Patents

Literature

1462 results about "Free energies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

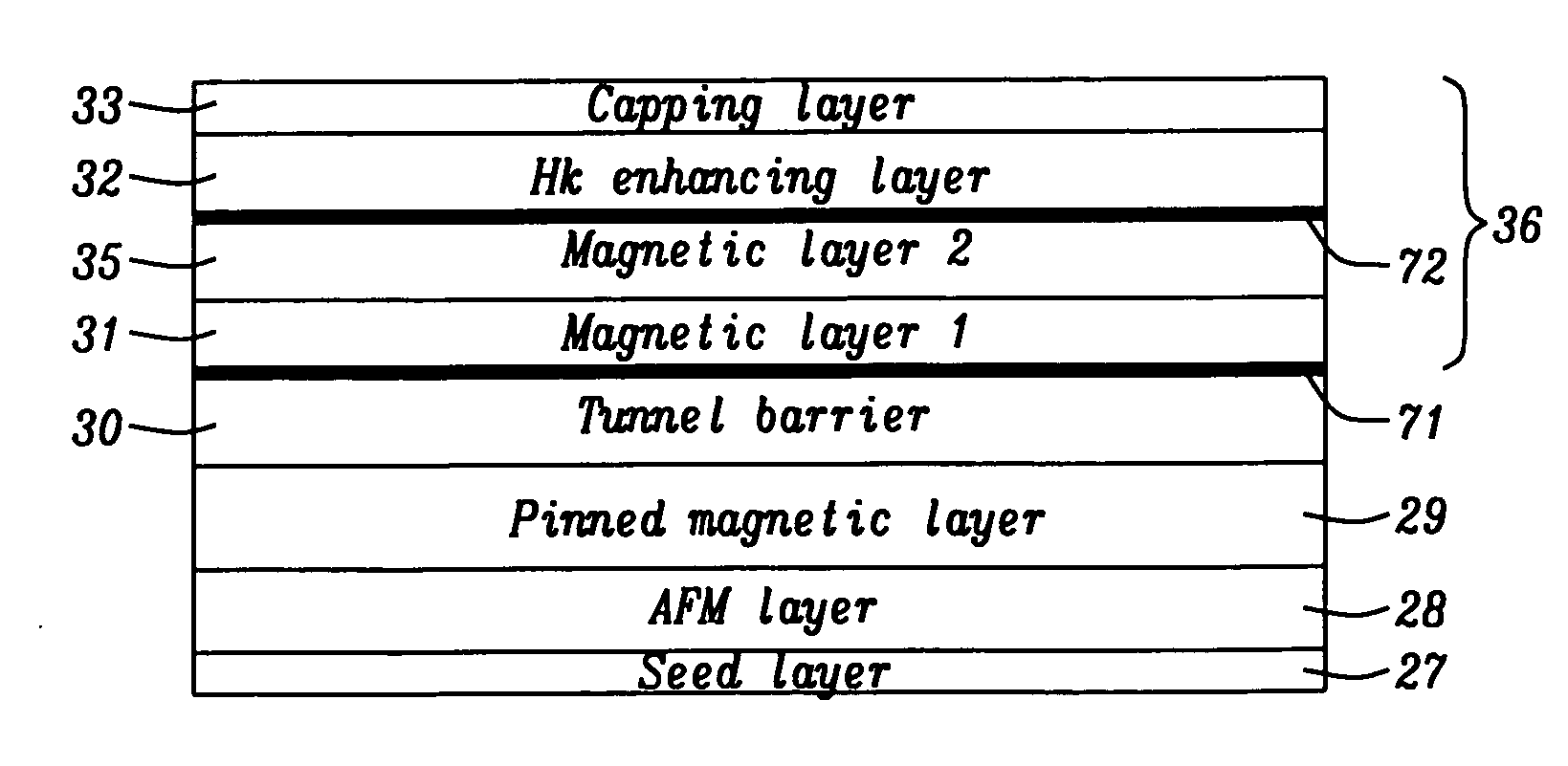

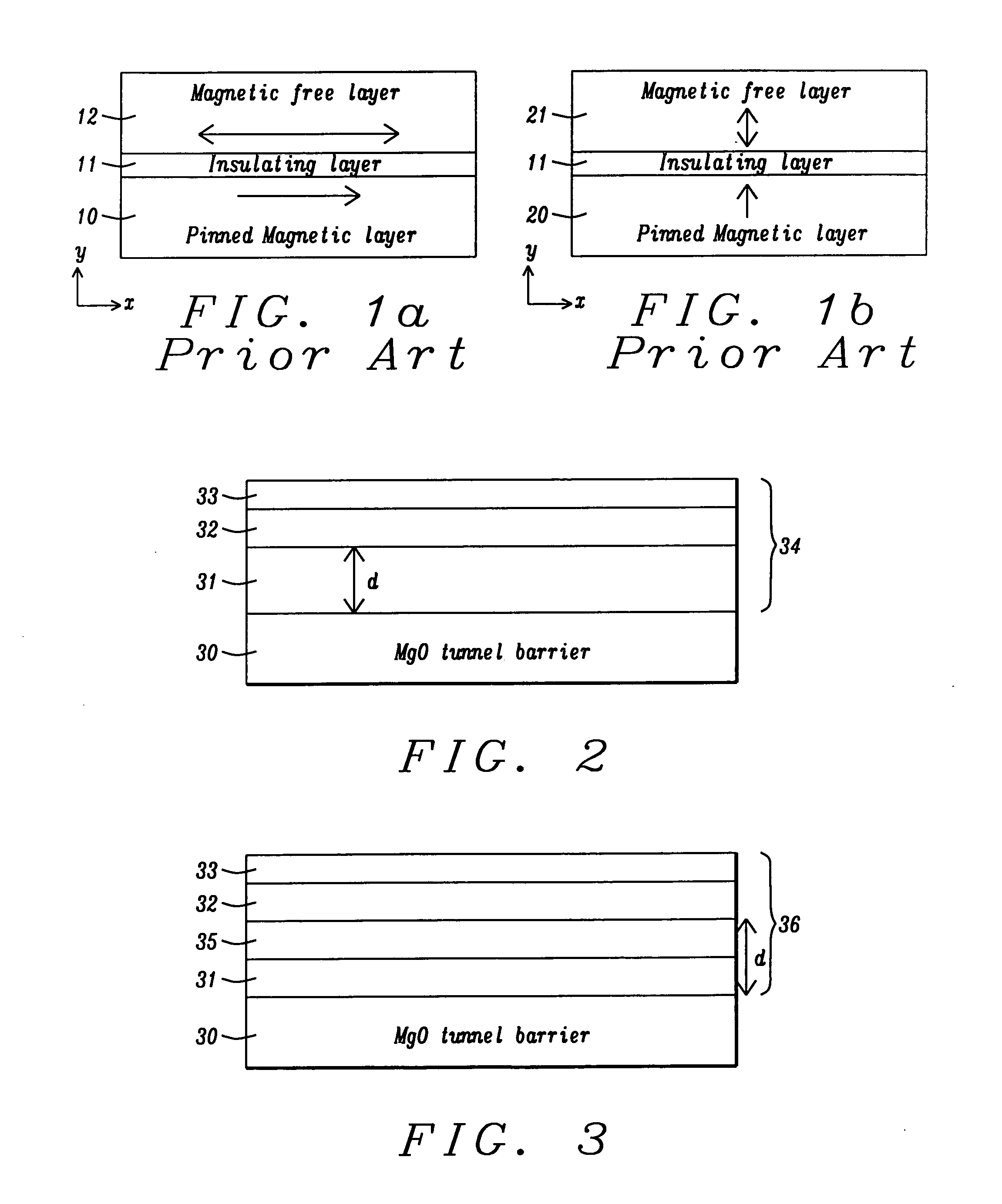

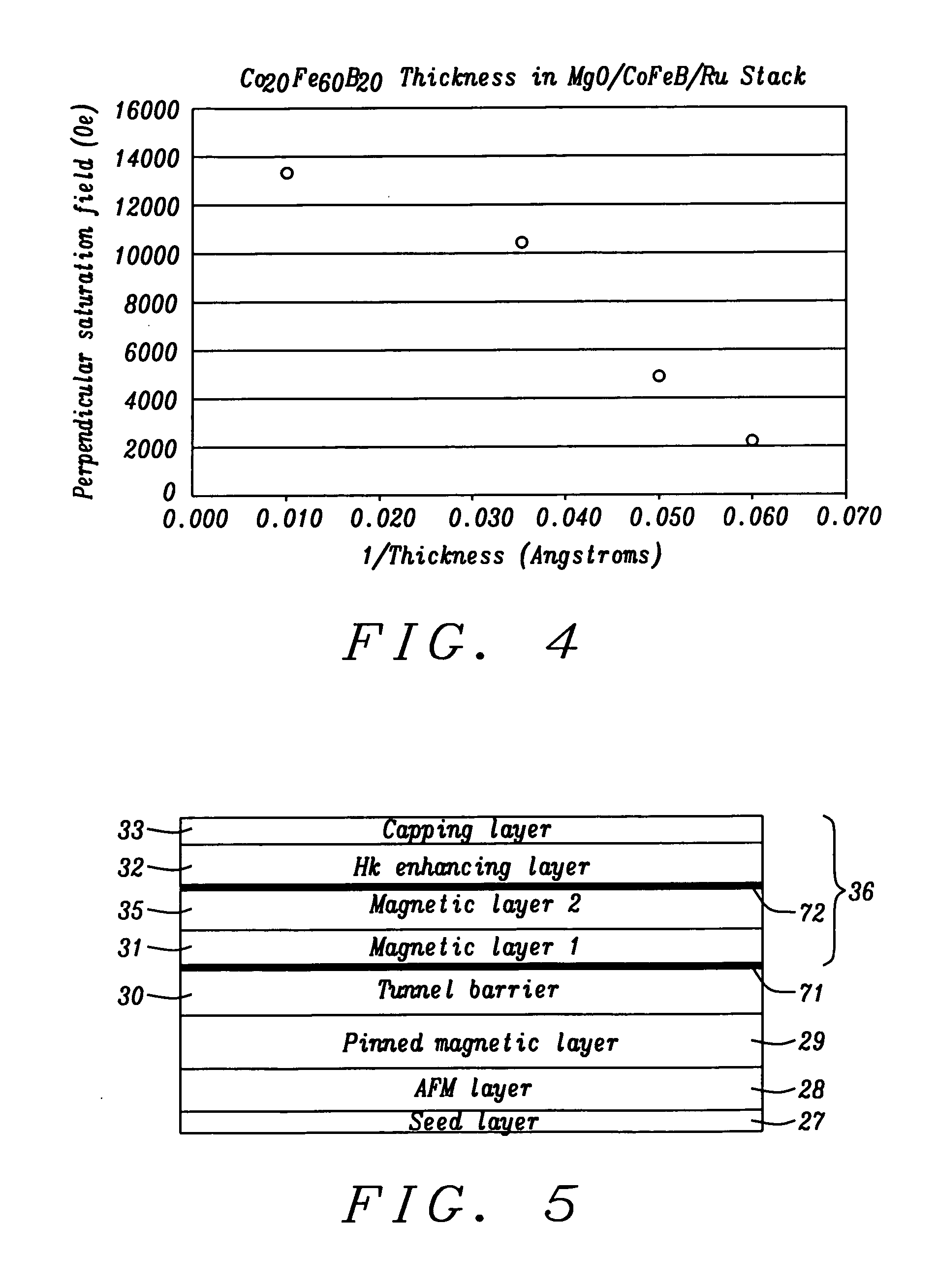

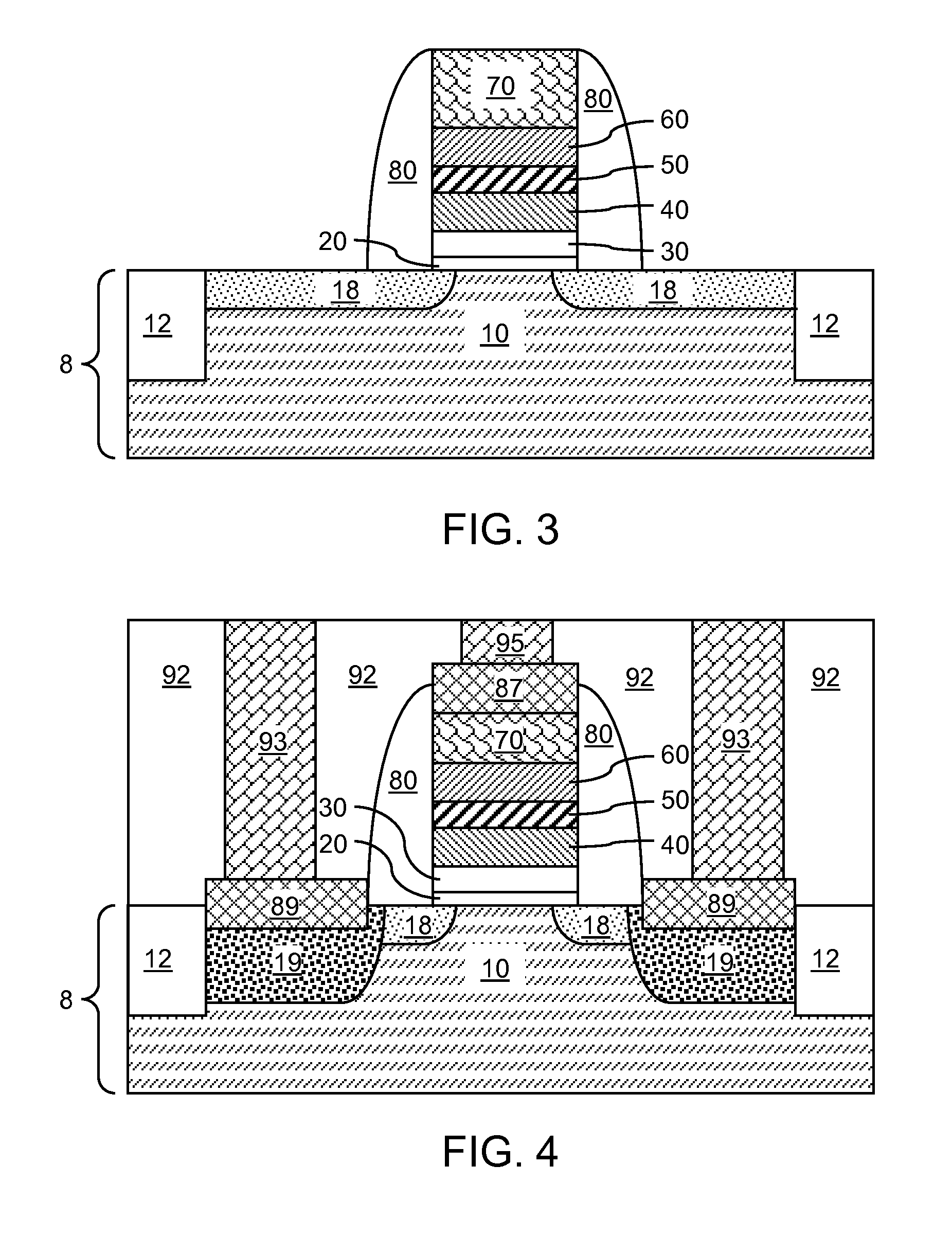

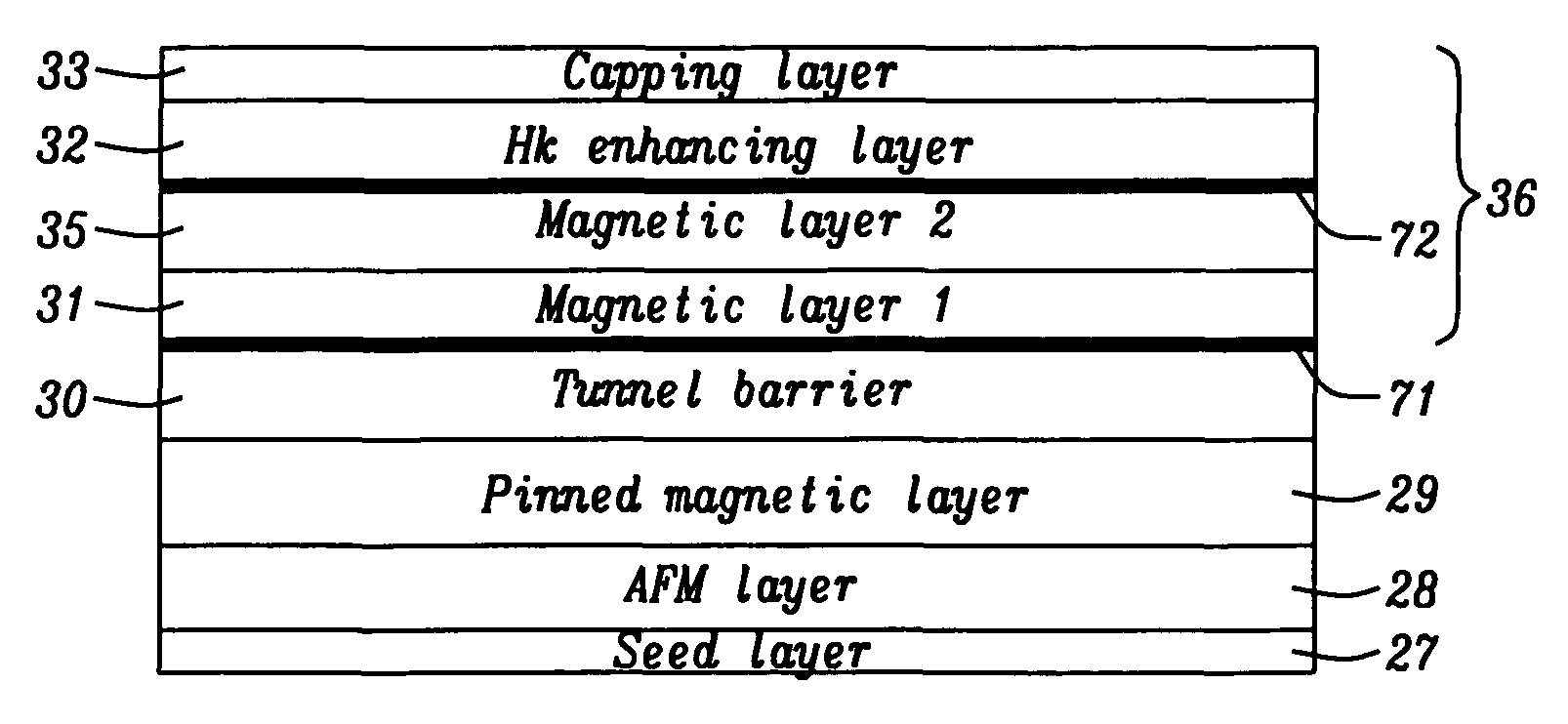

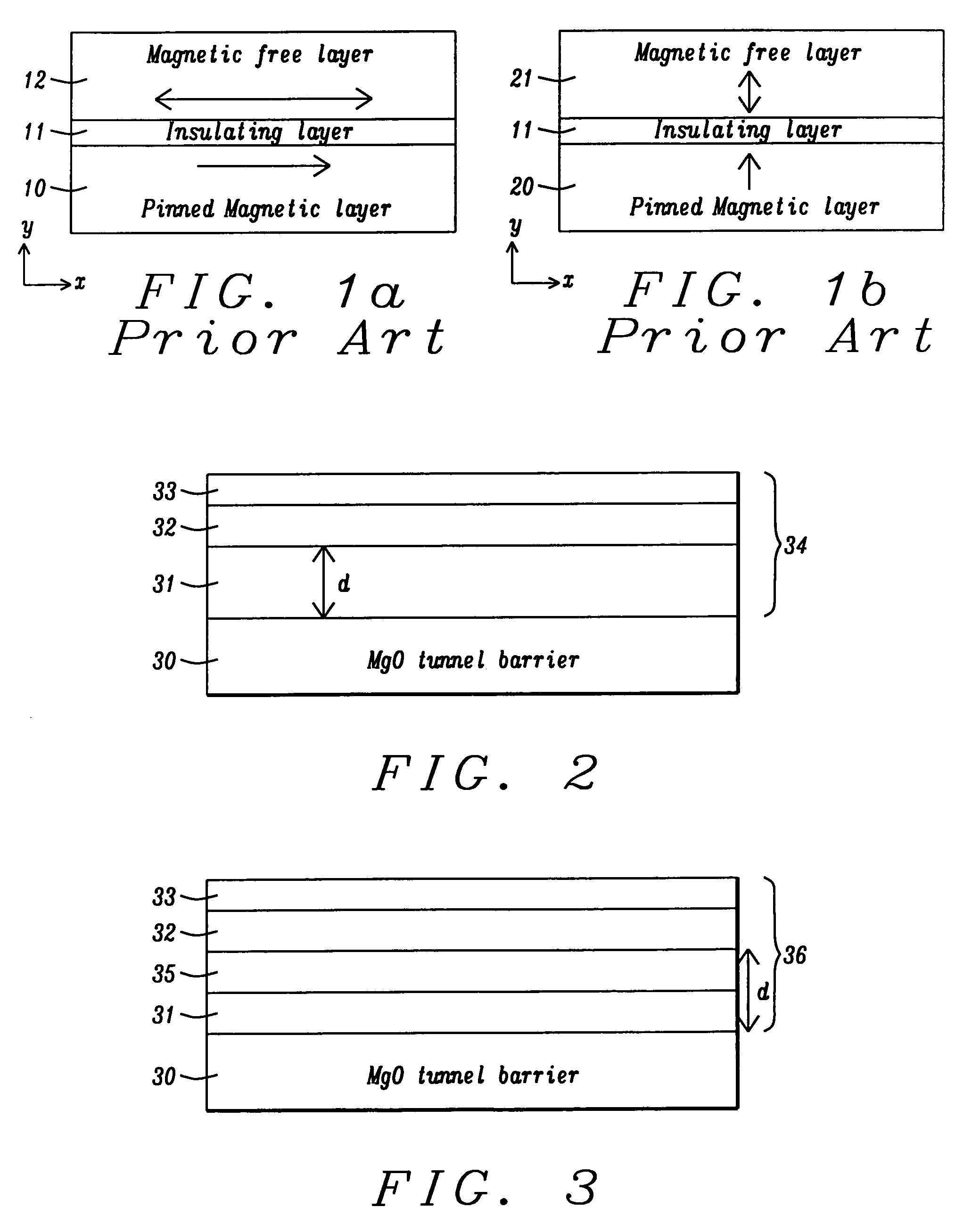

Magnetic element with improved out-of-plane anisotropy for spintronic applications

ActiveUS20120205758A1Without degrading thermal stability and MR ratioEnhanced interfacial perpendicular anisotropyMagnetic-field-controlled resistorsGalvano-magnetic material selectionPerpendicular anisotropyAlloy

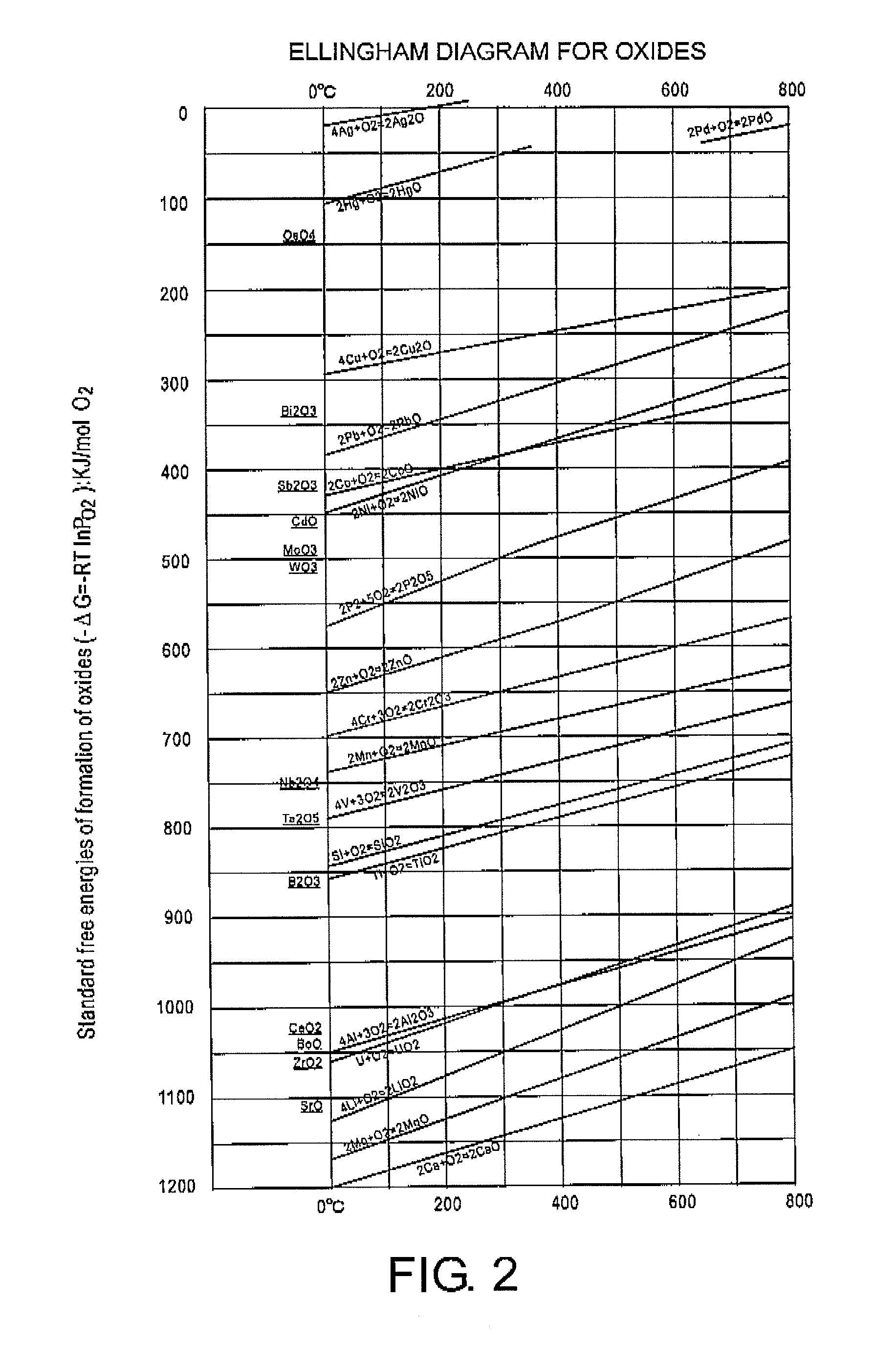

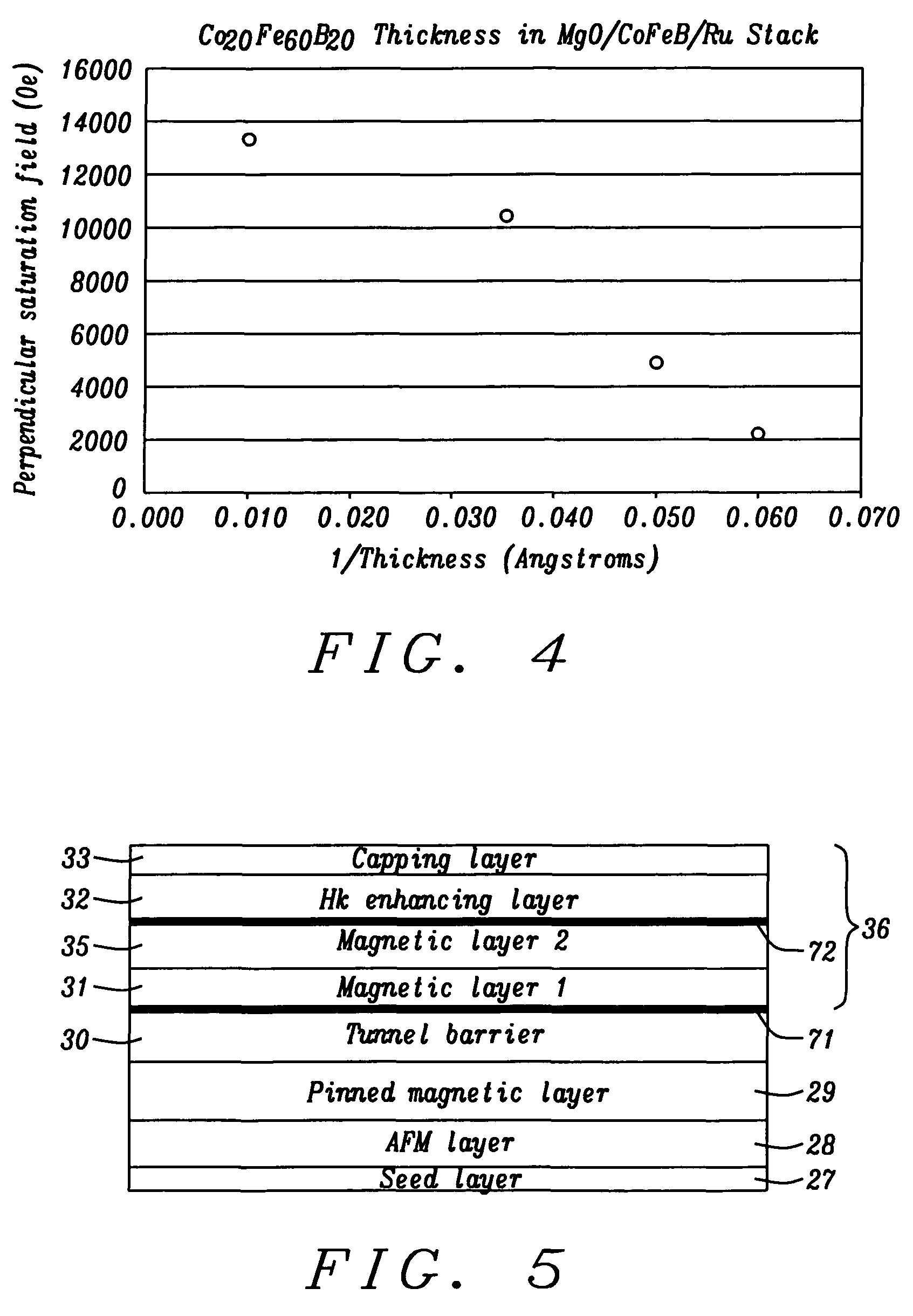

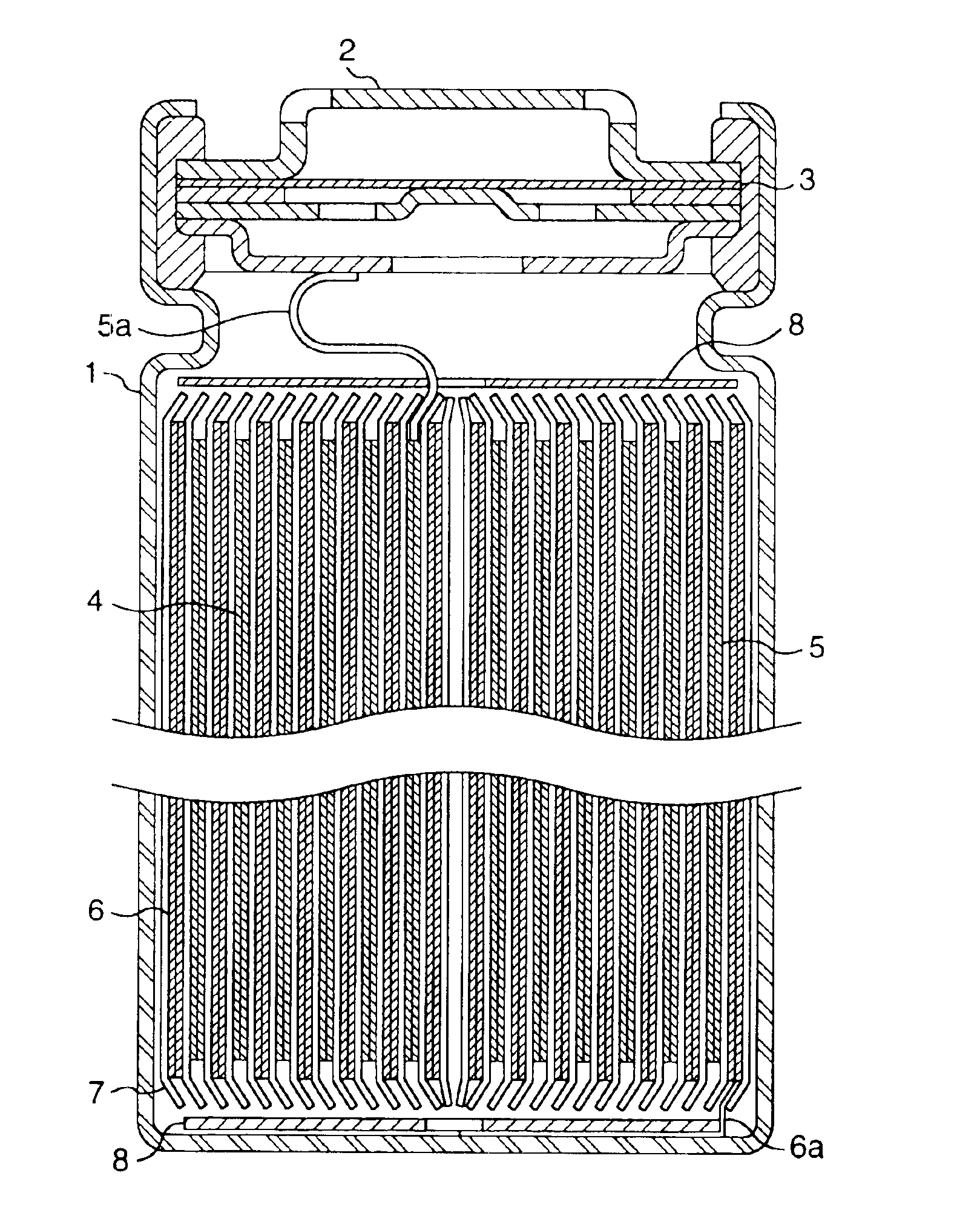

A magnetic element is disclosed wherein first and second interfaces of a free layer with a Hk enhancing layer and tunnel barrier, respectively, produce enhanced surface perpendicular anisotropy to lower switching current or increase thermal stability in a magnetic tunnel junction (MTJ). In a MTJ with a bottom spin valve configuration where the Hk enhancing layer is an oxide, the capping layer contacting the Hk enhancing layer is selected to have a free energy of oxide formation substantially greater than that of the oxide. The free layer may be a single layer or composite comprised of an Fe rich alloy such as Co20Fe60B20. With a thin free layer, the interfacial perpendicular anisotropy may dominate the shape anisotropy to generate a magnetization perpendicular to the planes of the layers. The magnetic element may be part of a spintronic device or serve as a propagation medium in a domain wall motion device.

Owner:TAIWAN SEMICON MFG CO LTD

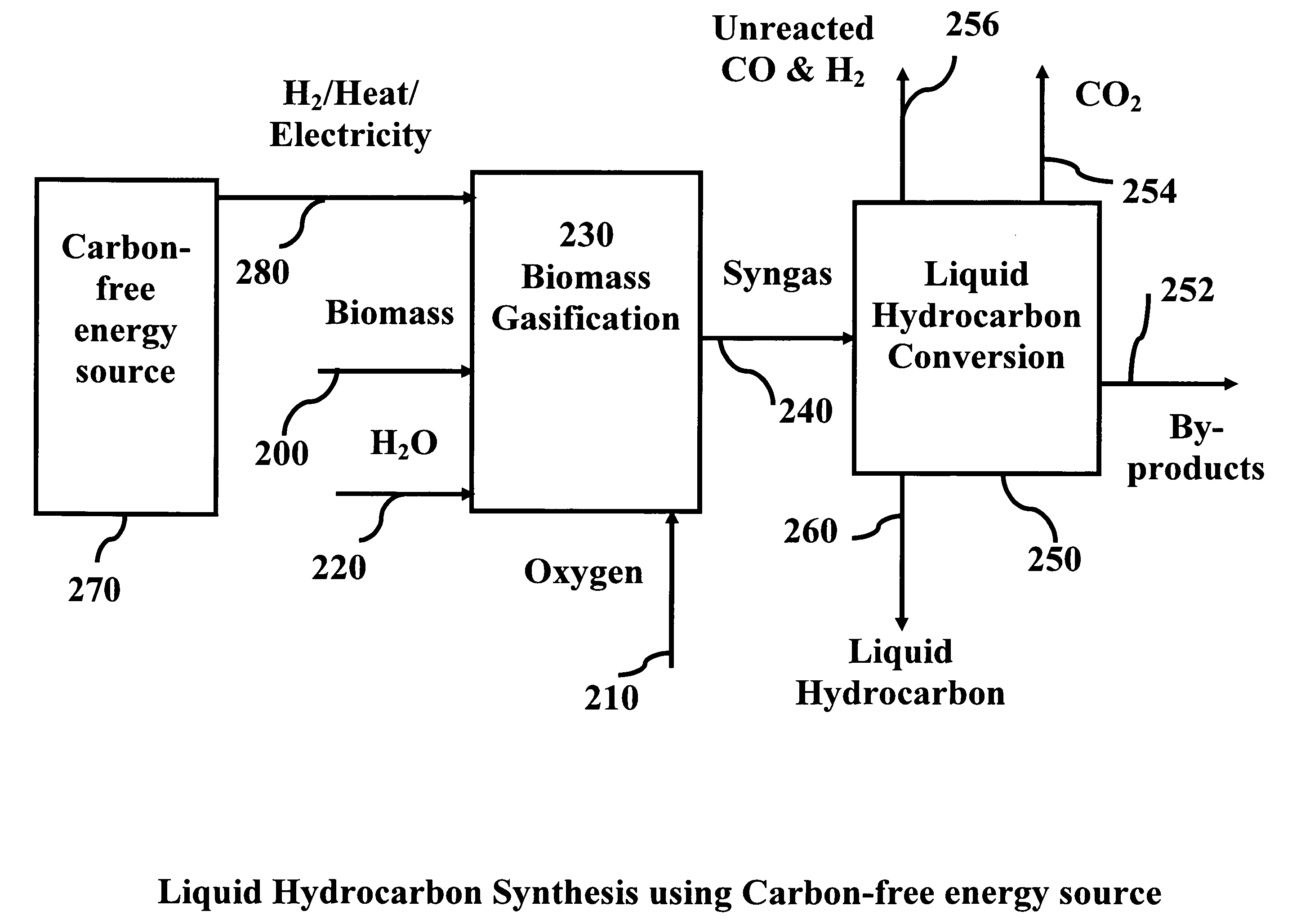

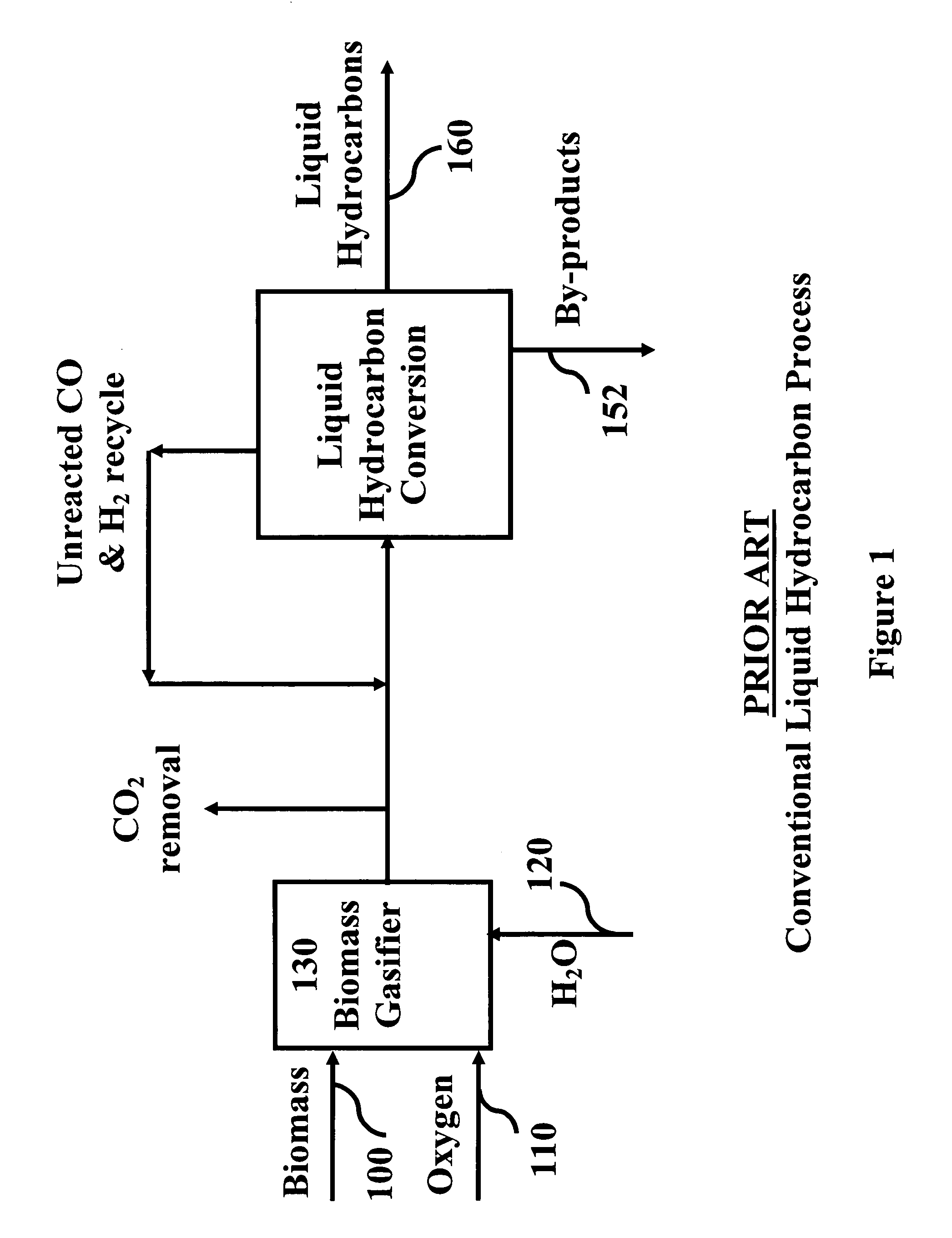

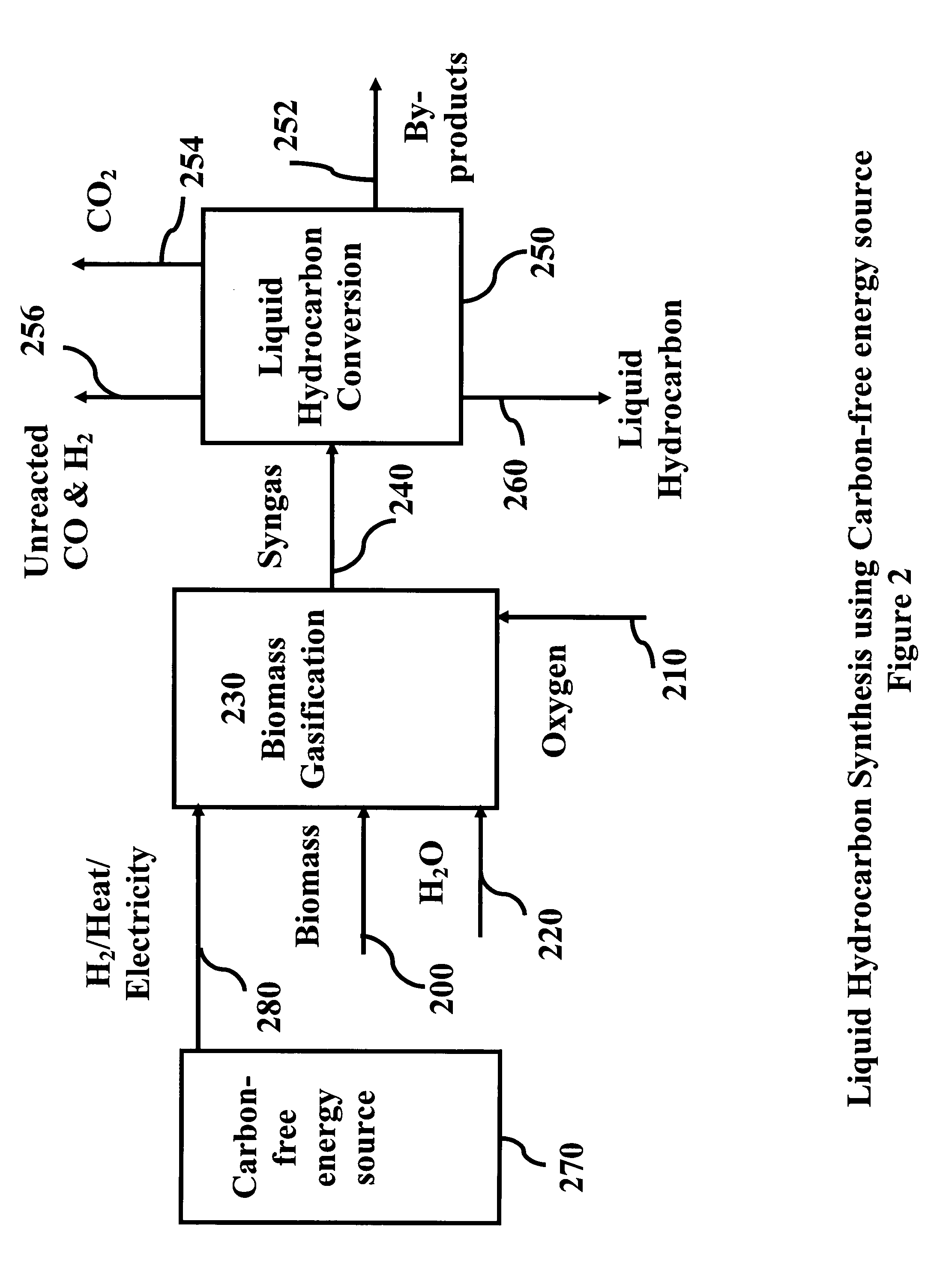

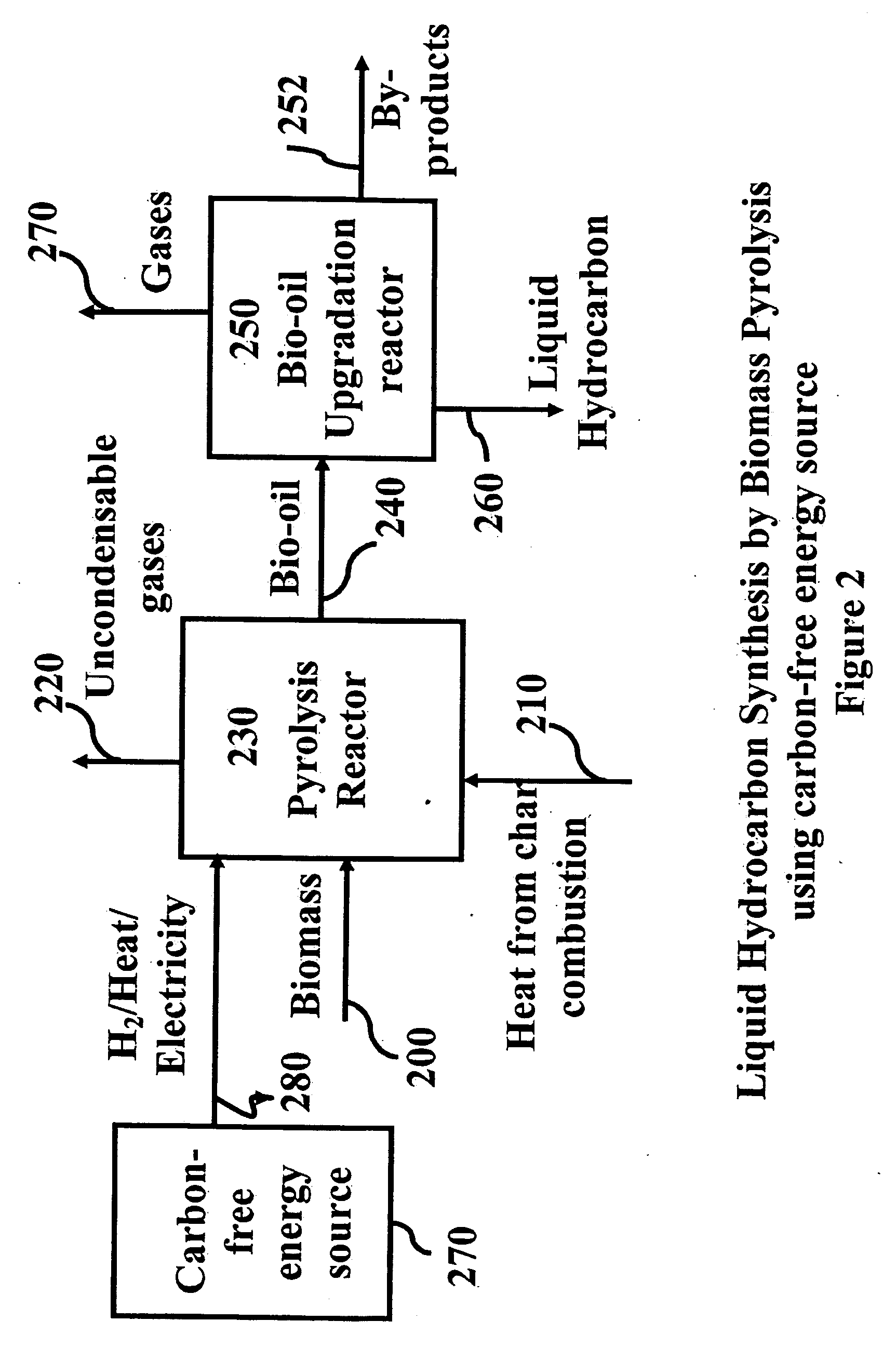

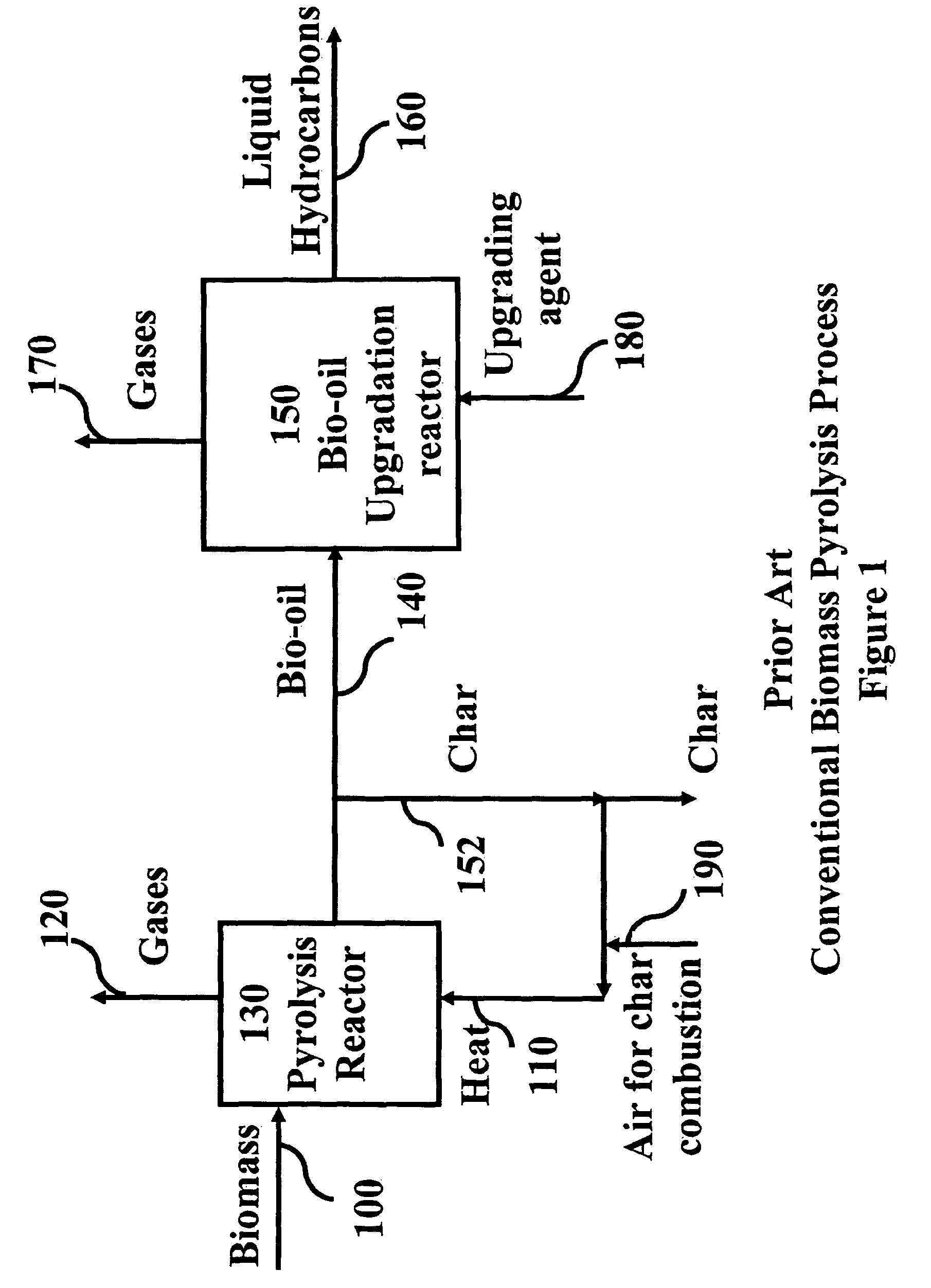

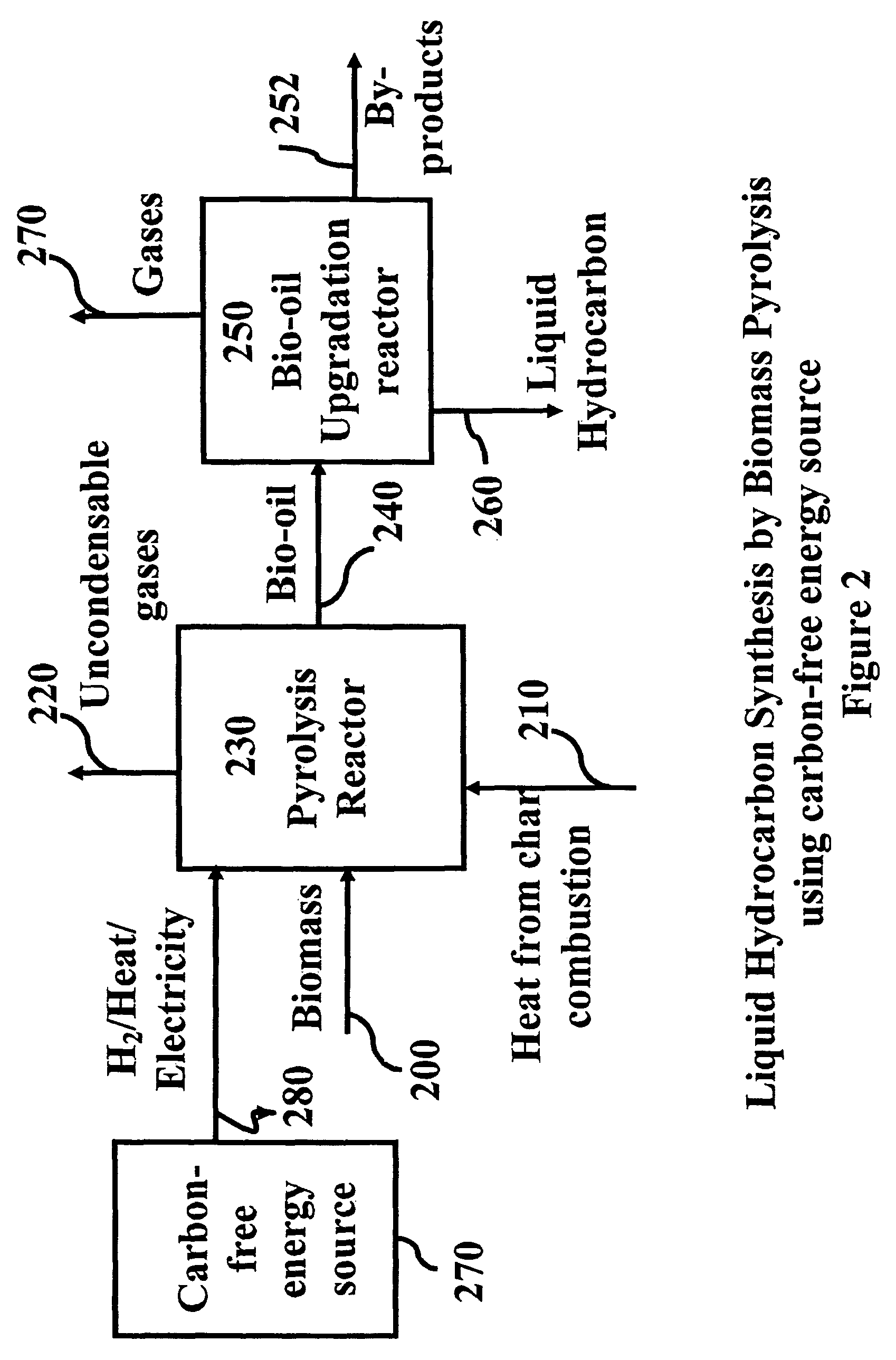

System and process for producing synthetic liquid hydrocarbon

ActiveUS20080115415A1Improve carbon efficiencyReduce area requirementsMuffle furnacesCarbon compoundsOxygenElectrolysis of water

Production of synthetic liquid hydrocarbon fuel from carbon containing moieties such as biomass, coal, methane, naphtha as a carbon source and hydrogen from a carbon-free energy source is disclosed. The biomass can be fed to a gasifier along with hydrogen, oxygen, steam and recycled carbon dioxide. The synthesis gas from the gasifier exhaust is sent to a liquid hydrocarbon conversion reactor to form liquid hydrocarbon molecules. Unreacted CO & H2 can be recycled to the gasifier along with CO2 from the liquid hydrocarbon conversion reactor system. Hydrogen can be obtained from electrolysis of water, thermo-chemical cycles or directly by using energy from carbon-free energy sources.

Owner:PURDUE RES FOUND INC

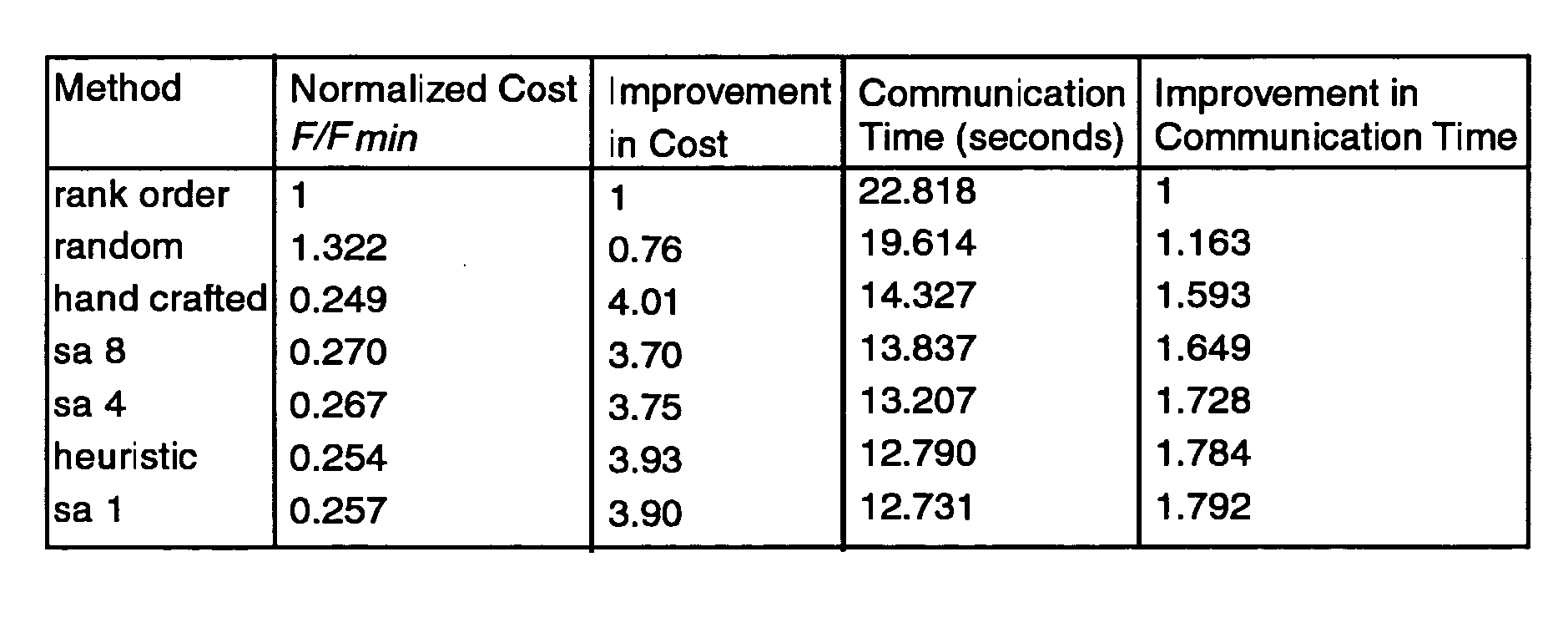

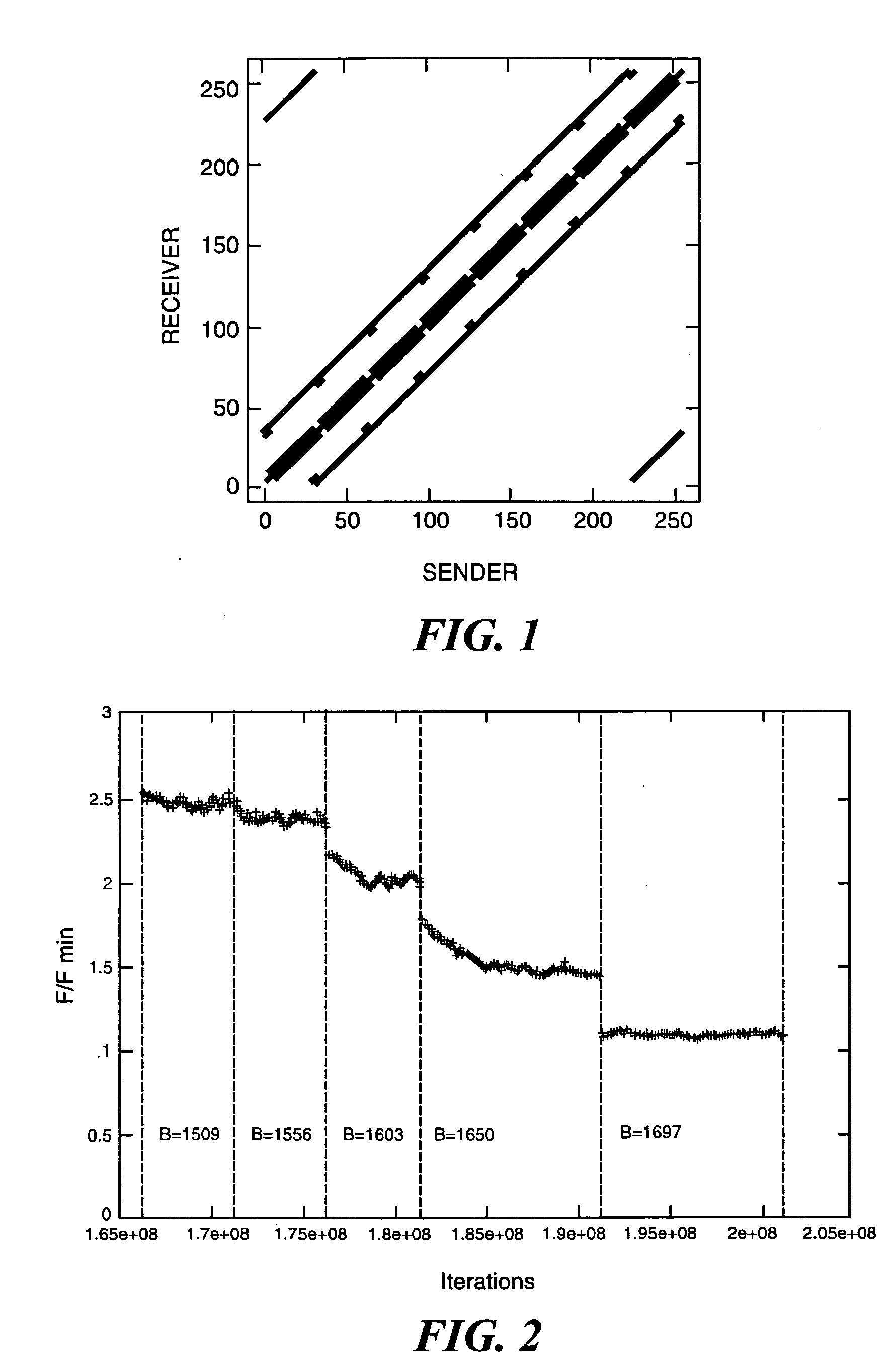

Optimizing layout of an application on a massively parallel supercomputer

InactiveUS20060101104A1Shorten the timeMinimize cost functionDigital data processing detailsDigital computer detailsMarkov chainSupercomputer

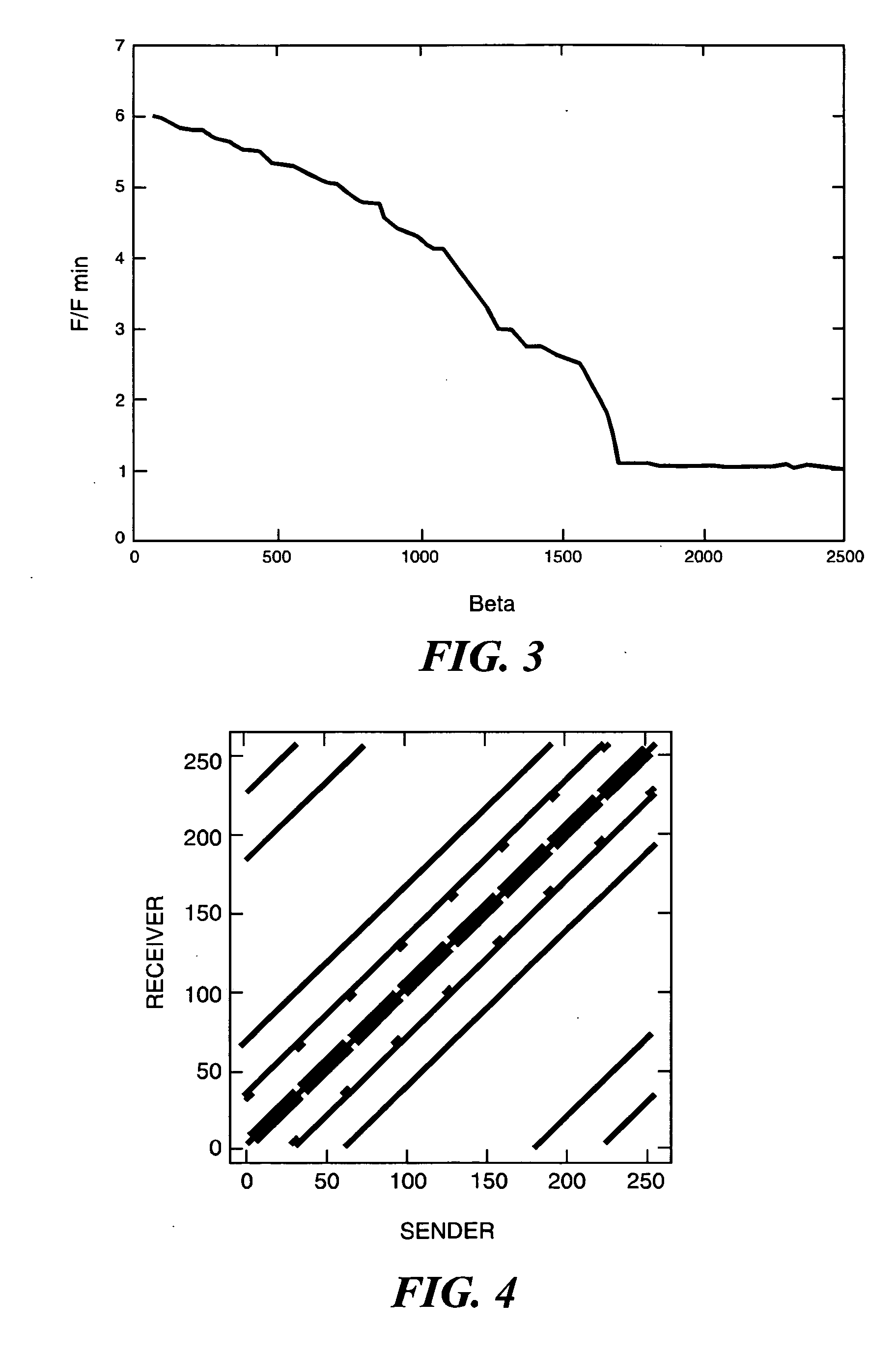

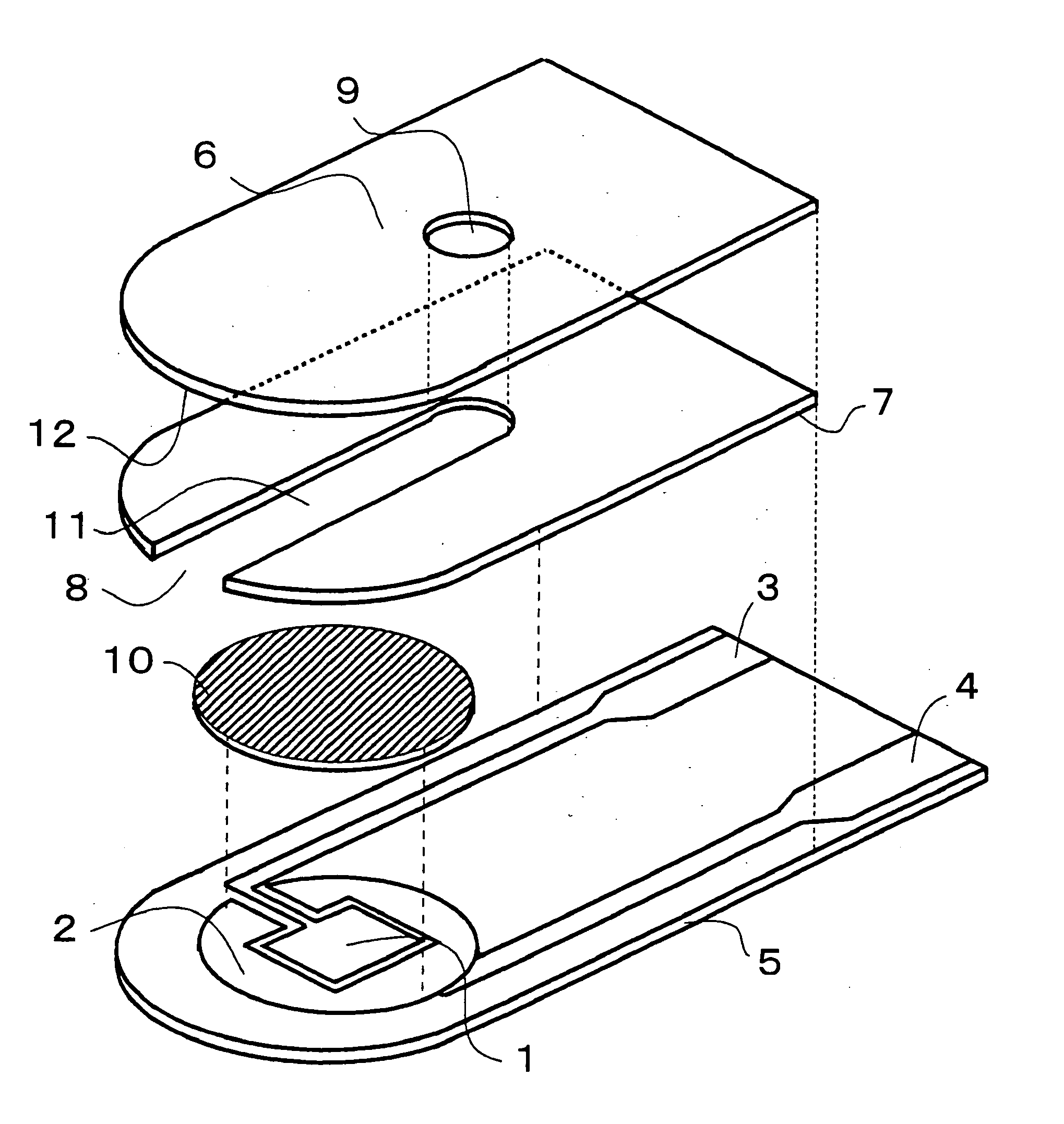

A general computer-implement method and apparatus to optimize problem layout on a massively parallel supercomputer is described. The method takes as input the communication matrix of an arbitrary problem in the form of an array whose entries C(i, j) are the amount to data communicated from domain i to domain j. Given C(i, j), first implement a heuristic map is implemented which attempts sequentially to map a domain and its communications neighbors either to the same supercomputer node or to near-neighbor nodes on the supercomputer torus while keeping the number of domains mapped to a supercomputer node constant (as much as possible). Next a Markov Chain of maps is generated from the initial map using Monte Carlo simulation with Free Energy (cost function) F=Σi,jC(i,j)H(i,j)—where H(i,j) is the smallest number of hops on the supercomputer torus between domain i and domain j. On the cases tested, found was that the method produces good mappings and has the potential to be used as a general layout optimization tool for parallel codes. At the moment, the serial code implemented to test the method is un-optimized so that computation time to find the optimum map can be several hours on a typical PC. For production implementation, good parallel code for our algorithm would be required which could itself be implemented on supercomputer.

Owner:IBM CORP

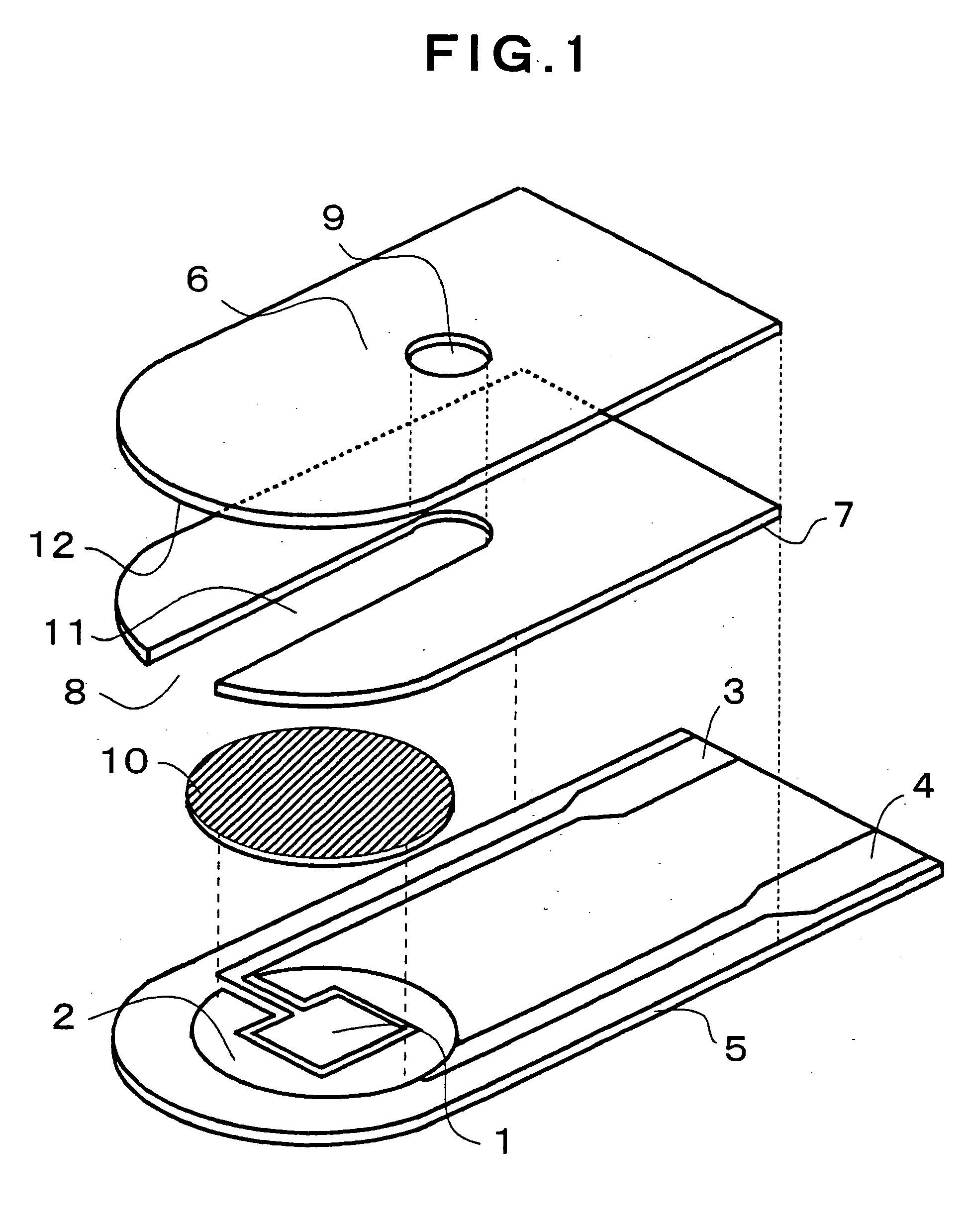

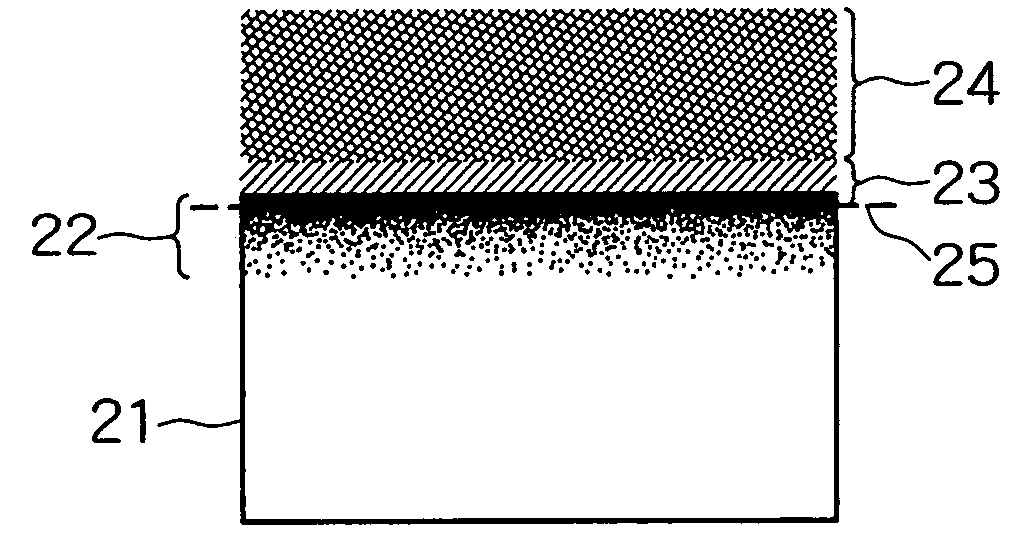

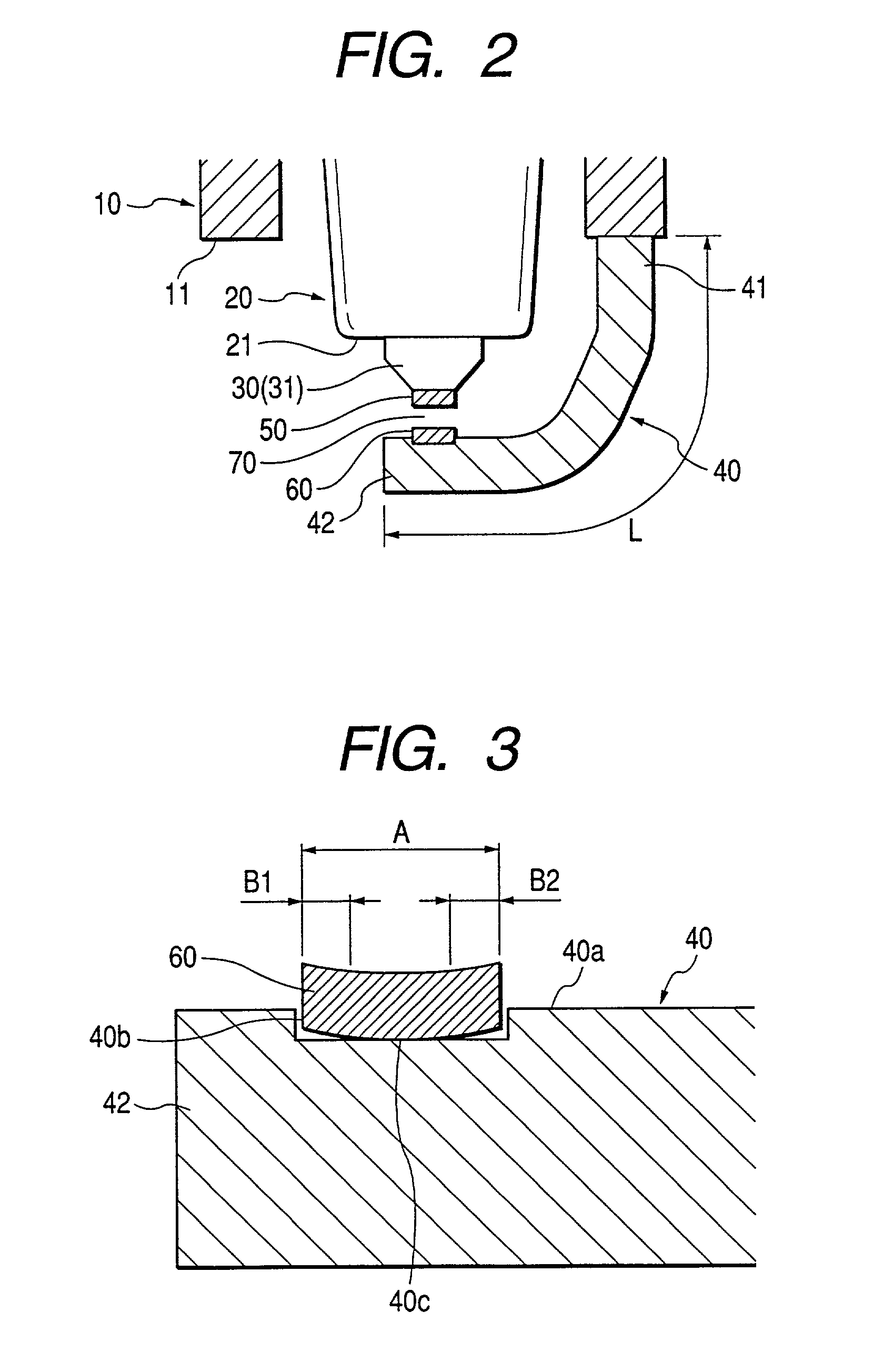

Biosensor

InactiveUS20050036906A1High measurement accuracyImmobilised enzymesBioreactor/fermenter combinationsFree energiesWater repellent

A biosensor for analyzing specific components in an introduced liquid sample by reaction of the liquid sample with a reagent comprises a cavity into which the liquid sample is introduced, an air hole communicating from the cavity to outside, and a water repellent part having a water repellency at 43 mN / m or less in surface free energy and provided to at least a portion around the outlet of the air hole. By the water repellent part around the air hole, the liquid sample can be prevented from flowing out through the air hole, thereby achieving a high-accuracy measurement.

Owner:PANASONIC CORP +1

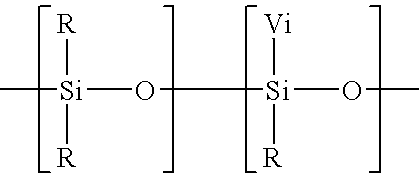

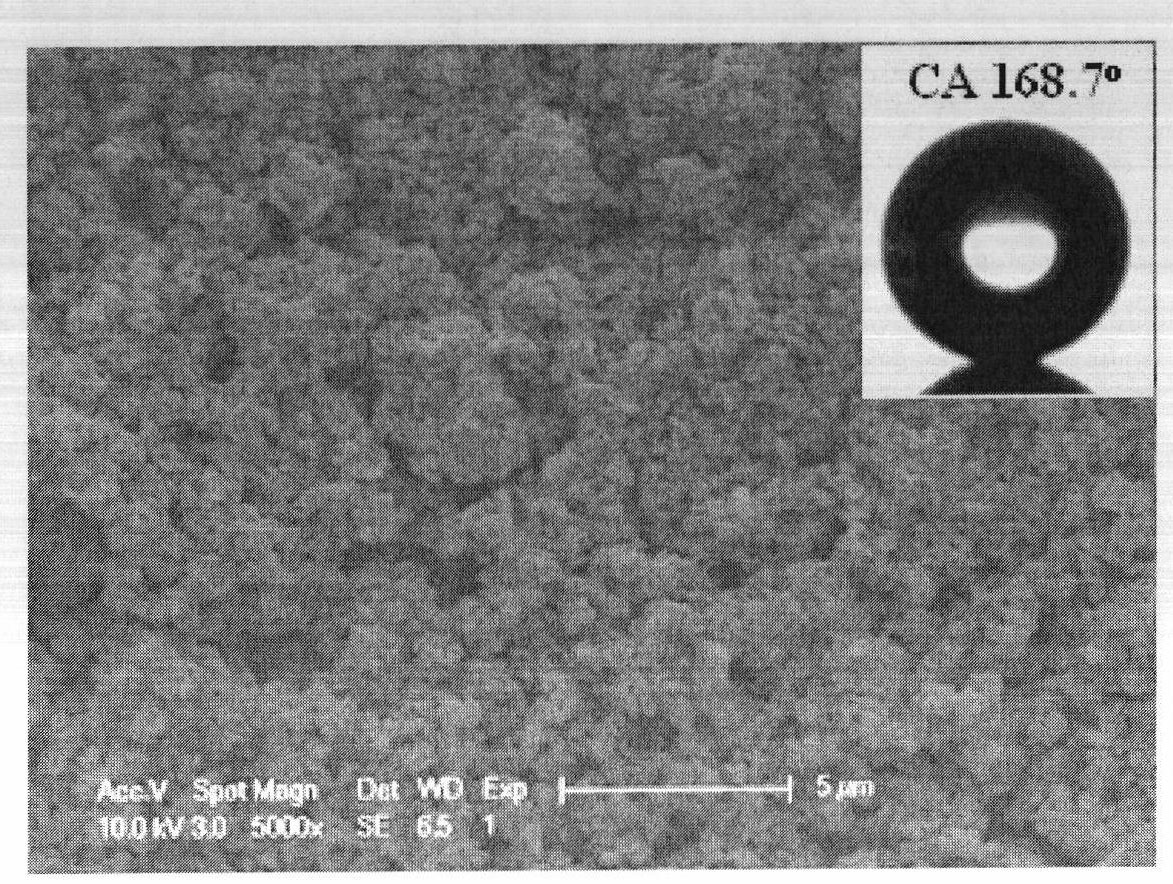

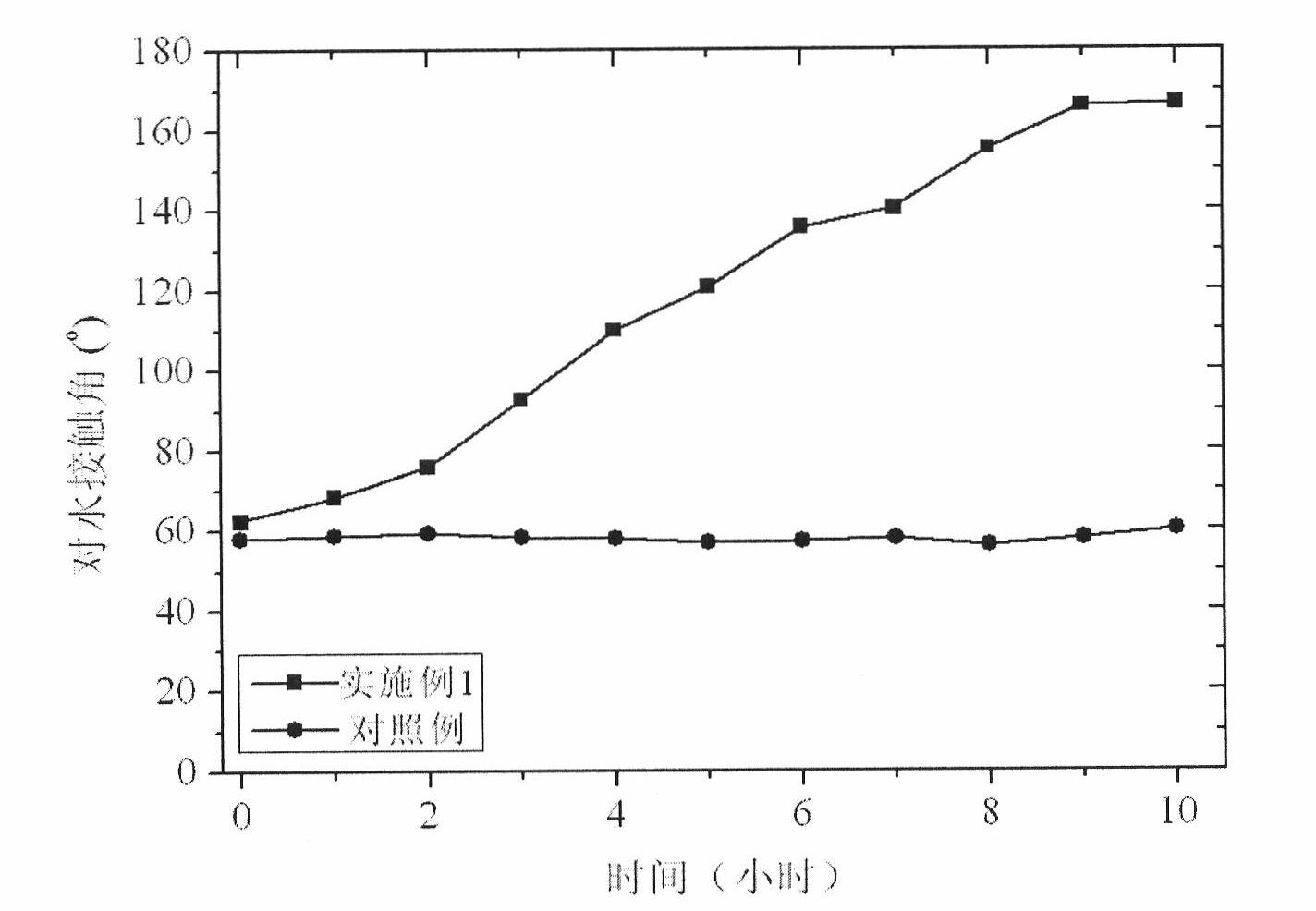

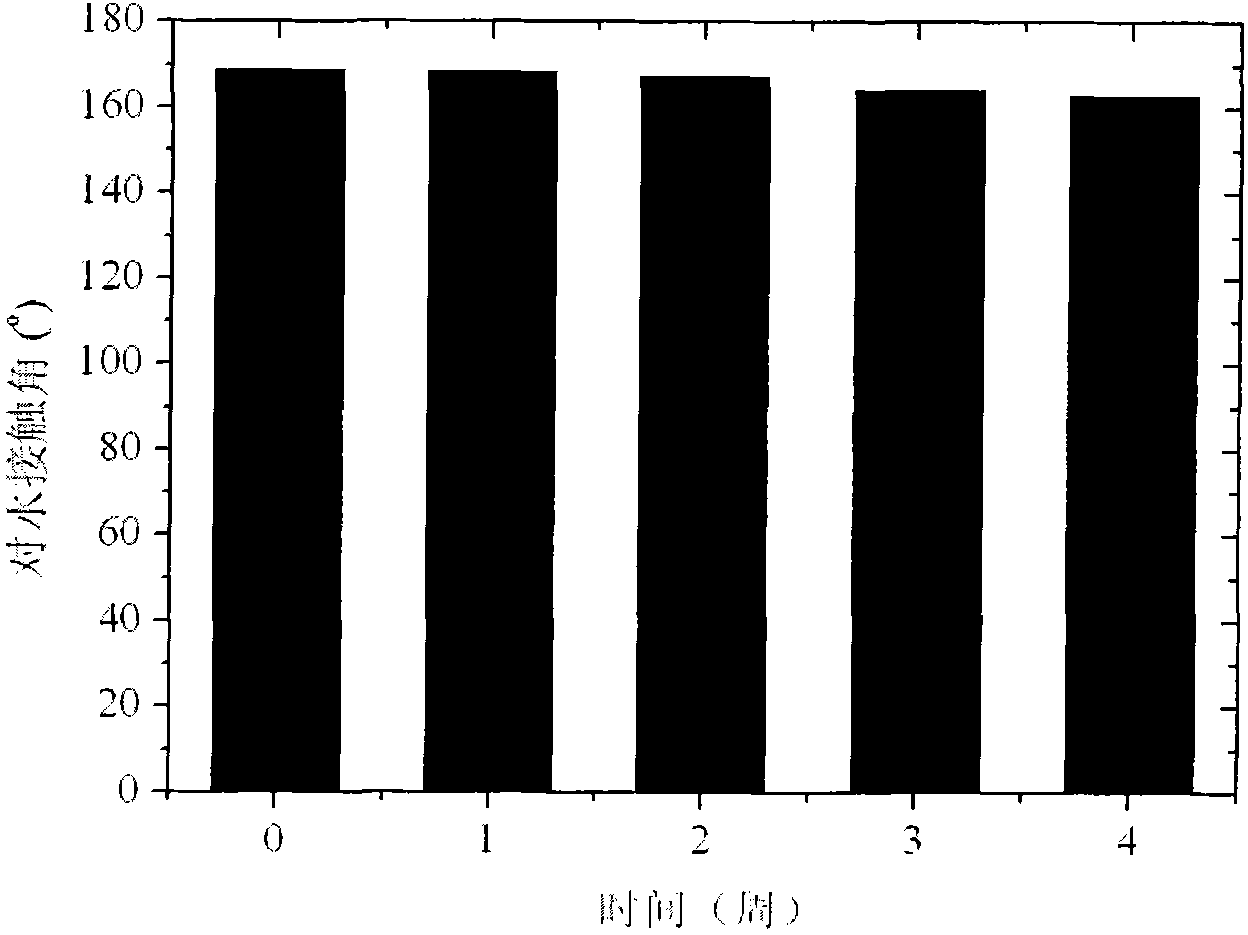

High-durability super-hydrophobic self-cleaning coating material and preparation method thereof

InactiveCN101962514AHas the following advantages: (1) cleanlinessHas the following advantages: (1) has the functionAntifouling/underwater paintsPaints with biocidesDouble bondDimethyl siloxane

The invention belongs to the technical field of a new chemical material, and in particular relates to a high-durability super-hydrophobic self-cleaning coating material and a preparation method thereof. The coating material of the invention is prepared by curing and drying nanoparticles with photo-catalytic activity, a low-surface-free-energy polymer and a cross-linking agent at the room temperature, wherein the low-surface-free-energy polymer consists of one or more of polysiloxane fluoride, dimethyl silicone polymer and polyphenylene methyl siloxane, which contain active groups, such as hydroxyl alkoxy group, carbon-carbon double bond, silanol group, siloxy group, and the like; the cross-linking agent is hydrogen-containing silicone oil or aminosilane; and the mass content of the photo-catalytic nanoparticles in the coating ranges from 10 to 60 percent. The coating is formed into a micro-nanostructure by nanoparticle self-organization; a super-hydrophobic self-cleaning coating with lotus effect is prepared from the coating and a cross-linked filming matrix with low surface energy; the persistence of a lotus-shaped super-hydrophobic characteristic of the coating is realized by using the photo-catalytic decomposition characteristic of an organic pollutant for the nanoparticles; and thus the material is suitable for large-area construction and has high weathering resistance andprominent self-cleaning characteristic.

Owner:FUDAN UNIV

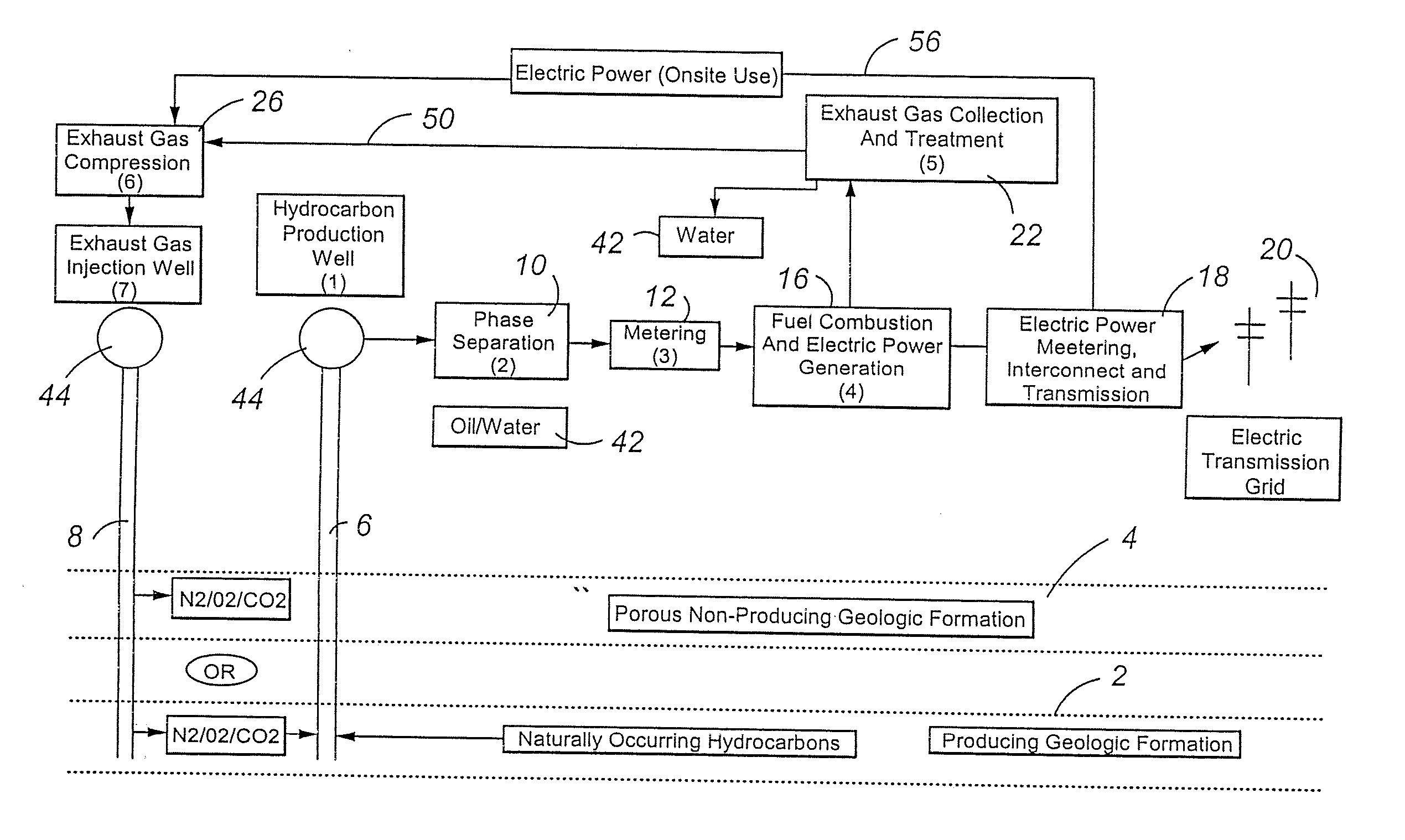

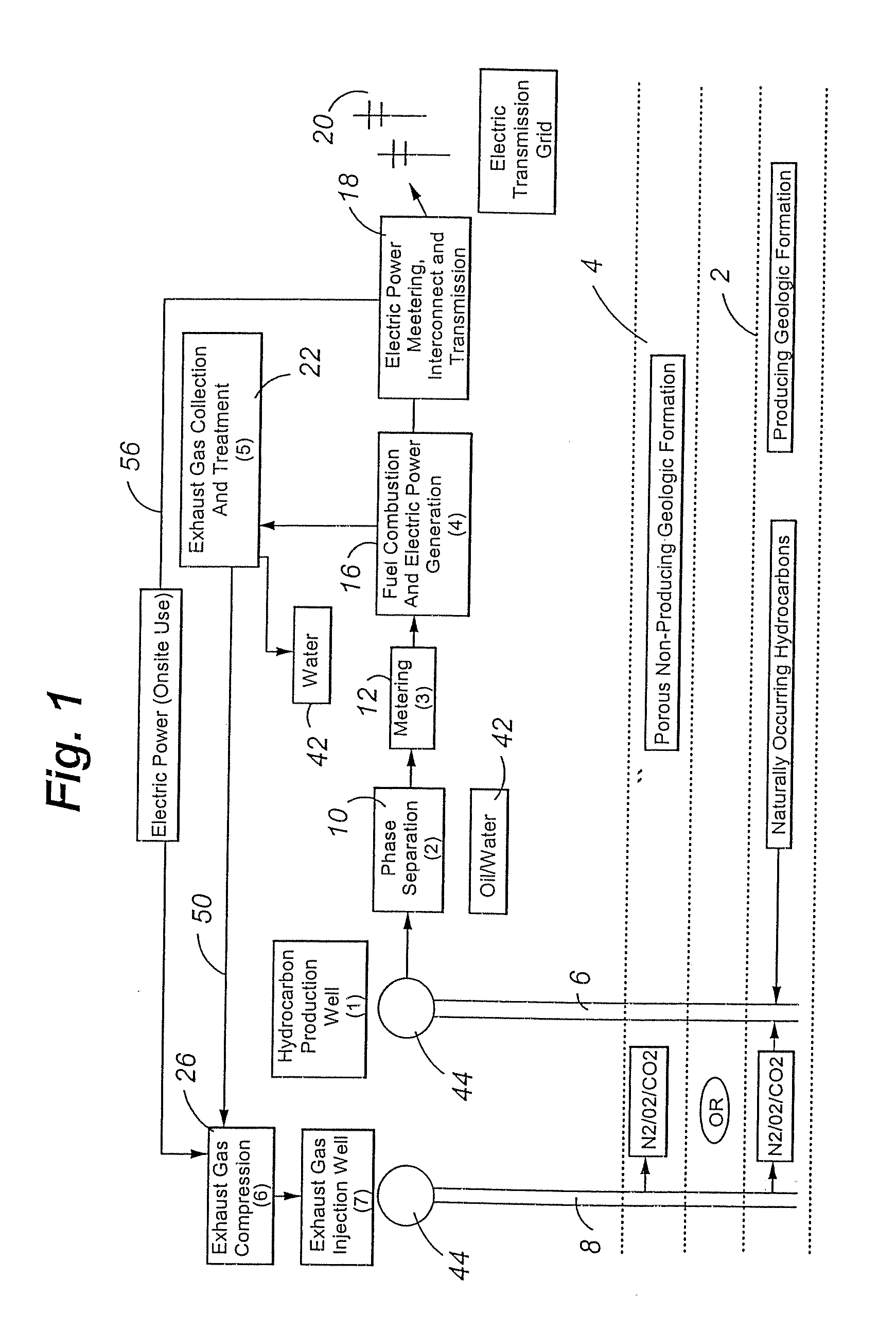

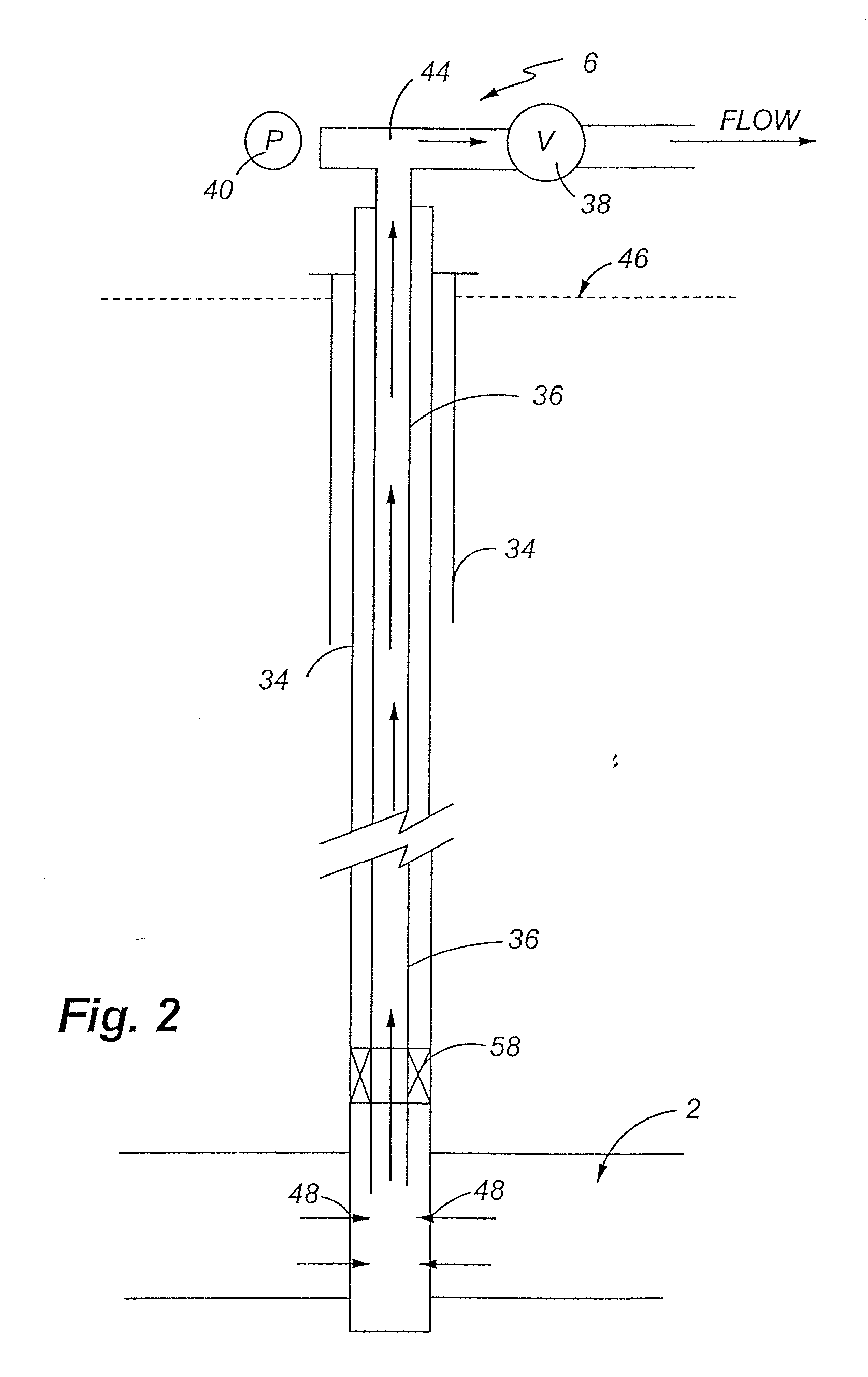

Method and apparatus for generating pollution free electrical energy from hydrocarbons

InactiveUS20080017369A1Cost effectivePollution free energyFluid removalThermal energyHydrocotyle bowlesioides

The present invention relates to the generation of substantially pollution free energy by utilizing hydrocarbons to create electrical energy, while reinjecting exhaust fumes or other byproducts into a subterranean formation. The present invention further relates to managing and supplying this electrical energy to at least one of a variety of subprocesses for producing a fuel product, such as hydrogen or ethanol. Alternatively, electrical power can be generated from a non-hydrocarbon source such as thermal, solar, wind or other power source to produce electrical energy, which in turn may be used to produce fuel products or other forms of usable energy. Thus, remote, low reserve oil and gas fields may be exploited and produced without requiring the construction of expensive gas transmission lines.

Owner:PRODN RESOURCES

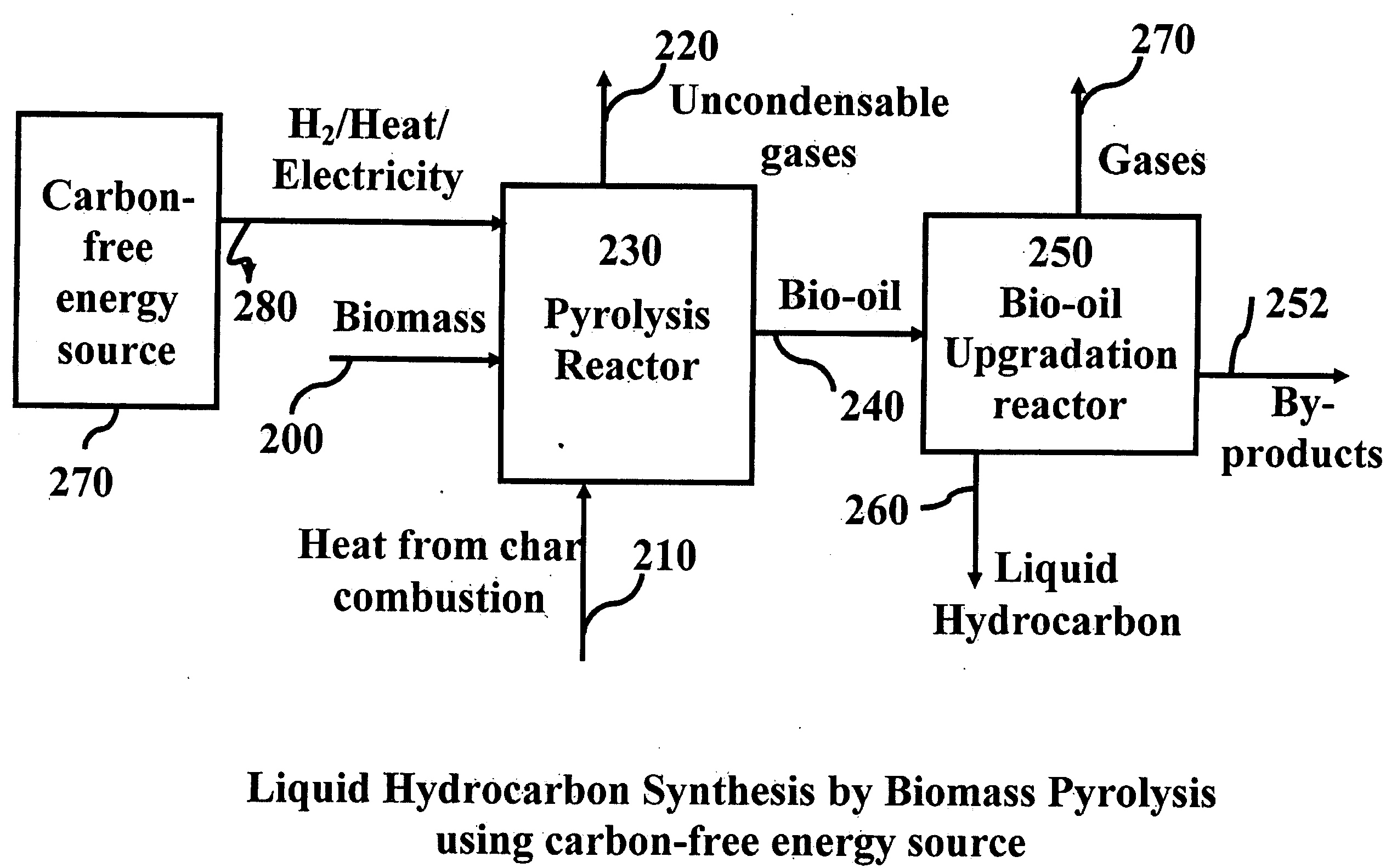

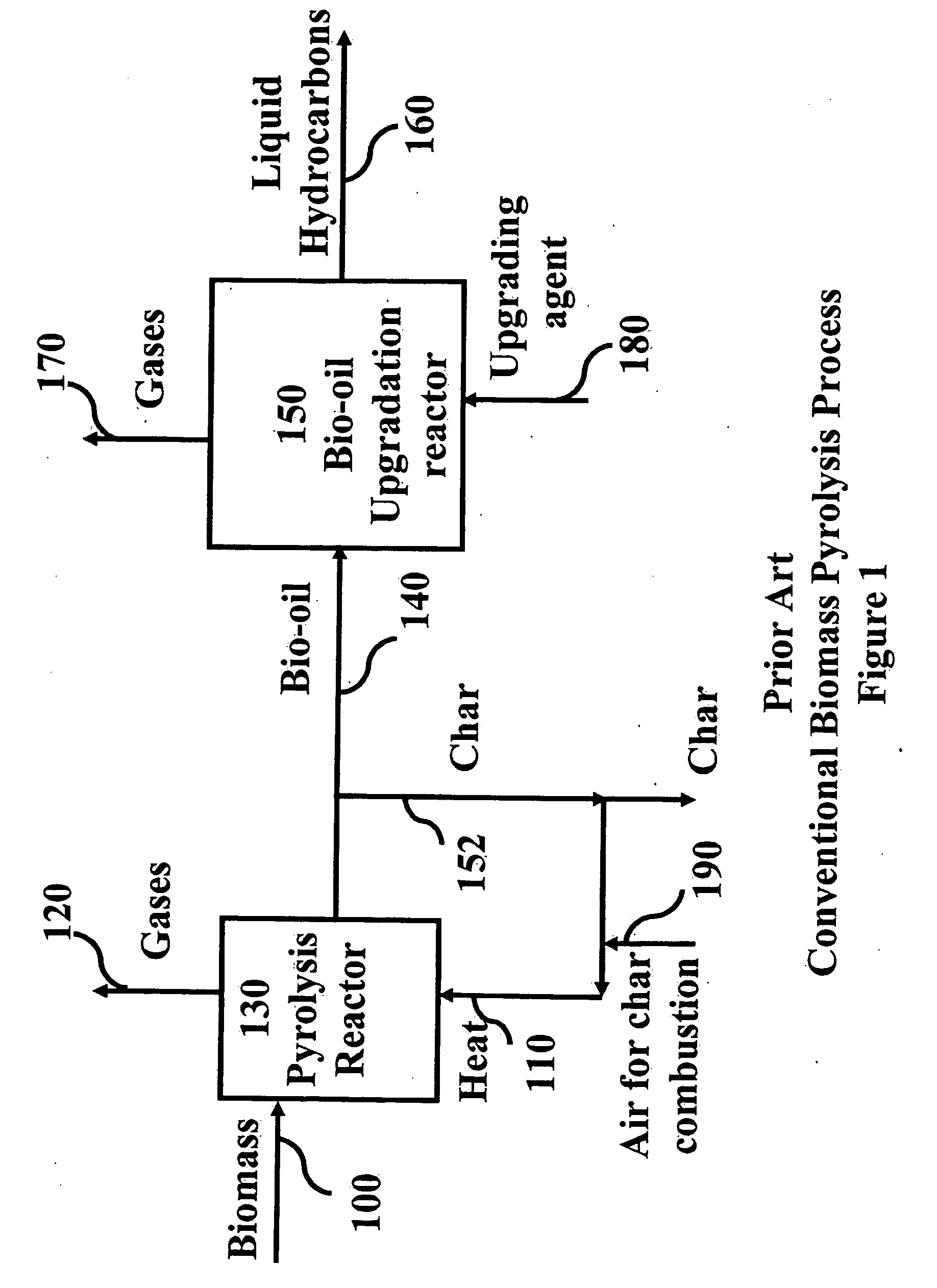

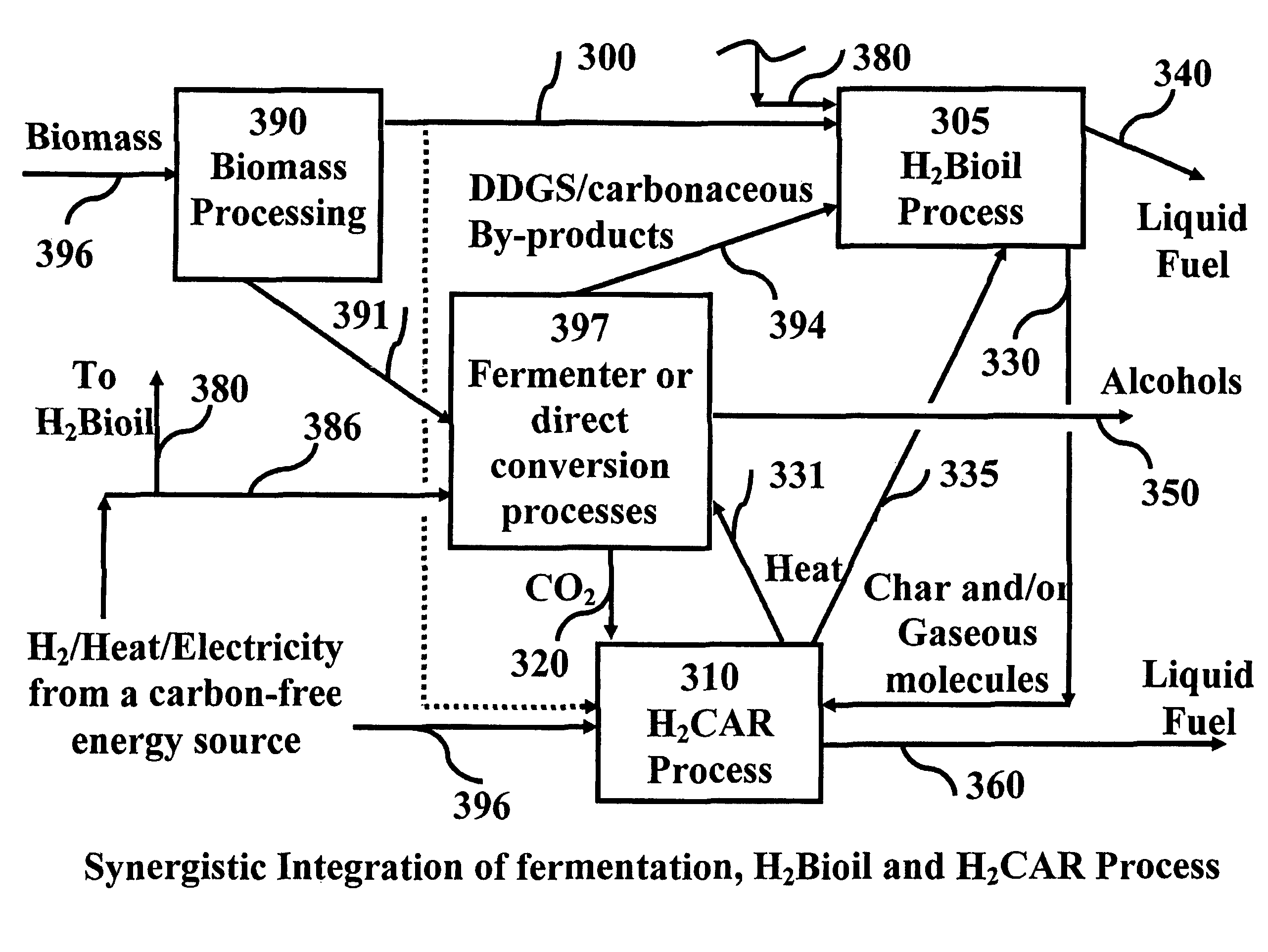

Novel process for producing liquid hydrocarbon by pyrolysis of biomass in presence of hydrogen from a carbon-free energy source

ActiveUS20090082604A1Process stabilityIncrease energy contentBioreactor/fermenter combinationsBiological substance pretreatmentsAlkaneHydrogen

In at least one embodiment of the present invention, a method for producing liquid hydrocarbons from biomass is provided. The method comprises pyrolizing the biomass with hydrogen (H2) to form bio-oil. The bio-oil comprises alkanes, alkenes, alcohols, aldehydes, ketones, aromatics, hydrocarbons or mixtures thereof. The H2 is formed from a carbon-free energy source.

Owner:PURDUE RES FOUND INC

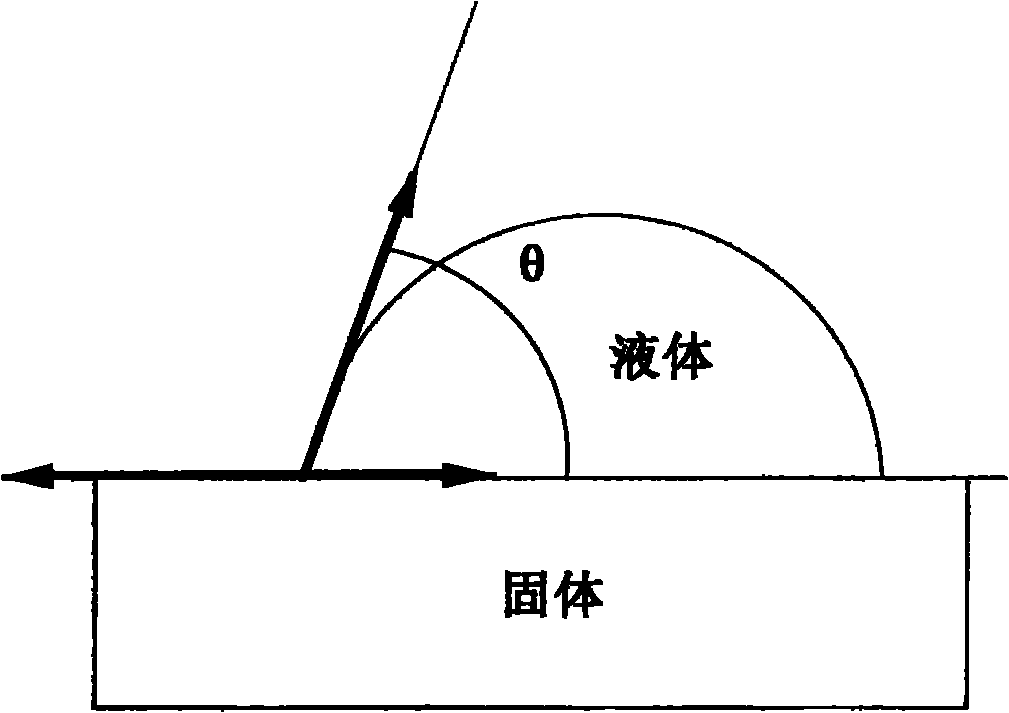

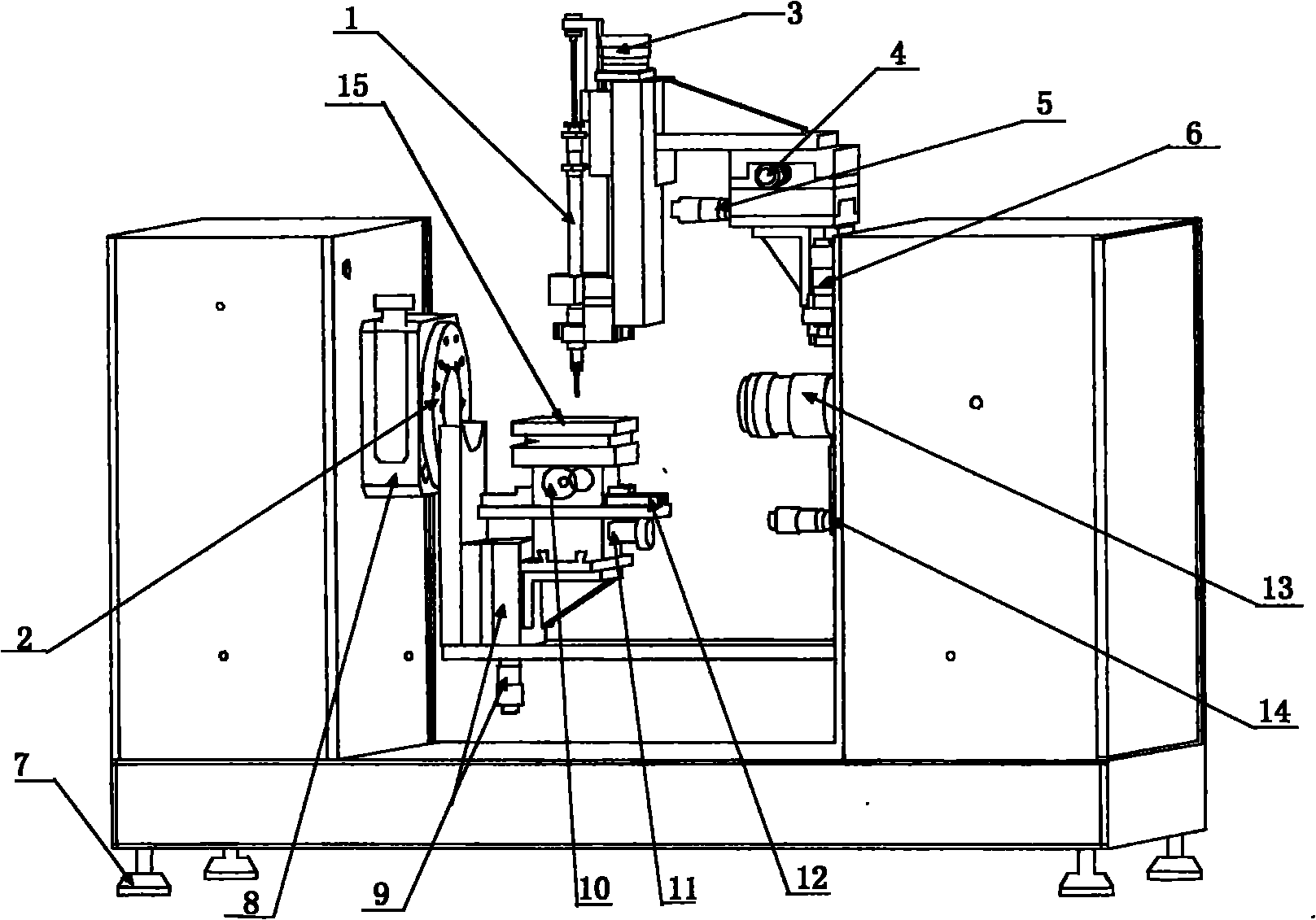

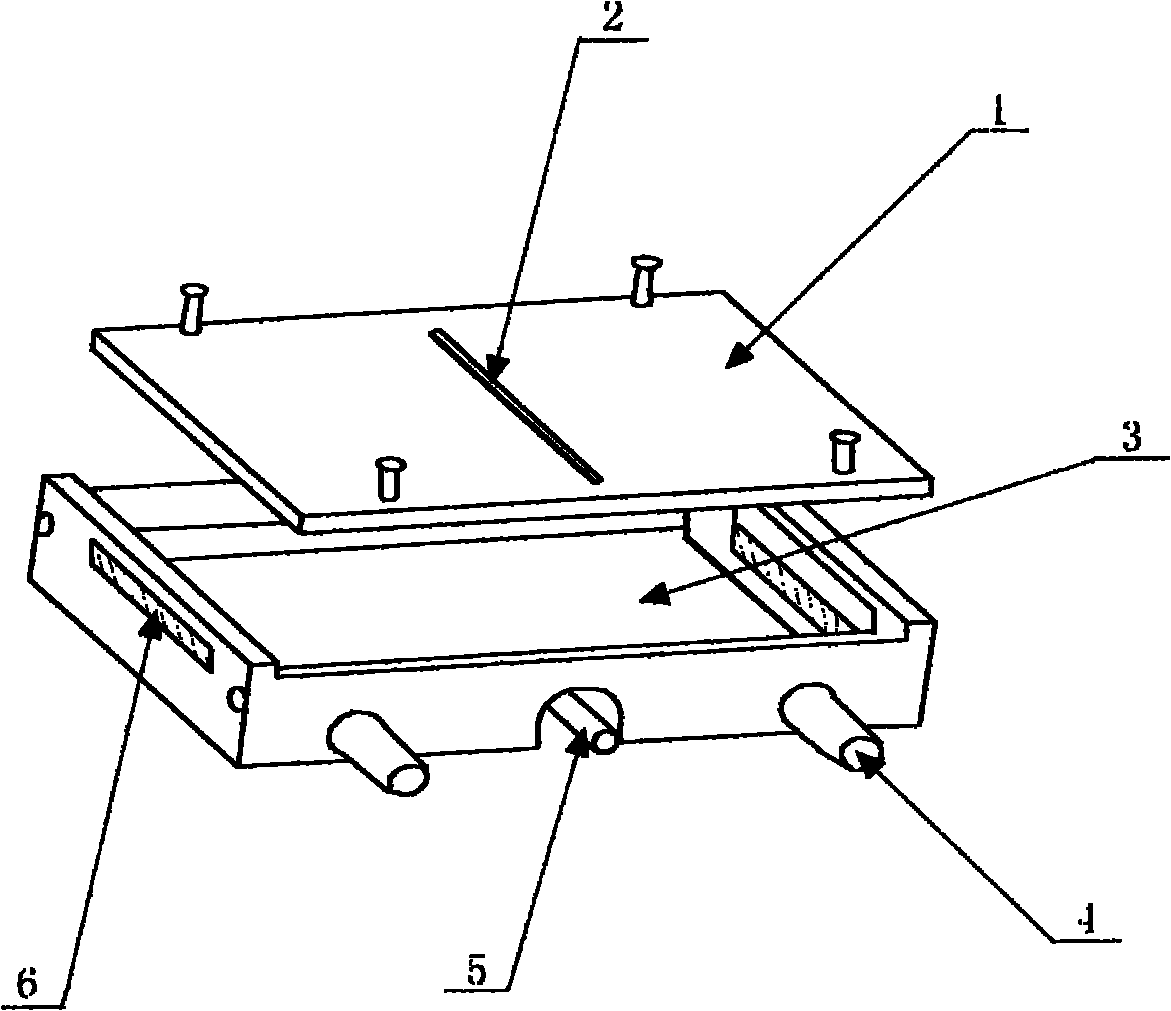

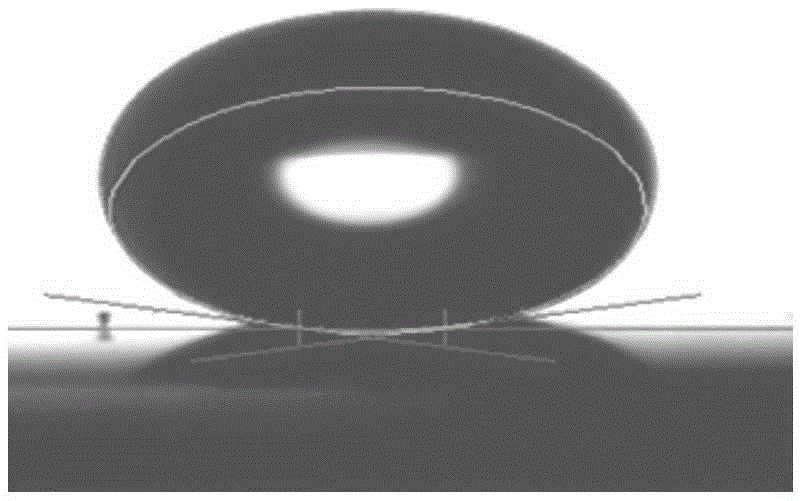

Apparatus and method for testing solid-liquid dynamic and static contact angles by actual liquid droplet method

InactiveCN101865807AHigh precisionEasy to operateSurface tension analysisPeristaltic pumpSmall droplet

The invention discloses an apparatus and a method for testing solid-liquid dynamic and static contact angles by an actual liquid droplet method. The method comprises the following steps of: during the testing, placing a solid phase sample on a sample table; controlling X, Y and Z of the sample table to move to a focusing position of a lens; sucking the liquid phase sample into a micro sample injector, injection pump or peristaltic pump; controlling the X, Y and Z of the sample injector to move to the focusing position; dripping a small droplet of the liquid and adsorbing the droplet to a needle head; moving the needle head to the surface of the solid phase sample until the liquid phase sample is adsorbed to the surface of the solid; making a software system control an optical imaging system (CCD) to capture a real-time picture and analyzing the picture by using the actual liquid droplet method; and displaying calculated solid-liquid contact angle value, solid surface free energy value and adhesion work value and managing the values by a database. The apparatus and the method can completely improve the accuracy of the analysis of the solid-liquid interfacial tension, are simple to operate, can be widely applied and have high popularization value.

Owner:上海梭伦信息科技有限公司

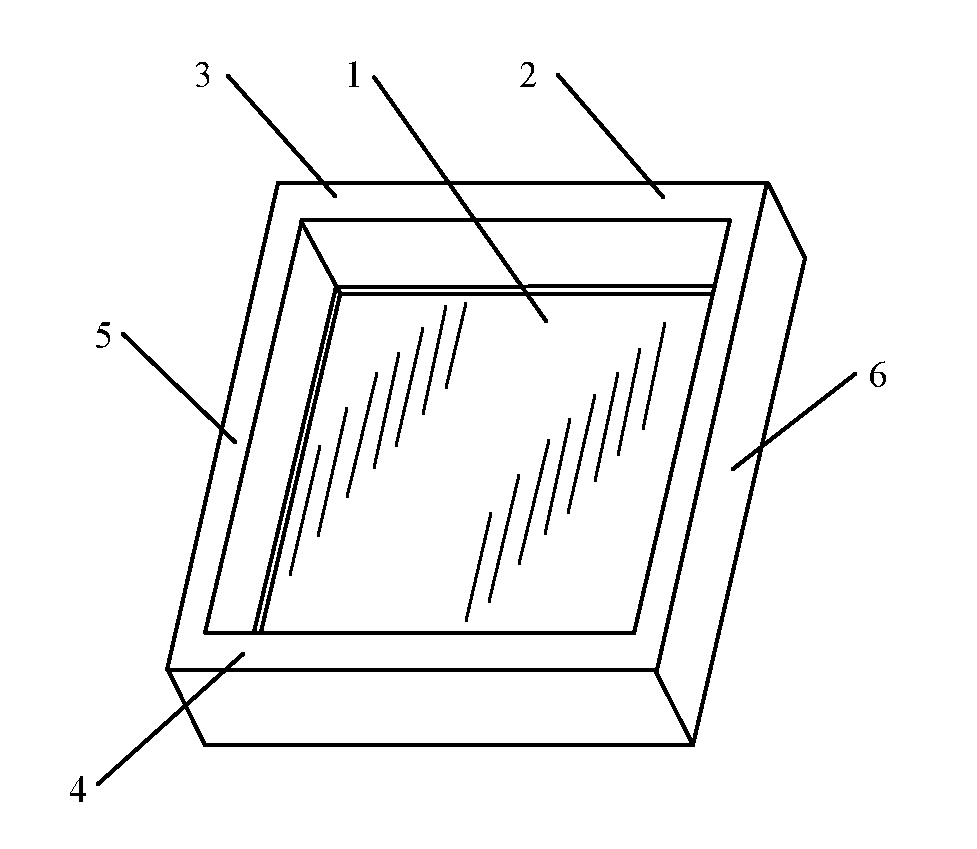

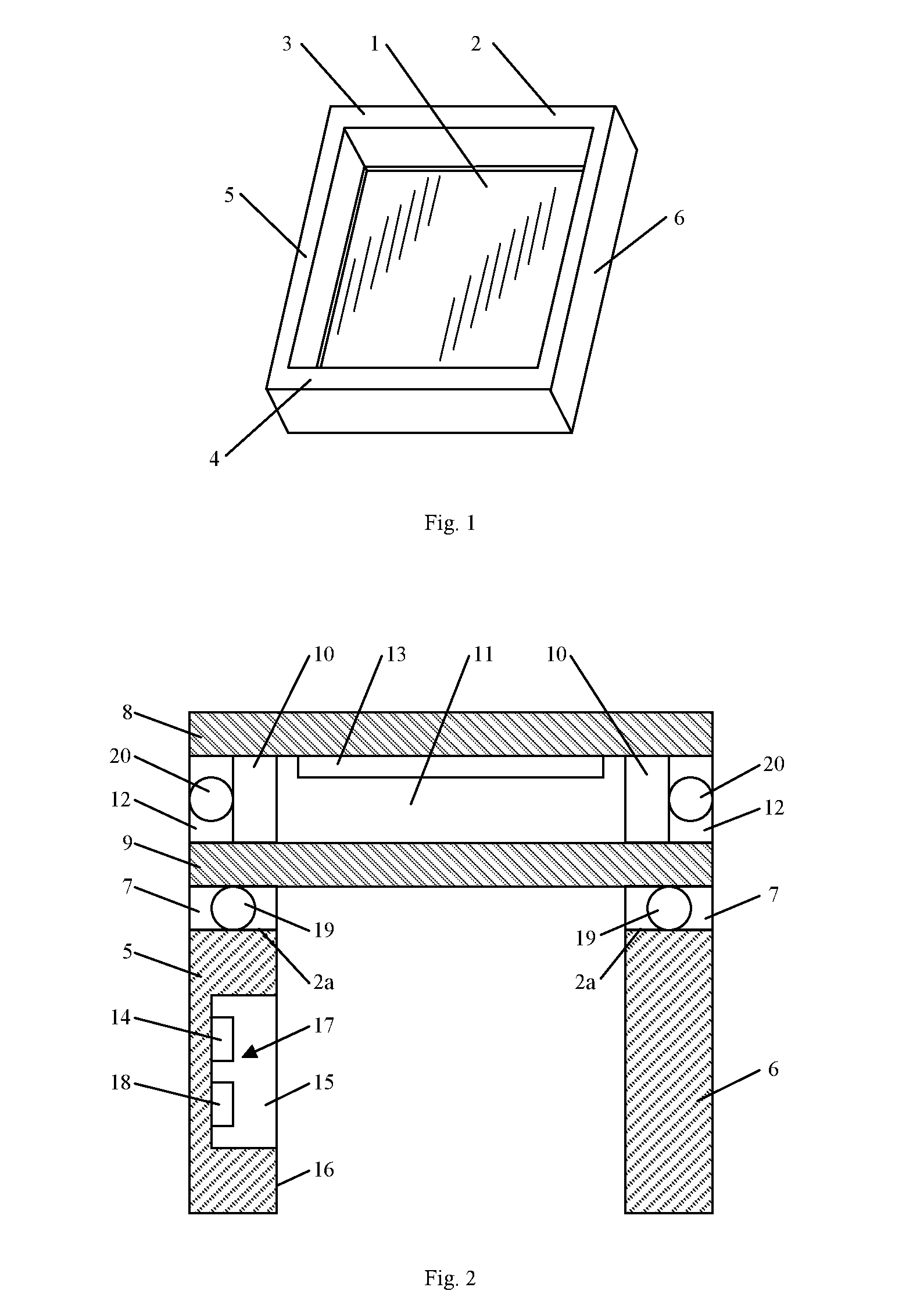

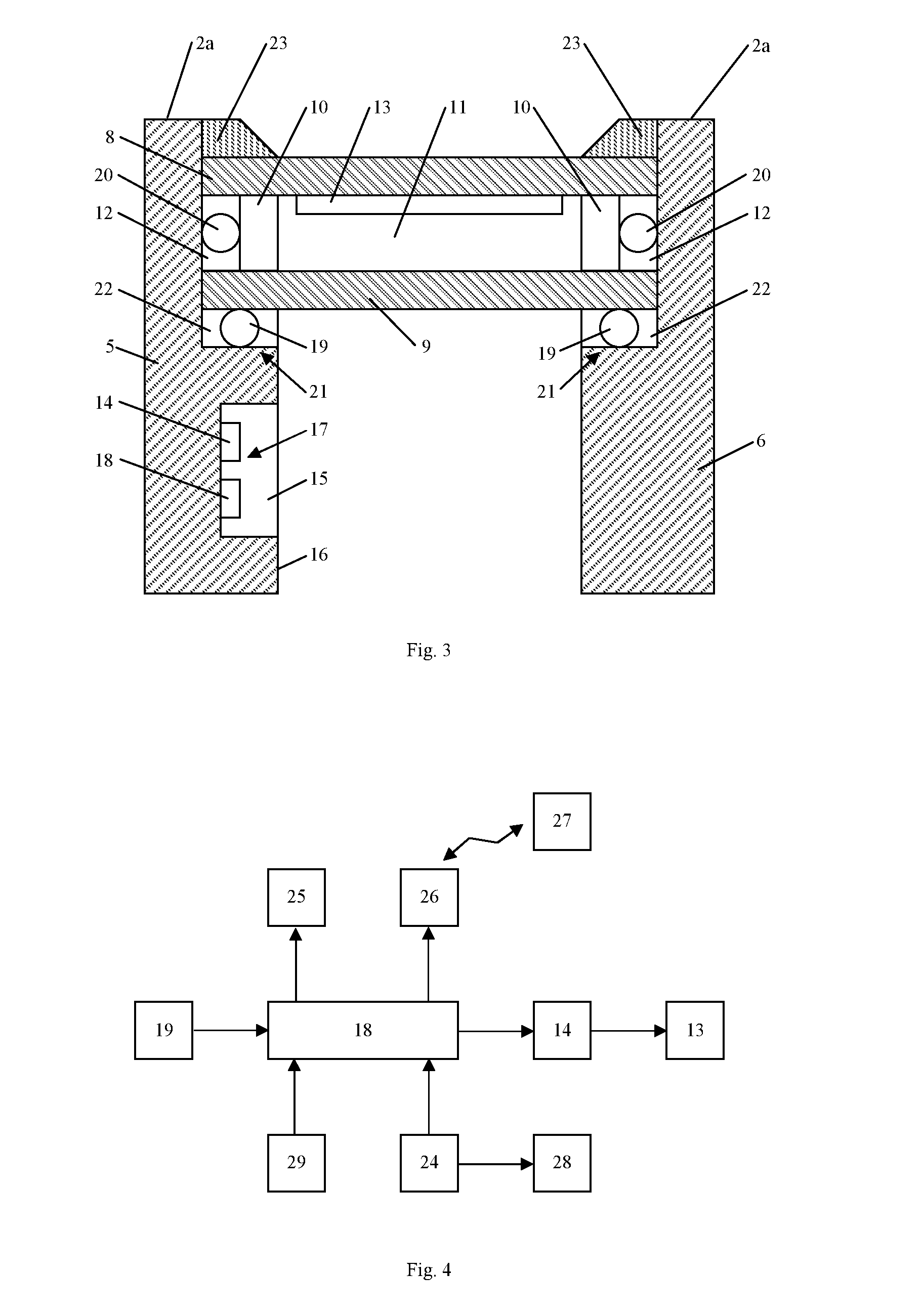

Temperature-controlled window and mehtod of controlling thereof

ActiveUS20150122474A1Less costlyTemperature control using digital meansElectric heatingCommunication unitFree energies

The invention concerns a window including a window pane with one or more glass panes, a window frame in which the window pane is provided, at least one temperature sensor arranged in or at the periphery of the window pane, and an electric circuit connected to the temperature sensor mounted on or in the window frame. The electric circuit is configured to be connected to an operation unit which is configured to regulate the incident light through the window pane. The invention furthermore concerns a method for controlling a window wherein the electric circuit controls the means configured to regulate the incident light through the window pane based on a set of parameters. The parameters are determined on the basis of the orientation and geographical position of the window whereby the supply of free energy is optimised and the amount of energy supplied from energy sources in the room is reduced. In an embodiment the window can be controlled by means of an application configured to run on a mobile communication unit.

Owner:WICURIT APS

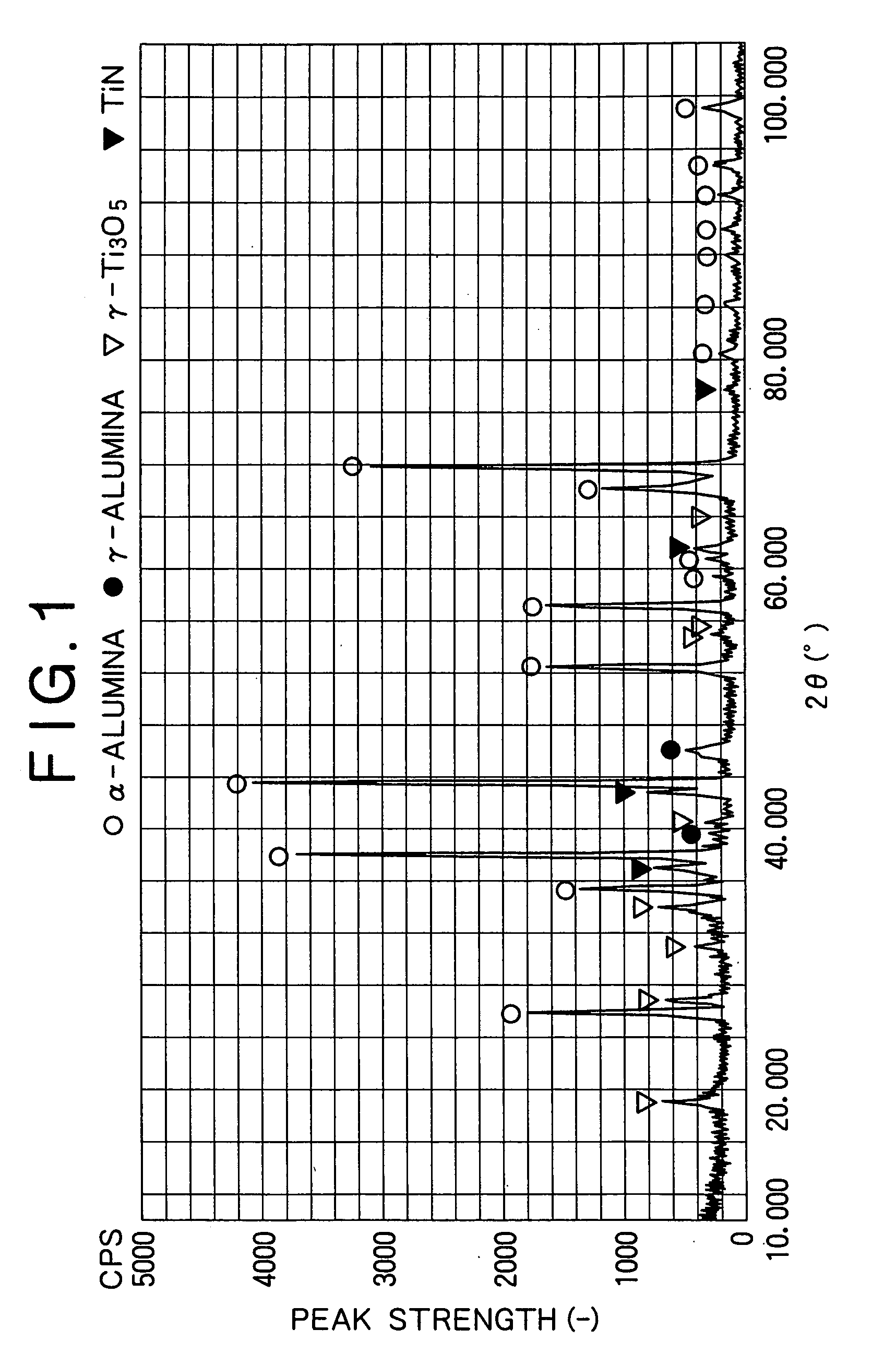

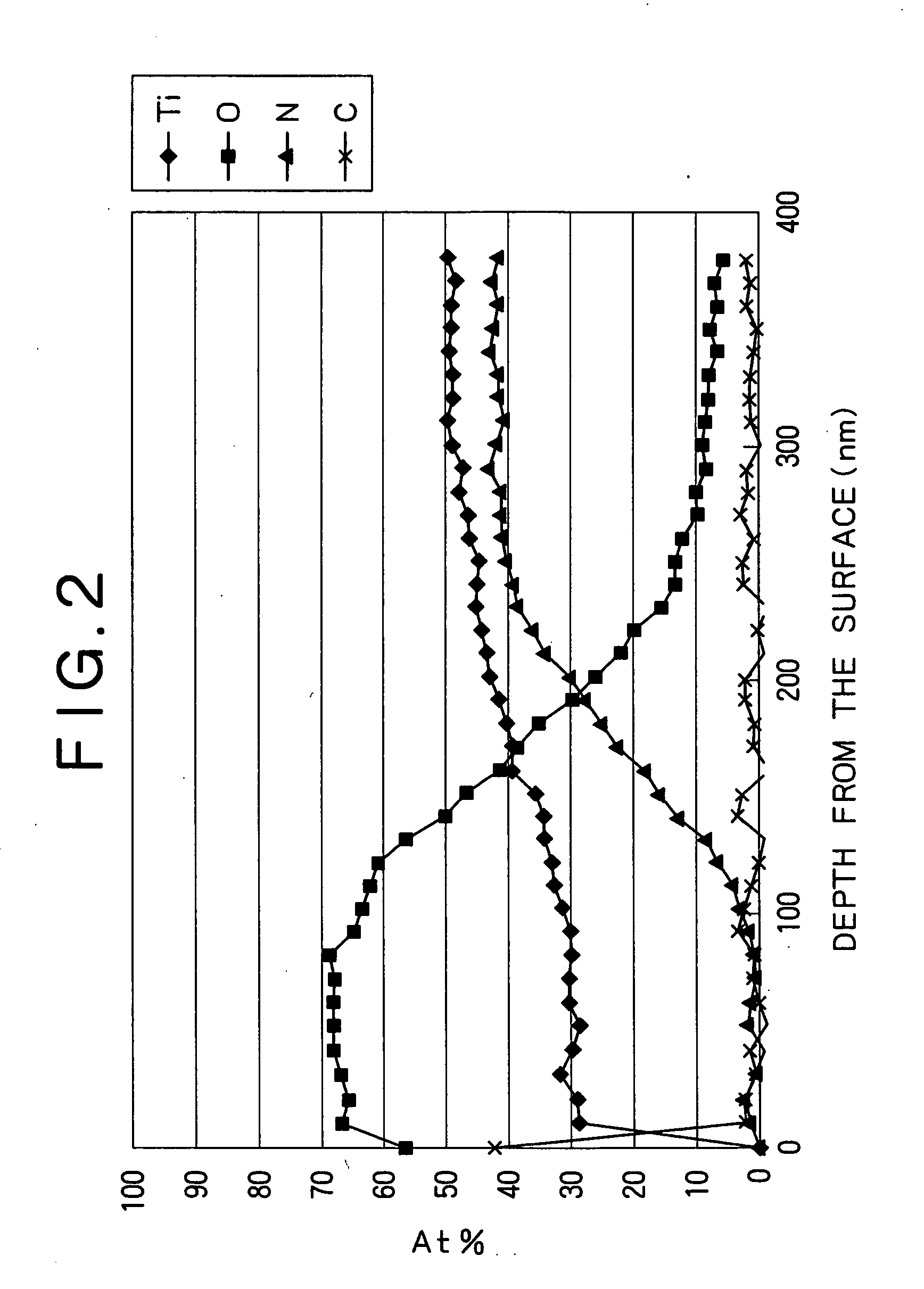

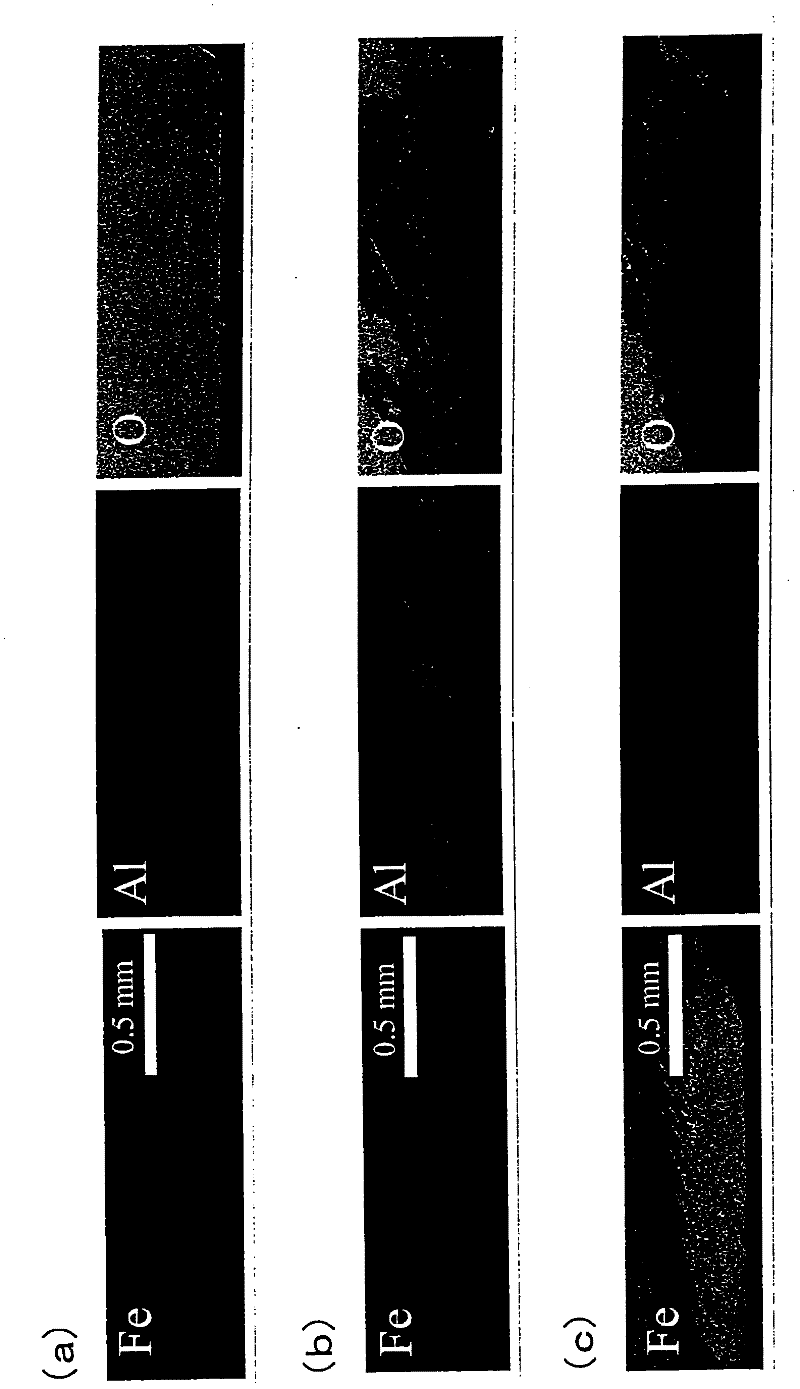

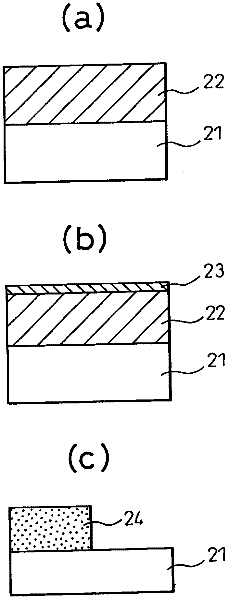

Process for producing alumina coating composed mainly of alpha-type crystal structure, alumina coating composed mainly of alpha-type crystal structure, laminate coating including the alumina coating, member clad with the alumina coating or laminate coating, process for producing the member, and physical evaporation apparatu

InactiveUS20050276990A1Improve heat resistanceImprove wear resistanceVacuum evaporation coatingPretreated surfacesFree energiesHeat resistance

A process for producing an alumina coating composed mainly of a-type crystal structure especially excelling in heat resistance, comprising (1) providing a laminate coating including a hard coating composed of a metal component containing Al and Ti as unavoidable elements and a compound of B, C, N, O, etc., oxidizing the hard coating to thereby form an oxide-containing layer, and forming an alumina coating composed mainly of a-type crystal structure on the oxide-containing layer. Alternatively, the process comprises (2) forming a hard coating composed of a metal whose standard free energy for oxide formation is greater than that of aluminum and a compound of B, C, N, O, etc., oxidizing the surface of the hard coating to thereby form an oxide-containing layer, and forming an alumina coating while being accompanied by reduction of the oxide at the surface of the oxide-containing layer.

Owner:KOBE STEEL LTD

Steel for machine structure use attaining excellent cutting-tool life and method for cutting same

InactiveCN102209798AImprove the lubrication effectSolid state diffusion coatingFurnace typesChemical compositionFree energies

Provided is a steel for machine structure use which attains an excellent cutting-tool life at cutting speeds in a wide range regardless of the mode of cutting, such as continuous or intermittent cutting, and in various cutting environments such as an environment using a cutting oil, a dry or semi-dry environment, and an oxygen-enriched environment. Also provided is a method for cutting the steel. The steel has a chemical composition containing, in terms of mass%, 0.01-1.2% C, 0.005-3.0% Si, 0.05-3.0% Mn, 0.0001-0.2% P, 0.0001-0.35% S, 0.0005-0.035% N, and 0.05-1.0% Al and satisfying [Al%]-(27 / 14)[N%]=0.05%, with the remainder being Fe and incidental impurities. The steel is characterized in that when the steel is cut with a cutting tool in which the surface to come into contact with the work material has been coated with a metal oxide having a higher value of standard free energy of formation at 1,300 C than Al2O3, then an Al2O3 coating film is formed on the surface of the cutting tool.

Owner:NIPPON STEEL CORP

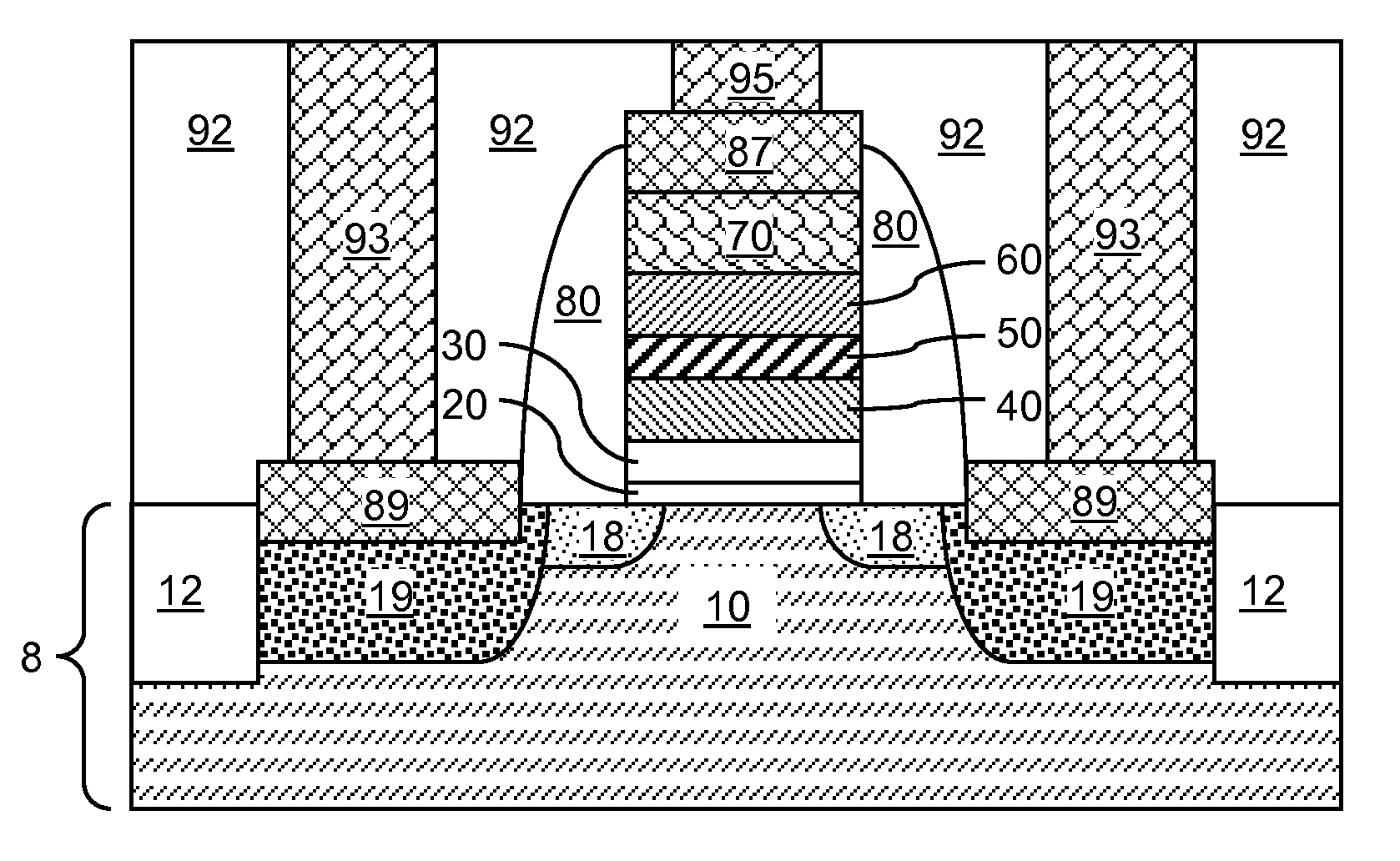

Scavanging metal stack for a high-k gate dielectric

ActiveUS20100320547A1Constant threshold voltageReduce equivalent oxide thicknessTransistorSemiconductor/solid-state device manufacturingDielectricEquivalent oxide thickness

A stack of a high-k gate dielectric and a metal gate structure includes a lower metal layer, a scavenging metal layer, and an upper metal layer. The scavenging metal layer meets the following two criteria 1) a metal (M) for which the Gibbs free energy change of the reaction Si+2 / y MxOy→2x / y M+SiO2 is positive 2) a metal that has a more negative Gibbs free energy per oxygen atom for formation of oxide than the material of the lower metal layer and the material of the upper metal layer. The scavenging metal layer meeting these criteria captures oxygen atoms as the oxygen atoms diffuse through the gate electrode toward the high-k gate dielectric. In addition, the scavenging metal layer remotely reduces the thickness of a silicon oxide interfacial layer underneath the high-k dielectric. As a result, the equivalent oxide thickness (EOT) of the total gate dielectric is reduced and the field effect transistor maintains a constant threshold voltage even after high temperature processes during CMOS integration.

Owner:GLOBALFOUNDRIES US INC

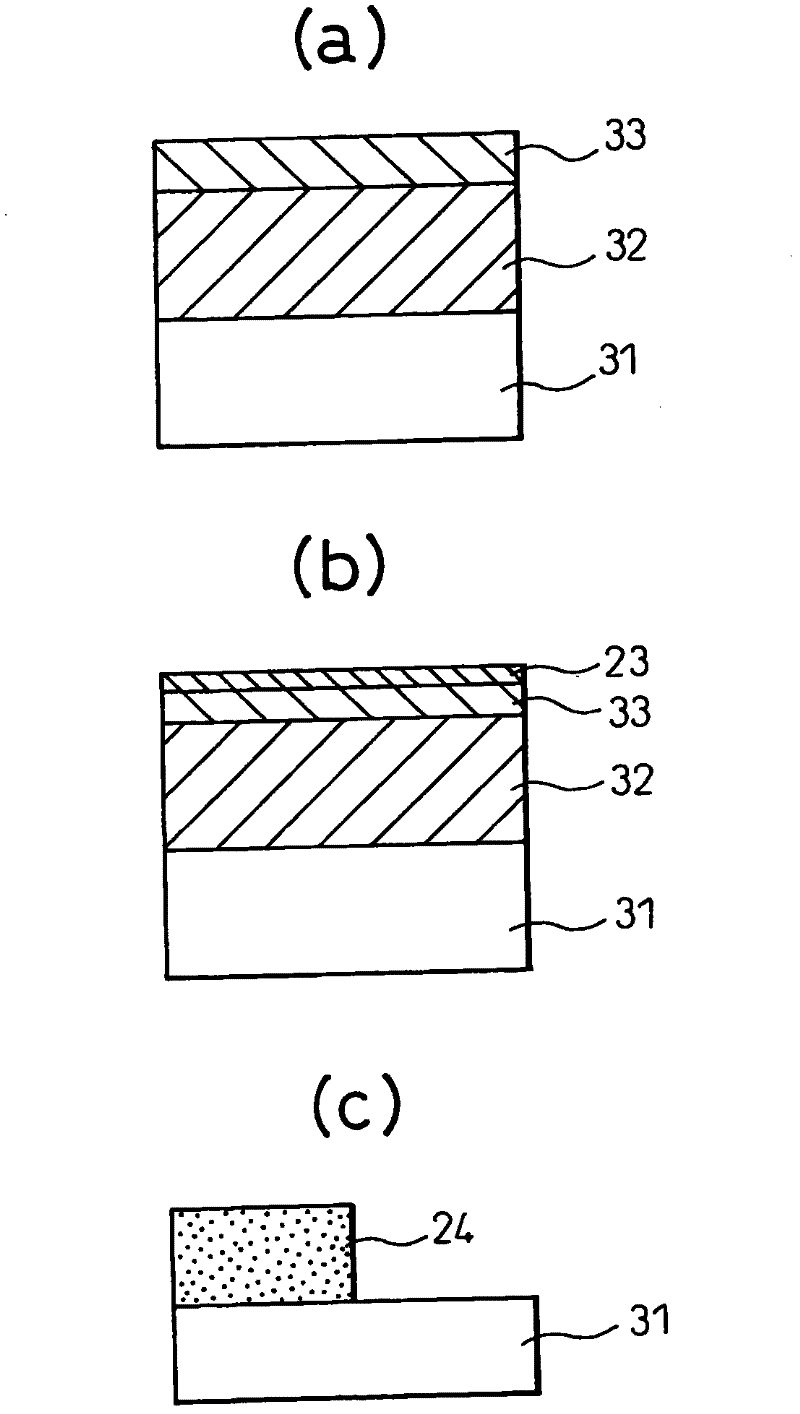

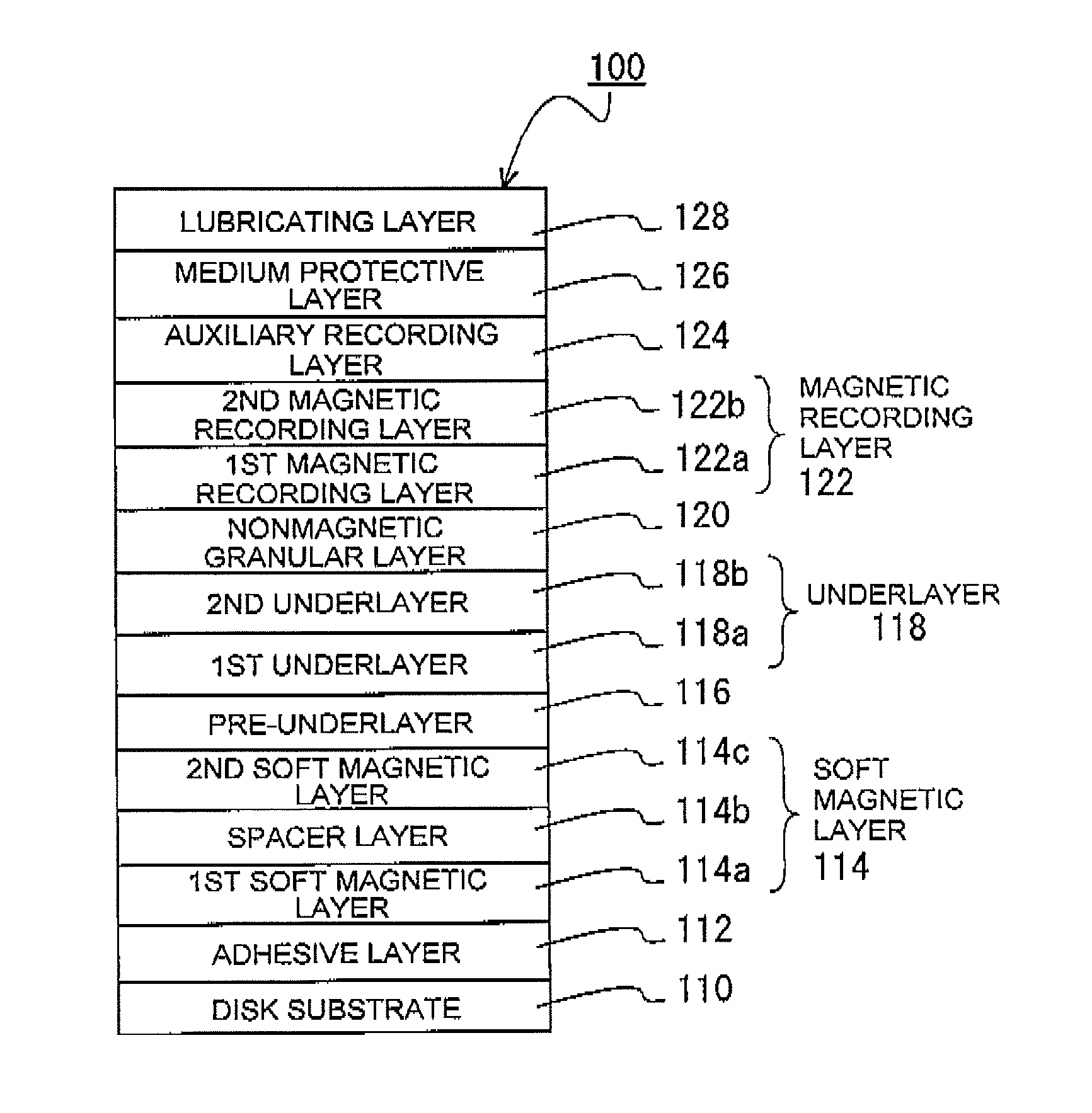

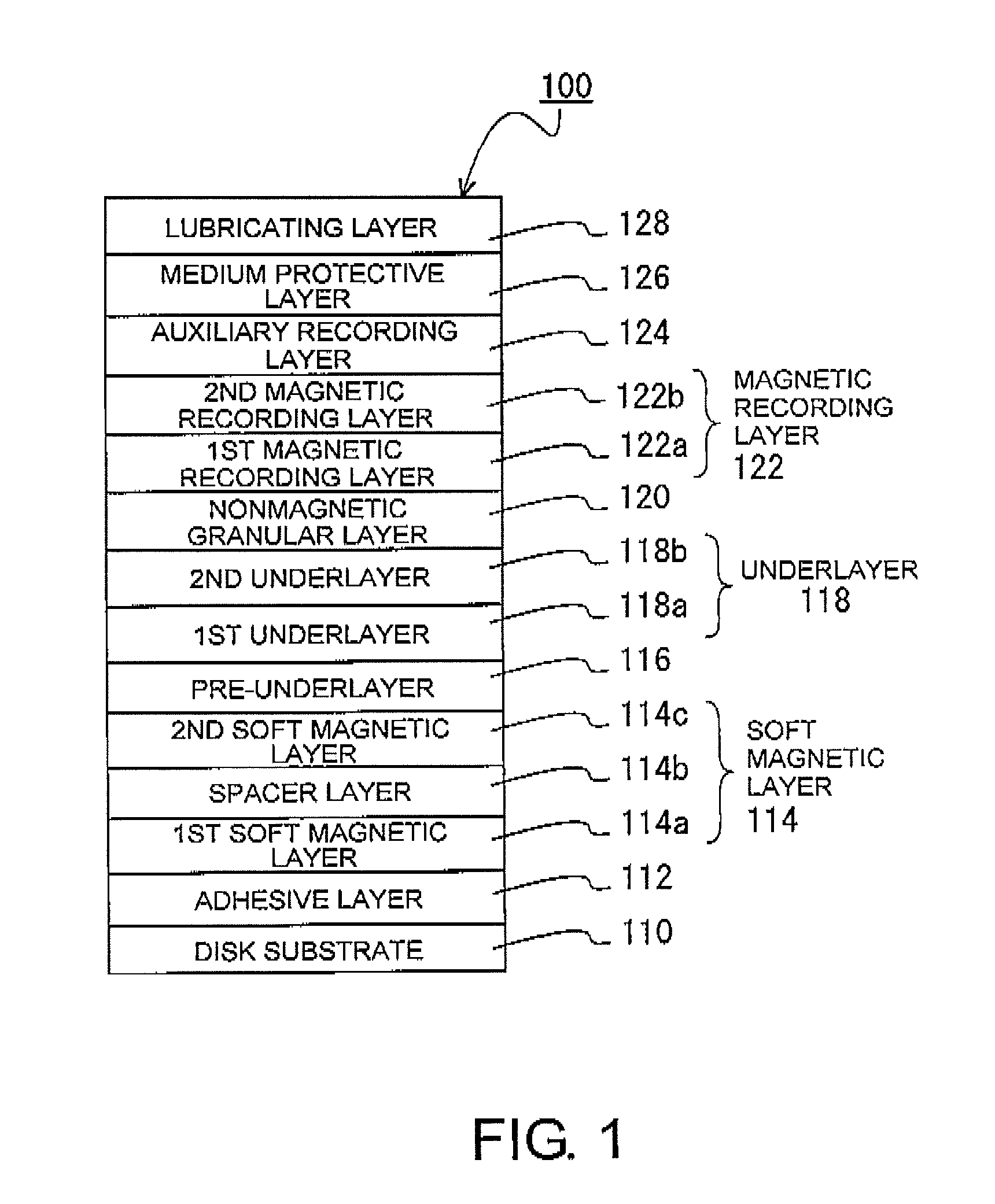

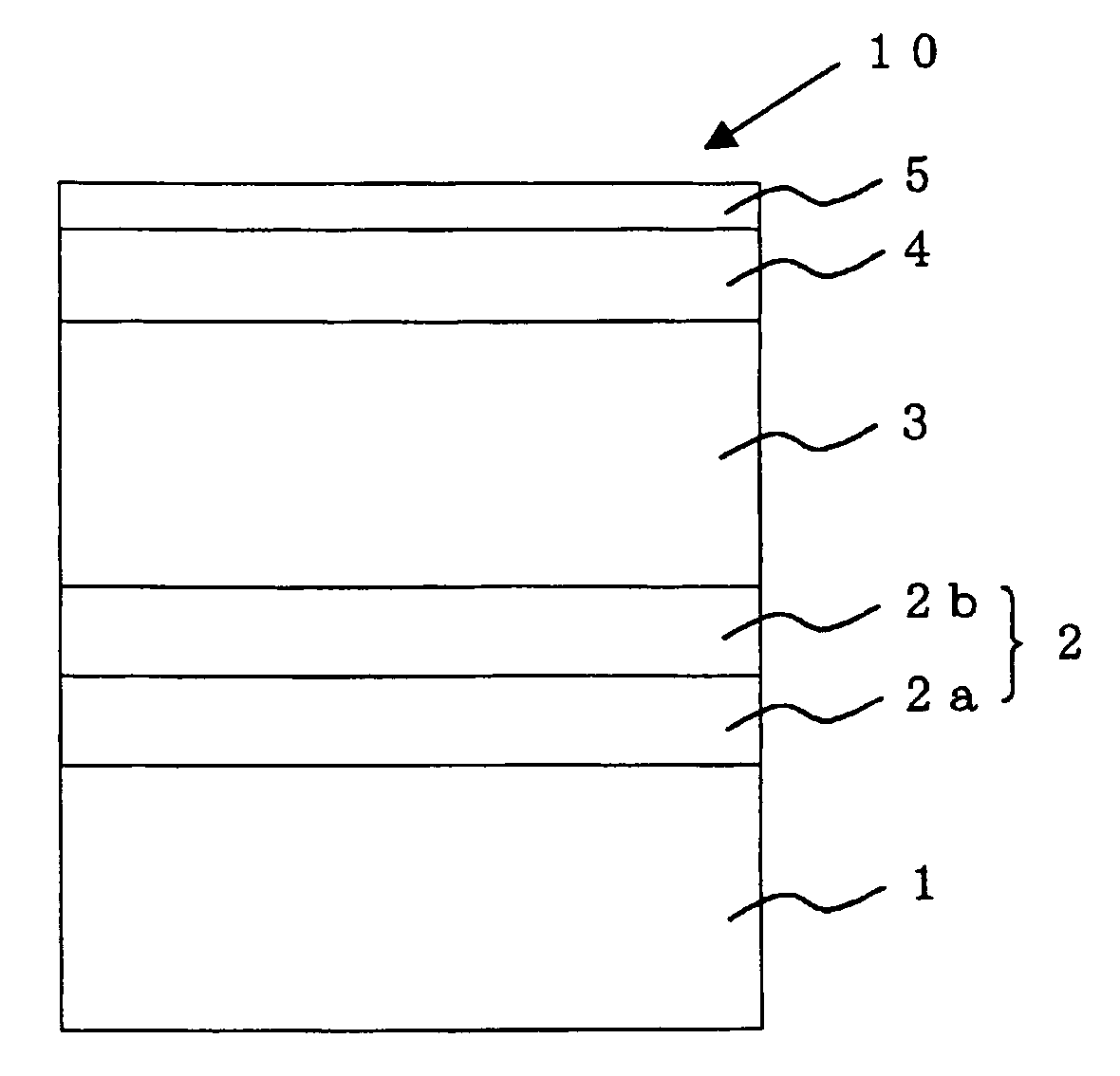

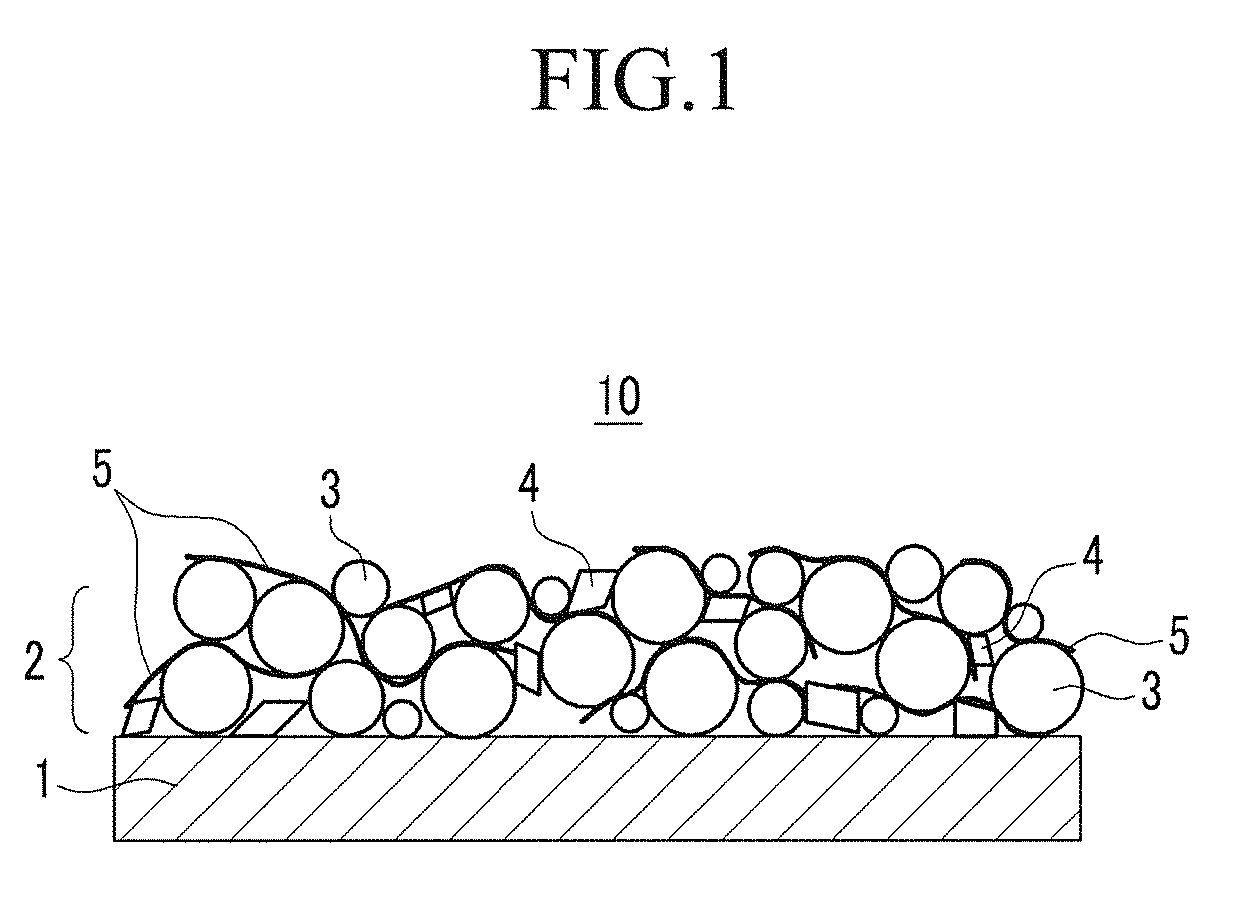

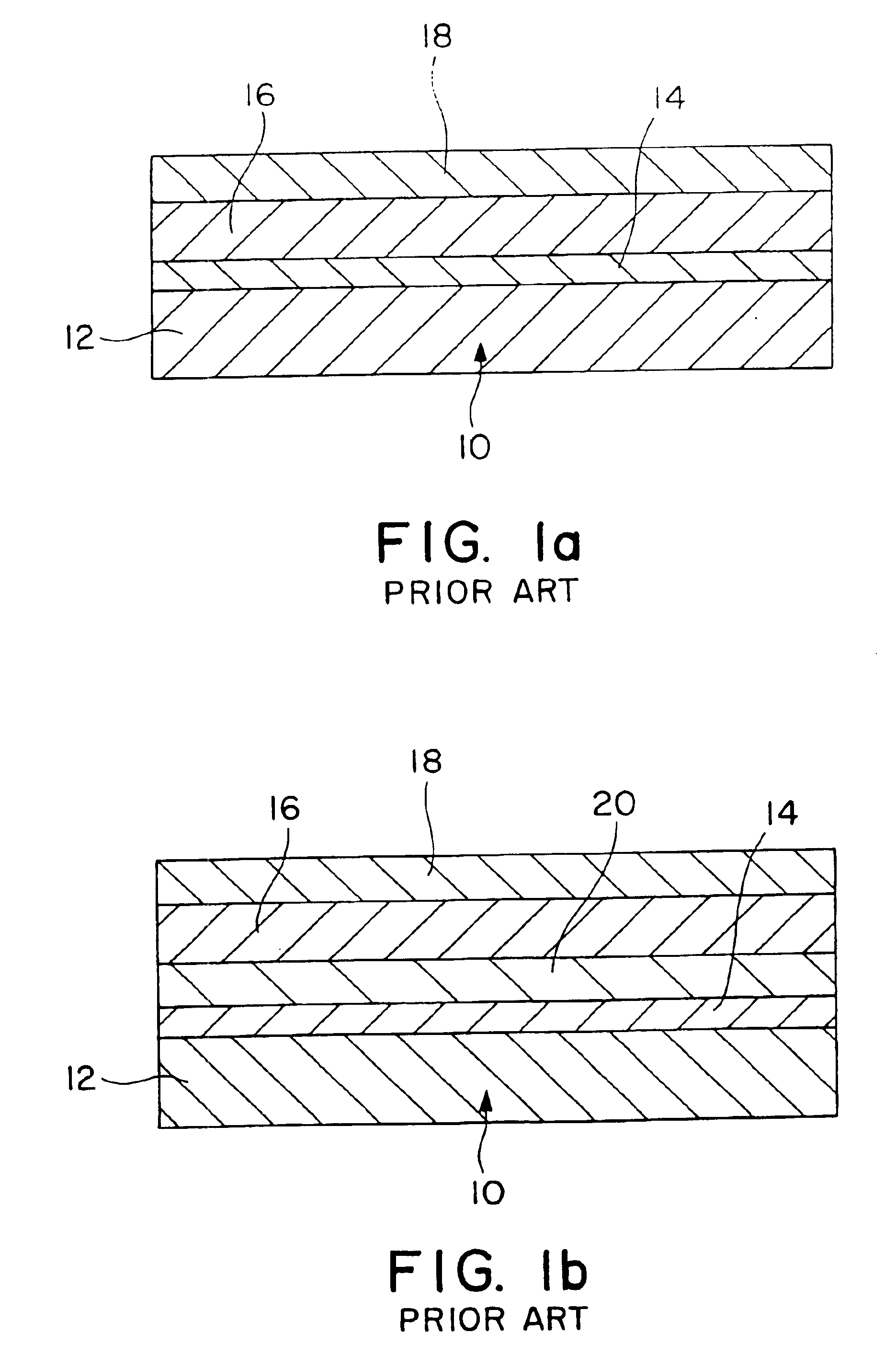

Perpendicular magnetic recording medium and method of manufacturing the same

InactiveUS8404370B2Improve signal-to-noise ratioImprove recording densityCellsVacuum evaporation coatingGibbs free energyFree energies

A perpendicular magnetic recording medium 100 has, over a substrate, at least a magnetic recording layer 122 with a granular structure in which nonmagnetic grain boundaries are formed between magnetic grains continuously grown into a columnar shape. The magnetic grains of the magnetic recording layer 122 contain Co, Cr, and Pt. The magnetic recording layer 122 contains at least one oxide selected from a group A including SiO2, TiO2, and Cr2O3, at least one oxide selected from a group B consisting of oxides each having a larger Gibbs free energy ΔG than the group A, and a reducing agent adapted to reduce the oxides of the group B.

Owner:WD MEDIA SINGAPORE PTE

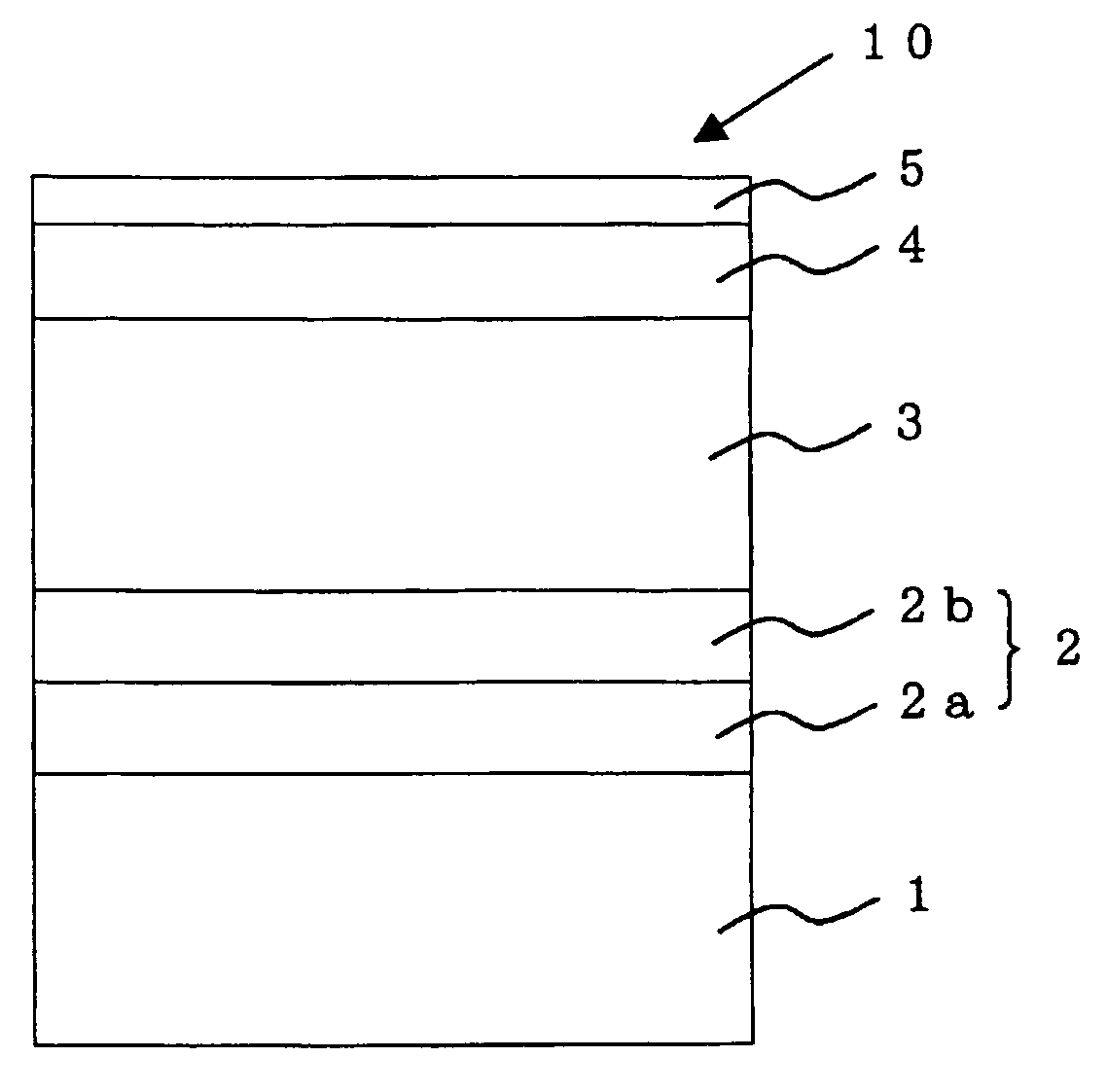

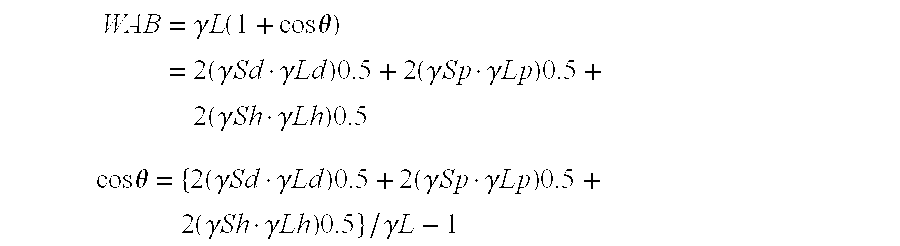

Magnetic disk and manufacturing method thereof

InactiveUS7722968B2Improve securityEfficient preparationProtective coatings for layersRecord information storageHydrogenFree energies

In a magnetic disk having a magnetic layer, a protection layer, and a lubrication layer formed on a substrate in this order, a surface free energy γS of a surface of the magnetic disk derived by an extended Fowkes equation is greater than 0 and no greater than 24 mN / m. γSd (dispersion force component of surface free energy) forming the surface free energy γS is greater than 0 and no greater than 17 mN / m, γSp (dipole component of surface free energy) forming the surface free energy γS is greater than 0 and no greater than 1 mN / m, and γSh (hydrogen bonding force component of surface free energy) forming the surface free energy γS is greater than 0 and no greater than 6 mN / m.

Owner:WD MEDIA SINGAPORE PTE

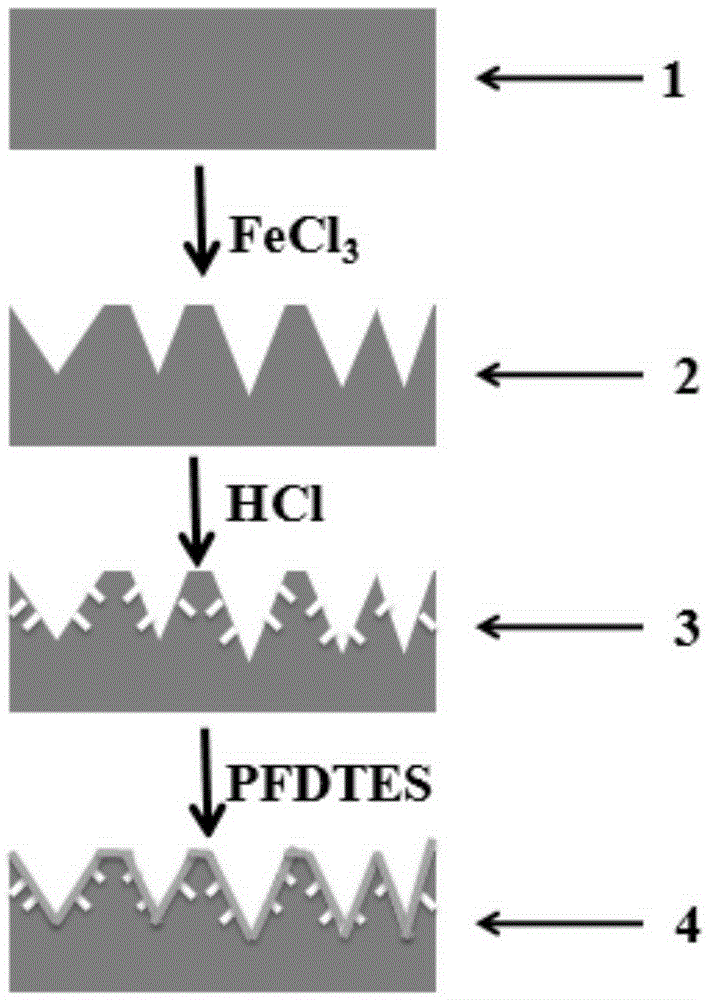

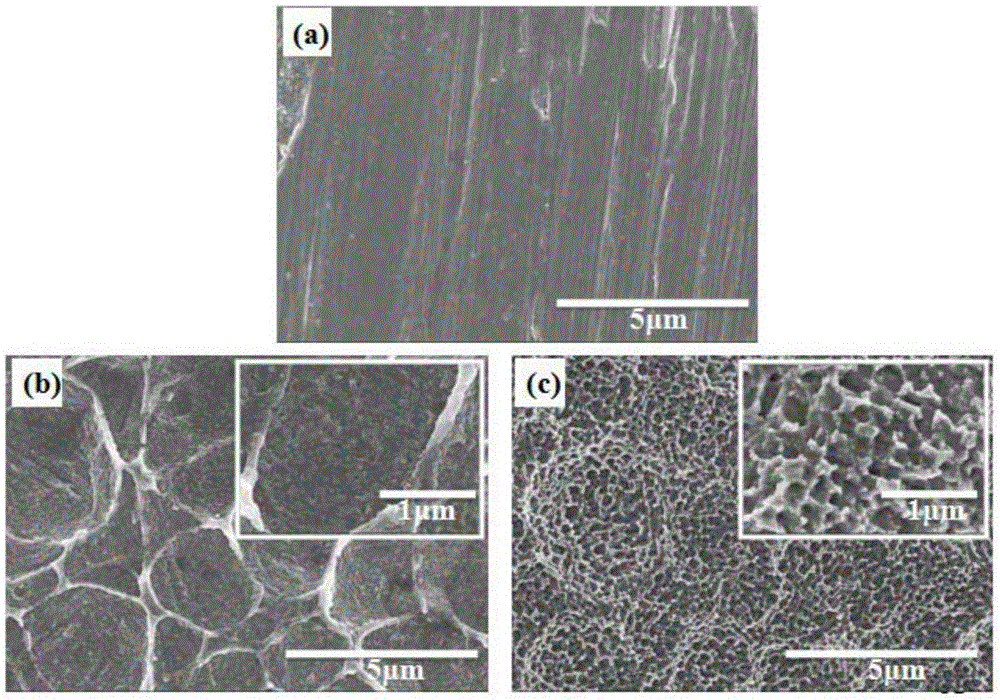

Preparation method for super-hydrophobic surface with bionic micro-nano composite structure

InactiveCN105413994AExcellent surface superhydrophobicityLow costPretreated surfacesSpecial surfacesMicro nanoElectrochemical response

The invention belongs to the technical field of preparation of super-hydrophobic surfaces, and relates to a preparation method for a super-hydrophobic surface with a bionic micro-nano composite structure. From the angle of the super-hydrophobic surface, the super-hydrophobic surface is prepared by virtue of a mesoscale two-step etching method; etching treatment is carried out on a substrate surface twice; a micro-nano composite structure similar to a lotus leaf surface is constructed by utilizing a chemical or an electrochemical reaction etching substrate, and surface modification is carried out by virtue of a surface modifier to reduce surface free energy. The size of the micro-nano structure can be controlled by virtue of reaction time, a reaction temperature and concentration. A contact angle, on the surface of the micro-nano composite structure, of water drops is as high as 170 degrees while a rolling angle of the water drops is smaller than 5 degrees. According to electrochemical test results, corrosion resistance of a super-hydrophobic stainless steel sheet is 22 times that of common stainless steel. The method provided by the invention does not need special equipment, is low in cost, good in stability, excellent in super-hydrophobic property, good in corrosion resistance and can be applied to metal corrosion-resistant protection.

Owner:DALIAN UNIV OF TECH

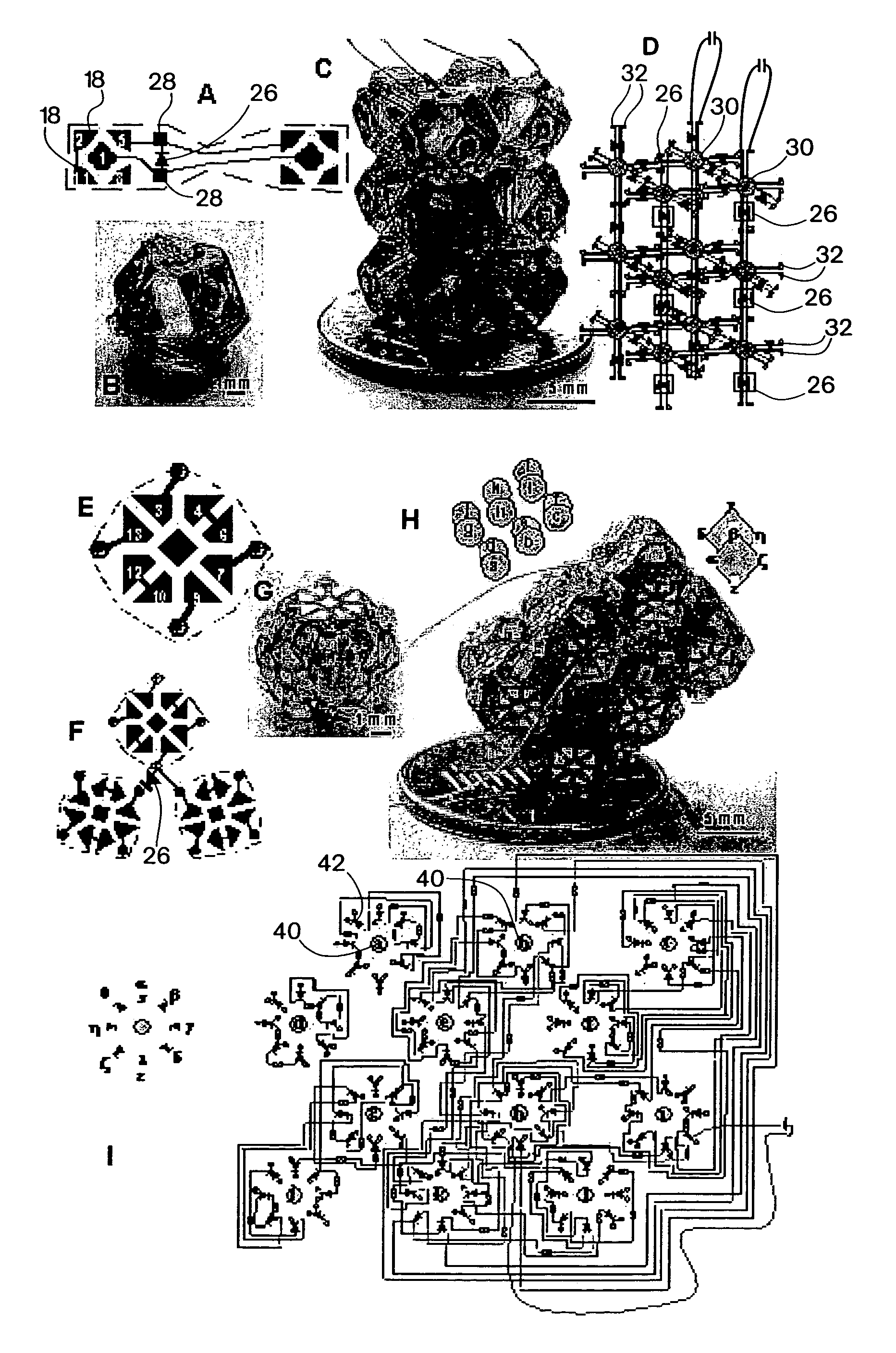

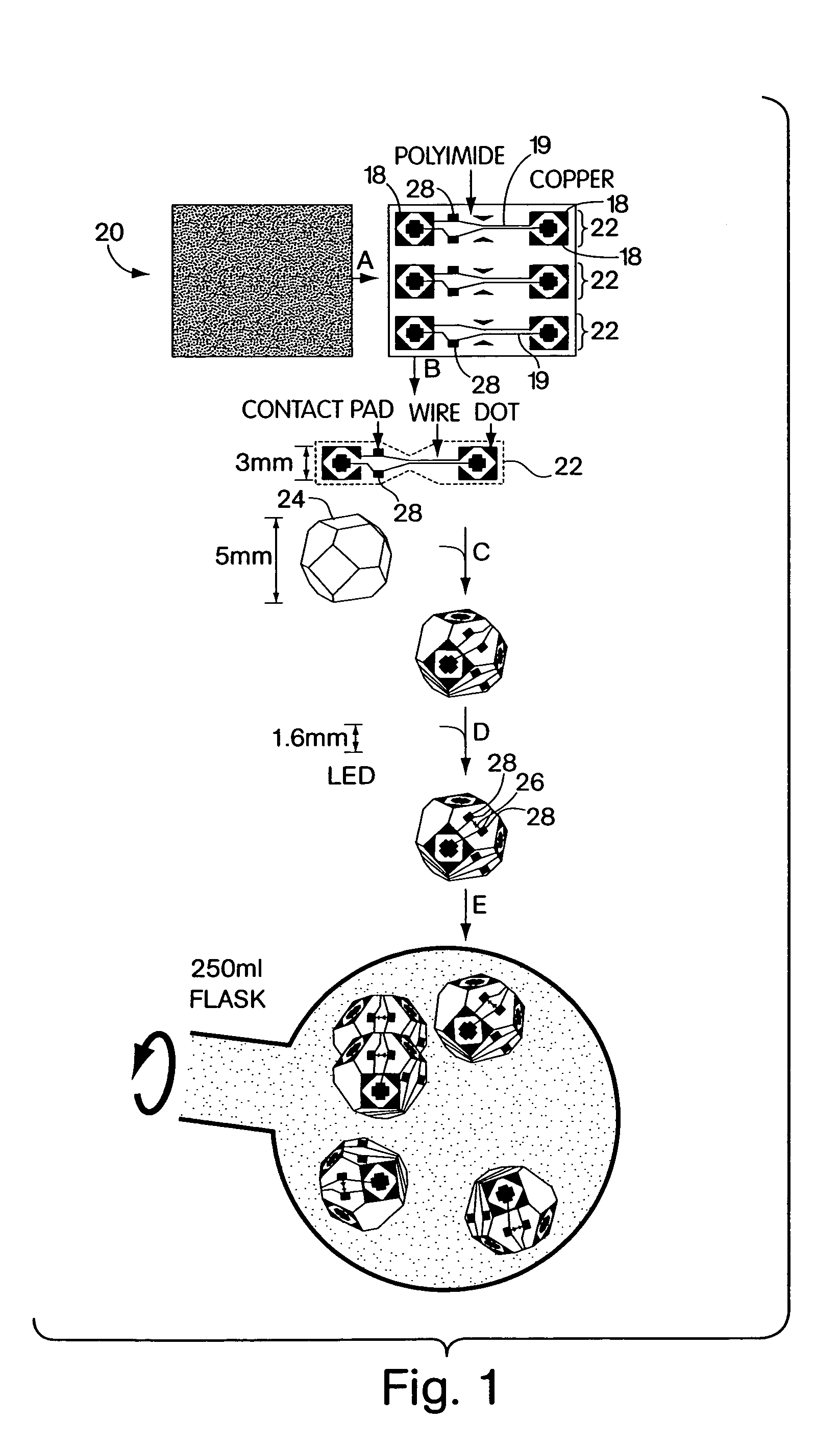

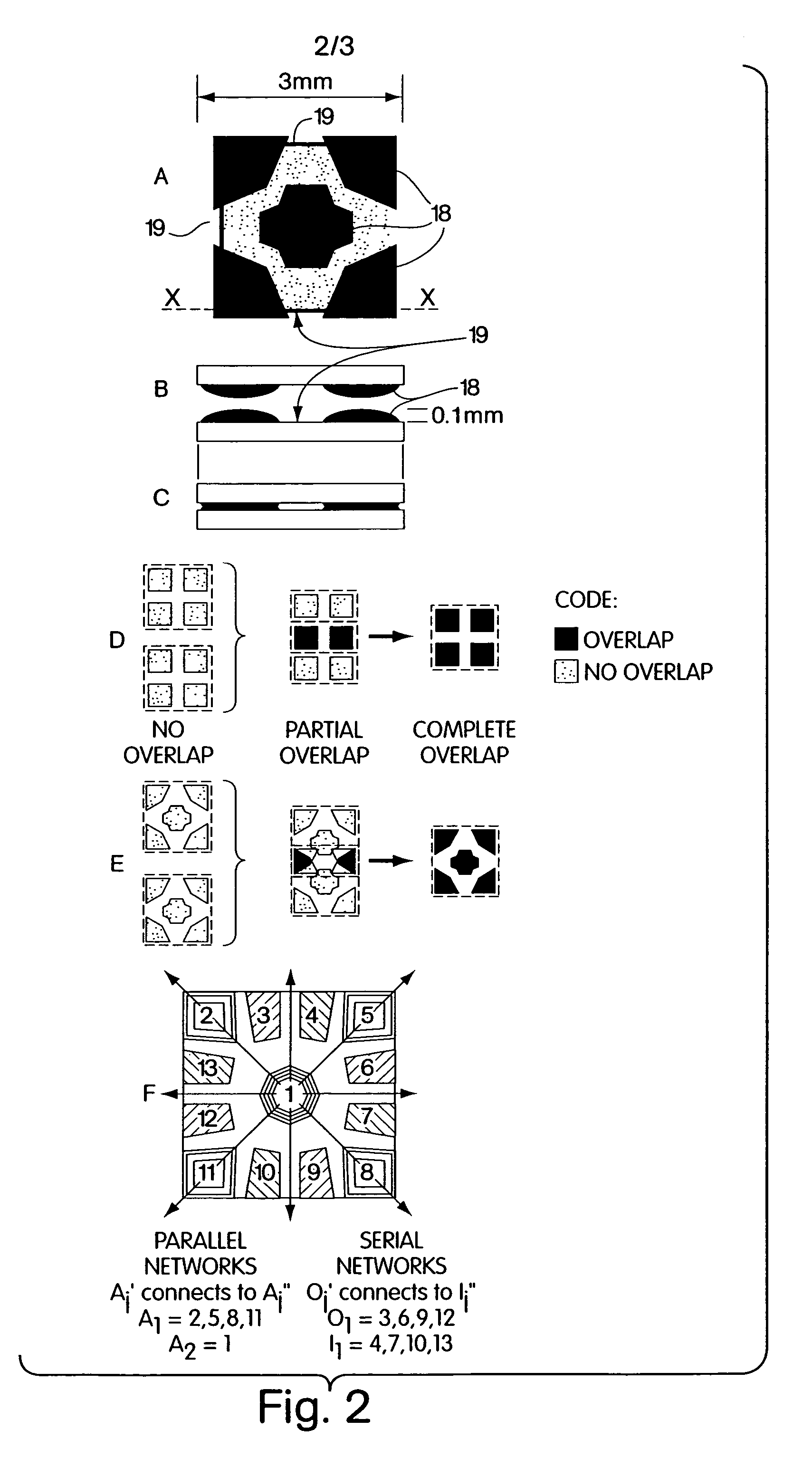

Self-assembled electrical networks

Techniques for self assembly of macro-scale objects, optionally defining electrical circuitry, are described, as well as articles formed by self assembly. Components can be joined, during self-assembly by minimization of free energy, capillary attraction, or a combination.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

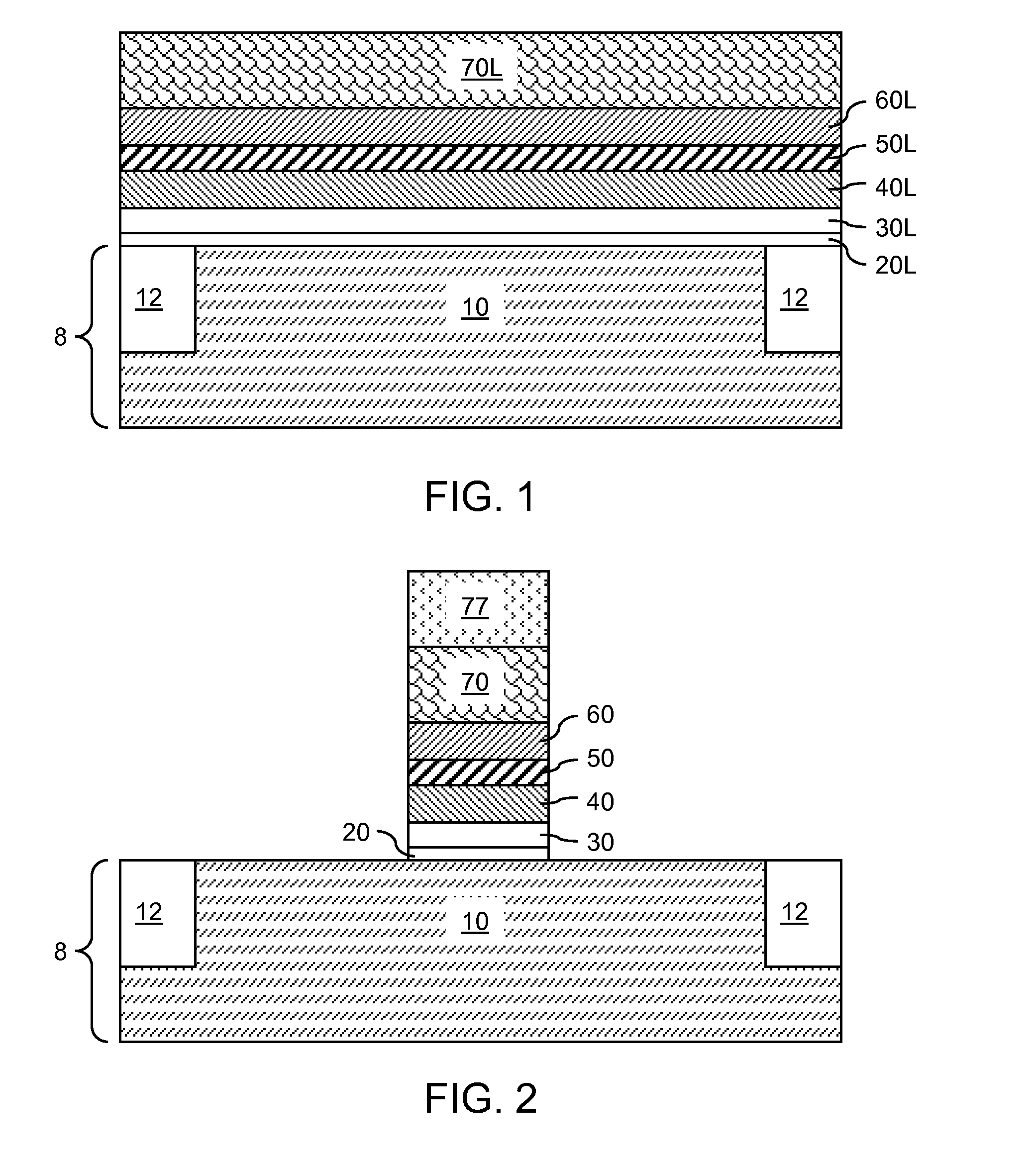

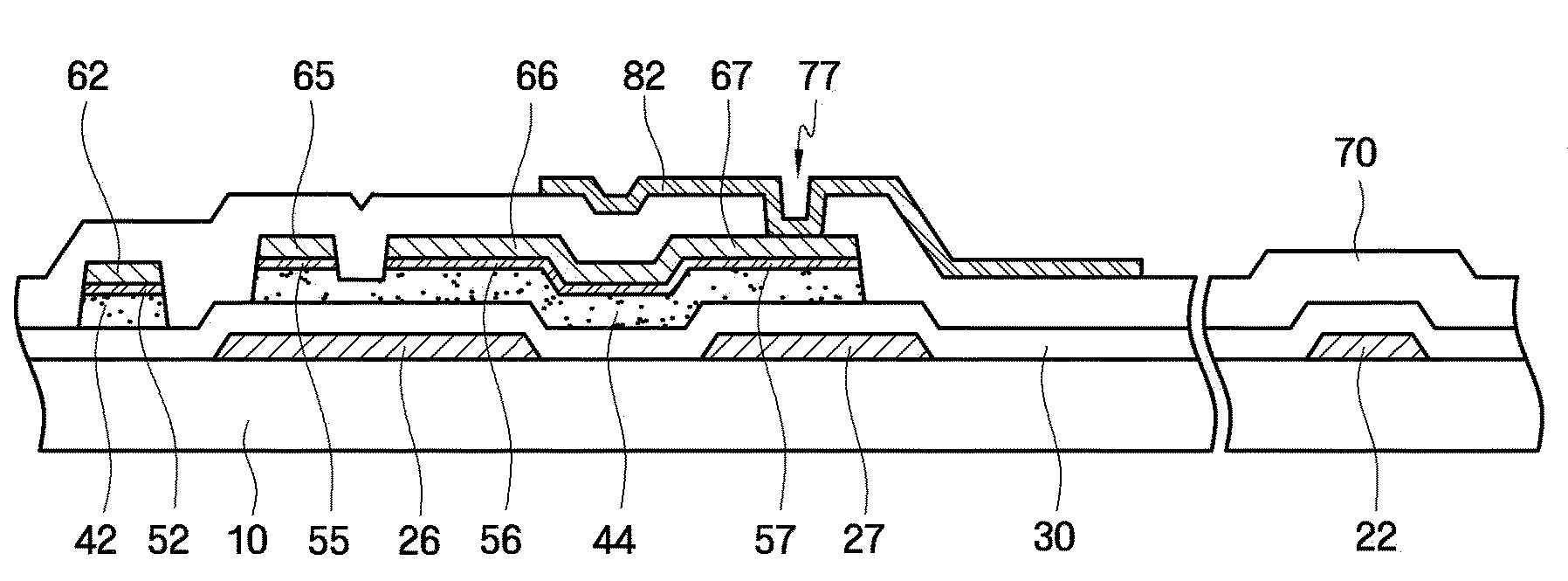

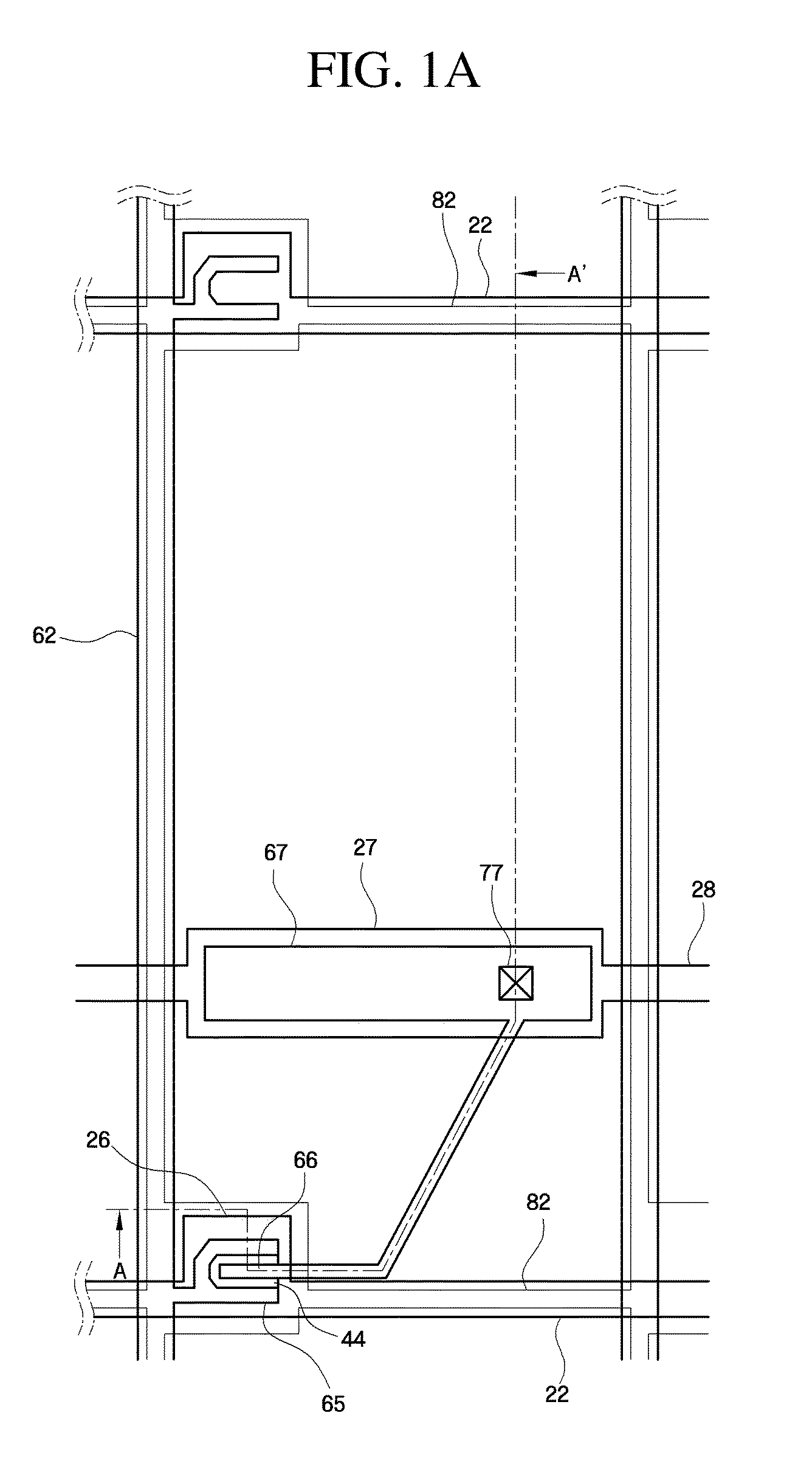

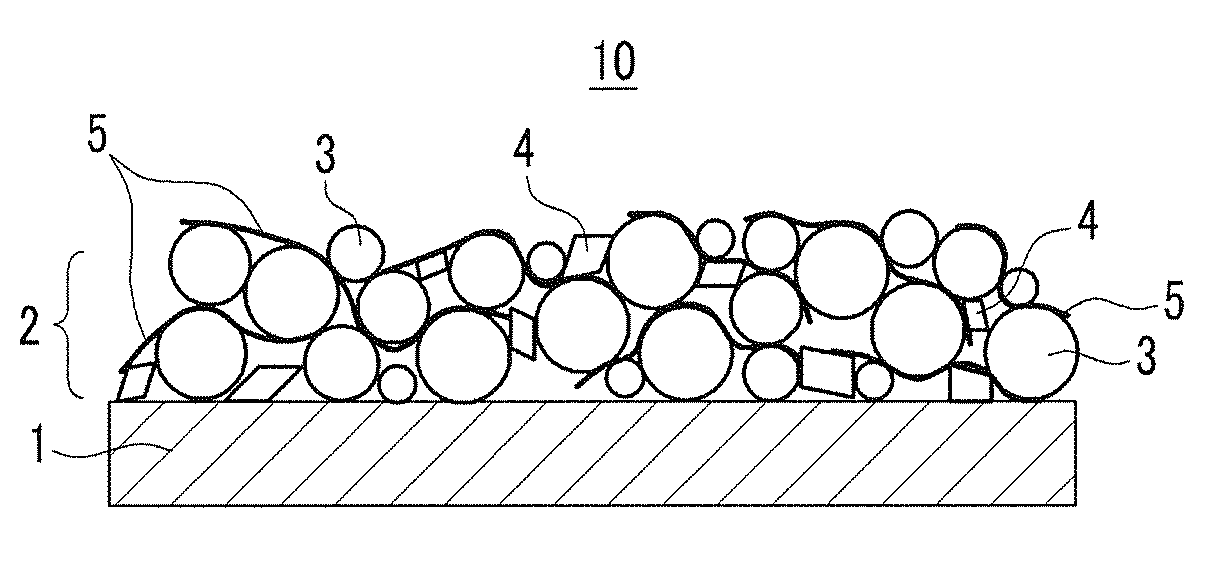

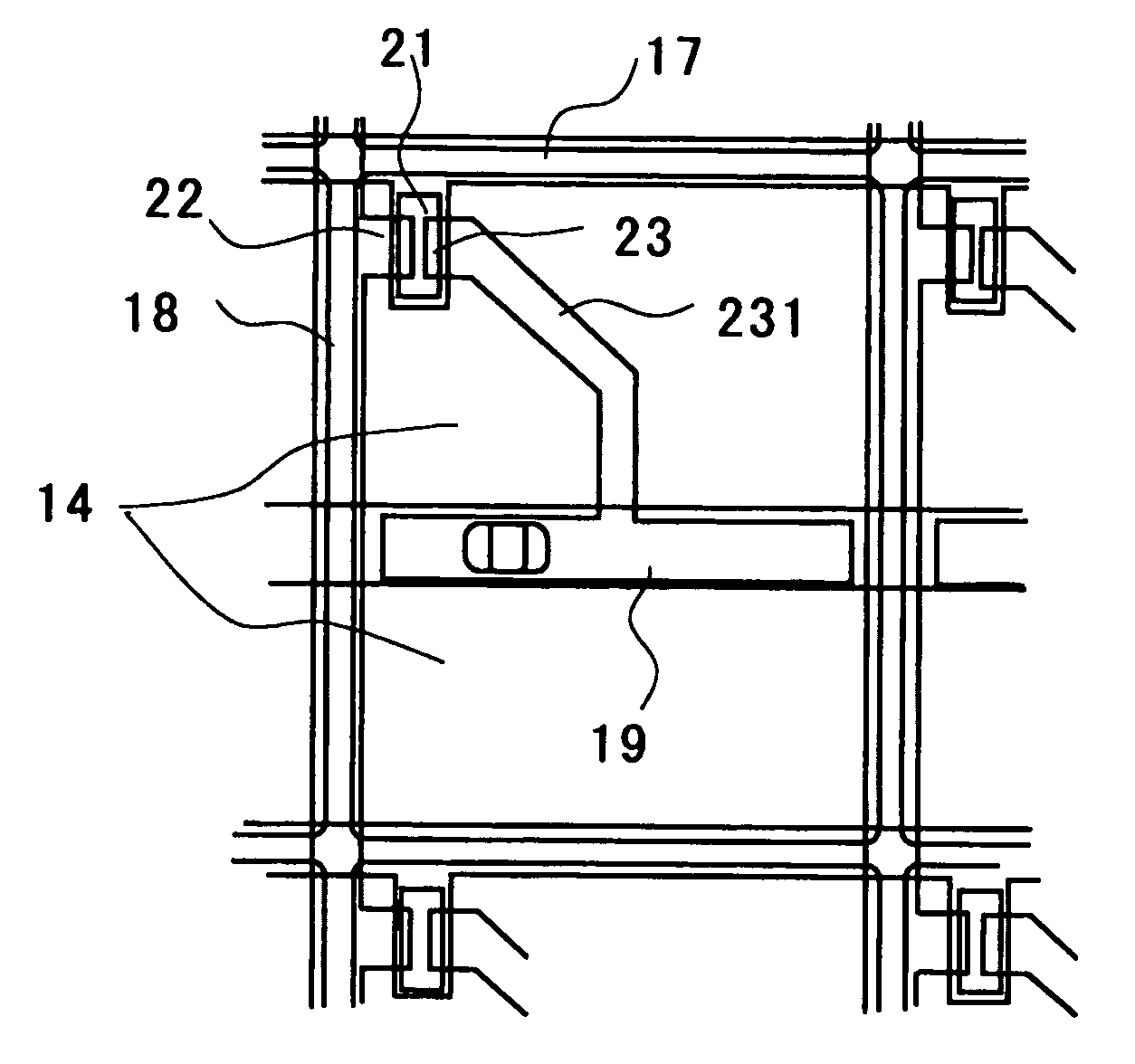

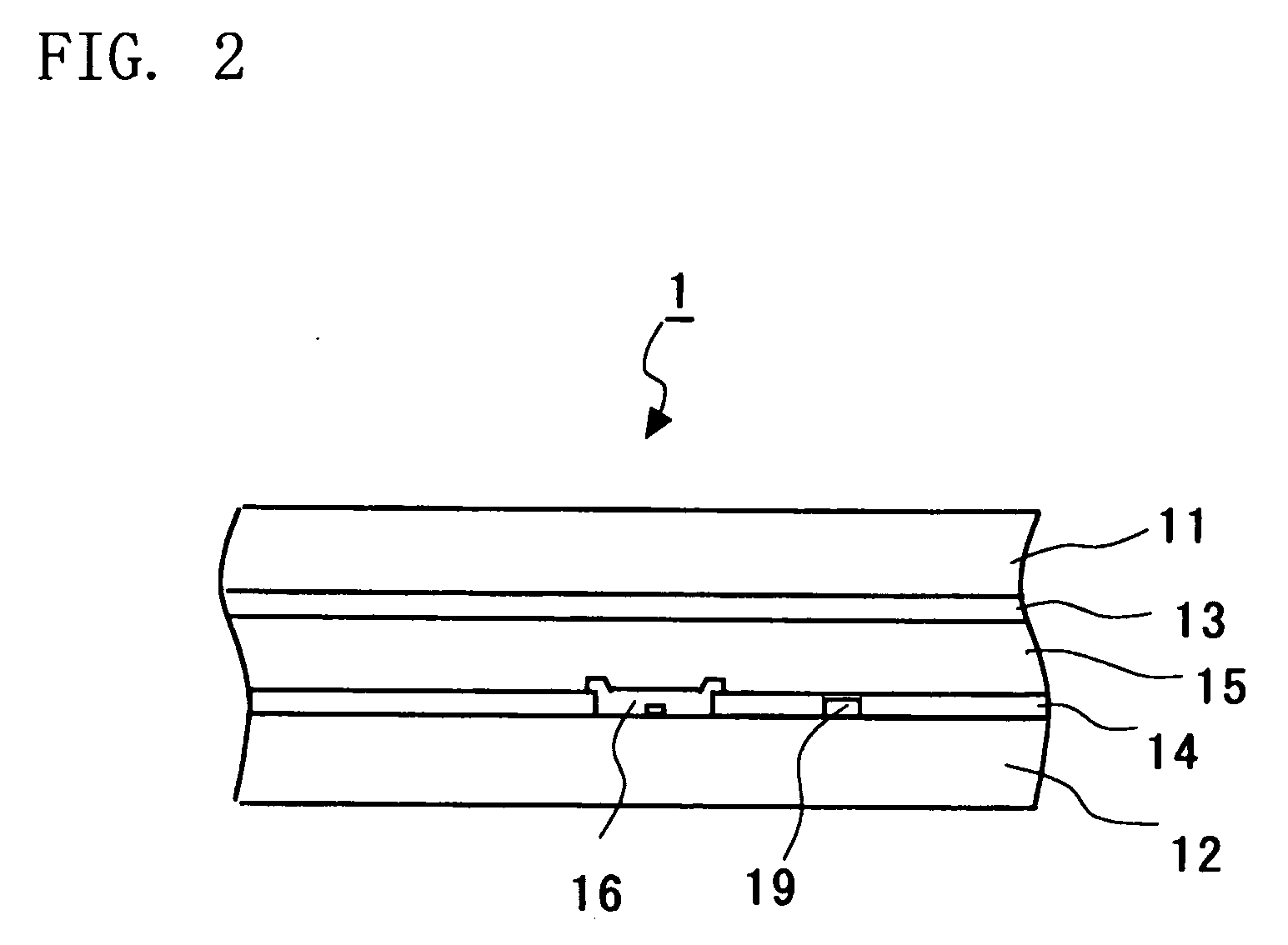

Thin-film transistor substrate and method of fabricating the same

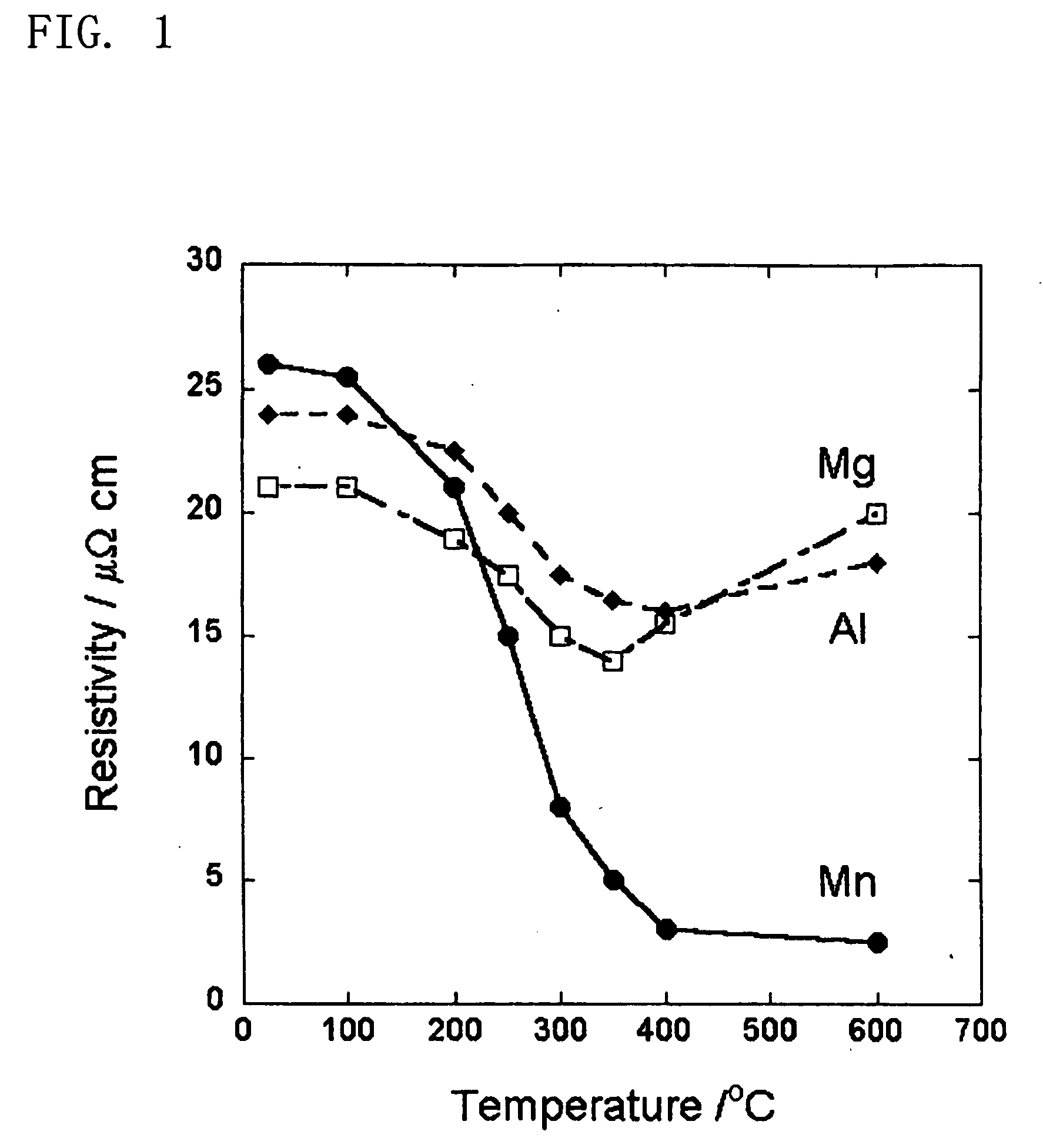

ActiveUS20100148169A1Improve electrical performanceReduce bad appearanceTransistorSolid-state devicesFree energiesGibbs free energy

A thin-film transistor (TFT) substrate has improved electrical properties and reduced appearance defects and a method of fabricating the TFT substrate, are provided. The TFT substrate includes: gate wiring which is formed on a surface of an insulating substrate; oxide active layer patterns which are formed on the gate wiring and include an oxide of a first material; buffer layer patterns which are disposed on the oxide active layer patterns to directly contact the oxide active layer patterns and include a second material; and data wiring which is formed on the buffer layer patterns to insulatedly cross the gate wiring, wherein a Gibbs free energy of the oxide of the first material is lower than a Gibbs free energy of an oxide of the second material.

Owner:SAMSUNG DISPLAY CO LTD

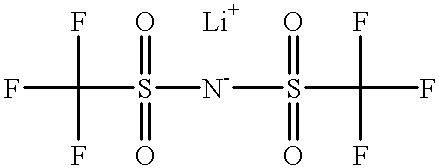

Negative active material for rechargeable lithium battery, and method of preparing the same

ActiveUS20090075173A1High initial capacityImprove initial efficiencyMaterial nanotechnologyElectrode thermal treatmentFree energiesEngineering

An negative active material for a rechargeable lithium battery includes a nano-composite including a Si phase, a SiO2 phase, and a metal oxide phase of formulation MyO, where M is a metal with an oxidation number x, a free energy of oxygen-bond formation ranging from −900 kJ / mol to −2000 kJ / mol, x, and x·y=2. The negative active material for a rechargeable lithium battery according to the present invention can improve initial capacity, initial efficiency, and cycle-life characteristics by suppressing its initial irreversible reaction.

Owner:SAMSUNG SDI CO LTD +1

Magnetic element with improved out-of-plane anisotropy for spintronic applications

ActiveUS9006704B2Enhanced interfacial perpendicular anisotropyImprove thermal stabilityNanostructure applicationMagnetic-field-controlled resistorsPerpendicular anisotropyAlloy

A magnetic element is disclosed wherein first and second interfaces of a free layer with a Hk enhancing layer and tunnel barrier, respectively, produce enhanced surface perpendicular anisotropy to lower switching current or increase thermal stability in a magnetic tunnel junction (MTJ). In a MTJ with a bottom spin valve configuration where the Hk enhancing layer is an oxide, the capping layer contacting the Hk enhancing layer is selected to have a free energy of oxide formation substantially greater than that of the oxide. The free layer may be a single layer or composite comprised of an Fe rich alloy such as Co20Fe60B20. With a thin free layer, the interfacial perpendicular anisotropy may dominate the shape anisotropy to generate a magnetization perpendicular to the planes of the layers. The magnetic element may be part of a spintronic device or serve as a propagation medium in a domain wall motion device.

Owner:TAIWAN SEMICON MFG CO LTD

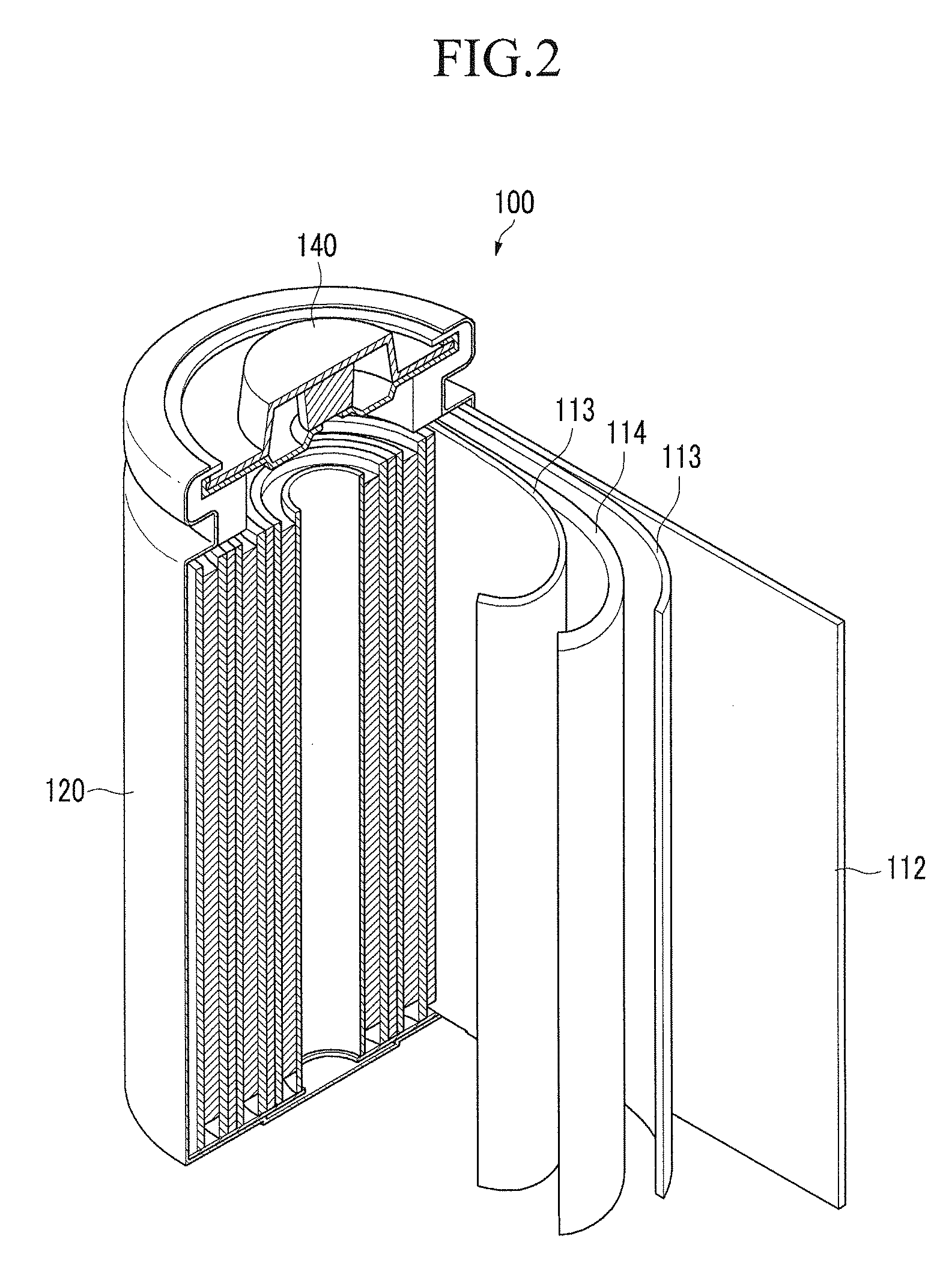

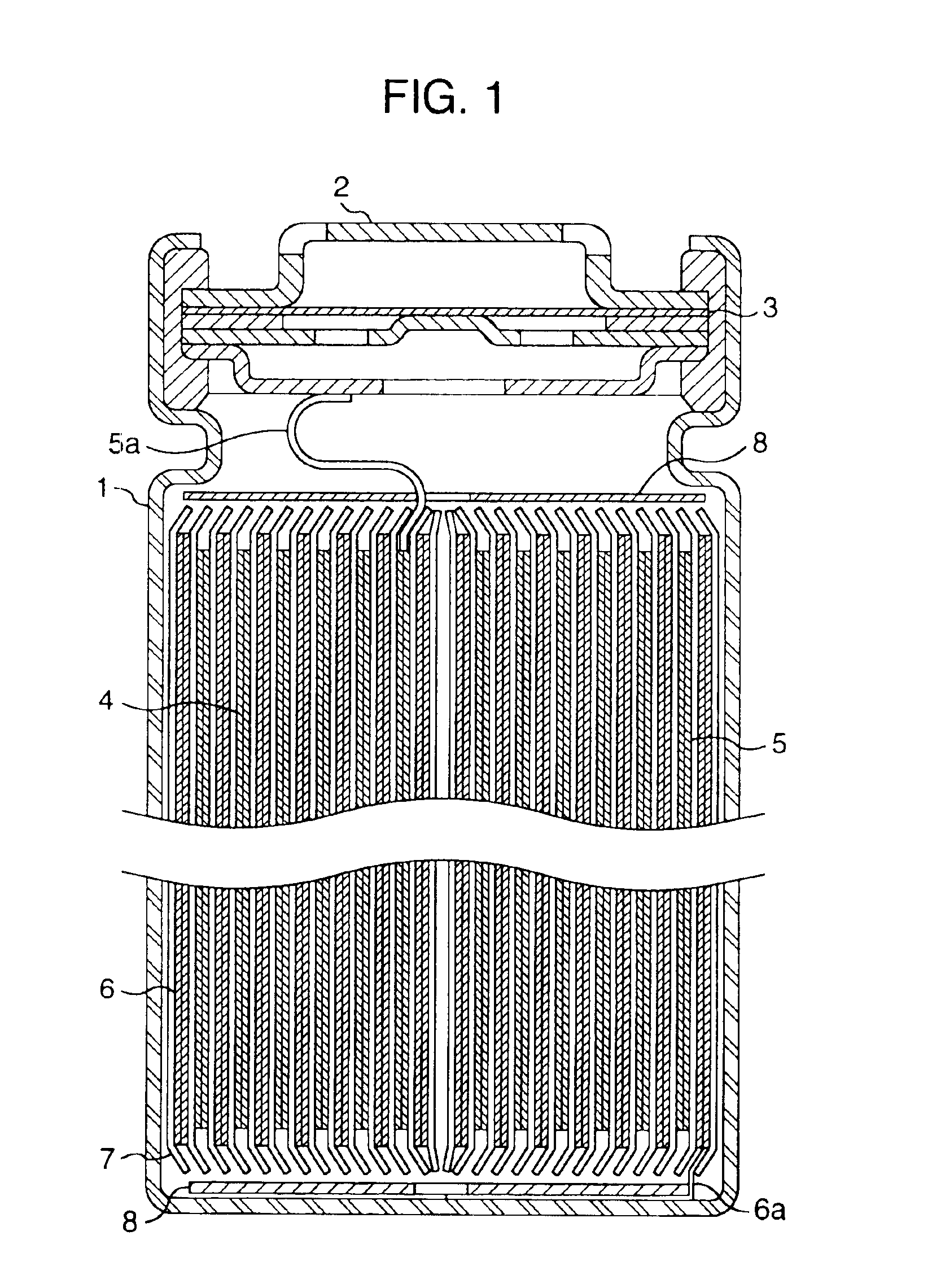

Non-aqueous electrochemical apparatus

InactiveUS6958198B2Improve featuresImprove wettabilityNon-aqueous electrolyte accumulatorsFinal product manufactureFree energiesDyne

The invention relates to a non-aqueous electrochemical apparatus in which the difference (γl−γse) between the surface tension γl of non-aqueous electrolyte and the surface free energy γse of electrode is not more than 10 dynes / cm.

Owner:PANASONIC CORP +1

Layered SOX tolerant NOX trap catalysts and methods of making and using the same

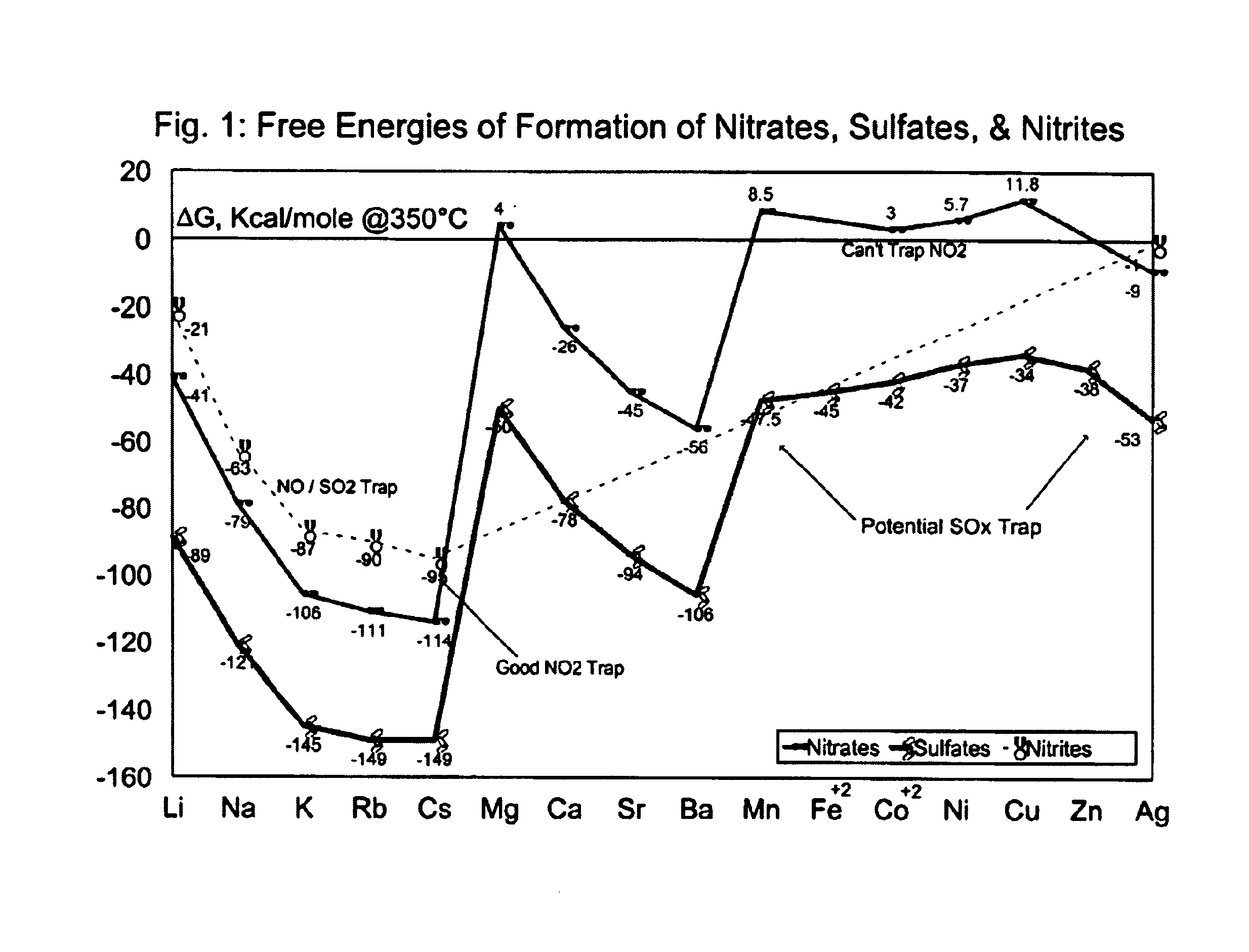

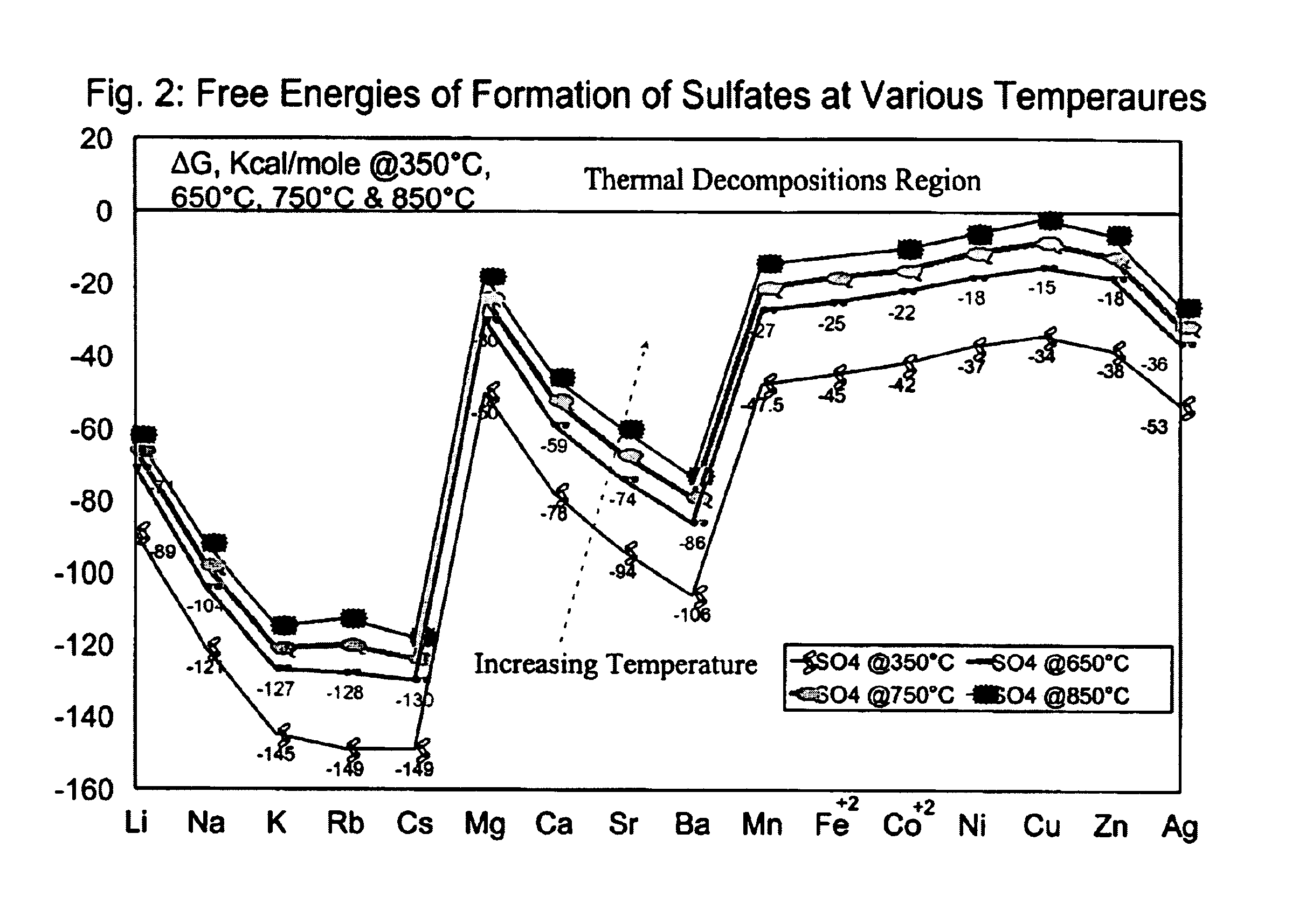

InactiveUS6923945B2Alleviates sulfur oxide poisoningMaintain long-term activityNitrogen compoundsInternal combustion piston enginesPlatinumFree energies

The present invention relates to a layered catalyst composite useful for reducing contaminants in exhaust gas streams, especially gaseous streams containing sulfur oxide contaminants. More specifically, the present invention is concerned with improved catalysts of the type generally referred to as “three-way conversion” catalysts. The layered catalysts trap sulfur oxide contaminants which tend to poison three-way conversion catalysts used to abate other pollutants in the stream. The layered catalyst composites of the present invention have a sulfur oxide absorbing layer before or above a nitrogen oxide absorbing layer. The layered catalyst composite comprises a first layer and a second layer. The first layer comprises a first support and at least one first platinum component. The second layer comprises a second support and a SOx sorbent component having a free energy of formation from about 0 to about −90 Kcal / mole at 350° C. The sulfur oxide absorbing layer selectively and reversibly absorbs sulfur oxides over nitrogen oxides and prevents or alleviates sulfur oxide poisoning of the nitrogen oxide trap.

Owner:ENGELHARD CORP

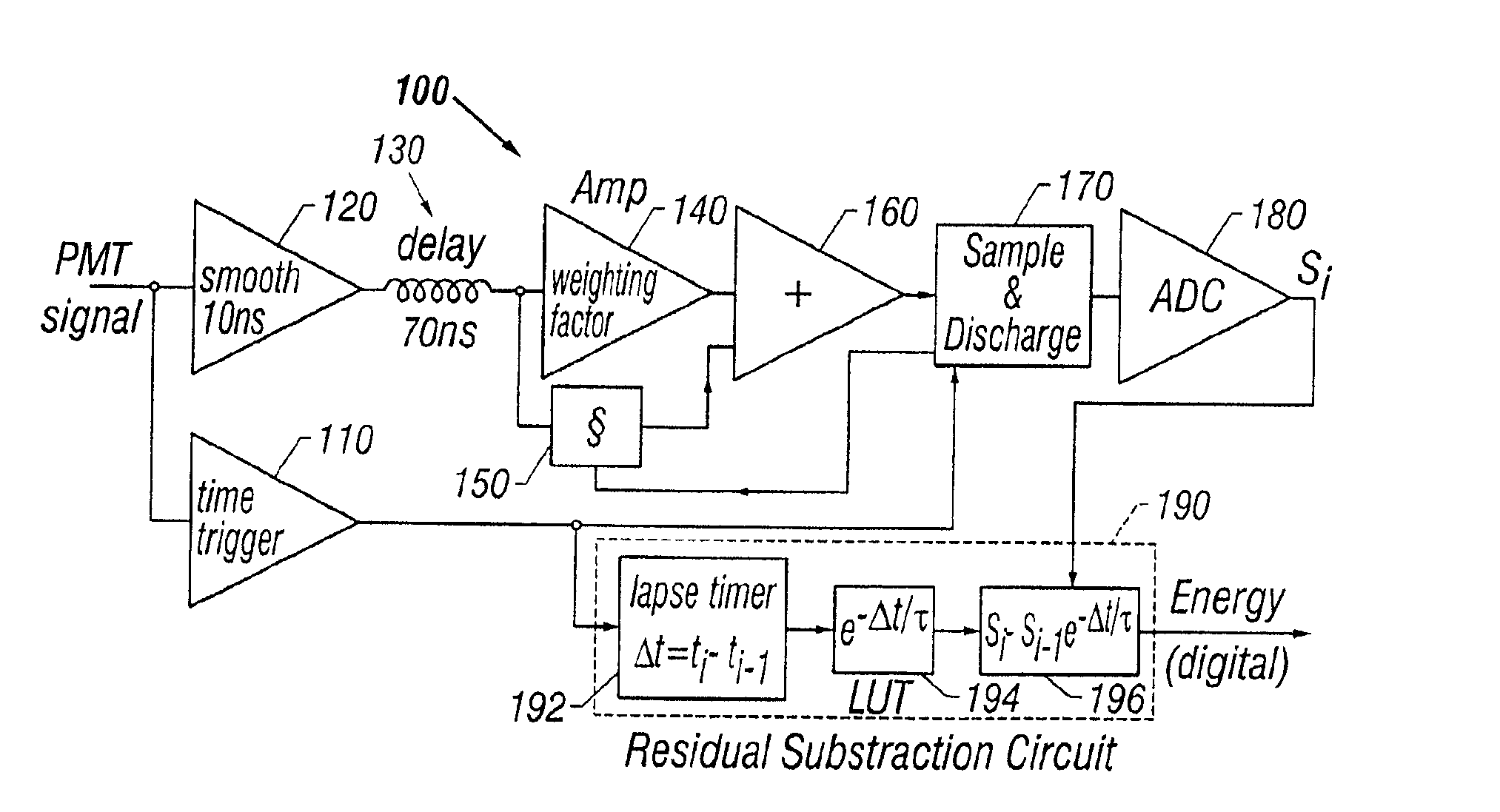

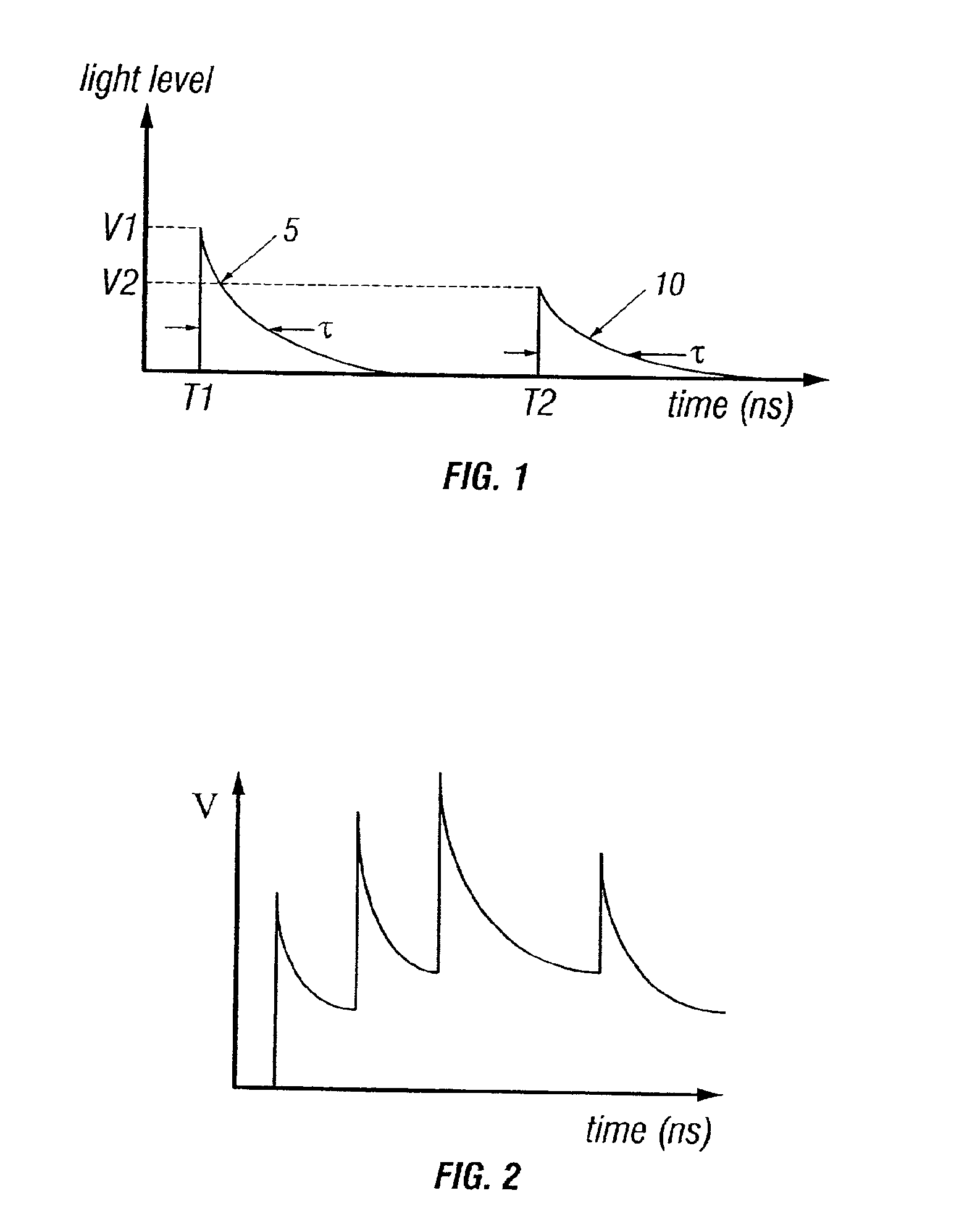

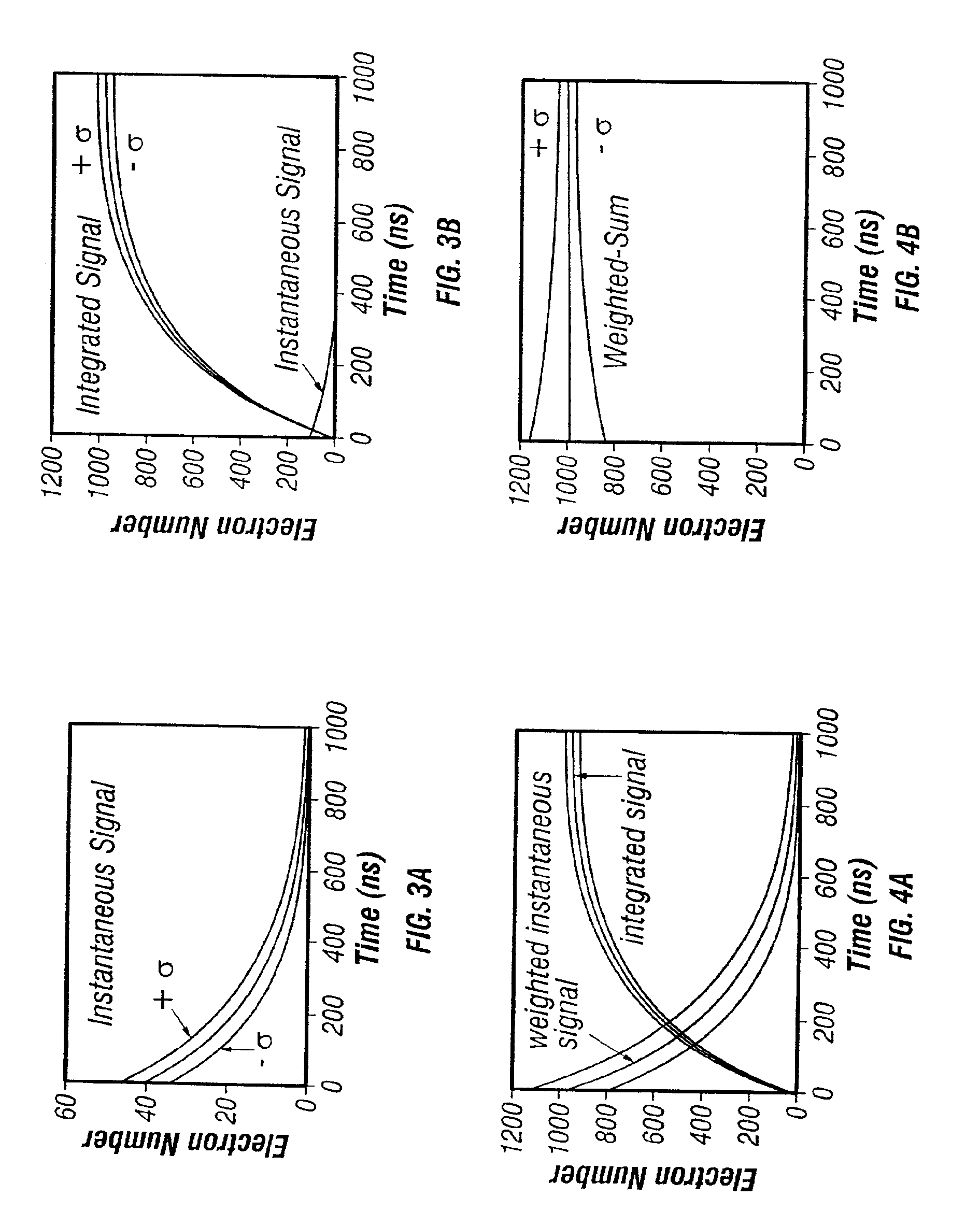

Method and apparatus to prevent signal pile-up

InactiveUS6936822B2Increase count-rate capabilityIncrease dose efficiencyMaterial analysis by optical meansTomographyFree energiesData treatment

Methods and apparatuses for obtaining position and energy information without pileup. Signal integration, which is triggered by a present event, stops when a subsequent event is detected. A weighted value for estimating the total energy in a scintillation is calculated, which includes the energy of the current event and a residual energy from previous events. Remnant correction is used to calculate a pile-up free energy from two consecutive weighted values. An analog filter may be applied to reduce noise. Dynamic digital weighting of integrated values, and / or digital integration may be used during data processing. Pileup can be avoided in conjunction with several types of applications, including multi-zone detector applications and coincidence detection applications. High-resolution timing techniques are also disclosed that facilitate one's ability to avoid pileup.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

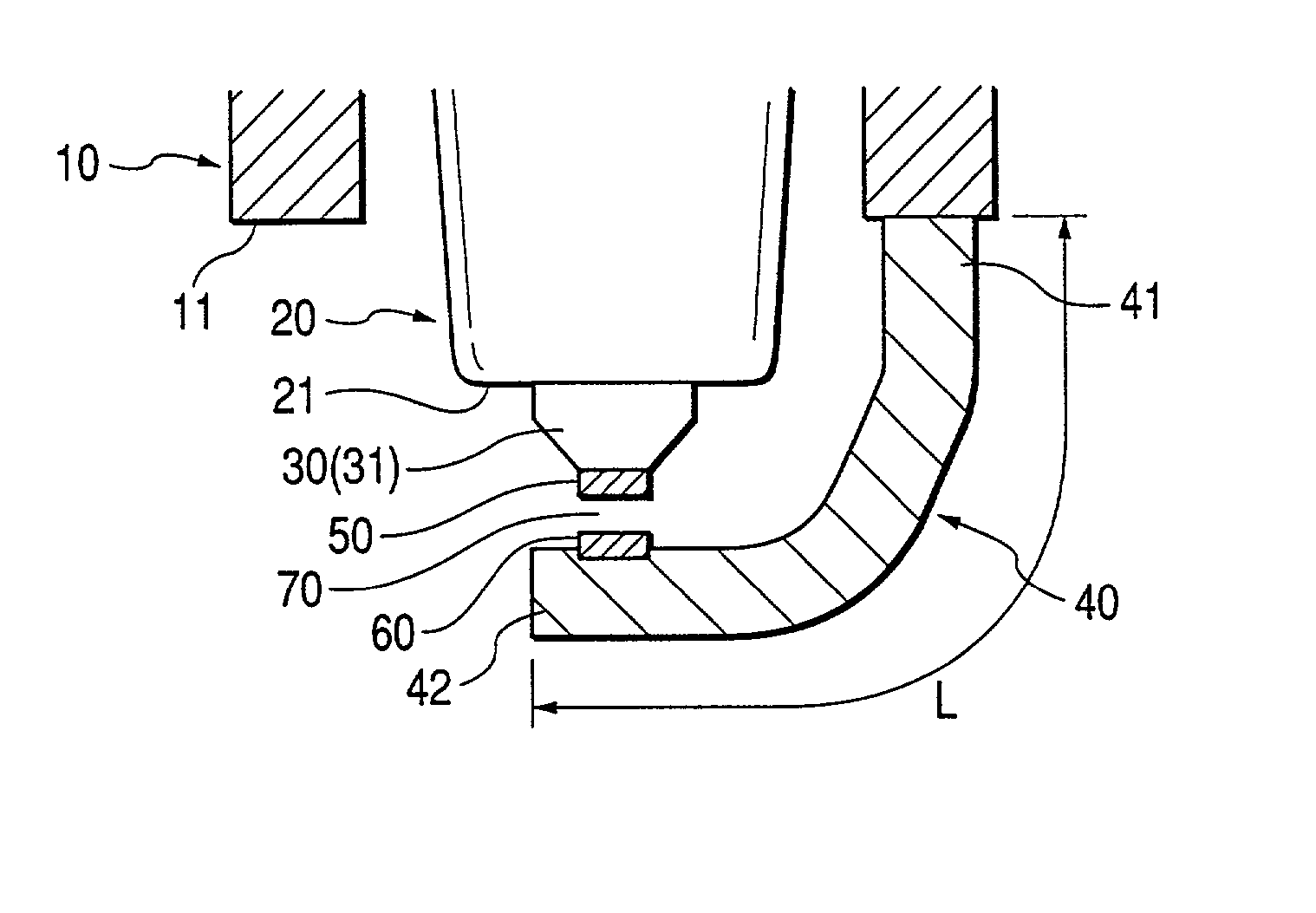

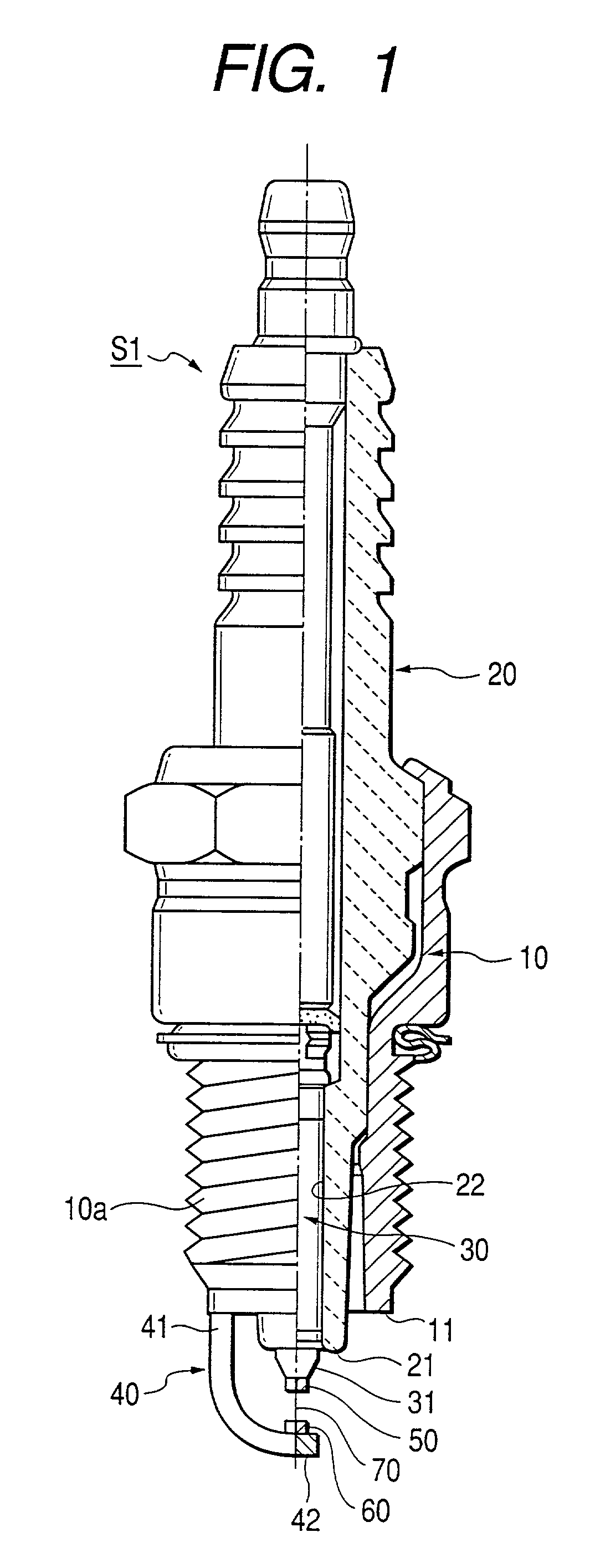

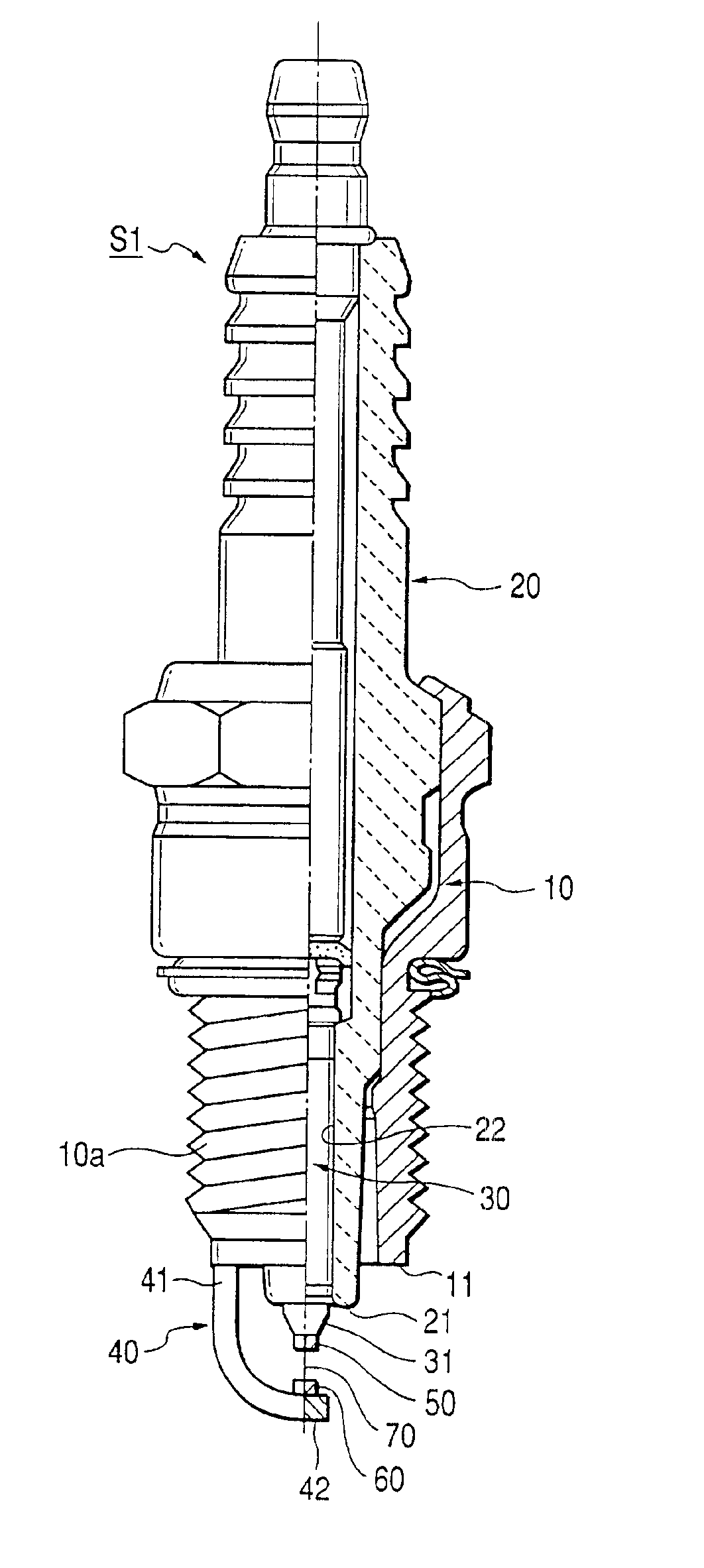

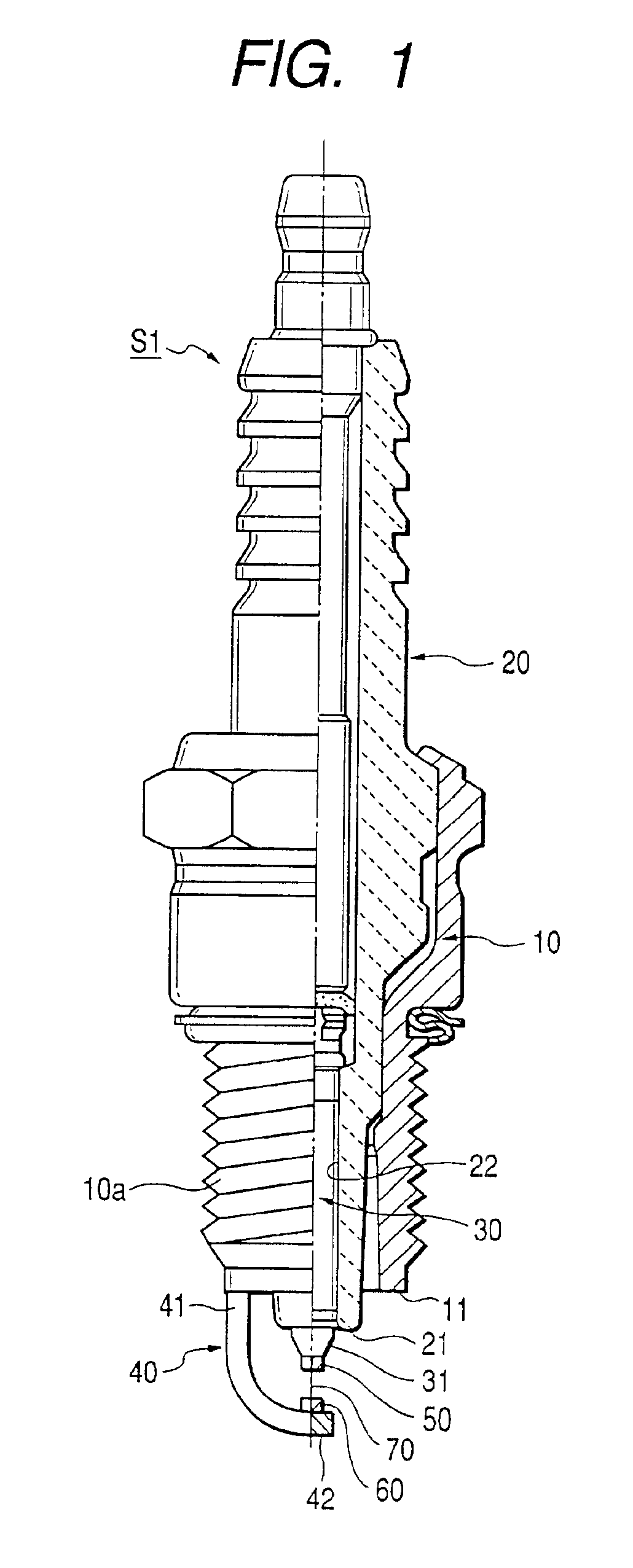

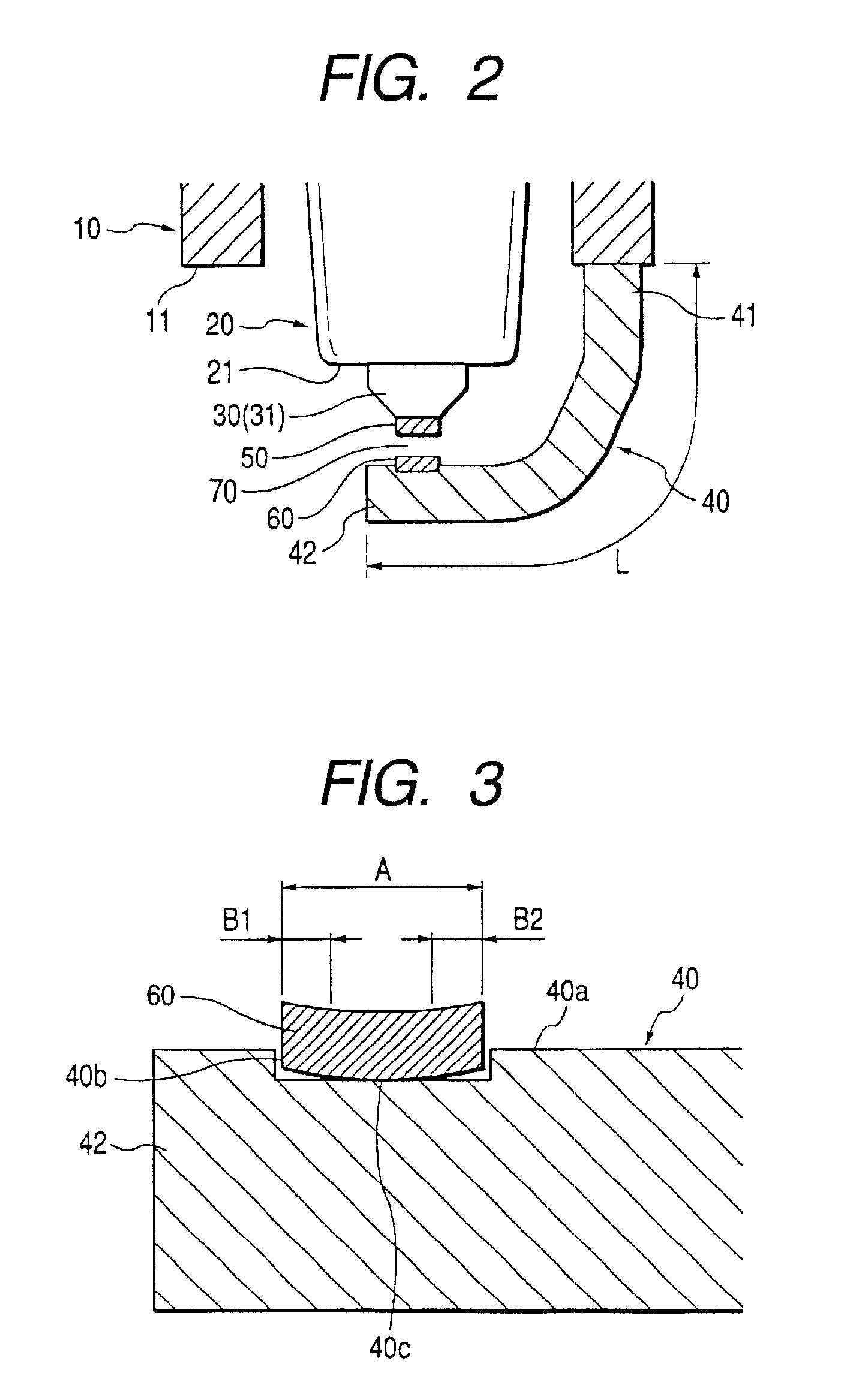

Spark plug and its manufacturing method

InactiveUS20020130602A1Satisfactory propertyImprove adhesion strengthSpark gapsSparking plugs manufactureFree energiesAlloy

Noble metallic tips, made of a Pt alloy or an Ir alloy, are fixed to electrode base materials. The electrode base materials are an alloy containing a chief element selected from the group consisting of Ni, Fe, and Co and a plurality of additive elements. At least two kinds of additive elements contained in this alloy have a standard free energy of formation smaller than that of the chief element.

Owner:DENSO CORP

Process for producing liquid hydrocarbon by pyrolysis of biomass in presence of hydrogen from a carbon-free energy source

ActiveUS8217211B2Yield maximizationInhibition formationBioreactor/fermenter combinationsBiological substance pretreatmentsAlkaneHydrogen

In at least one embodiment of the present invention, a method for producing liquid hydrocarbons from biomass is provided. The method comprises pyrolizing the biomass with hydrogen (H2) to form bio-oil. The bio-oil comprises alkanes, alkenes, alcohols, aldehydes, ketones, aromatics, hydrocarbons or mixtures thereof. The H2 is formed from a carbon-free energy source.

Owner:PURDUE RES FOUND INC

Environmental barrier coating for silicon based substrates

An article comprises a silicon based substrate, a bond layer and a protective top layer. The top layer is selected from the group consisting of rare earth disilicates, yttrium disilicates, rare earth monosilicates, yttrium monosilicates, silica and mixtures thereof. The protective layer described above is used in combination with a bond layer provided between the protective layer and the silicon based substrate which functions as oxygen getter and includes an oxygen gettering agent. By oxygen gettering agent is meant a refractory metal oxide former which forms an oxide at operational condition of (high temperature and aqueous environment) having a melting point of greater than 1500° C. wherein the negative free energy of formation of the refractory metal oxide from the refractory metal is more than 100 Kcal / mole. Suitable oxygen gettering agents include silicon and other refractory metals. An oxygen gettering agent may also be added to the protective layer.

Owner:RTX CORP

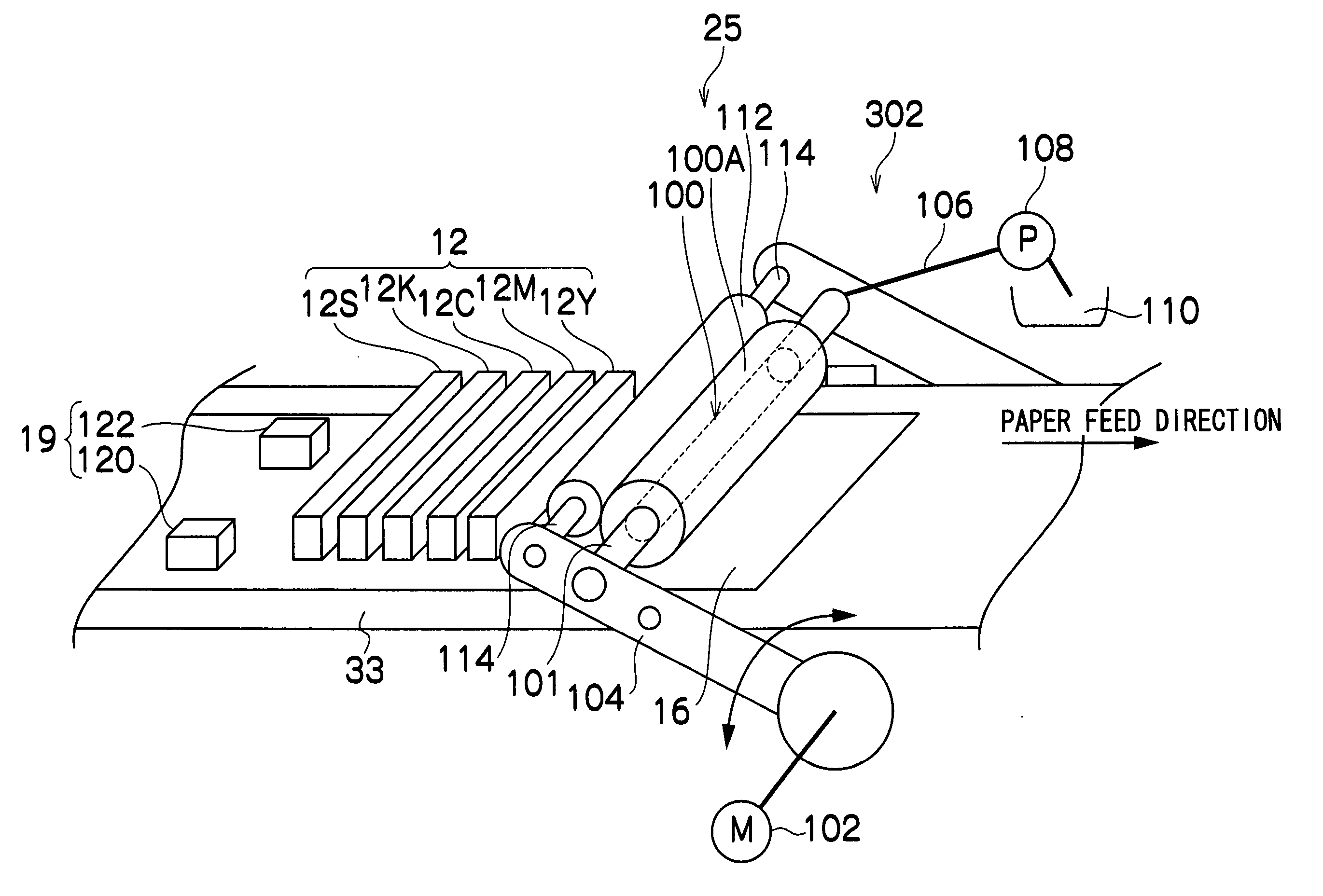

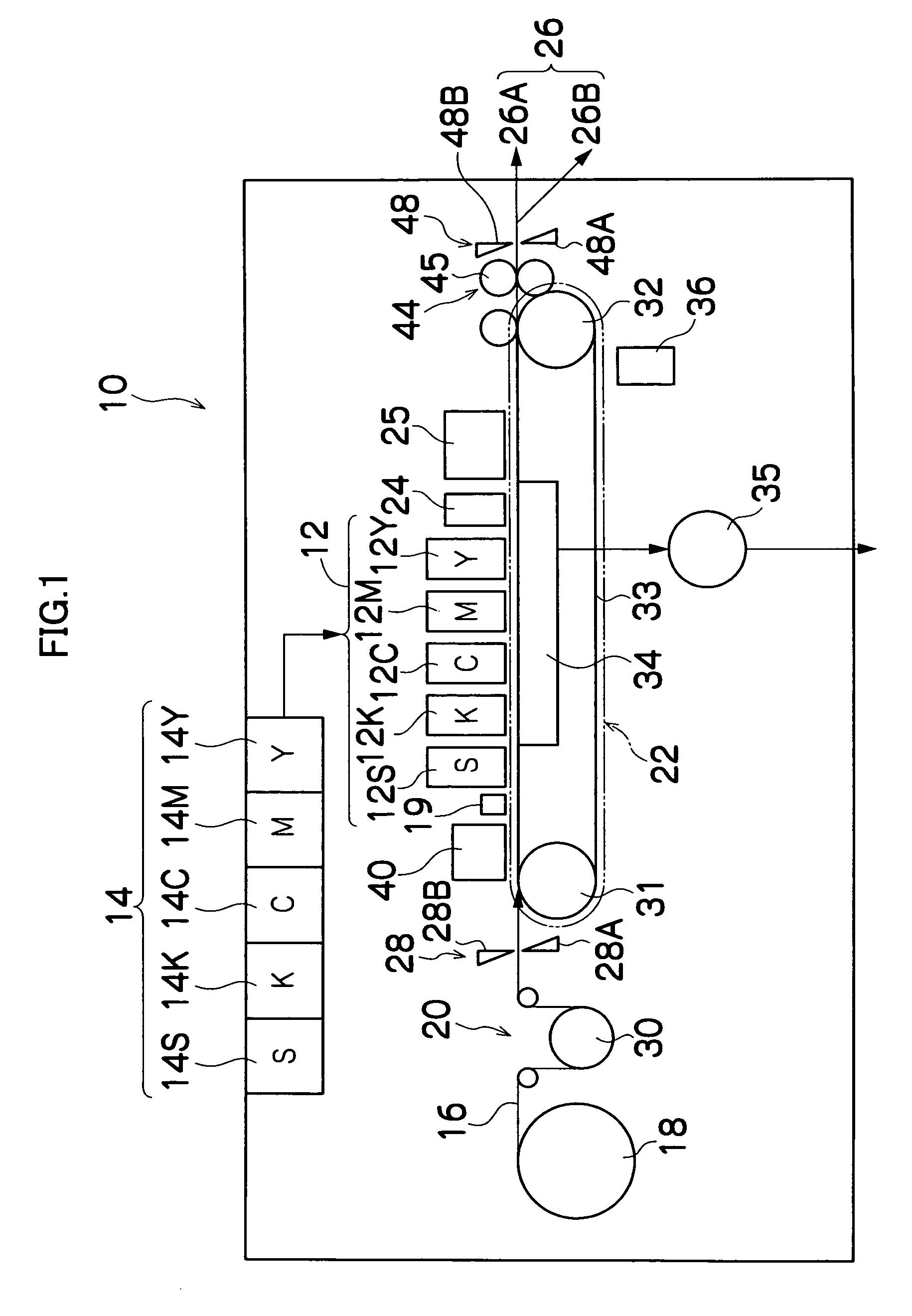

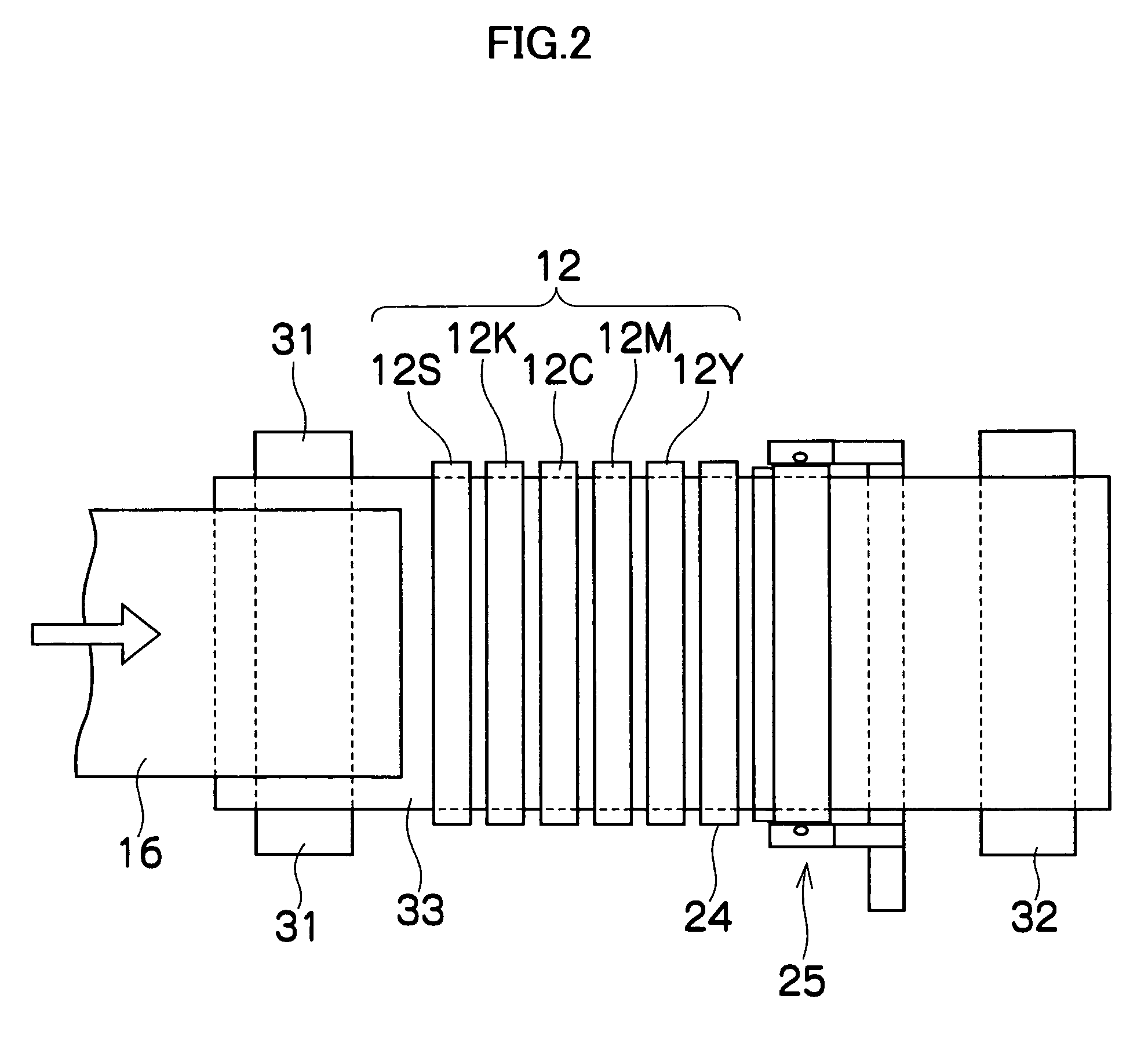

Image forming apparatus

InactiveUS20060221166A1Preventing Image Quality DeteriorationSuppressing the adherence of an image forming bodyOther printing apparatusPrinting after-treatmentFree energiesSurface roughness

The image forming apparatus comprises: an ejection head which ejects liquid onto a recording medium to form a desired image on the recording medium; a conveyance device which moves at least one of the recording medium and the ejection head so as to move the recording medium in a conveyance direction relatively to the ejection head; and a contact device which makes contact with the liquid on the recording medium and is arranged on a downstream side of the ejection head in the conveyance direction, the contact device having surface properties satisfying at least one of the following conditions: that a surface roughness of the contact device is greater than a surface roughness of the recording medium; that a surface free energy of the contact device is smaller than a surface free energy of the recording medium; and that a contact angle of the liquid on the contact device is smaller than a contact angle of the liquid on the recording medium.

Owner:FUJIFILM CORP

Spark plug and its manufacturing method

InactiveUS6885135B2Satisfactory propertyImprove adhesion strengthSpark gapsSparking plugs manufactureFree energiesAlloy

Noble metallic tips, made of a Pt alloy or an Ir alloy, are fixed to electrode base materials. The electrode base materials are an alloy containing a chief element selected from the group consisting of Ni, Fe, and Co and a plurality of additive elements. At least two kinds of additive elements contained in this alloy have a standard free energy of formation smaller than that of the chief element.

Owner:DENSO CORP

Copper alloy and liquid-crystal display device

ActiveUS20070002239A1Well formedSolid-state devicesSemiconductor/solid-state device manufacturingDiffusionSelf-diffusion

To provide a highly conductive Cu alloy which is advantageous in that an alloying element added to Cu is first reacted with oxygen contained in a gas atmosphere or solid in contact with the Cu member to form an oxide film which can prevent oxidation of Cu. The copper alloy comprises copper (Cu) containing an inevitable impurity, and an element added to the copper, wherein the added element is capable of being dissolved in the copper in an amount of 0.1 to 20 at. %, wherein the added element has an oxide formation free energy smaller than that of Cu and has a diffusion coefficient in Cu larger than the self-diffusion coefficient of Cu.

Owner:XENOGENIC DEV LLC

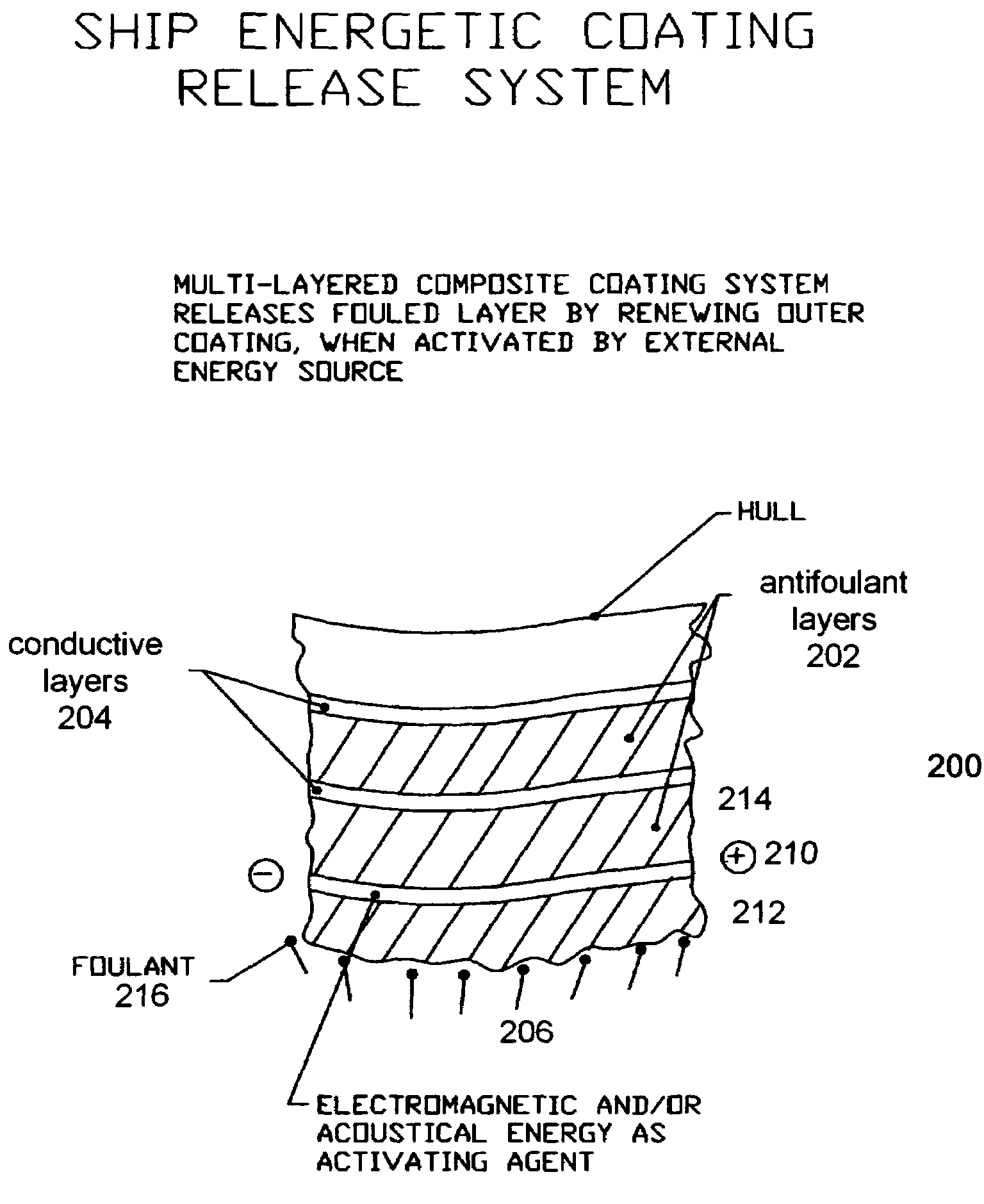

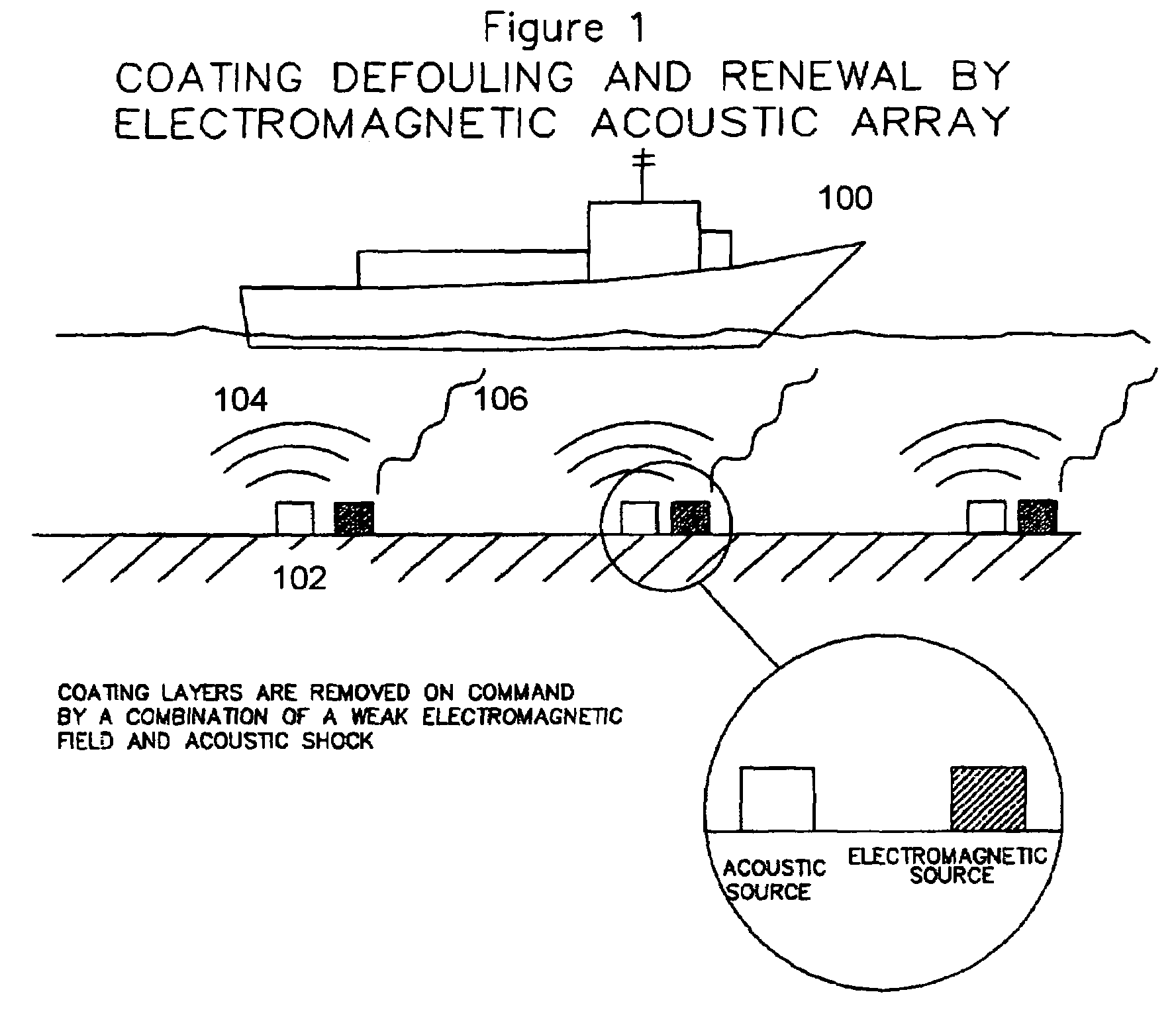

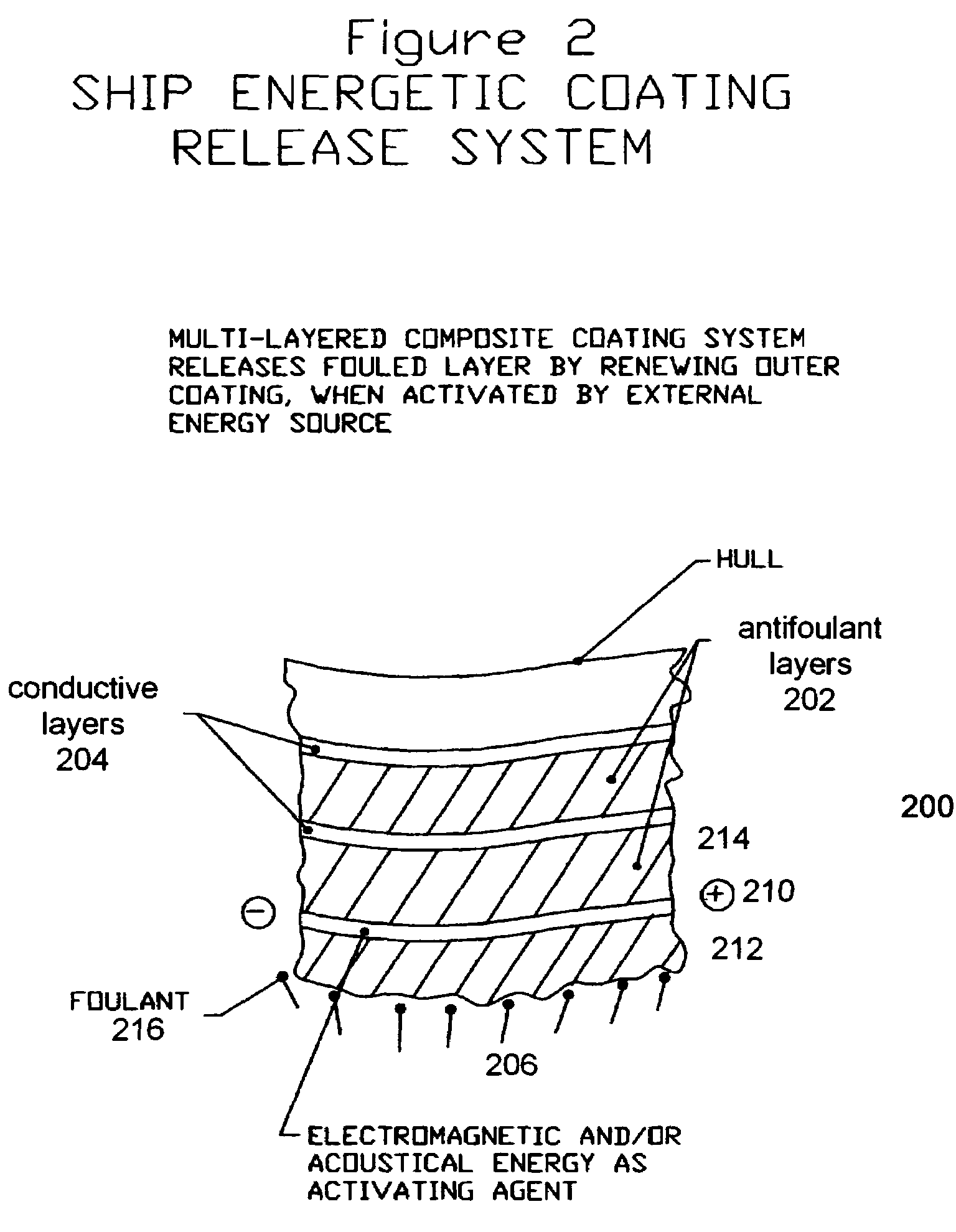

Smart coating systems

Owner:PEL ASSOCS

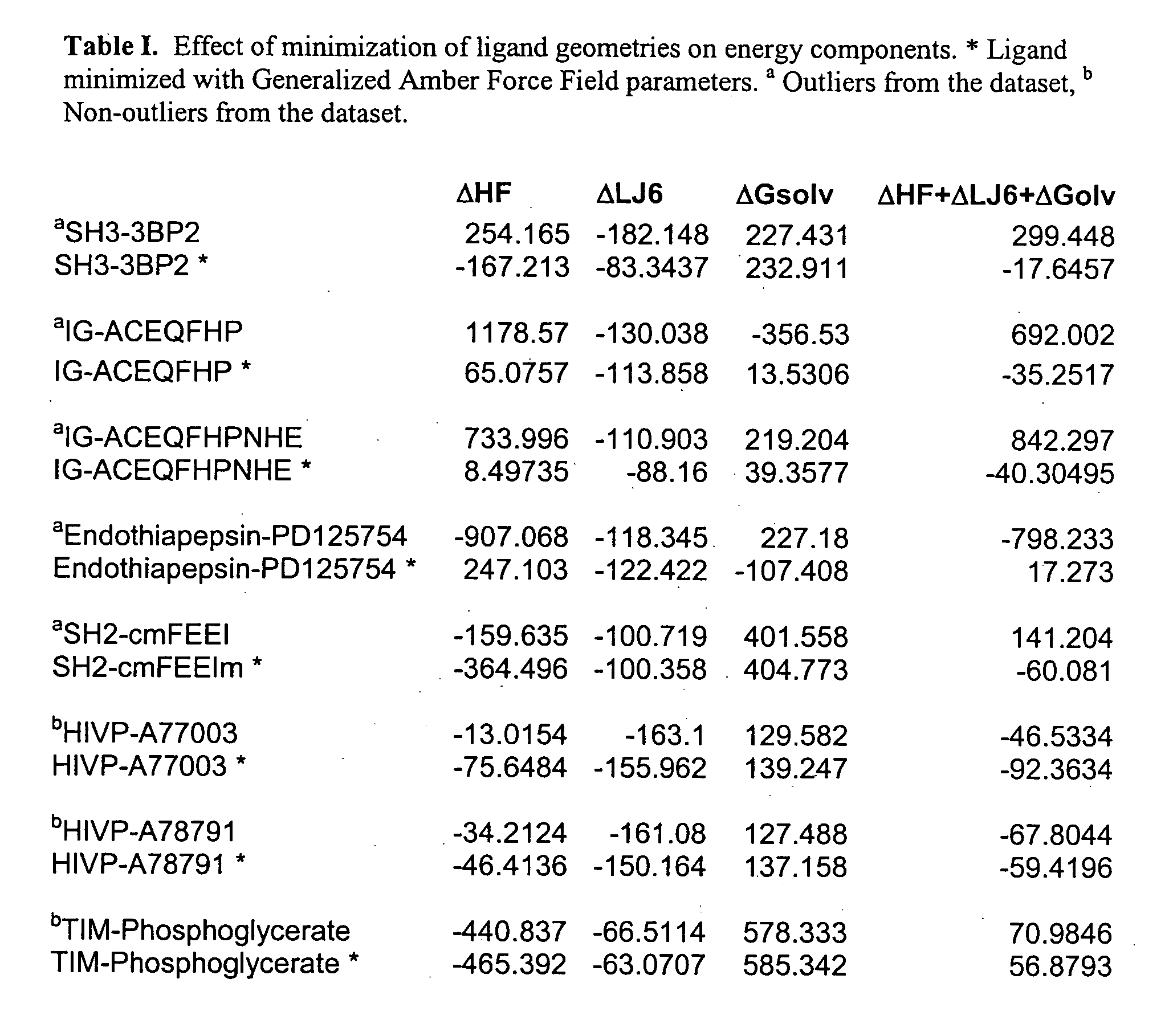

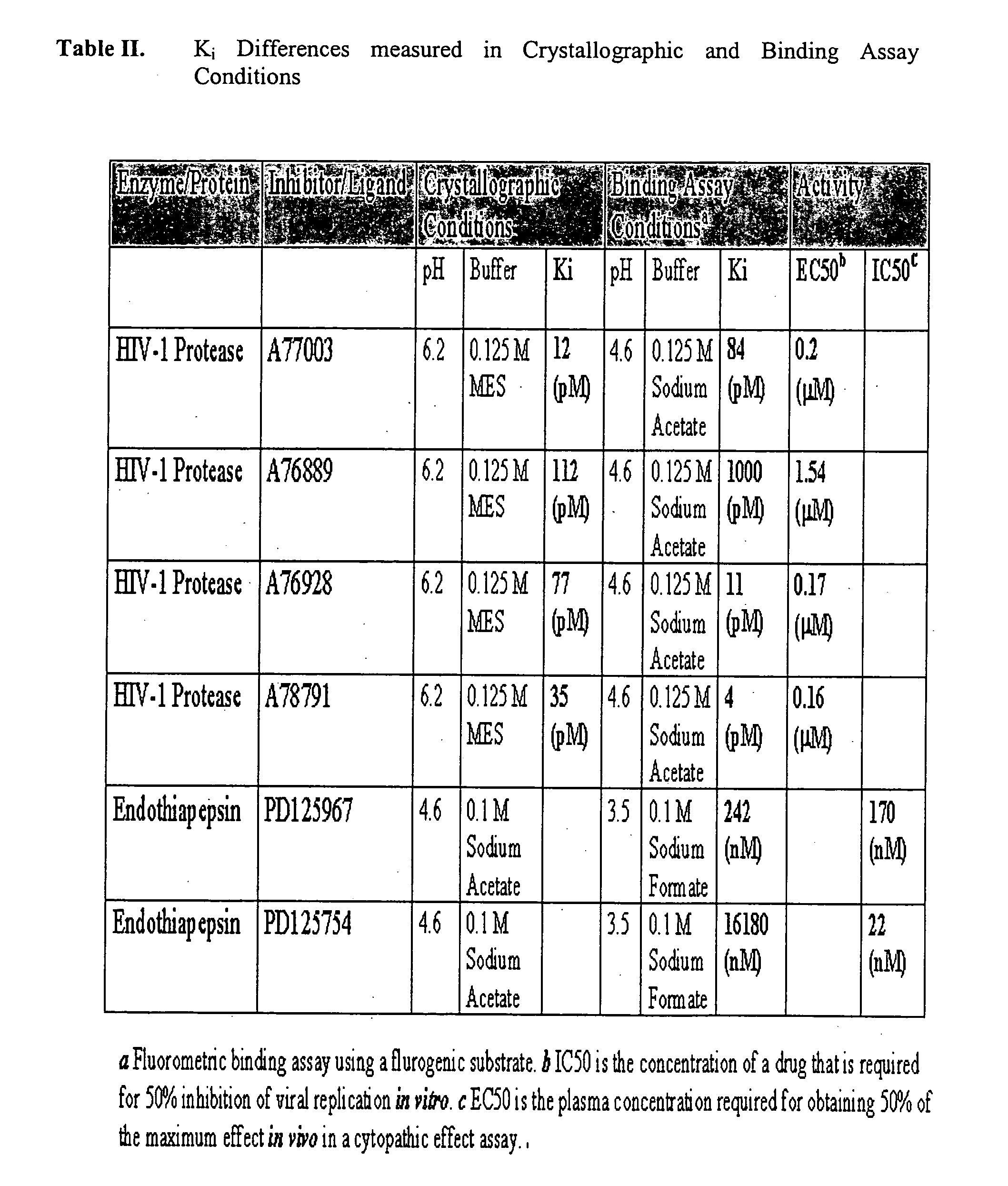

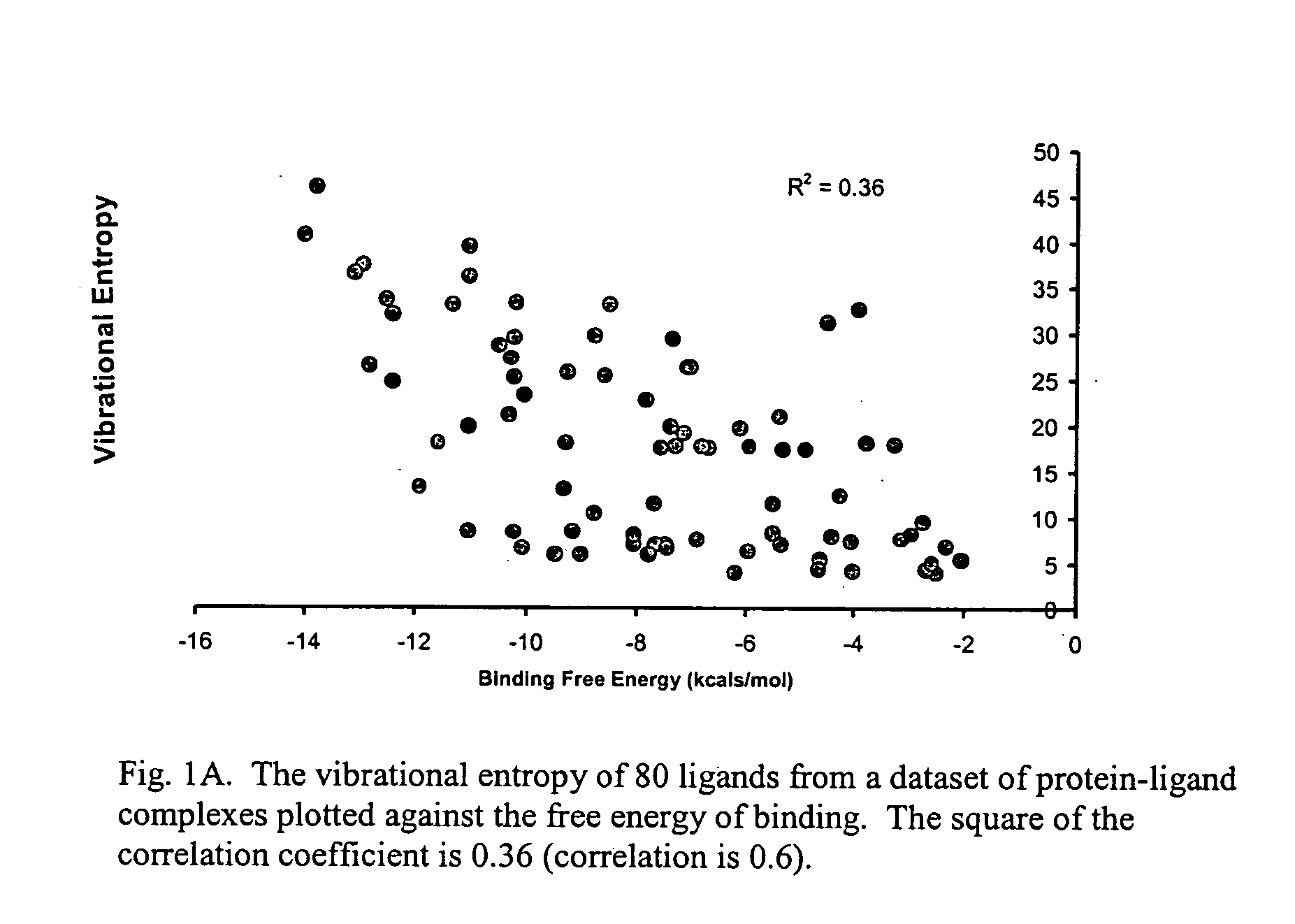

Quantum mechanics based method for scoring protein-ligand interactions

The present invention provides for the first time a quantum mechanics-based method for scoring protein-ligand interactions and binding affinity predictions, using quantum mechanical Hamiltonians and / or a combined quantum mechanical / molecular mechanical approach, and Poisson-Boltzmann (PB)-based solvation methods. Also provided is a method for using quantum mechanics to describe the enthalpic and solvation effects of binding. The method comprises comparing the calculated binding affinities to experimental values in order to measure the success of the method. The methods disclosed herein may further be used to score protein and drug or protein and inhibitor interactions. The present method can predict the free energy of binding of protein-ligand complexes with high accuracy so as to enable lead optimization, thus serving as a powerful tool in computational drug design.

Owner:PENN STATE RES FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com