Apple residue comprehensive utilizing and treating method

A processing method and technology for apple pomace, applied in the field of comprehensive treatment of agricultural and forestry wastes, can solve the problems of polluting the surrounding environment, wasting resources, polluting the environment, etc., achieving the effects of fast gas production, high efficiency, and solving the problem of waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

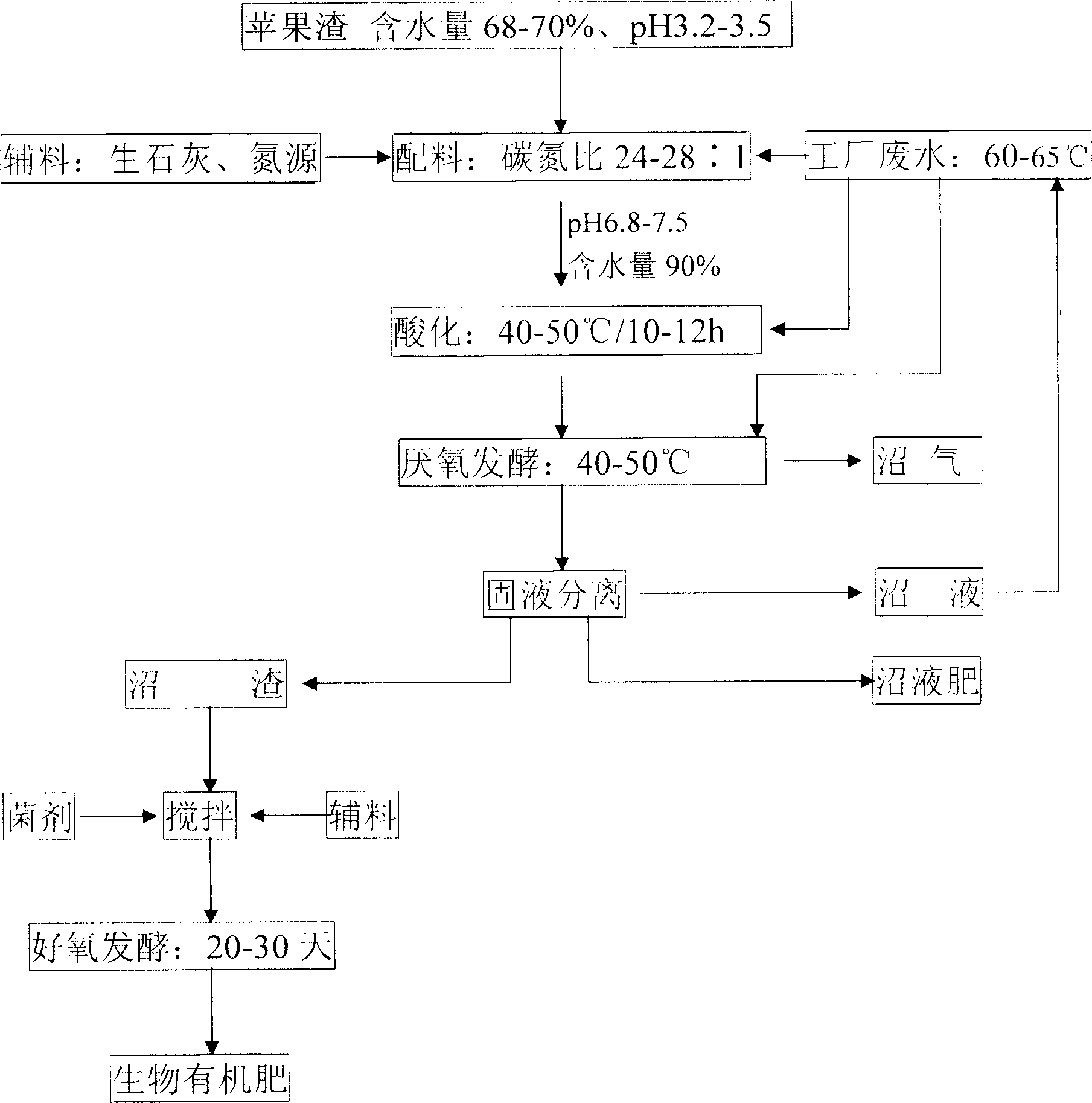

[0021] combine figure 1 The process flow is briefly described as follows:

[0022] 1. Ingredients processing: Pour the remaining fresh apple pomace (water content 65-75%, pH value 3.2-3.5) into the batching pool after squeezing out the apple juice. Mix and stir the wastewater so that the concentration of the mixed slurry reaches 8-10%, and the temperature is ≥50°C. At the same time, add 4-5 kg of quicklime for industrial use per ton of the mixed solution, adjust the pH value of the mixed solution to 6.8-7.5, and measure the mixed solution per ton Carbon-nitrogen ratio (generally apple pomace contains about 40% carbon and 1% nitrogen after drying), then add 14-18 kg of urea, ammonium bicarbonate, etc., adjust the carbon-nitrogen ratio of the mixed liquid to 24-28:1, and place it in the pool 10-12 hours;

[0023] The purpose of adding nitrogen fertilizer in the above steps is to adjust the carbon-to-nitrogen ratio of the apple pomace slurry so that it can produce biogas. Nit...

Embodiment 2

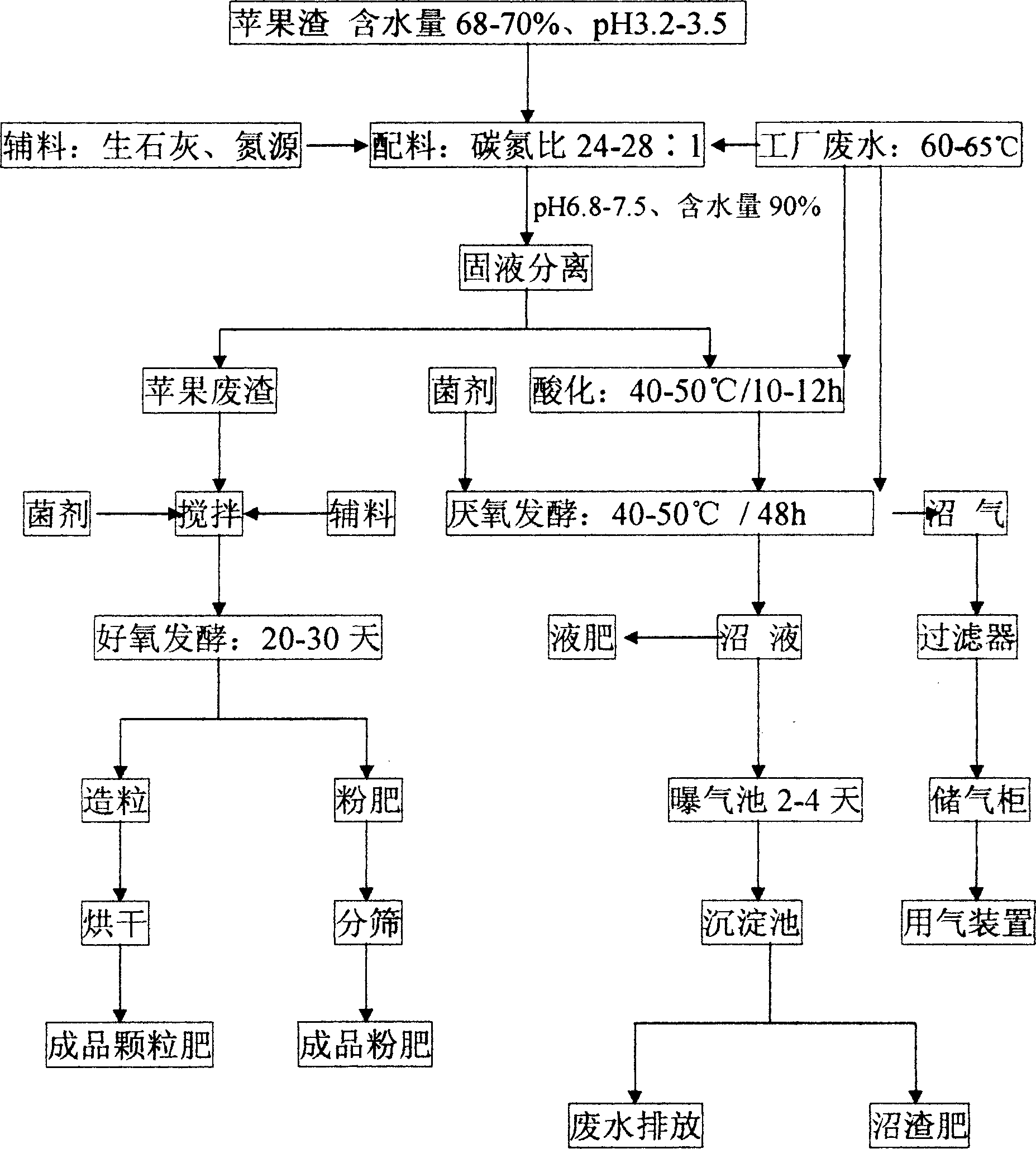

[0033] combine figure 2 The technical process provides another extended technical scheme of the present invention, the batching treatment is the same as in Example 1, the apple pomace slurry liquid after the deacidification of the batching is first subjected to liquid-solid separation, and the liquid enters the biogas tank for anaerobic fermentation for 1-2 days. Biogas is generated, and solid pomace is fermented aerobically for 20-30 days to produce organic fertilizer. The advantage of this process route is that it is based on liquid fermentation to produce gas quickly and has a high turnover rate. If the biogas slurry after gas production cannot be used in time and needs to be discharged, it needs to be aerated. The disadvantage is that the process route is slightly longer than that of Example 1, the aerobic fermentation treatment capacity is large and the time is long, and the overall gas production efficiency is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com