Measurement method for effective grain size of structural steel with complex microstructure

A technology of grain size and microstructure, applied in the field of measuring the effective grain size of steel with complex microstructure, can solve the problem that the effective grain size threshold is difficult to measure, and achieve the effect of intuitive and convenient measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

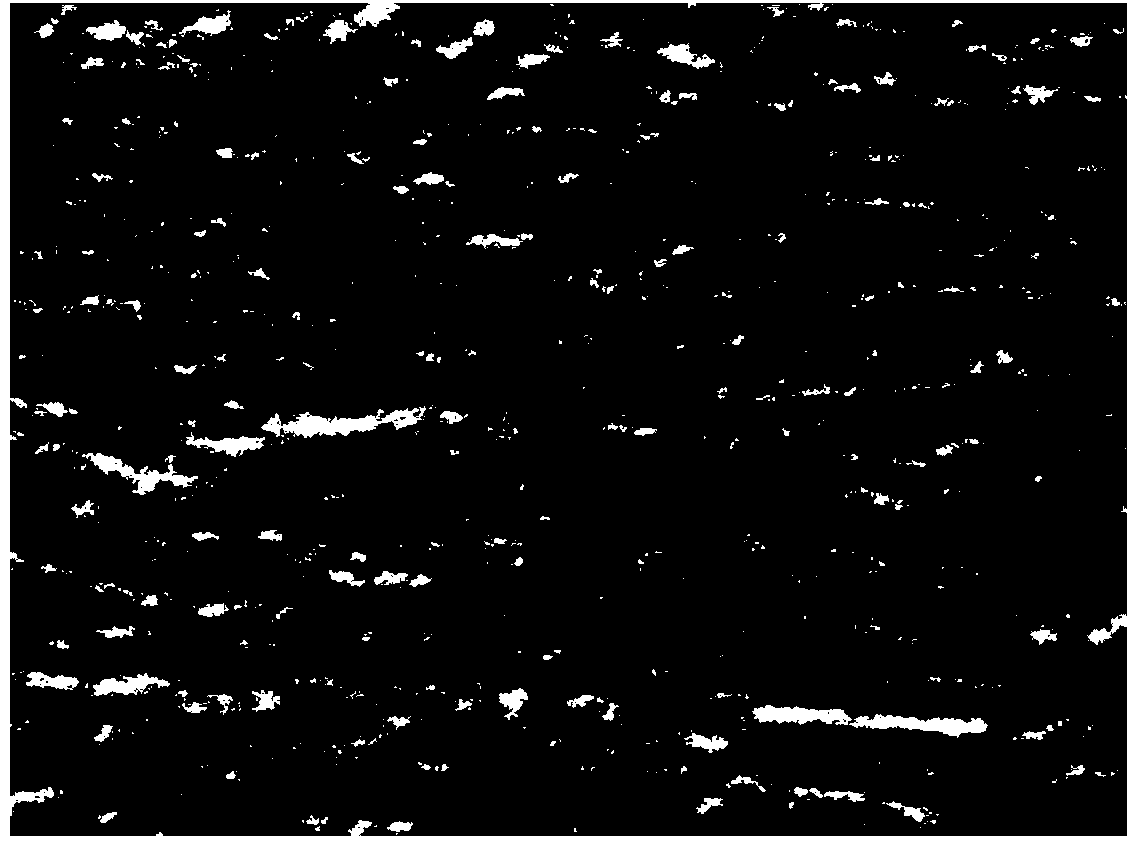

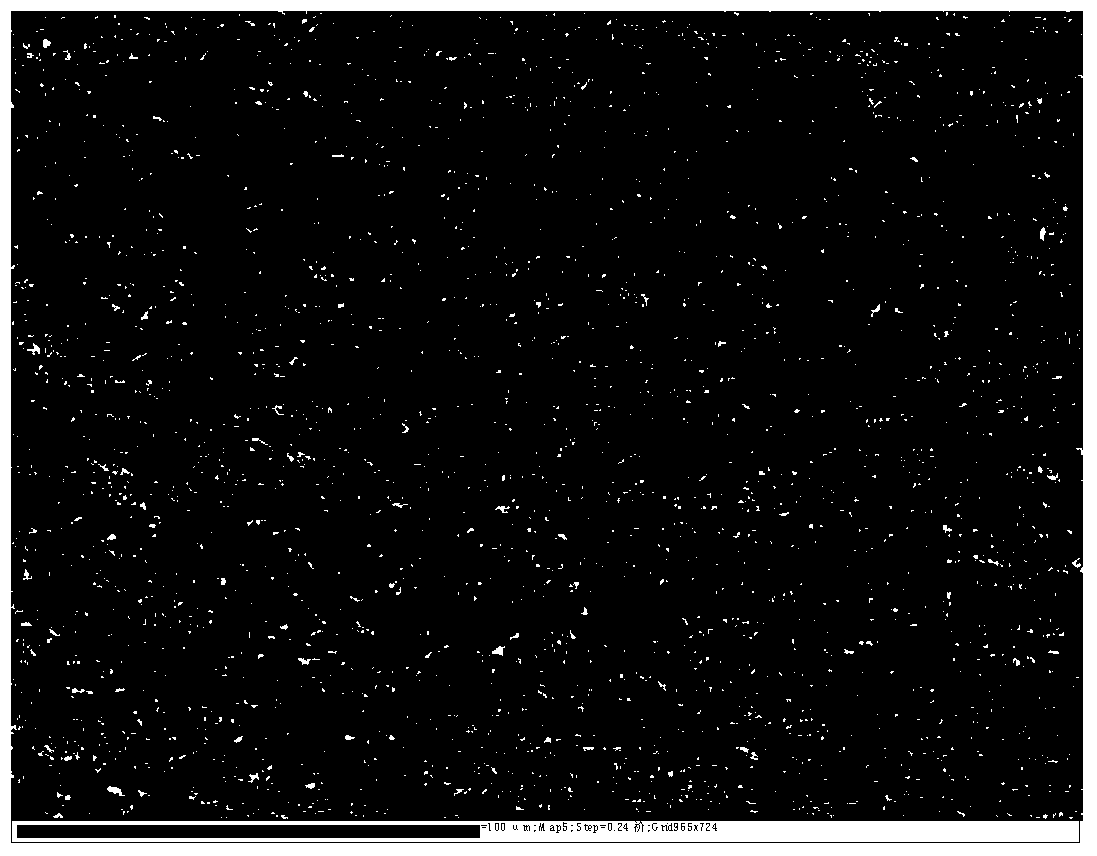

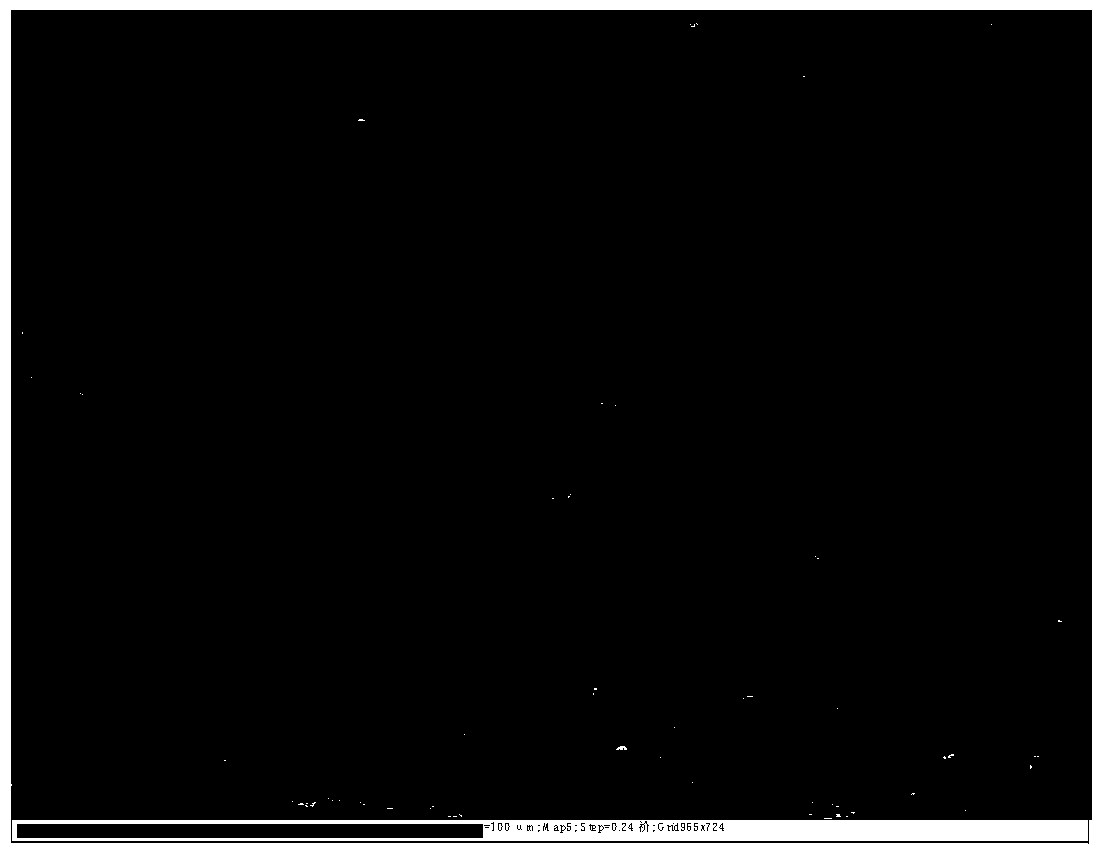

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0040] The materials used in the embodiment are X80 grade large deformation straight seam submerged arc welded pipeline steel pipes.

[0041] Sample interception: use wire cutting method to intercept 10×5×3(mm 3 ) size sample, when measuring, the long side of 10mm is parallel to the RD direction of the sample coordinate system, the short side of 5mm is parallel to the TD direction of the sample coordinate system, and the short side of 3mm is parallel to the ND direction of the sample coordinate system (see attached Figure 5 ). The measuring surface is the surface perpendicular to the TD direction, called the TD surface, and the measuring surface size is 10×3(mm 2 ).

[0042] Use No. 600 water sandpaper to polish each section of the sample, and use No. 600, No. 800, No. 1000, No. 1200, No. 1500, No. 2000 water sandpaper t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com