Patents

Literature

977 results about "Steam engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force is transformed, by a connecting rod and flywheel, into rotational force for work. The term "steam engine" is generally applied only to reciprocating engines as just described, not to the steam turbine.

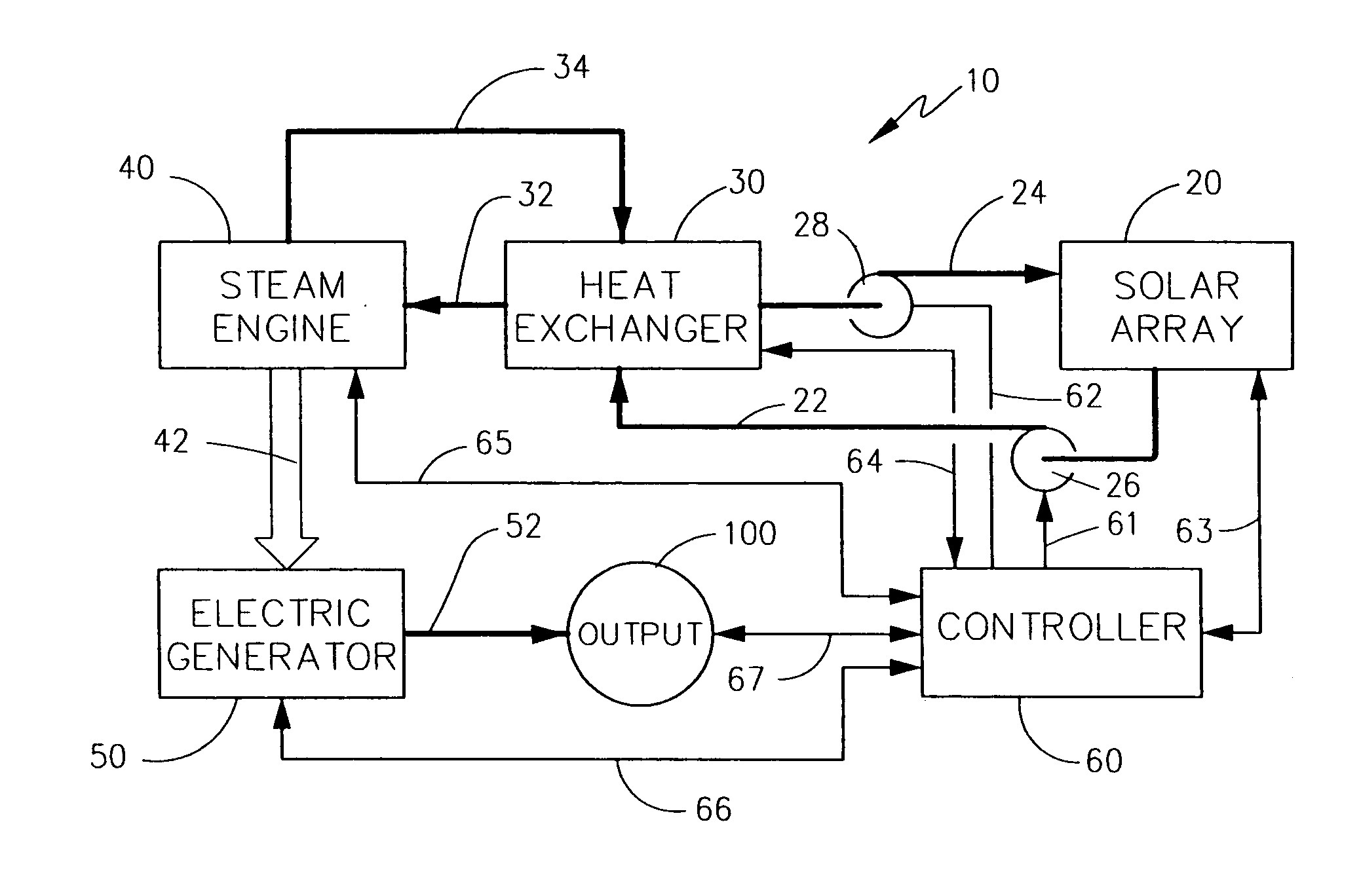

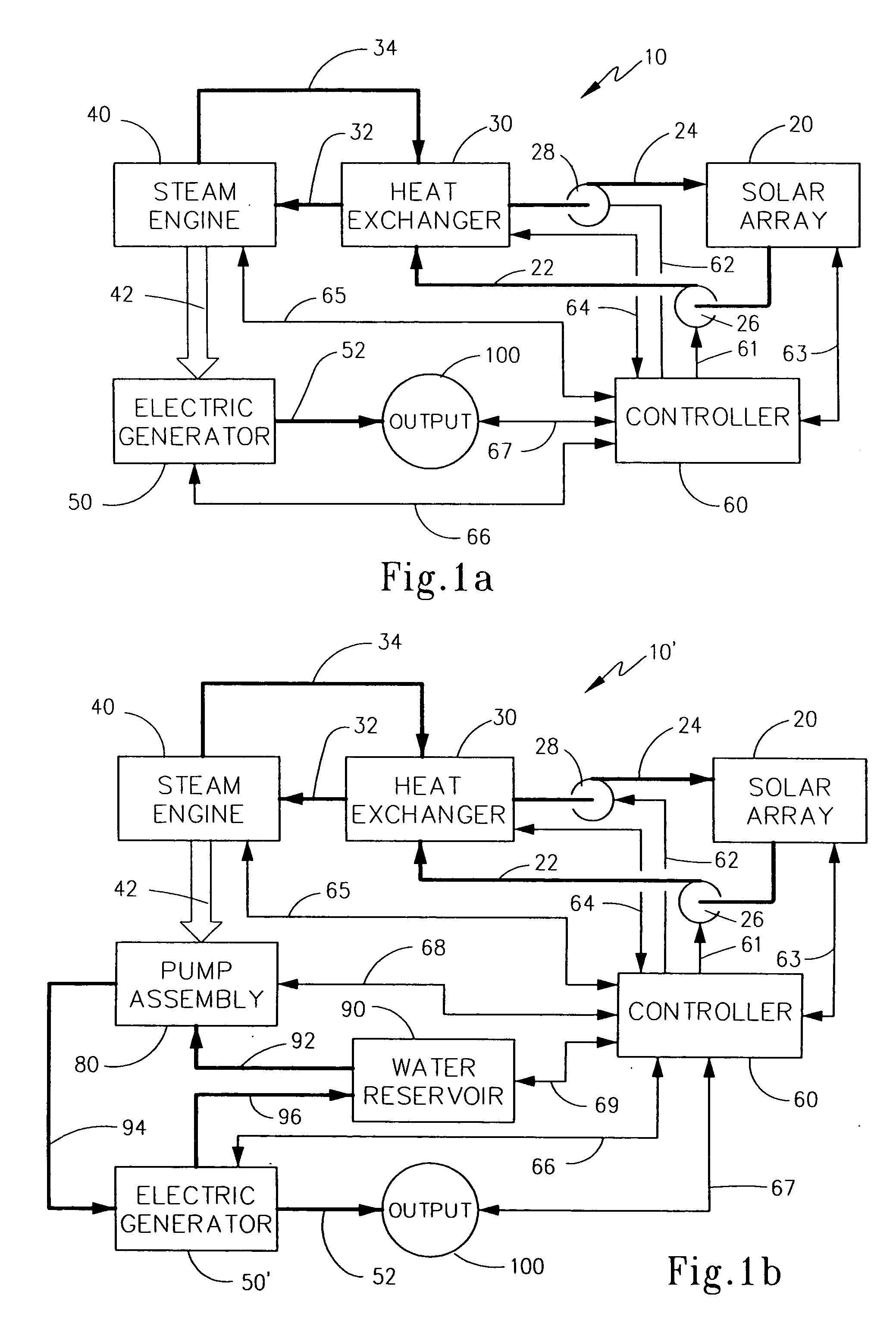

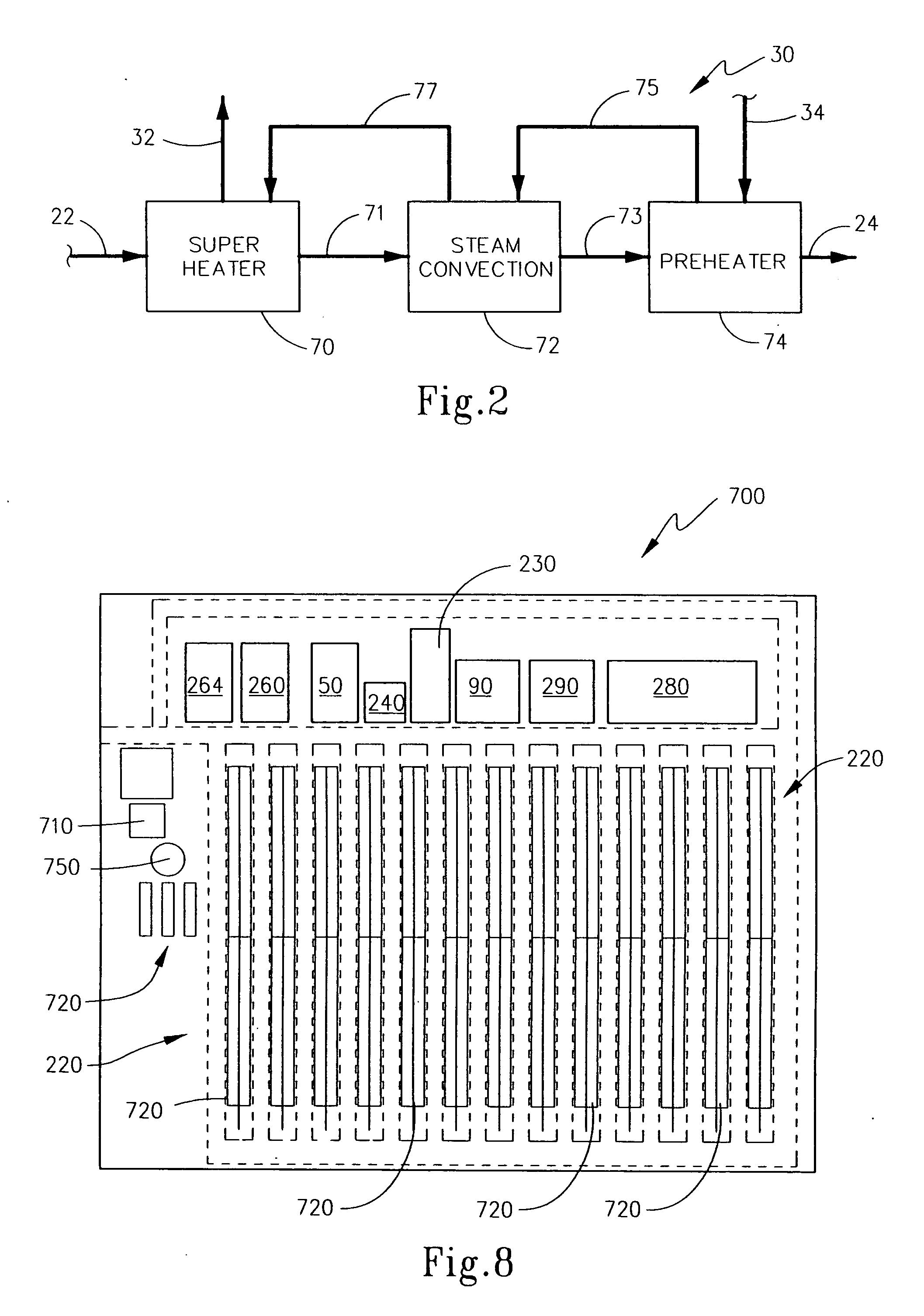

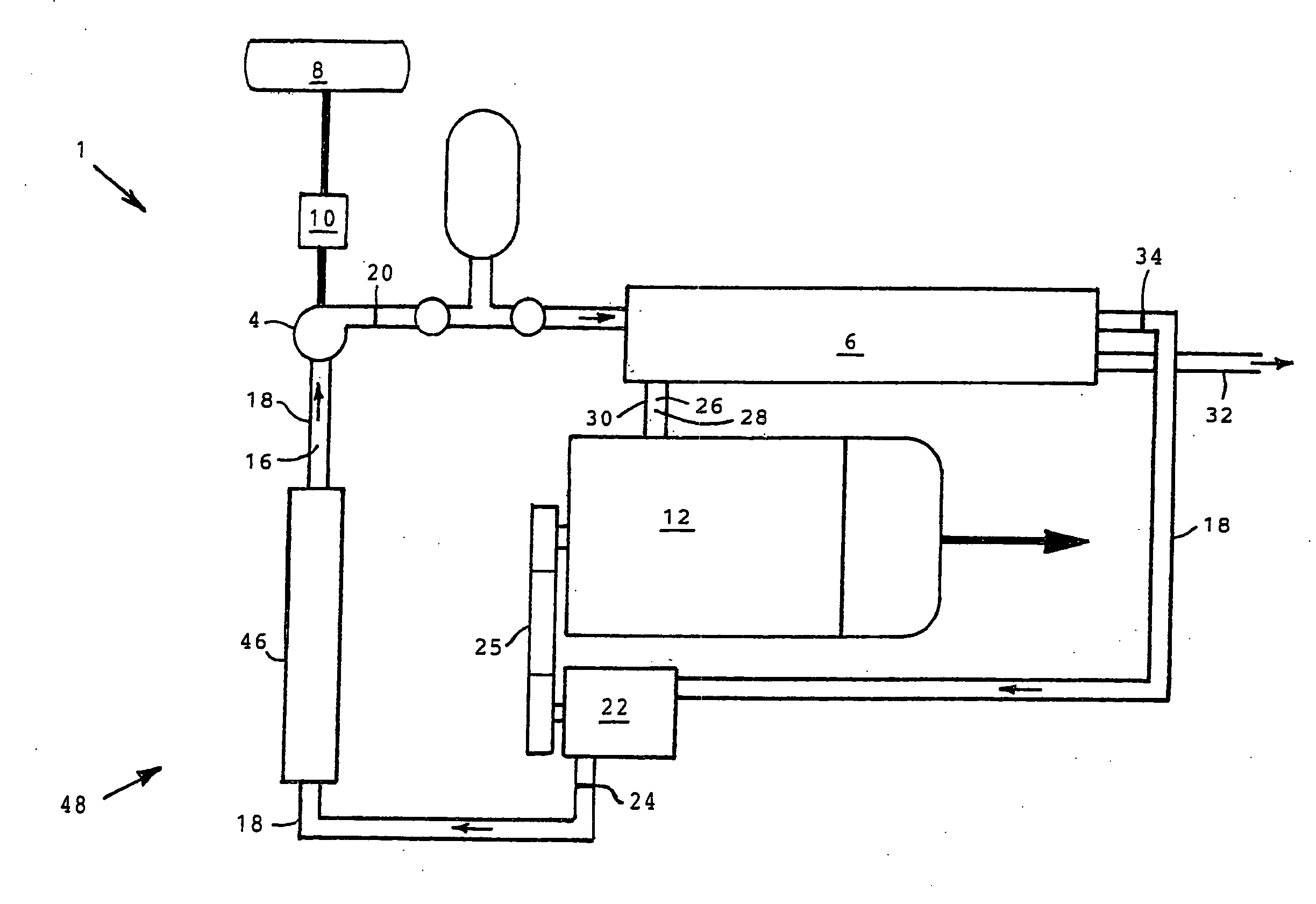

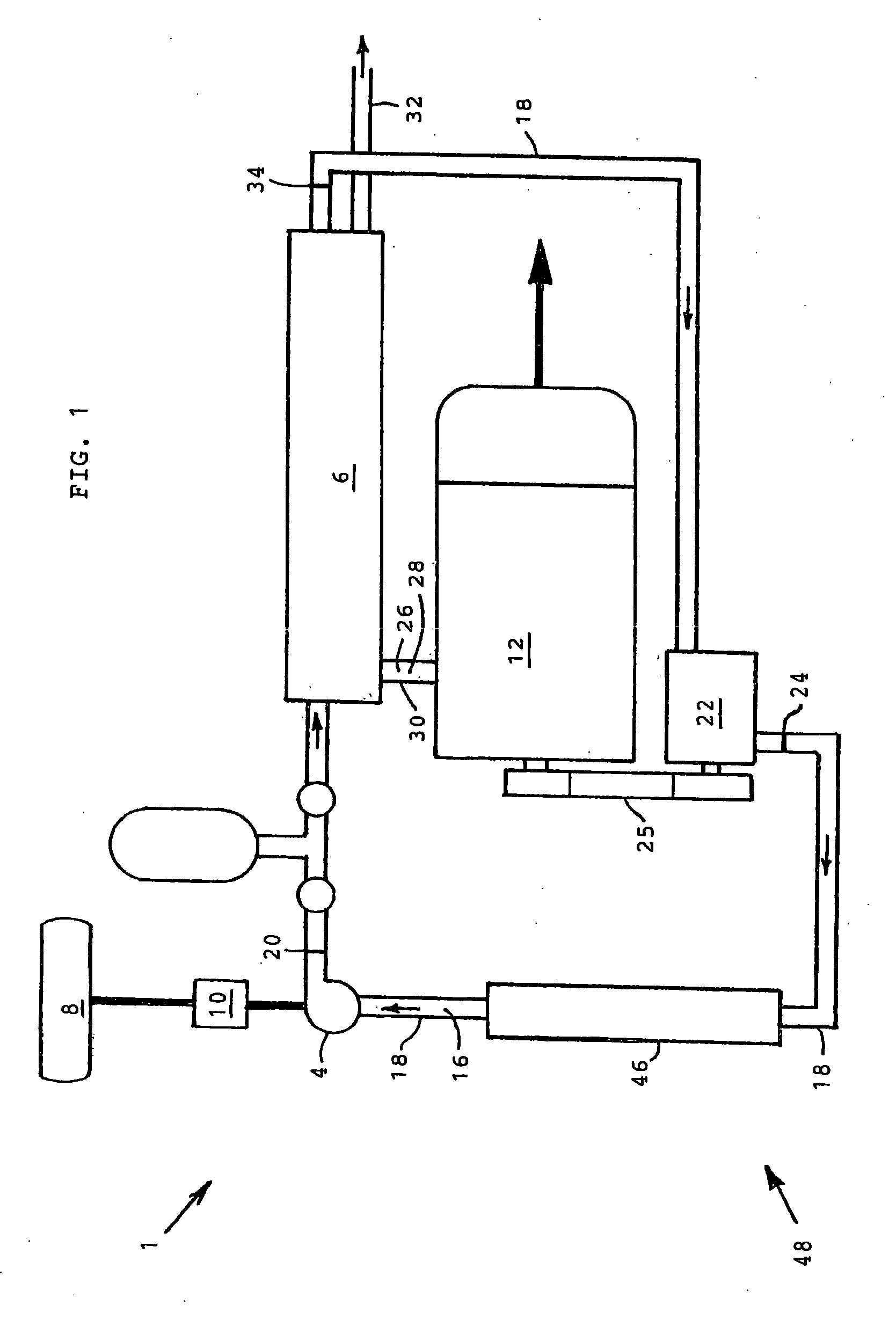

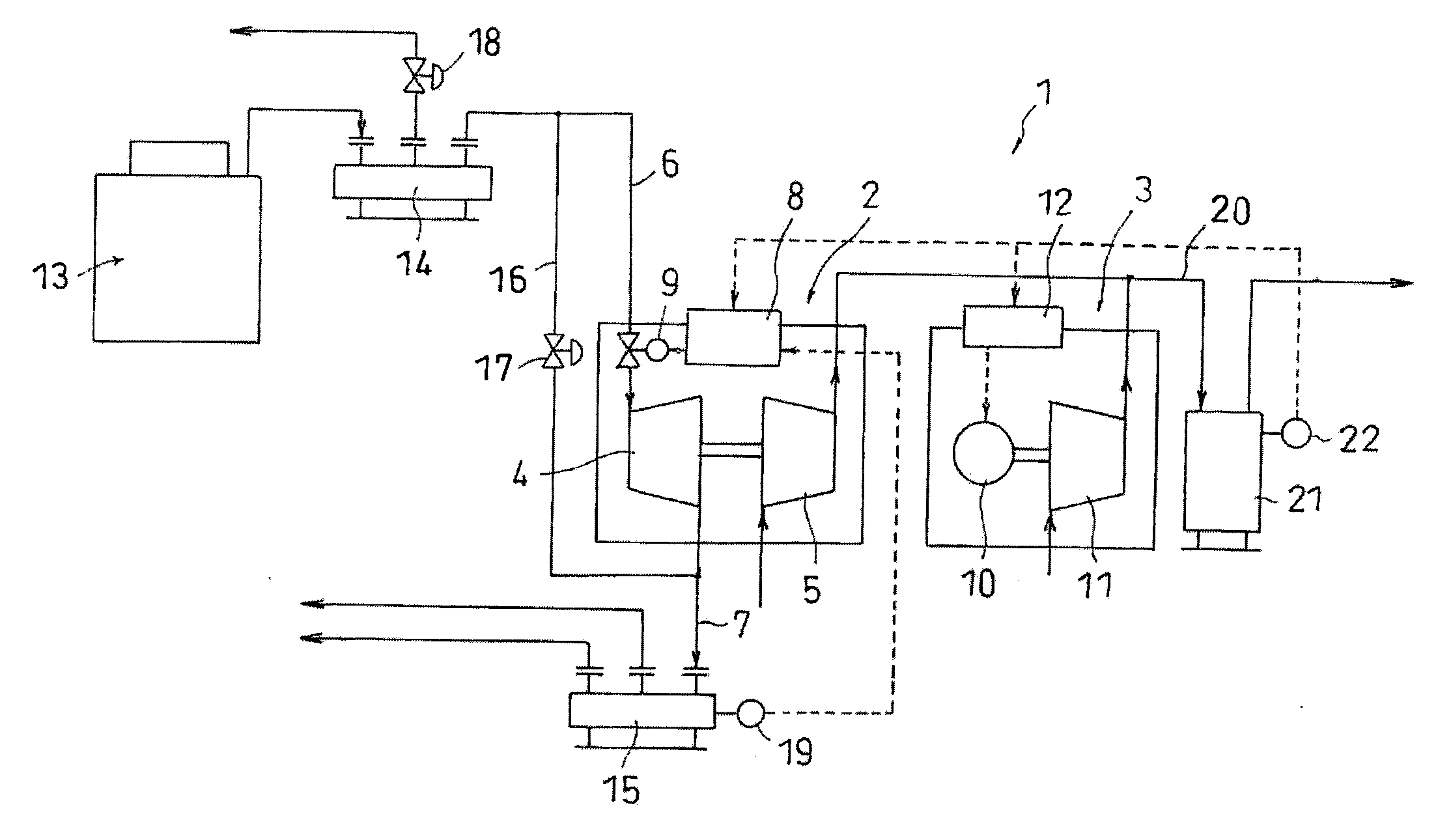

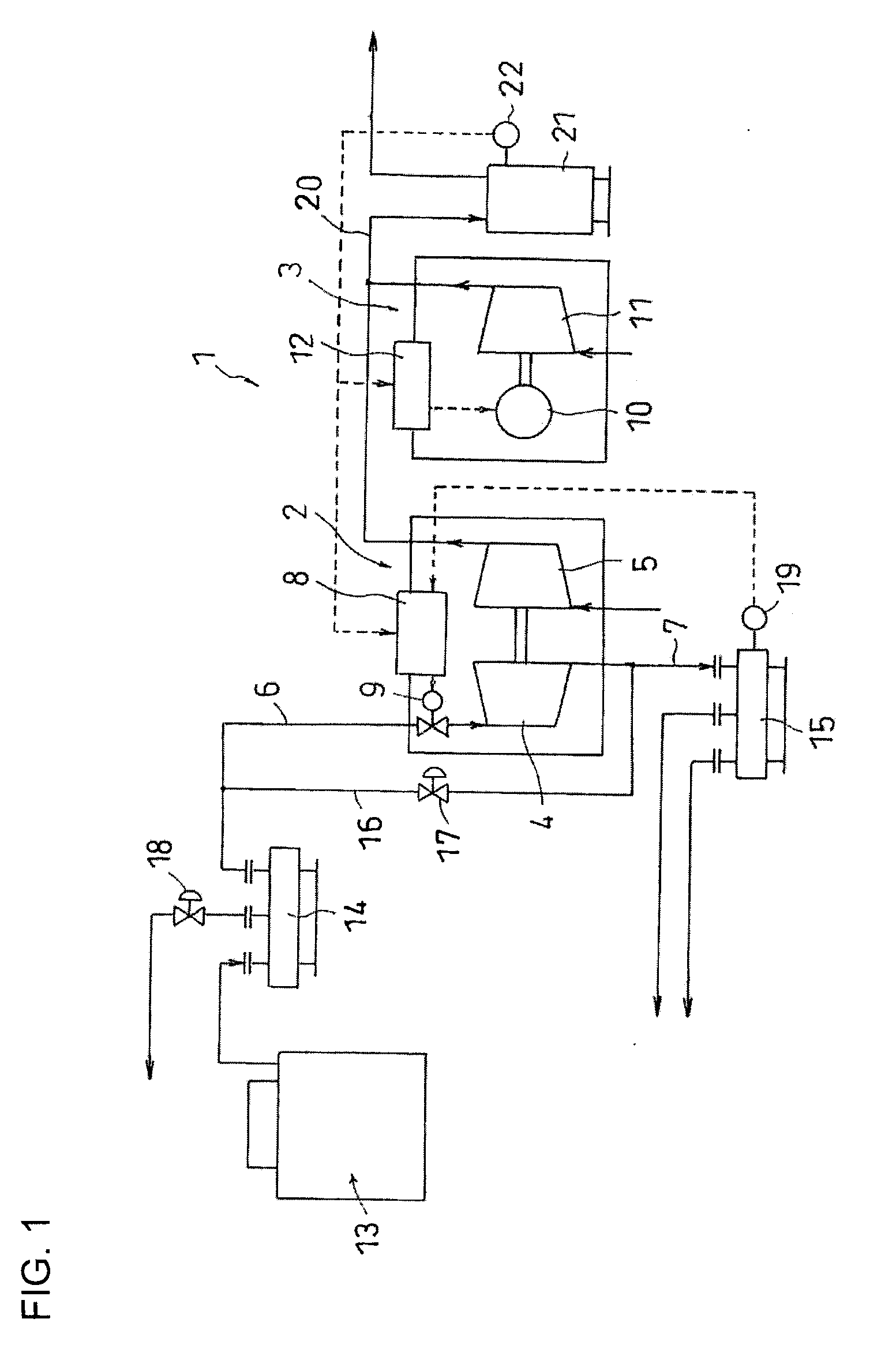

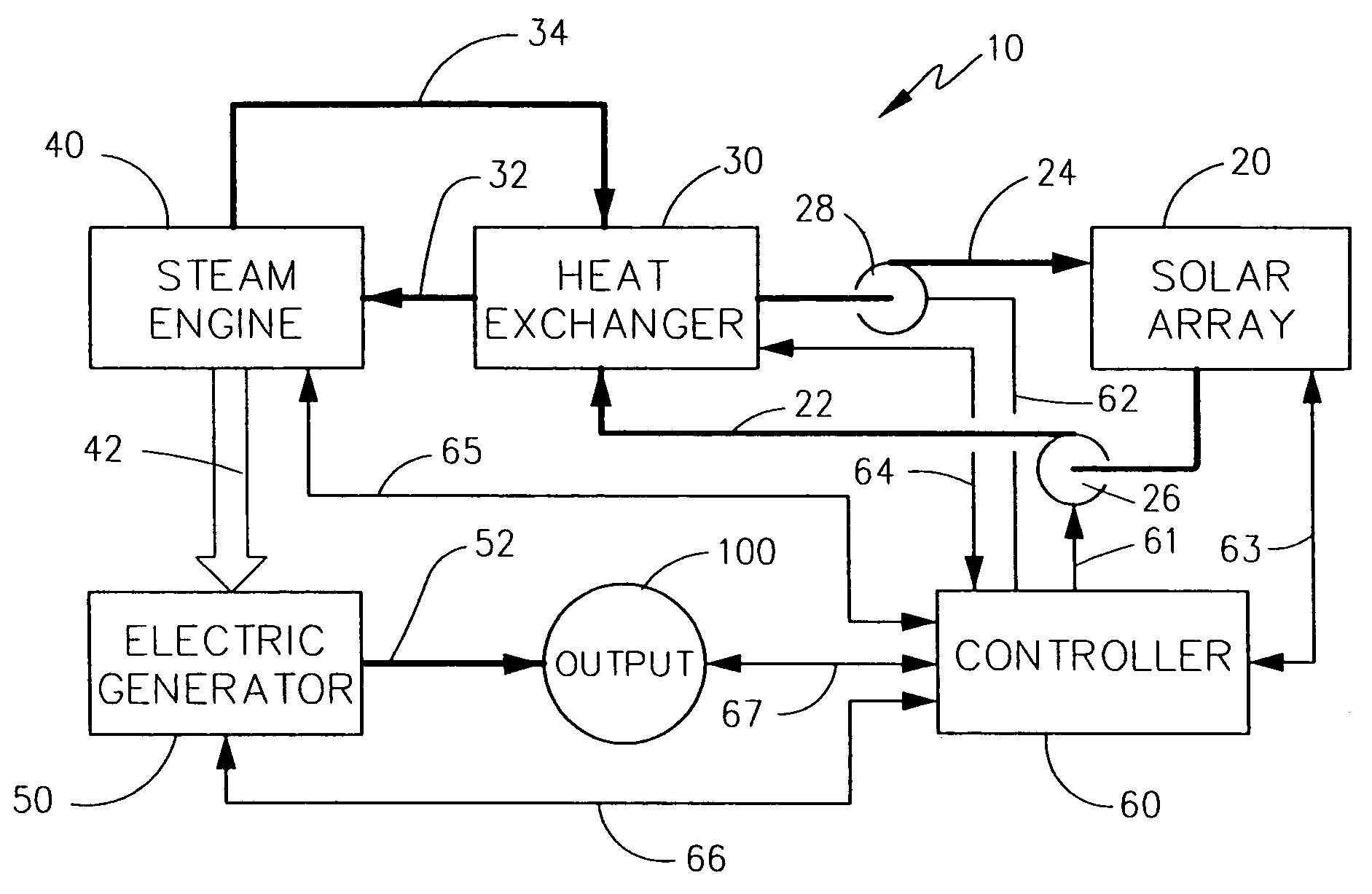

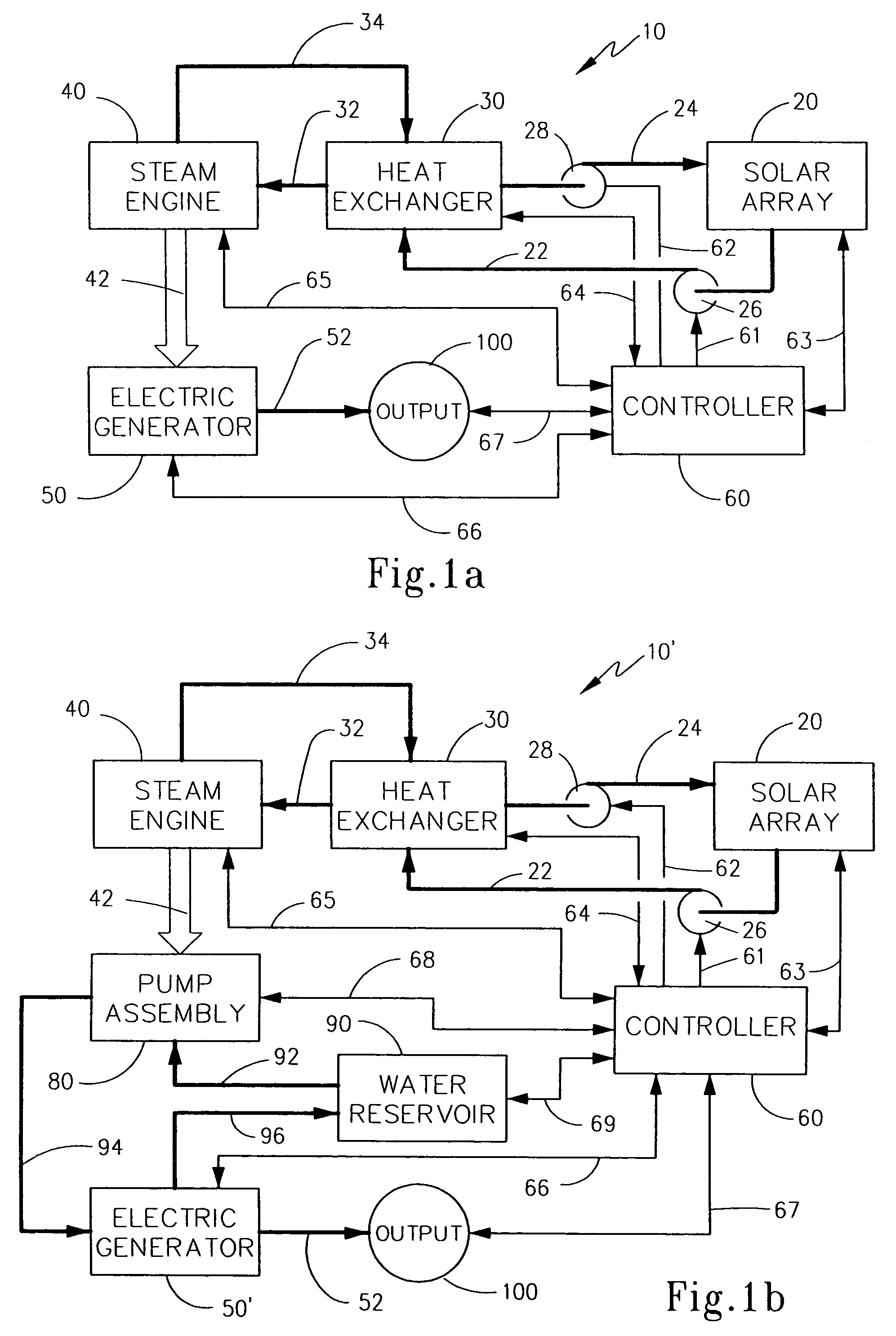

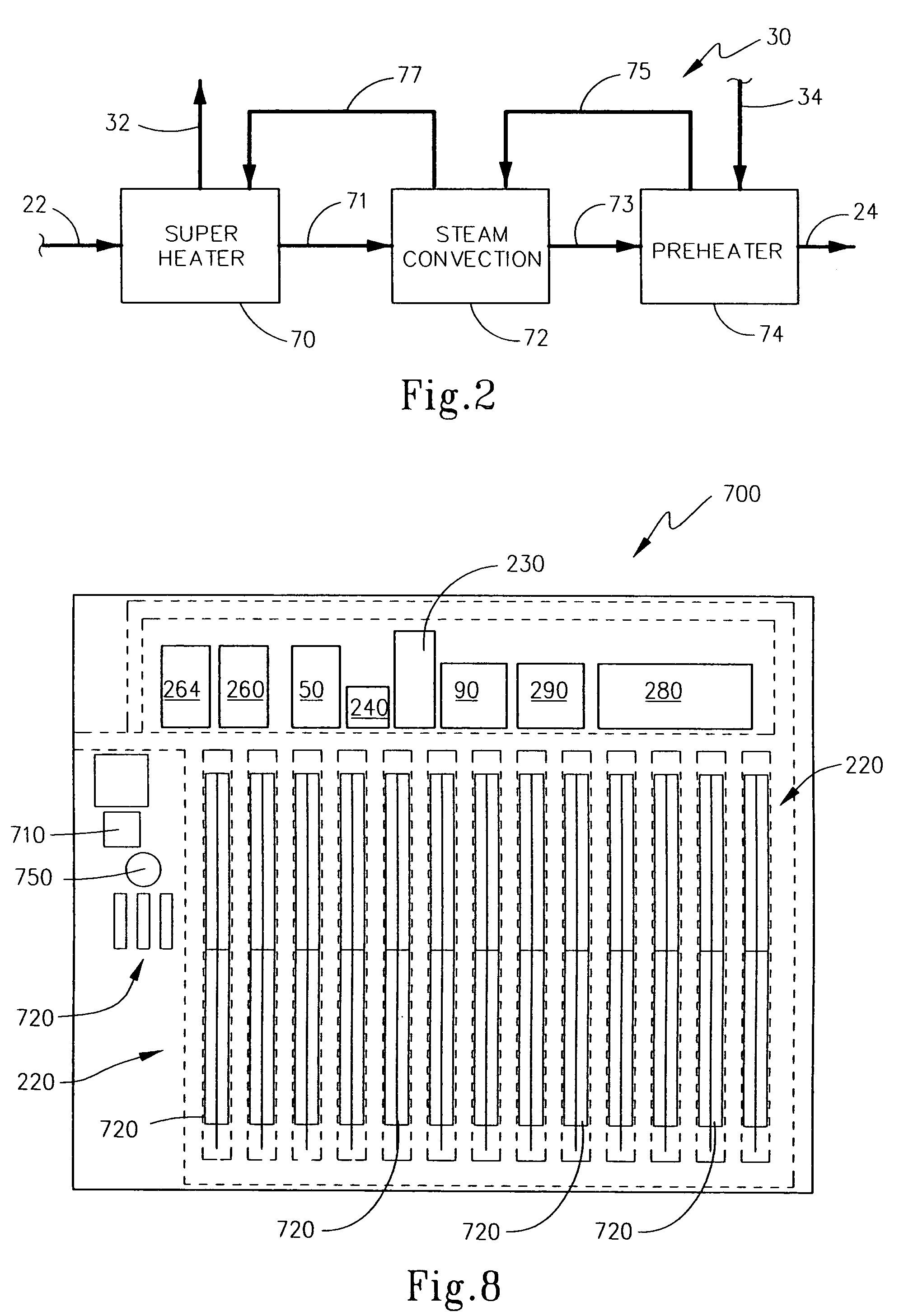

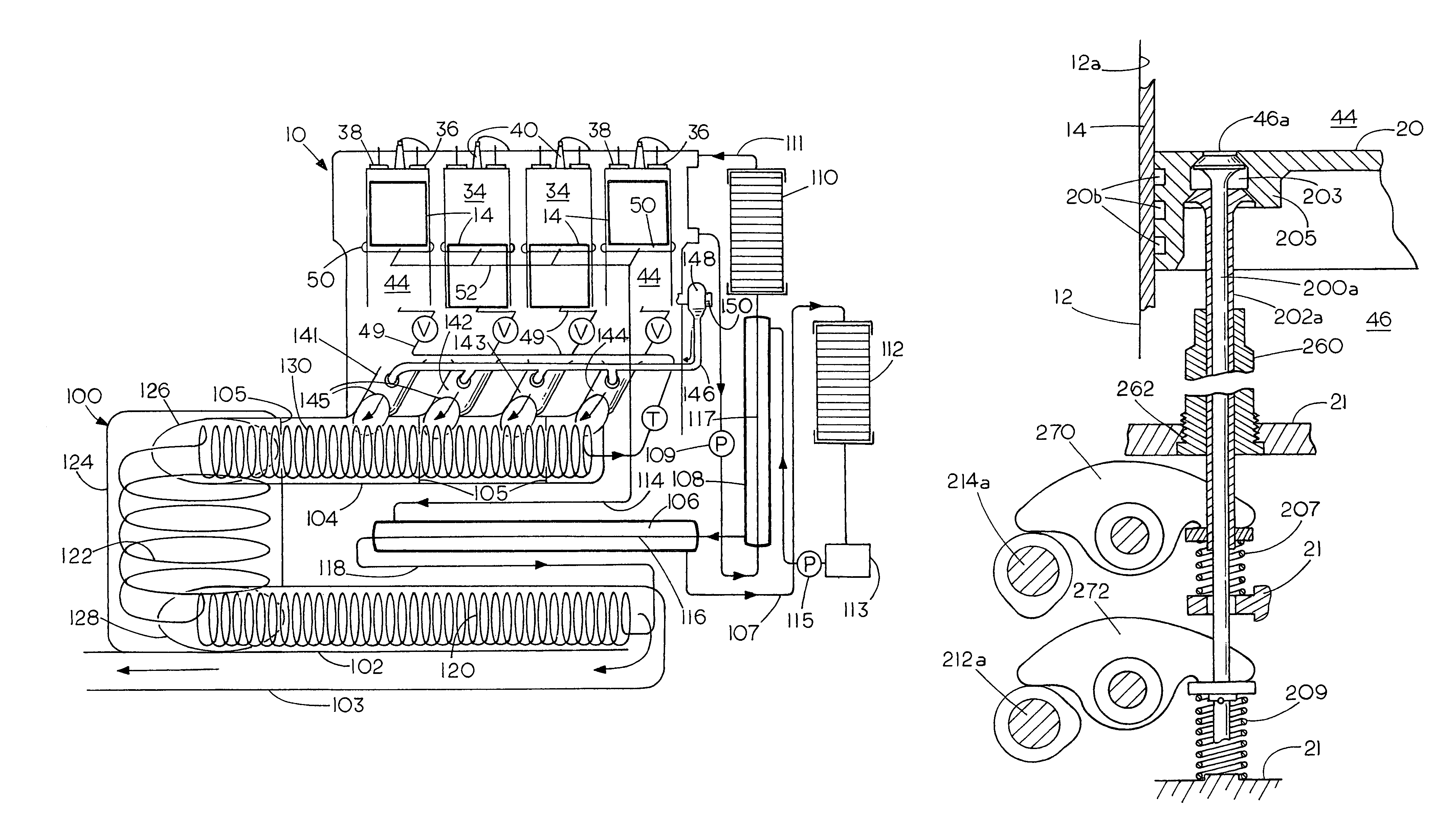

Electric generation facility and method employing solar technology

An electric generation station employs a solar array to heat a thermal transfer fluid that is supplied to a heat exchanger to produce steam. The heated steam drives a steam engine that operates either an electric generator to produce electricity or a pump assembly. The pump assembly can pump water to an elevated location for use during peak times by flowing water downwardly past an electric generator. The electric generators can be pelton turbines. One or more thermal fluid storage facilities can be used to store heated fluid, and heat may also be stored in a heat retaining material. Additional optional features and combinations of optional assemblies are disclosed. A method of generating electricity with these systems is also described.

Owner:POWERSTREAMS

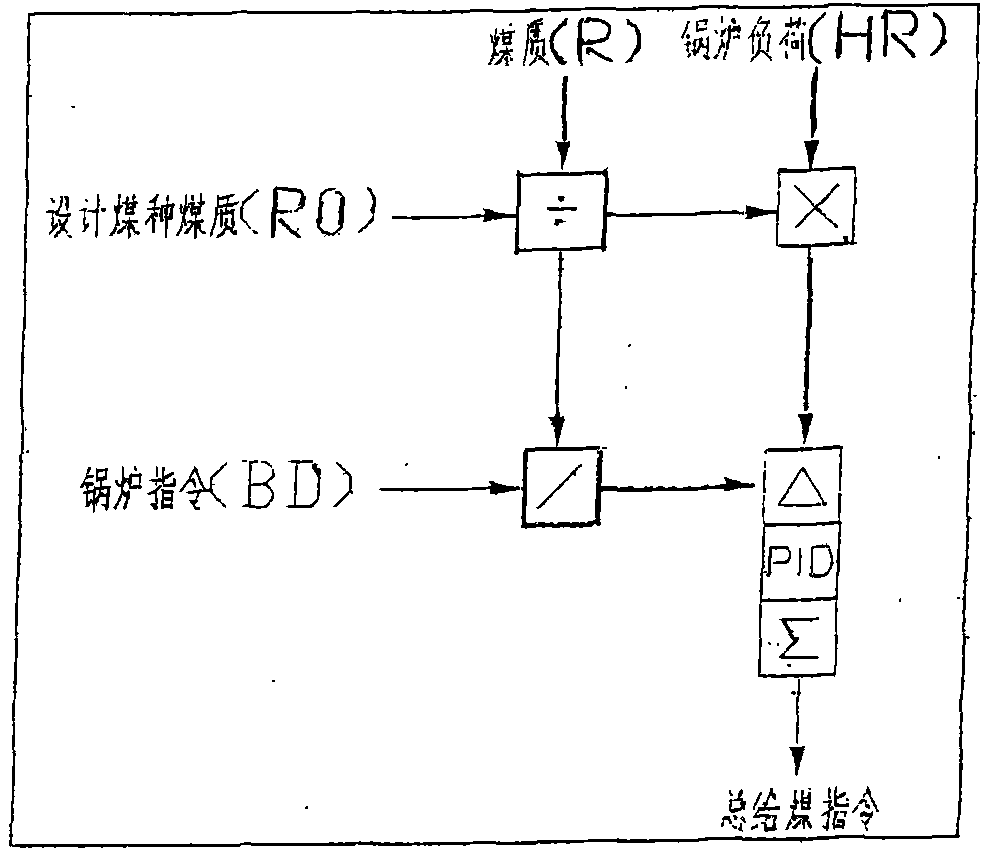

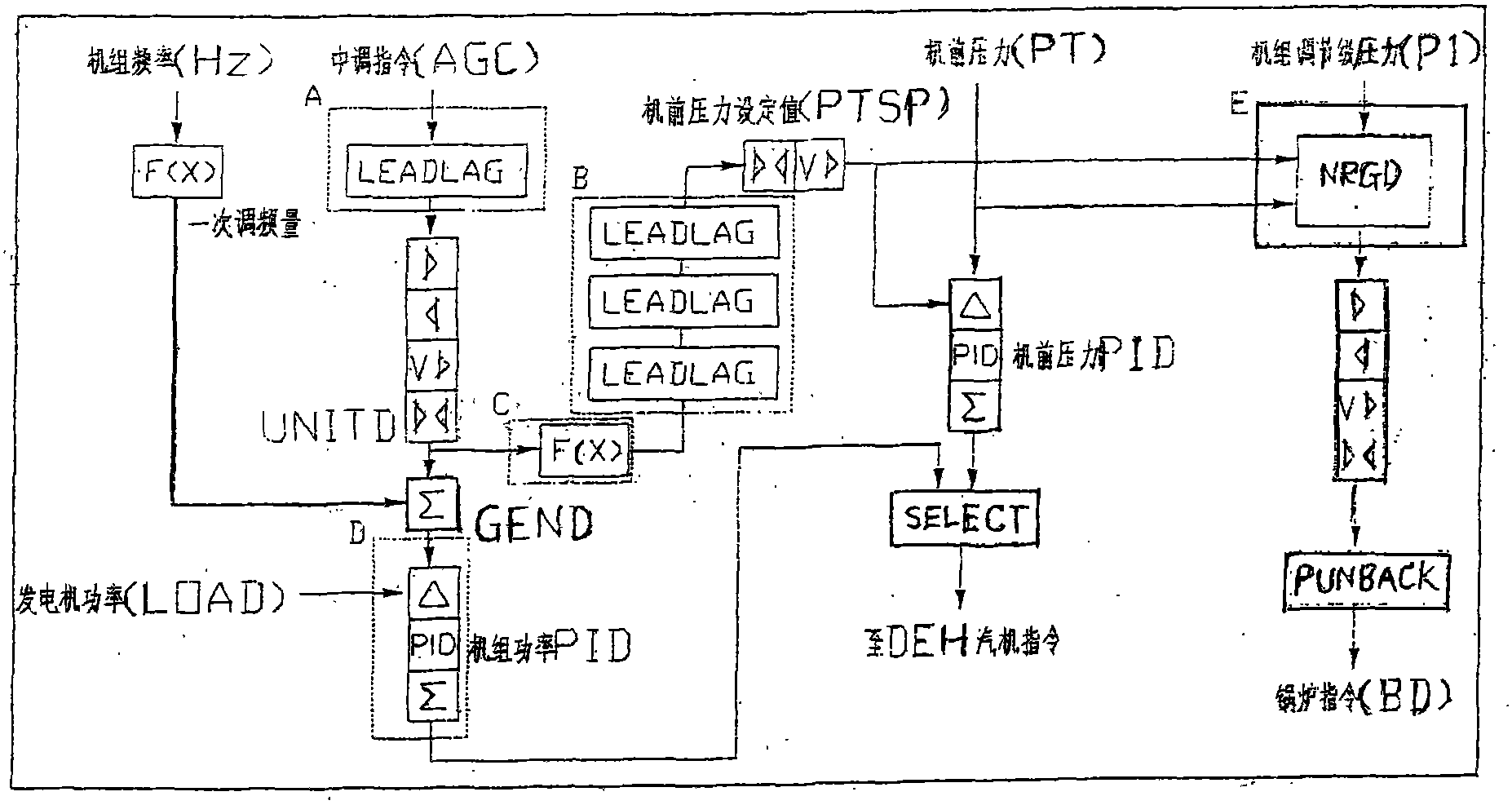

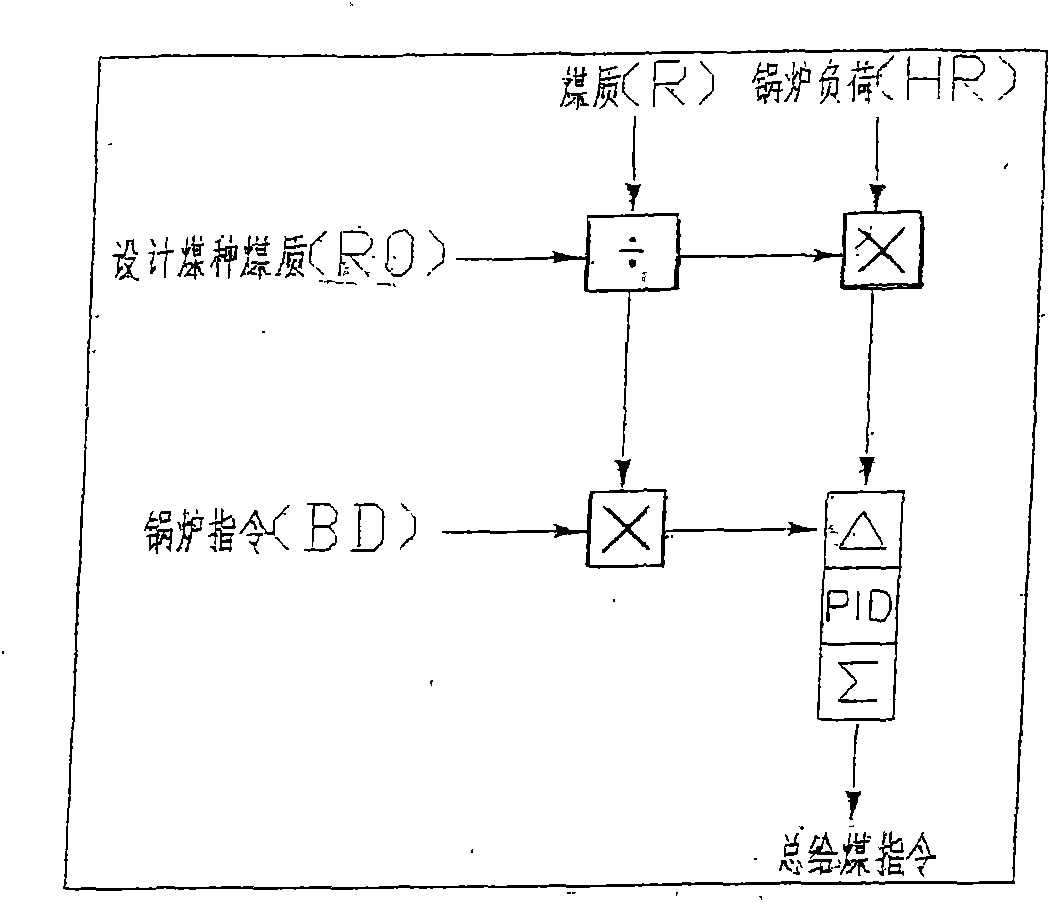

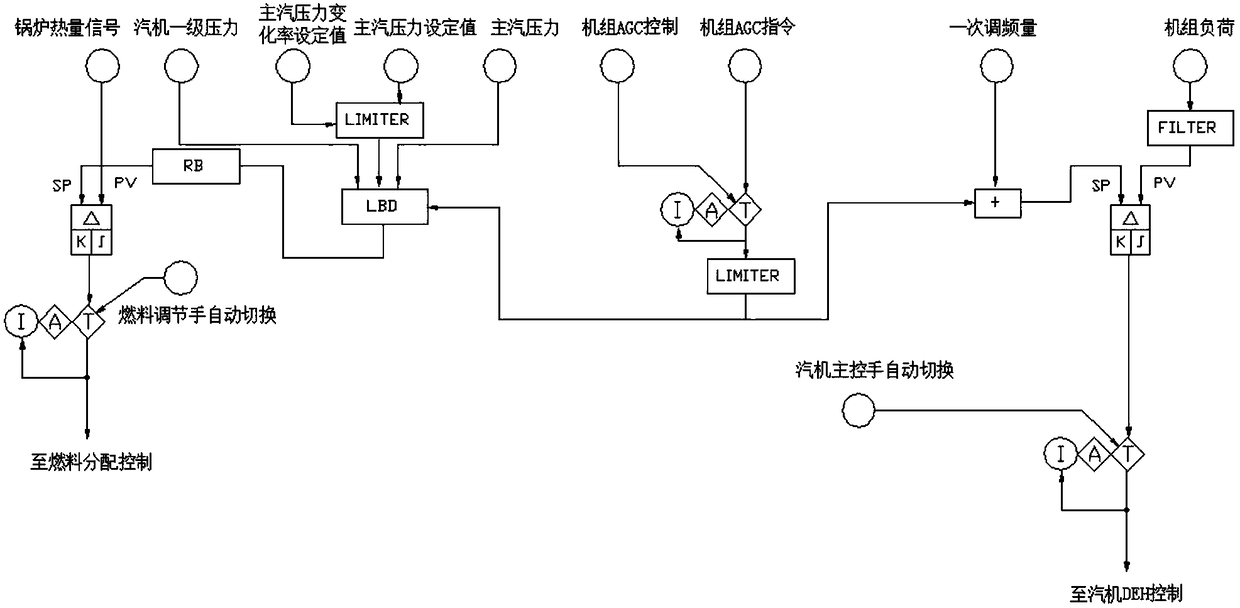

Control method for coordination and automatic power generation of coal quality self-adaptive thermal power generating unit

InactiveCN101788155AEnsure coordinationGuaranteed AGC control indicatorsFuel supply regulationSteam pressureAir volume

The invention provides a control method for coordination and automatic power generation of a coal quality self-adaptive thermal power generating unit. The method comprises the following steps of: 1, compressively determining the coal quality according to parameters including first-level pressure of a steam engine, drum pressure, coal feed, unit load and the like; 2, by the determined coal quality, performing the coal quality self-adaptive control over main control systems of fuel, coordination, air delivery and the like; 3, by core control strategies of boiler load commands, main steam pressure settings, a coal quality self-checking positive load upper limit and the like, realizing the control over the coal quality self-adaptive coordination and automatic power generation of the thermal power generating unit; and 4, realizing the automatic safe operation of the thermal power generating unit by improving safety locking conditions of the thermal power generating unit. The method has the following obviously advantages that: under a fluctuating condition of the coal quality of the thermal power generating unit, the automatic power generation and the coordination control of the thermal power generating unit are unnecessarily intervened by people, and the scheduling requirements are still met; and compared with the conventional control method, the control method of the invention has the advantages that: the accuracies of the main controlled parameters of the thermal power generating unit are further improved; and simultaneously, the automatic power generation control indexes and the safety and the economy of the thermal power generating unit are enhanced.

Owner:云南电力试验研究院(集团)有限公司

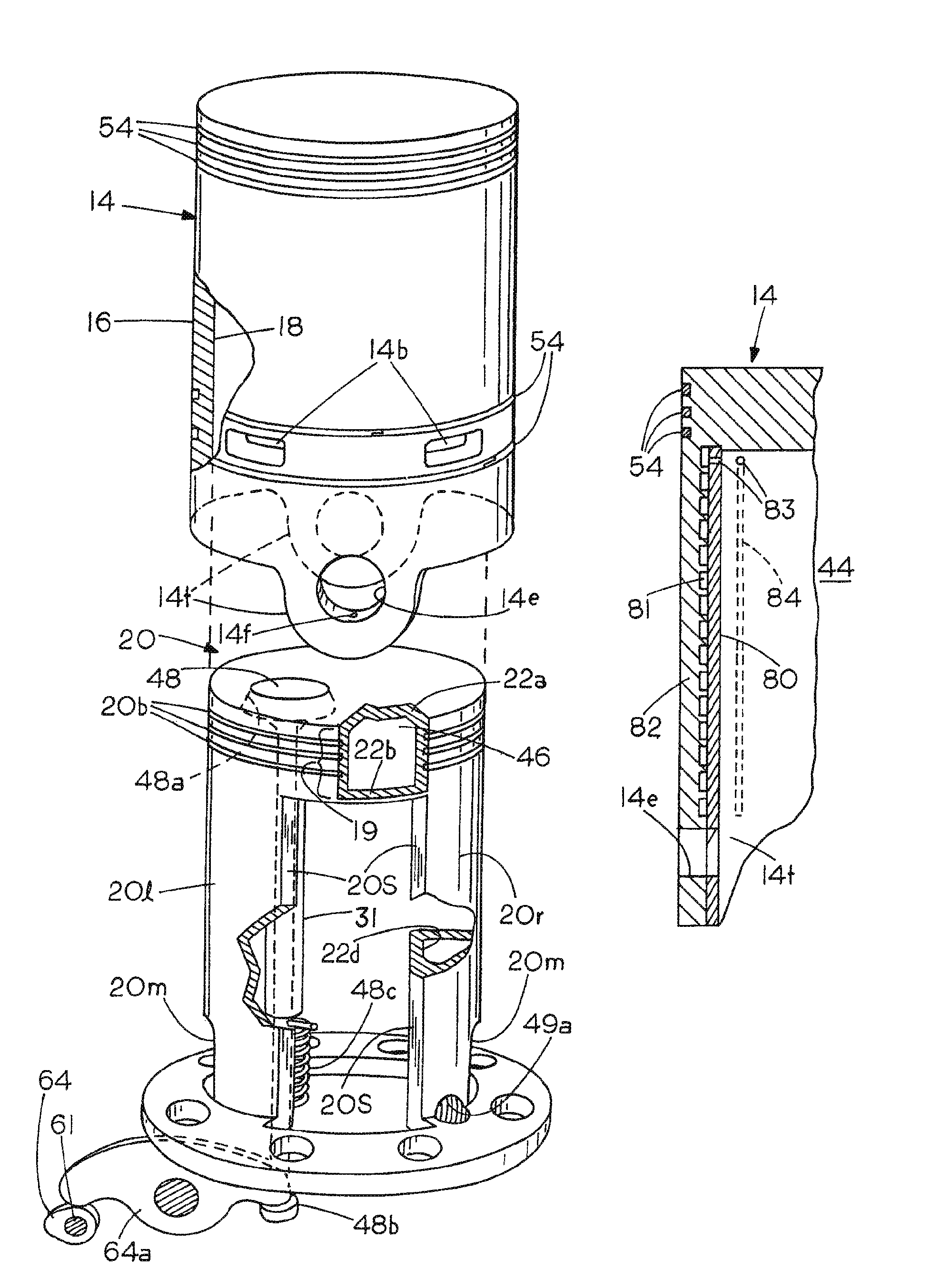

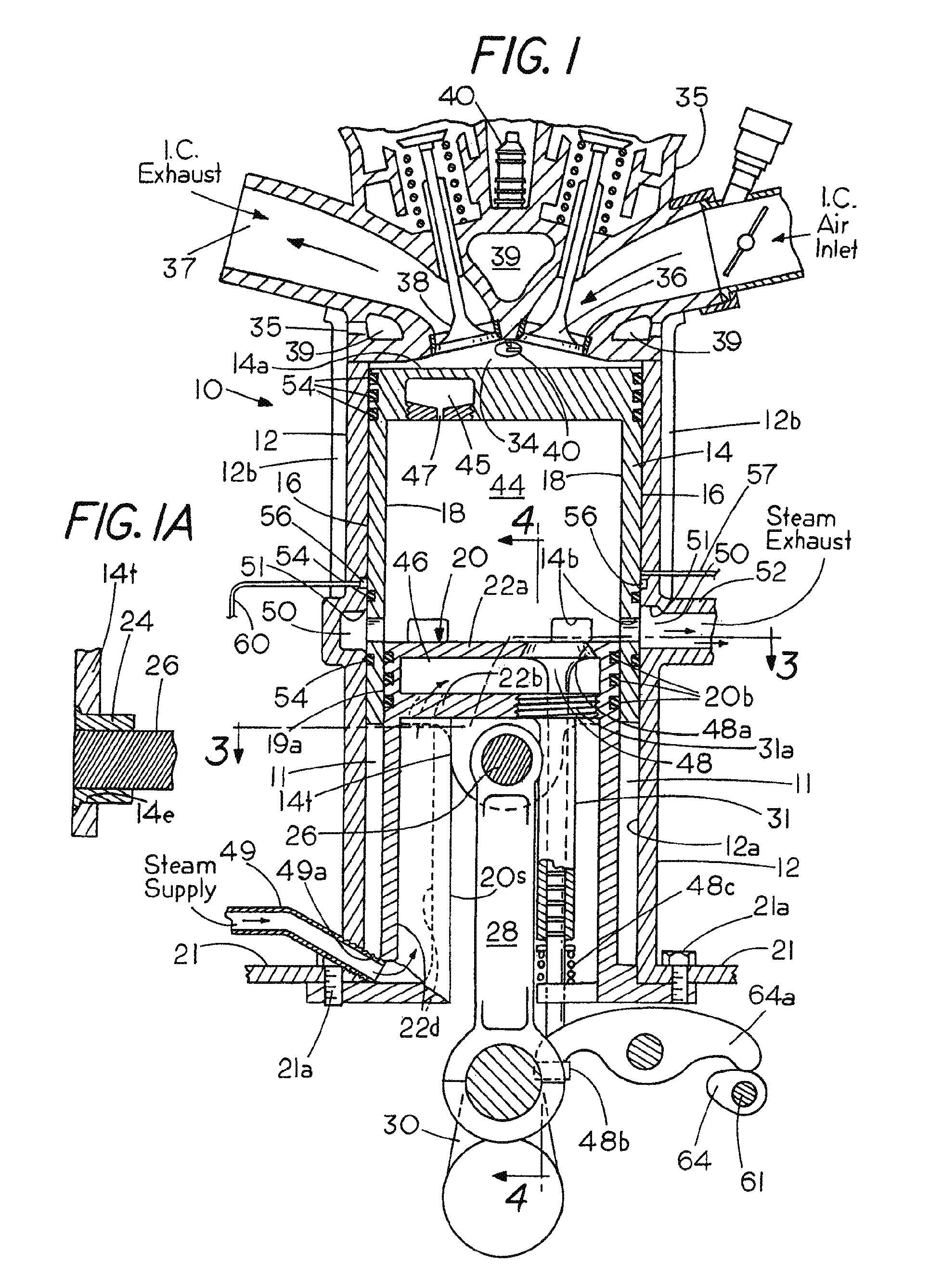

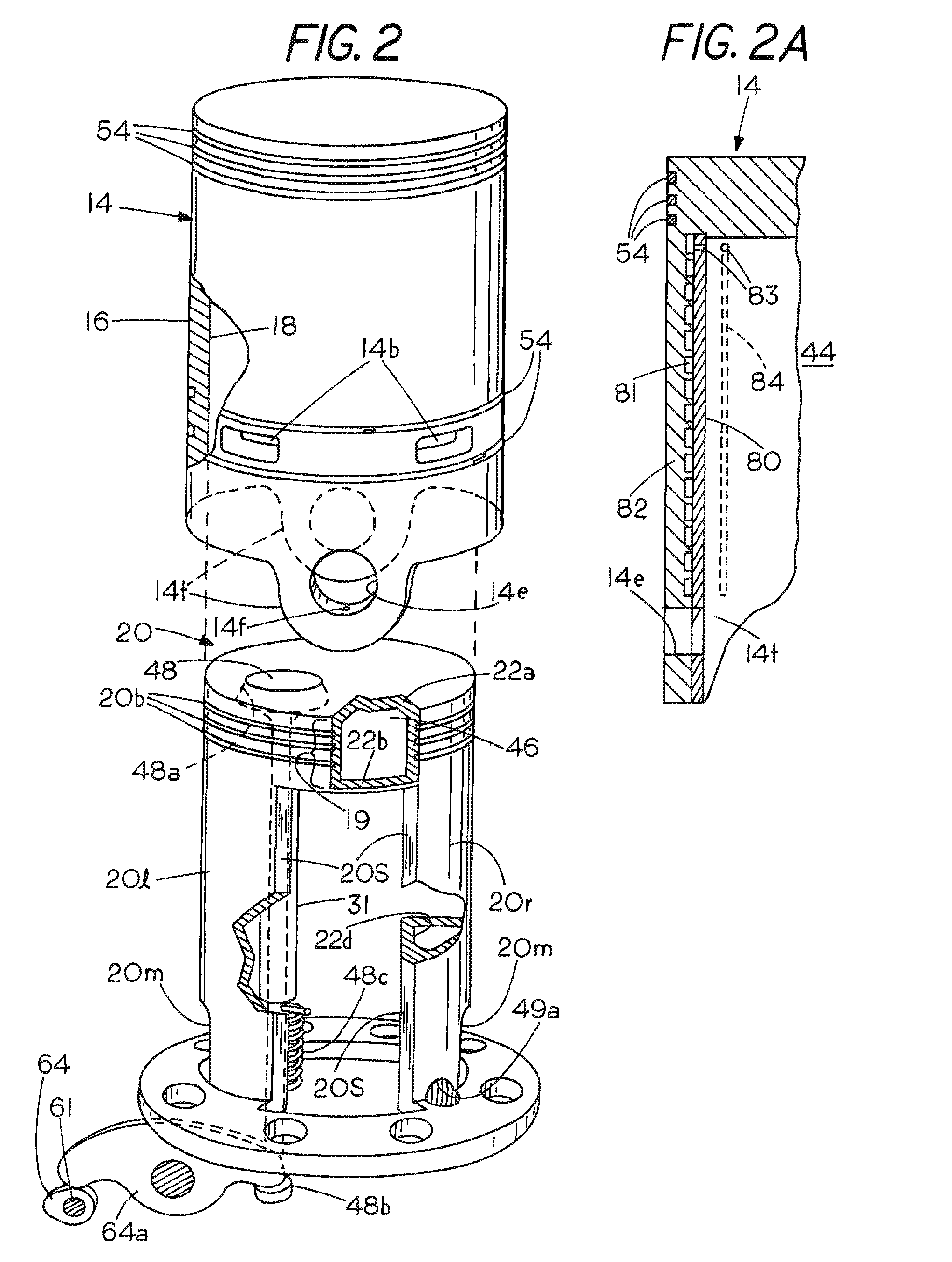

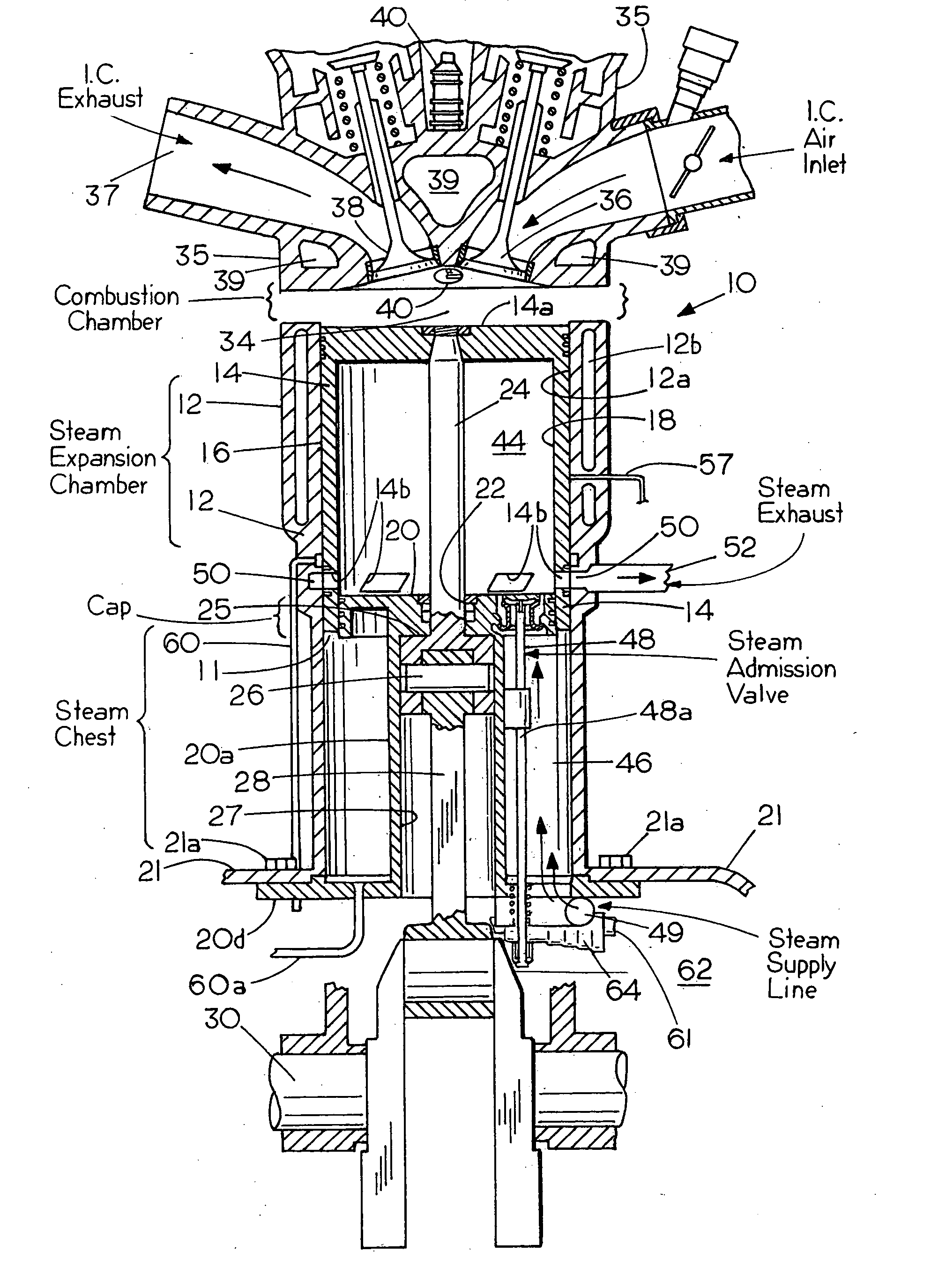

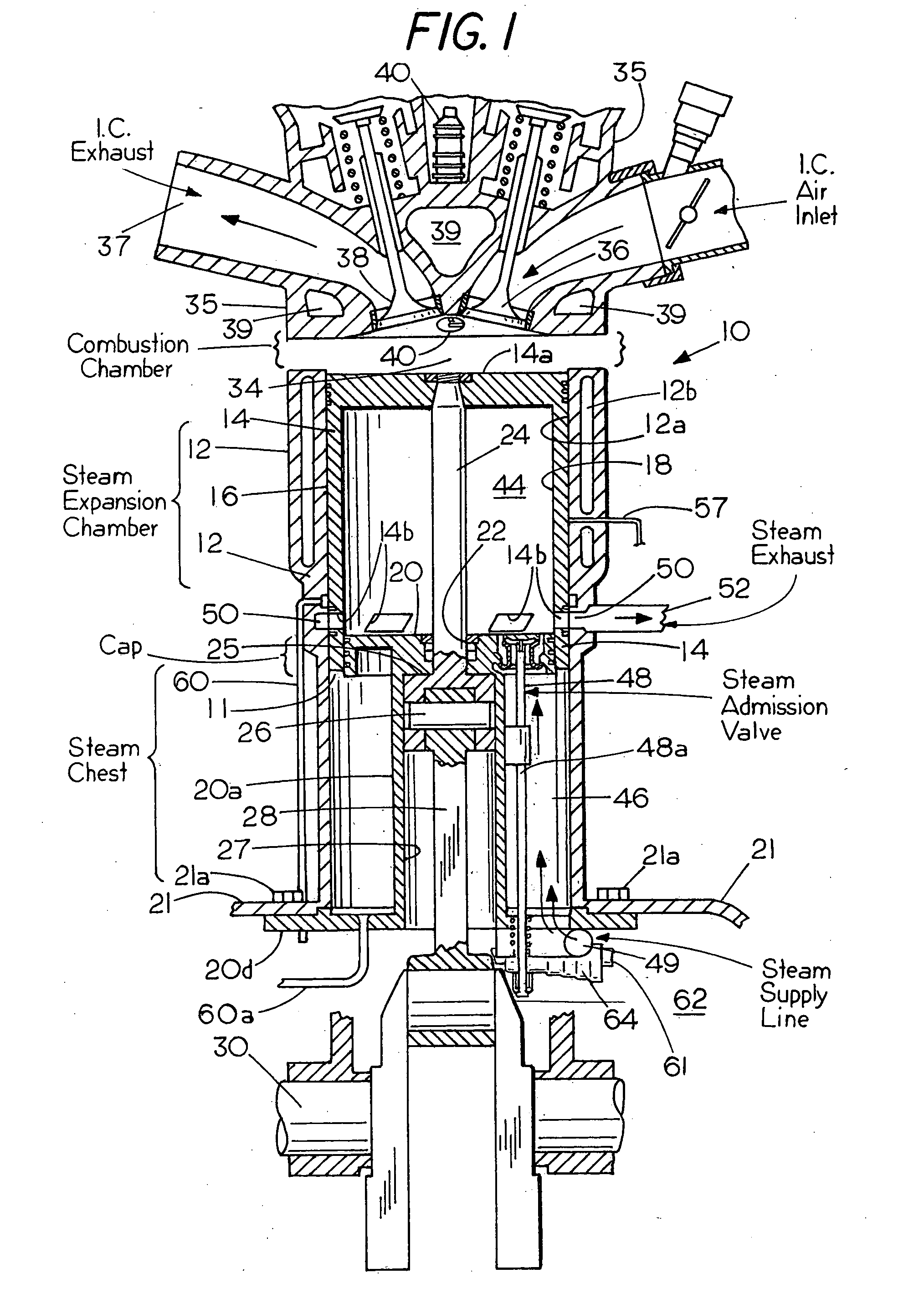

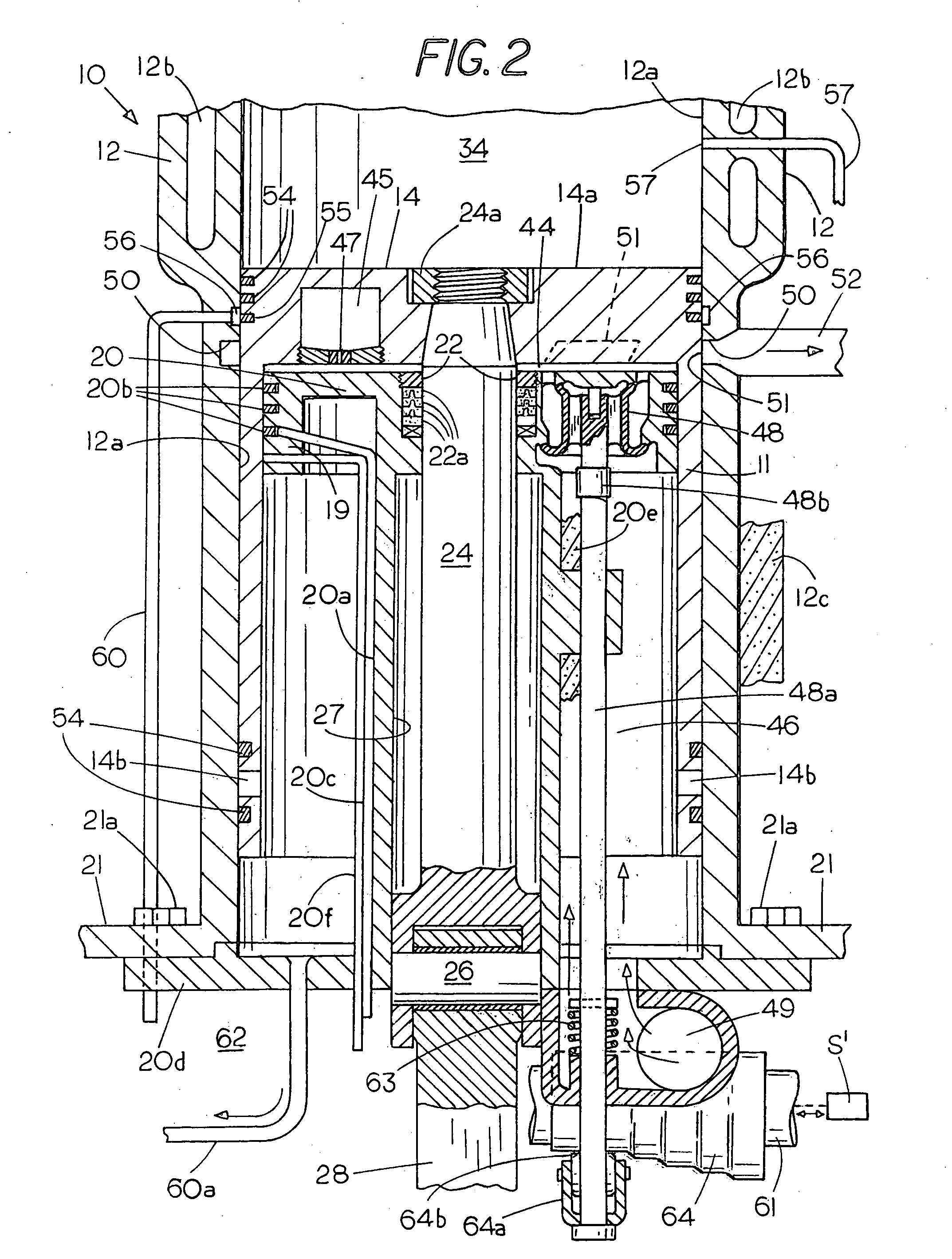

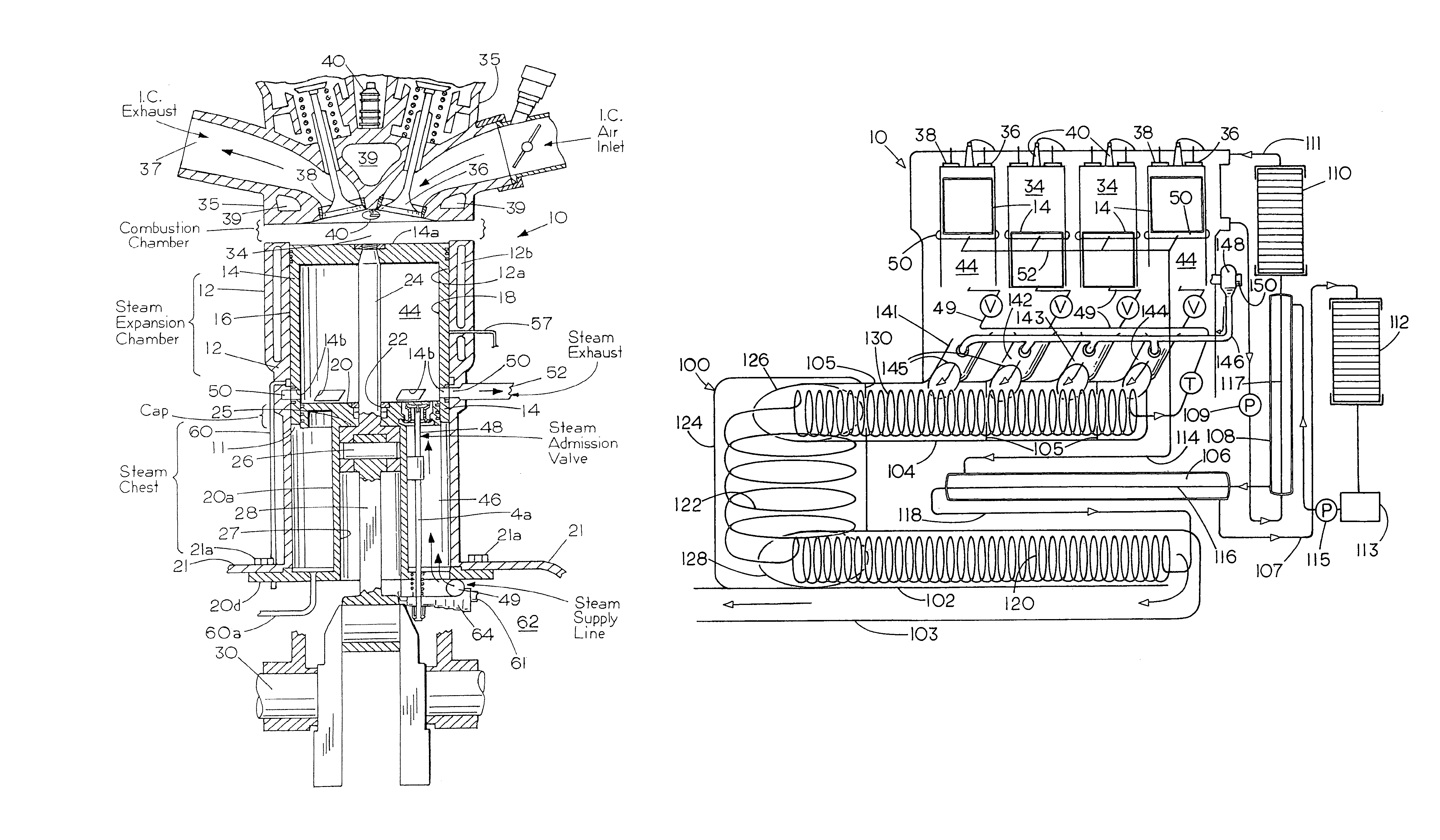

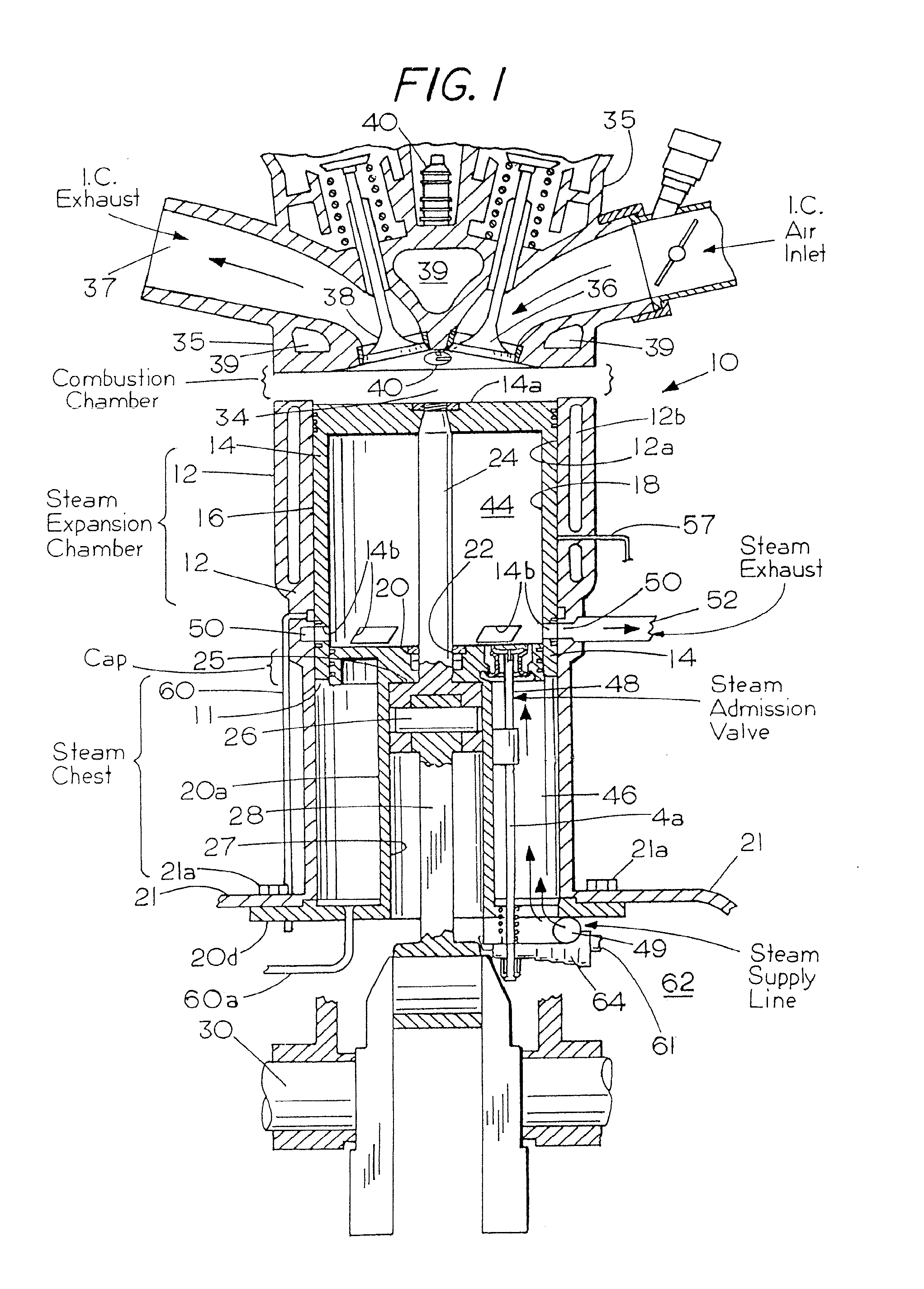

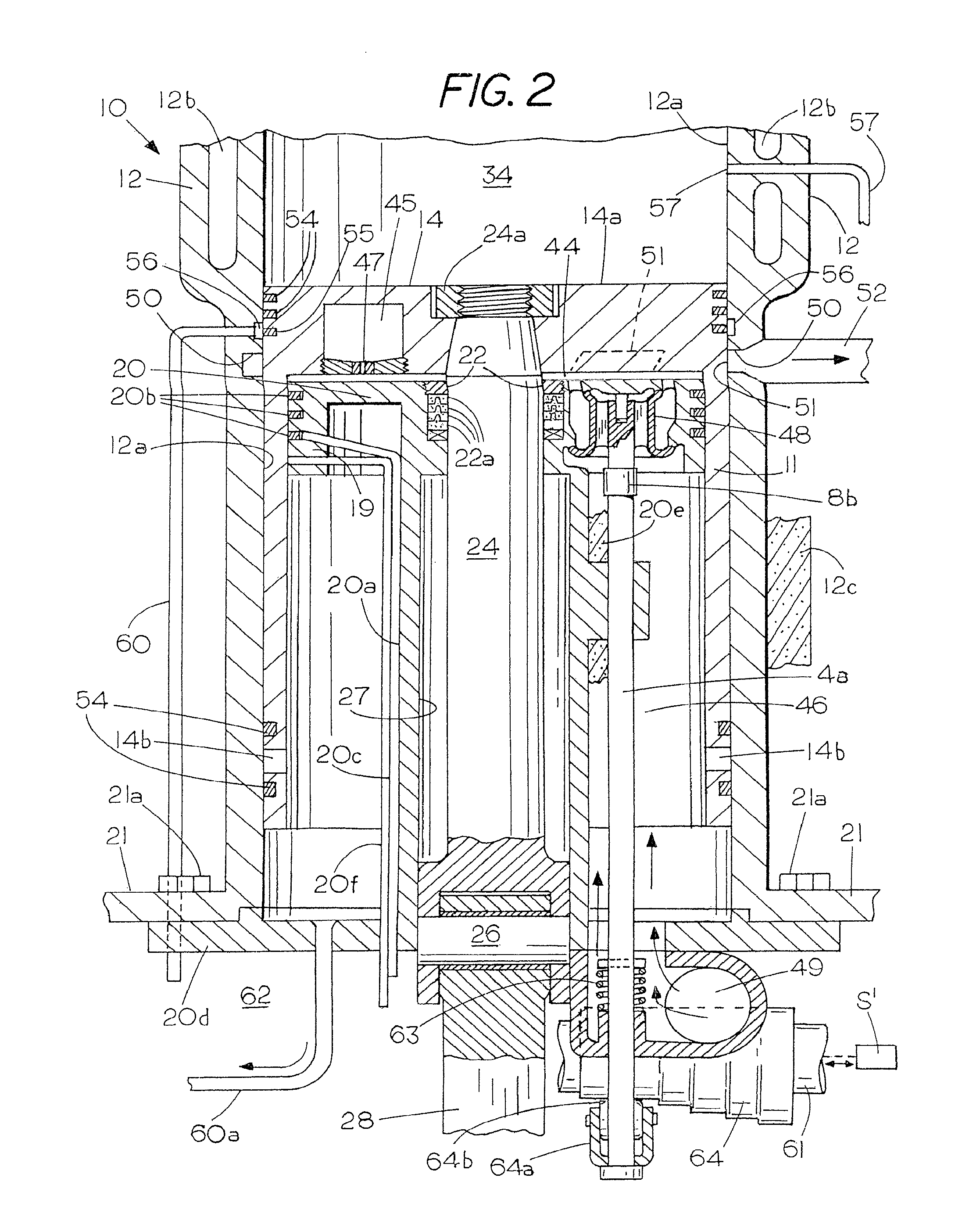

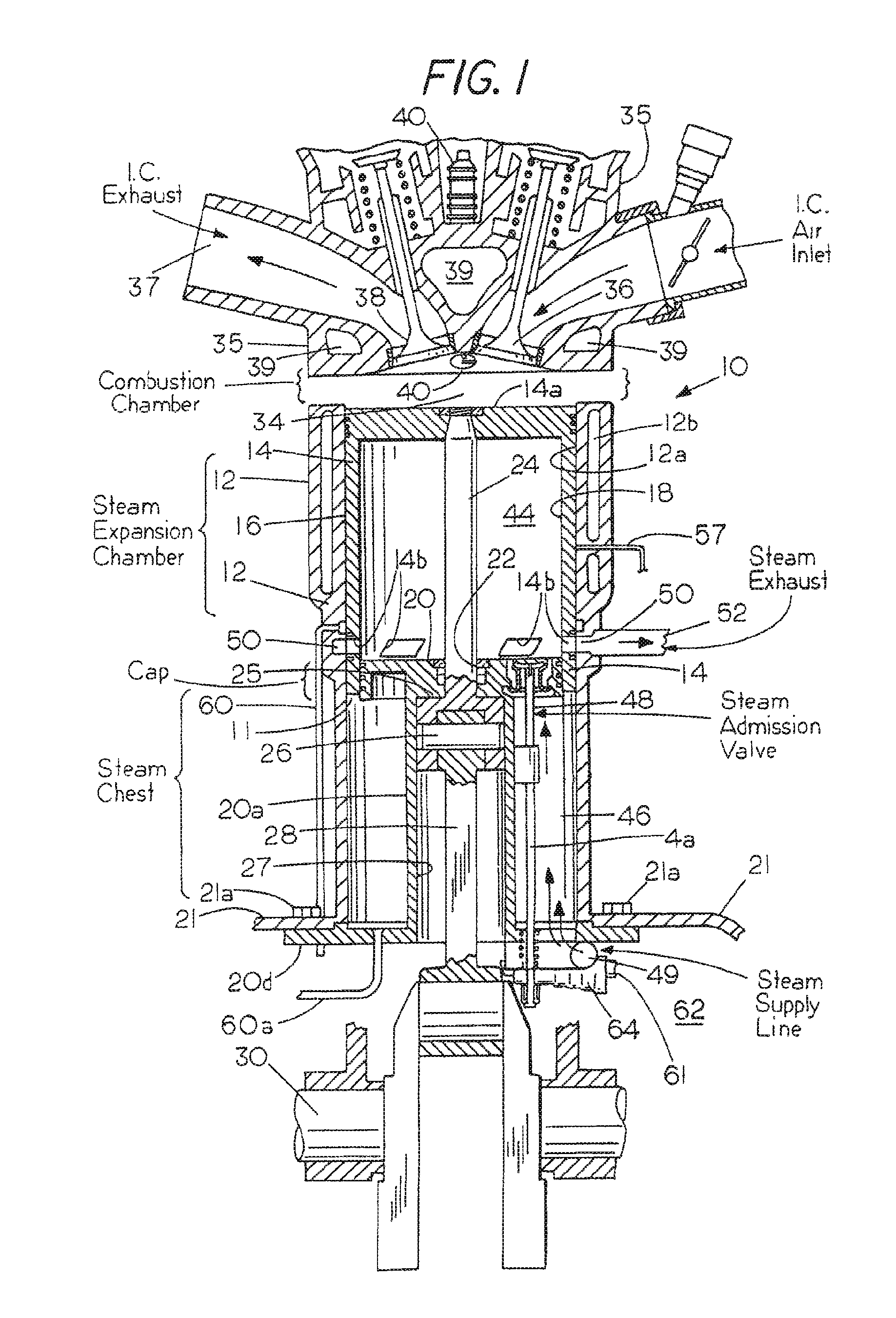

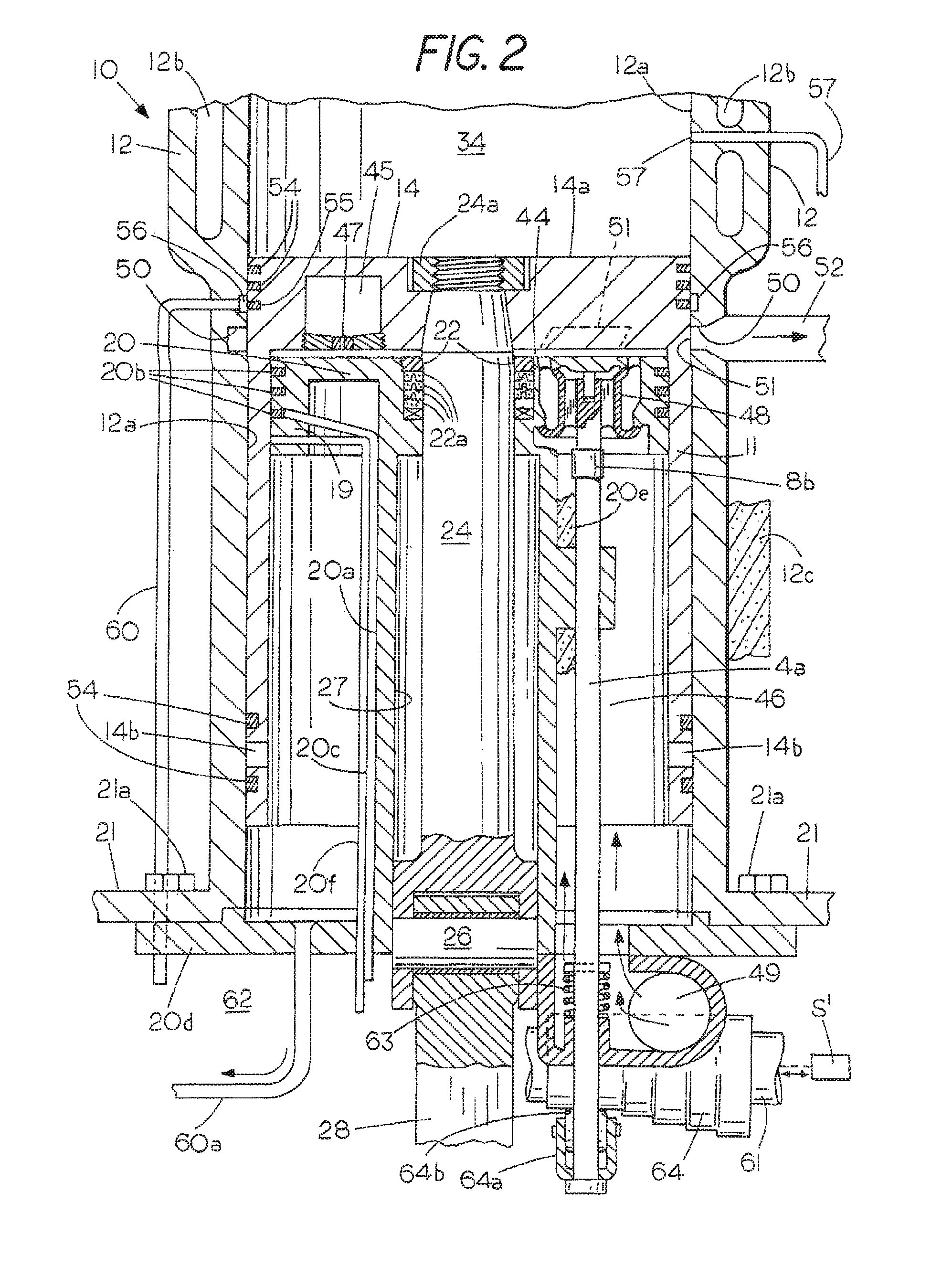

High efficiency multicycle internal combustion engine with waste heat recovery

ActiveUS8061140B2Effective recoveryIncrease enthalpyReciprocating combination enginesInternal combustion piston enginesCombustion chamberInlet valve

A high efficiency combined cycle internal combustion and steam engine includes a cylinder and a piston with an internal combustion chamber outward of the piston, a fixed cylinder cap and a steam expansion chamber inside the piston. The cylinder cap can be heated to reduce condensation of steam entering from a steam generator fired by waste combustion heat. Following exhaust, residual steam can be recompressed prior to admitting the next charge of steam. A wrist pin connected to an inner end of the piston skirt inwardly of the cylinder cap is coupled to a connecting rod secured to a crankshaft. One valve or a pair of steam inlet valves are connected to communicate in series within the cylinder cap inside the piston. The steam mass admitted is regulated to reduce fuel consumption. Coolant can be superheated in the combustion exhaust manifold.

Owner:THERMAL POWER RECOVERY

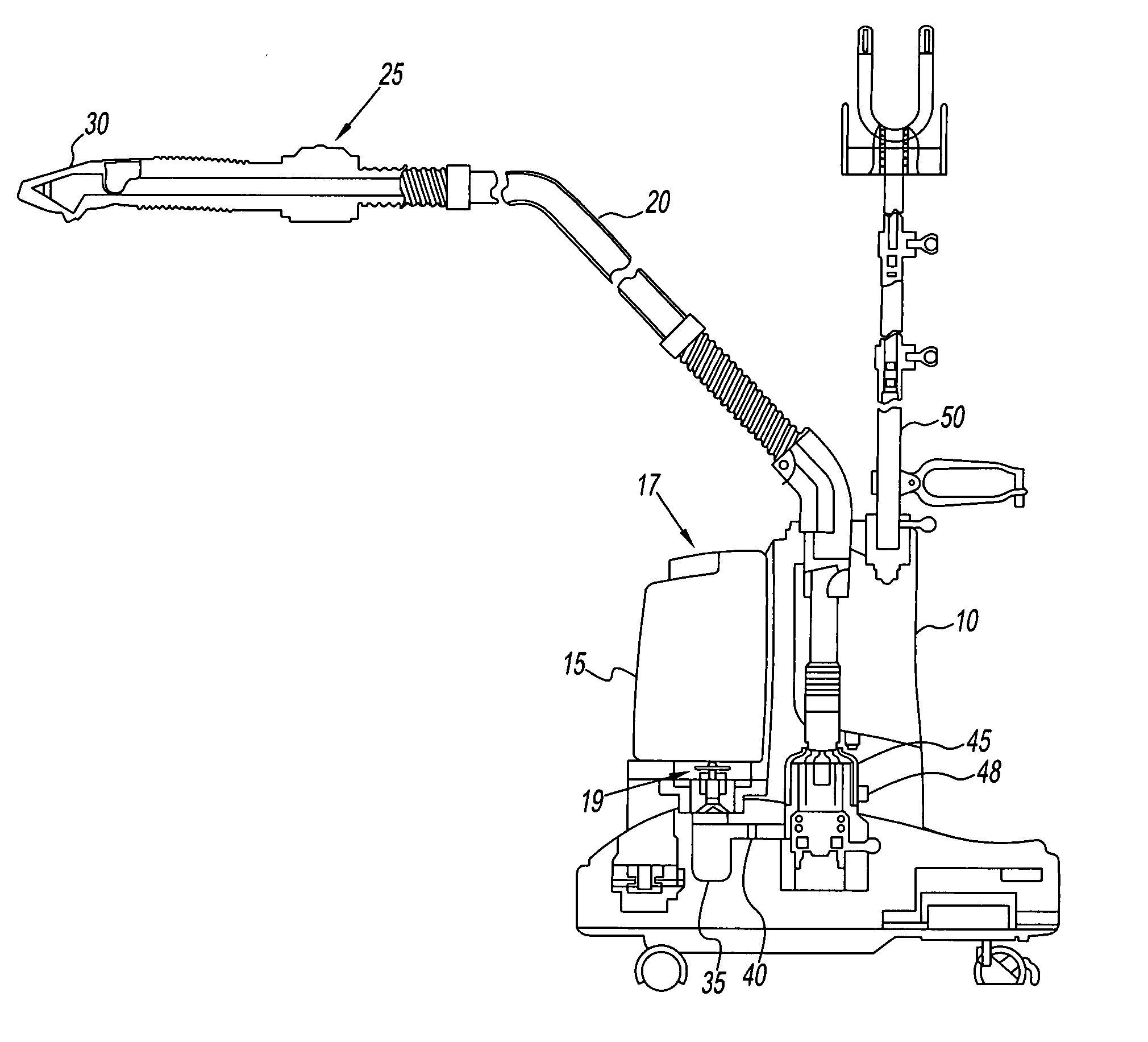

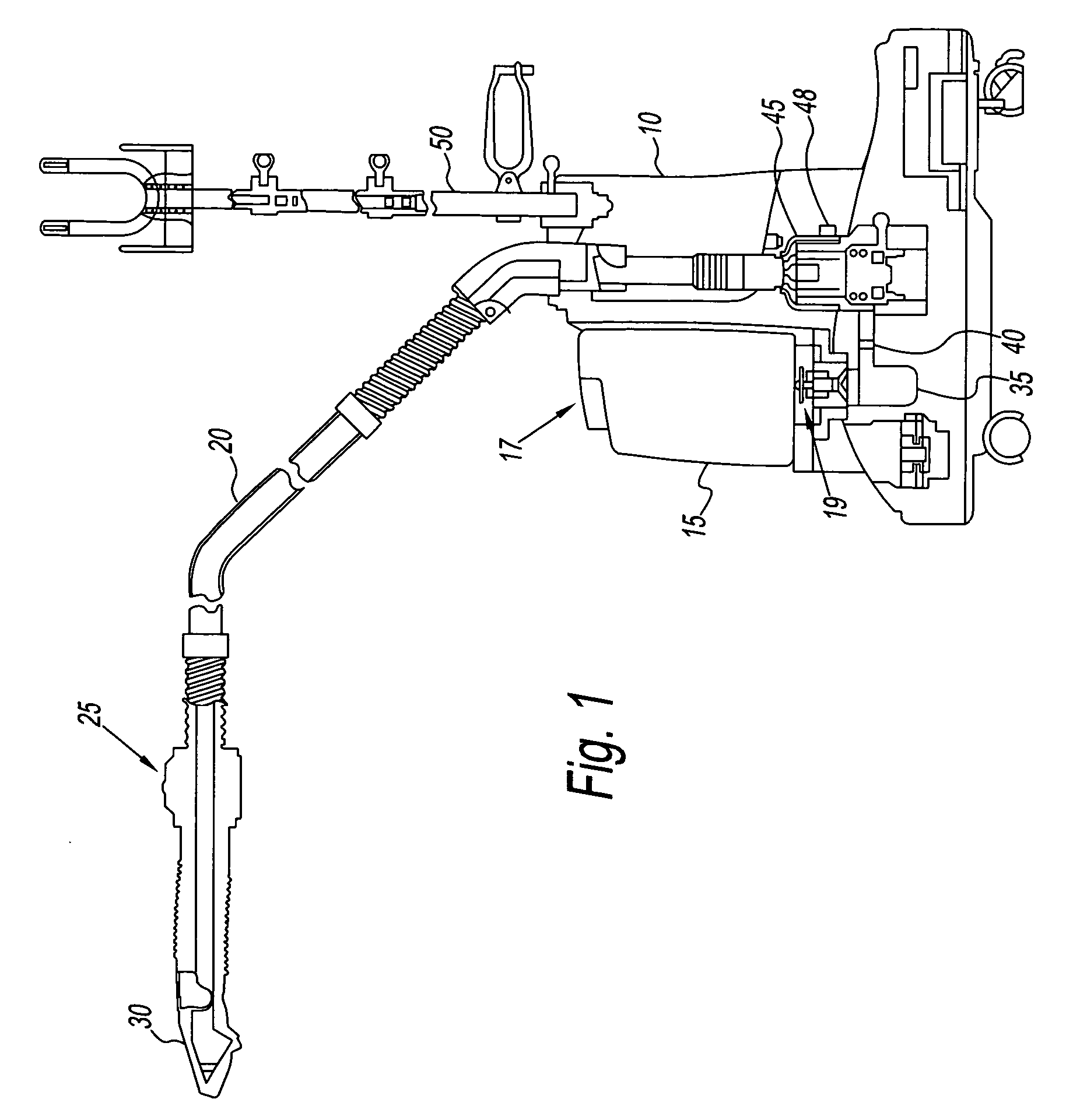

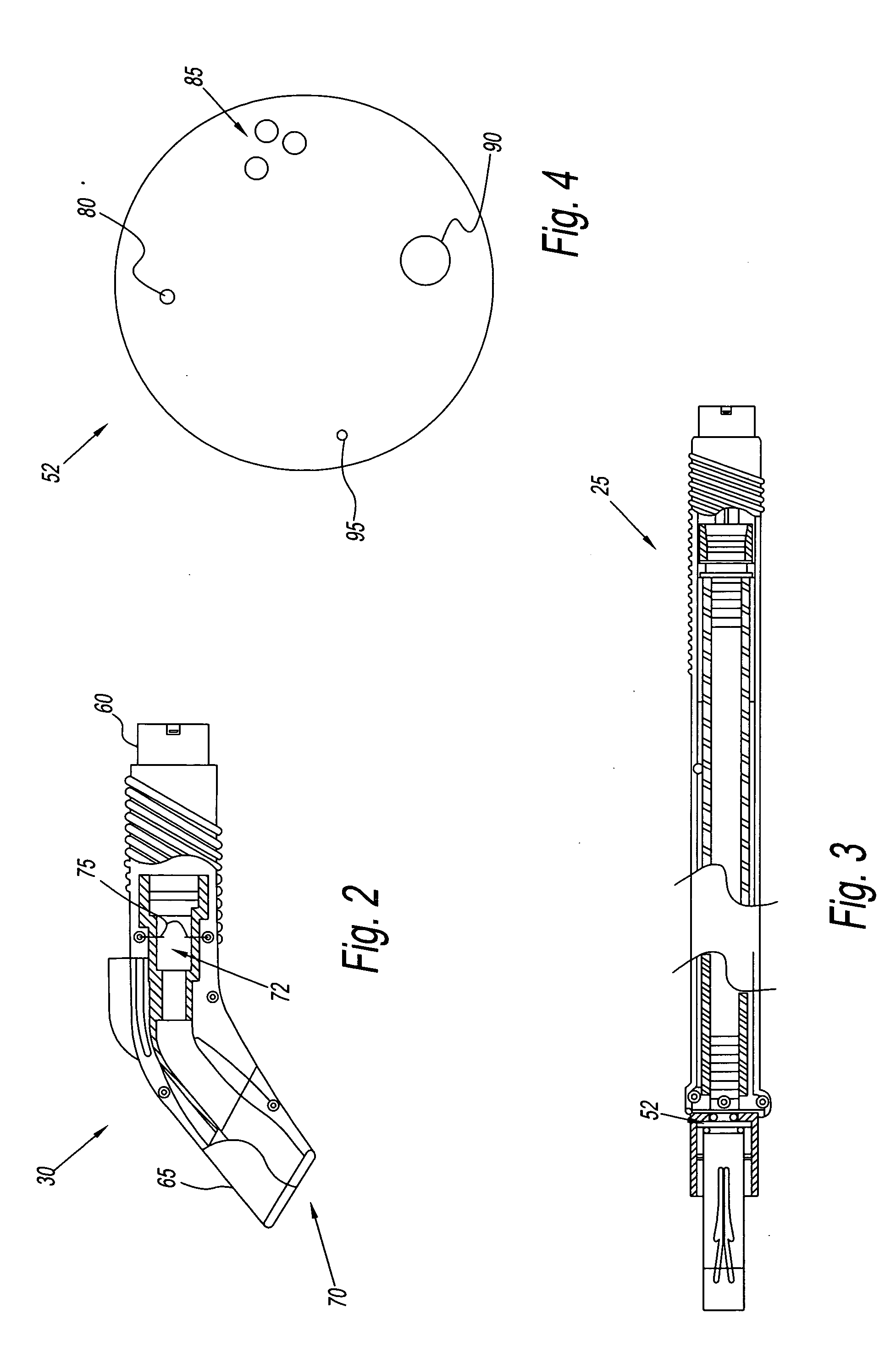

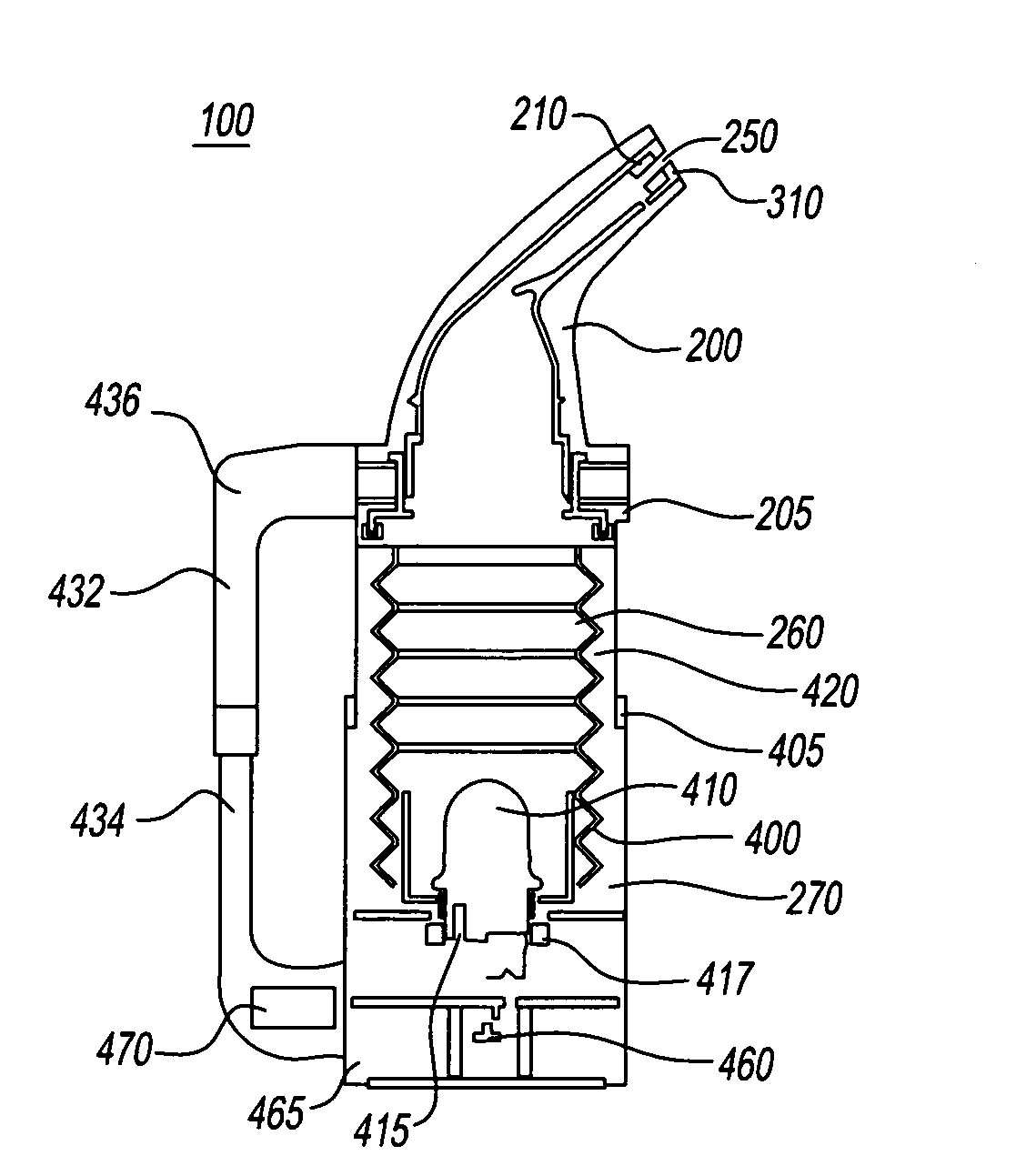

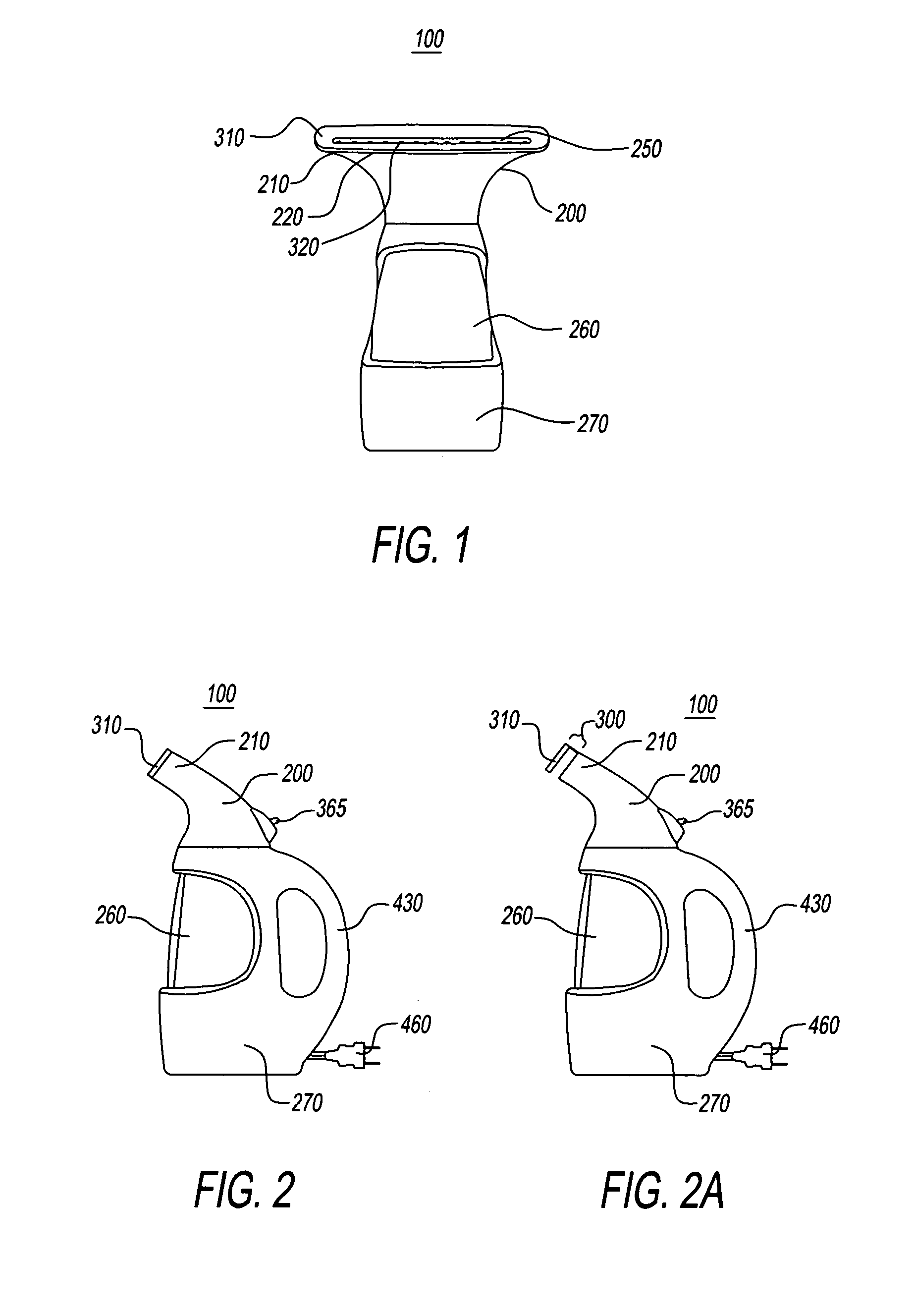

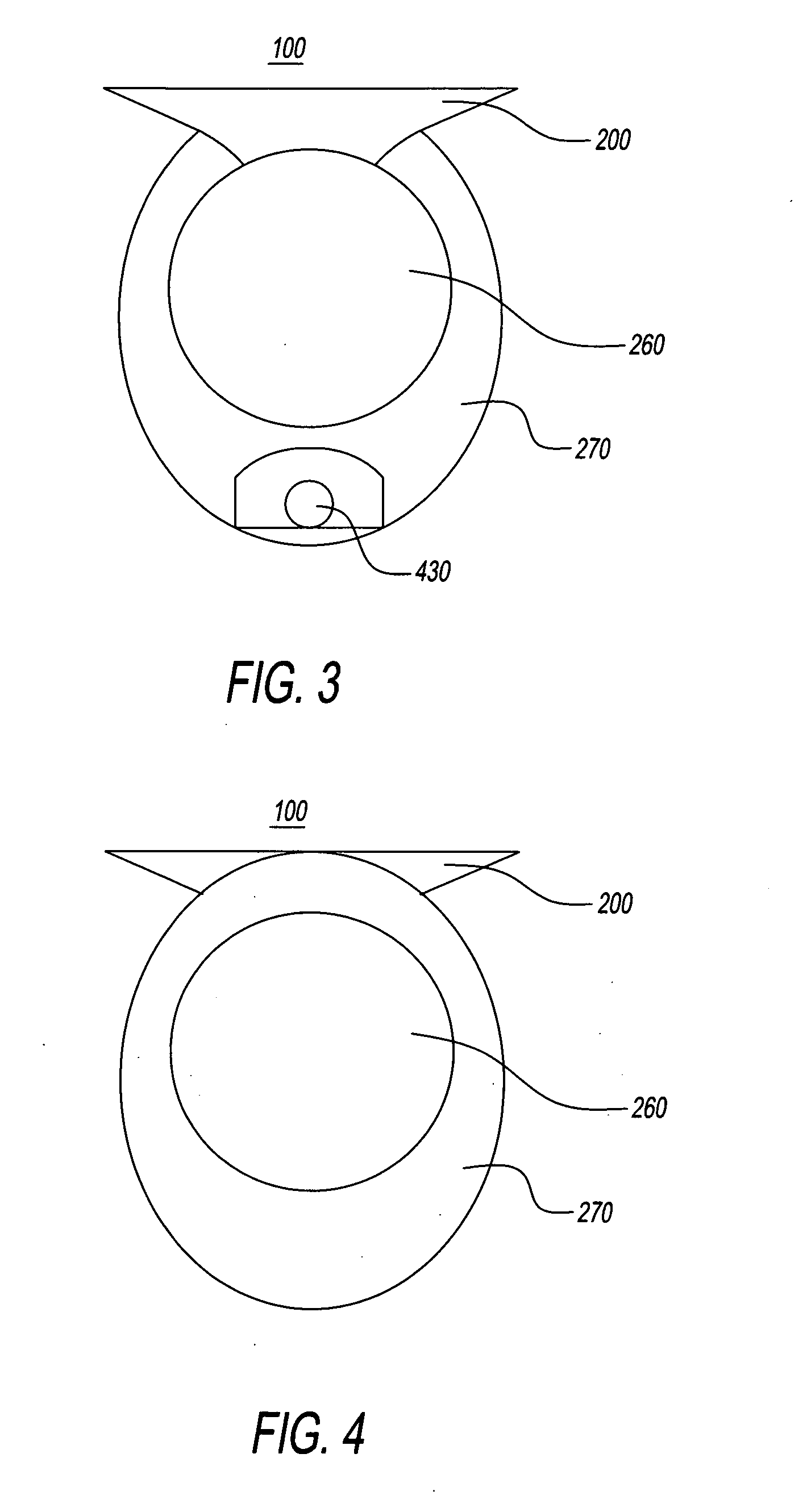

Garment steamer with improved heater and variable steam output

InactiveUS20050150261A1Constant deliveryFacilitate easy fillingHeating or cooling apparatusSteam generation heating methodsEngineeringSteam engine

A steamer for steaming and / or steam cleaning an object. The steamer includes a reservoir for containing a liquid therein, a pressurized boiler system for generating steam under pressure from a portion of the liquid in the reservoir, a thermostatic control device for controlling a flow rate of the liquid delivered from the reservoir to the pressurized boiler system, and at least one steam output discharge port having a variable aperture size in fluid communication with the output of the pressurized boiler system.

Owner:CONAIR CORP

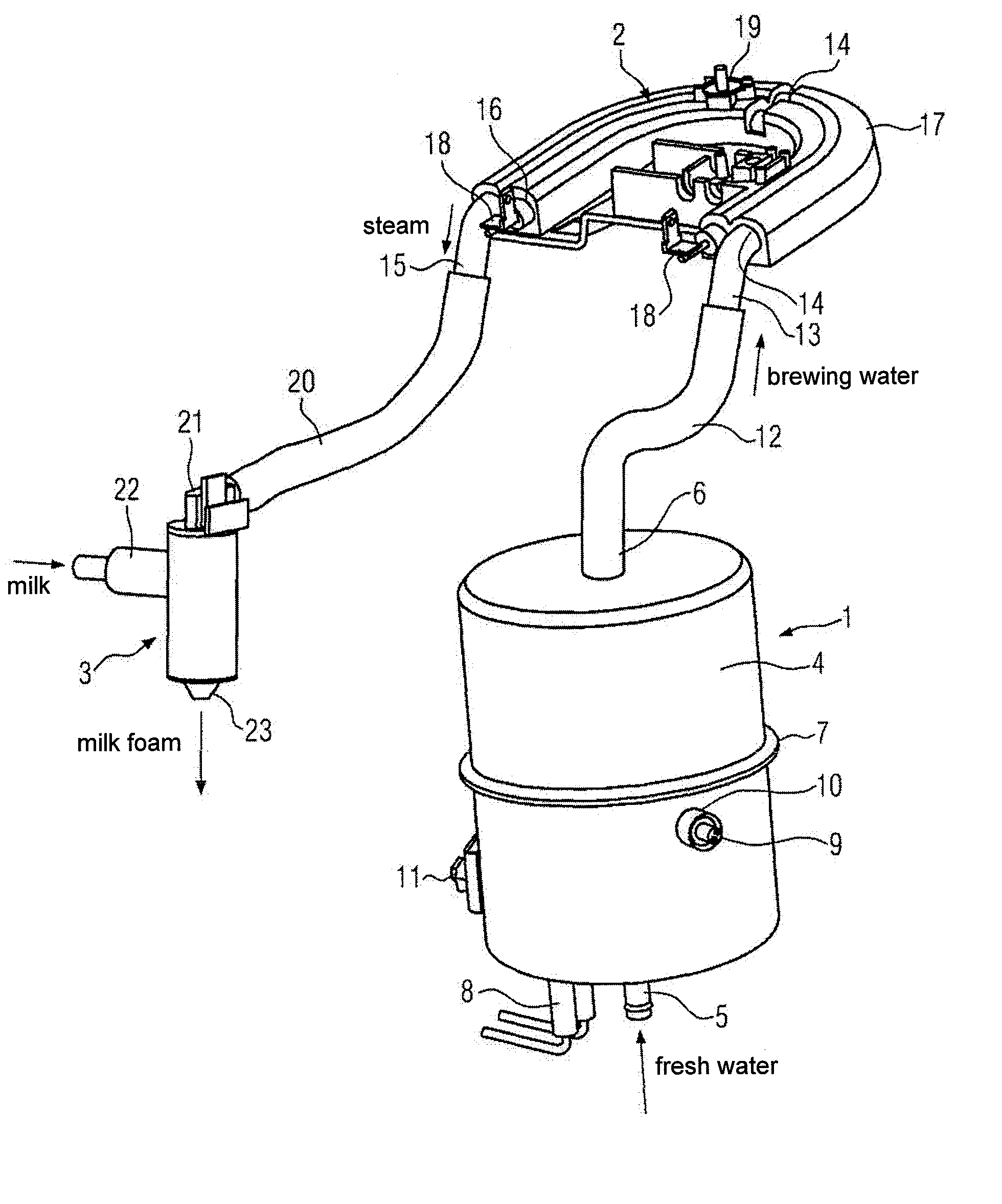

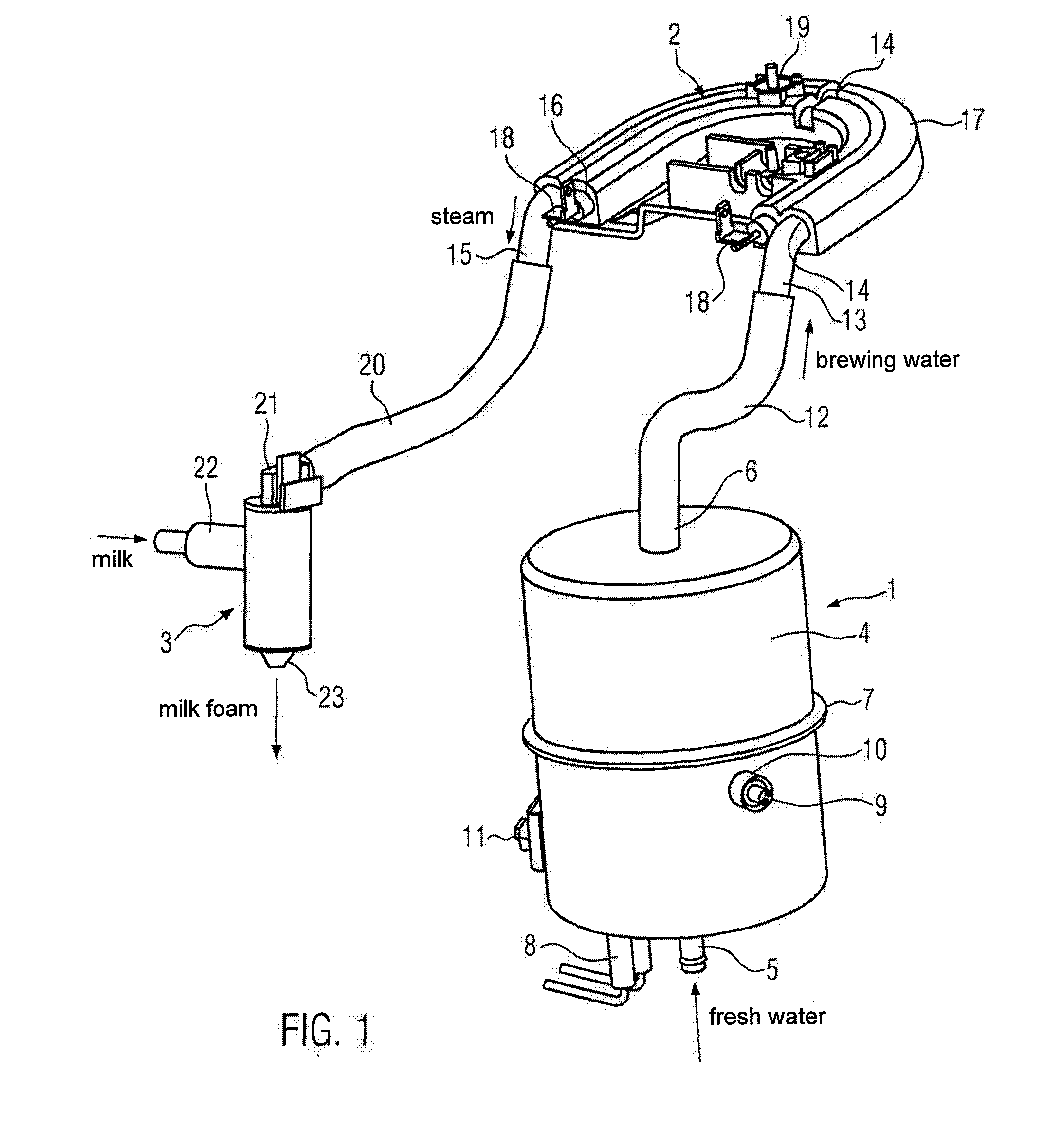

Hot water unit for a hot beverage maker including a milk foamer

InactiveUS20080216665A1Easy to assembleEasy to manufactureMilk preservationBeverage vesselsEngineeringThermal water

The present invention relates to a hot water unit for a hot beverage maker, in particular a coffee machine provided with a milk foamer, said hot water unit comprising a boiler for providing brewing water and an evaporator for providing steam. The boiler includes a boiler supply, a boiler heating means and a brewing water outlet. The evaporator includes an evaporator supply, an evaporator heating means and a steam outlet. According to the present invention, the boiler and the evaporator are arranged in series, the evaporator supply being implemented as a brewing water supply and connected to the brewing water outlet of the boiler. In addition, the present invention relates to the use of such a hot water unit for connection to a milk roamer and to a hot beverage maker comprising a milk foamer and such a hot water unit.

Owner:PAV PATENTVERW

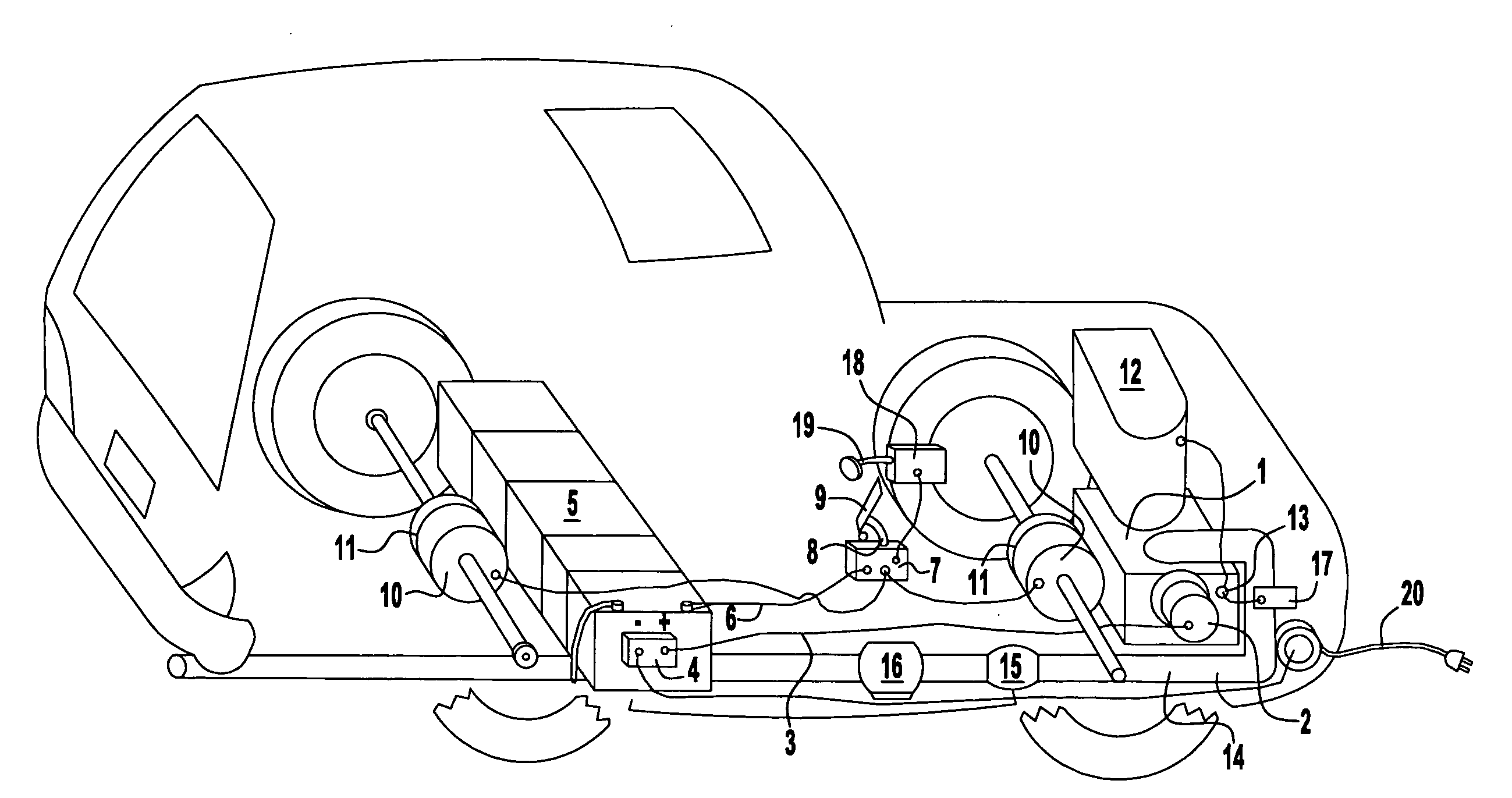

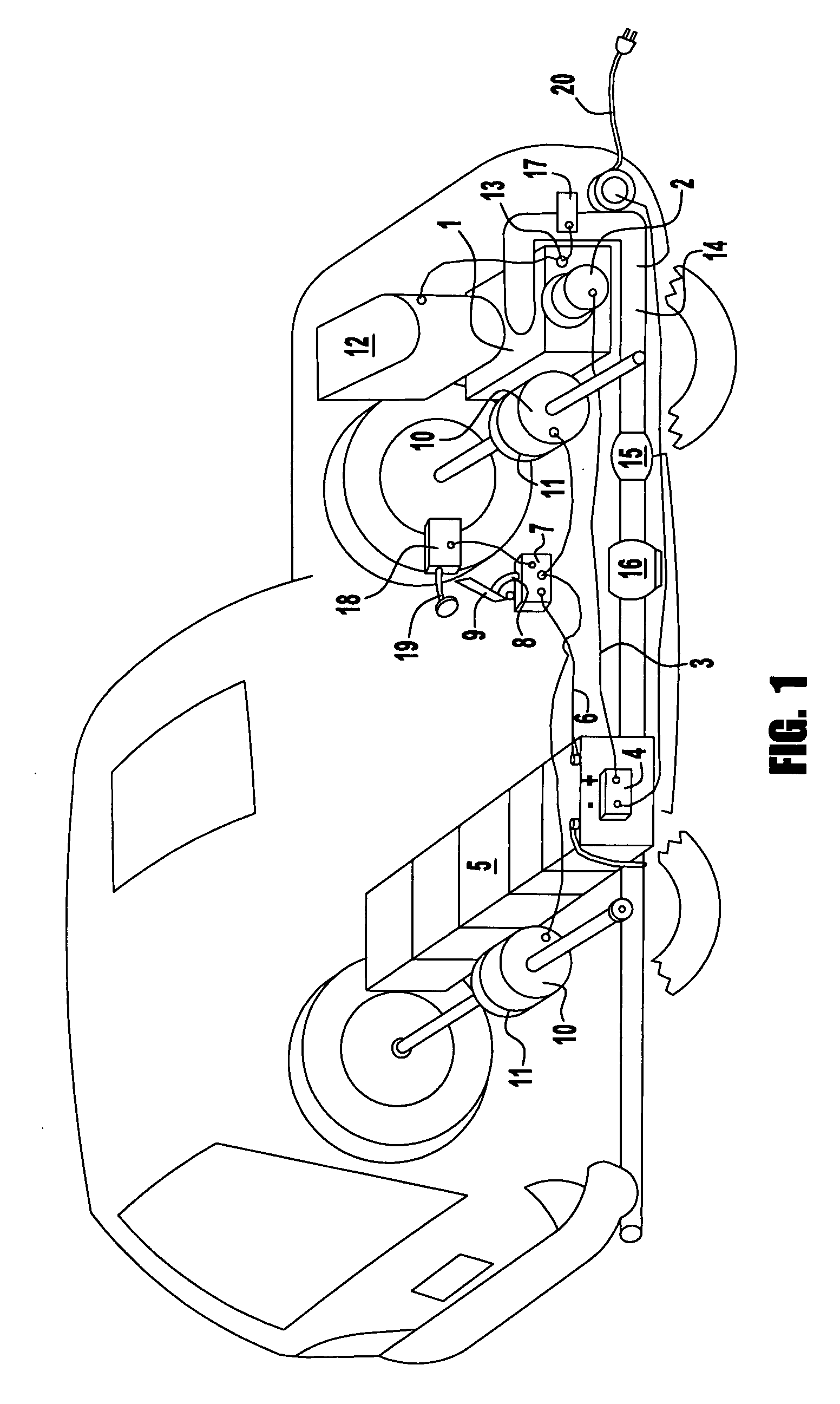

Hybrid electric vehicle and towable trailer that uses renewable solid fuel

InactiveUS20090090573A1SmallIncrease mileageInternal combustion piston enginesElectric propulsion mountingCelluloseElectrical battery

A hybrid electric vehicle having an array of batteries that recharge with a generator connected to a Stirling engine, steam engine and / or steam turbine powered by combusting a solid fuel product. The battery array for this vehicle, which is a series hybrid, can be recharged using residential electrical current. A preferred solid fuel product for burning in the generator-charging engine of this vehicle is selected from cellulose, lignin and combinations thereof, most preferably in the form of pellets or small logs.

Owner:BOONE DANIEL J

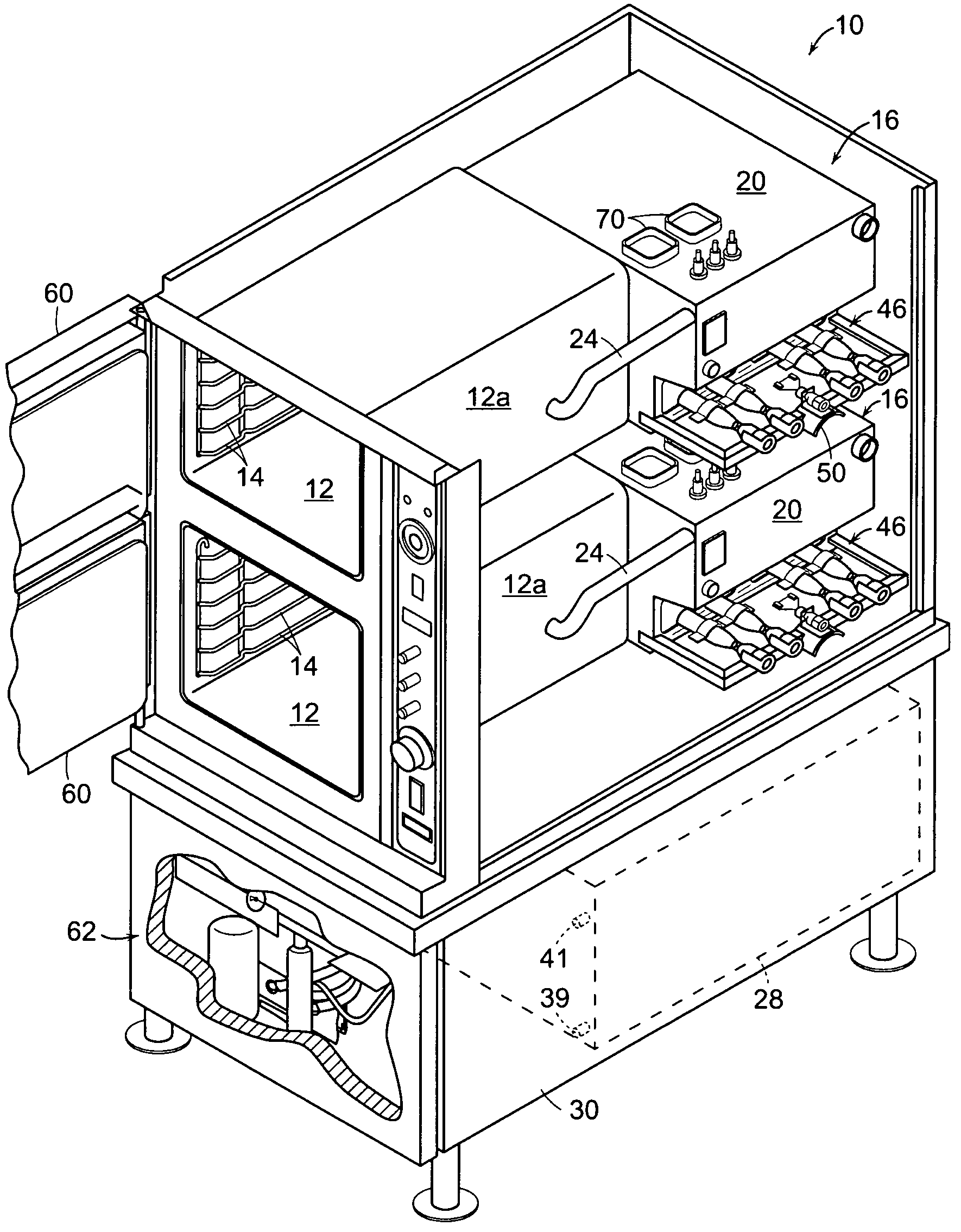

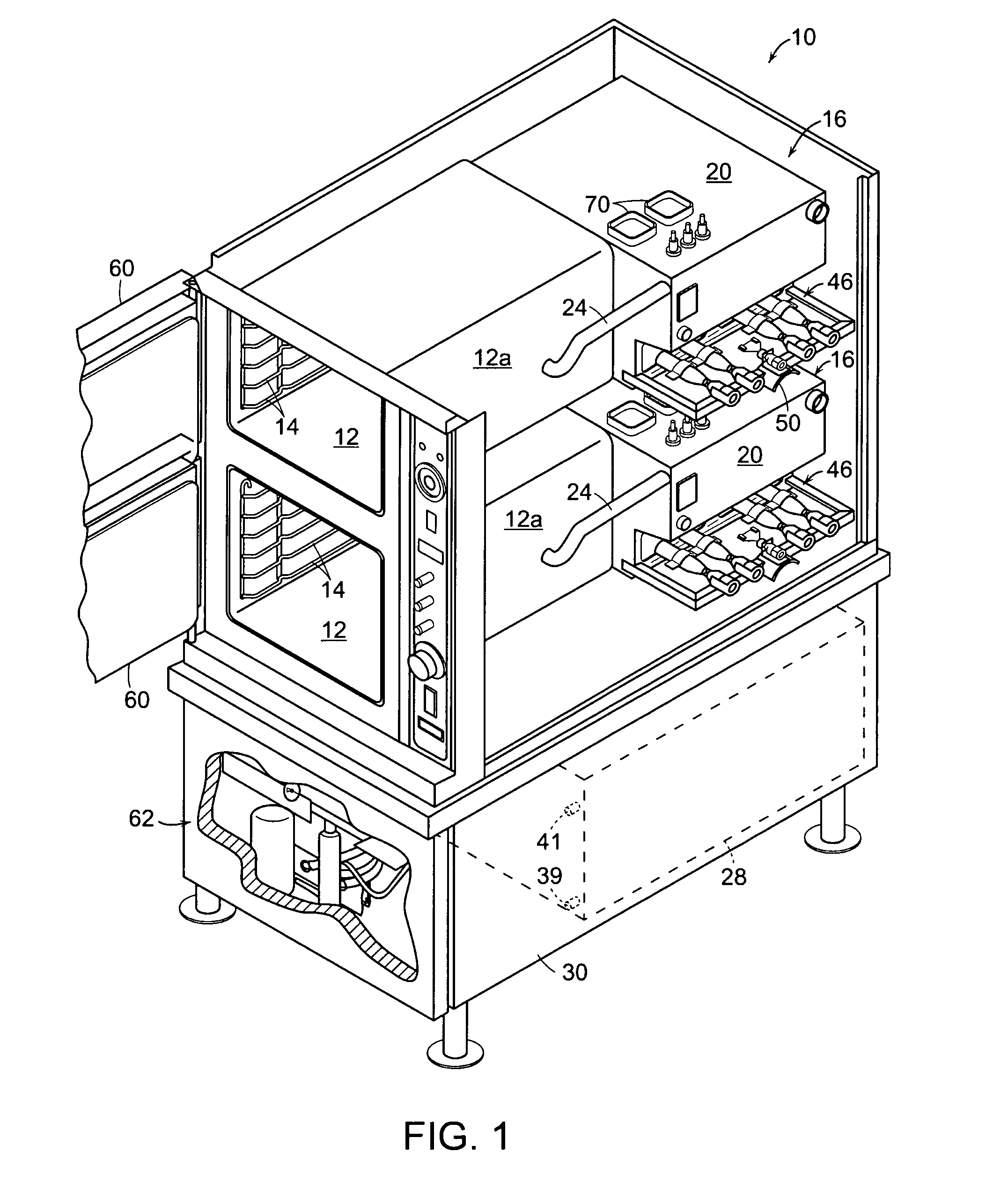

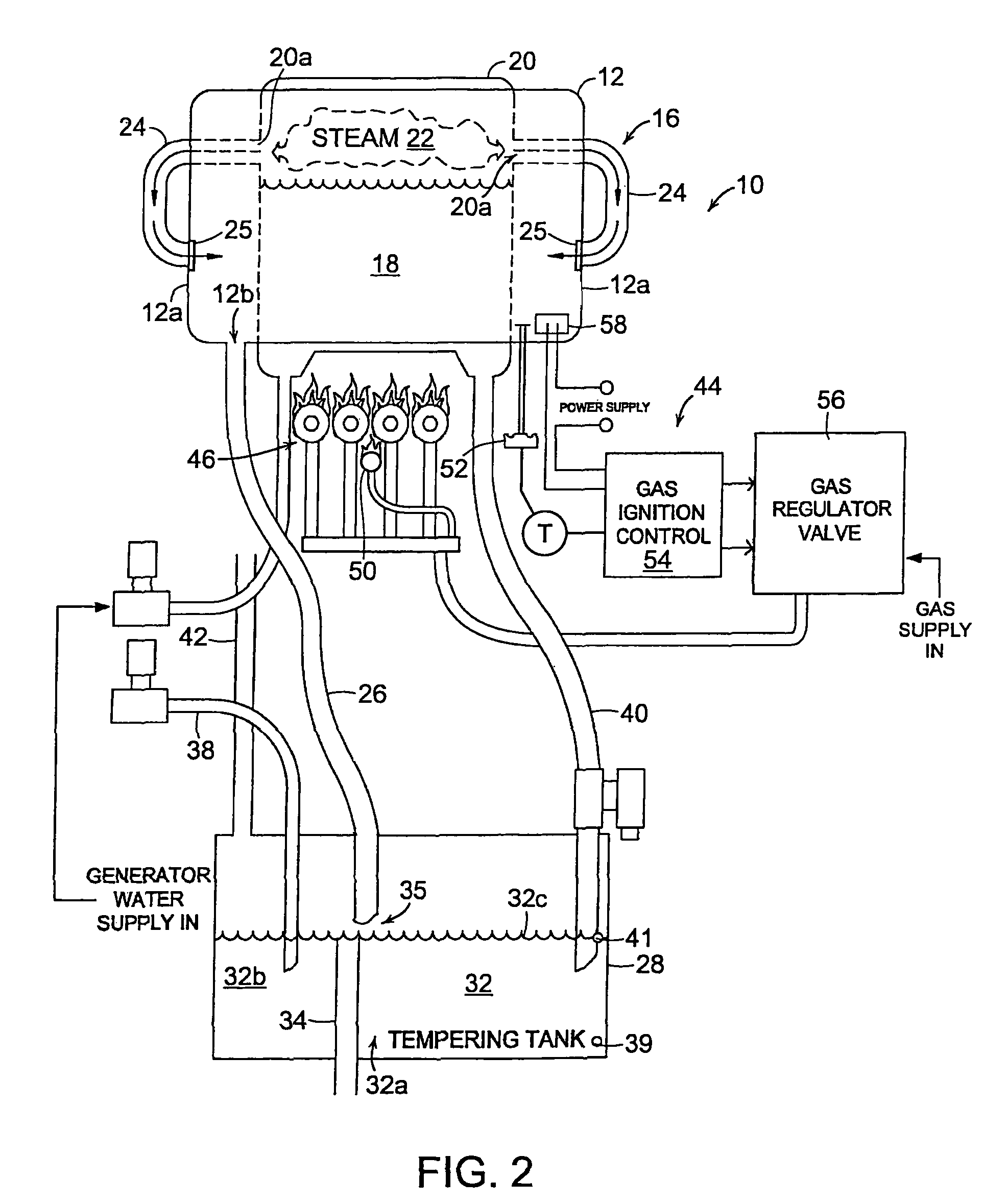

High efficiency atmospheric steamer

ActiveUS7810488B2Temperature control without auxillary powerDomestic stoves or rangesSteam pressureFiltration

A pressureless or atmospheric steamer for cooking food with a high cooking efficiency has a cooking compartment with an outlet for steam and condensate that feeds to a tempering tank via an outlet conduit. The outlet conduit is spaced closely from the controlled water level in the tempering tank, and is in fluid communication with the atmospheric vent to create an open steam cooker. A steam generator is adjacent the cooking compartment and has a water reservoir, a heat exchanger secured within the reservoir in a heat-transferring relationship at an exterior surface of the heat exchanger with the water held in the reservoir, and a heater that supplies heat to the interior of the heat exchanger. The tempering tank has a drain and level controls for a water supply held in the tempering tank. A pressure-sensitive device is disposed to measure the steam pressure in the cooking compartment and to generate electrical output signals indicative of minimum and maximum pressure values to control the operation of the heater to maintain the steam pressure in the cooking compartment within that operating range. The steamer has an in-built water filtration system for water supplied to the water reservoir.

Owner:MARKET FORGE INDS

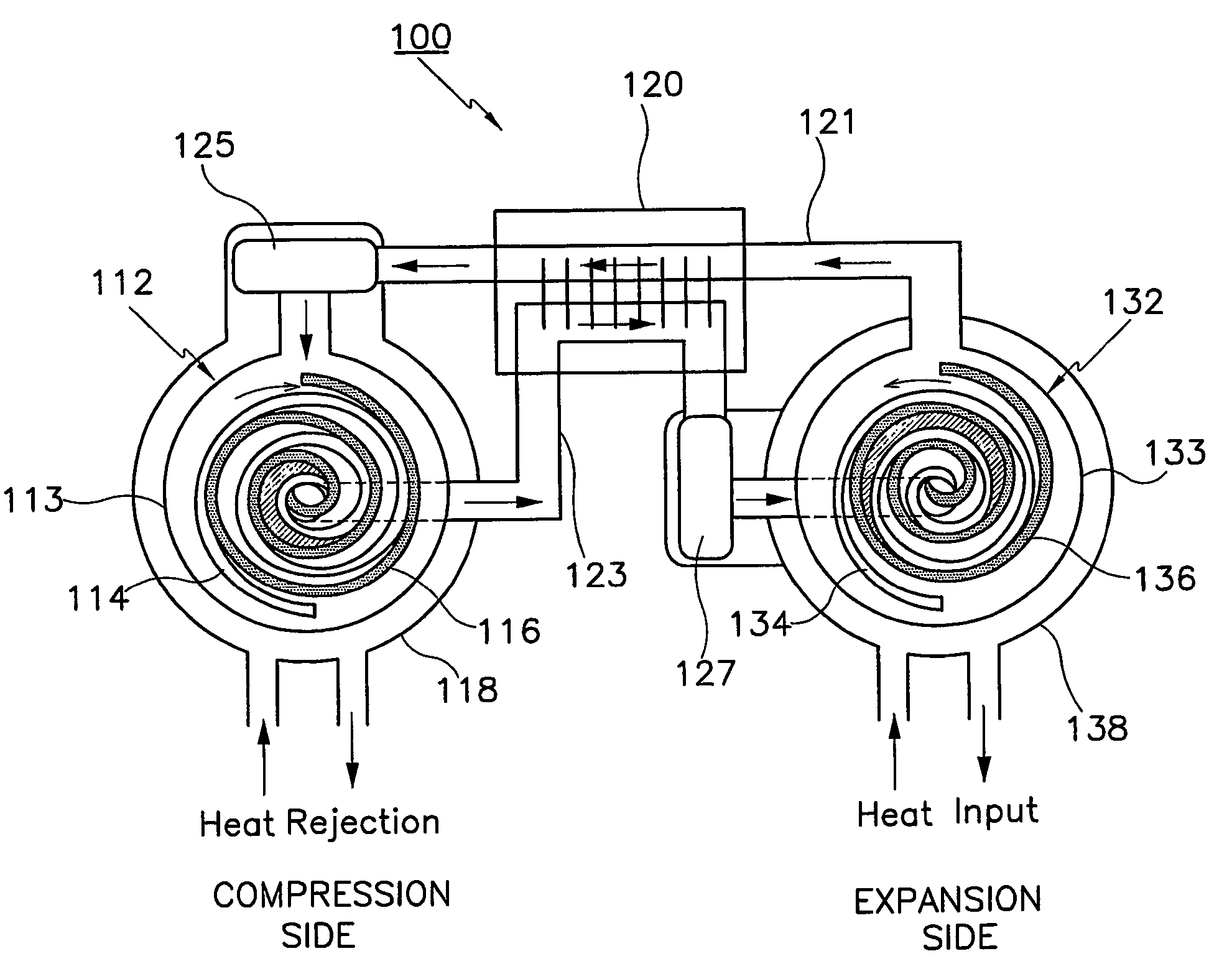

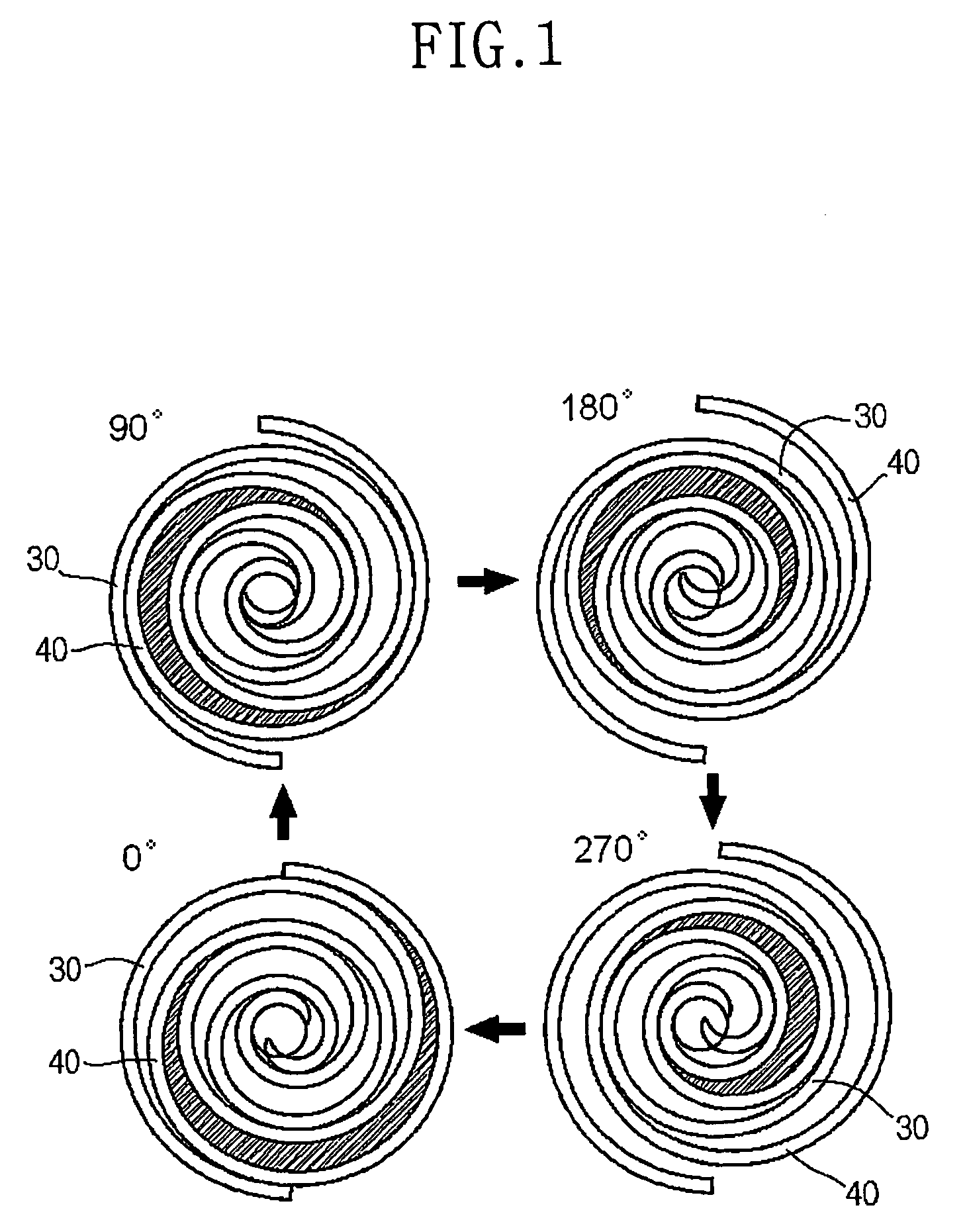

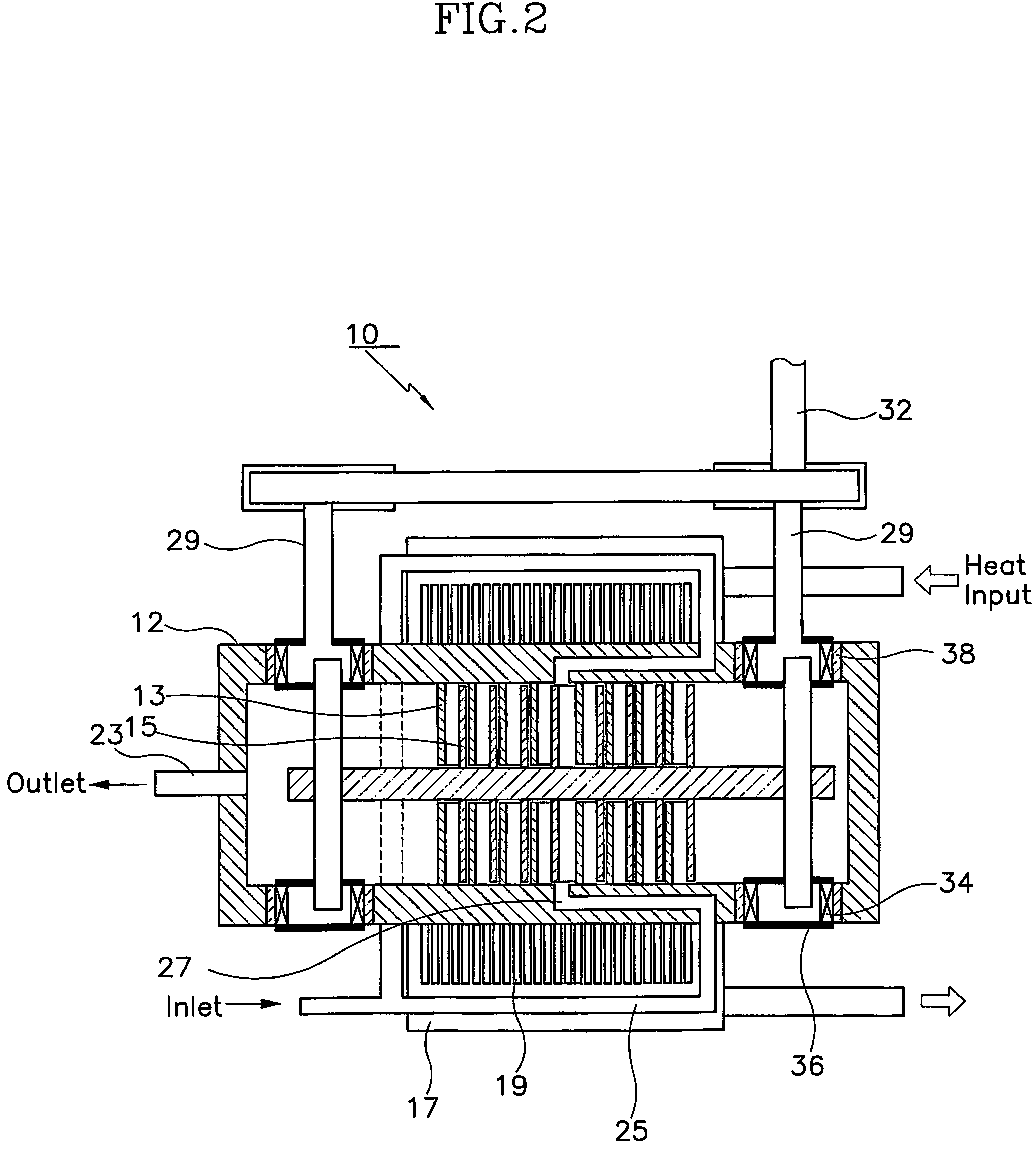

Scroll-type expander having heating structure and scroll-type heat exchange system employing the expander

InactiveUS7124585B2No reduction in efficiencyMinimizes difference in temperatureRotary/oscillating piston combinations for elastic fluidsInternal combustion piston enginesWorking fluidEngineering

The present invention provides a scroll-type expander that simultaneously performs expansion and re-heating such that efficient expansion is realized and there is no reduction in efficiency caused by pressure loss occurring during the supply of an working fluid to the scroll-type expander, and that minimizes a difference in temperature between a stationary scroll member and a rotating scroll member, as well as a temperature distribution of a scroll wrap. The present invention also relates to a heat exchange system that uses a scroll-type expander to replace pistons in a conventional reciprocating Stirling engine or refrigerator with a pair of scroll-type compressor and expander such that the heat exchange system may be used as a Stirling engine or refrigerator. The present invention also provides a steam engine, in which a steam turbine in the conventional steam engine (Rankine system) is replaced with a scroll-type expander such that the steam cycle has both a re-heating cycle and a regeneration cycle.

Owner:KOREA INST OF MACHINERY & MATERIALS

High efficiency dual cycle internal combustion engine with steam power recovered from waste heat

ActiveUS20090205338A1Operation efficiency can be improvedImprove efficiencyInternal combustion piston enginesSteam useCombustion chamberExhaust valve

A high efficiency combined cycle internal combustion and steam engine includes a cylinder having a piston mounted for reciprocation therein with an internal combustion chamber outward of the piston, a fixed cylinder cap sealingly and slideably mounted within the piston and a steam expansion / recompression chamber inside the piston adjacent the cylinder cap. The cylinder cap can be unheated or heated externally to reduce condensation of steam entering the steam chamber from a steam generator fired by waste combustion heat. Steam remaining in the cylinder when a steam exhaust valve closes at the top center position is recompressed during an inward stroke of the piston up to admission pressure prior to admitting the next charge of steam. One valve or a pair of retractable steam inlet valves connected in series within the cylinder cap act in cooperation with steam recompression and clearance volume to achieve an effective zero steam chamber clearance and a gain in mean Rankine cycle temperature to maximize efficiency. The amount of steam admitted each outward stroke is continuously regulated, e.g. by shifting the phase of one steam admission valve of a pair to vary their overlap for determining the steam mass admitted during each cycle to reduce specific fuel consumption. Other valves balance steam displacement with the steam generator output to use steam more efficiently. Engine coolant can be evaporated in a combustion chamber cooling jacket to form steam which is then superheated in a combustion exhaust manifold.

Owner:THERMAL POWER RECOVERY

Hydraulic hybrid power system

InactiveUS20100133031A1Big economyLow costAuxillary drivesElectrodynamic brake systemsHigh pressureHydraulic pressure

According to the present invention a pump is driven by one or more wheels of a hydraulic hybrid vehicle during braking. The inertial energy of the vehicle powers the pump during braking of the vehicle, and the pump pumps a hydraulic liquid into an hydraulic accumulator that stores the fluid at its elevated pressure. When additional power is required by the vehicle, the liquid is released into a heat exchanger that transfers heat from the exhaust gas of the engine to the liquid causing at least a portion of the liquid to become gaseous. The heated fluid is then fed into an expander that generates shaft power by expanding the pressurized and heated gaseous and / or liquid fluid mixture. The preferred embodiment of the present invention operates under the Rankine cycle or steam engine cycle where the liquid compression function is performed using power from regenerative braking, and the liquid heating and vaporization function is performed using exhaust gas waste heat. The present invention shows potential for more than tripling the regenerative braking power of hydraulic hybrid vehicles, thereby providing a large improvement in vehicle fuel economy.

Owner:MENDLER EDWARD CHARLES

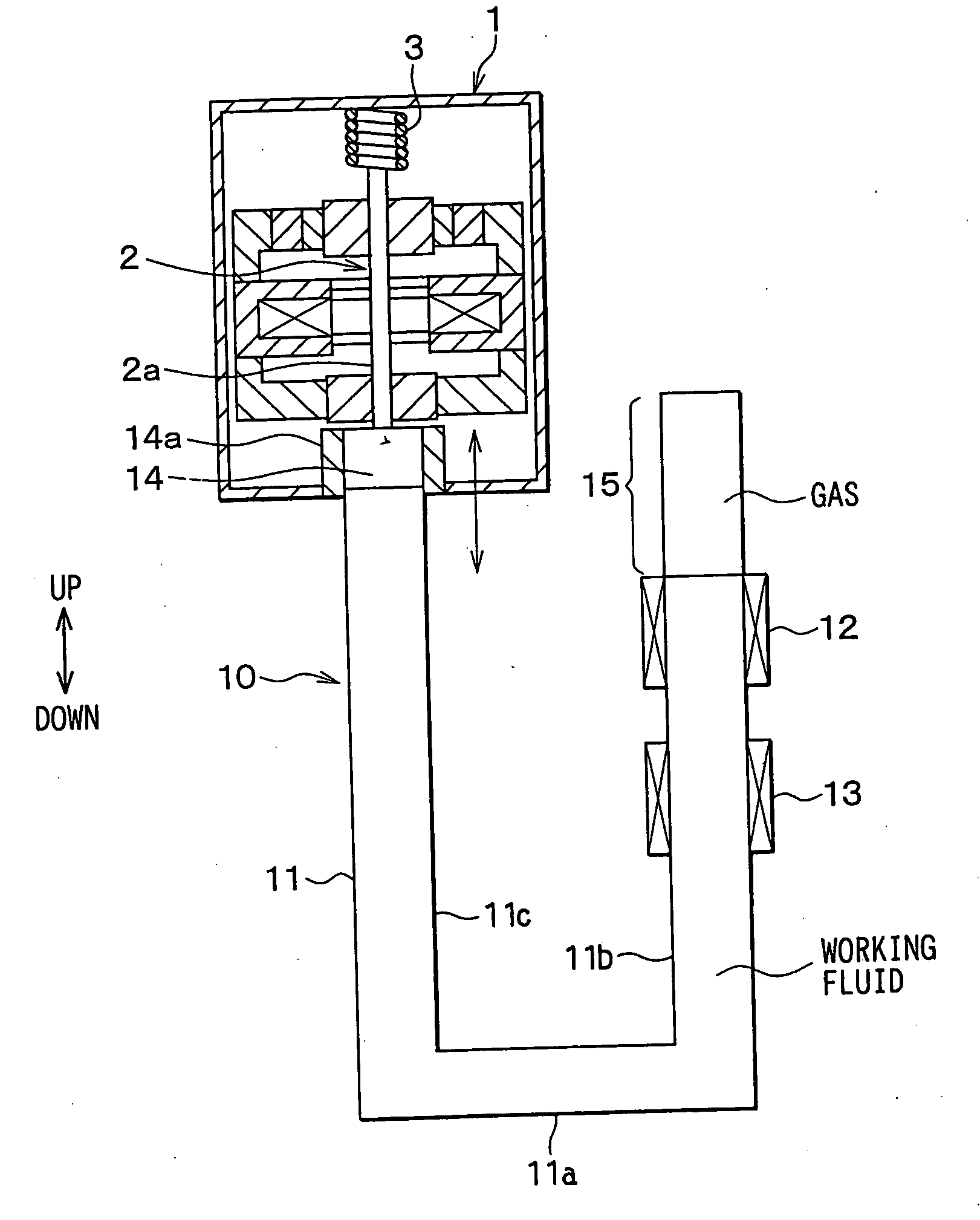

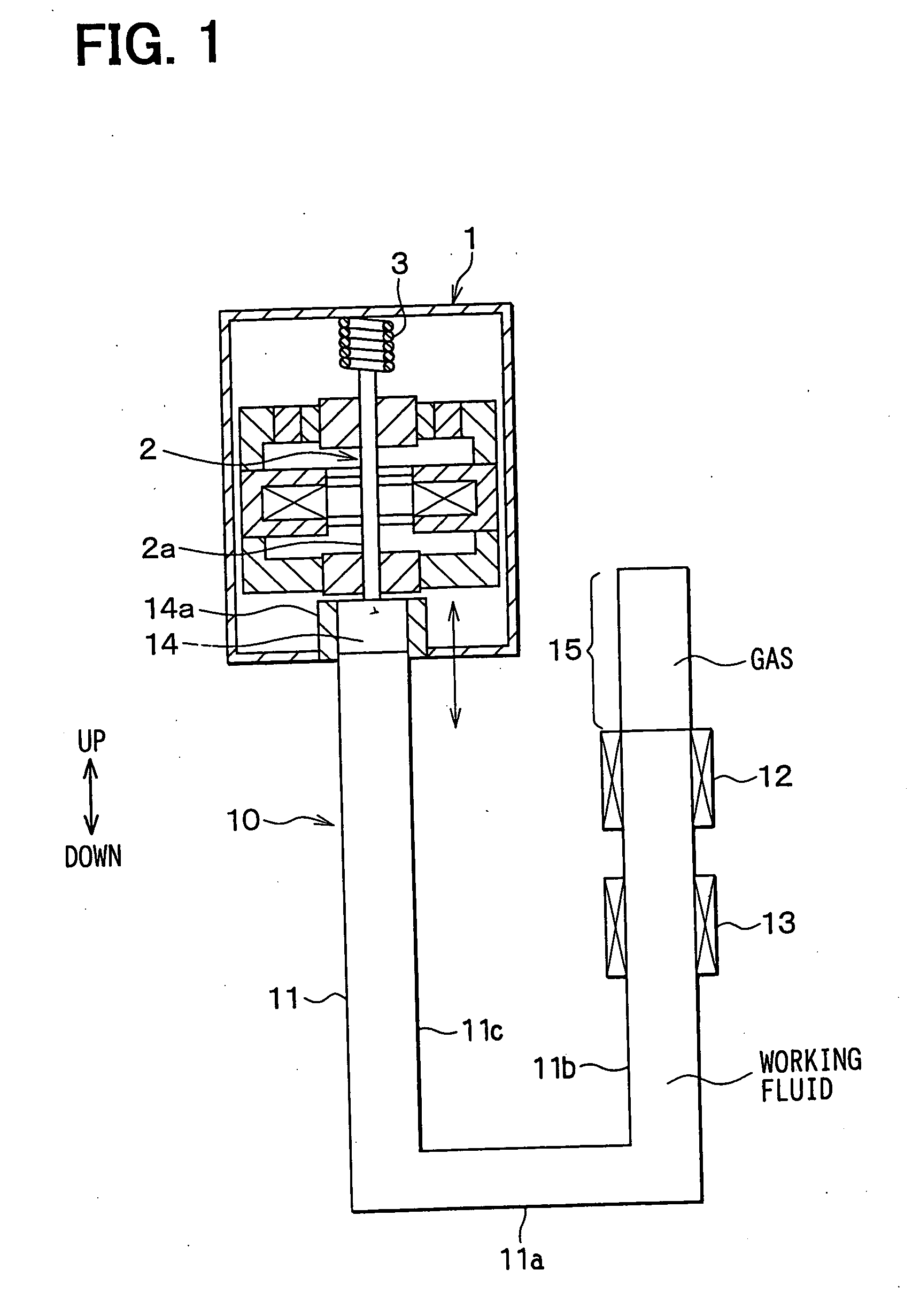

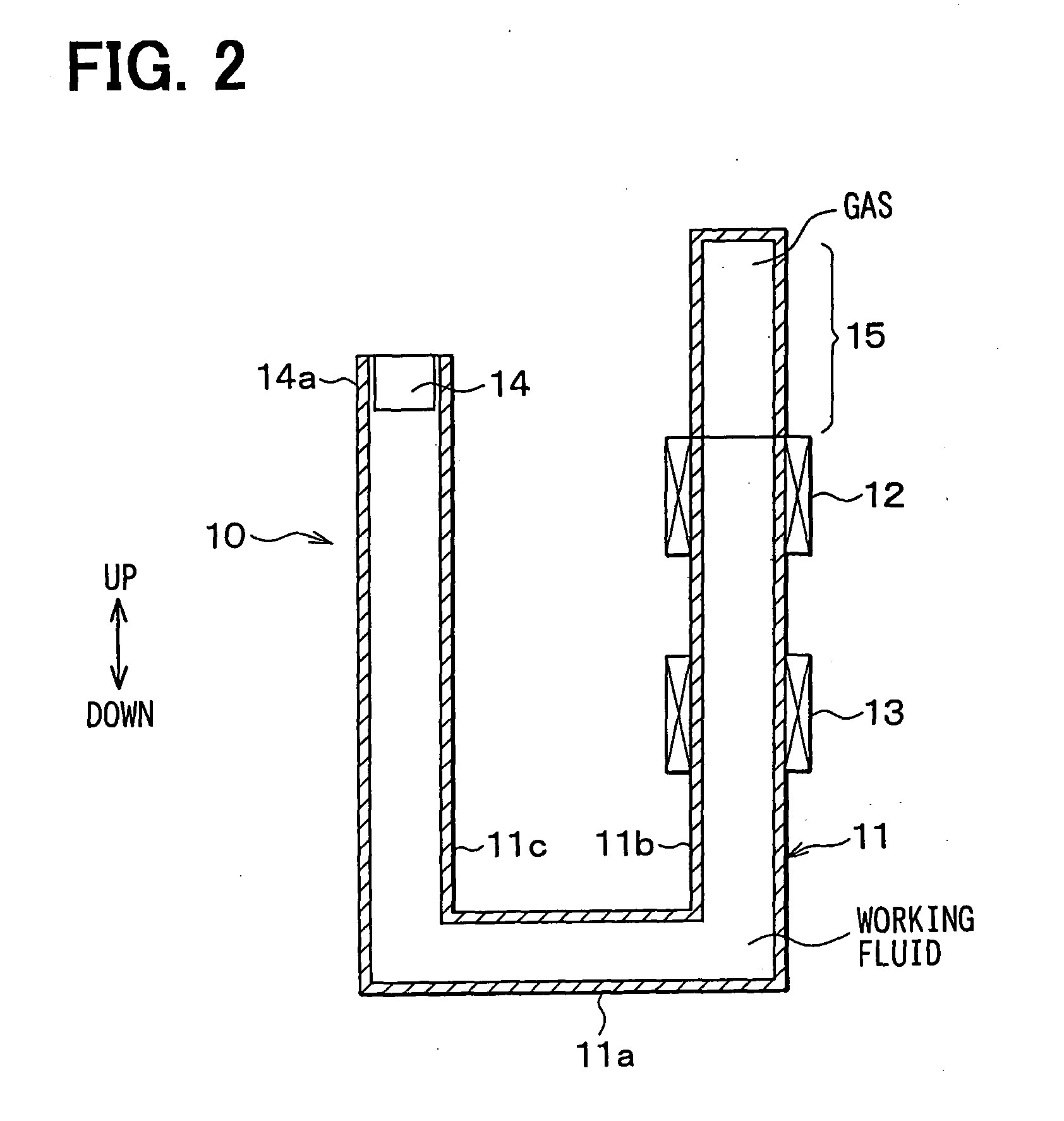

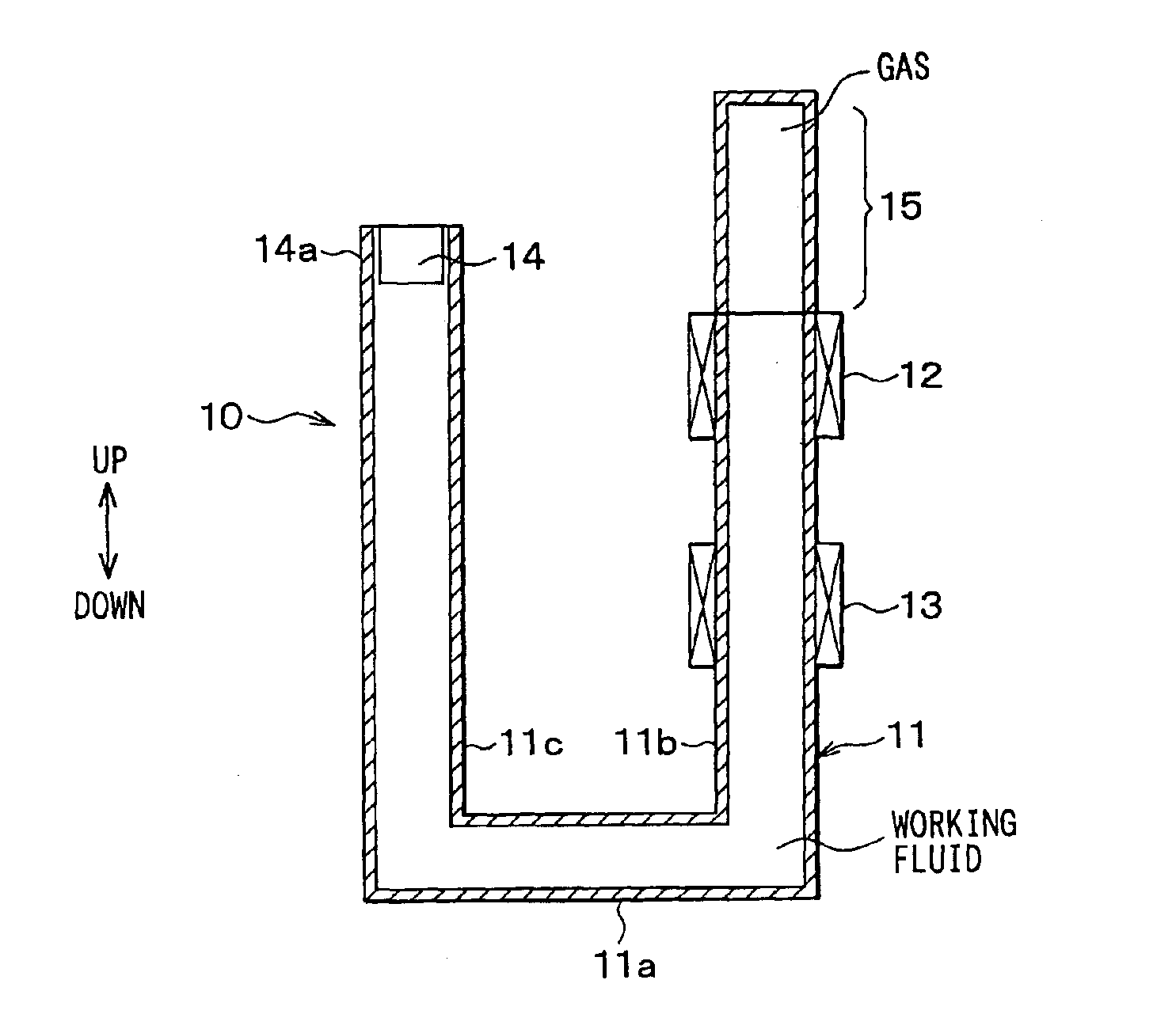

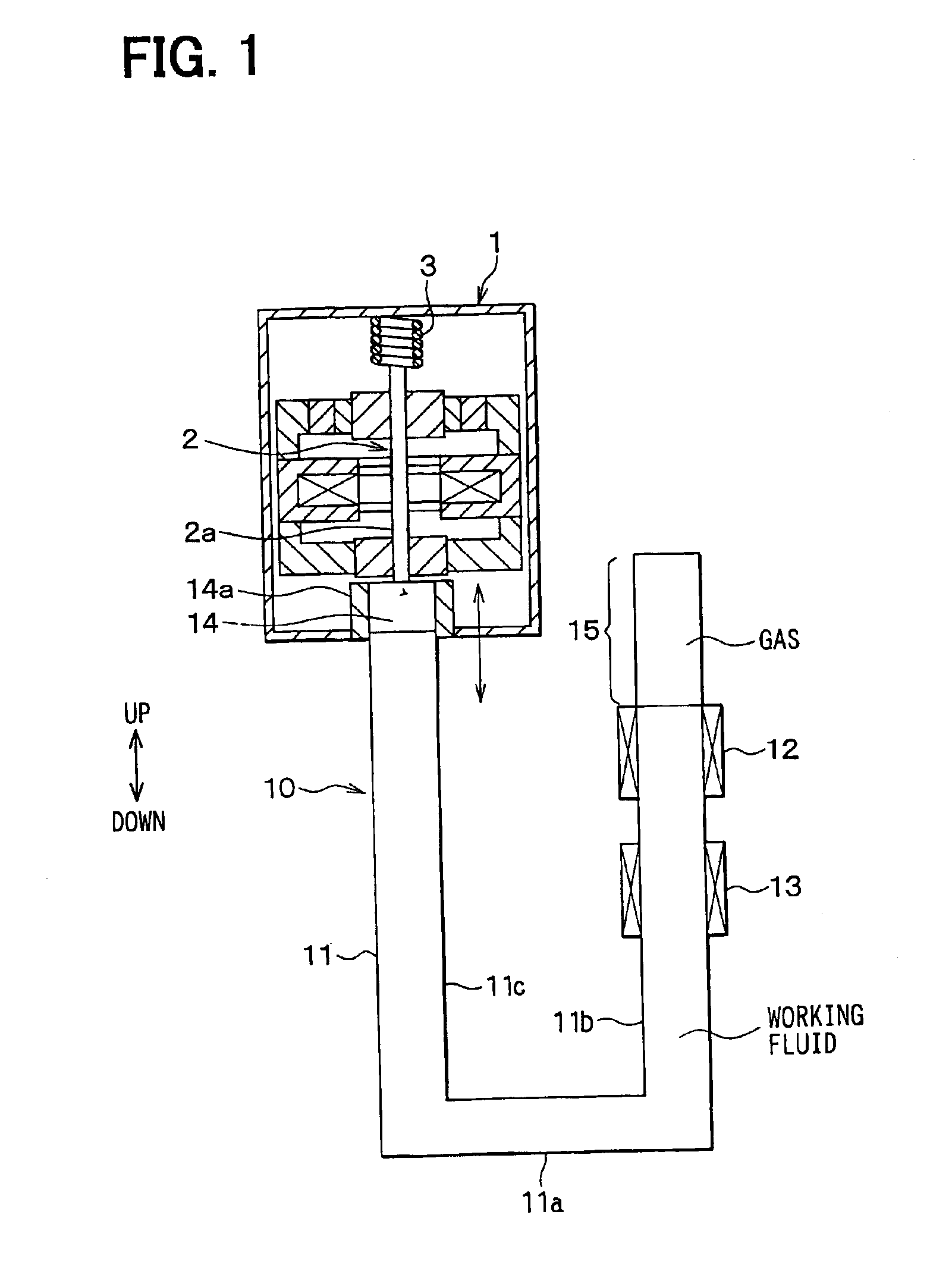

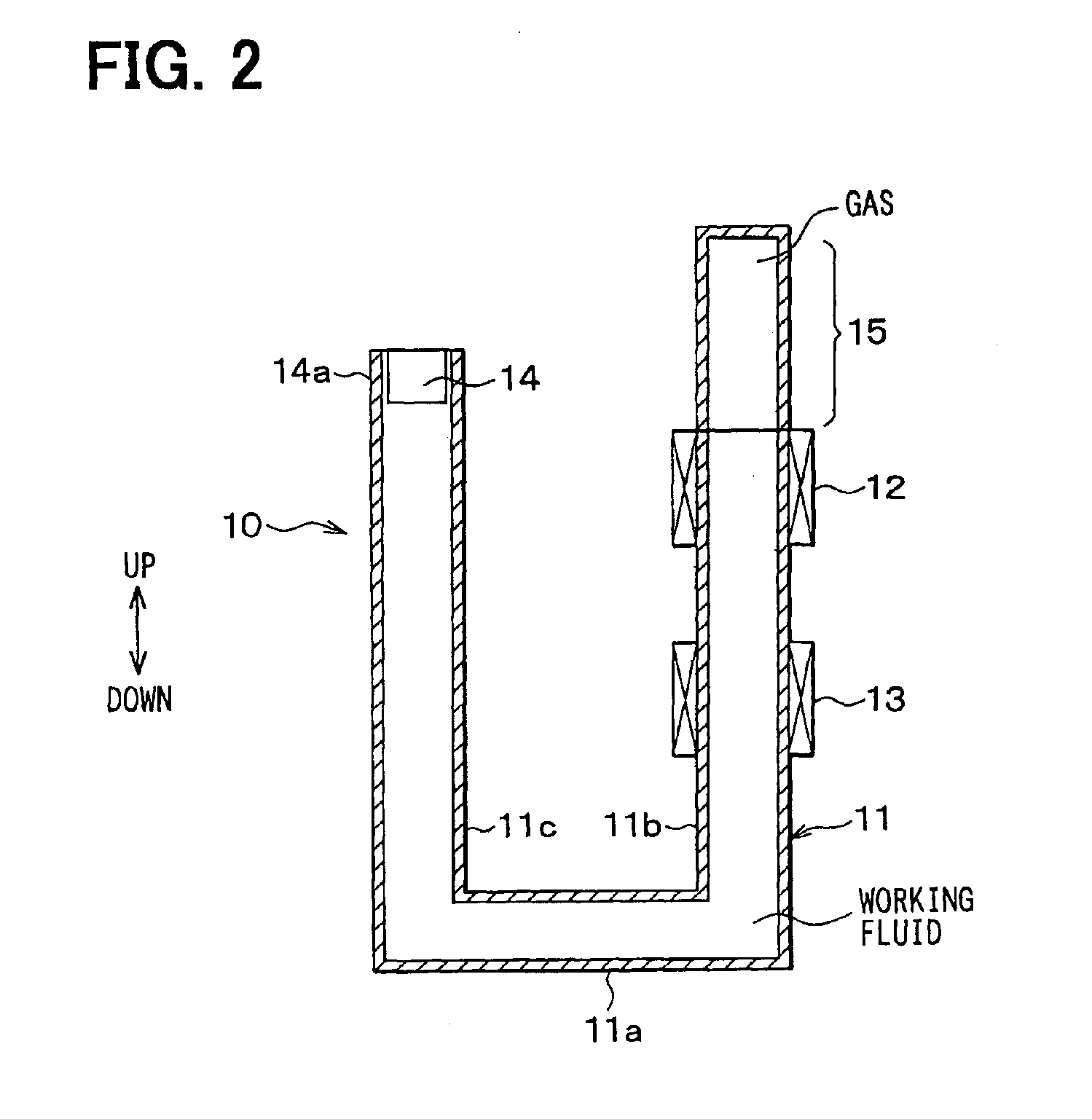

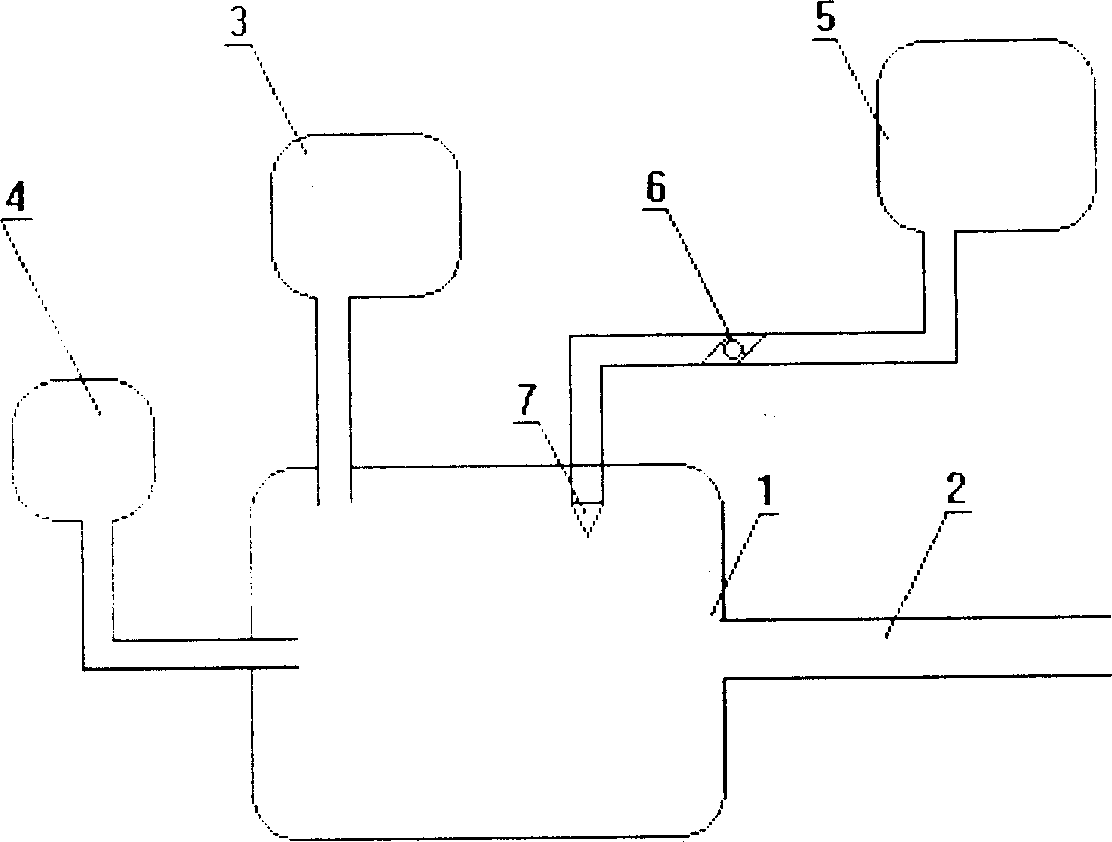

Steam engine

ActiveUS20040060294A1Avoid it happening againAvoid abrasionsSteam accumulatorsEngine componentsSteam pressureWorking fluid

A steam engine increases efficiency and prevents corrosion, abrasion, and the like in a part receiving steam pressure. A heater and a cooler are provided on one side of a U-shaped fluid container, and a piston for output is provided on its other side. The heater heats working fluid to vaporize the fluid. The expansion pressure of steam of the working fluid depresses a fluid level in a first vertical pipe. The liquid component of the working fluid flows from the first vertical pipe into a second vertical pipe, thereby applying pressure to the piston in an upward direction. Then, the liquid component of the working fluid functions as a liquid piston directly receiving the expansion pressure of the steam, so that it is possible to prevent the occurrence of corrosion, abrasion and the like in the part receiving steam pressure.

Owner:DENSO CORP

Drip-free garment steamer

Owner:TOBIAS ANDREW J

Steam engine

A steam engine increases efficiency and prevents corrosion, abrasion, and the like in a part receiving steam pressure. A heater and a cooler are provided on one side of a U-shaped fluid container, and a piston for output is provided on its other side. The heater heats working fluid to vaporize the fluid. The expansion pressure of steam of the working fluid depresses a fluid level in a first vertical pipe. The liquid component of the working fluid flows from the first vertical pipe into a second vertical pipe, thereby applying pressure to the piston in an upward direction. Then, the liquid component of the working fluid functions as a liquid piston directly receiving the expansion pressure of the steam, so that it is possible to prevent the occurrence of corrosion, abrasion and the like in the part receiving steam pressure.

Owner:DENSO CORP

Internal combustion engine with auxiliary steam power recovered from waste heat

ActiveUS7997080B2Effectively economizeImprove efficiencyInternal combustion piston enginesSteam regenerationExternal combustion engineEngineering

Owner:THERMAL POWER RECOVERY

Steam system

ActiveUS20110005228A1Conducive to stable operationSave energyReciprocating combination enginesCombination enginesSteam pressureEngineering

A steam engine and an electric motor are arranged, which respectively drives an air compressor. The compressed air from the air compressor is supplied to a compressed air using device through a common air tank. The steam is supplied to the steam engine through a steam supply path, and the steam used in the steam engine is supplied to a steam using device through a steam exhaust path. The steam pressure is monitored by a pressure sensor arranged in a steam header ahead of the steam exhaust path. The air pressure is monitored by a pressure sensor arranged in an air tank. A steam supply valve is controlled based on the steam pressure and the air pressure, and the electric motor is controlled based on the air pressure. The steam engine is preferentially driven over the electric motor by shifting the target value of the air pressure.

Owner:MIURA COMPANY LIMITED

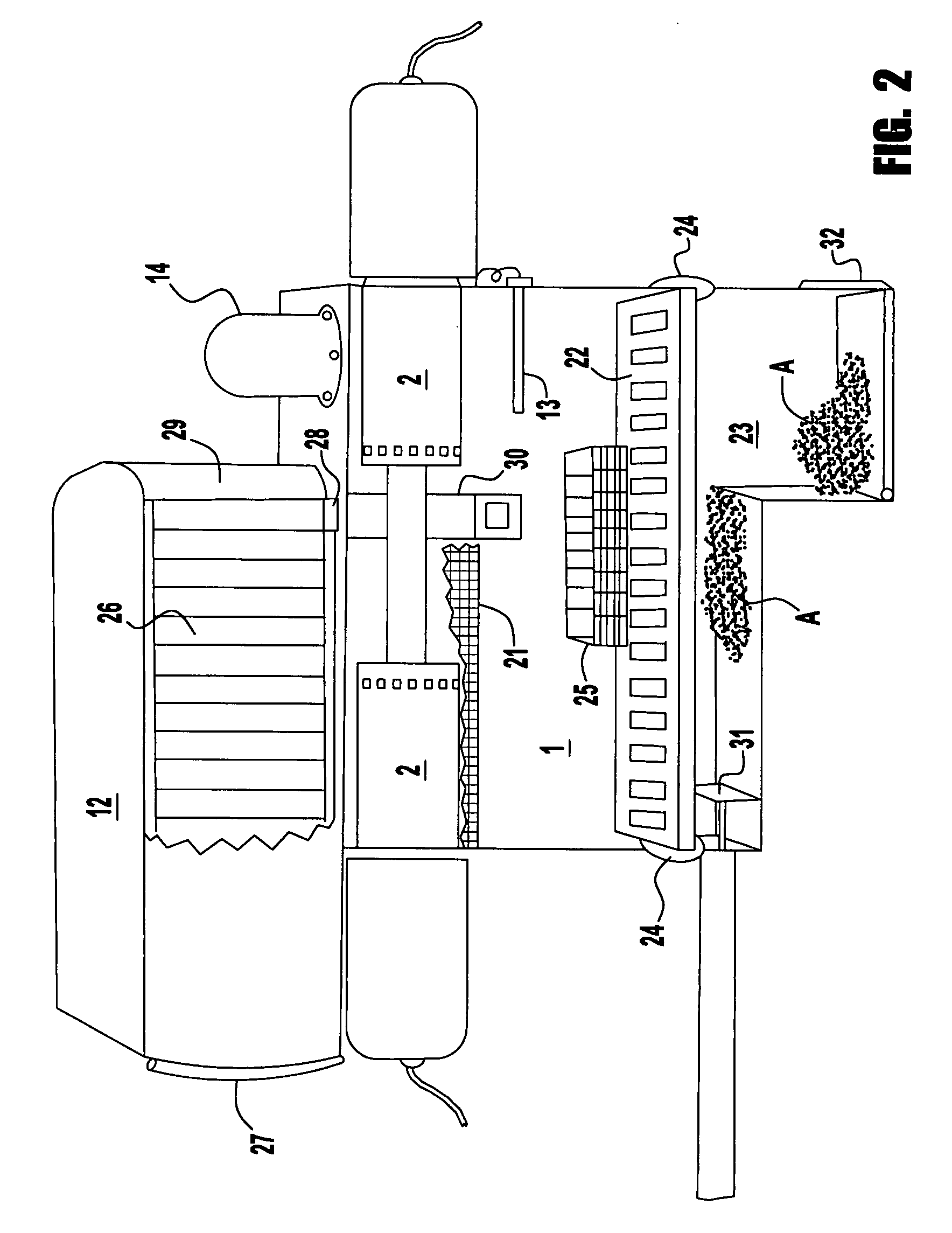

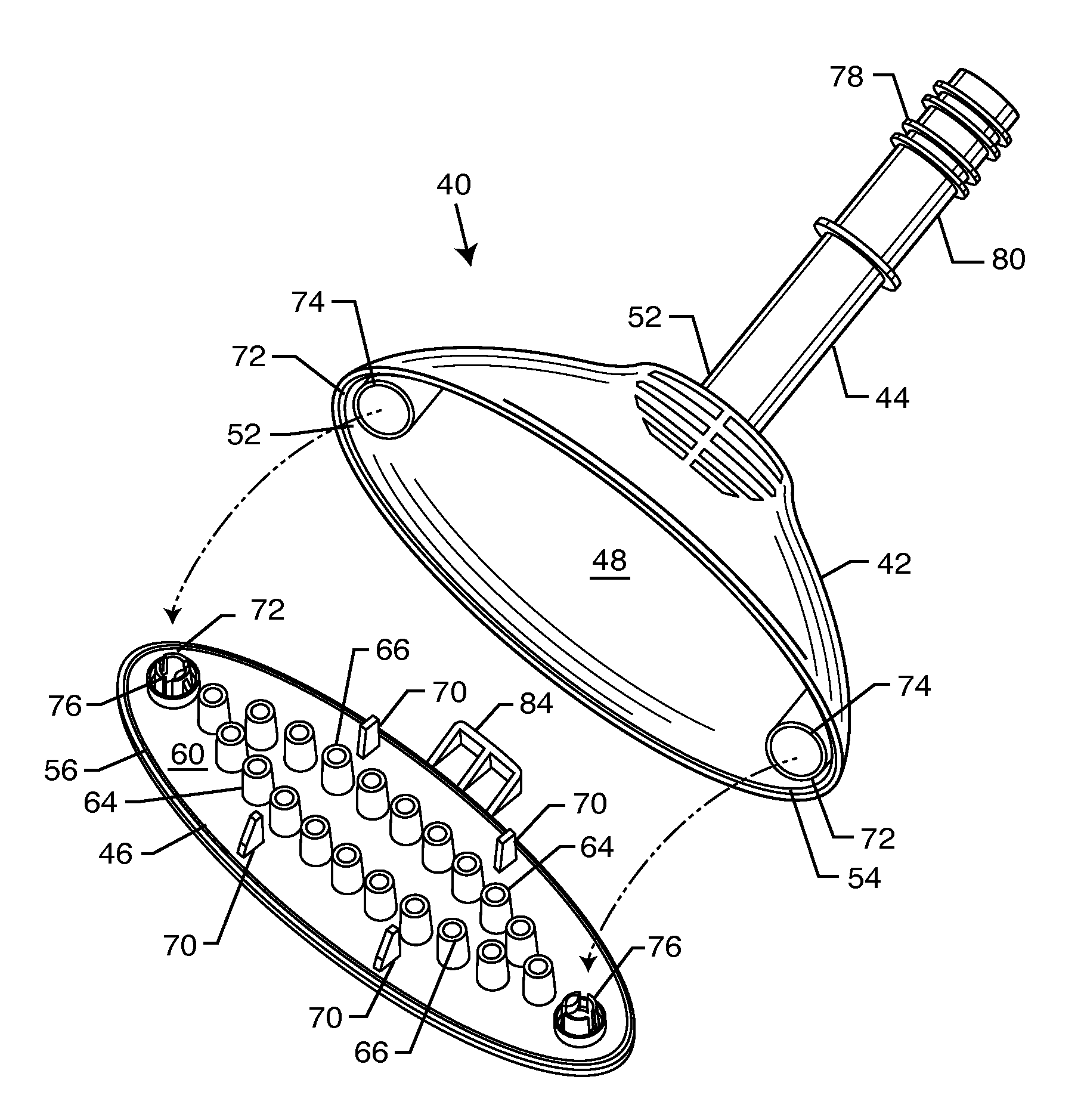

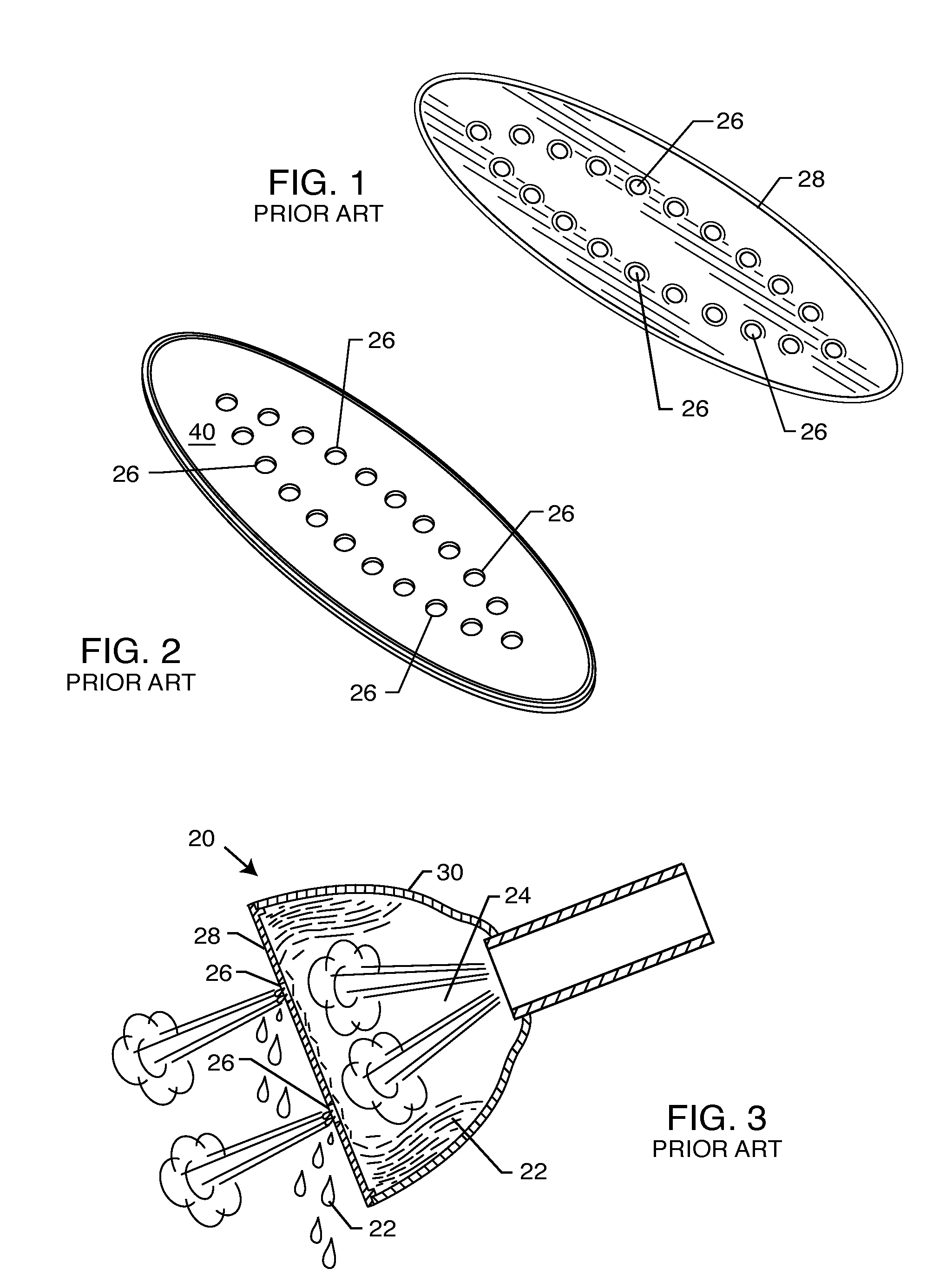

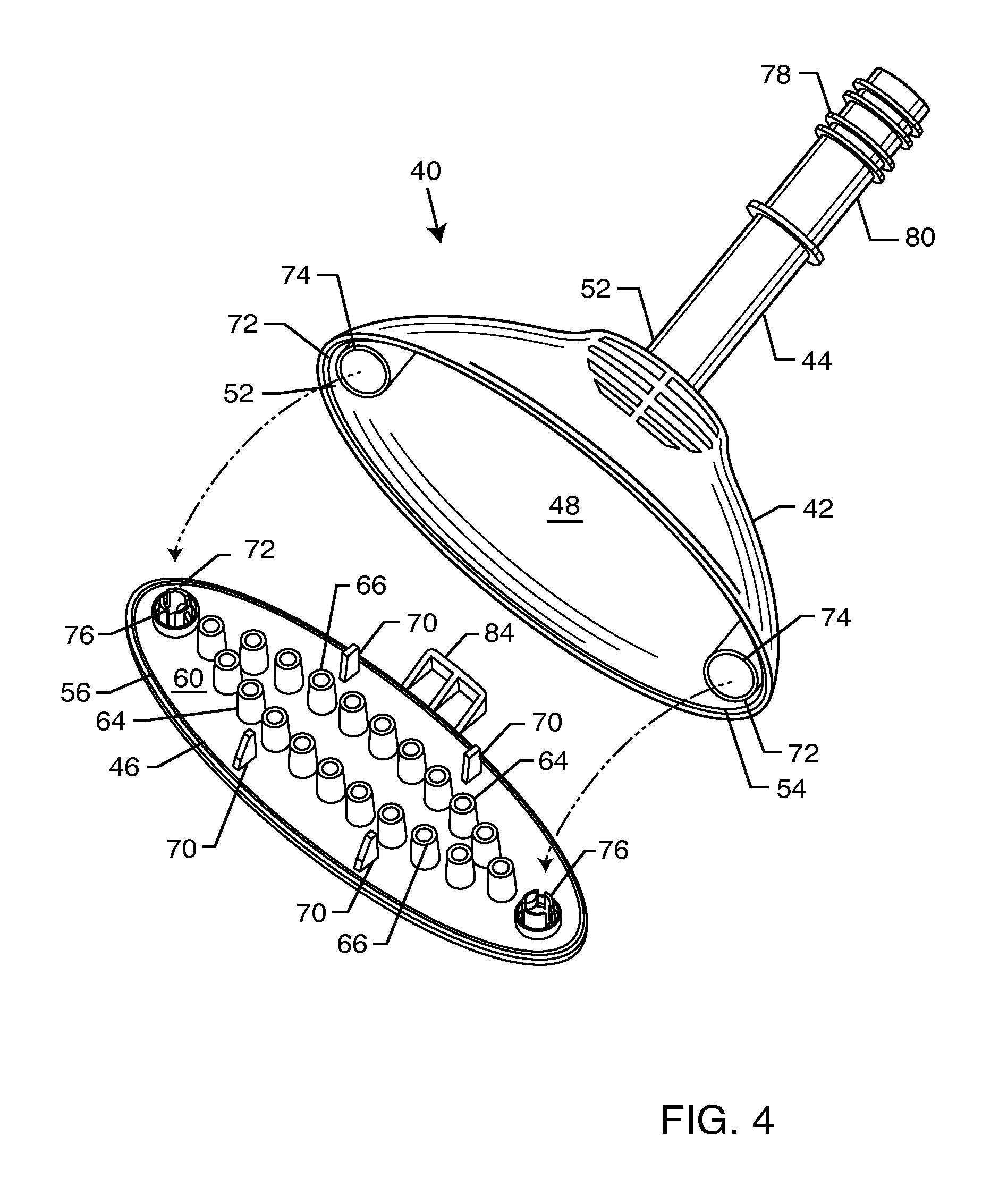

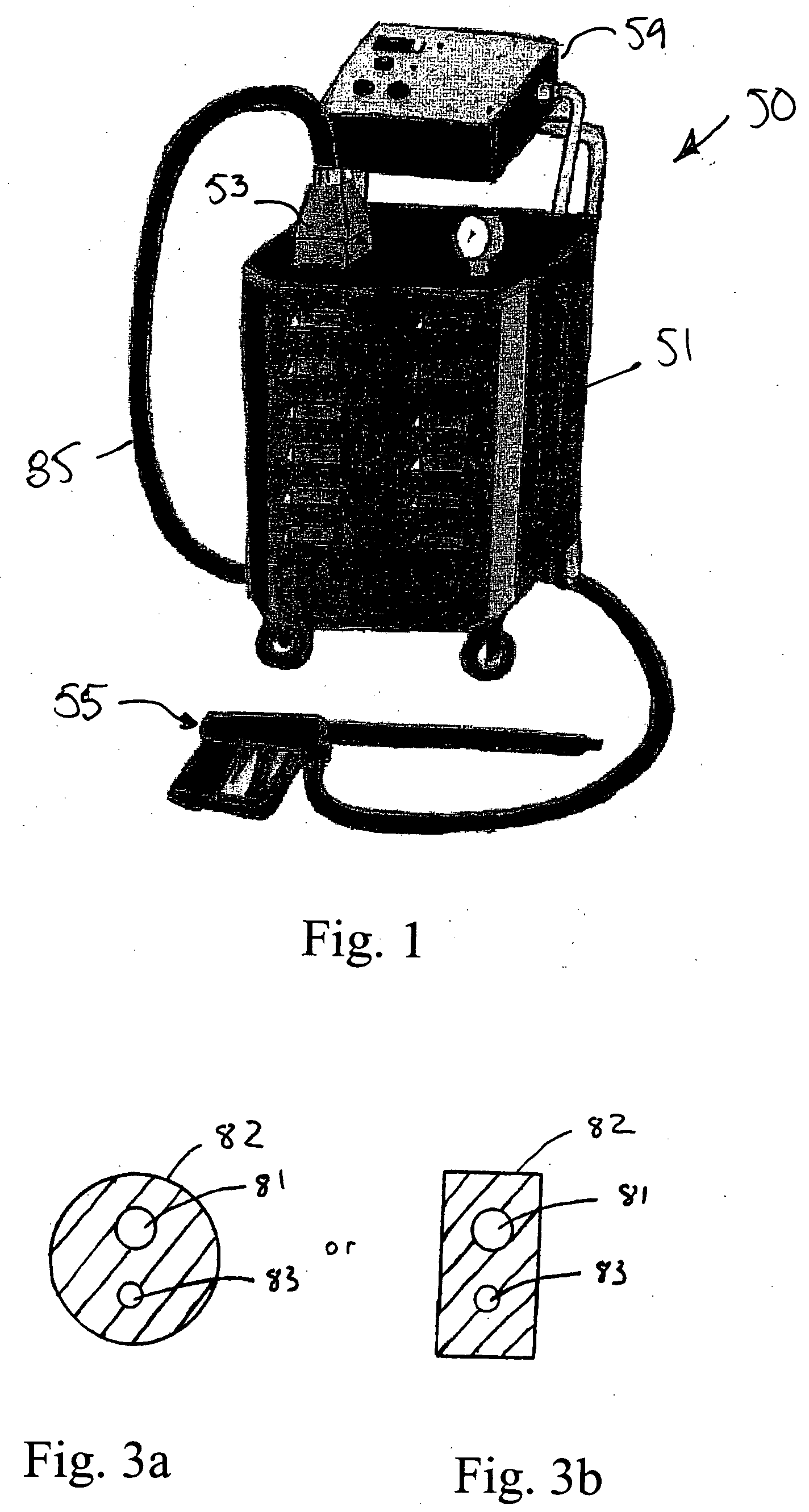

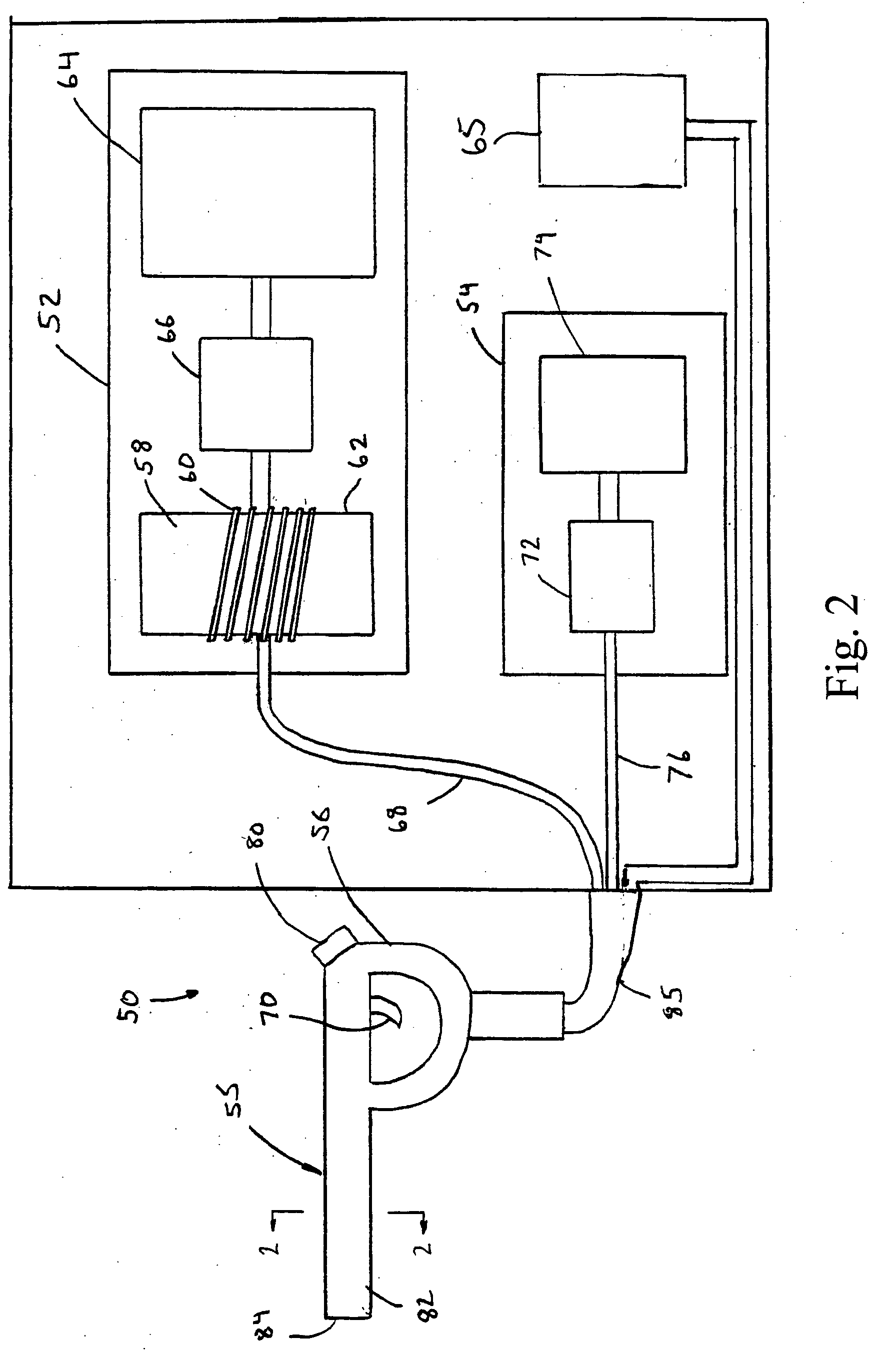

Low pressure saturated steam cleaning assembly with chemical delivery system

InactiveUS20050178410A1Low volumeAvoid collateral damageElectrostatic cleaningCleaning using liquidsSurface cleaningHigh pressure

The present invention provides a steam cleaning system comprising a housing and a steam generating system for producing a low pressure, superheated saturated steam. A steam dispensing system comprising a water reservoir and a pump feeding the water into a steam producing boiler, is coupled thereto for dispensing the steam from the system to at least one first outlet port. A cleaning solution dispensing system is provided, having at least one reservoir for a cleaning solution, and a pump system for dispensing a predetermined amount of a cleaning solution from said at least one reservoir to at least one second outlet port. The at least one first and second outlet ports are positioned adjacent one another, such that a mixture of cleaning solution and saturated steam at a low pressure and low volume of steam and cleaning solution is dispensed from the system. The present invention is particularly suited to clean objects off the floor, vertical surfaces such as glass, and small areas of floor. Because of the small volume of water and chemicals used, it can be used indoors, as well as mounted on mobile platforms such as trucks, buggies, utility vehicles, automatic floor scrubbers or the like. The system also provides for cleaning of roads, sidewalks, exterior structures, or for spot cleaning or cleaning of surfaces in difficult environments. The low pressure, superheated, saturated steam cleaning assembly of the present invention provides low pressure (10 Bar) operation, and relies upon superheated steam temperatures coupled with environmentally friendly chemicals as an abrasive force, thus avoiding any collateral damage usually caused by the high pressure output. The present invention only applies 3 to 10 gallons of water an hour, depending on the size of the machine, while a conventional high-pressure washer / steamer will use 240 gallons per hour.

Owner:LEVY MOISE MAURICE

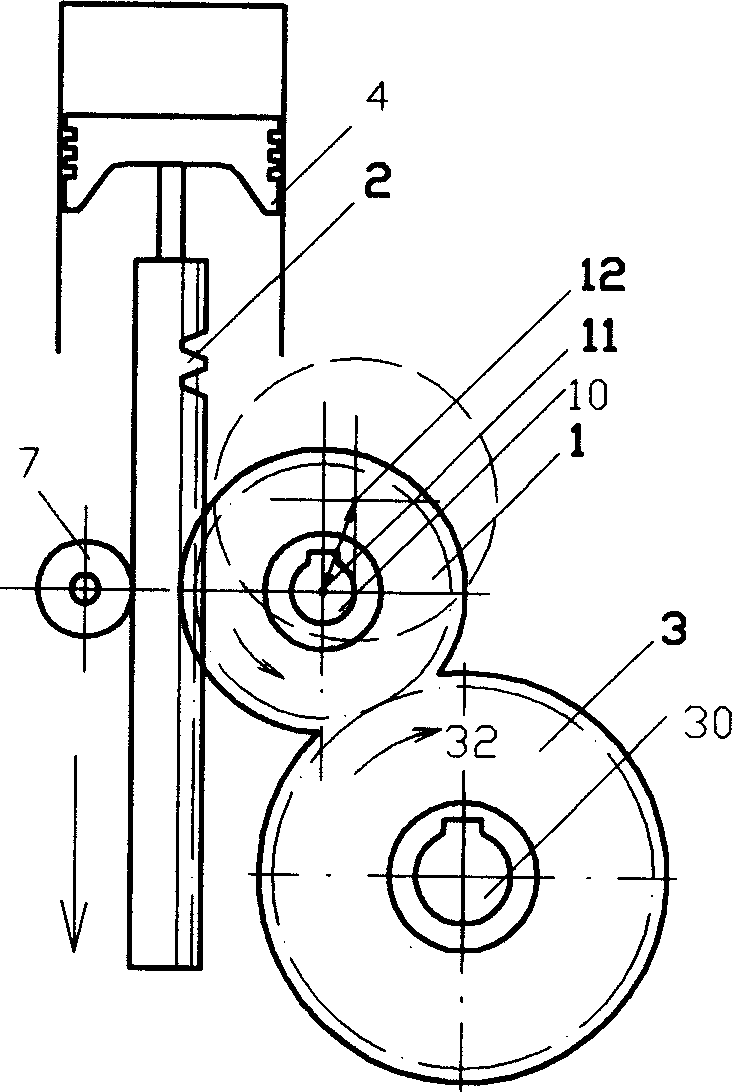

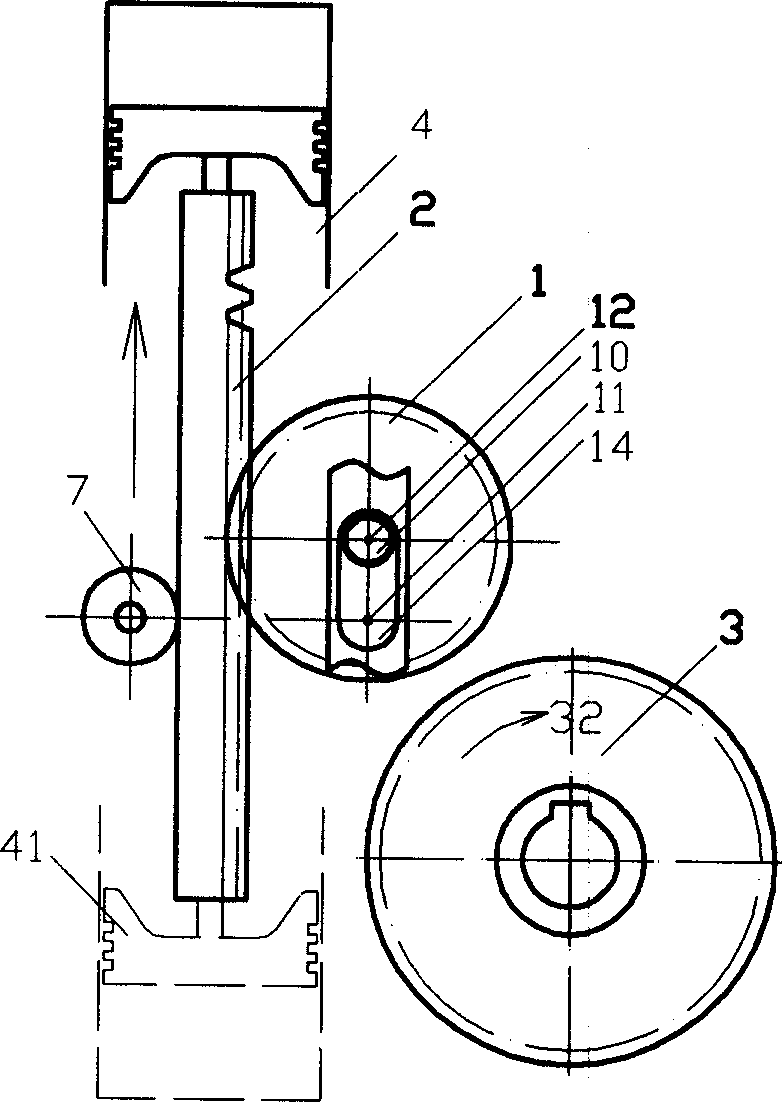

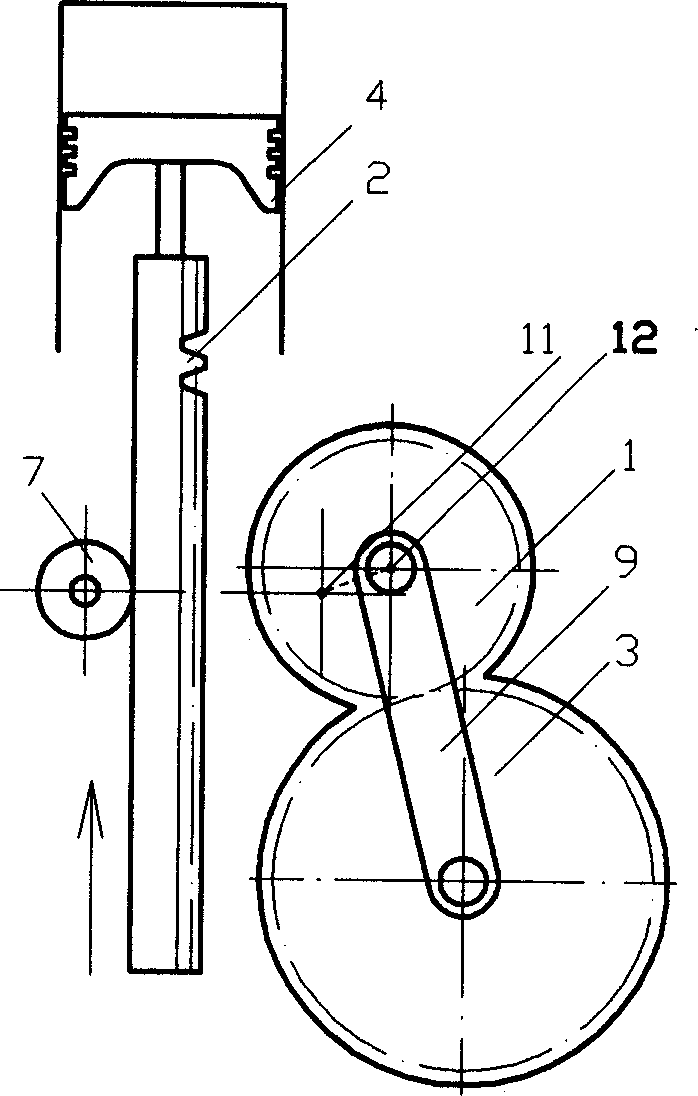

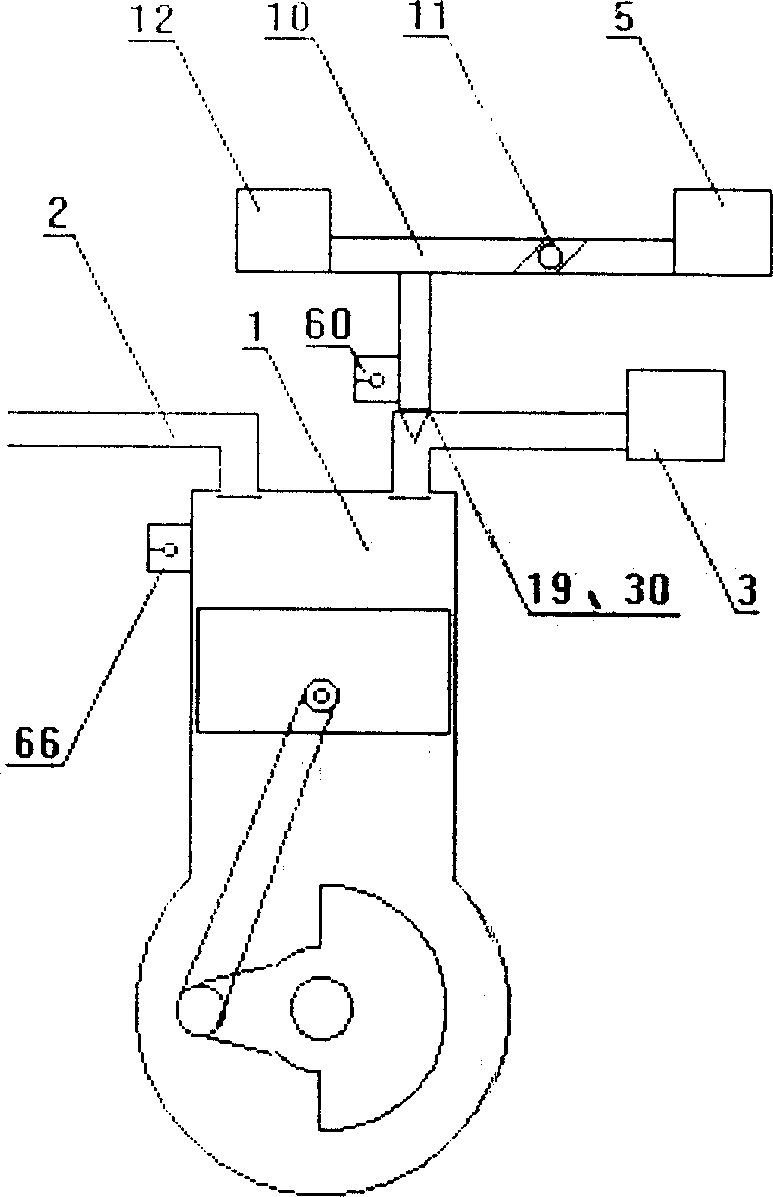

Piston crankshaftless engine

InactiveCN1529045ASimplify the constituent elementsSimple designMachines/enginesLine shaftGear wheel

The invention discloses a kind of piston engine without crank, a power converting mechanism made up of mobile gear, gear rack connected to the piston and the driving gear fixed on the straight output main shaft replaces traditional crank link mechanism, and it overcomes the deficiency of current crank-less engine; the mobile gear can move between the connection position and the non-connection position, thus the dynamic force device between the gear rack and the driving gear can be in on / off state; in the exposure distance of the piston, it can transmit force to the main shaft through the force transmitting chain; the back movement of piston doesn't affect the movement of the output main shaft; along with the joining movement of mobile gear, by mating with the other assistant system, the reciprocate straight movement can be changed into the power output with continuous single direction rotation of main shaft. The converter can be used in gasline, diesel, gas inner combustion machine.

Owner:程远

Steamer

InactiveUS20100058623A1Easy to controlReduce fatigueSteam generation heating methodsSpray nozzlesSteam engine

The invention is a steamer head, which includes a steamer body having a front face having at least one steam hole, the steam hole being in fluid communication with a steam chamber; and a crease panel assembly movably connected to the steamer body, the crease panel having a crease panel face, wherein the crease panel face has at least a portion in substantially parallel orientation to the front face.

Owner:PRODS OF TOMORROW

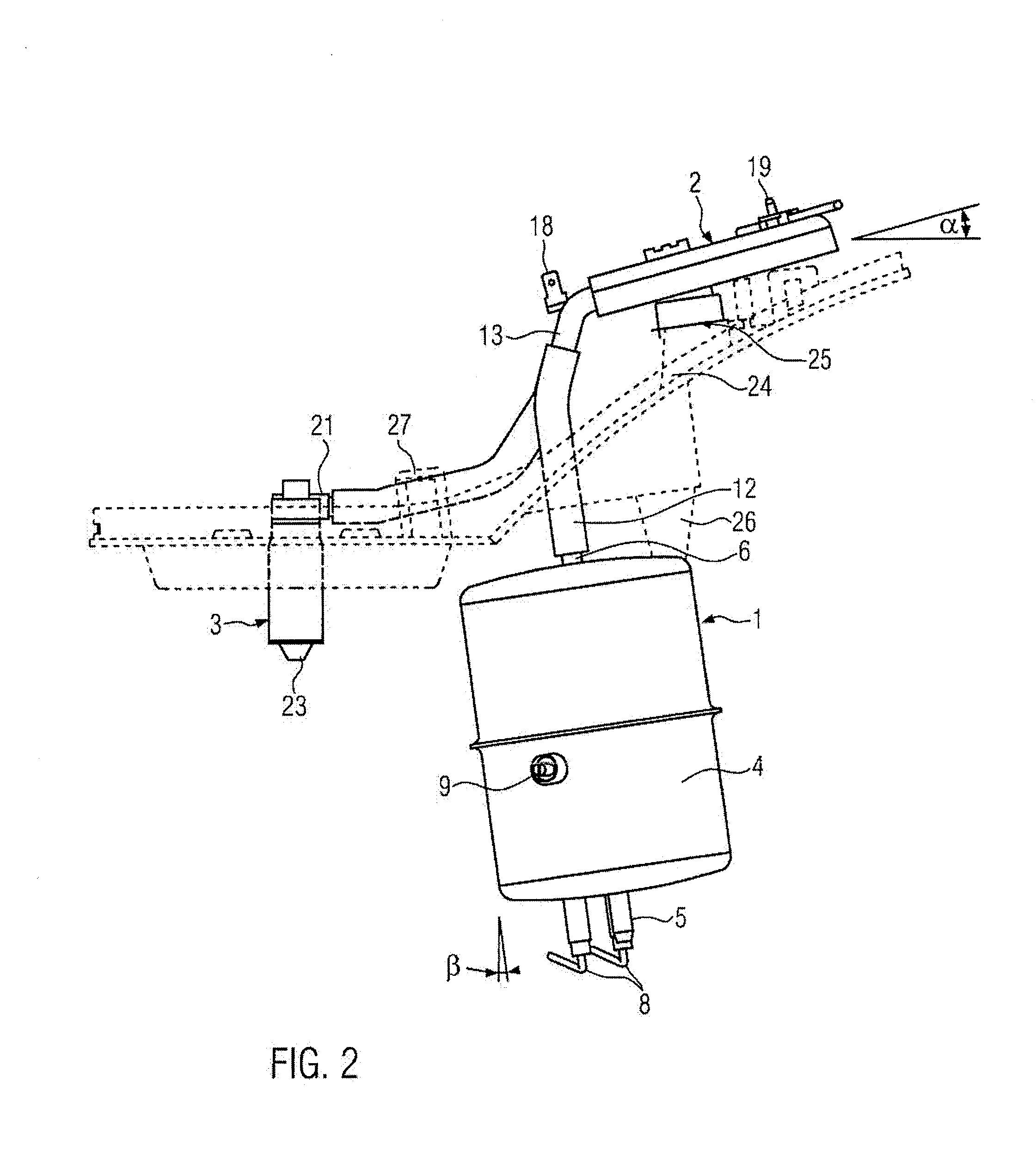

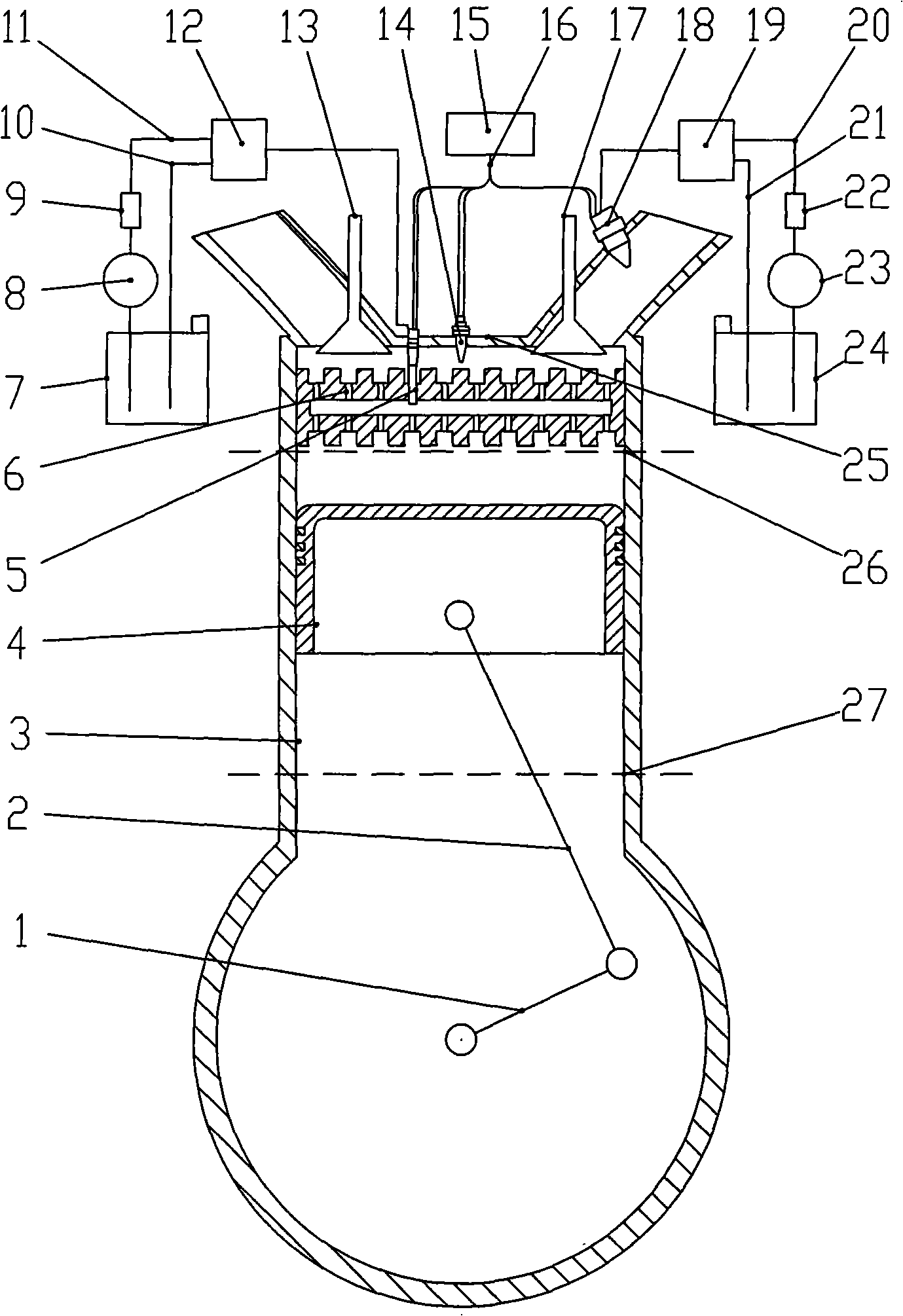

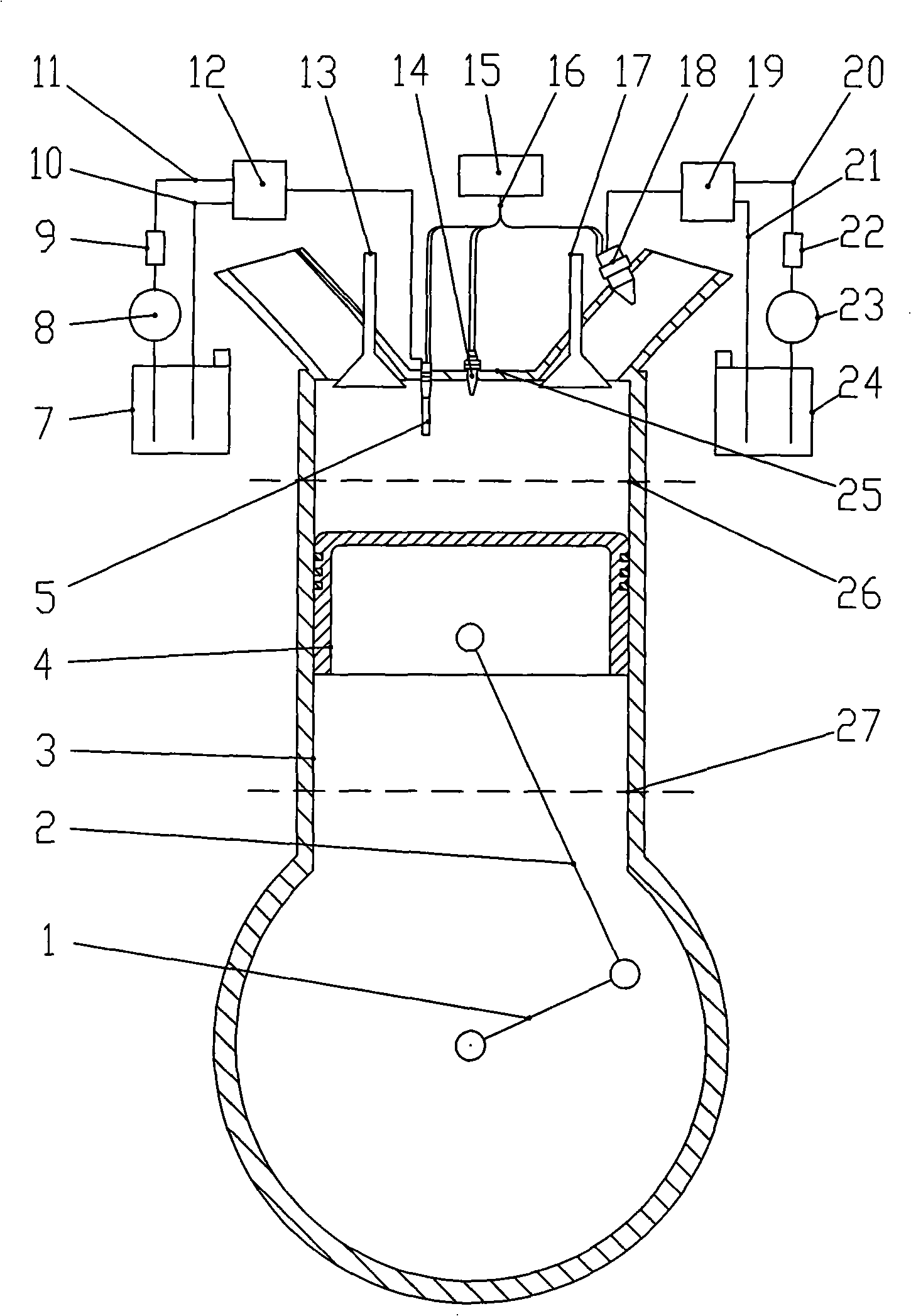

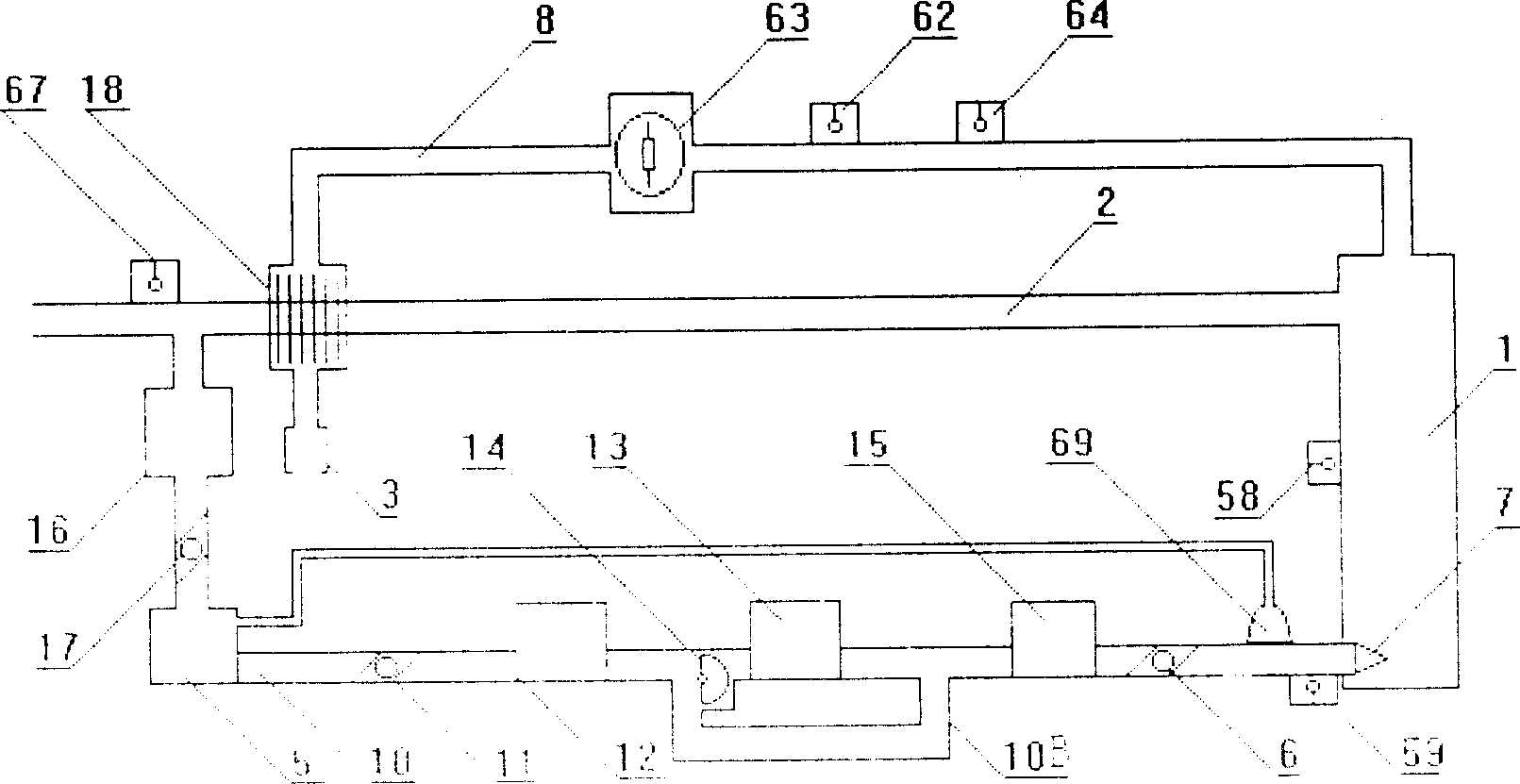

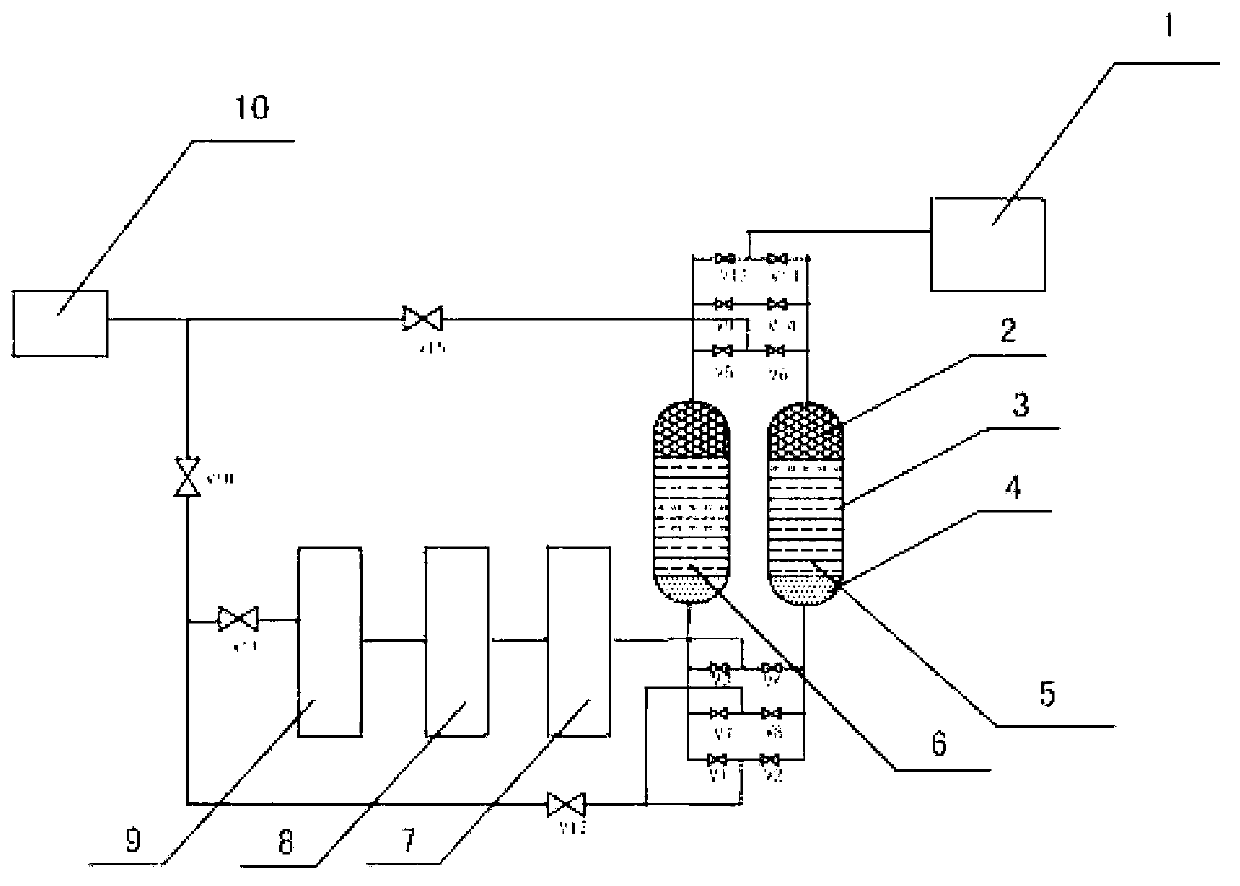

Internal combustion directly-heating steam engine

InactiveCN101403350AImprove thermal efficiencyLarge heat capacityNon-fuel substance addition to fuelInternal combustion piston enginesExhaust valveWater filter

The invention relates to an internal-combustion straight-heating steam engine which takes fuel as energy and is based on the structure of an internal-combustion engine. The internal-combustion straight-heating steam engine consists of a crankshaft 1, a connecting rod 2, a cylinder 3, a piston 4, a sprinkler 5, a heat storage carburetor 6, a water tank 7, a high-pressure hydraulic pump 8, a water filter 9, a return pipe 10, a conduit pipe 11, a water pressure regulator 12, an exhaust valve 13, a spark plug 14, an electrical control assembly 15, a wiring harness 16, an intake valve 17, an oil atomizer 18, an oil pressure regulator 19, an oil delivery pipe 20, an oil return pipe 21, a gasoline filter 22, a high-pressure oil pump 23, an oil tank 24 and a cylinder cover 25, and is characterized in that: the sprinkler is arranged on the cylinder cover, the heat storage carburetor is arranged in the cylinder, and the sprinkler is connected with the water pressure regulator which is connected with the water tank by the high-pressure hydraulic pump. In the expansion stroke, the gas combustion causes the temperature in the heat storage carburetor to rise, the sprinkler sprays right amount of water into the heat storage carburetor, then the water is vaporized, and the steam drives the piston to move so as to output mechanical energy. The internal-combustion straight-heating steam engine is characterized by high efficiency, energy saving, environmental protection, and the like.

Owner:张寅啸

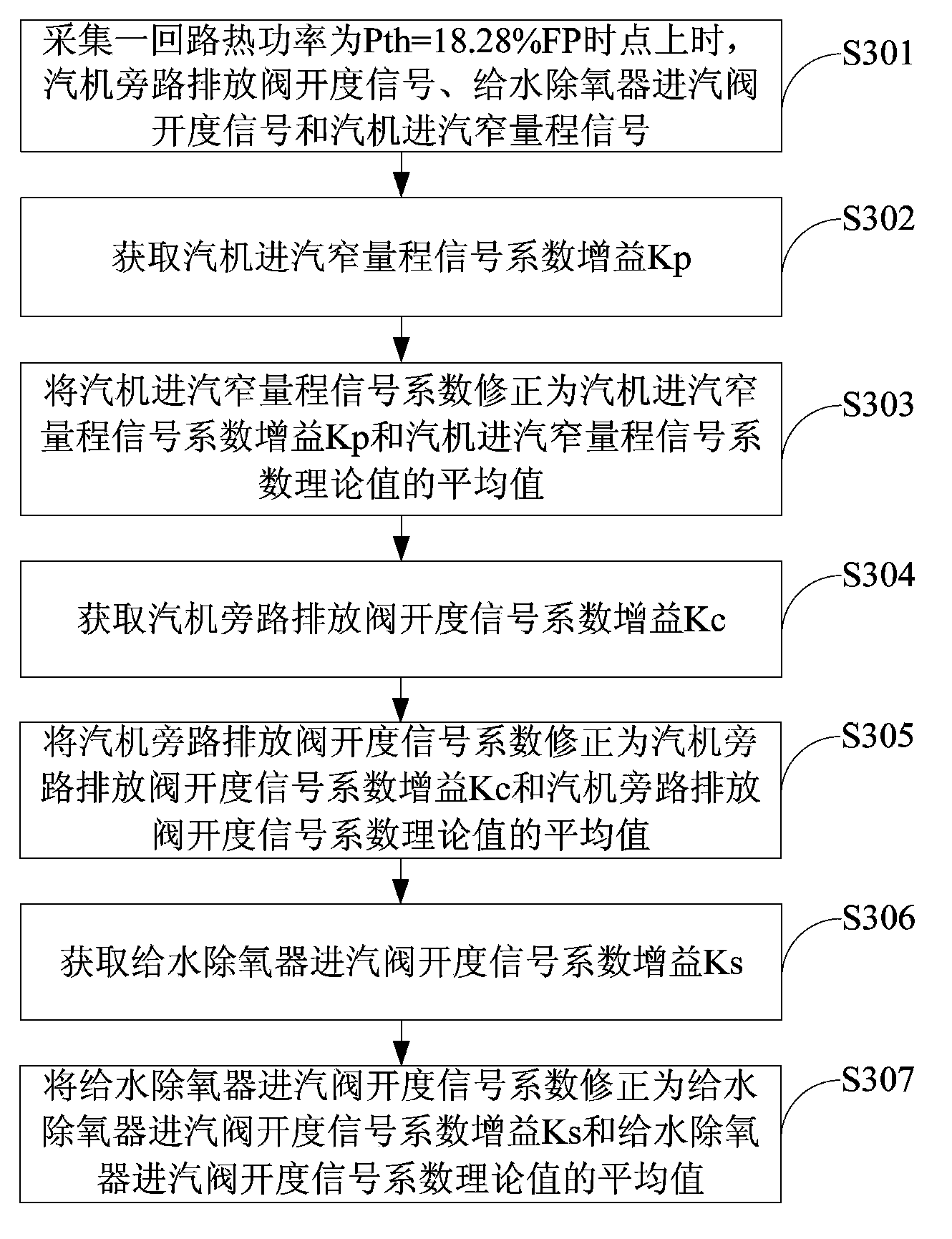

Coordination control method and system for rapid peak-load shaving of thermal power generating unit

The invention discloses a coordination control method and system for rapid peak-load shaving of a thermal power generating unit. An improved DEB boiler load command is adopted in the coordination control system of the thermal power generating unit for ensuring that the main vapor pressure control deviation is low when the load of the thermal power generating unit is changed in the peak-load shaving, the boiler can be rapidly adaptive to the output of a steam engine when the load of the thermal power generating unit is changed; a calculation method for the set value of the main vapor pressure of the thermal power generating unit is provided in order to stagger forward overlaying of dynamic compensation parts of the boiler command when the load is changed rapidly, and prevent the changing rate of the boiler command from exceeding an acceptable range of the thermal power generating unit. By adopting the coordination control method, load control rapidness and stability of the running working condition of the thermal power generating unit can be improved extremely; an effective solution is provided for a power grid to improve on the load control rapidness and stability of the unit scheduling, meanwhile, a powerful support is provided for the improvement of the AGC and primary frequency modulation evaluation index of a power plant, so that the method and system have important significance for improving the admission performance of new energy sources.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

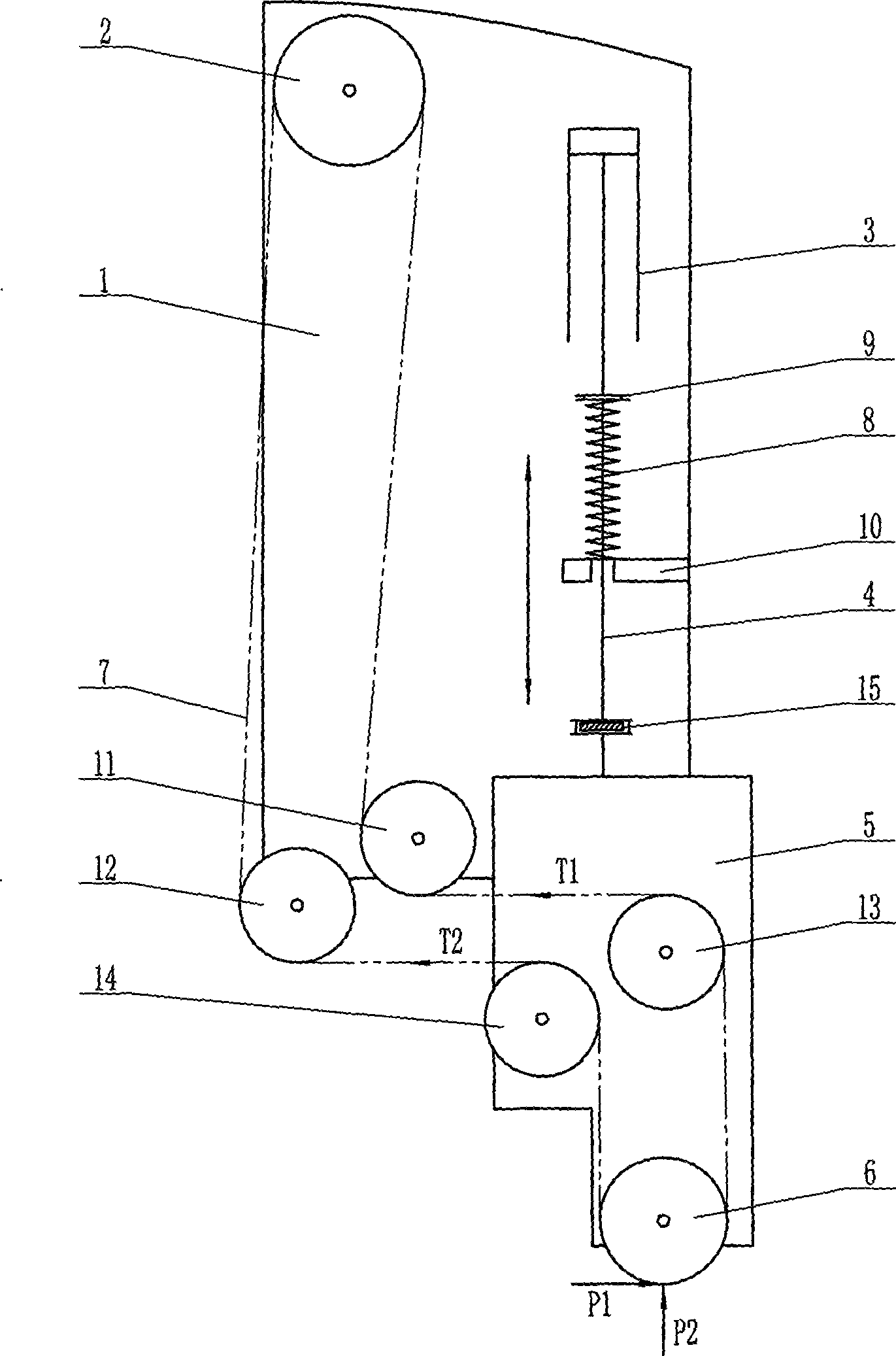

Floating belt grinding device with feed back and adjustable pressure

ActiveCN101439491AEliminate the effects of self-weightImprove machining accuracyBelt grinding machinesDrive wheelSlide plate

The invention provides a pressure-adjustable floating abrasive belt grinding device with a feedback. The upper part of a supporting plate is provided with a driving wheel and a cylinder; the piston rod of the cylinder faces downwards vertically and is connected with a fine-adjustment sliding plate by a guide column; the bottom end of the fine-adjustment sliding plate is provided with a contact wheel which is connected with the driving wheel by an abrasive belt which coils an idler wheel; a guide column is movably sheathed by a spring which is in a normal-compression state; the position of the upper end of the spring is limited by a nut which is fixed on a guide column; the position of the lower end of the spring is limited by a baffle which is fixed on the supporting plate; furthermore, the guide column passes through the baffle. The grinding device eliminates the effects of the self-gravity of the grinding head during the grinding process by an added spring mechanism, controls the grinding pressure of the contact wheel within an allowable error range, keeps constant pressure, thus effectively improving the processing precision of complex curved surfaces such as steam engine vanes; furthermore, the grinding device ensures the quality of the profile of the workpiece, and has the advantages of smart concept, simple structure, easy execution, low reconstruction cost, good consistency of product, wide applicable range, and the like.

Owner:CHONGQING SAMHIDA GRINDING MACHINE

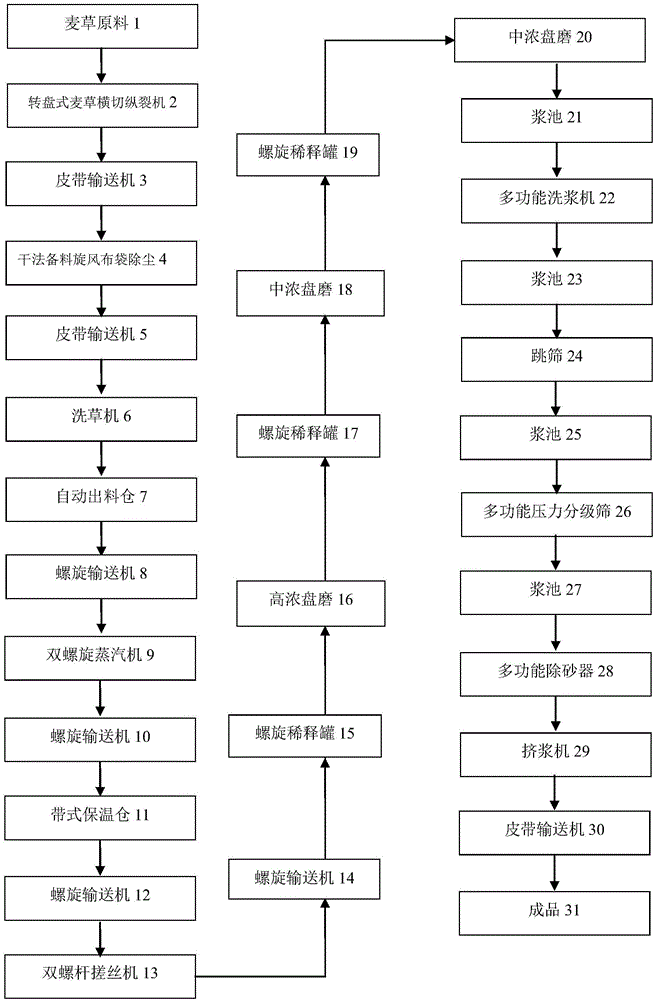

Production process method for novel crop straw environment-friendly material

InactiveCN104631204AHigh strengthDo not damagePretreatment with water/steamFibrous raw materialsHigh concentrationPollution

The invention relates to a production process method for a novel crop straw environment-friendly material. The method comprises the following steps: crushing, drawing and crushing straw raw materials by a rotary table type wheat grass cross-cutting vertical cracking machine; feeding the raw materials into a dry-method stock cyclone cloth bag by a belt conveyor to be subjected to dust removal; conveying the raw materials into a grass washing machine; conveying the raw materials into a double-spiral rotary steam engine, heating and softening; conveying the raw materials into a heat-preservation cabin, carrying out constant-temperature heat preservation and softening; conveying the raw materials into a double-spiral thread-rolling machine, and carrying out thread-rolling treatment; carrying out sub-sectioned grinding treatment on the raw materials by three middle-concentration and high-concentration disc mills in sequence; conveying the ground raw materials into a pulp washing machine; washing and sieving pulp by a jigging sieve pressure sieve; conveying good pulp into a sand removing device, and carrying out sand removing treatment; and finally, conveying the pulp into a pulp extruder to extrude surplus water to obtain a finished product, and conveying the tail pulp into the former link and treating. The production process adopts a pure mechanical treatment machining process and any chemical auxiliary agent is not added into the whole treatment process; and pollution to the environment is not caused and the environment is effectively protected.

Owner:BEIJING JINMENGDI MOLDING TECH DEV

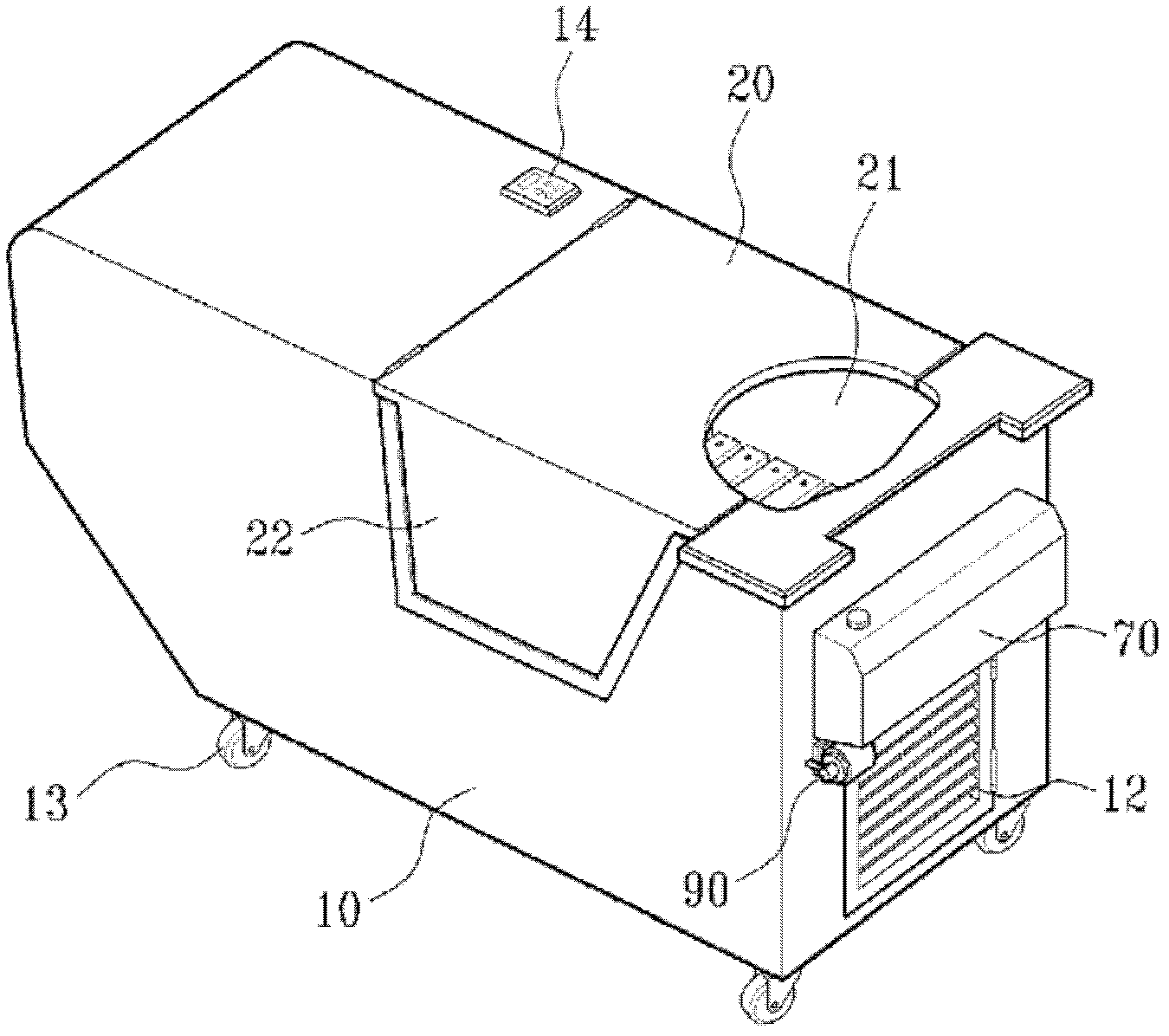

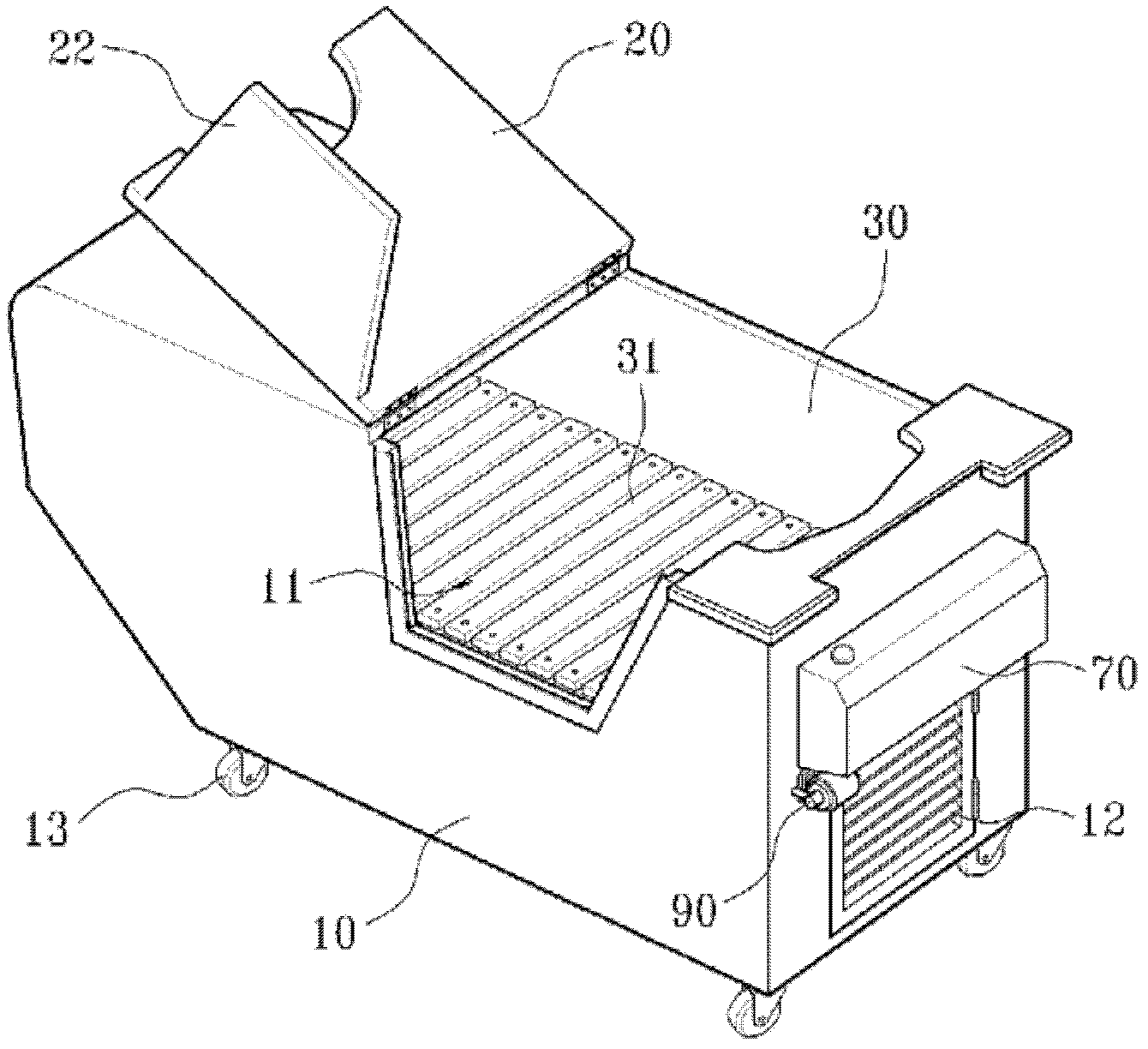

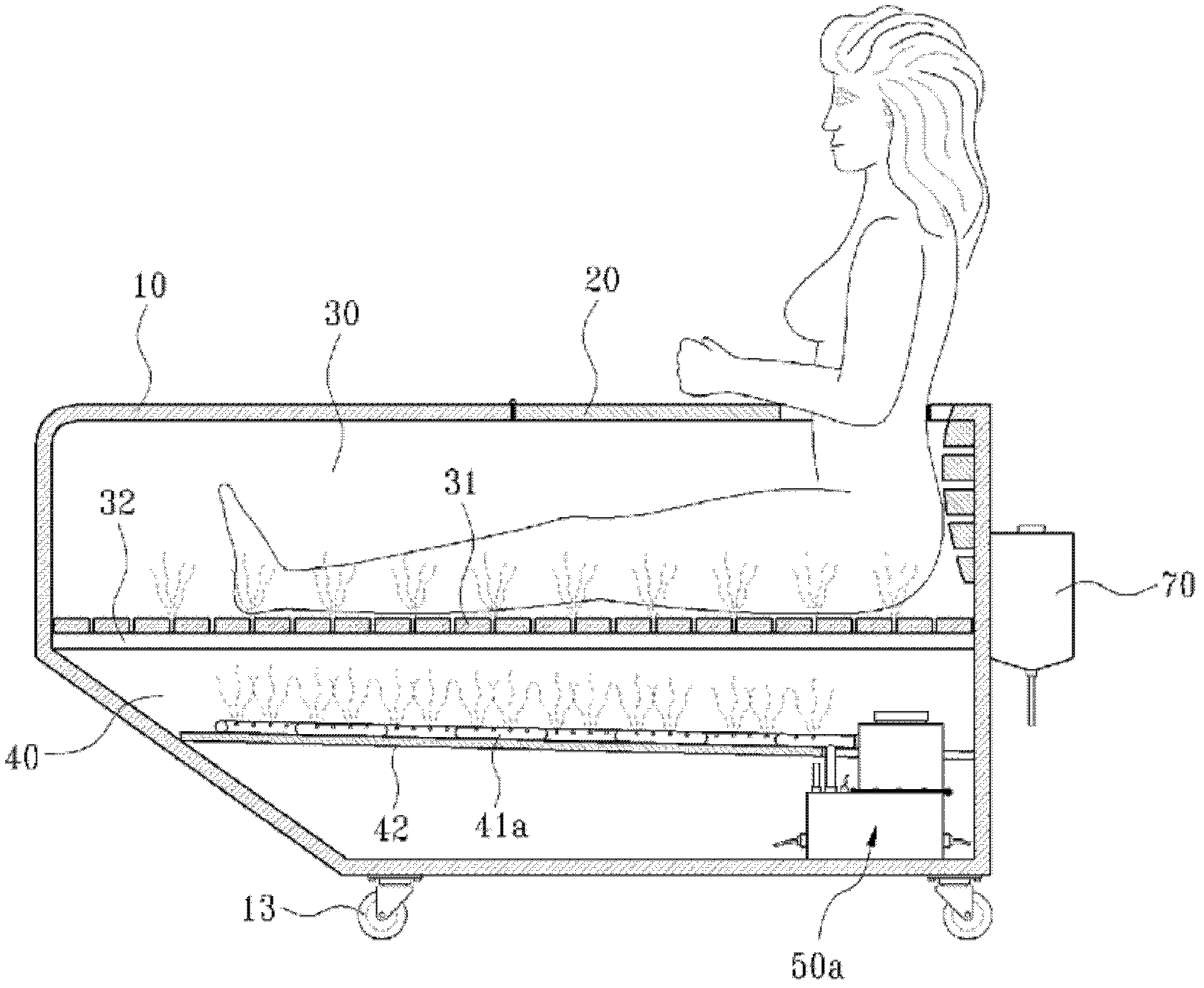

Steam warming half-body bath/sauna machine

InactiveCN102573751AEasy to stretchGenerate good effectBathing devicesDiseaseGynecological disorders

The present invention relates to a half-body bath / sauna machine for activating blood circulation and the metabolism by warming the lower half of the human body by means of steam, and more particularly, to a steam warming half-body bath / sauna machine for warming the lower half of the human body with medicated steam to prevent and treat blood circulation disorders, metabolic functional disorders, gynecological disorders, stress, poor circulation, geriatric diseases, skin disorders and the like, by providing a sauna compartment that enables a user to sit comfortably with the lower half of the body (the legs) straightened, while medicated steam is uniformly fed into the sauna compartment from a steam device through a steam tube, and providing a cover panel integrally formed with an ingress / egress door of the sauna compartment. In addition, the steam warming half-body bath / sauna machine of the present invention is provided with said sauna compartment that enables a user to sit comfortably with the lower half of the body (the legs) straightened, a steam device configured for good steam generation, and a steam tube, which enable the uniform feeding of medicated steam into the sauna compartment, and the amount of steam generated by the steam device can be suitably controlled through precisely controlling the amount of water supplied to the steam device.

Owner:李铉八

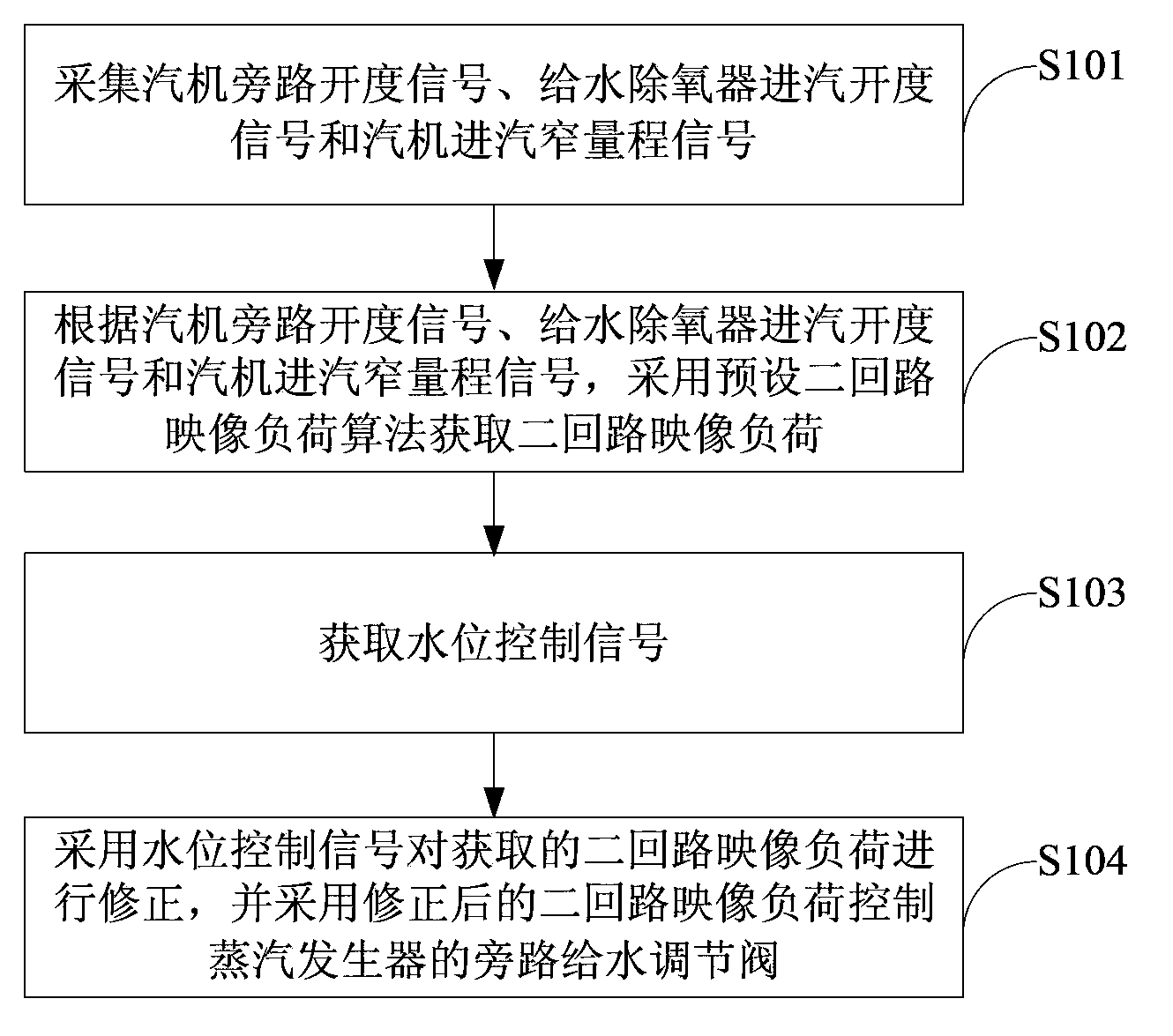

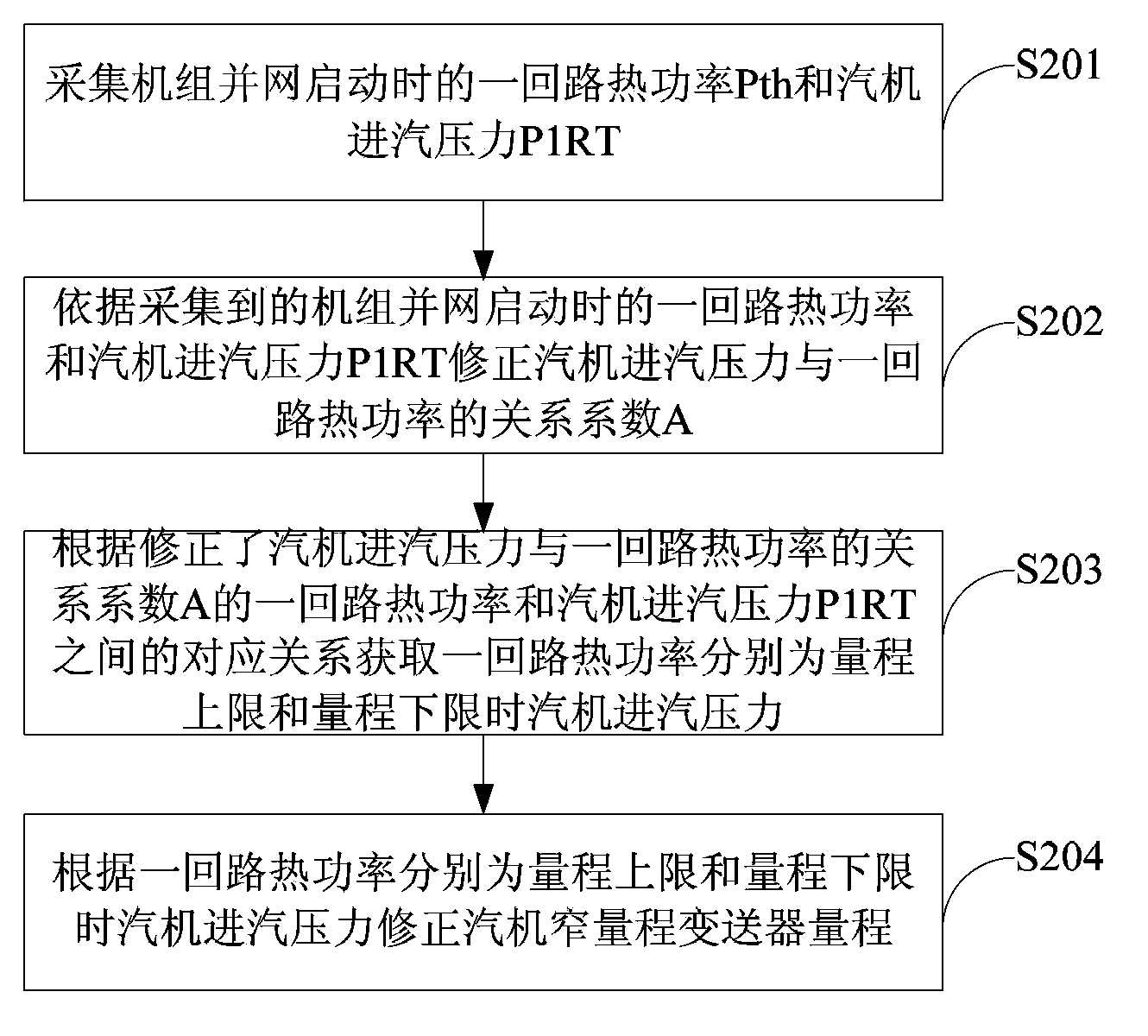

Pressurized water reactor nuclear power station steam generator water level control method and system

ActiveCN103811090AAvoid the problem of runaway water levelsPrevent jumpingPlant parameters regulationNuclear energy generationNarrow rangeNuclear engineering

The invention is applicable to the professional technical field of mega-kilowatt-class pressurized water reactor nuclear power stations and provides a pressurized water reactor nuclear power station steam generator water level control method and system. The method includes a steam engine bypass drain valve openness signal, a water feeding deaerator steam inlet valve openness signal and a steam engine steam inlet narrow range signal; adopting a preset secondary loop image load algorithm to acquire secondary loop image load according to the steam engine bypass drain valve openness signal, the water feeding deaerator steam inlet valve openness signal and the steam engine steam inlet narrow range signal; acquiring a water level control signal; adopting the water level control signal to modify the acquired secondary loop image load and adopting the modified secondary loop image load to control a bypass water feeding adjusting valve of the steam generator. By means of the method and system, the steam generator water level out-of-control problem is solved, and heap jumping caused by the fact that the steam generator water level is out of control is avoided.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

Internal combustion steam thermal engine

InactiveCN1405442ACombustion reductionReduced preparation processNon-fuel substance addition to fuelMachines/enginesCombustion chamberSprayer

The invention relates to an internal combustion steam engine that is based on the internal combustion thermodynamic generator. The variable radiators are taken out from the traditional engine, while the warm keep cover, and heat absorbing water spray system formed by water tank, low pressure water pump, water cooling heat exchanger, high pressure pump, high water sprayer, are installed on the outside of traditional engine and connected through the water delivery pipe according to the above order, thereof, the high pressure water sprayer if installed on the high temperature part of the firebox; besides, by reforming the fuel atomization and spraying device onto the air-changing channel to make engine save energy and the more environment-protective.

Owner:赵晶

Electric generation facility and method employing solar technology

An electric generation station employs a solar array to heat a thermal transfer fluid that is supplied to a heat exchanger to produce steam. The heated steam drives a steam engine that operates either an electric generator to produce electricity or a pump assembly. The pump assembly can pump water to an elevated location for use during peak times by flowing water downwardly past an electric generator. The electric generators can be pelton turbines. One or more thermal fluid storage facilities can be used to store heated fluid, and heat may also be stored in a heat retaining material. Additional optional features and combinations of optional assemblies are disclosed. A method of generating electricity with these systems is also described.

Owner:POWERSTREAMS

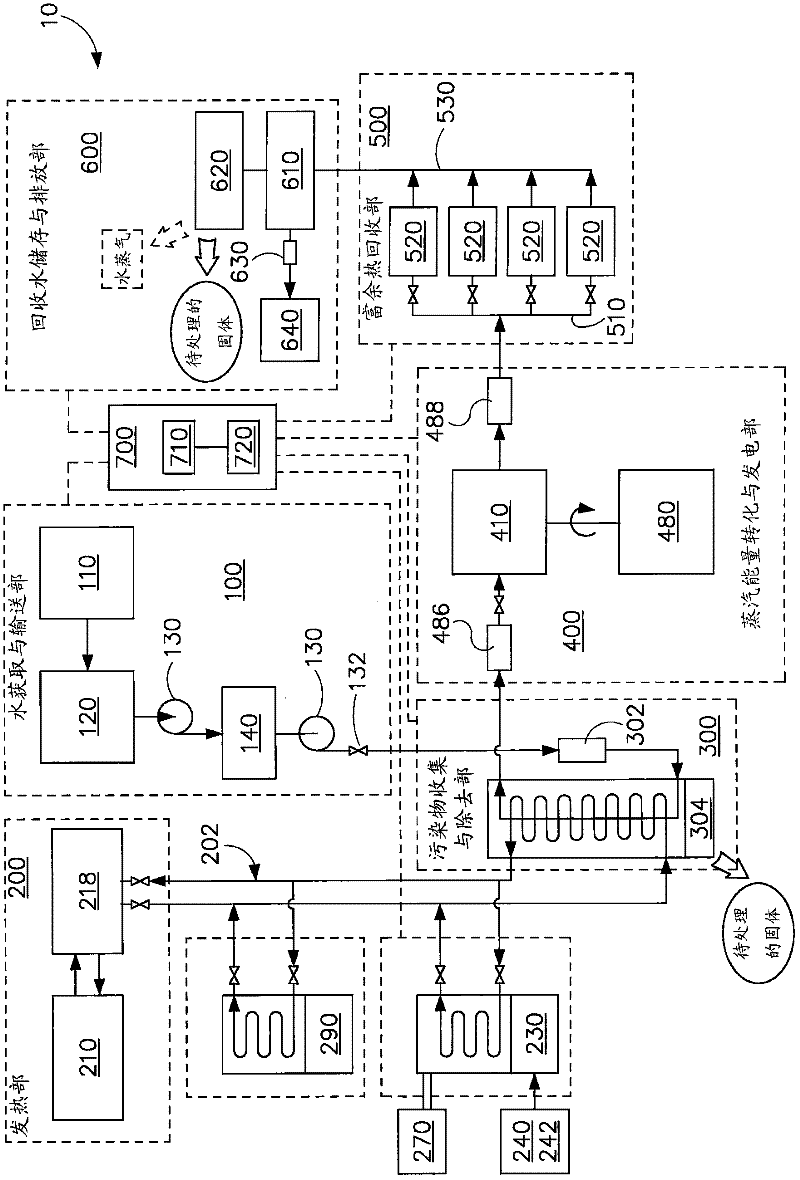

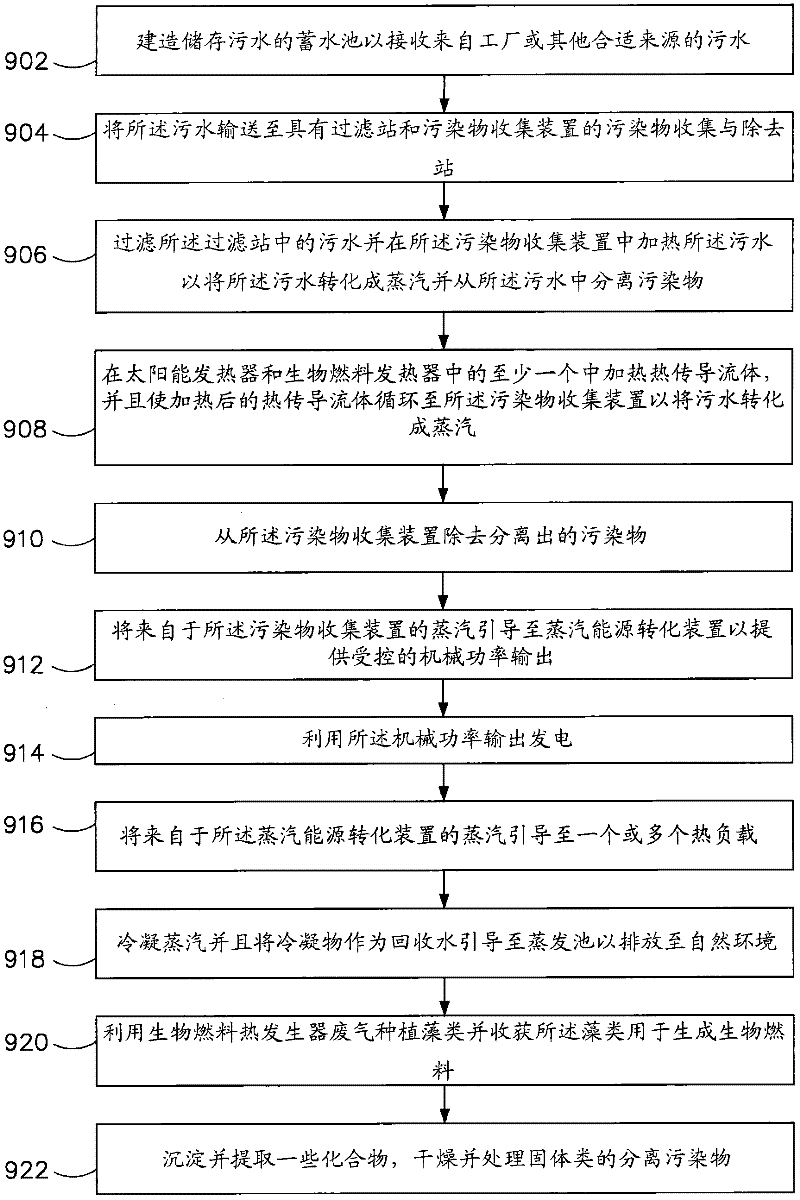

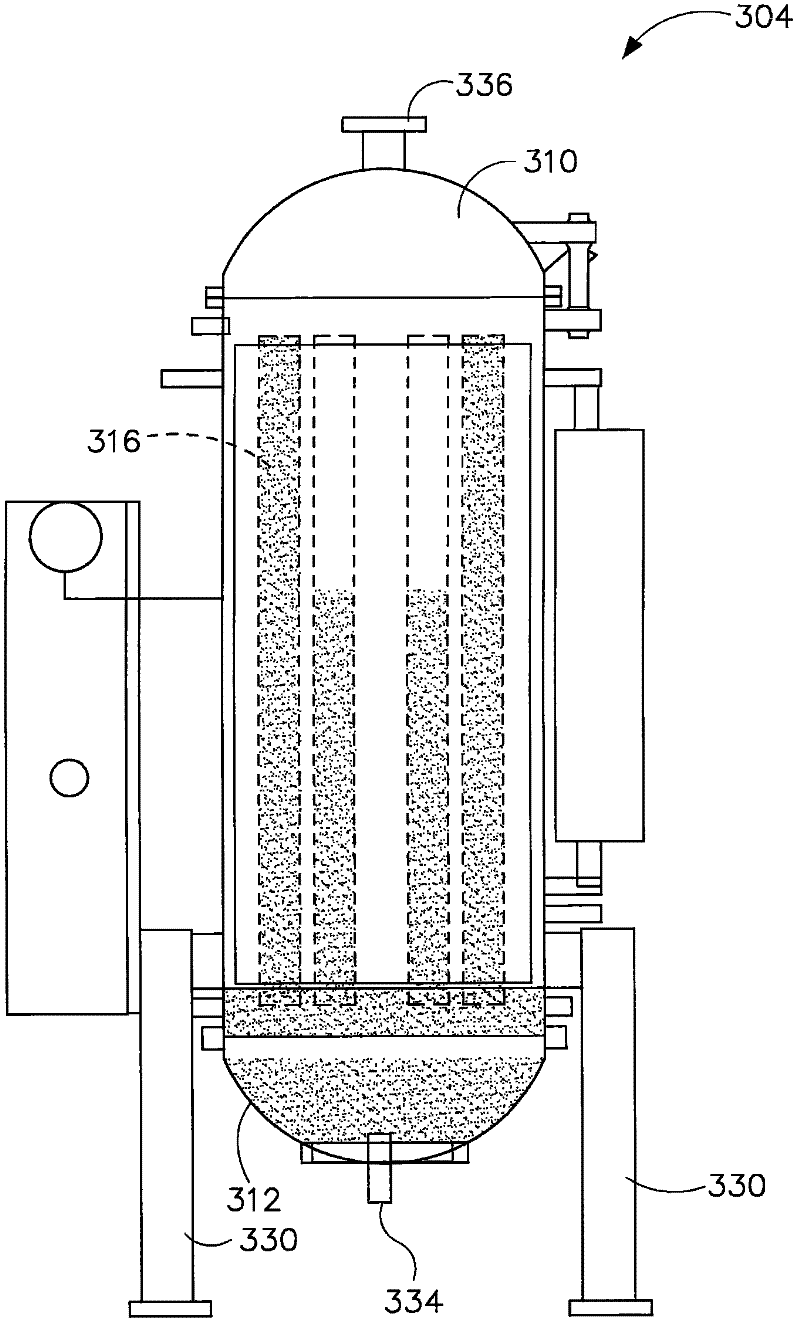

Water reclamation system and method

ActiveCN102056847APromote growthEmission reductionFrom solar energyGeneral water supply conservationBiofuelEvaporation

A system reclaiming contaminated water includes a heat exchanger that receives the contaminated water and converts at least a portion of the contaminated water into steam and collects at least a portion of the contaminants within the heat exchanger. A thermal transfer fluid is heated by a solar concentrator during daytime and by a biofuel combustion device during nighttime. The heated fluid is circulated through the heat exchanger to heat the contaminated water. A steam engine is coupled to a generator, the steam engine receives the steam from the heat exchanger to drive the generator to provide power for the system. Steam exhausted from the steam engine is supplied to supplemental heat loads. The collected contaminants are directed to an evaporation device to remove residual liquid.

Owner:联合太阳能科技有限公司

Waste heat regeneration absorption dryer

InactiveCN103272460ARealize external heat regenerationReduce power consumptionDispersed particle separationSorbentCooling effect

The invention belongs to the field of chemical equipment, and particularly relates to a waste heat regeneration absorption dryer. The waste heat regeneration absorption dryer comprises an air compressor, an absorption tower A, an absorption tower B, a first cooler, a second cooler, and a gas-water separator; valves of the absorption tower A and the absorption tower B are symmetrically arranged and use compressed air in the air compressor as a heat source during use, and the absorption tower A and the absorption tower B circularly work under programmed control. The waste heat regeneration absorption dryer fully utilizes waste heat of the compressor so that the power consumption of an electric heater, a fan and a steamer of traditional external heating or microheating drying is saved to achieve the external heating regeneration and maximally reduce the energy consumption; the two coolers are arranged so that the cooling effect is good; and the absorption towers have three-layer structures, and gas flow is distributed uniformly in a molecular sieve layer and an aluminum oxide layer under the action of a large water-absorption ball layer, so that the absorption time is prolonged, the absorption effect is enhanced, the gas flow is stable and uniform, the impact force on a sorbent is small, and the service life is prolonged.

Owner:山东道先为能源科技股份有限公司

High efficiency dual cycle internal combustion engine with steam power recovered from waste heat

ActiveUS8109097B2Valve arrangementsInternal combustion piston enginesCombustion chamberExhaust valve

A high efficiency combined cycle internal combustion and steam engine includes a cylinder with a combustion chamber outward of a piston, a cylinder cap slideably mounted within the piston and a steam expansion chamber inside the piston. The cap can be heated to reduce condensation of steam. Steam remaining when a steam exhaust valve closes can be recompressed prior to admitting the next charge of steam. One valve or a pair of steam inlet valves connected in series act in cooperation to help maximize efficiency. The amount of steam admitted each stroke is regulated by shifting the phase of one steam admission valve of a pair to vary their overlap for determining the steam mass admitted each cycle. Other valves balance steam displacement with the steam generator output to use steam more efficiently.

Owner:THERMAL POWER RECOVERY

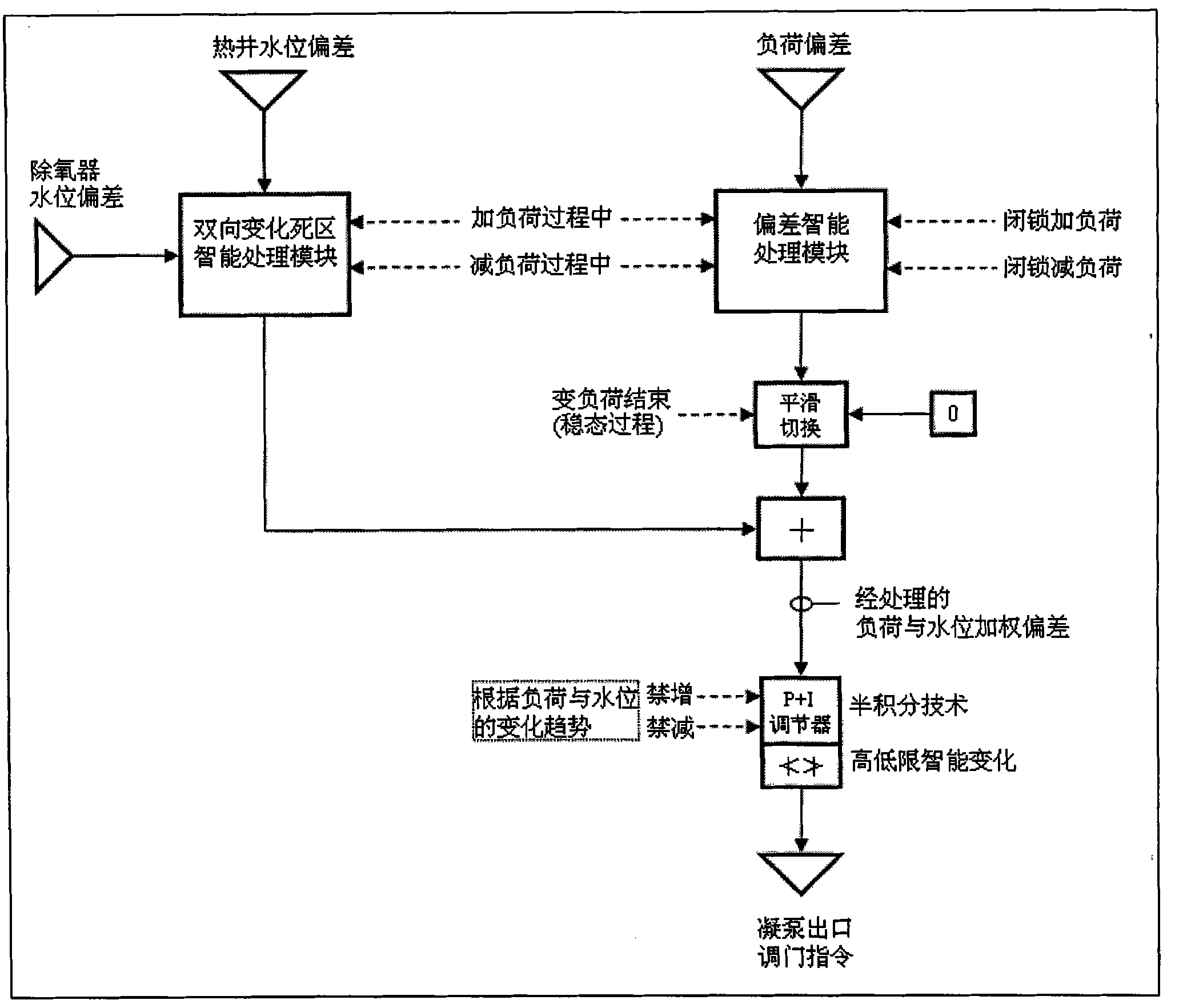

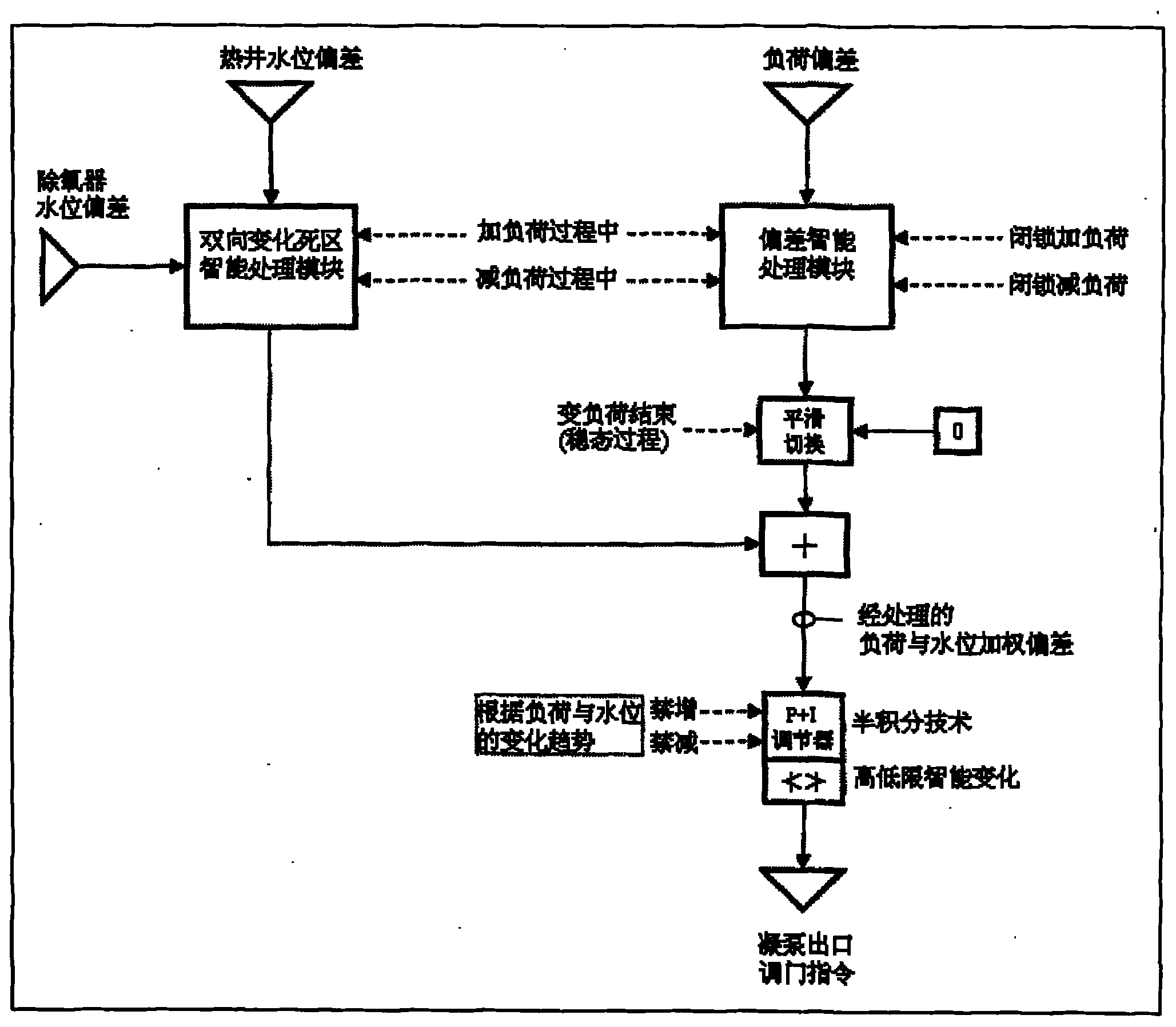

Thermal power unit cooperative load change control method

The invention provides a thermal power unit cooperative load change control method, including that: load deviation, thermal well water level deviation and deaerator water level deviation are acquired; steady state, loading or unloading process is carried out on the load deviation, thermal well water level deviation and deaerator water level deviation; according to different working conditions, the load deviation and the water level deviation are subject to weighting; the result is subject to half integral and high-low limit intelligent change; a condensate pump outlet door adjustment instruction is obtained; and control at the boiler side is reasonably combined, and performance requirement of thermal power unit load change is met. The thermal power unit cooperative load change control method provided by the invention is a new method utilizing unit energy storage, the control at the boiler side is reasonably combined, and the requirement of peak shaping can be met while greatly reducing steam engine door adjustment throttle loss, thus improving economy of unit operation.

Owner:EAST CHINA ELECTRIC POWER TEST & RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com