Patents

Literature

135results about How to "Fast gas production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

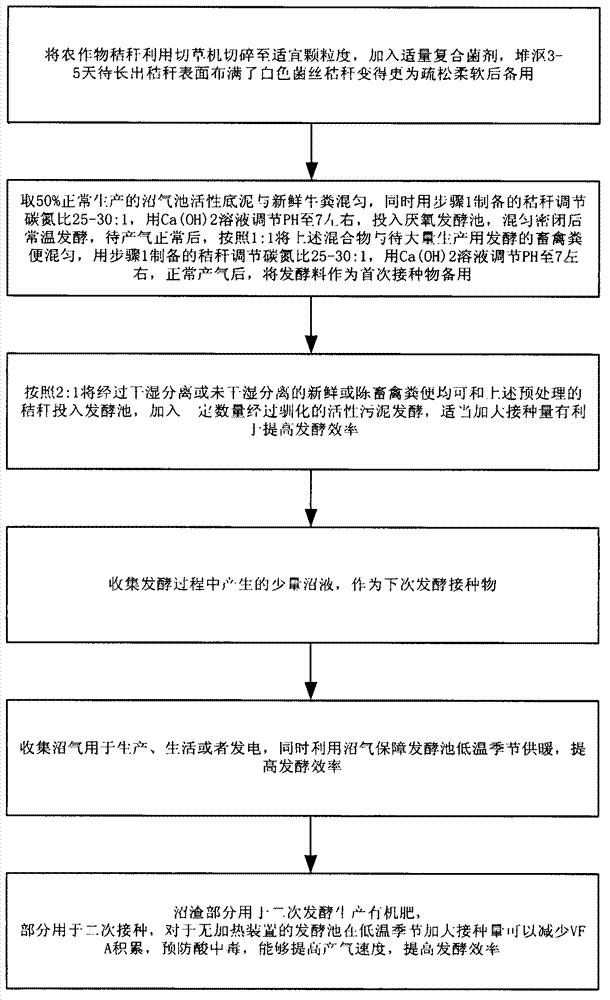

Method for producing methane by dry fermentation of beast and bird wastes and crop straws

InactiveCN102925494ANo ammonia poisoningReduce lossesBio-organic fraction processingClimate change adaptationFecesSlurry

The invention discloses a method for producing methane by dry fermentation of beast and bird wastes and crop straws. According to the method, solid beast and bird excrements with the dry material concentration of higher than 15% and crop straws which is subjected to pre-treatment are mixed according to a certain ratio and introduced to an anaerobic dry fermenting device together with naturalized active mud; a small deal of biogas slurry is recovered as inoculums, and fermentation residues are subjected to secondary compost to produce organic fertilizer. The method has the following advantages of high gas generation speed and high fermentation efficiency; the methane content is up to 50-65% which can meet the using demands of power generation and diary gas appliances; the produced organic fertilizer is unlikely to cause ammonia poison; eggs are killed completely; and the nitrogen fertilizer loss is low.

Owner:苏州市吴江区农业环境监测站

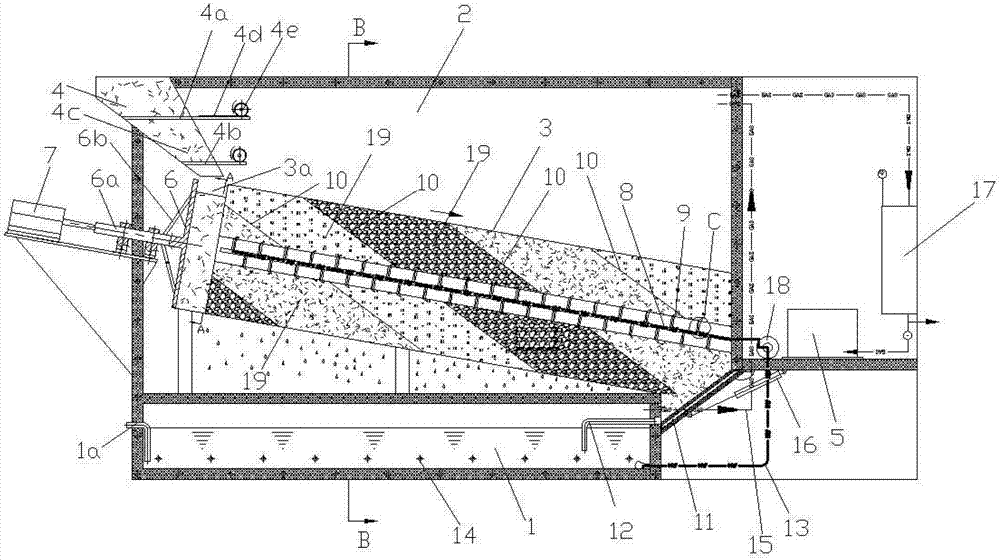

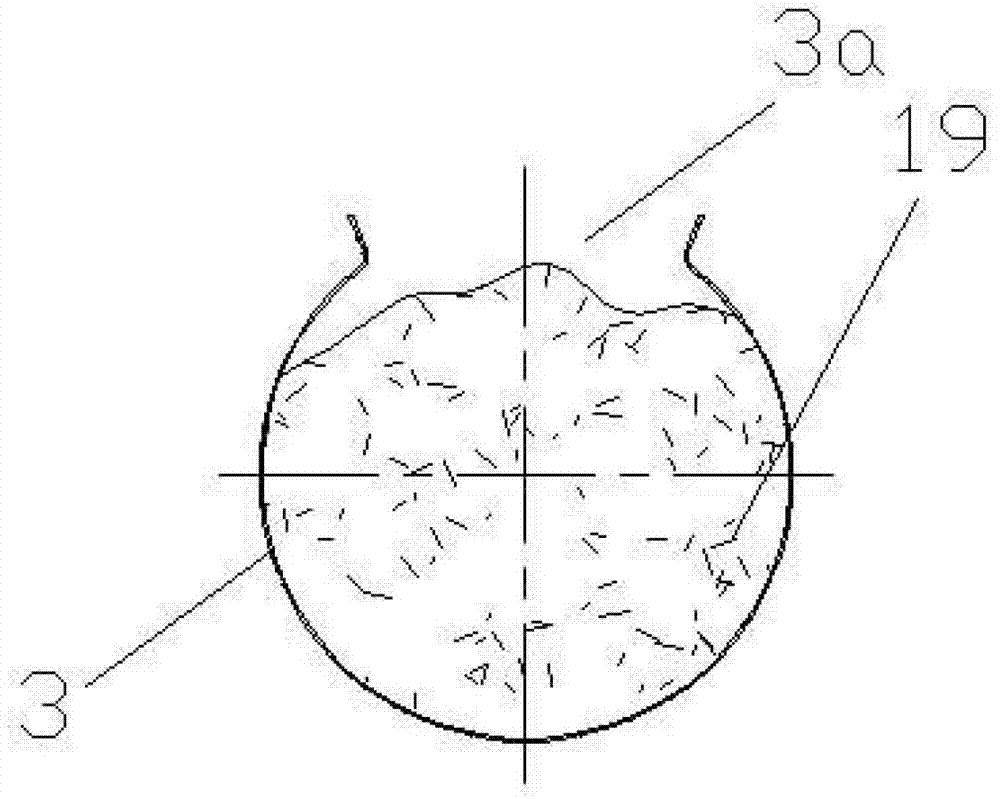

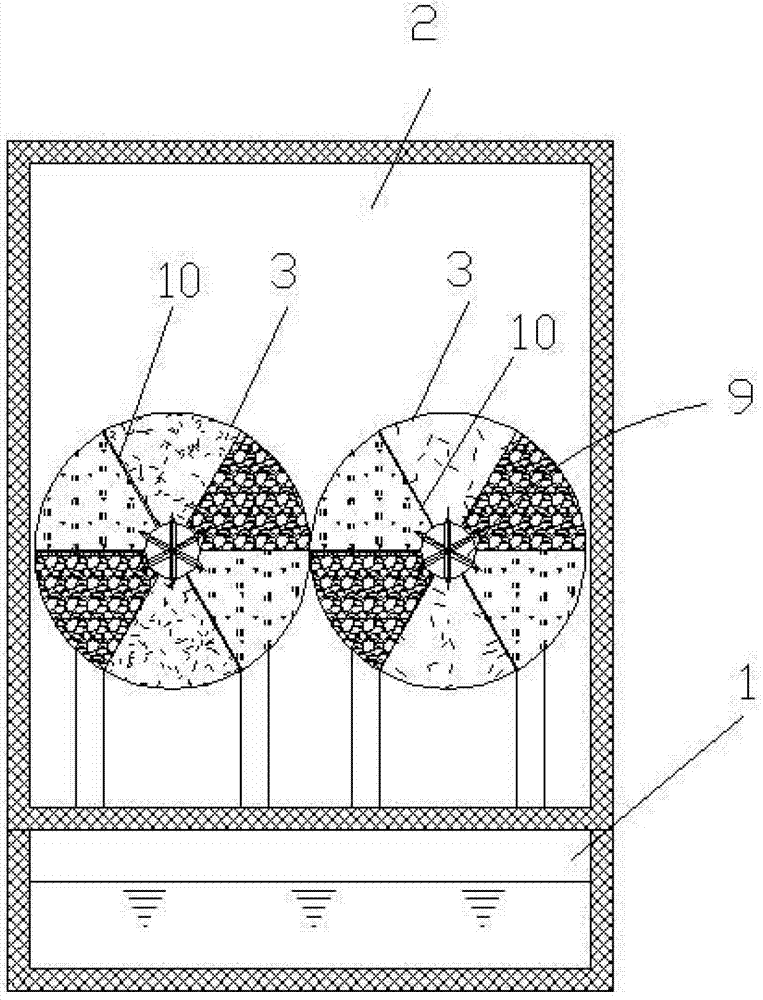

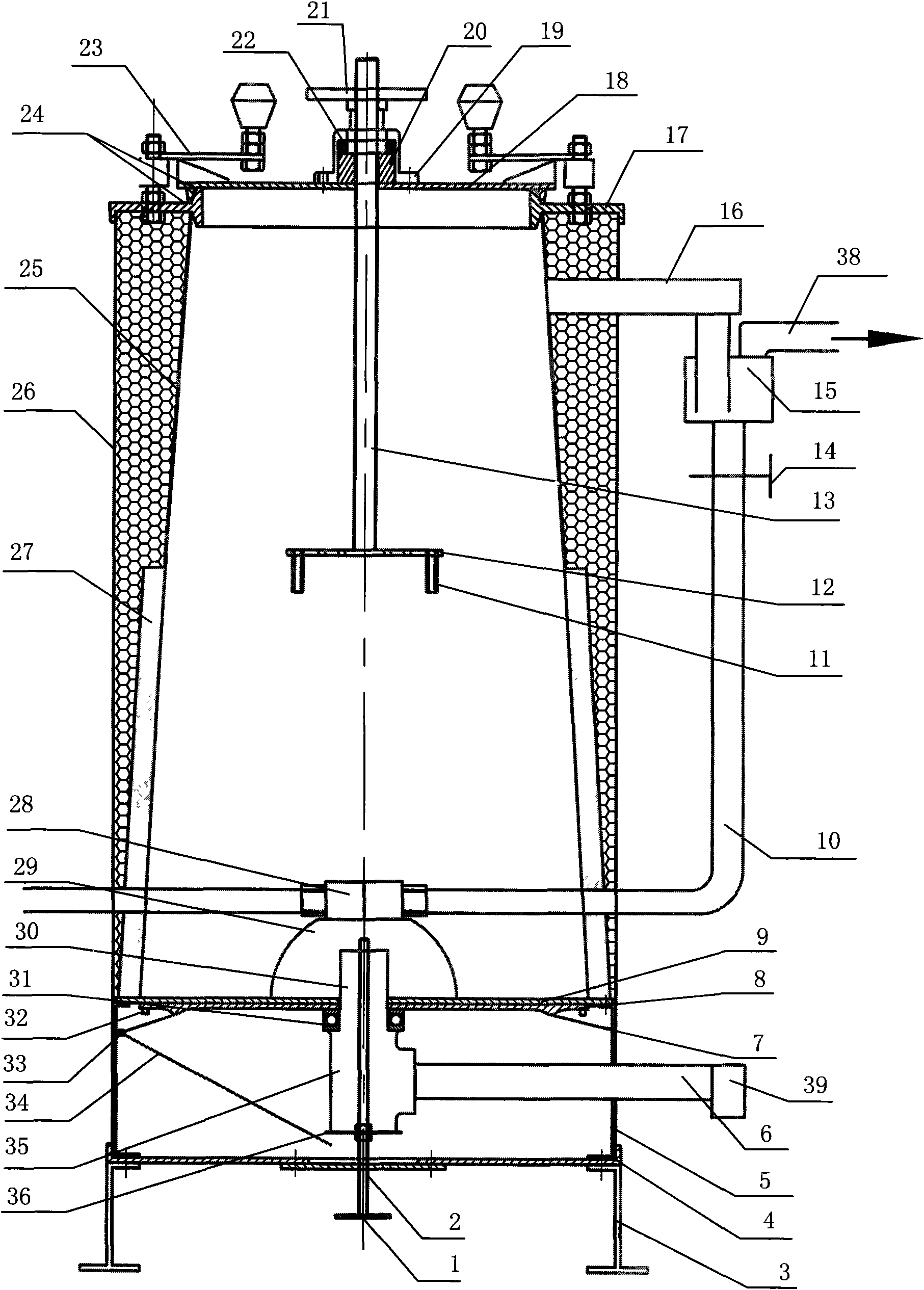

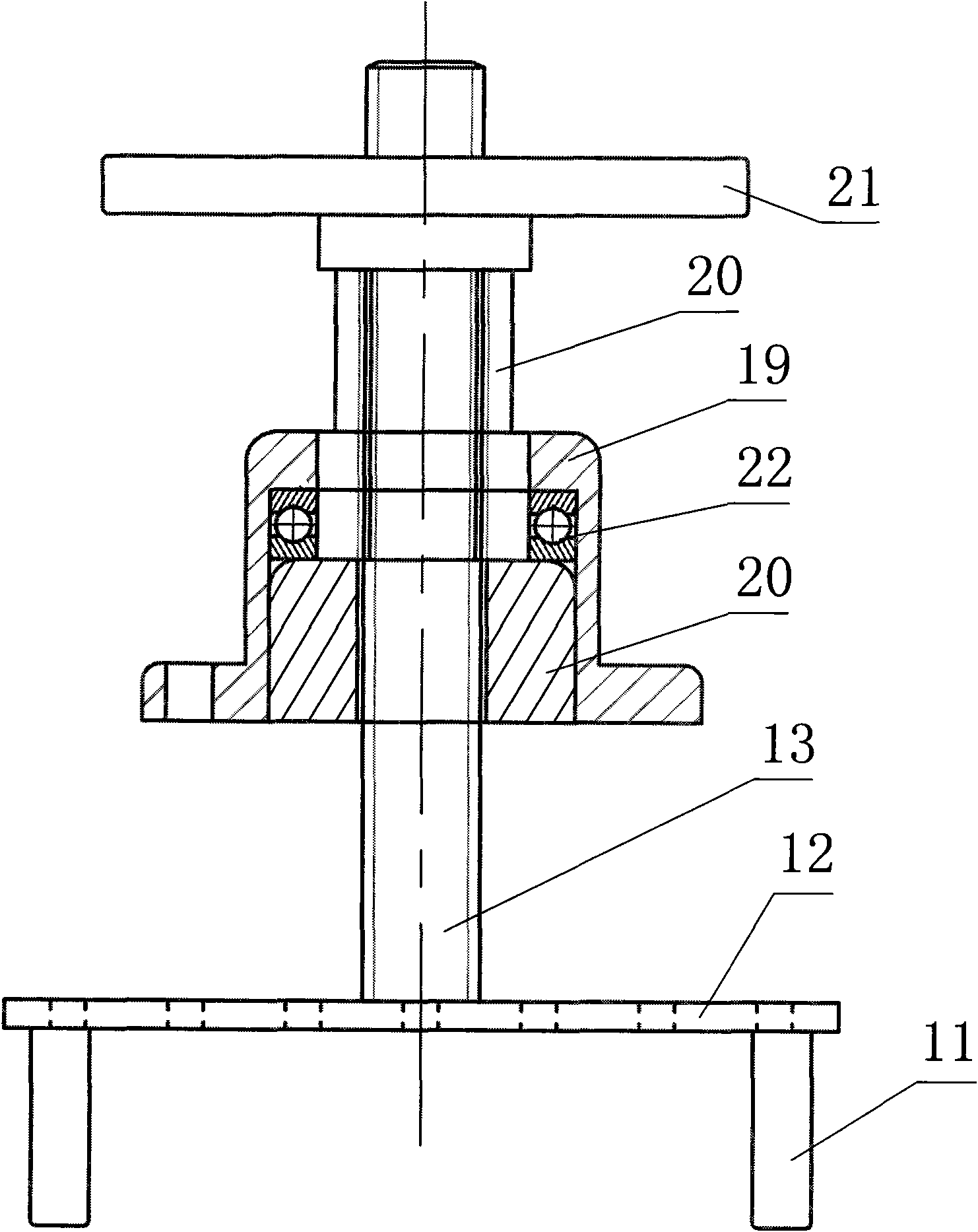

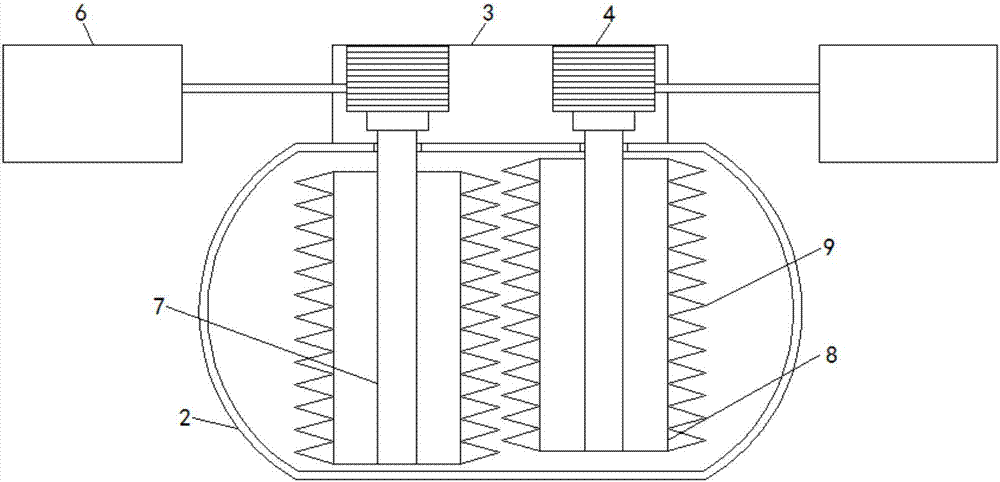

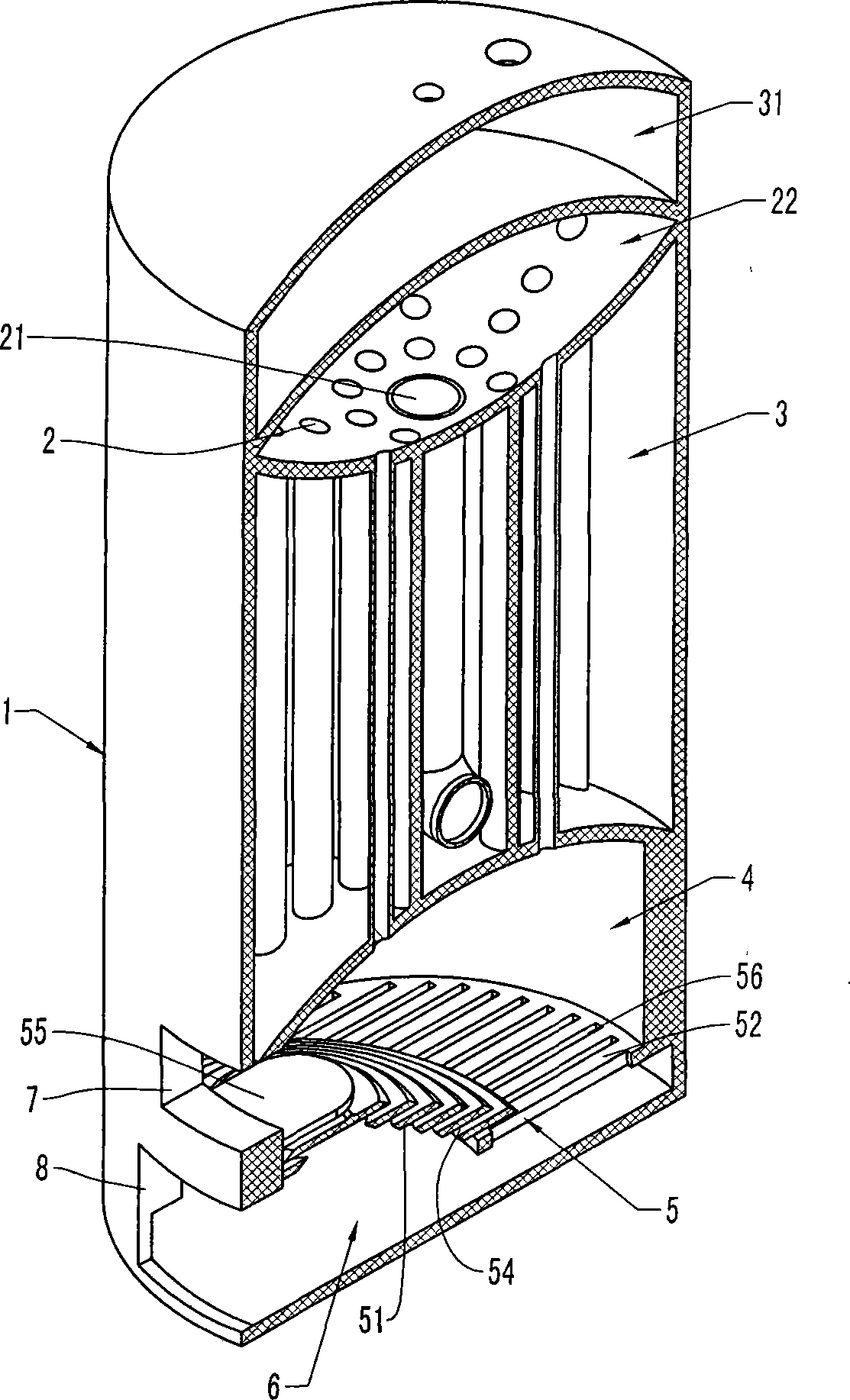

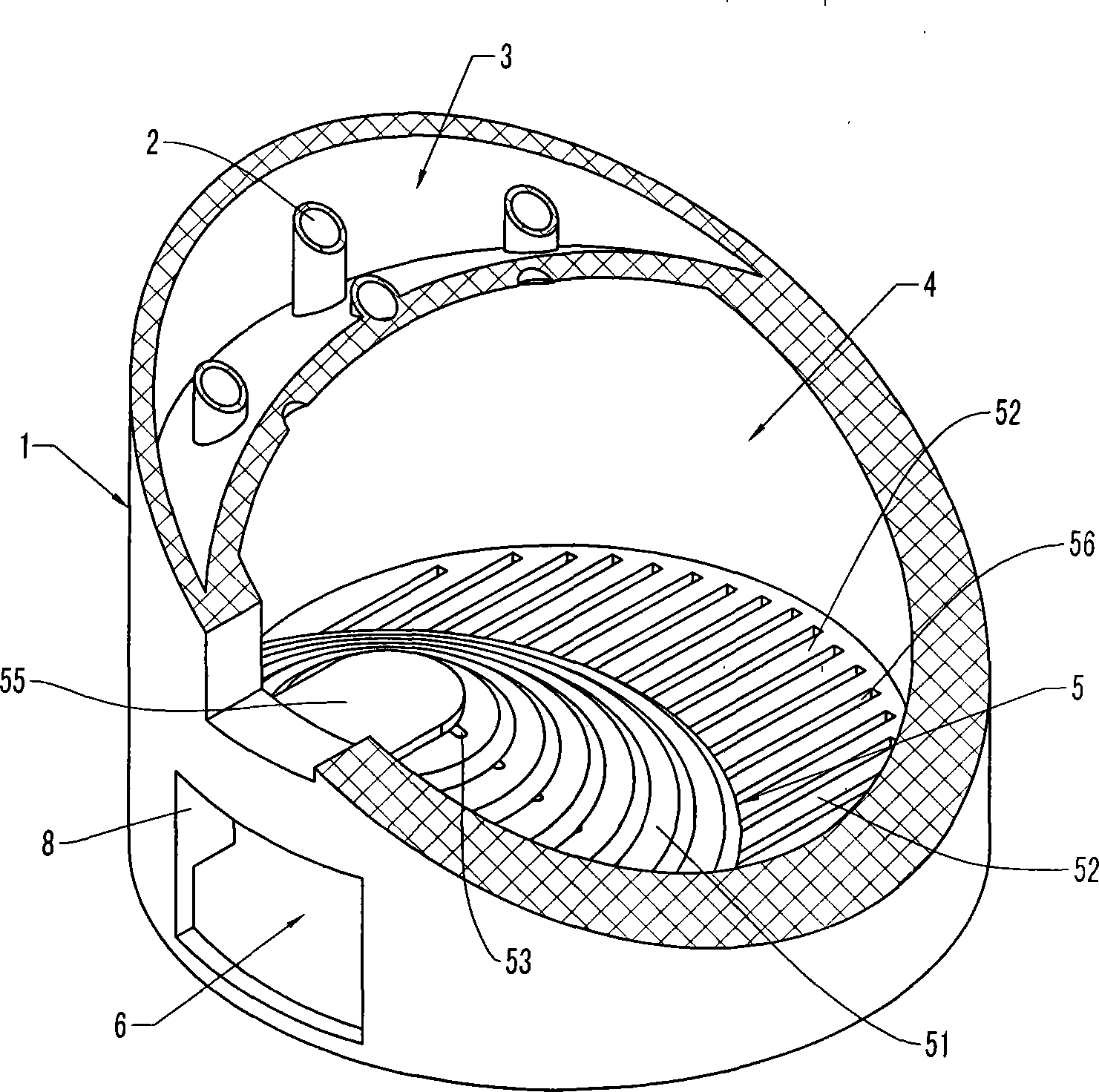

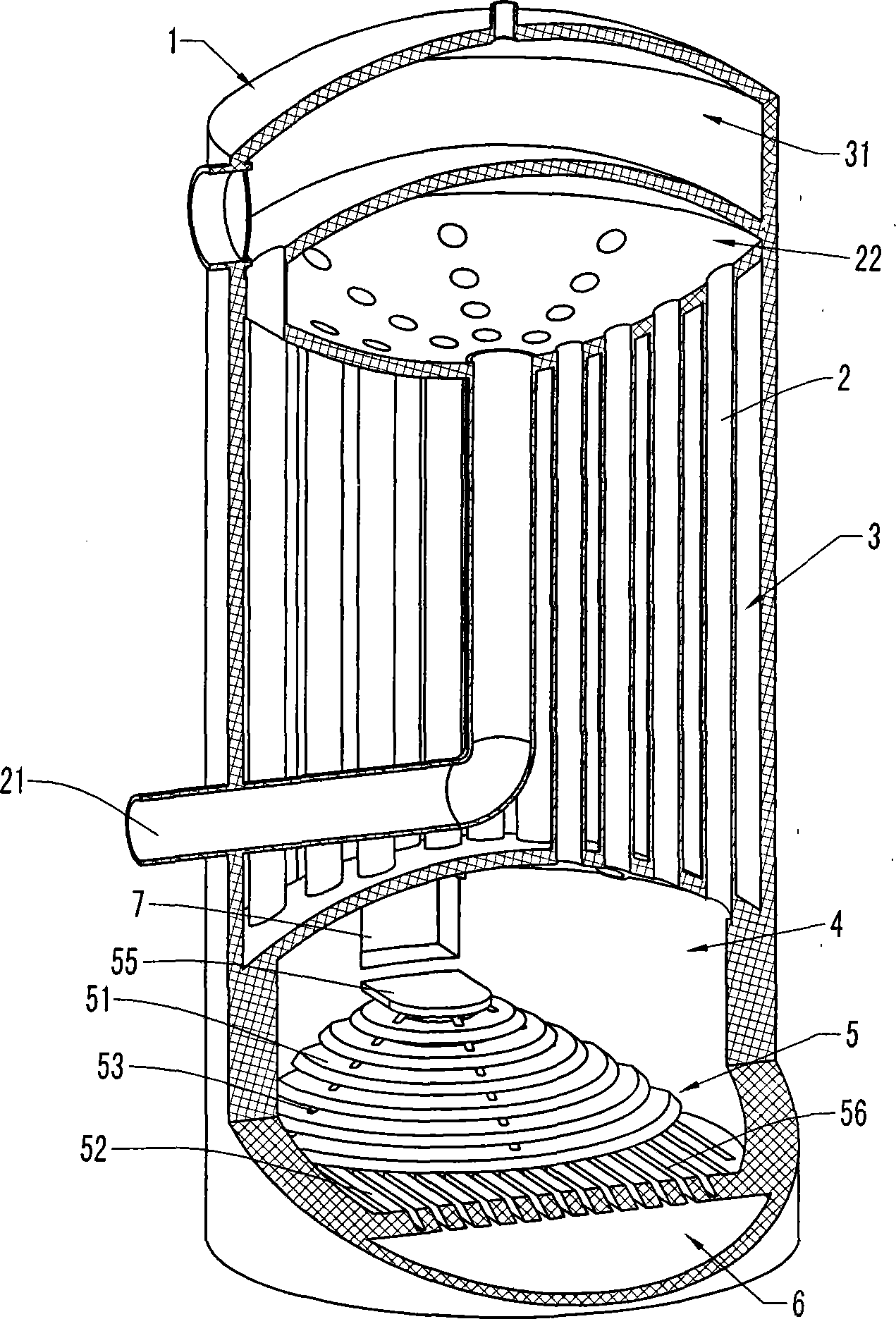

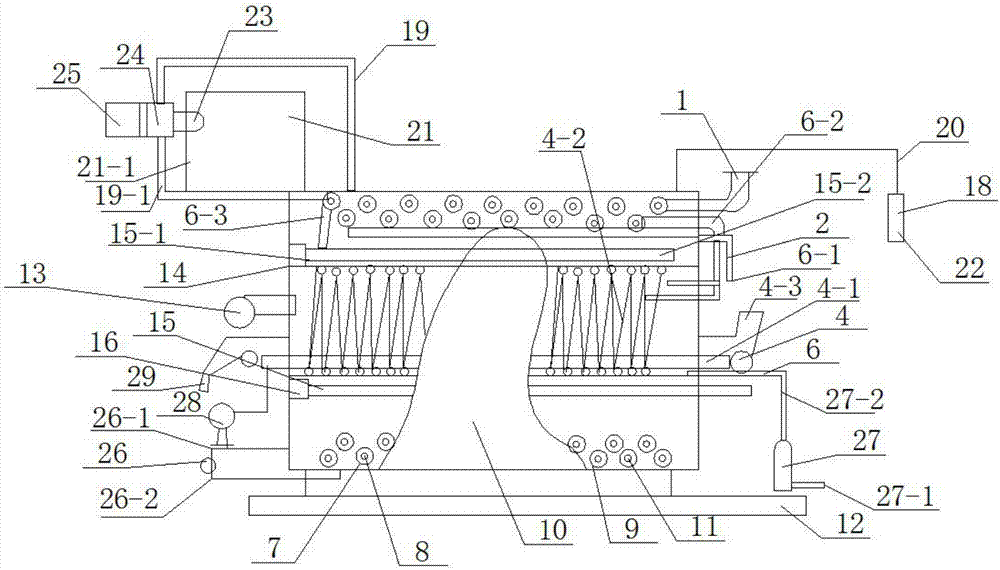

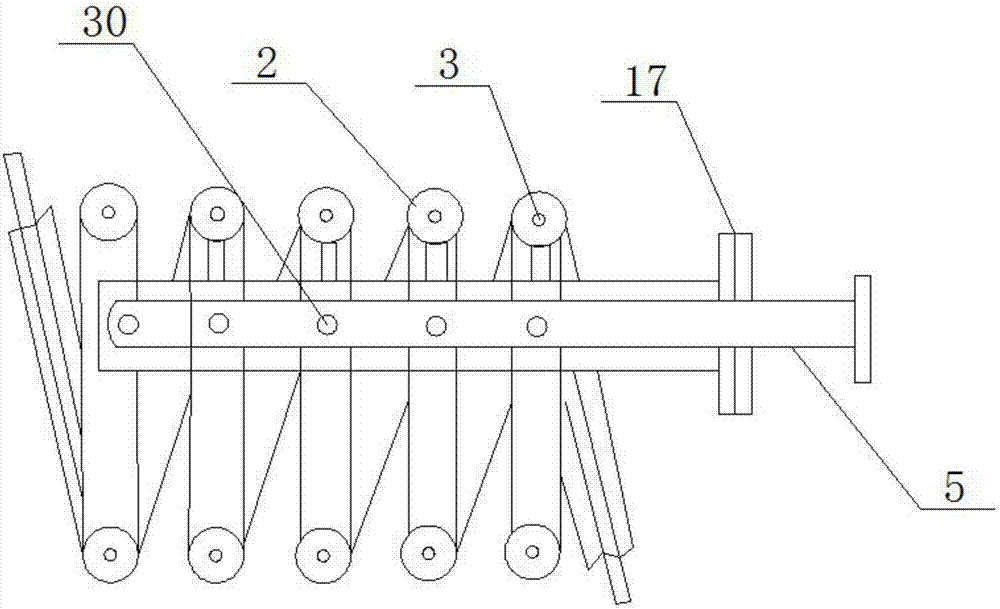

Spiral self-stirring dry fermenting device and method

ActiveCN102816690ARealize self-stirringReduced residence time required for anaerobic consumptionGas production bioreactorsWaste based fuelSlagSpray nozzle

The invention discloses a spiral self-stirring dry fermentation device and a method. Fermentation cylinders are obliquely arranged at the bottom in a gas storage tank which is installed on a top board of a leachate holding tank; an enclosed inner cylinder is arranged at the central part in each fermentation cylinder along an axial direction; a leachate jet pipe is mounted in the inner cylinder; nozzles are distributed on the leachate jet pipe and extend out from the inner cylinder; spiral separator plates are distributed in each fermentation cylinder along an axial direction, and initiating terminals of the spiral separator plates are located behind a feed inlet; a lower end of each fermentation cylinder is provided with a material outlet, a slag removal opening communicating with the material outlet of the fermentation cylinder is mounted on a base plate of the gas storage tank, and a slag removal door is arranged on the slag removal opening; the leachate holding tank is provided with a leachate return pipe communicating with the gas storage tank and a pipeline communicating with a leachate inlet of the leachate jet pipe; electric heating pipelines are distributed in the leachate holding tank; and a biogas conveying pipeline communicating with the upper part of the gas storage tank is arranged at the upper part of the leachate holding tank. The invention also provides the method of using the device for fermentation.

Owner:CHONGQING ACAD OF AGRI SCI +1

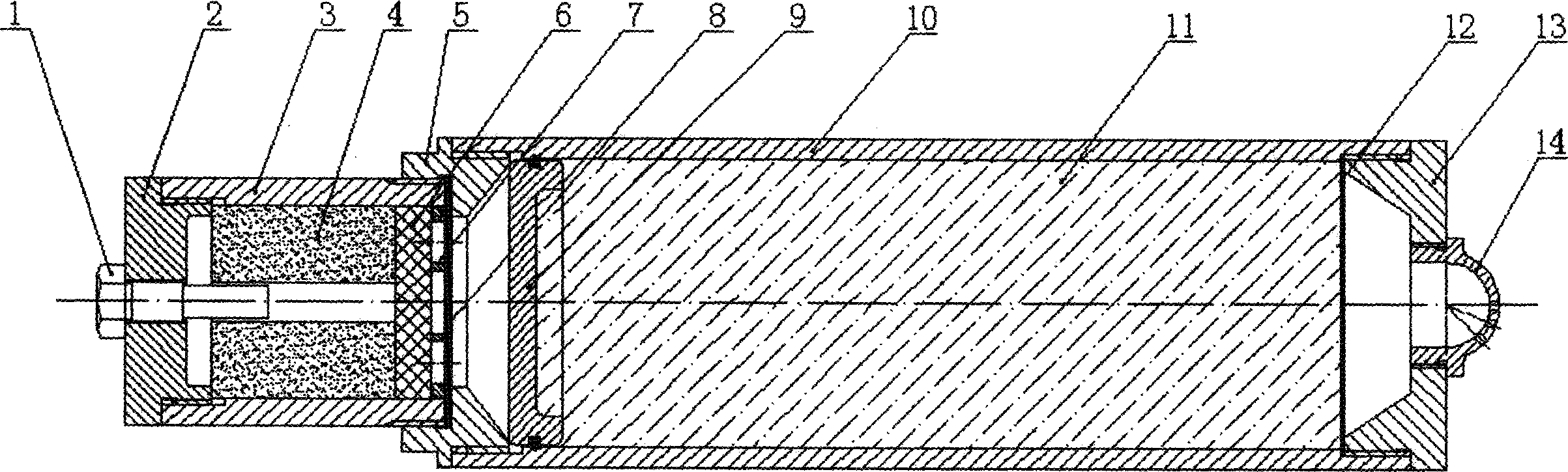

Multistage pulses enhanced perforation equpment in use for oil and gas well

ActiveCN1916357AImprove seam making abilityIncrease the amount of gunpowder chargeFluid removalGunpowderProduct gas

The present invention discloses a multi-stage pulse synergistic perforating system for oil-gas well. Said system is characterized by that on the basis of adopting detonator for resisting sand impact and synergistic perforating gun said invention utilizes synergistic gun tail, connecting component and threaded connecting component to make second-stage synergistic gunpowder with higher combustion velocity and third-stage synergistic gunpowder with lower combustion velocity be added into the construction pipe string, and the adopted partition board time-delay fire lighter can light the next-stage synergistic gunpowder after a period of time after the last-stage perforating gun is perforated so as to form several gunpowder pressure pulses to fracture formation and make the fracture be continuously extended. Besides, the proppants in two synergistic gunpowders can be fed into the formation fracture together with high-temperature high-pressure gas so as to prevent the formation fracture from being closed.

Owner:物华能源科技有限公司

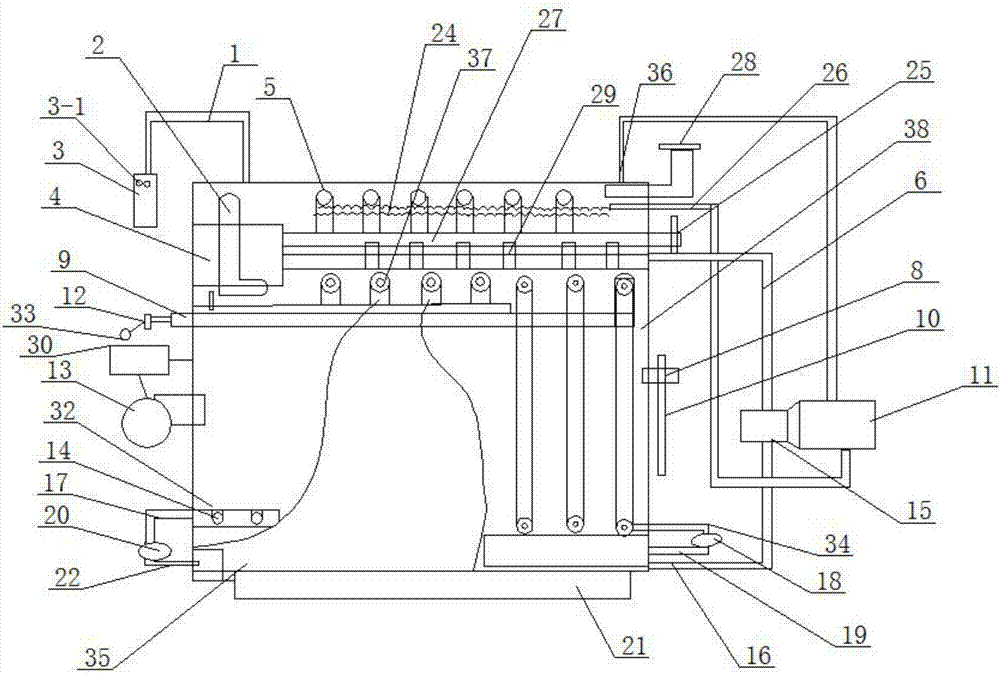

Method and apparatus for biomass instant gasification and combustion

InactiveCN101440971ASolve the energy consumption of clean lifeLow costCatalytic crackingDomestic stoves or rangesCatalytic effectEngineering

The present invention relates to an instant gasification combustion method for a biomass, which is characterized in that the method comprises that a mixed material picked out copper, aluminium and the like is led in a main furnace by smokeless feeding operation mode, an infrared heat accumulation catalytic effect and the unique dewatered technique of an infrared heating material are used to accelerate raw material and gas dehydration and promote gasification reaction and gas complete combustion. The present invention also provides a device for implementing the method, which is composed of a main furnace, a gas combustion range and a pipeline connecting component and is characterized in that the main furnace comprises an upper part and a lower part, wherein the upper part is a smokeless cleaning feeding gas-guiding device and the lower part is an infrared adiabatic reaction barrel. The inner wall of the barrel is provided with an infrared heating material, and simultaneously the lower part is provided an ignition air feeding device. The gas combustion range is provided with an annular clamping strap condenser, an infrared combusting device and a water sealing type oil-water separator or a liquid seal trough or a U-shaped liquid seal tube, the inner part of the gas combustion range is provided with an air-feeding regulating and controlling device. The present invention has the advantages of non smoke and tar oil pollution, high efficiency, energy-saving, safety, environmental protection and perfect development value.

Owner:刘伟奇

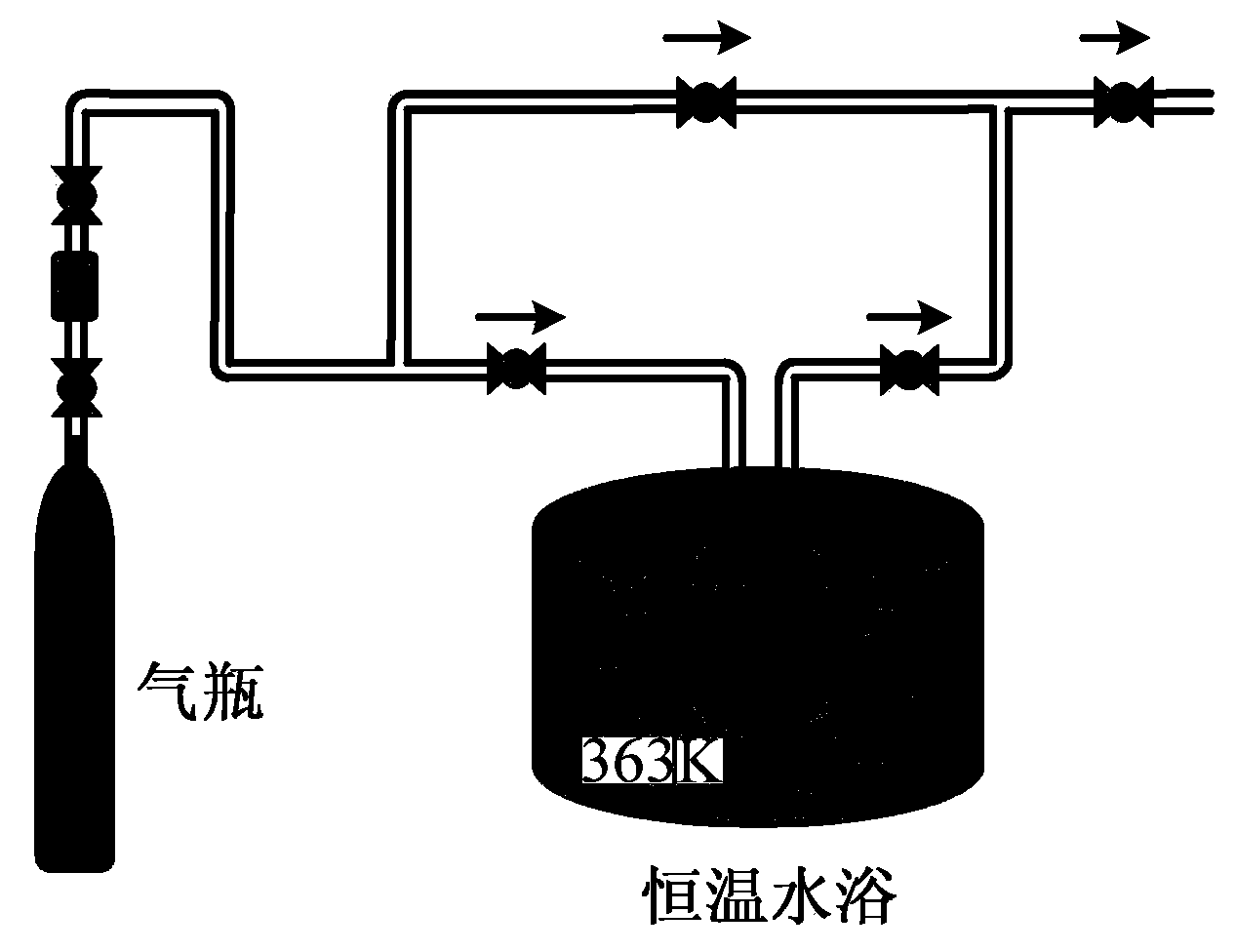

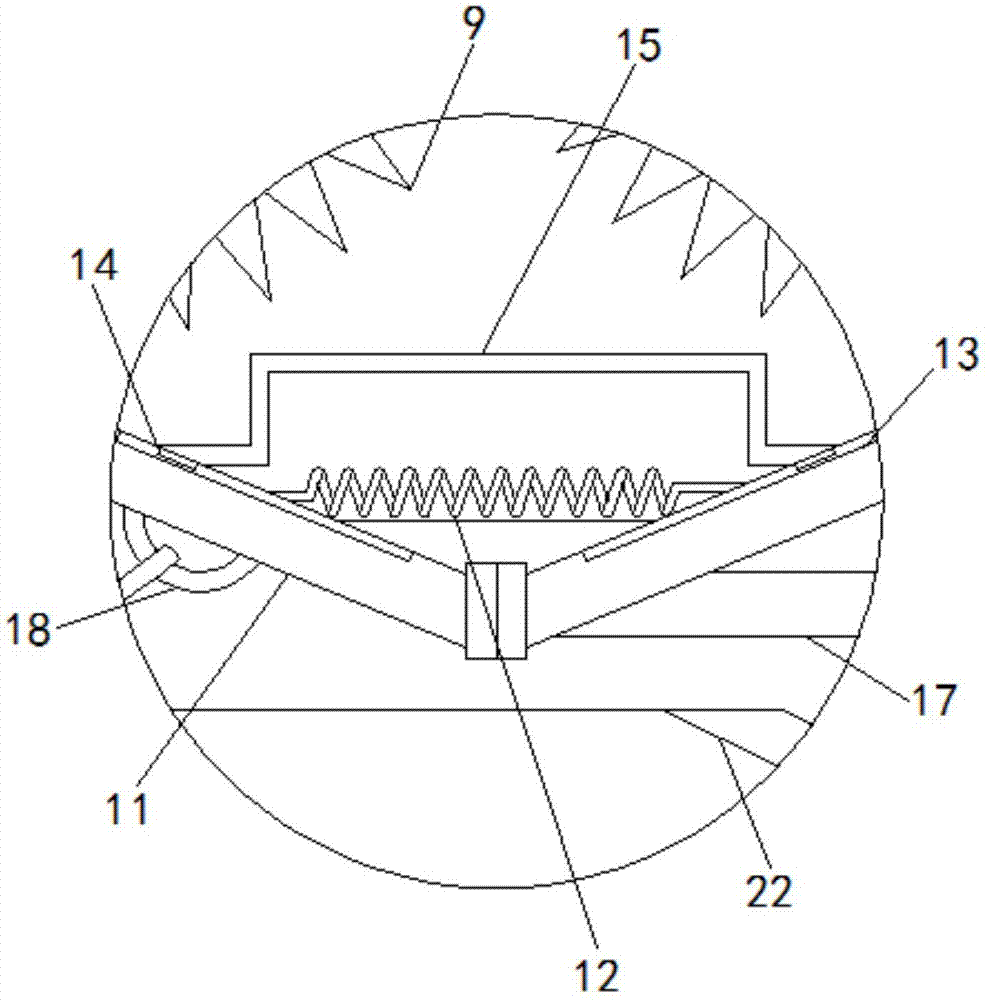

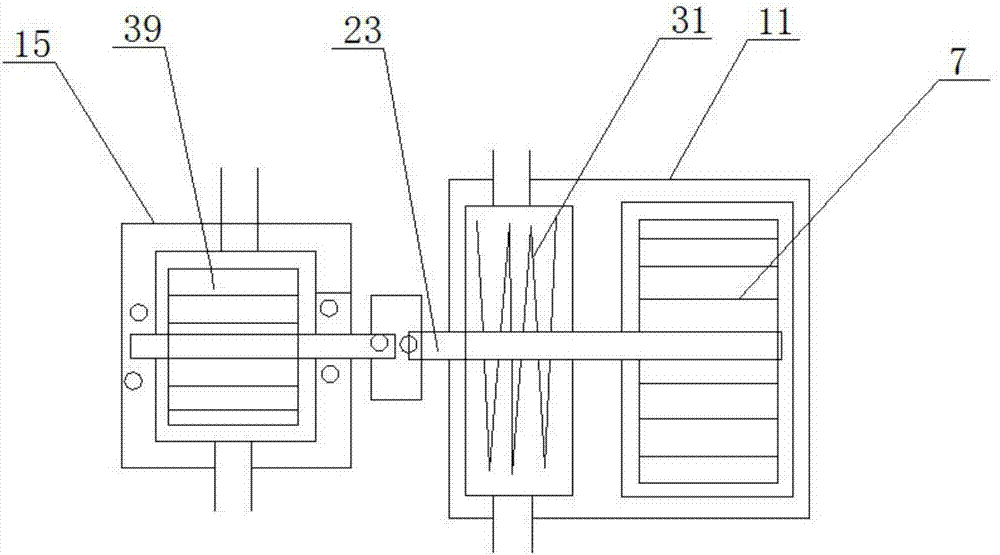

Gas injection type parallel gap device

InactiveCN103730834APrevent trippingEffective protectionSpark gap detailsInsulatorsTransformerElectric power system

The invention discloses a gas injection type parallel gap device. The protection device belongs to the field of lightening protection gap for power transmission lines of alternating-current and direct-current electric power systems. The device is connected with the two ends of a power transmission line insulator chain in parallel, under a lightening stroke, the device is broken down before the insulator chain can be broken down, and thus the insulator chain and the corresponding power transmission line can be protected; moreover, a high-speed high-voltage gas flow can be generated fast and acts on arcs to restrain formation and development of the arcs, the arcs are extinguished in a transient state, and thus the lightning trip-out rate and the lightening accident rate of an electric power system are reduced. The gas injection type parallel gap device comprises arc-control devices on the grounding side and the wire side, fixing devices and parallel spiral fittings installed at the two ends of the insulator train of the line. The arc-control device on the grounding side and the arc-control device on the wire side respectively comprise an arc extinguishing powder storage chamber, an arc air-termination ring, an insulating gas generation chamber, an arc spray channel and the like. With the device, the stability of the electric power system is improved, the on-load action frequency of a breaker is effectively reduced, the service life of electric power equipment such as a transformer is prolonged, and production, operation and maintenance cost is very low.

Owner:闫仁宝 +1

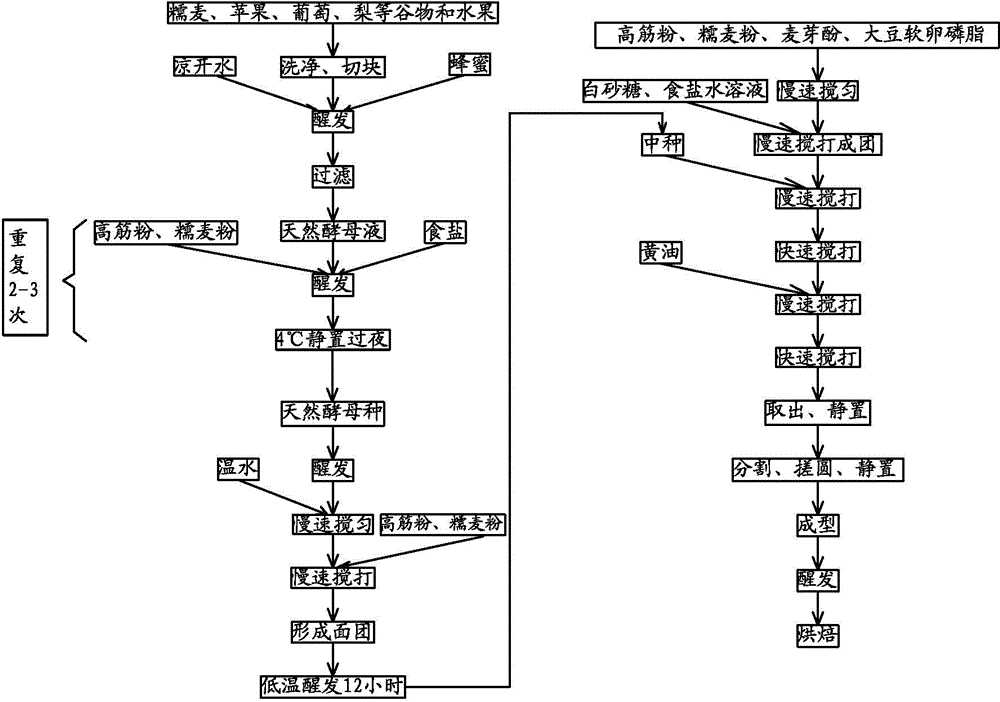

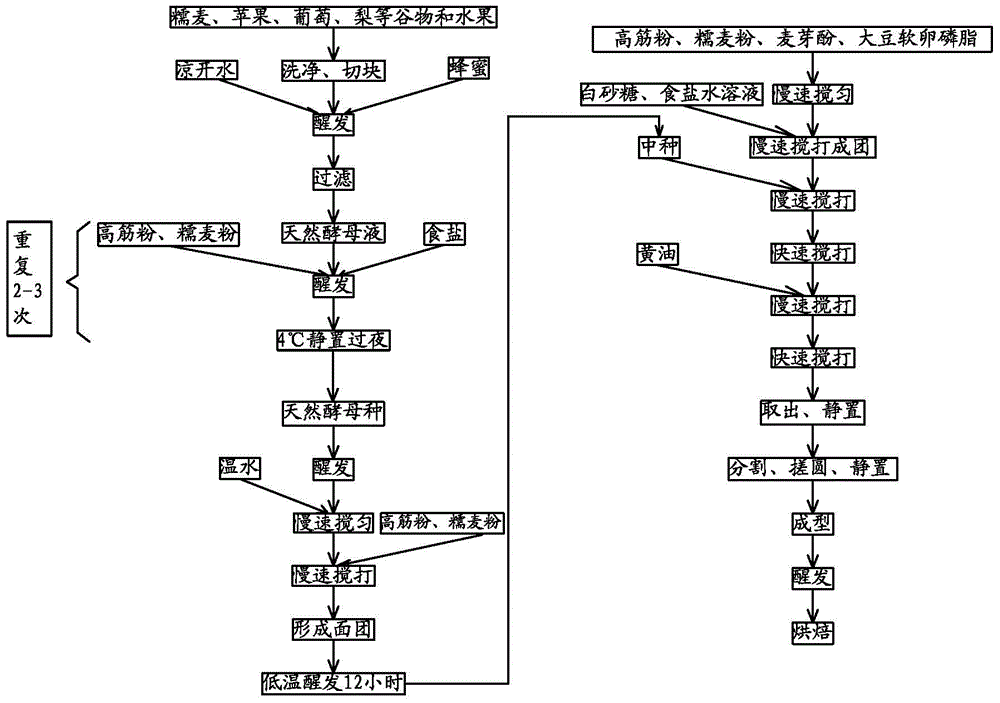

Natural yeast bread and manufacturing method thereof

InactiveCN104782702AAppropriate tasteUniform structureDough treatmentPre-baking dough treatmentNutritive valuesWarm water

The invention relates to a manufacturing method of natural yeast bread. The method includes the steps that a, natural yeast liquid raw materials selected from fruits and cereals at least including glutinous barley are fermented to obtain natural yeast liquid; b, high-gluten flour and glutinous barley flour are mixed to obtain mixed flour, the mixed flour and the natural yeast liquid are mixed to obtain a mixture, and the mixture is fermented to obtain primary natural yeast; c, after the primary natural yeast is fermented, the primary natural yeast, warm water, high-gluten flour and glutinous barley flour are stirred into mixed dough, and the mixed dough is fermented at low temperature to obtain sponge dough; d, high-gluten flour, glutinous barley flour, malt flour, soya bean lecithin and a water solution are stirred and then added into the sponge dough to form bread dough through stirring; e, the bread dough is fermented; f, a conventional method is used for baking to obtain the bread. The invention further discloses natural yeast bread manufactured by adopting the method. The high water absorption rate and the high aerogenesis capacity of the glutinous barley flour, the capacity of promoting yeast aerogenesis of the malt flour and the emulsifying capacity of the soya bean lecithin are used, and low-temperature secondary fermentation is combined to obtain the soft and healthy bread moderate in mouthfeel and high in nutritive value.

Owner:福建安麦高新生物技术有限公司

Firework fuel gas driven high speed sprinkling device

InactiveCN1701858AIncrease gas productionFast gas productionLiquid spraying apparatusLiquid jetEngineering

The present invention provides a liquid high speed spraying device, which uses solid propellant, gunpowder or gas propellant as power source and fuel gas with high pressure from the burn of agents spray from the nozzle to form high speed liquid jet with some spraying angle. The spraying device comprises gas generator, copper seal membrane, piston, liquid storage room and nozzle. All the agents has the characters of large gas product, quick speed, stable burn and easy to store for long term, to make liquid form moment stable jet, and benefit to device miniaturization for liquid spraying bomb with small volume. The jet from this device has the advantages of quick speed, good distribution, well direction and easy control cloud shape.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Resource utilization method for combined production of biogas and cultivation matrix through utilizing tobacco stalk fermentation

InactiveCN102851318AModerate granularityQuality improvementBio-organic fraction processingInternal combustion piston enginesSocial benefitsResource utilization

The invention provides a resource utilization method for the combined production of a biogas and a cultivation matrix through utilizing tobacco stalk fermentation. The method comprises the following steps: carrying out anaerobic fermentation of a main fermentation raw material which is waste tobacco stalks generated in the tobacco threshing redrying line to produce the biogas; carrying out solid-liquid separation of a biogas slurry and the tobacco stalks to obtain a tobacco stalk biogas residue and a biogas slurry; purifying the biogas to prepare clean fuels or to be used for electricity generation to provide partial energy for a plant area; and decomposing the tobacco stalk biogas residue, and carrying out dry molding to prepare the cultivation matrix, wherein the biogas slurry returns to a fermentation system to be recycled or to be used as a liquid organic fertilizer. The method provided by the invention has the advantages of simple production operation, concentrated and stable raw material, scale production benefiting, low production cost, realization of no pollution, zero discharge and cycle utilization of waste tobacco stalk resources of a threshing redrying plant, and generation of good economic, ecological and social benefits.

Owner:ZHENGZHOU UNIV

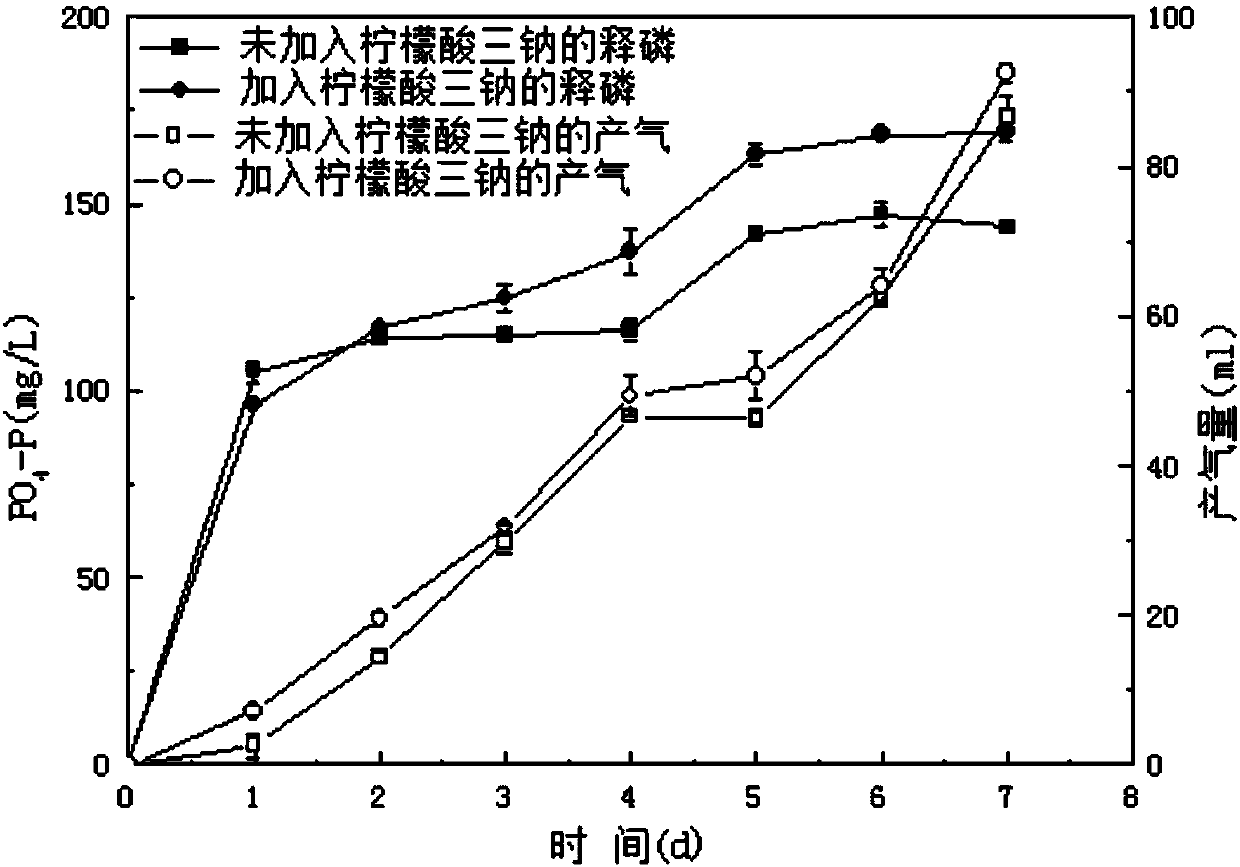

Method for promoting phosphorus release and gas production of phosphate-precipitate-containing sludge under room temperature condition

ActiveCN108046557AIncrease phosphorus release rateIncrease methane productionWater contaminantsWaste based fuelPhosphateSludge

The invention relates to a method for promoting the phosphorus release and the gas production of phosphate-precipitate-containing sludge under a room temperature condition. The method comprises: placing phosphate-precipitate-containing sludge in a reactor, carrying out static precipitation at a room temperature, and discharging the supernatant to obtain concentrated mixed sludge; adding trisodiumcitrate according to the total suspended solid content of the sludge, sealing the reactor, and carrying out anaerobic fermentation for more than 7 days under a room temperature condition, wherein thephosphorus release rate of the sludge can be increased, and the anaerobic fermentation of the sludge can be promoted so as to produce acid and methane. Compared to the method in the prior art, the method of the present invention has the following characteristics that the phosphorus release in the phosphate-precipitate-containing sludge can be promoted sp as to improve the recovery rate of the phosphorus resource at the late stage and promote the anaerobic fermentation of the sludge to produce acid and gas, and achieve the resource utilization of the residual sludge, and the operation is performed at the room temperature, such that the economic cost is low.

Owner:TONGJI UNIV

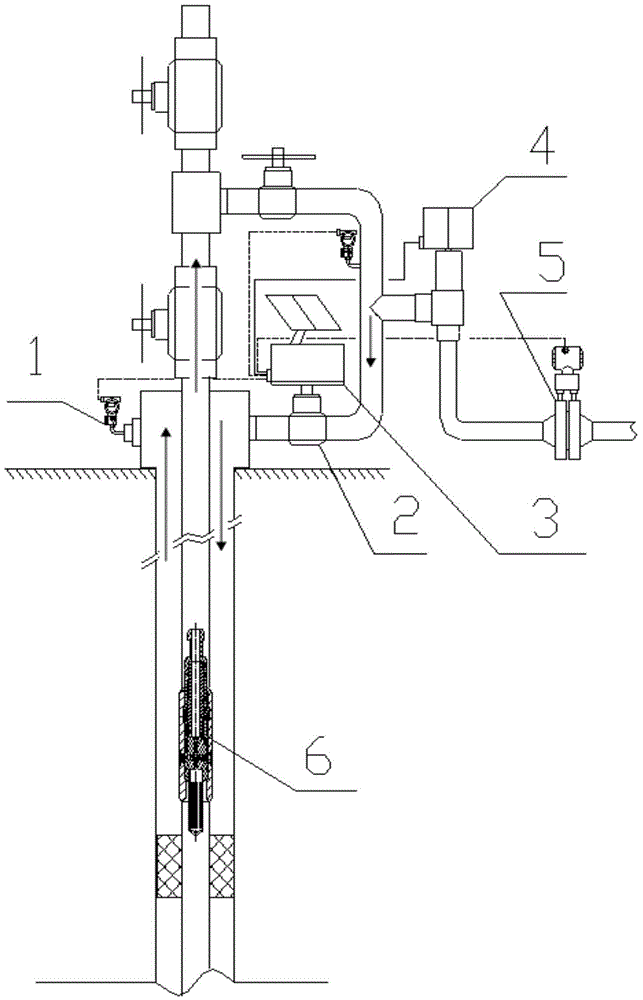

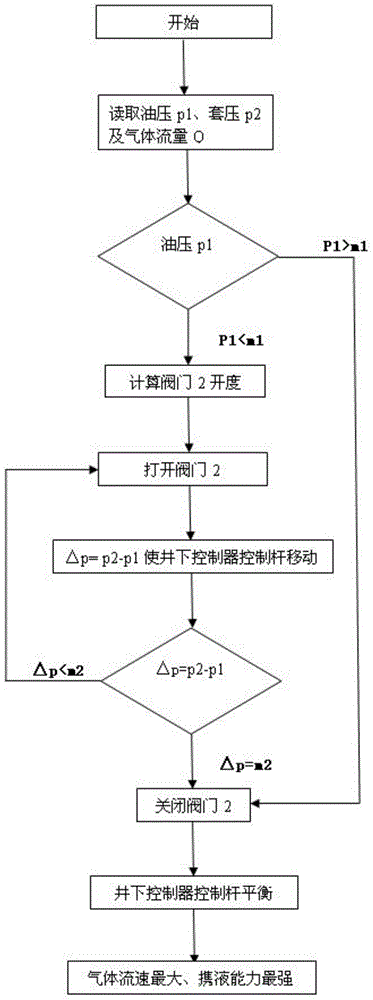

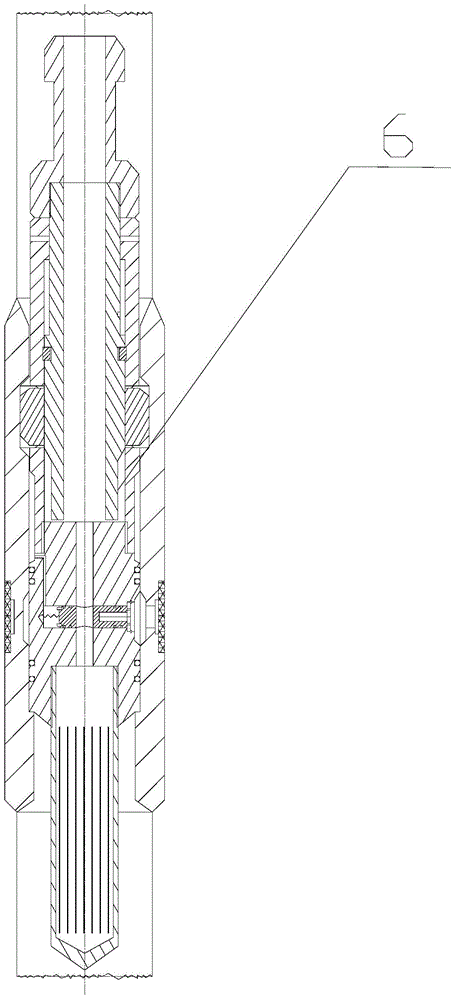

Intelligent production adjusting method and device for gas wells

ActiveCN105089572AChange flow rateGood drainage and gas recoveryFluid removalProduction rateOil pressure

The invention provides an intelligent production adjusting method and device for gas wells and belongs to the technical field of oil field digitization. When oil pressure is higher than a certain pressure value P1, the liquid carrying capability of gas is in a strong state, a control valve is in a circulation-closed state, and at the moment, an underground controller has the maximal opening degree; when the oil pressure is lower than a certain pressure value P2, the liquid carrying capability of gas is poor, or gas cannot carry liquid, and at the moment, the opening degree of the throttling hole of the underground controller is controlled to increase the gas flow rate so as to enhance the liquid carrying capability; and. therefore, the oil pressure value and the casing pressure value of a pressure gauge are read, a reasonable valve opening degree is calculated in combination with the gas production rate, a control box sends a command to the control valve to enable the control valve to reach an appropriate opening degree, a control rod of the underground controller, of which the left face receives a smaller stress than the right face, moves leftwards till a balance is achieved, and the opening degree of the throttling hole is between the maximal opening degree and the minimal opening degree, so that the gas flow rate is the maximal, and the goal of carrying the largest volume of liquid is achieved.

Owner:PETROCHINA CO LTD

Biomass gasification stoves

InactiveCN101275752AZero costSuitable for gas demandDomestic stoves or rangesLighting and heating apparatusCarbonizationEngineering

The invention discloses a biomass gasifier, wherein the propellant bottle is composed of a barrel (4) and a barrel cover (5), the berrel is divided into an upper carbonization gas making chamber (8) and a lower air chamber (9) through a clapboard (7) with ventholes (6), the turnnel wall of an air chamber (10) is provided with an air inlet (10), a fan (2) is arranged on the air inlet (10), the upper turnnel wall of the carbonization gas making chamber (8) is provided with an air supply opening (12), the top of the barrel (4) is equipped with the barrel cover (5) through a water seal trough (13), an air supply tube (14) on the air supply opening (12) is connected with a fuel gas filtering pot (3), which is connected with an oven (16) through a hose (15). The invention performs the deep exploitation and use on the agricultural resources, changes wastes into valuables, which can increase the utilance of the agricultural resources.

Owner:曾明友

Compound enzyme used for methane gas fermentation and capable of supplementing trace elements

The invention discloses compound enzyme used for methane gas fermentation and capable of supplementing trace elements, which is used for quickly decomposing raw materials in methane gas fermentation to supplement the trace elements so as to quicken gas production and increase gas yield. The compound enzyme comprises an enzyme preparation part and a trace element part, wherein the enzyme preparation part is prepared by compounding the following solid monomeric enzyme raw materials in percentage by weight: 20 to 30 percent of 20,000u / g xylanase, 20 to 30 percent of 20,000u / g cellulose, 5 to 10 percent of 1,500u / g lipase, 5 to 10 percent of 10,000u / g pectinase, 5 to 10 percent of 30,000u / g saccharifying enzyme and 5 to 10 percent of 10,000u / g glucanase; the trace element part is prepared from the following raw materials in percentage by weight: 10 to 15 percent of zinc sulfate, 20 to 30 percent of powdered rock phosphate, 10 to 20 percent of steelmaking slag, 12 to 16 percent of calcium carbonate, 20 to 25 percent of stove ash, 5 to 10 percent of active carbon and 4 to 8 percent of nonionic surfactant; and a weight ratio of the enzyme preparation part to the trace element part is 1:(1-2). The compound enzyme can produce gas quickly, increase gas yield, prolong fermentation time, reduce residual energy and improve utilization rate of the raw materials.

Owner:枣庄市杰诺生物酶有限公司

Advanced dry anaerobic digestion method based on sludge modification pretreatment

The invention relates to an advanced dry anaerobic digestion method based on sludge modification pretreatment. The method comprises the following steps: pre-treating dehydrated sludge for 10-60 minutes at a certain temperature and pressure, and cooling to a certain temperature value at the fermentation temperature of 35-42 DEG C or 50-60 DEG C so as to obtain modified sludge; fully mixing the modified sludge with inoculated sludge at a volume ratio of (1:10)-(1:1), putting the mixed sludge in an anaerobic fermentation tank, and starting a temperature control device so that the material temperature is controlled at the fermentation temperature to stand for 3-10 days; then carrying out continuous feed and discharge, controlling feed and discharge amount each day so as to gradually improve operation load, carrying out feed by using the modified sludge with the feed amount of 0.5-1m<3> / d, maintaining the operation for 12-30 days under the load level when the load is improved once, improving the load again after a digestion parameter discharge VS and daily gas production amount are stable until a planned load is reached; after starting the anaerobic digestion process, performing a stable operation stage; carrying out continuous feed and discharge, and controlling material retention period to 12-20 days so that the digestion load is maintained at a set level; and treating biogas residue. By using the method, the viscosity of the sludge can be reduced, dry digestion speed and gas production amount are improved; and compared with the wet fermentation, equipment investment and occupied soil are saved.

Owner:TONGJI UNIV

Method for producing biogas and curve tunnel type biogas digester

InactiveCN103755117ASolving the Span Limit DilemmaPest Control GuaranteeBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasBiomass

The invention provides a method for only fermenting and decomposing feces of livestock and poultry, and a method for simultaneously fermenting and decomposing feces of livestock and poultry and other organic waste to producing biogas continuously through an ecological type energy environmental-protection recycling system. The invention further provides a curve tunnel type biogas digester, a device capable for realizing automatic operation without energy consumption, and a device capable of achieving that the operation of the device is controlled remotely through a computer. The building of an oversized biogas digester with the monomer digester capacity of 1000 cubic meters is not limited by the span of a digester cover, and raw materials can be fermented, decomposed and sterilized at room temperature for at least 93 days and then are directly discharged into nature water. The ecological type energy environmental-protection recycling system can be used as a converter of biomass energy and can produce a large amount of biogas in modes of environmental protection, stable yield, low cost and large scale. The difficulties of environmental pollution and energy shortage can be solved, and the economic benefit can also be obtained.

Owner:罗显平

Household straw gasifying device

ActiveCN101624526AAvoid getting lostEven by forceSpecial form destructive distillationCombustible gas productionTarEngineering

The invention discloses a household straw gasifying device, comprising a furnace body, a furnace cover, a furnace bottom, and the like. The furnace cover is fixedly and hermetically connected with an upper end surface of the furnace body, and the furnace bottom is placed at the lower part of the furnace body. The furnace cover is provided with a top cover, and a sealing ring is added at the contact part of the furnace cover and the top cover; a material compaction device is arranged in the centre of the top cover; pressurizing sheets are all arranged at an outer edge of the upper end surface of the furnace body; and a big furnace tooth is embedded into the lower end surface of the furnace body, the big furnace tooth is fixed with a support, and the support is fixed with the furnace bottom. The material compaction device ensures even stress of the material and is difficult to form a cavity and deflection in the burning process, thereby prolonging gas production time, accelerating gas production speed, increasing gas production quantity, prolonging firing time and ensuring repeated use of fuel for a long time; and a tar re-melting burning device completely solves the problem of secondary pollution caused by no treatment to the tar generated by a household straw gasifying furnace, therefore, the invention can not only satisfy the requirement of cooking, bathing and warming, but also is particularly suitable for temperature rising of apparatuses for agricultural production .

Owner:程浩德

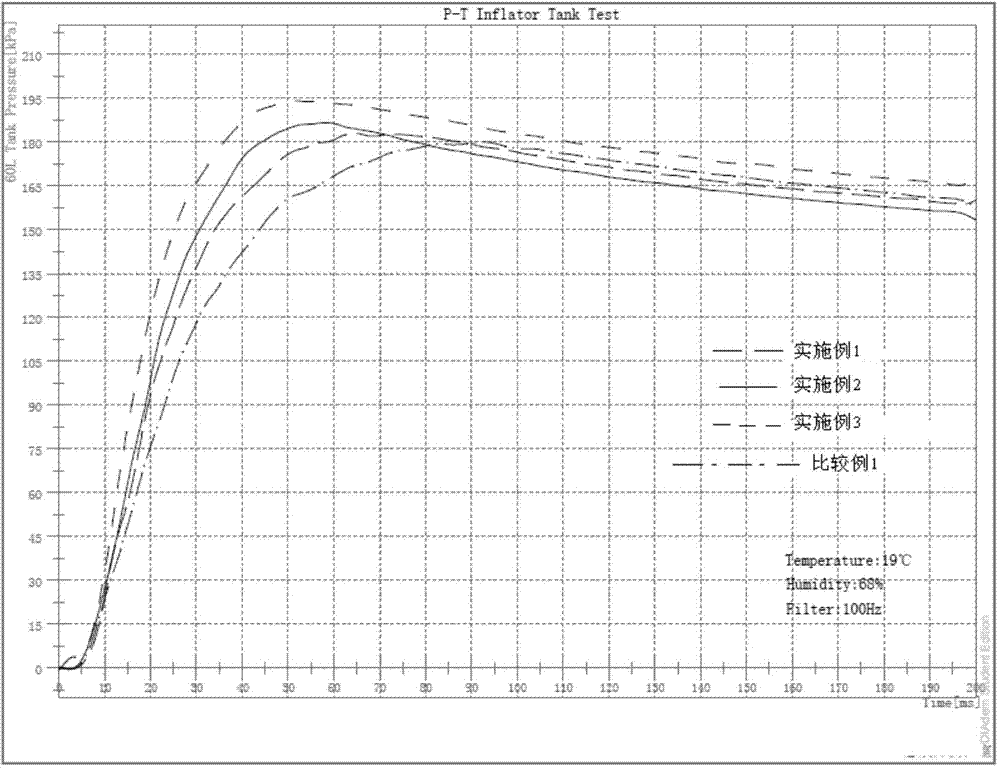

Gas generating agent composition and preparation method thereof

ActiveCN104744185AThe decomposition temperature is advancedPromote decompositionPressure gas generationProduction rateCombustion

The invention relates to a gas generating agent composition. The gas generating agent composition comprises fuel, an oxidizing agent, a rare earth metal organic salt and an azotetrazolate nonmetal salt which are used as raw material components. By adding the rare earth metal organic salt and the azotetrazolate nonmetal salt to the fuel and the oxidizing agent, the decomposition temperature of the fuel is ahead of time, the fuel decomposition is promoted, and the combustion rate and the gas production rate are increased; and lots of gases are generated after reaction of the azotetrazolate nonmetal salt with oxides, thus enhancing the ignitability, increasing the combustion rate and reducing the combustion temperature. The gas generating agent composition is capable of effectively improving the ignitability and reducing the combustion temperature, meanwhile does not generate residues and is high in gas generation efficiency, large in gas production rate and fast in combustion rate.

Owner:BYD CO LTD

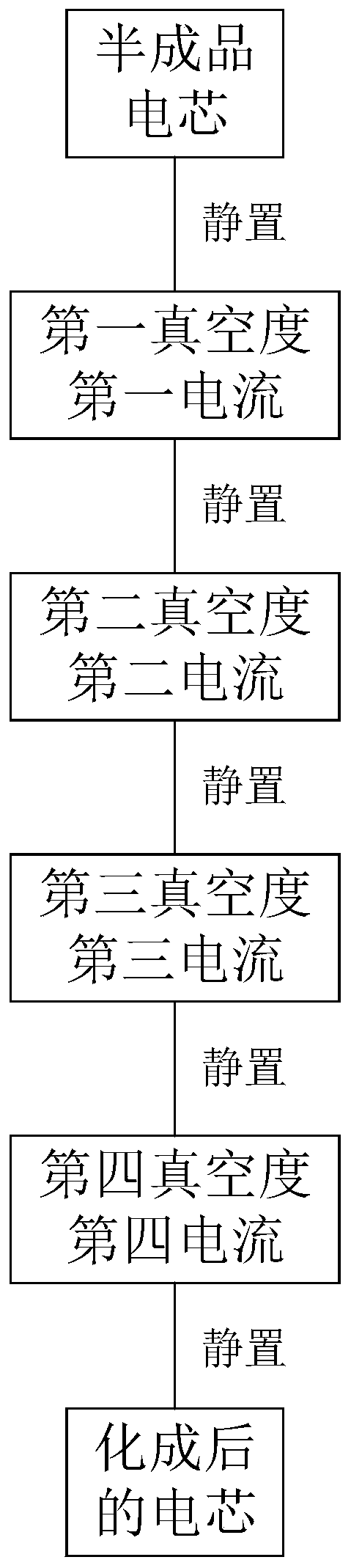

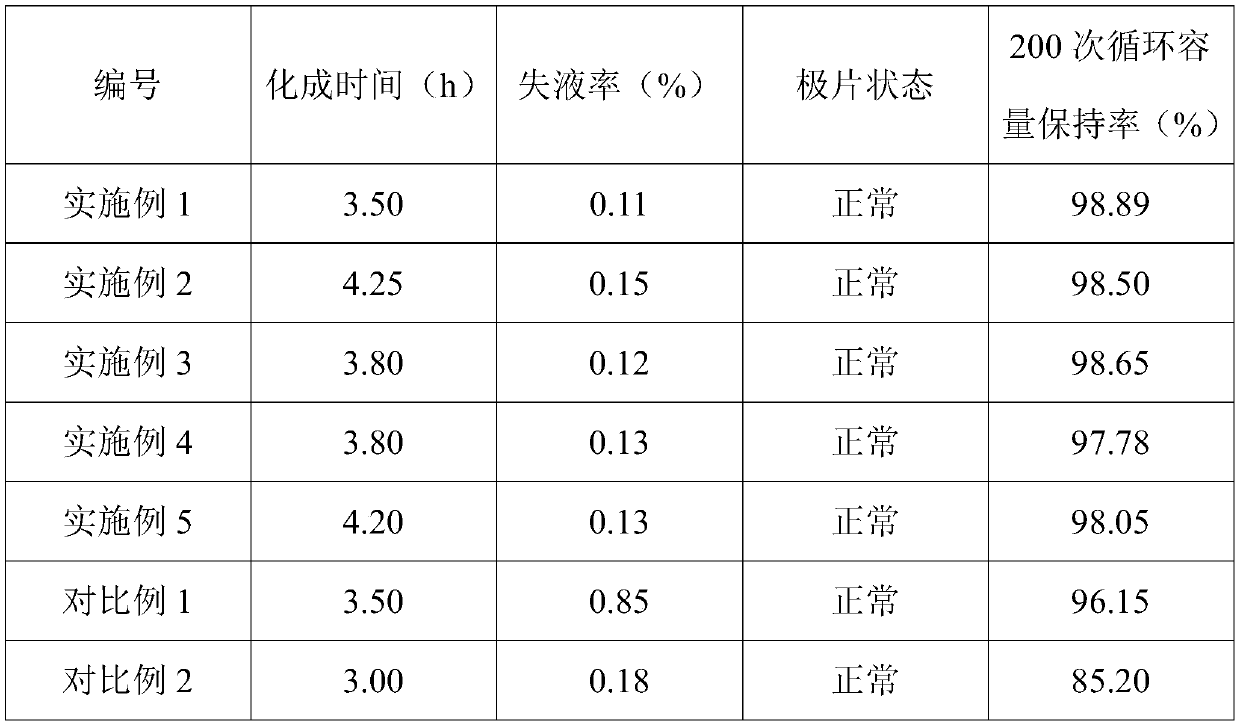

Negative pressure formation method and battery

ActiveCN111554991AFast growthFast formingSecondary cells charging/dischargingPower batteryCharge current

The invention discloses a negative pressure formation method and a battery. The method comprises the following steps: vacuumizing, charging and standing a semi-finished battery cell to obtain a formedbattery cell; performing vacuumizing and chargingt in multiple steps, gradually reducing the vacuum degree of each step, and gradually increasing the charging current. The method provided by the invention can shorten the formation time, reduce the liquid loss in the formation process, improve the consistency and stability of the SEI film, improve the cycle performance of the battery, meet the requirements of high specific energy, quick charging, long service life and the like of the power battery for the new energy automobile, and is particularly suitable for the formation of the lithium ionbattery.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

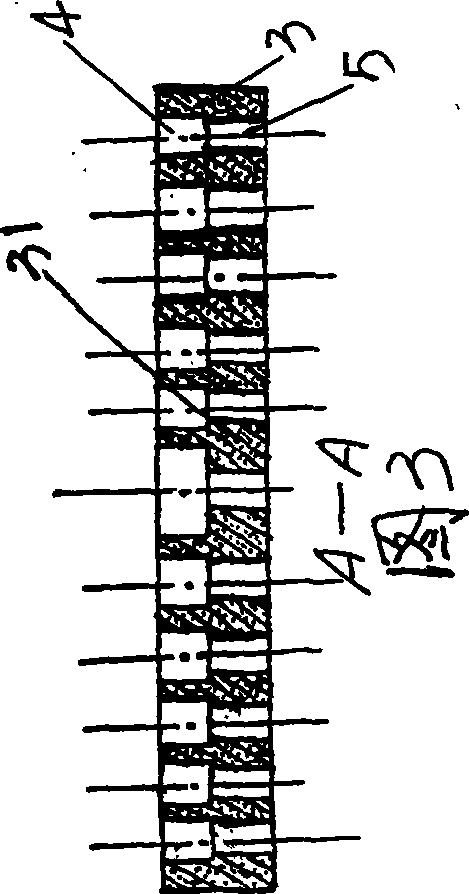

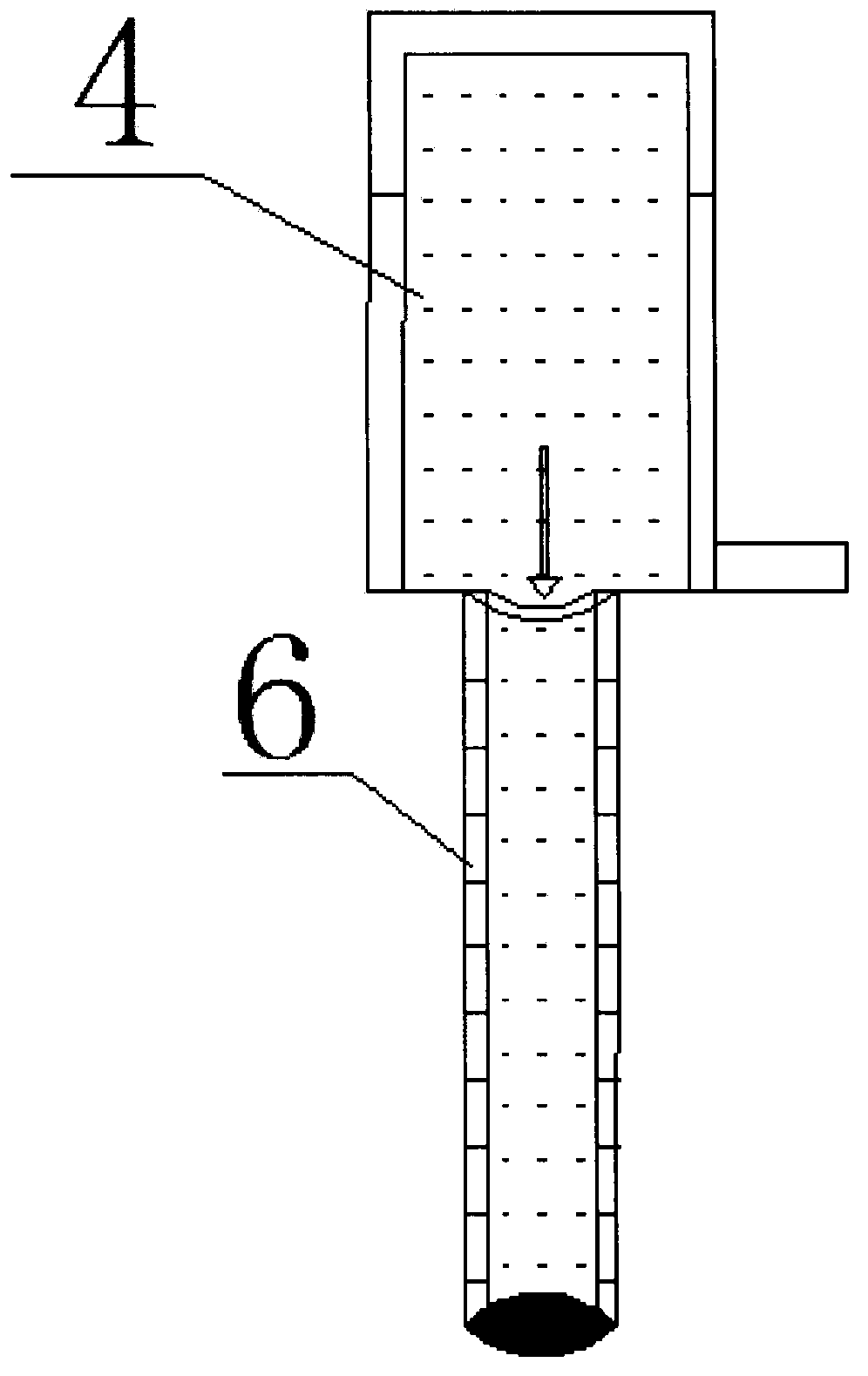

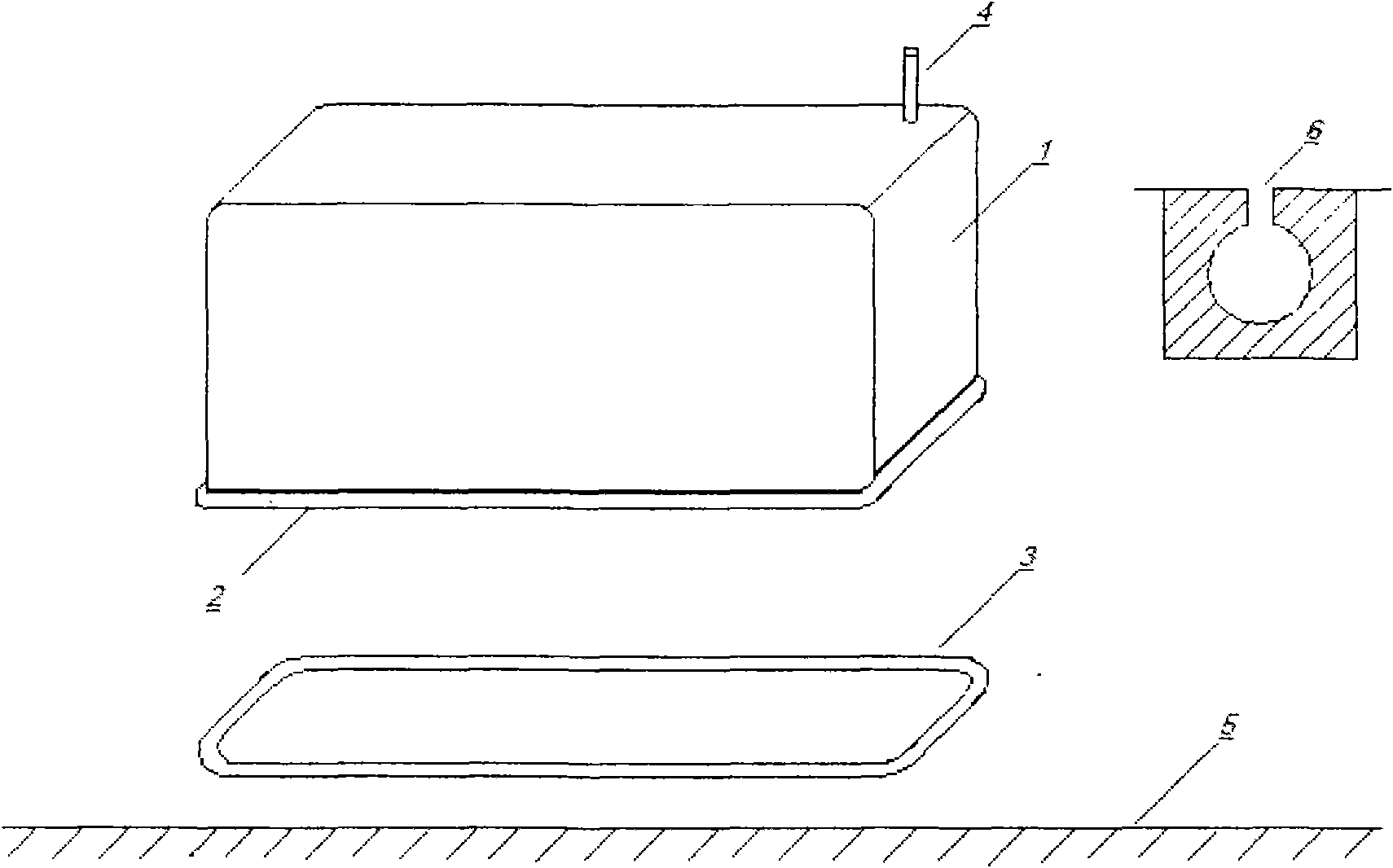

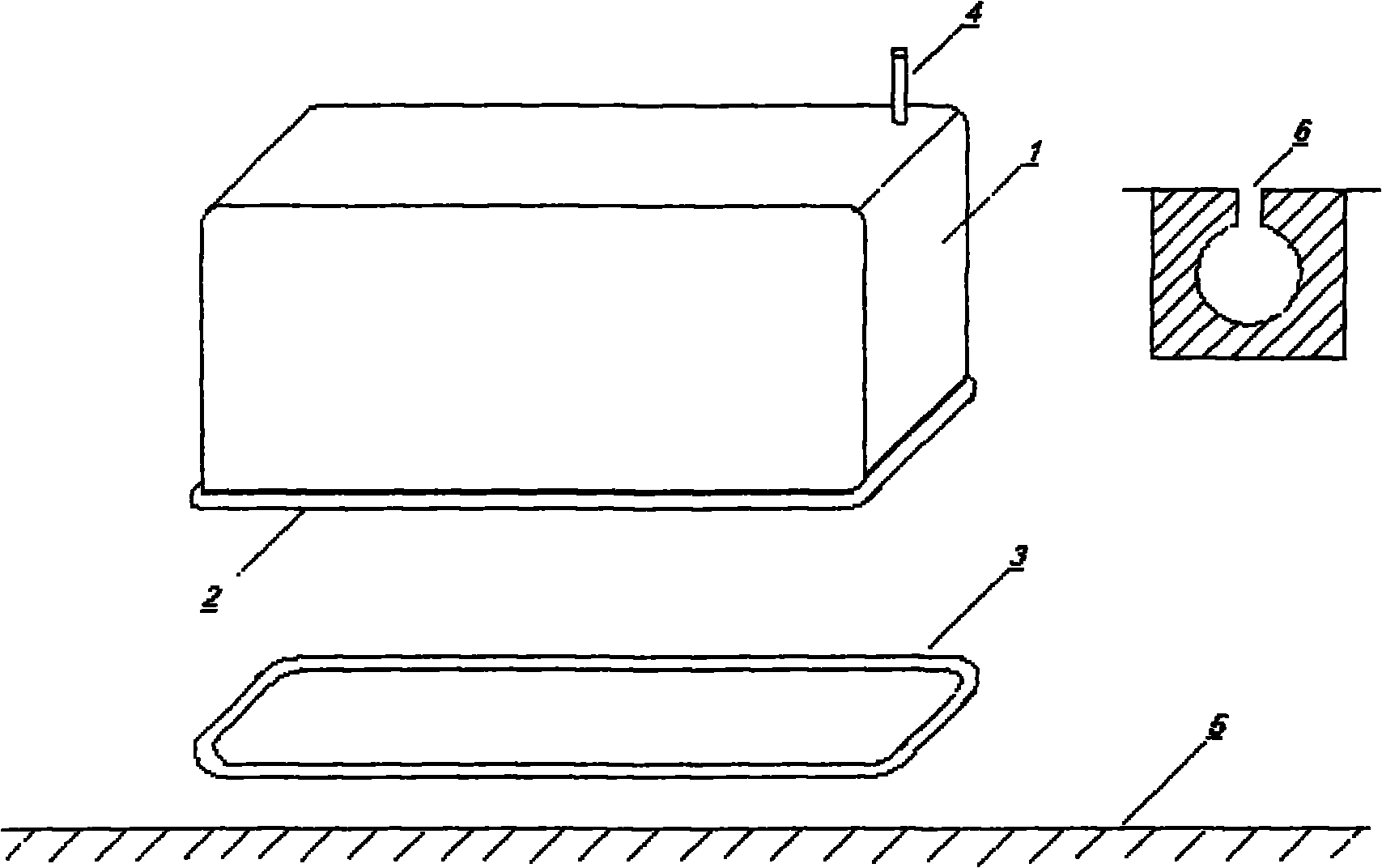

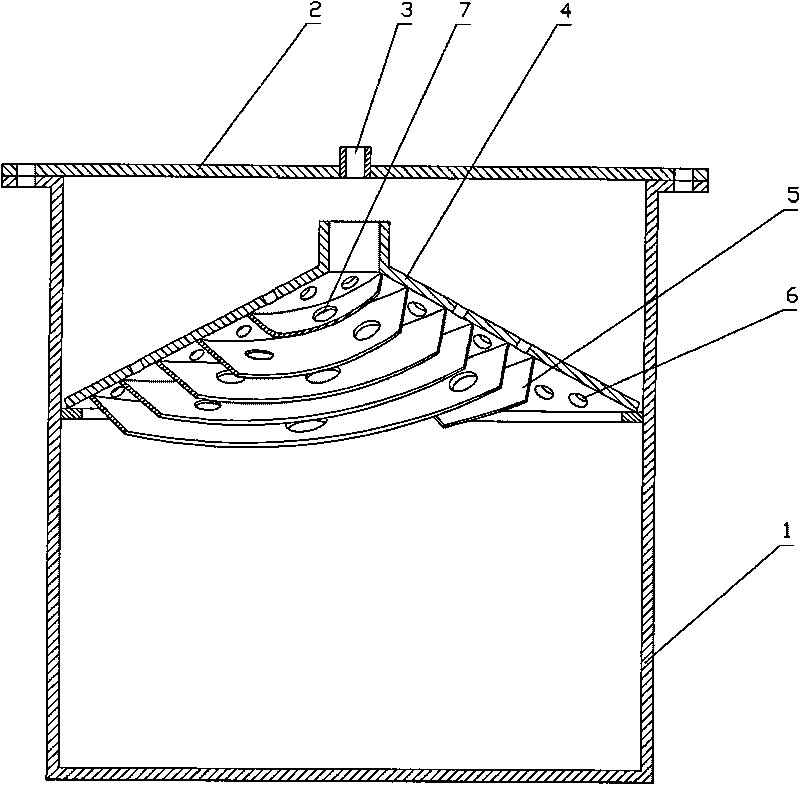

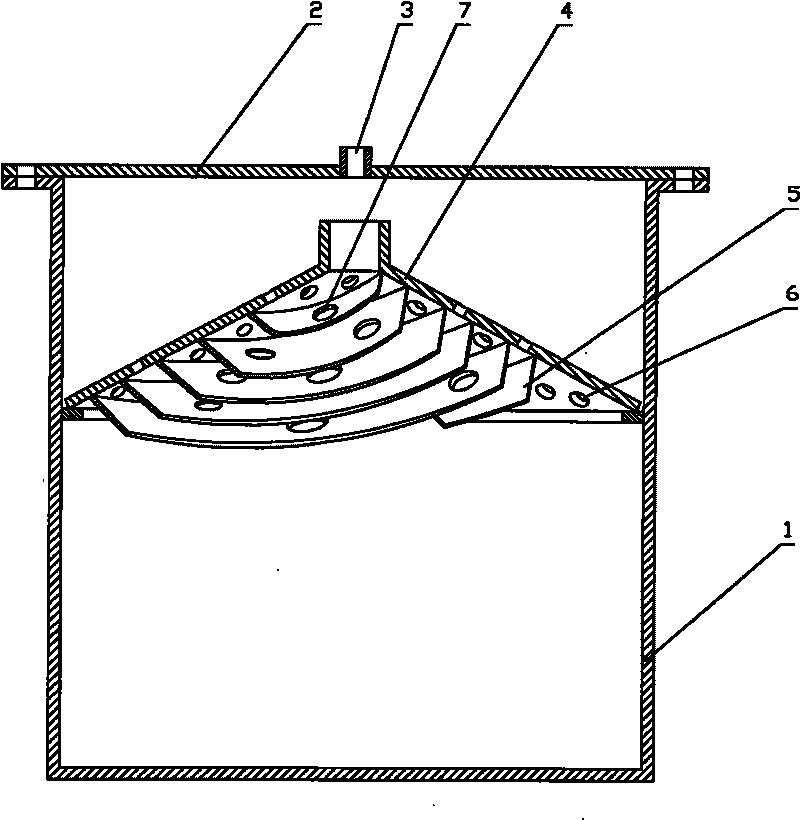

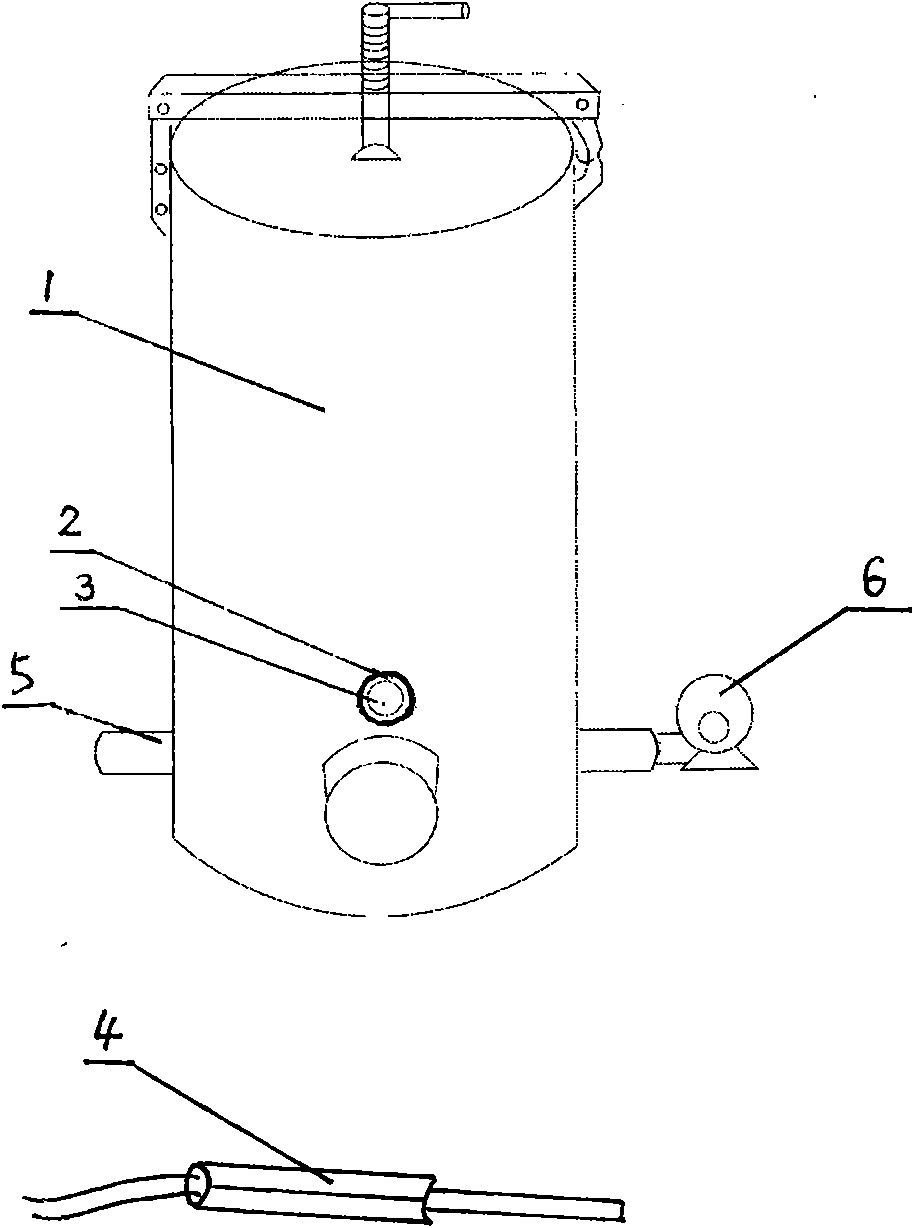

Rheid fermenting cellar and method for producing methane by utilizing rheid fermenting cellar

InactiveCN101928664AImprove securityAvoid explosionGas production bioreactorsWaste based fuelMechanical engineeringRheid

The invention discloses a rheid fermenting cellar and a method for producing methane by utilizing the rheid fermenting cellar. The rheid fermenting cellar comprises a seal housing (1) and cement floor (5), the seal housing (1) is made from flexible sealing membrane material and the lower edge of the seal housing (1) is a ring-shaped air inflation sealing ring (2).The cement floor (5) is embedded with a ring-shaped groove (3), the cross section of the groove is in the shape of an inverted ohm shape with the small opening and the large cavity. The air inflation sealing ring (2) is integrated with the ring-shaped groove (3) and tightly integrates the seal housing (1) and the cement floor (5) after being aerated, thus forming a sealed rheid fermenting cellar. The top of the rheid fermenting cellar is provided with a methane outlet pipe (4).In the invention, the solid state fermentation technology is adopted, the pretreated ferment raw material is charged in a split mode in plastic boxes( barrels) suitable for transportation, and piled up and stacked in advance in the rheid fermenting cellar. The method of the invention has large production of methane, simple device structure, easy construction, small investment and low cost.

Owner:刘慧敏

A kind of biogas preparation method using edible fungus chaff as raw material

InactiveCN102286539AReduce wasteSolve pollutionMicroorganism based processesWaste based fuelMicrobial agentBran

The invention discloses a biogas preparation method using edible fungus chaff as a raw material, and relates to a biogas preparation method. The invention aims to solve the problems of waste of resources and environmental pollution caused by discarding or burning the chaff after the production of edible fungi. Method: first remove the sundries in the chaff, crush it and dry it, then add the compound microbial agent, seal it, and ferment it anaerobically; mix the treated chaff with cow dung, then add it to the fermentation tank, and adjust the fermentation tank The content of solids, the temperature of the biogas fermentation, and the capacity of the fermentation tank are controlled. After 25 to 45 days, a batch of biogas fermentation is completed. The invention uses the waste fungus chaff after the production of edible fungi as the fermentation raw material, solves the problem of environmental pollution caused by the discarded fungus chaff, turns waste into wealth, and does not cause secondary pollution to the environment. Applied in the field of biogas fermentation.

Owner:INST OF MICROBIOLOGY HEILONGJIANG ACADEMY OF SCI

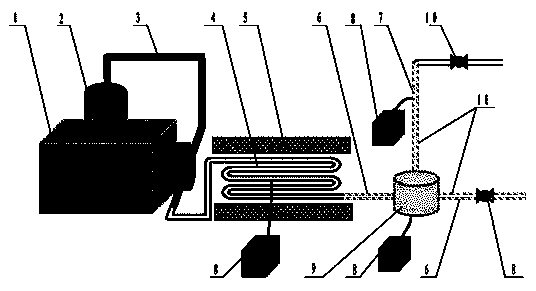

Controllable steam generation device

InactiveCN103925586ARealize micro-continuous supplyMicro continuous supply up toSteam generation heating methodsWater feed controlWater vaporWater storage tank

A controllable steam generation device comprises a mini-type water feed pump, a steam generation pipe, a heating device and a steam bearing device. The mini-type water feed pump is provided with silicone pipes of different specifications in a matched mode; one end of each silicone pipe is connected with a pure water storage tank; the other end of each silicone pipe is connected with the steam generation pipe; the steam generation pipe is a stainless steel coiled pipe; the heated part is arranged in the heating device, fed water is completely evaporated by being heated, and produced steam enters a mixing tank and is fed into a steam utilization device through the steam bearing device; a steam pipeline, a steam bearing pipeline and the mixing tank are respectively provided with a heat tracing device. The controllable steam generation device has the advantages of being convenient to install, easy to operate, controllable in flow and temperature and the like, meets the supply requirement of a trace of steam of laboratories, and solves the problem that online measurement of steam in mixed gas is difficult.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +2

Natural yeast bread dough and manufacturing method thereof

InactiveCN104782703AAppropriate tasteUniform structureDough treatmentPre-baking dough treatmentNutritive valuesWarm water

The invention discloses a manufacturing method of natural yeast bread dough. The method includes the steps that a, natural yeast liquid raw materials selected from fruits and cereals at least including glutinous barley are fermented to obtain natural yeast liquid; b, high-gluten flour and glutinous barley flour are mixed to obtain mixed flour, the mixed flour and the natural yeast liquid are mixed to obtain a mixture, and the mixture is fermented to obtain primary natural yeast; c, after the primary natural yeast is fermented, the primary natural yeast, warm water, high-gluten flour and glutinous barley flour are stirred into mixed dough, and the mixed dough is fermented at low temperature to obtain sponge dough; d, high-gluten flour, glutinous barley flour, malt flour, soya bean lecithin and a water solution are stirred and then added into the sponge dough to form bread dough through stirring. The invention further discloses natural yeast bread dough manufactured by adopting the method. The high water absorption rate and the high aerogenesis capacity of the glutinous barley flour, the capacity of promoting yeast aerogenesis of the malt flour and the emulsifying capacity of the soya bean lecithin are used, and low-temperature secondary fermentation is combined to obtain soft and healthy bread moderate in mouthfeel and high in nutritive value.

Owner:福建安麦高新生物技术有限公司

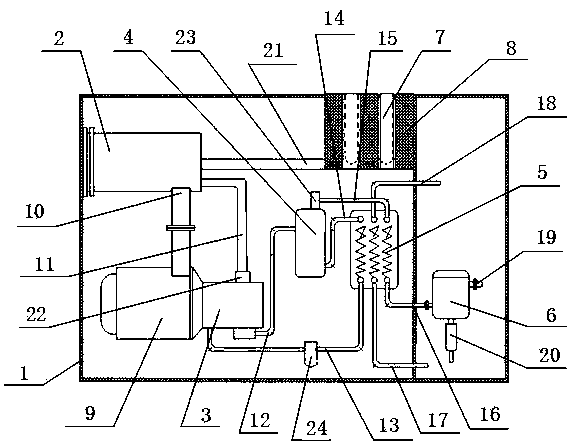

Multifunctional air compressor

ActiveCN104214072AReduce negative pressureReduce vibrationPositive displacement pump componentsPumpsElectricityVapor–liquid separator

The invention discloses a multifunctional air compressor which comprises a machine case, an air inlet device, a motor, a pressurization air filter, a compressor, an oil-gas separator, a total heat recovery water heater and a centrifugal gas-liquid separator. The air inlet device, the motor, the pressurization air filter, the compressor, the oil-gas separator, the total heat recovery water heater and the centrifugal gas-liquid separator are arranged in the machine case. Air outside the machine case enters the machine case after dust filtering of a filter bag and noise elimination of a noise elimination pressure relief device, heat in the machine case is collected by a motor cooling heat collection cover and is conveyed into the pressurization air filter through a heat collection and air supply pipe, heat energy of gas and radiation heat energy of equipment are recycled, and cold oil is conveyed to the compressor through an oil return pipe after hot oil in a separator engine oil conveying pipe is cooled by the total heat recovery water heater. According to the multifunctional air compressor, three kinds of heat are recycled, the generated gas rises and is improved by more than 10 percent, gas input is smooth and small in resistance, the whole energy-saving equipment is arranged in the machine case, air for cooling is reduced, cooling electricity consumption is reduced, electricity used by the air compressor is less, and the energy efficiency ratio is high. The good vibration and noise reduction and cooling effects are achieved.

Owner:江西汉诺斯压缩机科技有限公司

Marsh gas reactor with crusting resistance device

InactiveCN101724552AFully fermentedAccelerate emissionsGas production bioreactorsWaste based fuelSlagEngineering

The invention discloses a marsh gas reactor with a crusting resistance device, which comprises a fermenting tank, a sealing cover and a crusting resistance device, wherein the sealing cover covers the fermenting tank; a marsh gas outlet hole is arranged on the sealing cover; and the crusting resistance device comprises slag baffle plates and a gas collecting cover with a horn structure. The gas collecting cover is arranged on the inner wall of the fermenting tank, and the opening faces downwards. A gas through hole I is arranged on the gas collecting cover. The slag baffle plates are staggered and arranged on the periphery of the inner wall of the gas collecting cover, and form a certain included angle with the horizontal plane. As the gas collecting cover with the horn structure is arranged in the fermenting tank, and the slag baffle plates are staggered and arranged on the periphery of the inner wall of the gas collecting cover, and form a certain included angle with the horizontal plane, when the gas pressure in the fermenting tank is changed, the marsh gas liquid fluctuates up and down, the marsh gas slag is sheared by the slag baffle plates in a nonuniform way, is abraded and extruded by the slag baffle plates, and is prevented from further floating onto the liquid surface, and then the invention prevents the marsh gas slag from crusting on the liquid surface, and also can break the formed crust.

Owner:CHONGQING UNIV

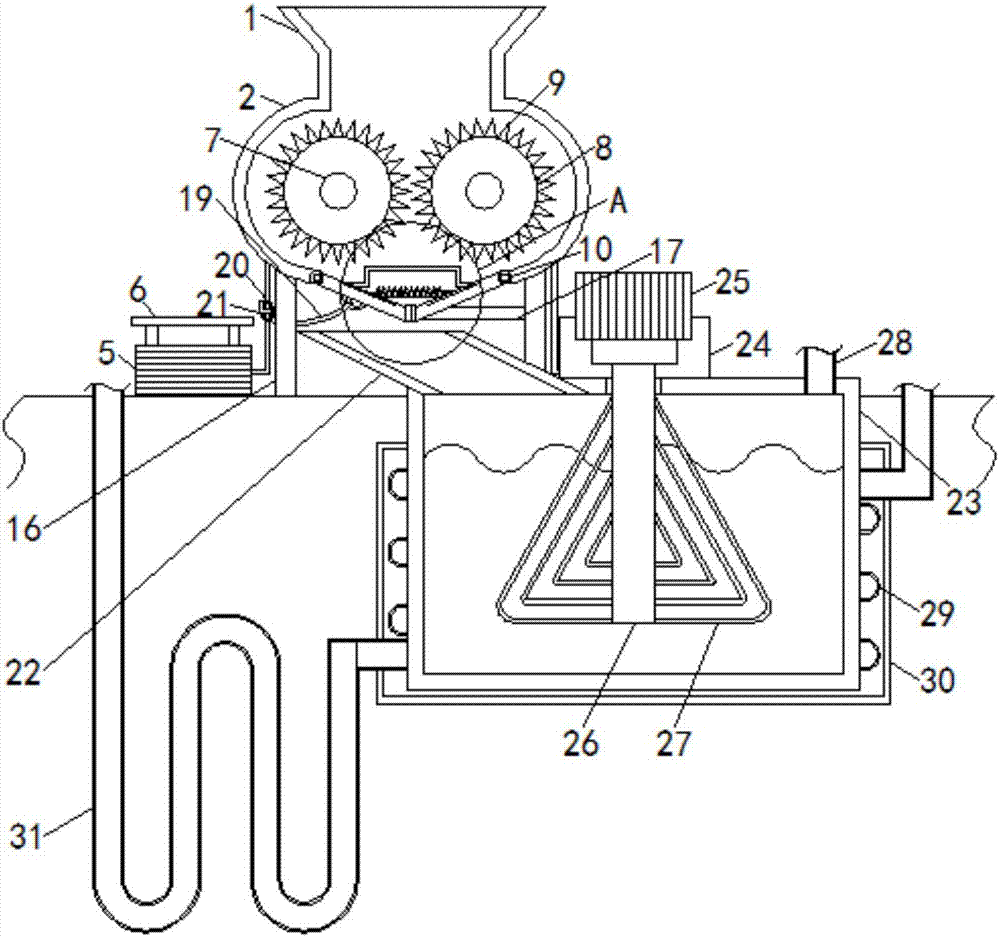

Biogas production device with high biomass energy utilization rate

ActiveCN107988050AHigh utilization rate of biomass energyIncrease profitBioreactor/fermenter combinationsBiological substance pretreatmentsEcological environmentNew energy

The invention relates to the technical field of new energy sources and discloses a biogas production device with a high biomass energy utilization rate. The biogas production device comprises a feeding hopper, wherein the bottom of the feeding hopper is fixedly connected with a crushing cylinder; the back surface of the crushing cylinder is fixedly connected with a supporting plate; two crushing motors are fixedly mounted at the top of the supporting plate; opposite sides of the two crushing motors are electrically connected with a power accumulation box. By adopting the biogas production device with the high biomass energy utilization rate, a lot of electric energy is saved and the utilization rate of the new energy sources is improved; the contact area of anaerobic fermentation materialsis enlarged and a proper reaction amount of reactants is controlled; the anaerobic reaction efficiency is improved; meanwhile, the reactants can be sufficiently and effectively mixed and the speed ofanaerobic reaction is improved; reaction temperature which is most suitable for the anaerobic reaction is provided and the decomposition of raw materials is accelerated so that the biogas productionamount is greatly improved and the energy sources are saved; meanwhile, the utilization rate of biomass energy is greatly improved and pollution to an ecological environment is effectively avoided.

Owner:杭州皖云科技有限公司

Energy-saving type boiler

InactiveCN101251249ABurn fullyExtended combustion strokeGratesFire-tube steam boilersSlagProcess engineering

The invention relates to an energy-saving type boiler, comprising a heat exchange chamber arranged on the upper part of a boiler body and a furnace hearth arranged on the lower part of the boiler body, wherein the heat exchange chamber consists of a water-storing cavity, a smoke exhaust pipe and a main smoke pipe; the furnace hearth consists of a furnace gate, a furnace slag chamber, a furnace door and a clearing slag port; the furnace gate is divided into a pyramidal part and a plane part; the furnace gate close to one side of the furnace door is the pyramidal part which radially extends into a furnace hearth from the furnace door in descending order. The furnace gate is divided into a pyramidal feed zone and a plane zone, which can ensure that: the fuels are gradually heated and burned along the pyramidal zone, rolled to the plane zone for continuous burning and then discharged from the plane zone. The energy-saving type boiler has the characteristics of ingenious design, reasonable structure and sufficient air supply as well as fuel burning; moreover, the long burning travel of fuels in the boiler ensures that the fuels are difficult to directly drop in the furnace slag chamber and discharge out, thereby saving energy and fuels. At the same time, as the energy-saving type boiler changes the direct discharging type into the backward-flow type for discharging smoke, the high-temperature fuel gas forms reheating, so as to ensure more sufficient heat exchange, larger gas producing quantity and quicker gas producing speed.

Owner:黄传柳

Macromolecule nonmetal energy oil unstressed container pulse steam method and pulse steam engine

InactiveCN107965745AUniform exchange temperatureTemperature balanceSteam generation heating methodsGear pumpCombustion

The invention provides a pulsating steam method and a pulsating steam engine in a pressureless container of polymer non-metallic energy oil. The tube is connected to the oil cylinder. A compressor is installed on one side of the oil cylinder. The compressor is connected to the oil cylinder through an air mixing tube. The other end of the compressor is connected to the oil cylinder through a high temperature conduit. The compressor is equipped with Gear pump, the top of the gear pump is connected to the oil cylinder through a delivery pipe, the bottom of the gear pump is connected to the oil cylinder through a liquid flow pipe, the compressor includes a shaft core, and one end of the shaft core is connected to the output shaft of the gear pump Connected, the oil cylinder is provided with a pulsating evaporator, and the top of the pulsating evaporator is provided with a burner. The polymer non-metallic energy oil pressureless container pulsating steam method and pulsating steam engine have reasonable design, high safety, and are easy to use.

Owner:程洪亮 +1

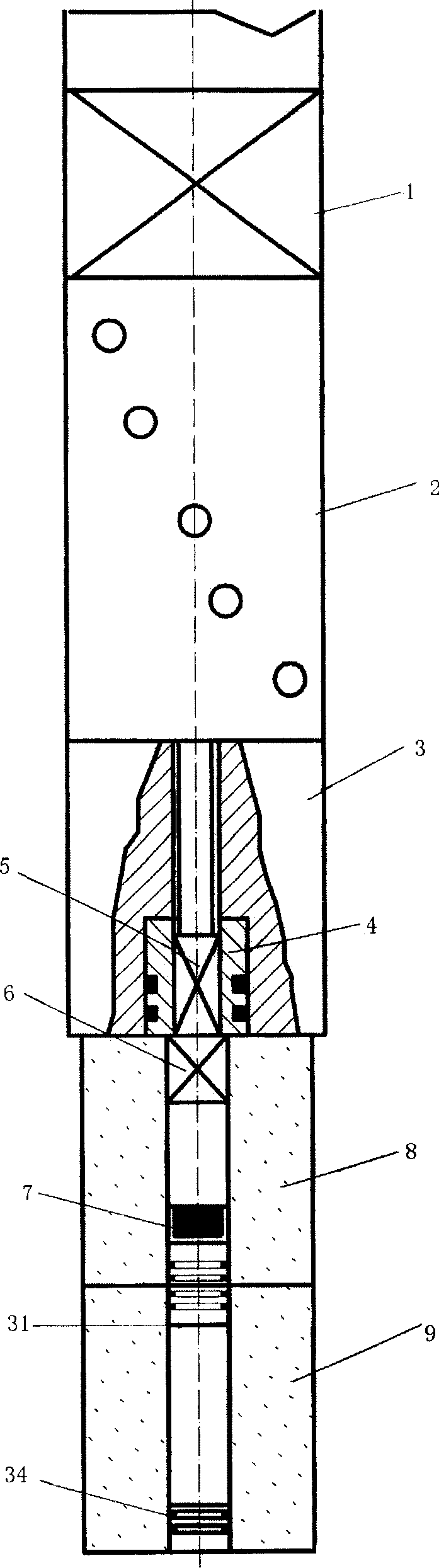

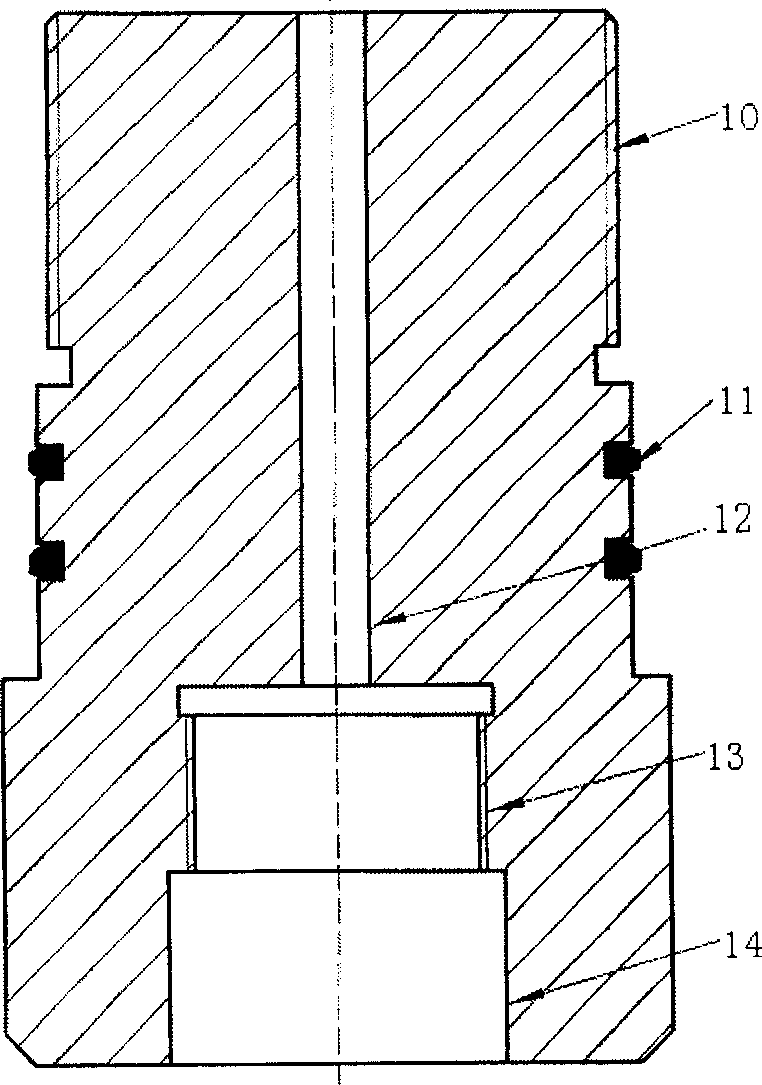

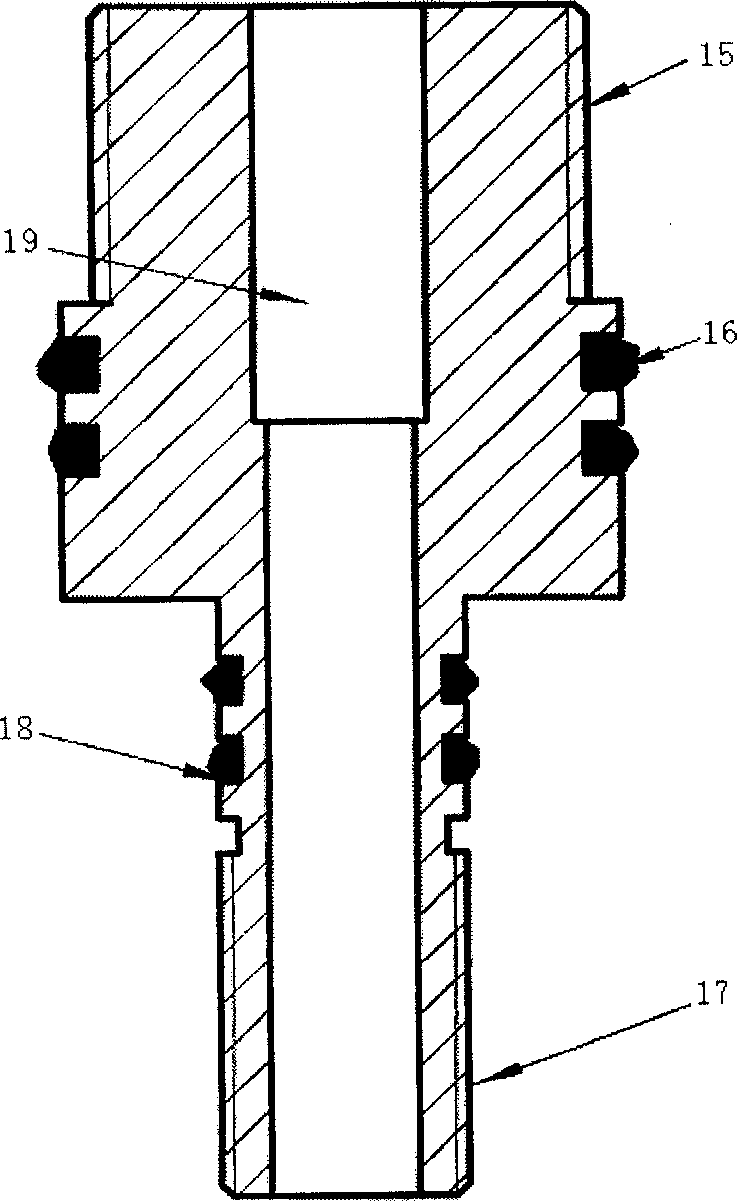

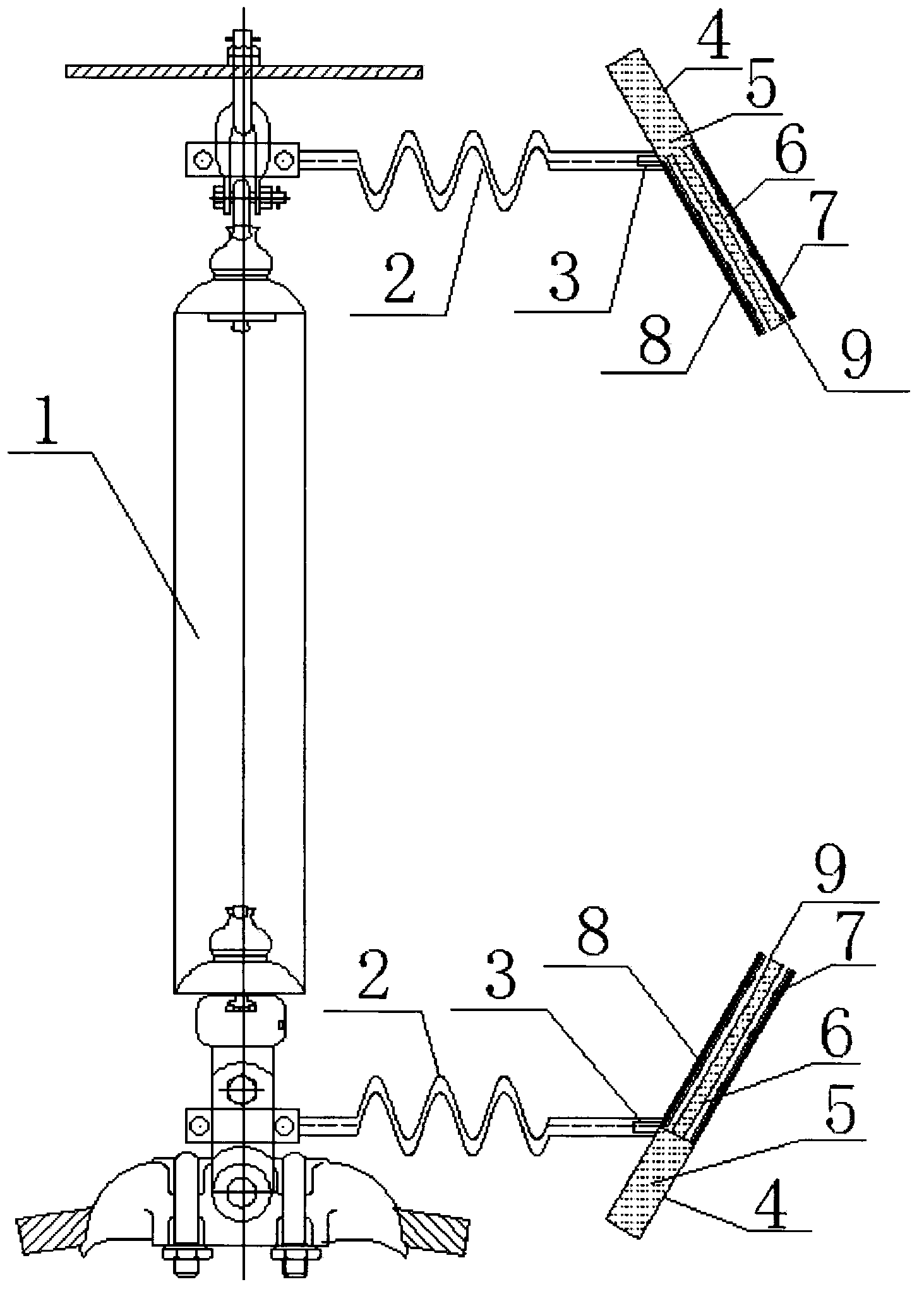

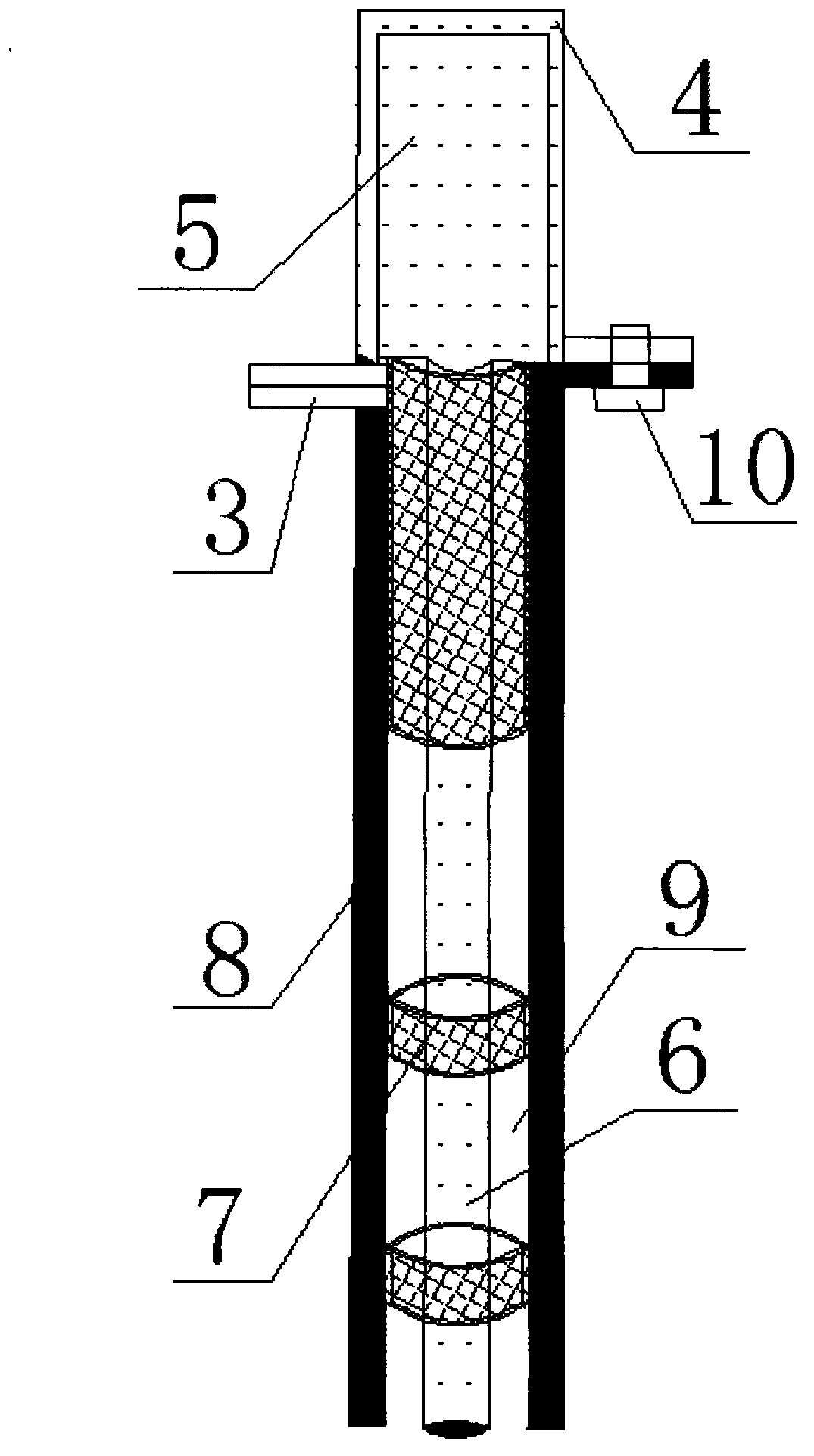

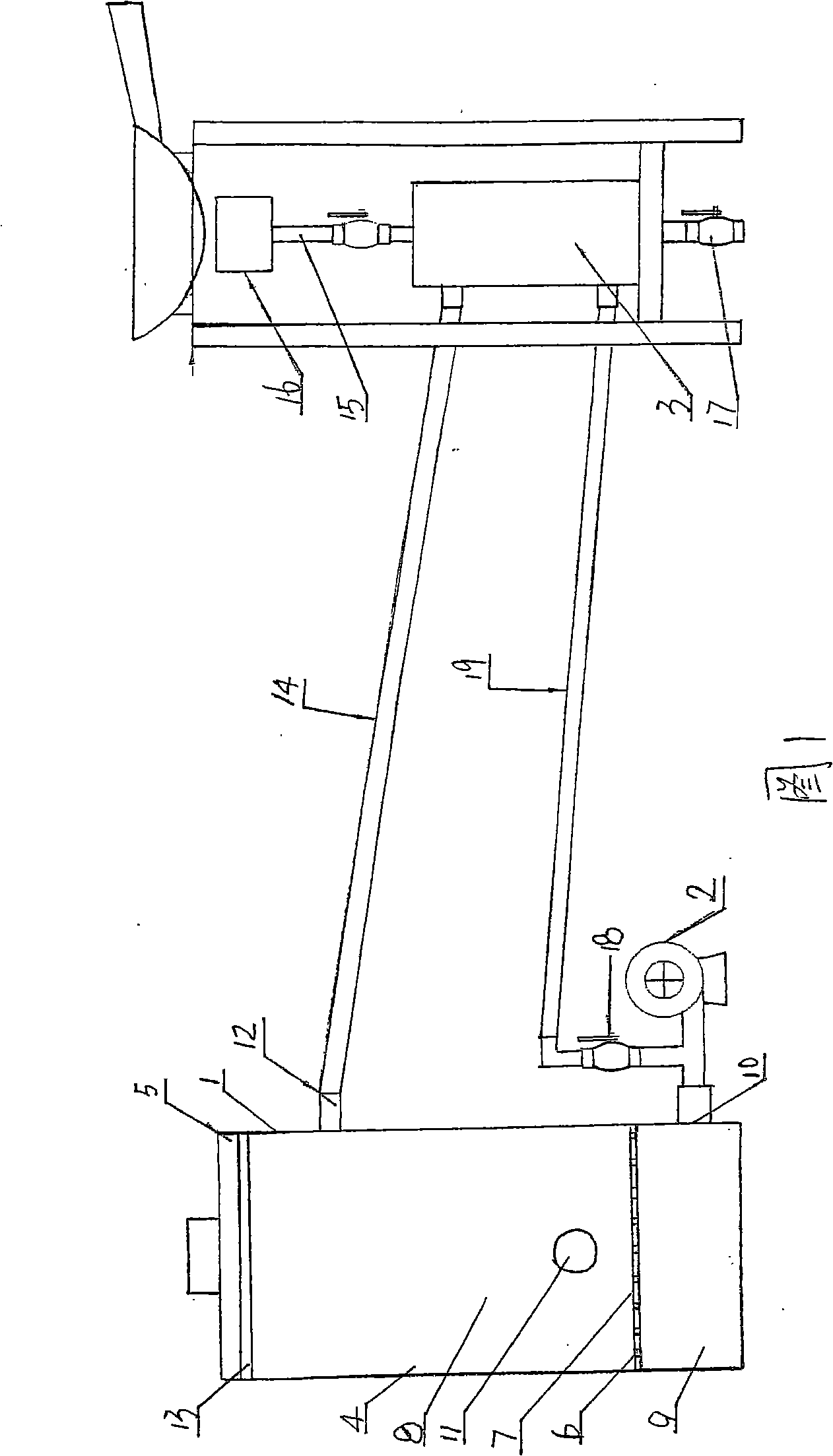

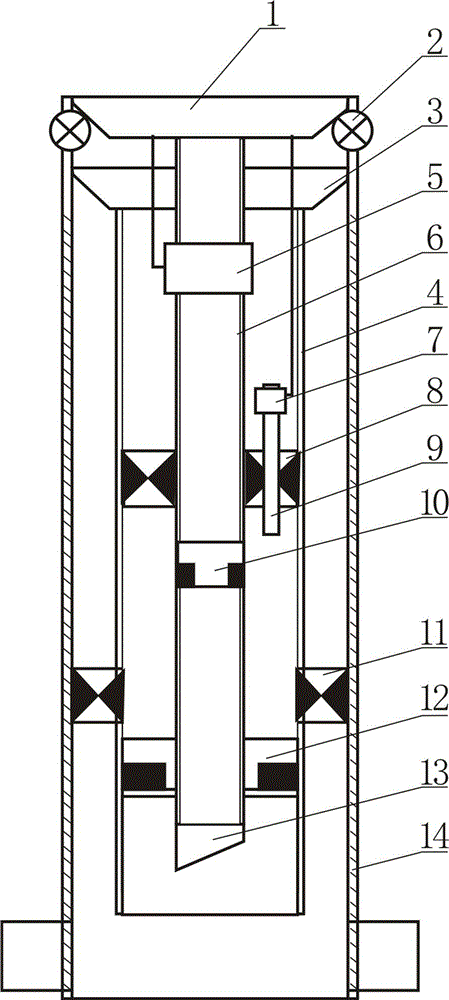

Concentric double-pipe gas well production pipe column

ActiveCN104879098AFast gas productionReduce environmental pollutionFluid removalDownhole safety valveButt joint

The invention discloses a concentric double-pipe gas well production pipe column. The pipe column comprises a casing pipe, a small oil pipe hanger, a small oil pipe four-way joint, a large oil pipe hanger, an outer pipe column, a downhole safety valve, an inner pipe column, an annulus downhole safety valve, a double-pipe packer, a small-diameter oil pipe nipple, a small working barrel, a single-pipe packer and a large working barrel, wherein the outer pipe column is hung in the casing pipe through the large oil pipe hanger, the casing pipe is packed by the single-pipe packer, and the large working barrel is butt-jointed on the outer pipe column; the small oil pipe four-way joint is arranged on an original four-way joint at the top of the casing pipe, the inner pipe column is sleeved with the outer pipe column and hung on the small oil pipe four-way joint through the small oil pipe hanger, the outer pipe column is packed by the double-pipe packer, the small working barrel is butt-jointed on the inner pipe column, the small-diameter oil pipe nipple is fixed on the double-pipe packer, the annulus downhole safety valve is arranged at the upper end of the small-diameter oil pipe nipple, and the downhole safety valve is butt-jointed on the inner pipe column. The pipe column has the characteristics that the gas producing rate is high, well repair is not required in the later period, the operating cost is reduced, and the environmental pollution is low.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Ignition device of environment-friendly and energy-saving biomass gasification furnace

InactiveCN101603693AAvoid pollutionEasy to start the ignitionIncandescent ignitionChemical industryElectricityEngineering

The invention discloses an ignition device of an environment-friendly and energy-saving biomass gasification furnace, which comprises a furnace body (1), an ignition opening (2), a buckle cover (3), an electric heating bar (4), an air inlet pipe (5) and a blower (6). The upper side of an ash cleaning opening on the bottom of the furnace body (1) is provided with the ignition opening (2), the buckle cover (3) is arranged on the ignition opening (2), the electric heating bar (4) is arranged in the ignition opening (2), the lower part in the furnace body (1) is provided with the air inlet pipe (5), and one end of the air inlet pipe (5) is connected with the blower (6). Because the furnace is provided with the ignition opening and the electric heating bar, the electric heating bar can be directly burned by electrification and then inserted into the ignition opening when the fire is extinguished and the furnace is restarted, the blower is started to blow for 15 minutes and then the electric heating bar is pulled out so as to conveniently ignite the fire and start the furnace; and the ignition device not only solves the problem of the pollution of initial ignition smoke, but also has quick air production speed, saves labor and time, is convenient to operate, and can meet the requirements of production and life.

Owner:席礼

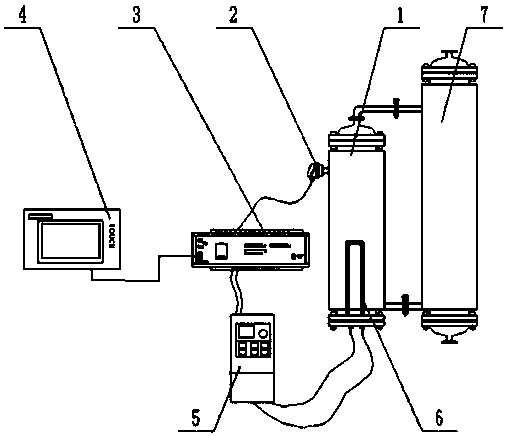

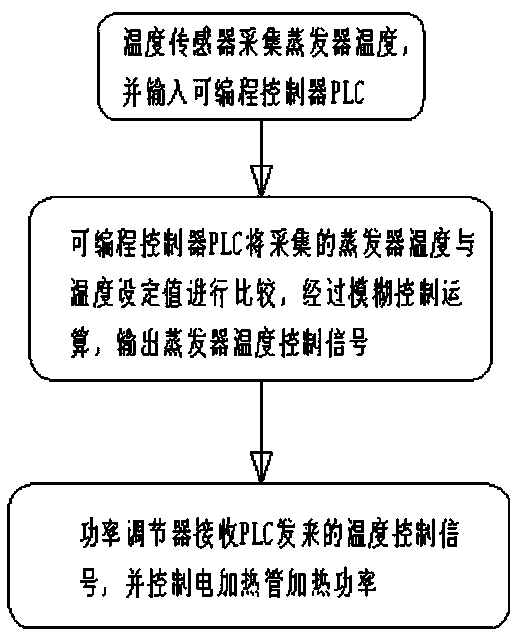

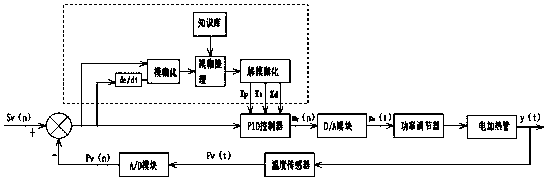

Electric heating pure steam generator based on fuzzy PID control

InactiveCN107608415AHigh precisionGood dynamic and steady state characteristicsTemperatue controlAdaptive controlControl signalEngineering

The invention discloses an electric heating pure steam generator based on fuzzy PID control. The electric heating pure steam generator comprises an evaporator, a temperature sensor, a programmable logic controller (PLC), a touch screen, a power regulator, an electric heating pipe and a separator. The PLC collects the temperature from the evaporator through the temperature sensor, compares the temperature with a temperature set value, and obtains a temperature control signal through a fuzzy control operation. The touch screen can set the initial temperature and display the corresponding temperature setting, actual evaporator temperature and operation status relevant information of the electric heating pipe. The power regulator can receive a power regulation control signal sent by the PLC and regulate the heating power of the electric heating pipe. The electric heating pure steam generator in the invention has the characteristics of quick reaction control and strong adaptability, a regulation system is ensured to have good dynamic and steady state characteristics, the anti-interference performance is good and the robustness is remarkably enhanced.

Owner:XIANGTAN UNIV

Macromolecule nonmetal energy oil unstressed container mixed fuel-electricity integrated pulse steam equipment

InactiveCN107965751AIncrease the heating areaExchange evenlyPulsating combustionSteam boilersElectricityDouble tube

The invention provides a high-molecular non-metallic energy oil pressureless container mixed fuel-electricity integrated pulsating steam equipment, including a base and an air mixing box, an oil cylinder is arranged on the base, a pulsating evaporator is arranged inside the oil cylinder, and the pulsating The evaporator includes a pulsating evaporator interlayer outer tube, a double-layer pipe valve flange connector and a porous pulsating core tube. The porous pulsating core tube is provided with porous pulsating water inlet core tube holes, and the interlayer outer tube of the pulsating evaporator is provided with The high temperature and high pressure heating tube of the pulsating evaporator, the oil cylinder is provided with a communication pipe, the other end of the communication pipe is connected to the air mixing box, the mixing box is provided with air holes, and the oil cylinder is provided with a high temperature and high pressure compressor Sports machine, the polymer non-metallic energy oil non-pressure container hybrid fuel-electricity integrated pulsating steam equipment has a reasonable structure, low energy consumption and high thermal efficiency, and is suitable for various types of steam-using units in enterprises and institutions.

Owner:程洪亮 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com