Patents

Literature

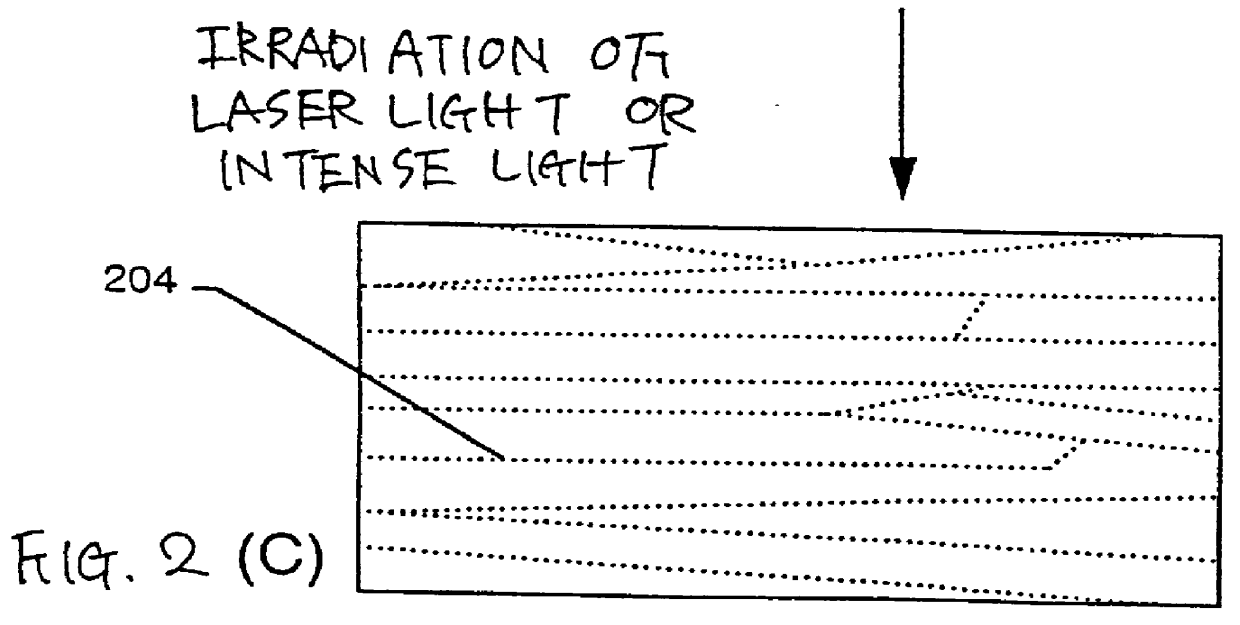

4899 results about "Grain boundary" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A grain boundary is the interface between two grains, or crystallites, in a polycrystalline material. Grain boundaries are 2D defects in the crystal structure, and tend to decrease the electrical and thermal conductivity of the material. Most grain boundaries are preferred sites for the onset of corrosion and for the precipitation of new phases from the solid. They are also important to many of the mechanisms of creep. On the other hand, grain boundaries disrupt the motion of dislocations through a material, so reducing crystallite size is a common way to improve mechanical strength, as described by the Hall–Petch relationship. The study of grain boundaries and their effects on the mechanical, electrical and other properties of materials forms an important topic in materials science.

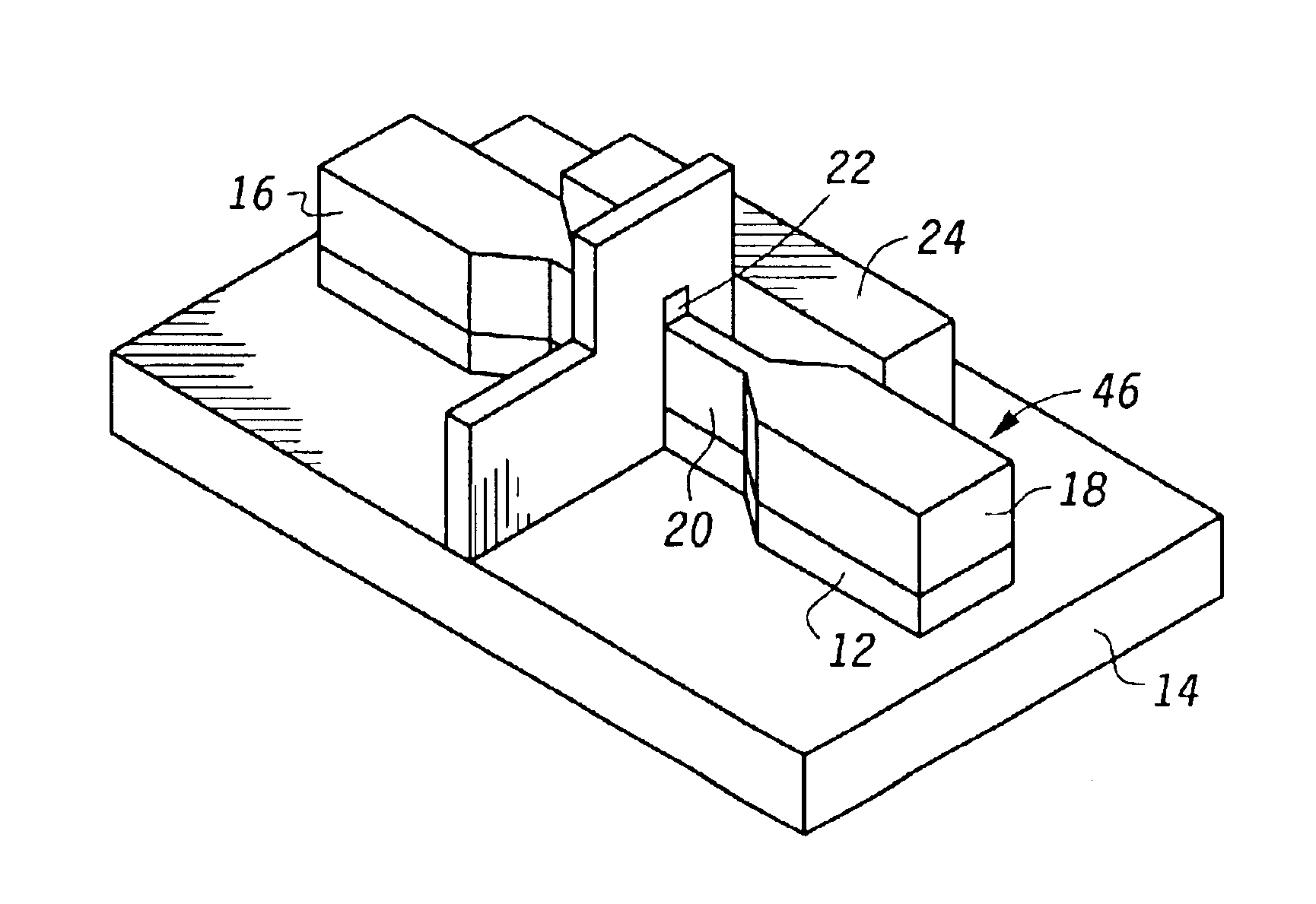

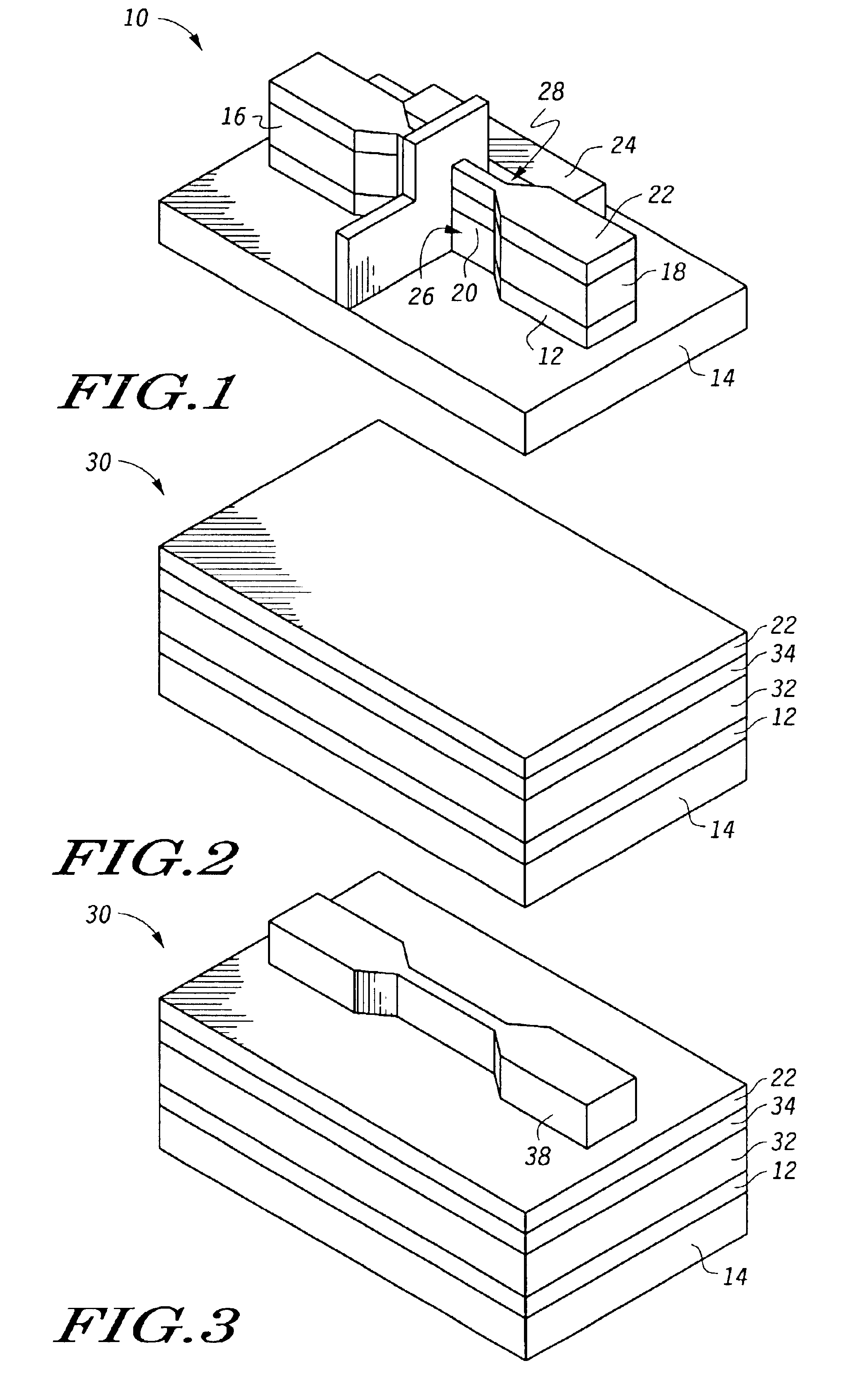

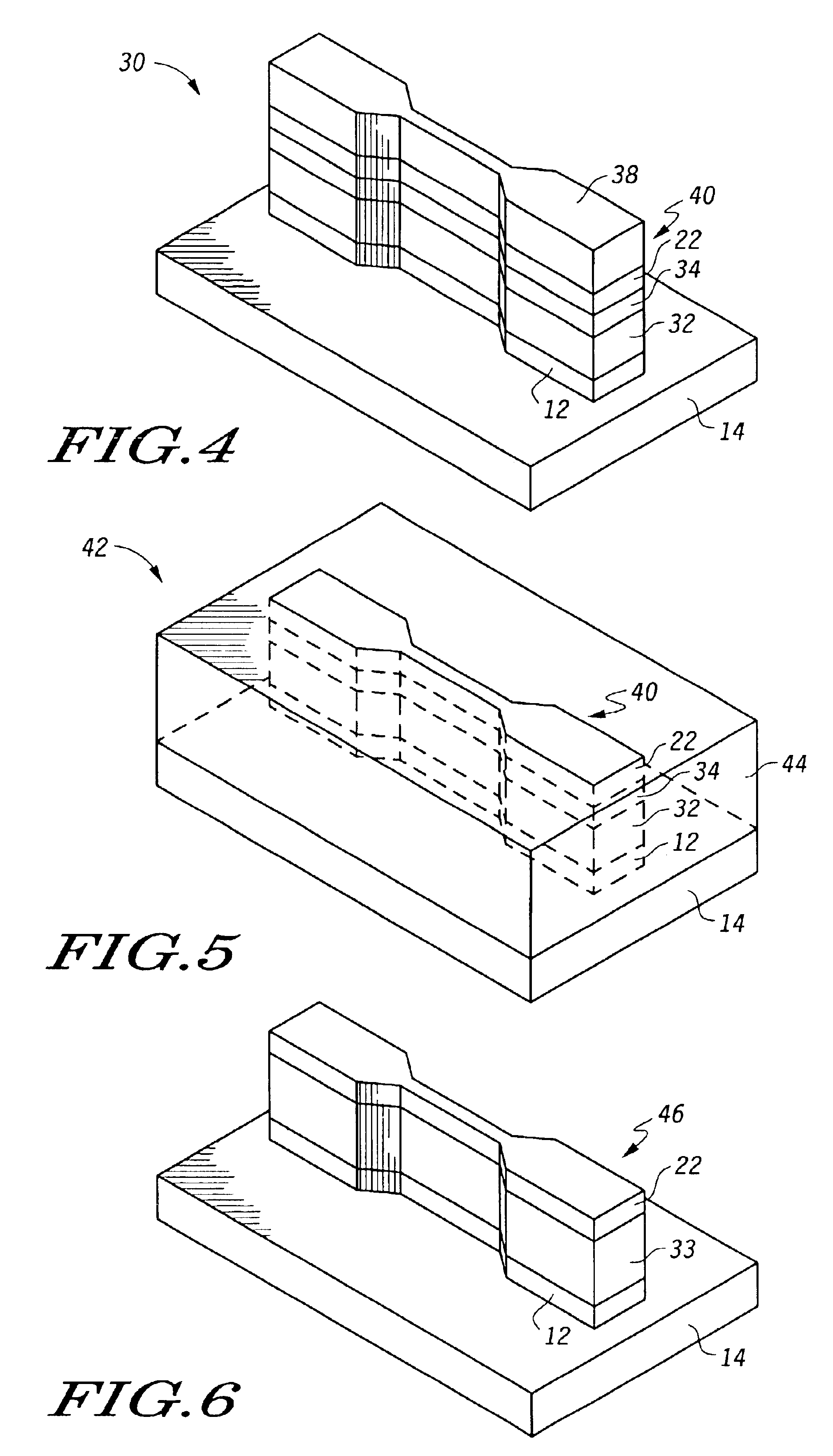

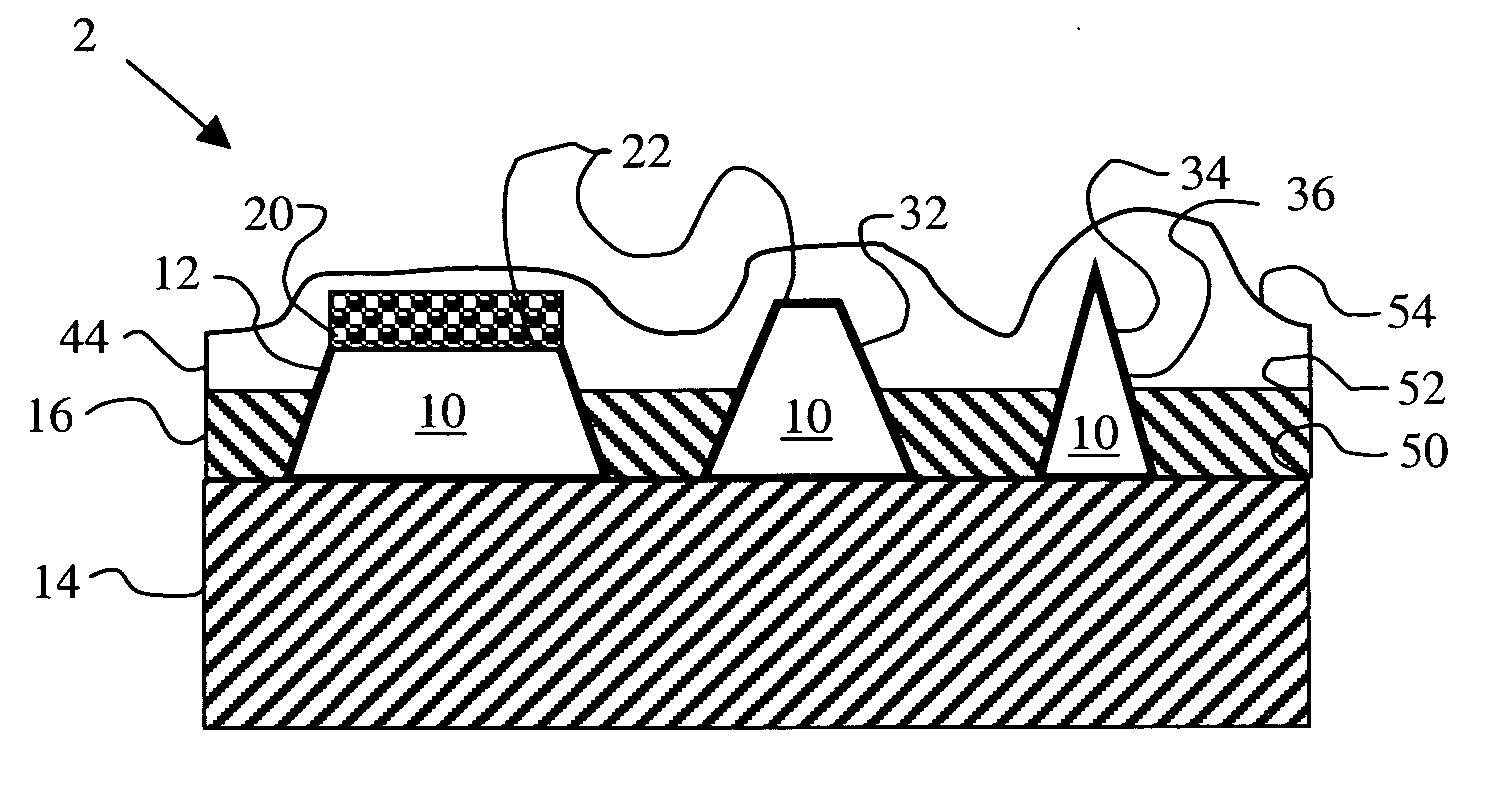

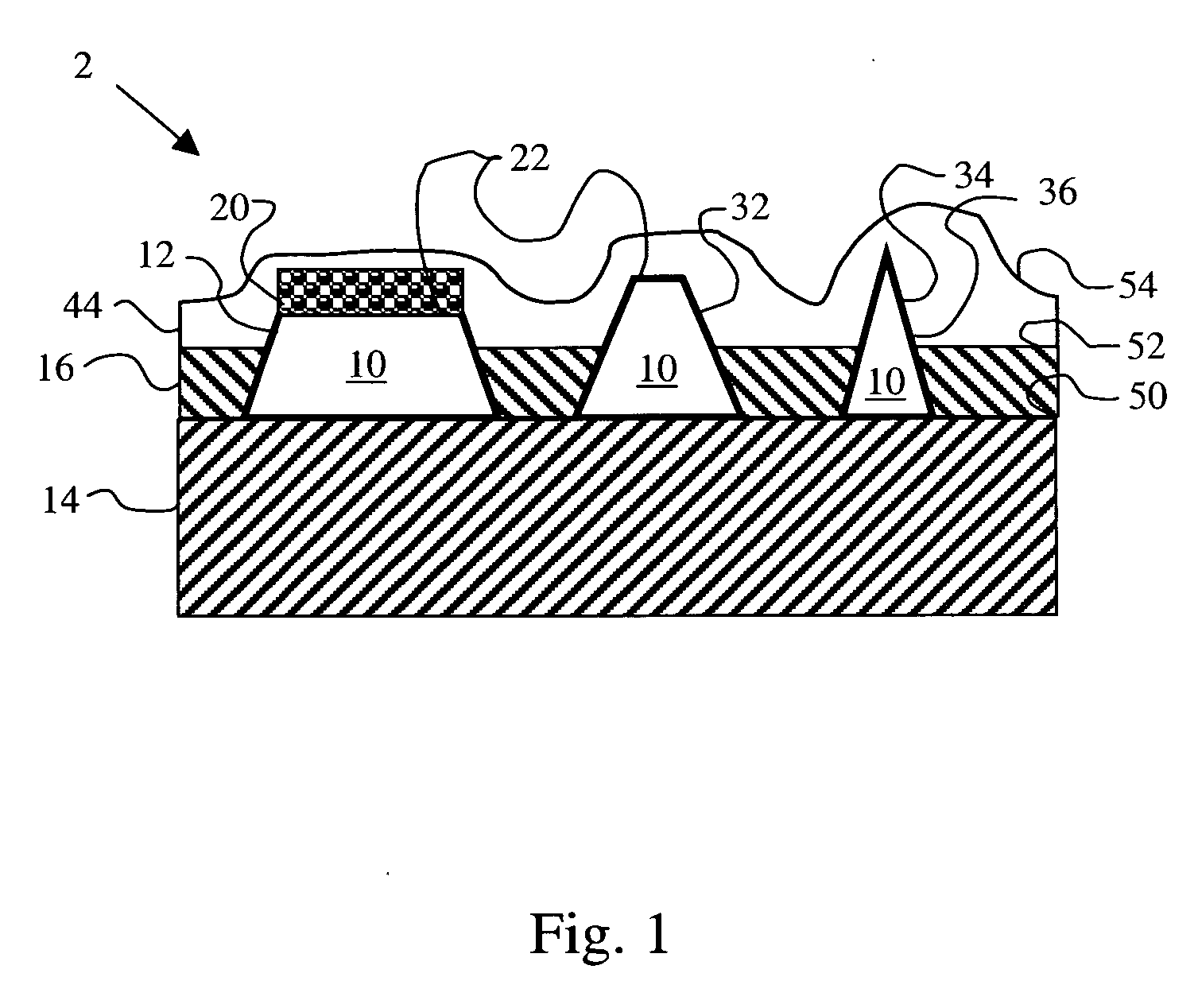

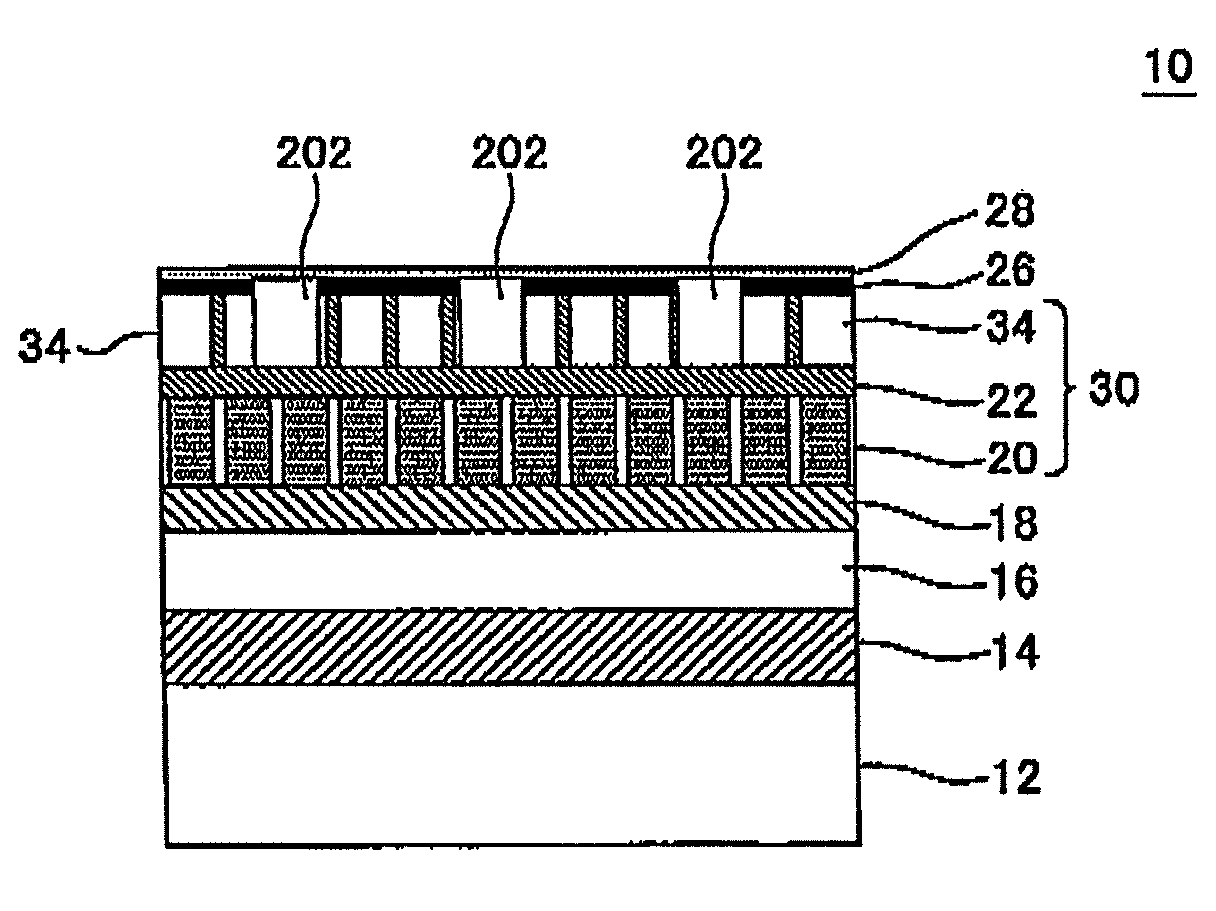

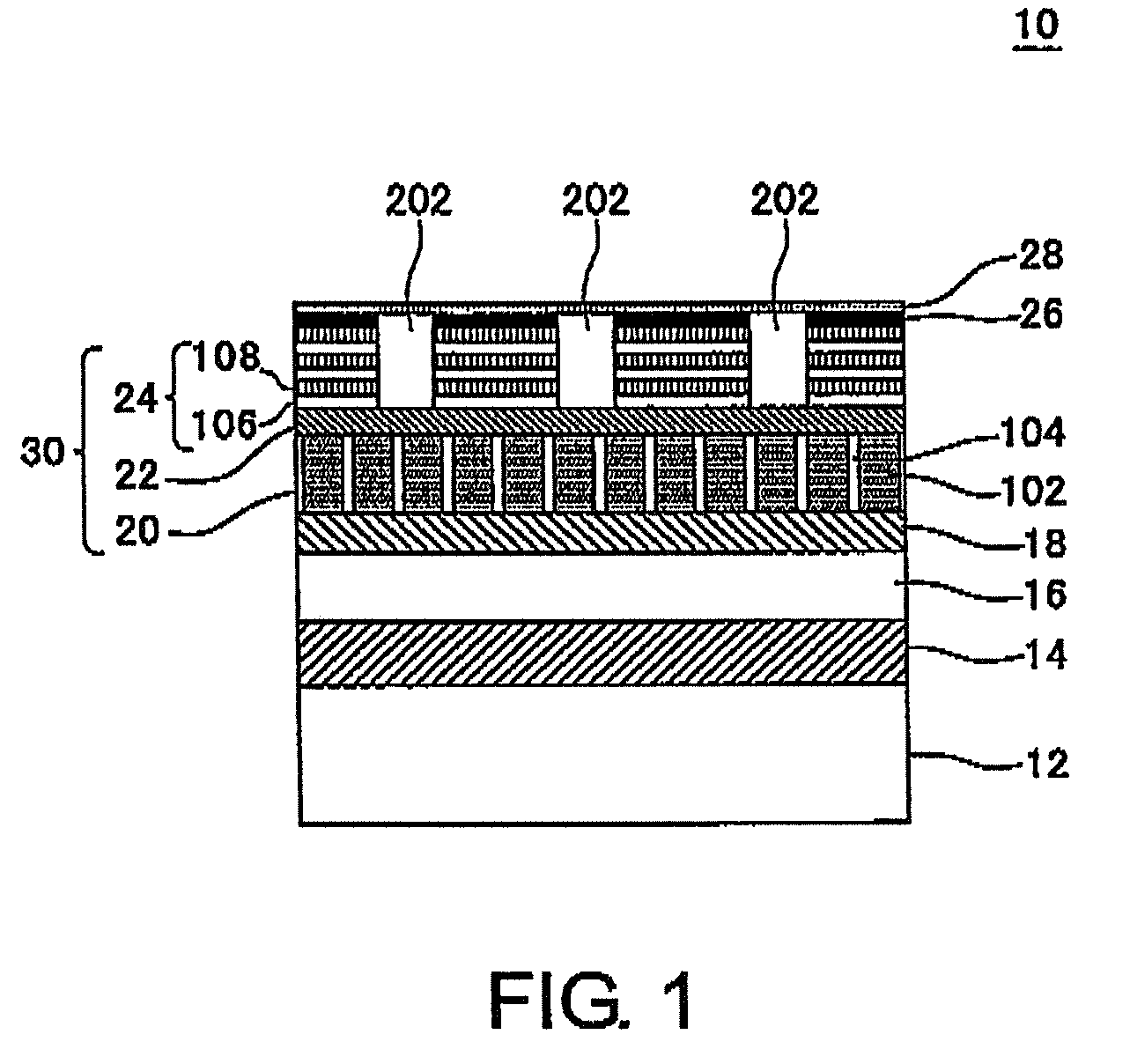

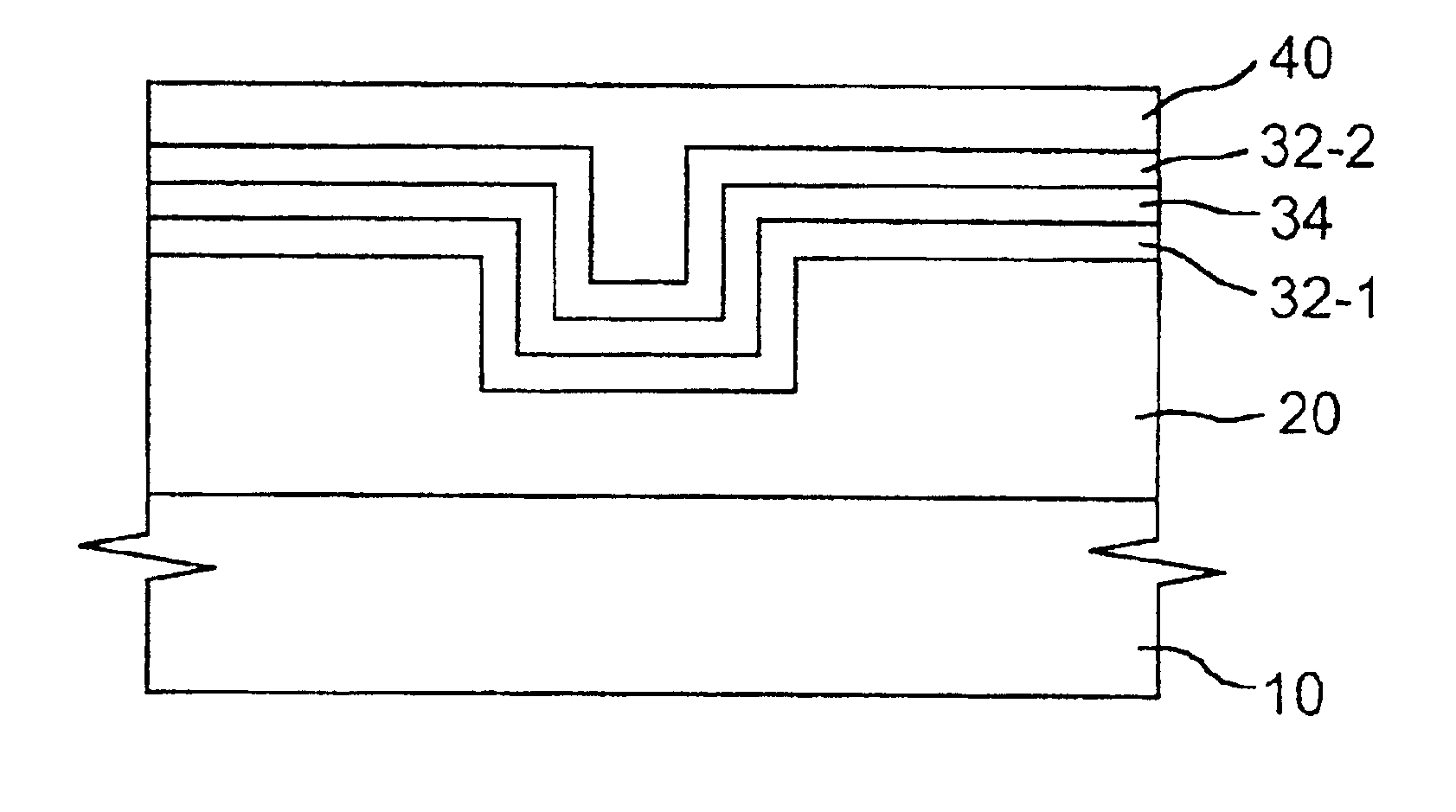

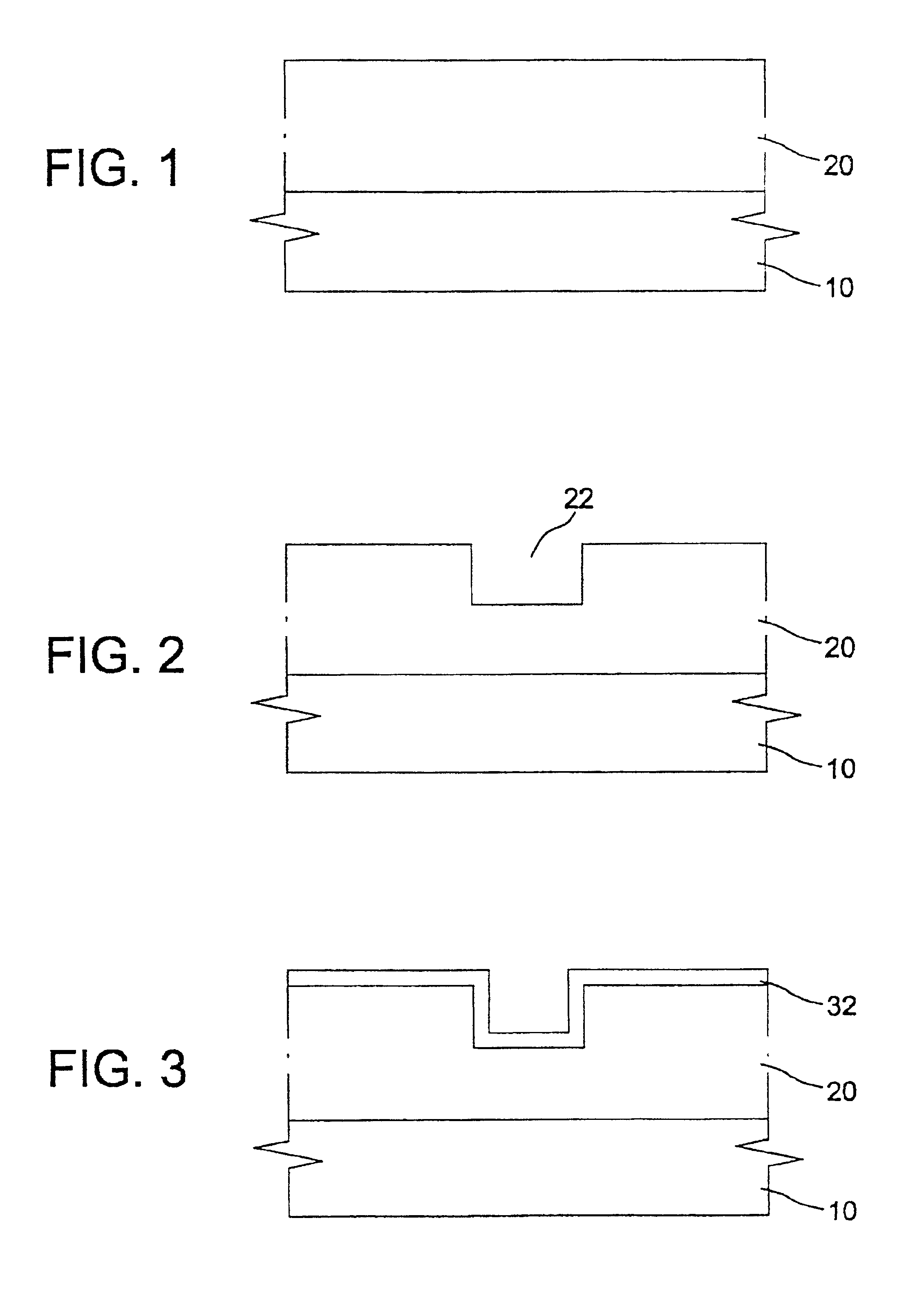

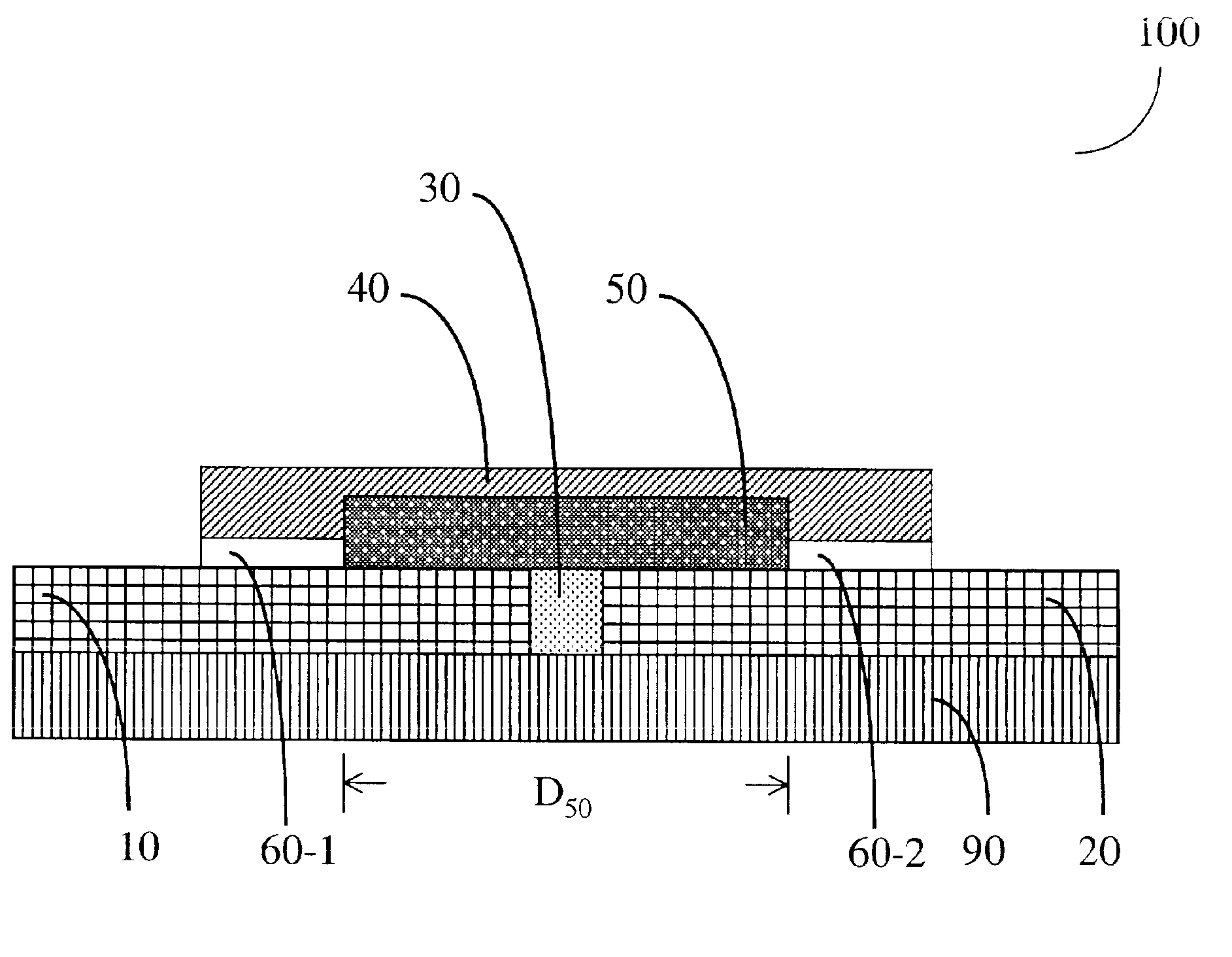

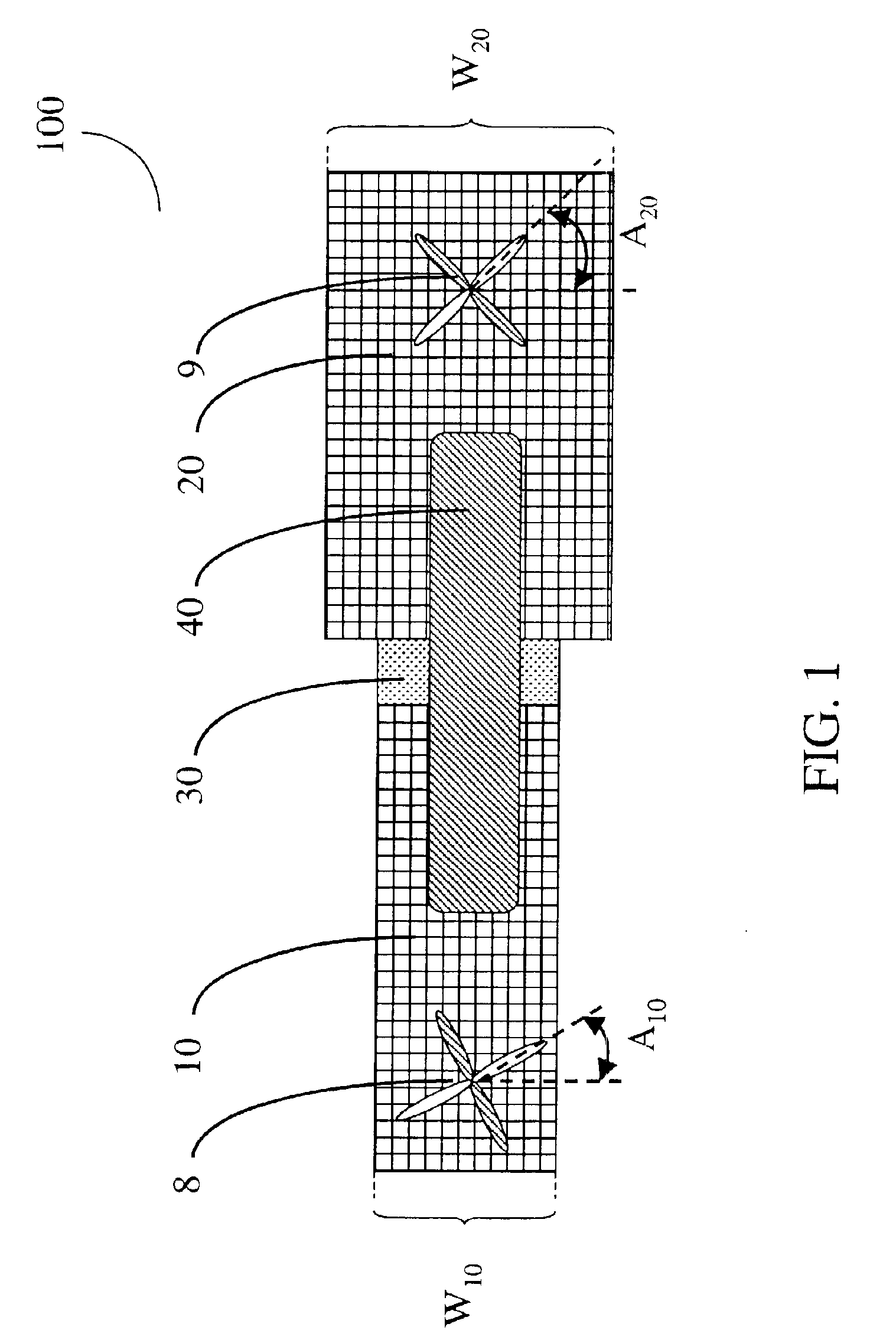

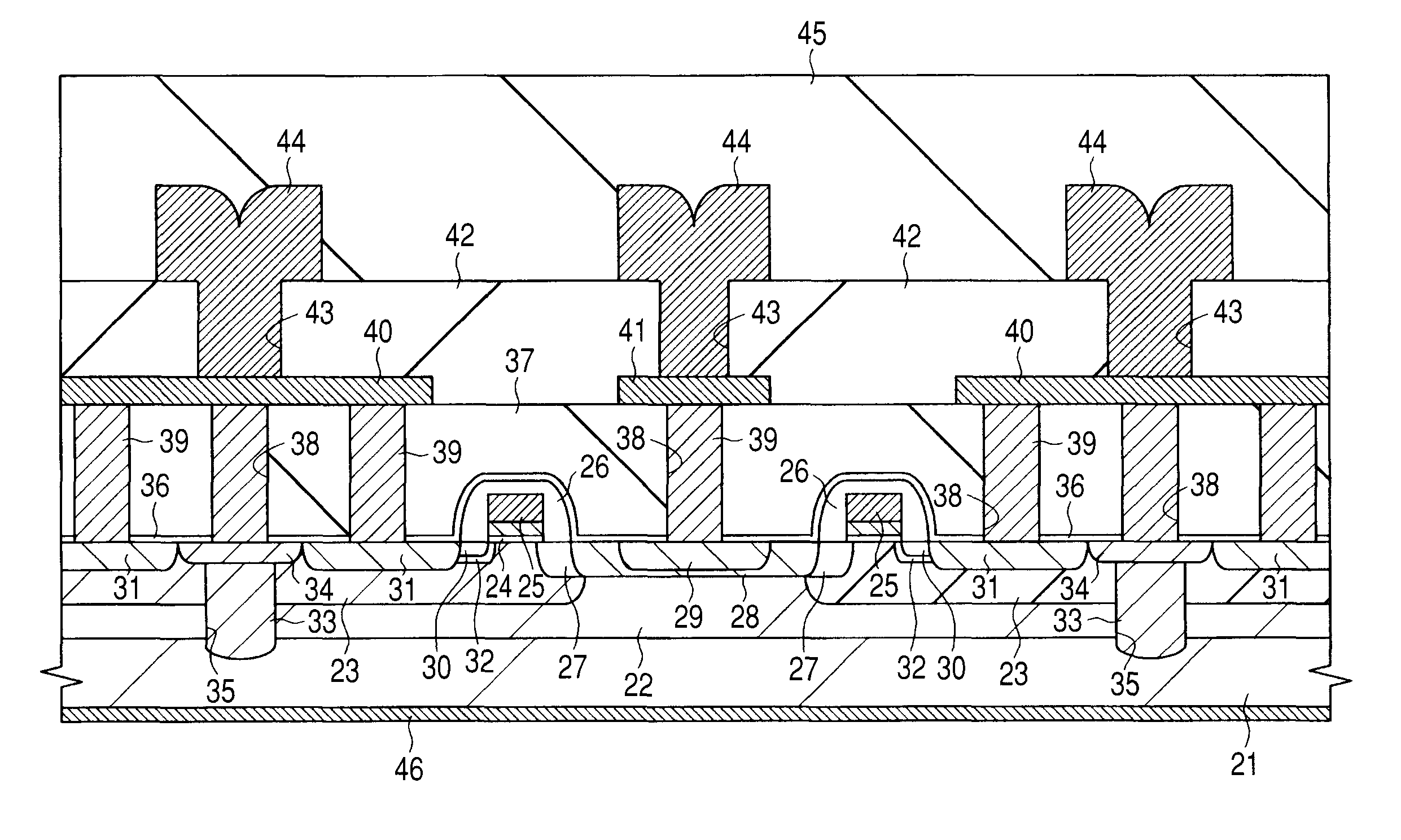

Method for forming a double-gated semiconductor device

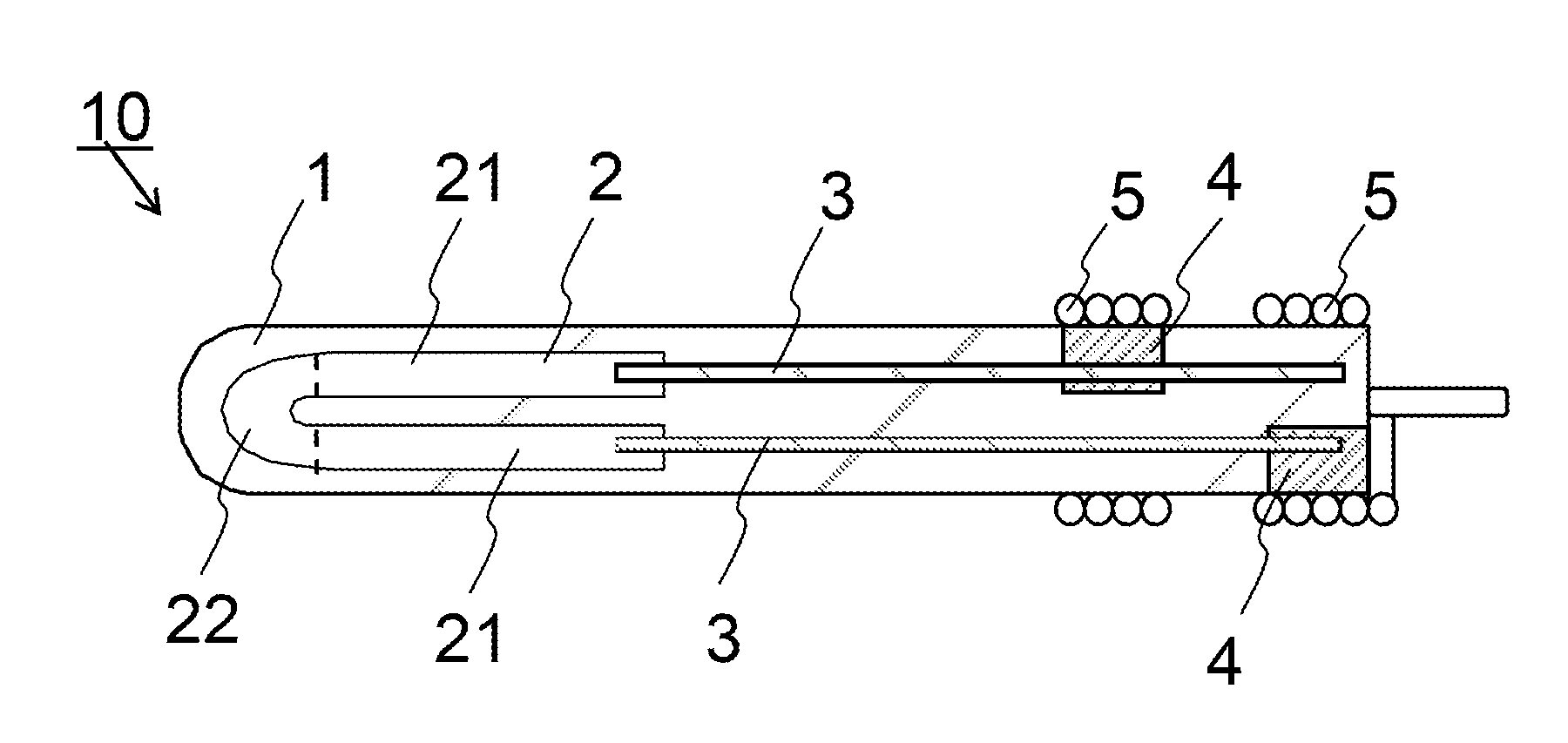

A method for forming a polysilicon FinFET (10) or other thin film transistor structure includes forming an insulative layer (12) over a semiconductor substrate (14). An amorphous silicon layer (32) forms over the insulative layer (12). A silicon germanium seed layer (44) forms in association with the amorphous silicon layer (32) for controlling silicon grain growth. The polysilicon layer arises from annealing the amorphous silicon layer (32). During the annealing step, silicon germanium seed layer (44), together with silicon germanium layer (34), catalyzes silicon recrystallization to promote growing larger crystalline grains, as well as fewer grain boundaries within the resulting polysilicon layer. Source (16), drain (18), and channel (20) regions are formed within the polysilicon layer. A double-gated region (24) forms in association with source (16), drain (18), and channel (20) to produce polysilicon FinFET (10).

Owner:NORTH STAR INNOVATIONS

Faceted structure, article, sensor device, and method

A faceted structure is provided that includes a crystalline composition comprising a metal nitride. The metal comprises one or more of aluminum, boron, indium, or gallium. The crystalline composition has at least one exposed surface that is a grain boundary, an etched surface, or a naturally formed facet, and the surface has the same crystallographic orientation of a substrate on which the crystalline composition is grown. A sensor device is provided that includes a faceted structure. Associated methods of making and using the faceted structure in a sensor device are provided.

Owner:MORPHO DETECTION INC

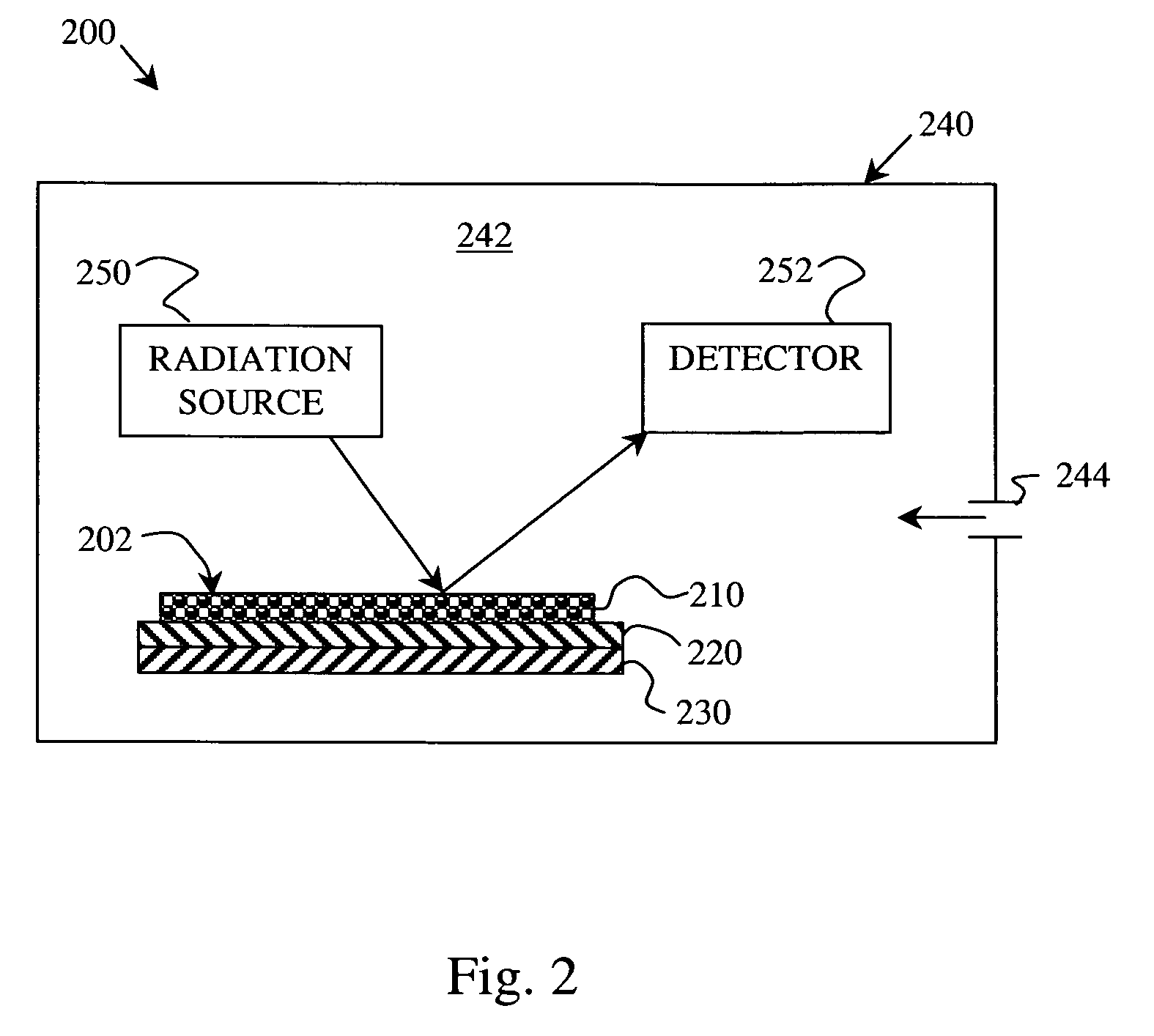

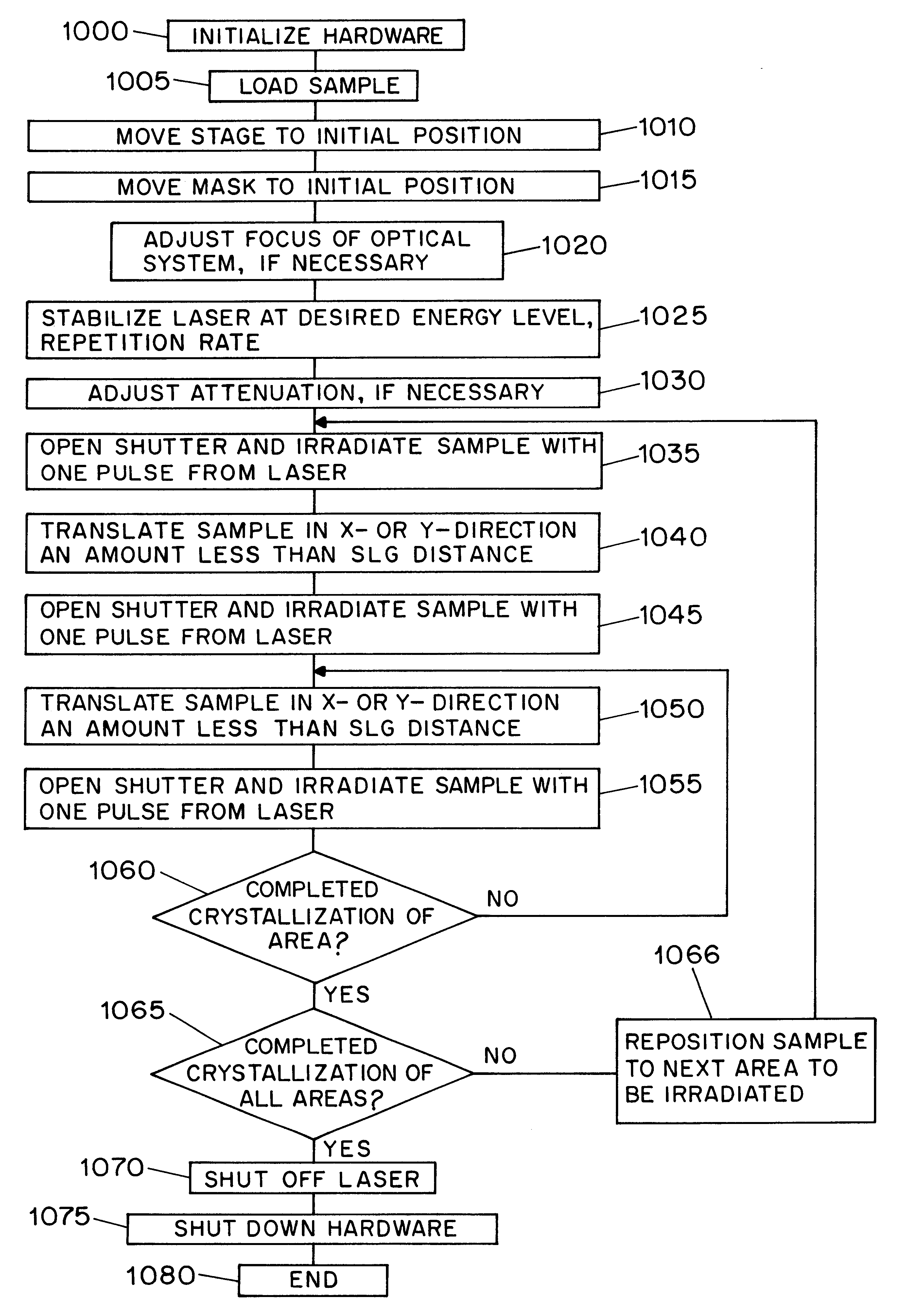

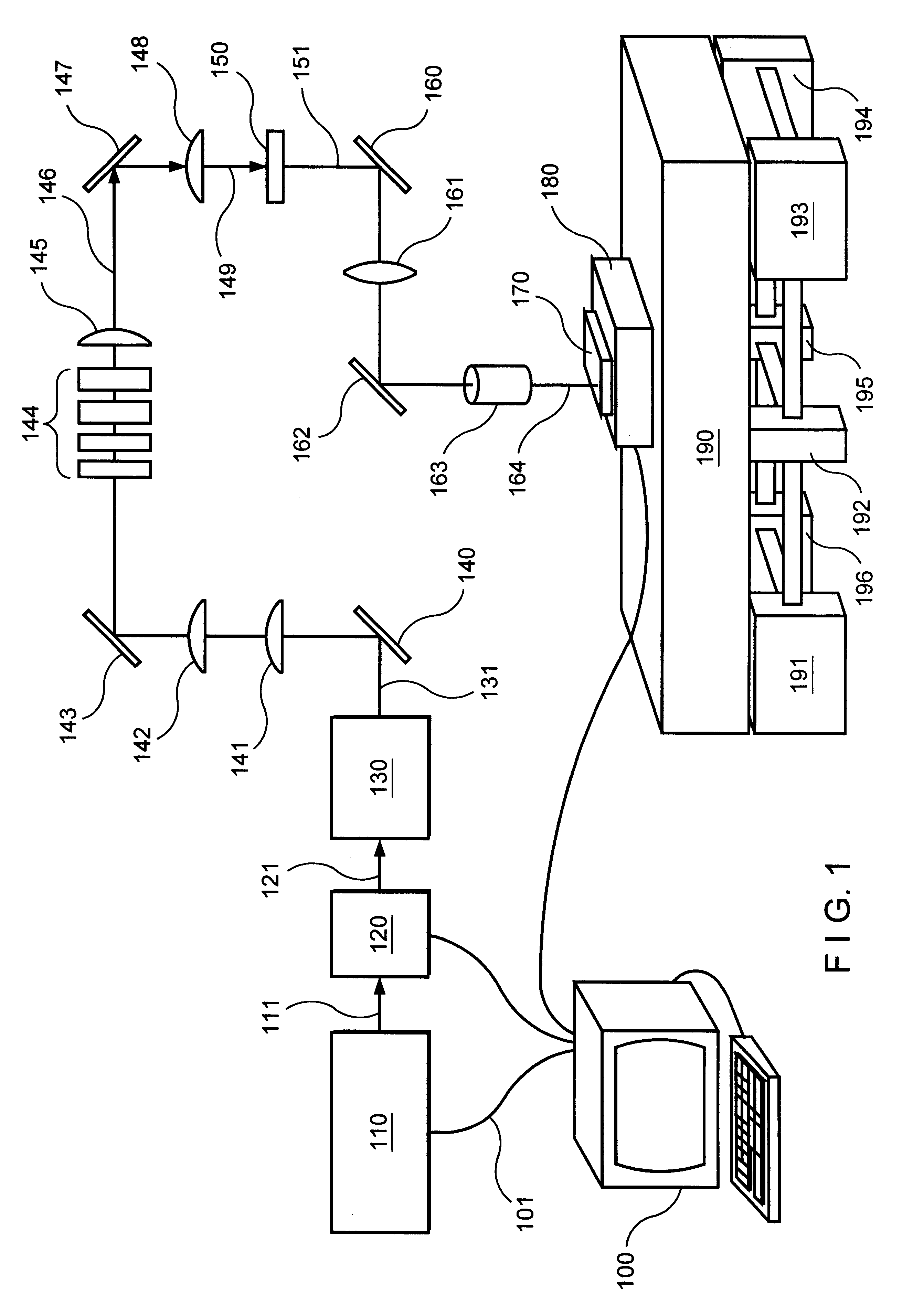

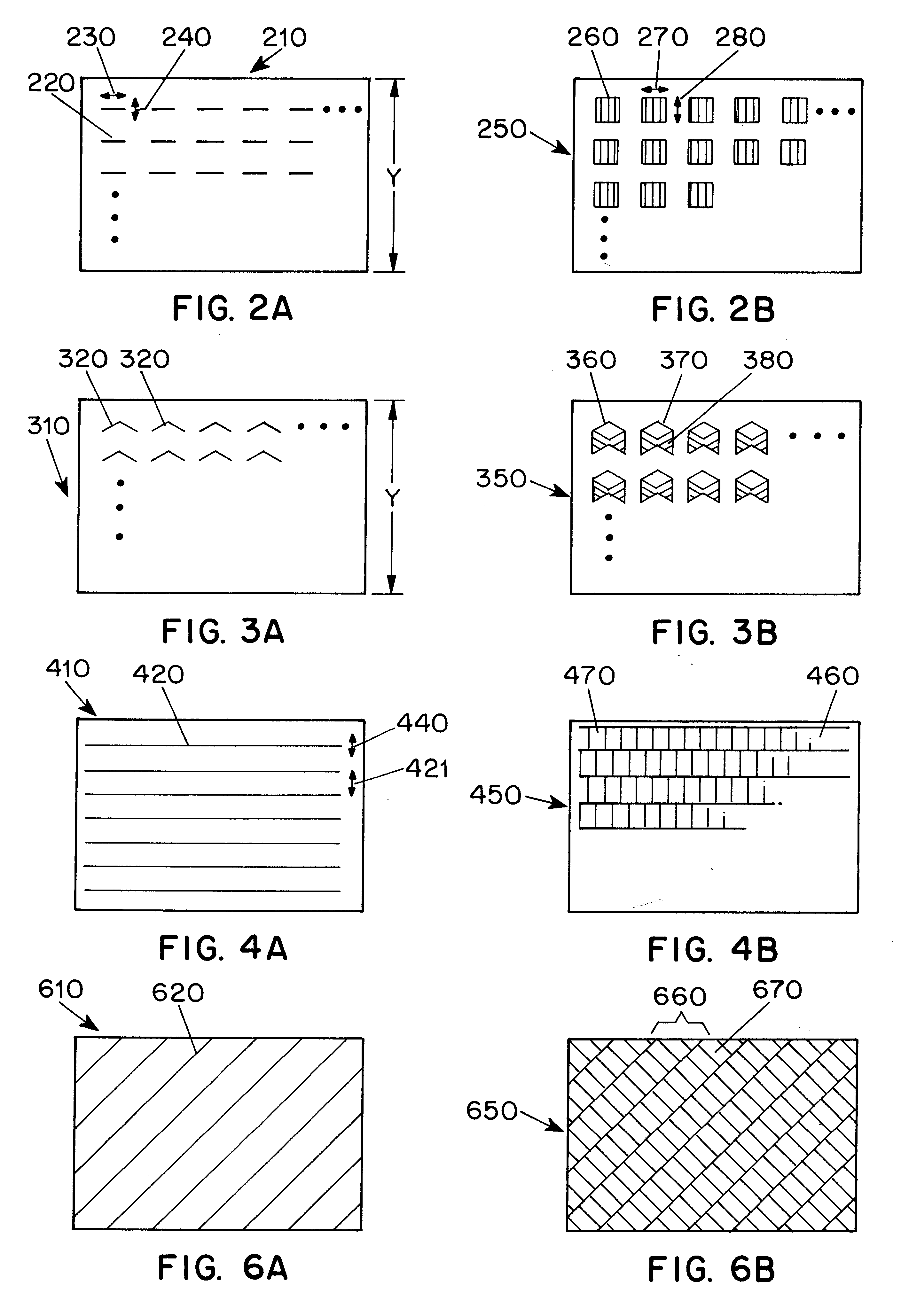

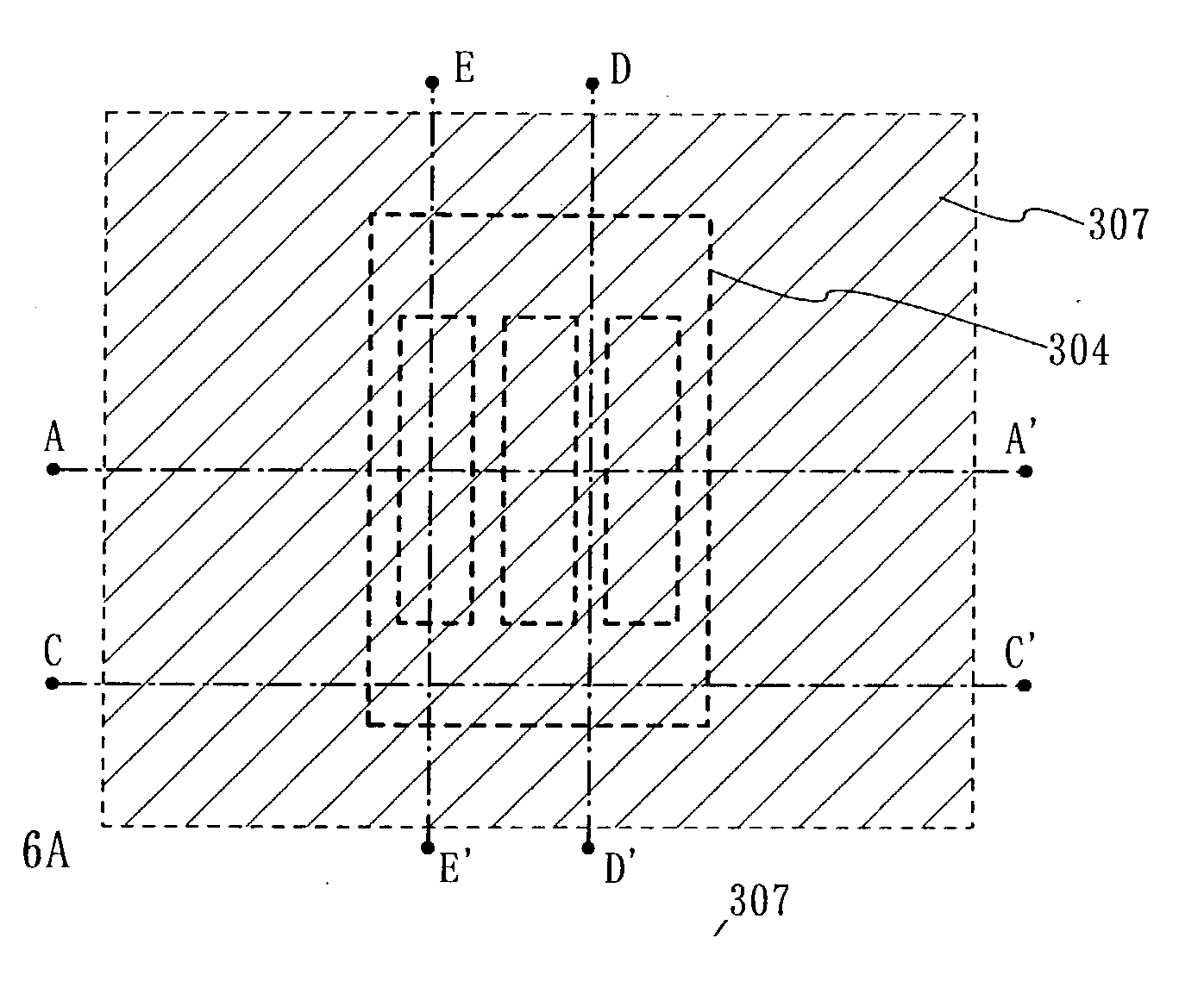

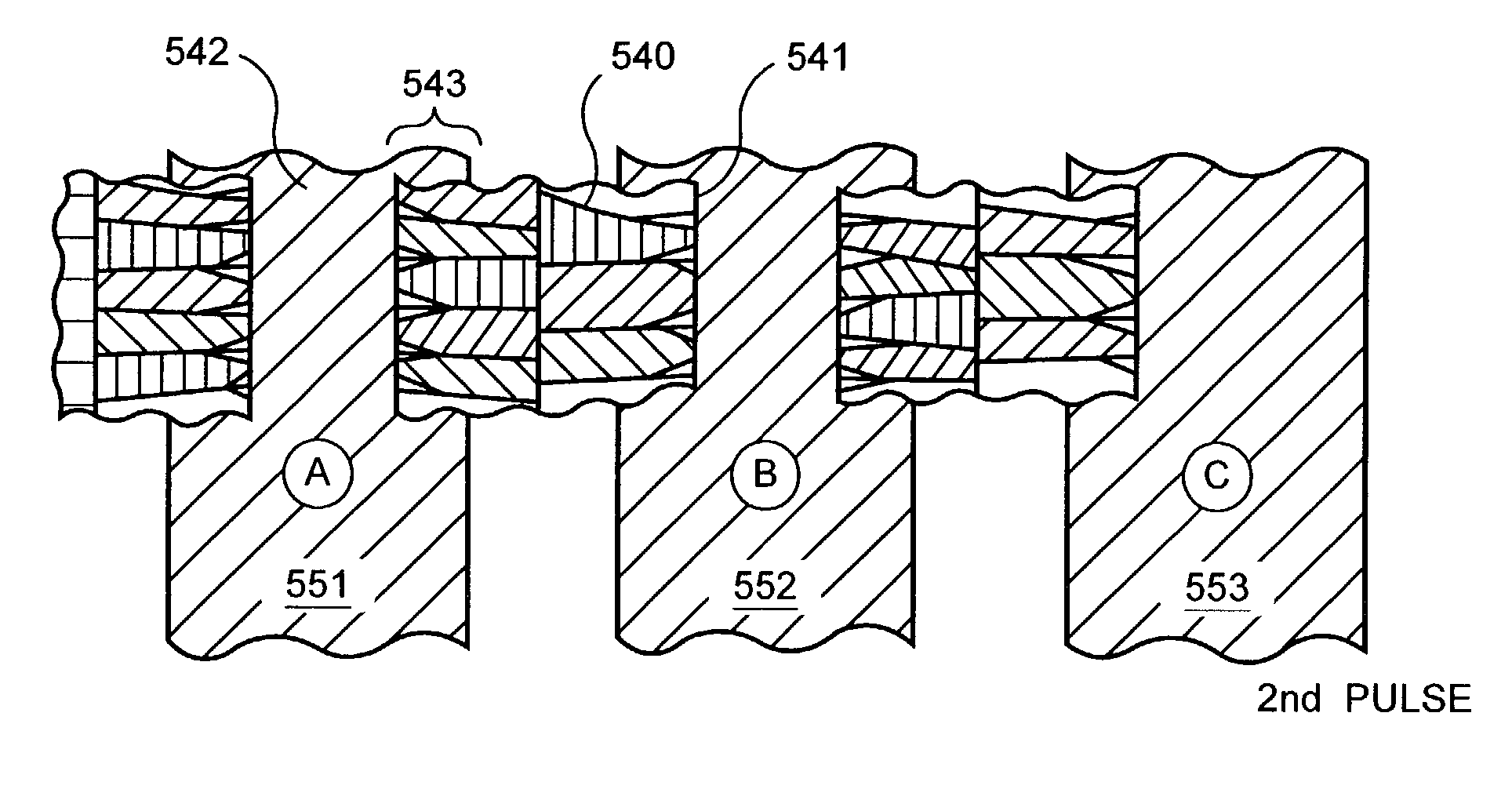

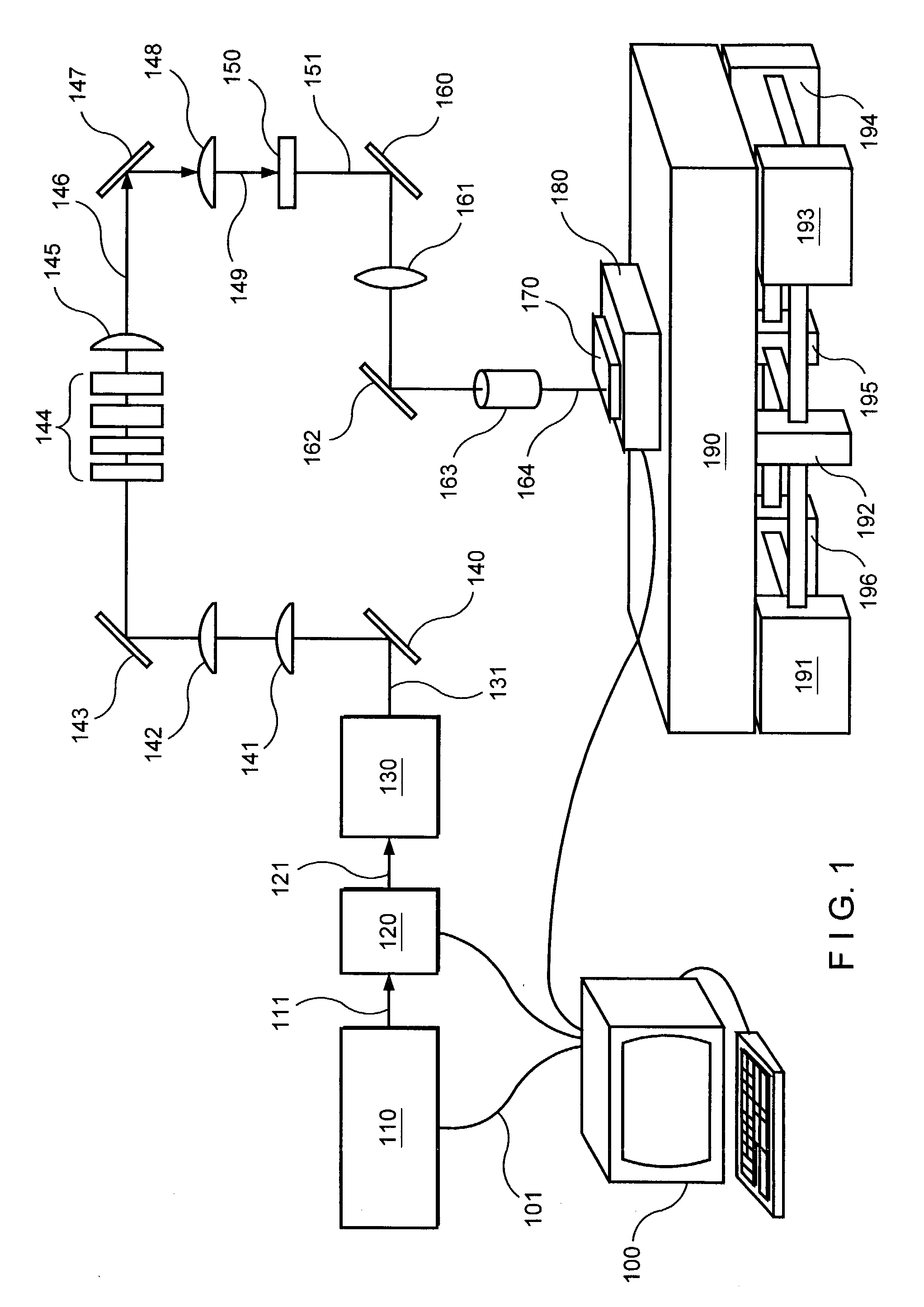

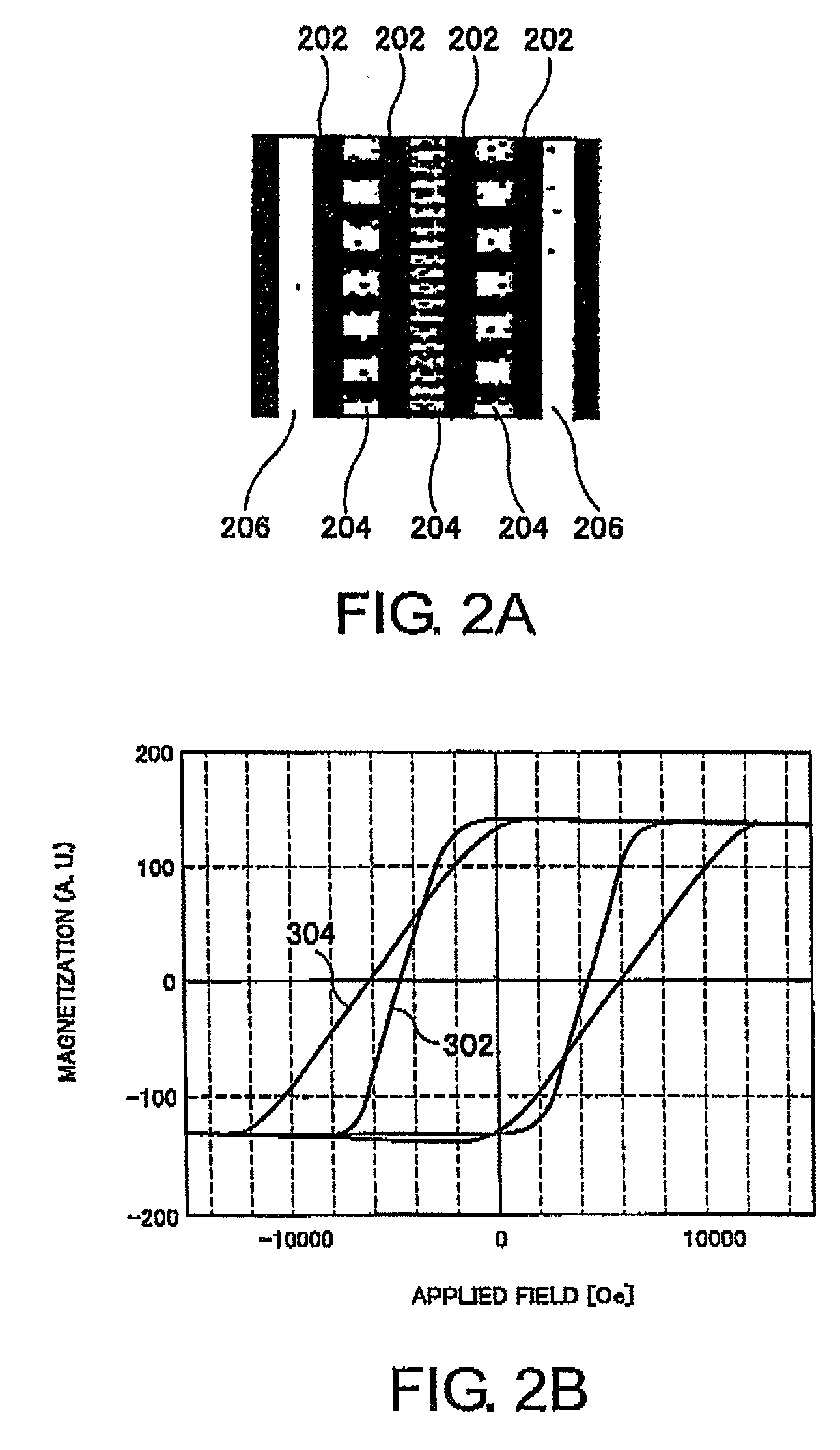

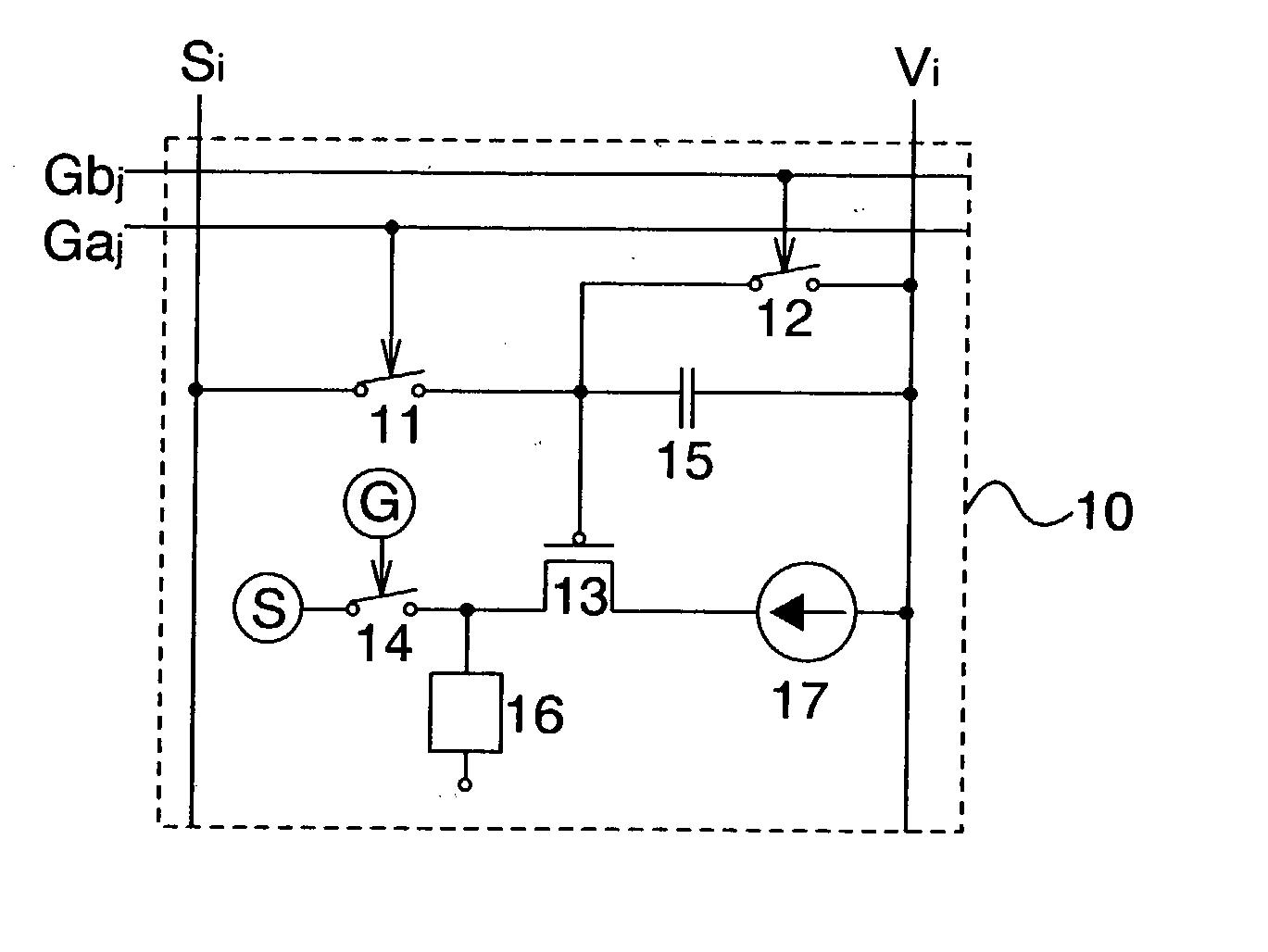

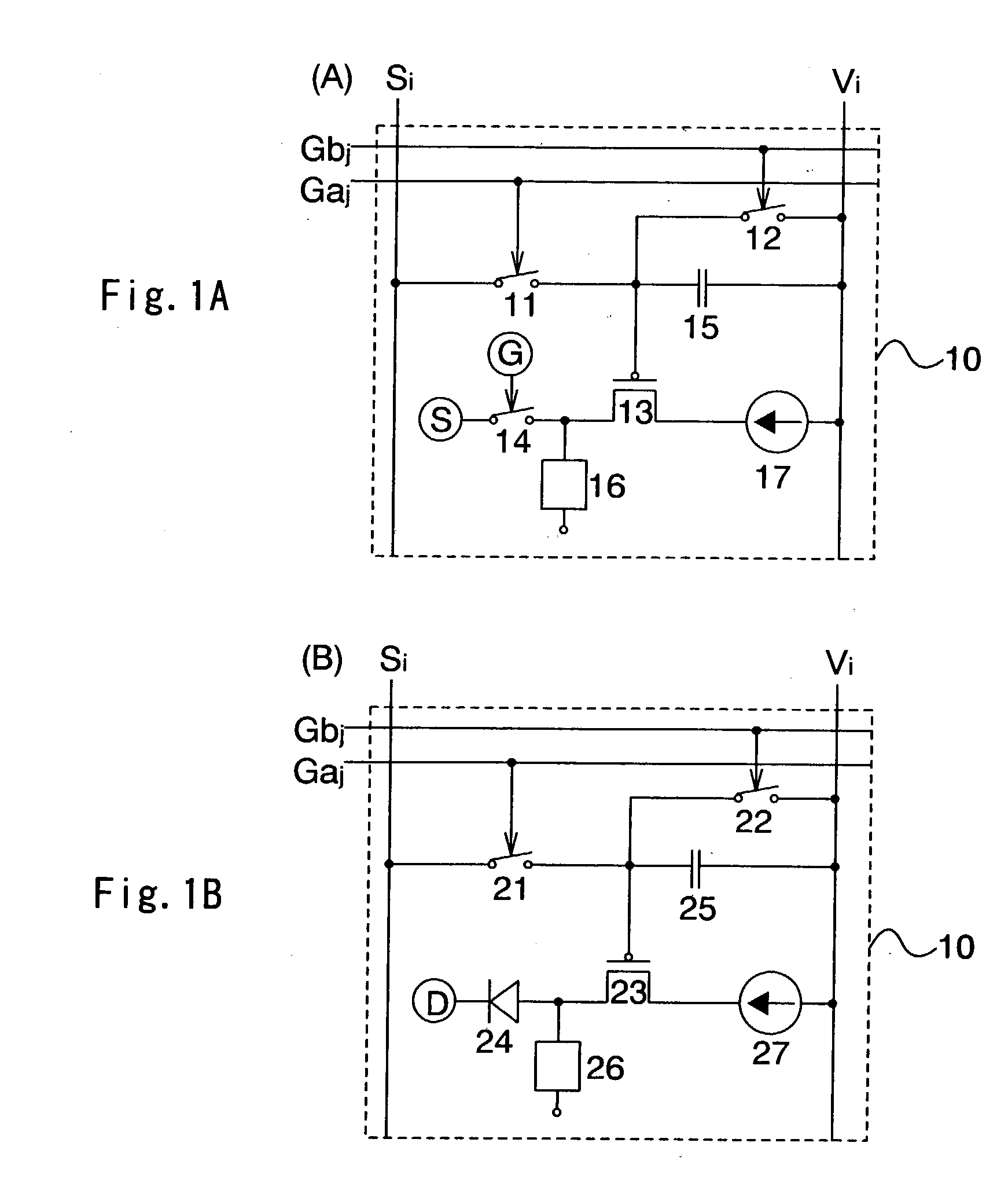

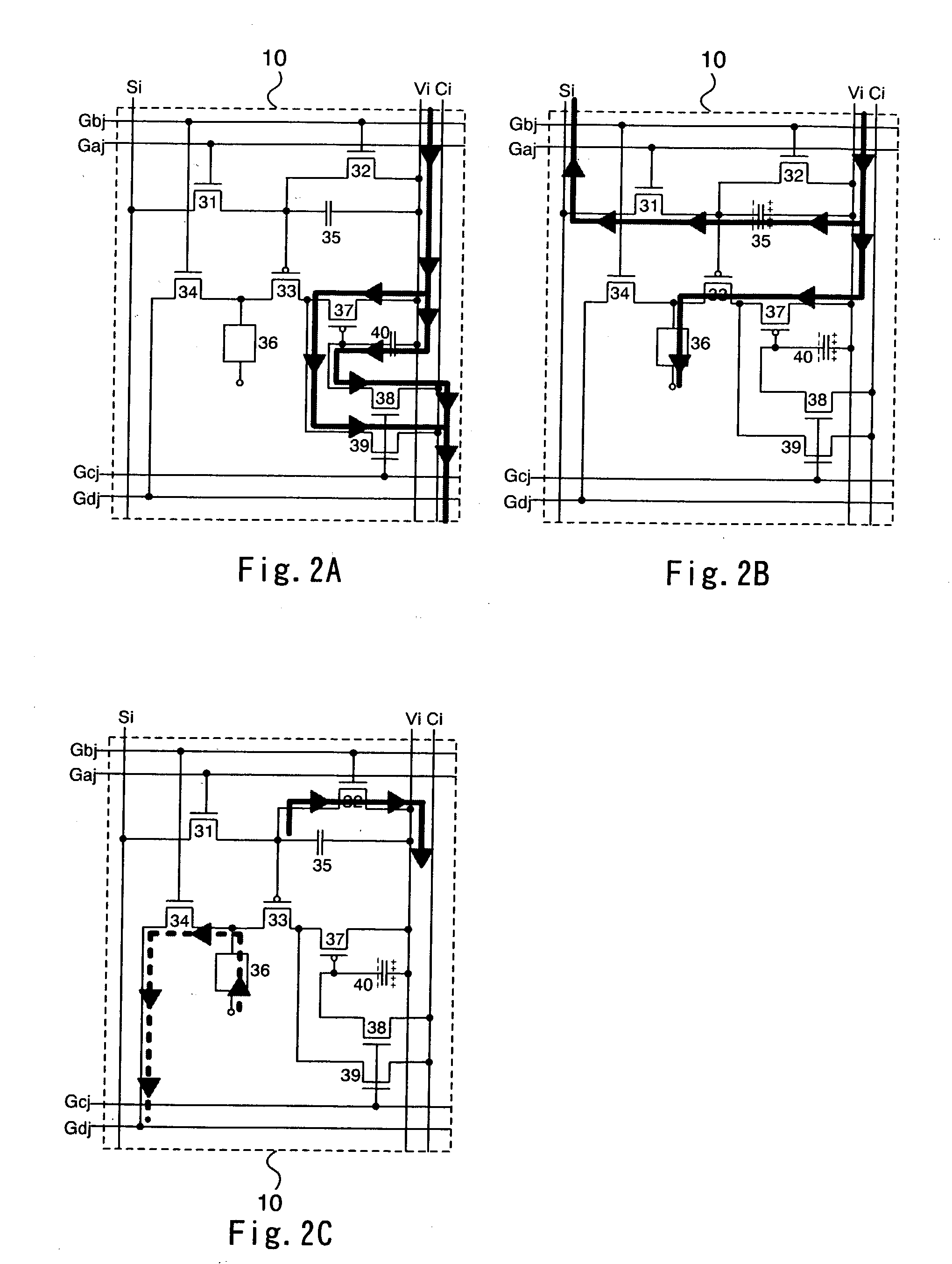

Methods for producing uniform large-grained and grain boundary location manipulated polycrystalline thin film semiconductors using sequential lateral solidification

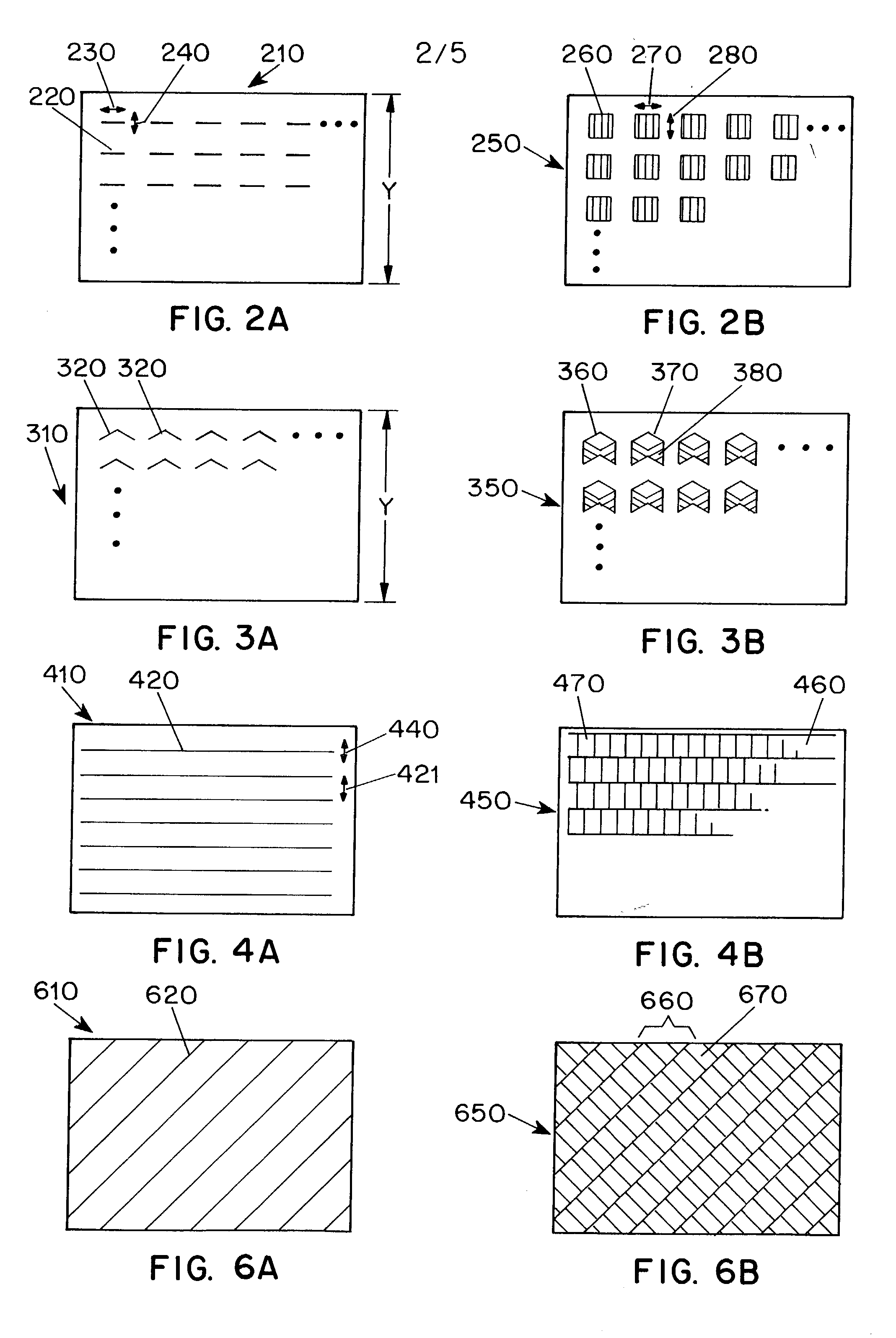

Methods for processing an amorphous silicon thin film sample into a polycrystalline silicon thin film are disclosed. In one preferred arrangement, a method includes the steps of generating a sequence of excimer laser pulses, controllably modulating each excimer laser pulse in the sequence to a predetermined fluence, homoginizing each modulated laser pulse in the sequence in a predetermined plane, masking portions of each homogenized fluence controlled laser pulse in the sequence with a two dimensional pattern of slits to generate a sequence of fluence controlled pulses of line patterned beamlets, each slit in the pattern of slits being sufficiently narrow to prevent inducement of significant nucleation in region of a silicon thin film sample irradiated by a beam let corresponding to the slit, irradiating an amorphous silicon thin film sample with the sequence of fluence controlled slit patterned beamlets to effect melting of portions thereof corresponding to each fluence controlled patterned beamlet pulse in the sequence of pulses of patterned beamlets, and controllably sequentially translating a relative position of the sample with respect to each of the fluence controlled pulse of slit patterned beamlets to thereby process the amorphous silicon thin film sample into a single or polycrystalline silicon thin film.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Heat and corrosion resistant cast CF8C stainless steel with improved high temperature strength and ductility

A CF8C type stainless steel alloy and articles formed therefrom containing about 18.0 weight percent to about 22.0 weight percent chromium and 11.0 weight percent to about 14.0 weight percent nickel; from about 0.05 weight percent to about 0.15 weight percent carbon; from about 2.0 weight percent to about 10.0 weight percent manganese; and from about 0.3 weight percent to about 1.5 weight percent niobium. The present alloys further include less than 0.15 weight percent sulfur which provides high temperature strength both in the matrix and at the grain boundaries without reducing ductility due to cracking along boundaries with continuous or nearly-continuous carbides. The disclosed alloys also have increased nitrogen solubility thereby enhancing strength at all temperatures because nitride precipitates or nitrogen porosity during casting are not observed. The solubility of nitrogen is dramatically enhanced by the presence of manganese, which also retains or improves the solubility of carbon thereby providing additional solid solution strengthening due to the presence of manganese and nitrogen, and combined carbon.

Owner:UT BATTELLE LLC

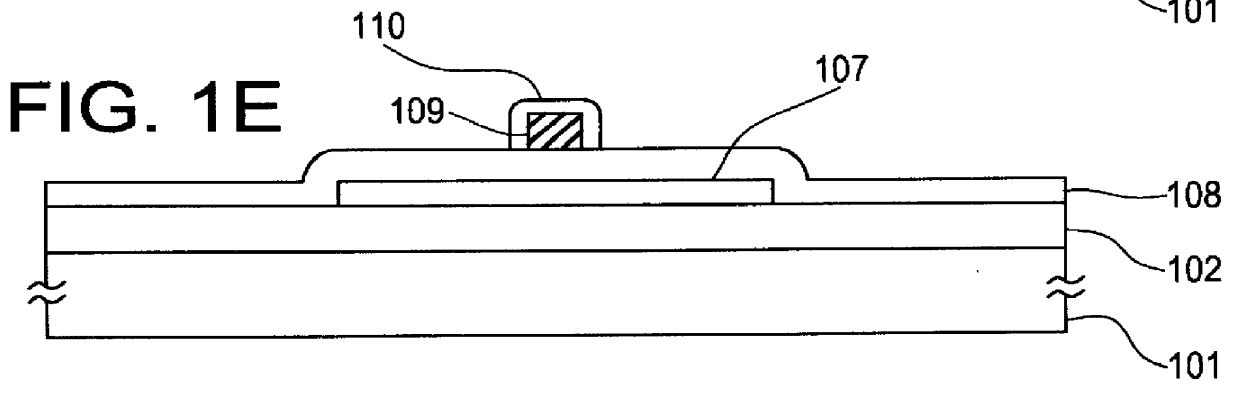

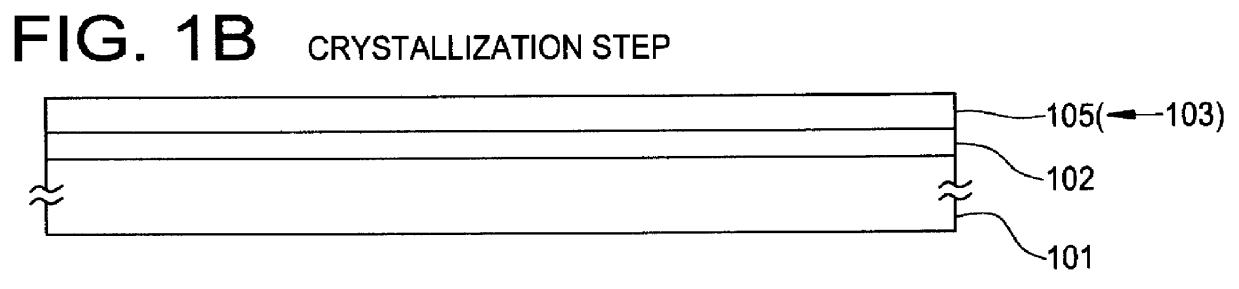

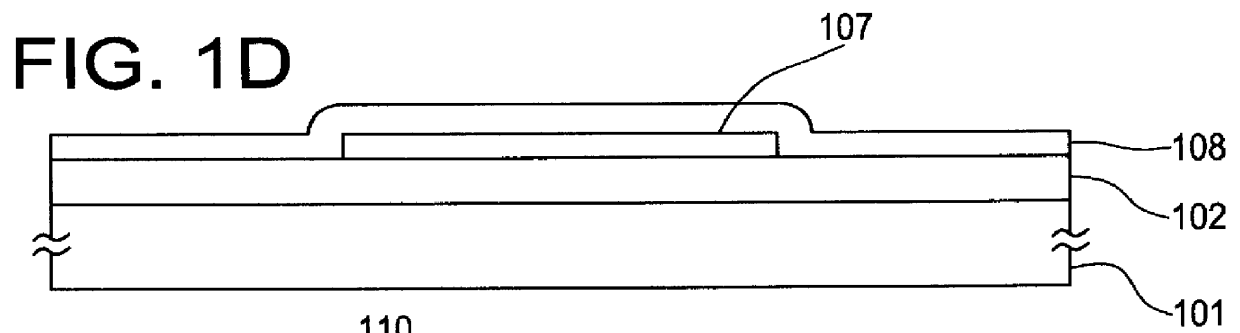

Method of manufacturing a thin film transistor involving laser treatment

InactiveUS6063654AImprove reliabilityEnhancing reliability and characteristicTransistorSolid-state devicesHydrogenAmorphous silicon

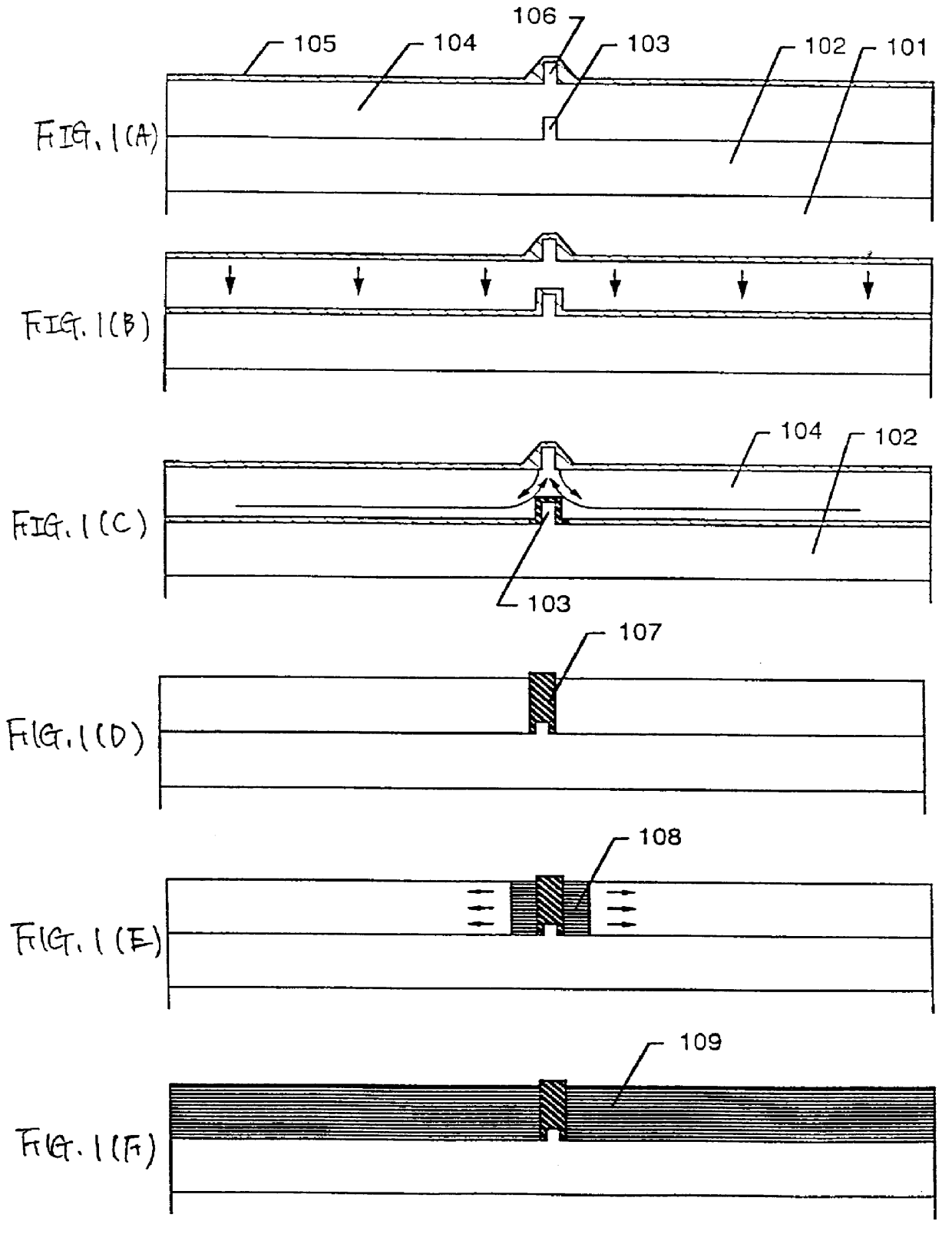

Defects at the grain boundaries of a crystal silicon film, which has been crystallized from an amorphous silicon film, are passivated without using a hydrogen plasma treatment. An underlying film and a crystal silicon film which has been crystallized from an amorphous silicon film are formed on a glass substrate. A thermal oxide film is grown on the surface of the crystal silicon film by heating in an oxygen atmosphere into which NF3 gas has been added. As the thermal oxide film is grown, non-coupled Si is generated. The defects at the grain boundaries of the crystal silicon film are passivated by the additional Si. Then, the thermal oxide film is removed and the crystal silicon film is patterned into an island shape to form an active layer of a TFT. A gate insulating film, a gate electrode and the like are then formed sequentially to complete the TFT.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and method of manufacturing the same

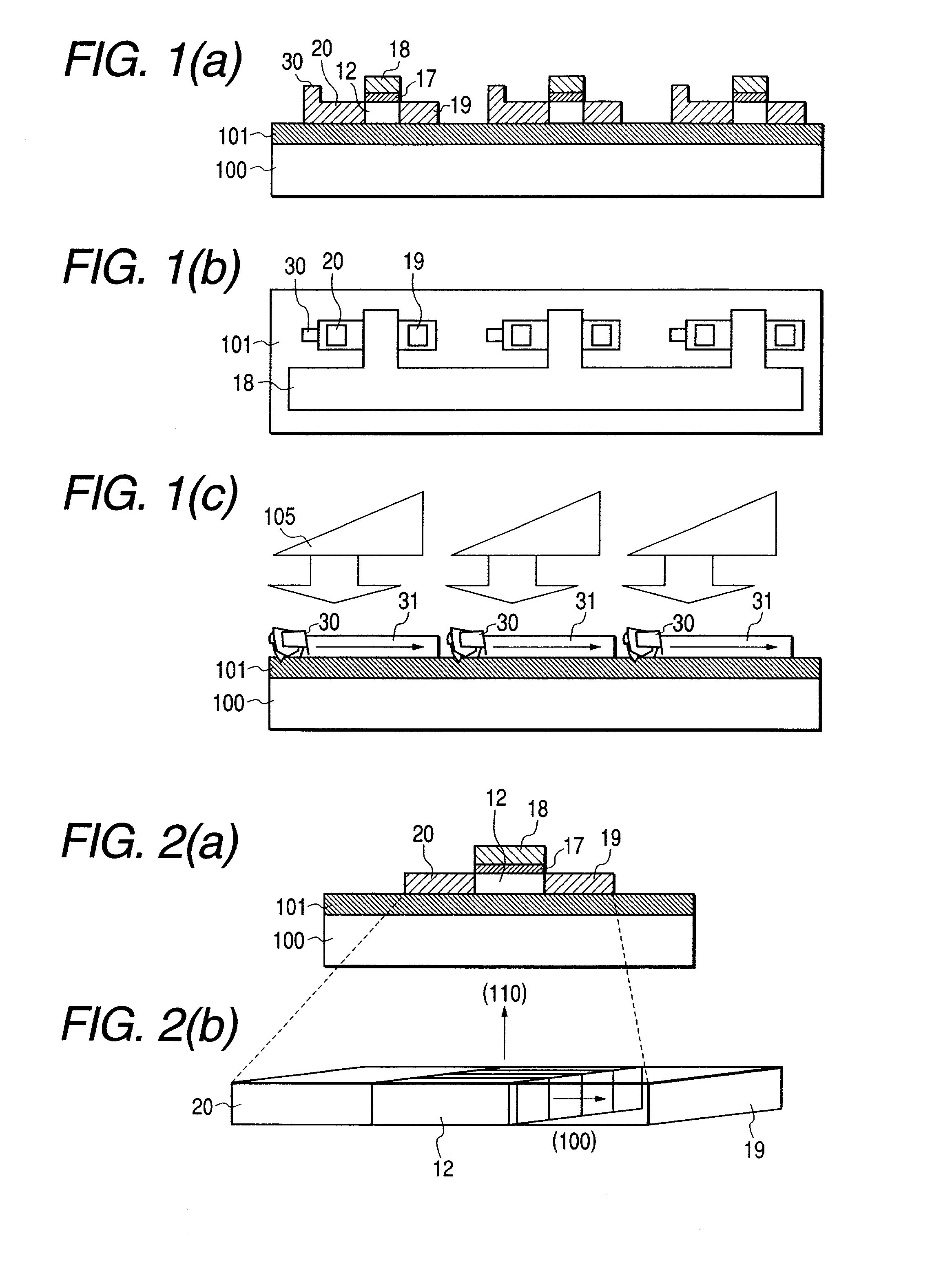

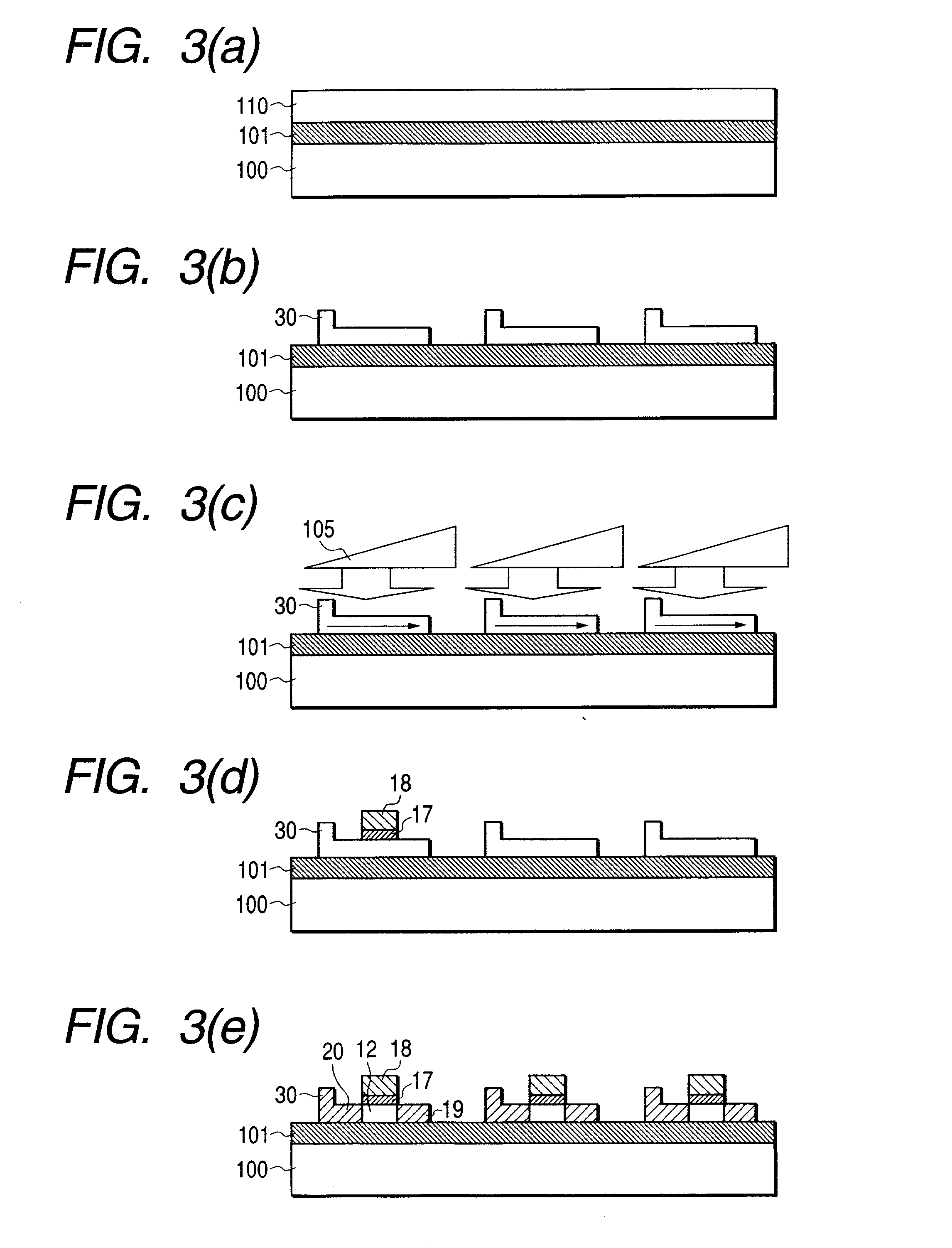

An objective is to provide a method of manufacturing a semiconductor device, and a semiconductor device manufactured by using the manufacturing method, in which a laser crystallization method is used that is capable of preventing the formation of grain boundaries in TFT channel formation regions, and is capable of preventing conspicuous drops in TFT mobility, reduction in the ON current, and increases in the OFF current, all due to grain boundaries. Stripe shape or rectangular shape unevenness or opening is formed. Continuous wave laser light is then irradiated to a semiconductor film formed on an insulating film. Note that although it is most preferable to use continuous wave laser light at this point, pulse wave oscillation laser light may also be used.

Owner:SEMICON ENERGY LAB CO LTD

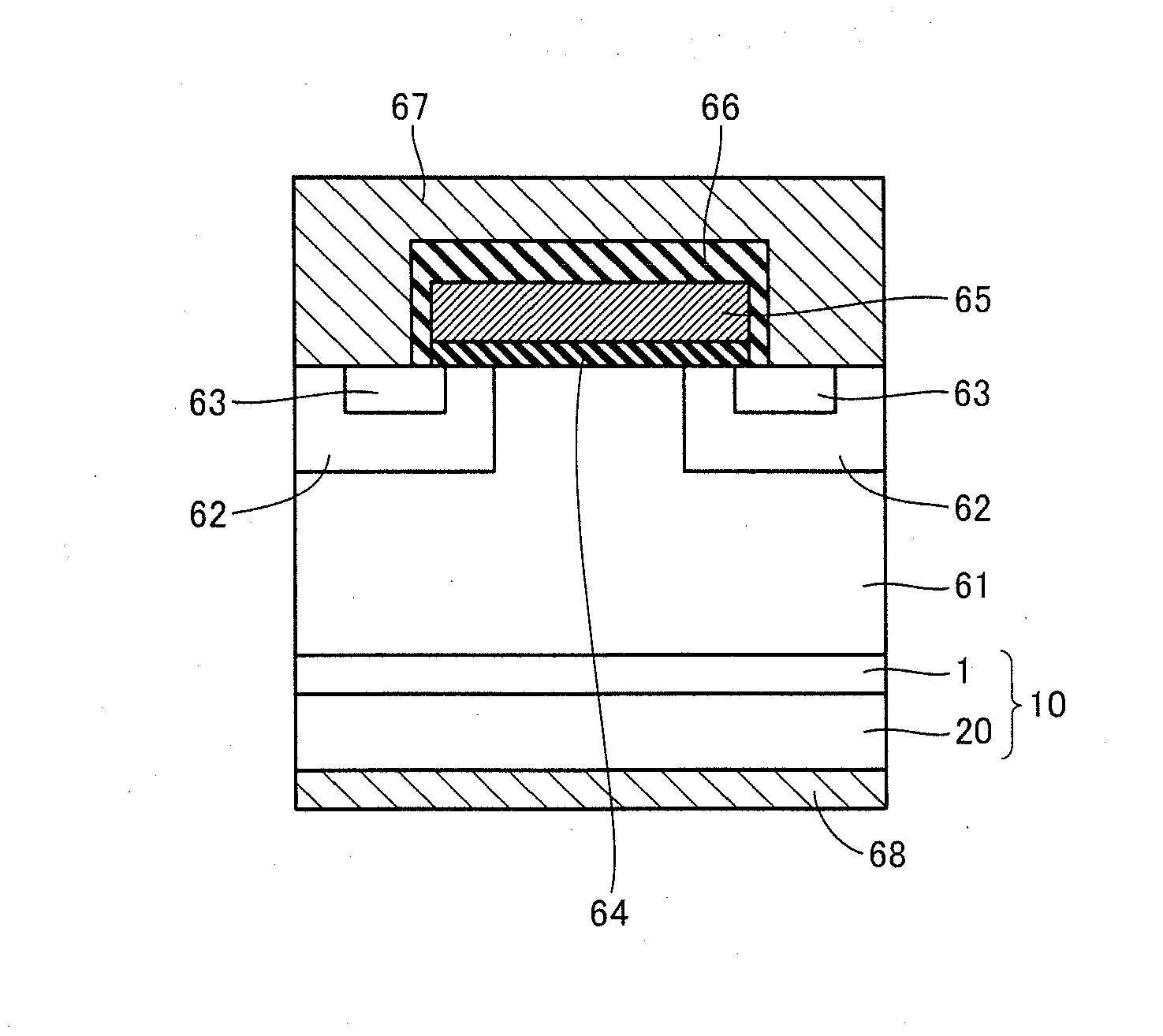

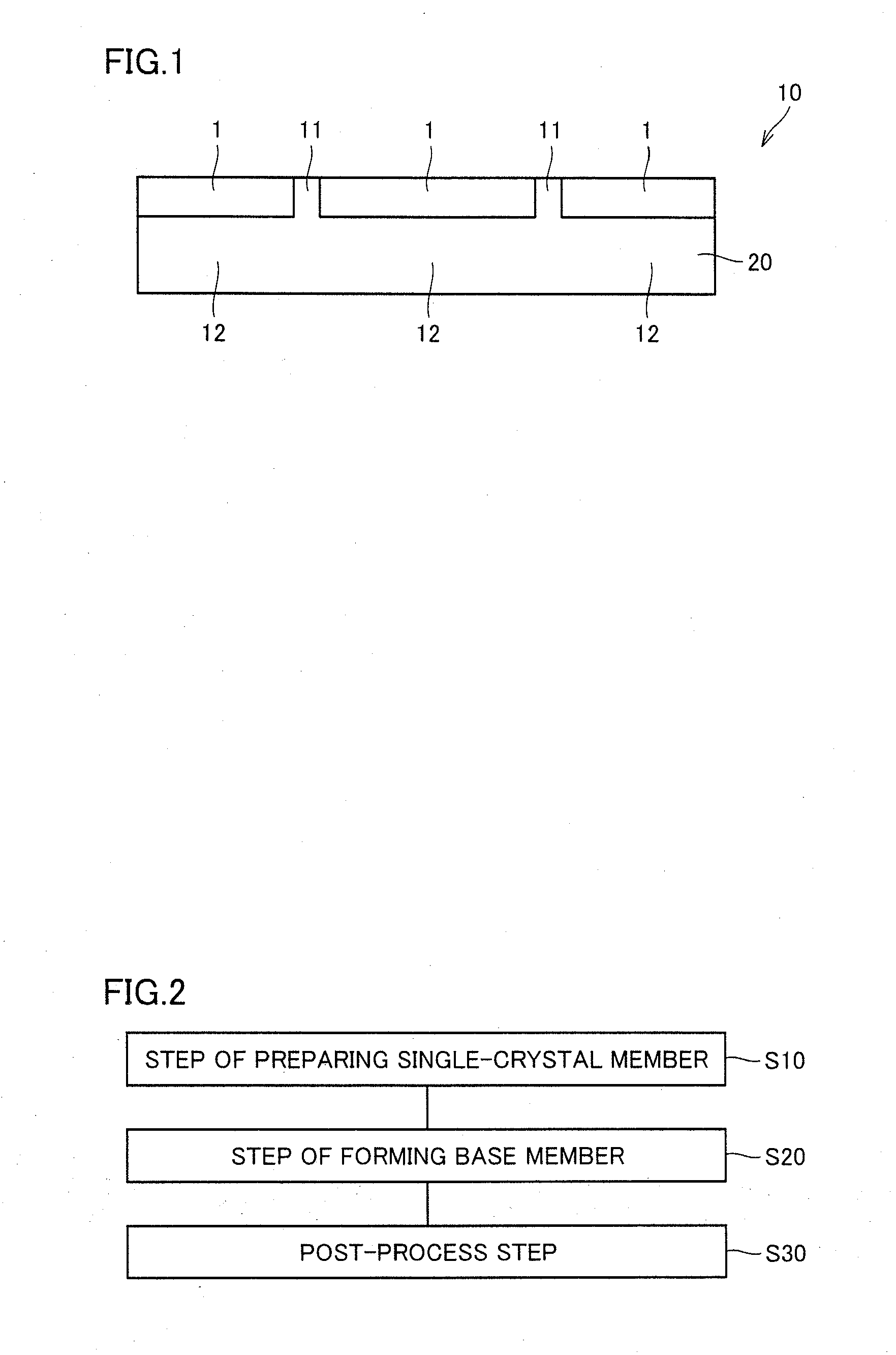

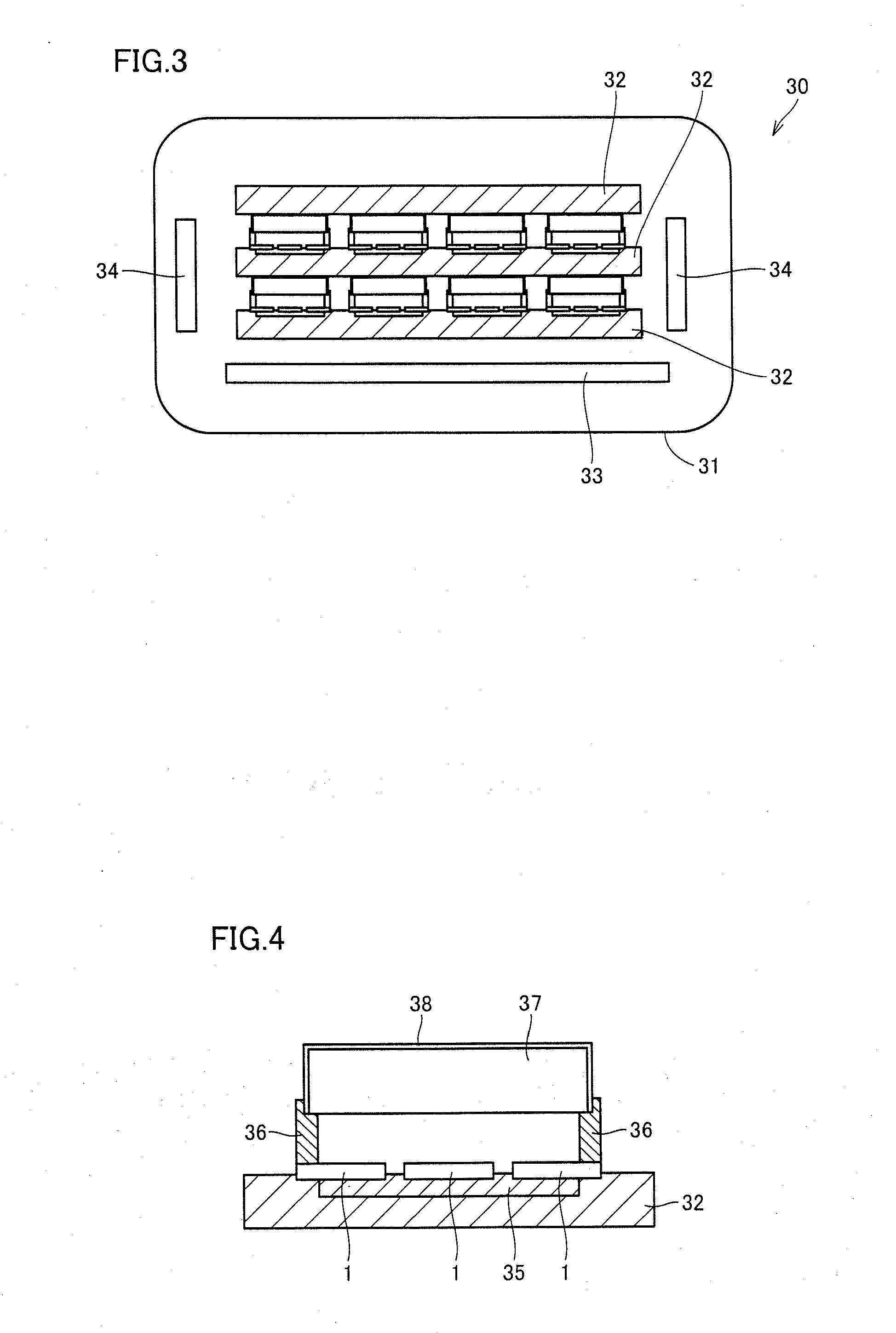

Silicon carbide substrate, epitaxial layer provided substrate, semiconductor device, and method for manufacturing silicon carbide substrate

InactiveUS20120119225A1Lower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesSingle crystal substrateSingle crystal

The present invention provides a silicon carbide substrate, an epitaxial layer provided substrate, a semiconductor device, and a method for manufacturing the silicon carbide substrate, each of which achieves reduced on-resistance. The silicon carbide substrate is a silicon carbide substrate having a main surface, and includes: a SiC single-crystal substrate formed in at least a portion of the main surface; and a base member disposed to surround the SiC single-crystal substrate. The base member includes a boundary region and a base region. The boundary region is adjacent to the SiC single-crystal substrate in a direction along the main surface, and has a crystal grain boundary therein. The base region is adjacent to the SiC single-crystal substrate in a direction perpendicular to the main surface, and has an impurity concentration higher than that of the SiC single-crystal substrate.

Owner:SUMITOMO ELECTRIC IND LTD

Methods for producing uniform large-grained and grain boundary location manipulated polycrystalline thin film semiconductors using sequential lateral solidification

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

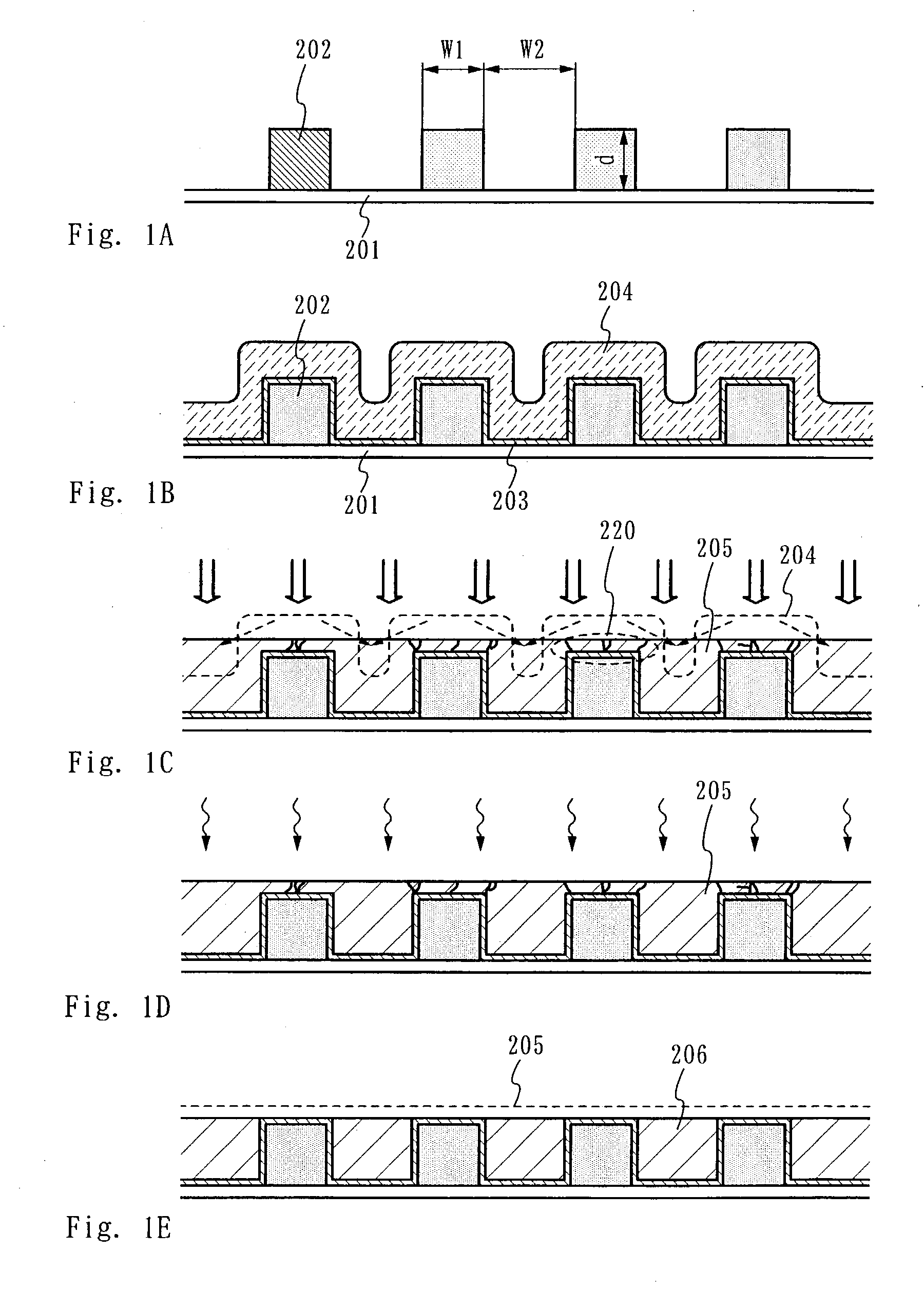

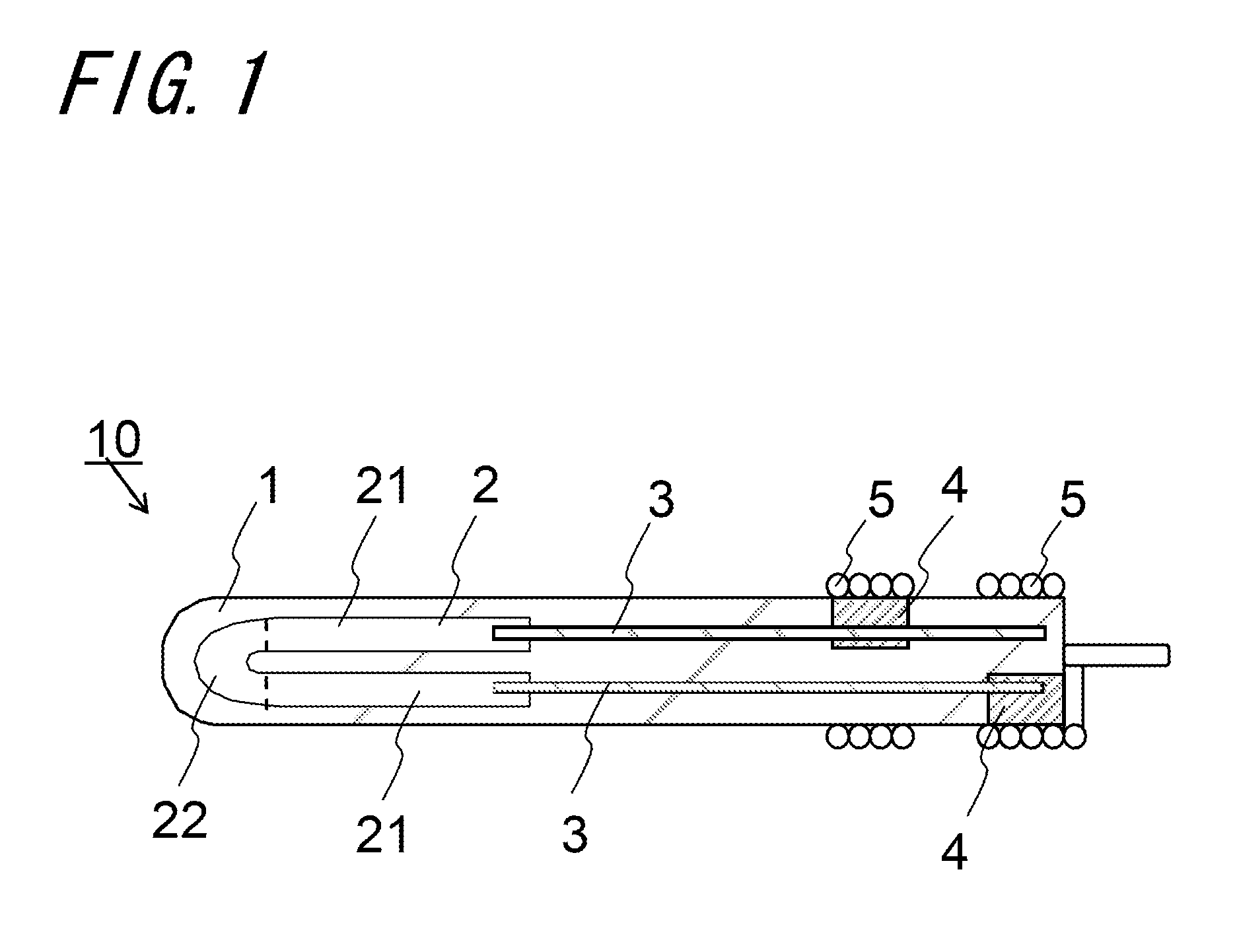

Thin film semiconductor and method for manufacturing the same, semiconductor device and method for manufacturing the same

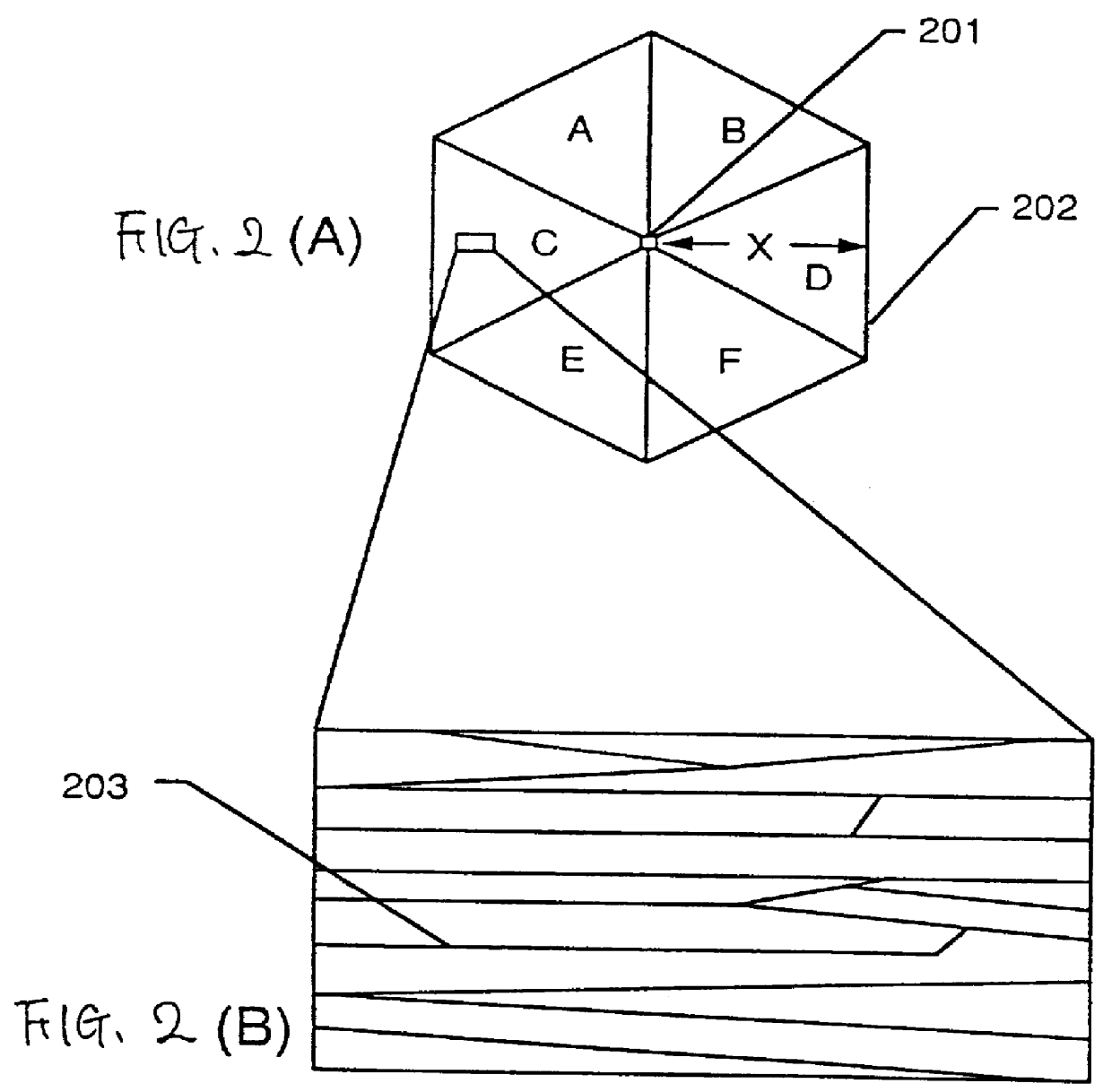

The present invention is related to a thin film semiconductor which can be regarded as substantially a single crystal and a semiconductor device comprising an active layer formed by the thin film semiconductor. At least a concave or convex pattern is formed intentionally on a insulating film provided in contact with the lower surface of an amorphous silicon film, whereby at least a site is formed in which a metal element for accelerating crystallization can be segregated. Therefore, a crystal nuclei is selectively formed in a portion where the concave or convex pattern is located, which carries out controlling a crystal diameter. Thus, a crystalline silicon film is obtained. A crystallinity of the crystalline silicon film is improved by the irradiation of a laser light or an intense light having an energy equivalent to that of the laser light, whereby a monodomain region in which no grain boundary substantially exit is formed.

Owner:SEMICON ENERGY LAB CO LTD

Ceramic heater

A ceramic heater of the invention includes a ceramic structure; a heat-generating resistor embedded in the ceramic structure; and a feeder line embedded in the ceramic structure so as to be connected, at one end thereof, to the heat-generating resistor. The feeder line is made of metal, and metal grains of a center region of the feeder line are greater in grain size than metal grains of an outer periphery region of the feeder line. Even if a crack developed in the outer periphery region of the feeder line propagates through grain boundaries in the outer periphery region and comes near the center region, propagation of the crack through the interior of the center region can be suppressed.

Owner:KYOCERA CORP

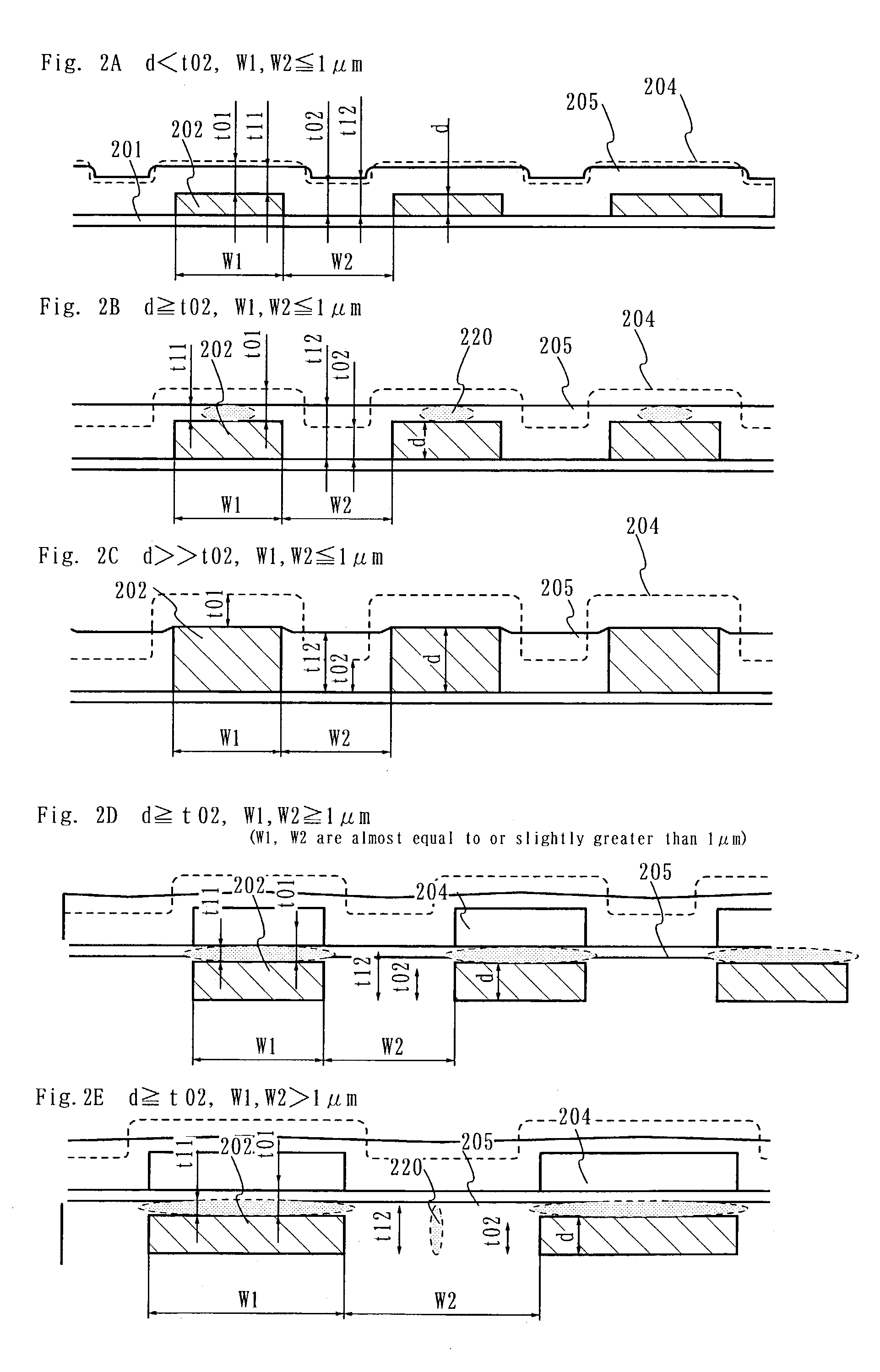

Thin film semiconductor device, polycrystalline semiconductor thin film production process and production apparatus

InactiveUS20020119609A1Reduce in quantityQuality improvementTransistorFrom solid stateElectrical conductorCrystal orientation

In an MIS field effect transistor having a gate electrode formed on a first semiconductor layer which is a polycrystalline silicon film on an insulating substrate through a gate insulating film, a channel region formed in the semiconductor layer and a source region and a drain region arranged on both sides of the channel region, a thin film semiconductor device has a main orientation of at least the channel region of {110} with respect to the surface of the gate insulating film. Further, a polycrystalline semiconductor film having a main orientation of the surface almost perpendicular to a direction for connecting the source and drain regions of {100} is preferably used in the channel of a semiconductor device. According to the present invention, a semiconductor device having a high-quality polycrystalline semiconductor film whose grain boundary, grain size and crystal orientation can be controlled and whose film roughness and crystal defects formed by crystallization have been reduced can be obtained on the insulating substrate.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

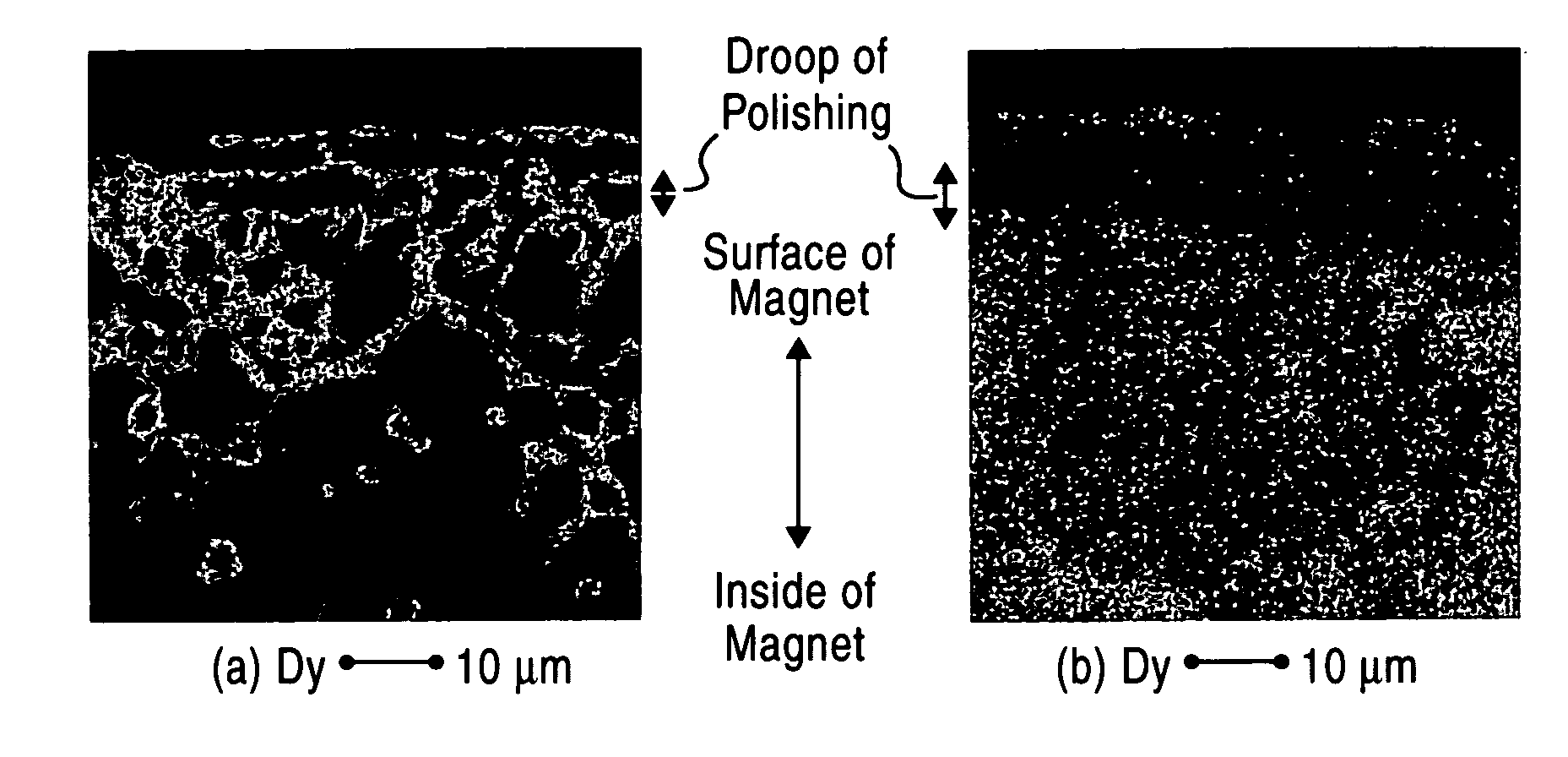

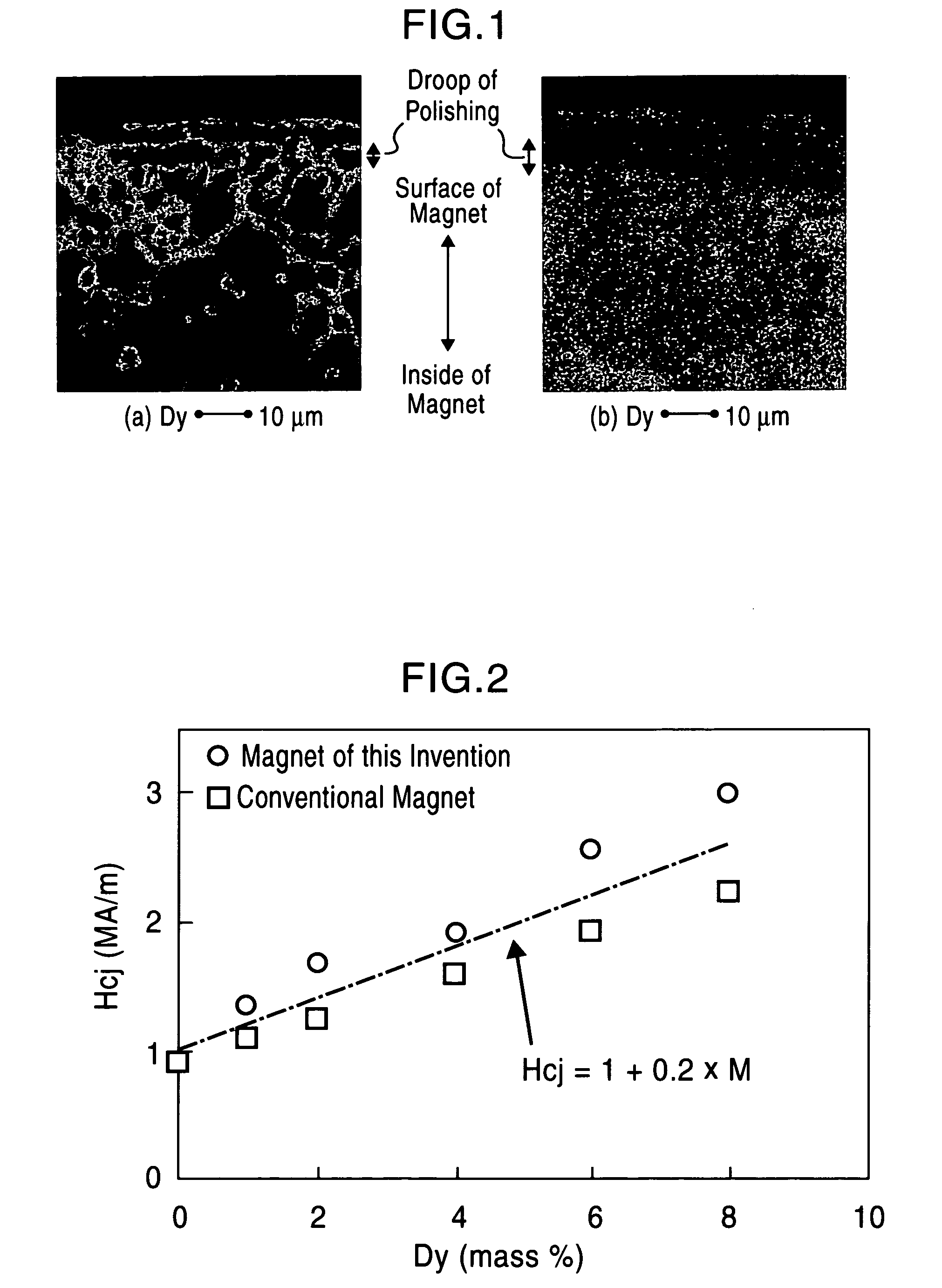

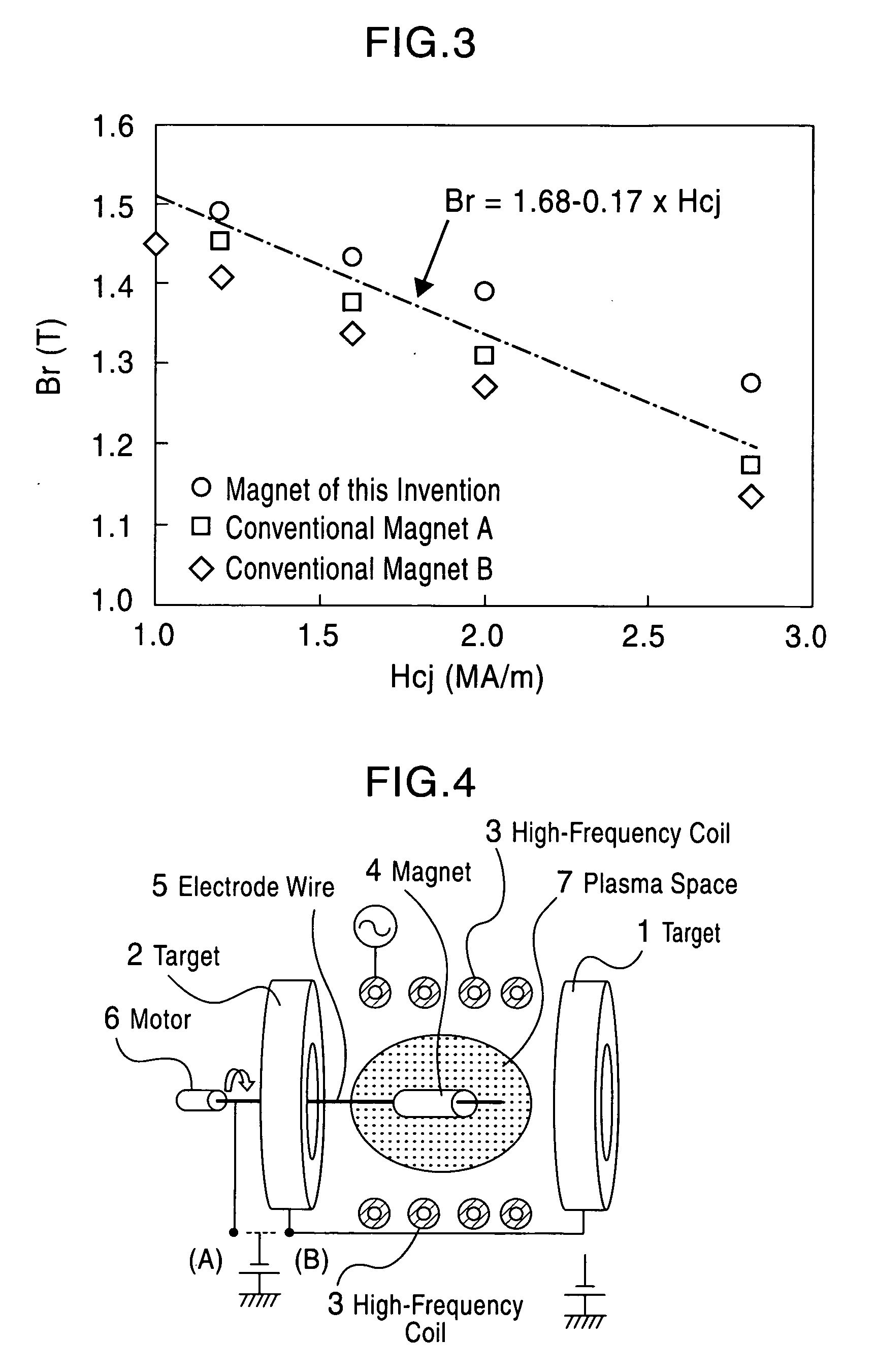

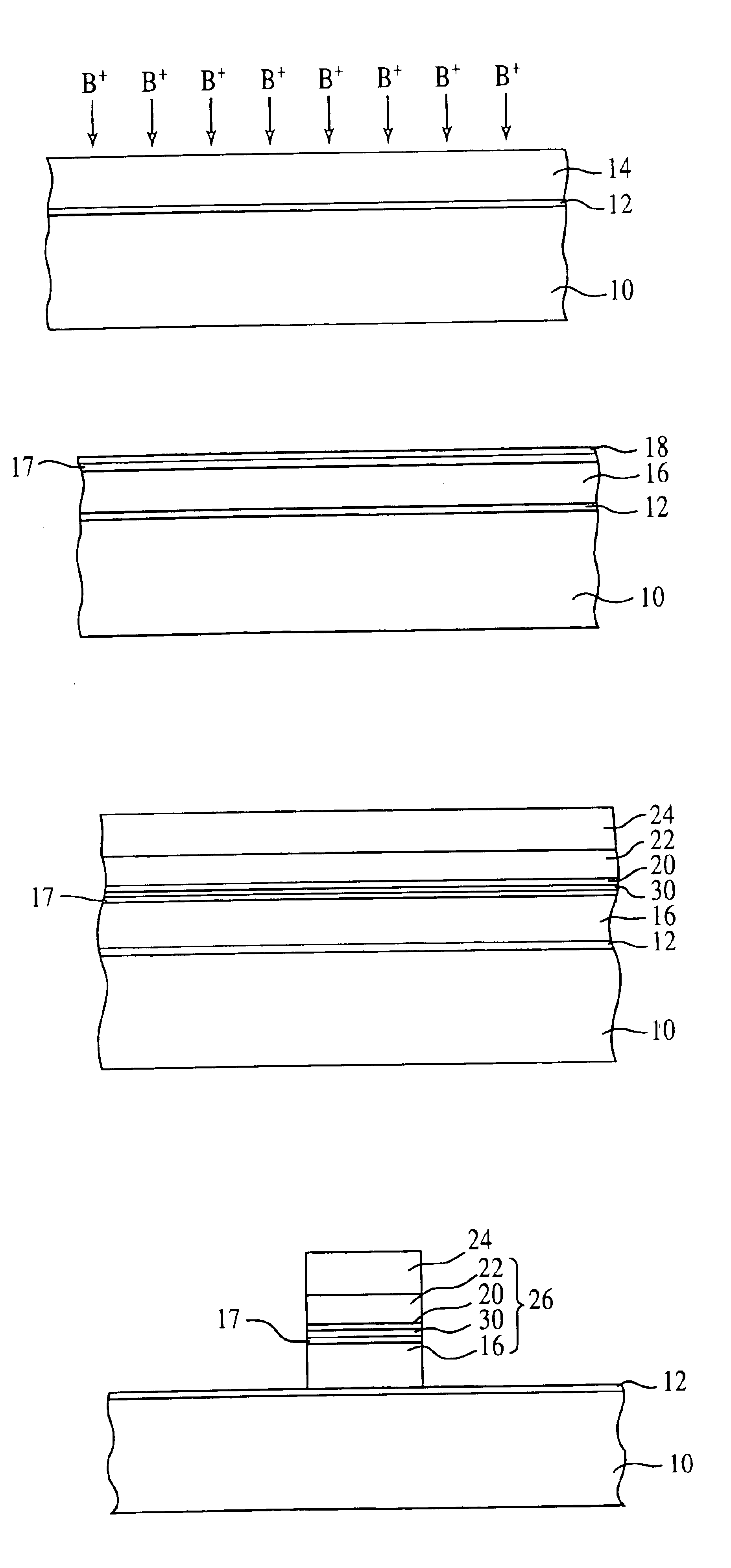

Rare earth - iron - bron based magnet and method for production thereof

InactiveUS20070034299A1High energyImprove resolutionInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementTrace element

[Object] To provide a high-performance rare earth-based magnet exhibiting a high coercive force or a high residual magnetic flux density even when the content of a rare earth element such as Dy or the like which is scarce is reduced. [Construction] A rare earth-iron-boron based magnet includes a crystal grain boundary layer enriched in element M (M is at least one rare earth element selected from Pr, Dy, Tb, and Ho) by diffusion of the element M from the surface of the magnet, wherein the relation between the coercive force Hcj and the content of the element M in the whole of the magnet is represented by the following expression: Hcj≧1+0.2×M (wherein 0.05≦M≦10) wherein Hcj is the coercive force (unit: MA / m), and M is the content of the element M in the whole of the magnet (% by mass). Furthermore, the magnet satisfies the following expression: Br≧1.68−0.17×Hcj wherein Br is the residual magnetic flux density (unit: T).

Owner:JAPAN SCI & TECH CORP +1

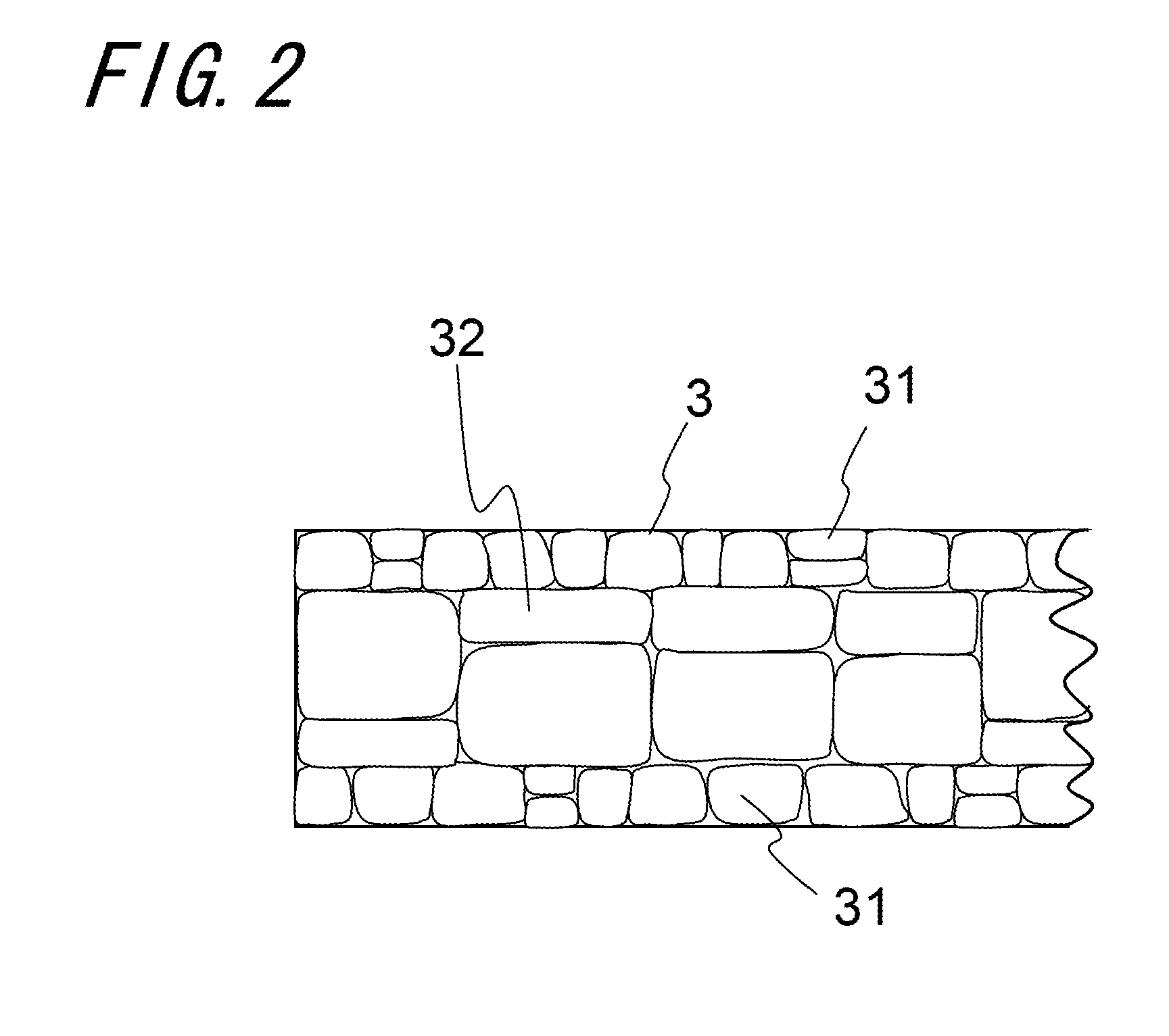

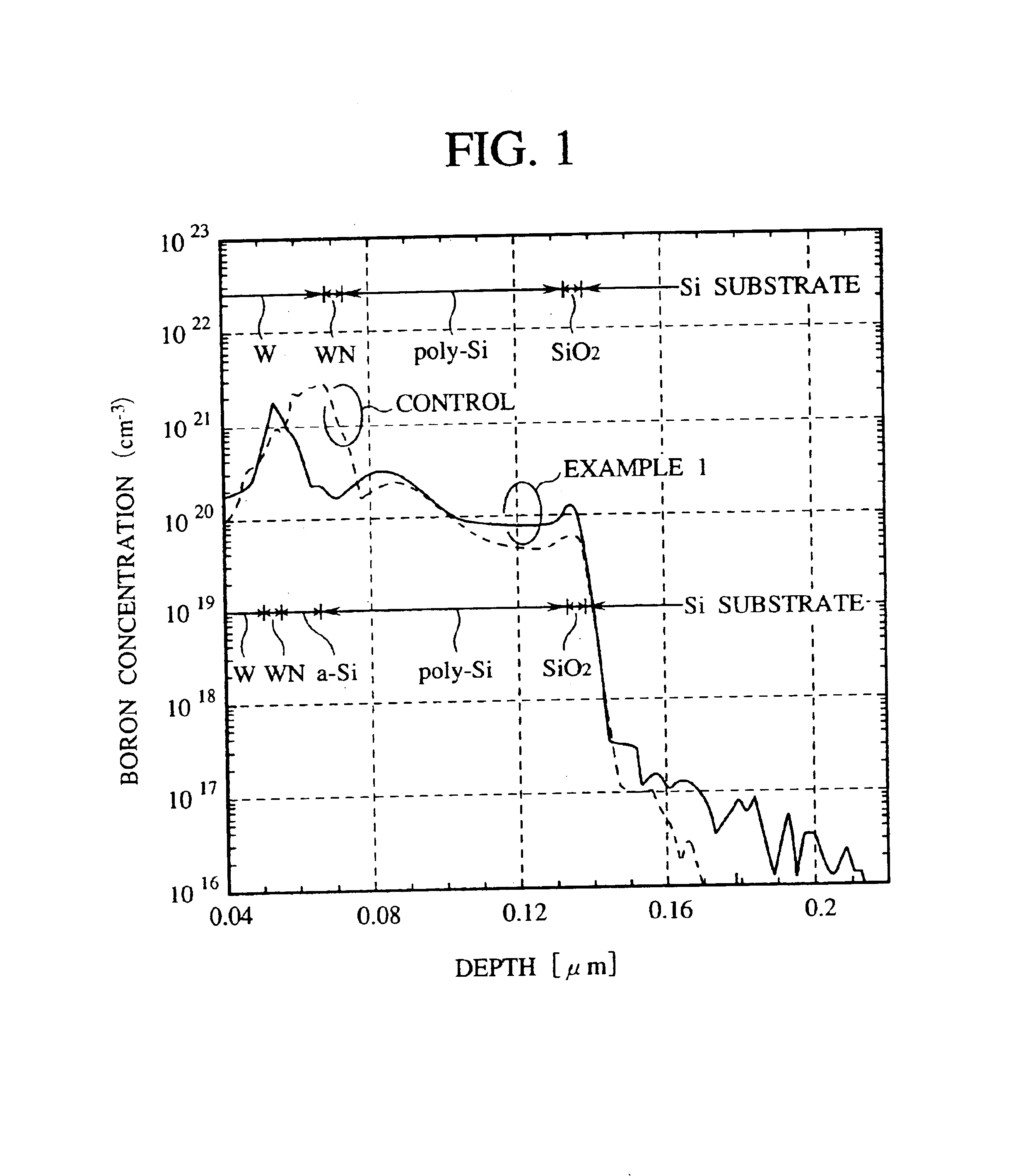

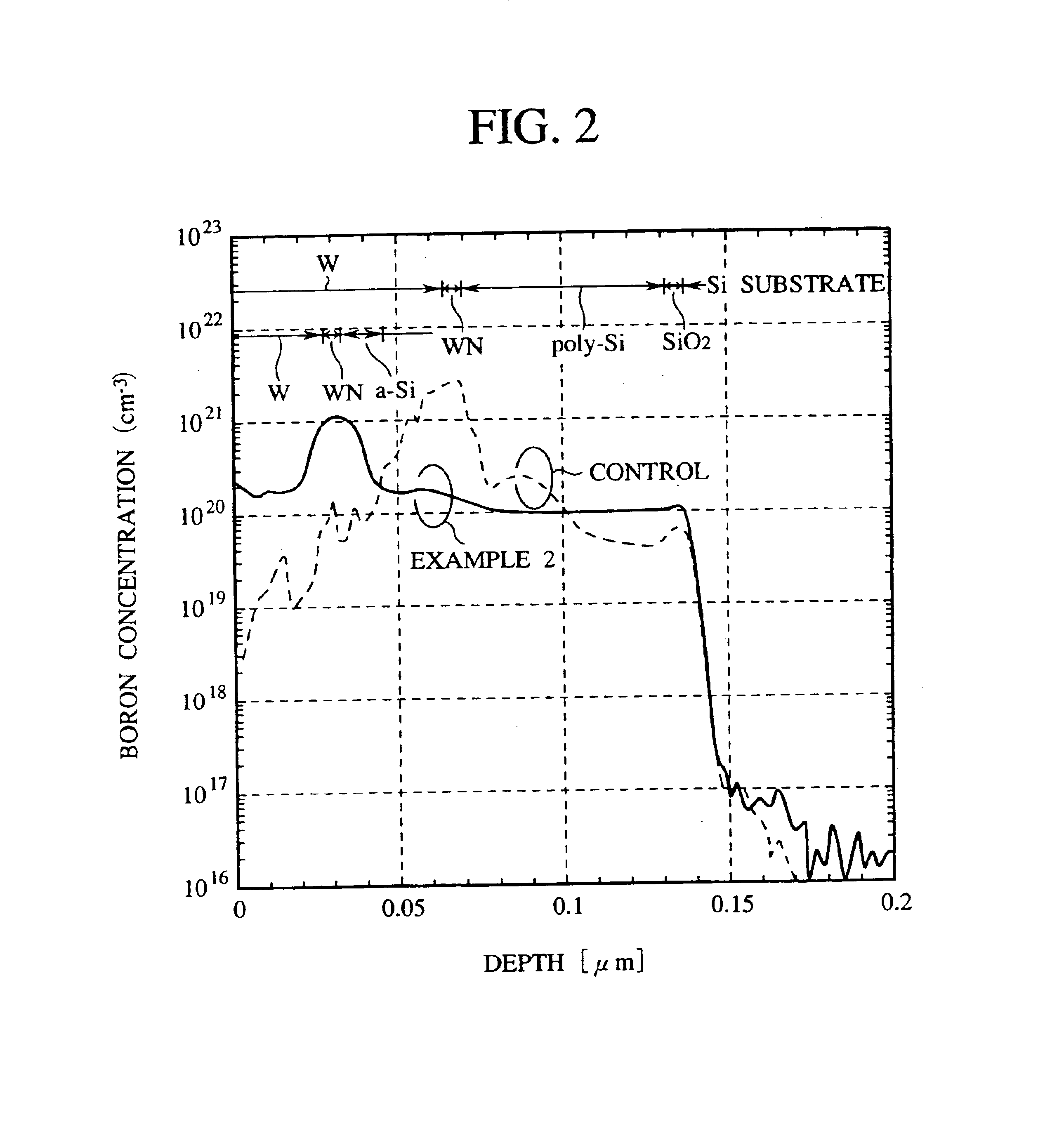

Method for fabricating semiconductor device having gate electrode with polymetal structure of polycrystalline silicon film and metal film

InactiveUS6939787B2Avoid exhaustionSemiconductor/solid-state device manufacturingSemiconductor devicesBoronNitride

The semiconductor device comprises a pair of impurity diffused regions formed in a silicon substrate 10, spaced from each other, and a gate electrode 26 formed above the silicon substrate 10 between the pair of impurity diffused regions 38 intervening a gate insulation film 12 therebetween. The gate electrode 26 is formed of a polycrystalline silicon film 16 formed on the gate insulation film 12, a polycrystalline silicon film 30 formed on the polycrystalline silicon film 16 and having crystal grain boundaries discontinuous to the polycrystalline silicon film 16, a metal nitride film 20 formed on the polycrystalline silicon film 30, and a metal film 22 formed on the barrier metal film 20. Whereby diffusion of the boron from the first polycrystalline silicon film 16 toward the metal nitride film 20 can be decreased. Thus, depletion of the gate electrode 26 can be suppressed.

Owner:TOSHIBA MEMORY CORP

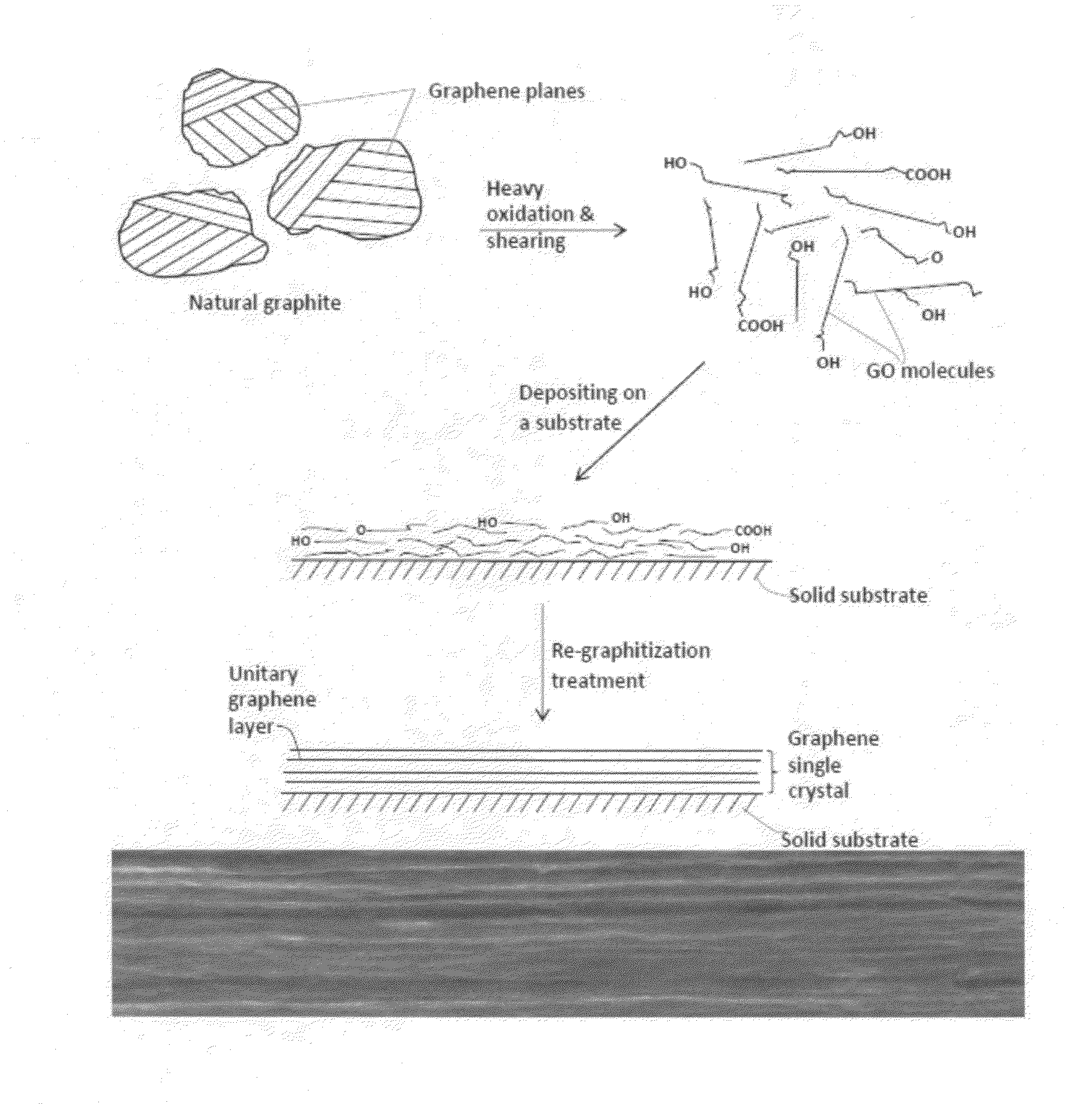

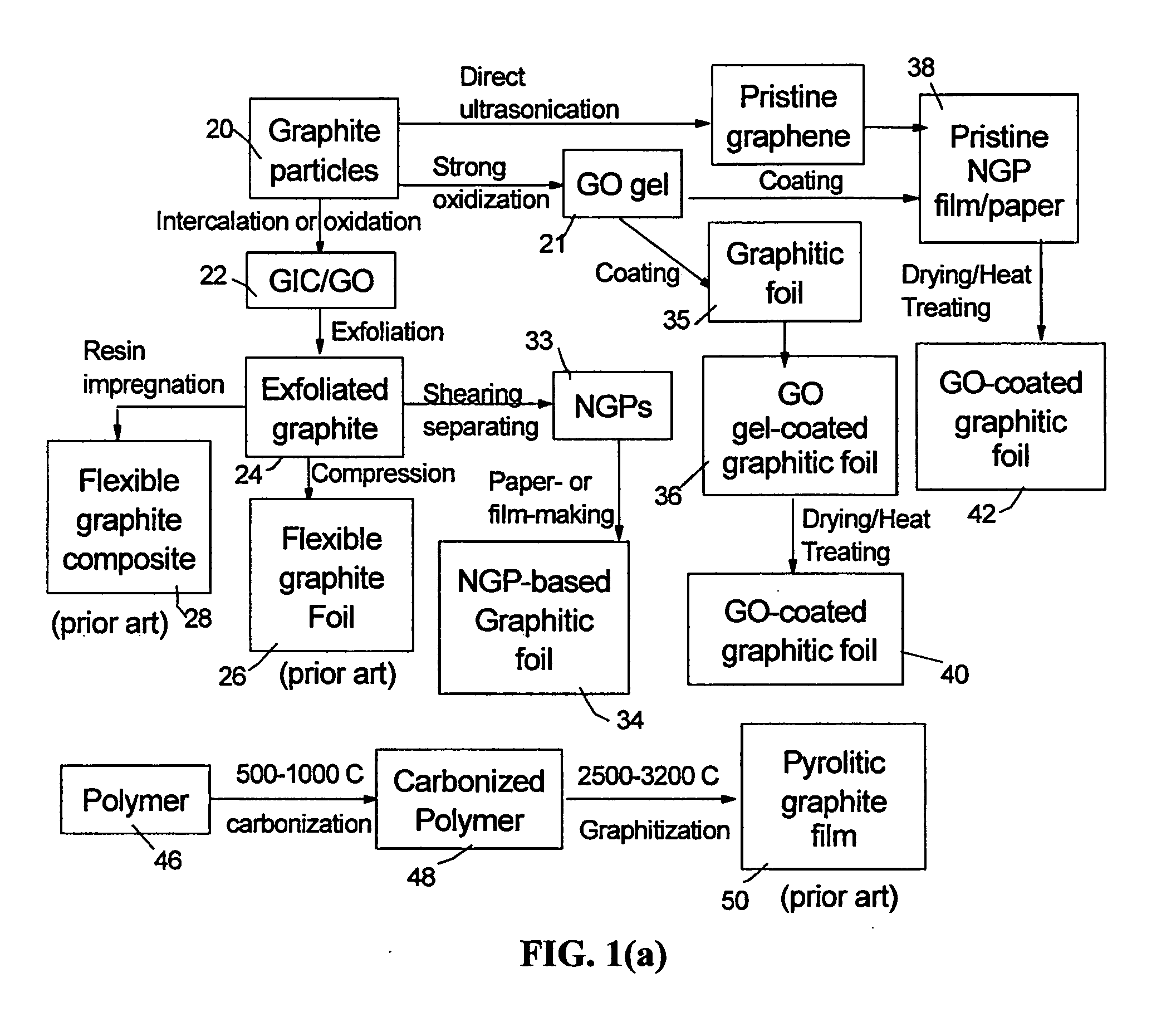

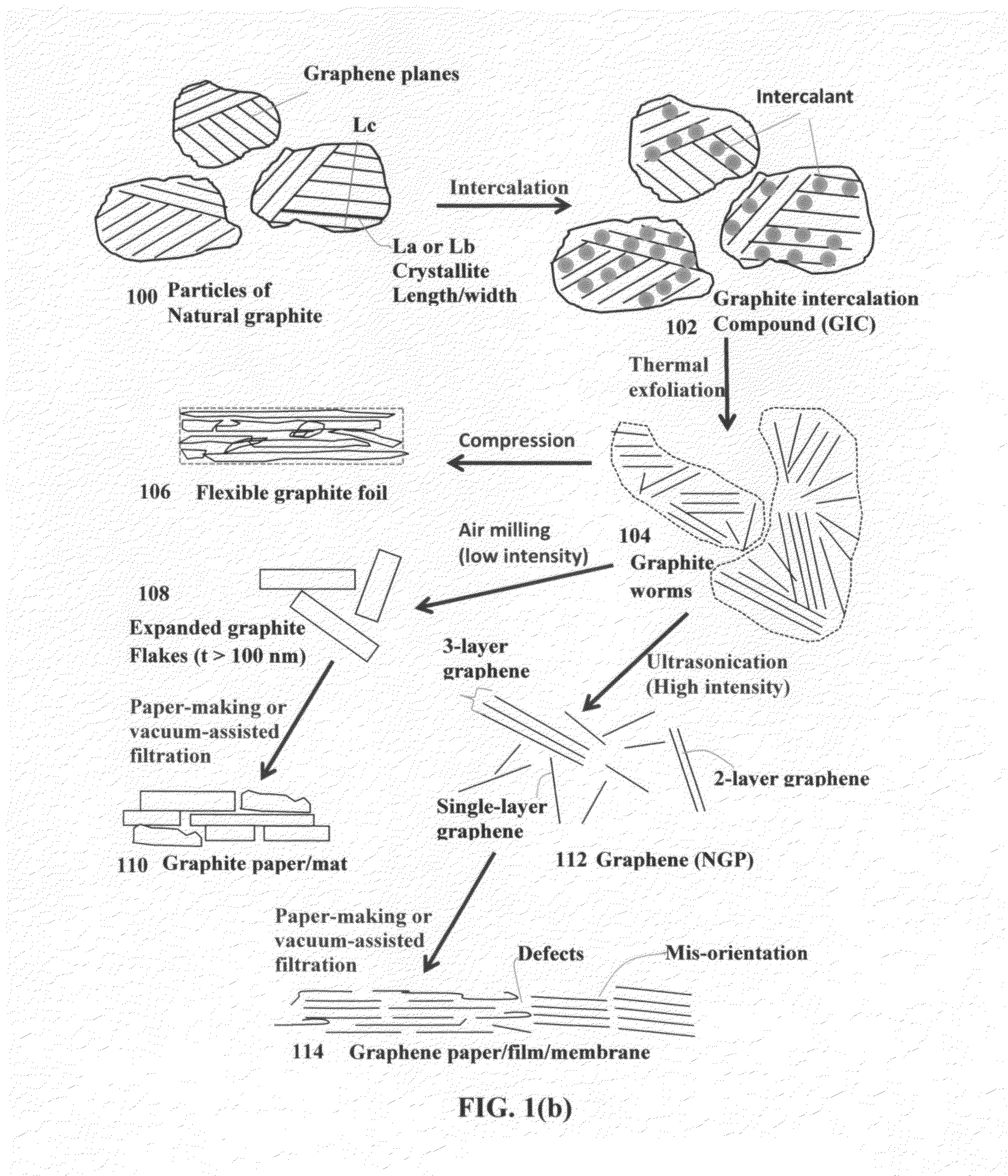

Unitary graphene material-based integrated finned heat sink

ActiveUS20140190676A1Outstanding mechanical strengthOutstanding scratch resistanceIndirect heat exchangersHeat-exchange elementsSingle crystalGraphene

A unitary graphene-based integrated heat sink comprising a heat collection member (base) and at least one heat dissipation member (e.g. fins) integral to the baser, wherein the base is configured to be in thermal contact with a heat source, collects heat therefrom, and dissipates heat through the fins. The unitary graphene material is obtained from heat-treating a graphene oxide gel at a temperature higher than 100° C., 500° C., 1,250° C., or 2,000° C., and contains chemically bonded graphene molecules having inter-graphene distance of 0.3354-0.4 nm (preferably <0.337 nm). The unitary graphene material is a graphene single crystal, a poly-crystal with incomplete grain boundaries, or a poly-crystal having large grain sizes (e.g. >mm or cm), exhibiting a degree of graphitization preferably from 1% to 100% and a Mosaic spread value less than 0.7 (preferably no greater than 0.4). The finned heat sink may also be made from a filler-reinforced graphene matrix composite.

Owner:GLOBAL GRAPHENE GRP INC

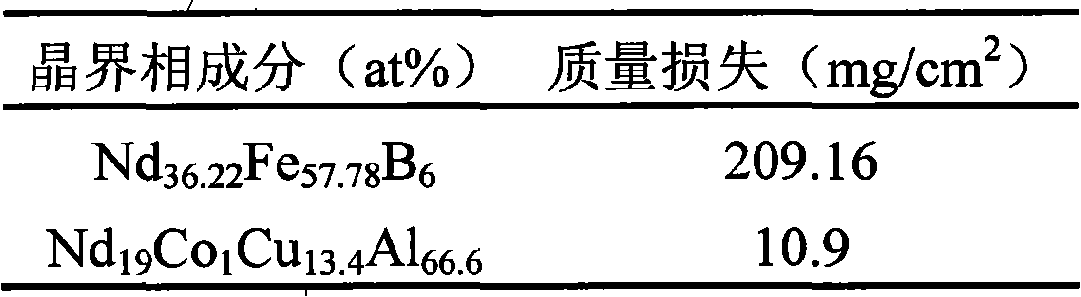

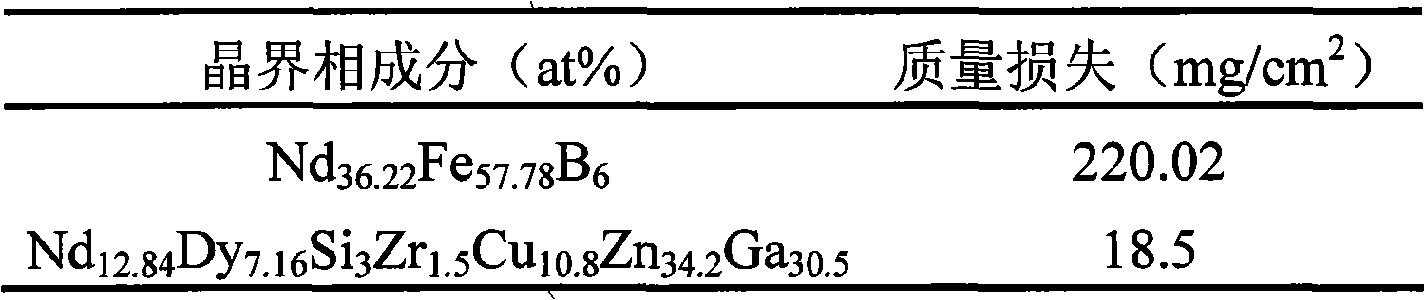

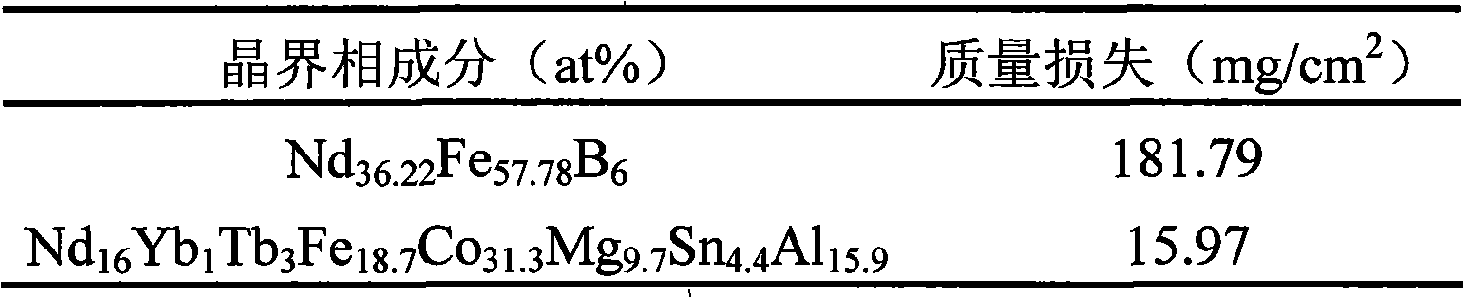

Grain boundary phase-reconstructed high-corrosion resistance Sintered NdFeB magnet and preparation method thereof

ActiveCN101320609ALow melting pointGuaranteed MagneticInorganic material magnetismInductances/transformers/magnets manufactureElectrode potentialPowder mixture

The invention discloses a sintered Nd-Fe-B magnet with high corrosion resistance and the grain boundary reconstruction and a preparation method thereof. The composition of the invention is that: NdeFe100-e-f-gBfMg, wherein, e is greater than or equal to 6 and equal to or less than 24, f is greater than or equal to 5. 6 and equal to or less than 7, g is greater than or equal to 0.03 and equal to or less than 8, M is one or some of elements Dy, Tb, Pr, Sm, Yb, La, Co, Ni, Cr, Nb, Ta, Zr, Si, Ti, Mo, W, V, Ca, Mg, Cu, Al, Zn, Ga, Bi, Sn and In; The method is that: main phrase alloy and reconstructed grain boundary phase alloy are respectively pulverized and mixed uniformly; the powder mixture is pressed to a mould in the magnetic field, and fabricated into a sintering magnet in a high vacuum sintering furnace. By the reconstruction of the grain boundary phase composition, the invention can obtain the grain boundary phase alloy with low melting point and high electrode potential, decrease the potential difference between the main phase and the grain boundary phase on the basis of ensuring the magnetic properties, promote the intrinsic corrosion resistance of magnet, and has the advantages of simple process, low cost and being suitable for the batch production. Therefore, by combining the grain boundary reconstruction and double alloy method, the sintered Nd-Fe-B magnet with high intrinsic corrosion resistance can be prepared.

Owner:ZHEJIANG UNIV

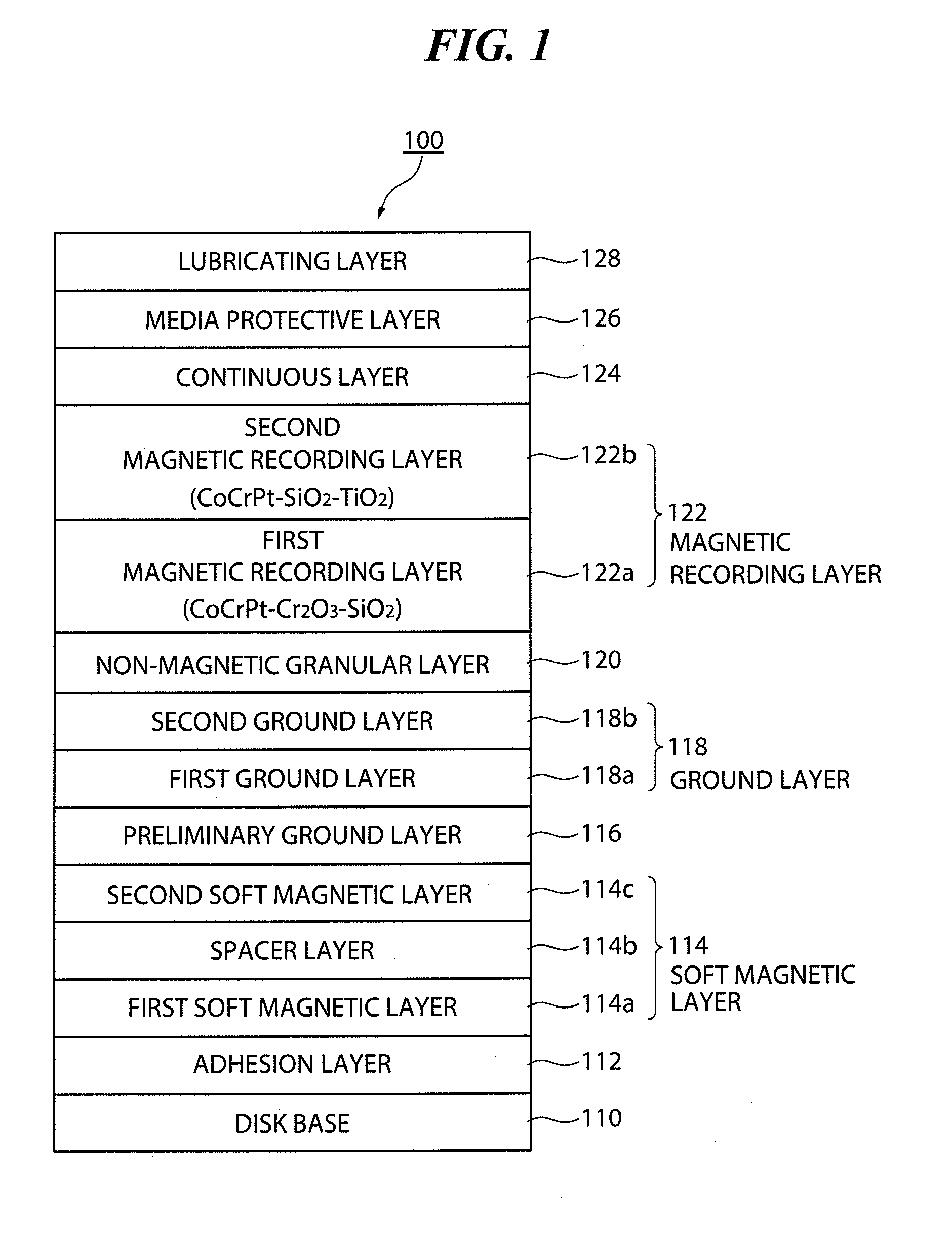

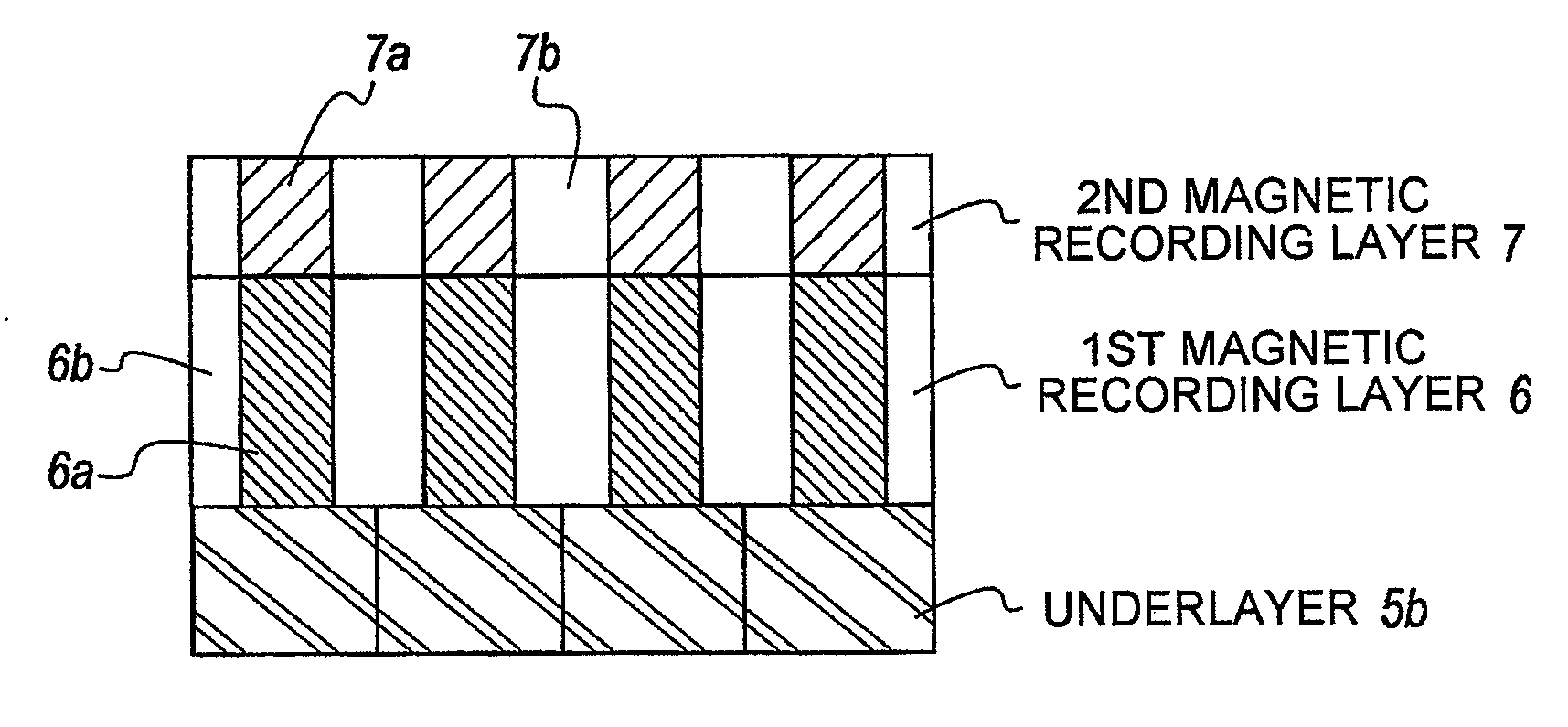

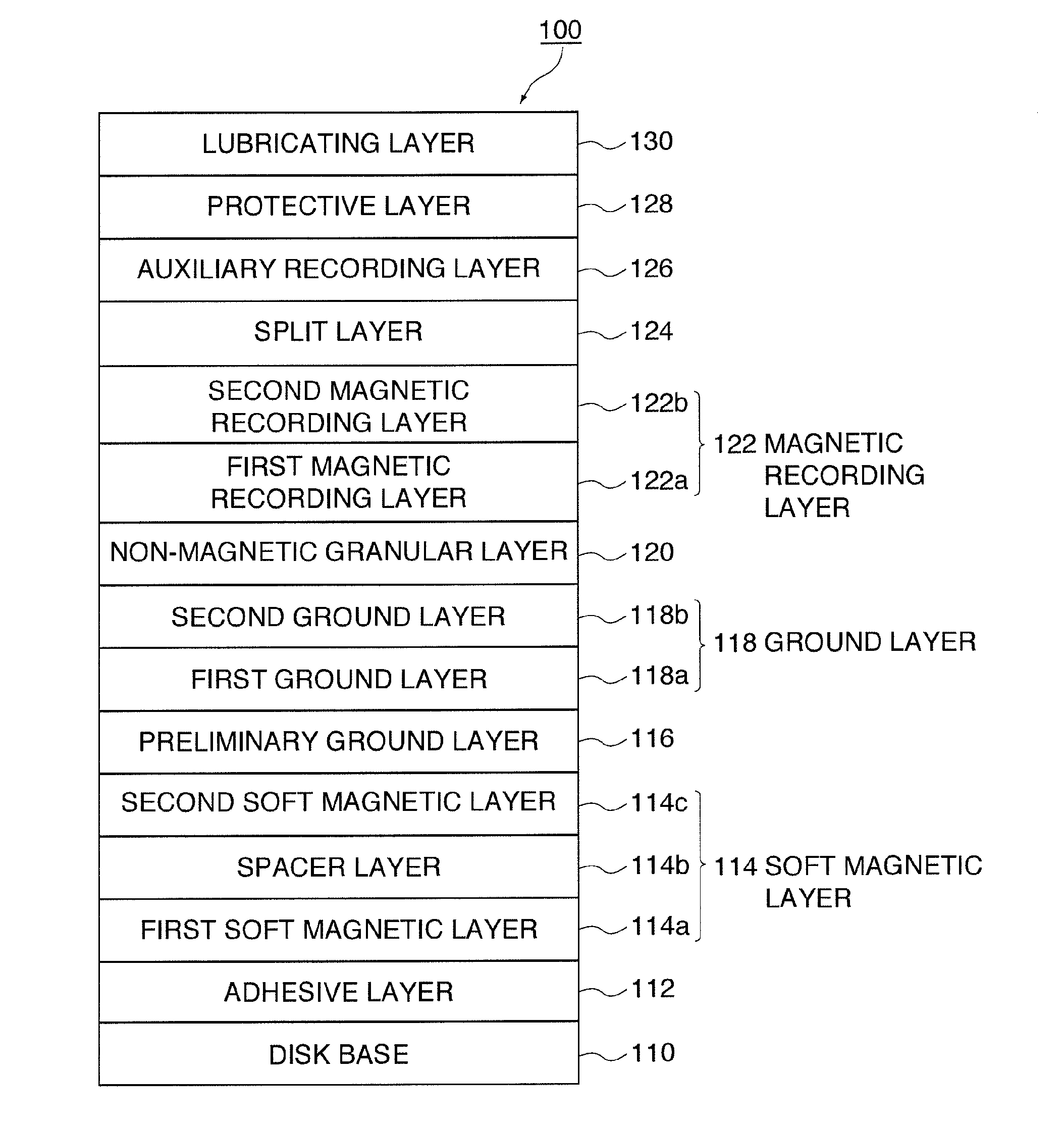

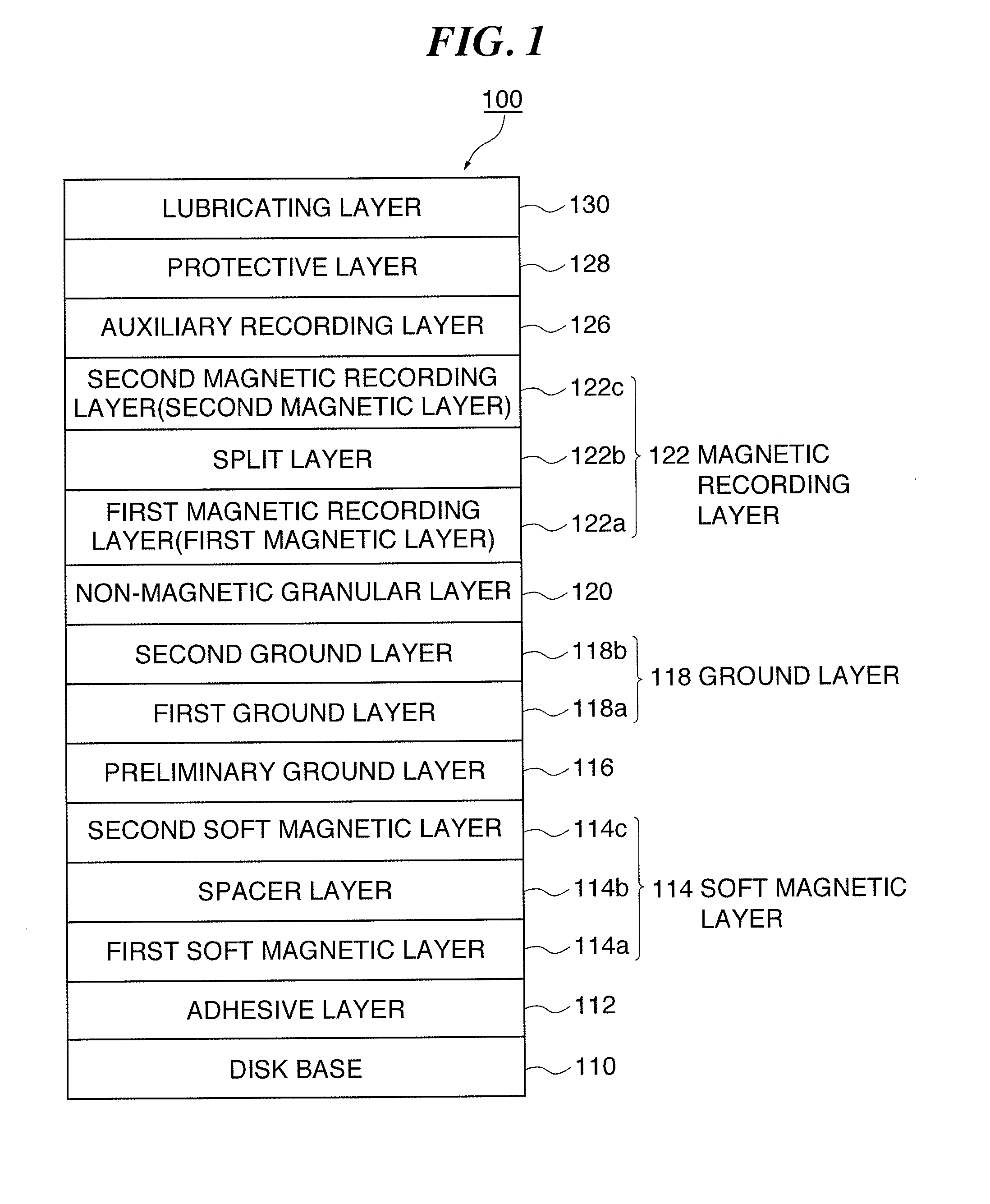

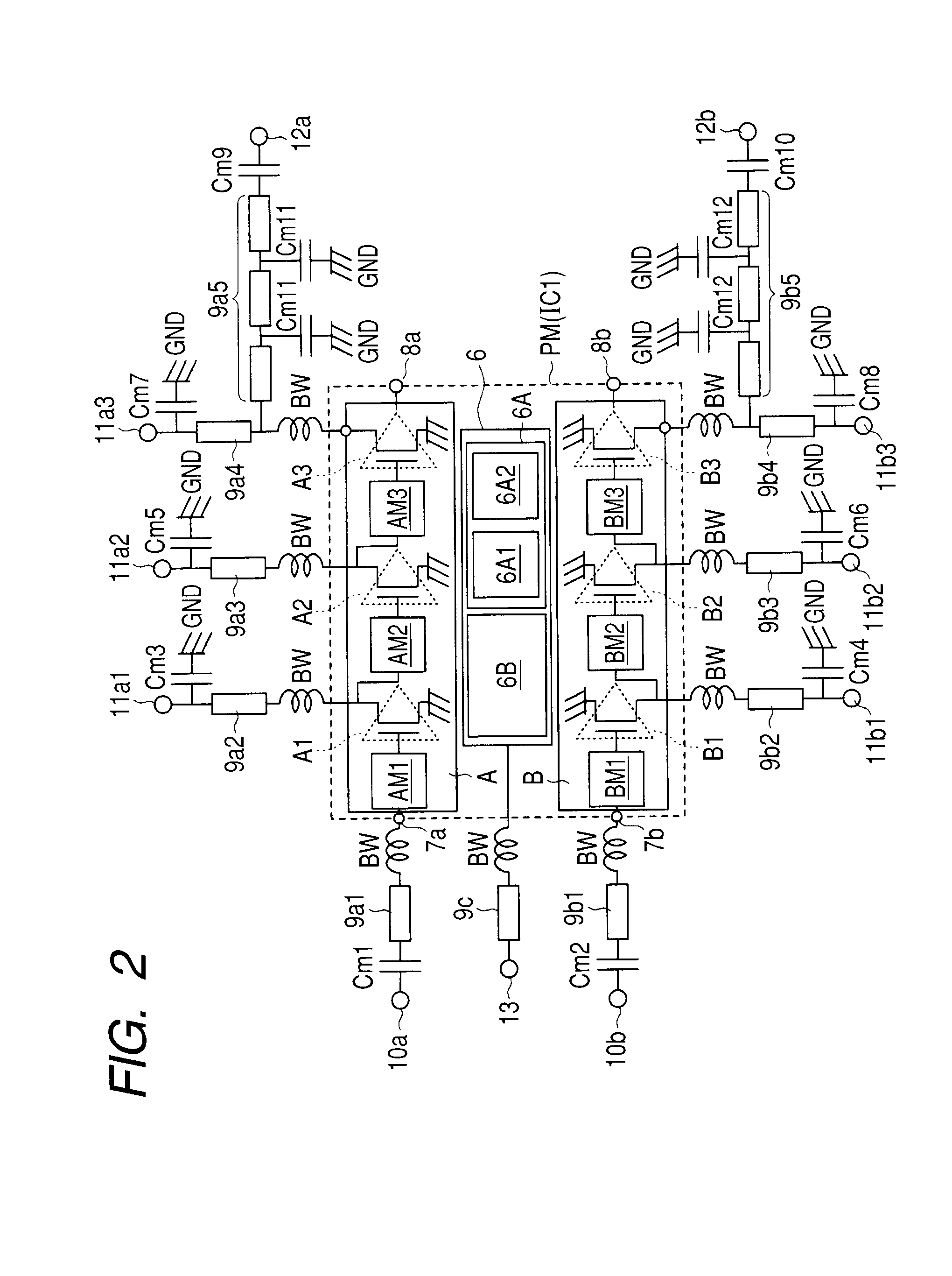

Magnetic recording medium and method for manufacturing magnetic recording medium

InactiveUS7833639B2Delay transitionImprove thermal stabilityPatterned record carriersNanoinformaticsGrain boundaryCrystallite

Owner:WD MEDIA SINGAPORE PTE

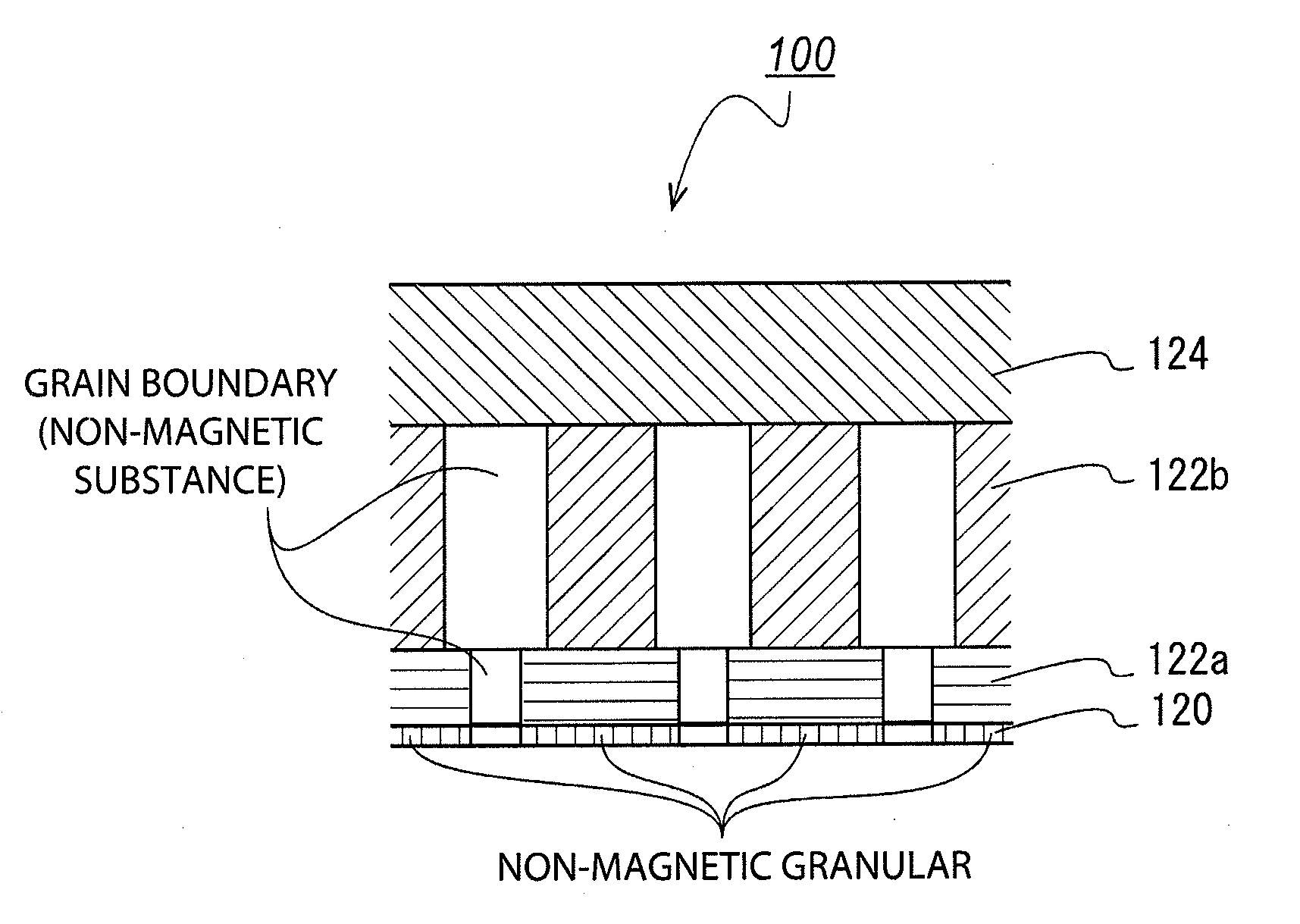

Perpendicular magnetic recording medium and process for manufacture thereof

ActiveUS20110097603A1Improve featuresDifferent record carrier formsRecord information storageShortest distanceNon magnetic

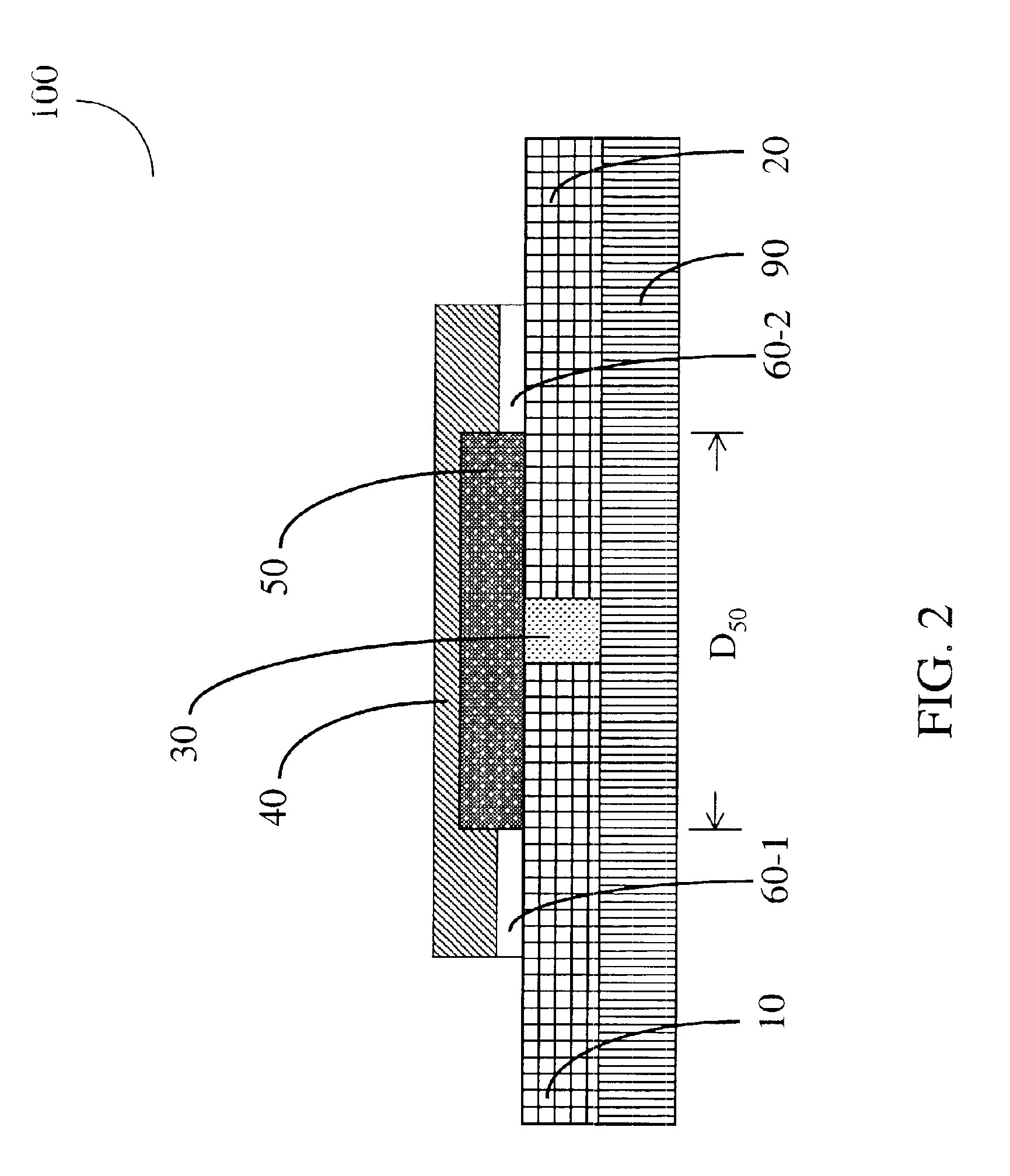

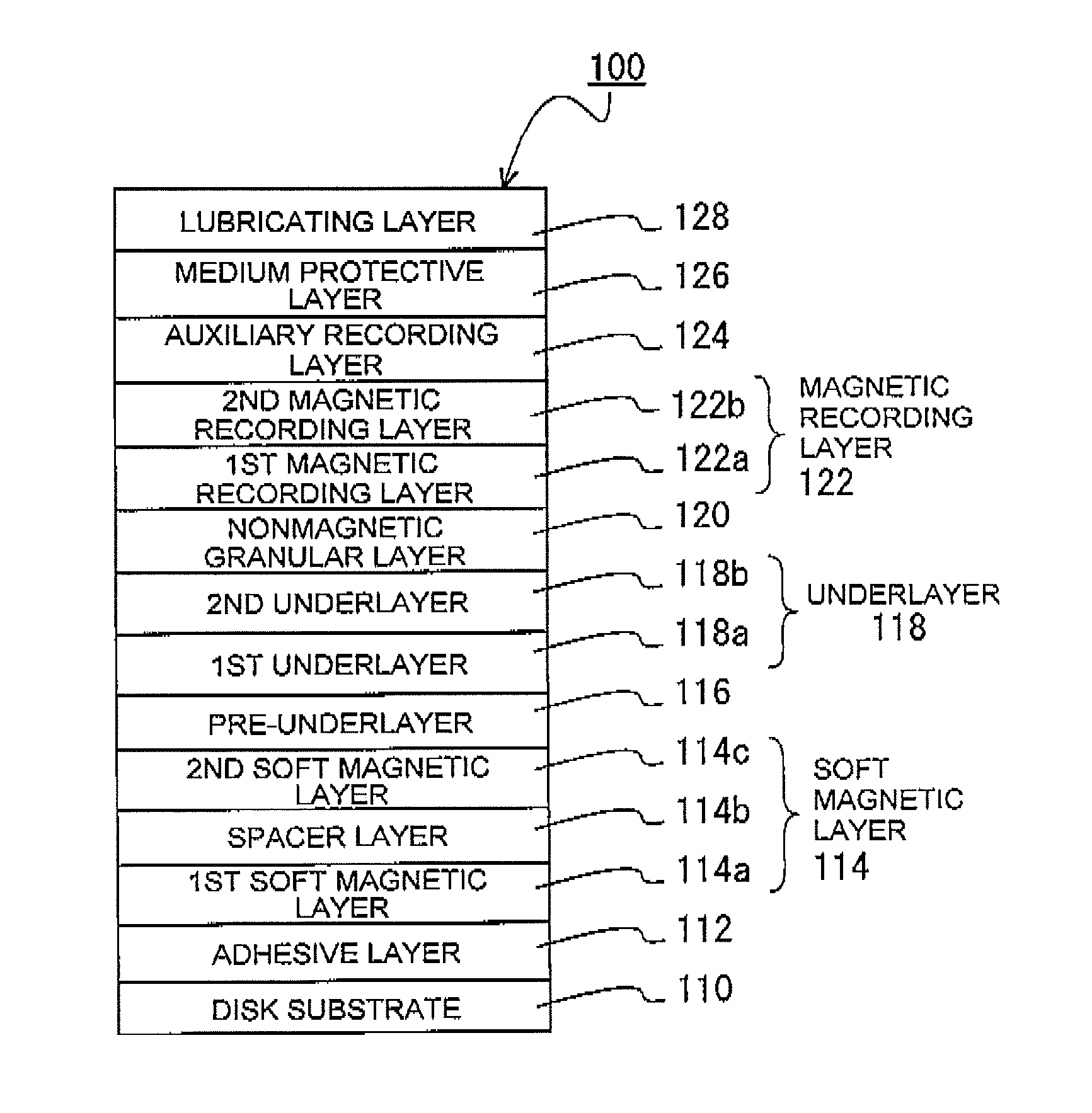

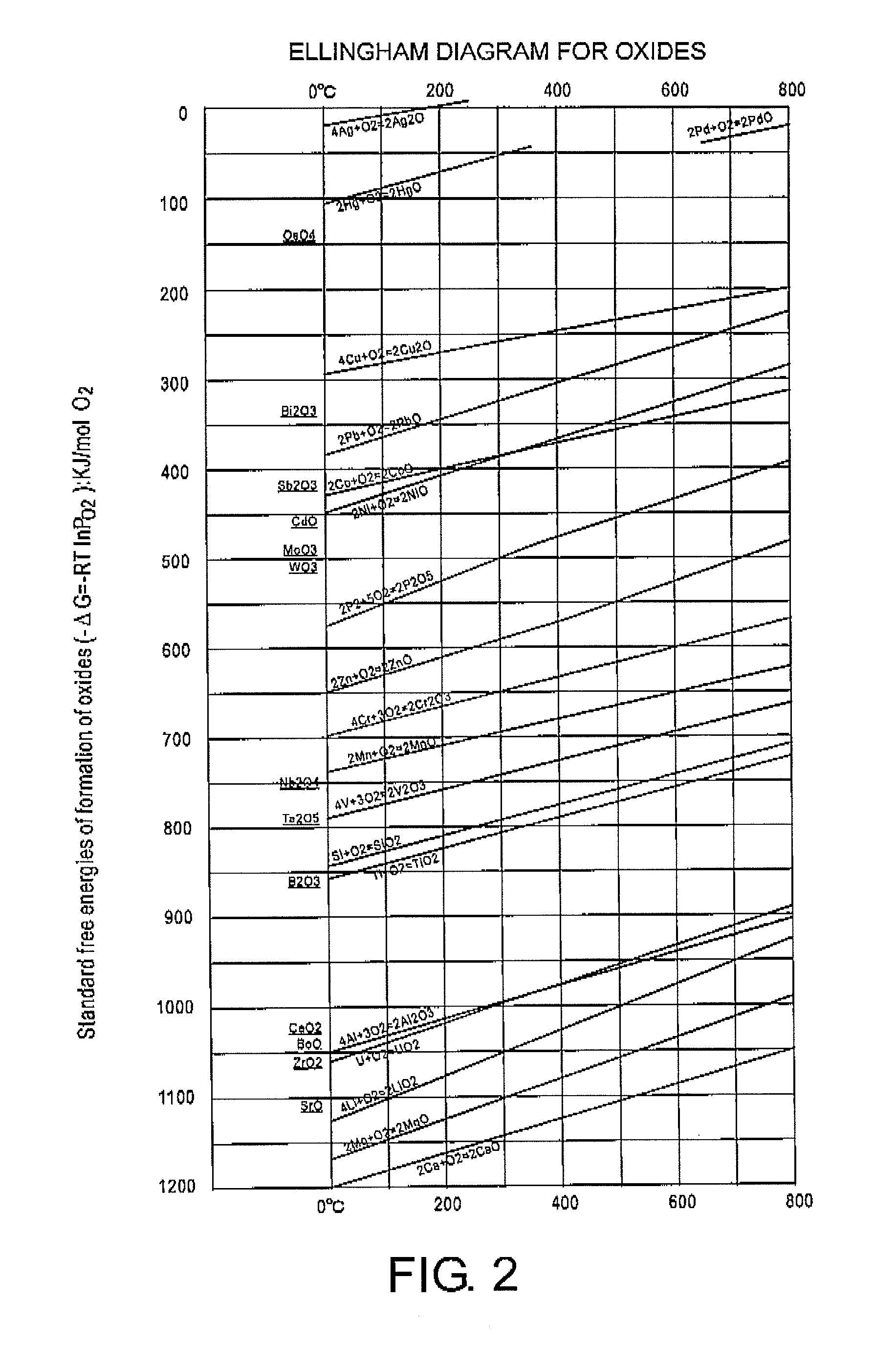

An object of the present invention is to provide a perpendicular magnetic recording medium in which each space between crystal grains of a first magnetic recording layer is so designed as to allow the layer to also have a function as a continuous layer, and a method of manufacturing a perpendicular magnetic recording medium. In a perpendicular magnetic recording medium 100 according to the present invention, a first magnetic recording layer 122a and a second magnetic recording layer 122b are ferromagnetic layers each having a granular structure in which a grain boundary part made of a non-magnetic substance is formed between crystal grains each grown in a column shape and, in the first magnetic recording layer 122a, an intergranular distance defined by an average of shortest distances between grain boundary parts each between a crystal grain and its adjacent crystal grain is equal to or shorter than 1 nm.

Owner:WESTERN DIGITAL TECH INC

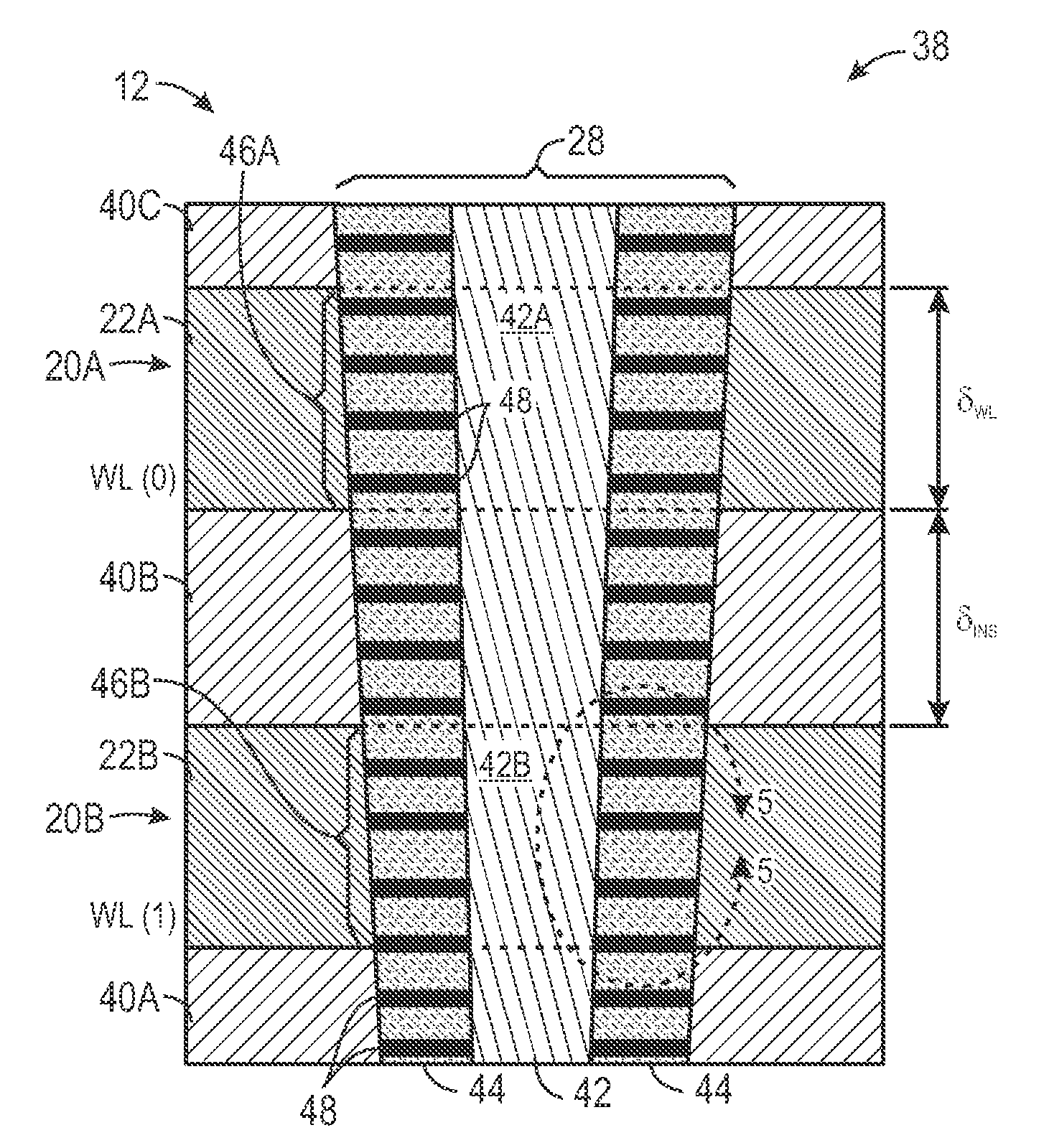

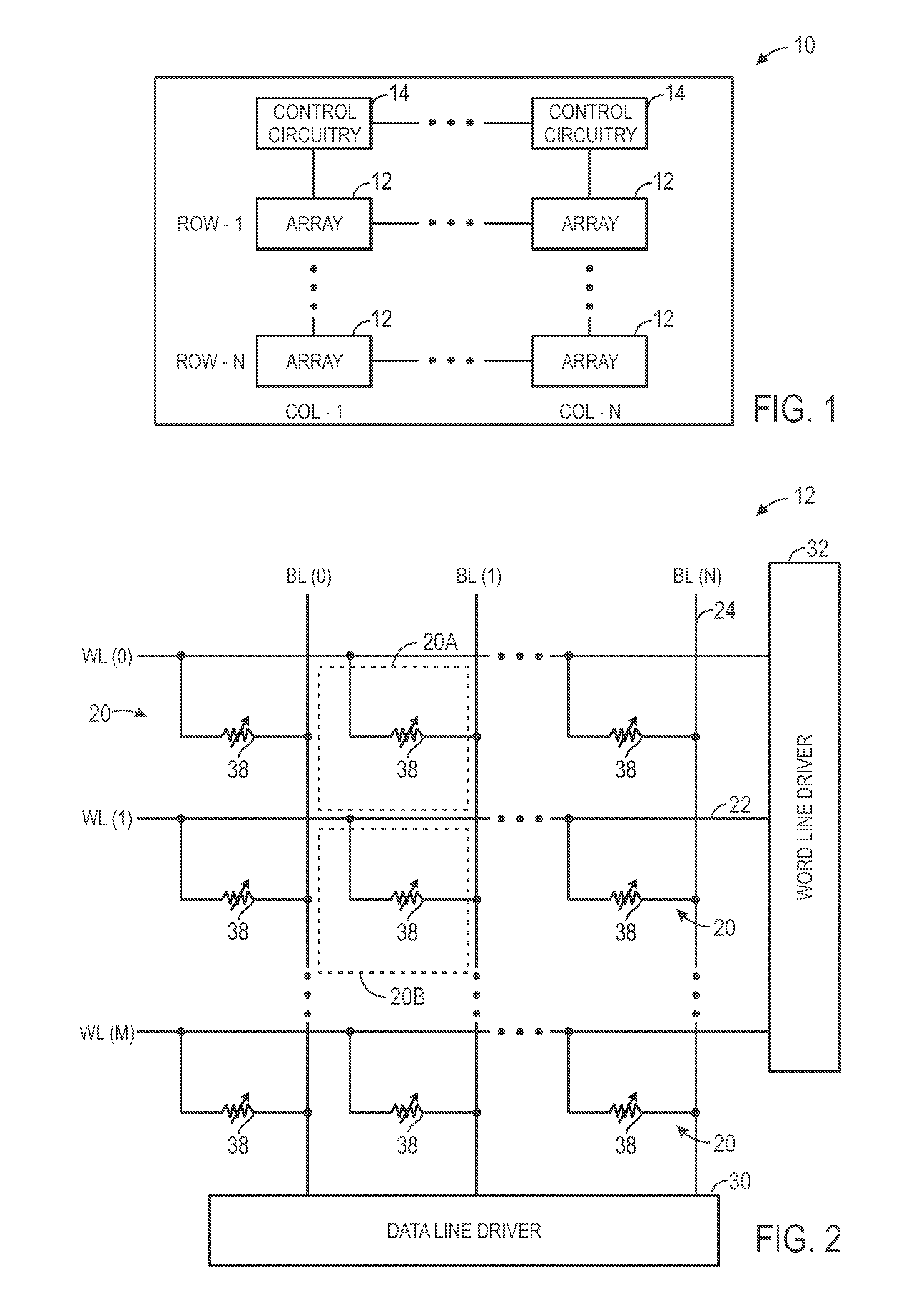

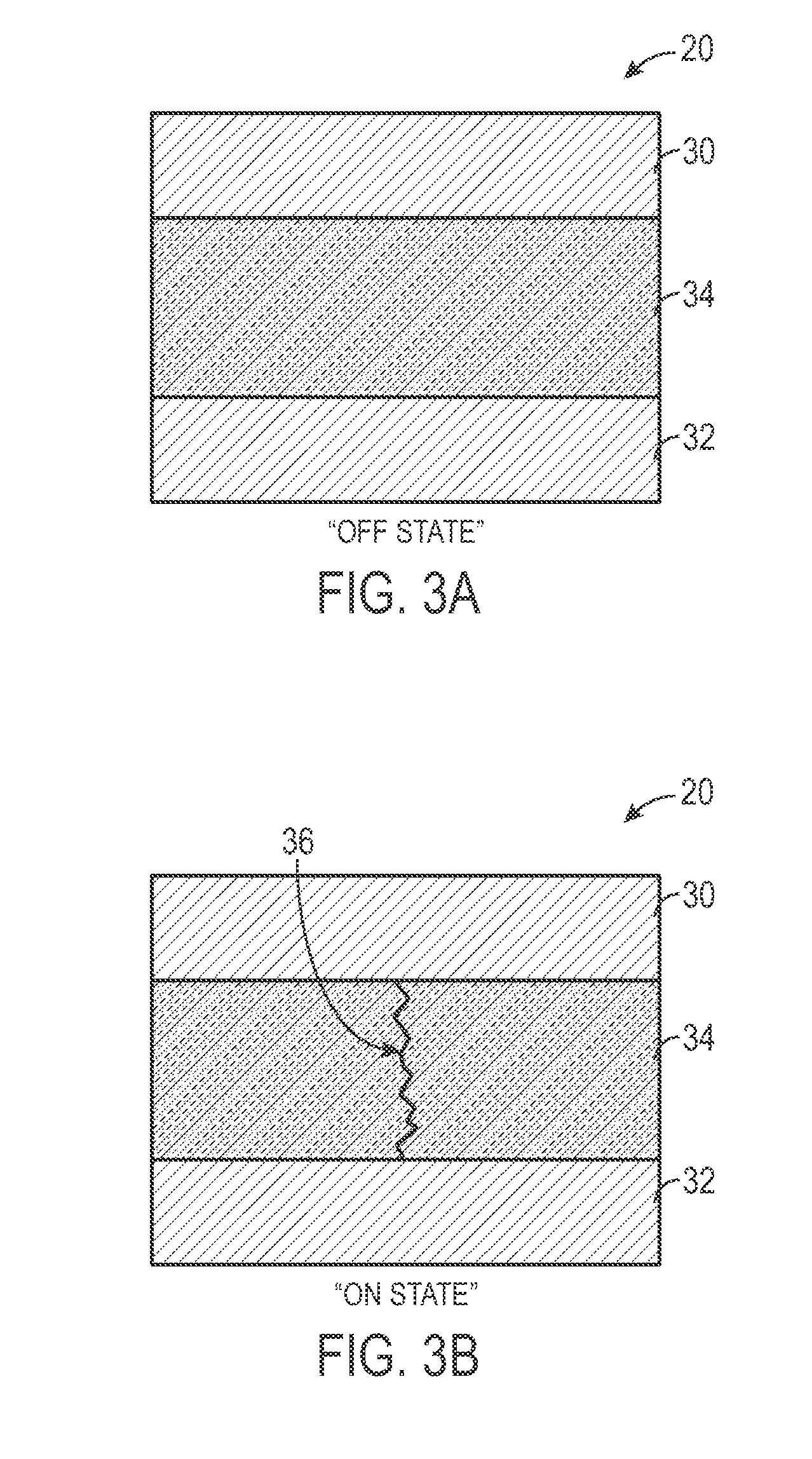

Vertical memory cell for high-density memory

ActiveUS20120261638A1Solid-state devicesBulk negative resistance effect devicesHigh densityUnit structure

This disclosure provides embodiments for the formation of vertical memory cell structures that may be implemented in RRAM devices. In one embodiment, memory cell area may be increased by varying word line height and / or word line interface surface characteristics to ensure the creation of a grain boundary that is suitable for formation of conductive pathways through an active layer of an RRAM memory cell. This may maintain continuum behavior while reducing random cell-to-cell variability that is often encountered at nanoscopic scales. In another embodiment, such vertical memory cell structures may be formed in multiple-tiers to define a three-dimensional RRAM memory array. Further embodiments also provide a spacer pitch-doubled RRAM memory array that integrates vertical memory cell structures.

Owner:MICRON TECH INC

Copper interconnect structure having stuffed diffusion barrier

InactiveUS6936535B2Semiconductor/solid-state device detailsSolid-state devicesMetal interconnectCopper interconnect

The present invention provides a method of fabricating a semiconductor device, which could advance the commercialization of semiconductor devices with a copper interconnect. In a process of metal interconnect line fabrication, a TiN thin film combined with an Al intermediate layer is used as a diffusion barrier on trench or via walls. For the formation, Al is deposited on the TiN thin film followed by copper filling the trench. Al diffuses to TiN layer and reacts with oxygen or nitrogen, which will stuff grain boundaries efficiently, thereby blocking the diffusion of copper successfully.

Owner:ASM INTERNATIONAL

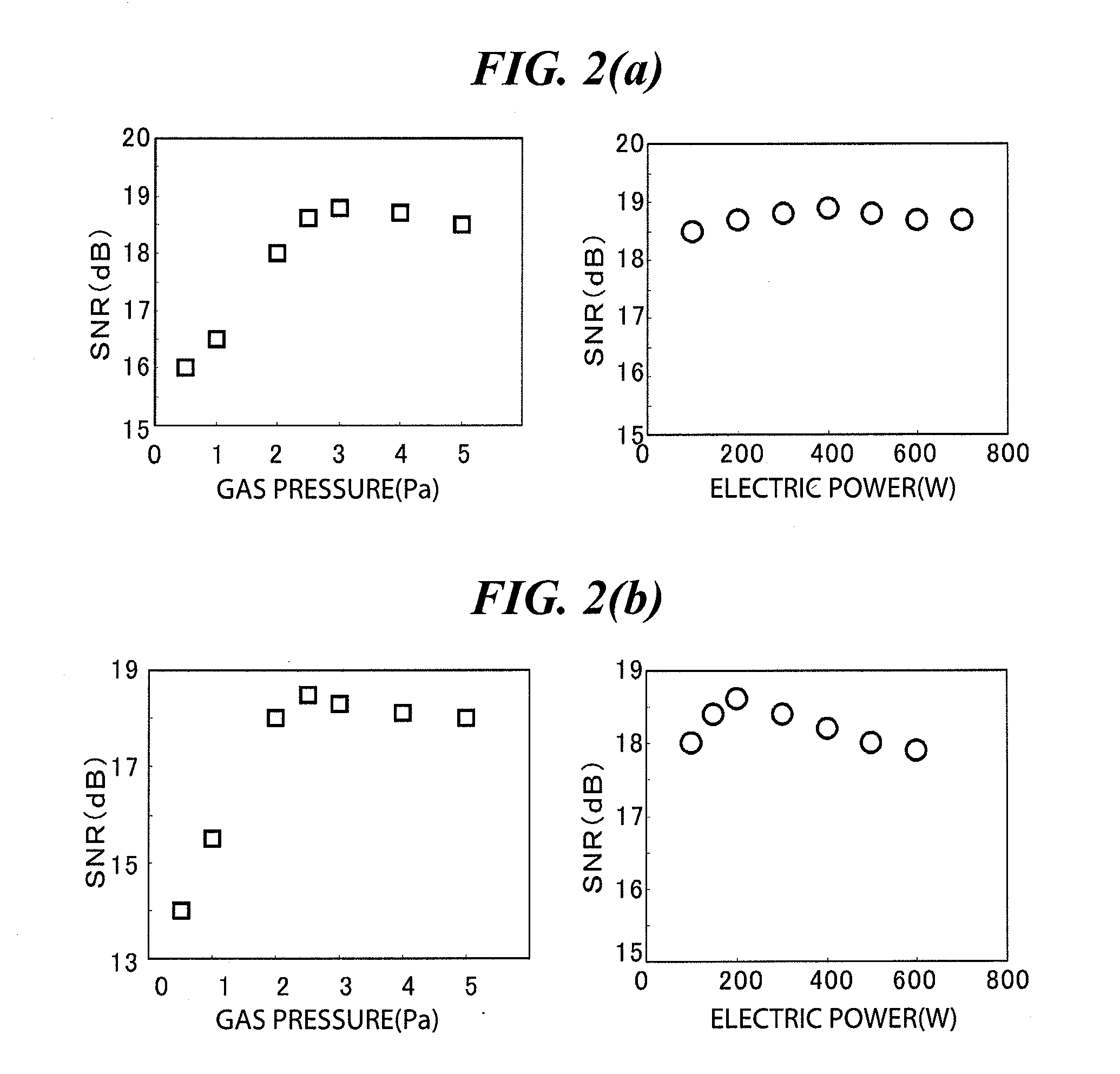

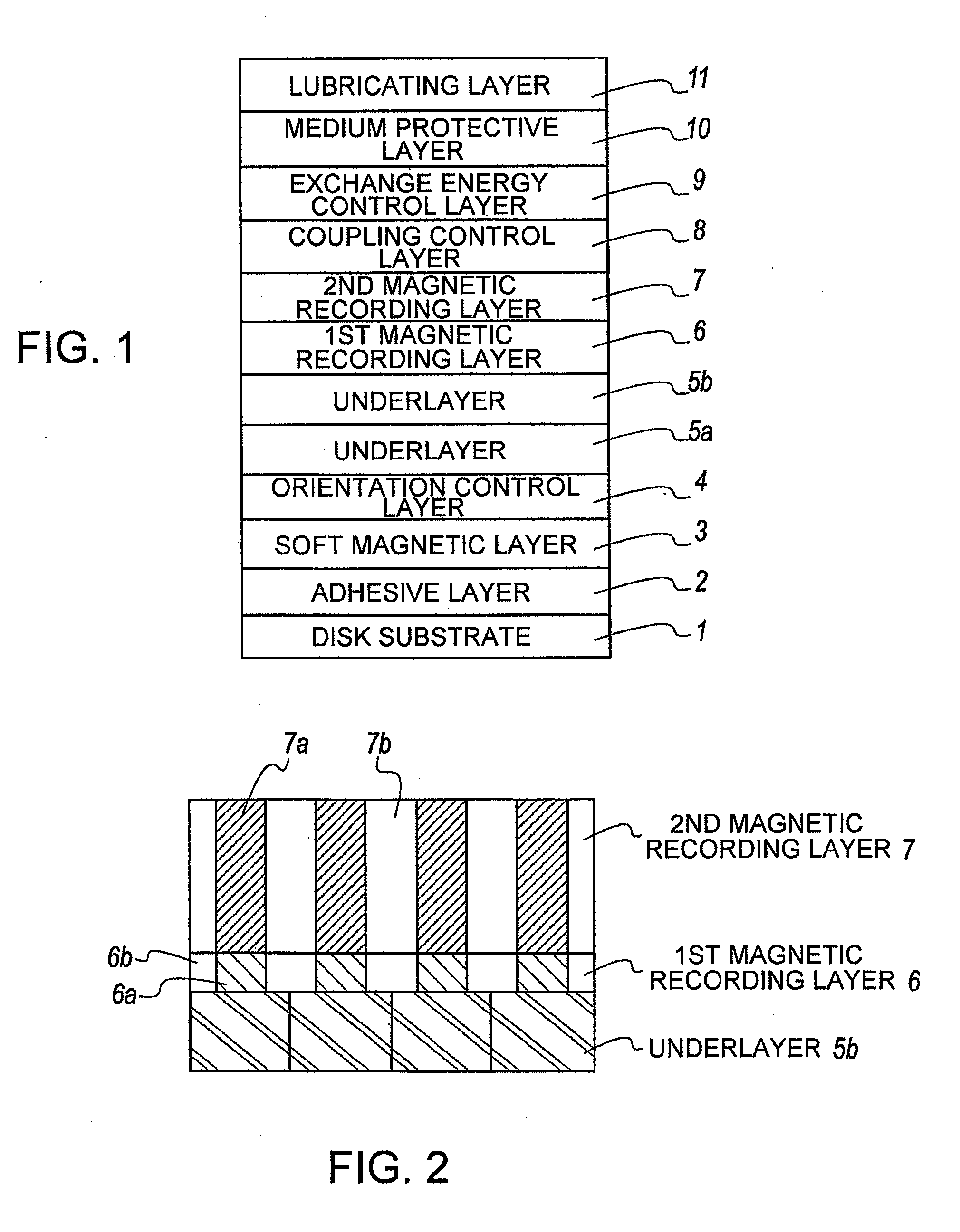

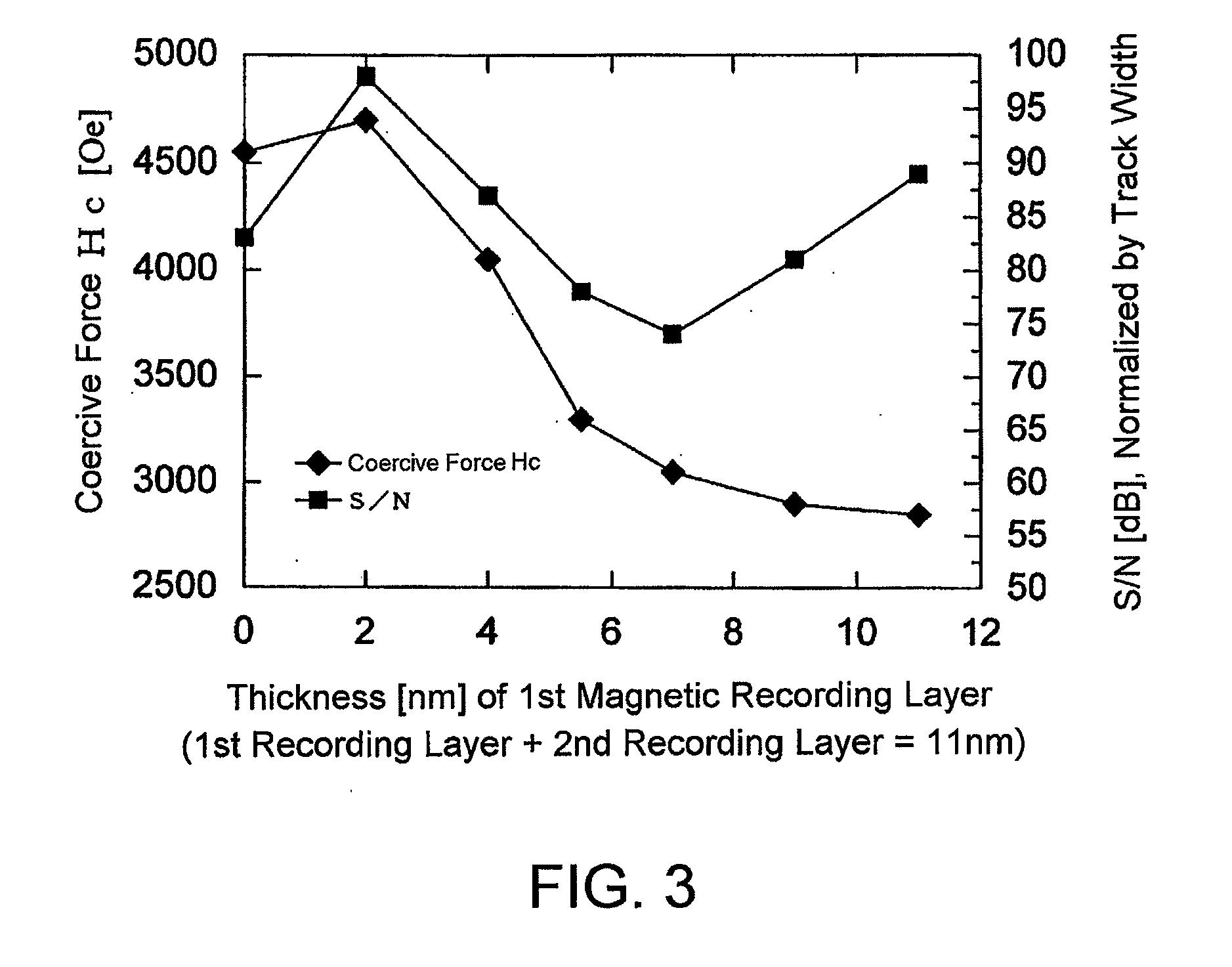

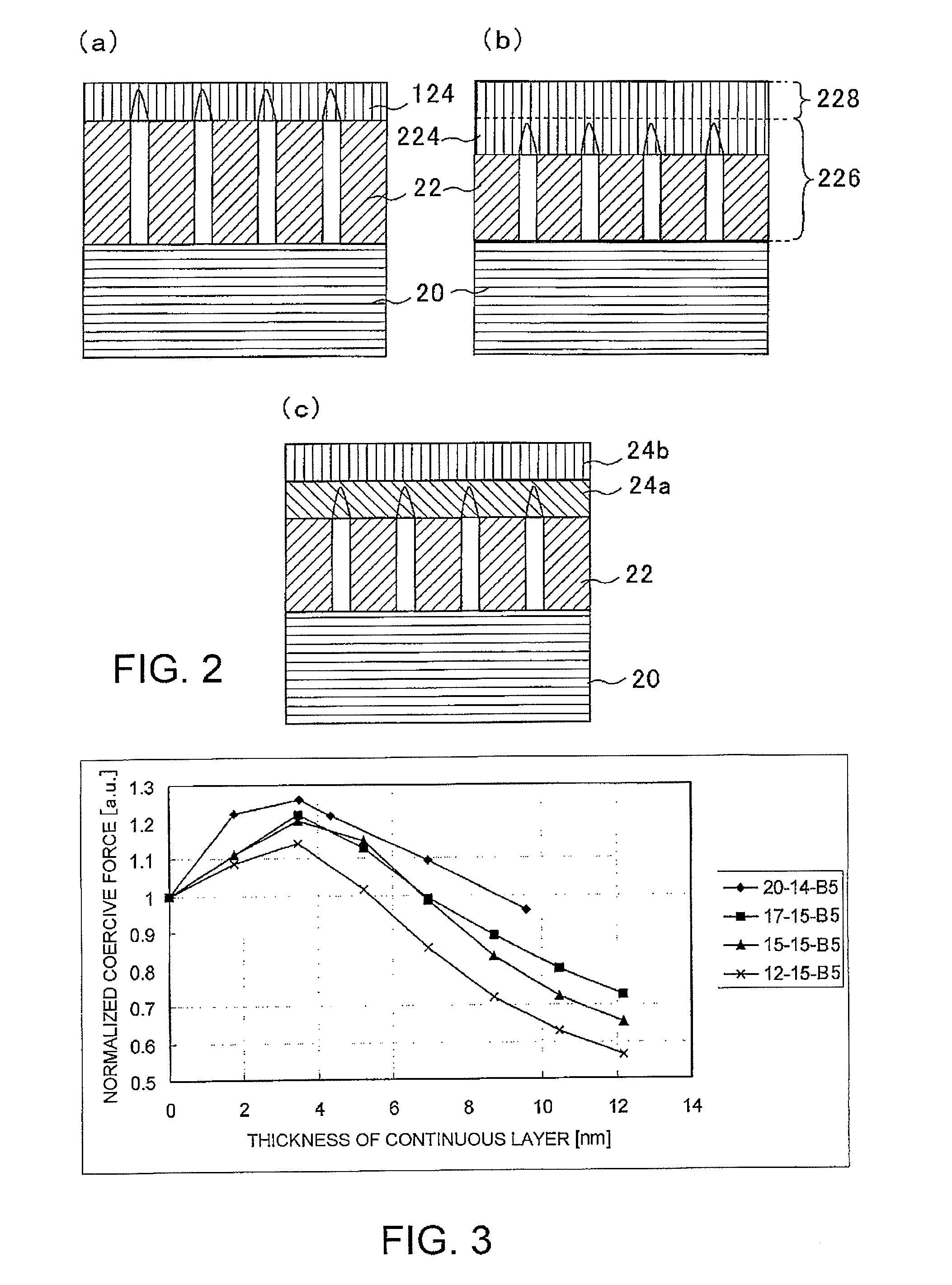

Perpendicular magnetic recording disk and method of manufacturing the same

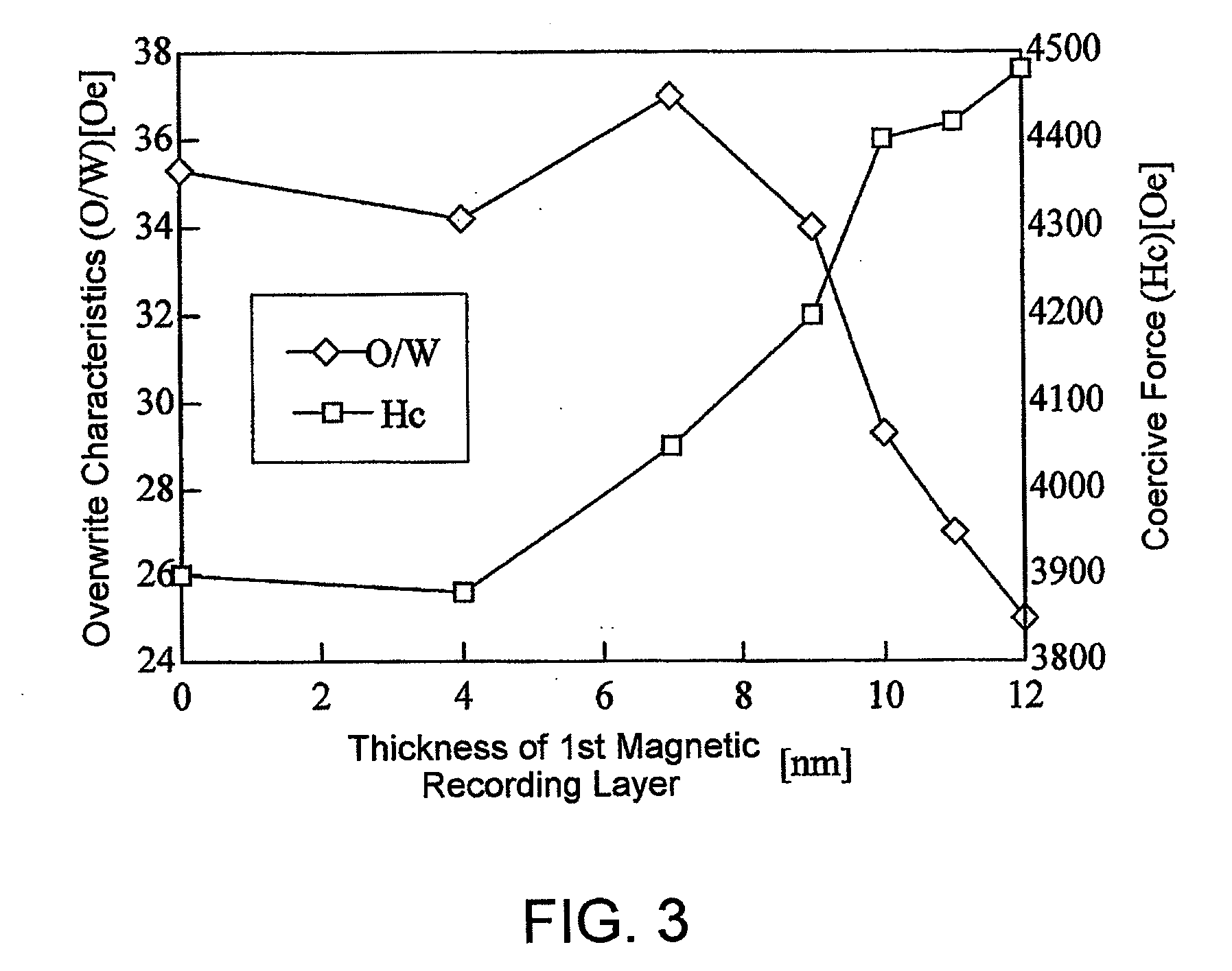

InactiveUS20090117408A1Good coverageMaintaining coercive forceVacuum evaporation coatingSputtering coatingNon magneticRecording layer

To provide a perpendicular magnetic recording disk having a film structure that improves overwrite characteristics (O / W) while maintaining a coercive force (Hc) high enough not to affect heat fluctuation resistance, and a manufacturing method thereof.A magnetic disk for use in perpendicular magnetic recording, having at least an underlayer, a first magnetic recording layer, and a second magnetic recording layer on a substrate in the order named, characterized in that the first magnetic recording layer and the second magnetic recording layer are each a ferromagnetic layer of a granular structure containing a nonmagnetic substance forming grain boundary portions between crystal grains containing at least Co (cobalt) and, given that the content of the nonmagnetic substance in the first magnetic recording layer is A mol % and the content of the nonmagnetic substance in the second magnetic recording layer is B mol %, A<B.

Owner:WD MEDIA SINGAPORE PTE

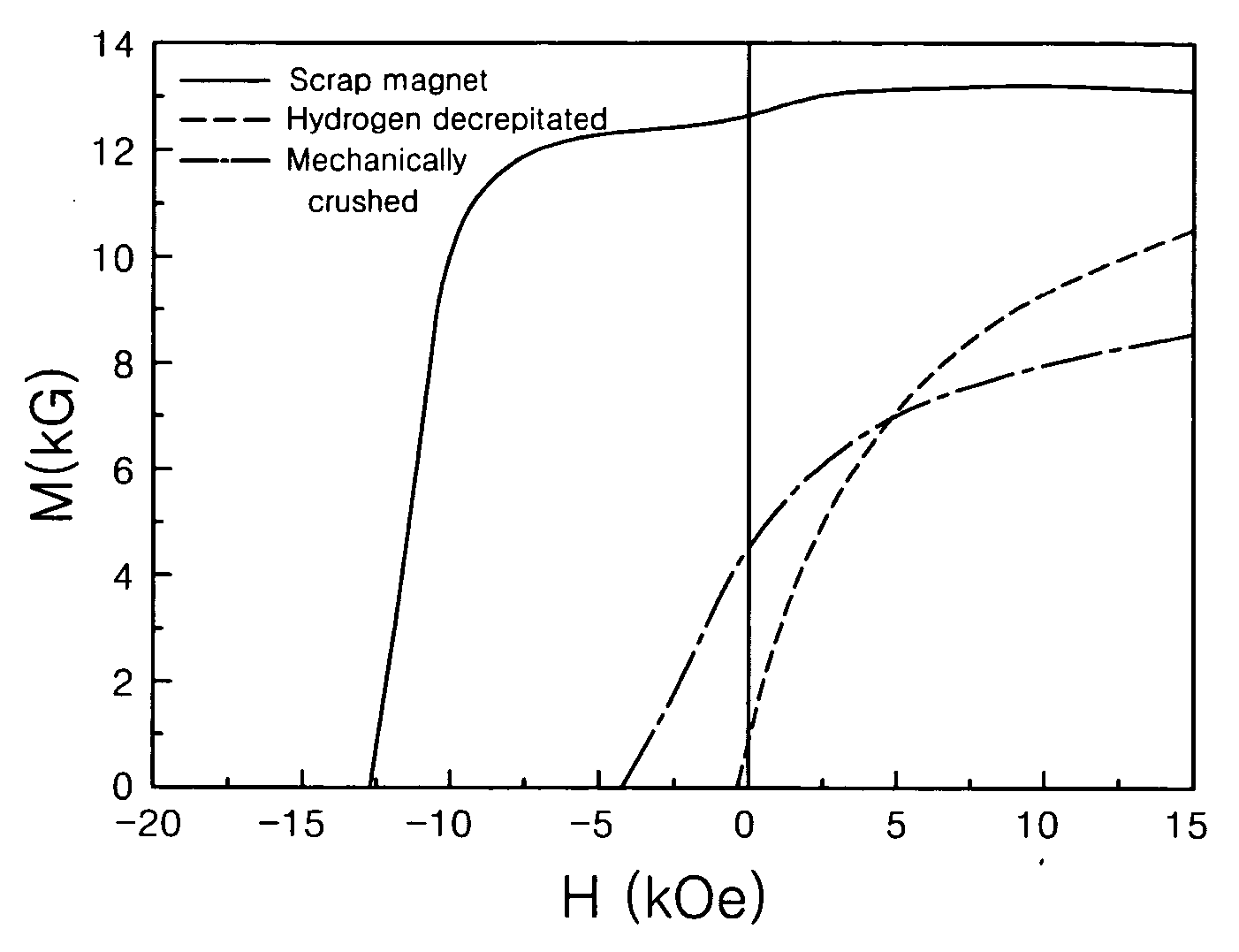

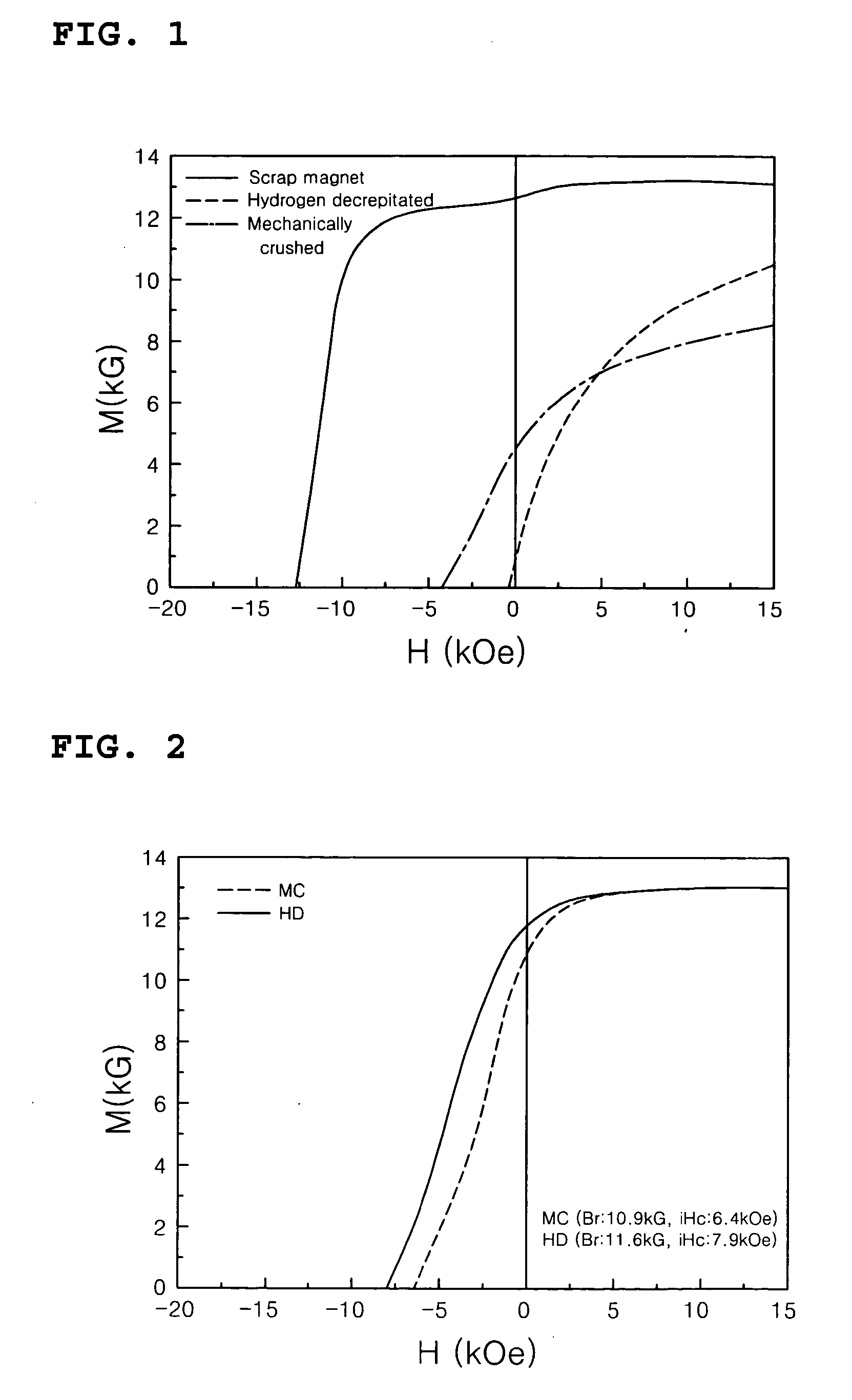

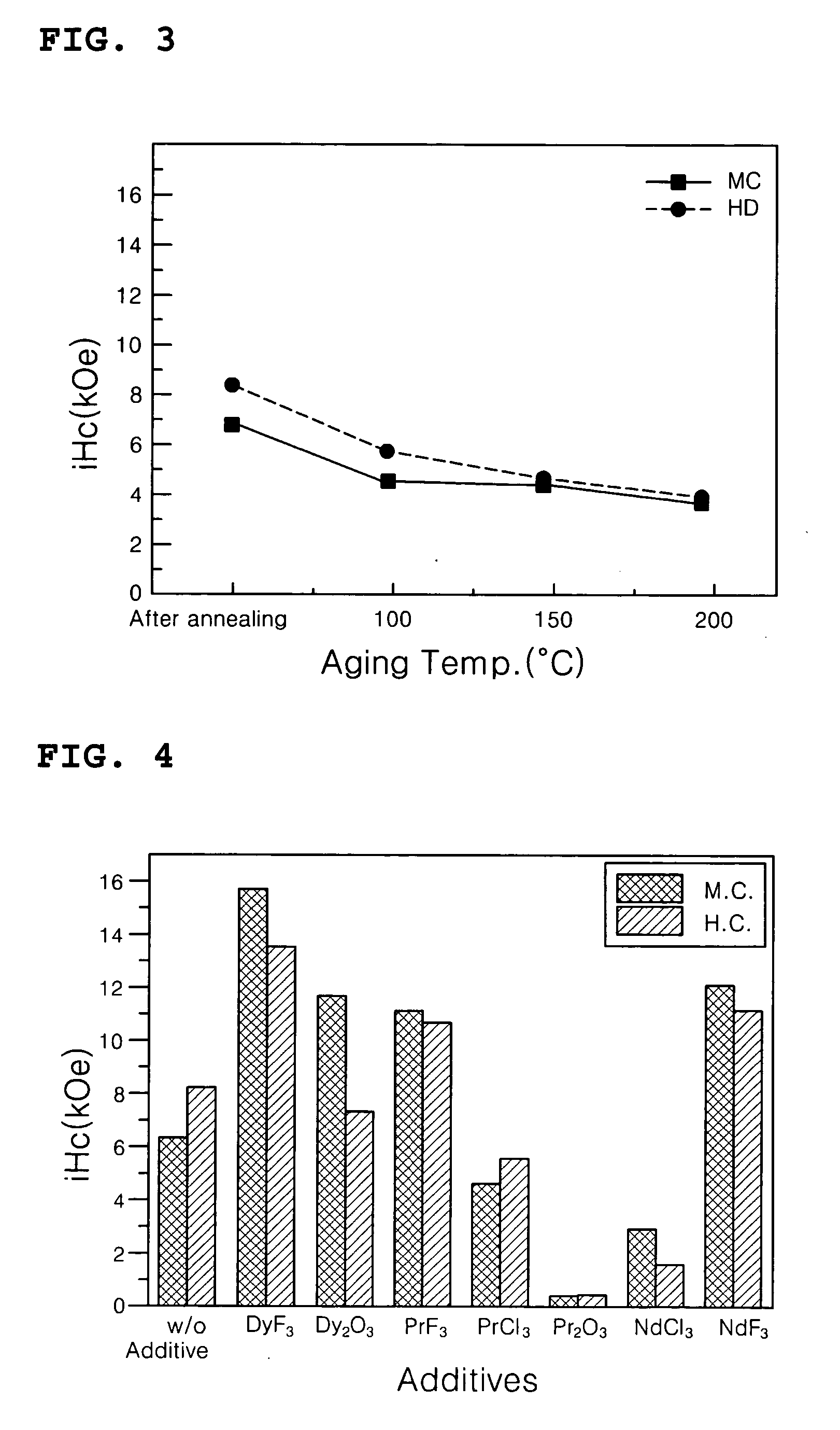

Method of preparing micro-structured powder for bonded magnets having high coercivity and magnet powder prepared by the same

InactiveUS20050081959A1Reduce manufacturing costSimplified mass productionInorganic material magnetismRare earthGrain boundary

Disclosed is a method of preparing a micro-structured powder for bonded magnets having high coercivity, which is advantageous in terms of low preparation costs by recycling magnet scraps, simplified mass production, minimal environmental contamination by such a recycling process, and the preparation of stable anisotropic powders having high coercivity. Further, a magnet powder prepared by the above method is provided. The current method is characterized in that R—Fe—B type anisotropic sintered magnets or scraps thereof are crushed to prepare 50-500 μm sized magnet powders, which are then mixed with 1-10 wt % of rare earth fluoride (RF3) powders and thermally treated at high temperatures (500-1100° C.) in a vacuum or an inert gas, to cause the change of matrix-near surface and grain boundary of the powders. Thus obtained powders include a matrix phase having R2Fe14B crystal structure, a R-rich grain boundary phase containing rare earth fluoride, and other phases, in which the matrix phase has an average grain size of 1-20 μm, and the powders have an average size of 50-500 μm with superior magnetic characteristics of (BH)max≧20 MGOe and iHc≧5 kOe.

Owner:JAHWA ELECTRONICS

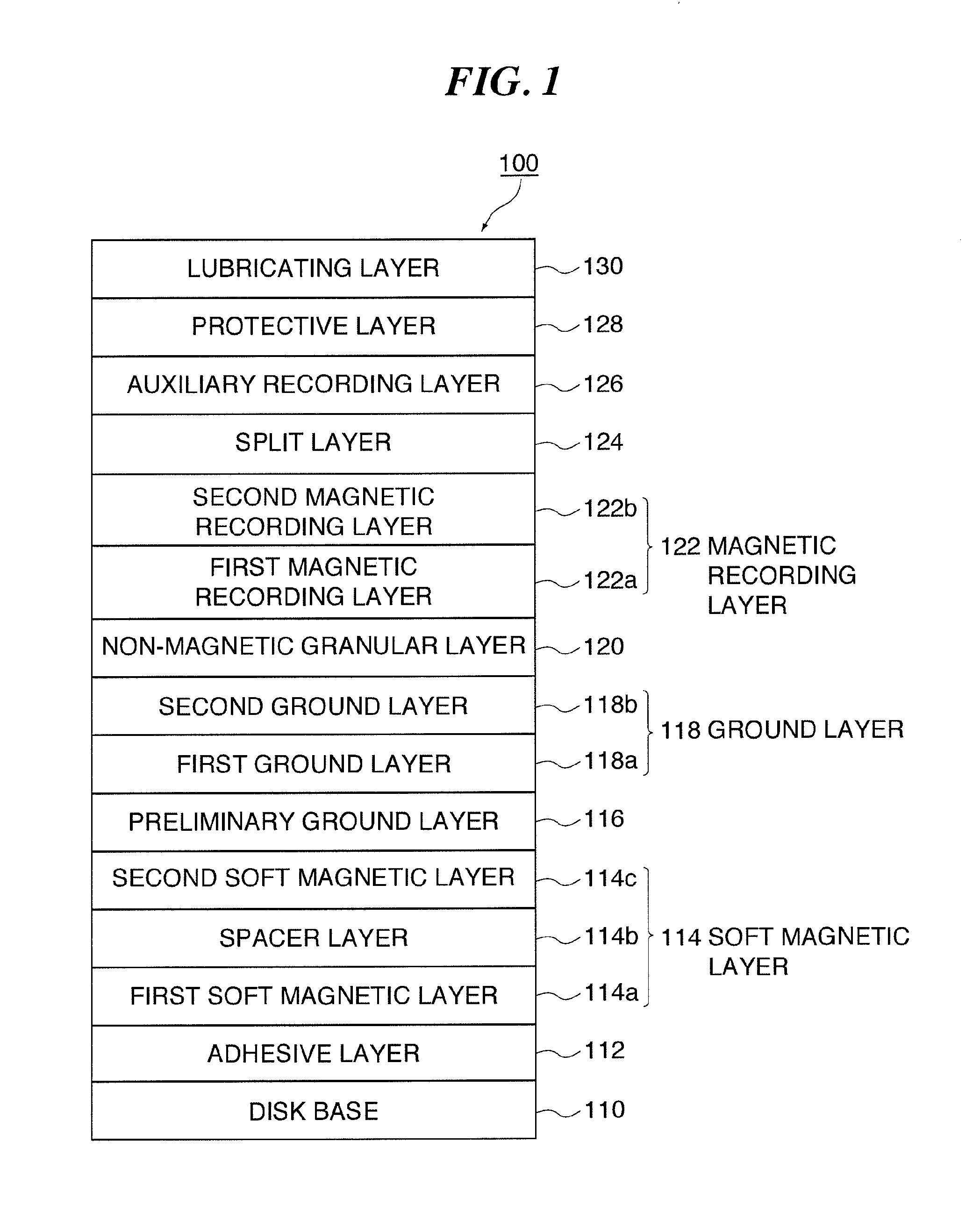

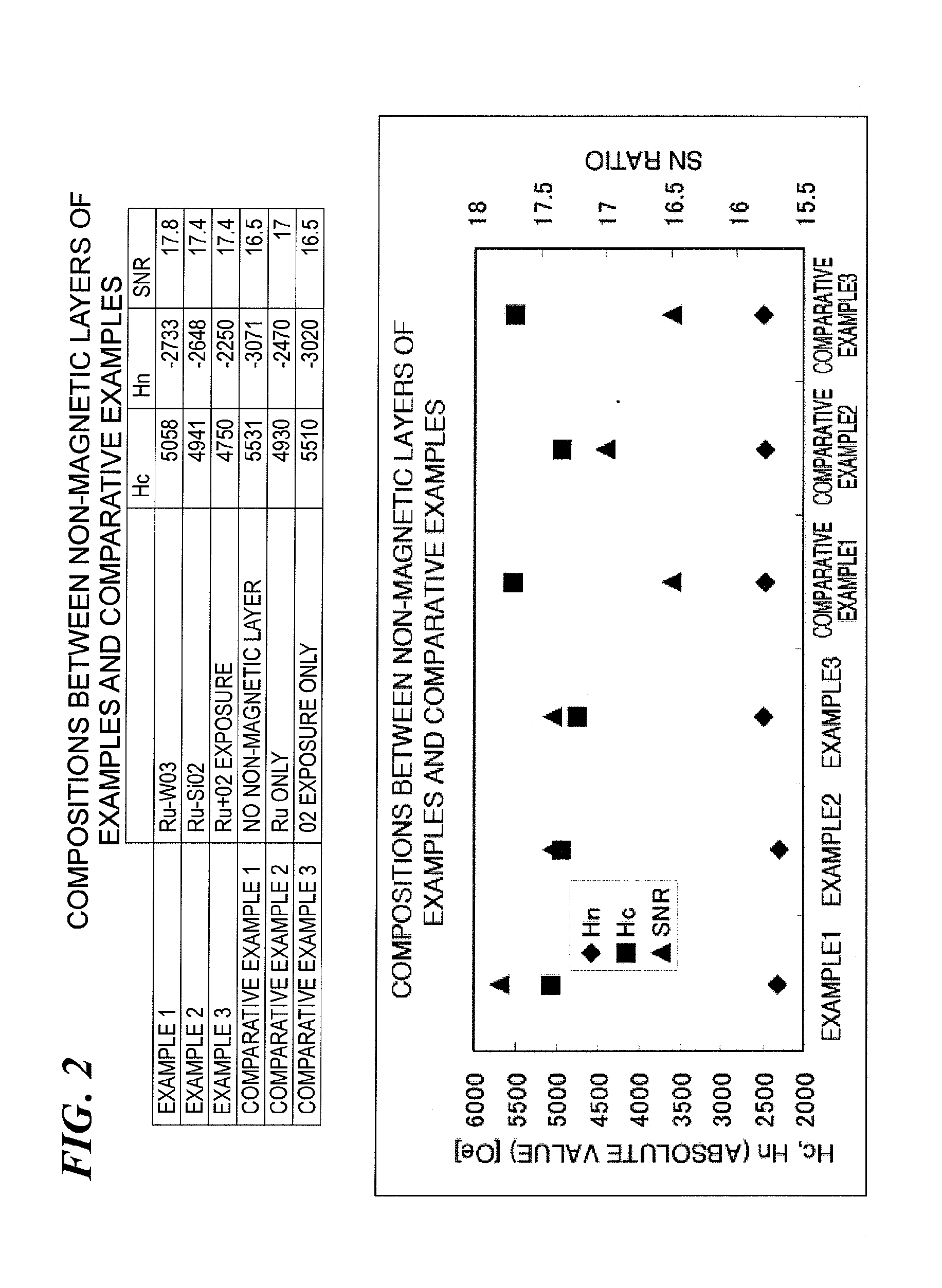

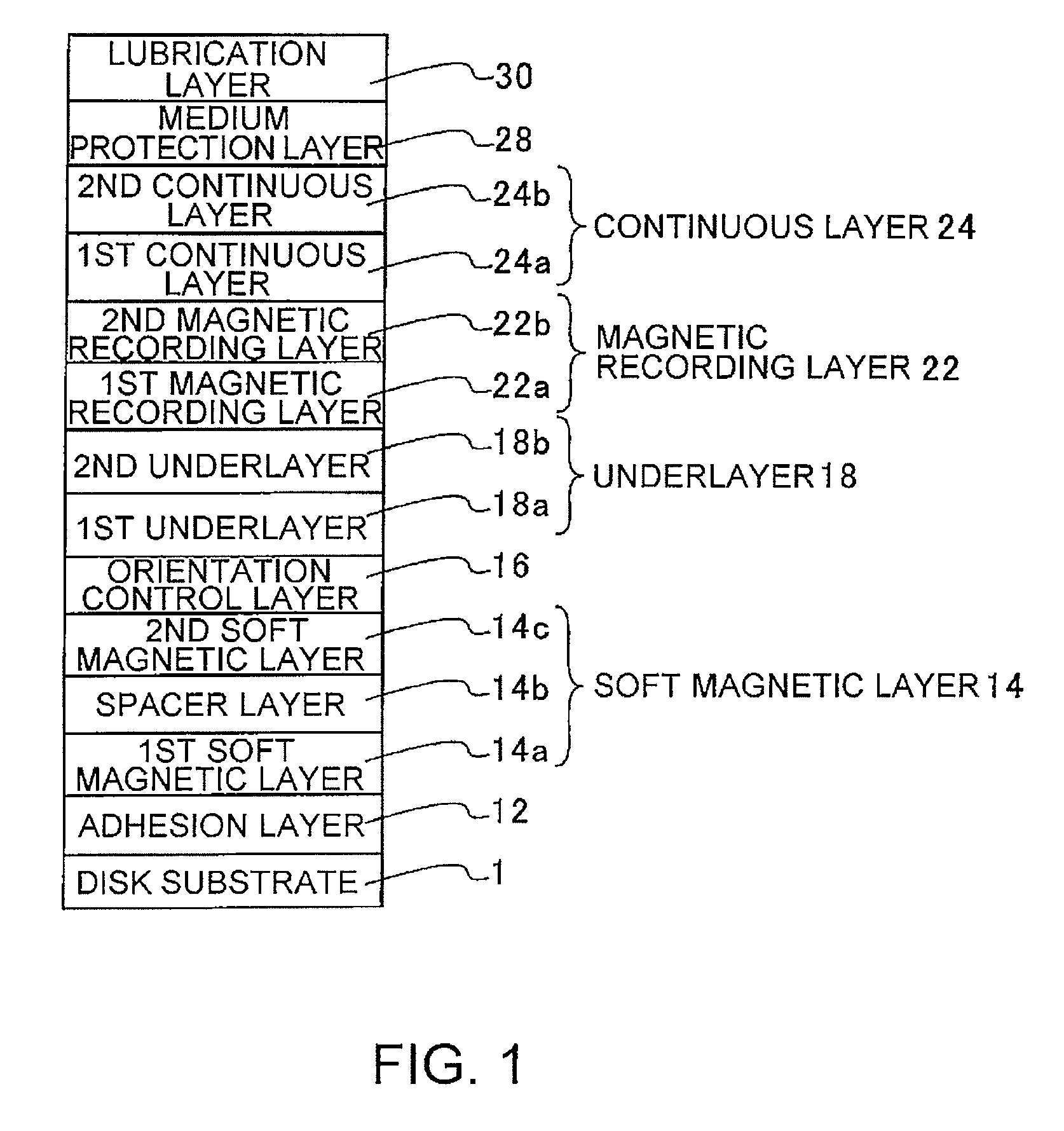

Perpendicular magnetic recording medium and process for manufacture thereof

ActiveUS20110212346A1Improve coercive forceIncrease forceProtective coatings for layersPretreated surfacesIn planeRecording density

An object of the present invention is to provide a perpendicular magnetic recording medium the SNR of which is improved by reducing noise thought to be due to an auxiliary recording layer so that a higher recording density can be achieved, and a method of manufacturing the same.In order to achieve the above object, a representative configuration of a perpendicular magnetic recording medium 100 according to the present invention includes, on a base, at least a magnetic recording layer 122 having a granular structure in which a non-magnetic grain boundary portion is formed between crystal particles grown in a columnar shape; a non-magnetic split layer 124 disposed on the magnetic recording layer 122 and containing Ru and oxygen; and an auxiliary recording layer 126 that is disposed on the split layer 124 and that is magnetically approximately continuous in an in-plane direction of a main surface of the base 110.

Owner:WESTERN DIGITAL TECH INC

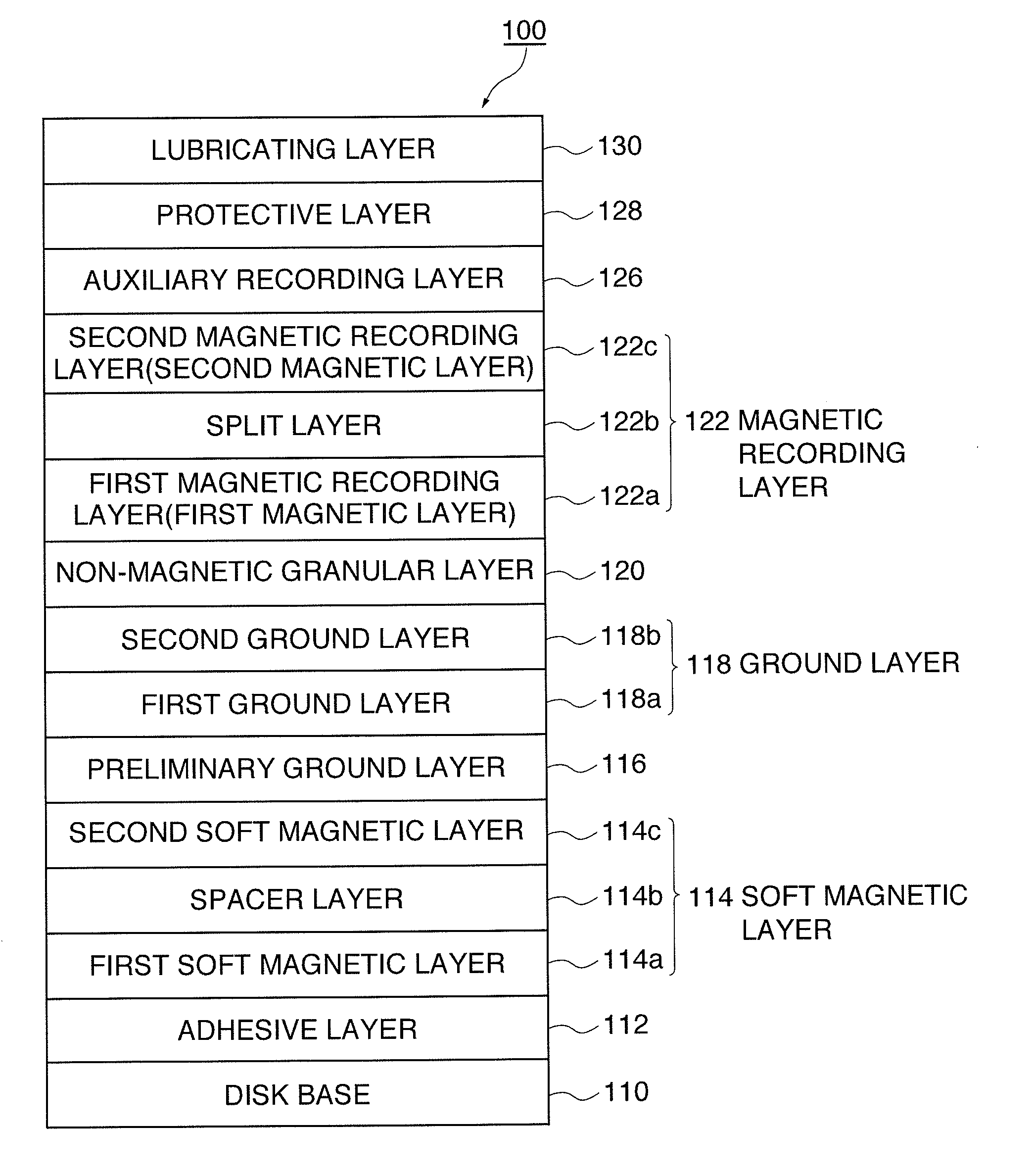

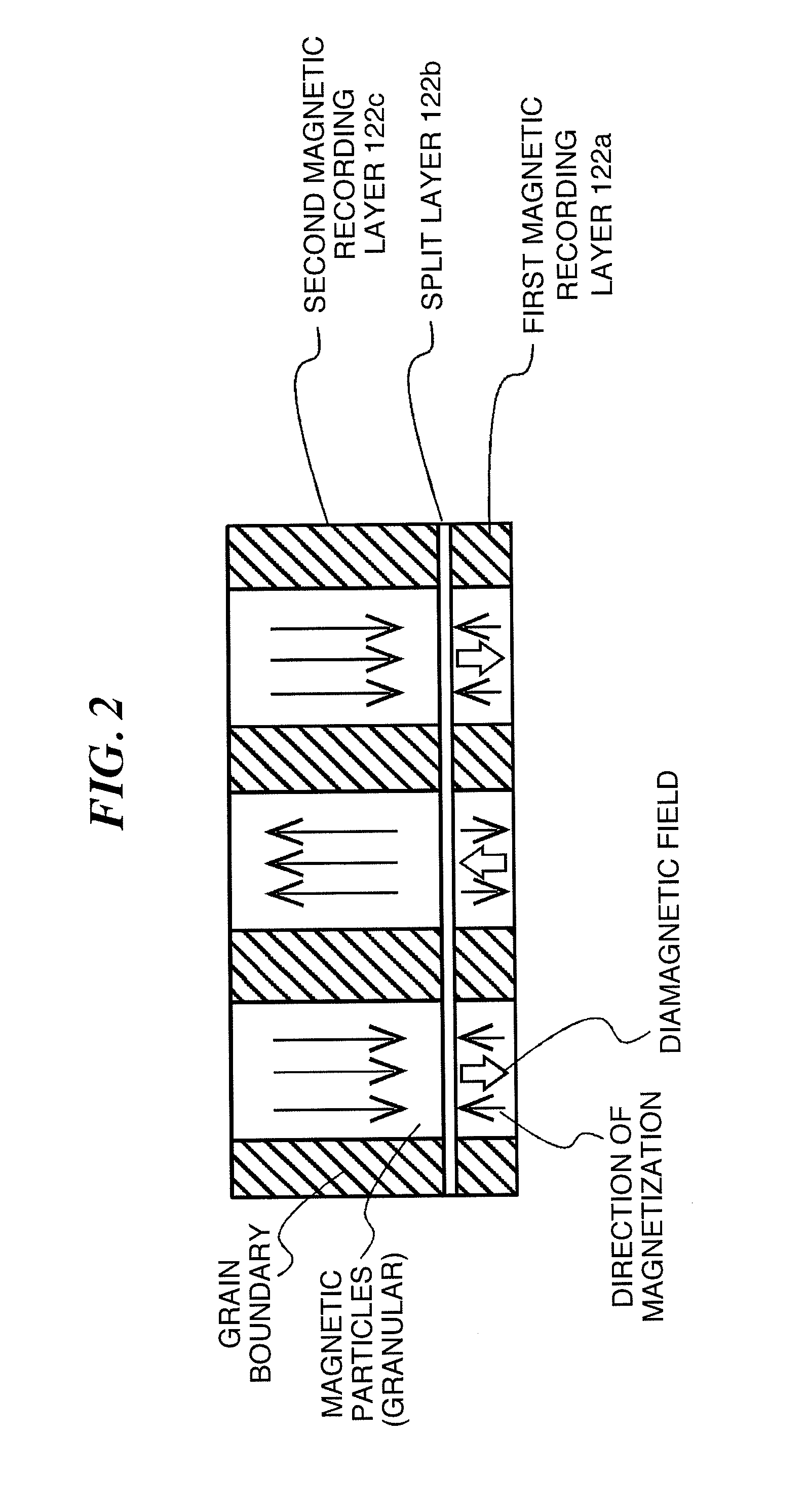

Perpendicular magnetic recording medium

InactiveUS20110223446A1Improve recording densityImprove signal-to-noise ratioRecord information storageMagnetic recordingRecording layerRecording density

An object of the present invention is to provide a perpendicular magnetic recording medium the SNR of which is further improved while a high coercive force Hc is secured so that a higher recoding density can be achieved.The structure of a perpendicular magnetic recording medium 100 according to the present invention includes, on a base, at least a first magnetic recording layer 122a having a granular structure in which a non-magnetic grain boundary portion is formed between crystal particles grown in a columnar shape; a non-magnetic split layer 122b containing Ru disposed on the first magnetic layer; and a second magnetic recording layer 122c that is disposed on the split layer and that has a granular structure in which a non-magnetic grain boundary portion is formed between crystal particles grown in a columnar shape, wherein the first magnetic layer and the second magnetic layer contain oxides that form the grain boundary, and when an oxide content of the first magnetic layer is represented by A and an oxide content of the second magnetic layer is represented by B, a relationship between the oxide contents A / B is in the range of 0.5<A / B<1.0.

Owner:WESTERN DIGITAL TECH INC

Superconducting low inductance qubit

A superconducting structure that can operate, for example, as a qubit or a superconducting switch is presented. The structure includes a loop formed from two parts. A first part includes two superconducting materials separated by a junction. The junction can, for example, be a 45° grain boundary junction. The second part can couple the two superconducting materials across the junction. The second part includes a superconducting material coupled to each of the two superconducting materials of the first part through c-axis junctions. Further embodiments of the invention can be as a coherent unconventional superconducting switch, or a variable phase shift unconventional superconductor junction device.

Owner:D WAVE SYSTEMS INC

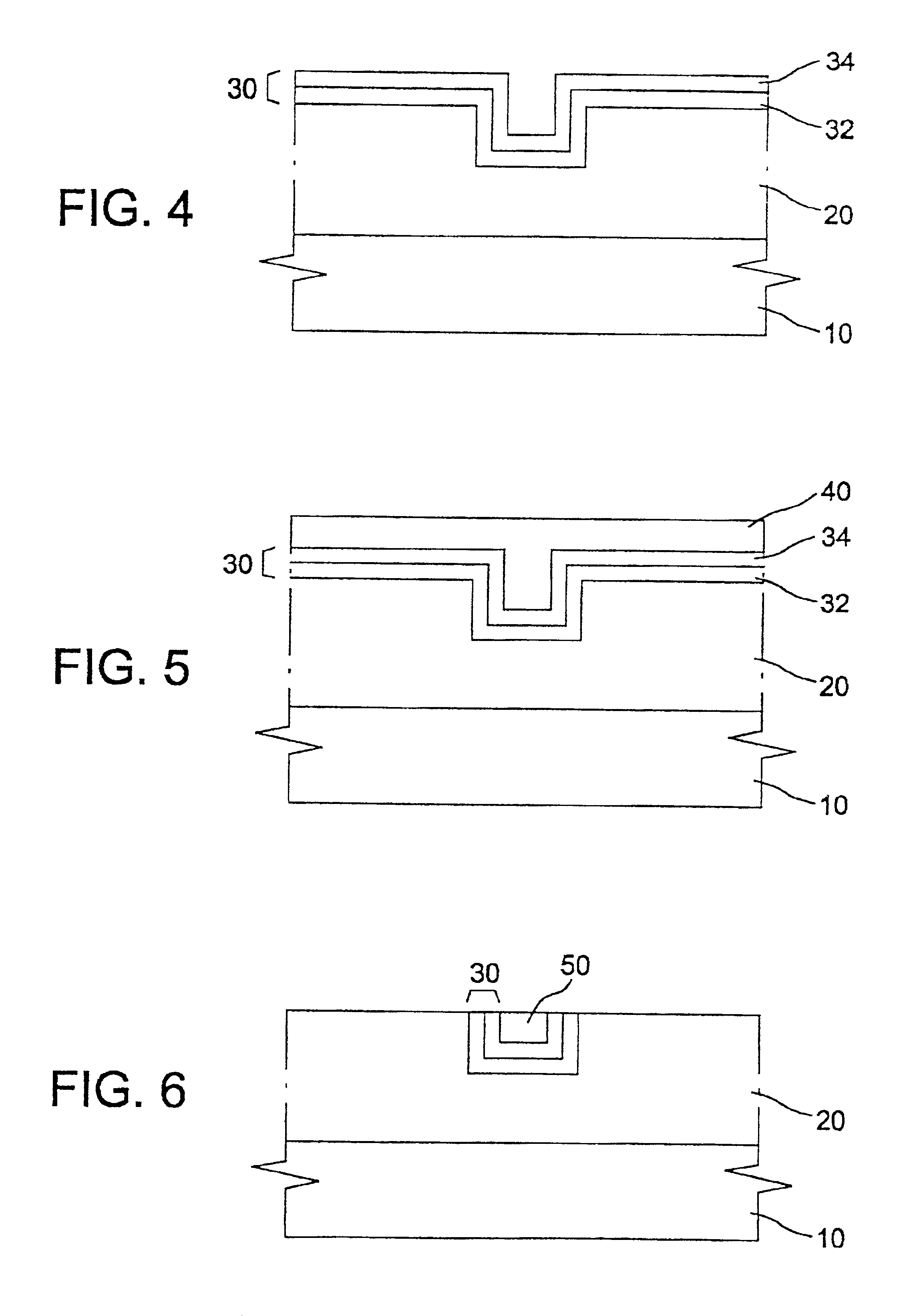

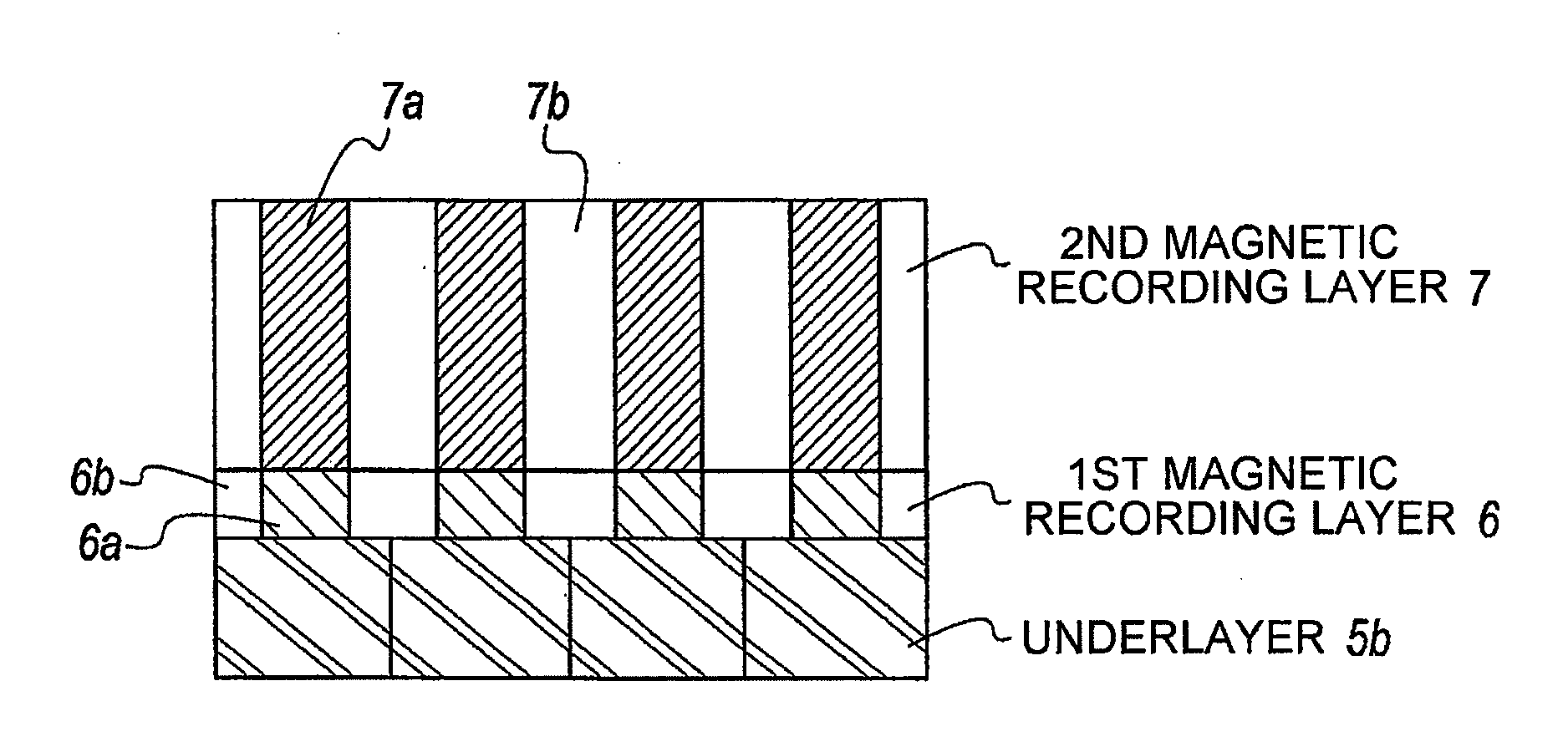

Perpendicular magnetic recording disk and method of manufacturing the same

InactiveUS20090311557A1Low noise characteristicsSignificant changeRecord information storageManufacture of flux-sensitive headsRecording layerNon magnetic

[Object] To achieve a high coercive force (Hc) and low-noise characteristics (high S / N ratio) through realization of both segregation of SiO2 and high perpendicular magnetic anisotropy by providing a two-layer structure having magnetic recording layers with different properties.[Solution] A magnetic disk for use in perpendicular magnetic recording, having at least an underlayer 5, a first magnetic recording layer 6, and a second magnetic recording layer 7 on a substrate in this order. The first magnetic recording layer 6 and the second magnetic recording layer 7 are each a ferromagnetic layer of a granular structure containing a nonmagnetic substance forming grain boundary portions between crystal grains containing at least Co (cobalt). Given that the content of the nonmagnetic substance in the first magnetic recording layer 6 is A mol % and the content of the nonmagnetic substance in the second magnetic recording layer 7 is B mol %, A>B.

Owner:WD MEDIA SINGAPORE PTE

Method for increasing sintering Nd-Fe-B coercive force by adding nano-oxide in crystal boundary phase

InactiveCN1688000ANot easily oxidizedIncrease the coercive force of the magnetInorganic material magnetismInductances/transformers/magnets manufactureIngotGrain boundary

This invention discloses a method for increasing sintered Nd FeB coercive force by adding nm oxide in grain-boundary phase including the following steps: 1,applying casting technology to produce NdFeB ingot alloy or applying rapid hardening film technology to produce NdFeB rapid hardening film of with host phase alloy, applying casting technology to produce ingot alloy or rapid hardening film technology to get rapid hardening film or rapid quench technology to manufacture a rapid quench strip with the grain boundary phase alloy, 2, processing powder with the two alloys, 3, adding a nm oxide to the grain boundary phase alloy powder, 4, pressing the mixed powder into formation, 5, producing sintered magnetic body in a vacuum sintering oven.

Owner:ZHEJIANG UNIV

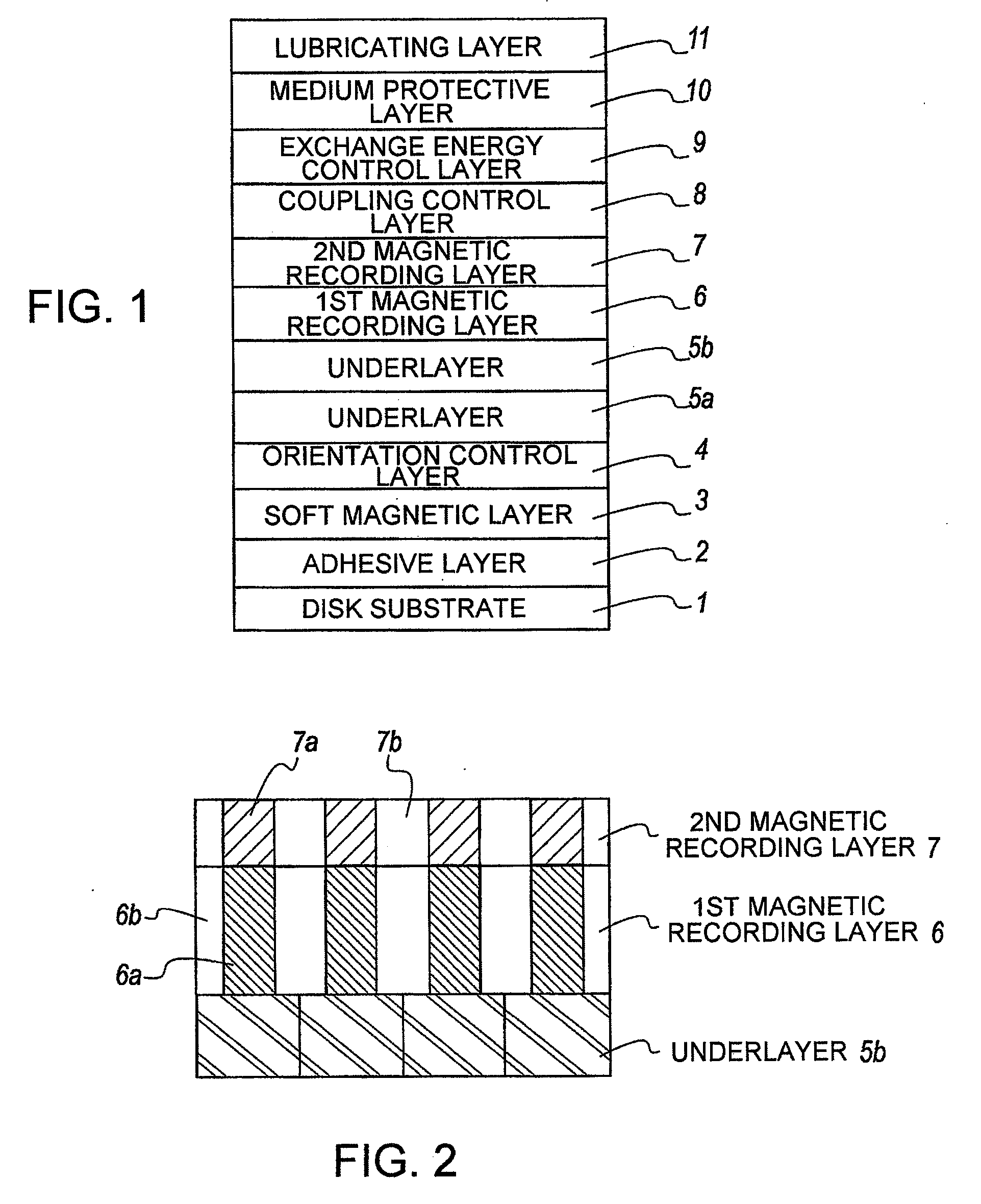

Perpendicular magnetic recording medium and method of manufacturing the same

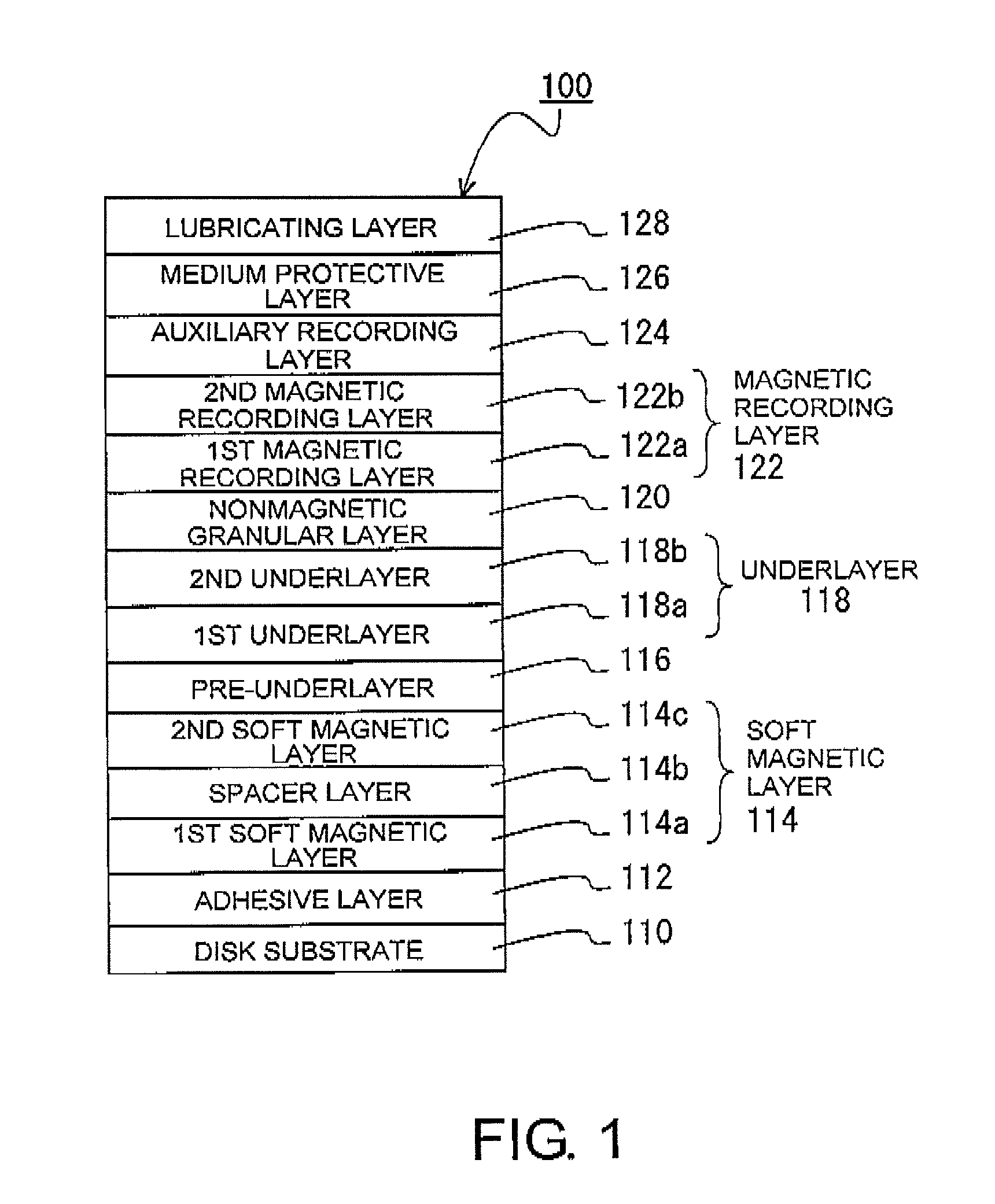

InactiveUS8404370B2Improve signal-to-noise ratioImprove recording densityCellsVacuum evaporation coatingGibbs free energyFree energies

A perpendicular magnetic recording medium 100 has, over a substrate, at least a magnetic recording layer 122 with a granular structure in which nonmagnetic grain boundaries are formed between magnetic grains continuously grown into a columnar shape. The magnetic grains of the magnetic recording layer 122 contain Co, Cr, and Pt. The magnetic recording layer 122 contains at least one oxide selected from a group A including SiO2, TiO2, and Cr2O3, at least one oxide selected from a group B consisting of oxides each having a larger Gibbs free energy ΔG than the group A, and a reducing agent adapted to reduce the oxides of the group B.

Owner:WD MEDIA SINGAPORE PTE

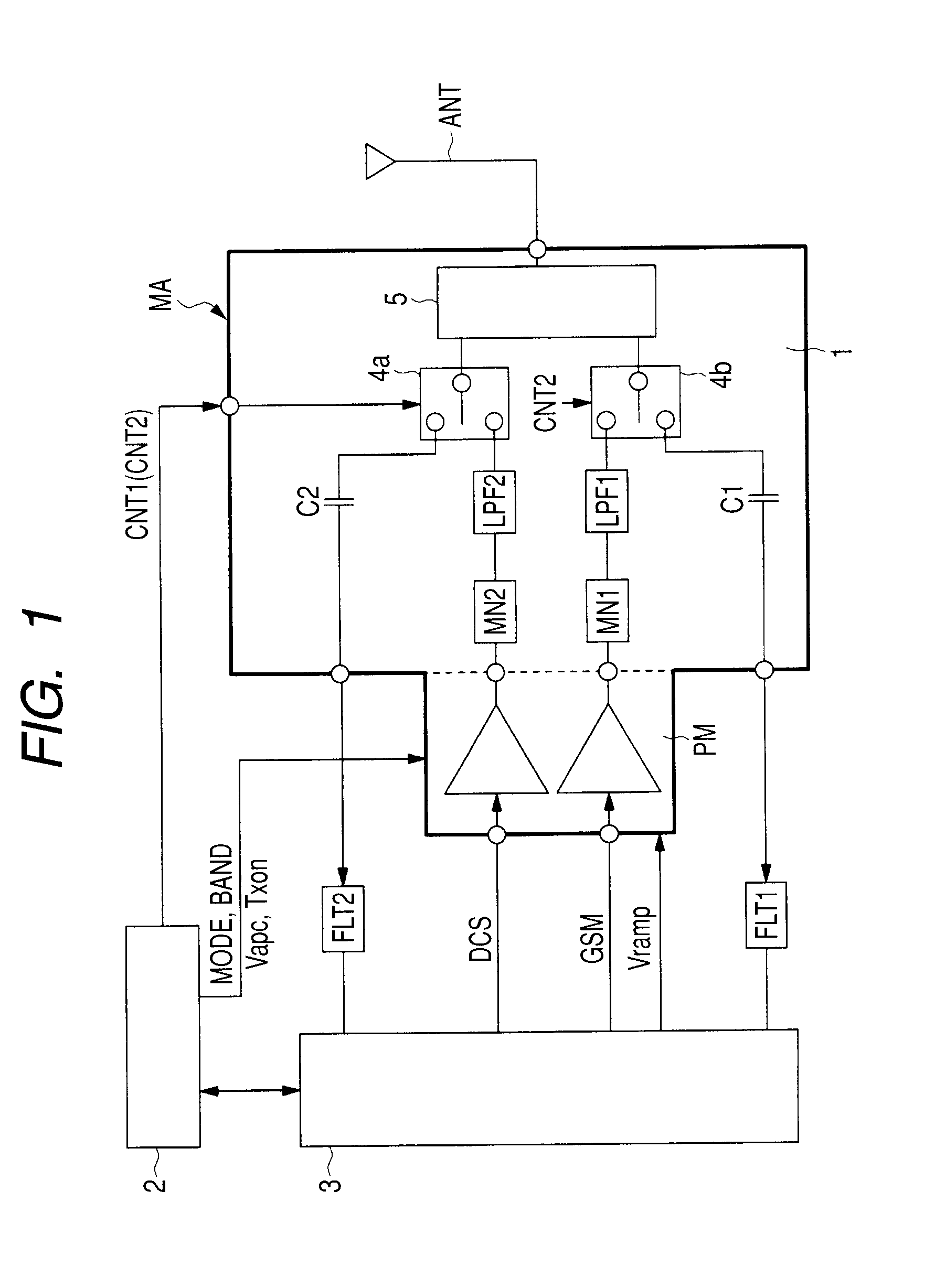

Light emitting device

InactiveUS20030214245A1Cathode-ray tube indicatorsInput/output processes for data processingElectricitySimple Organic Compounds

The light-emitting element has a problem that reliability, heat-resisting stability and durability are low because of the deterioration in an organic compound layer. The TFT for driving the light-emitting element has a problem that variation readily occurs in its electrical characteristic due to the defects existing in grain boundaries. The present invention provides a light-emitting device by using the fact that, by applying to the light-emitting element a drive voltage having a polarity reverse to that in light emission during each constant period, the light-emitting element is improved in current-voltage characteristic. Furthermore, the present invention provides a light-emitting device made not dependent upon transistor characteristic, by controlling the amount of a current flowing through the light-emitting element.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and manufacturing method thereof

InactiveUS20100230789A1Improve featuresSmall sizeMagnetic/electric field screeningSemiconductor/solid-state device detailsDevice materialElectromagnetic shielding

A technology is provided which allows a reduction in the size of a semiconductor device without degrading an electromagnetic shielding effect and reliability against reflow heating. After a plurality of components are mounted over a component mounting surface of a module substrate, a resin is formed so as to cover the mounted components. Further, over surfaces (upper and side surfaces) of the resin, a shield layer including a laminated film of a Cu plating film and an Ni plating film is formed. In the shield layer, a plurality of microchannel cracks are formed randomly along grain boundaries and in a net-like configuration without being coupled to each other in a straight line, and form a plurality of paths extending from the resin to a surface of the shield layer by the microchannel cracks.

Owner:RENESAS ELECTRONICS CORP

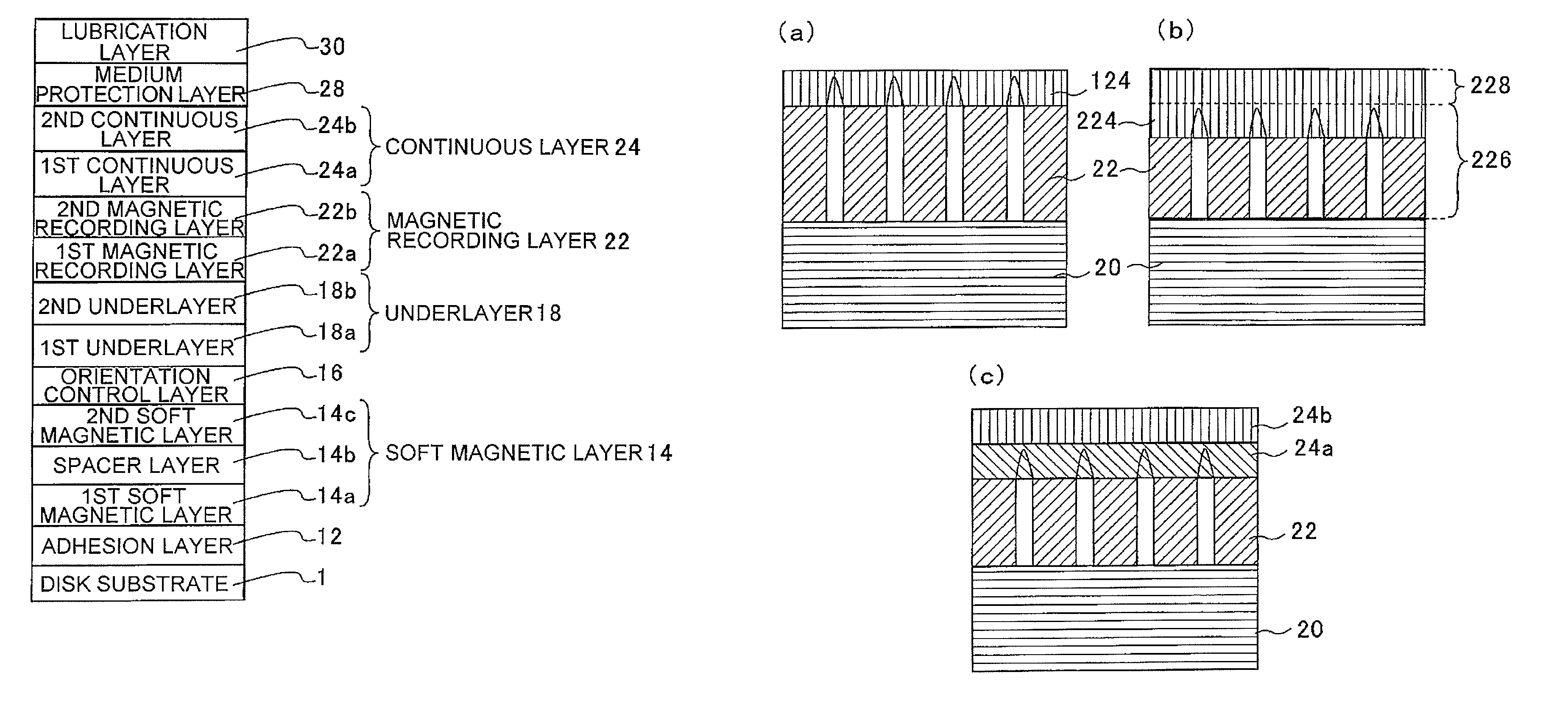

Perpendicular magnetic recording medium

ActiveUS8603649B2Improve recording densitySimple compositionRecord information storageMagnetic recordingPlatinumRecording layer

A perpendicular magnetic recording medium includes a magnetic recording layer 22 having a granular structure composed of crystal grains containing cobalt (Co) and grown in a columnar shape and a grain boundary portion comprising a nonmagnetic substance and formed between the crystal grains, and a continuous layer 24 of a thin film magnetically continuous in a film plane direction. The continuous layer 24 includes a plurality of layers 24a and 24b containing cobalt, chromium (Cr), and platinum (Pt). Among the layers, the layer 24a nearer to the magnetic recording layer has a greater chromium content.

Owner:WESTERN DIGITAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com