Thermal power unit cooperative load change control method

A technology of thermal power unit and control method, which is applied to control systems, steam generation, lighting and heating equipment, etc., can solve problems such as throttling loss of steam turbine regulating valve, and achieve the effect of economical unit operation and reduced throttling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the technical content of the present invention, specific embodiments are described below in conjunction with the accompanying drawings.

[0017] The present invention provides a control method for coordinated variable load of a thermal power unit, which can greatly reduce the throttle loss of the steam turbine valve while still meeting the demand of power grid peak regulation, thereby improving the economy of unit operation.

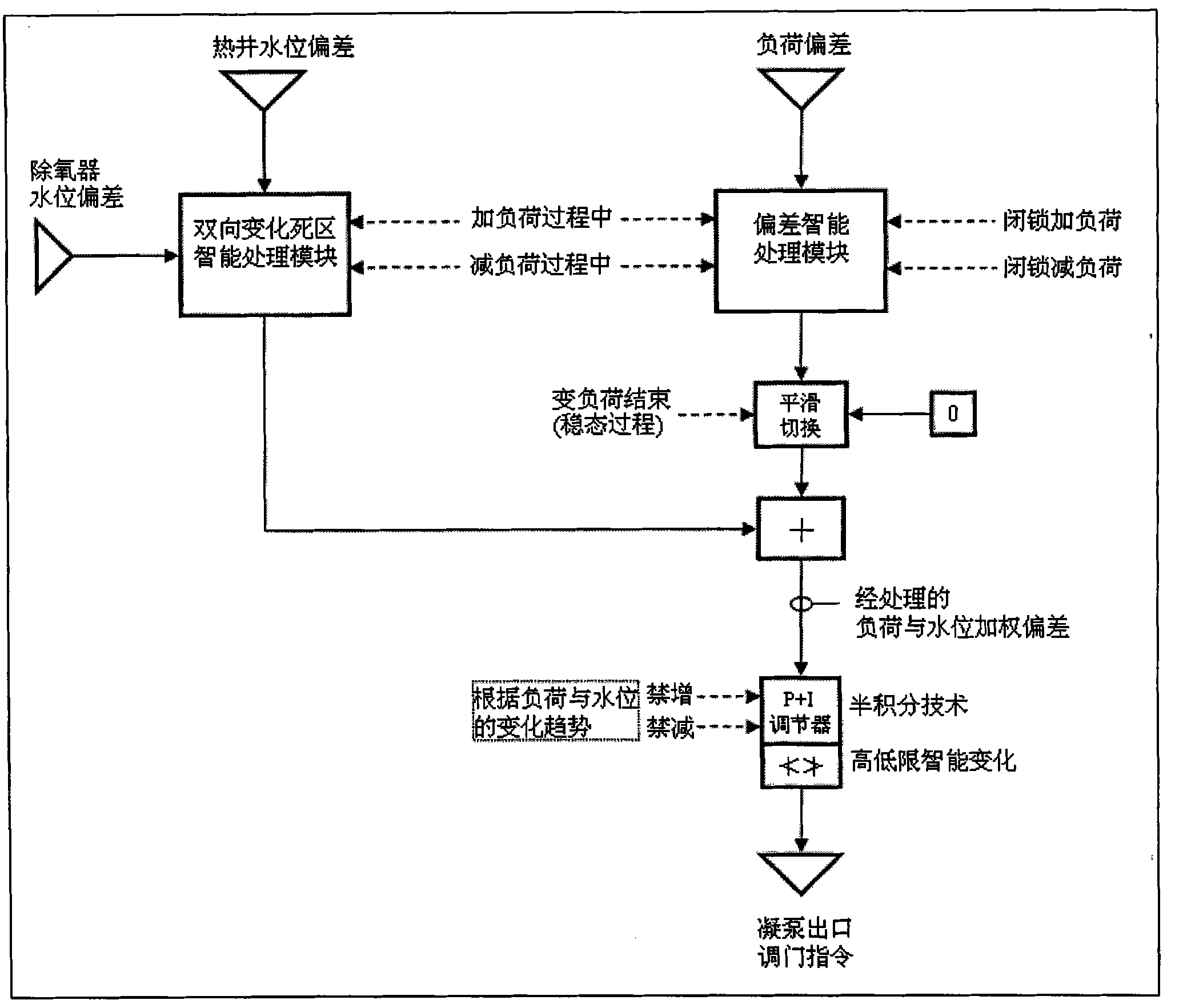

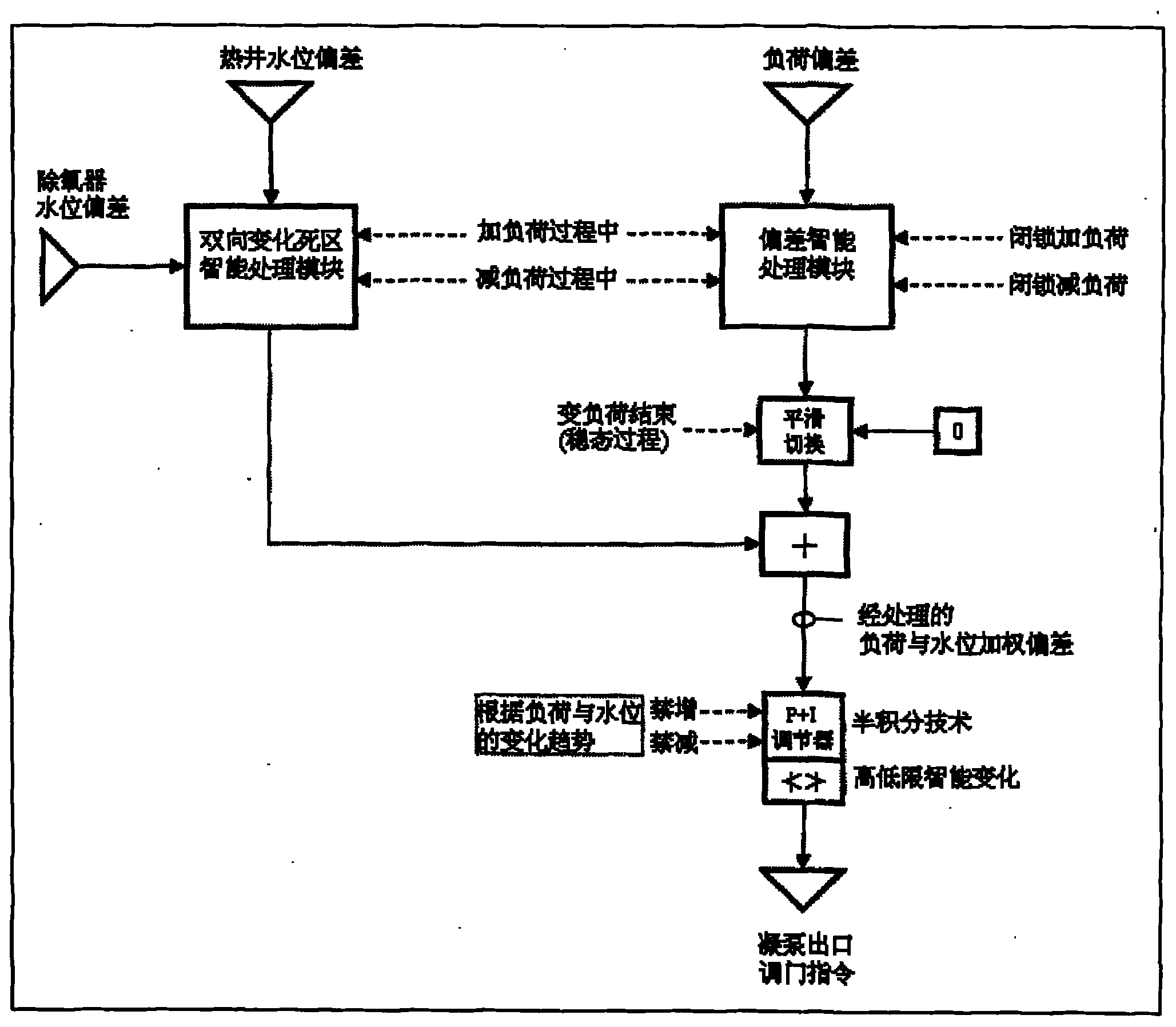

[0018] Please refer to figure 1 , figure 1 Shown is a schematic diagram of the principle of load regulation by condensate in a preferred embodiment of the present invention.

[0019] The present invention provides a control method for coordinated variable load of a thermal power unit, including:

[0020] Obtain load deviation, hot well water level deviation and deaerator water level deviation;

[0021] Perform steady-state, load-increasing process or load-reduction process for the load deviation, hot well water level deviatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com