Patents

Literature

482 results about "Marsh gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Marsh gas, swamp gas, and bog gas is a mixture of methane, hydrogen sulfide, and carbon dioxide, produced naturally within some geographical marshes, swamps, and bogs. The surface of marshes, swamps, and bogs is initially porous vegetation that rots to form a crust that prevents oxygen from reaching the organic material trapped below. That is the condition that allows anaerobic digestion and fermentation of any plant or animal material which incidentally also produces methane.

Special microorganism composite bacterial agent for directly decomposing and fermenting crops straws to generate marsh gas and application method thereof

InactiveCN101775359AGood degradation activityEasy to storeFungiBacteriaBacillus licheniformisVaccination

The invention discloses a special microorganism composite bacterial agent for directly decomposing and fermenting crops straws to generate marsh gas and application method thereof. The special microorganism composite bacterial agent is liquid or solid, and is formed by fermenting, culturing, combining and compositing one or a plurality of bacillus cereus, bacillus subtilis, bacillus licheniformis, bacillus megaterium, bacillus mucilaginosus, bacillus circulans, bacillus sphaerieus, clostridium sporogenes, clostridium acetobutylicum, clostridium barati, clostridium beijerinckii, clostridium thermocellum, trichoderma viride, trichodermareesei and aspergillus niger. Simultaneously, by taking the special microorganism composite bacterial agent as a vaccination bacterial agent, the invention provides an application method for decomposing the crops straws and accelerating the ferment to generate marsh gas; and the microorganism composite bacterial agent-treated crops straws have fast ferment speed, large marsh gas generation quantity, low treating cost and no secondary pollution, can be fermented to generate the marsh gas under the condition of no faeces of poultry, and have very wide application range.

Owner:刘相梅 +1

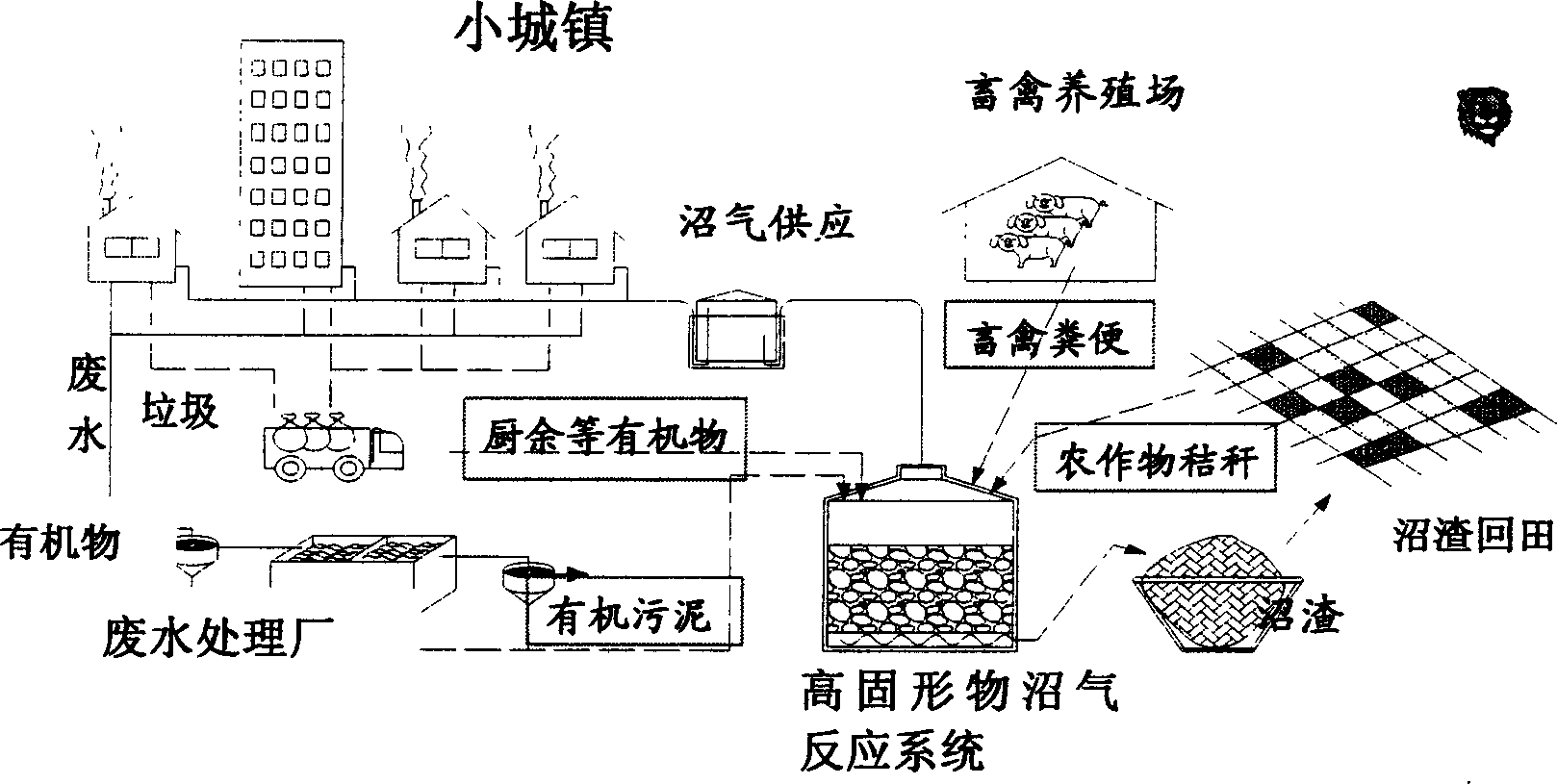

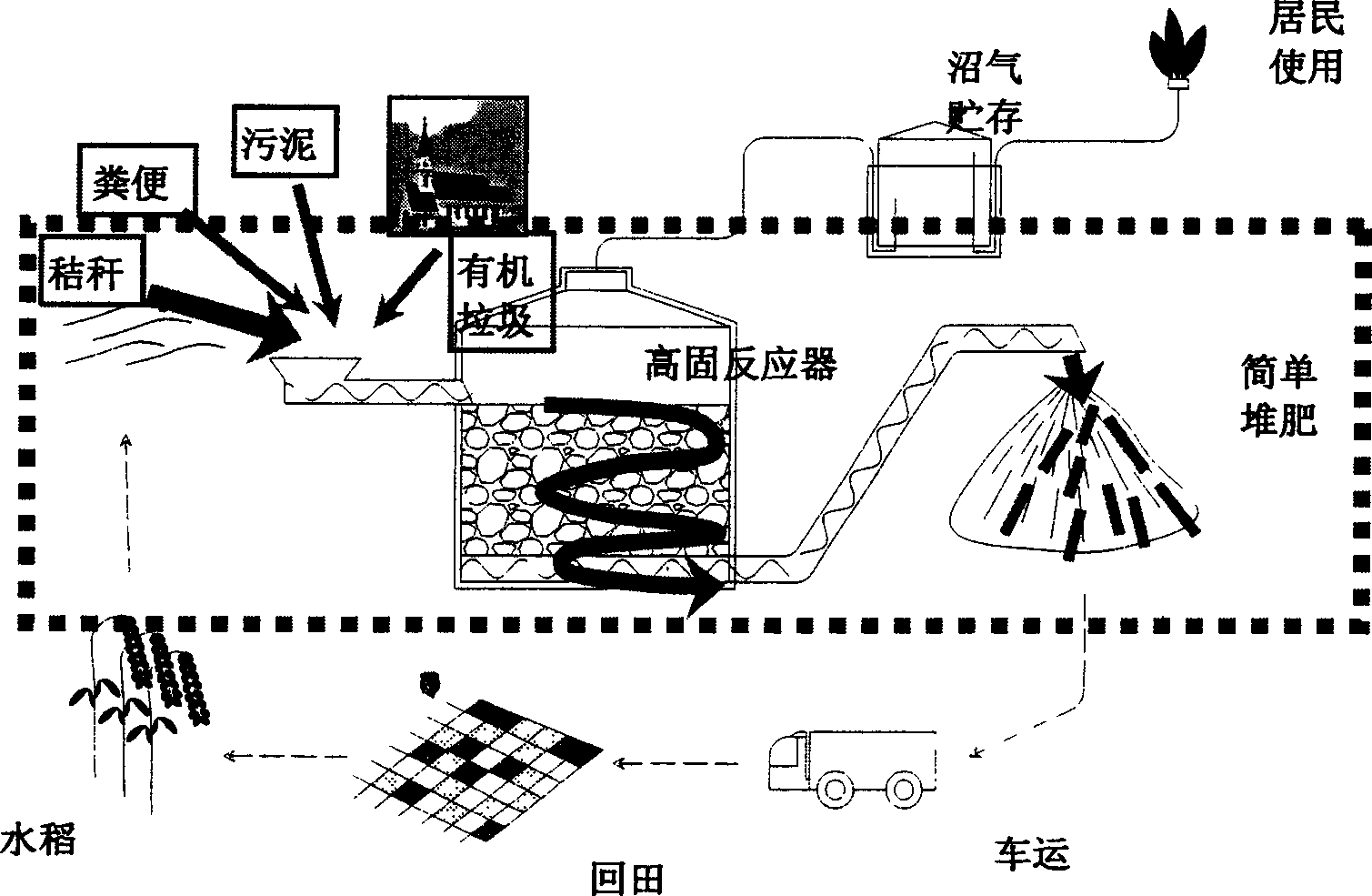

Marsh gas production technology using kitchen residue, straw, stock and fowl dejecta and active mud as material

InactiveCN1769220AReduce pretreatment costsHigh outgassing rateWaste based fuelEnergy based wastewater treatmentBiotechnologyFowl

The invention discloses a technique for producing methane with kitchen residue, straw fecal and active sludge as raw material, and relates to the key technique of methane production and a high solid methane fermentation reactor. It is characterized in: rigid anaerobic environment, adequate and good inoculum, necessary fermentation temperature, proper acid-base scale, proper fermentation concentration and carbon-hydrogen ration; the breeding speed safeguard of zymogeneous bacteria in fermentate; the killing of toxic and harmful bacterium; and the high solid reactor of stable operation. The invention is characterized in that it has significant academic meaning and practical meaning for producing methane with low investment, high stability and clean production.

Owner:JIANGNAN UNIV

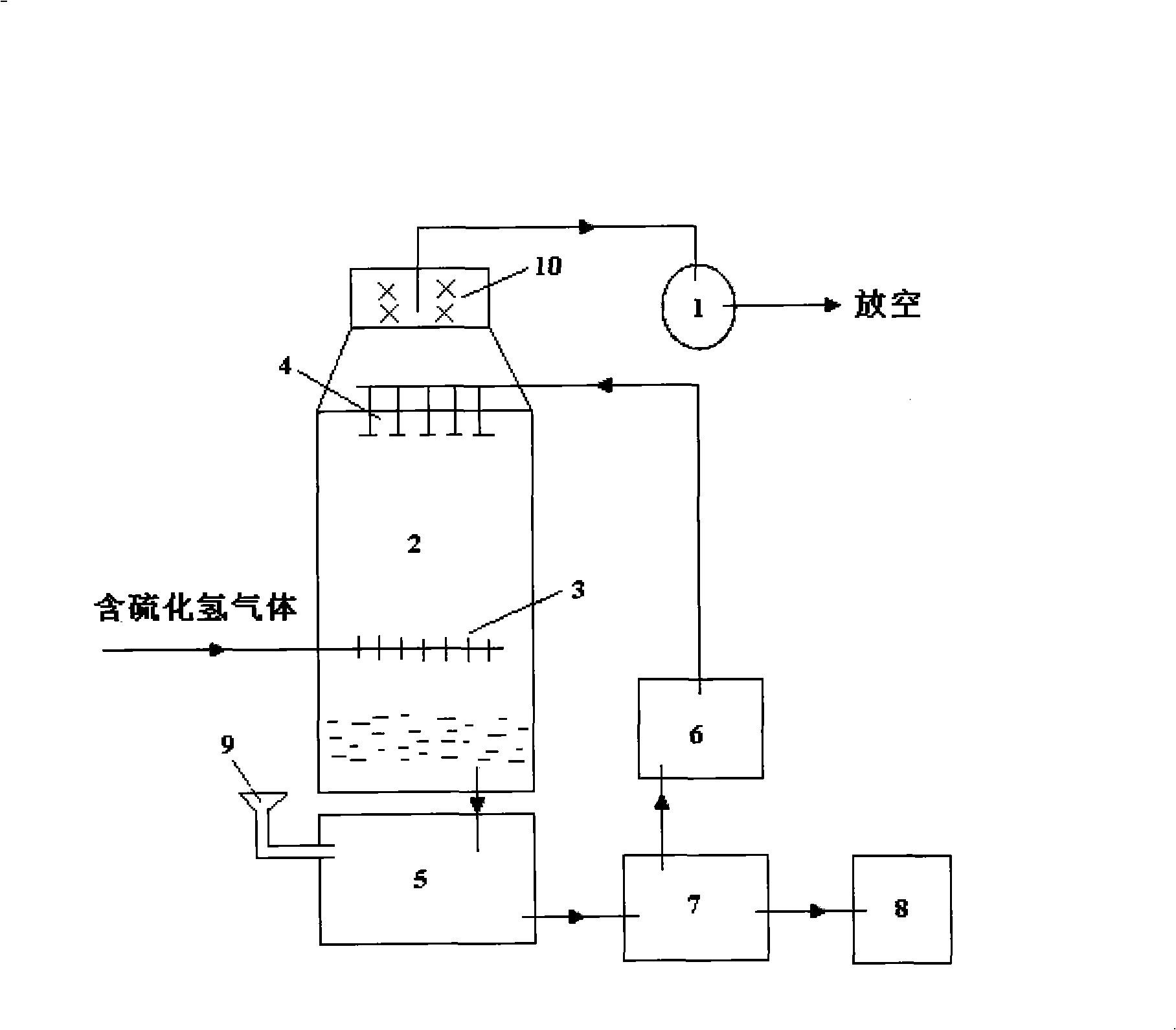

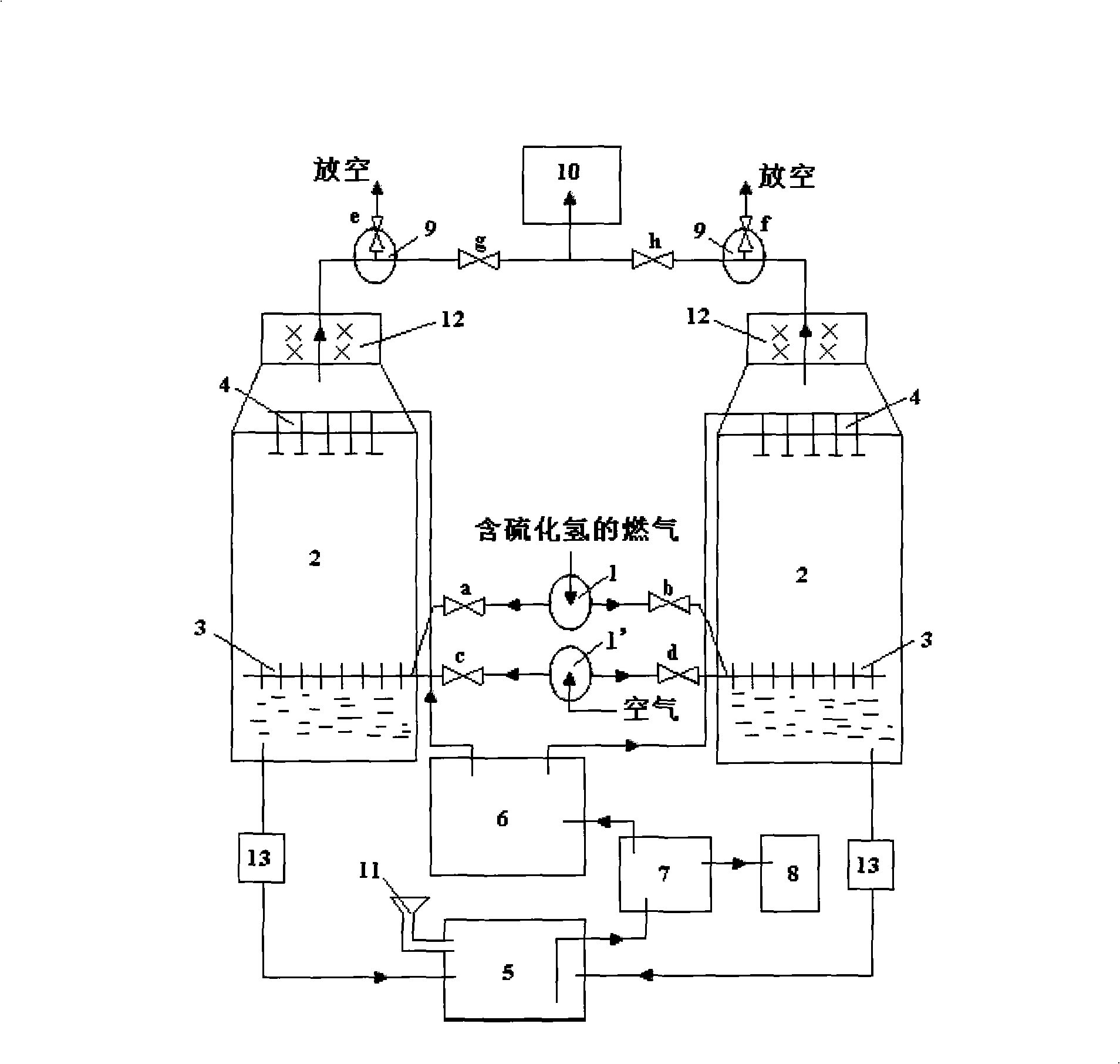

Method and device for removing hydrogen sulfide from gas containing hydrogen sulfide and recovering sulfer using catalytic oxidation

InactiveCN101327396AHigh removal and purification efficiencyFast conversionOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationEthylenediamineCatalytic oxidation

The present invention discloses a method for removing the hydrogen sulfide from the gas containing the hydrogen sulfide and for recycling the sulfur element with the catalytic oxidation effect, and discloses a device thereof. A catalytic oxidation system consisting of iron ion and ethylenediamine tetracetic acid is used, so that the hydrogen sulfide is transformed to the sulfur element so as to be removed from the air stream containing the hydrogen sulfide; the hydrogen sulfide removing rate reaches 99.9 percent. The method of the present invention not only can be used for removing the hydrogen sulfide in the gas from the manure processing field, the urban living garbage transshipping station, the public toilet, the sewage treatment plant, the solid waste processing field, the oil refining plant and the animal dead-body sanitary processing field, but also can be used for removing the hydrogen sulfide in the fuel gases such as the marsh gas, the land-filling gas, the natural gas, etc. During the treatment process, except the useful sulfur element is produced, no other product that influences the environment is produced.

Owner:深圳龙澄高科技环保股份有限公司

Marsh gas fermentation process with composite microbial prepn pre-treated stalk

InactiveCN1888073AReduce financial burdenInitial gas production time shortenedGas production bioreactorsMicroorganism based processesSodium bicarbonateFeces

The marsh gas fermentation process with composite microbial preparation treated stalk includes the following steps: crushing stalk material, wetting with water for 18 hr, adding composite microbial preparation and ammonium bicarbonate as the nitrogen source, replenishing water and mixing, stacking and covering with plastic foil, fermenting for 3-6 days and maintaining at temperature over 50 deg.c for 3 days, transferring to marsh gas tank, adding ammonium bicarbonate methane producing inoculum and sealing for 2-7 days to produce marsh gas. The present invention has fast marsh gas producing speed and raised marsh gas producing quantity.

Owner:北京合百意生态能源科技开发有限公司 +1

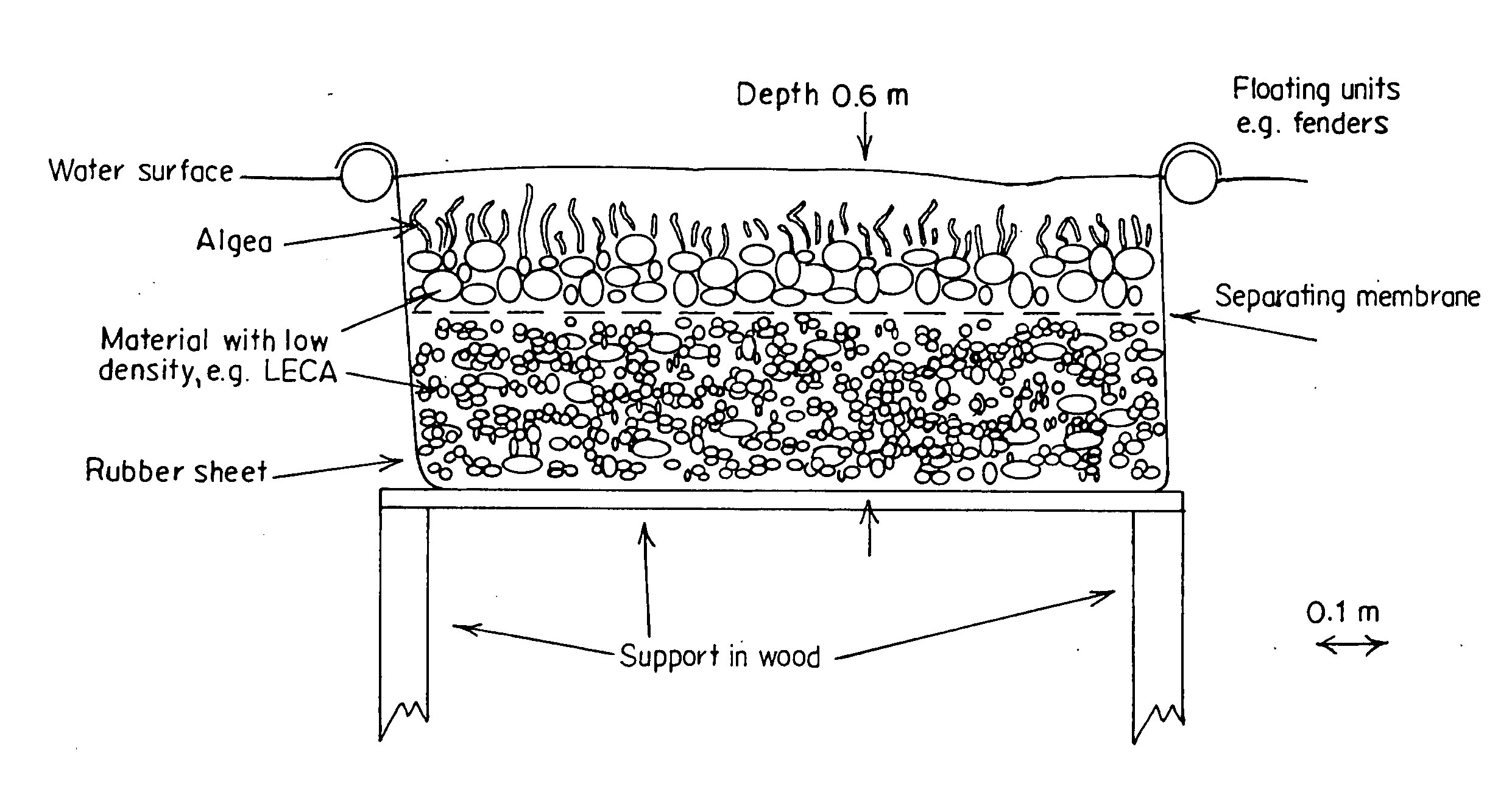

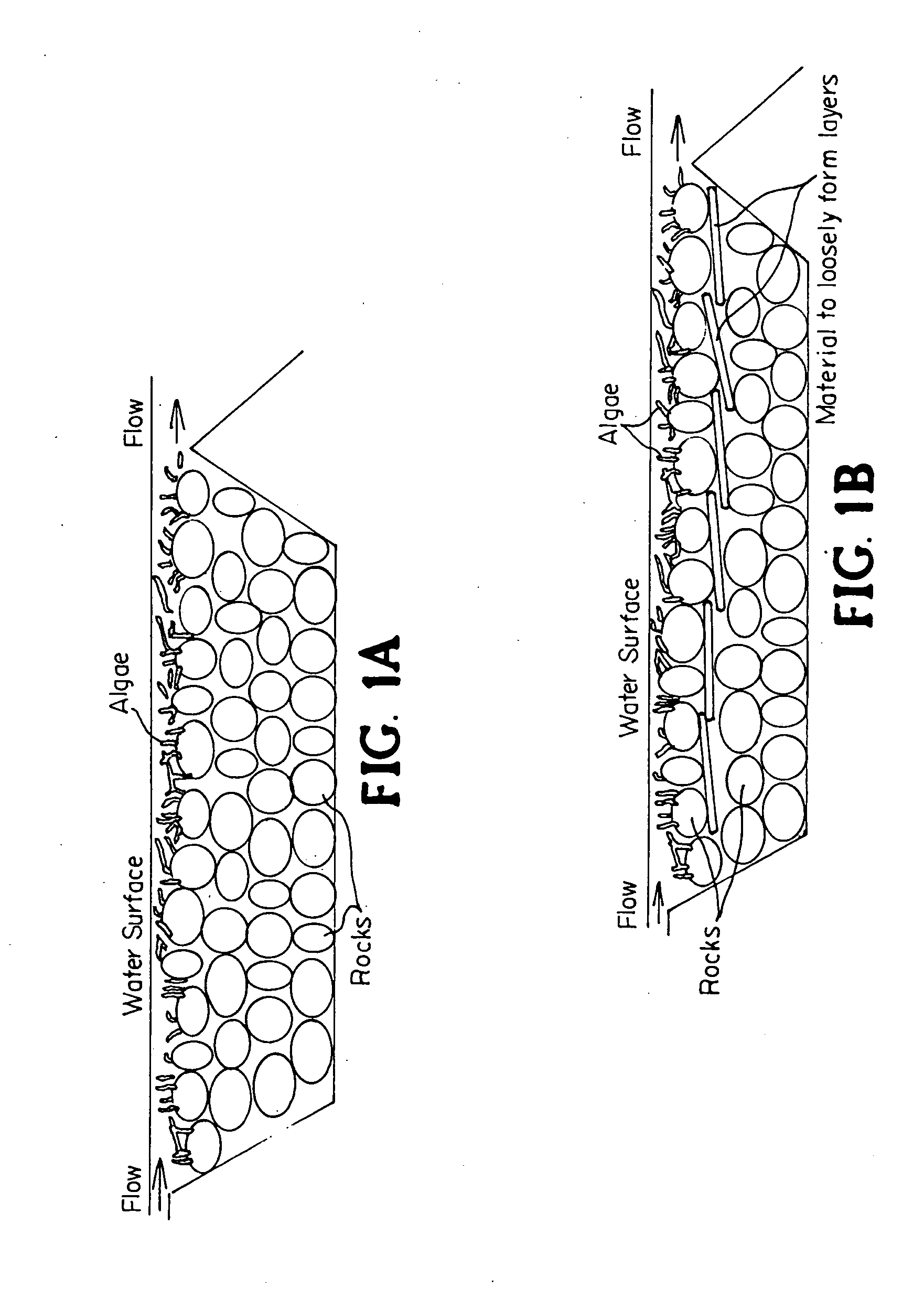

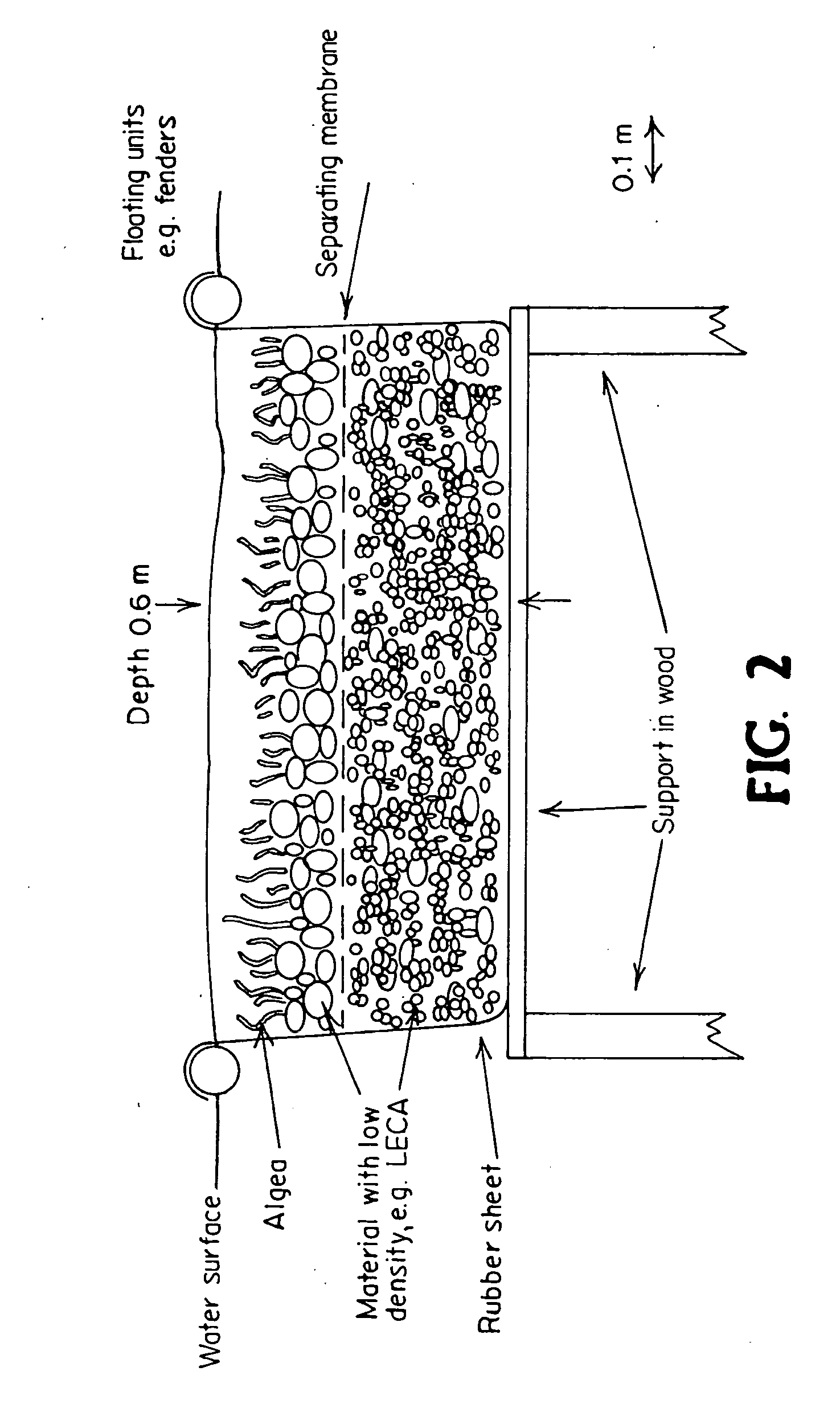

Water treatment plant for combined biomass and biogas production

InactiveUS20120024780A1Easily harvested/collectedIncrease flexibilityBio-organic fraction processingWaste based fuelNitrifying bacteriaBiogas production

A waste water treatment system is provided that includes a basin for holding water; nitrifying and denitrifying bacteria; macroalgae; and a biobed having a at least one layer and being constructed of materials selected to provide sufficient level of pH for enabling bacterial growth. In the biobed de-nitrification and nitrification bacterial processes are separated. Oxygen produced by algae is used by the nitrifying bacteria. Water is provided continuously to the biobed at an inlet and exits the system downstream after having gone through the biobed. The system may be used with waste water in water treatment plants, domestic waste water (sewage), waste water from diverse industries, drain water from waste deposits, runoff water from roads, water waste treatment and recycling plants, agricultural and farm land and surrounding land of populated areas. The algae and bacteria are combined for symbiotic remediation of water that may be flexibly controlled to adapt to a broad range of applications.

Owner:CLEAR WATER ENERGY NORDIC

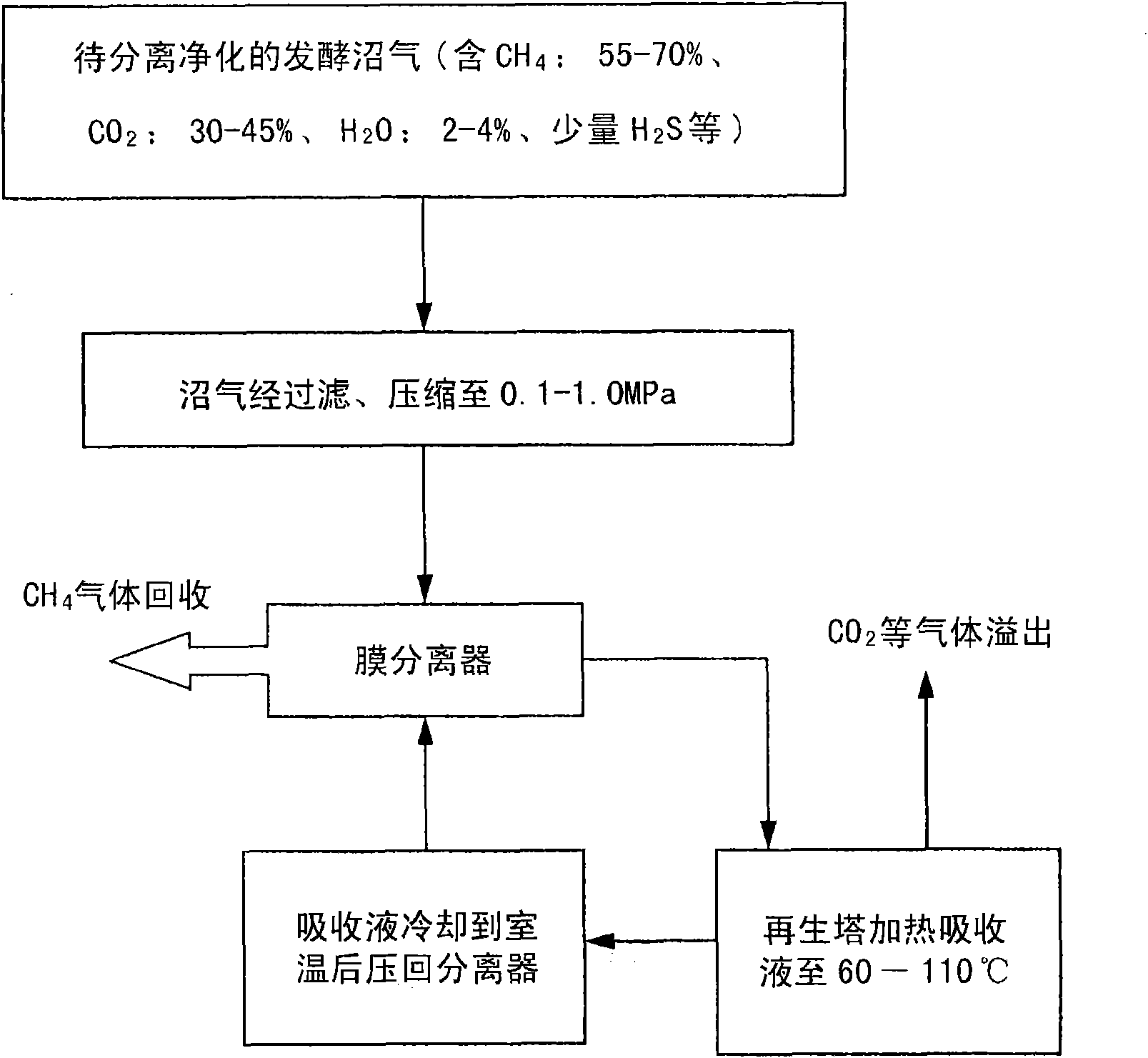

Method for purifying marsh gas by membrane separating technology

InactiveCN101028579ALess investmentGood effectGas production bioreactorsDispersed particle separationCompressed natural gasSeparation technology

Owner:张晓忠

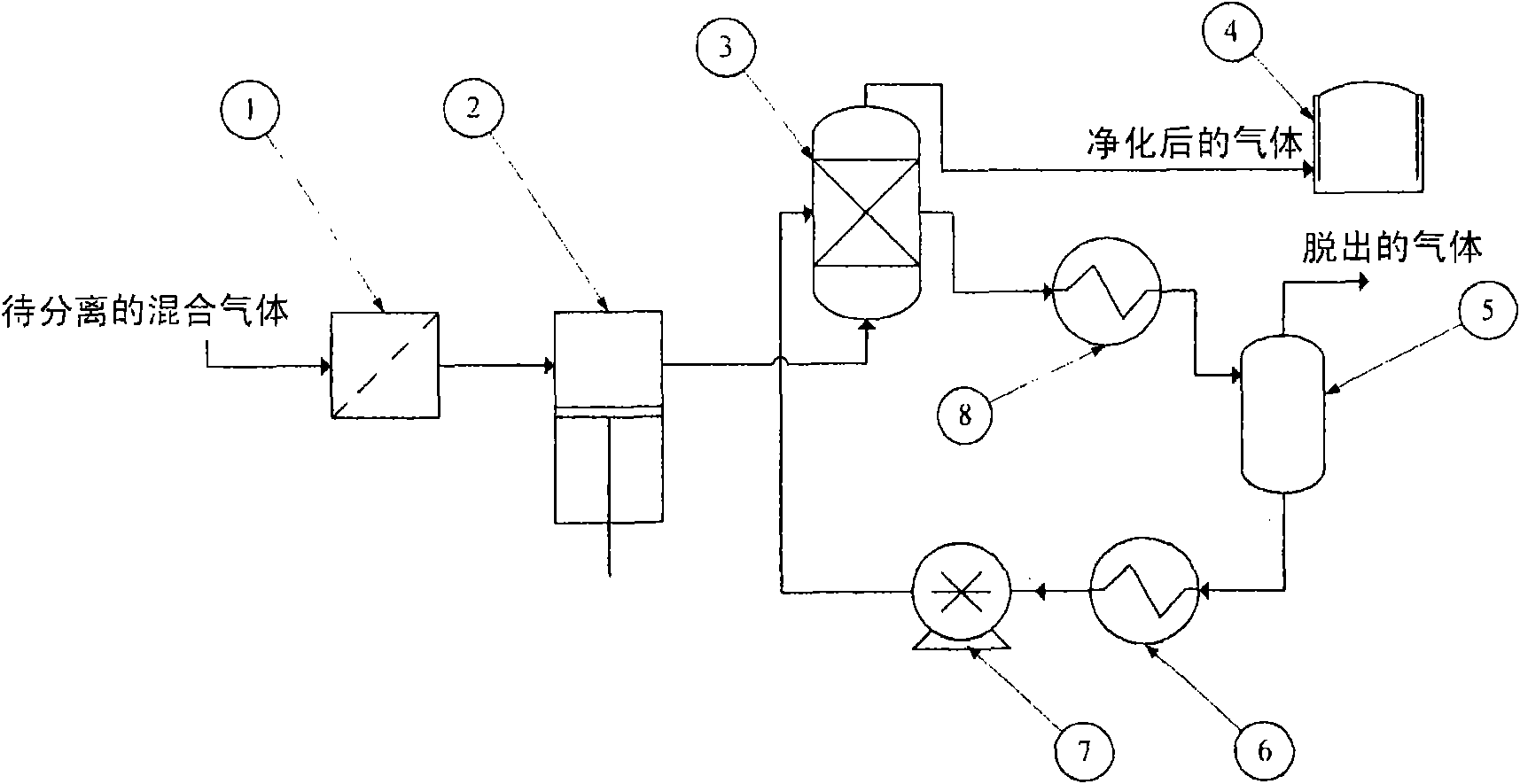

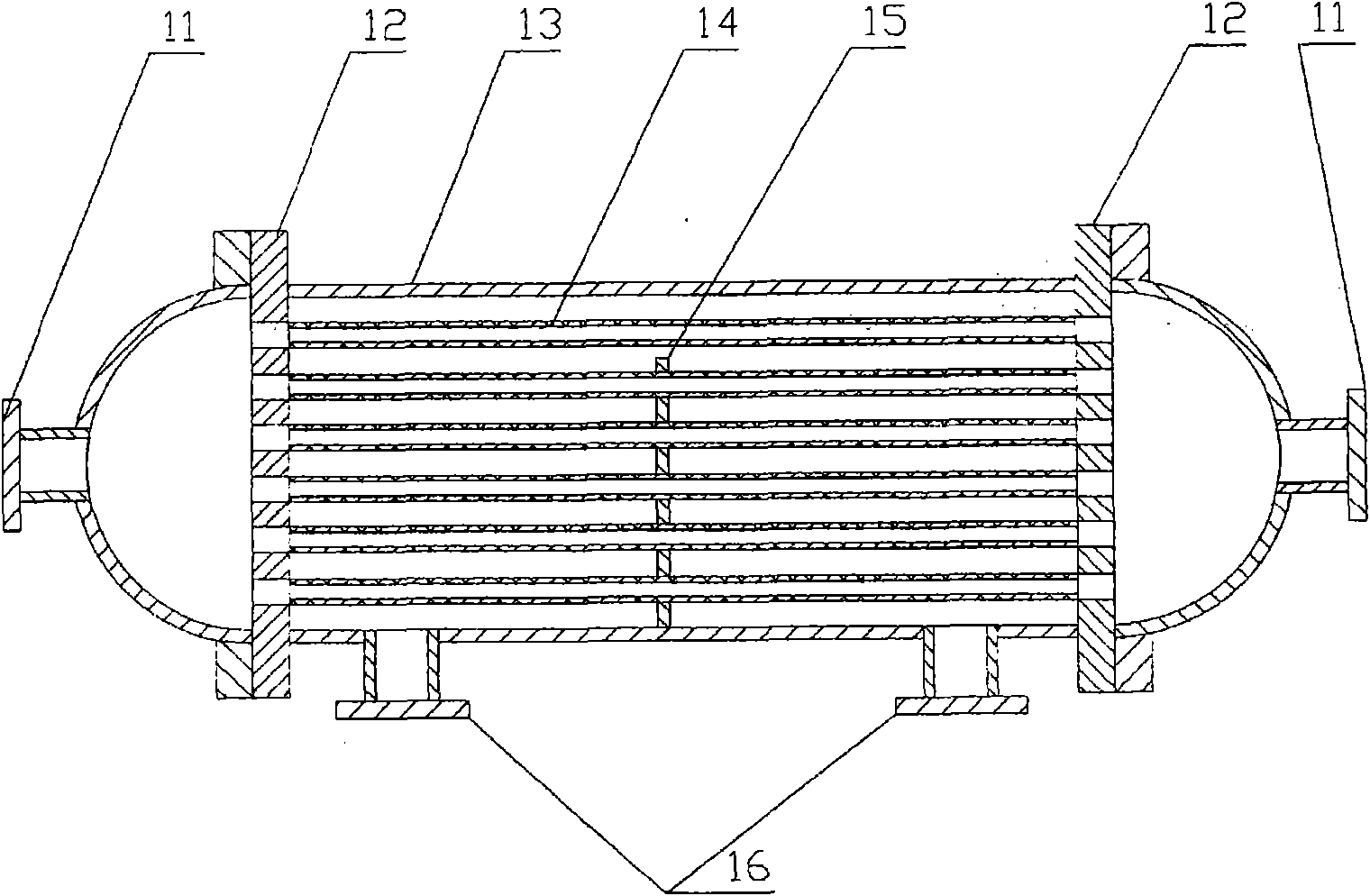

Separator and separation and purification method of gas-liquid phase absorbing membrane

InactiveCN101584960AFlexible designSmall footprintDispersed particle separationBy membranesSolubilityPurification methods

The invention relates to a separator and a separation and purification method of a gas-liquid phase absorbing membrane. The gas-liquid phase absorbing membrane is separated by utilizing different under penetration rates of membrane materials to different substances and different solubilities of liquid phase substances at the penetration side of the membrane to different substances and increasing the contact area of the gas-liquid phase under the dual functions of preferential penetration and selective absorption so that the purpose of purification is achieved. The technical scheme has the advantages of less equipment investment, high separation efficiency, high purity of separated gas, split-phase operation and separation of the gas-liquid phase and no secondary pollution, and is especially suitable for separating and removing CO2, H2S, and the like in petrochemical gas, combustible flue gas and marsh gas.

Owner:青岛生物能源与过程研究所

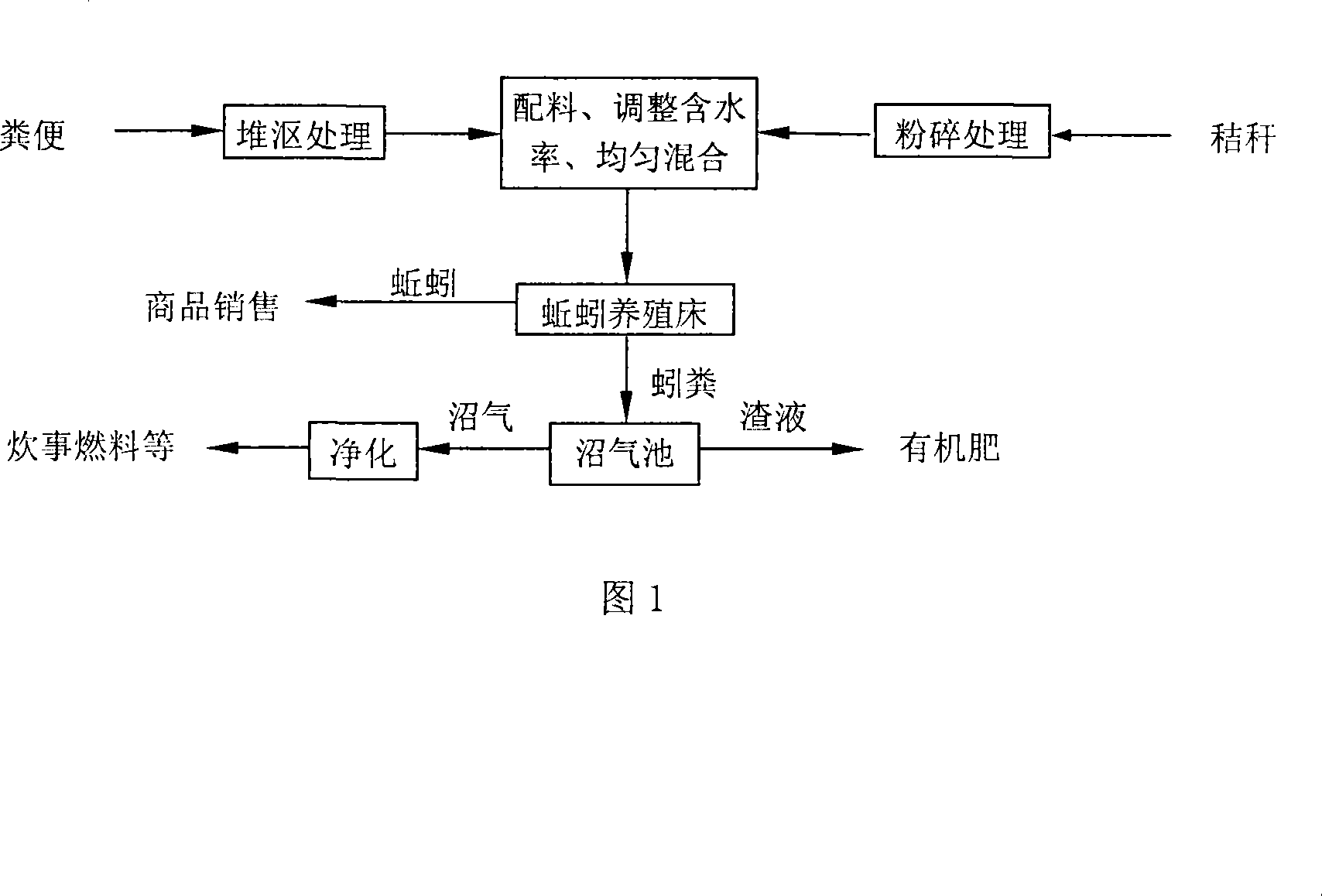

Anaerobic fermentation technique for combined treatment of dejection and straw

InactiveCN101235388AIncrease economic outputBio-organic fraction processingWaste based fuelProduction rateProduction effect

The invention relates to an anaerobic fermentation technique for combinely processing feces and straws. The method comprises doing pile treatment to feces, and then mixing with disintegrated straws, adjusting water-content coefficient to 60%-70% to be used as bait of earthworms cultivation, through wormcast which is produced after earthworms eat bait into a methane tank to do methane tank to produce marsh gas. The invention solves the technical difficult problems of layered raw material, incrusted floating upward, difficult discharging, bad gas production effect and the like which are caused by directly utilizing straws to be marsh gas fermentation material and restricts straws to be household methane tank fermentation material for a long term, and meanwhile, wormcast which is used as marsh gas fermentation material has the functions of improving raw material gas production rate, improving anaerobic sludge activity and strengthening the stability of anaerobic fermentation process, and earthworm production improves economic output of handling process.

Owner:NANJING UNIV

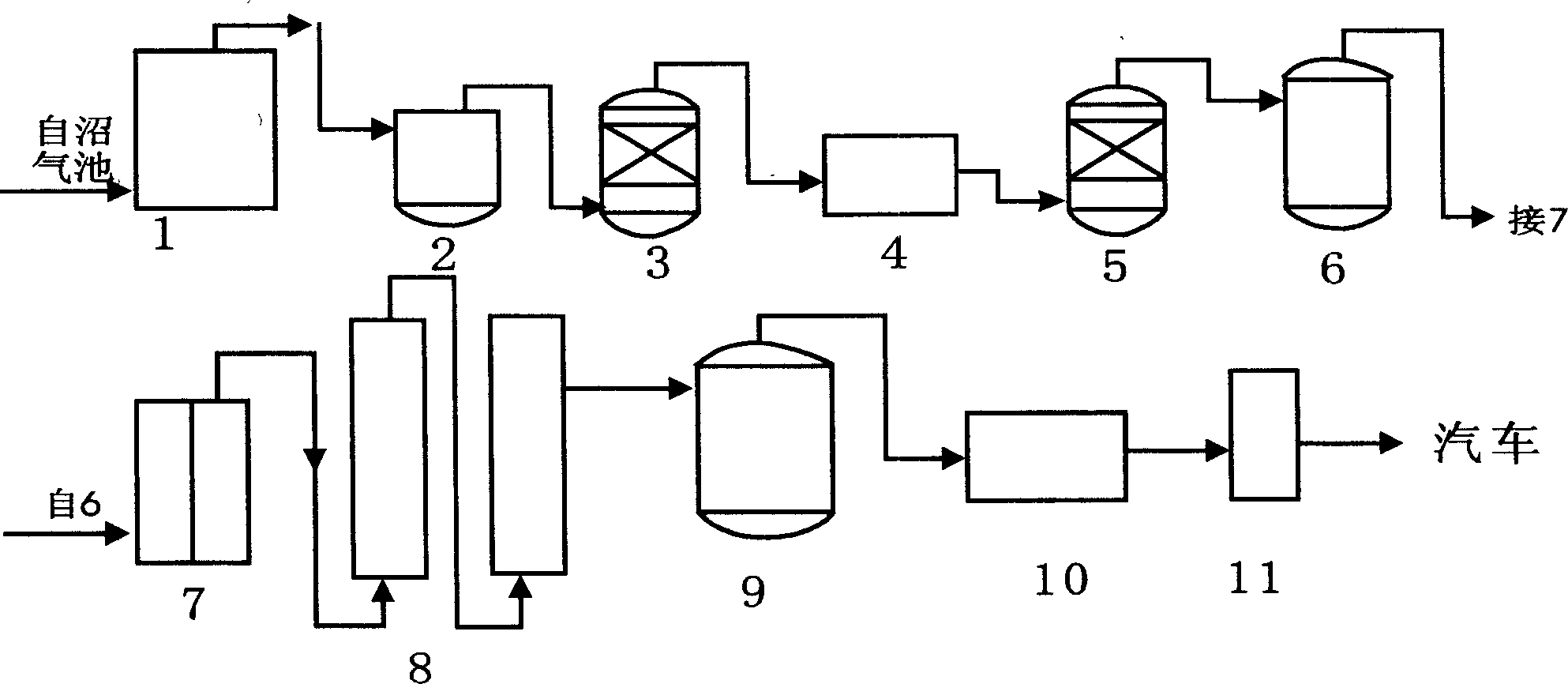

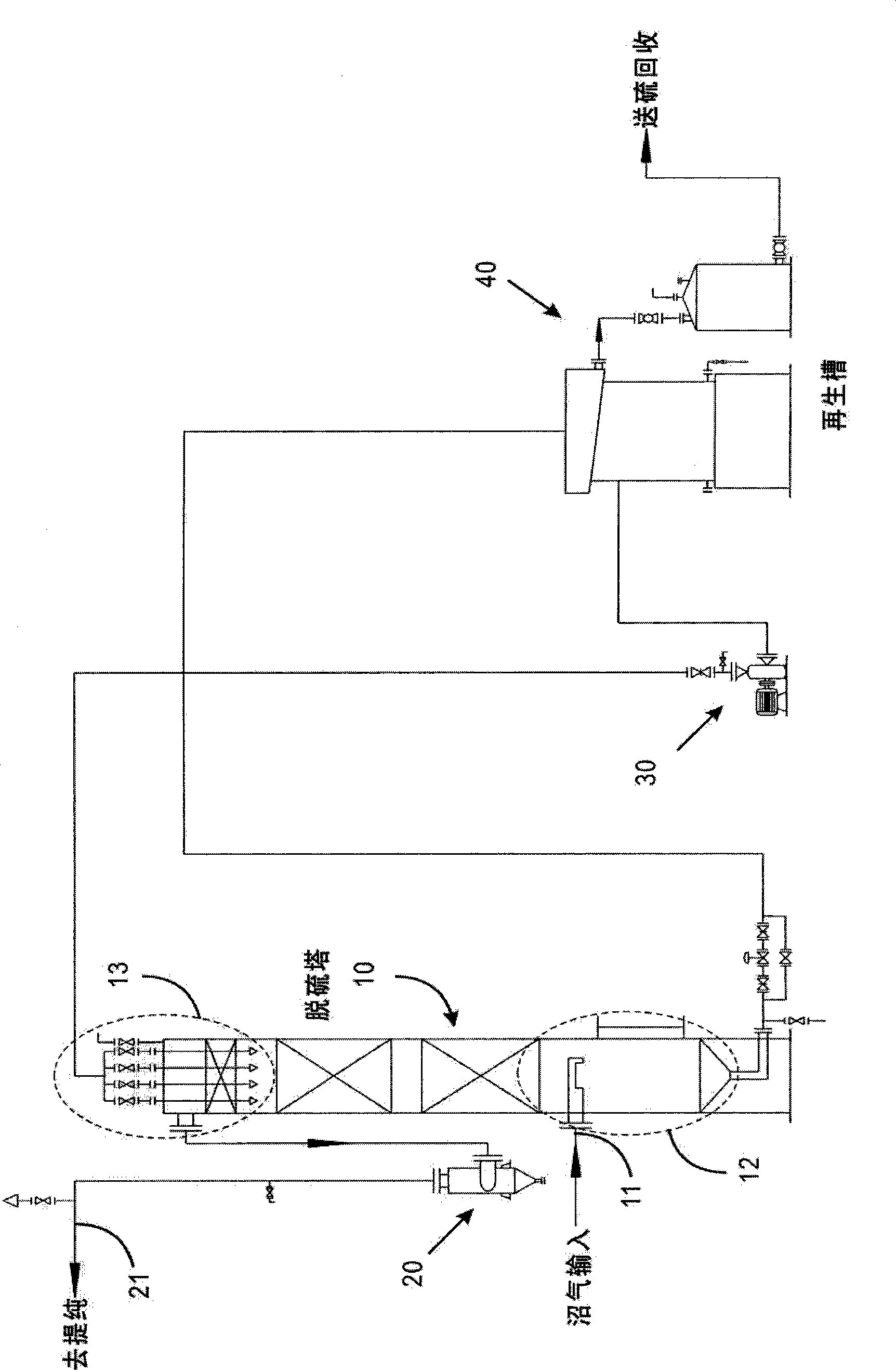

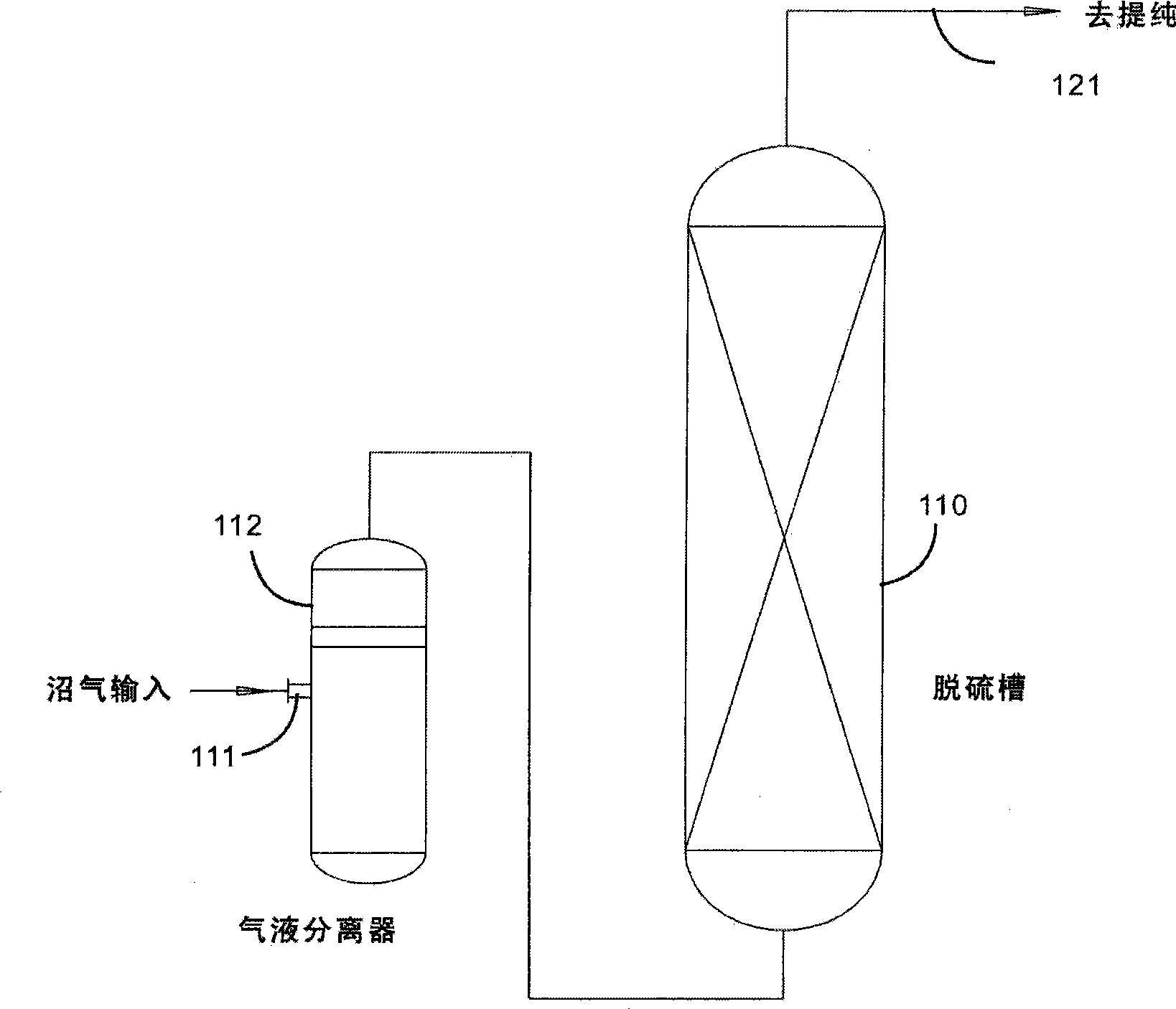

Method and apparatus for preparing sulfur-free natural gas from methane

The invention provides a method for preparing natural gas without sulfur by marsh gas, which comprises the steps of: a, impurity removal; b, desulfurization; c, pressurized pushing; d, absorption displacement, namely carbon dioxide gas contained in the marsh gas processed by the steps is absorbed through an absorption tower in a solution displacement mode; e, cooling dehydration, namely the marsh gas processed by the steps is cooled and finishes the dehydration, and the water content of the marsh gas is controlled to be below 80 percent of relative humidity; and f, secondary filtration, namely the marsh gas processed by the step e is further filtered through a secondary filtration device to remove other impurities in the marsh gas to obtain the natural gas without the sulfur (the content of methane is between 85 and 99 percent). The invention also discloses a device for preparing the natural gas without the sulfur by the marsh gas. The method has the advantages that the marsh gas has high purity and is suitable to be massively and efficiently utilized, the utilization rate of raw materials for preparing the marsh gas is improved and the like.

Owner:DONGGUAN CAMDA GENERATOR WORK

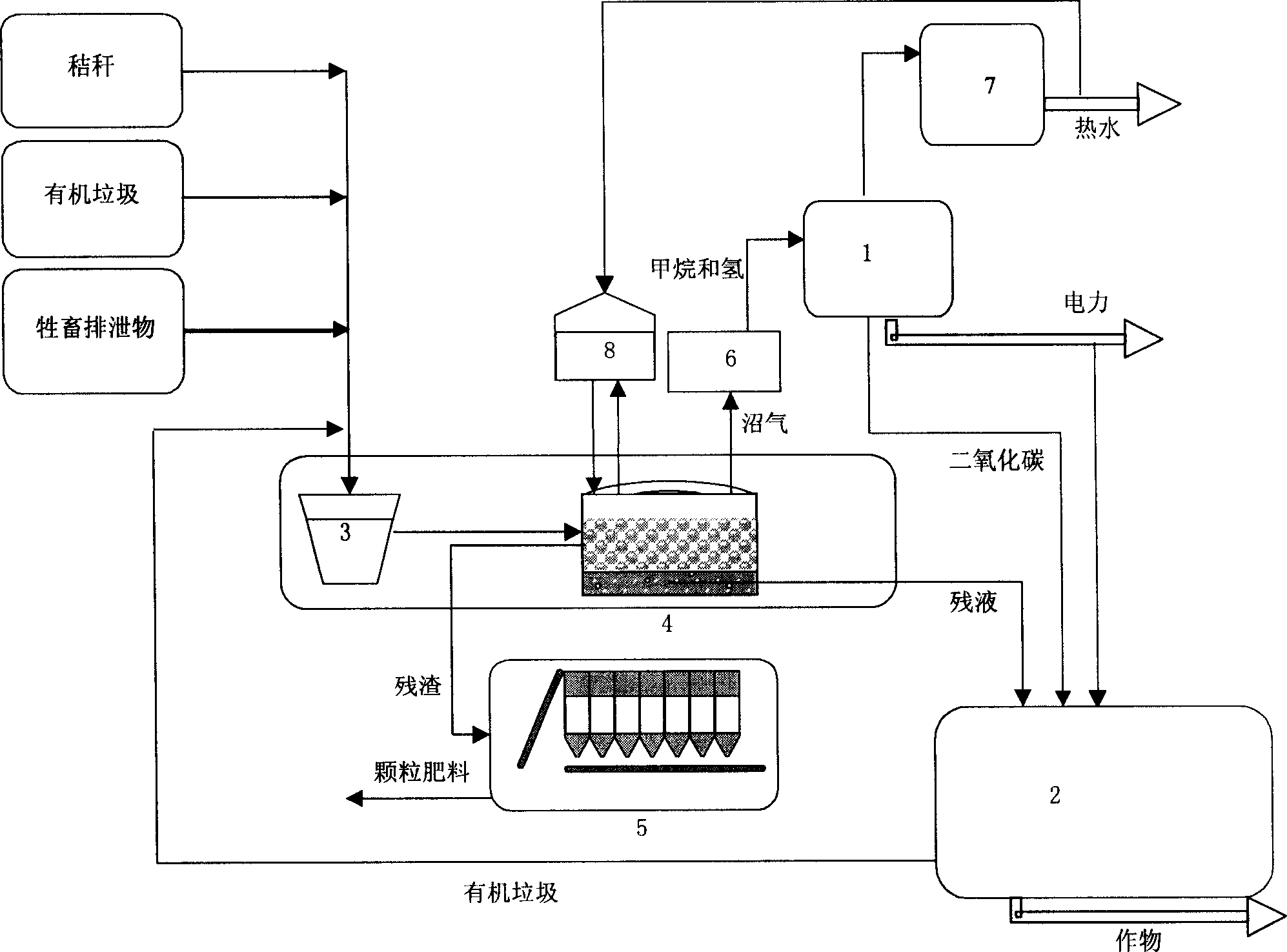

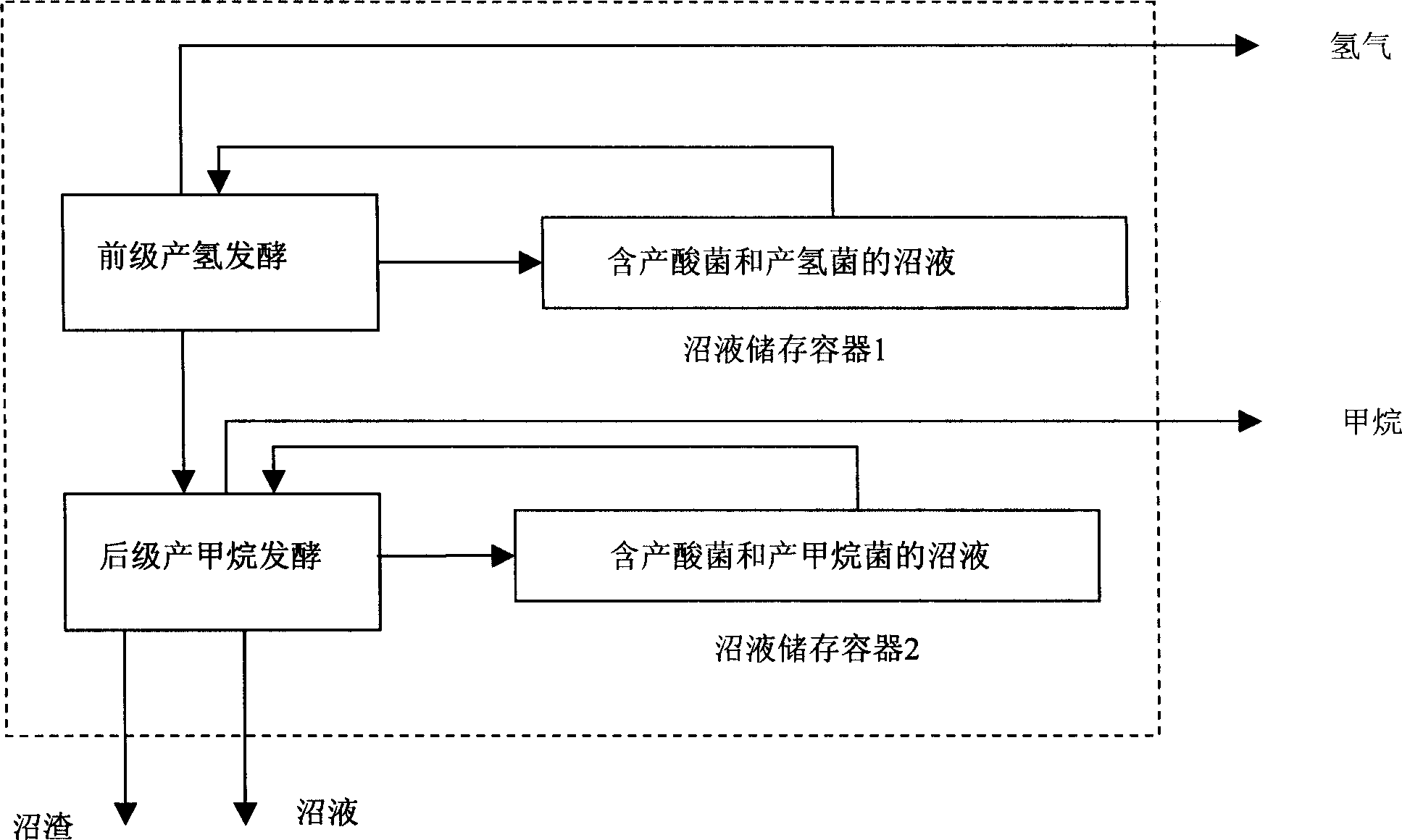

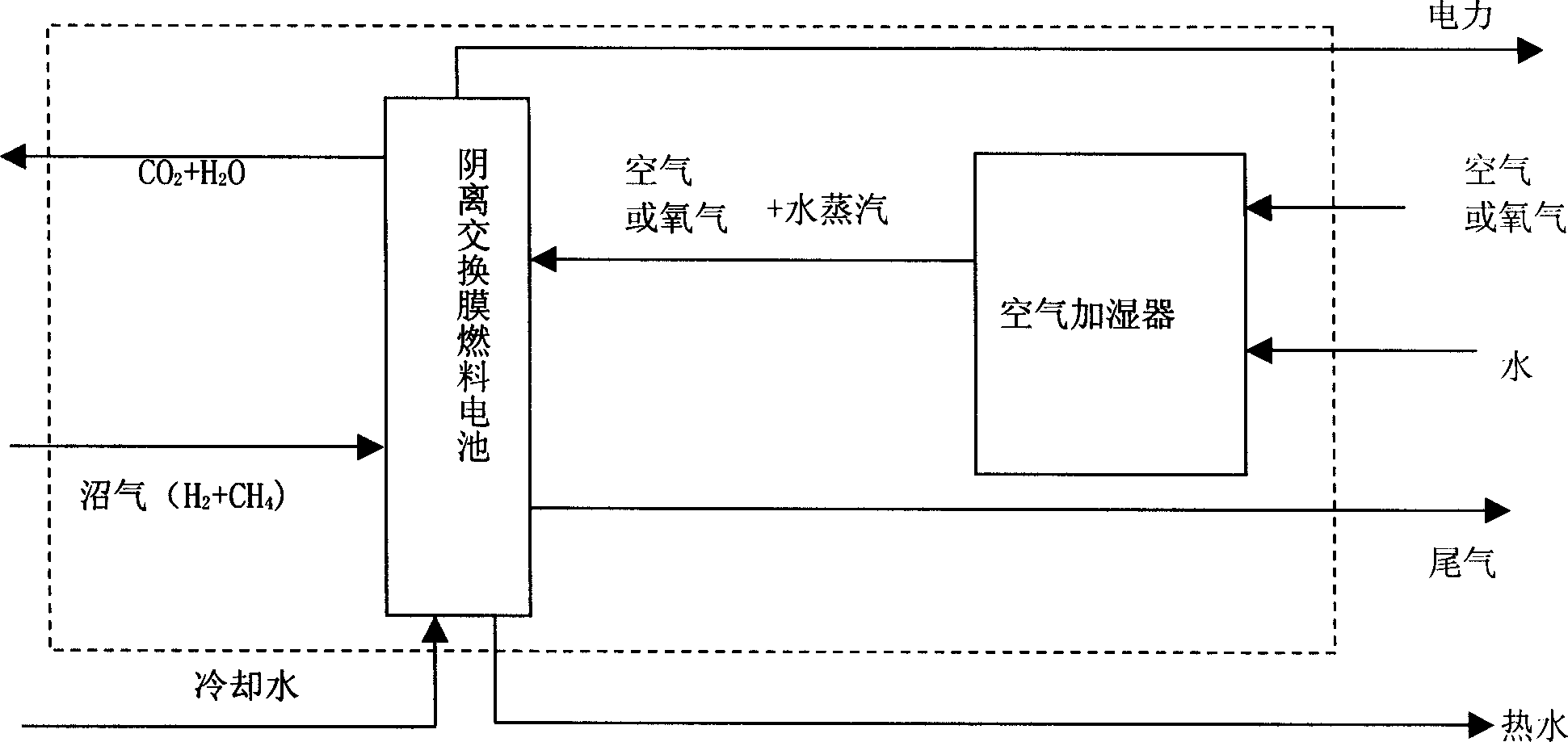

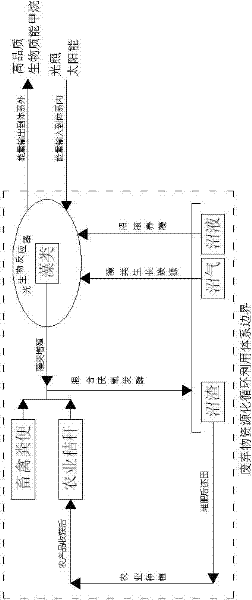

Method of biomass resources circulating utilization

InactiveCN1868933AReduce manufacturing costLow running costBio-organic fraction processingSolid waste disposalEngineeringResources of a Resource

A method for cyclic utilization of rejected biomass includes such steps as decomposing in a multi-class fermenting pool, gas-solid-liquid separation, desulfurizing the marsh gas containing H2 and methane, feeding the marsh gas in the fuel battery with anionic exchange membrane, generating CO2 at negative electrode, using the separated liquid for soilless culture of plants, using said fuel battery to power the artificial light source, and using the residual dregs as the crop culturing matrix or organic fertilizer.

Owner:ZHEJIANG UNIV

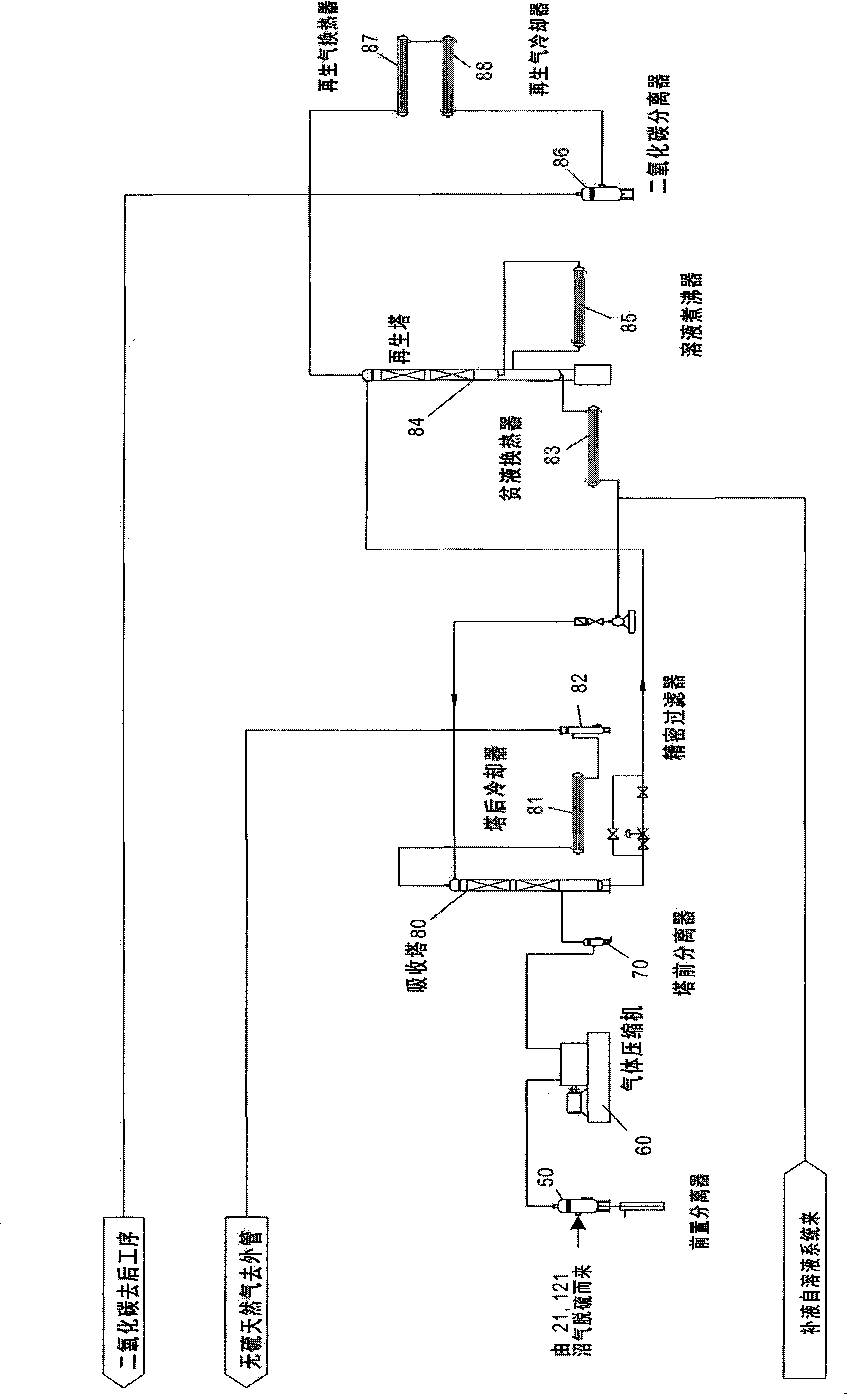

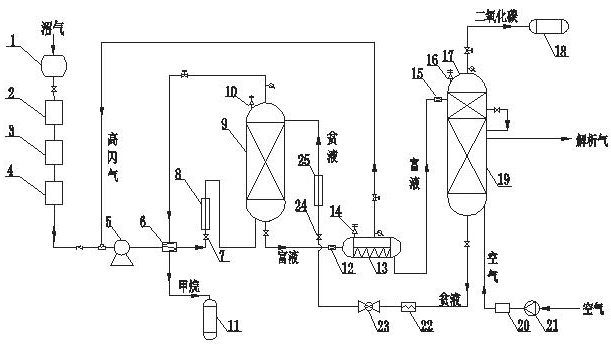

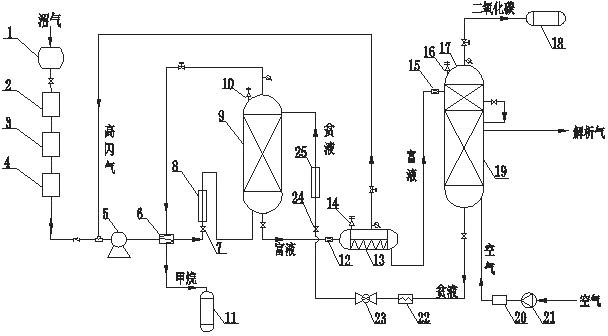

Method for separating and producing methane and carbon dioxide from marsh gas

ActiveCN102329672AImprove the degree of purificationAvoid pollutionCarbon compoundsGaseous fuelsSorbentVaporization

The invention relates to the fields of environment friendliness and renewable energy source recycle. A method for separating and producing methane and carbon dioxide from marsh gas, which is realized through five steps as follows: pretreatment, methane separation, rich liquid flash vaporization, carbon dioxide recycle and adsorbent regeneration. The volume ratio of the separated methane is up to over 96%, and the volume ratio of the carbon dioxide is up to over 98%. The invention has the characters tics of simple process, low energy consumption, nontoxicity, high purity and safety process. Byusing the method, not only is low-carbon circular flow of economy realized, but also pollution to the environment is prevented.

Owner:北京昊业怡生科技有限公司

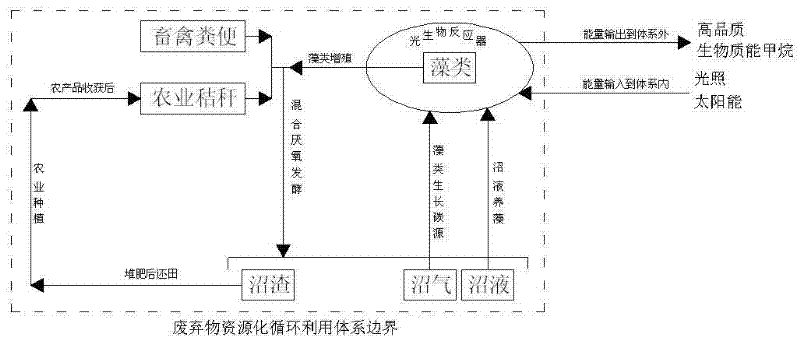

Method for biologically purifying marsh gas and recycling waste of marsh gas

InactiveCN102337302APromote growthAvoid harmBio-organic fraction processingUnicellular algaeSocial benefitsPhotobioreactor

The invention belongs to the technical field of recycling of resources, and in particular relates to a method for biologically purifying marsh gas and recycling waste of the marsh gas. The method comprises the following steps of: purifying carbon dioxide in the marsh gas by using a photo-bioreactor constructed by algae to obtain high-quality biomass energy methane; simultaneously, combining fermented liquid and residues which are residual after fermentation, and comprehensively recycling the algae proliferated in the photo-bioreactor to fulfill the aim of zero emission of the waste. By the method, the marsh gas has an obvious purification effect, the concentration of the methane in the marsh gas can be improved from the range of between 30 and 40 percent to 90 percent, the energy flow of solar energy from the algae to high-quality marsh gas and the matter cycle of nutrient elements such as C, N, P and the like are realized, and economic and social benefits are obvious.

Owner:FUDAN UNIV

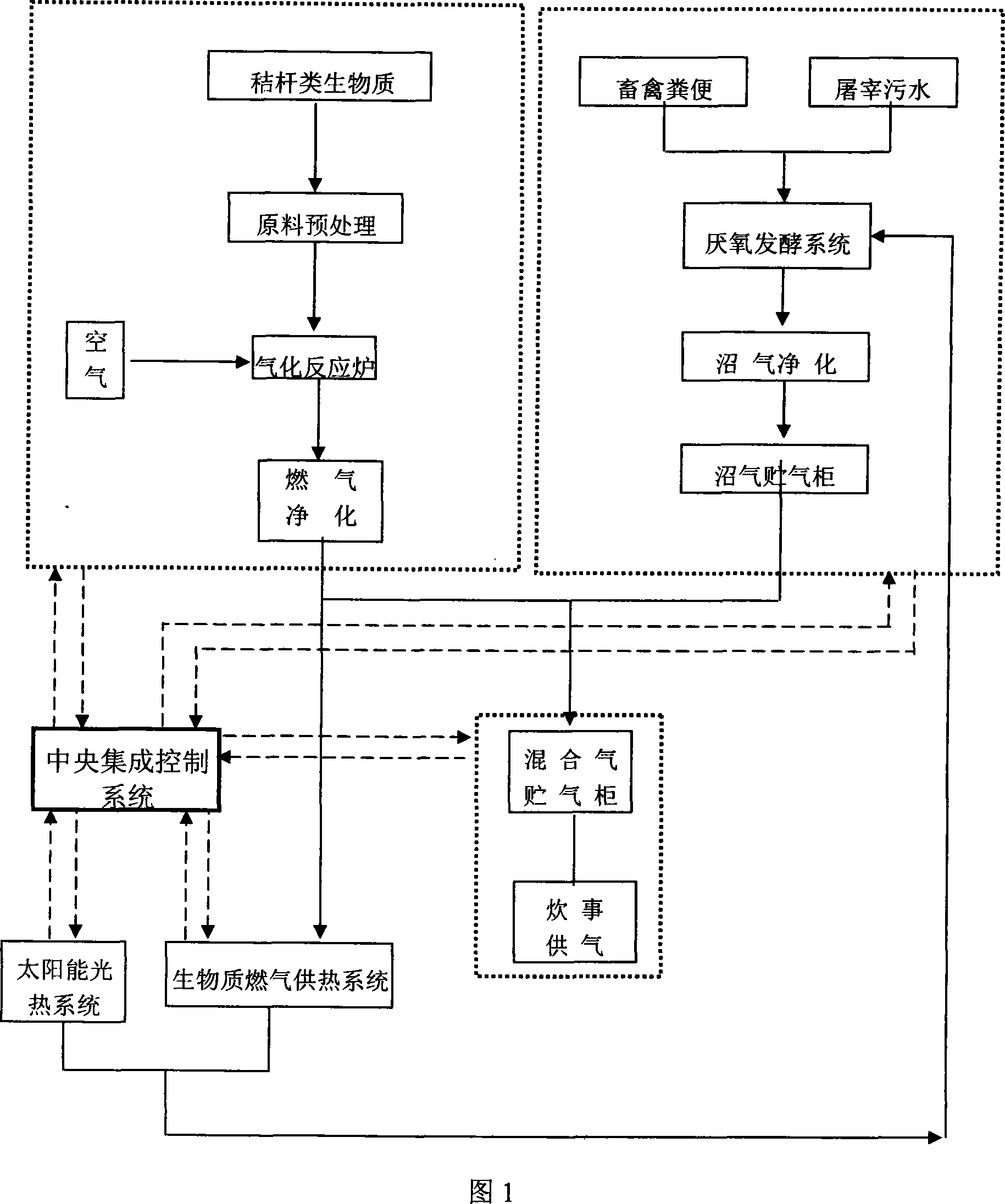

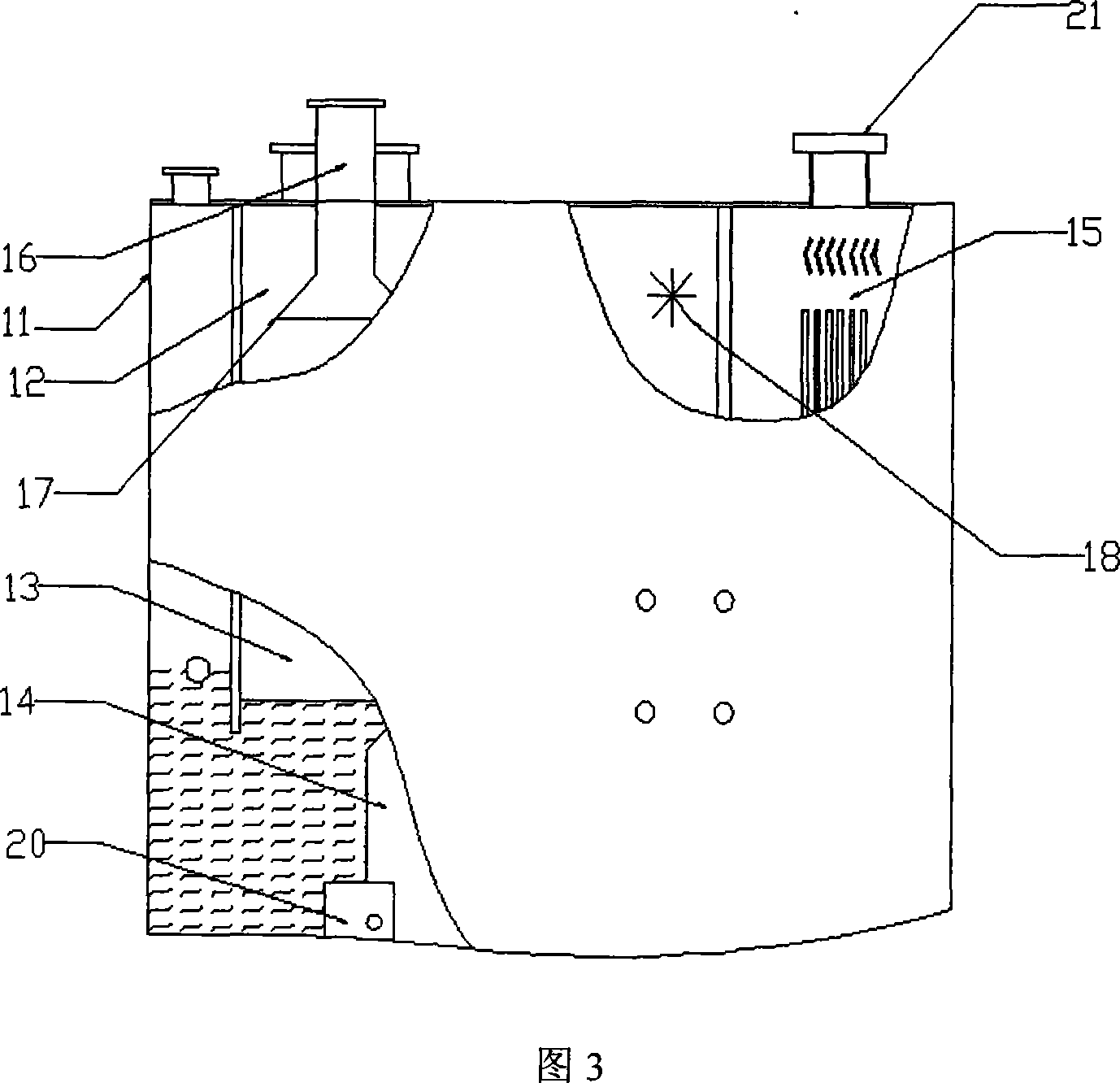

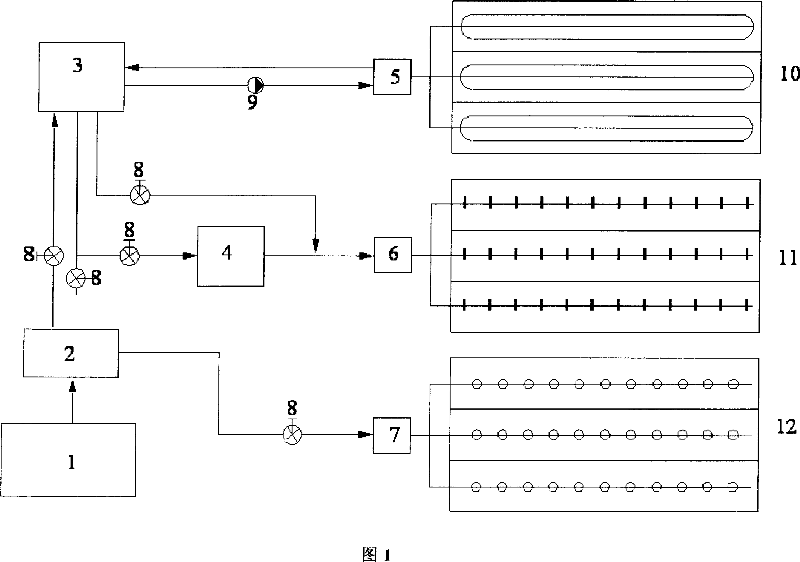

Biological energy-marsh gas fermentation-solar energy integrated utilization system

InactiveCN101063080AEfficient use ofAvoid corrosionSolar heat devicesGas production bioreactorsMarshFermentation

The invention discloses a biological mass energy-marsh gas fermentation-solar energy integrated usage system, which is characterized by the following: comprising biomass evaporated unit, marsh gas anaerobic fermentation unit, central integrated control unit, solar energy light hot unit, biomass gas heat supply unit, biomass fuel and marsh gas automatic mixed unit, fuel transmitting and distributing and user unit; connecting the central control unit and the other units separately; connecting the biomass gasifying unit with the biomass fuel heat supply unit, biomass fuel and marsh gas automatic mixed unit separately; connecting the marsh gas anaerobic fermentation unit with the biomass fuel and marsh automatic mixed unit; connecting the biomass fuel and marsh automatic mixed unit with fuel transmitting and distributing and user unit; connecting the solar energy light hot unit and biomass gas heat supply unit with the marsh gas anaerobic fermentation unit separately. This invention can transform the pollution as marsh gas source.

Owner:浙江网新百川环境科技有限公司

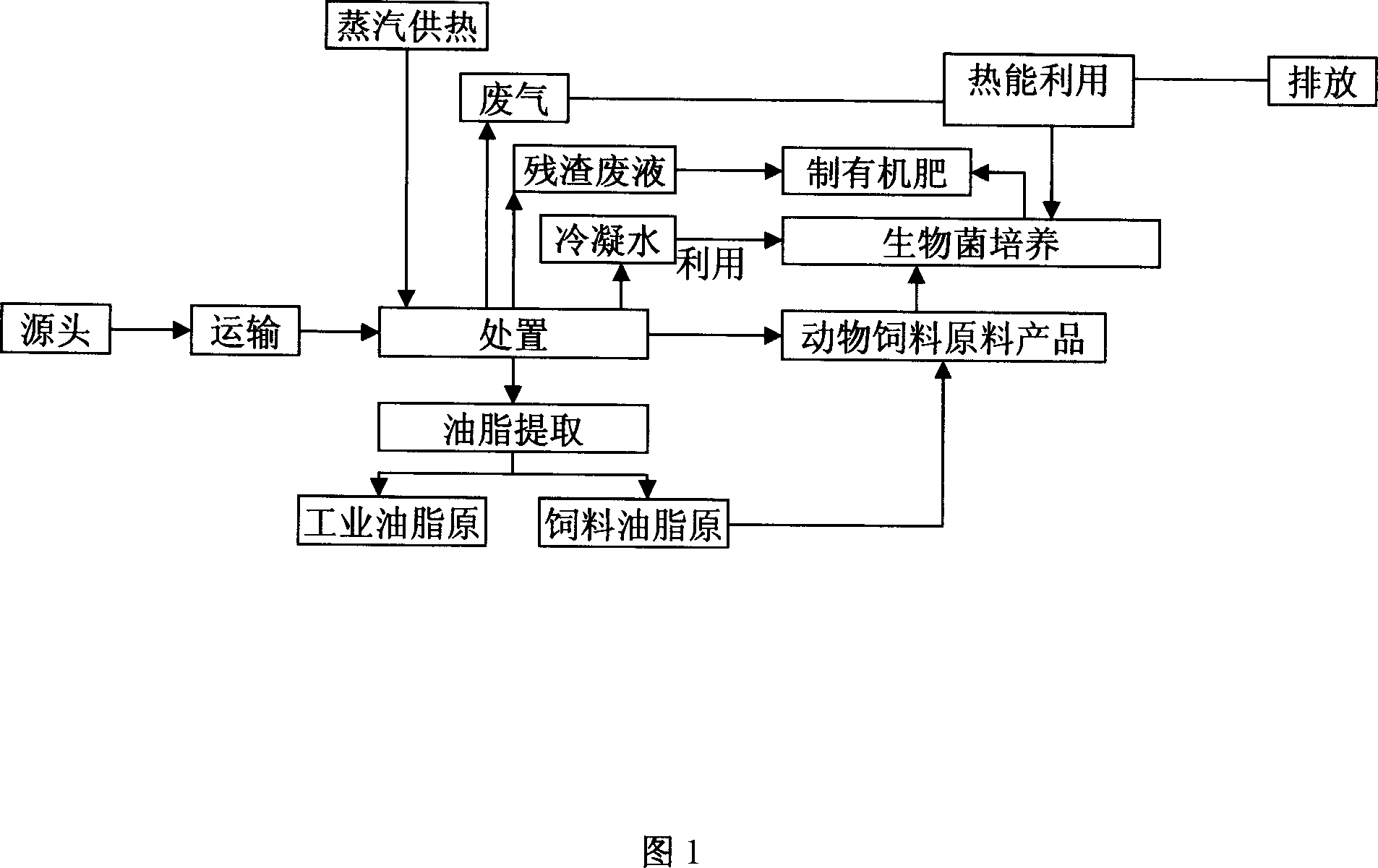

Process for utilization of kitchen refuse as resource

InactiveCN1923386AReduce processing costsFood processingSolid waste disposalOil and greaseLiquid waste

The invention relates to a method for cultivating fish via kitchen waste, which comprises dewatering kitchen waste, while it content is lower than 70%, and selecting metal foreign matters via magnetic method; boiling and disinfecting, to evaporate the water more then 60%, extracting liquid grease; drying and breaking solid to make into forge; using the waste liquid as industrial grease material and fertilizer; recycling the waste slag liquid as marsh gas to supply heat; using waste gas recycle heating technique to support fish cultivation; and recycling clean condensed water to support fish cultivation.

Owner:SHANGHAI FOODWASTE TREATMENT TECH

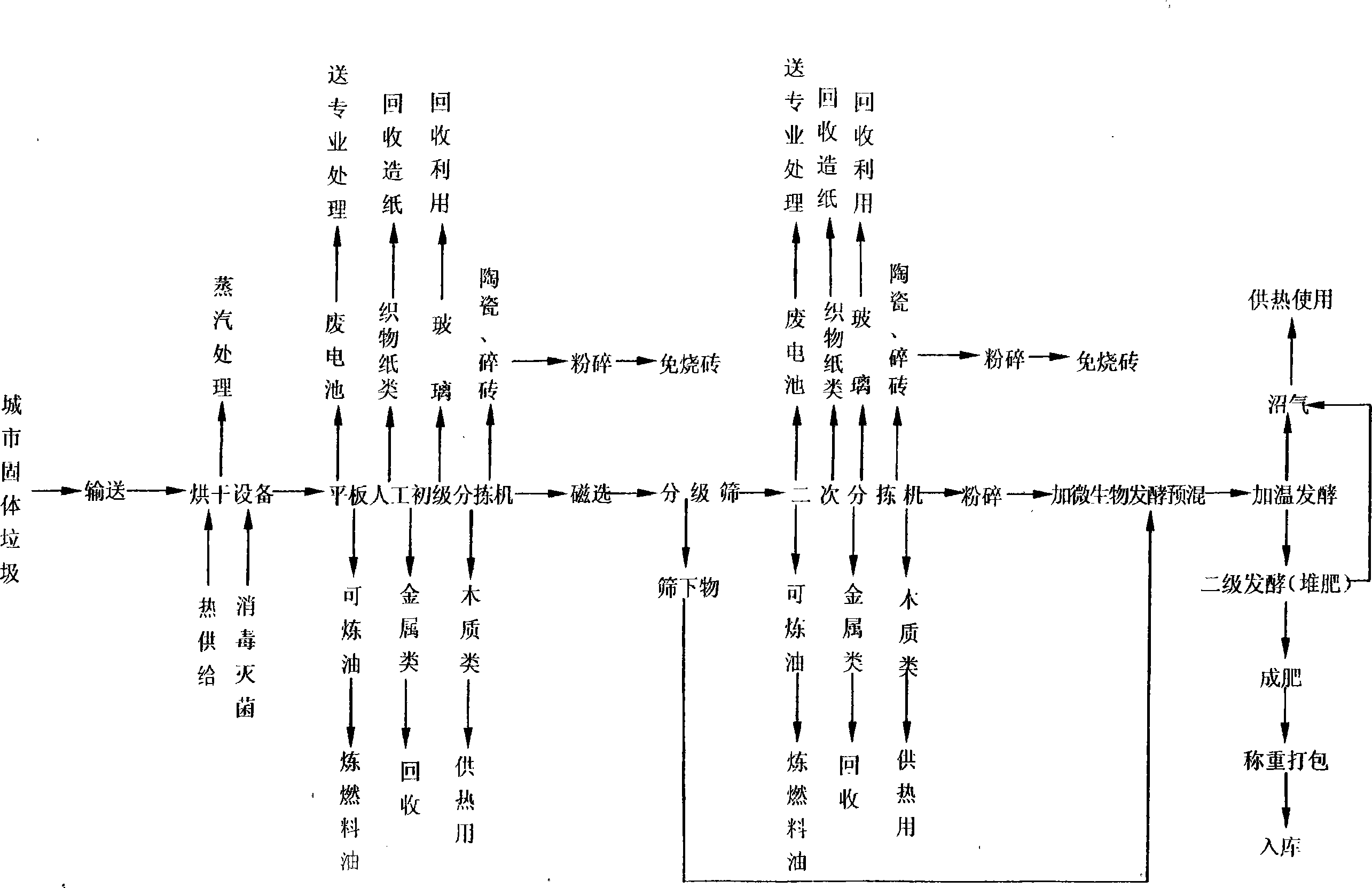

Integrated ulilization processing system for treating daily-life garbage without environmental pollution by reclaiming and regenerating

InactiveCN101081402ABe harmlessBe resourcefulBio-organic fraction processingSolid waste disposalBrickLitter

The present invention is one comprehensive innocuous city solid refuse treating system. In the system, the city solid refuse is first stoved, sterilized and sorted, then magnetically separated to separate out iron containing waste, and finally sieved into the undersize fed to one mixing tank and the oversize further sorted, with the rest matter being crushed and fed also to the mixing tank for fermentation to produce organic fertilizer. The sorted fabric, paper, iron, glass are reused; the sorted building refuses are crushed and further produced into no-burning brick; the waste battery is specially treated; the waste plastic and rubber are treated to produce oil; and the marsh gas generated in the fermentation process is used to provide heat for stoving refuse and refining oil. The present invention has excellent refuse treating effect.

Owner:周建华 +1

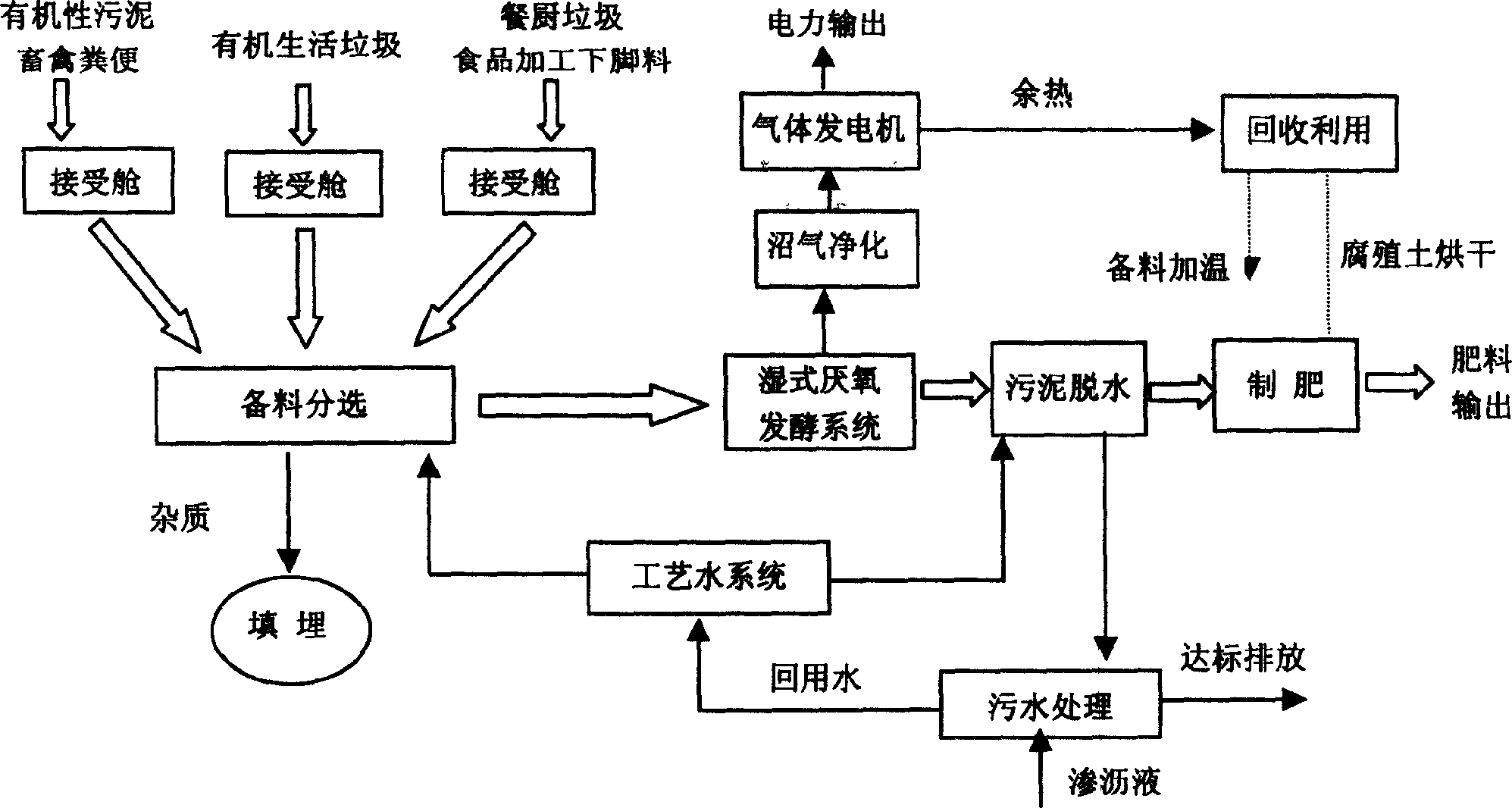

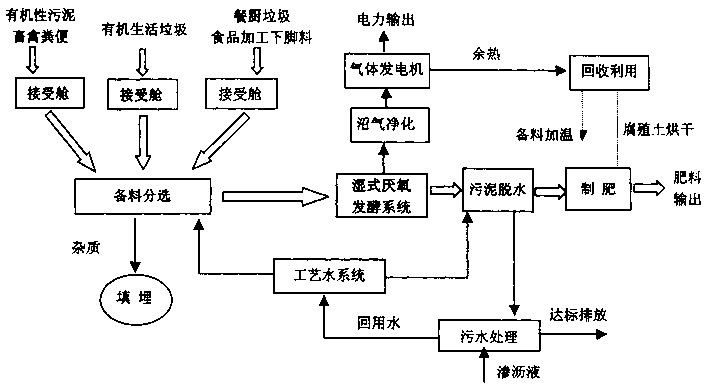

Resources comprehensive treatment technology for organic waste material

InactiveCN1478611AChange the status quo that is difficult to deal with effectivelyAdjustable temperatureBio-organic fraction processingSolid waste disposalMarshElectricity

A process for reclaiming the organic waste includes such steps as mixing it with hot water, pulverizing, removing impurities to obtain a suspended substance at 36-37 deg.C, wet-type anaerobic fermenting for 15-20 days to obtain humus and marsh gas, using humus to prepare fertilizer, and using marsh to generate electricity.

Owner:SHANGHAI SHENGONG ENVIRONMENTAL PROTECTION CO LTD

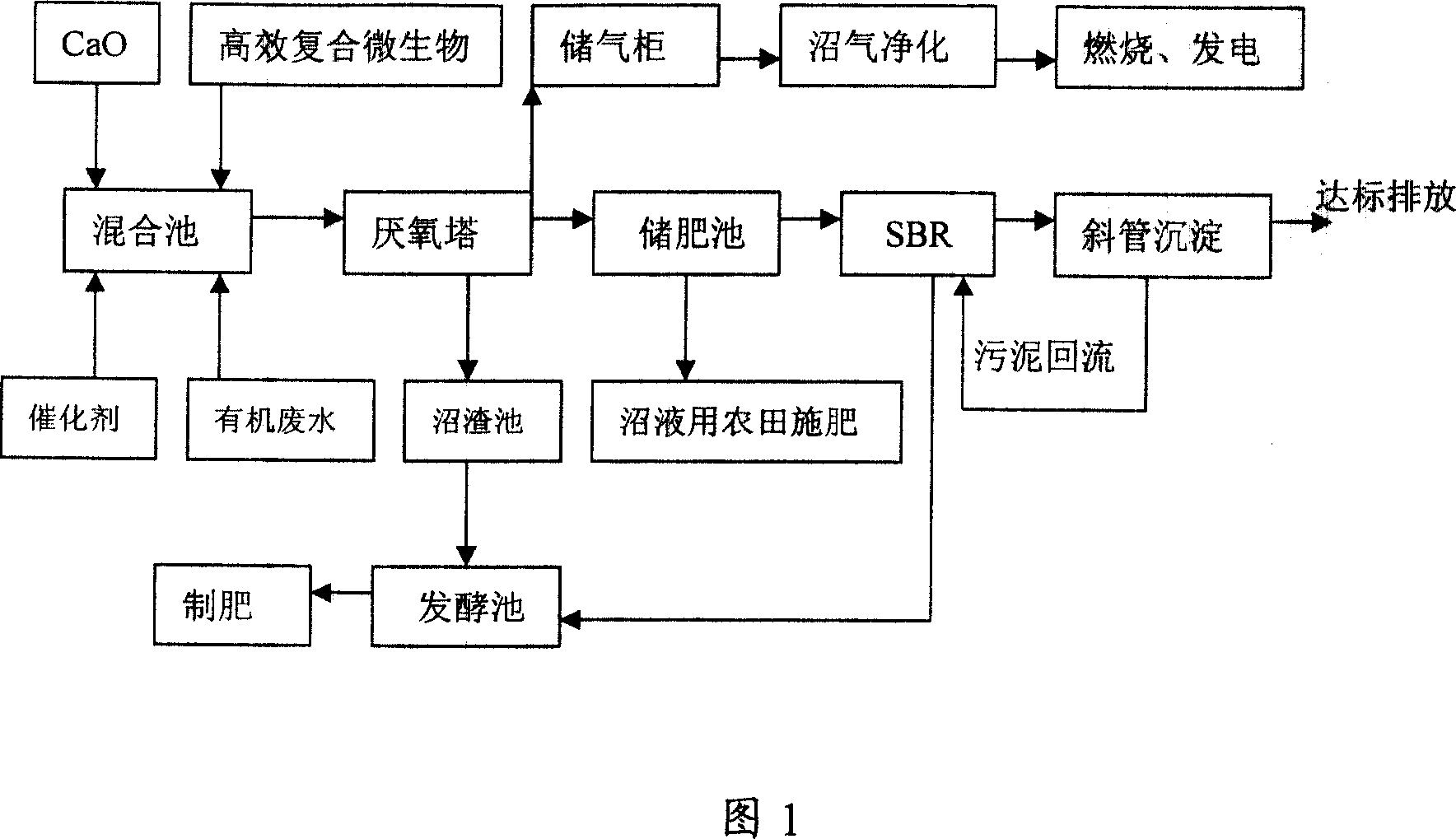

Innocuous treatment and utilization method for sludge

InactiveCN101033108ANo secondary pollutionImprove the ecological environmentSludge treatment by de-watering/drying/thickeningBio-organic fraction processingSlagSludge

This invention discloses a new method for innocuity of mud including the following steps: 1, putting dehydrated mud into a mixing basin to adjust the pH value to 8-9 and mixing them and inputting them to an anaerobic tower, 2, the mud mixture is fermented and separated automatically in the tower, 3, marsh gas is used in burning and generation, 4, the solution is used in fertilizing farms and the part can't be used passes through a SBR biochemical process device and enters into a slant pipe to be deposited and separated in solid and liquid, mud flows back and the water is discharged if meets the standard, 5, the slags are mixed with the mud discharged by the SBR process device and enter into a ferment basin for the second fermentation, 6, material of the fermentation basin is input into a fertilizing process to be dried, cooled, crushed, screened, packaged and get agricultural high efficient organic fertilizer.

Owner:浙江威尔斯生物能源开发有限公司

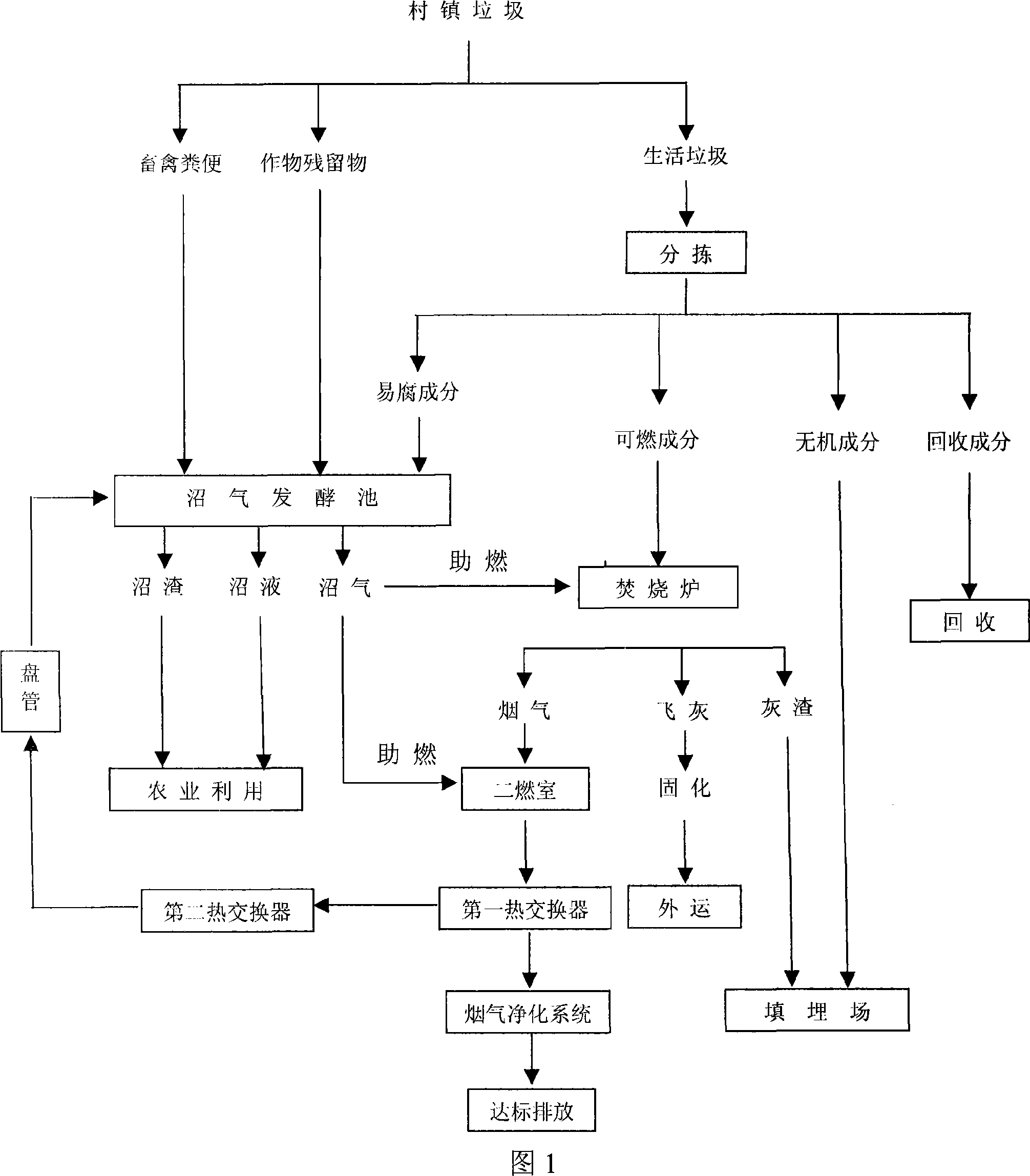

Rubbish comprehensive processing method adapted for village and small town

InactiveCN101062825AIncineration harmlessIncineration reductionBio-organic fraction processingChemical industryThermal energyResource utilization

The invention discloses a garbage comprehensive treatment method for village, which comprises the following steps: sorting life garbage of village to perishable element, combustible constituent, reclaiming element; inorganic element; allocating the perishable element, residues of crop, animal and poultry manure and water with mass ratio at 0. 8-1. 2:0. 8-1. 2:8; proceeding anaerobic fermentation under the insulation action of burning lose heat; generating marsh gas; burning the combustible constituent with combustion-supporting marsh gas completely; getting high temperature smoke gas; recovering thermal energy through the first and second heat exchanger; maintaining the temperature of marsh gas fermenting tank; obtaining resource utilization of marsh liquid or slag, marsh gas and reclaiming component; health-filling the inorganic element and burning ash slag. This invention can prevent twice pollution of the burning smoke gas, which can increase the efficiency and output of mash gas.

Owner:ZHEJIANG UNIV

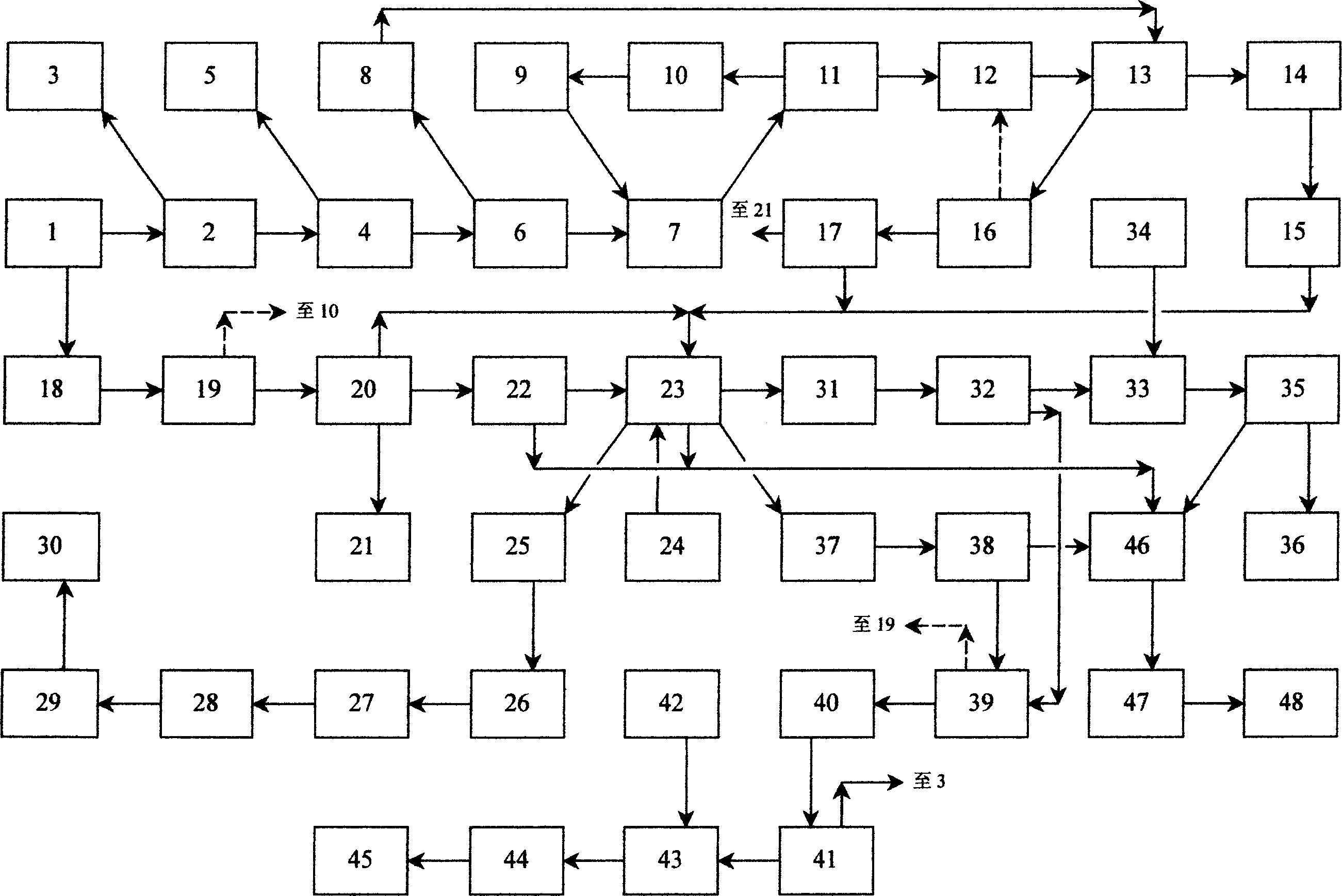

Six-segment process for kitchen garbage to regenerate grease, bio-natural gas, medicinal fertilizer, feedstuff

The invention relates to a method for treating kitchen waste regenerate grease, biological natural gas, fertilizer and forge, wherein it comprises forty eight devices, to form kitchen waste pretreatment section, regenerate grease section, regenerate biological natural gas section, regenerate fertilizer section, regenerate forge section, and sewage treatment section. The invention is characterized in that: the pretreatment section cleans the harmful foreign materials of kitchen waste; the regenerate grease section separates the grease of mixture discharged by pretreatment section; the regenerate biological natural gas section ferments the mixture liquid of pretreatment section and regenerate grease section to generate marsh gas, to be purified to obtain biological natural gas; then the regenerate fertilizer section and regenerate forge section treats the natural gas into liquid fertilizer and protein forge; the sewage treatment section discharges the sewage.

Owner:上海铭新环卫工程科技有限公司

Pollution-free synthetic treatment method for garbage in village and town

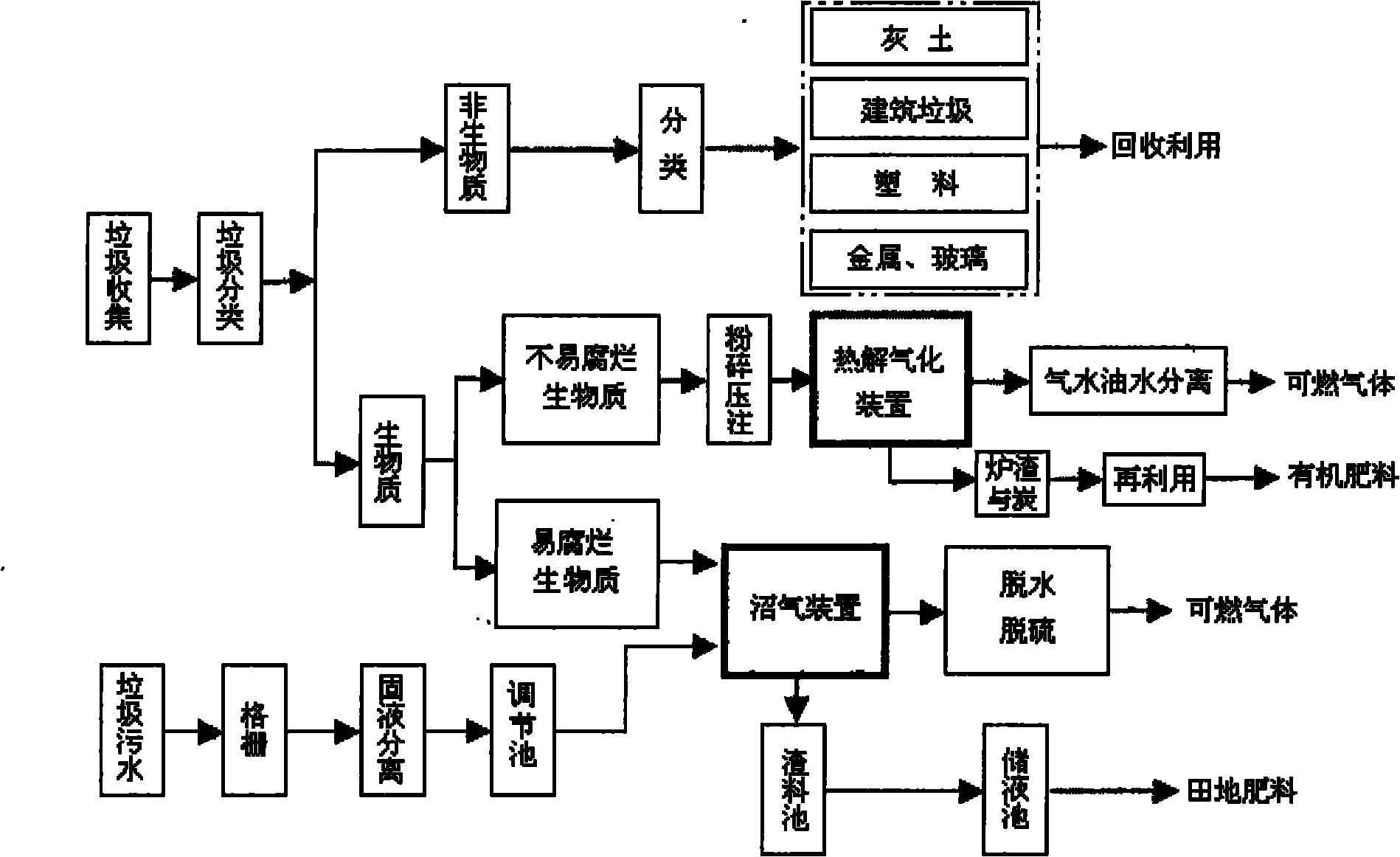

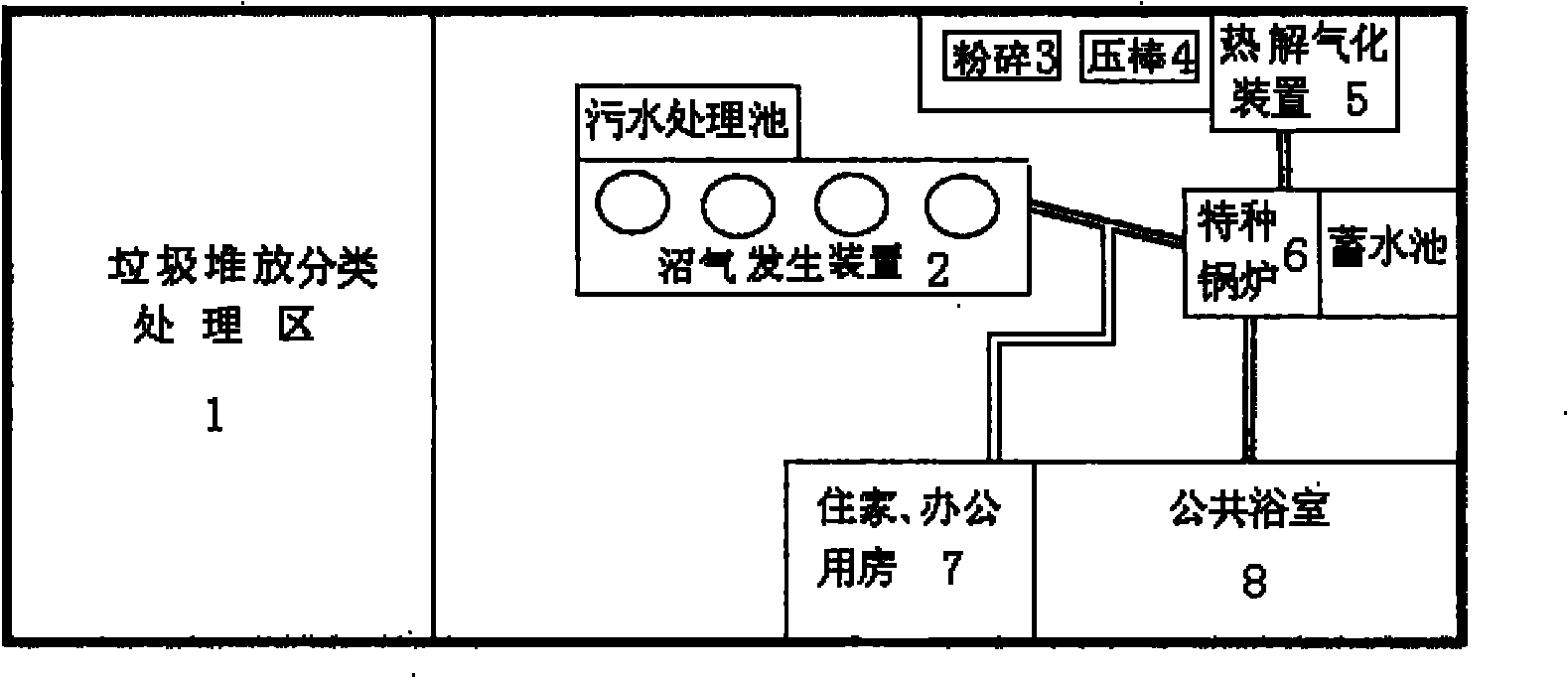

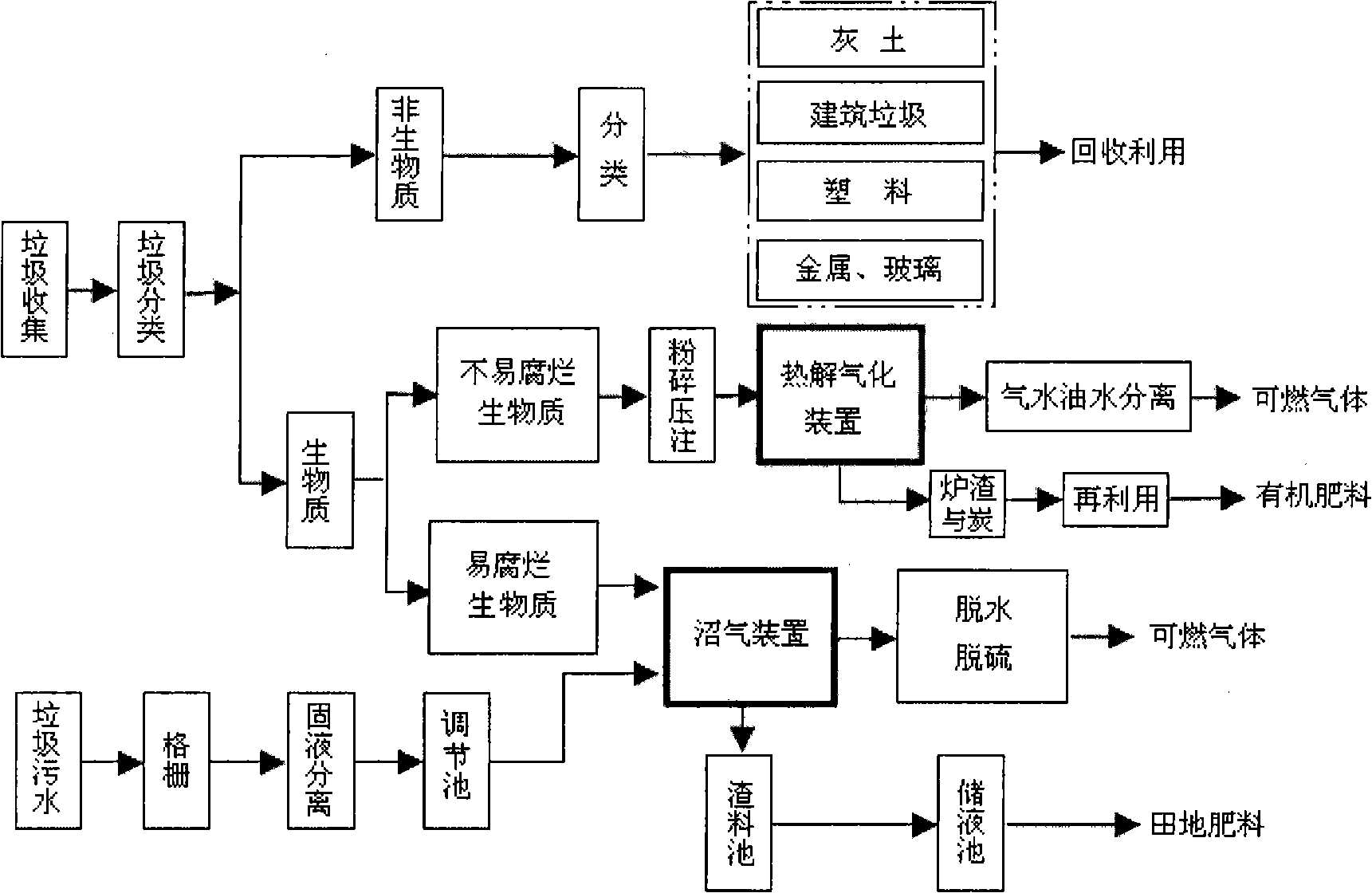

The invention relates to a pollution-free synthetic treatment method for garbage in villages and towns, comprising: after collecting the garbage in the villages and towns, classifying biomass garbage and non-biomass garbage, then classifying the biomass garbage into non-perishable biomass garbage and perishable biomass garbage, crushing the non-perishable biomass garbage and pressing into blocks, further feeding into a pyrolytic gasification device to perform the pyrolytic gasification so as to be combustible biomass gas, and sewage of the perishable biomass garbage entering into an anaerobic fermentation device, being marsh gas after the anaerobic fermentation, slag charges thereof entering into a slag tank, slag liquid entering into a liquid storage tank to be field fertilizer, accessing the biomass gas and the marsh gas into a furnace, and using the high temperature of the hearth to effectively treat dioxin in the biomass gas. The usable material, charcoal, fuel, hot water reclaimed and produced in the treatment procedure can bring benefits for the processors, thereby forming a good recycle of the garbage treatment.

Owner:张锦明 +1

Autothermal catalytic marsh gas reforming process of preparing synthetic gas

InactiveCN1468800ASelf-heating reactionHigh activityHydrogenWaste based fuelSyngasCatalytic reforming

The present invention relates to the efficient clean utilization of marsh gas and is especially one new kind of catalyst for reforming methane-CO2 to produce synthetic gas. The present invention is one green process to utilize marsh gas with methane and CO2 as main components to produce synthetic gas via reformation. The present invention is significant for sustained supply of power source and environment protection.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Alkaline land improving upper farming lower fishing zoology breeding method

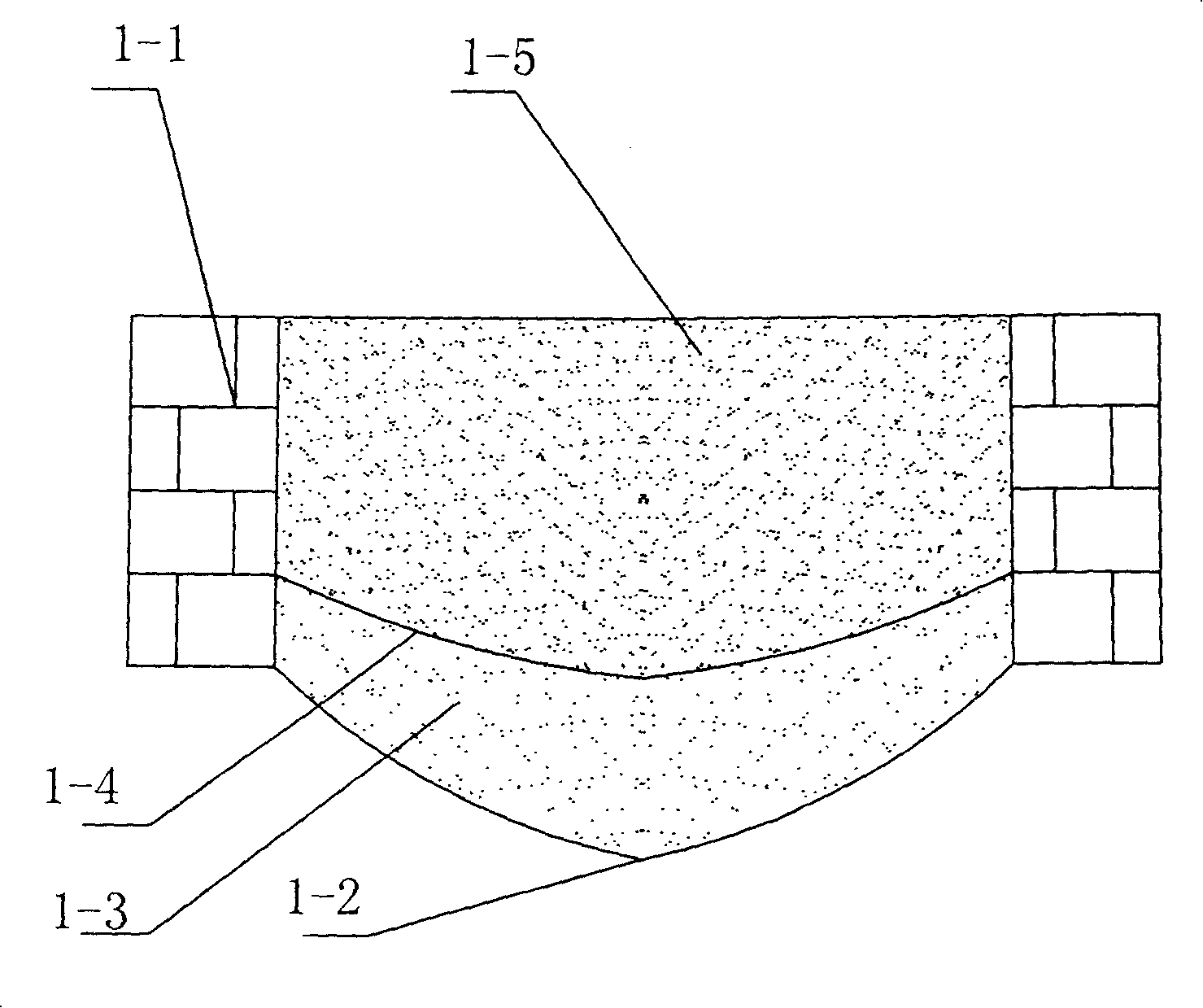

InactiveCN101156512AImprove output efficiencyGet rich fastAgricultural buildingsClimate change adaptationAnimal ForagingLivestock manure

The invention provides an improved farming-above and fishing-below ecology breeding method in the saline-alkali land. A sunlight greenhouse (1), a fish pond (4), a livestock breeding house (2), a residence house (5), and a methane pond (3) are arranged concentratively. The dejection can be used for feeding the fish or be put into the methane pond, the marshy liquid and the marshy dregs can be used for fertilizing the field or fatting the fish, and the methane can be used for lighting or cooking. Through matching the agricultural integrated producing technologies, the invention can make up the deficiency of the own condition of the earthiness, and can ensure that the saline-alkali wasteland tends towards the virtuous ecological cycle after the project is put in practice. The forage grass planted in the cropland can be used to feed the livestock, the dejection of the livestock can be used to feed the fish or produce methane, the silt and the marshy liquid of the fishing pond can be used to fertilize the cropland. The greenhouse and the fishing pond can produce the pollution-free and green food, which can improve yield benefit of the soil maximally. The peasants in the area can be led to be rich and to live a relatively comfortable life.

Owner:SHIZUSN AGRO TECHN EXTENSION & SERVICE CENT

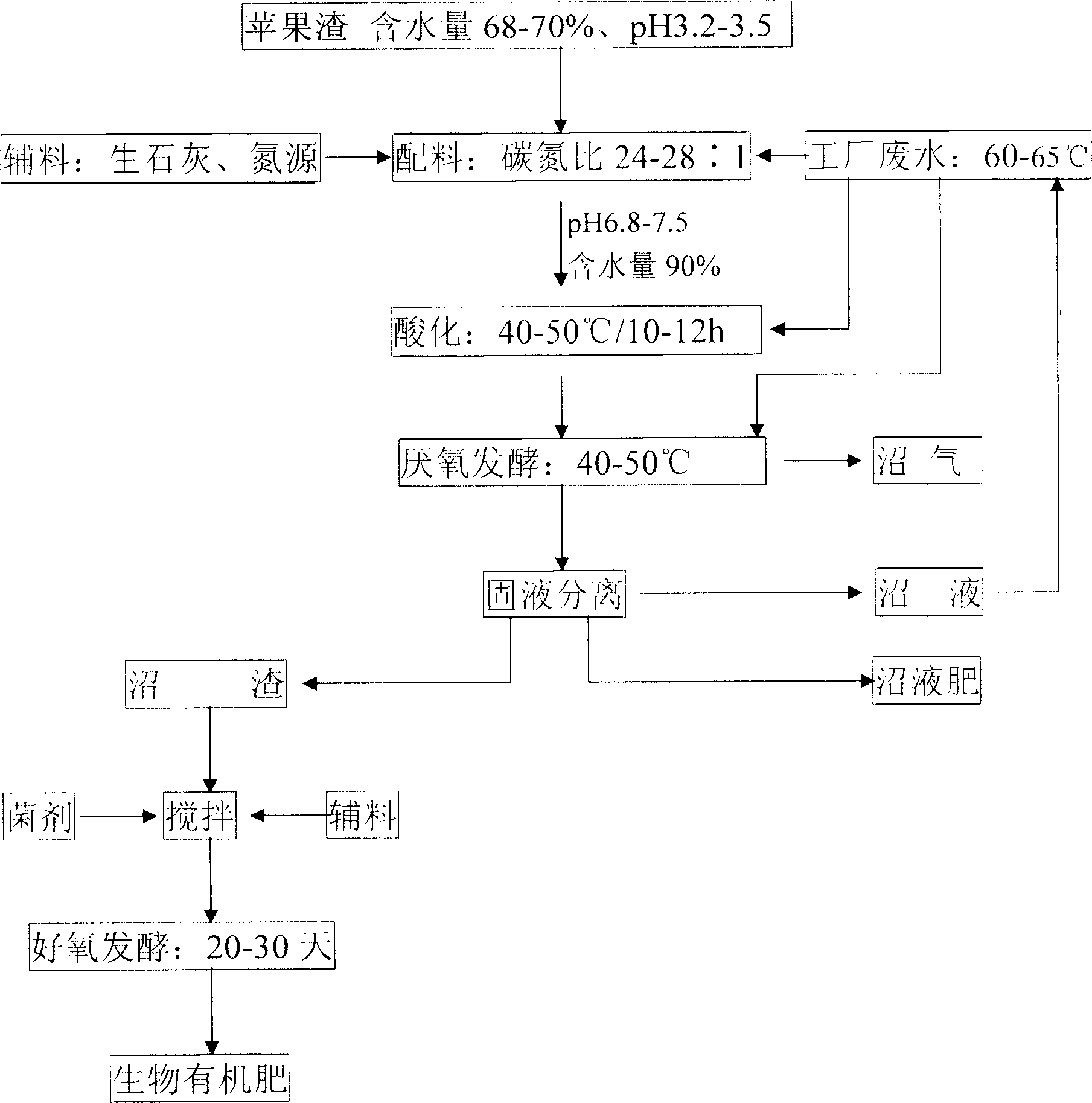

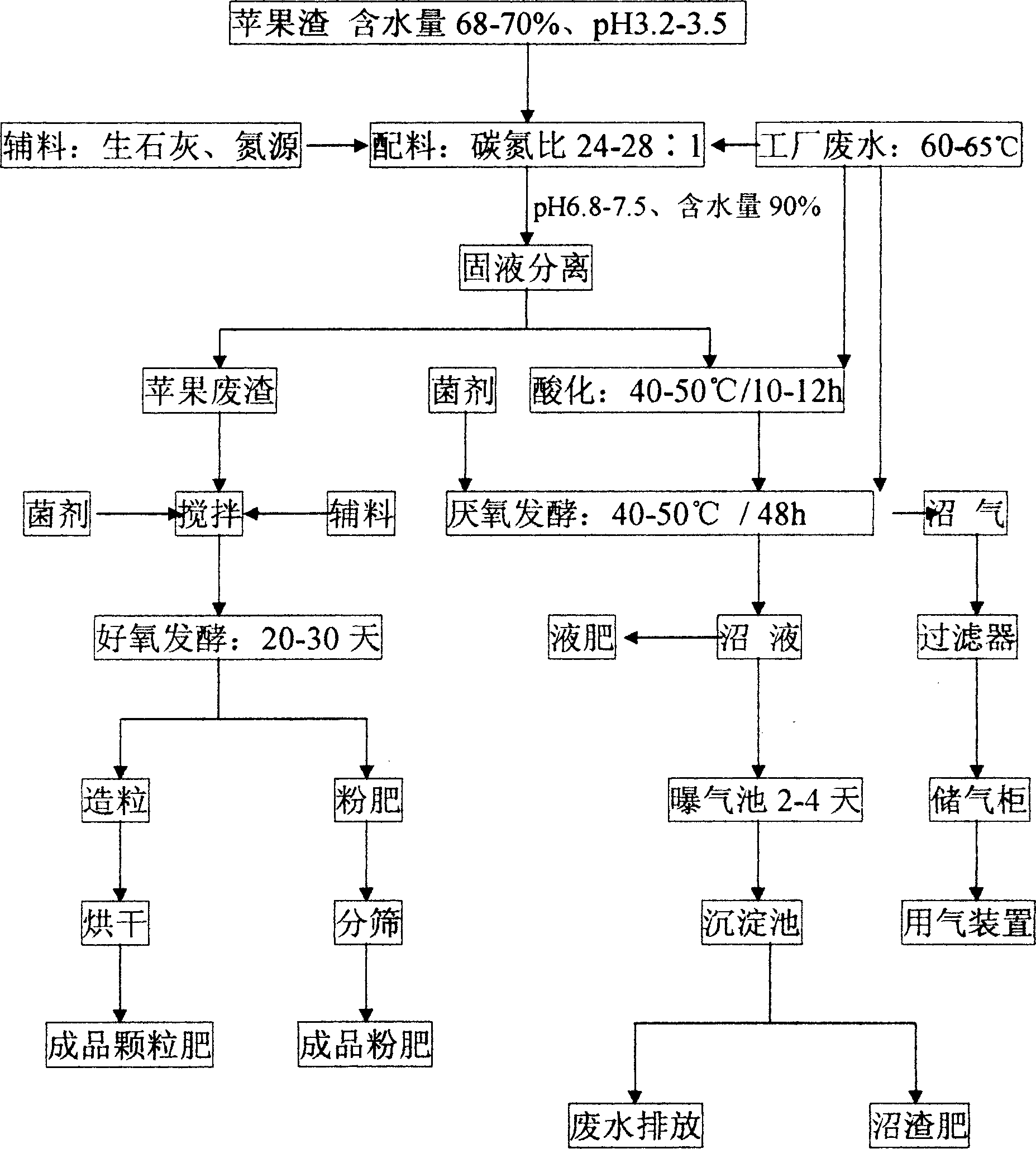

Apple residue comprehensive utilizing and treating method

InactiveCN1891677AComprehensive utilization of economyEfficient use ofBio-organic fraction processingWaste based fuelAdditive ingredientOxygen

The invention discloses a method for comprehensively utilizing apple pomaces including: a, ingredient process:diluting the pomaces with water to slurry state with the solid percentage below 10%, adding calces to adjust the pH, adding nitrogenous fertilizers to regulate the ratio of carbon and nitrogen, then it is placed in an acid bath for 8-12 hours. B, fermenting methane: anaerobic fermentation for 1-7 days, the generated marsh gas is used for the boiler of apple juice production. C, solid-liquid separation: the liquid is transferred back to step A which will be replenished with water or it will be used directly as fertilizer. D, Adding organic fertilizer and zymocyte of organic fertilizer in the residues, then the organic fertilizer will be achieved through oxygen fermentation for 7-10 days.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

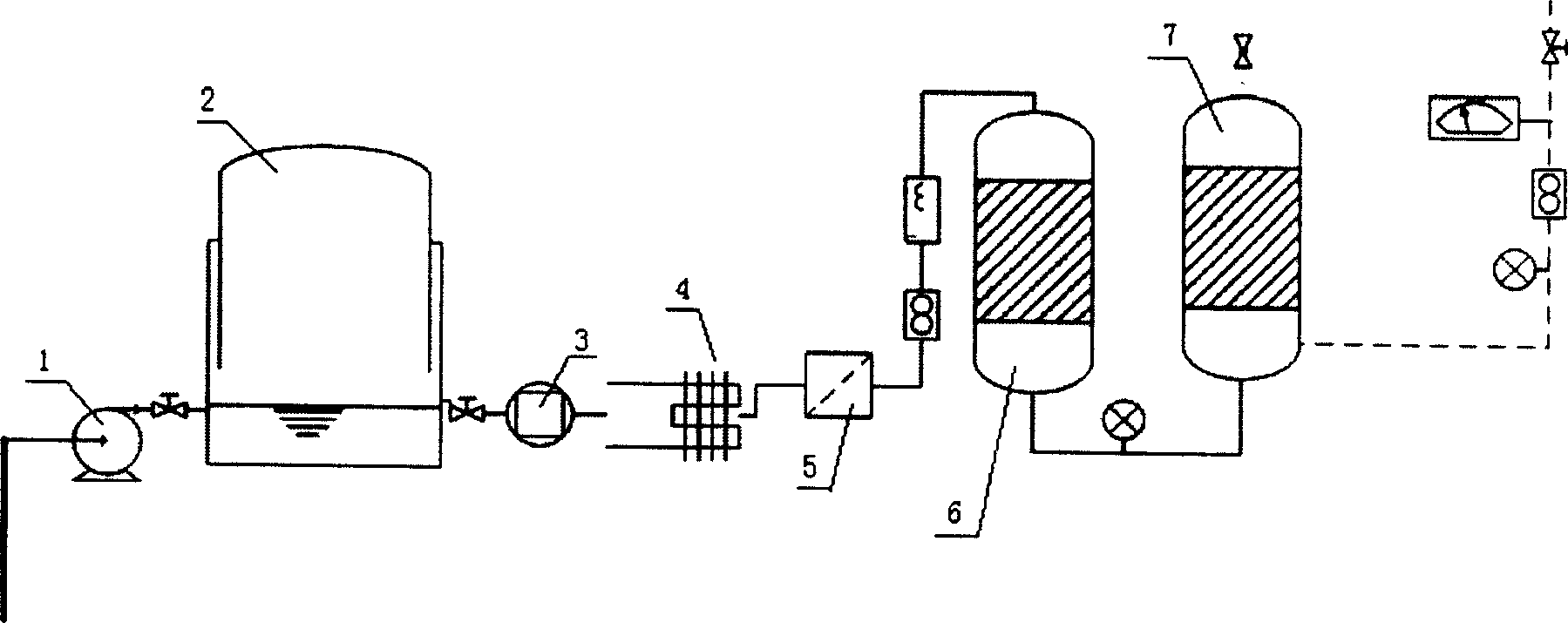

Production and apparatus for producing methane from refuse embedded gas

ActiveCN1680222ASimple and fast operationLess investmentSolid waste disposalAdsorption purification/separationCompressed natural gasFreeze-drying

Production of methane from land-filled garbage gas and its apparatus are disclosed. It is carried out by pressing the abstracted land-filled garbage gas, freezing drying, multi-stage filtering, pretreatment process of adsorption drying, high-pressure adsorbing, co-current pressure equalizing, constant-pressure recovering, and pressure varied adsorption circulating. The apparatus consists of compressors connected orderly, freezing direr, filter, drying tower and pressure varied adsorption circulating system with 2-6 parallel adsorbing columns. Its advantages include simple apparatus and operation, low cost and good flexibility.

Owner:TSINGHUA UNIV

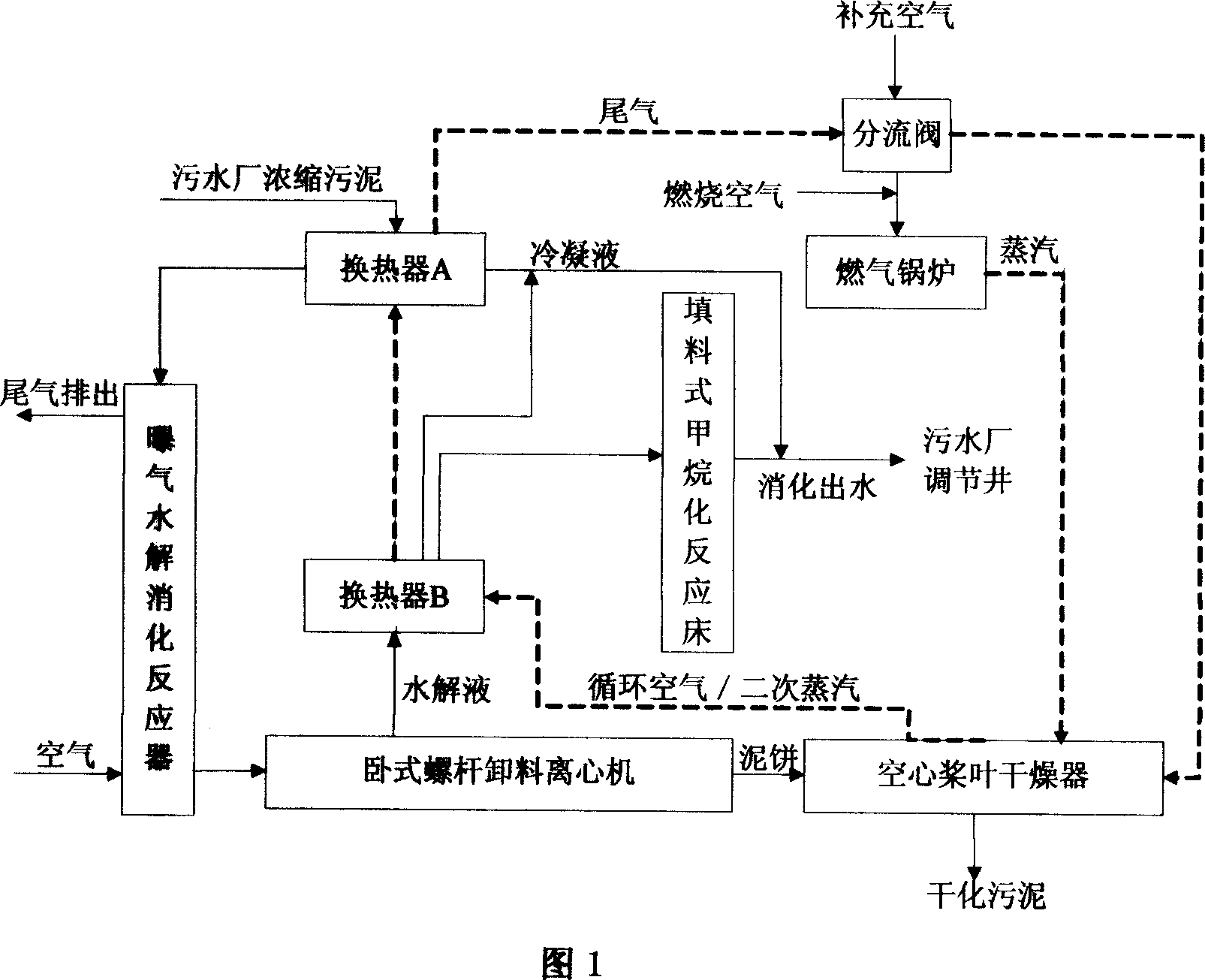

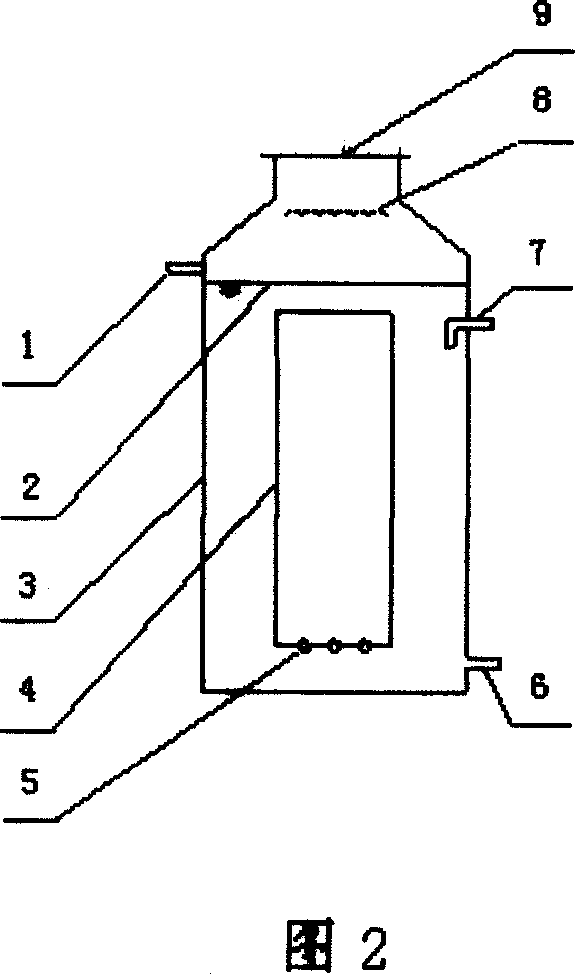

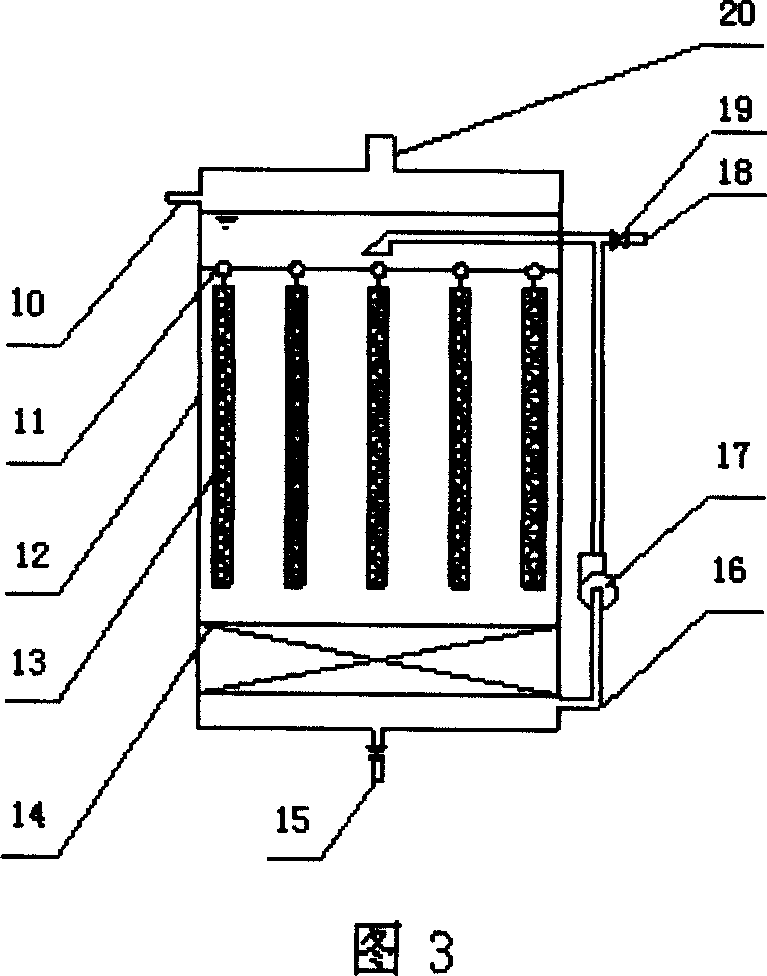

Sludge phase-splitting slaking method of water treatment plant

ActiveCN101041542AOptimize metabolic conditionsReduce aerobic conversion to CO <sub>2<</sub> Bio-organic fraction processingSludge treatment by de-watering/drying/thickeningPhase splittingMethanation

The invention disclose a sludge phase-splitting slaking method of waste water disposing plant involving to a sludge disposing and resource utilization technology, which comprises the following steps: proceeding aerate hydrolytic slaking reaction 6d with dissolved oxygen at 1.5-2 mg / L, pH value at 5.5-6.0 and temperature at 30-35 deg.c; getting hydrolytic slaking product; entering into centrifugal machine; proceeding solid-liquid separation; getting hydrolysate and mud cake; entering hydrolysate into filling-type methanation reacting bed with temperature at 32-38 deg.c and cycling speed at 0.005-0.02m / s; proceeding methanation slaking with waterpower residence time at 3d; getting marsh gas and slaking yielding water; leading marsh gas to gas-fired boiler; producing vapor; refluxing slaking yielding water to distribution well of sewage disposal plant; mixing mud cake with dry sludge till moisture percentage at 50-60%; heating and drying with vapor producing by boiler in dehumidifier; getting dry sludge with moisture percentage at 32-38%; using to land.

Owner:TONGJI UNIV

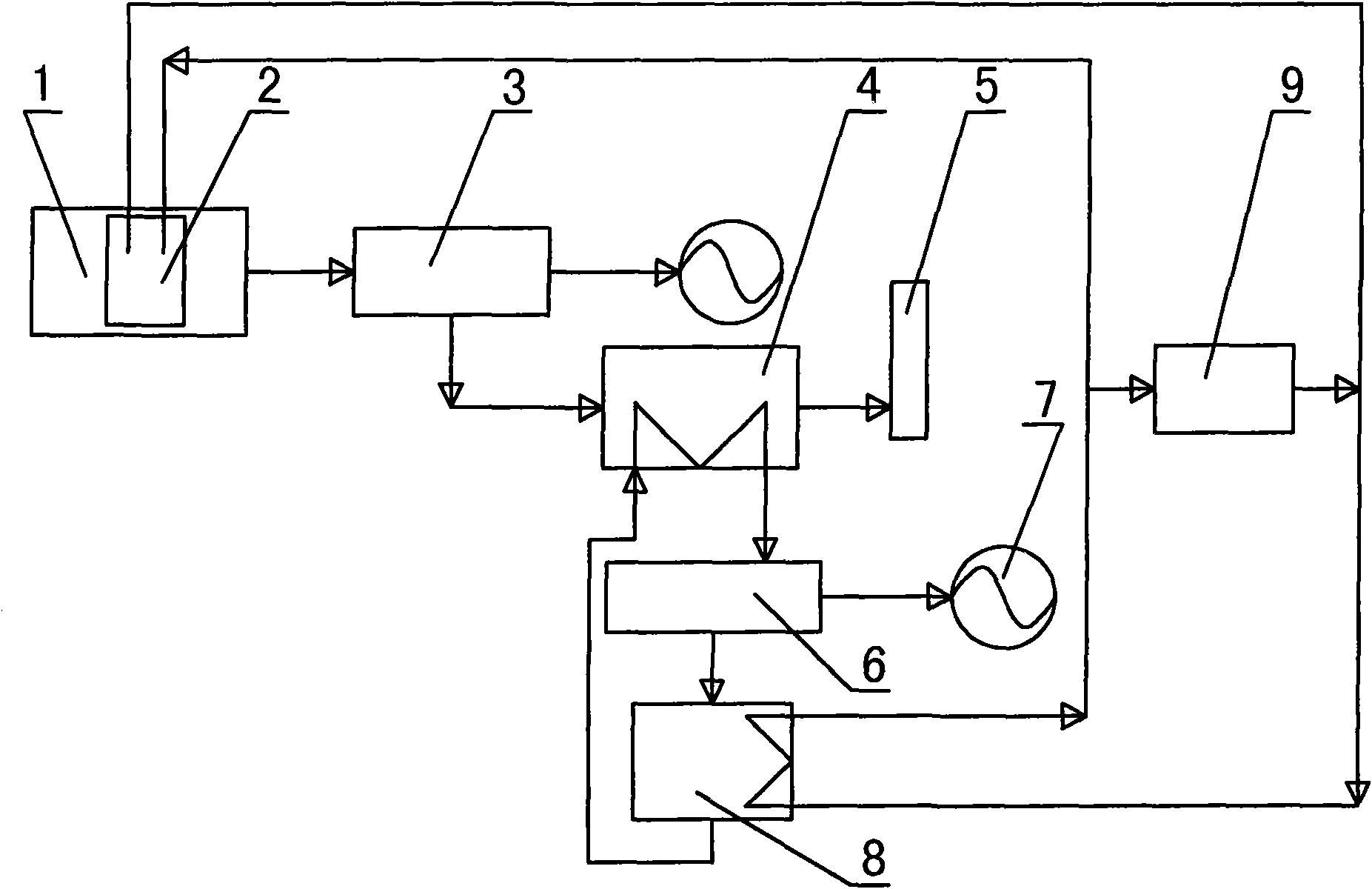

Method and device for recycling waste heat in discharged smoke of marsh gas power generation

ActiveCN101586513AOvercome limitationsEasy to implementInternal combustion piston enginesEnergy industryElectric networkEngineering

The present invention discloses a method and a device for recycling the waste heat in the discharged smoke of marsh gas power generation. According to the method of the invention, the discharged smoke after power generation of a marsh gas internal combustion engine (3) enters a waste heat boiler (4) for heat exchanging with the water, and the smoke after temperature reduction is discharged; the steam generated after heat absorption of the water enter a screw bolt expansion power machine (6) and a generator (7) for expanding, work applying and power generating, the discharged steam enters a condenser (8), and the condensed water enter the waste heat boiler (4) for recycling. Compared with the prior art, the invention uses the waste heat of the discharged smoke after marsh gas power generation for generating the steam. Then the steam enters a low-grade heat energy power machine-screw bolt expansion power machine for expanding, work applying and power generating. The low-grade heat is directly converted to the electric energy. The generated electric power can be combined with the electric power generated by the marsh gas internal combustion engine and sent to the electric network. The method and the device of the invention have the advantages of easy implement, strong operability and no effect by the position of the marsh gas power generating plant. The heat can be directly converted to the electric power and transmitted to the outside. The limitation of waste gas utilization mode of traditional smoke discharging is overcome.

Owner:CHINA HUADIAN ENG +1

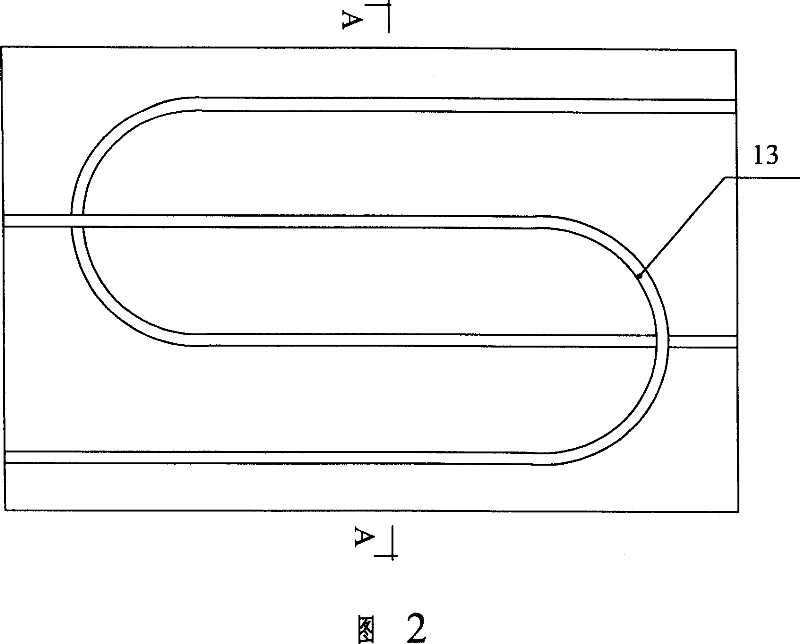

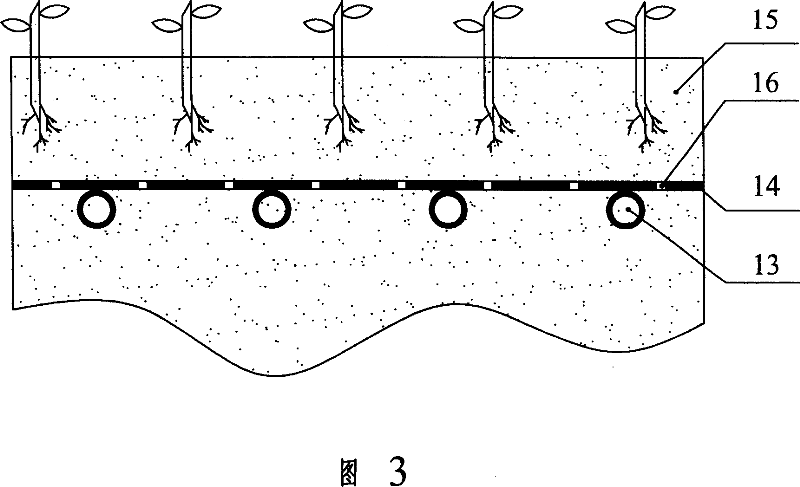

Integrated energy-providing system of greenhouse using methane as the raw material

ActiveCN101040592AEmission reductionReduce consumptionBioreactor/fermenter combinationsHot-air central heatingDistributorSupply energy

The invention relates to a greenhouse integral energy supply system with marsh gas as material, belonging to agriculture technique. The invention is formed by a greenhouse organic waste marsh gas ferment device, a marsh gas buffer storage device, a marsh gas hot air hot water supply device, a smoke washing purifier, a hot water distributor, a gas distributor, a marsh gas distributor, a soil hot water circular heat supplier, an elevated air tube system and a marsh gas lamp group, which are connected via tubes and valves. The marsh gas lamp group is formed by a marsh gas lamp rod and a marsh gas air tube. The marsh gas hot air hot water supply device is formed by a hot water tank, a burning heat exchange tank, a circular pump and a burner. The burning heat exchange tank via a smoke channel inlet is connected with the burner. The hot water tank is connected with the burning heat exchange tank via the circular pump, while the hot water tank contains a heat exchanger. The invention ferments greenhouse organic waste into marsh gas, supplies heat, light and carbon dioxide to greenhouse.

Owner:上海林海生态技术股份有限公司

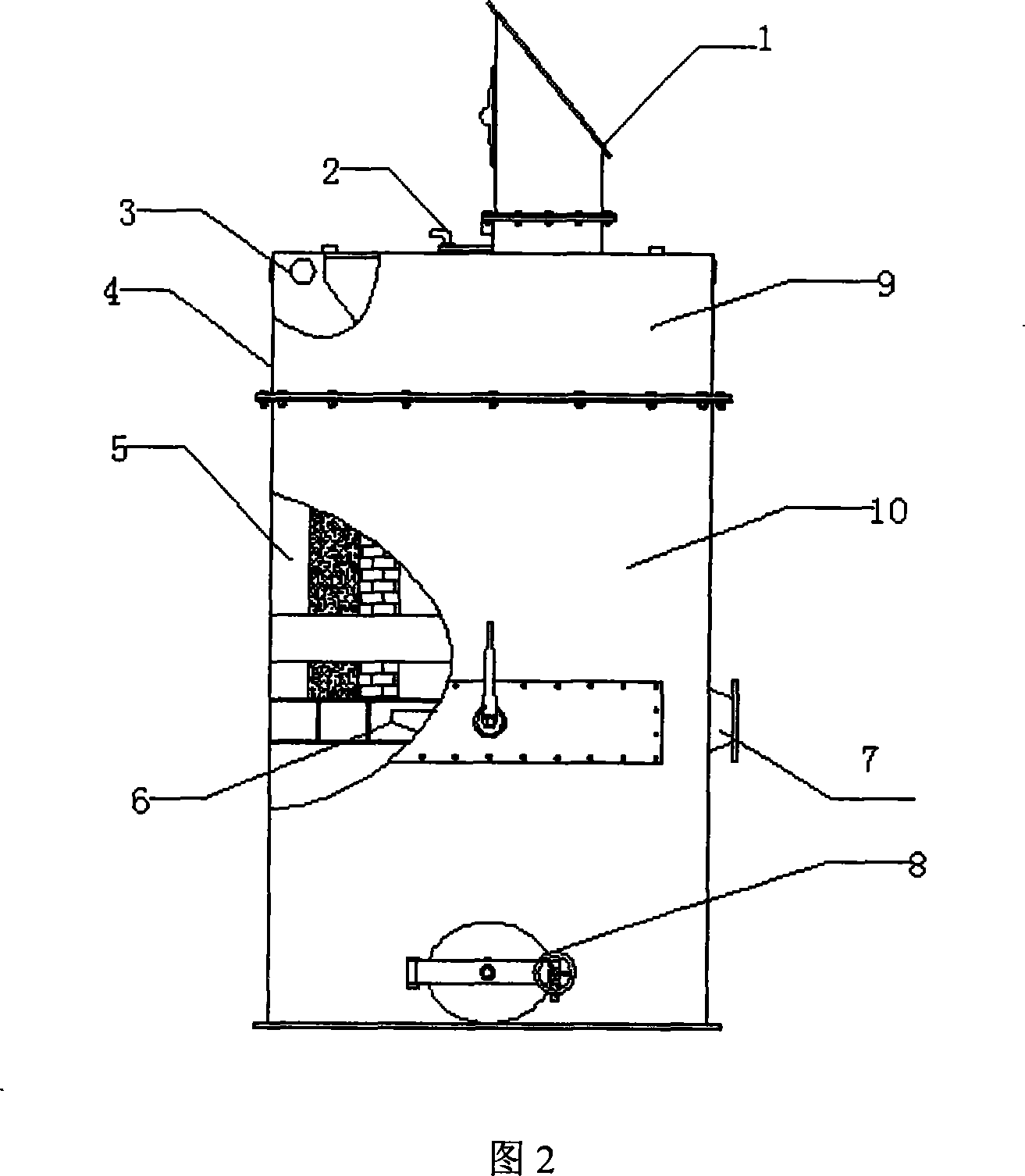

Air energy, solar energy and ground source heat pump marsh gas tank

InactiveCN101775352AGuaranteed uptimeImprove filtration efficiencyGas production bioreactorsWaste based fuelCold airControl system

The invention relates to a heat pump marsh gas tank, in particular to an air energy, solar energy and ground source heat pump marsh gas tank, which belongs to environment engineering equipment. The heat pump marsh gas tank consists of an anaerobic digestion system, a heat insulation and thermal preservation system, a solar energy hot water system, an air energy heat pump system, a ground source heat pump system and a control system, wherein the tail end heat exchange equipment of the ground source heat pump system, solar energy hot water pipelines and the air energy heat pump system are connected with the heat insulation and thermal preservation system and the anaerobic digestion system through hot water circulation pipes, a hot water transit box arranged in the thermal preservation system is used for regulating and balancing the hot water of heat resource systems, hot water heats the anaerobic digestion tank through circulation pipes for promoting the anaerobic digestion, and the hot water circulation pipes can be arranged inside the anaerobic digestion tank and can also be arranged outside the anaerobic digestion tank. The marsh gas tank can also provide hot water and cold air at the same time of producing marsh gas, and the invention can solve the problems of high production cost, great energy consumption and the like of winter production of the marsh gas engineering, and can be popularized easily.

Owner:刘军林

Comprehensive fermentation method for alga marsh gas and products therefrom

InactiveCN1970776AIncrease production capacityConducive to the sustainable development of agricultureWaste based fuelFermentationMicrobial inoculationBiotechnology

The invention discloses a fermenting method and product of algae methane power in the environment protective and new-energy technical domain, which comprises the following steps: adjusting the rate of carbon and nitrogen; controlling dried ferment; seeding microbe; controlling temperature; circulating ferment liquid; stirring; utilizing methane, liquid and slag effectively. The method makes methane content to 74%, which supplies gas stably.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

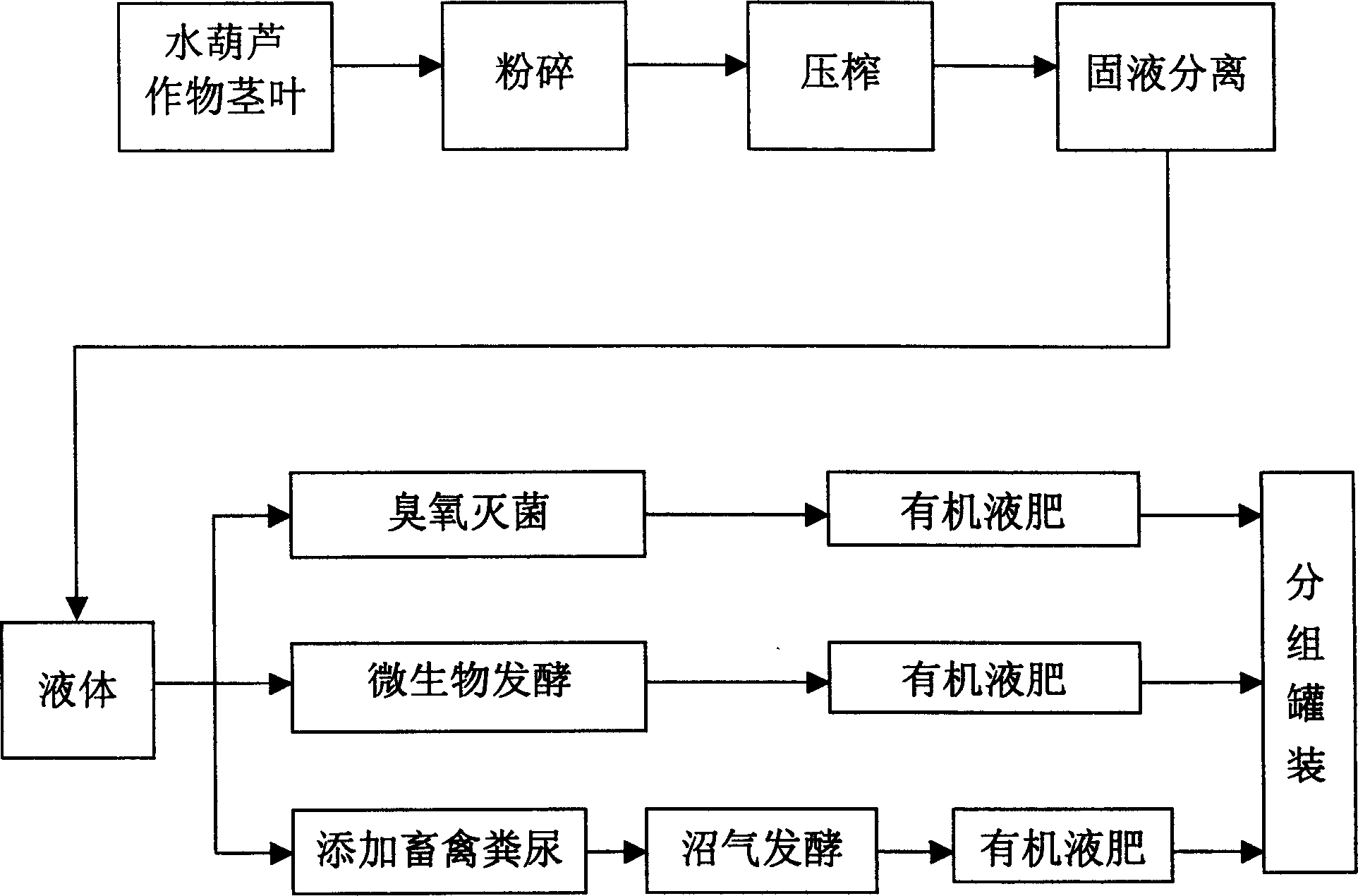

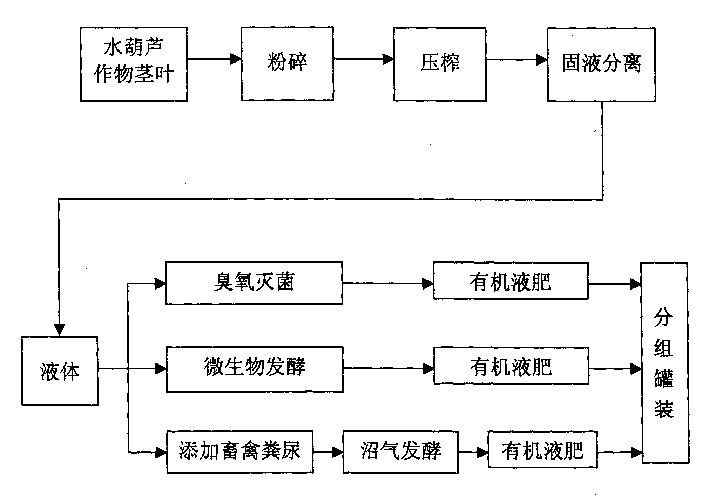

Technique for producing organic liquid dung from hyacinth, stem and leaf of crop

InactiveCN1539798AWide variety of sourcesLow priceBio-organic fraction processingWaste based fuelOrganic manureOrganic fertilizer

A process for preparing organic liquid fertilizer from water hyacinth and the stem and leaf of agricultural crops includes breaking raw materials, squeezing, solid-liquid separation, sterilizing the liquid by ozone, microbial fermenting, and mixing with the dregs generating by fermentation to prepare marsh gas. Its advantages are high fertility and no environmental pollution.

Owner:SHANGHAI SUNQIAO AGRI SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com