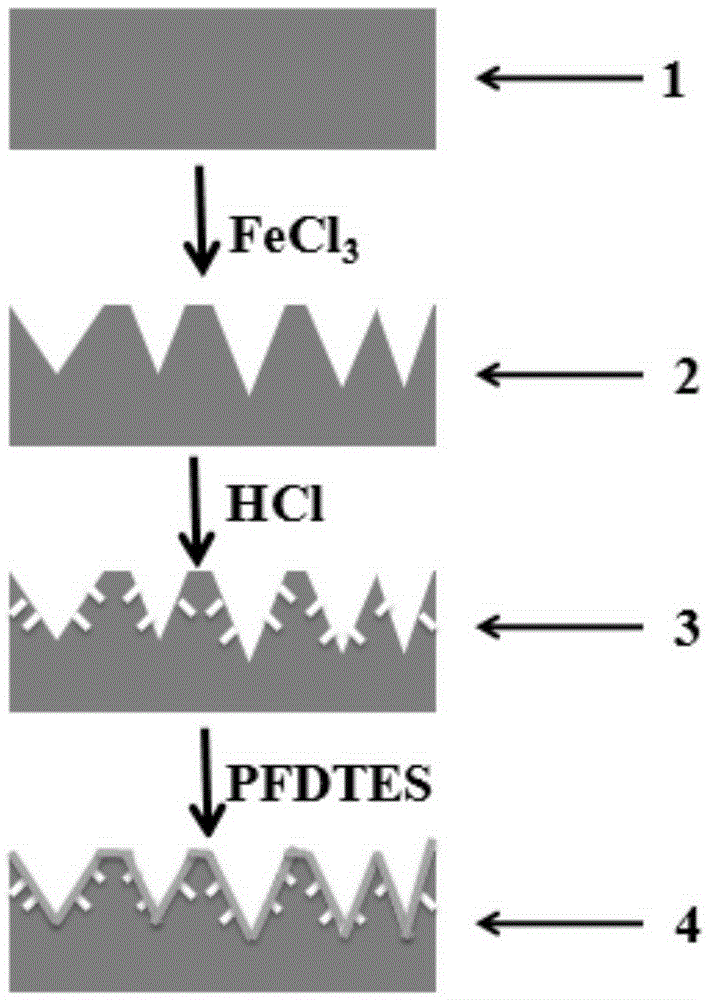

Preparation method for super-hydrophobic surface with bionic micro-nano composite structure

A technology of micro-nano composite structure and super-hydrophobic surface, which is applied to the device for coating liquid on the surface, special surface, pre-treated surface, etc., can solve the problems of expensive raw materials and processing equipment, complicated preparation process, poor stability, etc., and achieve Low cost, good repeatability, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

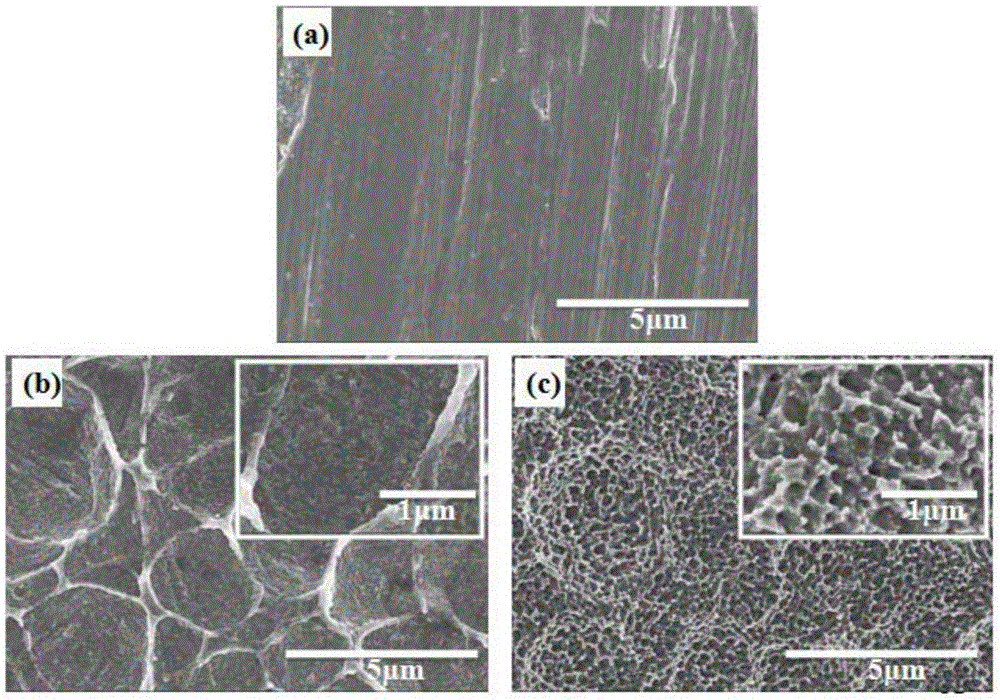

[0034] Ⅰ. Cut out a 304 stainless steel sheet with a size of 30×20×0.2mm, put it in an ultrasonic cleaning machine and use chloroform, acetone, absolute ethanol and deionized water to ultrasonically clean it for 10 minutes, after cleaning, take it out and blow it dry with nitrogen ,stand-by.

[0035] Ⅱ. Weigh 8.0g FeCl on electronic analytical balance 3 Put it in a beaker, use a graduated cylinder to measure 30mL of deionized water and add it to the beaker. After the ferric chloride is completely dissolved, add 2mL of HCl, 2mL of H 3 PO 4 , 2mLH 2 o 2 , stir evenly with a glass rod, and prepare a ferric chloride etching solution with a concentration of 0.22g / mL. The cleaned stainless steel sheet was first immersed in FeCl at room temperature 3 Etched in the etching solution for 4 minutes, then immersed in 1mol / L HCl solution and etched for 20 minutes. After the etching is completed, the stainless steel sheet is ultrasonically cleaned with deionized water for 5 min, taken...

Embodiment 2

[0041] Ⅰ. Cut out a silicon wafer with a size of 30×20×0.2mm, place it in an ultrasonic cleaning machine and use chloroform, acetone, absolute ethanol and deionized water to ultrasonically clean it for 10 minutes. After cleaning, take it out and blow it dry with nitrogen. stand-by.

[0042] II. At room temperature, firstly immerse the cleaned silicon wafer in 0.5g / mL KOH etching solution for 10min and then immerse in 2mol / LHF solution for 5min. After the etching is completed, the silicon wafer is ultrasonically cleaned with deionized water for 5 min, taken out and blown dry with nitrogen gas.

[0043] Ⅲ. Place the beaker on an electronic analytical balance, accurately weigh 30g of absolute ethanol, and slowly add 1.5g of fatty acid (perfluorooctanoic acid, CF 3 (CF 2 ) 6 COOH), made into a 5% perfluorooctanoic acid-ethanol solution. After the prepared solution was placed on a magnetic stirrer and stirred for 3 h, a uniform and transparent liquid was formed. Immerse the et...

PUM

| Property | Measurement | Unit |

|---|---|---|

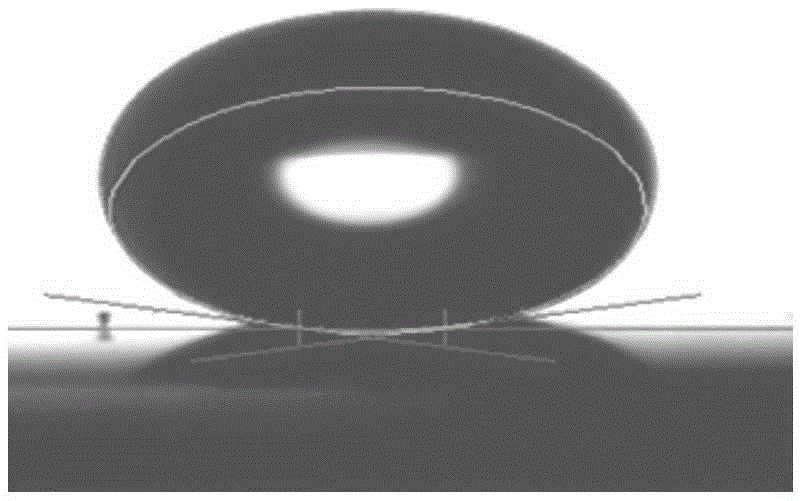

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com