Patents

Literature

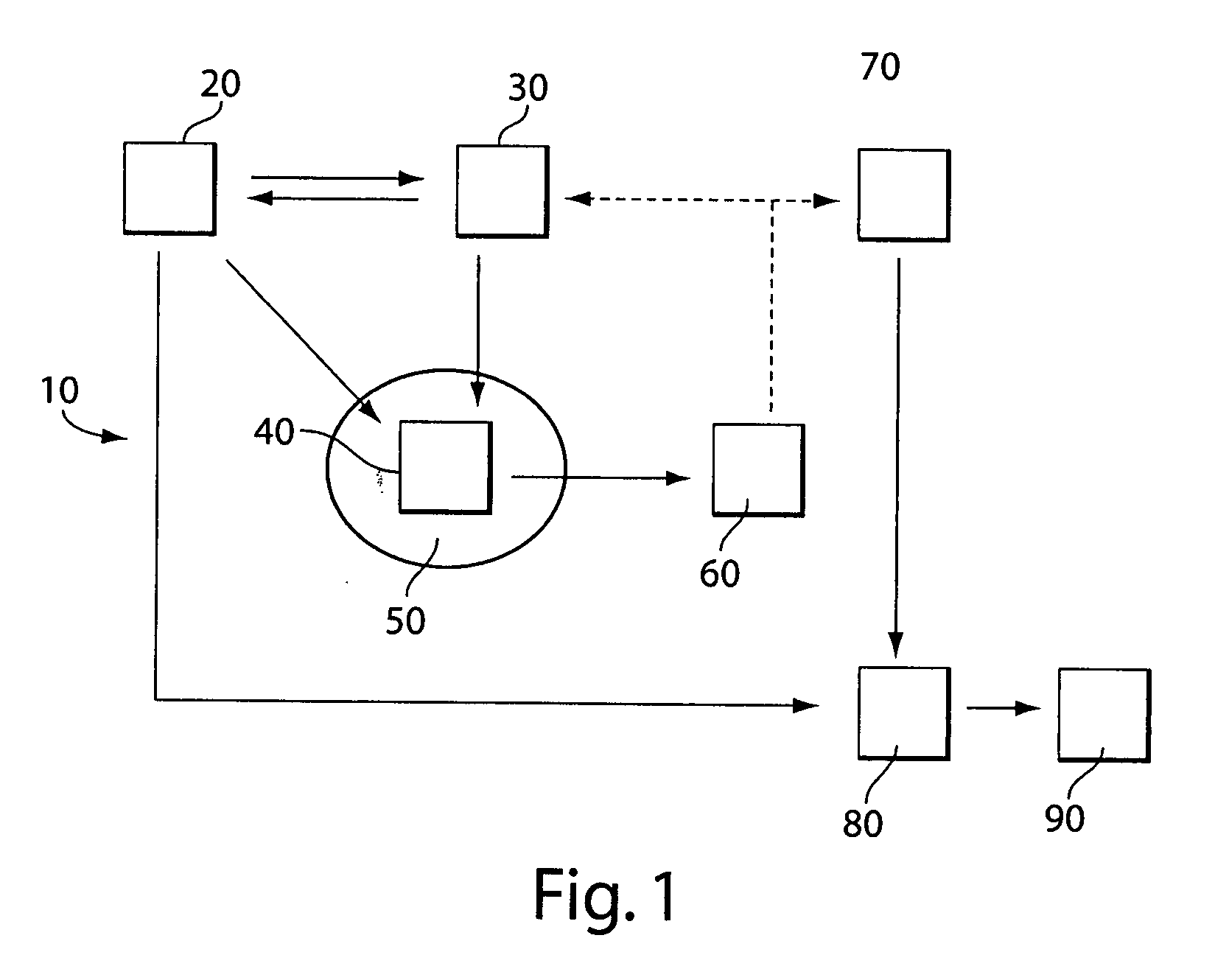

57872results about "Gas treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

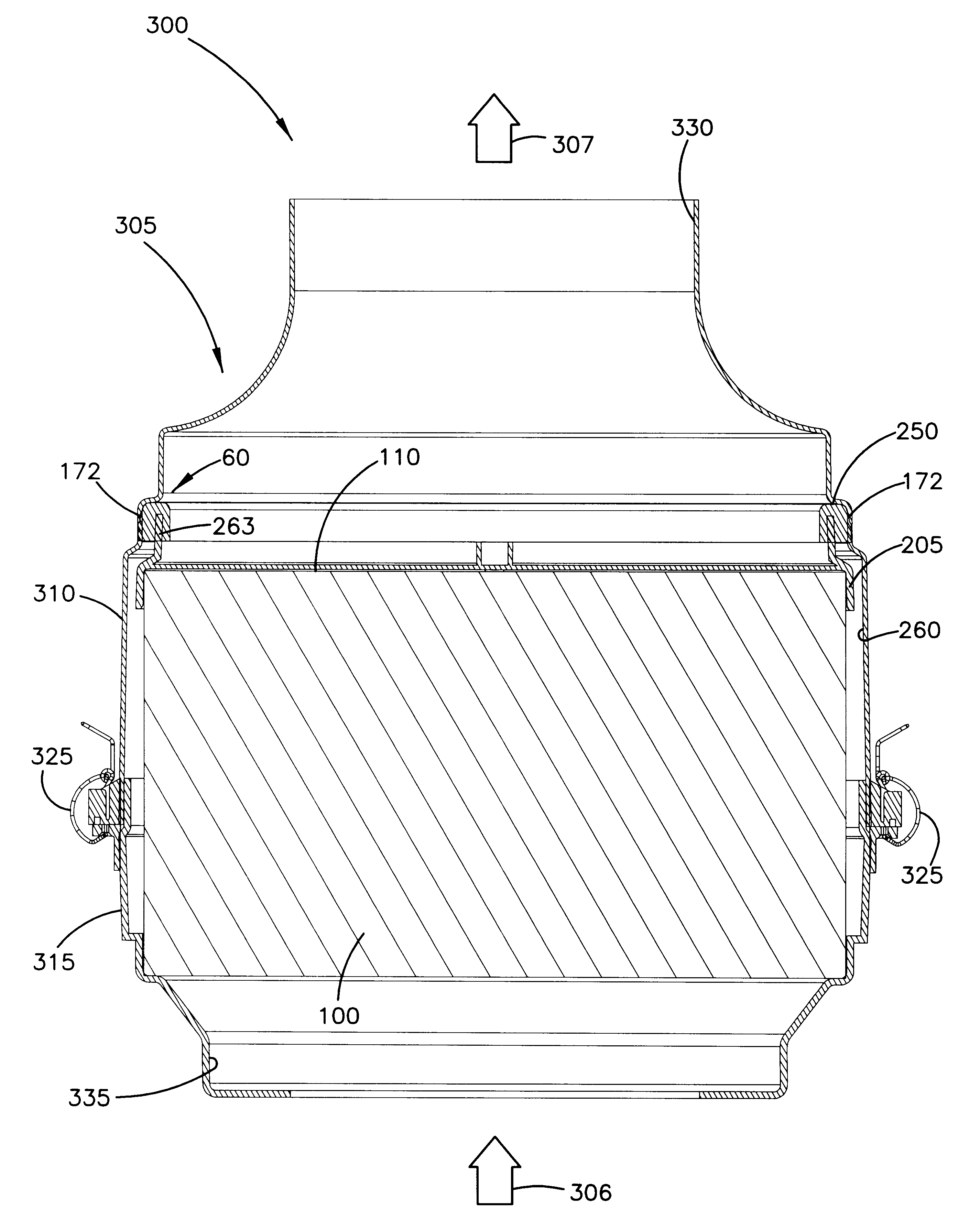

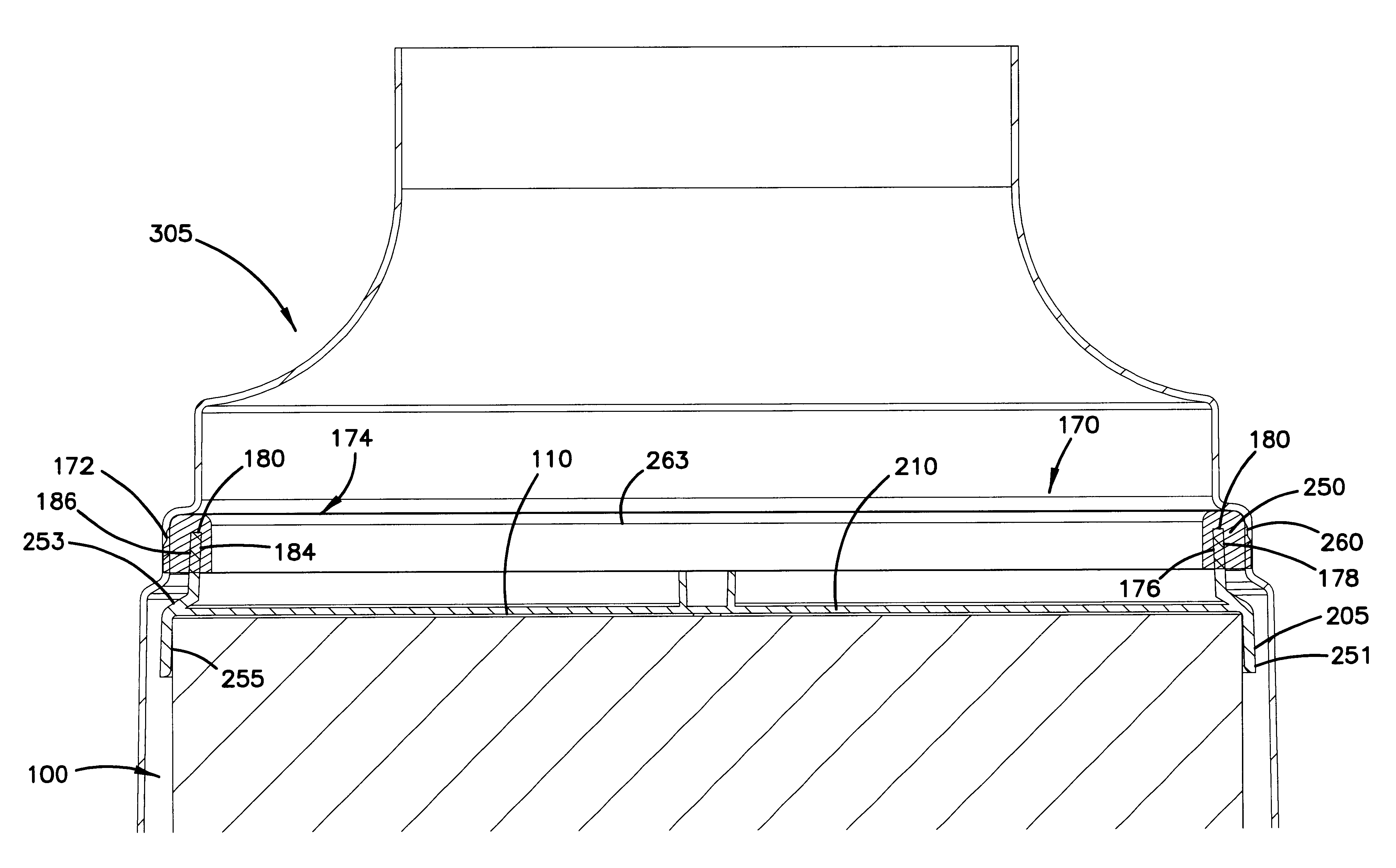

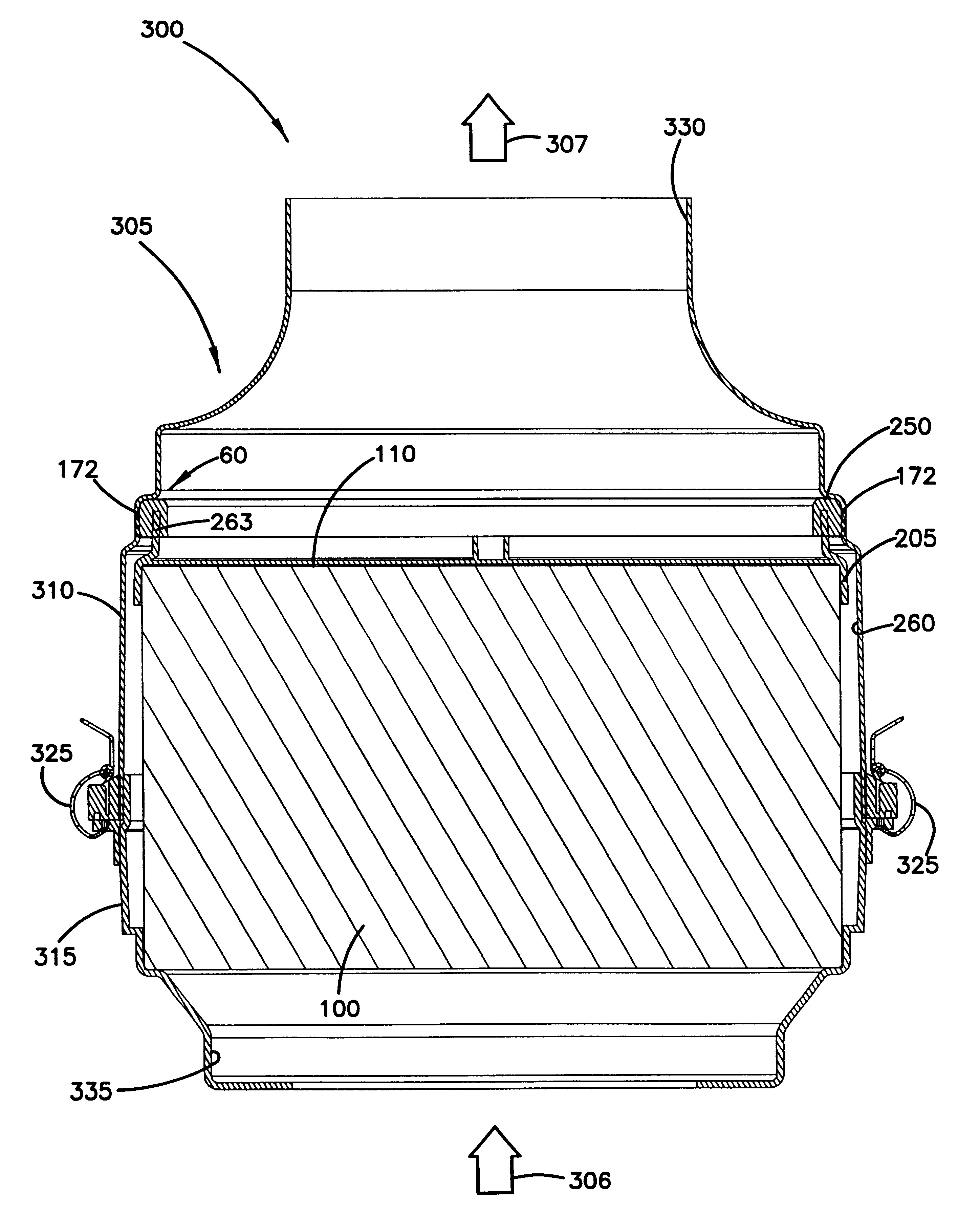

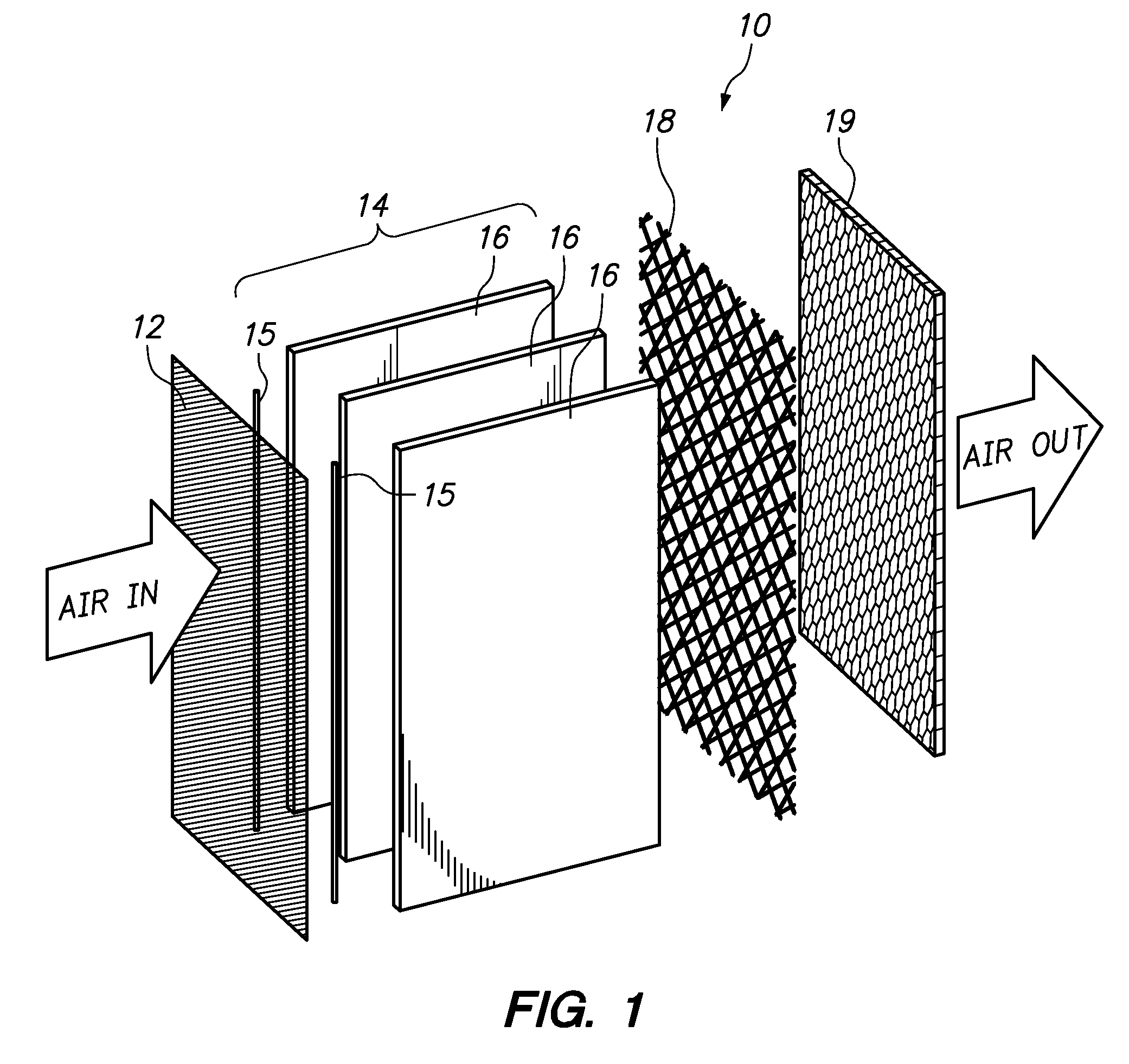

Filter arrangement; sealing system; and methods

InactiveUS6190432B1Prevent crashAvoid passingHuman health protectionCombination devicesEngineeringMechanical engineering

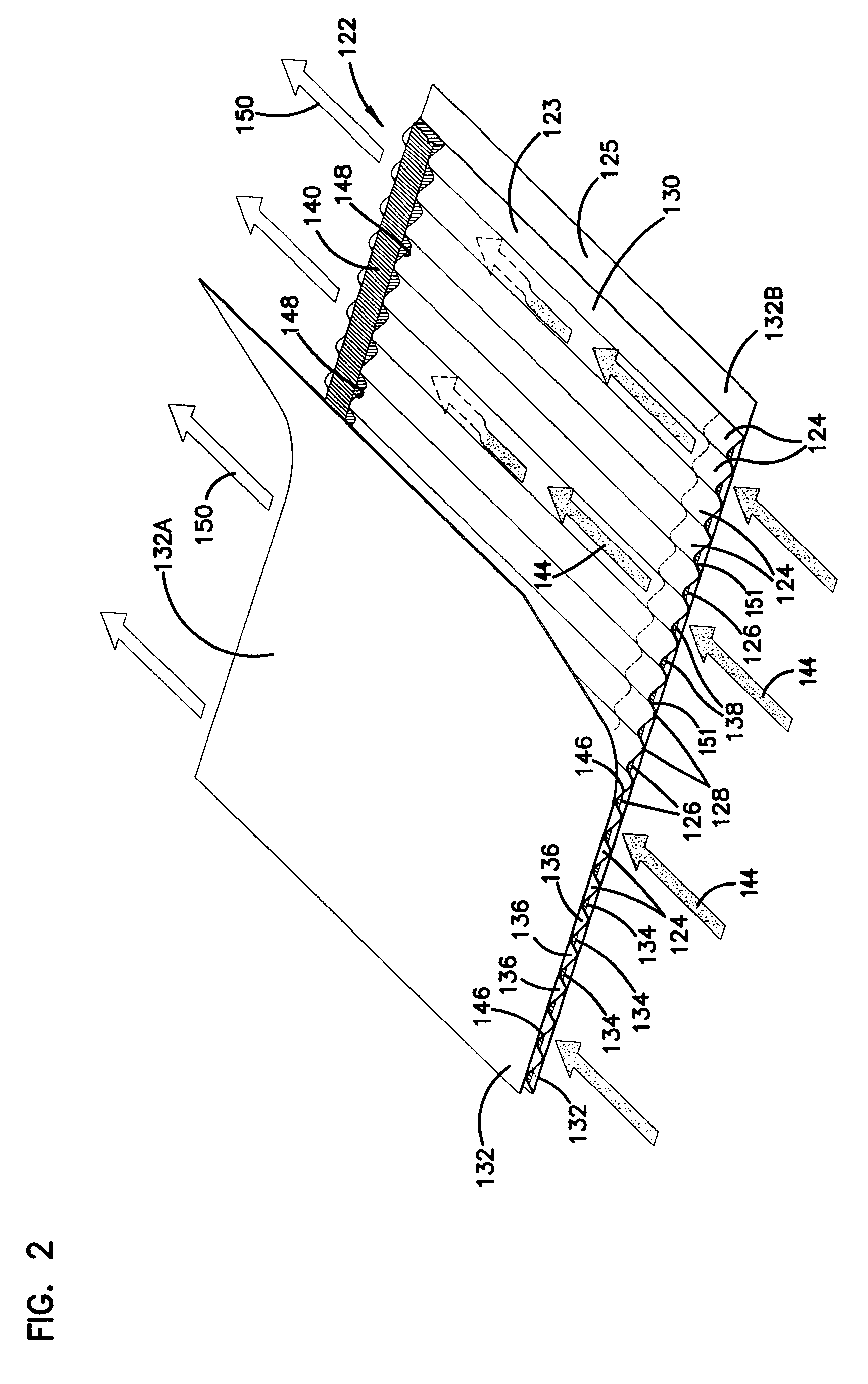

A filter pack includes a filter construction and a sealing system for sealing the construction within a duct or housing. The filter construction has first and second opposite flow faces and is configured for a straight-through flow. The sealing system includes a frame construction and a compressible seal member. The compressible seal member is molded around a portion of the frame construction. The compressible seal member is sufficiently compressible to form a radial seal between and against the frame construction and a surface of a housing when the filter pack is inserted within the housing.

Owner:DONALDSON CO INC

Filter arrangement; sealing system; and methods

InactiveUS6350291B1Avoid passingObstruct passageHuman health protectionCombination devicesEngineeringMechanical engineering

A filter pack includes a filter construction and a sealing system for sealing the construction within a duct or housing. The filter construction has first and second opposite flow faces and is configured for a straight-through flow. The sealing system includes a frame construction and a compressible seal member. The compressible seal member is molded around a portion of the frame construction. The compressible seal member is sufficiently compressible to form a radial seal between and against the frame construction and a surface of a housing when the filter pack is inserted within the housing.

Owner:DONALDSON CO INC

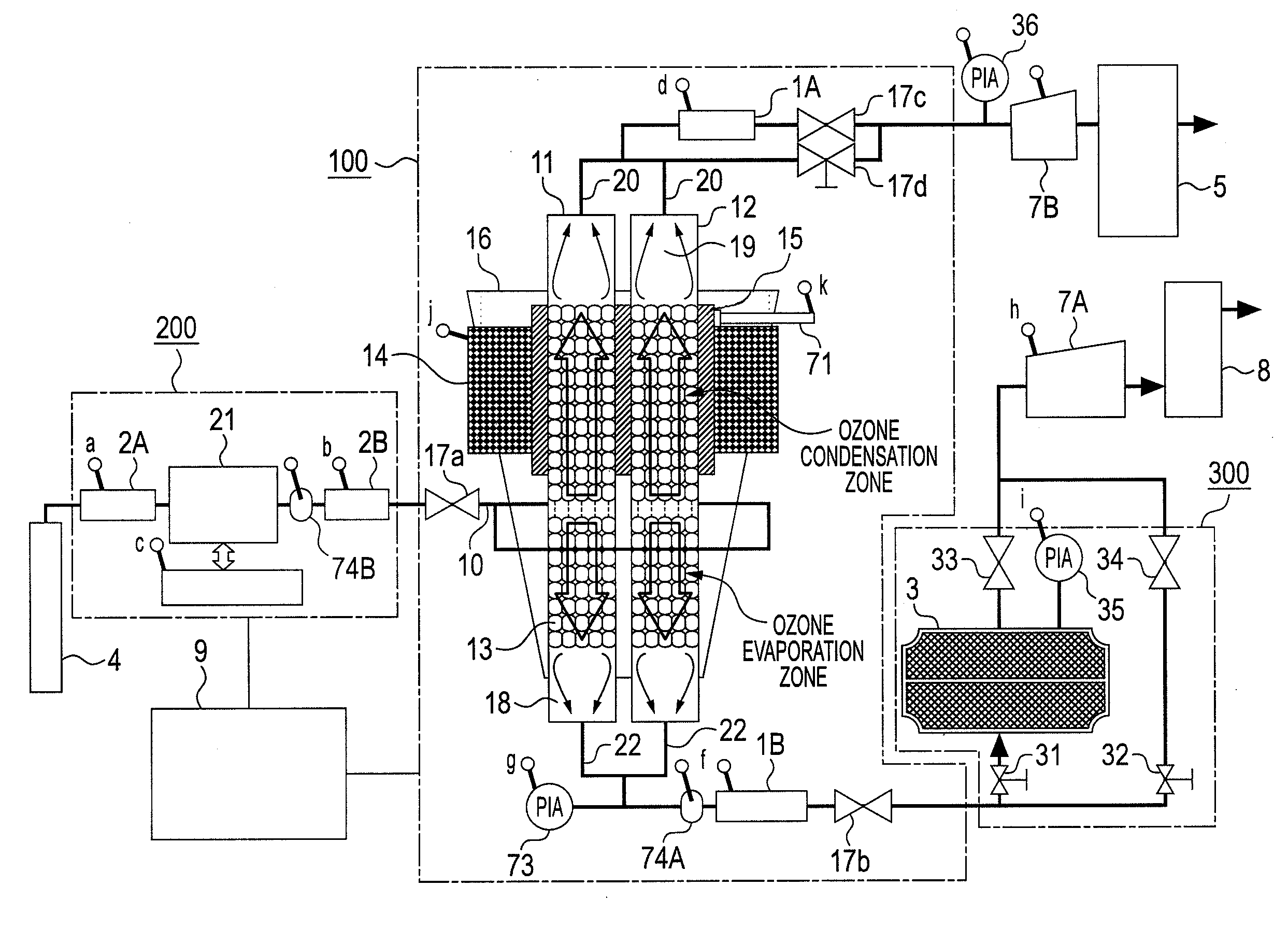

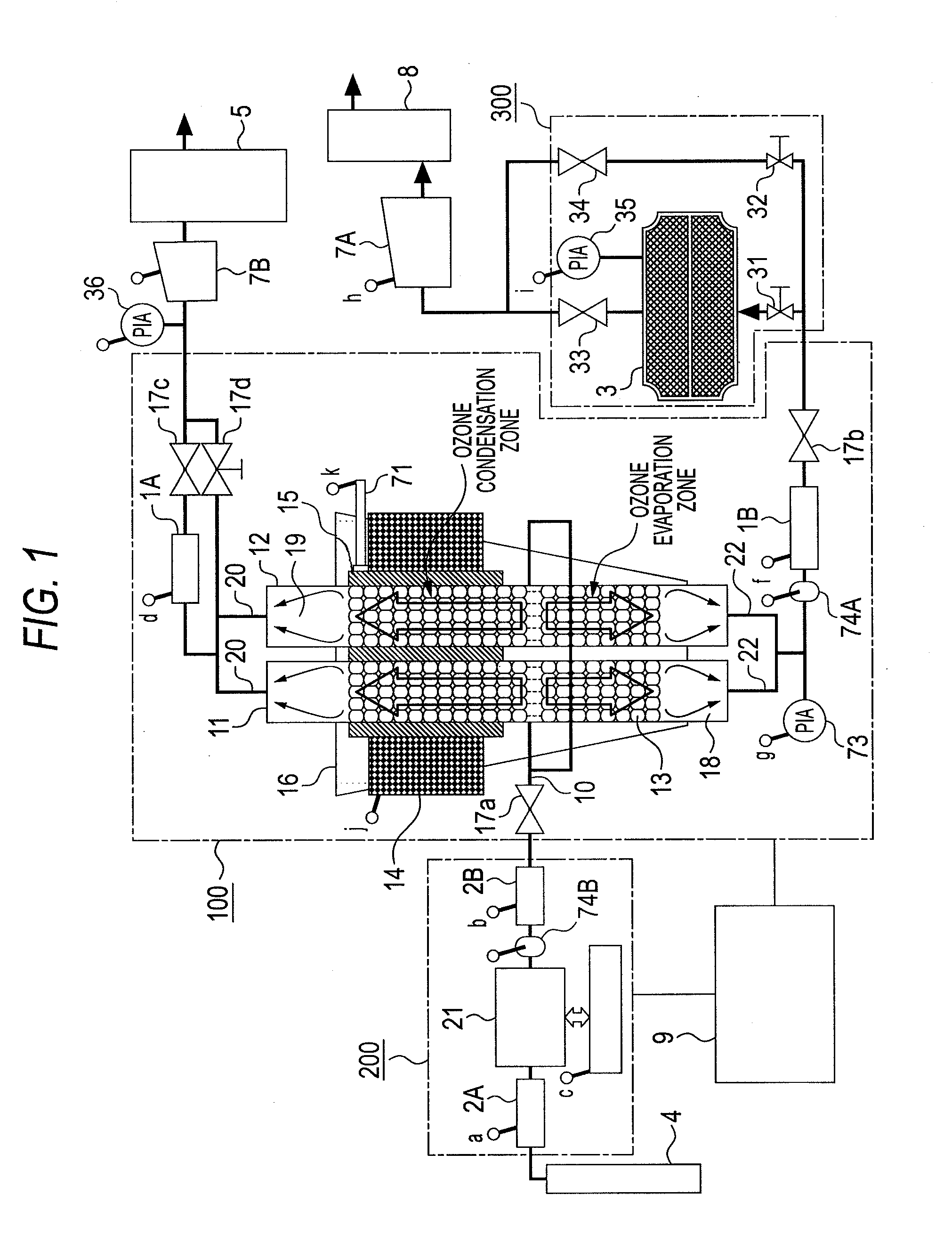

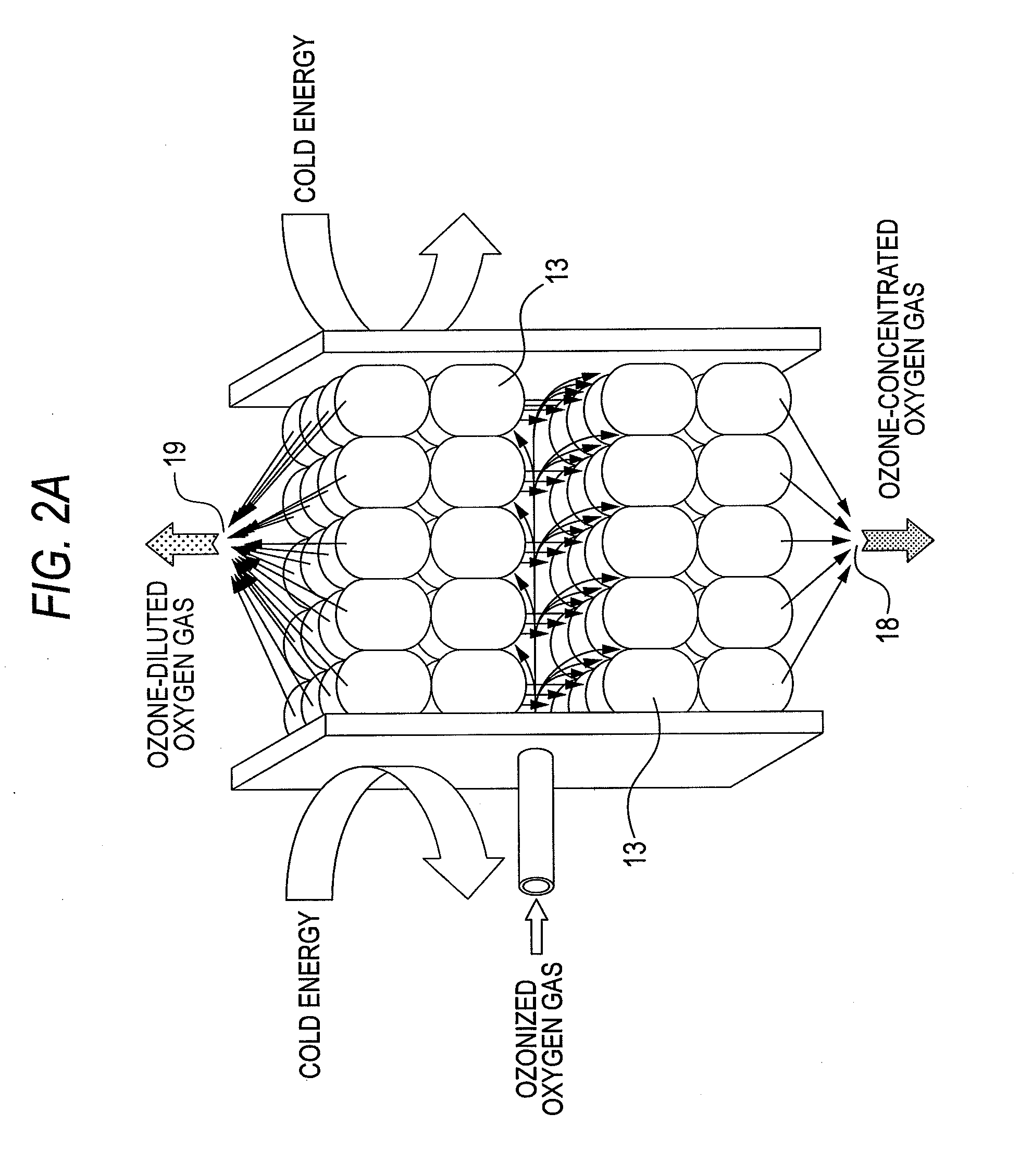

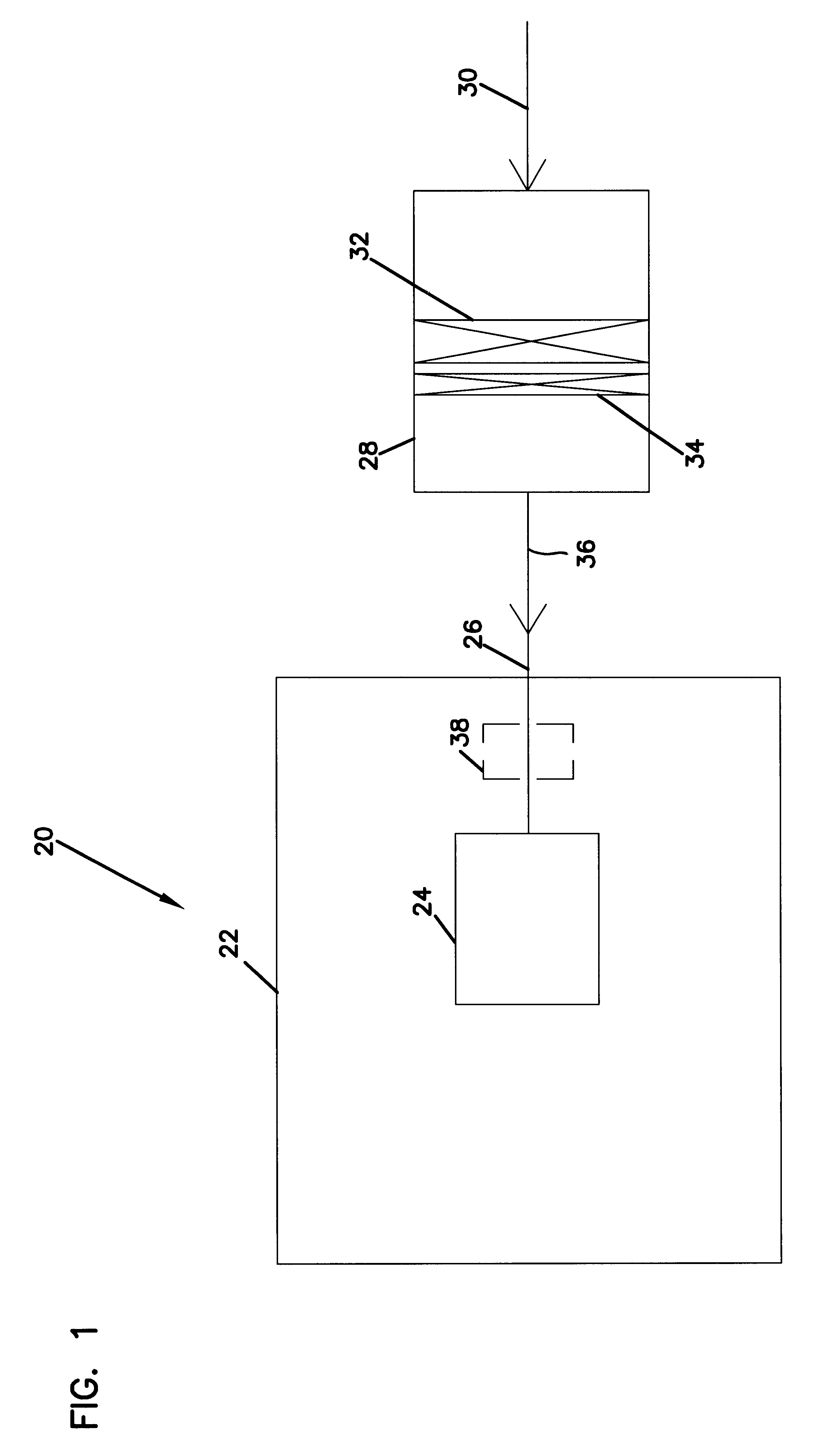

Apparatus for concentrating and diluting specific gas and method for concentrating and diluting specific gas

ActiveUS20100162752A1Improve processing efficiencySmall sizeSolidificationGas treatmentSpherical shapedVaporization

One ozone concentrating chamber is provided therein with a part of a cooling temperature range where ozone can be selectively condensed or an oxygen gas can be selectively removed by transmission from an ozonized oxygen gas, and a part of a temperature range where condensed ozone can be vaporized, and condensed ozone is vaporized by moving condensed ozone with flow of a fluid or by gravitation to the part where condensed ozone can be vaporized, whereby the ozonized oxygen gas can be increased in concentration. Such a constitution is provided that a particle material 13 for condensation and vaporization filled in the ozone concentrating chambers 11 and 12 has a spherical shape of a special shape with multifaceted planes on side surfaces, or an oxygen transmission membrane 130 capable of selectively transmitting an oxygen gas in an ozone gas is provided.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

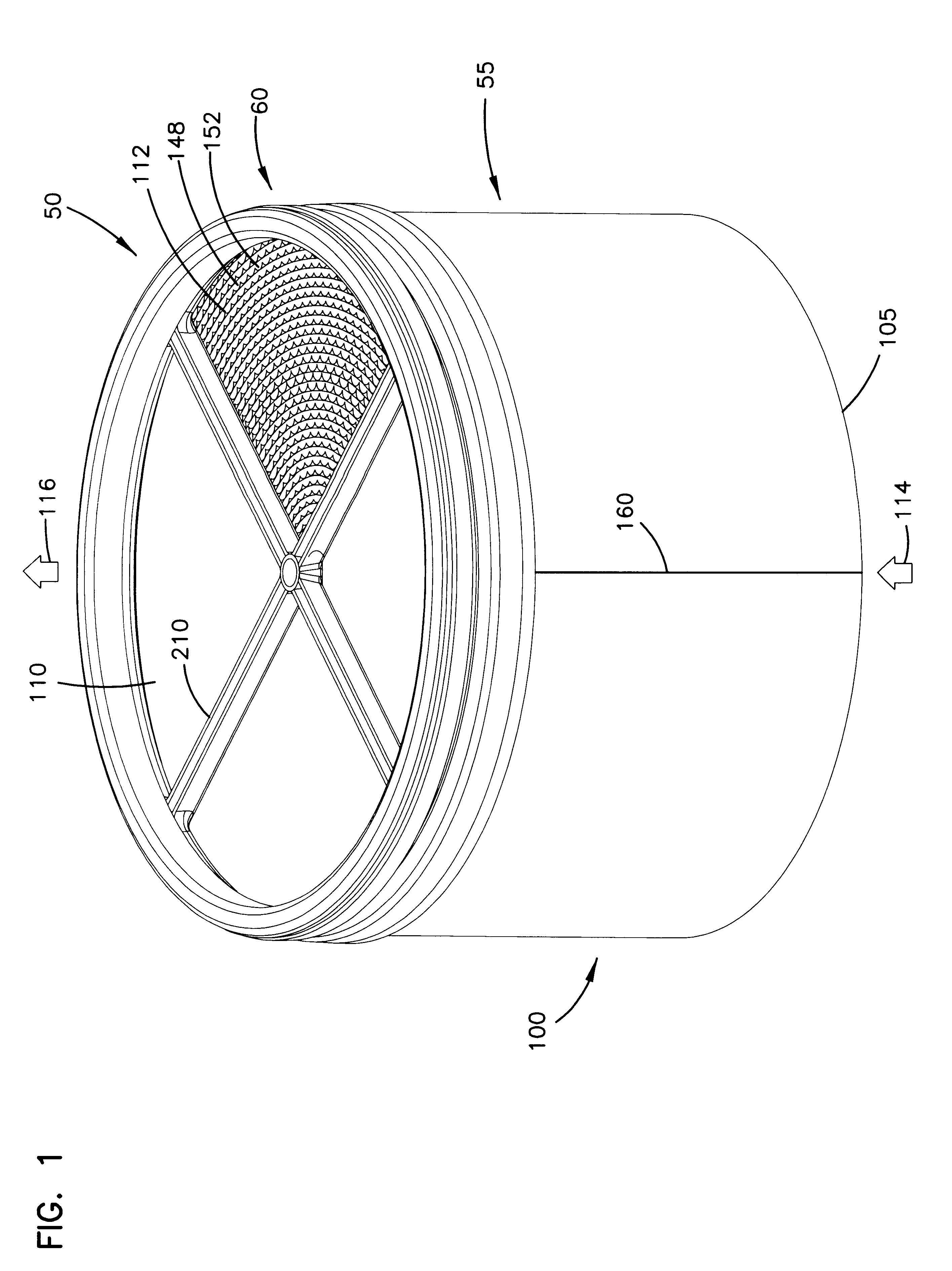

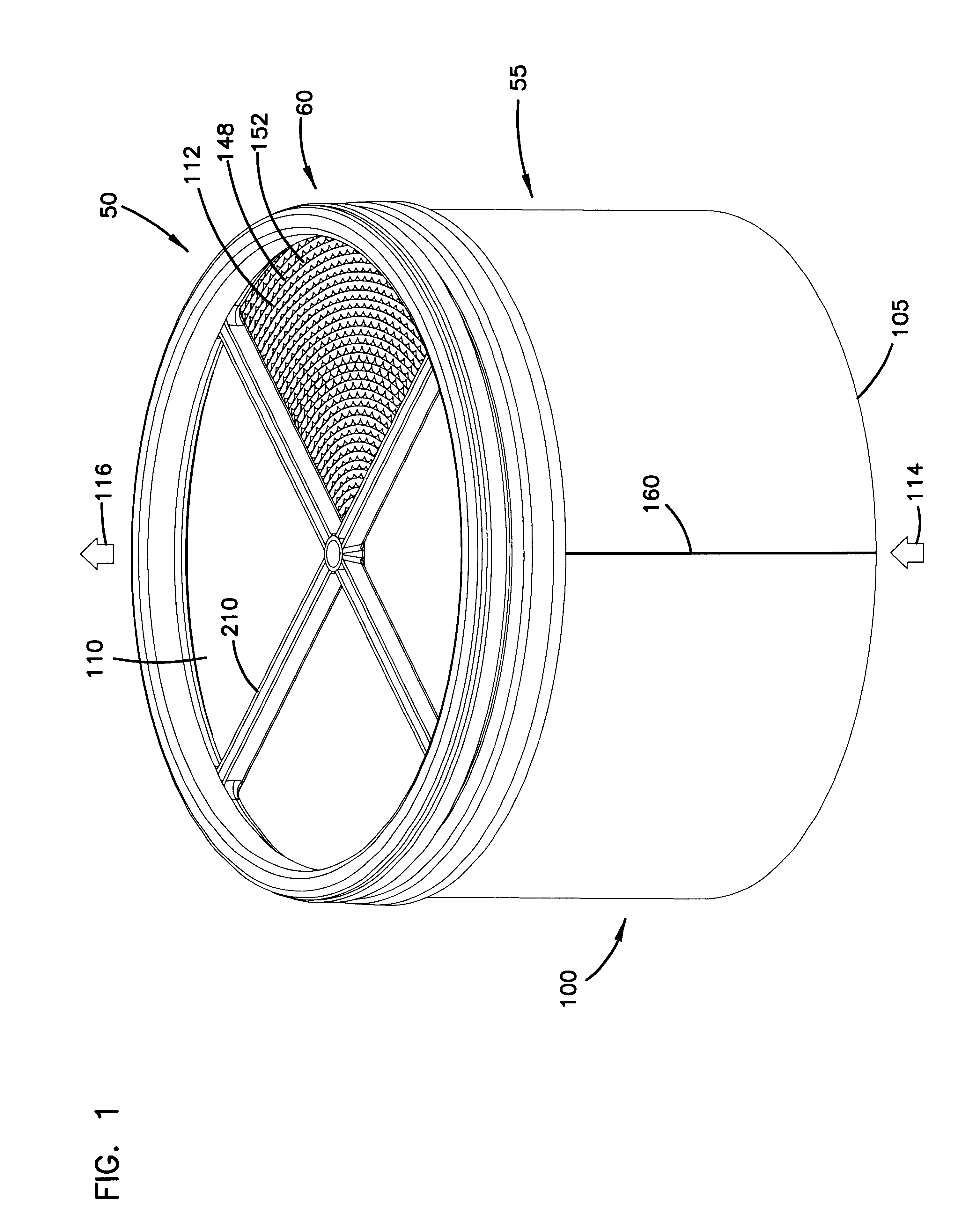

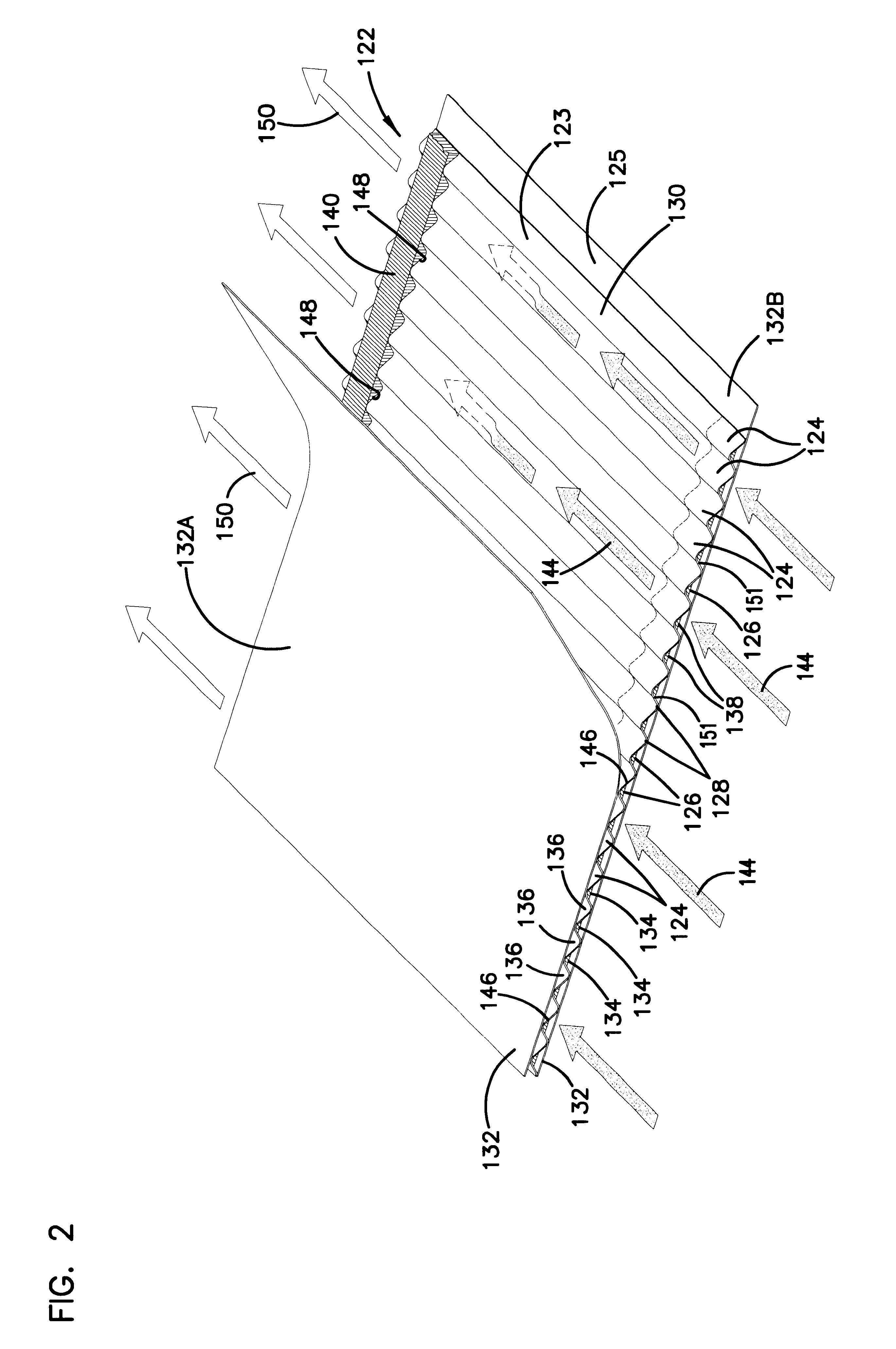

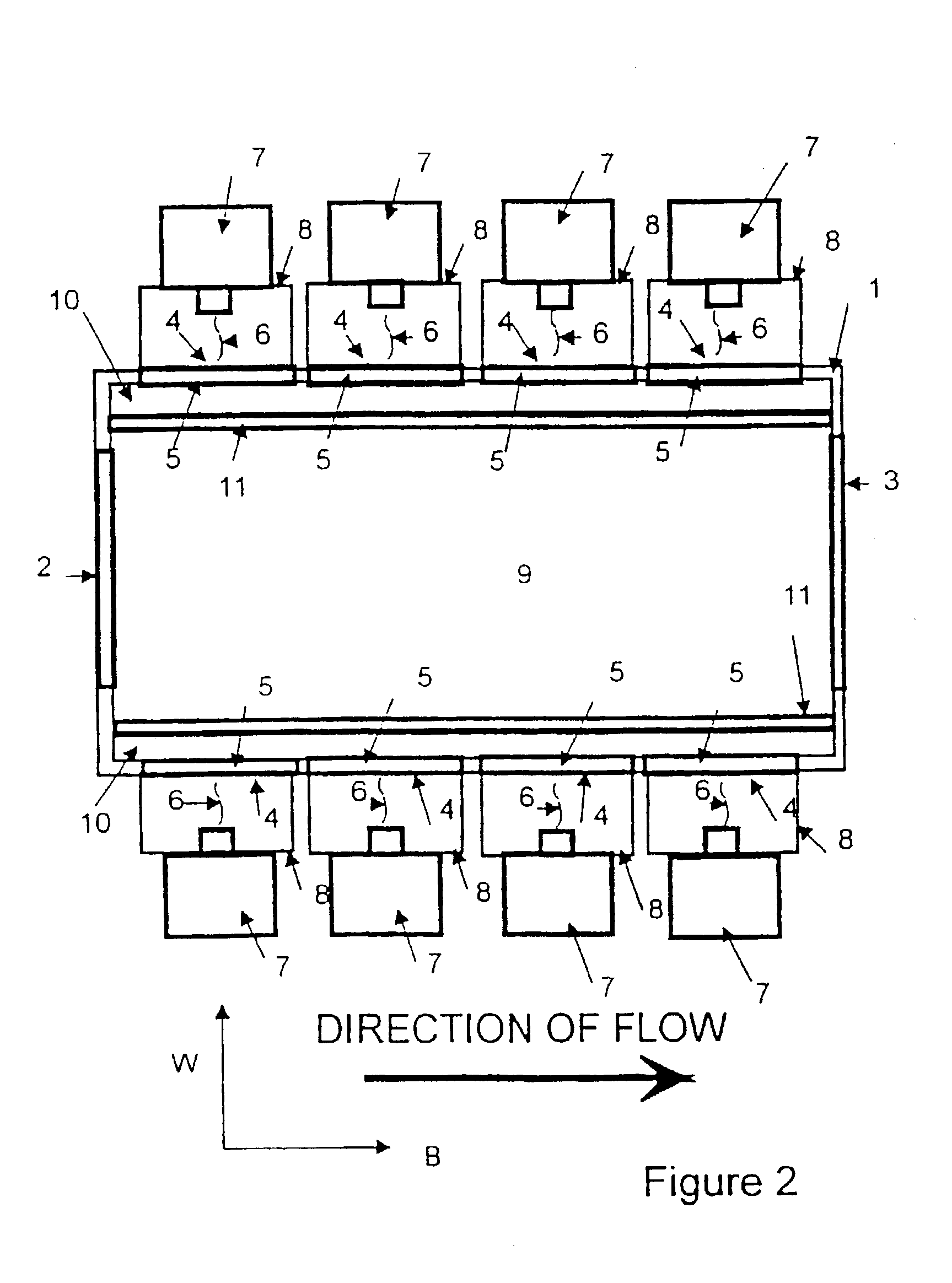

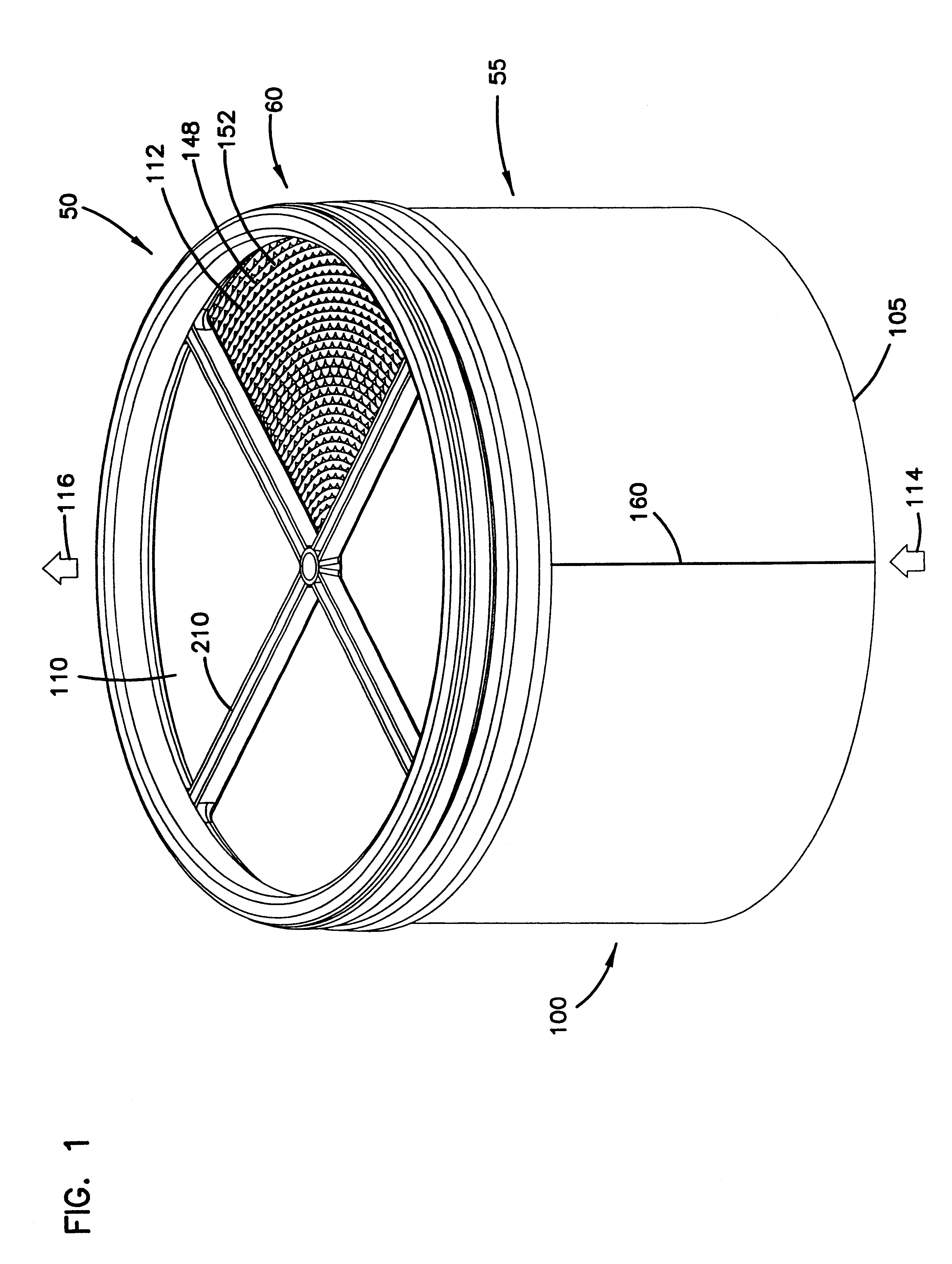

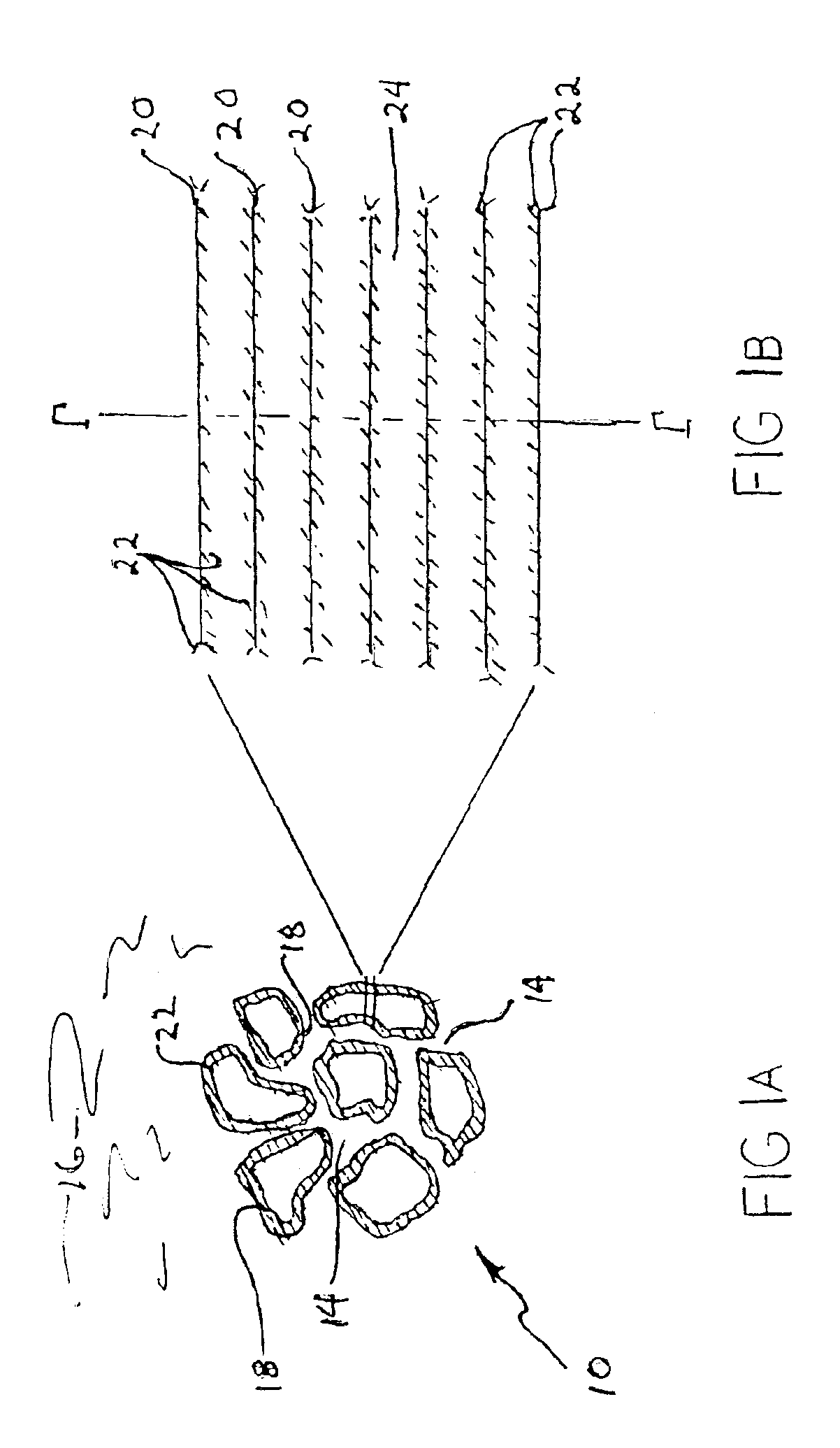

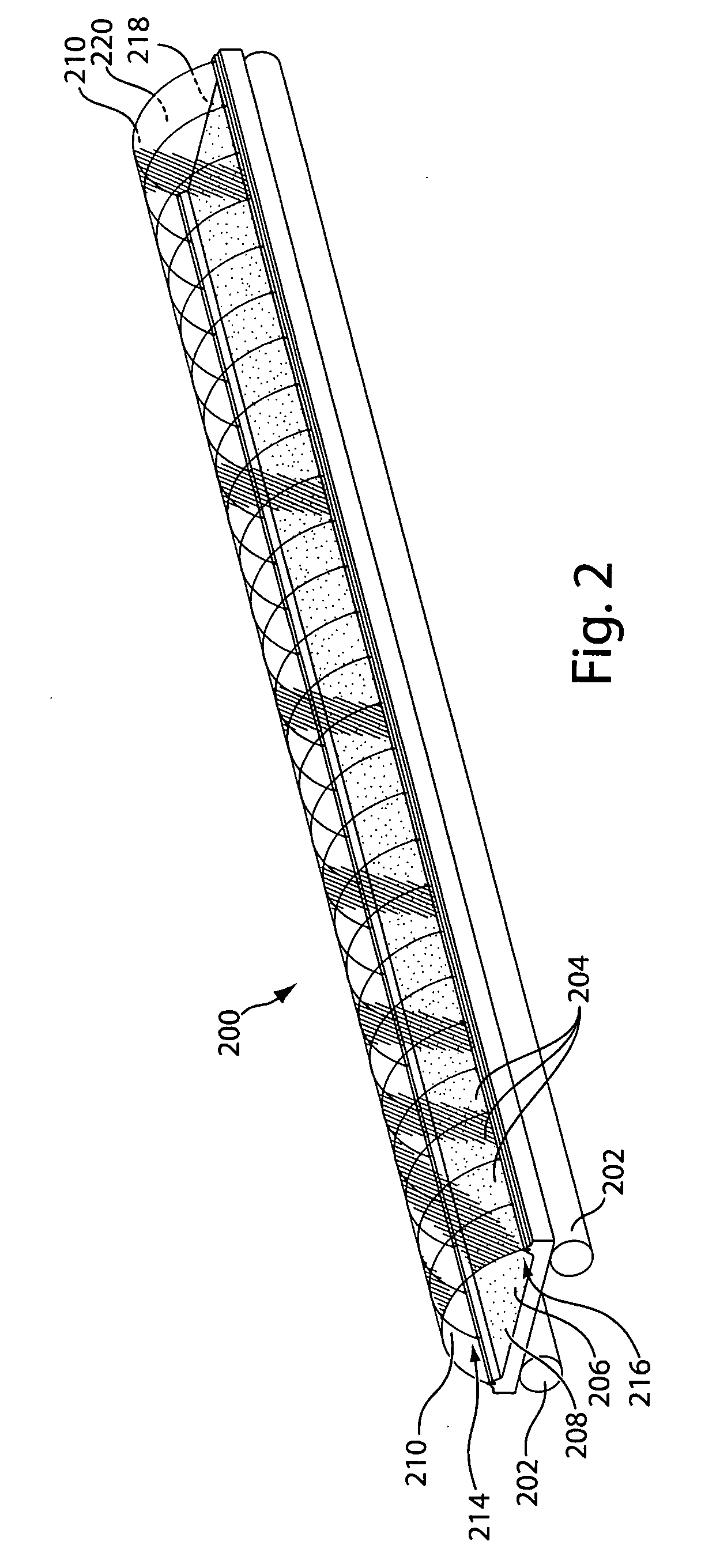

Filter element, air cleaner, and methods

A filter arrangement includes a filter element, a frame construction secured to the filter element, and a handle member secured to the filter element. In preferred embodiments, the handle member is secured to the frame construction. Preferably, the filter element includes a central core member, wherein fluted filter media is coiled around the central core member. Preferably, the central core member includes a plurality of corrugations, wherein the corrugations mateably engage at least some flutes. Preferably, the handle member is integral with the central core member, and also includes a fastening member for connection to a frame construction on the filter element. Methods for cleaning air and servicing an air cleaner preferably include constructions as described herein.

Owner:DONALDSON CO INC

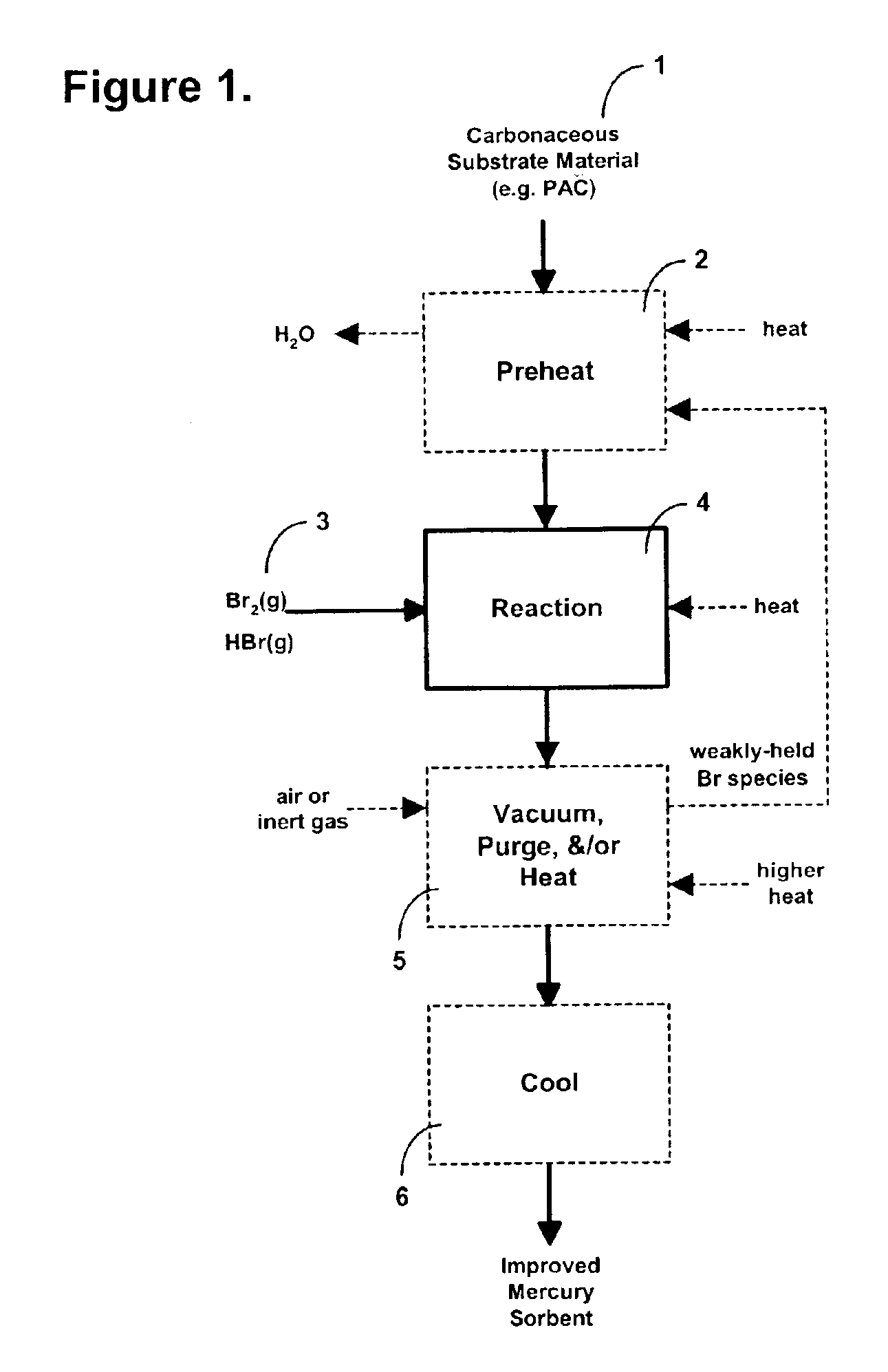

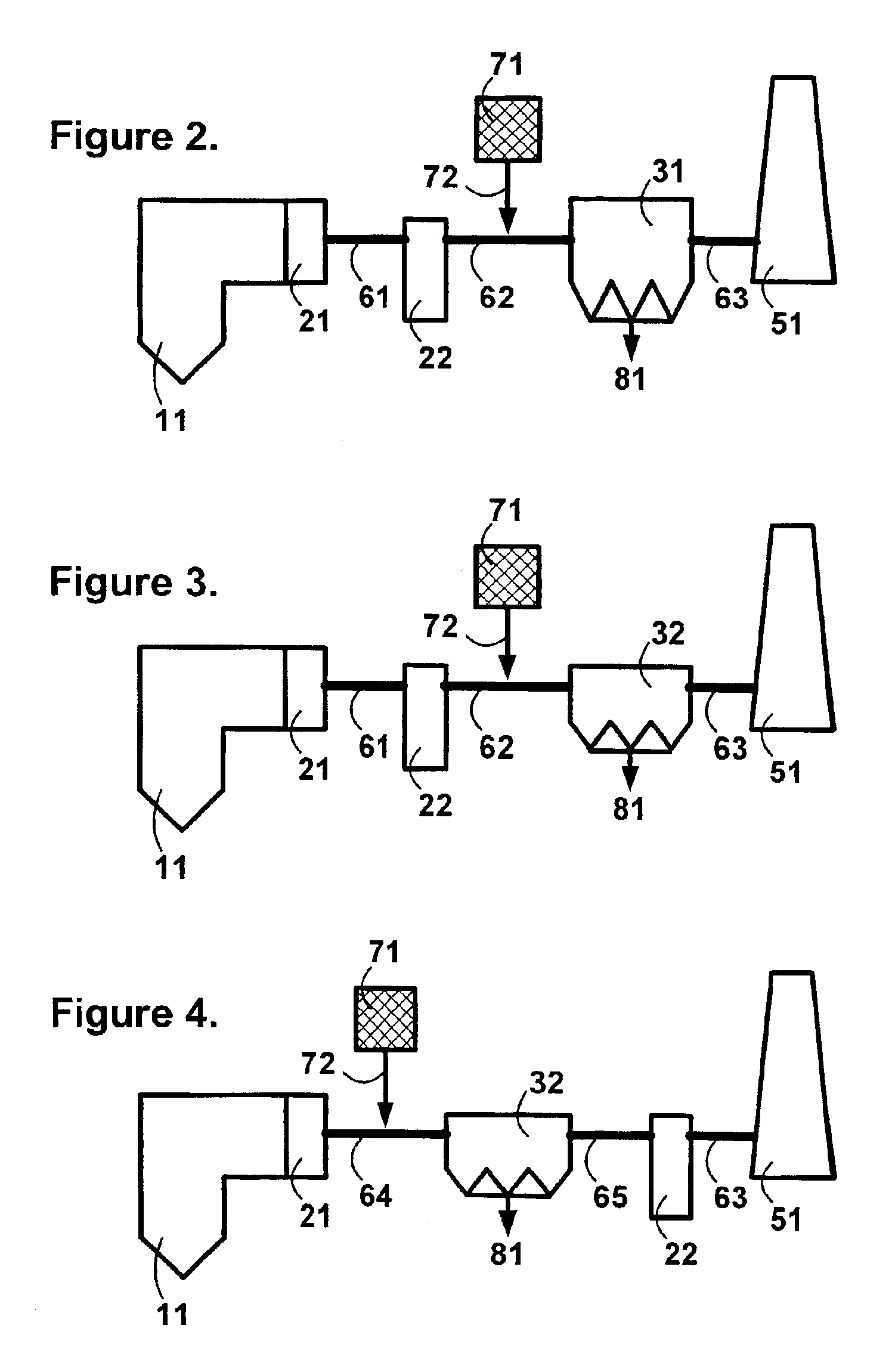

Sorbents and methods for the removal of mercury from combustion gases

InactiveUS6953494B2Improve abilitiesUnified processingGas treatmentOther chemical processesSufficient timeCombustion

A method for removing mercury and mercury-containing compounds from a combustion gas in an exhaust gas system has the steps of providing a mercury sorbent; injecting the mercury sorbent into a stream of the mercury-containing combustion gas for a sufficient time to allow at least an effective amount of the mercury and mercury-containing compounds in the combustion gas to adsorb onto the mercury sorbent, and collecting and removing the mercury sorbent from the combustion gas stream. The mercury sorbent is prepared by treating a carbonaceous substrate with an effective amount of a bromine-containing gas, especially one containing elemental bromine or hydrogen bromide, for a time sufficient to increase the ability of the carbonaceous substrate to adsorb mercury and mercury-containing compounds. The points of injecting and collecting and removing the mercury sorbent may be varied, depending upon the exact configuration of the exhaust gas system.

Owner:SORBENT TECH +1

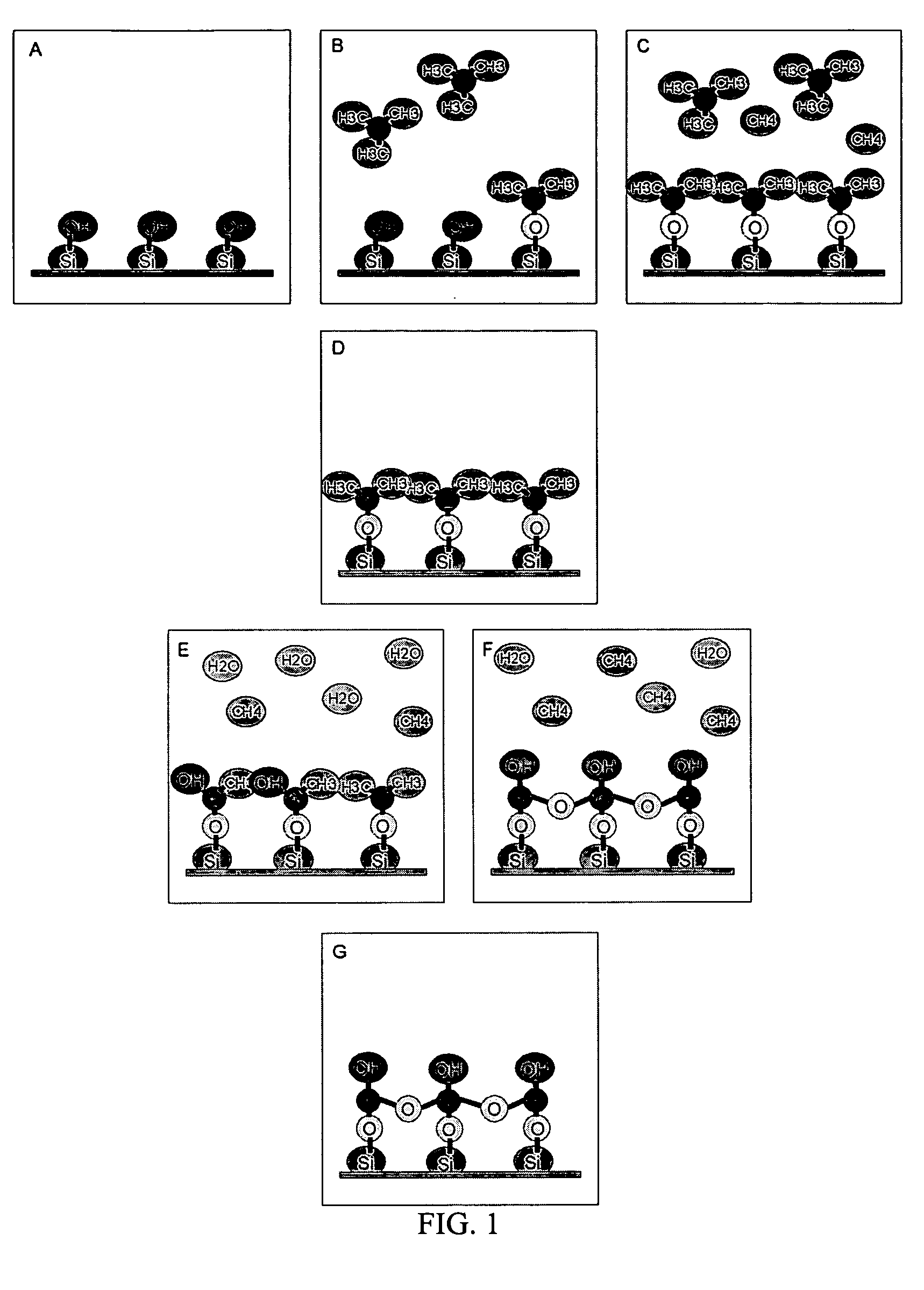

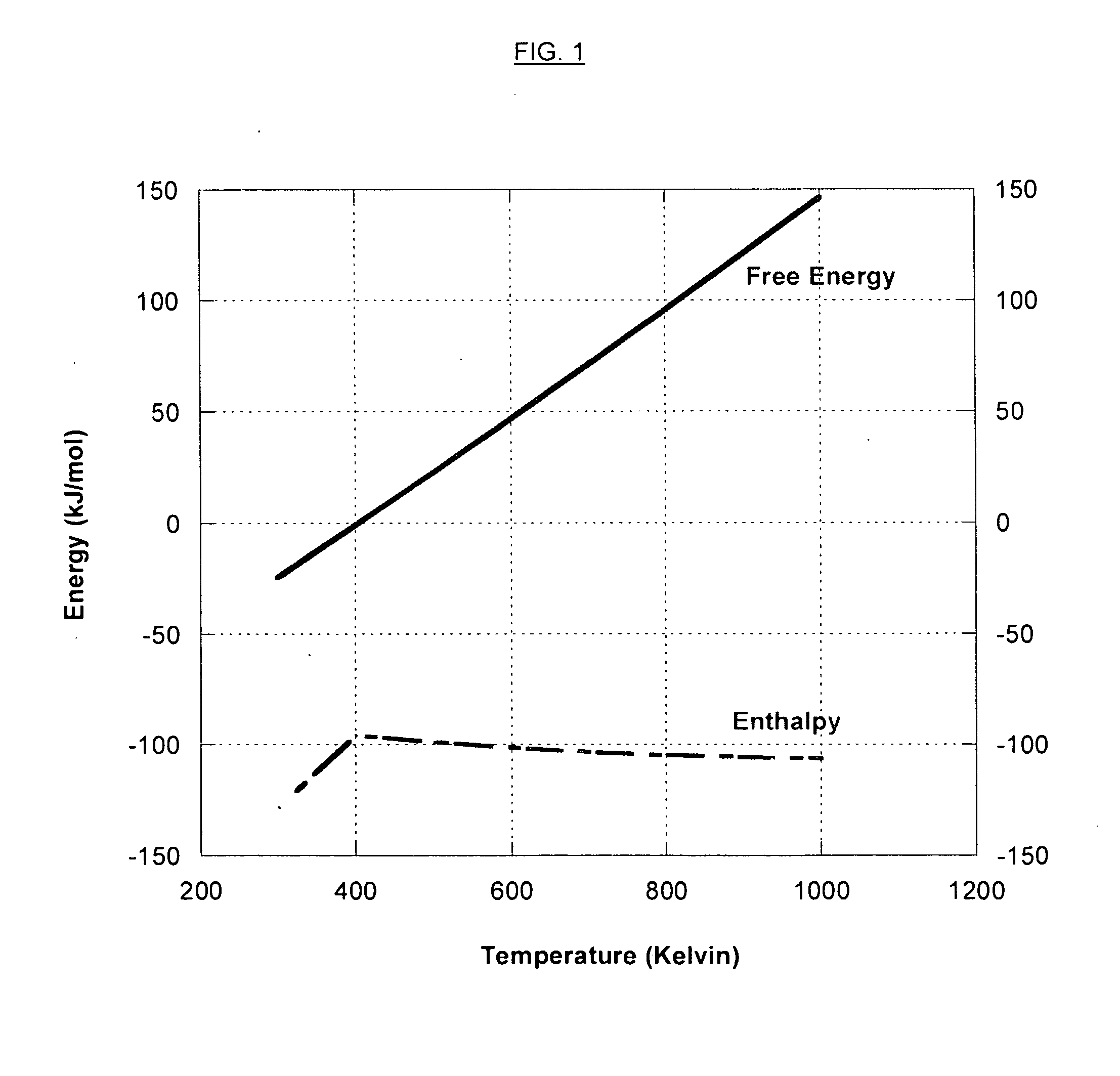

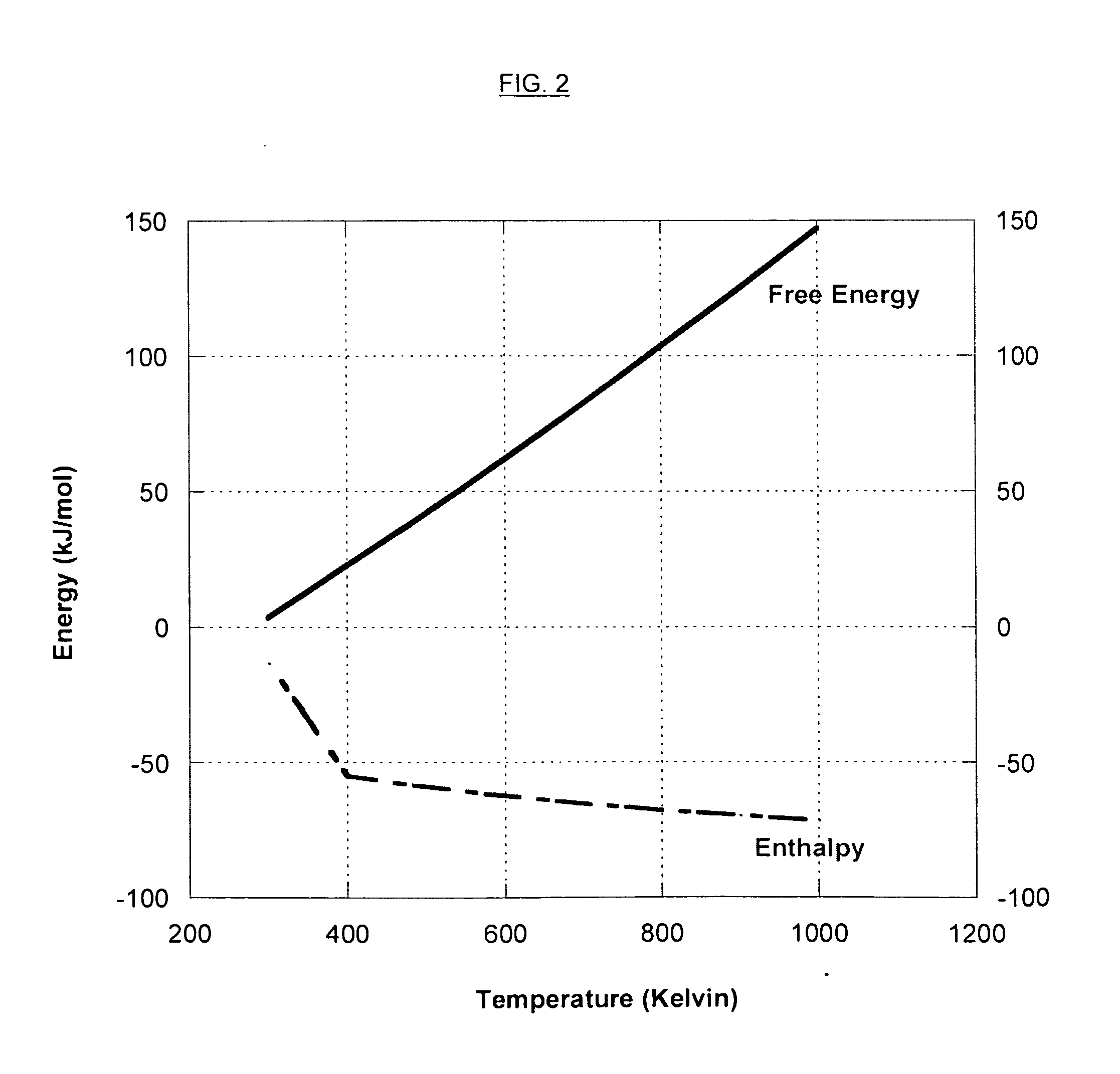

Electromagnetic susceptors with coatings for artificial dielectric systems and devices

InactiveUS20030226840A1Enhanced radiationLow dielectric constantGas treatmentMethane captureChemical treatmentSusceptor

A coated susceptor of electromagnetic energy for chemical processing made of a matrix material that surrounds a non-matrix material that is made from a material that is different from the matrix material, in which the matrix material is constructed of material having lower dielectric losses compared to the non-matrix material, the non-matrix material initially absorbs electromagnetic energy applied to the electromagnetic susceptor to a greater extent than the matrix material, the non-matrix material produces subsequent heat in the matrix material, and the surface of the susceptor is coated with a material that interacts with applied electromagnetic energy of at least one frequency and initially absorbs electromagnetic energy and produces heat.

Owner:DALTON ROBERT C

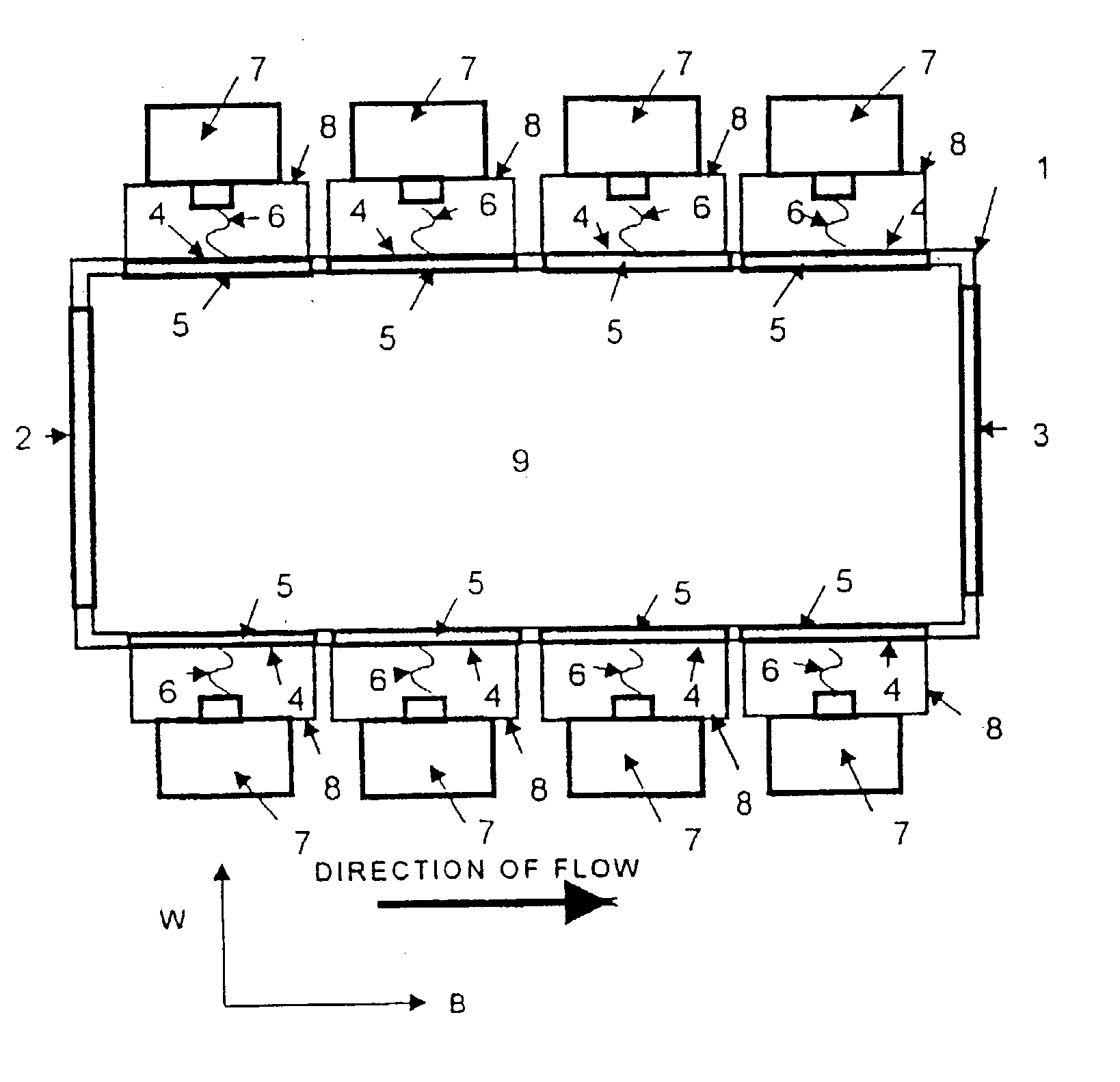

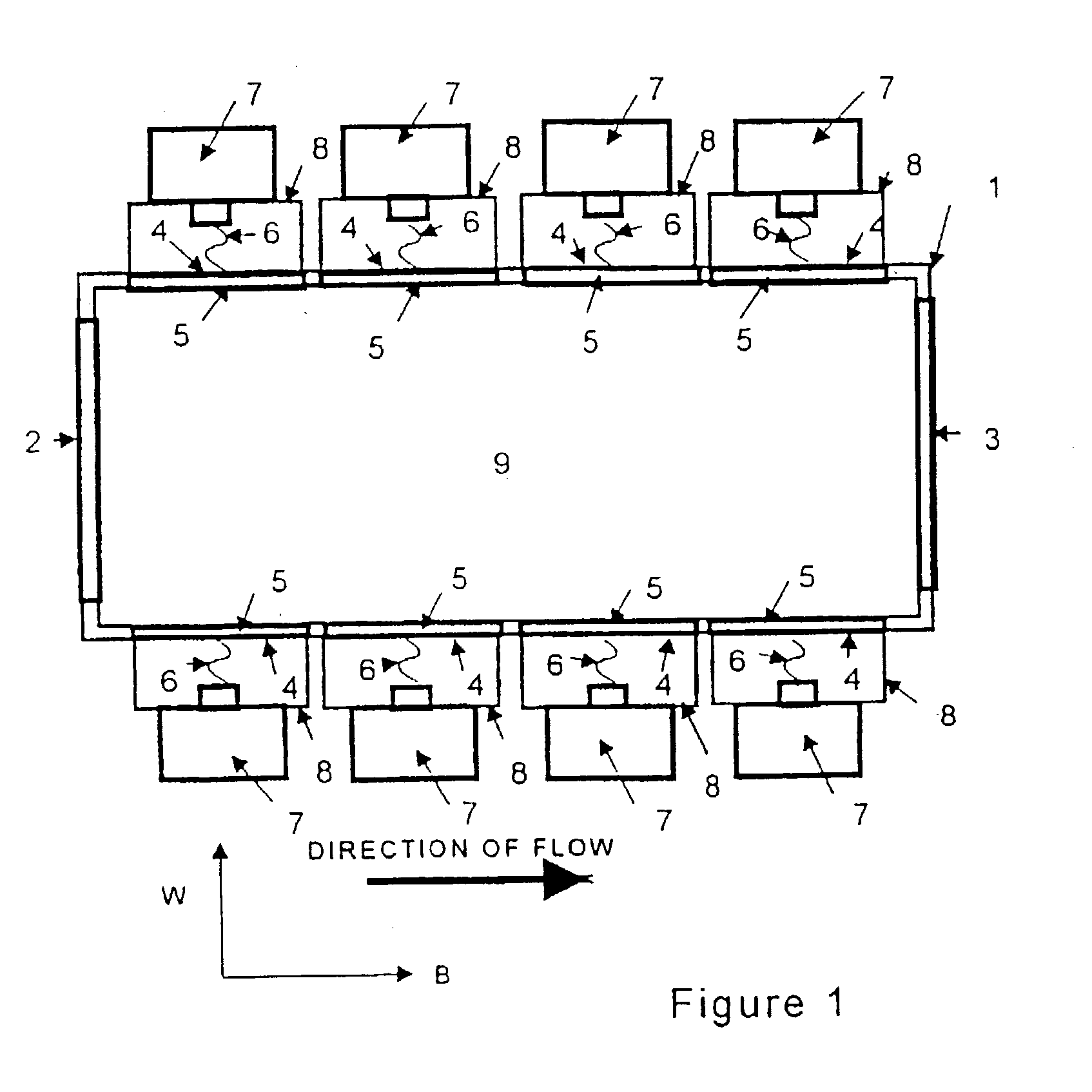

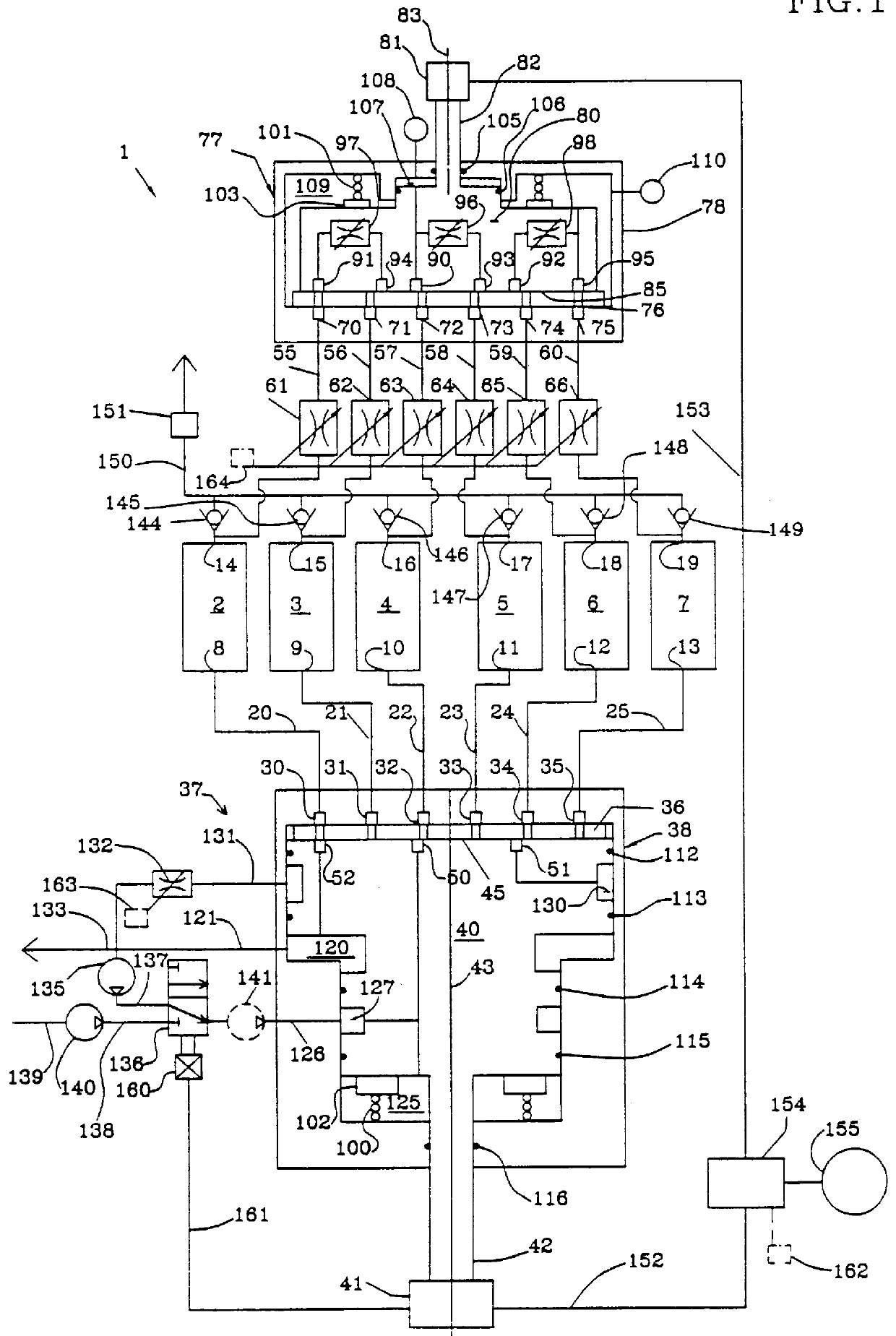

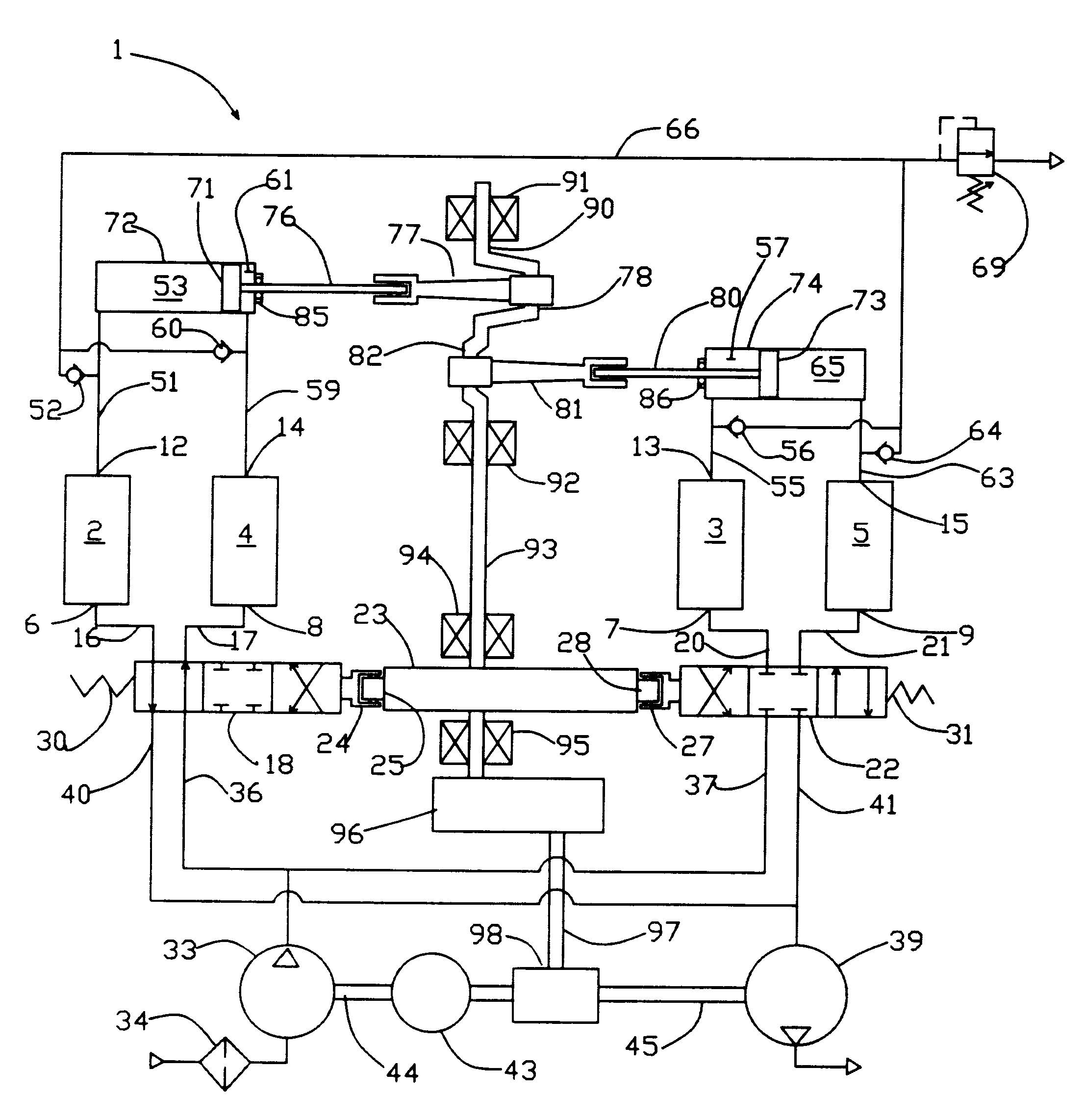

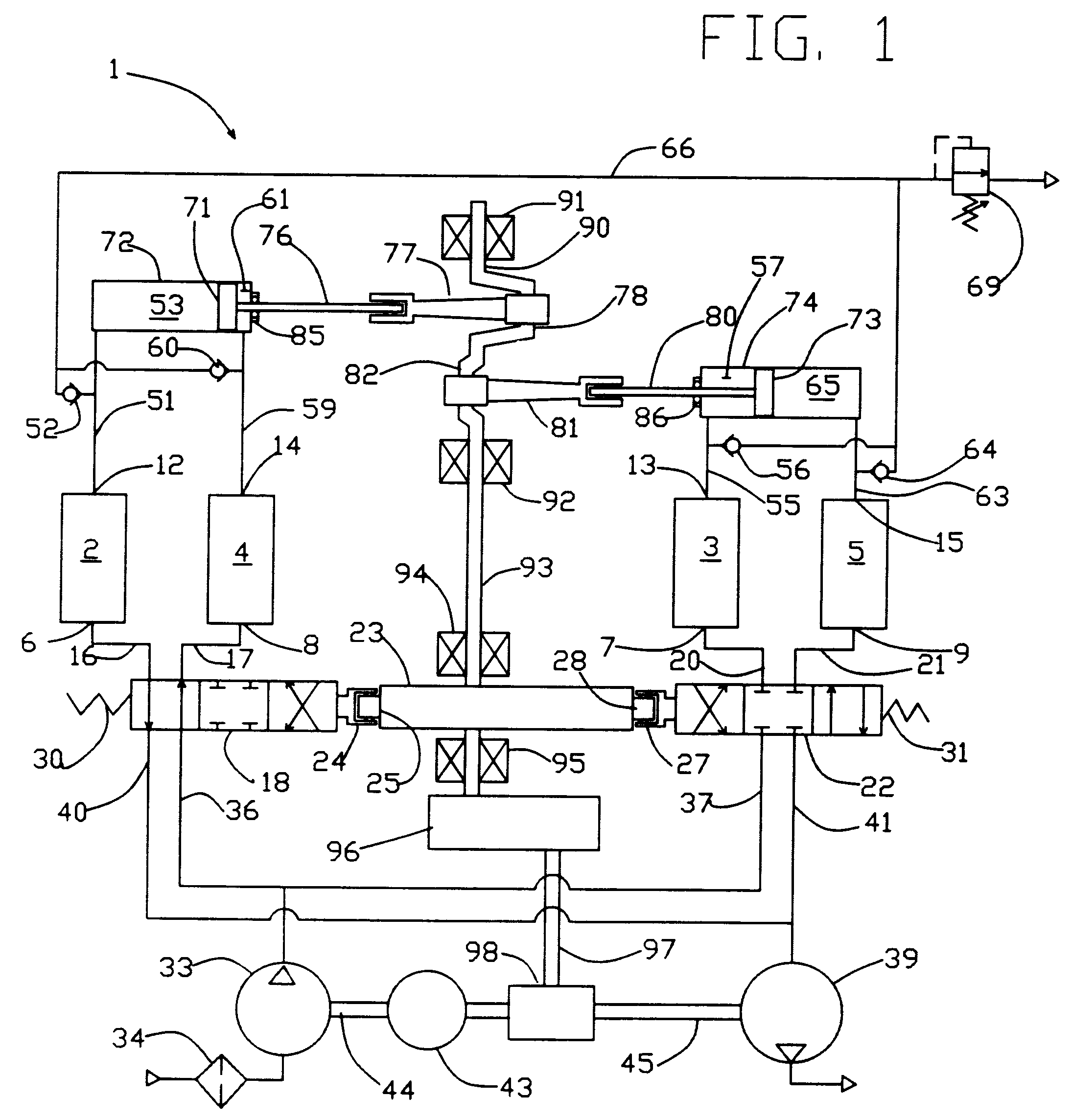

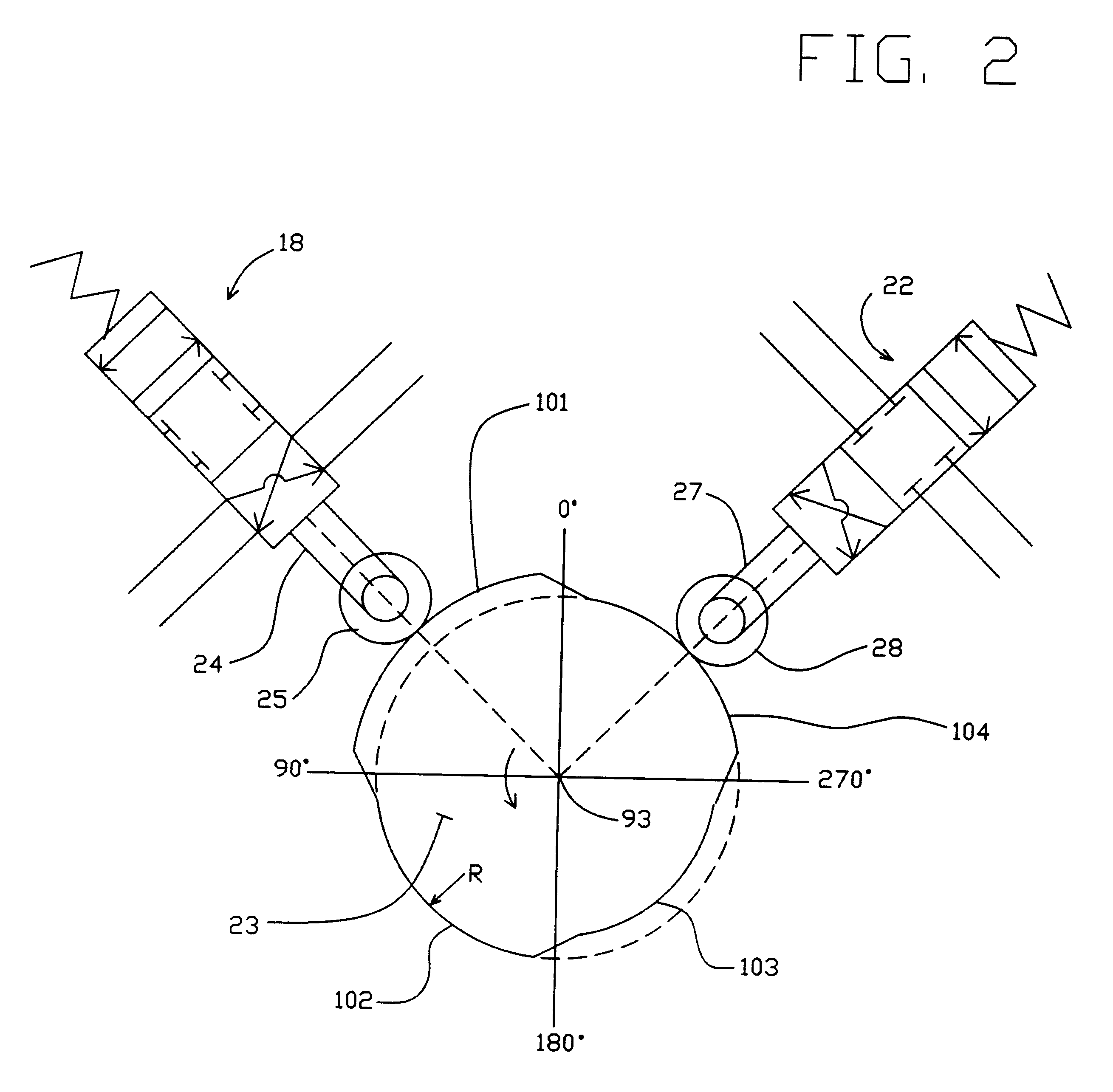

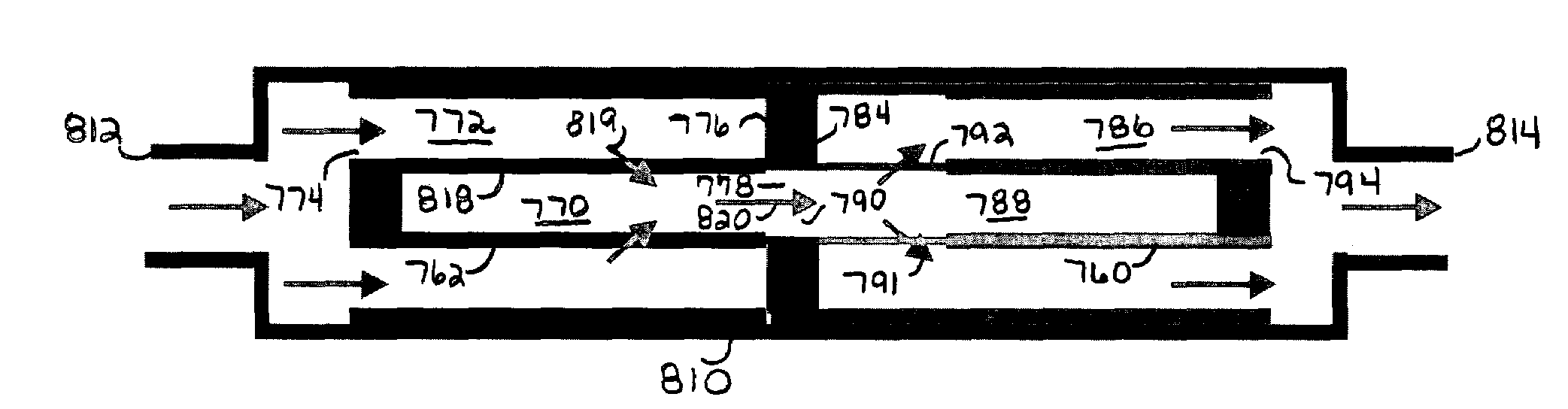

Flow regulated pressure swing adsorption system

InactiveUS6063161AAvoid damageGas treatmentHydrogen separation using solid contactSystem pressureProcess engineering

Pressure swing adsorption (PSA) separation of a gas mixture is performed in an apparatus with a plurality of adsorbent beds. The invention provides rotary multiport distributor valves to control the timing sequence of the PSA cycle steps between the beds, with flow controls cooperating with the rotary distributor valves to control the volume rates of gas flows to and from the adsorbent beds in blowdown, purge, equalization and repressurization steps.

Owner:QUSIR TECH +1

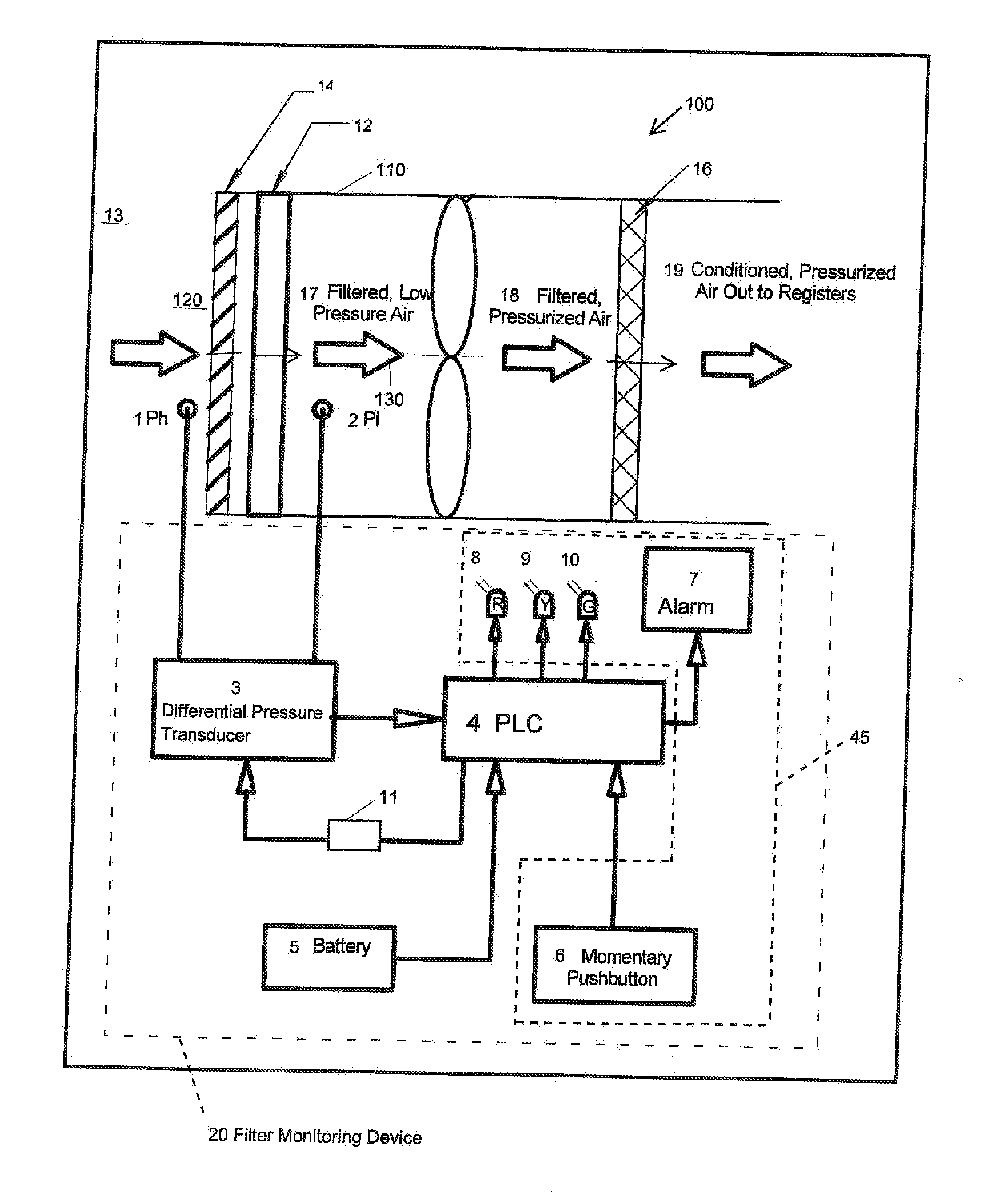

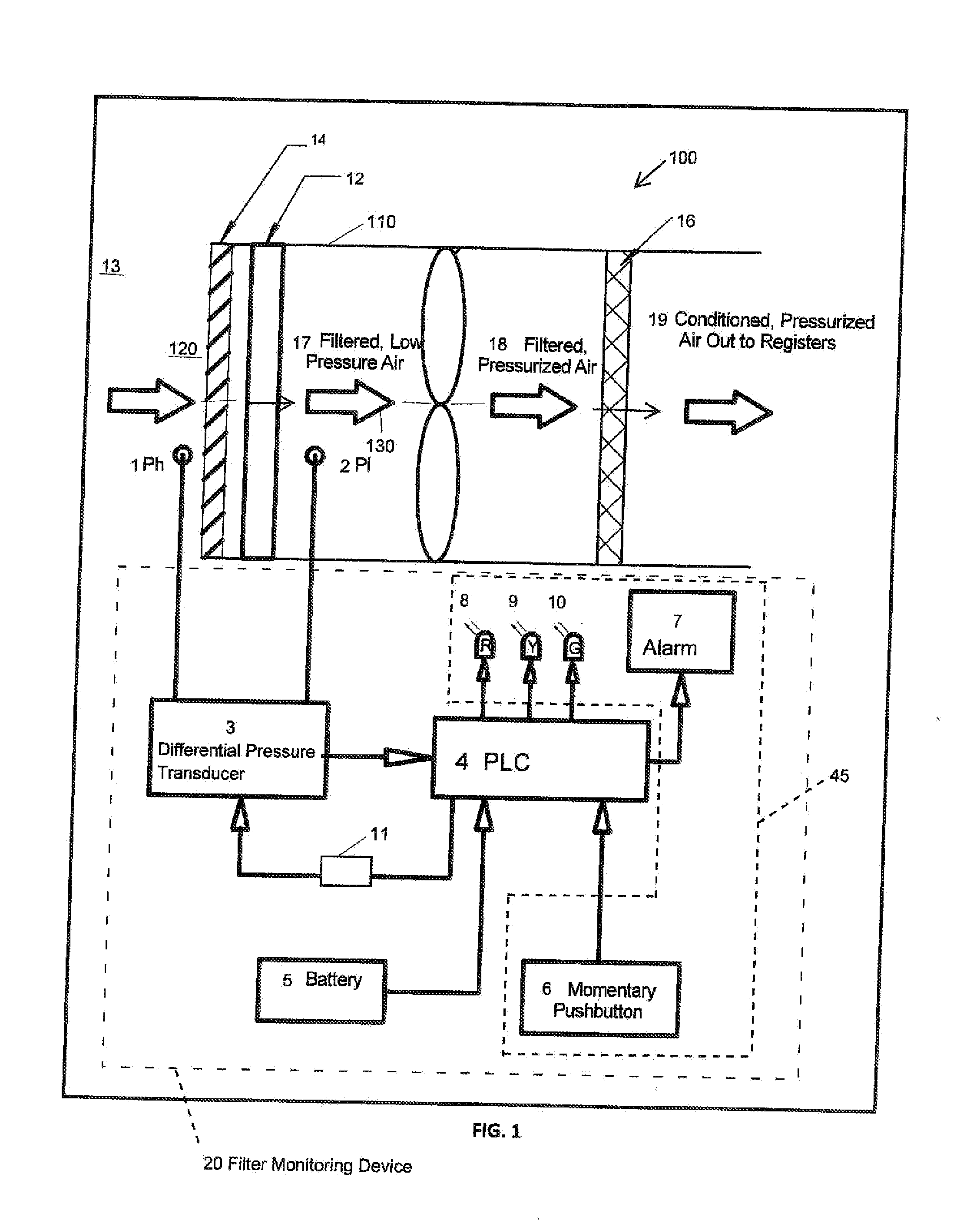

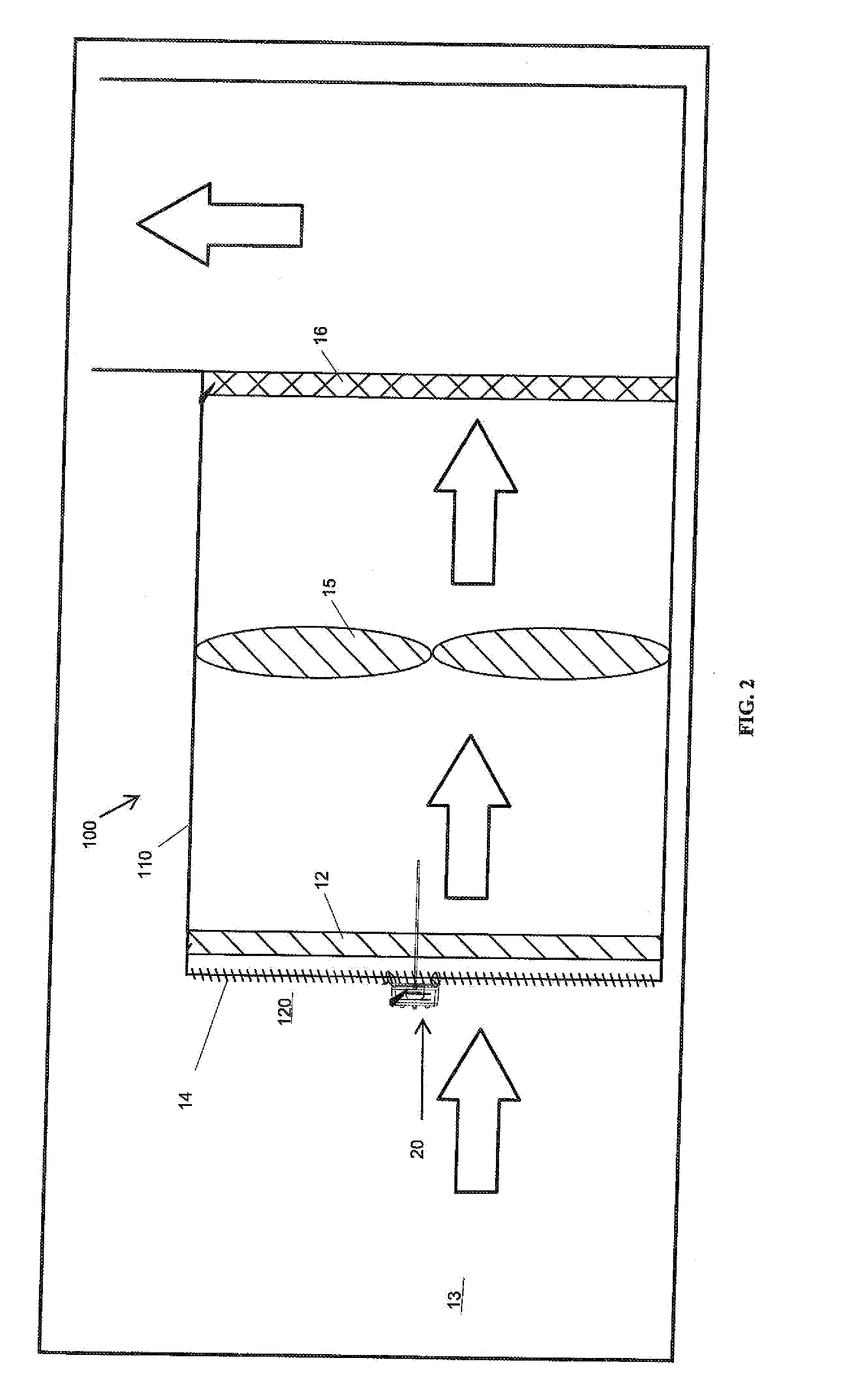

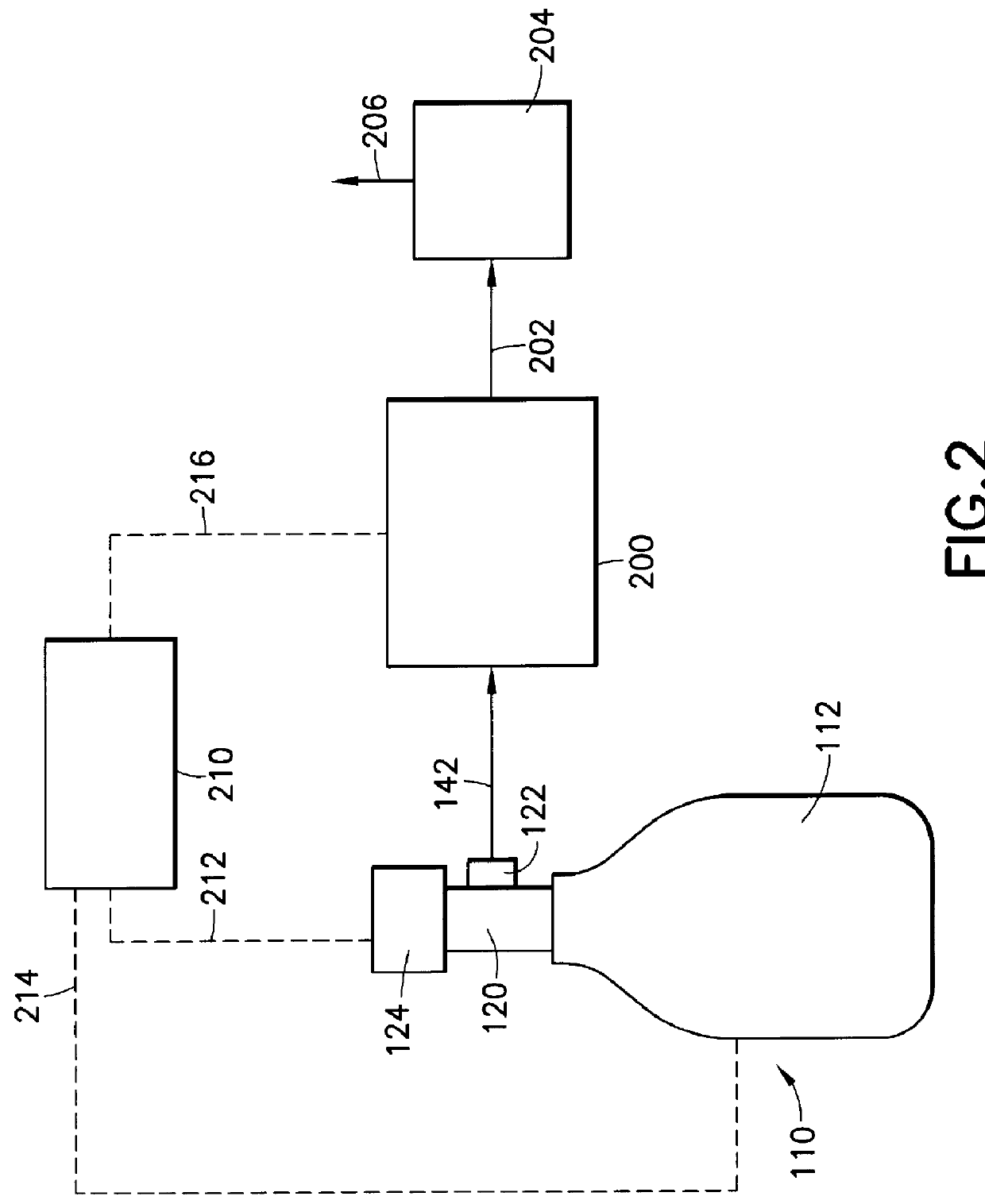

Filter apparatus and method of monitoring filter apparatus

Methods, systems, and products for monitoring an air filter. Methods involve determining a difference between a baseline pressure differential and a current pressure differential, the differential pressure between pressure at an upstream side of the filter and pressure at a downstream side of the filter. The baseline pressure differential may be set automatically or by a user. Reaching or exceeding a predetermined threshold triggers an indication of a clogged condition. The method also includes monitoring the air filter condition intermittently. The filter monitor may operate for extended periods in a sleep state and intermittently power up to a wake state to measure the current pressure differential and compare the current pressure differential with a baseline pressure differential.

Owner:FREEN PAUL

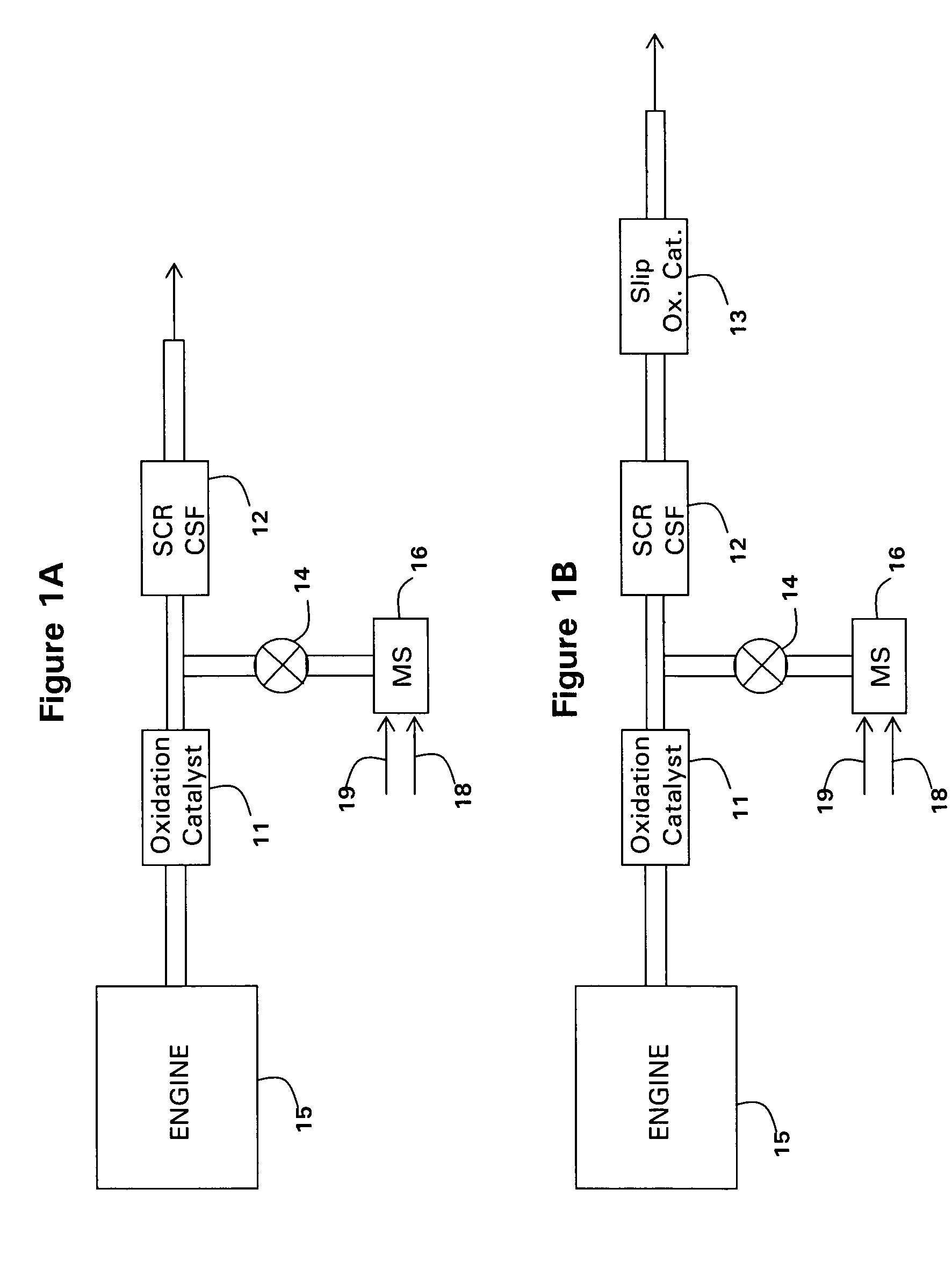

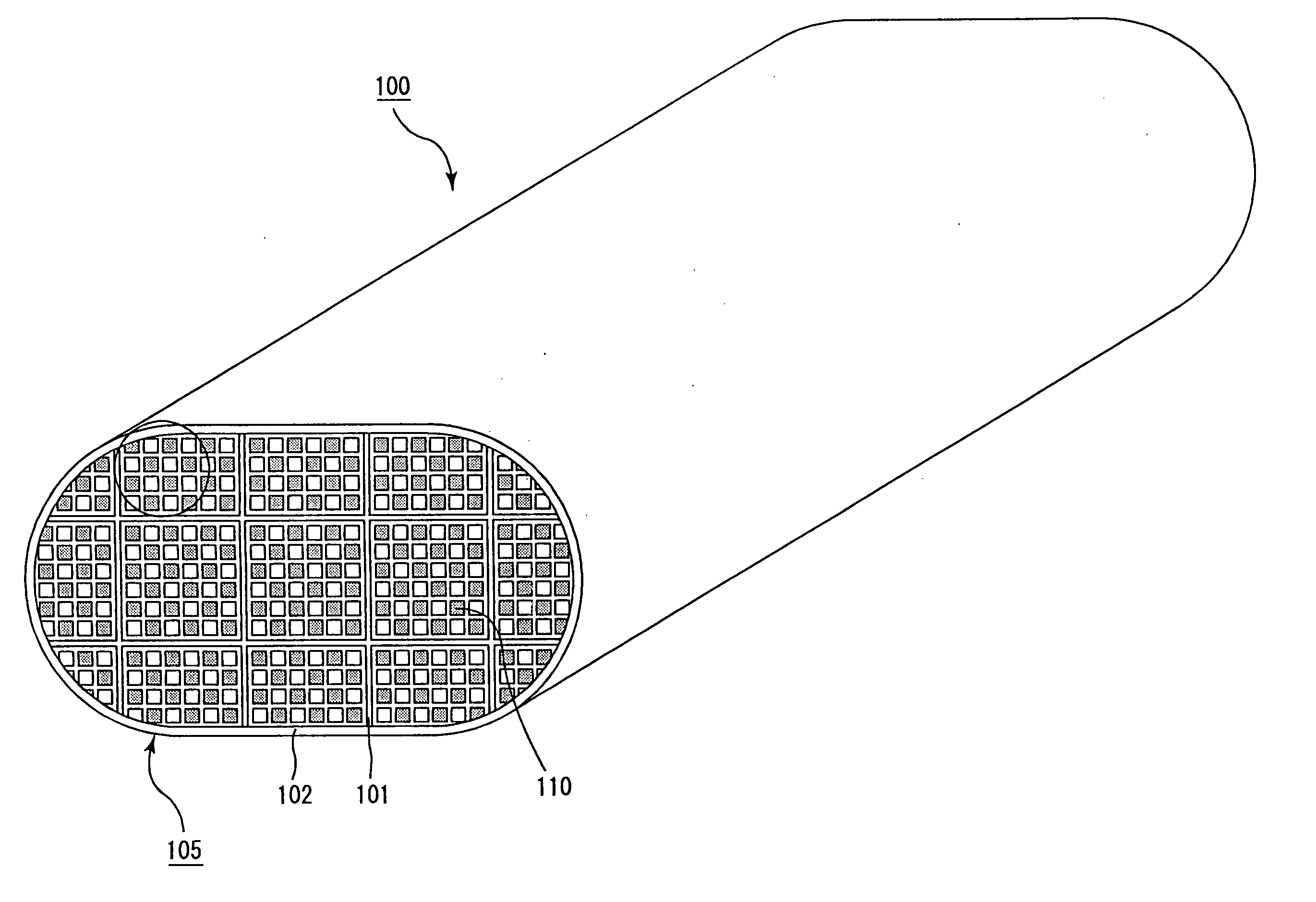

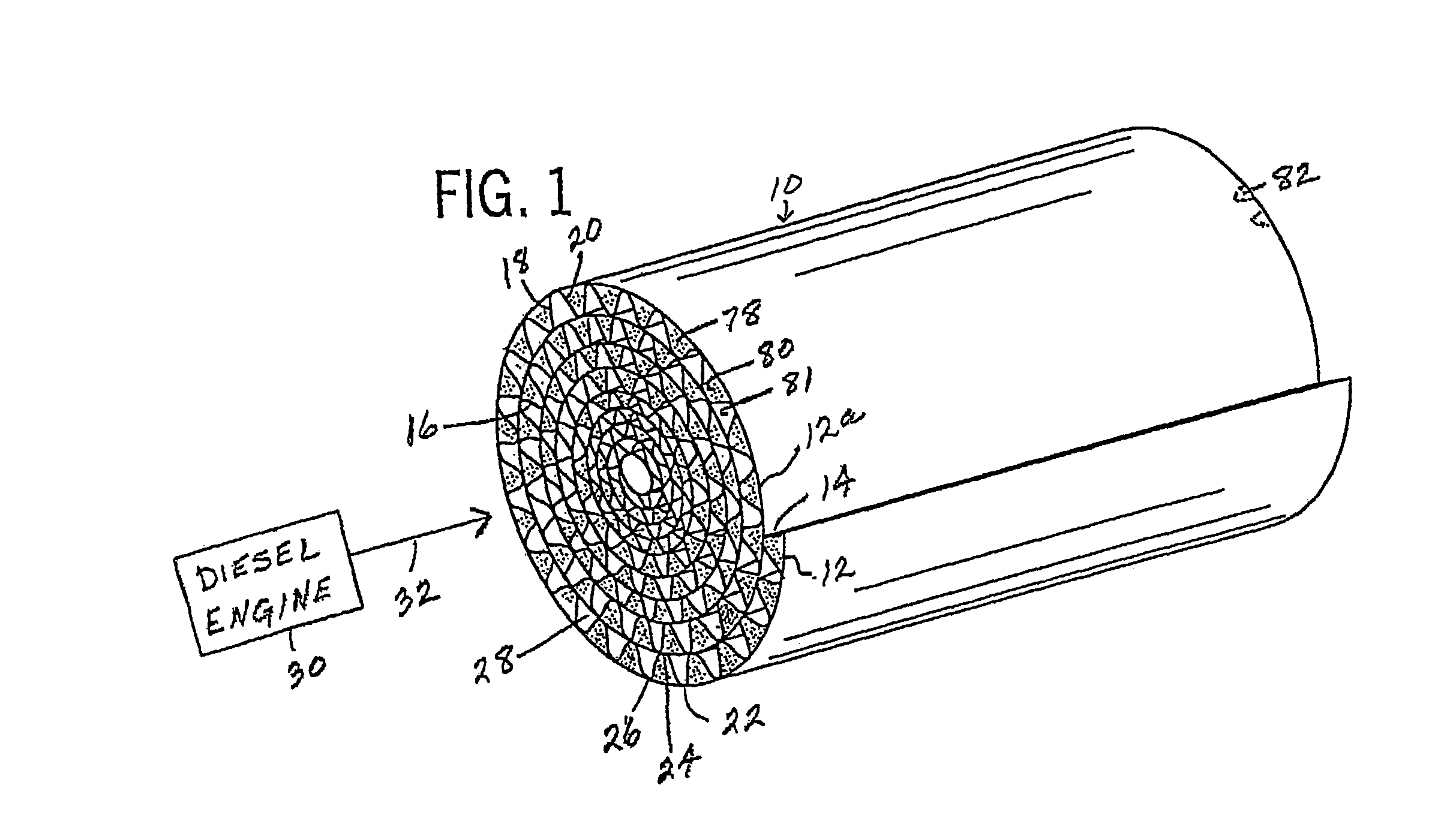

Catalyzed SCR filter and emission treatment system

ActiveUS7229597B2Reduce the temperaturePromote regenerationCombination devicesLiquid degasification with auxillary substancesNitrogen oxideSoot

Provided is an emission treatment system and method for simultaneously remediating the nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons present in diesel engine exhaust streams. The emission treatment system has an oxidation catalyst upstream of a soot filter coated with a material effective in the Selective Catalytic Reduction (SCR) of NOx by a reductant, e.g., ammonia. Also provided is a method for disposing an SCR catalyst composition on a wall flow monolith that provides adequate catalyst loading, but does not result in unsuitable back pressures in the exhaust.

Owner:BASF CORP

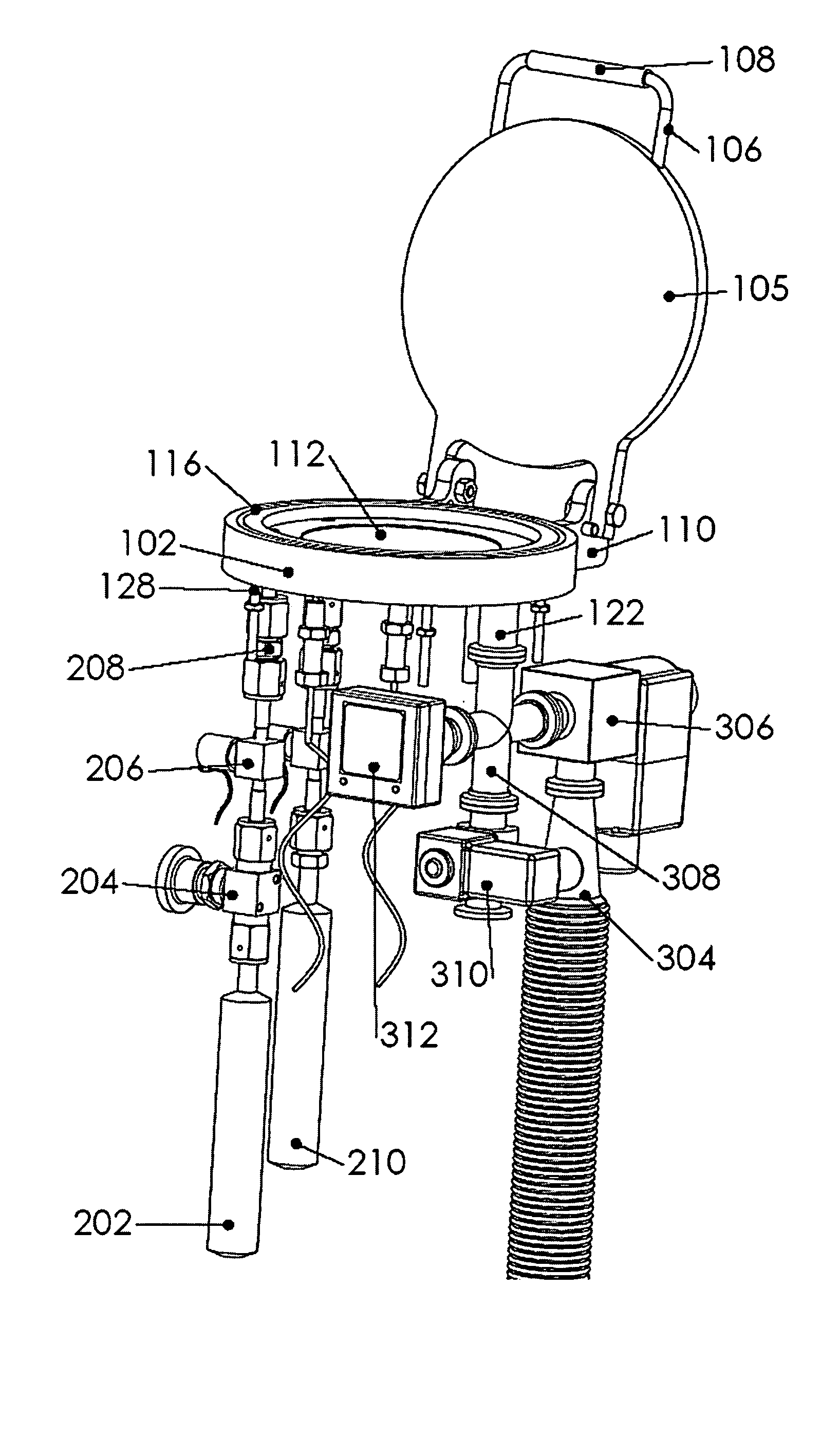

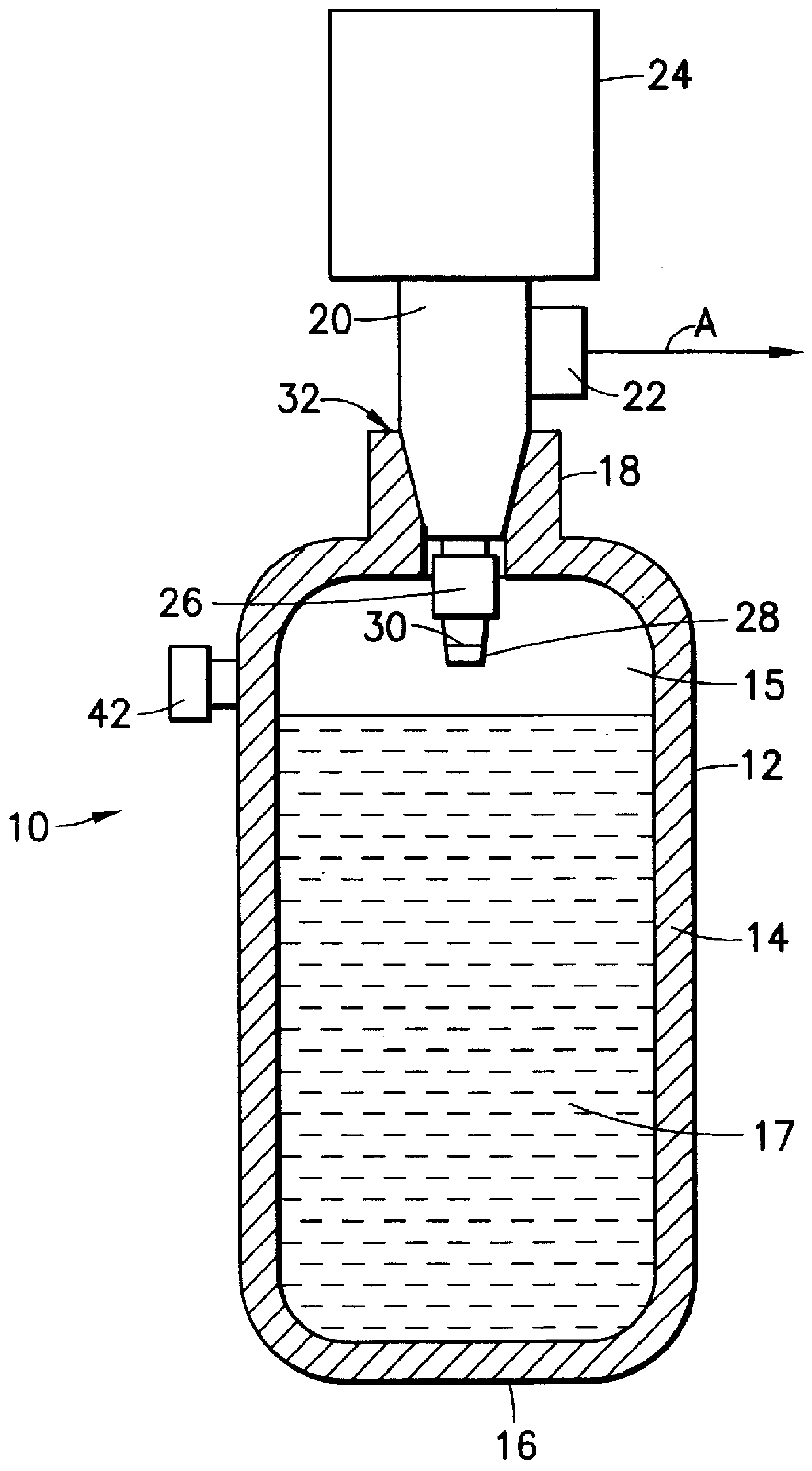

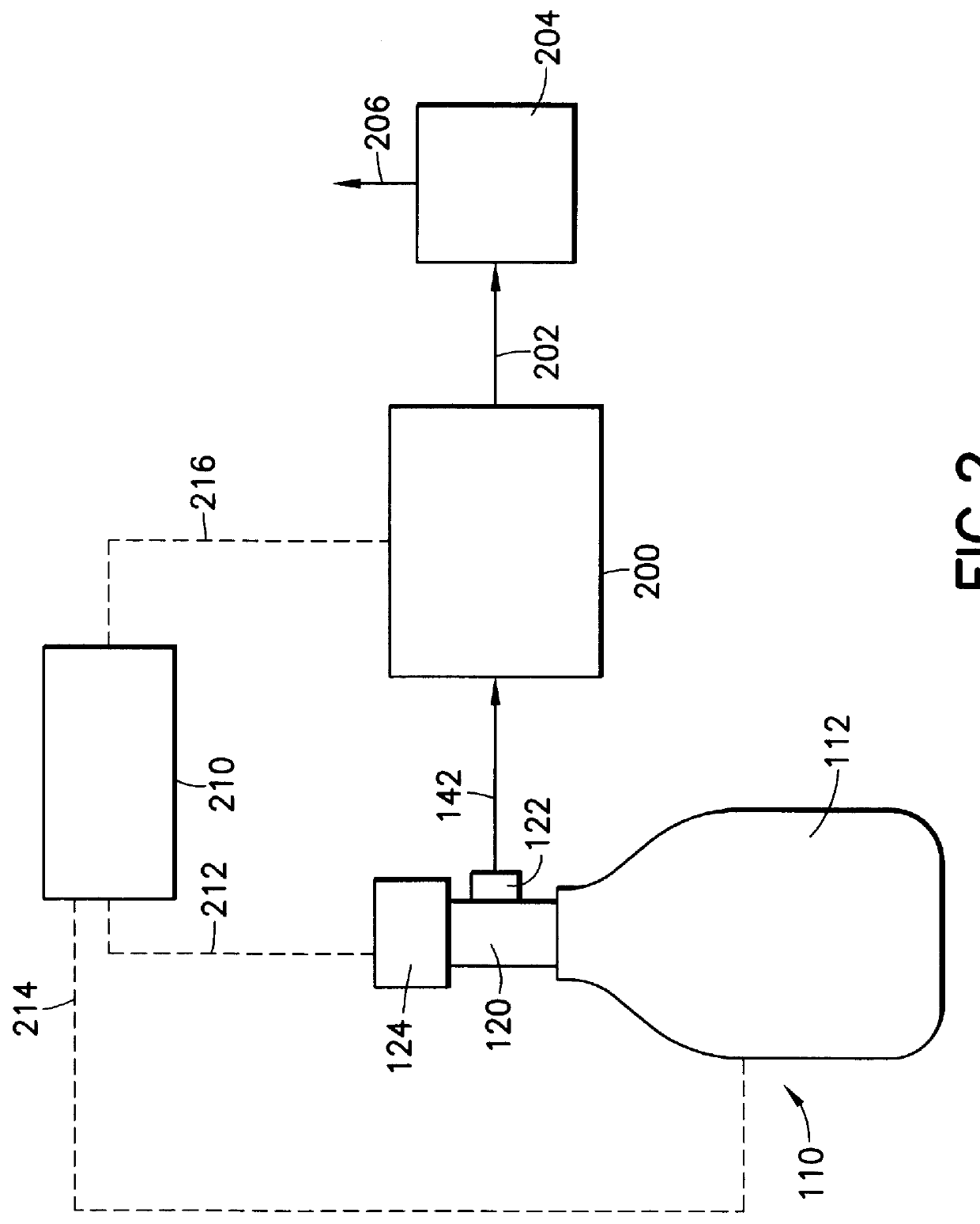

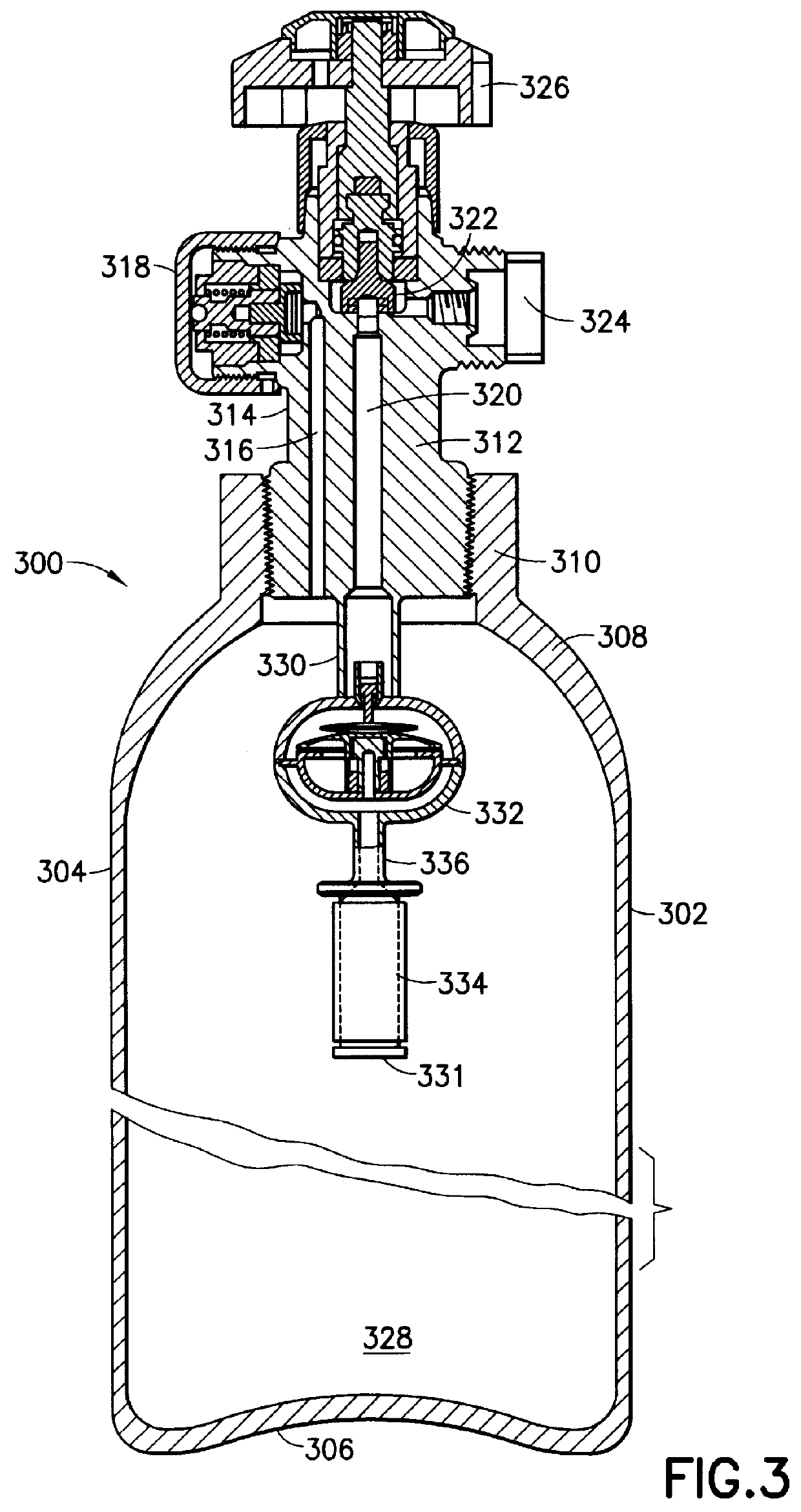

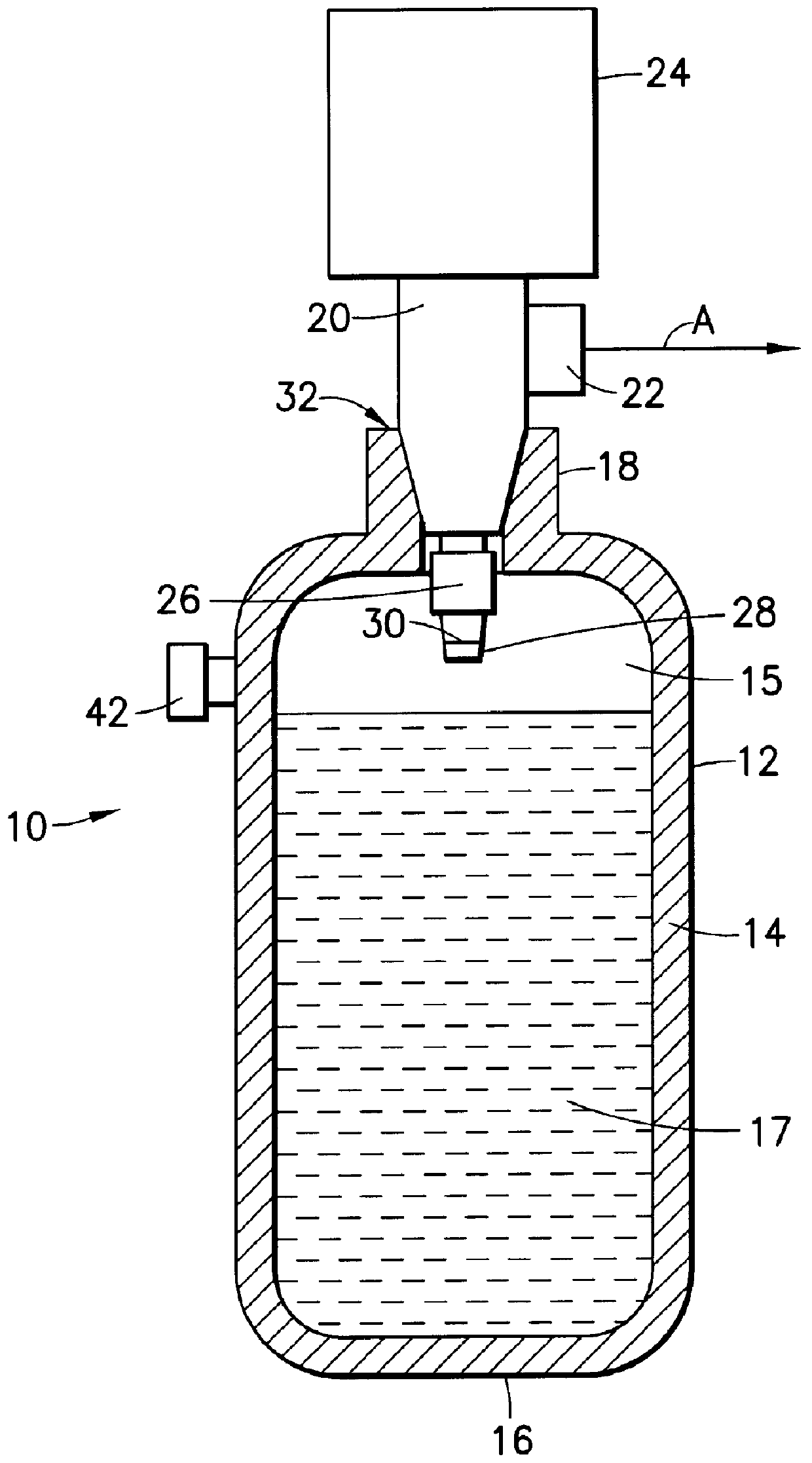

Fluid storage and dispensing system

InactiveUS6089027ACostPerformanceContainer filling methodsVacuum evaporation coatingSingle stageSorbent

A fluid storage and dispensing system comprising a vessel for holding a fluid at a desired pressure. The vessel has a pressure regulator, e.g., a single-stage or multi-stage regulator, associated with a port of the vessel, and set at a predetermined pressure. A dispensing assembly, e.g., including a flow control means such as a valve, is arranged in gas / vapor flow communication with the regulator, whereby the opening of the valve effects dispensing of gas / vapor from the vessel. The fluid in the vessel may be constituted by a liquid that is confined in the vessel at a pressure in excess of its liquefaction pressure at prevailing temperature conditions, e.g., ambient (room) temperature. In another aspect, the vessel contains a solid-phase sorbent material having sorbable gas adsorbed thereon, at a pressure in excess of 50 psig. The vessel may have a >1 inch NGT threaded neck opening, to accommodate the installation of an interior regulator.

Owner:ENTEGRIS INC

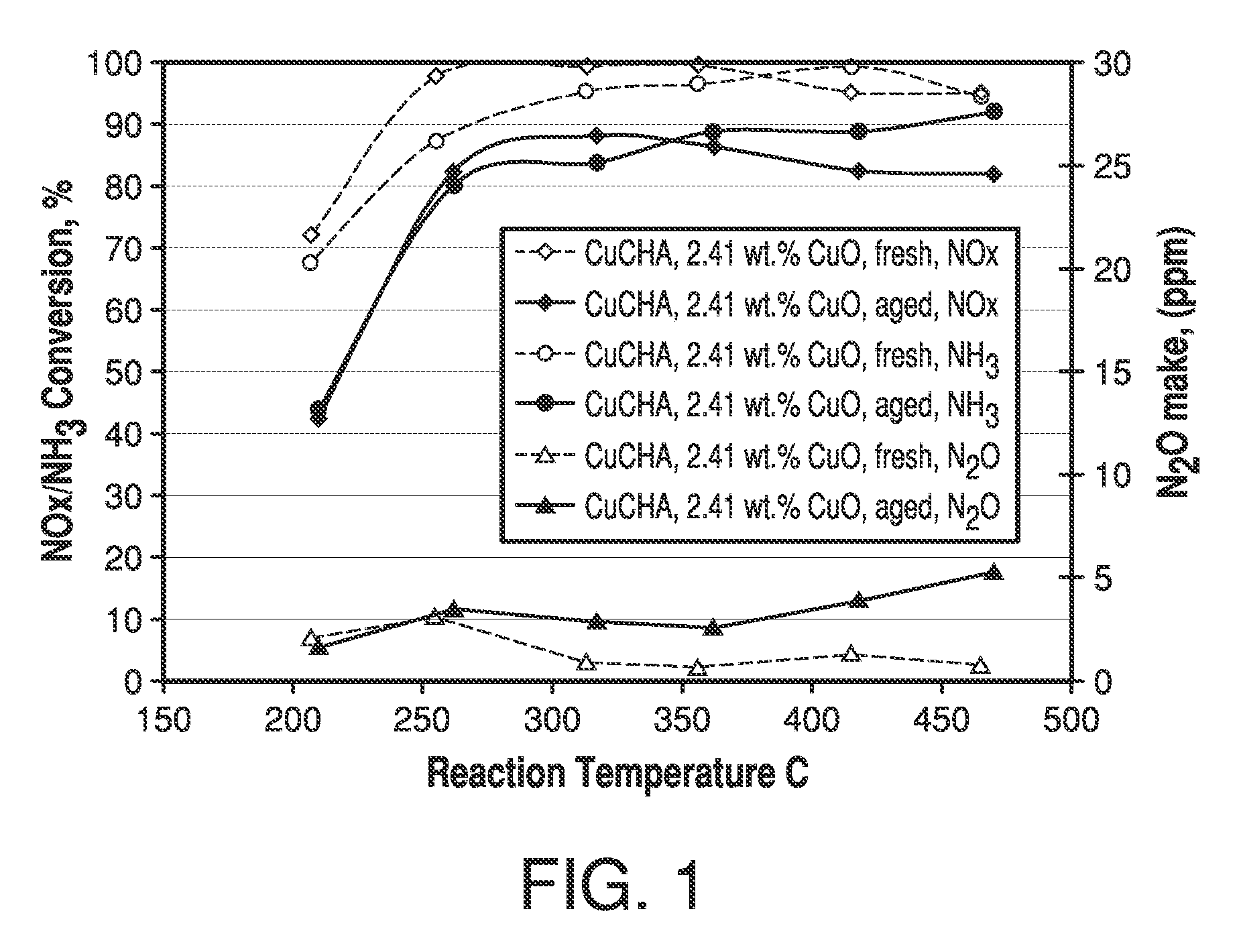

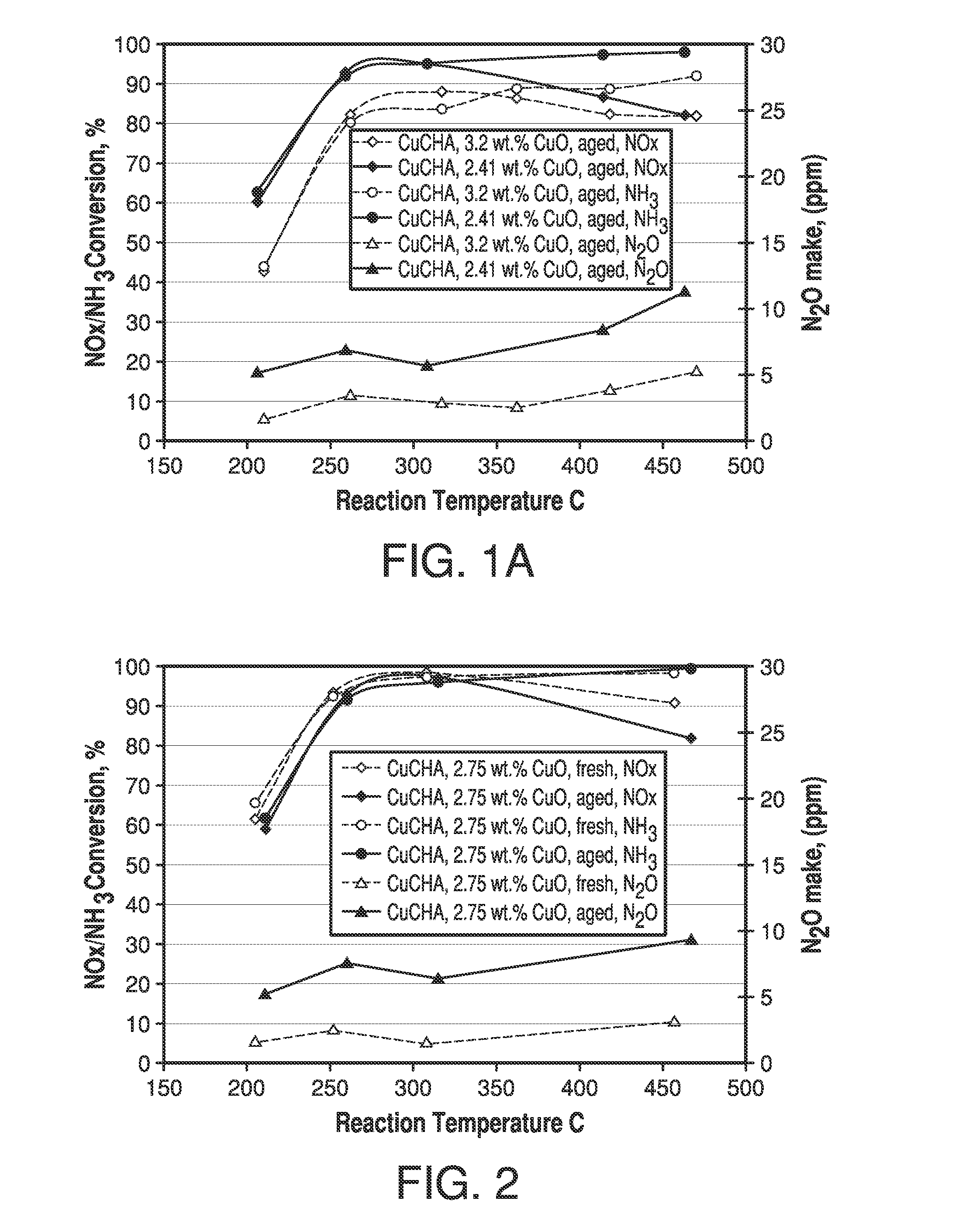

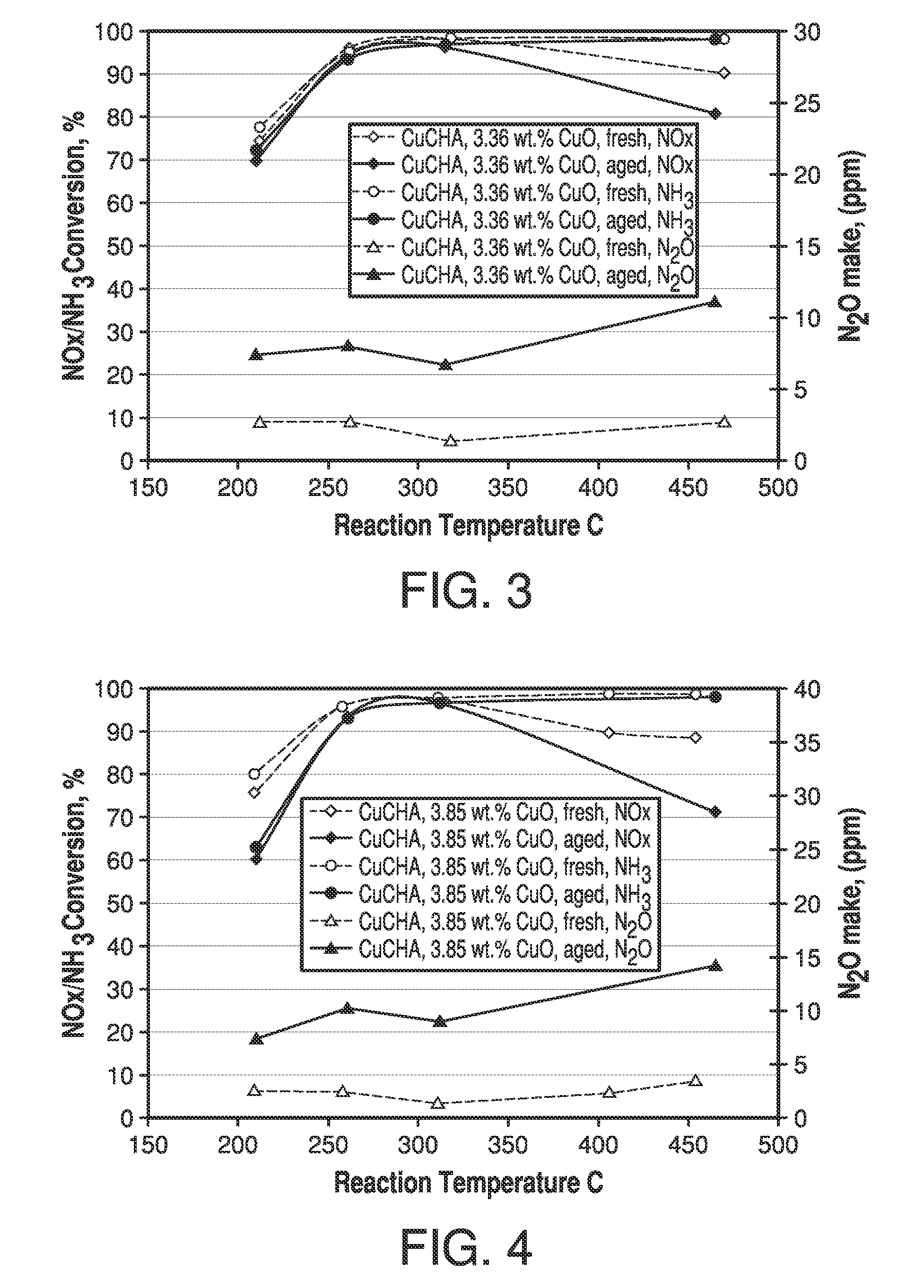

Copper CHA zeolite catalysts

ActiveUS7601662B2Good hydrothermal stabilityHigh catalytic activityCombination devicesAluminium compoundsReaction temperatureCrystal structure

Zeolite catalysts and systems and methods for preparing and using zeolite catalysts having the CHA crystal structure are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stable at high reaction temperatures. The zeolite catalysts include a zeolite carrier having a silica to alumina ratio from about 15:1 to about 256:1 and a copper to alumina ratio from about 0.25:1 to about 1:1.

Owner:BASF CORP

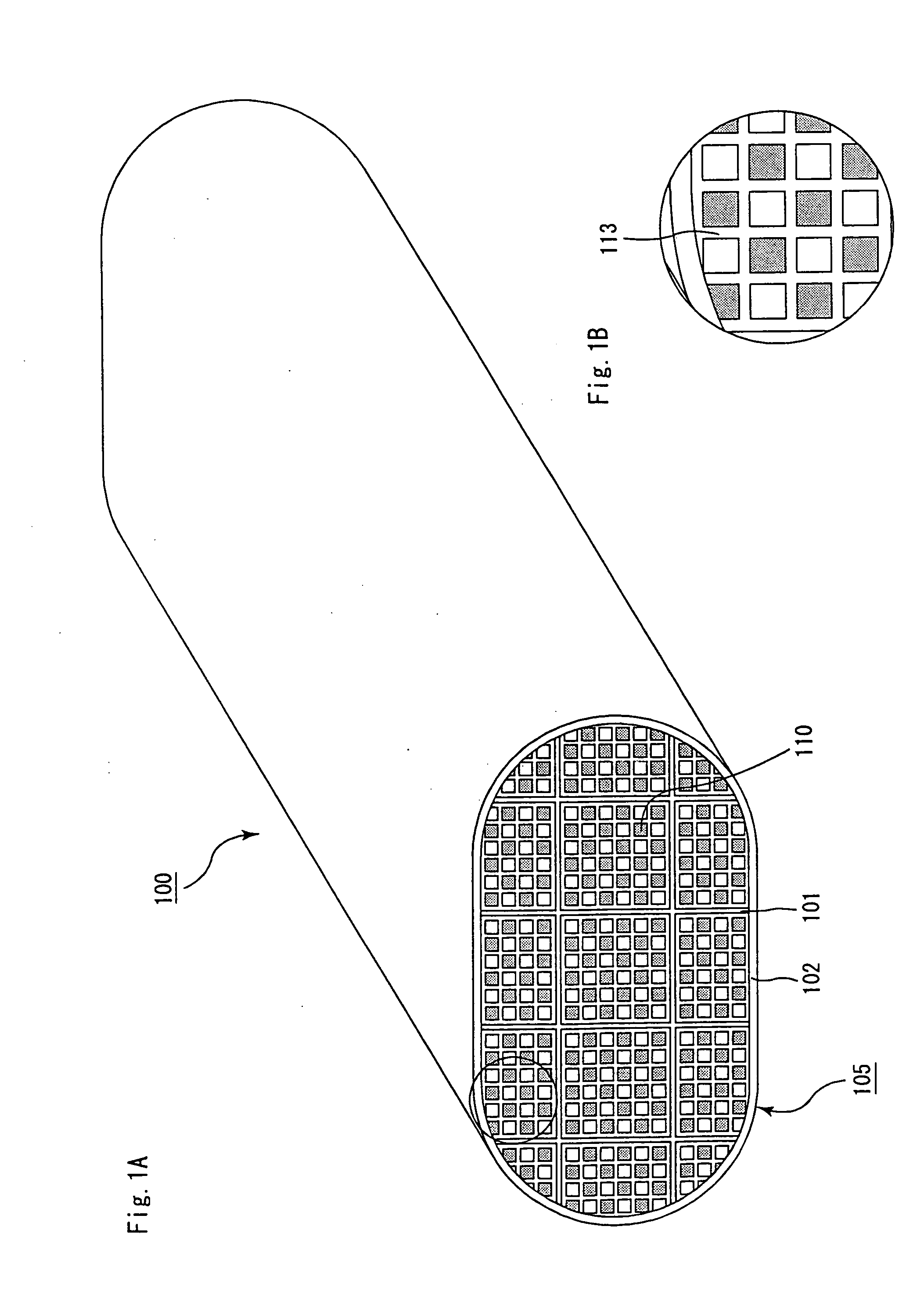

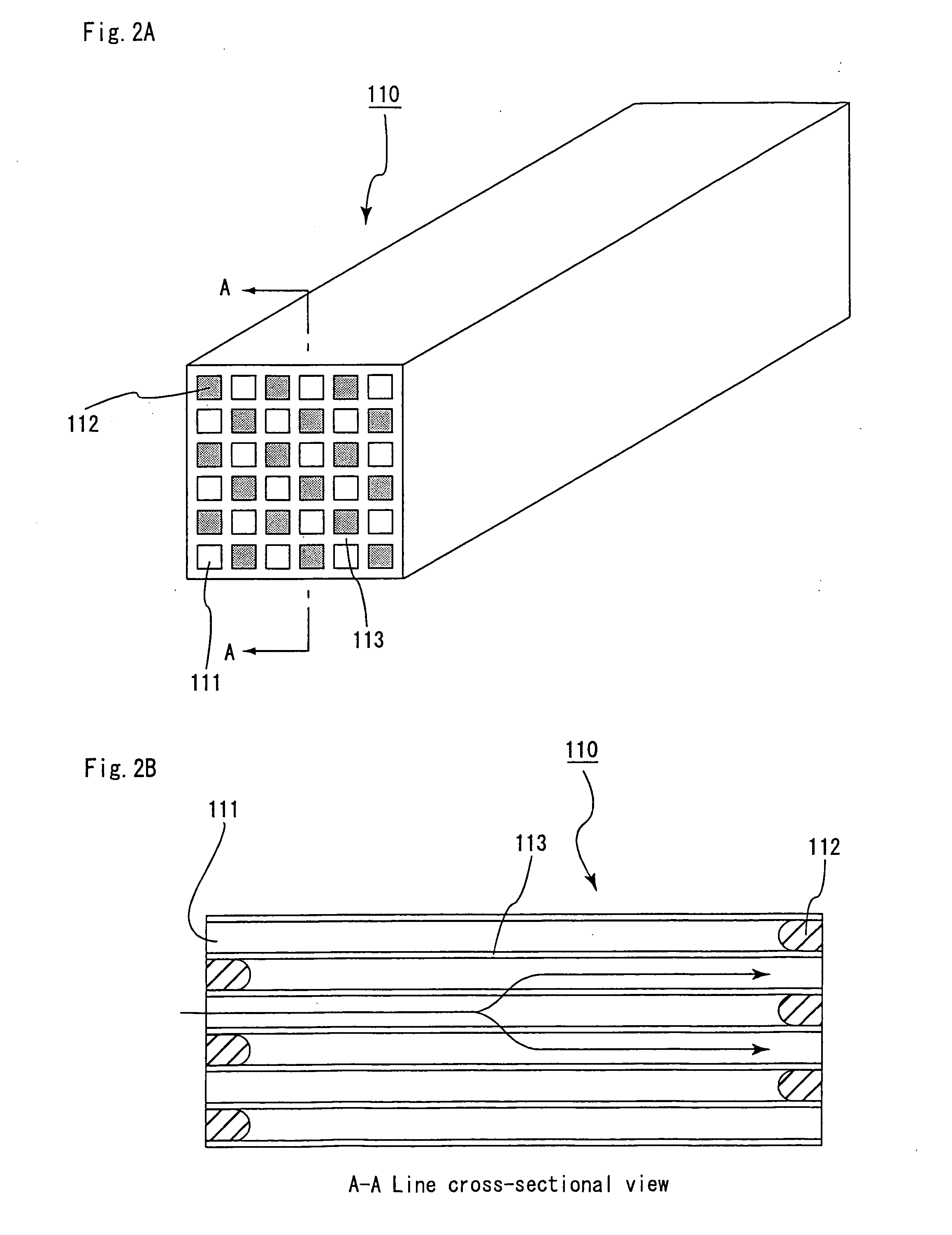

Honeycomb structural body and manufacturing method thereof

ActiveUS20050247038A1Great resistance to physical impactIncreased durabilityCatalyst carriersGas treatmentDiagonalHoneycomb structure

A honeycomb structural body comprising: a ceramic block having a flat shape in which a plurality of honeycomb units are bonded to each other through a sealing material layer, said honeycomb unit mainly comprises porous ceramic and includes a large number of through holes placed in parallel with one another in a longitudinal direction with a partition wall interposed therebetween; and a sealing material layer formed on a peripheral portion thereof, wherein the sealing material layer among the honeycomb units on a cross section perpendicular to the longitudinal direction has a pattern that is formed in a diagonal direction with respect to a major axis of a shape forming a contour of the cross section.

Owner:IBIDEN CO LTD

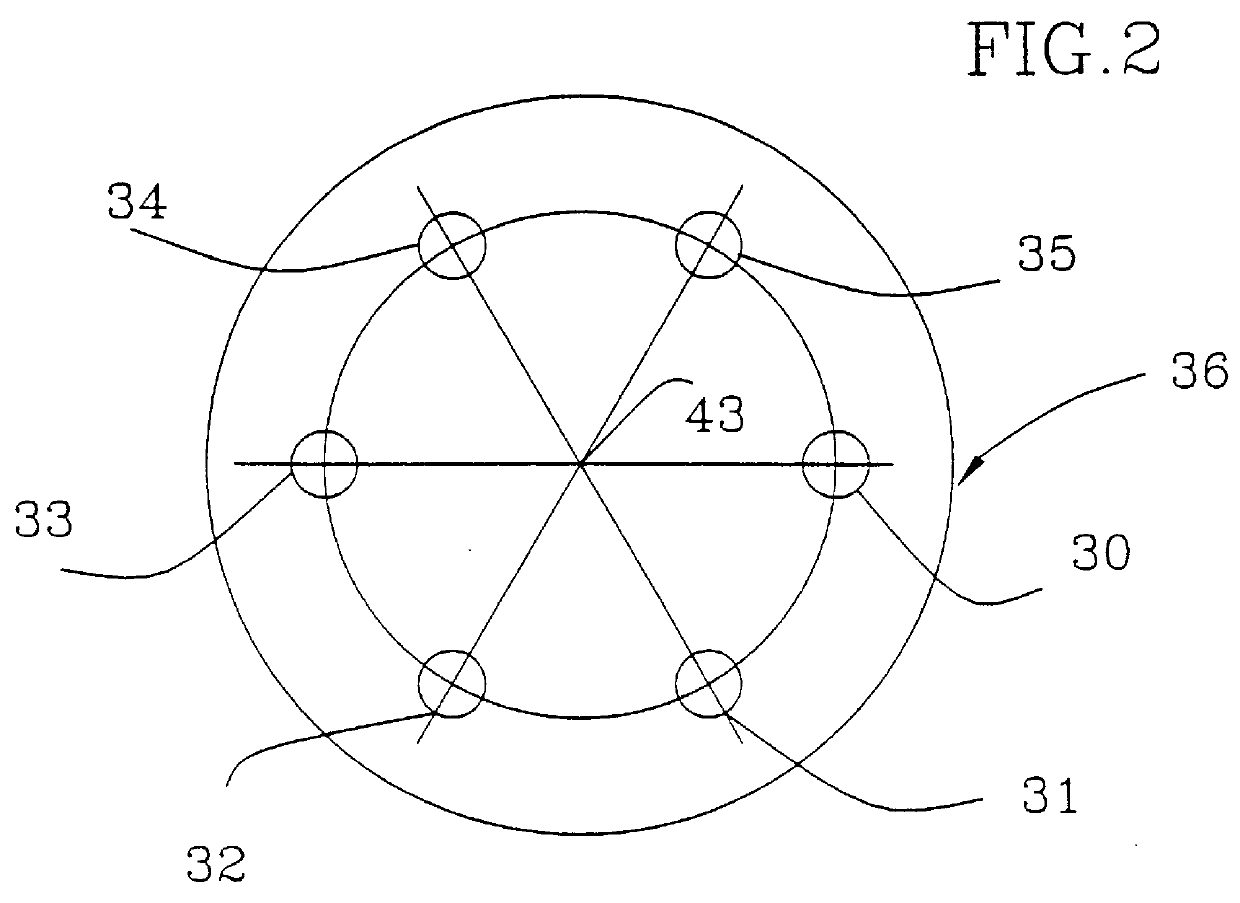

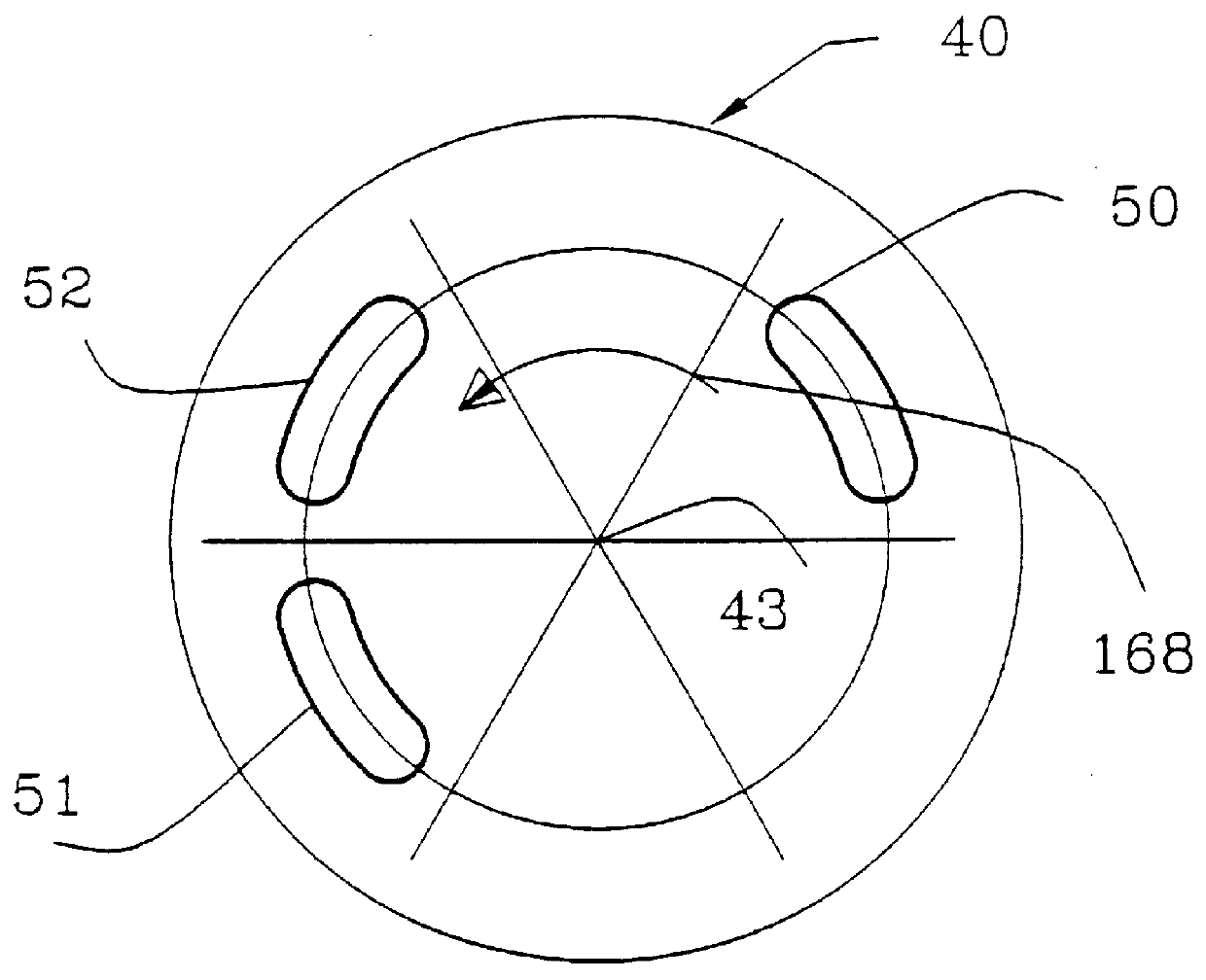

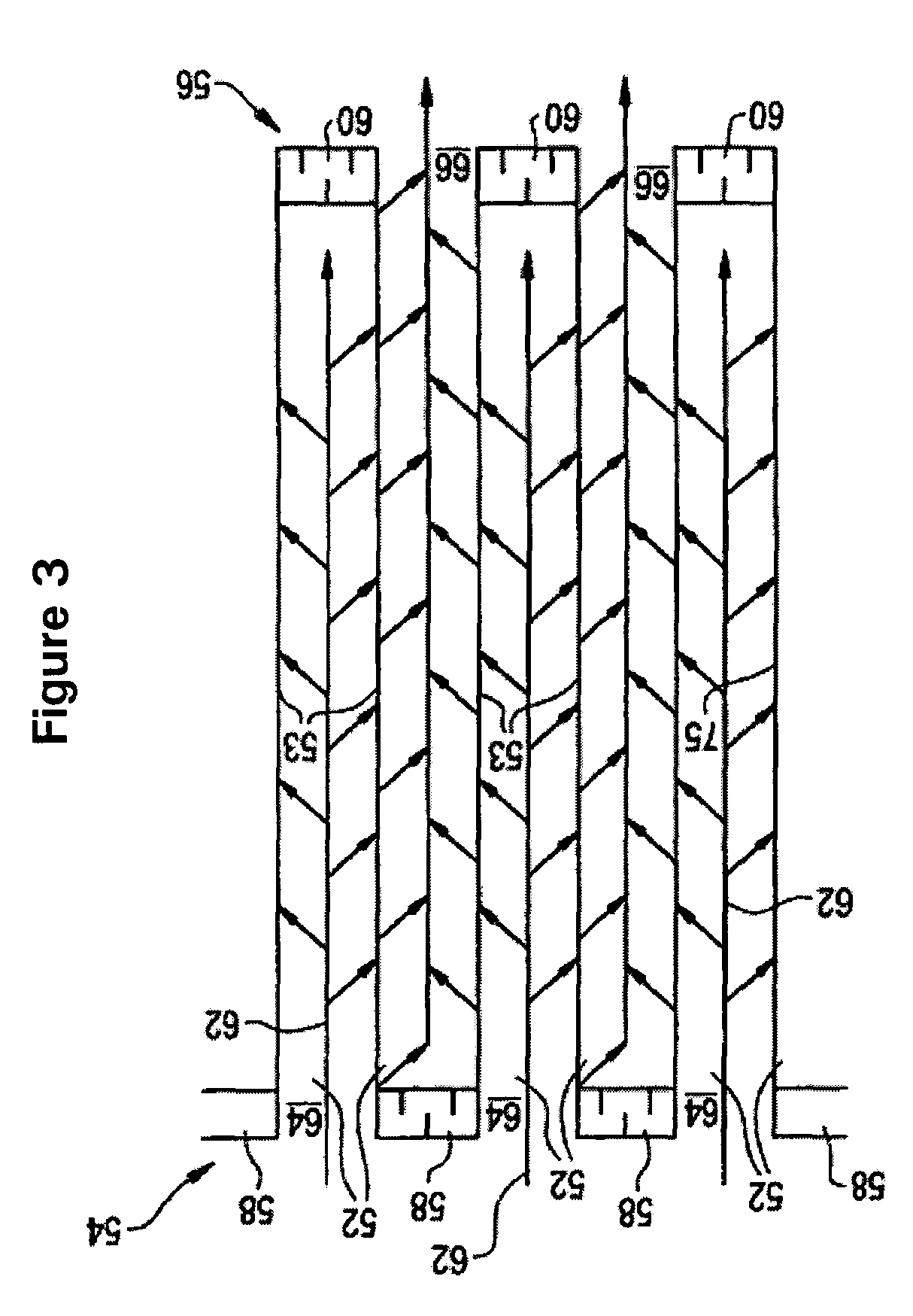

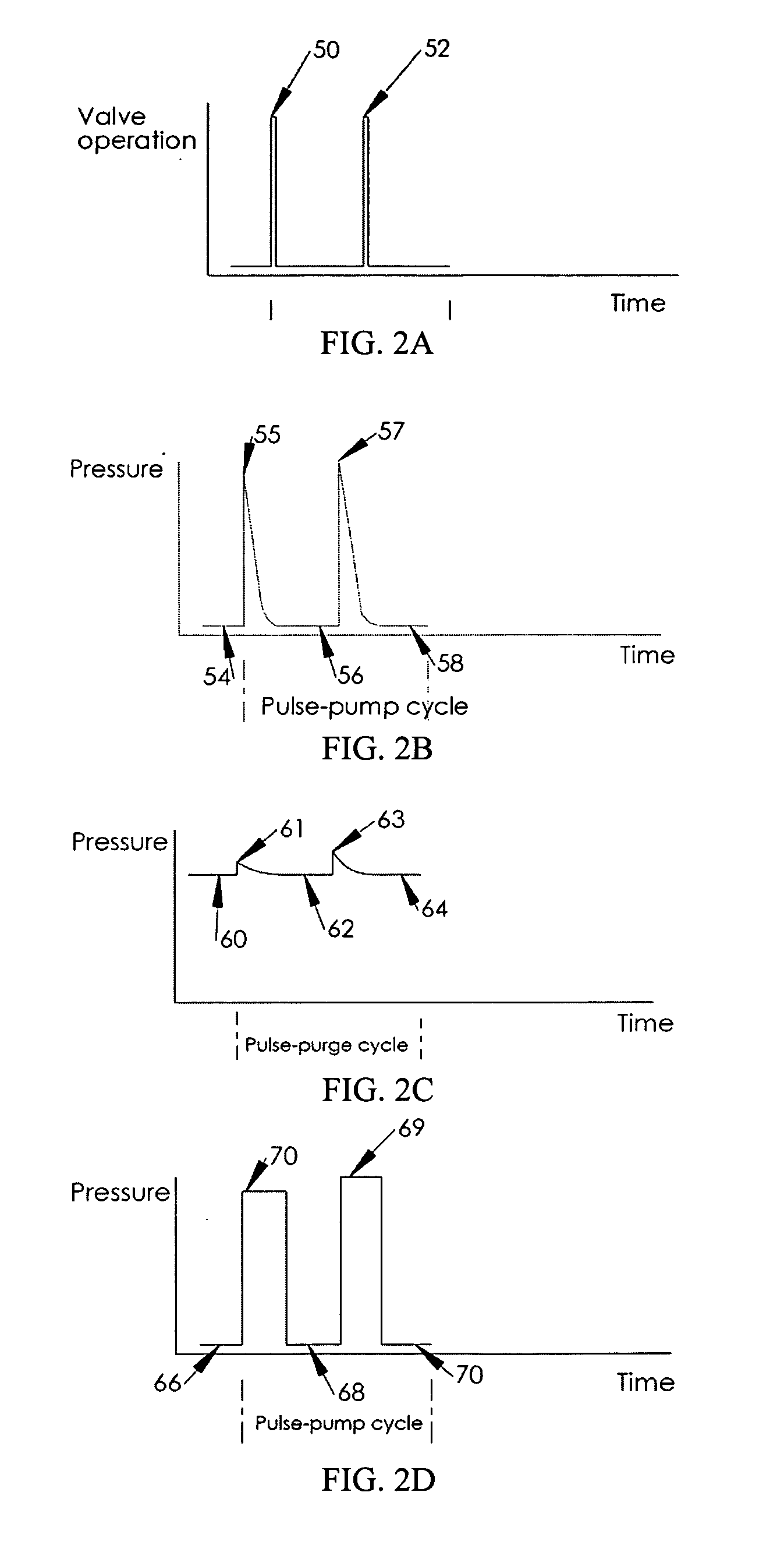

High frequency pressure swing adsorption

InactiveUS6176897B1High purityRecoverable expansion workNitrogen purification/separationGas treatmentSorbentEngineering

Pressure swing adsorption separation of a feed gas mixture, to obtain a purified product gas of the less strongly adsorbed fraction of the feed gas mixture, is performed in a plurality of preferably an even number of adsorbent beds, with each adsorbent bed communicating at its product end directly to a variable volume expansion chamber, and at its feed end by directional valves to a feed compressor and an exhaust vacuum pump. For high frequency operation of the pressure swing adsorption cycle, a high surface area layered support is used for the adsorbent. The compressor and vacuum pump pistons may be integrated with the cycle, reciprocating at twice the cycle frequency. Alternative configurations of the layered adsorbent beds are disclosed.

Owner:AIR PROD & CHEM INC

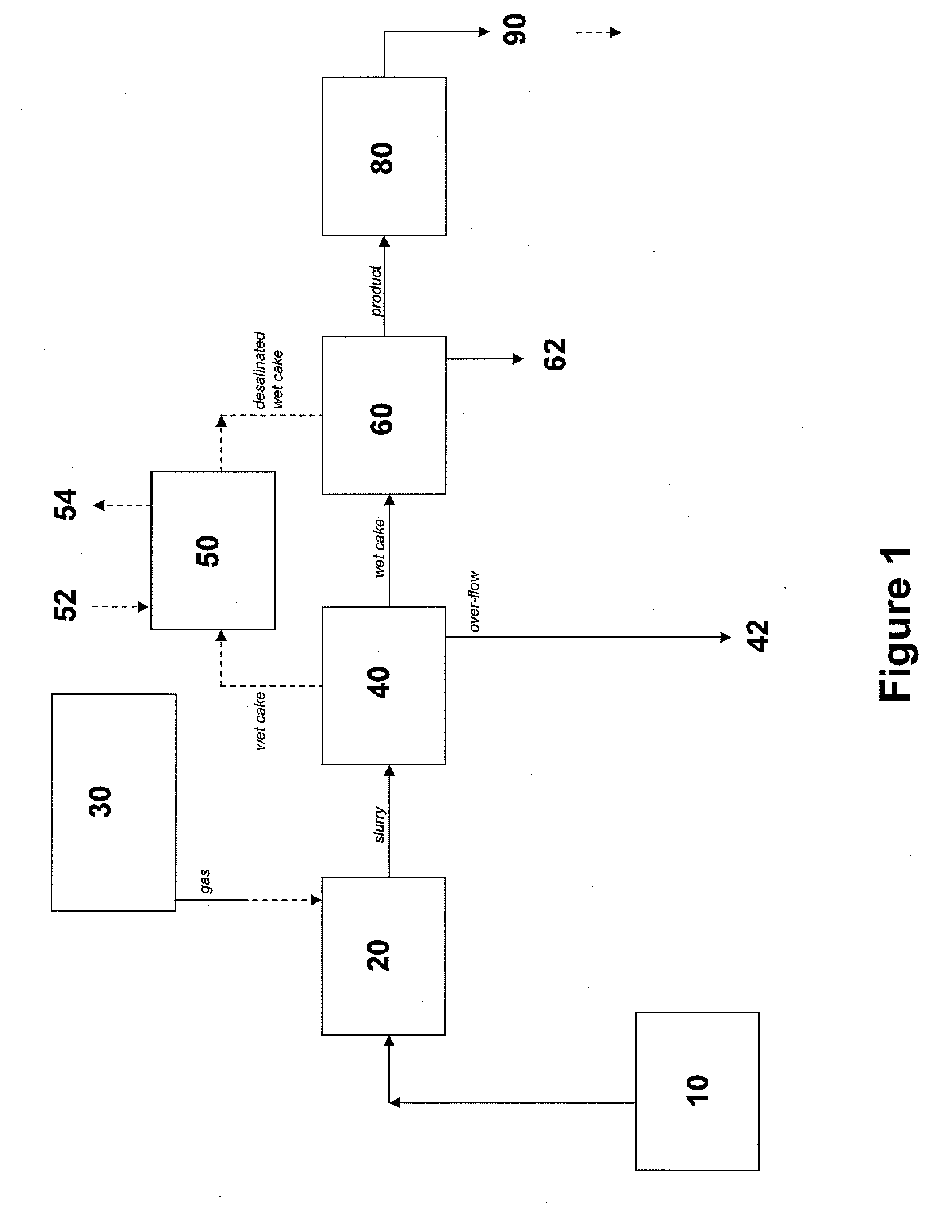

Methods of sequestering co2

Methods of sequestering carbon dioxide (CO2) are provided. Aspects of the methods include precipitating a storage stable carbon dioxide sequestering product from an alkaline-earth-metal-containing water and then disposing of the product, e.g., by placing the product in a disposal location or using the product as a component of a manufactured composition. Also provided are systems for practicing methods of the invention.

Owner:ARELAC INC

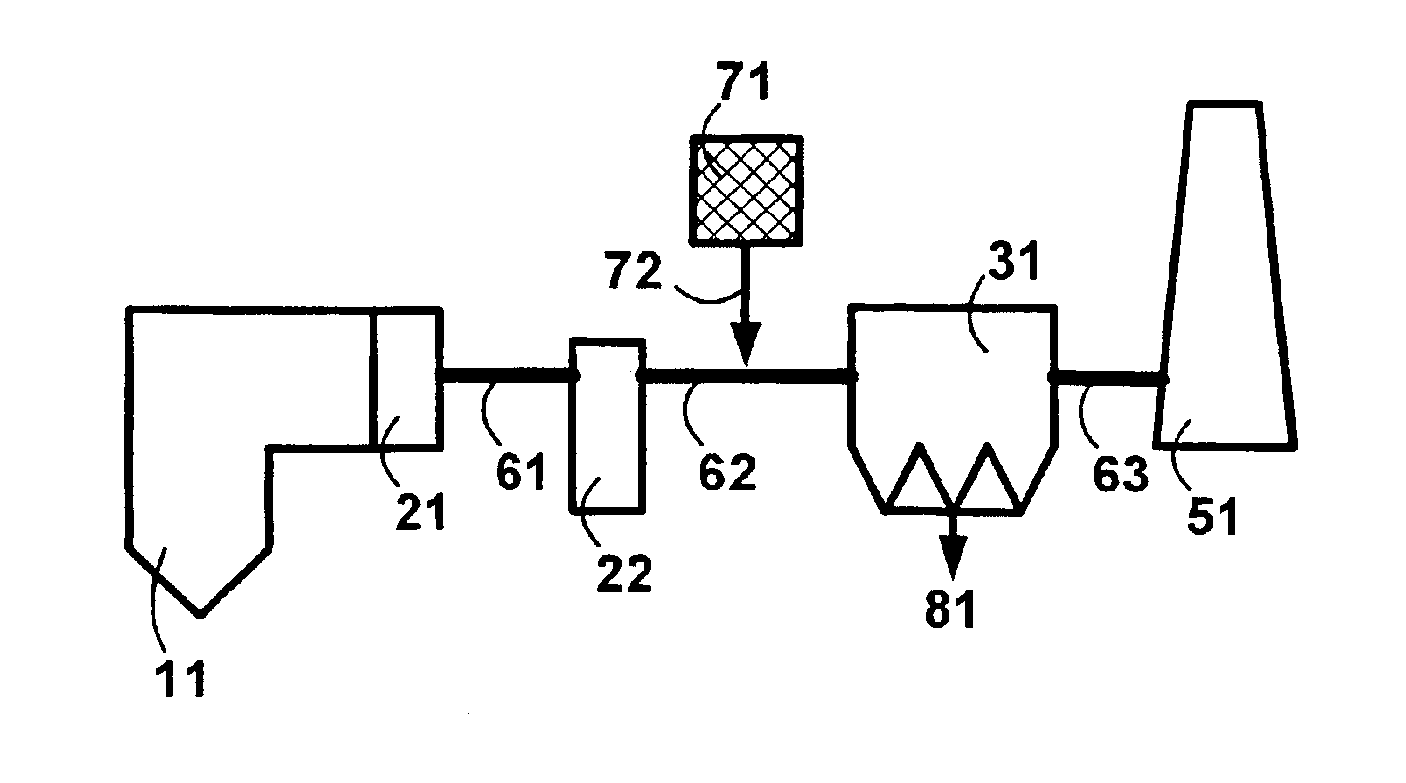

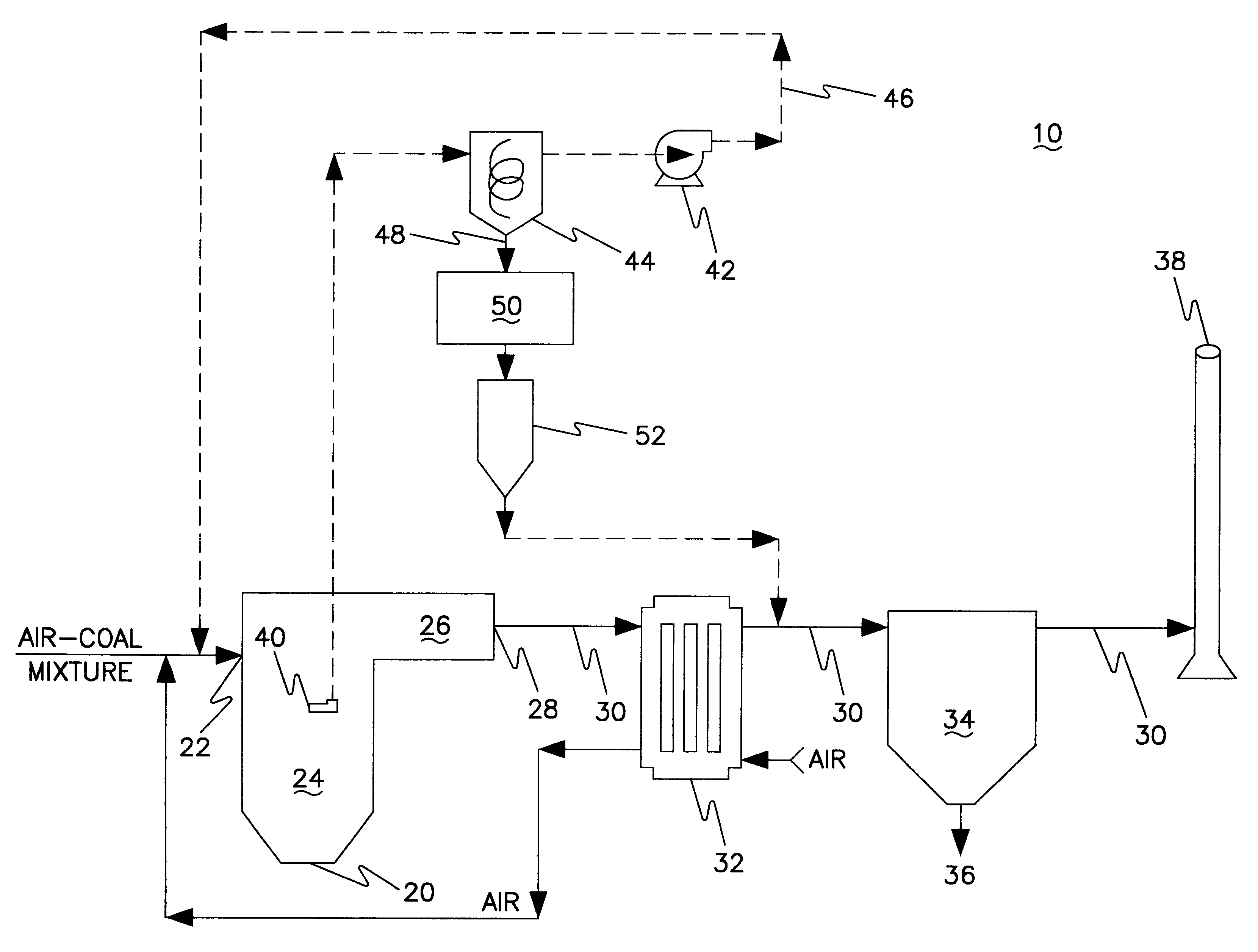

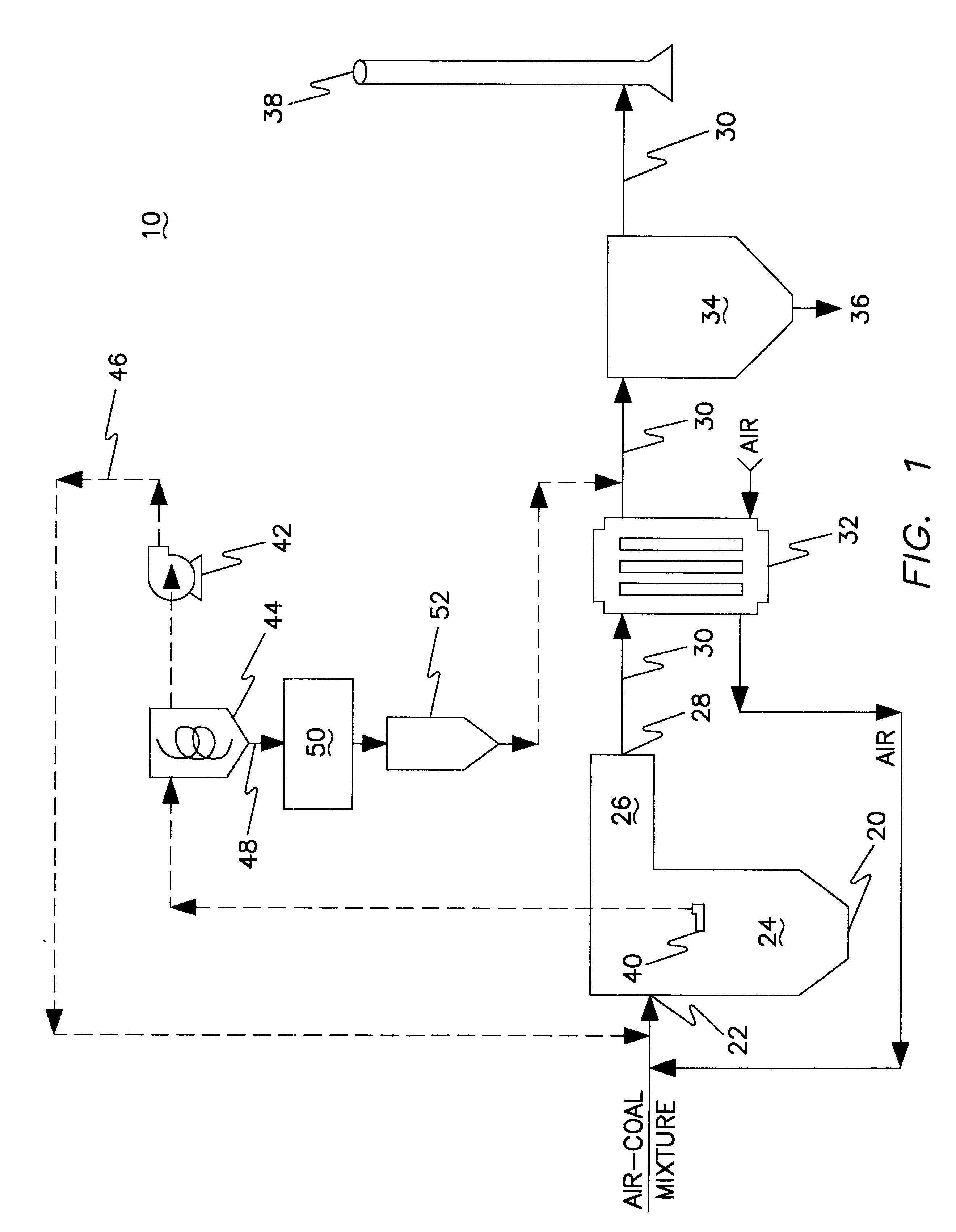

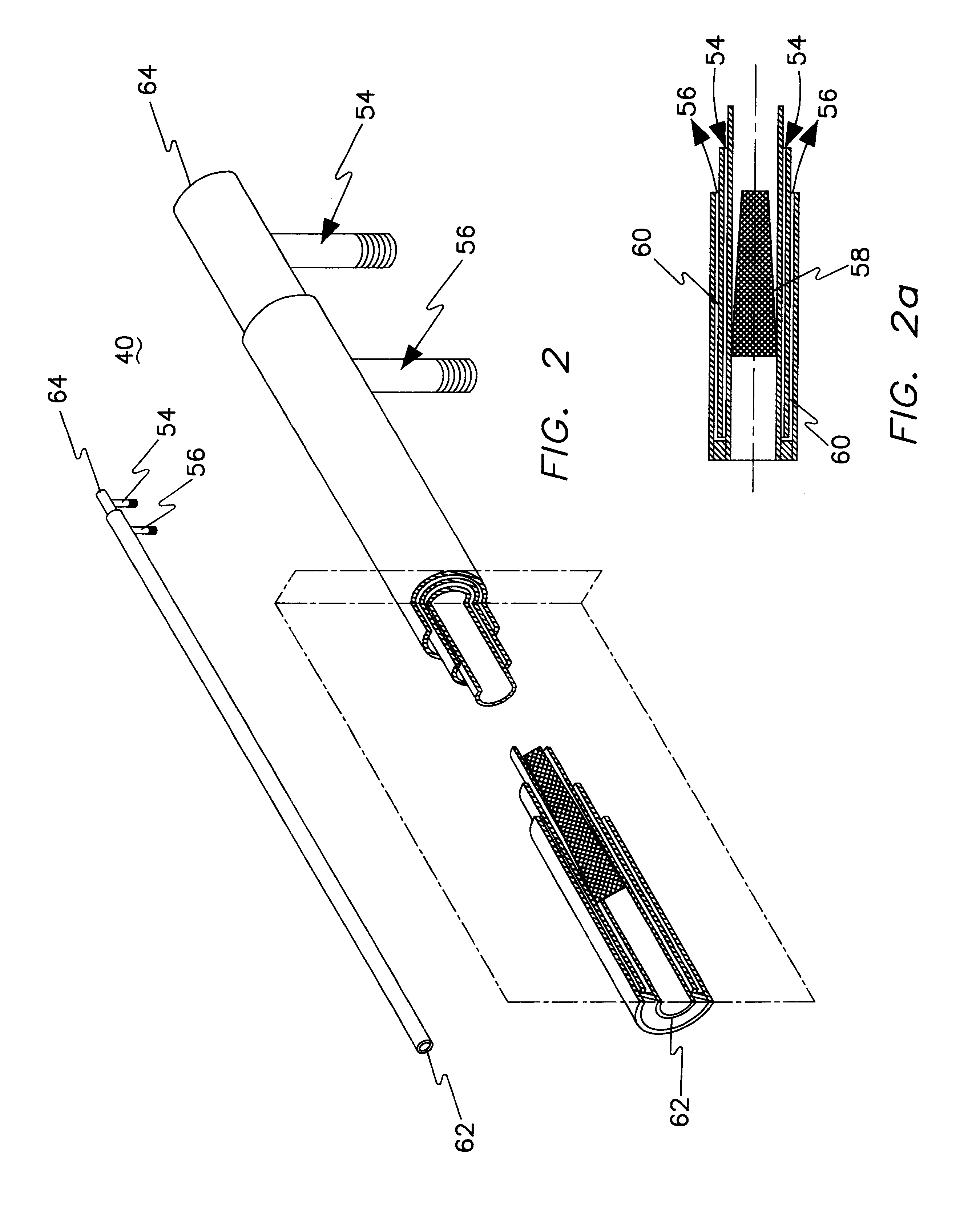

Thief process for the removal of mercury from flue gas

InactiveUS6521021B1Low costQuench oxidationGas treatmentUsing liquid separation agentParticulatesCombustion chamber

A system and method for removing mercury from the flue gas of a coal-fired power plant is described. Mercury removal is by adsorption onto a thermally activated sorbent produced in-situ at the power plant. To obtain the thermally activated sorbent, a lance (thief) is inserted into a location within the combustion zone of the combustion chamber and extracts a mixture of semi-combusted coal and gas. The semi-combusted coal has adsorptive properties suitable for the removal of elemental and oxidized mercury. The mixture of semi-combusted coal and gas is separated into a stream of gas and semi-combusted coal that has been converted to a stream of thermally activated sorbent. The separated stream of gas is recycled to the combustion chamber. The thermally activated sorbent is injected into the duct work of the power plant at a location downstream from the exit port of the combustion chamber. Mercury within the flue gas contacts and adsorbs onto the thermally activated sorbent. The sorbent-mercury combination is removed from the plant by a particulate collection system.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

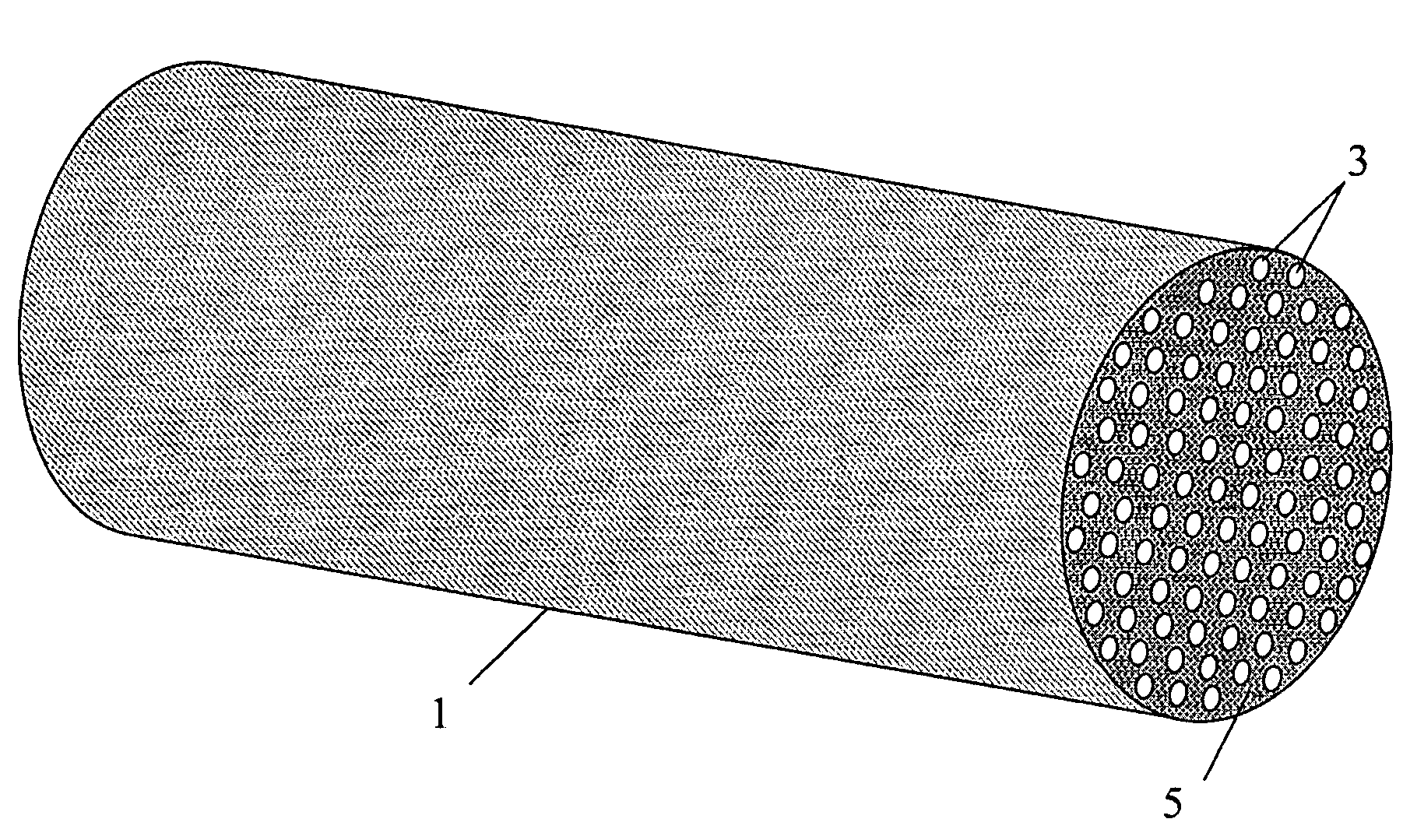

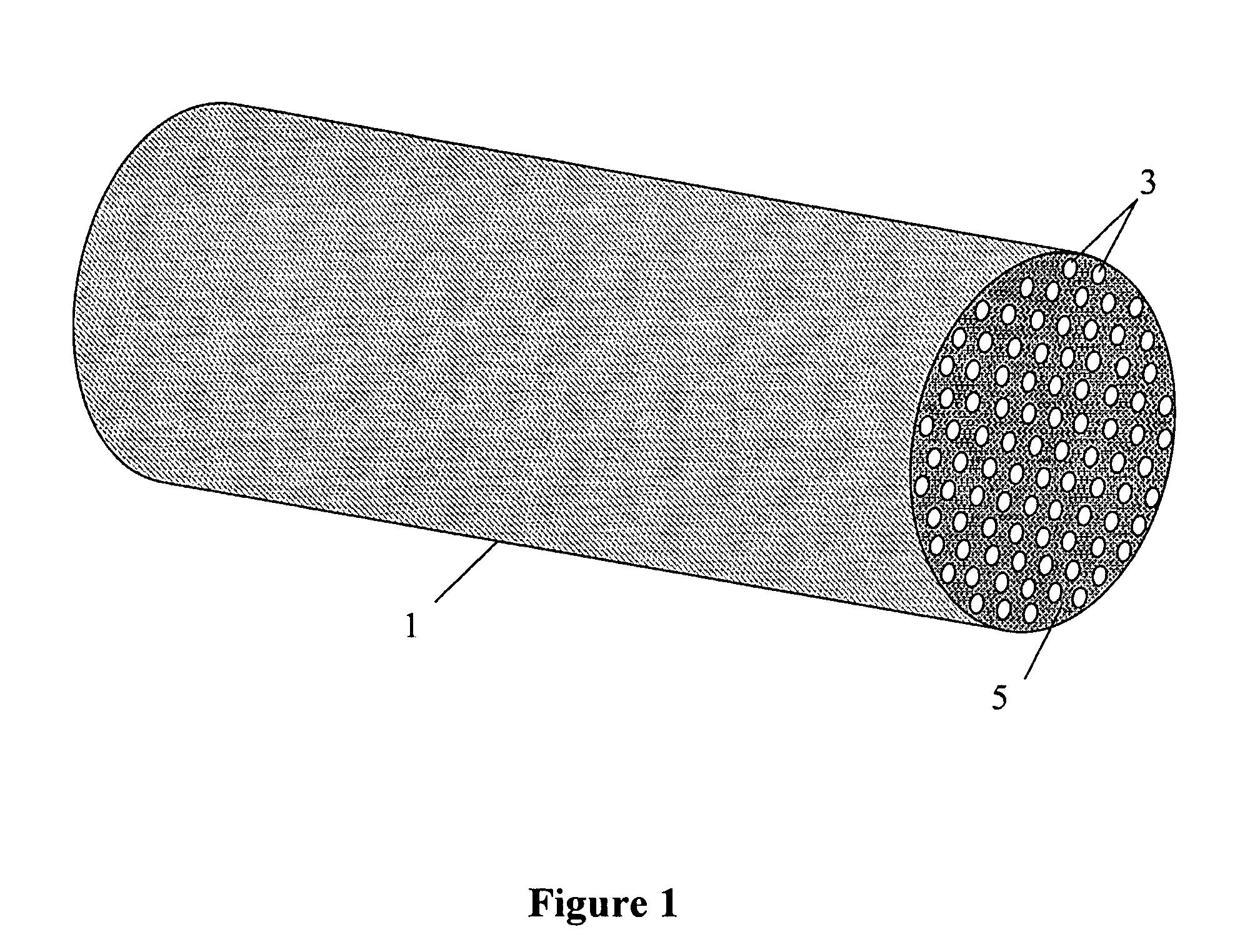

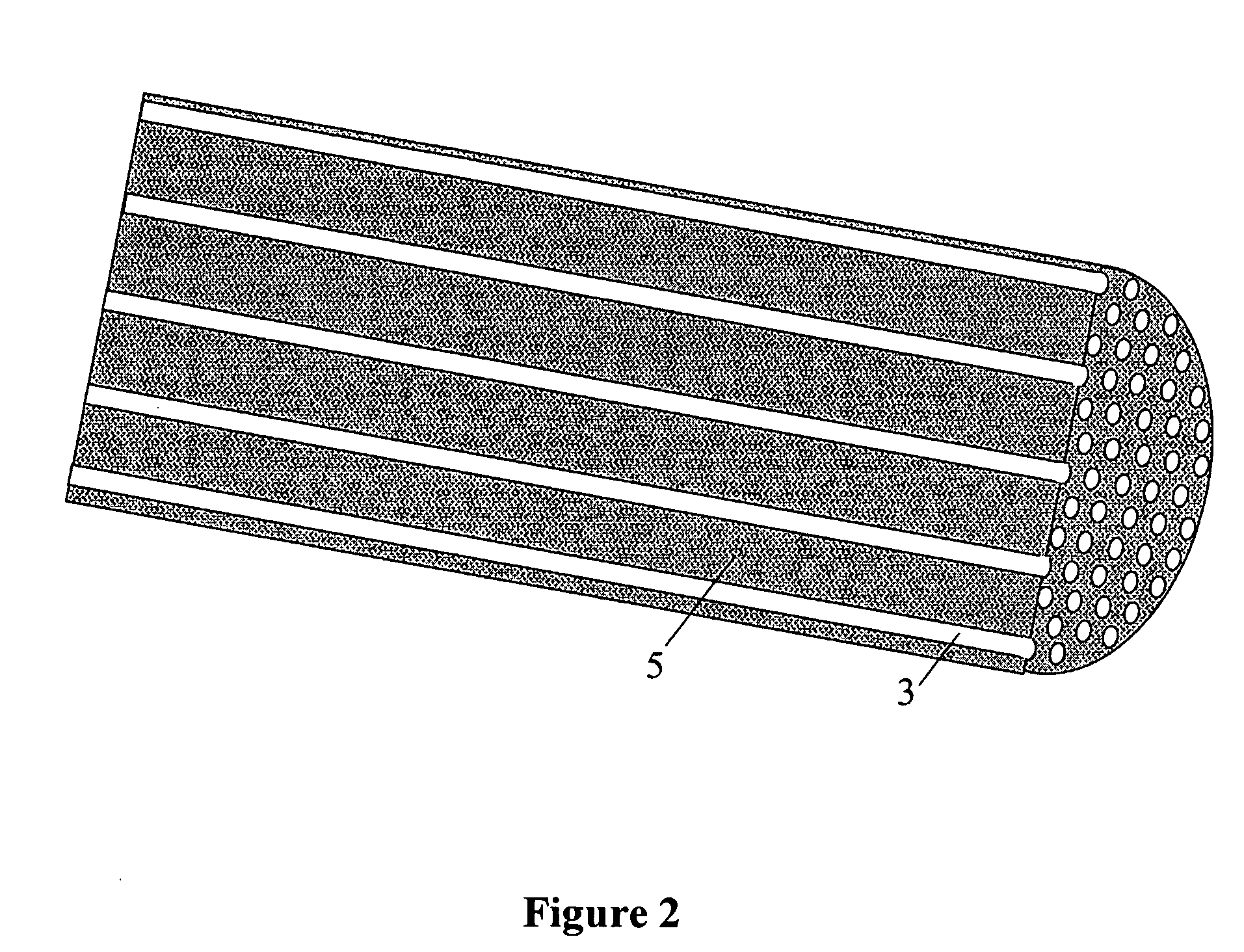

Low mesopore adsorbent contactors for use in swing adsorption processes

The present invention relates to engineered structured adsorbent contactors for use in pressure swing adsorption and thermal swing adsorption processes. Preferably, the contactors contain engineered and substantially parallel flow channels wherein 20 volume percent or less of the open pore volume of the contactor, excluding the flow channels, is in the mesopore and macropore range.

Owner:EXXON RES & ENG CO

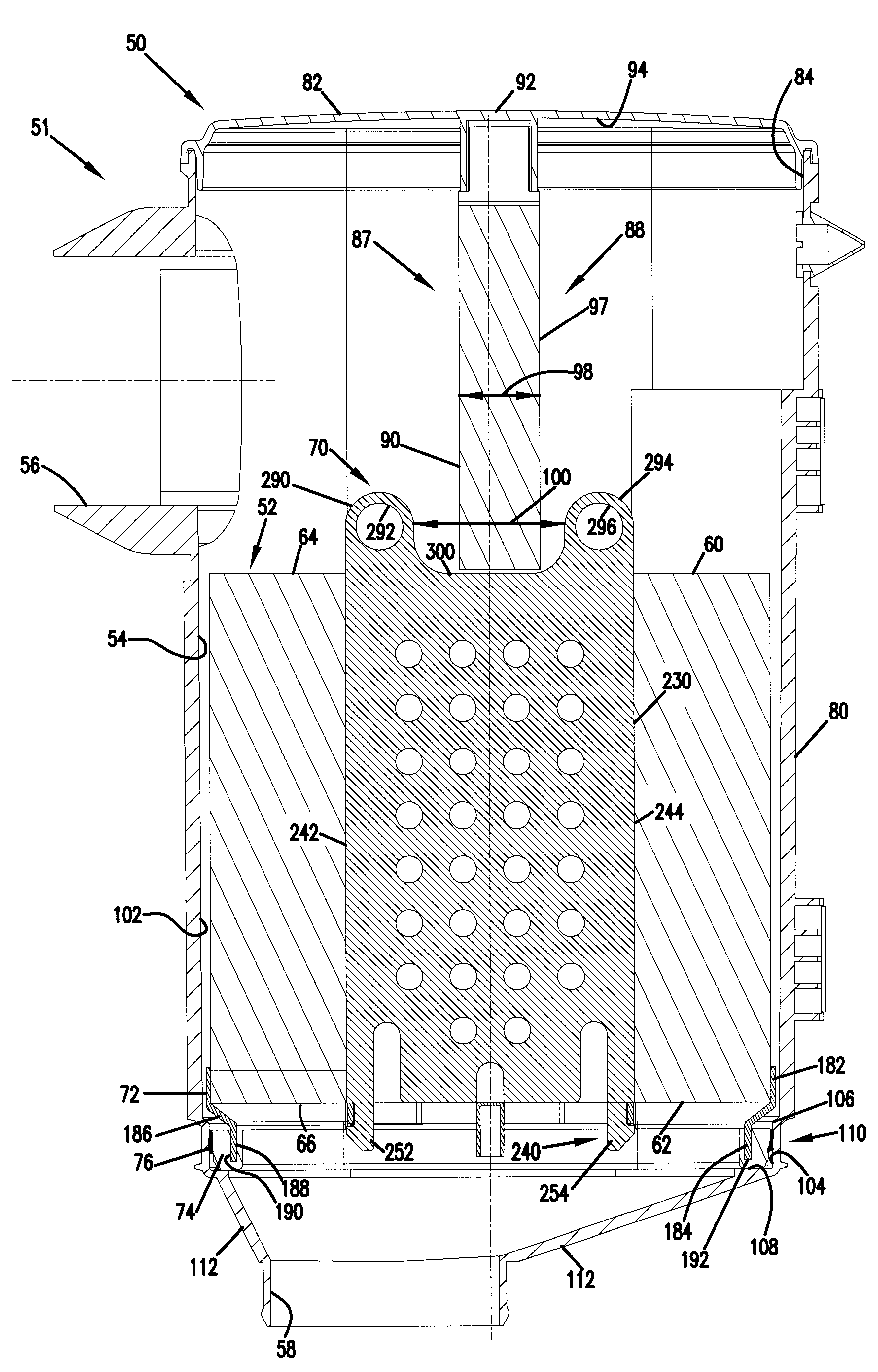

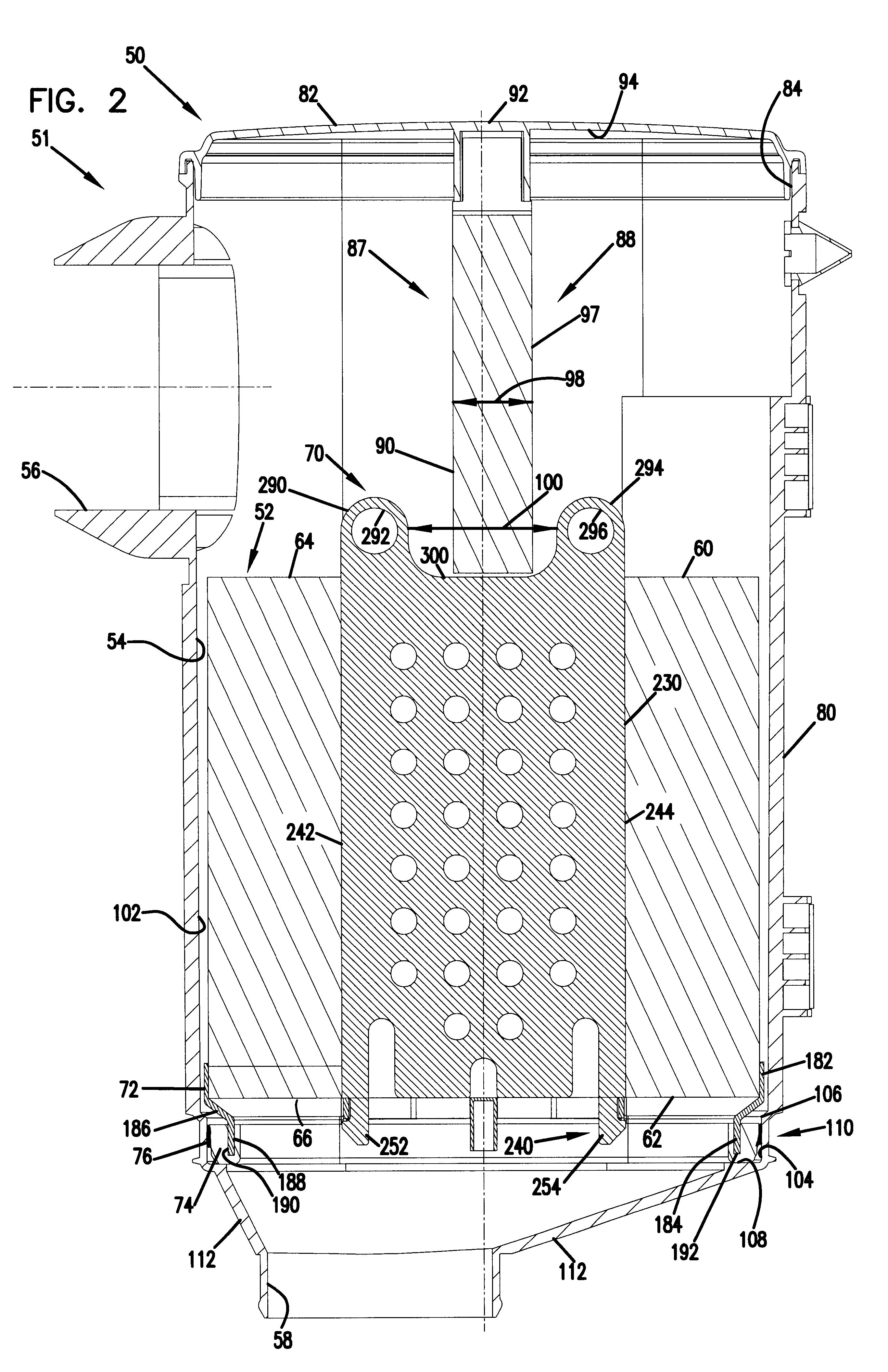

Filter arrangement; sealing system; and methods

InactiveUS6610117B2Avoid passingObstruct passageCombination devicesGas treatmentMechanical engineeringStructural engineering

A filter pack includes a filter construction and a sealing system for sealing the construction within a duct or housing. The filter construction has first and second opposite flow faces and is configured for a straight-through flow. The sealing system includes a frame construction and a compressible seal member. The compressible seal member is molded around a portion of the frame construction. The compressible seal member is sufficiently compressible to form a radial seal between and against the frame construction and a surface of a housing when the filter pack is inserted within the housing.

Owner:DONALDSON CO INC

Fluid storage and dispensing system

InactiveUS6101816AMinimize the possibilityUse minimizedContainer filling methodsVacuum evaporation coatingLiquid stateProduct gas

A fluid storage and dispensing system comprising a vessel for holding a fluid at a desired pressure. The vessel has a pressure regulator associated with a port of the vessel, and set at a predetermined pressure. A dispensing assembly, e.g, including a flow control means such as a valve, is arranged in gas / vapor flow communication with the regulator, whereby the opening of the valve effects dispensing of gas / vapor from the vessel. The fluid in the vessel may be constituted by a liquid which is confined in the vessel at a pressure in excess of its liquefaction pressure at prevailing temperature conditions, e.g., ambient (room) temperature. A phase separator such as a gas / vapor-permeable liquid-impermeable membrane, may be associated with the regulator, as a barrier to flow of liquid into the regulator, when the contained fluid in the vessel is in a liquid state.

Owner:ENTEGRIS INC

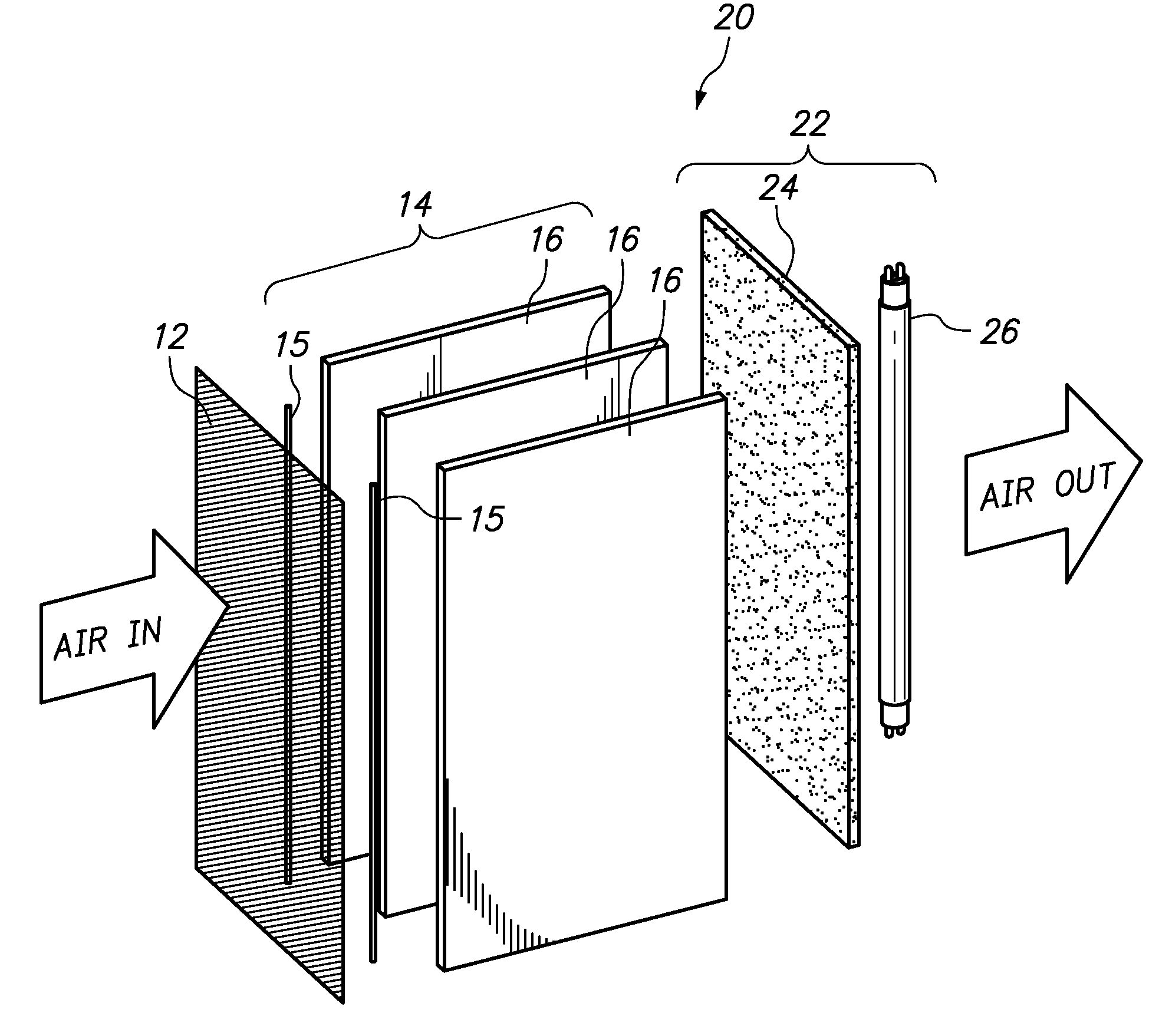

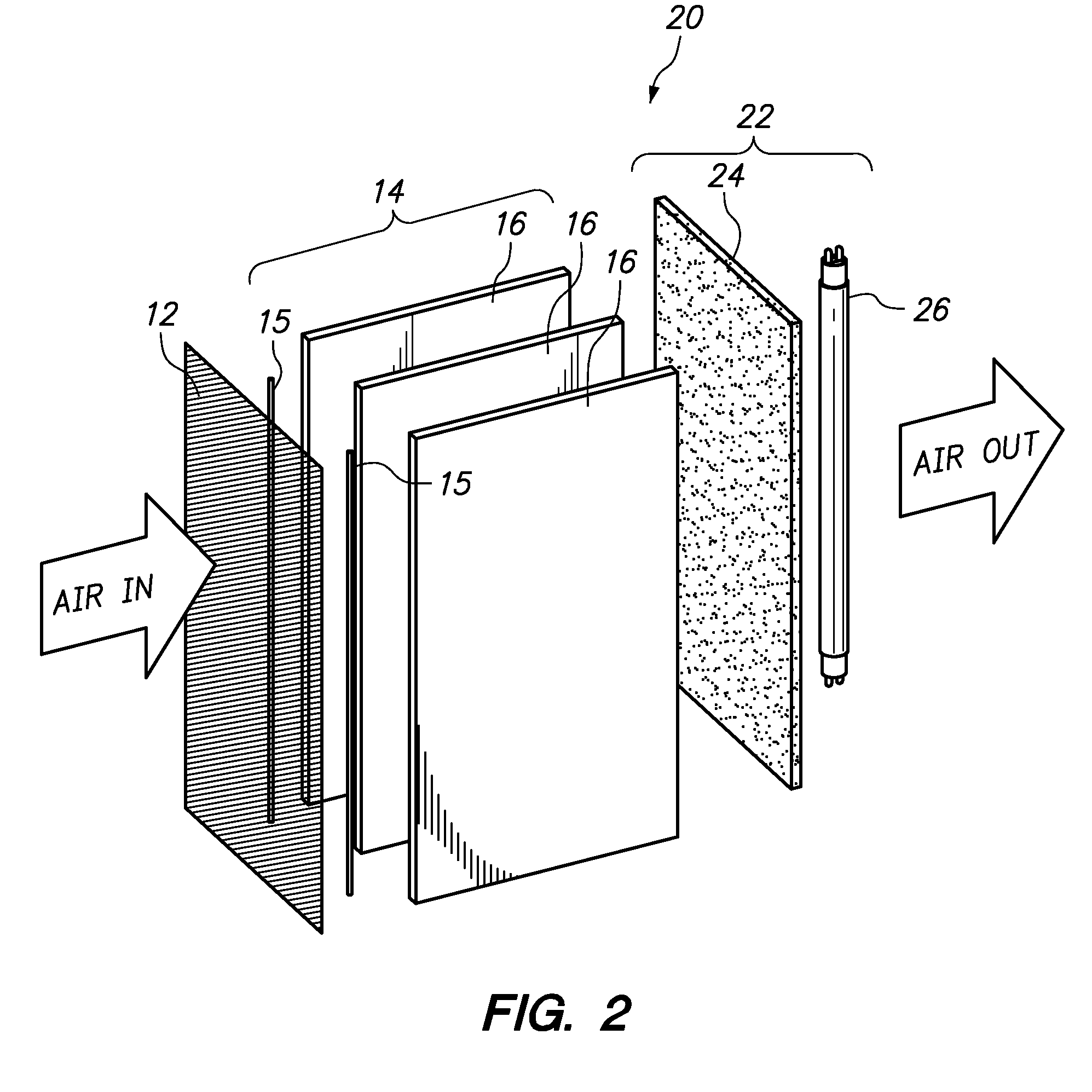

Air cleaner

InactiveUS20090010801A1Consume less spaceIncrease capacityCombination devicesMechanical apparatusPorous substrateParticulates

Apparatus and method for cleaning air. An air cleaner includes a housing that defines an airflow pathway and a catalytic reactor having a catalyst secured on a porous substrate that is disposed transverse to the airflow pathway. Preferably, the catalyst includes a light activated oxidizing photocatalyst or a thermally activated oxidizing catalyst. A photocatalytic reactor will include a light source directed at a light activated oxidizing photocatalyst, such as TiO2 particles or a binary oxide particle species, which is disposed on the porous substrate. Most preferably, a metal catalyst is disposed on the photocatalyst particles at a concentration or loading between about 0.01 wt % and about 5 wt %. The air cleaner may further comprise an adsorption matrix upstream of the catalytic reactor, optionally in combination with a heater. A particulate filter and / or an electrostatic precipitator may also be disposed upstream of the adsorption matrix and the catalytic reactor.

Owner:LYNNTECH

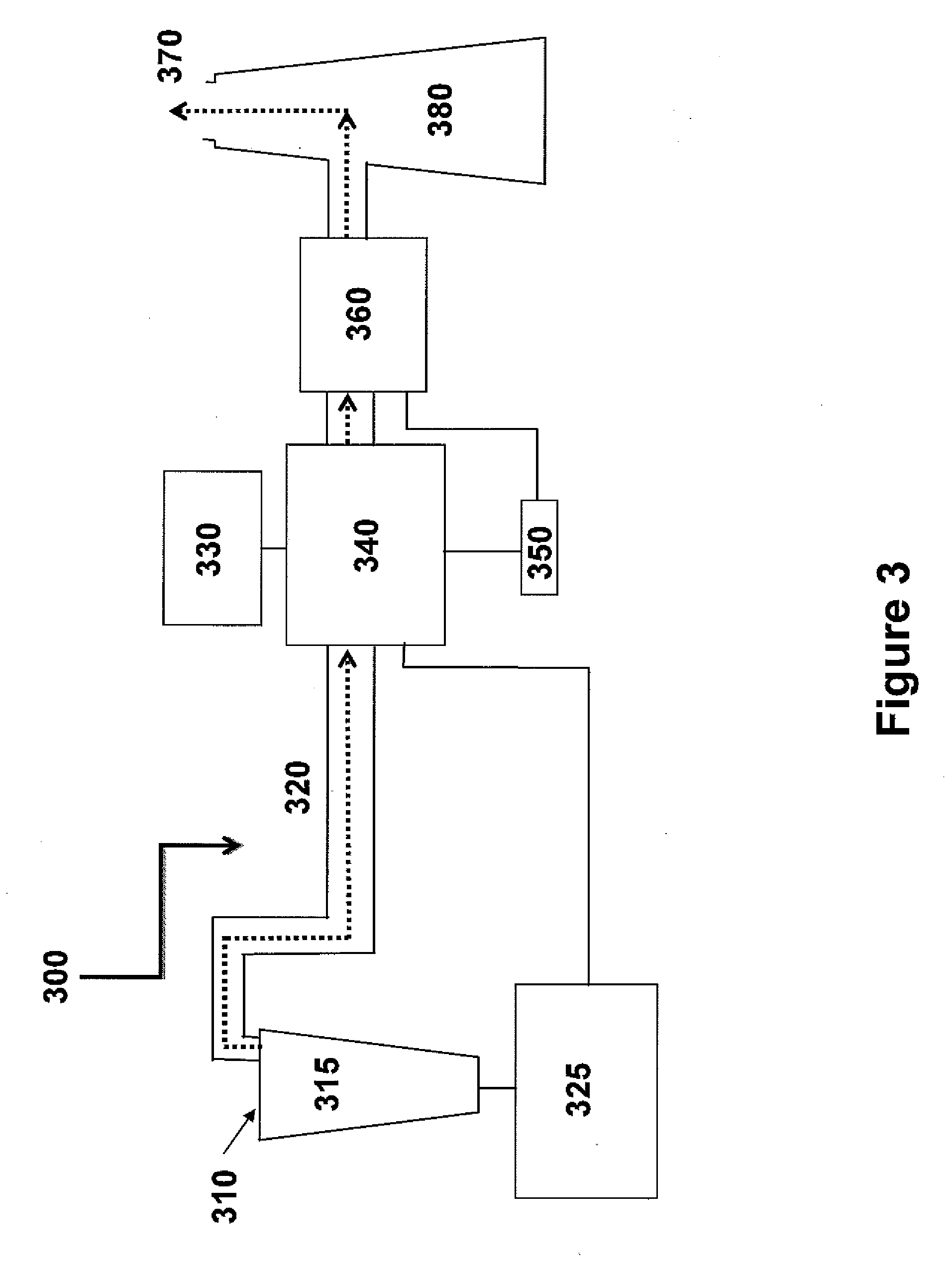

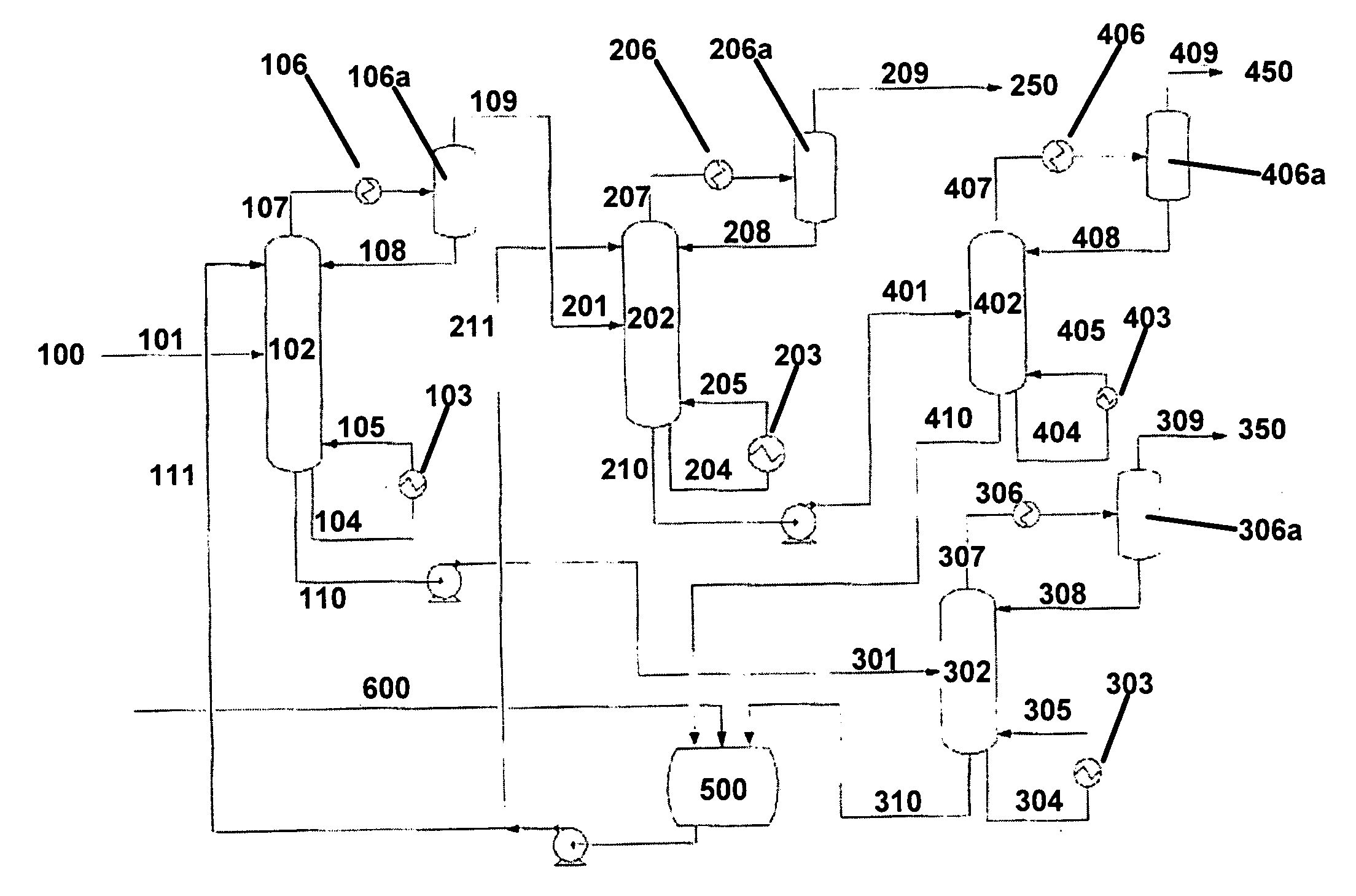

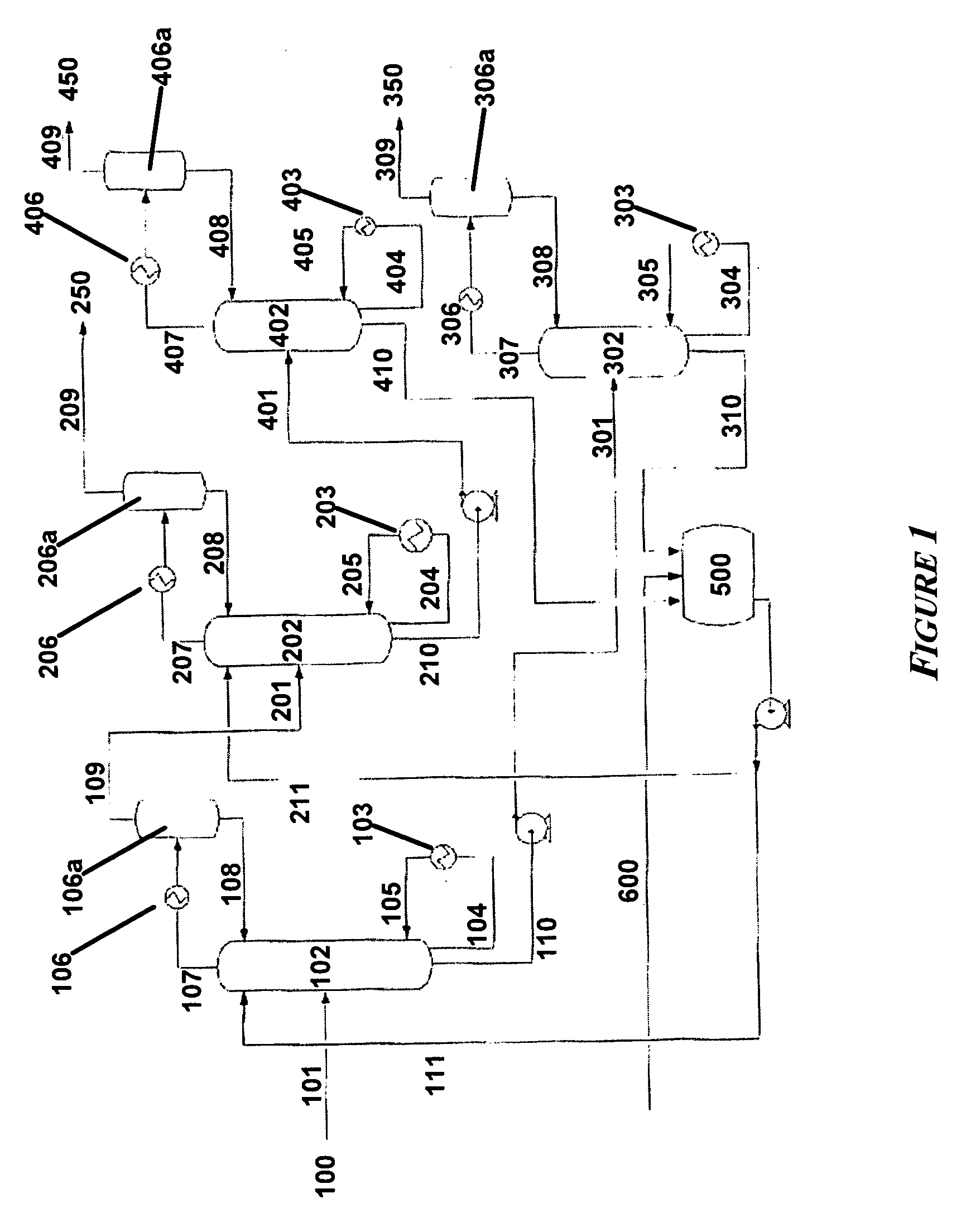

Selective Removal and Recovery of Acid Gases from Gasification Products

Processes and apparatuses are described for the selective removal and recovery of acid gases from a gas source comprising at least hydrogen sulfide and carbon dioxide. A step-wise approach is illustrated wherein hydrogen sulfide may be selectively removed from a gas source by treatment with methanol under conditions where substantially all the hydrogen sulfide may be removed. The partially purified gas source may then be provided with a second treatment with methanol under conditions which selectively remove carbon dioxide from the gas stream. Such methods are generally applicable to any gas source comprising at least hydrogen sulfide and carbon dioxide, for example, a gas source produced from the catalytic gasification of a carbonaceous material, the combustion of a carbonaceous material, or the oxy-blown gasification of a carbonaceous material.

Owner:SURE CHAMPION INVESTMENT LTD

High temperature nanofilter, system and method

InactiveUS7052532B1More laminar flowShort pleat heightDispersed particle filtrationTransportation and packagingFiberNanoparticle

A filter, system and method is provided for filtering nanoparticles in a hot gas, namely particles <about 1 micron in a gas >about 200° C. and further particularly >about 450° C. including diesel exhaust. The filter includes filter media material composed of fibrous filter media having a plurality of fibers and granular filter media having a plurality of granules extending from the surfaces of the fibers. The filter is characterized by a permeability >about 3×10−12 m2 and an inertial resistance coefficient <about 1×106 m−1. The filter captures particles in the Most Penetrating Region (MPR). A filter system includes a nanoparticle filter in series with a diesel exhaust treatment element.

Owner:3M INNOVATIVE PROPERTIES CO +1

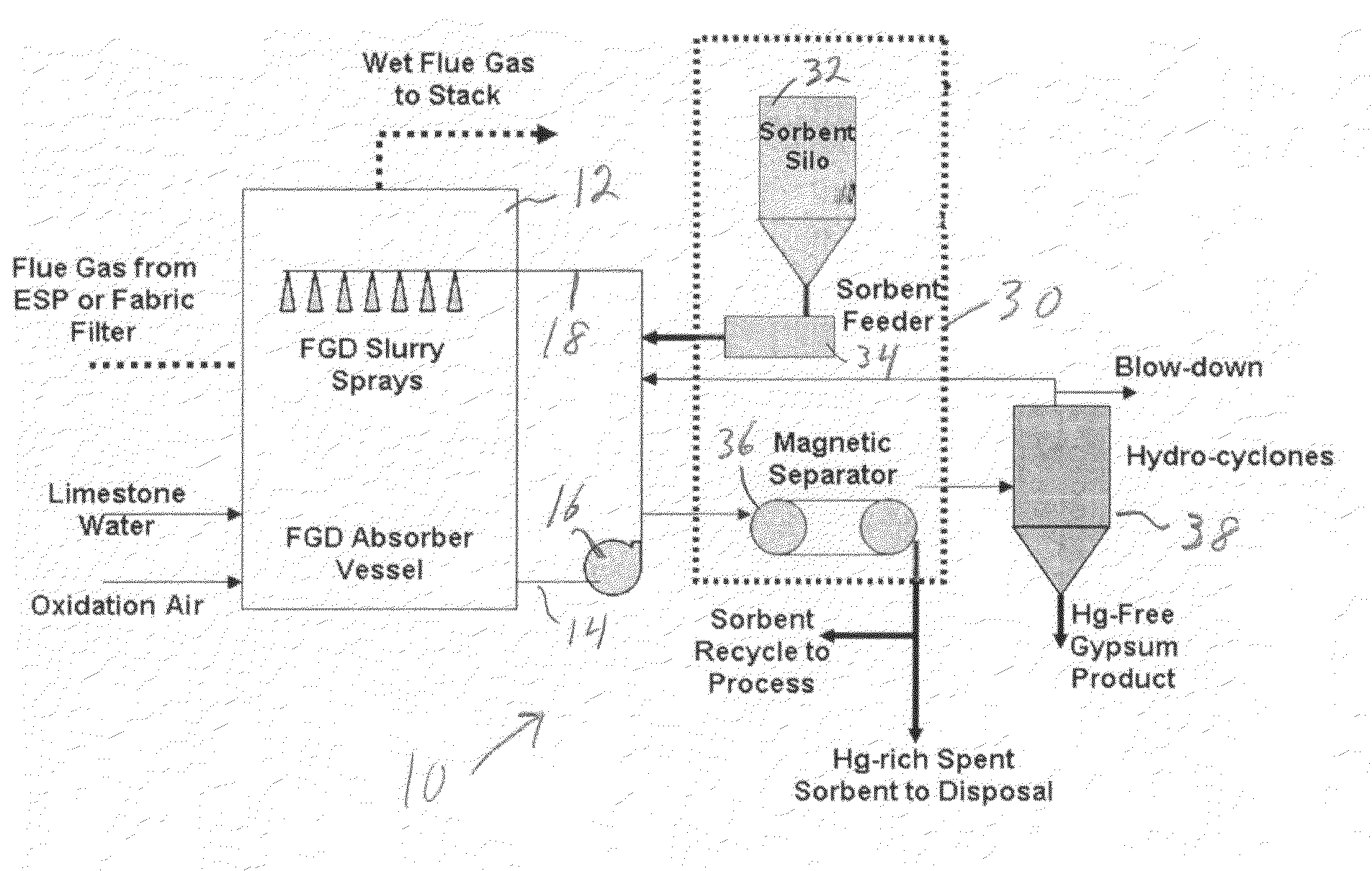

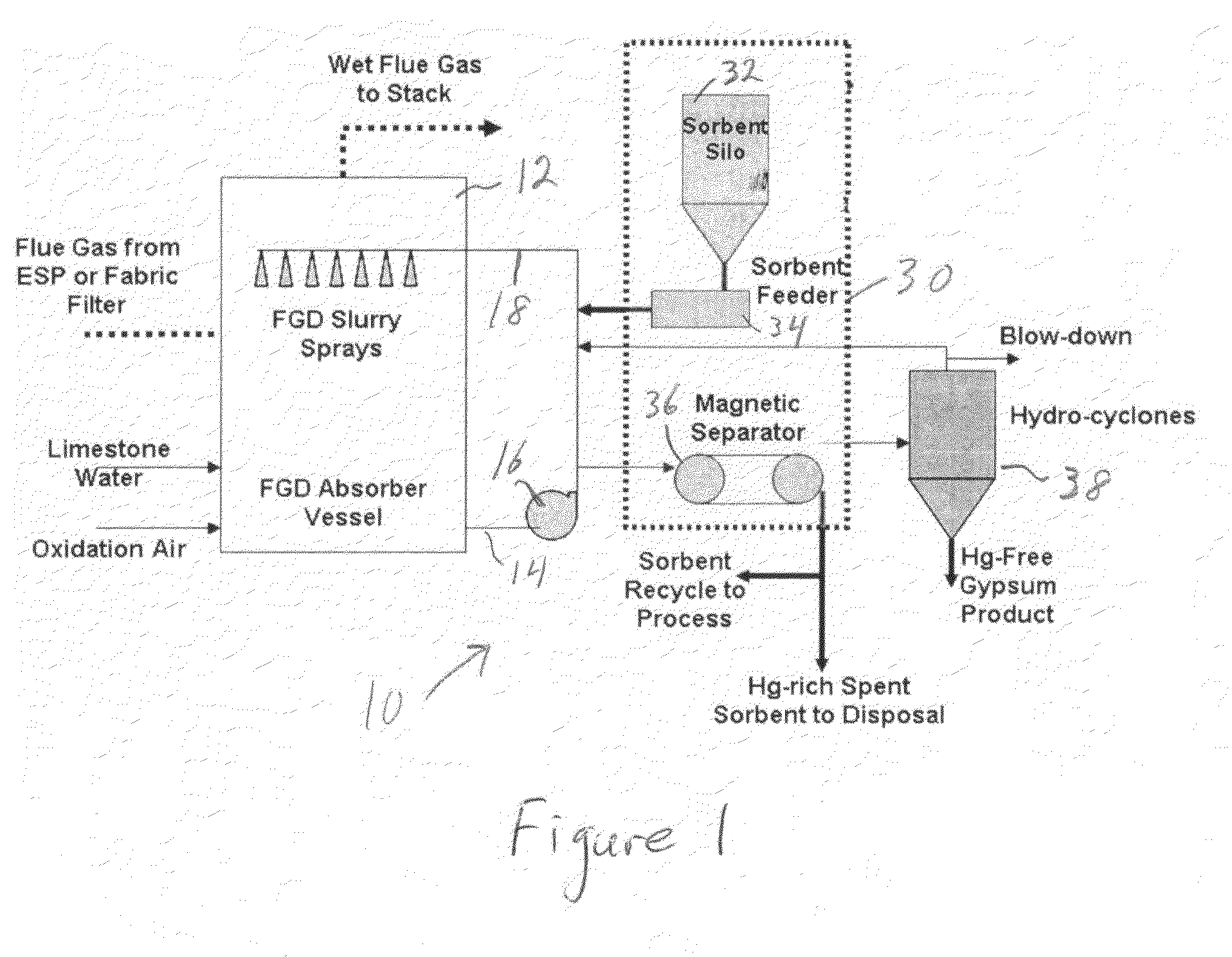

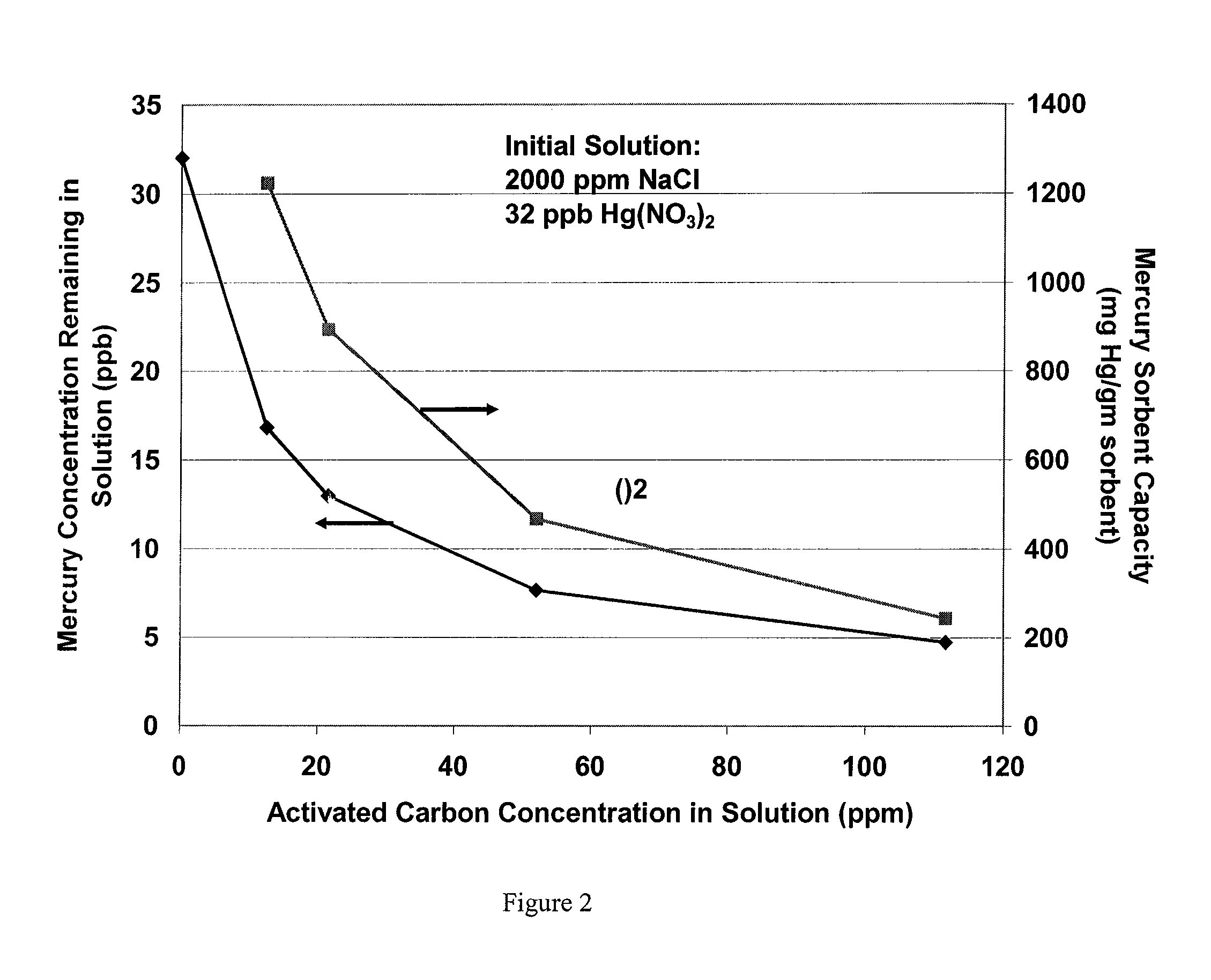

System and method for sequestration and separation of mercury in combustion exhaust gas aqueous scrubber systems

ActiveUS7722843B1Emission reductionMinimize re-emissionCombination devicesExhaust apparatusCombustionSorbent

A process, system and sorbent for removal of mercury from a combustion exhaust gas stream in a combustion exhaust gas purification scheme that includes a combustion exhaust scrubber system that uses an aqueous liquid to remove acid gases from the combustion exhaust gas. A powdered mercury sorbent is used. The sorbent is introduced into the aqueous scrubber liquid in the scrubber system. After introduction of the mercury sorbent into the scrubber liquid, at least some of the mercury sorbent is separated from the scrubber liquid.

Owner:SRINIVASACHAR SRIVATS

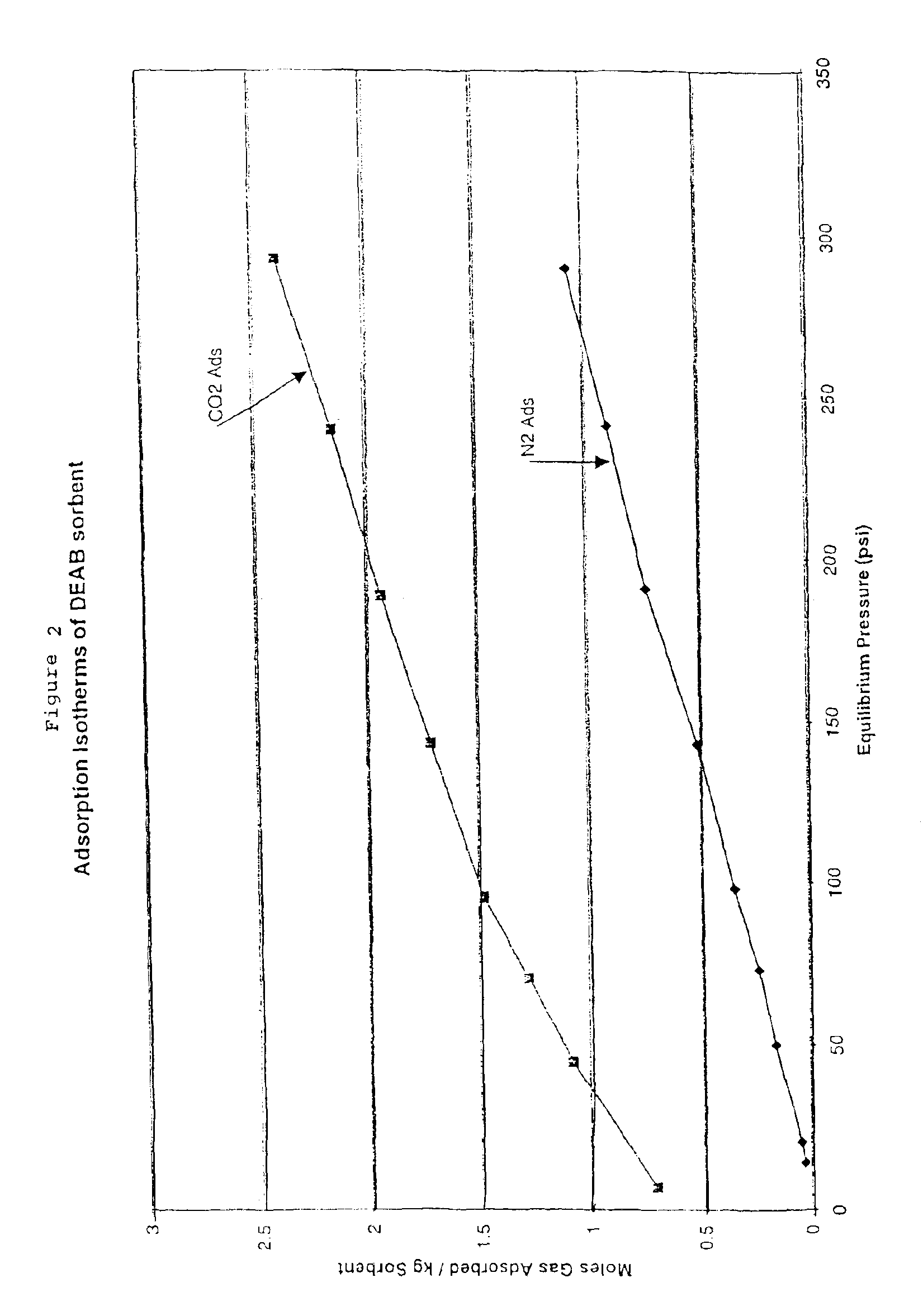

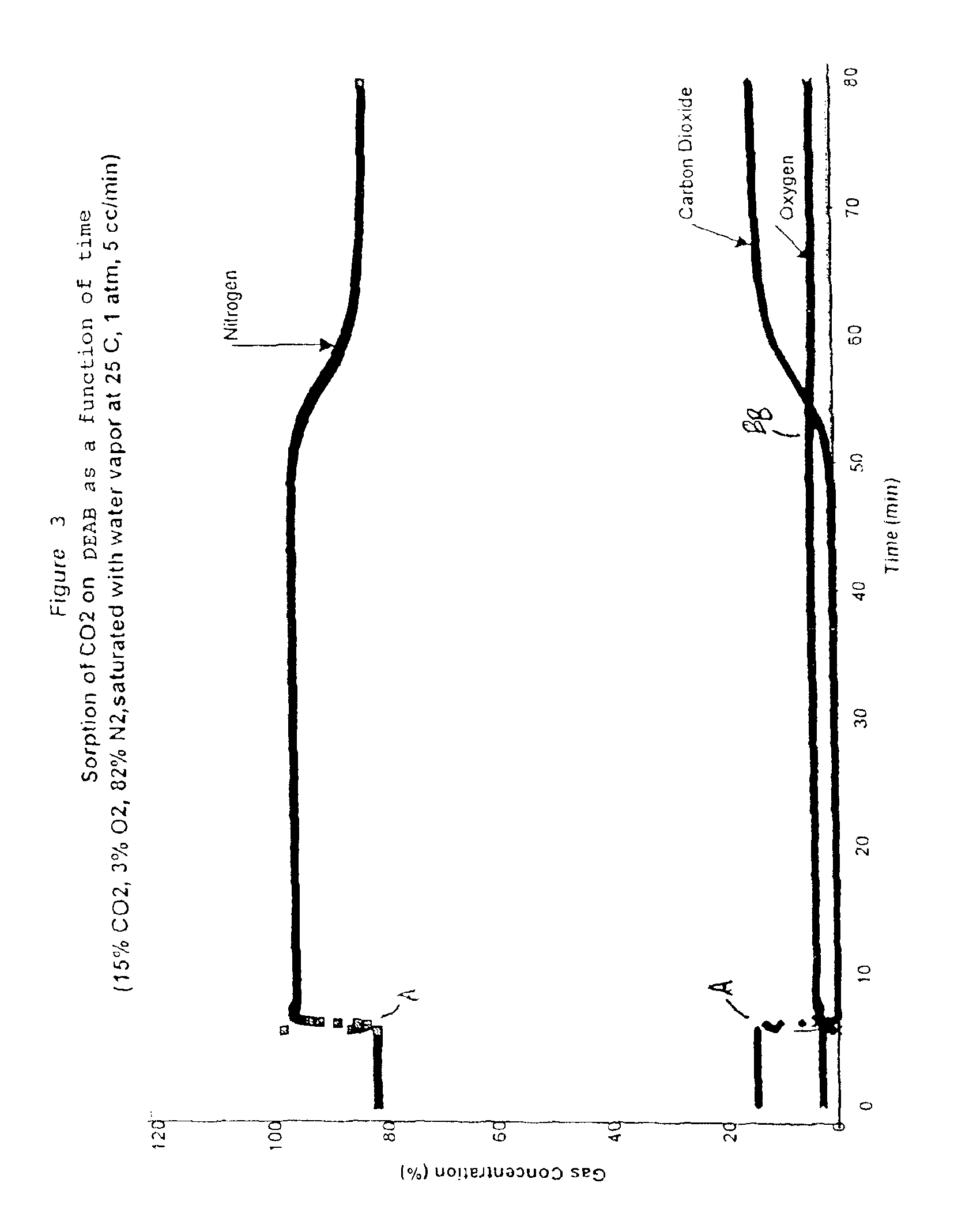

Solid sorbents for removal of carbon dioxide from gas streams at low temperatures

InactiveUS6908497B1Promote regenerationRegeneration process is inexpensiveGas treatmentOther chemical processesGas solidSorbent

New low-cost CO2 sorbents are provided that can be used in large-scale gas-solid processes. A new method is provided for making these sorbents that involves treating substrates with an amine and / or an ether so that the amine and / or ether comprise at least 50 wt. percent of the sorbent. The sorbent acts by capturing compounds contained in gaseous fluids via chemisorption and / or physisorption between the unit layers of the substrate's lattice where the polar amine liquids and solids and / or polar ether liquids and solids are located. The method eliminates the need for high surface area supports and polymeric materials for the preparation of CO2 capture systems, and provides sorbents with absorption capabilities that are independent of the sorbents' surface areas. The sorbents can be regenerated by heating at temperatures in excess of 35° C.

Owner:ENERGY U S DEPARMENT OF

Methods and devices for the production of Hydrocarbons from Carbon and Hydrogen sources

InactiveUS20080283411A1Reduce the environmentEasy to controlPhotography auxillary processesInternal combustion piston enginesElectrolysisAtmospheric air

Devices and methods are described for converting a carbon source and a hydrogen source into hydrocarbons, such as alcohols, for alternative energy sources. The influents may comprise carbon dioxide gas and hydrogen gas or water, obtainable from the atmosphere for through methods described herein, such as plasma generation or electrolysis. One method to produce hydrocarbons comprises the use of an electrolytic device, comprising an anode, a cathode and an electrolyte. Another method comprises the use of ultrasonic energy to drive the reaction. The devices and methods and related devices and methods are useful, for example, to provide a fossil fuel alternative energy source, store renewable energy, sequester carbon dioxide from the atmosphere, counteract global warming, and store carbon dioxide in a liquid fuel.

Owner:PRINCIPLE ENERGY SOLUTIONS

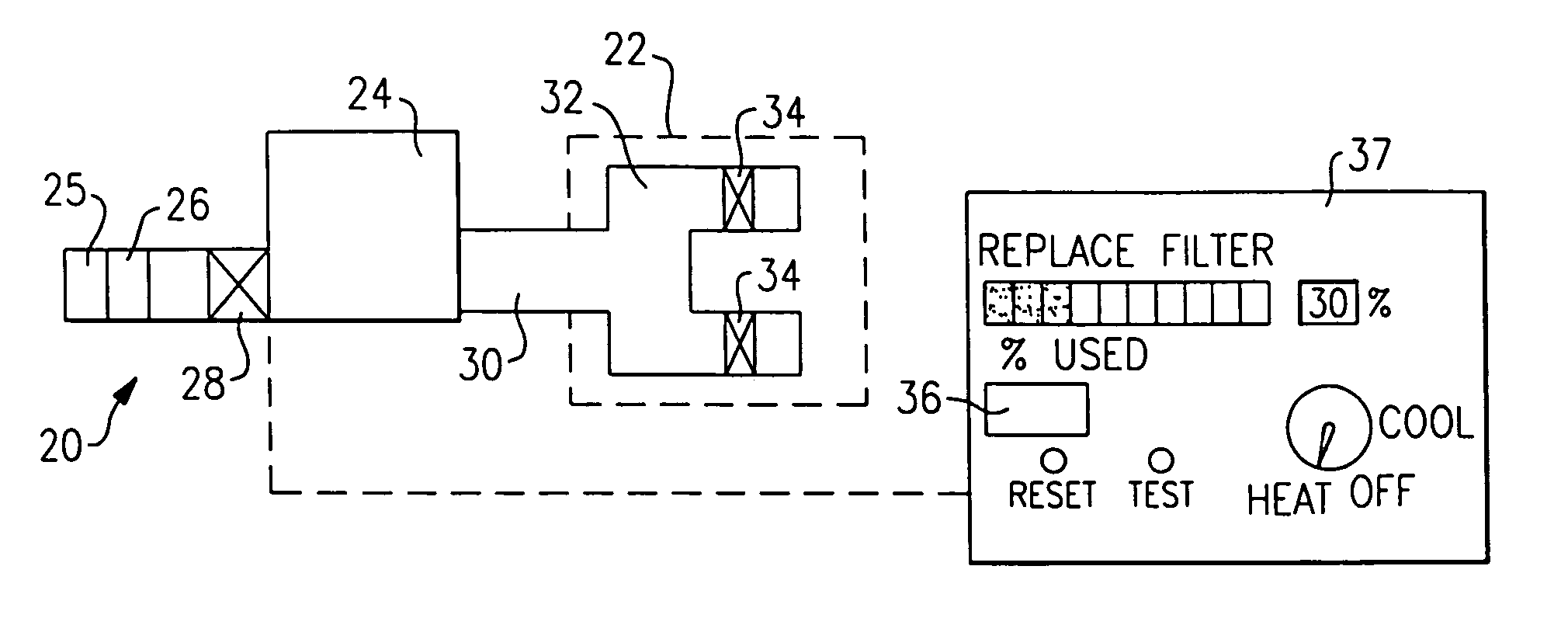

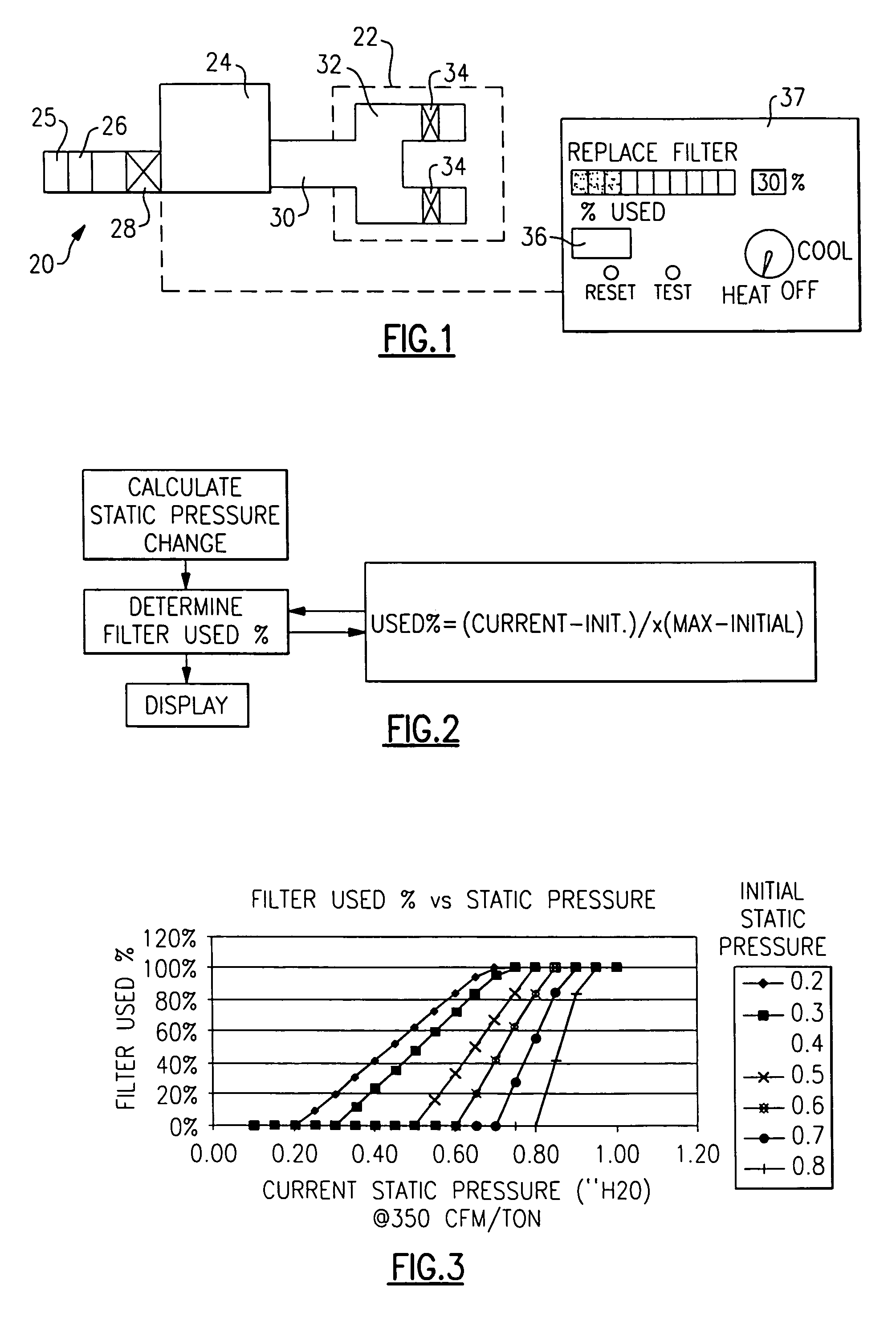

Detection of clogged filter in an HVAC system

Static pressures are measured in an HVAC system and utilized to predict the condition of a filter in the HVAC system. As the filter becomes clogged, the static pressure can be expected to increase. Changes in the static pressure are determined periodically, and utilized to predict the condition of the filter. A display provides a user with an indication of the current condition of the filter, and a recommendation to replace the filter once it reaches a predetermined condition.

Owner:CARRIER CORP

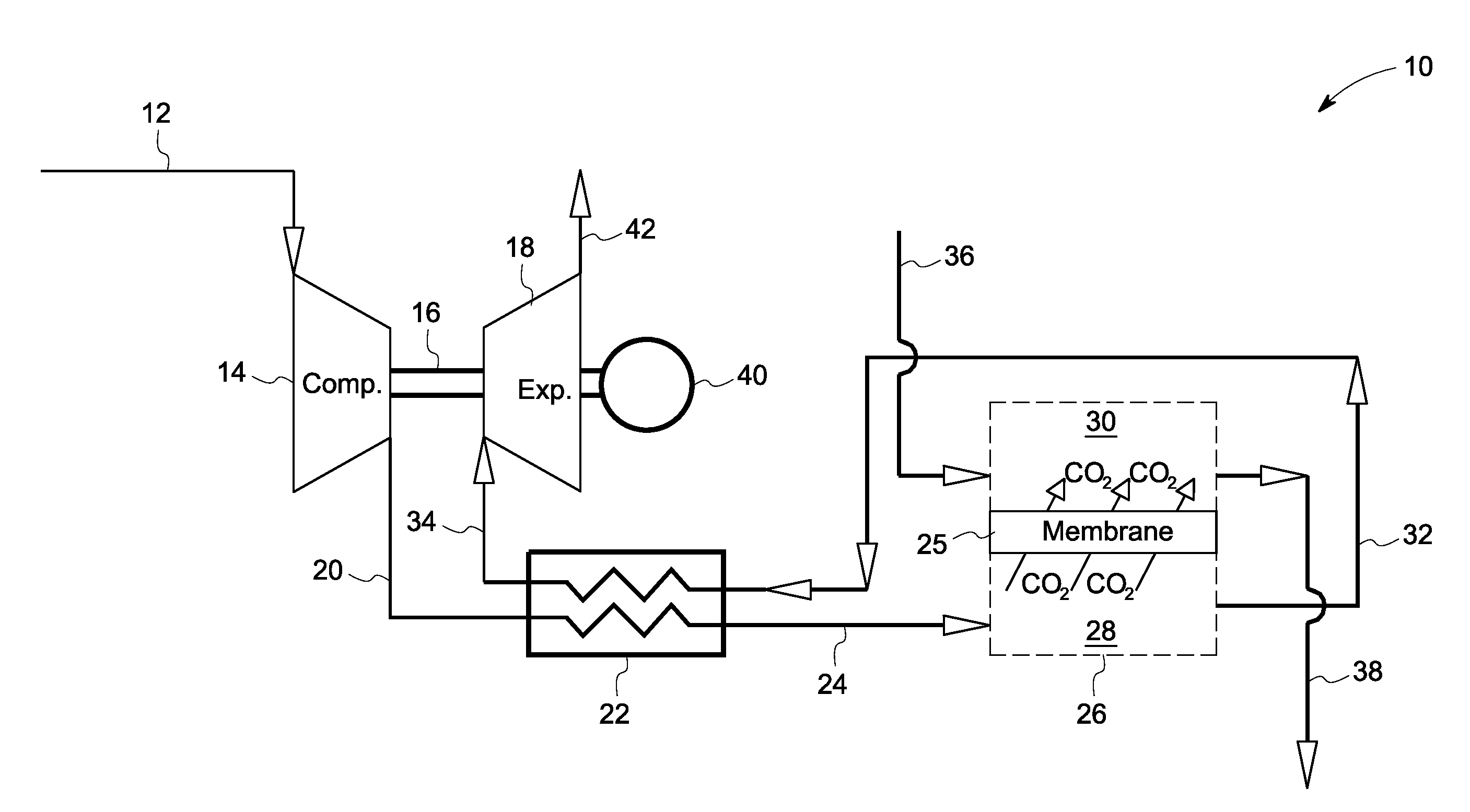

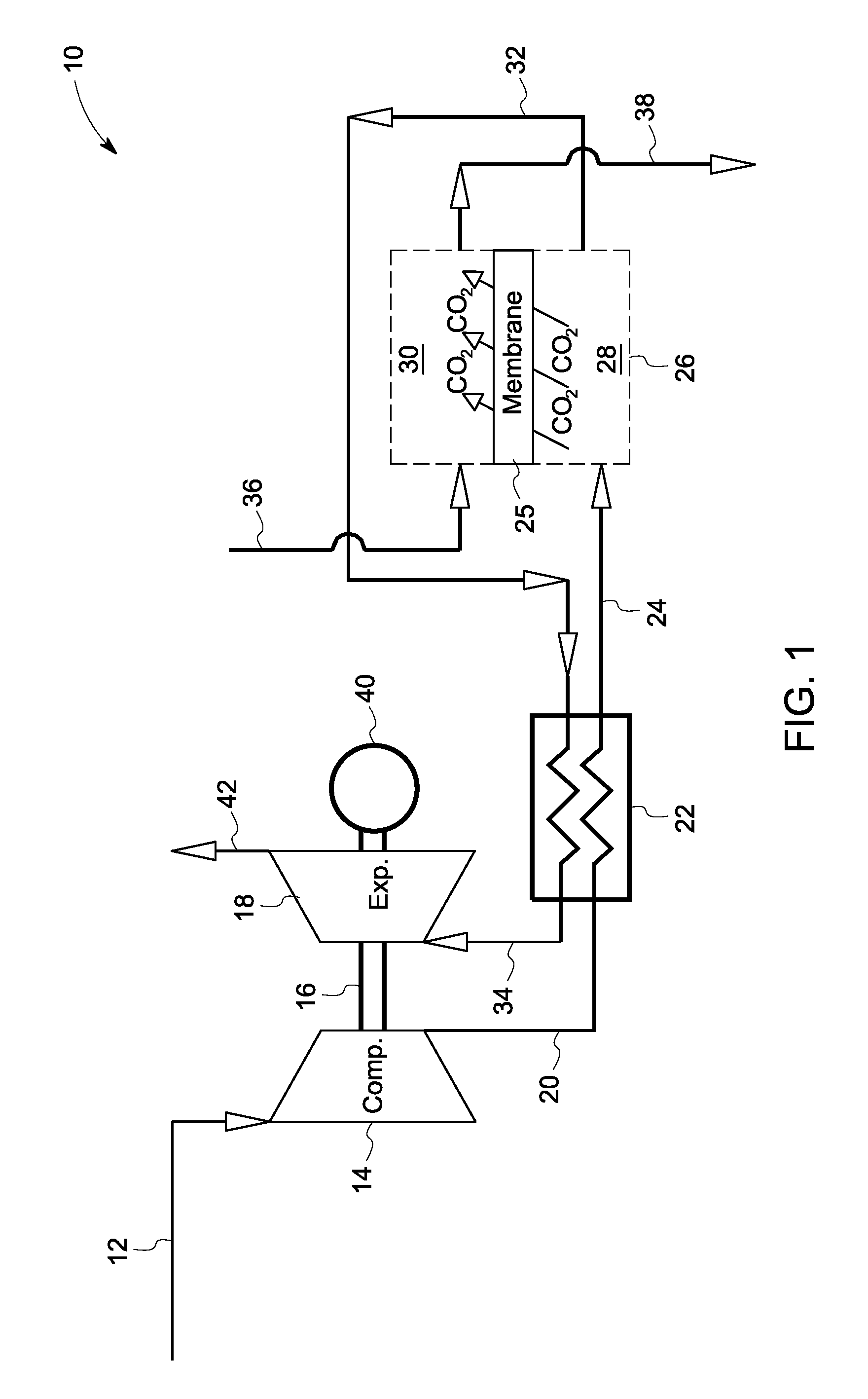

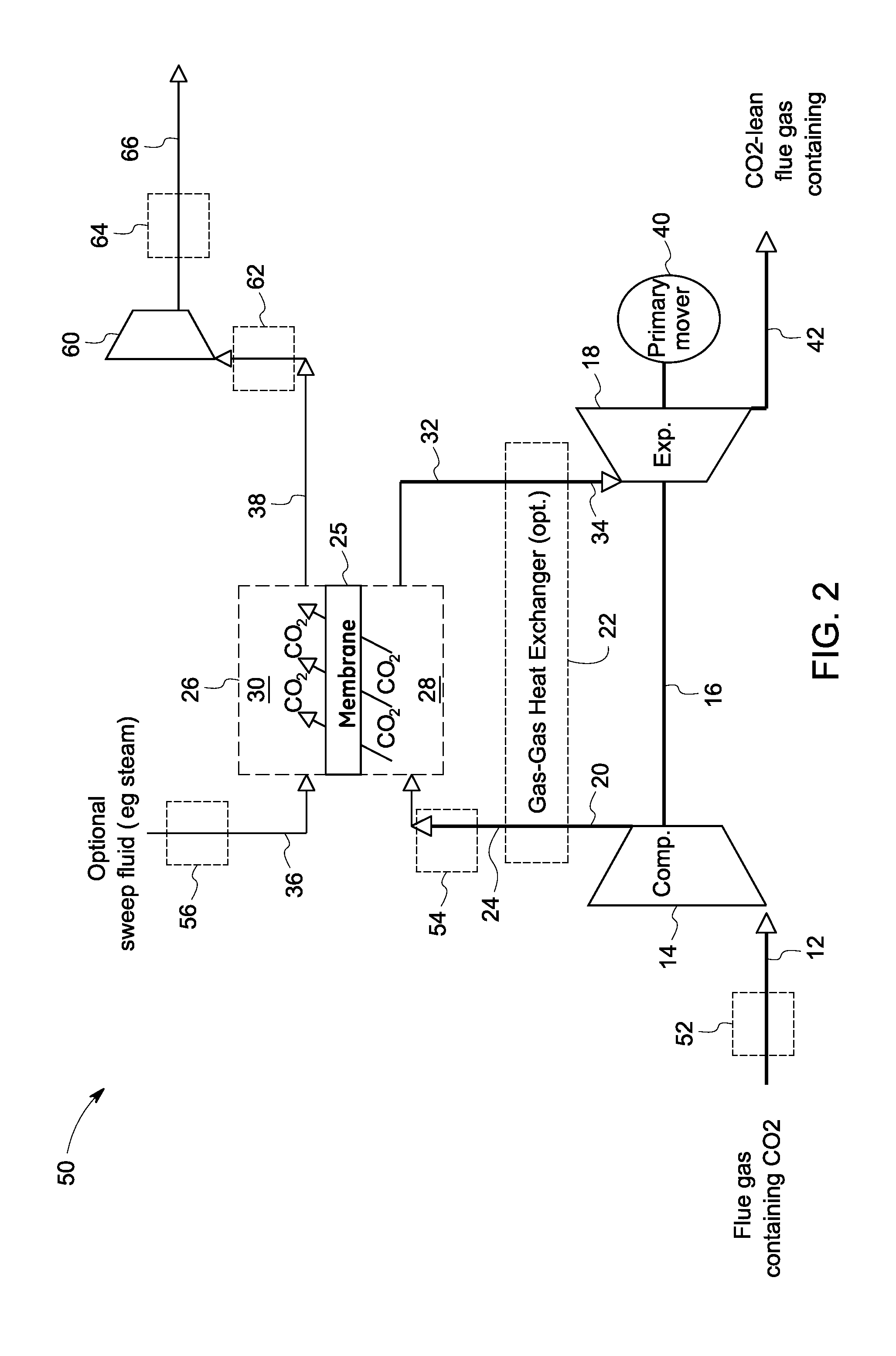

Carbon dioxide capture systems and methods

InactiveUS20080127632A1More cost-effectivelyEasy and cost-effectiveGas treatmentExhaust apparatusCarbon dioxide transportProcess engineering

A carbon dioxide separation system includes a compressor for receiving an exhaust gas comprising CO2 and generate a compressed exhaust gas and a separator configured to receive the compressed exhaust gas and generate a CO2 lean stream. The separator includes a first flow path for receiving the compressed exhaust gas, a second flow path for directing a sweep fluid therethrough, and a material with selective permeability of carbon dioxide for separating the first and the second flow paths and for promoting carbon dioxide transport therebetween. The system further includes an expander coupled to the compressor for receiving and expanding the CO2 lean stream to generate power and an expanded CO2 lean stream.

Owner:GENERAL ELECTRIC CO

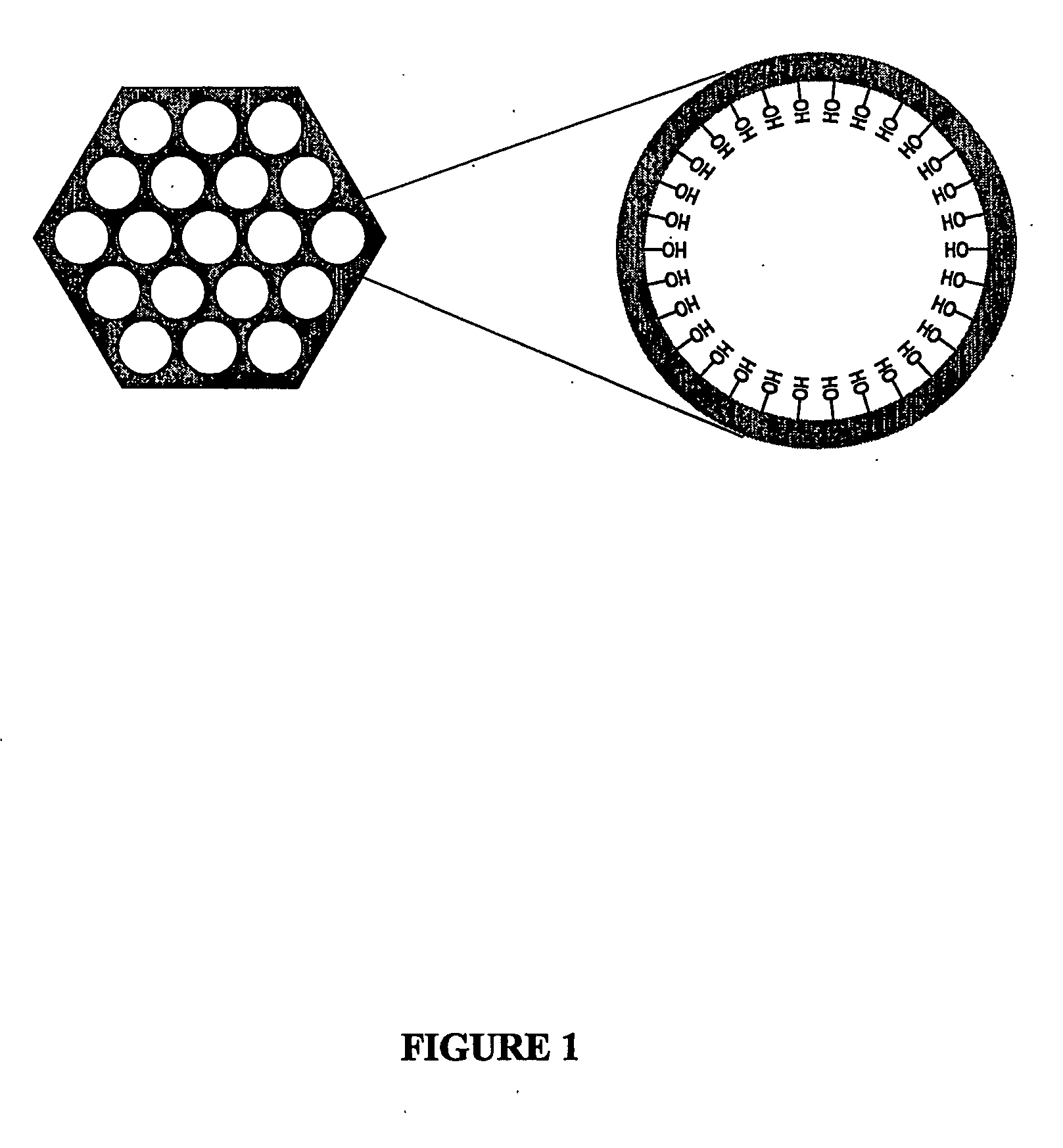

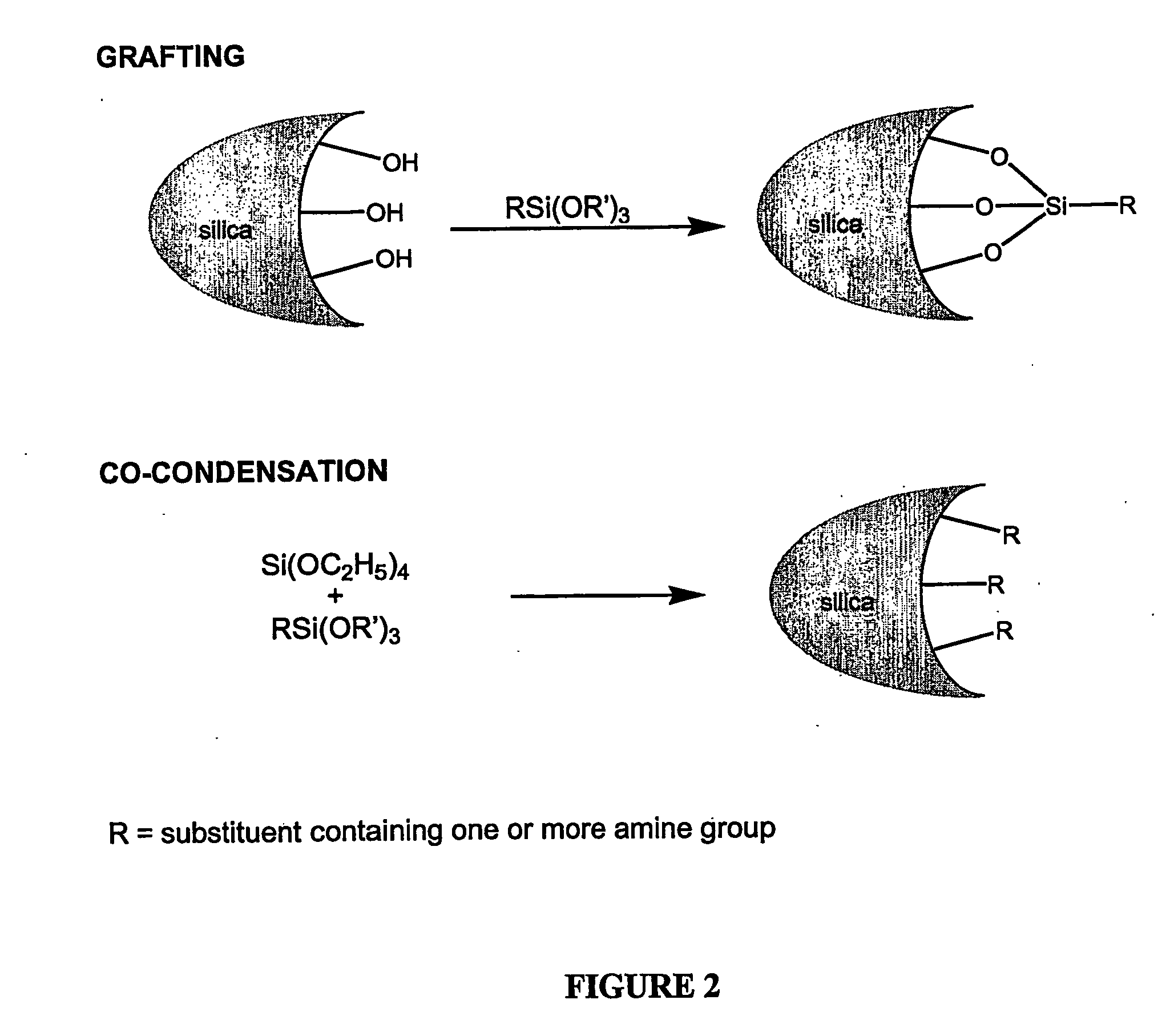

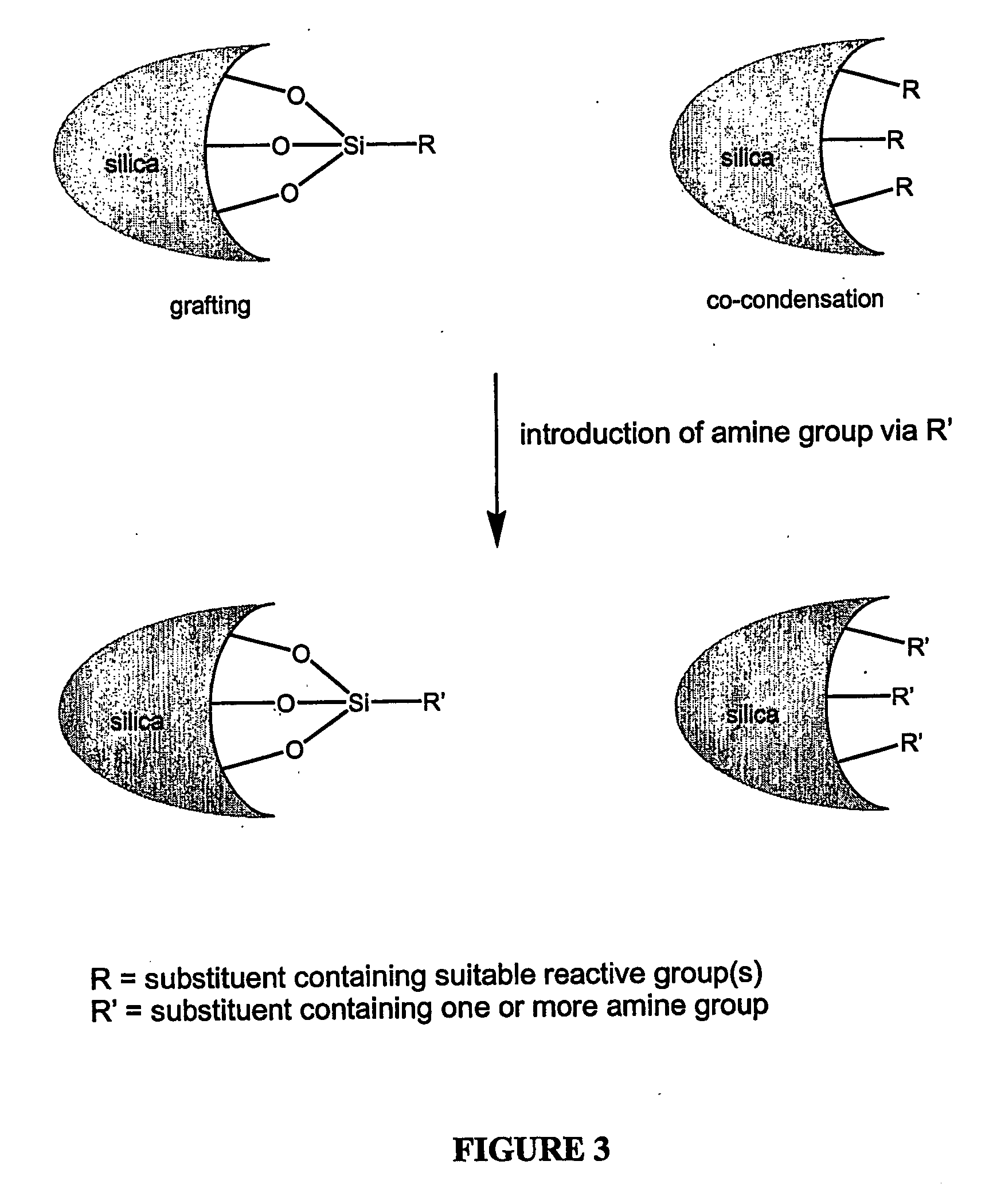

Modified adsorbent for dry scrubbing and use thereof

The present invention provides an amine functionalised adsorbent for use in dry scrubbing process. The adsorbent comprises amine functionalised mesoporous silica in which the amine groups are present at or near the surface of the silica, including within the pore walls and channels of the silica. The present invention further provides methods of preparing the adsorbent and of using the adsorbent for the adsorption of CO2 and / or other acid gases.

Owner:UNIVERSITY OF OTTAWA

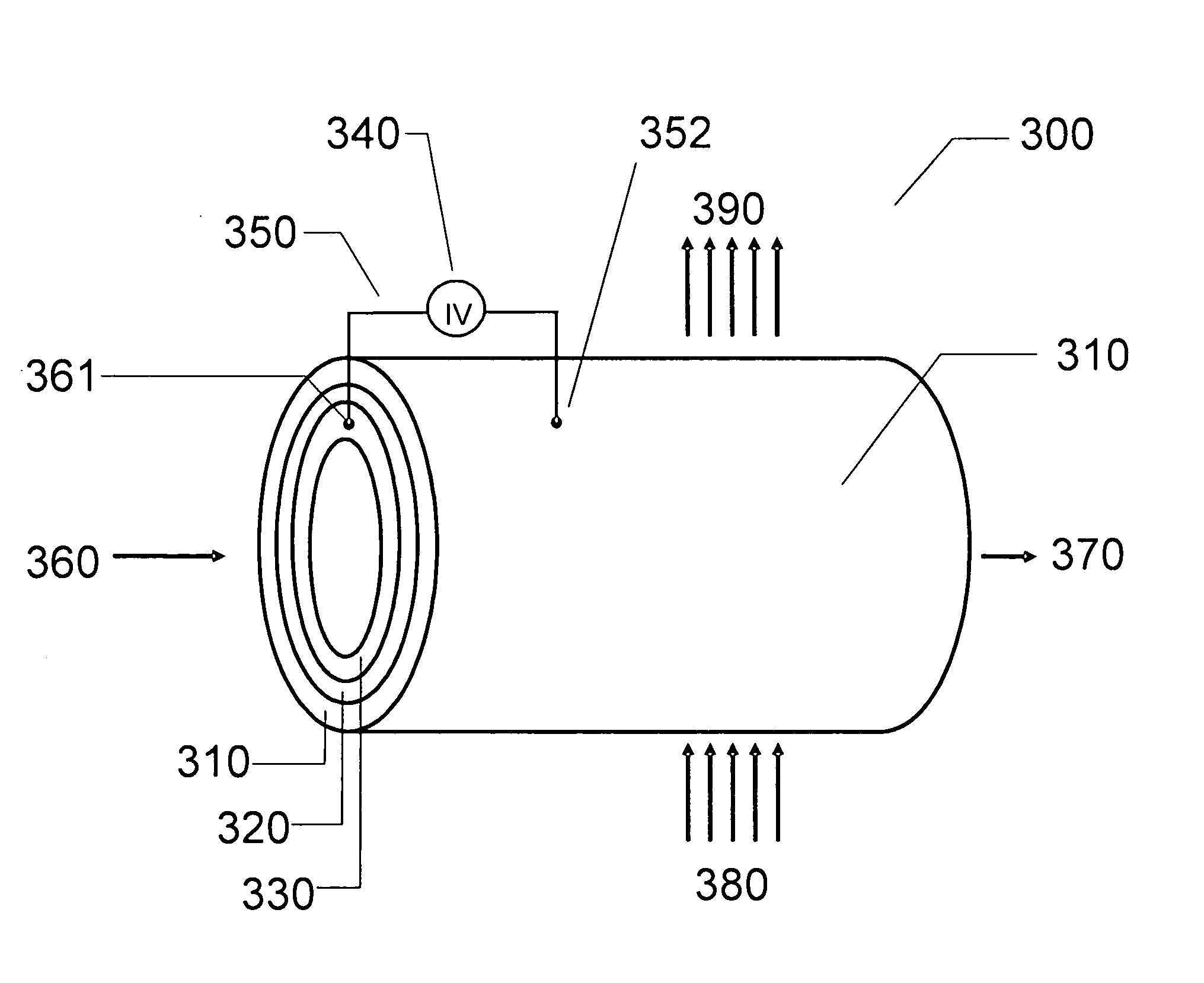

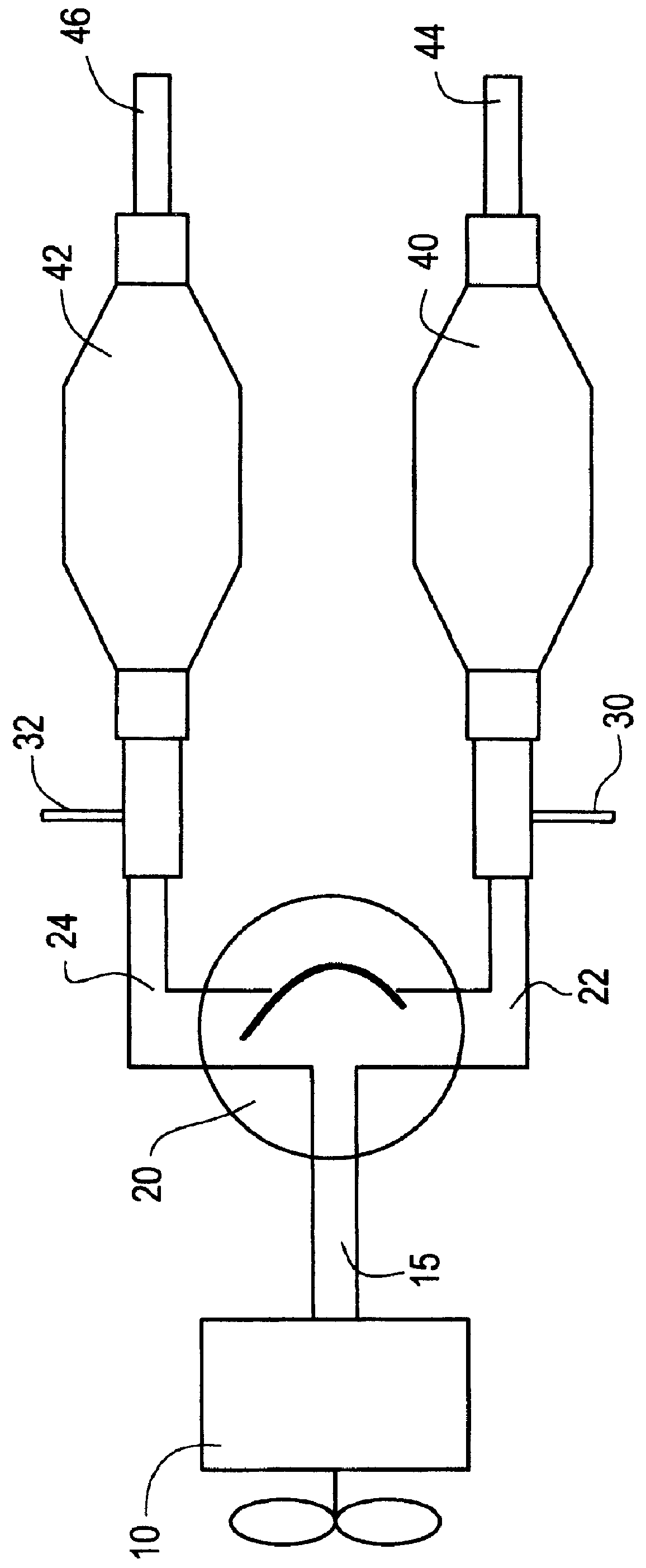

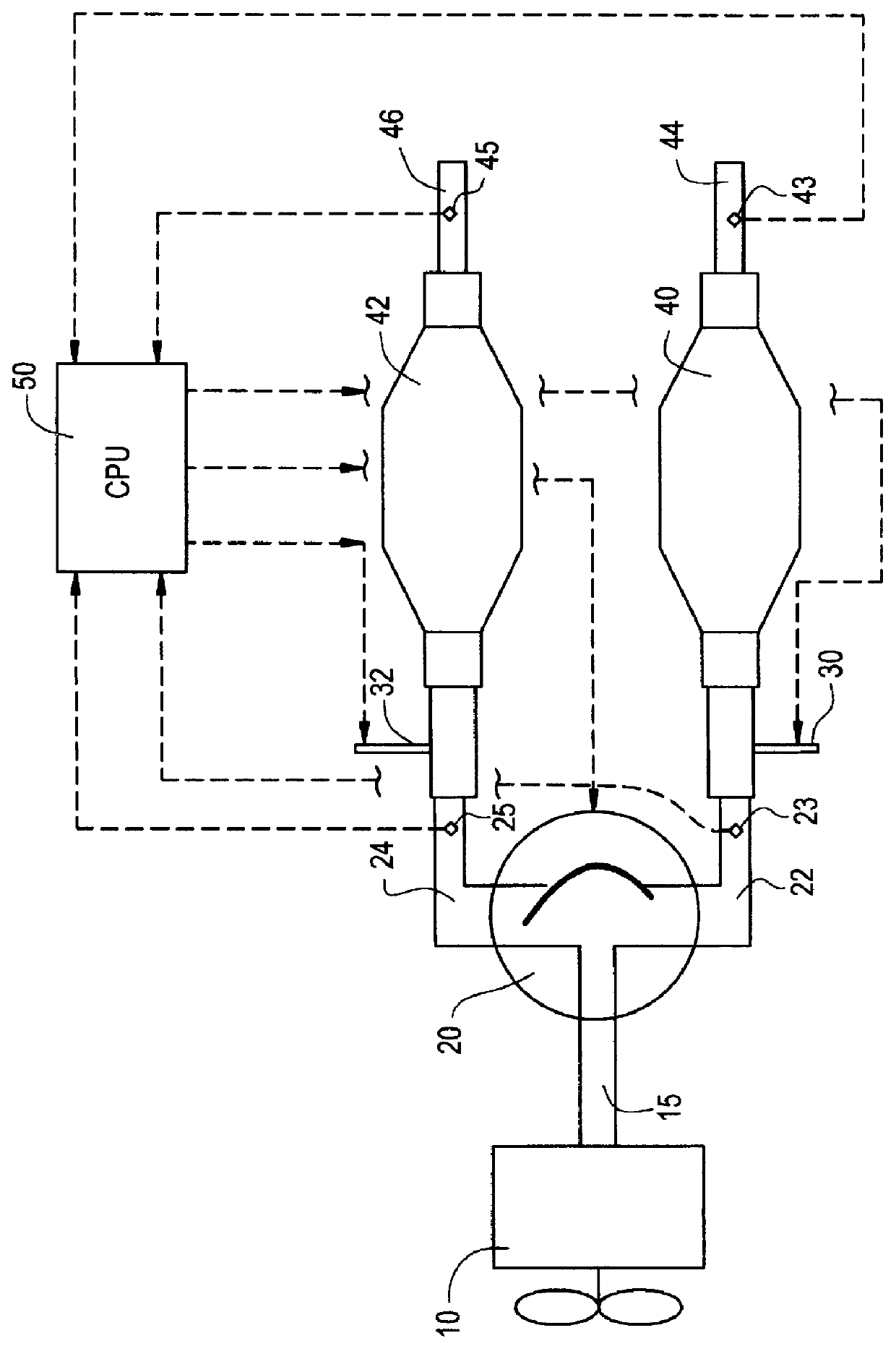

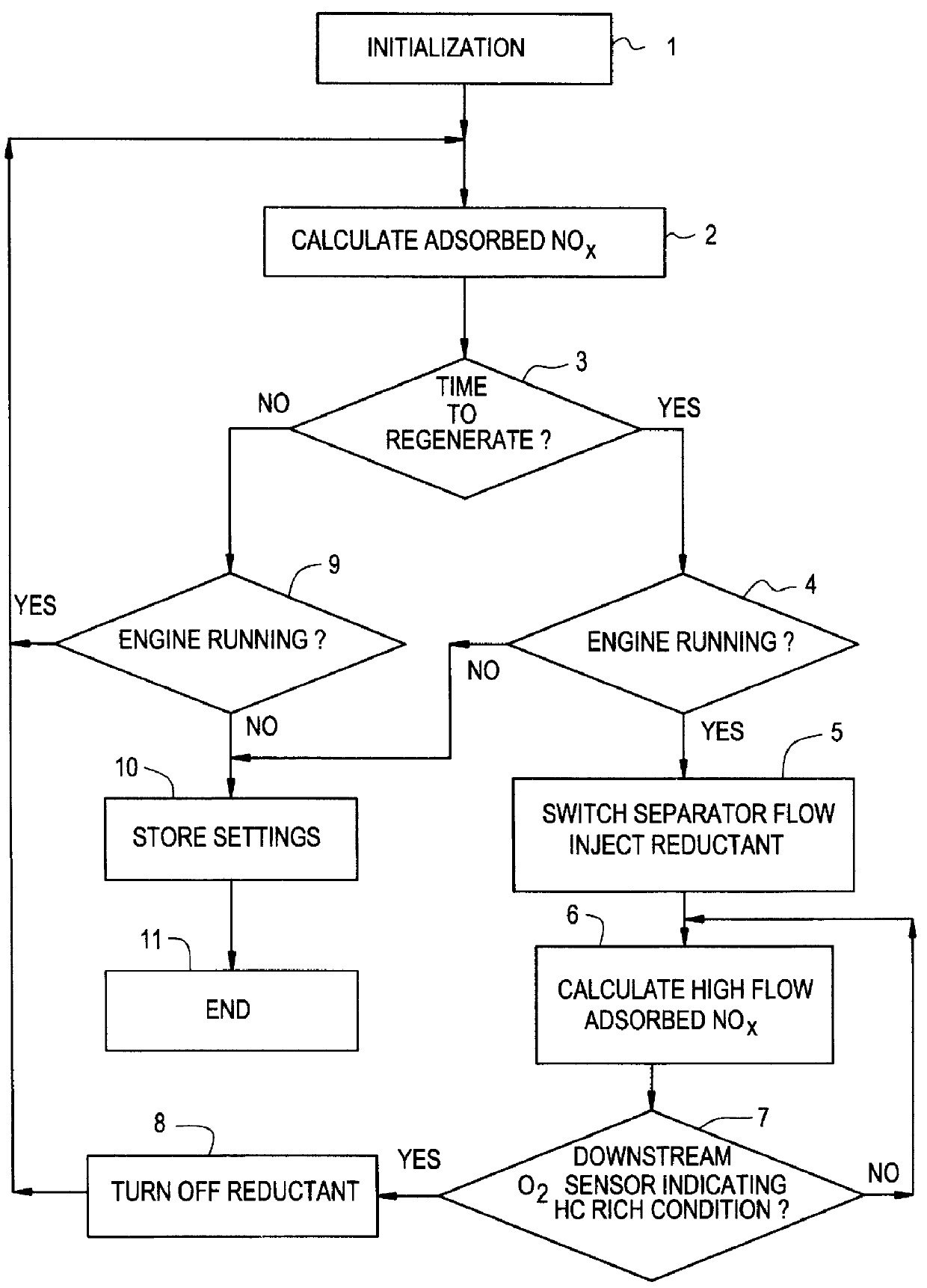

Apparatus, method, and system for concentrating adsorbable pollutants and abatement thereof

InactiveUS6105365ALess fuelLow oxygenGas treatmentInternal combustion piston enginesCombustionExhaust fumes

Owner:ENGELHARD CORP

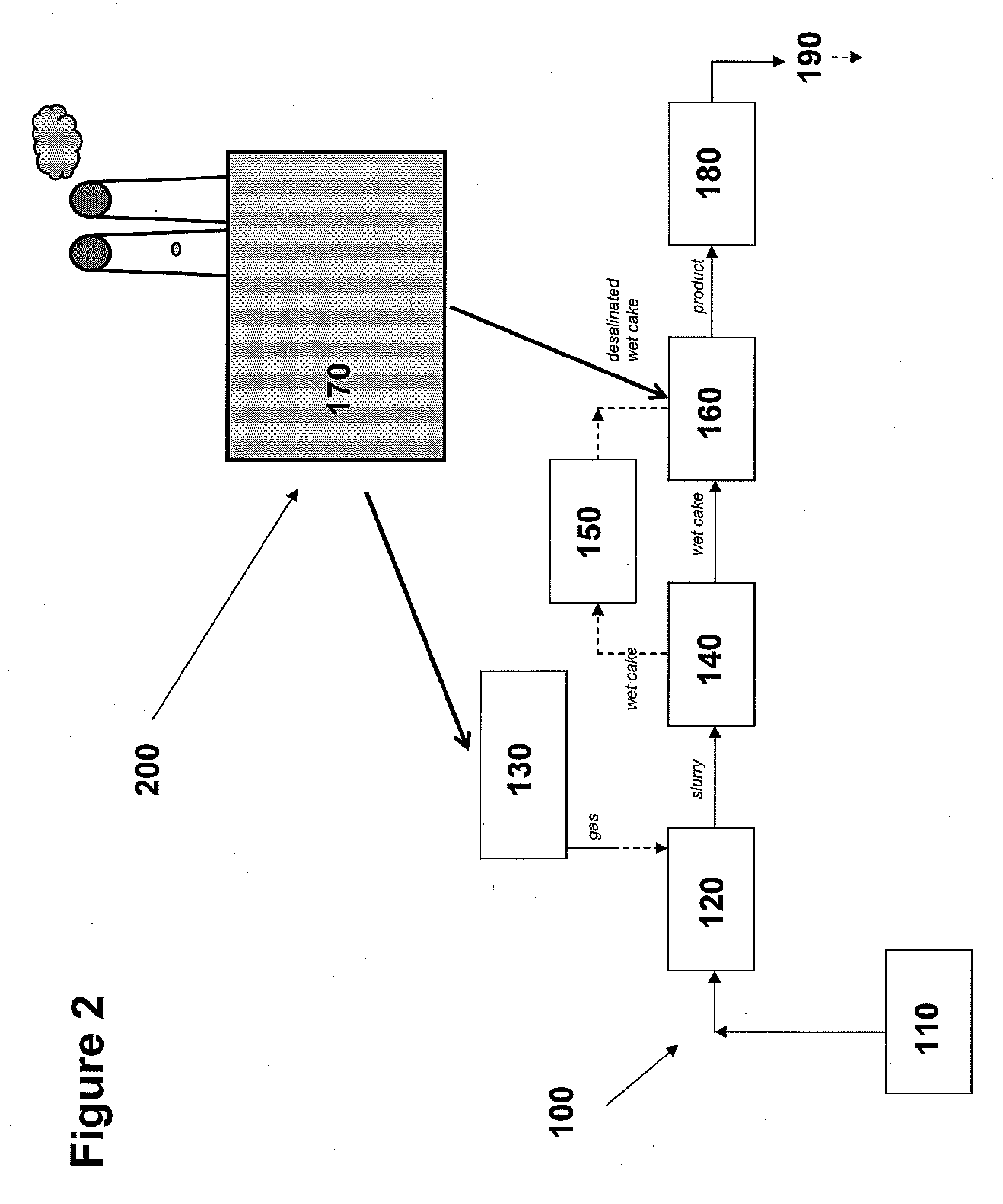

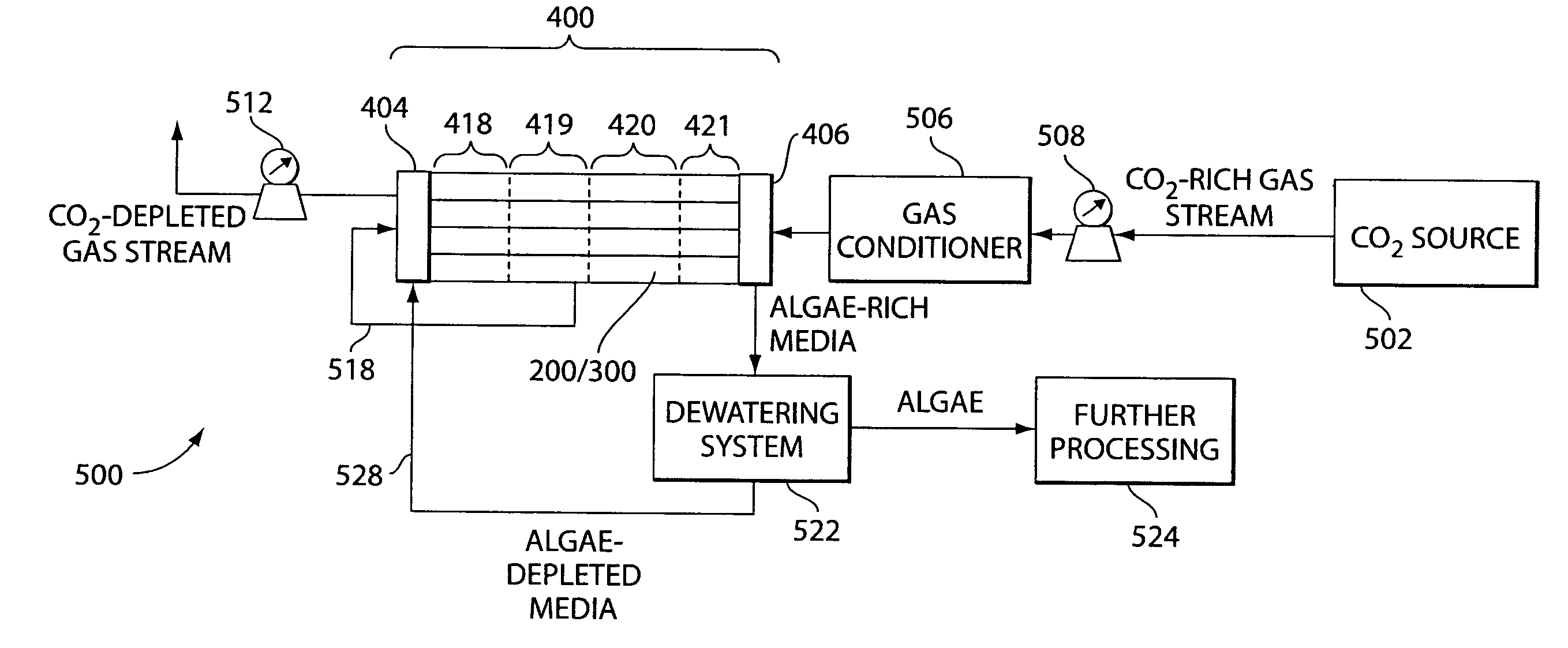

Integrated photobioreactor-based pollution mitigation and oil extraction processes and systems

InactiveUS20080009055A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiodieselLiquid medium

Integrated systems including a photobioreactor system designed to contain a liquid medium comprising at least one species of phototrophic organism therein, and a facility associated with extracting and / or processing oil extracted from mixtures of oil and solid material, such as an oil sands facility, are described. Processes for using a photobioreactor system as part of a gas-treatment process and system able to at least partially remove certain undesirable pollutants from a byproduct gas stream produced by an oil sands facility are also described. Examples of such pollutants that may be removed include compounds contained within combustion gases, e.g., CO2 and / or NOx. These pollutants processed with the photobioreactor system, and, in some embodiments, biomass produced with the photobioreactor system may be utilized to produce a fuel source (e.g., biodiesel) and cutting stock for further operation of or use in the oil sands facility. Such uses of certain embodiments can provide an efficient means for recycling carbon, thereby reducing CO2 emissions, fuel, and / or cutting stock requirements for a given quantum of energy produced. In addition, in some cases the photobioreactor can be integrated with a holding pond and waste heat from the oil extraction process can be used to maintain the photobioreactor temperature and / or provide energy for other processes. Accordingly, embodiments described herein can improve the overall environmental and economic profile of the oil sands facility.

Owner:GREENFUEL TECHNOLOGIES CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com