Patents

Literature

5923 results about "Construction waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction waste consists of unwanted material produced directly or incidentally by the construction or industries. This includes building materials such as insulation, nails, electrical wiring, shingle, and roofing as well as waste originating from site preparation such as dredging materials, tree stumps, and rubble. Construction waste may contain lead, asbestos, or other hazardous substances.

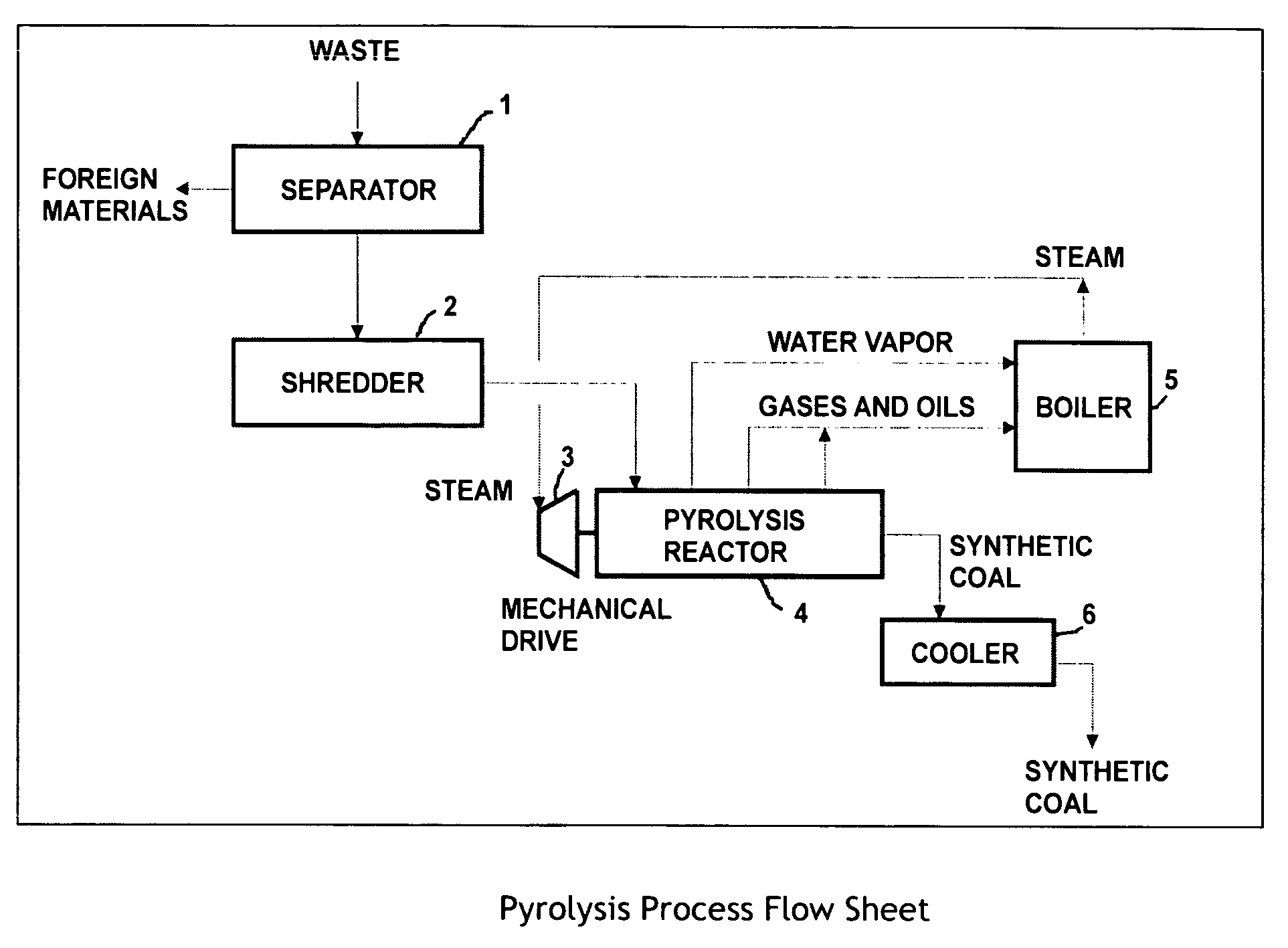

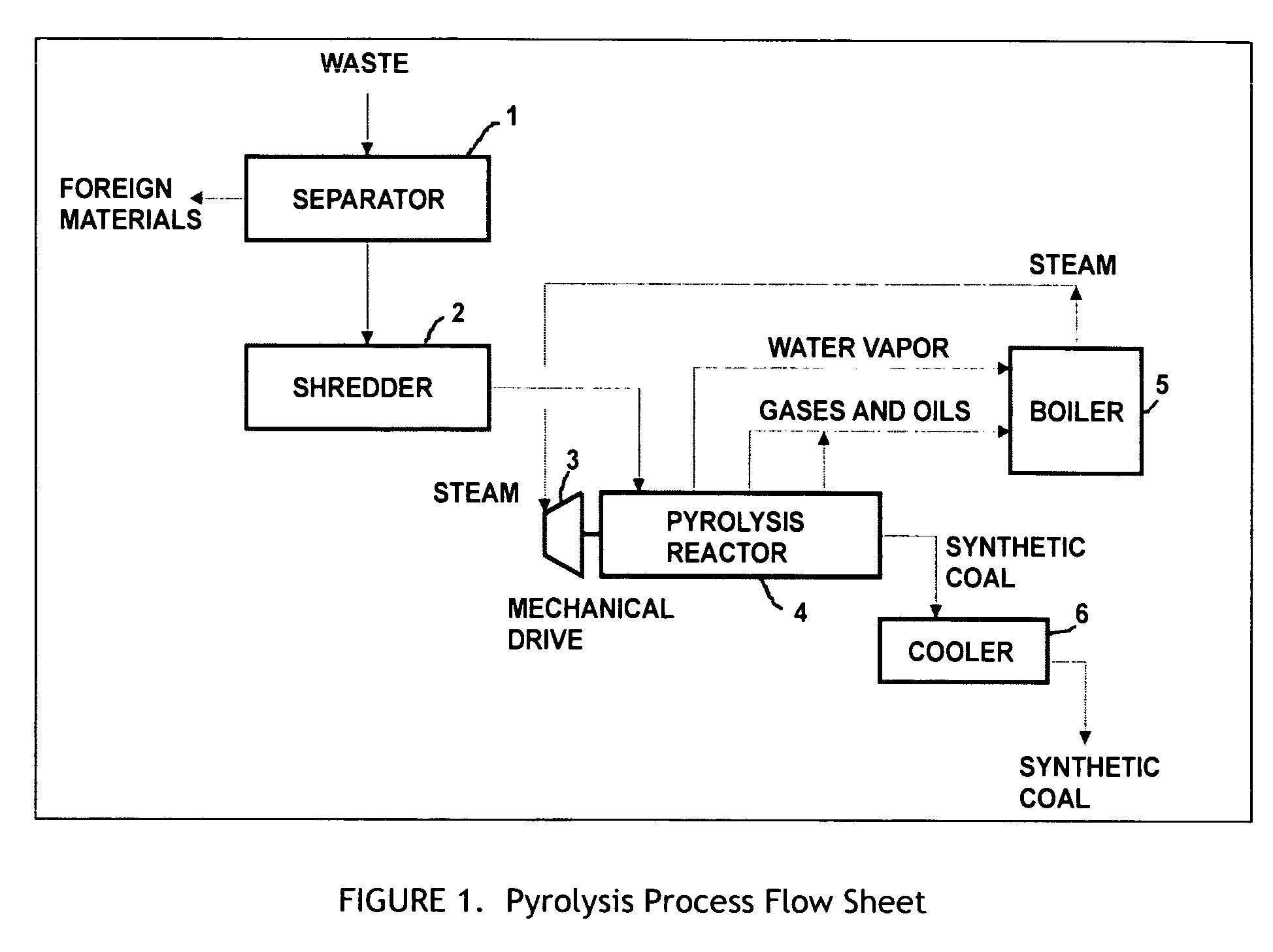

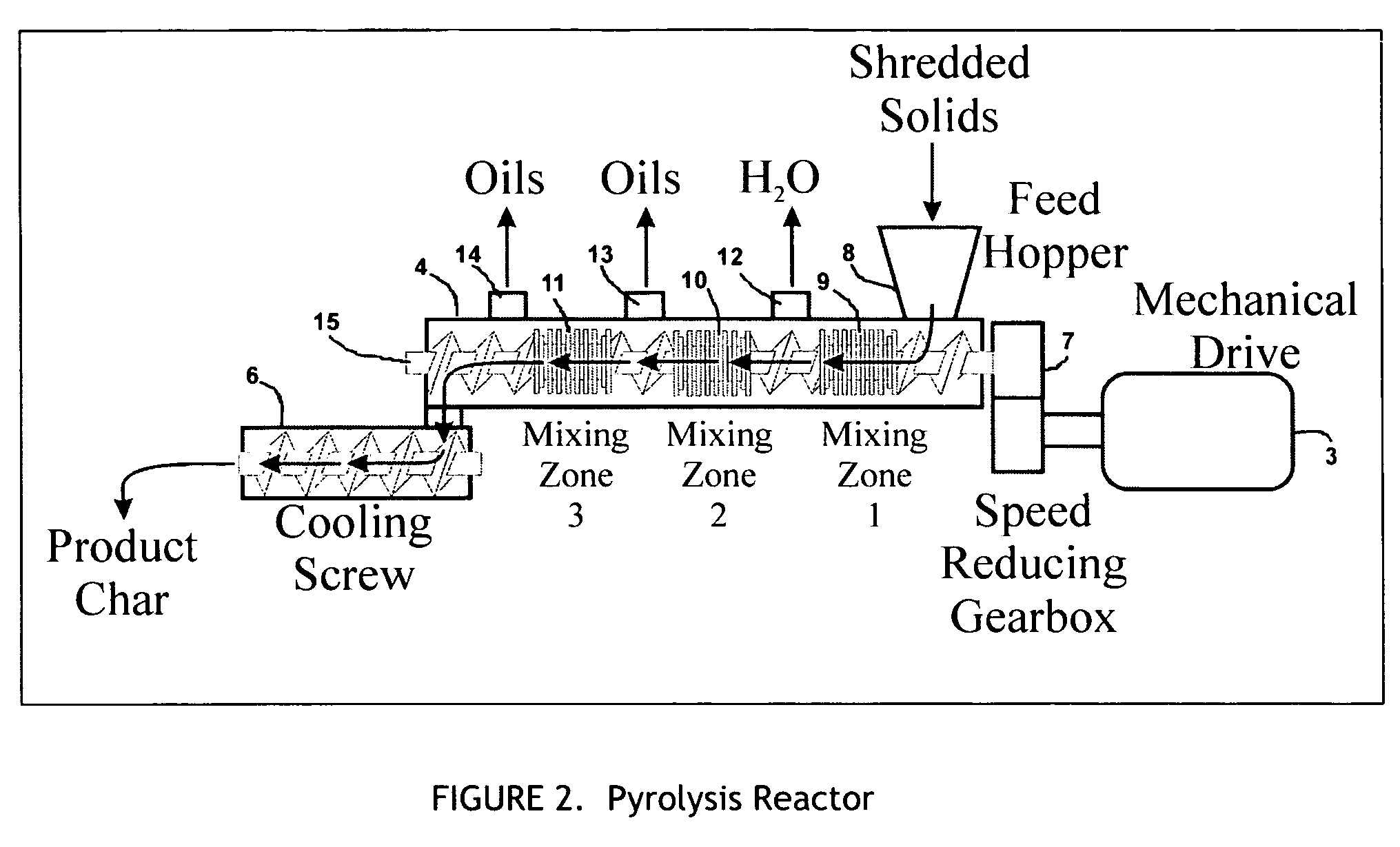

Waste conversion process

InactiveUS20060280669A1Good yieldMinimization requirementsBiofuelsIndirect and direct heating destructive distillationEnvironmental engineeringSand granules

A process for the preparation of high quality char from organic waste materials. The waste is first sorted to remove recyclable inorganic materials of economic value (metals, glass) and other foreign materials that would be detrimental to the quality of the final product (stone, sand, construction debris, etc.). After size reduction, the waste is pyrolyzed at a temperature range of 250 to 600° F., in a high capacity, continuous mixer reactor, using in-situ viscous heating of the waste materials, to produce a highly uniform, granular synthetic product similar in energy content and handling characteristics to, but much cleaner burning than, natural coal.

Owner:ENTROPIC TECH CORP

Method and Apparatus for Microwave Reduction of Organic Compounds

InactiveUS20070102279A1Maximum protectionElectrical coke oven heatingSolid waste disposalEngineeringVolumetric Mass Density

The invention described herein generally pertains to utilization of high power density microwave energy to reduce organic compounds to carbon and their constituents, primarily in a gaseous state. The process includes, but is not limited to, scrap tires, plastics, asphalt roofing shingles, computer waste, medical waste, municipal solid waste, construction waste, shale oil, and PCB / PAH / HCB-laden materials. The process includes the steps of feeding organic material into a microwave applicator and exposing the material to microwave energy fed from at least two linear polarized sources in non-parallel alignment to each other, and collecting the material. The at least two sources of microwave energy are from a bifurcated waveguide assembly, whose outputs are perpendicular to each other and fed through waveguide of proper impedance, such that the microwave sources are physically and electrically 90° out of phase to each other. The microwave frequency is between 894 and 1000 MHz, preferably approximately 915 MHz.

Owner:NOVAK JUDITH

Burning-free block brick prepared from bulky industrial waste residues

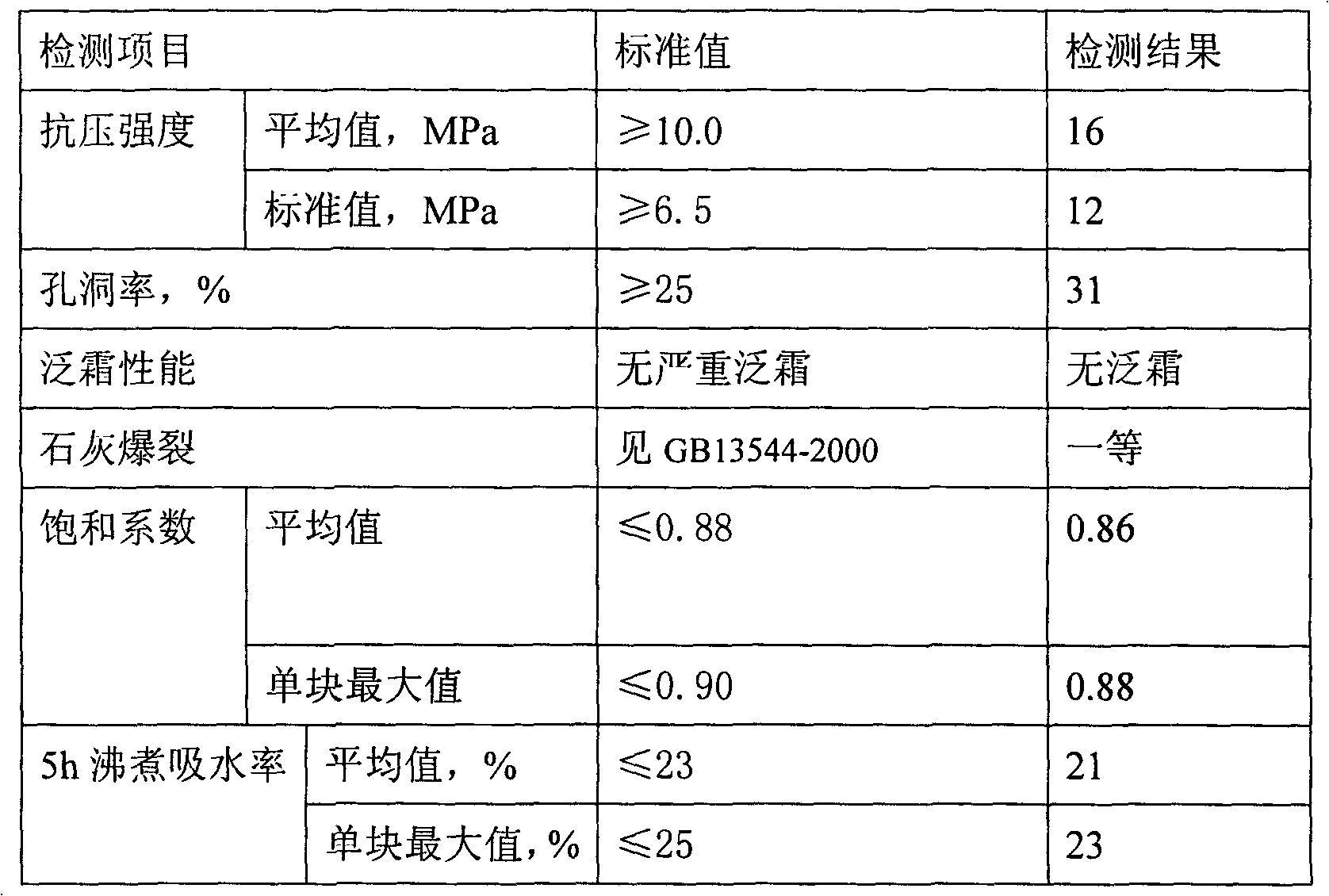

The invention relates to a burning-free block brick prepared from bulky industrial waste residues. The burning-free block brick is characterized in that the block brick comprises the following raw materials in parts by weight or volume: 10-80 parts of at least one of tailing, magnesium slag, basic slag, mountain flour, cinder, fly ash, coal gangue, oil shale waste and sulfuric acid slag, 0-80 parts of at least one of gravel, waste sand, construction waste, garbage to be burnt, steel slag, mineral slag, copper slag, iron slag with gold, ardealite, phosphorous slag and carbide slag, 0-50 parts of active cementing material, 0-30 parts of cement clinker, 2-15 parts of cement and a defined amount of water. The preparation method of all types of burning-free and steaming-free standard bricks, perforated bricks, hollow blocks, paving tiles, road edge bricks and fence railings which have low cost and high strength, is as follows: proportioning, stirring for 1-6 minutes, adding a defined amount of water to stir, placing in moulds to form in a machine and performing natural curing for 7-28 days. The burning-free block brick has high raw material selectability, simple technology and wide development and application prospects, and is environmental-friendly.

Owner:司密花 +2

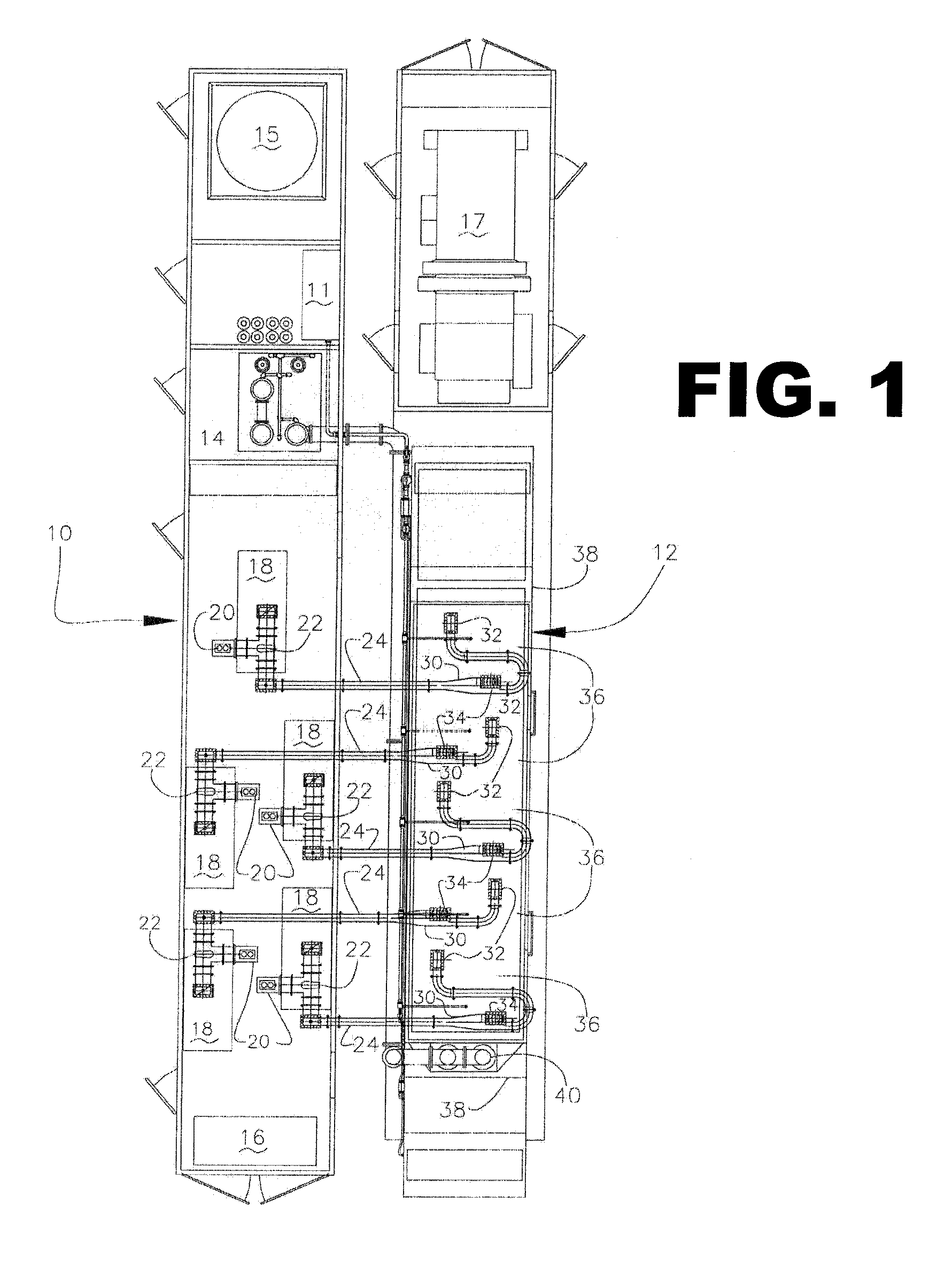

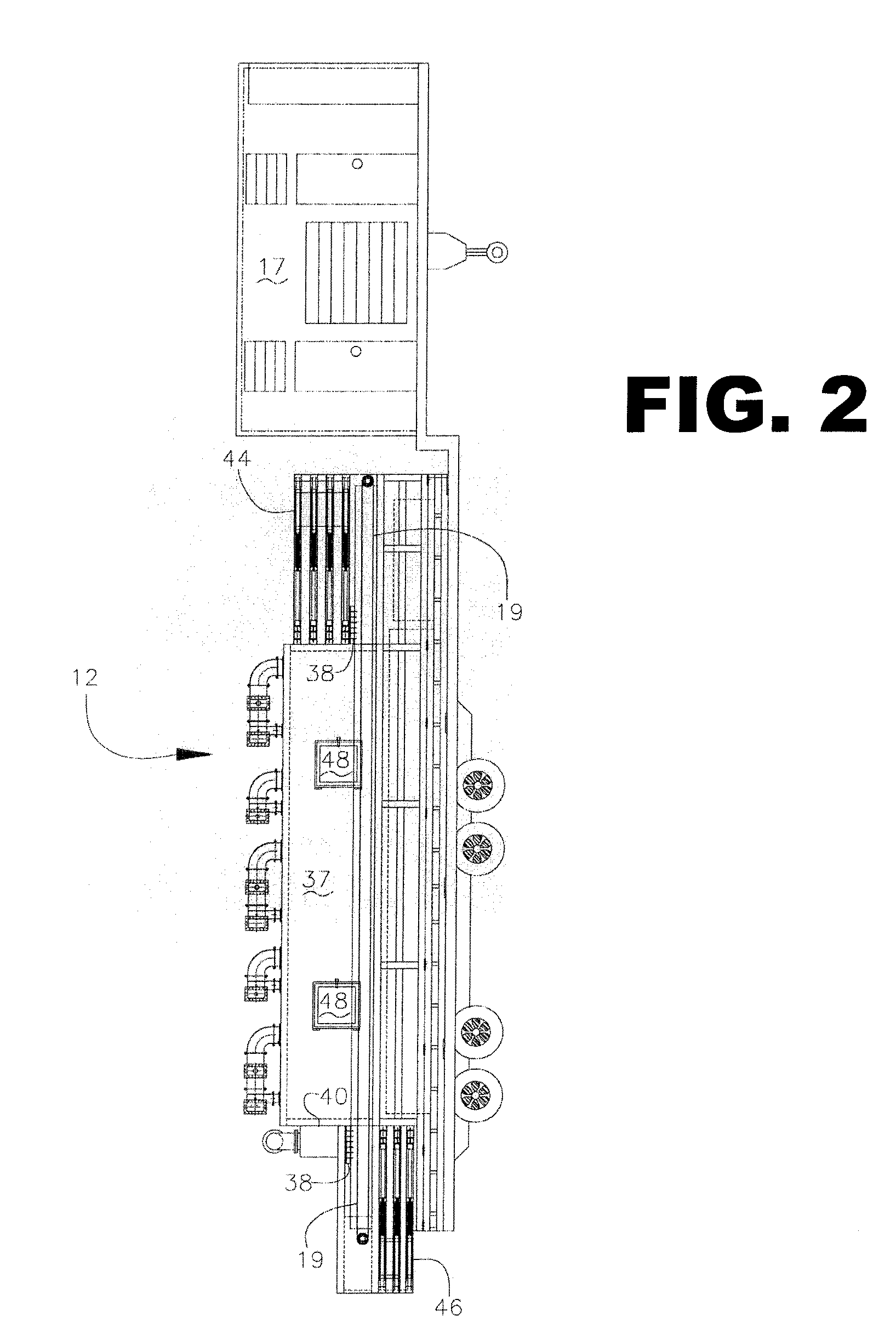

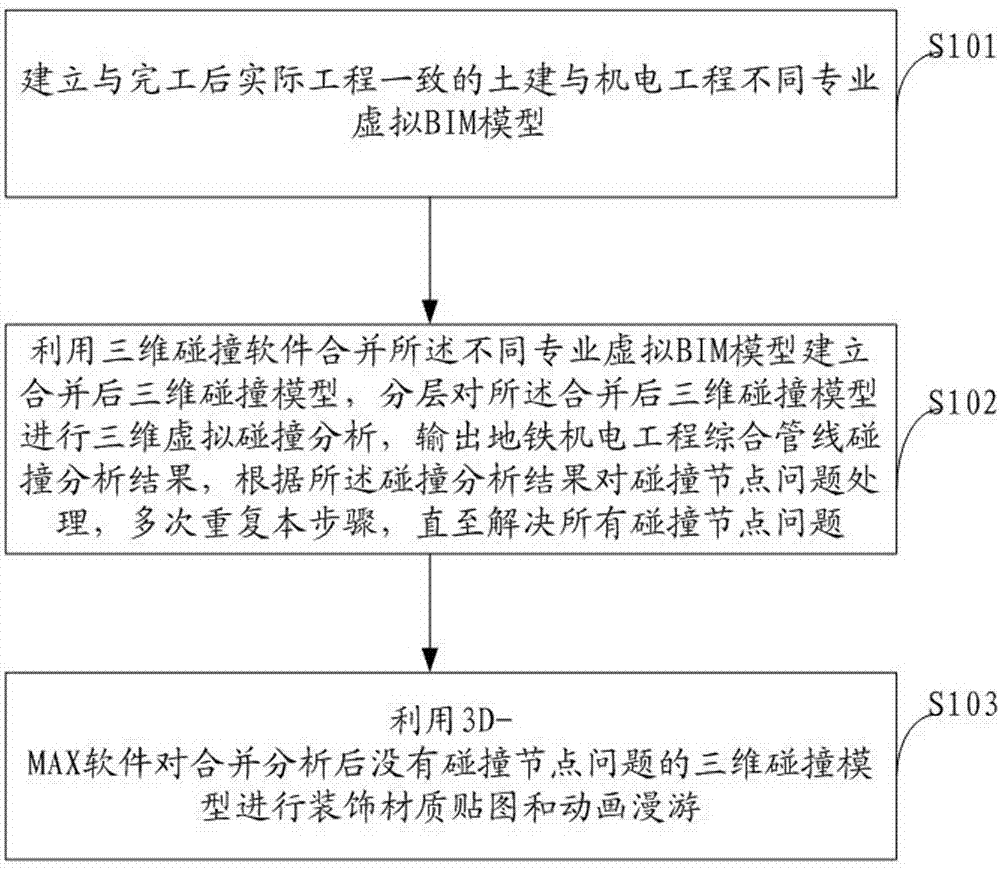

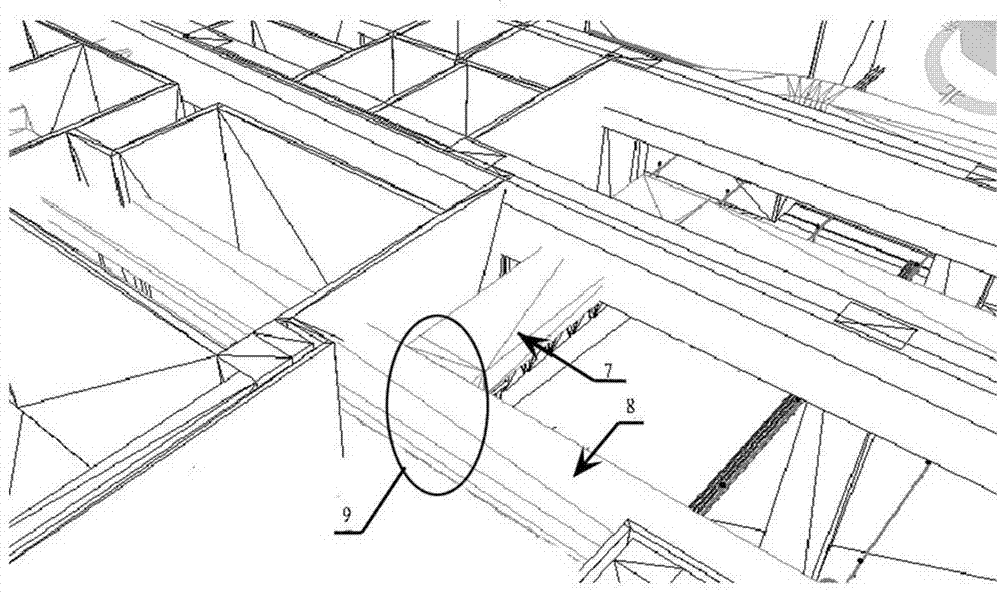

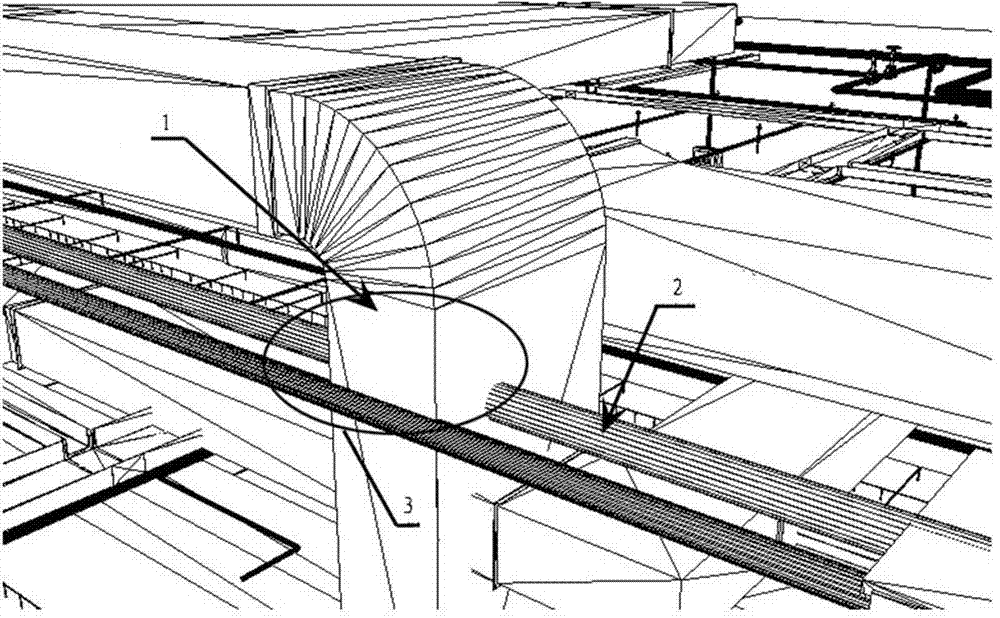

Complex pipeline collision optimization method of subway electromechanical engineering

ActiveCN103093061AOvercome the shortcomings of error-prone, omission and bump-to-missSolving technical issues with cross collisionsSpecial data processing applicationsNODALCollision analysis

The invention belongs to the technical field of electromechanical device installation and discloses a complex pipeline collision optimization method of subway electromechanical engineering. According to the method, three-dimensional bus interface module (BIM) software is used for establishing different professional virtual BIM models which are consistent with completed engineering and then output to three-dimensional collision software for establishment of a combined three-dimensional collision model for collision analysis, collision nodes are then processed and optimized, and then decorative texture mapping and animation roaming are carried out on the combined, analysed and processed three-dimensional collision model without the collision node problem through 3D - MAX software, and therefore collision optimization of complex pipelines of the subway electromechanical engineering is achieved. According to the complex pipeline collision optimization method of the subway electromechanical engineering, the BIM technology is utilized to solve the problem that collision of various complex pipelines causes construction ceasing during electromechanical installation, reasonable planning and utilization of electromechanical pipeline equipment and the like are achieved by means of the optimized design, construction waste is reduced, construction time is shortened, working efficiency at site is improved greatly, and initial investment of a proprietor is reduced.

Owner:ELECTRIFICATION ENG CO LTD OF CHINA RAILWAY 22TH BUREAU GRP +1

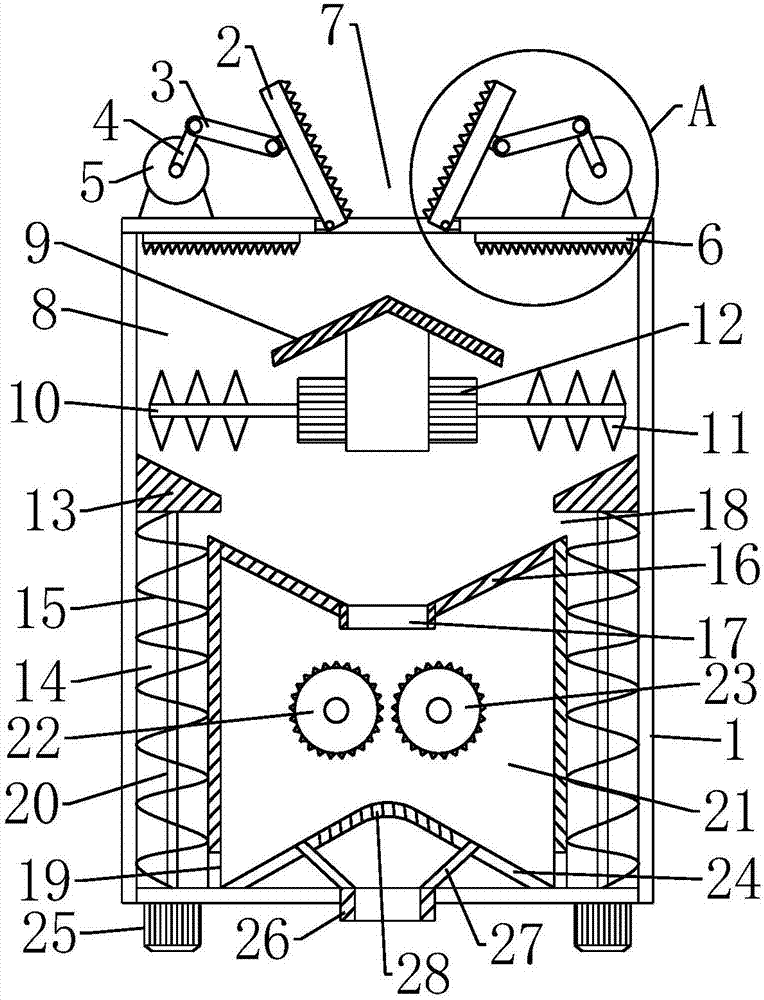

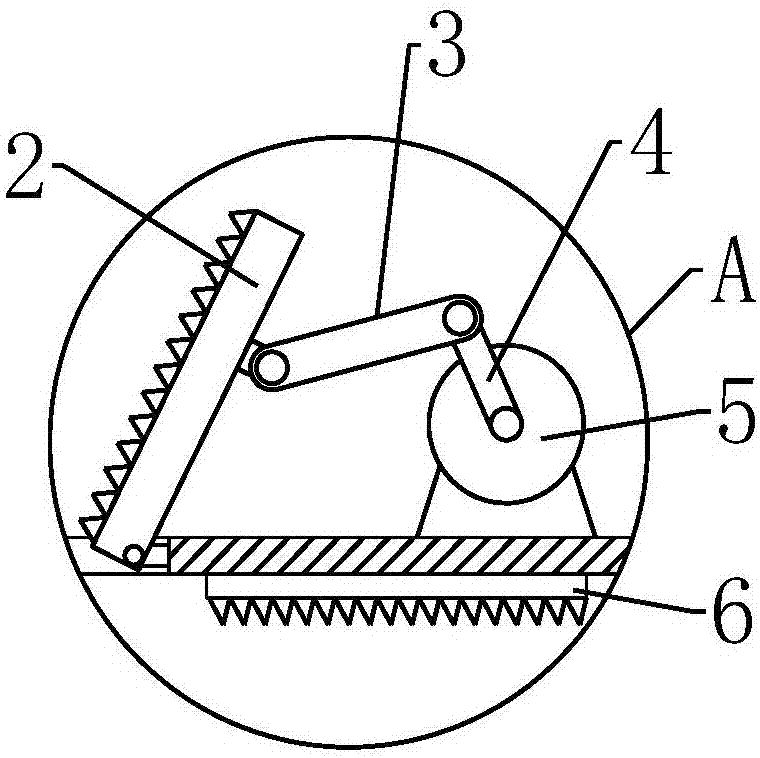

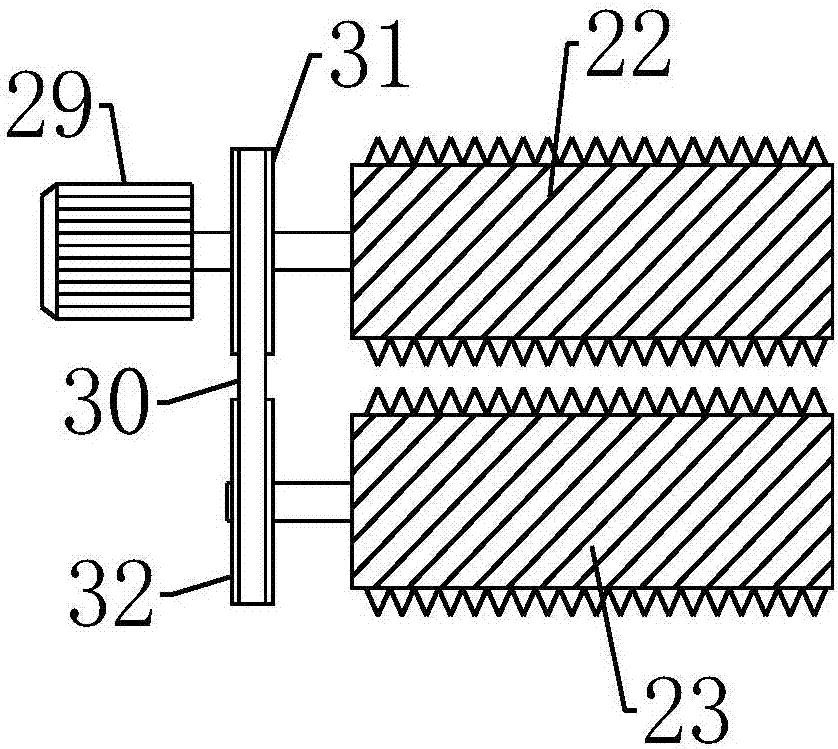

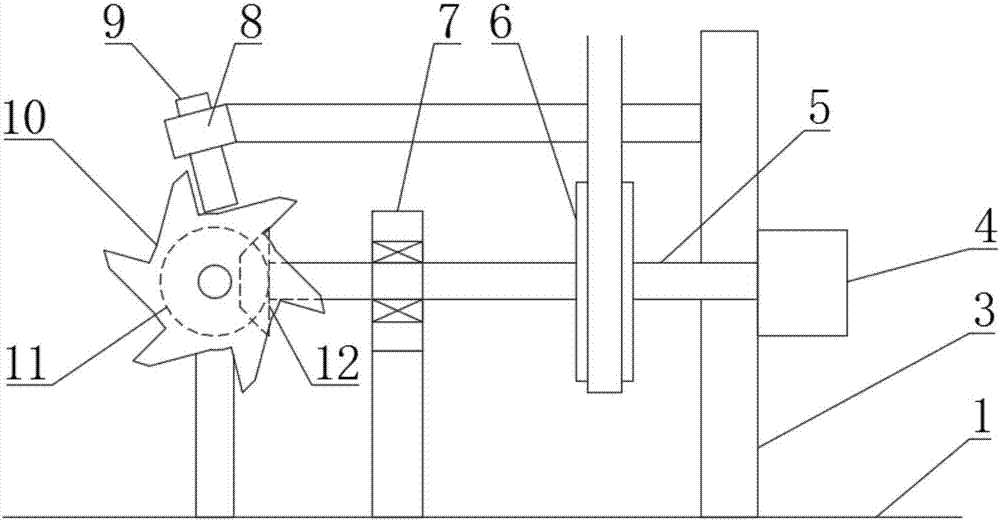

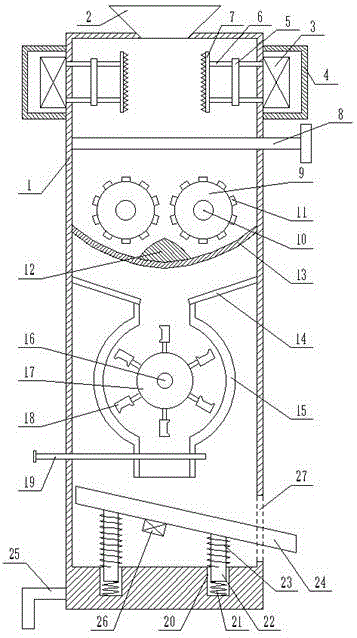

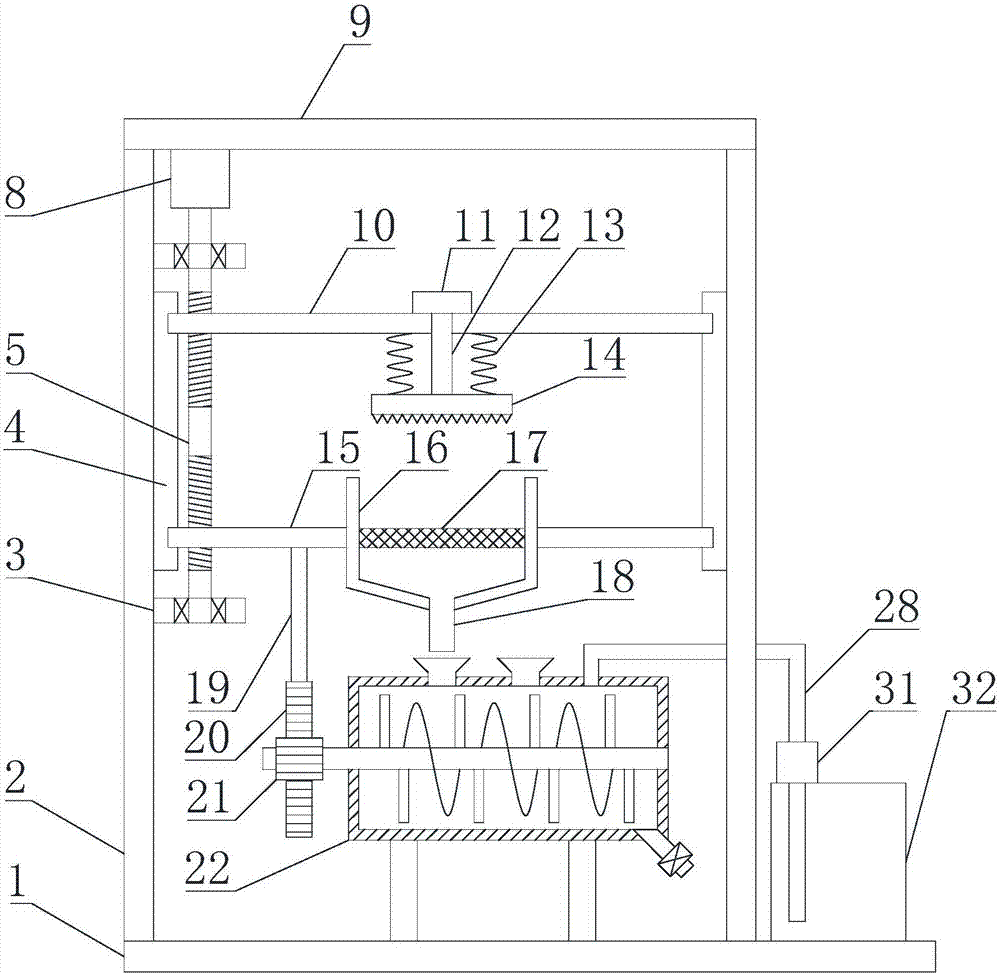

Building waste crushing and recycling device

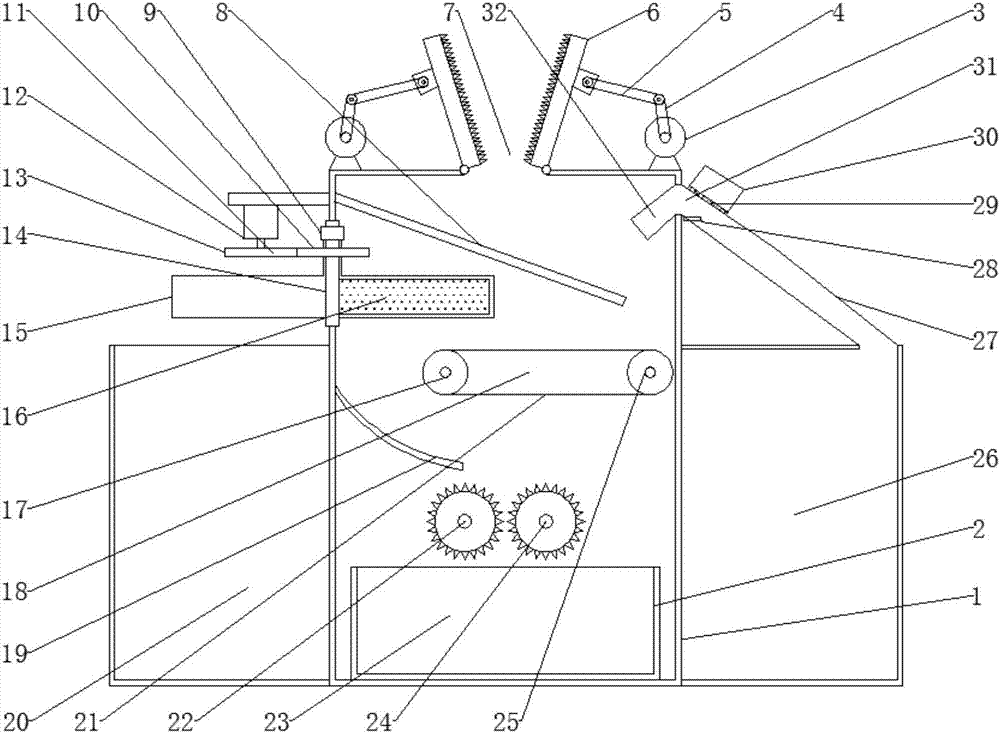

InactiveCN107088465AImprove crushing effectFully brokenGrain treatmentsElectric machineryArchitectural engineering

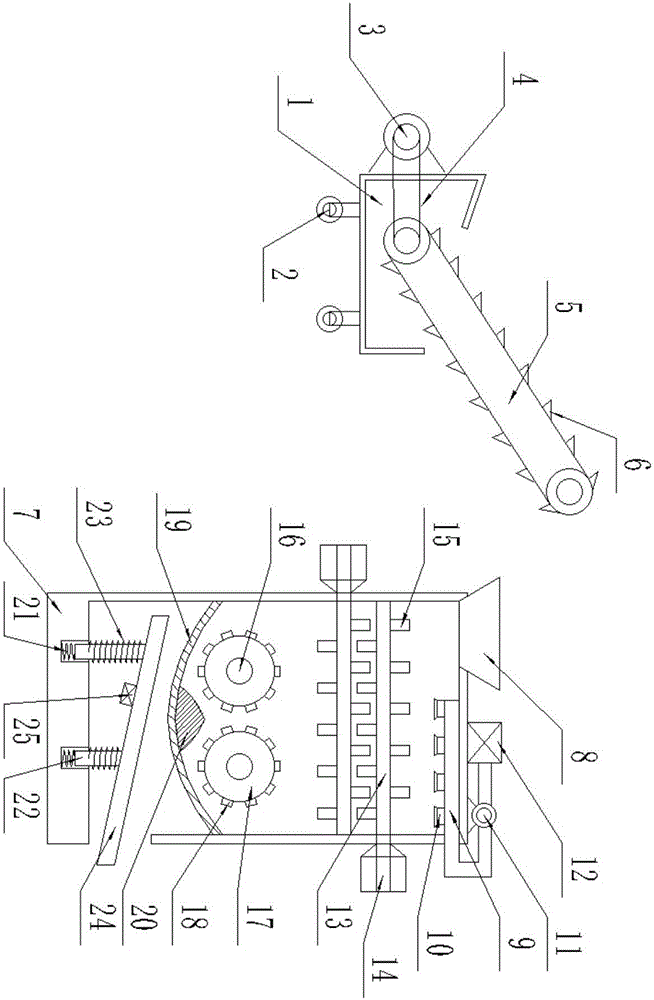

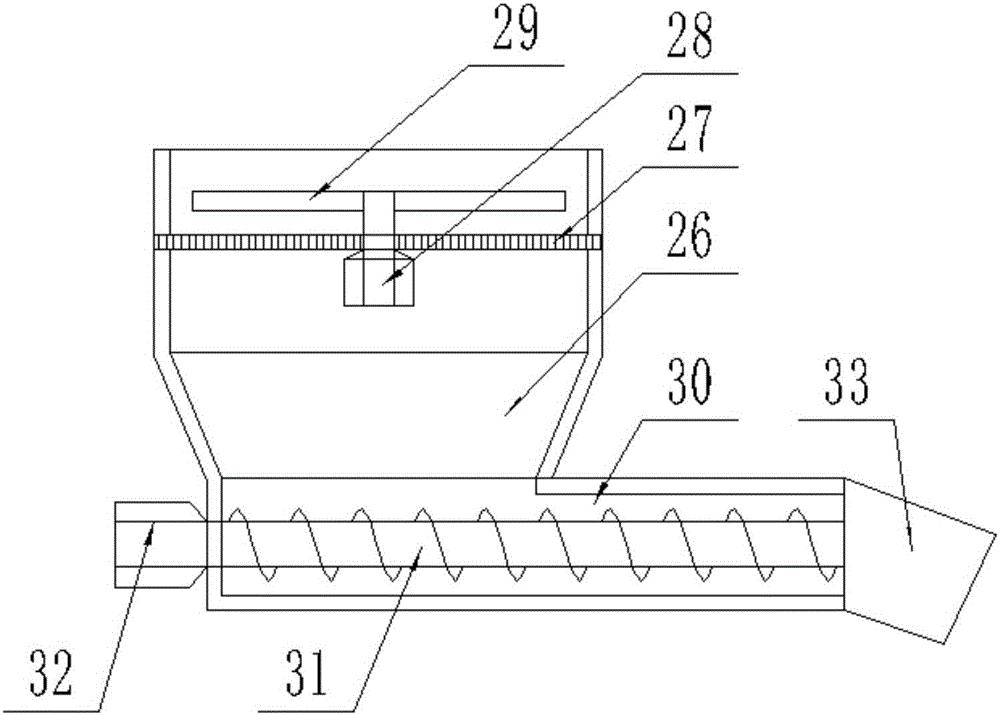

The invention discloses a device for crushing and recycling construction waste, which comprises a box body, a crushing chamber is arranged on the upper part of the inner cavity of the box body, a grinding chamber is arranged on the lower part of the inner cavity of the box body, and lifting chambers are arranged on both sides of the lower inner cavity of the box body The crushing chamber and the grinding chamber are separated by a partition. The movable jaw plate, the first connecting rod, the second connecting rod and the No. 1 motor are arranged symmetrically on the top plate of the box body. The fixed seat, the top fixed frame of the fixed seat is provided with a No. 1 material guide slant plate, and the No. 2 motor is symmetrically fixed on the two side walls of the fixed seat. The output shaft of the No. 2 motor is driven and connected with a rotating shaft. The outer ring of the rotating shaft is uniform Several crushing blades are fixedly installed, and the inner turret of the grinding chamber is equipped with No. 1 grinding roller and No. 2 grinding roller. The invention has simple structure, convenient use, can fully crush and grind construction waste, has good effect and high efficiency, and is beneficial to the recycling of construction waste.

Owner:CHANGSHA WUDAO IND DESIGN CO LTD

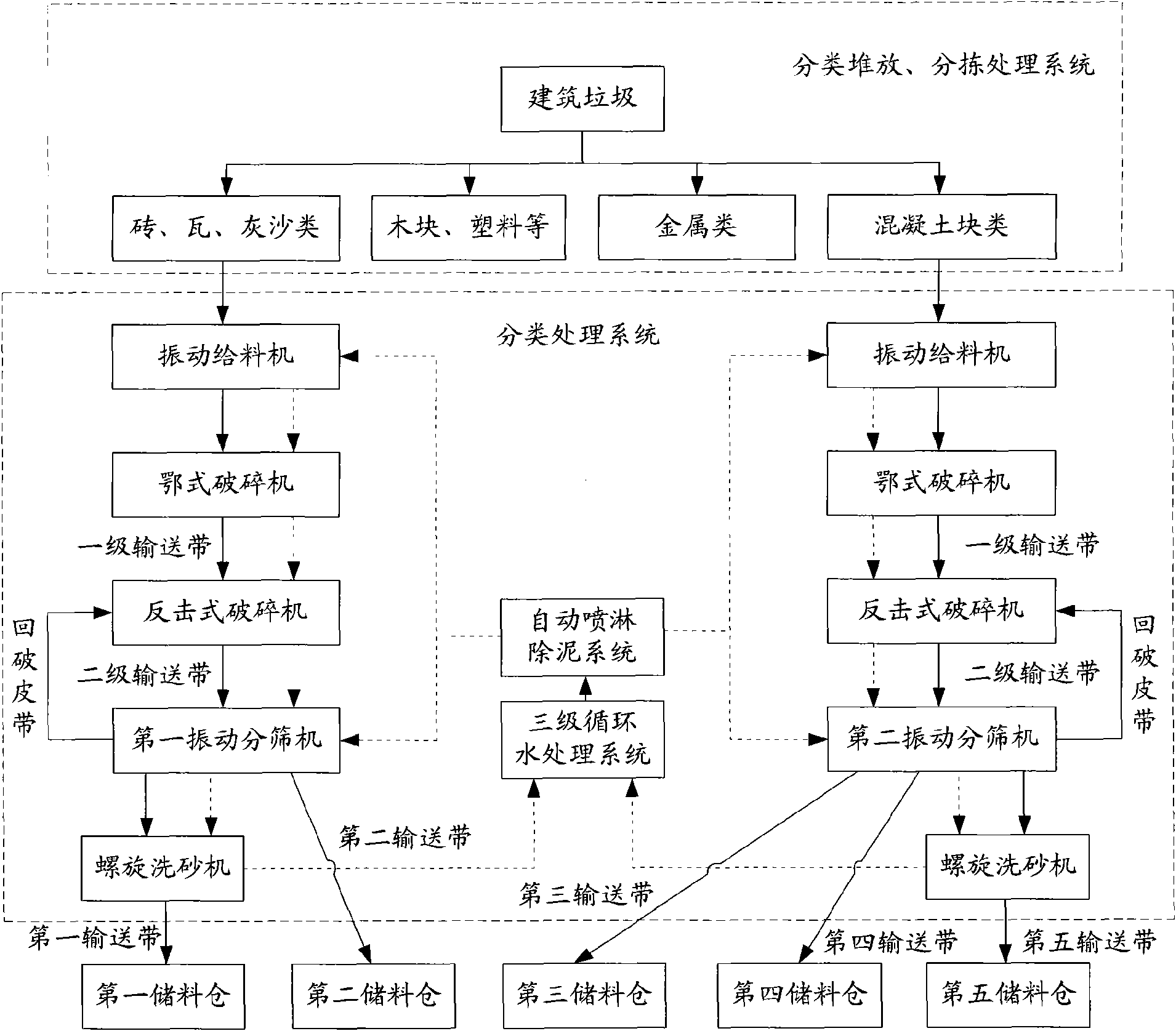

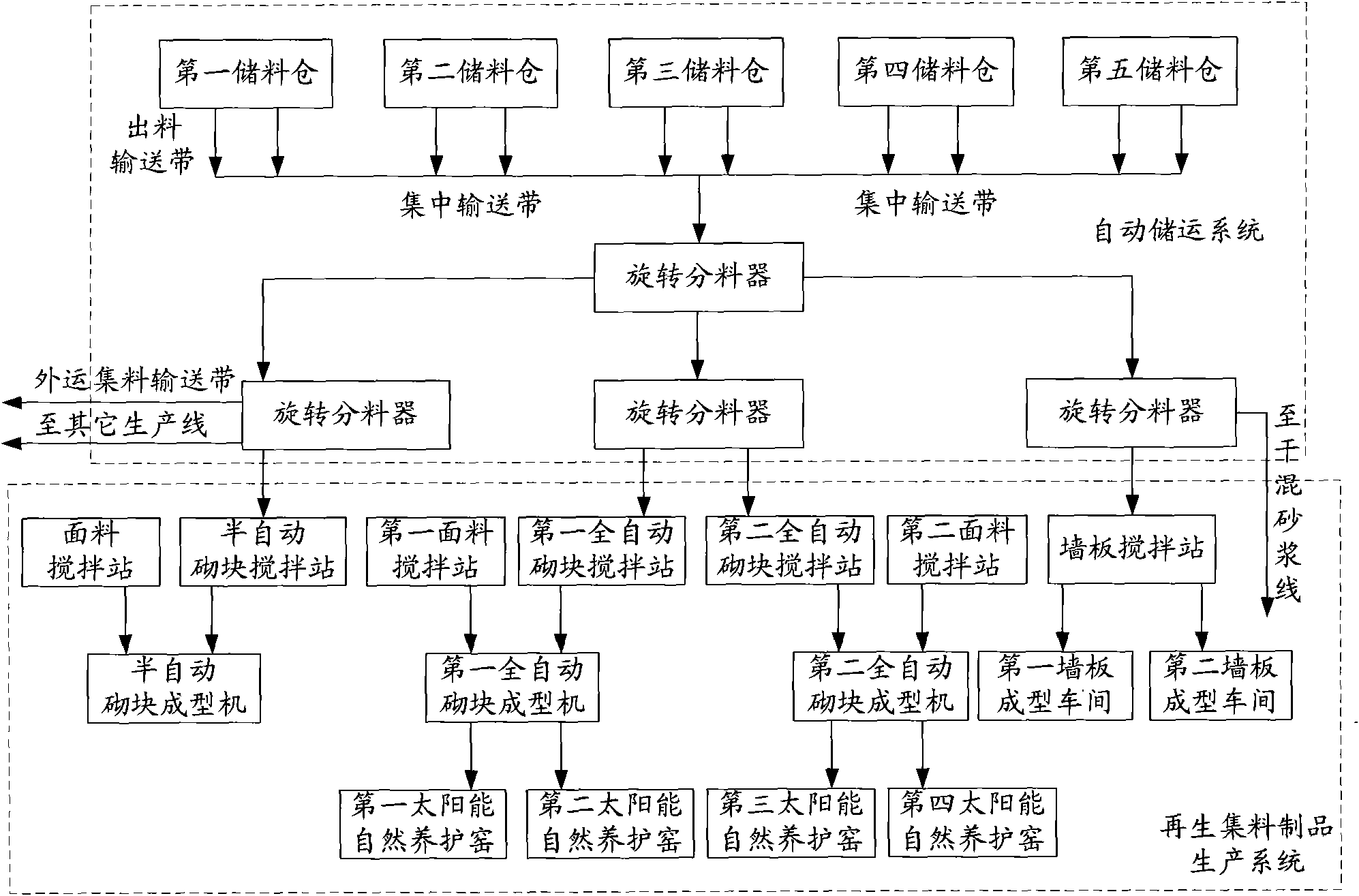

Building refuse treatment regeneration system

The embodiment of the invention discloses a building refuse treatment regeneration system, including a classification stacking, sorting processing system, a classification processing system and a plurality of storage bins, wherein, the classification processing system includes at least two parallel crushing screening process production lines and water circulating systems, each crushing screening process production line includes a feeder, crusher, as well as a screening machine connected in series in sequence, and a plurality of outlets of the screening machine are respectively connected to the plurality of storage bins through conveyor belts. By adoption of the building refuse treatment regeneration system of the embodiment of the invention, bricks, tiles, dust and sand and concrete blocks and the like in the building refuse can be divided into at least two production lines for parallel processing, which greatly enhancing the production efficiency and the purity of recycled aggregates, so that the recycled aggregates can be applied to a variety of uses, reproduced into a variety of high-quality recycled products, reducing the waste of resources and minimizing pollution that will be probably caused to the environment.

Owner:深圳市绿发鹏程环保科技有限公司

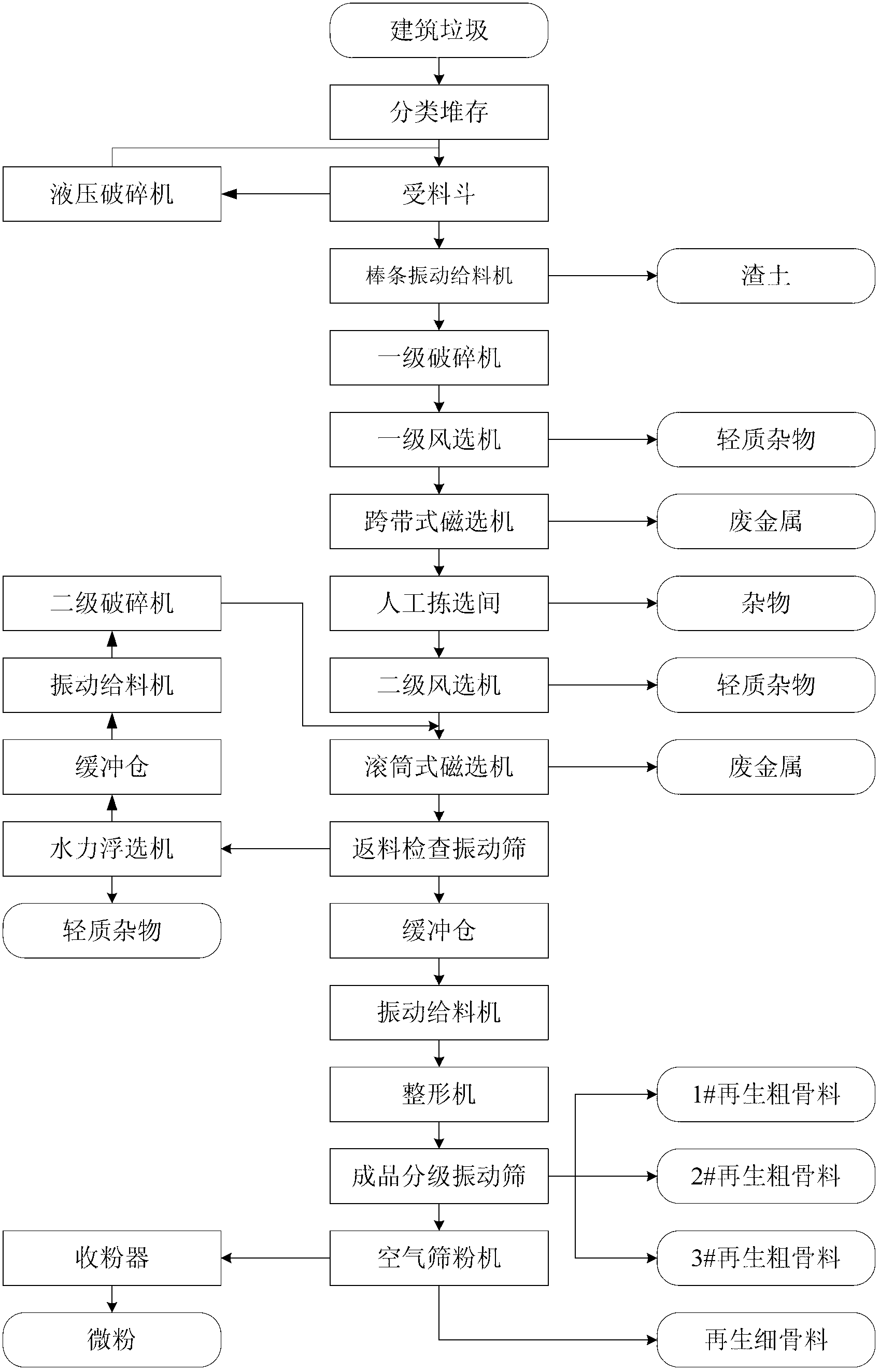

Method and system for treating construction waste

InactiveCN102838307AAchieve pre-separationReduce micronized contentSolid waste managementEngineeringNational standard

The invention discloses a method for treating construction waste, comprising the following steps of: performing feeding and dregs pre-screening, primary crushing, secondary crushing and product screening on a material in sequence; performing sorting and impurity removing treatment on the material subjected to the primary crushing; performing material returning screening on the material subjected to the sorting and impurity removing treatment, performing particle shaping on the material screened down after the material returning screening treatment, and returning the oversize material to the secondary crushing; and combining the material subjected to the secondary crushing with the material in the sorting and impurity removing treatment. The system and method treating construction waste, provided by the invention, have high-efficiency and systemic sorting and impurity-removing functions; the generated construction waste recycled aggregate product meets the requirements of national standard 'recycled coarse aggregate for concrete'(GB / T 25177-2010), 'recycled fine aggregate for concrete and mortar' (GB / T 25176-2010) and other recycled aggregate product raw materials.

Owner:SHOUGANG CORPORATION

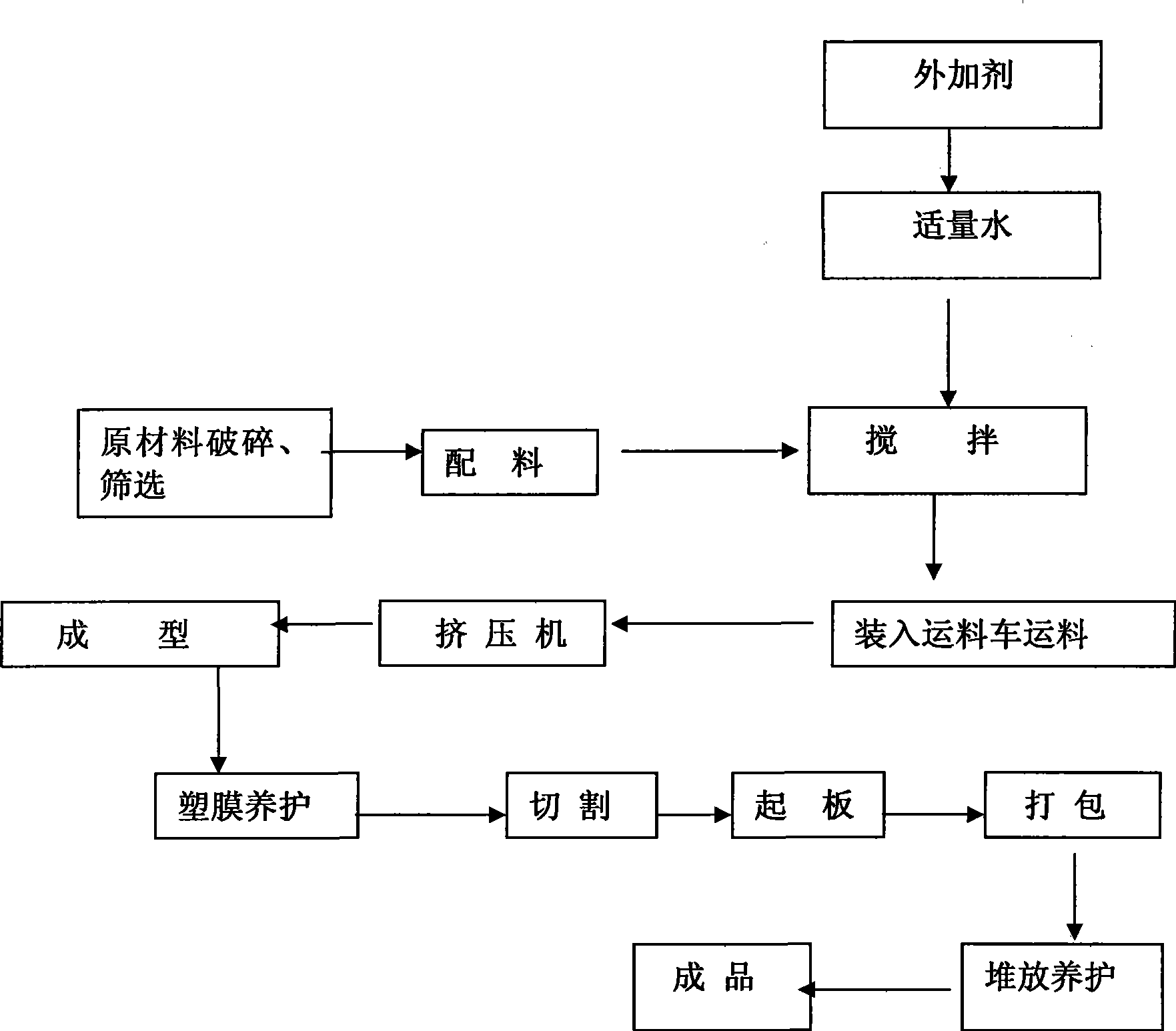

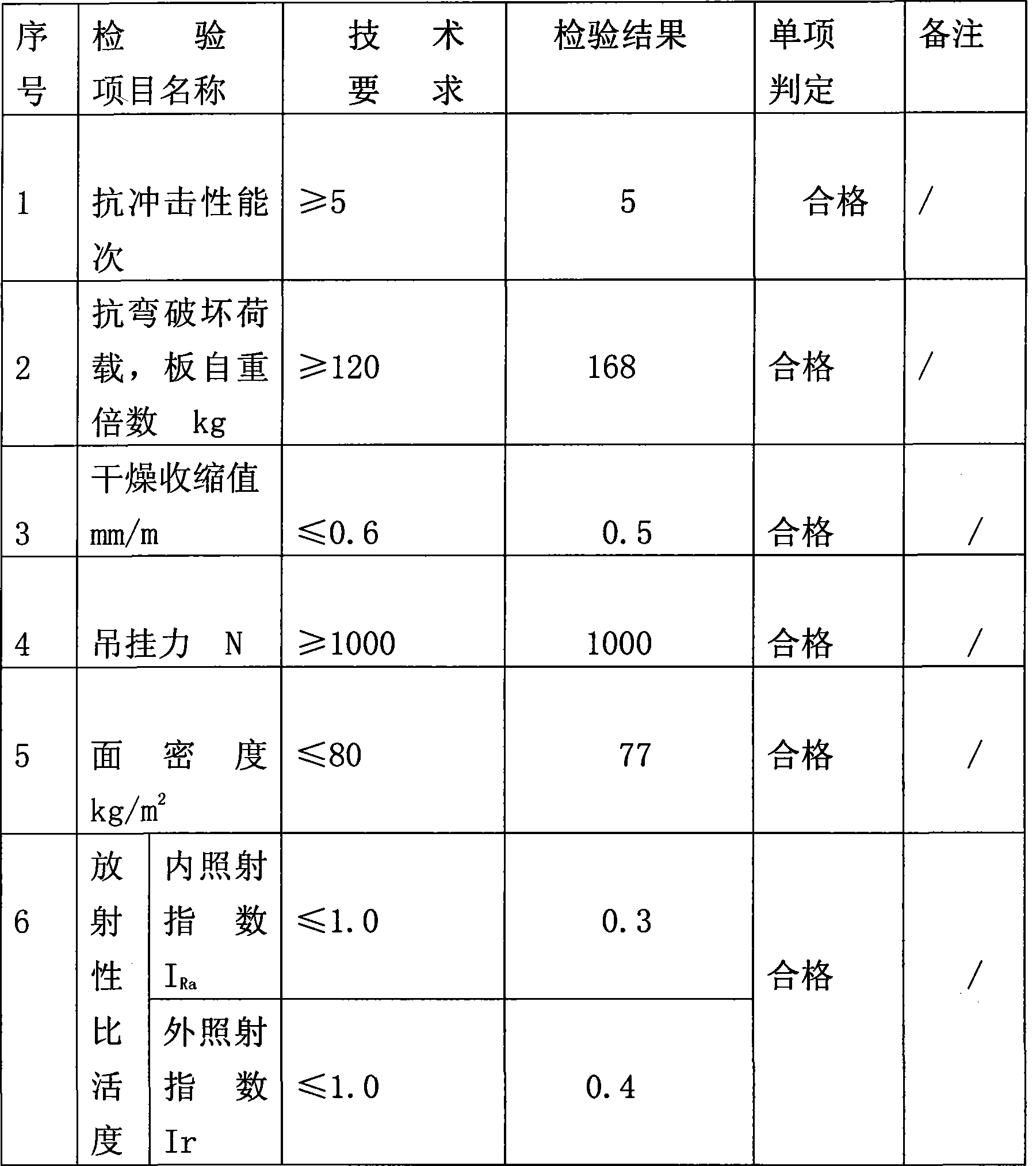

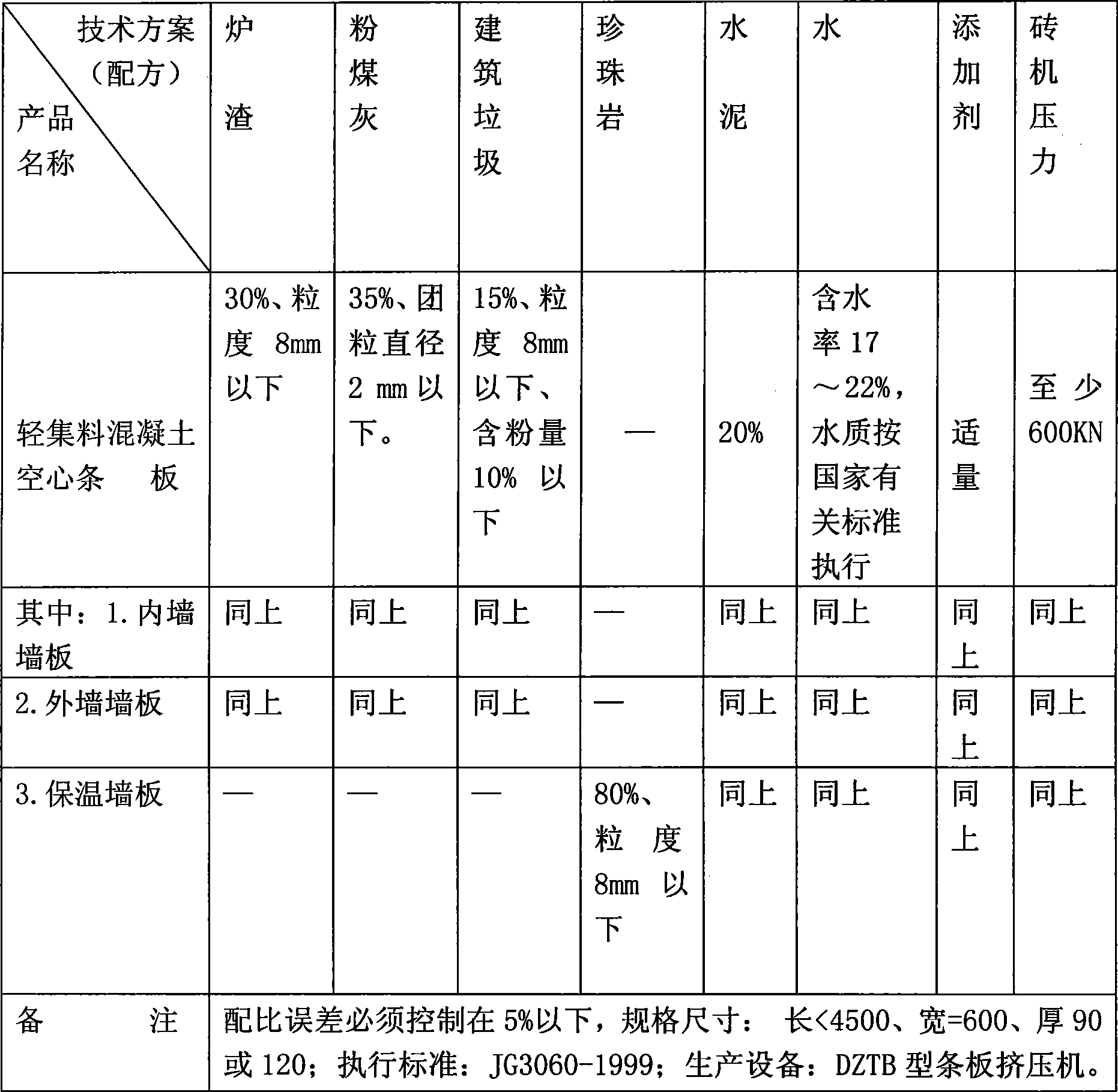

Light wall board and manufacturing technology thereof

InactiveCN101423368AFast constructionIncrease typeSolid waste managementManufacturing technologySlag

The invention provides a light wall slab, which is producing by the following materials in weight percentage: 30 percent of slag with the grain size of less than 8mm, 35 percent of fly ash with the pellet diameter of less than 2mm, 15 percent of construction waste with the grain size of less than 8mm and the power content of less than 10 percent, and 20 percent of cement; moreover, a water reducing agent, a water repellent and an accelerating agent are added into the materials, and water of which the weight accounts for the total weight of the slag, the fly ash, the construction waste and the cement dry material is between 17 and 22 percent is added into the mixture; and the production process comprises the following: crushing raw materials, screening, preparing materials, mixing and stirring the materials, extruding by a slat extruder, curing, cutting, lifting the slab and pile-curing. The light wall slab has the advantages of improving the construction speed of single buildings, saving energy, increasing usable floor areas, meeting building requirements on various levels and prompting the wall material to develop towards industrialization and modernization of the housing industry. The light wall slab can promote the development of internal wall slabs and external wall slabs, and increase types of heat preservation wall slabs. Compared with expanded perlite, the sound insulation property of the industrial residue light aggregate wall slab is improved by more than 30 percent.

Owner:丁志强

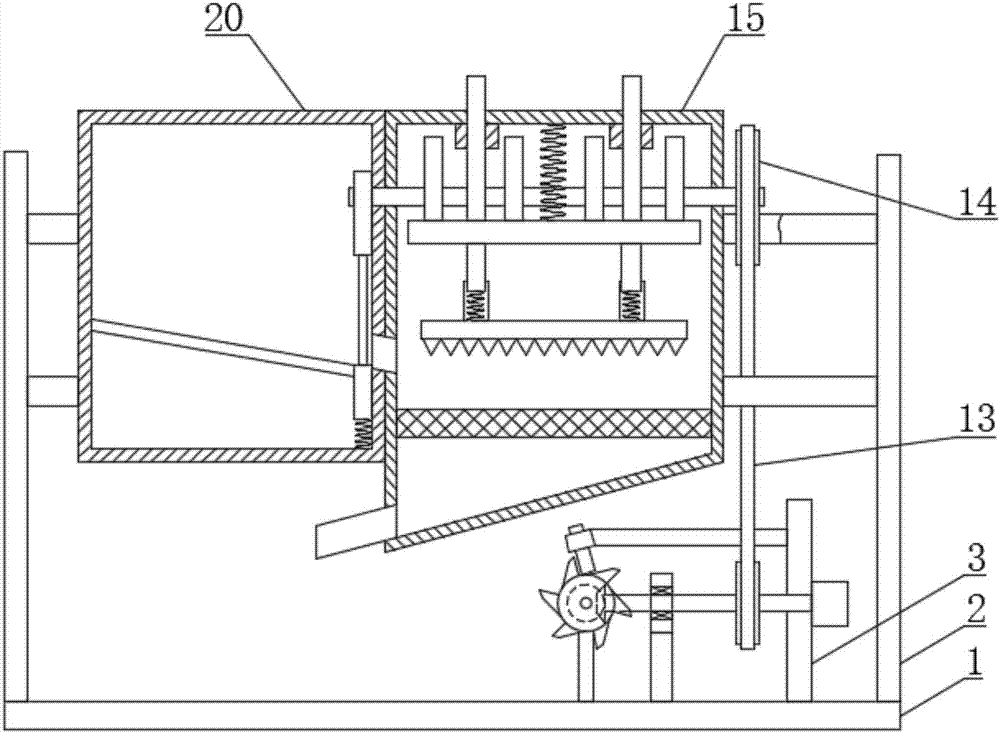

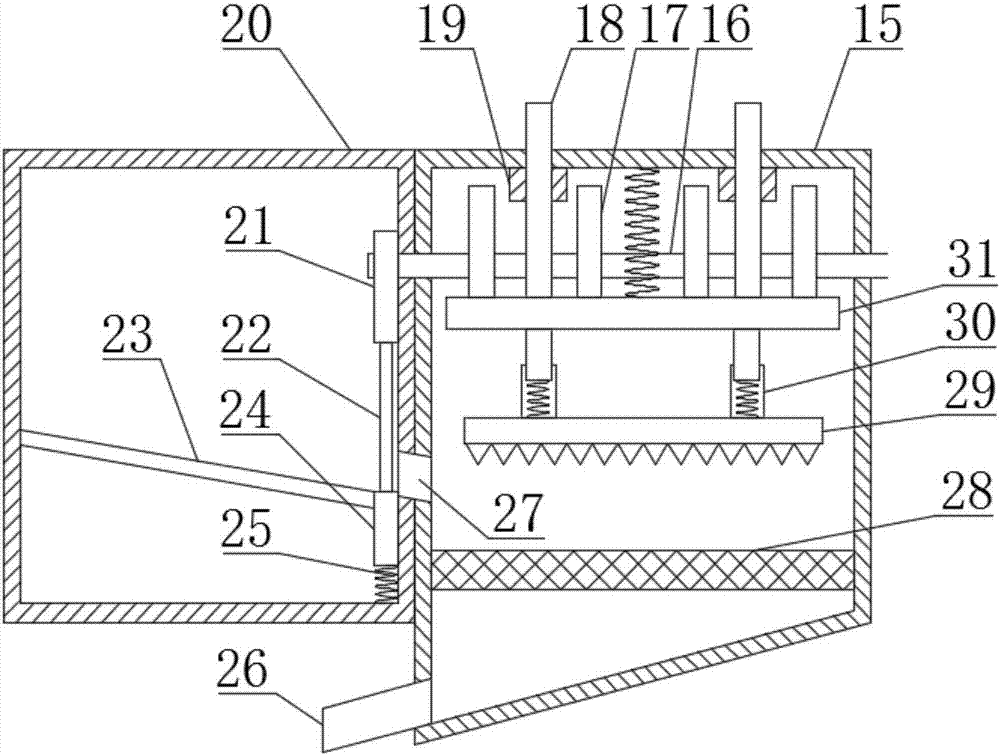

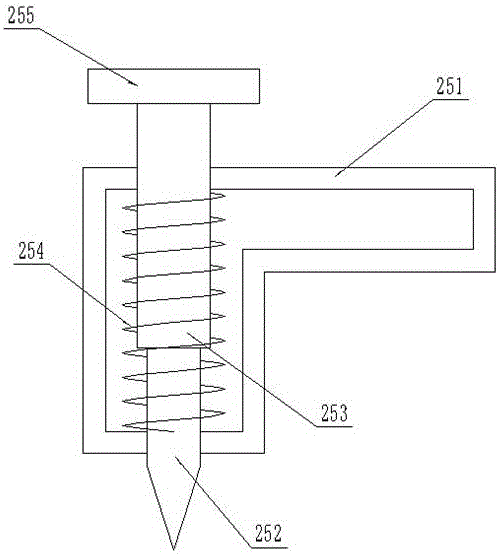

Periodic building rubbish crushing device

The invention discloses a periodical construction waste crushing device, which comprises support frames fixedly arranged on the left and right sides of the base base, the left support frame is fixedly connected with a material box through the support frame, and the right side support frame is fixedly connected with a crushing box through the support frame; The box is provided with a second rotating shaft, a second cam is fixedly installed on the left end of the second rotating shaft, a second pulley is fixedly installed on the right end of the second rotating shaft, and a number of evenly distributed first cams are fixedly installed on the second rotating shaft. A moving plate is provided, and a limit rod is set on the top of the moving plate. The limit rod passes through the top wall of the crushing box and is slidingly connected with the top wall of the crushing box. The top of the moving plate is also connected to the top wall of the crushing box through a spring; the bottom of the moving plate is connected with a The spring column is connected with a pressure plate at the bottom of the spring column. Through the rotation of the motor, multiple structures can be driven to perform various movements, and various functions can be realized, making the operation and control more convenient.

Owner:张艳艳

Geopolymeric concrete based on recycled aggregate and preparation method of geopolymeric concrete

InactiveCN103601424AReduce consumptionImprove thermal stabilitySolid waste managementCement productionAdhesiveRoad surface

The invention relates to geopolymeric concrete based on recycled aggregate, and a preparation method of the geopolymeric concrete. The concrete is prepared by taking construction waste as aggregate and inorganic geopolymer as an adhesive through an alkali activation process. The recycled aggregate geopolymeric concrete prepared by using the method has the characteristics that the concrete can be rapidly dried, the compressive strength, particularly the early-stage compressive strength is high, the volume shrinkage in the coagulation process is extremely low, the coefficient of volume expansion is approximate to 0, and acid-base corrosion resistance is good. Due to the adoption of the method, the defects that the conventional concrete is low in early-stage strength and the coagulation time is long are overcome; a method for rapidly repairing concrete pavement is provided, and problems of recycling and reusing construction waste aggregate and environment problems caused by the construction waste aggregate are solved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Self-cleaning water permeable brick and preparation method thereof

InactiveCN101445340AWide variety of sourcesImprove pollutionSolid waste managementEcological environmentBrick

The invention discloses a self-cleaning water permeable brick comprising a surface material and a base material. The base material is weighed according to weight percentage, comprising 68.4 percent to 77.5 percent of rubble or building rubbish granule or slag, 10 percent to 25 percent of cement, and 5.3 percent to 12 percent of water. The surface material is weighed according to weight percentage, comprising 66.7 percent to 71.8 percent of high-intensity sand, 10.8 percent to 26.5 percent of cement, 3.4 percent to 10.4 percent of water, and 0.1 percent to 1.0 percent of nanometer titanium dioxide. The surface material and the base material are compacted together to form an integrated water permeable brick. The invention further discloses a preparation method of the self-cleaning water permeable brick. The method comprises the following steps: 1) the base material and the surface material are weighed, respectively premixed and then stirred as raw materials for standby application; 2) molding is carried out; 3) steam curing is carried out; and 4) liquid titanium dioxide is sprayed. Road surfacing of the self-cleaning water permeable brick in the invention can reduce water permeable hole plugging and surface pollution, thereby having the effects of road surface temperature decrease and high-efficient sterilization, regaining circulatory system of natural soil air and water, preventing soil pollution and improving ecological environment.

Owner:程卫国

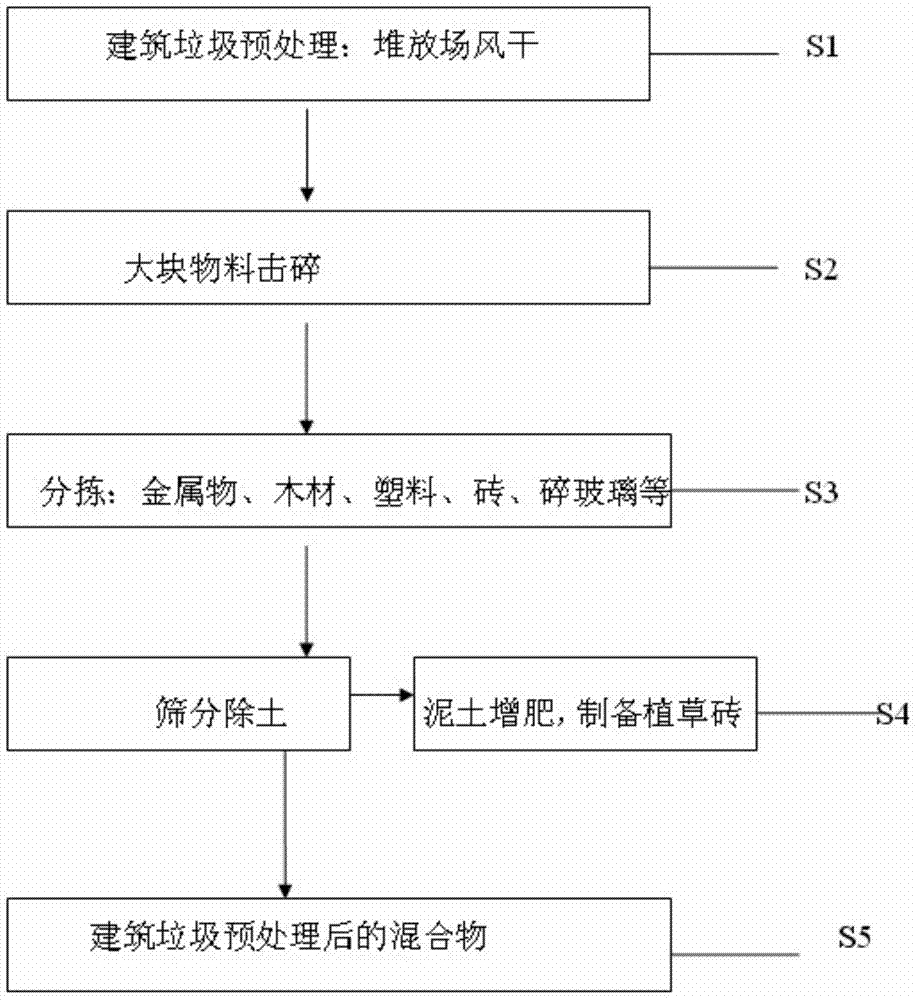

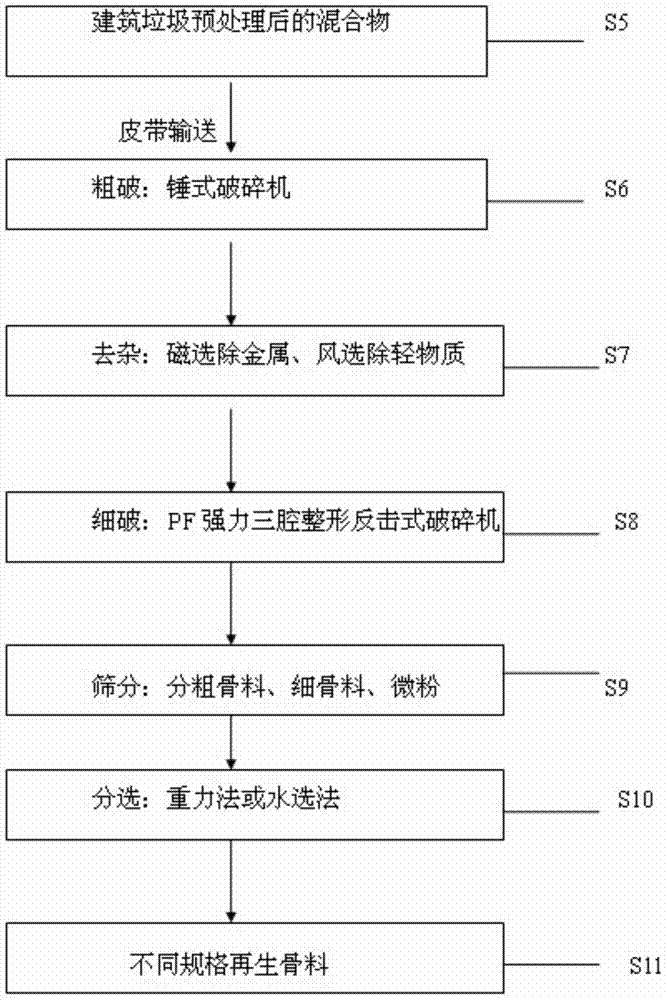

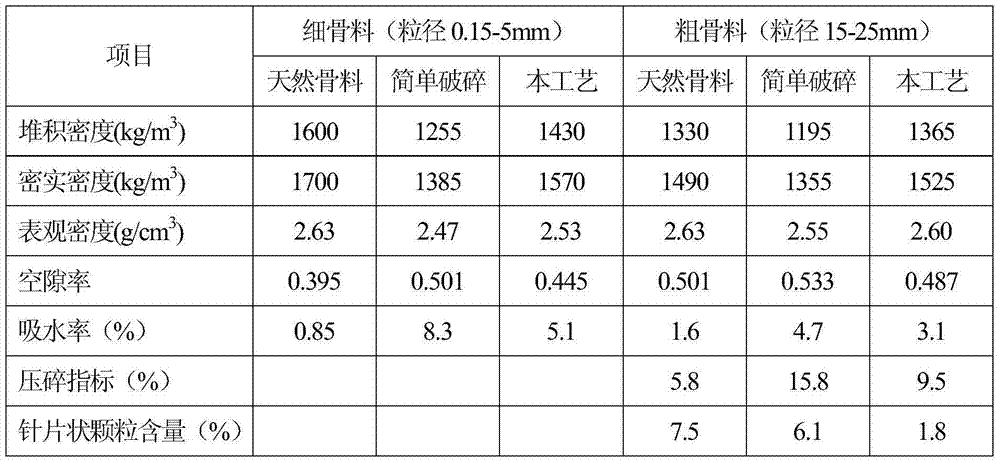

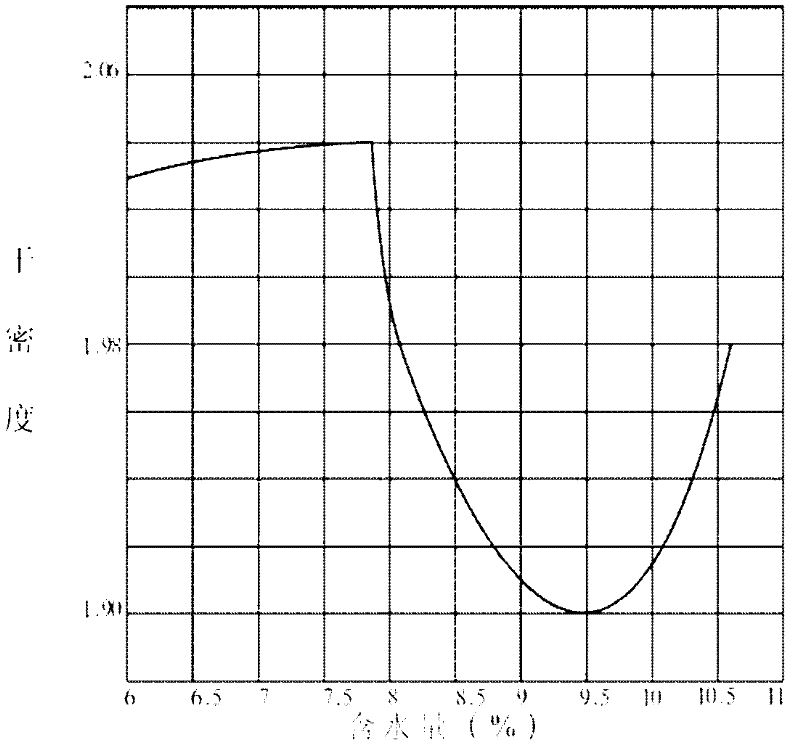

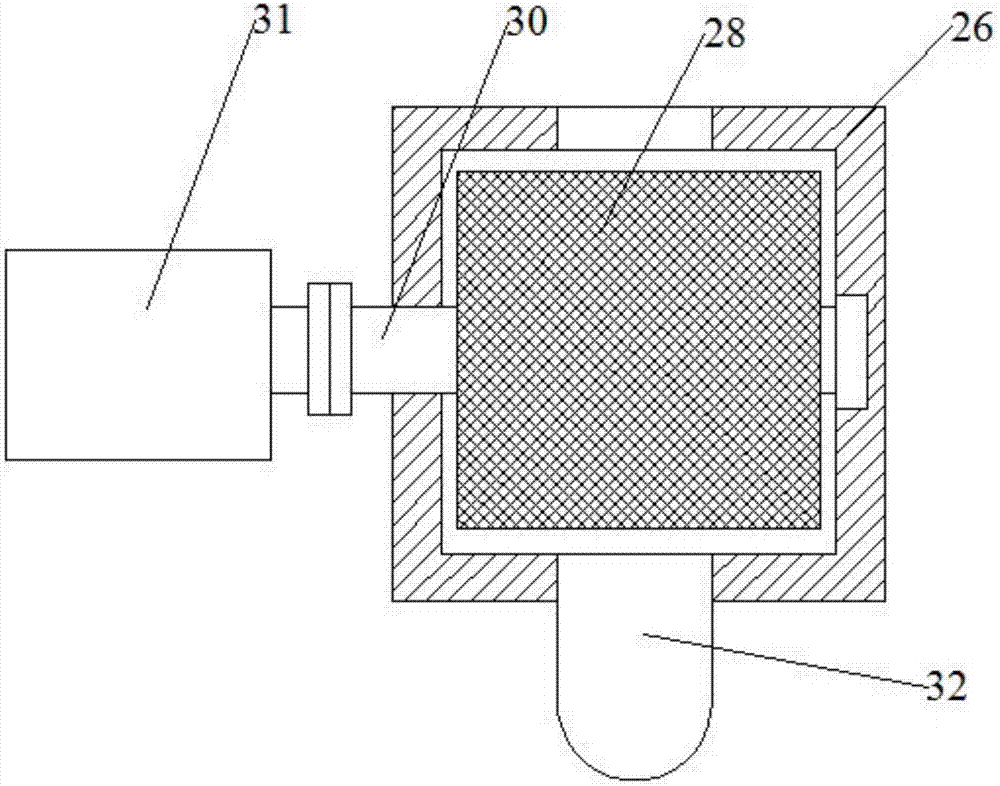

Ecological treatment technology for construction waste

The invention belongs to the field of recycling of construction waste, energy conservation and environment protection, and construction materials, and relates to an ecological treatment technology for construction waste, and particularly relates to the ecological treatment technology for construction waste and a preparation method for regenerated novel construction materials, which can efficiently use the construction waste and does not generate secondary pollution. The ecological treatment technology comprises the following steps of pretreating in a construction waste dump, namely, air drying the construction waste, crushing big blocks, sorting and removing soil through vibrating, adding a fertilizer in the soil to be used for filling grass planting bricks; preparing recycled aggregate, namely, crushing roughly, removing impurities, precisely crushing and simultaneously reinforcing and shaping the recycled aggregate, screening out the recycled aggregate with particle size less than 0.15mm as well as 0.15-5mm, 5-15mm and 15-25mm and micro powder for the secondary time, finally, separating the brick from concrete by a gravitational method or a hydraulic mineral beneficiation method according to different densities of the brick and concrete in the mixed recycled aggregate. Recycling and high value-added utilization of the construction waste are realized, and the ecological treatment technology gets major breakthrough in recycling industry of construction waste.

Owner:DALIAN HONG YUAN GREEN BUILDING MATERIALS

Unsteamed concrete air-filled insulating brick produced from building waste, and production method thereof

InactiveCN102617076AReduce encroachmentReduce pollutionSolid waste managementCeramicwareCelluloseBrick

The invention relates to an unsteamed concrete air-filled insulating brick produced from building waste, and a production method of the insulating brick. The insulating brick is prepared from the raw materials in parts by weight: 30-40 parts of cement, 20-30 parts of aggregate, 8-10 parts of CaO, 3-5 parts of CaSO4, 3-5 parts of carbamide, 3-5 parts of polyvinyl alcohol, 5-10 parts of cellulose hydroxypropyl methyl, 3-5 parts of calcium formate, 5-10 parts of foaming agent and 40-60 parts of external water, wherein cement contains one or more than two of common silicate, high-alumina cement, fly ash cement, alumina cement and aluminate cement; the aggregate is building waste with the particle size being less than or equal to 5mm; and the foaming agent contains one or more than two of aluminium powder, aluminium powder paste, hydrogen peroxide and sodium hydrogen carbonate. The unsteamedconcrete insulating brick is prepared by material preparing, mixing, injection molding and curing. Therefore, the land occupation and the living environmental pollution caused by the building waste can be effectively reduced, and the produced unsteamed concrete air-filled insulating brick has the advantages of good heat insulation effect, light weight, good sound insulation effect and high strength, and can be nailed and sawed; and the construction intensity can be reduced.

Owner:ANSHAN QUANYIJU ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

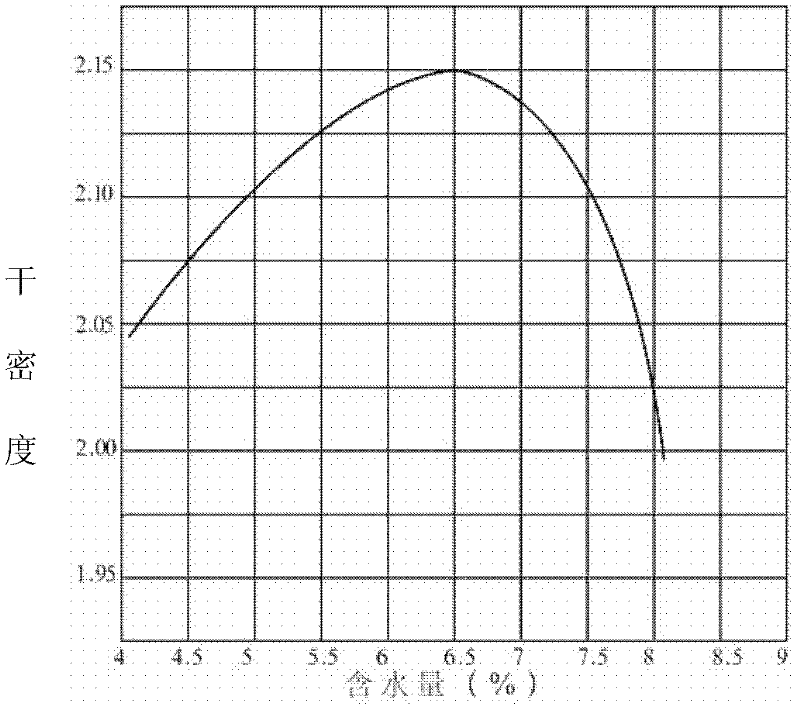

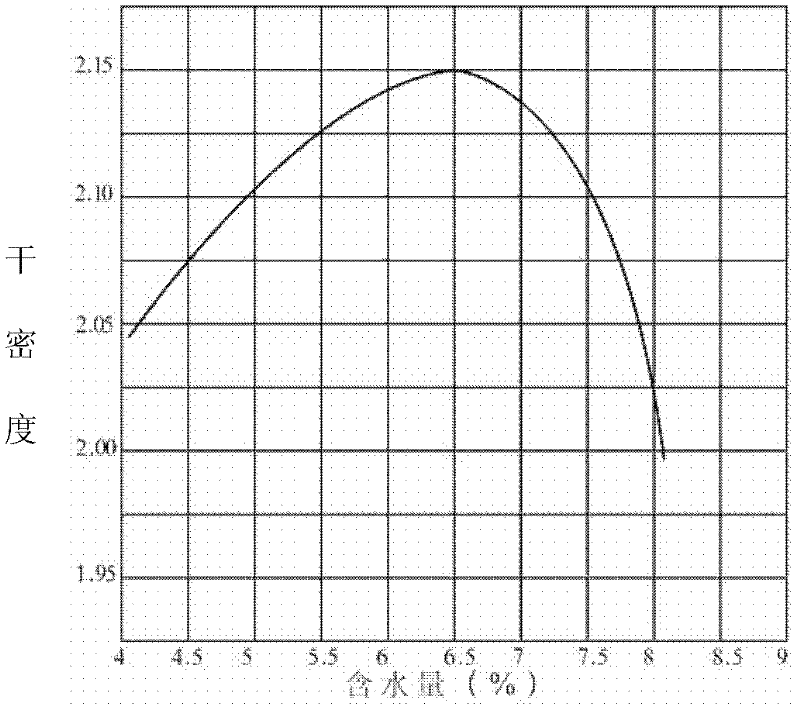

High-performance sand-soil consolidation material, as well as preparation method and using method thereof

The invention relates to a high-performance sand-soil consolidation material, as well as a preparation method and a using method thereof. The high-performance sand-soil consolidation material belongs to a mortar composition and is characterized by comprising the following raw materials in parts by weight: 5-40 parts of cement clinker, 3-6 parts of gypsum, 4-10 parts of alkali additive, 0.5-6 parts of compound activating agent, 1-4 parts of early strength agent, 2-10 parts of mineral activating agent, 3-8 parts of expansion agent and 22-77 parts of micro-powder formed by fine grinding of blast furnace water-quenched slag. The invention provides the high-performance sand-soil consolidation material which has the advantages of simple operation, convenient construction, good water resistance, fast consolidation, high early strength, stable improvement of post-strength, resistance to erosion of underground inorganic salt water, excellent anti-seepage performance and low production cost, as well as the preparation method and the using method thereof. The high-performance sand-soil consolidation material is suitable for consolidating mine tailings, natural weathered sand, fly ash, gravel, stone chips, stone powder, soil, sludge, construction waste, coal gangue and phosphorus slag into a solid material, and can be used for laying a subgrade, constructing a wall body and constructing a site foundation.

Owner:淄博乾耀固结材料有限公司

Construction waste treatment device

InactiveCN107214179AEfficient crushingPromote fragmentationConstruction waste recoverySolid waste disposalWater storageArchitectural engineering

The invention discloses a construction waste treatment device, which comprises a crushing chamber, an atomizing nozzle is arranged on the upper side of the crushing chamber, a water suction pipe is arranged on the upper side of the atomizing nozzle, a water storage chamber is arranged inside the upper end of the suction pipe, and a water storage chamber is arranged on the left upper side of the crushing chamber. There is a feeding pipe, the lower end of the right side of the feeding pipe is provided with a drainage plate, the lower side of the drainage plate is provided with a crushing plate, the lower left end of the crushing chamber is provided with a connecting pipe, the right side of the connecting pipe is provided with a rebar storage chamber, and the upper end of the rebar storage chamber is provided with a There is an electromagnet, there is a discharge port on the lower side of the crushing chamber, a crushing chamber is provided on the lower side of the discharge port, a screen is provided at the lower end of the crushing chamber, a discharge pipe is provided in the middle of the lower side of the crushing chamber, and a discharge pipe is provided on the lower side of the discharge pipe. There is a grinding chamber, the four corners of the lower side of the crushing chamber are provided with support columns, the lower side of the grinding chamber is provided with a discharge pipe, the lower side of the support column is provided with a base, the inside of the base is provided with a vibration-damping pad, and the upper middle of the base is provided with a pulley. The construction waste is crushed, separated, crushed, screened, ground and transported, which can effectively protect the environment and save resources.

Owner:彭利辉

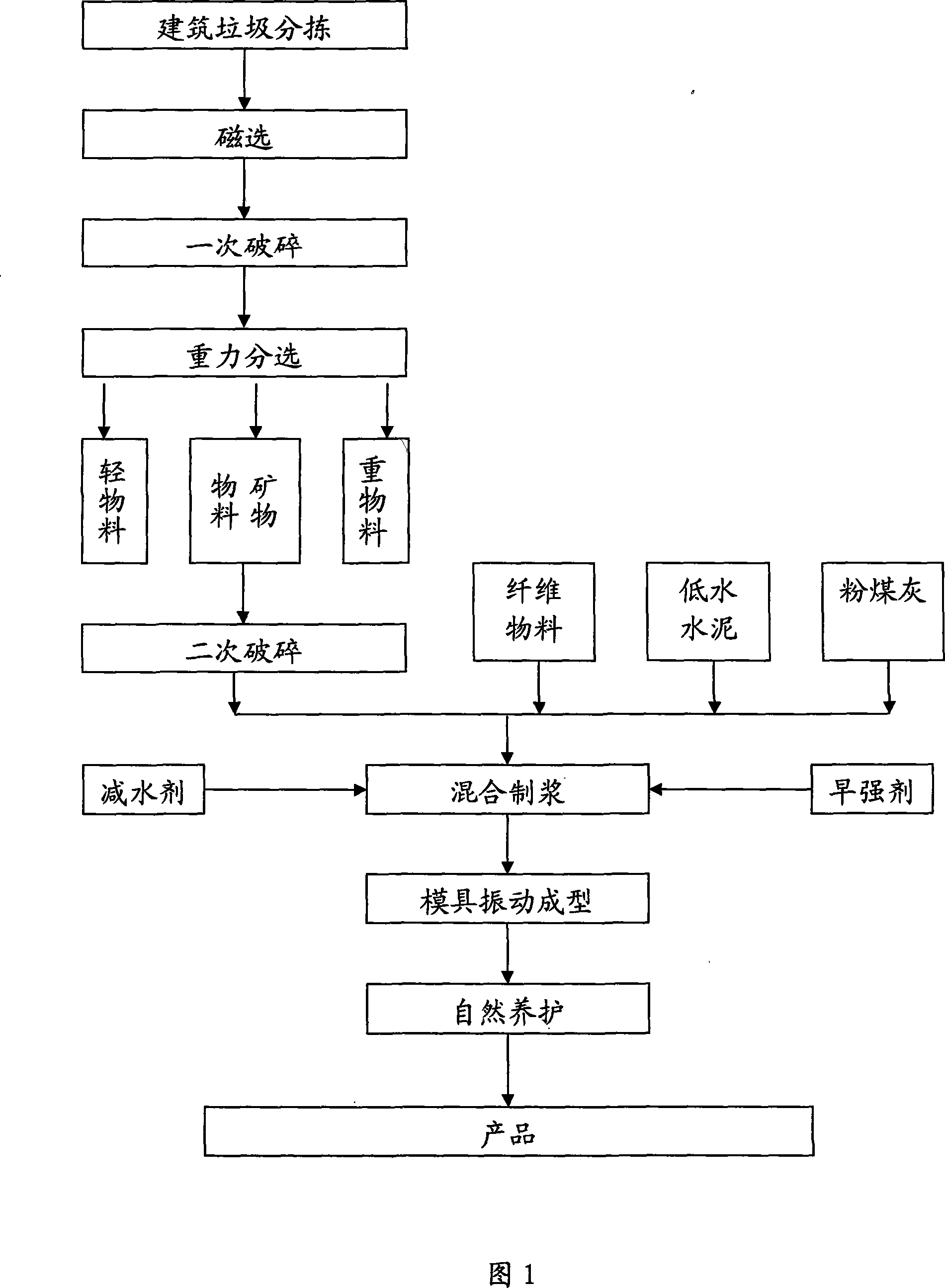

Method for manufacturing building material from building garbage

InactiveCN101239804AReduce final emissionsReduce dosageConstruction waste recoveryTransportation and packagingFiberBrick

The present invention relates to a method for manufacturing the building material with the building garbage, the method executes sorting, magnetic separation, primary crushing and gravity sorting to the city building material, and the building material is separated to heavy material, light material and mineral material, the mineral material is used for manufacturing the building material after the secondary crushing, and the raw material of the building material comprises the following components: fiber material 5-10 parts, mineral material 40-60 parts, low-water cement 20-30 parts and other material 0-30 parts, the production process of the building material comprises the steps of mixing the fiber material, mineral material and other material to uniform, then adding the low-water cement for mixing to uniform, adding water and stirring to slurry, placing into the mold for jolt molding or extrusion molding, and forming the building used sheet material after natural curing. The method of the invention has the advantages of full utilization of the mineral material comprising the major component of the building garbage, saving the material resource, reducing the final discharging amount of the building garbage, and the method can be used for manufacturing the building materials such as hollow brick, hollow block, partition plate and the like.

Owner:BEIJING HENGYECUN S&T

Mechanical multiple-stage building rubbish crushing device

InactiveCN106807475ASimple structureReduce manufacturing costSievingScreeningConstruction wasteMultiple stages

Owner:殷晓晴

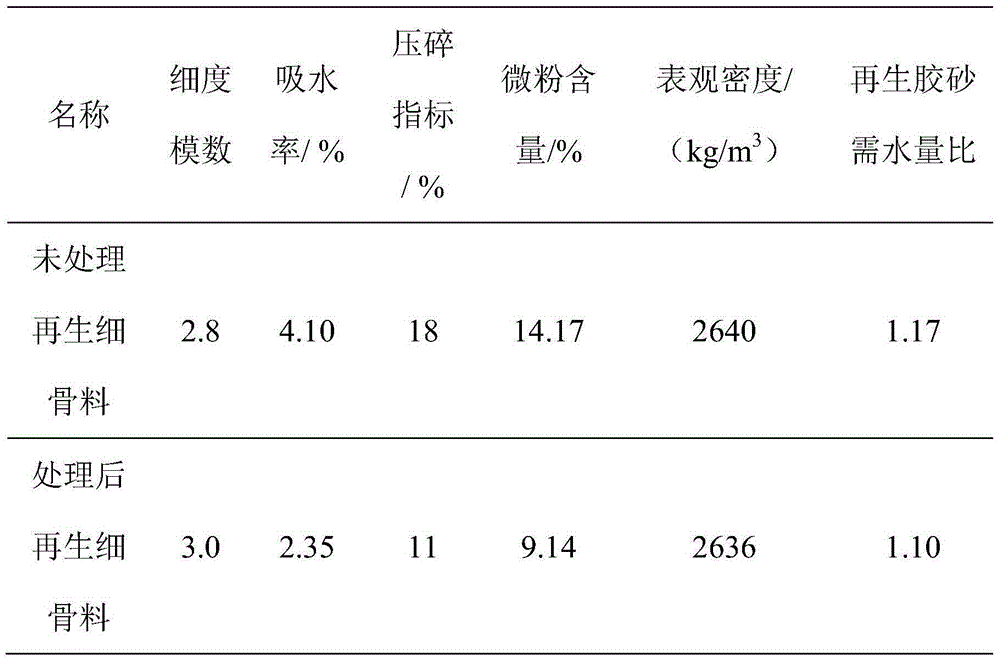

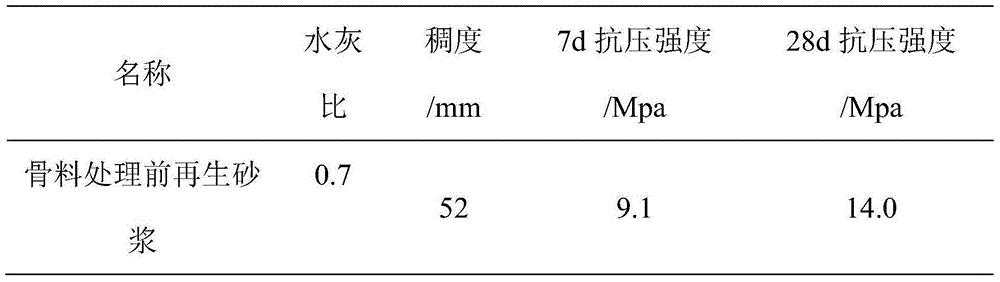

Method for reinforcing recycled concrete fine aggregate by using carbon dioxide

ActiveCN105174766AImprove water absorptionLow water absorptionSolid waste managementCALCIUM HYDROXIDE SOLUTIONCalcification

The invention discloses a method for reinforcing recycled concrete fine aggregate by using carbon dioxide, which comprises the following steps: (1) calcium hydroxide solution or calcium salt calcification treatment: spreading recycled fine aggregate prepared from construction waste on a tray, spraying a calcium hydroxide or calcium salt solution, and stirring uniformly; (2) CO2 curing: putting the recycled fine aggregate subjected to calcium hydroxide solution or calcium salt calcification treatment in a closed carbonization box, and carrying out carbonization curing until the surface is completely carbonized; and (3) recycled mortar preparation: preparing recycled mortar with the substitution rate of 100% by using the treated recycled fine aggregate. Compared with the unreinforced recycled aggregate, the crushing value of the recycled fine aggregate prepared by the method is lowered by nearly 45%, and the water absorptivity is lowered by nearly 53%. Compared with the recycled mortar prepared from the unreinforced recycled aggregate, the consistency of the recycled mortar prepared by the method is enhanced by 42% or so, the 7d strength of the mortar is enhanced by 15-26%, and the 28d strength can be enhanced by 17-24%.

Owner:SOUTHEAST UNIV +1

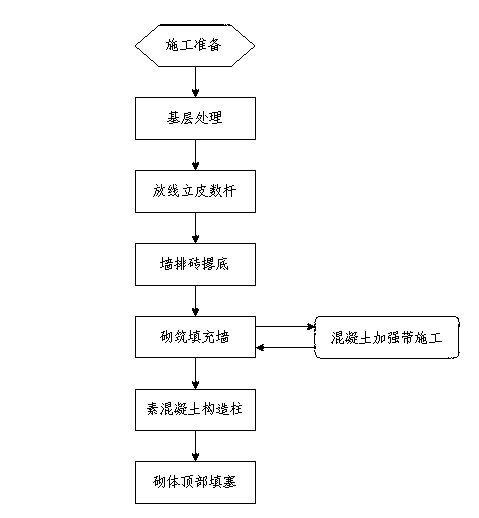

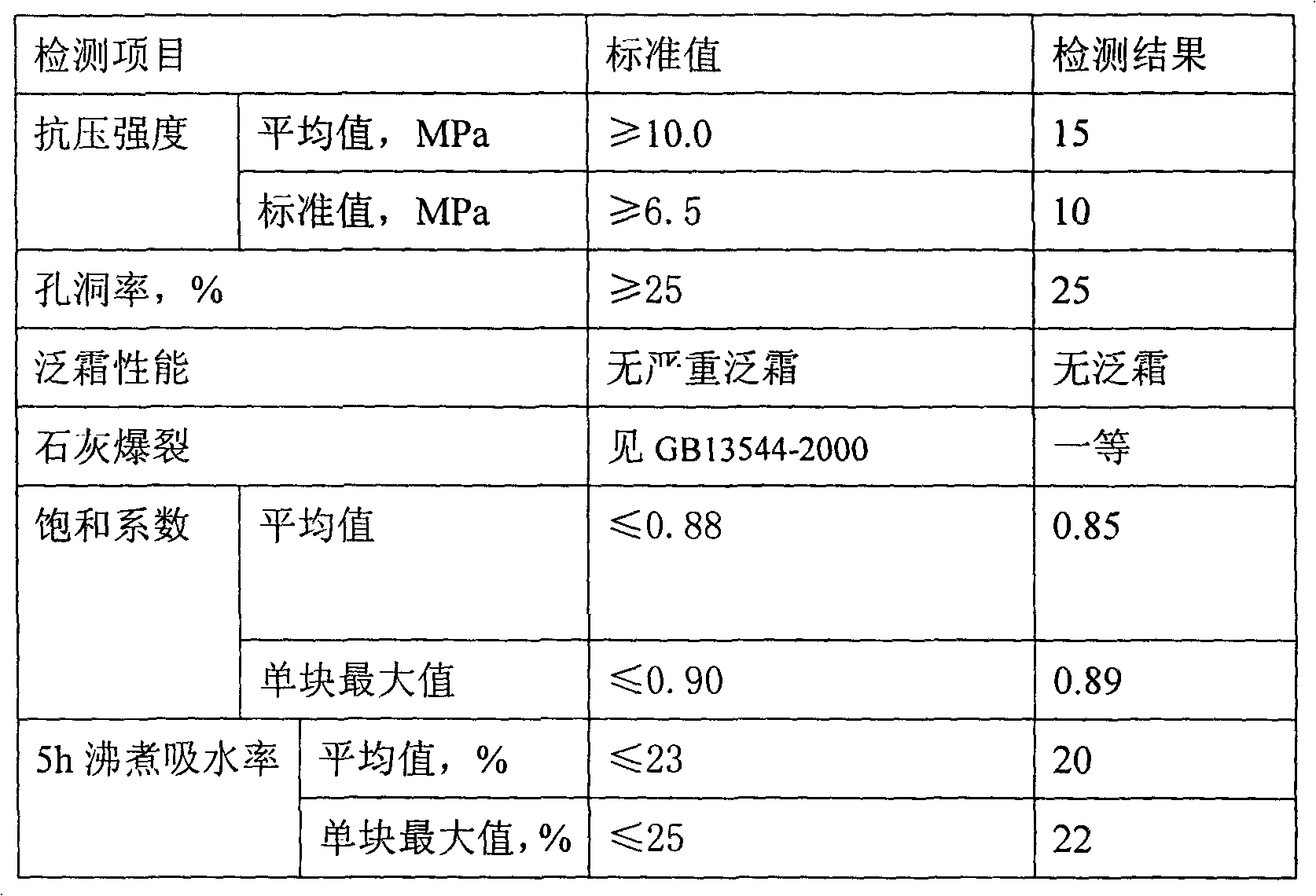

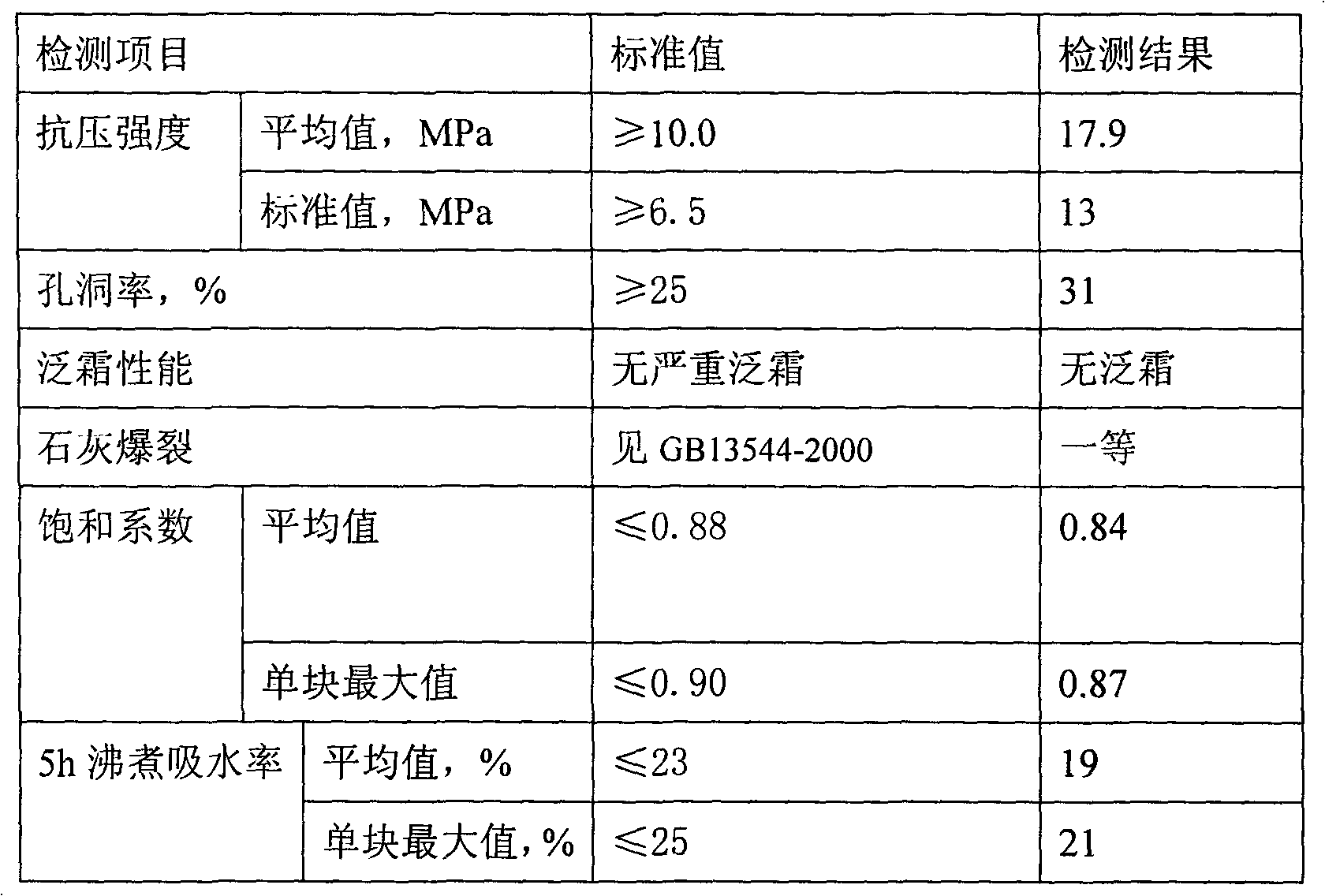

Construction method for preventing and treating cracks between concrete structure and filler wall

The invention discloses a construction method for preventing and treating cracks between a concrete structure and a filler wall. The construction method particularly comprises the following operation steps of step one, preparing construction; step two, treating a basic layer; step three, conducting paying off wire and setting up height pole; step four, conducting brick laying and putting down the bottom row of bricks; step five, masoning the filler wall; step six, constructing plain concrete constructional columns; step seven, filling the top of masonry. The construction method for preventing and treating the cracks between the concrete structure and the filler wall has the advantages of being wide in application range, and applicable to masonry construction of the filler wall with hollow bricks, autoclaved aerated concrete blocks and the like of the industrial and civil construction concrete structure; when the method compared with traditional processes, being capable of saving cost due to the fact that the main difference in procedure is that the plain concrete constructional columns, concrete reinforcing bands, wall crown filled with hard concrete and other portions replace the masonry; fundamentally solving the problem that cracks of a plaster layer and a coating layer caused by the cracks of the contact surface of the concrete structure and the filler wall, improving a project impression level and project quality, eradicating leakage risks of outer wall surfaces, reducing reworking cost and maintenance cost, saving materials, reducing production of construction waste, lowering a complaint rate of users, and being capable of setting up a corporate image in society and considerable in social benefit.

Owner:CHINA AEROSPACE CONSTR GROUP +1

Plant growing matrix prepared by construction wastes

A plant growing matrix prepared by construction wastes is characterized by comprising bricks, stones or concrete blocks in the construction wastes, bentonite, organic matters, composite fiber, a soil stabilizer, an aggregating agent, a fertilizer and an acidic substance, wherein the acidic substance comprises sulfur or sulfuric acid. The plant growing matrix prepared by the construction wastes has the benefits as follows: a new way for disposing the construction wastes is provided; the land consumption and waste cleaning and transporting fees for disposing the construction wastes by the conventional method are greatly saved; blockage to a soil biological chain by landfill is avoided; the secondary pollution caused by the construction wastes to the environment is greatly reduced; and the nutrient soil has a good effect of preserving moisture and fertility and can be applied to roof greening, slope greening and other engineering.

Owner:青岛冠中生态股份有限公司

Construction waste sintering brick and production method thereof

The invention relates to a construction waste sintering brick and a production method thereof. The construction waste sintering brick comprises sintering raw materials of 24-30 percent of sludge and 35-45 percent of construction waste, 25.5-33 percent of one or two of coal ash or coal refuses and 1-3 percent of binding agent. The construction waste sintering brick has wide raw material sources, enables the construction waste to be recycled, saves the land resource, protects the tiled land, and fully utilizes construction waste with wide and large sources to change the waste into valuable. Theproduced sintering brick has temperature preservation and heat insulation, shock and compression resistance, no distortion and high yield, is suitable to industrial large-scale production.

Owner:上海鑫晶山淤泥研发有限公司

Baking-free gravel attapulgite building garbage ceramsite

InactiveCN102503281AUniform particle sizeImprove yieldSolid waste managementExpanded clay aggregateWaste material

The invention discloses baking-free gravel attapulgite building garbage ceramsite. The key point of the technical scheme is that the baking-free gravel attapulgite building garbage ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, building garbage powder, red bentonite powder, kieselguhr tailing powder and cement. The baking-free gravel attapulgite building garbage ceramsite is produced by the following steps of mixing the ingredients, granulating, maintaining, sieving and packaging.. The baking-free gravel attapulgite building garbage ceramsite is an irregularly-shaped granule and has a rough and hard surface light weight, high strength, high durability and a good heat-preserving and sound-insulating effect; and a large amount of fine pores are formed in the granule. The baking-free gravel attapulgite building garbage ceramsite is produced by utilizing the building garbage and tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the baking-free gravel attapulgite building garbage ceramsite is suitable for producing concrete heat-preserving building blocks and heat-preserving and sound-insulating materials.

Owner:许庆华

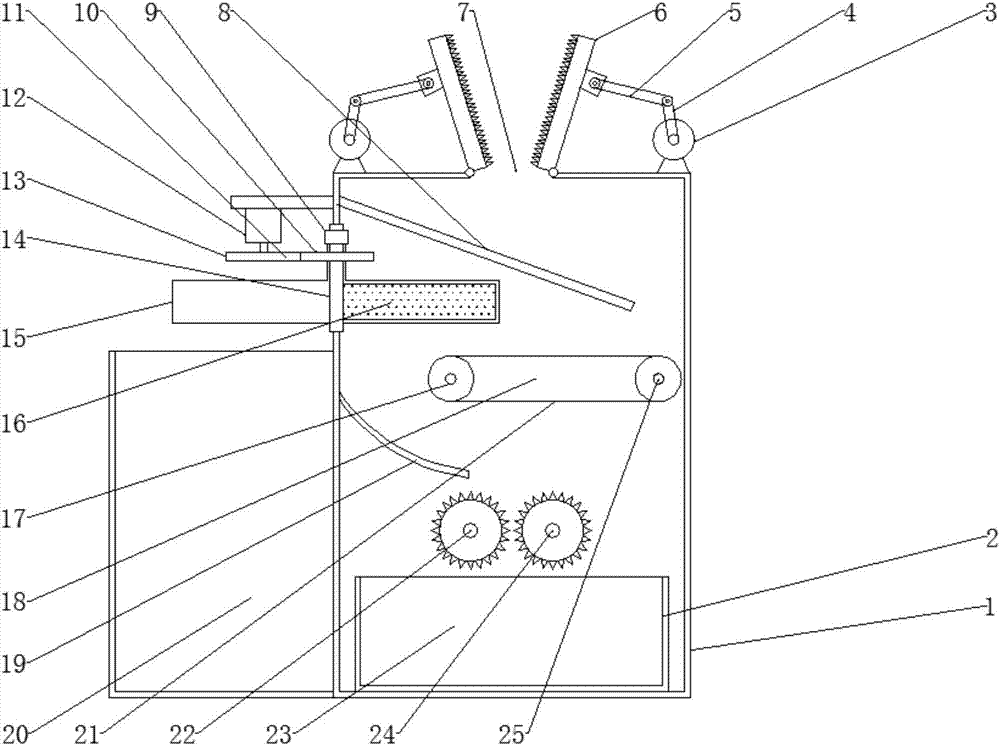

Construction waste treatment device with dual functions of crushing and screening

InactiveCN106824485ASimple structureReduce manufacturing costSievingScreeningMotor driveDual function

The invention discloses a construction waste treatment device with dual functions of crushing and screening. The construction waste treatment device has the advantages of being reasonable and simple in structure, low in production cost, convenient to install, good in crushing effect, convenient to use and the like. Multiple crushing is conducted on construction waste by a multi-level crushing device, the crushing effect is good, and the size of the construction waste after the crushing can meet the requirements of recycling and reusing; when the construction waste treatment device is in use, the construction waste is put into a lifting box and carried to a crushing chamber through a material net on a synchronous belt, firstly the construction waste is crushed through crushing blades and ground through grinding teeth, when the construction waste becomes thin and small particles, the particles are filtered by a first filtering net, when the particles are relatively large, grinding continues to be carried out, filtered particles enter a screening chamber through an oblique plate, a screening motor drives a screening plate, and the particles are screened on a screening net, fall into a transport chamber, and finally go to a transport vehicle to be collected.

Owner:徐勇

Construction garbage concrete segment and method for producing the same

InactiveCN101508544AGuaranteed StrengthGuaranteed durabilitySolid waste managementMixing operation control apparatusBrickAdditive ingredient

The invention discloses a building waste concrete brick and a manufacturing method thereof. The brick is manufactured by mixing, molding, maintaining and drying regenerative raw materials of the building waste, cement, fly ash, a tackifier, a waterproof agent, an excitant and water. The regenerative raw materials of the building waste is obtained by processing waste concrete and such inorganic hard ingredients as manufactured products, waste tiles, waste stones and the like, with the maximum grain size of 8mm; the tackifier is the carbide slag, high-viscosity attapulgite clay powder, cellulose ether and the like; the waterproof agent is the products of stearate series; the excitant is quicklime powder, calcium chloride, sodium sulfate and the like. The brick of the invention prepared through the steps of raw material stirring, molding, maintaining and drying has simple technique, easy operation, low cost and stable product quality; the wall bodies built with the brick have good impermeability and anti-cracking performance. A large amount of building wastes which are low in price are utilized for the brick, thus reducing the consumption of natural resources, conforming to the strategy of sustainable development and witnessing obvious social and environmental benefits.

Owner:CHINA BUILDING MATERIALS ACAD

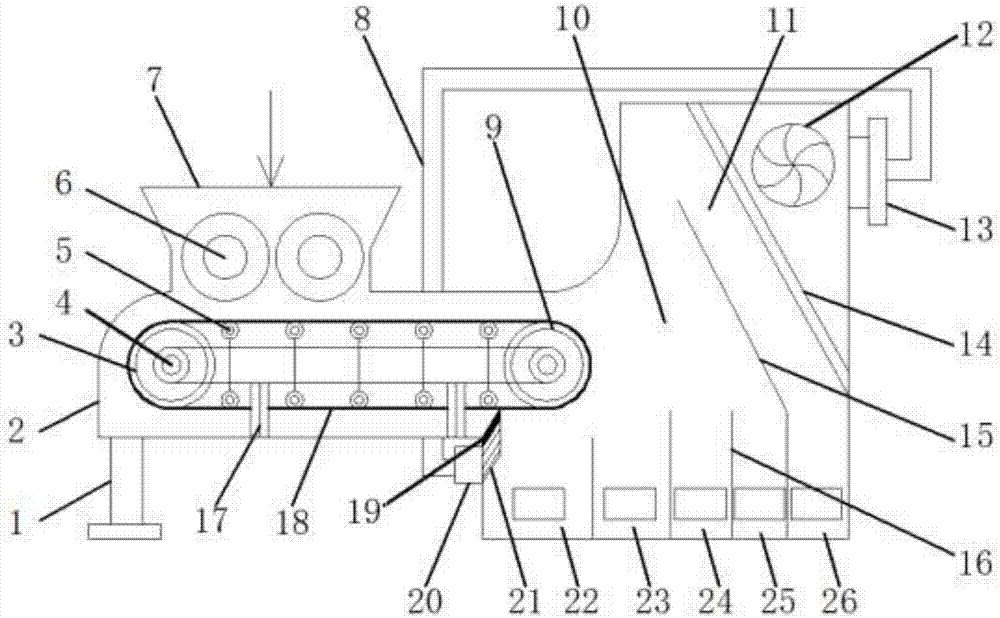

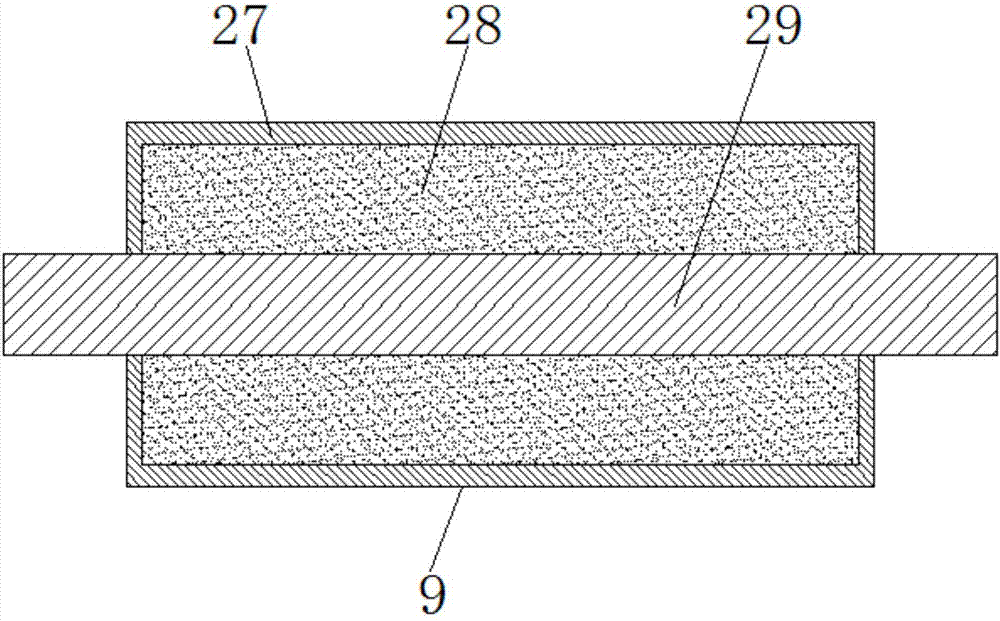

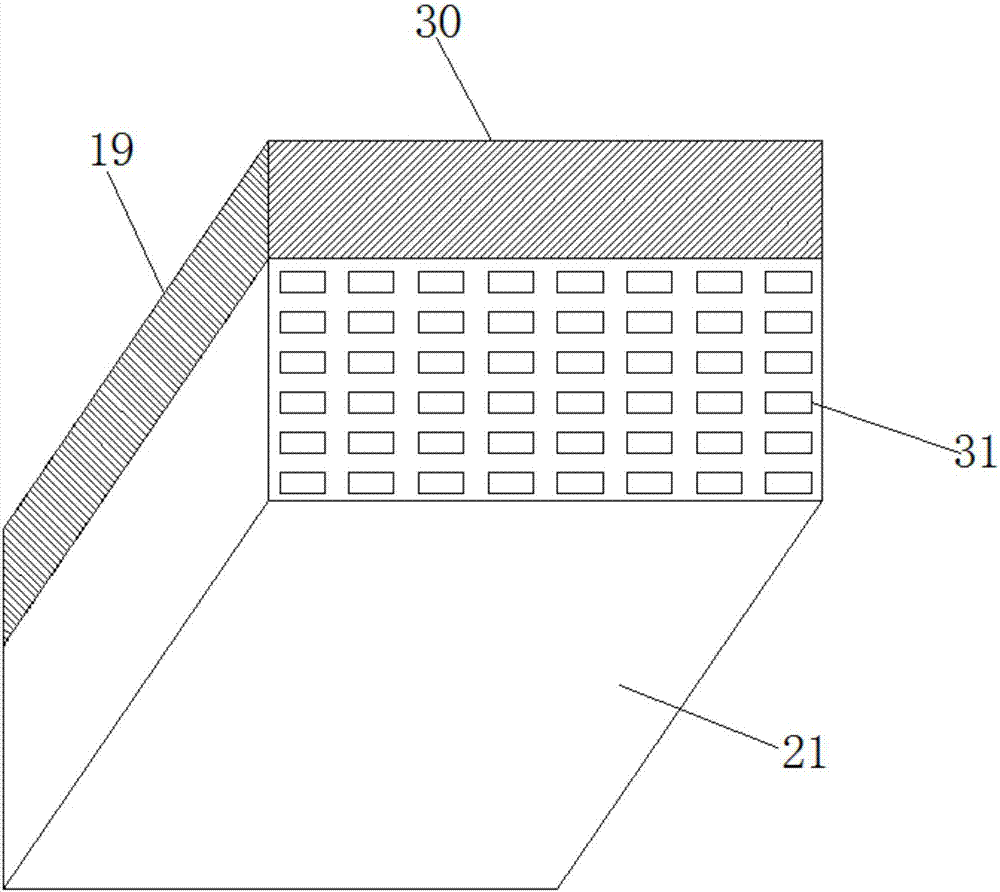

Transportation magnetic separation equipment for crushing and processing construction waste

InactiveCN107282175APromote fragmentationAchieve brokenGas current separationMagnetic separationSlagArchitectural engineering

The invention discloses a transportation magnetic separation equipment for crushing and processing construction waste, which comprises a frame, a transmission box, a magnetic separation roller and a conveyor belt. The transmission box is installed on the upper end of the frame, and a conveyor frame is installed inside the transmission box , a driving roller and a magnetic separation roller are installed on the conveyor frame, and a conveyor belt is set between the driving roller and the magnetic separation roller; the upper left end of the transmission box is welded with a construction waste adding bucket, and the bottom of the construction waste adding bucket is A crushing roller is installed inside; the right end of the conveyor belt is provided with a winnowing chamber, and the bottom side of the right end of the conveyor belt is installed in sequence from left to right with an iron collection box, a heavy material box, a light material box, a slag collection box and Dust settling box; it is convenient to add construction waste into the hopper and crush it through the two crushing rollers; the magnetic separation roller absorbs and screens the construction waste containing ferromagnetism to realize the crushing and transportation of construction waste , Removal of ferromagnetism, screening, separation and dust removal, the operation is convenient and quick.

Owner:寿涵红

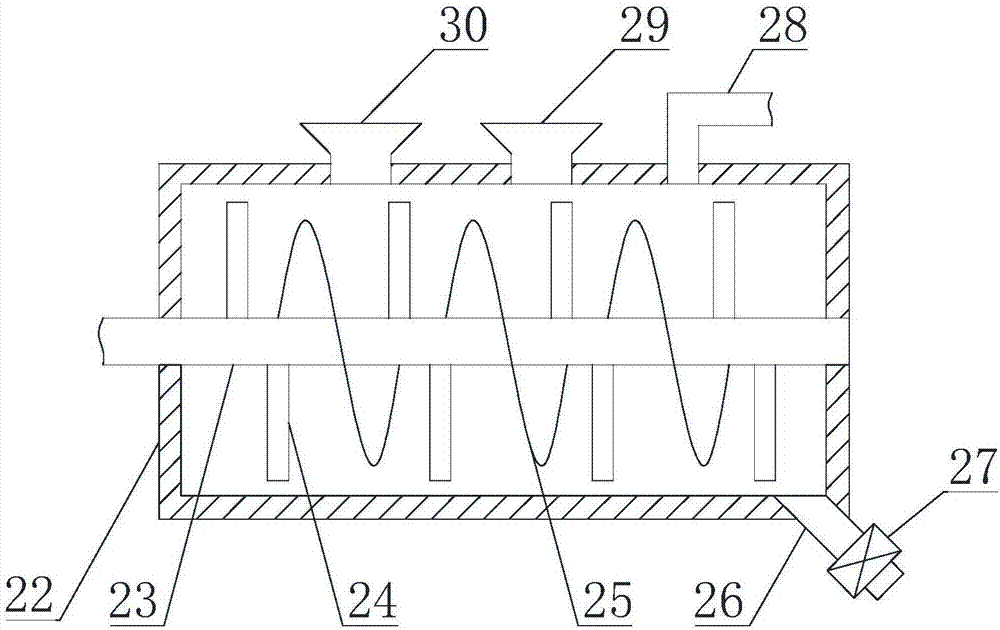

Efficient crushing device for construction waste recovery

InactiveCN107350004AAdjustable sizeGood for subsequent crushingMagnetic separationGrain treatmentsHydraulic cylinderIron removal

The invention discloses an efficient crushing device for construction waste recovery. The efficient crushing device comprises a box body, and a preliminary breaking mechanism is fixedly arranged at the upper part of the inner chamber of the box body. The preliminary breaking mechanism comprises a fixed breaking plate, a movable breaking plate, a disc, a hydraulic cylinder and a motor. An iron removal mechanism is arranged under the preliminary breaking mechanism, and a first crushing roller and a second crushing roller are arranged under the iron removal mechanism. In the falling process of massive construction wastes, the preliminary breaking mechanism breaks the massive construction wastes step by step, so that metal in the wastes is exposed. Moreover, follow-up crushing is facilitated, and the crushing efficiency is improved. The size of broken particles of construction wastes can be adjusted, and the breaking degree can be adjusted. The construction wastes are subjected to second level of crushing through the first crushing roller and the second crushing roller, and the construction wastes are crushed more thoroughly. The crushing effect is good, and the crushing efficiency is high. The metal, such as steel bars in the construction wastes can be removed through the iron removal mechanism and are collected. The efficient crushing device has the advantages of simple structure and convenience in operation.

Owner:广西综改咨询服务有限公司

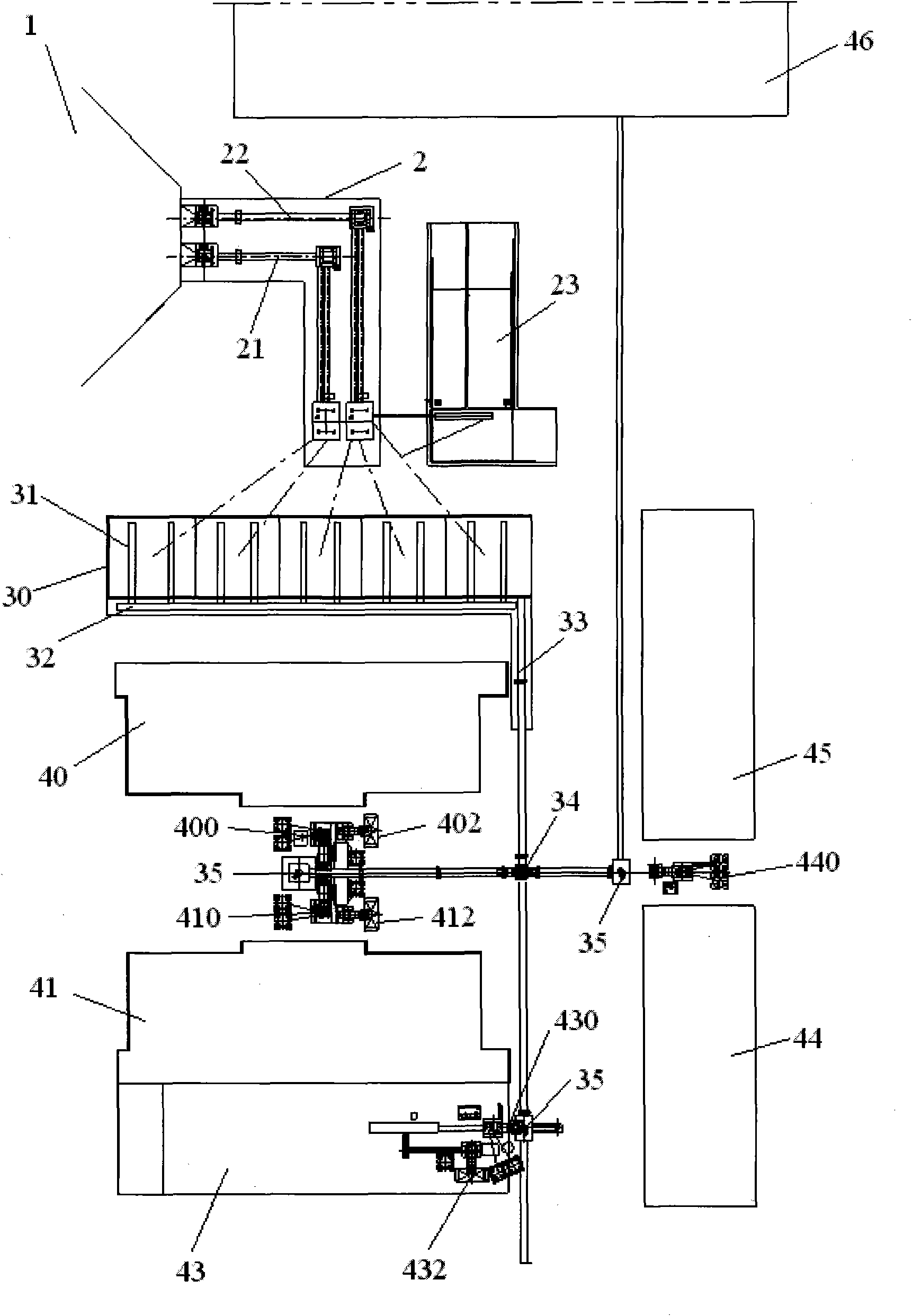

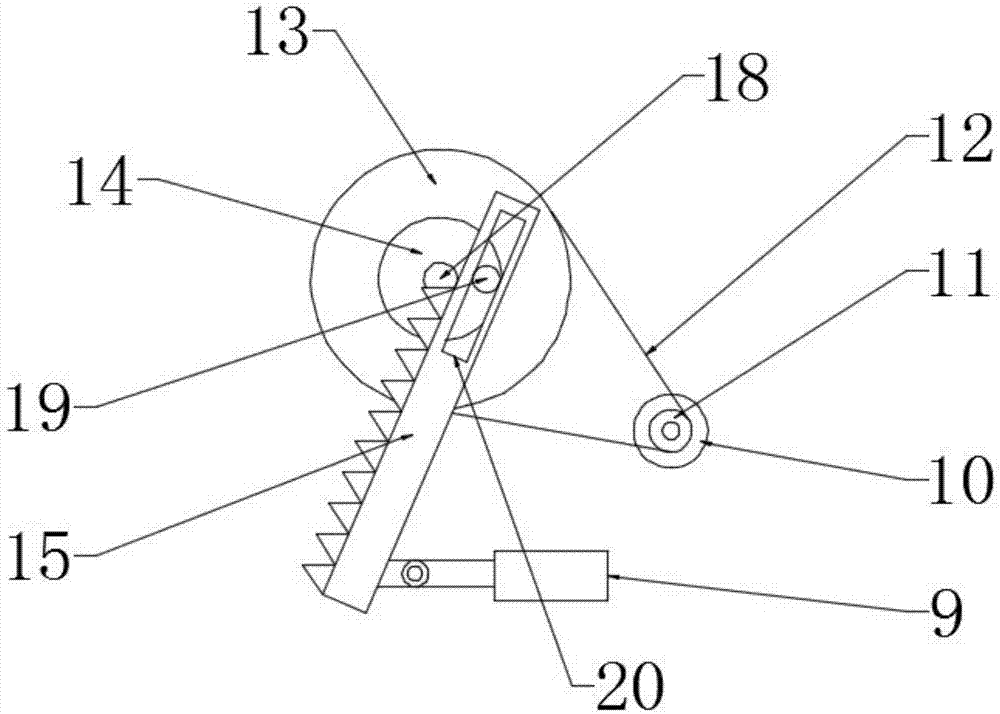

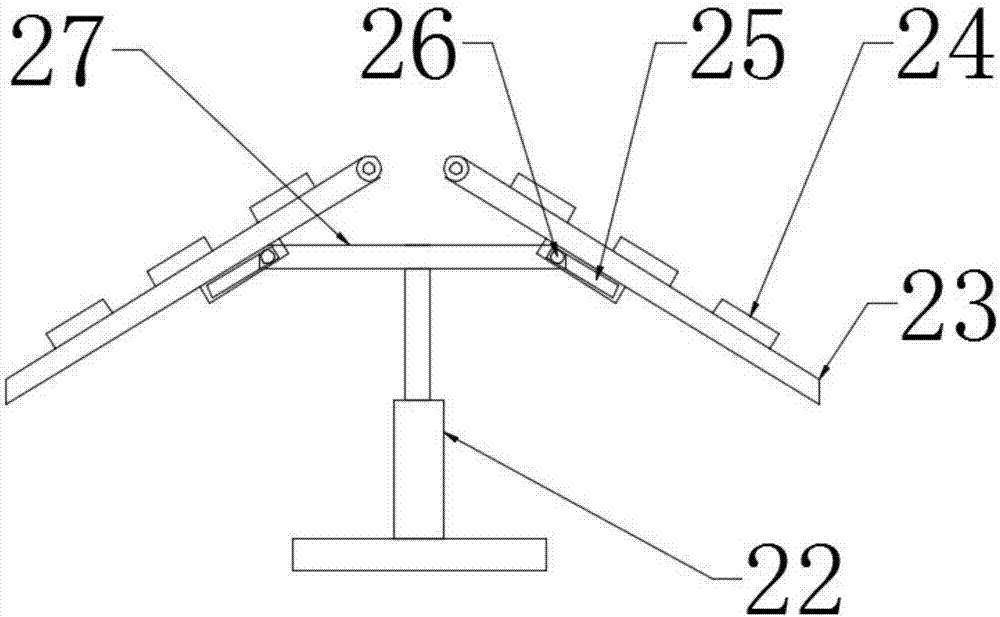

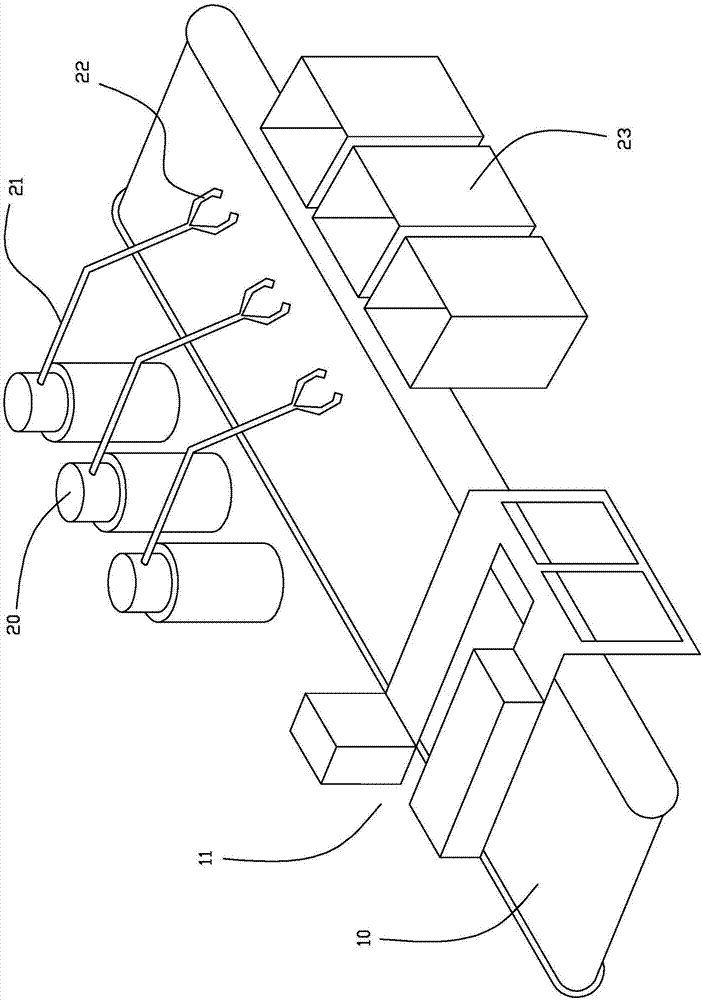

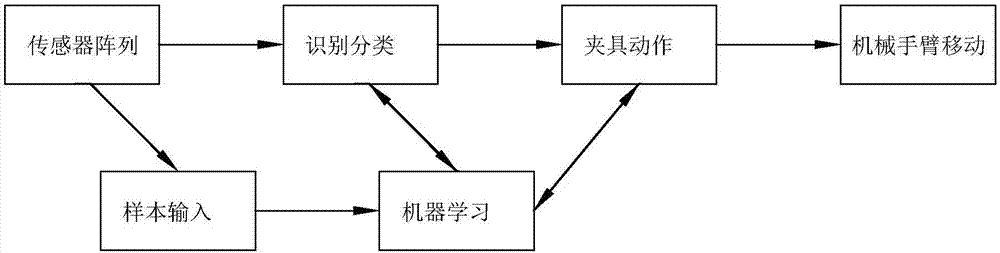

Massive solid building waste sorting system based on multiple detection modes

The invention relates to a massive solid building waste sorting system based on multiple detection modes. A sensor detection and recognition mechanism is composed of a conveyor belt and a sensor array with multiple detection functions; an industrial robot sorting mechanism is composed of a plurality of industrial robots and a plurality of sorting boxes; and a control system is connected with the sensor array and the industrial robots respectively, the sensor array carries out real-time detection, and the control system analyzes information collected by the sensor array and controls the industrial robots to sort massive solid building wastes in different types into corresponding sorting boxes. As for the massive solid building waste sorting system based on multiple detection modes, as a mechanical arm of each industrial robot is provided with a clamp, the massive solid building wastes on the conveyor belt are grabbed by the clamps and moved above the corresponding sorting boxes through movement of the mechanical arms, the clamps release the massive solid building wastes, and the sorted massive solid building wastes fall into the corresponding sorting boxes, so that effective sorting of the massive solid building wastes is realized.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

Construction refuse crushing recycling device

InactiveCN107234724AQuality assurancePlay a buffering effectSolid waste managementCement mixing apparatusArchitectural engineeringHigh pressure

The invention discloses a construction refuse crushing recycling device which comprises a base, a support and a top plate. The support is arranged on the base, and the top plate is arranged at the top of the support. A motor is arranged at the left side of the bottom of the top plate and is further connected with a lifting screw rod. The support is provided with sliding rails, and the sliding rails are connected with a first supporting plate and a second supporting plate in a sliding mode. The first supporting plate is provided with a through hole, and the through hole is connected with a first connecting rod in a sliding mode. The bottom end of the first connecting rod is fixedly connected with a pressing plate, and a high-pressure spring is arranged between the pressing plate and the first supporting plate. The second supporting plate is fixedly provided with a material crushing box, and a filtering plate is arranged inside the material crushing box. The bottom of the material crushing box is further connected with a discharging pipe. According to the construction refuse crushing recycling device, the lifting screw rod rotates to drive the pressing plate and the filtering plate inside the material crushing box to be drawn together in the middle, and thus construction refuse can be squeezed and crushed; and the crushed construction refuse is filtered through the filtering plate so as to be squeezed and crushed to be in a fine state continuously, and the phenomenon that the construction refuse is too large and thus later-period recycling cannot be facilitated is prevented.

Owner:ANHUI YIQI SOFTWARE TECH

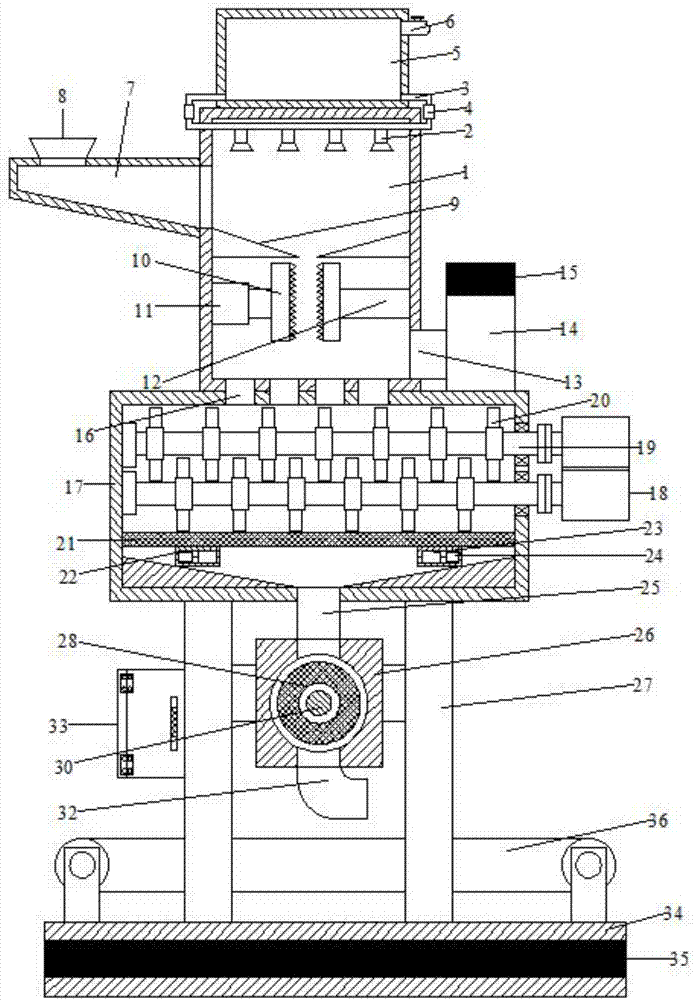

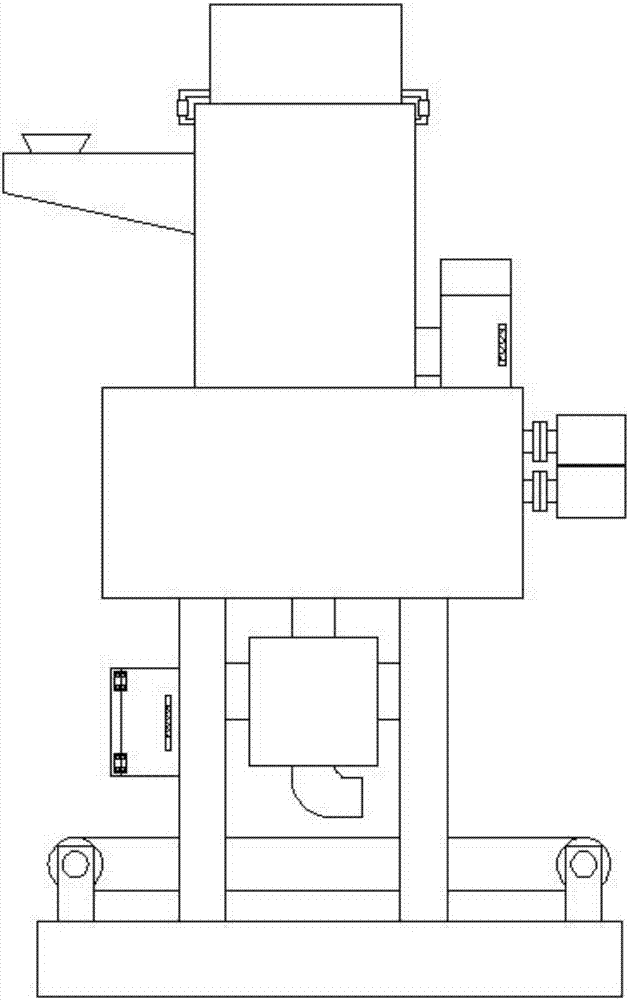

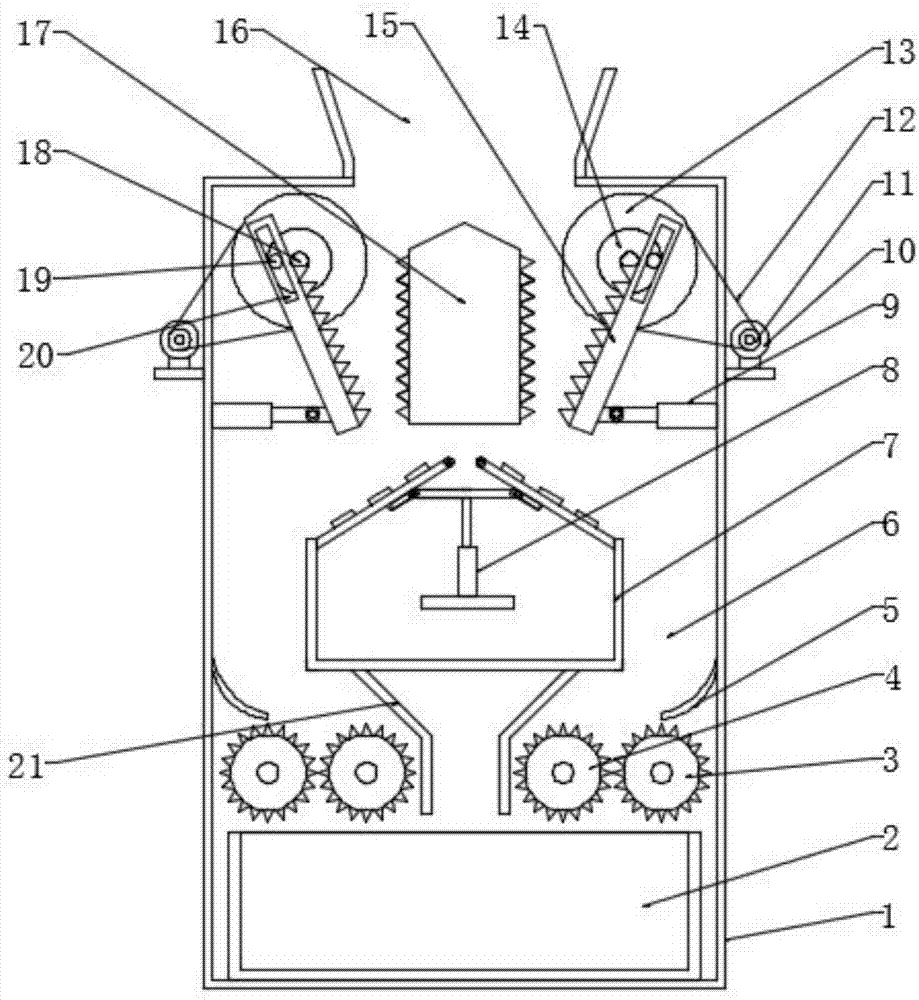

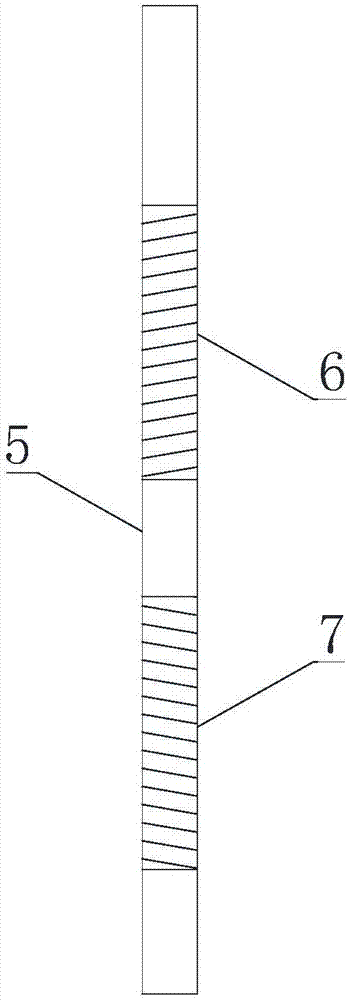

High-efficiency crushing device for construction waste recovery

InactiveCN106944182AEasy to reproduceAvoid affecting service lifeGas current separationMagnetic separationIron removalArchitectural engineering

The invention discloses a high-efficiency crushing device for recycling construction waste, which includes a machine body, a first motor, a first connecting rod, a second connecting rod and a movable jaw plate are symmetrically arranged on the top of the body, and the first motor is driven to connect the first connecting rod. The other end of the first connecting rod is hinged with the second connecting rod, and the other end of the second connecting rod is hinged with a movable jaw plate. The bottom of the movable jaw plate is connected to the top of the body through a hinge. An inclined plate is fixed in the lower part of the body, a conveying device is arranged under the inclined plate, an iron removal device is arranged above the conveying device, an arc-shaped plate is fixed under the left end of the conveying device, and a secondary crushing device is arranged under the right end of the arc-shaped plate. The invention is provided with a first motor, a first connecting rod, a second connecting rod and a movable jaw plate, which can pre-shred the construction waste, and is provided with an iron removal device to remove metals such as steel bars and steel bars in the construction waste to avoid Damage the device and affect the service life of the device.

Owner:合肥红蔻健康管理有限公司

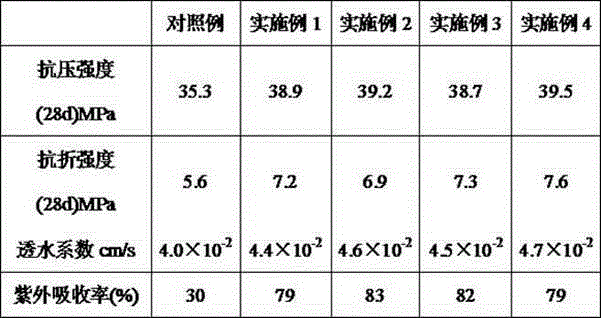

Construction waste recycled aggregate water milled colorful paving brick and preparation method thereof

ActiveCN104860593AReduce heat island effectResistant to UV radiationSolid waste managementClimate change adaptationBrickPolyamide

The invention discloses a construction waste recycled aggregate water milled colorful paving brick and a preparation method thereof, and belongs to the field of building materials. The colorful paving brick is prepared by the following raw materials in parts by weight: 200-260 parts of fine aggregates, 60-80 parts of rough aggregates, 5-10 parts of aggregate modifier, 30-80 parts of nanometer silicon dioxide, 50-70 parts of polyamide, 0.3-0.5 parts of water reducing agent, 100-140 parts of cement and 40-70 parts of water. The product adopts construction waste recycled aggregates as the main raw material, thus being naturally multicolored, reducing processes and expenses for doping stones and pigments, beautifying the environment, reducing cost and saving natural resources. Meanwhile, the invention also provides a preparation method of the water milled colorful paving brick, the preparation method is simple in process, the prepared product is high in permeability performance and mechanical performance, and strong in ultraviolet ray and thermal radiation absorbing ability, and reduces urban heat island effect in the summer.

Owner:刘勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com