Patents

Literature

434 results about "Fast scanning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The clinician performed eFAST scan is not intended to replace formal diagnostic ultrasound tests, nor is it designed to diagnose solid organ injury or other pathology. The FAST scan should be documented, by saving images of the standard views, plus any additional images to document pathology.

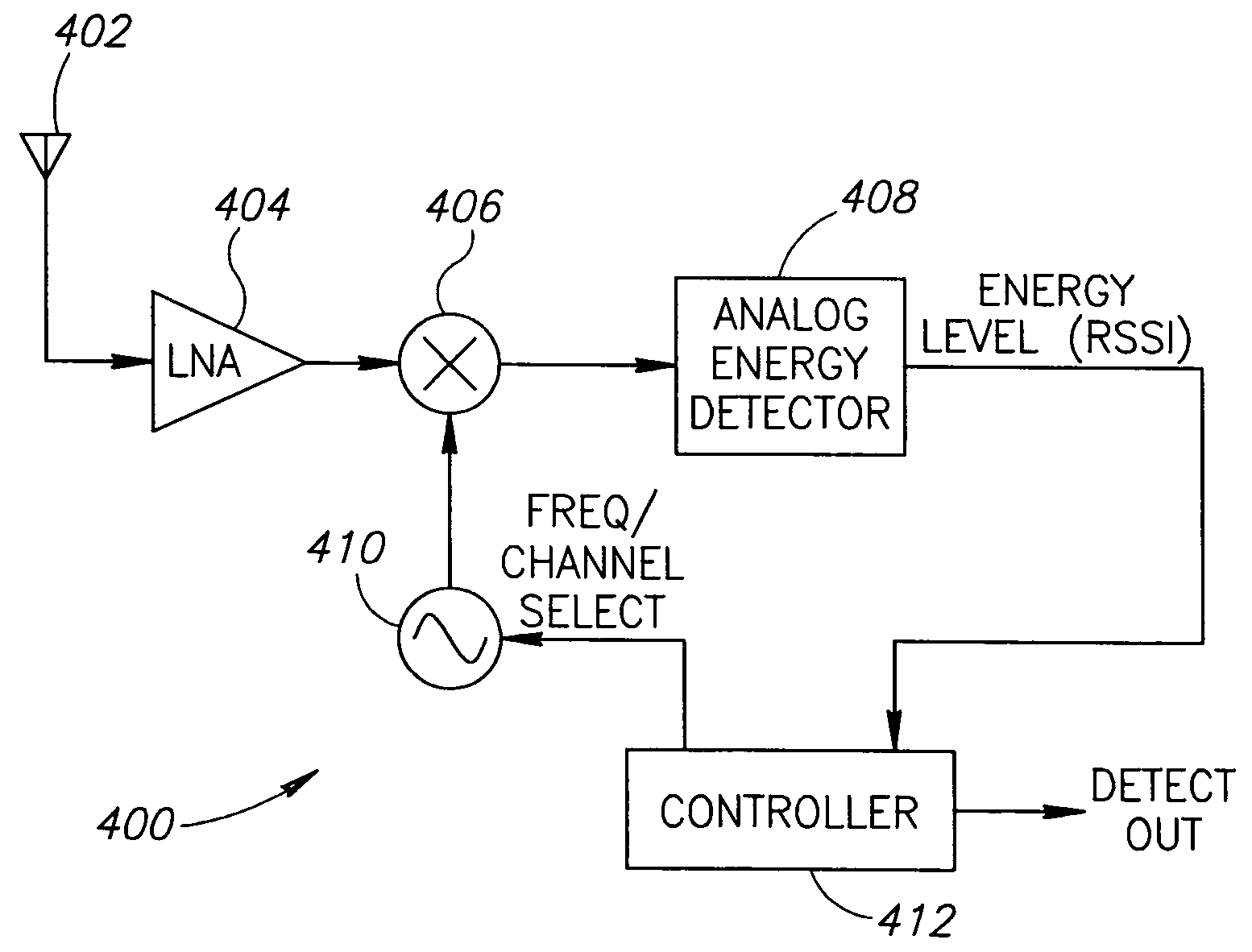

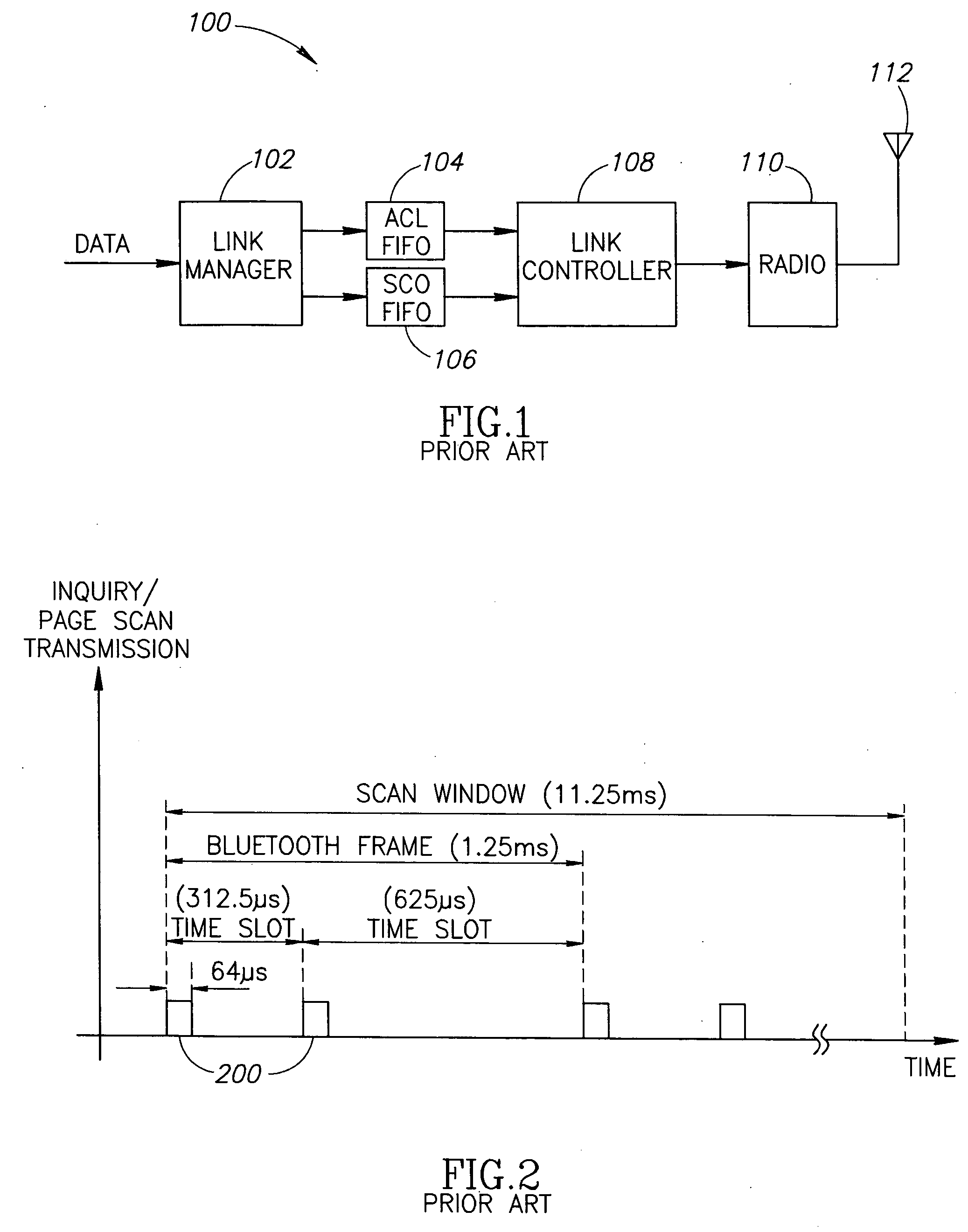

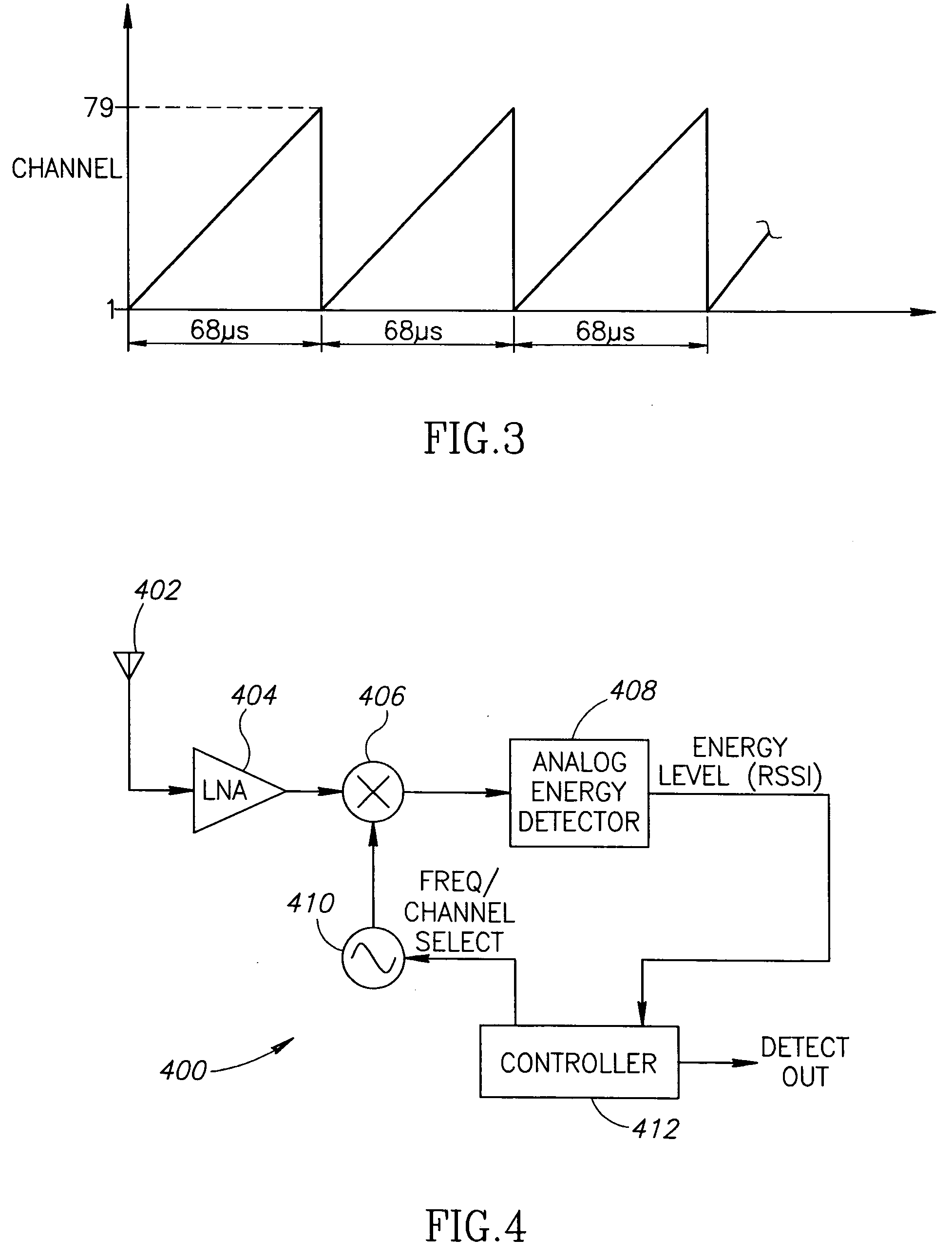

Low power bluetooth page and inquiry scan

InactiveUS20060128308A1Low powerQuickly andPower managementEnergy efficient ICTBluetoothComputer science

A novel and useful low power Bluetooth page and inquiry scan mechanism. Efficient and low power page and inquiry scans are performed by measuring the energy received at each frequency and comparing it to a threshold. If the energy sensed is greater than the threshold, normal Bluetooth page or inquiry scans are then performed within the scan window. The energy sensing is done by quickly sweeping the receiver in the radio over all 79 Bluetooth frequencies in less than 68 μs at least 19 times in order to cover at least 1.25 ms thus ensuring capturing any page or inquiry message transmissions. For noisy environments, a mechanism is provided to turn frequency sweeping off until interference is at a low enough level to reduce the number of false positive detections to an acceptable level.

Owner:TEXAS INSTR INC

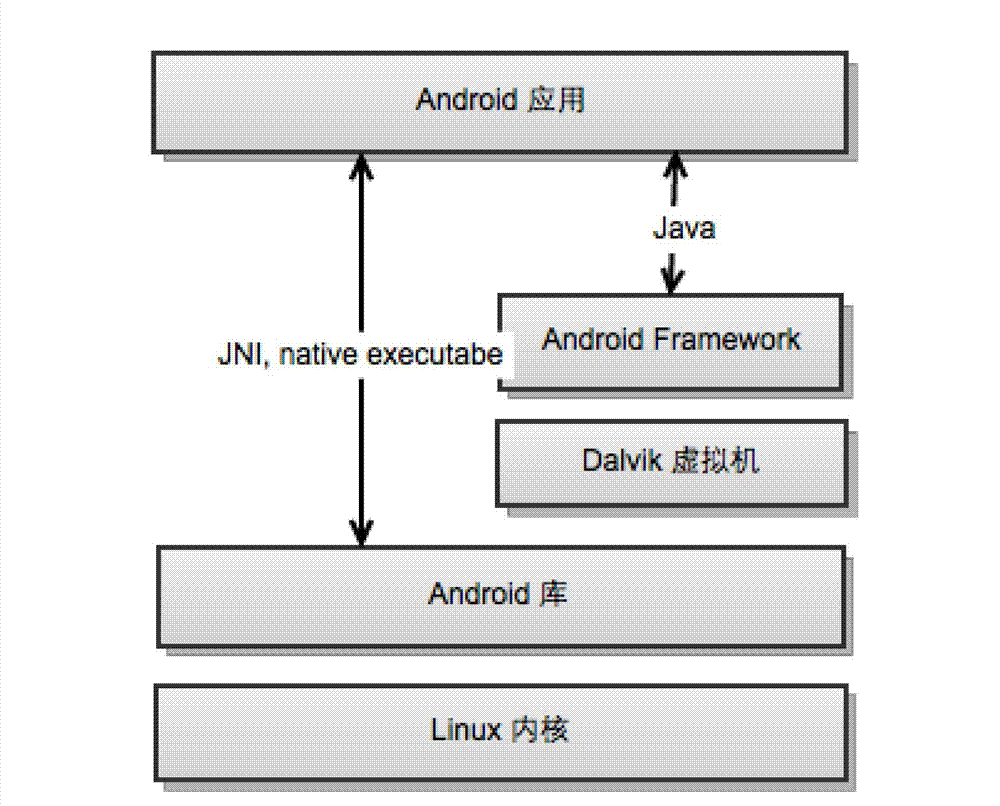

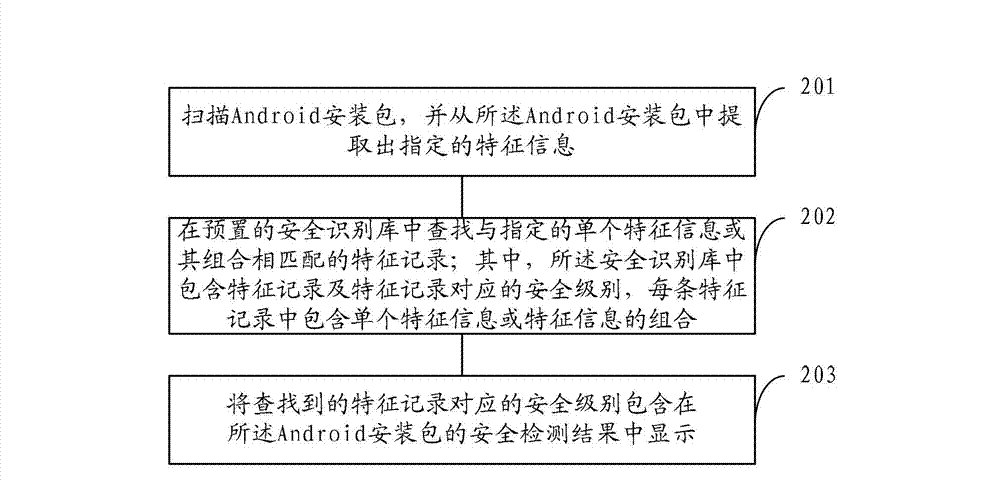

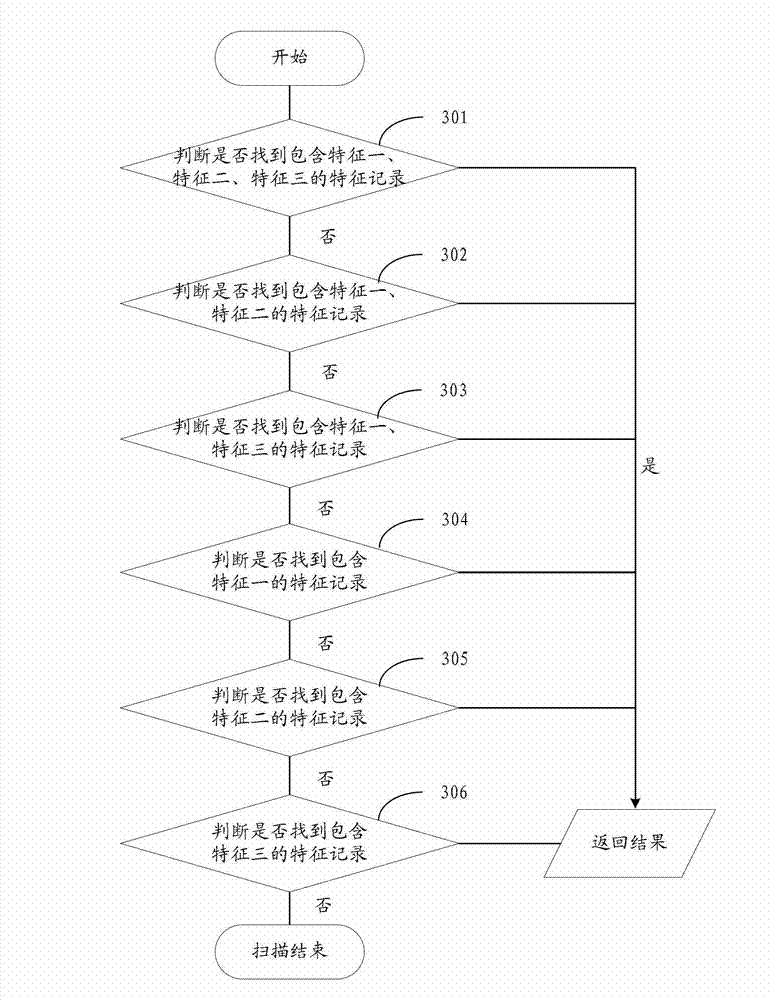

Security detection method and system of Android application program

ActiveCN102779257ACause harmImprove scanning efficiencyComputer security arrangementsSoftware engineeringApplication software

The invention provides a security detection method and system of an Android application program, aiming to solve the problems of an antivirus method of the existing Android platform that the scanning speed is slow and the false positive ratio is high. The method comprises the following steps of: scanning an Android installation package and extracting appointed characteristic information from the Android installation package; finding characteristic records which are matched with the appointed single characteristic information or a combination thereof from a pre-arranged security identification base, wherein the security identification base comprises the characteristic records and security grades corresponding to the characteristic records, and each characteristic record comprises single characteristic information or the combination of the characteristic information; and respectively displaying the security grade corresponding to the found characteristic records in a security detection result of the Android installation package. The security detection method and system of the Android application program disclosed by the invention have the advantages of fast scanning speed and high searching and killing accuracy.

Owner:360 TECH GRP CO LTD

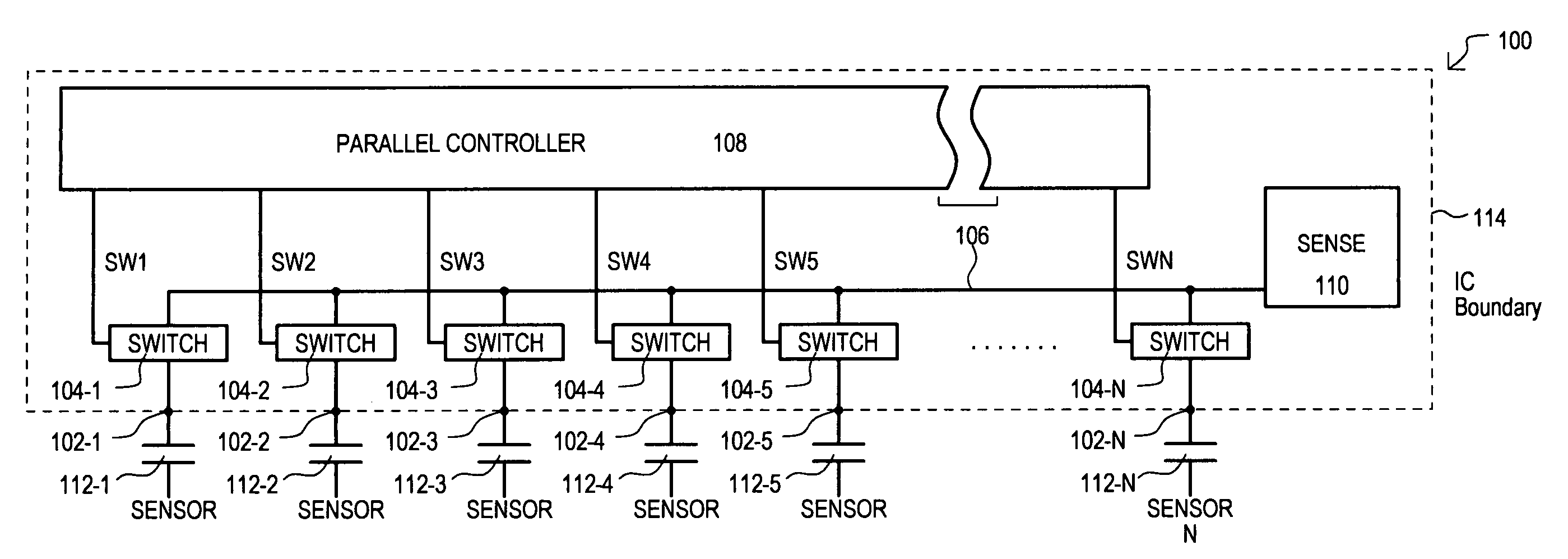

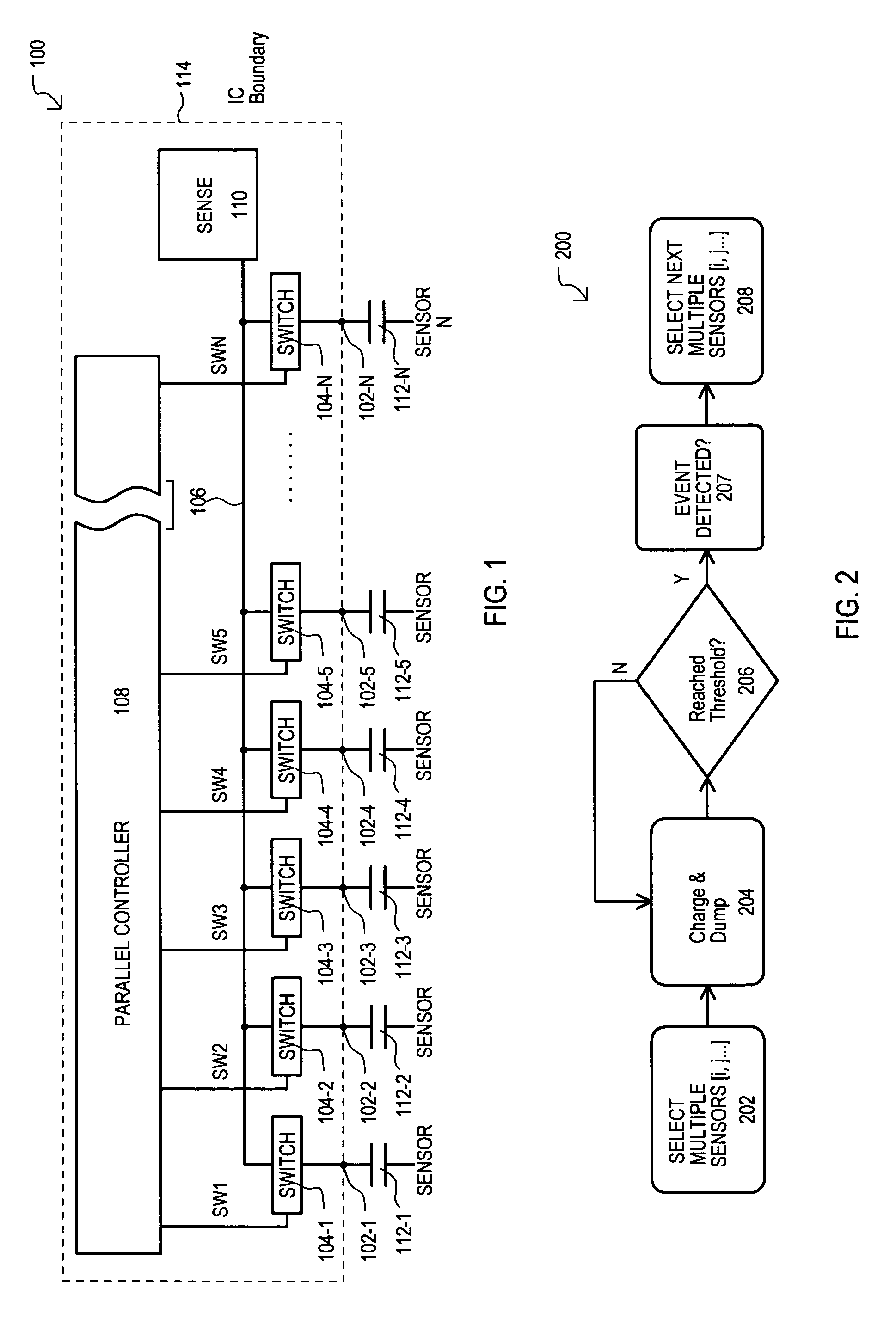

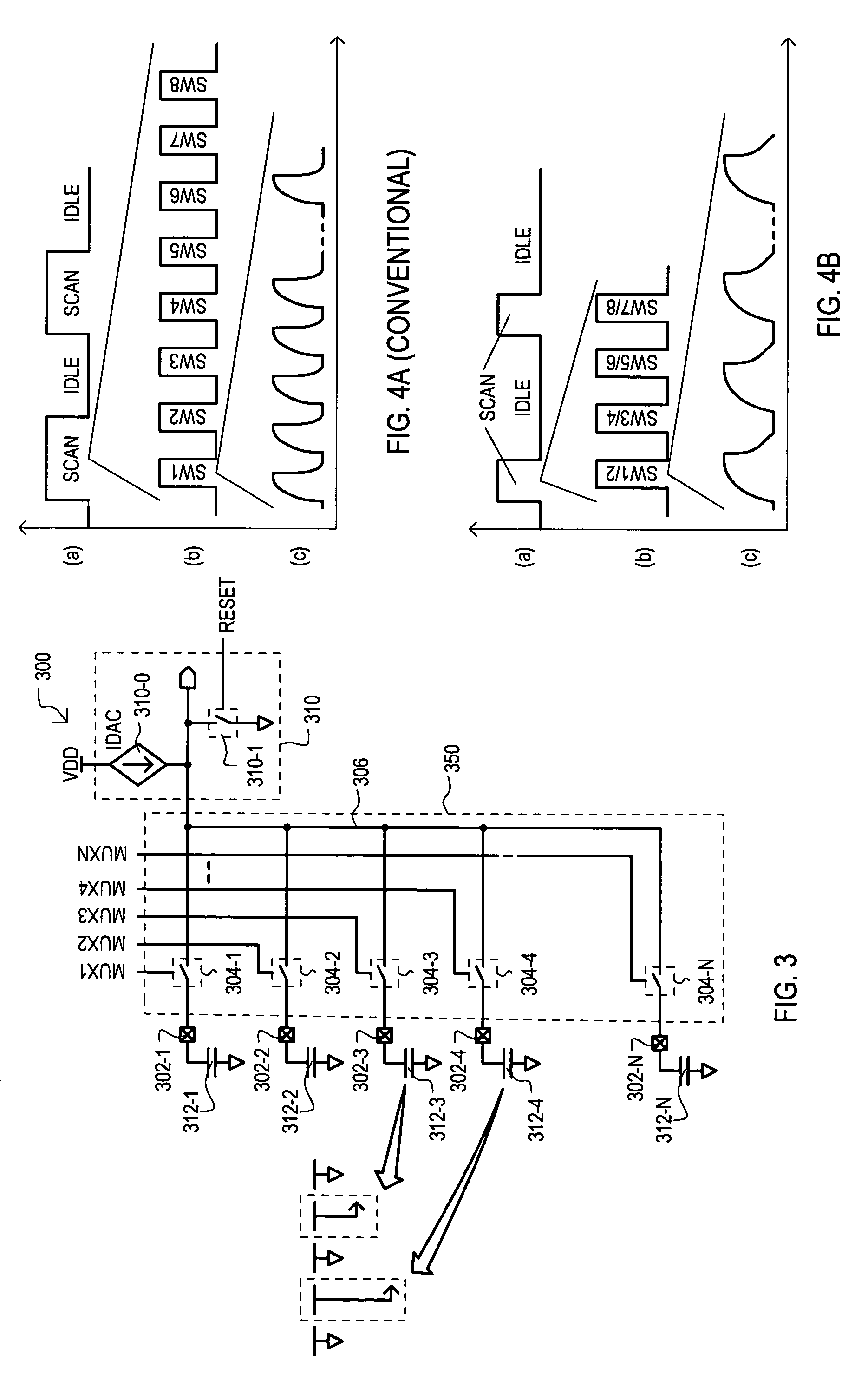

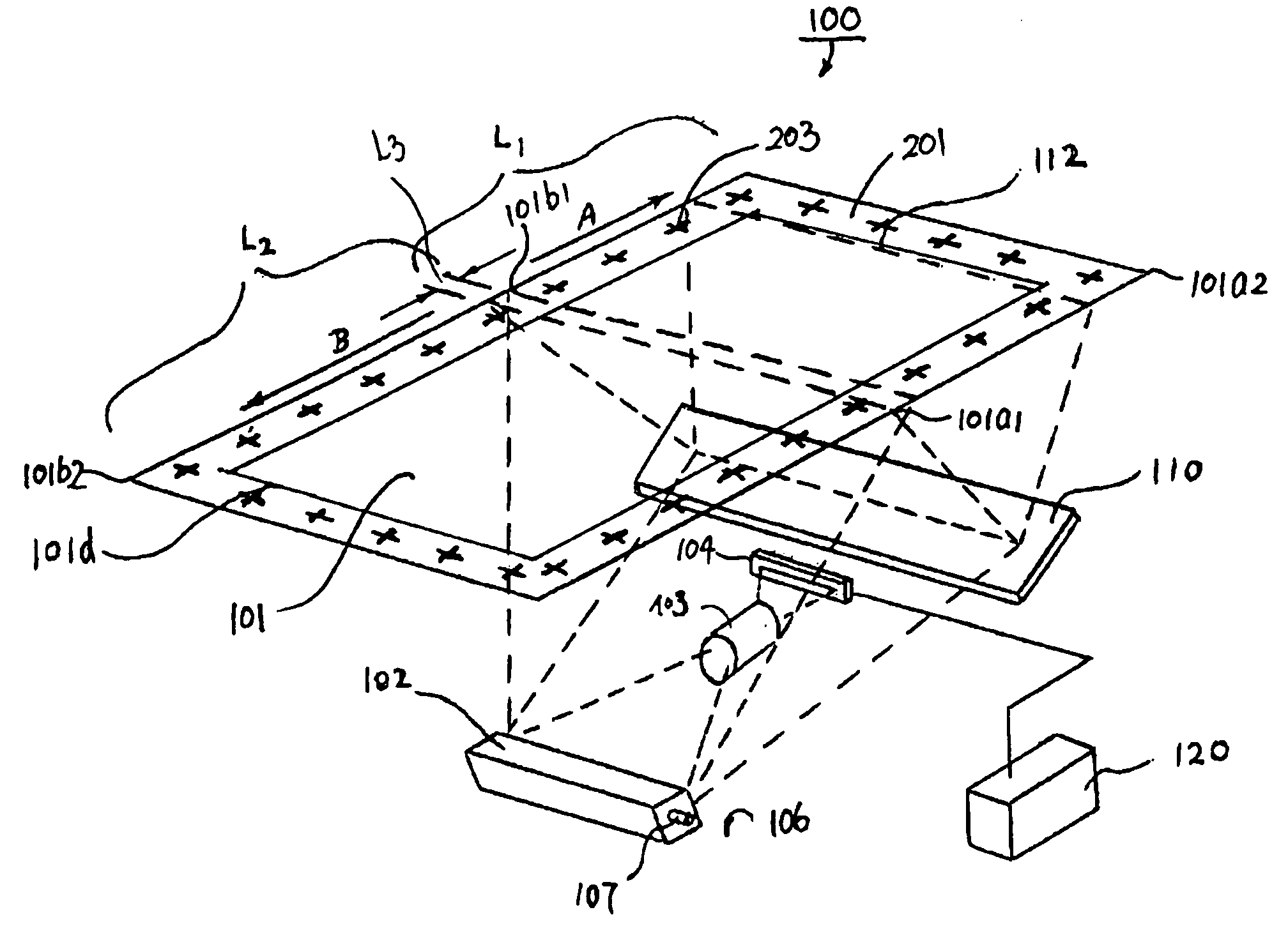

Scan method and topology for capacitive sensing

InactiveUS7375535B1Faster completion timeAvoid excessive currentResistance/reactance/impedenceConverting sensor output electrically/magneticallyEngineeringCapacitive sensing

A capacitive sensing system (100) can connect groups of capacitive sensors (112-1 to 112-N) to a common node (106) to detect change in capacitance. States of a set of capacitive sensors (112-1 to 112-N) can thus be scanned faster than approaches that scan such sensors one-by-one. Faster scanning can allow for reduced power consumption in applications that only periodically scan the set of capacitive sensors (112-1 to 112-N).

Owner:MONTEREY RES LLC

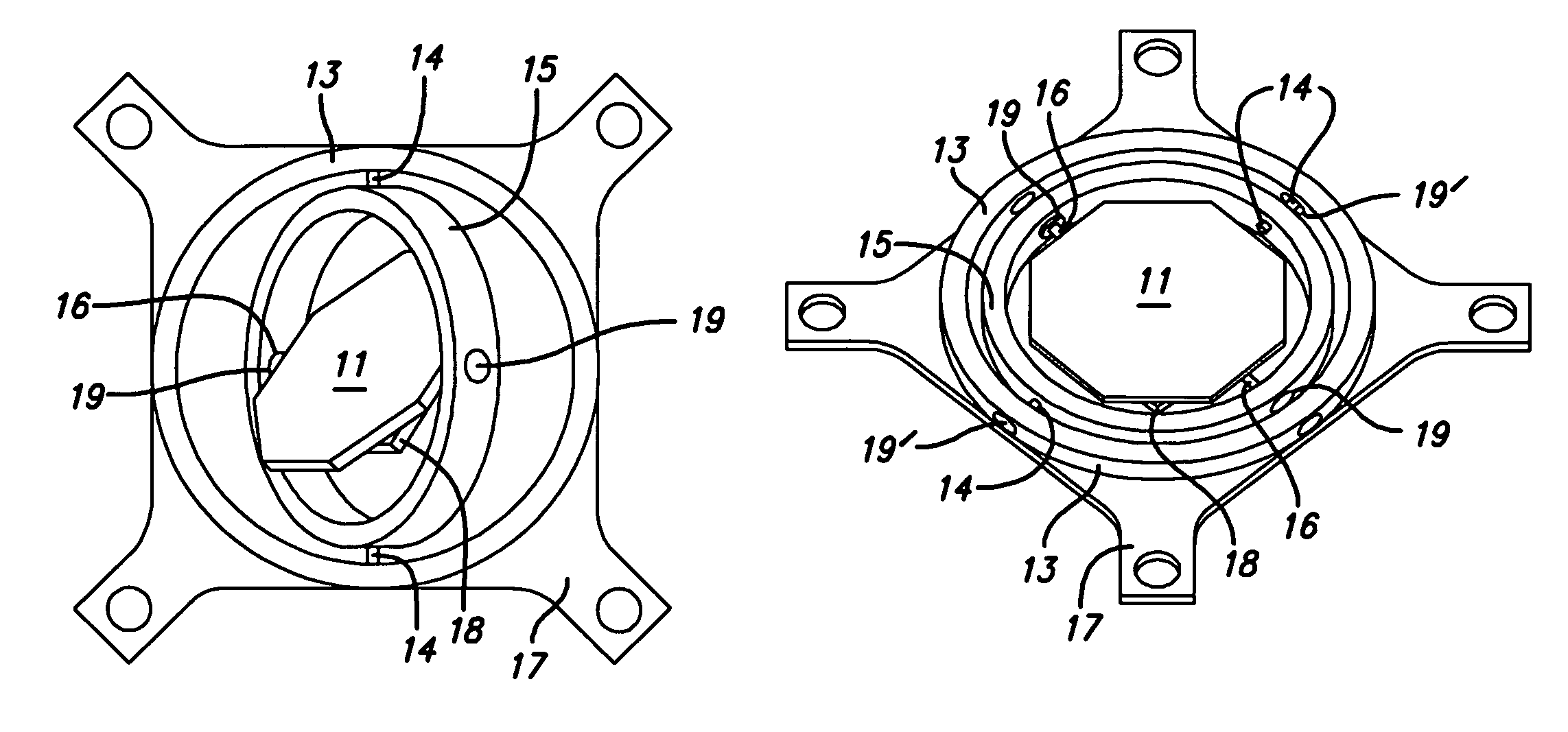

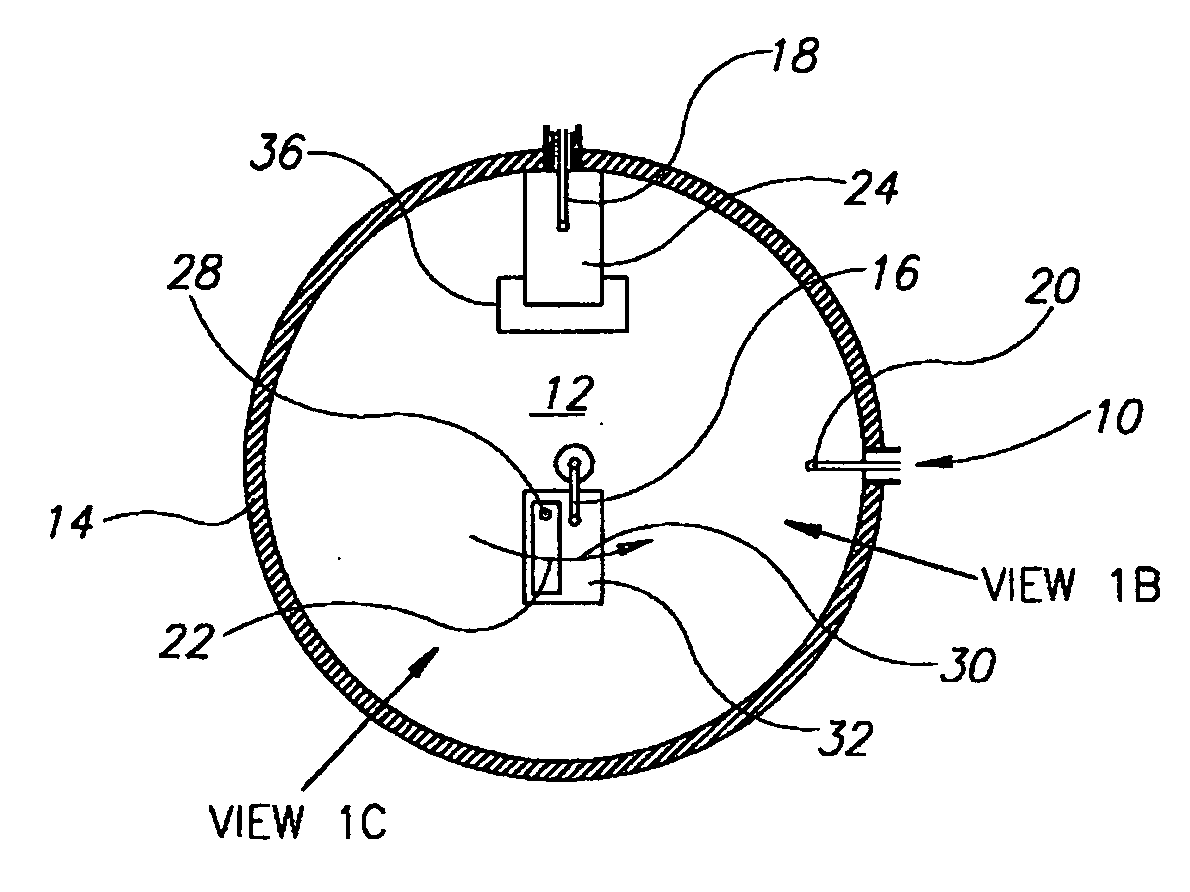

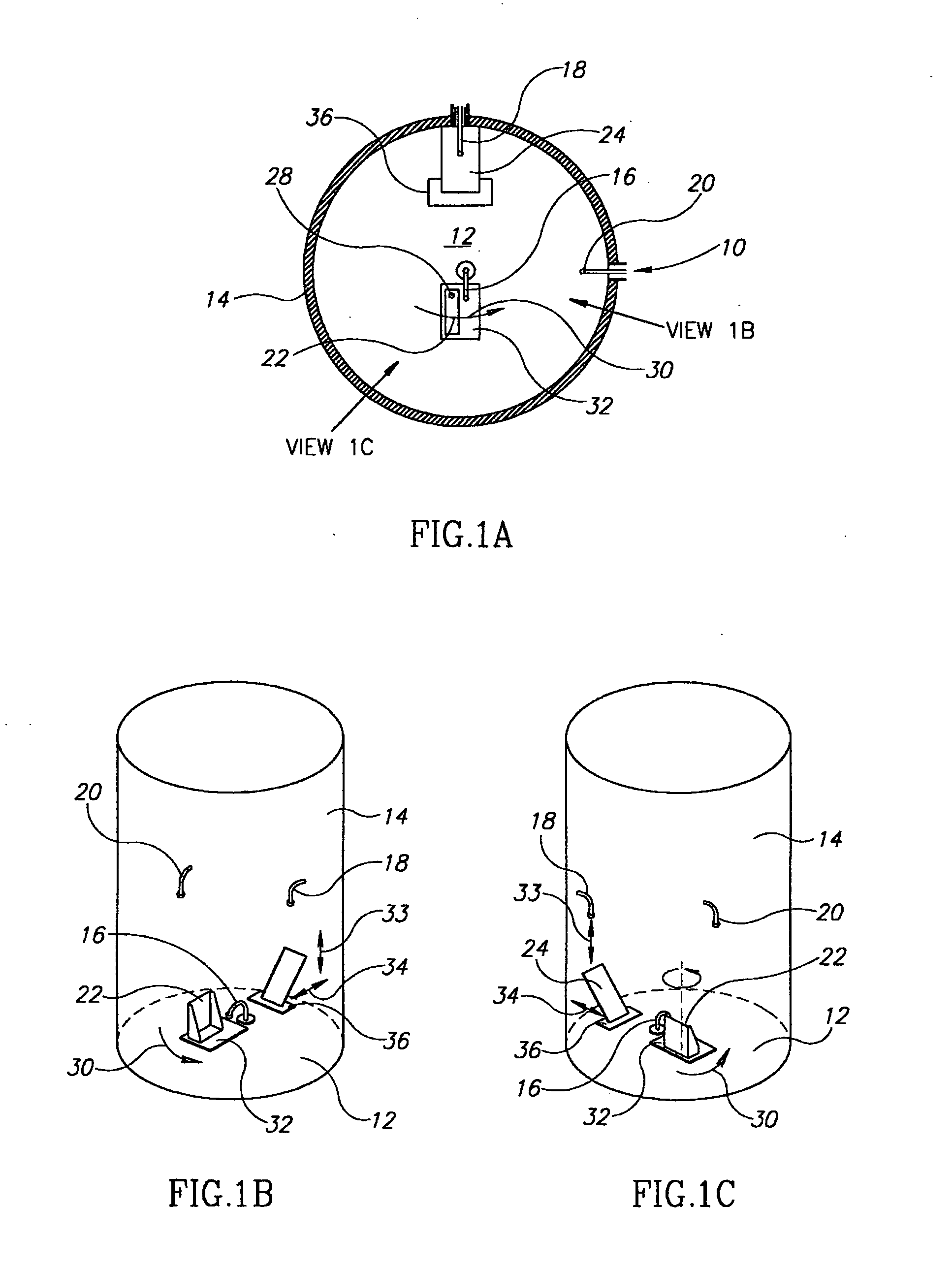

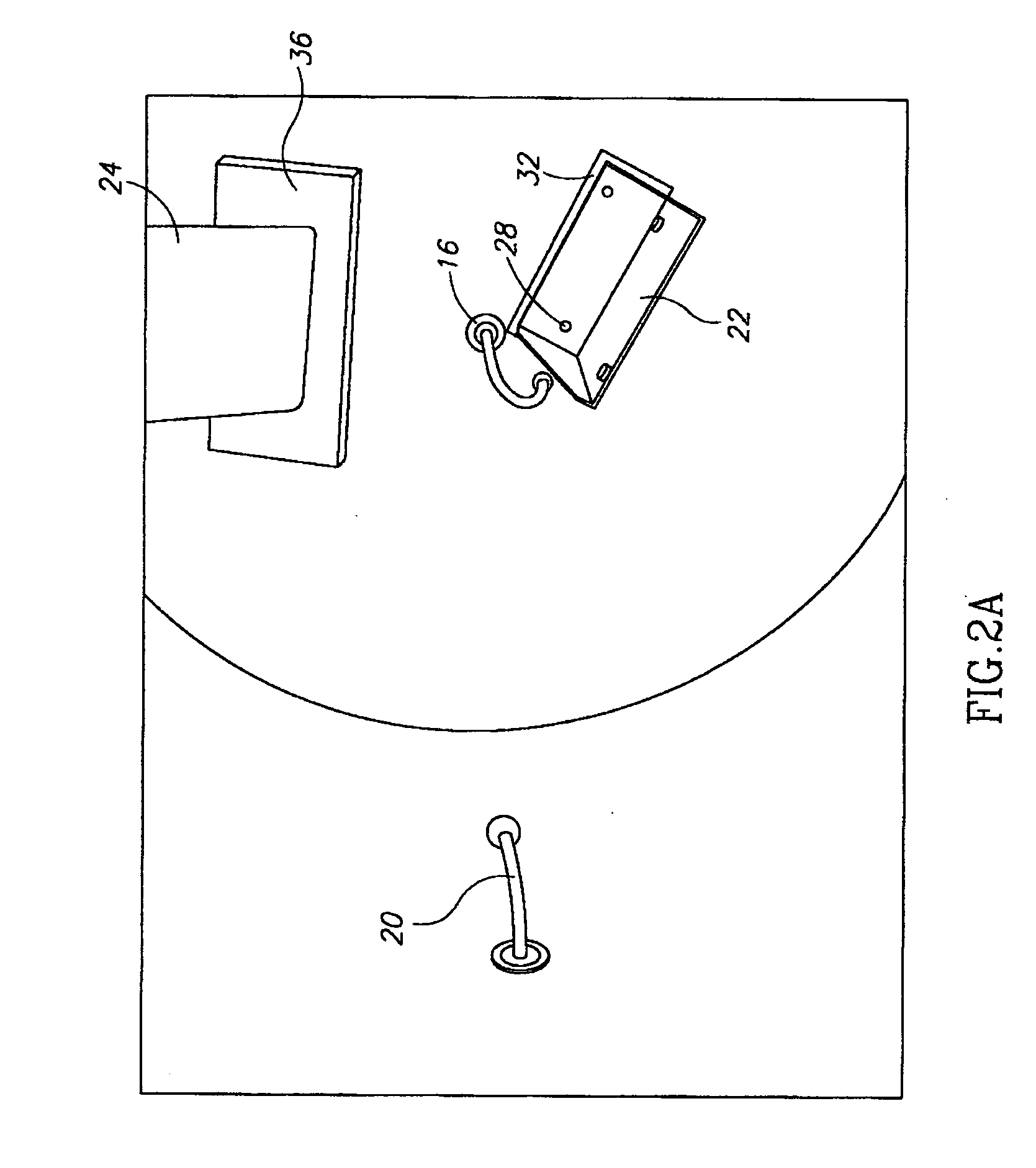

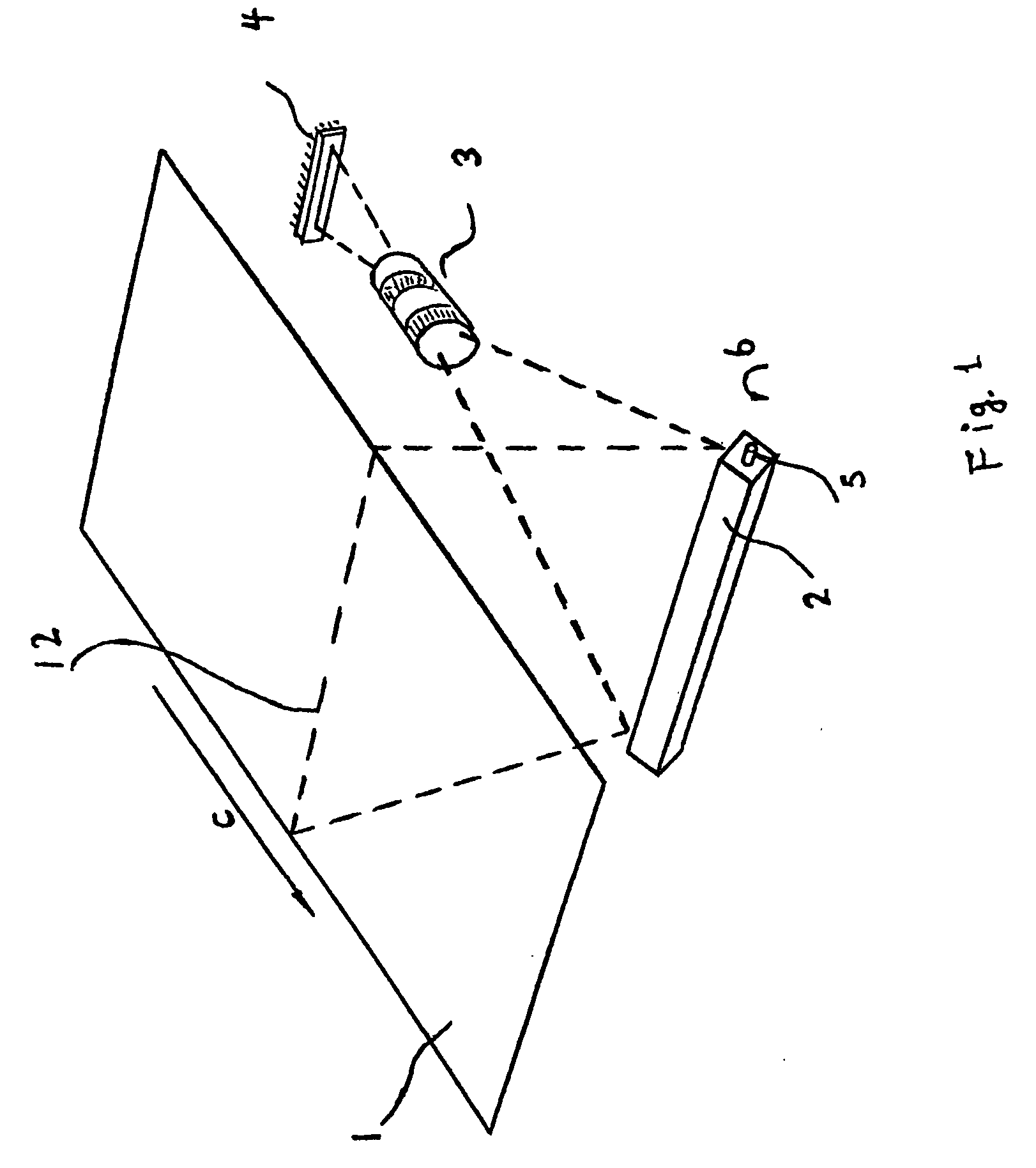

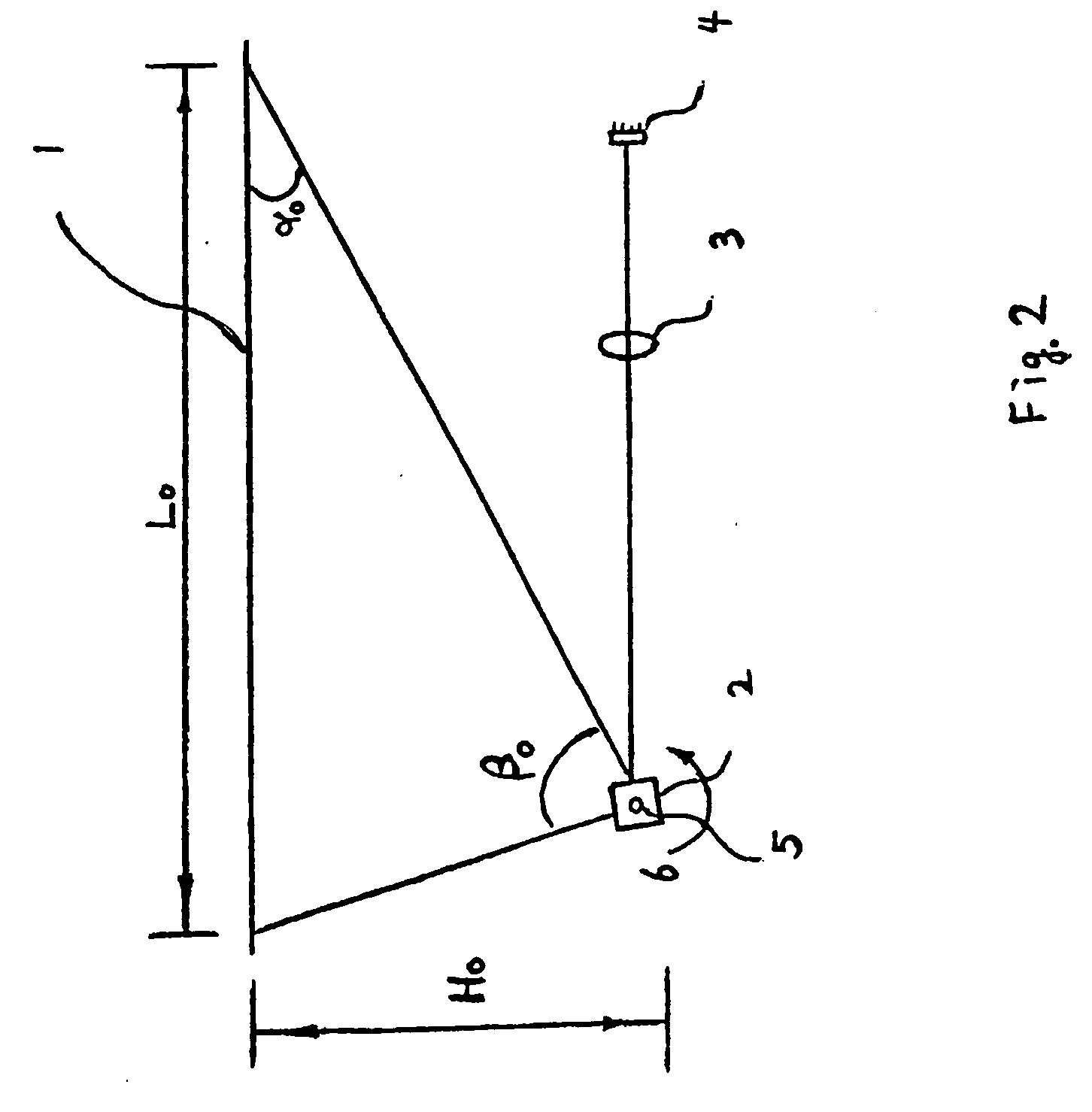

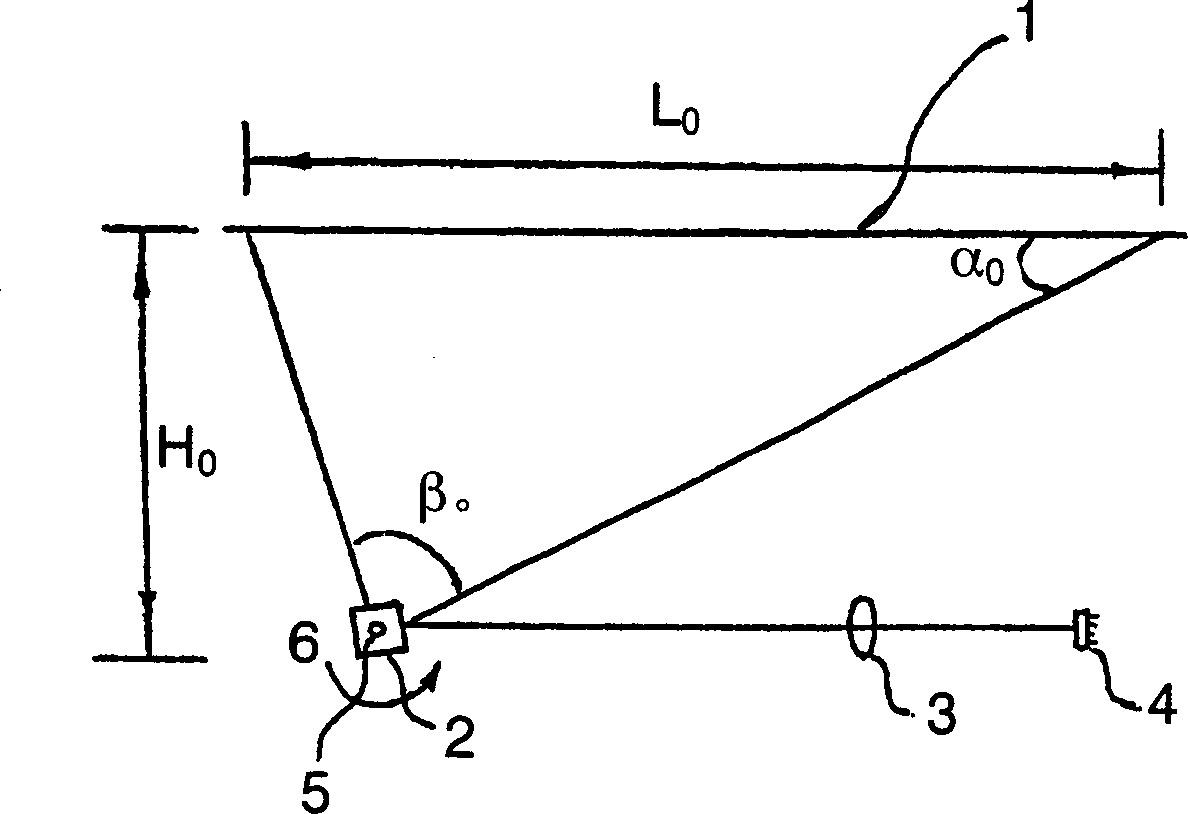

Method of operating a fast scanning mirror

ActiveUS8752969B1Reduce frictionRapid responseAngle measurementAdditive manufacturing apparatusObject structureLight beam

The mirror has a base, inner stage, reflector, controller, and mechanical subsystems pivotally supporting stage and reflector: subsystem #1, the stage (about one rotation axis, relative to the base); subsystem #2, the reflector (about another axis, relative to the stage). Stage and reflector each rotate on respective jewel, ceramic or other refractory bearings. Controller establishes stage / base and reflector / stage angles. Subsystems include respective bearings. The method includes (1) using the two-axis mechanism to receive, and measure an incident angle of, incident rays from an external object; (2) then using that mechanism to direct a radiation beam from a laser source toward the external object, responsive to incident rays. Optionally step (1) operates the mirror at peak acceleration, or minimum response time, as function of mirror thickness; and provides two- to three-millimeter mirror thickness. Optionally step (2) directs the beam to disrupt object function or impair object structure.

Owner:ARETE ASSOCIATES INC

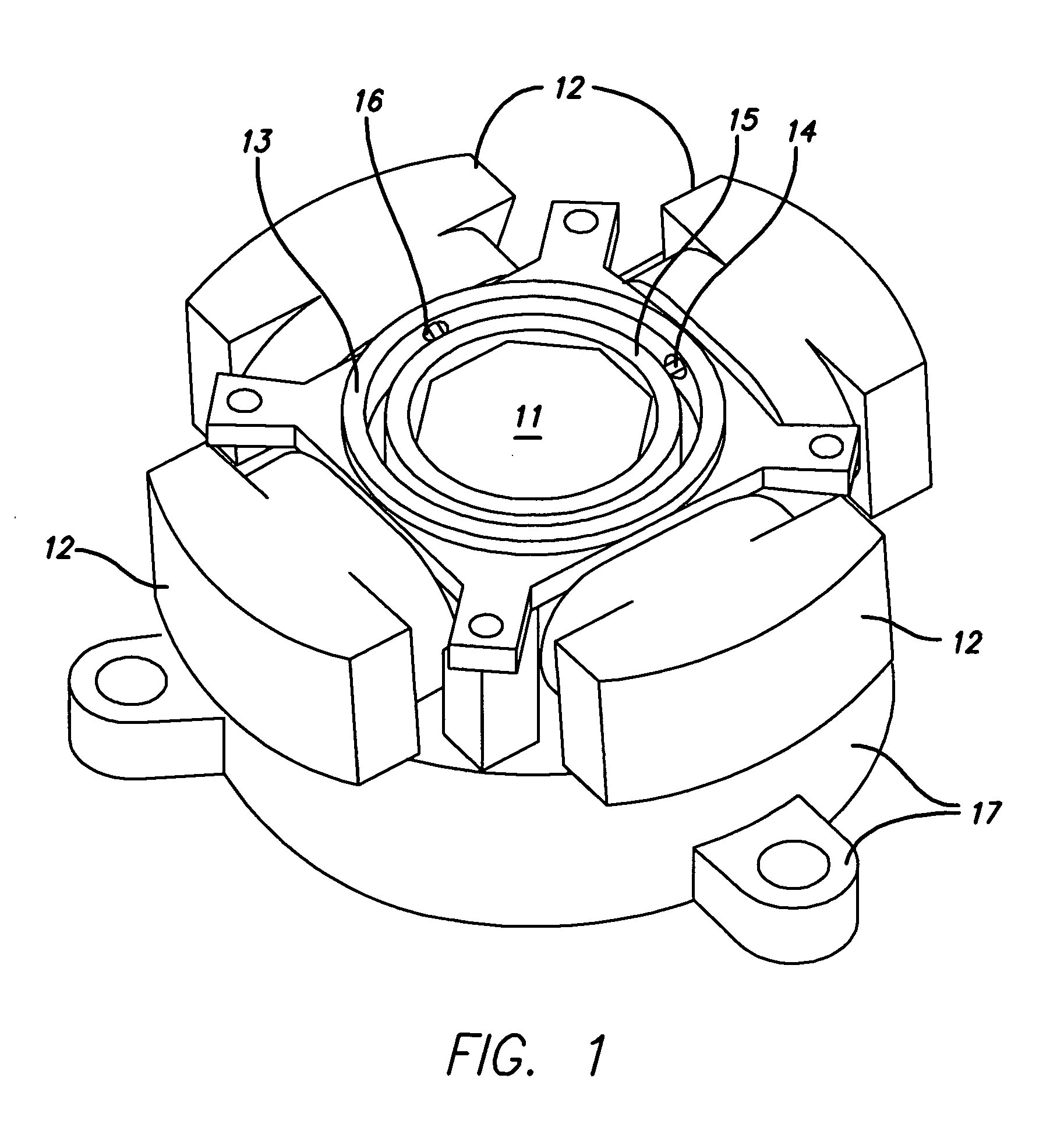

Electromagnetic heating

ActiveUS20080290087A1Improve efficiencyIncrease net powerLighting and heating apparatusFood preservationElectromagnetic heatingFast scanning

Owner:JOLIET 2010 LTD

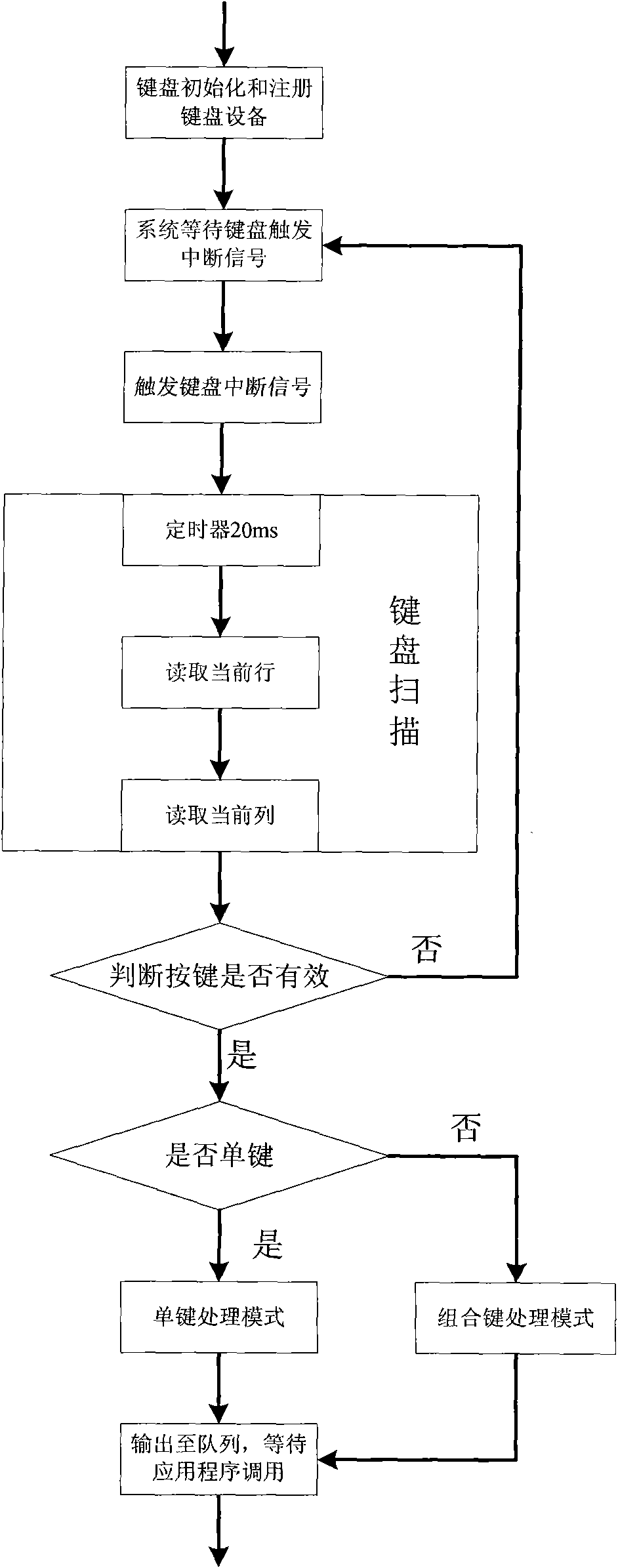

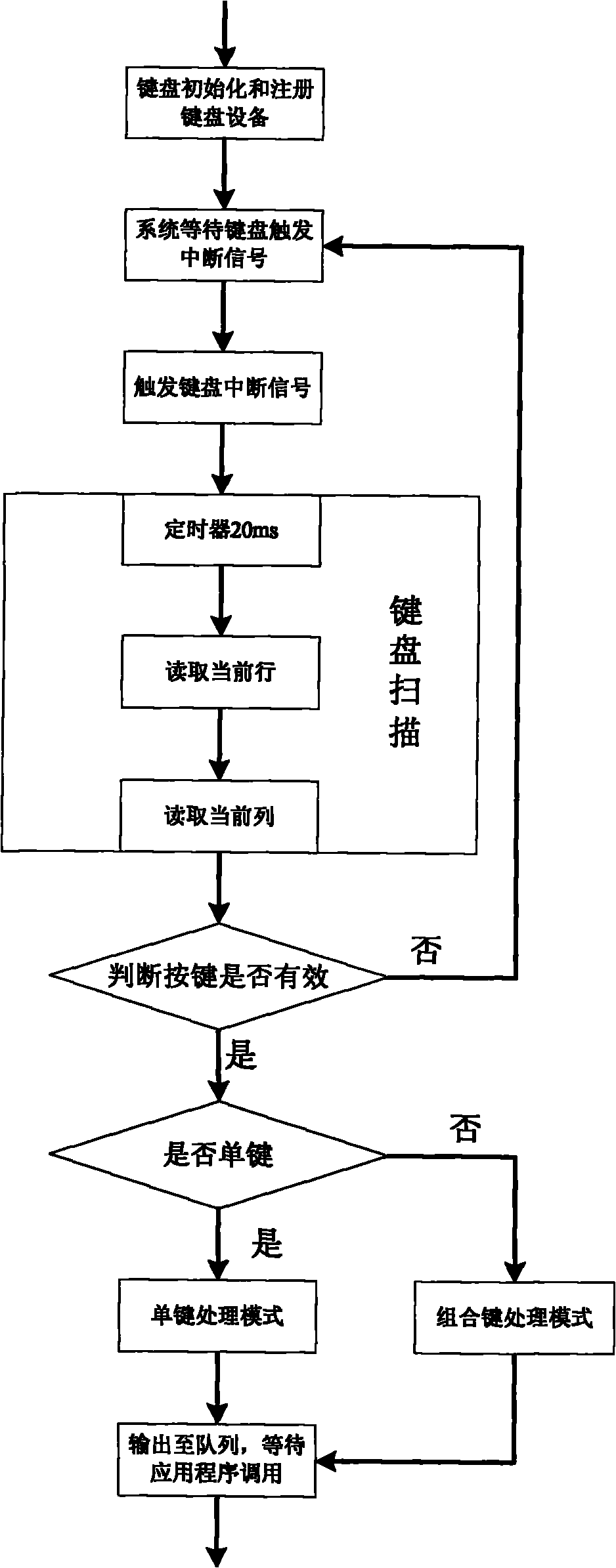

Method for fast scanning and positioning of matrix keyboard

ActiveCN101840268AAvoid level instabilityAvoid jitterInput/output for user-computer interactionTerminal equipmentFast scanning

The invention discloses a method for fast scanning and positioning of a matrix keyboard, which relates to a method for the fast scanning and positioning of the matrix keyboard in the field of controlling an embedded system, and is particularly suitable for designing the matrix keyboard of an embedded terminal device. The method comprises the following steps of: initializing a keyboard device and registering the keyboard device; waiting for the keyboard to trigger an interruption signal by a system; triggering a keyboard interruption signal; responding to the interruption signal by the system; performing keyboard scanning; judging whether keys are effective; and outputting a keyboard key value to a queue, and waiting for an application program to read the key value. The method can effectively avoid instable and dithering levels of the matrix keyboard because of per se mechanical properties, improves the accuracy of the scanning and the positioning of the matrix keyboard, and has the characteristics of simple algorithm, steady performance, high control accuracy and the like.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

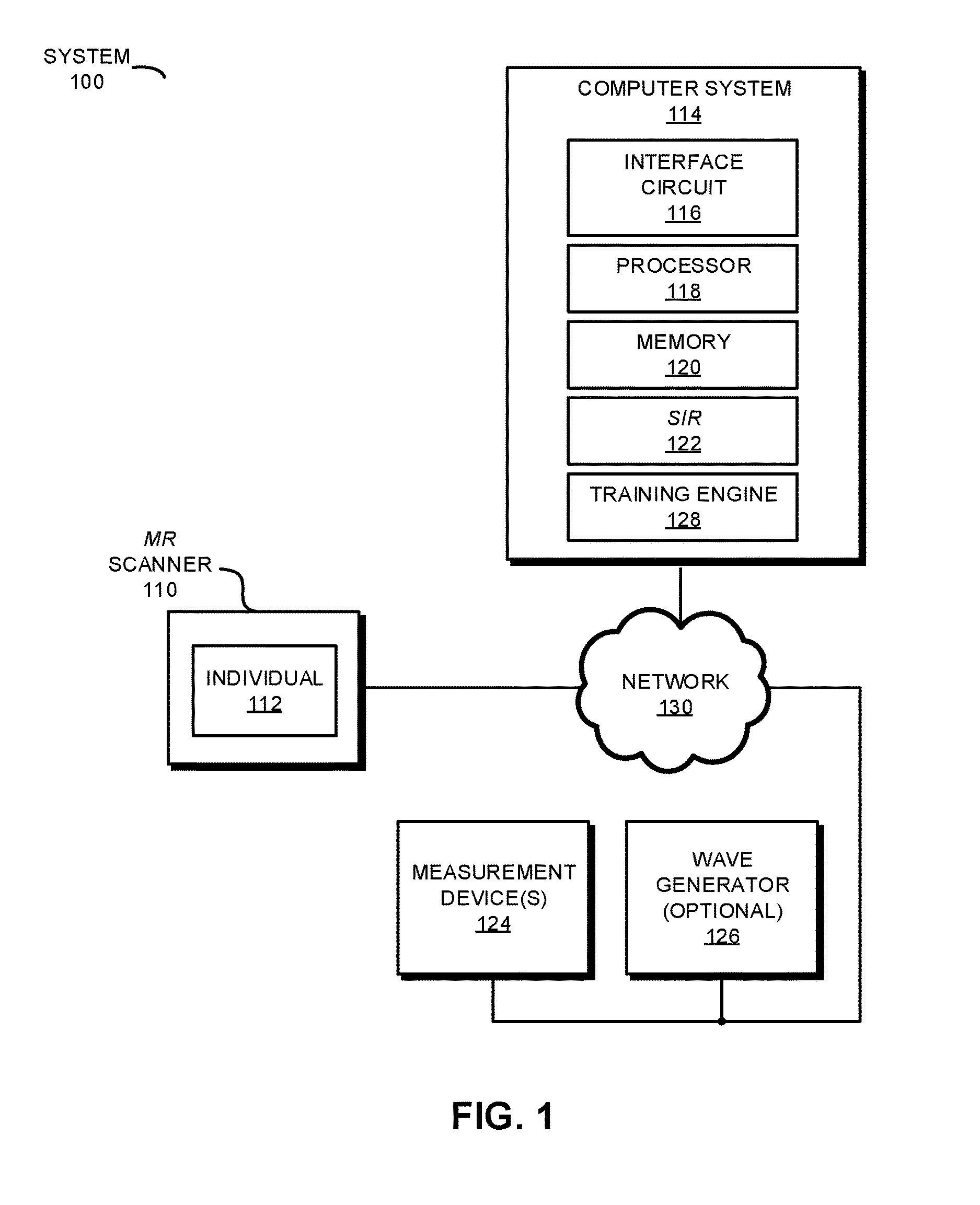

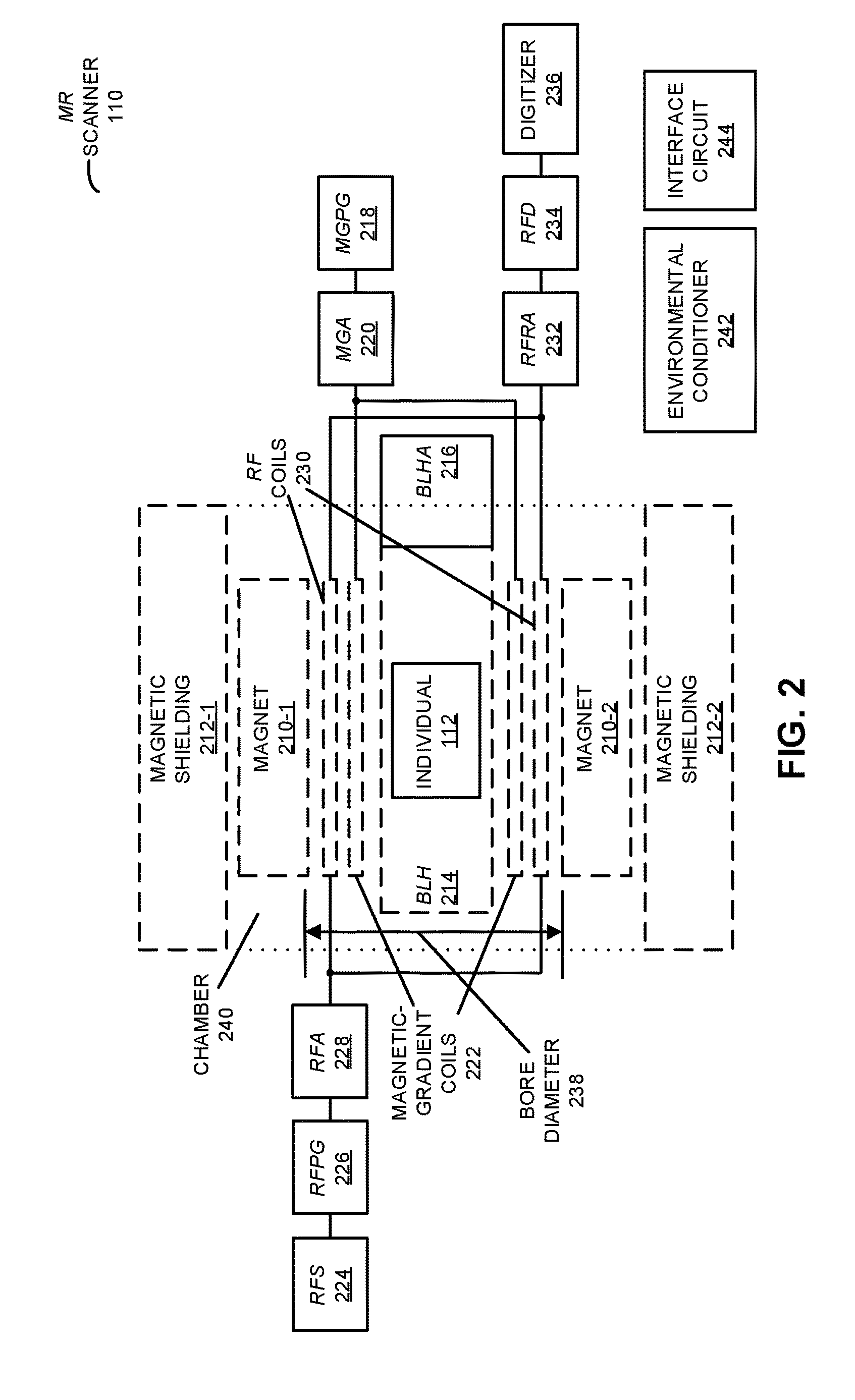

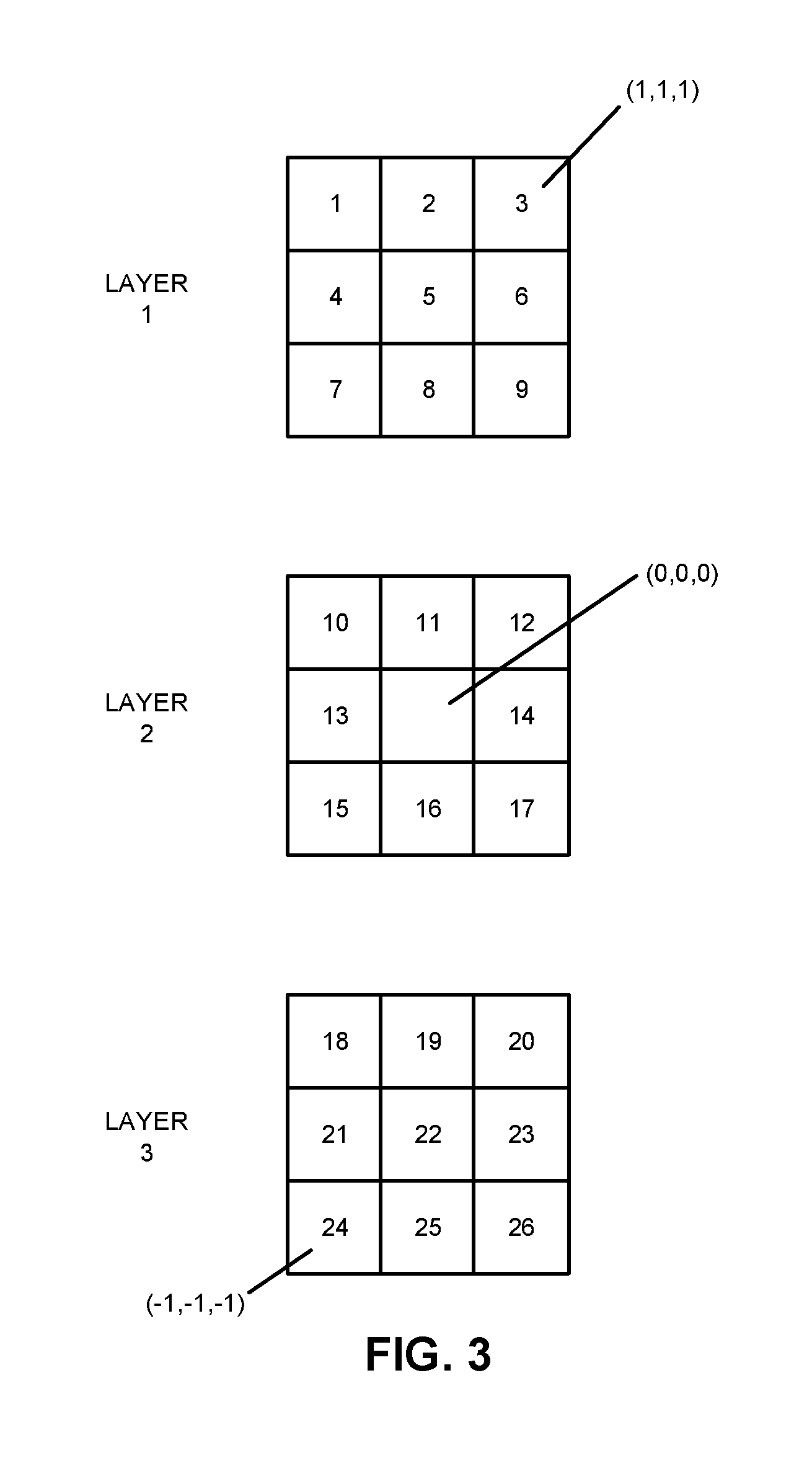

Fast scaning based on magnetic resonance history

During operation, a system iteratively captures MR signals of one or more types of nuclei in one or more portions of a biological lifeform based on scanning instructions that correspond to a dynamic scan plan. The MR signals in a given iteration may be associated with voxels having associated sizes at three-dimensional (3D) positions in at least a corresponding portion of the biological lifeform. If the system detects a potential anomaly when analyzing the MR signals from the given iteration, the system dynamically modifies the scan plan based on the detected potential anomaly, a medical history and / or an MR-scan history. Subsequent measurements of MR signals may be associated with the same or different: types of nuclei, portions of the biological lifeform, voxels sizes and / or 3D positions.

Owner:Q BIO INC

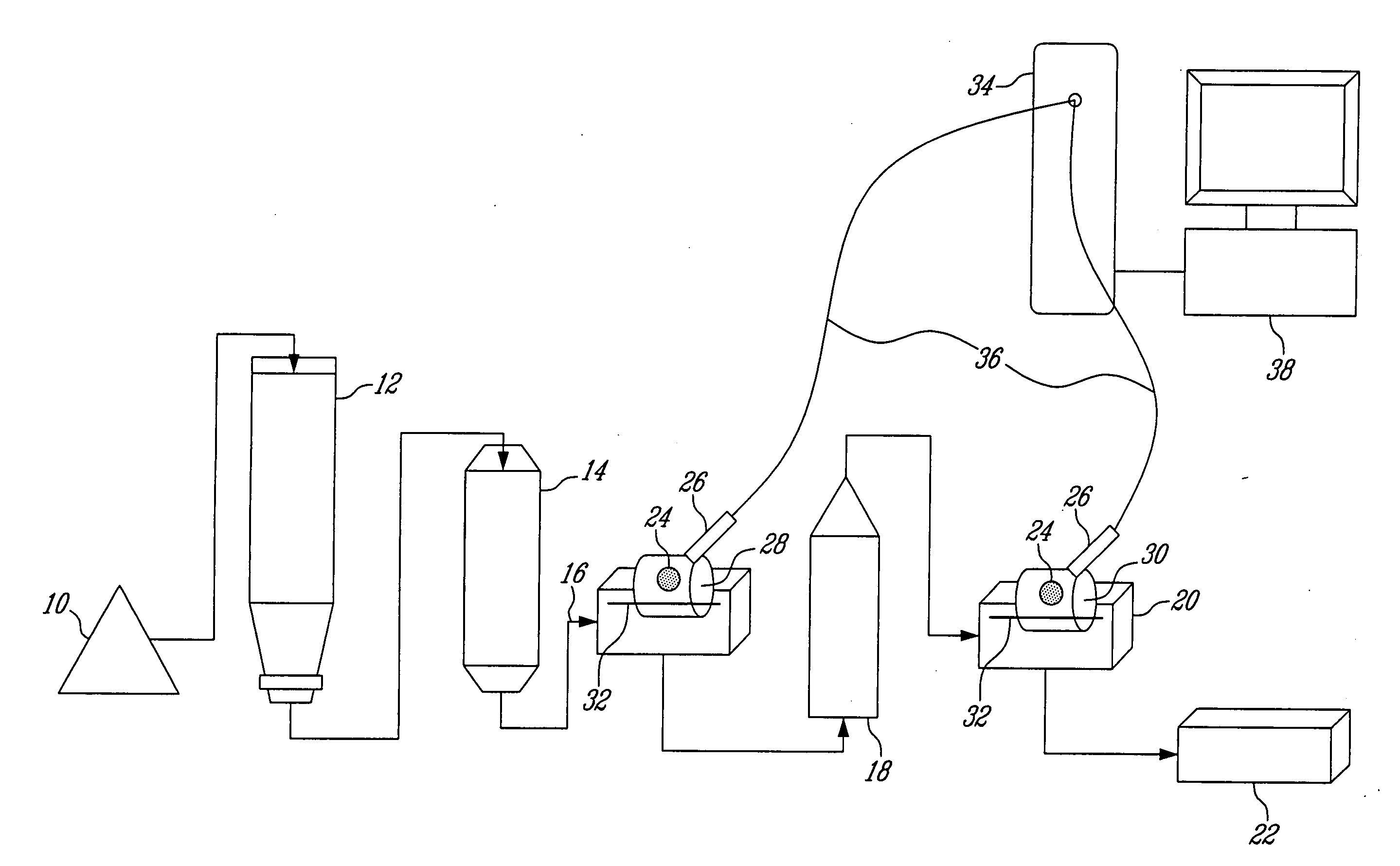

Fast laser depositing process of preparing antinwear heat resistant composite coating on surface of crystallizer

InactiveCN1932082ANo pollution in the processRadiation-freeMolten spray coatingArc welding apparatusAutomatic controlHigh power lasers

The fast laser depositing process of preparing antiwear heat resistant composite coating on the surface of crystallizer features that high power laser is first utilized in fast scanning to form transition layer in excellent metallurgical binding with the substrate of crystallizer copper plate on the surface of the plate and then utilized in wide band deposition to form Co base alloy with excellent heat resistance and high wear resistance on the surface of the transition layer. Compared with convenient technological process, the present invention has the advantages of precise control in laser power, position, shape and other parameters, easy automatic control of the whole process, no environmental pollution, high production efficiency, low power consumption, etc. and may be used widely.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

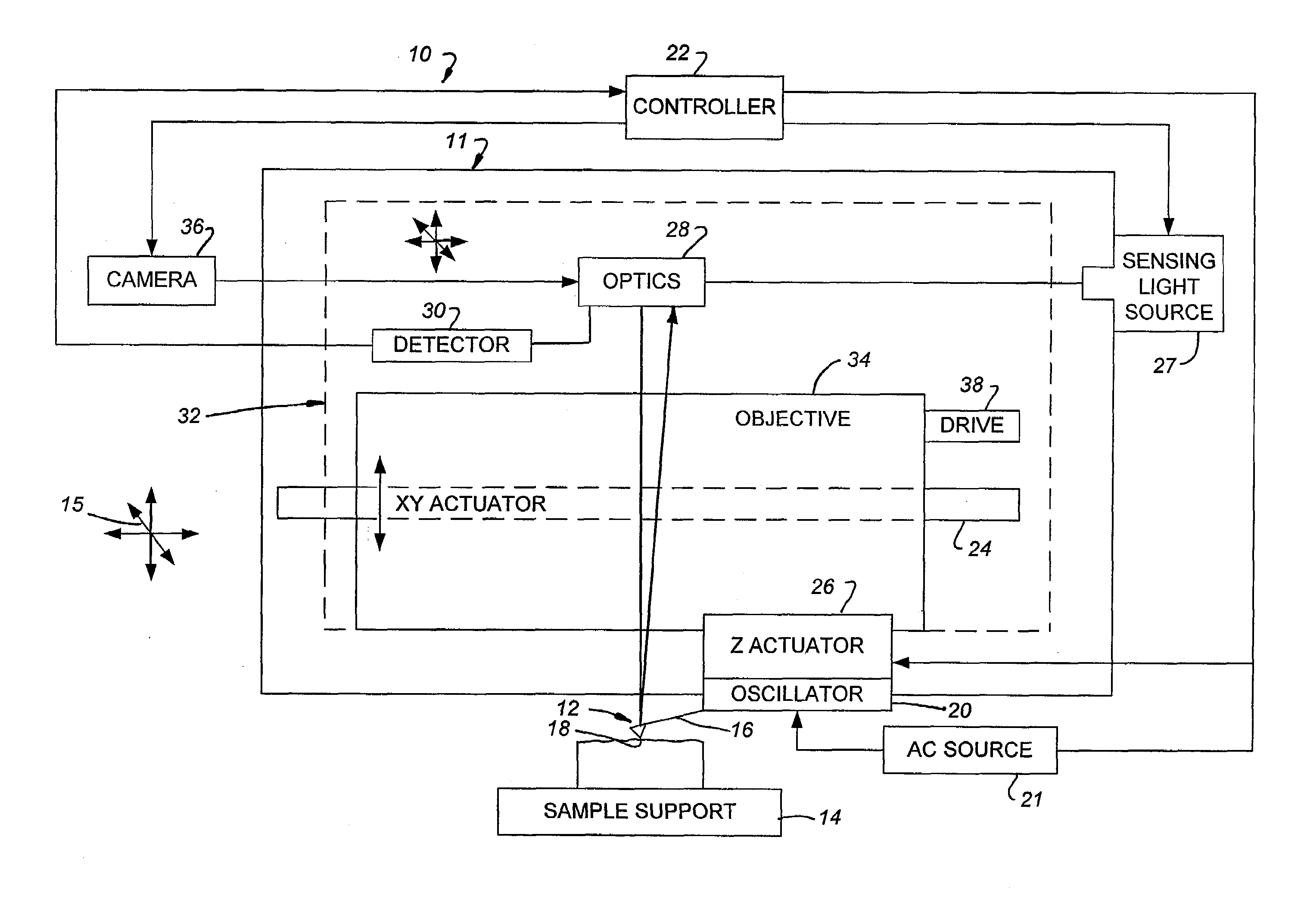

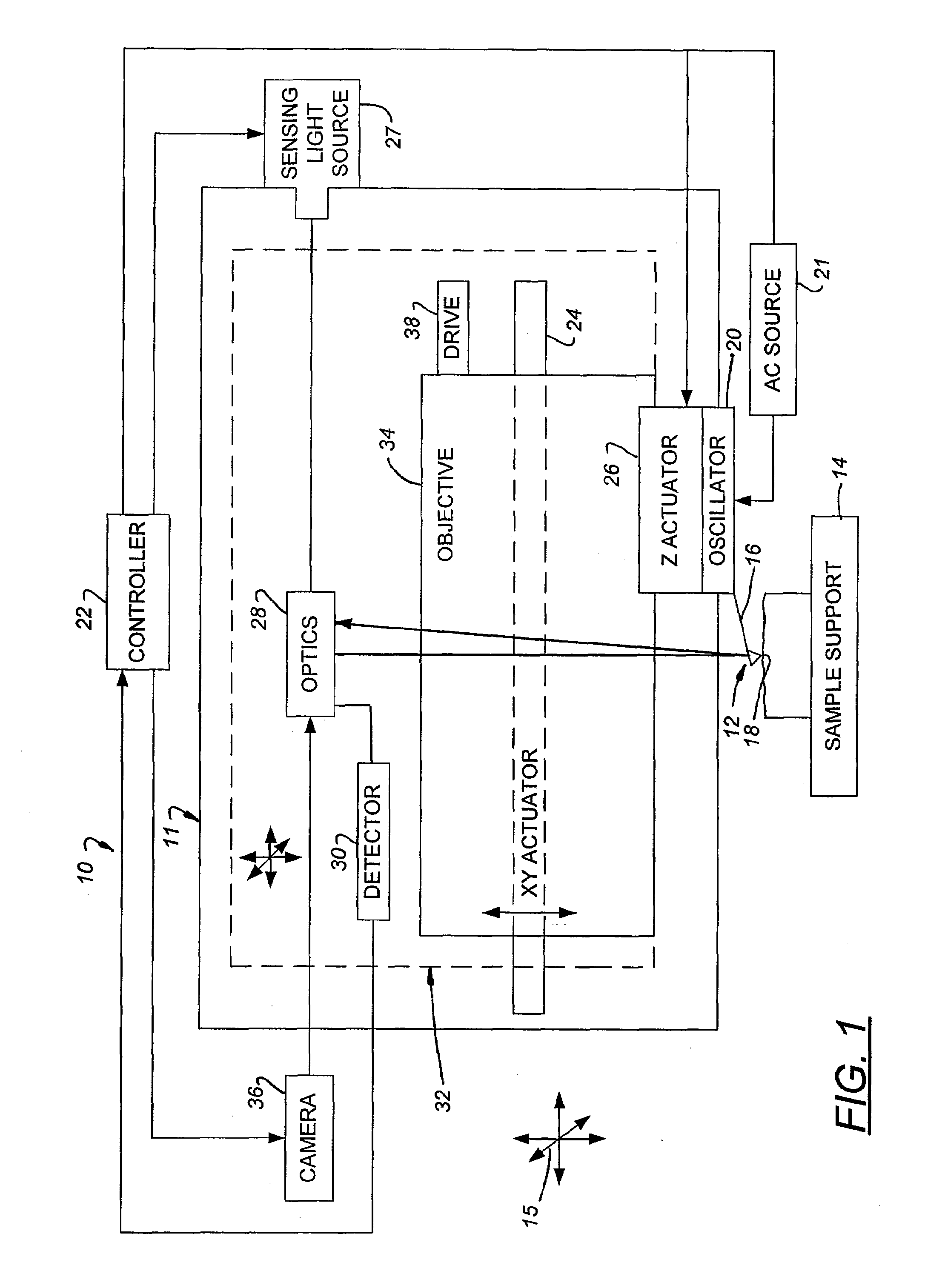

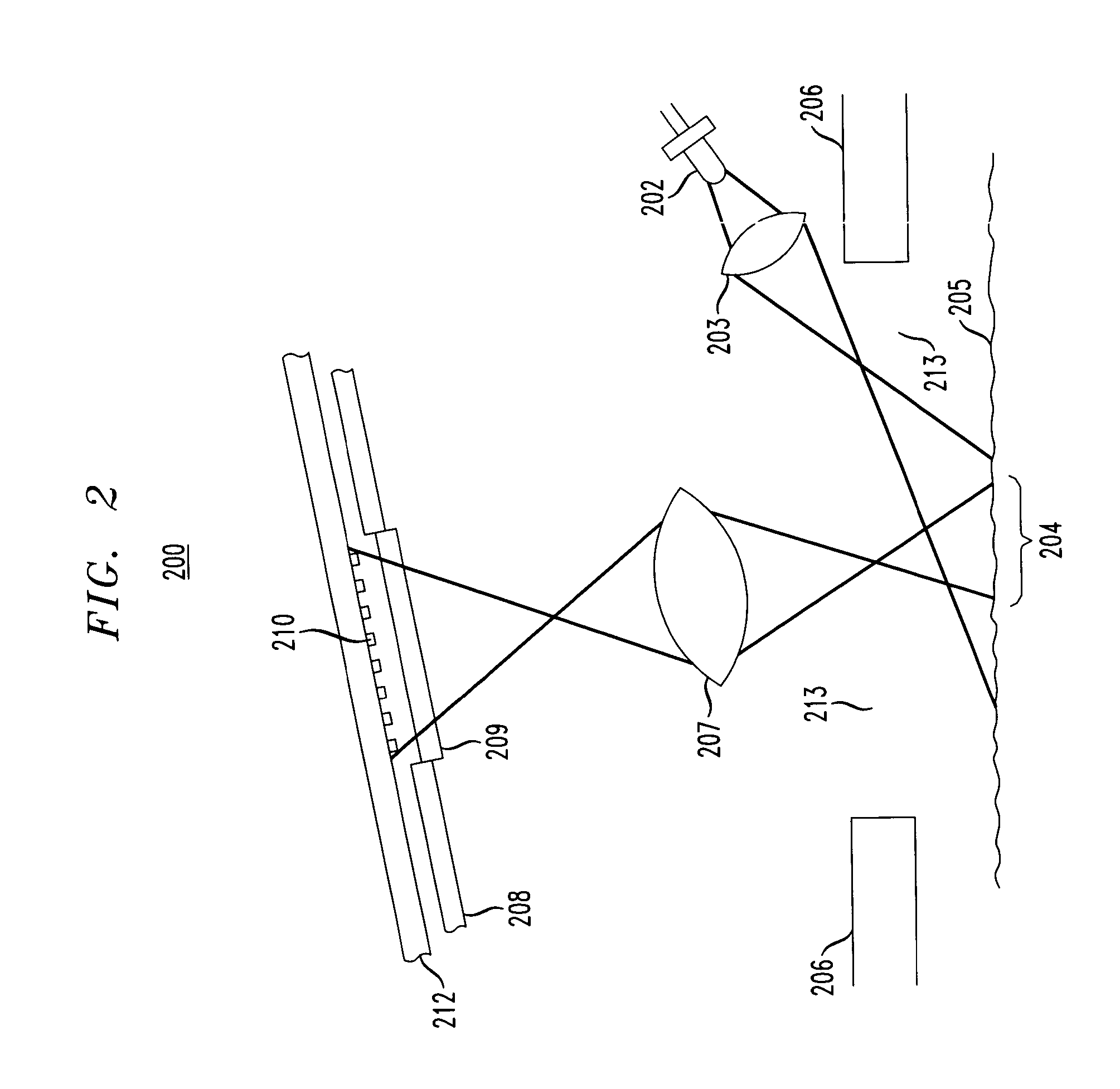

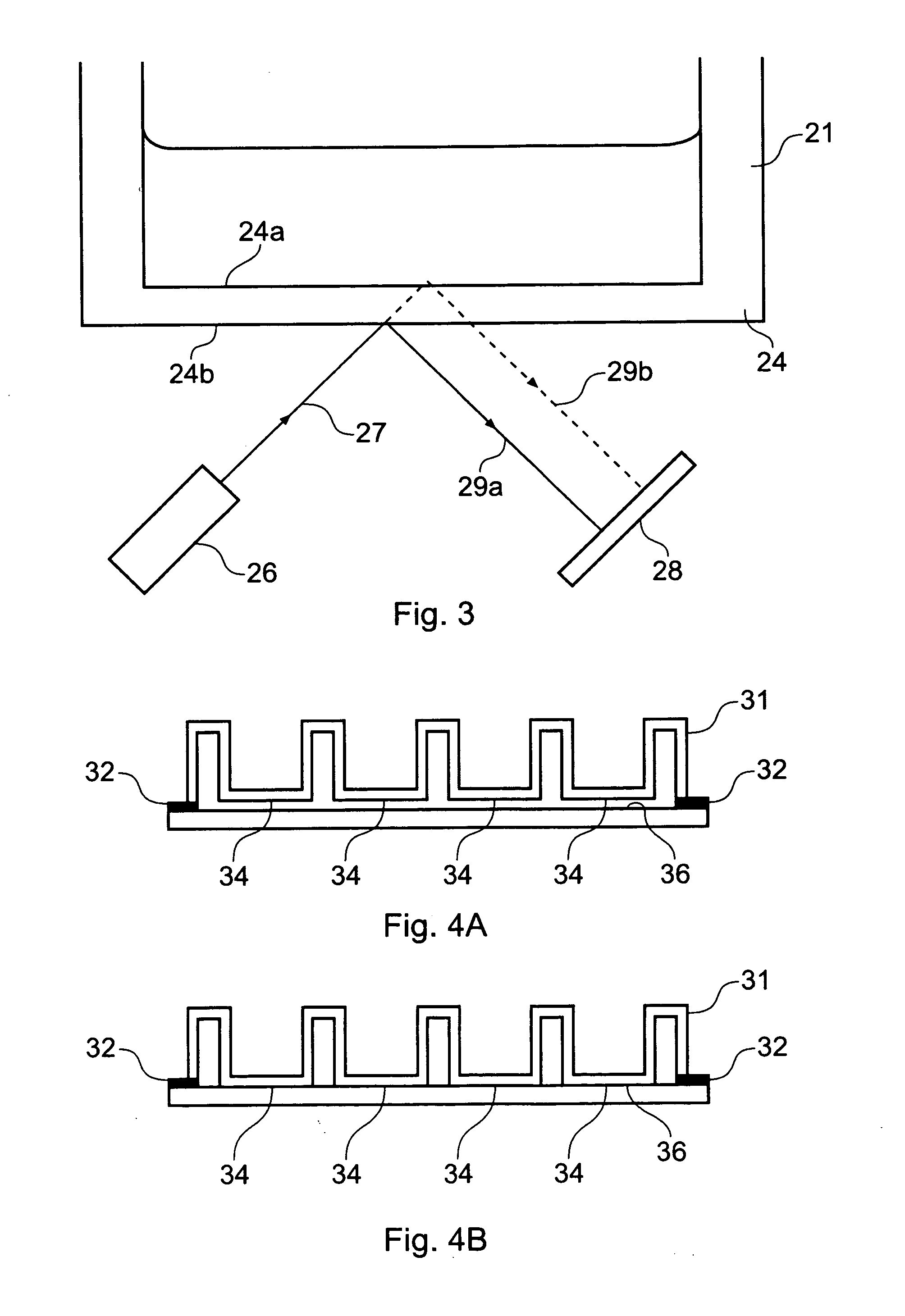

Fast-Scanning SPM Scanner and Method of Operating Same

ActiveUS20080223119A1Increased focus rangeImage data is accurateNanotechnologyMechanical roughness/irregularity measurementsHigh bandwidthImage resolution

A high-bandwidth SPM tip scanner is provided that additionally includes an objective that is vertically movable within the scan head to increase the depth of focus for the sensing light beam. Movable optics also are preferably provided to permit targeting of the sensing light beam on the SPM's probe and to permit the sensing light beam to track the probe during scanning. The targeting and tracking permit the impingement of a small sensing light beam spot on the probe under direct visual inspection of focused illumination beam of an optical microscope integrated into the SPM and, as a result, permits the use of a relatively small cantilever with a commensurately small resonant frequency. A high-bandwidth tip scanner constructed in this fashion has a fundamental resonant frequency greater than greater than 500 Hz and a sensing light beam spot minor diameter of less than 10 μm. Images can be scanned on large samples having a largest dimension exceeding 7 mm with a resolution of less than 1 Angstrom and while scanning at rates exceeding 30 Hz.

Owner:BRUKER NANO INC

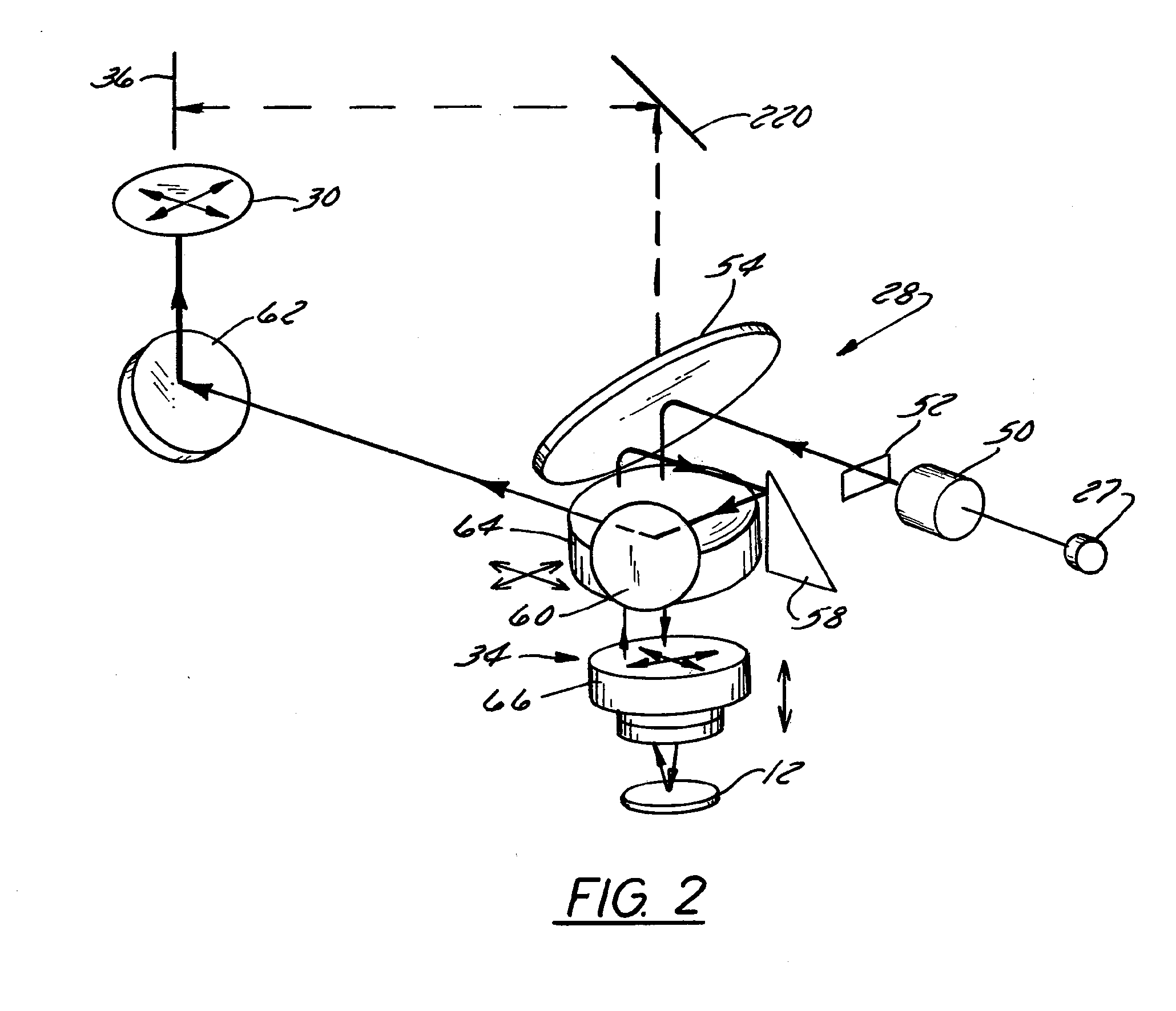

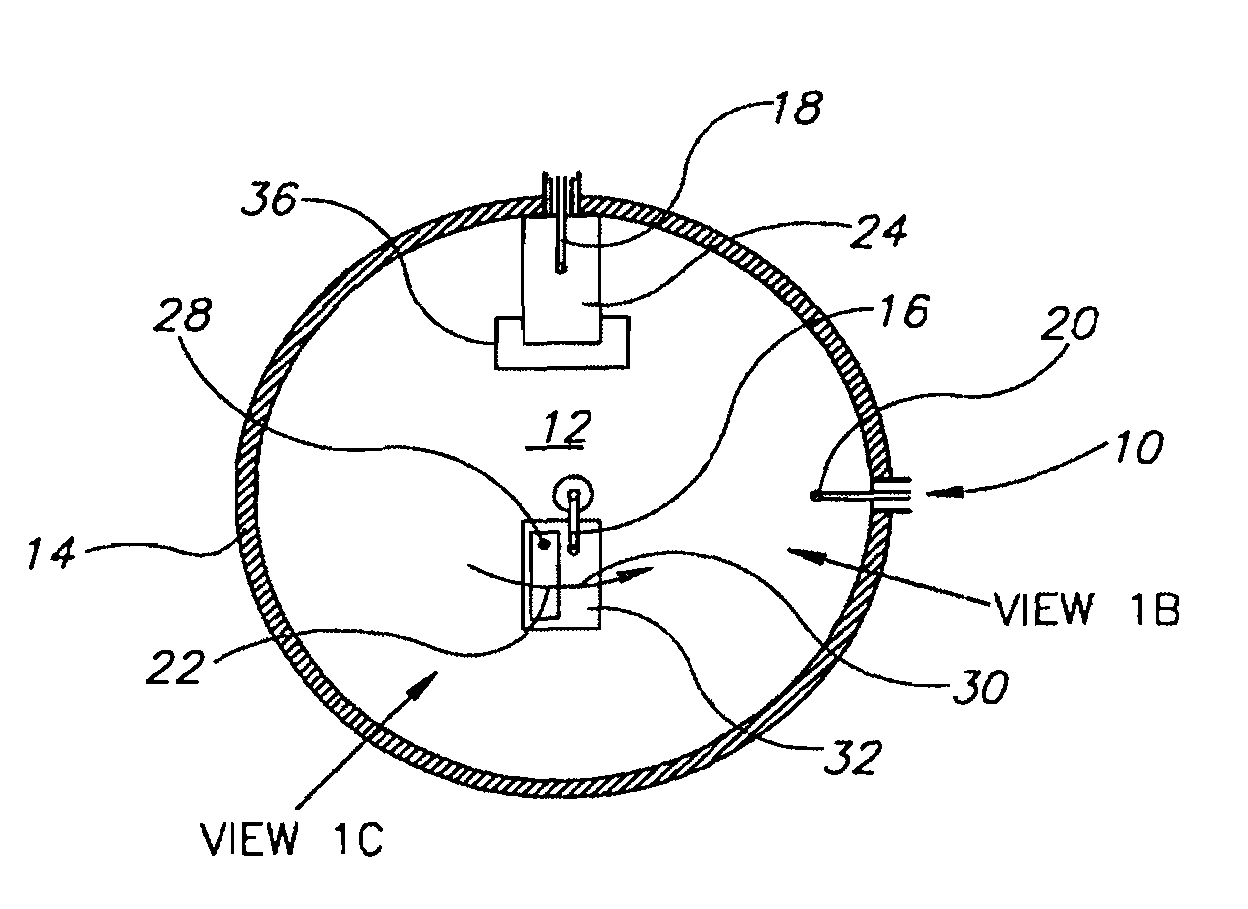

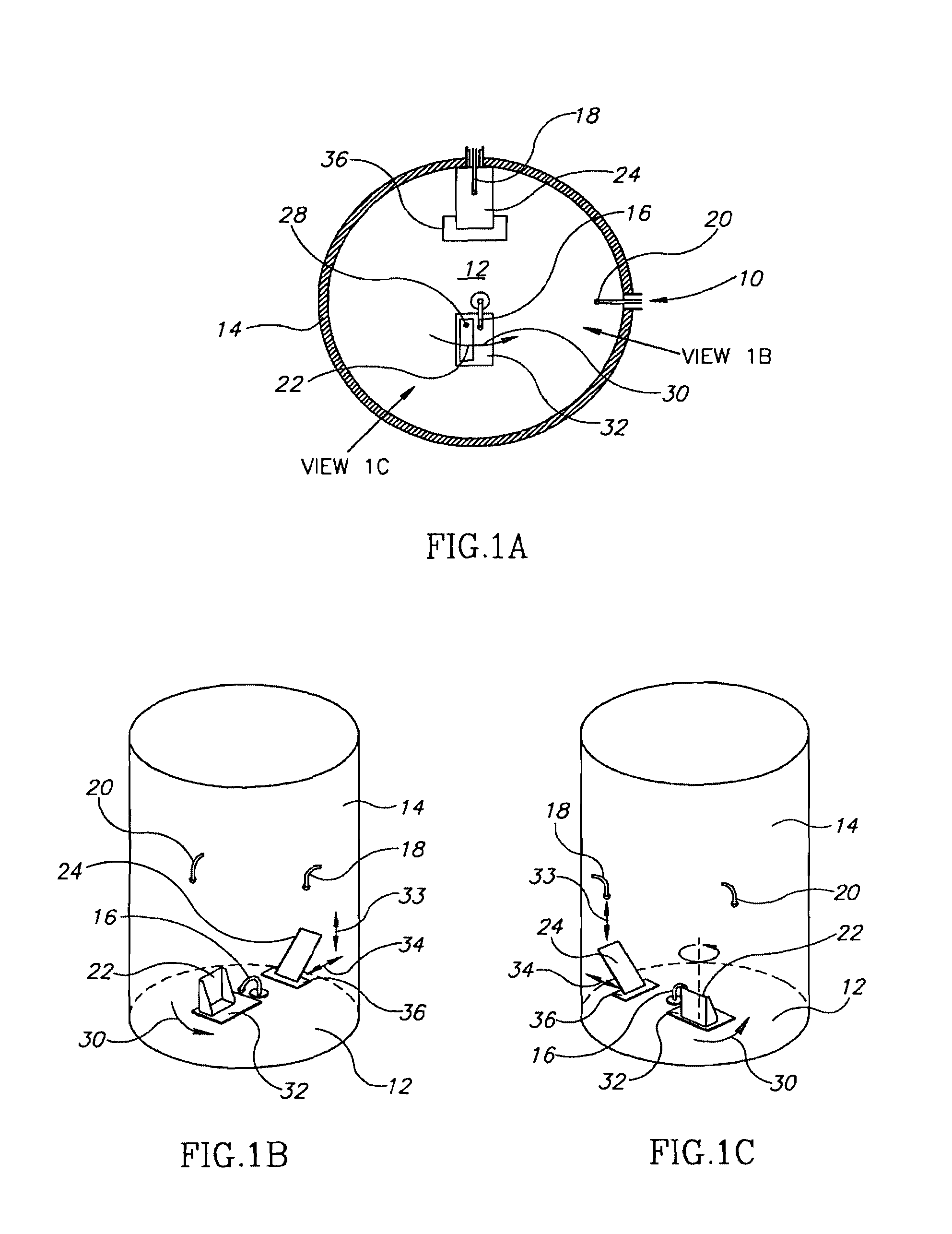

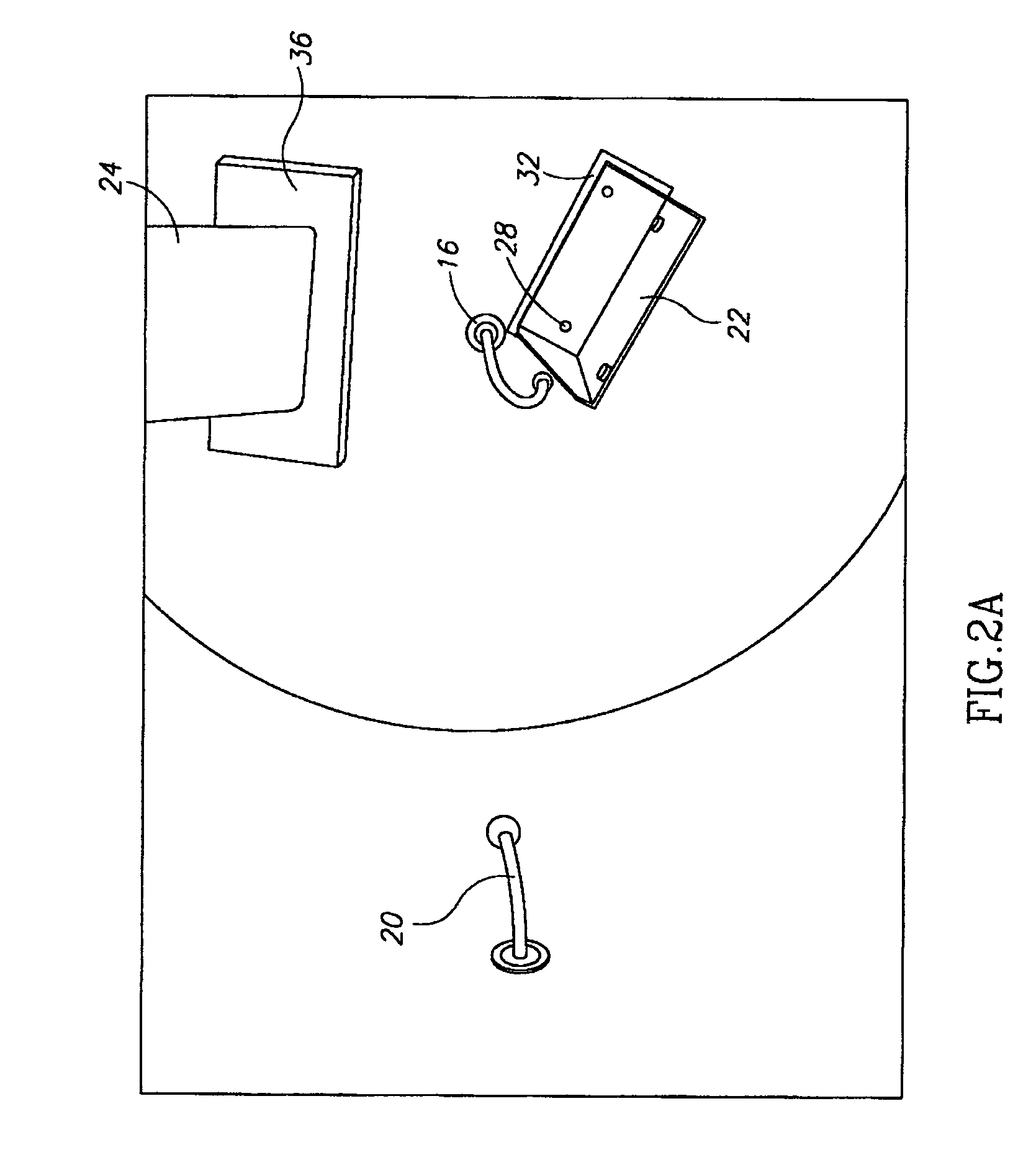

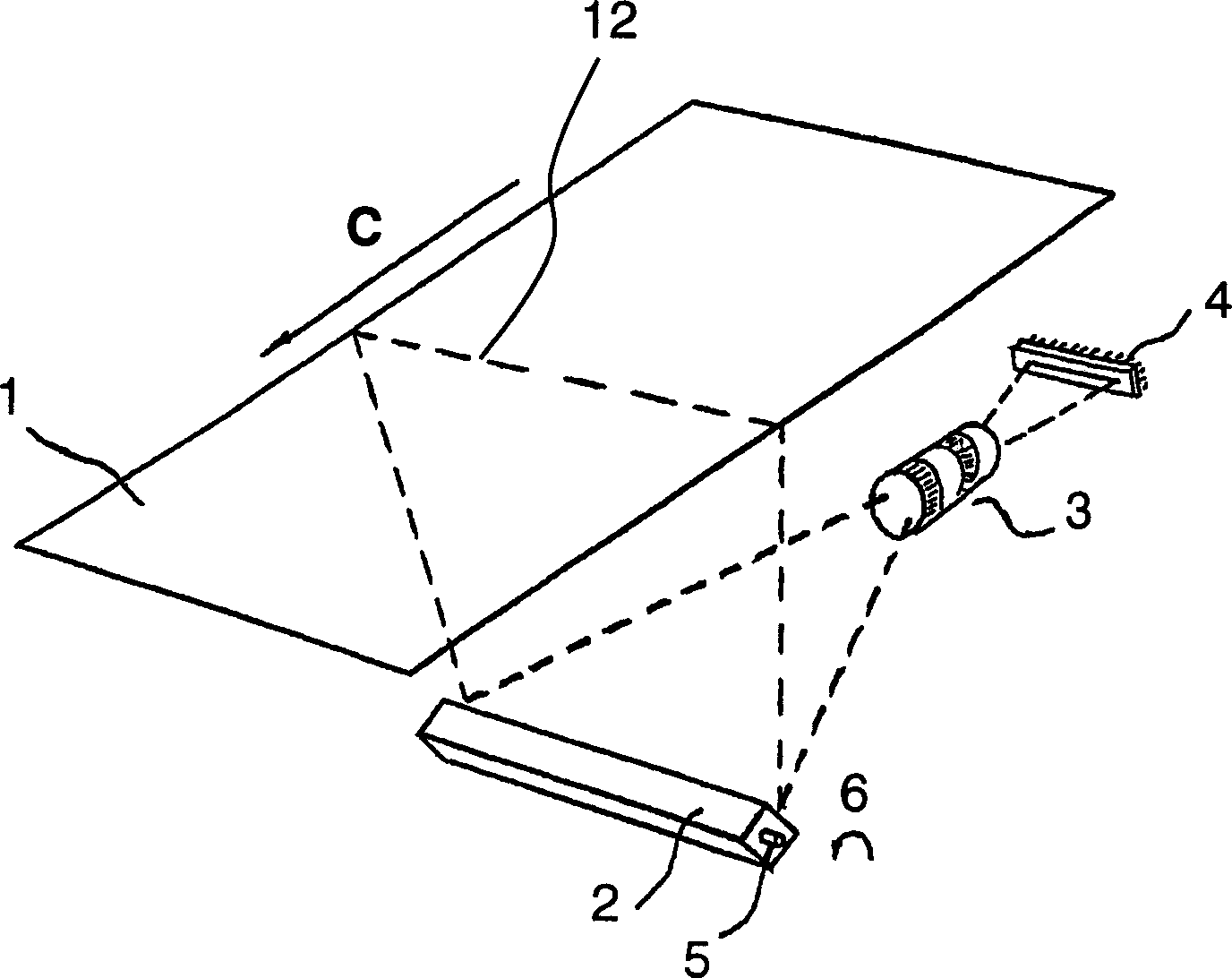

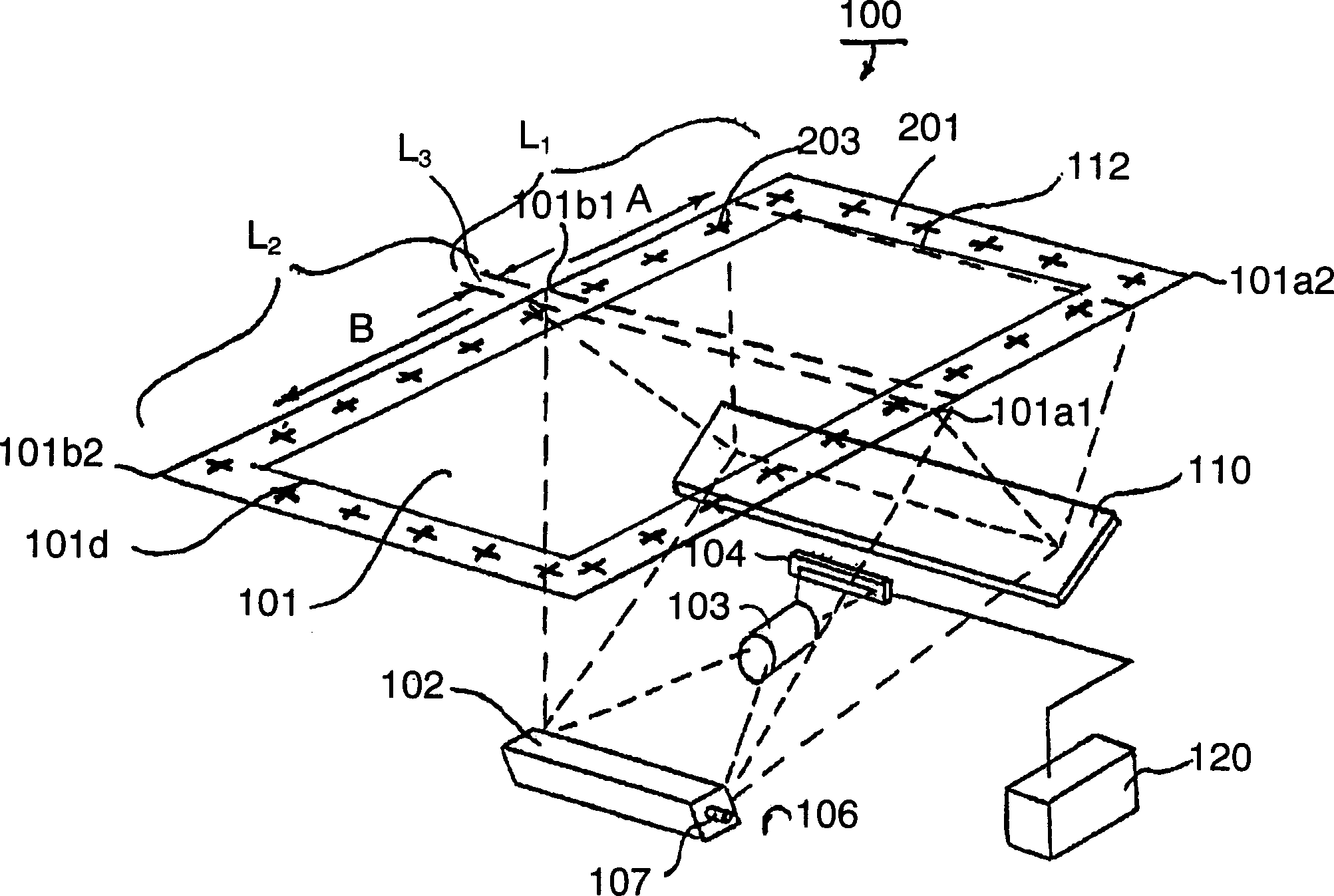

Fast scanner with rotatable mirror and image processing system

A scanner for obtaining an image of an object placed on an at least partially transparent platform, wherein the platform is defined by edge portions and has at least including a first scan area and a second scan area. In one embodiment, the scanner includes a white area formed at least partially around the edge portions of the platform with a plurality of markers, optical means for sequentially scanning consecutive partial images of the object from the first scan area and the second scan area, respectively, wherein each of the consecutive partial images include an image of at least one of the plurality of markers, and an image processing system for using the image of the at least one of the plurality of markers in each of the consecutive partial images as a reference to combine the consecutive partial images so as to form a substantially complete image of the object corresponding to a full scan of the first scan area and the second scan area.

Owner:RUILING OPTICS

Electromagnetic heating

ActiveUS8389916B2Duty cycleTime stableLighting and heating apparatusFood preservationElectromagnetic heatingFast scanning

Owner:JOLIET 2010 LTD

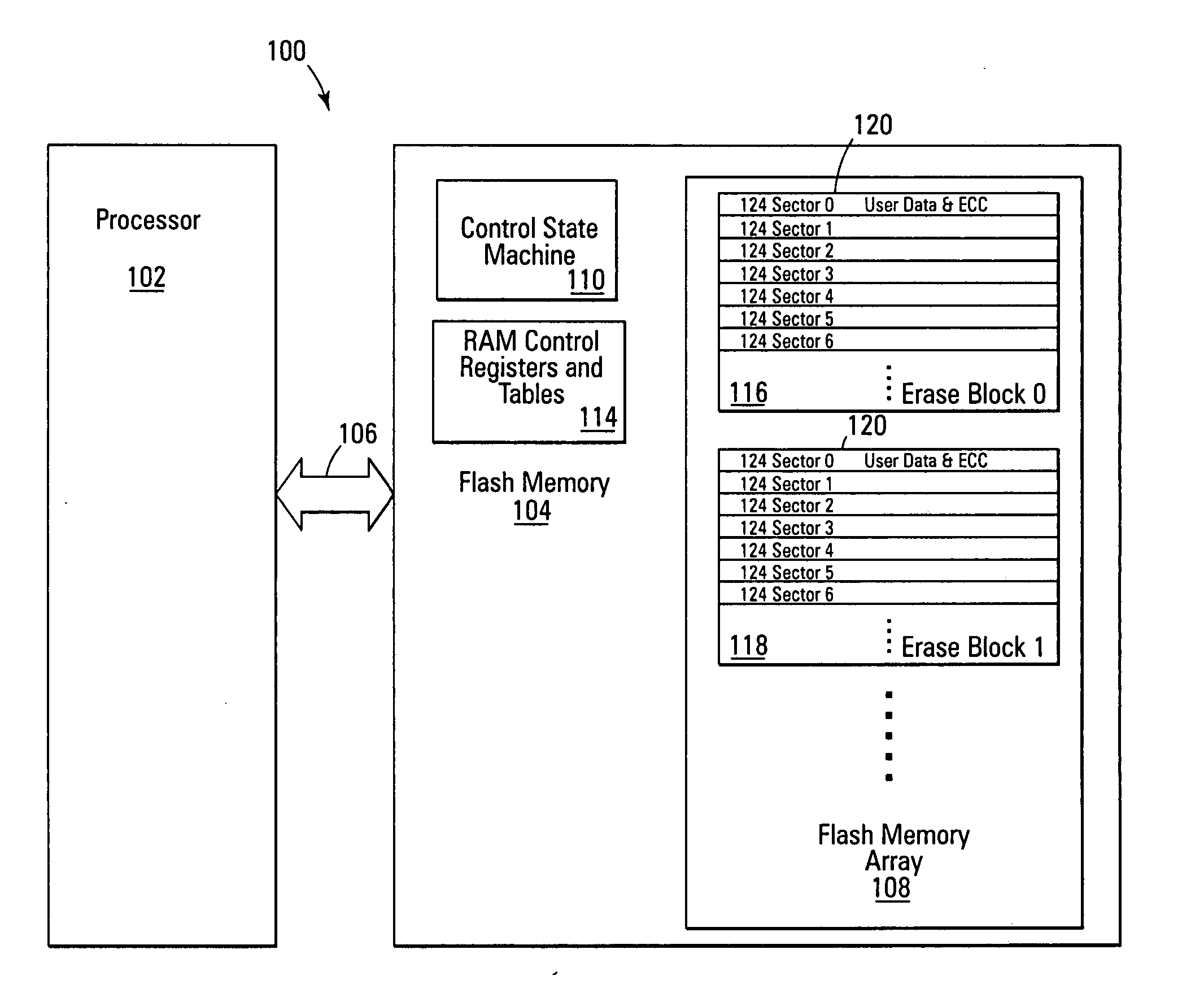

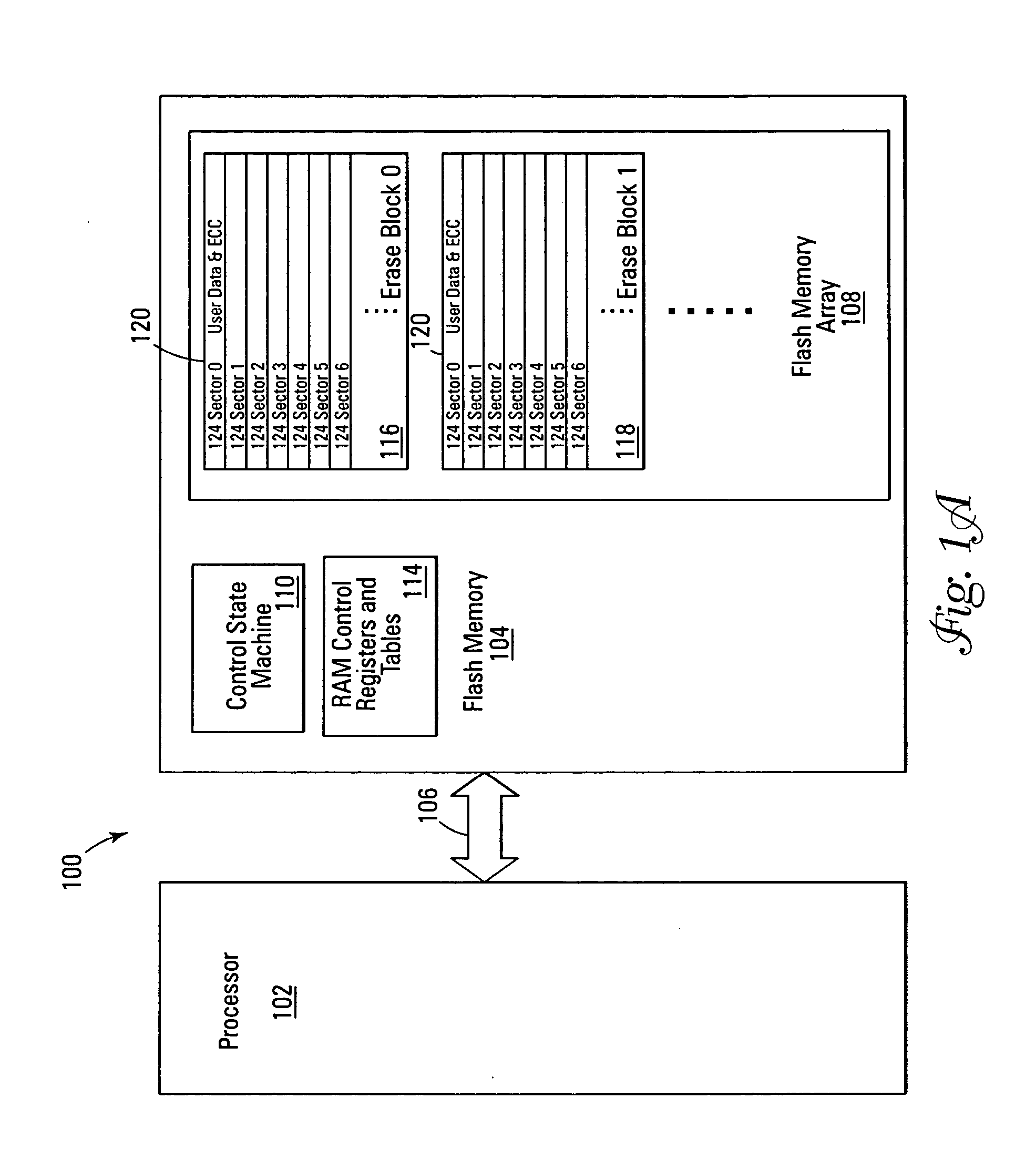

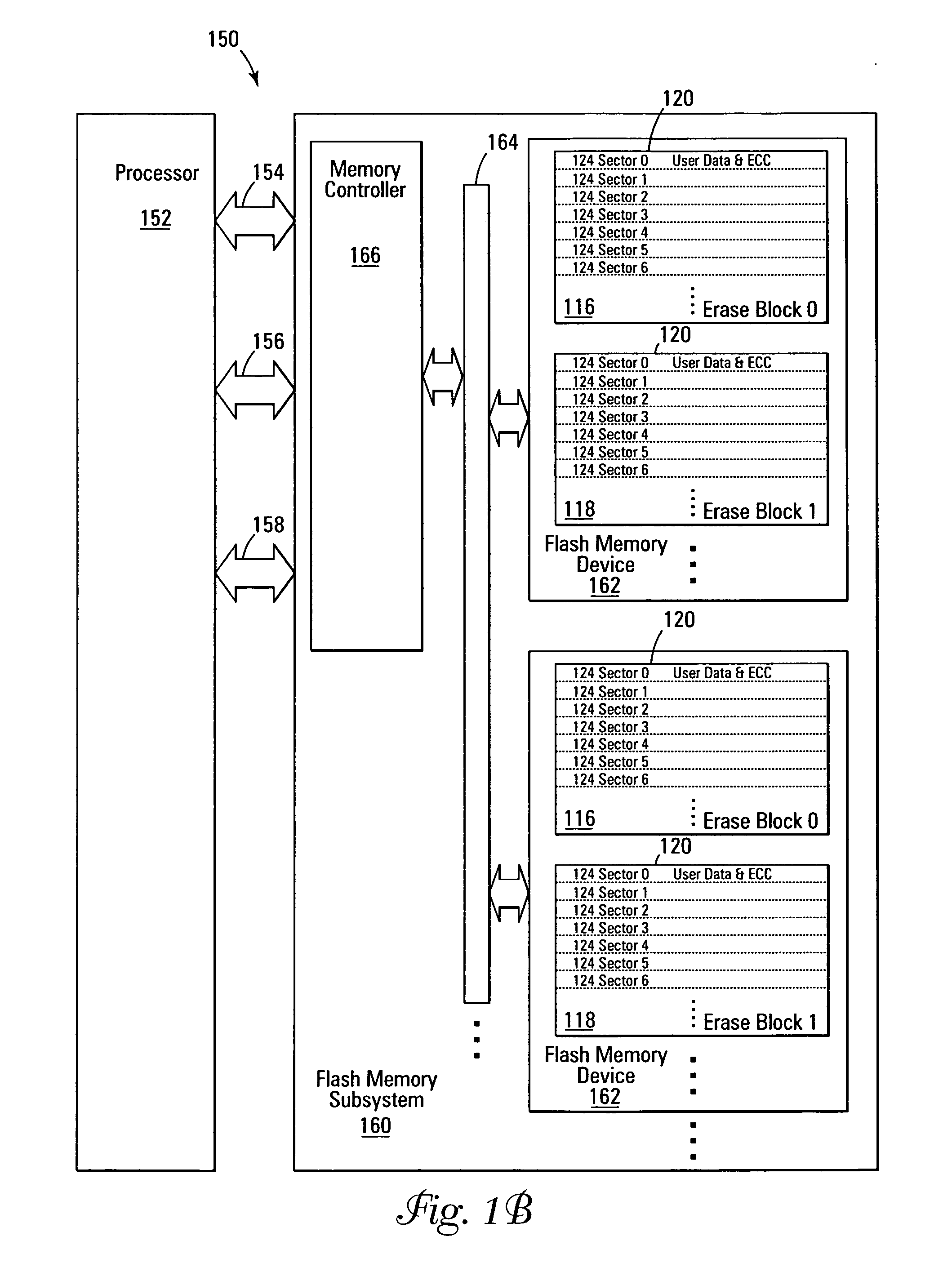

Cluster based non-volatile memory translation layer

InactiveUS20060044934A1Quick scanMemory architecture accessing/allocationDigital storageLogical block addressingCluster based

An improved non-volatile memory and logical block to physical block address translation method utilizing a cluster based addressing scheme is detailed. The translation of logical blocks / sectors to the physical blocks / sectors is necessary for a non-volatile memory to appear as a freely rewriteable device to a system or processor. Embodiments of the present invention utilize cluster based address translation to translate logical block addresses to physical block addresses, wherein each cluster contains a plurality of sequentially addressed logical blocks. This allows the use of a smaller RAM table for the address translation lookup and / or faster scanning of the memory device or memory subsystem for the matching cluster address. In one embodiment, a specially formatted cluster is utilized for frequently updated sectors / logical blocks, where the cluster stores a single logical block and a new sequential physical block of the cluster is written in turn with each update.

Owner:MICRON TECH INC

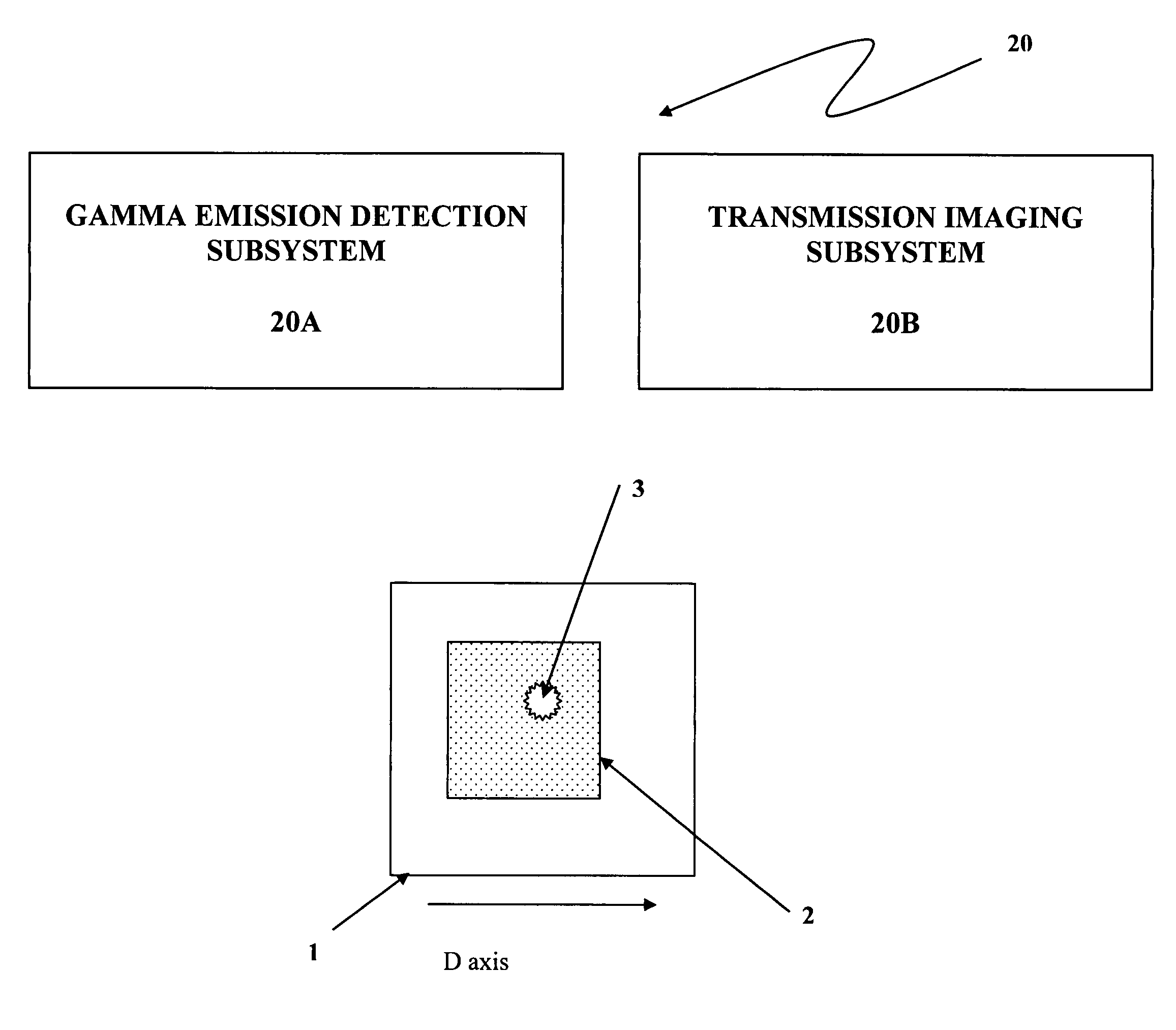

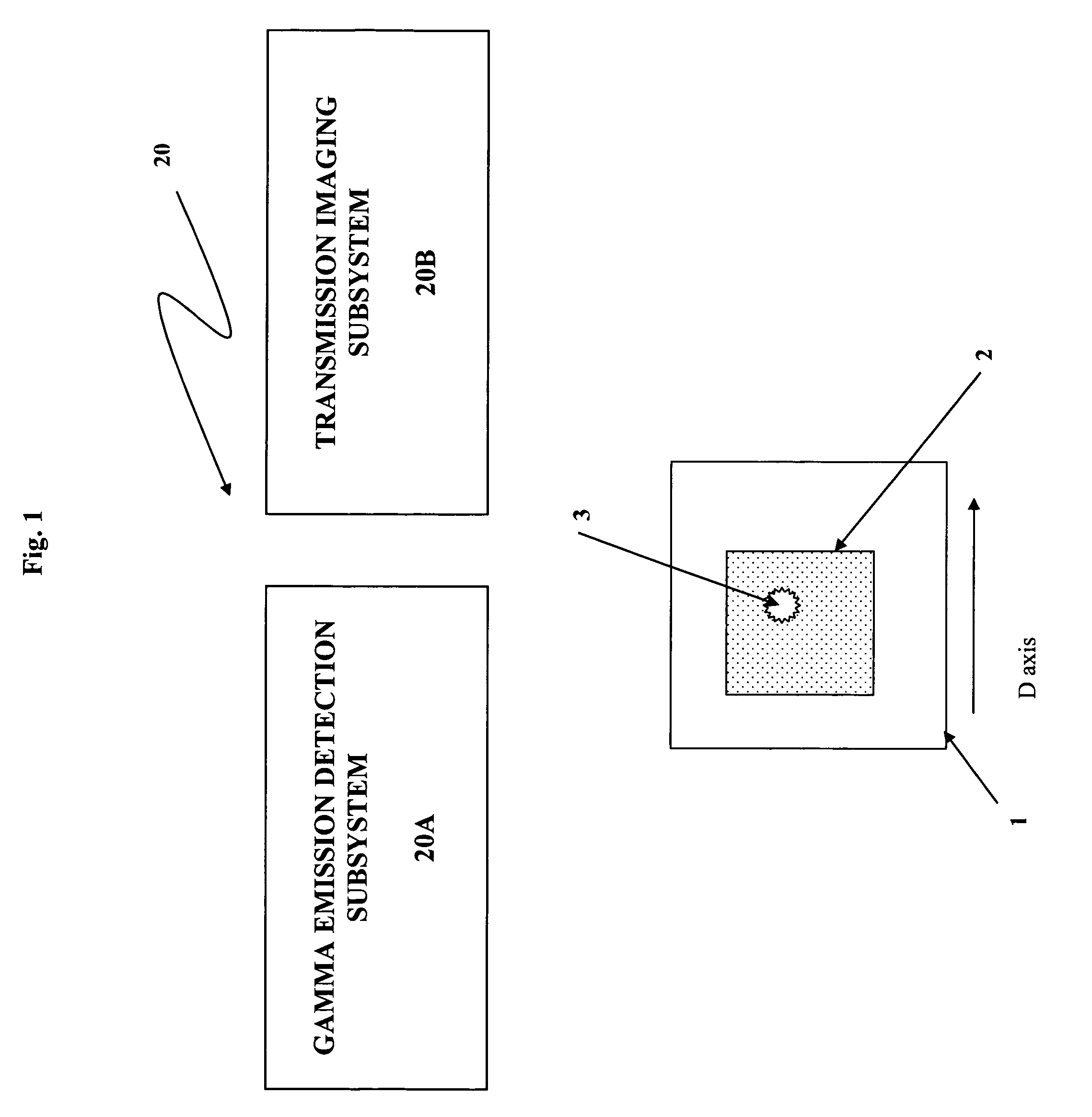

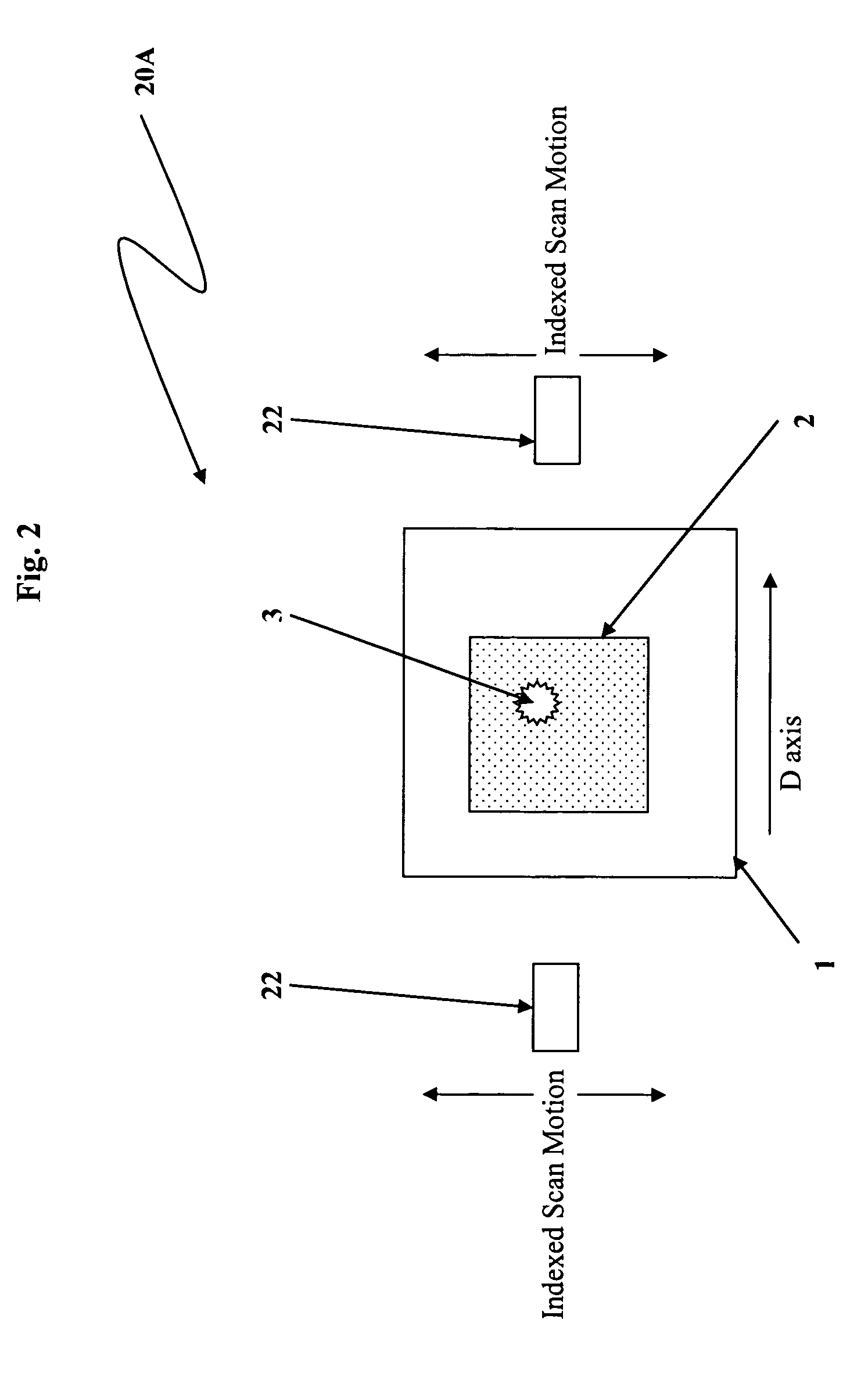

Quantitative transmission/emission detector system and methods of detecting concealed radiation sources

InactiveUS7317195B2Electroluminescent light sourcesSolid-state devicesRadioactive agentFast scanning

Owner:EIKMAN EDWARD A

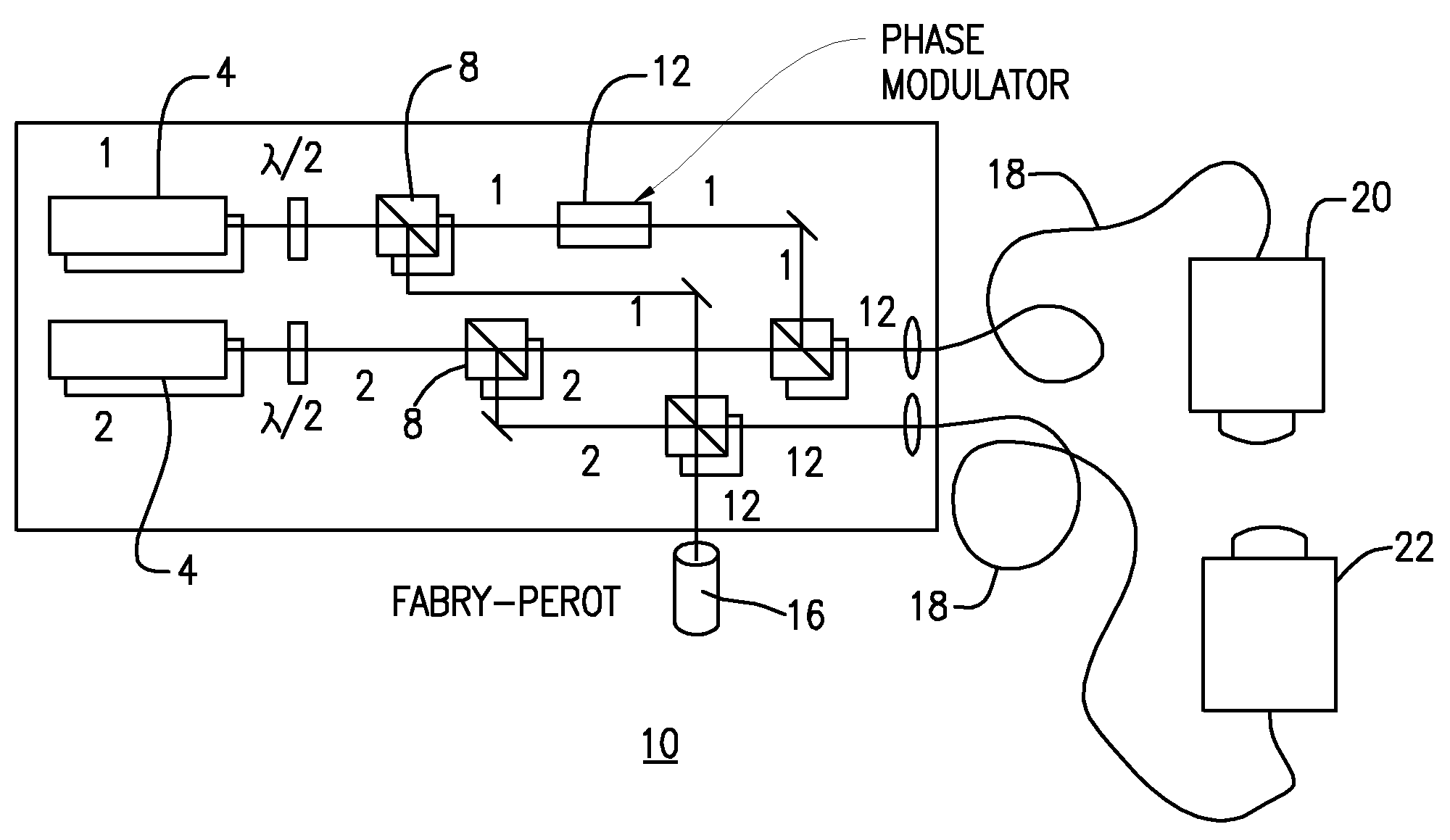

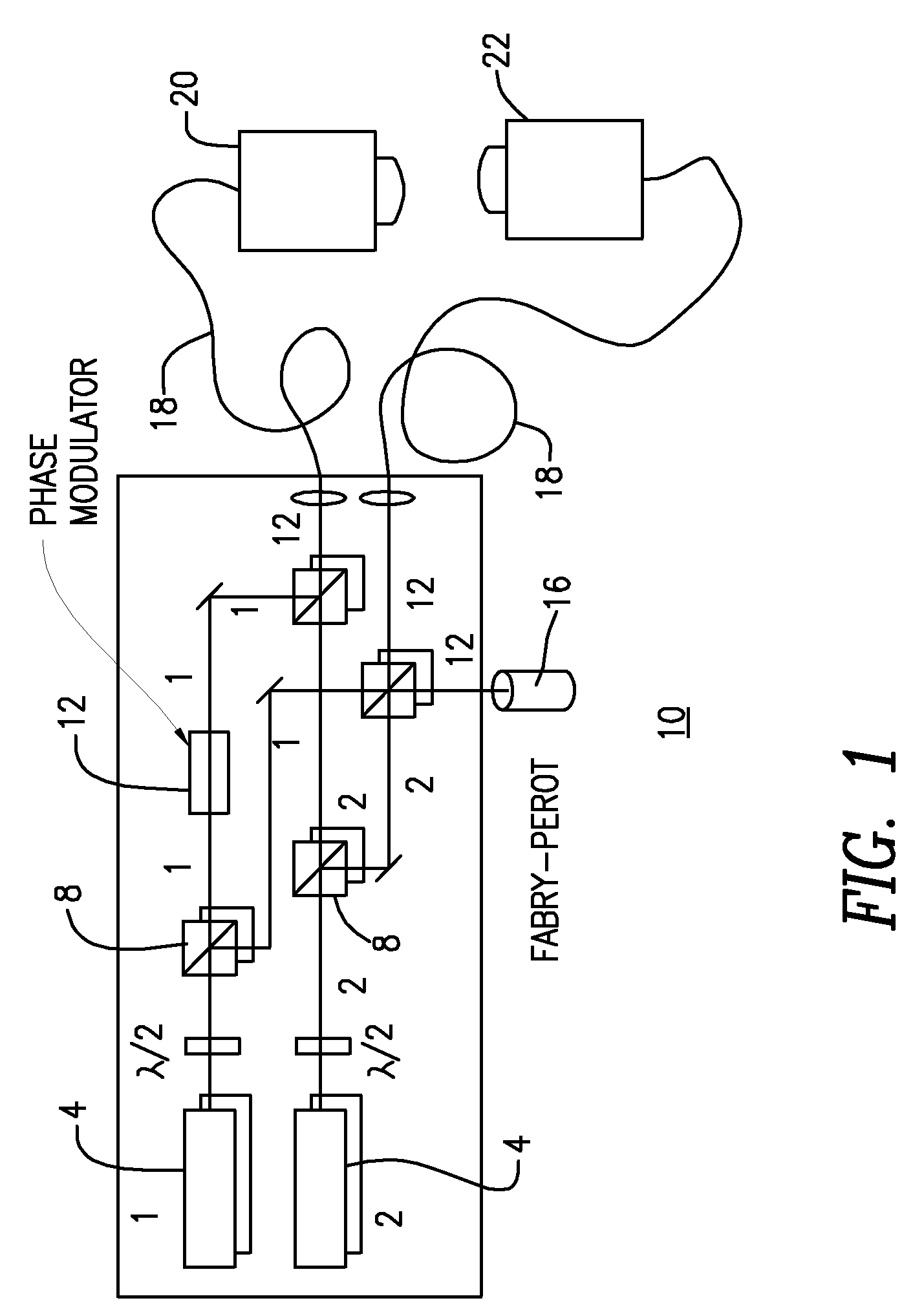

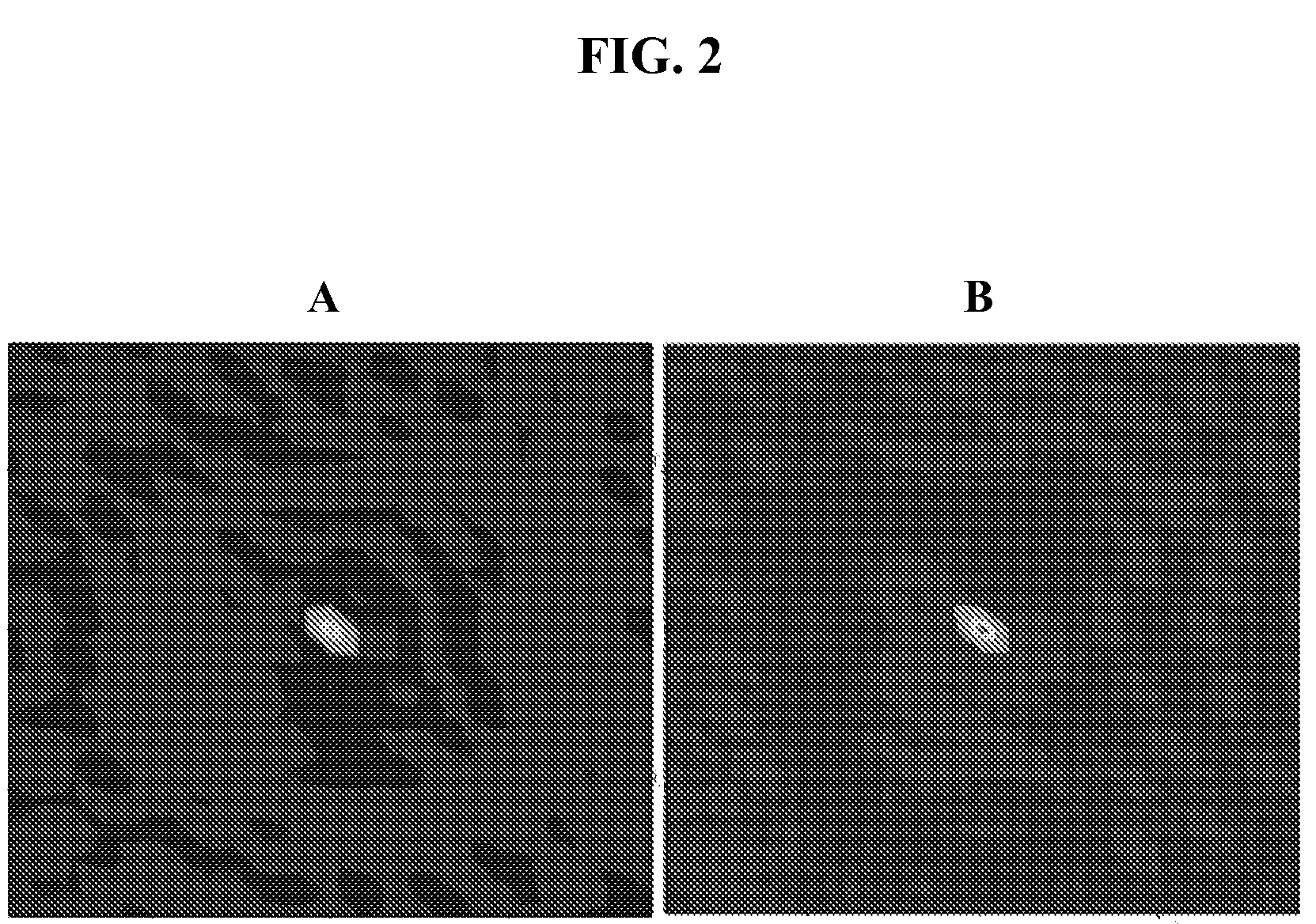

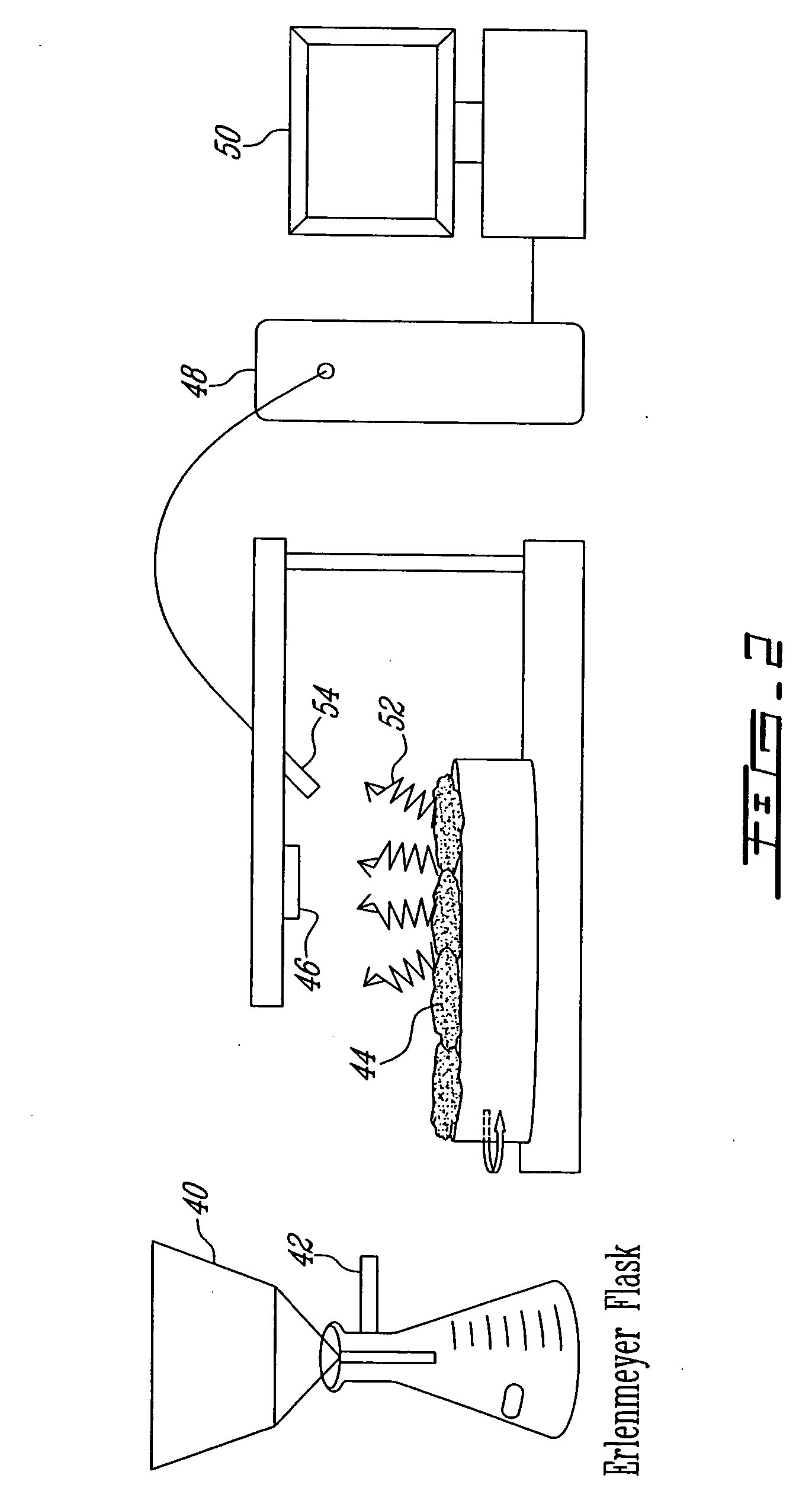

Methods and apparatus for rapid scanning continuous wave terahertz spectroscopy and imaging

Methods and apparatus are provided employing rapid scanning continuous wave terahertz spectroscopy and imaging for the non-destructive evaluation of materials such as animal hides and natural cork, and explosive detection, concealed weapon detection, and drug detection. A system employing an aperiodic detector array and implementing phase modulation at 100 kHz significantly reduces the imaging time and enables interferometric images of a THz point source to be obtained at several frequencies between 0.3 and 0.95 THz.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

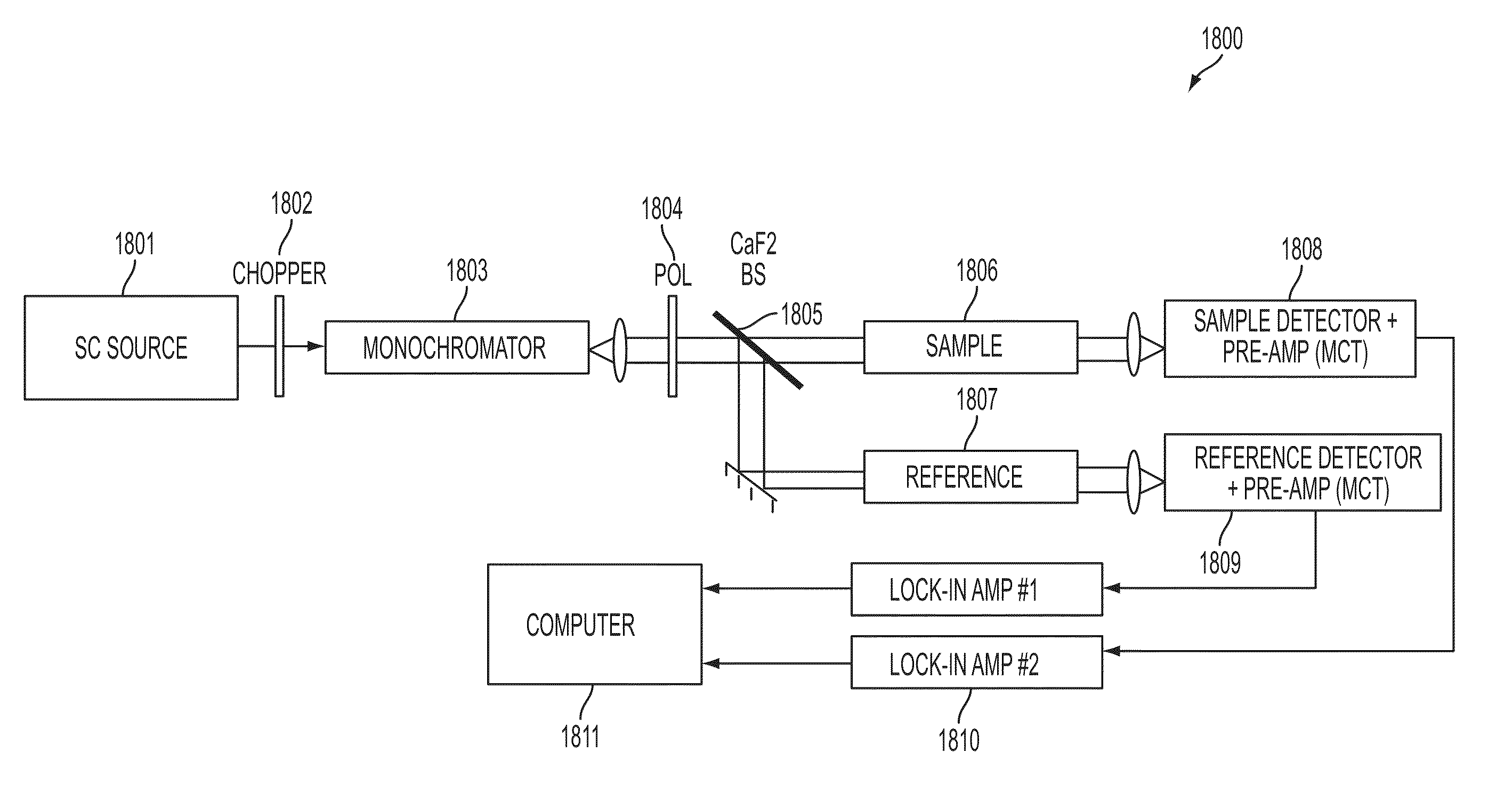

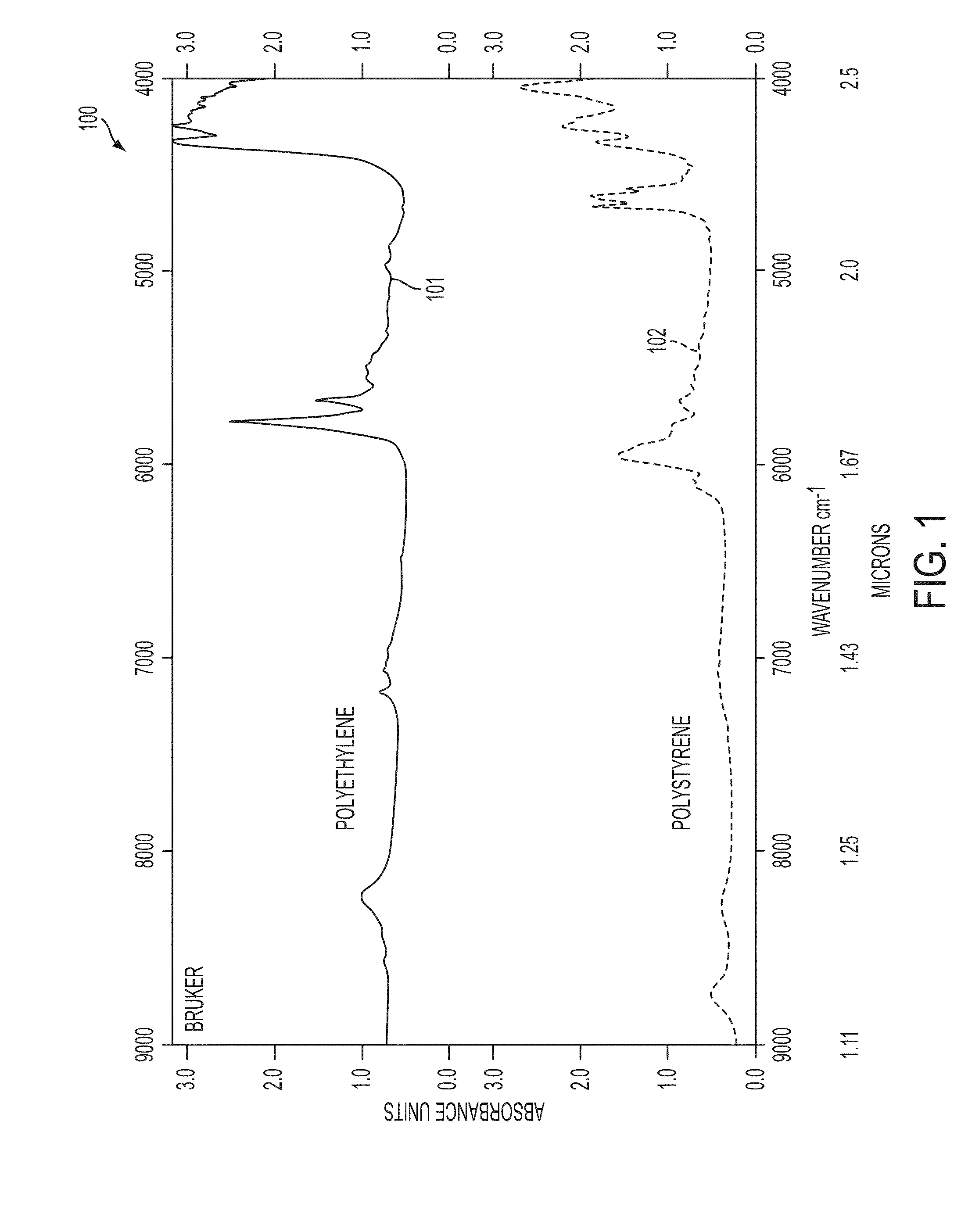

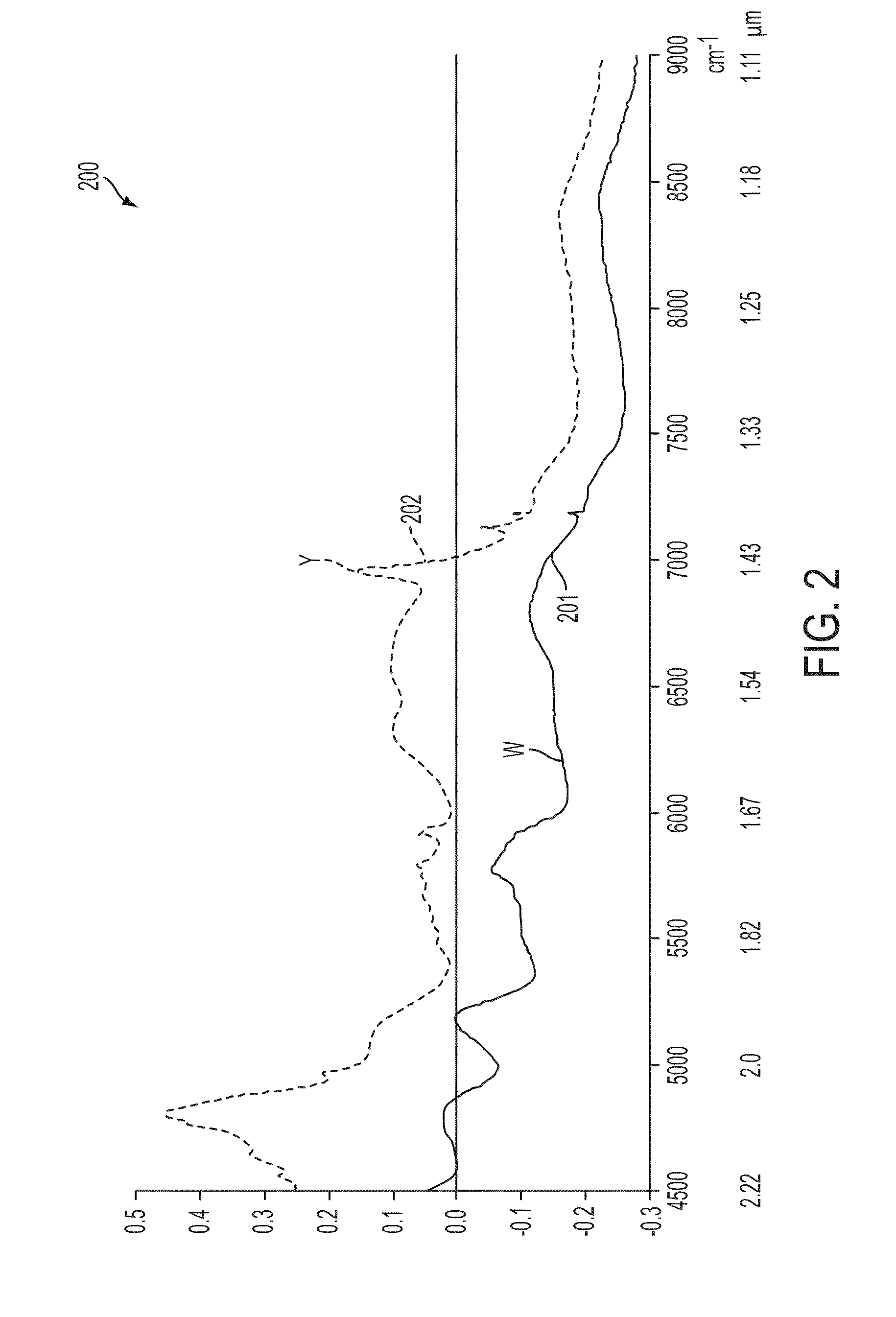

Short-wave infrared super-continuum lasers for detecting counterfeit or illicit drugs and pharmaceutical process control

A system and method for using near-infrared or short-wave infrared (SWIR) light sources for identification of counterfeit drugs may perform spectroscopy using a super-continuum laser to provide detection in a non-contact and non-destructive manner at stand-off or remote distances with minimal sample preparation. Also, near-infrared or SWIR light may penetrate through plastic containers and packaging, permitting on-line inspection and rapid scanning. The near-infrared or SWIR spectroscopy may also be used to detect illicit drugs and their chemical composition. Moreover, the spectroscopic techniques may also be applied to quality assessment and control in pharmaceutical manufacturing, thus permitting the implementation of smart manufacturing with feedback control. Fiber super-continuum lasers may emit light in the near-infrared or SWIR between approximately 1.4-1.8 microns, 2-2.5 microns, 1.4-2.4 microns, 1-1.8 microns. In particular embodiments, the detection system may be a dispersive spectrometer, a Fourier transform infrared spectrometer, or a hyper-spectral imaging detector or camera.

Owner:OMNI MEDSCI INC

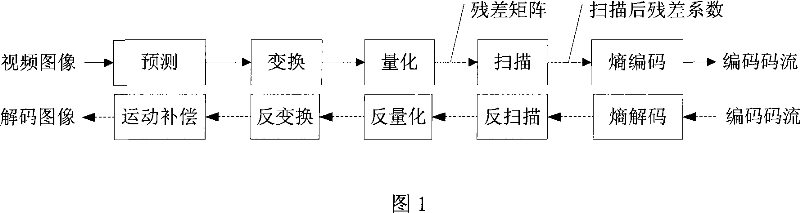

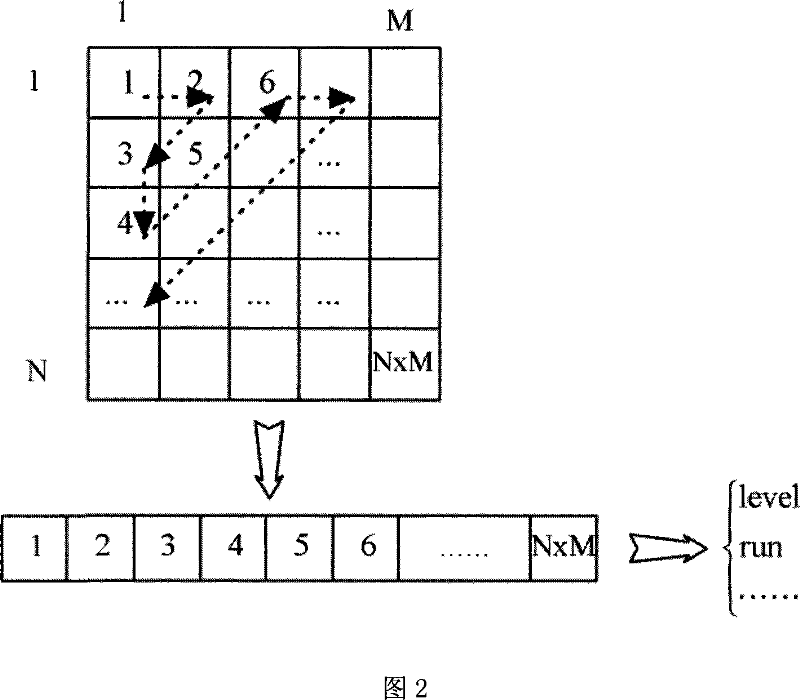

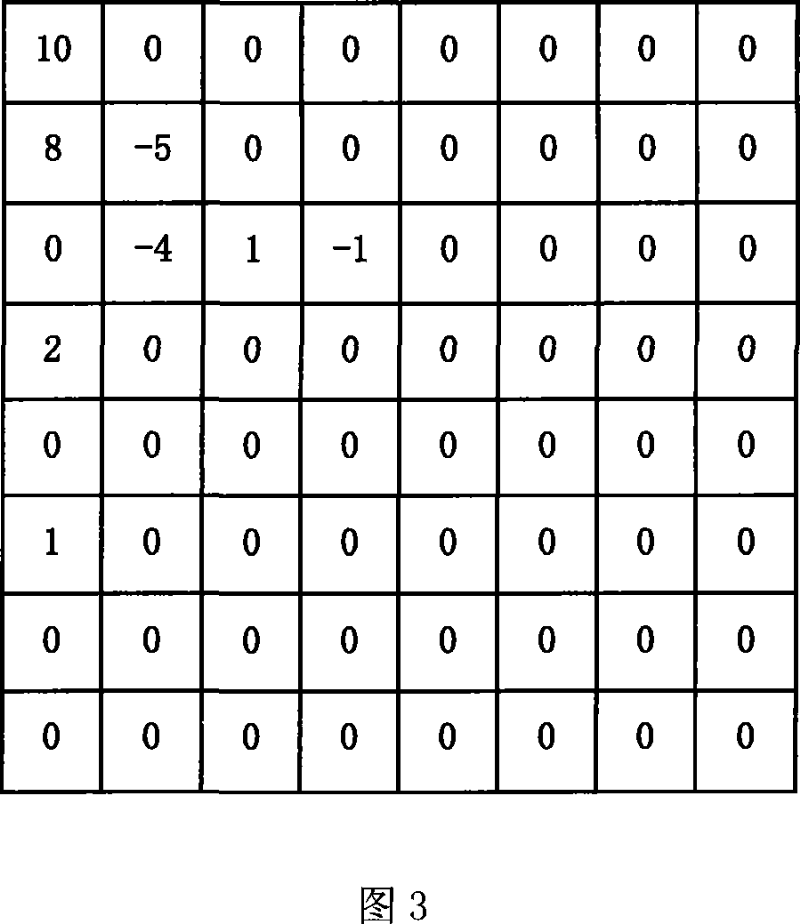

Method for scanning quickly residual matrix in video coding

InactiveCN101039430AReduce the number of clock cyclesTo achieve parallel operationPulse modulation television signal transmissionDigital video signal modificationResidual matrixTime cost

The present invention relates to a quick scanning method for a residual error matrix in video coding process, which belongs to the field of video coding in signal processing. The method comprises: storing elements in a two dimension residual error matrix to a one-dimension serial according to a preset mapping way; extracting the lots of residual error elements gradually and orderly from the one-dimension serial, computing a level value, a map value and a run value of each residual error element, and storing them respectively. In the process of scanning the residual error matrix, the invention can parallelizably and effectively read the residual error element, accomplish parallelizably data computing and information extracting, and can quickly obtain the required scanning results, thereby, the invention greatly reduces the time cost in whole scanning process, enhances the coding rate of a coder, and facilitates the realization of real-time encoding under high distinguishability.

Owner:TSINGHUA UNIV

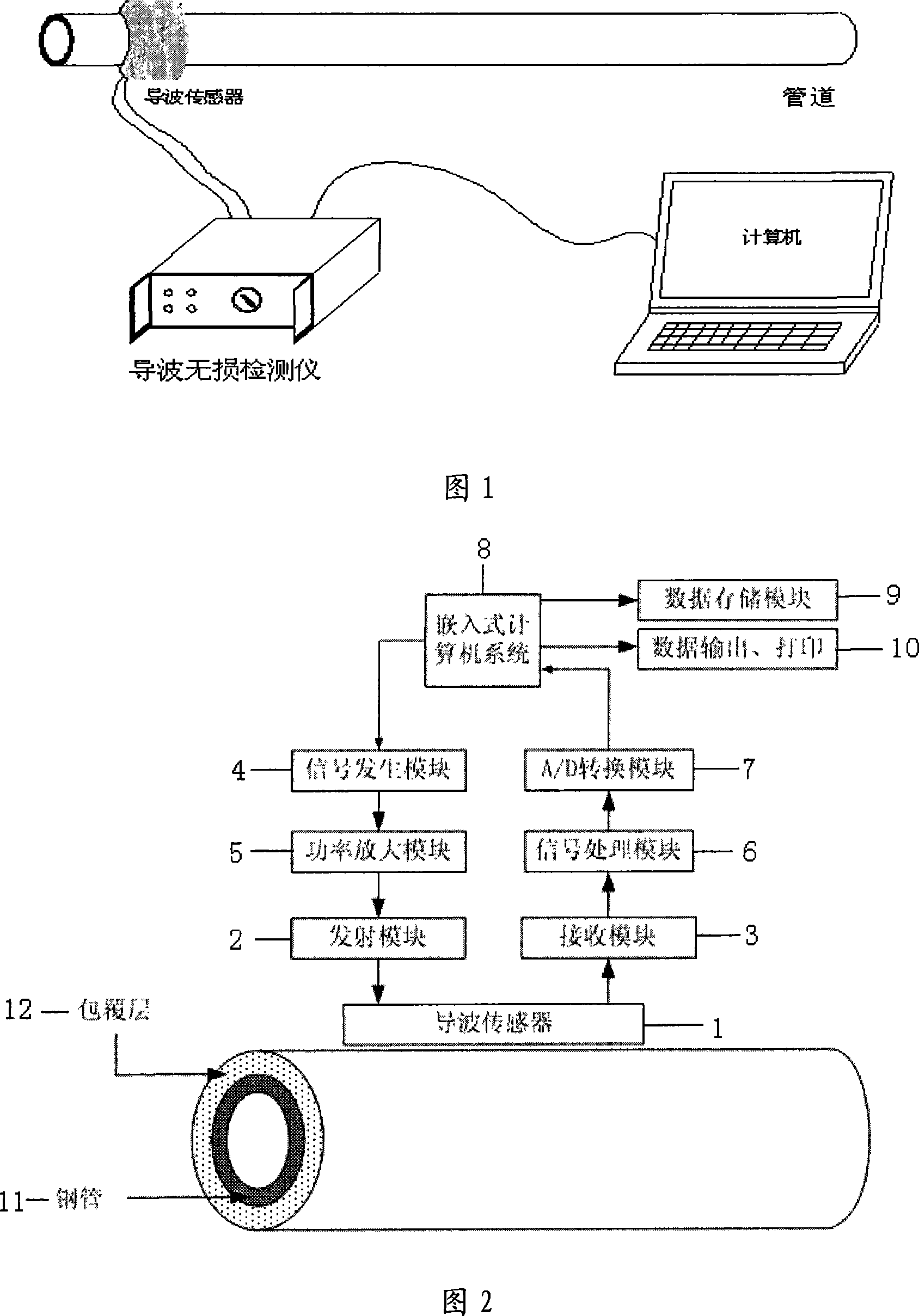

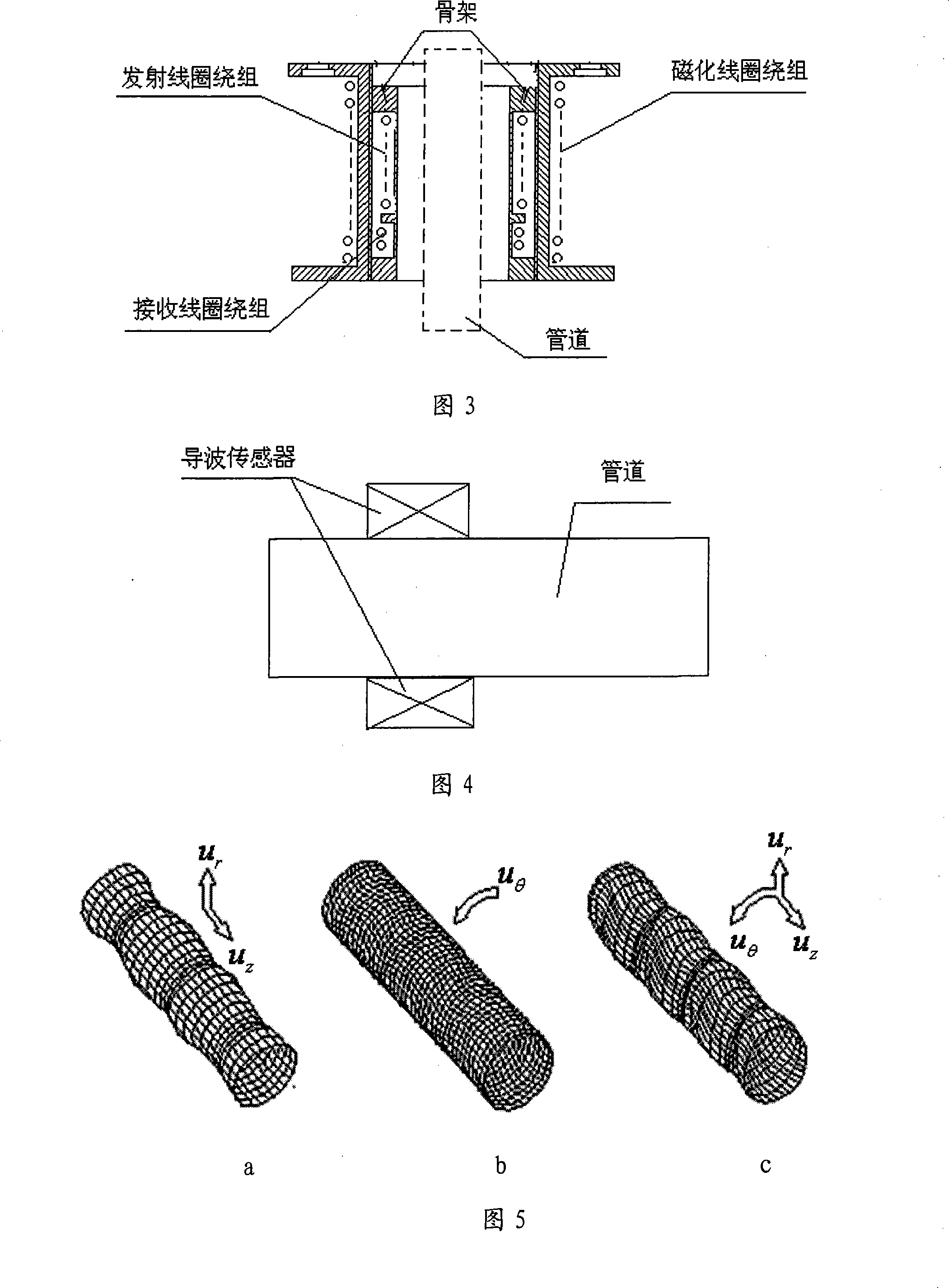

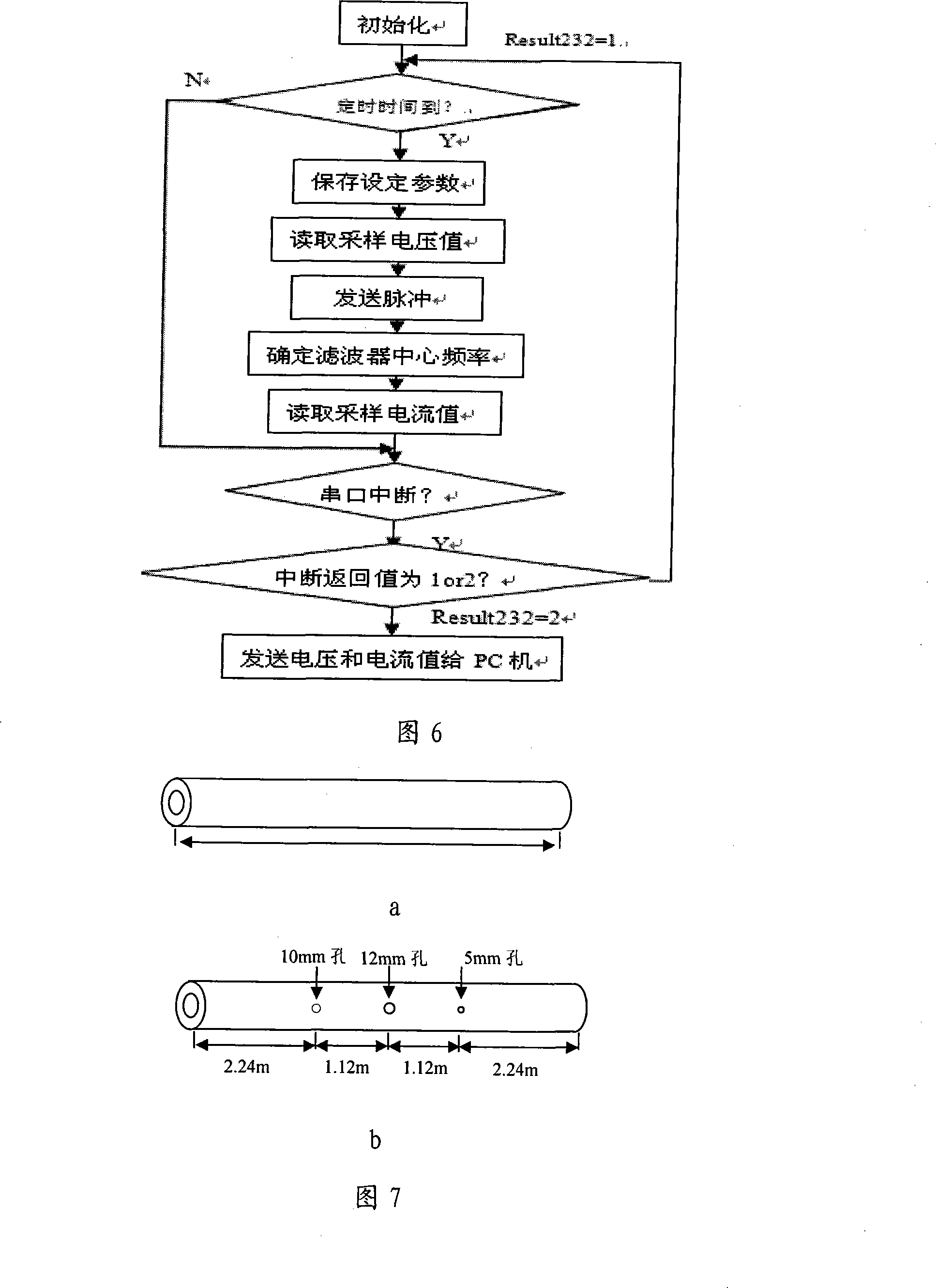

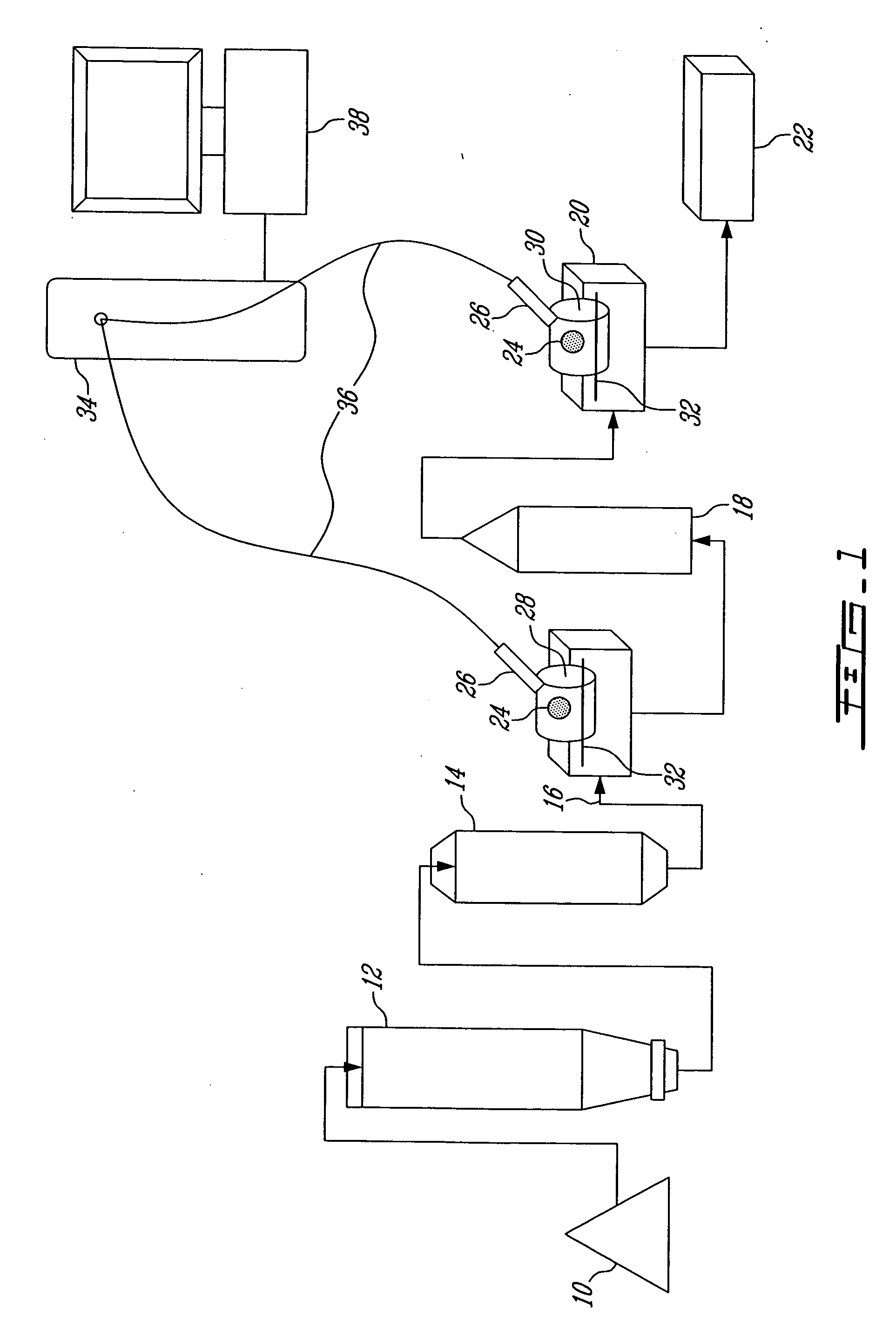

Fast checking method for pipe defect and nondestructive testing apparatus

InactiveCN101173911AQuick scanImprove detection efficiencyUltrasonic/sonic/infrasonic wave generationNon destructiveComputerized system

The invention relates to a fast scanning method of pipeline drawbacks and a non-destructive detection device, which is more particularly suitable for fast scanning and non-destructive detection of drawbacks of the pipelines with insulation. The invention is composed of a guided wave sensor, a transmitting module, a receiving module, a signal generating module, a power amplifying module, a signal processing module, an A / D conversion module and an built-in computer system. The invention is suitable for comprehensive detection of drawbacks of pipelines with different diameters, detection of long distance pipelines, and detection of pipelines in inaccessible places. The invention has the advantages of fast and large-scale detection ability without contact, high efficiency; overcoming a plurality of limitations of the conventional non-destructive detection method; overcoming the restriction conditions of oil pollution, fouling, bending or heat insulation protective layer, judging and locating the drawbacks of the pipelines, reducing the maintenance range, avoiding unnecessary disassembly and replacement, reducing the intensity of artificial detection, and saving the human and material resource. In addition, the invention can achieve on-line monitoring, and evaluate the health condition of the element or predicts the service life of the element.

Owner:NAVAL UNIV OF ENG PLA

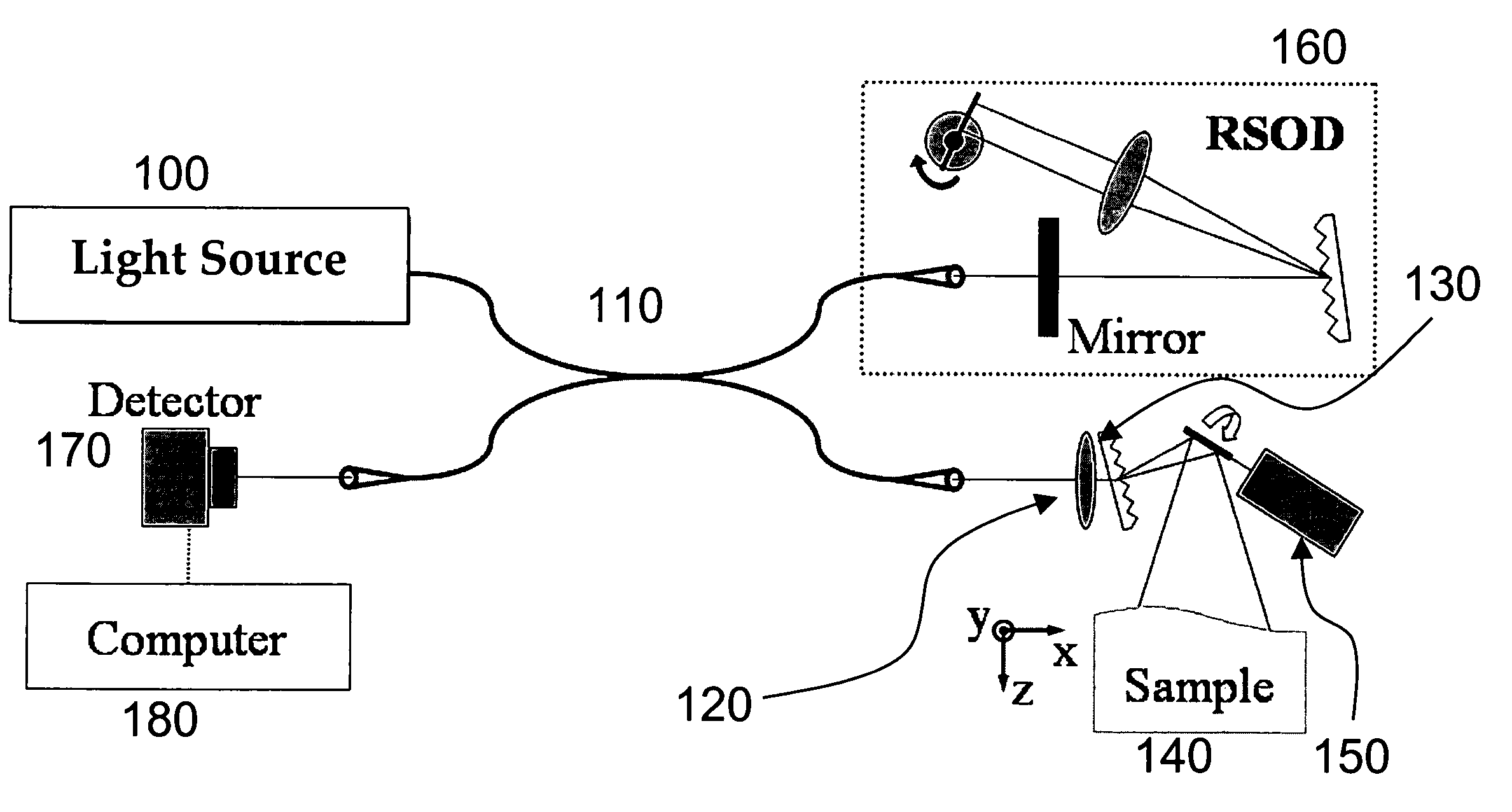

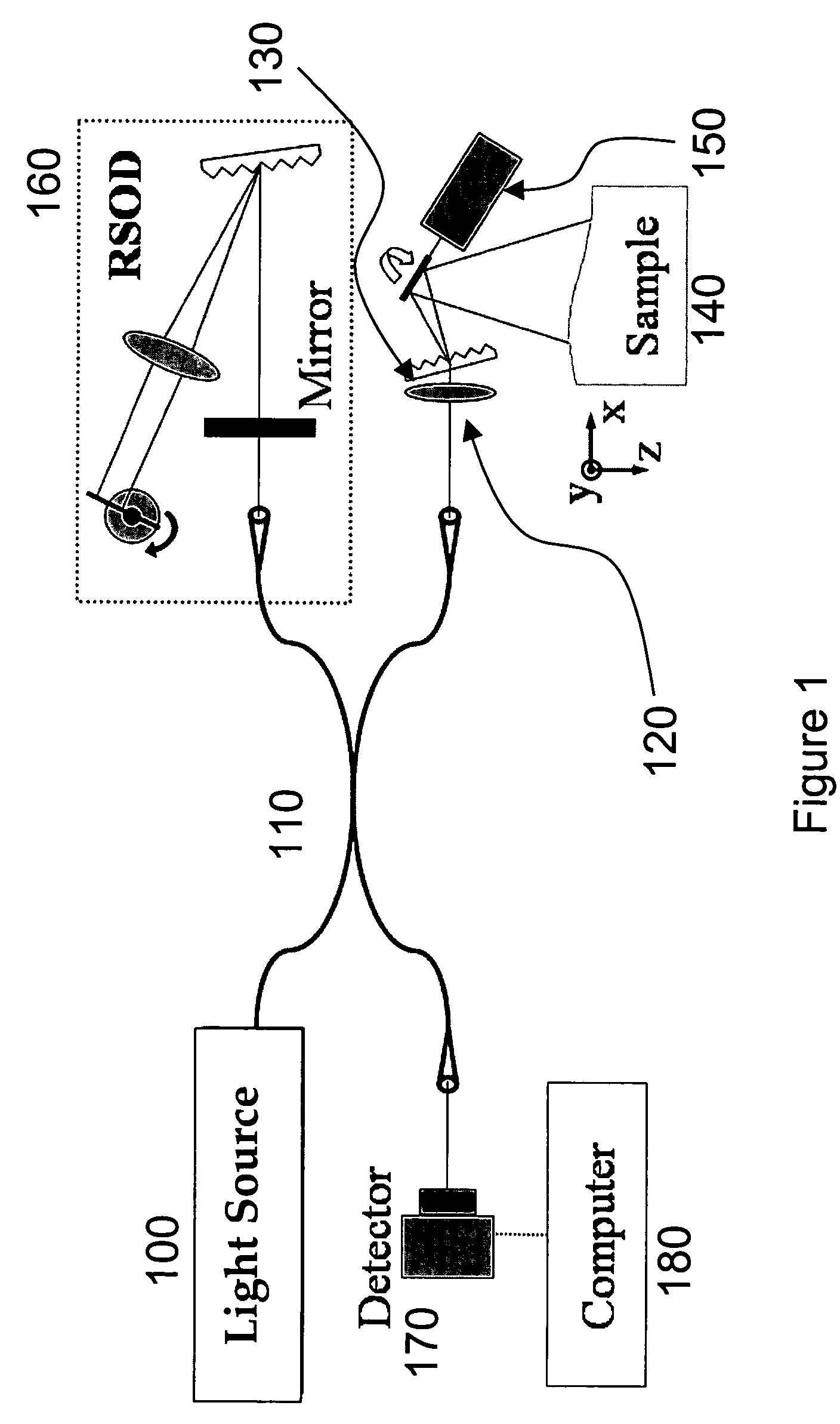

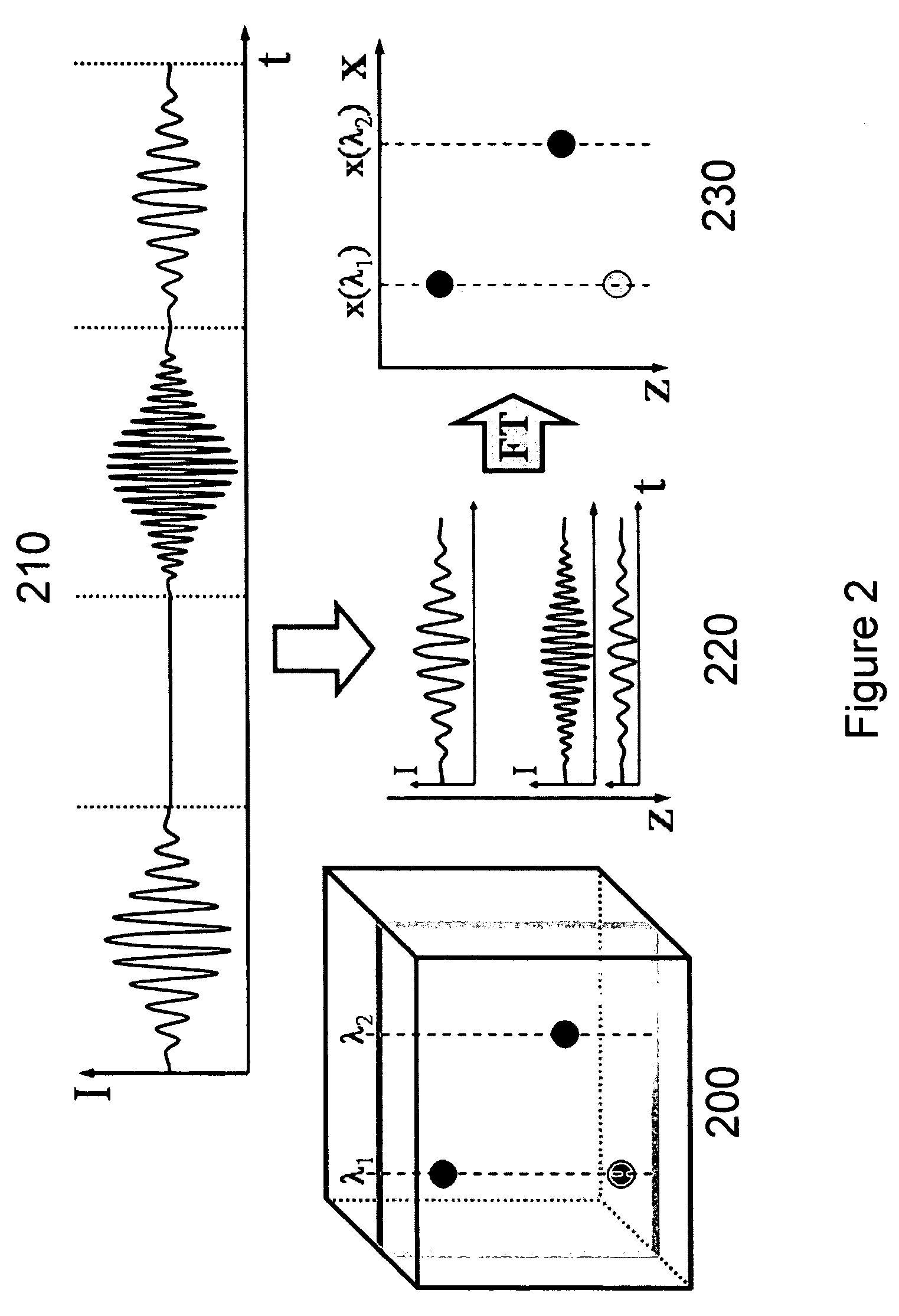

System, method and arrangement which can use spectral encoding heterodyne interferometry techniques for imaging

Systems, arrangements and methods for obtaining three-dimensional imaging data are provided. For example, a broadband light source can provide a particular radiation. A first electro-magnetic radiation can be focused and diffracted, and then provided to at least one sample to generate a spectrally-encoded line. A second electro-magnetic radiation may be provided to a reference, which may include a double-pass rapidly-scanning optical delay, where the first and second electro-magnetic radiations can be based on the particular radiation. An interference between a third electro-magnetic radiation (associated with the first electro-magnetic radiation) and a fourth electro-magnetic radiation (associated with the second electro-magnetic radiation) can be detected. The spectrally-encoded line may be scanned over the sample in a direction approximately perpendicular to the line. Image data containing three-dimensional information can then be obtained based on the interference. The exemplary imaging methods and systems can be used in a small fiber optic or endoscopic probe.

Owner:THE GENERAL HOSPITAL CORP

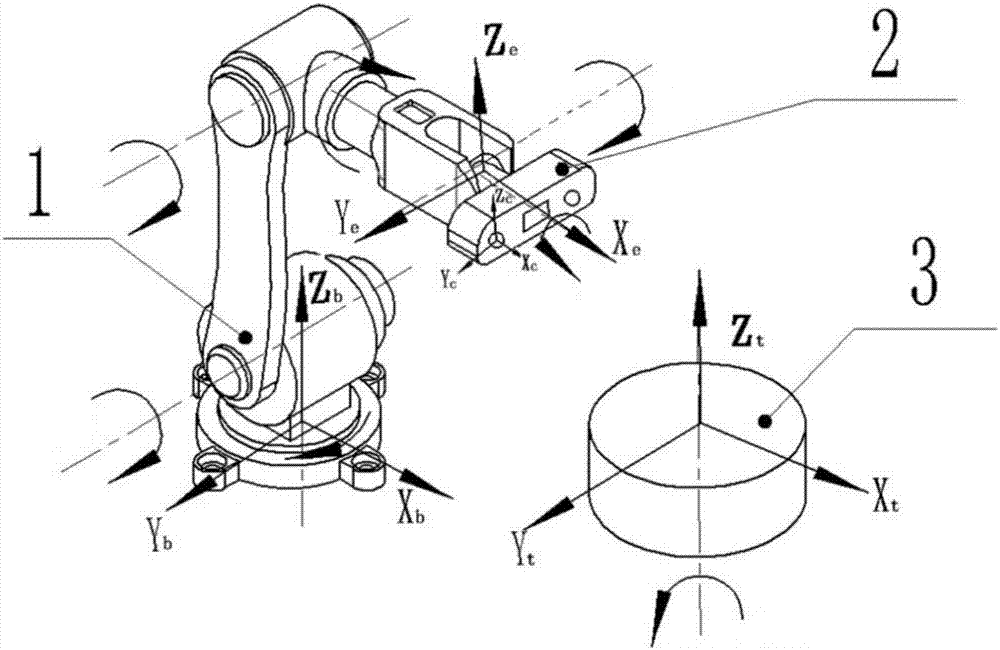

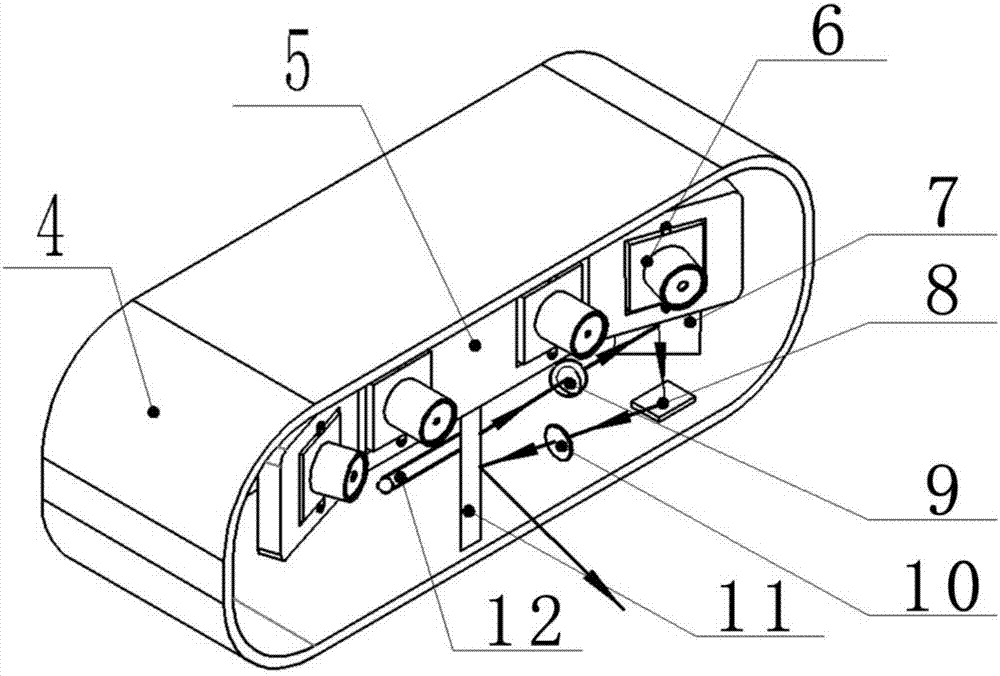

Robot three-dimensional scanning device and robot three-dimensional scanning method

InactiveCN107121062ASolve the problems of blind spots in scanning, long scanning time and low scanning accuracyExpand the scope of workUsing optical meansGratingPoint cloud

The invention discloses a robot three-dimensional scanning device and a robot three-dimensional scanning method. The device comprises an MEMS scanning galvanometer laser three-dimensional probe for generating three-dimensional point cloud data, a six-axis machine arm for clamping the MEMS scanning galvanometer laser three-dimensional probe, a turntable for placing a measured object and a controller for controlling the robot and the turntable, wherein the MEMS scanning galvanometer laser three-dimensional probe is arranged at the tail end of the machine arm; and the measured object is placed in the center of the turntable. In comparison with a digital and physical grating technology, the robot three-dimensional scanning device has the advantages of large depth of field, fast scanning speed, small size and high scanning accuracy; the device combines the high-accuracy turntable and the six-degree-of-freedom robot to a seven-degree-of-freedom device, the working range of the machine arm can be increased, flexibility of scanning on a large object can be improved, scanning dead angles can be reduced, and finally, fully-automatic three-dimensional scanning can be realized.

Owner:SUZHOU DEKA TESTING TECH CO LTD

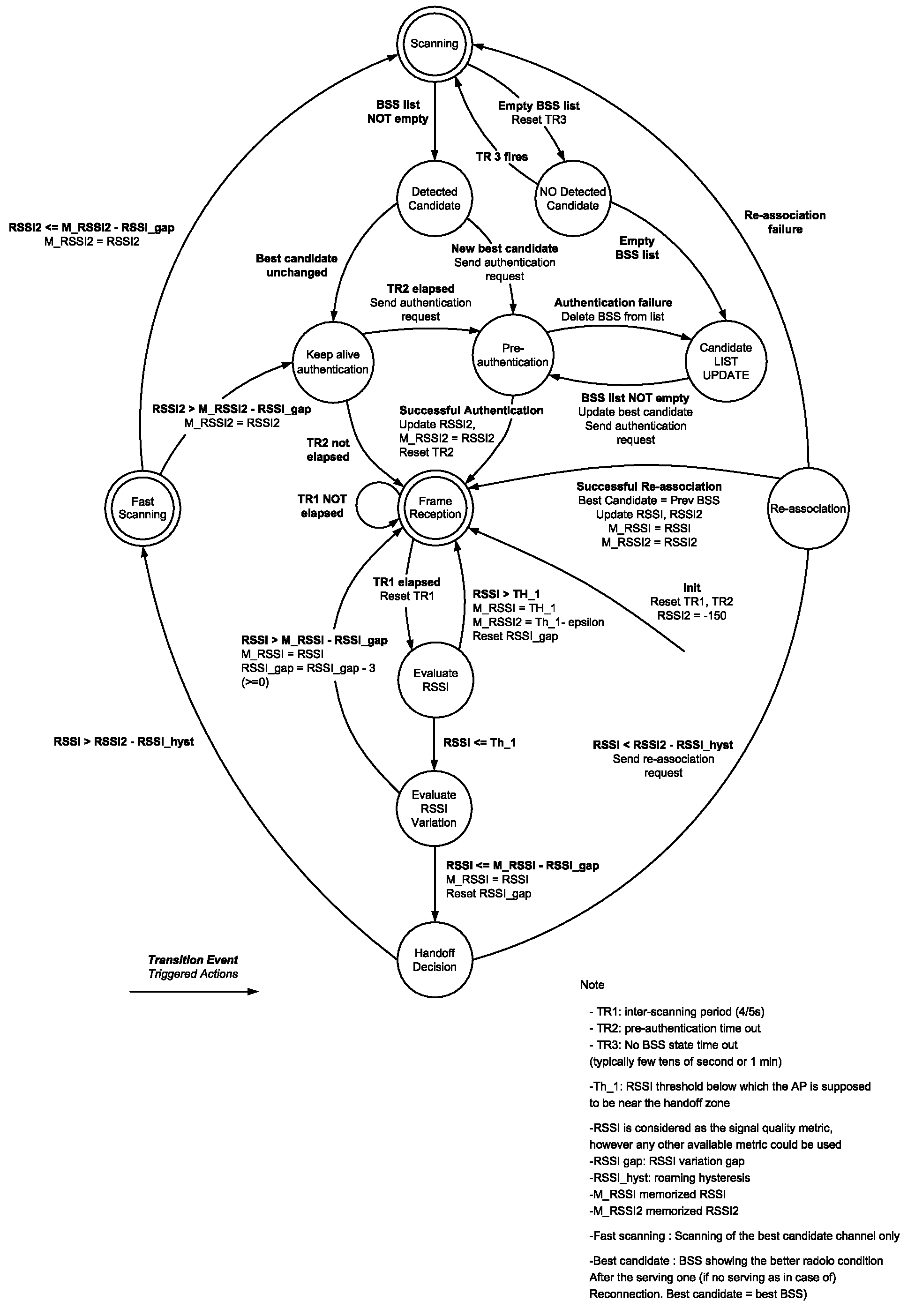

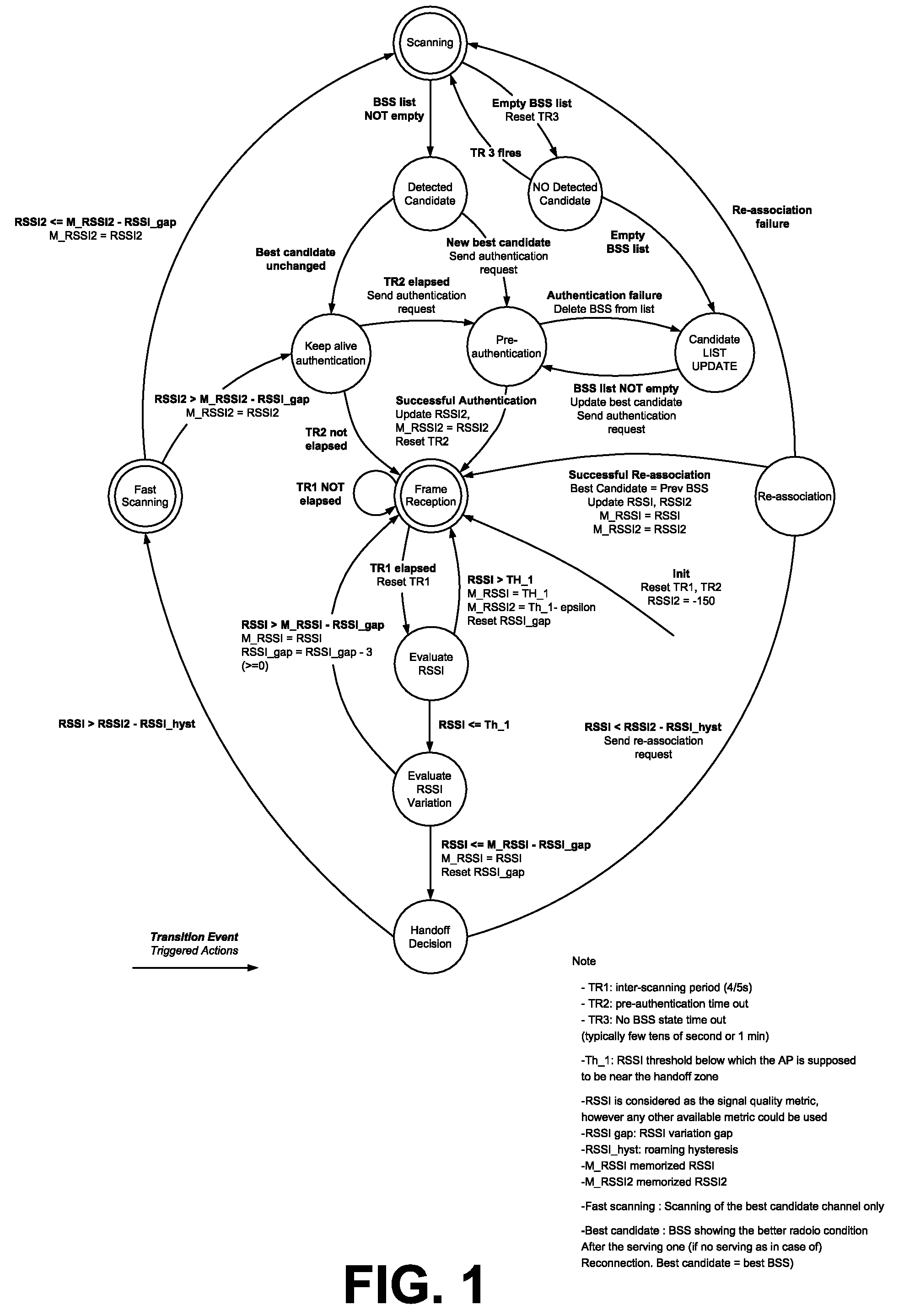

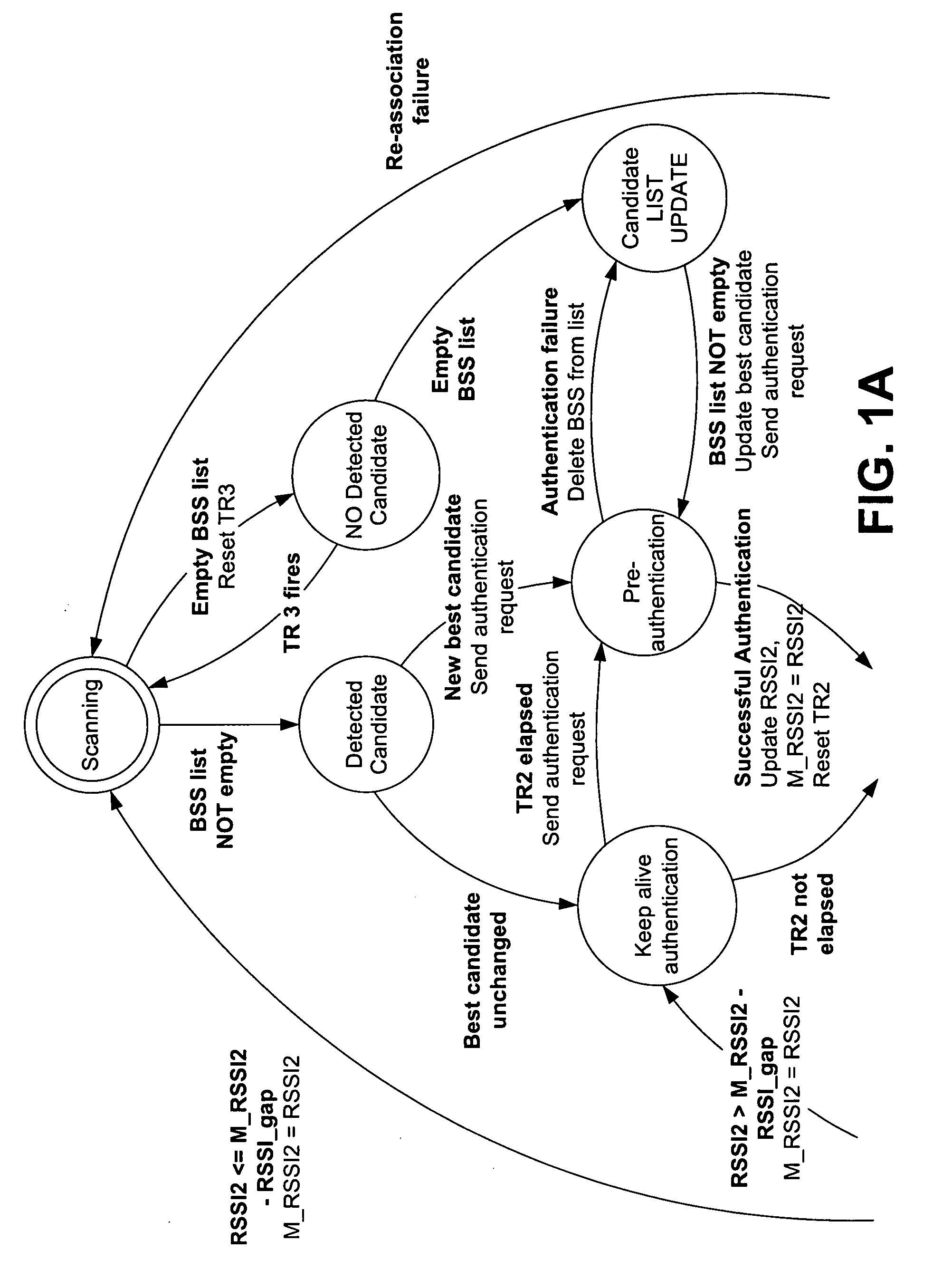

VoWLAN ROAMING CONTROLLER WITH STATION PRE-AUTHENTICATION

ActiveUS20090010222A1Increasing RSSIDecreasing RSSIRadio/inductive link selection arrangementsWireless commuication servicesTelecommunicationsMobile station

A method of triggering handoff of a mobile station to a candidate BSS, for VoWLAN communication, uses a roaming controller for monitoring link qualities of the serving and candidate BSS by selective / controlled fast scanning through RSSI screening at each packet reception. Using link qualities, a list of candidate BSSs for handoff is maintained. The controller selects a candidate BSS for handoff and completes pre-authentication of the mobile station with the selected best candidate BSS. When the link quality of the of the selected candidate BSS becomes better than that of the serving BSS, handoff is triggered. Link qualities may be monitored by screening a metric other than RSSI. When no candidate BSS is found, scanning is reduced / temporarily interrupted, to conserve power. When the serving BSS link quality is above a given threshold when the mobile station is in the serving BSS center, the functions of fast scanning and pre-authentication are interrupted.

Owner:WIPRO LTD

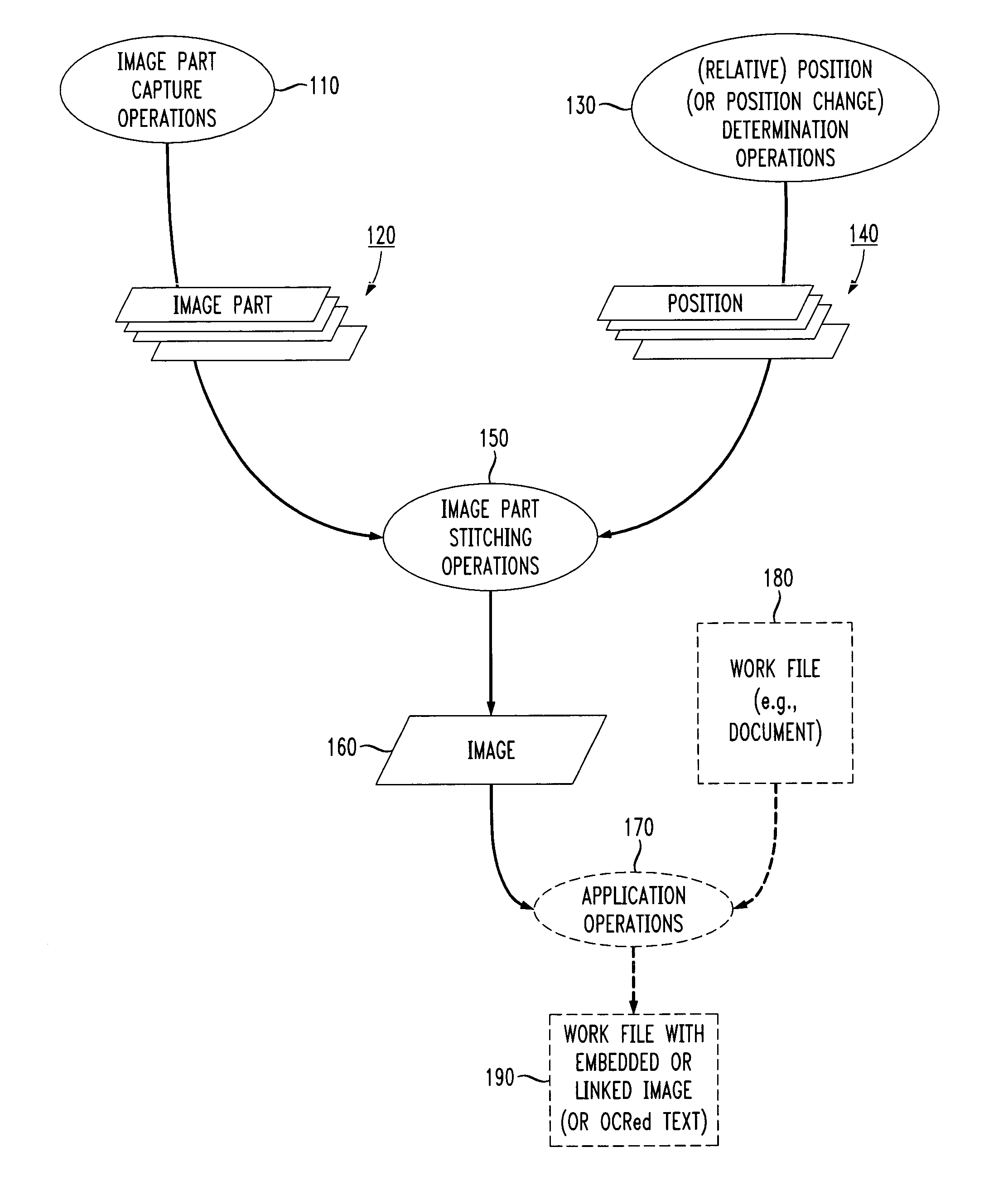

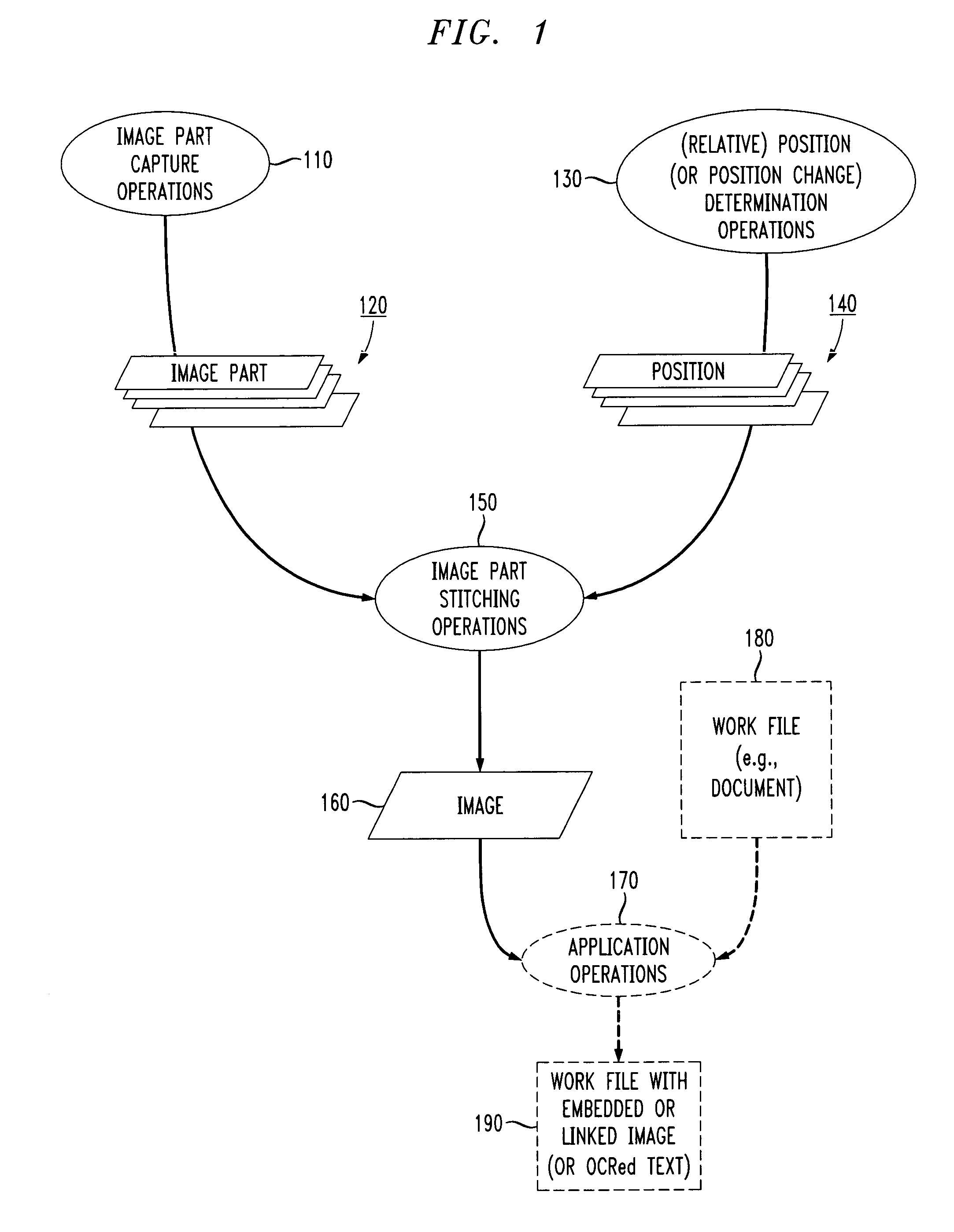

Scanning optical mouse

InactiveUS20050057510A1Input/output for user-computer interactionCharacter and pattern recognitionPaper documentComputer science

An optical mouse scanner allows users to perform quick scans of paper documents (or of some other surface) without requiring a separate, standalone scanner. Scanning functionality may be provided to an optical mouse, such as a wireless optical mouse. The scanning sensor and / or the scanning light source could be same as that used for the optical motion detection for the mouse. Alternatively, a separate light source and / or imaging element could be provided for purposes of scanning. Image stitching software could use a number of captured images (e.g., a stream of captured frames) alone, or in association with mouse orientation and / or position information, to assemble a larger image from smaller captured image frames.

Owner:AGERE SYST INC

Method for determining chemical pulp Kappa number with visible-near infrared spectrometry

ActiveUS20060196622A1Overcomes shortcomingCellulosic pulp after-treatmentRadiation pyrometryContinuous measurementPresent method

A method for the determination of cellulosic-fibre properties, such as, but not limited to, residual lignin content of chemical pulp, with the aid of a spectroscopic technique obtained over a range covering the visible and the near-infrared regions of the electromagnetic spectrum, comprising the steps of obtaining a sample from the process line, minimally removing some excess water, exposing the fibres in the sample to a large beam light source, optionally moving the sample at a constant speed, and acquiring the spectral data over a pre-determined length of time, and correlating the spectrum to a previously determined calibration so as to determine the Kappa number. Alternatively, as an arrangement for process control, along with other varying configurations, the instant invention includes the mounting of the excitation light source and fibre-optic probe along the various locations of the kraft cooking and bleaching process, such as 1) at the drum brownstock washers and 2) throughout the bleach plant deckers, located just before the doctored blade, the probe being connected to a fast scanning spectrometer, via fibre optic cables, with a computer sequencing spectral acquisition and correlating the spectrum against a predetermined calibration, and logging the results. The process configuration, with the use of the instant invention, overcomes all limitations of prior art, including sampling hardware and sample preparation, and provides true online Kappa number determinations of the order of seconds, as compared to current state of the art Kappa analyzers which require 10 to 15 minutes per analysis. The present method is capable of measuring residual lignin content of chemical pulps with varying consistency, accounts for species effects to provide species insensitivity and can provide analysis in less than 10 seconds. The method can provide true online continuous measurement of Kappa number for feedforward and feedback control of the bleaching, paper machine and kraft cooking processes.

Owner:FPINNOVATIONS INC

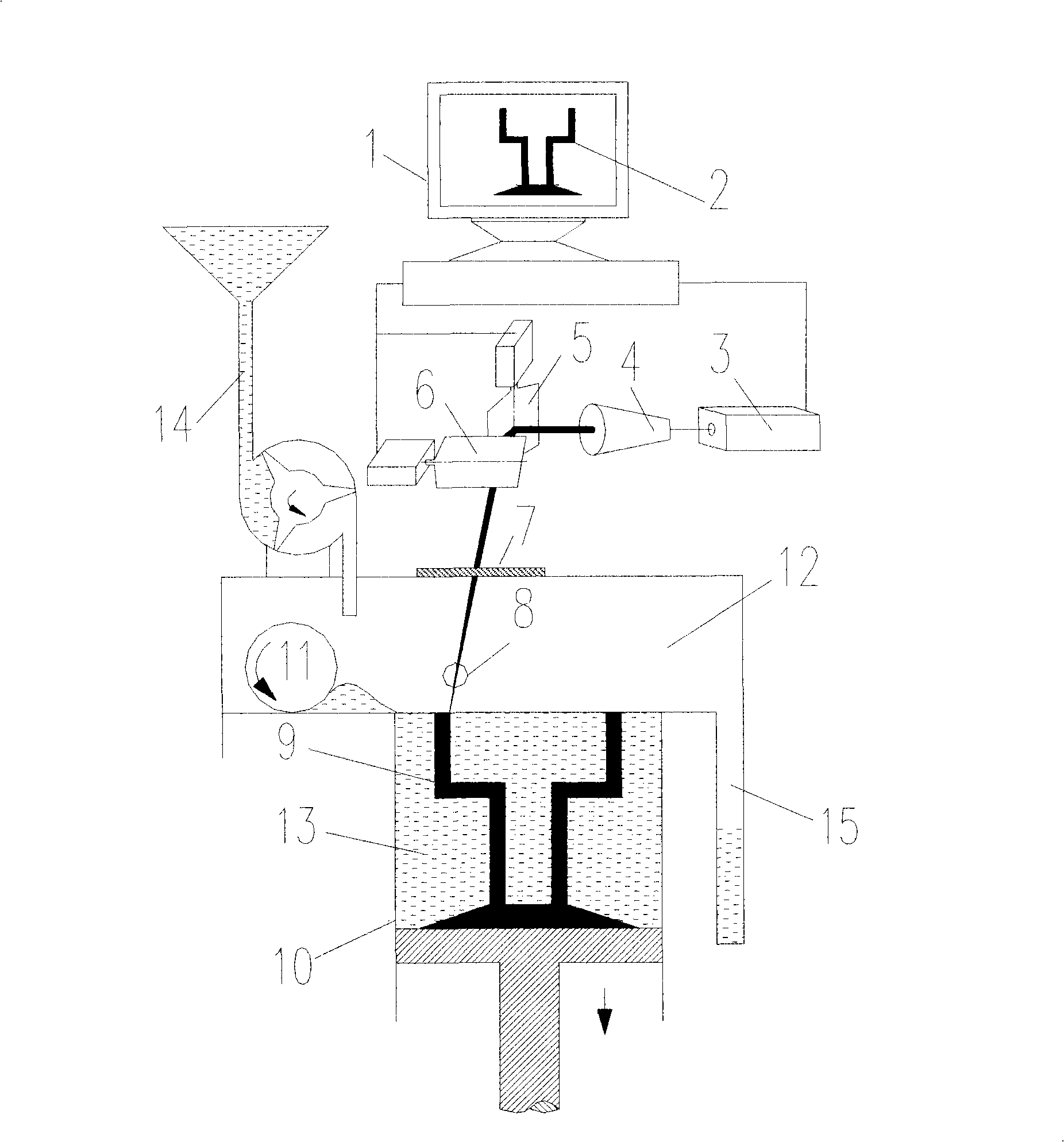

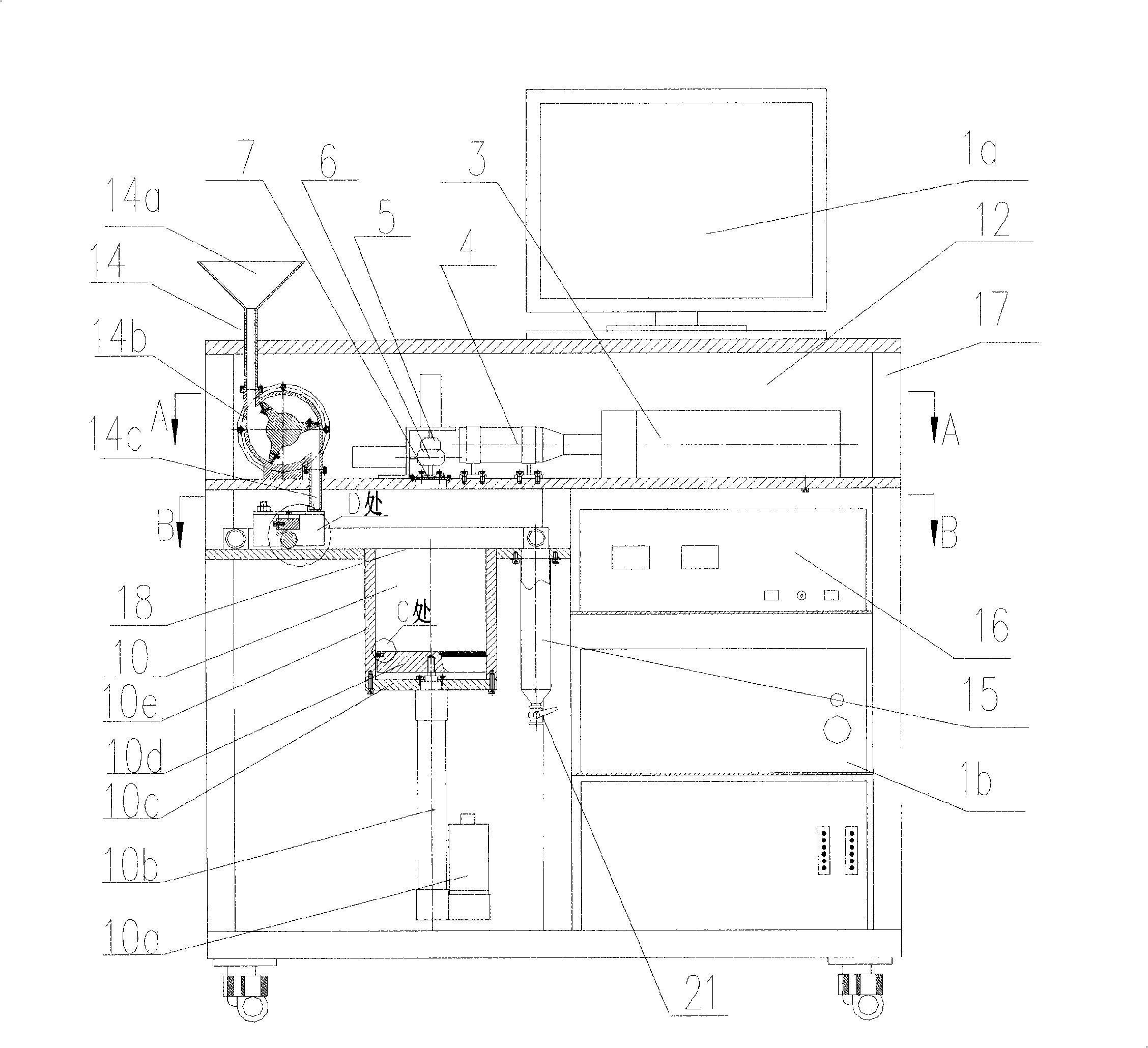

Precinct laser fusion rapid molding method and device of medical implantation material wax mould

InactiveCN101310964ADense tissueSimplify the manufacturing processComputerised tomographsTomographyWaxOriginal data

The invention provides a method for laser-melting and fast forming of a choosing area of a medical implant moulage, which refers to measuring an organ of a patient to obtain the original data for a medical implant; three-dimensional CAD software is adopted to transform the original data into a three-dimensional CAD model for secondary processing and then for slicing processing so as to obtain a multi-layer-slice two-dimensional CAD data model of the medical implant; scanning path planning is carried out to the two-dimensional CAD data model of each slice to obtain scanning path data which is guided into a host computer of a choosing area laser-melting and fast forming device, and a layer-to-layer fast scanning method is adopted to carry out the choosing area laser-melting and fast forming to paraffin powder so as to prepare and obtain the medical implant moulage; the medical implant moulage is taken out to clear redundant paraffin power on the surface. The slicing processing of the invention does not relate to STL format data; the formed moulage has dense tissue, thus no more processing is needed after infiltration of the paraffin, small scale forming equipment can be realized, equipment producing cost can be reduced and forming time is shortened.

Owner:SOUTH CHINA UNIV OF TECH

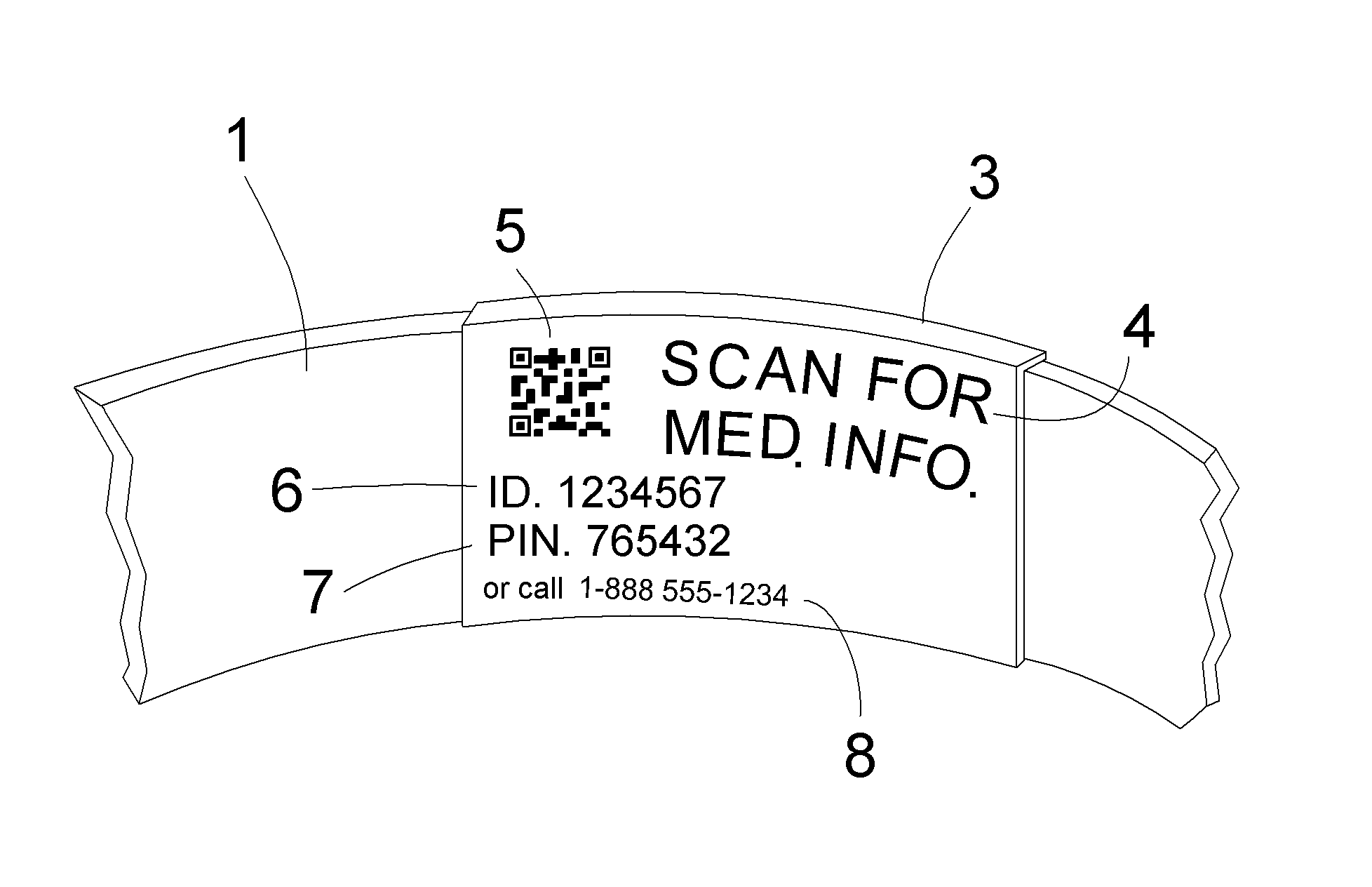

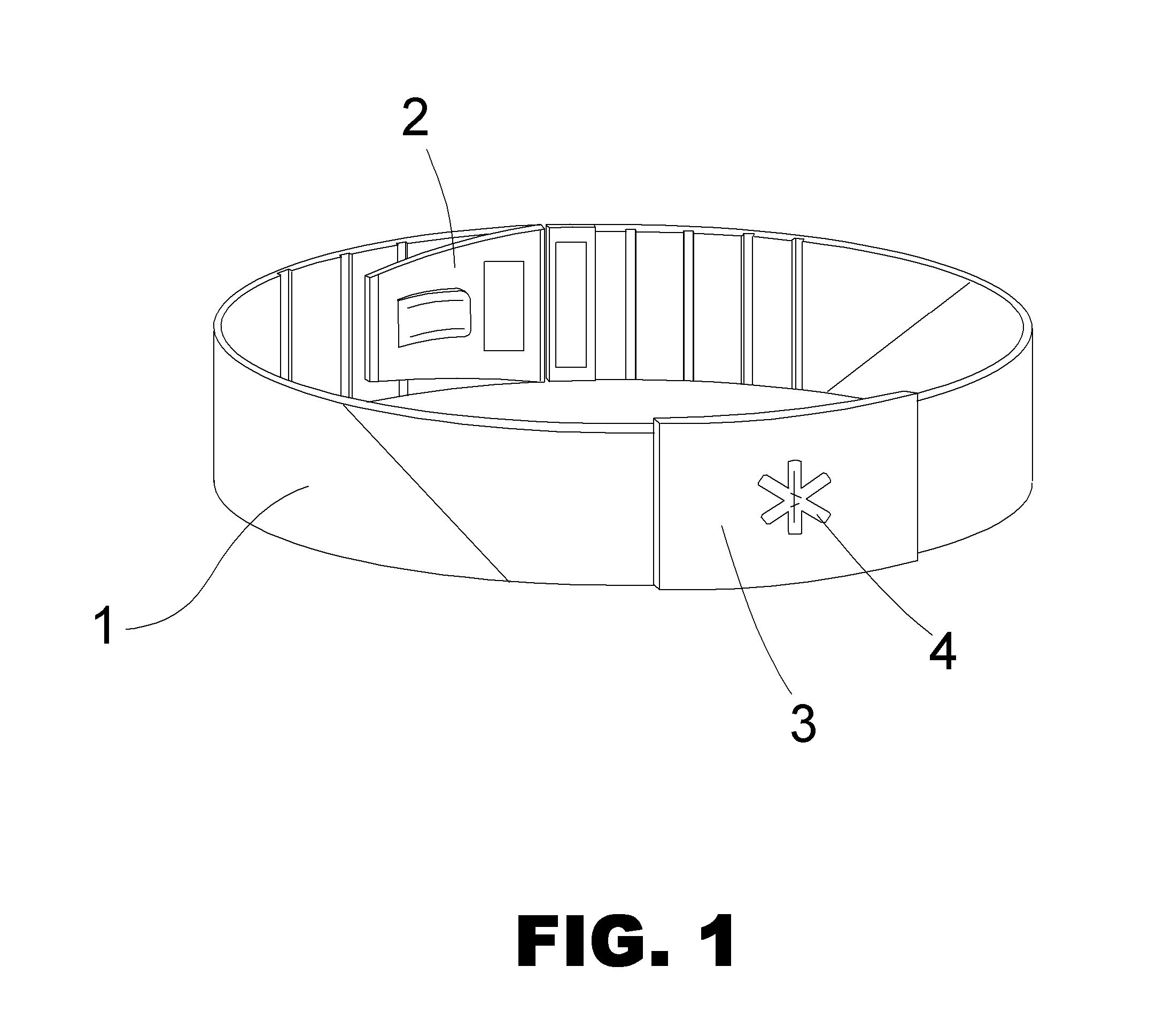

System and Method for Quickly Obtaining Medical Information

ActiveUS20140070012A1Easy accessHighly visibleStampsPerson identificationHand held devicesComputer science

A medical bracelet, wrist-band device, watch, piece of jewelry, or any other worn item contains a OR code for fast scanning by emergency first responders, ER teams or any other medical personnel. Scanning the QR code with a handheld device like a smartphone results in immediate retrieval of pertinent medical information either directly from the QR code, or from a dedicated website. Further security of medical information can be provided by a numerical or alphanumerical patient ID. and a PIN that can be printed on the device for fast access.

Owner:MYID LLC +1

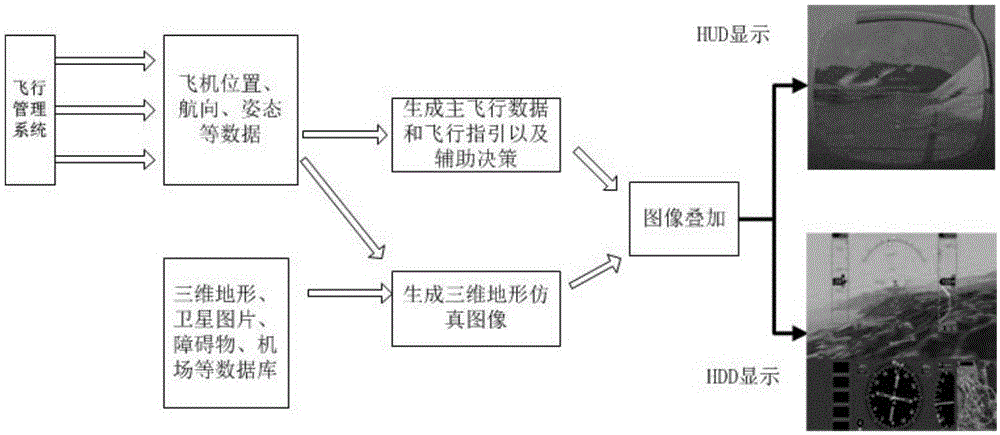

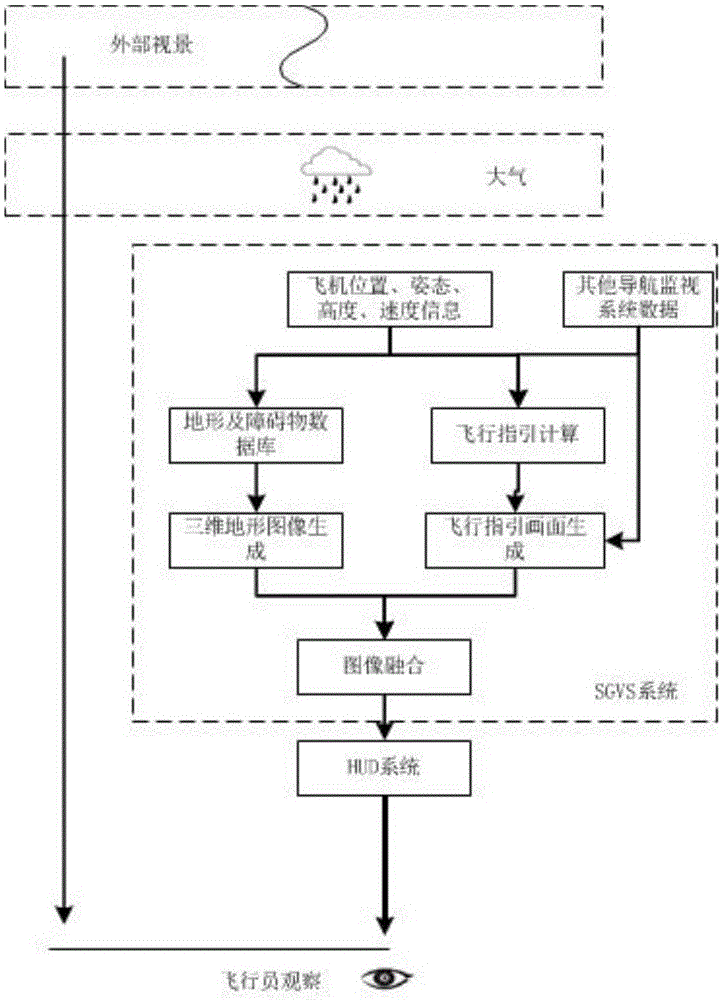

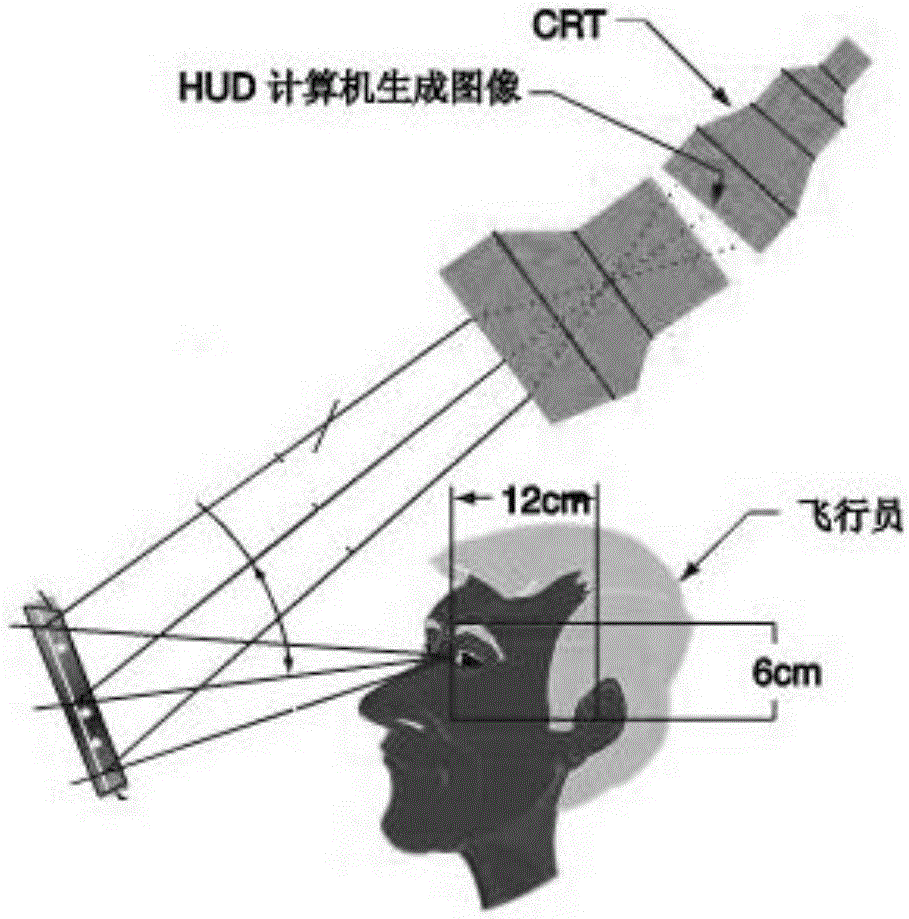

HUD (head-up display) based synthetic vision guiding display system

ActiveCN105139451ASave money on upgradesClosed circuit television systemsICT adaptationGuidance systemHead-up display

The invention belongs to the field of aviation electronic systems and particularly relates to an HUD based synthetic vision guiding display system. At present, an SVS (synthetic vision system) only can be displayed in a head-down display, and during high-speed taxiing, even the fastest scanning of a lower traditional instrument can lead to vision interruption with the outside world. An HGS (head-up guidance system) is not endowed with ability of displaying a three-dimensional terrain synthetic vision, and when inclement weather is encountered, it is difficult to provide better vision awareness for a pilot. With the adoption of the HUD based synthetic vision guiding display system provided by the invention, fused display of a synthetic image of the SVS and a flight guiding image is realized on an HUD system, and a civil aircraft cockpit display system capable of strengthening situation sensing ability especially combines a three-dimensional image display technology with a flight guiding information calculation display technology to simulate an outer aircraft environment and display flight guiding data in a cockpit head-up display.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

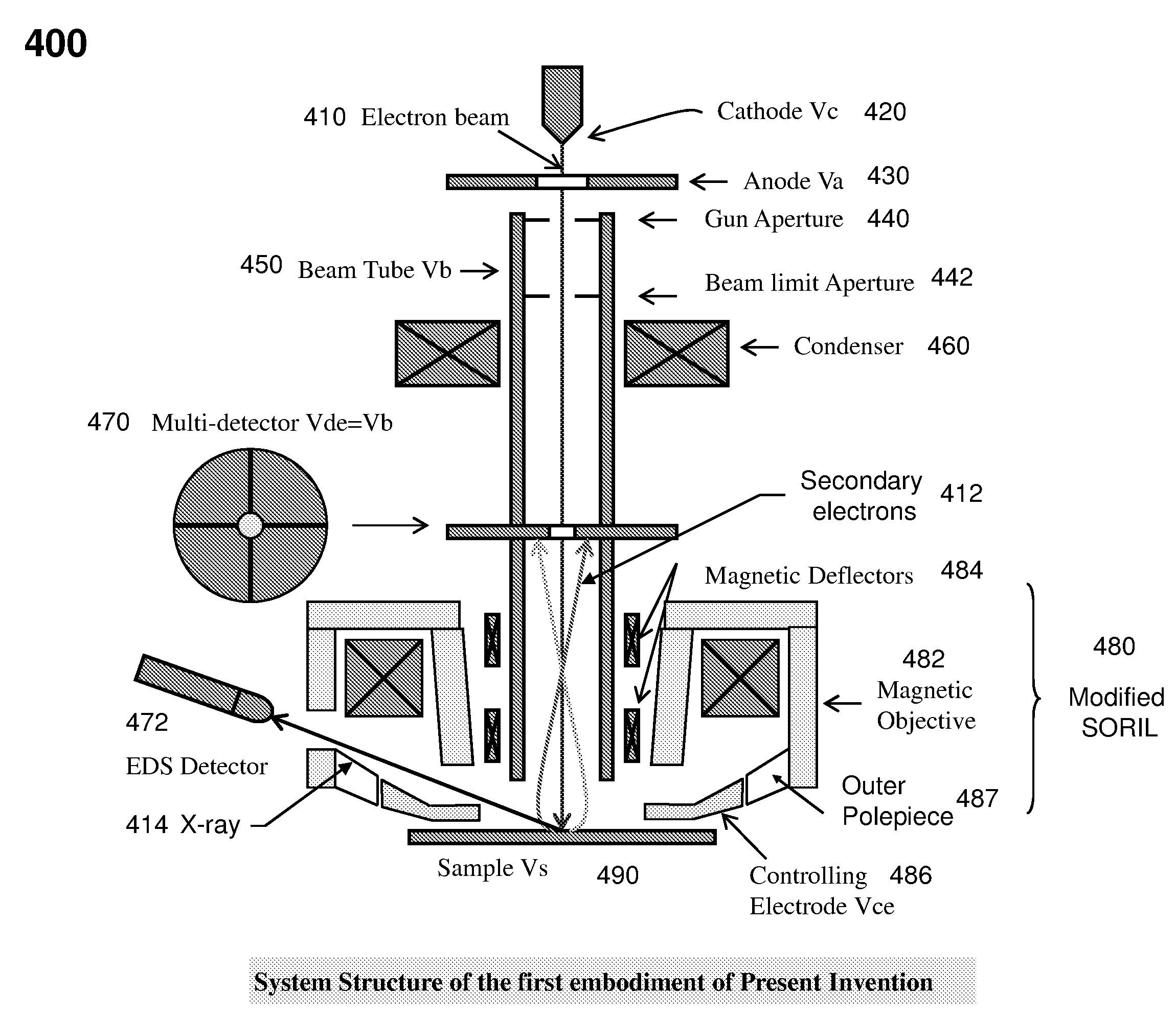

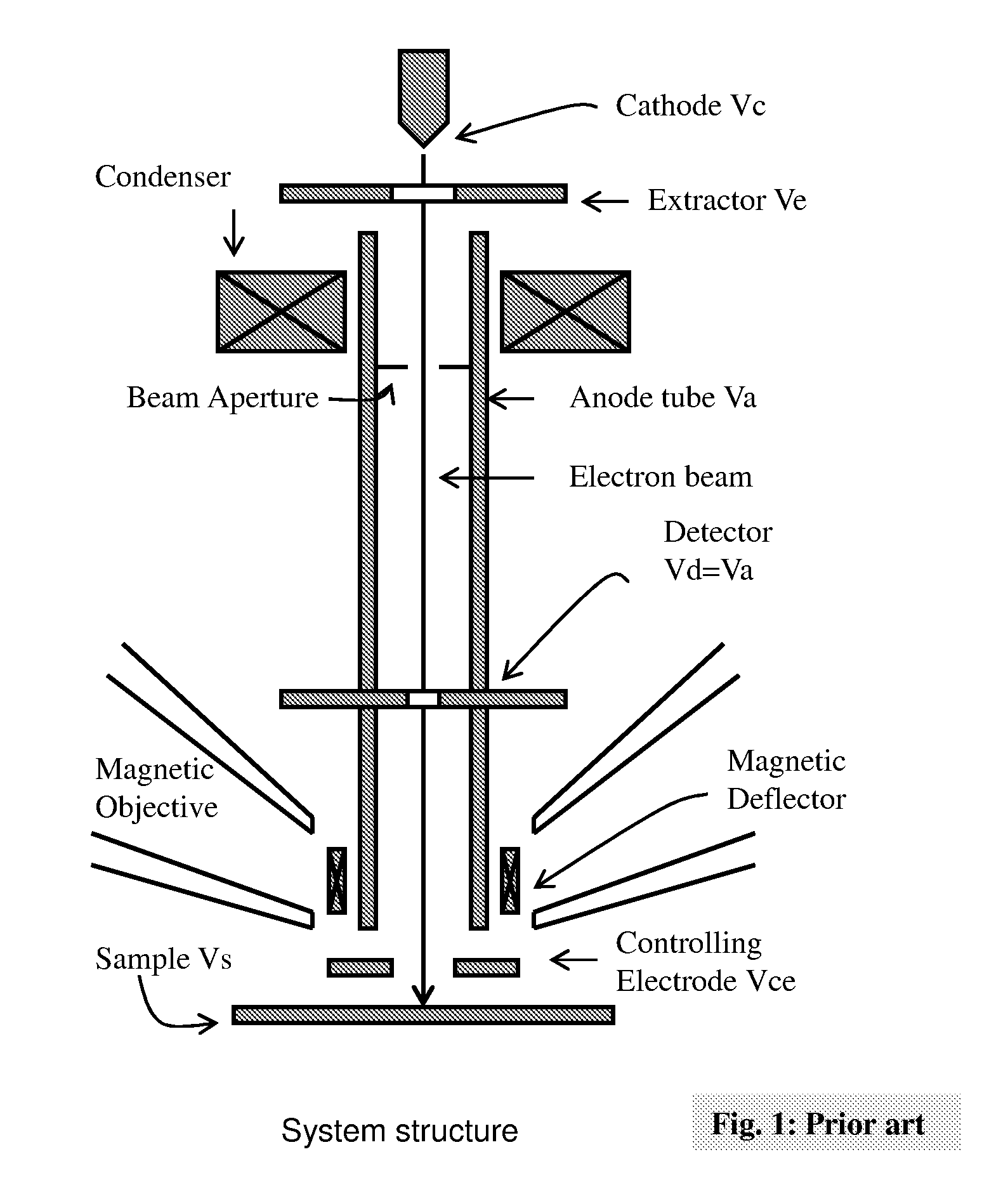

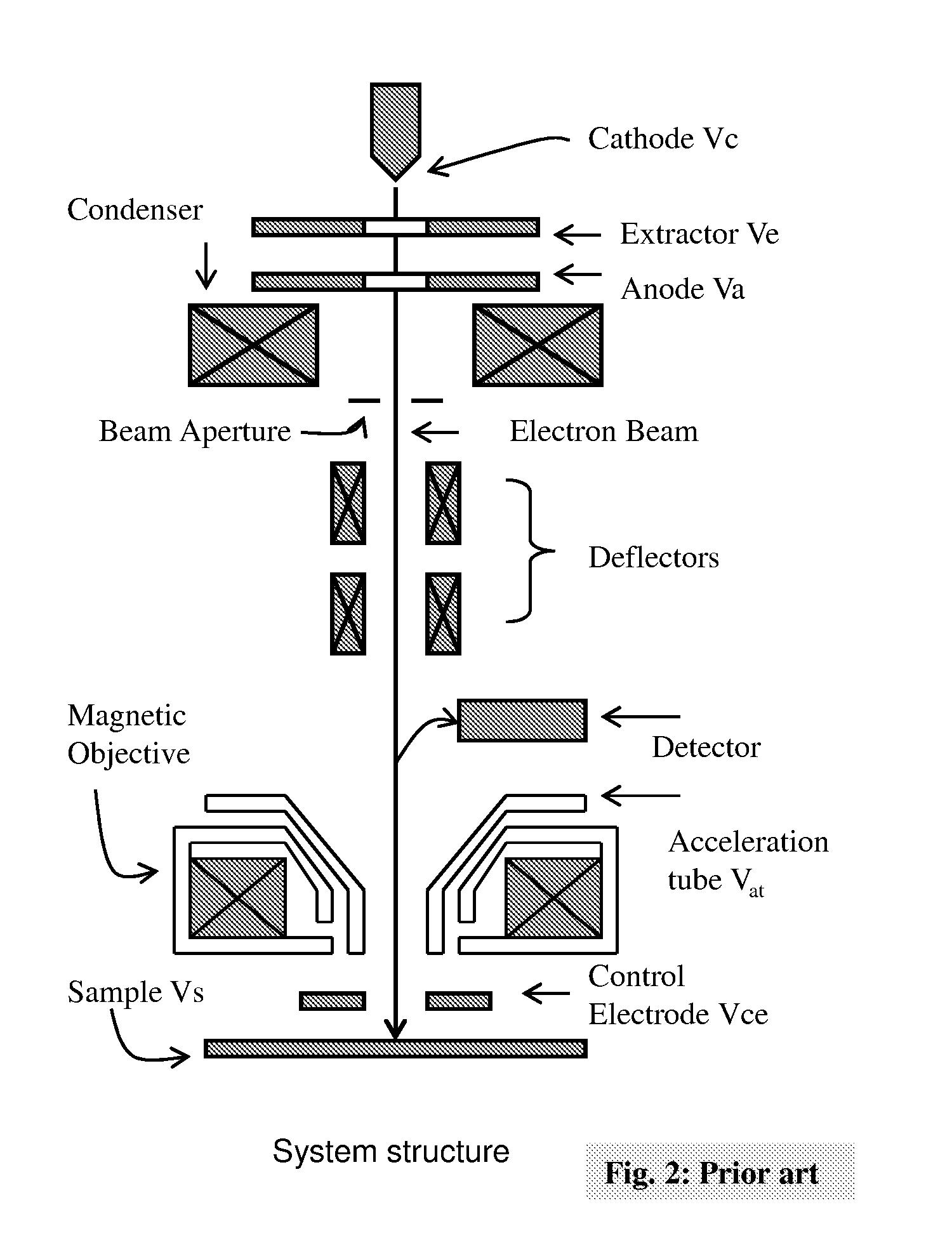

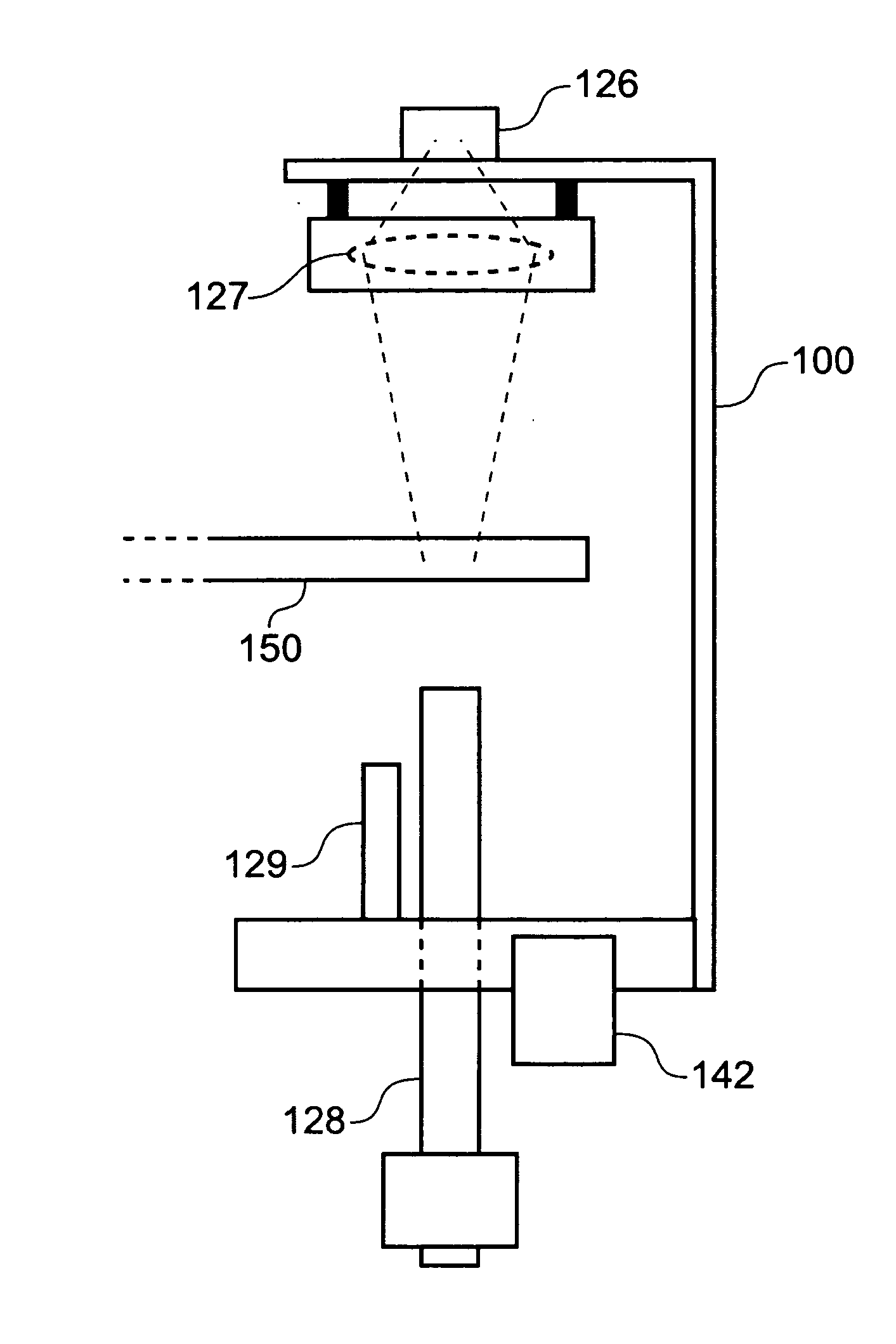

Electron beam apparatus

InactiveUS20100102227A1Improve imaging resolutionLarge aberrationThermometer detailsMaterial analysis using wave/particle radiationScanning electron microscopeAcceleration voltage

The present invention relates to a charged particle beam apparatus which employs a scanning electron microscope for sample inspection and defect review.The present invent provides solution of improving imaging resolution by utilizing a field emission cathode tip with a large tip radius, applying a large accelerating voltage across ground potential between the cathode and anode, positioning the beam limit aperture before condenser lens, utilizing condenser lens excitation current to optimize image resolution, applying a high tube bias to shorten electron travel time, adopting and modifying SORIL objective lens to ameliorate aberration at large field of view and under electric drifting and reduce the urgency of water cooling objective lens while operating material analysis.The present invent provides solution of improving throughput by utilizing fast scanning ability of SORIL and providing a large voltage difference between sample and detectors.

Owner:ASML NETHERLANDS BV

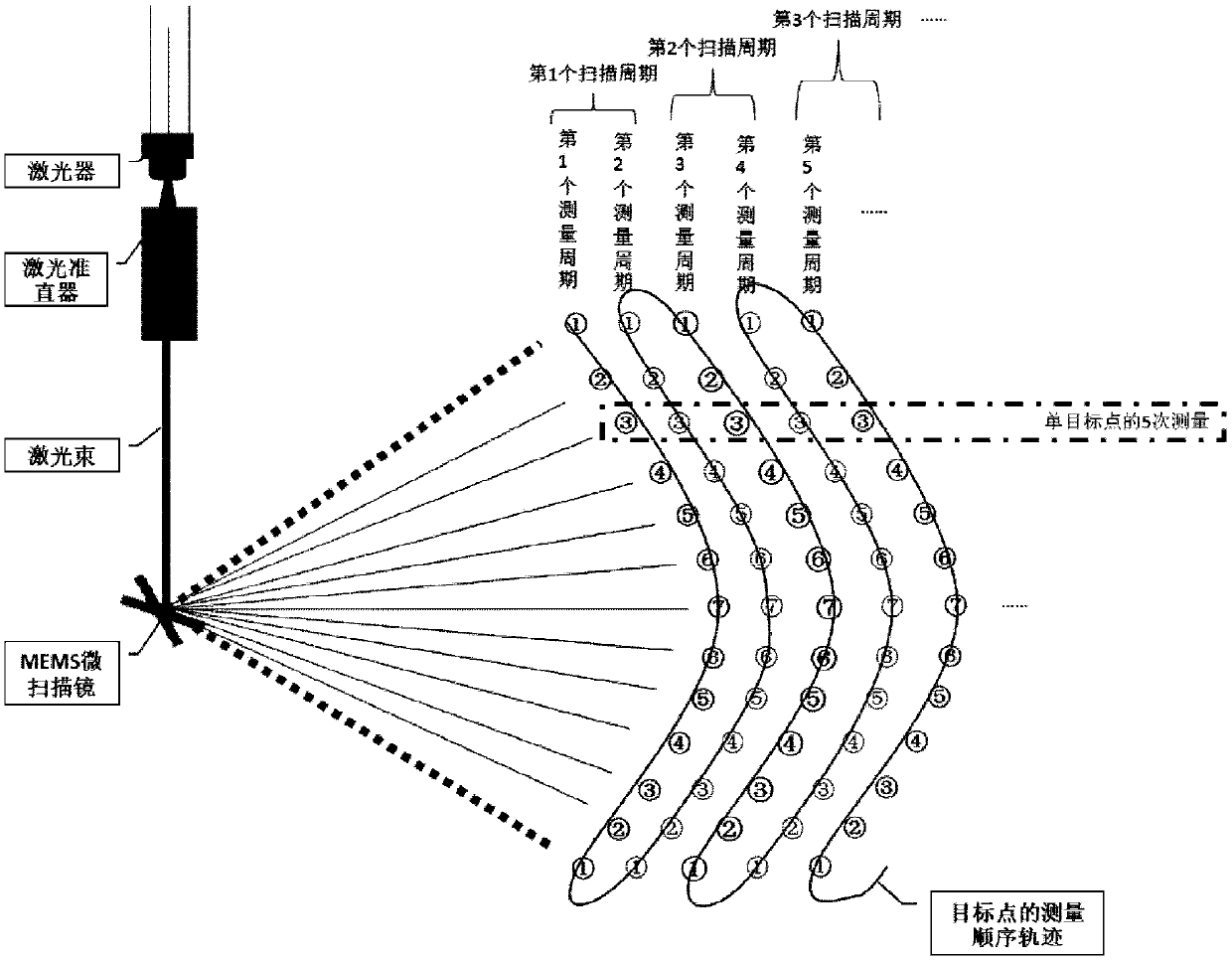

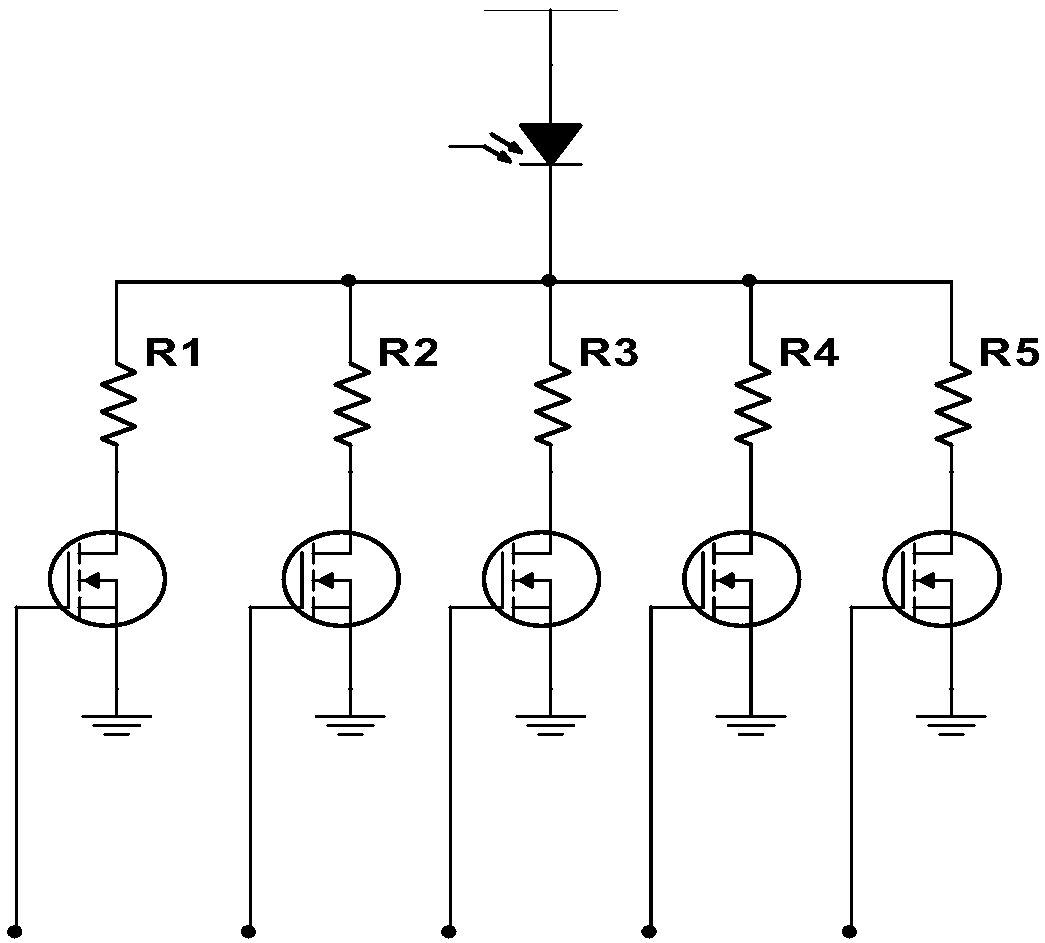

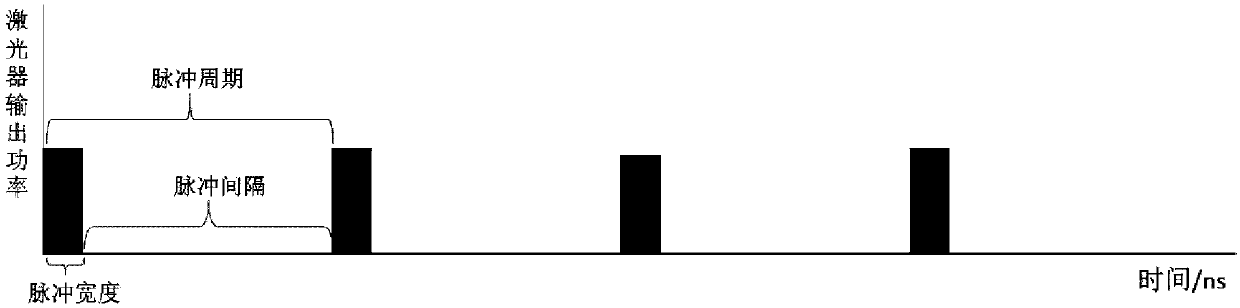

Laser radar interference immunity enhancing method and system

ActiveCN107728156AGuaranteed reliabilityIncrease refresh rateElectromagnetic wave reradiationWhole bodyOptoelectronics

The invention provides a laser radar interference immunity enhancing method comprising the following steps: carrying out non-continuous multiple scanning for a random single target point, and carryinglaser fast coding for each time scanned laser signal. The multiple measuring behaviors aiming at each target point are non-continuous under fast scanning conditions, thus ensuring the measuring result high refresh rate and reliability; the laser fast coding is to convert the pulse signals in a single pulse period of the existing pulse laser into continuous and / or discrete subpulses with at leasttwo different pulse intensities and / or pulse widths; a series of subpulses as a whole body in the single pulse period can form a detection signal unit of the single target point emitted by the laser radar. The fast coding method is applied to each measuring time of the single target multiple measures, thus further enhancing the laser radar measuring reliability in each time, reducing the single target measuring frequency on said basis, and further improving the measuring result refresh rate.

Owner:XI AN ZHISENSOR TECH CO LTD

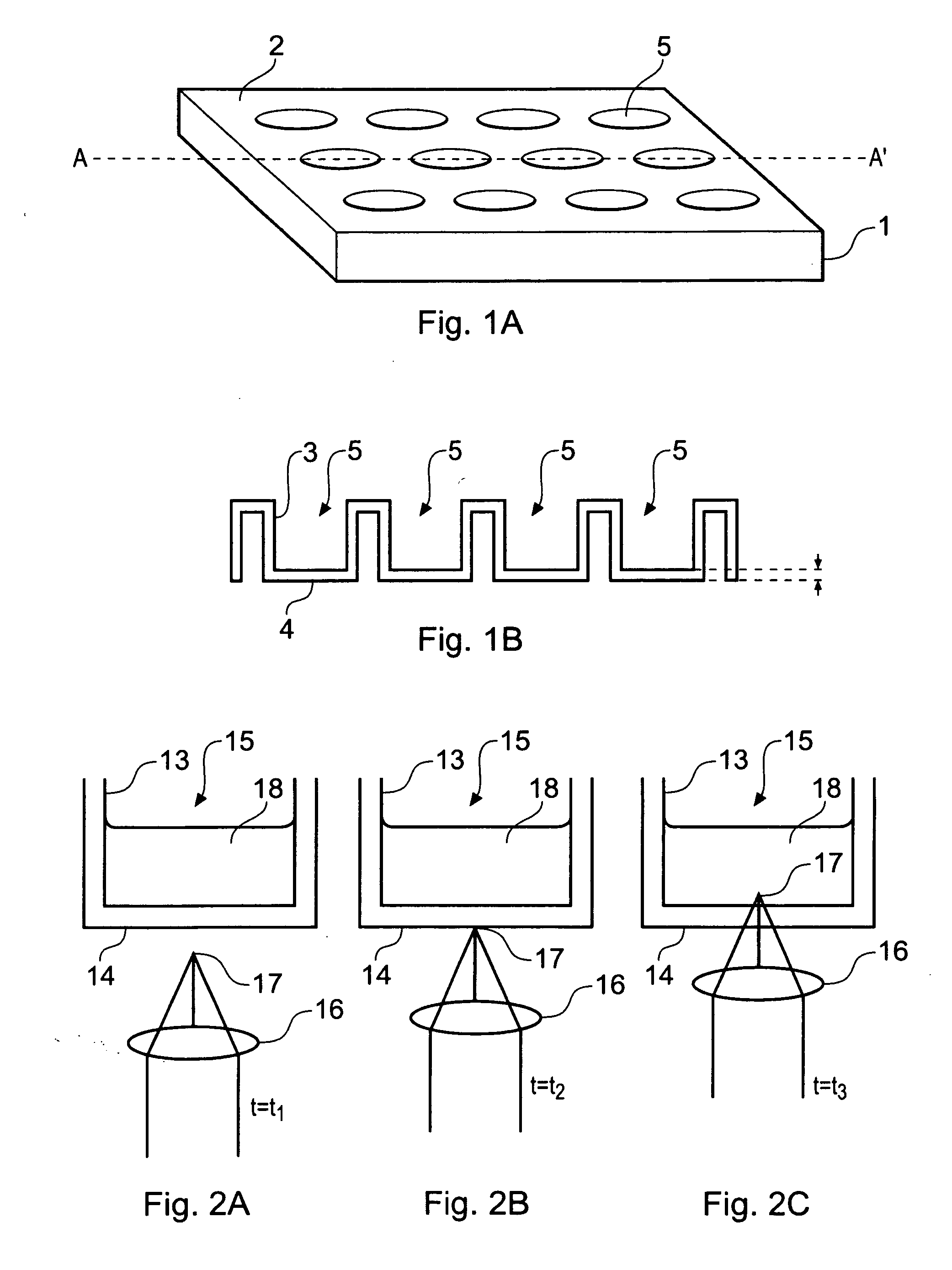

Methods and apparatus for optical analysis of samples in biological sample containers

ActiveUS20080297774A1Accurately knowAccurately determineRadiation pyrometrySpectrum investigationFast scanningCELLULAR SHEET

An apparatus and method for optically analyzing samples in a biological sample container containing samples arranged at different locations on the base of the container. An optical acquisition device is provided comprising a detector and an objective. The position of the upper and lower surfaces of the base at each of the sample locations is determined by a confocal polychromatic displacement sensor. Light is collected from each of the sample locations by adjusting the focal plane to be coincident with, or vertically offset from, the upper surface of the base, as determined from the displacement sensor. This allows for rapid scanning of large numbers of samples in a multi-well plate or other biological sample containers.

Owner:GENETIX LTD

Fast scanner with rotatable mirror and image processing system

A scanner for obtaining an image of an object placed on an at least partially transparent platform, wherein the platform has at least a first scan area and a second scan area. The scanner includes a white area formed at least partially around the edge portions of the platform with a plurality of markers, one rotatable mirror, one or more image sensors. In scanning, each partial image from each of the scan areas includes an image of at least one portion of the plurality of markers. An image processing system uses the image of the at least one portion of the plurality of markers in each of the consecutive partial images as a reference to combine the consecutive partial images so as to form a substantially complete image of the object corresponding to a full scan of the first scan area and the second scan area.

Owner:RULING OPTICS

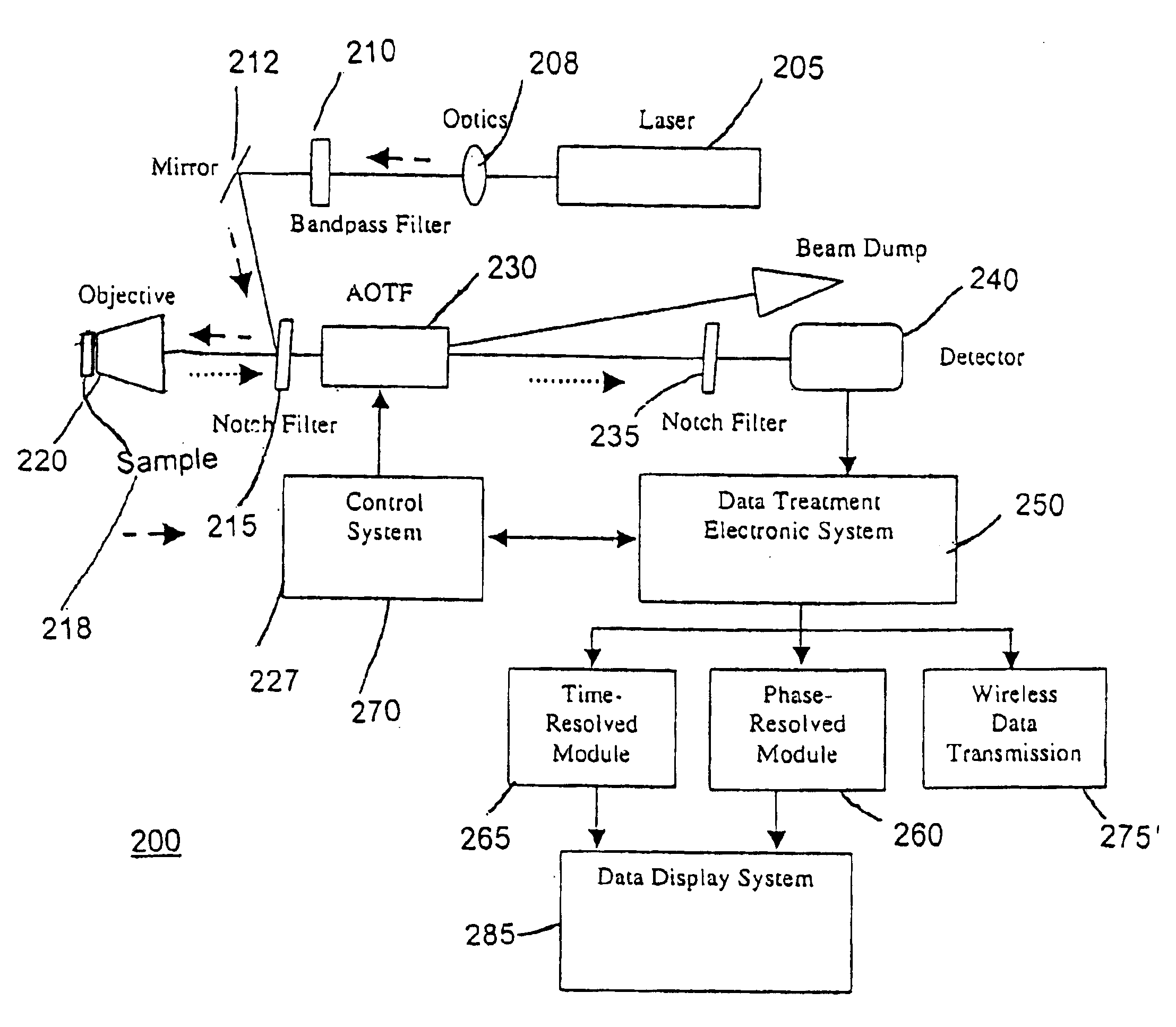

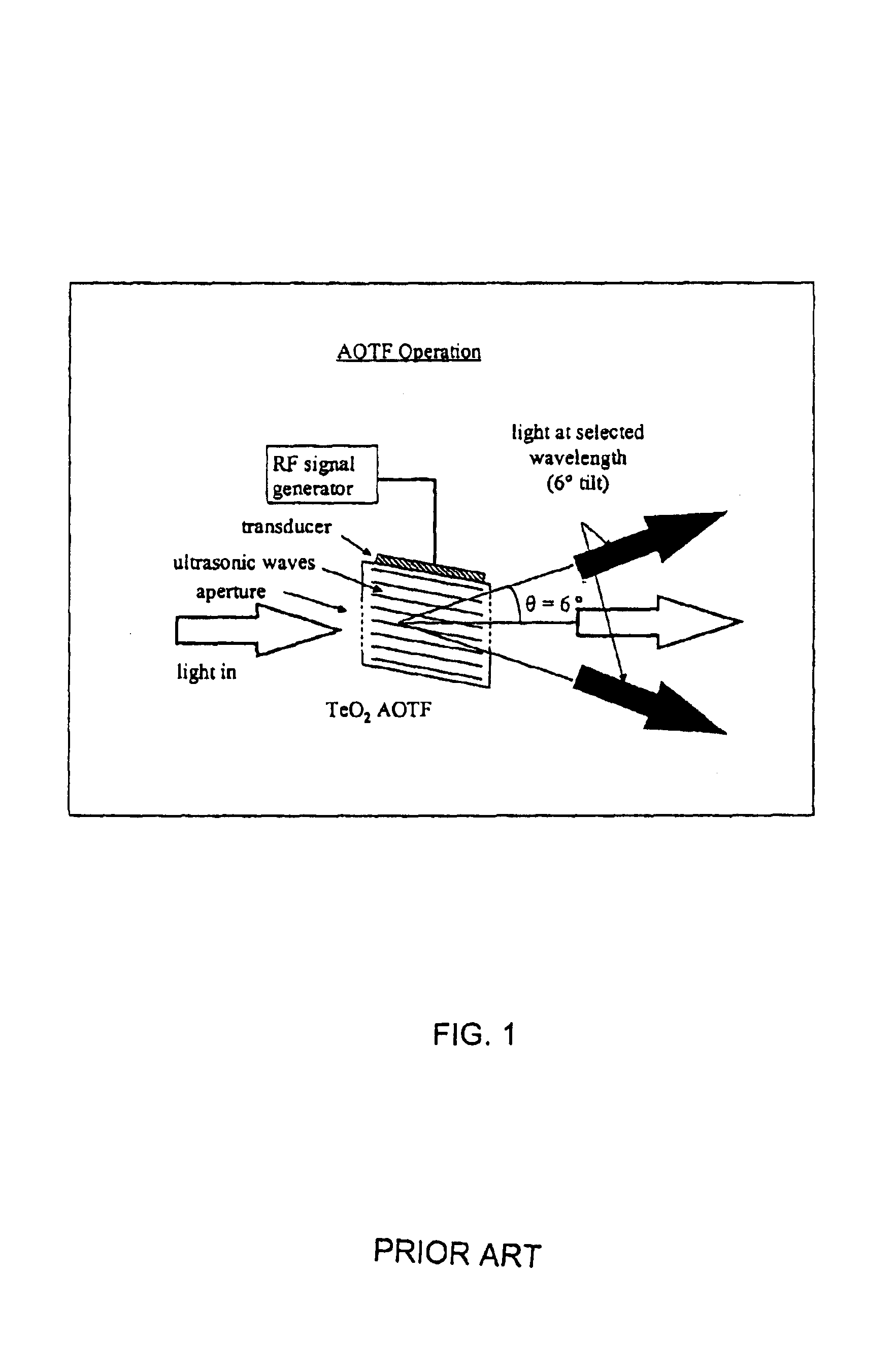

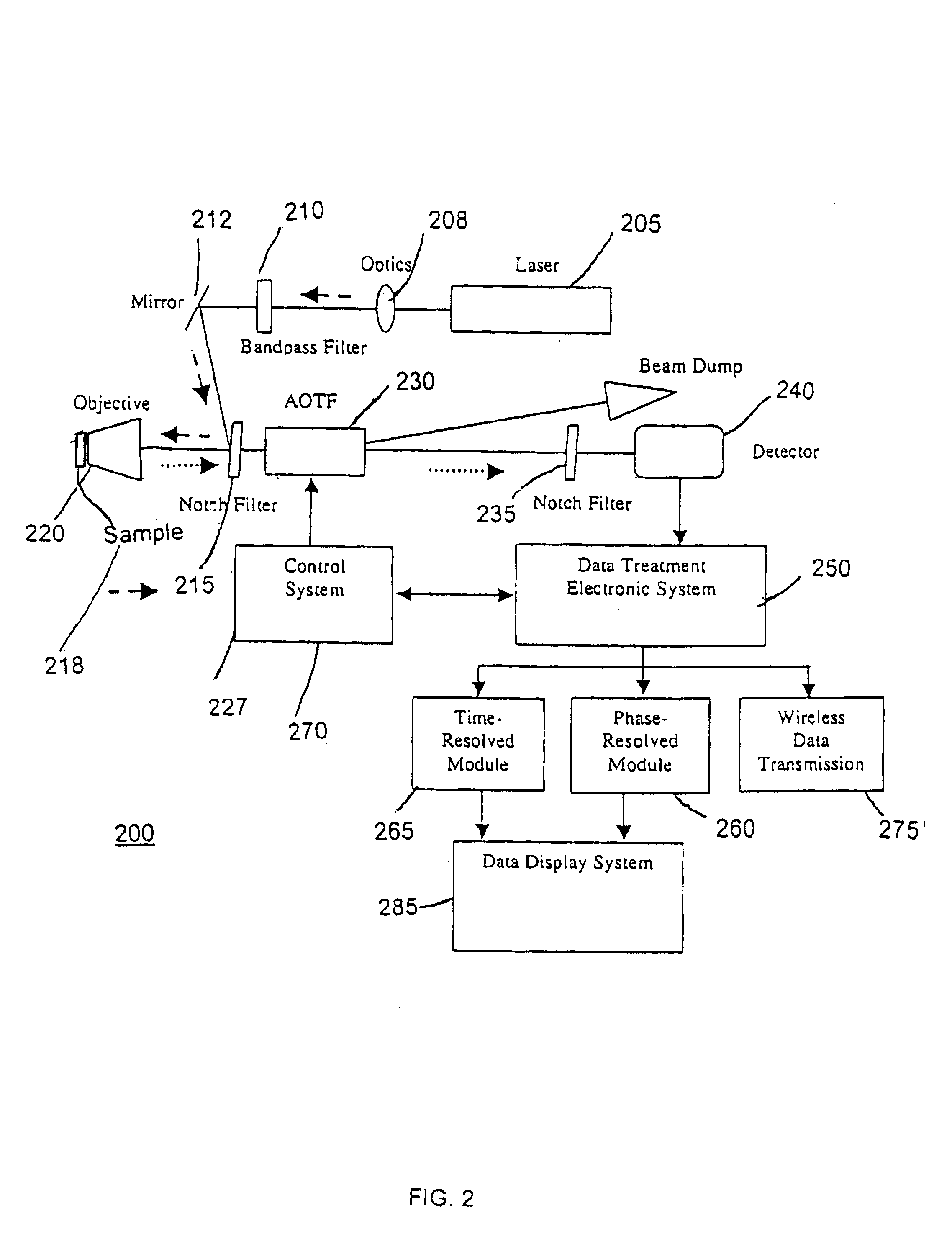

Integrated tunable optical sensor (ITOS) system

A scanning tunable detection system and related method for analyzing samples includes a source of time varying excitation signals and a tunable optical filter for selectively transmitting time-varying optical signals emanated from a sample following irradiation with the time varying excitation signals. A detector is provided for converting the time-varying optical signals to electrical detection signals. The system can identify components in a sample using phase sensitive or time sensitive detection. A slew scan mode can be used to permit slow scanning through spectral regions rich in information but quickly in regions without such information.

Owner:UT BATTELLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com