Drip-free garment steamer

a garment steamer and liquid water technology, applied in the direction of washing apparatus, conditioning apparatus, textiles and paper, etc., can solve the problems of liquid water spitting and dripping from the area of the device used to steam garments, and the steamer does not have an ironing function,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The present invention is useful in a variety of applications that require drip-free steaming. This device is usable in any situation where an object needs to be steamed. These situations can occur anywhere there is a need to steam an object, such as in the home, in a hotel, at the office, or the like.

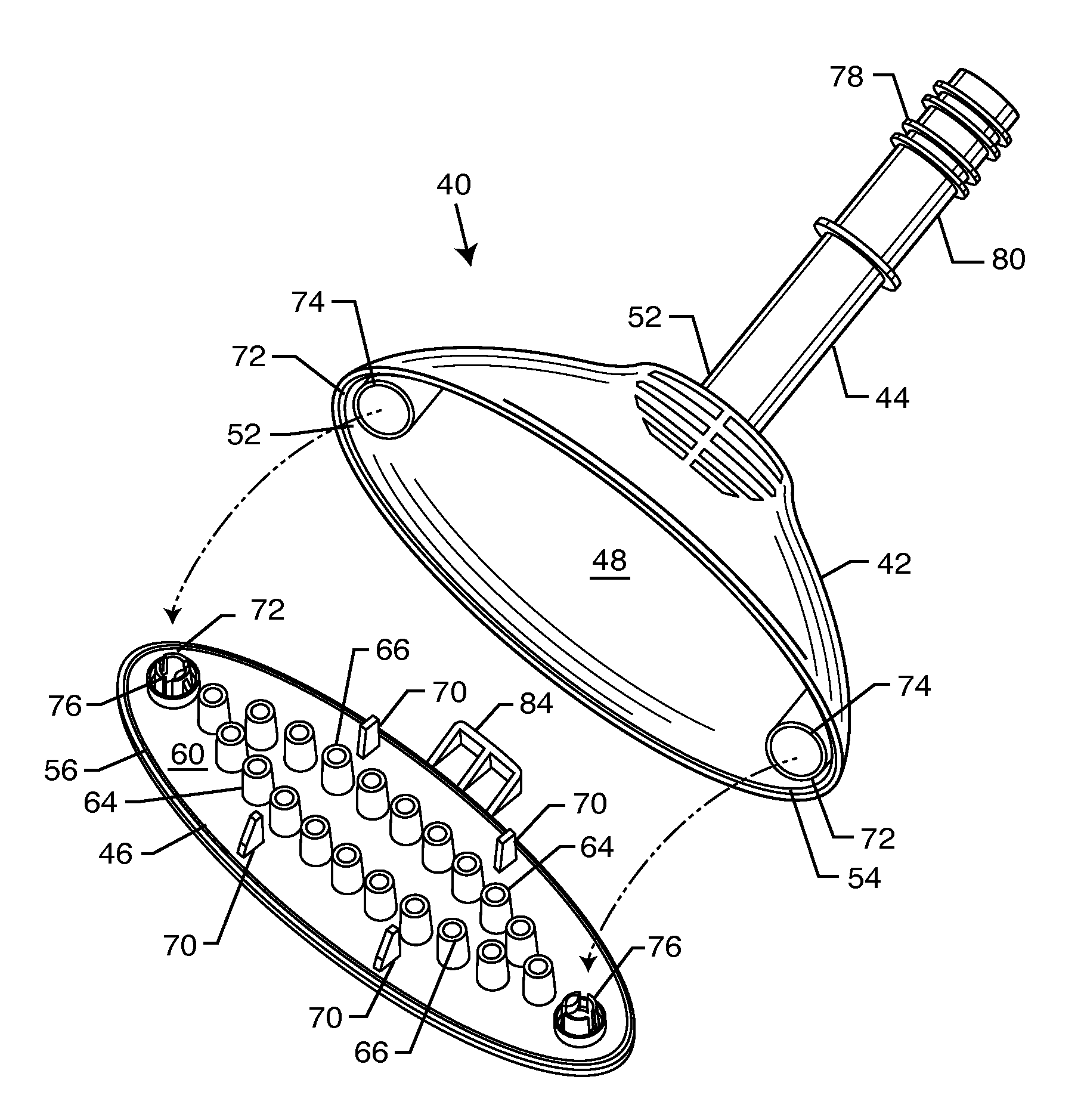

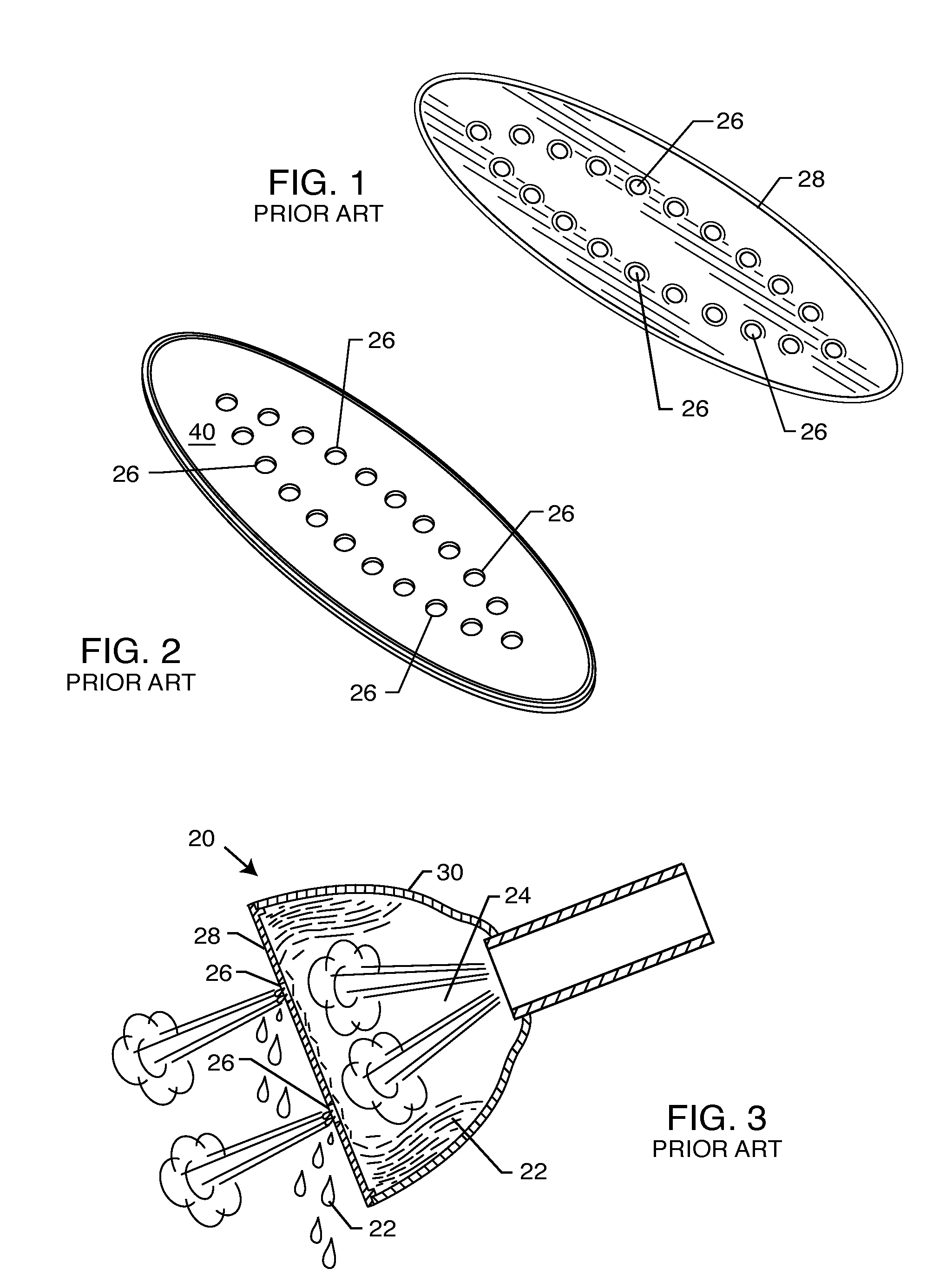

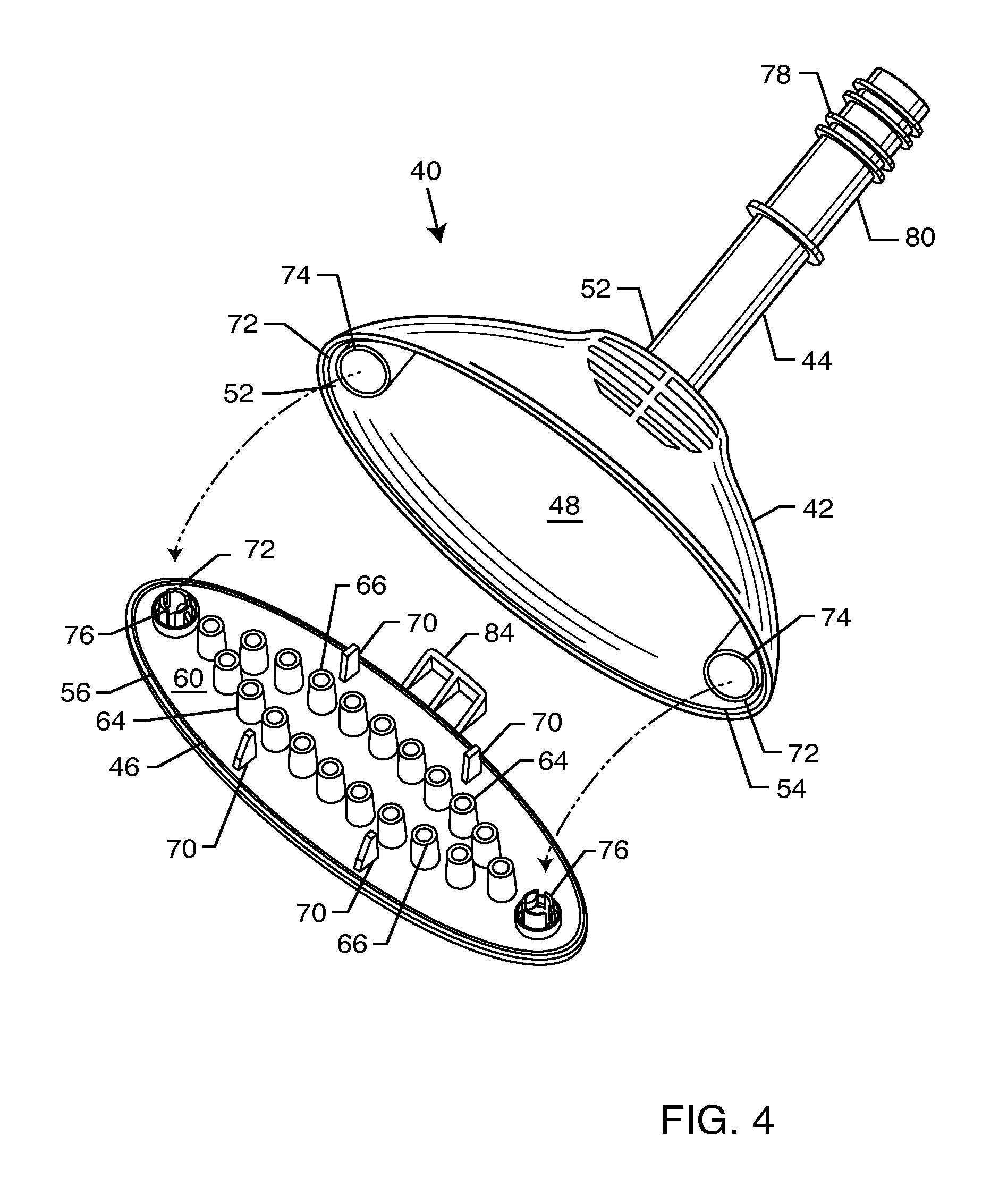

[0024]As shown in the drawings for purposes of illustration, the present invention resides in a drip-free garment steamer 40. With reference to FIGS. 4-12, a garment steamer 40 is of single-piece construction with or attachable to a hand-held steam generating device (not shown) or a portable steam generating device (not shown) used in conjunction with a wheeled truck carriage (not shown) upon which the steam generating device rests. In general, the steam generating device includes a housing for electrical and mechanical parts, and a water tank for holding a certain amount of water that is to be converted into steam. Water within the water tank drains to a steam chamber within the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com