Fuel and air mixing device for low-pollution burning chamber of gas turbine

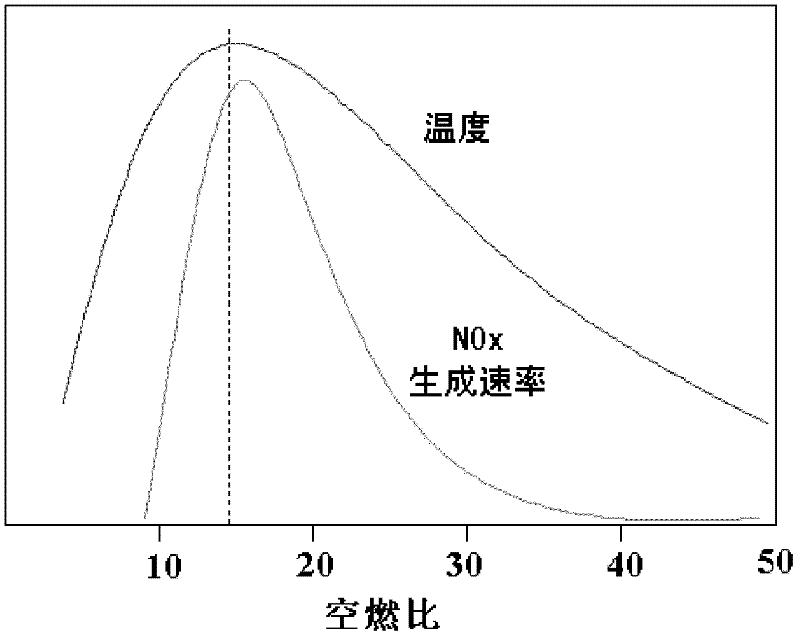

A technology of gas turbines and mixing devices, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., to achieve the effects of strengthening interaction, broadening the stable working range, and reducing pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the invention will be further described in detail below with reference to the accompanying drawings and examples.

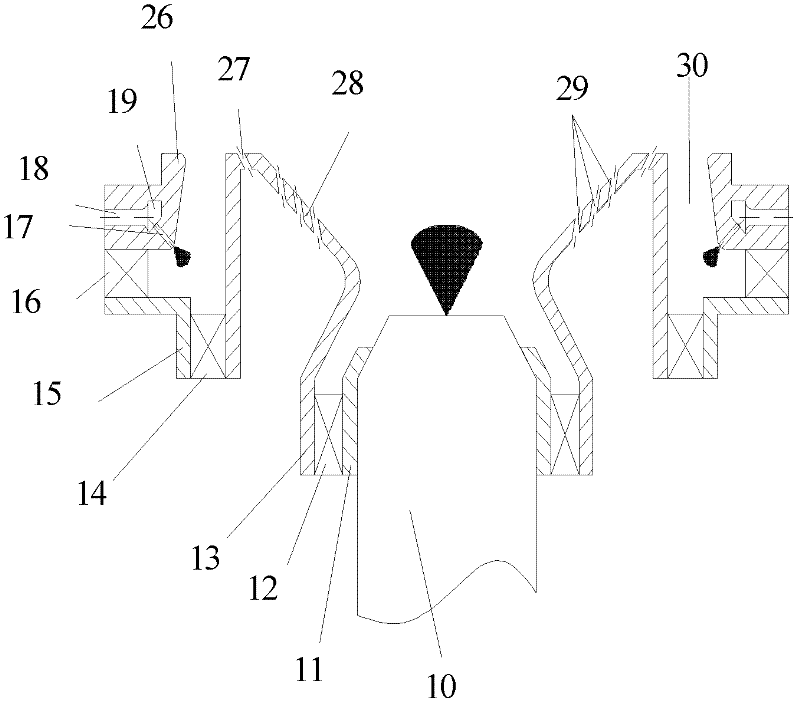

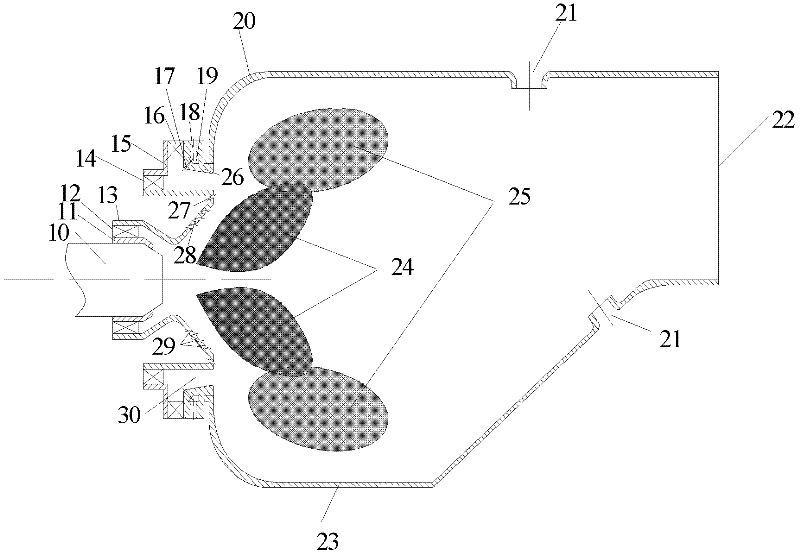

[0030] figure 1 It is a cross-sectional view of the structure of the fuel and air mixing device used in the low-pollution combustion chamber of a gas turbine. It adopts the scheme of staged fuel supply, including the main combustion stage and the duty stage. The duty stage includes a centrifugal atomizing nozzle 10, a first-stage axial air Cyclone 12 and conical flame stabilizer 28, wherein, centrifugal atomizing nozzle 10 is positioned at the center of described device, and primary axial air swirler 12 is arranged on the outer ring of centrifugal atomizing nozzle 10, conical The flame stabilizer 28 is located behind the centrifugal atomizing nozzle 10. The fuel on duty is sprayed through the centrifugal atomizing nozzle 10 for primary atomization, and then se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com