Patents

Literature

2271 results about "Volume expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Volume expansion refers to an increase in the total amount of fluid present in the body.

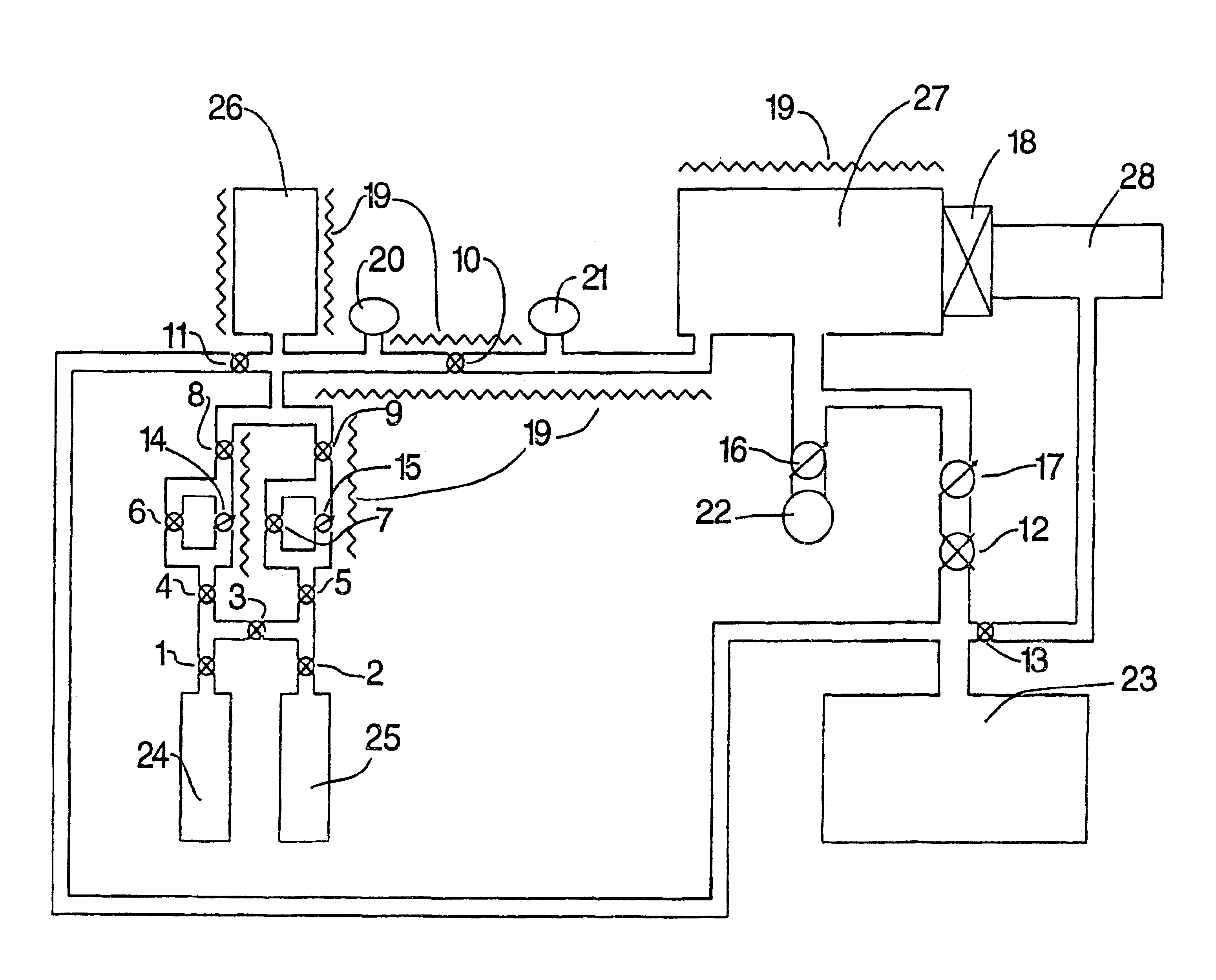

High frequency pressure swing adsorption

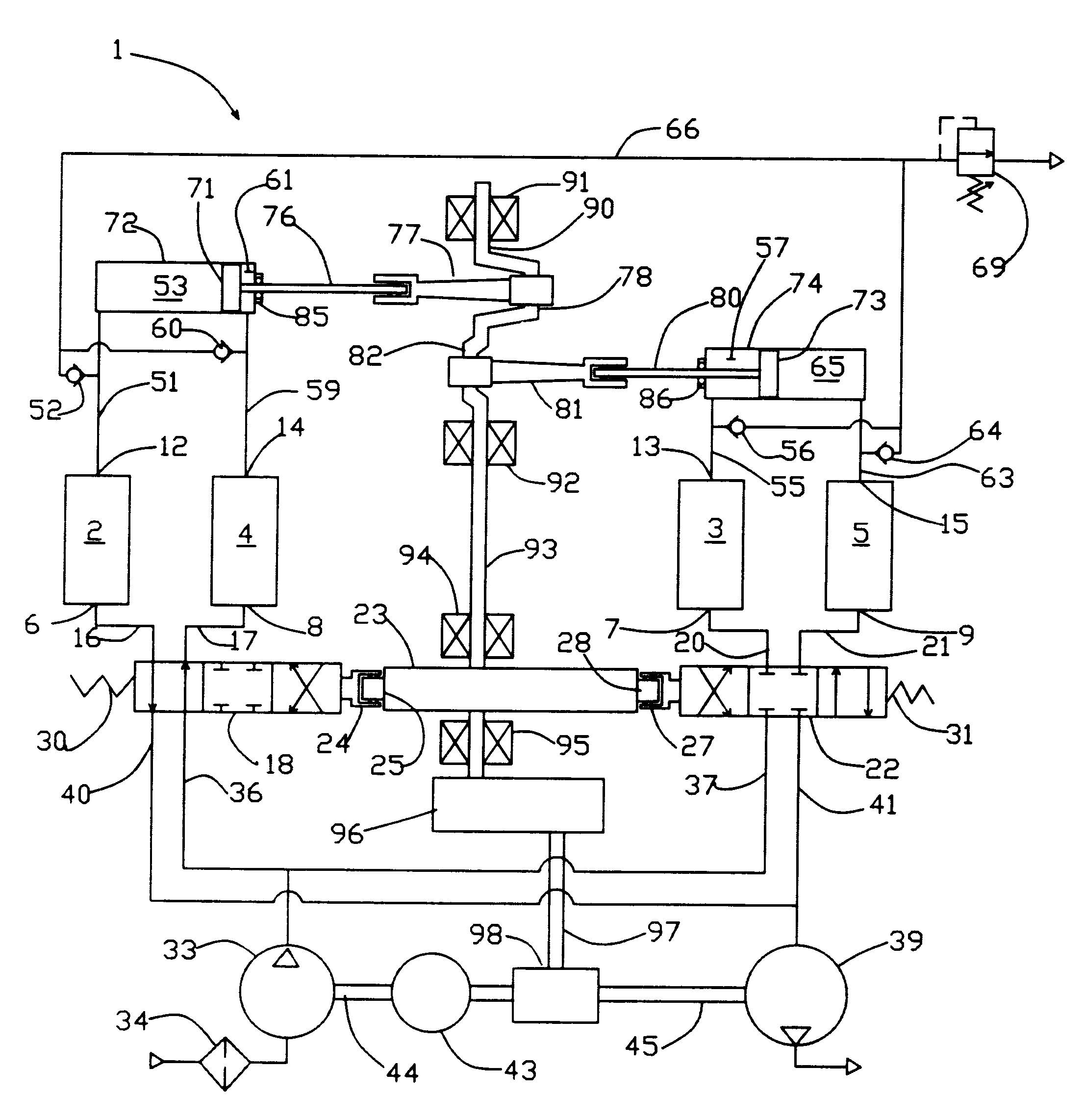

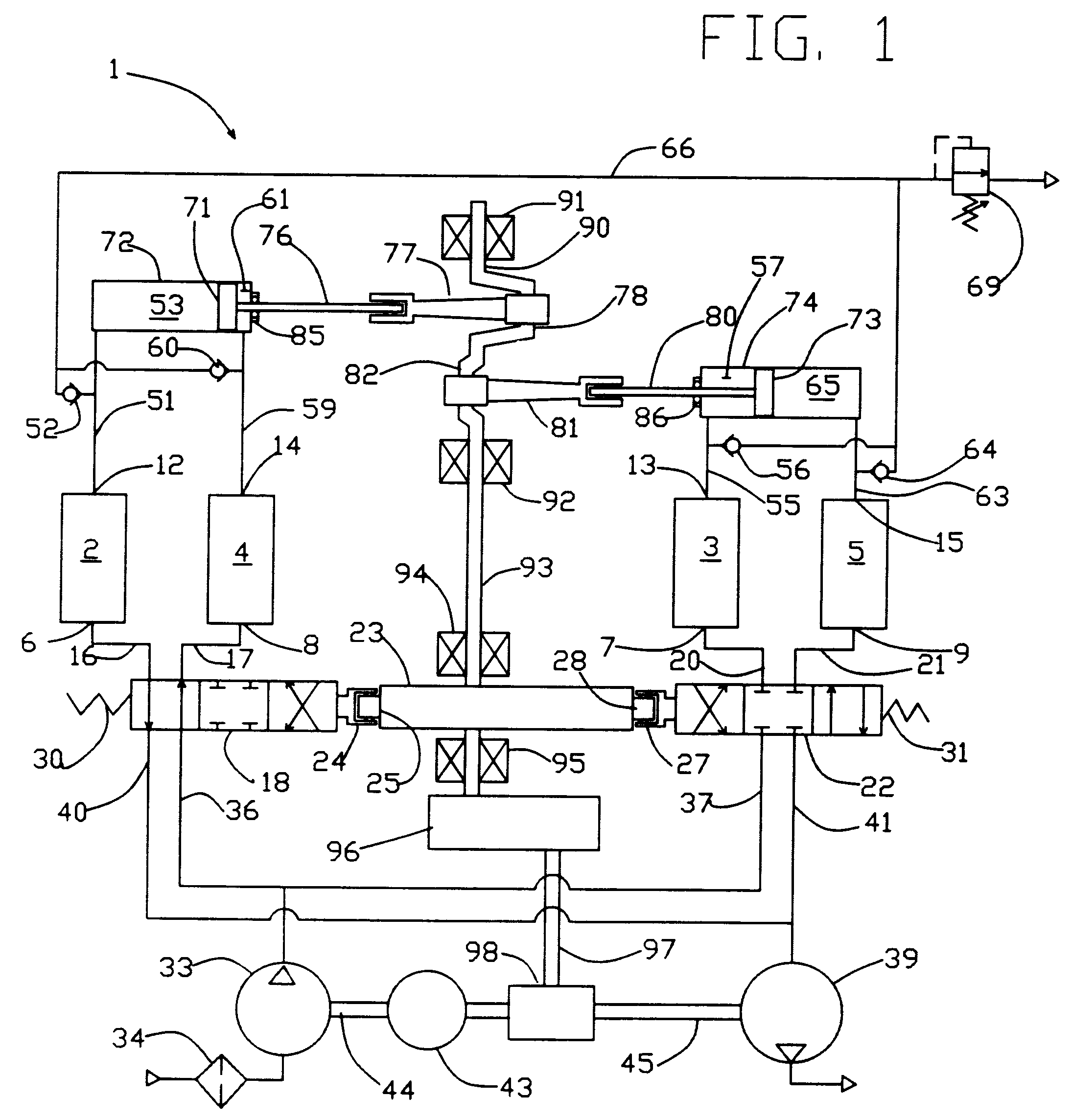

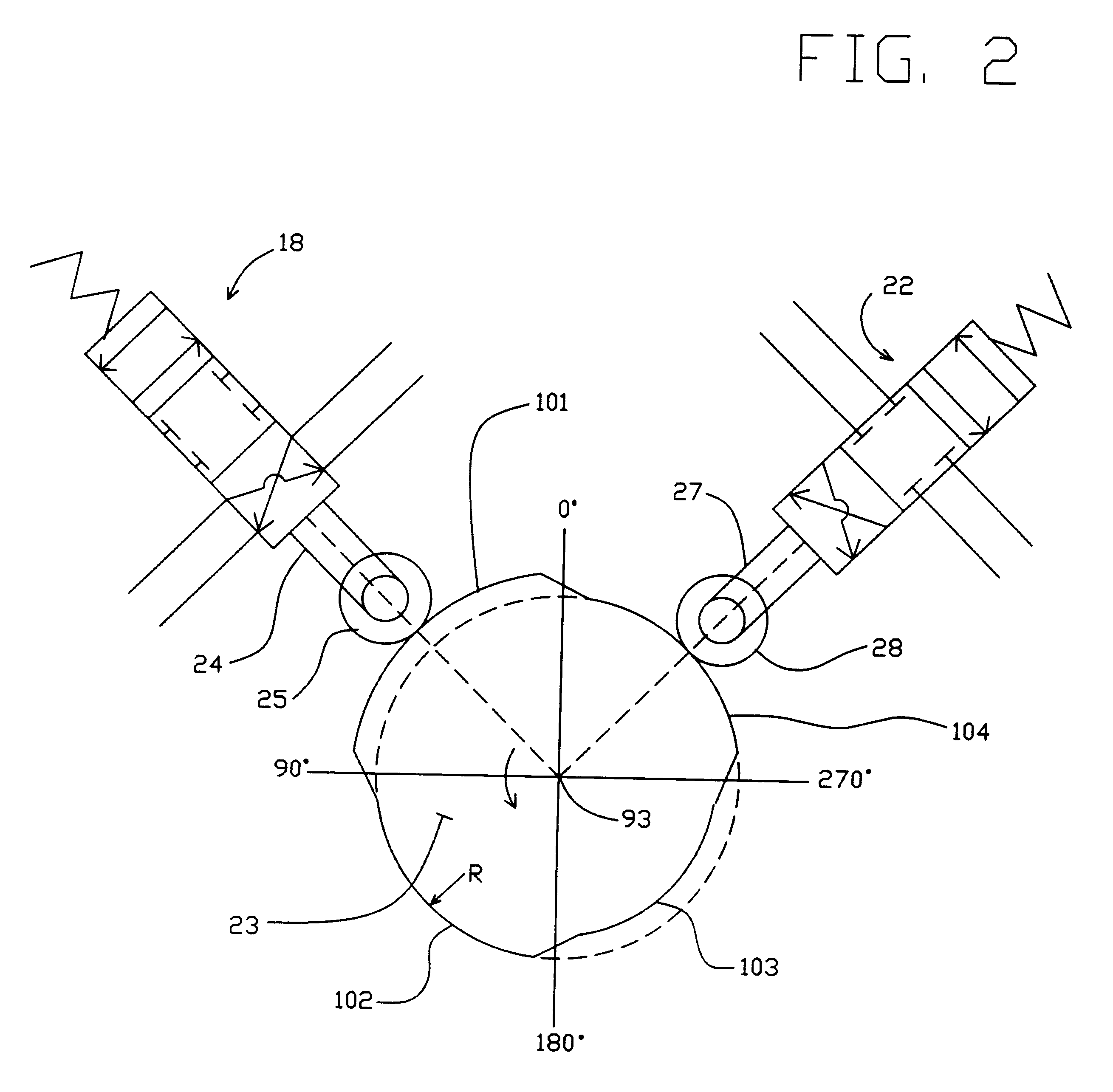

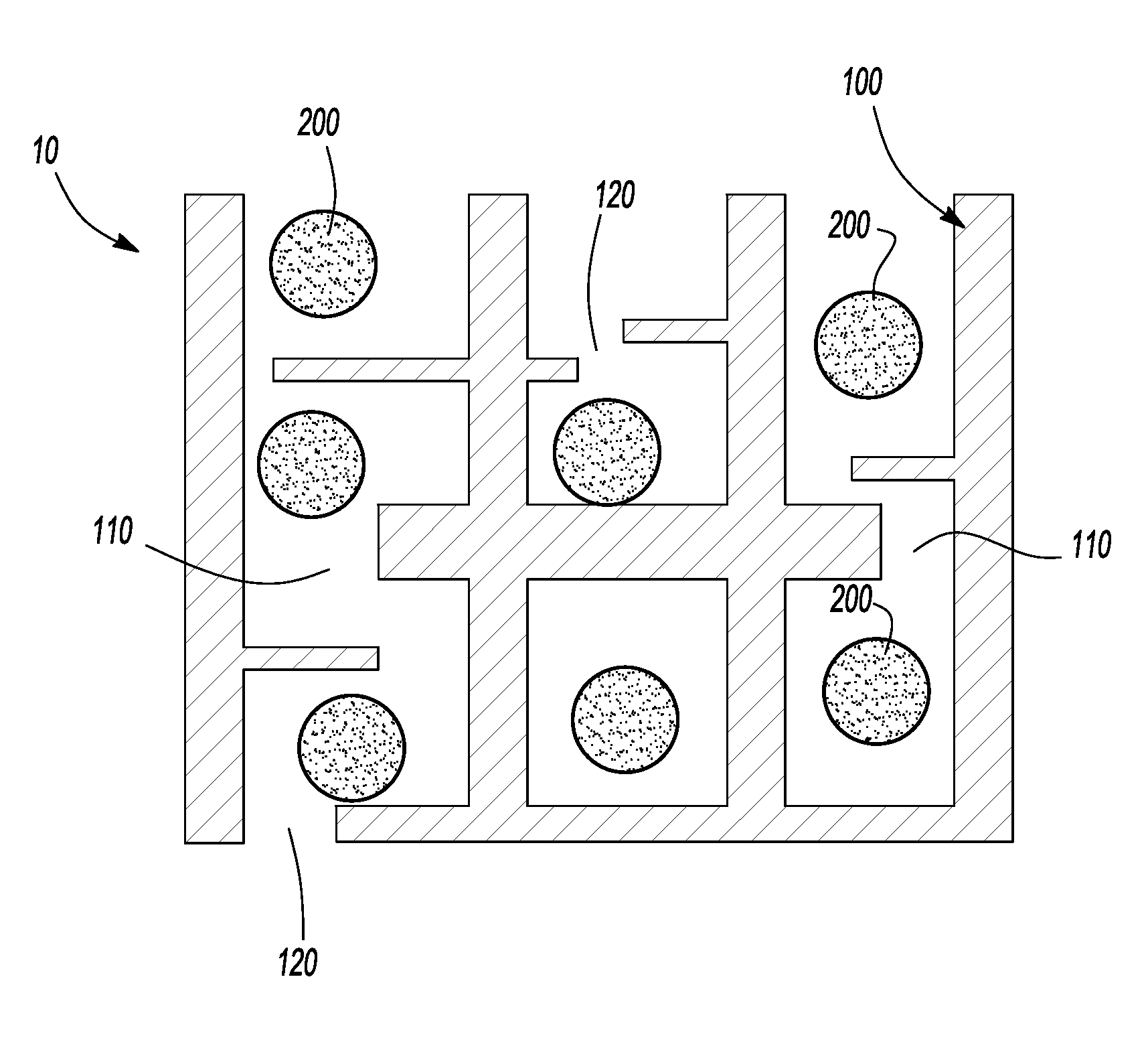

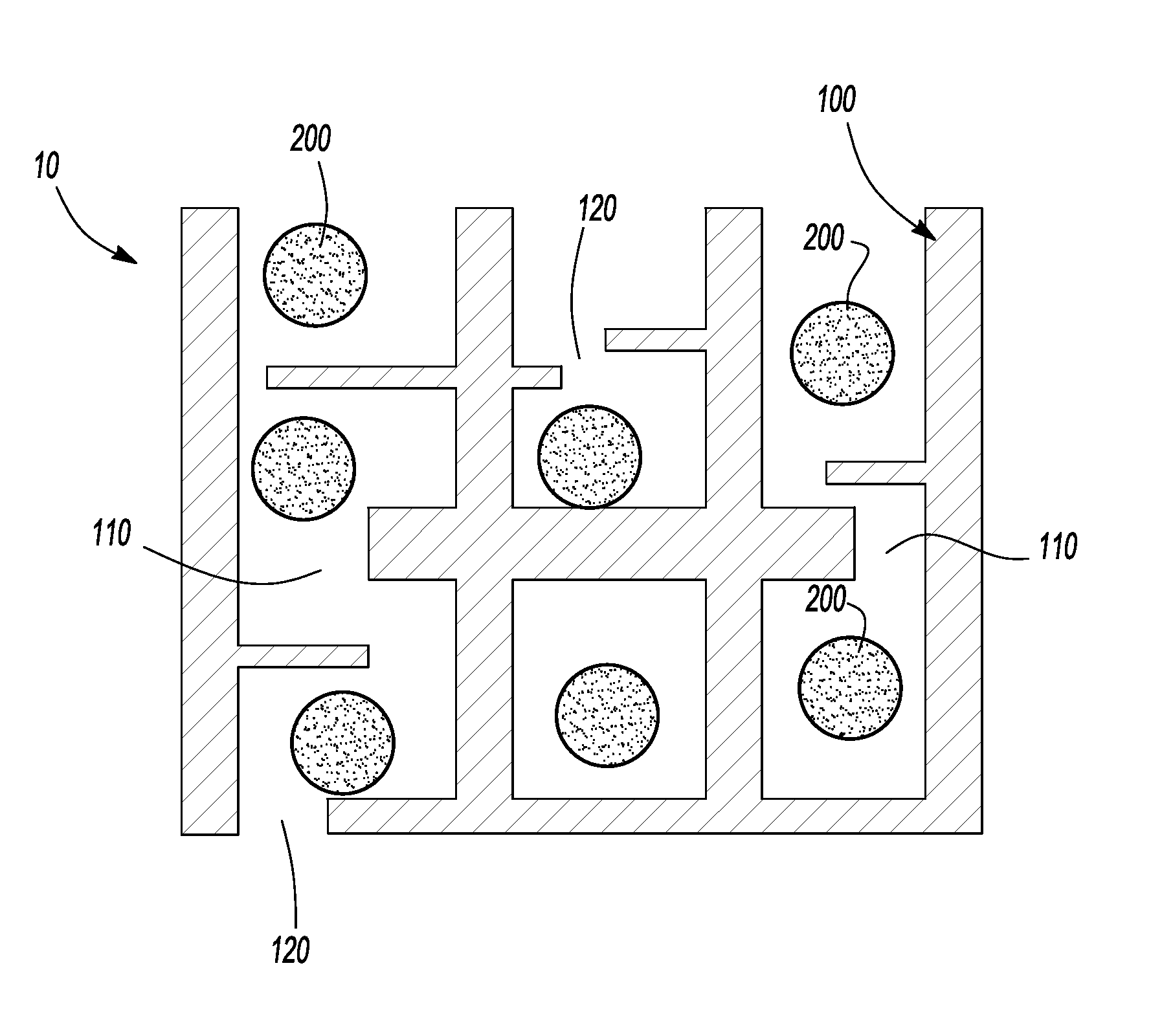

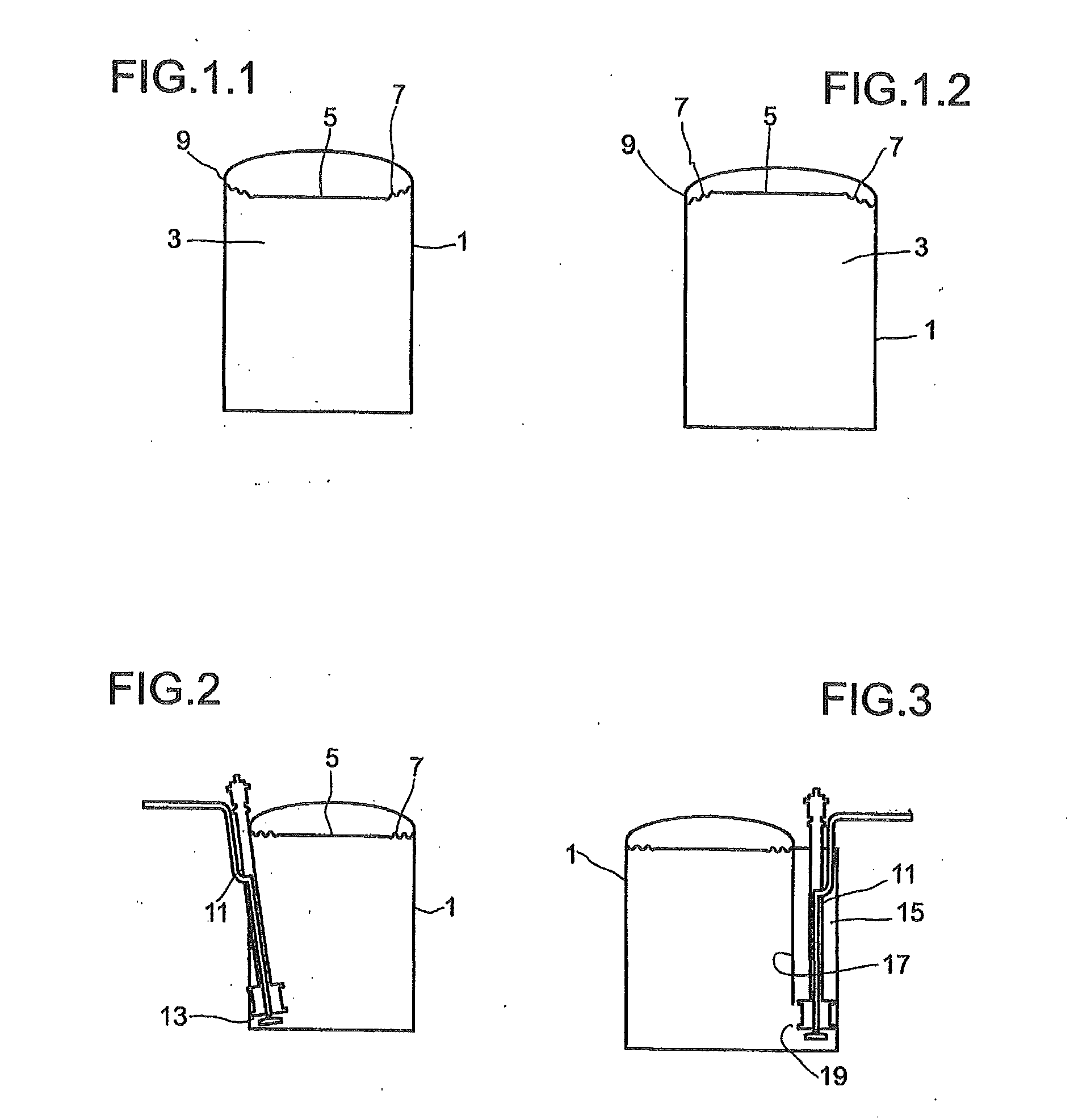

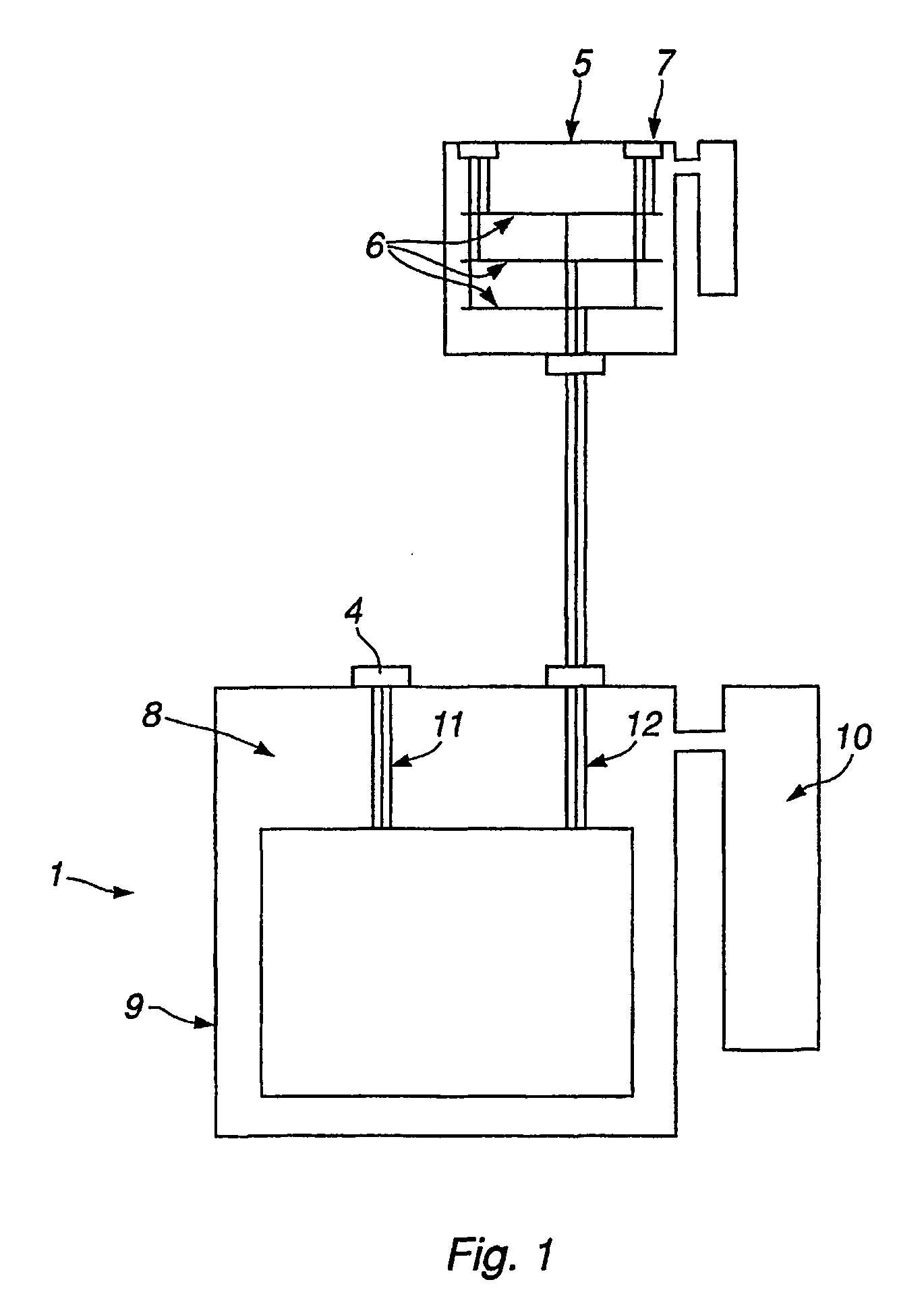

InactiveUS6176897B1High purityRecoverable expansion workNitrogen purification/separationGas treatmentSorbentEngineering

Pressure swing adsorption separation of a feed gas mixture, to obtain a purified product gas of the less strongly adsorbed fraction of the feed gas mixture, is performed in a plurality of preferably an even number of adsorbent beds, with each adsorbent bed communicating at its product end directly to a variable volume expansion chamber, and at its feed end by directional valves to a feed compressor and an exhaust vacuum pump. For high frequency operation of the pressure swing adsorption cycle, a high surface area layered support is used for the adsorbent. The compressor and vacuum pump pistons may be integrated with the cycle, reciprocating at twice the cycle frequency. Alternative configurations of the layered adsorbent beds are disclosed.

Owner:AIR PROD & CHEM INC

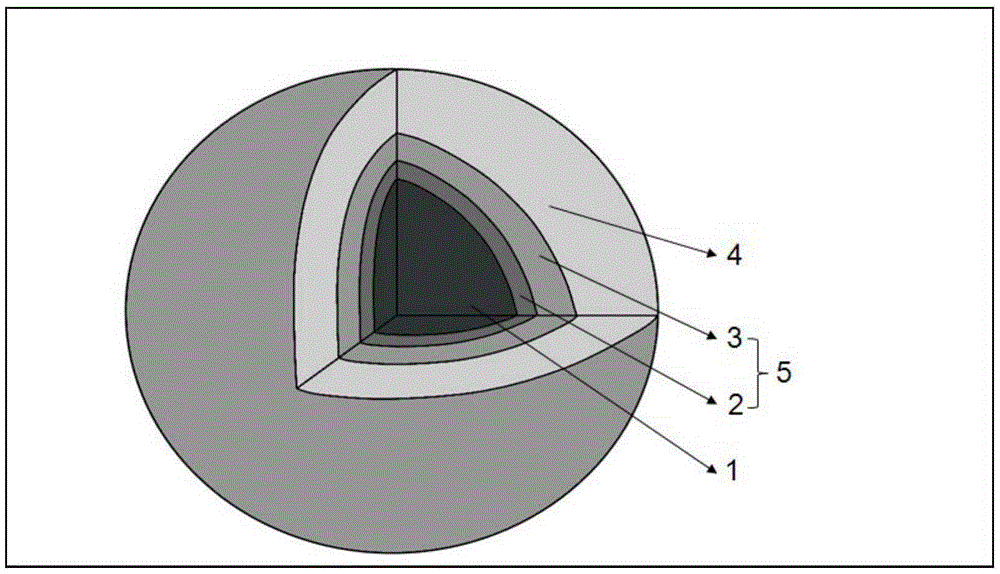

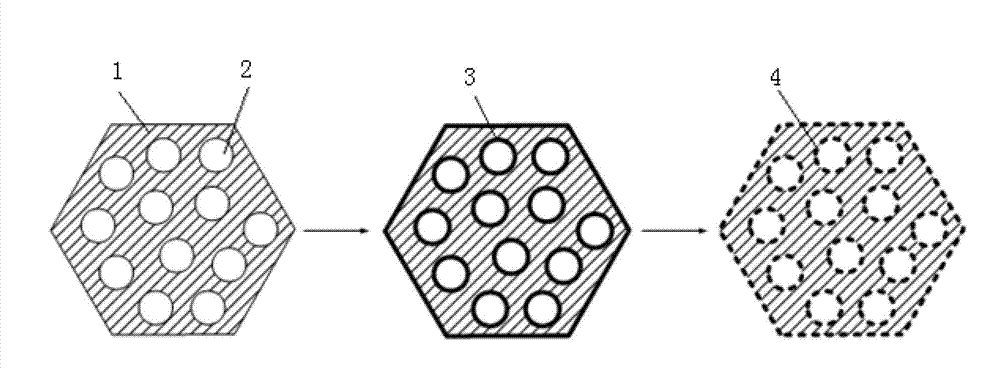

Silicon-carbon composite negative electrode material for lithium ion battery and preparation method thereof

ActiveCN103474667AImprove cycle performanceHigh charge and discharge capacityMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

The invention relates to a silicon-carbon composite negative electrode material and a preparation method thereof. The silicon-carbon composite negative electrode material successively comprises nano silicon / graphite particles, a first carbon coating layer and an organic cracking carbon layer from inside to outside. The nano silicon / graphite particles are globular or globular-like composite particles formed by employing graphite as an inner core of a volume expansion buffer substrate and coating a nano silicon particle layer; the first carbon coating layer comprises carbon nanotubes and / or amorphous carbon, the carbon nanotubes and / or amorphous carbon are interspersed in a gap network formed by gaps of the nano silicon particles and / or are coated outside the nano silicon particle layer, so that the nano silicon is tightly wrapped between the carbon nanotubes and / or between the carbon nanotubes and the graphite substrate, and besides, the material ion conductivity is effectively enhanced; the organic cracking carbon layer is an outermost coating layer of the silicon-carbon composite negative electrode material. The silicon-carbon composite negative electrode material has excellent cycle performance, excellent multiplying power charging and discharging performance and lower volume expansion effect.

Owner:BTR NEW MATERIAL GRP CO LTD

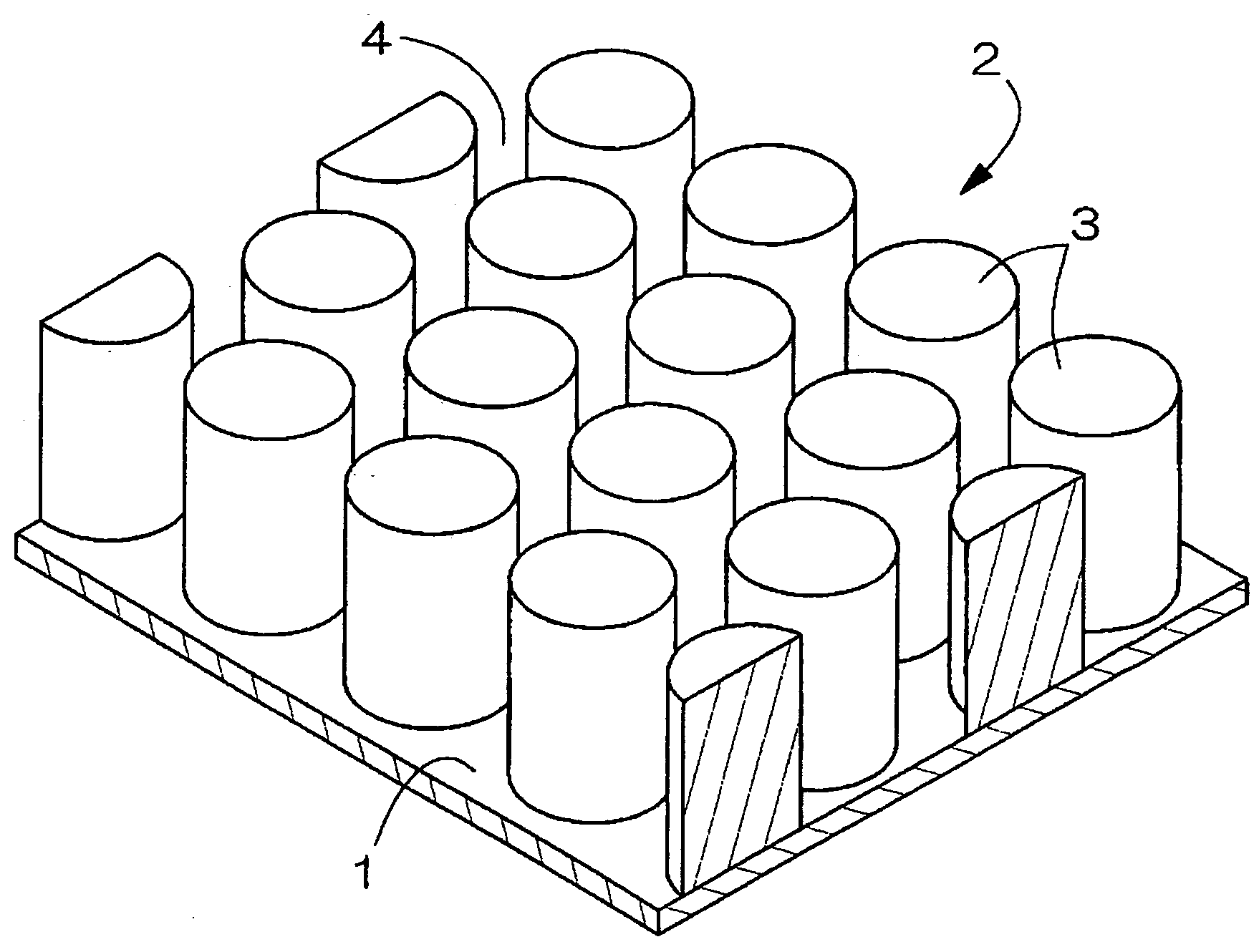

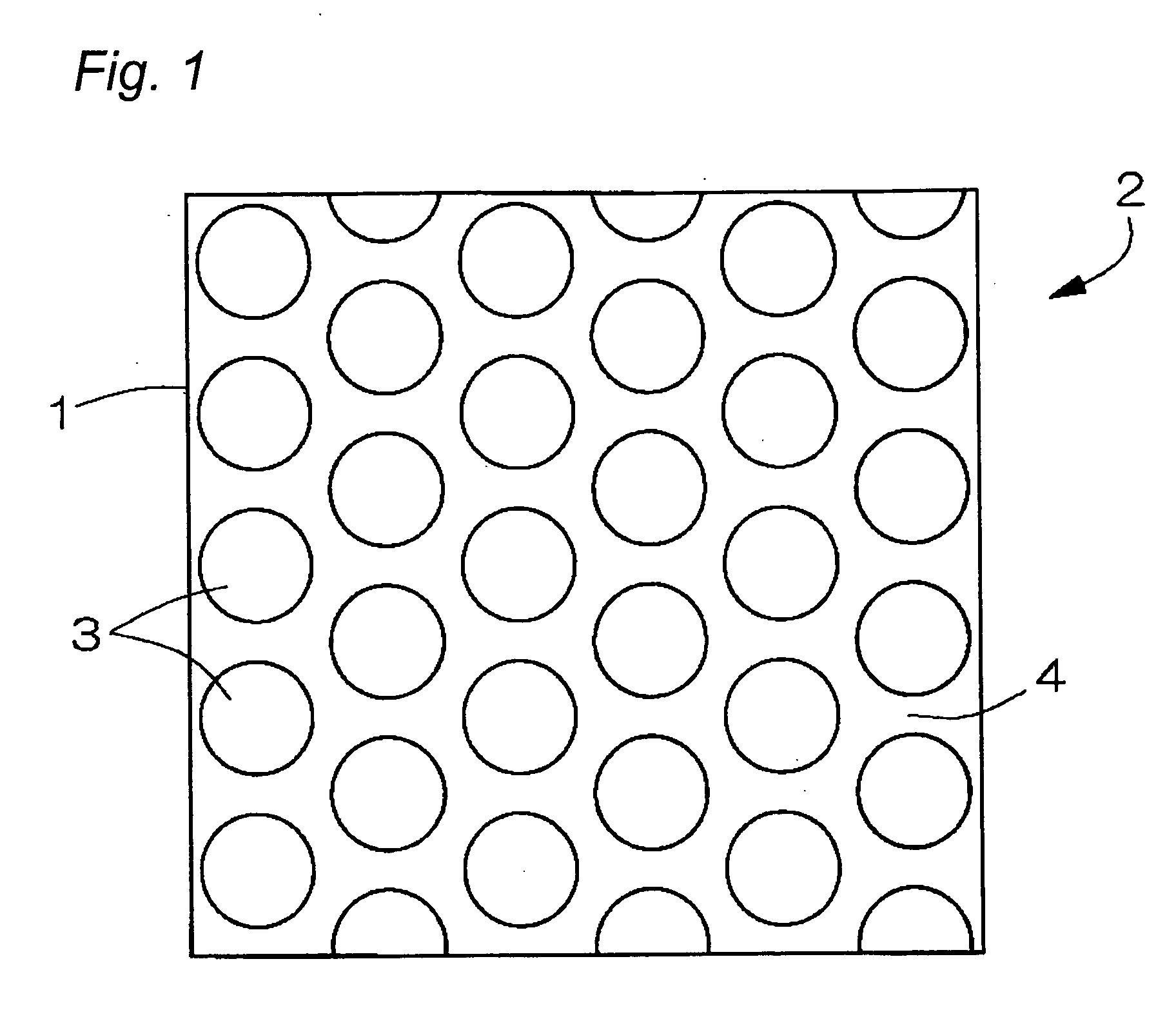

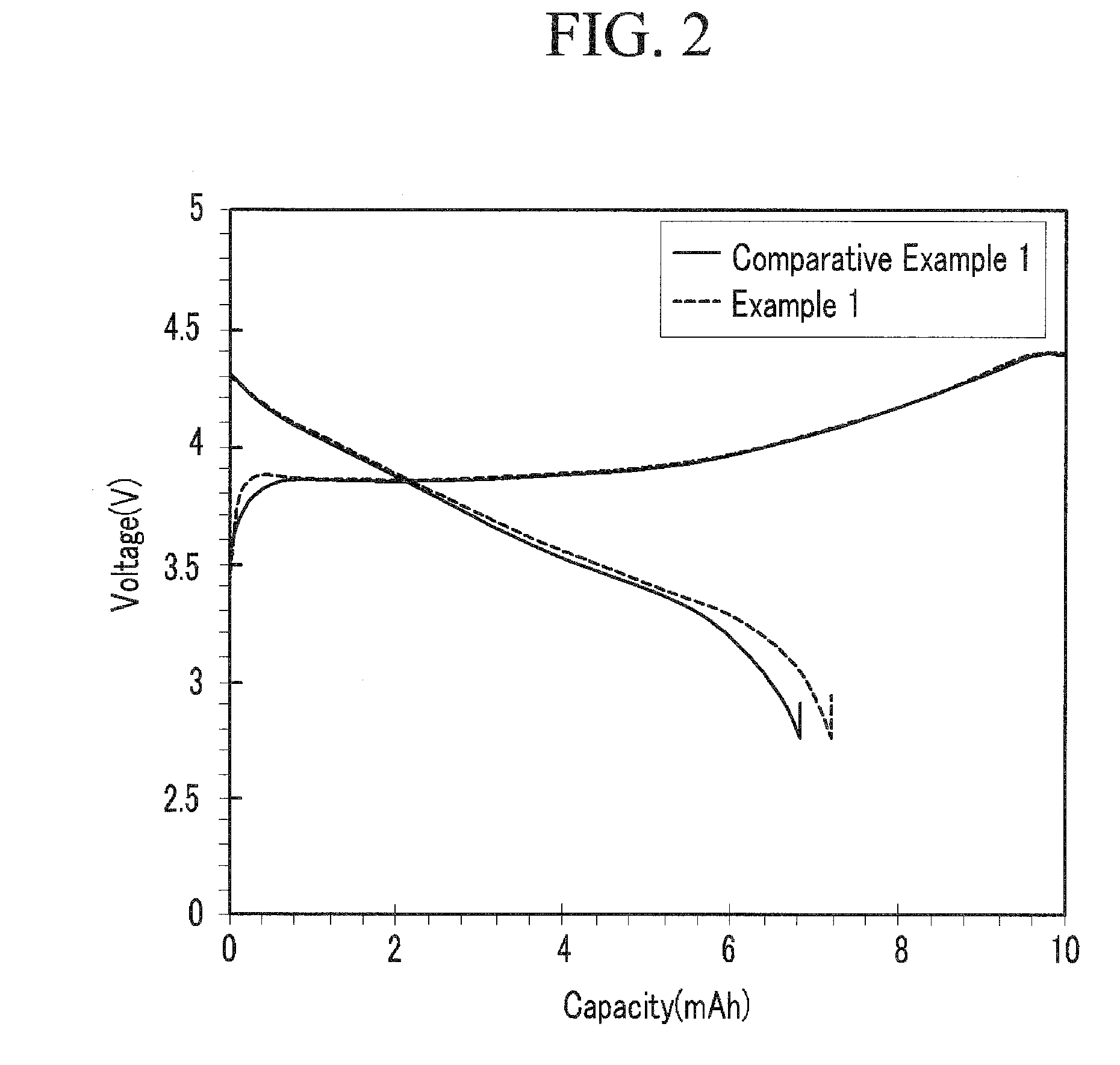

Electrode used for a non-aqueous electrolyte secondary battery and a non-aqueous electrolyte secondary battery using the same for a negative electrode

InactiveUS20050074671A1Increase capacityInsufficient releaseElectrode carriers/collectorsLi-accumulatorsPorosityMetallic materials

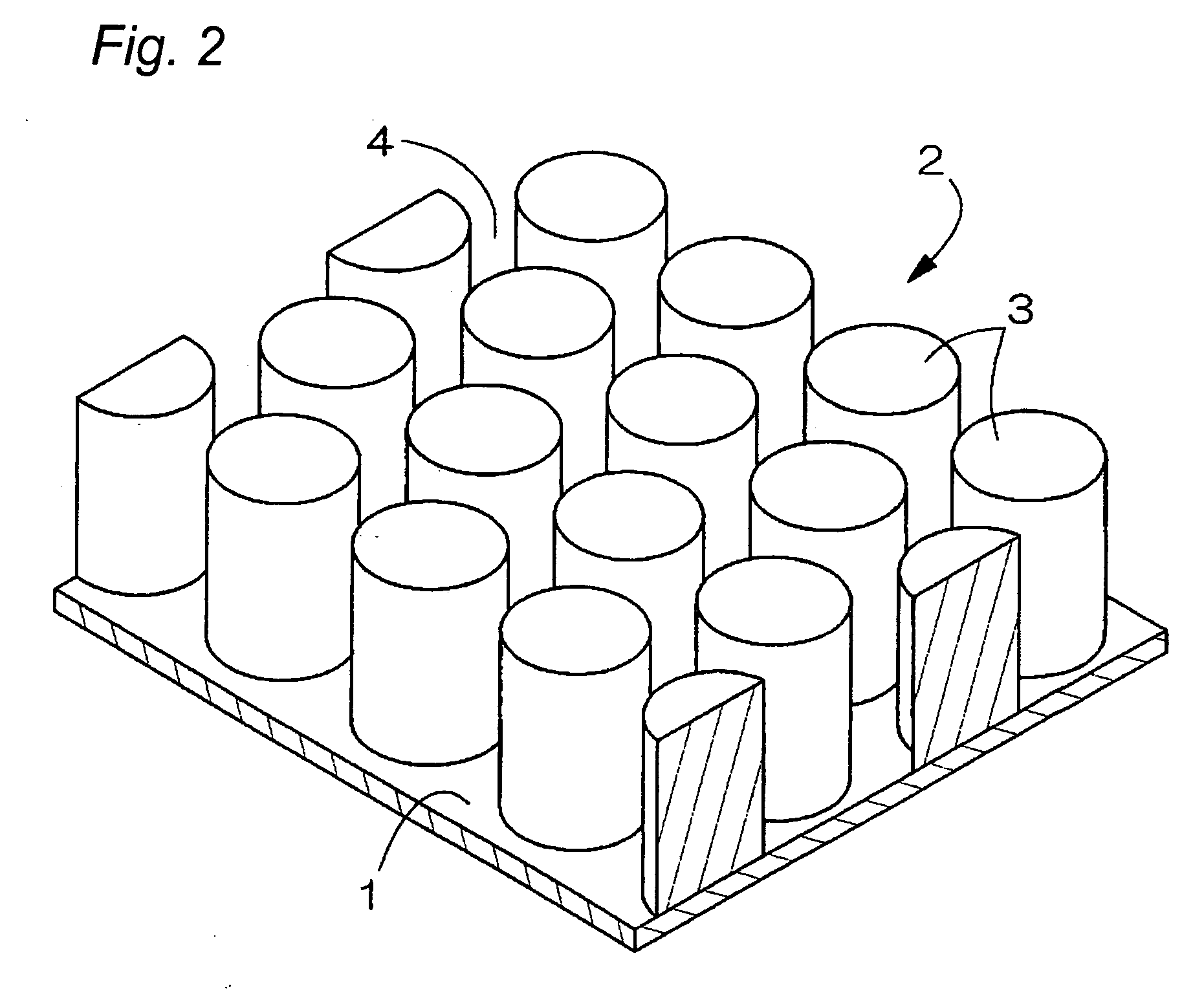

An electrode according to the invention can provide a non-aqueous electrolyte secondary battery having an ability to release a volume expansion at the time of charge and discharge as well as the time of a cycle. The electrode comprises a current collector made of a material which is not alloyed with Li, and a dot pattern 2 of a metallic material able to be alloyed with Li formed on the current collector. At the time of charge, since the volume expansion of each dot 3 is carried out so as to bury adjoining crevices 4 between the dots, a stress generated is released, thereby degradation of an electrode being avoided. Each dot may also be made into porosity.

Owner:HITACHI MAXELL ENERGY LTD

Preparation method of composite lithium metal anode

InactiveCN108365200AReduce chalkingImprove cycle stabilityCell electrodesLi-accumulatorsLiquid metalLithium-ion battery

The invention discloses a preparation method of a composite lithium metal anode and belongs to the technical field of lithium metal batteries. The preparation method of the composite lithium metal anode comprises steps as follows: firstly, the surface of a framework material is modified, the framework material with the lithiophilic surface is prepared, the framework material is contacted with liquid metal lithium, so that the liquid metal lithium is injected into the framework material with the lithiophilic surface, and the composite lithium metal anode is prepared after cooling. The lithiophilic surface can be obtained through modification of various framework materials (including a conductive framework material and an insulated framework material), the framework materials are efficientlycomposited with the liquid metal lithium, and the composite lithium metal anode material is obtained. When the obtained composite lithium metal anode material is assembled in a total battery, growthof lithium dendrites can be effectively inhibited, the volume expansion effect of the anode is relieved, the pulverization phenomenon of the lithium metal anode is reduced, and the cycling stability and the safety of the lithium metal battery are substantially improved, and the cycle life of the lithium metal battery is substantially prolonged.

Owner:TSINGHUA UNIV

Emulsion deep profile/displacement control agent and preparation method of emulsion deep profile/displacement control agent containing gel microspheres of core shell structure

The invention relates to a preparation method of an emulsion deep profile / displacement control agent containing gel microspheres of a core shell structure. According to the method, materials are fed many times to carryout inverse emulsion low-temperature oxidation and reduction to initiate free radical polymerization so that water-solubility monomers (including acrylamide, ionic monomer I, the ionic monomer II and the third monomer) react with a cross-linking agent to generate the emulsion deep profile / displacement control agent containing gel microspheres of a core shell structure. The invention also relates to the emulsion deep profile / displacement control agent containing gel microspheres of a core shell structure, which is prepared by using the method. The profile / displacement control agent is a water-solubility microgel oil displacement material containing gel microspheres from nano scale to micron scale; with small initial grain size, the profile / displacement control agent can enter into the deep part of stratum; in addition, the profile / displacement control agent has high emulsion active component content and good flowability, can have volume expansion and mutual cementation under the actions of formation water and temperature according to the condition whether charges carried by the ionic monomers at a core layer and a shell layer are same or not; therefore the profile / displacement control requirements of different geological oil deposits of oil fields can be met.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Chemically attached coaxial connector

ActiveUS7331820B2Increase volumeOptimize volumeRelieving strain on wire connectionSoldered/welded conductive connectionsCoaxial cableChemical composition

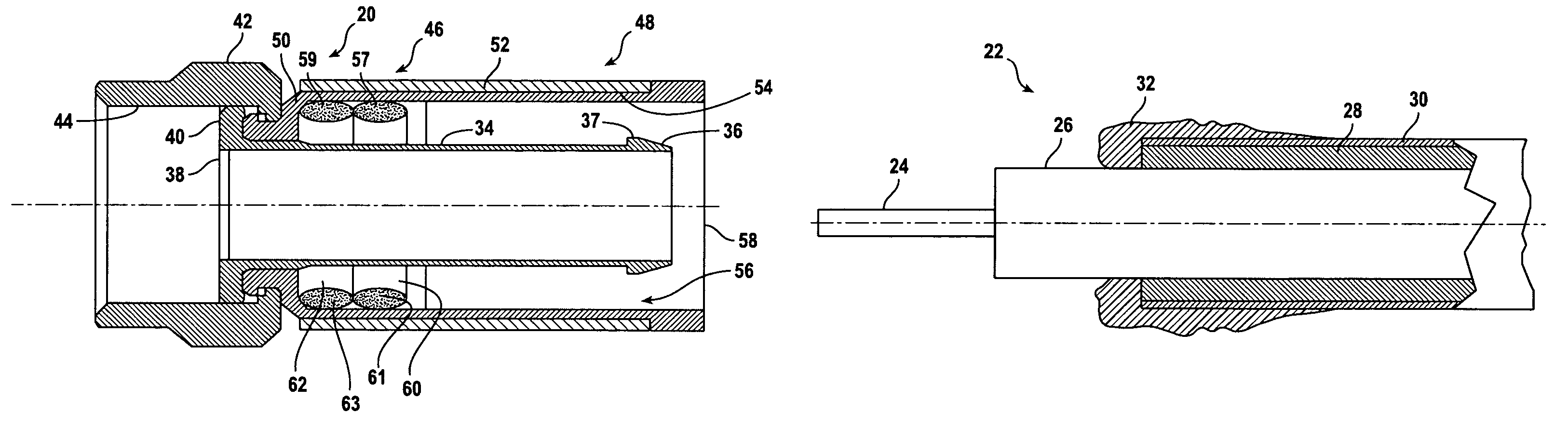

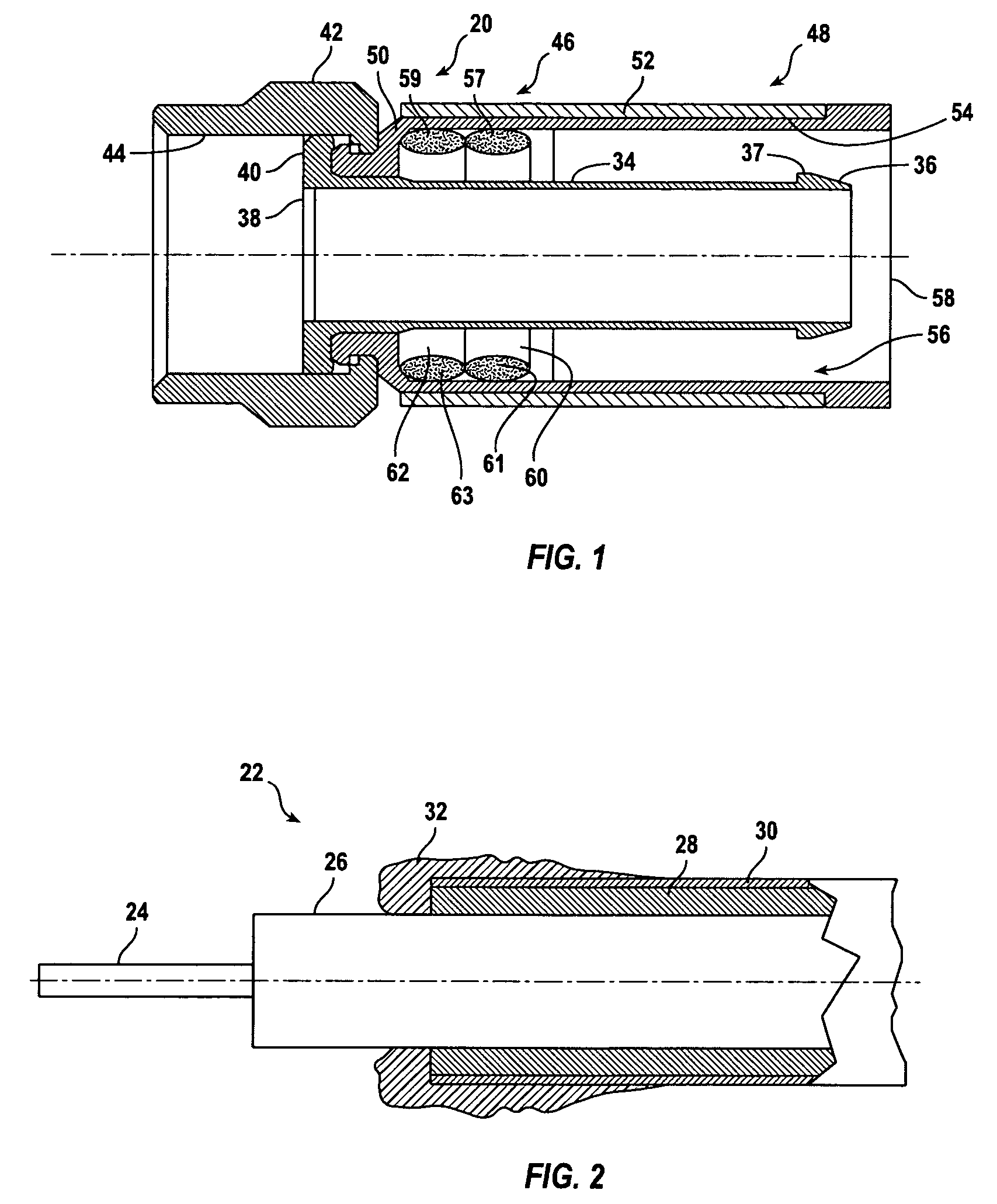

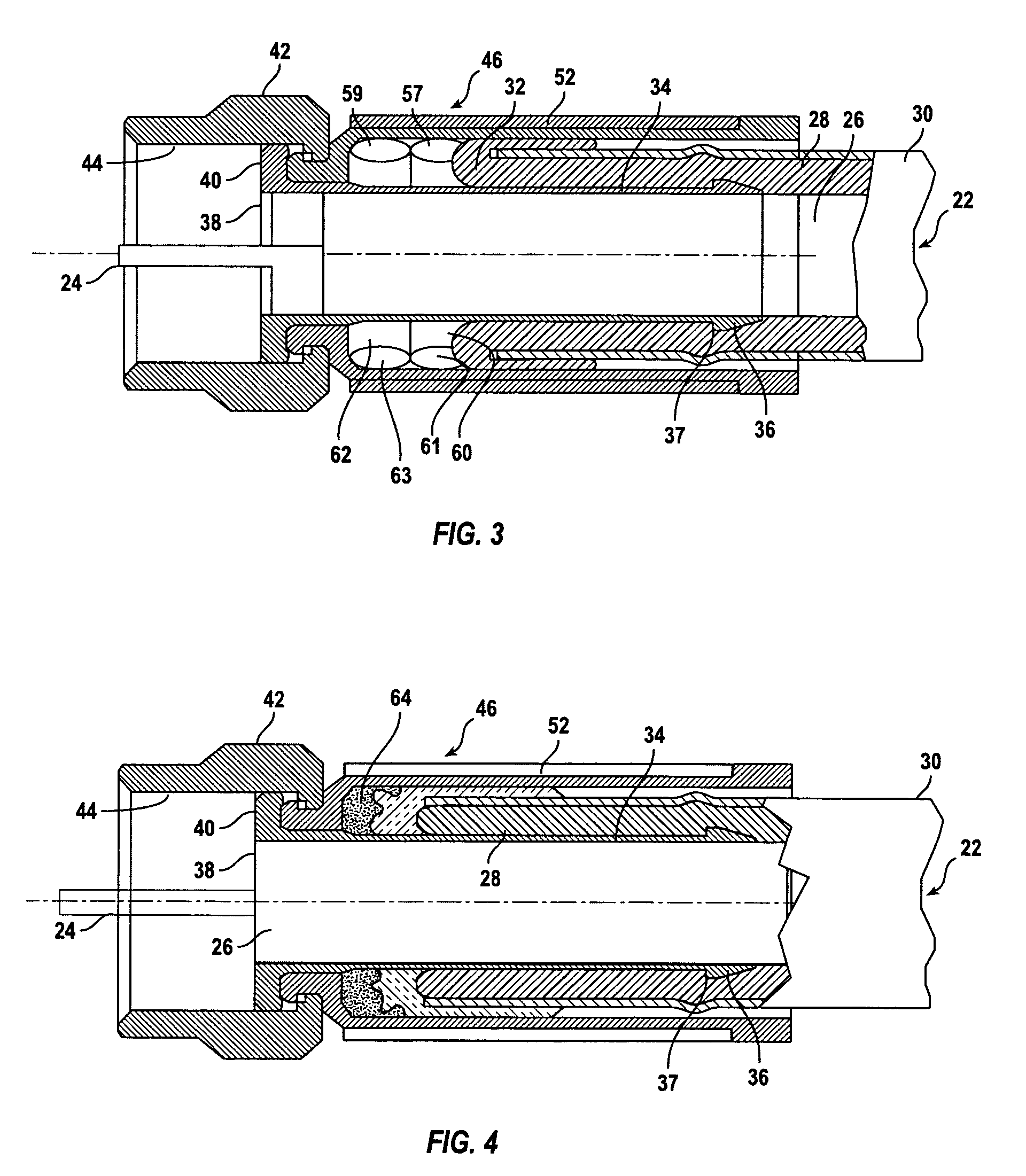

A coaxial connector for attaching the end of a coaxial cable to an equipment port includes a tubular post, a coupler, a body member having a cylindrical sleeve, and one or more reservoirs containing a chemical component disposed between the post and the cylindrical sleeve. Insertion of the coaxial cable into the connector opens the reservoir, releases the chemical component, and secures the jacket of the cable within the cylindrical sleeve. The chemical component(s) can include an adhesive, a volume-expanding material, and / or an agent that swells the jacket of the cable. Two or more chemical components may be stored in two or more adjacent reservoirs.

Owner:PPC BROADBAND INC

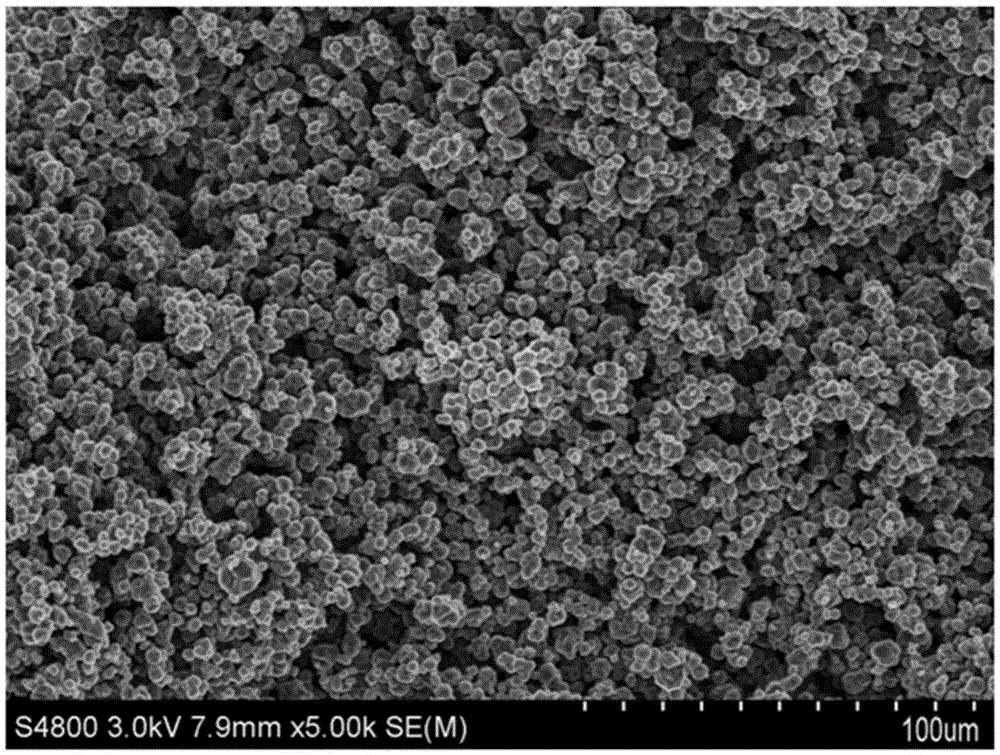

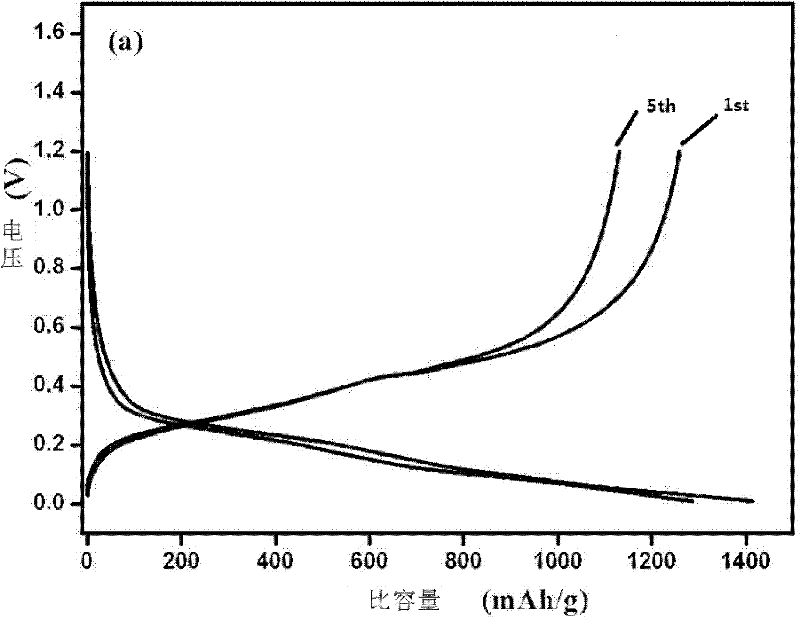

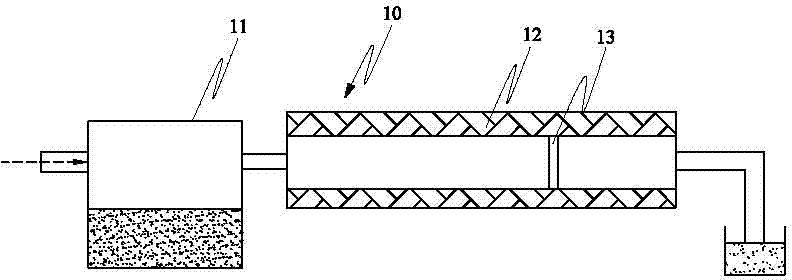

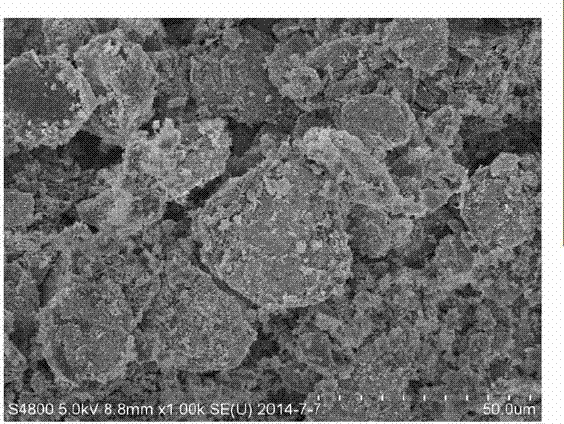

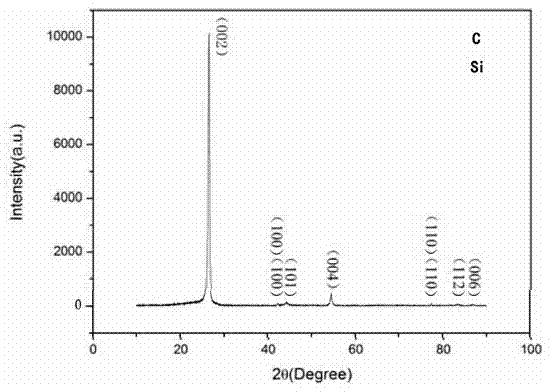

Composite silicon negative electrode material, and preparation method and application thereof

ActiveCN105406050AGood electrical conductivityIncrease capacitySiliconElectrode thermal treatmentCarbon layerLithium

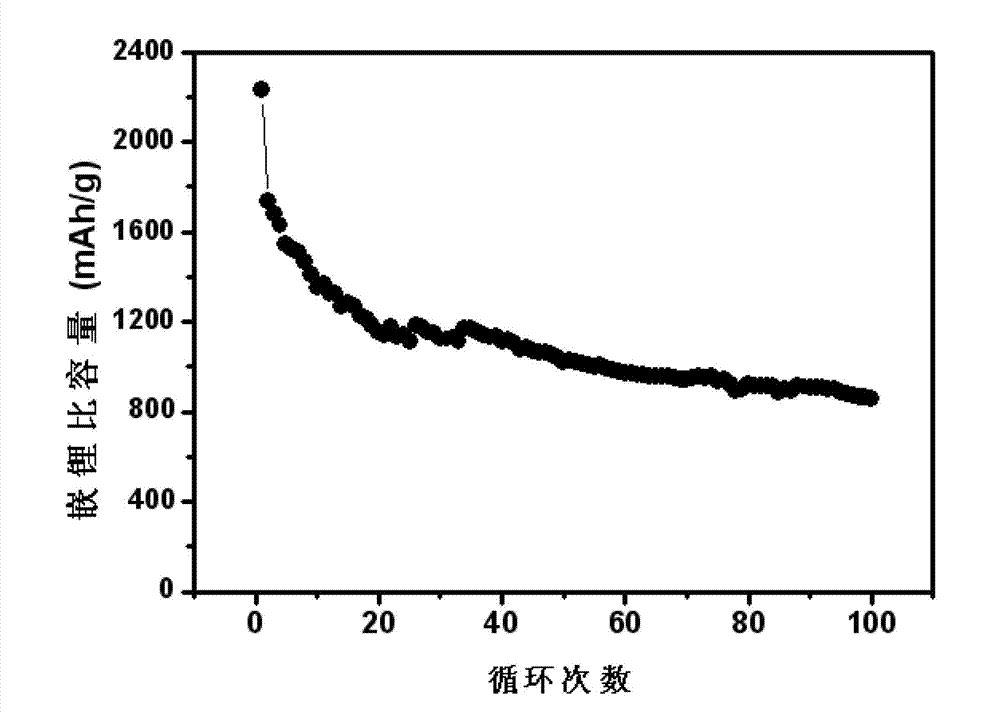

The invention relates to a composite silicon negative electrode material. The composite silicon negative electrode material comprises nanometer silicon, a nanometer composite layer coating the surface of nanometer silicon and a conductive carbon layer uniformly coating the nanometer composite layer, wherein the nanometer composite layer is silicon oxide and metal alloy. According to the composite silicon negative electrode material with a three-layer structure, the nanometer composite layer composed of the silicon oxide and the metal alloy coating the surface of the silicon oxide effectively reduces volume expansion of the nanometer silicon, maintains the characteristic of high conductivity of the silicon material, improves mobility of lithium ions, prevents direct contact between a silicon negative electrode and an electrolyte, and can form a hard SEI film on the surface of the composite silicon negative electrode material, thereby allowing the cycle performance of the material to be substantially enhanced. The composite silicon negative electrode material has the characteristics of high capacity (greater than 1500 mAh / g), long cycle life (with a capacity retention ratio of more than 90% after 300 cycles) and high conductivity. The preparation method for the composite silicon negative electrode material is simple, easily controllable, and applicable to industrial production.

Owner:DINGYUAN NEW ENERGY TECH CO LTD

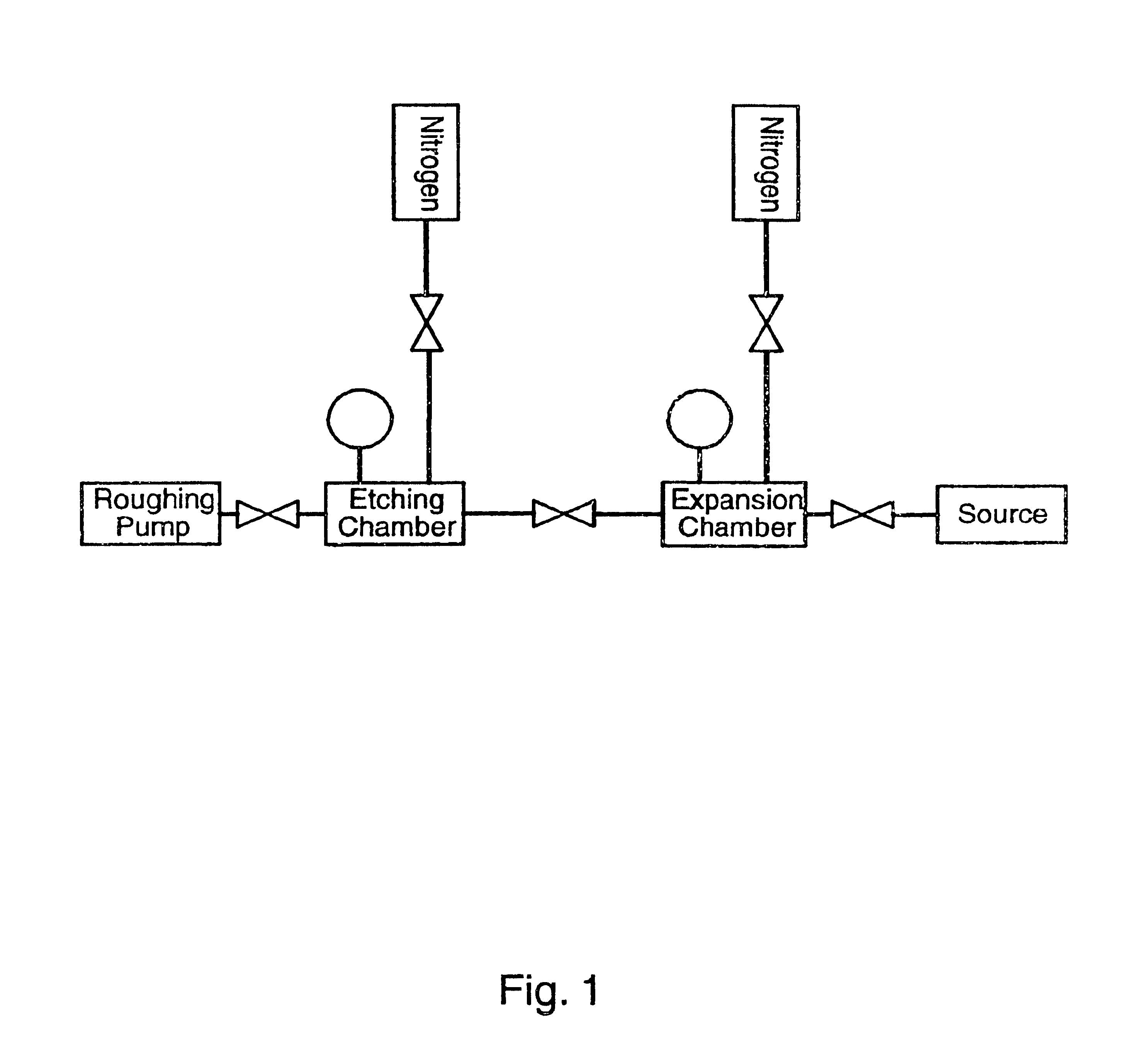

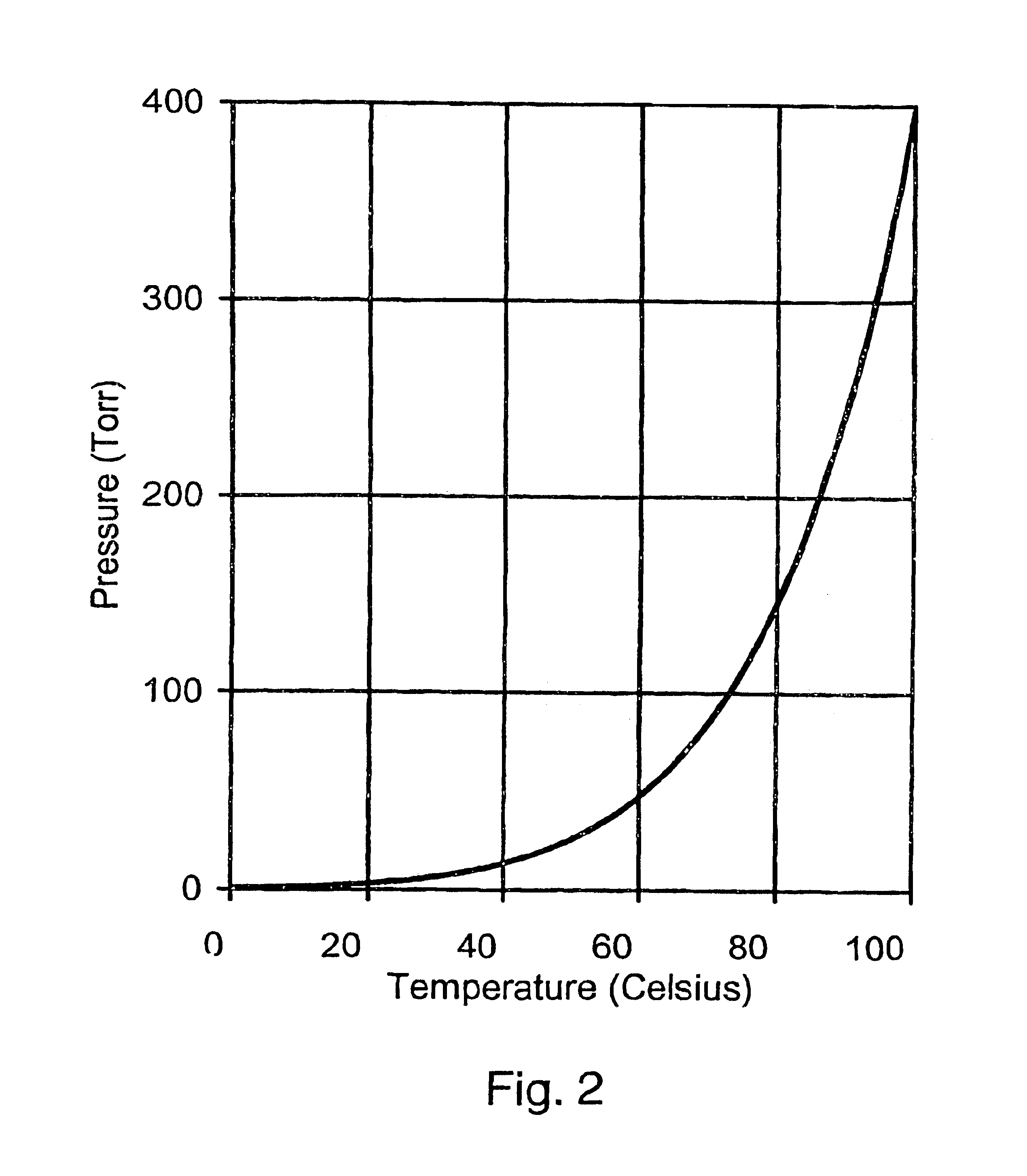

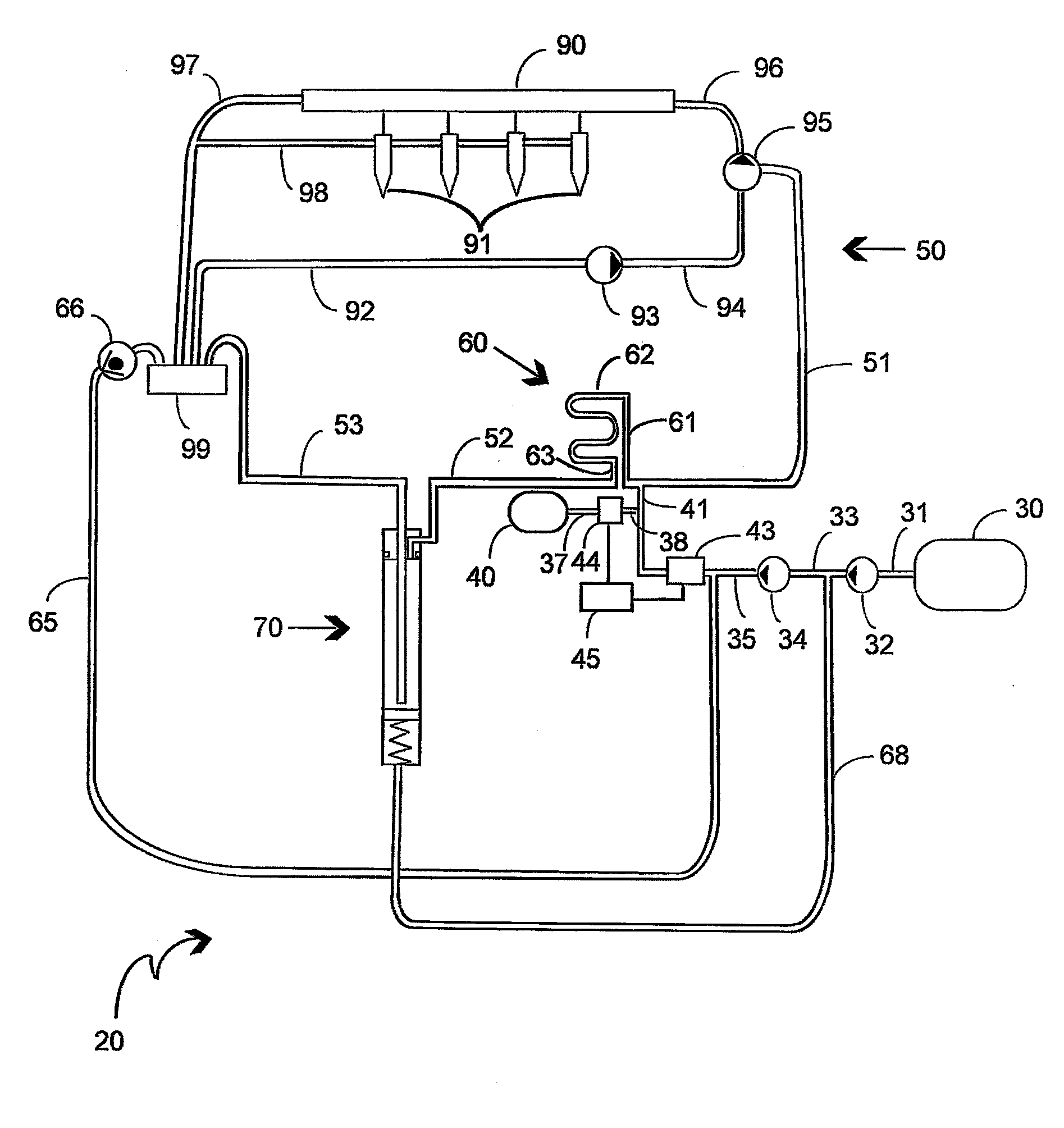

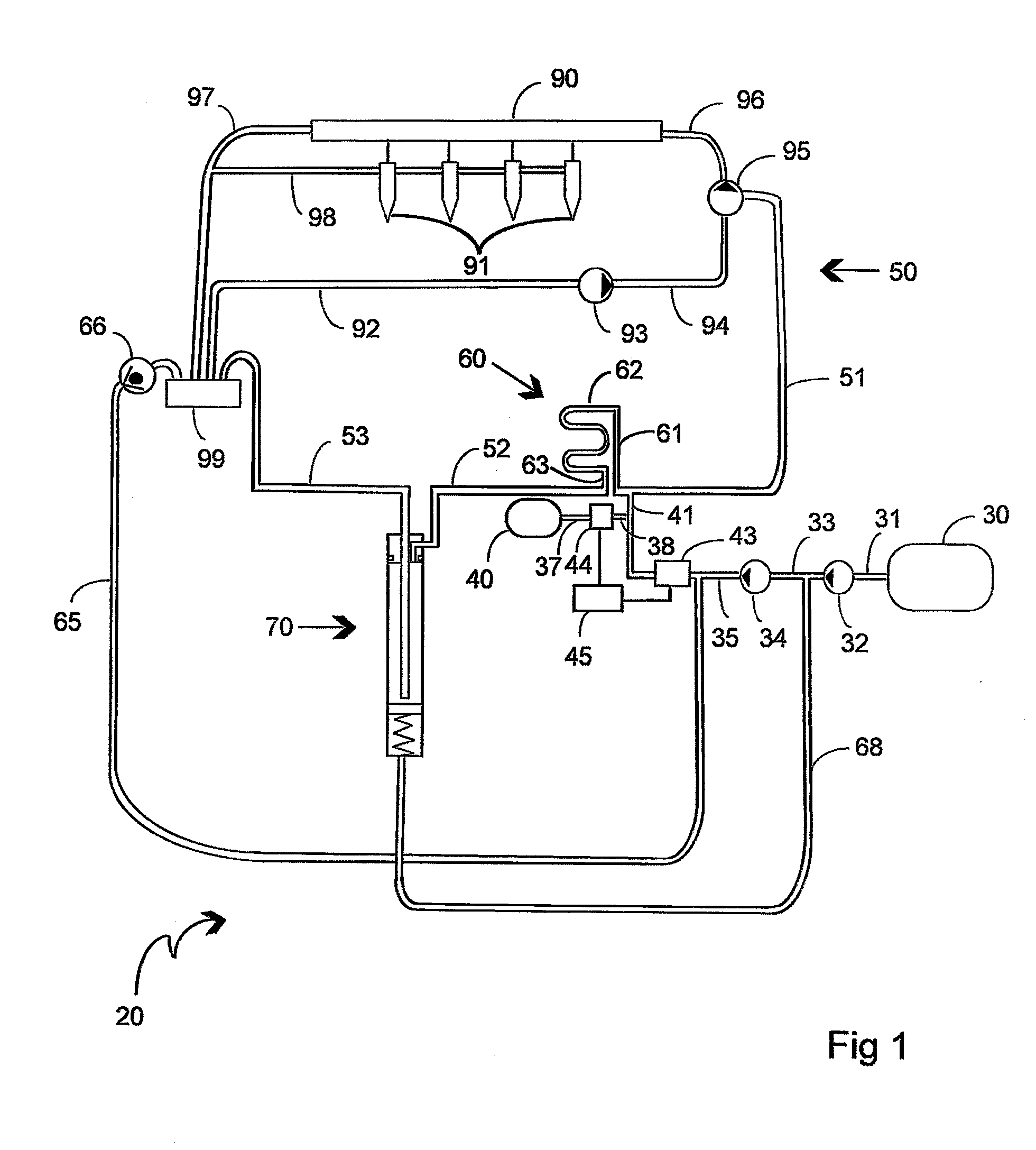

Apparatus for etching semiconductor samples and a source for providing a gas by sublimation thereto

An etching apparatus for etching semi combustion samples may include one or more variable volume expansion chambers, two or more fixed volume expansion chambers, or combinations thereof in fluid communication with an etching chamber and a source of etching gas, such as xenon difluoride. The apparatus may further include a source of a mixing gas. An etching apparatus may also include a source of etching gas, an etching chamber in fluid communication with the source of etching gas, a flow controller connected between the source of etching gas and the etching chamber, and a vacuum pump in fluid communication with the etching chamber. A source for providing a gas by sublimation from a solid material is also provided, including a vacuum tight container and a mesh mounted in the interior of the vacuum tight container, wherein the mesh is adapted to receive and restrain the solid material.

Owner:SPTS TECH LTD

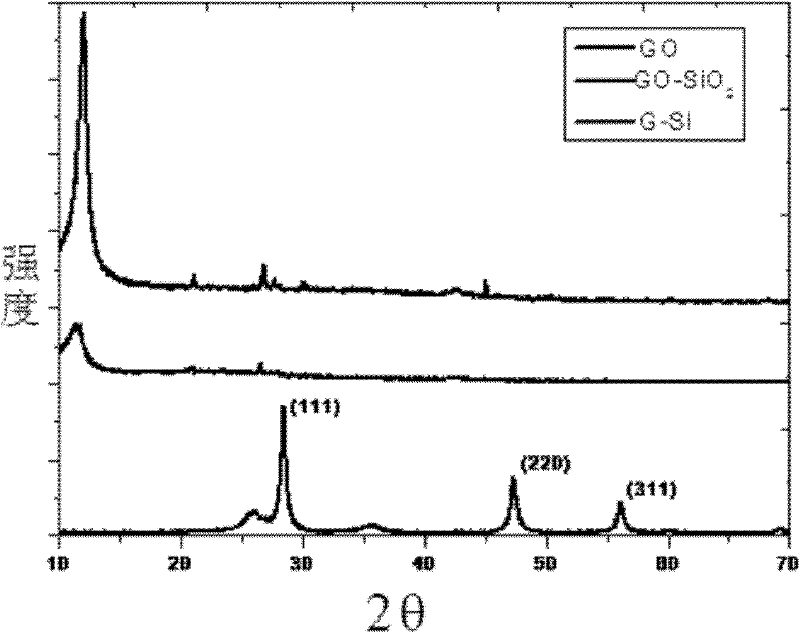

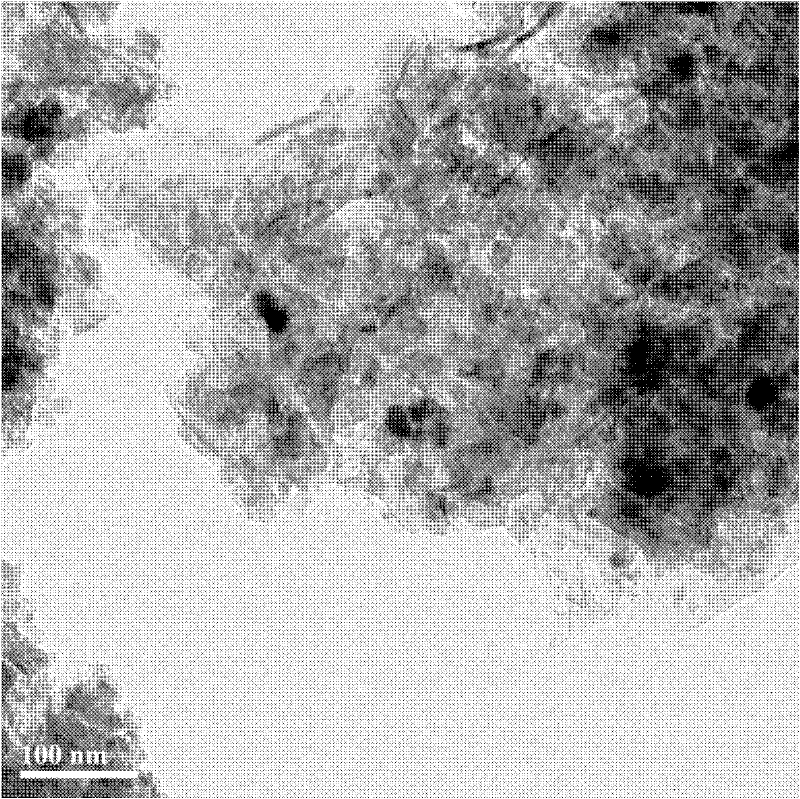

Preparation method of silicon/graphene nanocomposite material for cathode of lithium ion battery

ActiveCN102569756ASimple methodRaw materials are easy to obtainMaterial nanotechnologySilicaGraphene nanocompositesSodium-ion battery

The invention relates to a preparation method of a silicon / graphene nanocomposite material for a cathode of a lithium ion battery, which comprises the steps of: preparing oxidized graphite; preparing a silica / graphene nanocomposite material under the existence of a surfactant; then preparing the silicon / graphene nanocomposite material for the cathode of the lithium ion battery through the magnesiothermic reduction reaction. Compared with the prior art, the graphene in the composite material, prepared by the invention, can better inhibit volumetric expansion of silicon material in the insertion and separation process of lithium ions so as to improve the circulating performance of the composite material greatly, so that the volume of the material after 30 circulations under the current of 200mA / g is still maintained to be above 1100mAh / g.

Owner:SHANGHAI JIAO TONG UNIV

Lithium ion battery silicon-carbon composite negative material and its preparation method

ActiveCN104332613AGood electrical contactShorten the diffusion pathElectrode manufacturing processesCarbon compositesGas phase

The invention discloses a lithium ion battery silicon-carbon composite negative material and its preparation method. A one-step coating granulation technology is adopted to disperse nanometer silicon powder in a three-dimensional conductive network formed by graphene in order to maintain close contact between the nanometer silicon powder and graphene, shorten the diffusion path of lithium ions and ensure no deprivation of electron conduction of the electrode material. Graphite with very high toughness can buffer the volume expansion of silicon in the charge and discharge process, and amorphous carbon formed through gas phase coating can maintain the stable structure of the material, so the lithium ion battery silicon-carbon composite negative material has excellent cycle performances and rate performances. The preparation method of the lithium ion battery silicon-carbon composite negative material has the advantages of simplicity, high efficiency, few steps and high yield, is suitable for large-scale industrial production.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Lithium-alloying-material/carbon composite

ActiveUS8361659B2Avoid damageSecondary cellsNon-aqueous electrolyte accumulator electrodesCarbon compositesLithium

An electrode material having carbon and lithium-alloying-material is provided. The carbon is in the form of a porous matrix having nanoporosity and the lithium-alloying-material is sorbed into the nanoporosity of the carbon matrix. The carbon matrix can have a volume of nanoporosity between 10 and 99%. In addition, the lithium-alloying-material can occupy between 5 to 99% of the nanoporosity. A portion of the carbon structure that is only partially filled with the lithium-alloying-material remains vacant providing room for volume expansion on alloying with lithium and allowing electrolyte egress. In some instances, the nanoporosity has nanopores and nanochannels with an average diameter between 1 nanometer and 999 nanometers. The lithium-alloying-material is sorbed into the nanoporosity using liquid transport or other mechanisms providing a material having intimate contact between the electronically conductive carbon structure and the electroactive lithium-alloying-material.

Owner:TOYOTA MOTOR CO LTD

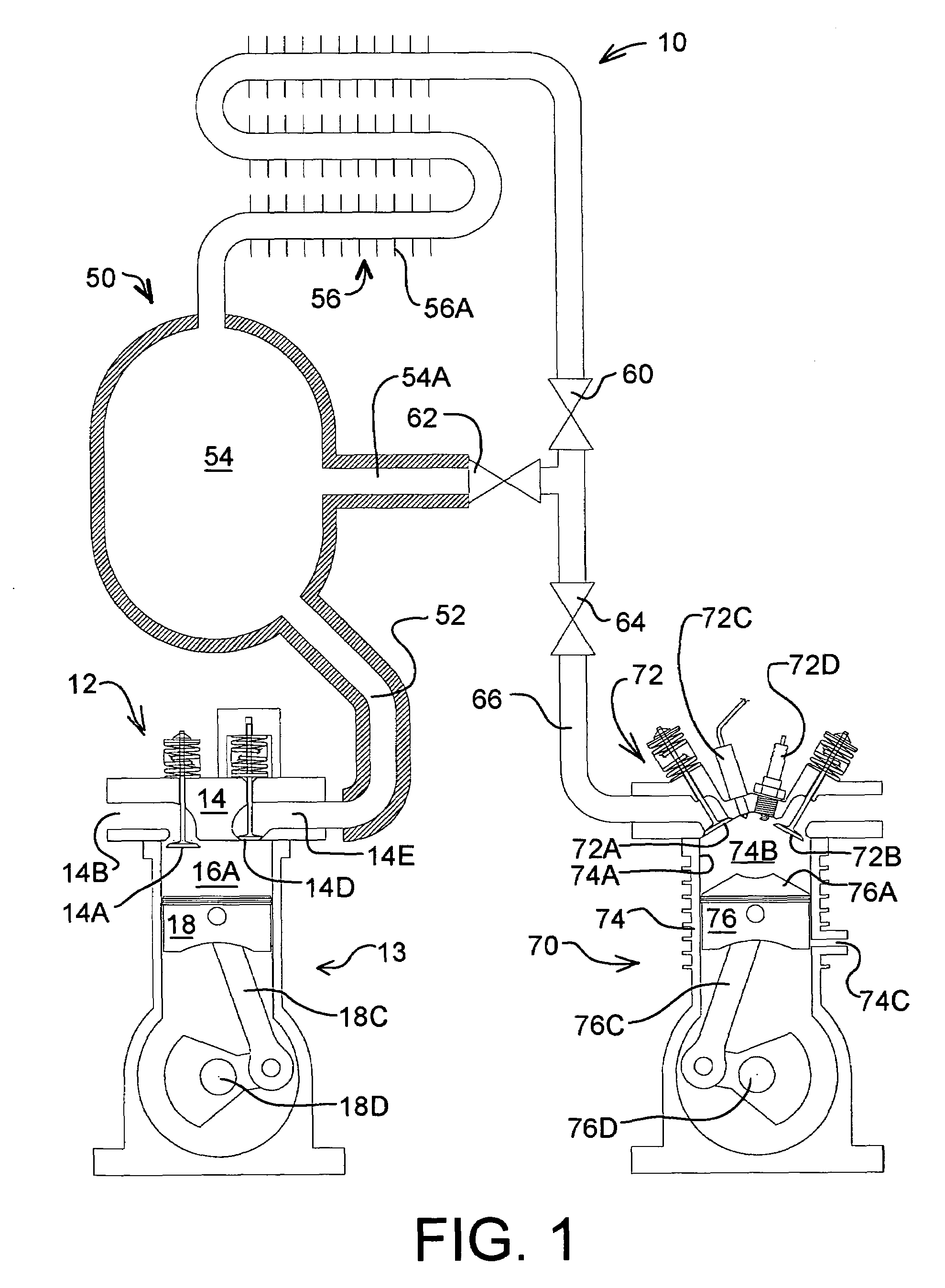

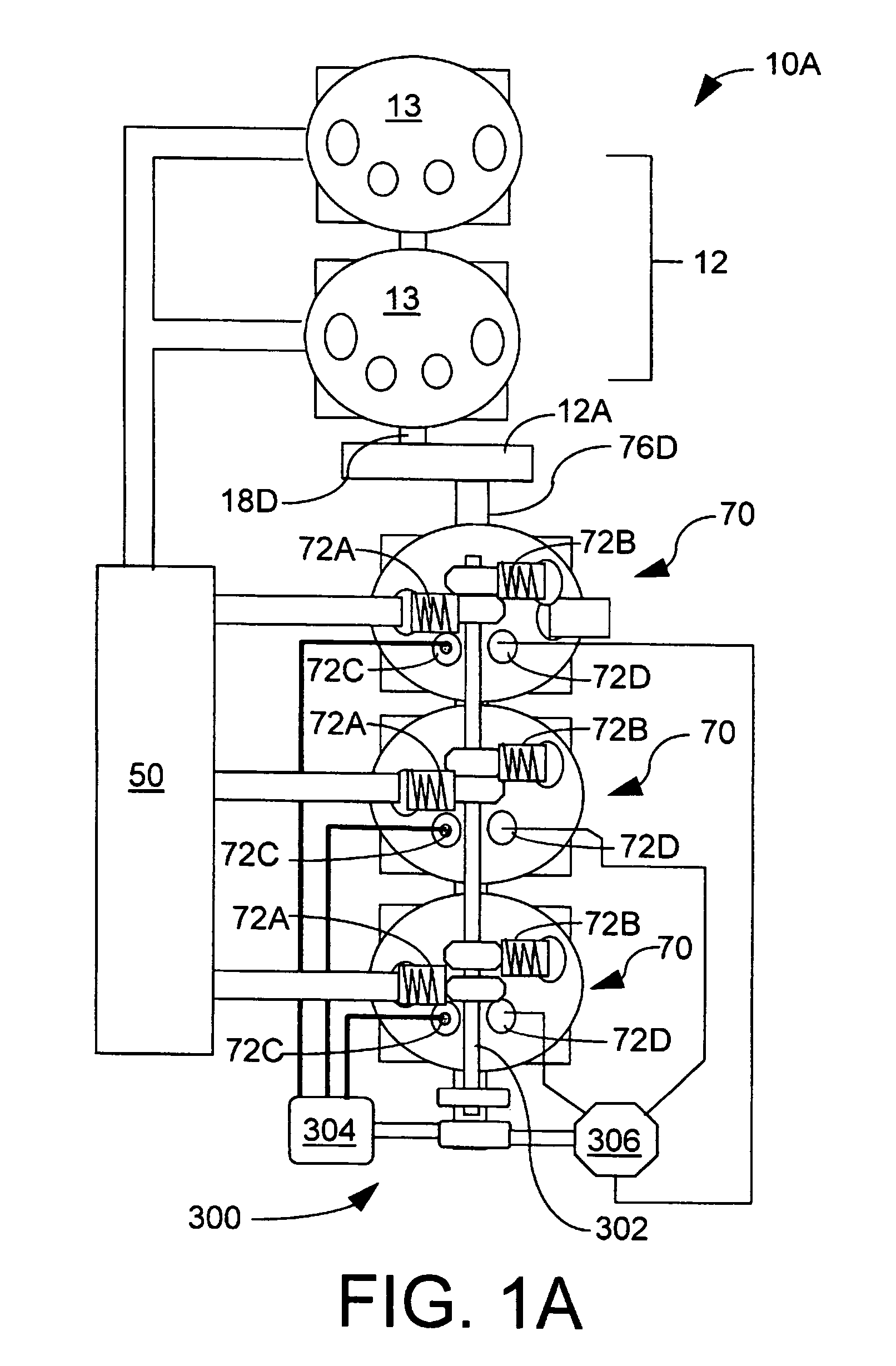

Homogenizing fuel enhancement system

A homogenizing fuel enhancement system involves at least one circulation loop existing outside of the injection system for continuously circulating and maintaining the homogeneity of a multi-fuel mixture apart from any demands by or delivery to the engine's injection system (whether mechanical injection or a common rail), and at least one infusion tube configured within the at least one circulation loop for providing a volumetric expansion wherein the fuel mixture is infused and thereby rendered more homogeneous.

Owner:EXEN HLDG

Geopolymeric concrete based on recycled aggregate and preparation method of geopolymeric concrete

InactiveCN103601424AReduce consumptionImprove thermal stabilitySolid waste managementCement productionAdhesiveRoad surface

The invention relates to geopolymeric concrete based on recycled aggregate, and a preparation method of the geopolymeric concrete. The concrete is prepared by taking construction waste as aggregate and inorganic geopolymer as an adhesive through an alkali activation process. The recycled aggregate geopolymeric concrete prepared by using the method has the characteristics that the concrete can be rapidly dried, the compressive strength, particularly the early-stage compressive strength is high, the volume shrinkage in the coagulation process is extremely low, the coefficient of volume expansion is approximate to 0, and acid-base corrosion resistance is good. Due to the adoption of the method, the defects that the conventional concrete is low in early-stage strength and the coagulation time is long are overcome; a method for rapidly repairing concrete pavement is provided, and problems of recycling and reusing construction waste aggregate and environment problems caused by the construction waste aggregate are solved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Solid-state composite metal lithium negative electrode

InactiveCN108511708AIncrease profitAlleviate volume expansionCell electrodesLi-accumulatorsSolid state electrolyteSpray coating

The invention provides a solid-state composite metal lithium negative electrode. The solid-state composite metal lithium negative electrode consists of a composite layer and a solid-state electrolyteprotecting layer, wherein the composite layer consists of metal lithium and lithium-favoring framework material; the solid-state electrolyte protecting layer comprises an inorganic solid-state electrolyte and an organic solid-state electrolyte; the composite layer of metal lithium and lithium-favoring framework material is provided by melting and lithium filling, electrochemical deposition or physical and mechanical mixing; the solid-state electrolyte protecting layer is applied to the surface of the composite layer by impregnating, scrape coating, rotary coating, spray coating or spattering.Compared with the common lithium piece negative electrode, the solid-state composite metal lithium negative electrode has the advantages that the problem of volume expansion of the negative electrodeis relieved, the deposition behavior of the metal lithium can be regulated and controlled, the growth of lithium dendrites can be inhibited, the safety property of a metal lithium battery is improved,and the cycle life of the metal lithium battery is prolonged; in the testing process of a lithium and copper semi-battery, the volume is expanded by 1 to 20% in the charge and discharge process, theobvious dendrites do not occur in the 20 to 5000 cycles of the battery, and the utilization rate is increased to 80 to 99.9999%.

Owner:TSINGHUA UNIV

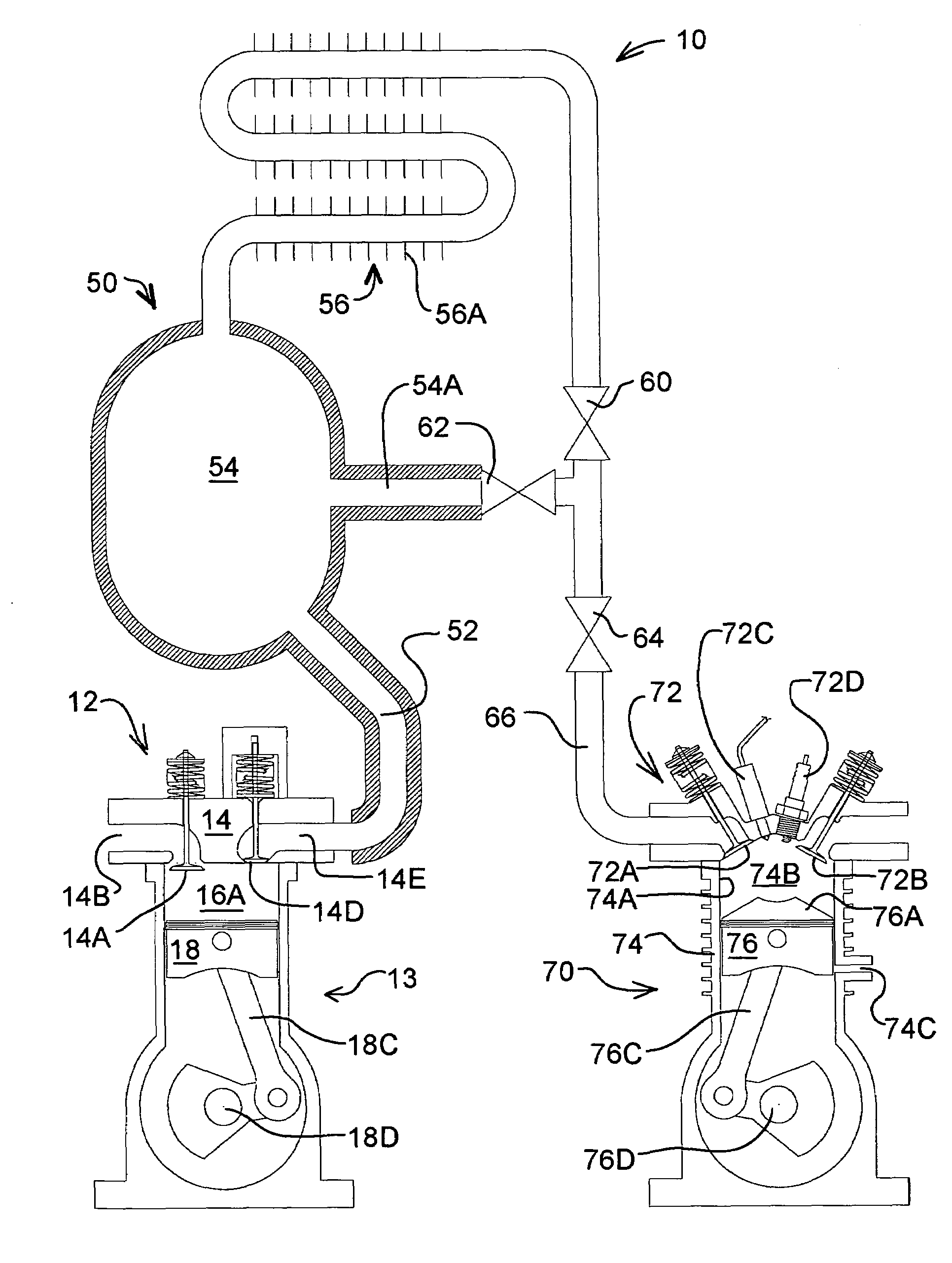

Air injection engine

InactiveUS7007639B1Improve power densityHigh expansion rateInternal combustion piston enginesOutput powerCombustionExternal combustion engine

An internal combustion engine of the present invention features separate compression and expansion cycles. The engine includes a separate compressor device which pressurizes air by a ratio greater than 15 to 1, at least one two stroke combustion cylinder and a compressed air conduit for transferring compressed air from the compressor to the at least one combustion cylinder. An air injection valve injects the compressed air into the combustion cylinder during the second half portion of the return stroke of the combustion cylinder. The compressed air is mixed with fuel and combusted for expansion during a power stroke. In this engine compression occurs only to a minor degree in the combustion cylinder. Accordingly, the compression ratio of the present engine may be significantly higher or lower than the volumetric expansion ratio of the combustion cylinder thus resulting in corresponding increases in either power density or thermodynamic efficiency respectively.

Owner:D J ENG

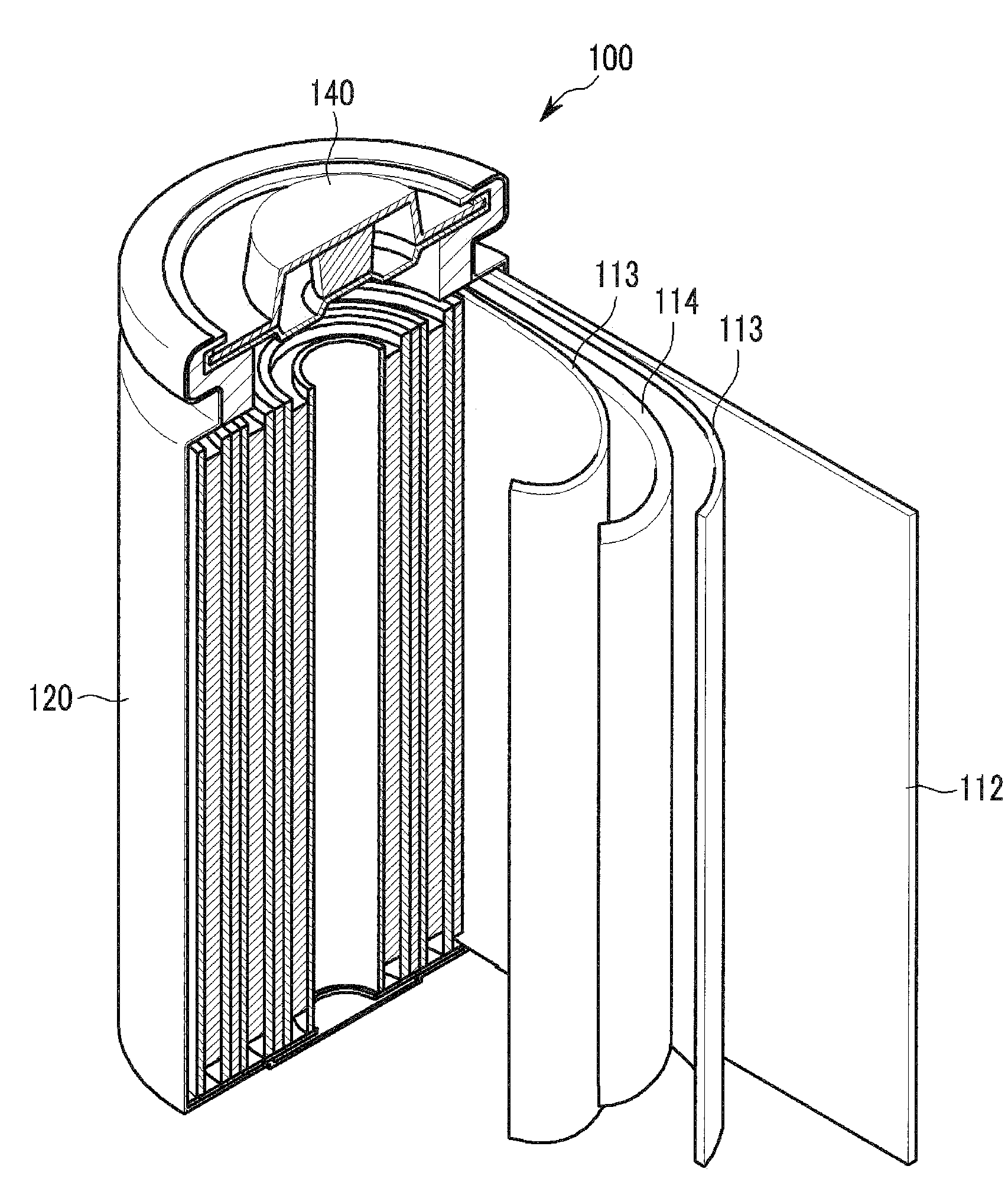

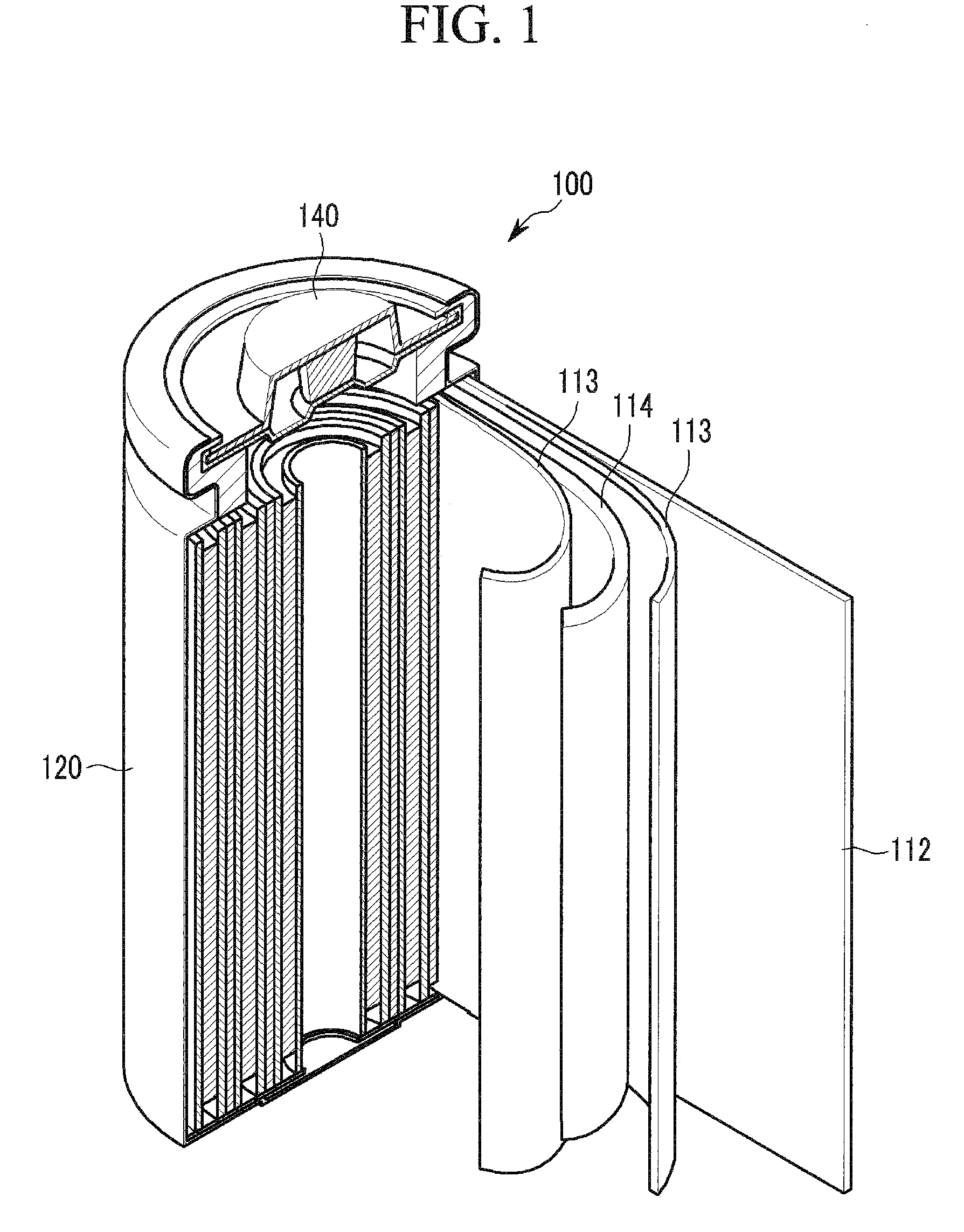

Negative electrode for rechargeable lithium battery, and rechargeable lithium battery including the same

ActiveUS20090136845A1Improved initial formation efficiency and cycle-life characteristicImproved cycle life characteristicsNon-fibrous pulp additionElectrode thermal treatmentCross-linkEngineering

A negative electrode for a rechargeable lithium battery and a rechargeable lithium battery including the same are provided. The negative electrode for a rechargeable lithium battery includes a current collector, and a negative active material layer on the current collector. The negative active material layer includes an interpenetrating network network, and a negative active material in the interpenetrating network network. The interpenetrating network is formed by cross-linking a first polymer having a hydroxyl or amine group and a second polymer having a carboxylic acid group. The negative electrode for a rechargeable lithium battery minimizes volume expansion and imparts good cycle-life characteristics and initial formation efficiency.

Owner:SAMSUNG SDI CO LTD

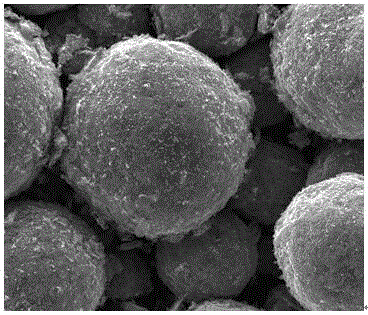

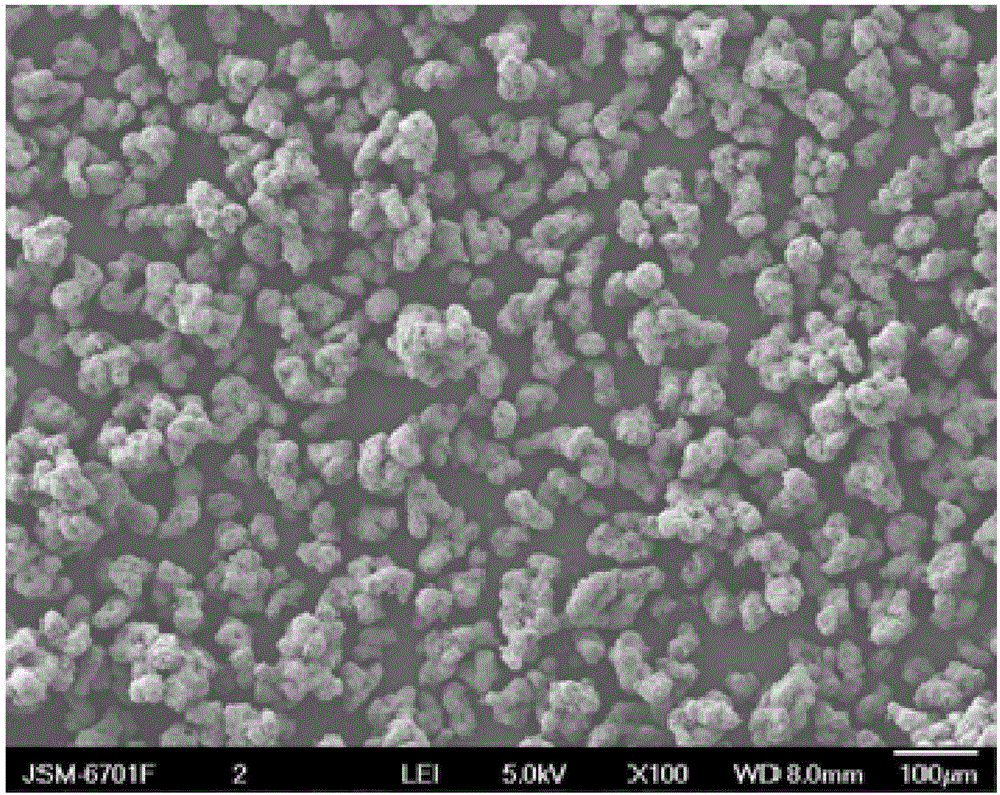

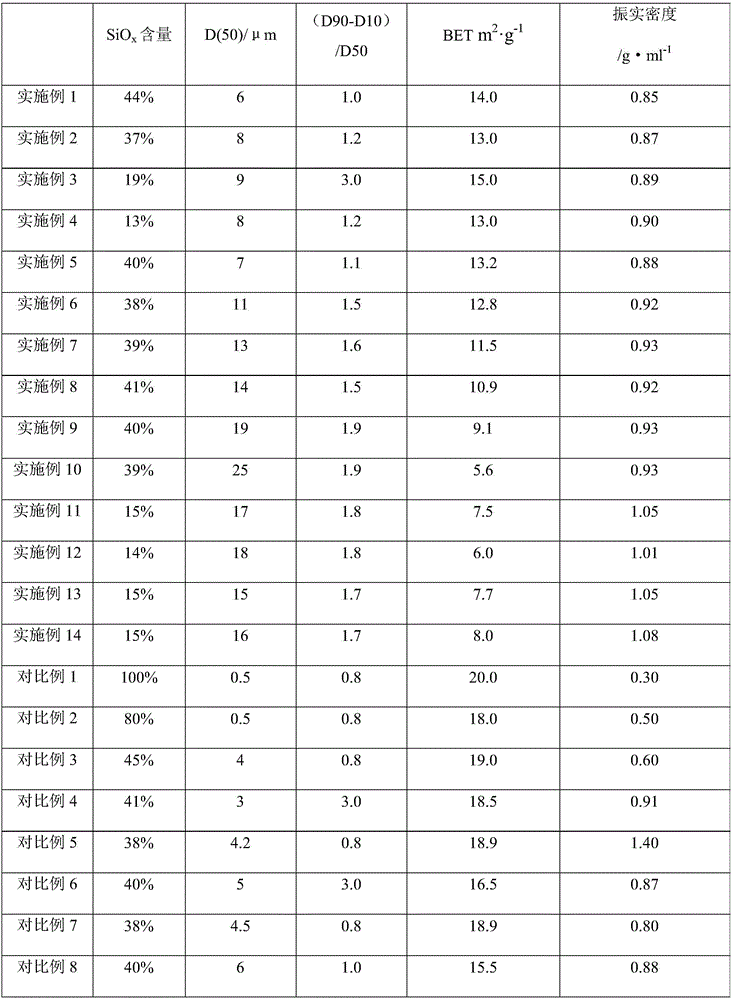

Spherical porous silicon/carbon composite material as well as preparation method and application thereof

InactiveCN106711461AHigh specific capacityPromote circulationCell electrodesCarbon compositesAdhesive

The invention discloses a spherical porous silicon / carbon composite material as well as a preparation method and application thereof. The spherical porous silicon / carbon composite material is structurally characterized in that a SiOx / C matrix, graphite with small particle size and a conductive agent are dispersed in porous amorphous carbon, wherein the average particle diameter is 12-25mu m; the method comprises the following steps of carrying out first coating on a SiOx raw material with powder pitch, and performing heat treatment so as to obtain a SiOx / C material; then performing ball milling by use of a wet method so as to reduce the particle diameter of powder, adding a carbon source adhesive, the graphite with the small particle diameter and the conductive agent, and performing high-speed dispersion, thereby obtaining pulp; and finally performing spray granulation and sintering on the pulp, thereby obtaining the final spherical porous silicon / carbon composite material. According to the invention, SiOx is dispersed in cracking carbon, the graphite and the conductive agent, so that SiOx volume expansion during a charge / discharge process is buffered, and the conductibility is enhanced; by virtue of the porous structure, the imbibition rate and cycle performance of the material can be effectively improved; by virtue of bitumencarb coating and high-heat treatment performed in advance, SiOx is prevented from being directly contacted with an electrolyte, and furthermore, the stability and first efficiency of the silicon / carbon material are improved.

Owner:ZHONGTIAN ENERGY STORAGE TECH

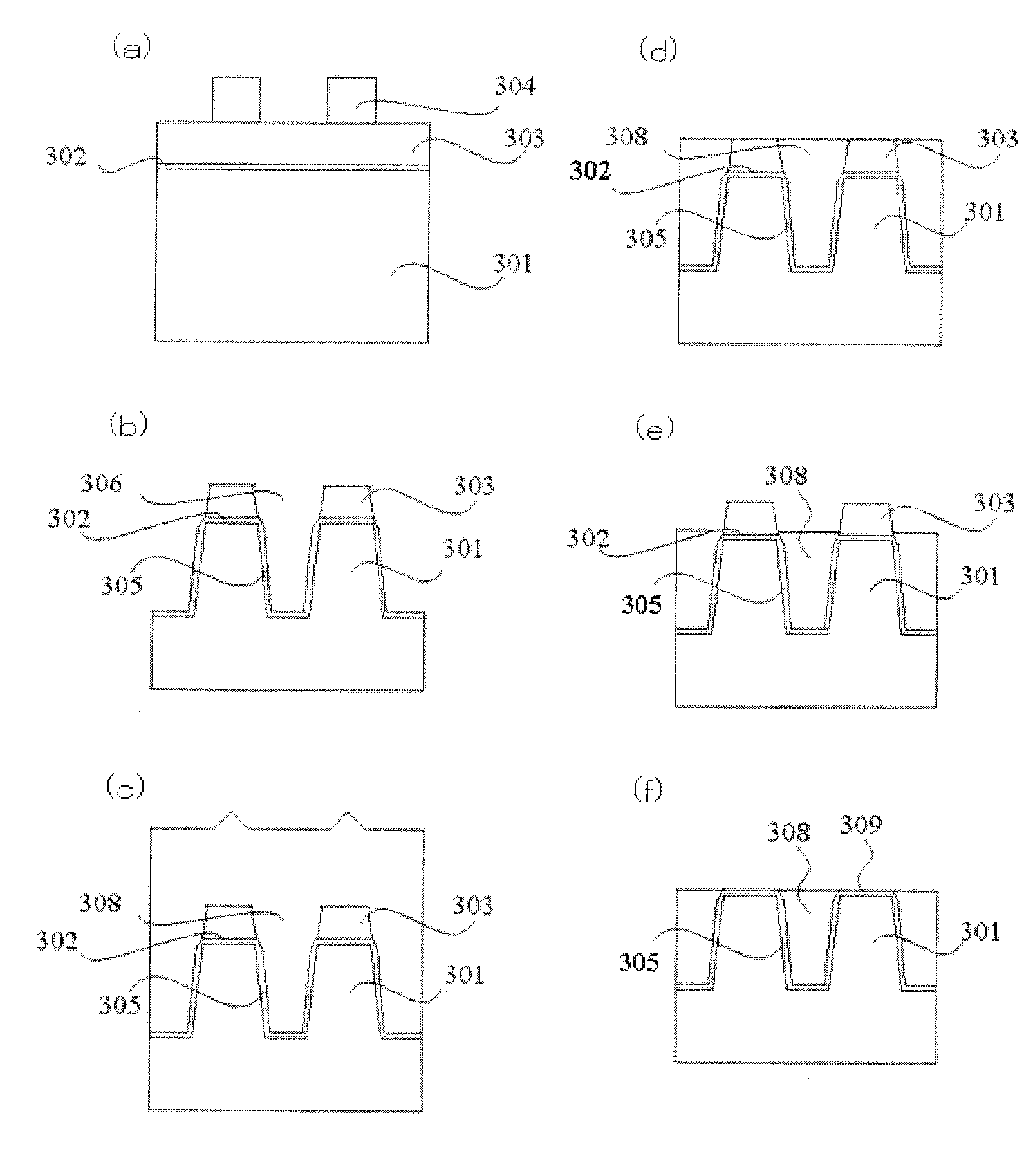

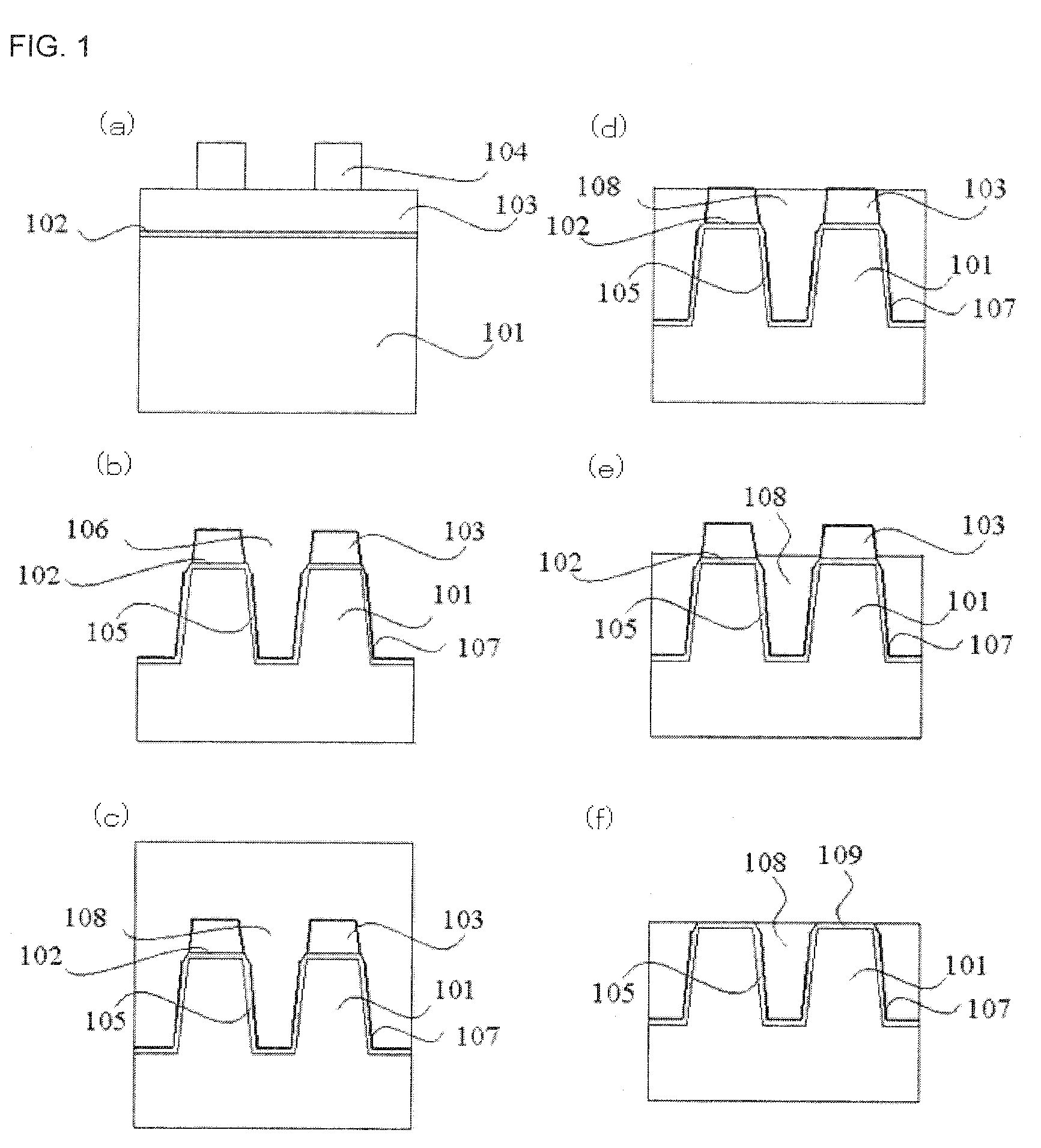

Coating composition for forming oxide film and method for producing semiconductor device using the same

InactiveUS20080305611A1Increase ratingsSuppress the volume expansion coefficientSemiconductor/solid-state device manufacturingCoatingsDielectricPolysilane

A coating composition for forming an oxide film, which can suppress the phenomenon of an increased wet etching rate caused by a part of the SOG film embedded inside a groove becoming low-density, and which can suppress the volume expansion coefficient to a low level, and a method for producing a semiconductor device using the same are provided. An oxide film is formed inside a groove by: coating a coating composition for forming an oxide film, which contains a polysilazane or a hydrogenated silsesquioxane, and a polysilane, on a substrate having a groove; and thereafter heat treatment in an oxidizing atmosphere. This method is suitable for forming a device isolation region and a wiring interlayer dielectric film.

Owner:ELPIDA MEMORY INC

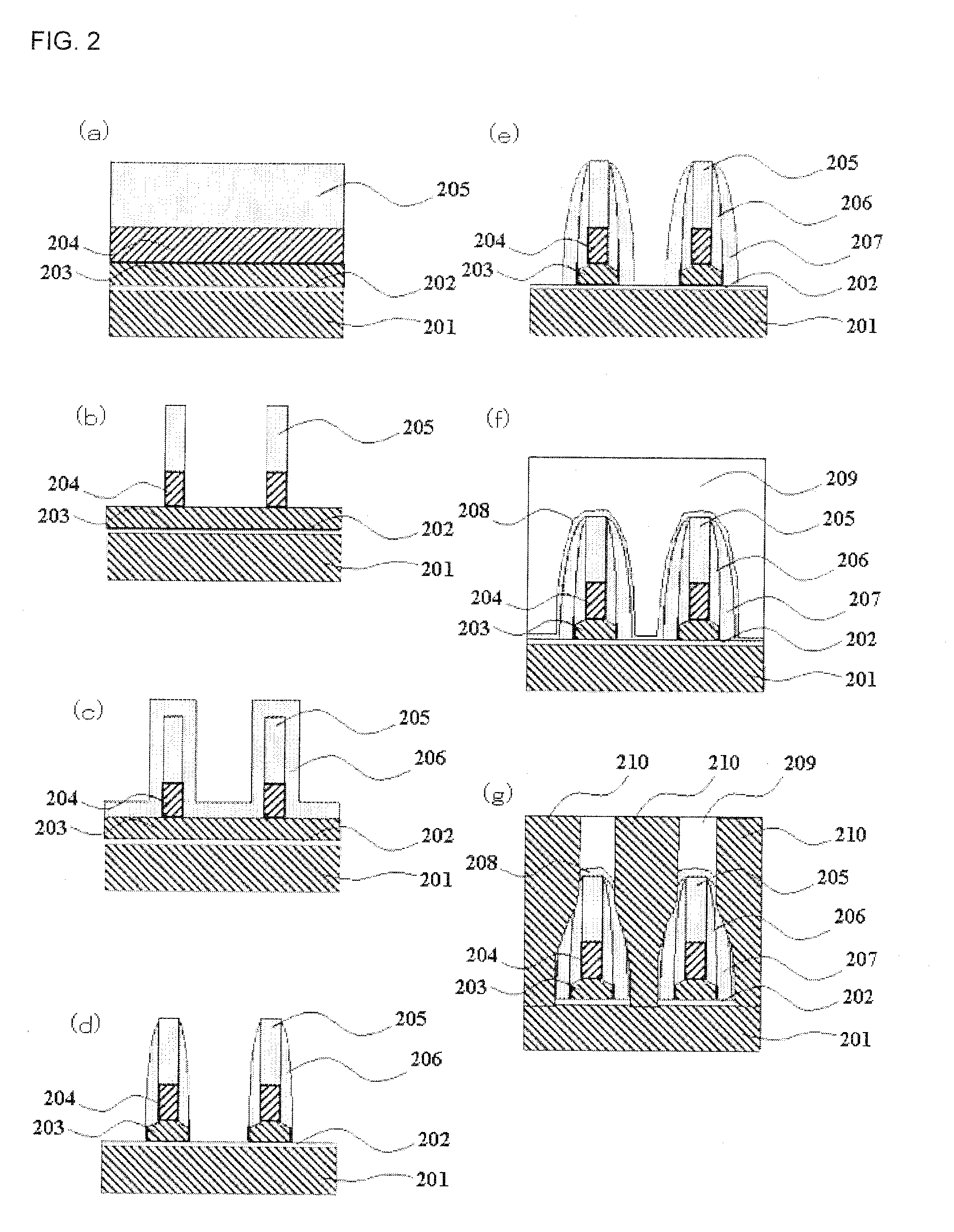

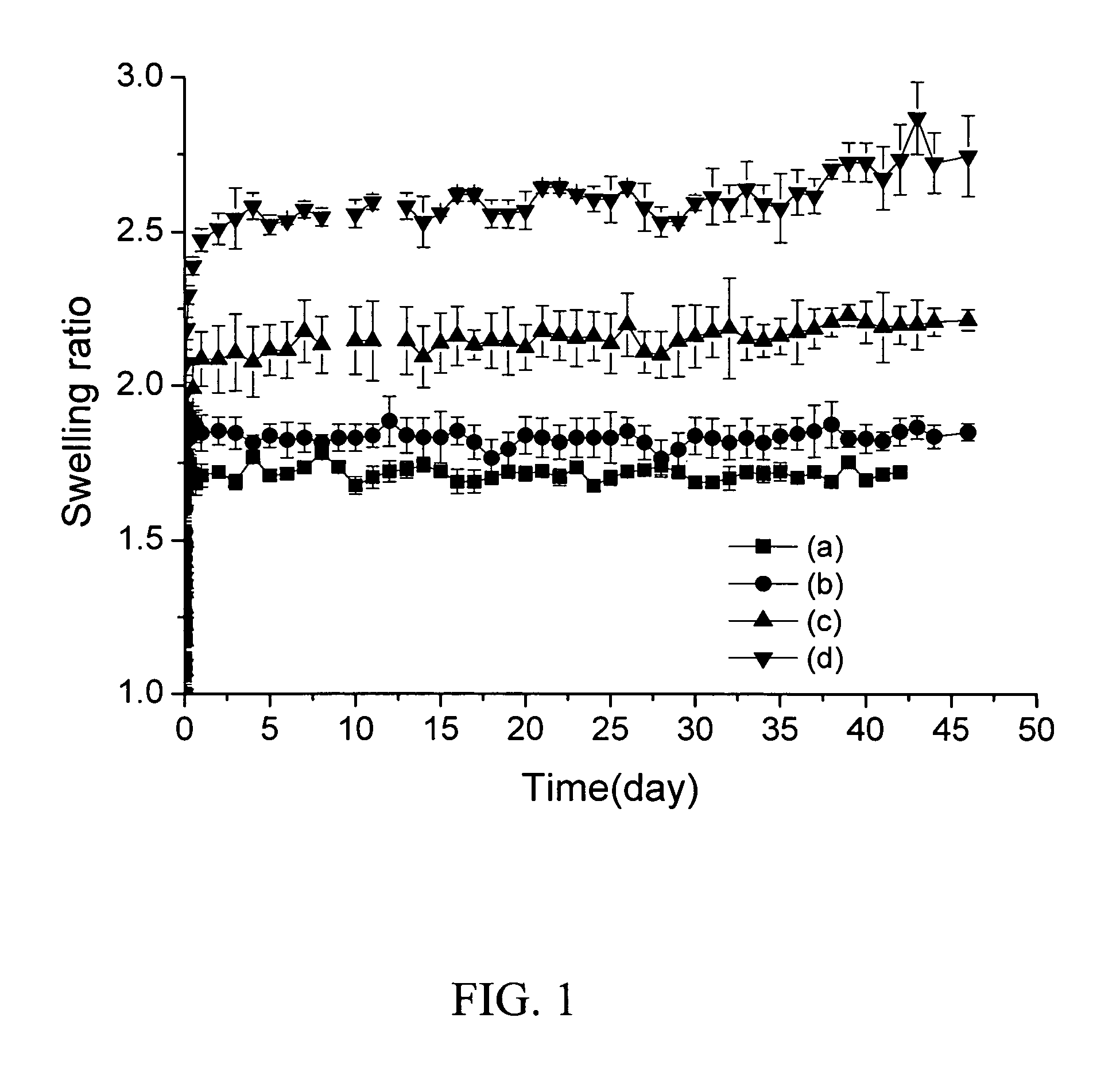

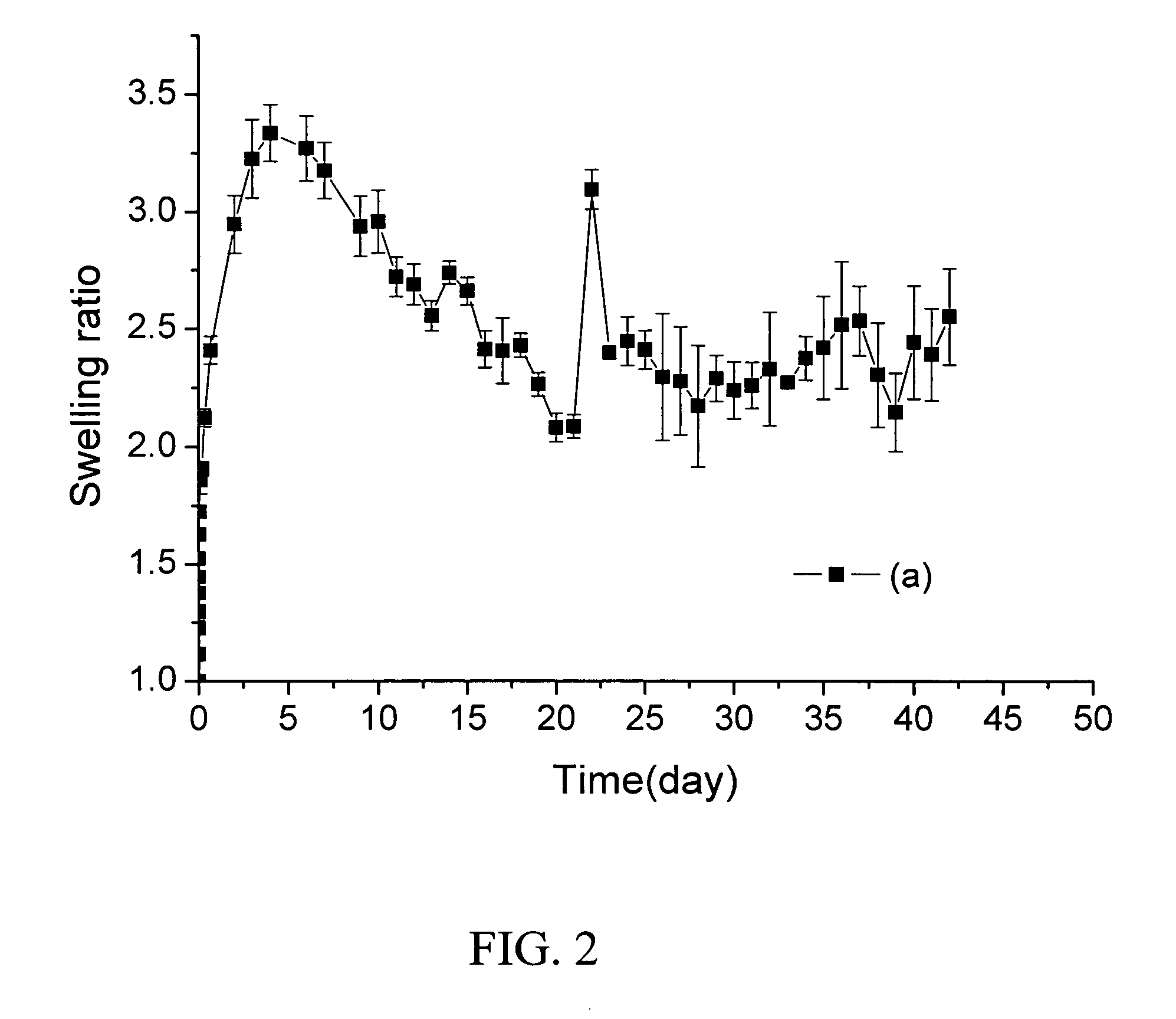

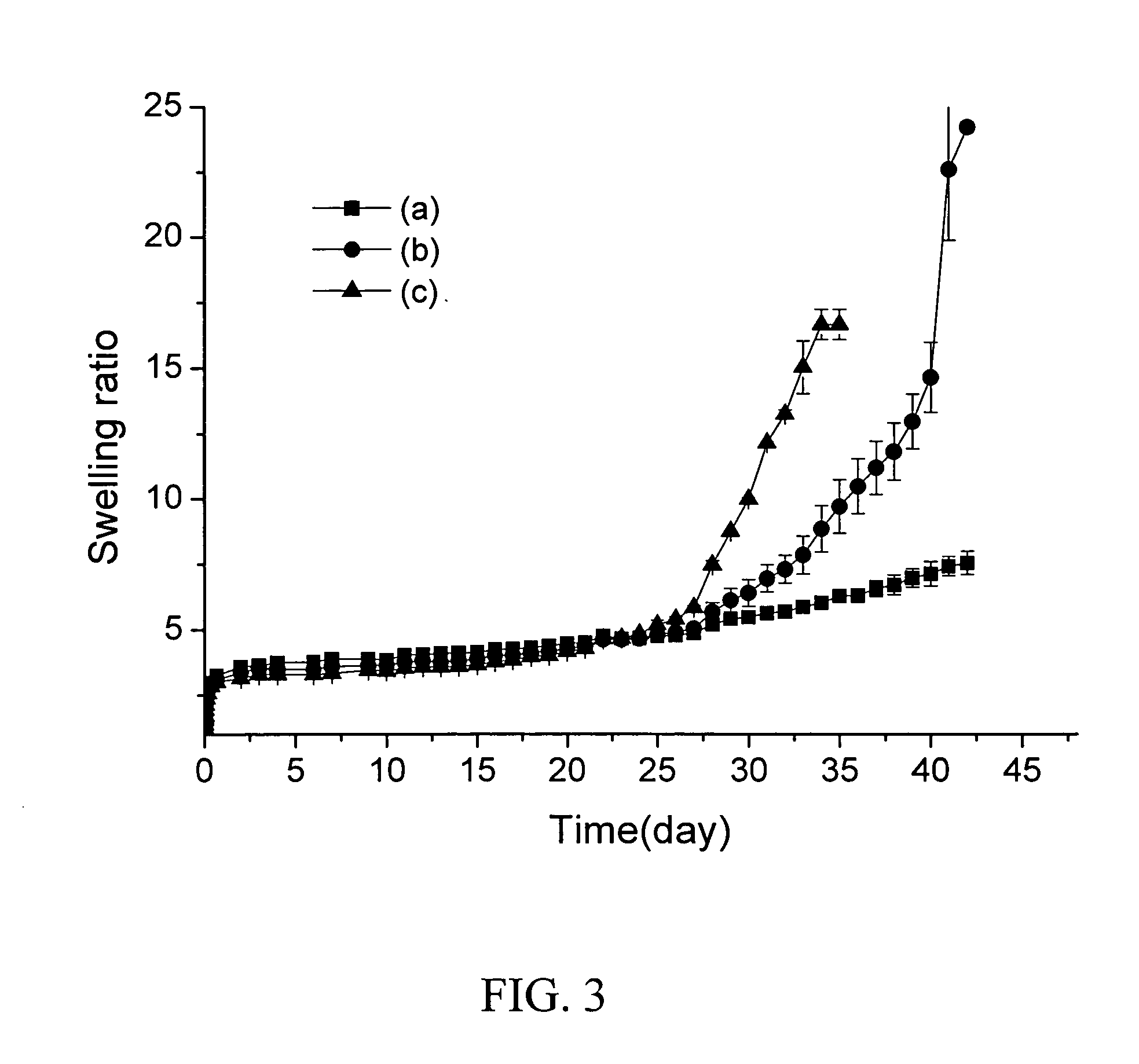

Readily shapeable xerogels having controllably delayed swelling properties

InactiveUS20070031499A1Impart flexible and elastic propertyPowder deliverySurgeryHydrophilic monomerPliability

Hydrogels are described which have delayed swelling properties. A hydrogel is formed by reacting a hydrophilic monomer, a first crosslinker, and a second crosslinker. The first crosslinker defines the volume expansion of the hydrogel in an aqueous environment, and the second crosslinker, which is biodegradable, can modulate the swelling rate of the hydrogel in aqueous solution. In its dry state, the hydrogel (xerogel) is flexible and elastic. It can also be cut with a knife or scissors, or molded or shaped by hand. The ready shapeability of the xerogel by trimming or compression affords a superior hydrogel for medical applications.

Owner:AKINA INC

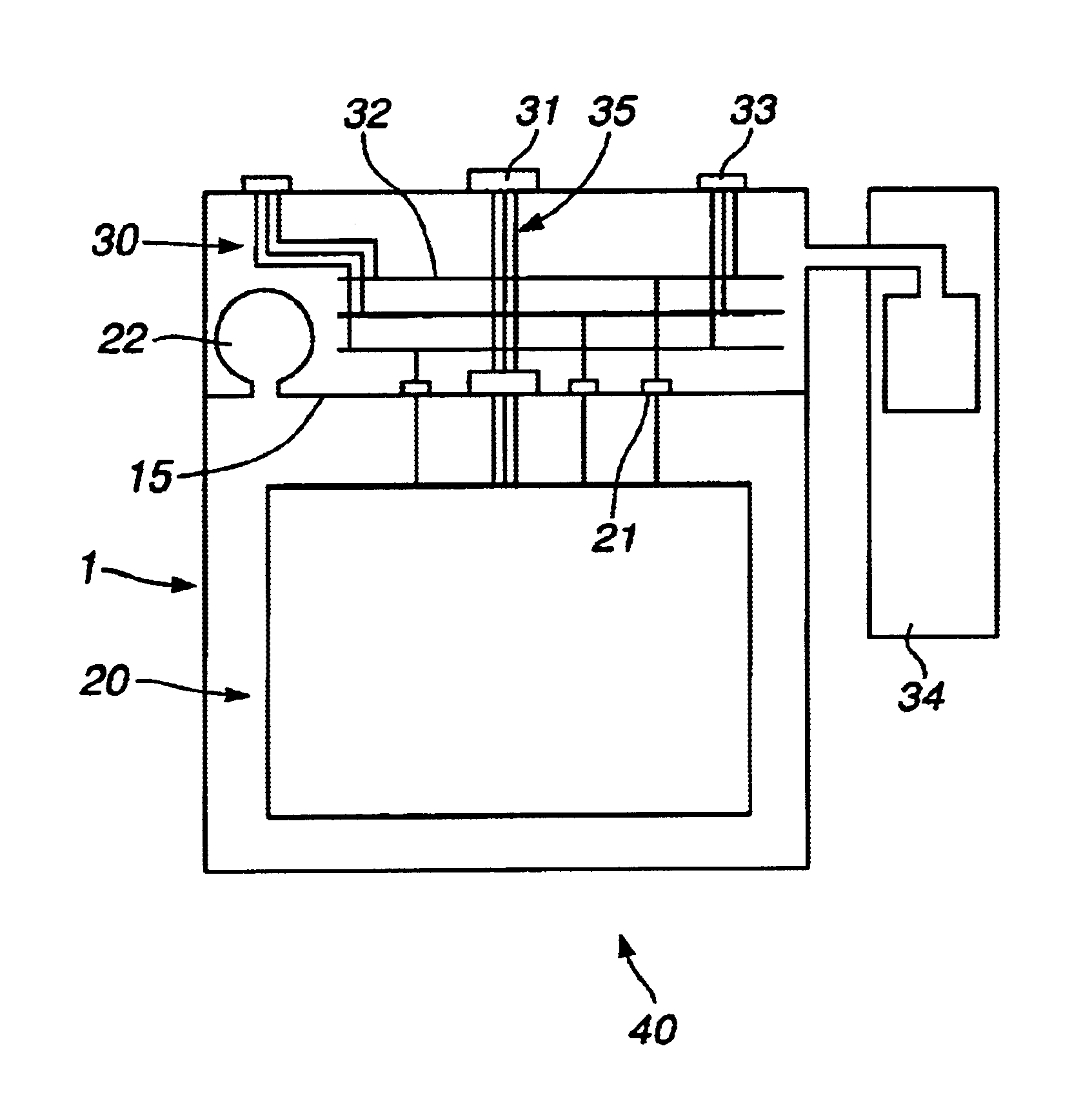

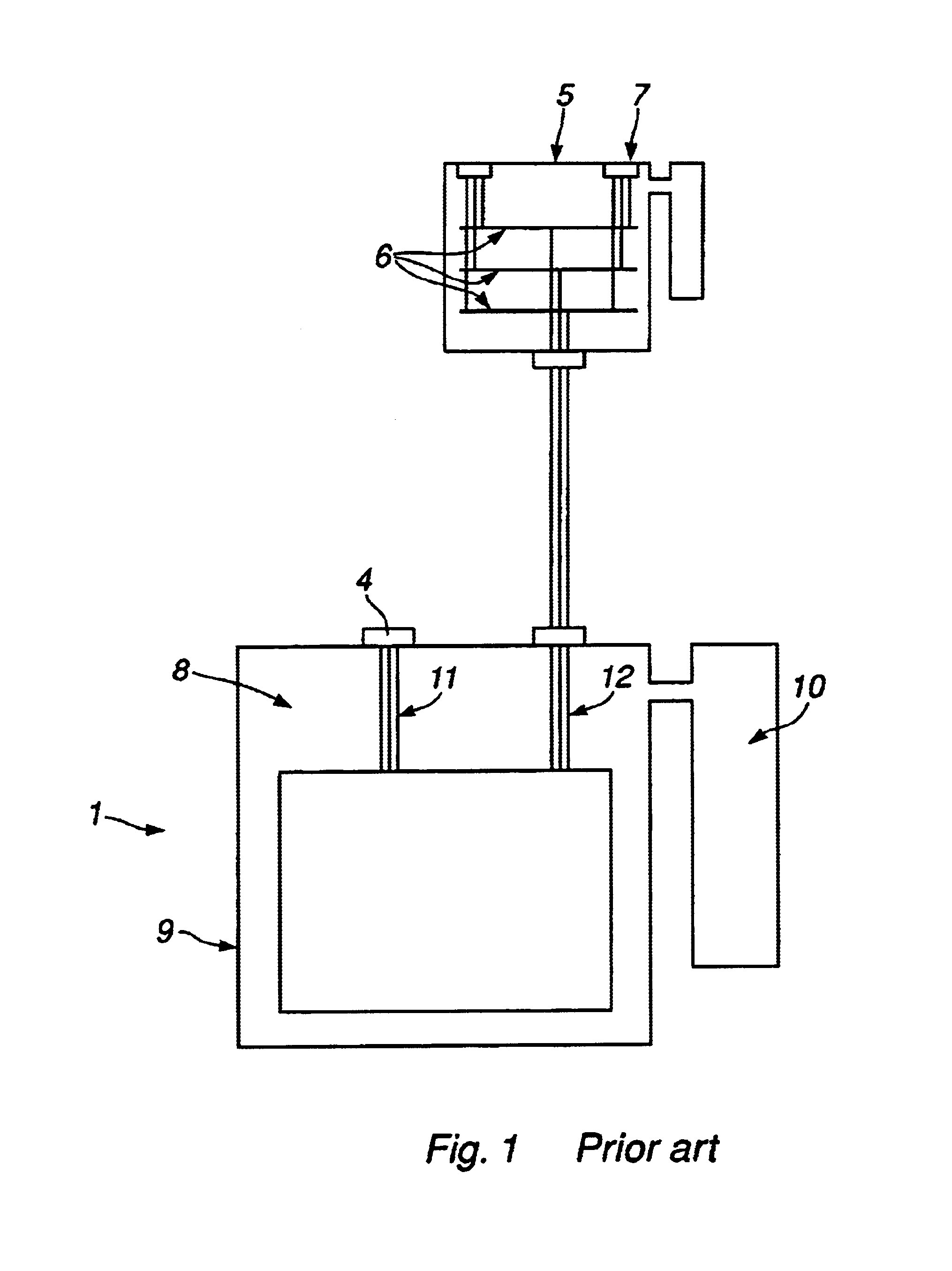

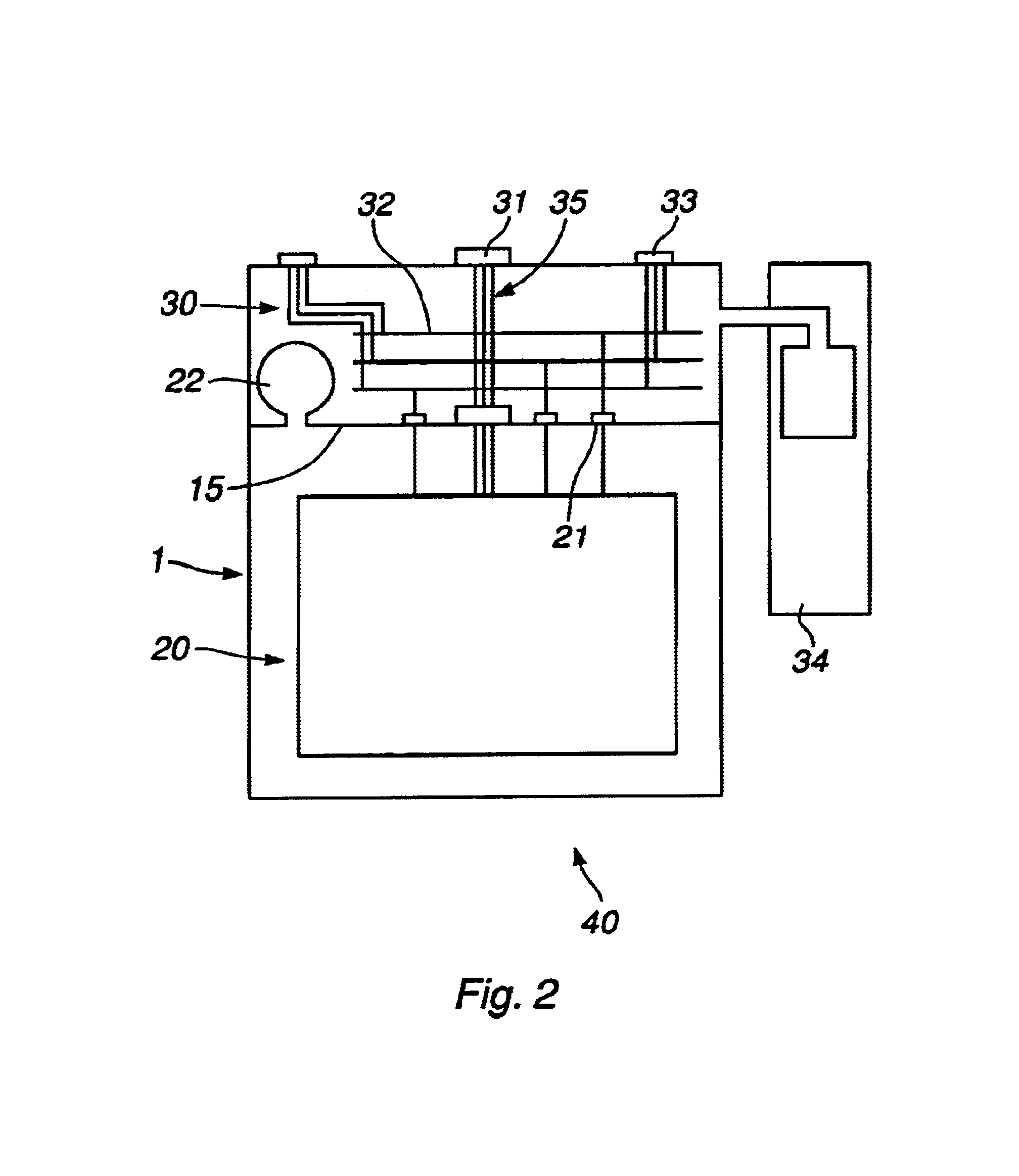

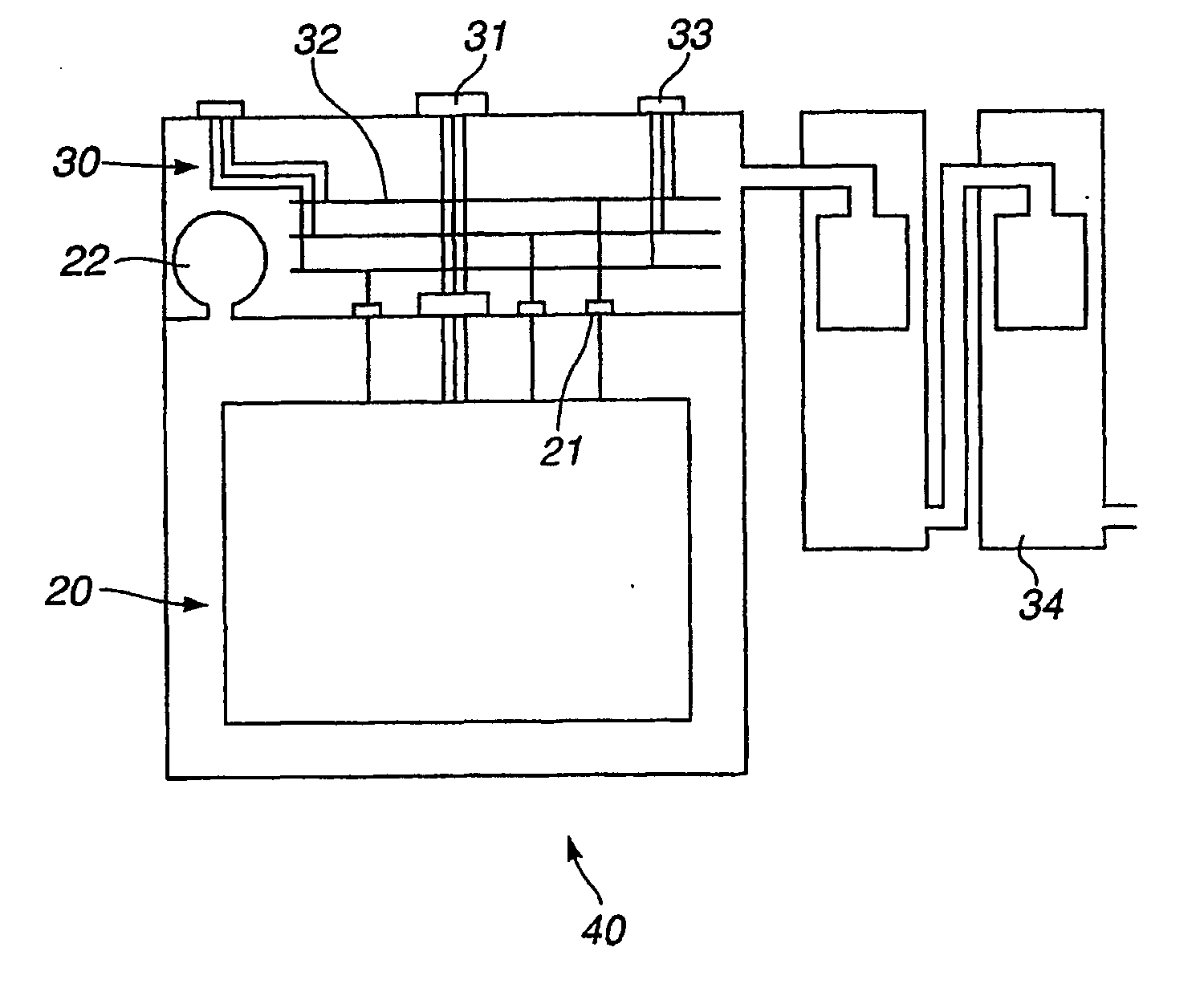

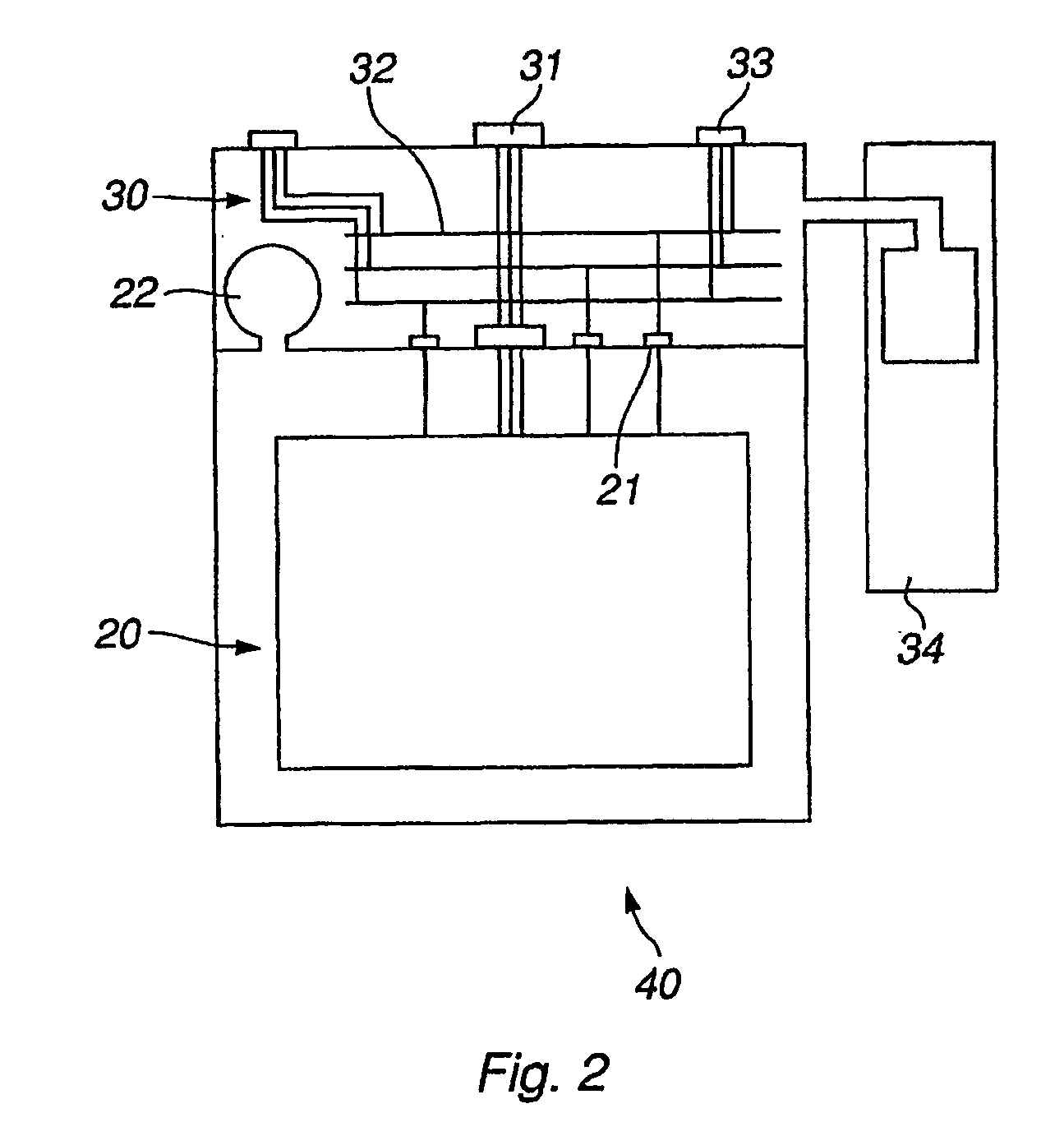

System for distribution of electric power

InactiveUS6867364B2Raise the barrierEliminate needOverhead installationTransformers/inductances coolingTransformerBusbar

A subsea electrical power distribution system including a first chamber (20) housing a transformer, a second chamber (30) housing a power distribution system with busbars (32) for distribution of power to individual consumers connected to said busbars via connectors (33). The interface between the first and second chamber includes a flexible membrane (22) allowing the oil in the first chamber to expand into the second chamber and vice versa. The second chamber being connected to an external volume expansion chamber (34) allowing the pressure in the second chamber to balance against the pressure of the ambient sea.

Owner:VETCO GRAY SCANDINAVIA

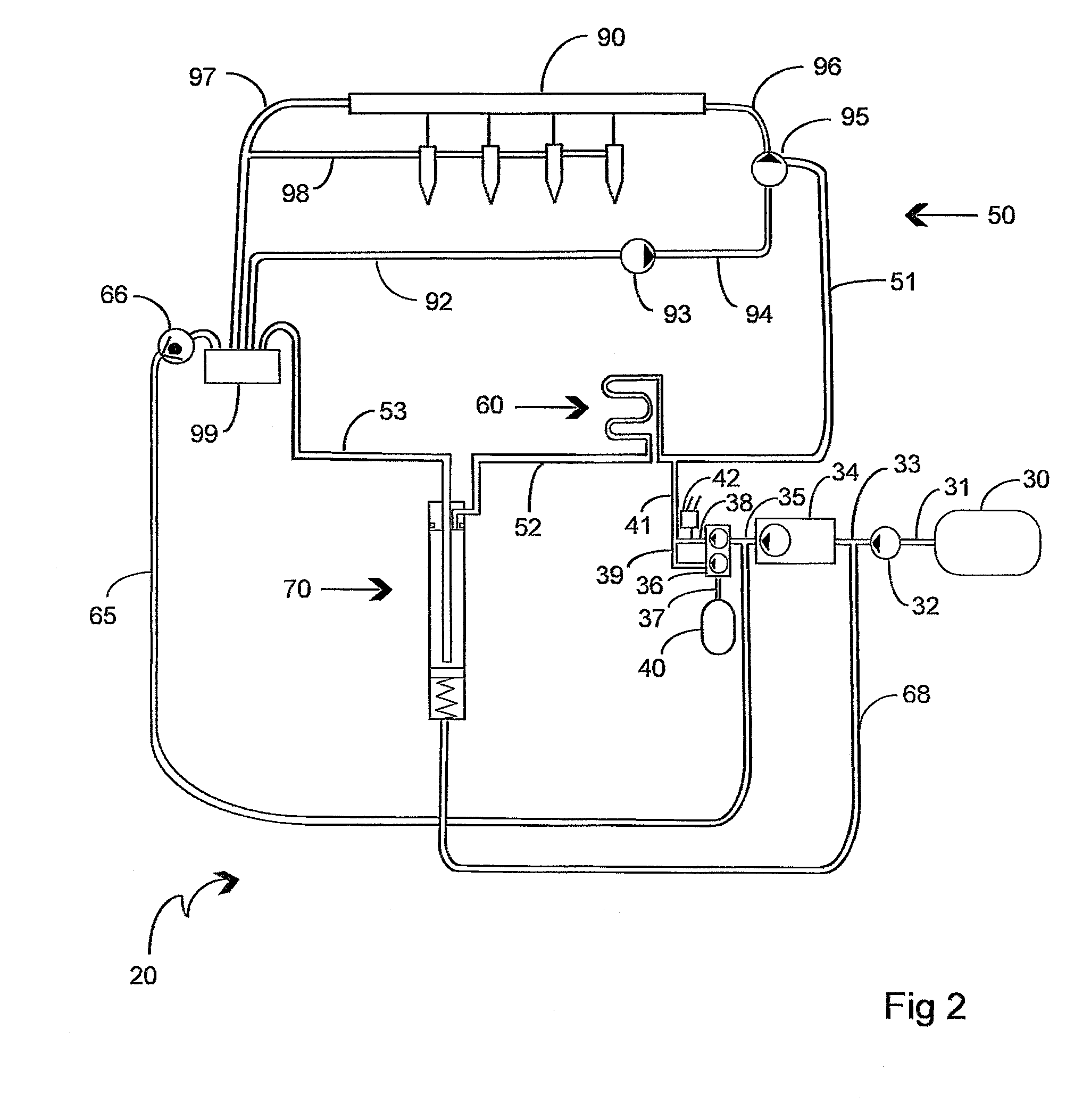

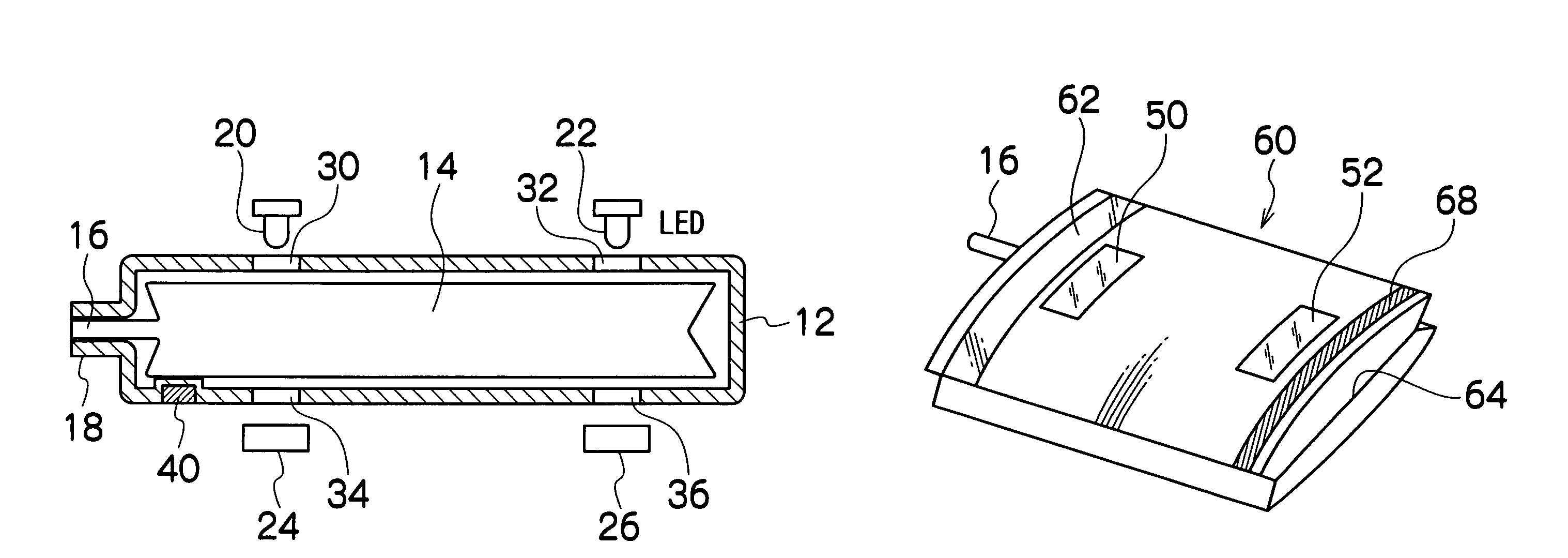

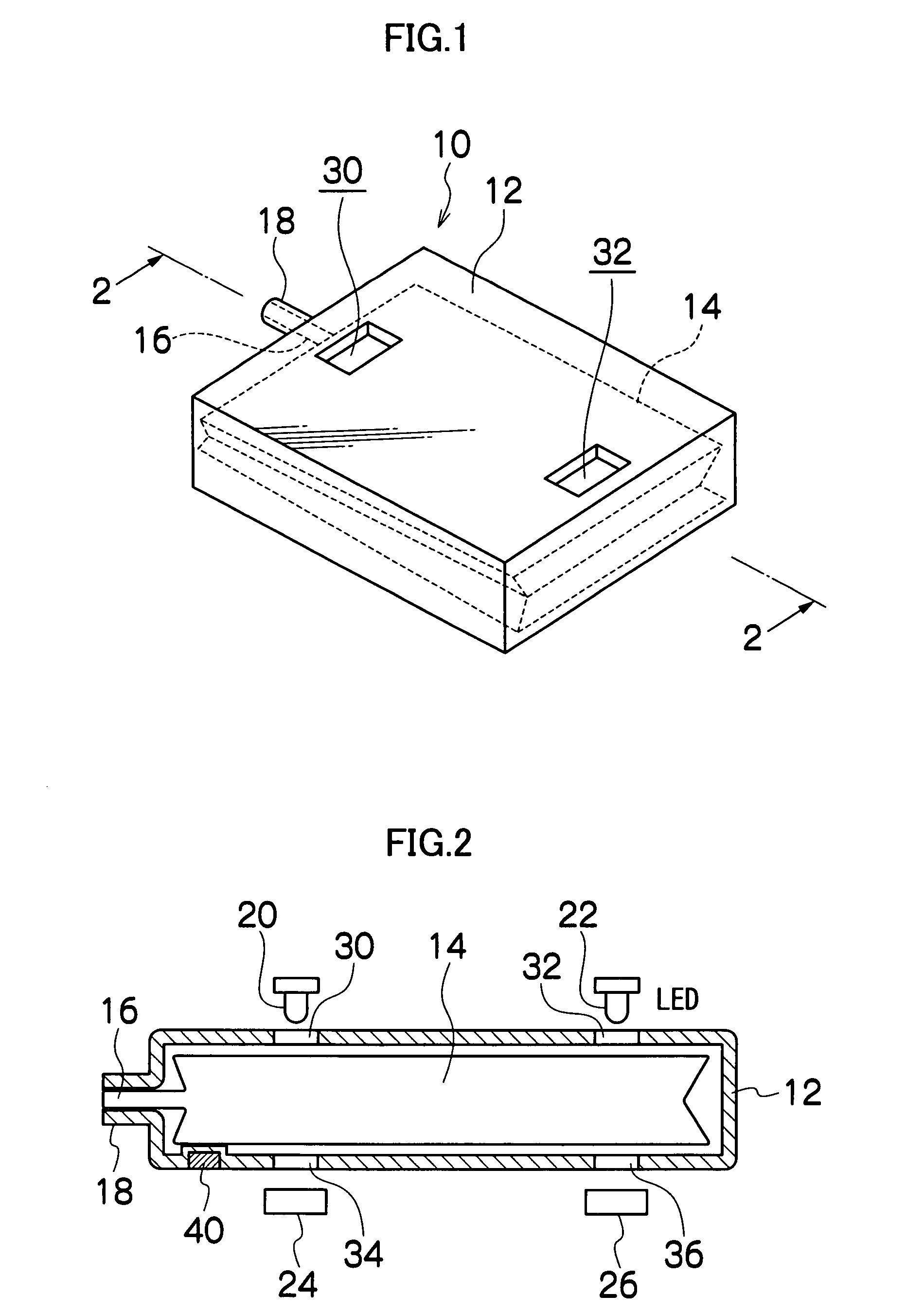

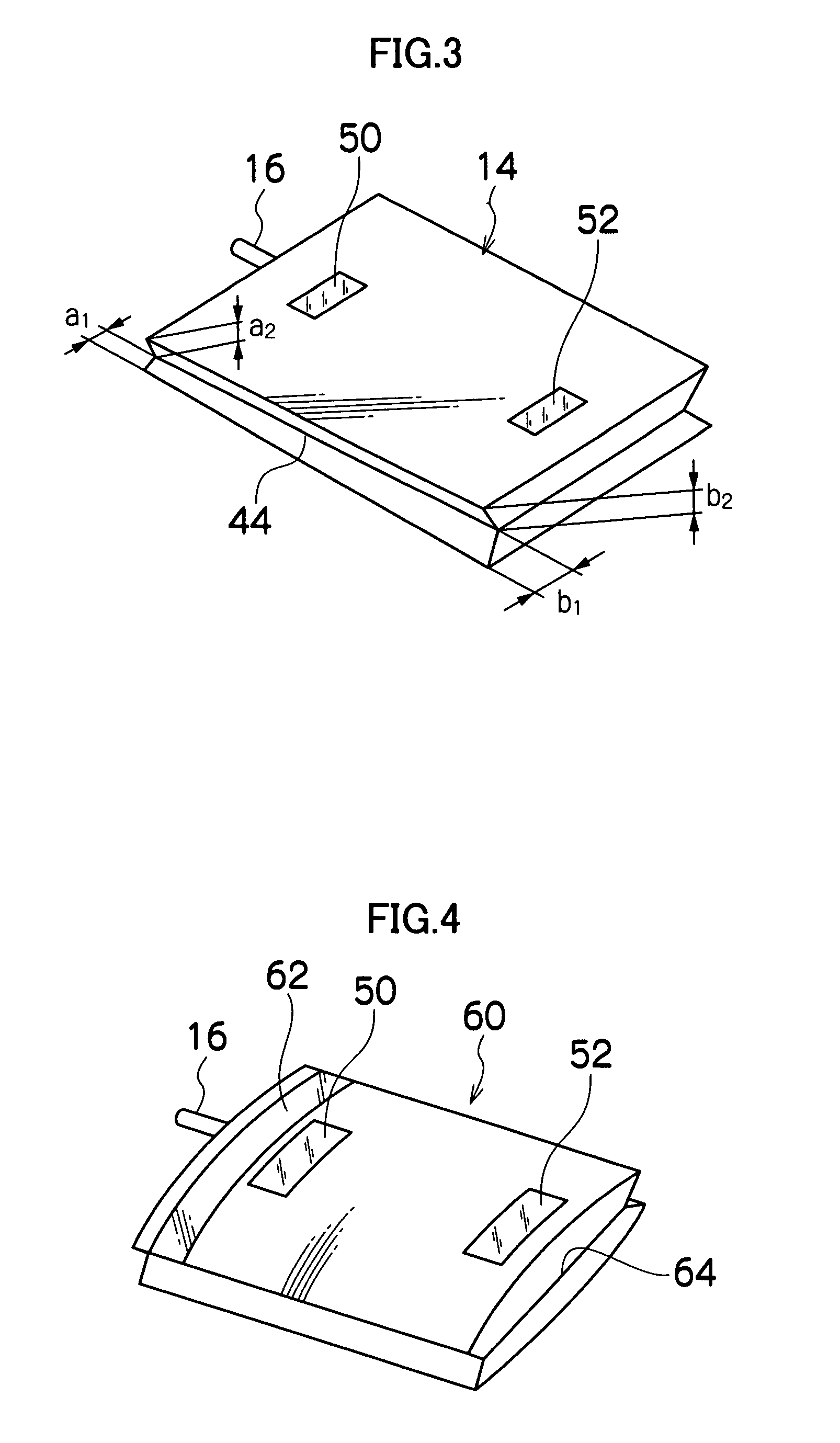

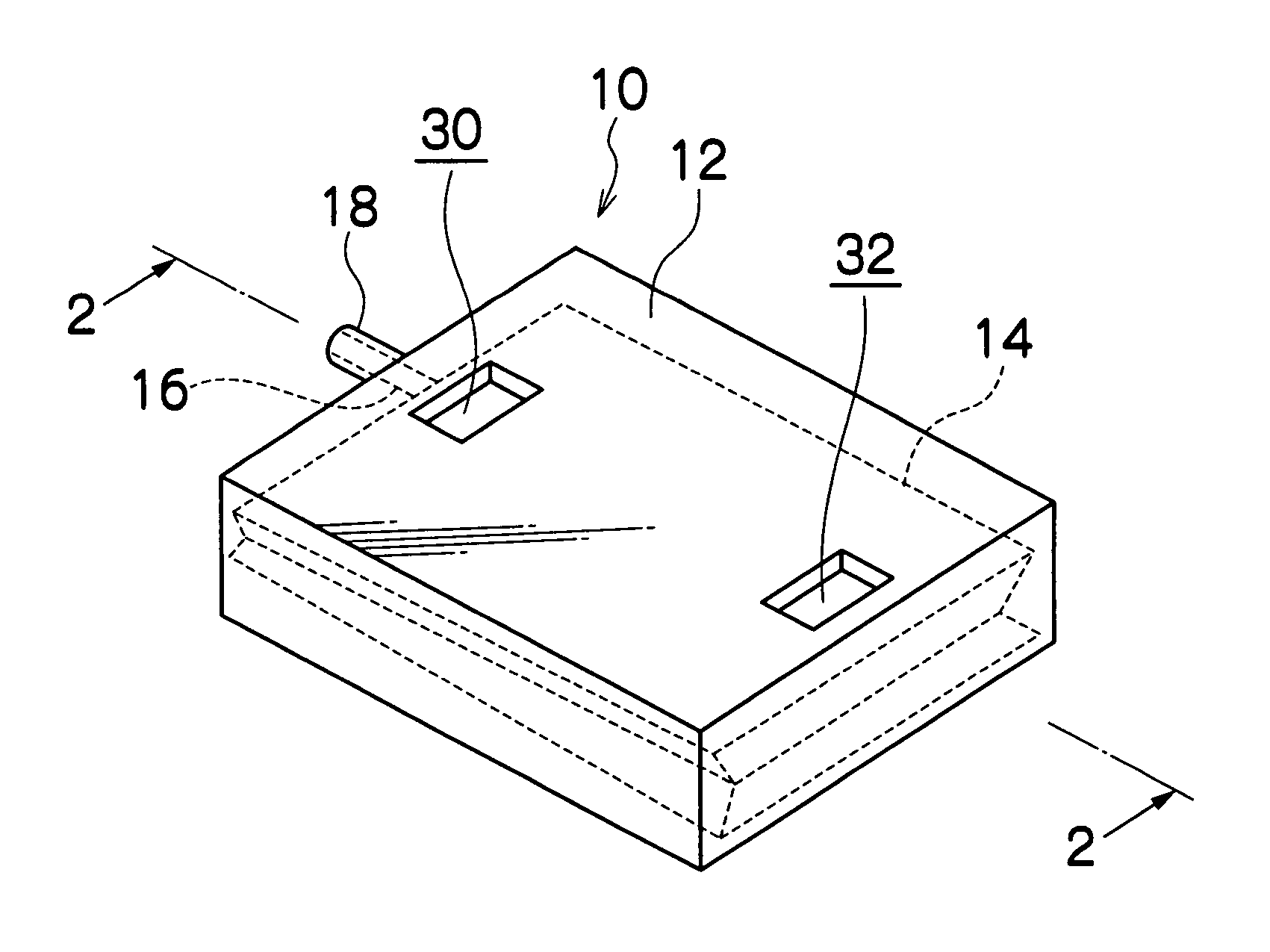

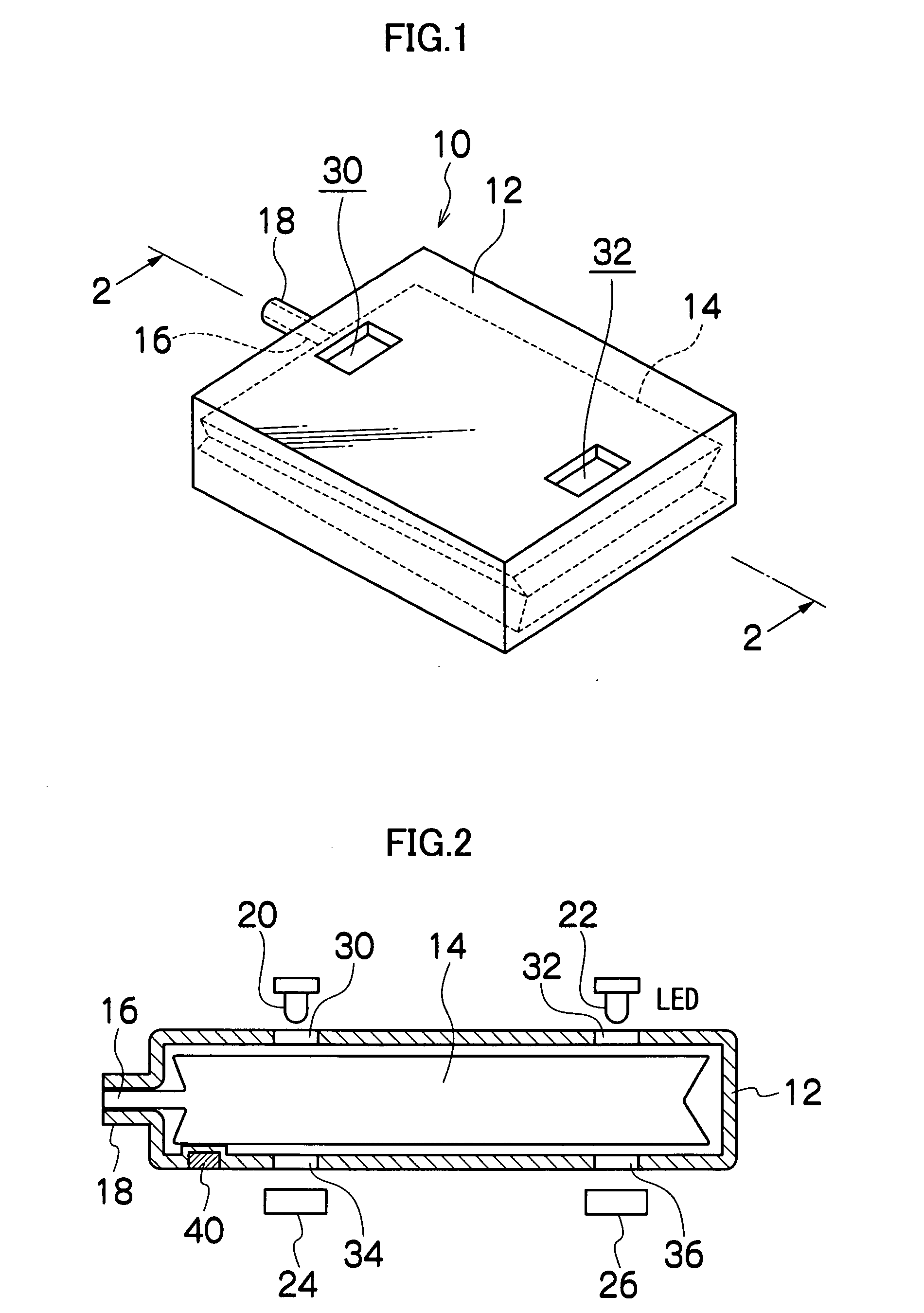

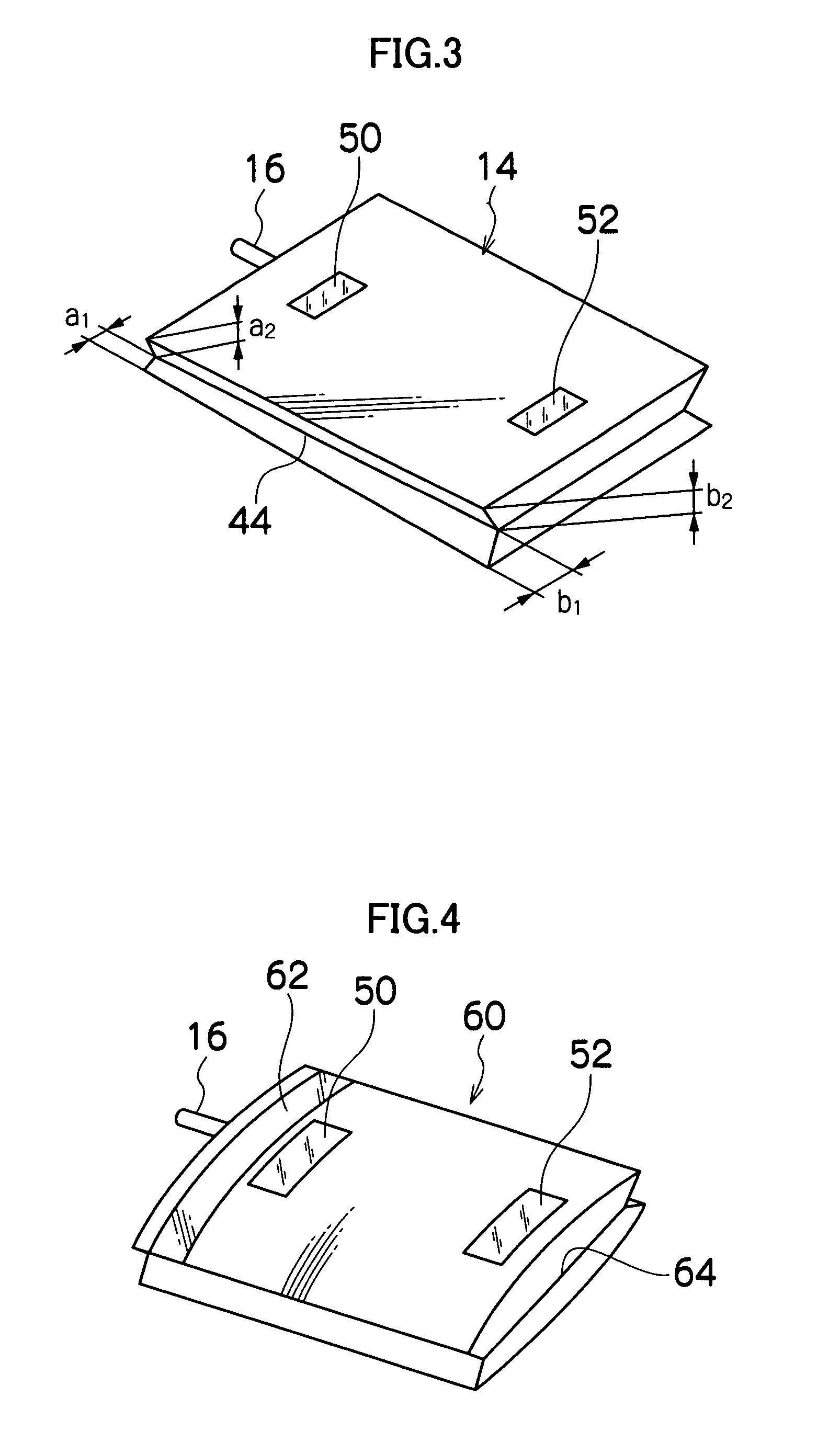

Ink cartridge and inkjet recording apparatus

The ink cartridge has: a cartridge container having a flat box shape; an ink bag that is made of a plastic material or an elastic body, accommodates ink, is disposed in the cartridge container, and has an ink supply port via which the ink is extracted from the ink bag, wherein: the cartridge container has an air connection port by which an interior of the cartridge container in which the ink bag disposed is able to connect to an atmospheric air; the ink bag has a flat shape matching the flat box shape of the cartridge container; the ink bag is provided with a negative pressure generating device which applies impelling force to the ink bag in a direction of expanding a volume of the ink bag to generate a negative pressure inside the ink bag; and the impelling force applied to generate the negative pressure inside the ink bag by the negative pressure generating device, becomes less in a continuous or a stepwise fashion, as a distance from the ink supply port of the ink bag increases.

Owner:FUJIFILM CORP

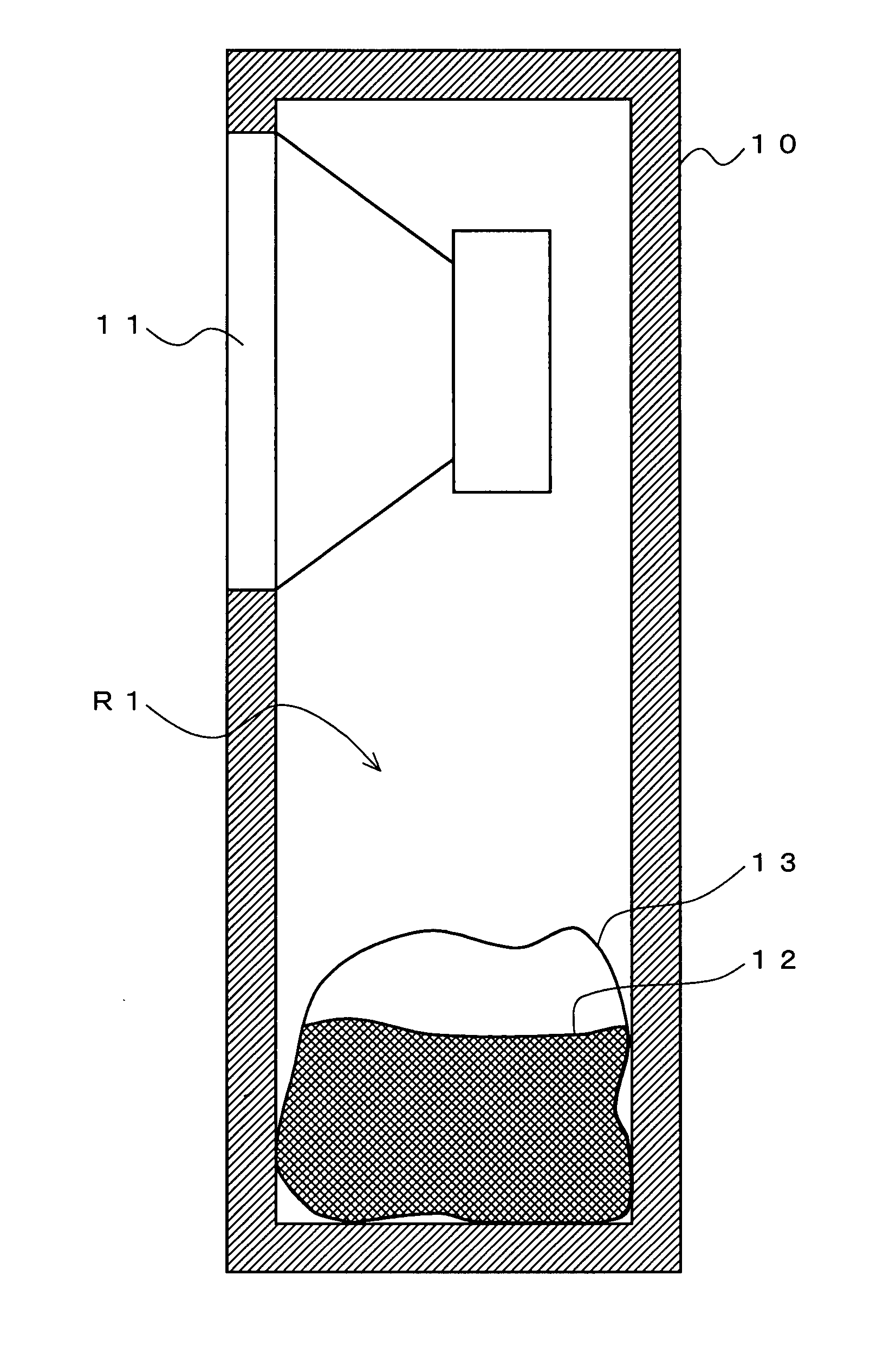

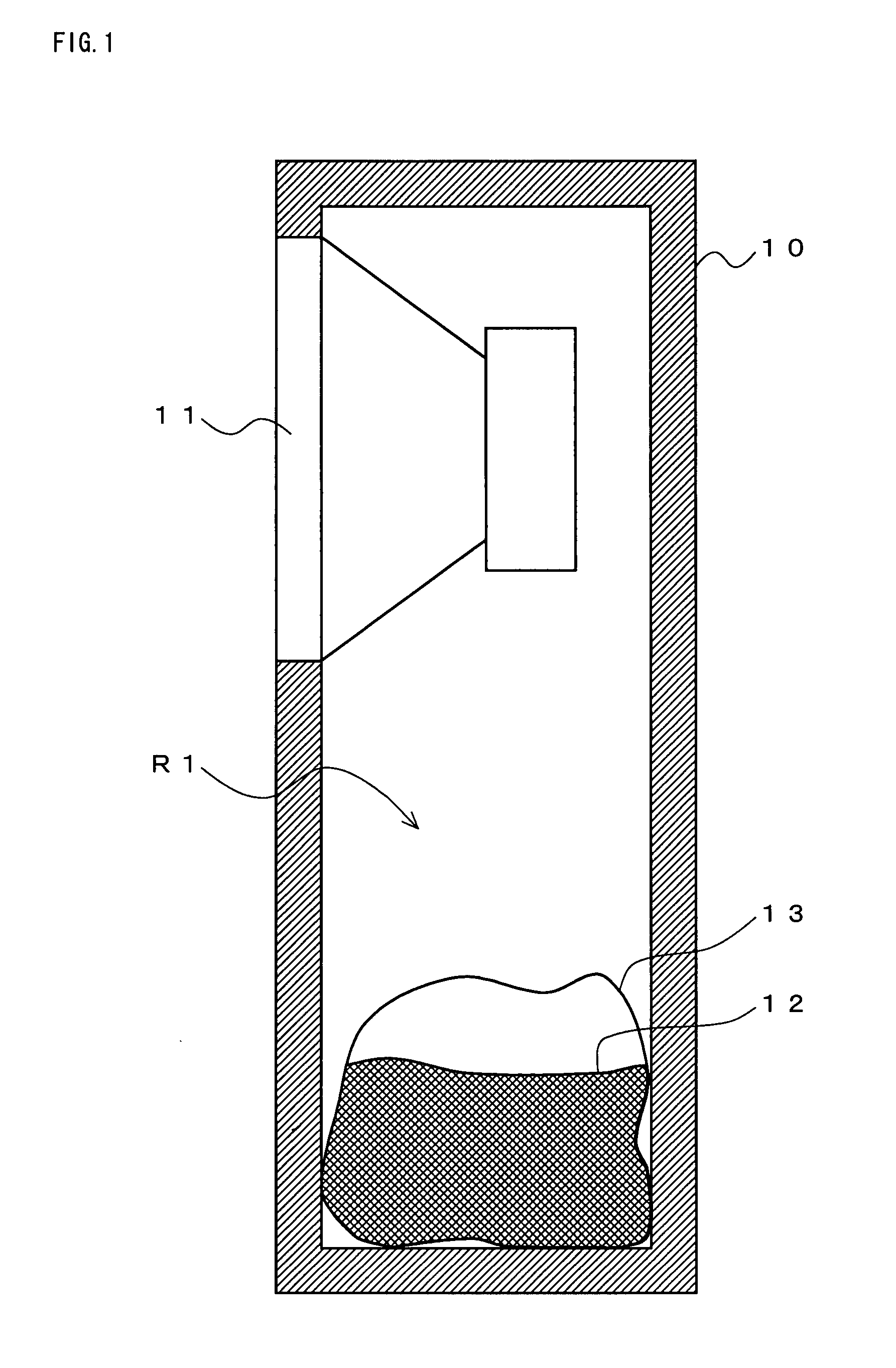

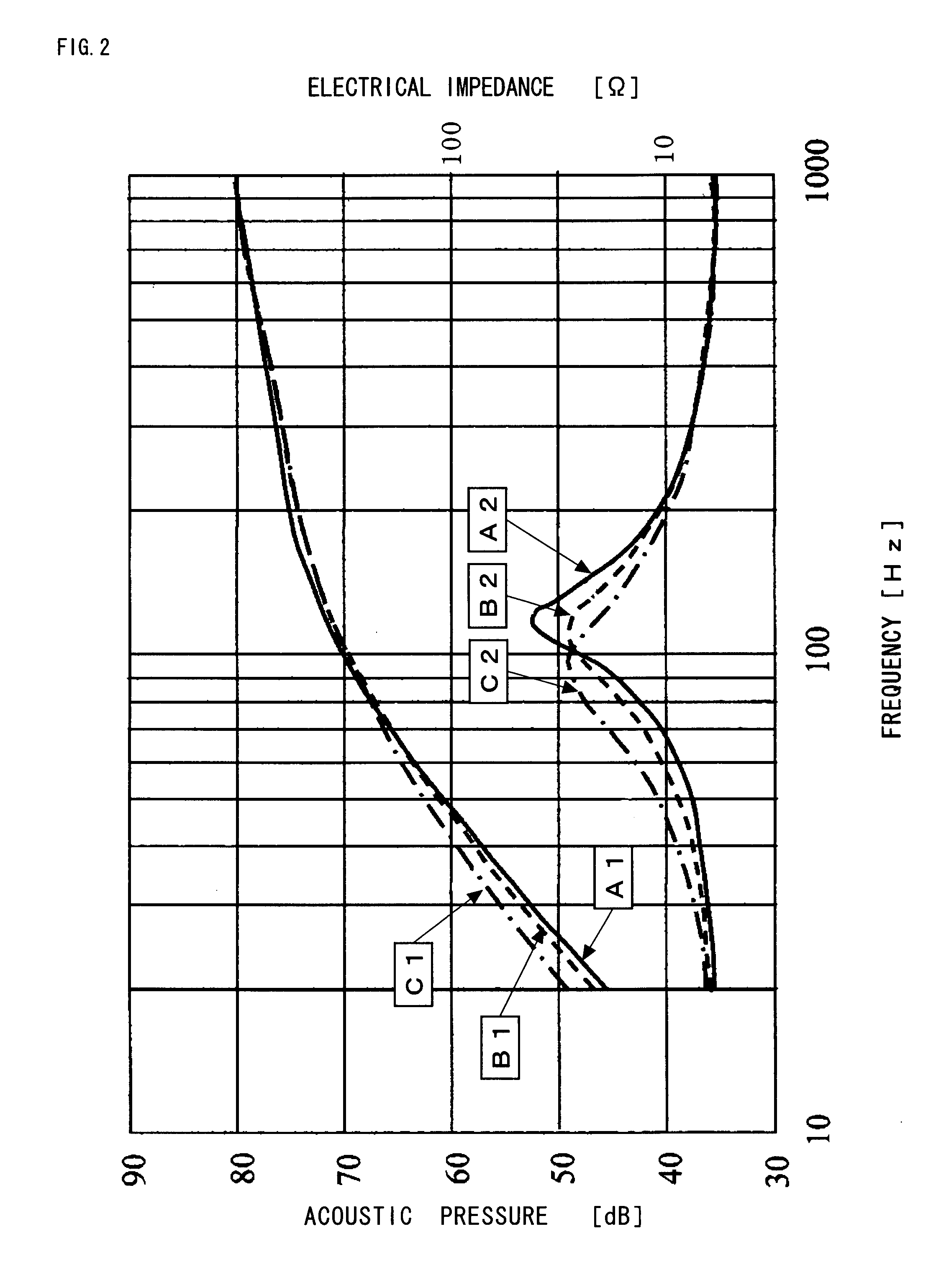

Loudspeaker System

InactiveUS20080170737A1Improve scalabilityReduce gas volumeFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsInterior spaceLow frequency band

A loudspeaker system according to the present invention comprises a cabinet, a speaker unit mounted in the cabinet, and a powdery gas absorption material which is disposed in an internal space of the cabinet and physically absorbs gas being present in the internal space of the cabinet. An average particle diameter of the gas absorption material is less than 0.1 mm. Thus, according to the present invention, the loudspeaker system which expands a low frequency band, prevents a reduction in an acoustic pressure level, exhibits a volume expansion effect also in a high frequency band of 100 to 200 Hz or more, is compact, and enables enriched bass reproduction can be realized.

Owner:PANASONIC CORP

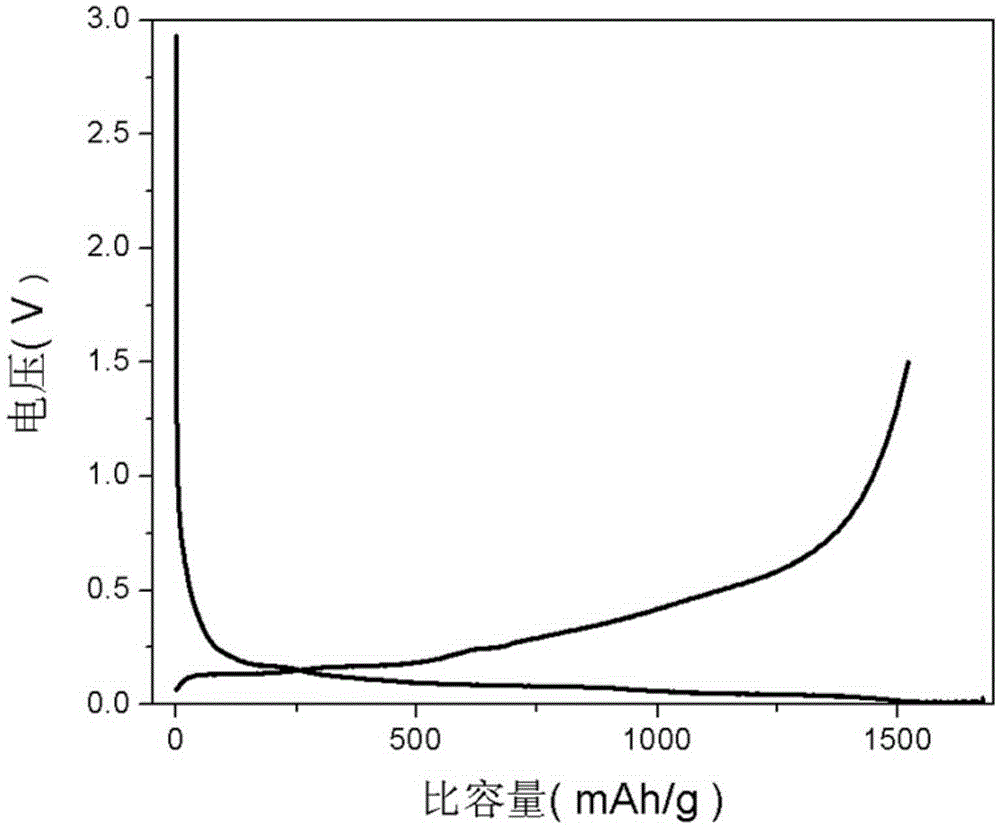

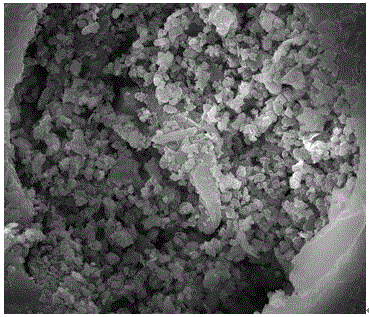

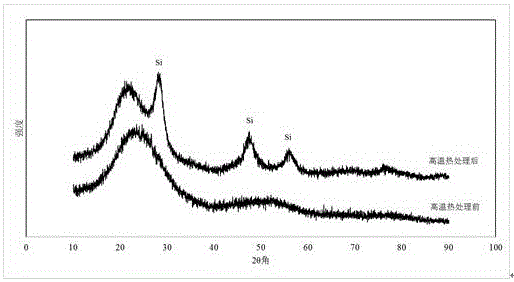

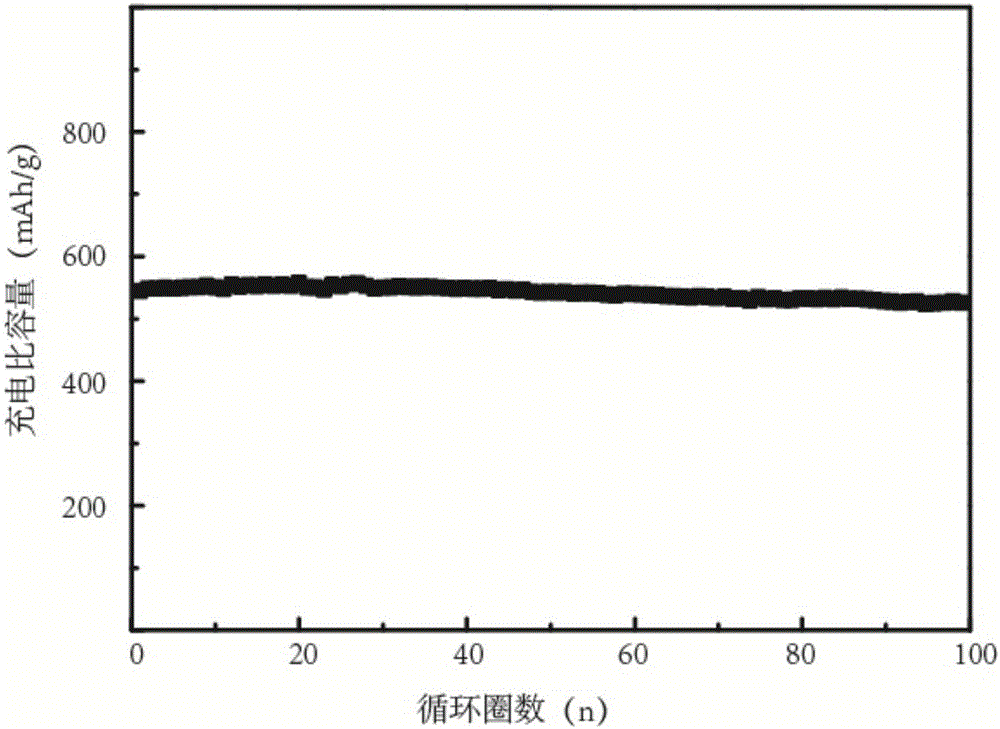

Silicon-carbon composite material, preparation method of silicon-carbon composite material, and lithium ion battery containing silicon-carbon composite material

ActiveCN102969489AImprove conductivityImprove charge and discharge cycle lifeCell electrodesSecondary cellsCarbon compositesCarbon layer

The invention discloses a silicon-carbon composite material, a preparation method of the silicon-carbon composite material, and a lithium ion battery containing the silicon-carbon composite material. The preparation method comprises the following steps of: (1) reducing silicon dioxide by using metal with activity larger than that of silicon, so as to obtain a porous silicon-metal oxide composite; (2) corroding the metal oxide by acid, so as to obtain porous silicon; and (3) coating the surface of the porous silicon by carbon by taking a carbon source as a raw material, so as to obtain the silicon-carbon composite material. The silicon in the silicon-carbon composite material is prepared through using a metallothermic reduction method and porous silicon particles prepared through using the metallothermic reduction method are micron-sized and hardly agglomerate; the pore walls and the pore diameters in the porous silicon particles are nano-sized; compared with imporous micron-sized silicon powder, for the silicon-carbon composite material, the porous silicon particles have the characteristics that a diffusion path of a lithium ion in a silicon substrate is shortened, thus being beneficial to charging and discharging with large current, the pores can hold the volume expansion of silicon during silicon intercalation and the charging and discharging cycle life of the material is prolonged. The surfaces of the porous silicon particles are coated with a carbon layer with the certain pores and the conductivity of the silicon-carbon composite material is enhanced.

Owner:CHERY AUTOMOBILE CO LTD

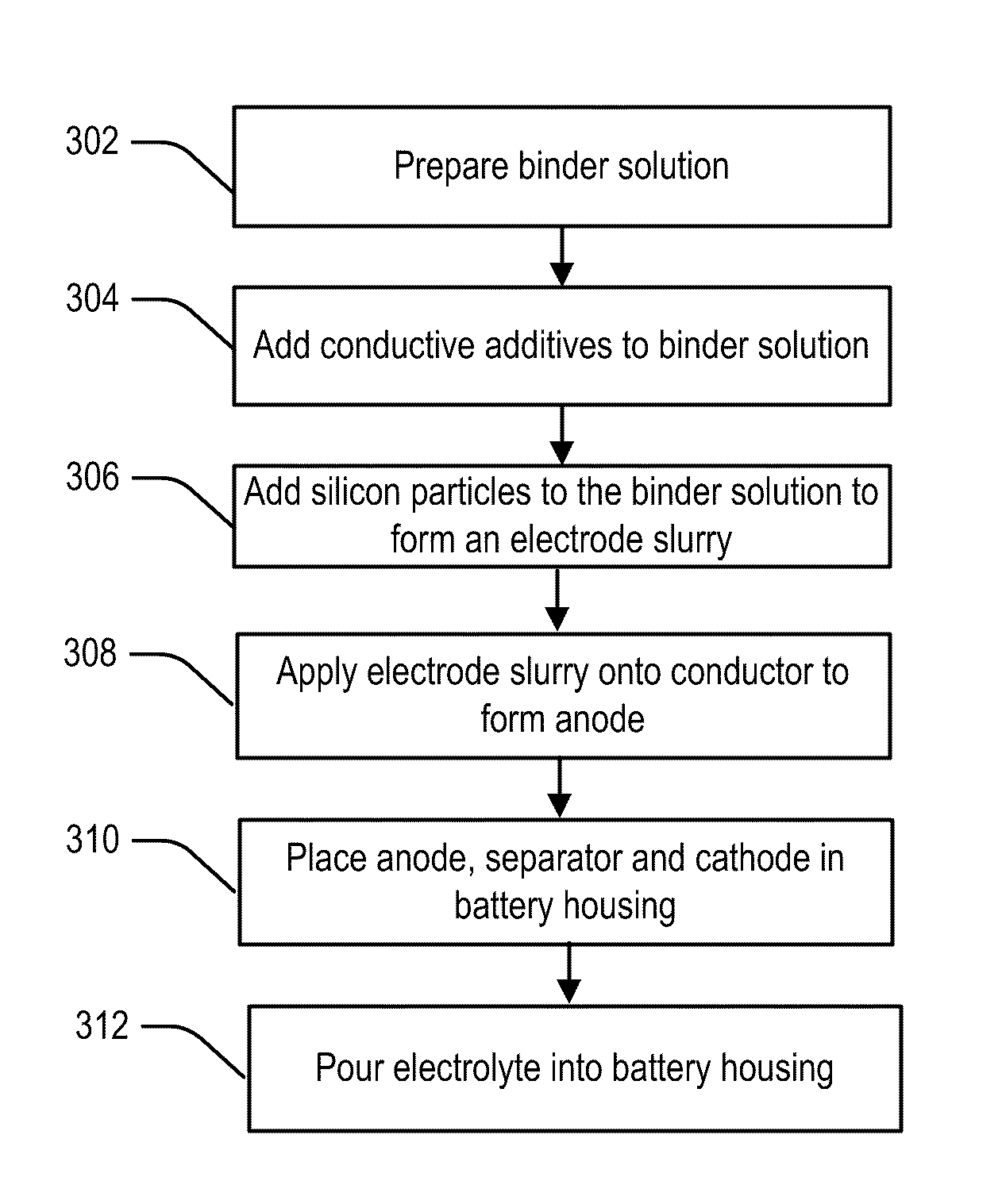

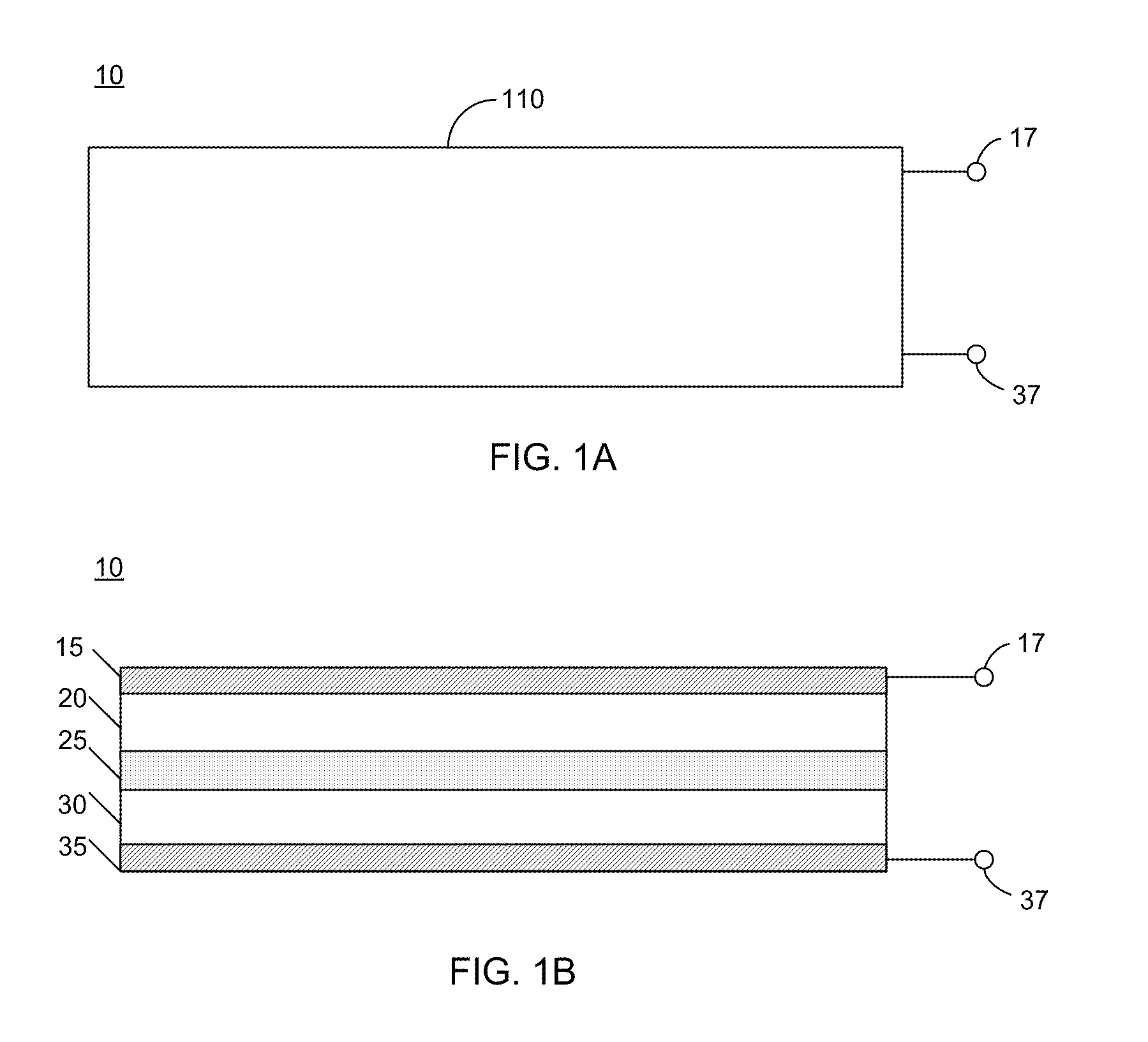

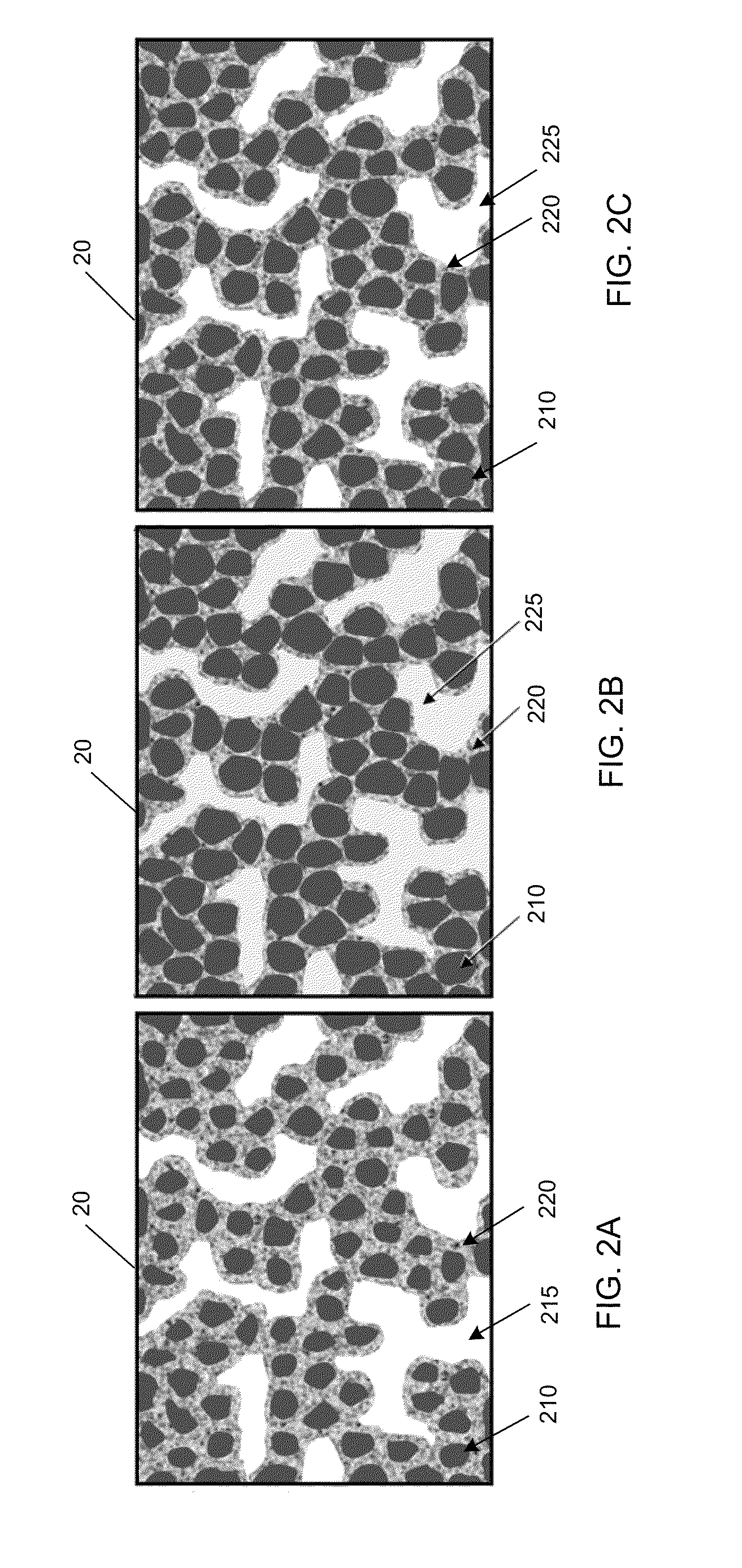

Nanostructured anode for high capacity rechargeable batteries

InactiveUS20100062338A1Increase storage capacityMitigate active material degradationSecondary cellsNon-aqueous electrolyte accumulator electrodesVolume expansionSilicon nanoparticle

Nanostructured anodes for high capacity rechargeable batteries are provided according to various aspects of the disclosure. The nanostructure anodes may comprise silicon nanoparticles for the active material of the anodes to increase the storage capacity of the batteries. The silicon nanoparticles are able to move relative to one another to accommodate volume expansion during lithium intercalation, and therefore mitigate active material degradation due to volume expansion. The anodes may also comprise elastomeric binders that bind the silicon nanoparticles together and prevent capacity loss due to separation and electrical isolation of the silicon nanoparticles.

Owner:LOCKHEED MARTIN CORP

Ink cartridge and inkjet recording apparatus

The ink cartridge has: a cartridge container having a flat box shape; an ink bag that is made of a plastic material or an elastic body, accommodates ink, is disposed in the cartridge container, and has an ink supply port via which the ink is extracted from the ink bag, wherein: the cartridge container has an air connection port by which an interior of the cartridge container in which the ink bag disposed is able to connect to an atmospheric air; the ink bag has a flat shape matching the flat box shape of the cartridge container; the ink bag is provided with a negative pressure generating device which applies impelling force to the ink bag in a direction of expanding a volume of the ink bag to generate a negative pressure inside the ink bag; and the impelling force applied to generate the negative pressure inside the ink bag by the negative pressure generating device, becomes less in a continuous or a stepwise fashion, as a distance from the ink supply port of the ink bag increases.

Owner:FUJIFILM CORP

Lead free solder paste and application thereof

ActiveCN101232967ADamage causedAvoid short circuitPrinted circuit assemblingWelding/cutting media/materialsDicarboxylic acidCarboxylic acid

A solder paste composed of solder alloy powder and flux, the volume expansion rate of which is 0.5% or less when the solder alloy is melted, and the flux contains bisphenol A type epoxy resin and a hardening agent selected from carboxylic anhydrides and dicarboxylic acids agent, the solder paste can be used for high temperature solder applications. In terms of mass%, the solder alloy has the following alloy composition: 70-98 mass% of Bi; 0-0.5% of Ag, Cu, Sb, In, Zn, Ni, Cr, Fe, Mo, P, Ge and One or more elements selected from Ga; the balance is composed of Sn.

Owner:SENJU METAL IND CO LTD +1

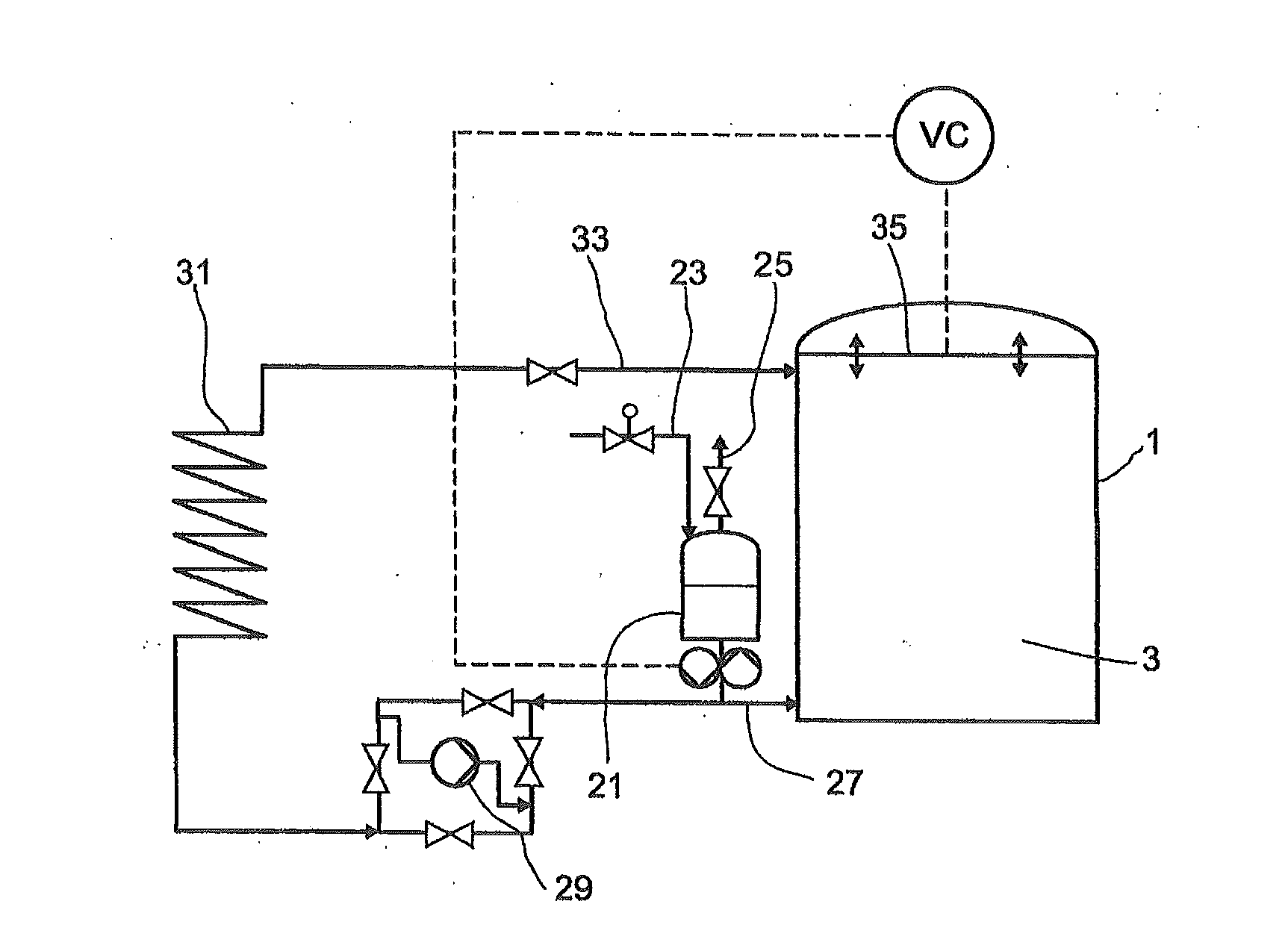

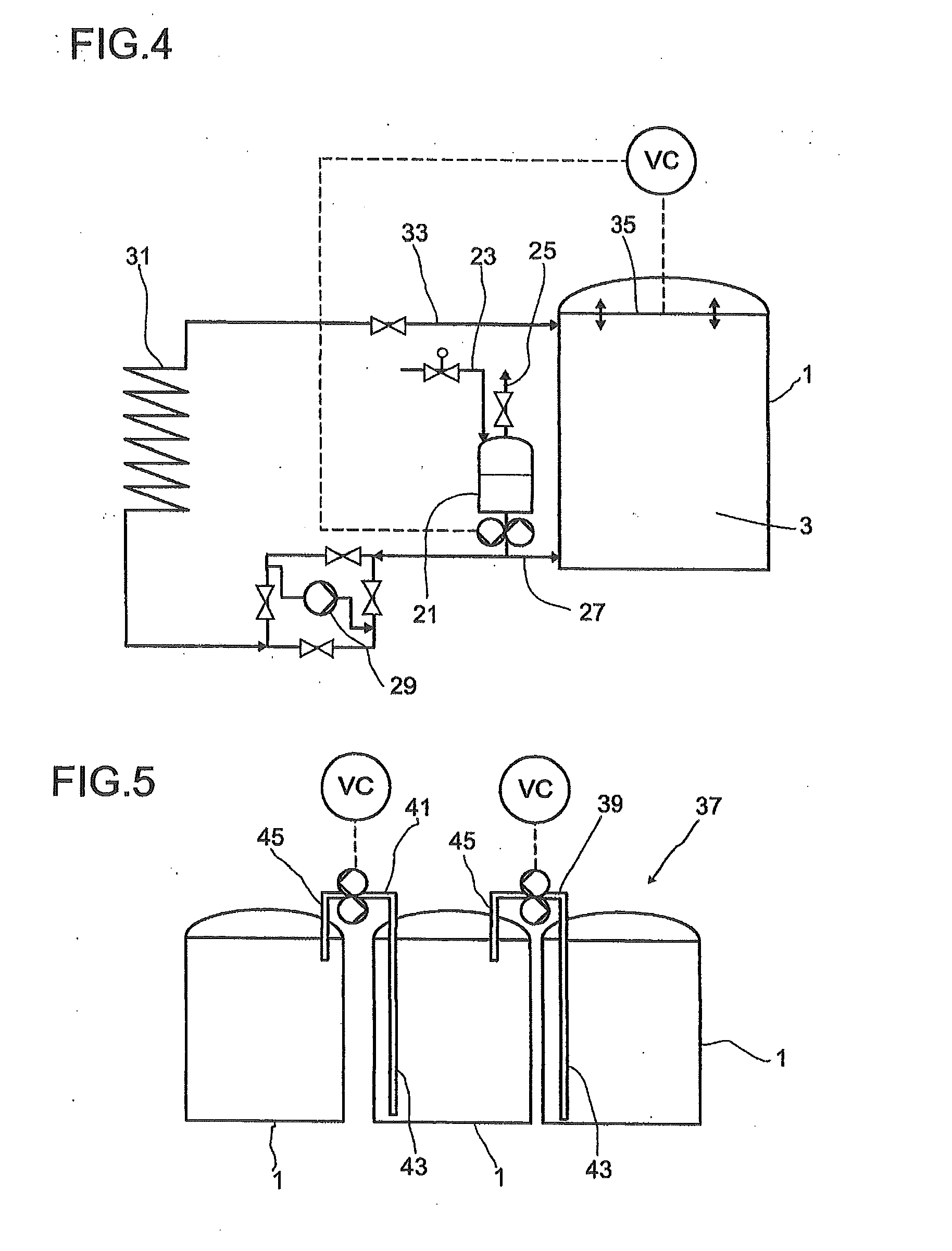

Device and method for storing heat

InactiveUS20110271953A1Guaranteed uptimeSolar heating energySolar heat devicesHeat carrierEngineering

The invention relates to a device for storing heat, comprising a heat storage medium which absorbs heat in order to store heat and releases heat in order to use the stored heat, and a container for holding the heat storage medium, the container being closed by a gastight cover, and the device comprising volume compensation means in order to compensate for a volume increase of the heat storage medium (3) due to a temperature rise and a volume decrease due to a temperature reduction. The invention furthermore relates to a method for storing heat, in which heat is transferred to a heat storage medium in order to store heat or heat is discharged from the heat storage medium to the heat carrier in order to use the heat, the heat storage medium being held in a container which is closed by a gastight cover, wherein a volume expansion of the heat storage medium (3) is compensated for by a volume increase of the container (1) or by heat storage medium (3) flowing out of the container (1) into a buffer container (21; 63, 65), and a volume decrease of the heat storage medium (3) is compensated for by a volume decrease of the container (1) or by heat storage medium (3) flowing out of the buffer container (21; 63, 65) into the container (1).

Owner:BASF AG

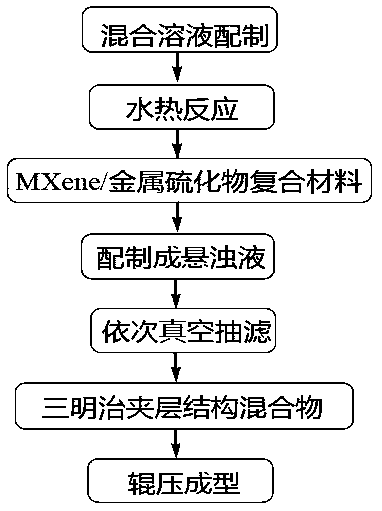

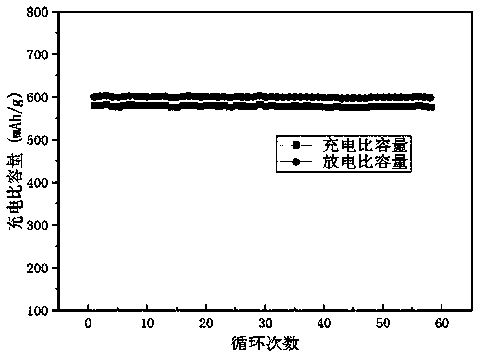

MXene-based flexible composite negative electrode material and preparation method thereof

InactiveCN109671949AIncrease energy densityImprove conductivityCell electrodesGrapheneCapacitanceCharge discharge

The invention discloses an MXene-based flexible composite negative electrode material and a preparation method thereof. According to the MXene-based flexible composite negative electrode material andthe preparation method thereof, a transition metal sulfide is loaded on a two-dimensional layered structure of the MXene material through a hydrothermal method. The agglomeration effect of the MXene material is overcome, and the collapse of a layered structure is prevented. Meanwhile, the energy density of the composite material is improved. The MXene material with high conductivity acts as a three-dimensional conductive network skeleton, so that the conductivity and the mechanical strength of the composite material are enhanced. The volume expansion of the transition metal polysulfide material in the charging process is buffered. Meanwhile, the material has good charge-discharge cycle stability. The composite material and expanded graphite are combined to prepare a self-supporting high-flexibility negative electrode material. In the charging and discharging process, the hydrophilic MXene material has high affinity to polysulfides. The electrochemical performance and the capacitive deionization performance of the composite negative electrode material can be further improved. Sulfides generated by transition metal sulfides are eliminated. The shuttle effect of the polysulfides is limited, and the service life of the negative electrode material is prolonged.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Graphene modified silicon monoxide and carbon composite microsphere, and preparation method and application thereof

ActiveCN106410158AAlleviate volume expansionActive connectionCell electrodesBatteriesCarbon compositesSilicon monoxide

The invention provides a graphene modified silicon monoxide and carbon composite microsphere prepared from graphene, asphalt and silicon monoxide, and a preparation method and an application thereof. Asphalt and silicon monoxide bulk are adopted as raw materials, so the cost is low; a high temperature and high pressure reaction is adopted to obtain a silicon monoxide and carbon composite material in a liquid phase, so the technology is simple; and a dispersant can be recycled, so no waste liquid is generated, and no toxic substances are discharged. The above obtained material has a small specific surface area, and is in favor of forming a stable SEI film; a graphene two-dimensional material has an obvious modification effect, effectively connects active substances, and alleviates volume expansion of an electrode, and good dispersion and reasonable cavity of silicon monoxide make the material have excellent cycle performances.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

System for distribution of electric power

InactiveUS20040051615A1Raise the barrierEliminate needTransformers/inductances coolingTransformers/inductances casingsBusbarTransformer

A subsea electrical power distribution system including a first chamber (20) housing a transformer, a second chamber (30) housing a power distribution system with busbars (32) for distribution of power to individual consumers connected to said busbars via connectors (33). The interface between the first and second chamber includes a flexible membrane (22) allowing the oil in the first chamber to expand into the second chamber and vice versa. The second chamber being connected to an external volume expansion chamber (34) allowing the pressure in the second chamber to balance against the pressure of the ambient sea.

Owner:VETCO GRAY SCANDINAVIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com