Patents

Literature

2395results about How to "Expand the scope of work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

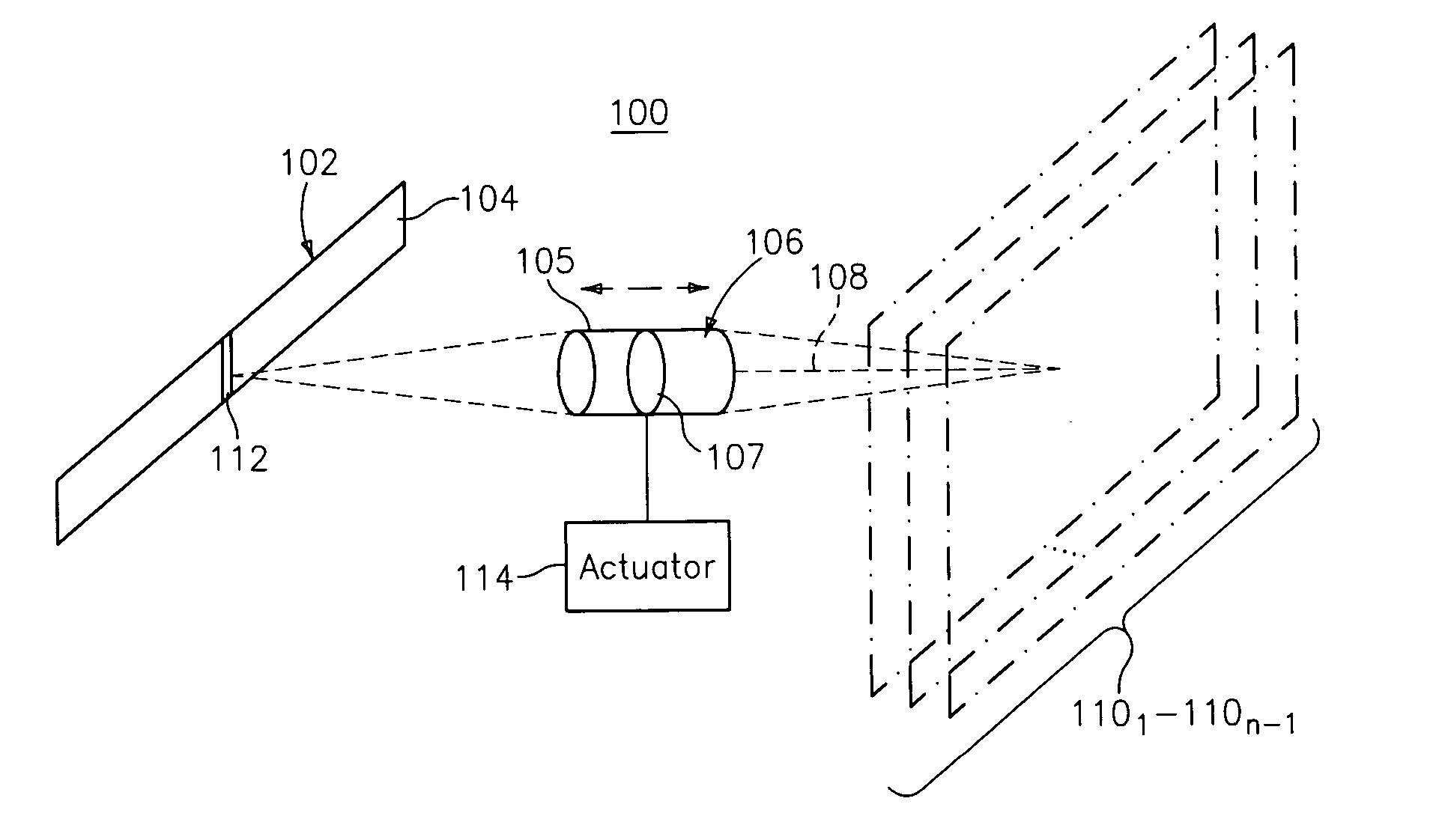

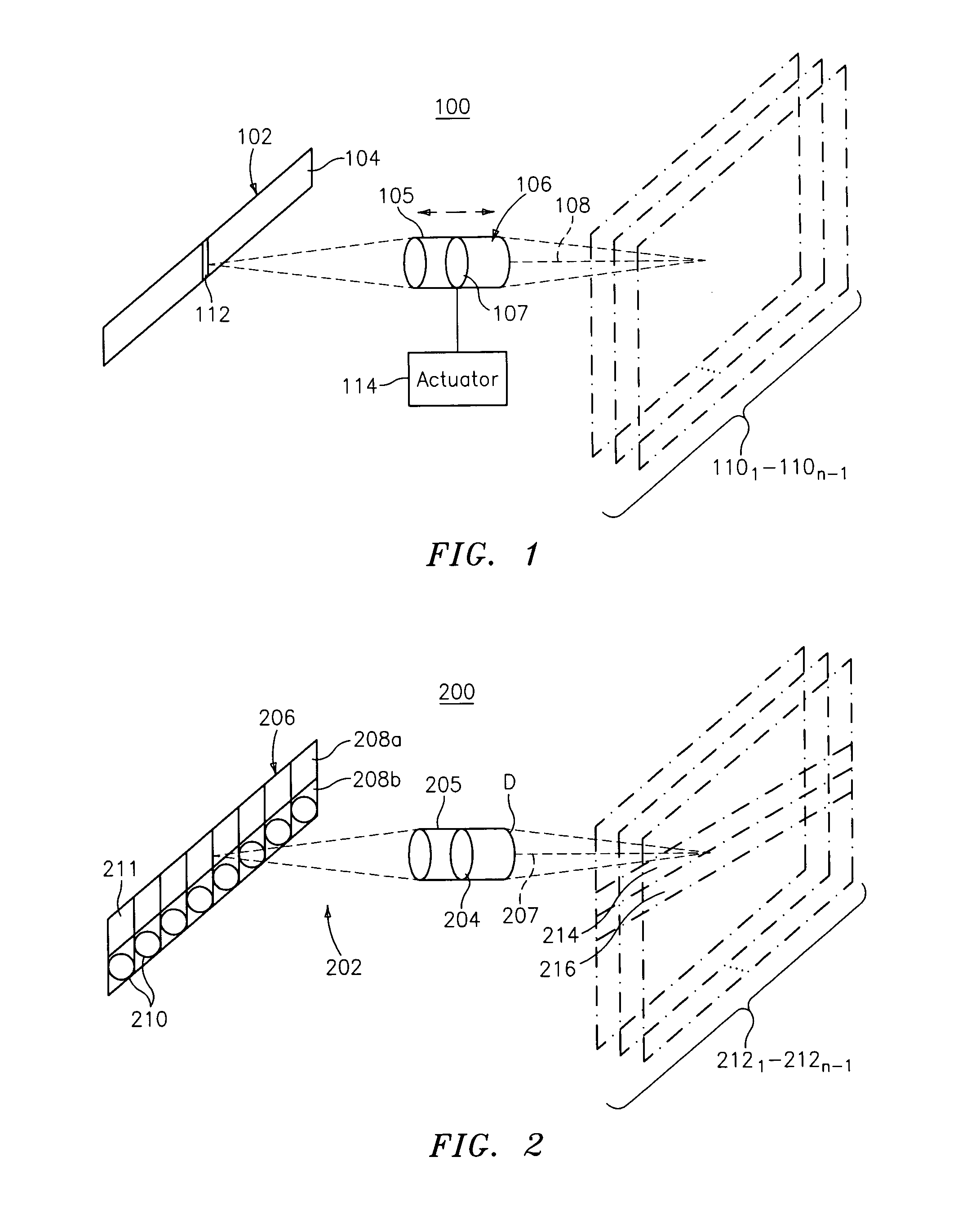

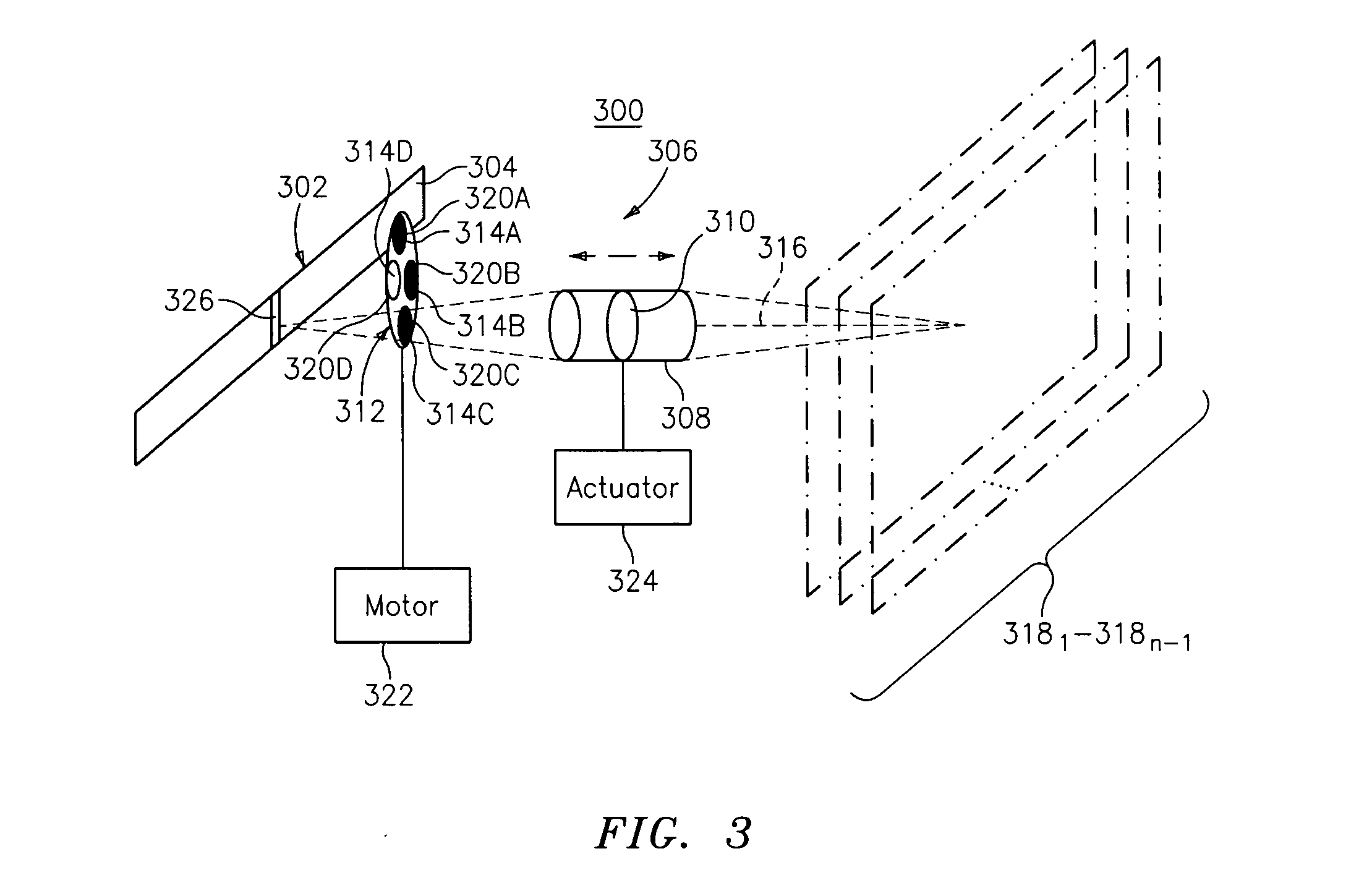

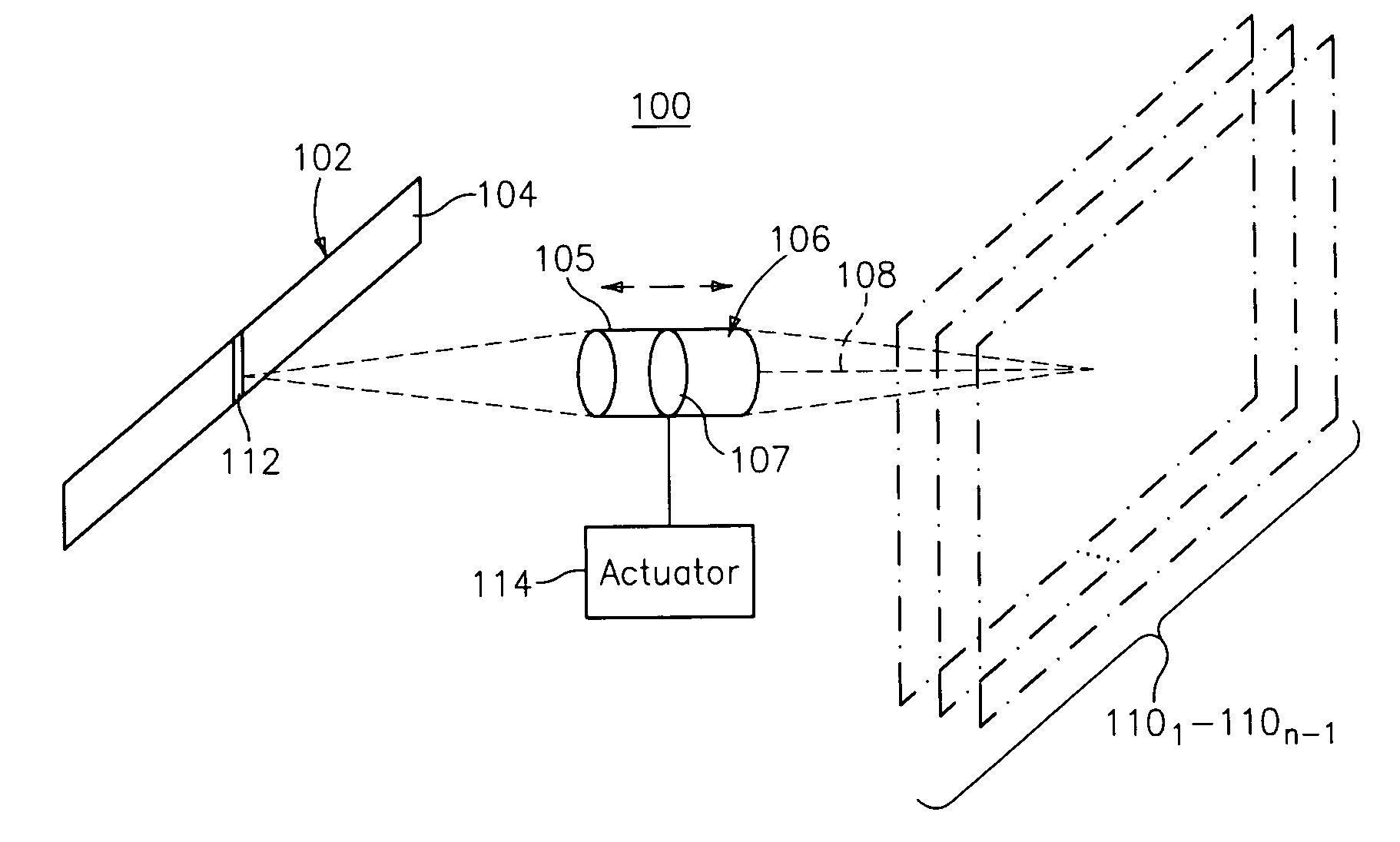

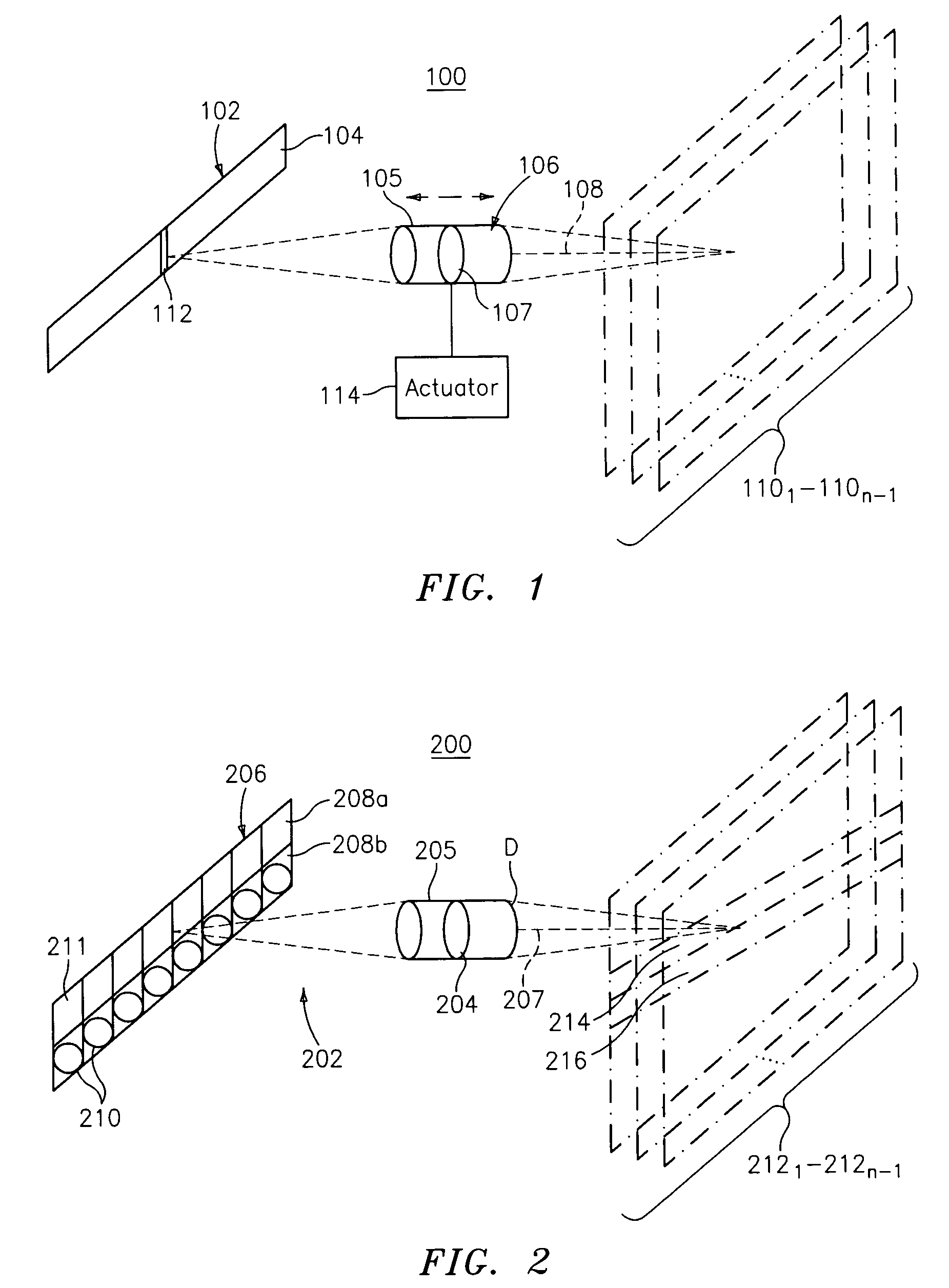

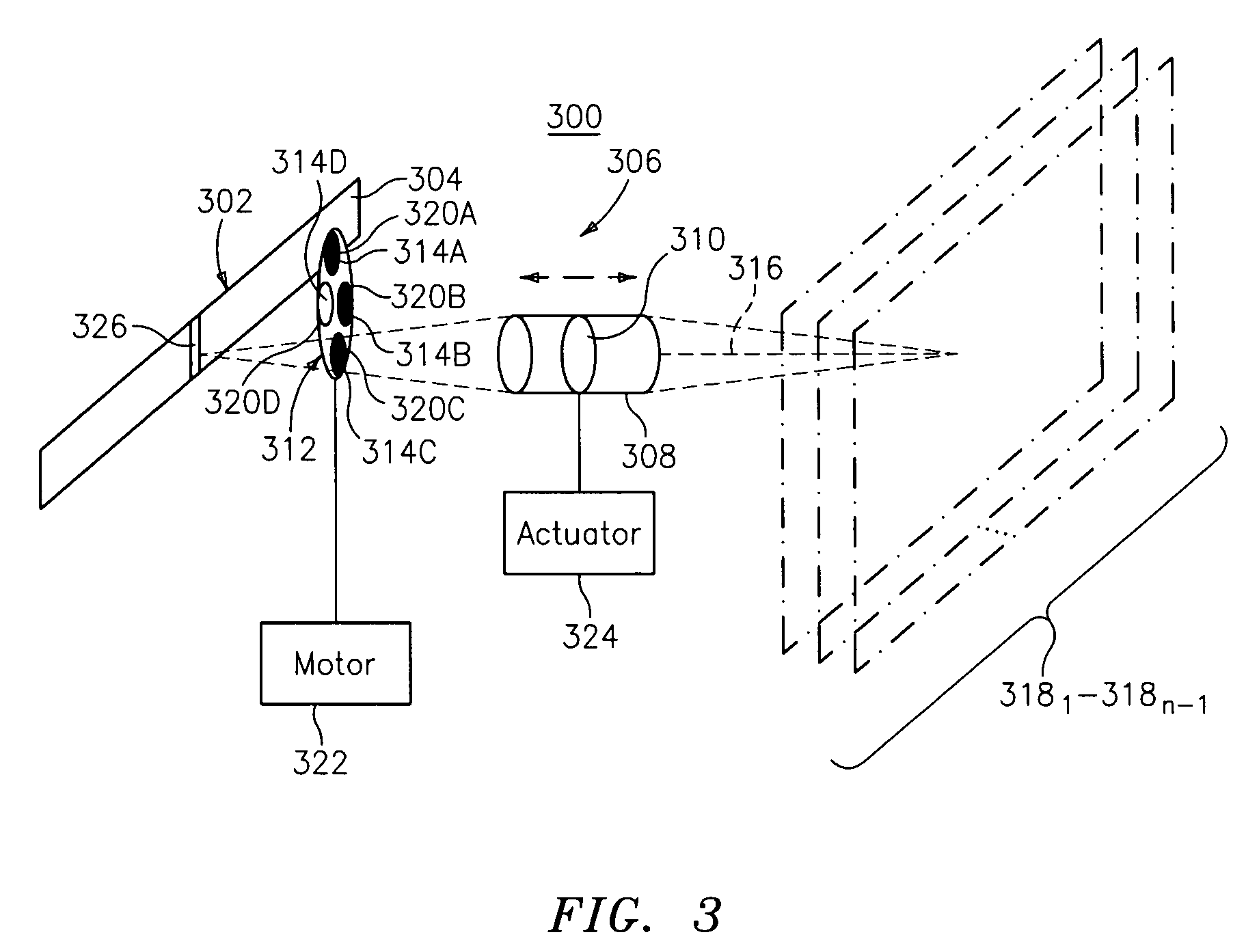

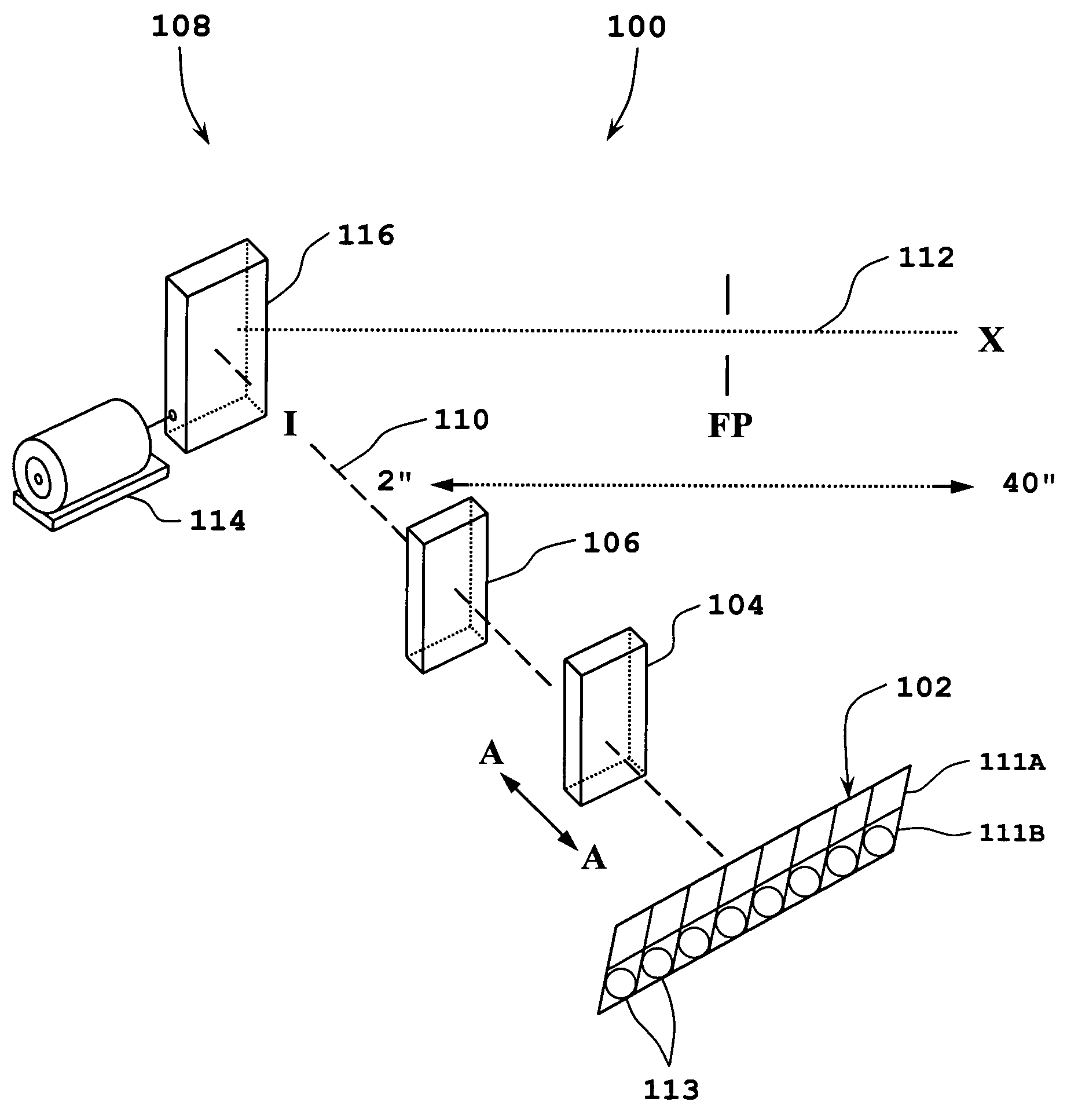

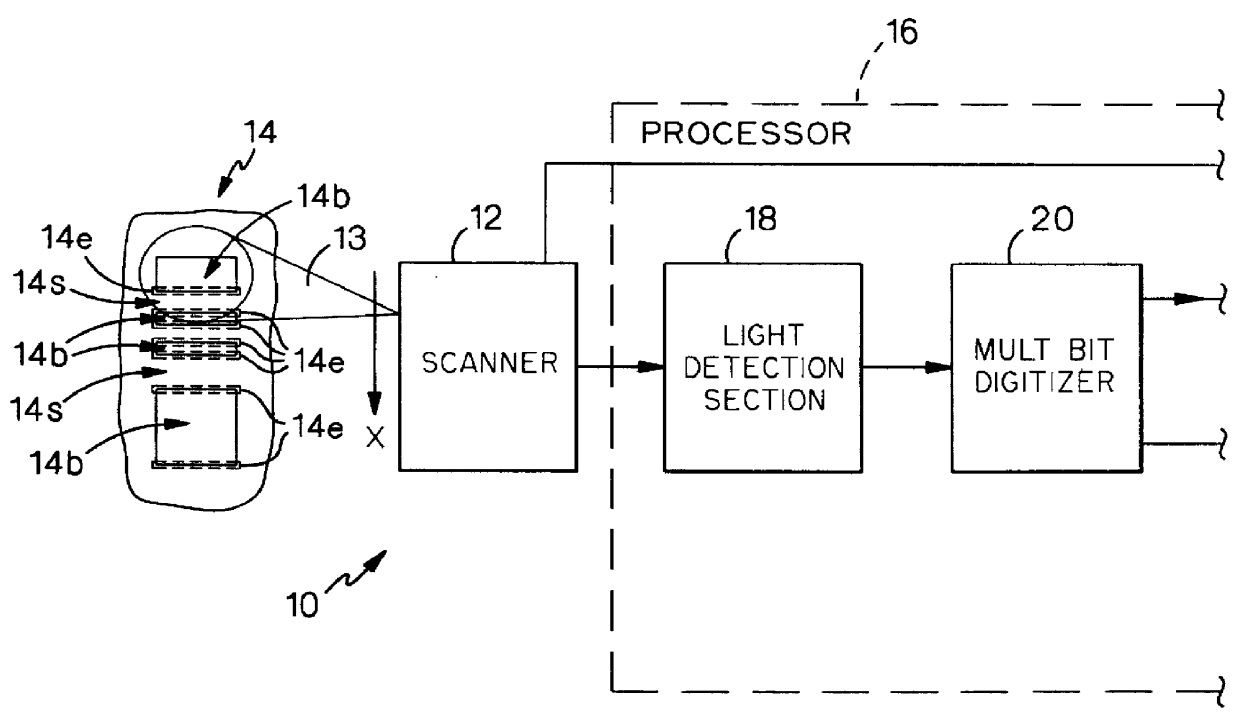

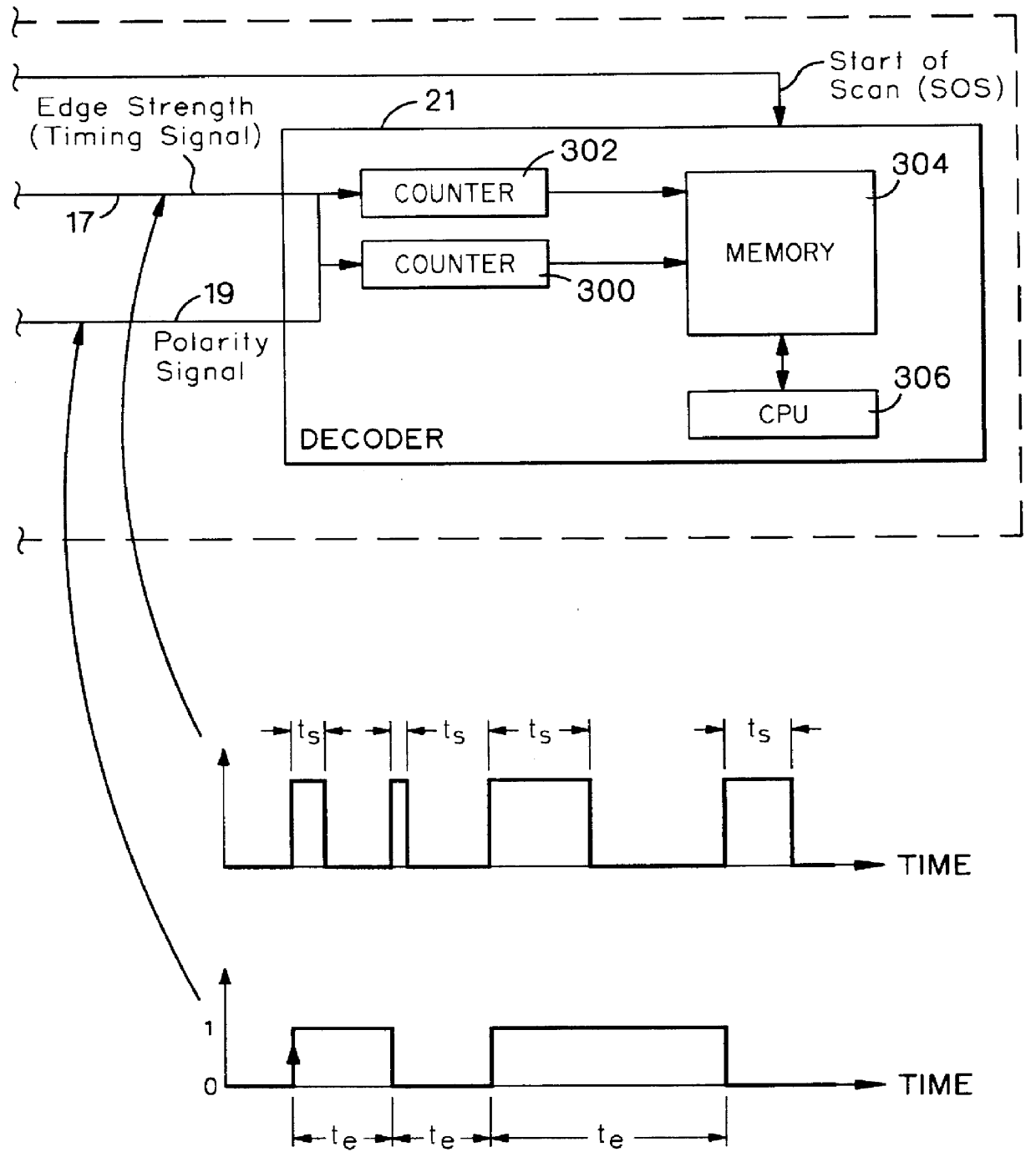

Imaging arrangement and barcode imager for imaging an optical code or target at a plurality of focal planes

ActiveUS20050006477A1Requirement be complexExpand the scope of workCharacter and pattern recognitionExposure controlImage sensorBarcode

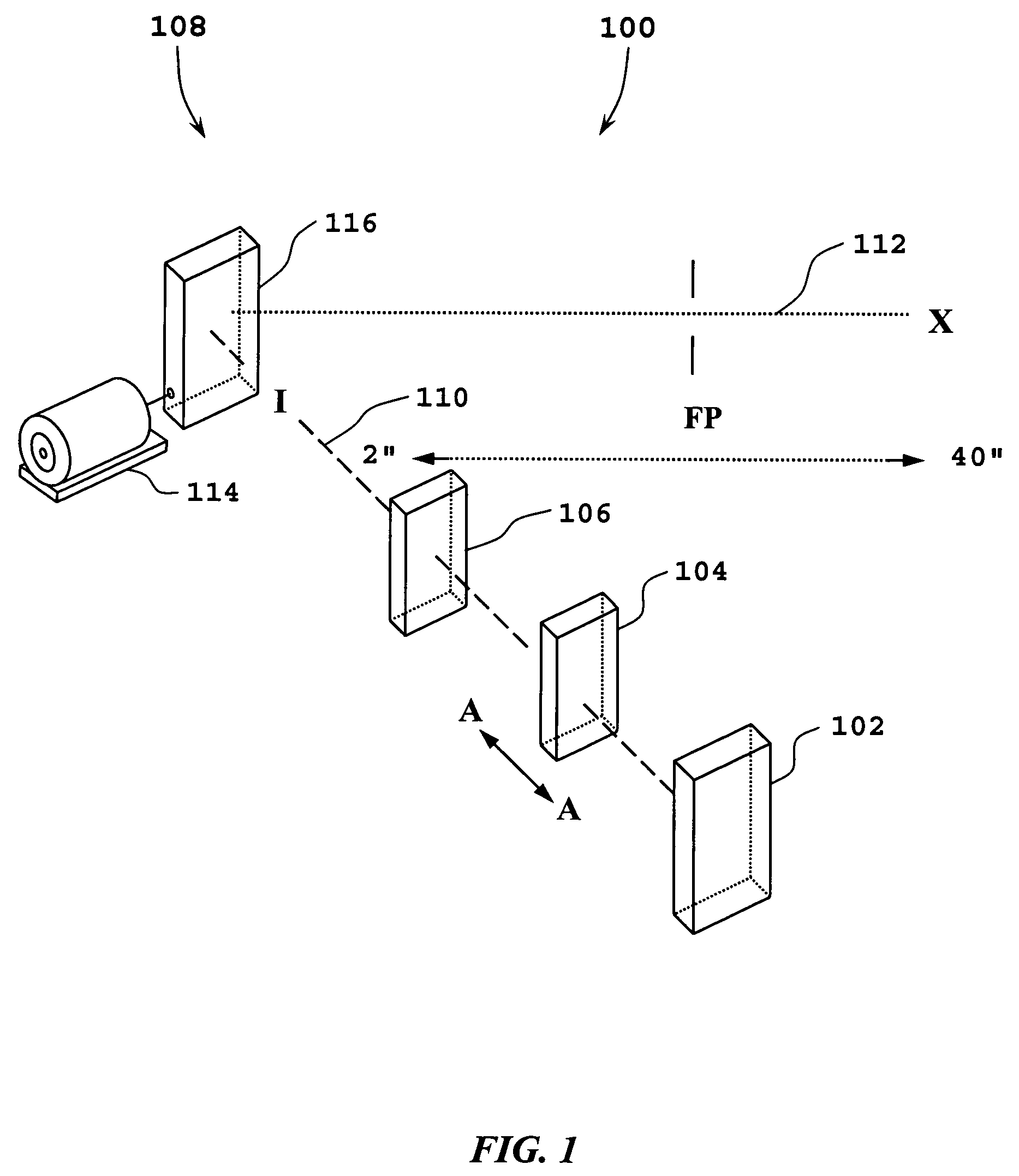

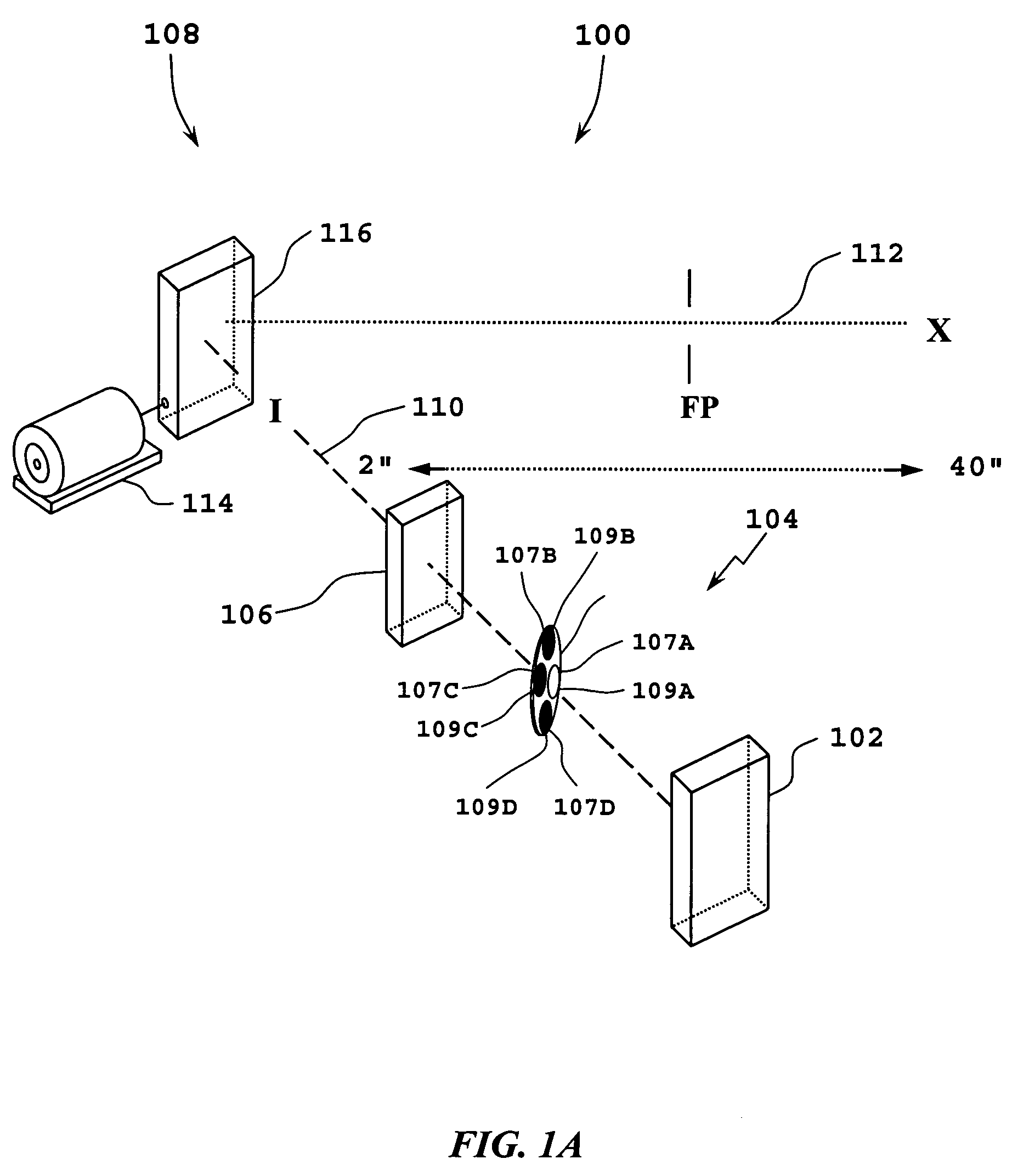

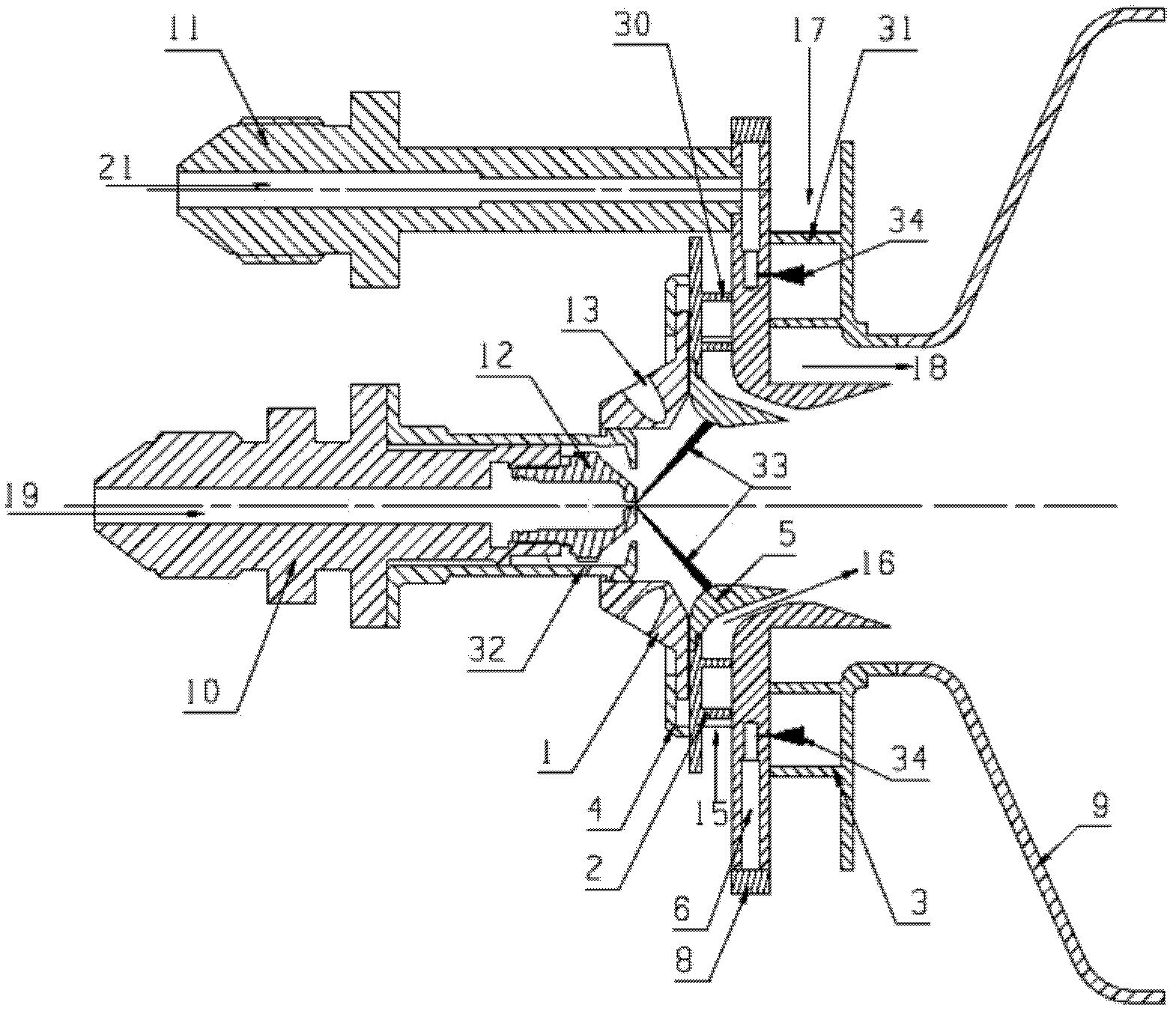

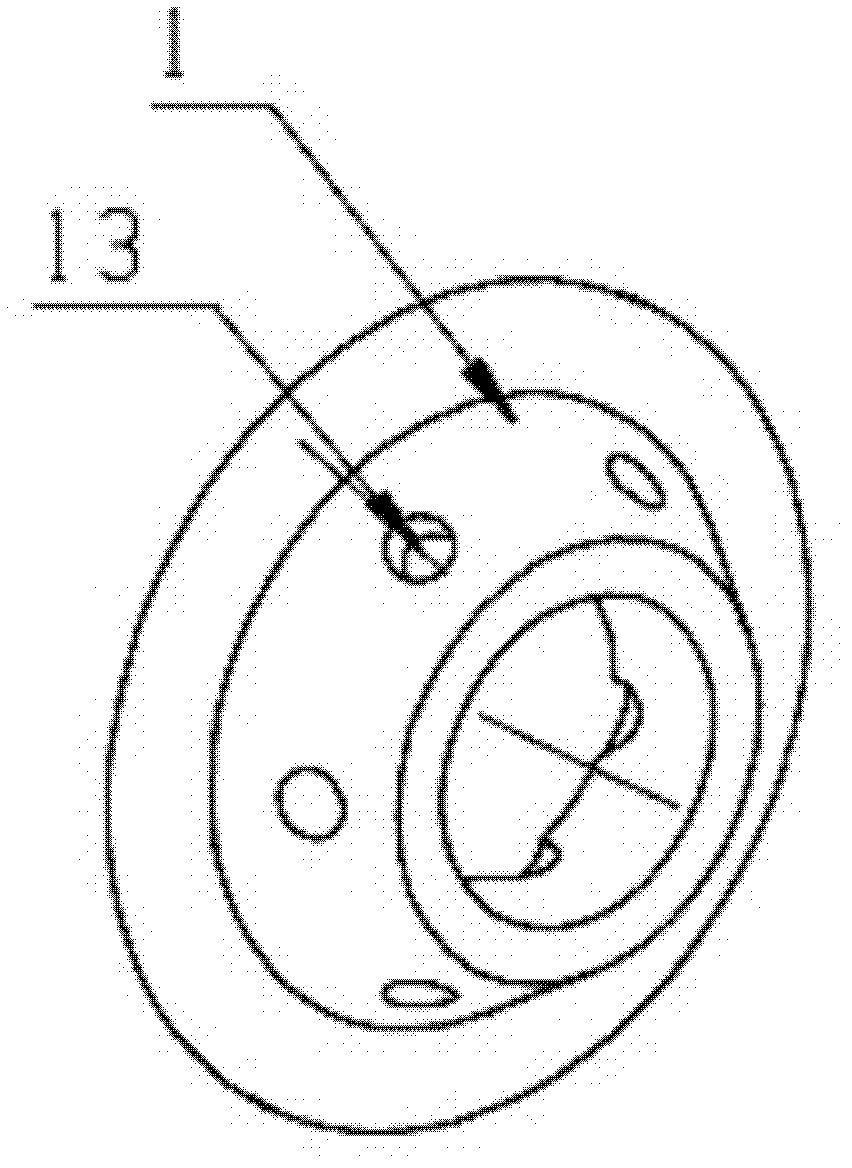

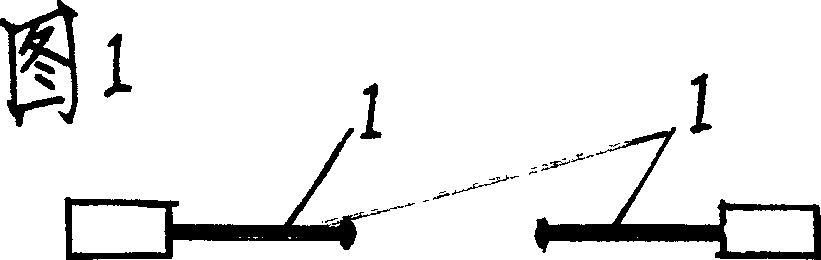

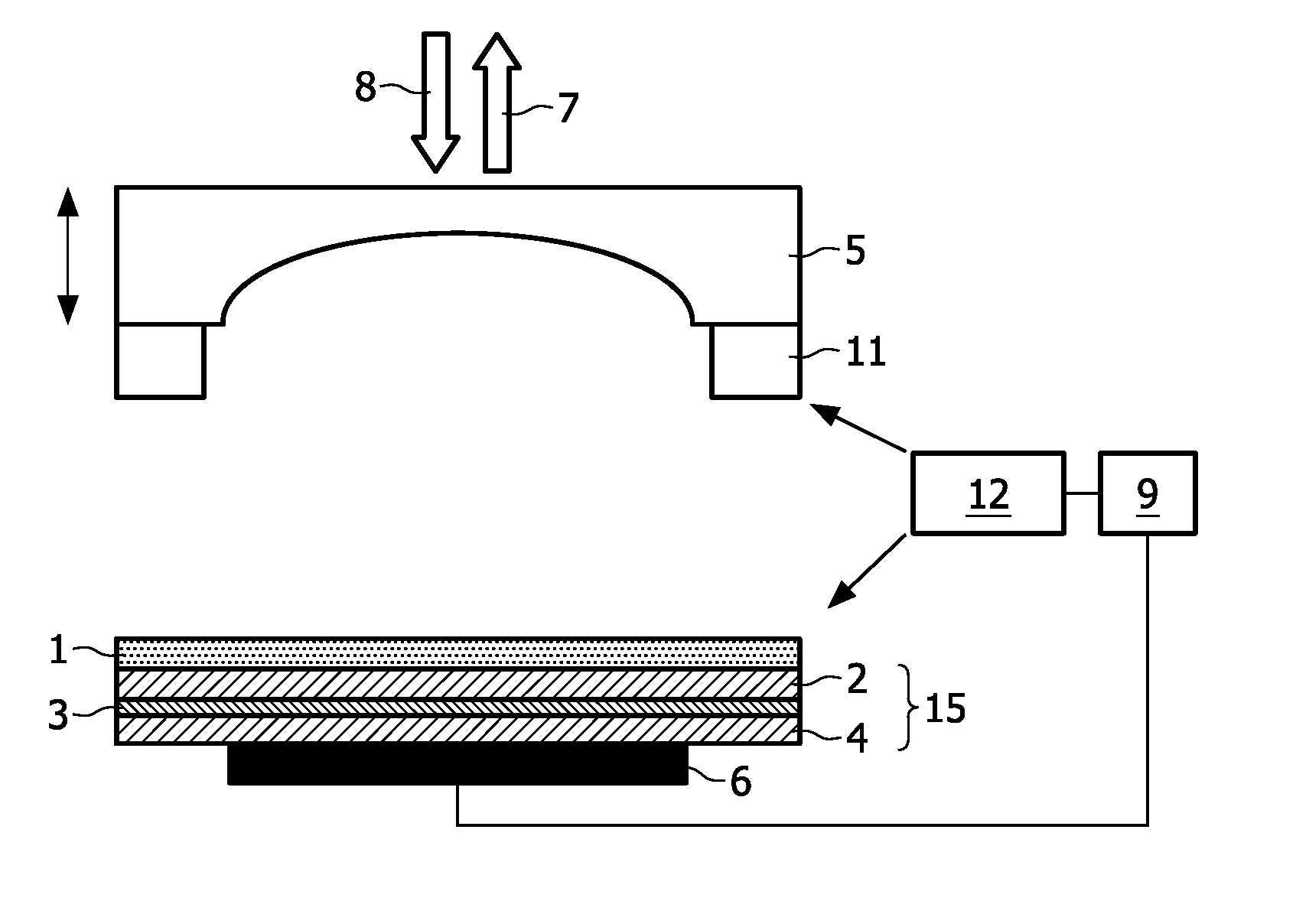

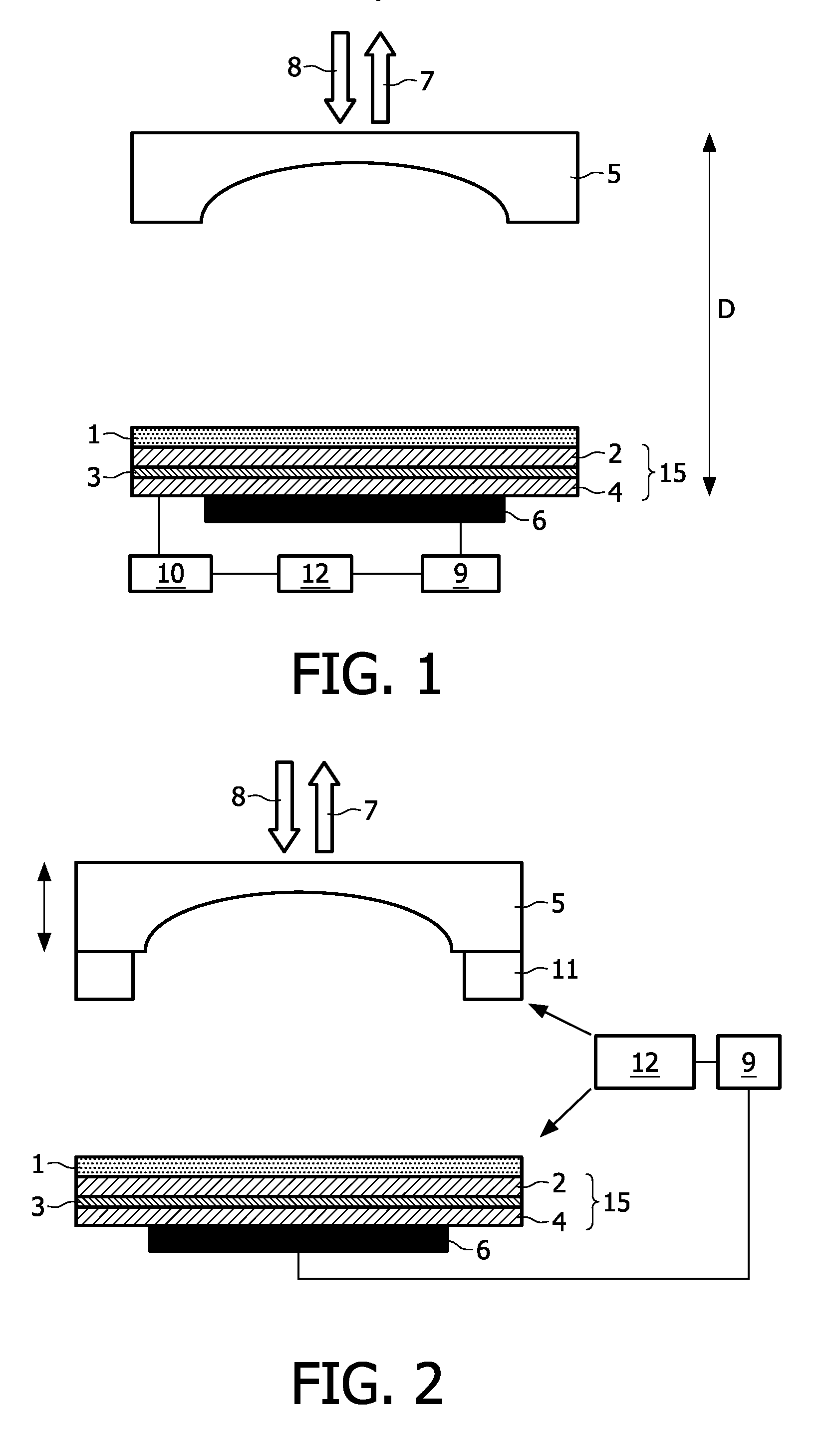

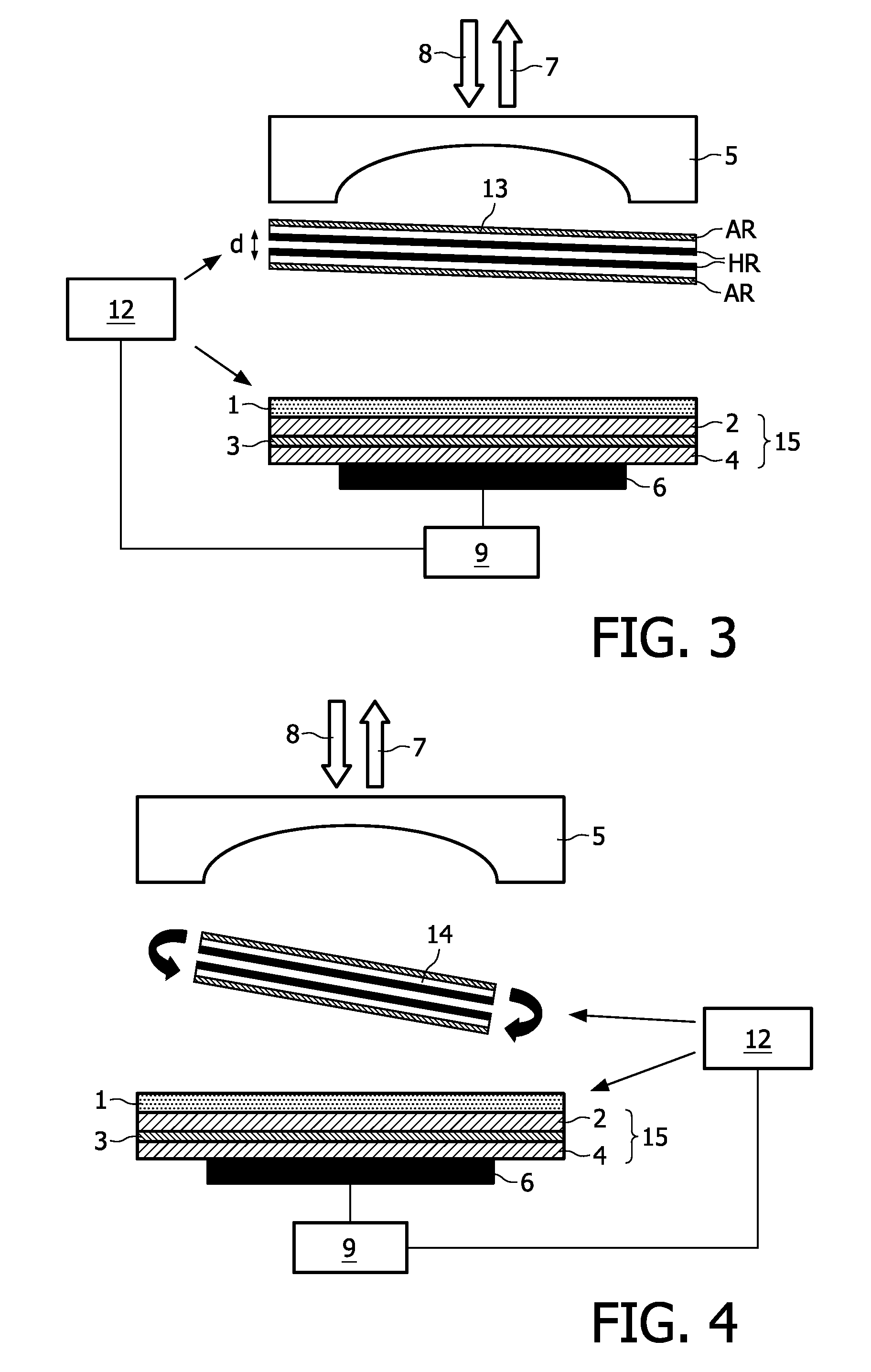

Three non-complex imaging arrangements are provided where in two of the imaging arrangements a moveable carrier housing at least one objective lens is provided and, in the other imaging arrangement, at least one stationary objective lens and additional optical elements are provided. Each embodiment includes at least one fixed image sensor array for imaging thereon an optical code or target, such as a one-dimensional barcode symbol, or label, marking, picture, etc. Each imaging arrangement provides an extended working range of approximately 5-102 cm. The imaging arrangements are capable of being incorporated within a barcode imager to provide a non-complex barcode imager having an extended working range which is comparable to or greater than the working ranges of conventional image-based barcode imagers.

Owner:SYMBOL TECH LLC

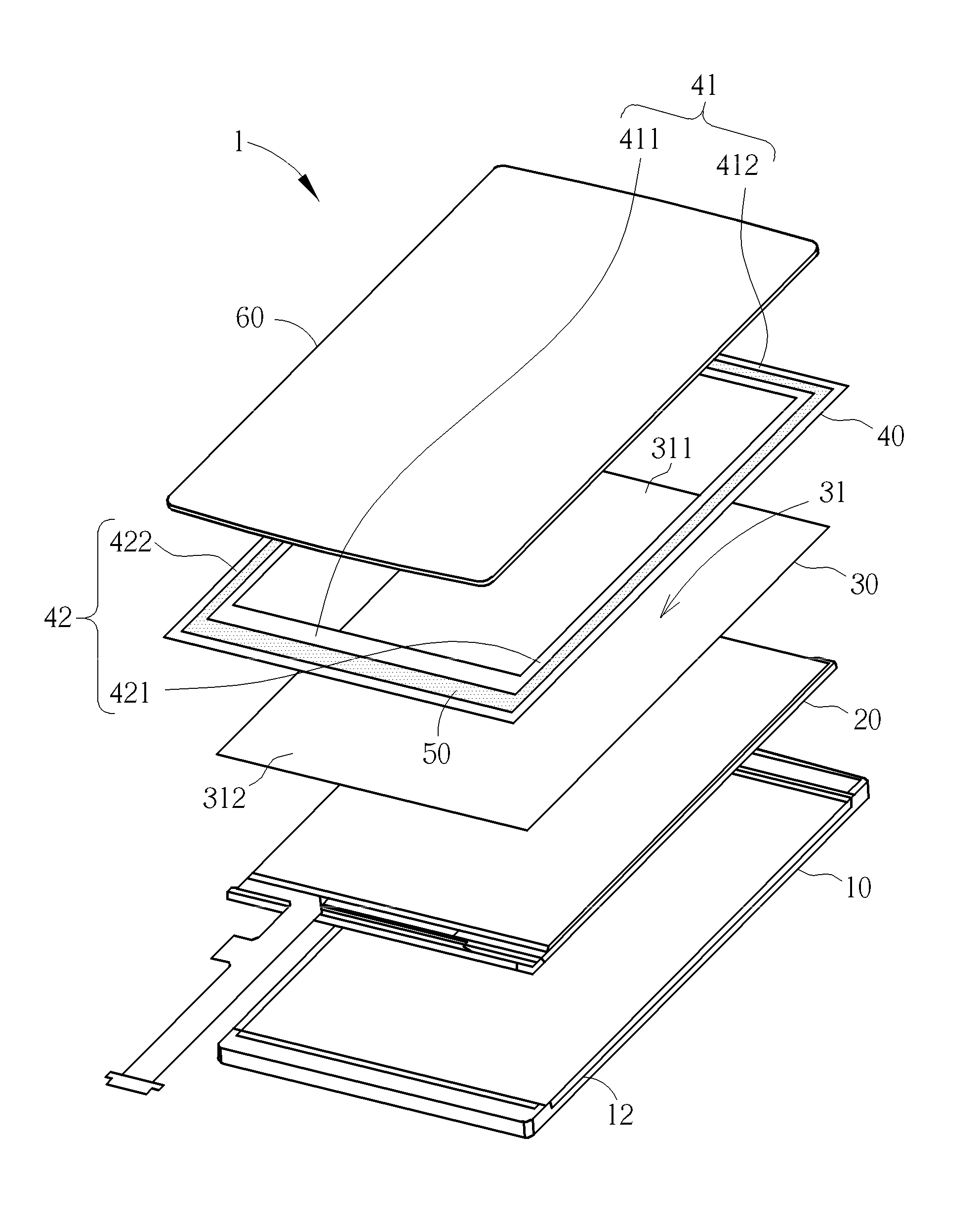

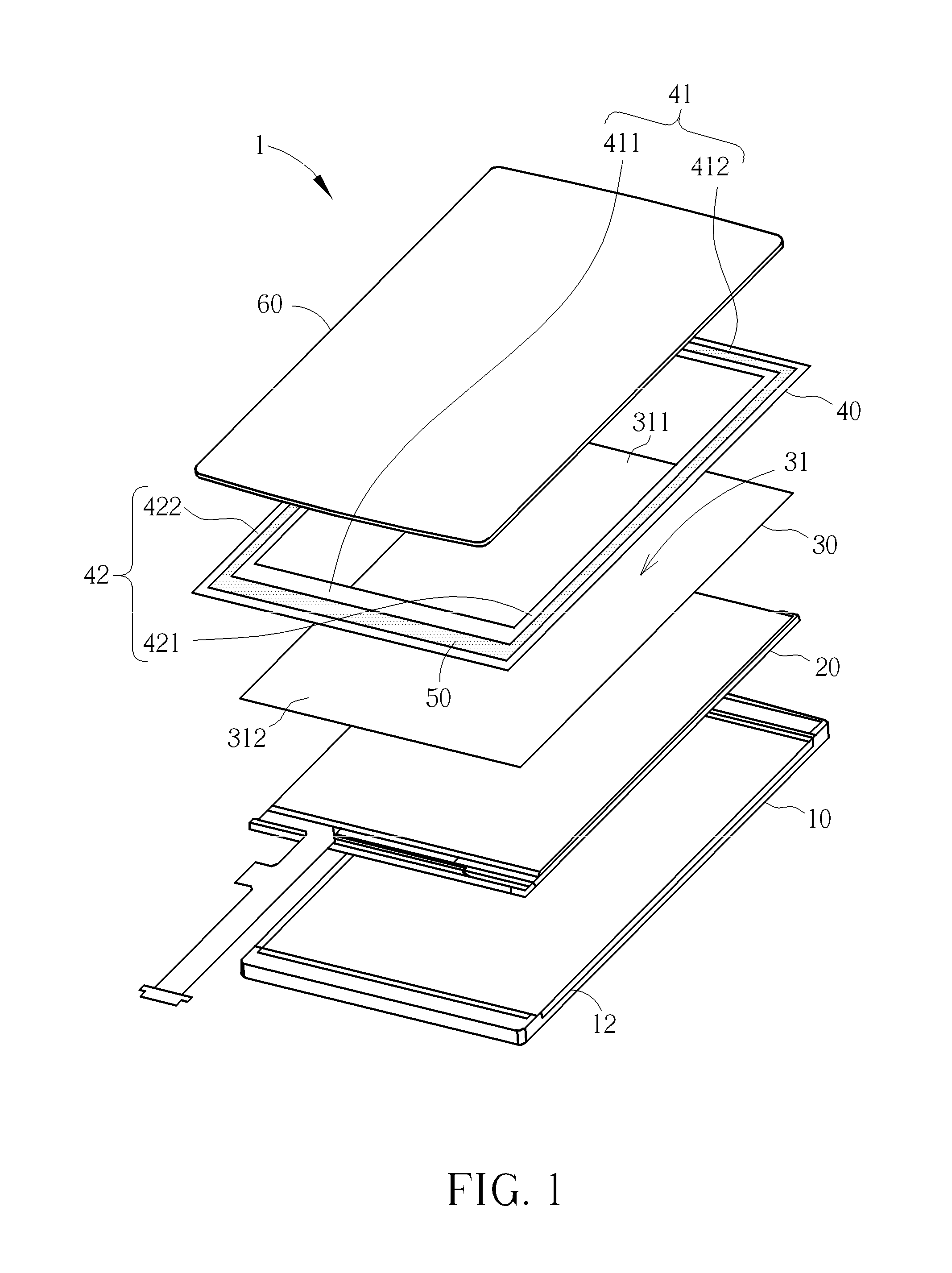

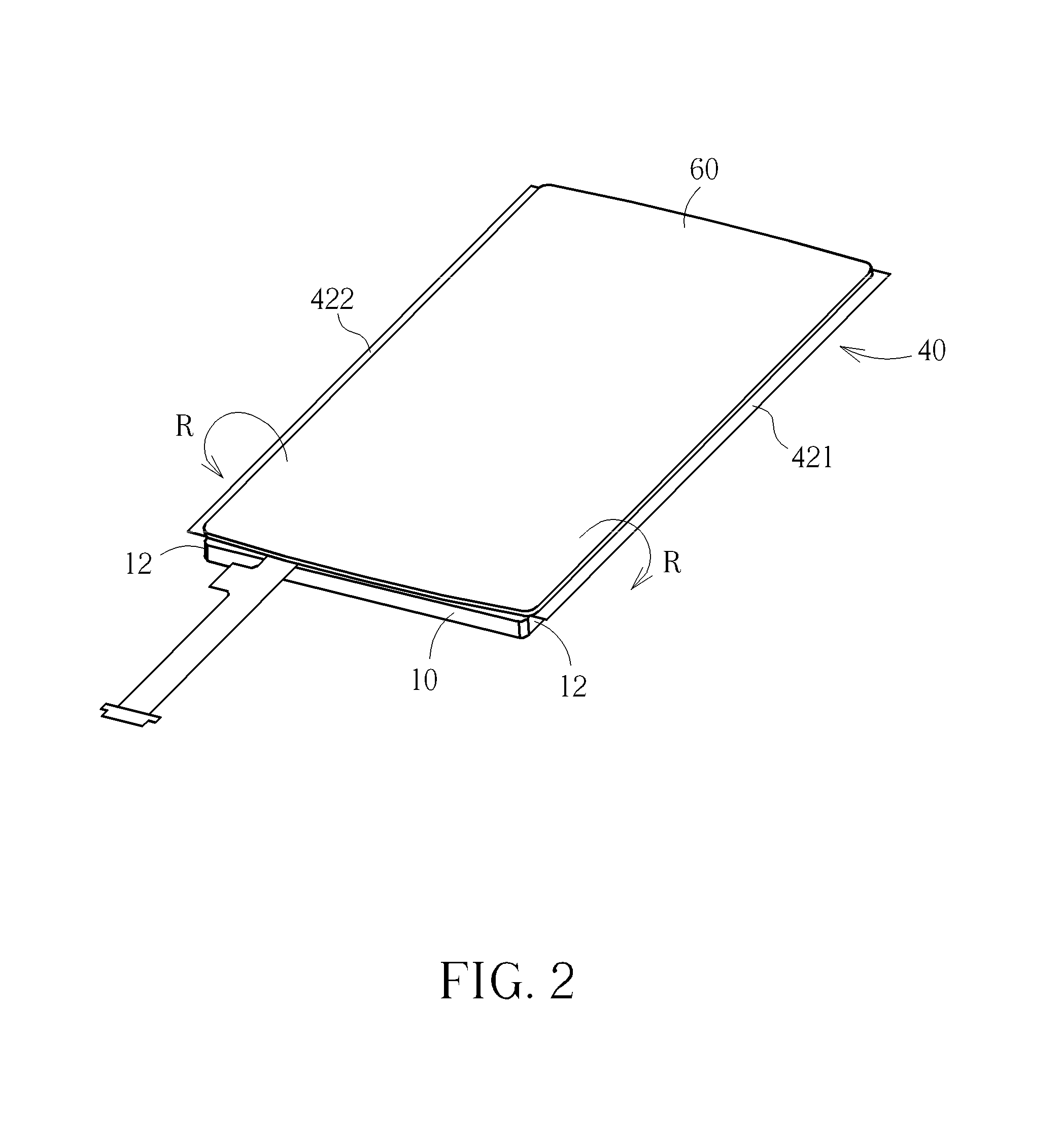

Touch panel structure, touch and display panel structure, and integrated touch display panel structure having antenna pattern and method of forming touch panel having antenna pattern

ActiveUS20140043248A1Reduce areaConvenience to workRadiating elements structural formsLoop antennasEngineeringElectronic component

In a touch panel and display panel structure or an integrated touch display panel structure, an antenna pattern is disposed on a touch module, a display module or an integrated touch display module for an increased distance between the antenna pattern and electronic components below the structure, reducing electromagnetic effect caused by the electronic components and improving the antenna performance. The antenna pattern is arranged at two opposite edges of a top surface of the touch and display module or the integrated touch display module, and also at side surfaces of a housing non-coplanar to the top surface such that the antenna pattern is located outside the displaying area of the display module. Maintaining the effective antenna area and enhancing the working bandwidth of the antenna, the side width of surface of the touch panel and display panel structure or the integrated touch display panel structure is significantly reduced.

Owner:HTC CORP

Imaging arrangement and barcode imager for imaging an optical code or target at a plurality of focal planes

ActiveUS7090135B2Expand the scope of workCharacter and pattern recognitionSensing by electromagnetic radiationSensor arrayBarcode

Three non-complex imaging arrangements are provided where in two of the imaging arrangements a moveable carrier housing at least one objective lens is provided and, in the other imaging arrangement, at least one stationary objective lens and additional optical elements are provided. Each embodiment includes at least one fixed image sensor array for imaging thereon an optical code or target, such as a one-dimensional barcode symbol, or label, marking, picture, etc. Each imaging arrangement provides an extended working range of approximately 5–102 cm. The imaging arrangements are capable of being incorporated within a barcode imager to provide a non-complex barcode imager having an extended working range which is comparable to or greater than the working ranges of conventional image-based barcode imagers.

Owner:SYMBOL TECH LLC

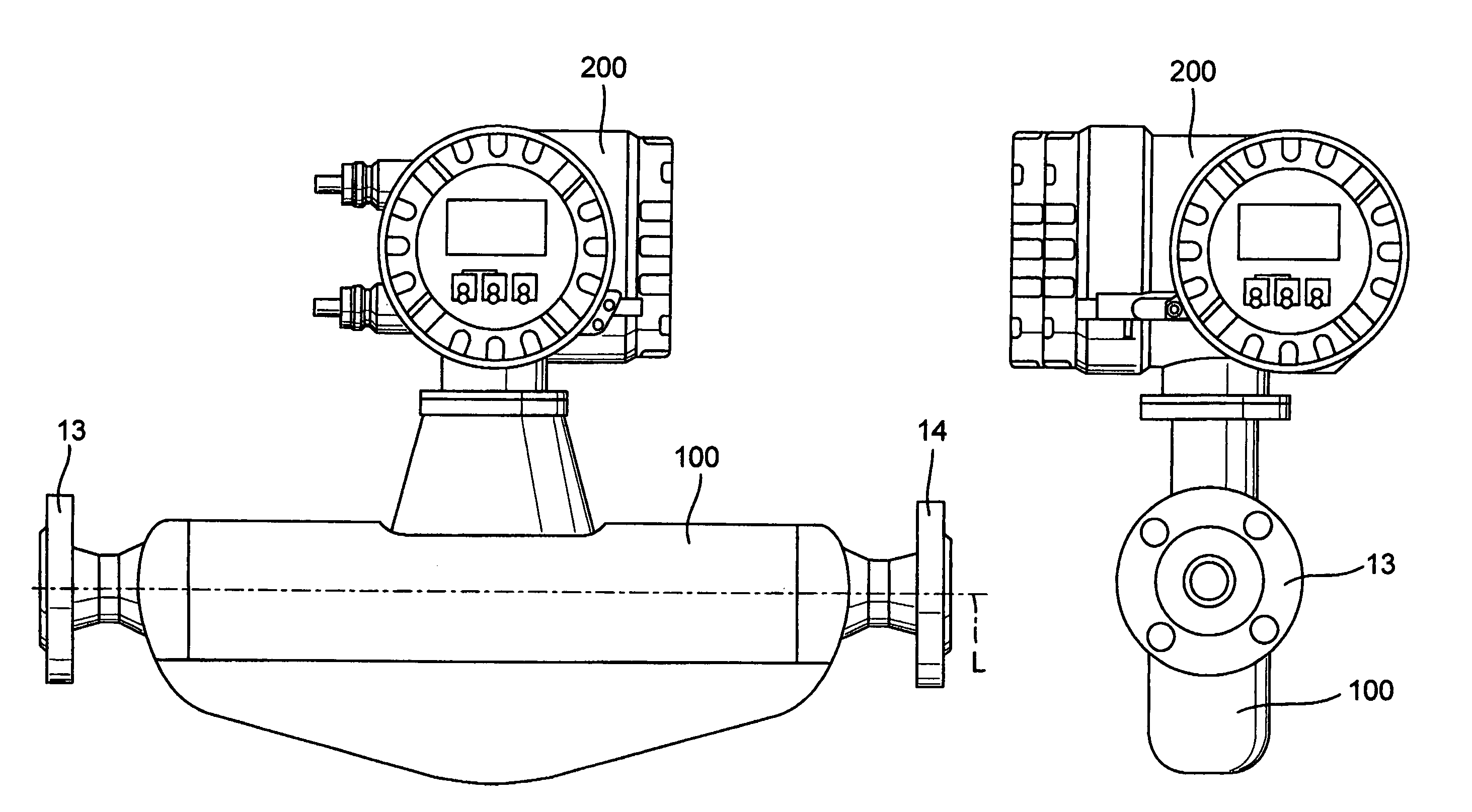

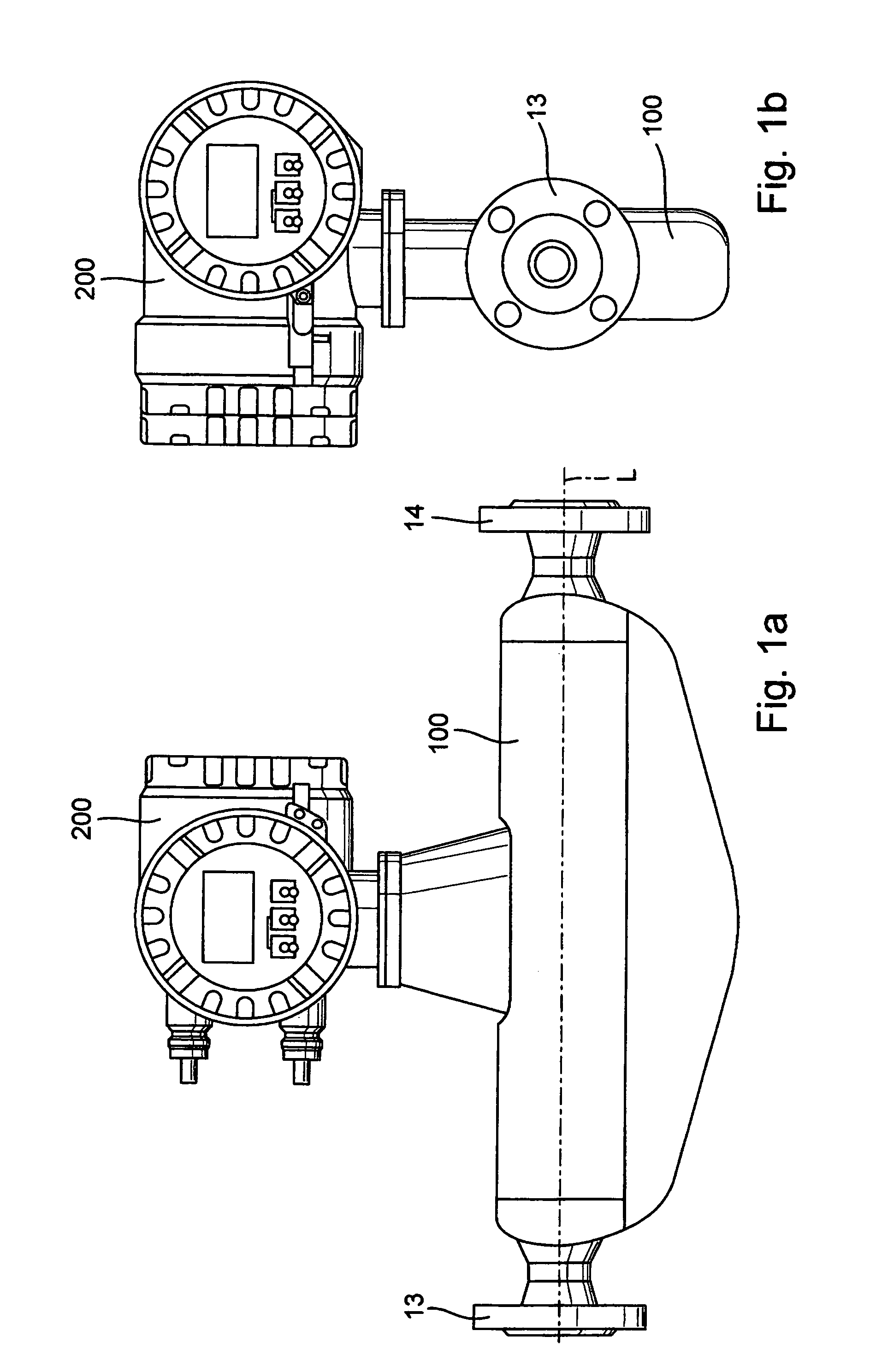

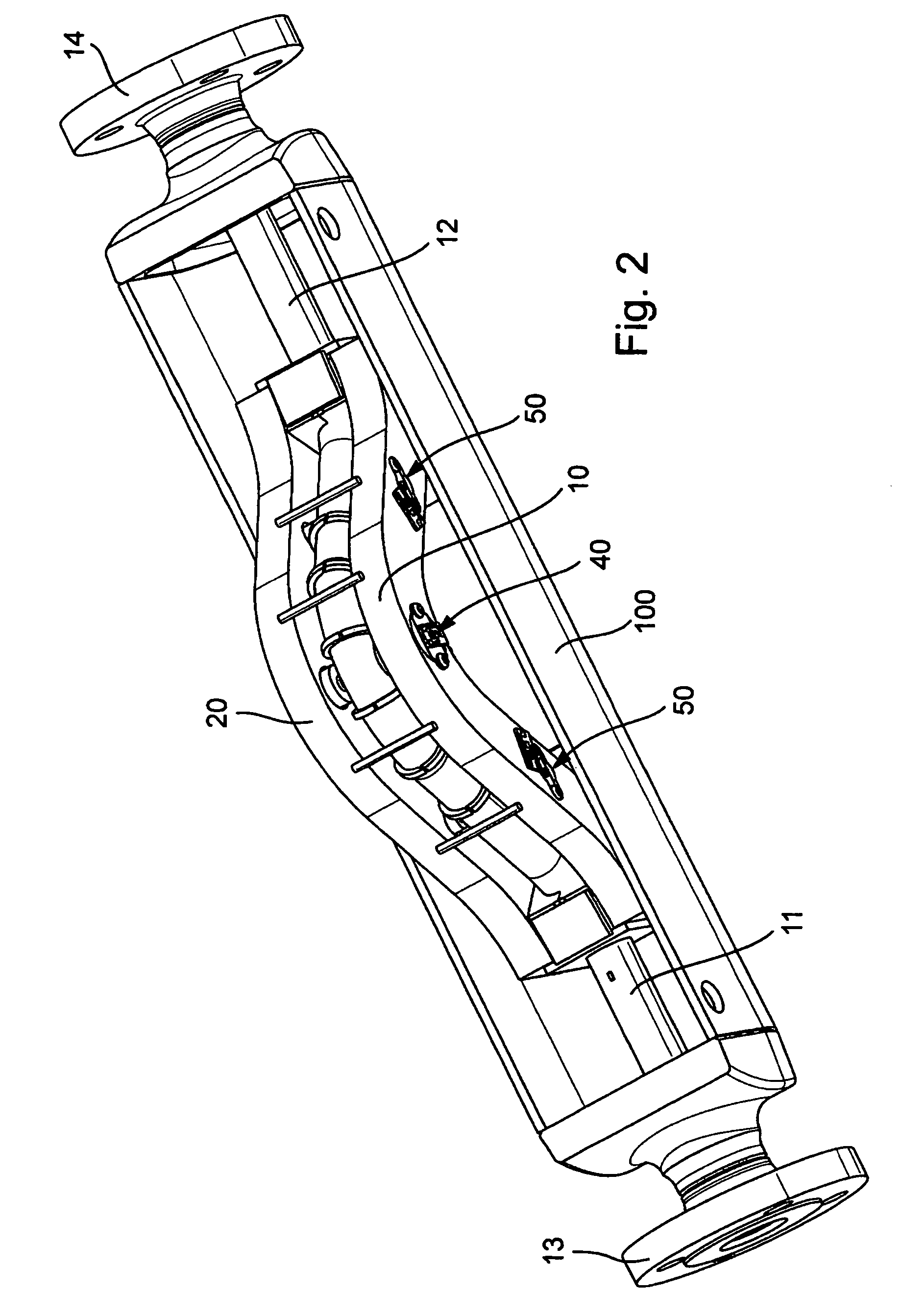

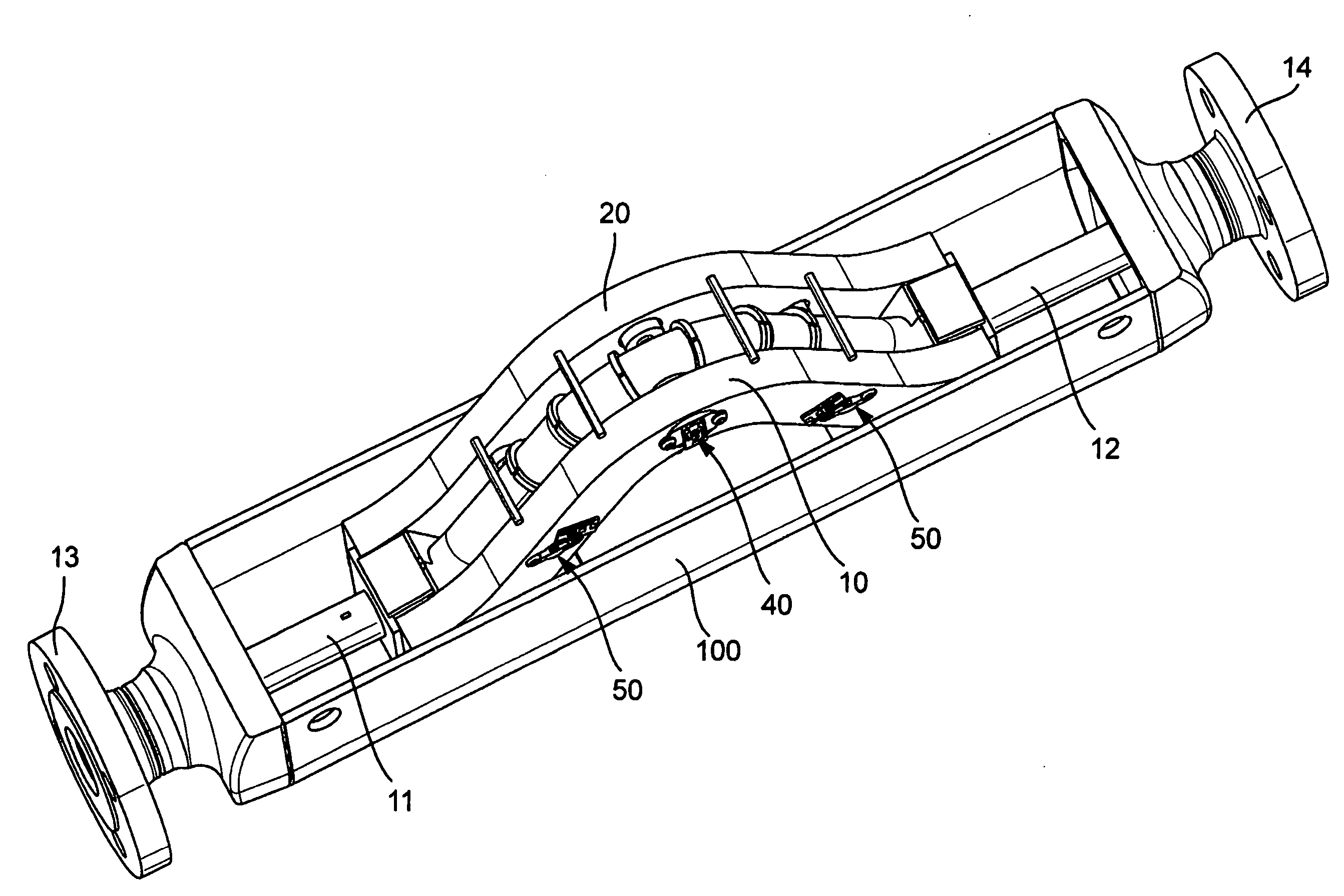

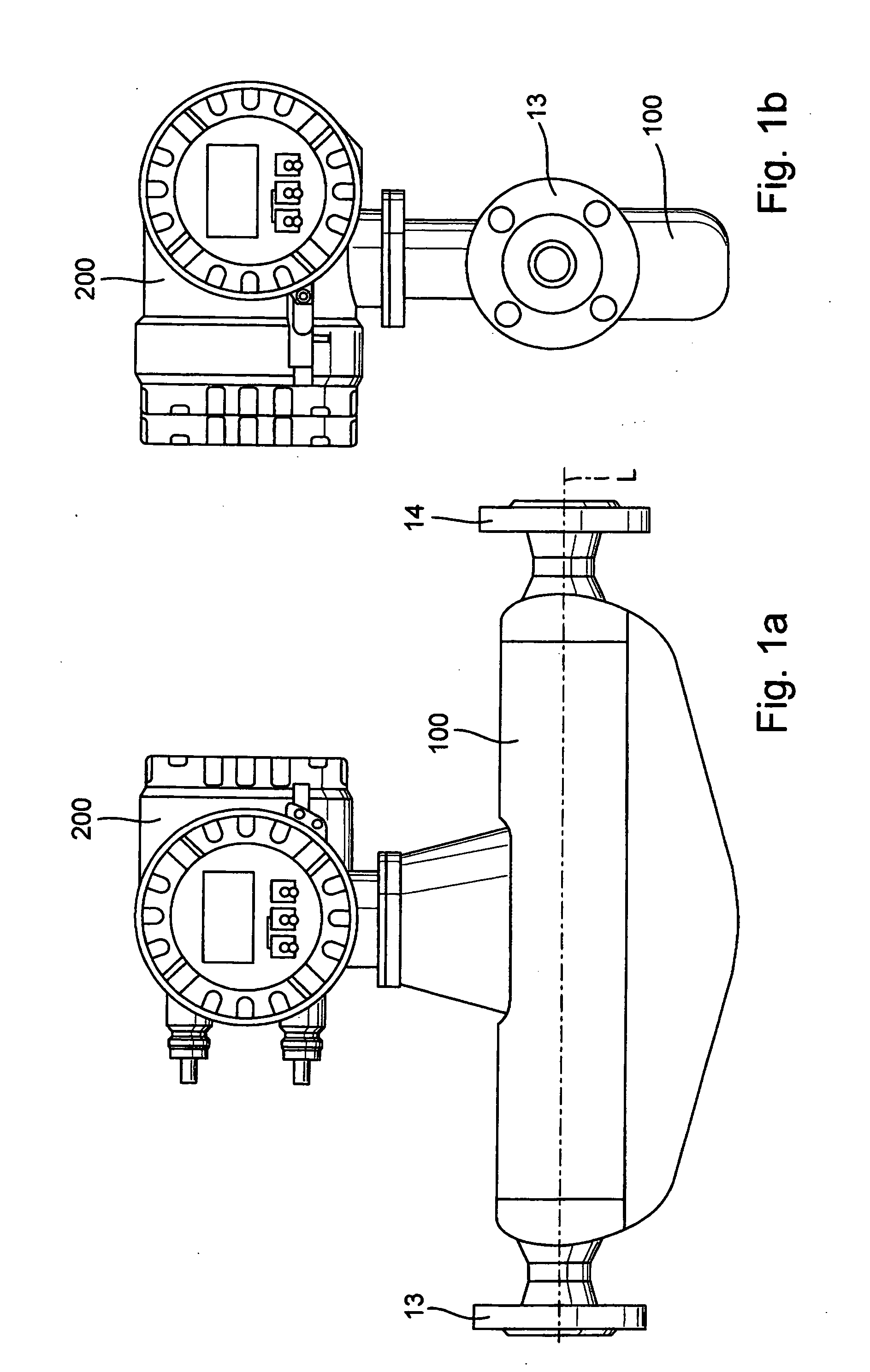

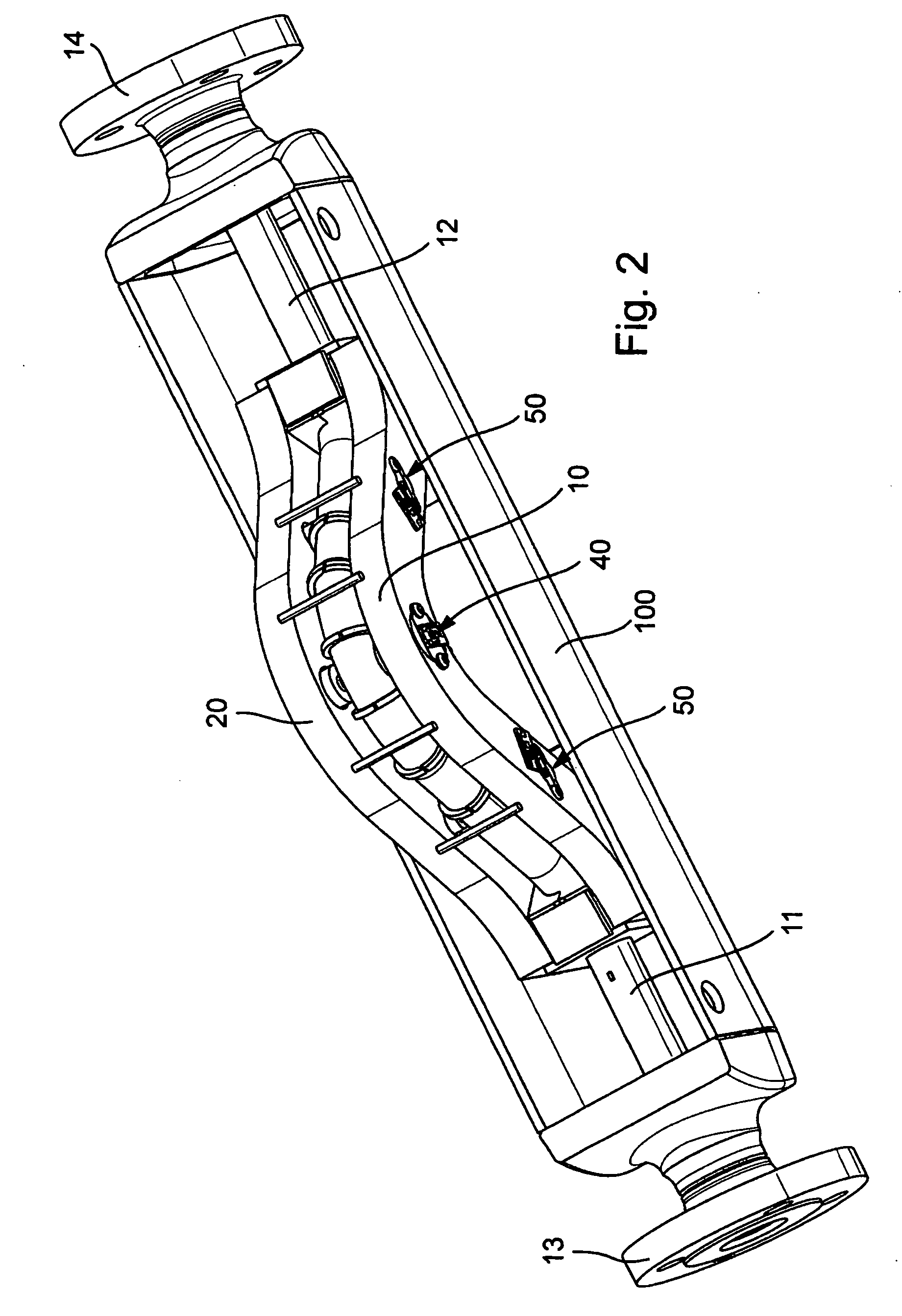

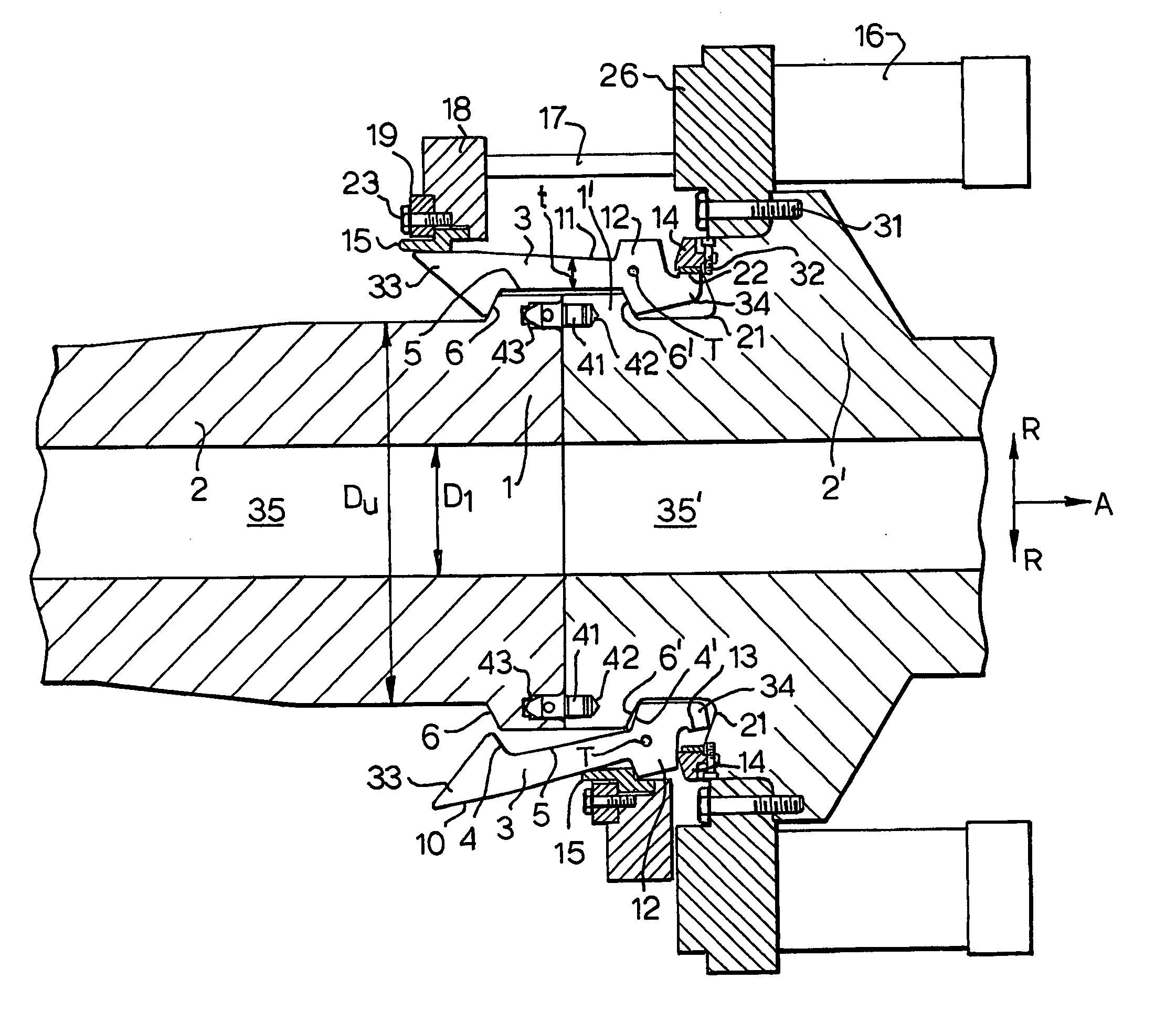

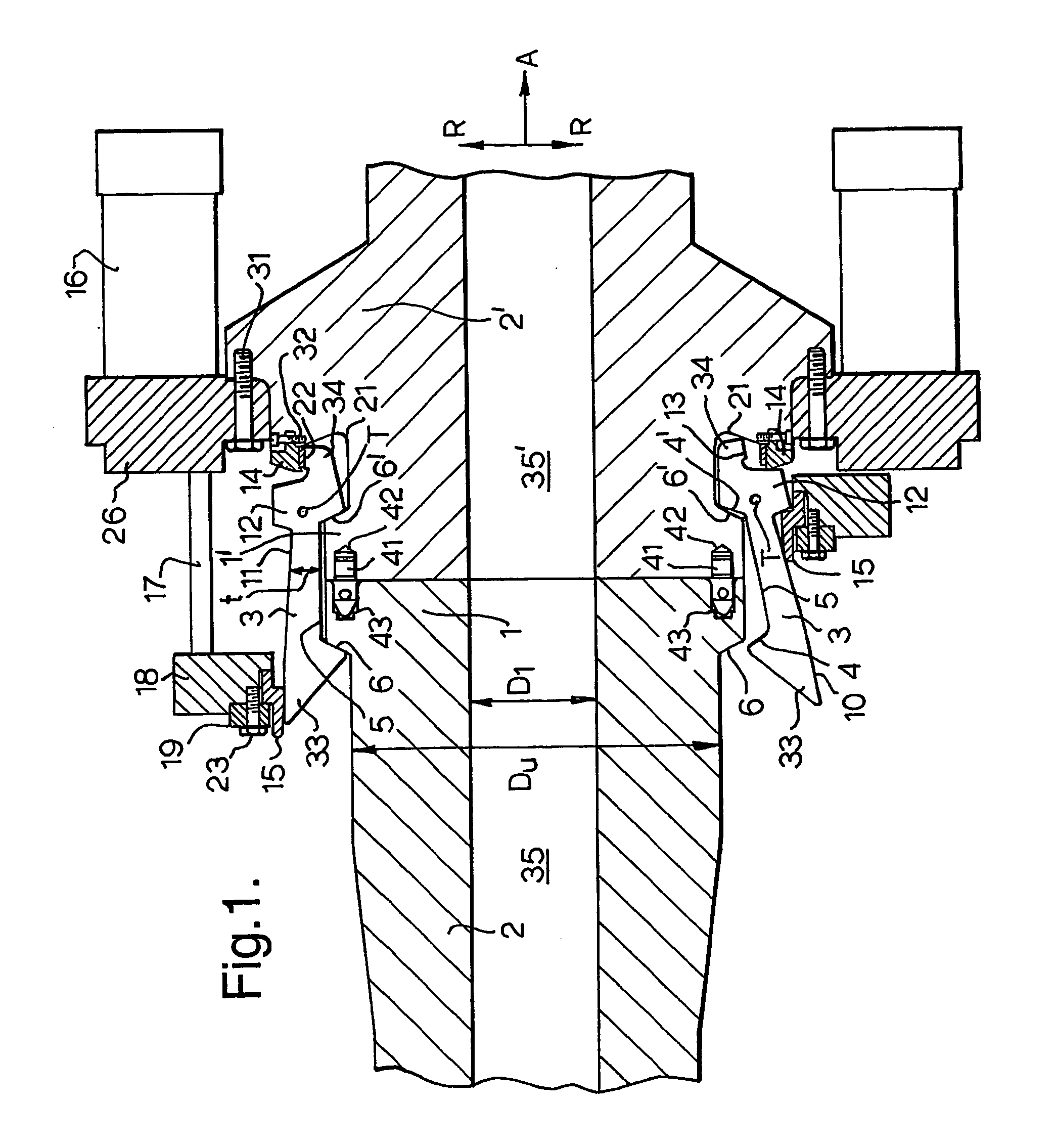

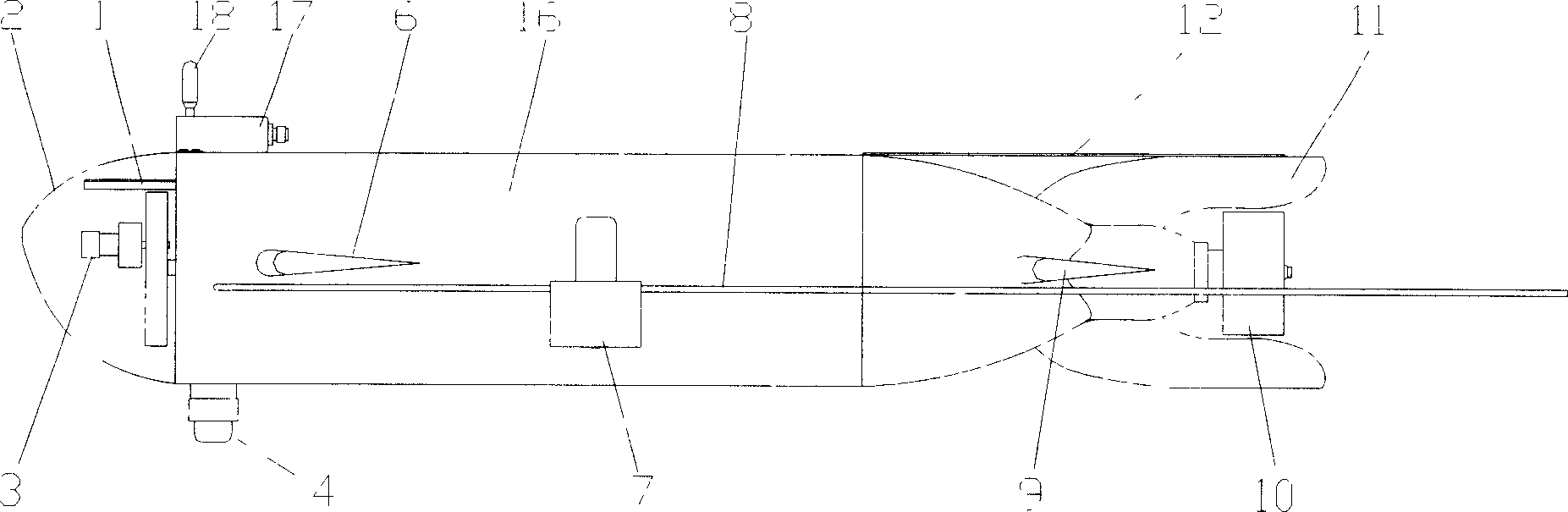

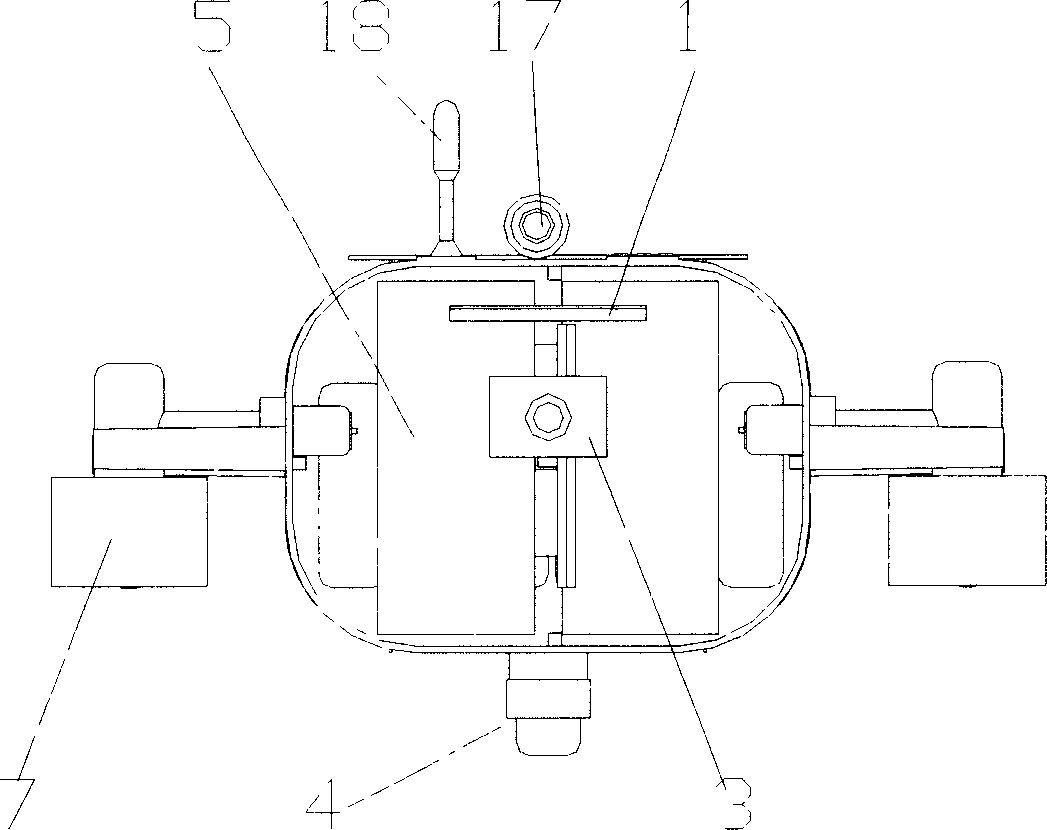

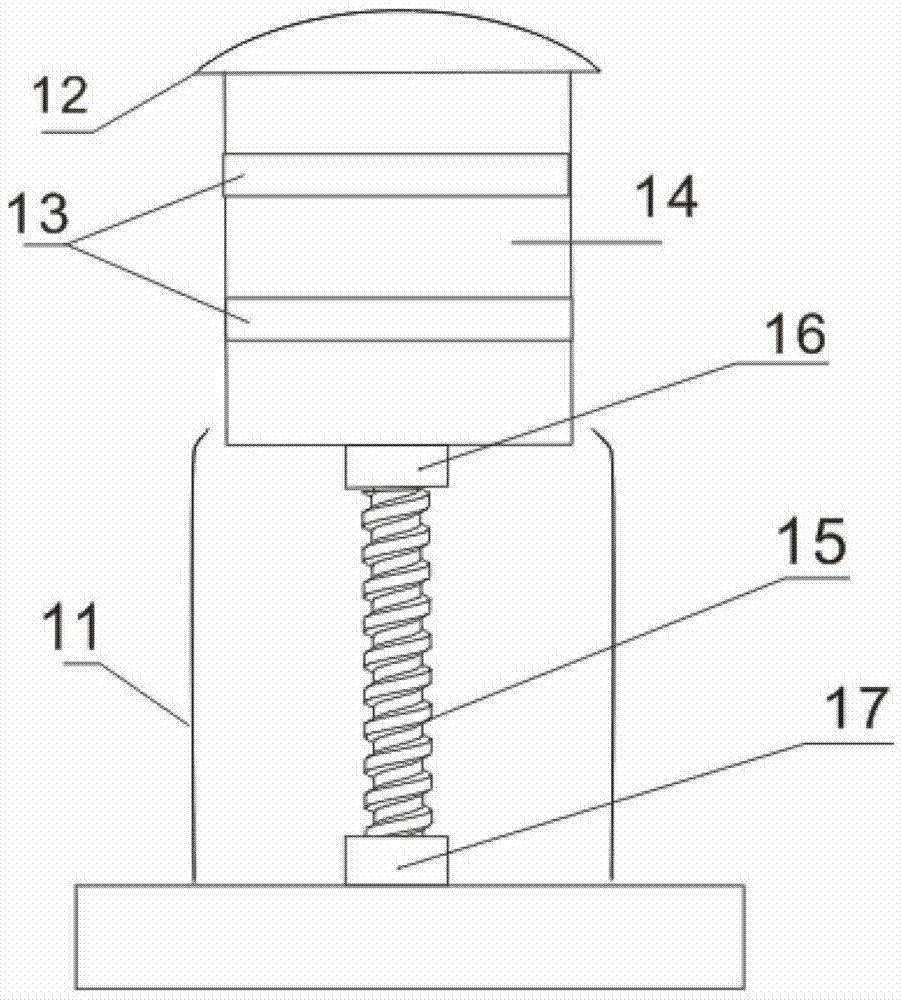

Measuring transducer of vibration-type

ActiveUS7360451B2Improve density dependence of zero-pointWorking range of the measuring transducer can,Direct mass flowmetersDirect flow property measurementCouplingTransducer

A measuring transducer includes a transducer housing, as well as an internal part arranged in the transducer housing. The internal part includes at least one curved measuring tube vibrating, at least at times, during operation and serving for conveying the medium, as well as a counteroscillator affixed to the measuring tube on the inlet-side, accompanied by formation of a coupling zone, and to the measuring tube on the outlet-side, accompanied by the formation of a coupling zone. The internal part is held oscillatably in the transducer housing, at least by means of two connecting tube pieces, via which the measuring tube communicates during operation with the pipeline and which are so oriented with respect to one another, as well as with respect to an imaginary longitudinal axis of the measuring transducer, that the internal part can move during operation in the manner of a pendulum about the longitudinal axis. The measuring tube and the counteroscillator are additionally so embodied and so oriented with respect to one another that both a center of mass spaced from the imaginary longitudinal axis of the measuring tube, as well as also a center of mass of the counteroscillator spaced from the imaginary longitudinal axis, lie in a common region of the measuring transducer spanned by the imaginary longitudinal axis and the measuring tube, and that the center of mass of the measuring tube is spaced farther from the longitudinal axis than the center of mass of the counteroscillator.

Owner:ENDRESS HAUSER FLOWTEC AG

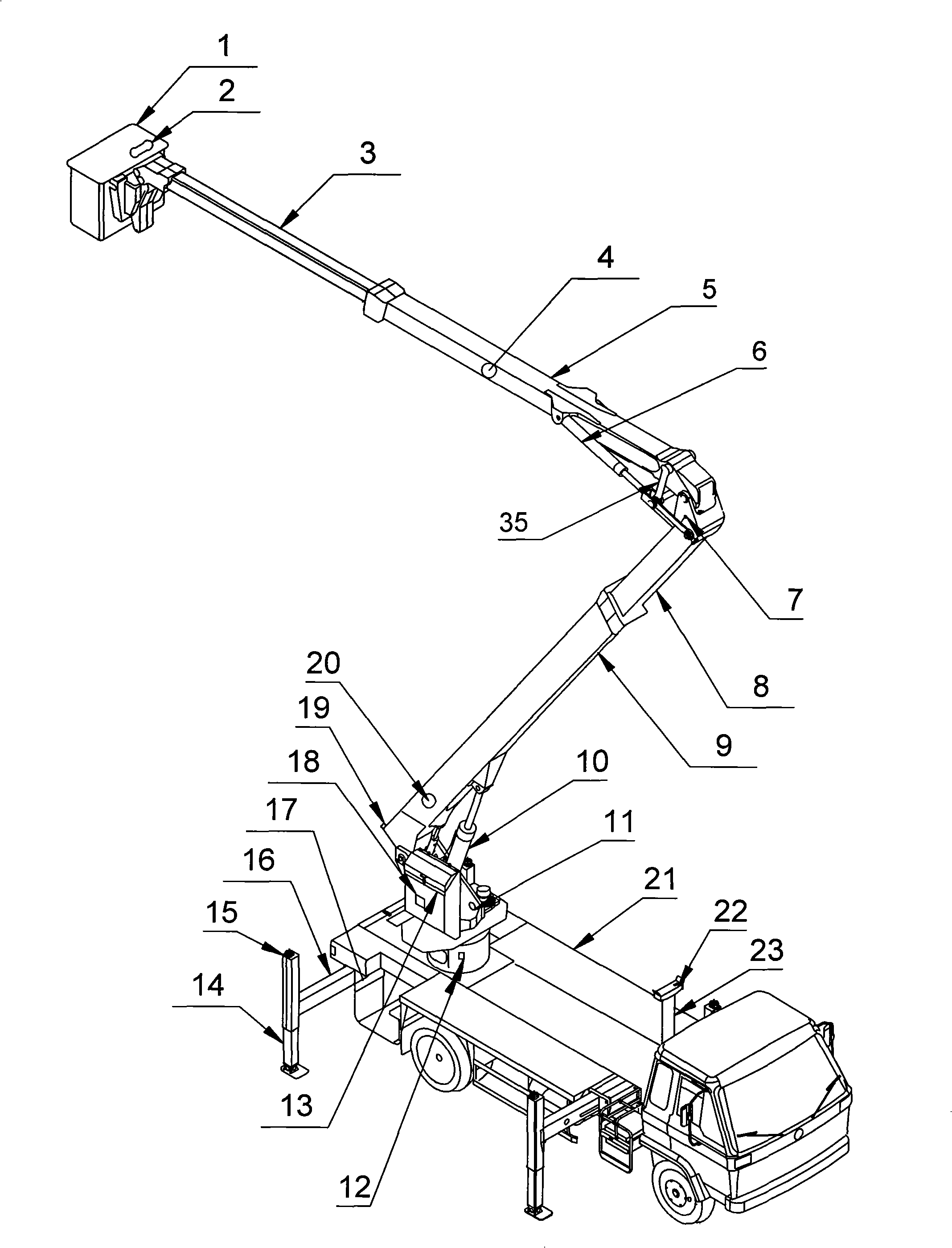

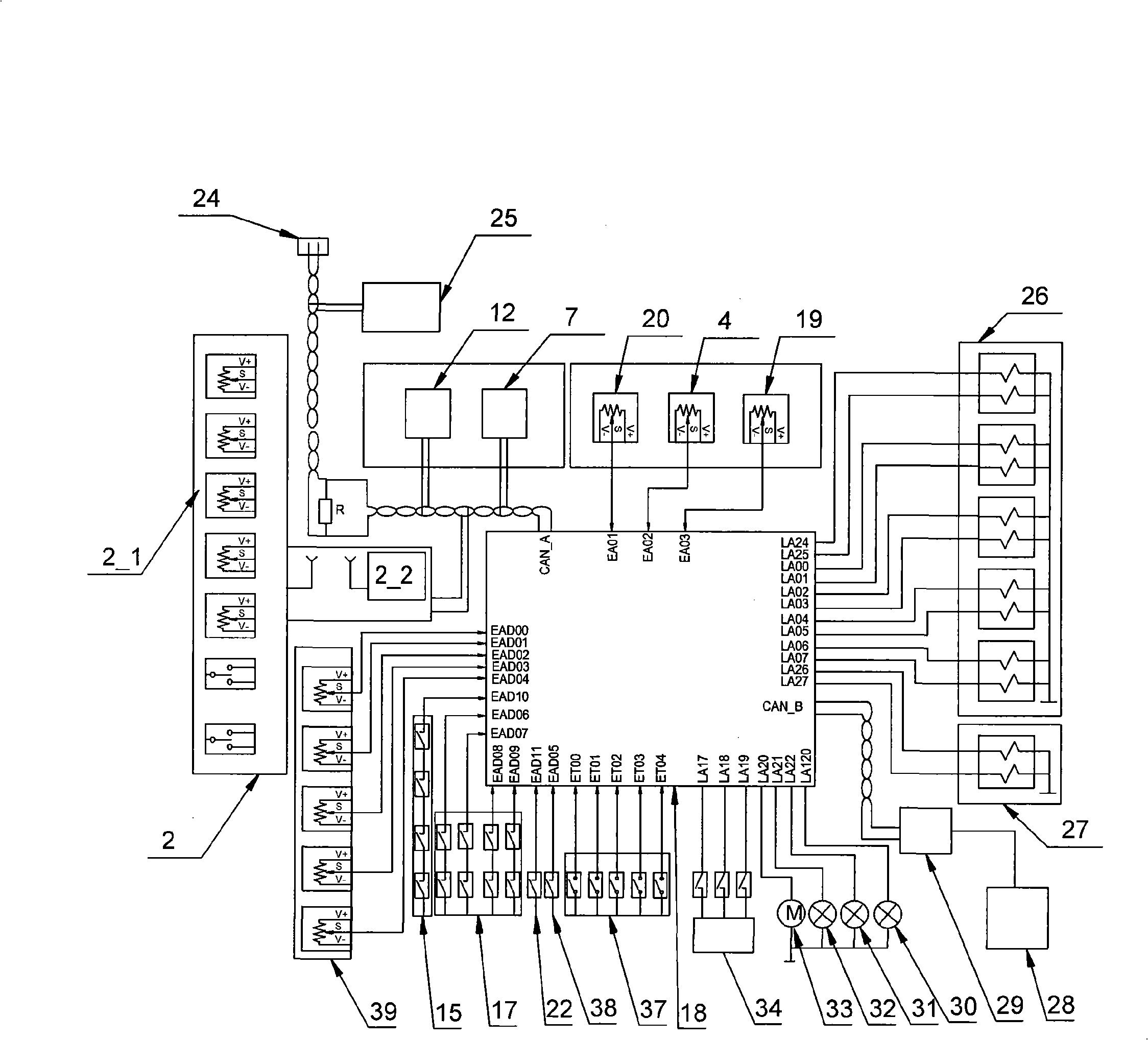

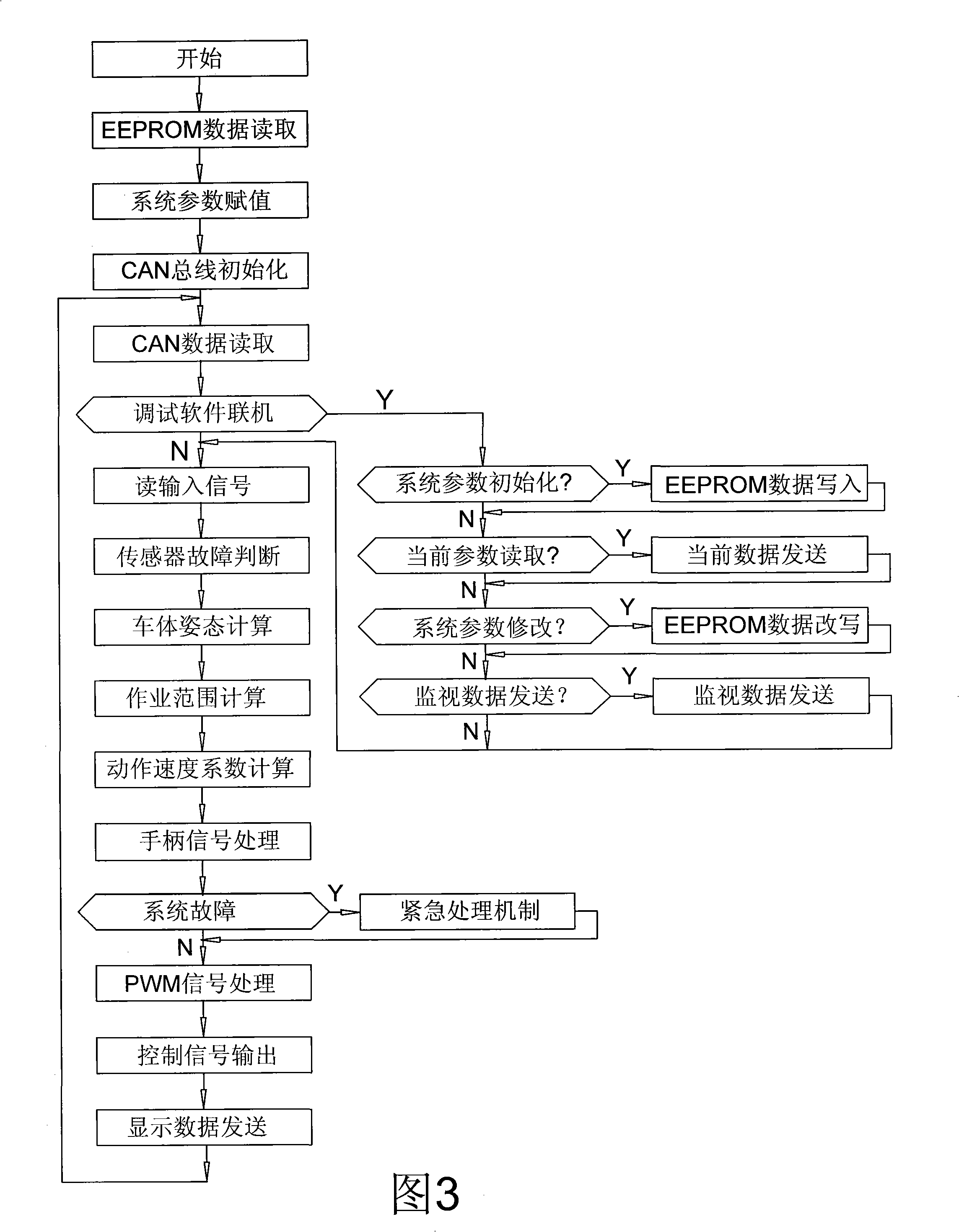

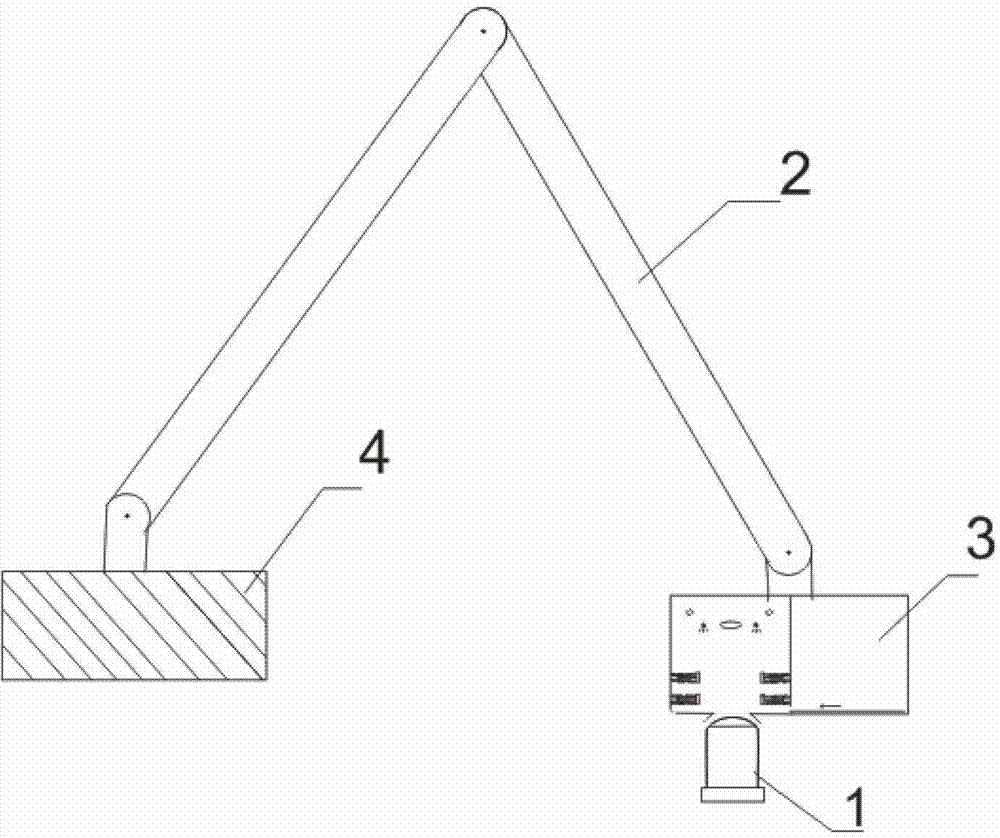

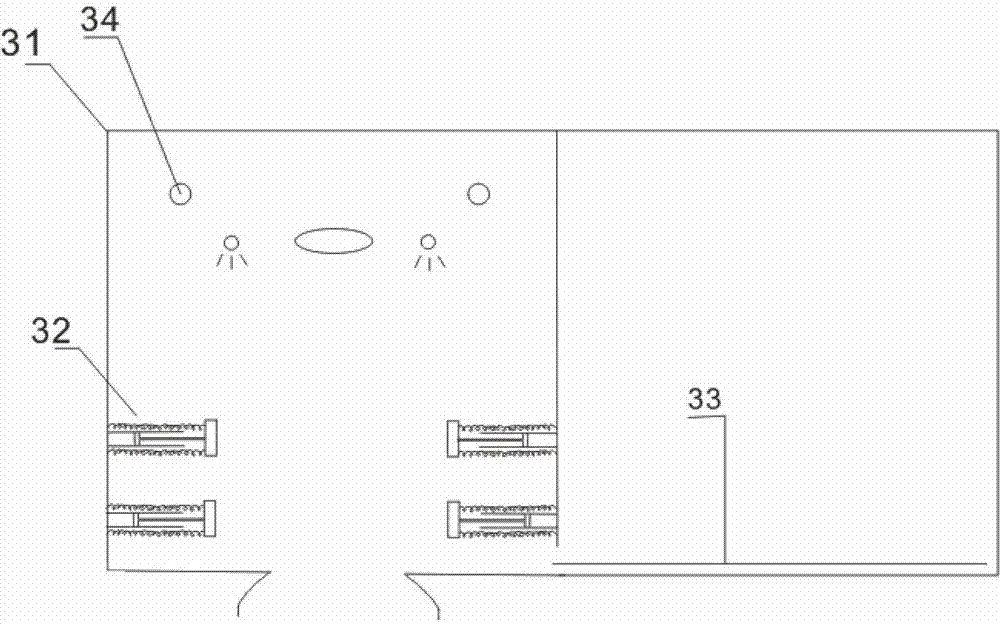

Intelligence control system for aerial platform, aerial platform and control method thereof

The invention relates to an intelligent control system of an insulative aerial platform vehicle, an aerial platform vehicle with the intelligent control system and a control method thereof. The intelligent control system of the aerial platform vehicle comprises a wireless remote control device, an upper arm length sensor, an upper and lower arm angle encoder, a turntable rotating angle encoder, a leg grounding detection travel switch, a horizontal extending detection travel switch, a controller, a lower arm angle sensor, a lower arm length sensor, an arm bracket travel switch, a program download port, a liquid crystal screen, a quintuple proportional valve group, an oil circuit switching valve, a turntable operating switch, a leg action switch and a turntable potentiometer handle. A TTC200 controller is adopted as the controller of the aerial work platform, a wireless remote control handle is arranged at the insulative bucket part, the turntable is provided with the potentiometer handle to control the mechanism movement; the setting and the adjustment of various important parameters in the controller are completed through displaying the work condition of the vehicle body on the LCD display and debugging the software. The method has wide operational range, safety, reliability and high automatization through controlling the work condition of the entire vehicle by the controller.

Owner:杭州爱知工程车辆有限公司

Arrangement and method of imaging one-dimensional and two-dimensional optical codes at a plurality of focal planes

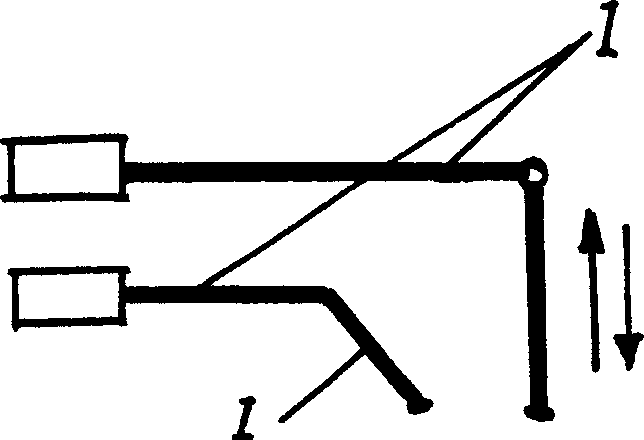

ActiveUS7222793B2Expand the scope of workCharacter and pattern recognitionExposure controlOptical axisBarcode

A non-complex imaging arrangement is aligned along an imaging axis. A mirror assembly is configured to reflect an image from an optical axis, which intersects the imaging axis, toward the optics assembly. The imaging arrangement includes at least one fixed image sensor for imaging thereon an optical code or target, such as a one-dimensional or two-dimensional barcode symbol, or label, signature, marking, picture, etc. The imaging arrangement provides an extended working range of approximately 5–102 cm. The imaging arrangement is capable of being incorporated within a barcode imager to provide a non-complex barcode imager having an extended working range which is comparable to or greater than the working ranges of conventional image-based barcode imagers.

Owner:SYMBOL TECH LLC

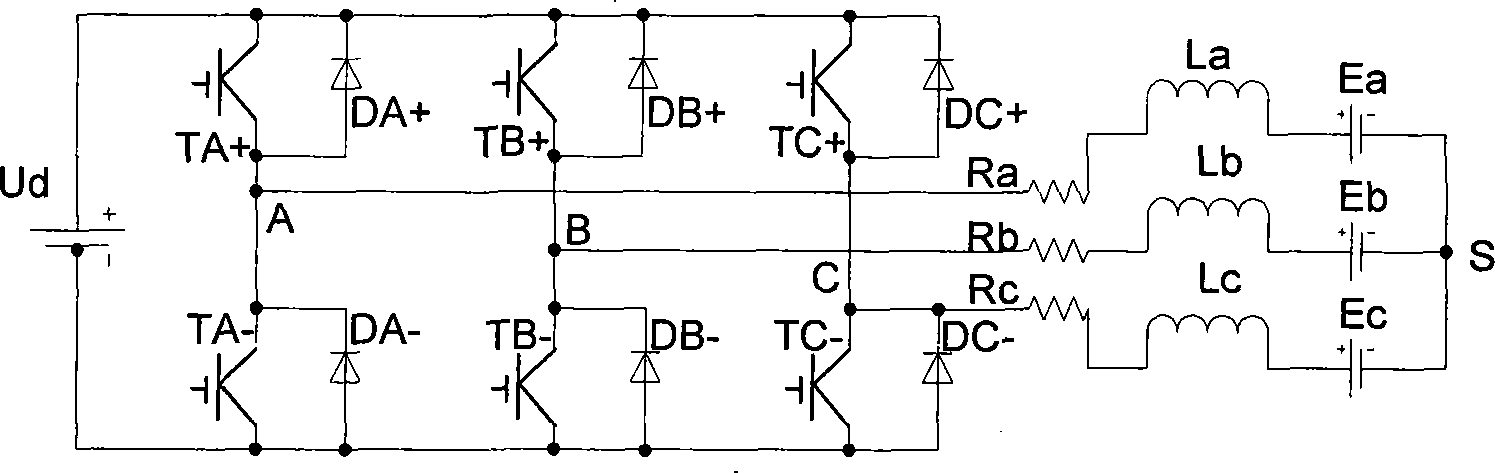

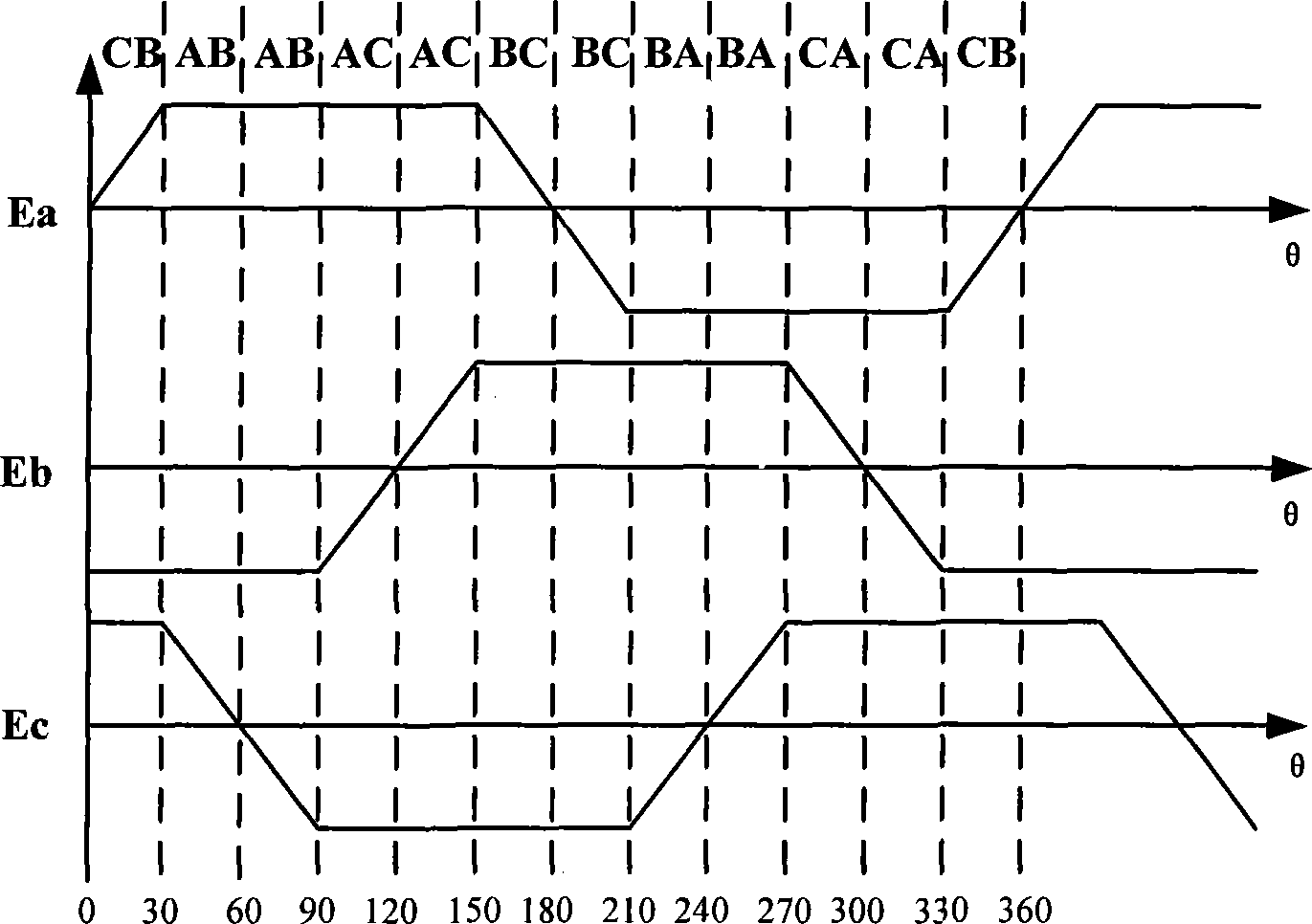

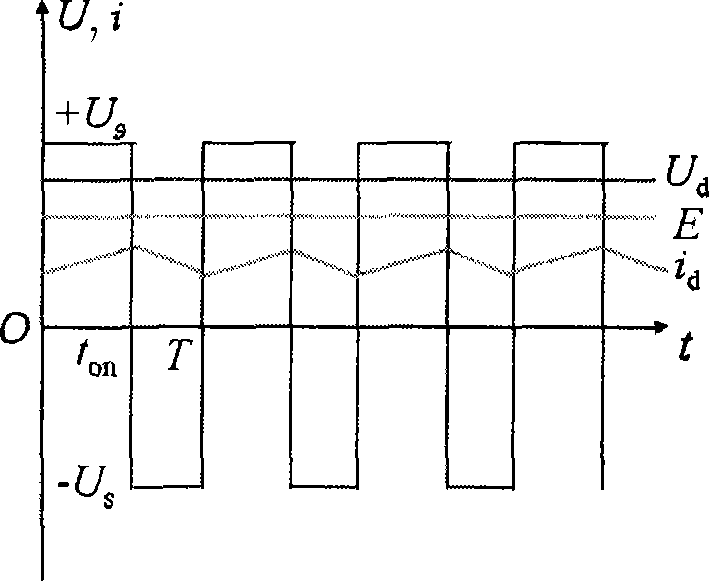

A built-in permanent magnetic brushless DC motor control system for no position sensor

InactiveCN101242154AOvercome failureExpand the scope of workSingle motor speed/torque controlEmergency protective circuit arrangementsZero crossingLow speed

The invention relates to an embedded permanent brushless DC motor non-position sensor control system, composed of a microprocessor controller, a IPM module and a drive unit, a current detection circuit, a phase voltage detection circuit, an output display circuit, a control input circuit, an embedded rotor structured permanent brushless DC motor, a drive and control power source, etc. The invention judges the position of rotor by detecting variation of inductance of stator winding indirectly according to the character that the inductance of rotor winding of the embedded rotor structured permanent brushless DC motor is the function of rotor position theta. In the embedded rotor structured permanent brushless DC motor with star-shaped connection adopted by stator winding, when self inductance of two phase windings therein are equal, the position is the counter potential zero-crossing point without phase connection. Therefore, adopting non-connection phase voltage to ground continuously in one PWM period, and comparing the difference value, to judge non-connection phase counter potential zero-crossing point, and lagging behind for 30 degrees electric angel as phase-exchange time of next time. The method of the invention is indirect induction method. The non-position sensor control method of indirection induction method is nothing to do with rotating speed of motor, so that the invention overcomes the problem of malfunction at low speed of the conventional non-position sensor control method-the detection method of counter potential zero-crossing point. The invention can work reliably at ultra-low speed even if the rotating speed of motor is close to zero.

Owner:CHONGQING KECEN MOTOR MFG

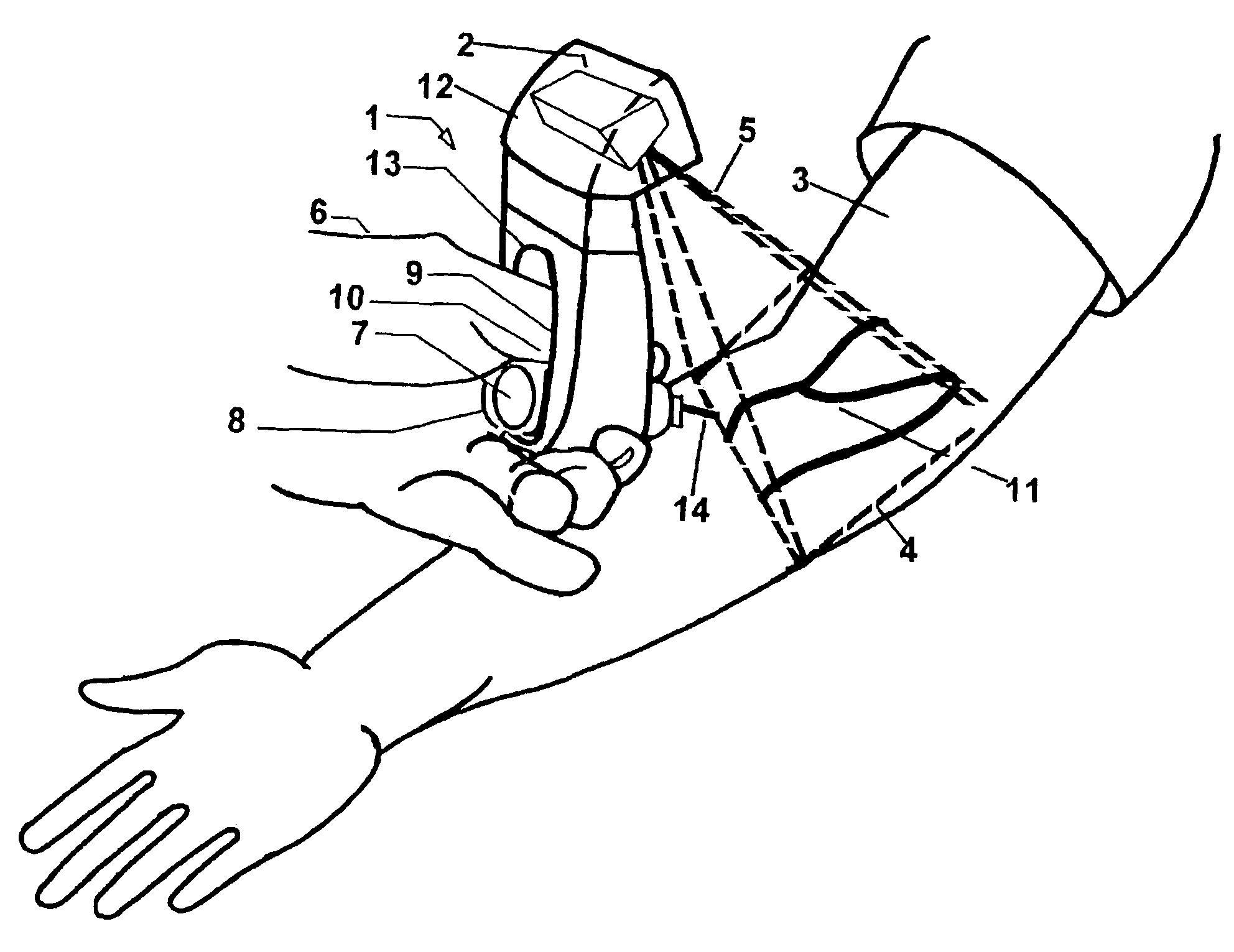

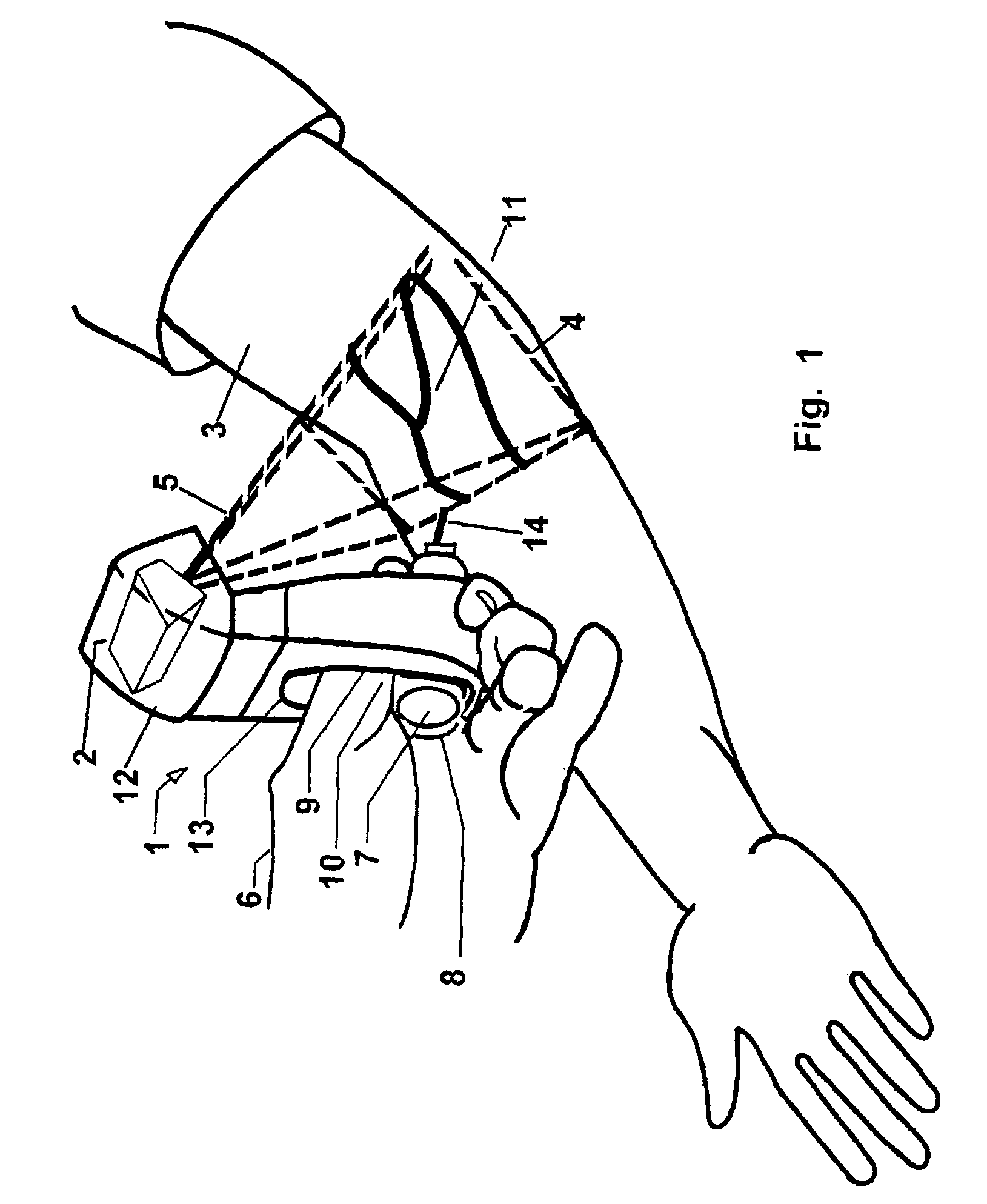

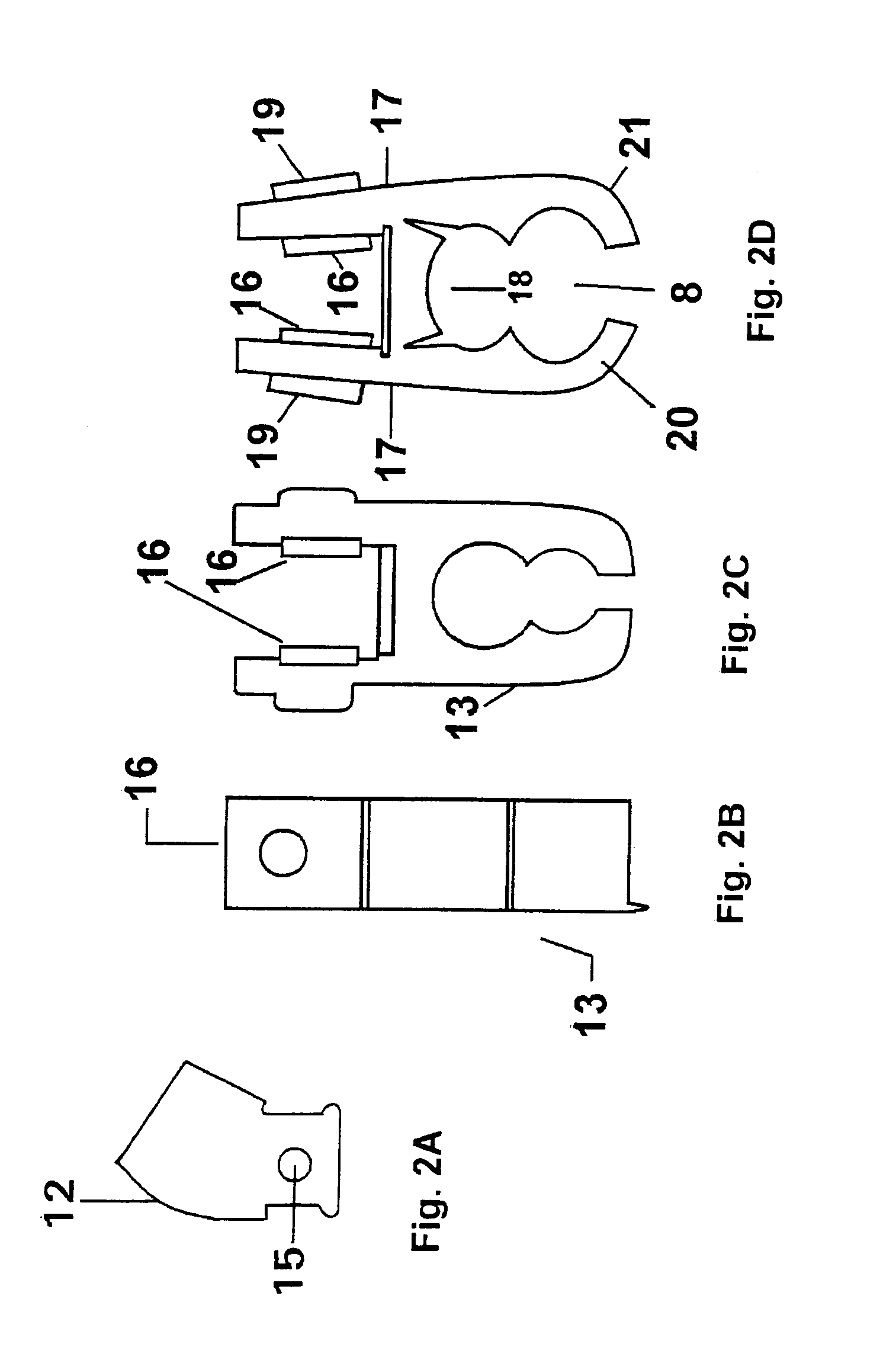

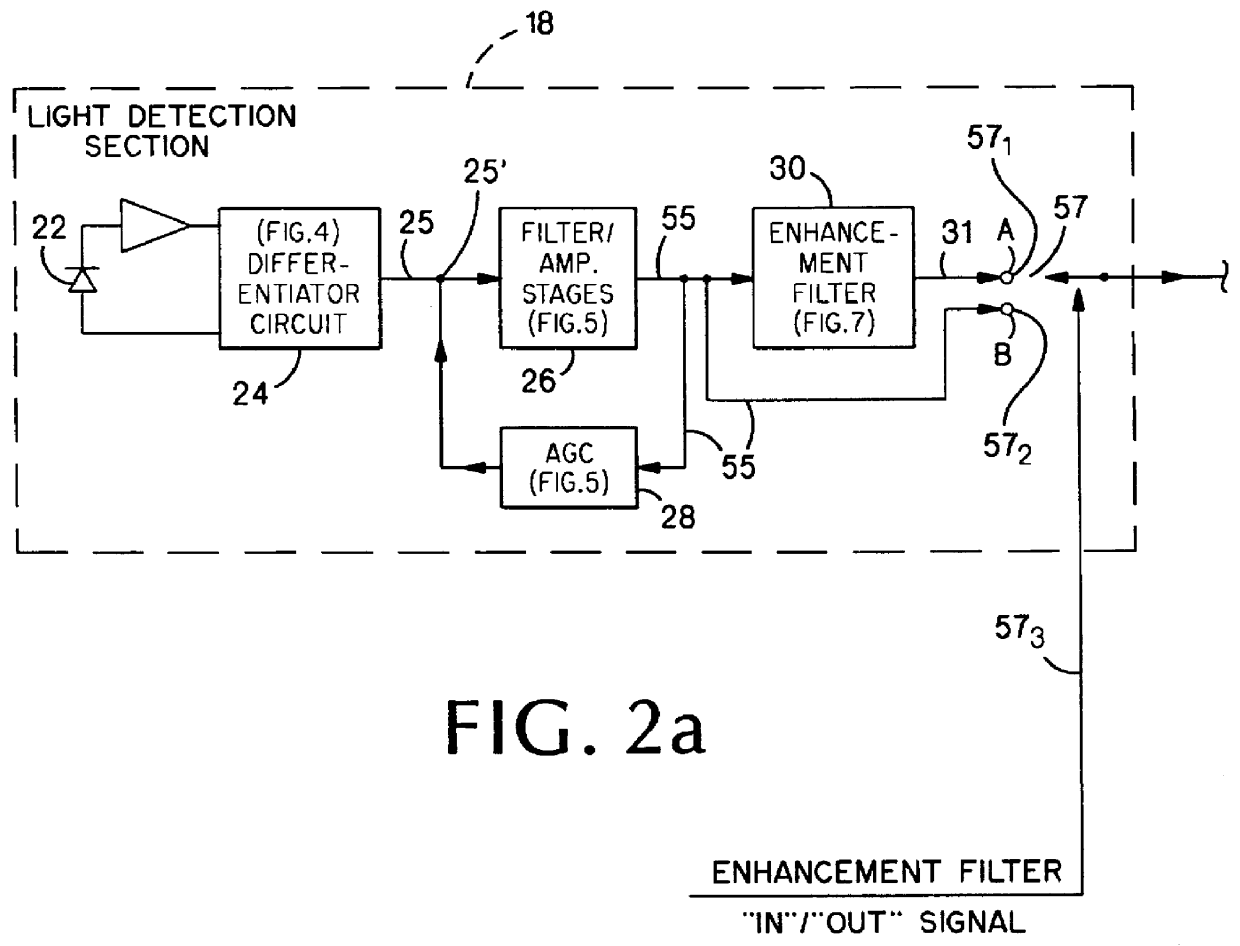

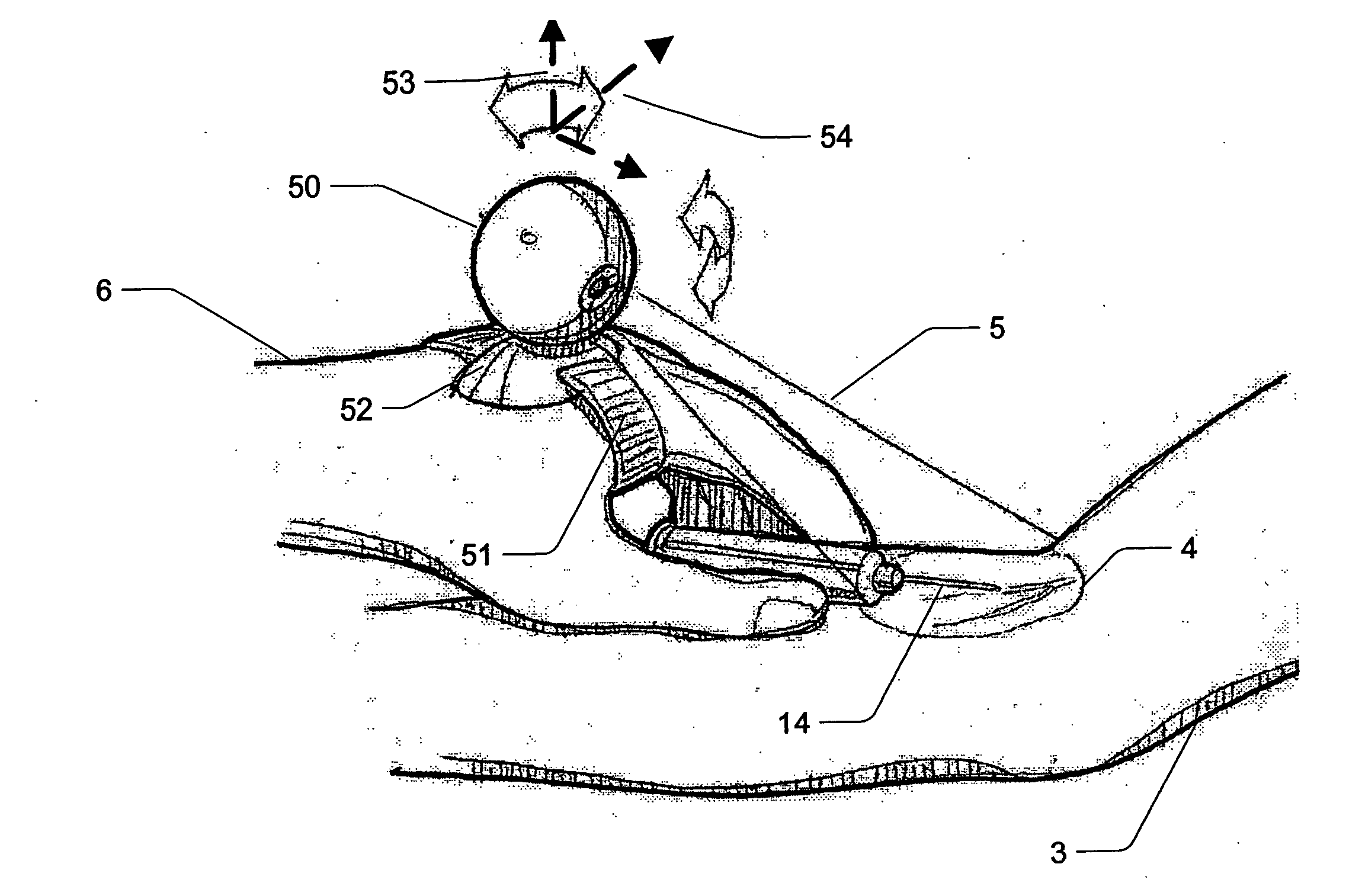

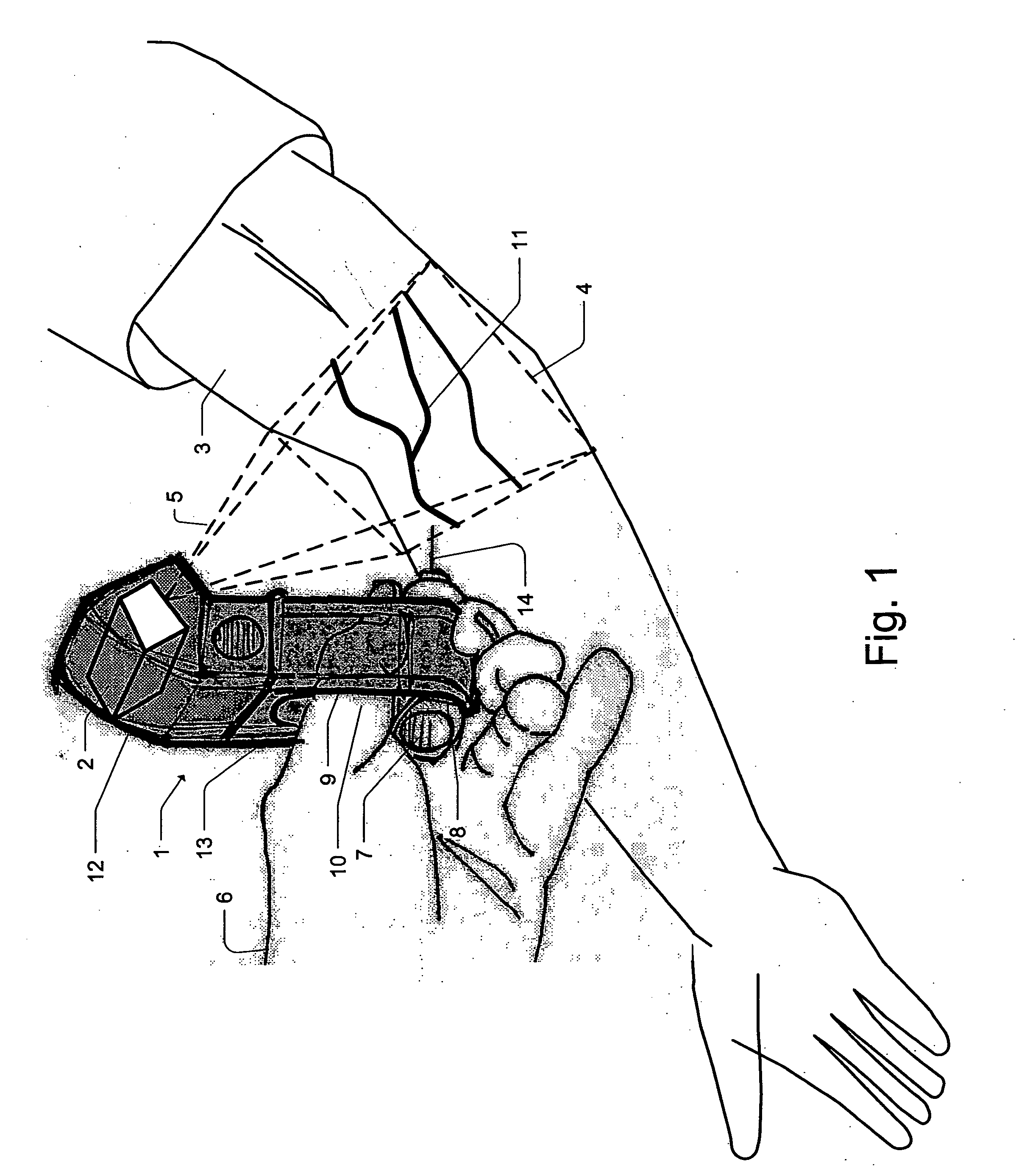

Micro vein enhancer

ActiveUS7904138B2Reduce impactExpand the scope of workImage analysisDiagnostics using lightVeinBlood test

The present invention is a Miniature Vein Enhancer that includes a Miniature Projection Head. The Miniature Projection Head may be operated in one of three modes, AFM, DBM, and RTM. The Miniature Projection Head of the present invention projects an image of the veins of a patient, which aids the practitioner in pinpointing a vein for an intravenous drip, blood test, and the like. The Miniature projection head may have a cavity for a power source or it may have a power source located in a body portion of the Miniature Vein Enhancer. The Miniature Vein Enhancer may be attached to one of several improved needle protectors, or the Miniature Vein Enhancer may be attached to a body similar to a flashlight for hand held use. The Miniature Vein Enhancer of the present invention may also be attached to a magnifying glass, a flat panel display, and the like.

Owner:ACCUVEIN

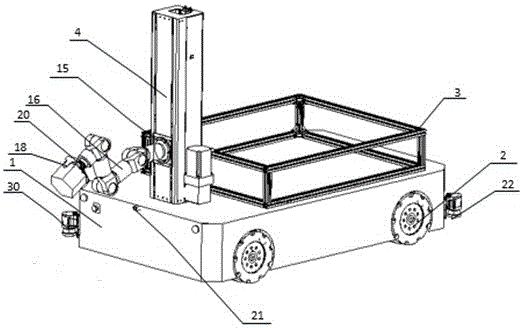

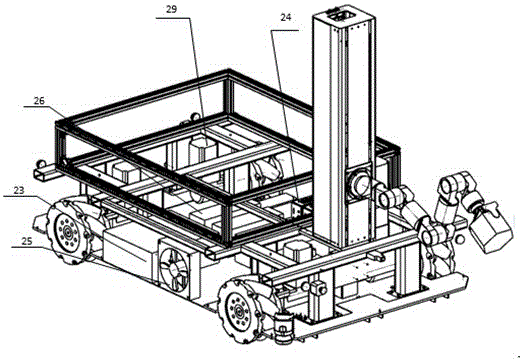

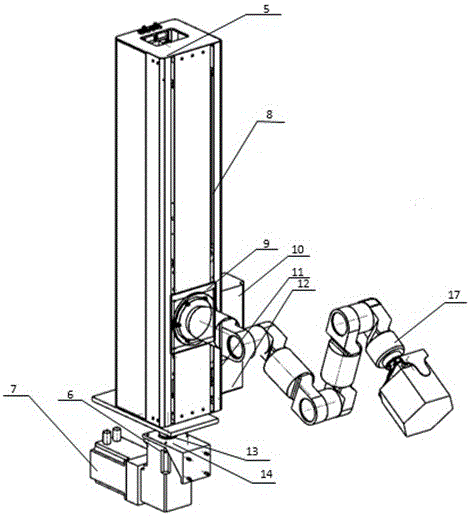

Omni-directional mobile transfer robot

InactiveCN106272415AImprove automationImprove completenessProgramme-controlled manipulatorControl systemSimulation

The invention discloses an omni-directional mobile transfer robot. The omni-directional mobile transfer robot comprises a mobile chassis, a carrying rack, a rotating mechanism, a lifting mechanism, a manipulator, a visual system, a laser sensor, a control system and a charging system. The mobile chassis is provided with Mecanum wheels for realizing omni-directional moving. The lifting mechanism can adjust the height of the manipulator. Rotational motion of a stand column at any angle can be realized through the rotating mechanism. Moreover, through cooperation of the manipulator having seven degrees of freedom, the working range is larger. Precision guidance can be realized through the laser sensor and the visual system. Operation is convenient. Motion is fast. The omni-directional mobile transfer robot is used for replacing manual operation, the working strength is reduced, and the production efficiency is improved. The omni-directional mobile transfer robot has high flexibility.

Owner:SHANGHAI UNIV

Measuring transducer of vibration-type

ActiveUS20070151371A1Improve density dependence of zero-pointEffective applicationDirect mass flowmetersDirect flow property measurementCouplingTransducer

A measuring transducer includes a transducer housing, as well as an internal part arranged in the transducer housing. The internal part includes at least one curved measuring tube vibrating, at least at times, during operation and serving for conveying the medium, as well as a counteroscillator affixed to the measuring tube on the inlet-side, accompanied by formation of a coupling zone, and to the measuring tube on the outlet-side, accompanied by the formation of a coupling zone. The internal part is held oscillatably in the transducer housing, at least by means of two connecting tube pieces, via which the measuring tube communicates during operation with the pipeline and which are so oriented with respect to one another, as well as with respect to an imaginary longitudinal axis of the measuring transducer, that the internal part can move during operation in the manner of a pendulum about the longitudinal axis. The measuring tube and the counteroscillator are additionally so embodied and so oriented with respect to one another that both a center of mass spaced from the imaginary longitudinal axis of the measuring tube, as well as also a center of mass of the counteroscillator spaced from the imaginary longitudinal axis, lie in a common region of the measuring transducer spanned by the imaginary longitudinal axis and the measuring tube, and that the center of mass of the measuring tube is spaced farther from the longitudinal axis than the center of mass of the counteroscillator.

Owner:ENDRESS HAUSER FLOWTEC AG

Optical scanners

InactiveUS6164540AExpand the scope of workAdd depthCharacter and pattern recognitionSensing by electromagnetic radiationOptical scannersLight beam

An optical scanner with plural scan beam generation. Scan angle stress is configured in the beam generation.

Owner:SYMBOL TECH LLC

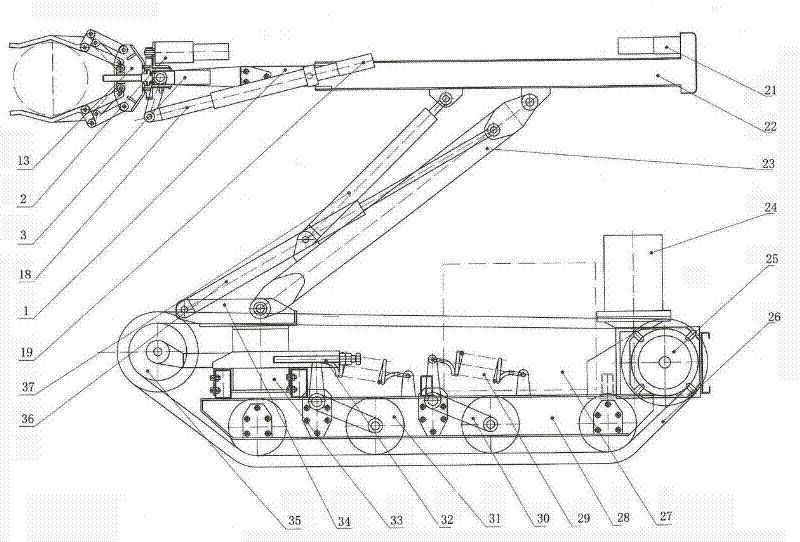

Robot for disposing dangerous goods and ammunition

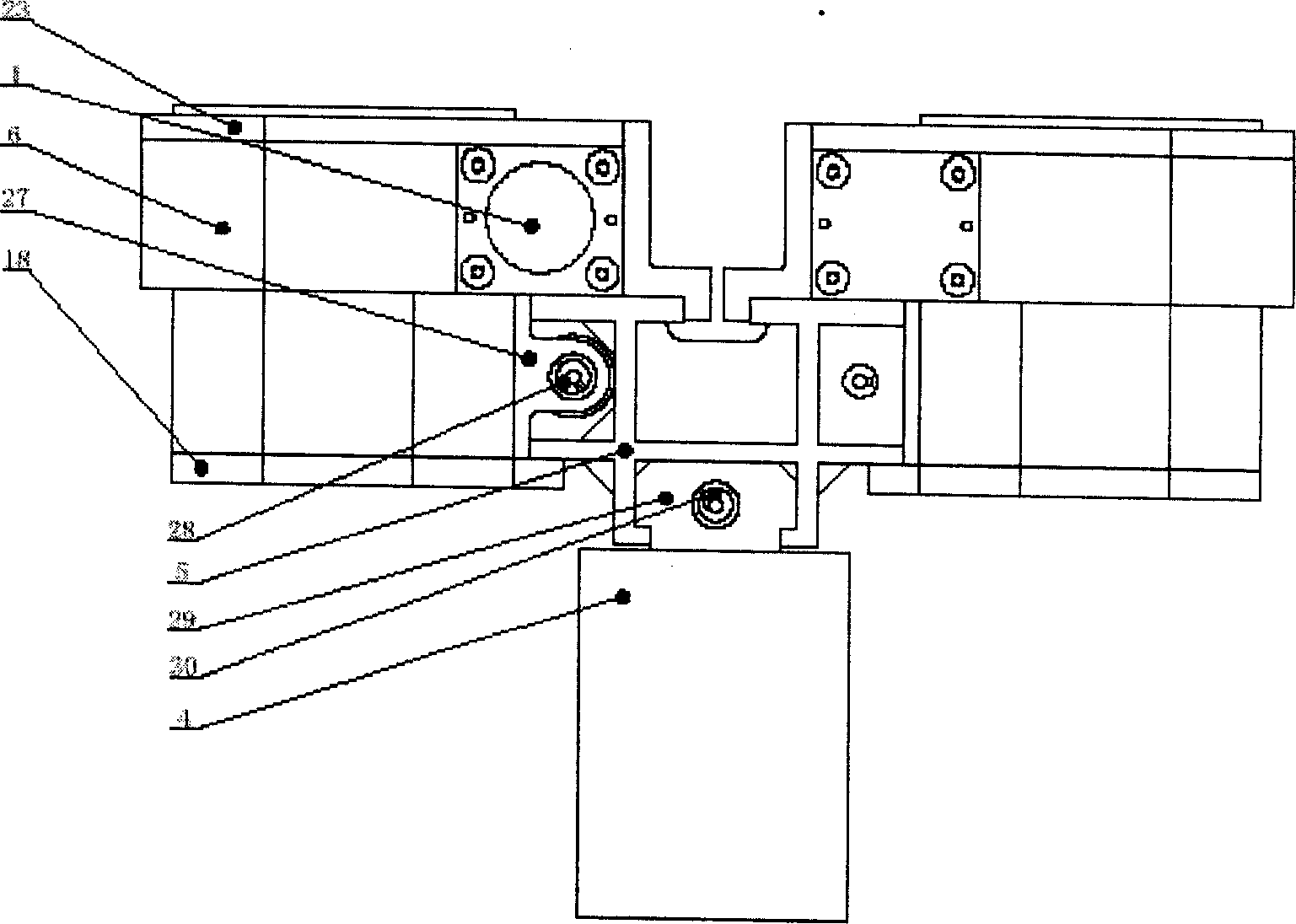

InactiveCN102490171ASimple structureEasy maintenanceProgramme-controlled manipulatorGripping headsRemote controlEngineering

The invention relates to a robot for disposing dangerous goods and ammunition, which is structurally characterized in that a rotation platform and a crawler-type travelling mechanism are mounted on a frame, a mechanical arm is mounted on the rotation platform, a manipulator is connected to the front end of the mechanical arm, a rotation cylinder is mounted on the lower portion of the rotation platform, the mechanical arm comprises a large arm, a small arm, a telescopic arm, a large arm cylinder, a small arm cylinder and a telescopic control motor, and the manipulator comprises a wrist lifting mechanism, a wrist rotating mechanism and a pick-and-place mechanism. The robot is large in grabbing torque, high in precision, fine in stability, wide in operation range, convenient and flexible in control, convenient in operation, stable and reliable in running, high in cost performance and capable of disposing the dangerous goods, the ammunition and the like within a limited distance by means of remote control.

Owner:ORDNANCE TECH RES INST OF THE GENERAL ARMAMENT DEPT PLA

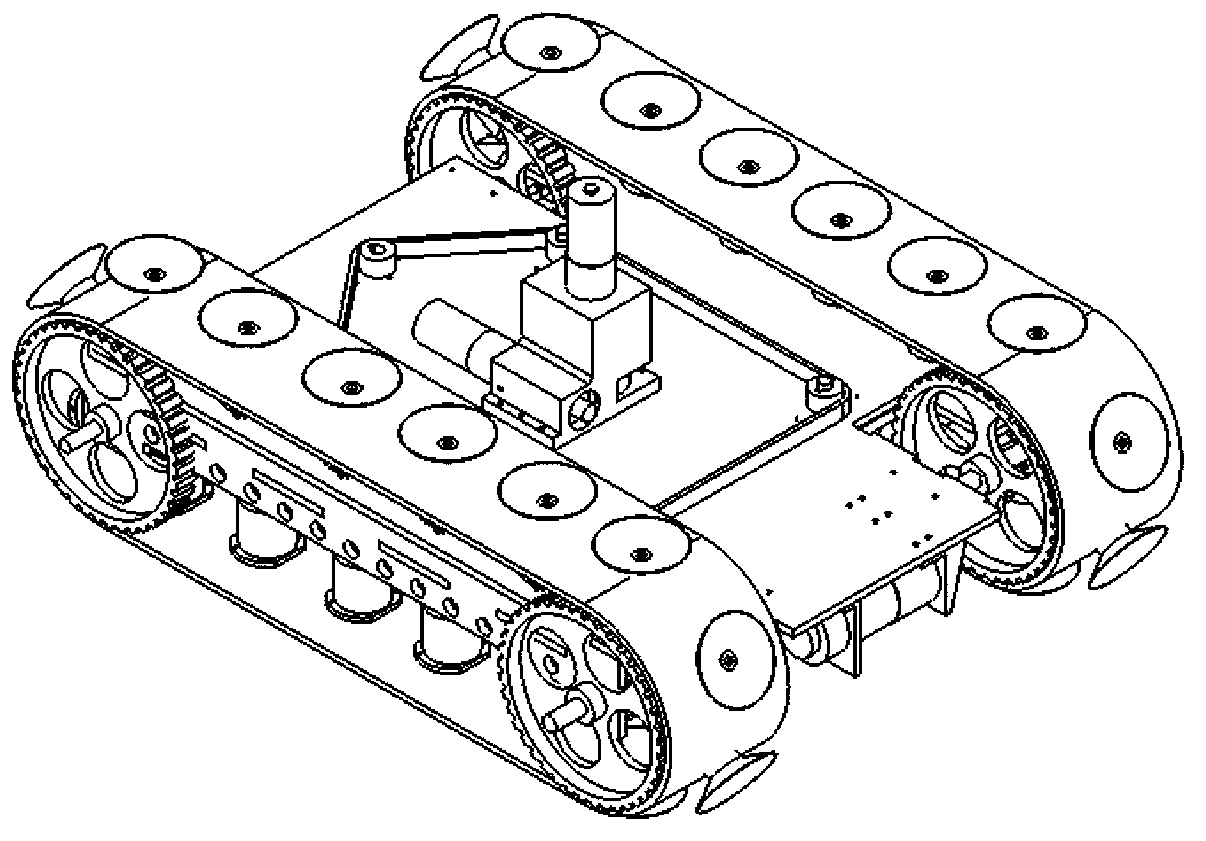

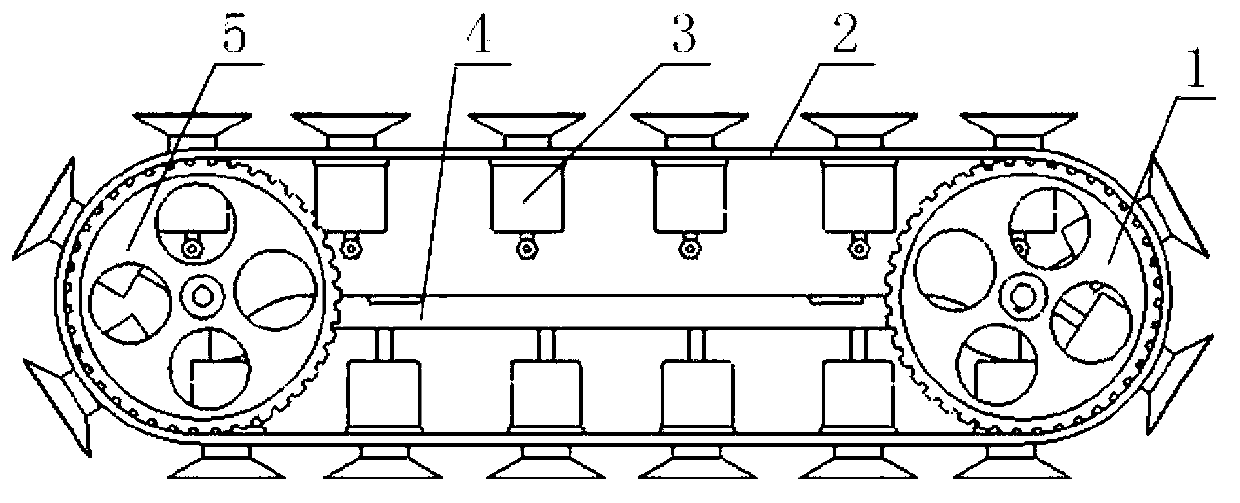

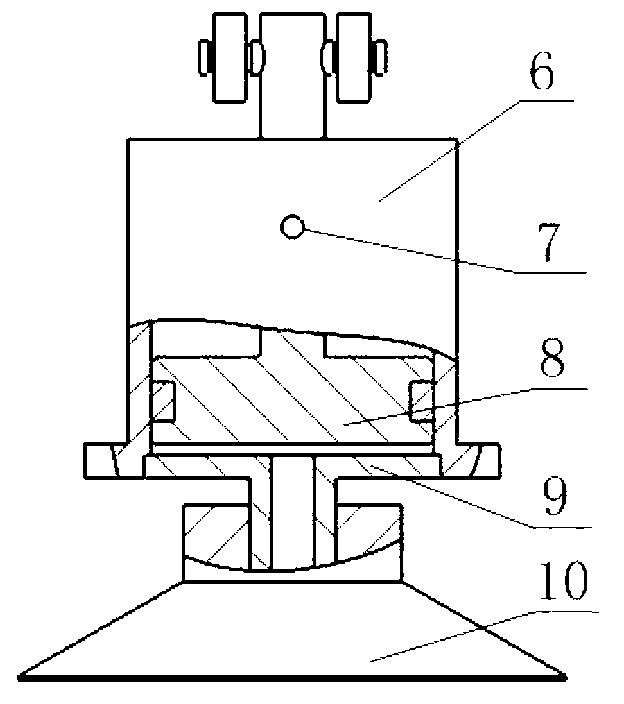

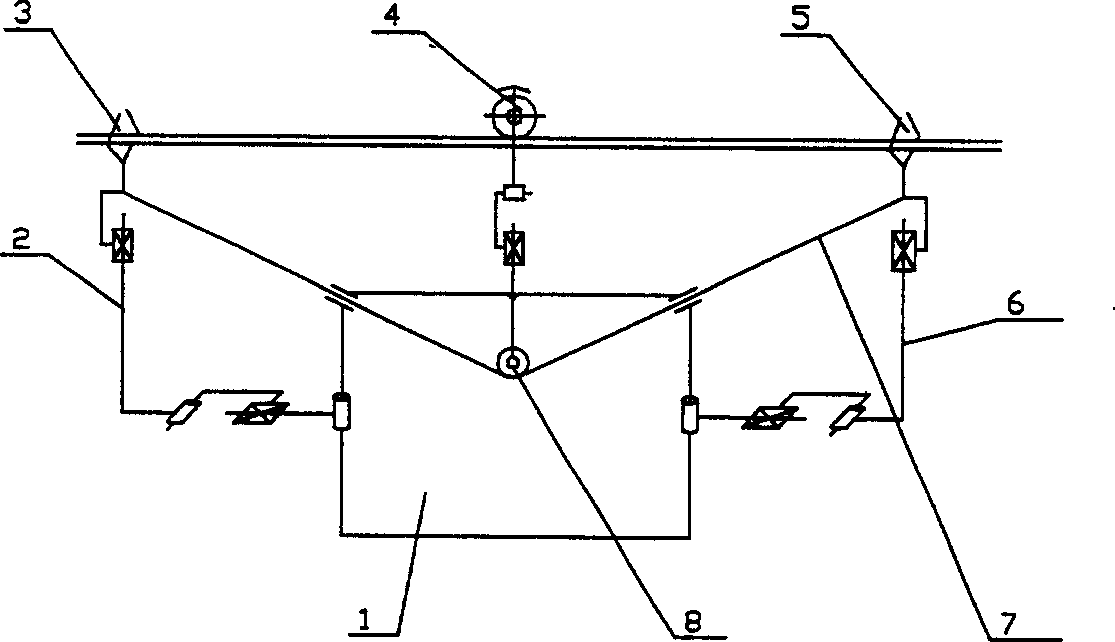

Cam-type negative pressure adsorption wall-climbing robot

The invention discloses a cam-type negative pressure adhering wall-climbing robot. By means of an inverse cam mechanism and a passive vacuum absorption mechanism, the negative pressure absorption function of a sucker is achieved and the limitation brought by a vacuum source device is eliminated. The adsorbing and detaching process of the vacuum sucker is easy through a mechanical structure. The structure is simple and the absorption force of the sucker is strong due to the negative pressure. By means of an adsorbing steering mechanism, the limitation of the minimum turning radius of a tracked robot is avoided and the pivot steering function is achieved. Adsorbing moving mechanisms are positioned on the two sides of a main baseboard of the robot; a steering power mechanism is fixed on the main baseboard; steering wheel components are connected with the steering power mechanism through flexible threaded rods; and by adjusting the position of a cam track groove, a steering auxiliary mechanism mounted on the main baseboard enables the adsorbing steering mechanism to work. The linear moving portion is connected with the linear steering portion through a screw transmission manner, the moving process of the robot is achieved through reasonable step arrangements, so that the cam-type negative pressure adsorption wall-climbing robot is easy to control and applicable to wide working range.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

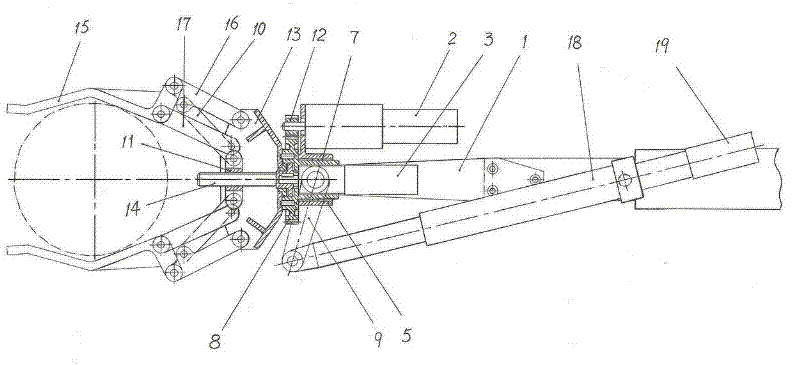

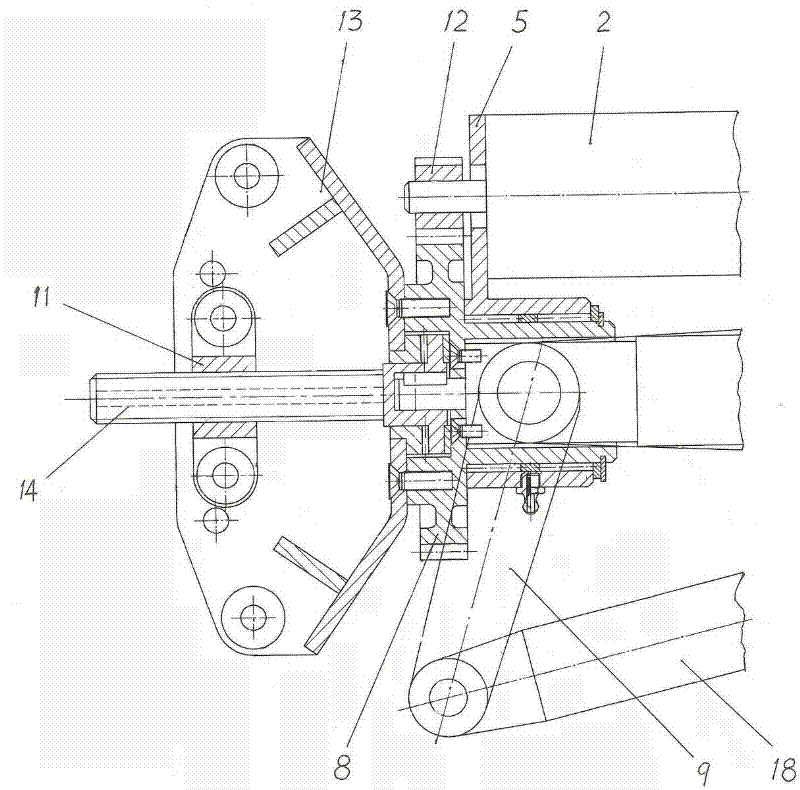

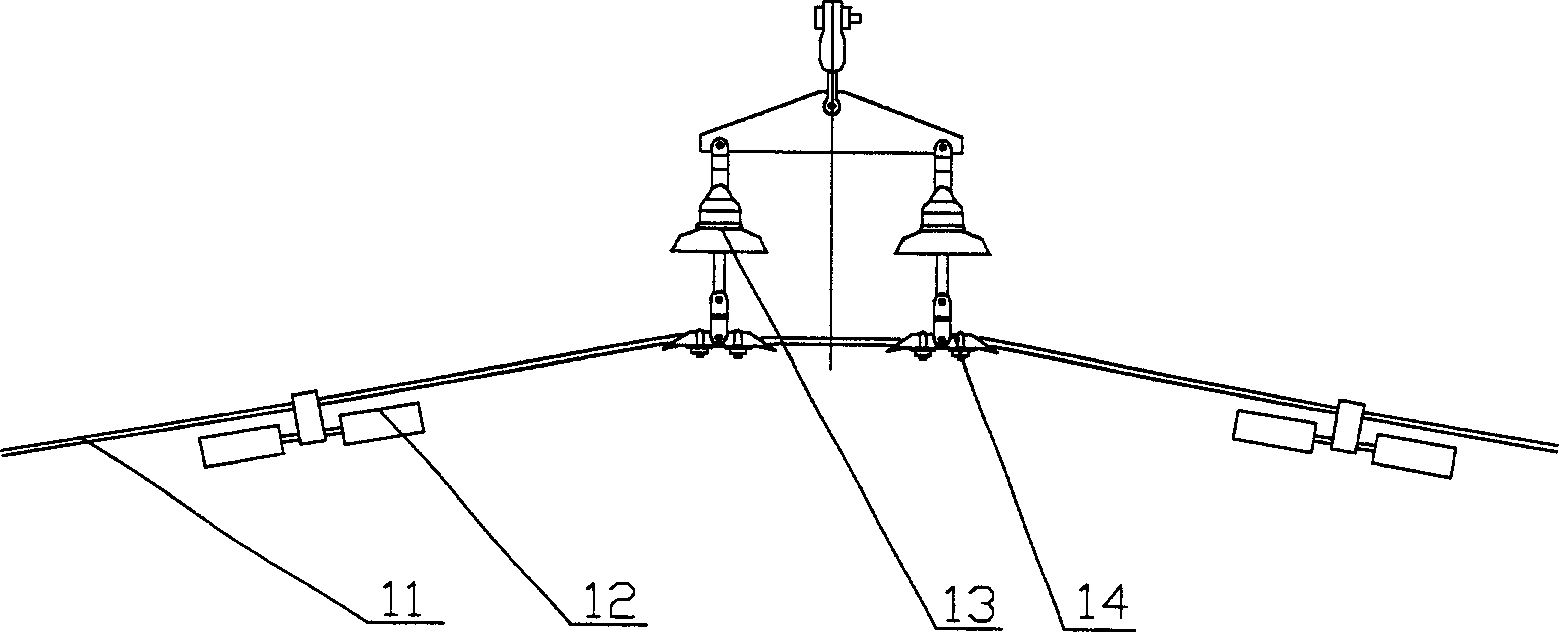

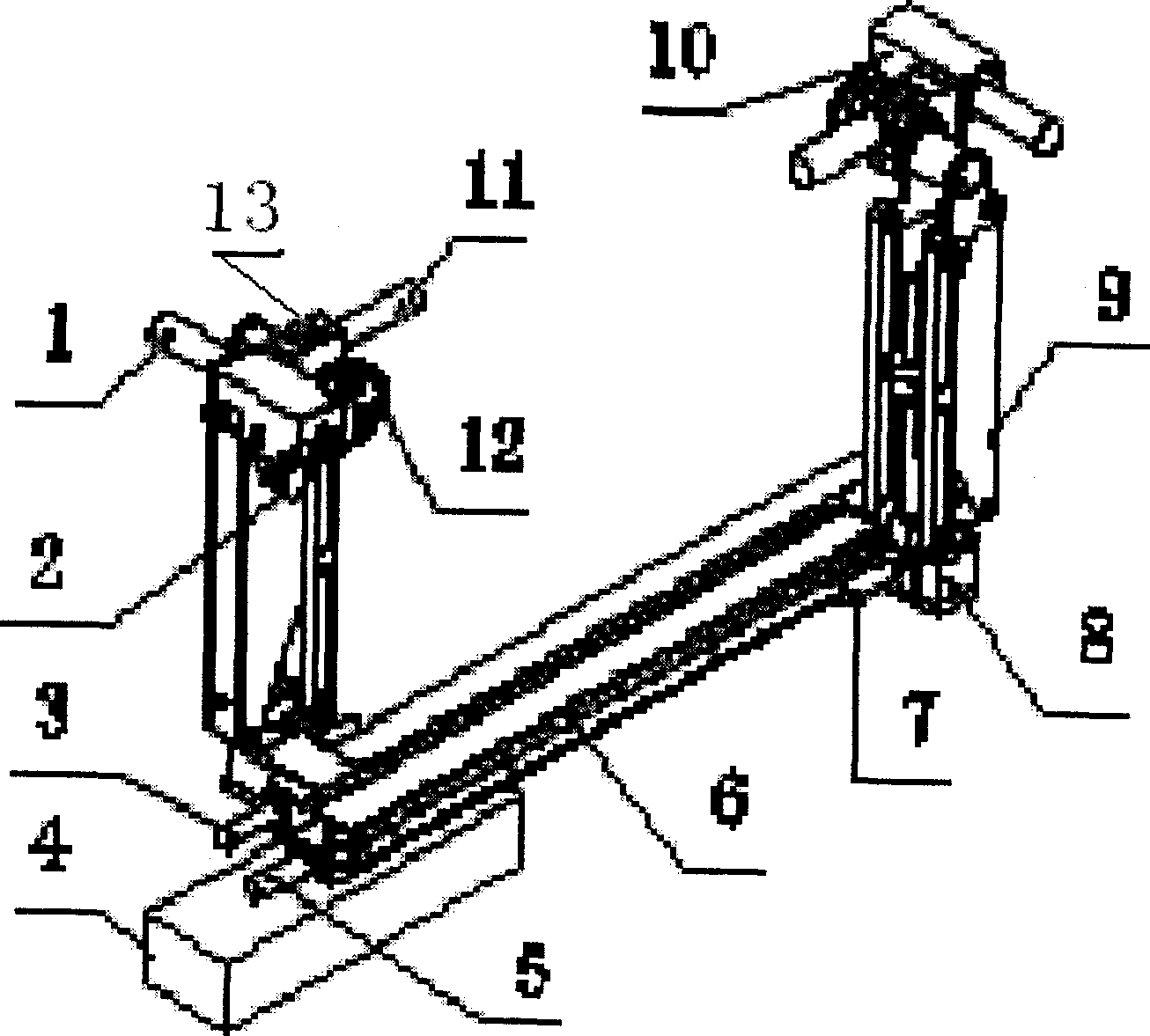

Super-voltage transmission line monitoring and detecting robot mechanism

InactiveCN1689769AEasy to walkConducive to overcoming obstaclesManipulatorMobile vehicleUltra high voltage

The present invention relates to movable robot mechanism, and is especially ultra high voltage power line polling robot mechanism. The polling robot mechanism consists of moving vehicle, back arm and front arm. The moving vehicle consists of vehicle body and walking wheel, the walking wheel is installed onto the vehicle body via horizontal rotation pair and moving pair and grasps the wire, and the vehicle body is connected via the rotation pair to the front arm and the back arm. The arm has hand claw in the end, the front arm and the back arm have the same structure, and each of the front arm and the back arm consists of two parts, upper arm and lower arm. The upper arm as one combined structure of link rod, ball lead screw and block is connected via horizontal rotation pair to the lower arm; and the lower arm is one great stroke telescopic mechanism. The present invention has great work space, light weight, low power consumption and powerful obstruction crossing capacity.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

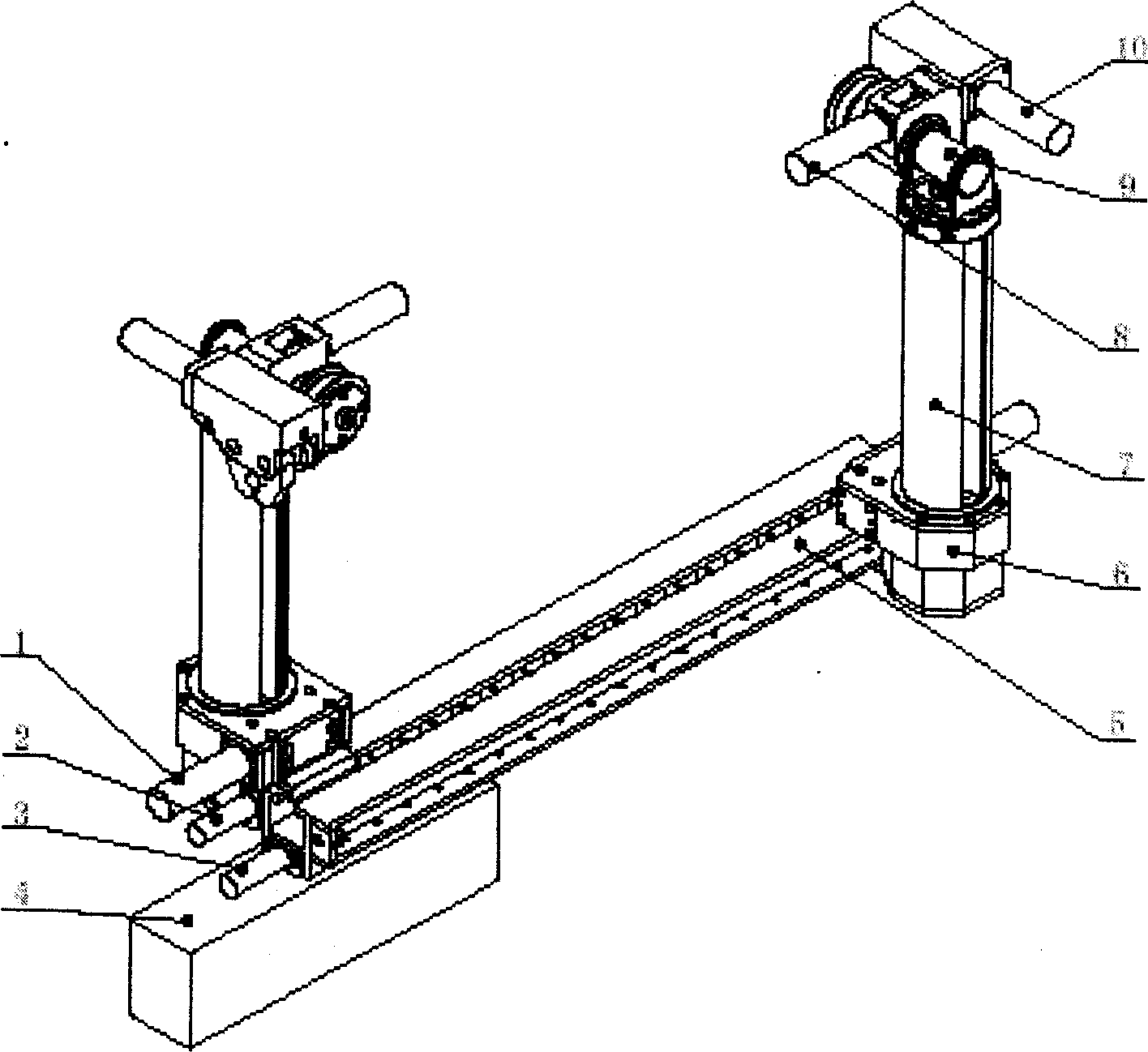

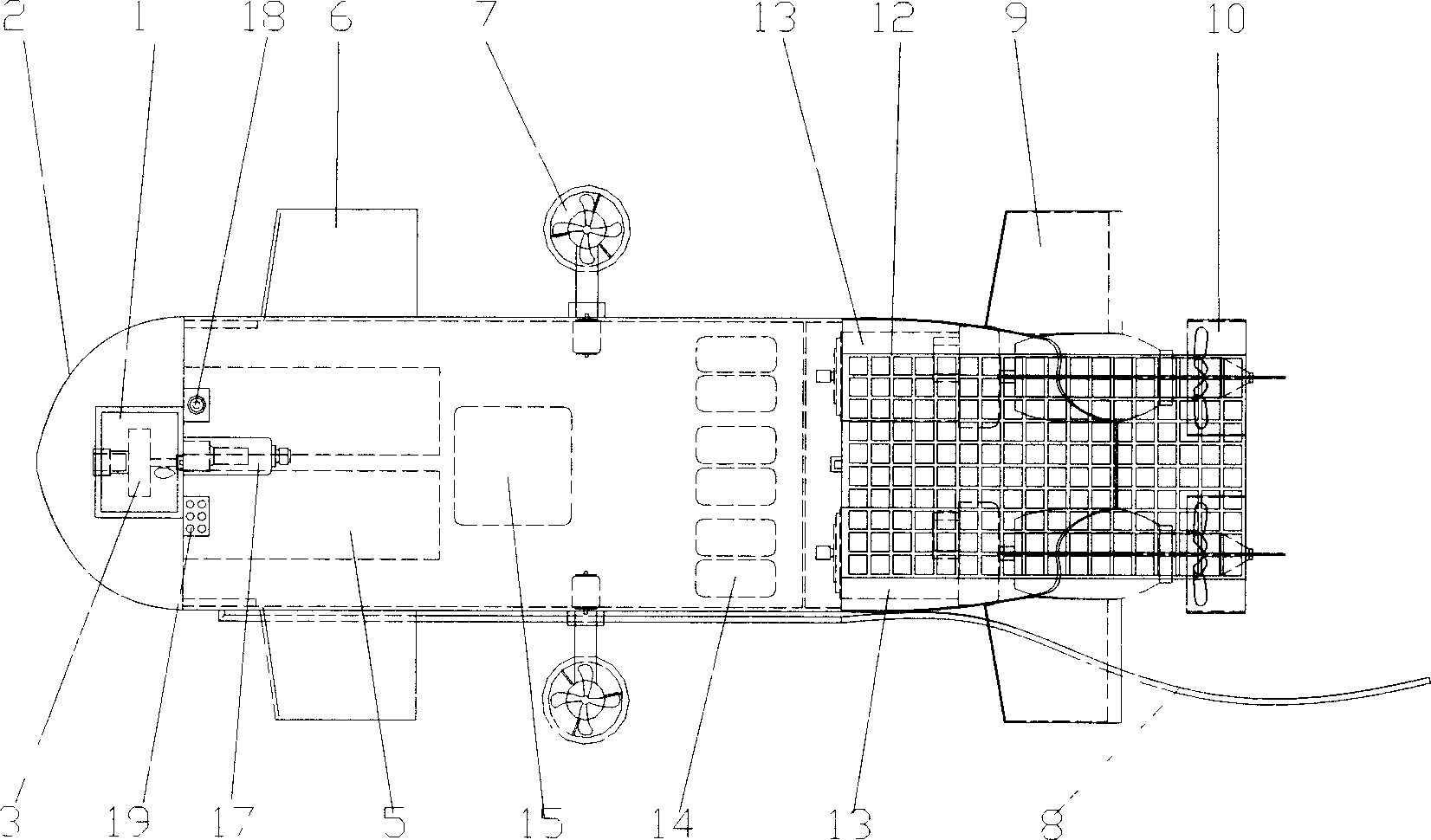

Arm lifting type high voltage transmission line automatic polling robot

InactiveCN101168252AReduce motion torqueOvercoming full automationProgramme-controlled manipulatorGripping headsGravity centerHigh pressure

Provided is an automatic robot for inspection of high air transmission lines, comprising two pairs of hand-paw mechanisms, two pairs of arm mechanisms and an engine base. The hand-paw mechanisms are composed of roller mechanisms, clamping mechanisms and wrist mechanisms and are capable of realizing that the robot slides along electric lines. In the process of obstacle navigation, the hand-paw mechanisms not only can clamp the electric lines but also can clamp a steel tower angle-bar. The arm mechanisms are connected with the hand-paw mechanisms and the engine base, being capable of realizing that the hand-paw mechanisms moves up and down relative to the engine, and driving hand-paws to rotate around a vertical shaft. Feed screw nuts arranged on the engine are capable of enabling the arms to parallel move along the length direction of an engine base guide rail. Elements of image collecting, controlling and driving are installed inside an electric equipment box and are hung under the guide rail, and the regulation of the integral center-of-gravity position of the robot can be realized through the parallel moving of the electric equipment box along the length direction of the guide rail. The invention is powerful, is convenient to realize moving, is capable of easily cross over all forms of tower frames, is adaptable with a wide range, and can actually realize the automatic inspection on a whole line.

Owner:上海求是机器人有限公司 +1

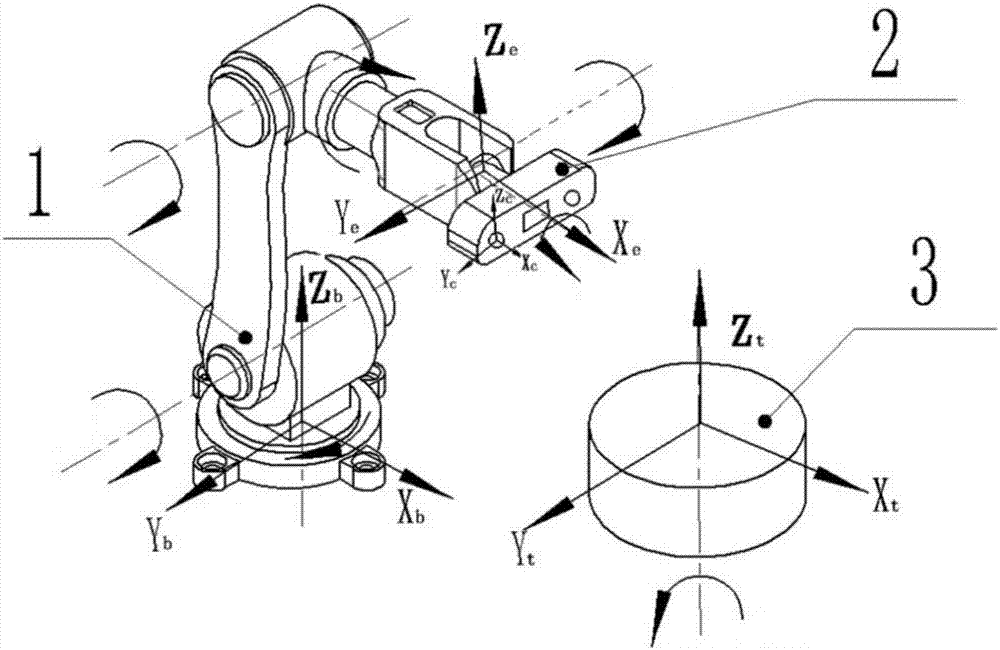

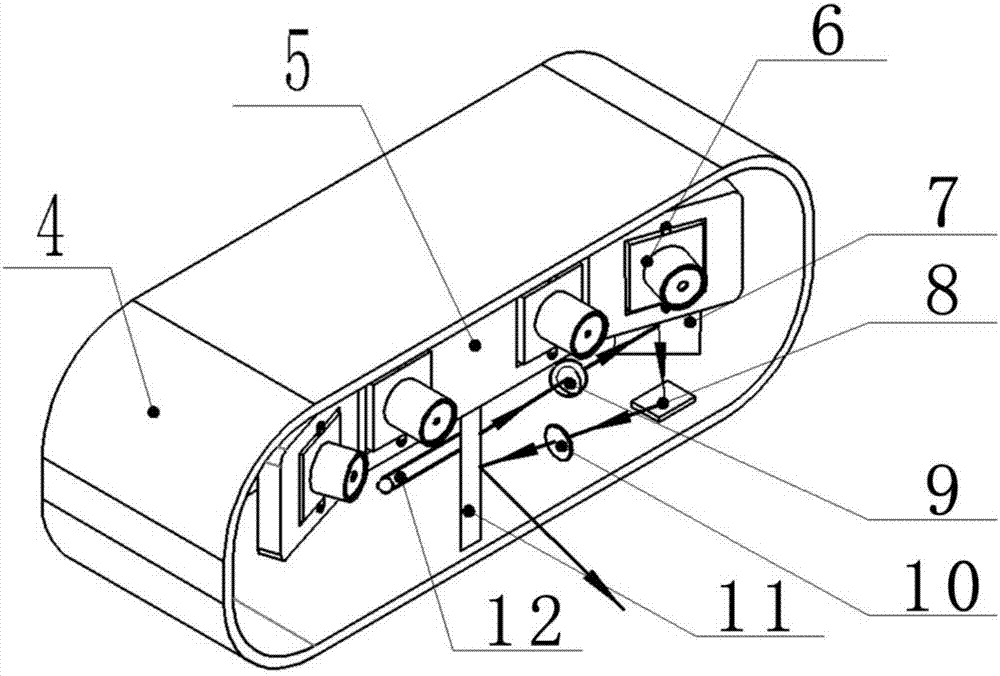

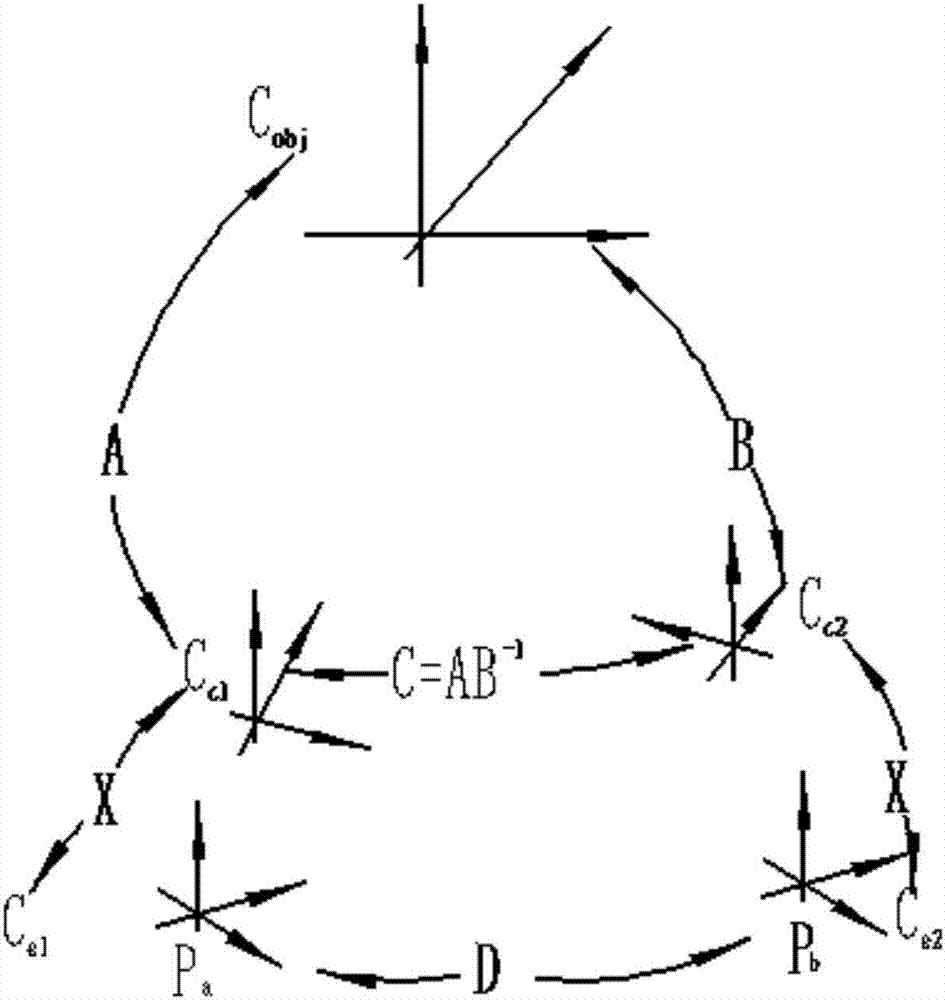

Robot three-dimensional scanning device and robot three-dimensional scanning method

InactiveCN107121062ASolve the problems of blind spots in scanning, long scanning time and low scanning accuracyExpand the scope of workUsing optical meansGratingPoint cloud

The invention discloses a robot three-dimensional scanning device and a robot three-dimensional scanning method. The device comprises an MEMS scanning galvanometer laser three-dimensional probe for generating three-dimensional point cloud data, a six-axis machine arm for clamping the MEMS scanning galvanometer laser three-dimensional probe, a turntable for placing a measured object and a controller for controlling the robot and the turntable, wherein the MEMS scanning galvanometer laser three-dimensional probe is arranged at the tail end of the machine arm; and the measured object is placed in the center of the turntable. In comparison with a digital and physical grating technology, the robot three-dimensional scanning device has the advantages of large depth of field, fast scanning speed, small size and high scanning accuracy; the device combines the high-accuracy turntable and the six-degree-of-freedom robot to a seven-degree-of-freedom device, the working range of the machine arm can be increased, flexibility of scanning on a large object can be improved, scanning dead angles can be reduced, and finally, fully-automatic three-dimensional scanning can be realized.

Owner:SUZHOU DEKA TESTING TECH CO LTD

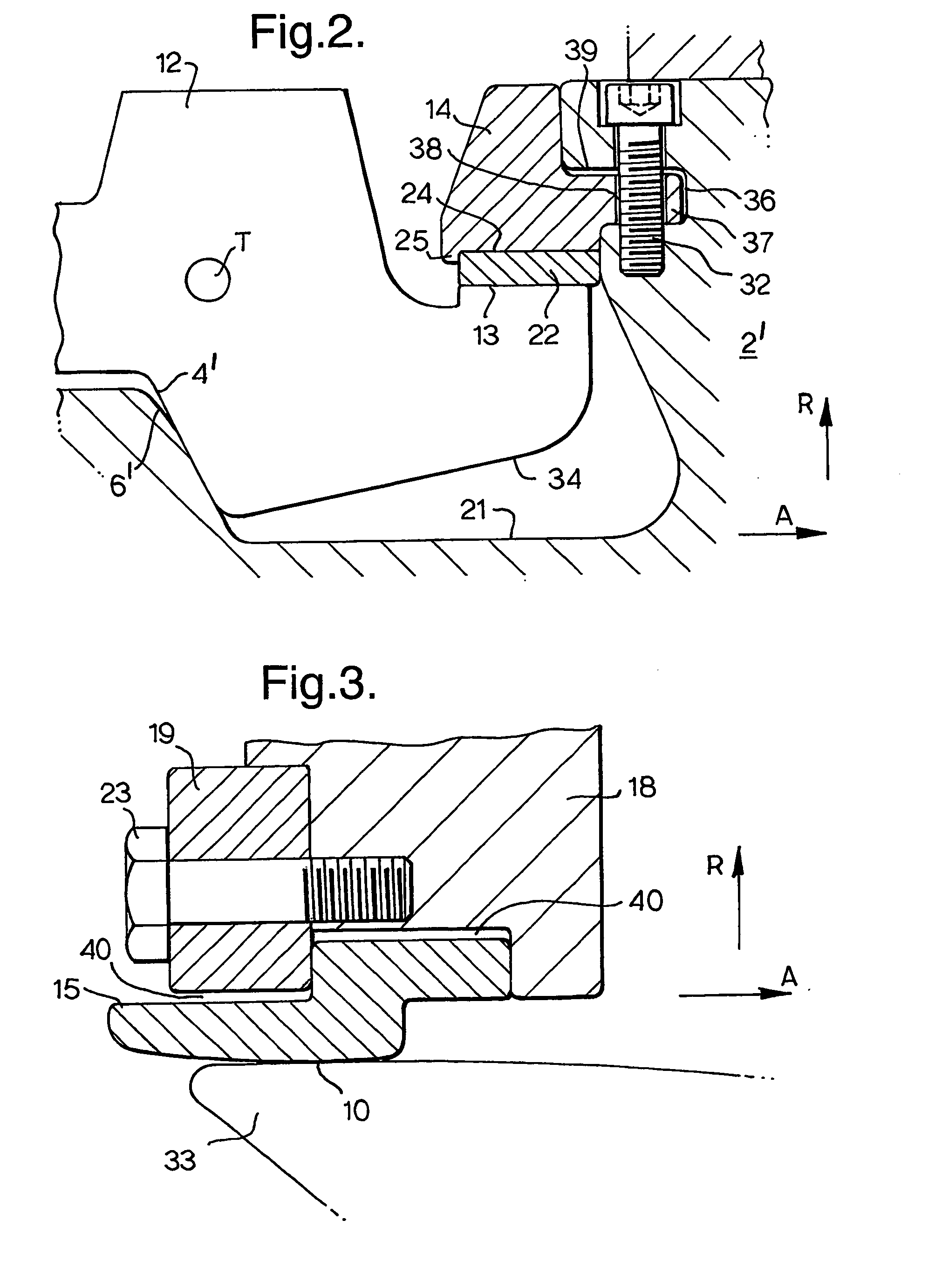

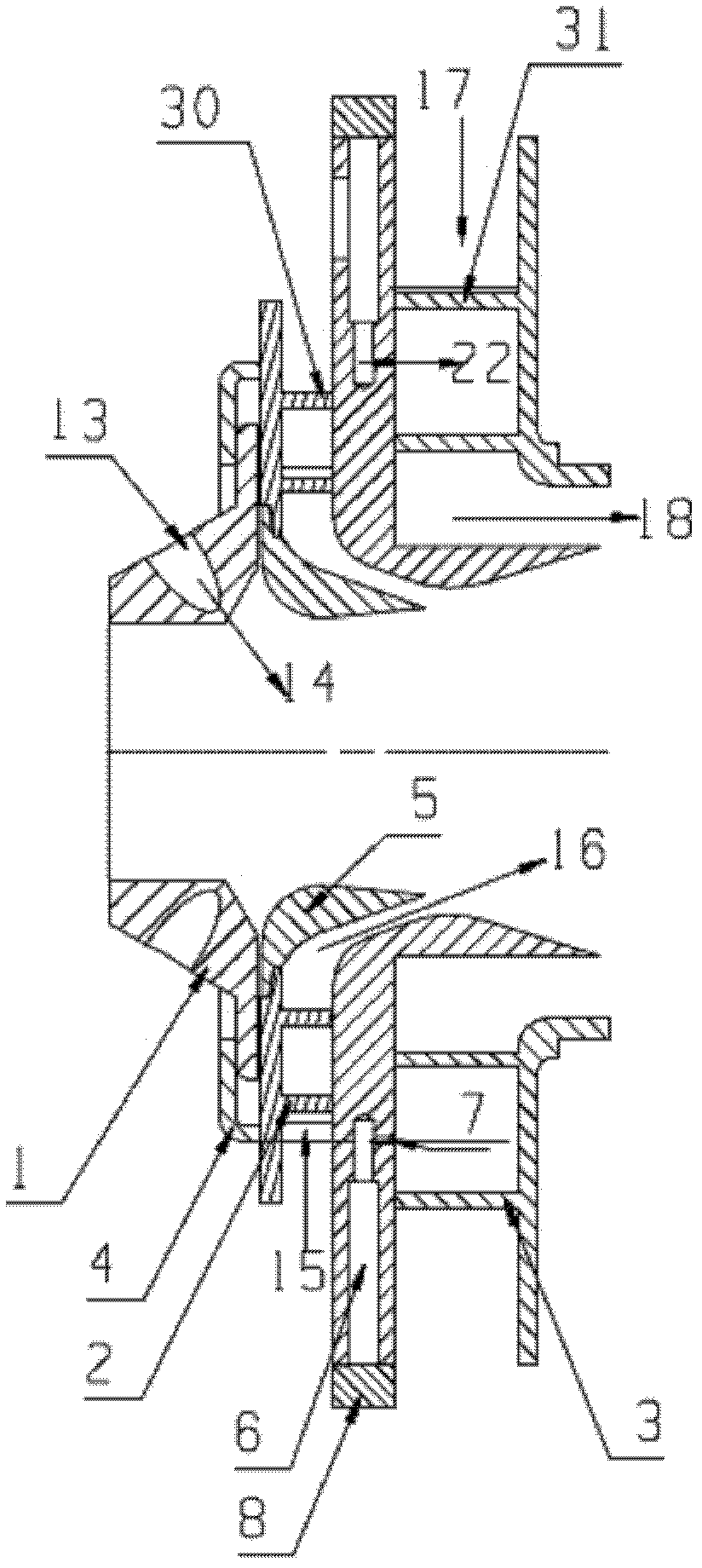

Mechanical joints for subsea equipment

InactiveUS20050146137A1Large dimensional toleranceExpand the scope of workSleeve/socket jointsPipe laying and repairJoint componentEngineering

A mechanical connector for oil and gas well apparatus applies a predetermined preload across the connection, the preload being adapted to accommodate relatively large dimensional tolerances in the loadpath of the connector preload by placing a component with a low modulus of elasticity within that load path. In one embodiment, the connector comprises fingers (3) of a pair of pipe flanges (1, 1′), a stationary retainer ring (14) against which a finger reaction surface (13) is pressed, a runner ring (15) located outside the fingers and movable lengthwise along the fingers by an actuator (16), the retainer ring and the runner ring having an elasticity that is so large that deviations in their elongation only have a small influence on the retainer ring and the runner ring radial pressure against the fingers and clamping forces of the fingers against the flanges. In a second embodiment, the connector comprises dogs (103, FIG. 4) located around the circumference of a first tubular joint component, a follower located outside the dogs (103) and movable axially of the dogs, the low elastic modulus component being a ring located in the loadpath below the dogs. In a third embodiment, the connector comprises a lockdown mechanism acting between nested components, the low elastic modulus component being an insert comprising a load shoulder transferring loads between the nested components.

Owner:FMC TECH INC

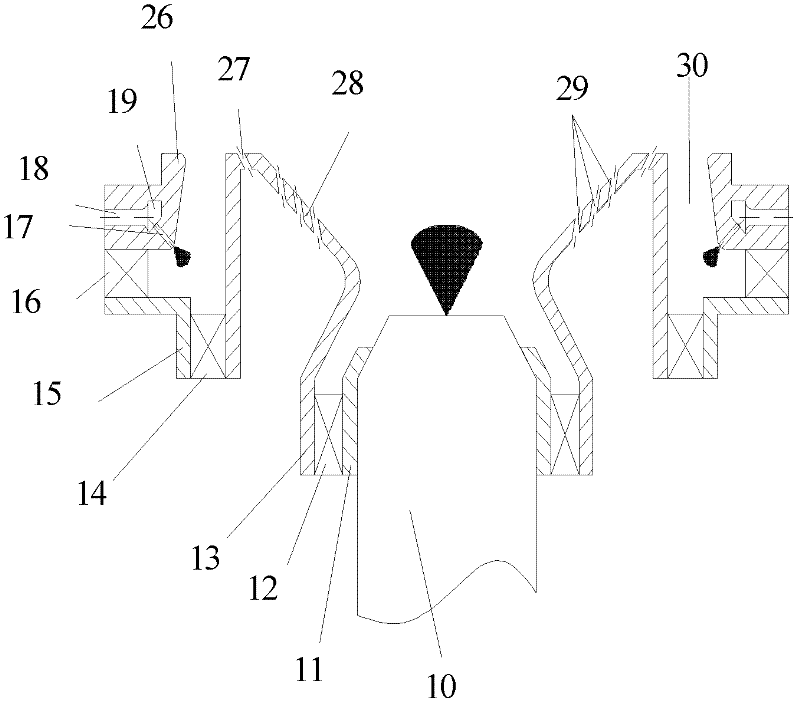

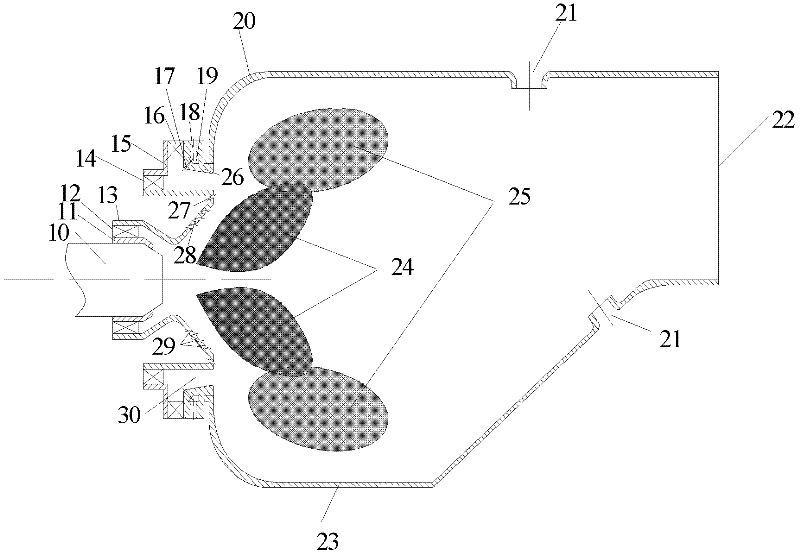

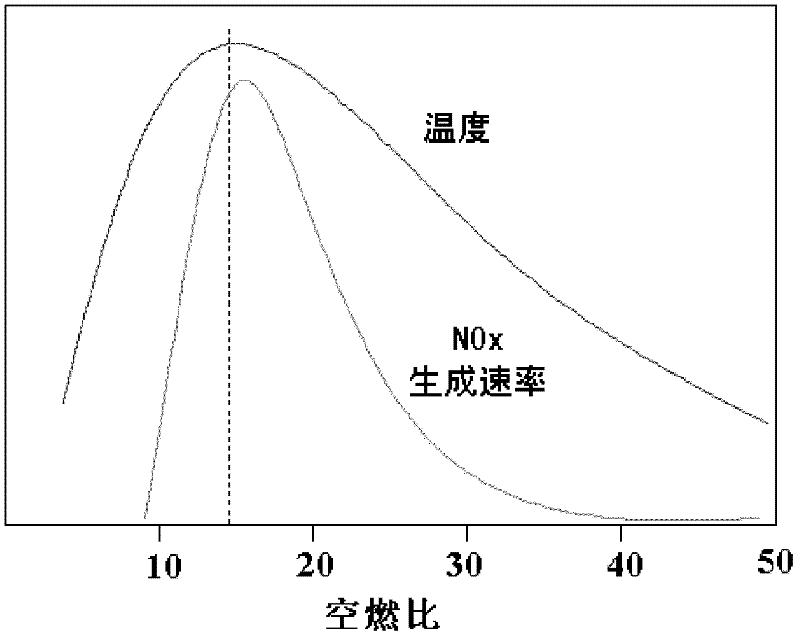

Low-pollution combustion chamber adopting fuel-grading and three-stage cyclone air inlet

ActiveCN103256633AEvenly distributedInhibition formationContinuous combustion chamberCycloneCombustion chamber

The invention discloses a low-pollution combustion chamber adopting fuel-grading and three-stage cyclone air inlet. The low-pollution combustion chamber comprises an on-duty oil supply nozzle, a primary-combustion oil supply nozzle, three-stage cyclones and a flame tube. Fuel is respectively provided for the on-duty oil supply nozzle and the primary-combustion oil supply nozzle in two ways, and the three-stage coaxial cyclones supply air to the head of a combustion chamber. The two stages of cyclones on the inner side of the combustion chamber refer to an oblique-cutting hole cyclone and a radial cyclone, cyclone of the two-stage cyclones are in opposite directions. A centrifugal atomizing nozzle is arranged at the center of the oblique-cutting hole cyclone, and the second-stage cyclone on the inner side are combined and matched with a center on-duty nozzle. The cyclone on the outside of the combustion chamber is a radial cyclone with cyclone direction opposite to that of a second-stage cyclone. Primary combustion fuel enters a cyclone blade channel from small holes of a front wall surface of a third-stage cyclones by way of multipoint direct injection and is accelerated to be crushed and atomized in a cyclone channel to be mixed with the air, and forms premixed or partly premixed fuel-air mixture at an exit of the tertiary swirling influx to enter a primary combustion zone to be combusted. The low-pollution combustion chamber is applicable to aircraft engine combustion chambers or industry fuel turbine combustion chambers.

Owner:中科航空动力(株洲)装备制造研究院有限公司

Working device setted on one place and engineering machinery using it

InactiveCN1831253AShorten the timeImprove operational skillsMechanical machines/dredgersVehiclesState of artEngineering

The invention is a working device arranged in some place, composed of two or above working devices arranged in some place, back-to-back, side-arranged, opposite, staggered, side-by-side, up and down, rotatable, inclinable, turnable, movable, liftable or in other form. And an engineering machine applying it is composed by arranging it in corresponding position on a corresponding vehicle or chassis or connecting it with the correspond position. And it can compose various engineering machines by various vehicles or chassises, compact, multifunctional, low-cost, high-efficiency and energy-saving, and having strong practicality.

Owner:姚实现

Micro vein enhancer

The present invention is a Miniature Vein Enhancer that includes a Miniature Projection Head. The Miniature Projection Head may be operated in one of three modes, AFM, DBM, and RTM. The Miniature Projection Head of the present invention projects an image of the veins of a patient, which aids the practitioner in pinpointing a vein for an intravenous drip, blood test, and the like. The Miniature projection head may have a cavity for a power source or it may have a power source located in a body portion of the Miniature Vein Enhancer. The Miniature Vein Enhancer may be attached to one of several improved needle protectors, or the Miniature Vein Enhancer may be attached to a body similar to a flashlight for hand held use. The Miniature Vein Enhancer of the present invention may also be attached to a magnifying glass, a flat panel display, and the like.

Owner:ACCUVEIN

Laser sensor for self-mixing interferometry with increased detection range

ActiveUS20100134803A1Low cost processingIncrease cavity lengthLaser detailsLaser optical resonator constructionPhotovoltaic detectorsPhotodetector

The present invention relates to a laser sensor for self-mixing interferometry. The laser sensor comprises at least one semiconductor laser light source emitting laser radiation and at least one photodetector (6) monitoring the laser radiation of the laser light source. The laser light source is a VECSEL having a gain medium (3) arranged in a layer structure (15) on a front side of a first end mirror (4), said first end mirror (4) forming an external cavity with an external second end mirror (5). The proposed laser sensor provides an increased detection range and can be manufactured in a low-cost production process.

Owner:TRUMPF PHOTONIC COMPONENTS GMBH

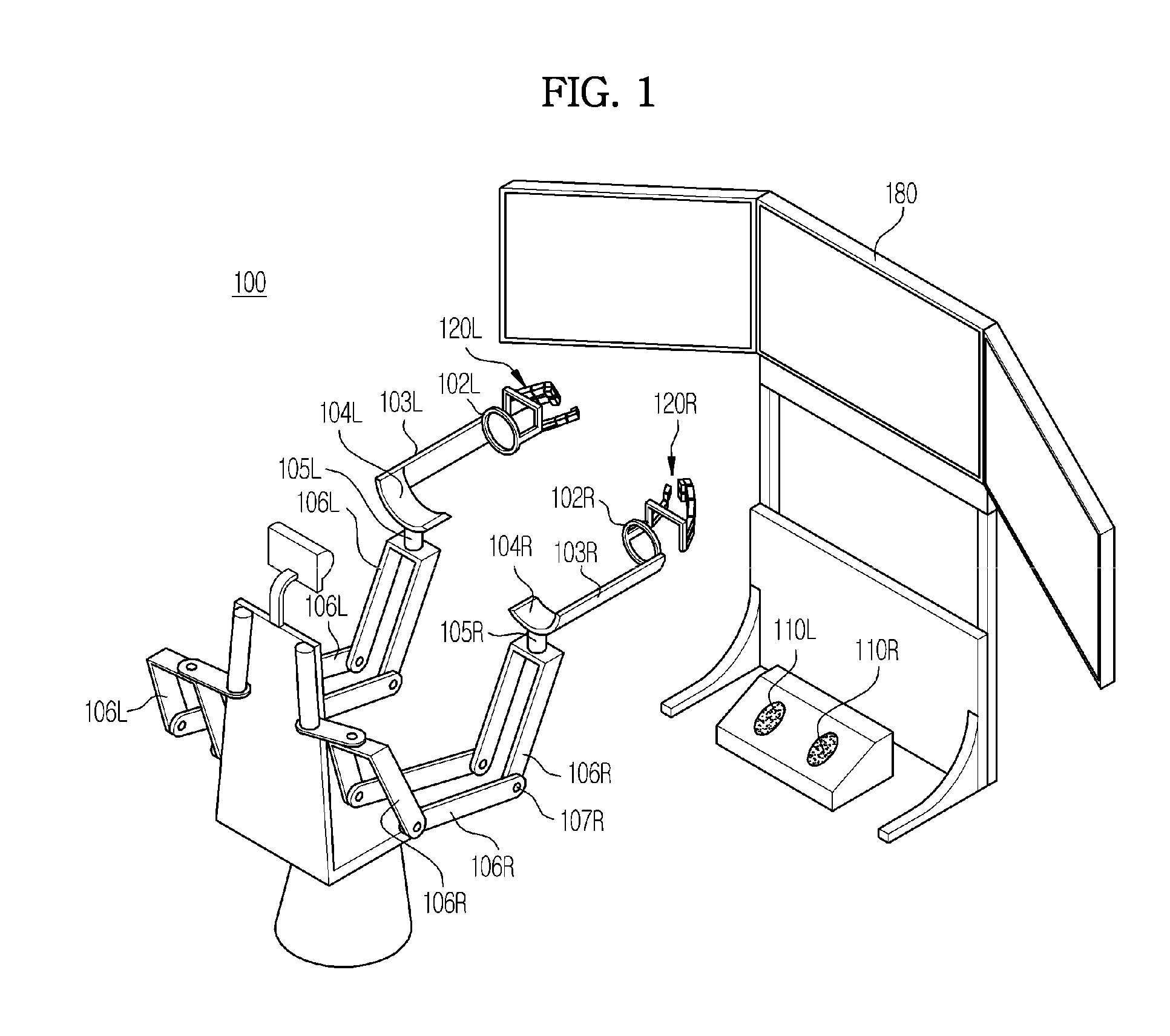

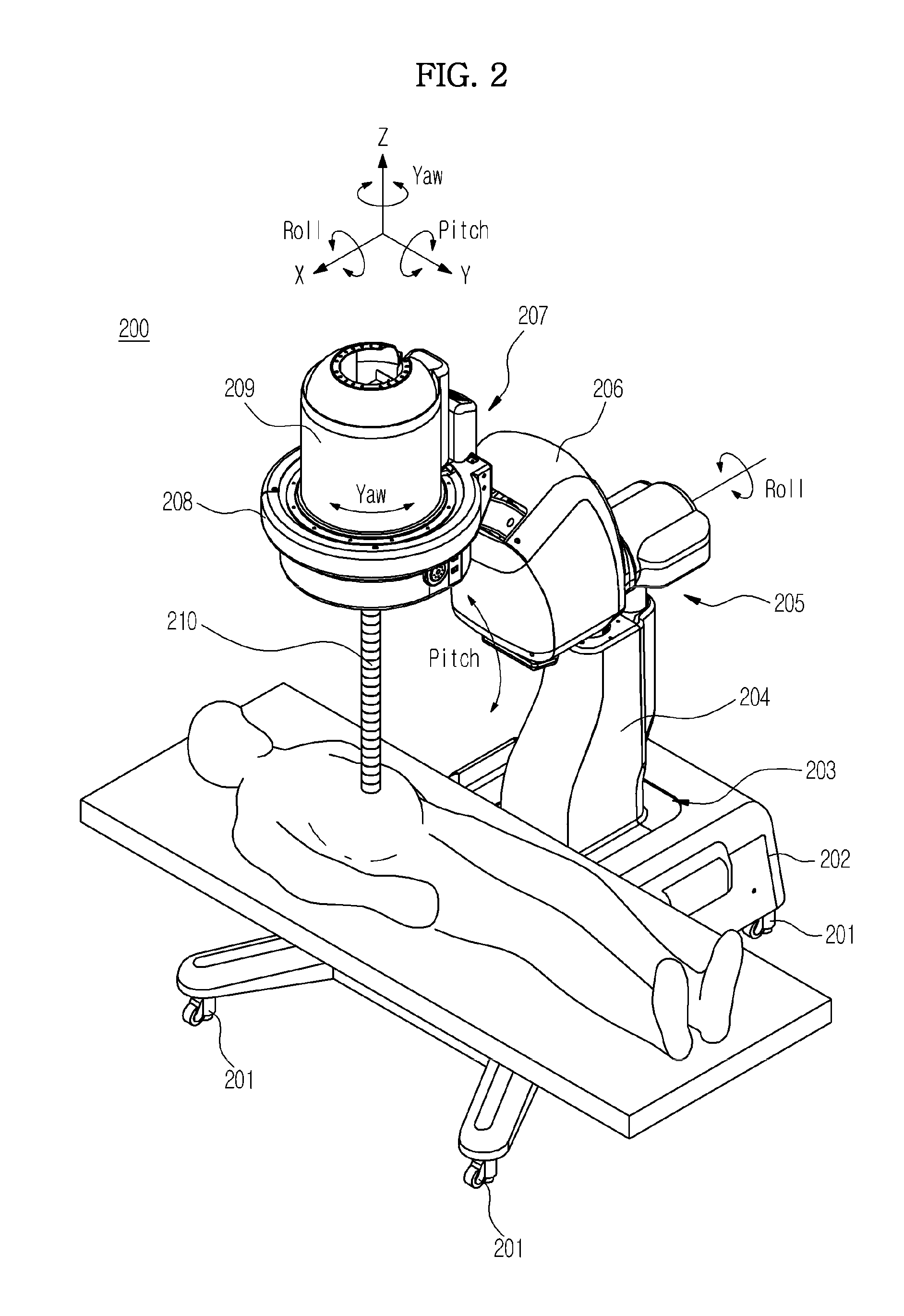

Surgical robot system and method of controlling the same

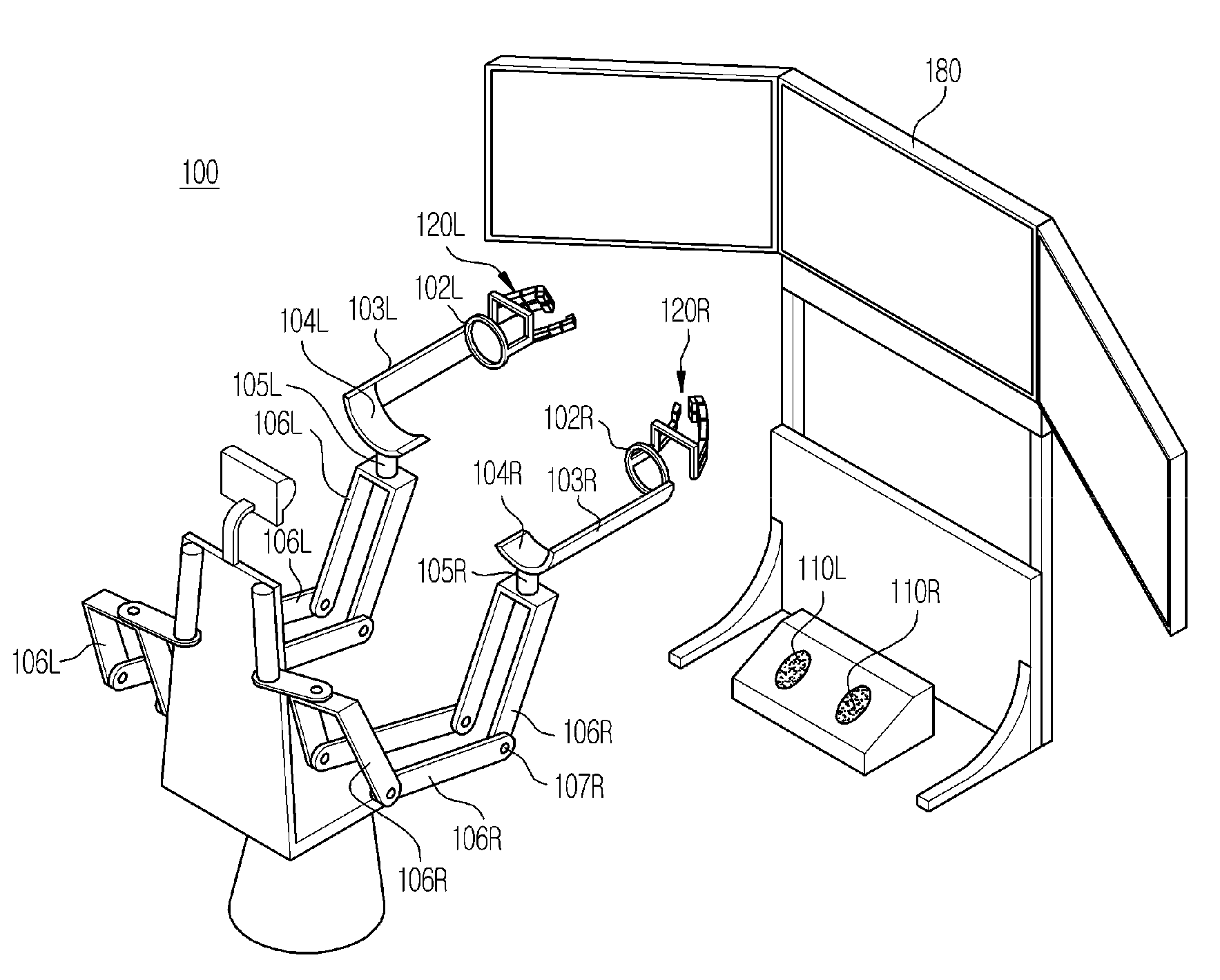

ActiveUS20150045812A1Expand the scope of workReduce defectsDiagnosticsSurgical manipulatorsSurgical robotControl signal

A surgical robot system may include a slave device having a surgical instrument; and a master device configured to transmit a control signal to the surgical instrument. The slave device may include a guide tube to which the surgical instrument is coupled; and a controller operating the surgical instrument in response to the control signal transmitted from the master device, and operate the guide tube so as to move the surgical instrument to a target position if the target position of the surgical instrument according to the control signal corresponds to a position out of a range of a current working space for the surgical instrument.

Owner:SAMSUNG ELECTRONICS CO LTD

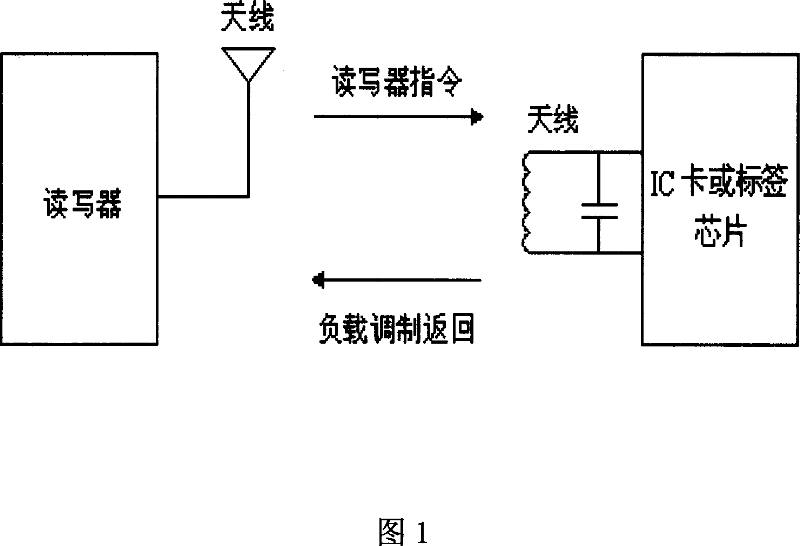

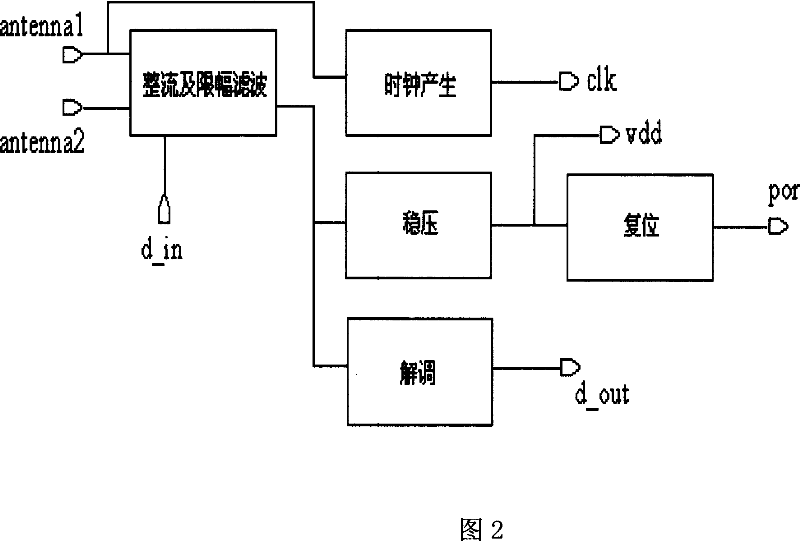

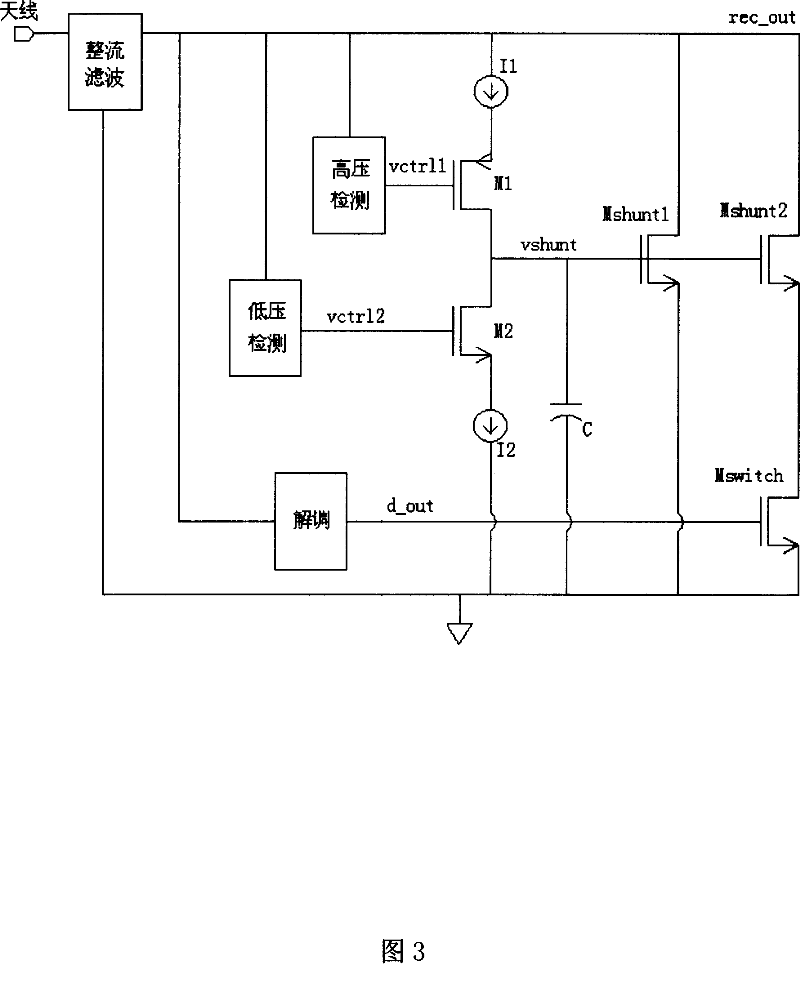

Limiting amplitude protection circuit used in non-contact IC card and radio frequency identification label

ActiveCN101038616AAvoid the problem of easy power offExpand the scope of workElectronic switchingSensing record carriersCapacitanceControl signal

The invention discloses an amplitude-limiting circuit used for the non-contact type IC card and the radio frequency identified tag chip comprising a bypass grounding transistor being paralleled to the rectified filter circuit of the chip radio frequency interface, a high voltage and a low voltage detection circuits for detecting the output signal from the rectified filter circuit, wherein the high voltage and low voltage circuit controls the opening of a charging current source for charging a capacitor and a discharging current source, the capacitor forms an amplitude-limiting signal by discharging, and the amplitude-limiting signal controls the opening of the bypass grounding transistor. The invention can implement amplitude-limiting function without affecting the posterior demodulation, voltage stabilization, and normal operation of the clock and the reset circuit.

Owner:SHANGHAI HUAHONG INTEGRATED CIRCUIT

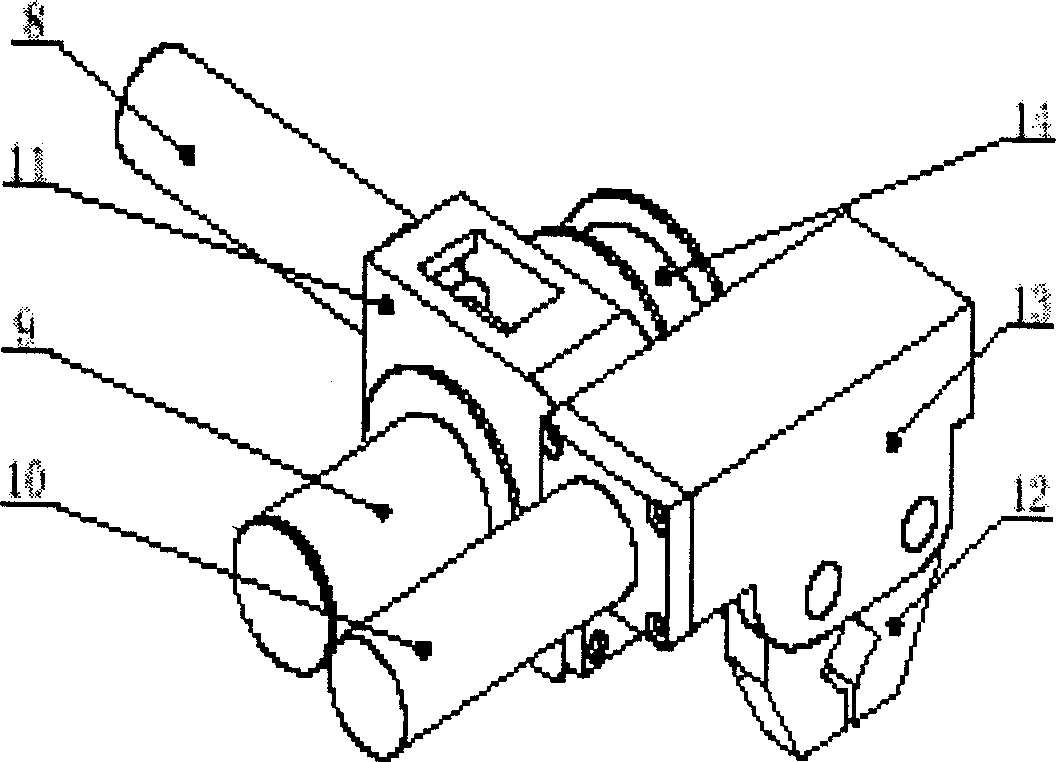

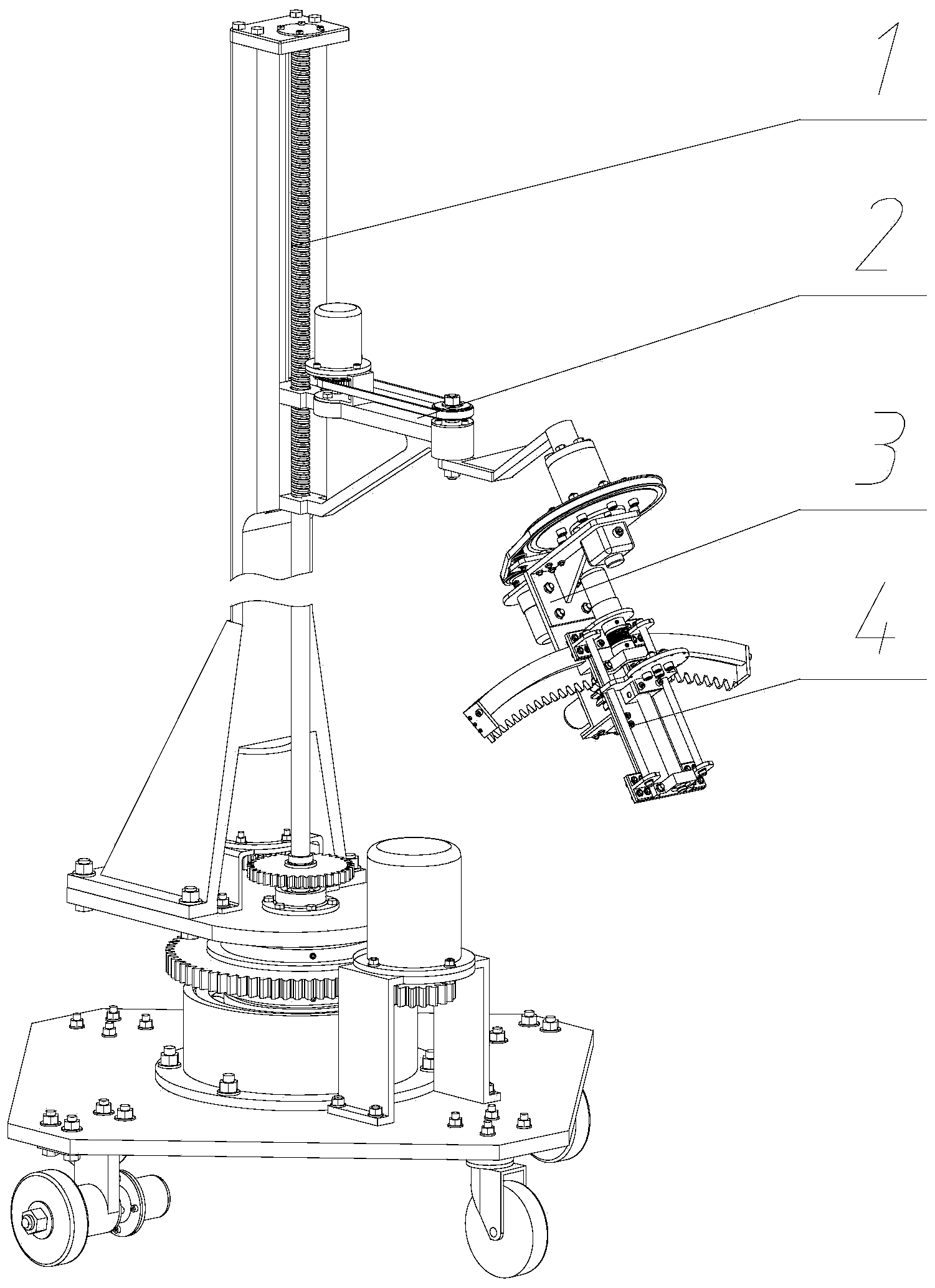

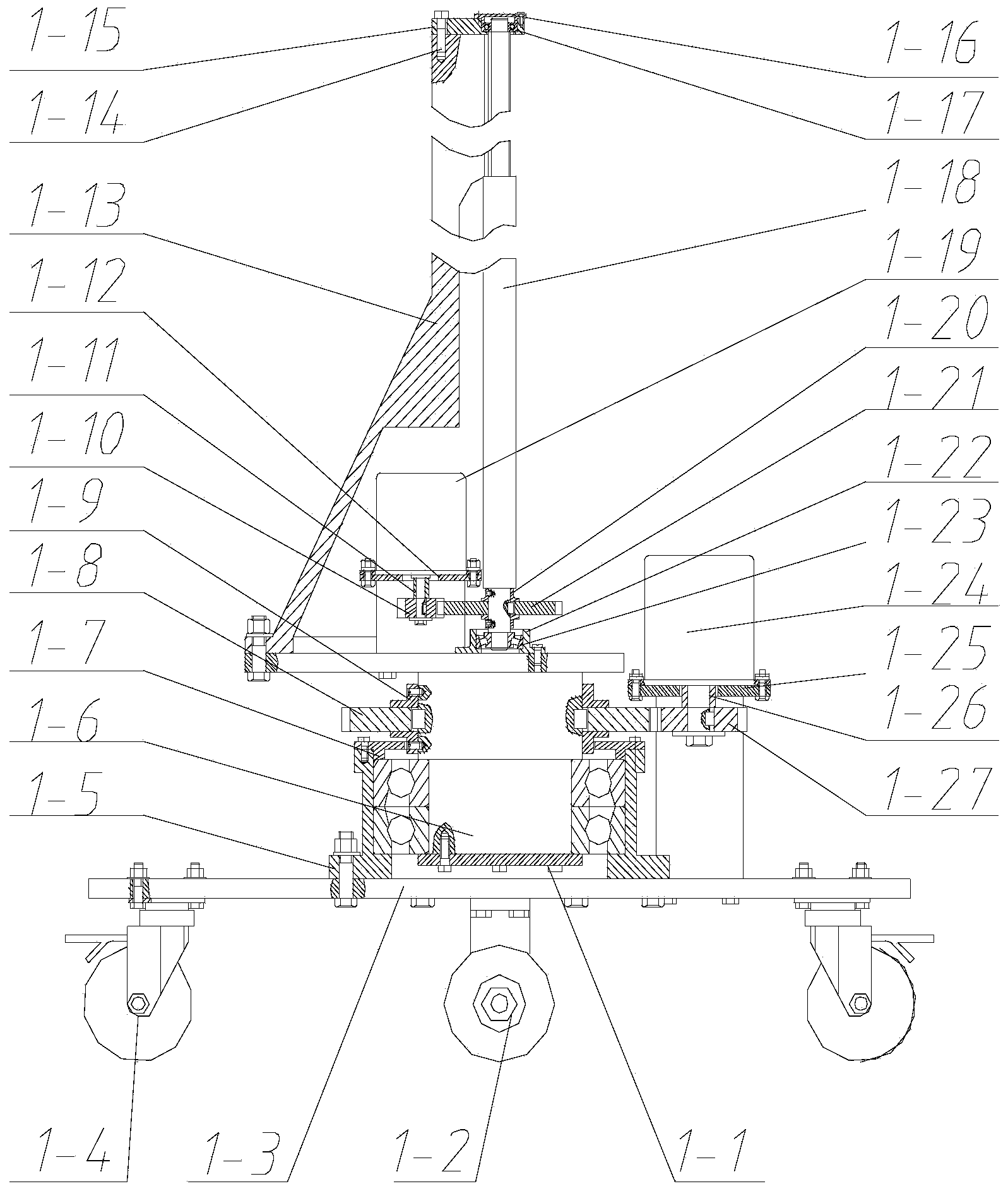

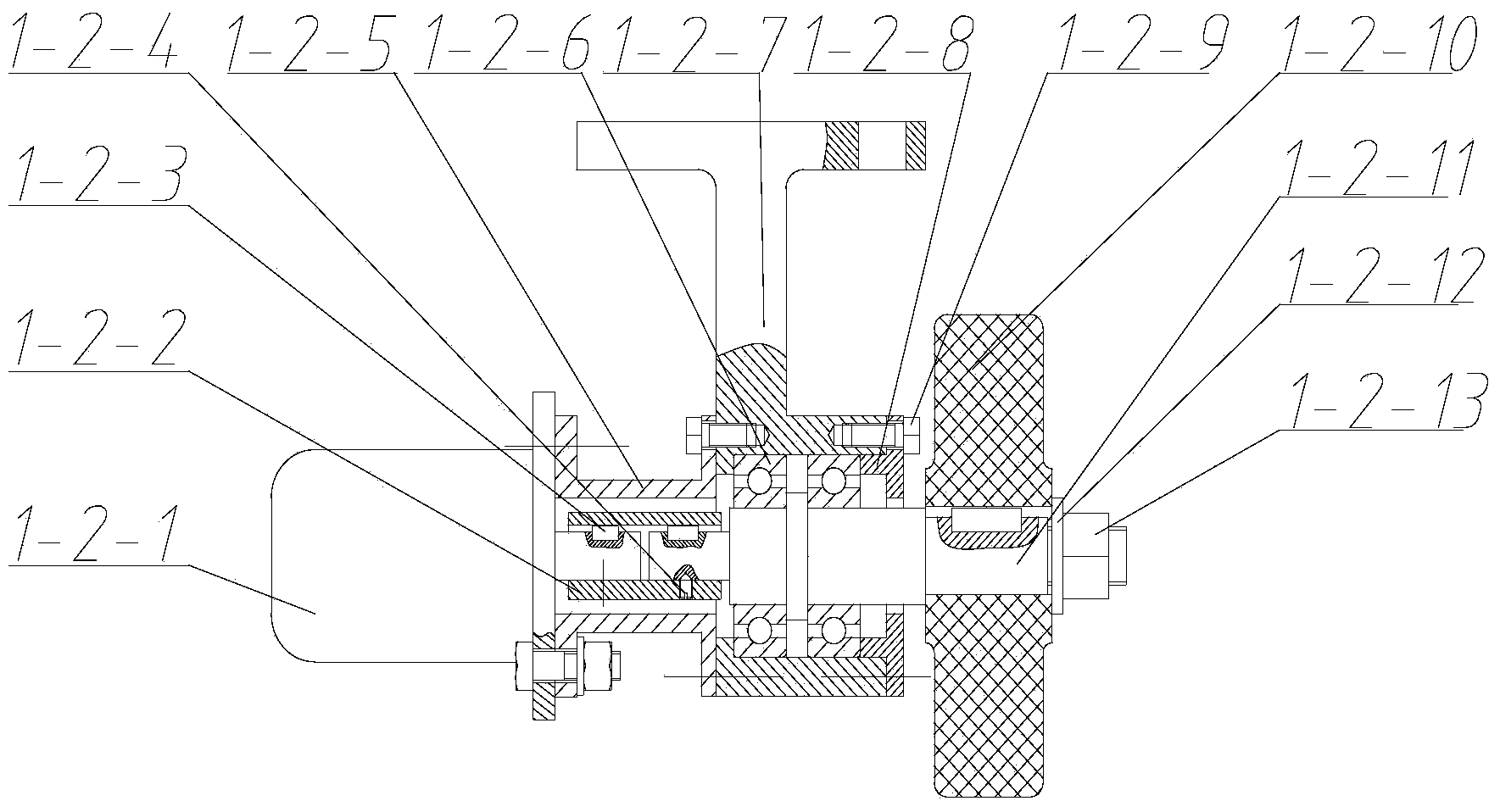

Multi-freedom-degree minimally-invasive-surgery instrument-holding arm structure

InactiveCN103919610AEffective use of experienceUse experienceDiagnosticsSurgerySurgical operationDrive wheel

The invention provides a multi-freedom-degree minimally-invasive-surgery instrument-holding arm structure. A braking universal wheel and a driving wheel are arranged on a bottom plate in a mobile support mechanism. By driving of two motors and meshing transmission of gears, rotating of a base and rotating of a lead screw are achieved respectively, and by thread transmission at the upper end of the lead screw, a sliding block of an arm rotating joint achieves sliding motion along the lead screw and a sliding groove track of a stand column. Small arm rotating is achieved through the motors by belt transmission. The motors achieve the rotating freedom degree of a wrist around a main shaft by belt transmission. One motor achieves swinging of a sliding track mechanism along an arc rack by inner meshing of the gears and the rack, the other motor is connected with the sliding lead screw through a coupler, and the sliding lead screw rotates to drive a finger connecting plate to move front and back. The multi-freedom-degree minimally-invasive-surgery instrument-holding arm structure has the advantages of being stable in state, accurate in locating, good in dexterity, large in working range and the like, and the mobile support mechanism has the overall rotating freedom degree similar to the human waist and the lifting freedom degree of a lead screw part.

Owner:HARBIN ENG UNIV

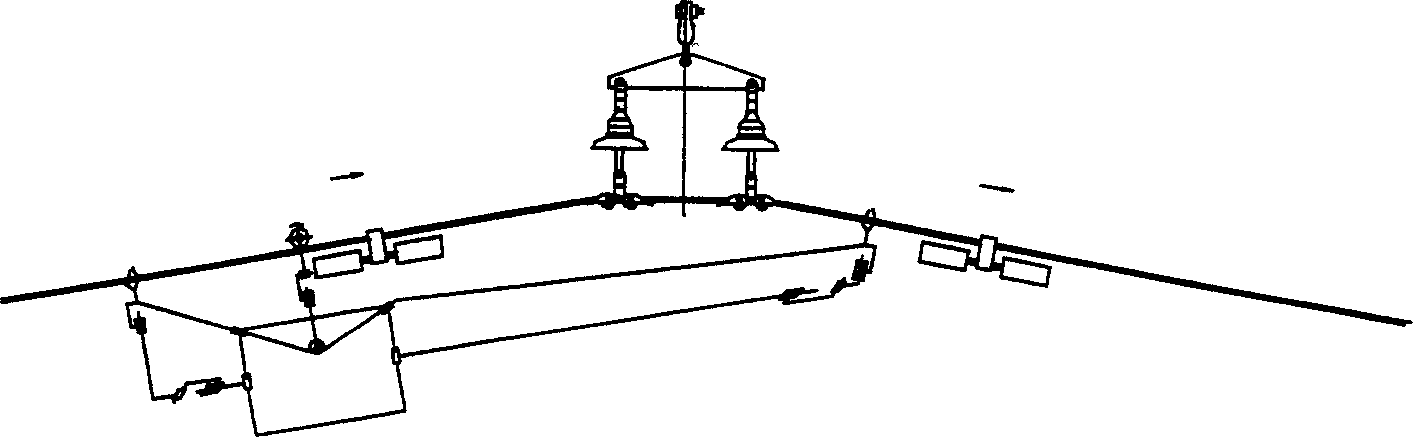

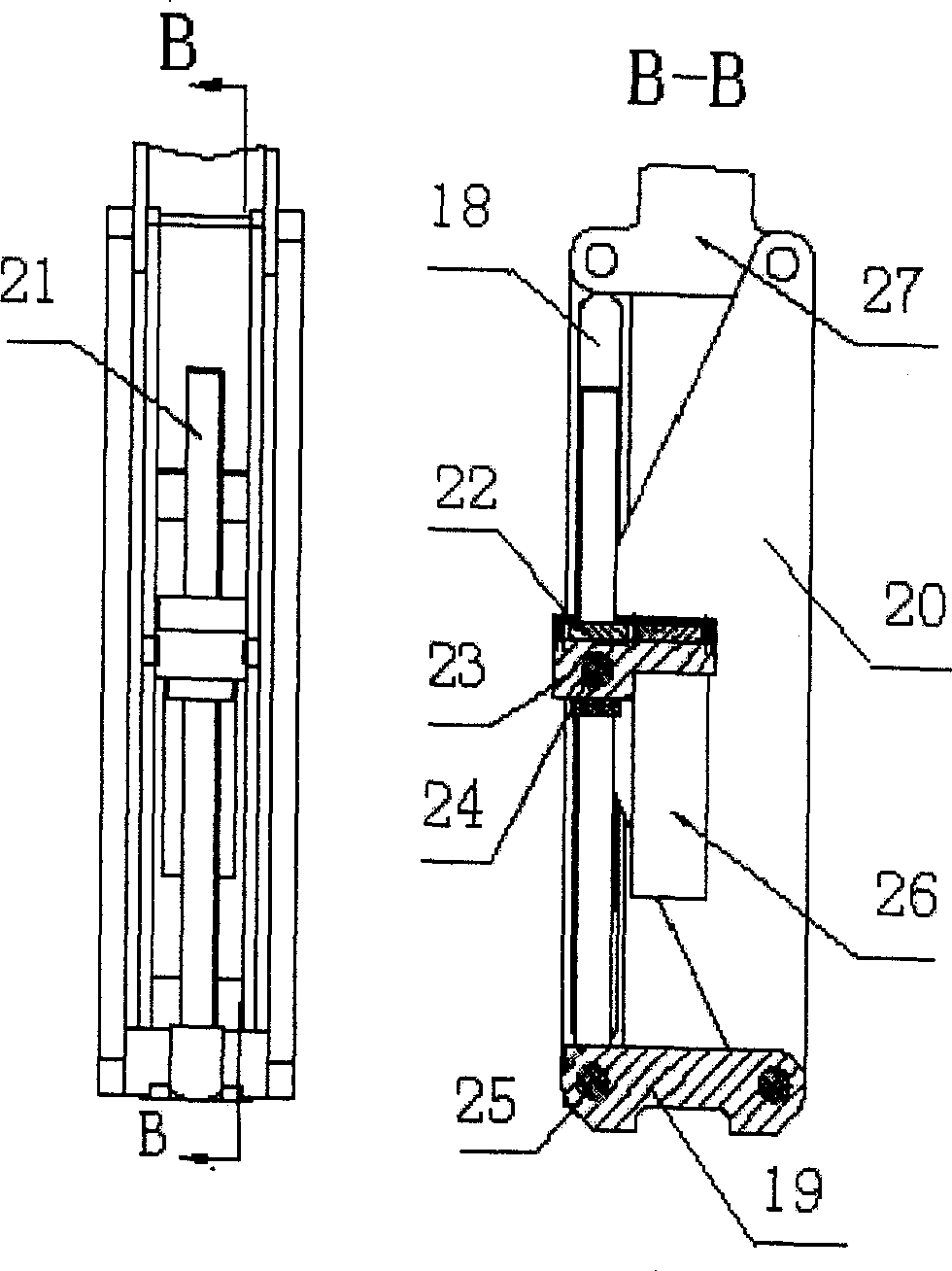

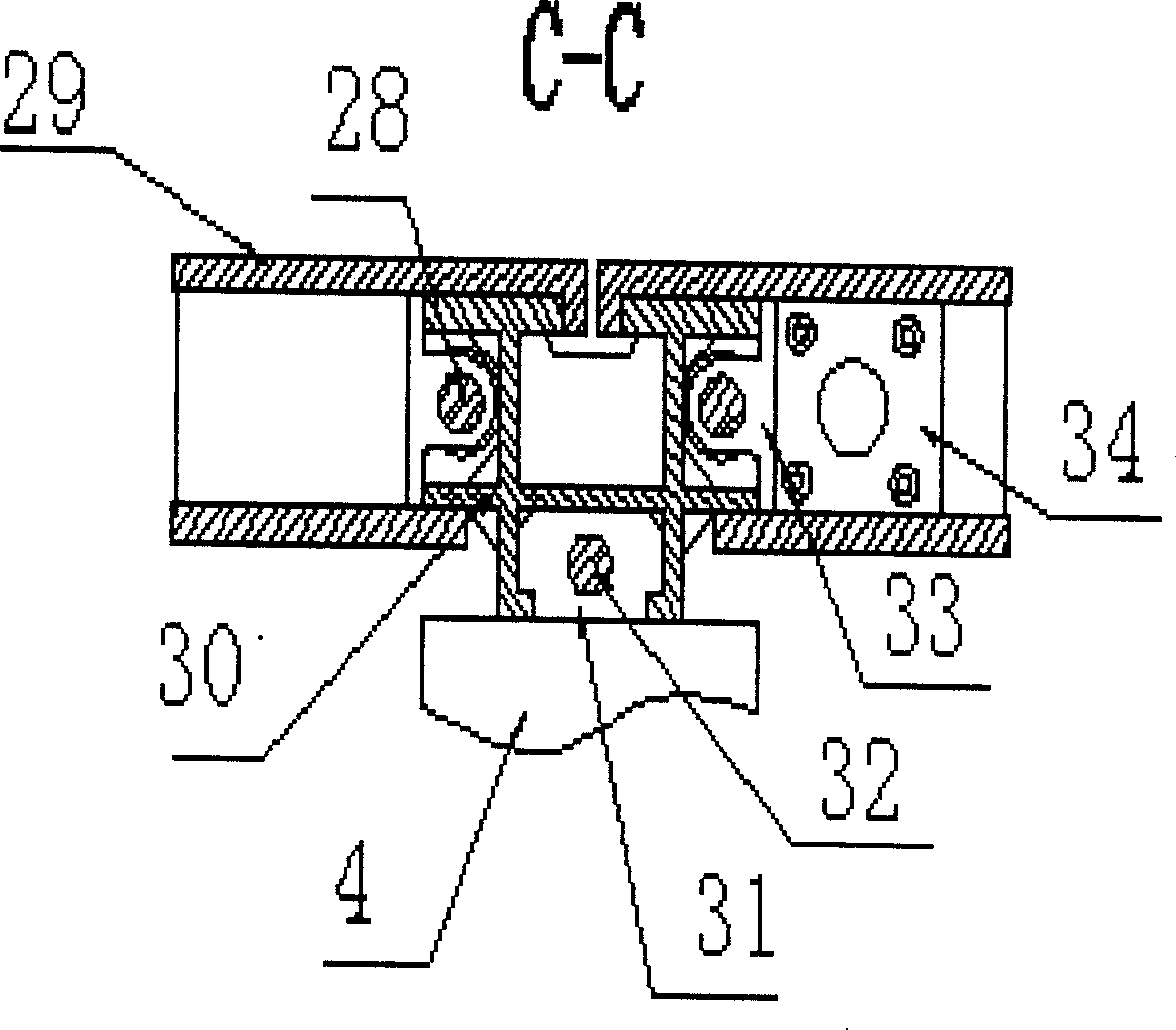

Swinging arm type transmission line polling robot

InactiveCN101168254AStrong ability to overcome obstaclesExpand the scope of workProgramme-controlled manipulatorGripping headsTransmission lineEngineering

Provided is a robot used to ride on power transmission lines or climb between power transmission steel towers, comprising a pair of mechanical arms. The upper ends of the mechanical arms are equipped with a clamping device which is capable of rotating around a mounting shaft, and the clamping device is provided with a gripping jaw which is capable of clamping a strain tower angle-bar and directing lines, and a roller which can be hung on the directing lines. Lower ends of the mechanical arms are installed on a slipway which can relatively slide along a guide rail, arms are capable of rotating around the mounting shaft and can do swaying movement, a control and driving unit is installed in an electric box which is arranged at the bottom portion of a hanger and the slipway, and the control and driving unit can slide along the guide rail, playing a key role in regulating the center-of-gravity position of the robot. The invention is compact in structure, the articulated linkwork is capable of accomplishing complex operation among different vertical planes, and the invention can climb over all structural forms of steel towers and has wide using range, being capable of realizing the automatic inspection on the full power transmission lines and replacing human workers.

Owner:上海求是机器人有限公司 +1

Semi-independent submersible device

InactiveCN1640765AExpand the scope of workGuaranteed real-time and concealmentUnderwater vesselsUnderwater equipmentData transmissionPropeller

The semi-autonomous submarine has water sealed hull comprising transparent pressure-proof glass cover and main hull; video camera capable of rotating in several directions and LCD screen inside the glass cover; underwater video camera, operating handle and keyboard for diver to use; imaging sonar in the bottom for detecting sea bed topography; control computer, gyroscope, cell and driving motor inside the main hull; one pair of stabilizing prow wings and one pair of stern hydroplanes for stabilizing navigation direction and regulating the depth of the submarine separately; one pair of auxiliary propellers capable of rotating in vertical planes to provide the submarine with vertical lift and auxiliary running function and horizontal steering performance; two main propellers and one pair of stern fins for stable navigation; and optical cable for the data transmission between the submarine and the mother ship.

Owner:SHANGHAI JIAO TONG UNIV

Fully automatic butted system of electrode and method through mechanical arm

ActiveCN103094813AImprove slipAchieve connectionBatteries circuit arrangementsCoupling device engaging/disengagingElectricityEngineering

The invention relates to the technical field of an electric car charging, in particularly to a fully automatic butted system of electrode and a method through a mechanical arm. The system can manufacture an electrode assembly which can be fully automatic and safe butted and enables the user of the electric car to enjoy the quick and safe charging service. Compared with the prior art, the fully automatic butted system of an electrode and a method through a mechanical arm has the advantages that better flexibility can be achieved and the automatic docking of two sets of electrodes can be achieved on the condition that the other set of the electrode is in the working range of the mechanical arm without the requirement for a fixed relative location of the electrode combination. Accidents can be reduced caused in the process of connecting the electricity through the automation of connecting the electricity. The automatic docking of the electrode can be achieved within certain realms facilitating greatly the removable electric equipment.

Owner:蒋健棠

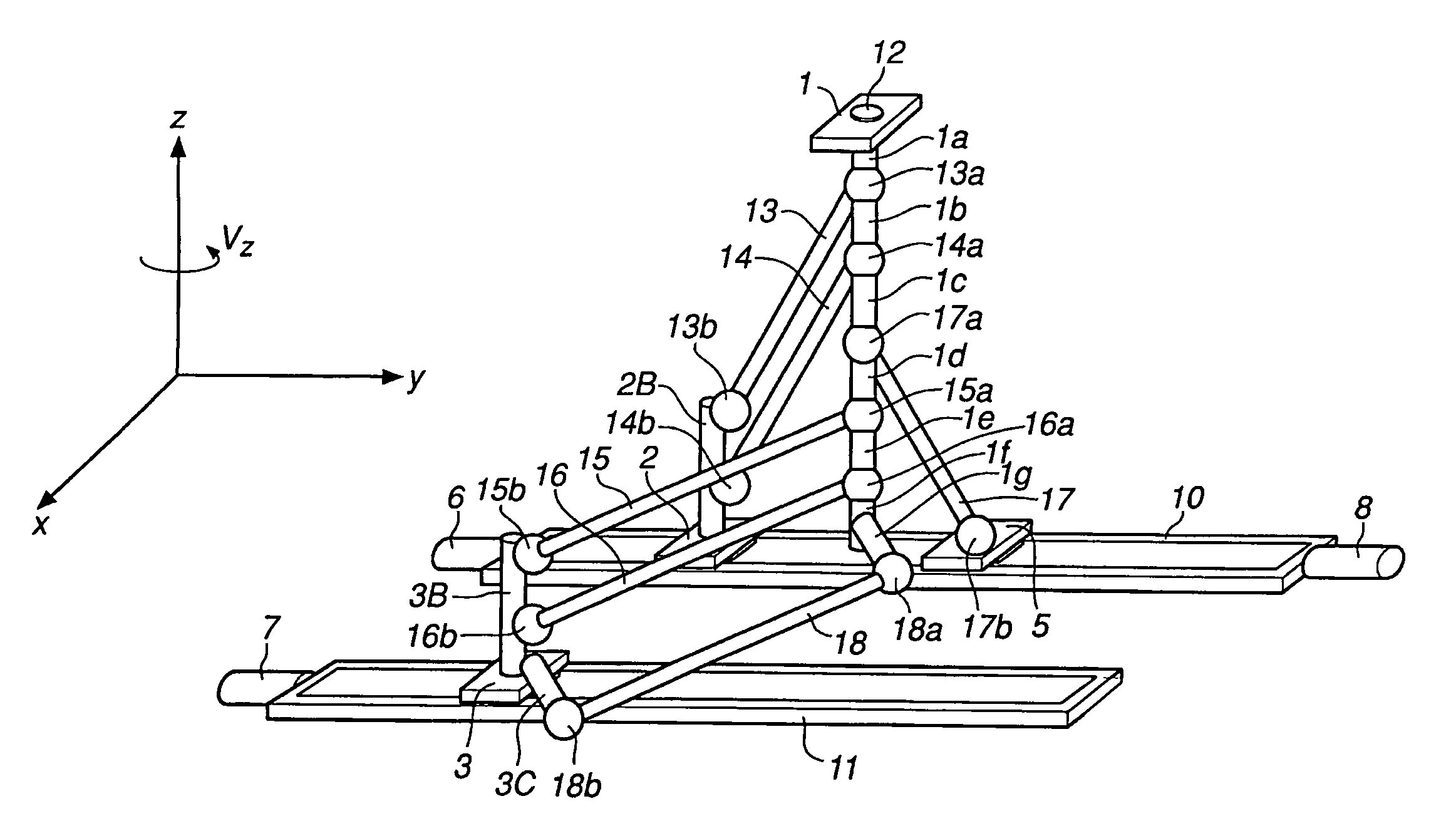

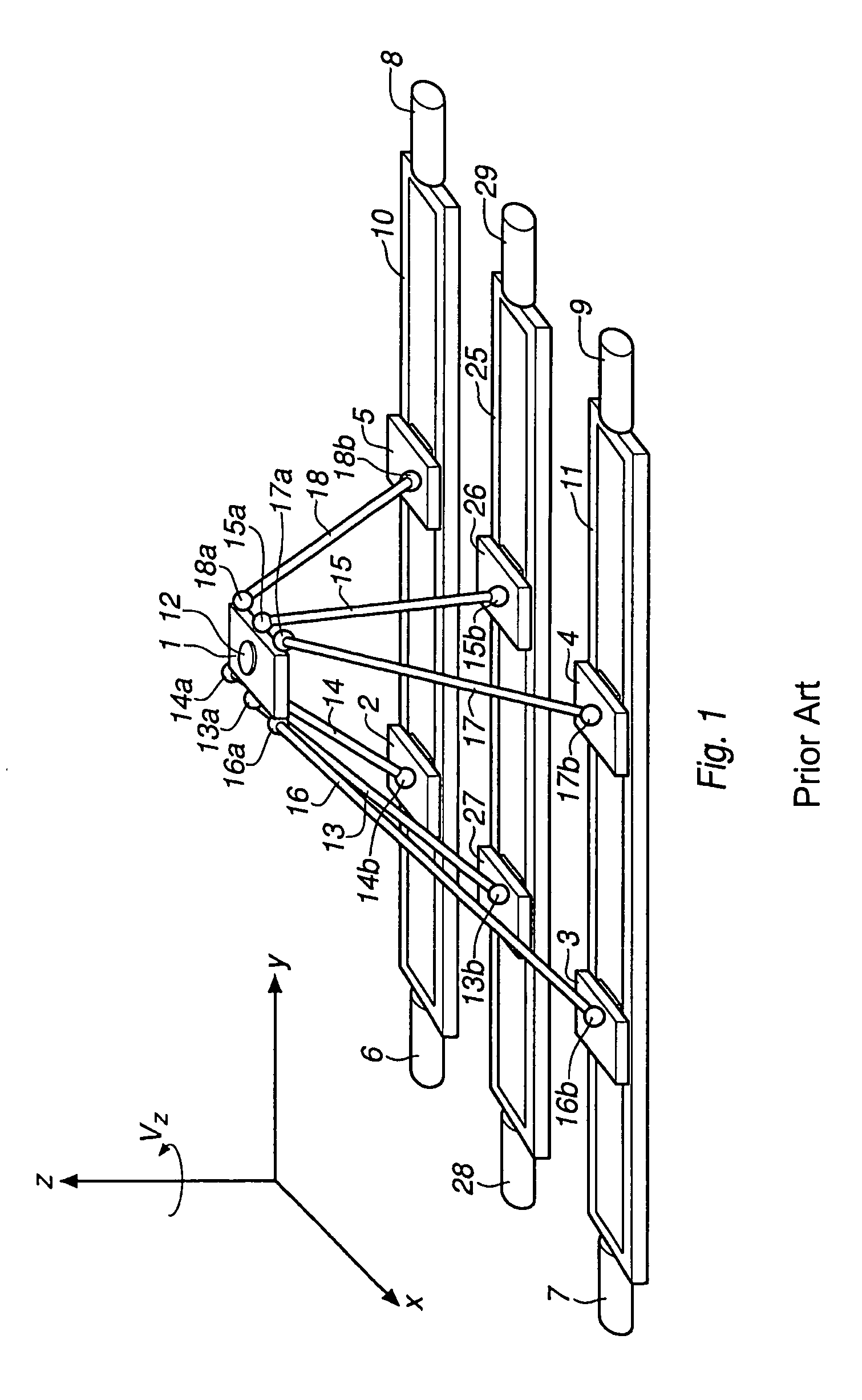

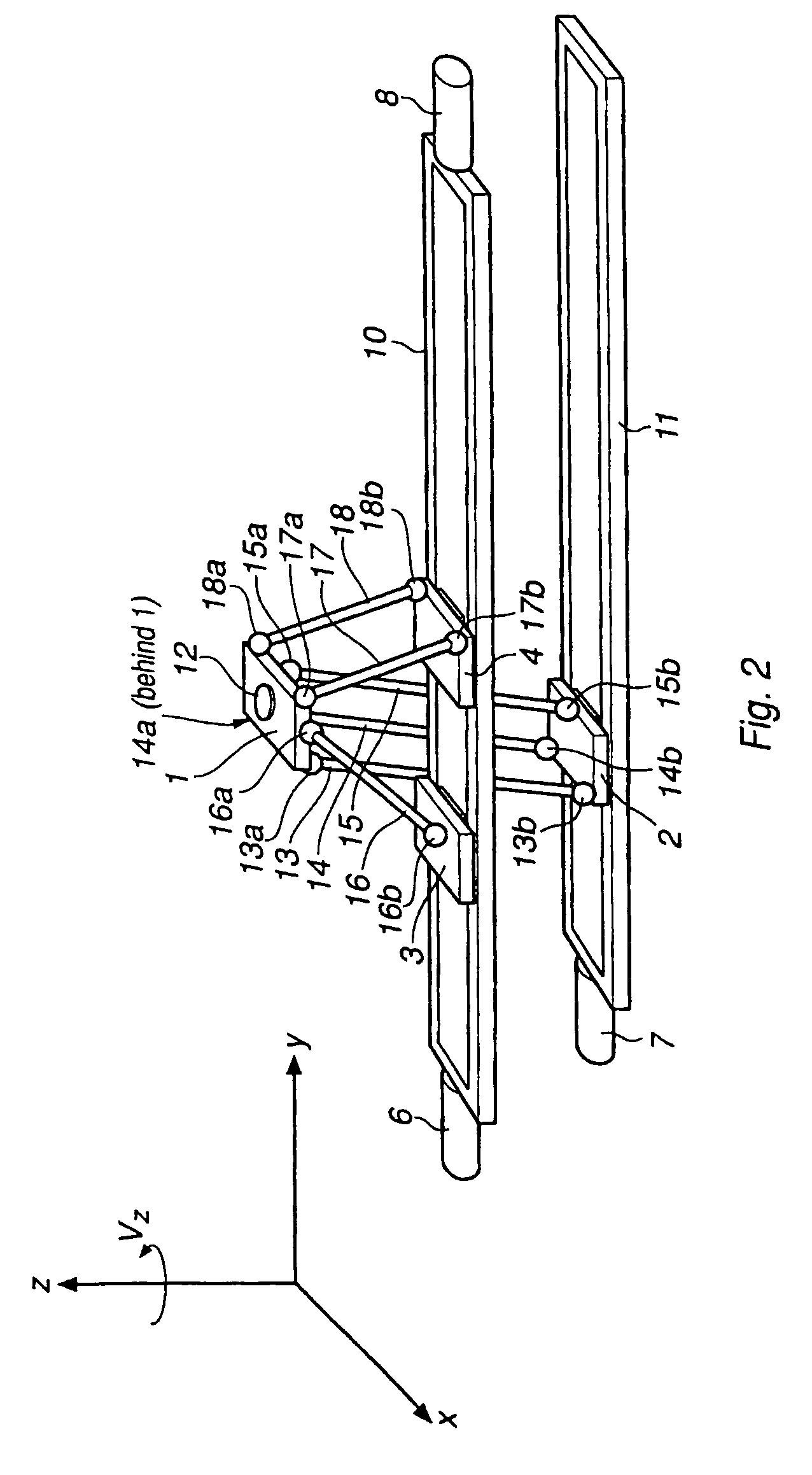

Industrial robot

InactiveUS6974297B2Expand the scope of workImprove mobilityProgramme-controlled manipulatorJointsActuatorControl theory

An industrial robot for movement of an object in space comprising a platform arranged for carrying the object, a first arm arranged for influencing the platform in a first movement and comprising a first actuator and two links, each of which comprises an outer joint arranged in the platform and an inner joint arranged in the first actuator, a second arm arranged for influencing the platform in a second movement and comprising a second actuator and two links, each of which comprises an outer joint arranged in the platform and an inner joint arranged in the second actuator, and a third arm arranged for influencing the platform in a third movement and comprising a third actuator and a link, which comprises an outer joint arranged in the platform and an inner joint arranged in the third actuator. The first actuator comprises a first motor, a first path arranged in a first plane and a first carriage linearly movable along the first path, whereby the two inner joints are displaceable in parallel, the second actuator comprises a second motor, a second path arranged in a second plane and a second carriage linearly movable along the second path, whereby the two inner joints are displaceable in parallel, and the third actuator comprises a third motor, a third path arranged in a third plane and a third carriage linearly movable along the third path, whereby the inner joint is linearly displaceable.

Owner:ABB (SCHWEIZ) AG

Fuel and air mixing device for low-pollution burning chamber of gas turbine

ActiveCN102506446AFast evaporationQuick blendContinuous combustion chamberIndustrial gasCombustion chamber

The invention discloses a fuel and air mixing device for a low-pollution burning chamber of a gas turbine. Fuel comprises a main burning level and a duty burning level; and air is supplied by a three-stage cyclone. The fuel and air mixing device is characterized in that the central duty level adopts diffusive burning, and the peripheral main burning level adopts premixing or semi-premixing burning. The central duty level consists of a centrifugal atomizing nozzle and first-stage cyclone air; and the rotating directions of the first-stage cyclone air and second-stage cyclone air are opposite. The fuel of the main burning level is supplied by a multipoint direct-injection type nozzle, the air is respectively supplied by the second-stage cyclone air and third-stage cyclone air, and the rotating directions of the second-stage cyclone air and third-stage cyclone air are opposite. The central duty level is used when in low working conditions such as starting and slowing and the like, so that the stable burning range can be widened, the burning efficiency can be improved and the emission of CO and UHC is reduced; and when in large working conditions, the duty level and the main burning level work simultaneously, the duty level provides a stable ignition source for the main burning level, a main burning area is in a lean-oil state, and the temperature is far lower than the temperatureof insulated flame, so that the emission of NOx under the large working conditions can be obviously reduced. The fuel and air mixing device can be used for an aerial gas turbine engine or an industrial gas turbine.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

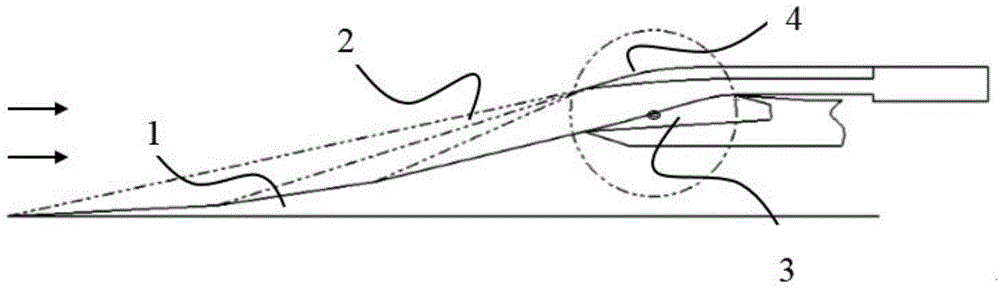

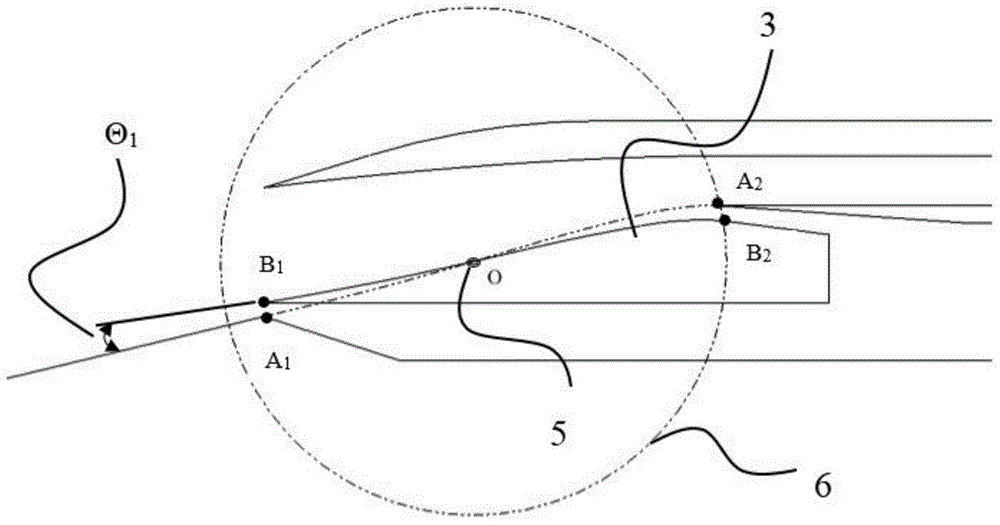

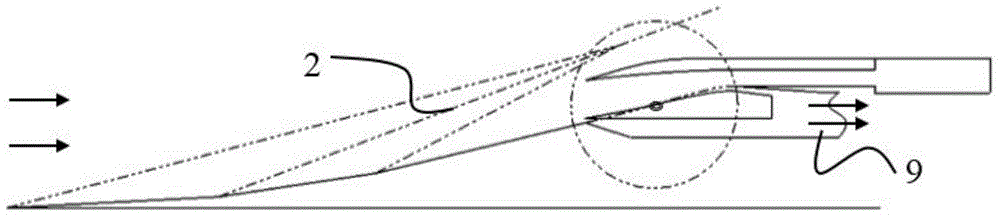

Binary hypersonic-velocity variable-geometry air inlet way with rectangular inlet, design method thereof and working method thereof

ActiveCN104863715AReduce the starting Mach numberImprove starting performanceGas turbine plantsJet propulsion plantsFlight vehicleTrailing edge

The invention discloses a binary hypersonic-velocity variable-geometry air inlet way with a rectangular inlet, a design method thereof and a working method thereof, and is applied to an air breathing type hypersonic flight vehicle propelling system. A part adjustable top plate capable of partially rotating is designed and mounted based on a traditional hypersonic-velocity air inlet way structure with a rectangular section; the position of the part adjustable top plate is adjusted according to flying conditions of a flight vehicle; the part adjustable top plate rotates by a small angle to form front and back two flow leakage windows; a front edge is designed near the section of the inlet; and a back edge is designed in the connected place of the part adjustable top plate and a throat way. A boundary layer developed from a part precursor or a large separation package formed by not starting is discharged by using simple rotation; and the starting capacity of the air inlet way is improved through the flow leakage of the throat way. The starting performance of the air inlet way can be prominently improved by only two times of rotating adjustments of the air inlet way in the starting acceleration process. The small-angle rotation variable-geometry process is easier to realize; the restarting control timeliness is better; the flowing control to the air inlet way is more comprehensive; and the pneumatic performance of the air inlet way is comprehensively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com