Patents

Literature

424 results about "Glass vessel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

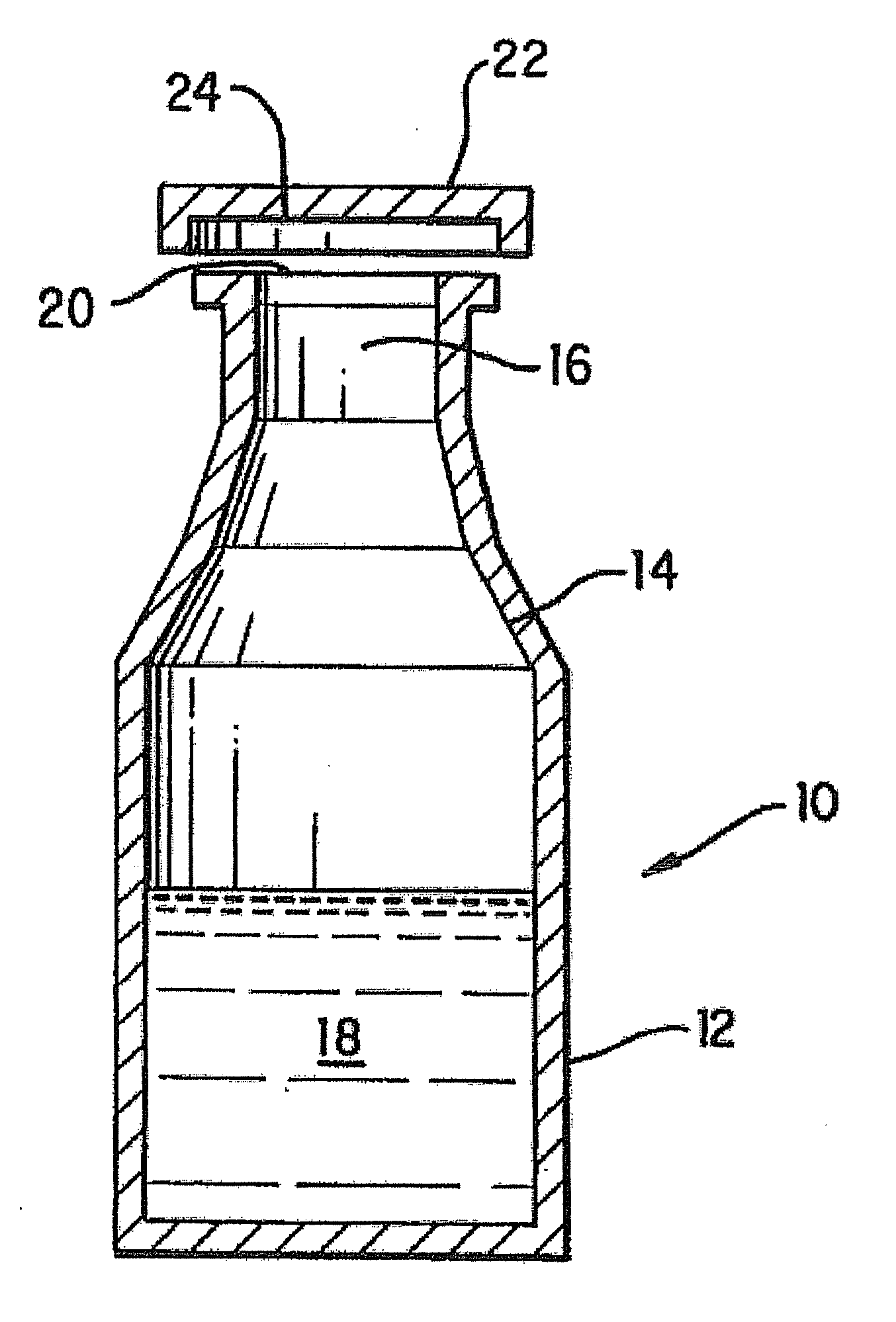

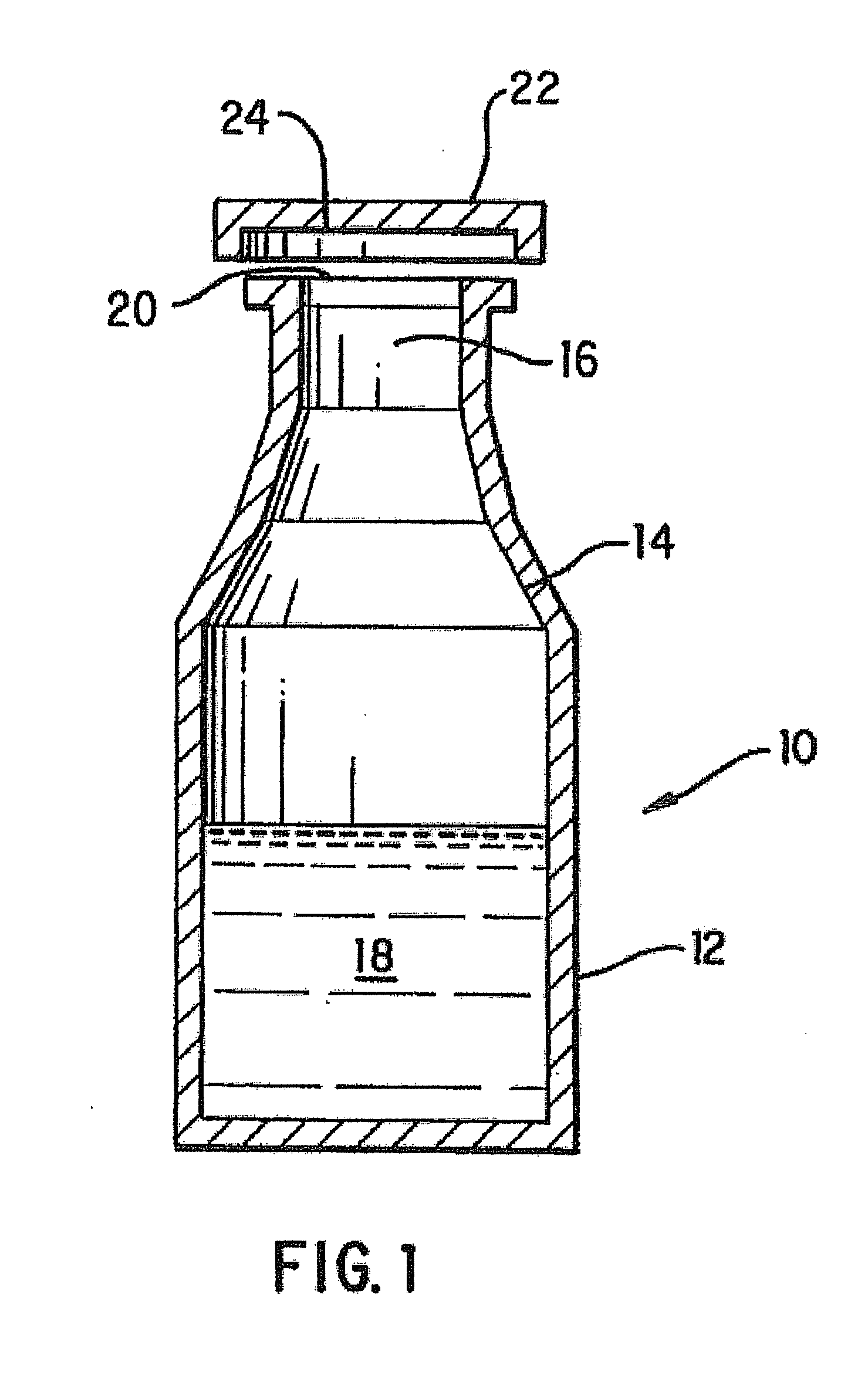

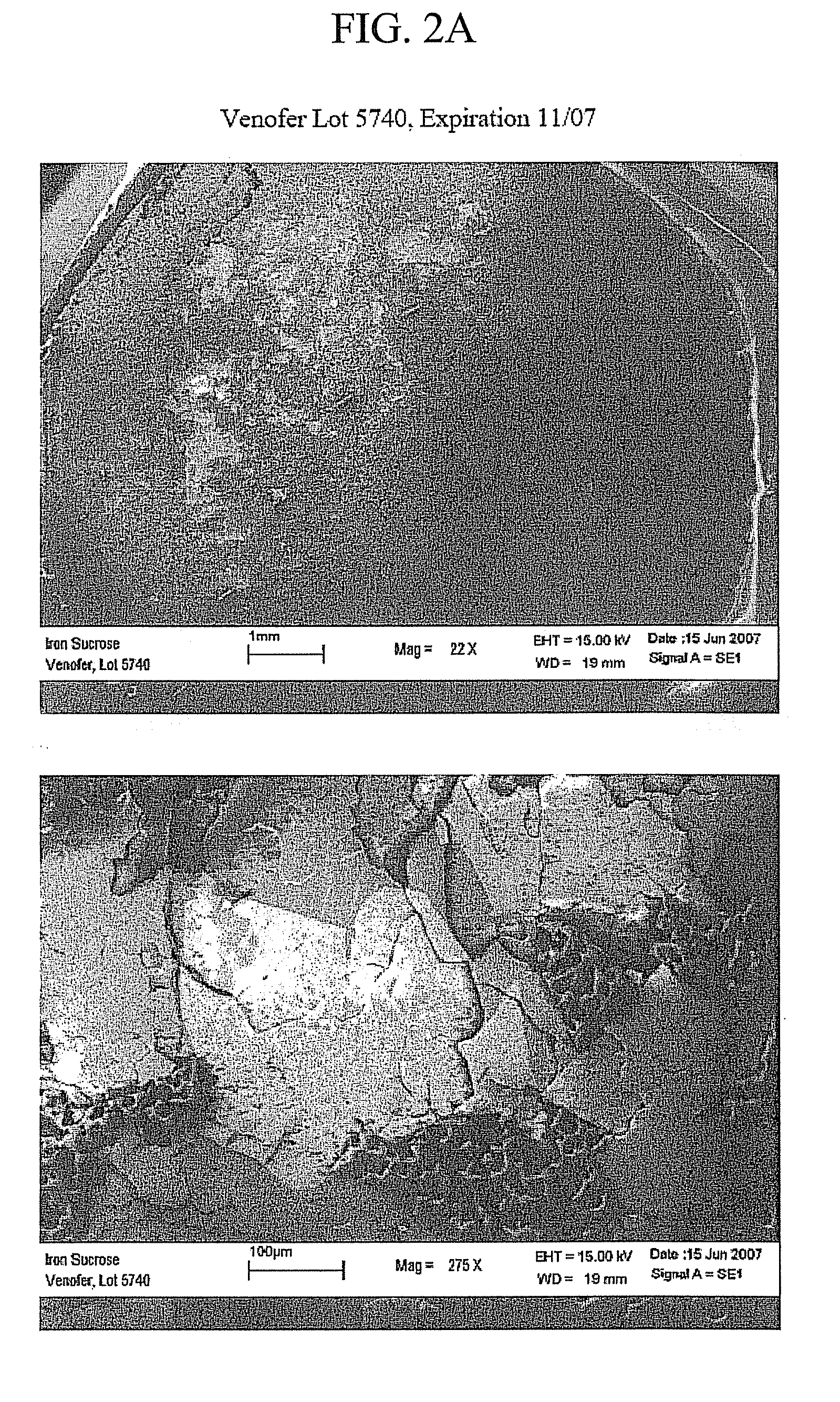

Packaged Iron Sucrose Products

A packaged iron sucrose formulation including a container with an interior glass surface that is coated with layer of material containing silicon, such as a silicone polymer or silicon dioxide. The iron sucrose formulation is packaged inside the glass vessel and in contact with the layer of material containing silicon. The packaged formulation can be stored for extended periods without glass delamination.

Owner:HOSPIRA

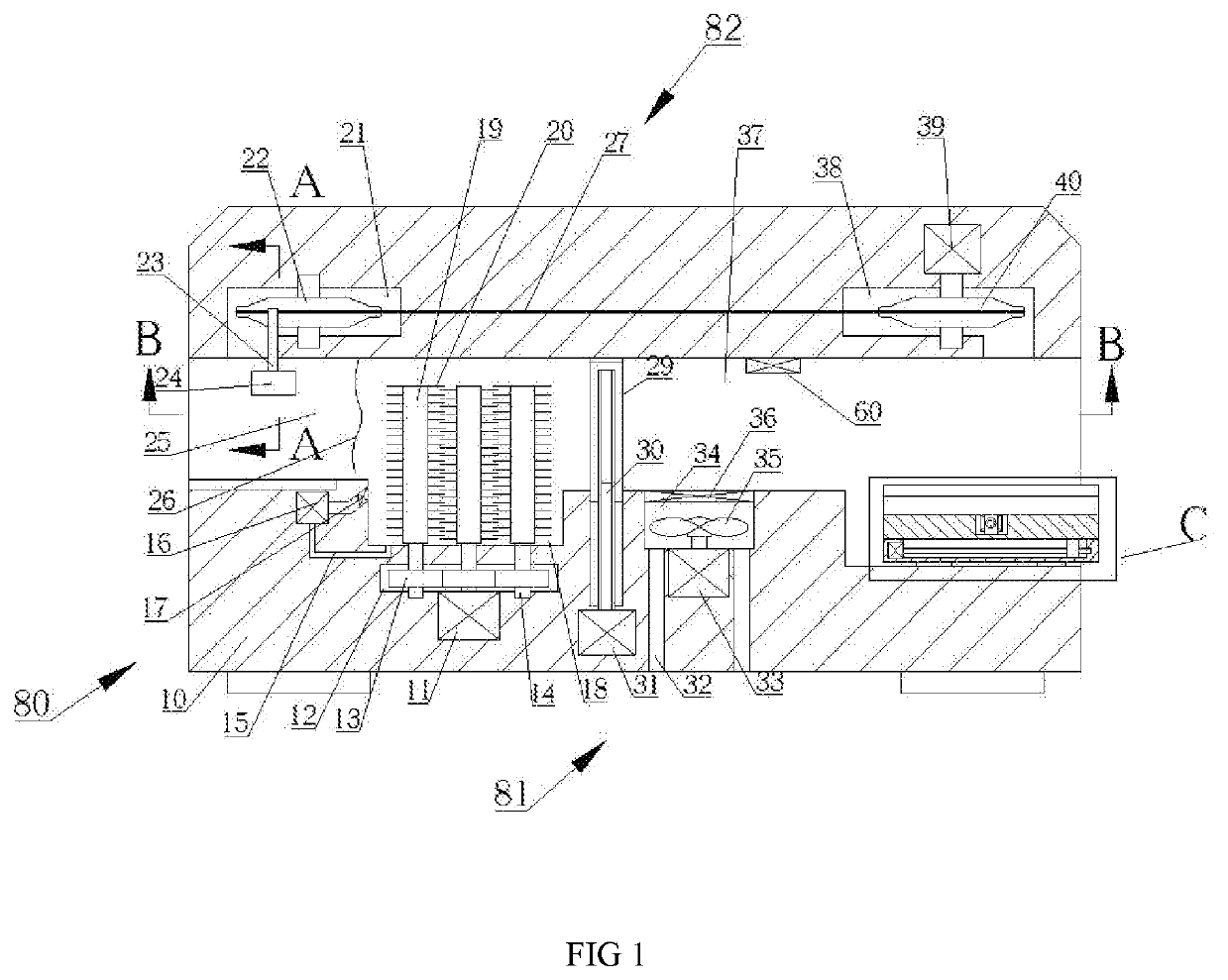

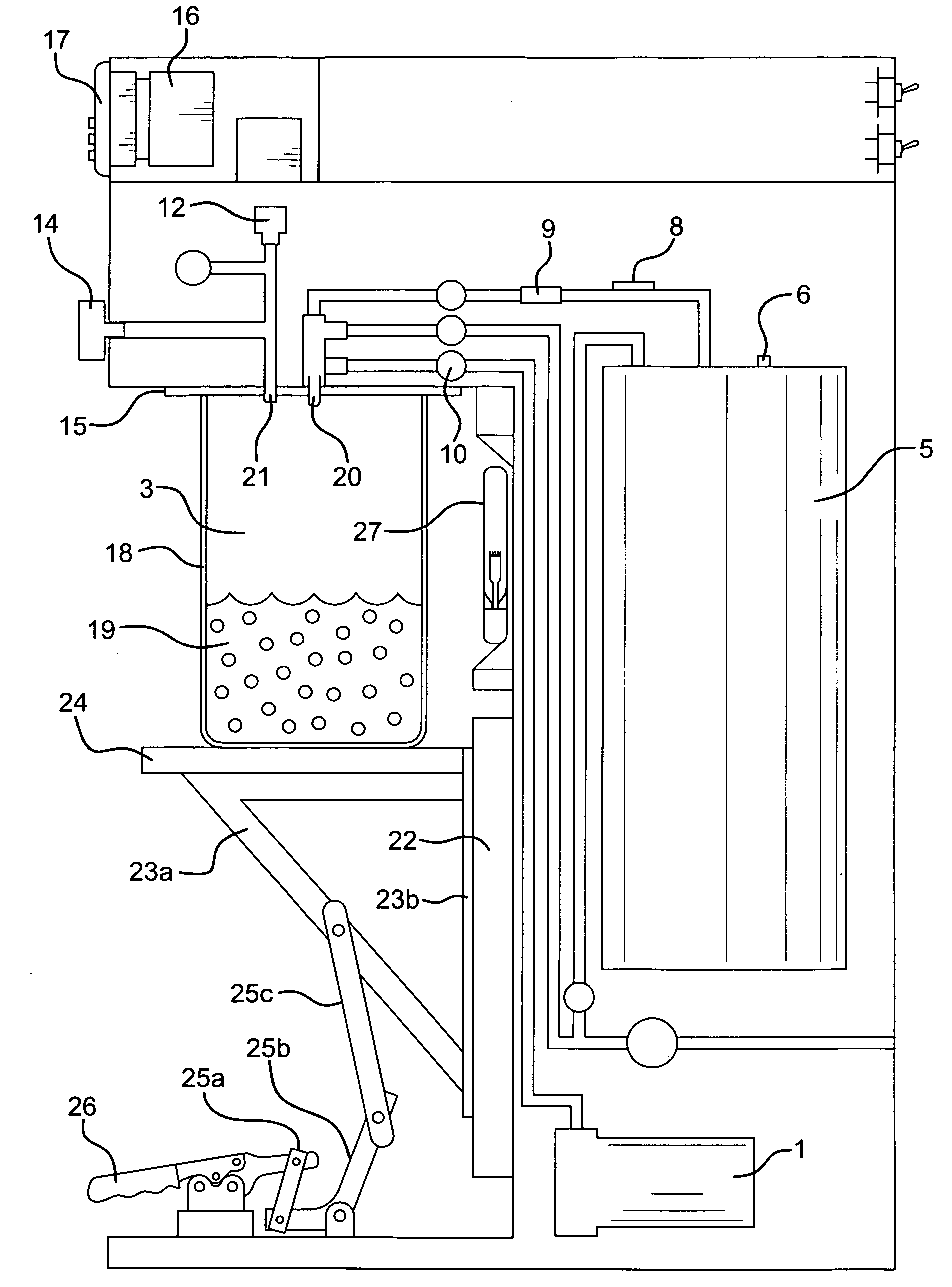

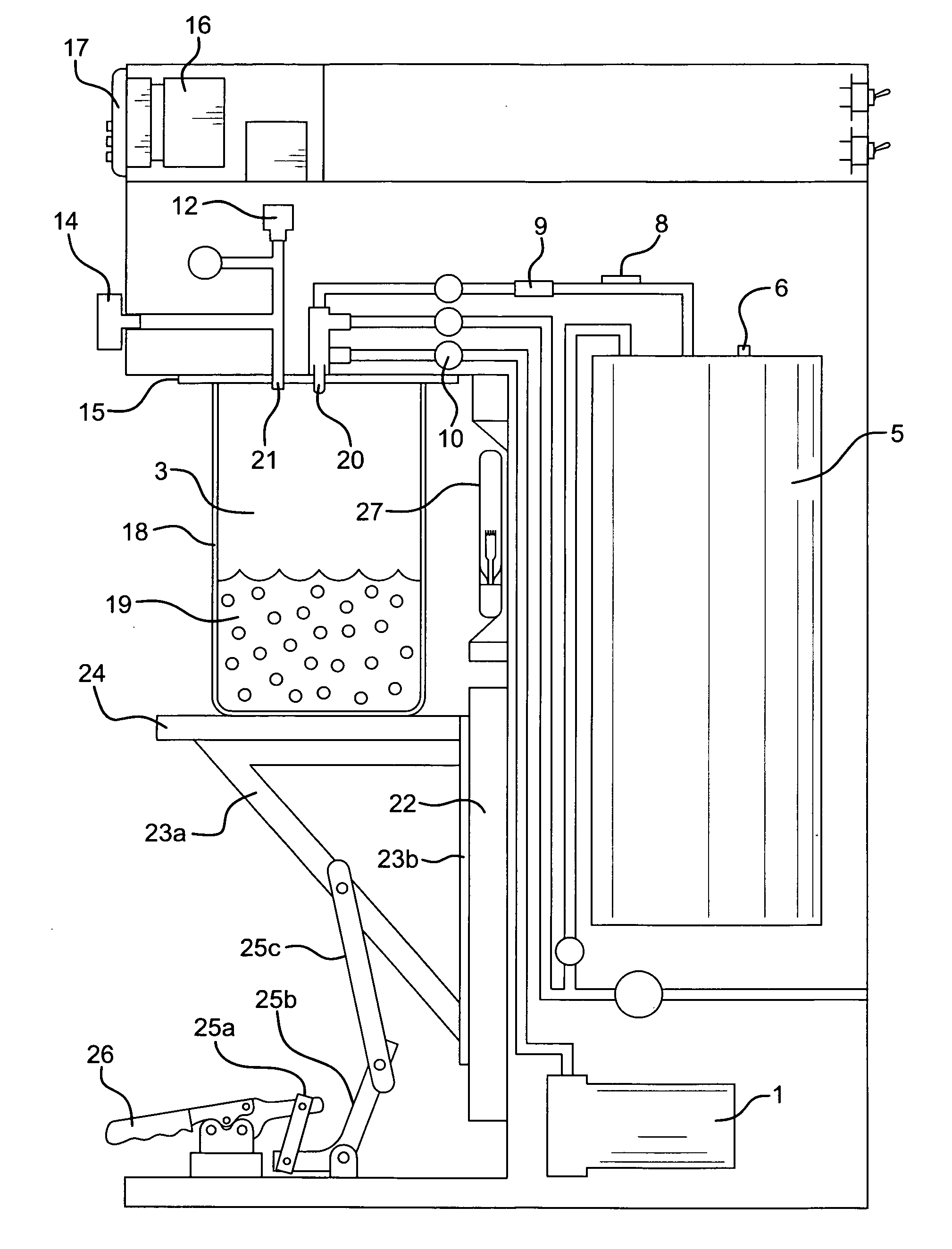

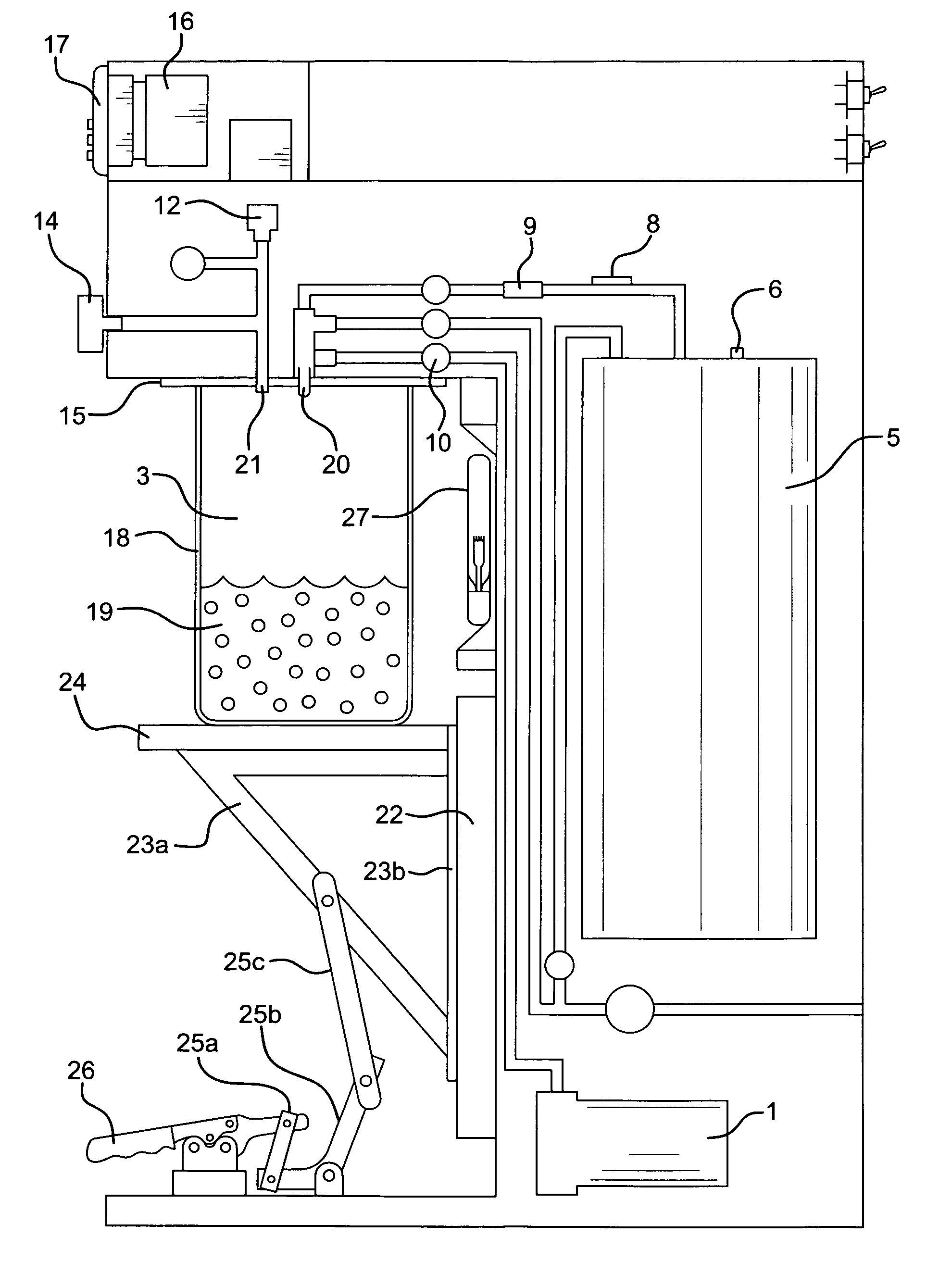

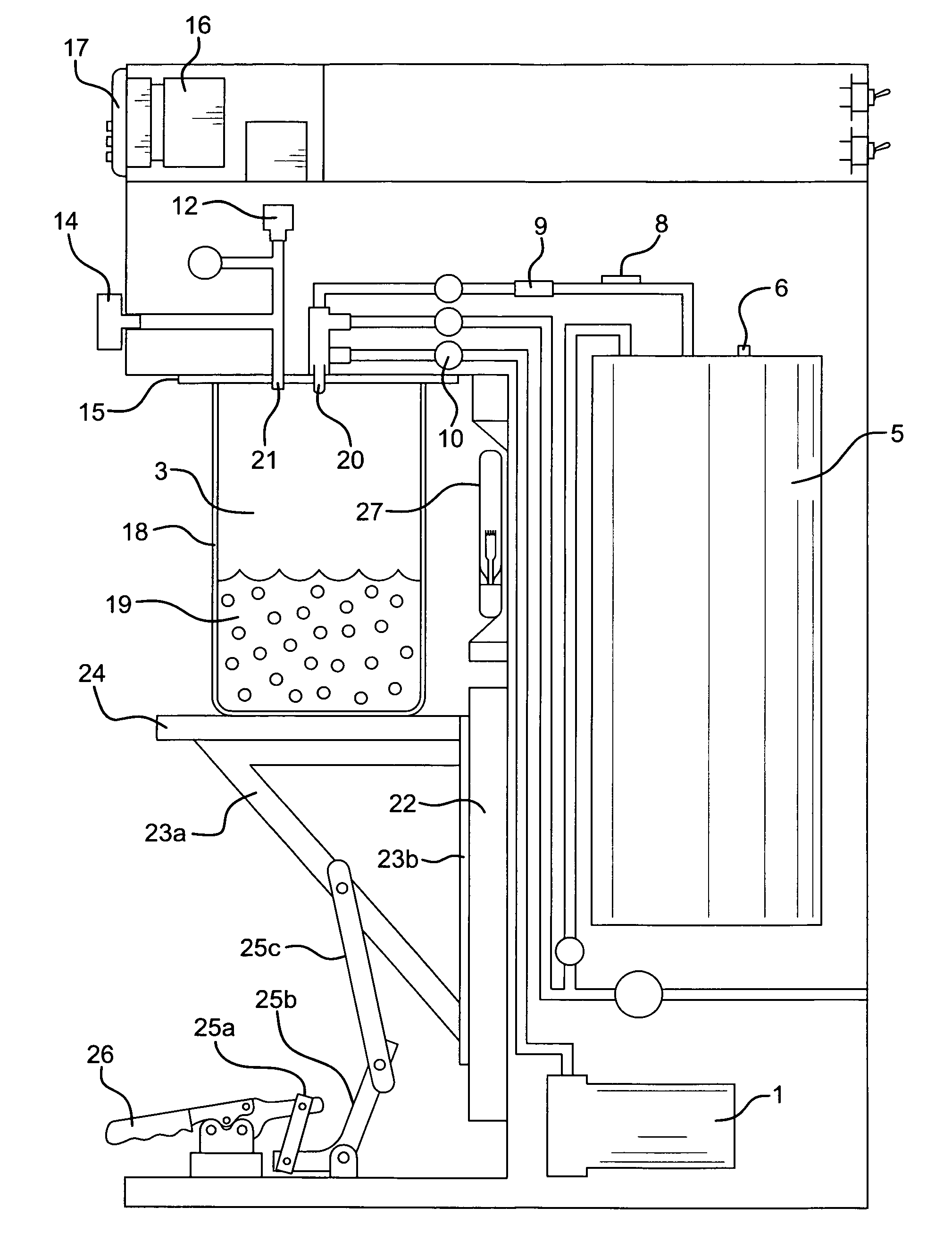

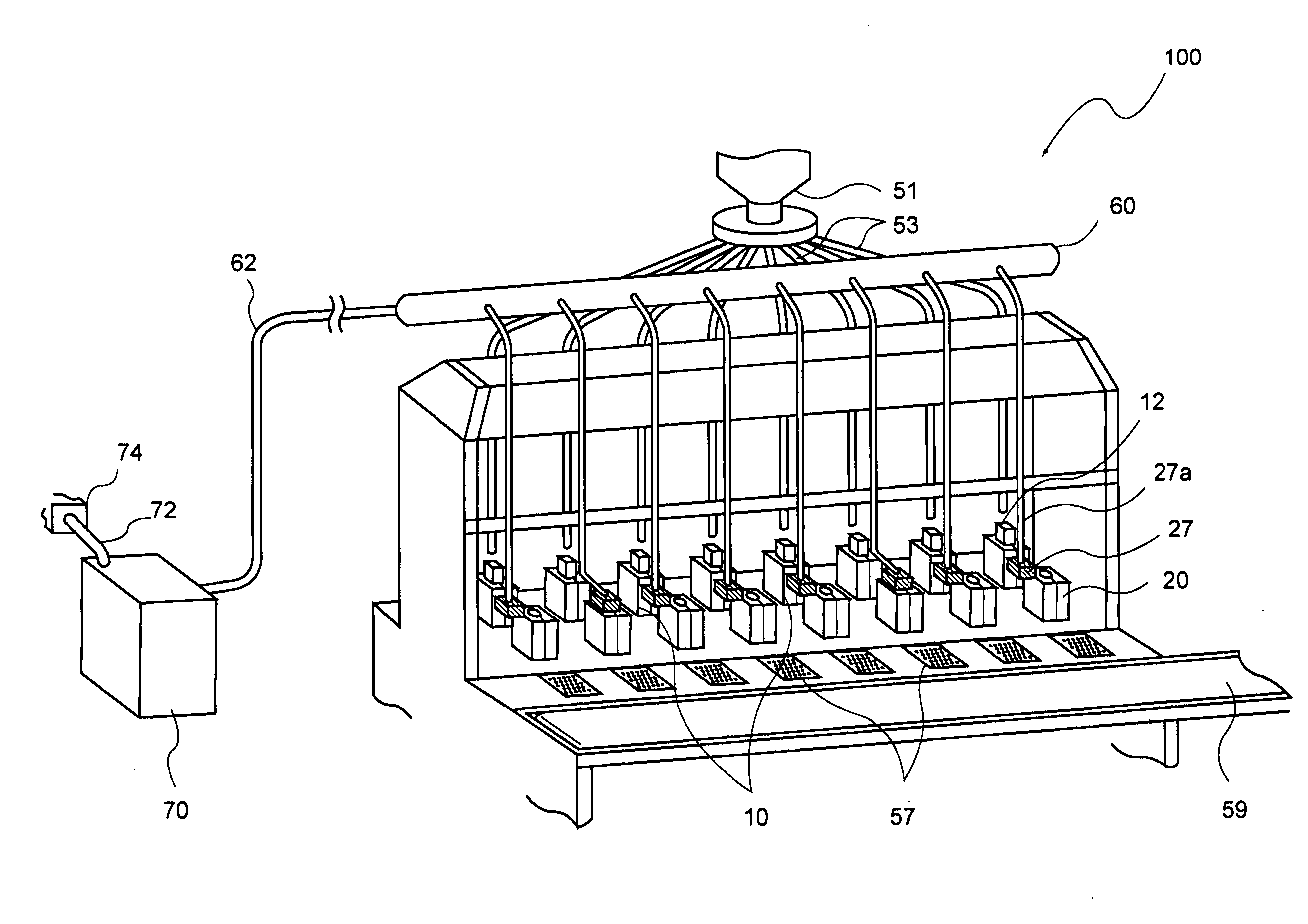

Glassware cleaning and drying equipment for medical experiments

InactiveUS20200108426A1Continuous cleaningIncrease flexibilityHollow article cleaningDrying gas arrangementsGlass vesselElectric machinery

The invention discloses a glassware cleaning and drying equipment for medical experiments, which includes a device cabinet, wherein a cleaning space is provided in the device cabinet, a brushing space communicating with the cleaning space is provided on a bottom wall of the cleaning space, and a water pump is fixedly installed in the left inner wall of the brushing space. The nozzle is fixedly installed on the output pipe. The brushing motor is started. The brushing motor drives the gear shaft to rotate. The brush cylinder and the washing brush that the gear shaft rotates rotate. The medical glassware is cleaned and disinfected. The effect of individual treatment is better and the disinfection is more thorough. The chuck can be changed according to the size of the clamped utensils. There is no need to change the mold for clamping the utensils.

Owner:WU MEIJUN

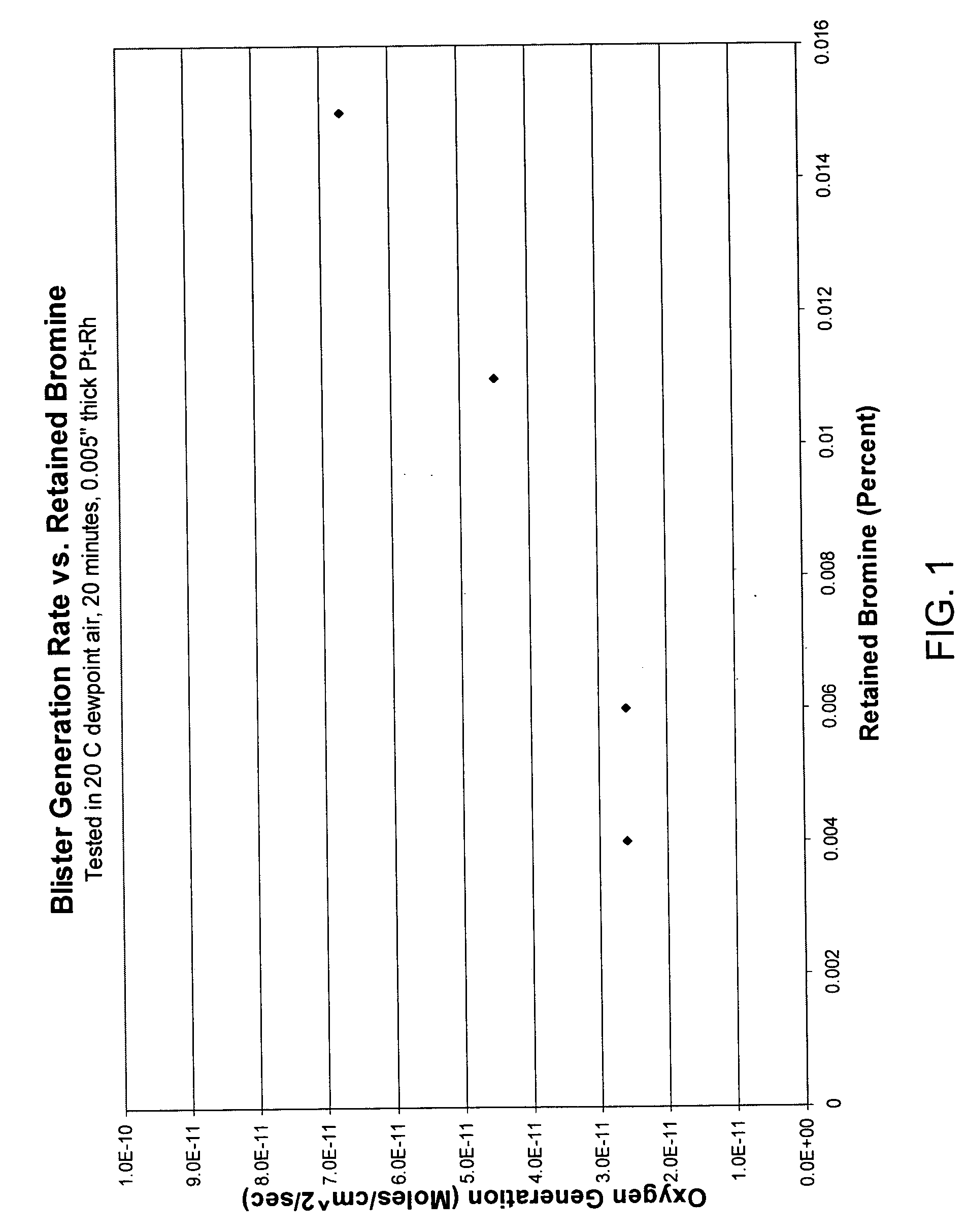

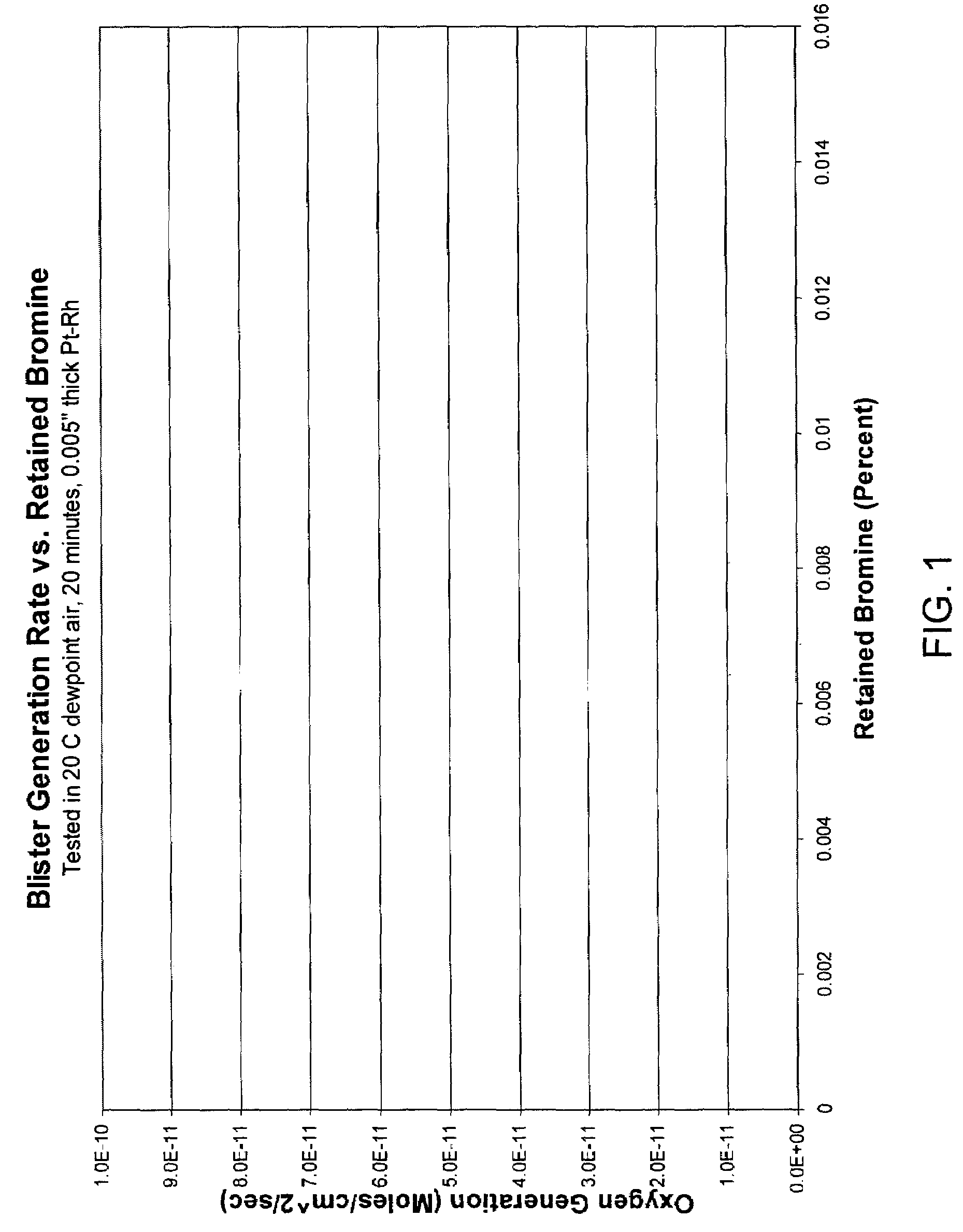

Method of fining glass

InactiveUS20060242995A1Increased hydrogen permeationAvoid formingGlass furnace apparatusGlass vesselAlloy

A method of forming an oxide glass including heating a glass melt having a β—OH concentration of at least about 0.35 in a vessel comprising a metal selected from the group consisting of platinum, molybdenum, palladium, rhodium, and alloys thereof, there being an interface present between the vessel and the glass, and controlling a partial pressure of hydrogen in an atmosphere in contact with an outside surface of the vessel in an amount such that hydrogen permeation blisters form in a region of the glass adjacent the glass-vessel interface.

Owner:CORNING INC

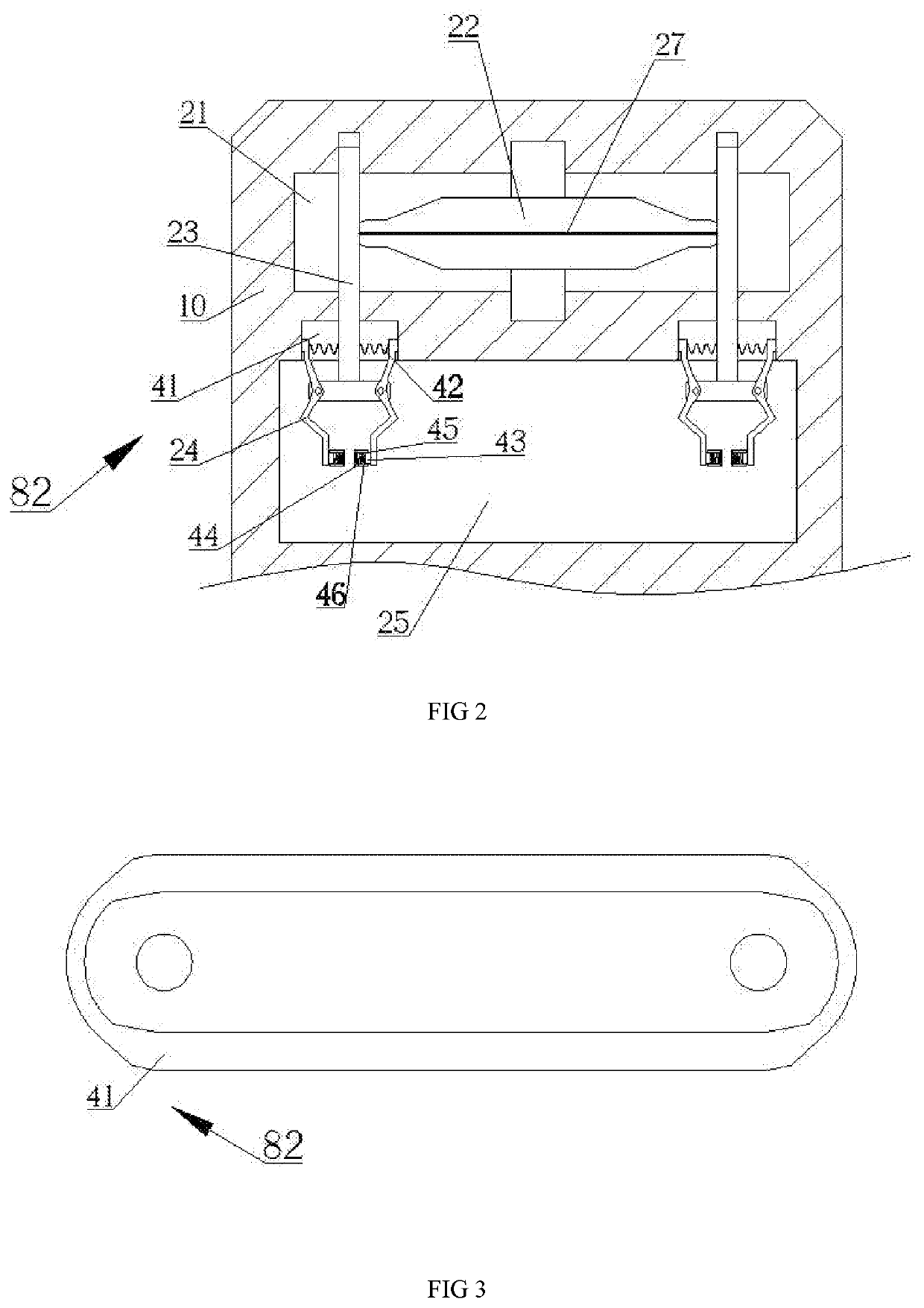

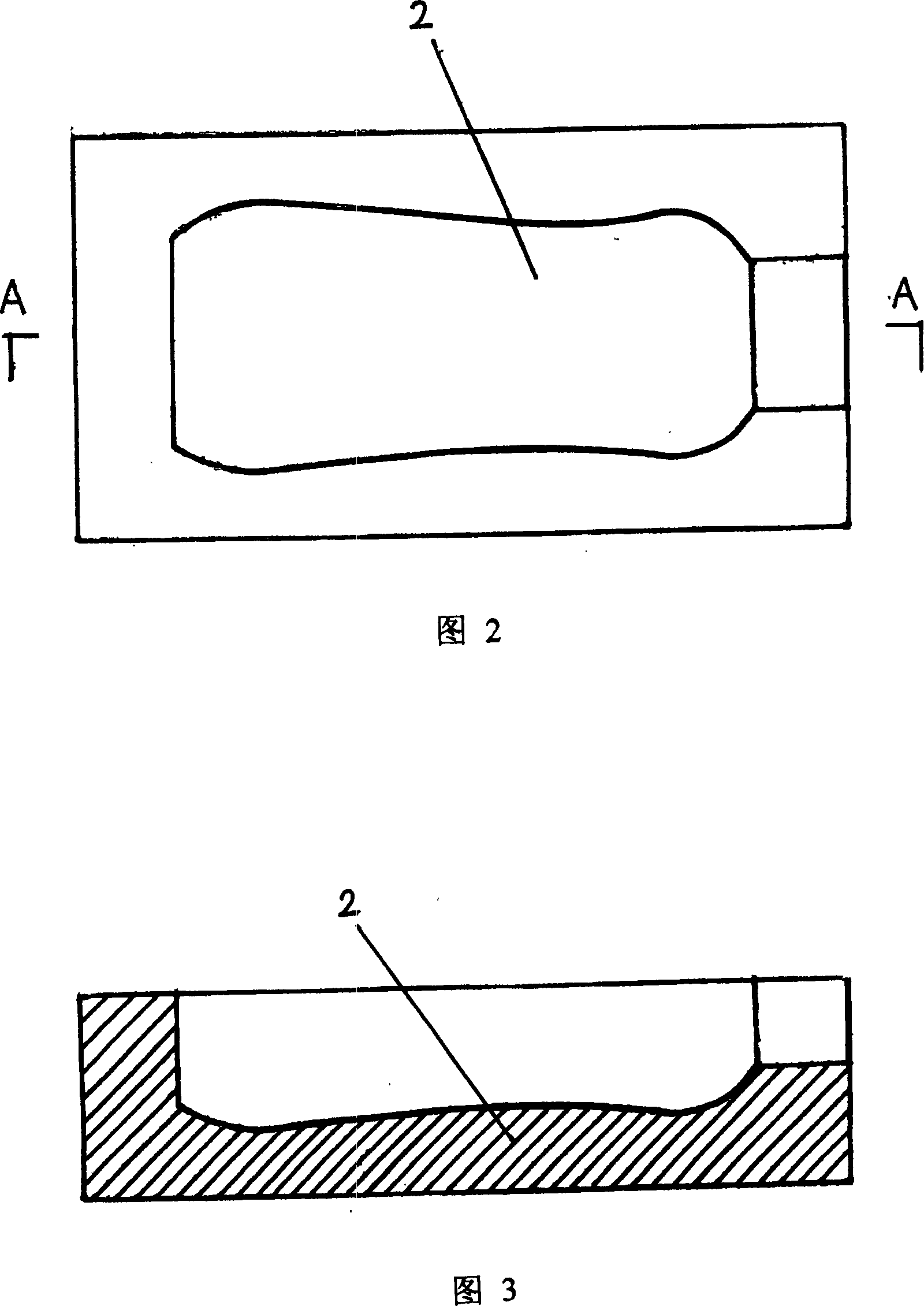

Mould for manufacturing bottle glass vessels

The invention provides a mould for manufacturing bottle glass vessels, belonging to a glass mould. The mould comprises a pair of bottle semi-moulds which are oppositely arranged and provided with a semi-mould cavity respectively. The mould is characterized in that valve holes are reserved on positions of the bottle semi-moulds, correspond to the neck shoulders of the bottle semi-moulds respectively, and are communicated with the bottle semi-mould cavities; air valves are arranged in the valve holes, and are fixed with the bottle semi-moulds; exhaust holes communicated with the valve holes are reserved on the bottle semi-moulds respectively, extend to the tops of the bottle semi-moulds from the bottoms of the bottle semi-moulds and the valve holes and are communicated with the outside. In the technical scheme, when the bottle glass vessel with the neck shoulder is manufactured, gas between the neck shoulders of the mould and glass solution can be exhausted from the exhaust holes through the valve holes and the air valves to ensure that the glass solution is in plump state at the neck shoulder position of the bottle neck shoulders, and the deformation of the bottle neck shoulders can be inhibited finally.

Owner:CHANGSHU JIANHUA MOLD TECH

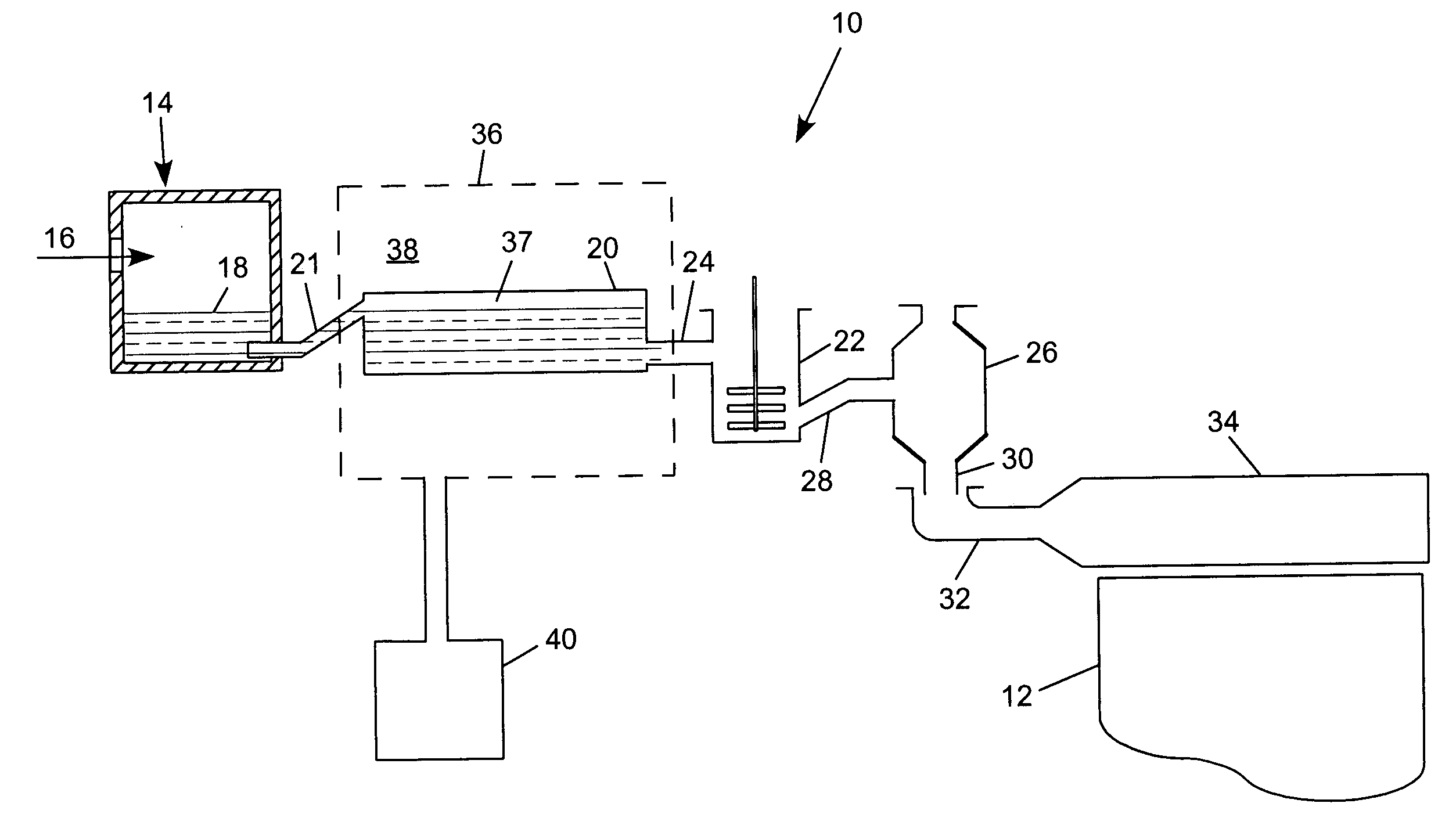

Vacuum brewed beverage machine and vacuum brewing method

ActiveUS20110097466A1Brewed quickly and easilyCooking-vessel materialsTea substituesGlass vesselAtmospheric pressure

The desired amount of coffee grounds, tea leaves, herbs or other beverage making material is placed in a chamber of glass vessel located on a moveable table top in its lowered position. The table top is then elevated until the upper edge of the vessel seals against a top seal. With the top sealed, the desired amount of water of about 185°-212° F. is introduced into the chamber through a port in the top. Thereafter, a vacuum is drawn in the chamber and is held within the range of about −5 to −20 Hg in. Using an external heat source, the brewing liquid is maintained at about 185°-212° F. Alternatively, the vacuum can be pulsed by turning it on and off several times during the brewing cycle. After the beverage has brewed for the desired amount of time, the heat and vacuum are removed, the chamber is returned to atmospheric pressure and the table top is lowered to release the vessel. The contents of the chamber are then strained to remove solids from the beverage.

Owner:BKON

Vacuum brewed beverage method

ActiveUS8383180B2Brewed quickly and easilyCooking-vessel materialsTea substituesGlass vesselEngineering

Owner:BKON

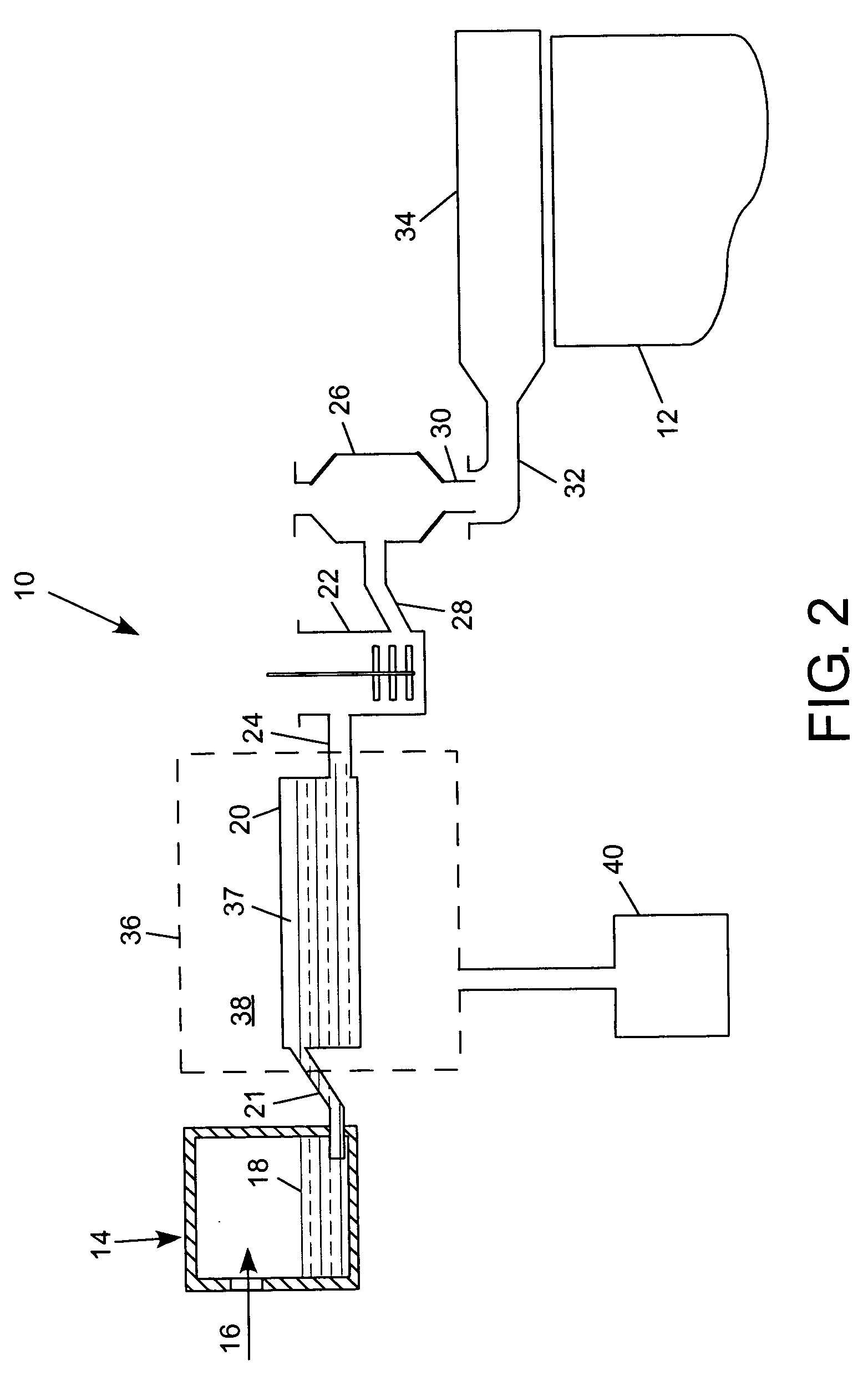

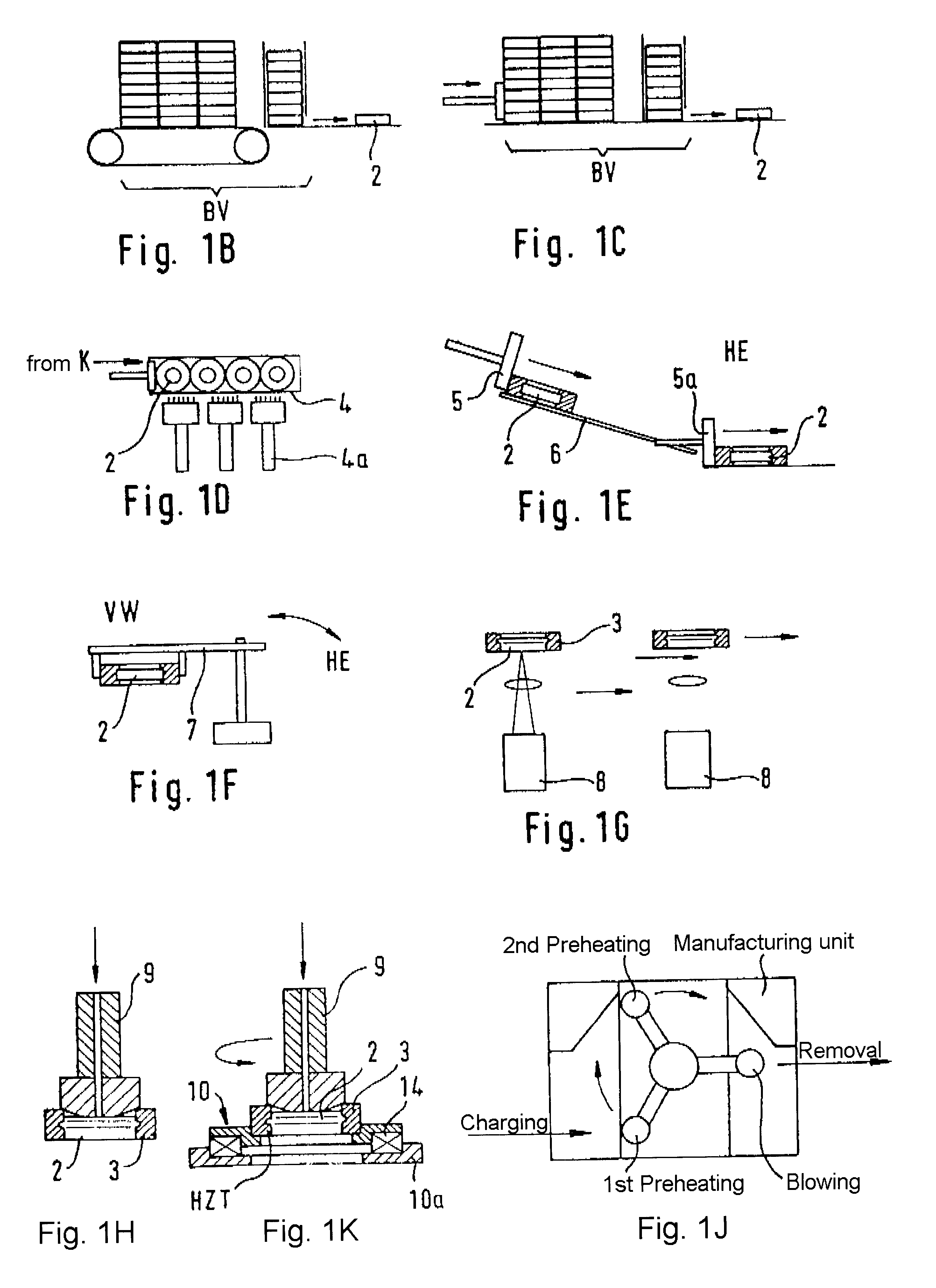

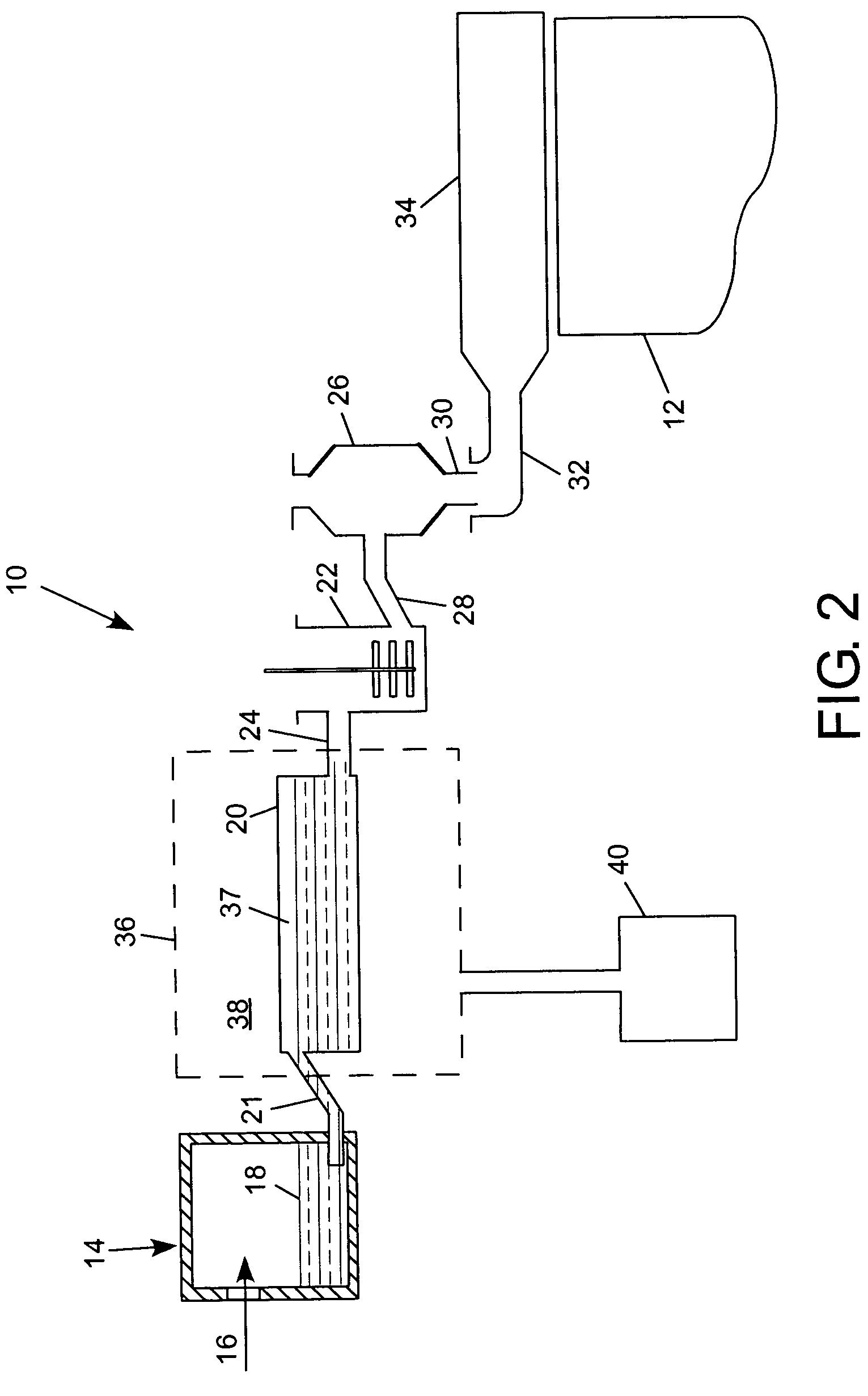

Electronic control system for container indexing and inspection apparatus

A glassware inspection apparatus that includes an electronic control system and method for optimum control of indexing and inspecting glass containers. The control system generally includes a driver circuit for each servo motor of the apparatus, an electronic control unit, and an operator interface. Information about the apparatus and the particular containers being inspected is entered into the control system through the operator interface. The electronic control unit executes a recursive algorithm that utilizes the inputted information, as well as predetermined constraints of the apparatus, to develop an optimum motion profile for each servo motor. The optimum motion profiles provide the overall apparatus with coordinated control and increased container throughput speed, while efficiently distributing cycle time and thermal energy between the various servo motors.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

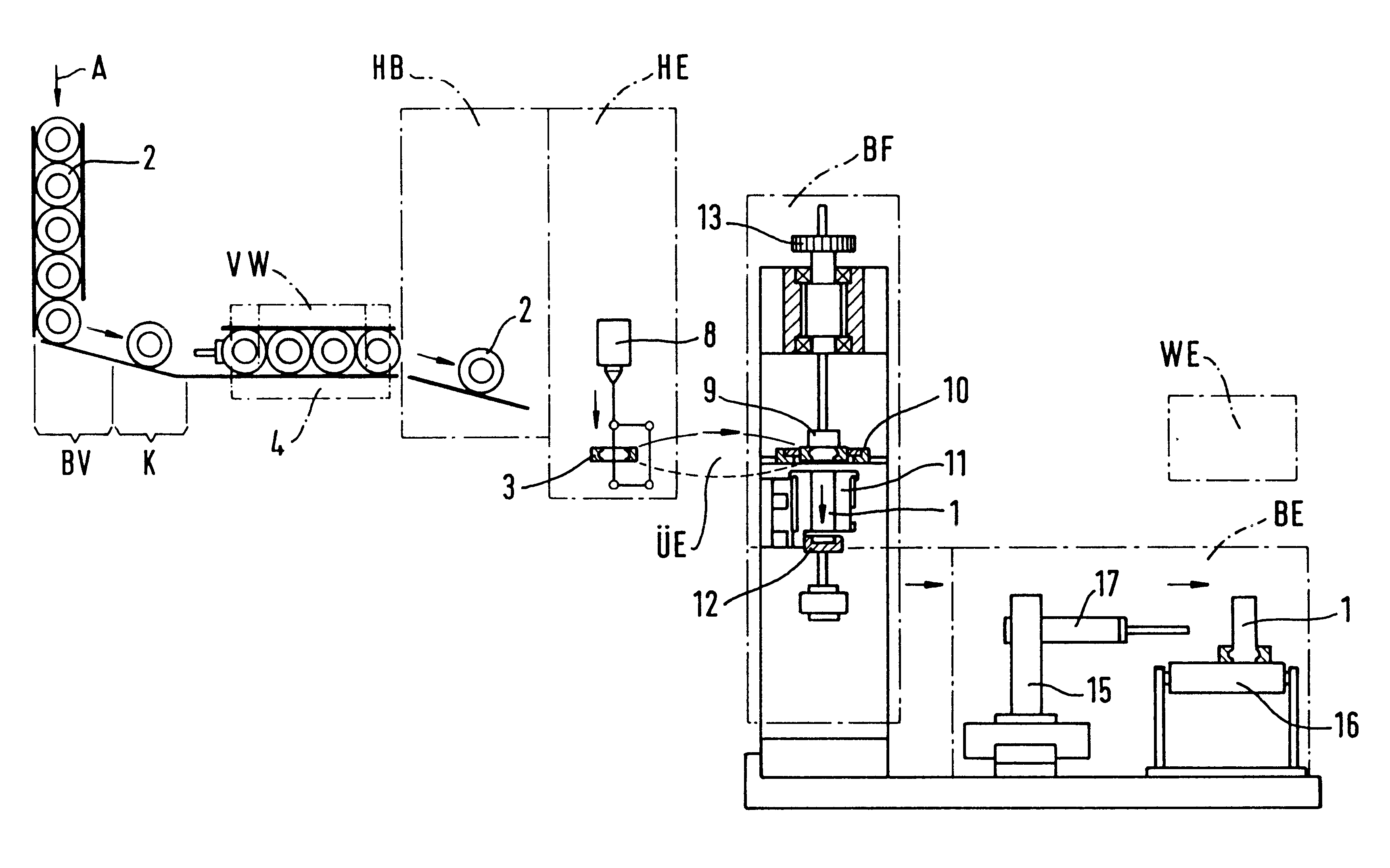

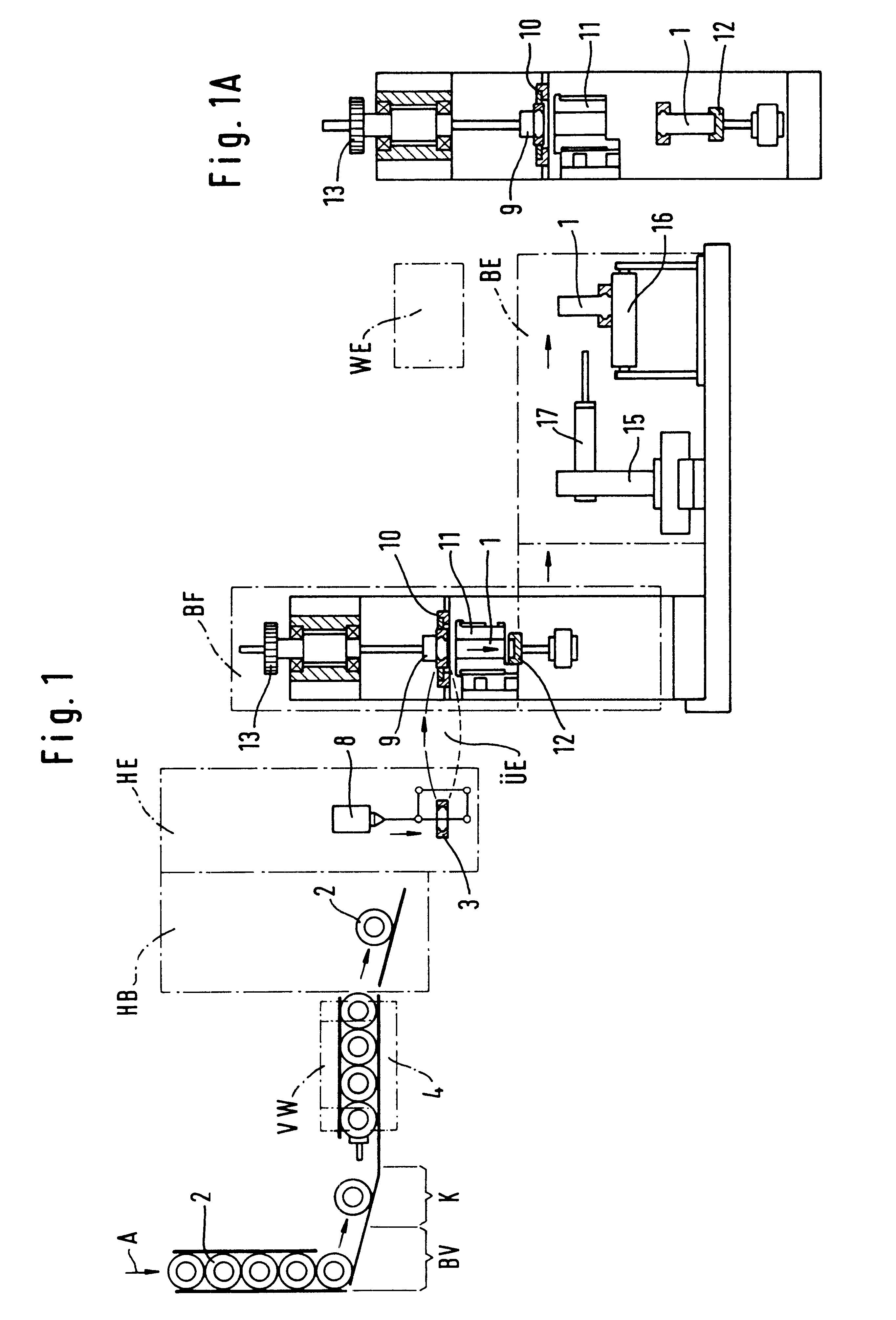

Method for producing glass goblets, tumblers and similar hollow glasses, and corresponding device for carrying out said method

InactiveUS6497119B1Cheap productionInexpensive productionBlowing machine gearingsGlass drawing apparatusBlow moldingEngineering

A device and process for forming hollow glassware comprising producing solid glass blanks in a manufacturing line, storing the blanks, feeding the blanks to a manufacturing line for forming hollow glassware, preheating the blanks during the feeding step, supplying the preheated blanks to a heating stage, heating to form solid plastically deformable glass globs, transferring the glass gobs to a blow molding stage and blow molding the glass gobs supported by a bottom lifter in a blow mold.

Owner:SCHOTT ZWIESEL

Method of fining glass

InactiveUS7475568B2Increased hydrogen permeationAvoid formingGlass furnace apparatusGlass vesselAlloy

A method of forming an oxide glass including heating a glass melt having a β—OH concentration of at least about 0.35 in a vessel comprising a metal selected from the group consisting of platinum, molybdenum, palladium, rhodium, and alloys thereof, there being an interface present between the vessel and the glass, and controlling a partial pressure of hydrogen in an atmosphere in contact with an outside surface of the vessel in an amount such that hydrogen permeation blisters form in a region of the glass adjacent the glass-vessel interface.

Owner:CORNING INC

Amorphous and nanocrystalline glass-coated articles

InactiveUS20050000599A1Rapidly solidify molten alloyGlass making apparatusInorganic material magnetismDynamic balanceGlass vessel

A drawn glass-coated metallic member has a thermal contraction coefficient differential such that the thermal contraction coefficient of the glass is less than that of the metallic member. The thermal contraction coefficient differential is maintained within a predetermined range during drawing. The glass is placed under residual compression, interfacial bonding between said glass and said wire is substantially uniform, and surface cracking and bond breaks between metal and glass are substantially prevented. A dynamic balance is maintained between the surface tension of the molten alloy and the resistance to high temperature deformation by the glass vessel in which it is contained, enabling the production of glass-coated amorphous or nanocrystalline alloy members having predefined cross-sectional shapes.

Owner:DEMODULATION

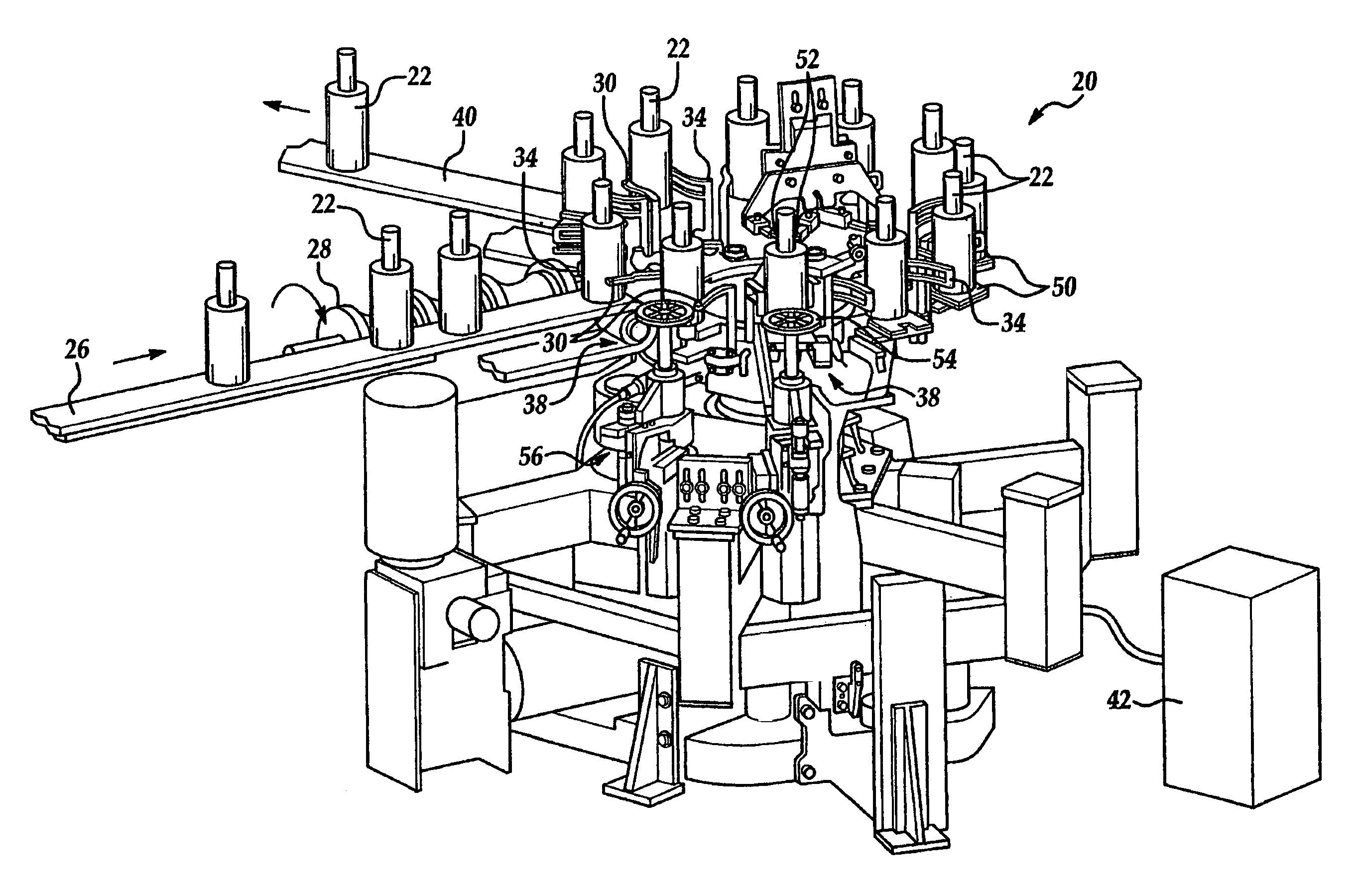

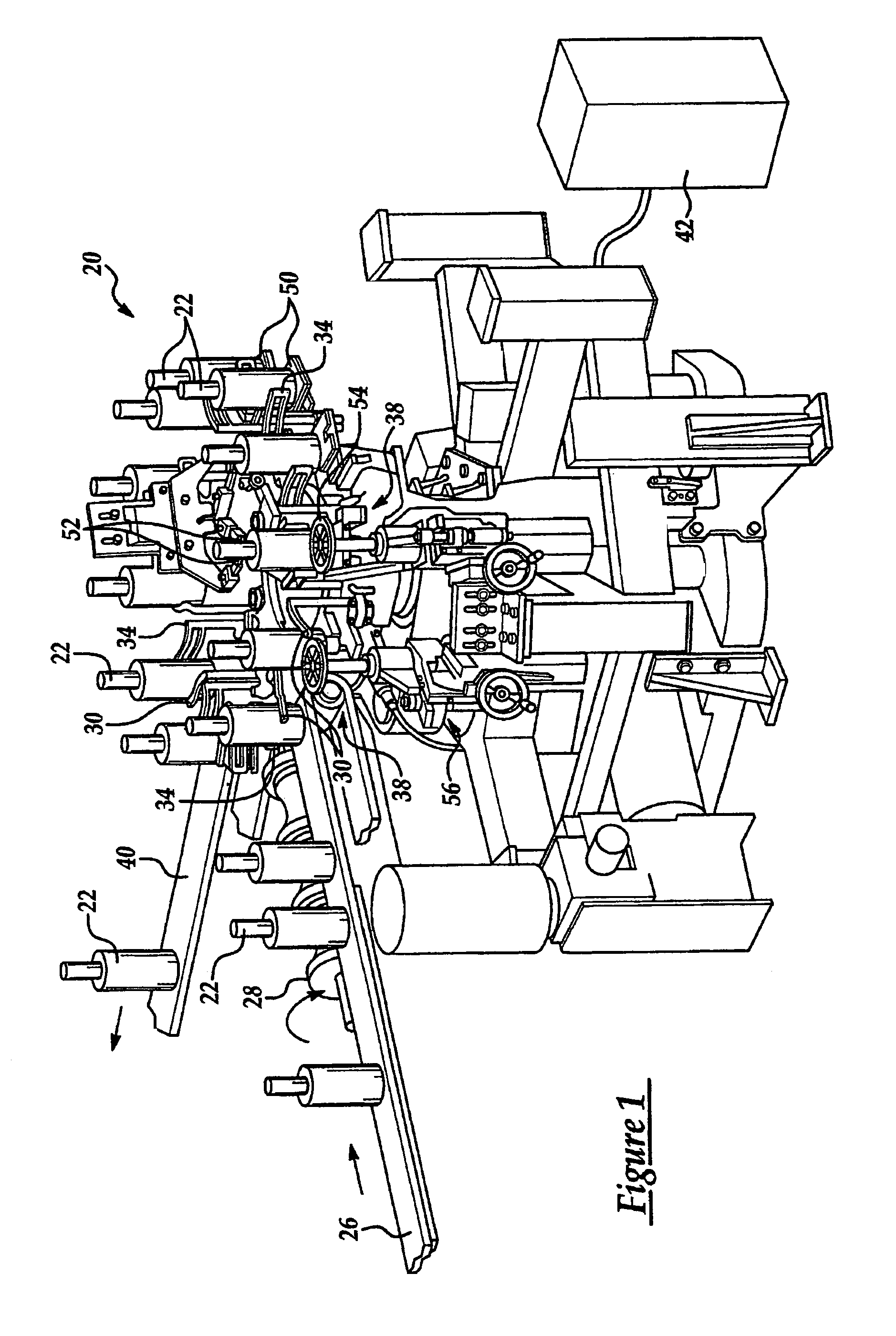

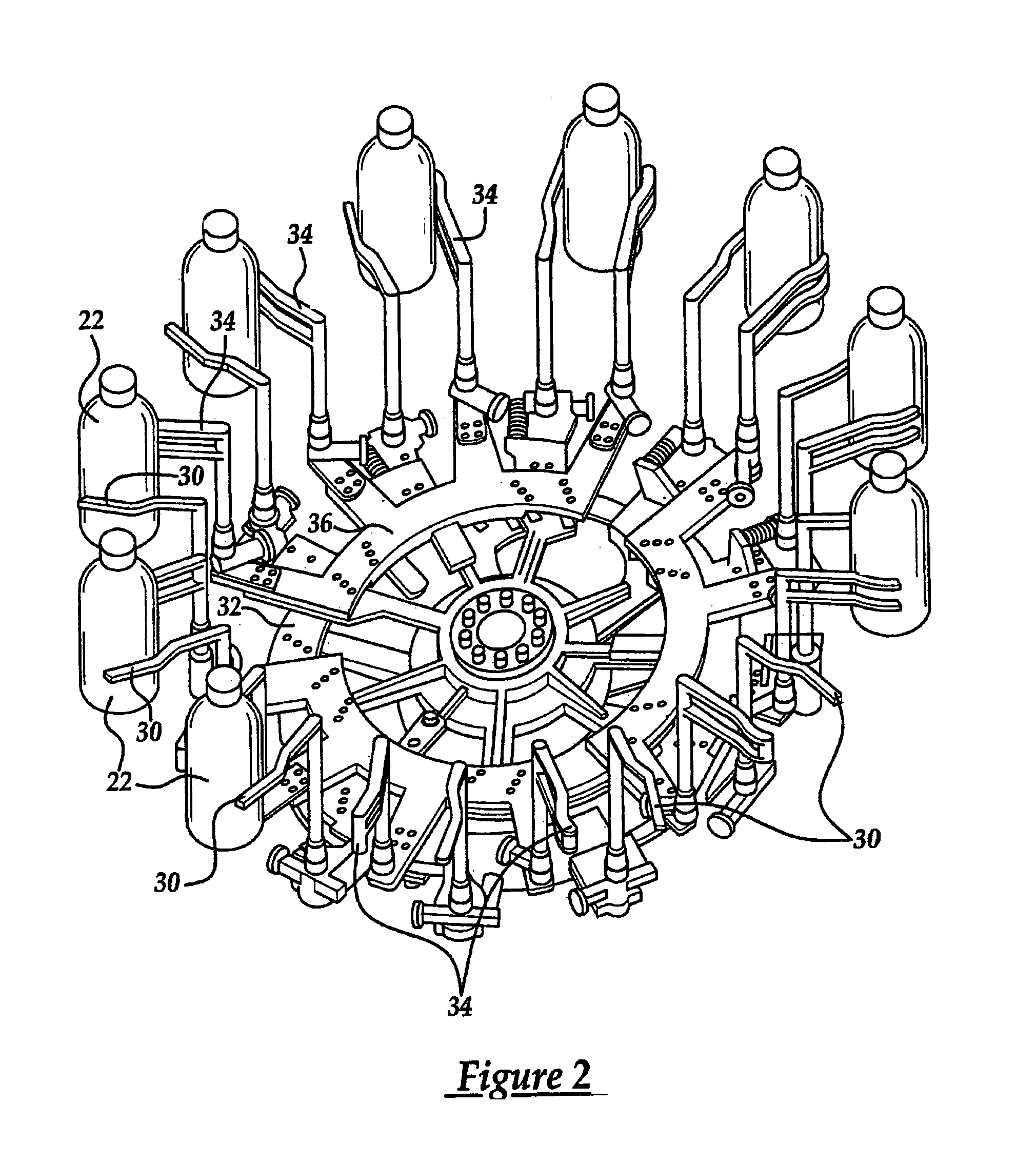

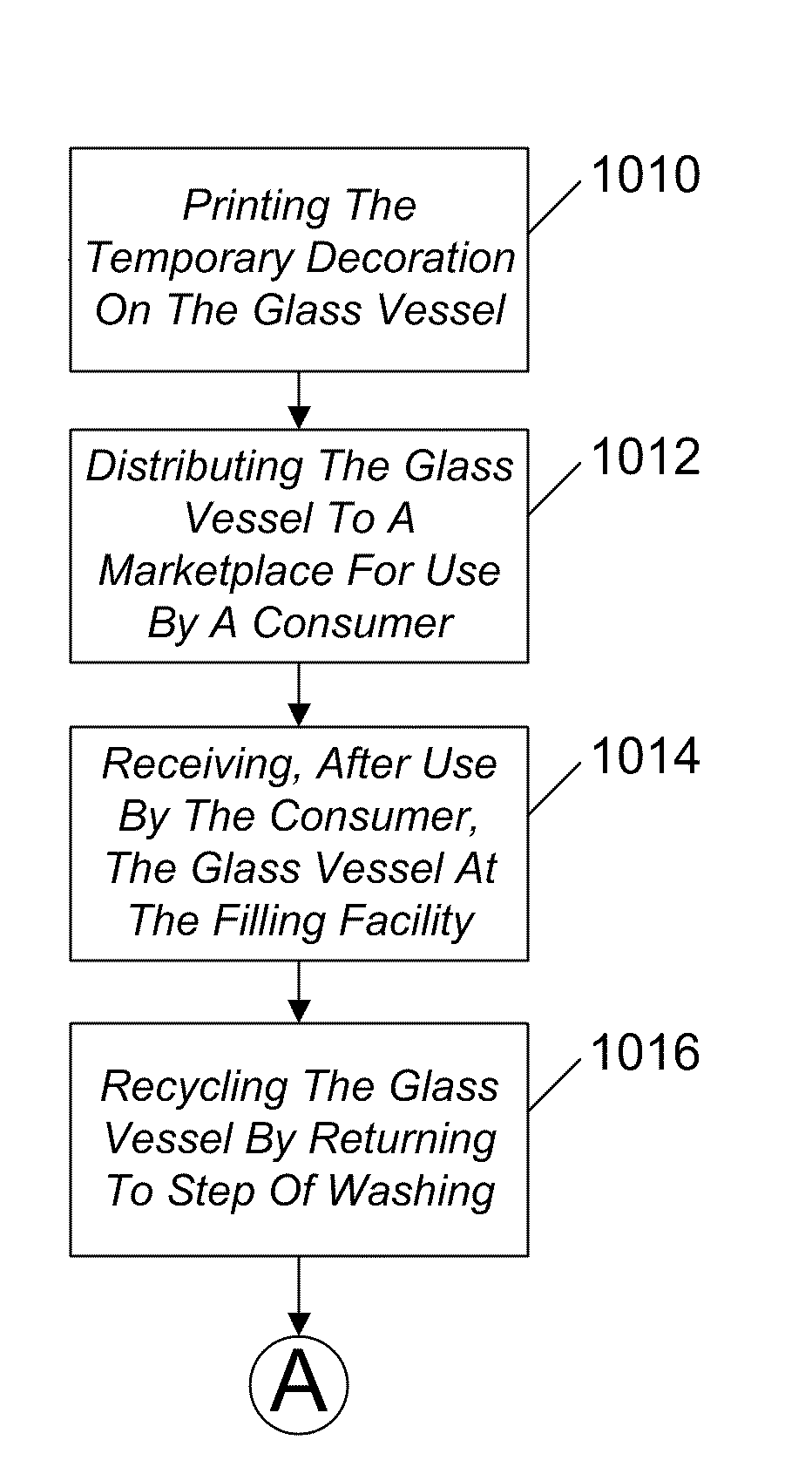

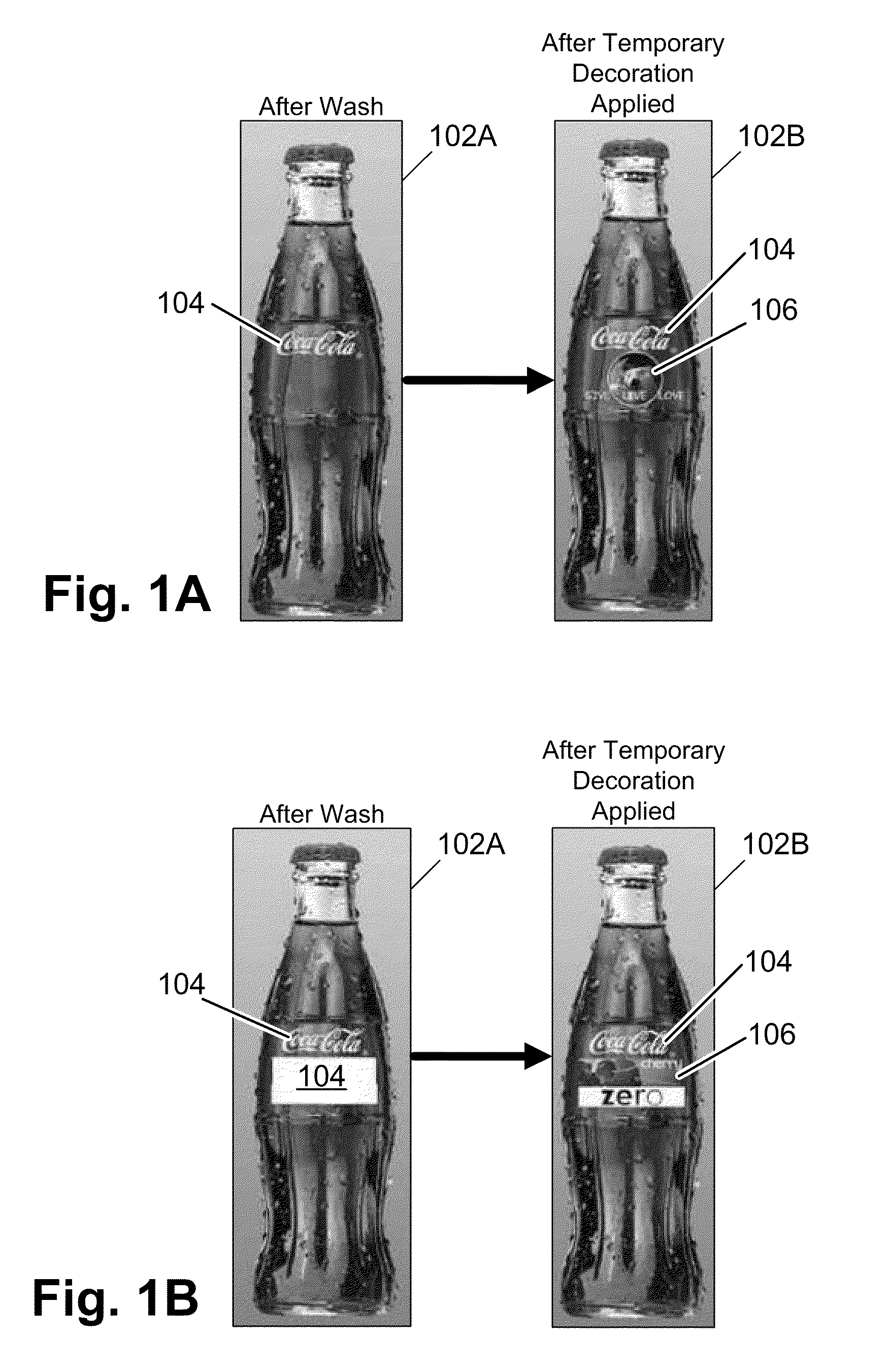

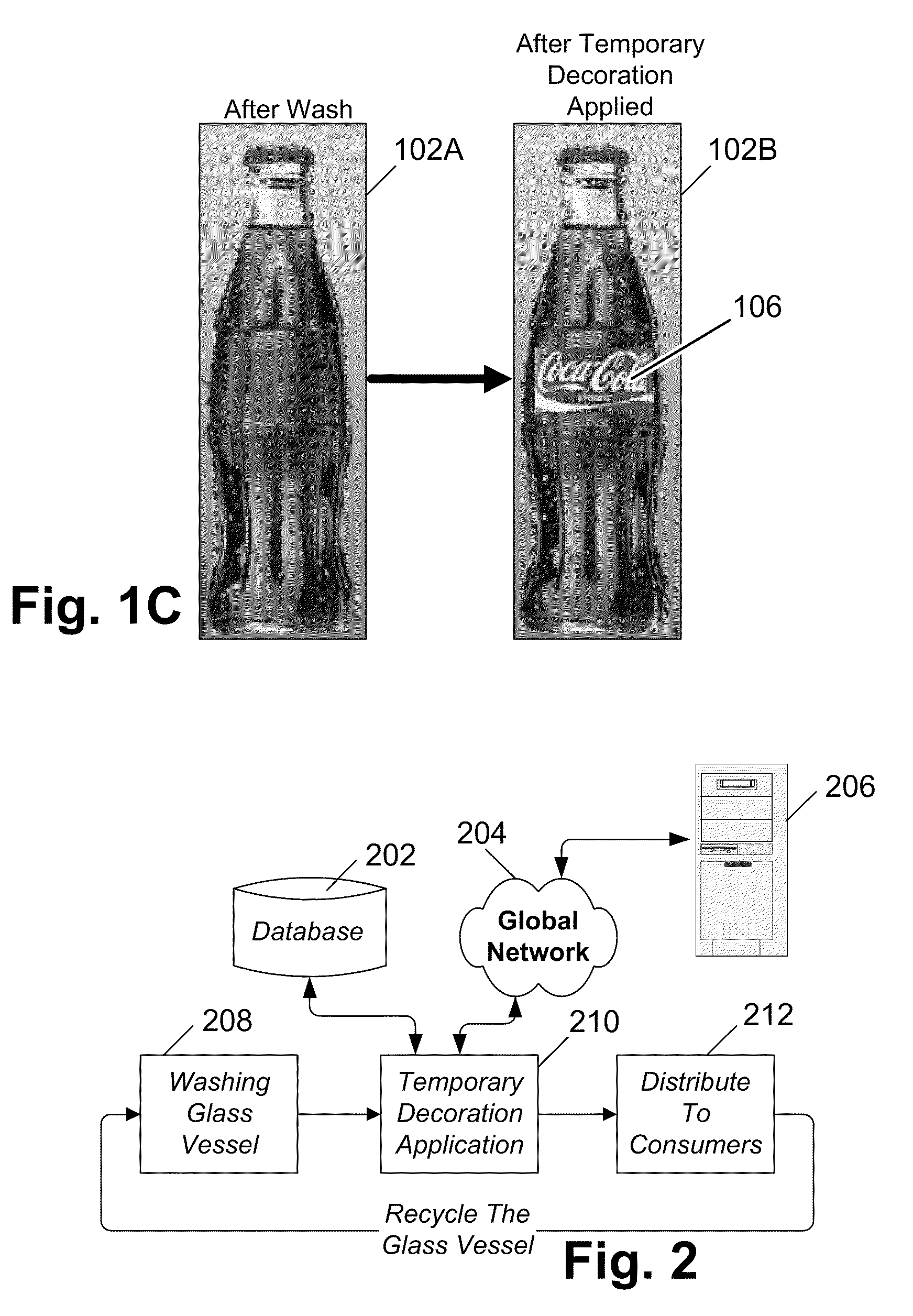

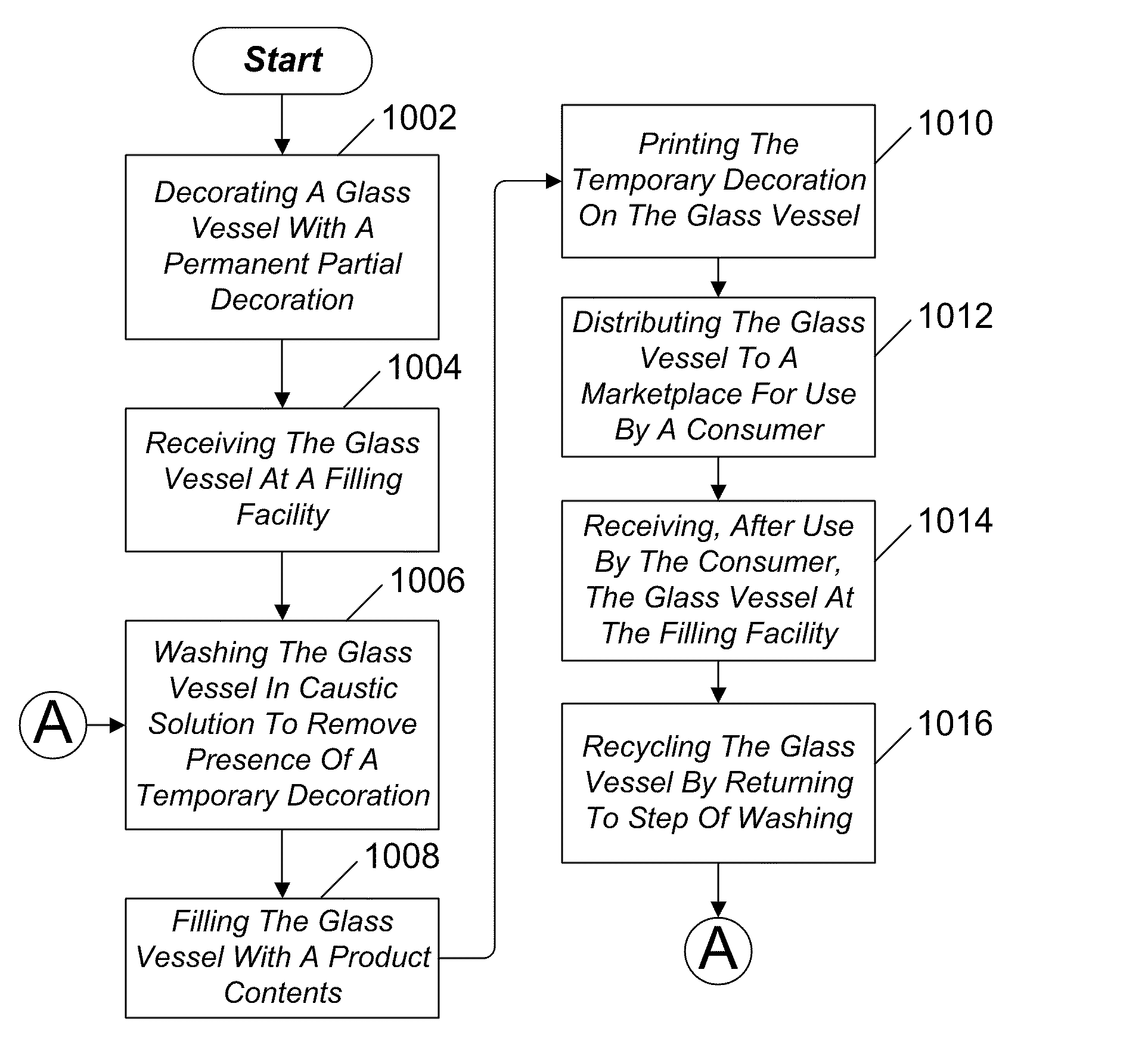

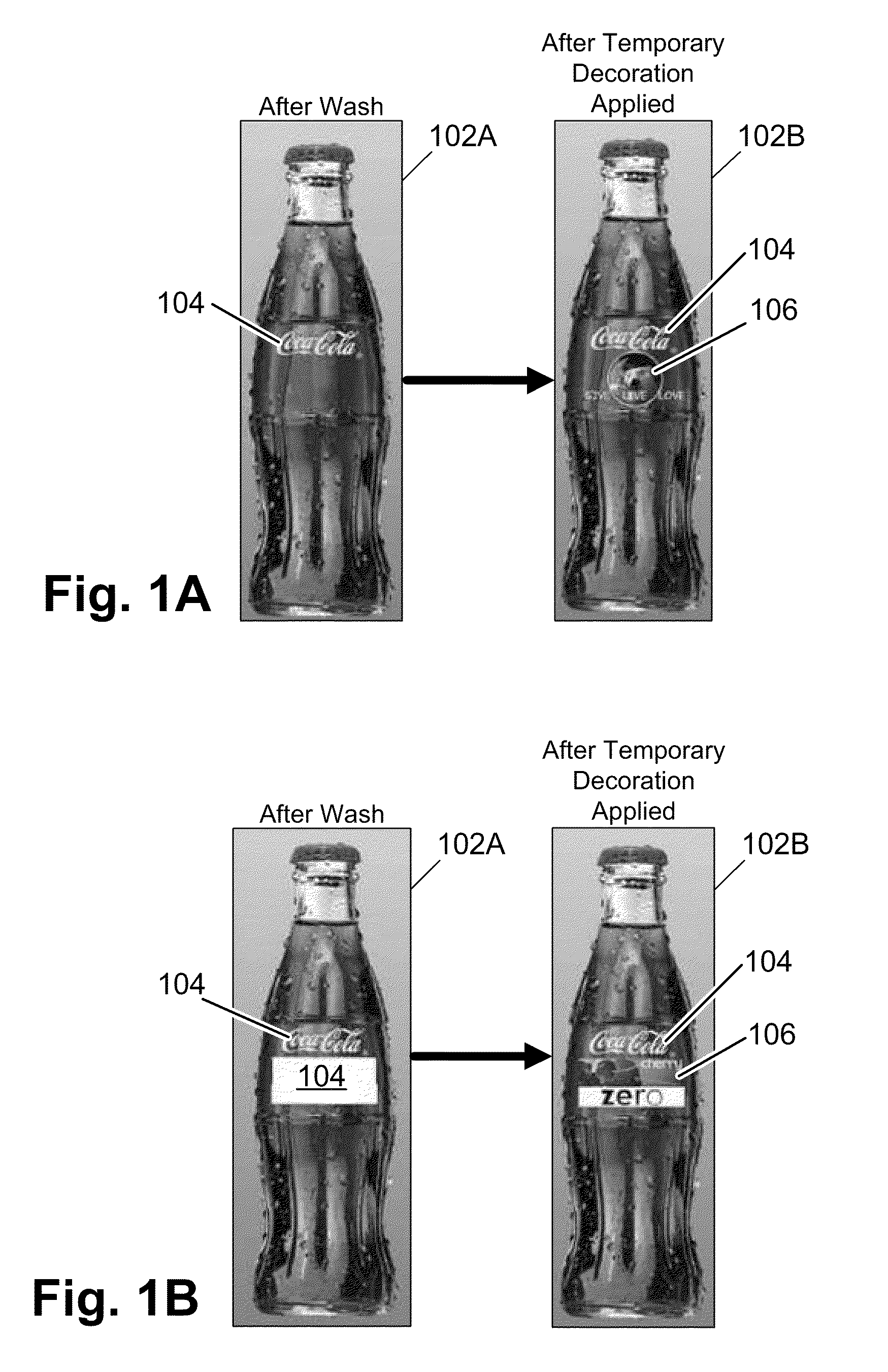

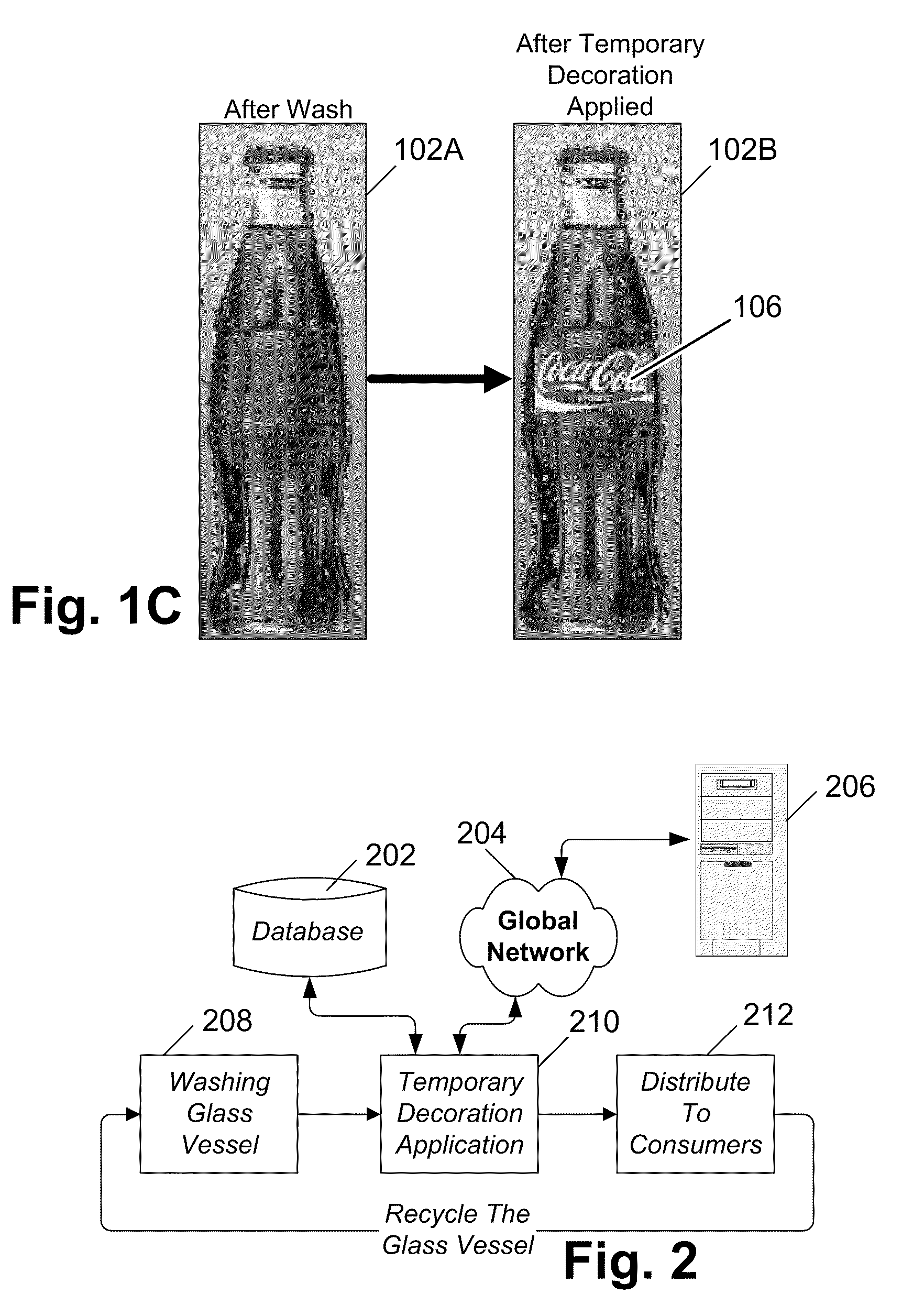

Method of using temporary decoration to mass customize refillable glass vessels

ActiveUS20100281833A1Improve brightness qualityOvercomes shortcomingPower operated devicesScreen printersMass customizationGlass vessel

The present invention relates to a method of using a combination permanent partial decoration and temporary decoration to mass customize refillable glass vessels. The method comprising: decorating a glass vessel with a permanent partial decoration, receiving the glass vessel at a filling facility, washing the glass vessel in caustic solution to remove presence of a temporary decoration, filling the glass vessel with a product contents, printing the temporary decoration on the glass vessel, distributing the glass vessel to a marketplace for use by a consumer, receiving the consumer used glass vessel at the filling facility, and recycling the glass vessel by returning to the step of washing. Other embodiments include not using the permanent partial decoration and printing the temporary decoration on the glass vessel, wherein at least some of the temporary decoration is printed on top of a background region to increase the luminance qualities of the temporary decoration.

Owner:THE COCA-COLA CO

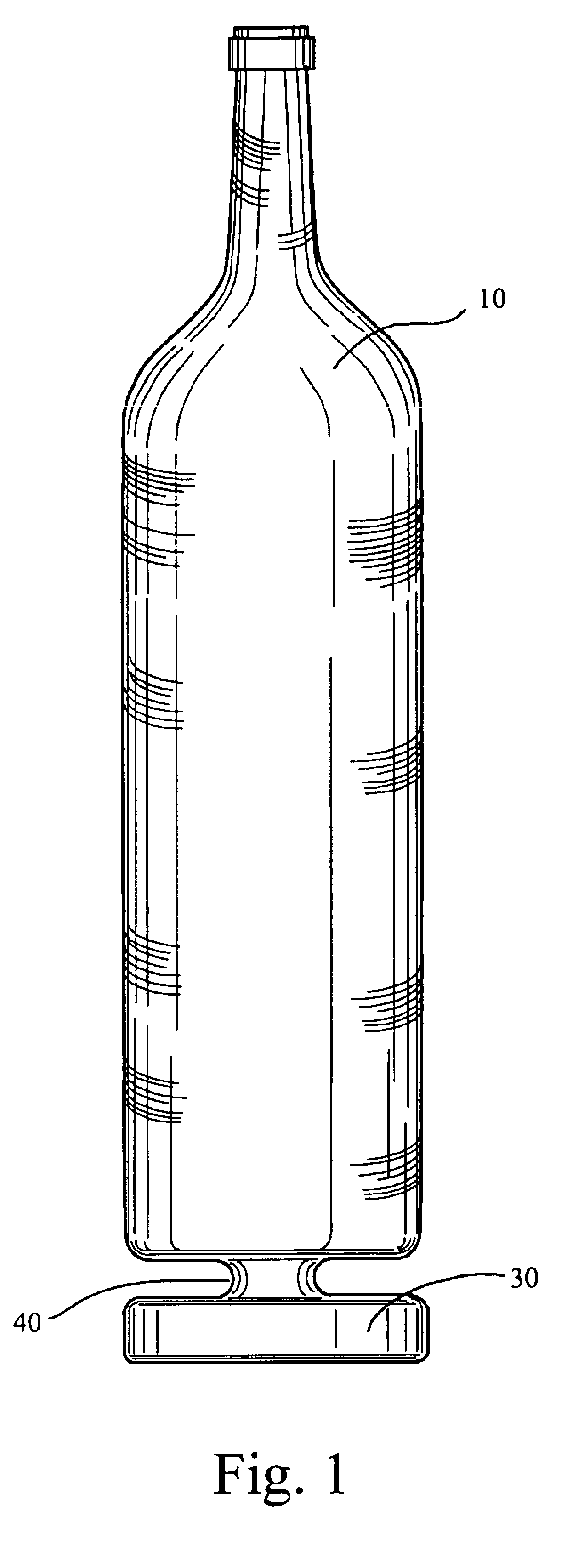

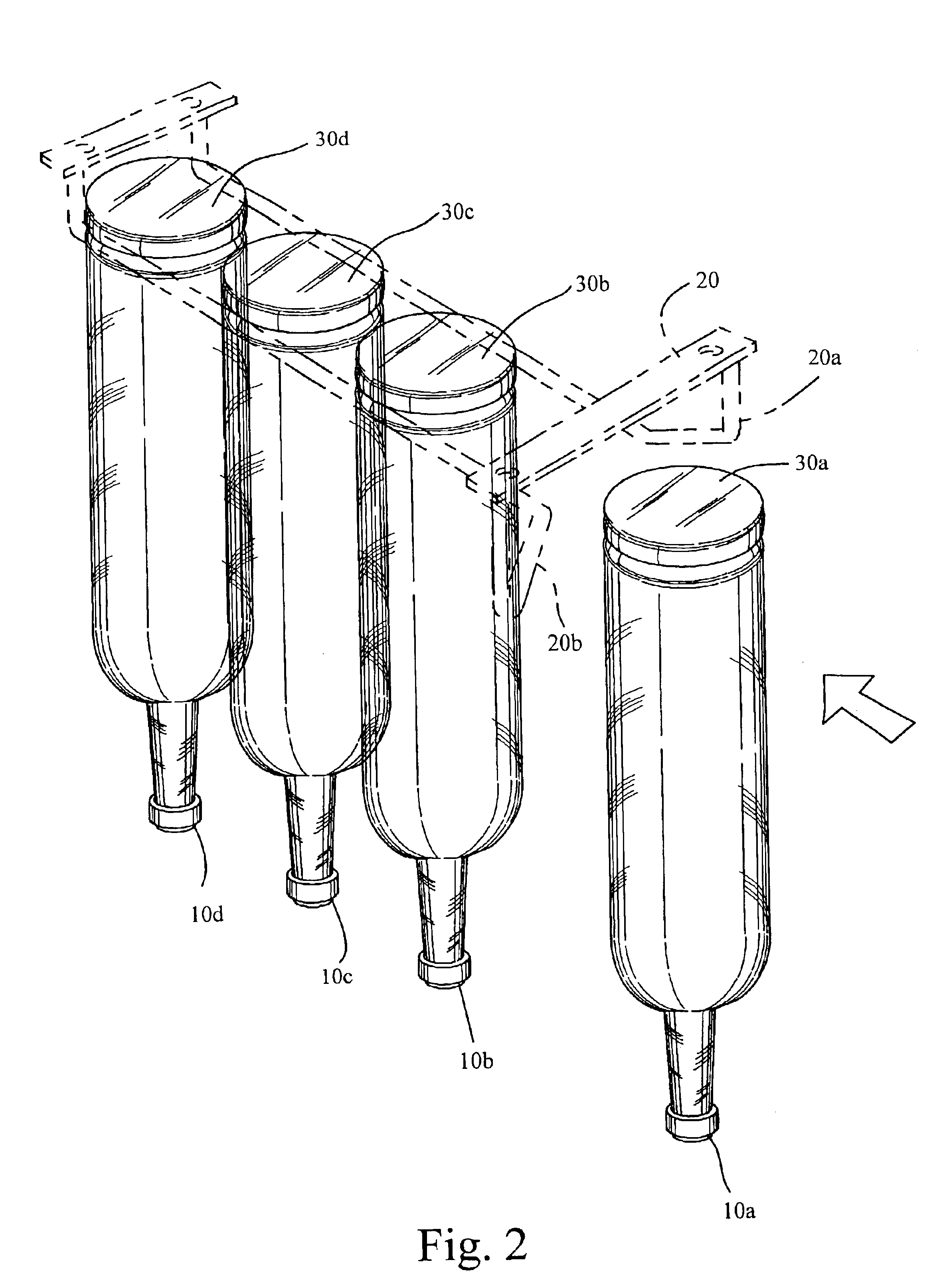

Rack mountable beverage bottle

InactiveUS6945418B2Limited storage and display spaceProtected contentBottlesLarge containersGlass vesselWine bottle

This invention discloses a storage vessel, namely a wine bottle having a liquid volumetric capacity of from about 750 milliliters to about 1,500 milliliters and including an integral pedestal base configured to fit typical glassware fixtures employed in restaurants and taverns. The stem and base portions of the pedestal may be solid or hollow. A hollow pedestal may be advantageous to capture sediments settling out of the wine when the bottle is in an upright position. Pigments may be included in the glass construction to minimize photochemical reactions with the wine contained within the bottle.

Owner:AMARAL JOSEPH F +1

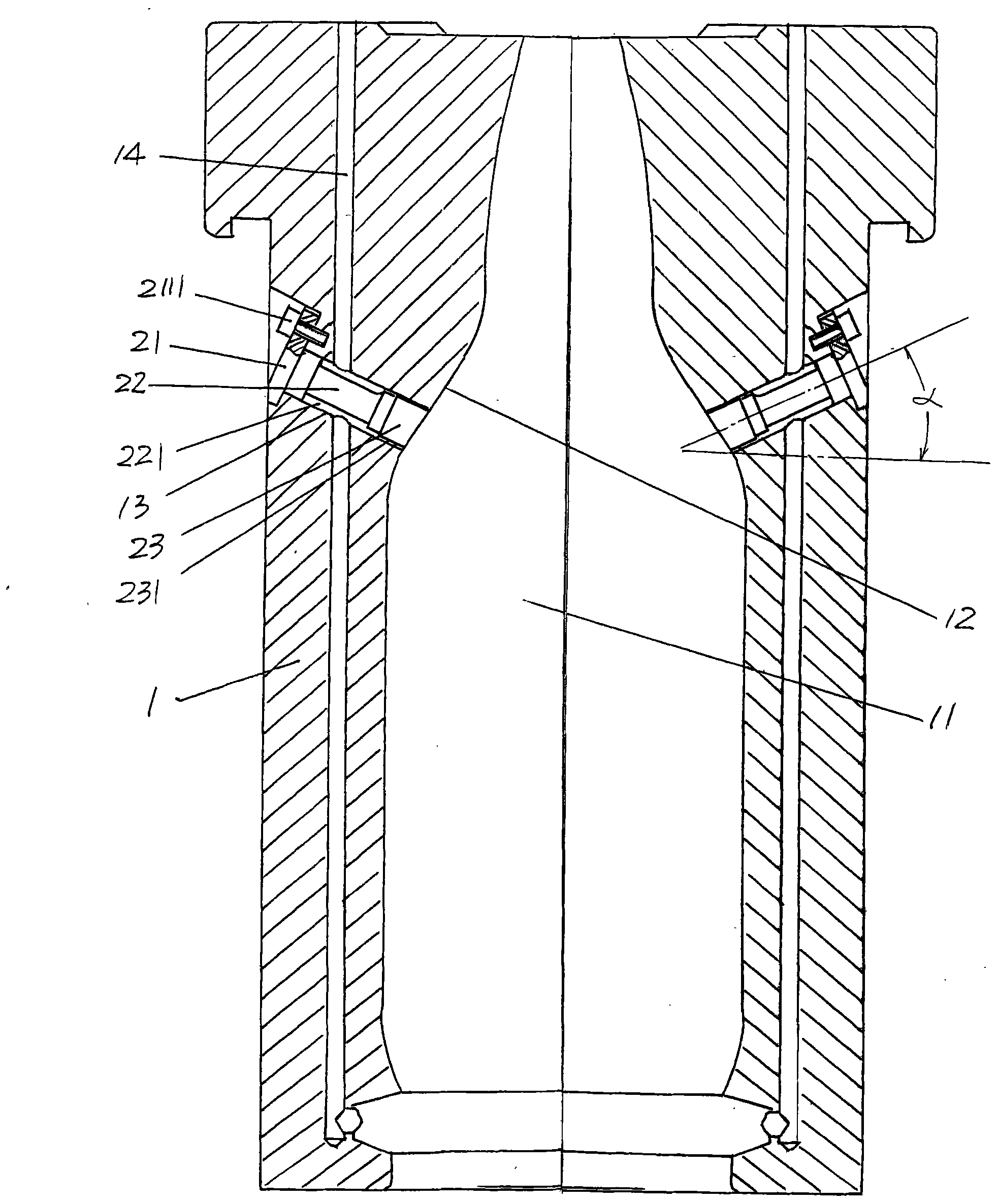

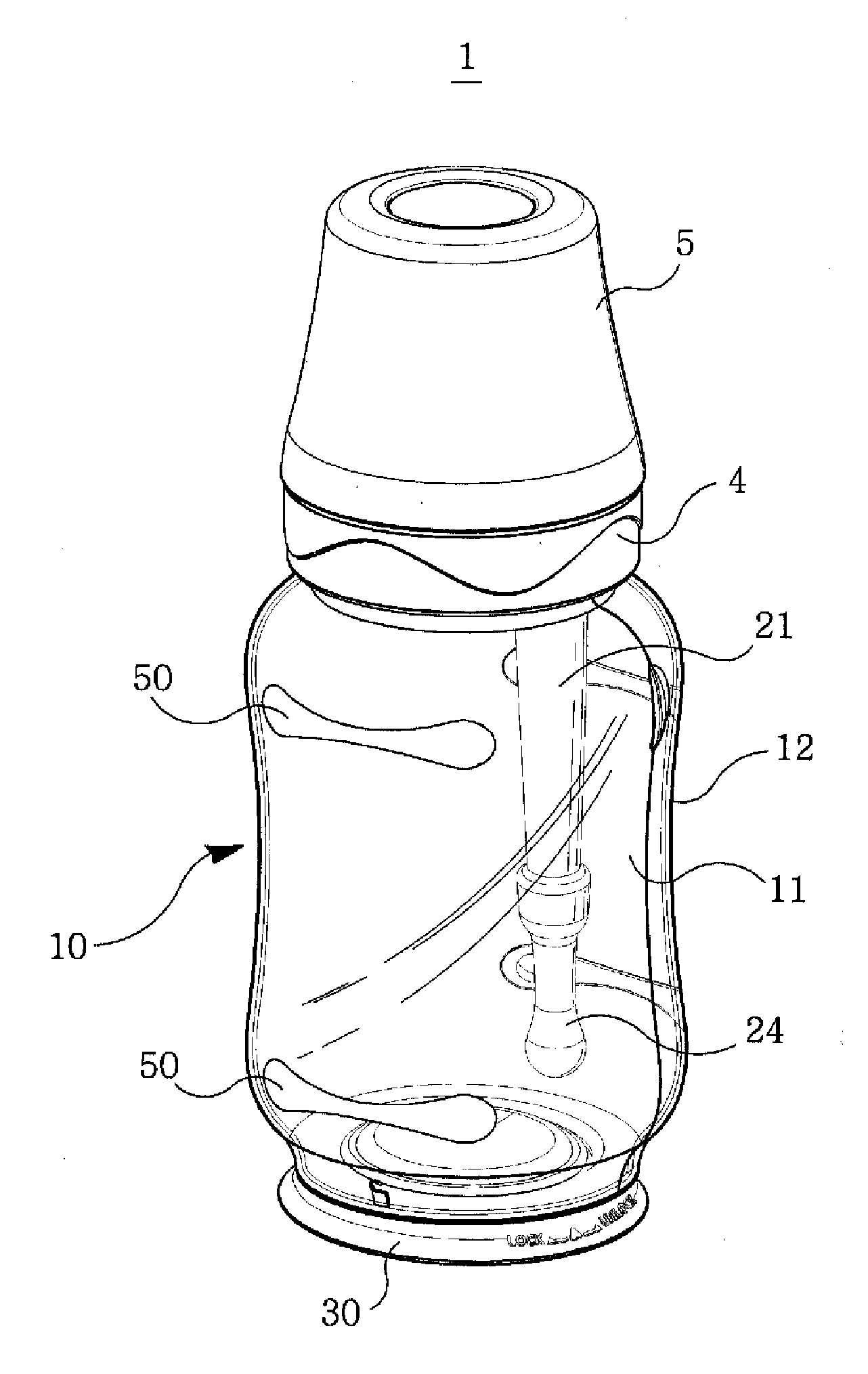

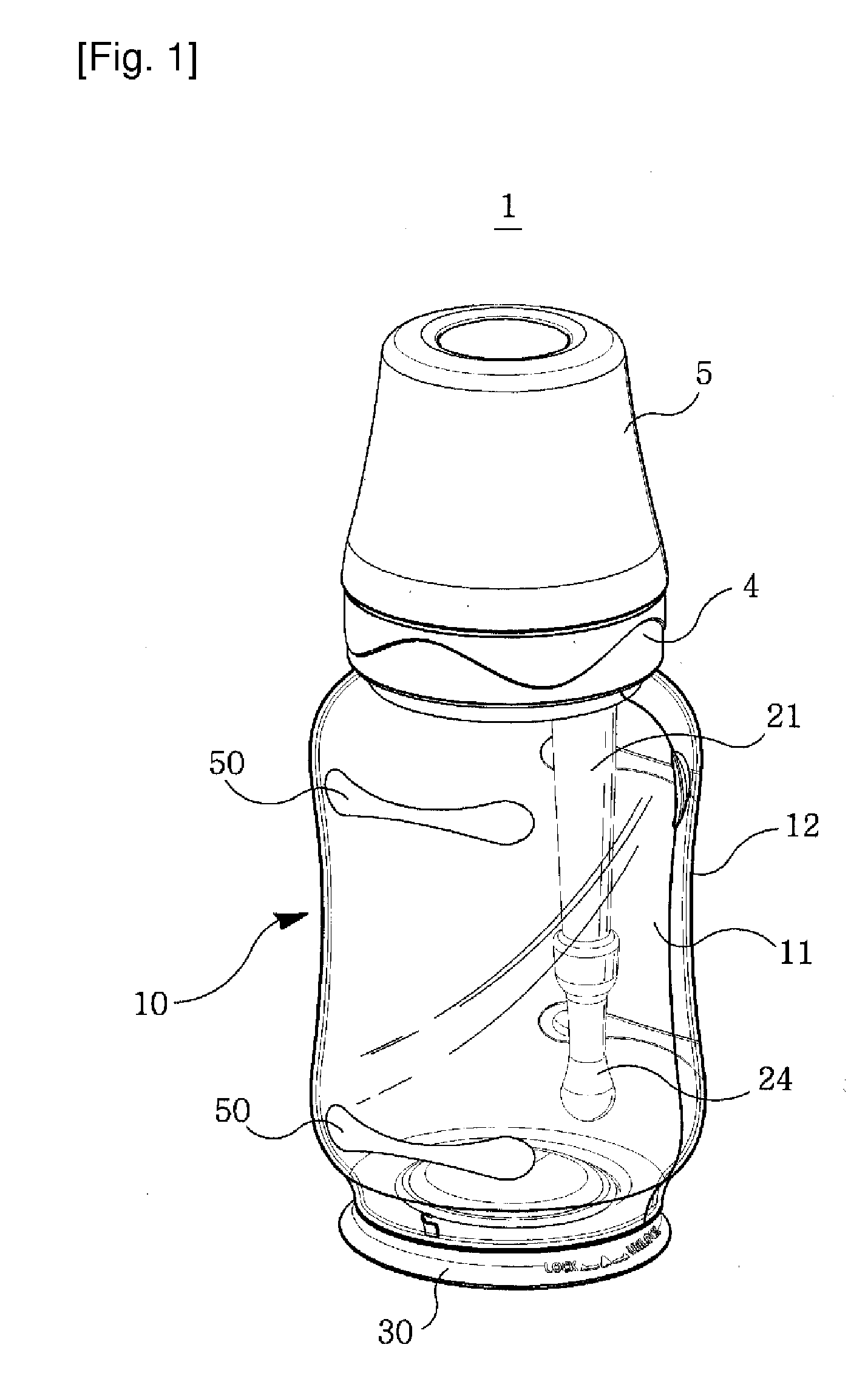

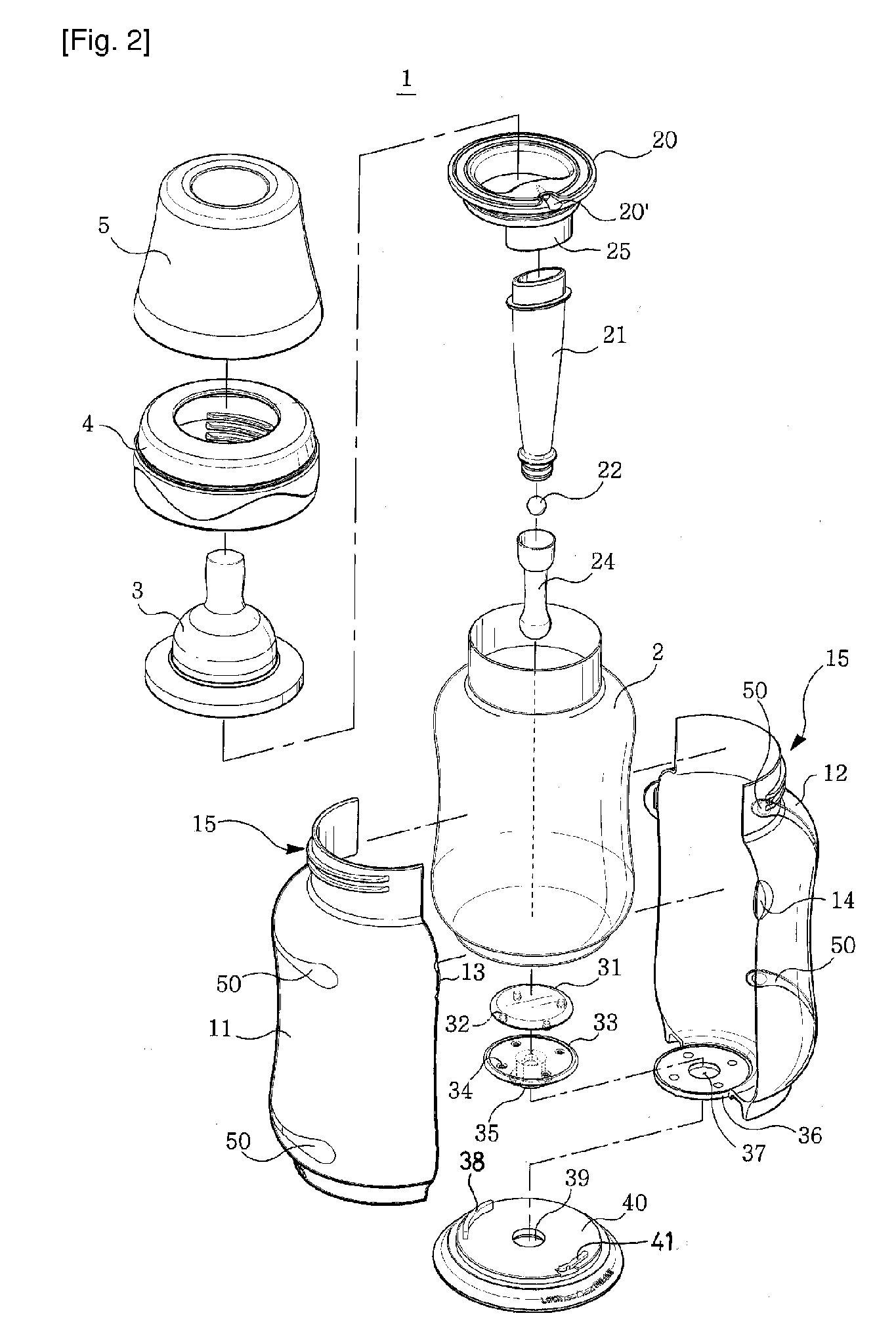

Baby bottle

InactiveUS20100072162A1Avoid excessive forceWell mixedFeeding-bottlesTeatsVentilation tubePerturbateurs endocriniens

A baby bottle for preventing the release of endocrine disrupters is disclosed. The baby bottle includes a glass vessel containing milk. A protective cover has shock absorbing members to protect the glass vessel, and includes left and right cover bodies having a fastening protrusion and a fastening hole, respectively. An air inlet packing is placed on the upper end of the glass vessel to control inflow of external air, and is coupled to a ventilation tube and a nipple. A support cap is fastened to the upper end of the protective cover in such a way that the nipple is in close contact with the upper portion of the air inlet packing, when the air inlet packing is in close contact with the glass vessel. Thus, the baby bottle protects a baby from endocrine disrupters, and prevents air from flowing backwards during feeding, thus preventing the baby from spitting

Owner:PARK YONG JICK +1

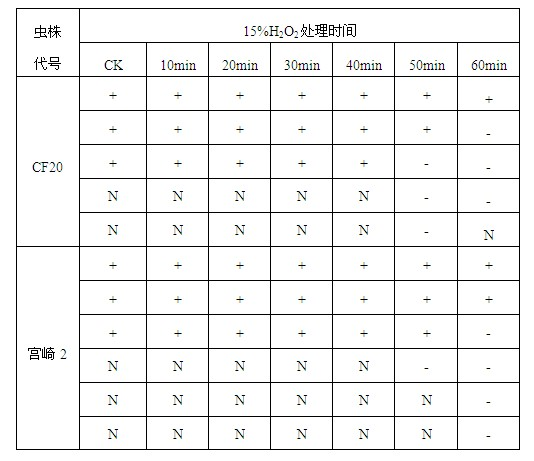

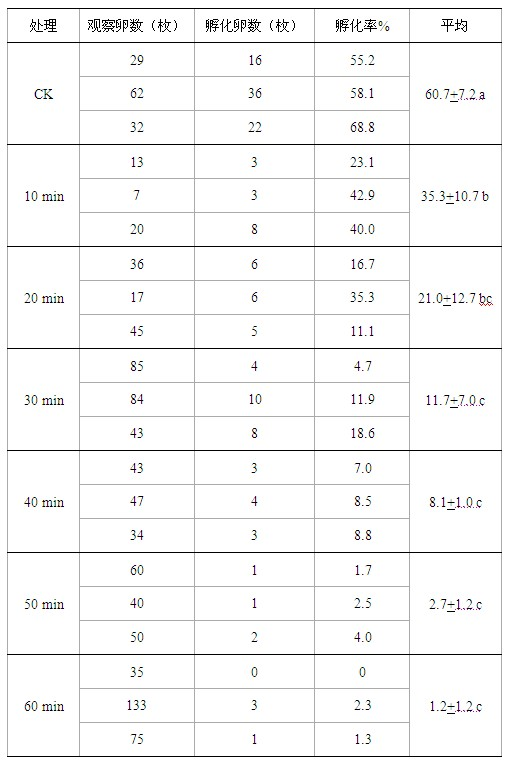

Method for preparing bacteria-free pine wood nematodes

The invention discloses a method for preparing bacteria-free pine wood nematodes. The method for preparing the bacteria-free pine wood nematodes comprises the following steps: culturing the pine wood nematodes; preparing pure pine wood nematode eggs; soaking the pine wood nematode eggs in 15% H2O2 for 50-60 minutes; incubating the pine wood nematodes; and culturing the pine wood nematodes and performing bacteria-free identification, thereby preparing the bacteria-free pine wood nematodes. As for the method for preparing the bacteria-free pine wood nematodes, the property of being capable of being adhered on a glass vessel of the pine wood nematode eggs is utilized, a small culture dish is adopted for collecting the eggs, the newly prepared 15% H2O2 is further used for performing sterilization treatment, the bacteria-free pine wood nematode eggs are obtained, the bacteria-free eggs are incubated, mass propagation is further performed on botrytis cinerea, and then the bacteria-free pine wood nematodes are finally obtained. Under sterile conditions, the obtained bacteria-free pine wood nematodes are used for performing an inoculation test on seedlings cultured by spruce bacteria-free tissues, and the result shows that the inoculation of the bacteria-free pine wood nematodes can still enable the bacterial-free seedlings to wilt. The method can be adopted for enabling the pine wood nematodes to be bacteria-free and lose pathogenicity, thereby being the simple and successful method.

Owner:NANJING FORESTRY UNIV

Freeze-etching agent of ultra-low-carbon steel casting billet macrograph grain structure, and preparation method thereof

ActiveCN102401759ALow S.P contentEasy to distinguishPreparing sample for investigationFreeze EtchingGlass vessel

The invention discloses a freeze-etching agent of ultra-low-carbon steel casting billet macrograph grain structure, and a preparation method thereof. The freeze-etching agent is prepared from materials of: 30 to 50g of ferric chloride, 0.5 to 1.2g of stannous chloride, 2 to 3 parts of trinitrophenol, 10 to 20ml of sodium alkyl phenyl sulfonate, 200 to 500ml of absolute alcohol, and 600 to 1000ml of hydrochloric acid. Solid agents of the formulation are mixed and placed into a glass vessel according to the ratio; 1500 to 2000ml of distilled water is divided into two parts; one part is added to the solid mixed agents, and the other part is preserved for later use; absolute alcohol is added to the preserved part of distilled water; hydrochloric acid is added to the alcohol solution; sodium alkyl phenyl sulfonate is added to the aqueous solution containing agents such as ferric chloride, and the mixture is uniformly stirred; the alcohol + hydrochloric acid solution is then added to the aqueous solution containing the agents such as ferric chloride; the solution is sufficiently stirred, such that the freeze-etching agent is prepared. With the freeze-etching agent, the form of the ultra-low-carbon continuous casting steel billet macrograph grain structure can be clearly shown. The freeze-etching agent provided by the invention has advantages of high detection speed, low pollution, and convenient operation. Also, the freeze-etching agent is energy-saving.

Owner:ANGANG STEEL CO LTD

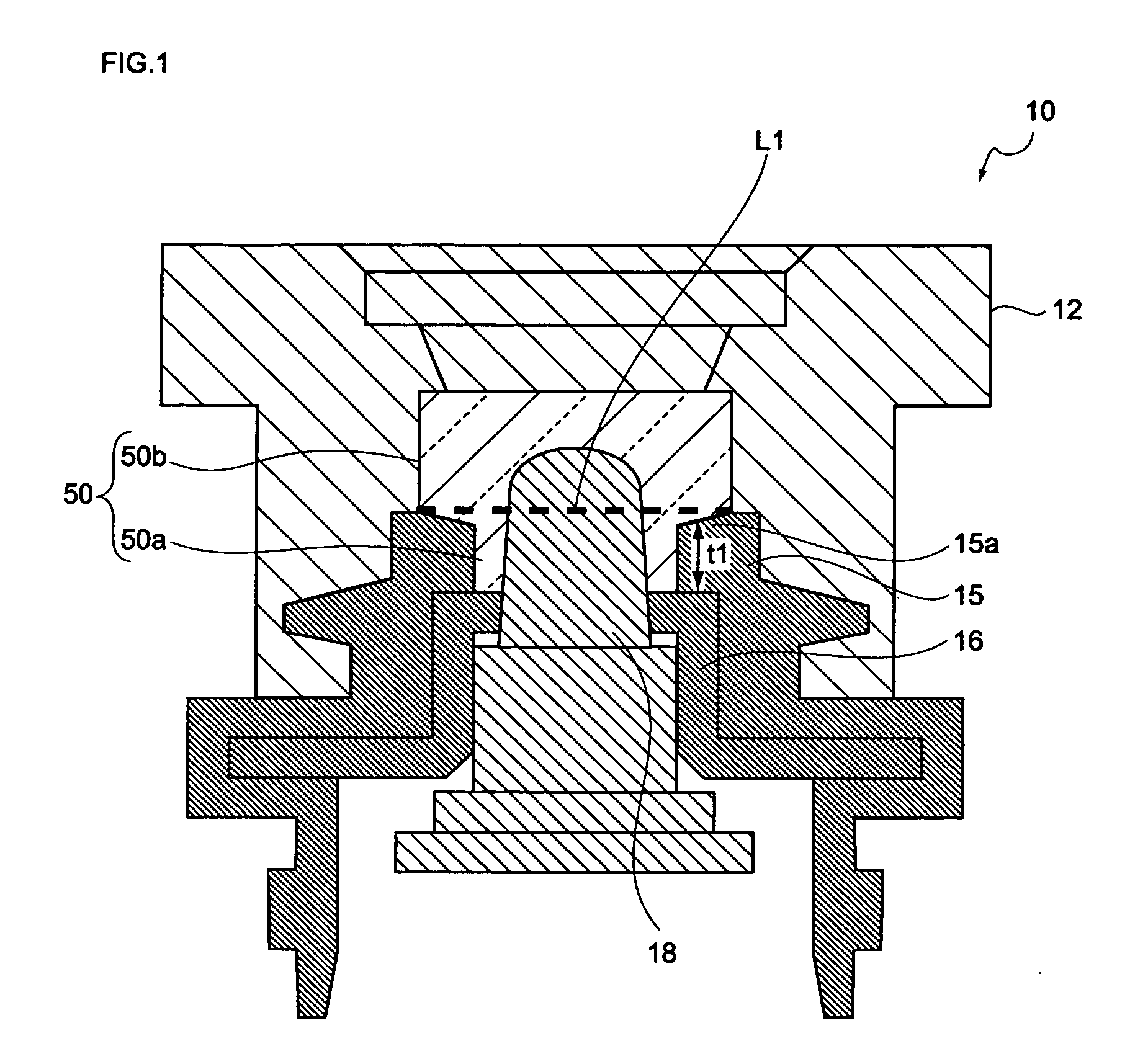

One-press method for producing glass vessel

ActiveUS20100147029A1Efficiently obtainedLow costGlass drawing apparatusGlass forming apparatusGlass vesselThick wall

There is provided a one-press method for producing a glass vessel, the method enabling efficient production of even a glass vessel having the maximum thick wall part having a thickness larger than a predetermined value by using a divided type forming mold having a specific parting line. The one-press method for producing a glass vessel, the method including (A) a press step of molding, by one press, a parison having a finish form from the gob by using a forming die including a forming die base part and a mouth die which are each divided into two parts by a predetermined parting line, (B) a transfer step of transferring the parison having a finish form to a cooling mold, and (C) a cooling step of making the parison having a finish form into a glass vessel by blowing off a first cooling air along the inside peripheral surface of the parison having a finish form and supplying a second cooling air that cools the outside peripheral surface of the parison having a finish form, wherein the press step (A) is carried out using a forming die having a parting line positioned at the shoulder part between the mouth ring part and body part of the parison having a finish form.

Owner:KOA GLASS CO LTD

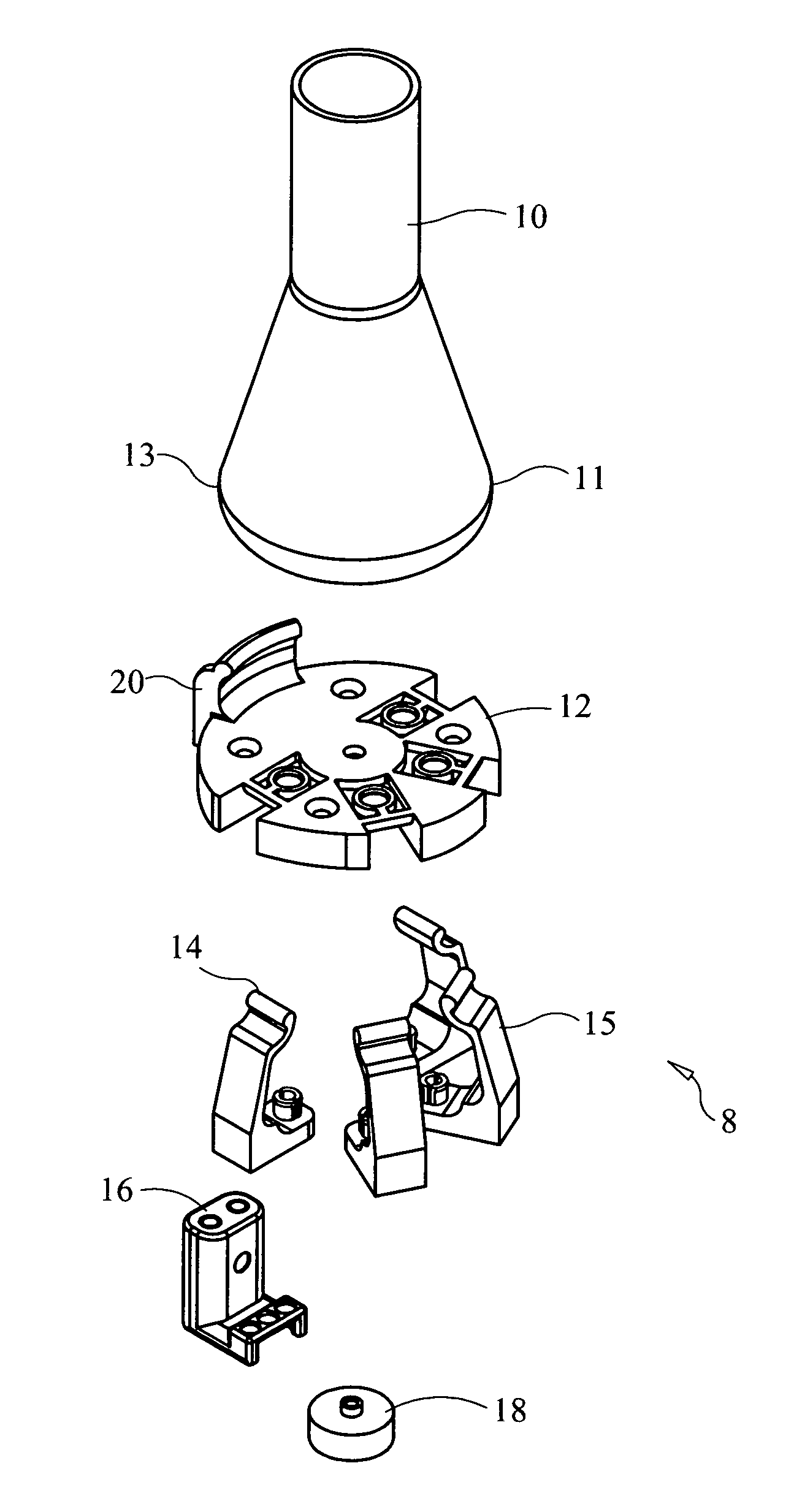

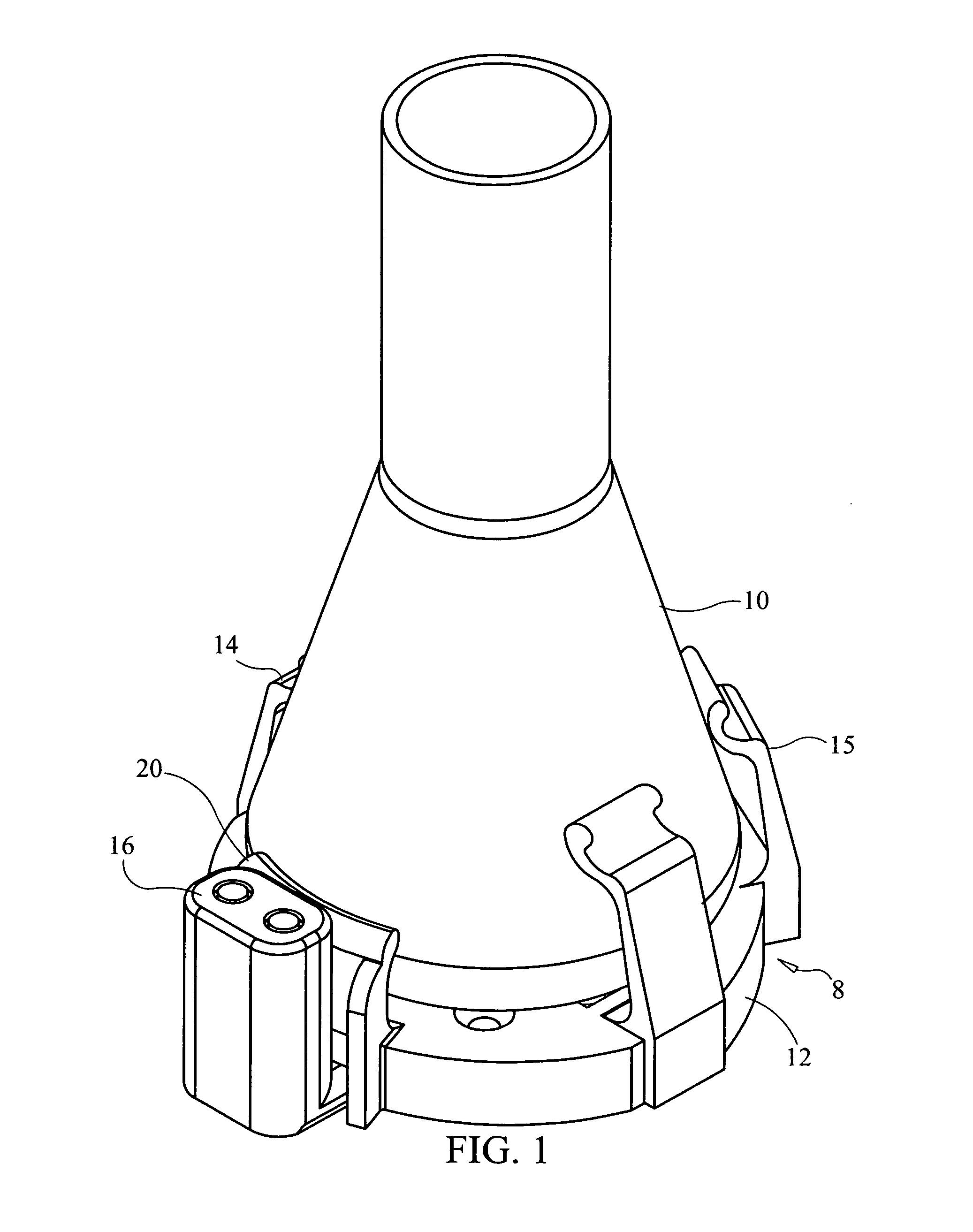

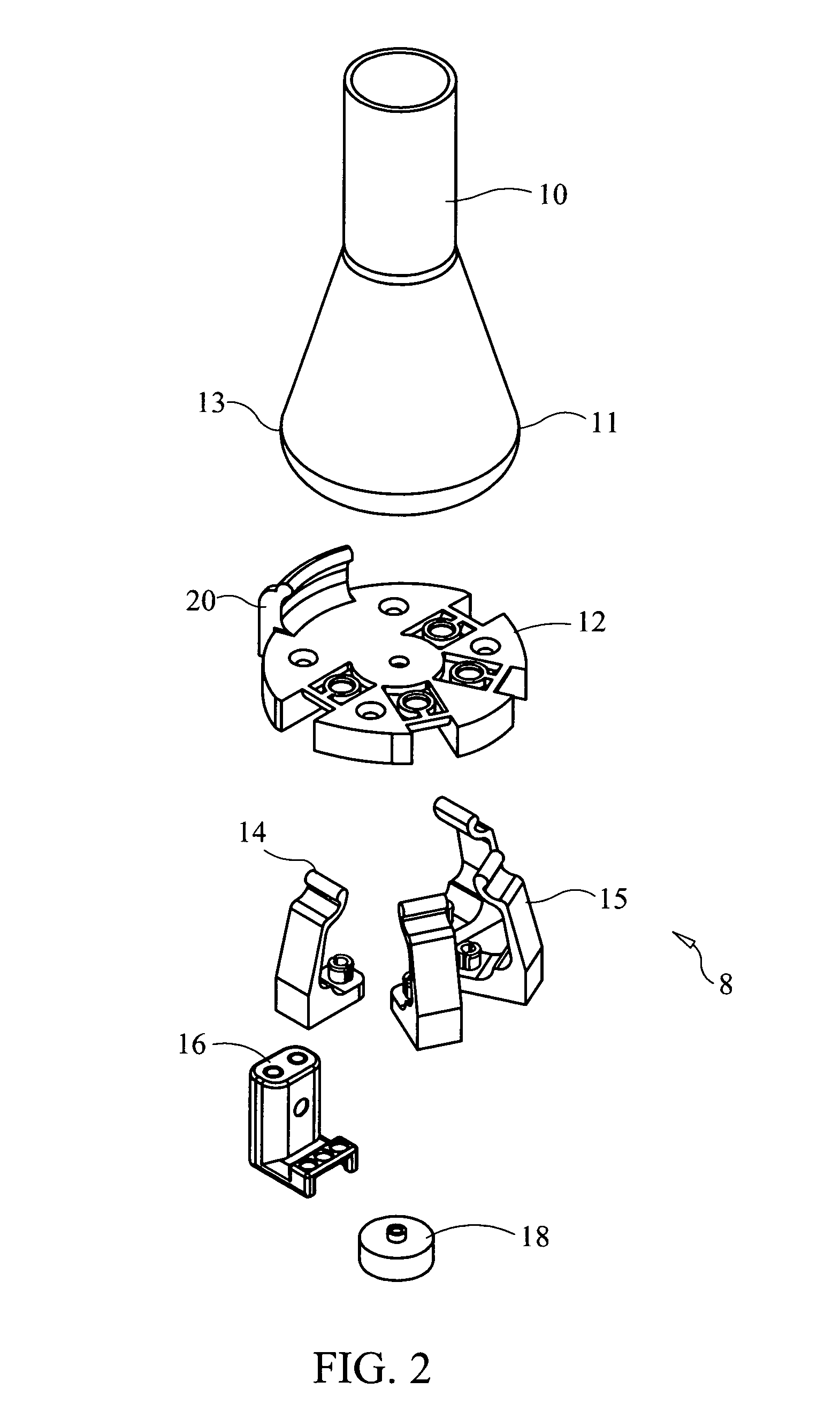

Container holder for mixers

InactiveUS8876367B1Increase profitEasy to optimizeShaking/oscillating/vibrating mixersPicture framesChemical industryMultiple use

An apparatus and method for use in the biopharmaceutical and chemical industries to facilitate the temporary attachment of standard laboratory glassware to vibratory mixers and other types of aggressive shaking equipment. The container holder couples the entire flask or container to the mixing equipment in a secure fashion. The technology may be used with conventional glass flasks, or with plastic flasks that can be configured for either single-use or multiple-use. The invention allows for single handed, low force insertion of the flaskware as well as the incorporation of sensors into the container holder.

Owner:HOWE HAROLD W +1

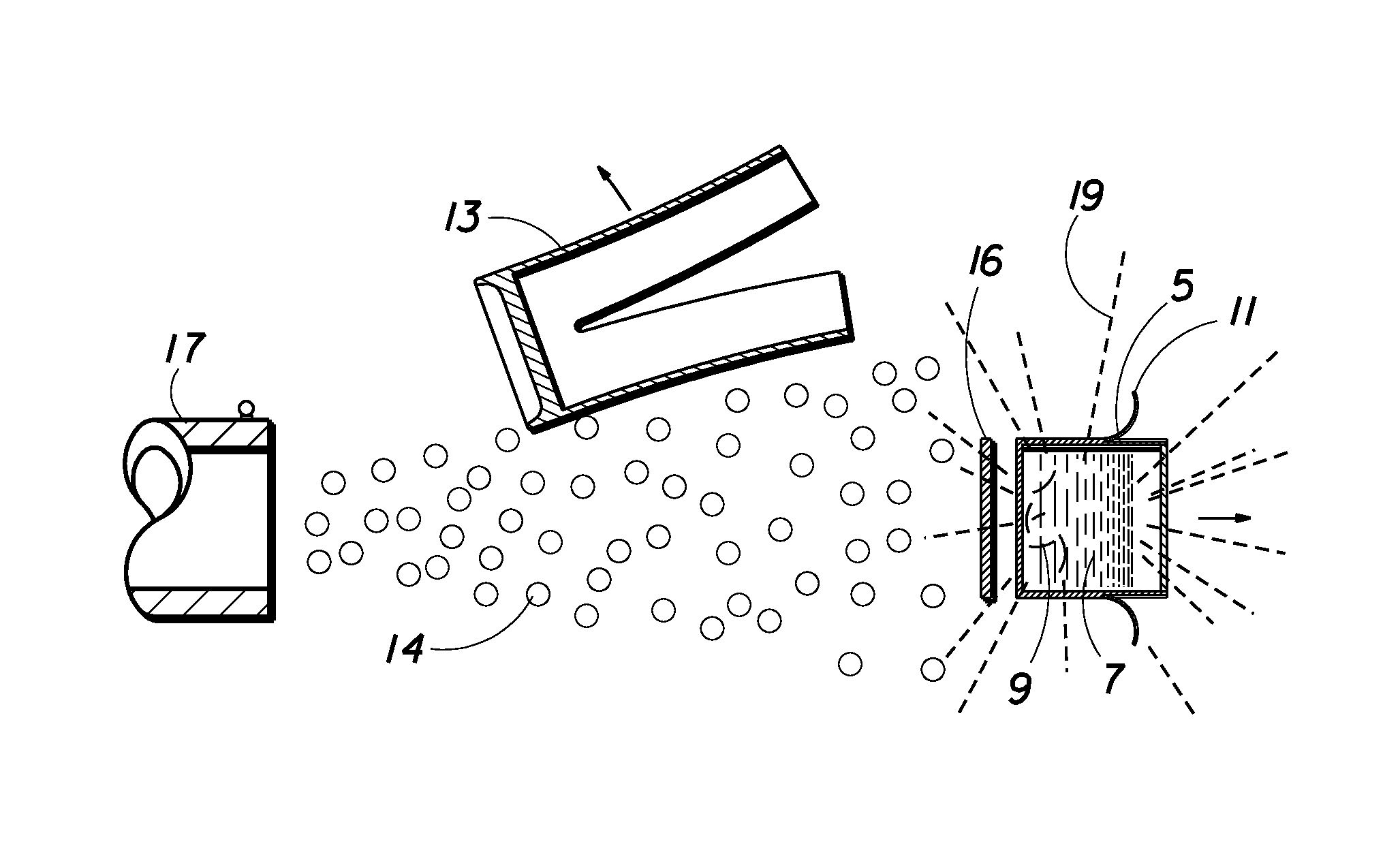

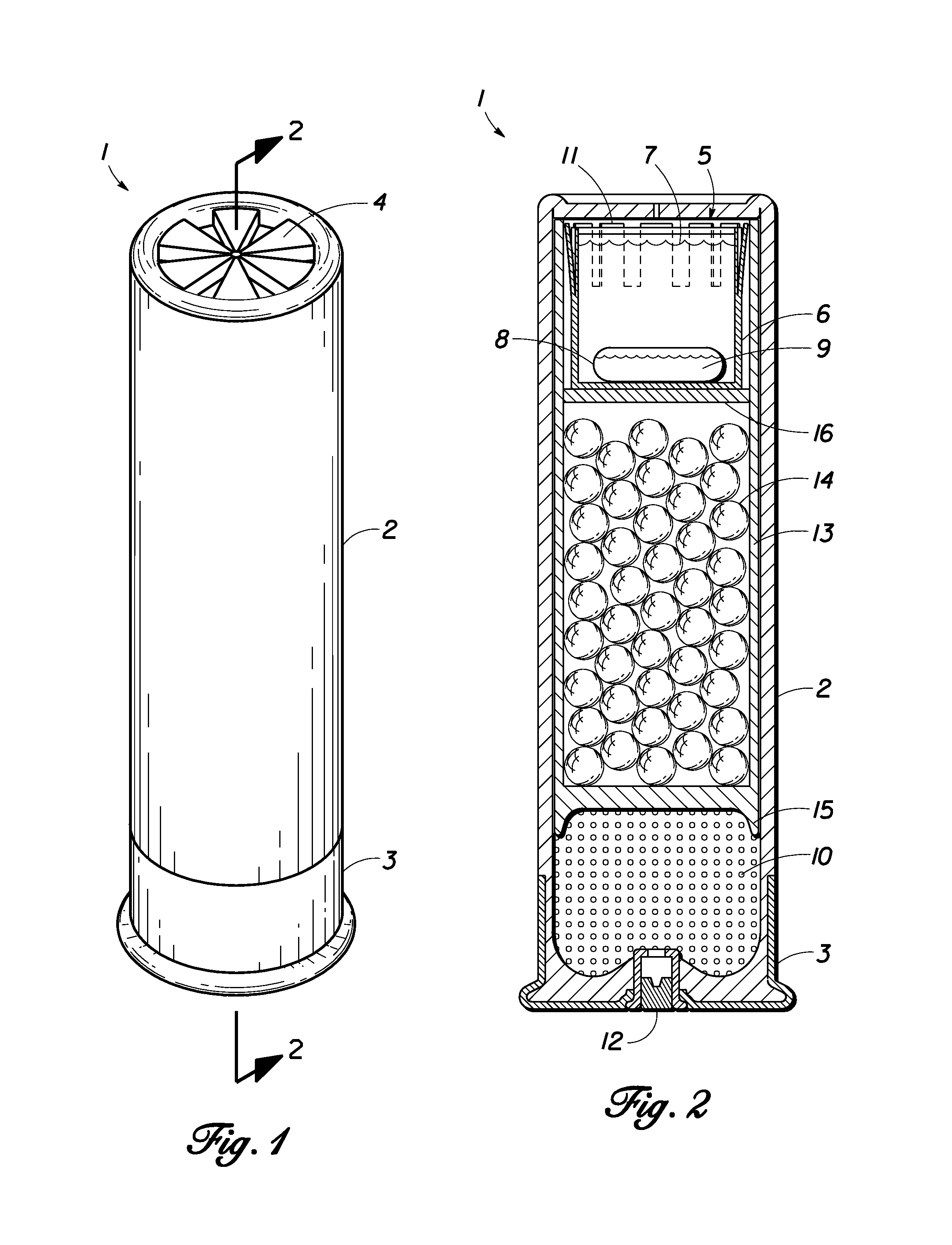

Chemiluminescent shotgun tracer insert with decelerator

A chemiluminescent tracer insert with decelerator for use with a shotgun shell to provide an aiming and training aid for shotgun shooting activities, including skeet, trap, sporting clays, hunting, law enforcement and military applications. The tracer insert can be used in shotgun shells of all gauges. The tracer insert comprises a translucent, resilient, elastic, cylindrical container in which the reactants, an oxalate and fluorescent-colored dye solution, and an activator encased in a glass vessel, are held. Ignition of the shell causes the glass vessel to break. The resulting chemiluminescent reaction causes emission of light visible to the shooter. Unattached ends of thin-flaps on the tracer insert extend outwardly when drag forces act upon them during flight, slowing the speed of the tracer insert, which makes it more visible to the shooter, thereby providing a consistent reference to enable a shooter to make corrections to his lead and / or shooting techniques.

Owner:QUINTANA MAURICIO F +1

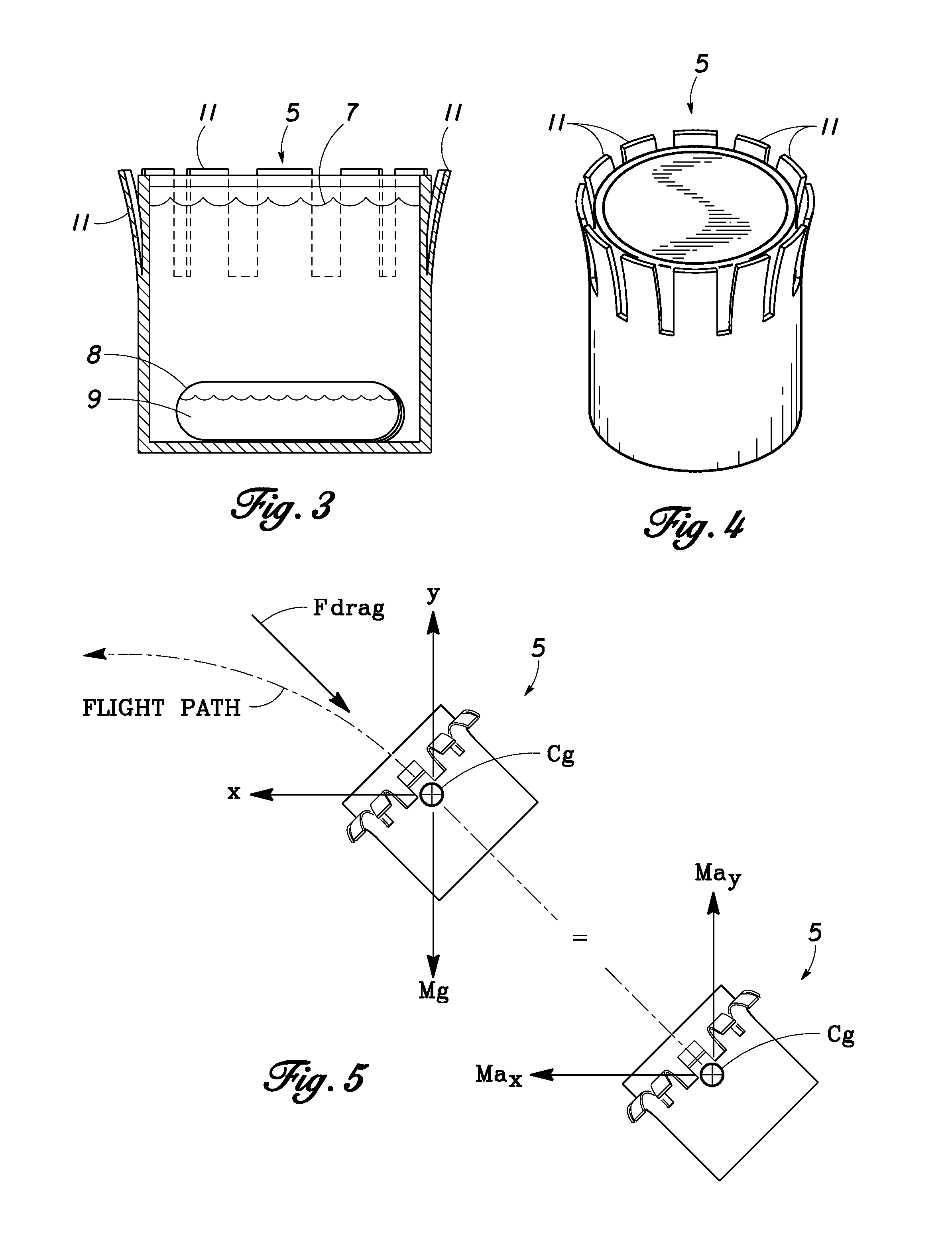

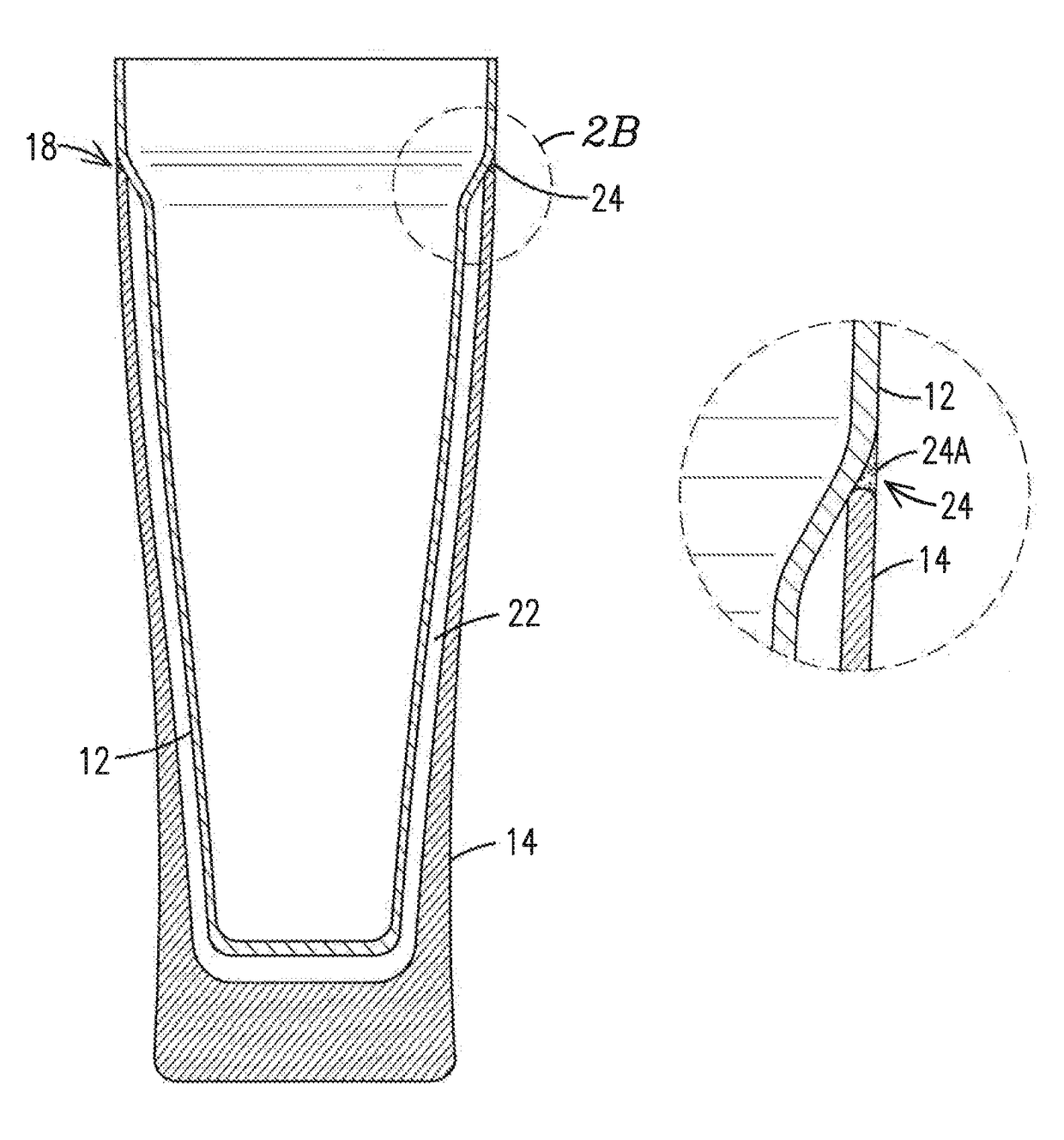

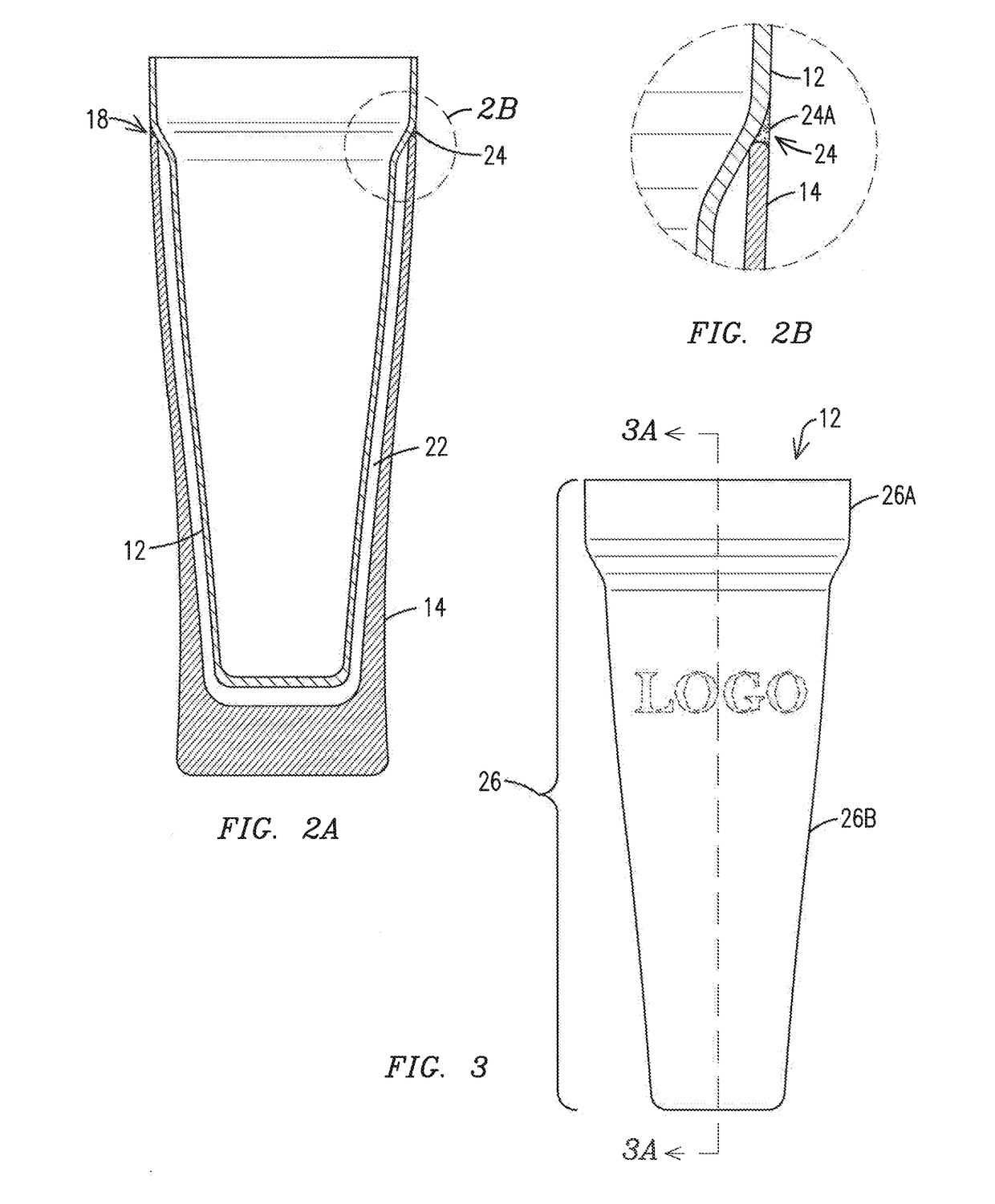

Double-walled glass insulated containers and method for producing same

A double walled glass container comprising an inner glass vessel for containing a liquid beverage is nested and hermetically sealed to an outer glass vessel, forming a unitary assembly with a co-extensive planar surface between inner and outer vessels. Said inner vessel is so constructed as to provide a gap between the two vessels wherein the interstitial space is an insulating air gap providing an insulating effect between the inner and outer vessels. The inner vessel also extends above the hermetic seal creating a single wall drinking rim. In addition, a customizable brand name or logo can be applied to the outer face of the inner vessel such that it is protected from the harsh environment of chemical cleaning and everyday use.

Owner:PRICE JEFF

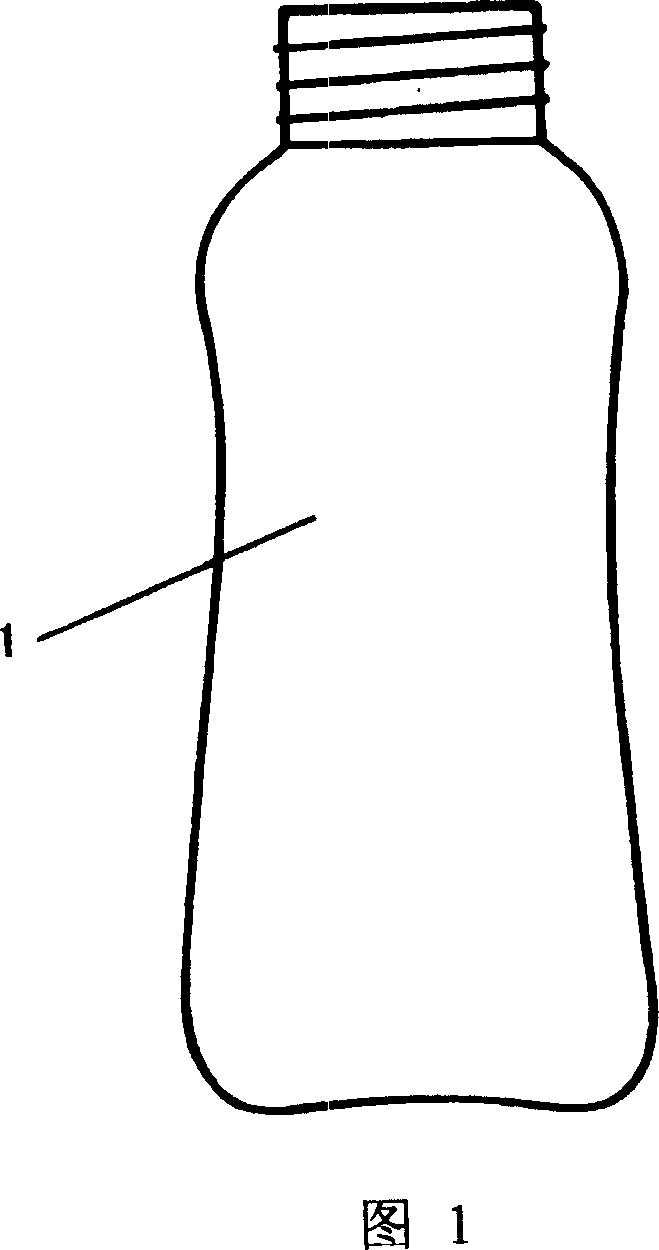

Super-thin wall bottle-gourd shaped milk bottle made of high borosilicate glass and its making method

InactiveCN100998542AExcellent physical and chemical propertiesEasy to cleanFeeding-bottlesGlass blowing apparatusGlass vesselBottle

Owner:肖文珍

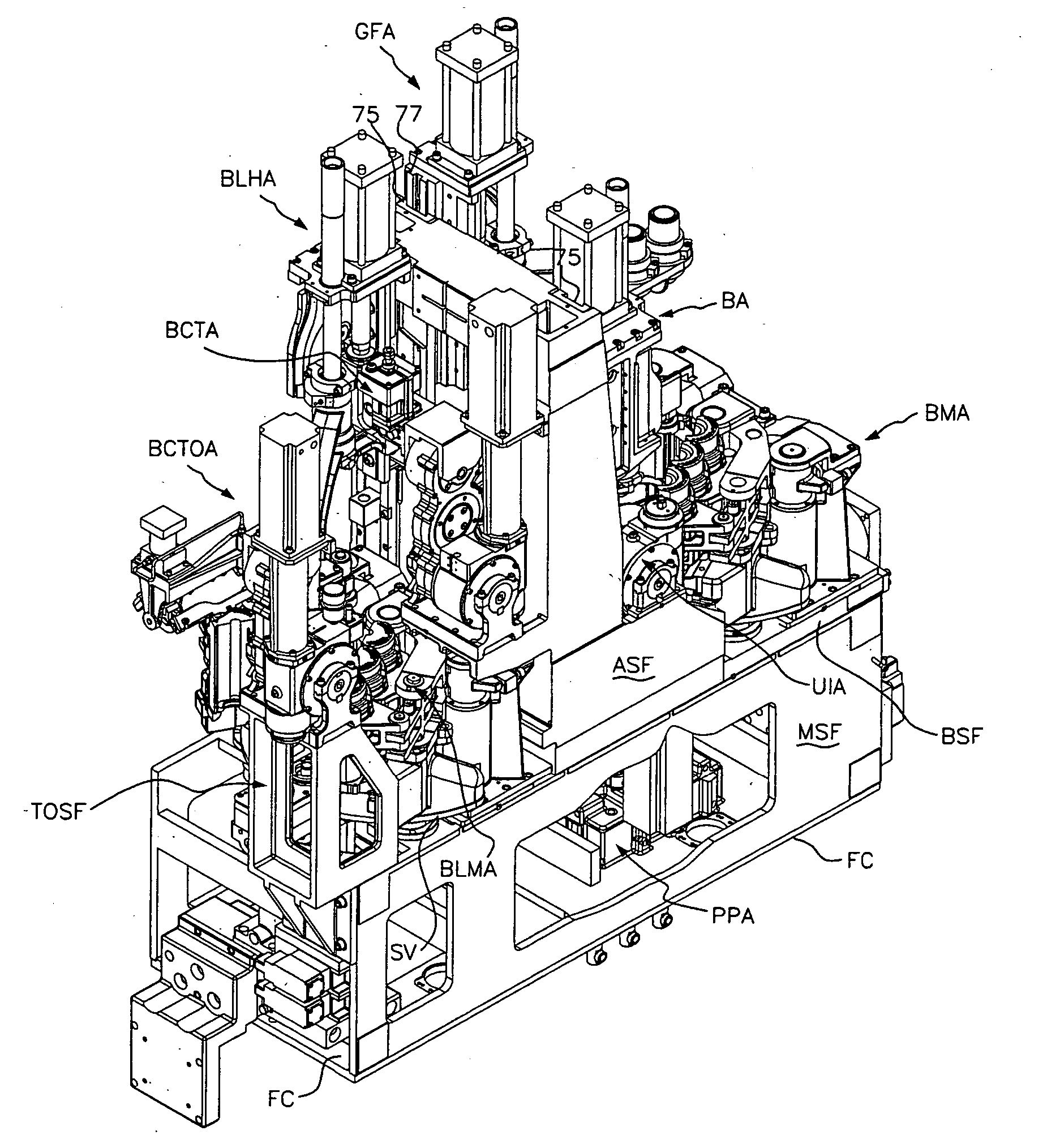

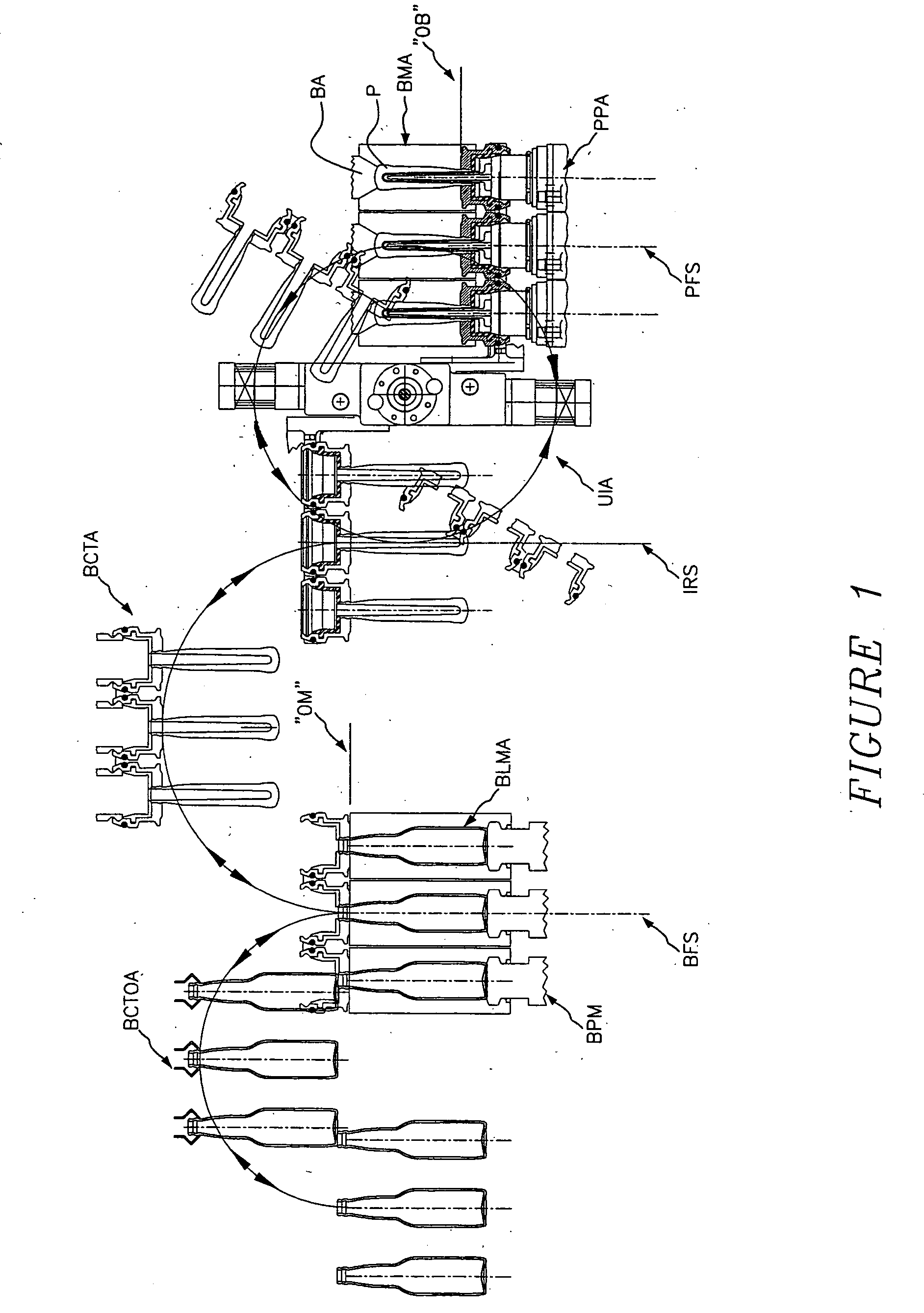

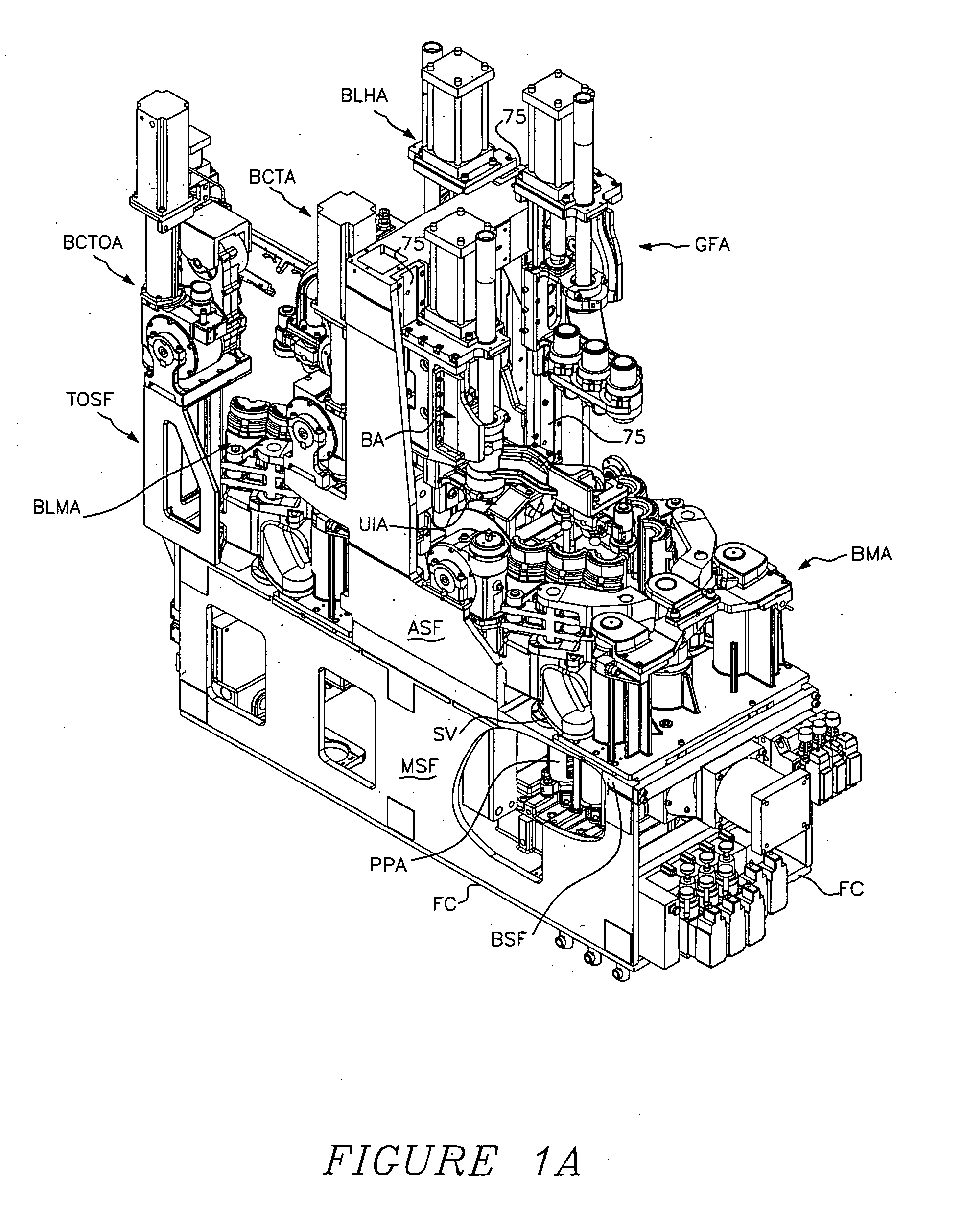

Method and a machine for the production of hollow glassware articles

InactiveUS20050235697A1Reduction in forming cycle time of machineQuality improvementGlass drawing apparatusGlass forming apparatusMolding machineGlass vessel

A method and a machine for the production of hollow glassware articles, by the blow-and-blow, press-and-blow, press-and-blow paste mold and direct-press processes in a glassware forming machine including single or multiple machine sections each having single or multiple-cavity, comprising: forming a parison in an inverted orientation, into a blank mold and a first transferable and open-able neck ring mold held by an inverting apparatus having a first and a second diametrically opposed arms, each arm holding a transferable and open-able neck ring mold; inverting the parison held by the first transferable and open-able neck ring mold, by rotating the first arm 180° to an upright orientation at an intermediate station, while the second arm with a second transferable and open-able neck ring mold is simultaneously placed at the parison forming station; transferring the first transferable and open-able neck ring mold holding the parison in an upright orientation, from the intermediate station, to a blow mold station, by a transference apparatus; releasing the first parison into a blow mold, and turning back the first transferable and open-able neck ring mold empty to the first arm of the inverting apparatus, at the intermediate station to be placed again at the parison forming station by rotating the first arm additional 180°, completing a 360° turn, while the second arm reaches to the intermediate station; blowing the parison into a blow mold to form a finished article; and transferring the finished article in an upright orientation, once the blow mold is opened, by a take out apparatus, to place it at a dead plate or at a carrying conveyor.

Owner:VITRO SAB DE CV

Method of using temporary decoration to mass customize refillable glass vessels

ActiveUS8020359B2Overcomes shortcomingPower operated devicesScreen printersMass customizationGlass vessel

The present invention relates to a method of using a combination permanent partial decoration and temporary decoration to mass customize refillable glass vessels. The method comprising: decorating a glass vessel with a permanent partial decoration, receiving the glass vessel at a filling facility, washing the glass vessel in caustic solution to remove presence of a temporary decoration, filling the glass vessel with a product contents, printing the temporary decoration on the glass vessel, distributing the glass vessel to a marketplace for use by a consumer, receiving the consumer used glass vessel at the filling facility, and recycling the glass vessel by returning to the step of washing. Other embodiments include not using the permanent partial decoration and printing the temporary decoration on the glass vessel, wherein at least some of the temporary decoration is printed on top of a background region to increase the luminance qualities of the temporary decoration.

Owner:THE COCA-COLA CO

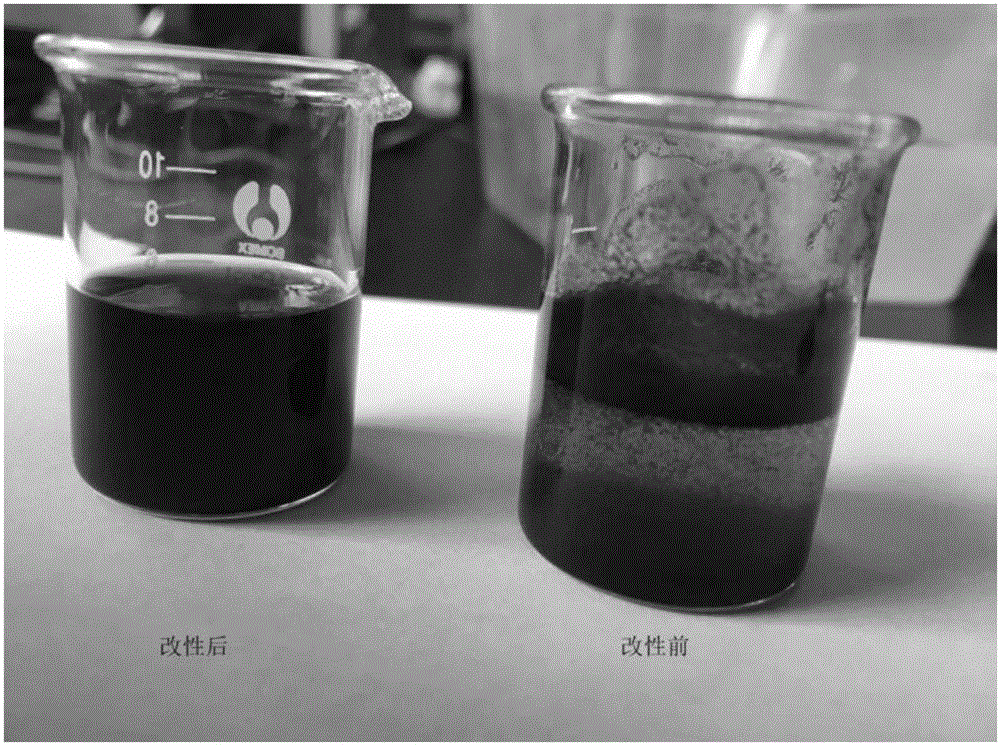

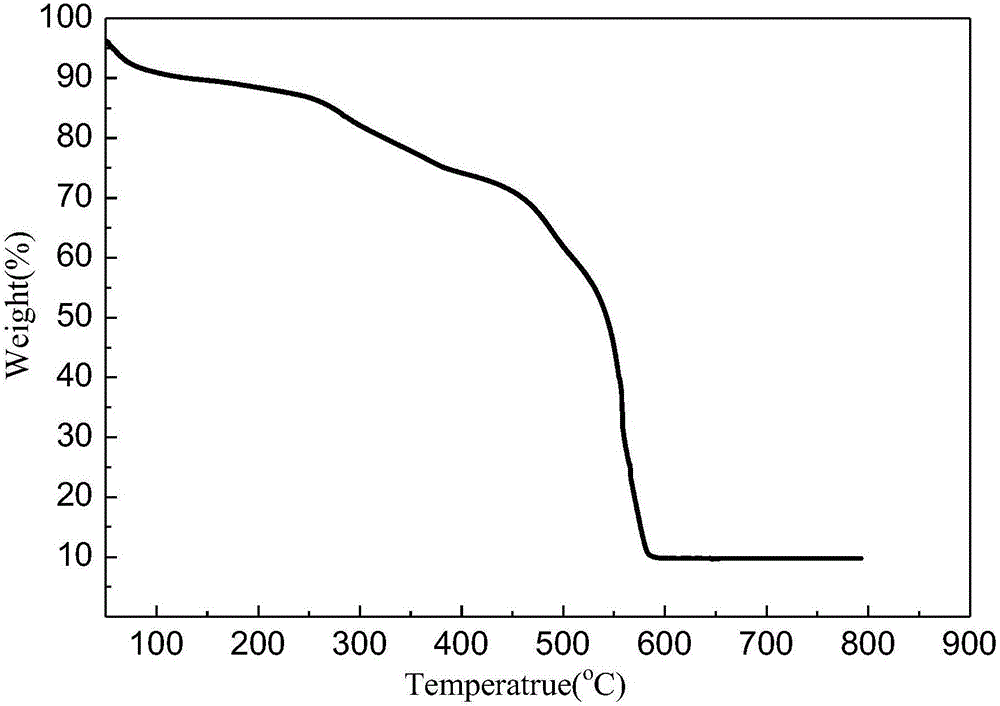

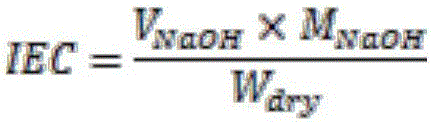

Preparation method of lignosulphonate proton exchange membrane material

The invention provides a preparation method of a lignosulphonate proton exchange membrane material. The method includes the steps of: 1) adding sodium lignosulphonate powder to deionized water, adding an initiator, and dropwise adding styrene and a graft copolymerization monomer, performing a reaction for 20-24 h, cooling and evaporating the reaction products to obtain pure grafted lignosulphonate; 2) adding the grafted modified lignosulphonate and sulfonated polyarylenesulfidesulfone polymer to an organic solvent, and performing ultrasonic dispersion and filtration to obtain a solution, and coating the surface of a glass vessel with the solution, and drying the solution at 50-120 DEG C for 12-24 h to obtain the proton exchange membrane material. The raw materials of the material are easy to obtain. The method has simple modification process and easy conditions. The proton exchange membrane material is low in cost, is stable even at 300 DEG C, is high in capacity, and reaches 0.105 S / cm in proton conductivity.

Owner:HEBEI UNIV OF TECH

All-electric viilo drawn medicinal glass tube and method for making the same

ActiveCN101182115ASolve acid resistanceSolve weak alkalineGlass drawing apparatusLithium oxideSesquioxide

The invention provides a medicinal glass tube which is made through a whole fused villo method and a preparation method, belonging to the medicine packing technical field and aiming at solving problems of weak acid-resistance and alkaline-resistance, low mechanical-resistance strength and easy break of a present medicinal glass tube. Used raw materials in weight portion include 71.0-77.1 portions of silicon dioxide (SiO2), 5.2-7.1 potions of aluminium sesquioxide (Al2O3), 8.2-11.6 potions of boron trioxide (B2O3), 0.2-2.6 potions of barium oxide (BaO), 0.2-2.4 portions of calcium oxide (CaO), 0.2-1.0 portions of lithium oxide (LiO), 0.5-7.4 portions of potassium oxide (K2O) and 5.1-7.6 portions of sodium oxide (Na2O). The manufacturing method consists of procedures of the raw materials preparation, the fused melting plastics heating, the villo stretching forming, the precise cutting, the mouth rounding and the packing. The invention has the advantages of optimal expansion coefficient and high mechanical-resistance strength and is applied to the manufacturing of medicinal glass vessels for containing medicine liquids and medicines, the chemical pipes, etc.

Owner:沧州四星玻璃股份有限公司

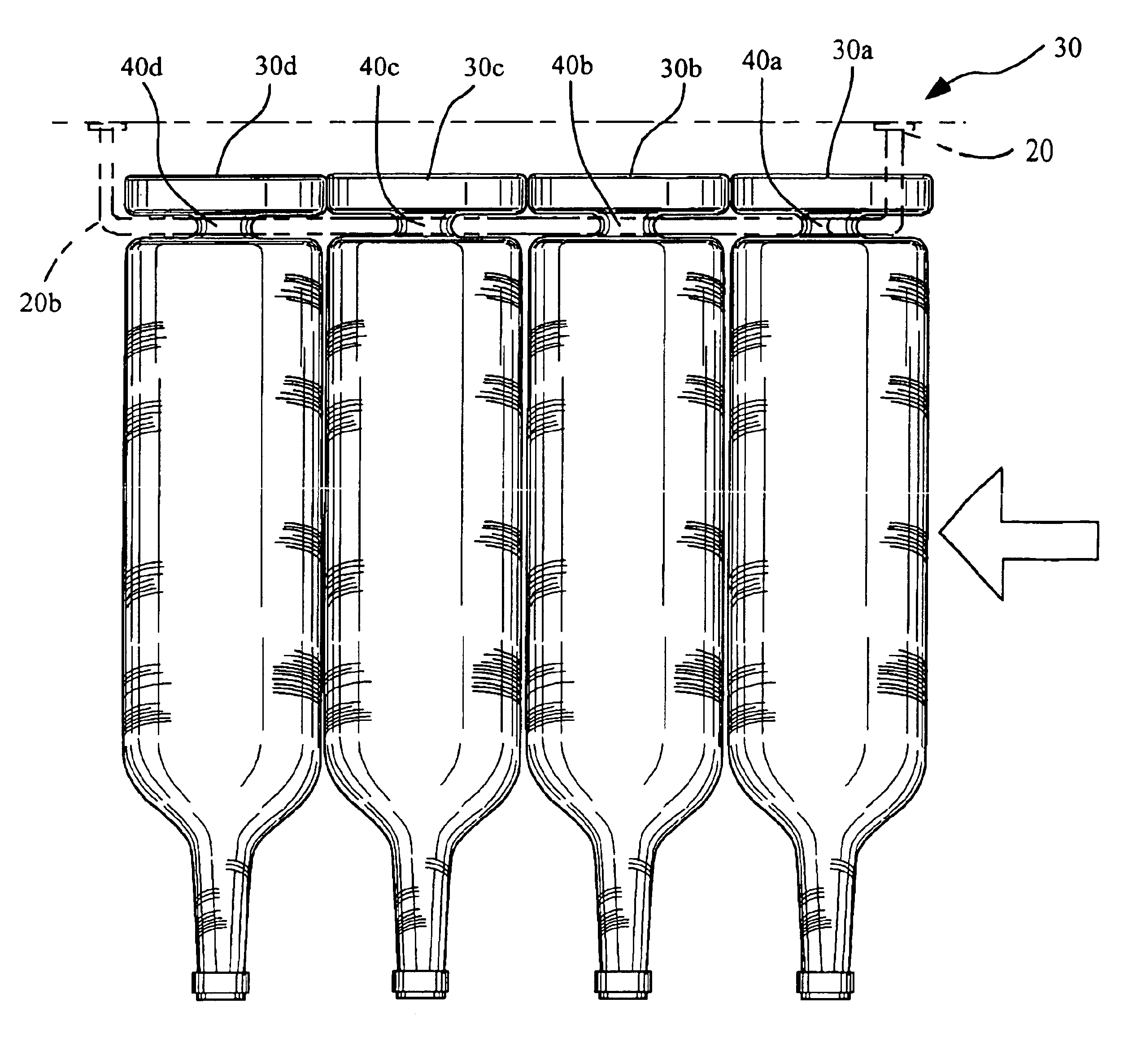

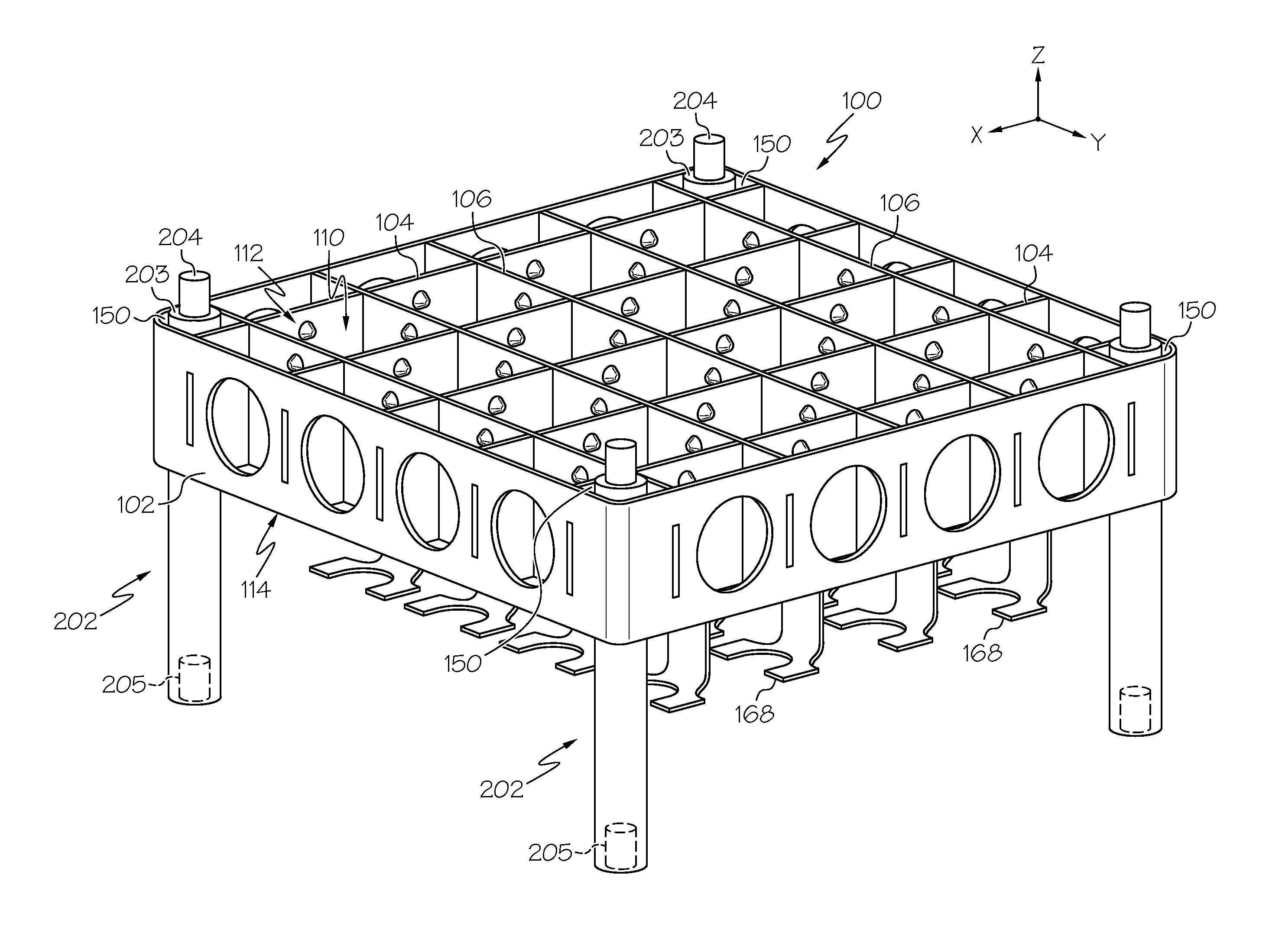

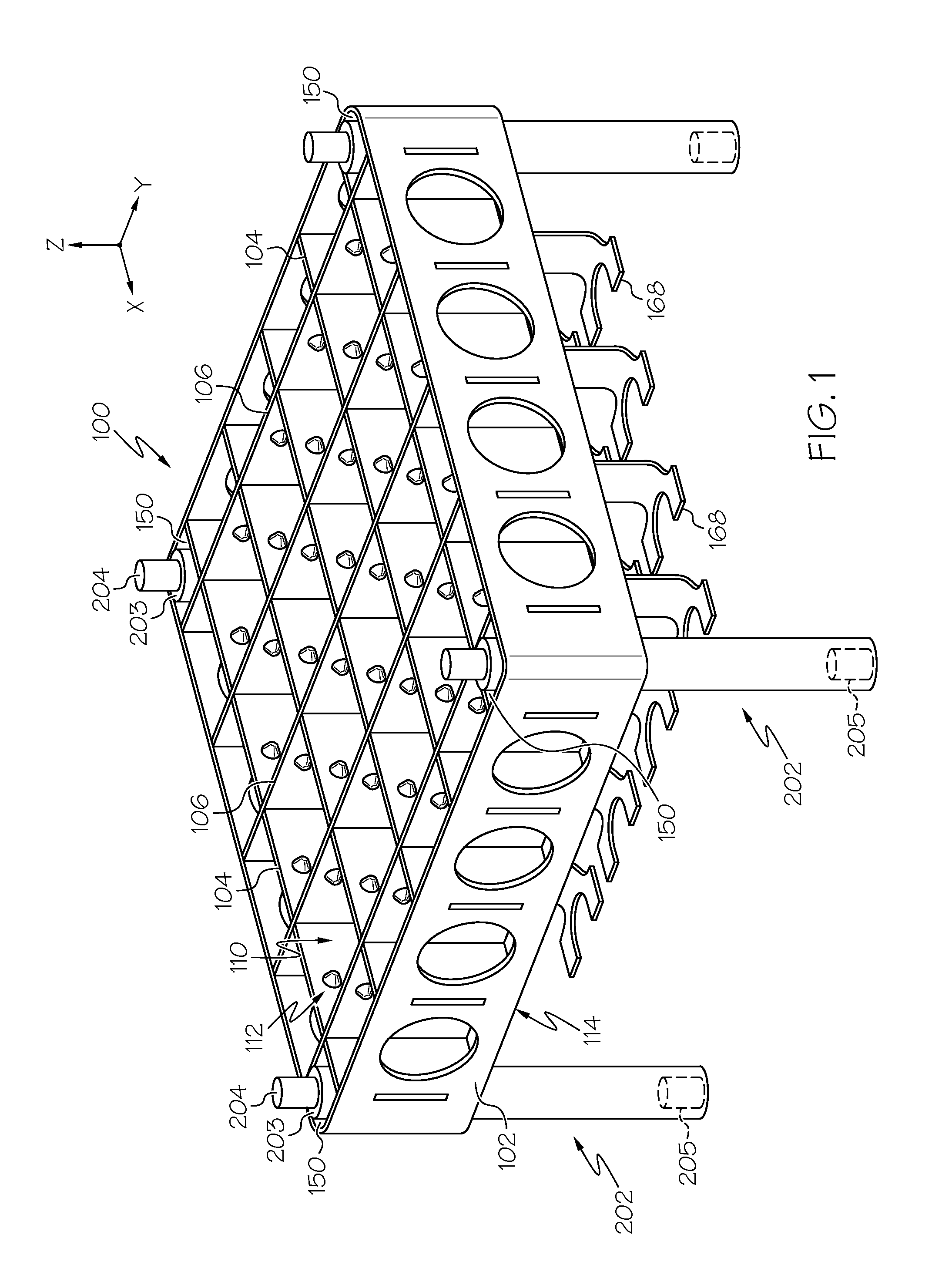

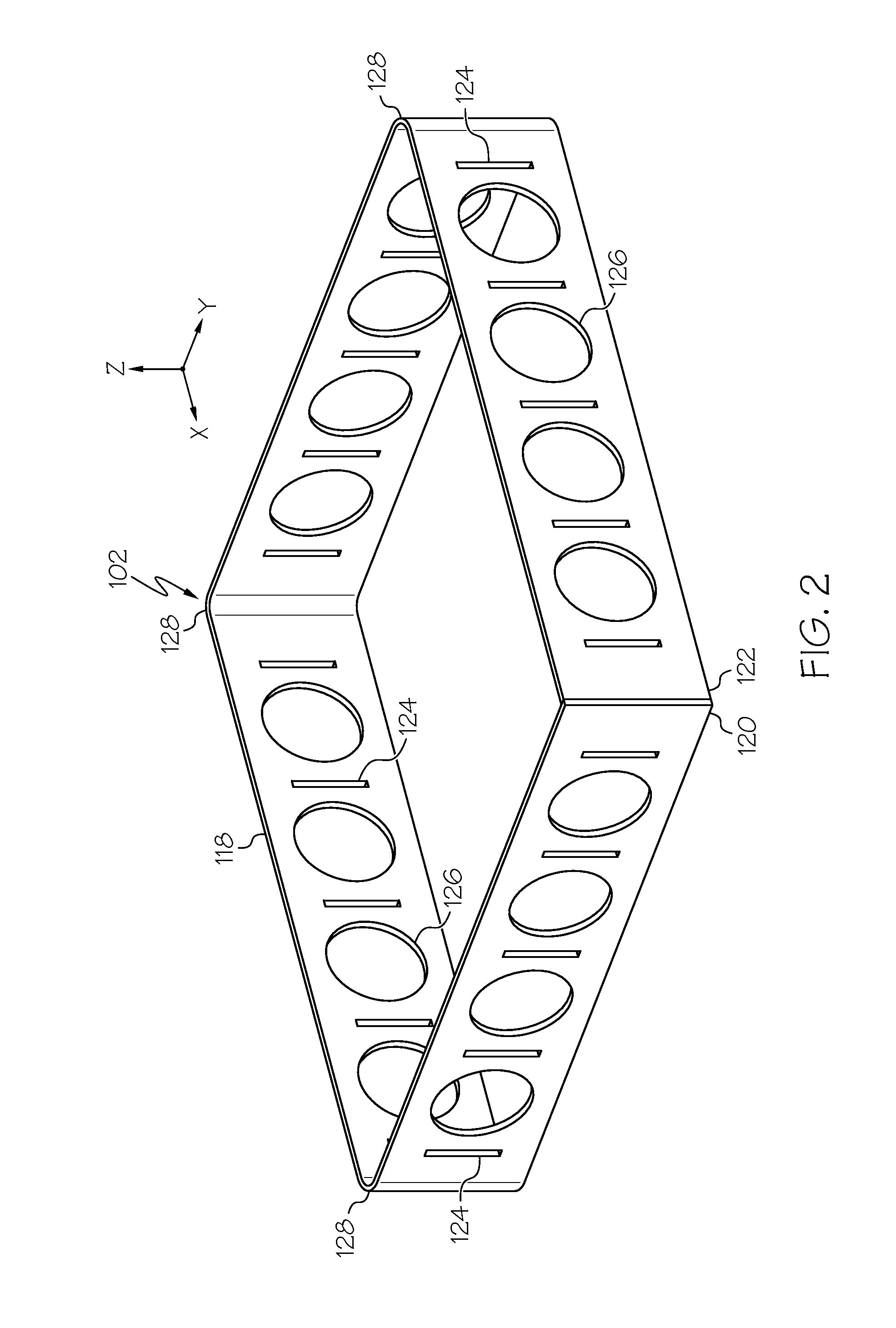

Magazine apparatuses for holding glass articles during processing

According to one embodiment, a magazine apparatus may include a plurality of dividing straps positioned substantially parallel with one another and a plurality of support straps positioned substantially parallel with one another. The plurality of support straps may intersect with the plurality of dividing straps to form a plurality of ware receiving channels. An upper end and a lower end of each ware receiving channel may be at least partially open. The magazine apparatus may also include a plurality of ware seats. Each ware seat may extend at least partially across a corresponding ware receiving channel proximate a lower end of the corresponding ware receiving channel. Each ware seat may provide a seat for glassware positioned in the corresponding ware receiving channel. A plurality of ware spacers may be positioned below and spaced apart from a corresponding ware seat and extending at least partially across the corresponding ware receiving channel.

Owner:CORNING INC

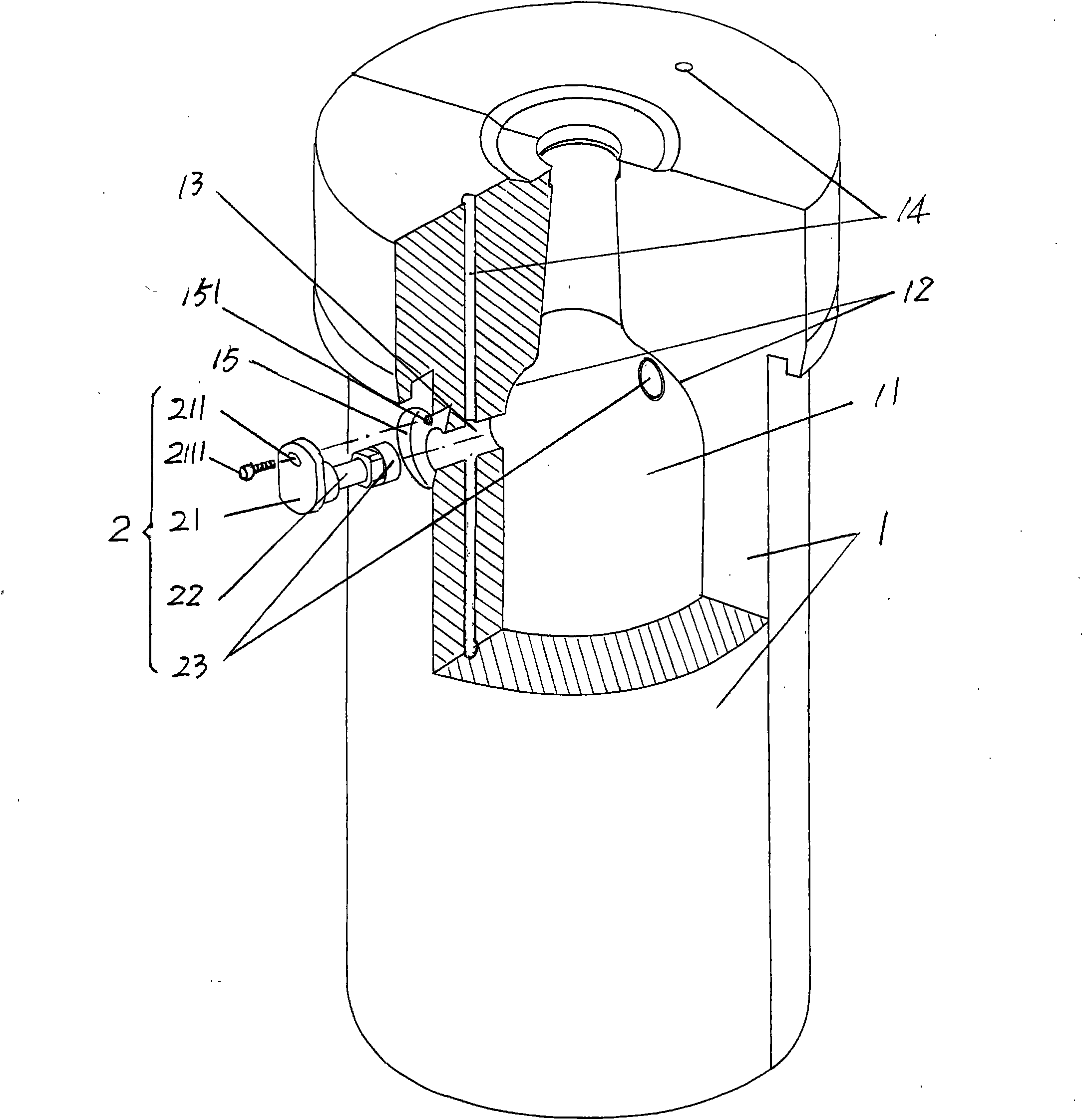

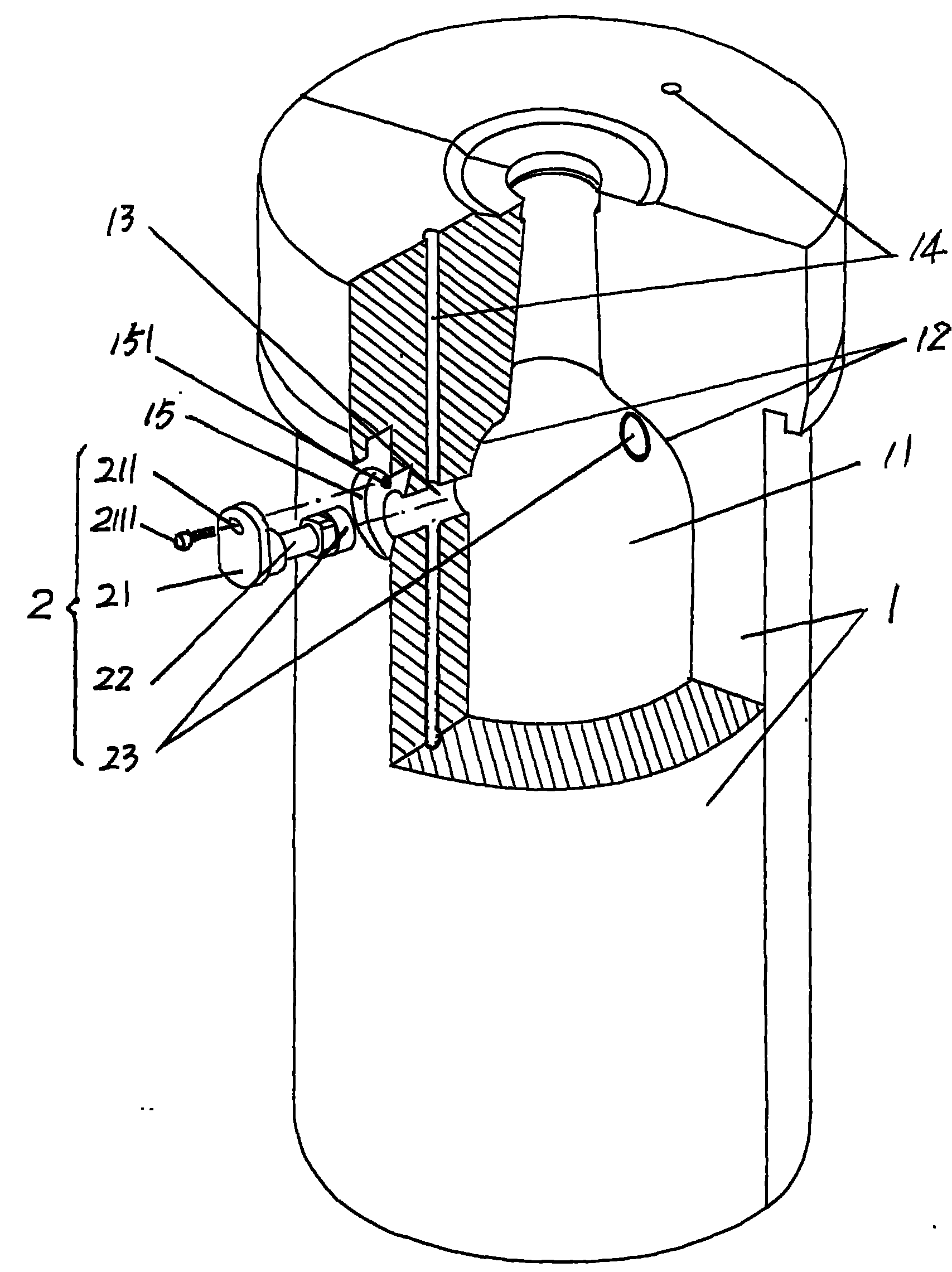

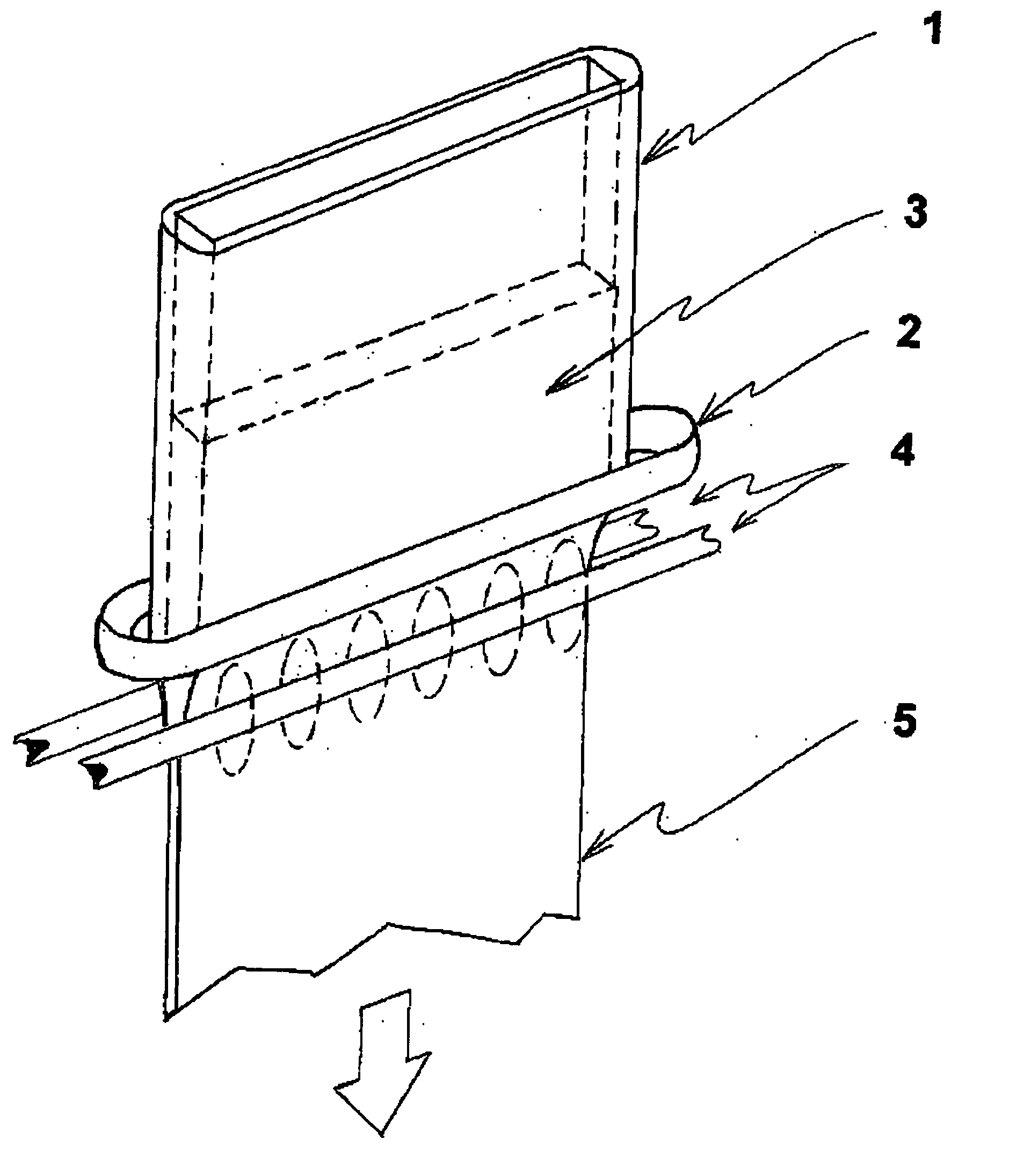

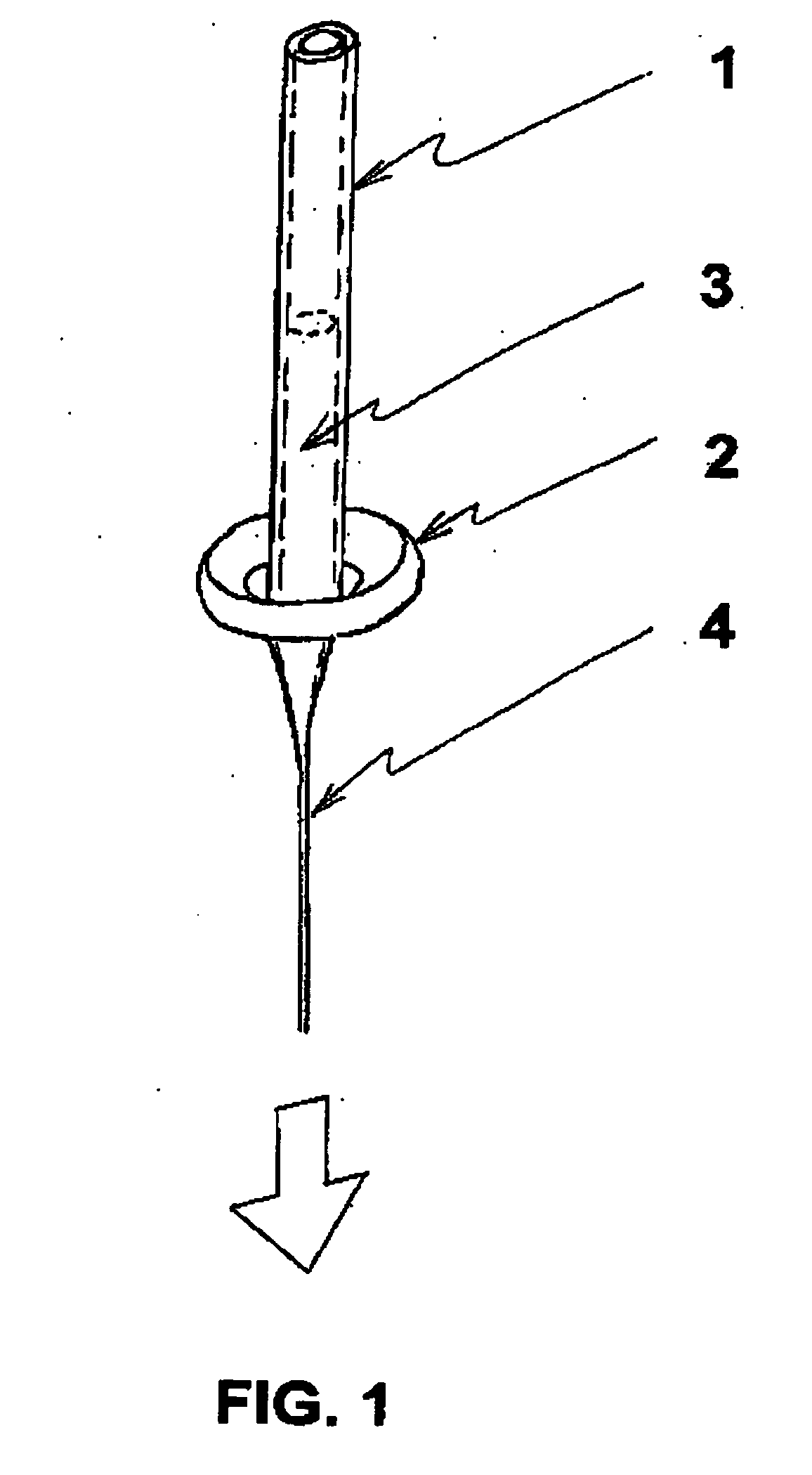

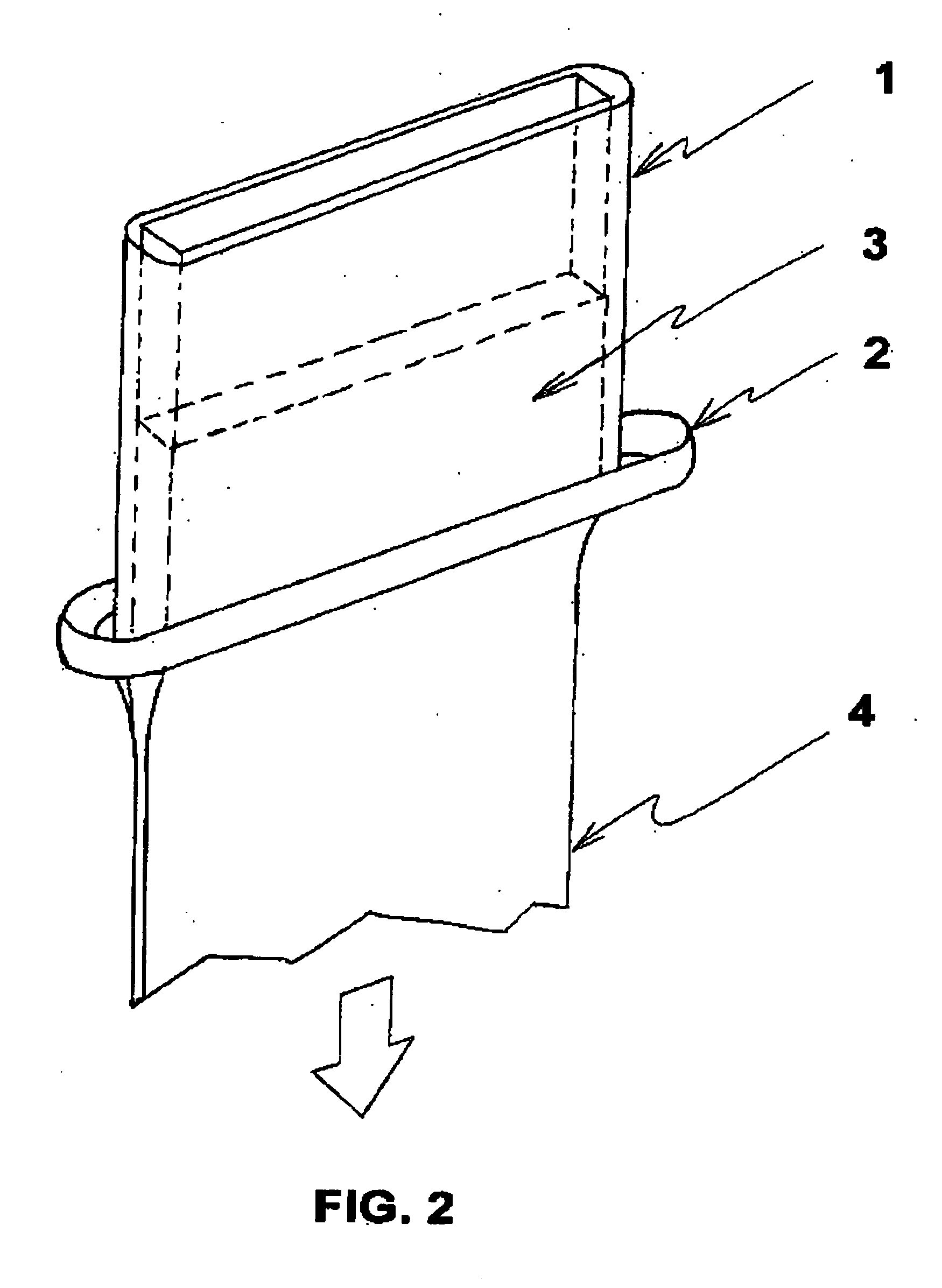

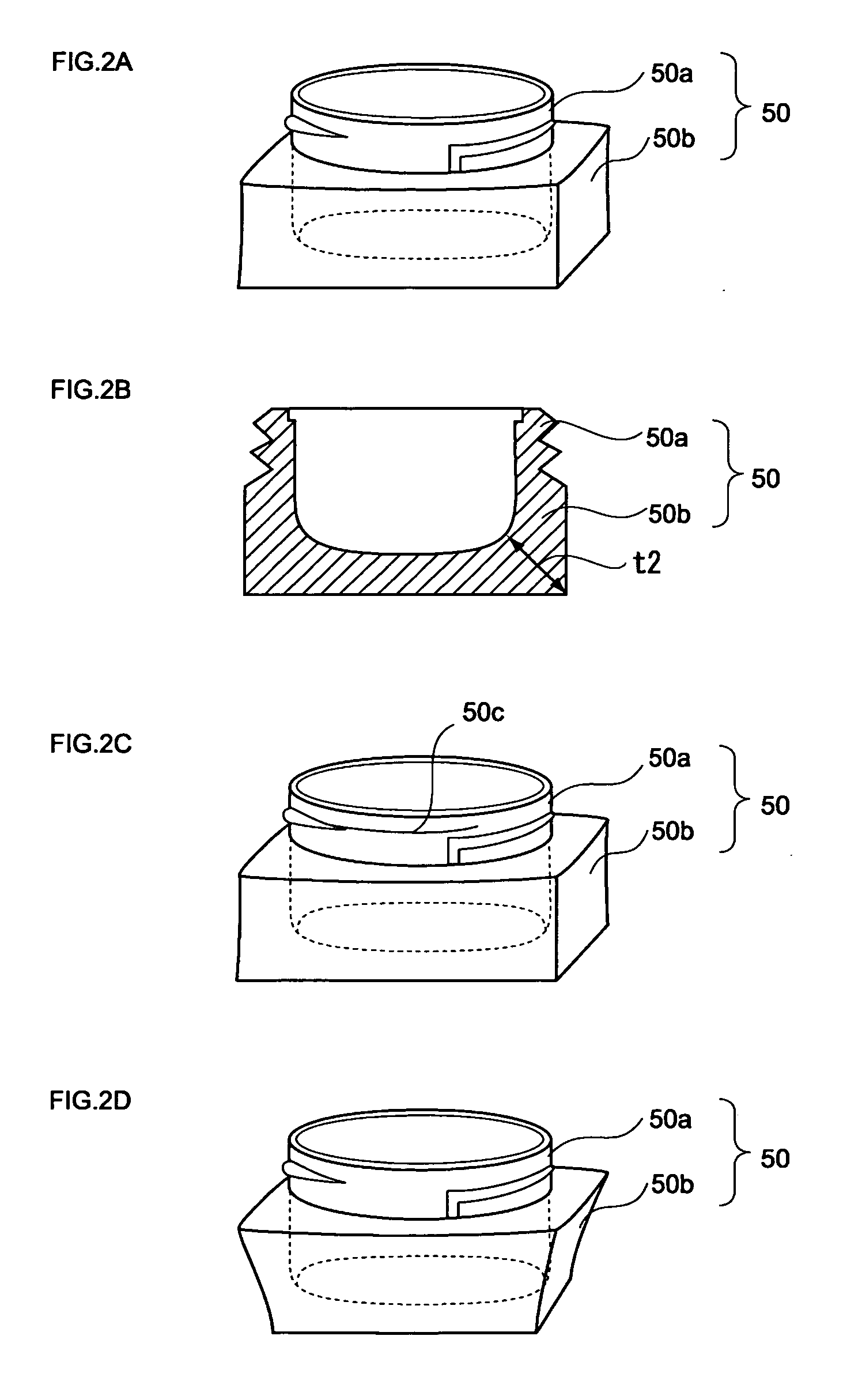

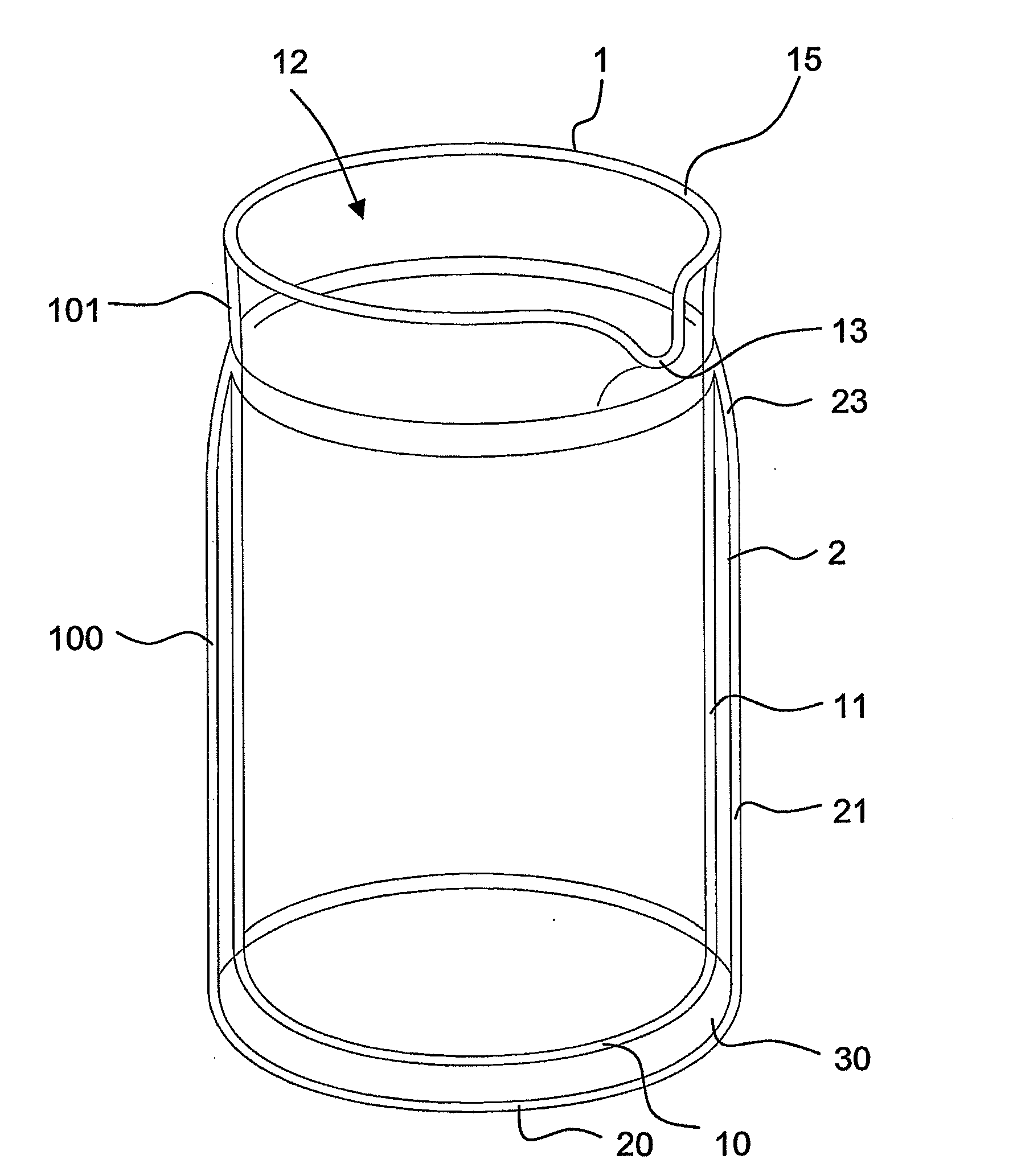

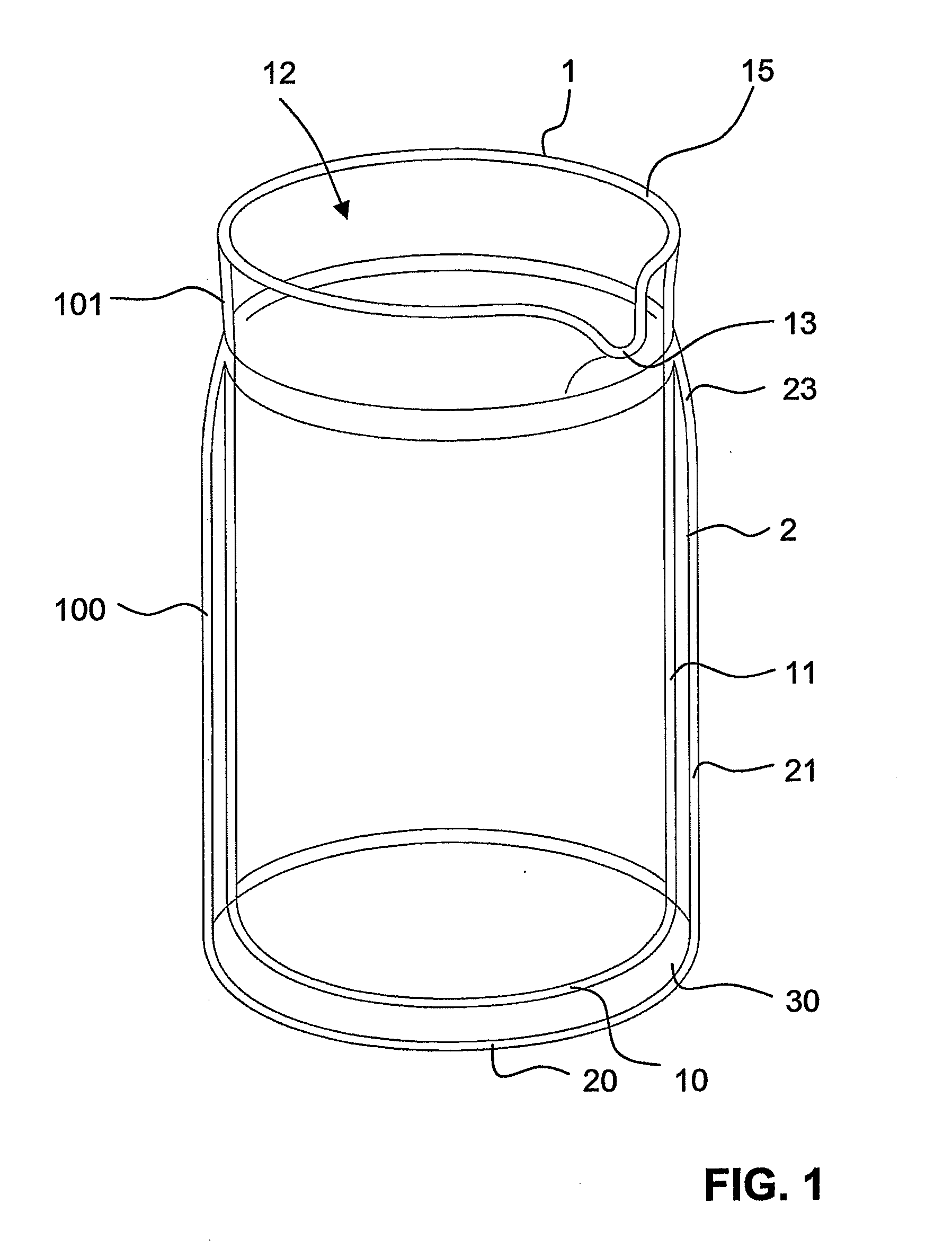

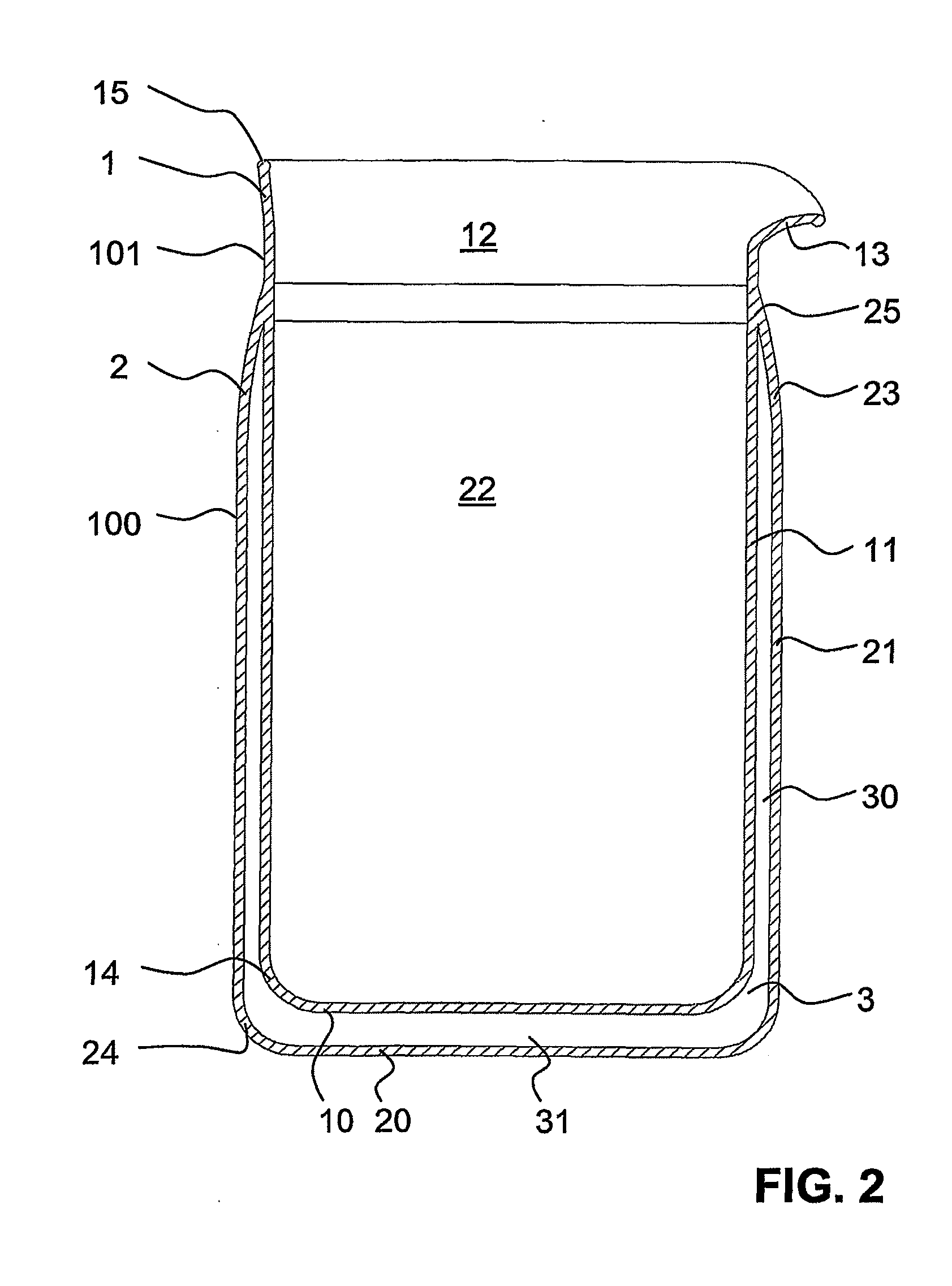

Double-walled vessel

InactiveUS20090199719A1Prevents the hot beverage from cooling down quicklyImprove securityBeverage vesselsLiquid dispensingGlass vesselMarine engineering

The invention discloses a glass vessel for a beverage-making machine, which glass vessel is at least partly of double-walled design. In a first refinement, an inner part (1) projects beyond an outer part (2) which partly surrounds said inner part, with the result that a double-walled lower region (100) and a single-walled upper region (101) with a pouring region (13) arranged therein are provided. In another refinement, the inner part and outer part are connected at their upper edge, and the pouring region is of double-walled design. The invention also specifies a method for producing the vessel.

Owner:PI-DESIGN AG

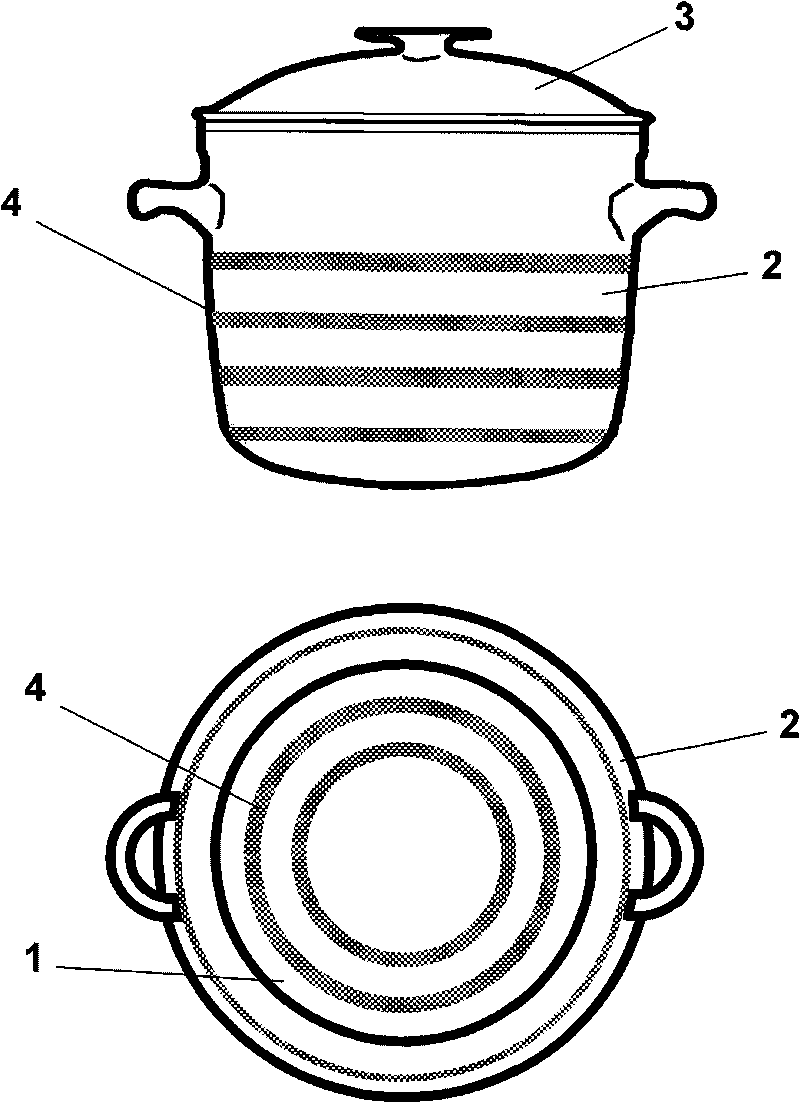

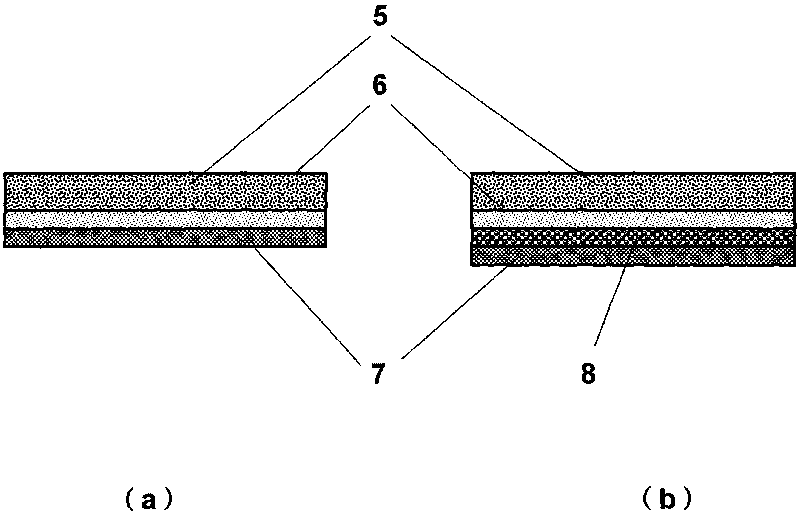

Metal magnetic conduction ceramic pot

InactiveCN101717277AGood low impedance conductivityHigh molecular weightCooking-vessel materialsGlass vesselGraphite

The invention relates to the field of ceramic ware manufacturing, in particular to a ceramic pot of which the outer surface of a pot bottom and the outer side of a pot body are coated with silver-based metal layers. The ceramic pot comprises the pot bottom, the pot body, a pot cover and an annular magnetic conduction layer; the outer surface of the pot bottom and the outer side of the pot body of the magnetic conduction ceramic pot are provided with one or more annular silver-based metal magnetic conduction coatings; the magnetic conduction coating (4) of the magnetic conduction ceramic pot comprises the following components in percentage by weight: 85 to 98 percent of argentums (Ag), 0 to 15 percent of graphite (C) and 0 to 2.5 percent of nickel (Ni); and the thickness of the magnetic conduction coating is between 0.5 to 0.8 millimeters. Under the same external condition, compared with a traditional product, the ceramic pot can integrally receives electromagnetic radiation energy of an induction cooker, has the advantages of high heating speed, large and even heating area, energy conservation and environmental protection, is not only suitable for pots and boilers, but also suitable for the tea sets needing the induction cooker for heating and the medicinal ceramic ware or glassware.

Owner:SHANGHAI KANGDE IND DEV

Micro atom steam bubble making method

InactiveCN101598772AReduce manufacturing costHigh implementabilityApparatus using atomic clocksTurn-sensitive devicesHigh power lasersGlass vessel

The invention relates to atom steam bubble, in particular to a micro atom steam bubble making method. The method solves the problem that the existing micro atom steam bubble making method is too high in production cost owning to high requirement on technology and device and includes the following steps: a micro glass cavity with two parallel end faces and a minor diameter through hole opened on the sidewall is selected; the micro glass cavity is placed in an enclosed glass ware with a ZnSe glass window on the sidewall and just below a glass rod in the enclosed glass ware, wherein the through hole is over against the glass rod, and the enclosed glass ware is vacuumized and filled with inert gases and alkaline metal steam; the enclosed glass ware is heated, the end part of the glass rod is radiated by high power laser through the ZnSe glass window by a laser, so that the glass rod is dissolved to small liquid beads and drops into the through hole to seal the through hole; the micro glass cavity is taken out; the parallel end faces of the micro glass cavity are polished and plated with an anti-reflection film. The technology is simple and reasonable, the applying device is simple, and the production cost is low, thus being applicable to making micro atom steam bubble and having important significance.

Owner:ZHONGBEI UNIV

Municipal garbage automatic processing system

InactiveCN101372014ALess investmentEasy to manageSolid waste managementSolid waste disposalBrickGlass vessel

The invention relates to a municipal refuse automatic treatment system which is characterized in that: the hand-sorting garbage is transported to a magnetic separator by a belt conveyor for the magnetic separation; after the iron-containing material is separated, the garbage is sent into a marsh gas generating pool for fermentation. The generated marsh gas is pressured to become liquid and supplied to users for use; the dry matter of a marsh gas tank is discharged from a sewage draining exit and enters into a centrifuge to be removed a majority of moisture content, and is sent into a kiln for dry; after being dried, the dry matter contains 5-10% of moisture content; after the dry matter is crashed by a muller, the dry matte enters into a brick press to be manufactured into bricks. The system has the advantages of little investment; the generated marsh gas is used by users, the iron content matter, aluminum matter and glass vessels which are sorted out are reused. The refuse is manufactured into bricks for building; therefore, the system is beneficial to the municipal environment comprehensive treatment, and can reduce secondary pollution and changes waste into valuable.

Owner:沈阳利泰自控技术有限责任公司

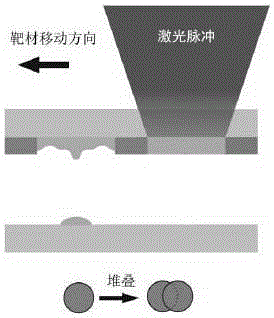

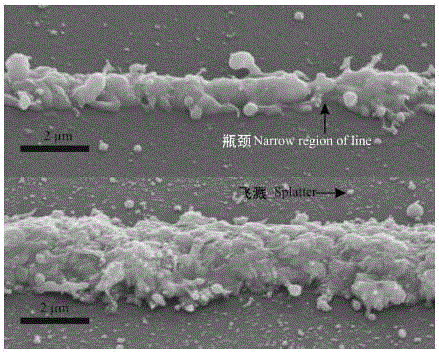

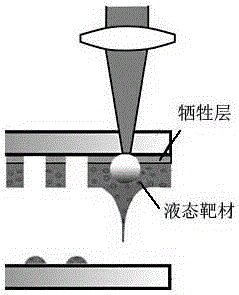

Microstructure laser-induce implantation method and device based on turbid liquid target

The invention discloses a microstructure laser-induce implantation method based on a turbid liquid target. The method comprises the steps that a base material is placed in turbid liquid, containing fine particles, in glassware; laser light is focused on the position, wherein fine particles need to be implanted, of the base material through a convex lens after passing through a reflector; when focused laser energy is higher than the breakdown threshold value of liquid, laser breaks down the turbid liquid to cause plasma expansion and plasma shock waves radiate out; shock waves can radiate out when cavitation bubbles generated through induction after plasma disappears burst; high-speed microjet is generated through interaction between the cavitation bubbles and the surface of the base material; the generated shock waves and high-speed microjet push the fine particles to be implanted into the base material under impact. According to the method, laser energy does not directly act on the implanted target and can not damage the target, and the turbid liquid in any depth containing the fine particles is adopted to replenish the implanted target continuously, so that continuous microstructure preparation efficiency is improved. The invention further discloses a device using the method.

Owner:GUANGDONG UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com