Patents

Literature

38653results about How to "Improve yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

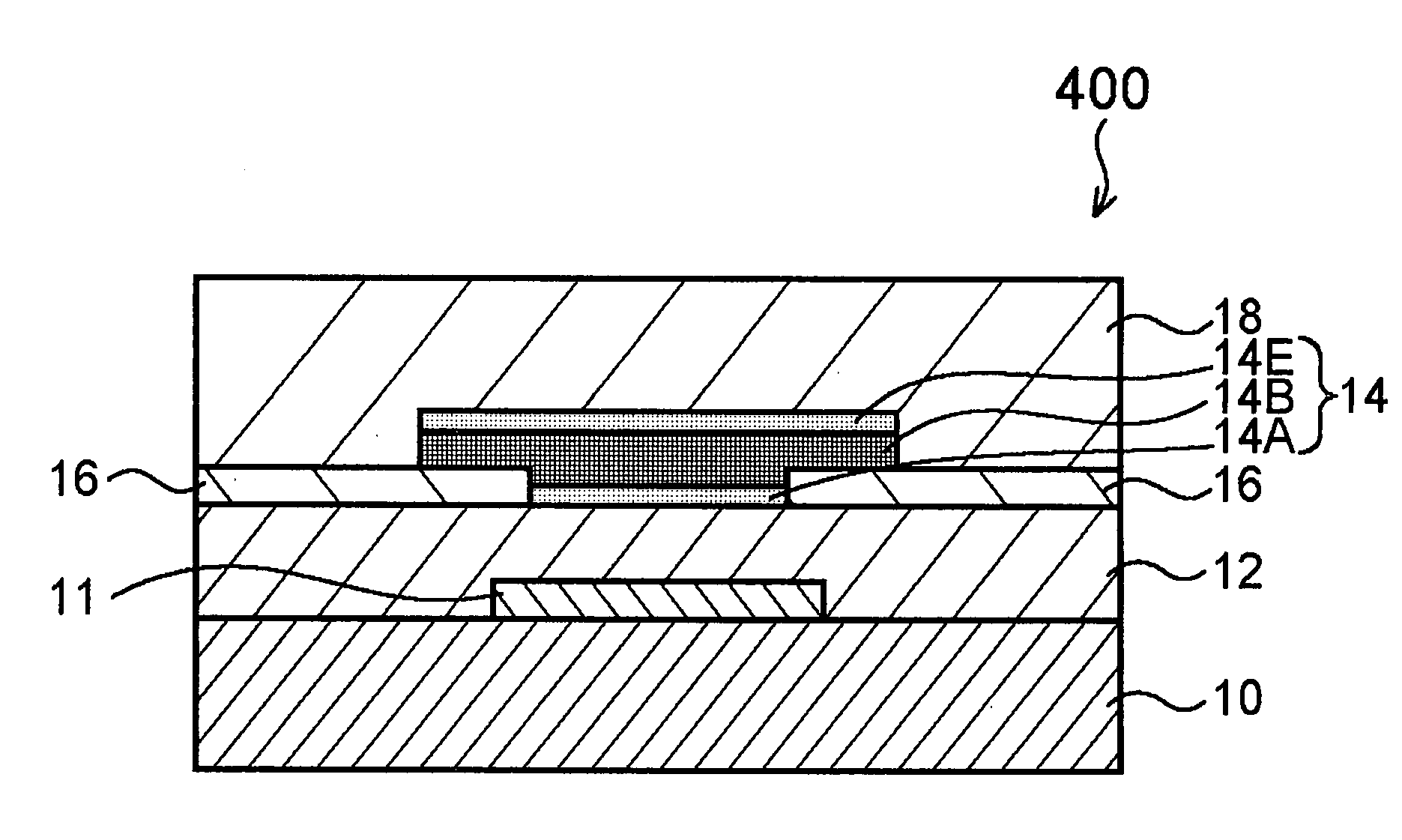

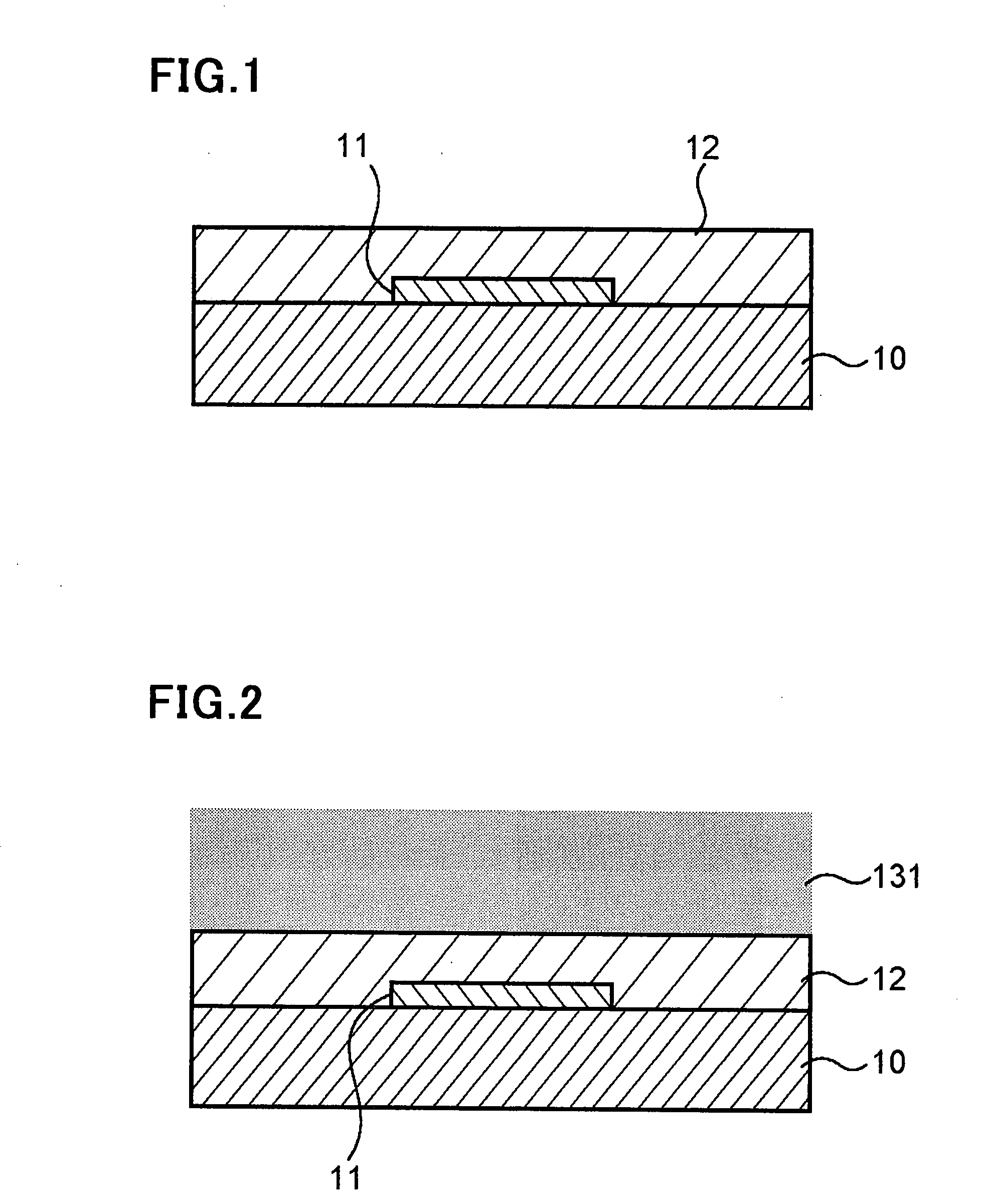

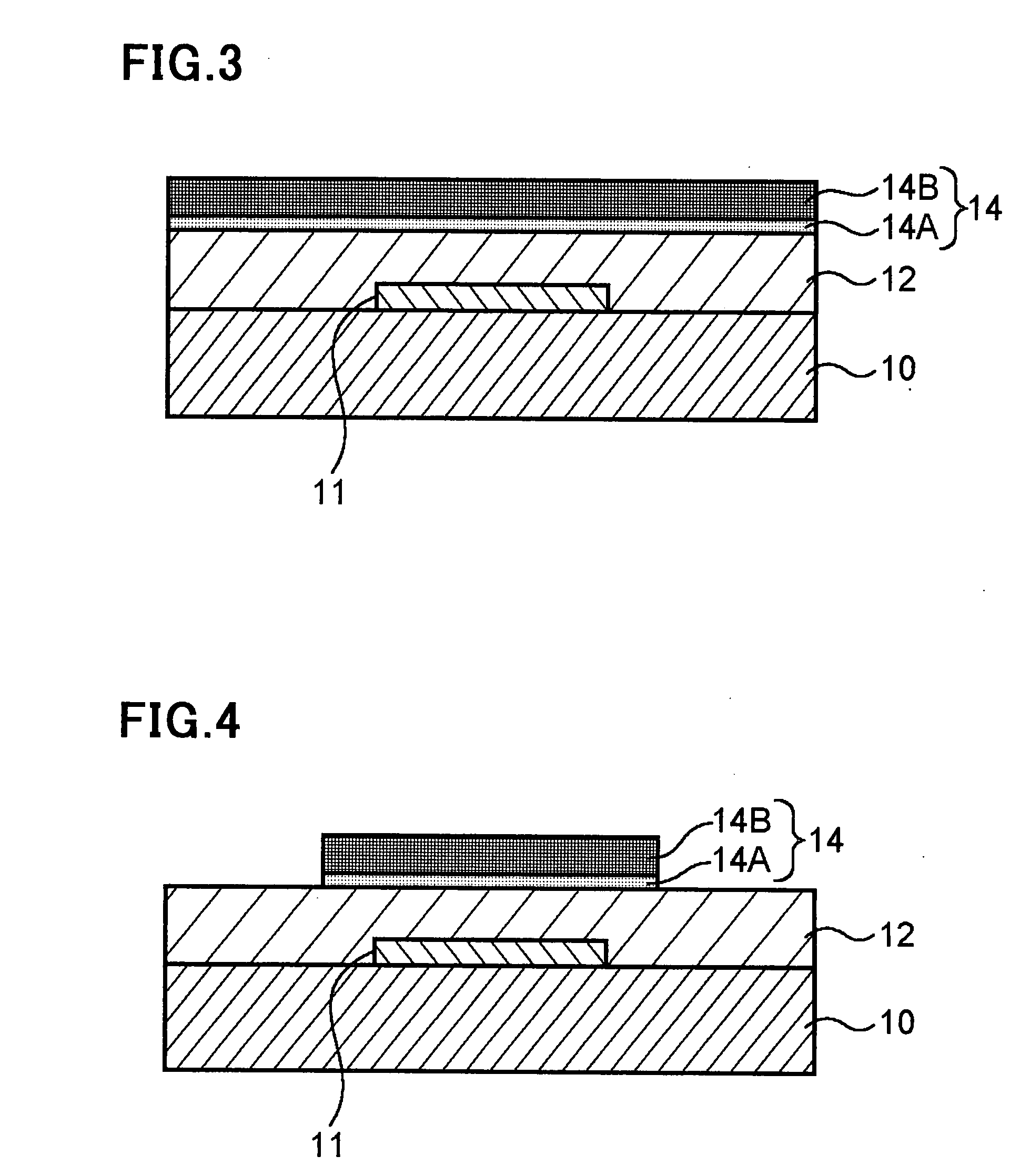

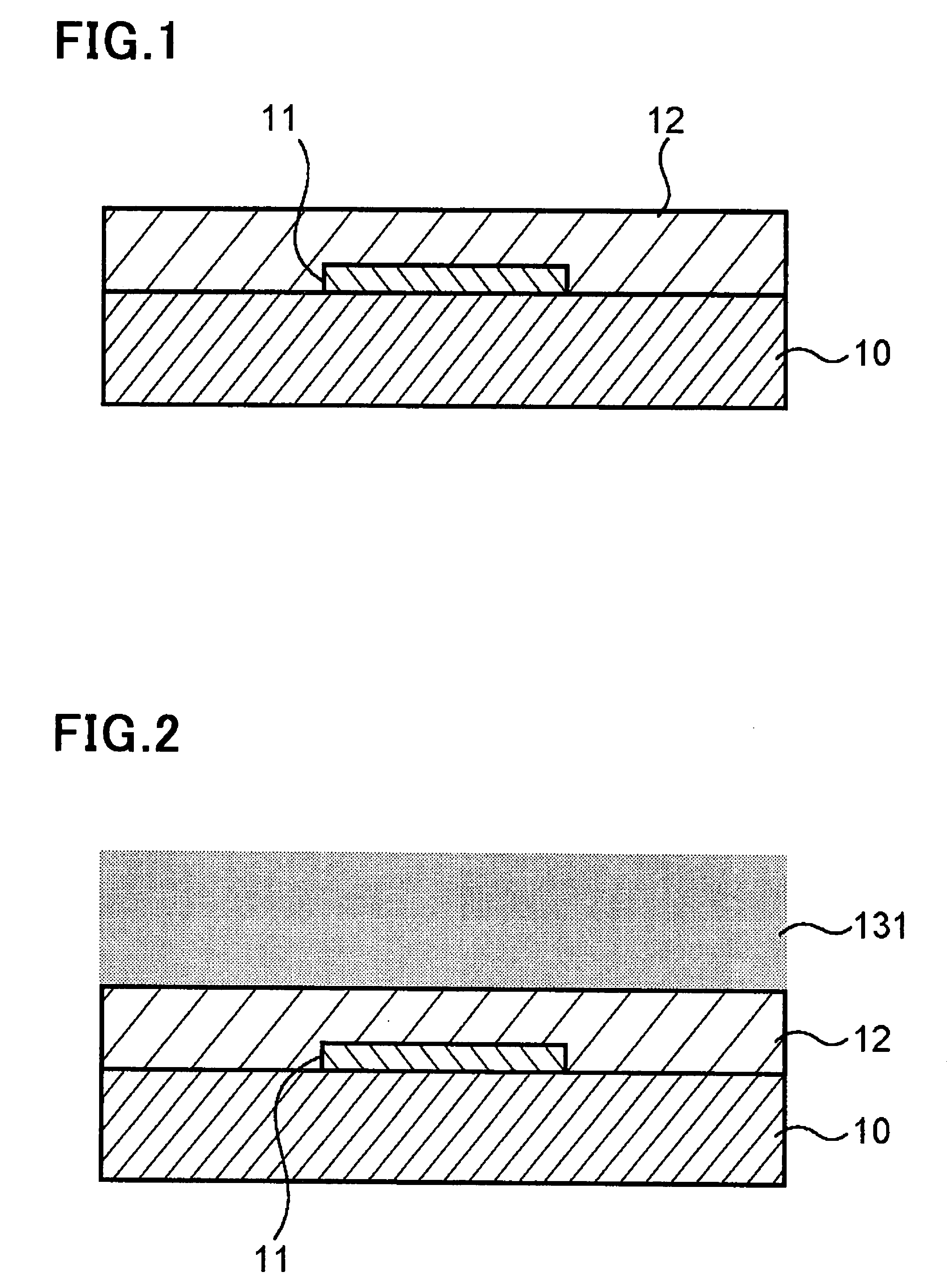

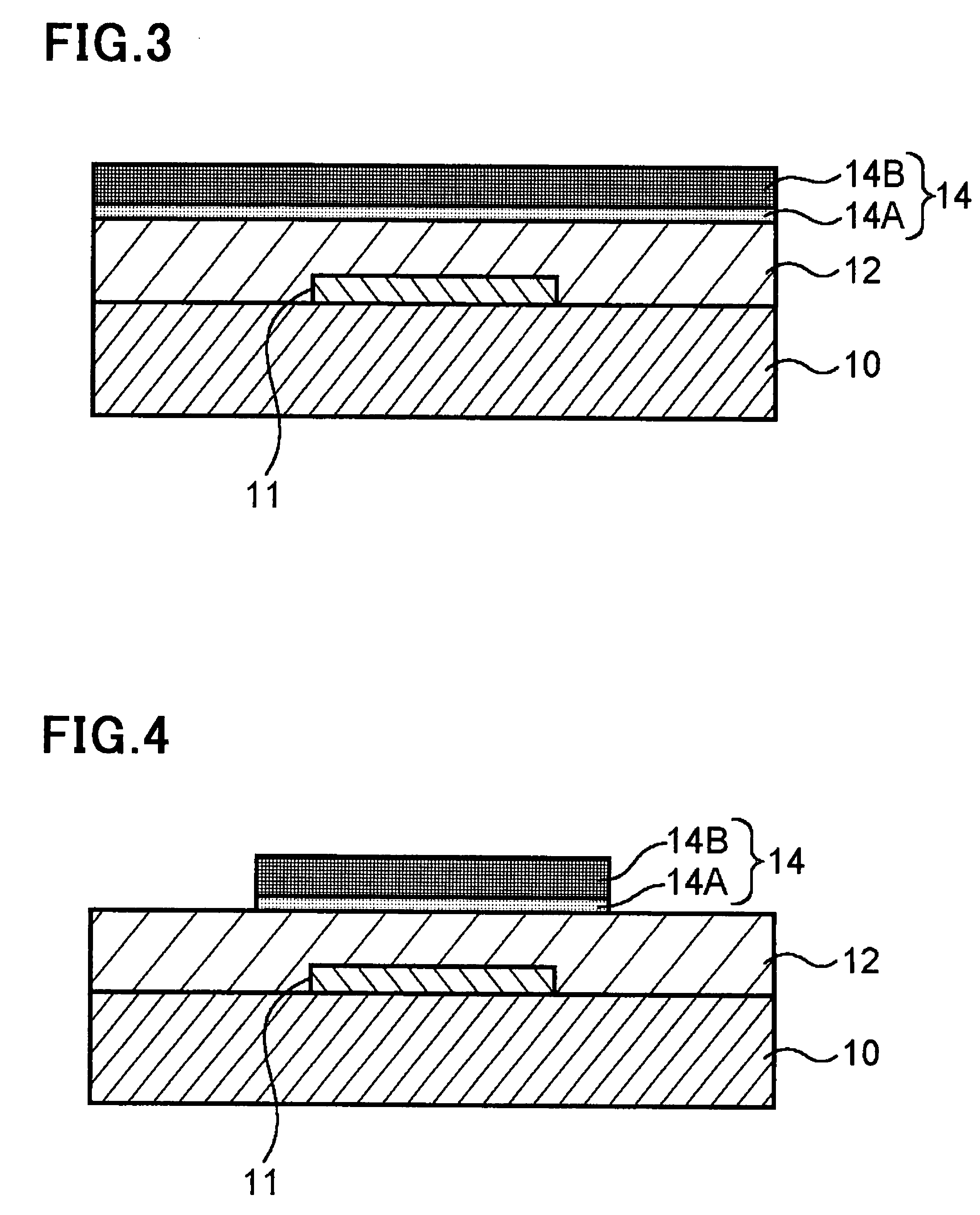

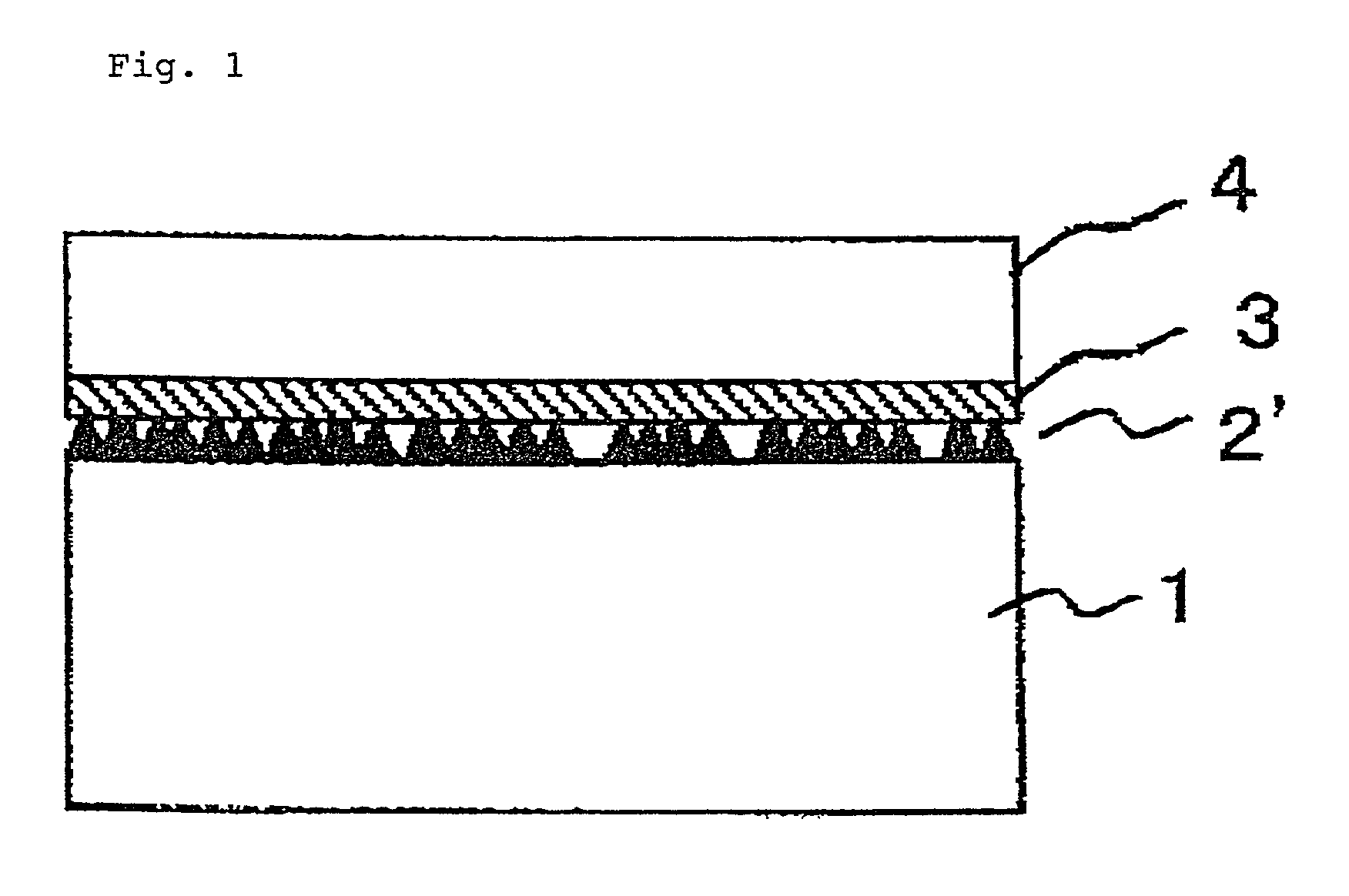

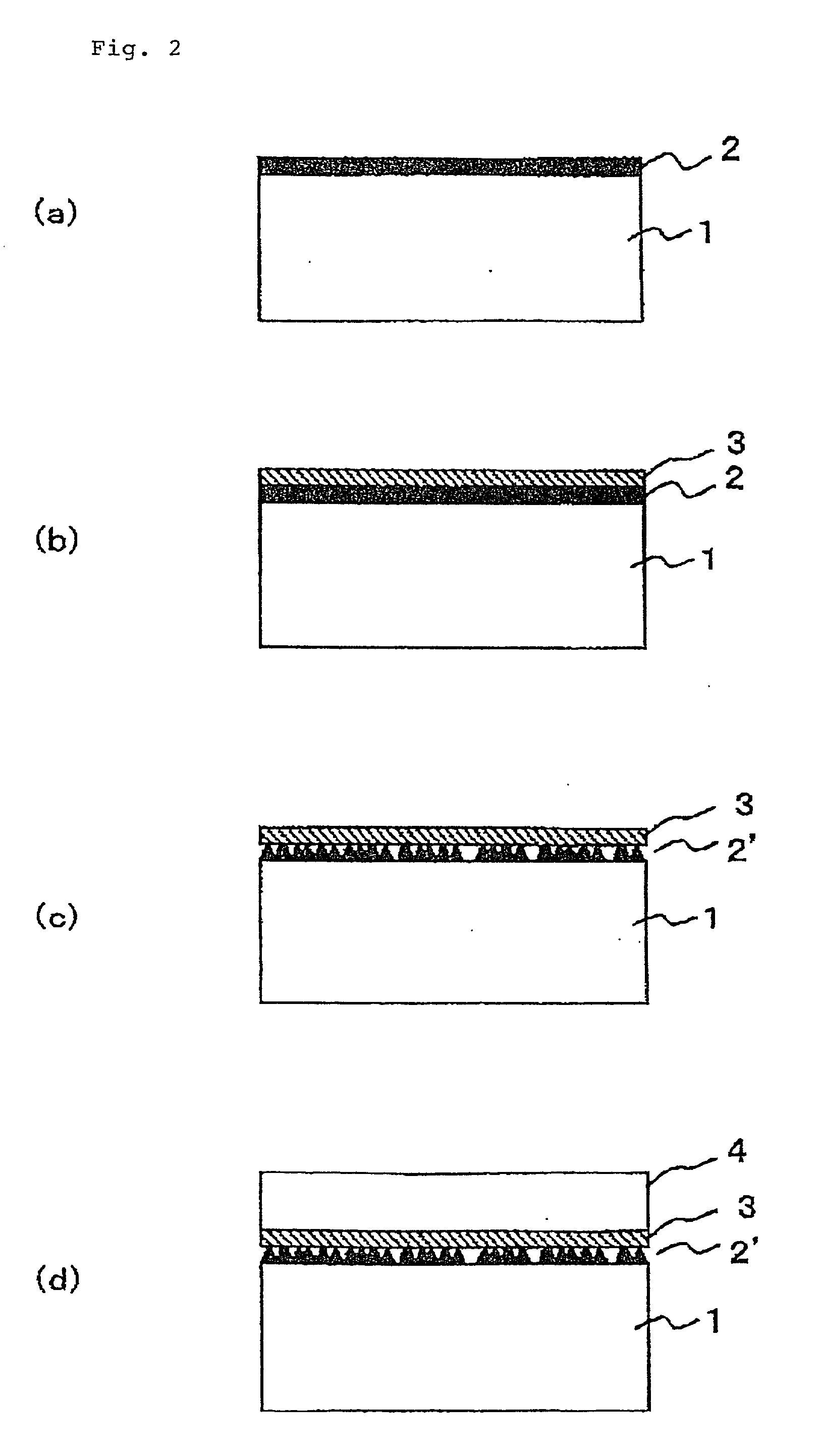

Thin-film device and method of fabricating the same

ActiveUS20080038882A1Low densityGood reproducibilitySemiconductor/solid-state device manufacturingSemiconductor devicesOxide semiconductorOxide

A thin-film device includes a first electrical insulator, an oxide-semiconductor film formed on the first electrical insulator, and a second electrical insulator formed on the oxide-semiconductor film, the oxide-semiconductor film defining an active layer. The oxide-semiconductor film is comprised of a first interface layer located at an interface with the first electrical insulating insulator, a second interface layer located at an interface with the second electrical insulator, and a bulk layer other than the first and second interface layers. A density of oxygen holes in at least one of the first and second interlayer layers is smaller than a density of oxygen holes in the bulk layer.

Owner:NEC LCD TECH CORP

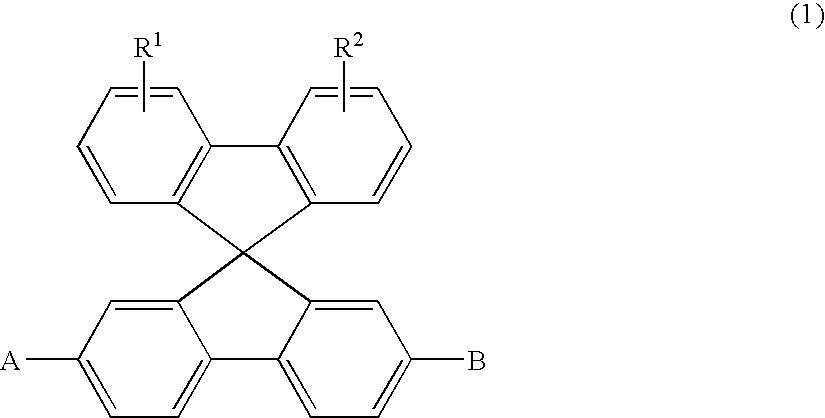

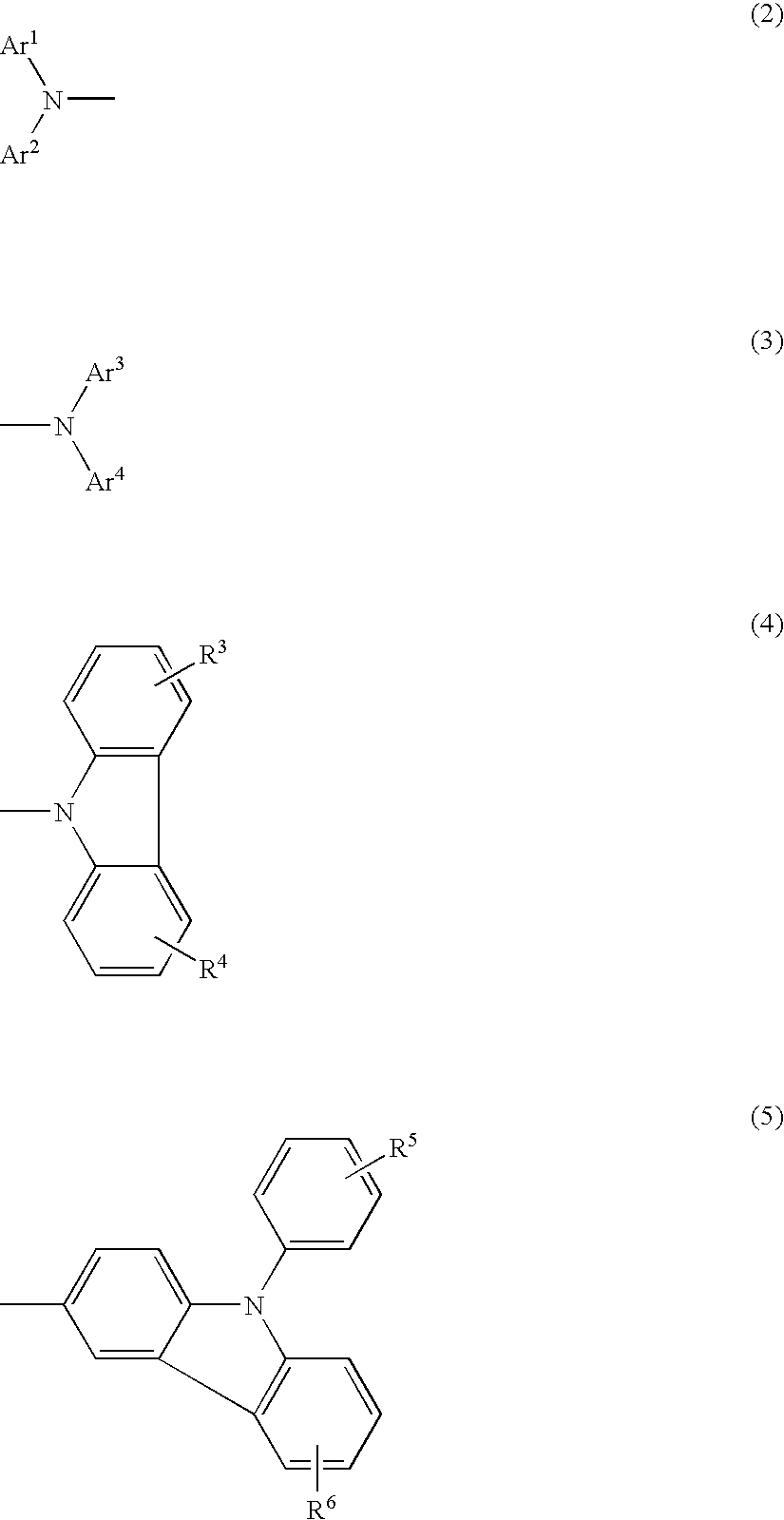

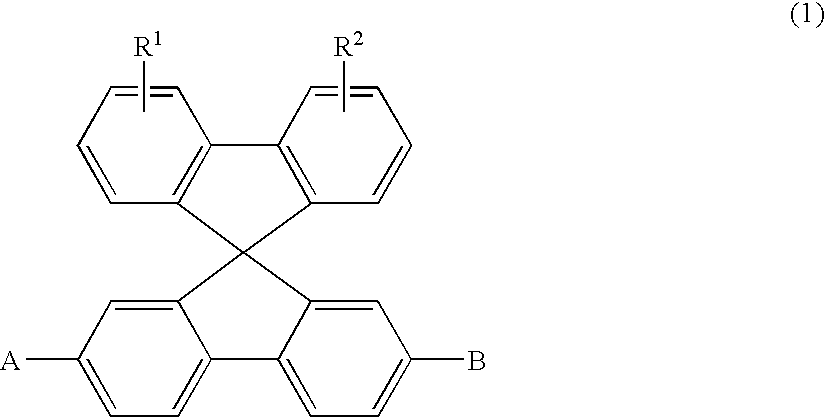

Aromatic amine derivatives and organic electroluminescence device using the same

InactiveUS20090167161A1Increase productionLong life-timeOrganic chemistryDischarge tube luminescnet screensOrganic electroluminescenceHole transport layer

Provided are an organic electroluminescence device and an aromatic amine derivative for realizing the device. The aromatic amine derivative improves the luminous efficiency of an organic electroluminescence device using the derivative, and its molecules hardly crystallize. The organic electroluminescence device has an organic thin film layer composed of one or a plurality of layers including at least a light emitting layer, the organic thin film layer being interposed between a cathode and an anode, and at least one layer of the organic thin film layer, especially a hole transporting layer contains the aromatic amine derivative alone or as a component of a mixture, so the organic electroluminescence device can be produced in improved yield, and has a long lifetime.

Owner:IDEMITSU KOSAN CO LTD

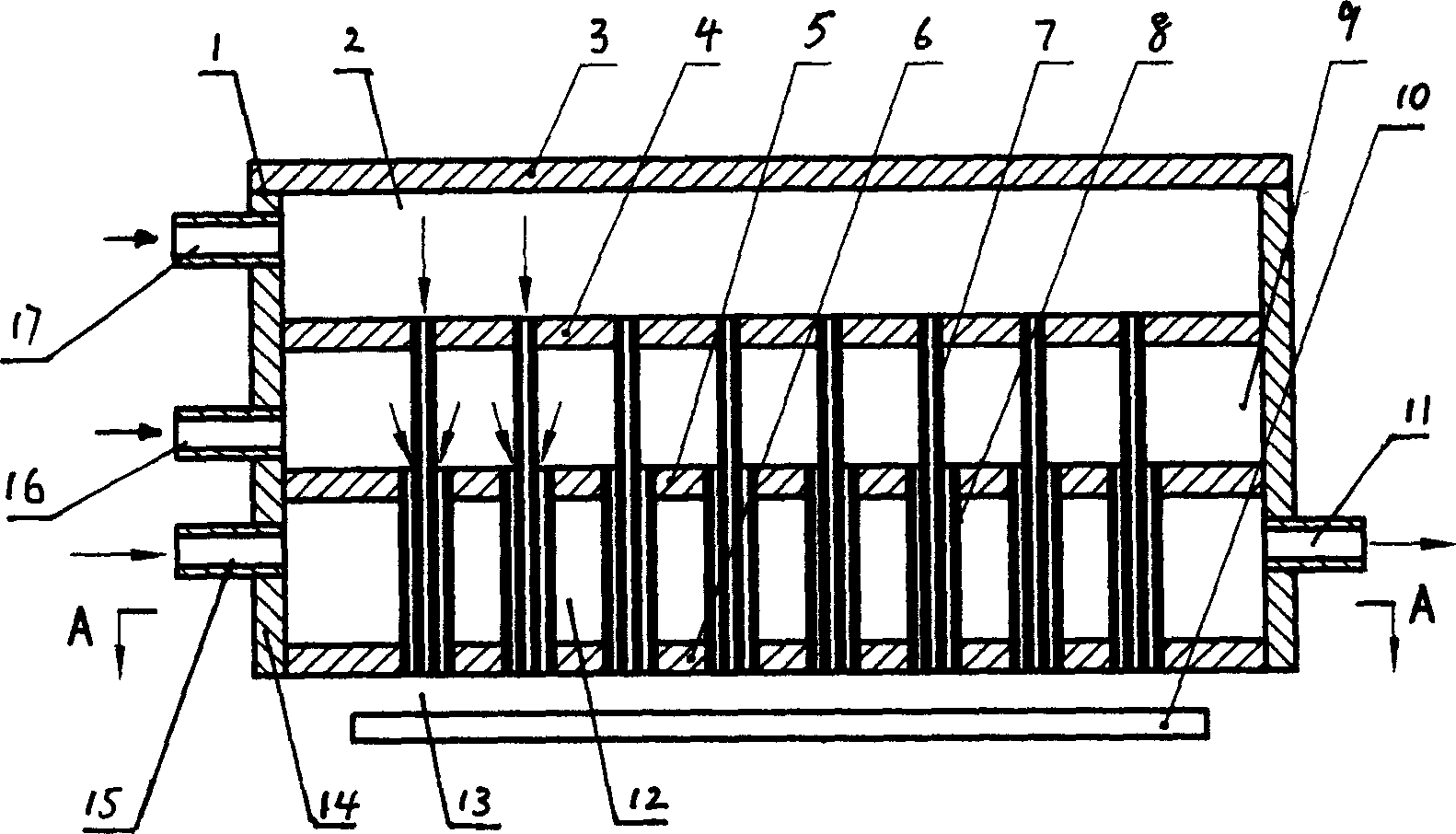

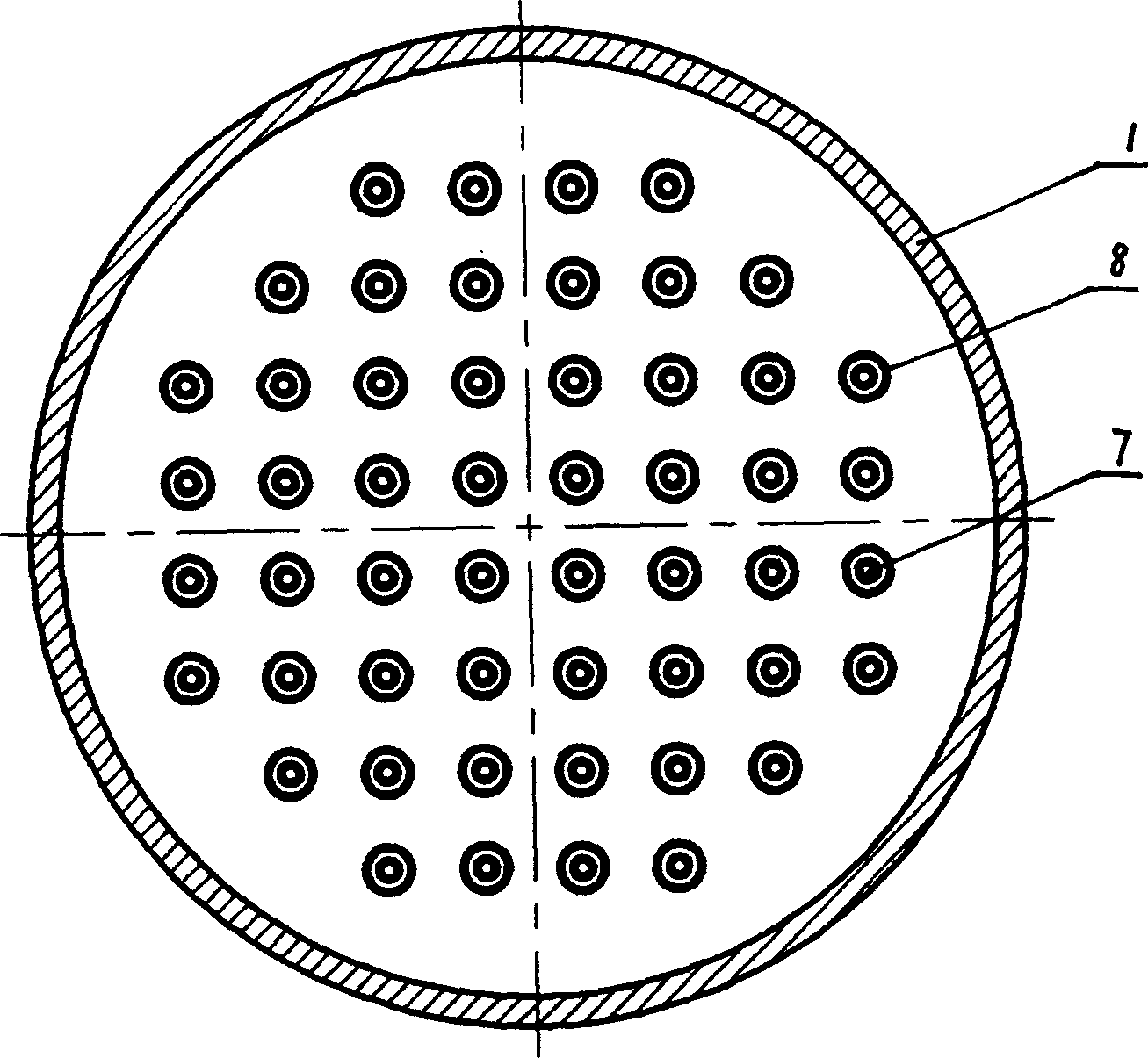

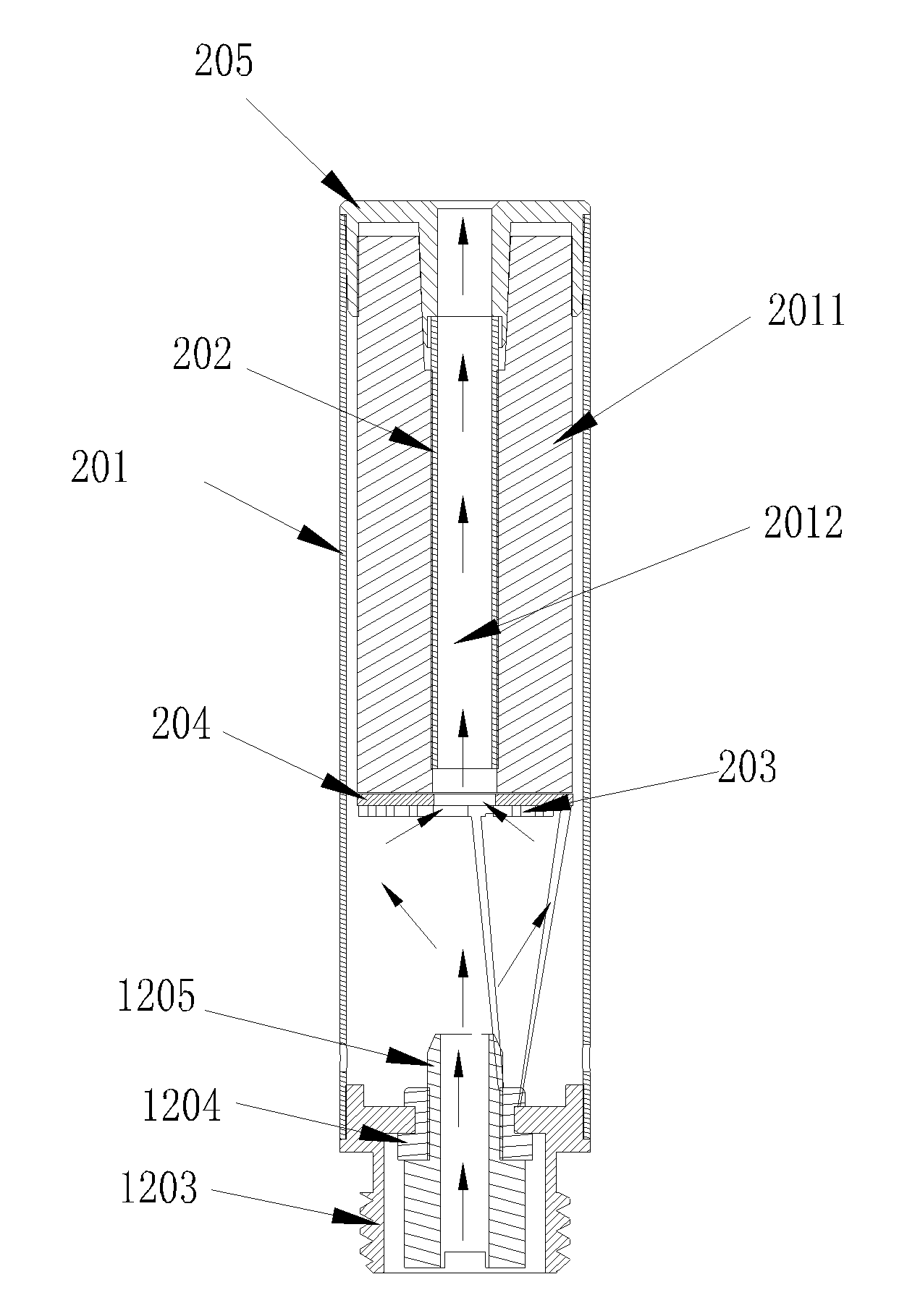

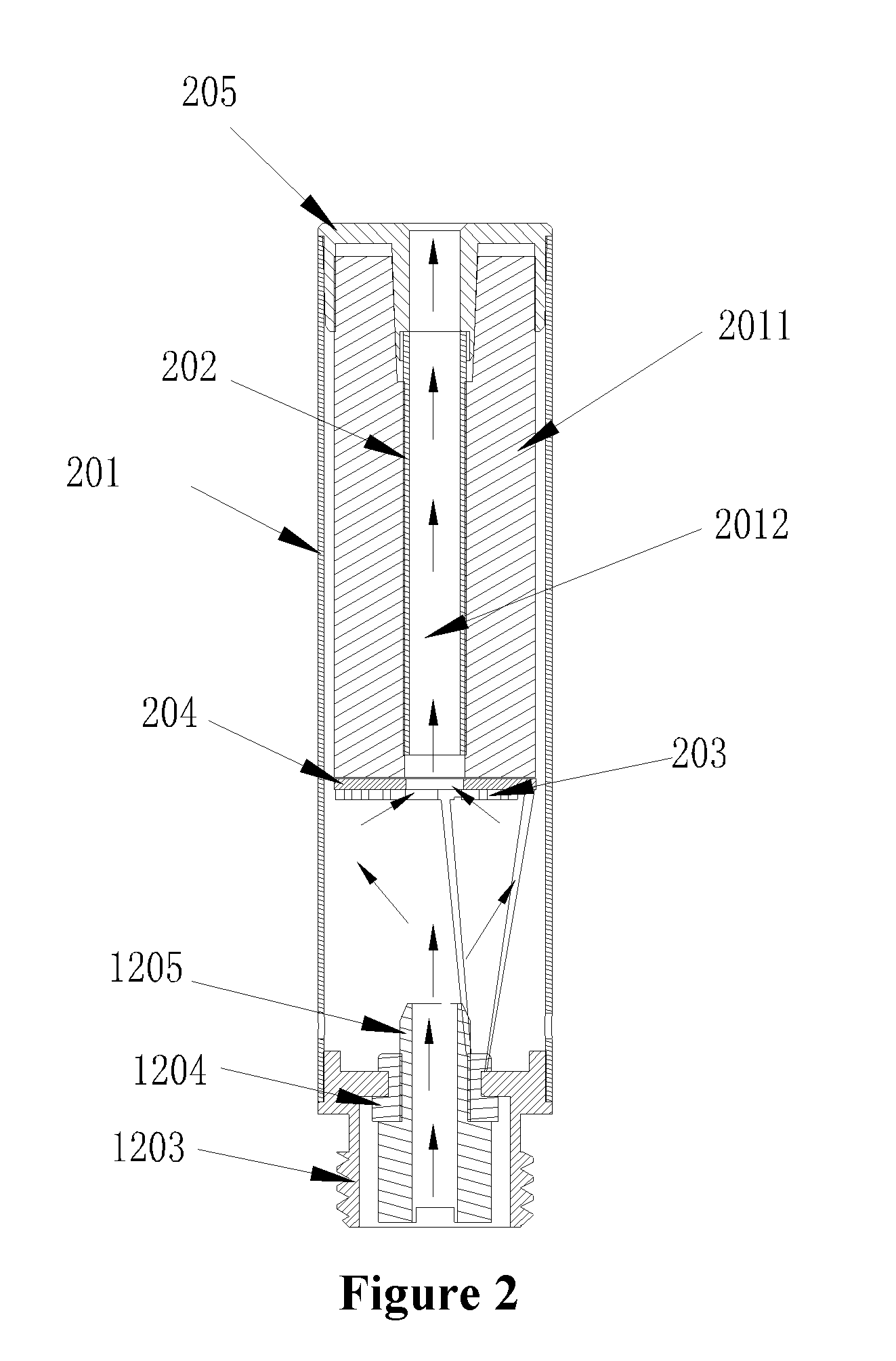

Bilayer inlet gas spray nozzle in use for metal-organic chemical vapor deposition device

This invention discloses a two-layer gas inlet blow head of a metal organic chemical gas phase deposit device including a closed shell having an upper gas inlet cavity and a lower gas inlet cavity, an upper escape pipe communicating with the upper gas cavity and reaction chamber is set between the upper-middle and the base plate and a lower escape pipe communicating with a lower gas inlet cavity and the reaction chamber is set between the lower plate and base plate characterizing that diameter of the lower escape pipe is layer than the upper and the upper is put in the lower. A cooling cavity is designed, the first reaction gas enters into the reaction chamber at the substrate surface from the upper and lower escape pipes separately.

Owner:南昌硅基半导体科技有限公司

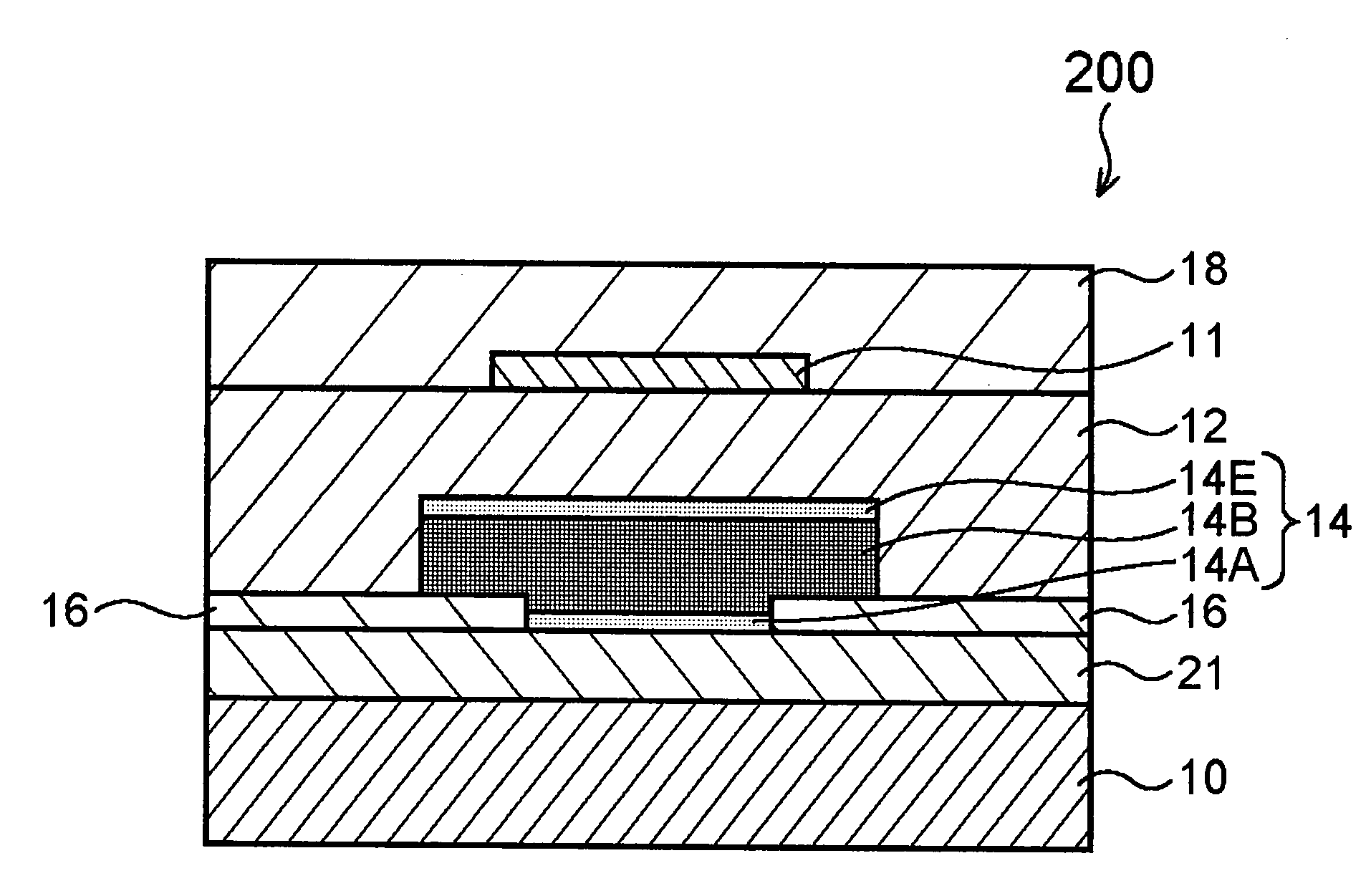

Thin-film device and method of fabricating the same

ActiveUS7884360B2Good reproducibilityImprove yieldSemiconductor/solid-state device manufacturingSemiconductor devicesInterface layerEngineering

A thin-film device includes a first electrical insulator, an oxide-semiconductor film formed on the first electrical insulator, and a second electrical insulator formed on the oxide-semiconductor film, the oxide-semiconductor film defining an active layer. The oxide-semiconductor film is comprised of a first interface layer located at an interface with the first electrical insulating insulator, a second interface layer located at an interface with the second electrical insulator, and a bulk layer other than the first and second interface layers. A density of oxygen holes in at least one of the first and second interlayer layers is smaller than a density of oxygen holes in the bulk layer.

Owner:NEC LCD TECH CORP

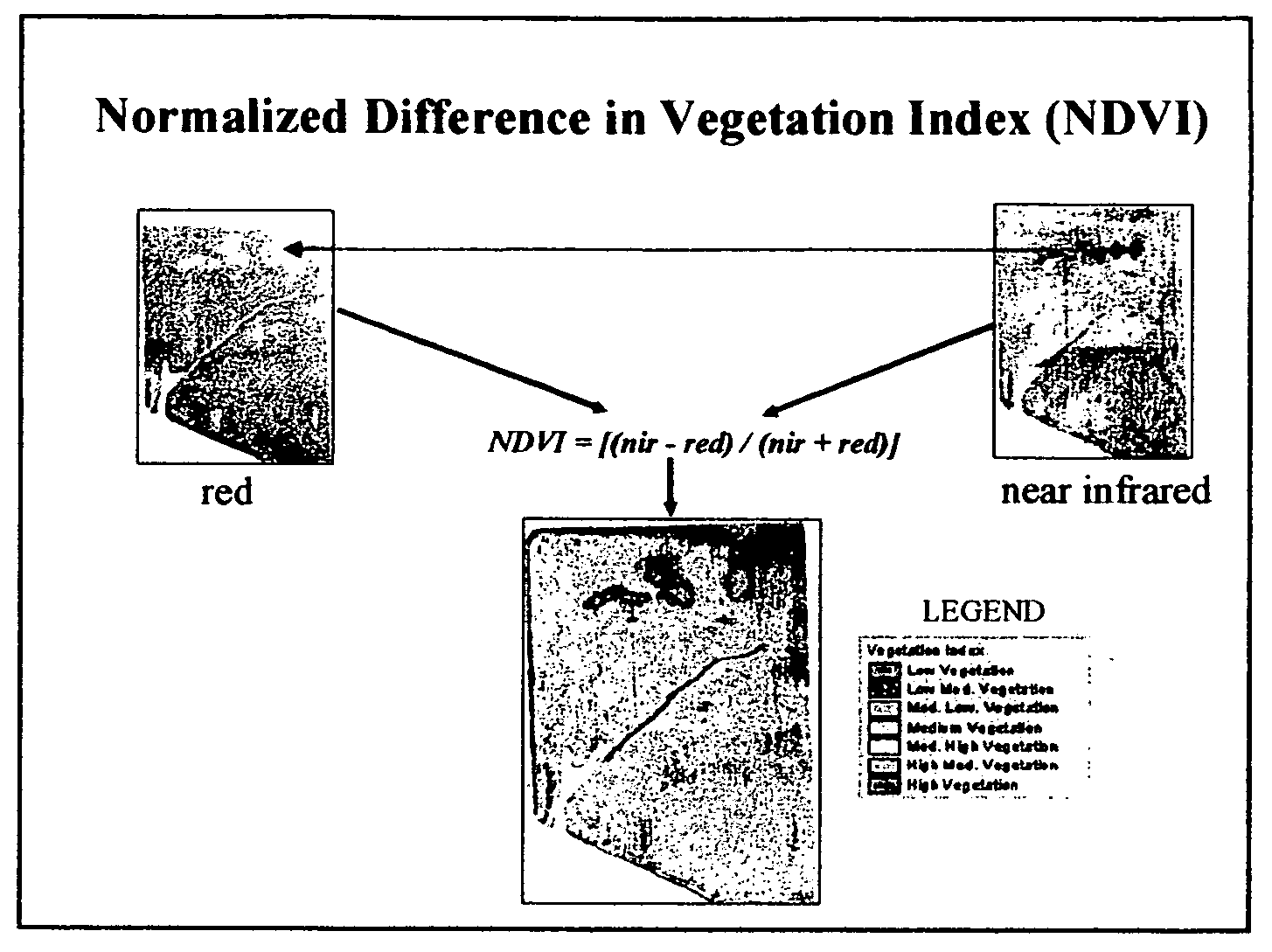

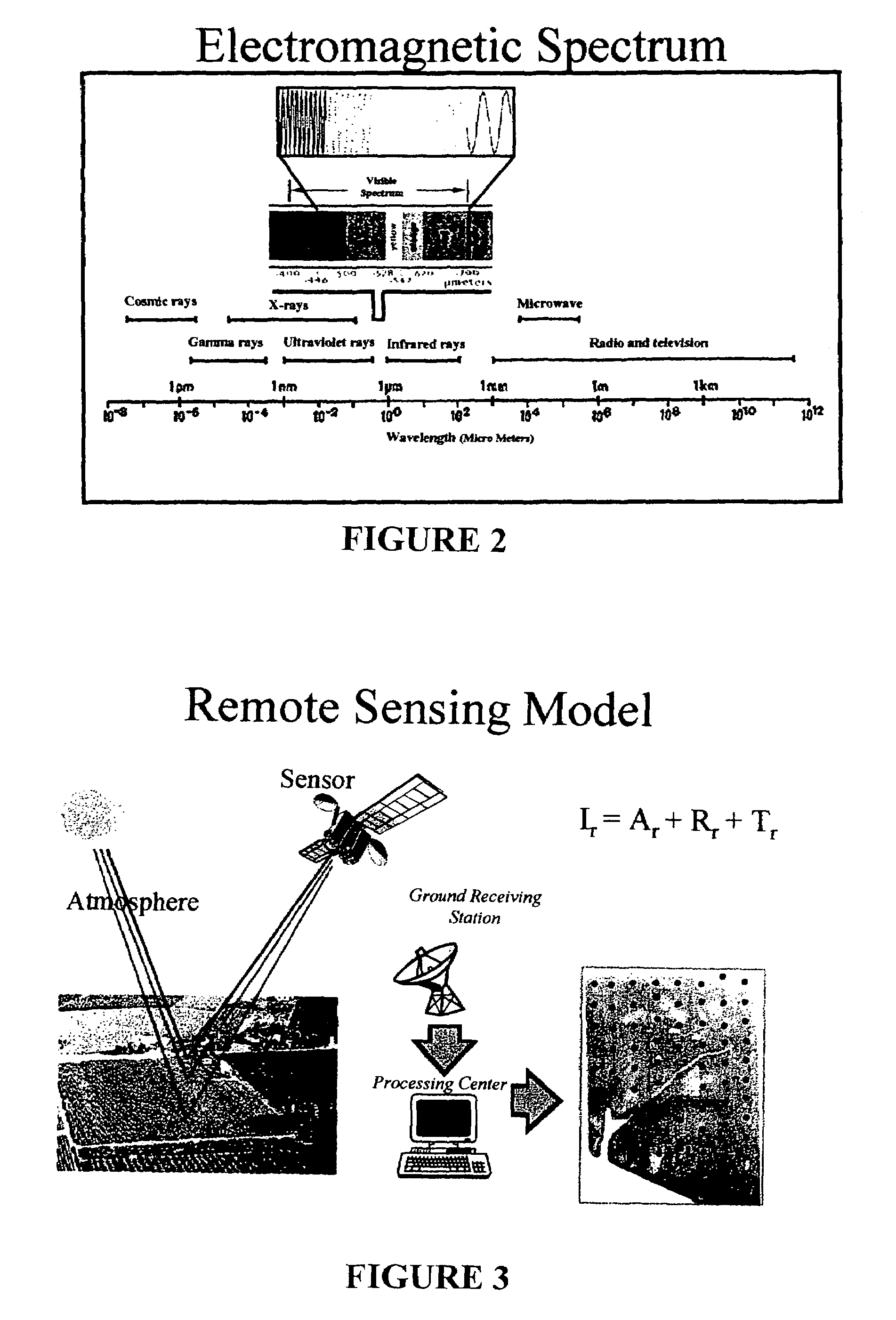

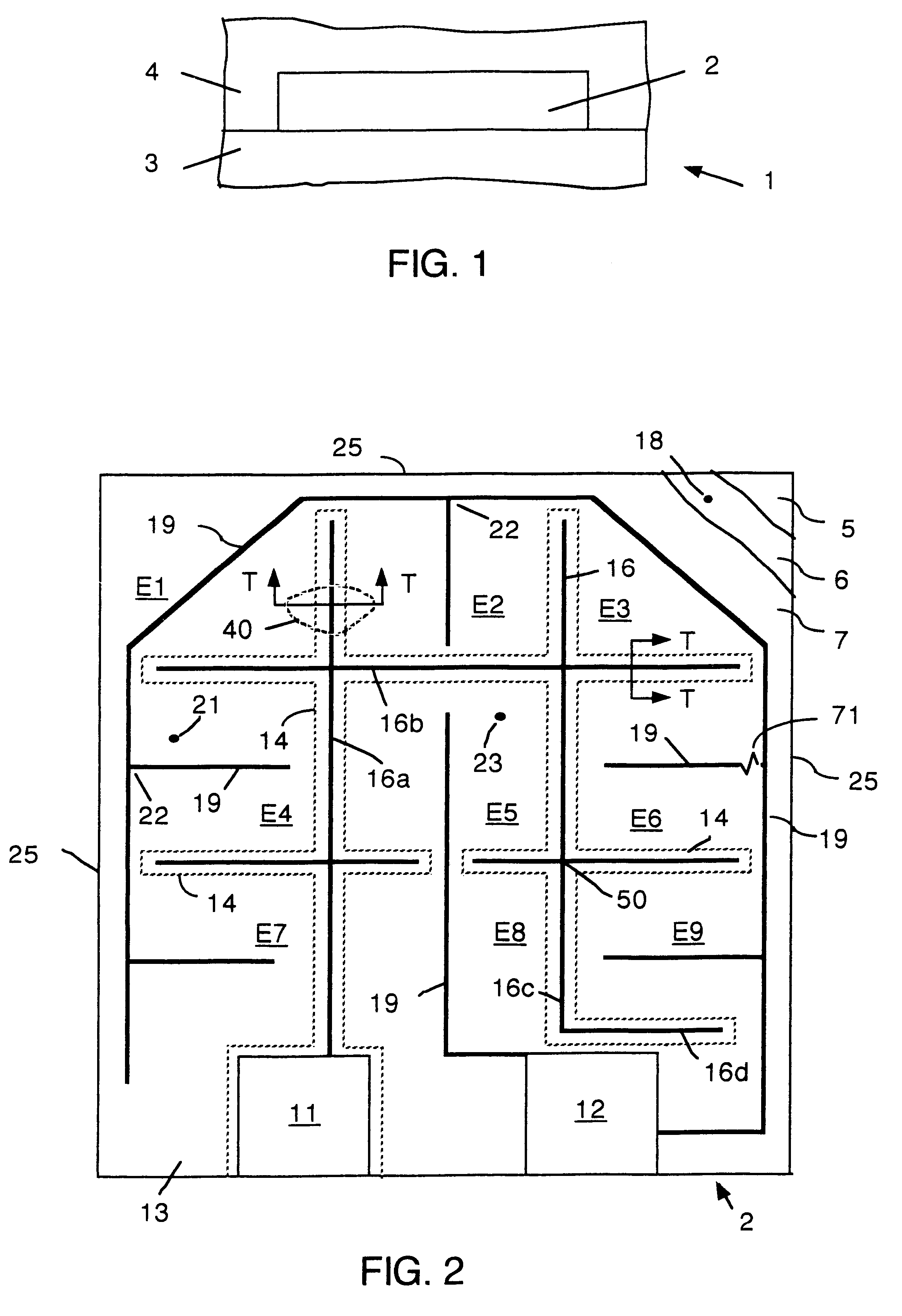

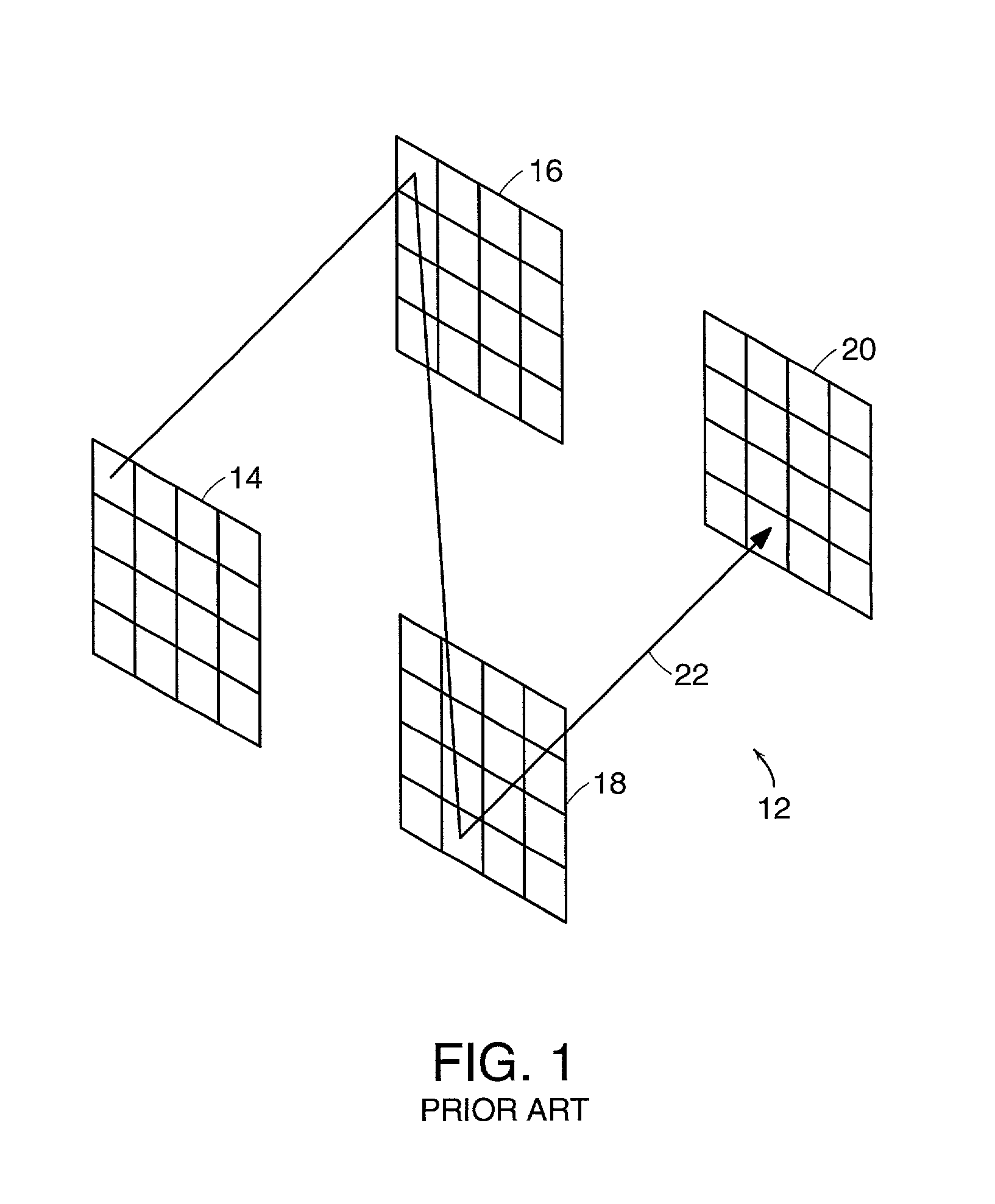

Multi-variable model for identifying crop response zones in a field

InactiveUS7058197B1Increased leaf areaEliminate the effects ofImage enhancementImage analysisVegetationGrowing season

An computer implemented apparatus and method are disclosed for defining areas of a field in which a crop or other vegetation is grown based on their selective ability to grow such vegetation through a growing season, or some shorter preselected time period. The method includes making a number of temporally separated measurements through air borne imaging of a field, registering the data to the geography of the field and each other, normalizing the data including converting the data to a vegetative index indicative to the presence of vegetation in the field, comparing the data to identify clusters of like value, and classifying the clusters and images to learn how the different field areas responded in growing vegetation through the season. With this method, the field may be segregated into a number of like areas called crop response zones which exhibit similar vegetative growth characteristics as an aid to a grower in his decision making regarding how to maximize yield in his field.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

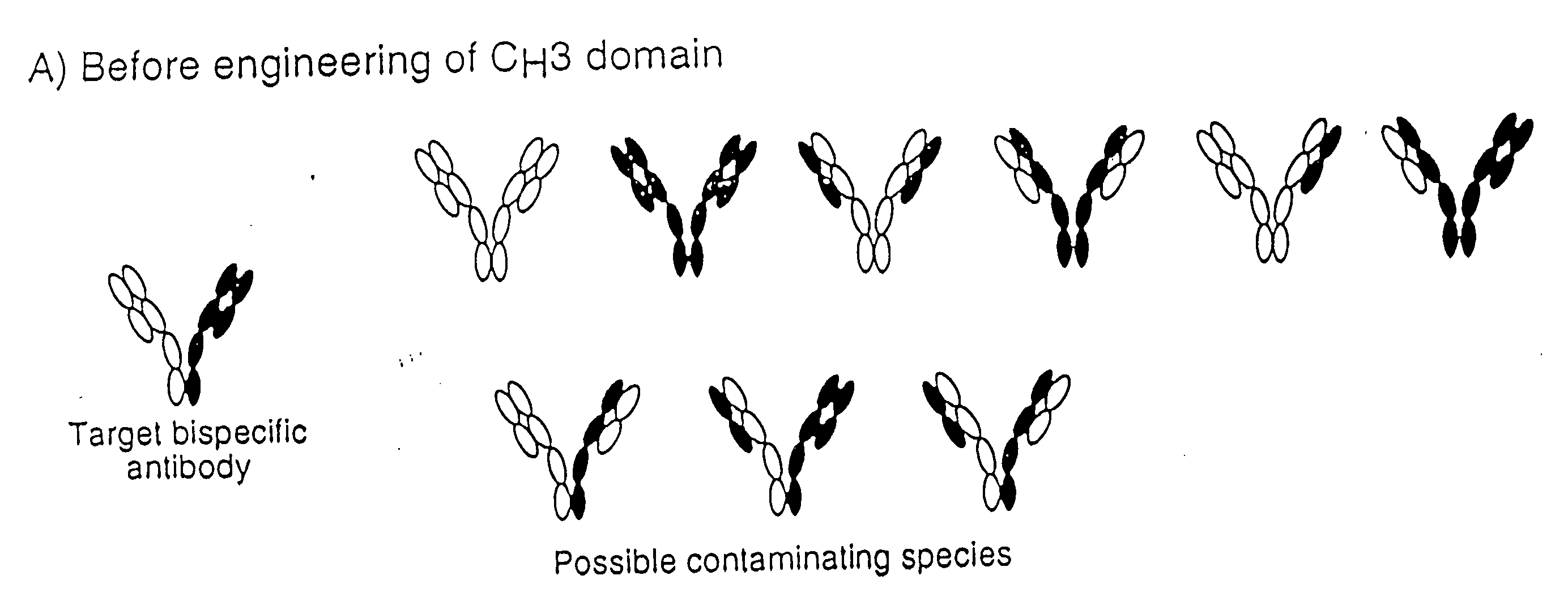

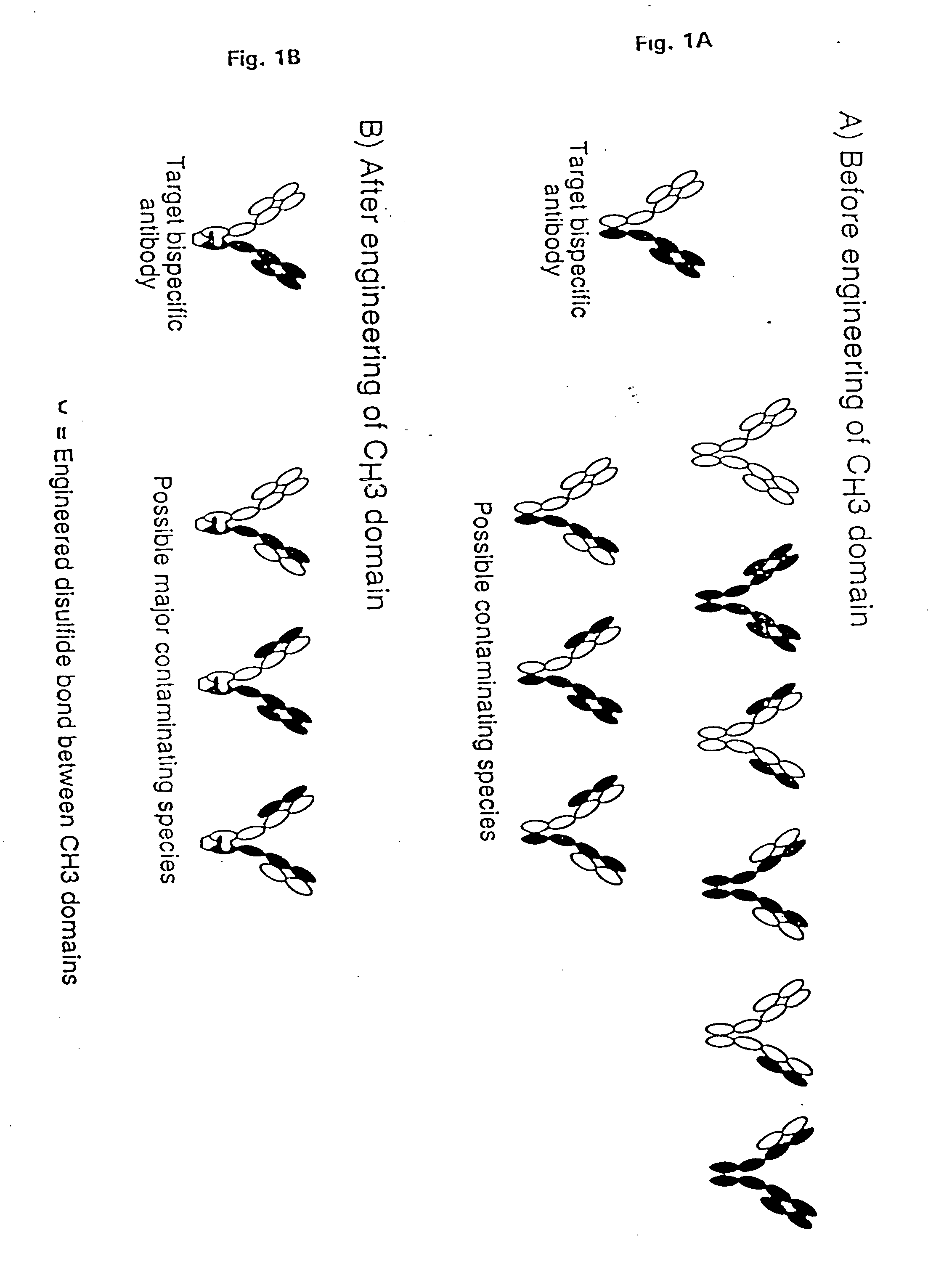

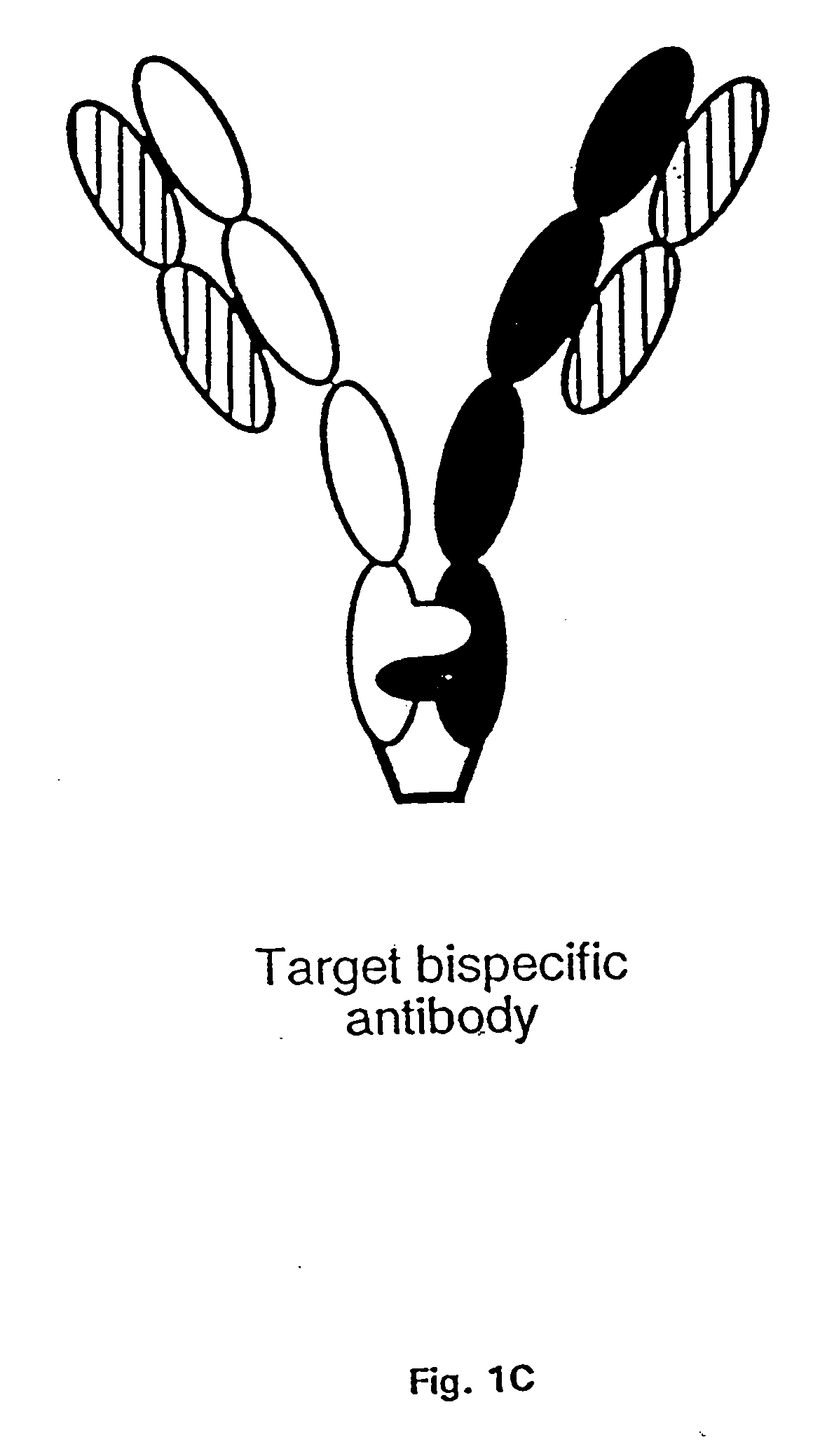

Method for Making Multispecific Antibodies Having Heteromultimeric and Common Components

InactiveUS20070178552A1Increased formationIncrease productionAnimal cellsHybrid immunoglobulinsSpecific immunityBiology

The invention relates to a method of preparing heteromultimeric polypeptides such as bispecific antibodies, bispecific immunoadhesins and antibody-immunoadhesin chimeras. The invention also relates to the heteromultimers prepared using the method. Generally, the method provides a multispecific antibody having a common light chain associated with each heteromeric polypeptide having an antibody binding domain. Additionally the method further involves introducing into the multispecific antibody a specific and complementary interaction at the interface of a first polypeptide and the interface of a second polypeptide, so as to promote heteromultimer formation and hinder homomultimer formation; and / or a free thiol-containing residue at the interface of a first polypeptide and a corresponding free thiol-containing residue in the interface of a second polypeptide, such that a non-naturally occurring disulfide bond is formed between the first and second polypeptide. The method allows for the enhanced formation of the desired heteromultimer relative to undesired heteromultimers and homomultimers.

Owner:GENENTECH INC

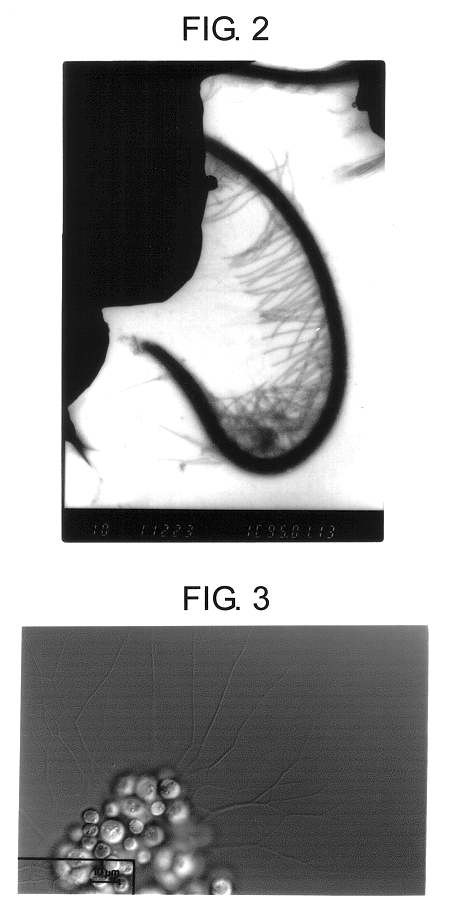

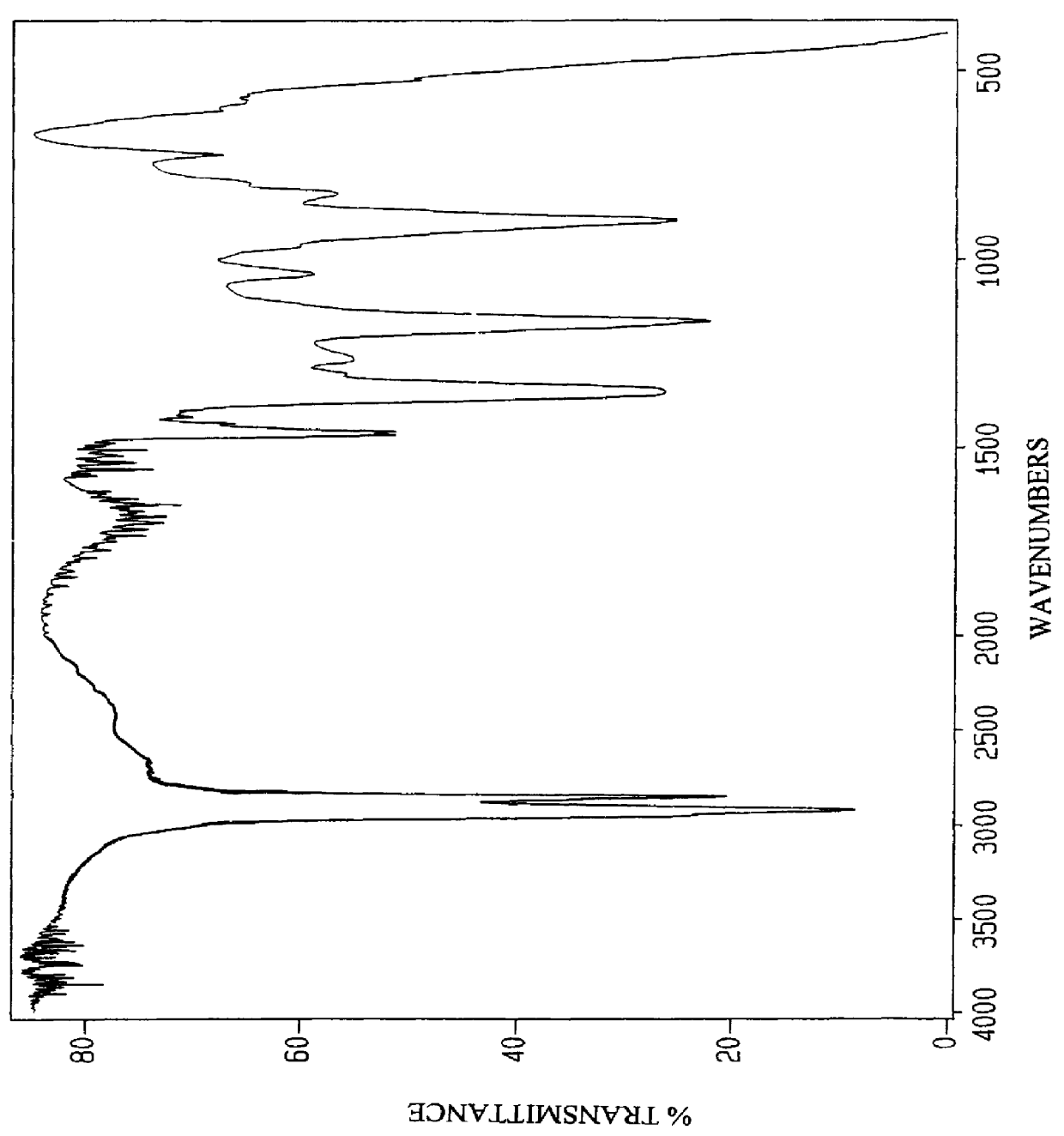

Microorganisms capable of producing highly unsaturated fatty acids and process for producing highly unsaturated fatty acids by using the microorganisms

InactiveUS6582941B1High speedIncrease productionBiocideOrganic active ingredientsMicroorganismSchizochytrium

The present invention relates to the Schizochytrium genus SR21 strain and a microorganism belonging to the same species as does said SR21 strain or having substantially the same fungological properties as does said SR21 strain, the said SR21 strain and microorganism having the ability to produce the (n-3) series of docosahexaenoic acid (DHA) and the (n-6) series of docosapentaenoic acid (DPA), and the invention also relates to a process for preparing the (n-3) series of DHA and the (n-6) series of DPA utilizing said microorganisms. The microorganisms according to the present invention are superior in their proliferation character and their propensity to produce fat, and have the ability to produce the (n-3) series of DHA and the (n-6) series of DPA very well. Accordingly, it is possible to effectively produce the (n-3) series of DHA and / or the (n-6) series of DPA, which are useful in the fields of foods and pharmaceuticals, using the microorganisms according to the present invention. In addition, the present invention provides a fat obtained by culturing the present microorganisms. Since the fat composition contains the (n-6) series of DPA in addition to the (n-3) series of DHA having various physiological activities, it is possible to stably and effectively supply the (n-6) series of DPA and / or the (n-3) series of DHA to subjects in need of these highly unsaturated fatty acids by adding the fat composition to various feedstuffs or foods.

Owner:DIRECTOR GENERAL OF THE AGENCY OF IND SCI & TECH +1

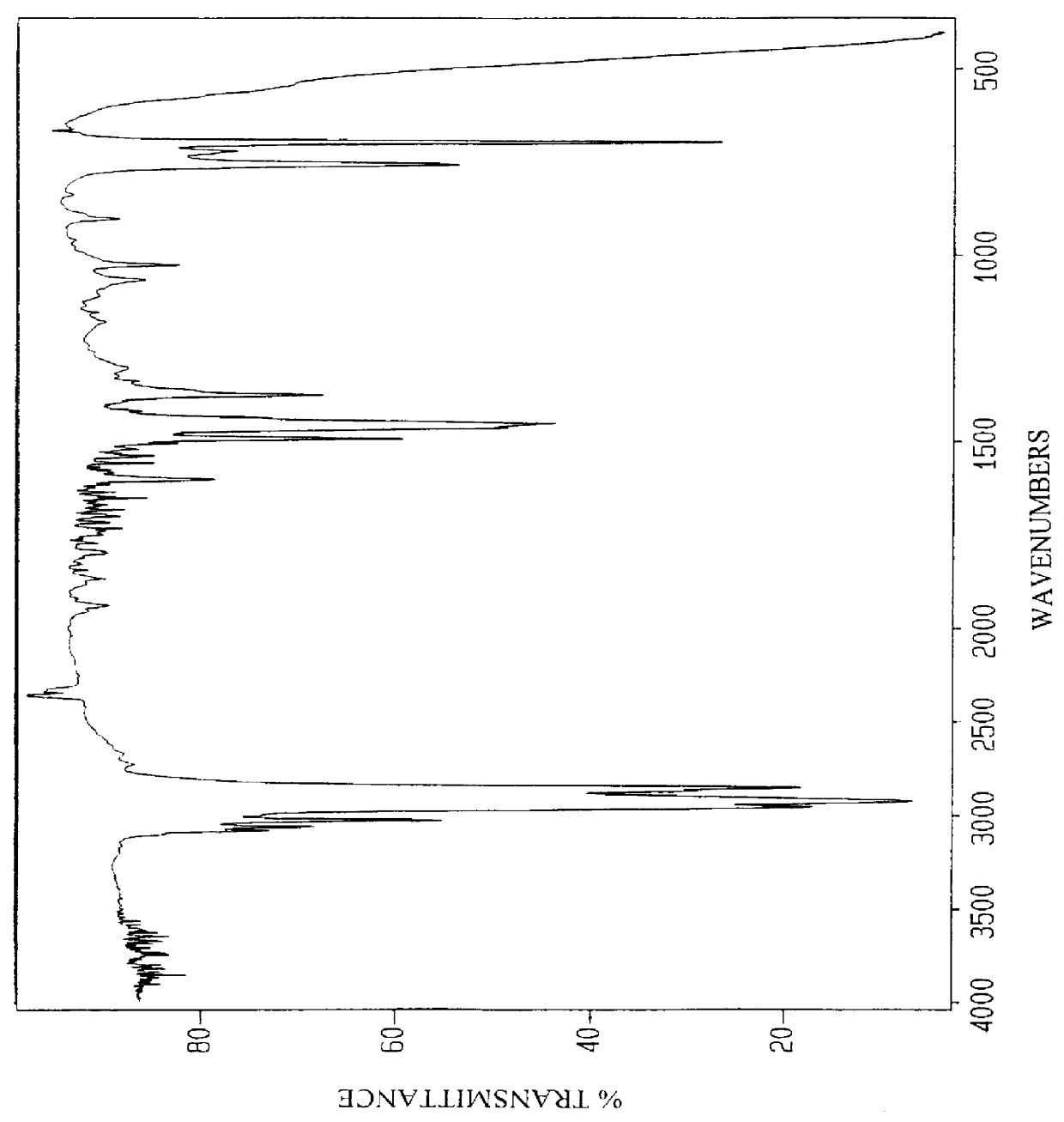

Krill oil process

InactiveUS20110130458A1Improve yieldReduce product costBiocideFatty-oils/fats refiningOmega 3 fatty acidChemistry

The present invention relates to a process for preparing compositions of high concentrations of omega-3 fatty acids from krill. Furthermore, the invention relates to a composition comprising high concentrations of omega-3 fatty acids, and a lipid fraction from krill comprising high amounts of fatty acids with chain length C14 and C16.

Owner:PRONOVA BIOPHARMA NORGE

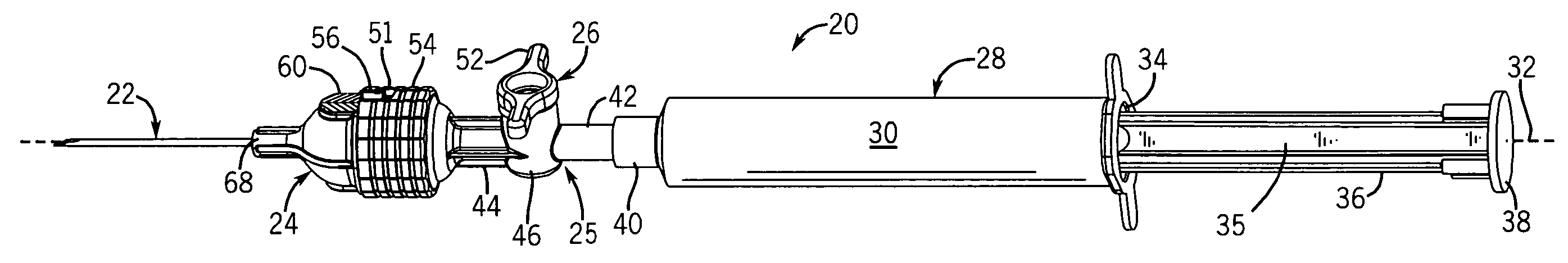

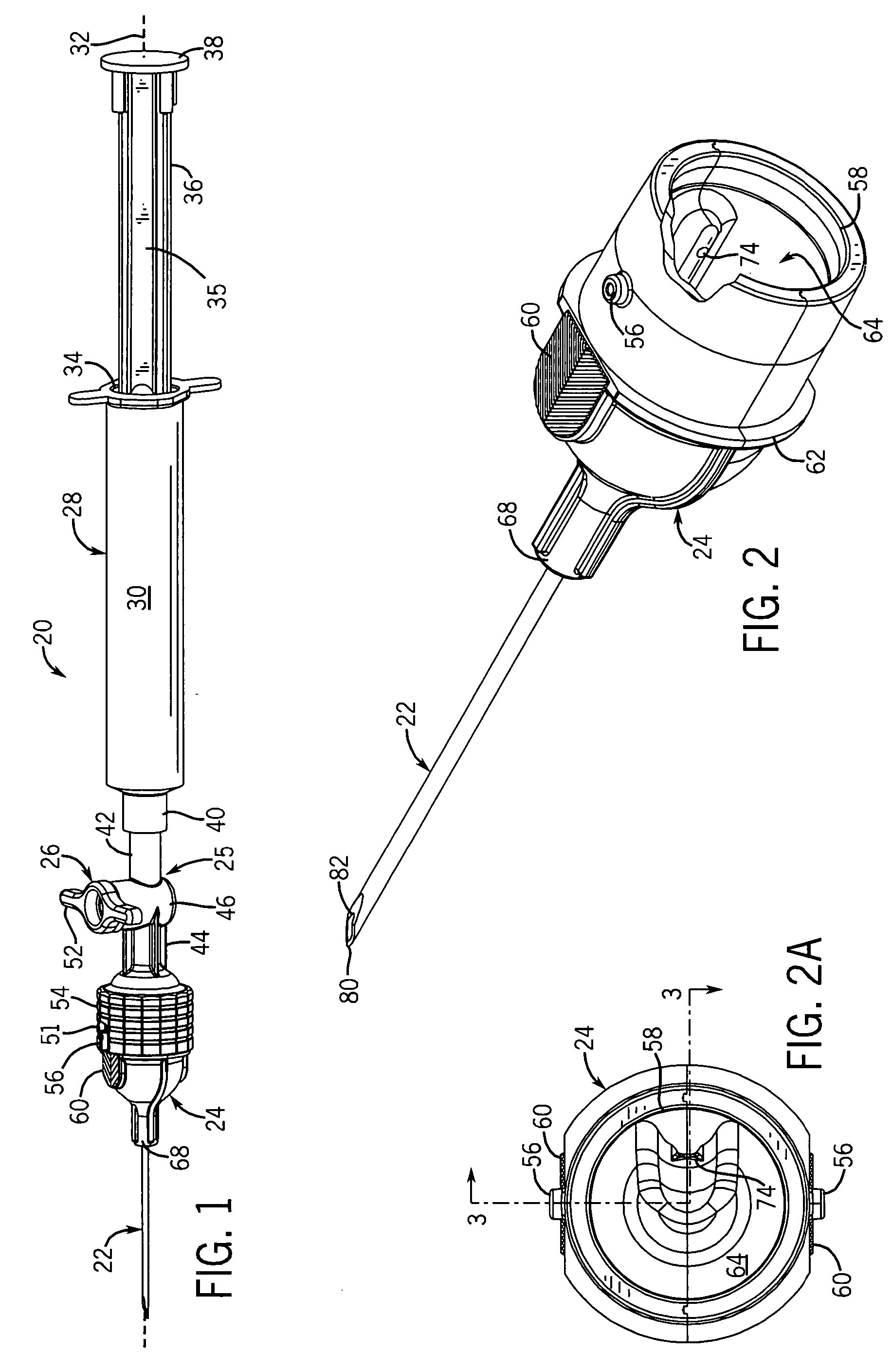

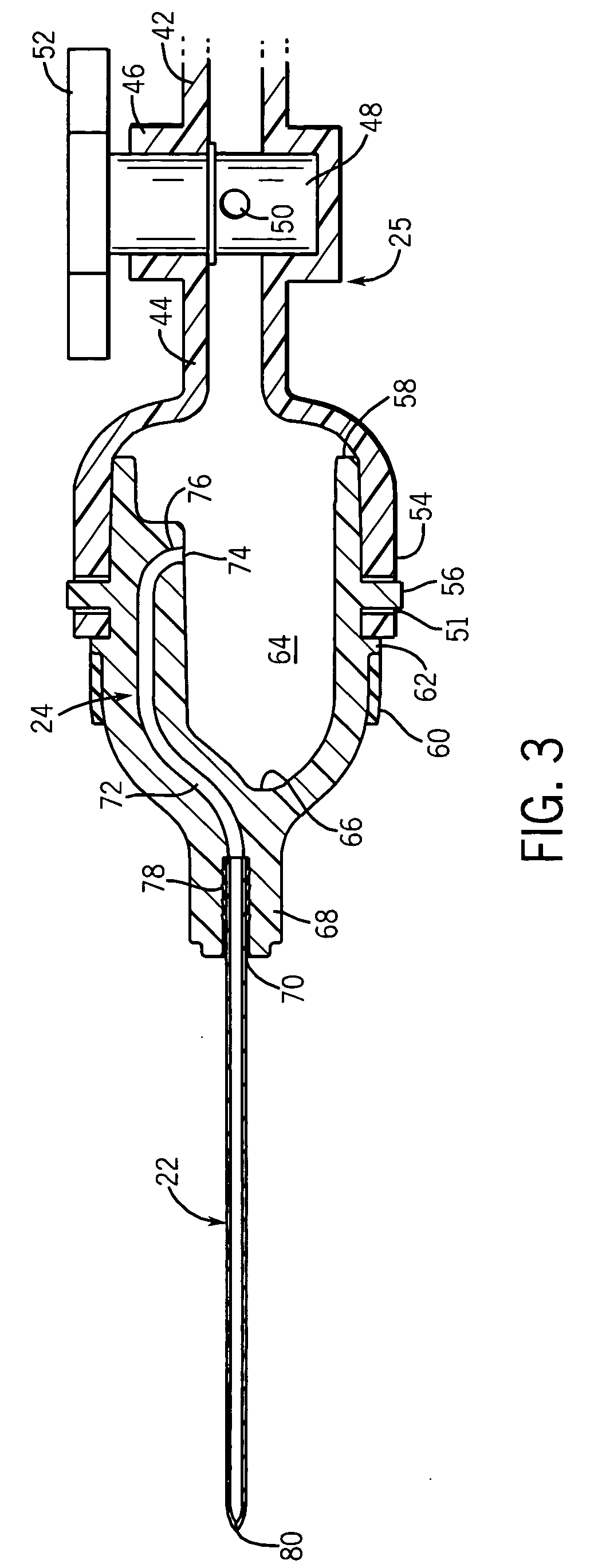

Needle aspiration biopsy device and method

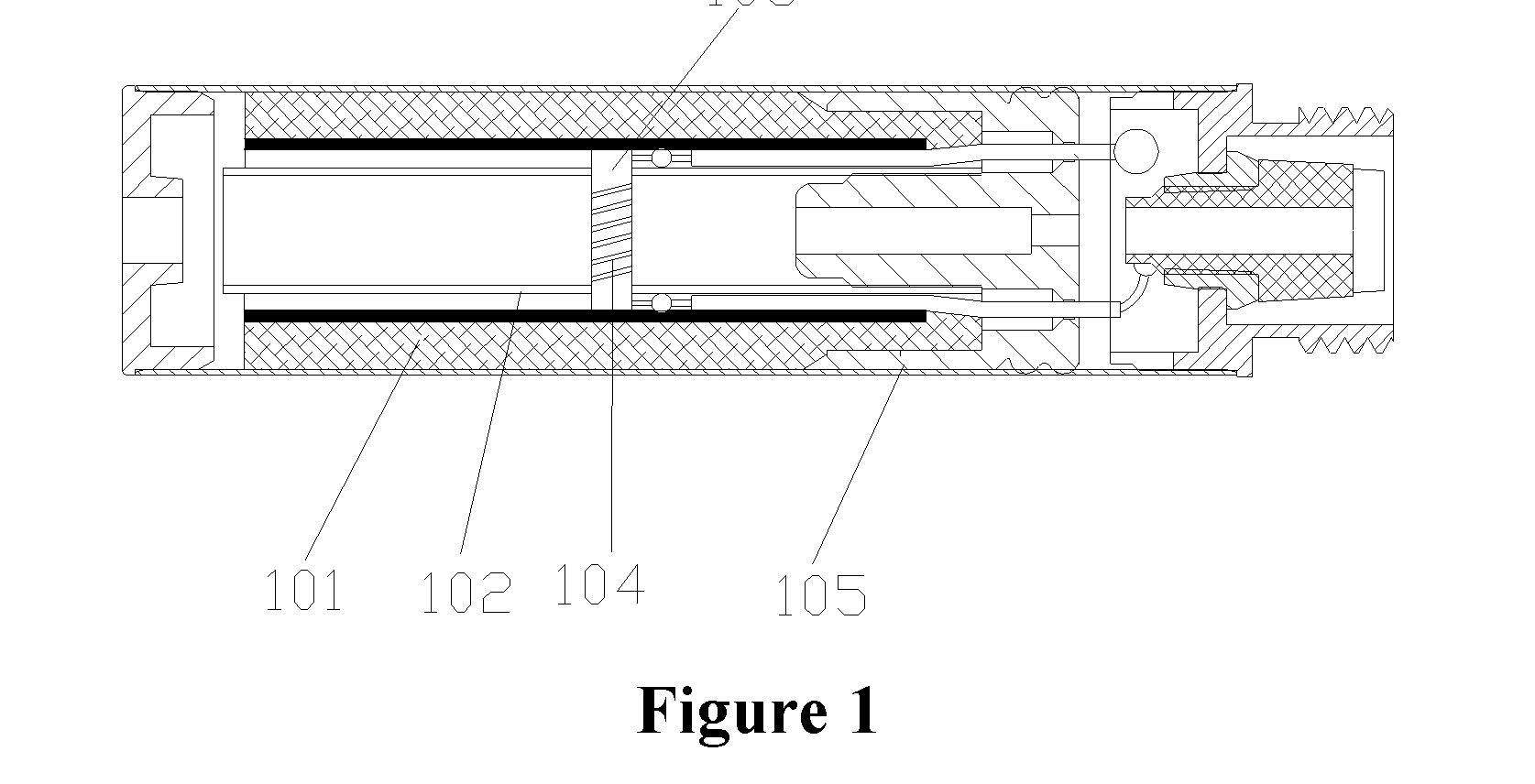

InactiveUS20050101879A1Improve yieldIncrease in amountSurgical needlesVaccination/ovulation diagnosticsSyringeHead parts

A needle aspiration biopsy device includes a syringe, a valve coupler for controlling a vacuum in the syringe barrel, and an anti-reflux head. The head includes a hub, defining a large collection well preferably several hundred micro liters in volume, and a needle mounted to the hub. A passageway is defined either by a contoured needle or a straight needle and an internal channel in the hub wall such that a proximal end of the passageway extends inside the hub and opens in spaced relation to a floor of the collection well. A method of biopsy using the device is also disclosed.

Owner:MCW RES FOUND INC

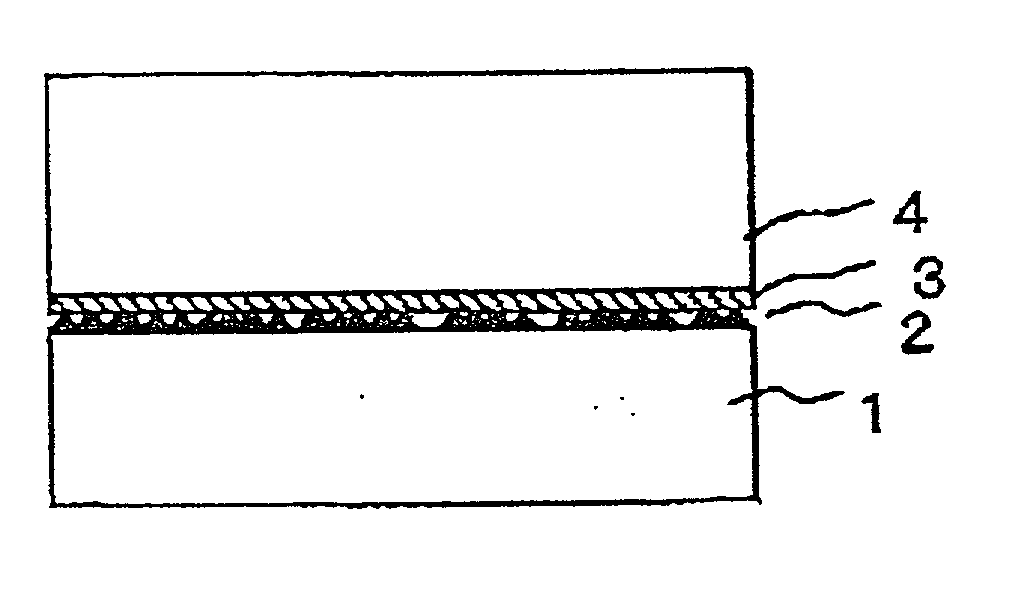

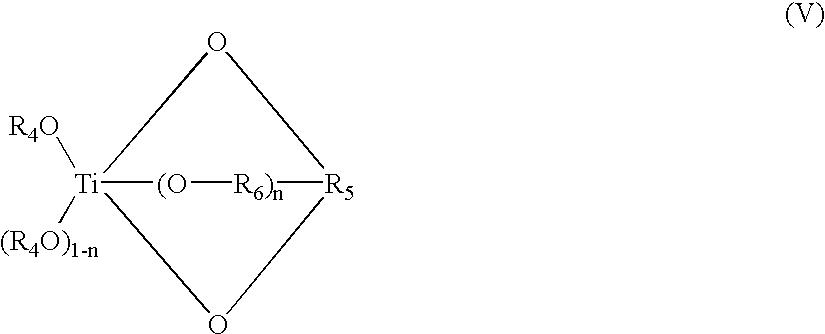

Semiconductor substrate made of group III nitride, and process for manufacture thereof

InactiveUS20020197825A1Reduce defect densityImprove crystal qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingHydrogen compoundsTitanium

To provide a semiconductor substrate of a group III nitride with low defect density and little warp, this invention provides a process comprising such steps of: forming a GaN layer 2 on a sapphire substrate 1 of the C face ((0001) face); forming a titanium film 3 thereon; heat-treating the substrate in an atmosphere containing hydrogen gas or a gas of a compound containing hydrogen to form voids in the GaN layer 2; and thereafter forming a GaN layer 4 on the GaN layer 2'.

Owner:SUMITOMO CHEM CO LTD

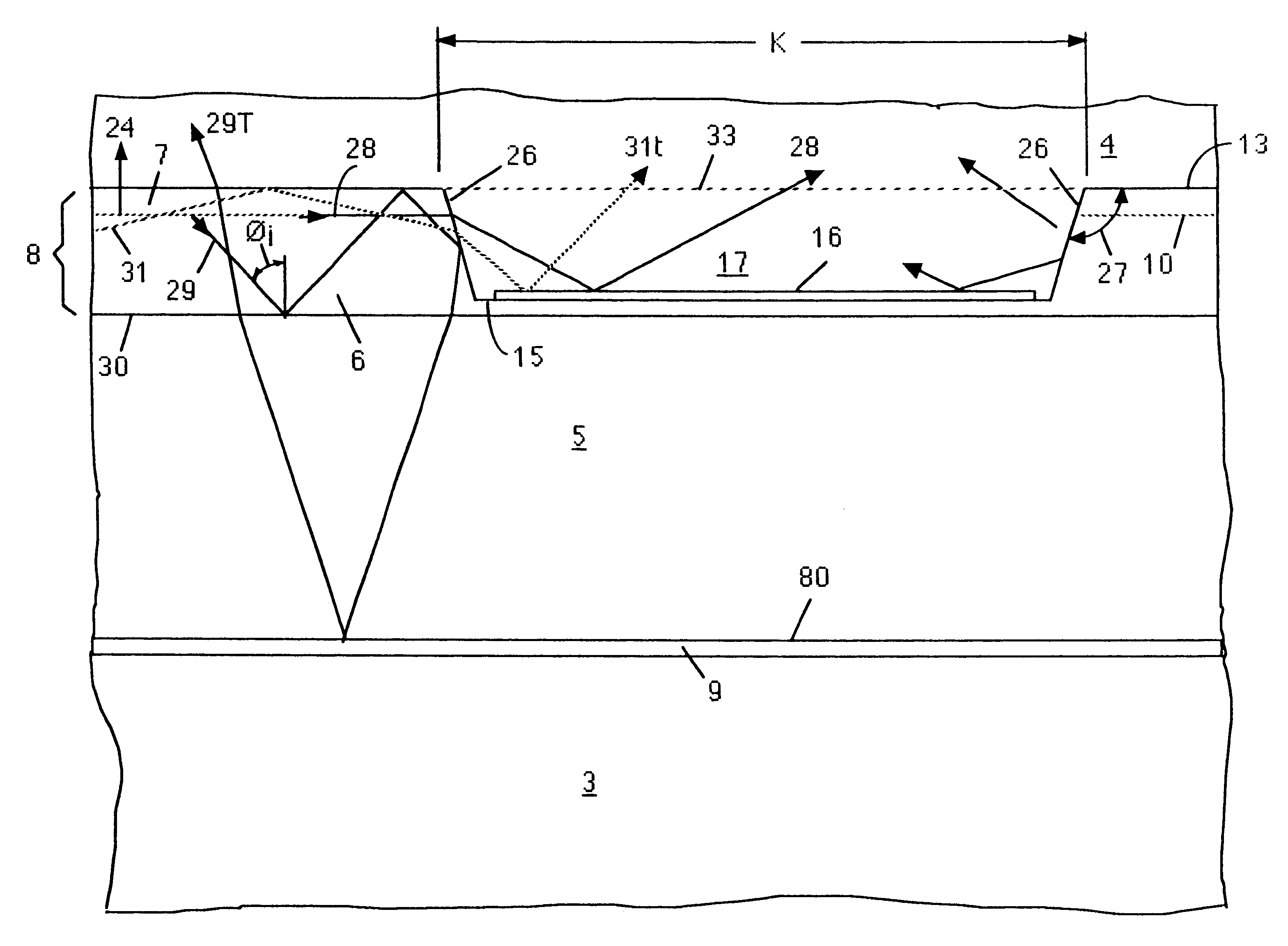

High power led lamp

InactiveUS6346771B1Improve uniformityReduce chip sizeDischarge tube luminescnet screensLamp detailsEngineeringLED lamp

A high-power LED lamp uses an LED chip that can be larger than 1mm square. The chip has trenches that can convert light trapped in the semiconductor into light that passes through a major surface of the chip. The trenches include light-reflecting tracks joined to a chip terminal and feeding a semiconductor layer. The chip can have triangular light emitting elements that improve light extraction from the semiconductor. The elements can be fused, resulting in improved manufacture yield of chips. A 25 watt single chip lamp with a heat sink very close to the active region is described.

Owner:EPISTAR CORP

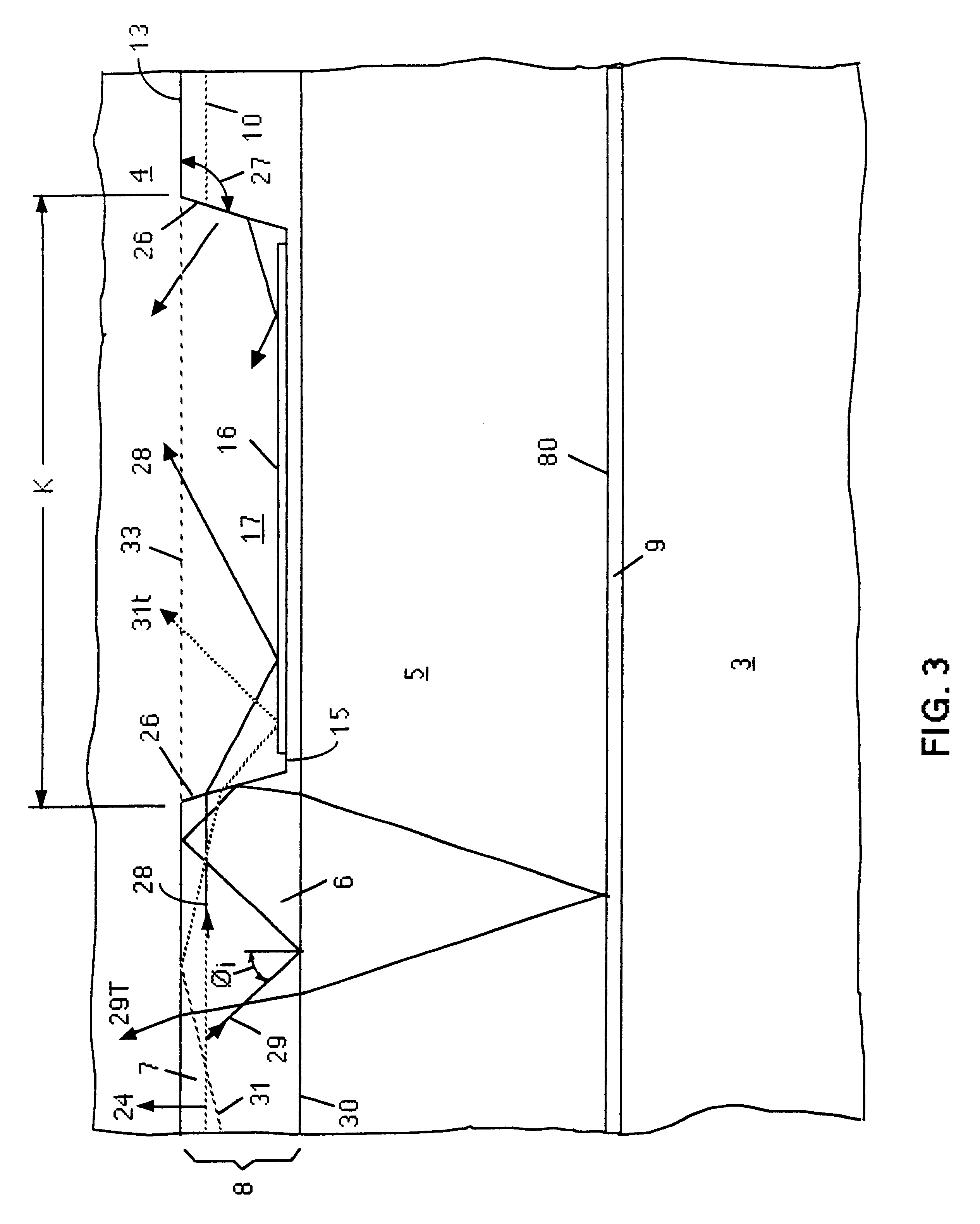

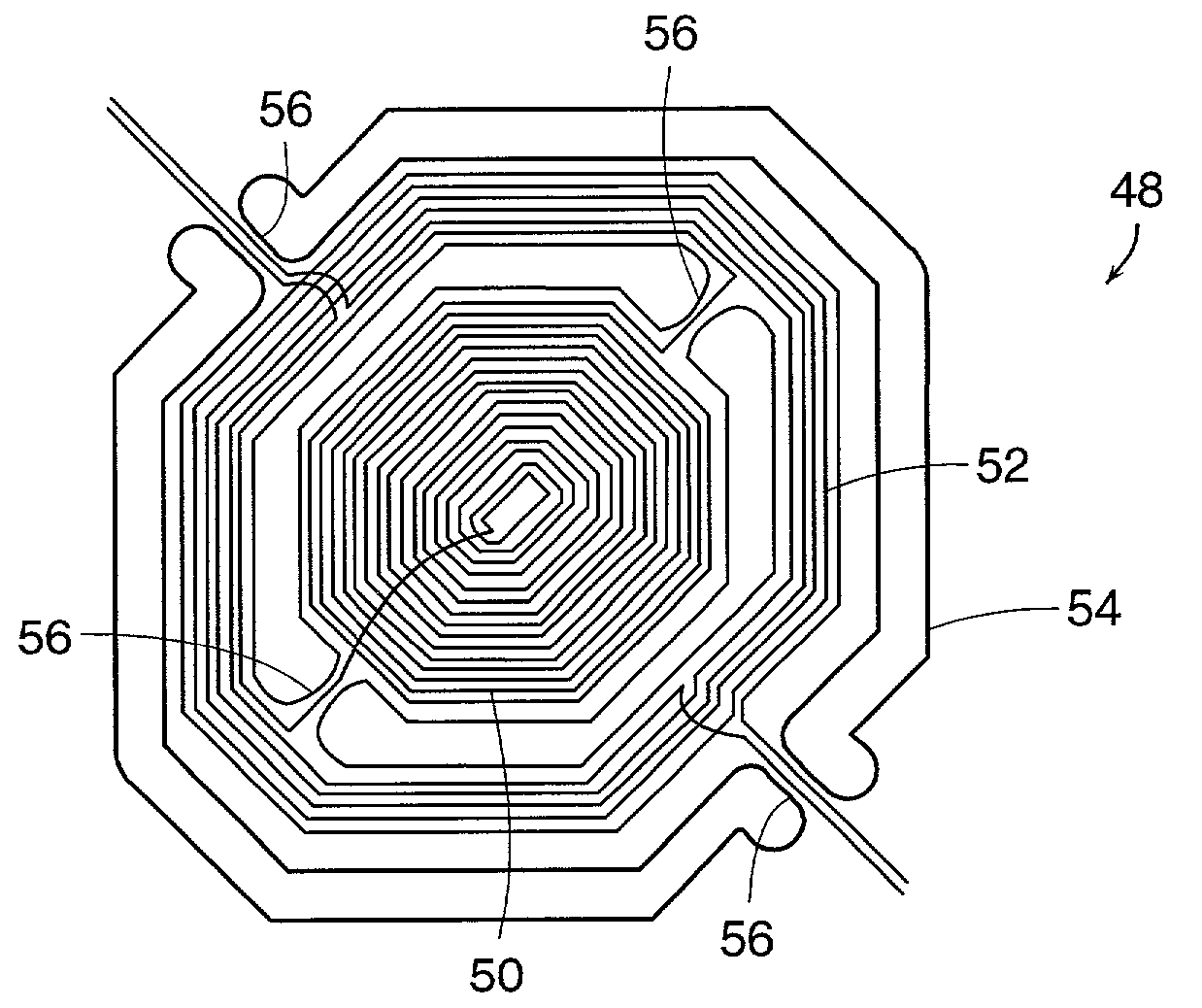

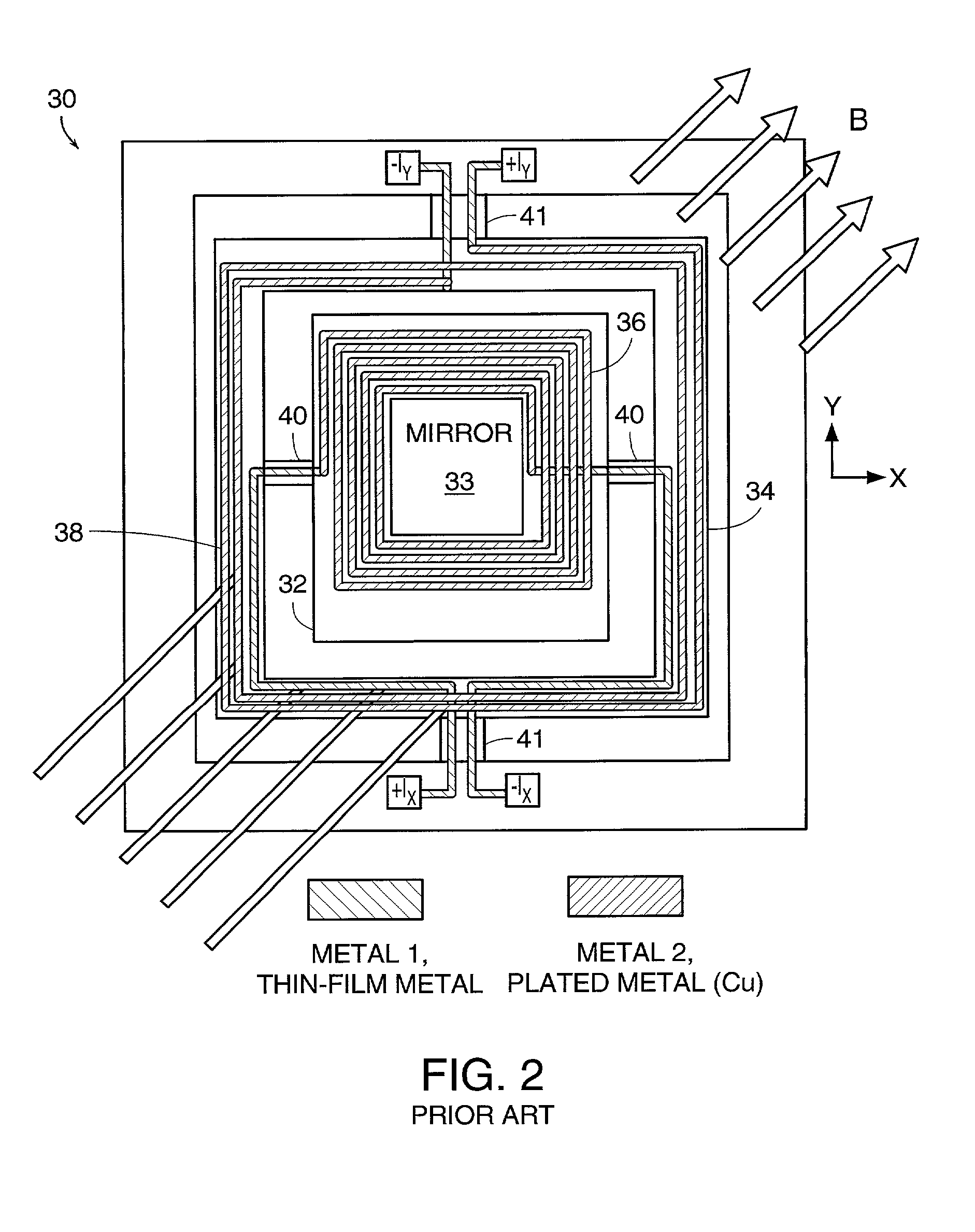

Magnetically actuated micro-electro-mechanical apparatus and method of manufacture

InactiveUS20020050744A1Increase torqueReduce the numberForming microstructural systemsElectrostatic generators/motorsEngineeringMagnet

An array of magnetically actuated MEMS mirror devices is provided having stationary magnets configured to provide strong magnetic fields in the plane of the mirrors without any magnets or magnet-system components in the plane of the mirrors. Also, a magnetically actuated mirror device is provided that includes an improved actuation coil configuration that provides greater torque during mirror actuation. In addition, a mechanism is provided to detect the angular deflection of a moveable mirror. Also, an improved process is provided for manufacturing MEMS mirror devices.

Owner:CORNING INC

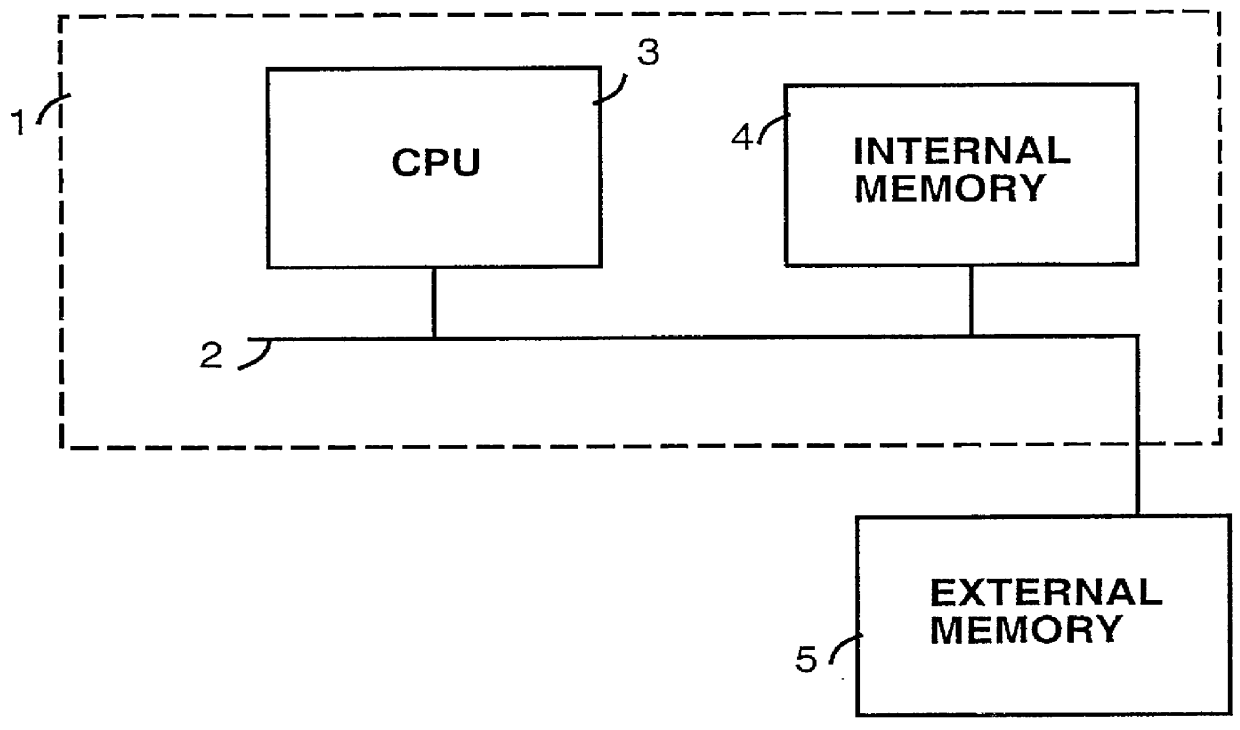

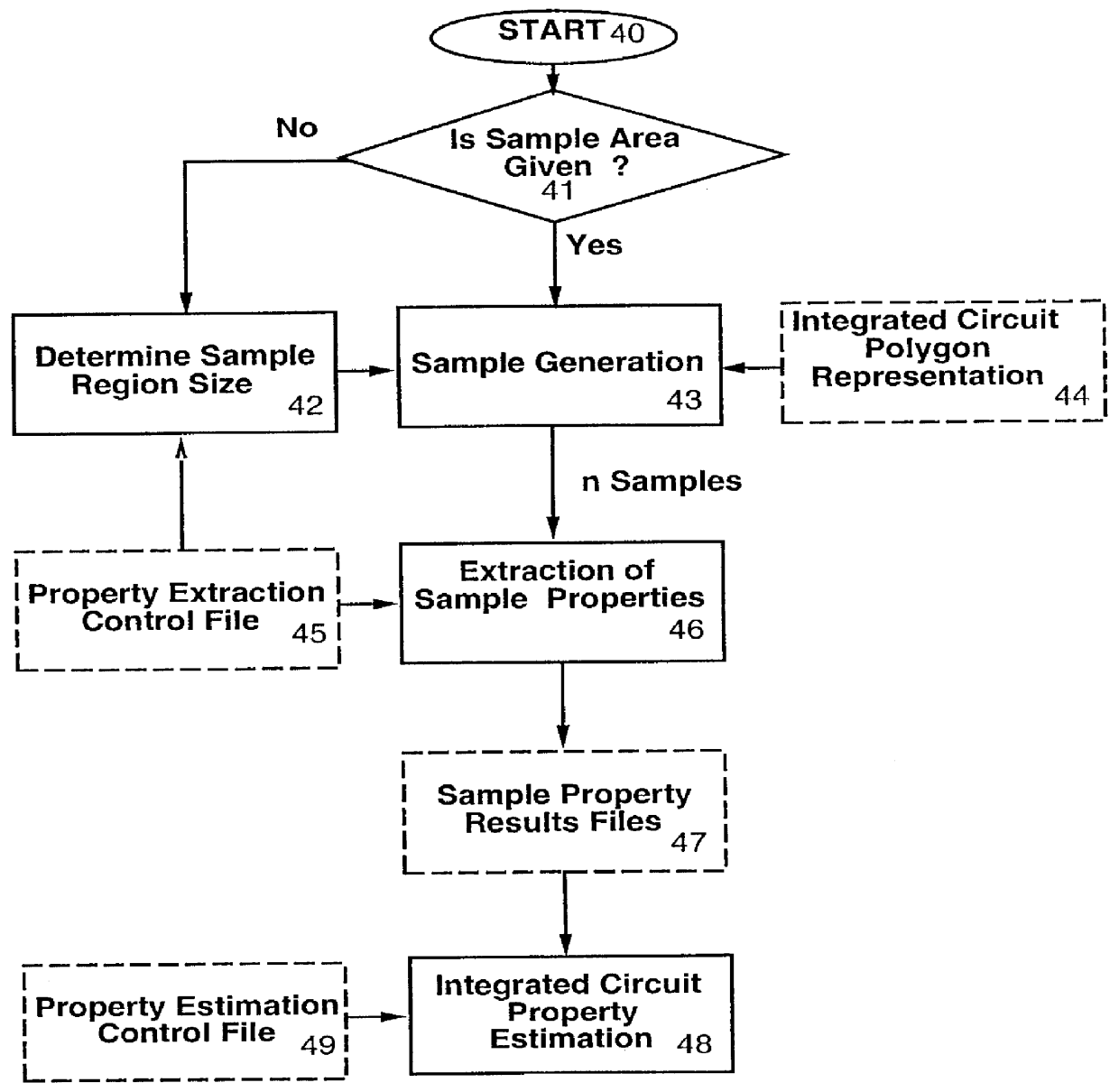

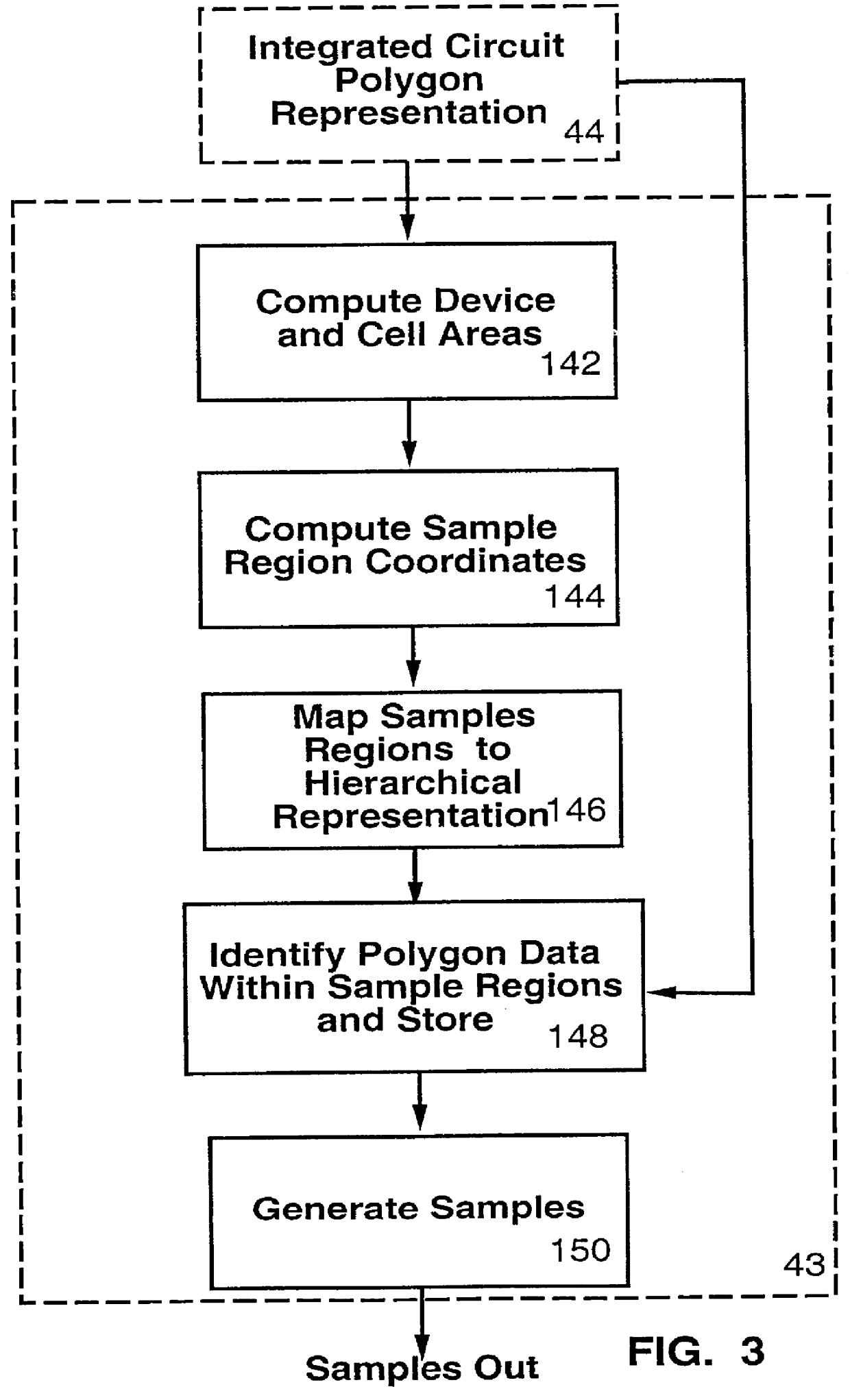

Property estimation of an integrated circuit

InactiveUS6066179AImprove robustnessIncrease productionSemiconductor/solid-state device testing/measurementError detection/correctionSurvey samplingGeneral purpose computer

A method and apparatus to estimate properties of an integrated circuit device utilizes reduced resources. The representation of an integrated circuit is sampled using the statistical techniques of survey sampling. An average value of a property is determined from these samples and used to determine the property of the integrated circuit as a whole. Thus a property of an integrated circuit is determined from an analysis of a fraction of the integrated circuit representation. Error bounds associated with the property can be optionally determined from the estimated variance of the sampled property measurements. The method is realized using a general purpose computer. The invention has application to the estimation of integrated circuit manufacturability, yield and other properties.

Owner:EDINBURGH UNIV OF

Atomizer and electronic cigarette

InactiveUS20170035109A1Improve user experienceIncrease electric lengthSteam generation heating methodsTobacco devicesSpiral coilBurning out

An atomizer and an electronic cigarette are provided. The atomizer includes: an atomizer cartridge; a liquid storage area arranged inside the atomizer cartridge; an electric heating element coiled spirally to form a plate-shape structure; and a first liquid guide cloth. The first liquid guide cloth is arranged covering an opening of the liquid storage area, and the electric heating element is laid on a side of the first liquid guide cloth away from the liquid storage area. With the first liquid guide cloth, the quantity of the cigarette liquid transferred to the electric heating element is ensured to be equable. The electric heating element is arranged along the transverse direction of the atomizer, thereby avoiding conventional problems of non-uniform smoke volume and burning-out of the liquid storage cotton due to gravity or vibration of the spiral coils.

Owner:KIMREE HI TECH

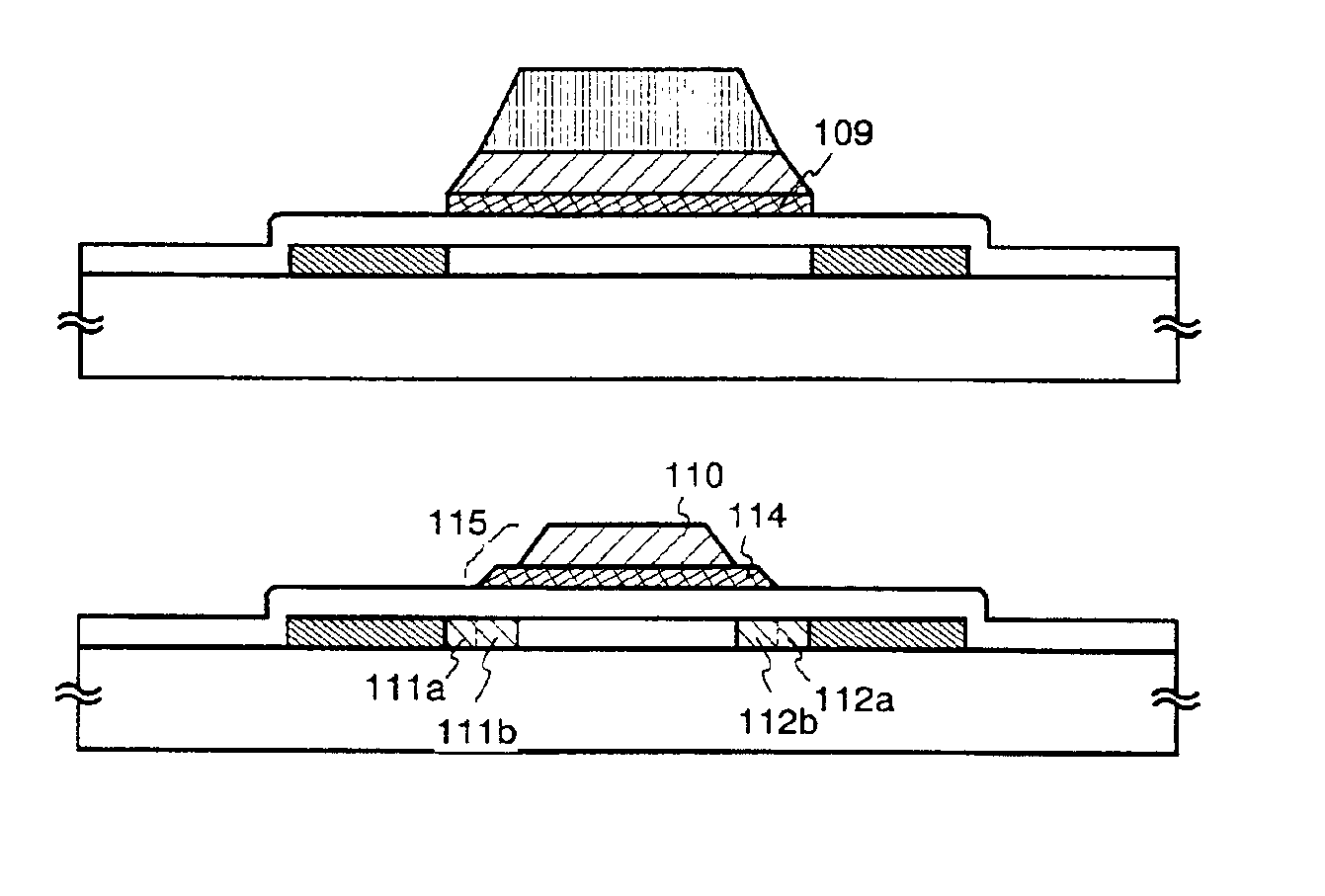

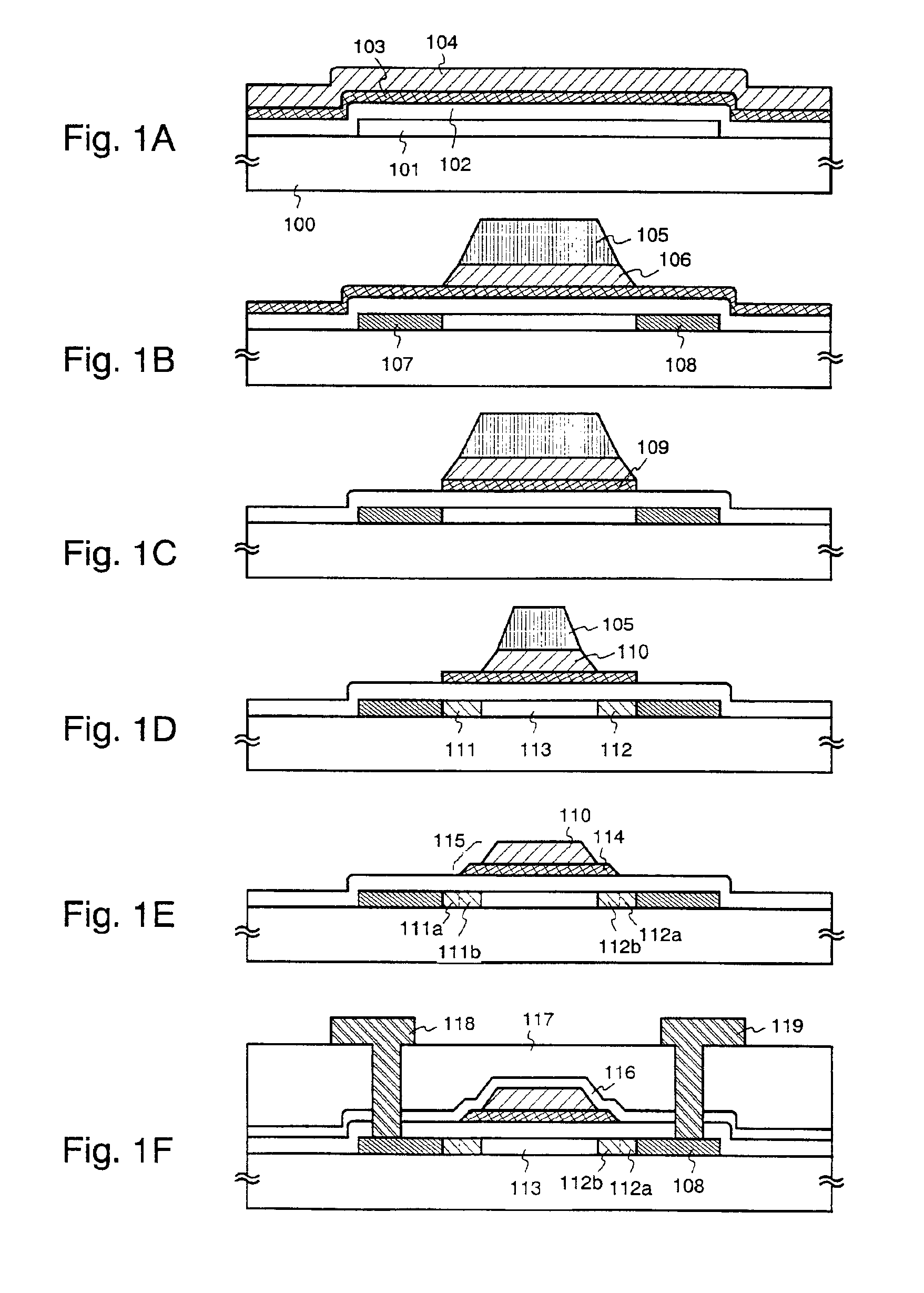

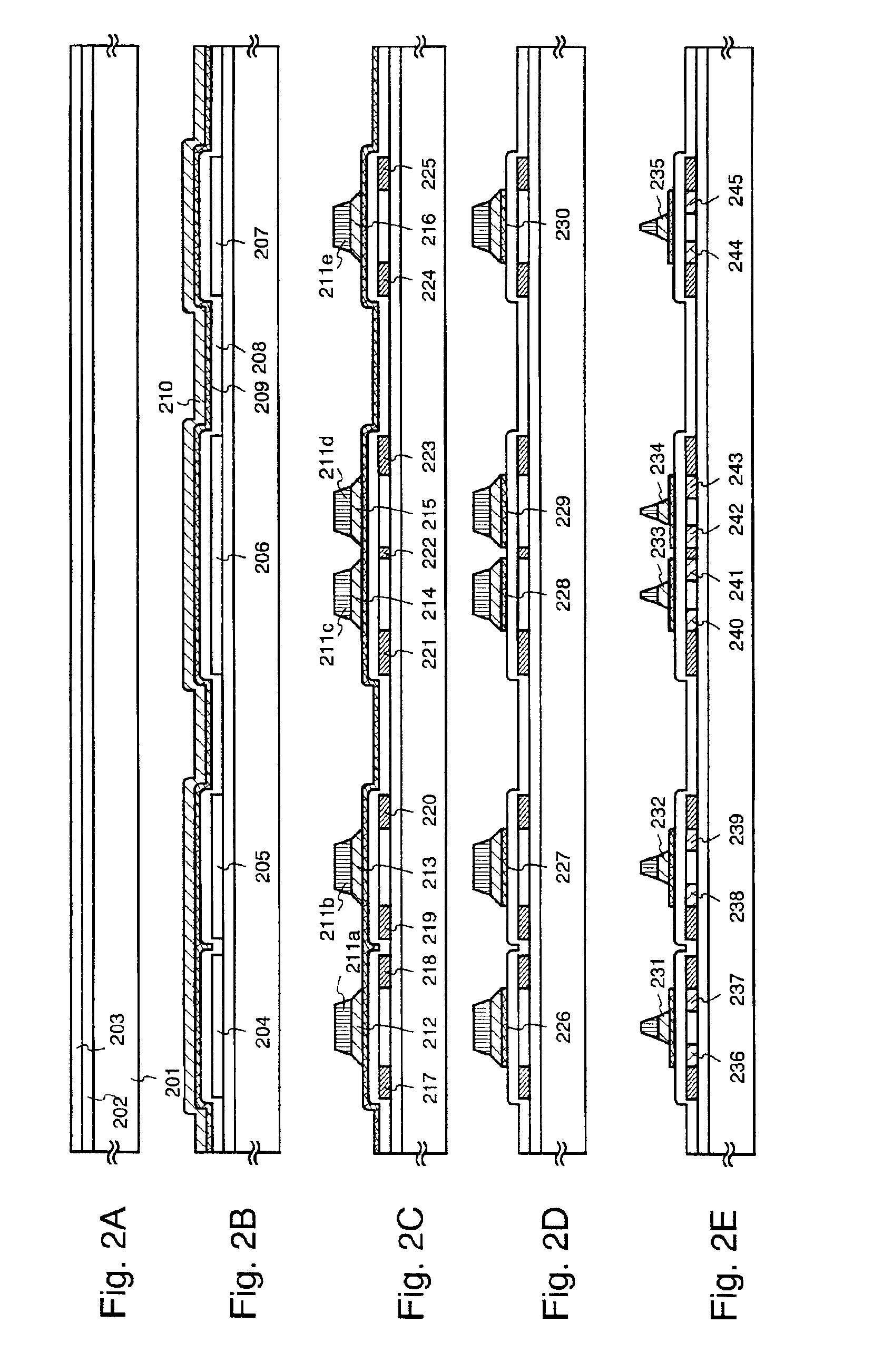

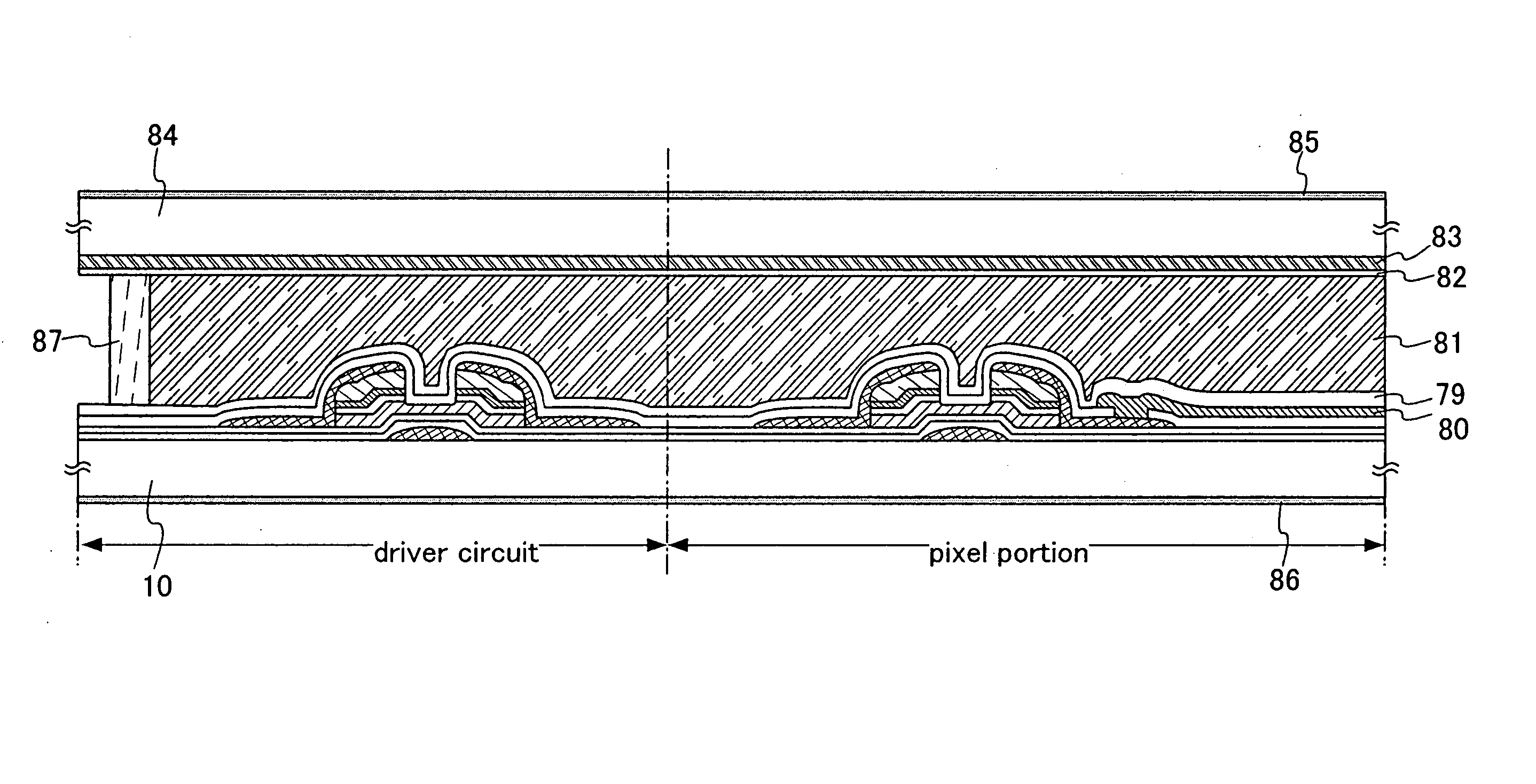

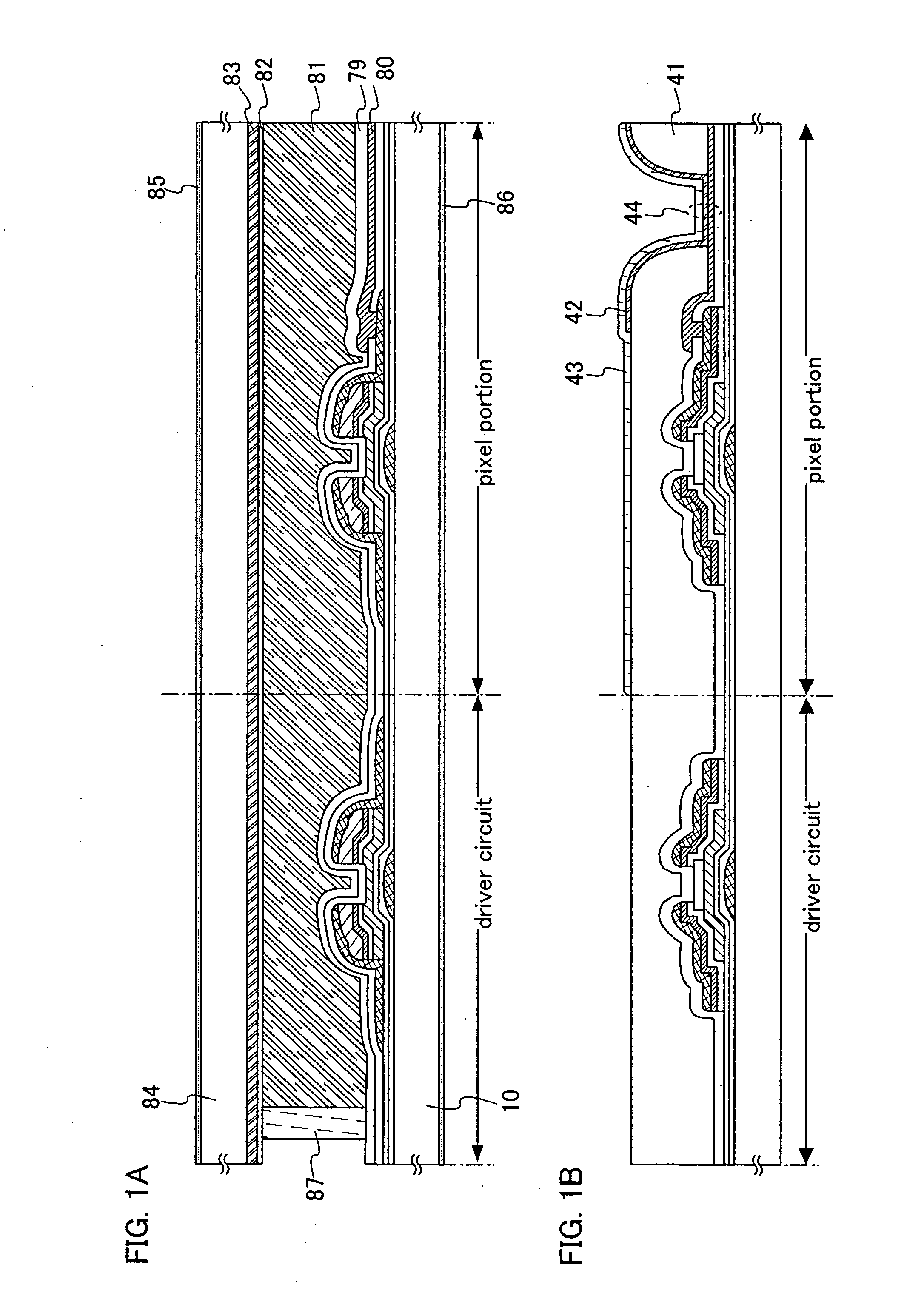

Method of fabricating a light emitting device

InactiveUS6872604B2Reduce manufacturing costReduce electricity costsTransistorSolid-state devicesElectronic instrumentActive layer

There is provided an inexpensive light emitting device and an electronic instrument using the same. In this invention, photolithography steps relating to manufacture of a transistor are reduced, so that the yield of the light emitting device is improved and the manufacturing period thereof is shortened. A feature is that a gate electrode is formed of conductive films of plural layers, and by using the selection ratio of those at the time of etching, the concentration of an impurity region formed in an active layer is adjusted.

Owner:SEMICON ENERGY LAB CO LTD

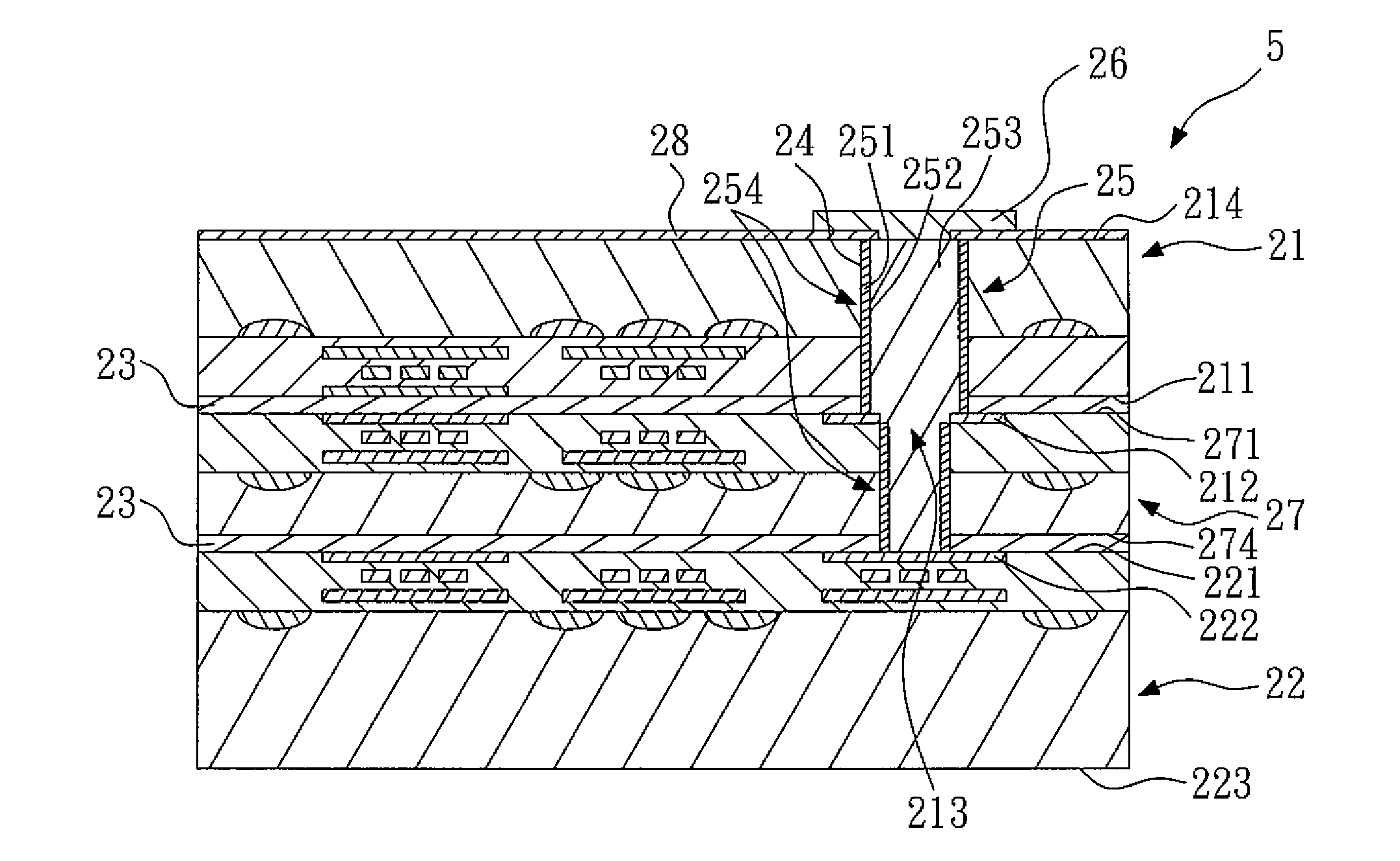

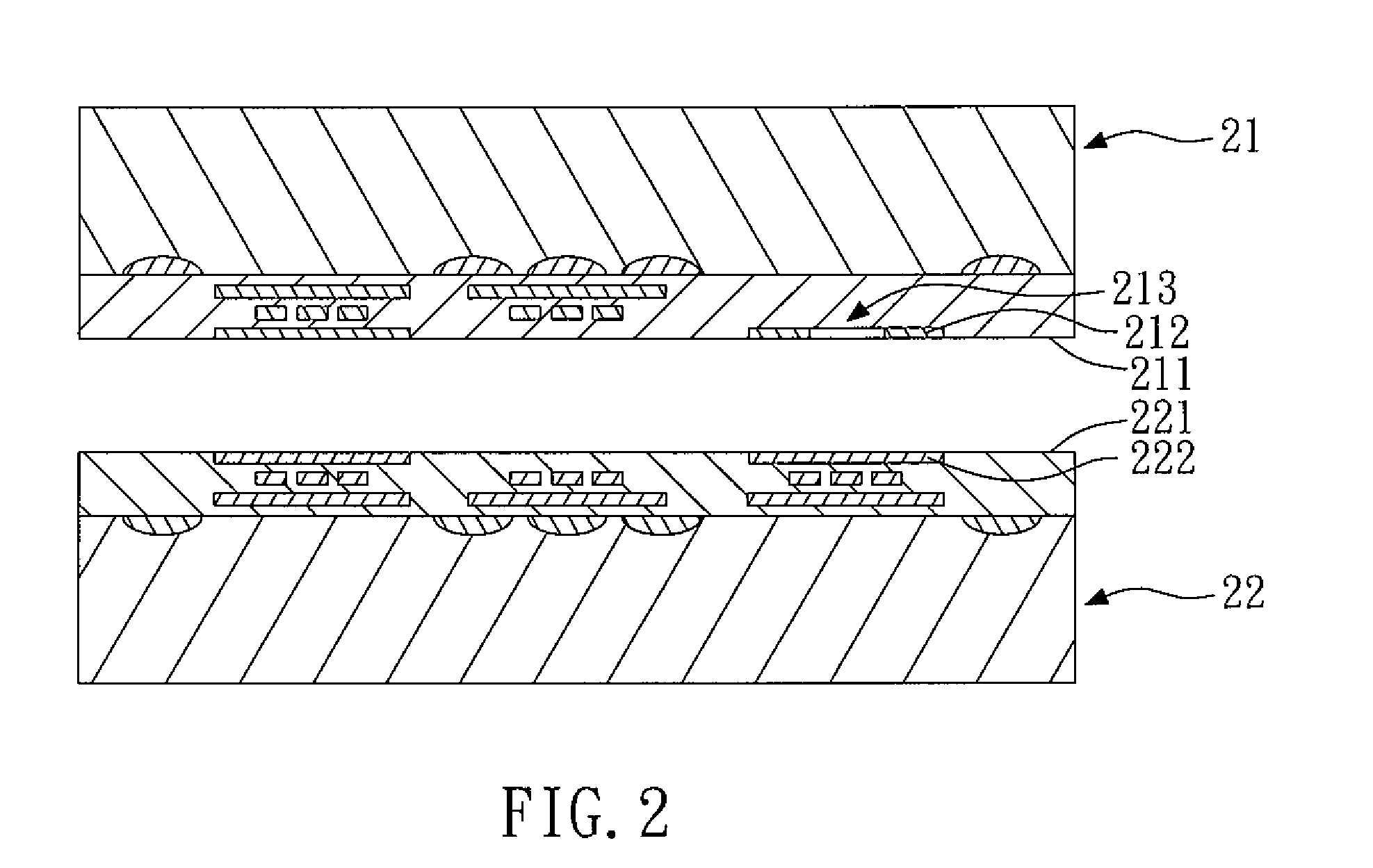

Semiconductor Structure and Method for Making the Same

ActiveUS20110133339A1Simple processReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesElectricitySemiconductor structure

The present invention relates to a semiconductor structure and a method for making the same. The method includes the following steps: (a) providing a first wafer and a second wafer; (b) disposing the first wafer on the second wafer; (c) removing part of the first wafer, so as to form a groove; (d) forming a through via in the groove; and (e) forming at least one electrical connecting element on the first wafer. Therefore, the wafers are penetrated and electrically connected by forming only one conductive via, which leads to a simplified process and a low manufacturing cost.

Owner:ADVANCED SEMICON ENG INC

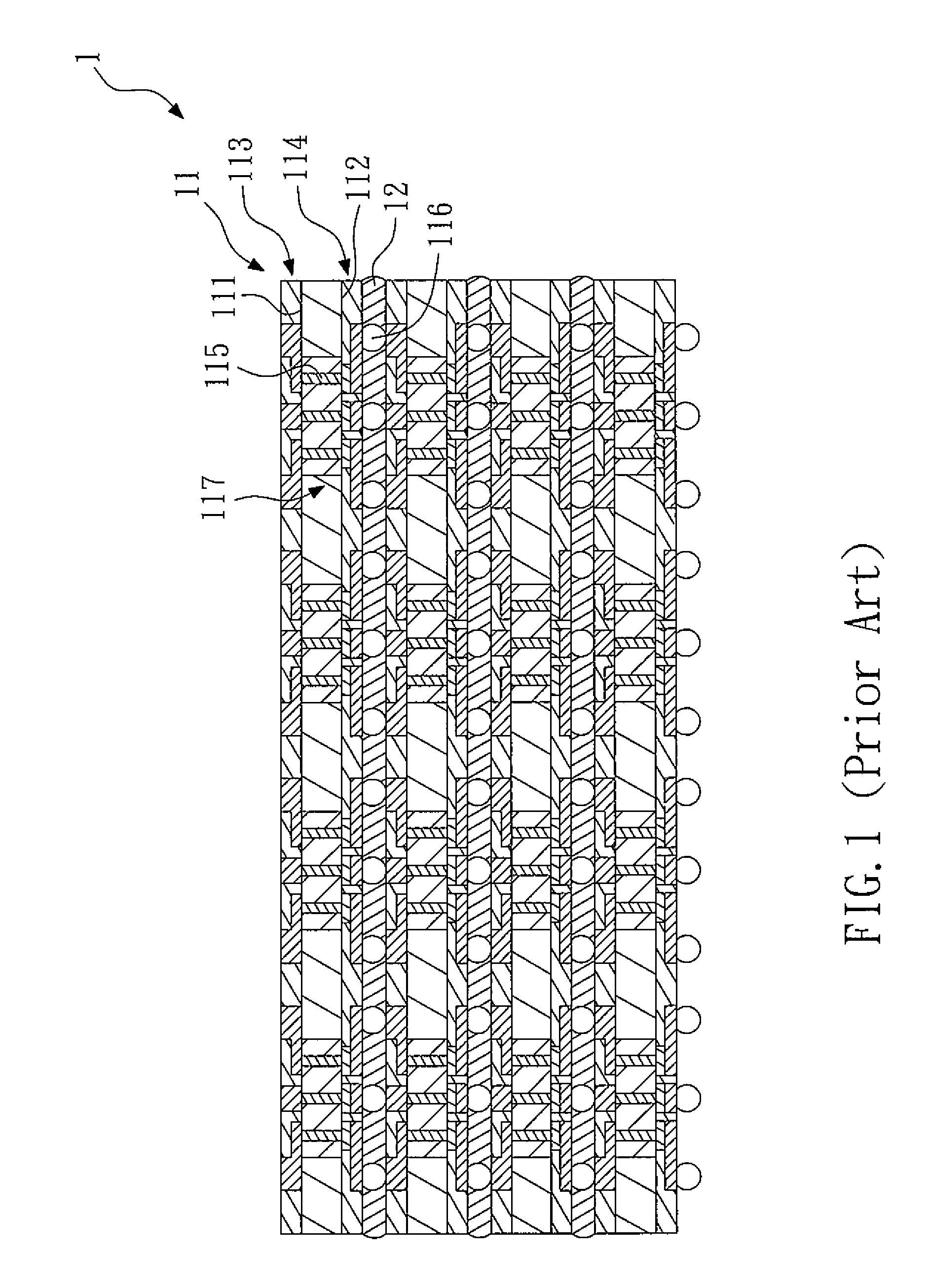

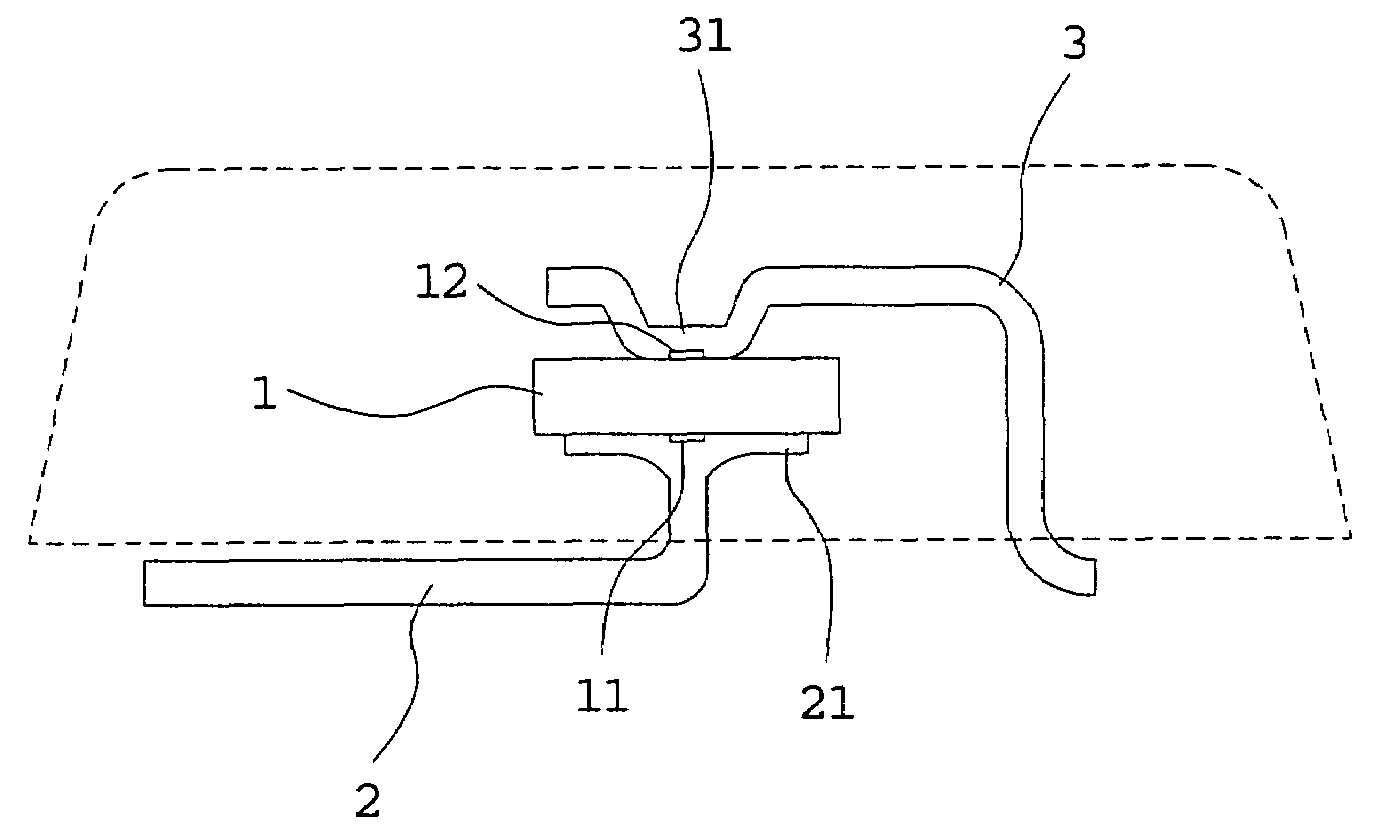

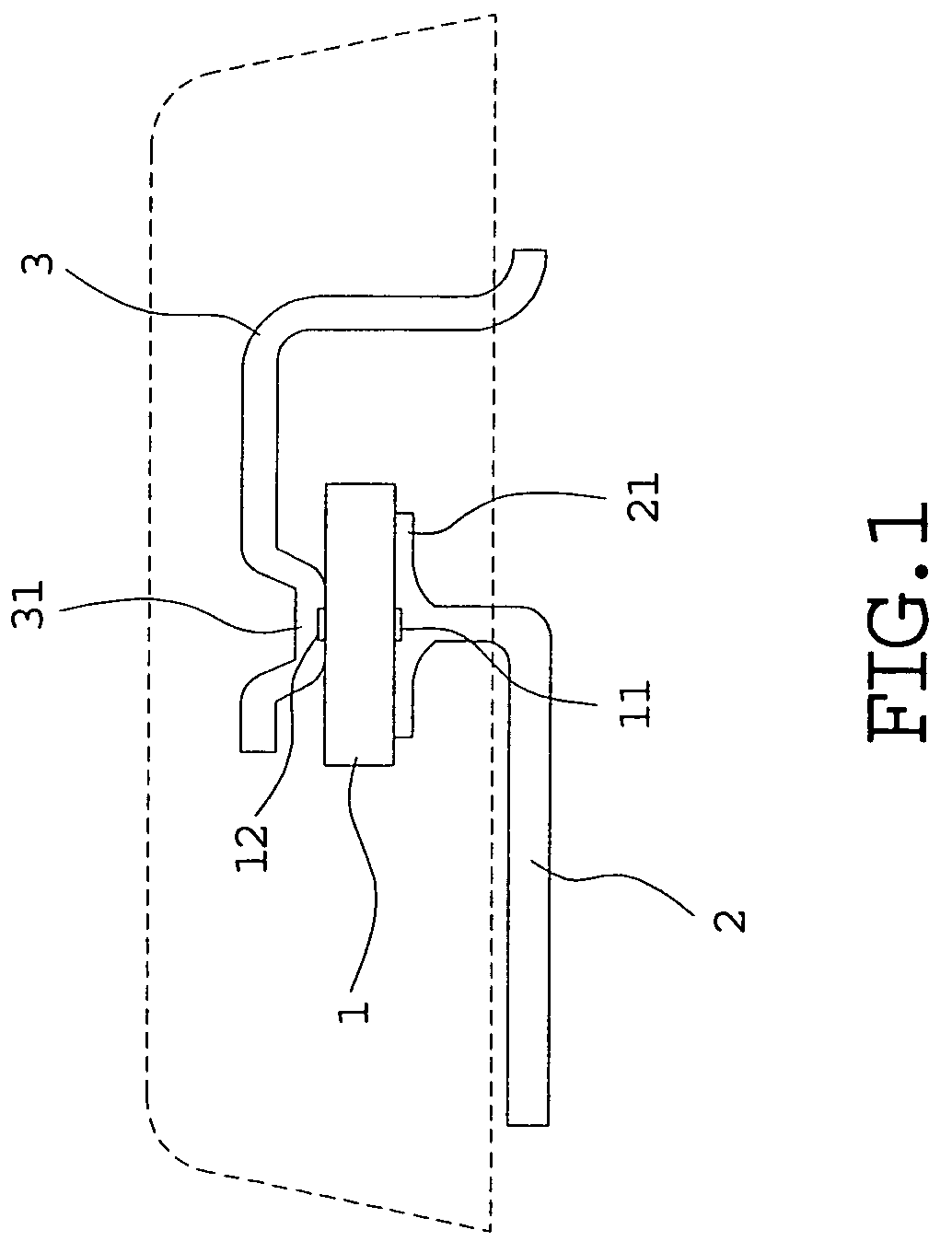

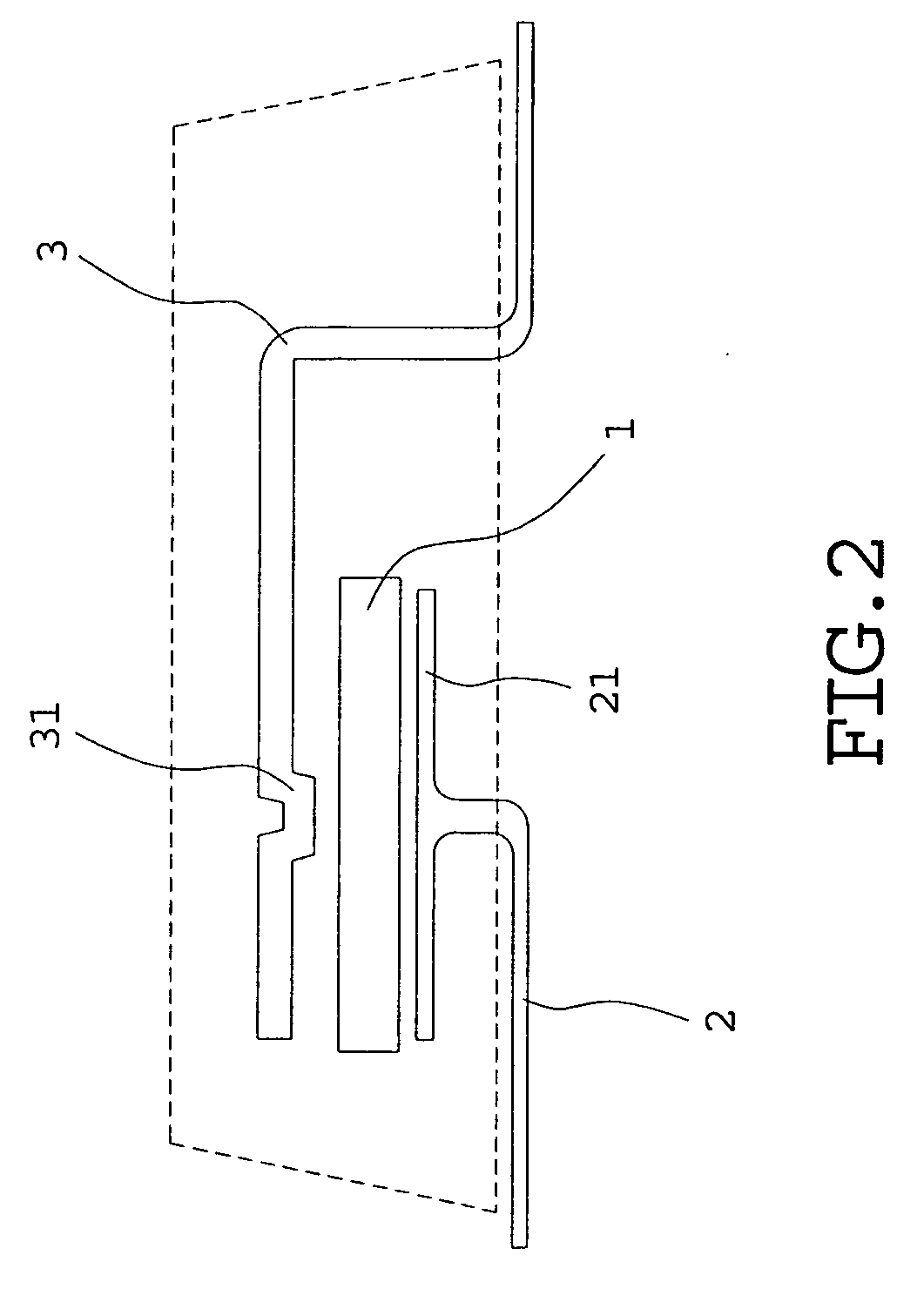

Surface mounting structure and packaging method thereof

InactiveUS20070290325A1Improve space utilizationSimplify System DesignSemiconductor/solid-state device detailsSolid-state devicesState of artSystems design

A surface mounting structure and a packaging method thereof comprises a chip, a first conducting wire and a second conducting wire. The two conducting wires instead of lead frame architecture of the prior art is that the lead frame and a bridge jumper connected with N junction and P junction instead of the two conducting wires. The two conducting wires are drawn out from a bottom of a package, and are pressed and bent to original surface of the surface mounting pins so as to increase space utilization rate. Thereby it is to improve a complicated lead frame architecture of the prior art, increase use space and simplify system design.

Owner:LITE ON SEMICON

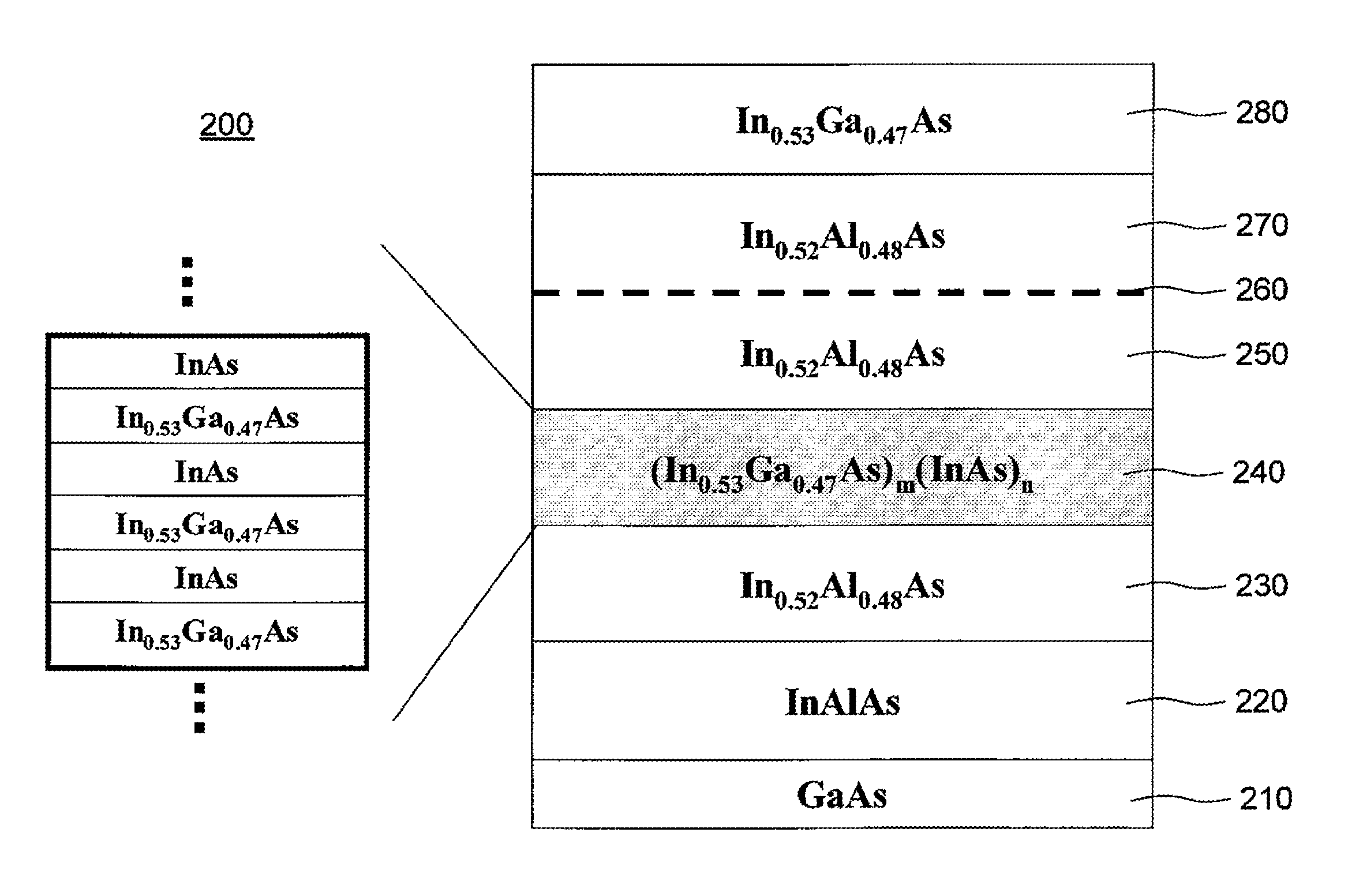

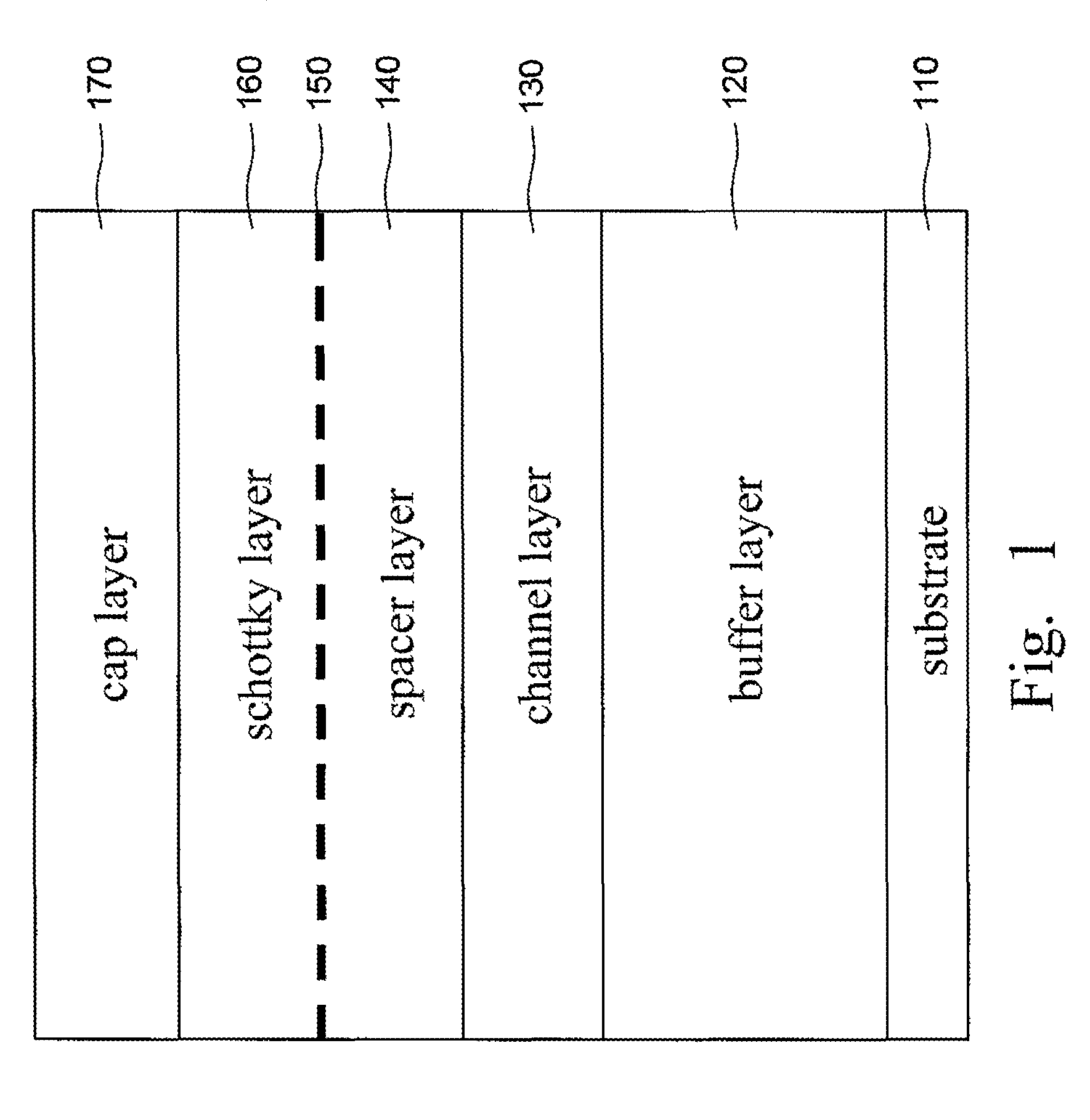

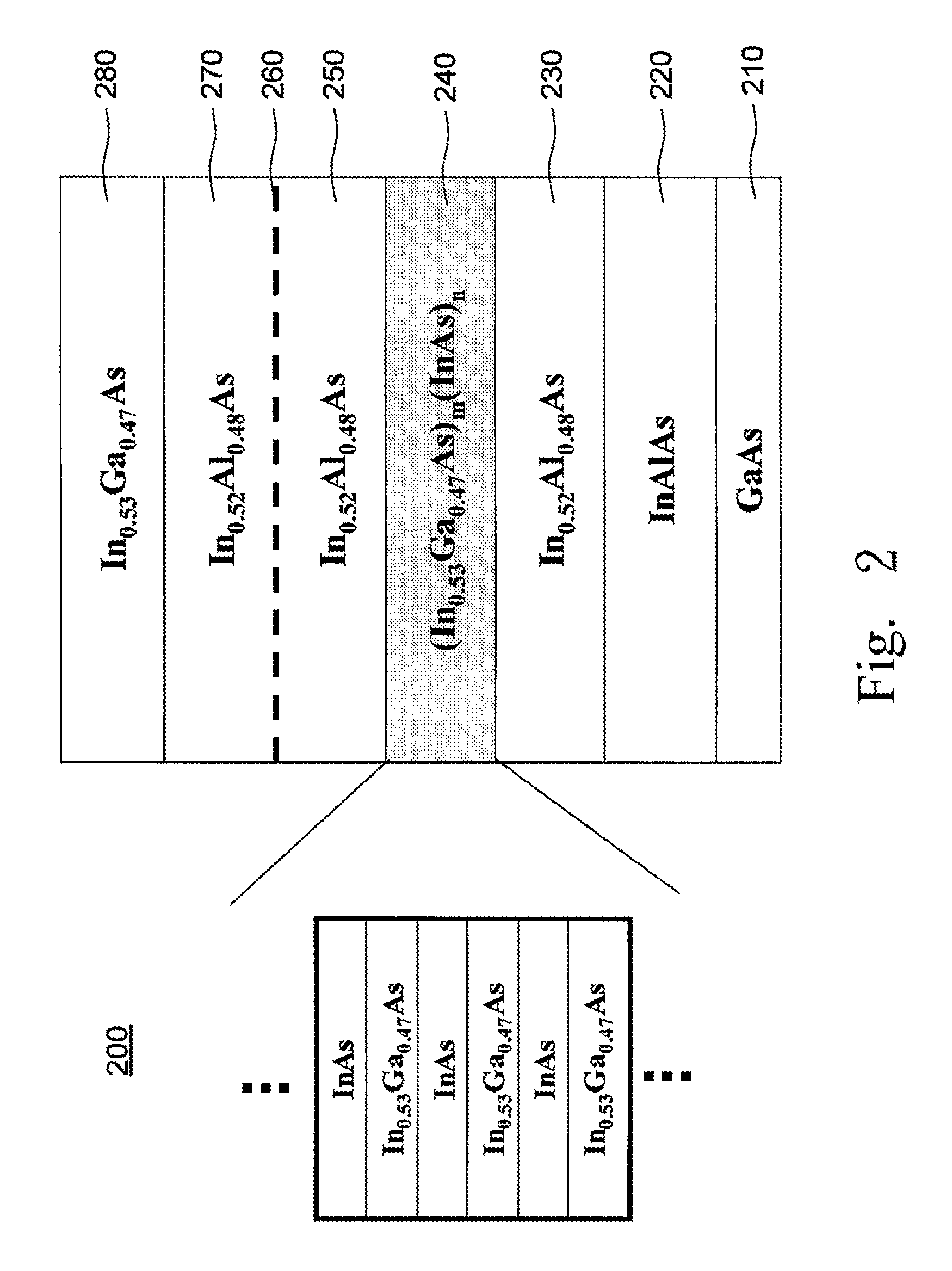

High electron mobility transistor and method for fabricating the same

ActiveUS8169002B2Improve high-frequency characteristicHigh electron mobilityTransistorNanoinformaticsIndium arsenideIndium gallium arsenide

A high electron mobility transistor includes a substrate, a buffer layer, a channel layer, a spacer layer, a schottky layer and a cap layer. The buffer layer is formed on the substrate. The channel layer is formed on the buffer layer, in which the channel layer comprises a superlattice structure formed with a plurality of indium gallium arsenide thin films alternately stacked with a plurality of indium arsenide thin films. The spacer layer is formed on the channel layer. The schottky layer is formed on the spacer layer. The cap layer is formed on the schottky layer.

Owner:YLTLINK TECH CORP

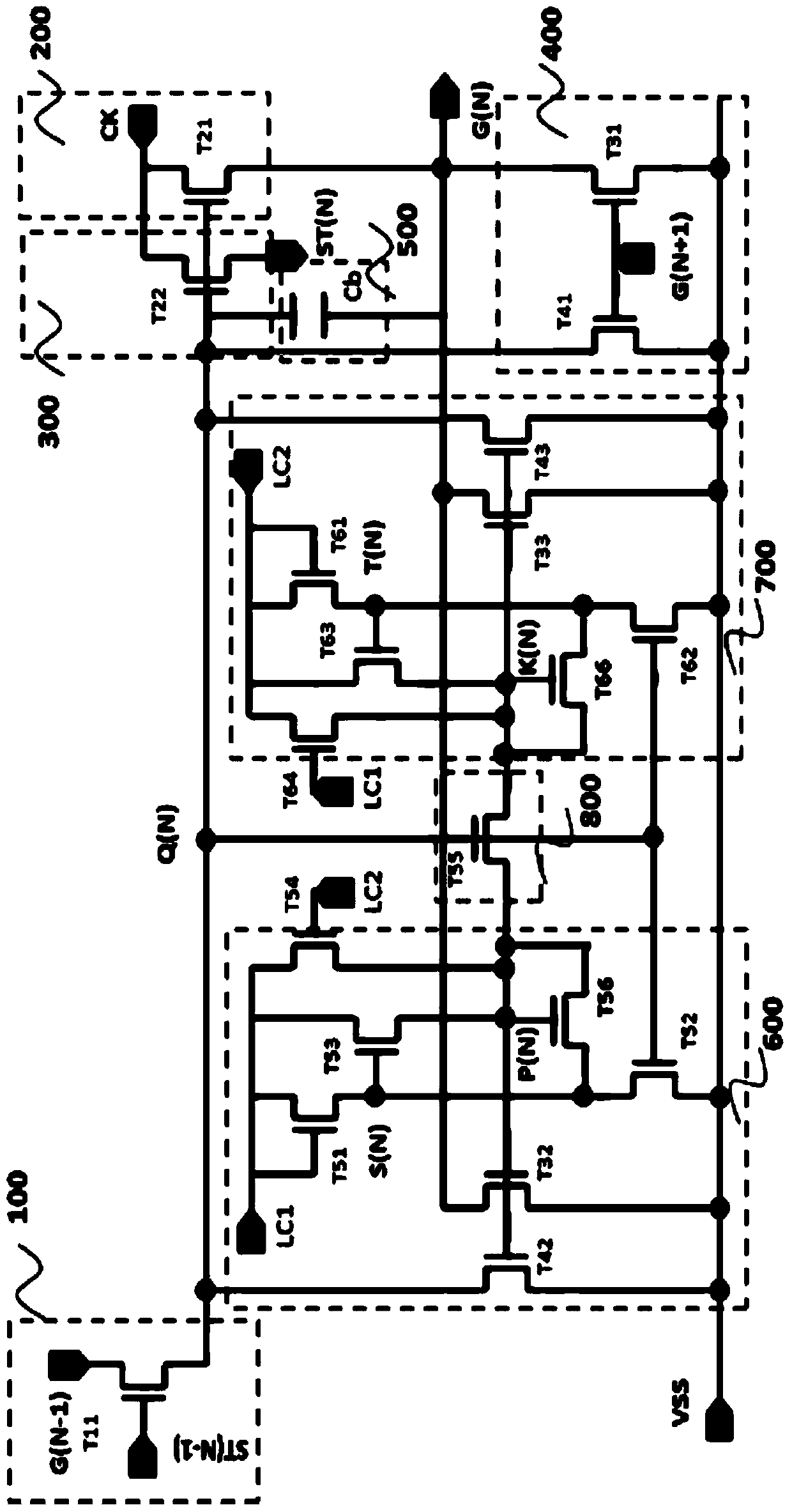

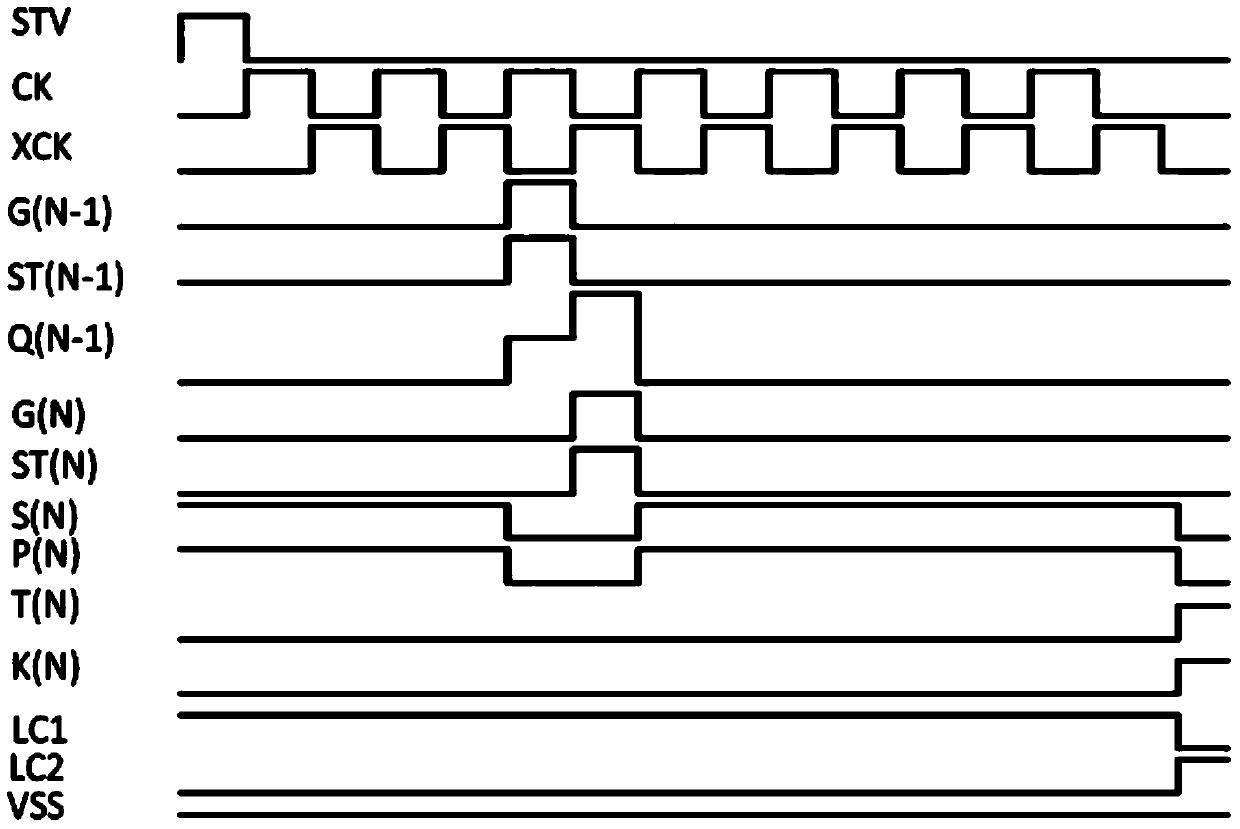

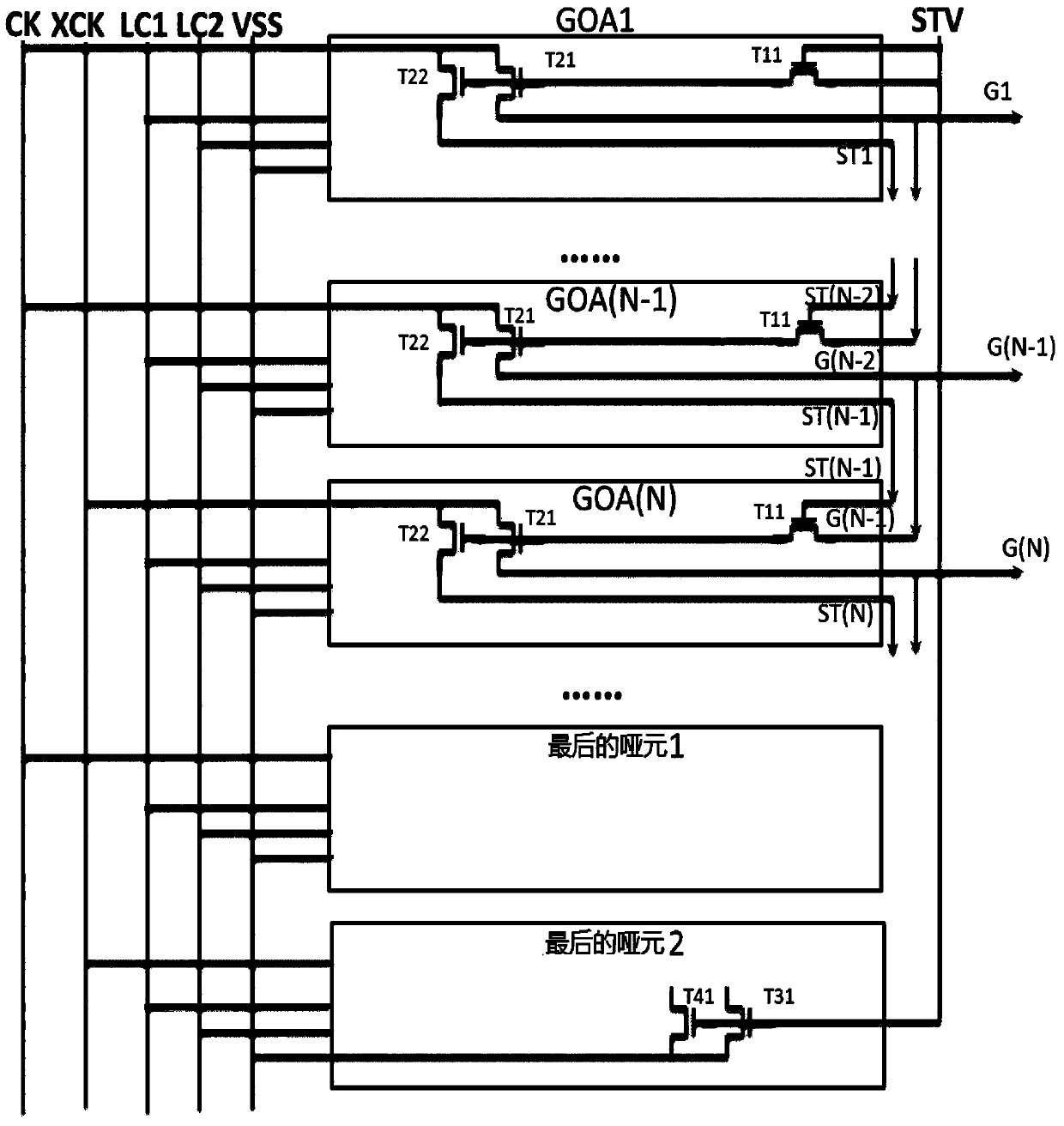

Self-repairing type grid drive circuit

ActiveCN103745700AReduce the risk of failureRealize self-healing functionStatic indicating devicesEngineeringControl circuit

The present invention relates to a self-repairing type grid drive circuit. The self-sepairing type grid drive circuit includes a plurality of cascaded GOA units, wherein the n-th stage GOA unit comprises a pull-up control circuit (100), a pull-up circuit (200), a download circuit (300), a pull-down circuit (400), a bootstrap capacitor (500), a first pull-down holding circuit (600), a second pull-down holding circuit (700), and a bridge circuit (800). The bridge circuit (800) comprises a first thin film transistor (T55), wherein a grid electrode is connected to the grid signal point (Q (N)), a drain electrode and a source electrode are respectively connected to a first circuit point (K (N)) and a second circuit point (P (N)). When operating, the first circuit point (K (N)) and the second circuit point (P (N)) are alternately arrange on a high potential. The self-repairing type grid drive circuit of the present invention can reduce the failure risk of the pull-down holding circuit caused by a long time operation of production process or GOA circuit, thereby realizing the self-repairing function of the circuit.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

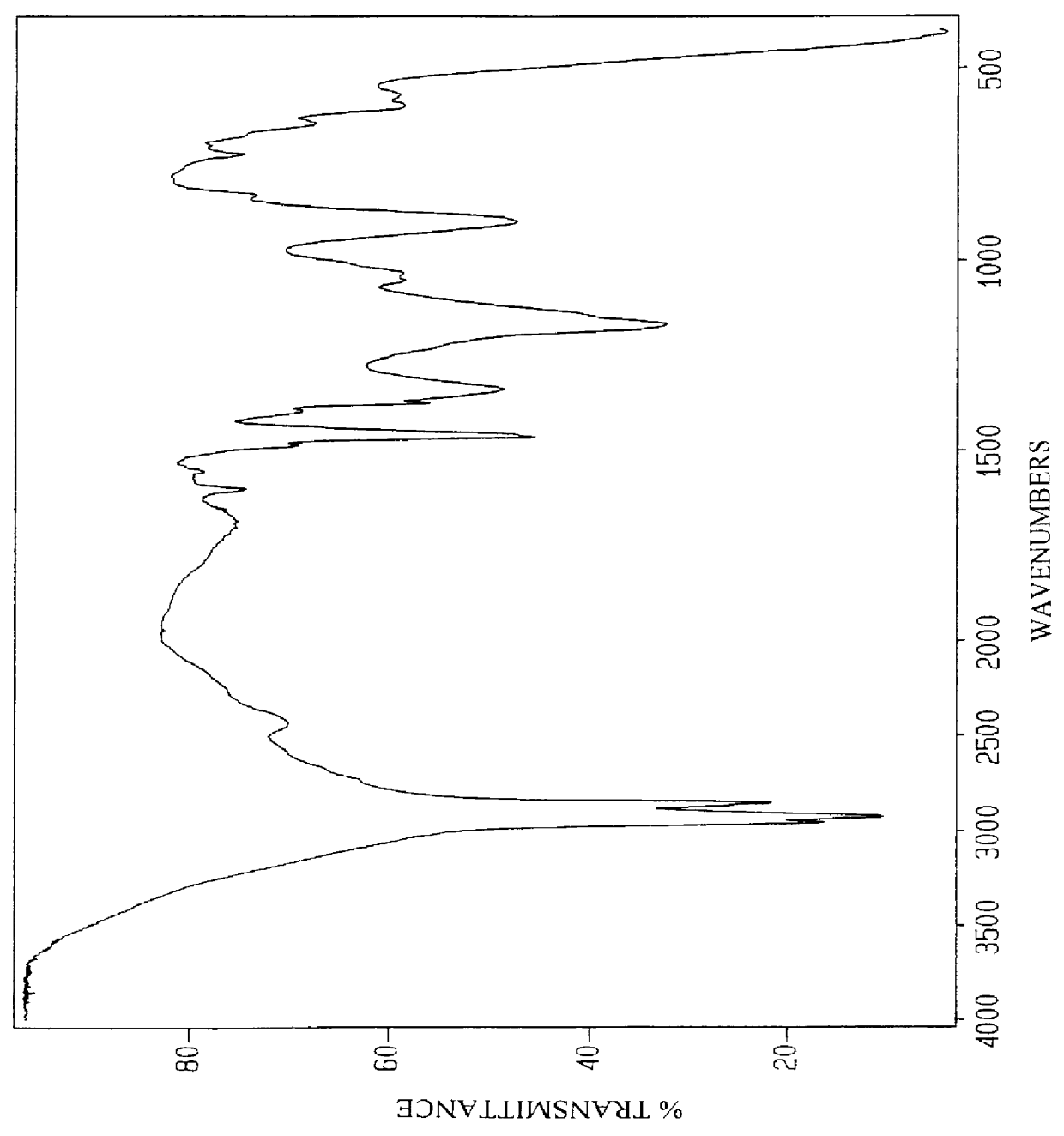

Methods for converting linear polyesters to macrocyclic oligoester compositions and macrocyclic oligoesters

InactiveUS6525164B2Low viscosityCost-effectivePreparation by ester-hydroxy reactionOrganic compound preparationPolyesterDicarboxylic acid

Owner:LIQUID THERMO PLASTICS

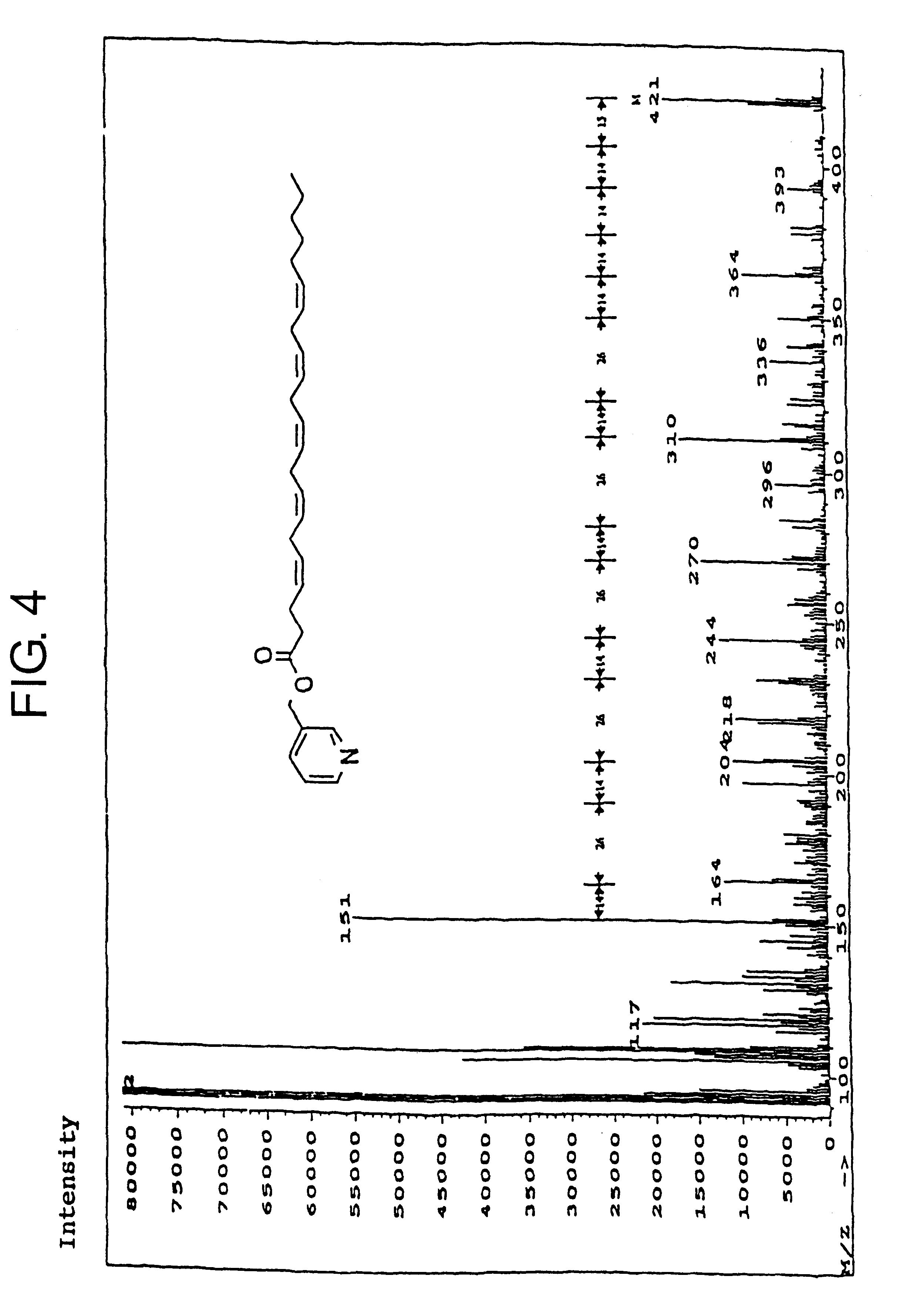

Anionic surfactants based on alkene sulfonic acid

InactiveUS6043391AIncrease productionImprove yieldGroup 3/13 element organic compoundsFlushingAlkylphenolAlpha-olefin

New anionic surfactants and methods of preparation which are derived from aromatic or substituted aromatic molecules and alkenesulfonic acid. Wherein the aryl compound is alkylated and sulfonated in one-step with an alkene sulfonic acid prior to sulfonic acid neutralization. The methods allow the functional sulfonate group to be attached to the end of the alkyl chain rather than to the aromatic ring thus allowing for selective substituted groups, either branched, linear or alkoxylated or combinations thereof to be placed on the aryl compound prior to sulfonation and alkylation. The invention uses the alkene sulfonic acid produced from thin-film sulfonation of an alpha-olefin to alkylate benzene, mono-substituted aromatic, poly-substituted aromatic, alkylbenzene, alkoxylated benzene, polycyclic aromatic, mono-substituted polycyclic aromatic, poly-substituted polycyclic aromatic, naphthalene, alkylnaphthalene, phenol, alkylphenol, alkoxylated phenol, and alkoxylated alkylphenolalkyl substituted or polysubstituted cyclic or polycyclic compounds to produce the corresponding sulfonic acid having an additional alkyl group derived from the alpha-olefin used during the thin-film sulfonation which is either linear or branched.

Owner:OIL CHEM TECH

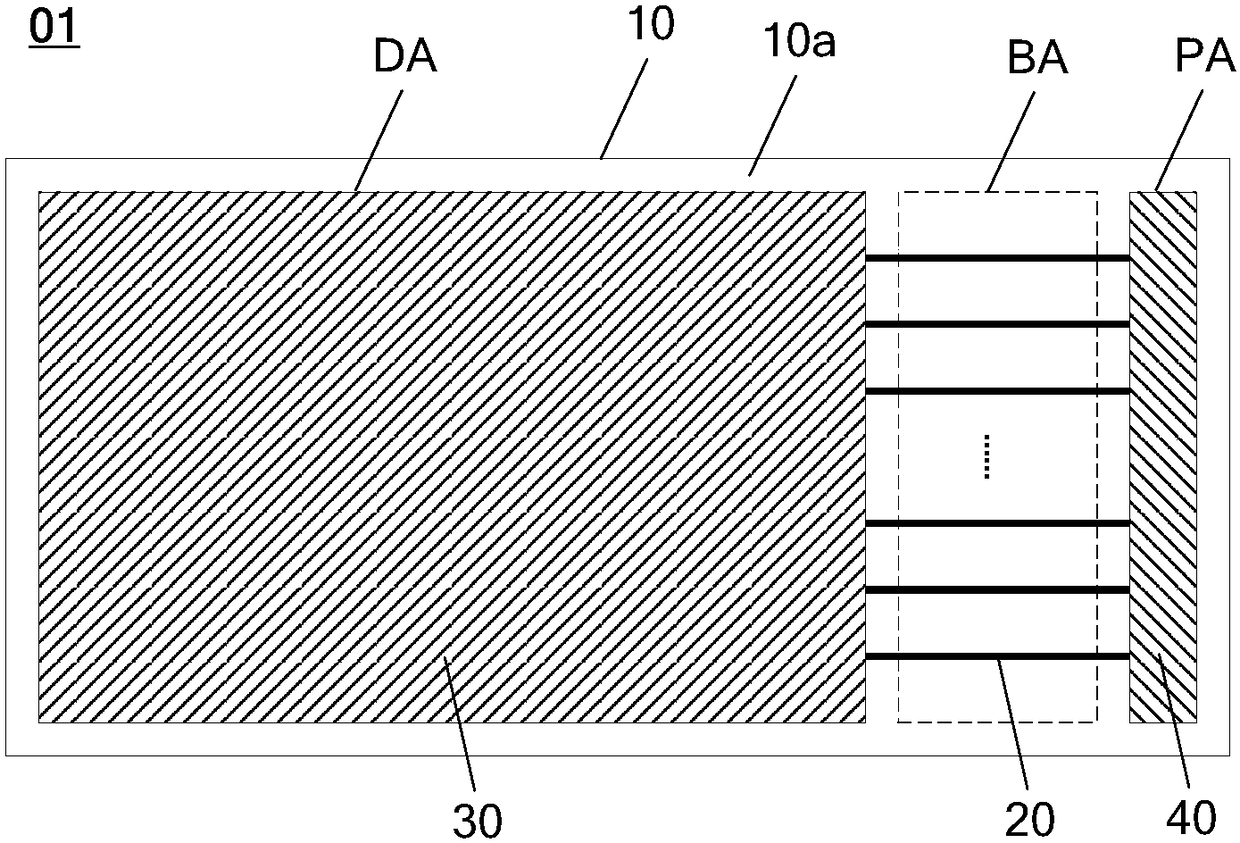

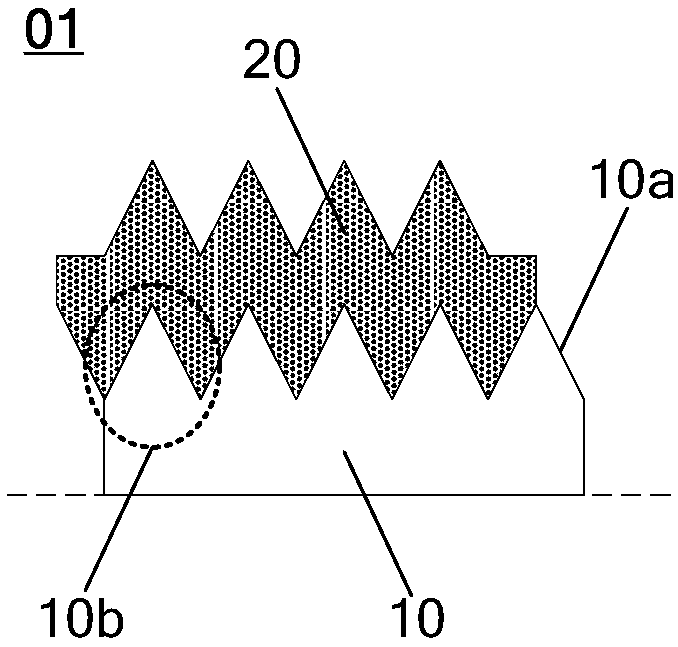

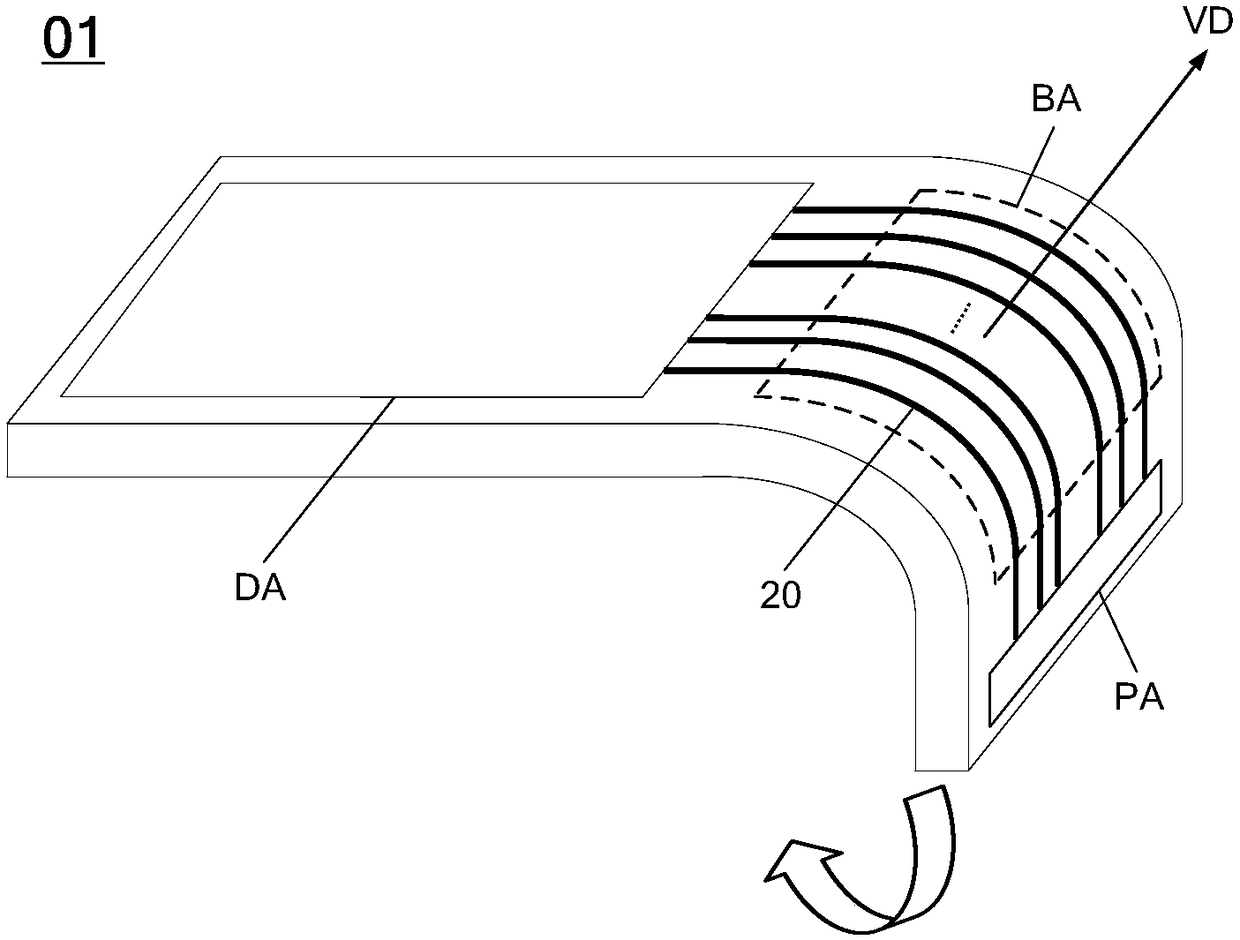

Flexible display panel, preparation method and display device thereof

ActiveCN108231800AAvoid breakingRealize the design effectDigital data processing detailsSolid-state devicesDisplay deviceEngineering

The invention provides a flexible display panel, a preparation method and display device thereof, and relates to the technical field of flexible display. The strain stressed in a vertical direction ofa signal outgoing line on the part located in a bending area can be reduced when the flexible display panel is bent, it is avoided that the signal outgoing line ruptures when bending, and the yield after products bend is improved. The flexible display panel comprises a flexible substratum substrate; the flexible substratum substrate comprises a first surface; the first surface is divided into a bent area; multiple bulges are arranged in the bent area on the first surface; and the signal outgoing line is located above the first surface and runs through the bent area. The preparation method isused for preparing the flexible display panel and the display device including the flexible display panel.

Owner:BOE TECH GRP CO LTD +1

Boiling bed hydrogenation treatment catalyst and its preparing process

ActiveCN101240190AThe reaction equipment is simpleReduce operating costsRefining to eliminate hetero atomsLow speedSpherical shaped

The invention relates to a boiling bed hydrogenation catalyst and a preparation method. The boiling bed hydrogenation catalyst of the invention is spherical shape which diameter is 0.1mm to 0.8mm, and has appropriate amount of additives and hydrogenation of metal components, and has reasonable hole distribution. The catalyst preparation method of the invention is spherical carrier impregnation, the process of spherical carrier preparation is following: making catalyst carrier raw material which is in appropriate temperature into appropriate size grain, then spheroidizing the grain, heating the conglobation and making them into spherical catalyst carrier. The process for making the catalyst carrier raw material into the appropriate size grain is that wet stock passes screen stencil by mechanical action and generates grain. Between the processes of the making grain and nodularization, granular material primely is placed for a period of time or operates in low-speed in nodularization device for a period of time. The catalyst of the invention appropriately conducts the boiling bed hydrogenation for heavy oil, residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

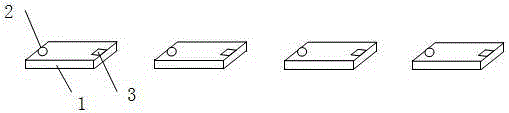

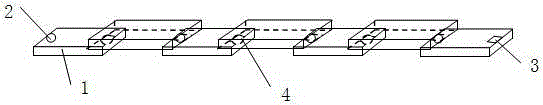

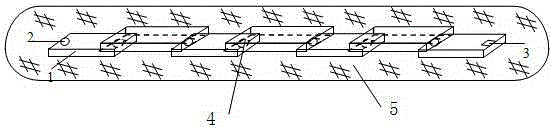

LED lamp filament illuminating strip and preparation method therefor

ActiveCN105161608AImprove yieldImprove uniformitySolid-state devicesSemiconductor devicesFluorescenceLap joint

The invention discloses an LED lamp filament illuminating strip and a preparation method therefor. The illuminating strip comprises LED chips in upper and lower rows, wherein all LED chips in the lower row are distributed at intervals, and all LED chips in the upper row are respectively connected between two adjacent LED chips in the lower row in a lap joint manner. The illuminating surfaces of the LED chips in the upper and lower rows are opposite to each other. The positive and negative electrodes of all LED chips in the upper row are respectively welded with the negative and positive electrodes of two adjacent LED chips, in lap joint connection with the LED chips in the upper row, in the lower row. The preparation method comprises the steps: coating solder paste on the positive and negative electrodes of all LED chips in the lower row; heating the solder paste and enabling the solder paste to be melted, welding the corresponding electrodes, coating the front and back surfaces of chip strips in series connection with fluorescent glue, and solidifying the fluorescent glue. The illuminating strip employs the chips which are not overlapped with each other, and the illuminating surfaces of the chips are arranged oppositely, thereby improving the light-emitting uniformity and facilitating heat dissipation. The wire crossing and tandem among chips is avoided, the packaging cost is reduced, and the yield of finished products is improved.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

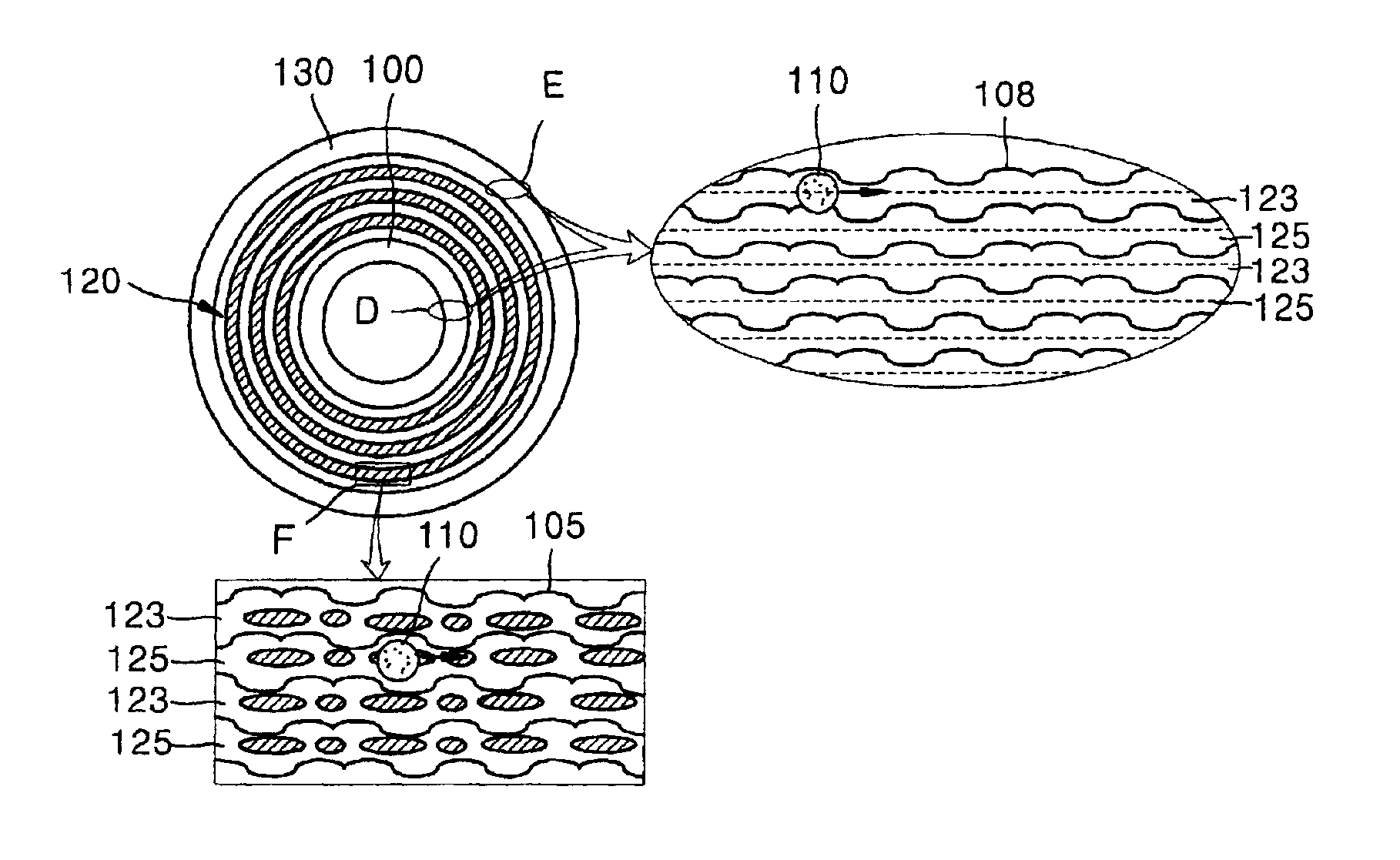

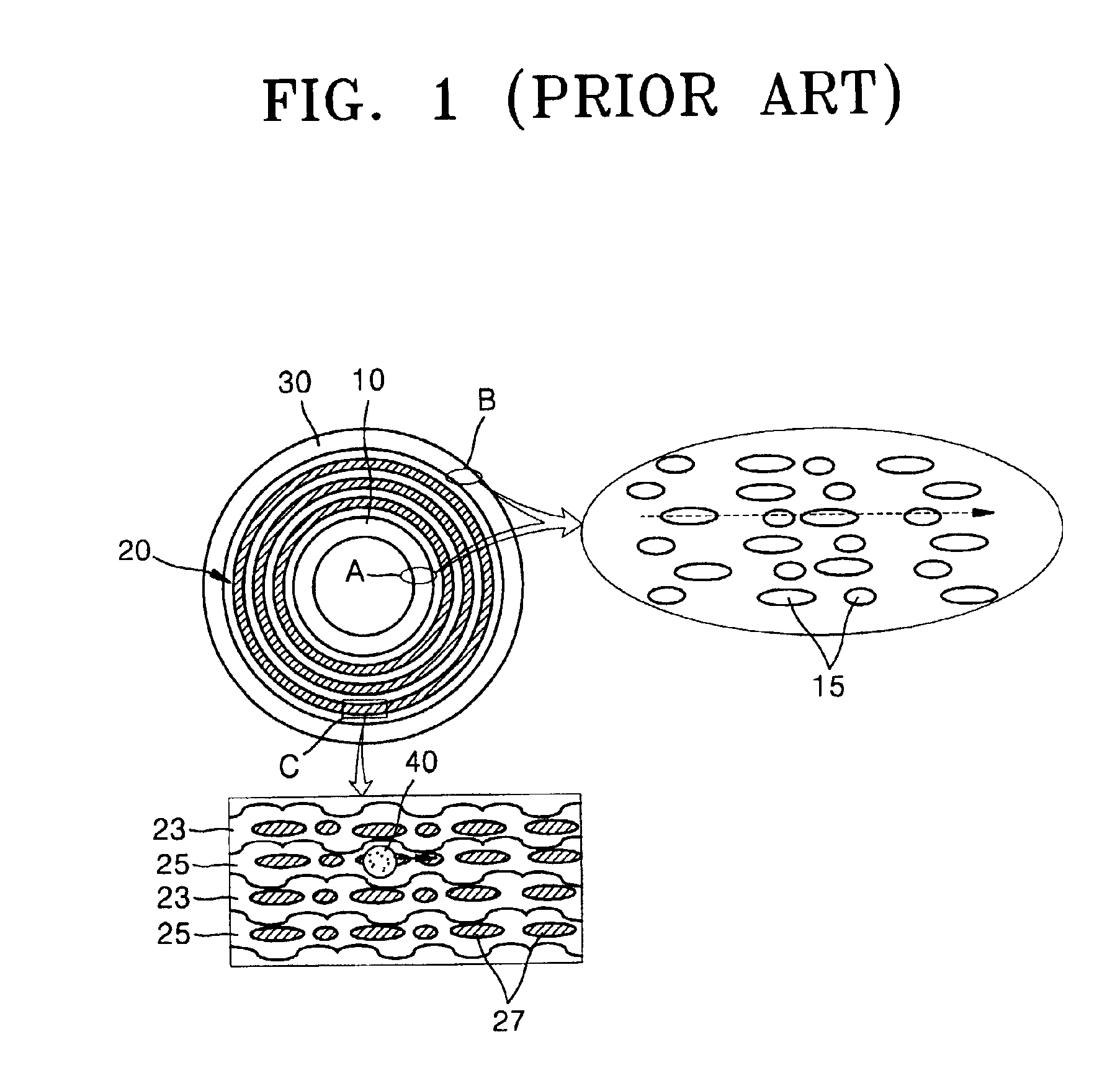

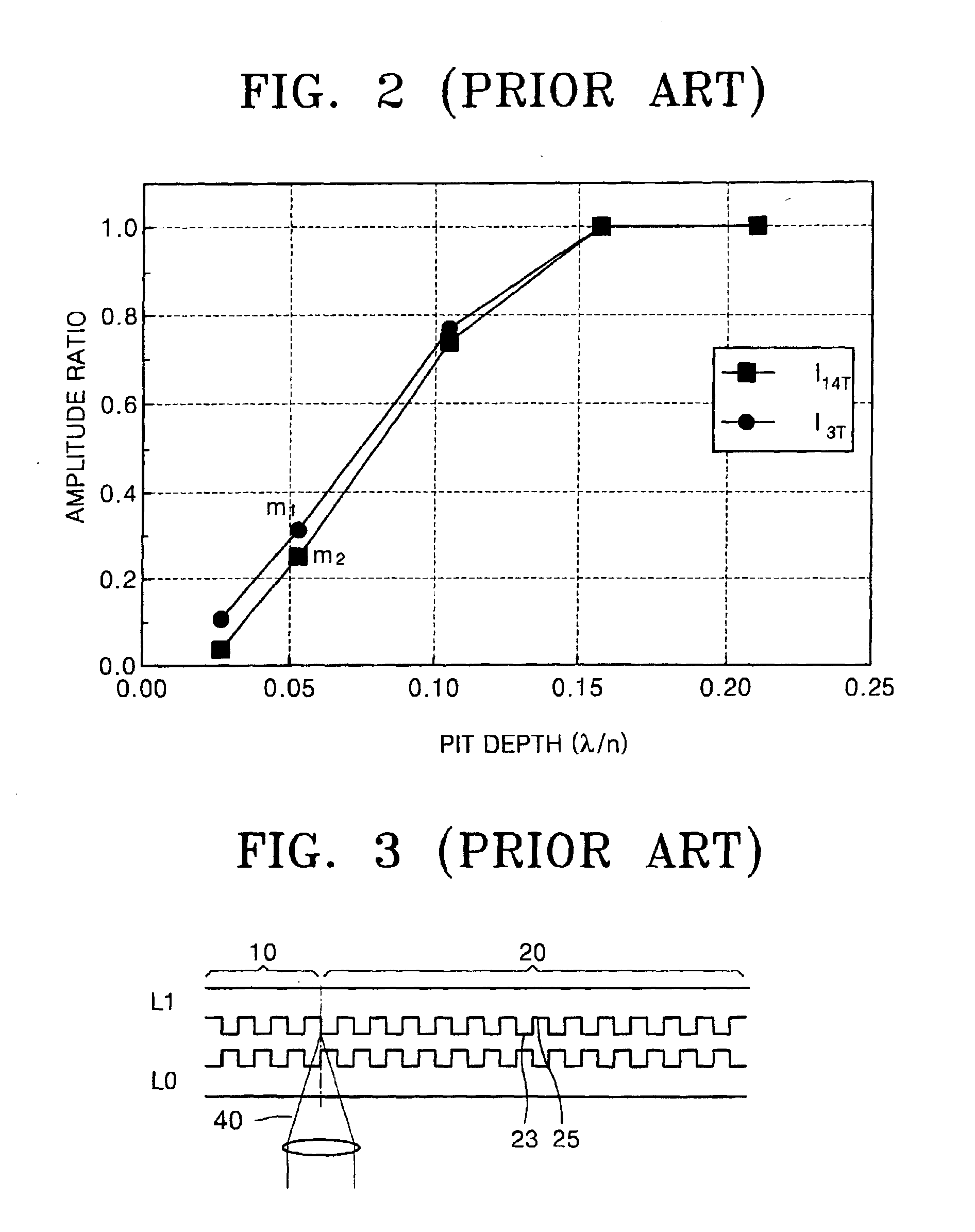

Optical disc having uniform structure

InactiveUS7065015B2Increase productionReduce manufacturing costFilamentary/web record carriersRecord information storageManufacturing cost reductionEngineering

An optical disc is manufactured under a uniform condition by forming grooves and lands on the entire surface of the disc. The optical disc is configured to obtain a reliable reproduction signal, and the grooves and lands are formed on a lead-in area, a user data area and a lead-out area of the optical disc. Since the same manufacturing condition can be adopted in mastering discs, the yield can be enhanced and the manufacturing cost can be reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

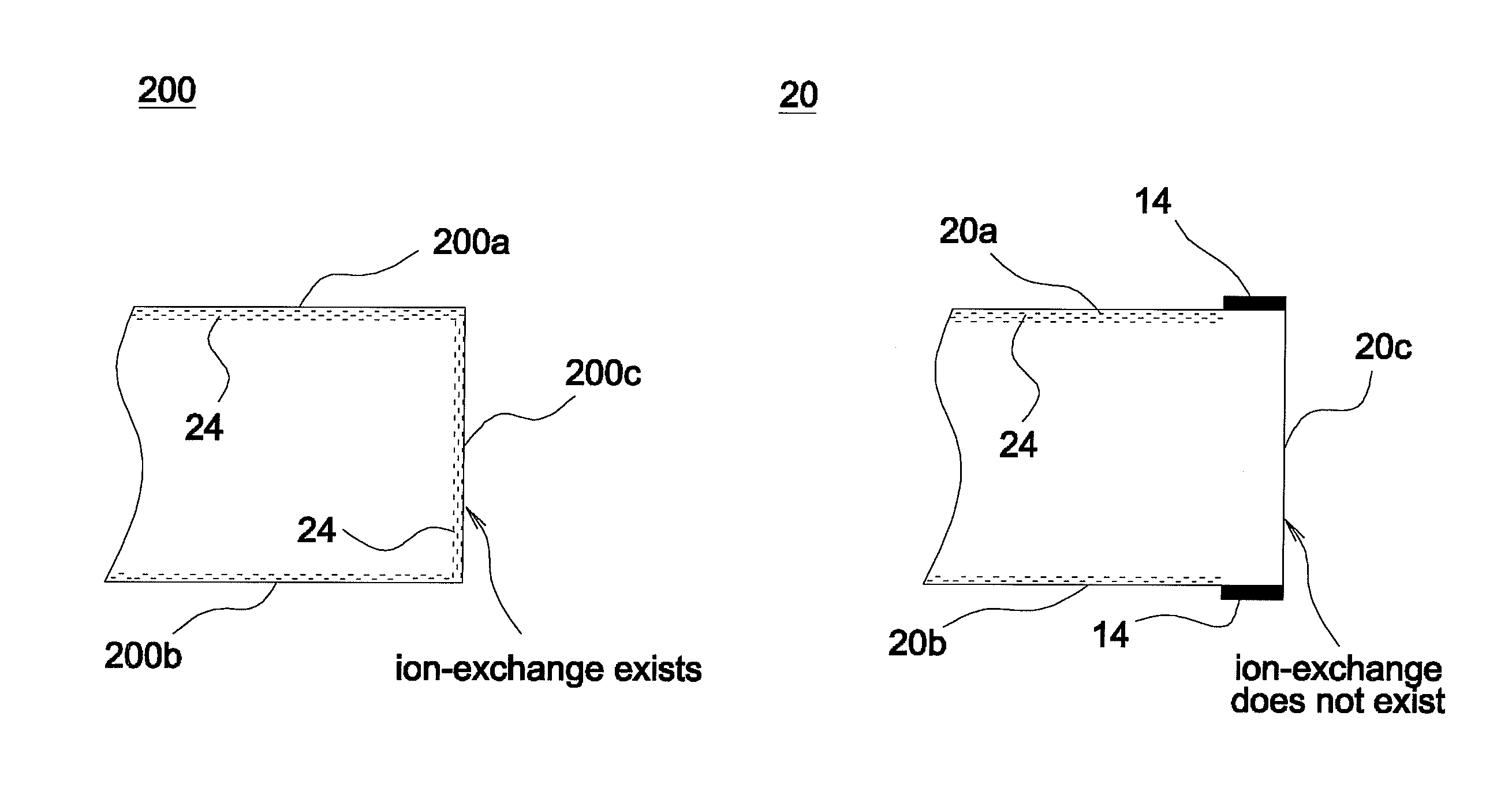

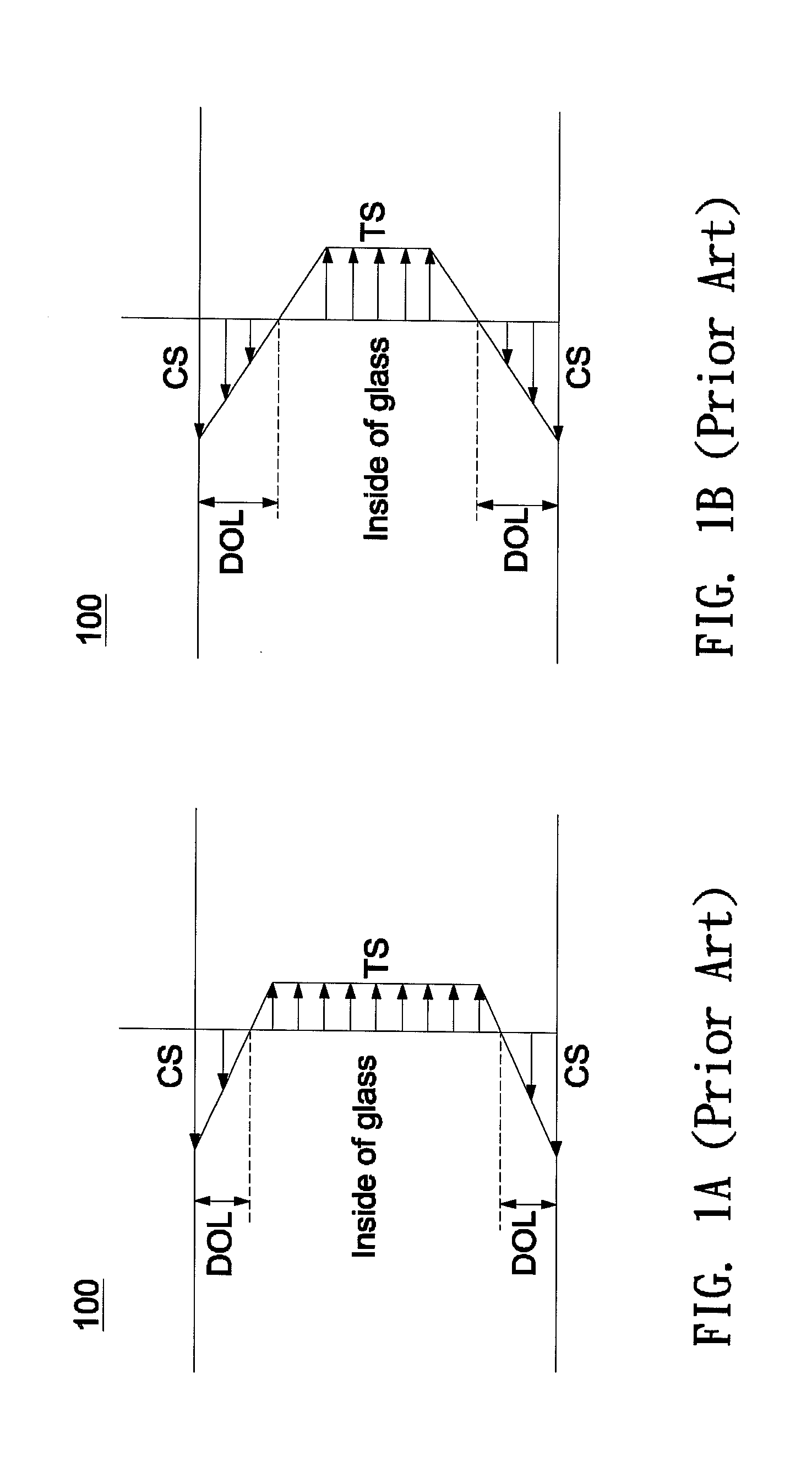

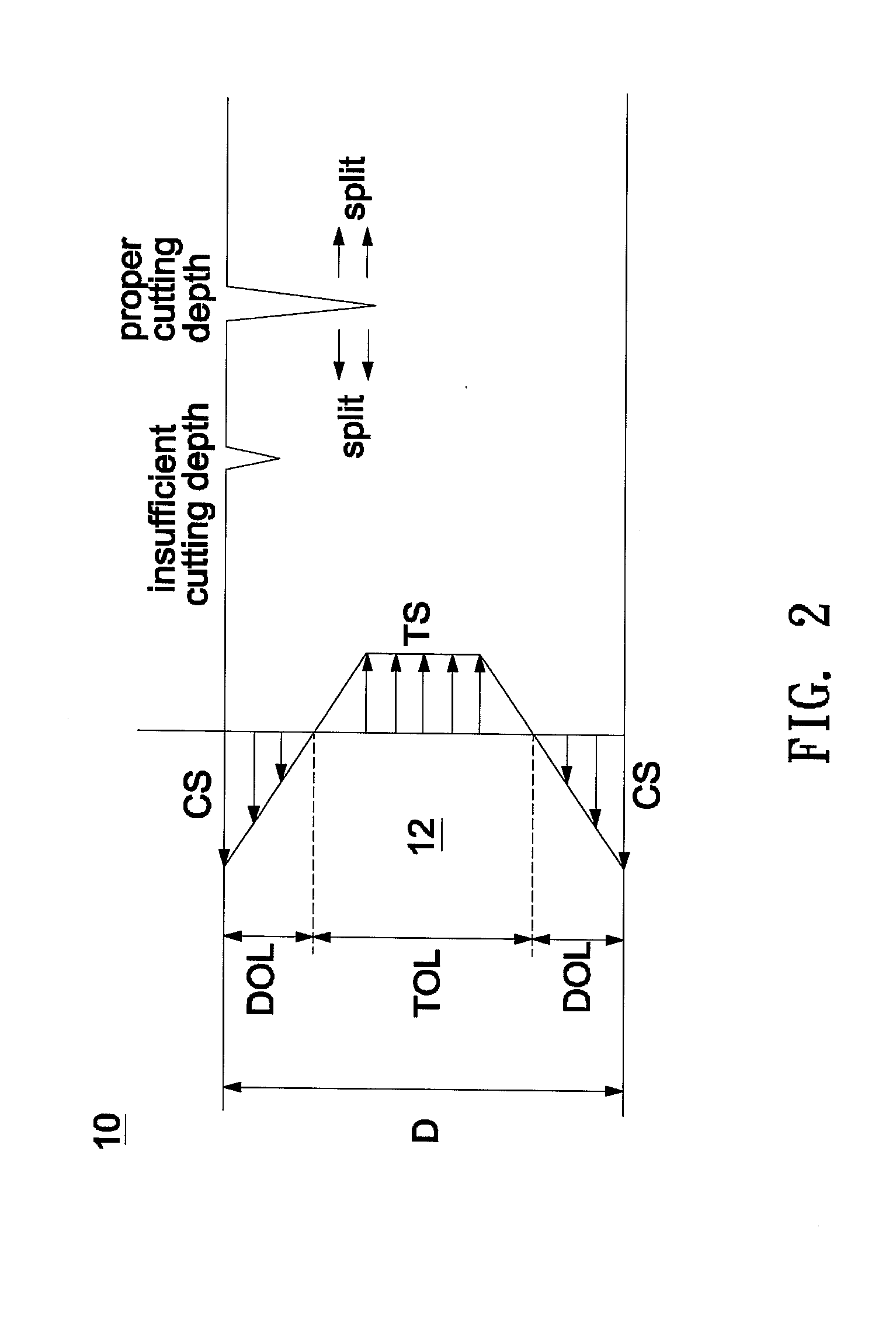

Method for cutting tempered glass, preparatory structure used in cutting tempered glass, and glass block cut from tempered glass substrate

InactiveUS20120064306A1Improve yieldReduce tensile stressCellulosic plastic layered productsCeramic layered productsMetallurgyIon exchange

A method for cutting a tempered glass includes the following steps. First, a shielding layer is formed on a part of a surface of a glass substrate, and a predetermined cutting path passes through the part of the surface. Then, a glass substrate is given an ion-exchange strengthening treatment, and the part of the surface covered by the shielding layer substantially does not undergo ion-exchange. Finally, the glass substrate is cut along the predetermined cutting path.

Owner:WINTEK CHINA TECH LTD +1

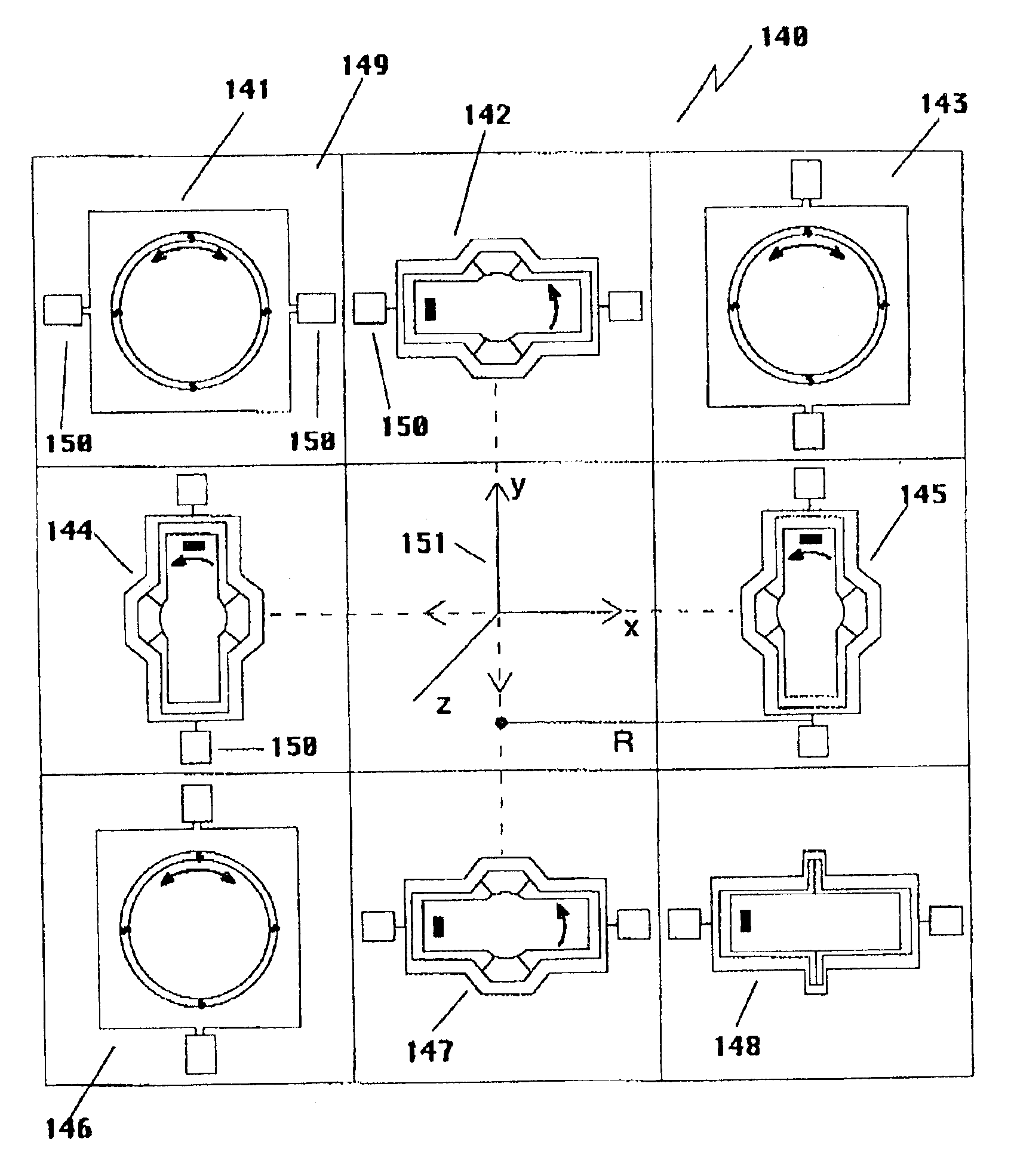

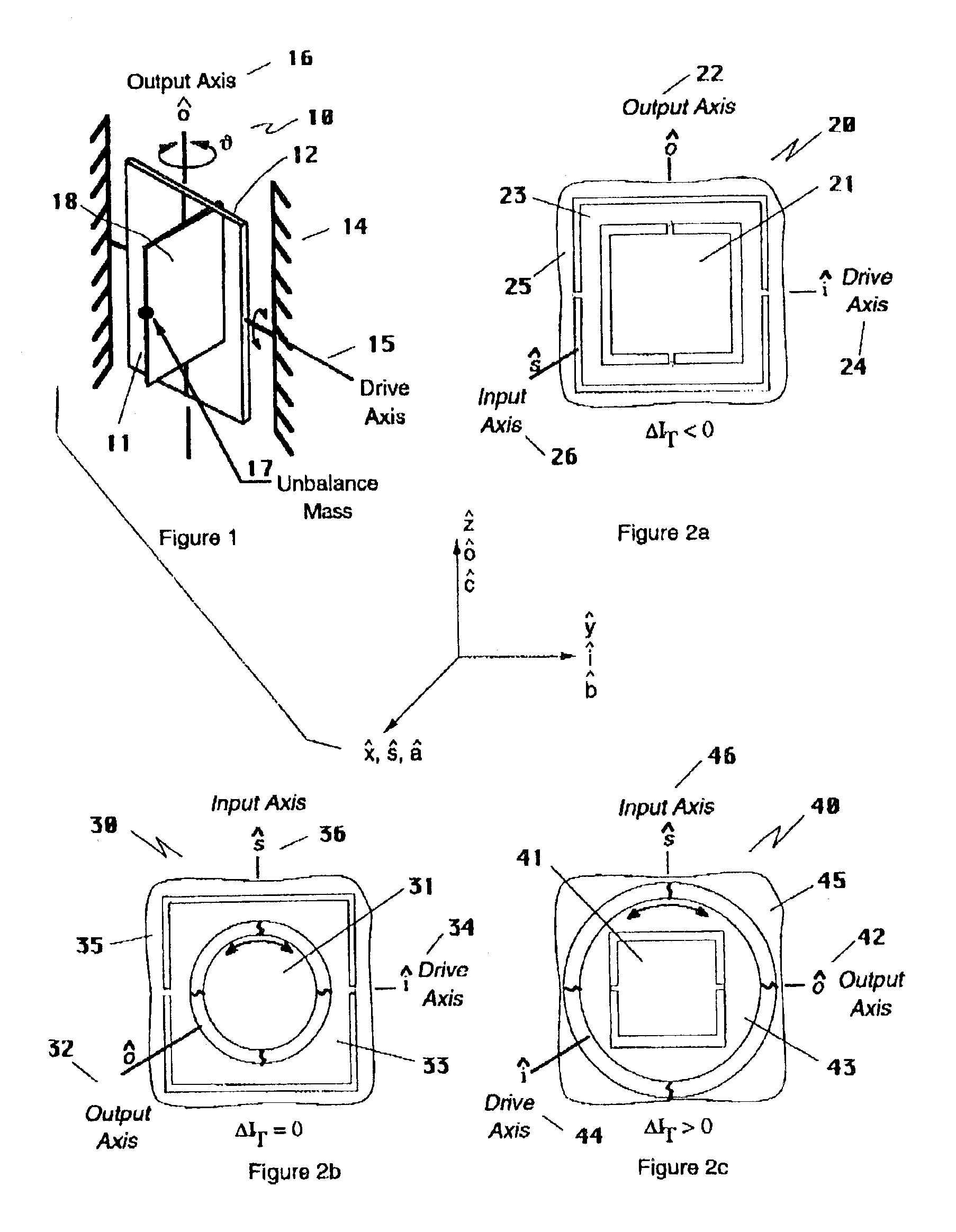

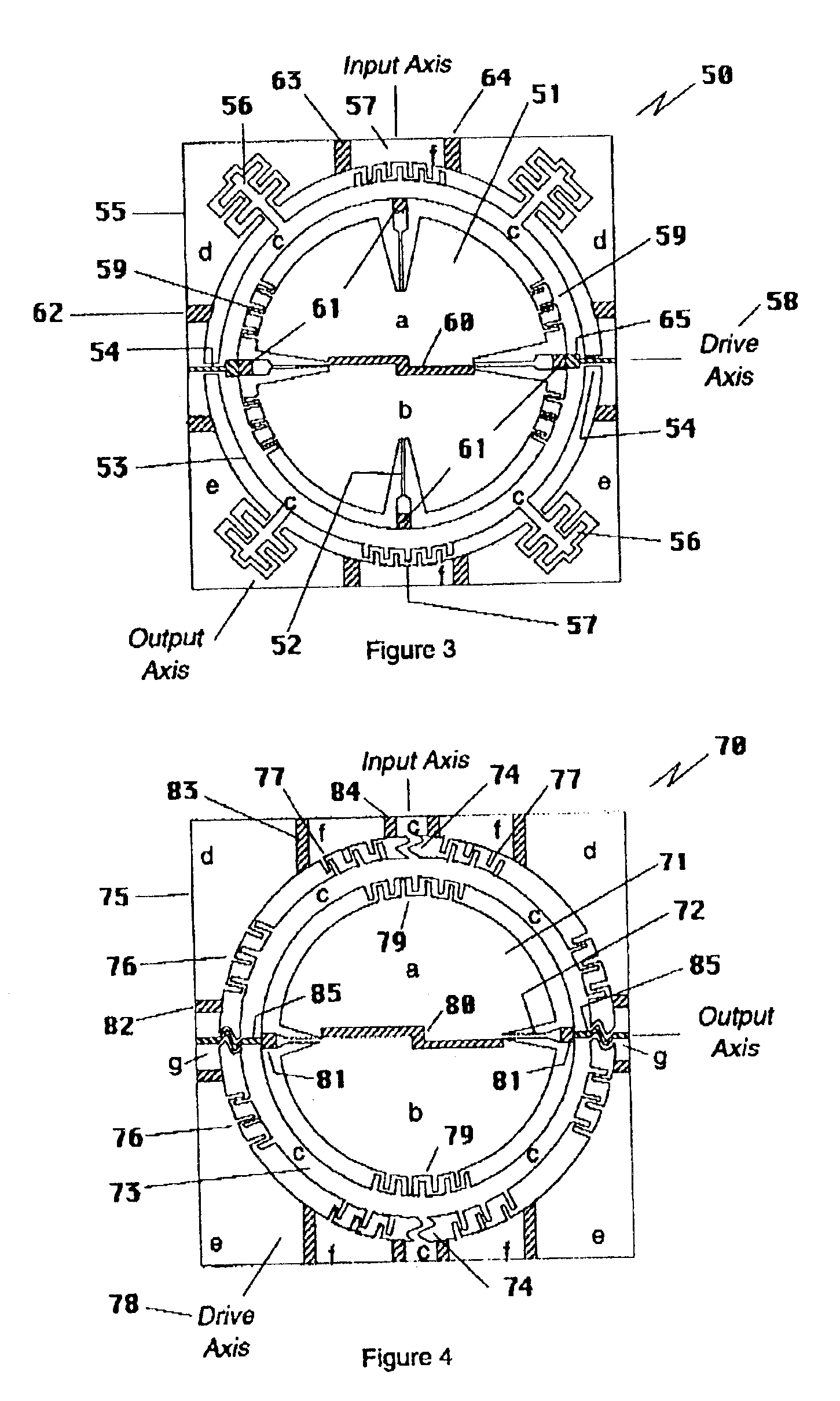

Planar inertial measurement units based on gyros and accelerometers with a common structure

InactiveUS6859751B2Simple structural designEasy to buildAcceleration measurement using interia forcesDigital computer detailsAccelerometerGyroscope

Inertial Measurement Units based on integrated designs to reduce alignment and assembly costs. Integration also leads to performance improvement, increased miniaturization and simplification as well as reduced cost. Also disclosed are gyroscopes and accelerometers that are identical, yet by their mechanization, can be made to act as separate sensors. Miniaturization and simplification is improved by combining instruments that can share a common member. Savings in space and complexity are also possible in the electronics when elements are shared.

Owner:MILLIE SENSOR SYST & ACTUATORS

Fast laser depositing process of preparing antinwear heat resistant composite coating on surface of crystallizer

InactiveCN1932082ANo pollution in the processRadiation-freeMolten spray coatingArc welding apparatusAutomatic controlHigh power lasers

The fast laser depositing process of preparing antiwear heat resistant composite coating on the surface of crystallizer features that high power laser is first utilized in fast scanning to form transition layer in excellent metallurgical binding with the substrate of crystallizer copper plate on the surface of the plate and then utilized in wide band deposition to form Co base alloy with excellent heat resistance and high wear resistance on the surface of the transition layer. Compared with convenient technological process, the present invention has the advantages of precise control in laser power, position, shape and other parameters, easy automatic control of the whole process, no environmental pollution, high production efficiency, low power consumption, etc. and may be used widely.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

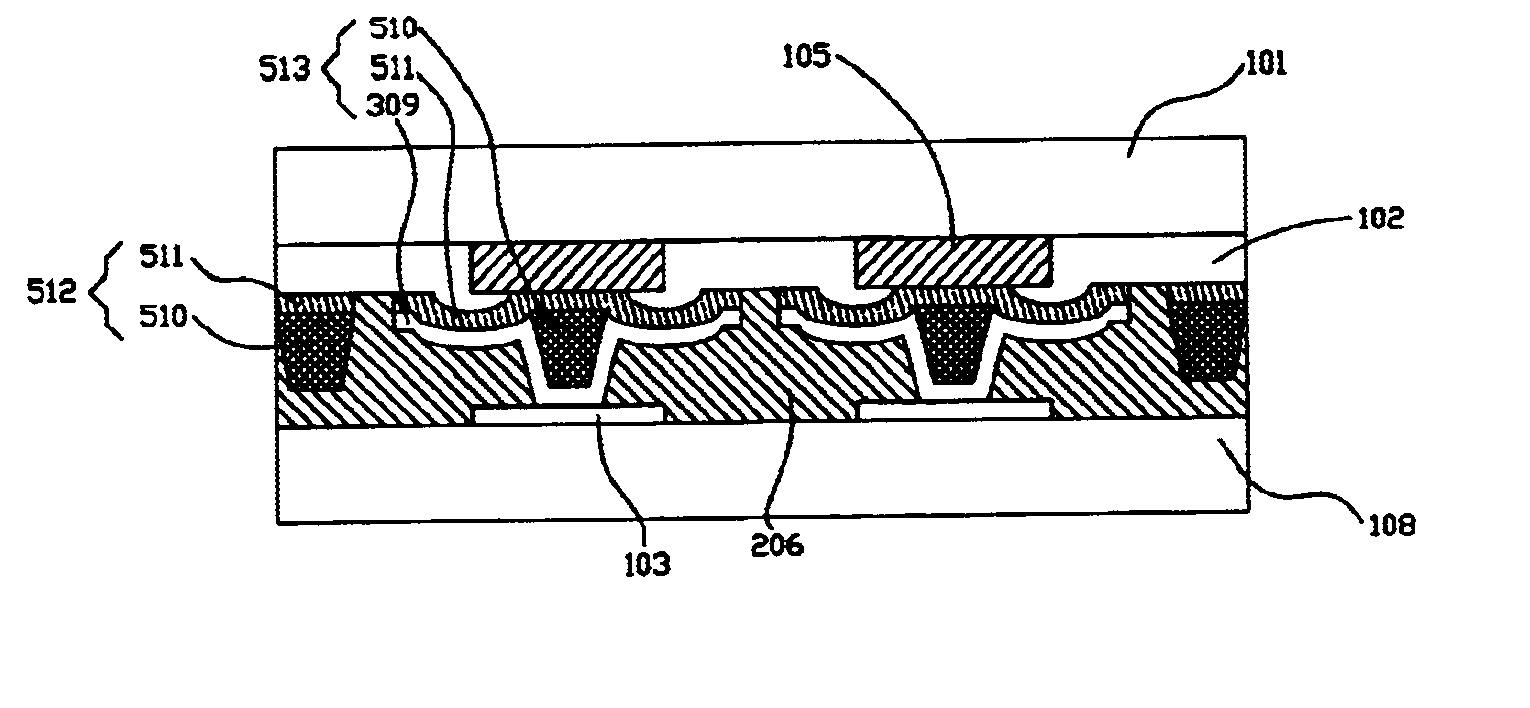

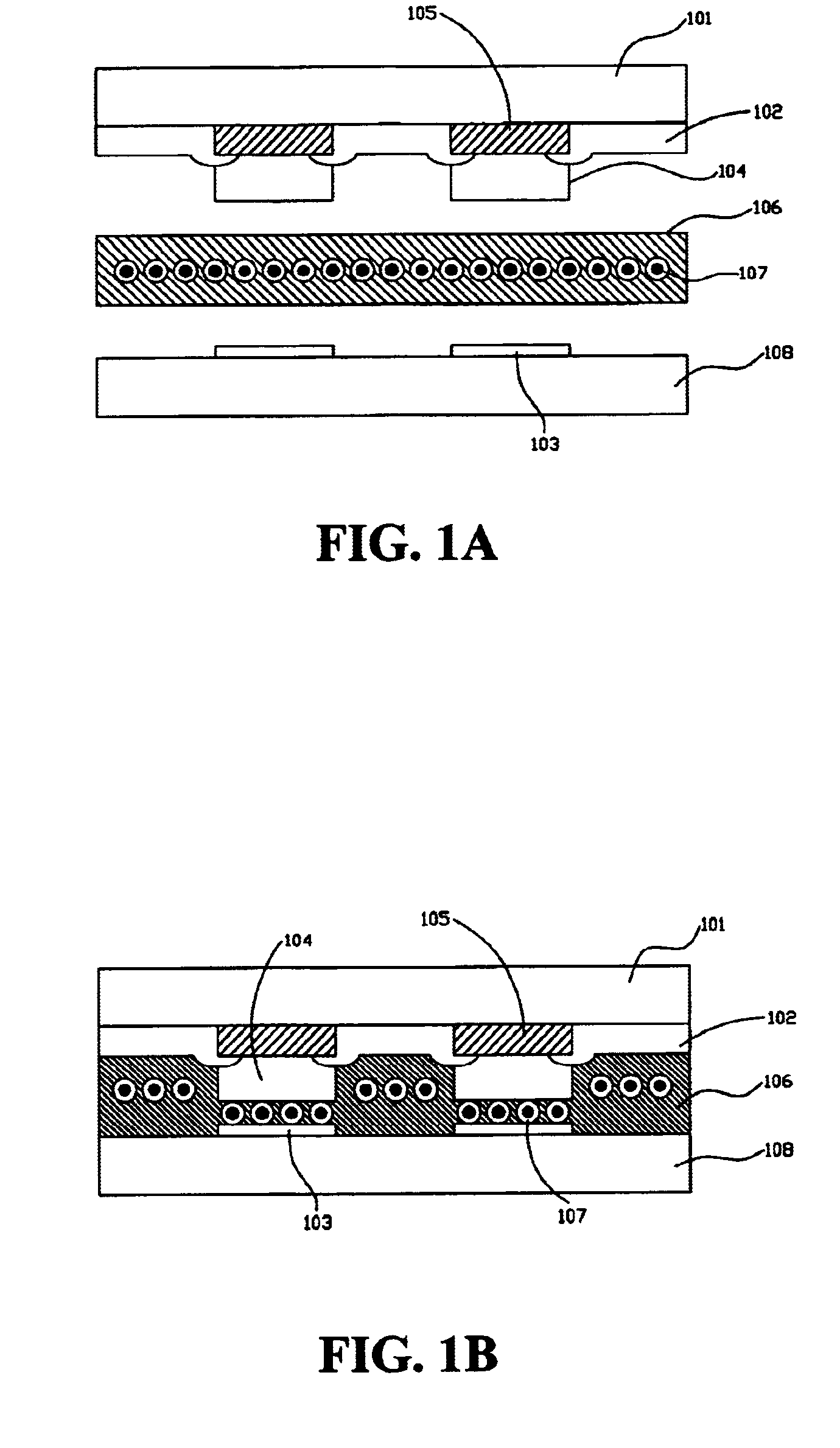

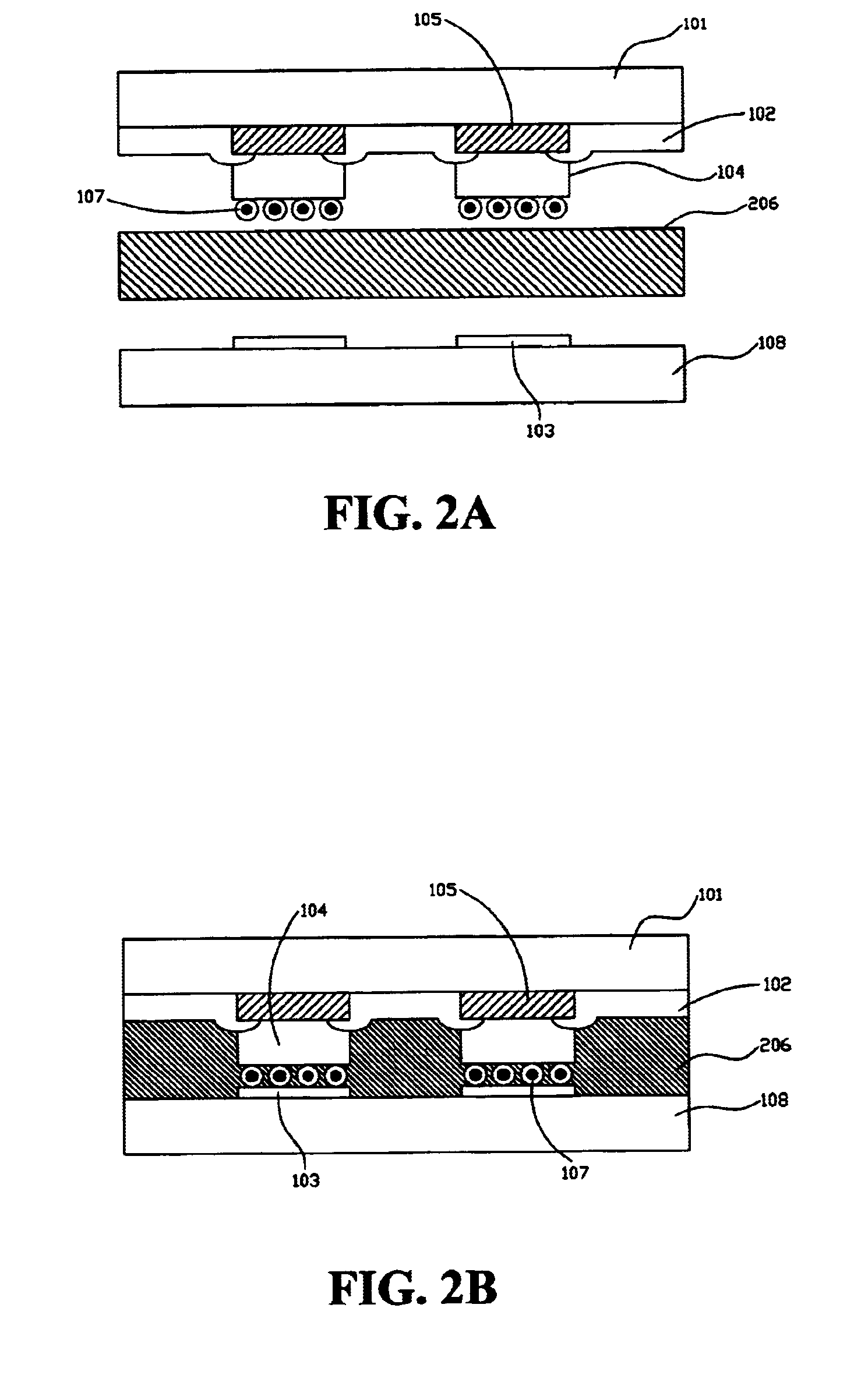

Bonding structure with compliant bumps

InactiveUS6972490B2Reduce the modulus of elasticityReduce pressurePrinted circuit assemblingSemiconductor/solid-state device detailsBonding processEngineering

A bonding structure with compliant bumps includes a stopper structure and a protection layer. Compliant bumps include at least a polymer bump, a metal layer and a surface conductive layer. Both the stopper structure and protection layer are formed with polymer bumps and metal layer. Compliant bumps provide bonding pad and conductive channel. Stoppers are used to prevent compliant bumps from crushing for overpressure in bonding process. The protection layer provides functions of grounding and shielding. The stoppers can be outside or connected with the compliant bumps. The protection layer has thickness smaller than the stopper structure and compliant bumps. It can be separated or connected with stoppers.

Owner:IND TECH RES INST

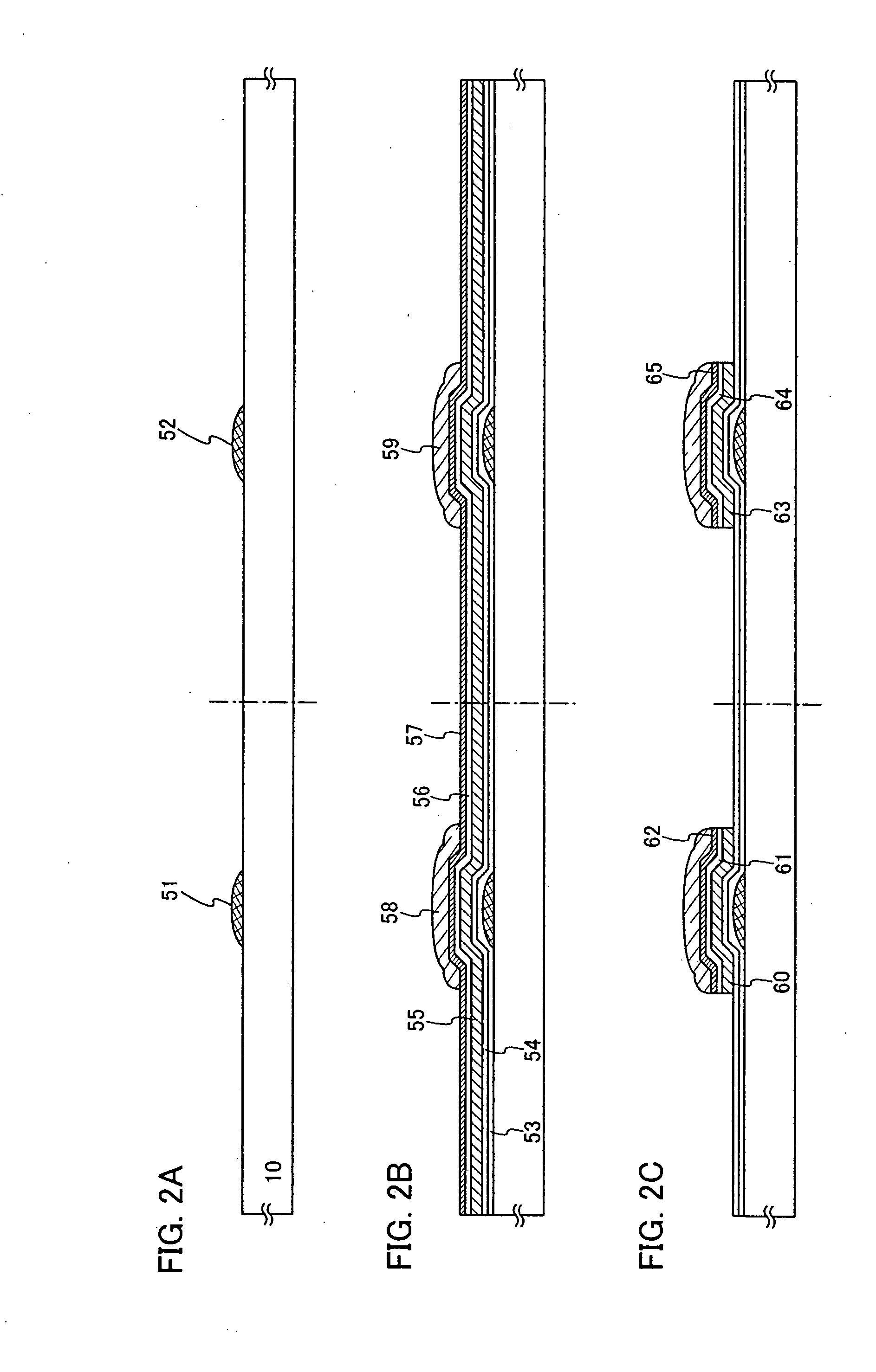

Method for manufacturing semiconductor device

An object of the present invention is to provide a method for manufacturing a semiconductor device of which manufacturing process is simplified by improving usage rate of a material. A method for manufacturing a semiconductor device of the invention comprises the steps of: forming gate electrodes with a droplet discharge method on a substrate having an insulating surface; laminating gate insulating layers, semiconductor layers, and a semiconductor layer containing one-conductivity type impurity over the gate electrodes; forming first conductive layers serving as masks with a droplet discharge method in a position overlapping the gate electrodes, etching the semiconductor layer and the semiconductor layer containing one-conductivity type impurity with the first conductive layers, forming a second conductive layer serving as a source wiring or a drain wiring with a droplet discharge method over the first conductive layers; and etching the first conductive layers and the semiconductor layer containing one-conductivity type impurity, using the second conductive layers as masks.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com