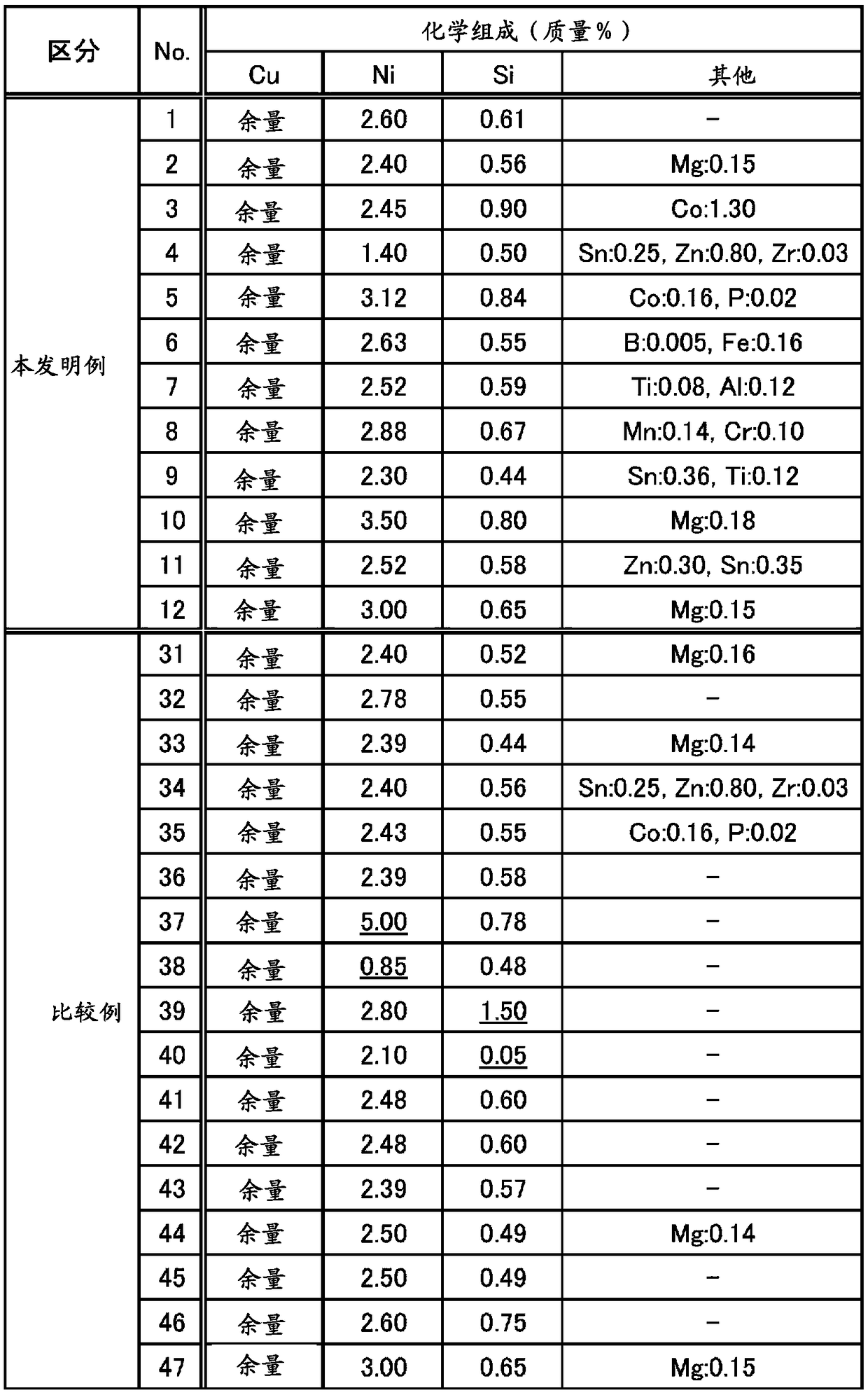

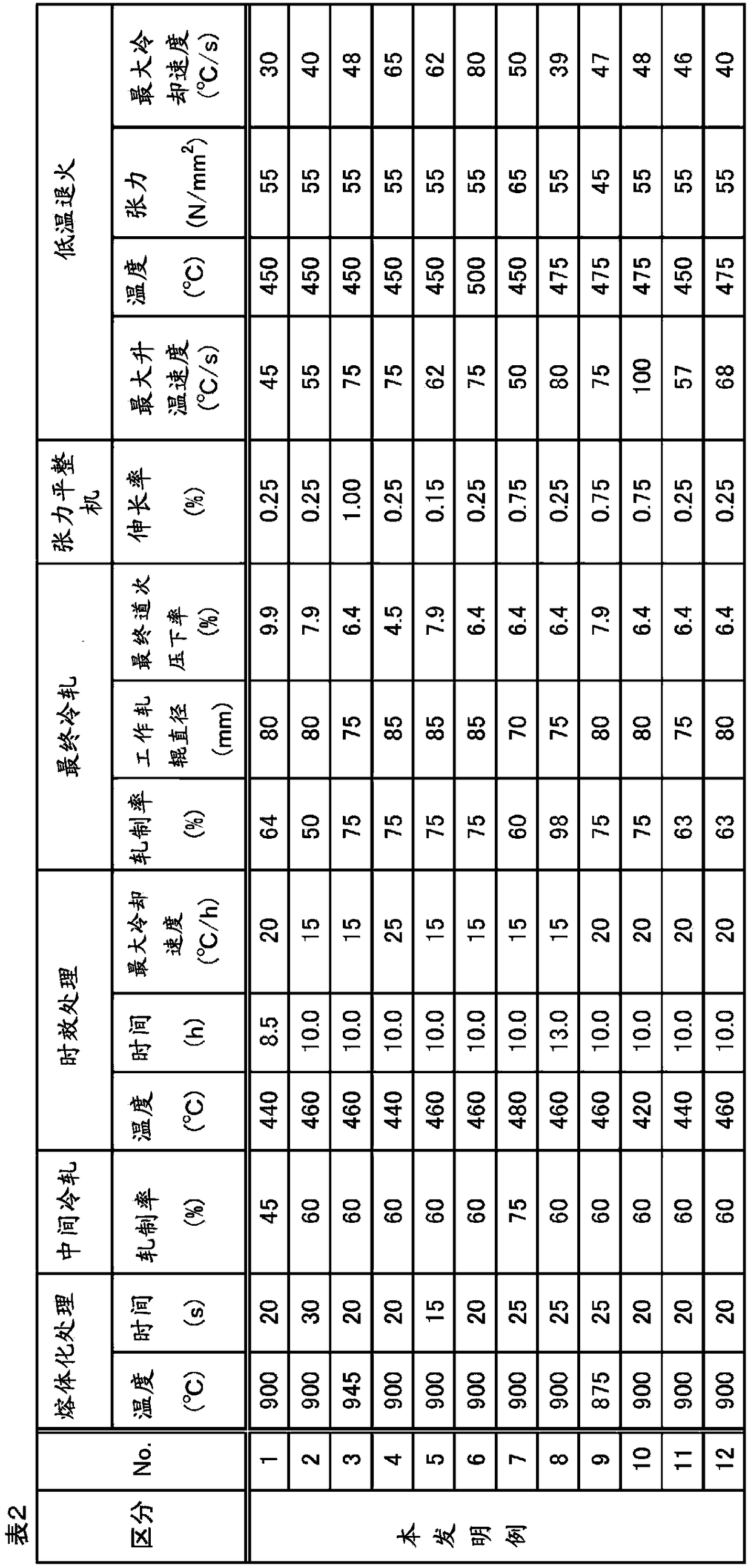

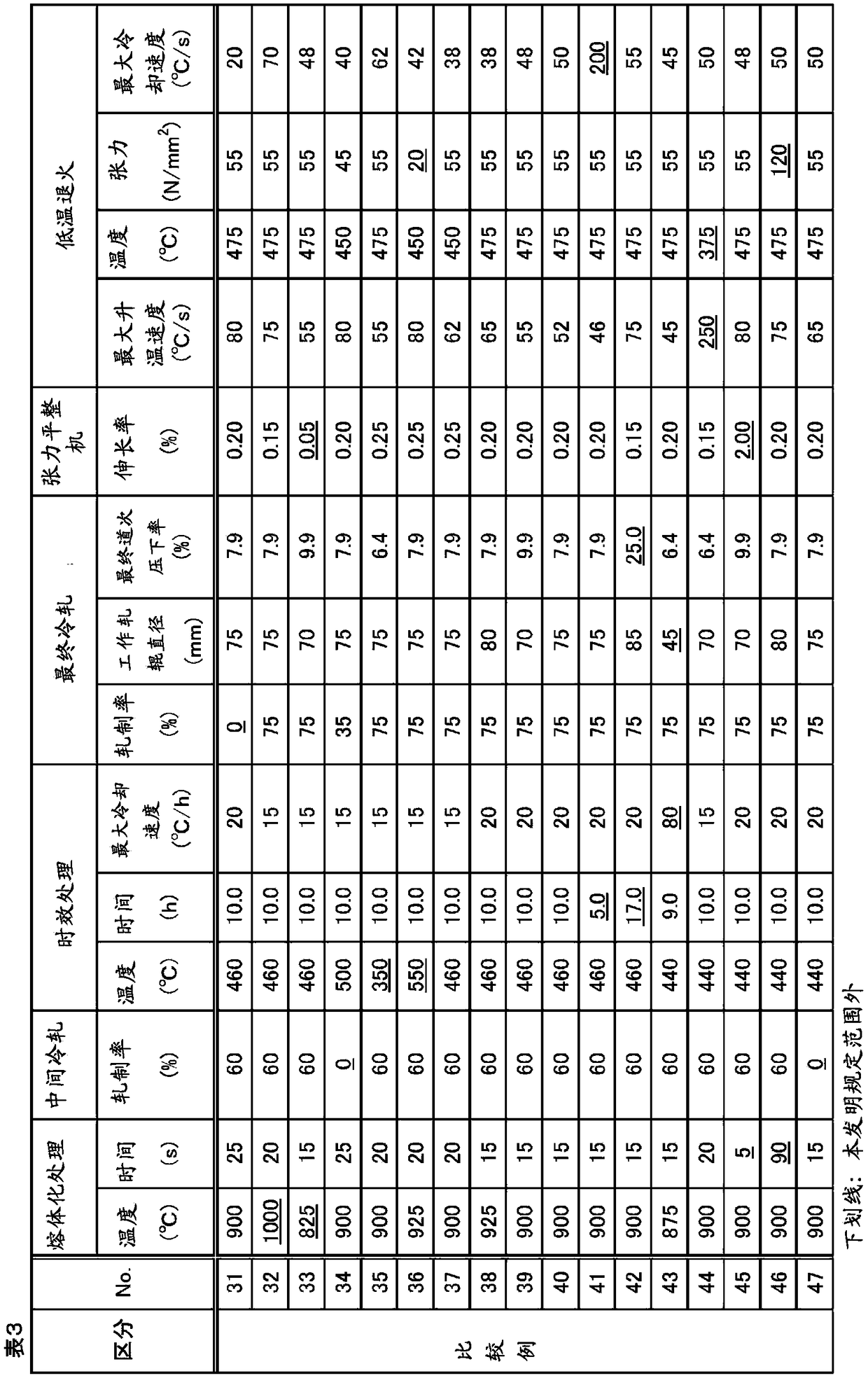

Cu-Ni-Si COPPER ALLOY SHEET AND MANUFACTURING METHOD

ActiveCN109072341AImprove surface smoothnessHigh dimensional accuracyMetal rolling arrangementsImpuritySurface smoothness

The invention provides a high strength Cu-Ni-Si copper alloy sheet with excellent surface smoothness of the etching surface. The copper alloy sheet having a composition made, in mass%, of Ni: 1.0-4.5%, Si: 0.1-1.2%, Mg:0-0.3%, Cr: 0-0.2%, Co: 0-2.0%, P: 0-0.1%, B: 0-0.05%, Mn: 0-0.2%, Sn: 0-0.5%, Ti: 0-0.5%, Zr: 0-0.2%, Al: 0-0.2%, Fe: 0-0.3%, and Zn: 0-1.0%, the balance being Cu and unavoidable impurities. In an observation plane parallel to the sheet surface, the number density of coarse second phase particles with a major axis of at least 1.0 [mu]m is 4.0 * 10<3> / mm2 or less and the KAM value in crystal grains measured by EBSD with a step size of 0.5 [mu]m when boundaries with crystal misorientations of at least 15 DEG are considered to be crystal grain boundaries is greater than 3.00.

Owner:DOWA METALTECH CO LTD

Connector

ActiveUS10249969B2Improve reliabilityIncorrect coupling preventionCoupling contact membersMating connectionLeft direction

High reliability is achieved with a protected state guaranteed for housings with reinforcing brackets being rigid to be free from displacement and misorientation. A connector includes: a connector body; a terminal installed in the connector body; and a reinforcing bracket fit to the connector body. The connector body includes a recess in which a mating connector body of a mating connector fits, and an insular part that is in the recess and fits in a groove part of the mating connector body. The reinforcing bracket includes an inner reinforcing bracket fit to an insular end part that is an end portion of the insular part in a longitudinal direction. The inner reinforcing bracket includes a body part that is disposed on an upper surface of the insular end part, an end plate that is connected to the body part and is disposed on an end surface of the insular end part, a pair of side plates that are connected to right and left ends of the body part and are disposed on right and left side surfaces of the insular end part, and a pair of connecting legs that are each connected to a lower end of a corresponding one of the side plates and extend outward in a right and left direction of the connector body.

Owner:MOLEX INC

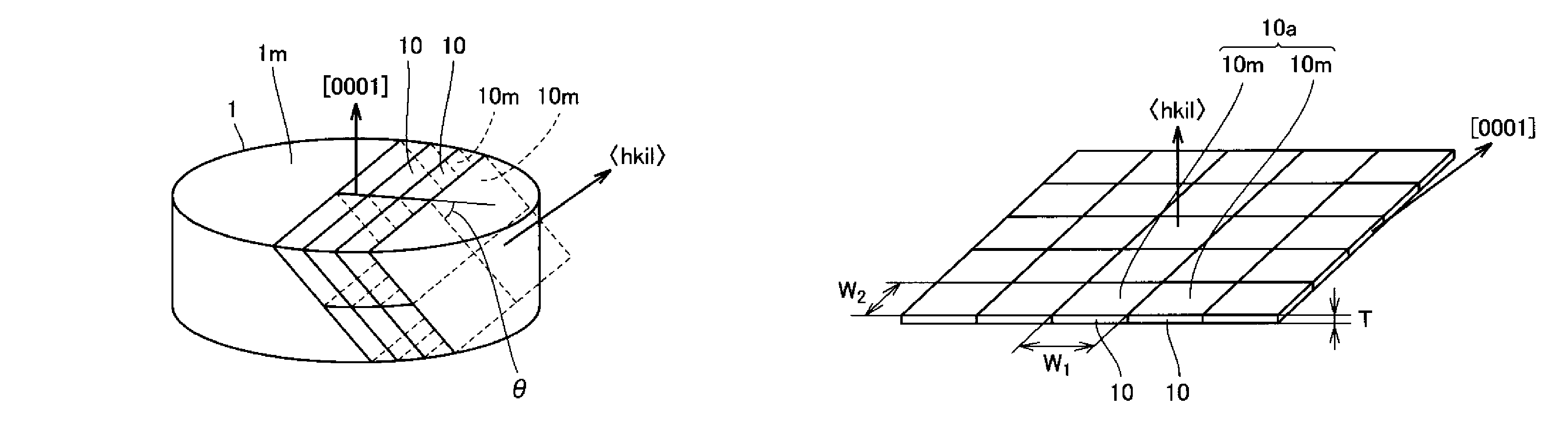

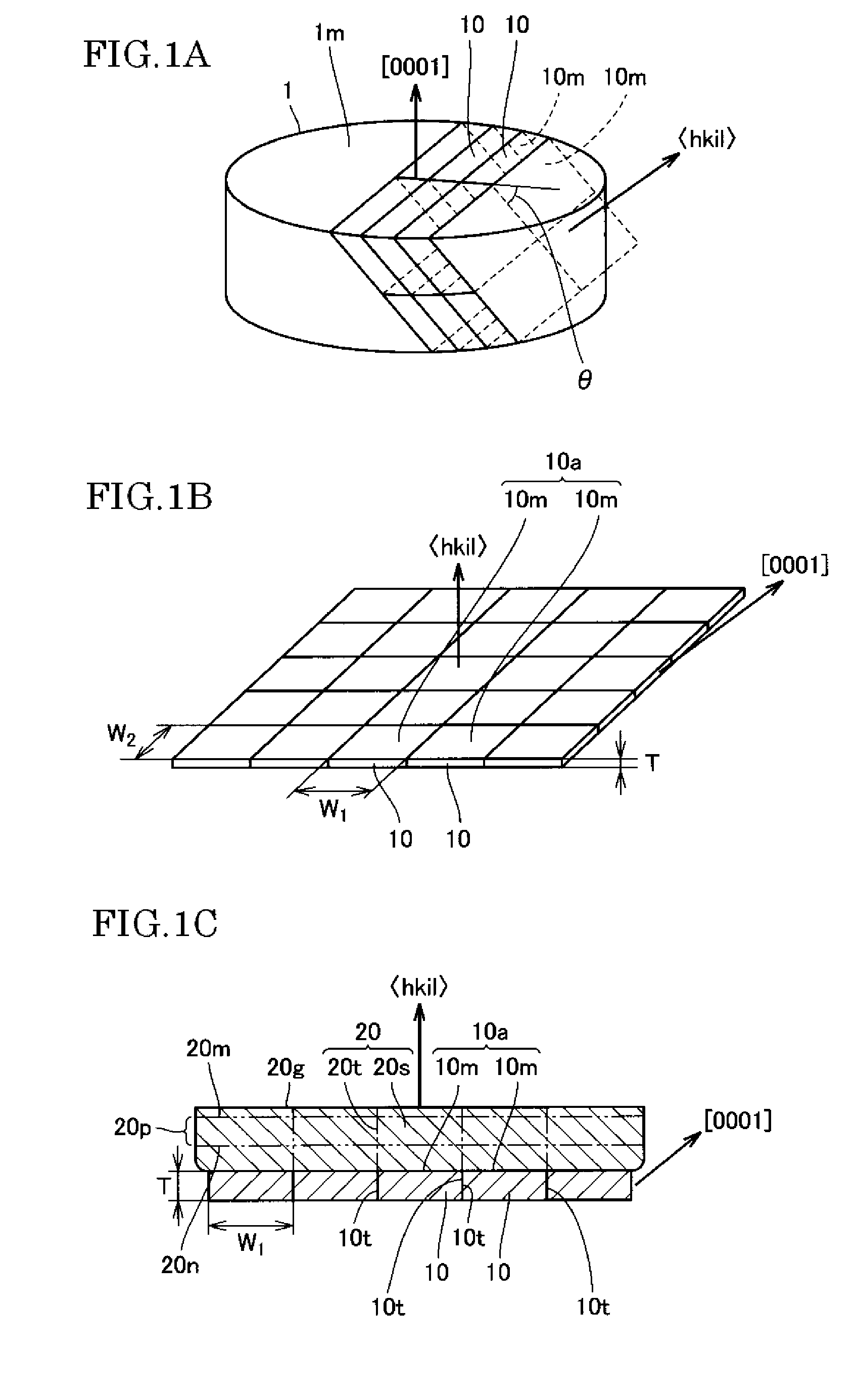

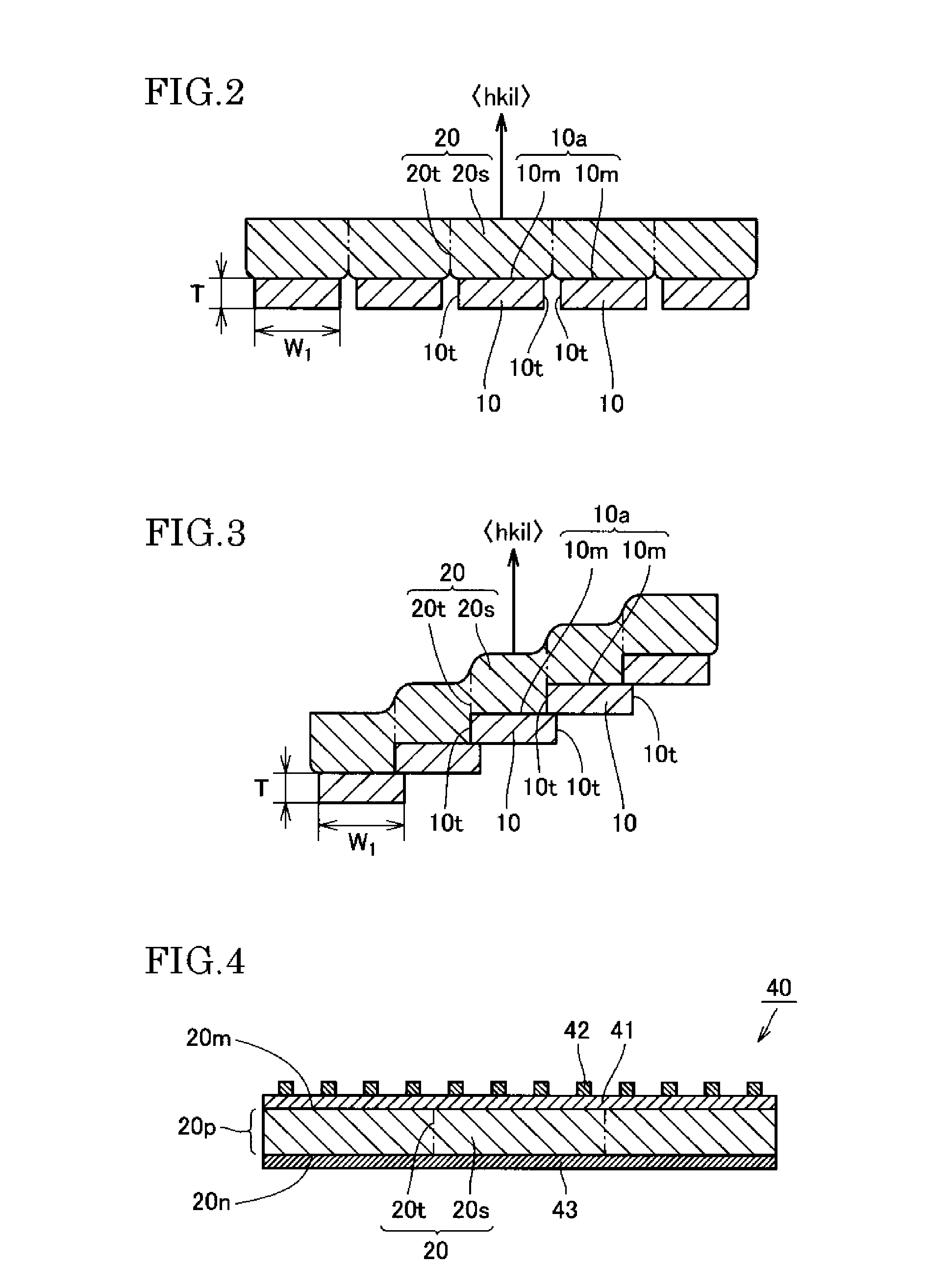

Method of manufacturing III nitride crystal, III nitride crystal substrate, and semiconductor device

ActiveUS7964477B2Polycrystalline material growthLiquid-phase epitaxial-layer growthDevice materialPlane orientation

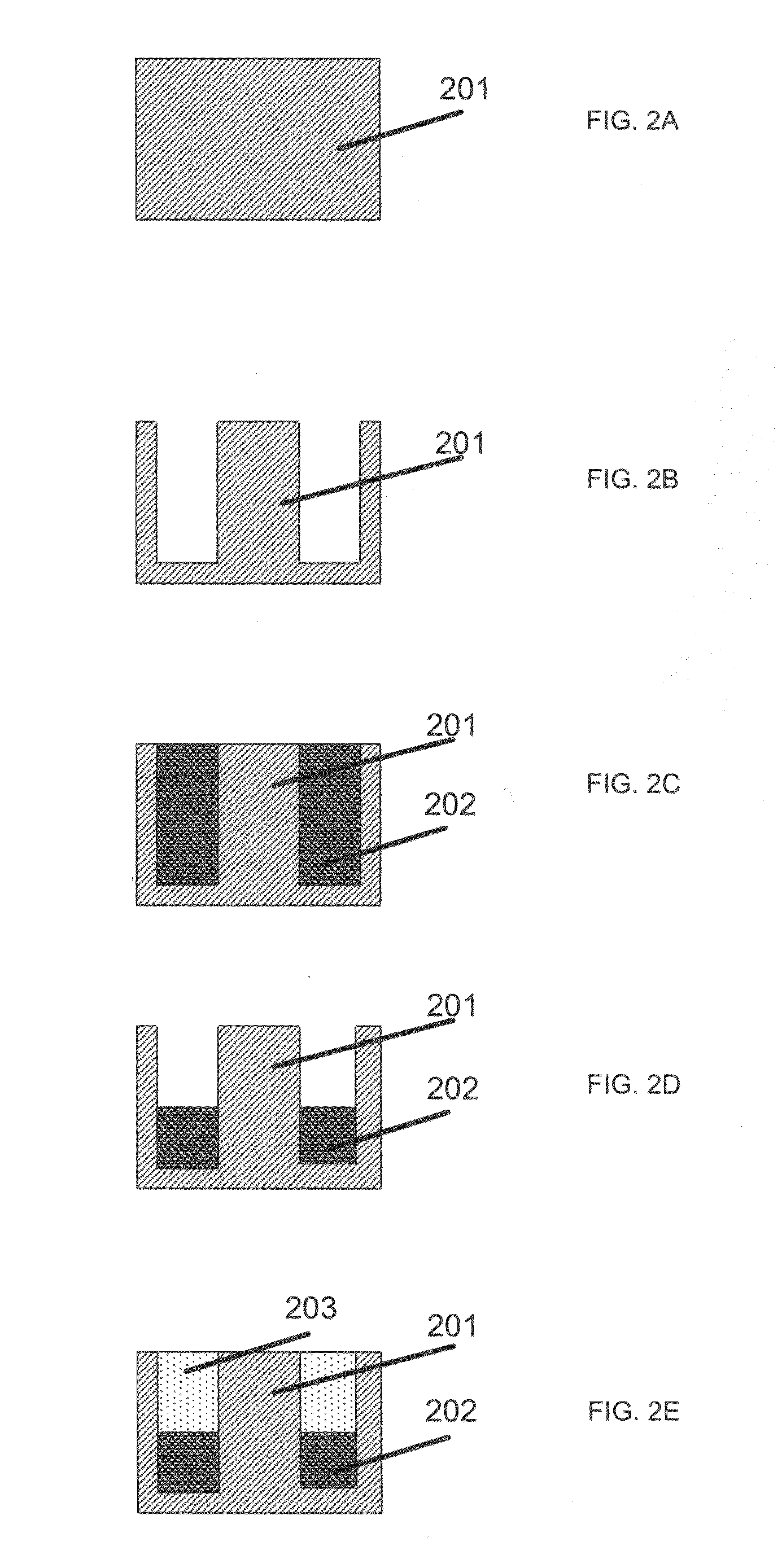

Affords III-nitride crystals having a major surface whose variance in crystallographic plane orientation with respect to an {hkil} plane chosen exclusive of the {0001} form is minimal. A method of manufacturing the III-nitride crystal is one of: conditioning a plurality of crystal plates (10) in which the deviation in crystallographic plane orientation in any given point on the major face (10m) of the crystal plates (10), with respect to an {hkil} plane chosen exclusive of the {0001} form, is not greater than 0.5°; arranging the plurality of crystal plates (10) in a manner such that the plane-orientation deviation, with respect to the {hkil} plane, in any given point on the major-face (10m) collective surface (10a) of the plurality of crystal plates (10) will be not greater than 0.5°, and such that at least a portion of the major face (10m) of the crystal plates (10) is exposed; and growing second III-nitride crystal (20) onto the exposed areas of the major faces (10m) of the plurality of crystal plates (10).

Owner:SUMITOMO ELECTRIC IND LTD

Steel sheet and plated steel sheet

ActiveUS20190233926A1High strengthImprove ductilityHot-dipping/immersion processesFurnace typesMaximum diameterMetallurgy

A steel sheet has a specific chemical composition and has a structure represented by, by area ratio, ferrite: 5 to 95%, and bainite: 5 to 95%. When a region that is surrounded by a grain boundary having a misorientation of 15° or more and has a circle-equivalent diameter of 0.3 μm or more is defined as a crystal grain, the proportion of crystal grains each having an intragranular misorientation of 5 to 14° to all crystal grains is 20 to 100% by area ratio. Hard crystal grains A in which precipitates or clusters with a maximum diameter of 8 nm or less are dispersed in the crystal grains with a number density of 1×1016 to 1×1019 pieces / cm3 and soft crystal grains B in which precipitates or clusters with a maximum diameter of 8 nm or less are dispersed in the crystal grains with a number density of 1×1015 pieces / cm3 or less are contained, and the volume % of the hard crystal grains A / (the volume % of the hard crystal grains A +the volume % of the soft crystal grains B) is 0.1 to 0.9.

Owner:NIPPON STEEL CORP

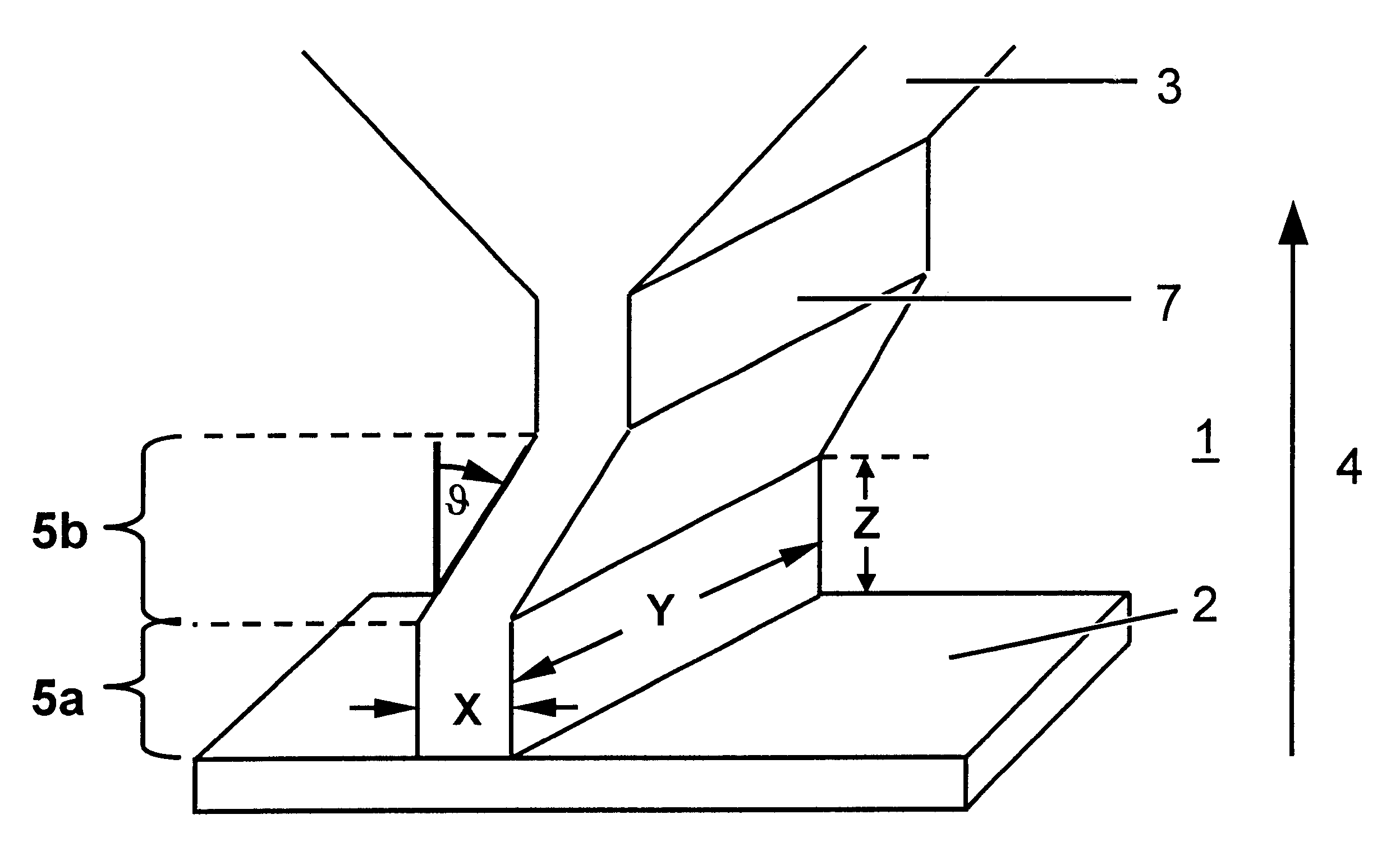

Method for manufacture of a directionally solidified columnar grained article

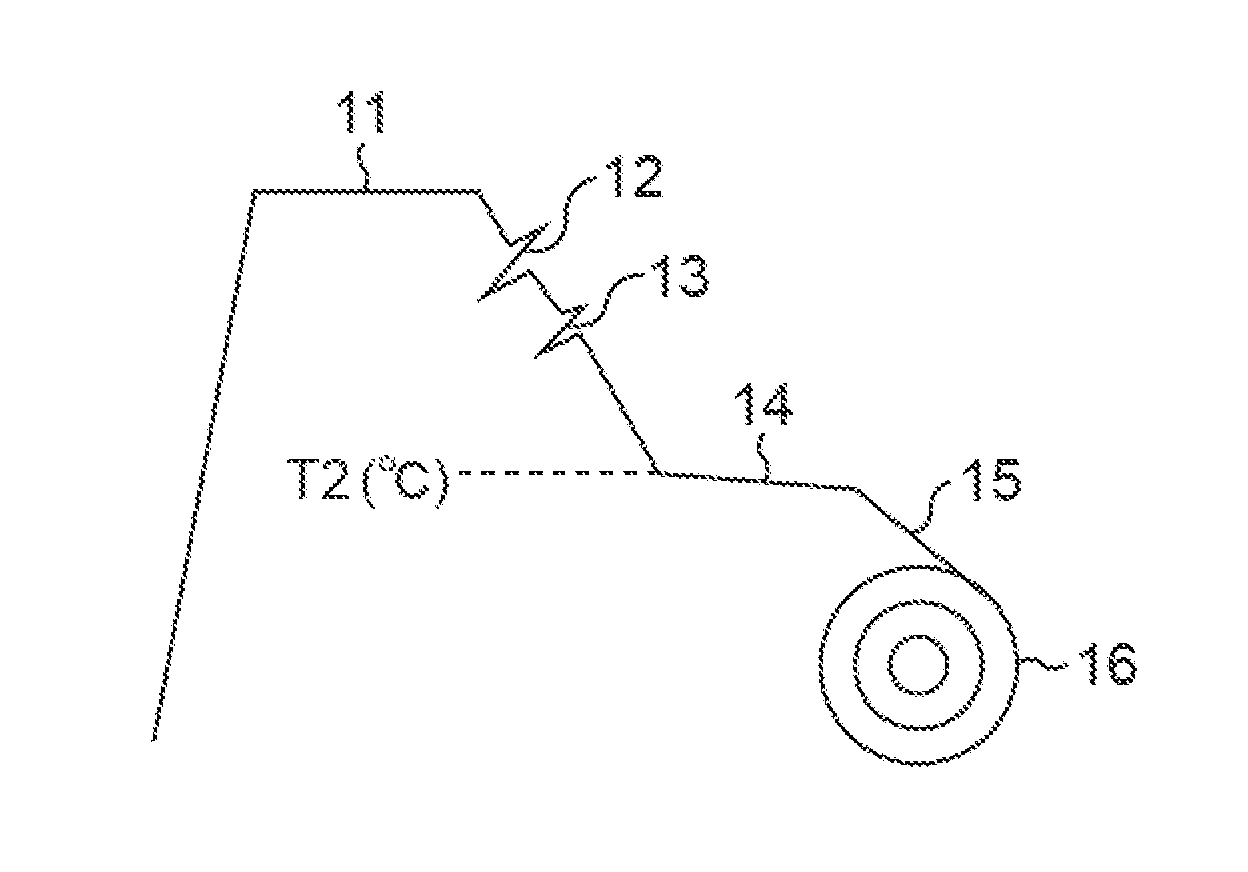

InactiveUS6568456B1Strong transverse propertyLow incremental costPolycrystalline material growthFrom frozen solutionsCooling chamberLiquid metal

A method and an apparatus for manufacturing a directionally solidified columnar grained article with a reduced amount of secondary misorientation of the columnar grains. The method employs a casting assembly comprising a mold with a cavity, a selector section at a lower end of the mold, a heating chamber and a cooling chamber. The mold is fed with a liquid metal and then removed from the heating chamber to the cooling chamber where the columnar grained article is solidified. The article is solidified with at least two dendrites or grains emerging from the selector section and entering the main cavity of the shell mold. Further, the selector section is configured so that no dendrite or grain grows from the bottom of the selector section into the shell mold cavity along a continuous path of purely vertical growth.

Owner:ANSALDO ENERGIA IP UK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com